Cathode of lithium-ion secondary battery, preparation method and lithium-ion secondary battery

A secondary battery, lithium ion technology, used in electrode manufacturing, ion implantation and plating, active material electrodes, etc., can solve the problems of poor cycle performance, poor charge-discharge capacity and cycle performance, and large irreversible capacity, and achieve discharge capacity. The effect of improving, charging and discharging efficiency, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

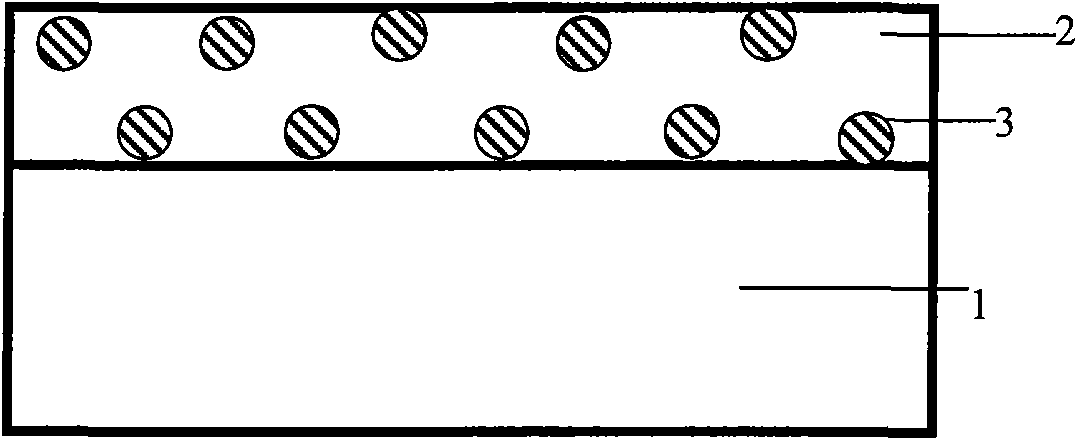

[0042] In this embodiment, DC magnetron sputtering technology is used to deposit a Si-C composite film on a current collector Cu foil with a thickness of 12 μm as the negative electrode material layer, using the crystal Si target and the C target as the target materials, wherein the Si layer is the active material layer. The material layer, the C layer covered on the Si layer is a buffer layer, thereby forming the negative electrode of the lithium ion secondary battery. Among them, during the sputtering process, the temperature of the cavity naturally rises, and when the temperature is stable, the temperature of the Cu foil is about 140°C. 2 The flow rate is 10 sccm, the pressure in the sputtering chamber is about 0.6 Pa, and the total sputtering time is 4.5 hours, wherein the Si target sputtering time is 4 hours.

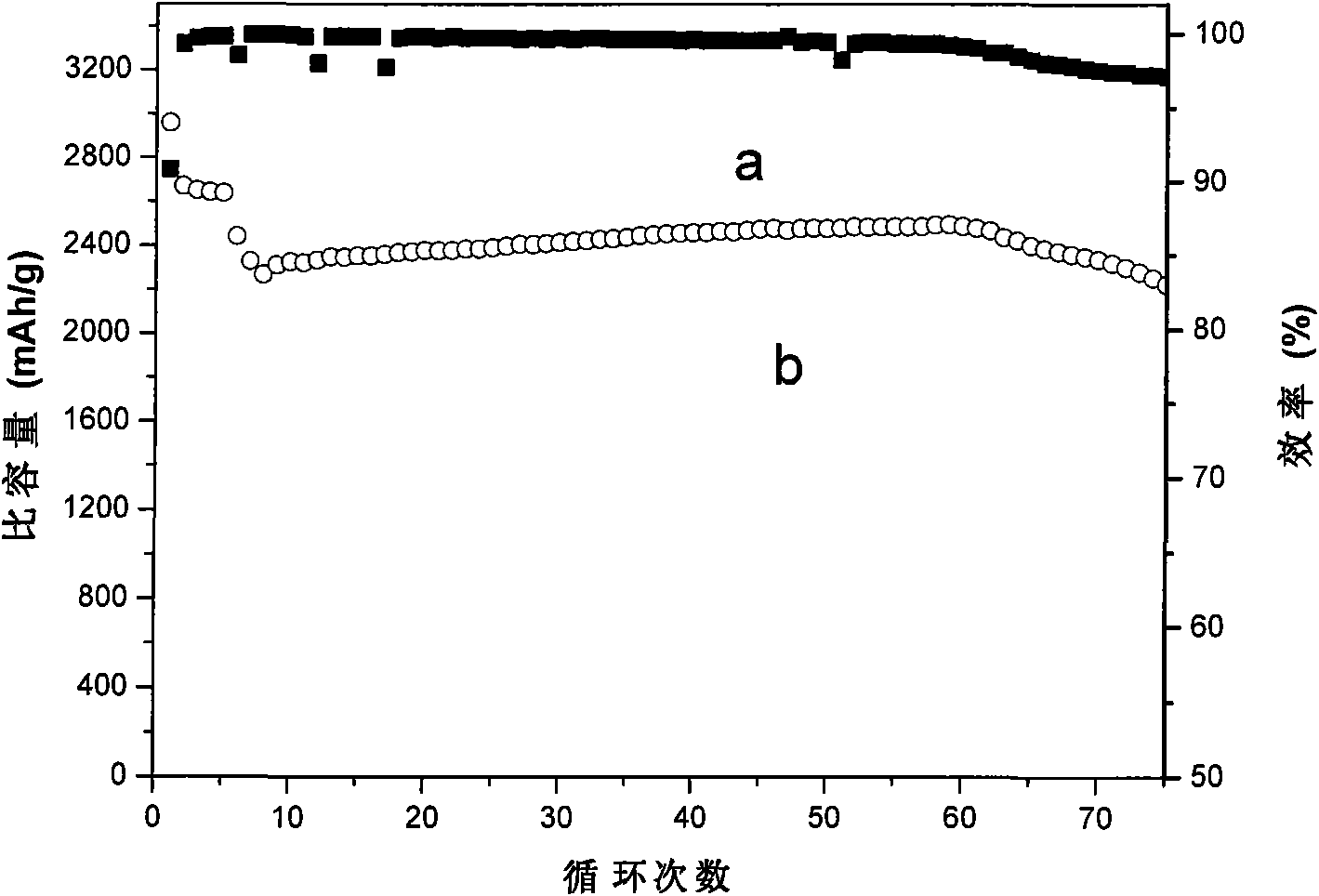

[0043] The half-cell composed of the obtained thin-film negative electrode sheet and metal Li was tested for electrochemical performance. At a current density of 0...

Embodiment 2

[0045] Using magnetron sputtering technology, using crystal Si target and C target as target materials respectively, deposited Si-C composite thin film on the current collector Cu foil with a thickness of 12 μm as the negative electrode material layer, in which the Si layer is the active material layer, covering The C layer on the Si layer is a buffer layer, thereby forming the negative electrode of the lithium ion secondary battery. Among them, during the sputtering process, the temperature of the cavity naturally rises. When the temperature is stable, the temperature of the Cu foil is about 120°C. 2 h 2 The flow rate is 3sccm, the pressure in the sputtering chamber is about 1.6Pa, and the total sputtering time is 4.5 hours, wherein the Si target sputtering time is 4 hours.

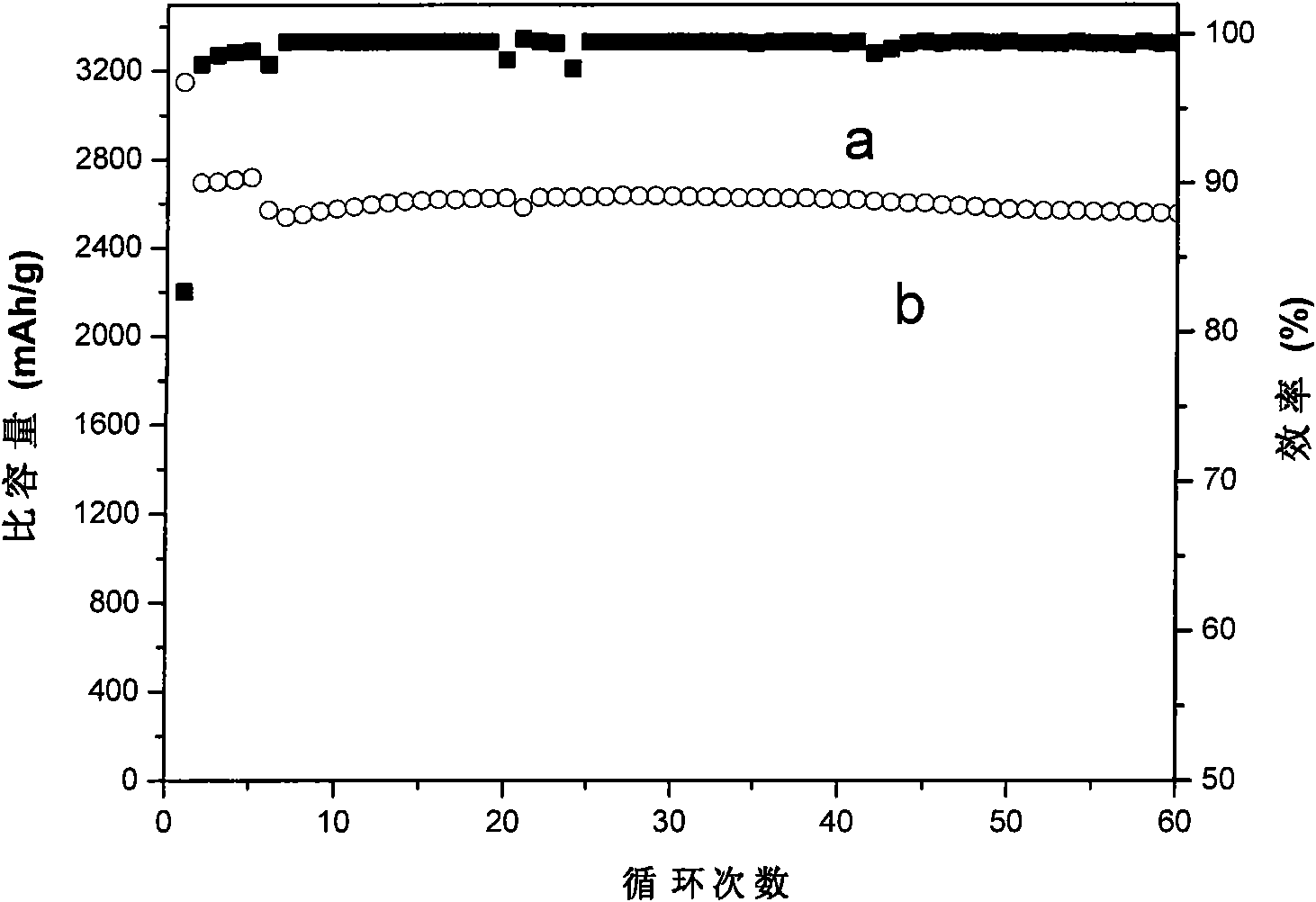

[0046] The half-cell composed of the obtained thin-film negative electrode sheet and metal Li was tested for electrochemical performance, and the test current density was 1.2mA / cm 2 , The charge and di...

Embodiment 3

[0048] Using DC magnetron sputtering technology, using crystal Si target and C target as target materials, Si-C composite thin film is deposited on the current collector Cu foil with a thickness of 12 μm as the negative electrode material layer, in which the Si layer is the active material layer. The C layer covered on the Si layer is a buffer layer, thereby forming the negative electrode of the lithium ion secondary battery. Among them, the temperature of the Cu foil is 150°C, the sputtering power of the two targets is 1400W, the flow rate of the working gas Ar is 46 sccm, the doping gas C 2 h 2 The flow rate is 3 sccm, the pressure in the sputtering chamber is 1.6 Pa, and the total sputtering time is 4.5 hours, wherein the Si target sputtering time is 4 hours.

[0049] The half-cell composed of the obtained thin-film negative electrode sheet and metal Li was tested for electrochemical performance, and the test current density was 1.1mA / cm 2 , The charging and discharging v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com