Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13014results about How to "Improve electrochemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

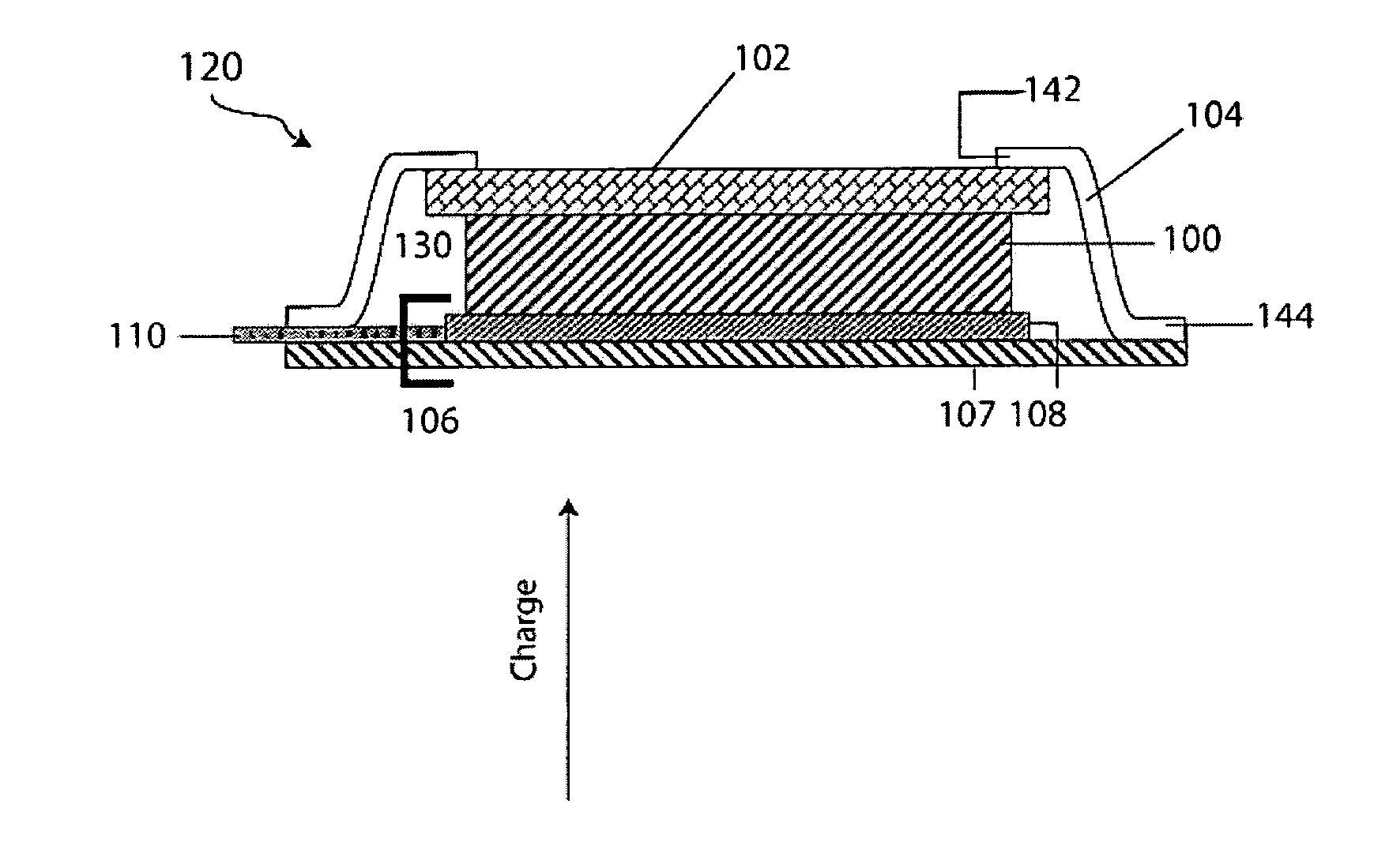

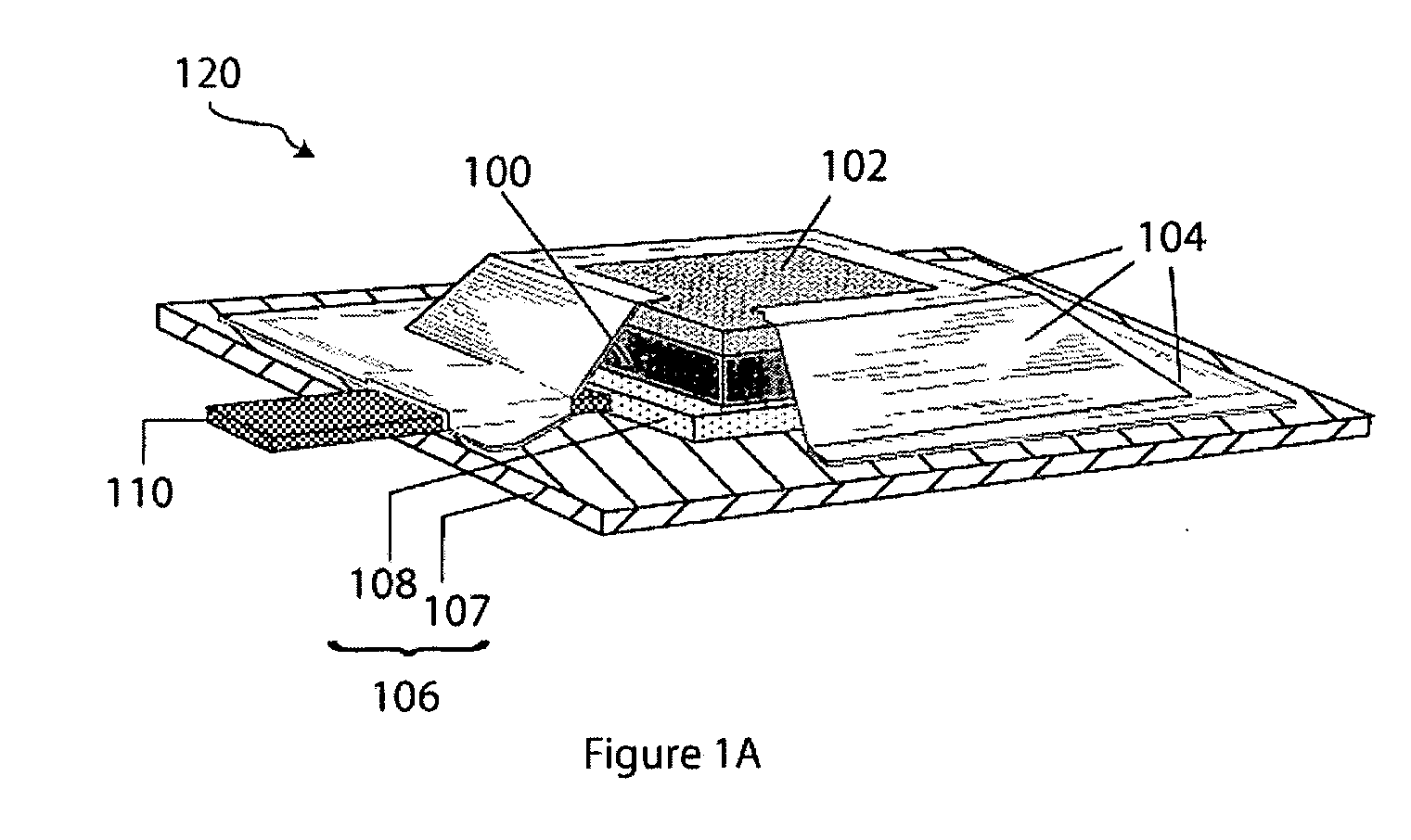

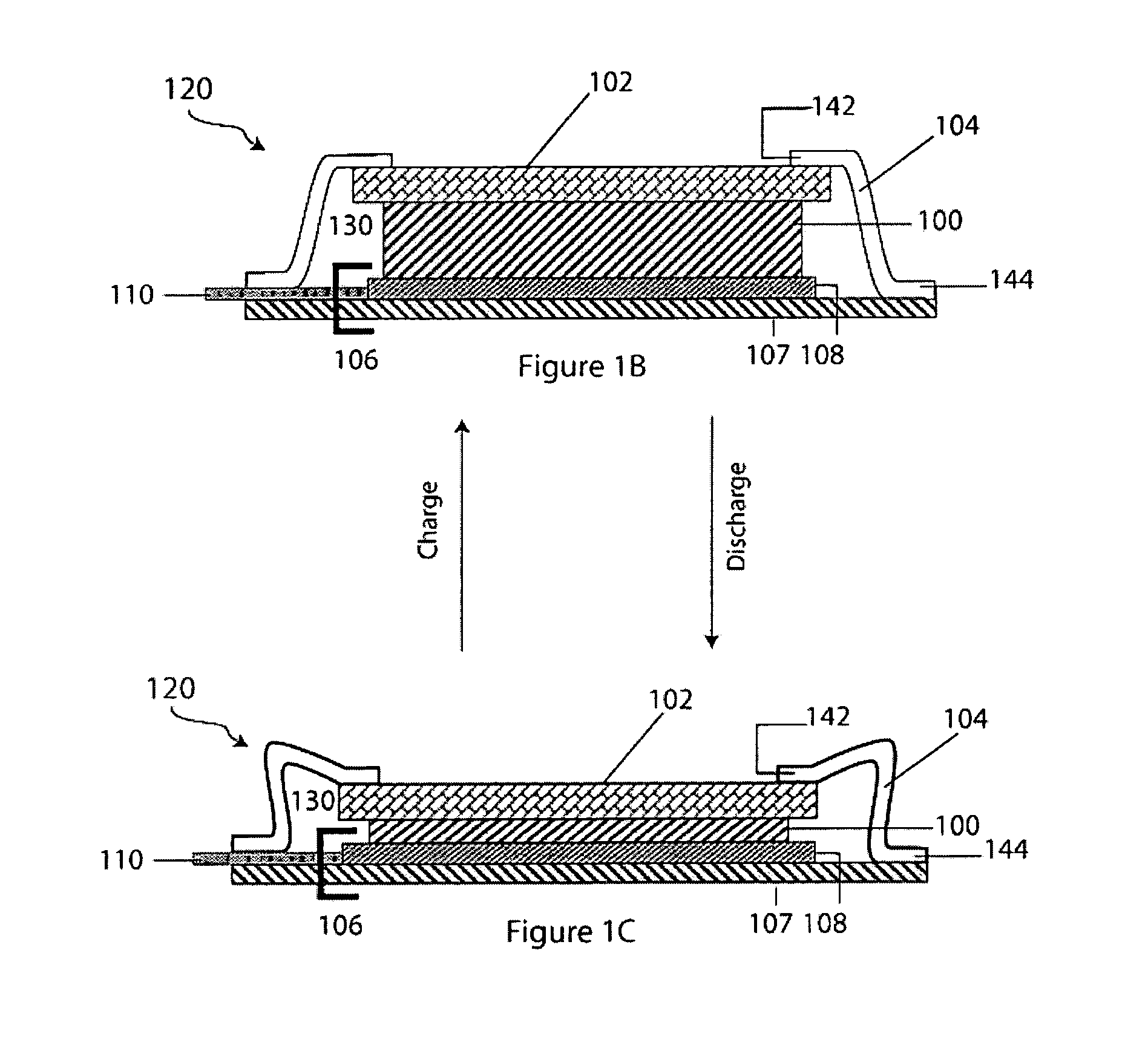

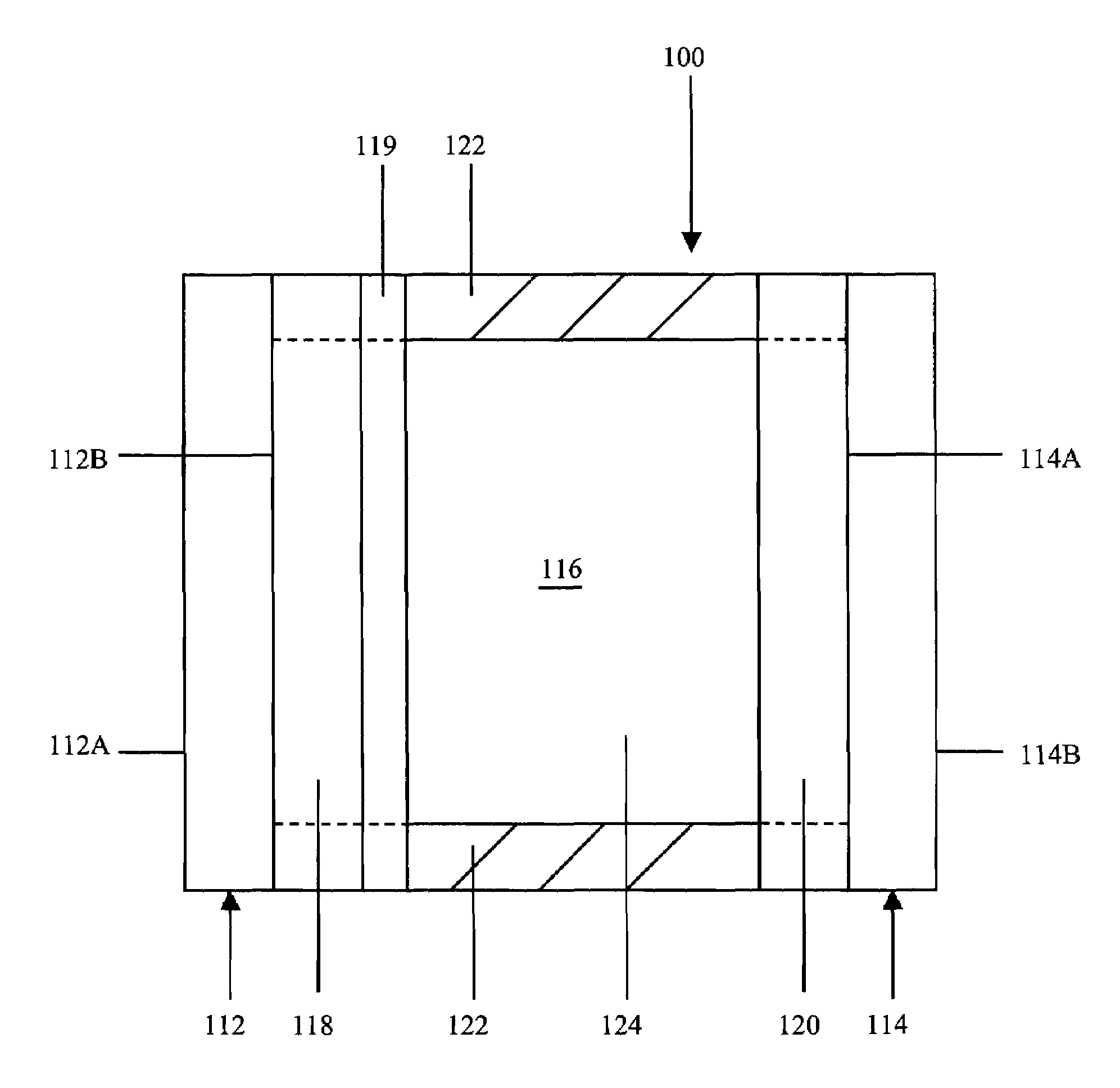

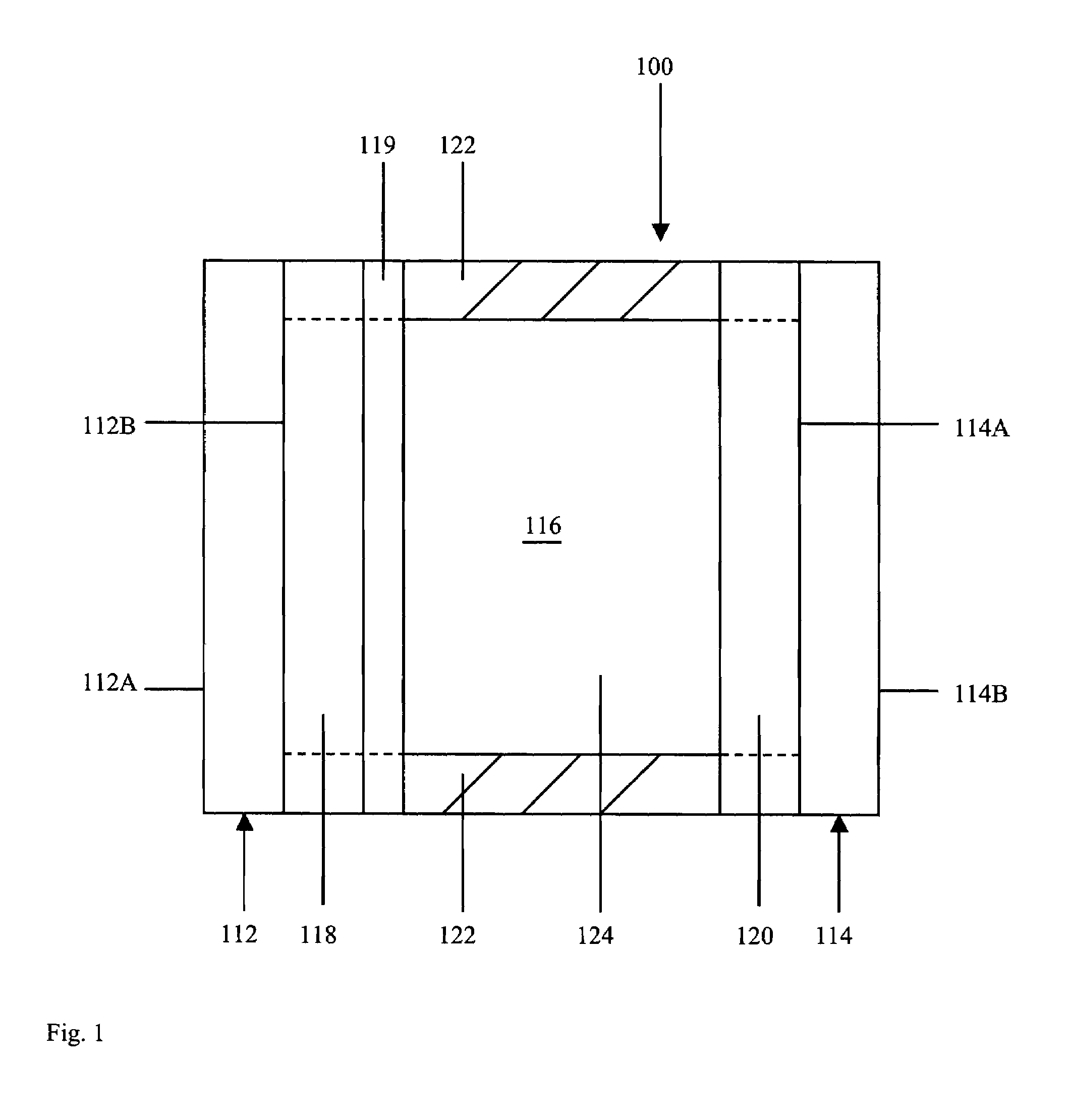

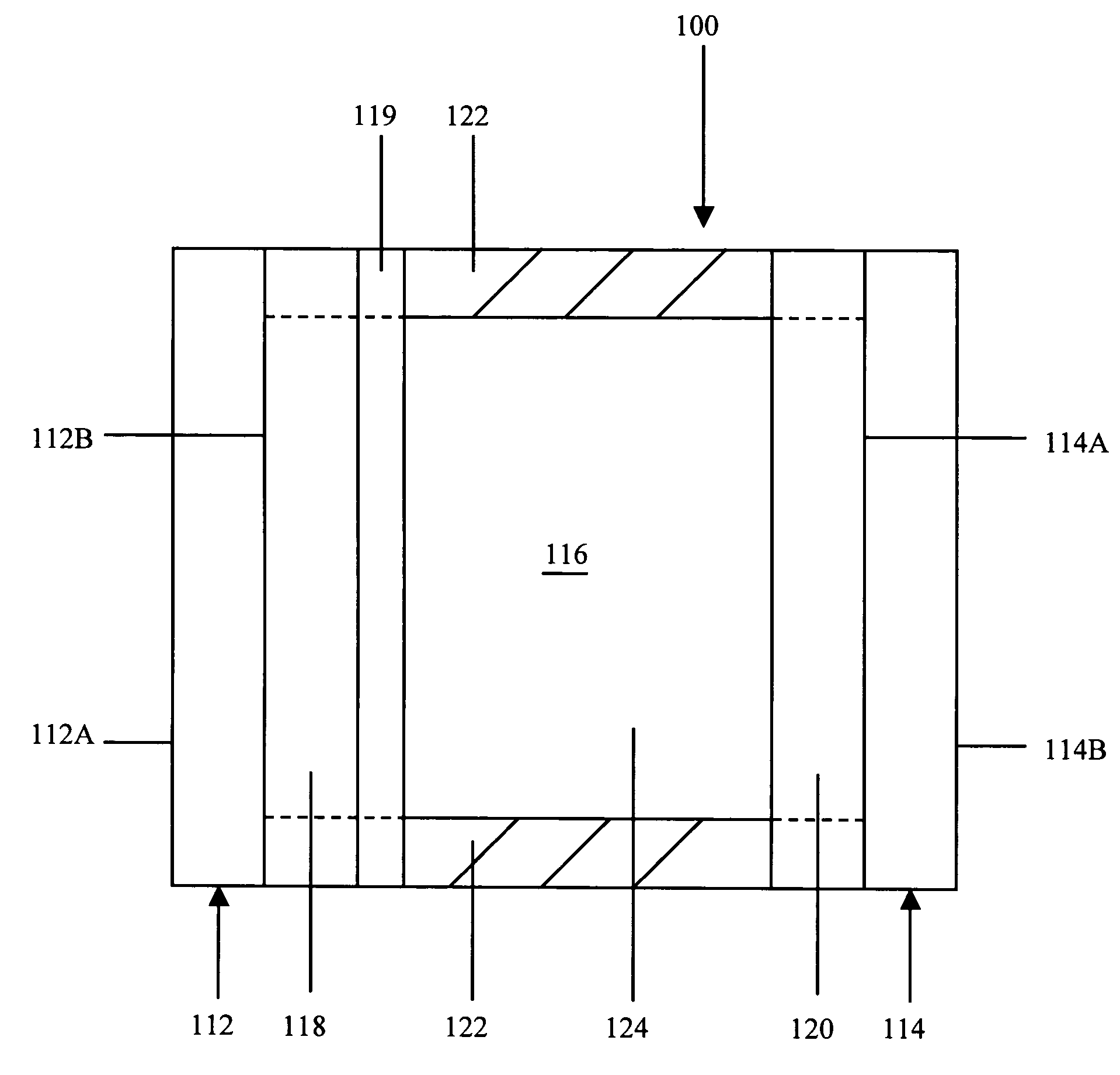

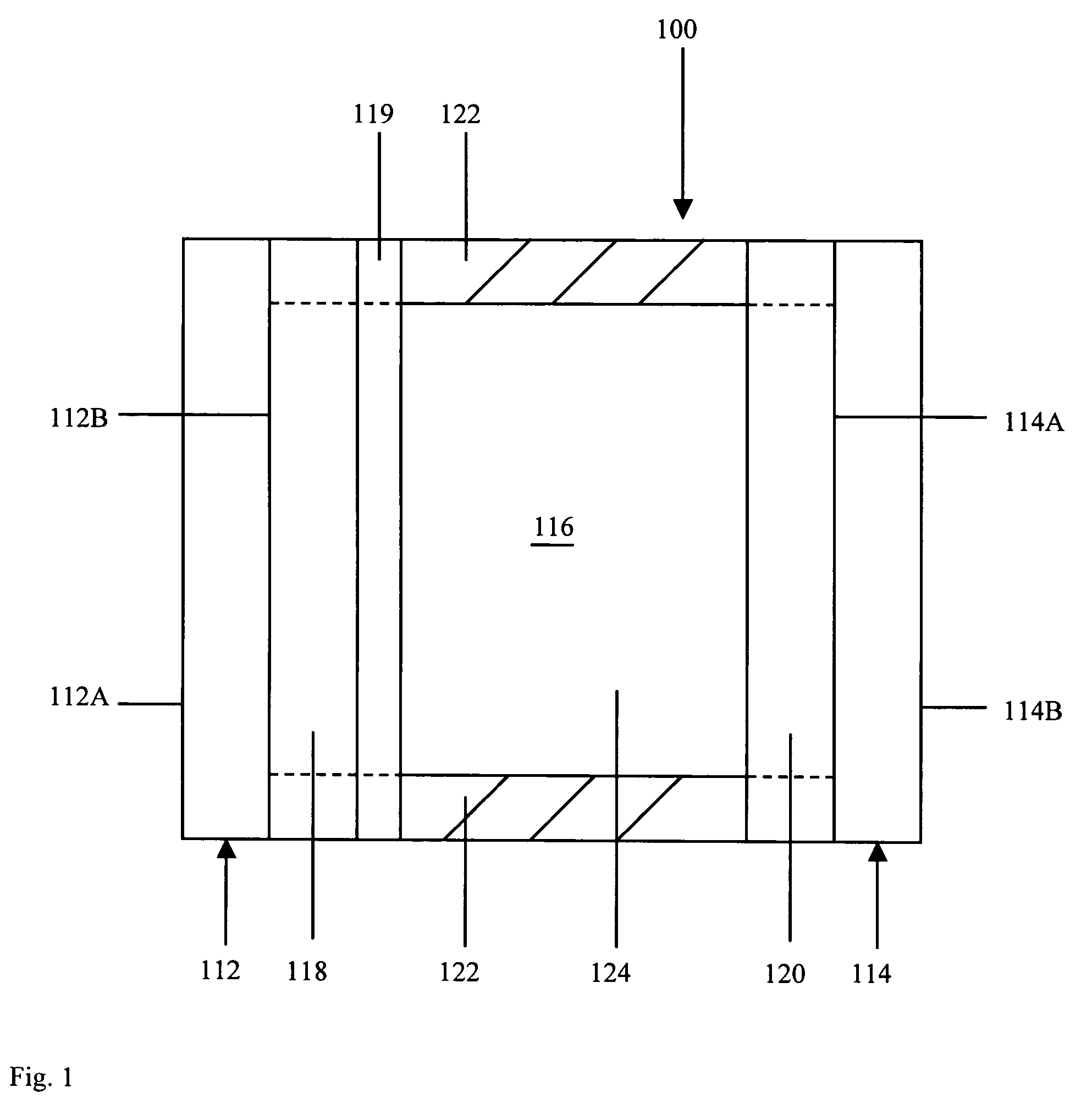

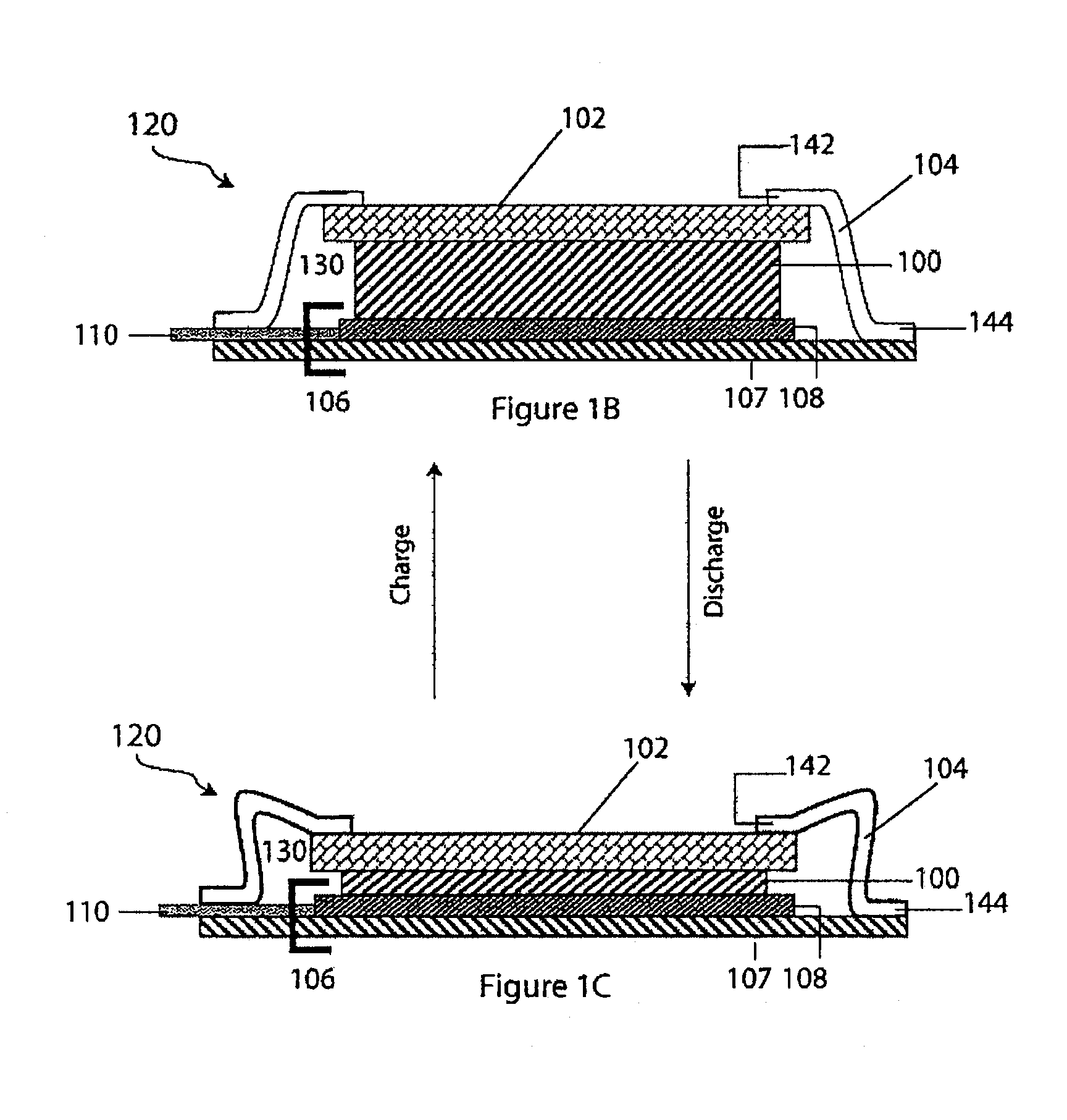

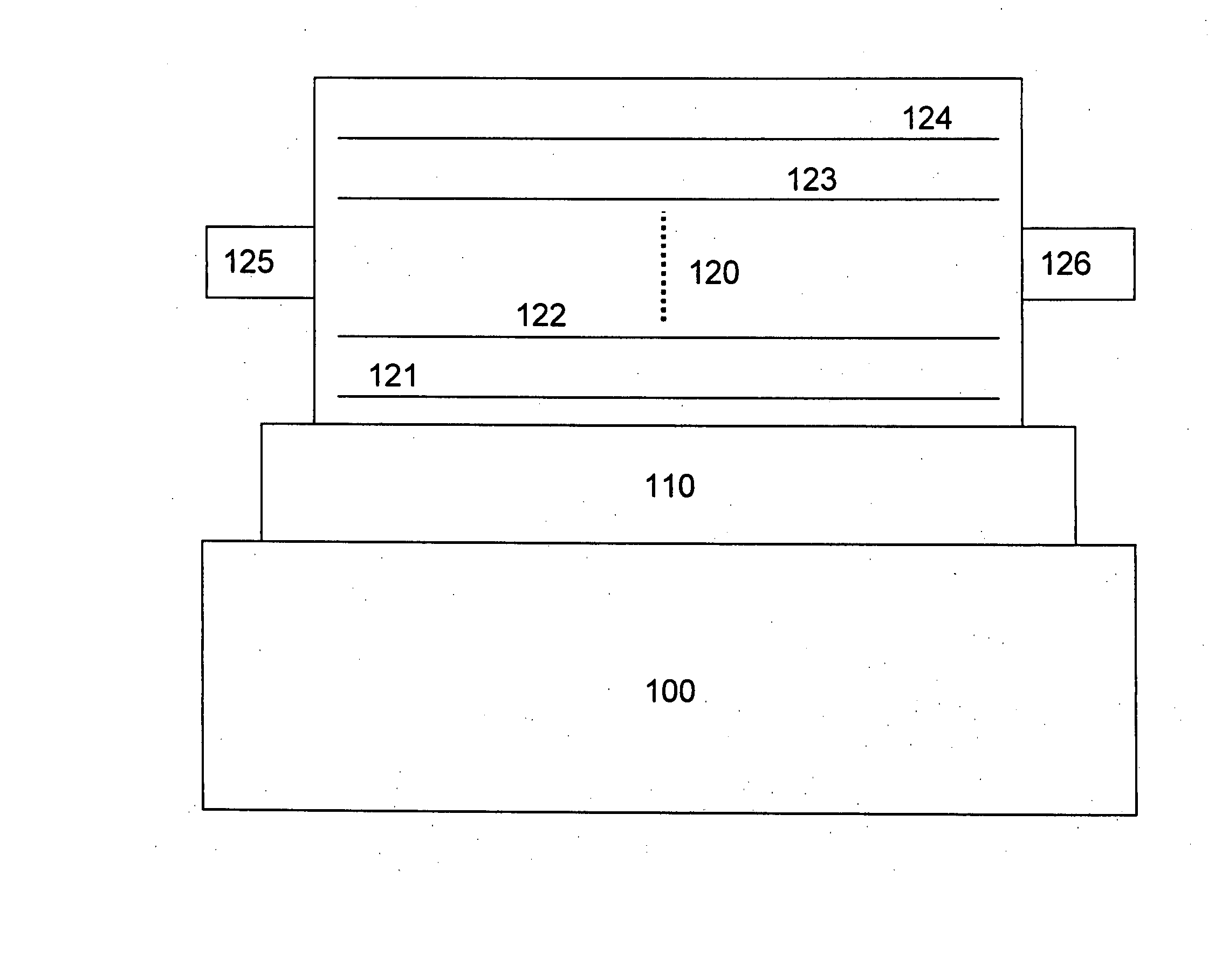

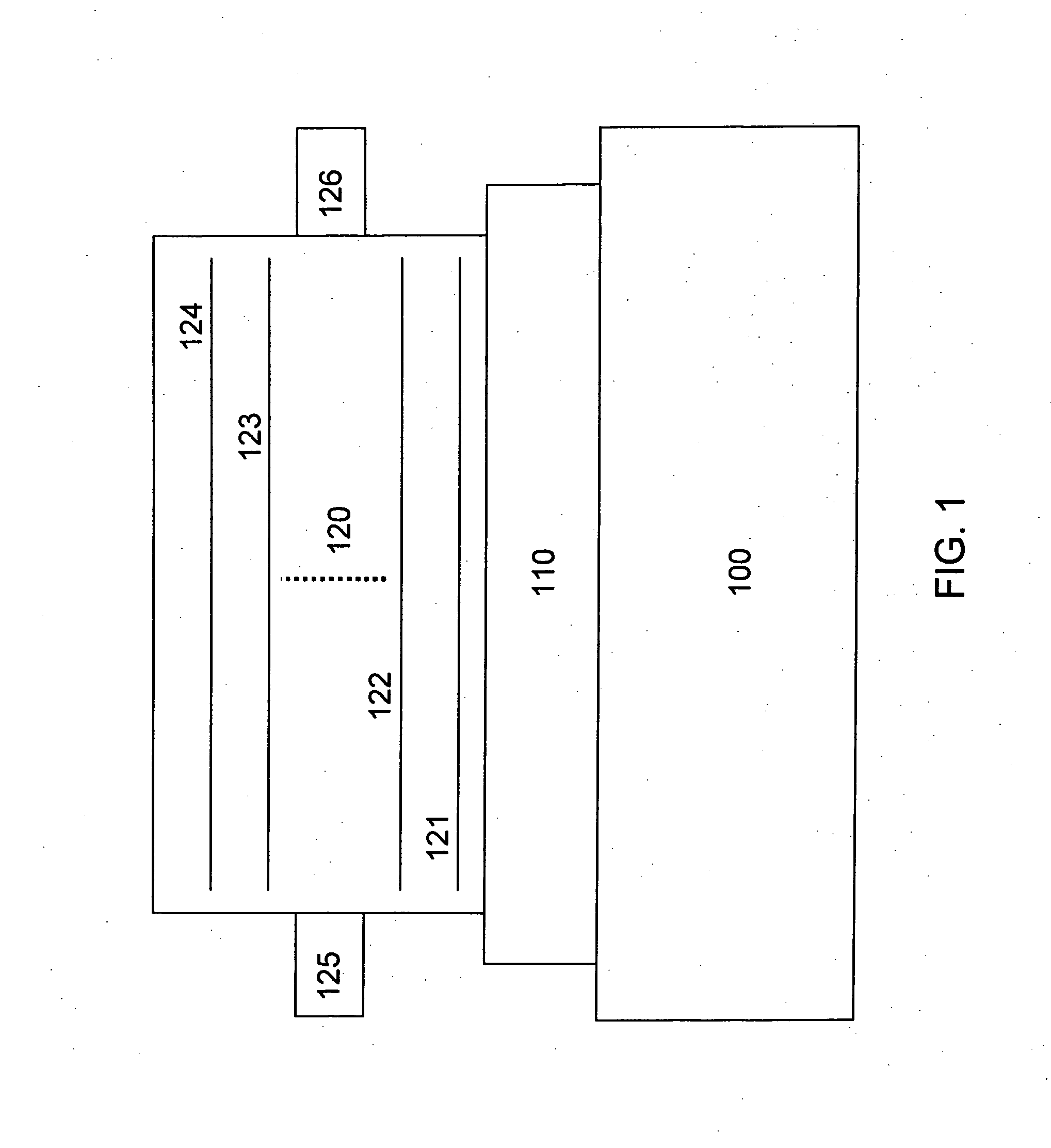

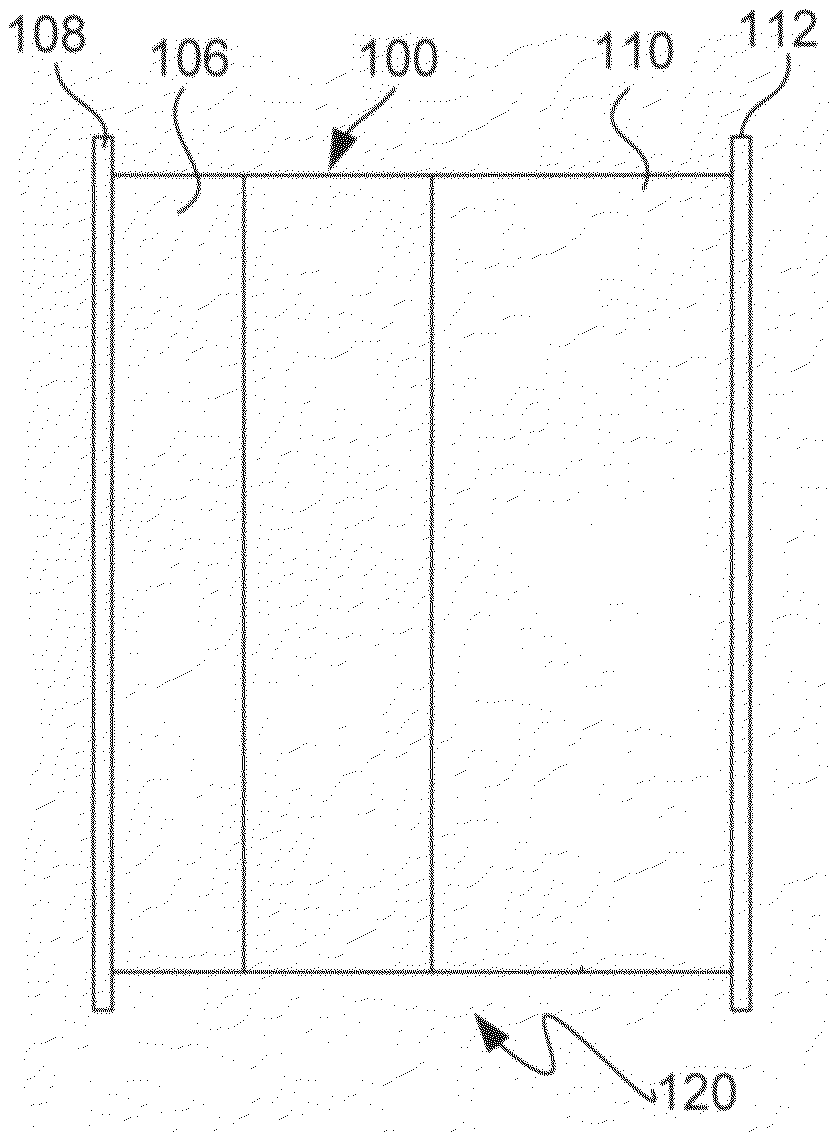

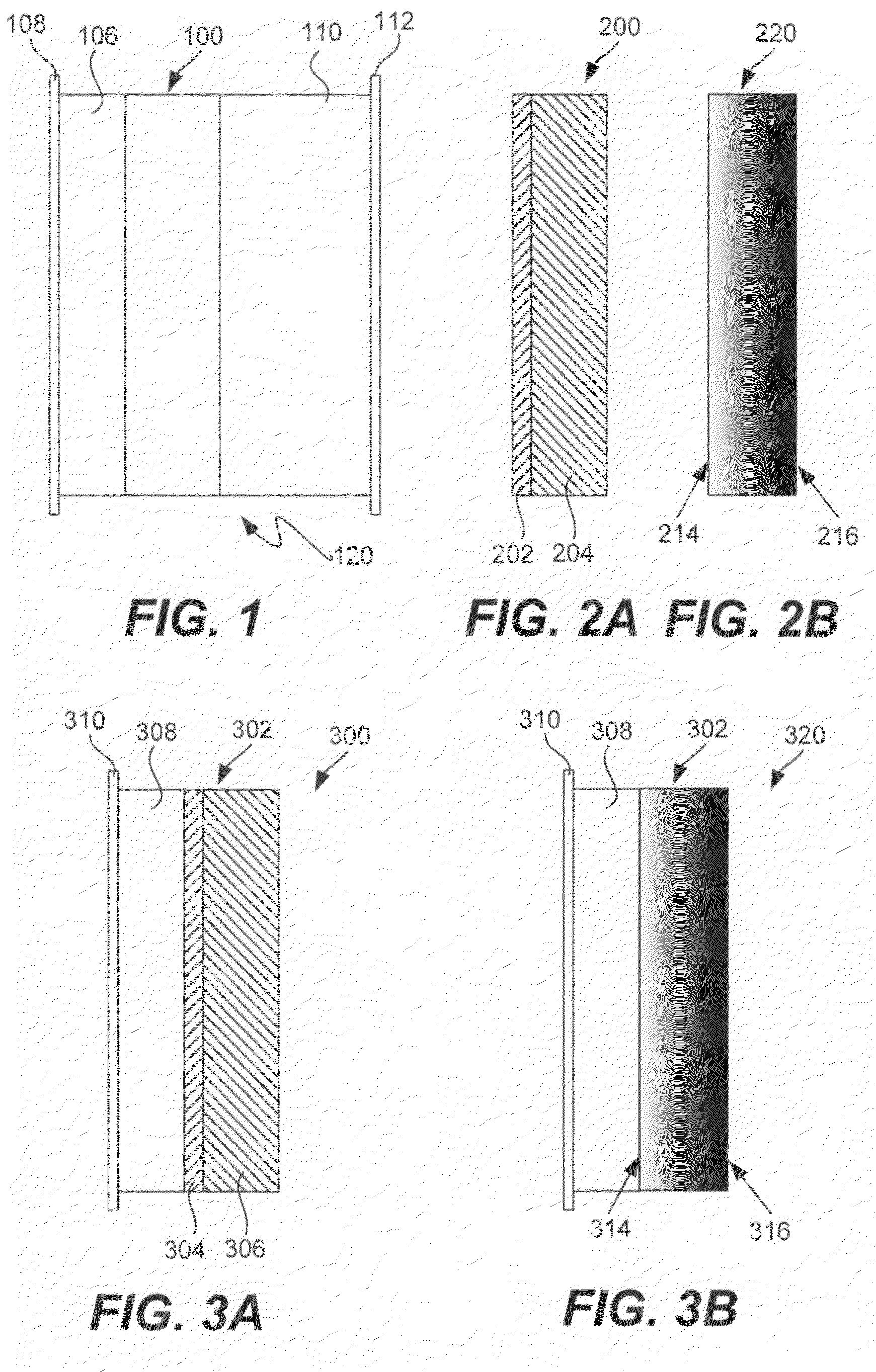

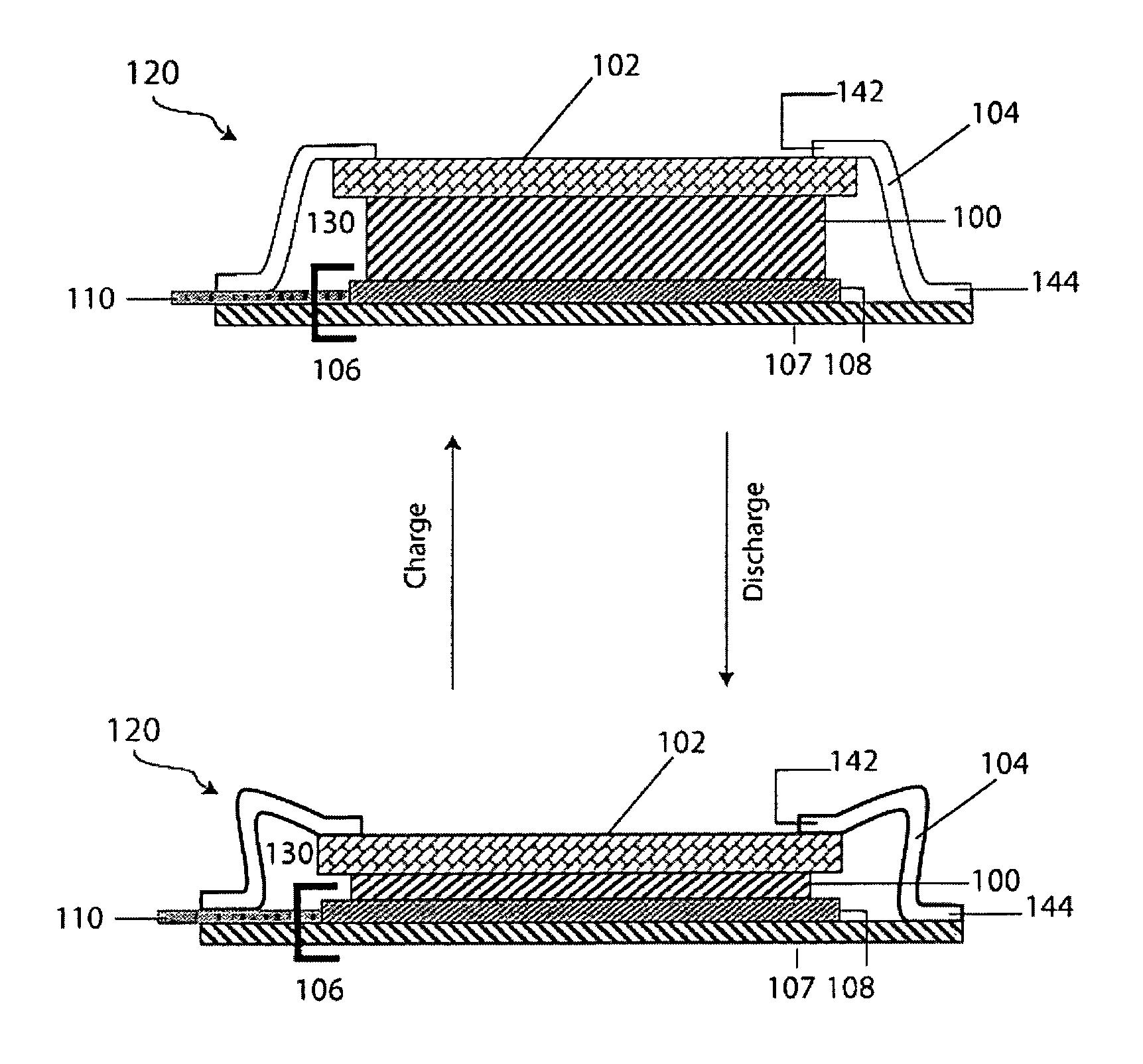

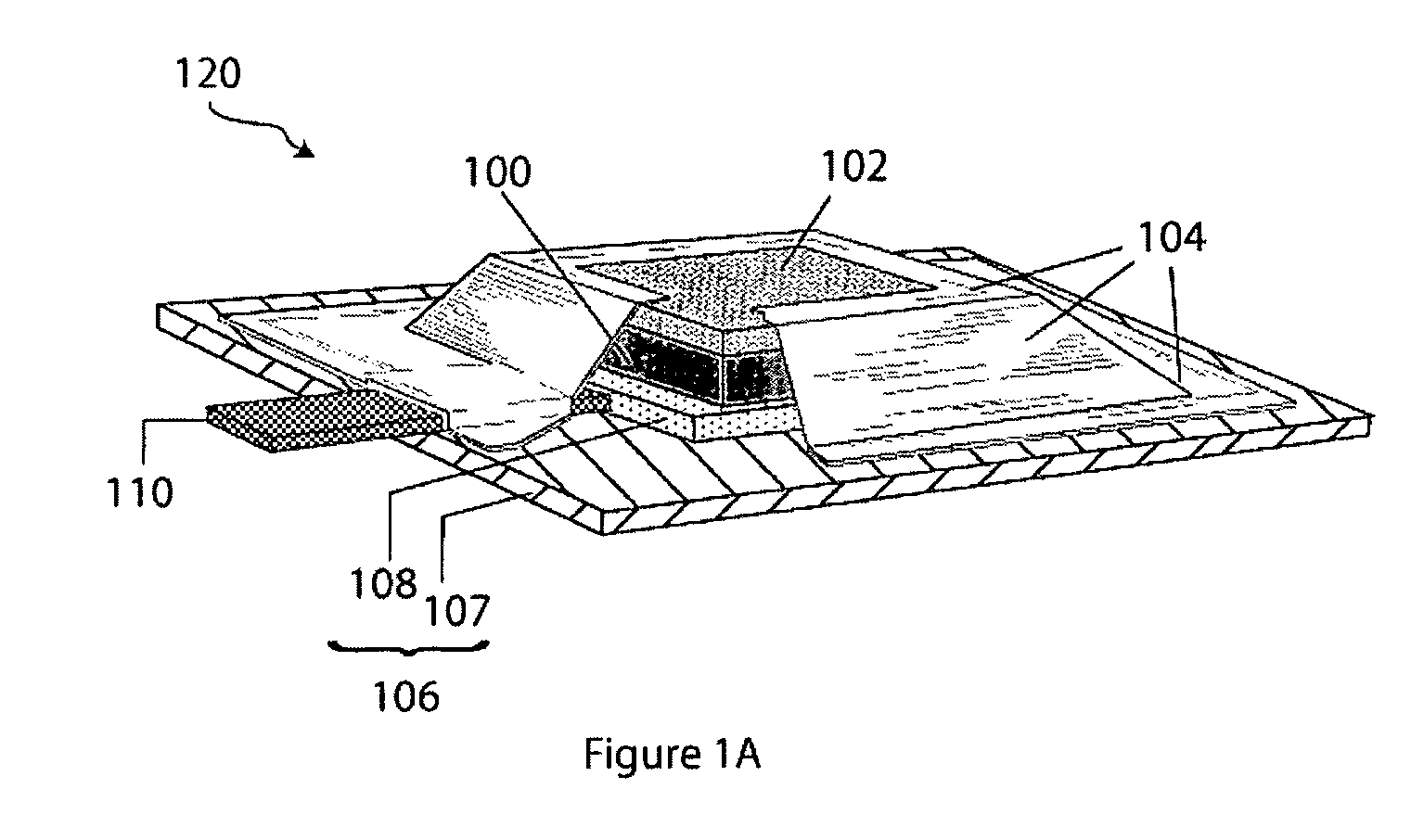

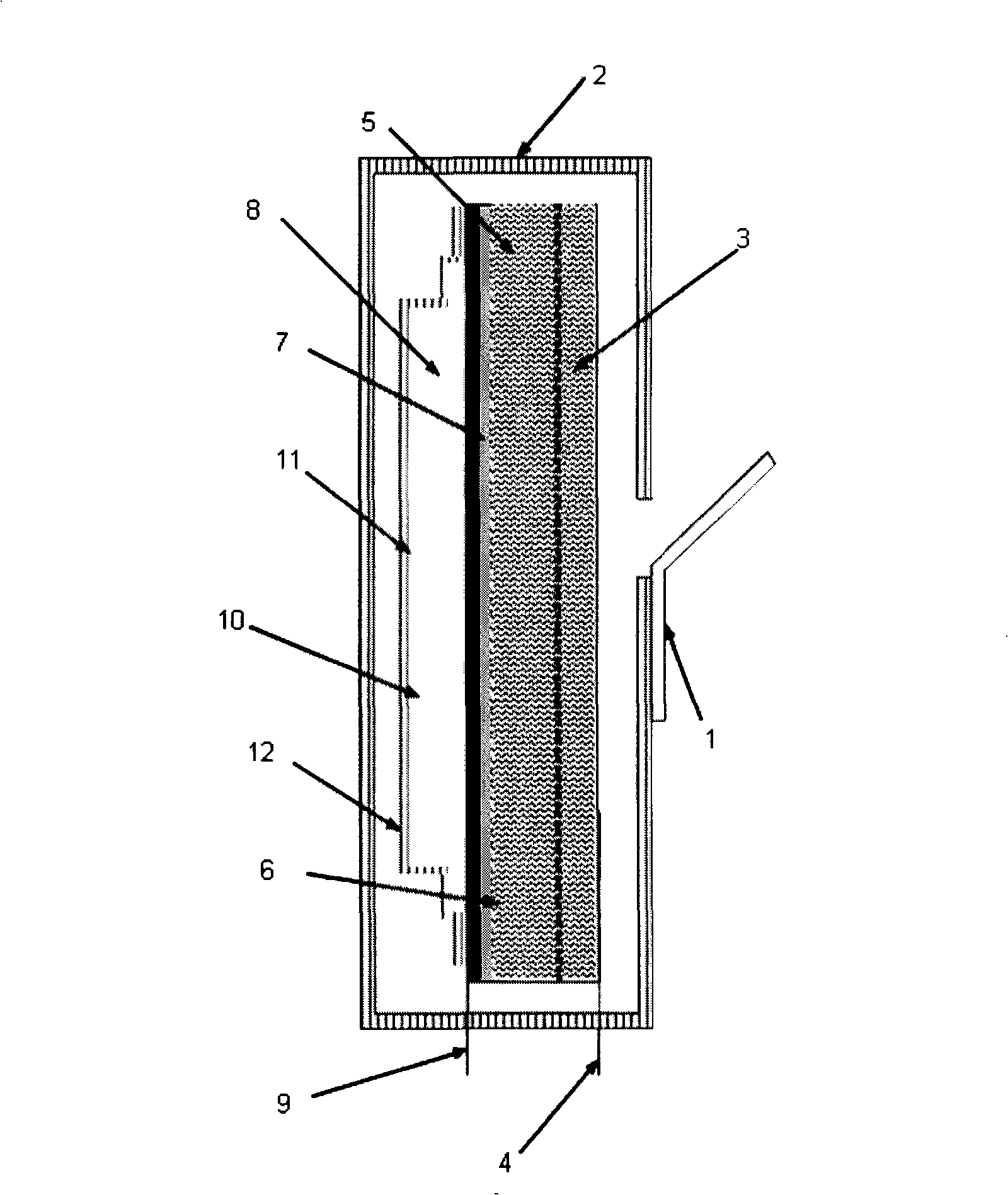

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

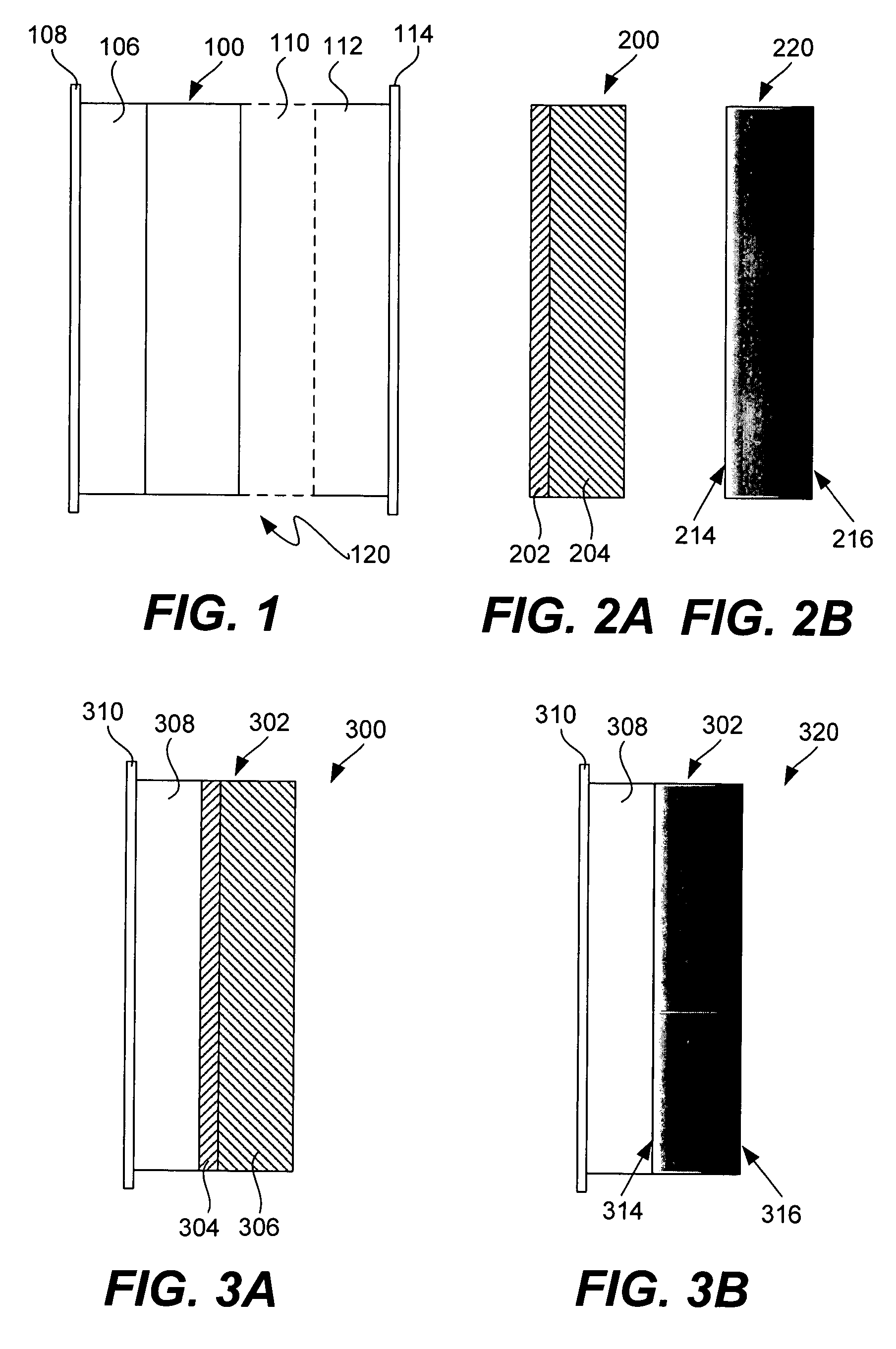

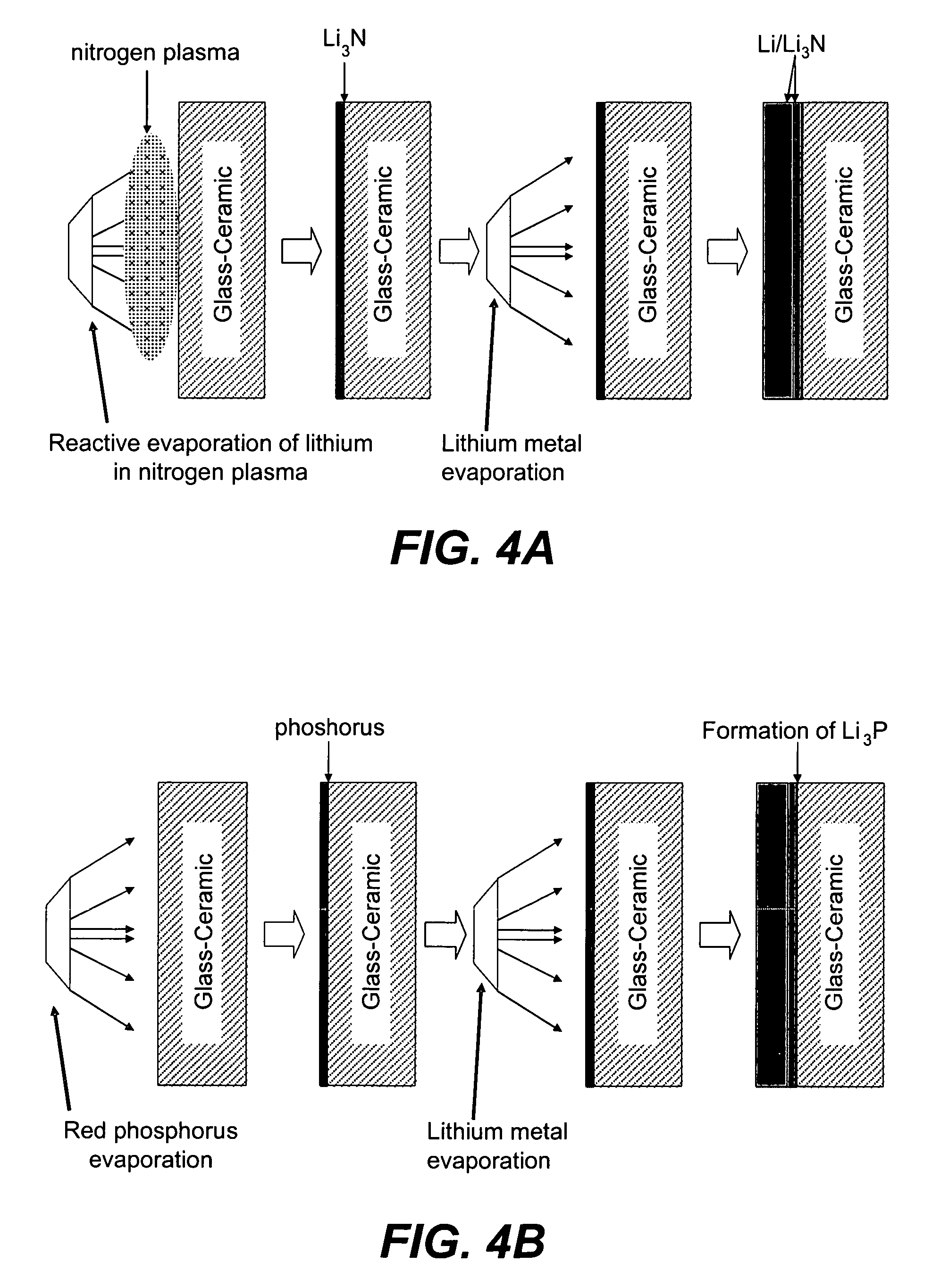

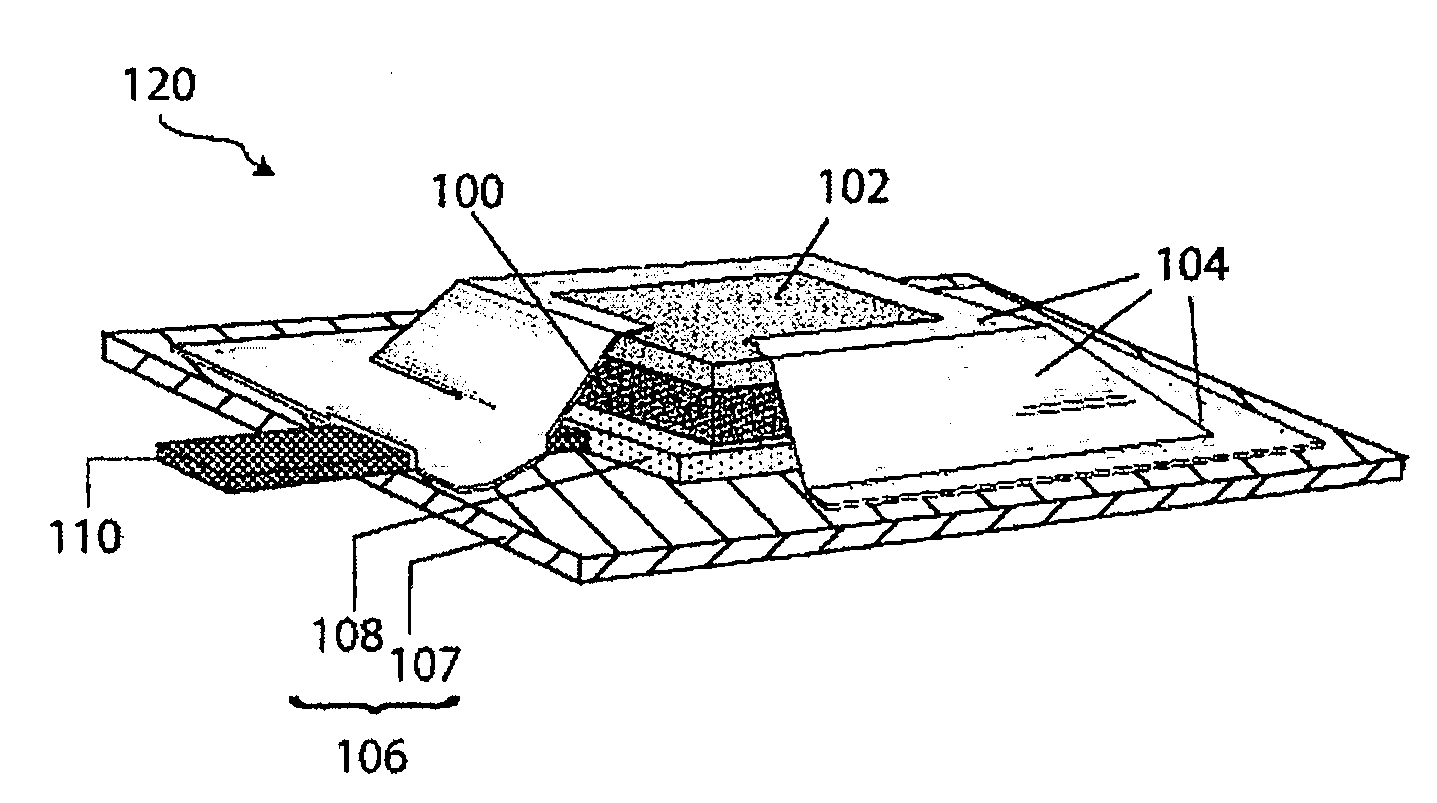

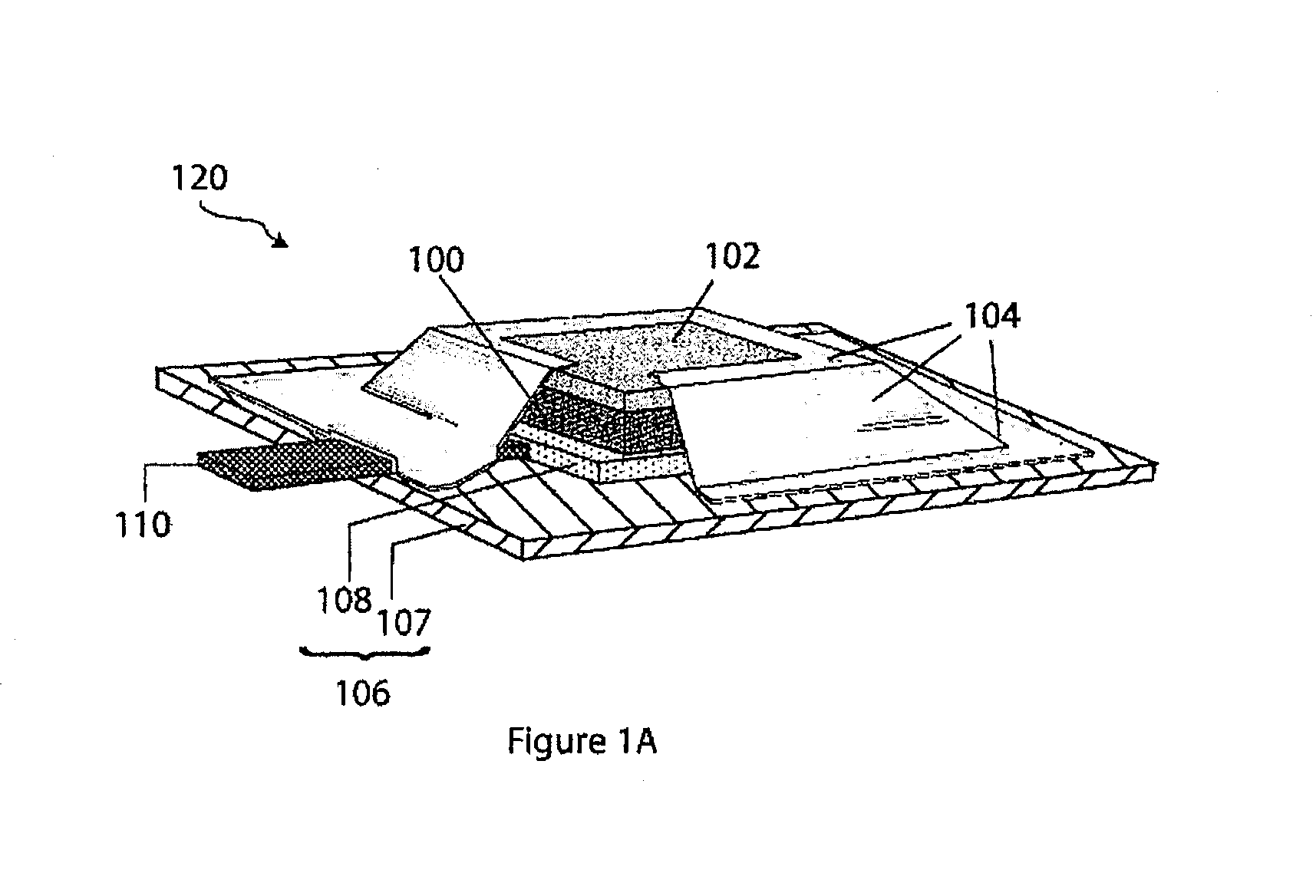

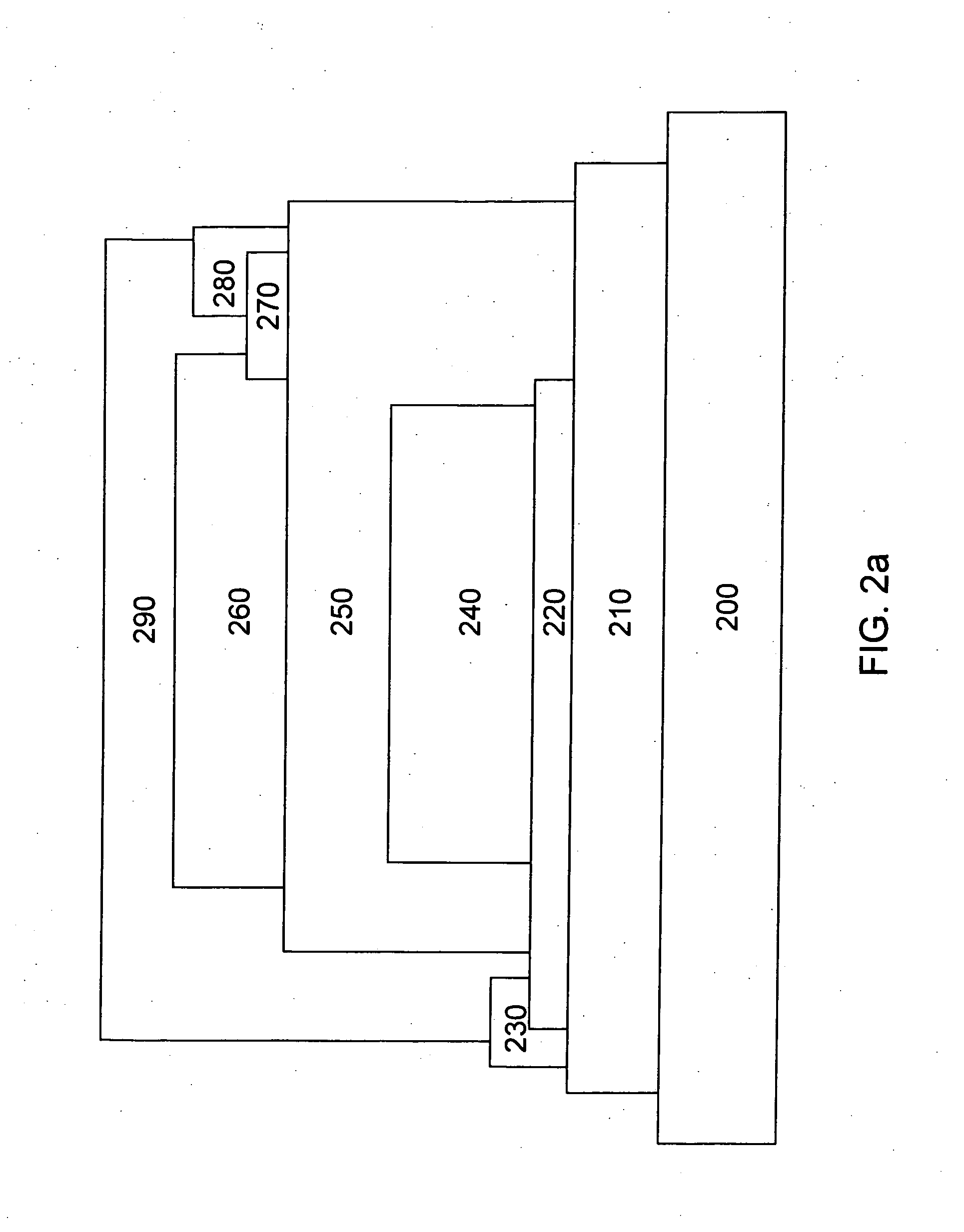

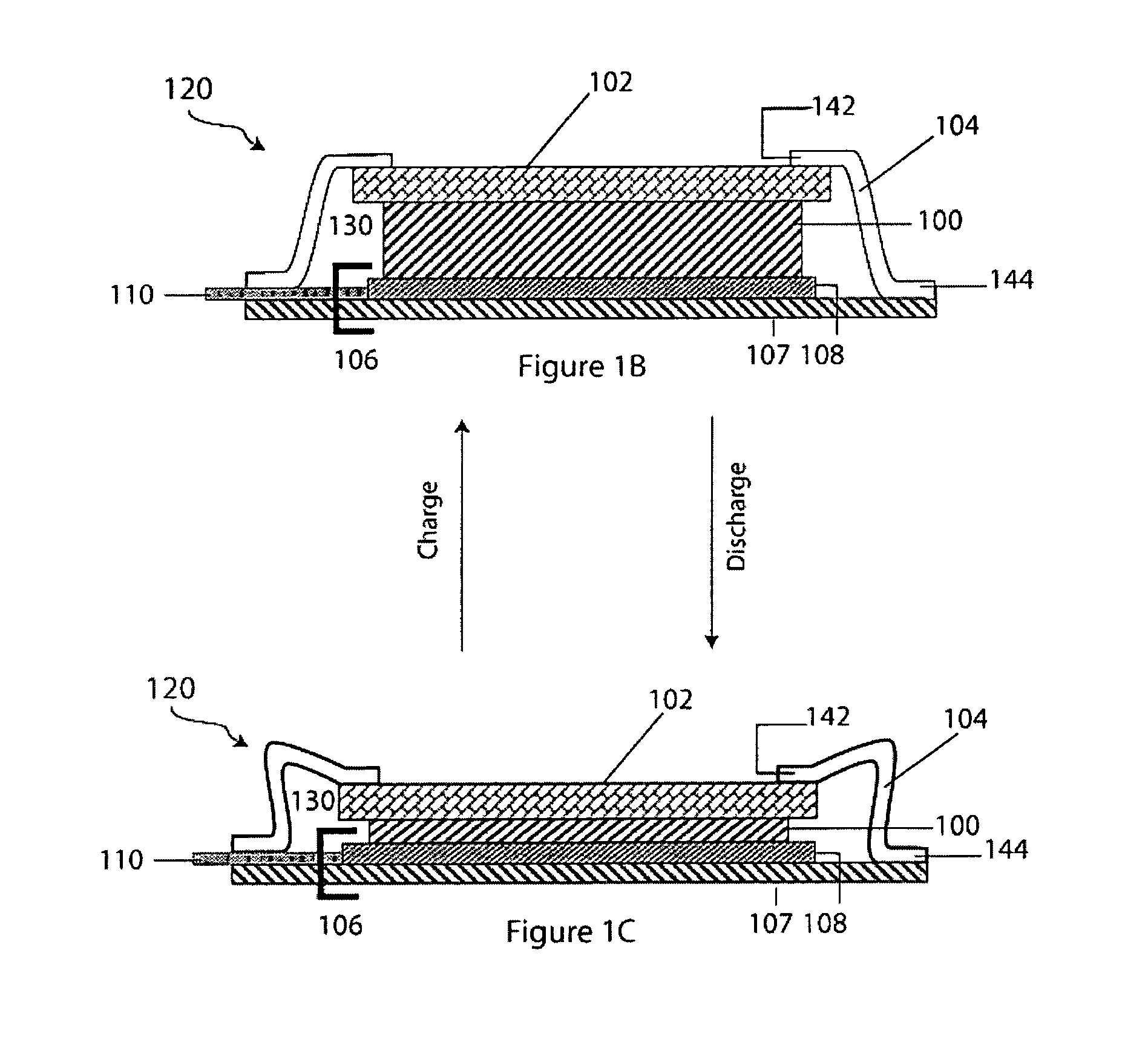

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

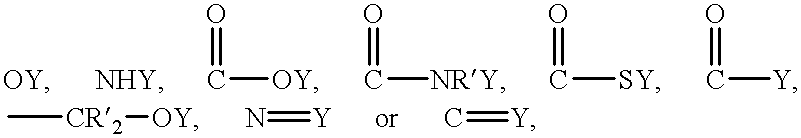

Reversible electrodeposition devices and associated electrochemical media

InactiveUS7046418B2Improve electrochemical performanceIncreased durabilityTenebresent compositionsNon-linear opticsConductive materialsEngineering

Owner:GENTEX CORP

Reversible electrodeposition devices and associated electrochemical media

InactiveUS7193764B2Improve electrochemical performanceSolid separationTenebresent compositionsEngineeringConductive materials

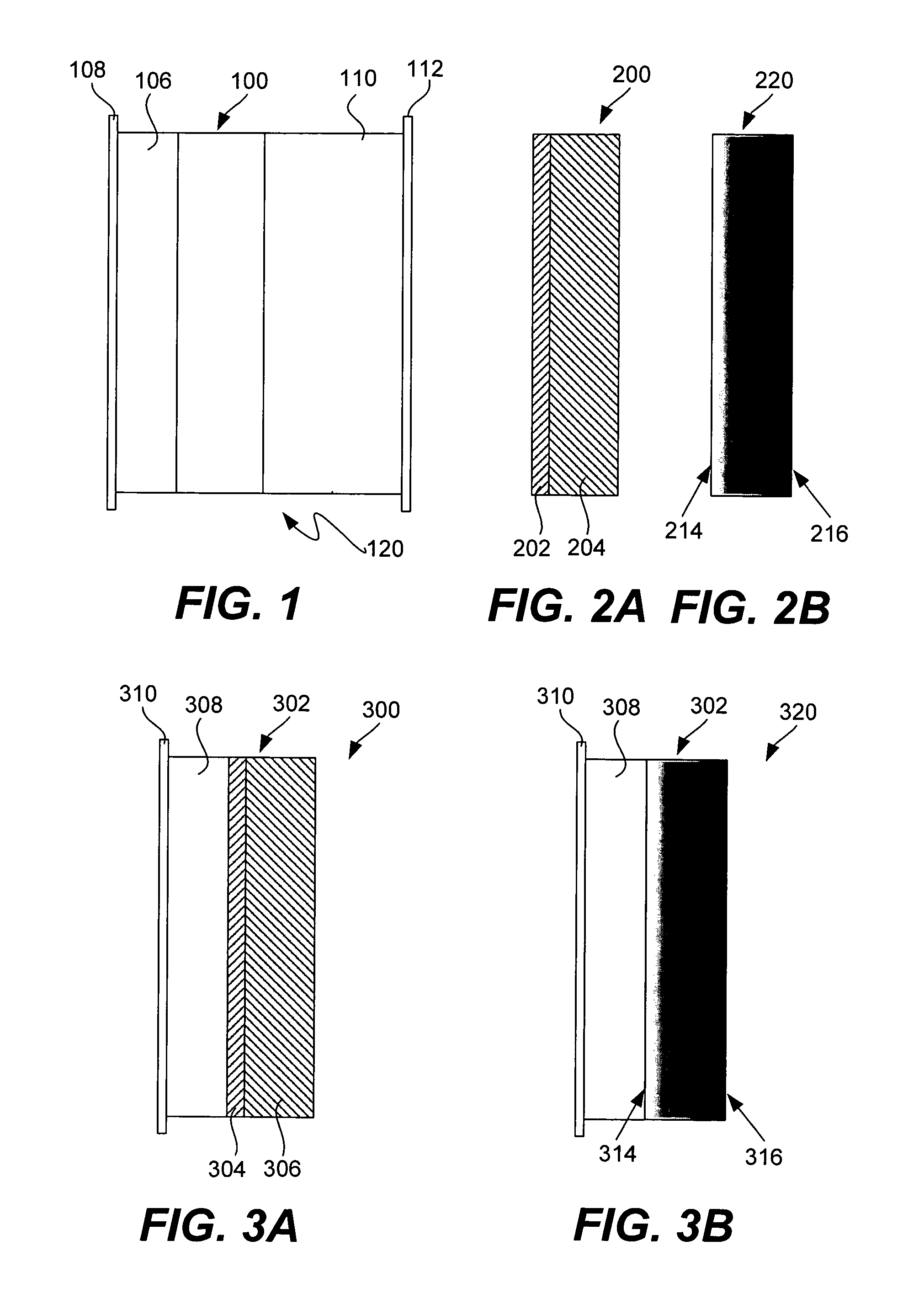

The present invention is directed to a reversible electrodeposition device comprising: a first substrate having an electrically conductive material associated therewith; a second substrate having an electrically conductive material associated therewith; a nucleation layer at least partially covering at least one of the electrically conductive materials of the first and second substrates; an electrochemical medium contained within a chamber positioned between the first and second substrates.

Owner:GENTEX CORP

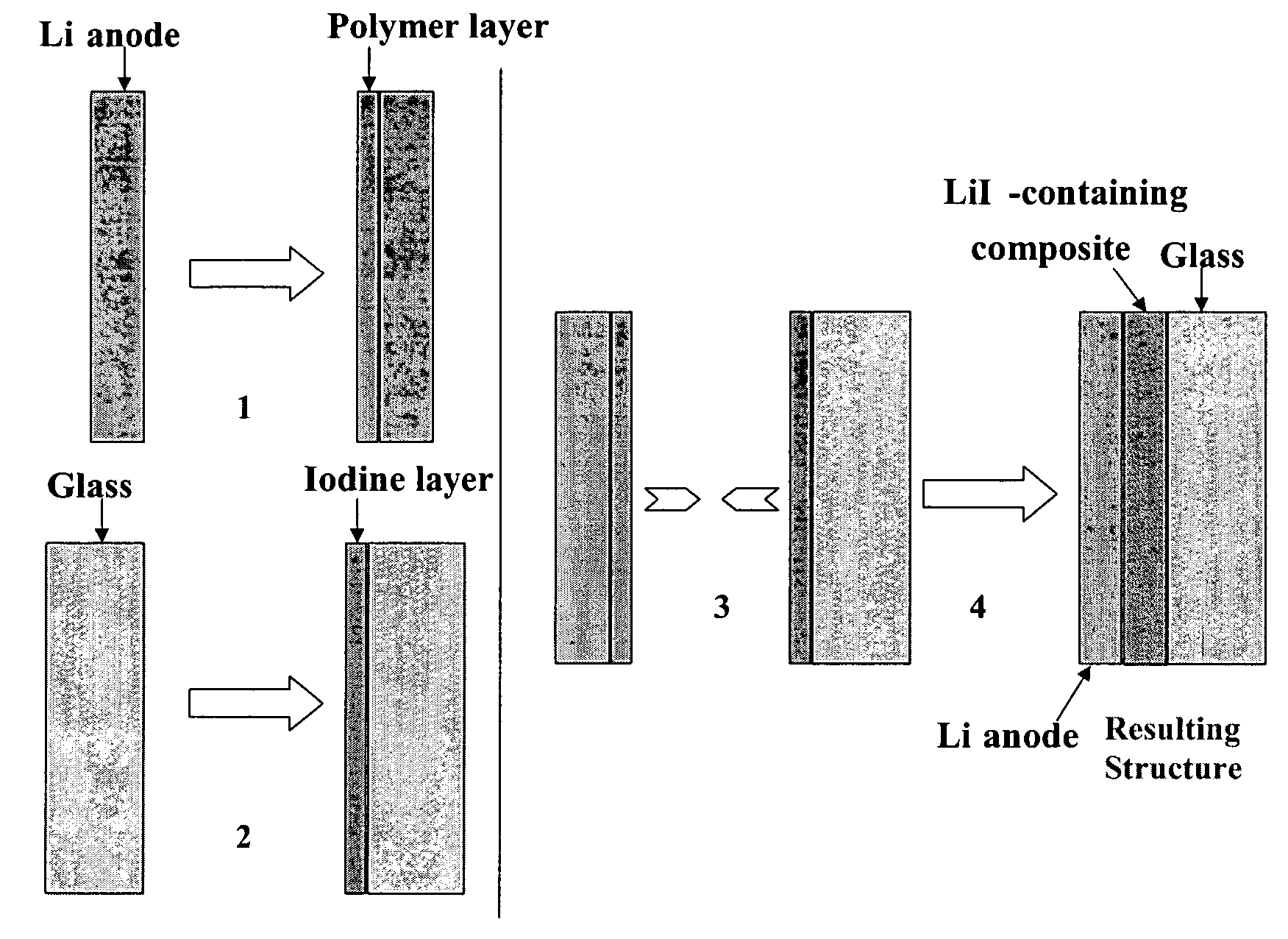

Ionically conductive membranes for protection of active metal anodes and battery cells

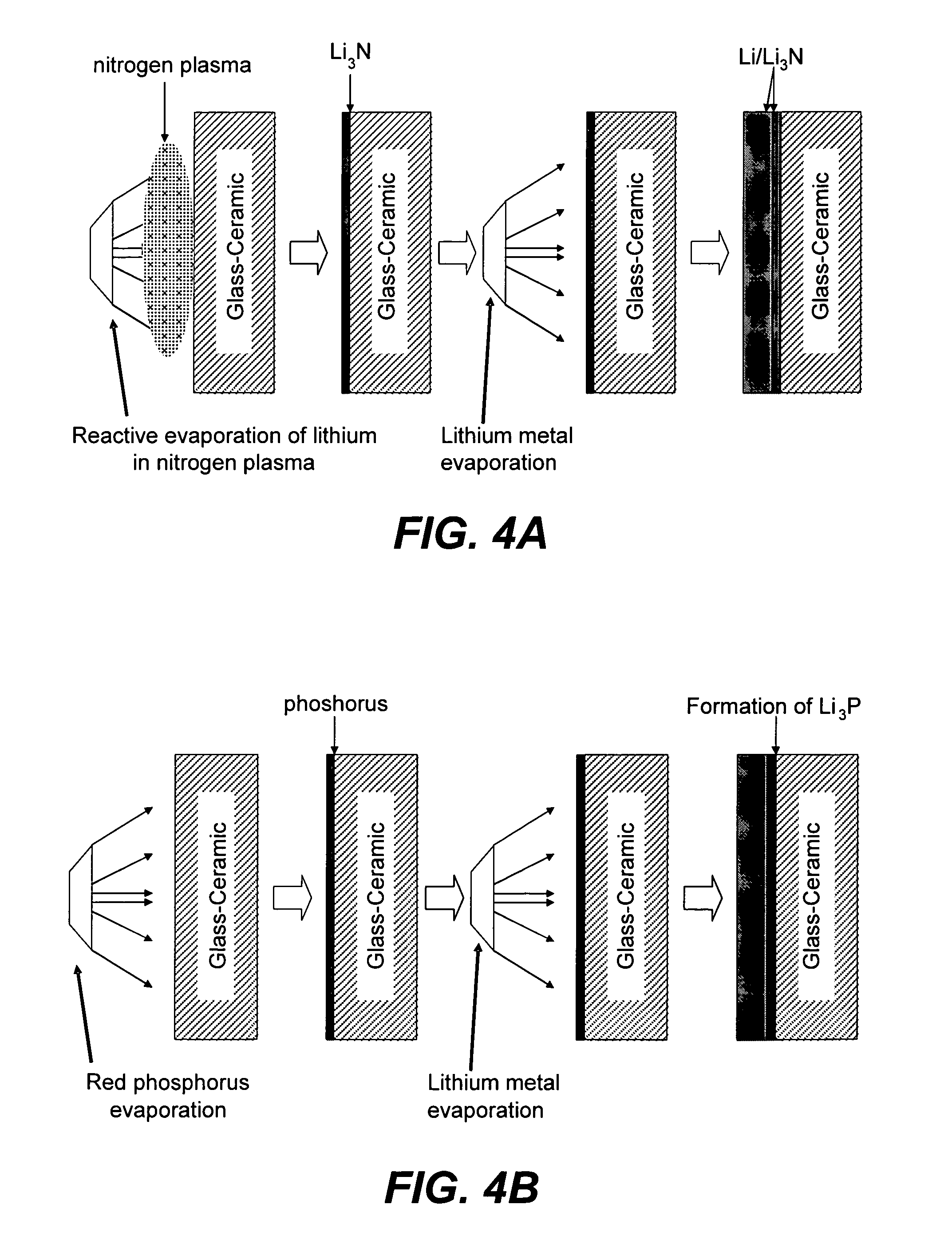

InactiveUS7390591B2Improve conductivityEasy to manufactureSolid electrolytesSolid electrolyte cellsChemical stabilityBattery cell

Disclosed are ionically conductive membranes for protection of active metal anodes and methods for their fabrication. The membranes may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the membrane has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The membrane is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the membrane is incorporated.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

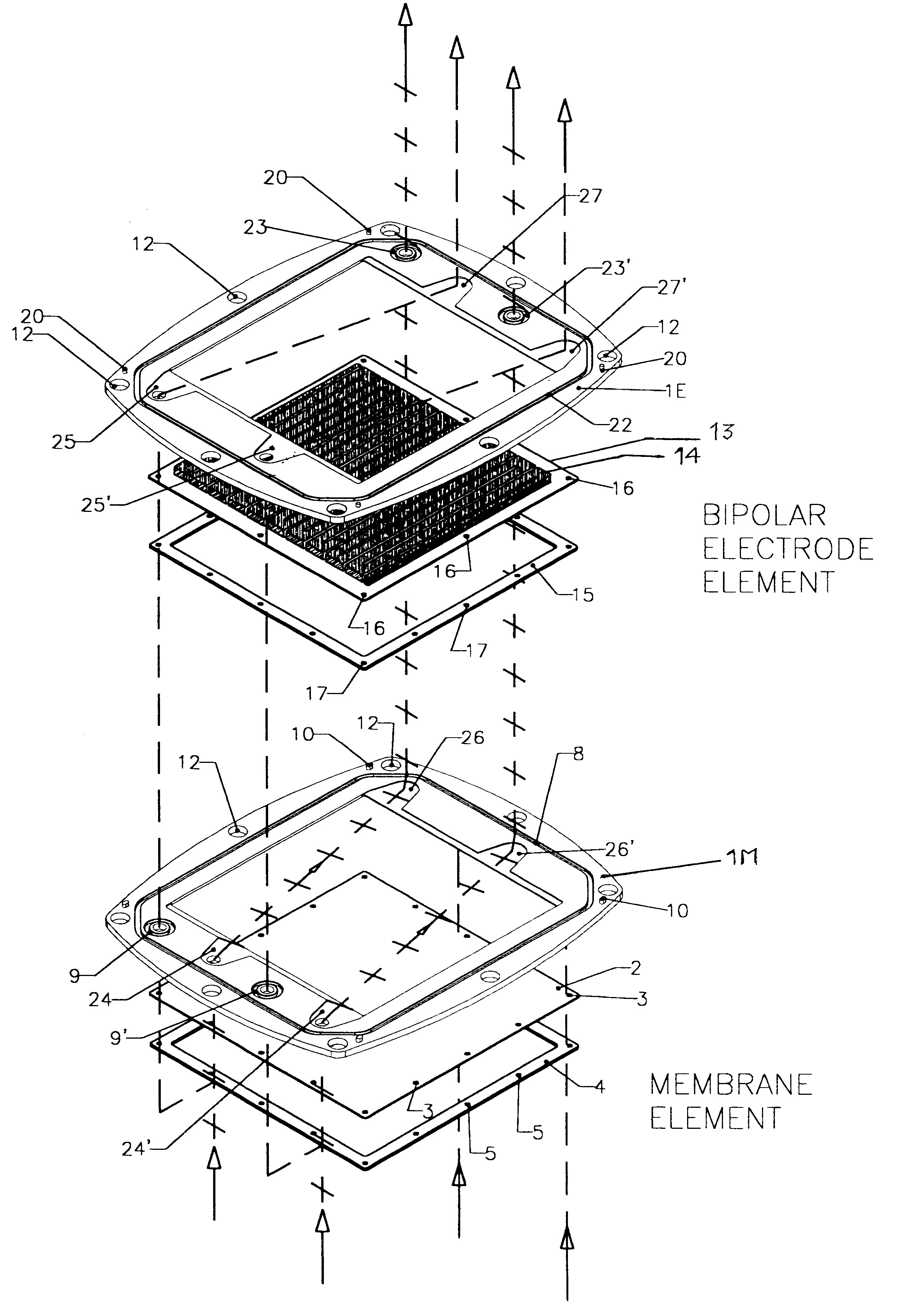

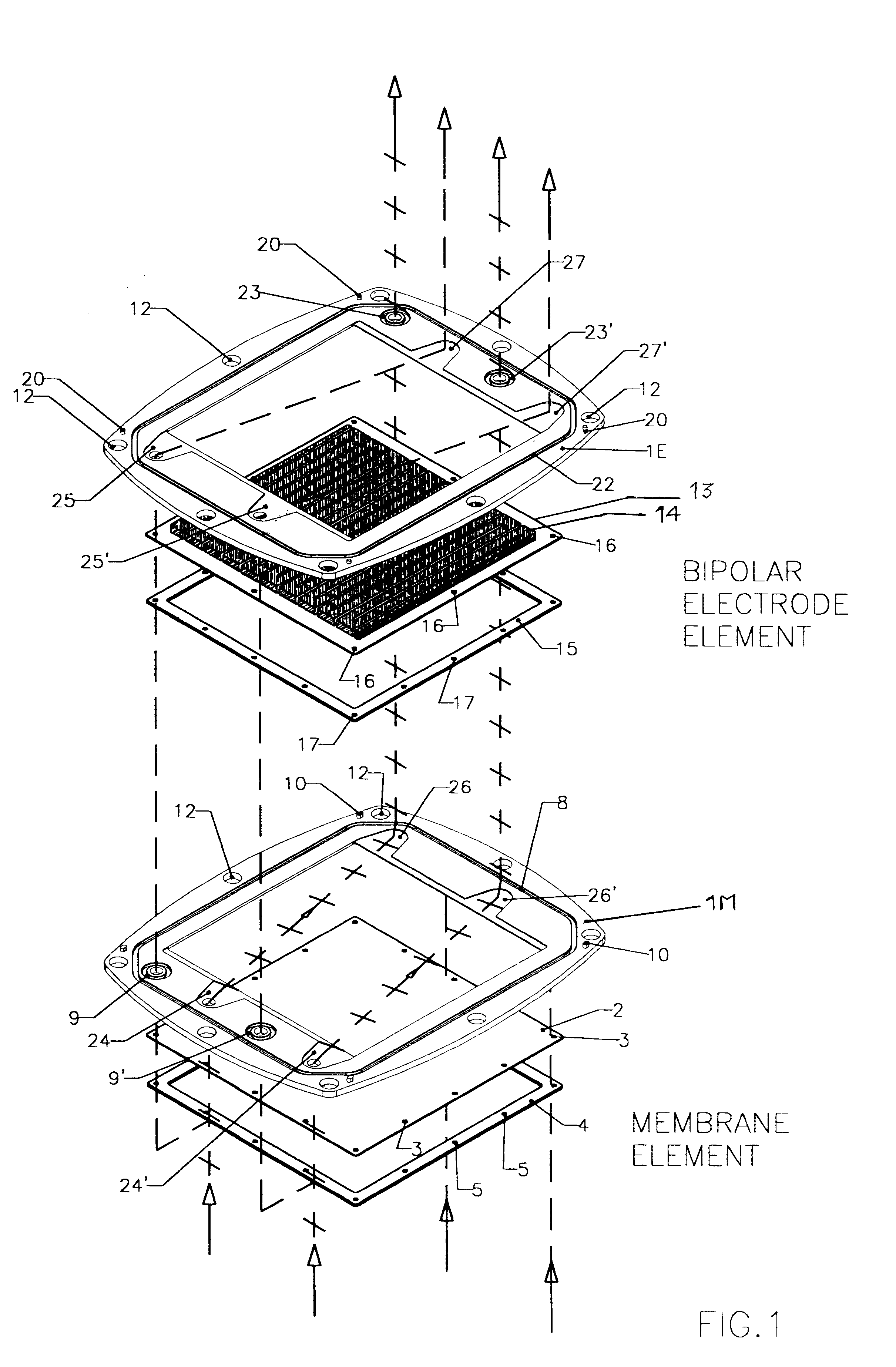

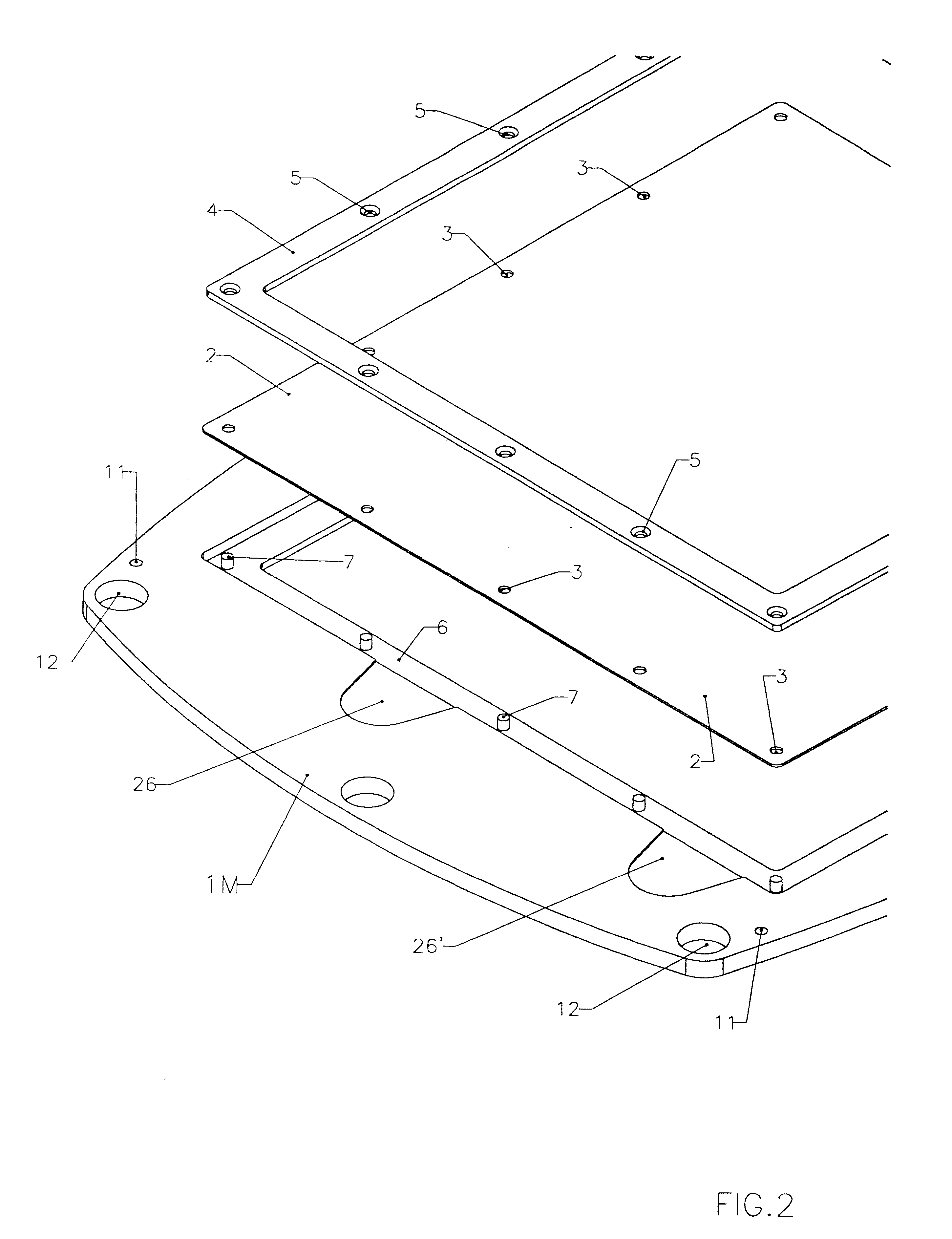

Membrane-separated, bipolar multicell electrochemical reactor

InactiveUS6555267B1Improve electrochemical performanceLower overall pressure dropFuel cells groupingFuel cell auxillariesPlastic materialsIon-exchange membranes

A multicell assembly is constituted by alternately stacking two types of pre-assembled elements: a bipolar electrode holding subassembly and a membrane holding subassembly. The alternate stack of elements is piled over a bottom end element and the stack is terminated by placing over the last membrane holding element a top end electrode element. Each bipolar plate electrode holding element and each ion exchange membrane separator holding element includes a substantially similar rectangular frame piece, made of an electrically nonconductive and chemically resistant material, typically of molded plastic material, having on its upper (assembly) face grooves for receiving O-ring type gasket means, and having through holes and recesses in coordinated locations disposed along two opposite sides of the rectangular frame forming, upon completion of the assembling, ducts for the separate circulation of the negative electrolyte and of the positive electrolyte through all the negative electrolyte flow chambers and all positive electrolyte flow chambers, respectively, in cascade.

Owner:SQUIRREL HLDG

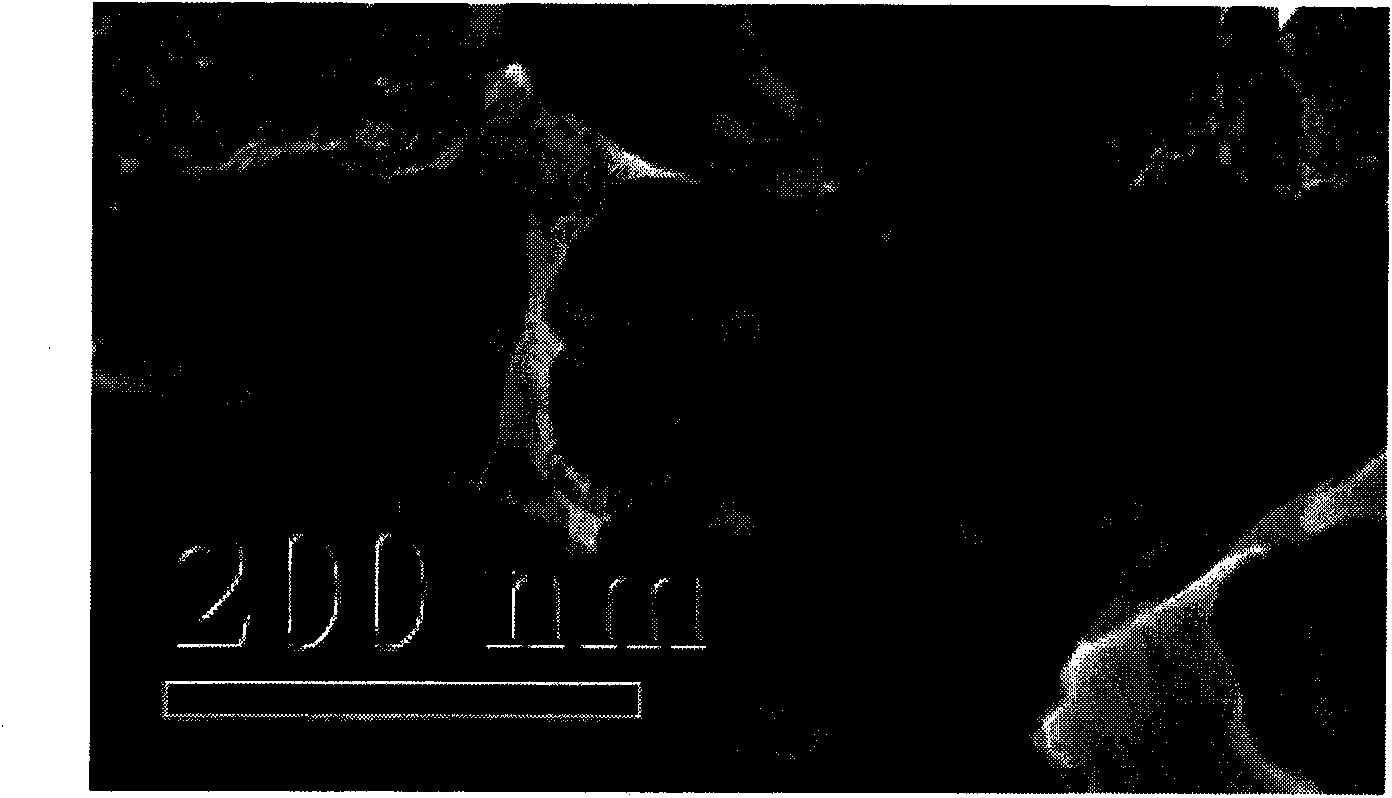

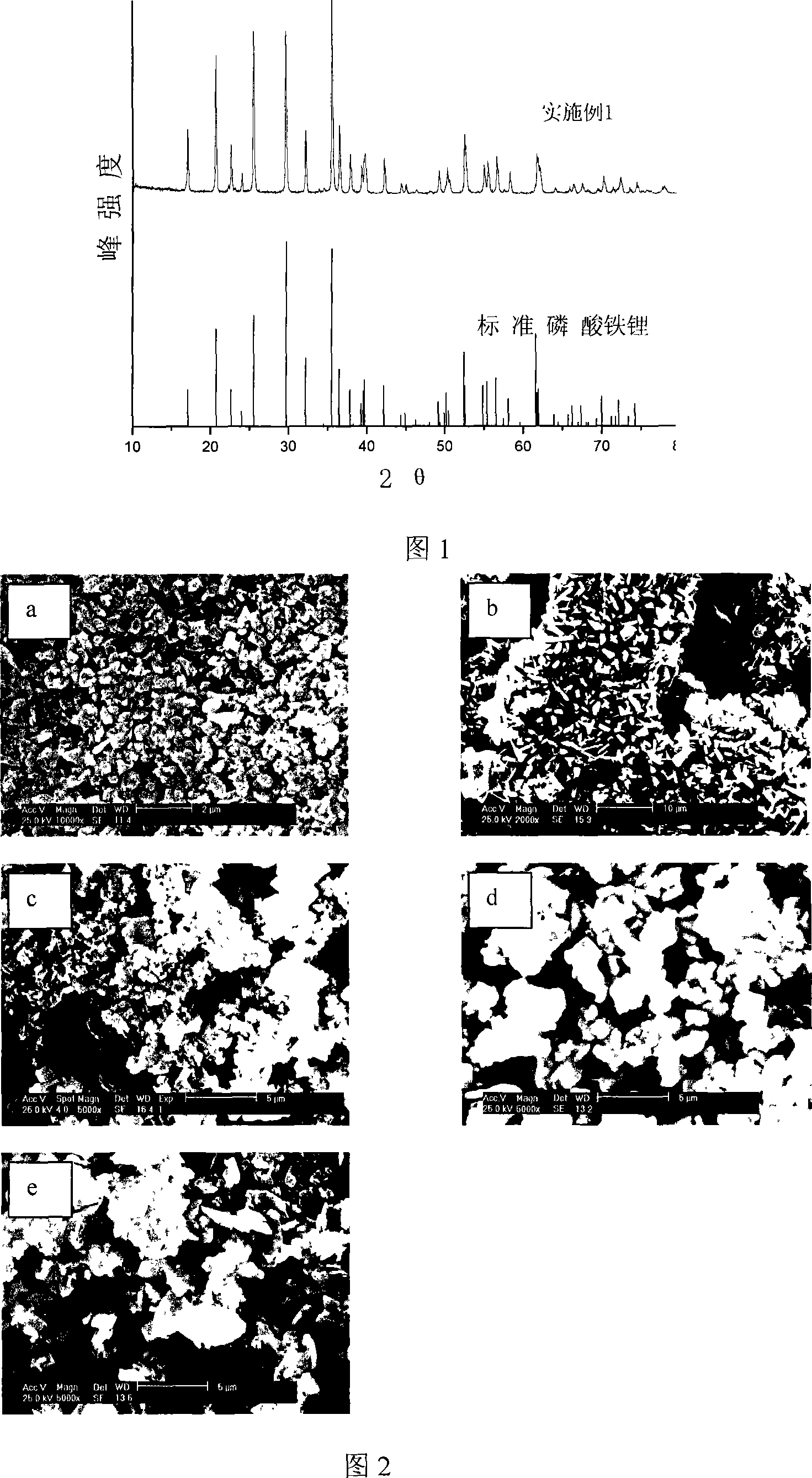

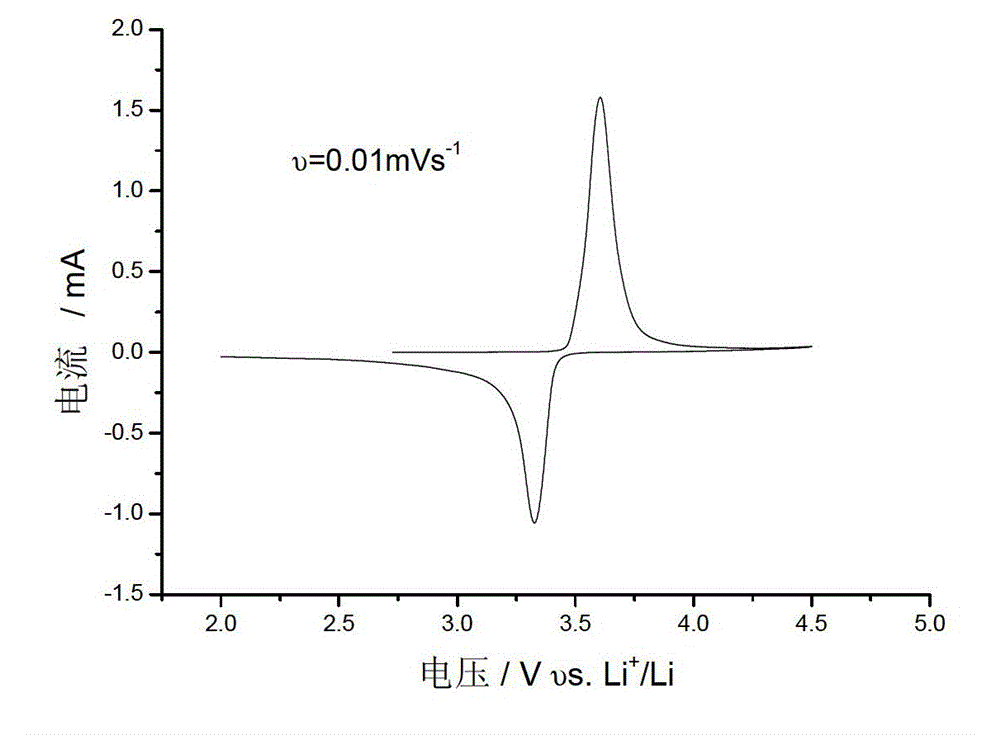

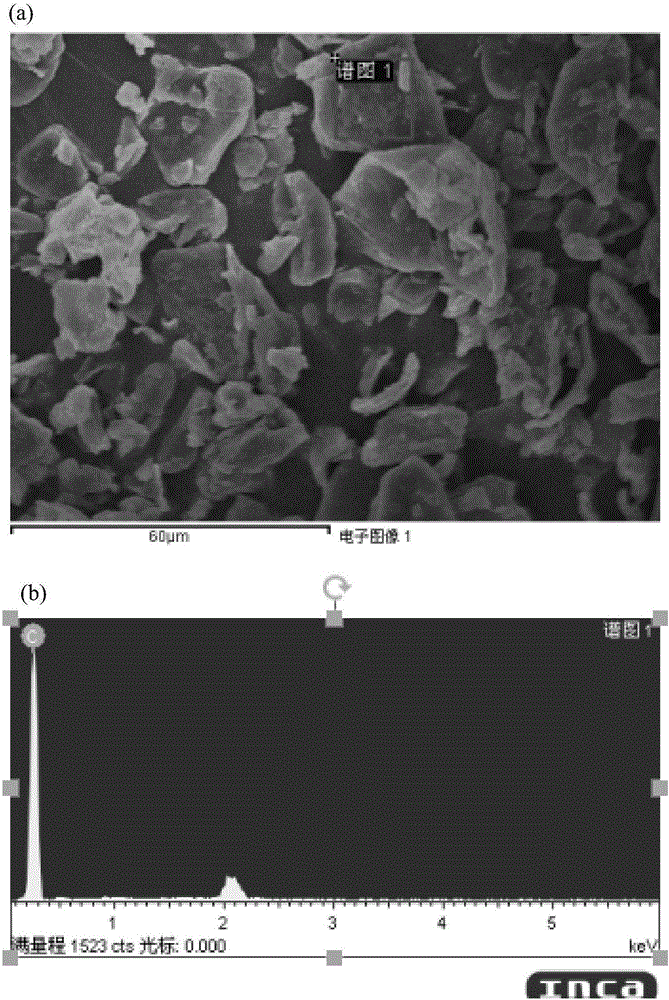

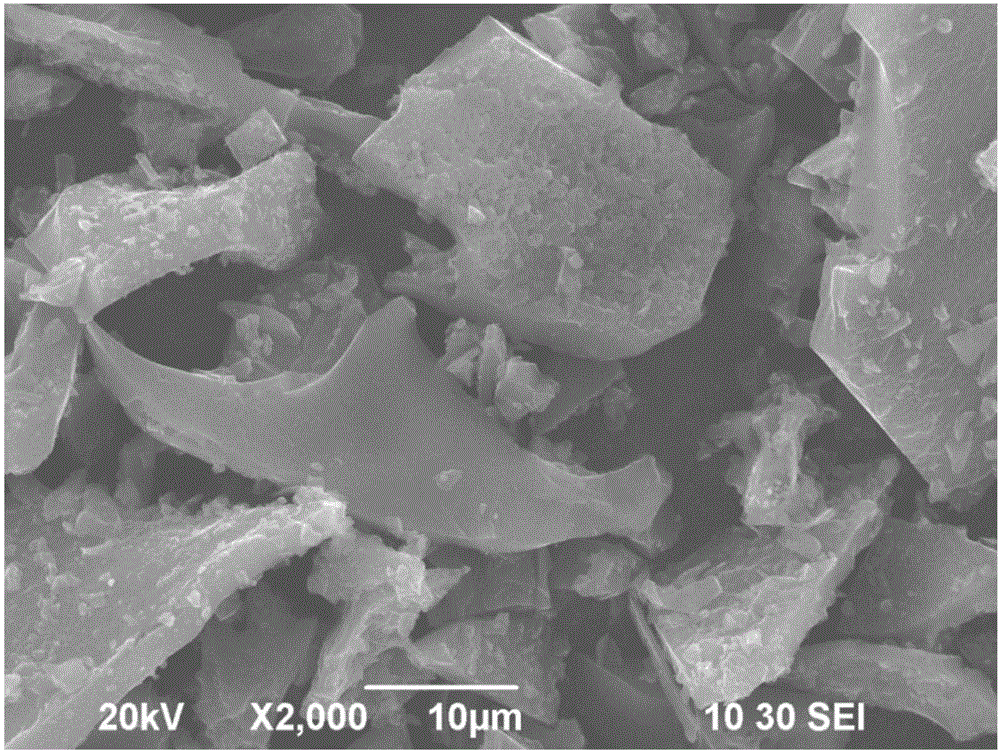

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

Method for preparing lithiumion cell positive material Iron-lithium phosphate

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

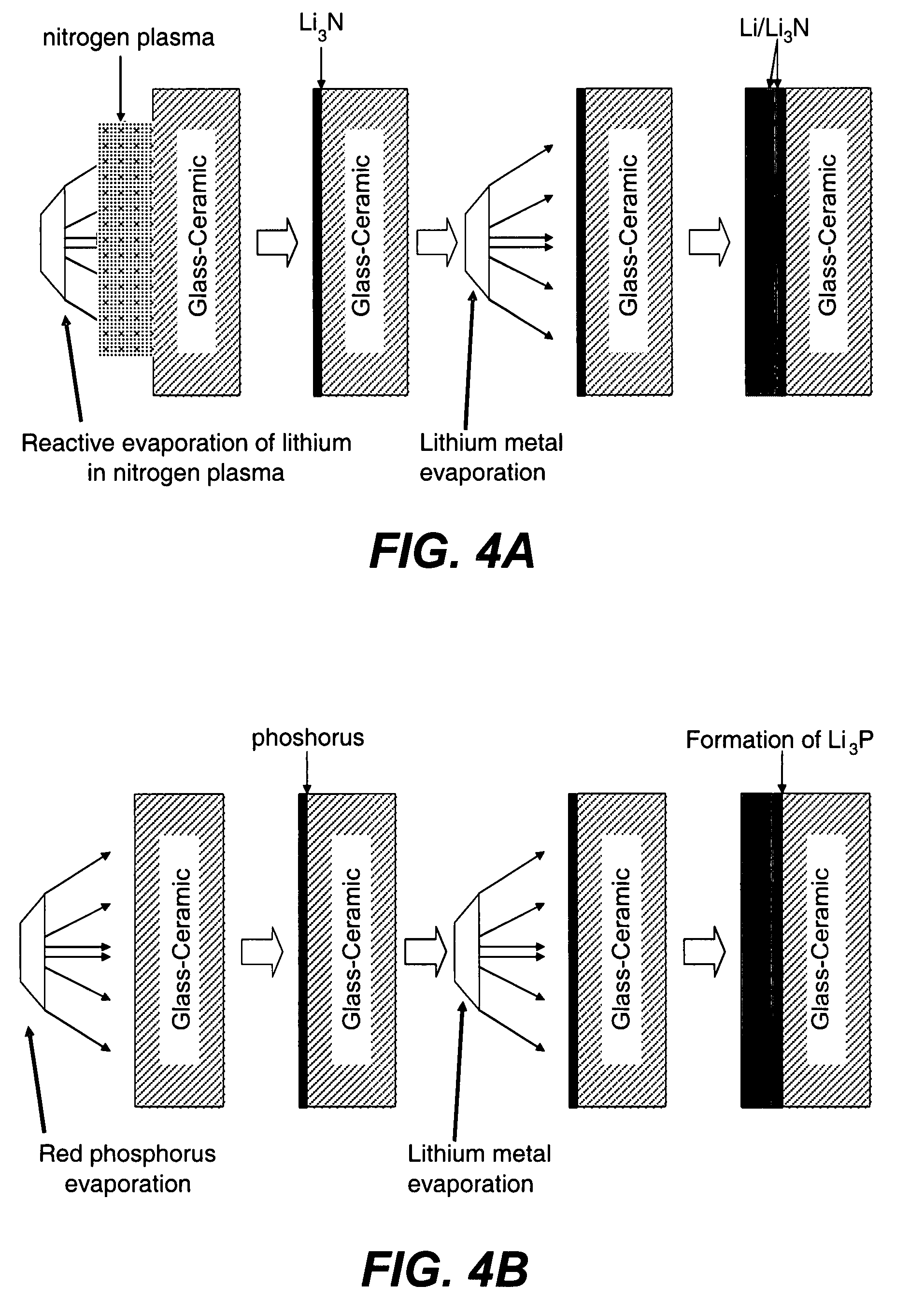

Electrochemical apparatus with barrier layer protected substrate

InactiveUS20080003496A1High crystallinityMore flexibleCell electrodesBattery isolationDiffusion barrierElectrochemistry

The present invention relates generally to fabricating well performing thin-film batteries onto metallic substrates, polymeric substrates, and doped and undoped silicon substrates. More specifically, the invention may include fabricating an appropriate diffusion barrier layer between the substrate and the battery part of the present invention that separates said two parts chemically during the entire battery fabrication process and the operation and storage conditions of the electrochemical apparatus during its entire lifetime. In one embodiment of the present invention, thin-film batteries fabricated onto a thin, flexible, stainless steel foil substrate using an appropriate diffusion layer show uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for the LiCoO2 positive cathode.

Owner:SAPURAST RES

Active metal/aqueous electrochemical cells and systems

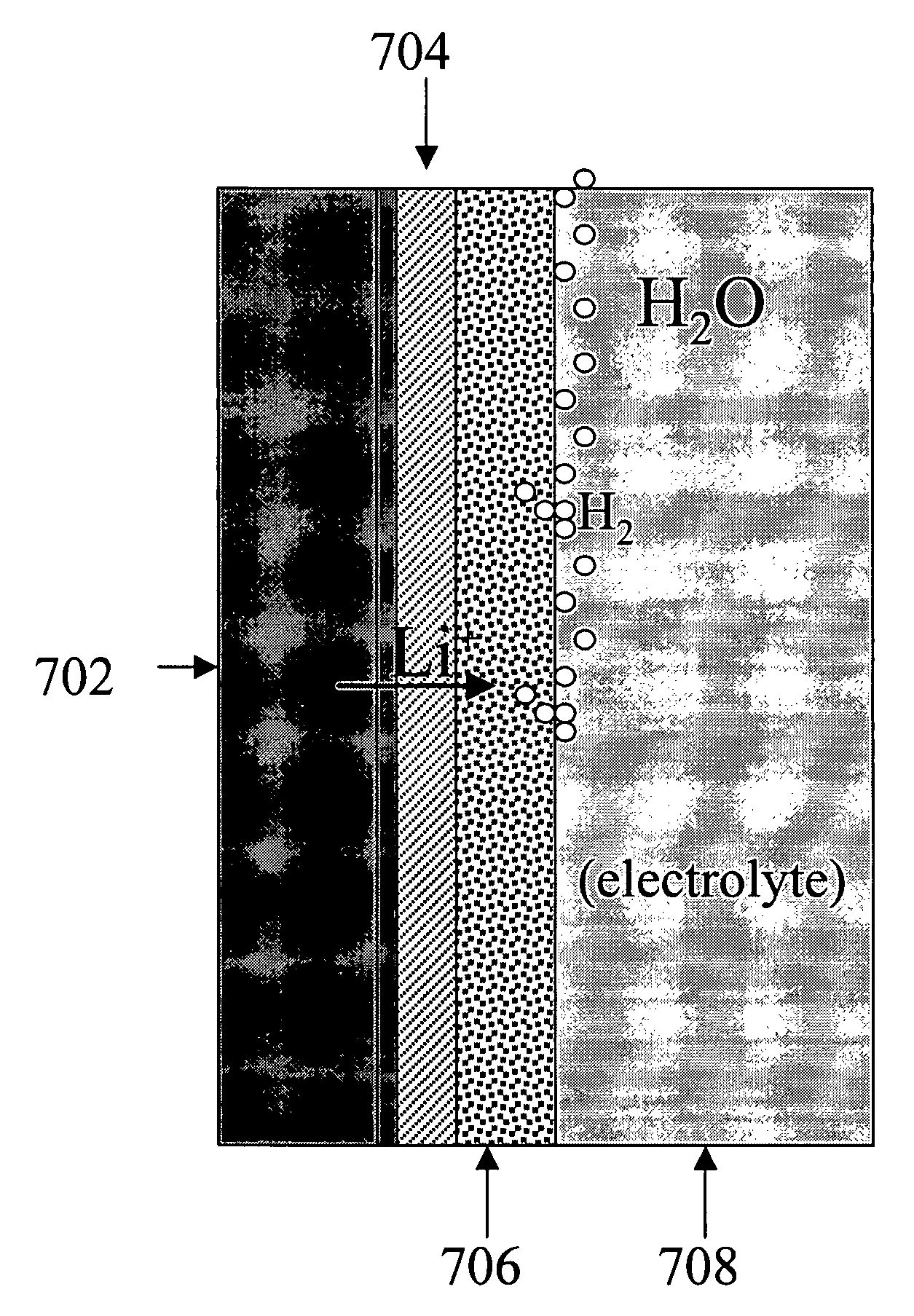

InactiveUS7645543B2Degree of flexibilityWithout performanceFuel and primary cellsAlkaline accumulatorsElectrochemical cellBattery cell

Alkali (or other active) metal battery and other electrochemical cells incorporating active metal anodes together with aqueous cathode / electrolyte systems. The battery cells have a highly ionically conductive protective membrane adjacent to the alkali metal anode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the anode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or cathode material in conjunction with the anode. Also, optimization of electrolytes or cathode-side solvent systems may be done without impacting anode stability or performance. In particular, Li / water, Li / air and Li / metal hydride cells, components, configurations and fabrication techniques are provided.

Owner:POLYPLUS BATTERY CO INC

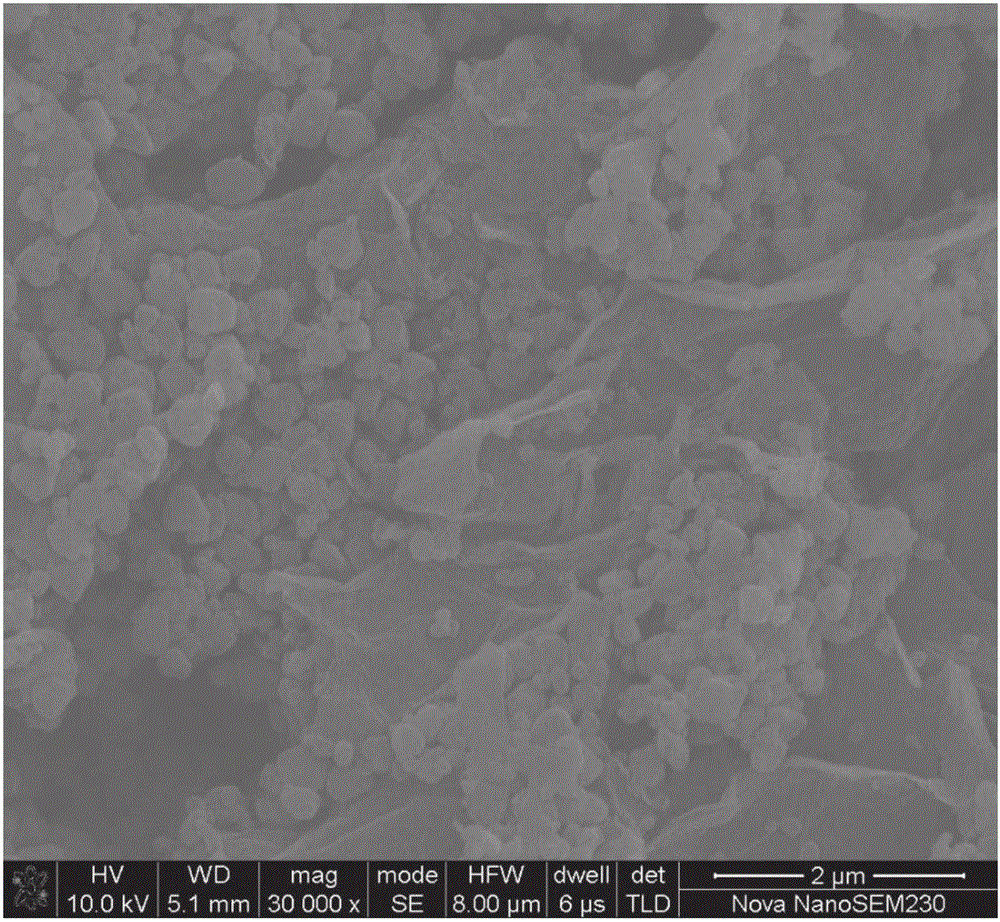

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

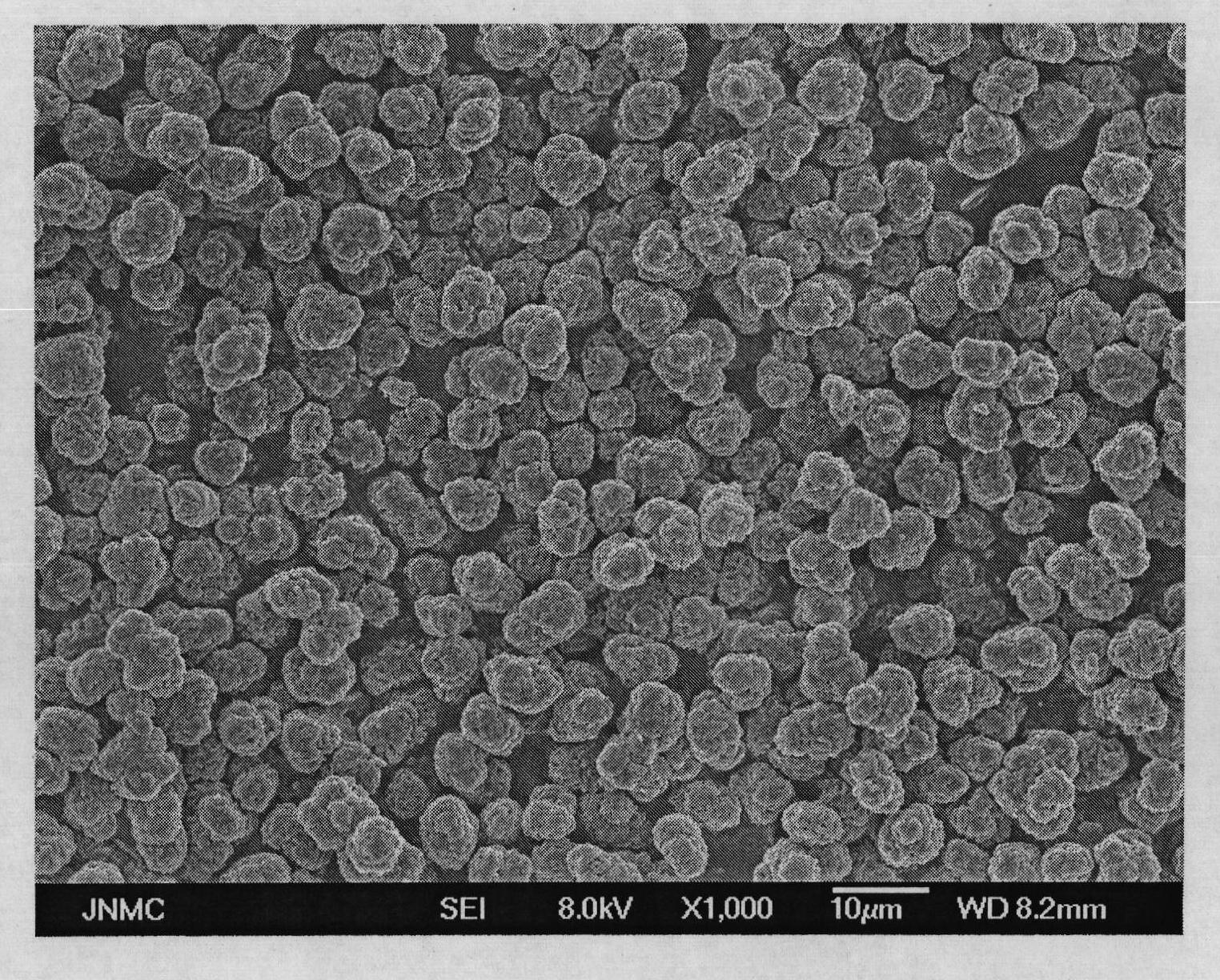

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

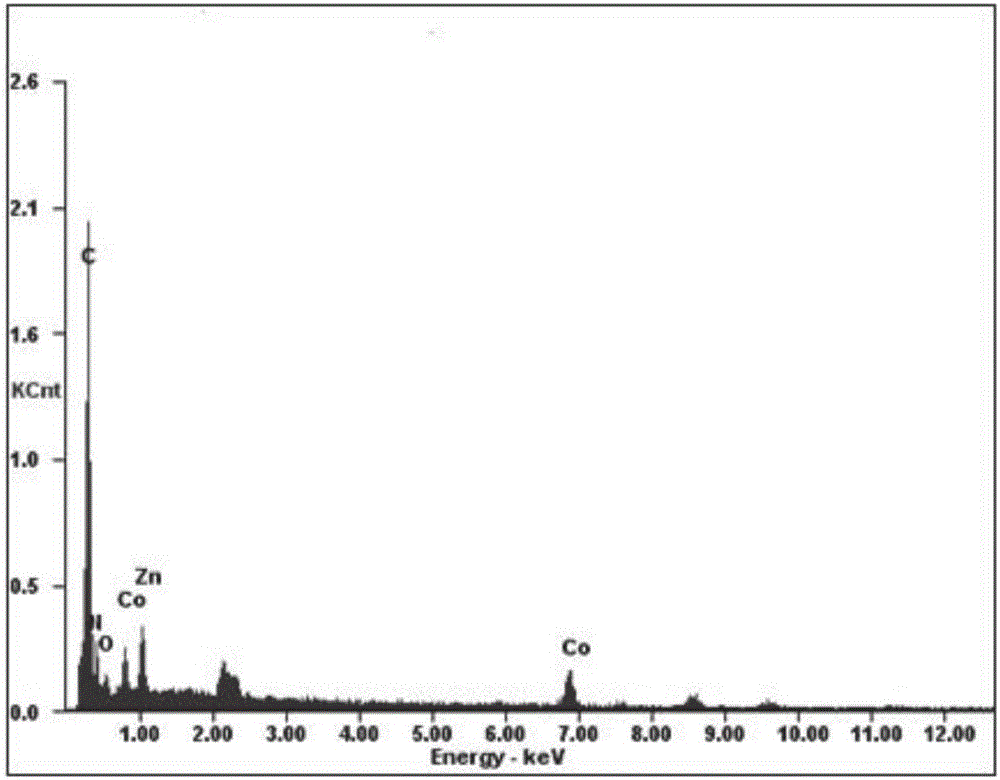

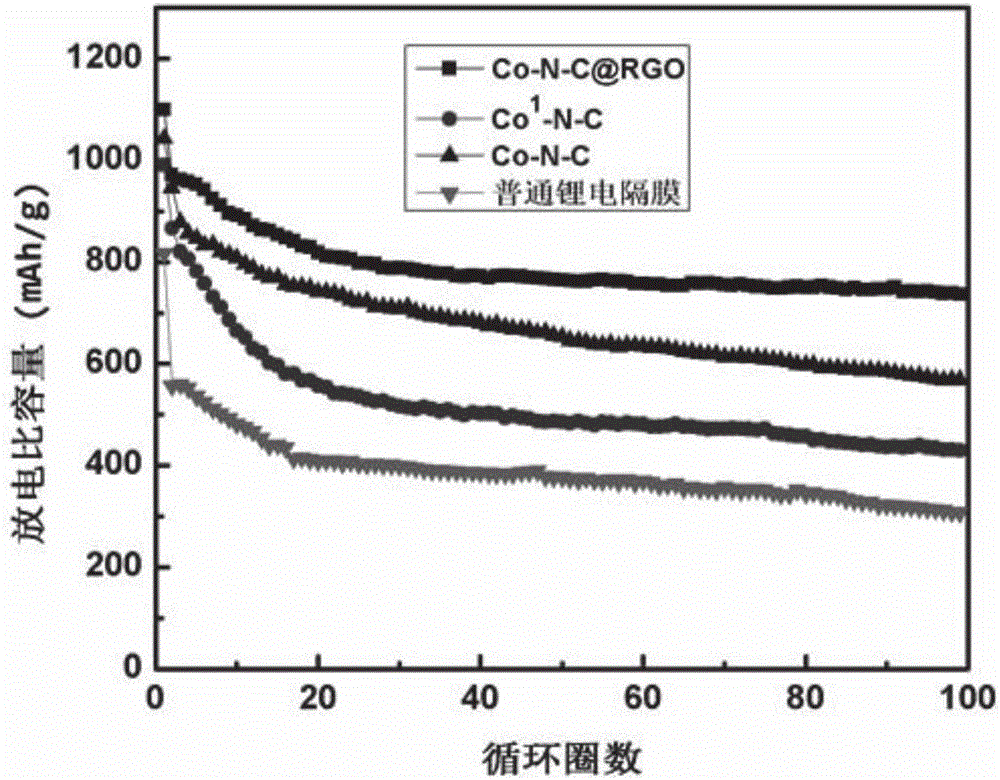

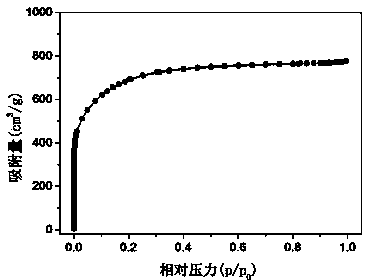

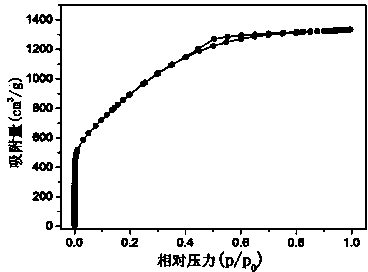

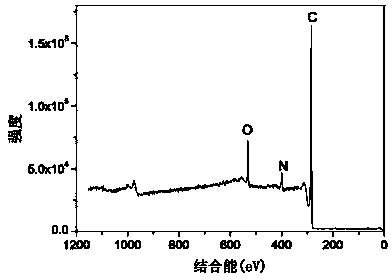

Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

ActiveCN106784525AIncrease the areaHigh porosityLi-accumulatorsCell component detailsPorous carbonElectrical battery

The invention discloses a method for preparing porous carbon@graphene composite material by taking a bimetal organic framework material as a precursor and application to modification of lithium-sulfur battery diaphragms thereof. The preparation method comprises the following steps: taking zinc salt and cobalt salt in a certain ratio as the raw materials, synthesizing a zinc / cobalt-bimetal organic framework@graphene composite material through a room-temperature liquid phase method, taking the zinc / cobalt-bimetal organic framework@graphene composite material as the precursor, carrying out high-temperature reaction under inert atmosphere, pickling and drying to obtain a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite material. Co-N-C@RGO has high conductivity; the specific surface area of Co-N-C@RGO reaches up to 750-1000m<2> / g; the content of Co is 2-4At%; the content of N is 10-20At%. When the material is applied to the modification of the lithium-sulfur battery diaphragms, the material has the function of obviously inhibiting polysulfide shuttle effect and is capable of greatly improving actual specific capacity and cyclic performance of the lithium-sulfur batteries; meanwhile, the raw materials needed for synthesizing the material are simple; the operation is convenient; the large-scale production can be achieved; the material has certain promoting effect on commercialization of lithium-sulfur battery systems.

Owner:CENT SOUTH UNIV

Active metal/aqueous electrochemical cells and systems

InactiveUS7666233B2Degree of flexibilityWithout performanceFuel and primary cellsElectrode manufacturing processesManufacturing technologyElectrochemical cell

Owner:POLYPLUS BATTERY CO INC

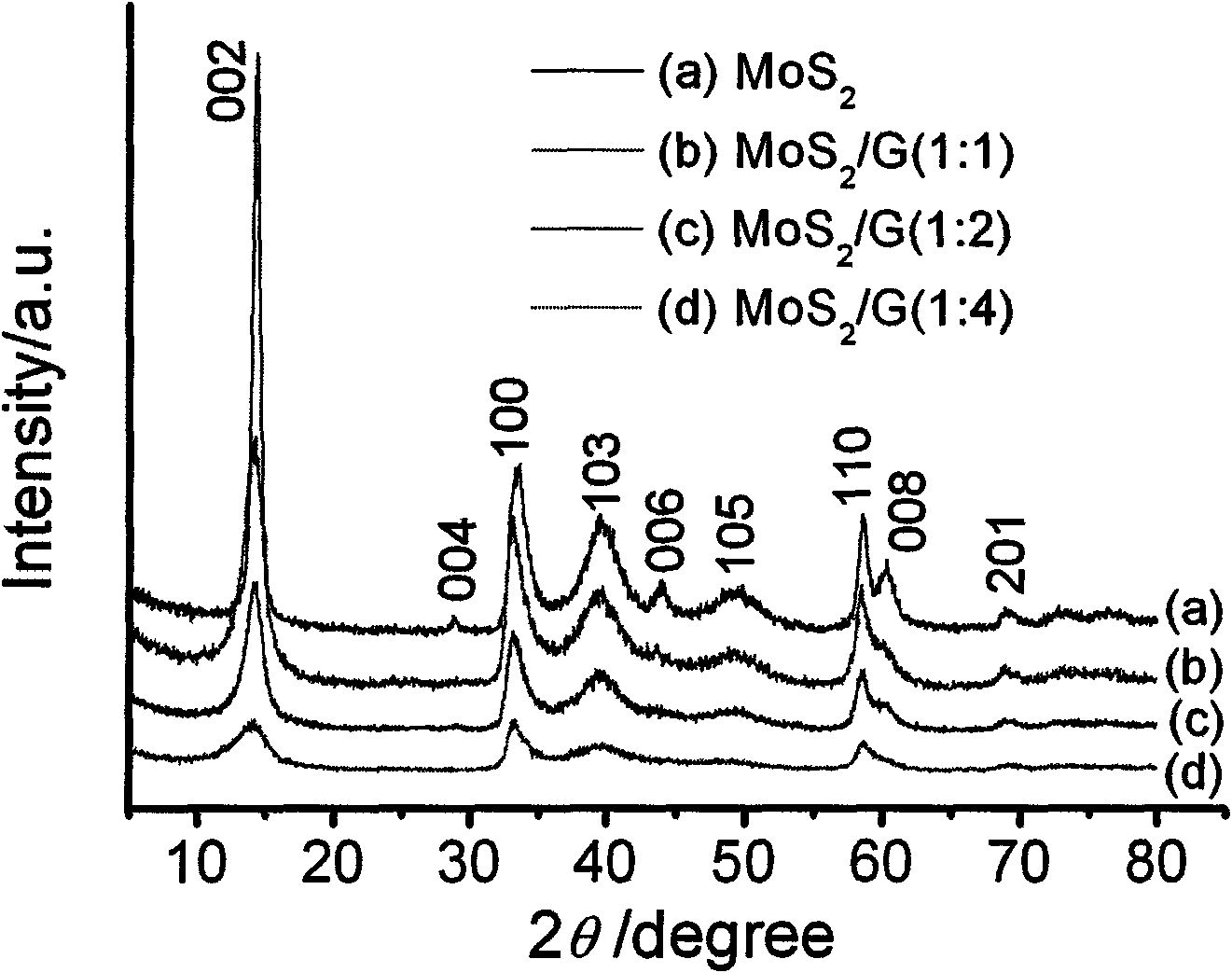

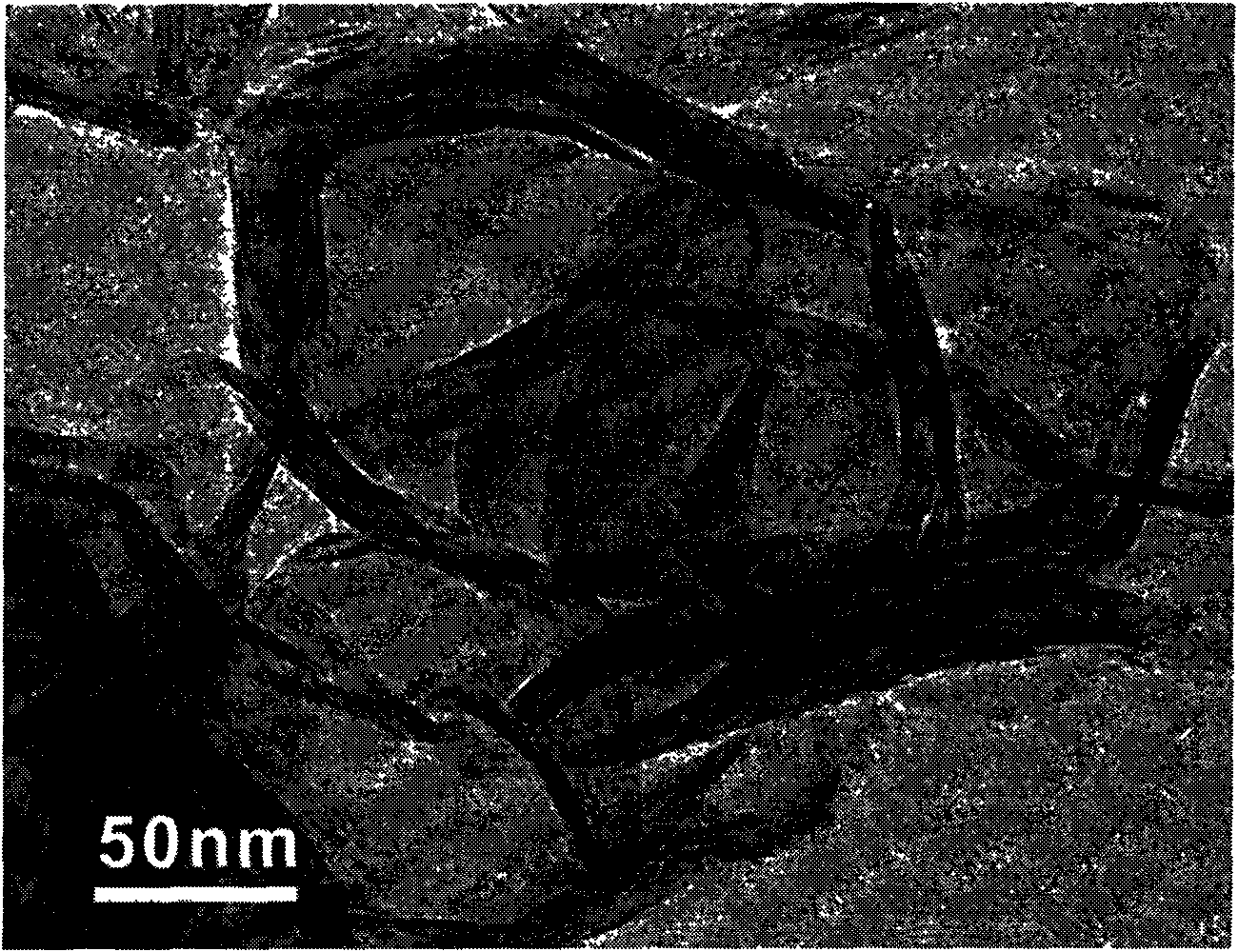

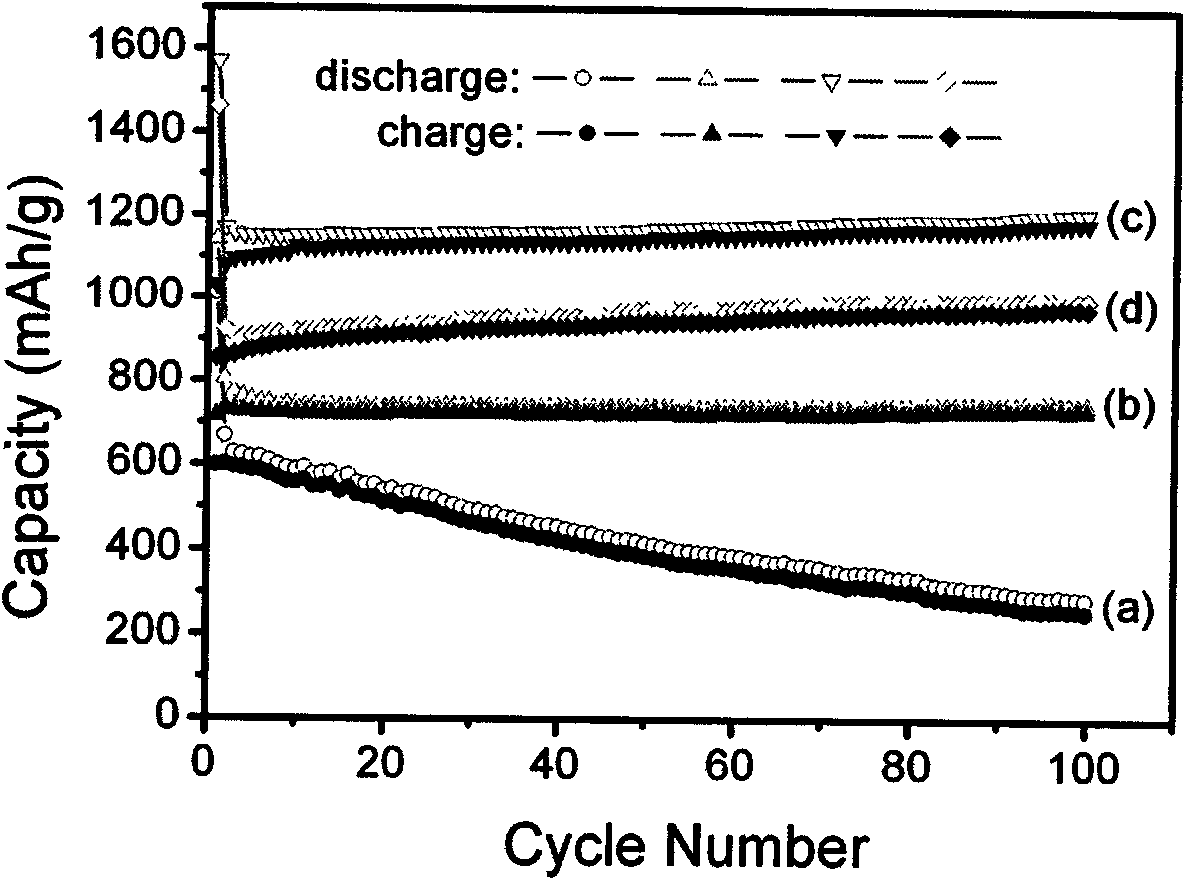

Graphene/MoS2 compound nano material lithium ion battery electrode and preparation method thereof

InactiveCN102142537ALarge specific surface areaImprove mechanical propertiesNon-aqueous electrolyte accumulator electrodesLithium-ion batteryMaterials science

The invention discloses a graphene / molybdenum disulfide (MoS2) compound nano material lithium ion battery electrode and a preparation method thereof. The electrode comprises the following components in percentage by mass: 75 to 85 percent of compound nano material serving as an active substance, of a graphene nano slice and MoS2, and 5 to 10 percent of acetylene black and 10 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method of the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

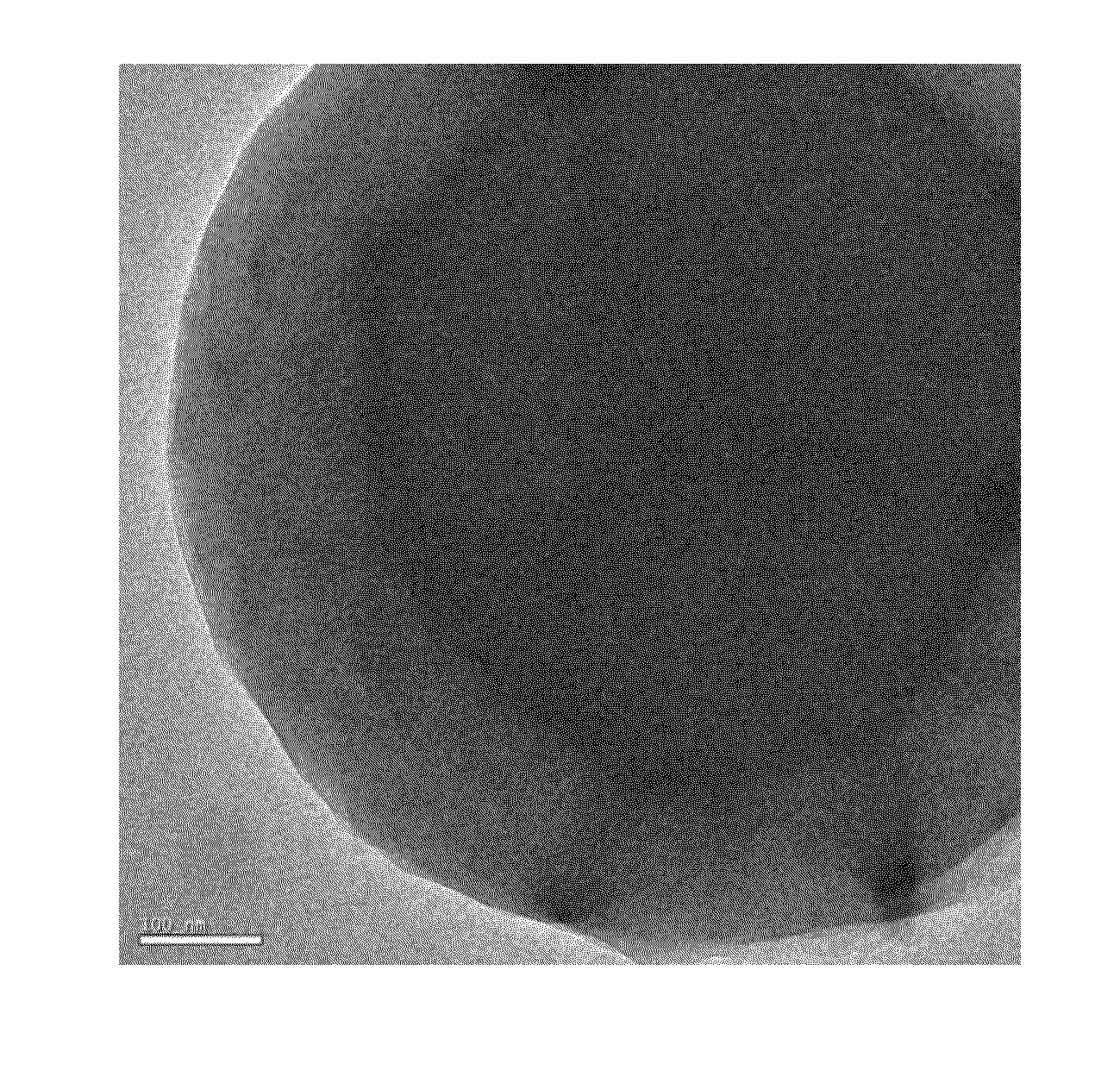

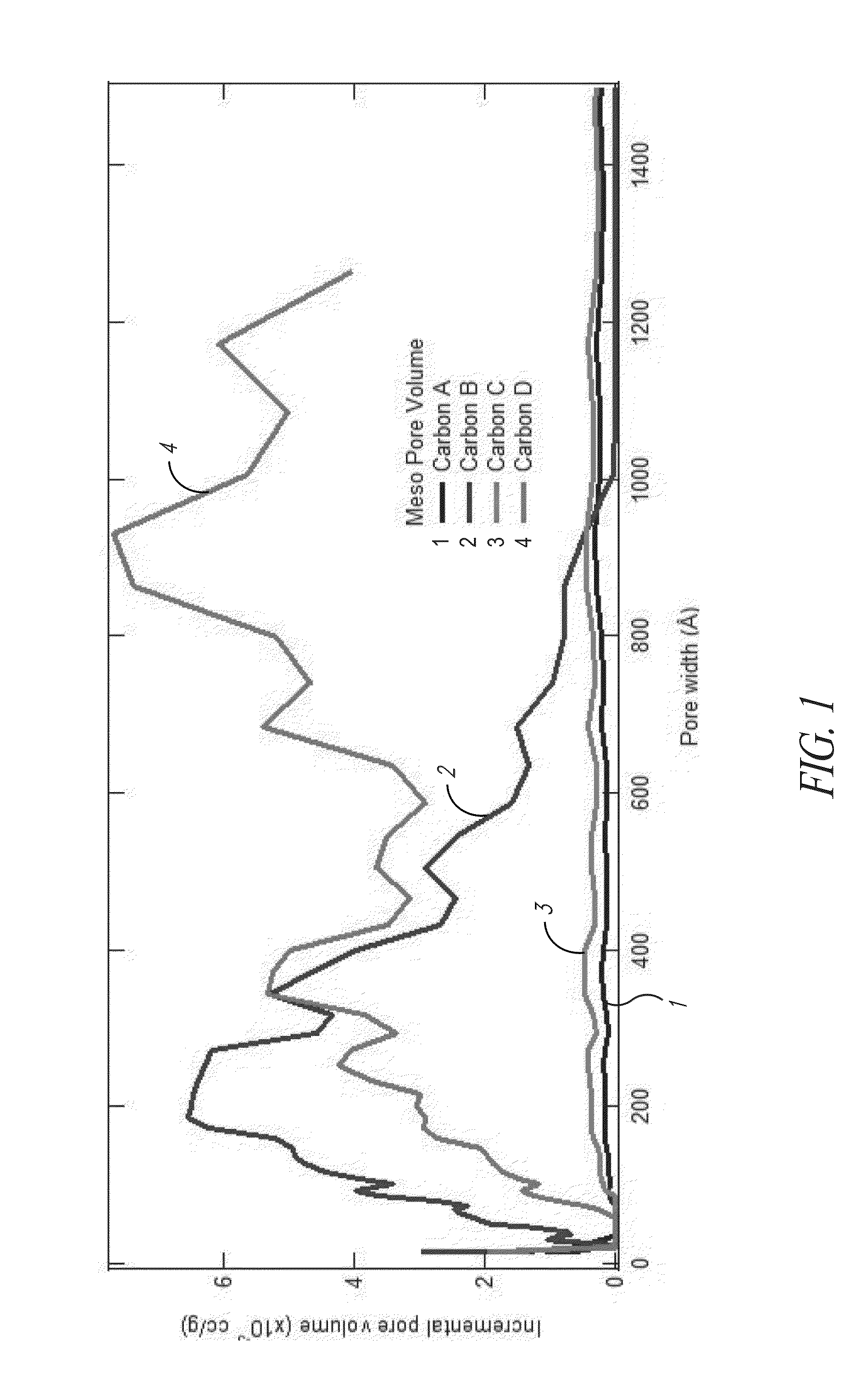

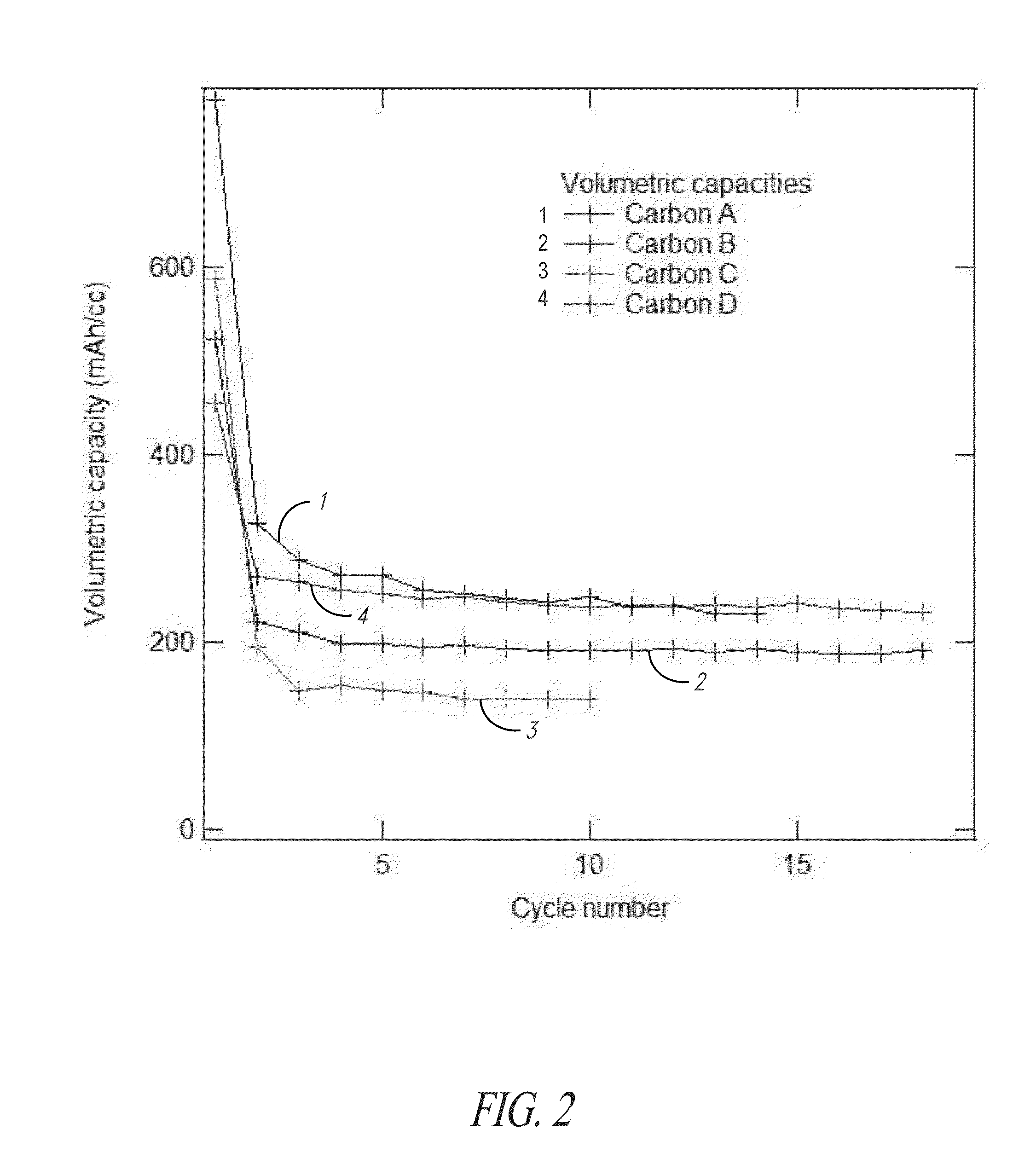

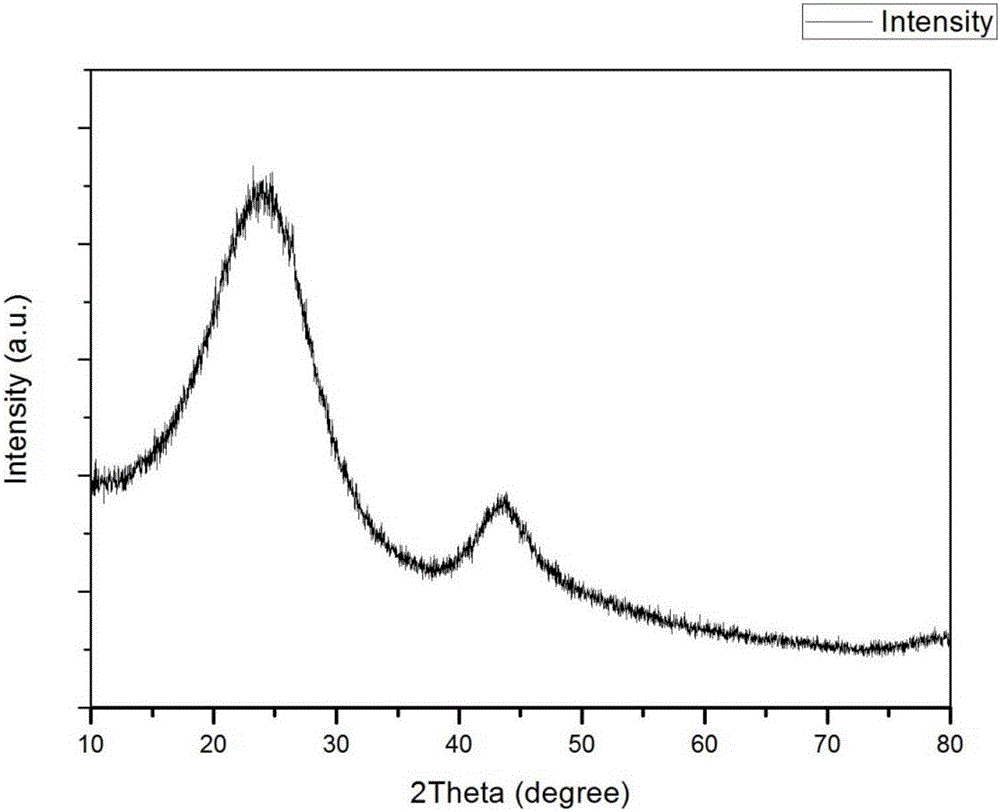

Hard carbon materials

InactiveUS20130252082A1Optimized lithium storageOptimized utilization propertyHybrid capacitor electrodesSecondary cellsElectrical devicesLithium-ion battery

The present application is directed to hard carbon materials. The hard carbon materials find utility in any number of electrical devices, for example, in lithium ion batteries. Methods for making the disclosed carbon materials are also disclosed.

Owner:BASF AG

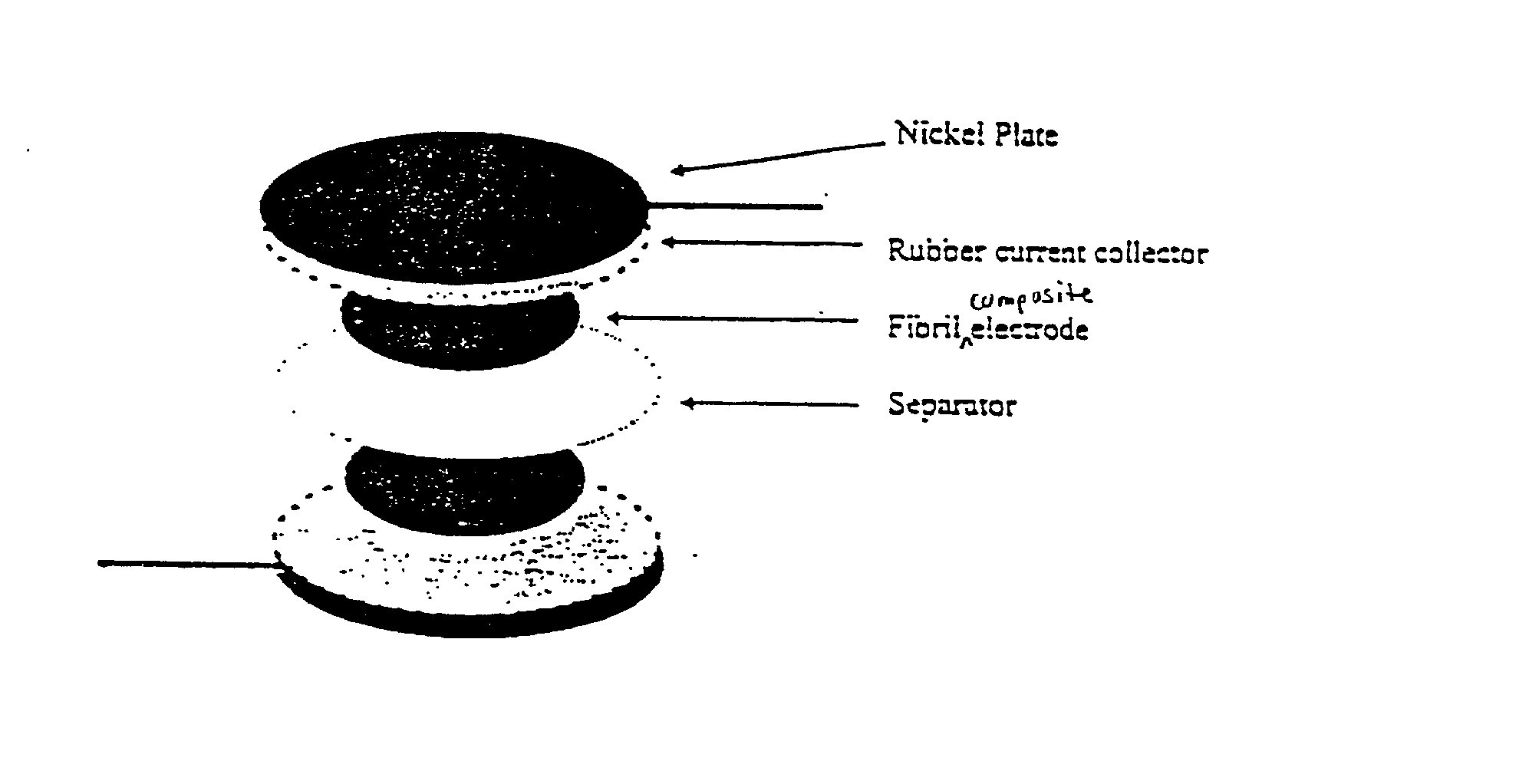

Fibril composite electrode for electrochemical capacitors

InactiveUS20020008956A1Improve electrochemical performanceReadily and highly dispersible in polar solventsNon-fibrous pulp additionNanotechComposite electrodeCarbon nanofiber

Composite electrodes comprising carbon nanofibers (fibrils) and an electrochemically active material are provided for use in electrochemical capacitors. The fibril composite electrodes exhibit high conductivity, improved efficiency of active materials, high stability, easy processing, and increase the performance of the capacitor. A method for producing the composite electrodes for use in electrochemical capacitors is also provided.

Owner:HYPERION CATALYSIS INT

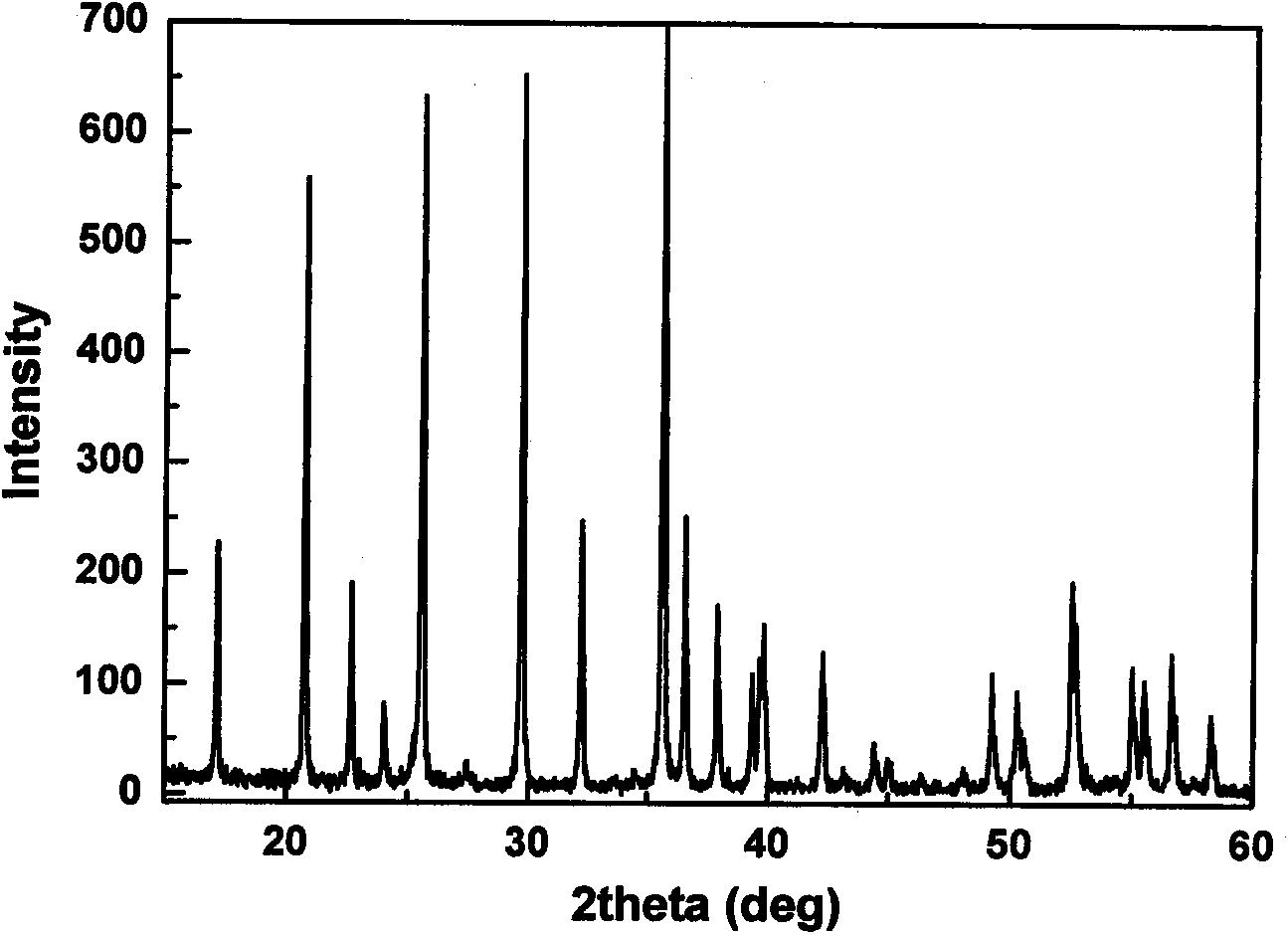

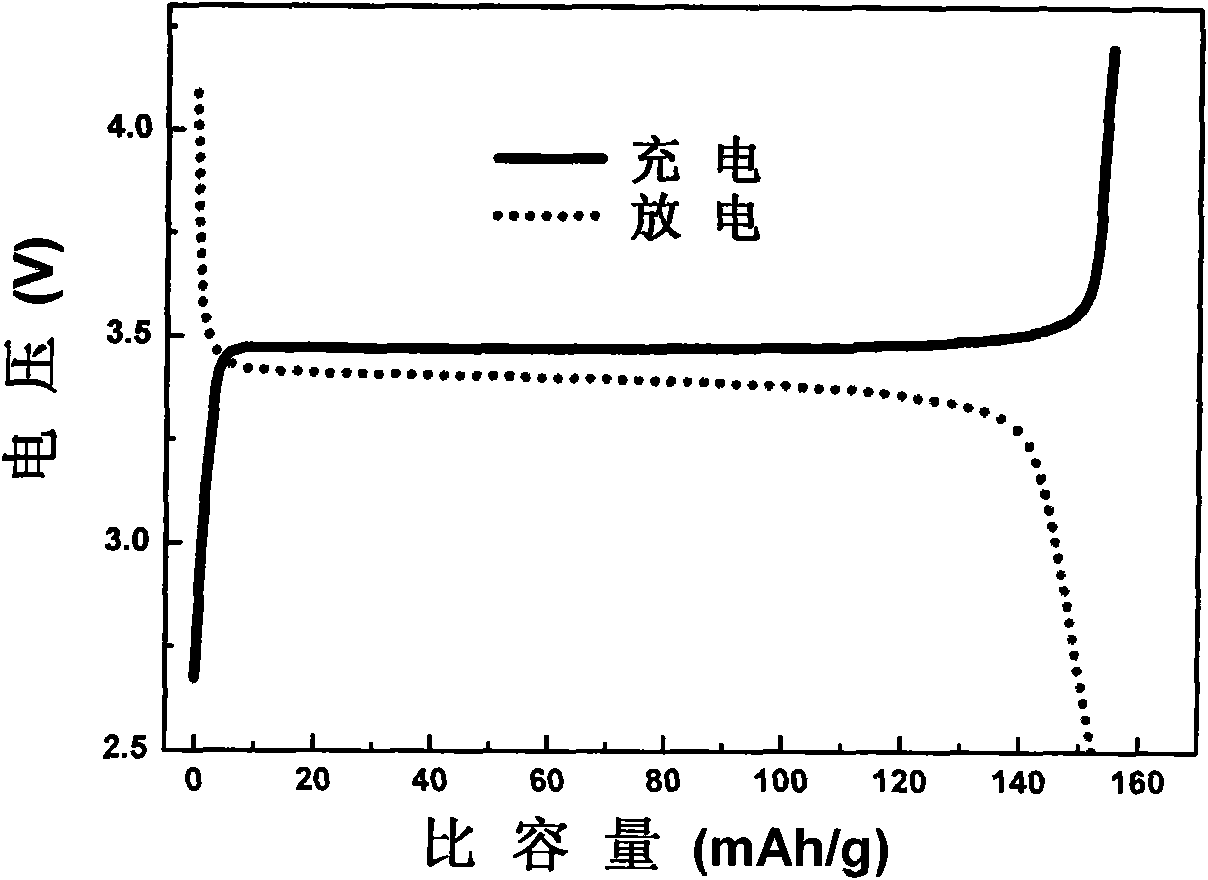

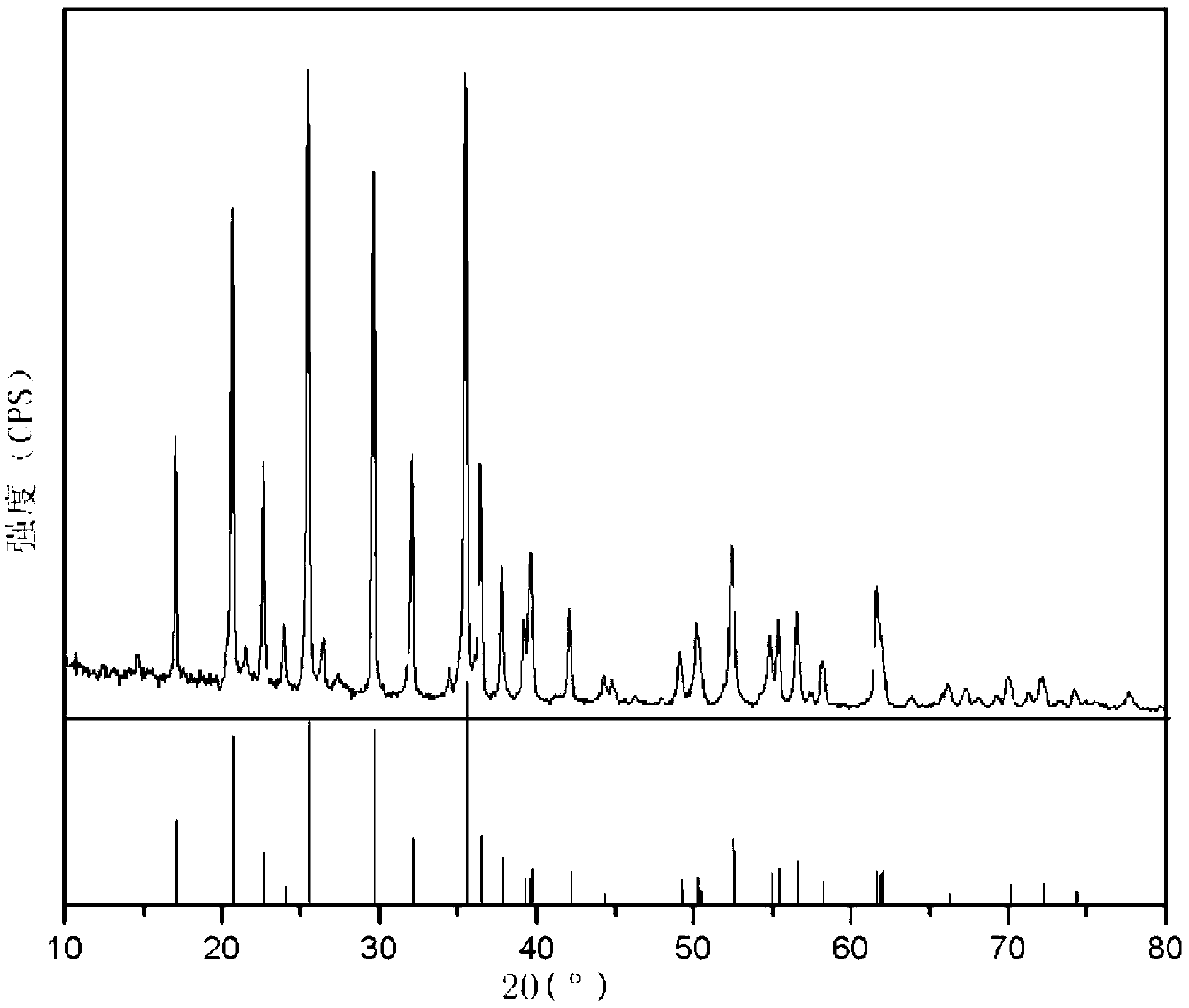

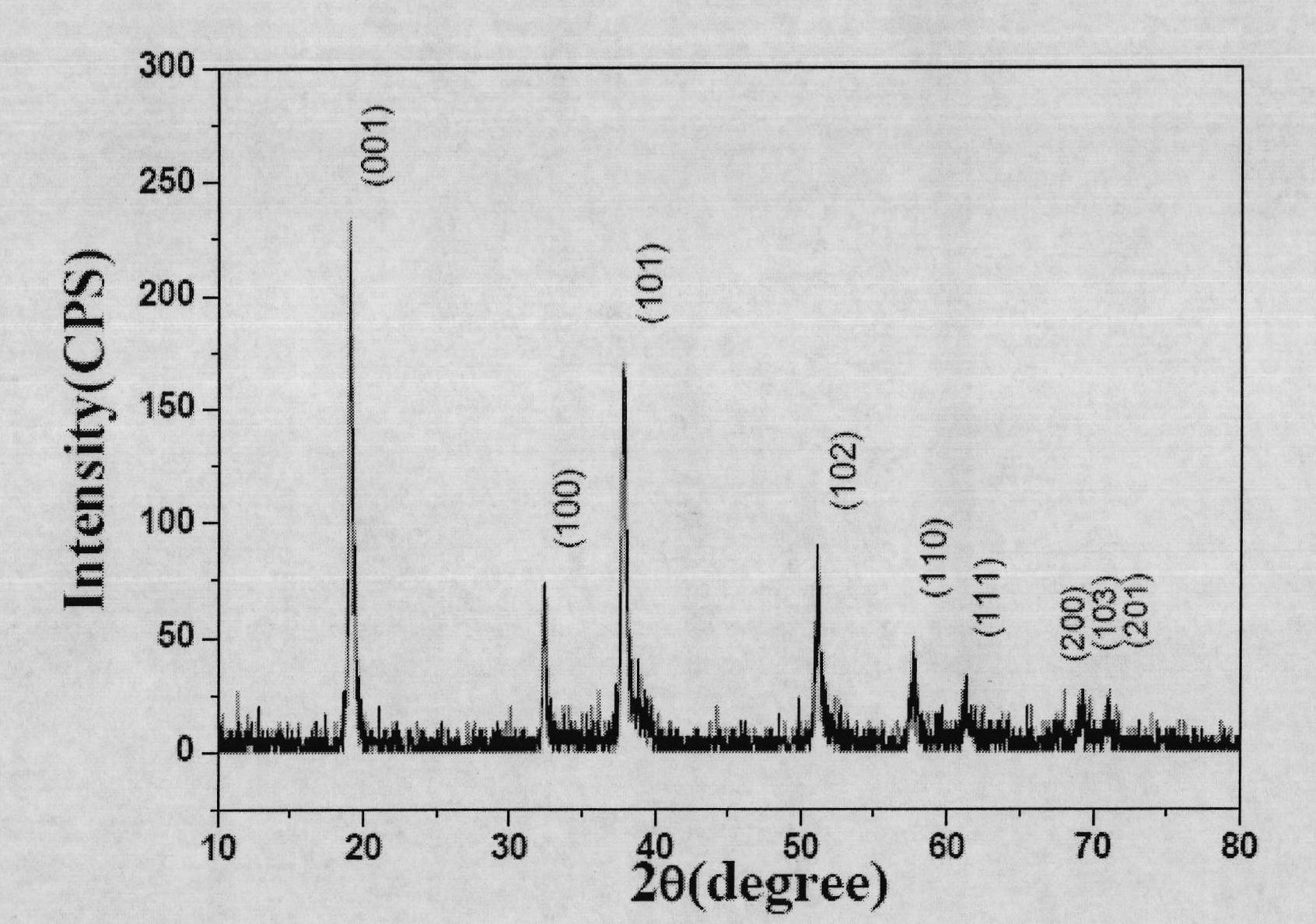

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

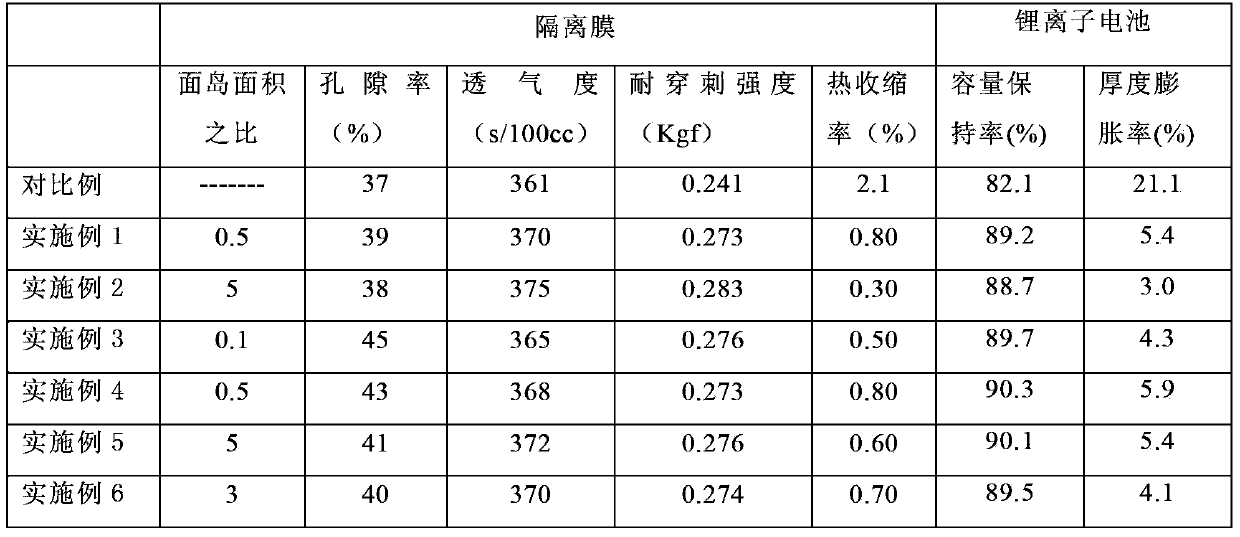

Ceramic and polymer composite coated lithium ion diaphragm and preparation method thereof

ActiveCN107275550AImprove ionic conductivityHigh bonding strengthCell component detailsSecondary cells servicing/maintenanceLithiumPolyolefin

The invention discloses a ceramic and polymer composite coated lithium ion diaphragm and a preparation method thereof. The ceramic and polymer composite coated lithium ion diaphragm comprises a polyolefin porous diaphragm, a ceramic coating coated on one side or the two sides of the diaphragm surface and a polymer coating coated on the ceramic surface or the diaphragm surface. The composite diaphragm prepared by the preparation method disclosed by the invention has the advantages that the heat resistance of the diaphragm is greatly improved, and the infiltration of an electrolyte is improved; the bonding strength of the diaphragm and a positive and negative pole piece is improved, so that the internal short-circuit caused by staggering between the diaphragm and an electrode is prevented; meanwhile, the hardness of a battery is improved, so that the safety performance of the battery is greatly improved. In the production process, the ceramic coating and the polymer coating are uniform in thickness and good in uniformity and facilitate continuous and large-scale production.

Owner:SHENZHEN SENIOR TECH MATERIAL

Lithium ion battery and anode strip thereof and stabilization lithium metal powder

ActiveCN102642024AImprove lithiation efficiencyImprove electronic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical conductorElectrical battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to stabilization lithium metal powder. The stabilization lithium metal powder has a core shell structure; and the core layer is formed by lithium metal and is a composition consisting of an electron good conductor and a lithium ion good conductor. Compared with the prior art, the stabilization lithium metal powder provided by the invention has the advantages that: in the process of performing pre-lithiation of the anode-active material by use of the stabilization lithium metal powder, no limitation is imposed on the pressure of the cold pressing process, the 'dead lithium' disabling lithiation reaction is not produced, and the lithiation efficiency of the lithium metal powder is improved; and moreover, since the shell layer left on the electrode surface has good electron and lithium ion conductivity after the pre-lithiation, the electron and ion conductivity of the anode can be effectively improved so as to improve the electrochemical performance of the battery. In addition, the invention also discloses an anode strip performing pre-lithiation by use of the stabilization lithium metal powder, and a lithium ion battery comprising the anode strip.

Owner:NINGDE AMPEREX TECH +1

Lithium ion battery anode film, preparation and application thereof

InactiveCN104037418AImprove reversible charge and discharge capacityPerformance is not affectedLi-accumulatorsNon-aqueous electrolyte accumulator electrodesAdhesiveLithium electrode

Provided is a positive electrode film of a lithium battery, comprising: (i) a positive electrode material of a lithium intercalated transition metallic oxide; (ii) a lithium ion replenisher; and (iii) a conductive agent and an adhesive. The lithium ion replenisher in the positive electrode film decomposes during initial charging and then releases lithium ions, so as to make up for a loss of lithium ions forming an SEI film on a negative electrode surface, thereby improving the reversible charging and discharging capacity of the lithium ion battery. In the prepared positive electrode film, the lithium ion replenisher can be mixed in the positive electrode material or the conductive agent in advance, and can be coated on the surface of the positive electrode of the lithium ion battery as well.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

ActiveCN106299365AImprove the first charge and discharge efficiencyImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to a biomass hard carbon negative electrode material for a sodium ion battery, a preparing method and the sodium ion battery and belongs to the technical field of sodium ion energy storage equipment. The biomass hard carbon negative electrode material is prepared through the method including the following steps that firstly, a biomass raw material is smashed, and precursor particles are obtained; secondly, in a protection atmosphere, the precursor particles are heated to 400-600 DEG C to be pre-sintered for 1.5-2.5 h, then cooled to the room temperature along with a furnace, then heated to 800-1600 DEG C to be sintered for 2-5 h and cooled, and an intermediate is obtained; thirdly, the intermediate is put into an alkali solution to be soaked, taken out, then put into an acid solution to be soaked, then washed with water to be neutral and dried, and a purified product is obtained; fourthly, the purified product is subjected to microwave vacuum activation for 3-15 s at the power of 1000-2000 W, and then the biomass hard carbon negative electrode material is obtained. The first-time charging and discharging efficiency of the obtained biomass hard carbon negative electrode material reaches up to 90% or above, the circulation stability is good, the reversible specific capacity is 300 mAh / g or above, and the biomass hard carbon negative electrode material has a good electrochemical property.

Owner:浙江瓦司特钠科技有限公司

Method for preparing nitrogen-doped active carbon from nitrogen-enriched biomass raw material

InactiveCN104386685AExcellent electrochemical performanceIn situ dopingCarbon compoundsActivated carbonBiomass

The invention relates to a method for preparing nitrogen-doped active carbon from a nitrogen-enriched biomass raw material, and belongs to the technical field of preparation of carbon materials. In the method, an active carbon material with relatively high nitrogen doping amount and a large specific surface area is prepared from the biomass raw material with rich nitrogen through carbonization and activation in an inert atmosphere. The method has the advantages as follows: the raw material is environment-friendly and renewable; the preparation process is simple; in-situ nitrogen doping can be achieved; the nitrogen doping amount and a pore structure can be controlled at the same time; a new way is provided for high-added value utilization of the nitrogen-enriched biomass raw material. The prepared nitrogen-doped active carbon can be used as an efficient electrode material, an absorbent material and a catalyst carrier and applied to the field of energy and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

High ratio energy chargeable full-solid lithium air battery

InactiveCN101267057AImprove electrochemical performanceImprove securityFuel and primary cellsElectrochemical responseSpecific energy

The present invention belongs to electrochemical technical field, specifically a high specific energy charging full-solid lithium air battery. The battery structure is: firstly an air diffusion layer, then an air electrode, composed of a meso-porous carbon / manganese oxide composite material, an oxygen-reduction catalyst and a macromolecule lithium electrolyte, next a multilayer aqueous vapour cover, not only serving as a electrolyte layer of the battery, but also blocking water an oxidation entering of the air, finally a metal lithium. The whole battery is sealed in the multiplayer metal / plastic, a portable sealing is on the top of the air diffusion layer which is opened when the battery is used, closed when the battery is not used. The invention adopts lithium air battery made by the meso-porous carbon / manganese oxide composite material and the room temperature ionic liquid electrolyte, the capacity achieves 800mAh / g, cycling more than 50 times. In the lithium air battery, the metal lithium has effective protection, making the Li / O2 reaction only in the electrochemical reaction, the lithium air battery not only has battery electrochemical capability, but also has excellent safety ability.

Owner:FUDAN UNIV

A method for preparing porous silicon by magnesia thermal reduction

InactiveCN102259858AImprove luminous efficiencyStable electrochemical performanceSilicon compoundsMagnesiumOxide

The invention belongs to the synthesis field of porous silicon materials, and particularly relates to a method for preparing porous silicon by magnesiothermic reduction. The method comprises the following steps: carrying out magnesiothermic reduction reaction based on silicon oxide SiOx (x = 0.5-2) as a raw material to generate a mixture of silicon and magnesium oxide; and then selectively dissolving away magnesium oxide with an acid so as to ultimately obtain a self-supported porous silicon material. Compared with the previous conventional electrochemical anodic etching methods, the method provided by the invention has the advantages that the use of expensive monocrystal silicon wafers is avoided, but simple, easily available and low-cost silicon oxide is used as the raw material, thereby not only reducing the cost but also increasing the yield; and the method has the advantages of simple preparation process, environmental friendliness, high preparation efficiency and good repeatability, is more suitable for industrial production, and is expected to be widely applied in the fields of lithium ion secondary batteries, optical materials, biomedical devices, gas-sensitive devices, etc.

Owner:TONGJI UNIV

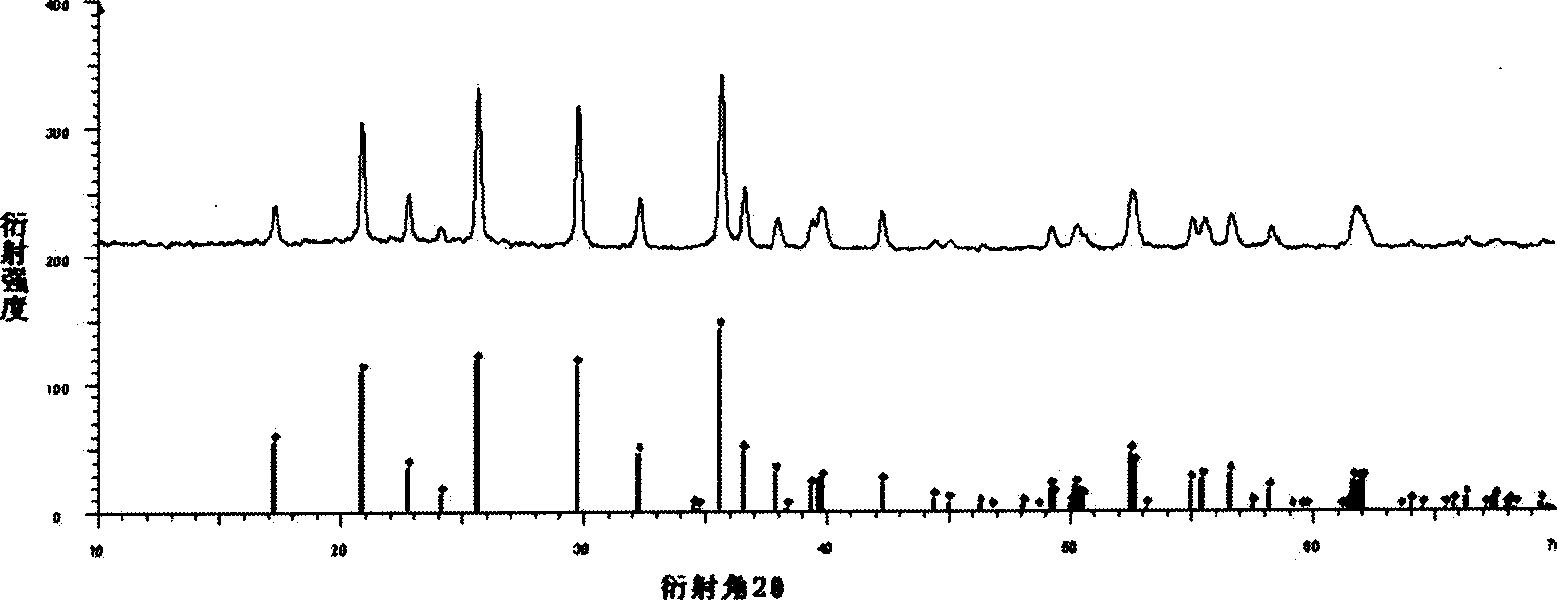

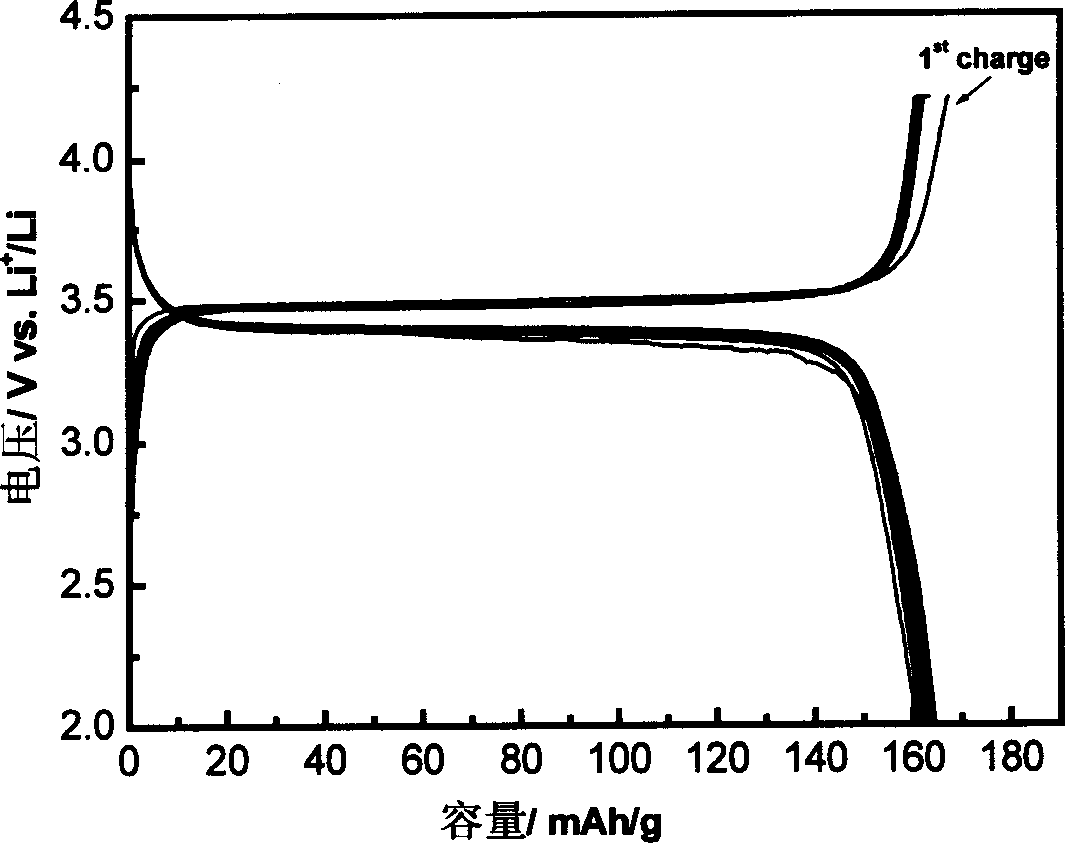

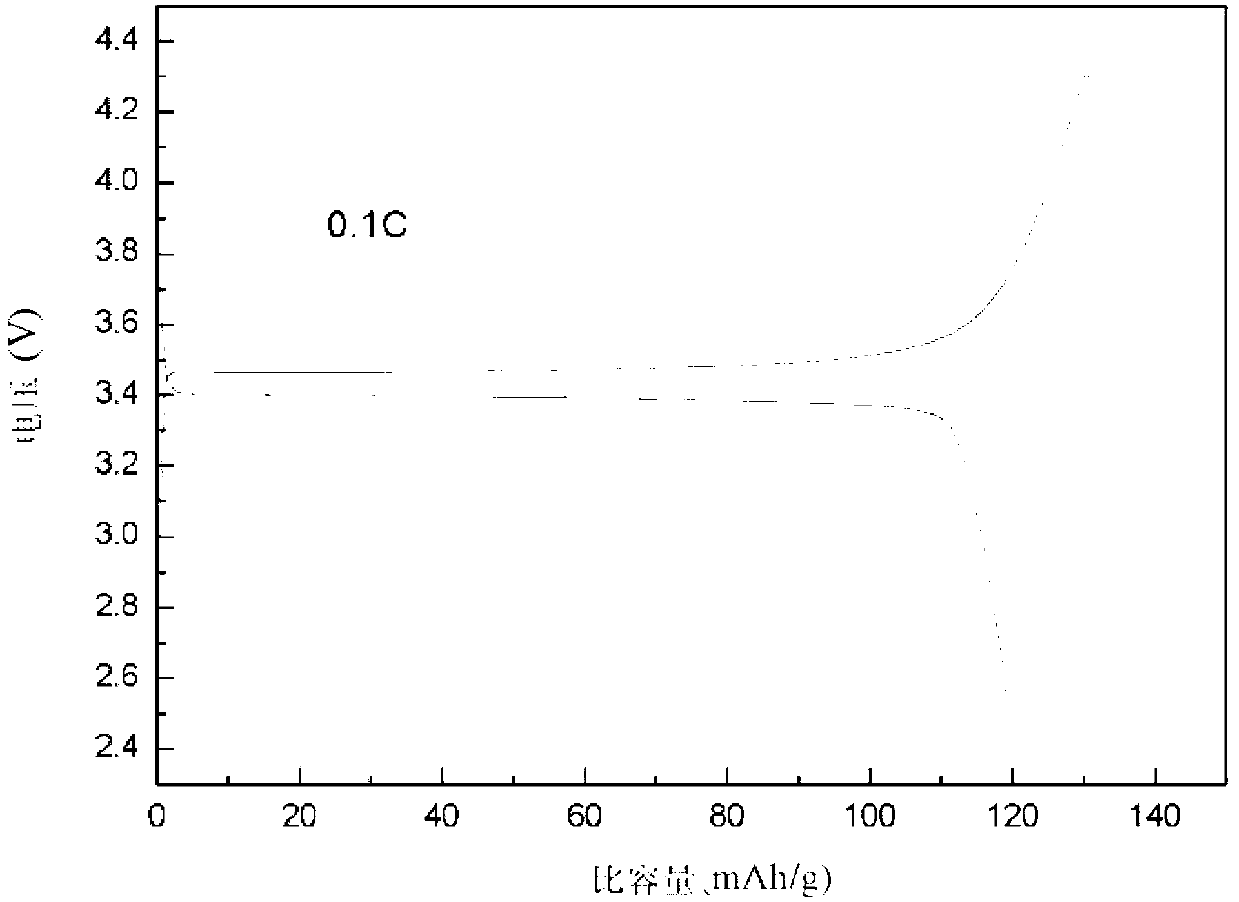

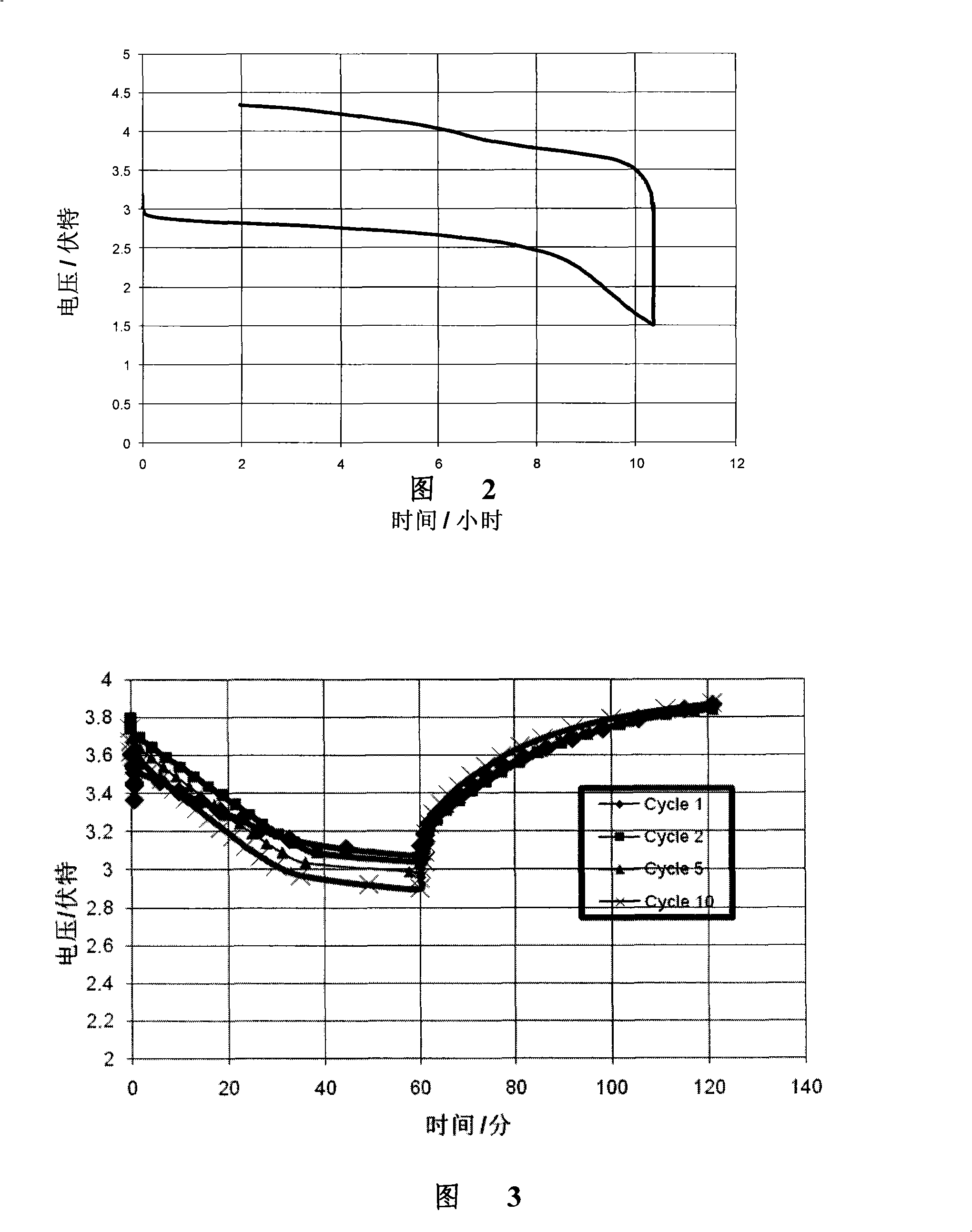

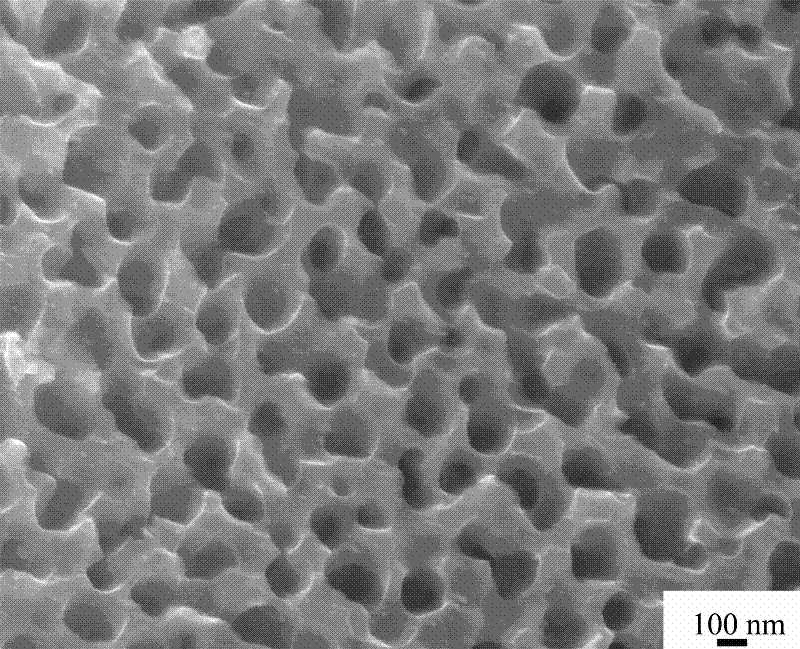

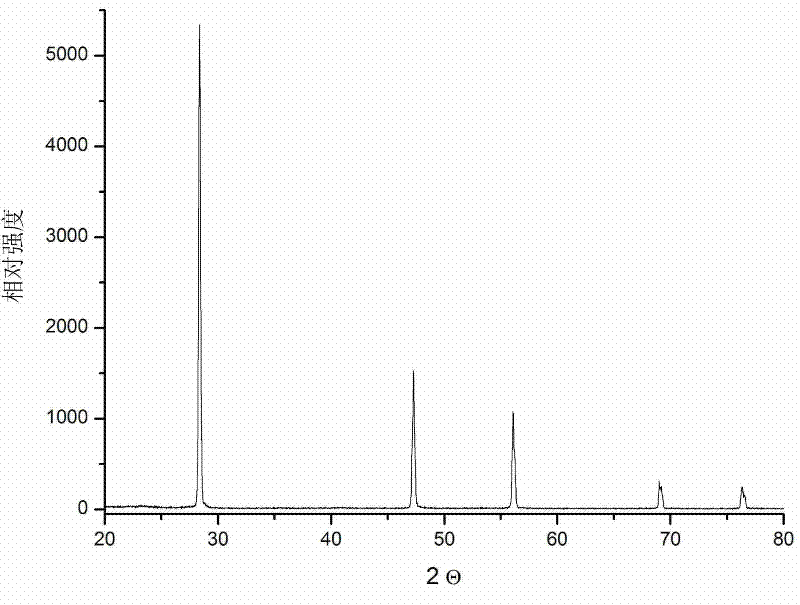

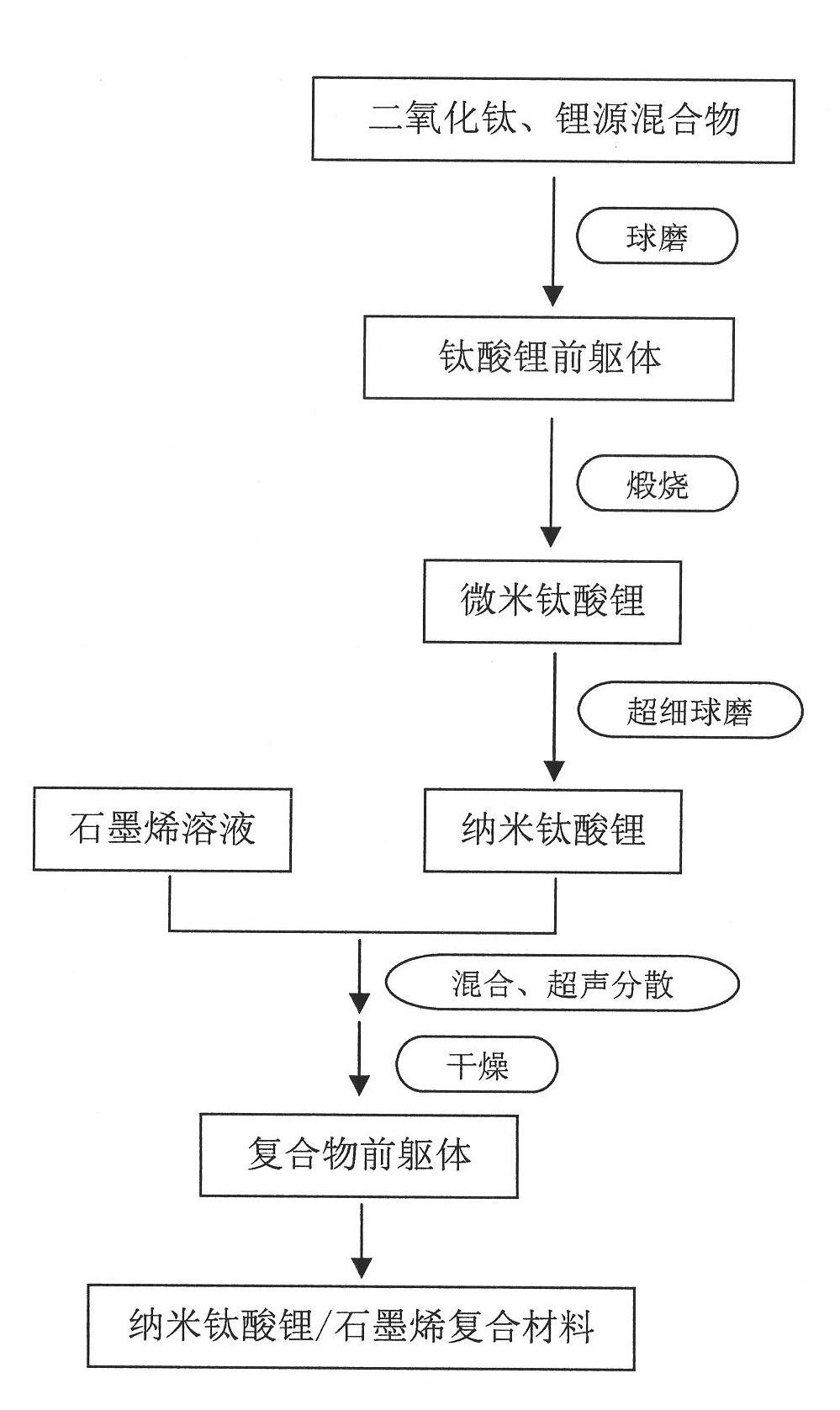

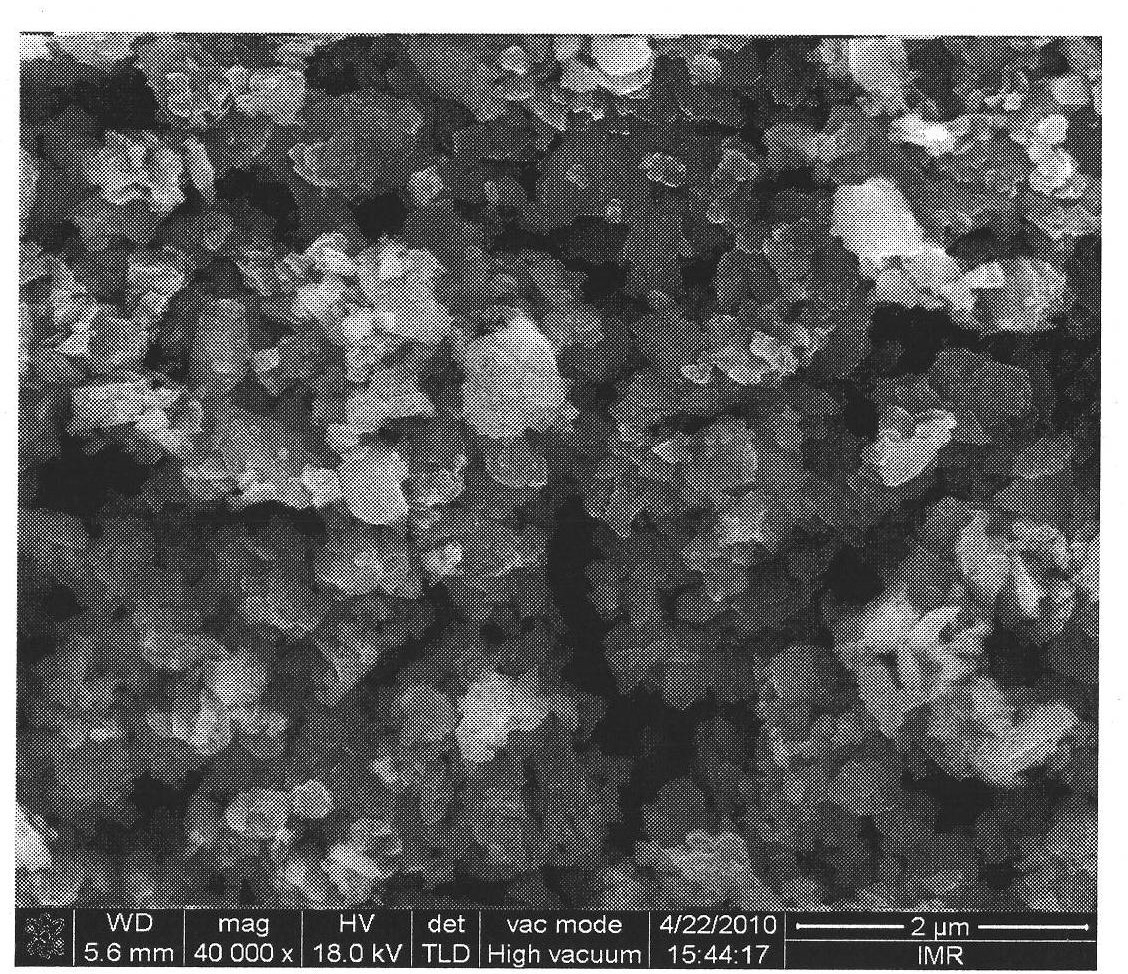

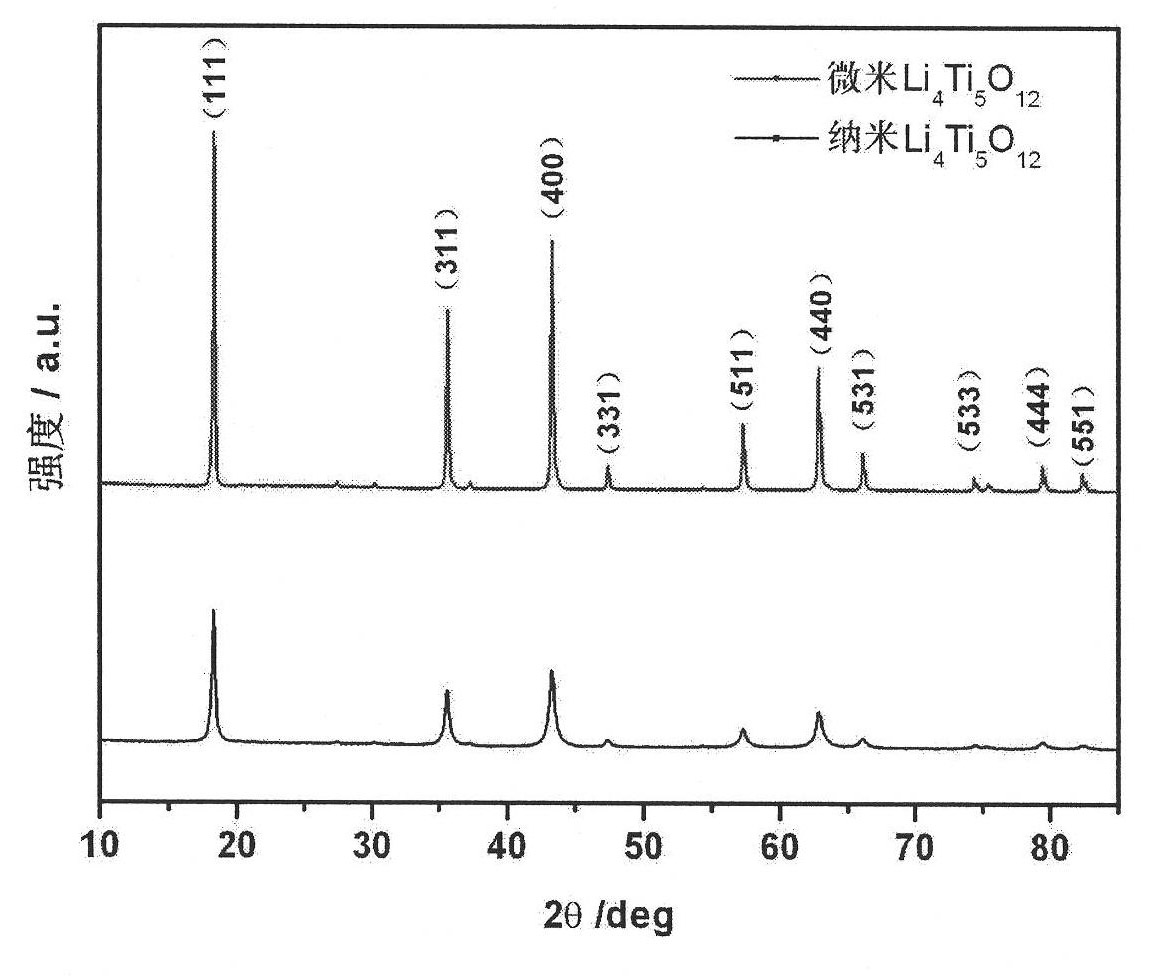

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

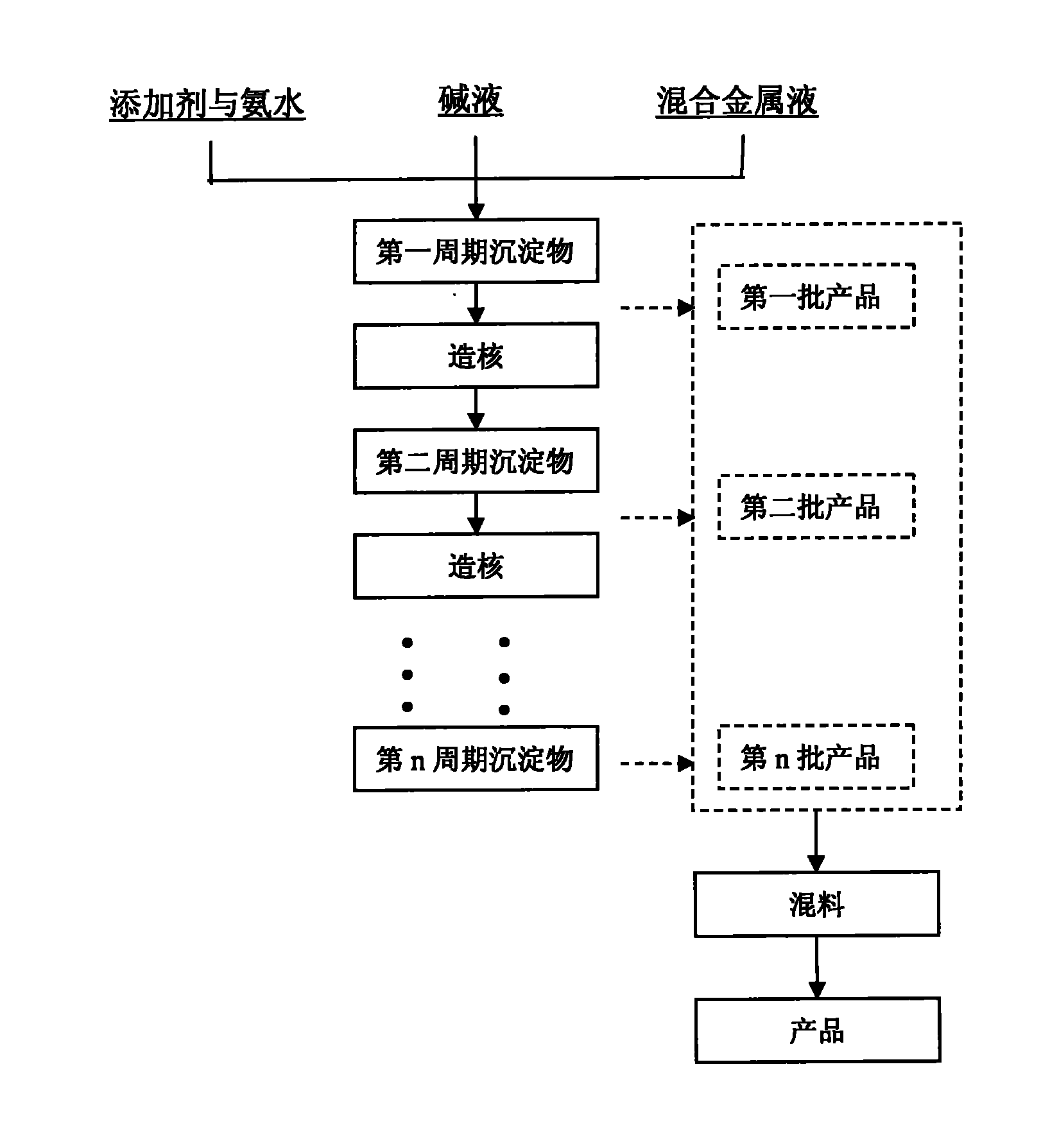

Method for continuously synthesizing precursor of lithium ion battery positive material

InactiveCN102092798AInhibition formationSolve the problem of easy oxidationCell electrodesManganese oxides/hydroxidesSynthesis methodsManganese

The invention provides a method for continuously synthesizing a precursor of a lithium ion battery positive material, relating to an improvement of a synthesis method of a nickle cobalt manganese termary positive material nickle cobalt lithium manganate of the lithium ion battery positive material. The method is characterized in that the synthesis process is as follows: merging a complexing agent ammonia, an aqueous solution of metal nickle cobalt manganese ions and a precipitator sodium hydroxide solution and then continuously adding the substances into a reaction kettle for a synthesis reaction under the strong stirring condition in the presence of protective gas; and aging, filtering and washing the effluent from the reaction kettle, and then drying to obtain the lithium ion battery positive material precursor spherical nickle cobalt manganese termary hydroxide. The method has the advantages that the preparation process is continuous, the particle size of the prepared nickle cobalt manganese compound hydroxide powder is controlled in a range of 5-20 microns, and the prepared nickle cobalt manganese compound hydroxide powder is even in distribution and excellent in electrochemistry property. The method has the advantages of high production efficiency, low production cost and significant economic and social benefits, and the energy is saved.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH +1

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com