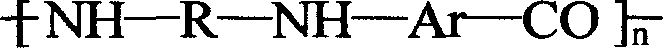

Thermosol of polyamide and preparation process thereof

A polyamide hot-melt adhesive and caprolactam technology, which is applied in the direction of adhesives, etc., can solve the problems that cannot meet the requirements of high-temperature occasions, the melting point of hot-melt adhesive is low, and the amount of component c is large, and achieves high flexibility, low cost, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Caprolactam, nylon 66 salt, piperazine, C 12Put the dibasic acid into the polycondensation reactor with stirring in the weight ratio of 41.0:53.0:1.4:4.0, replace with nitrogen, heat the material in the reactor to 250°C, and keep the reaction pressure at 1.6MPa for 2.5h. Then at this temperature, the reaction pressure was reduced to normal pressure, the depressurization time was 2.5 hours, the reaction temperature was kept constant, and the reaction was continued for 1.8 hours before the polycondensation ended. The stirring speed of the whole polycondensation reaction process is 50r / min. After discharging, cooling, and slicing, the obtained product is a light yellow translucent solid slice with a melting point range of 178°C to 185°C and a melt index of 17.2g / 10min (240°C, 0.216MPa).

Embodiment 2

[0031] According to the method of embodiment 1, the weight ratio of each polymerization monomer material is caprolactam: adipic acid: hexamethylenediamine: C 10 ~C 15 Mixed dicarboxylic acid trimethylhexamethylene diamine salt = 22.0: 26.6: 21.2: 13.0, where C 10 ~C 15 The composition of mixed dicarboxylic acids is C 10 Dicarboxylic acid 0.8wt%, C 11 Dicarboxylic acid 3.2wt%, C 12 Dicarboxylic acid 26.1wt%, C 13 Dicarboxylic acid 51.4wt%, C 14 Dicarboxylic acid 17.4wt%, C 15 Dicarboxylic acid 1.1 wt%. The pressure polycondensation reaction conditions are: temperature 260°C, pressure 1.6MPa, reaction time 2.0h, depressurization time 2.0h. The normal compression polymerization conditions are: the reaction temperature is 260°C, the reaction time is 2.0h, and the stirring speed is 80r / min during the reaction process. The melting point range of the obtained product is 163-169° C., and the melt index is 35.9 g / 10 min (240° C., 0.216 MPa).

Embodiment 3

[0033] According to the method of embodiment 1, the weight proportion of each polymerization monomer material is caprolactam: adipic acid: decanedidiamine: C 10 ~C 15 Mixed dicarboxylic acid butanediamine salt = 30.0: 26.6: 31.4: 12.0, where C 10 ~C 15 The composition of mixed dicarboxylic acids is C 10 Dicarboxylic acid 0.8wt%, C 11 Dicarboxylic acid 3.2wt%, C 12 Dicarboxylic acid 26.1wt%, C 13 Dicarboxylic acid 51.4wt%, C 14 Dicarboxylic acid 17.4wt%, C 15 Dicarboxylic acid 1.1 wt%. The pressure polycondensation reaction conditions are: temperature 260°C, pressure 1.6MPa, reaction time 2.0h, depressurization time 2.0h. The normal compression polymerization conditions are: the reaction temperature is 260°C, the reaction time is 2.0h, and the stirring speed is 70r / min during the reaction process. The melting point range of the product obtained by the polycondensation reaction is 161-167°C, and the melt index is 36.4g / 10min (240°C, 0.216MPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com