Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low initial efficiency of sodium ion batteries, achieve wide application prospects, abundant raw materials, and improve charging and discharging efficiency and the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

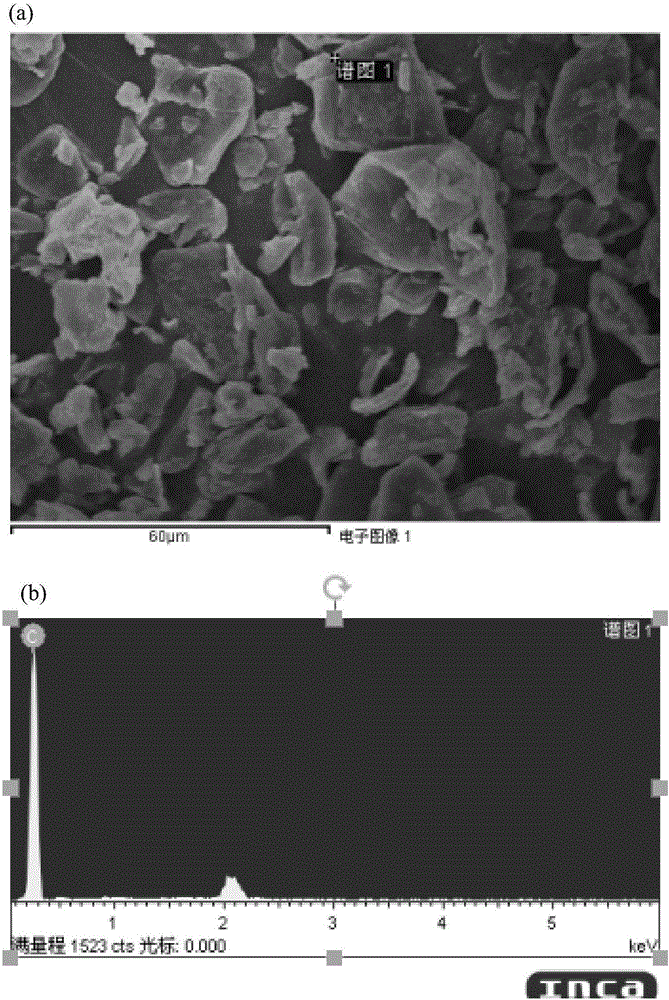

[0055] The biomass hard carbon negative electrode material for sodium ion battery of the present embodiment is prepared by the following method:

[0056] 1) Biomass raw material pretreatment: put the pine cones in a container filled with deionized water and ultrasonically for 30min (ultrasonic power 400W), then rinse with deionized water several times until there is no obvious residue; Put the fruit in a drying oven to dry;

[0057] 2) Pulverization: the pretreated pine cones are pulverized in a pulverizer to obtain precursor particles with a particle size of 400 mesh;

[0058] 3) Firing: Put 10 g of the precursor particles obtained in step 2) into a corundum crucible, place in an open atmosphere tube furnace, and under the protection of Ar atmosphere (argon flow rate is 80 sccm), at a rate of 2 °C / min Heat up to 500°C for 2 hours, then cool down to room temperature with the furnace, filter and remove impurities after deionization, and vacuum dry at 120°C; then, heat up to 12...

Embodiment 2

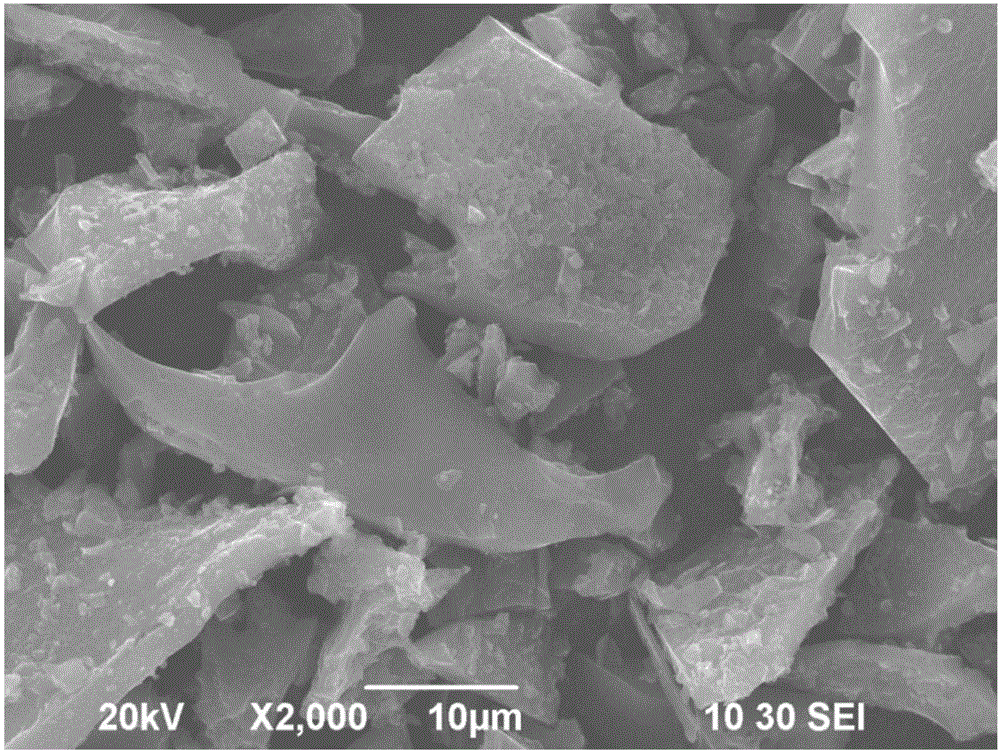

[0065] The biomass hard carbon negative electrode material for sodium ion battery of the present embodiment is prepared by the following method:

[0066] 1) Biomass raw material pretreatment: put the pine cones in a container filled with deionized water and ultrasonically for 30min (ultrasonic power 400W), then rinse with deionized water several times until there is no obvious residue; Put the fruit in a drying oven to dry;

[0067] 2) Pulverization: the pretreated pine cones are pulverized in a pulverizer to obtain precursor particles with a particle size of 500 mesh;

[0068] 3) Firing: Take 10 g of the precursor particles obtained in step 2) and put them into a corundum crucible, place them in an open atmosphere tube furnace, and under the protection of Ar atmosphere (argon flow rate is 100 sccm), at a rate of 5 ° C / min Heat up to 600°C for 2 hours, then cool down to room temperature with the furnace, filter and remove impurities after deionization cleaning, and vacuum d...

Embodiment 3

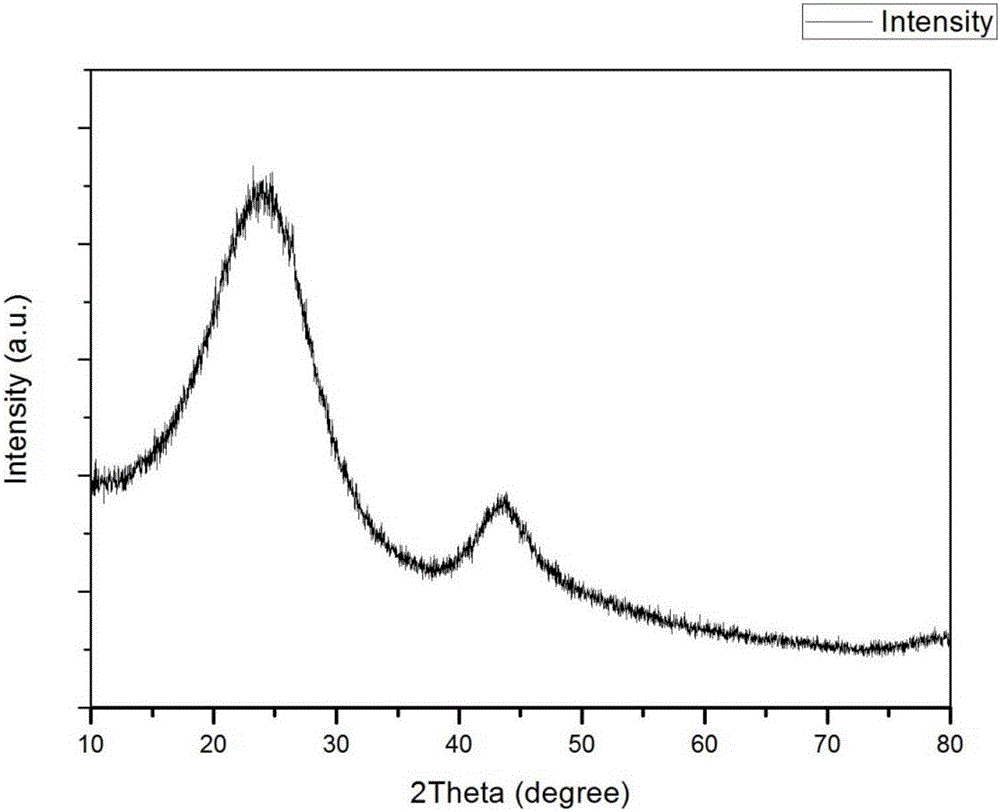

[0075] The biomass hard carbon negative electrode material for sodium ion battery of the present embodiment is prepared by the following method:

[0076] 1) Biomass raw material pretreatment: put the pine cones in a container filled with deionized water and ultrasonically for 30min (ultrasonic power 400W), then rinse with deionized water several times until there is no obvious residue; Put the fruit in a drying oven to dry;

[0077] 2) Pulverization: the pretreated pine cones are pulverized in a pulverizer to obtain precursor particles with a particle size of 400 mesh;

[0078] 3) Firing: Take 10 g of the precursor particles obtained in step 2) and put them into a corundum crucible, place them in an open atmosphere tube furnace, and under the protection of Ar atmosphere (argon gas flow rate is 140 sccm), at a rate of 10 °C / min Heat up to 600°C for 3 hours, then cool down to room temperature with the furnace, filter and remove impurities after deionization, and vacuum dry at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com