Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1151results about How to "High charge and discharge capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode for use in lithium battery and rechargeable lithium battery

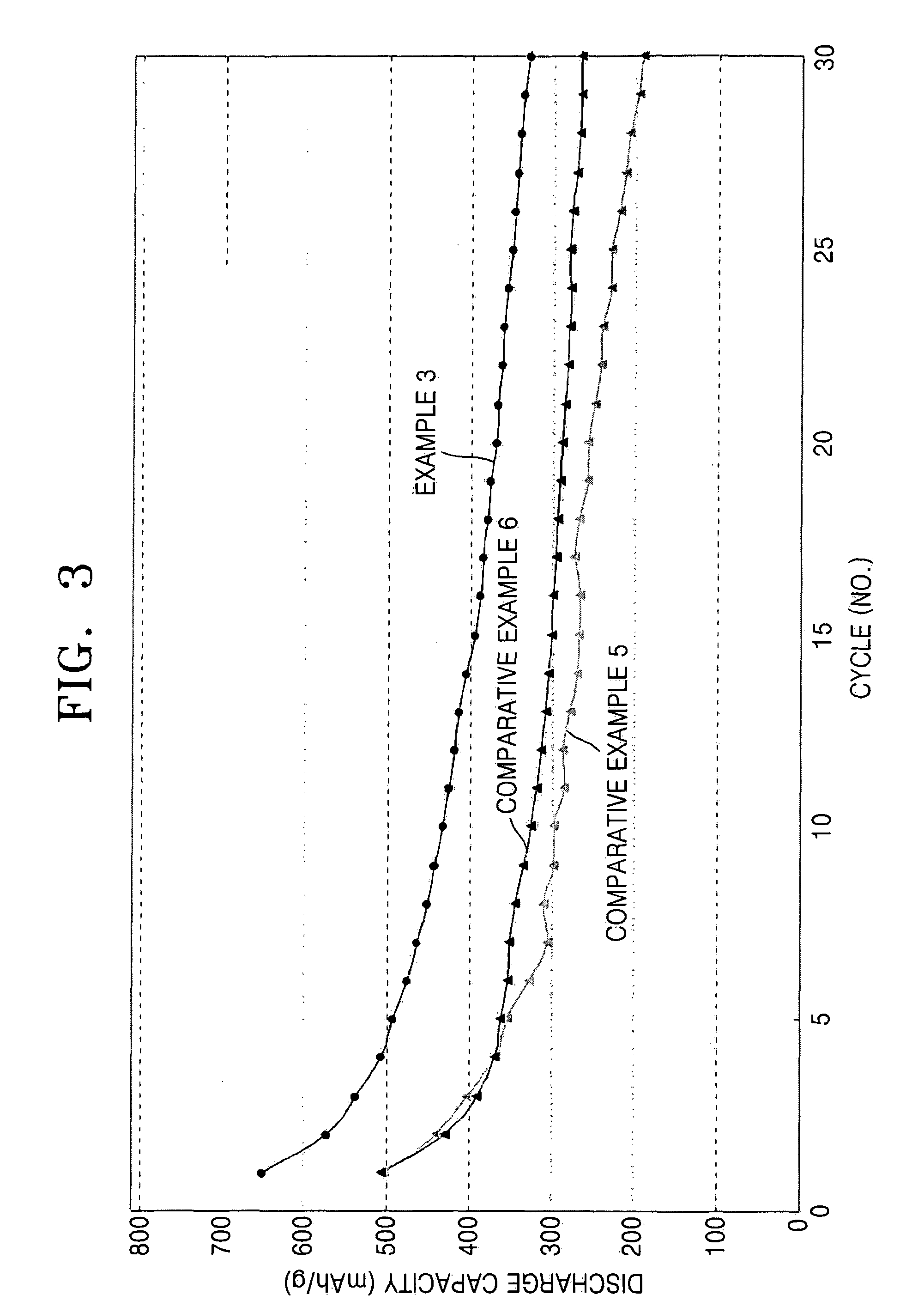

InactiveUS7235330B1High charge and discharge capacityImprove featuresElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconSurface roughness

Owner:SANYO ELECTRIC CO LTD

Electrode material, and production method and use thereof

InactiveUS20060035149A1High charge-discharge capacityExcellent characteristicElectrode thermal treatmentOrganic electrolyte cellsSilicon particleLithium ion intercalation

An electrode material comprising a particle containing at least one member selected from the particles containing silicon, tin, silicon compound and tin compound, and fibrous carbon. The particle includes: (1) a particle comprising at least one member of a silicon particle, tin particle, particle containing a lithium-ion-intercalatable / releasable silicon compound and particle containing a lithium-ion-intercalatable / releasable tin compound; or (2) a particle comprising a silicon and / or silicon compound-containing carbonaceous material deposited onto at least a portion of the surfaces of a carbon particle having a graphite structure. The lithium secondary battery using the electrode material as a negative electrode has high discharging capacity and is excellent in cycle characteristics and characteristics under a load of large current.

Owner:SHOWA DENKO KK

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

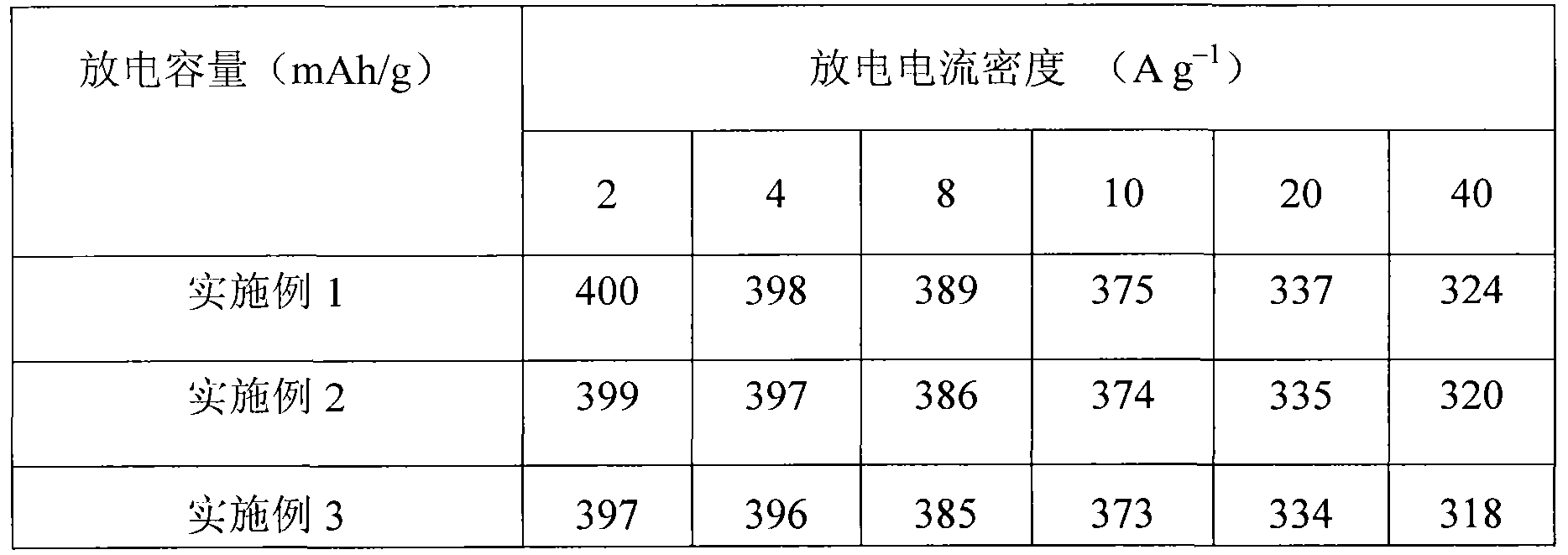

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

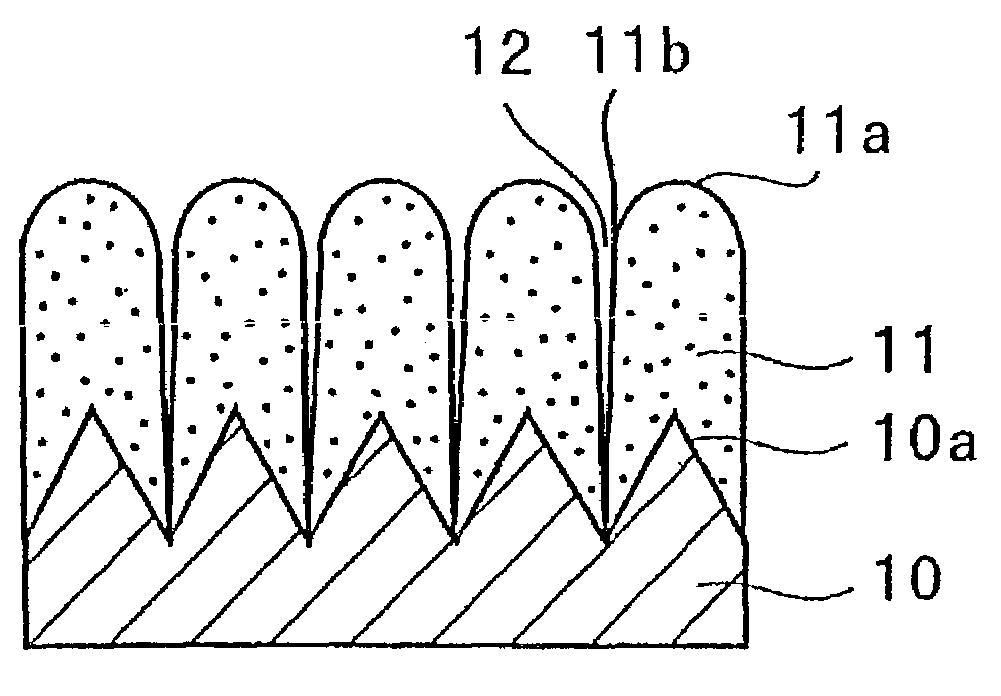

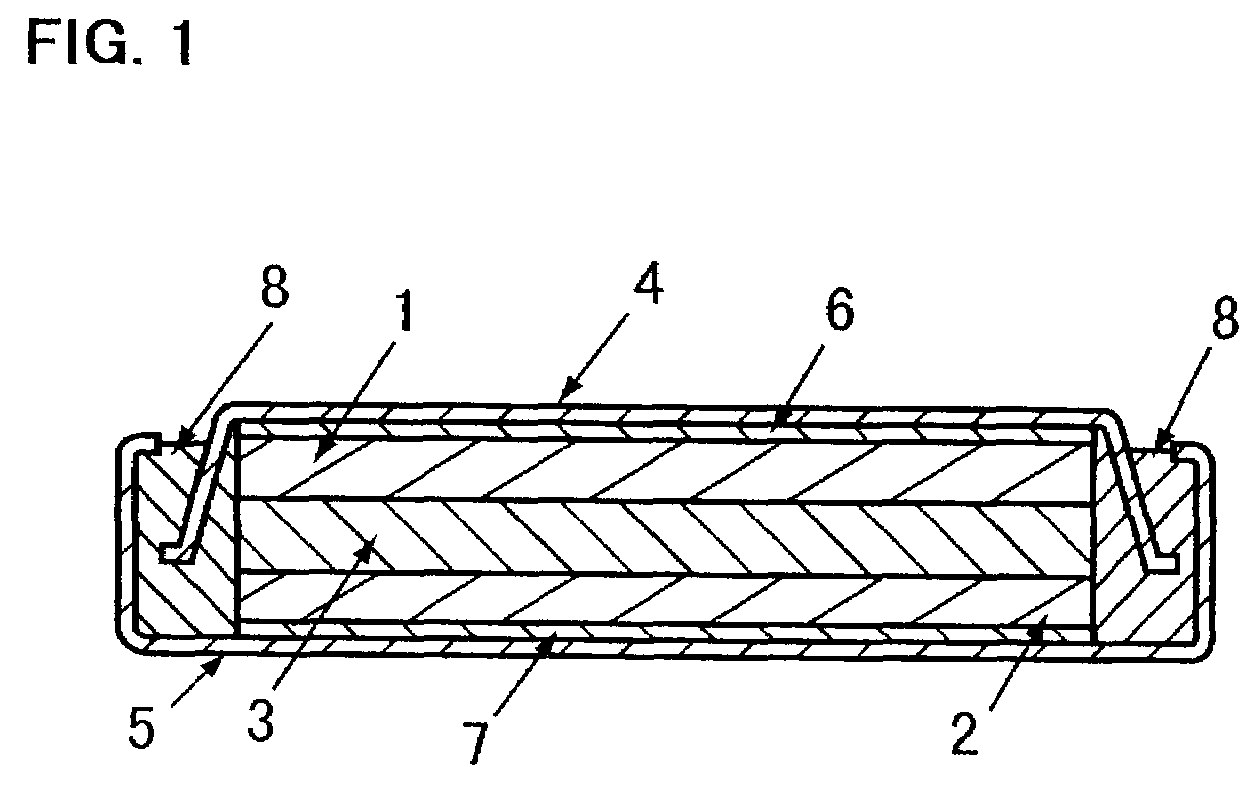

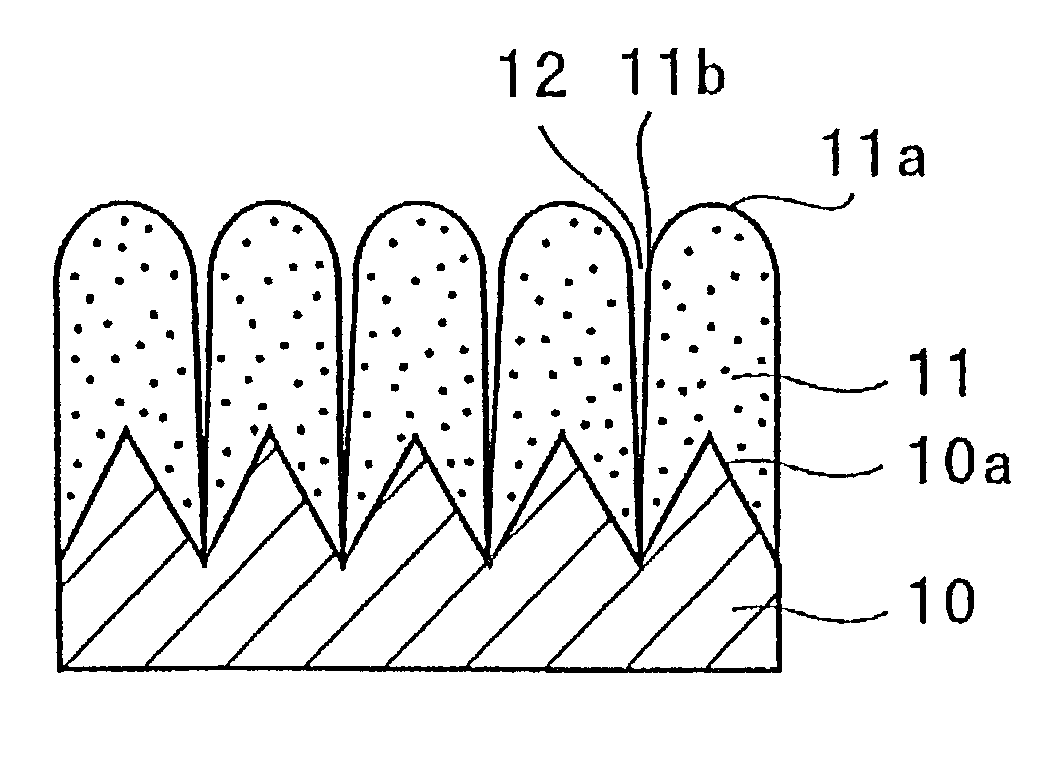

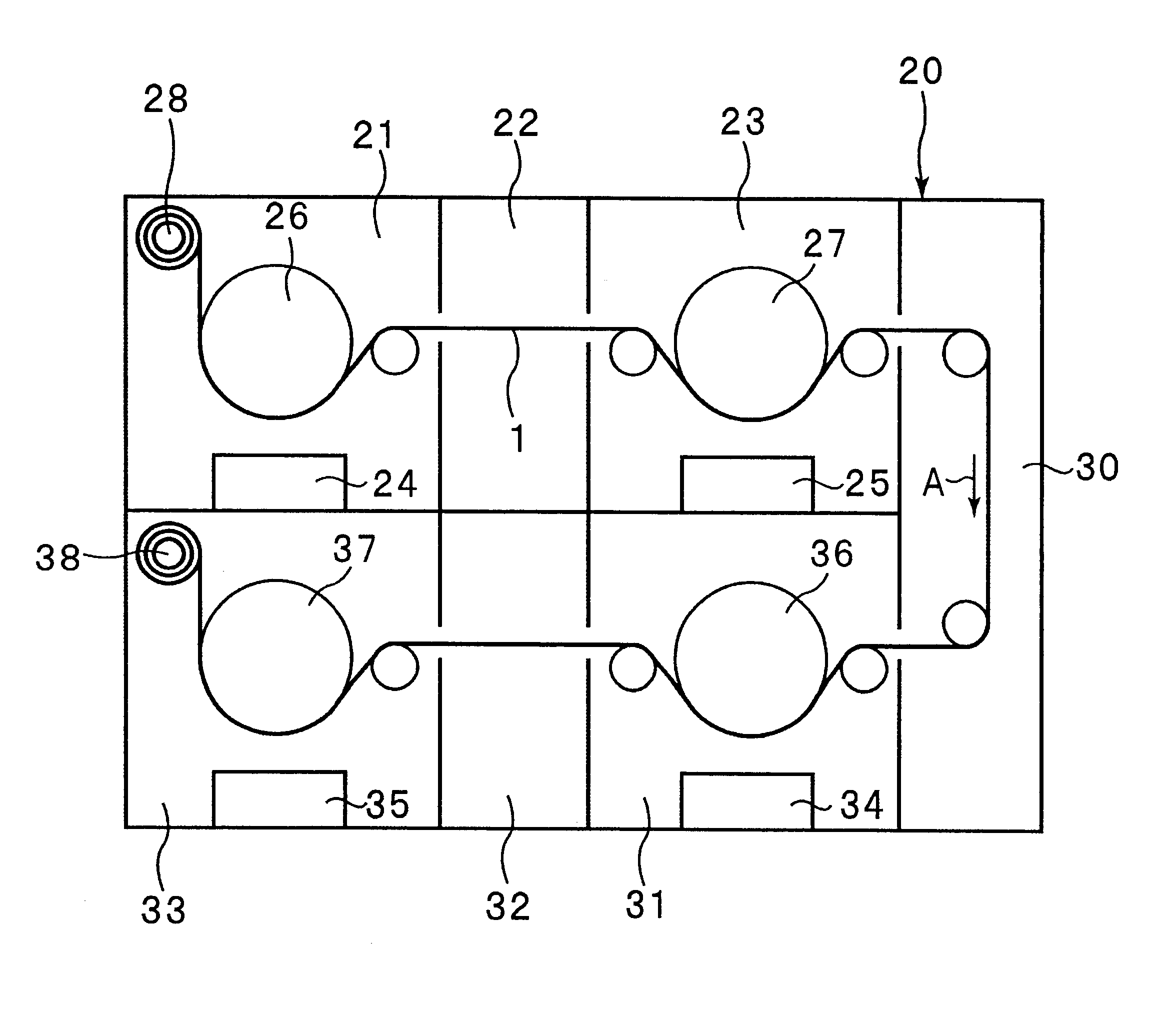

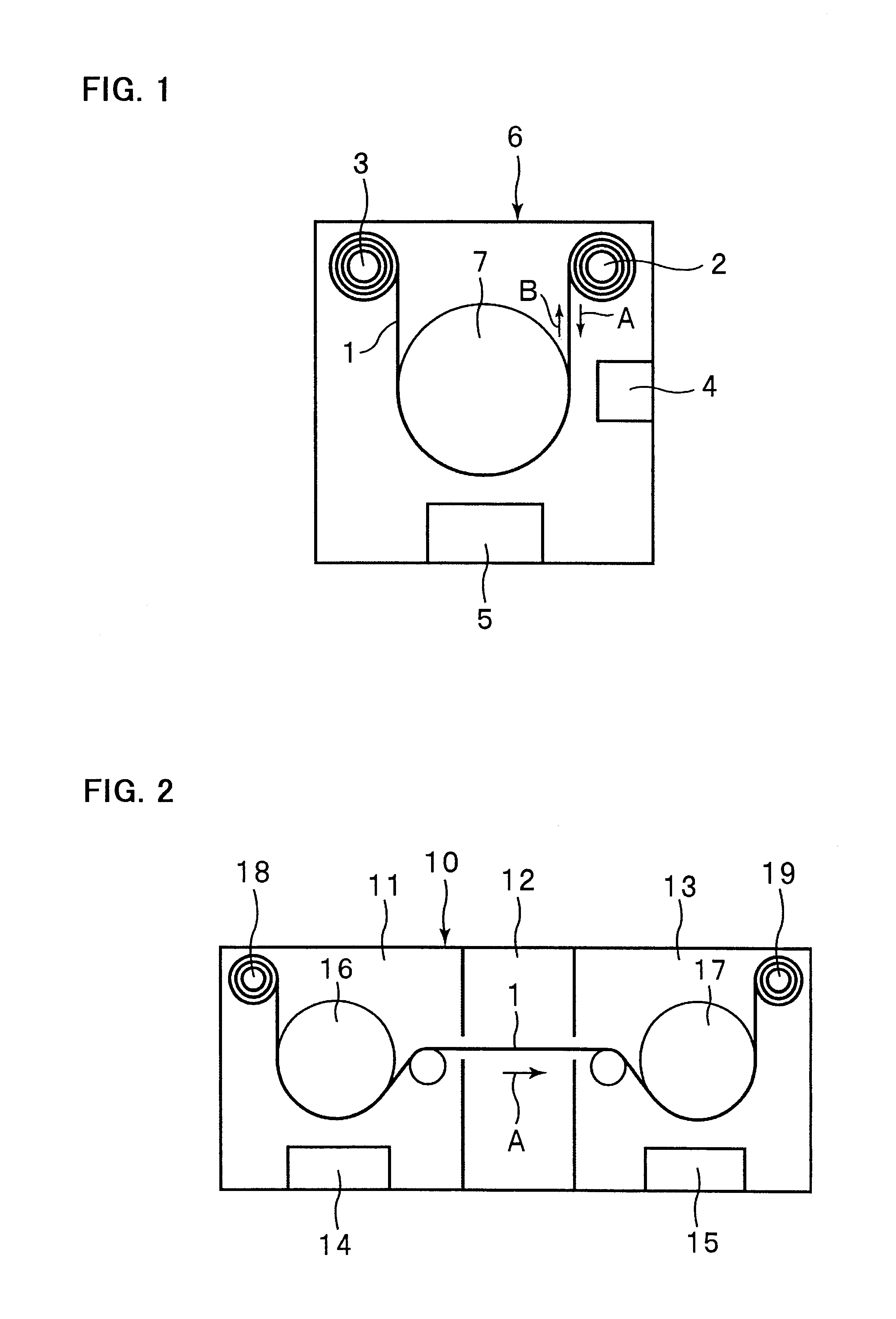

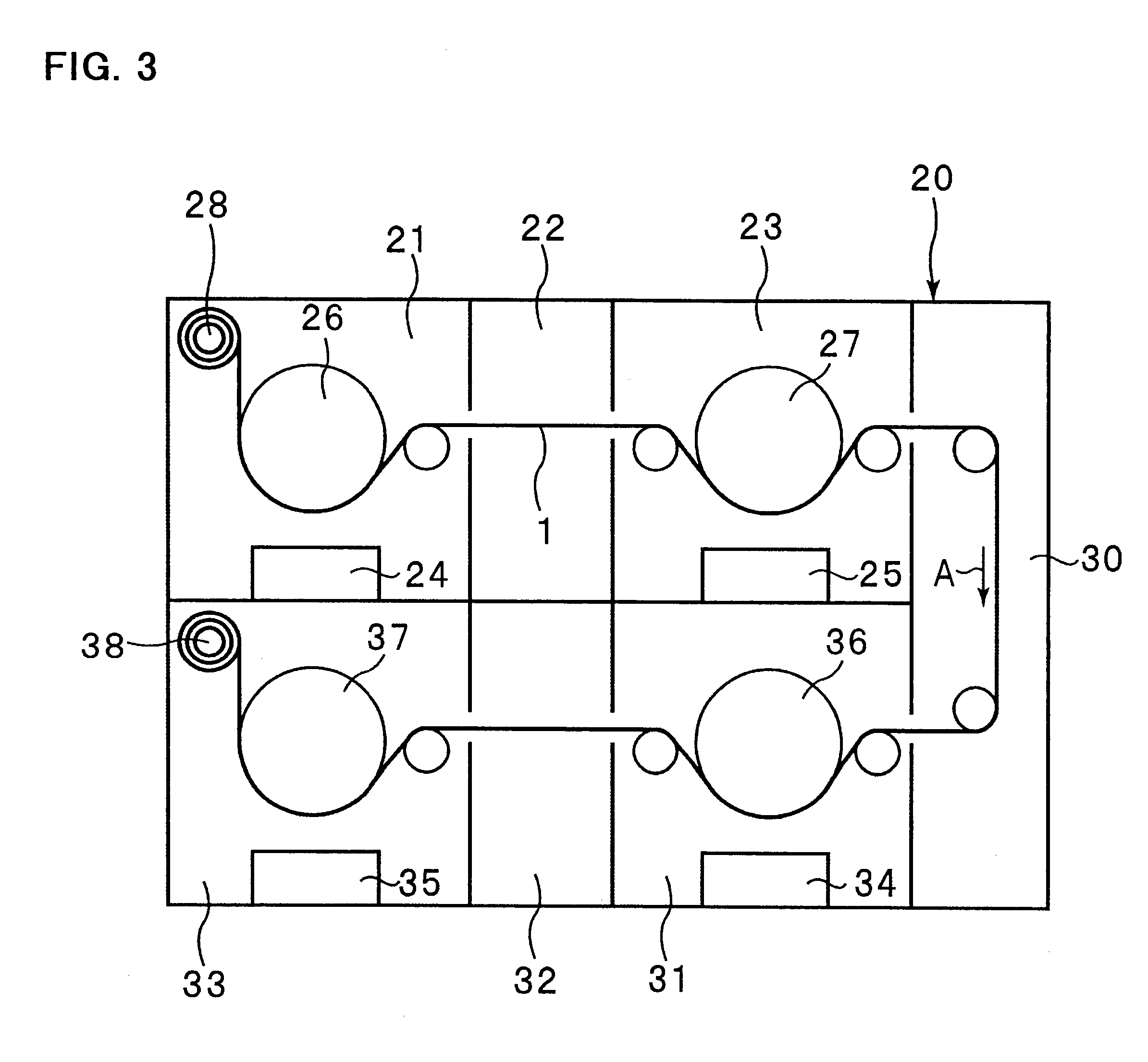

Electrode for lithium batteries and rechargeable lithium battery

InactiveUS7410728B1Improve charge and discharge cycle characteristicsImprove featuresElectrode carriers/collectorsPrinted batteriesAmorphous siliconOptoelectronics

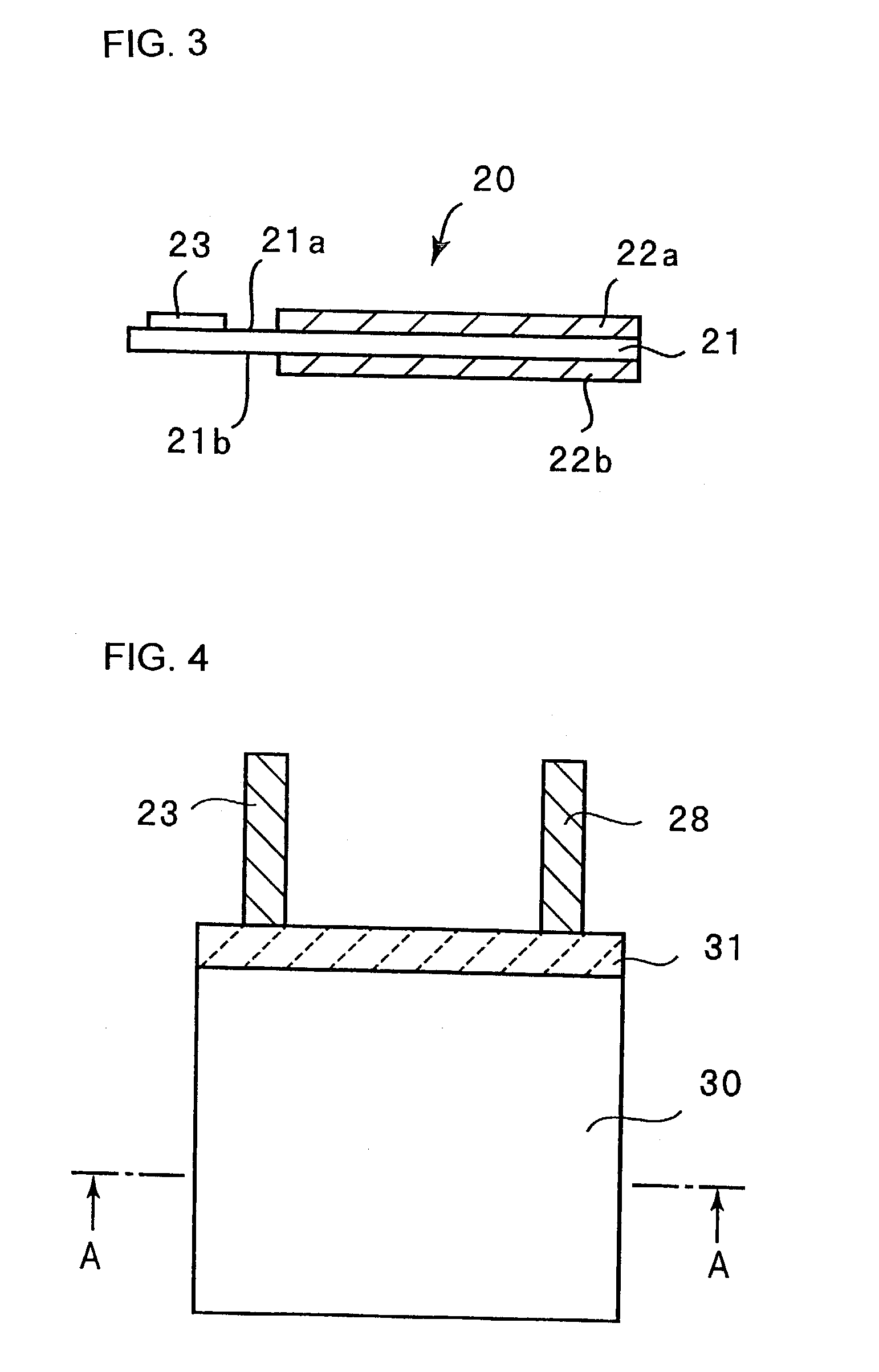

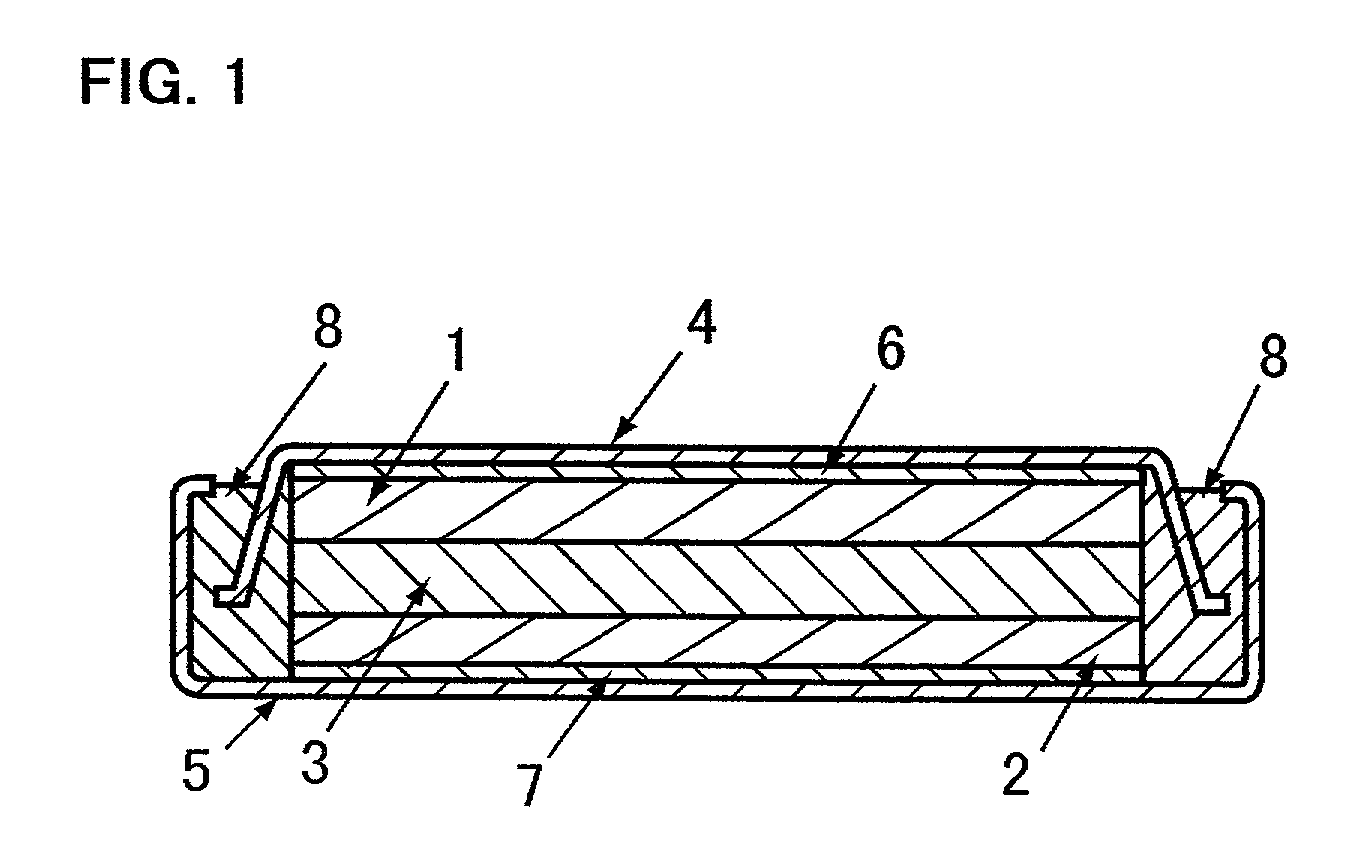

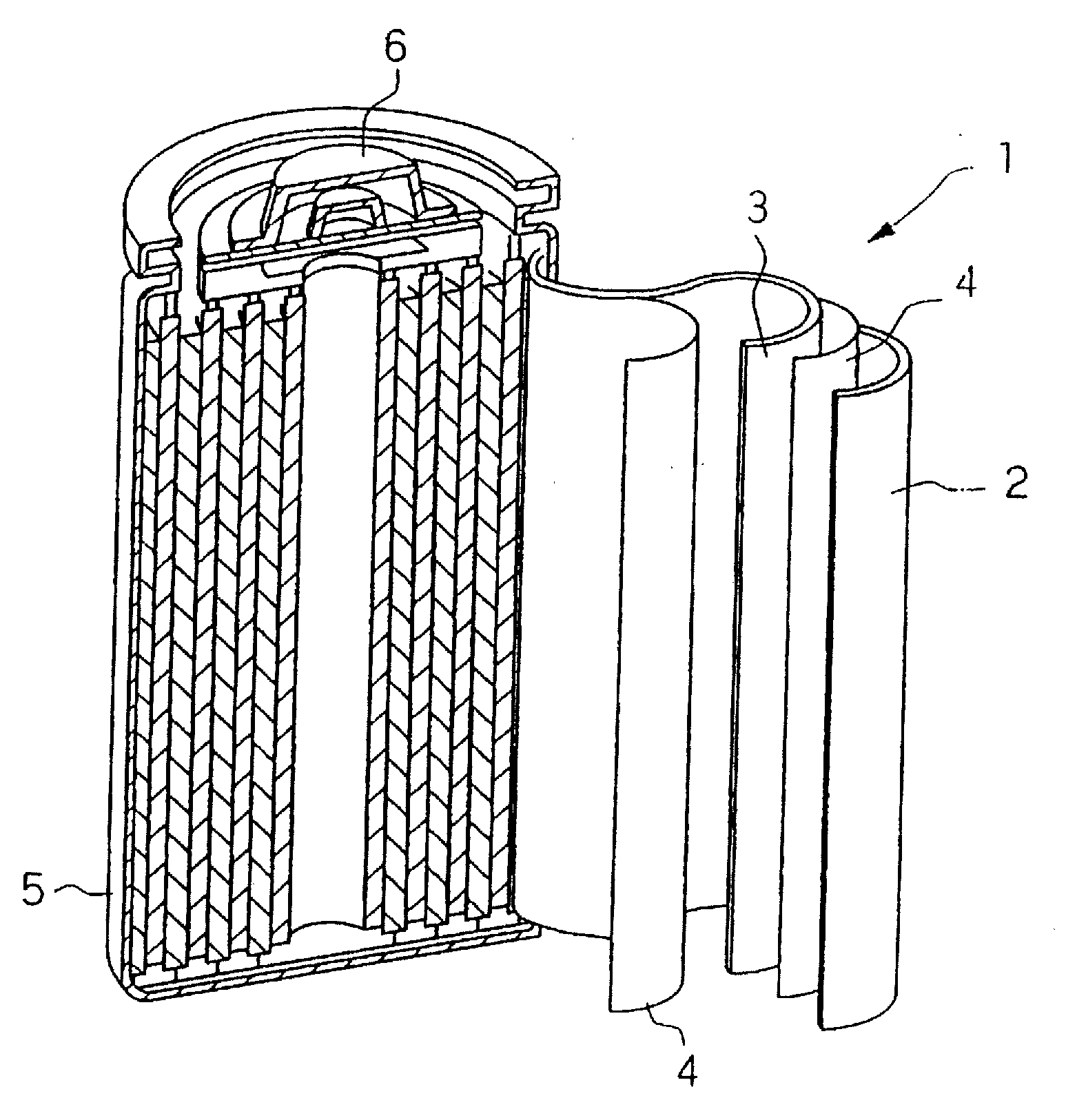

An electrode for lithium batteries, in which a thin film of active material capable of storage and release of lithium, such as a microcrystalline or amorphous silicon thin film, is provided, through an interlayer, on a current collector, the electrode being characterized in that the interlayer comprises a material alloyable with the thin film of active material.

Owner:SANYO ELECTRIC CO LTD

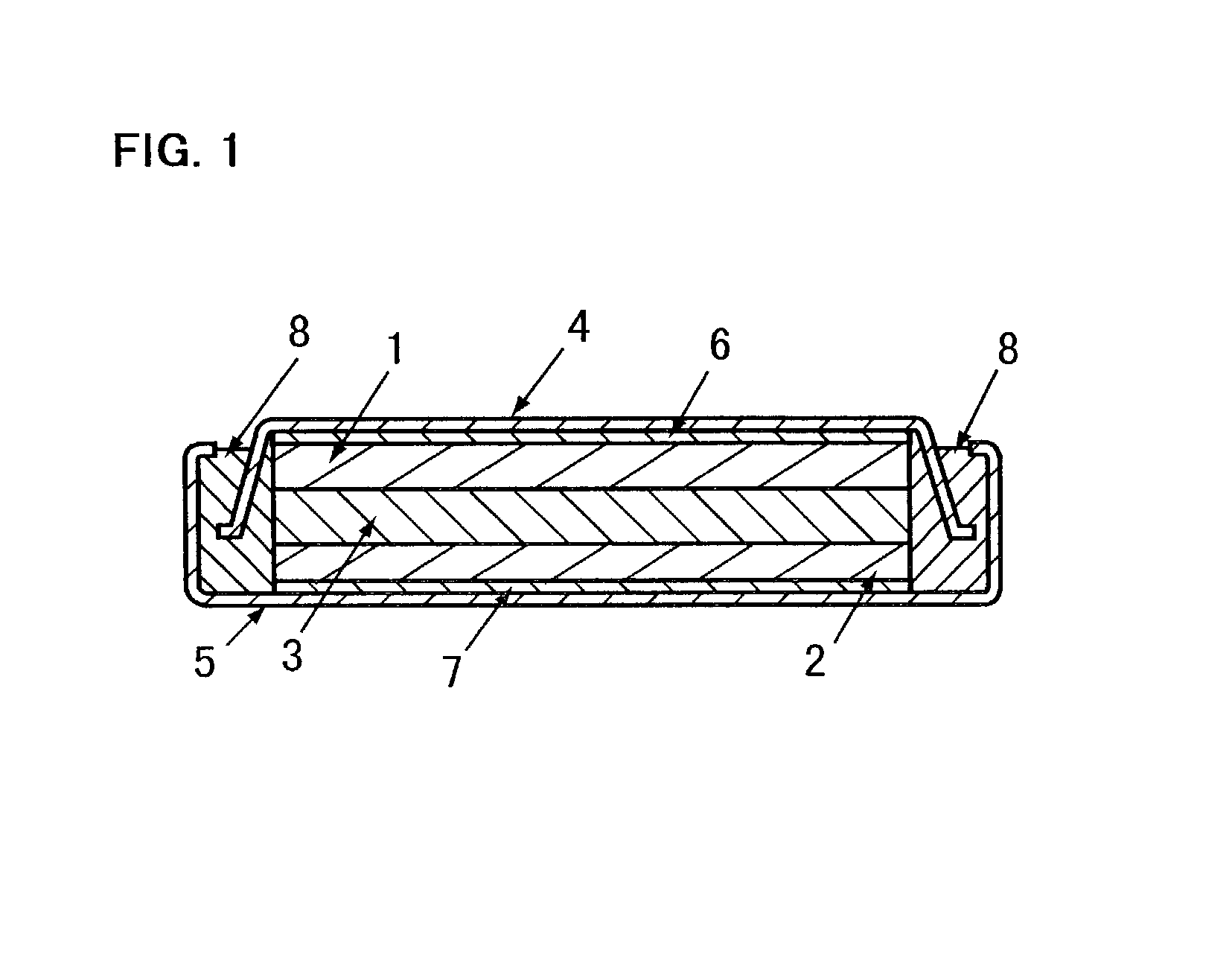

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7241533B1High charge and discharge capacityImprove charge and discharge cycle characteristicsElectrode manufacturing processesFinal product manufactureAmorphous siliconEngineering

An electrode for a rechargeable lithium battery characterized in that thin films of active material capable of lithium storage and release, i.e., microcrystalline or amorphous silicone thin films are deposited on opposite faces of a plate-form current collector.

Owner:SANYO ELECTRIC CO LTD

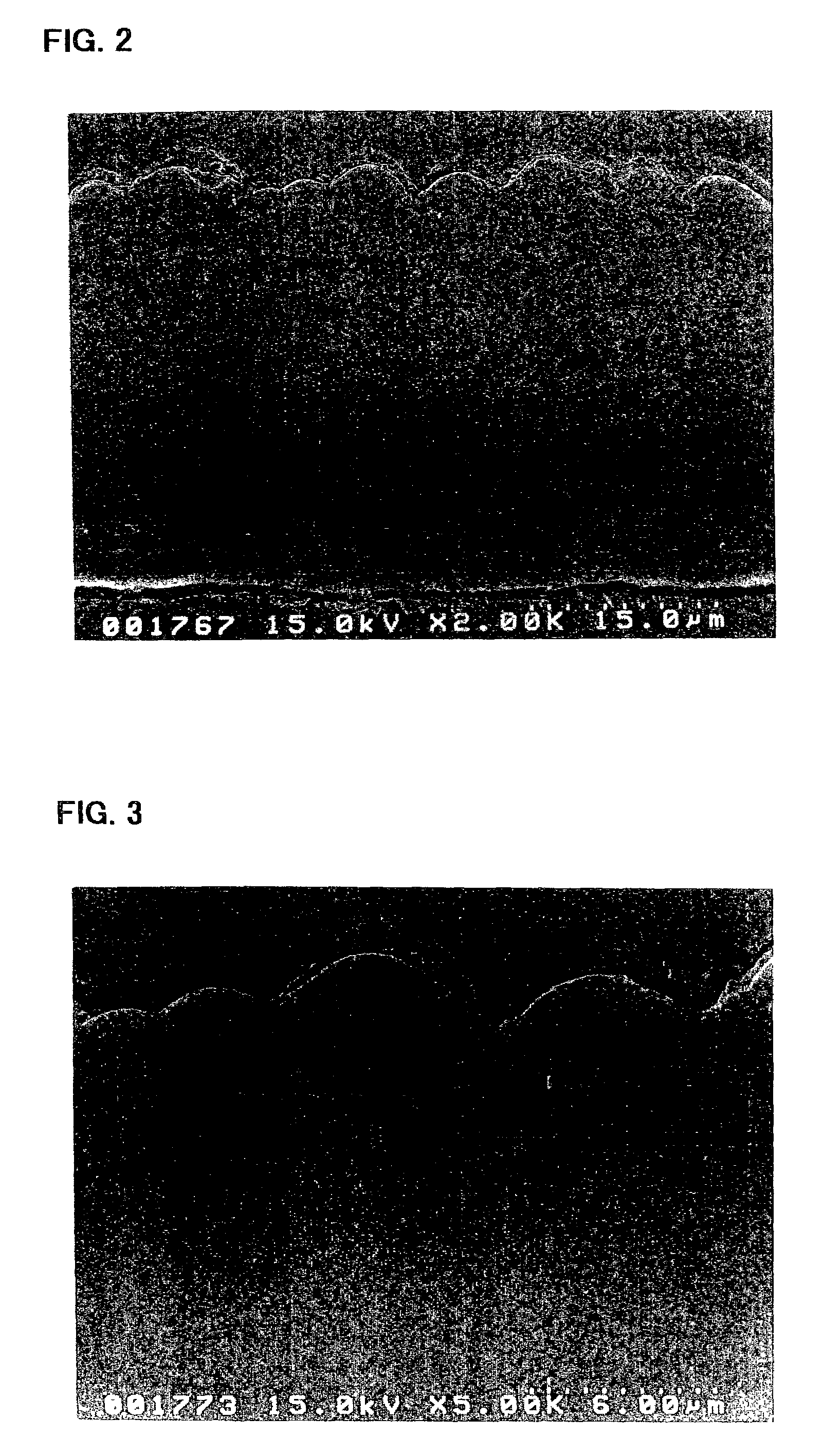

Electrode for use in lithium battery and rechargeable lithium battery

InactiveUS7195842B1High charge and discharge capacityImprove featuresElectrode manufacturing processesSmall-sized cells cases/jacketsPhysical chemistryAmorphous silicon

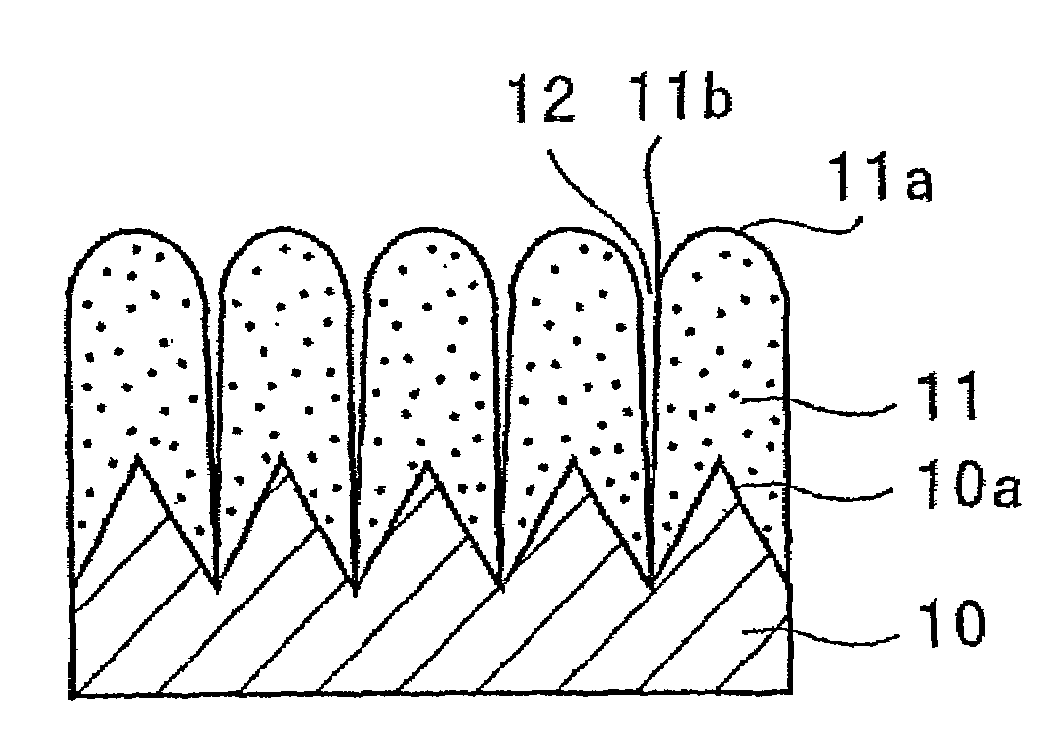

In an electrode for a lithium battery having a lithium storing and releasing active thin film provided on a current collector, such as a microcrystalline or amorphous silicon thin film, the electrode is characterized in that the thin film is divided into columns by gaps formed therein in a manner to extend in its thickness direction and that the columnar portions are at their bottoms adhered to the current collector.

Owner:SANYO ELECTRIC CO LTD

Negative active material including metal nanocrystal composite, method of preparing the same, and anode and lithium battery including the negative active material

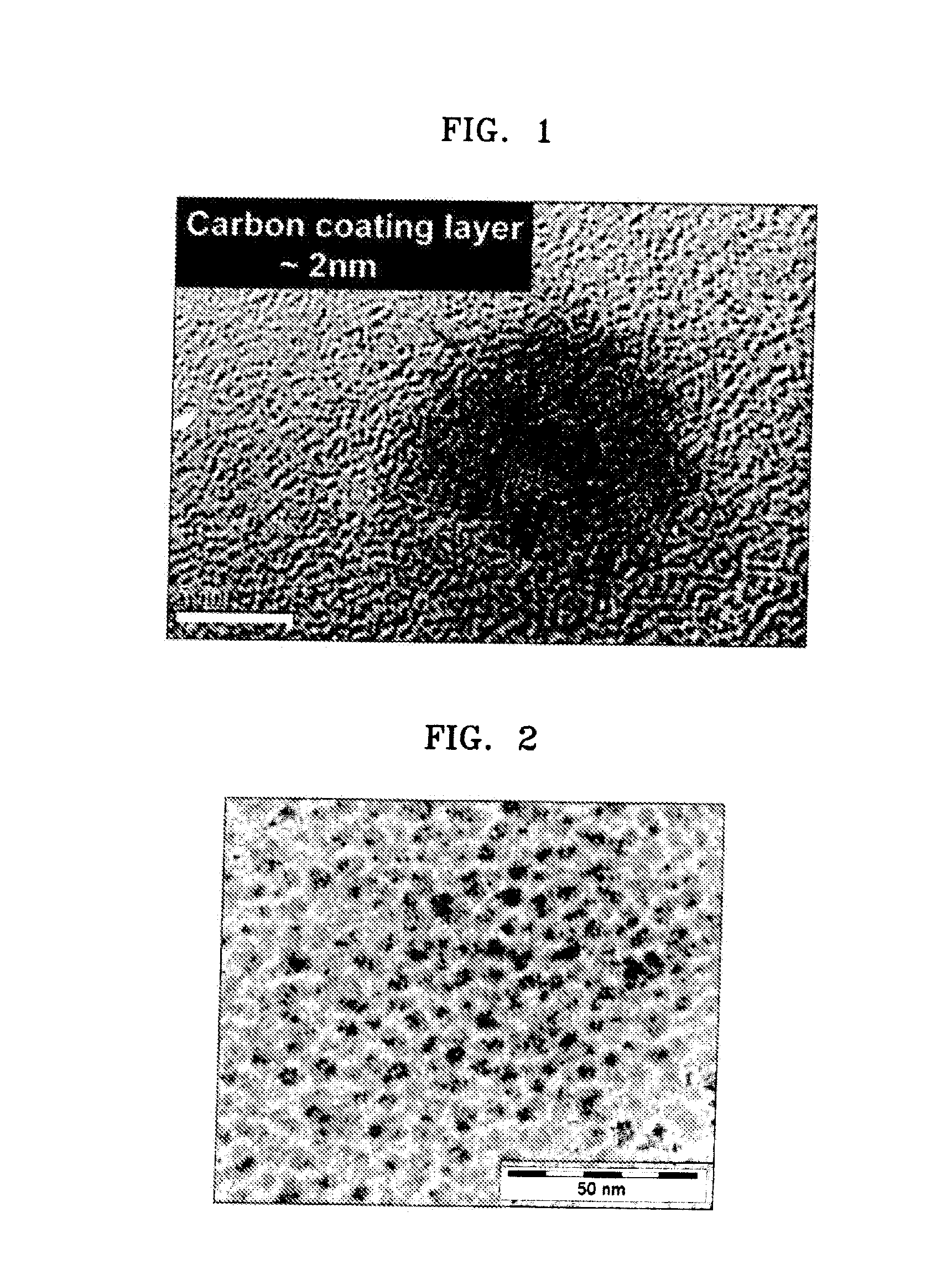

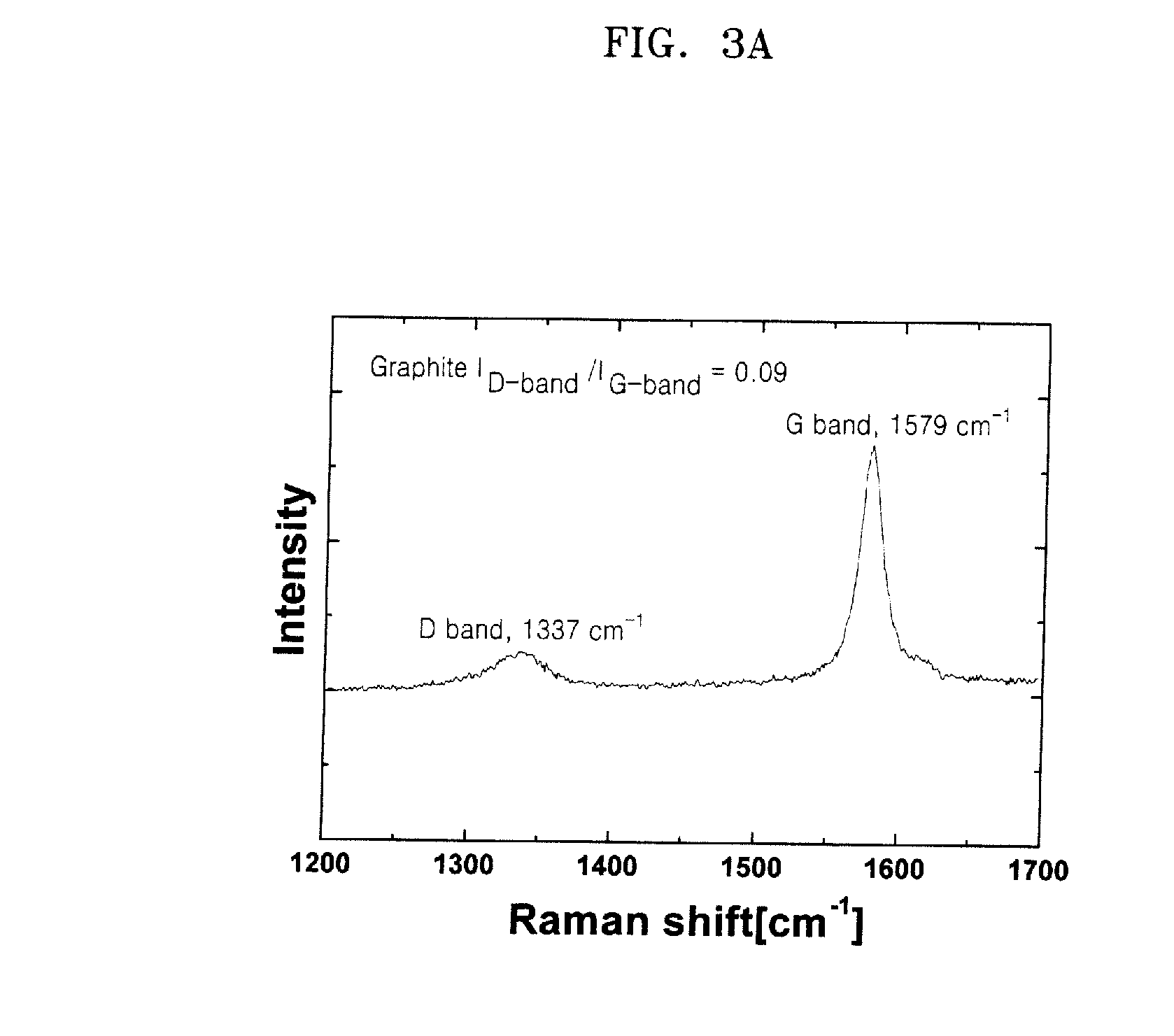

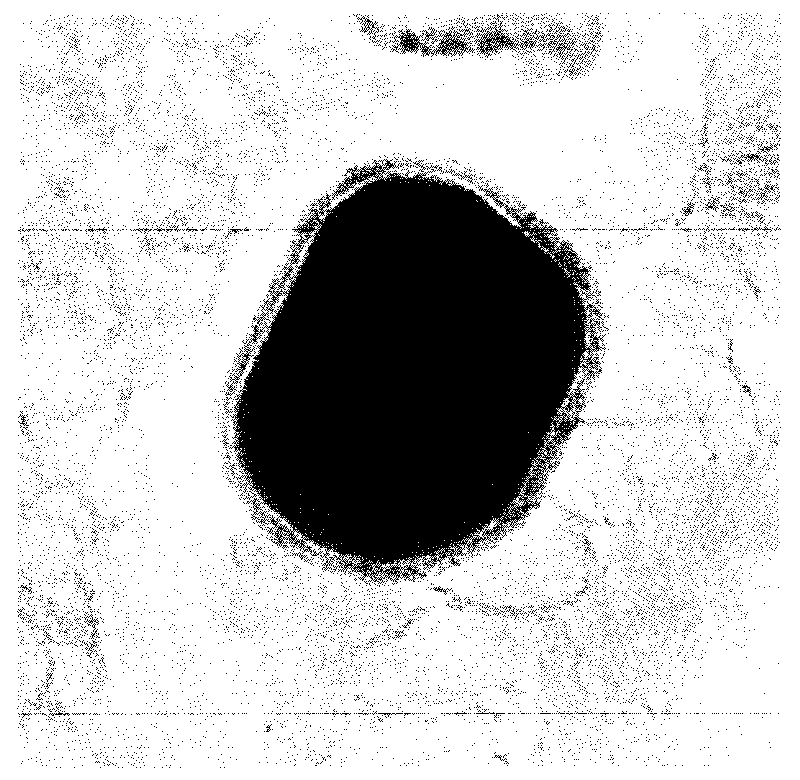

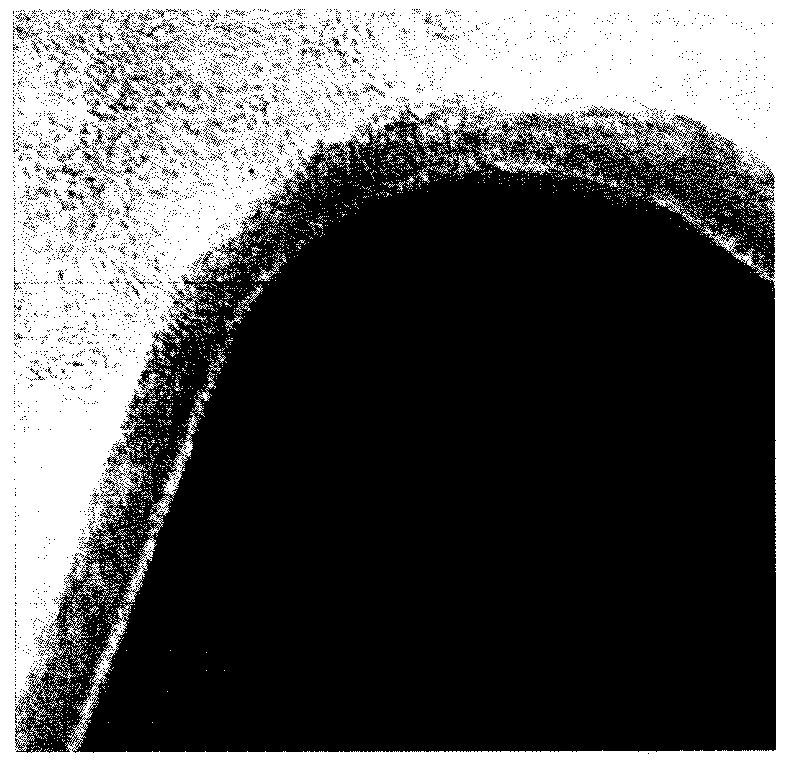

InactiveUS20070264574A1Reduce formationHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerCarbon coating

Negative active materials including metal nanocrystal composites comprising metal nanocrystals having an average particle diameter of about 20 nm or less and a carbon coating layer are provided. The negative active material includes metal nanocrystals coated by a carbon layer, which decreases the absolute value of the change in volume during charge / discharge and decreases the formation of cracks in the negative active material resulting from a difference in the volume change rate during charge / discharge between metal and carbon. Therefore, high charge / discharge capacities and improved capacity retention capabilities can be obtained.

Owner:SAMSUNG SDI CO LTD

Core-shell composite anode material for lithium ion battery and preparation method thereof

ActiveCN101740752AImprove conductivityHigh specific capacitySecondary cellsIron compoundsLithium iron phosphateElectrical battery

The invention discloses a core-shell composite anode material for a lithium ion battery. The composite anode material has a core-shell structure; the core-shell structure consists of a core-layer active material and a shell-layer active material; the core-layer active material is LiFePO4 or lithium manganate; the shell-layer active material is carbon-containing LiFePO4; the LiFePO4 has an Li1-XMXFePO4 or LiFe1-yMyPO4 structure; the lithium manganate has a LiMnO2 or LiMn2O4 structure; the carbon is selected from one or more of carbon nano tubes, superfine conductive black and an agraphitic carbon material; and the composite anode material comprises 65 to 99 mass percent of core-layer active material and 1 to 35 mass percent of shell-layer active material. The composite anode material of the invention has stable performance and excellent electrochemical properties; and the lithium ion battery manufactured by using the material has relatively high charge-discharge capacity and excellent cycle performance, can perform quick charging and large multiplying-factor discharging, can adapt to an ultra-low temperature working environment and is safe and stable.

Owner:SHENZHEN DYNANONIC

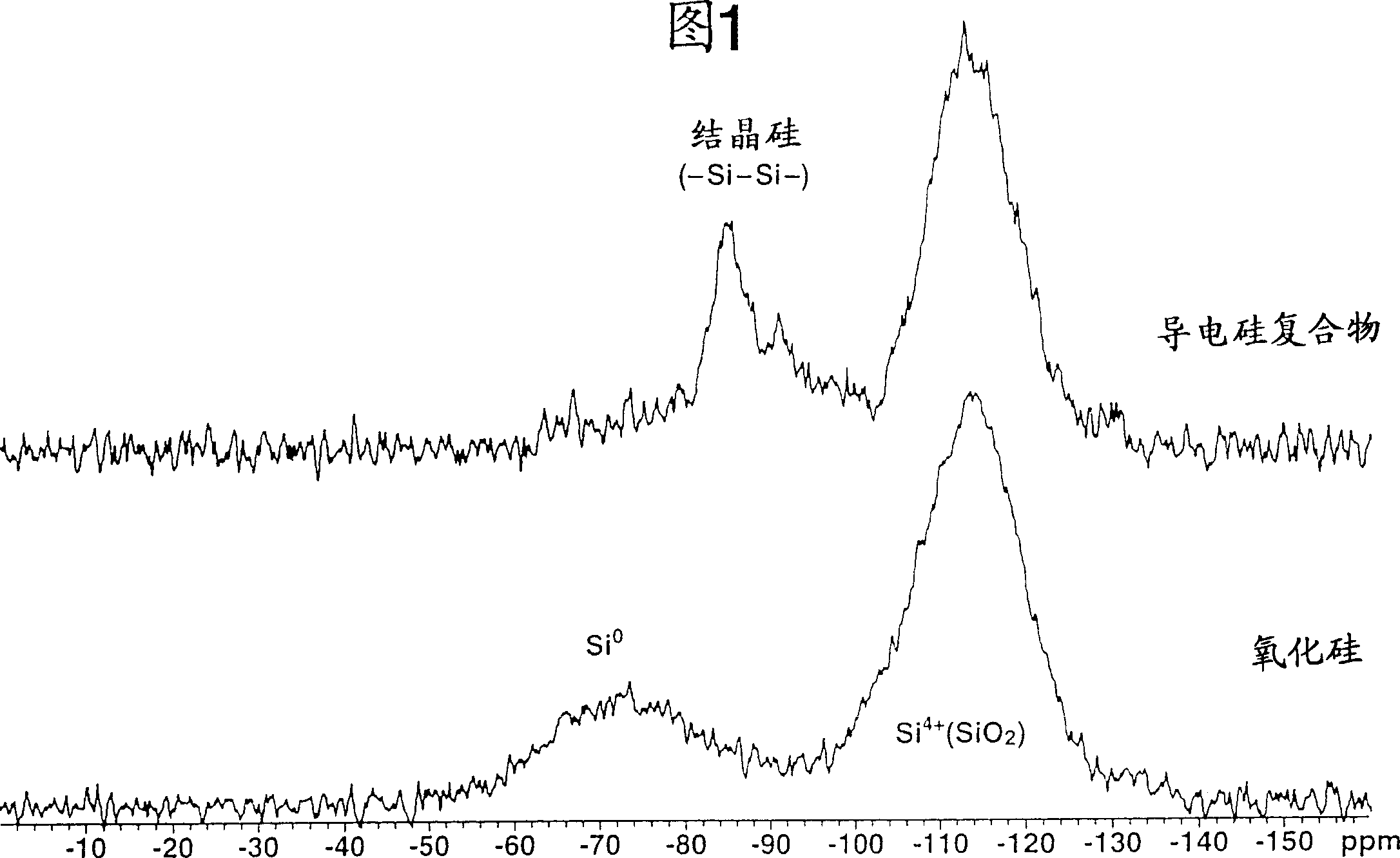

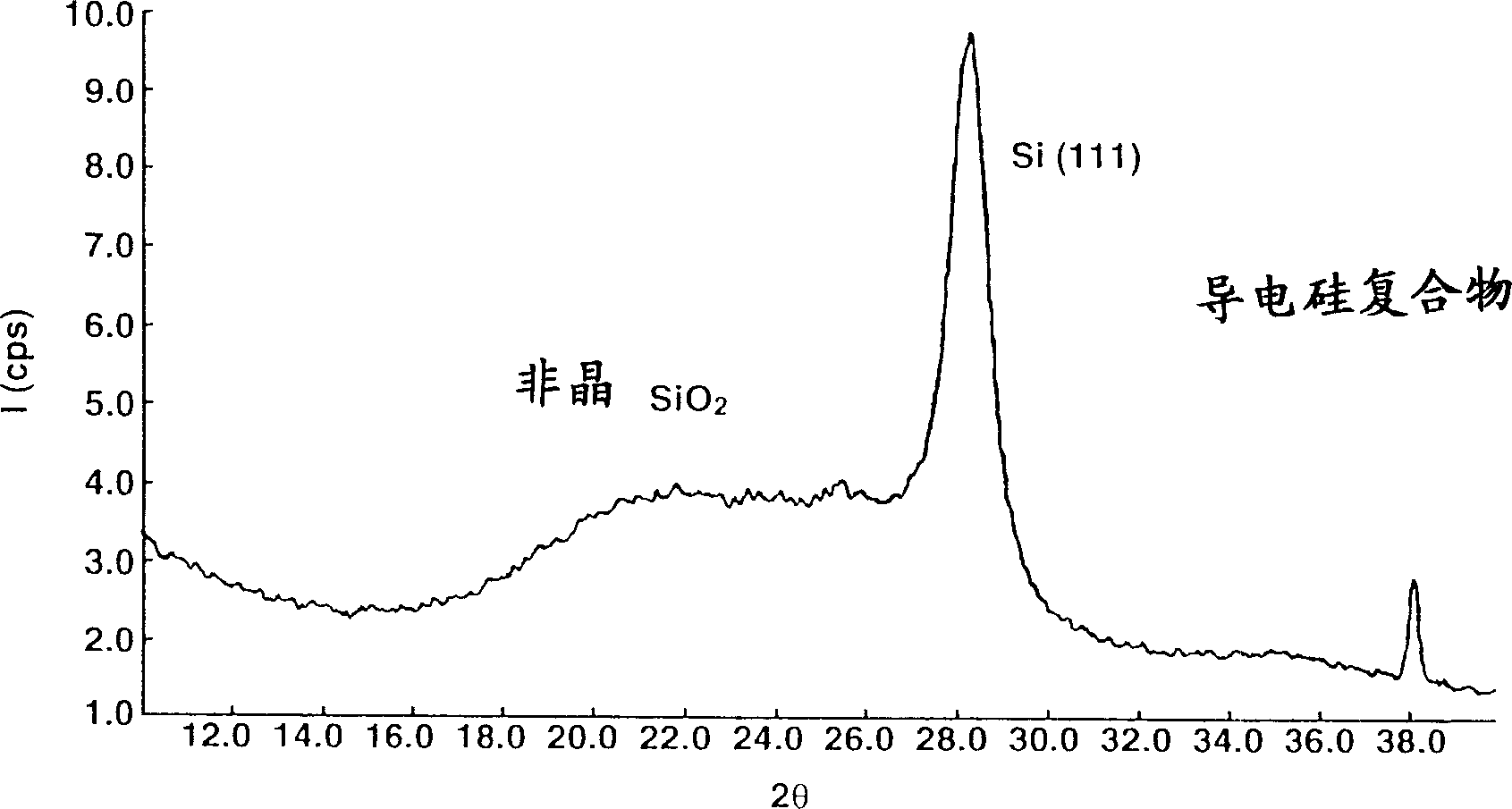

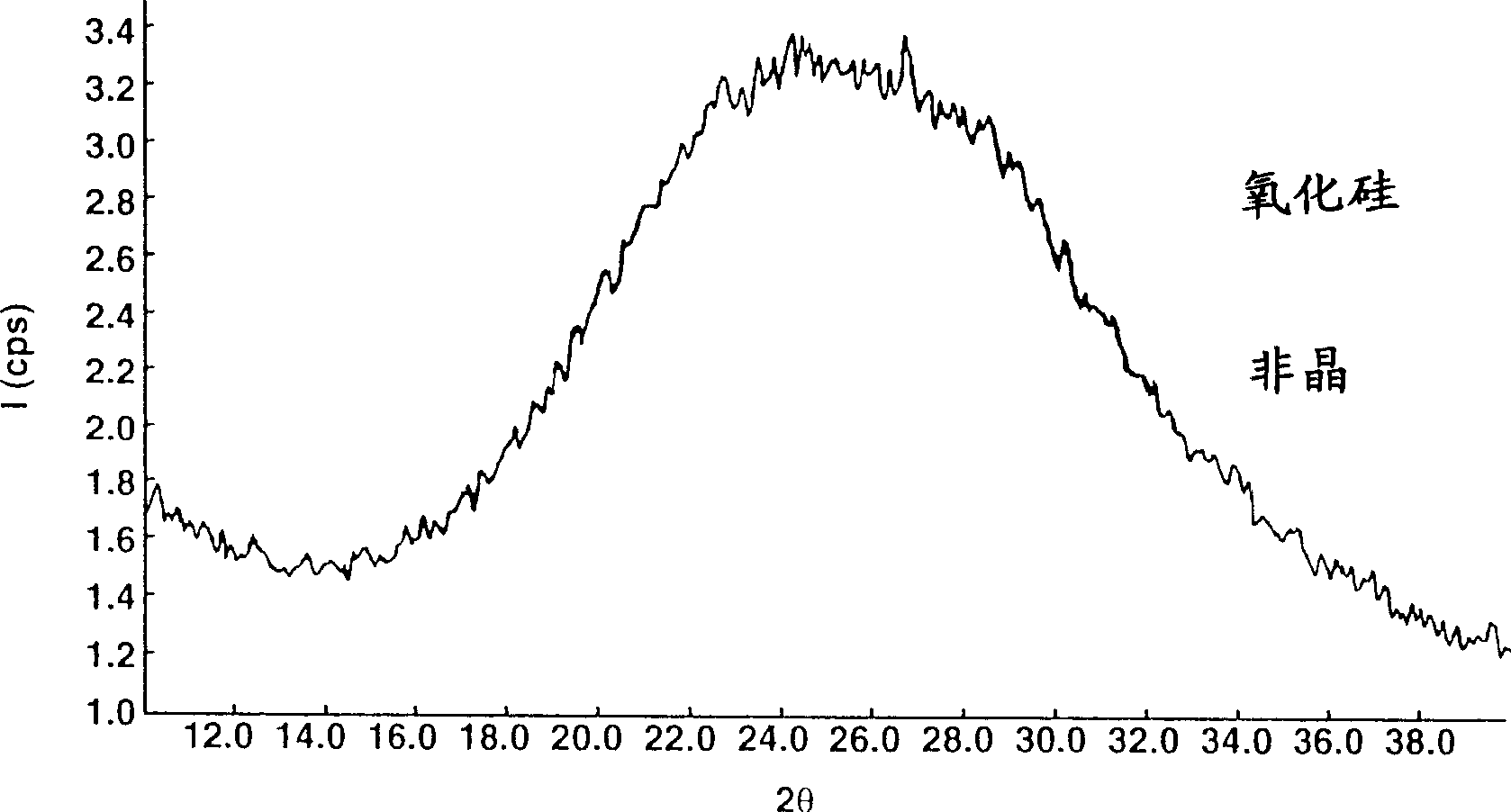

Conductive silicon compound, its preparation and negative electrode material of non-aqueous electrolyte secondary battery

InactiveCN1513922AImprove cycle performanceAvoid defectsMaterial nanotechnologyInorganic pigment treatmentSilicon dioxideSilicon

A conductive silicon composite in which particles having a structure in which crystallites of silicon are dispersed in silicon dioxide are coated on their surfaces with carbon affords satisfactory cycle performance when used as the negative electrode material in a non-aqueous electrolyte secondary cell.

Owner:SHIN ETSU CHEM IND CO LTD

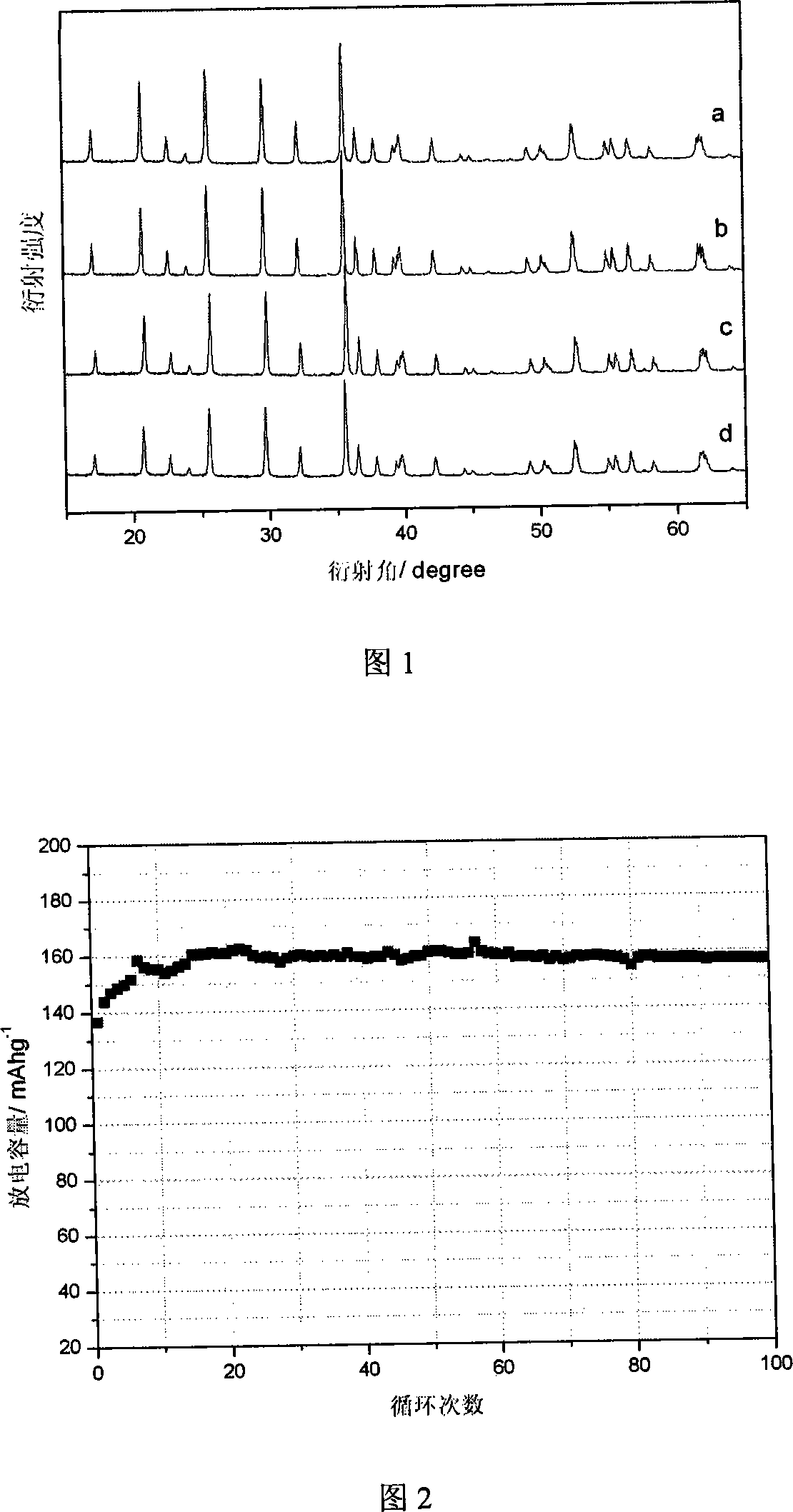

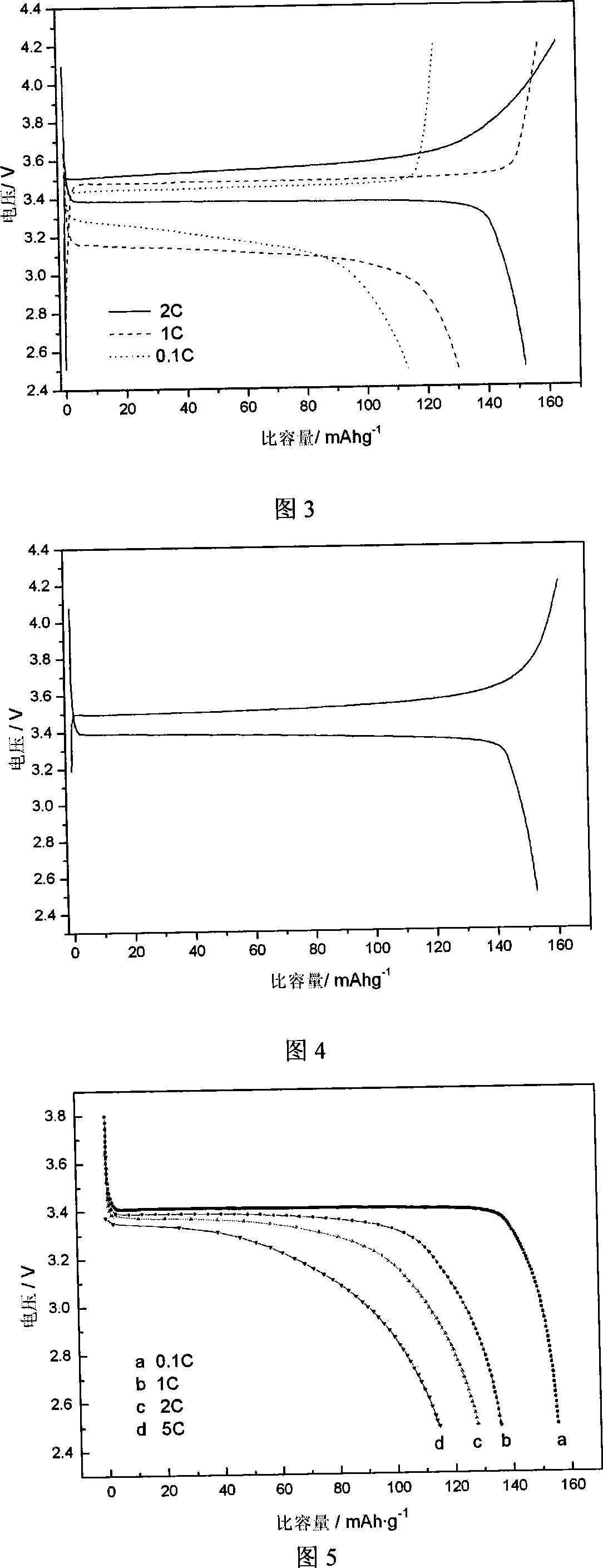

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Nonflammable non-aqueous electrolyte and non-aqueous electrolyte cells comprising the same

InactiveUS6924061B1Improve rate performanceEffective and stableElectrolytic capacitorsOrganic electrolyte cellsPhysical chemistryCarbonate

A non-aqueous electrolyte to be used in a Li-ion battery includes a lithium salt, a cyclic carbonate, a linear carbonate and an alkyl fluorinated phosphate, of the following general formula wherein R1, R2 and R3, independently, are selected from the group consisting of straight and branched alkyl groups having 1-5 carbon atoms, and at least one of said alkyl groups is fluorinated, with the locations of said fluorination being at least β-positioned away from the phosphorous of said phosphate, such that said alkyl phosphate has a F / H ratio of at least 0.25, and said electrolyte solution is non-flammable.

Owner:ARMY US SEC THE

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

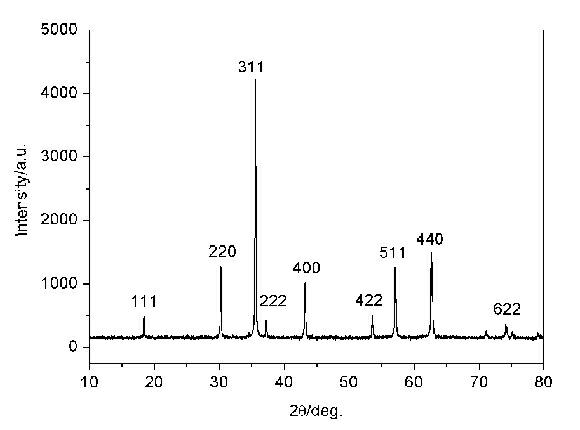

Nano lithium iron phosphate material and preparation method thereof

InactiveCN101546830ASolve the real problemSmall particlesElectrode manufacturing processesChemical/physical/physico-chemical processesChemical compositionLithium iron phosphate

The invention relates to a nano lithium iron phosphate material and a preparation method thereof. A lithium source, an iron source, a phosphate radical source and a doped element compound are dissolved in water solution containing a complexing agent according to a stoichimetric proportion and added with high-conductive carbon nano tubes scattered by assistant to form a cladding material, the obtained solution is sintered in an inert atmosphere furnace, the reaction temperature is between 500 and 900 DEG C, and the reaction time is 3 to 16 hours. The method effectively controls the chemical components, phase components and grain diameters of LiFePO4; and the obtained lithium iron phosphate is the nano lithium iron phosphate clad by the carbon nano tubes, has fine and even grains with high purity, high charge / discharge capacity, good multiplying power performance and good cycle performance, and is an ideal material for manufacturing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

Graphene-coated mesoporous metallic oxide, and preparation method and use thereof

InactiveCN102437320AHigh charge and discharge capacityImprove cycle performanceCell electrodesMesoporous silicaSilicon dioxide

The invention relates to a graphene-coated mesoporous metallic oxide, and a preparation method and use thereof. The preparation method for the graphene-coated mesoporous metallic oxide comprises the following steps of: 1) synthesizing mesoporous metallic oxides with different pore passage structures by taking mesoporous silicon dioxides with the different pore passage structures as templates; 2) preparing a graphene oxide by using an oxidation method; 3) absorbing mesoporous metallic oxide particles on the surface of the graphene oxide by using a heterocoagulation method; 4) reducing the graphene oxide into graphene by adding a reducing agent; and 5) performing centrifugal separation, washing and drying. The graphene-coated mesoporous metallic oxide provided by the invention has high electrochemical properties, and can be used as an electrode material of a lithium battery.

Owner:BEIJING NORMAL UNIVERSITY

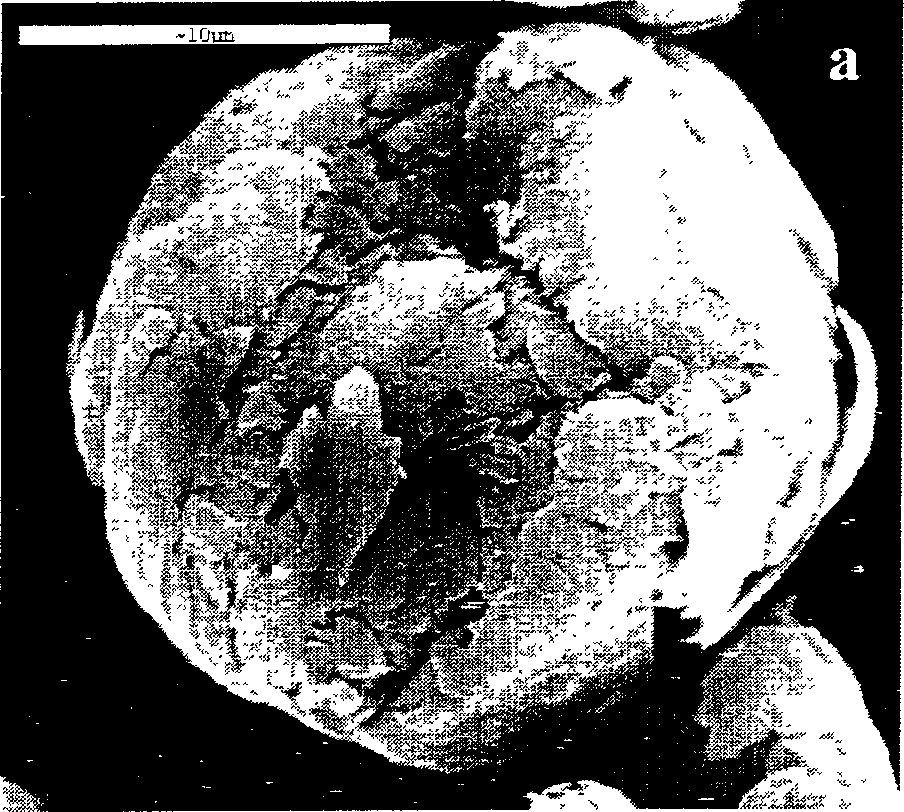

Anode active material, method of preparing the same, and anode and lithium battery containing the material

ActiveUS7767346B2Excellent initial charge/discharge efficiencyHigh charge and discharge capacityMaterial nanotechnologyElectrode manufacturing processesDischarge efficiencyNanowire

An anode active material comprises metal core particles, metal nano wires formed on the metal core particles, pores between the metal core particles and the metal nano wires, and a carbon-based coating layer formed on a surface of the metal core particles and metal nano wires. In the anode active material according to the present invention, the metal core particles and metal nano wires are combined to form a single body, and a carbon-based coating layer is formed on the surface of the metal nano wires and metal core particles. Thus, volume changes in the pulverized metal core particles can be effectively buffered during charging and discharging, and the metal core particles are electrically connected through the metal nano wires. As a result, volume changes in the anode active material and degradation of the electrode can be prevented, thereby providing excellent initial charge / discharge efficiency and enhanced charge / discharge capacity.

Owner:SAMSUNG SDI CO LTD

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

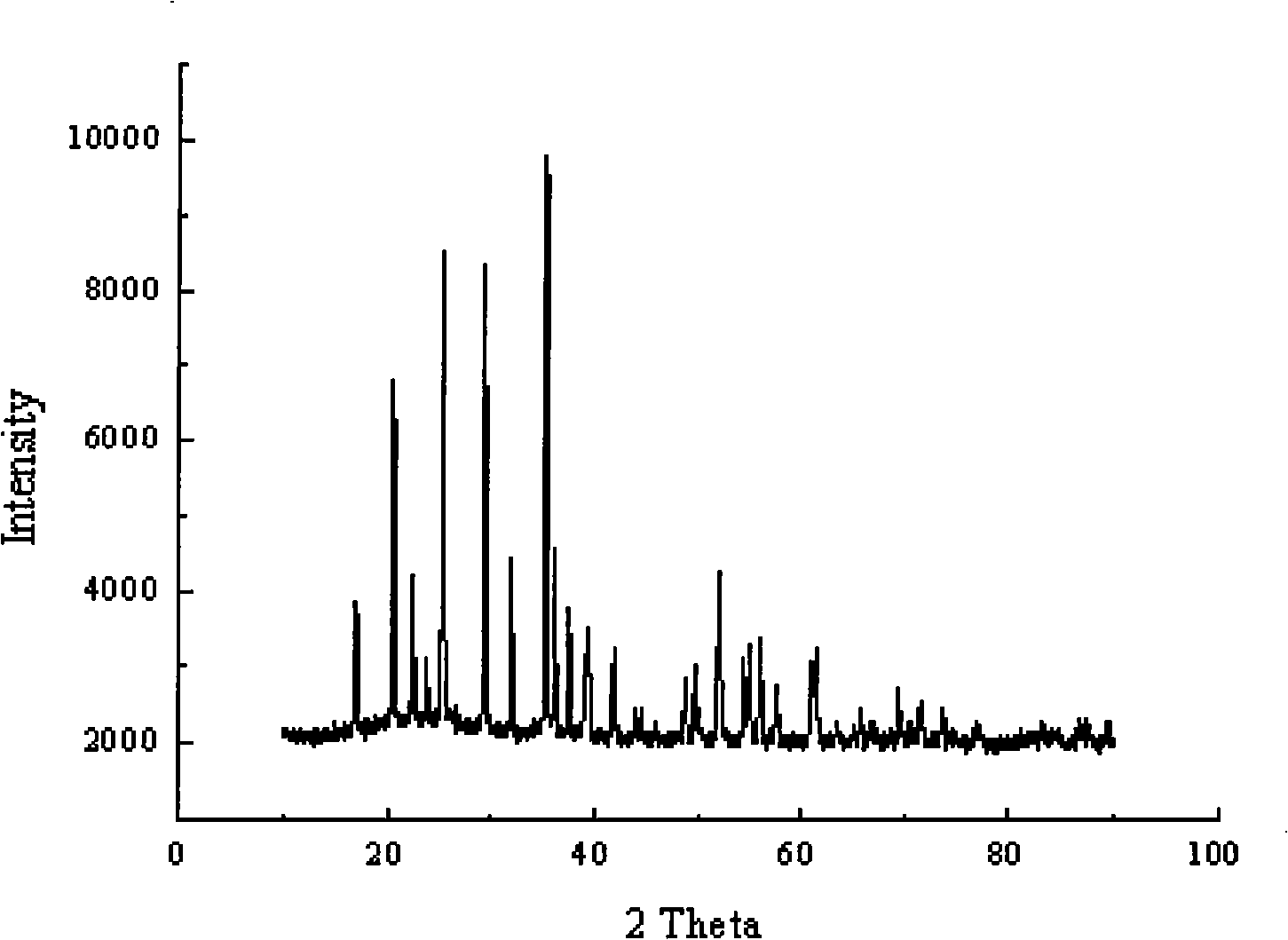

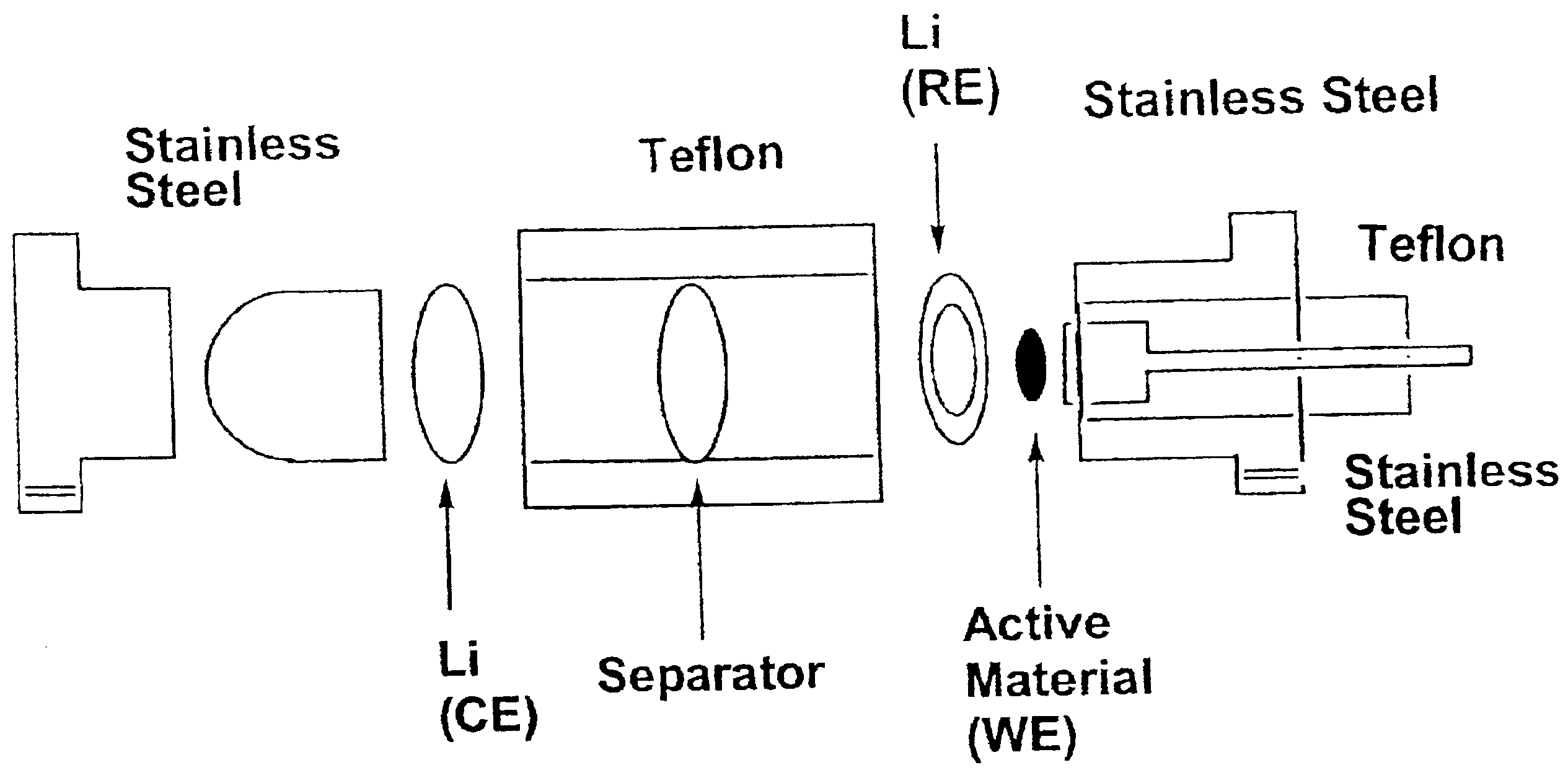

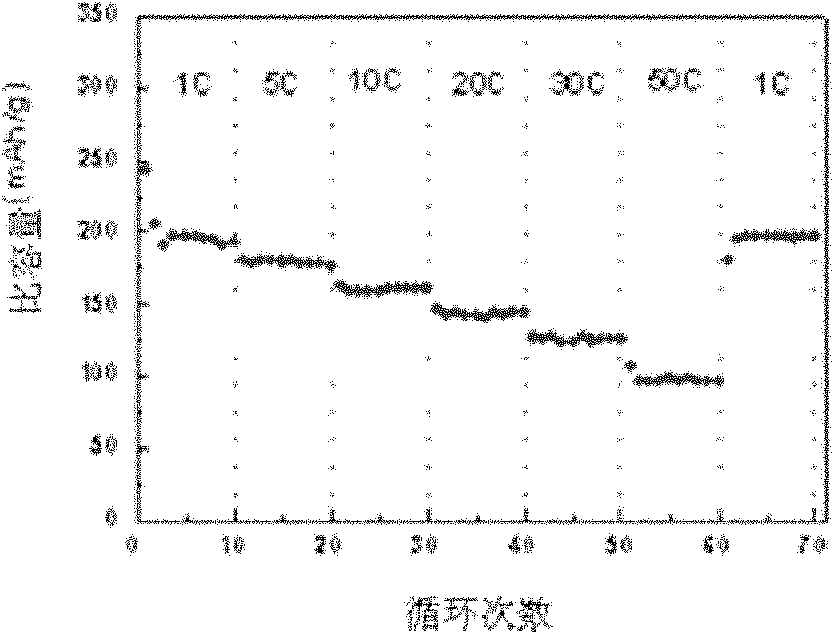

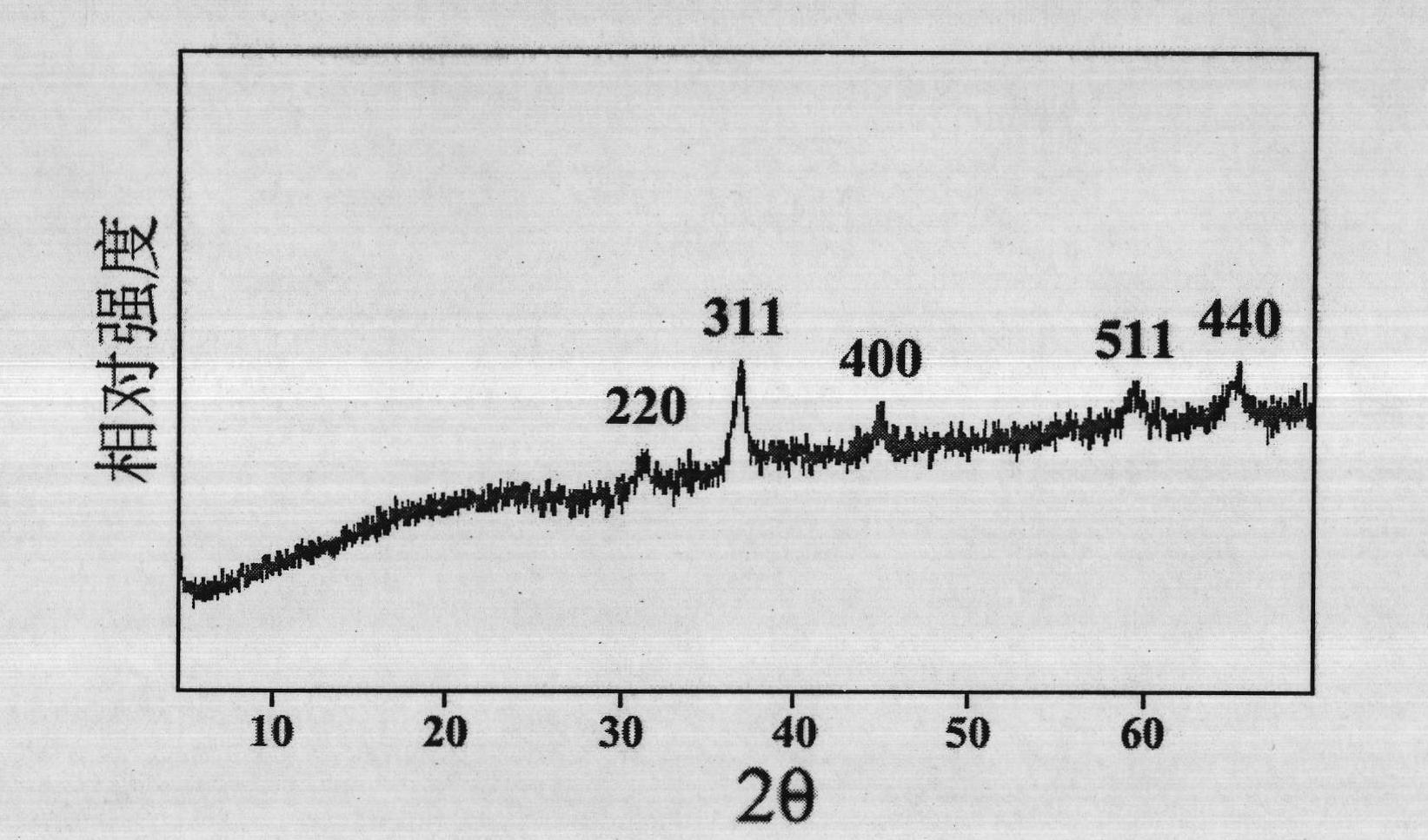

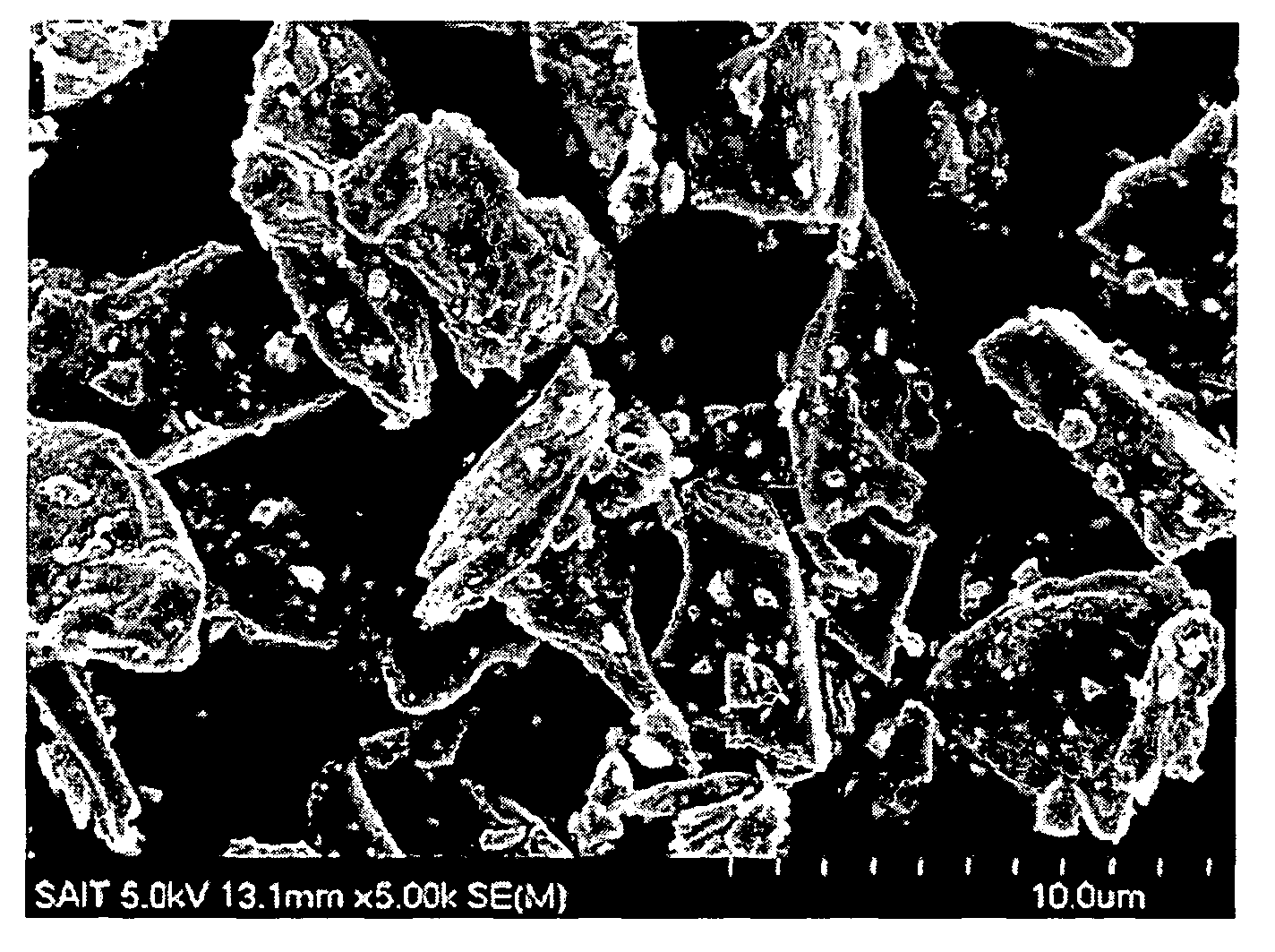

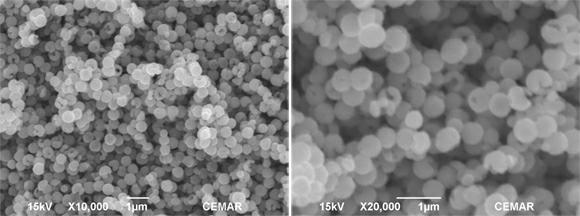

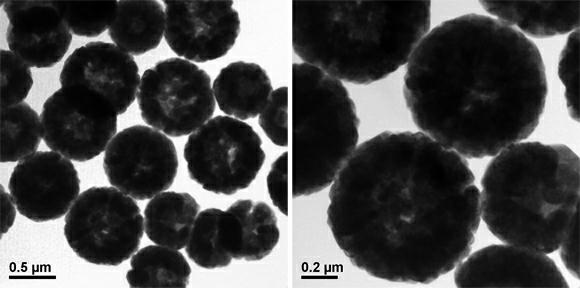

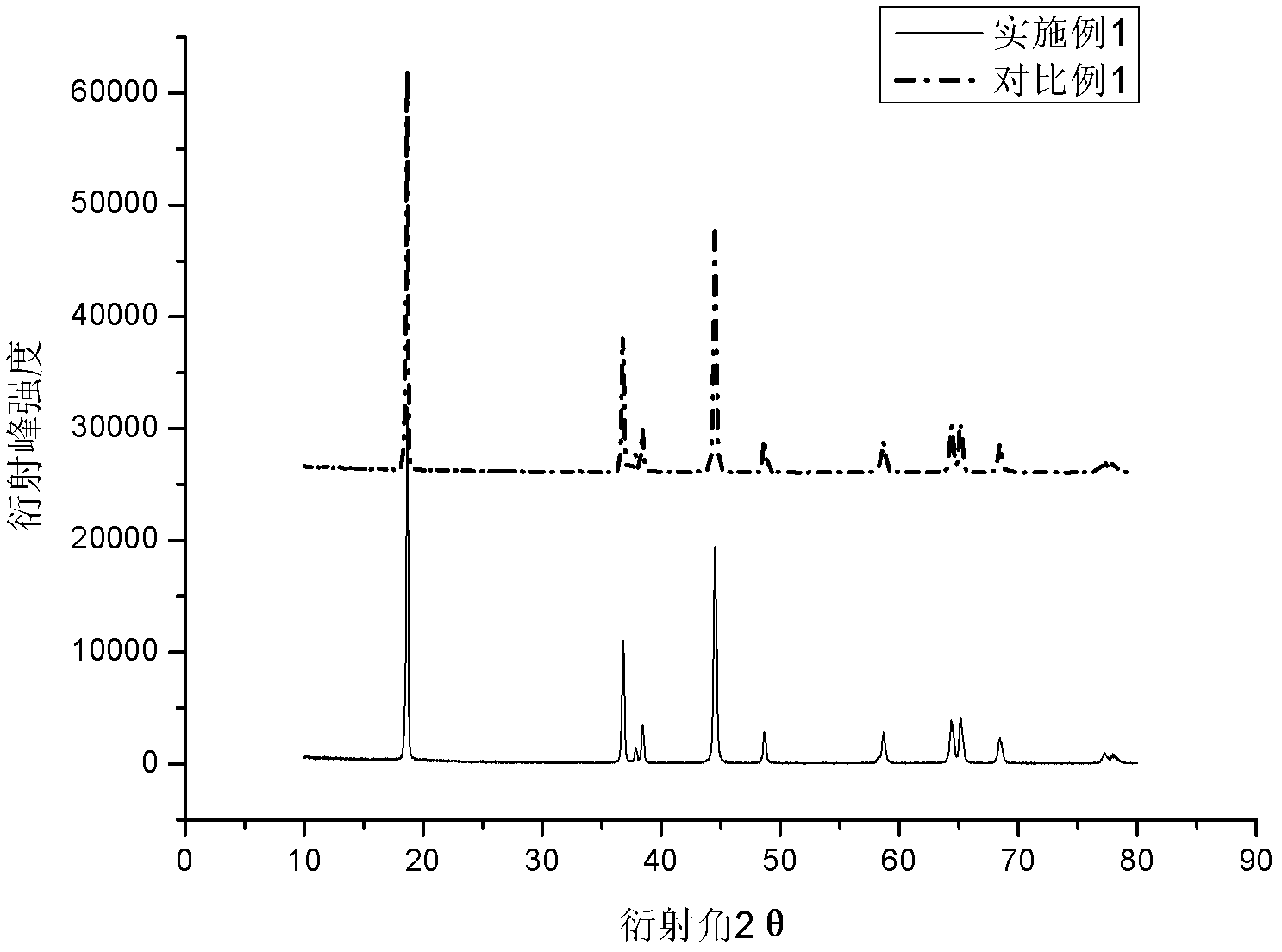

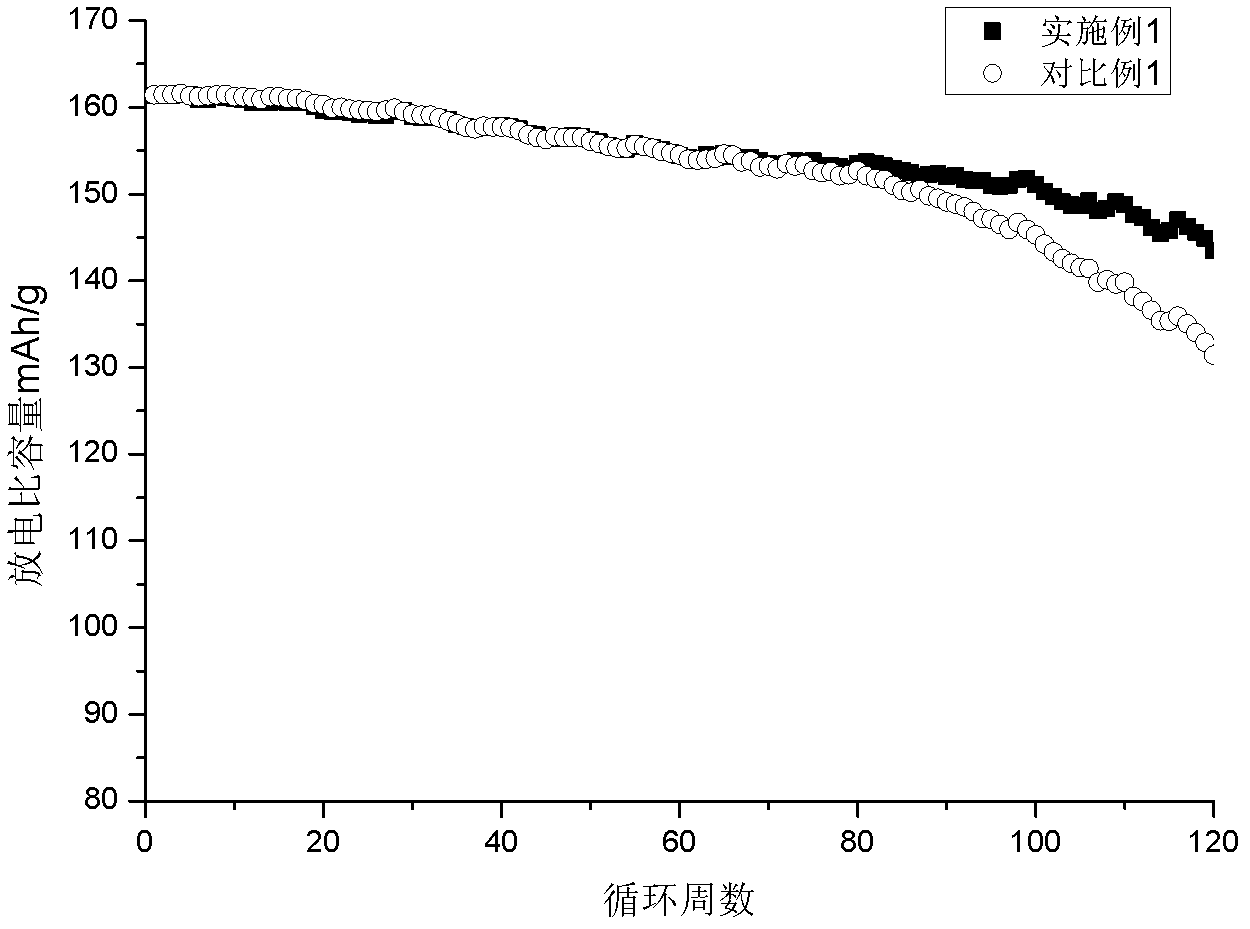

Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

The invention discloses a preparation method of a lithium-stored composite material Fe3O4 / C with a hollow sphere structure and an application of the lithium-stored composite material Fe3O4 / C with a hollow sphere structure in a lithium ion battery, belonging to the technical fields of material synthesis and high-energy lithium-ion storage batteries. The preparation method is characterized in that a solvothermal method or hydrothermal method is utilized to prepare the Fe3O4 / C composite material with a hollow sphere and narrower particle size distribution, wherein the Fe3O4 / C composite material is high in purity; and the mean particle size of the Fe3O4 / C composite material is 750 nanometers and the wall thickness of the Fe3O4 / C composite material is 250 nanometers. An electrochemical test proves that the first discharging specific capacity of the Fe3O4 / C composite material prepared by the method can be 1157mAh / g, and the discharging specific capacity of the Fe3O4 / C composite material can be 900mAh / g after being circulated for 65 times, thus showing the perfect cyclical stability. The Fe3O4 / C composite material has good rate performance; and the charging specific capacity of the Fe3O4 / C composite material is 620mAh / g and 460mAh / g respectively under 2C and 5C charge-discharge rates, thus the rate performance is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The Fe3O4 / C lithium ion battery cathode material is low in cost, simple in process and easy to industrialize, and has wide application prospects in the high-energy lithium ion battery field.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

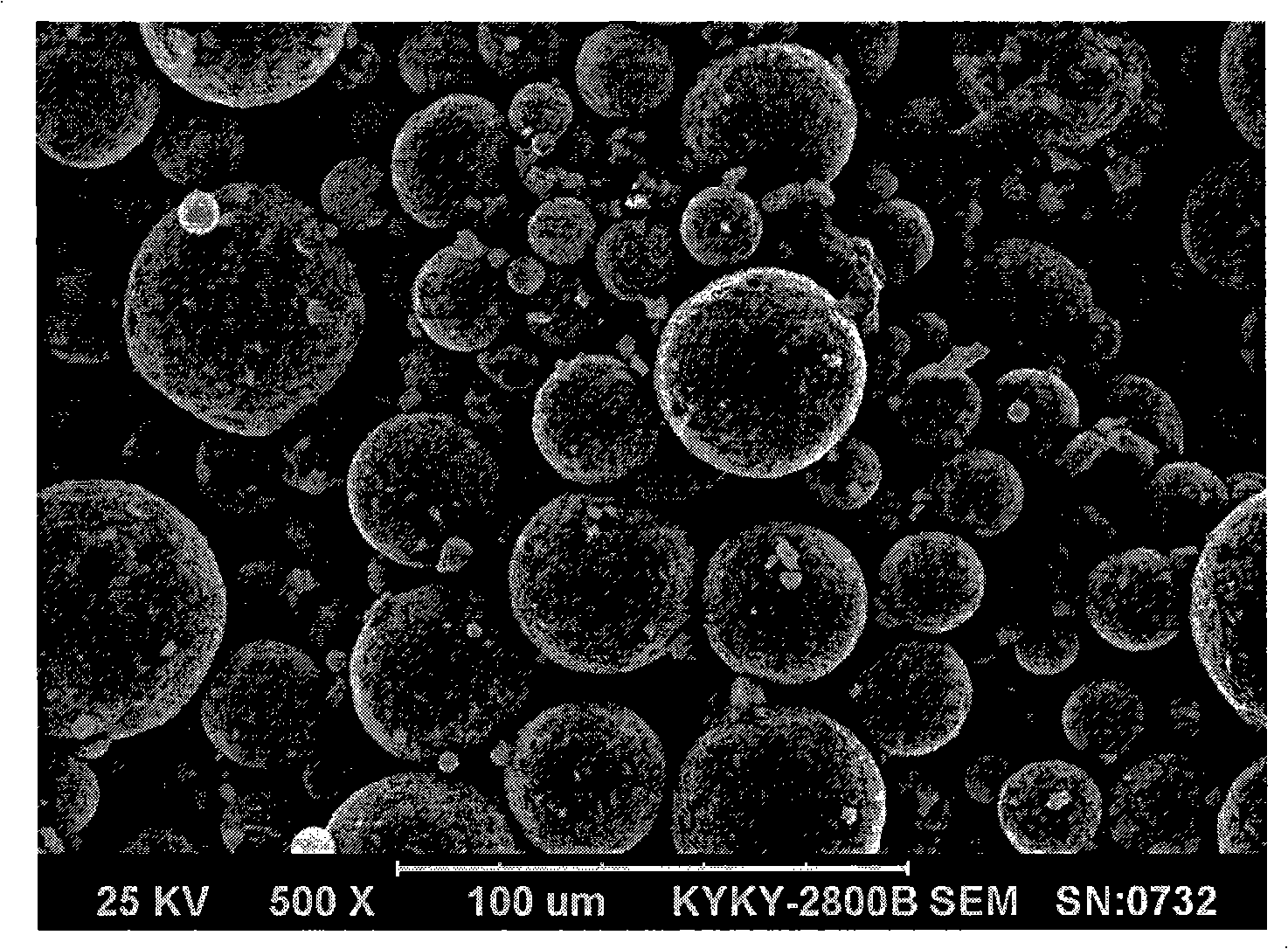

Multi-stage core and shell structure multi-element material, precursor thereof and preparation method for multi-stage core and shell multi-element material and precursor

InactiveCN102631875AHigh charge-discharge specific capacityGood cycle stability and thermal stability and safety performanceCell electrodesMicroballoon preparationLithium electrodeCompound structure

The invention relates to a multi-stage core and shell structure multi-element material precursor used for an anode material of a lithium ion battery. The molecular formula of the multi-stage core and shell structure multi-element material precursor is (1-x)Li[NiaMnbCo1-a-b][OH]2 x [NimConM1-m-n][OH]2, wherein M=Mn, Al, Mg andTi, the x is larger than or equal to 0.2 and smaller than or equal to 0.9, the a is larger than or equal to 1 / 3, the b is smaller than or equal to 1 / 2, the m is larger than or equal to 0.6 and smaller than 1, and the n is larger than or equal to 0 and smaller than or equal to 0.3. A core and shell multi-layered compound structure is adopted, a core of the core and shell multi-layered compound structure is made of a high-nickel-based and high-specific-capacity multi-element material, a shell of the core and shell multi-layered compound structure is made of a high-safety material with the identical nickel and manganese molar content, wherein the high-safety material contains a small quantity of cobalt or does not contain the cobalt, a space between the core and the shell is made of a multi-layered material and is configured according to proportions different from those of the shell and proportions of the core, the proportions of core materials in the multi-layered material from inside to outside are gradually reduced while the proportions of shell materials in the multi-layered material from inside to outside are gradually increased, and accordingly the multi-stage core and shell structure is formed. The multi-stage core and shell structure multi-element material precursor not only has a high specific capacity performance of the core materials, but also has characteristics of high circulatory stability and safety of the shell materials, and is low in large-scale manufacturing cost. The cost is not increased as compared with a homogeneous multi-element material. Besides, repeatability is high, batch stability is good, and the multi-stage core and shell structure multi-element material precursor meets requirements of large-scale commercial application.

Owner:SHANGHAI PYLON TECH CO LTD

Method for producing electrode for lithium secondary battery

InactiveUS6649033B2Simple interfaceImprove adhesionElectrode carriers/collectorsVacuum evaporation coatingSputteringEvaporation

Owner:SANYO ELECTRIC CO LTD

Cathode active material for a nonaqueous electrolyte secondary battery and manufacturing method thereof, and a nonaqueous electrolyte secondary battery that uses cathode active material

ActiveUS20080311473A1Improve discharge capacityExcellent cycle characteristicsFinal product manufacturePositive electrodesManganeseSlurry

The present invention provides a cathode active material that makes possible a high capacity nonaqueous electrolyte secondary battery that has excellent discharge load characteristics that provide both good cycle characteristics and thermal stability. The cathode active material comprises a lithium nickel composite oxide having the compositional formula LiNi1−aMaO2 (where, M is at least one kind of element that is selected from among a transitional metal other than Ni, a group 2 element, and group 13 element, and 0.01≦a≦0.5) to which fine lithium manganese composite oxide particle adhere to the surface thereof. This lithium nickel composite oxide is obtained by adding manganese salt solution to a lithium nickel composite oxide slurry, causing manganese hydroxide that contains lithium to adhere to the surface of the lithium nickel composite oxide particles, and then baking that lithium nickel composite oxide.

Owner:SUMITOMO METAL MINING CO LTD +1

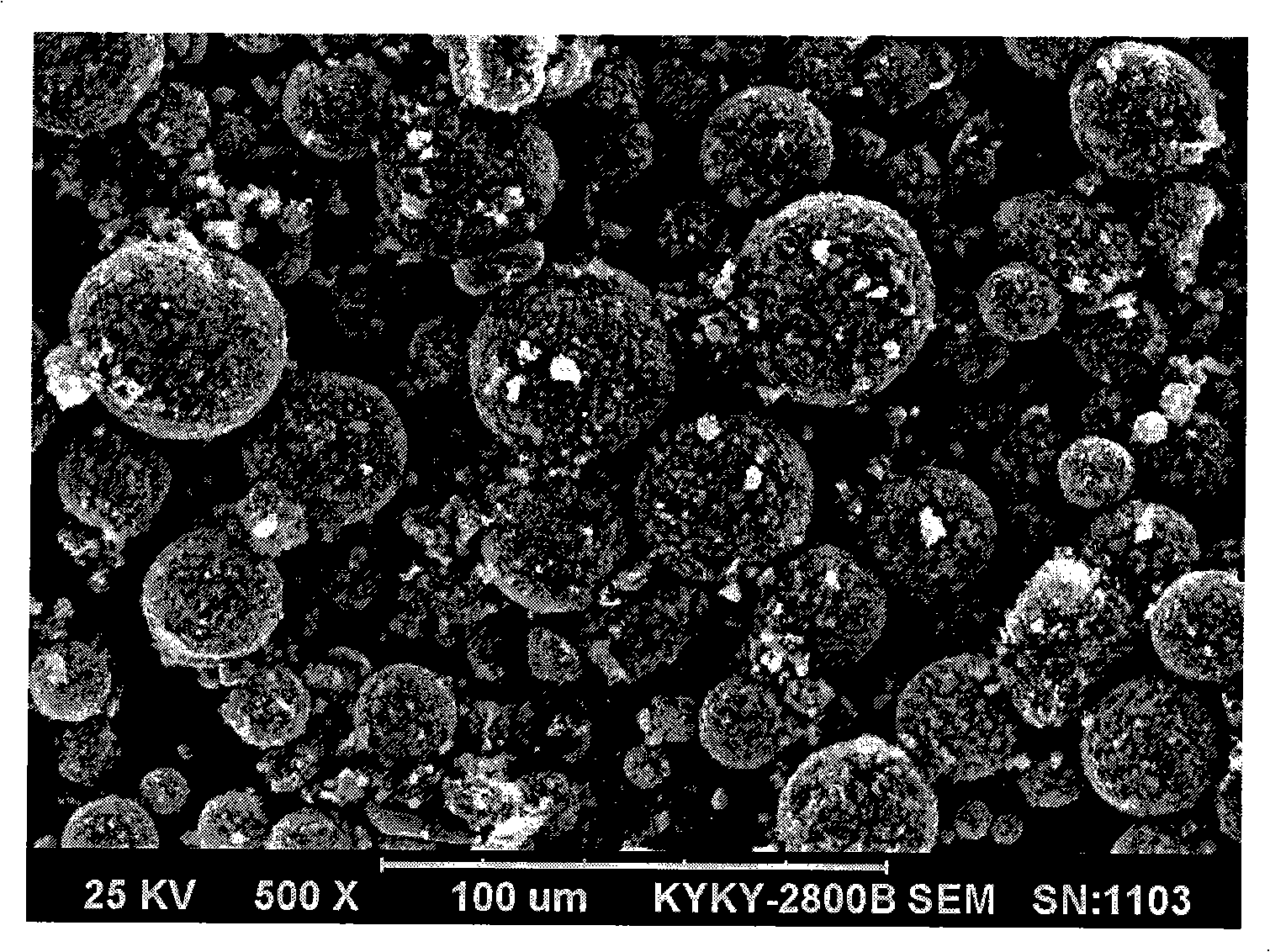

Nickel-cobalt lithium aluminate and preparation method of precursor thereof

ActiveCN103400973AHigh crystallinityHigh charge and discharge capacityCell electrodesHigh densityCobalt salt

The invention relates to a preparation method of a nickel cobalt aluminum material precursor. The method used in the invention comprises the steps: carrying out a complexation reaction of an aluminum salt and a complexing agent to form a stable aluminum complex, then injecting the aluminum complex simultaneously with a nickel-cobalt salt solution into a reaction kettle for carrying out a co-precipitation reaction to prepare a high-density precursor of nickel-cobalt lithium aluminate, and then carrying out a lithium mixed roasting to form a high-density spherical nickel-cobalt lithium aluminate material. At the same time, the invention also discloses an application of the nickel-cobalt lithium aluminate material used in a cathode material of a lithium ion battery. The high-density spherical nickel-cobalt lithium aluminate material which has atomic level mixture of nickel cobalt aluminum elements and good crystallinity can be produced under a premise without mass increase of cost, and the charge and discharge capacity and the first time efficiency have a certain improvement compared with those of current products. The process is simple and easy to implement, and can be used in large-scale industrialized production.

Owner:郭建

SiCO-Li COMPOSITE, MAKING METHOD, AND NON-AQUEOUS ELECTROLYTE SECONDARY CELL NEGATIVE ELECTRODE MATERIAL

InactiveUS20070224509A1Satisfactory initial efficiencySatisfactory cycle performanceElectrode thermal treatmentCarbon compoundsSiloxaneNon aqueous electrolytes

A SiCO—Li composite is prepared by causing a reactive silane and / or siloxane having crosslinkable groups to crosslink, sintering the crosslinked product into an inorganic Si—C—O composite, and doping the Si—C—O composite with lithium. When the SiCO—Li composite is used as a negative electrode, a lithium ion secondary cell exhibits good cycle performance, unique discharge characteristics and improved initial efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

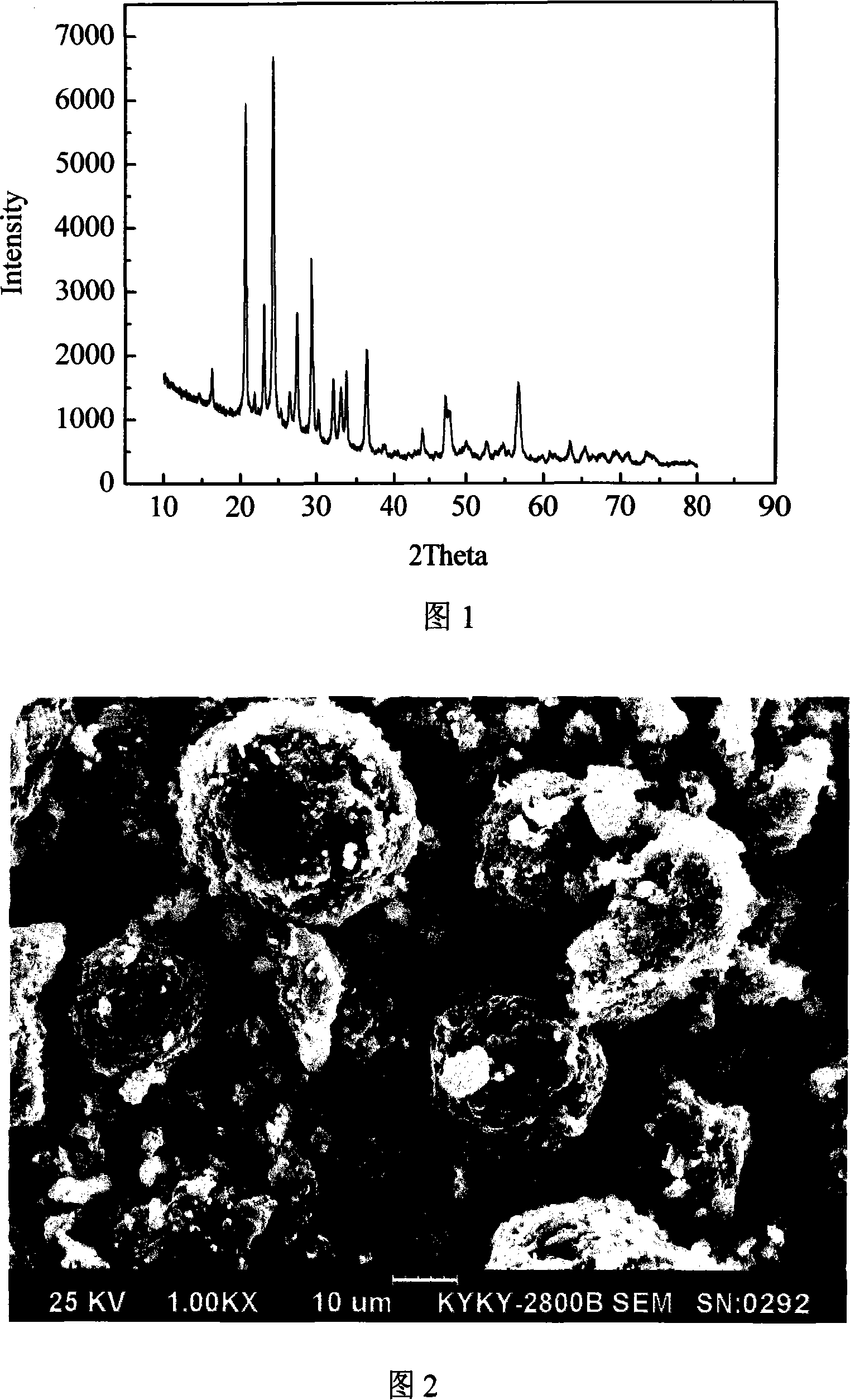

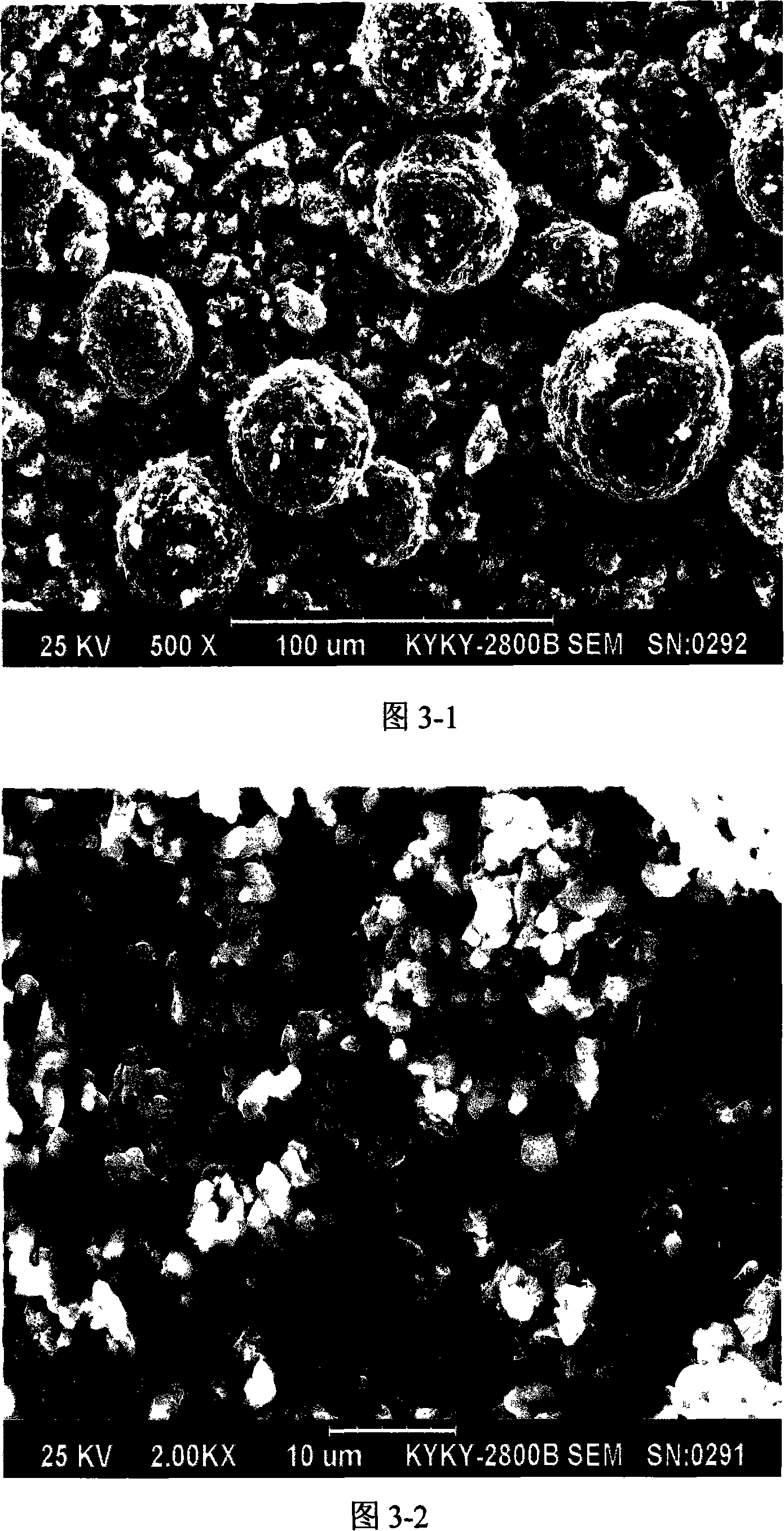

Cathode material Li3V2(PO4)3 of lithium ion battery and its making method

ActiveCN101106194ASmall and evenly dispersedAvoid reunionElectrode manufacturing processesChemical/physical/physico-chemical processesNanoparticlePhysical chemistry

The invention discloses a lithium-ion battery positive material-lithium vanadium phosphate, and the preparation method thereof, the main technical proposal is to enhance the purity of positive material and simplify the synthesizing method. The positive material in the invention is provided with a base body of lithium vanadium phosphate, carbon materials are coated outside the base body, the positive material is provided with some microscopic features like spheres, semi-spheres with the length of long axis and short axis of 5-30 micron, diamonds, cones, flakes, laminates and / or blocks, the size thereof is 5-30 micron, and the specific surface area is 5-15m2 / g. The preparation method includes preparing nano particles, liquid mixing reacting, preparing precursors, pretreament, activated roasting, coating the organic materials which can be carbonized, and then high-temperature processing. Compared with the prior art, by utilizing the nano particle secondary-molding liquid method for synthesizing the positive material-lithium vanadium phosphate, the invention simplifies operation processes and reduces production cost, with the positive material with higher charging-discharging capacity and excellent cyclical steady.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Nonaqueous electrolyte, and rechargeable battery with the nonaqueous electrolyte

InactiveCN101663790AIncrease capacityExcellent cycle characteristicsSecondary cellsHigh current densityChemical structure

A subject is to provide a nonaqueous electrolyte excellent in cycle performances such as capacity retention after cycling, output after cycling, discharge capacity after cycling, and cycle discharge capacity ratio, output characteristics, high-temperature storability, low-temperature discharge characteristics, heavy-current discharge characteristics, high-temperature storability, safety, high capacity, high output, high-current-density cycle performances, compatibility of these performances, etc. Another subject is to provide a nonaqueous-electrolyte secondary battery employing the nonaqueouselectrolyte. The subjects have been accomplished with a nonaqueous electrolyte which contains a monofluorophosphate and / or a difluorophosphate and further contains a compound having a specific chemical structure or specific properties.

Owner:MITSUBISHI CHEM CORP

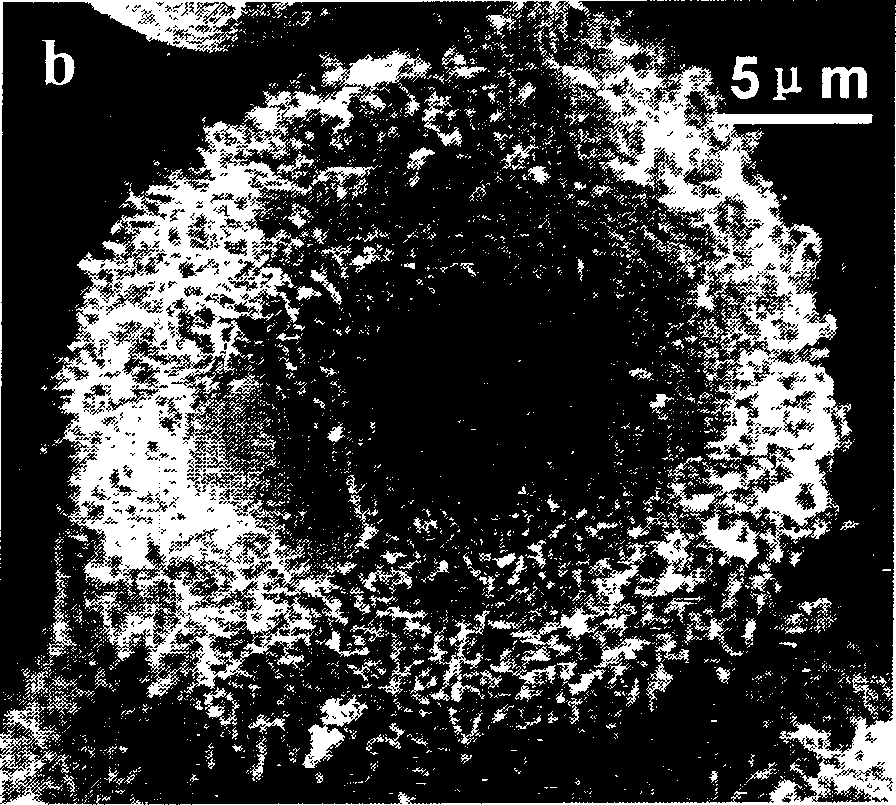

Modified method for lithium ion cell negative electrode material

InactiveCN1812168AGood battery performanceImprove battery performanceElectrode manufacturing processesSecondary cellsModified methodCarbon source

This invention relates to a kind of improving method of lithium ionic cell cathode materials. The cathode materials in need of improving are mixed evenly with catalyst which has 0.1úÑ-10úÑ weight percent of cathode materials. The materials are then put into reaction furnace, which uses hydrocarbon as carbon source. The cathode materials are mixed with buffer gas according to 1í†(0-10) volume ratio. Then the mixture are reacted in reaction furnace at 600-1300íµ for 1-900 minutes. A kind of improved composite cathode materials, at the surface of which in-situ grows nanometer carbon fibrin / carbon tube, are gained. The improved materials have good cell kinetic ability, circulating ability, charge-discharge capacity and consistency with electrolyte.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

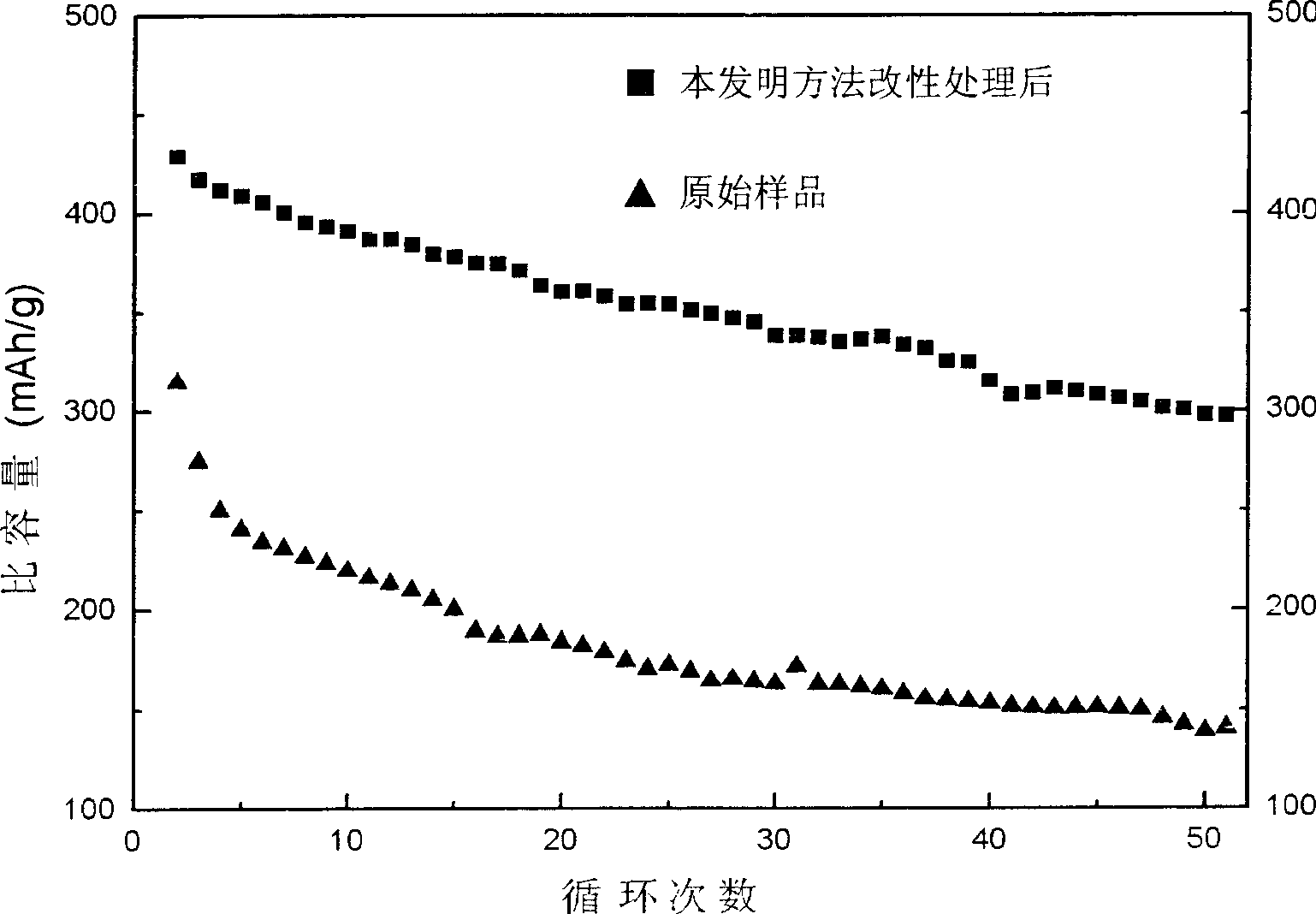

Film for graphene/porous nickel oxide composite super capacitor and preparation method thereof

InactiveCN102013330AIncrease contact areaShorten the diffusion distanceCapacitor electrodesCapacitanceElectron

The invention discloses a film for a graphene / porous nickel oxide composite super capacitor. The invention is characterized in that the film is of a disordered nano porous structure, the aperture range is 10 to 350nm, the thickness of the film is 1 to 5 mu m, and the weight ratio of graphene to nickel oxide is (0.5:100) to (2:100). The method for preparing the film comprises the following steps: dissolving graphite oxide sheets and magnesium nitrate into an isopropanol solution so as to form a positively-charged graphite oxide sheet sol, then carrying out electrophoretic deposition on the obtained sol so as to obtain a graphene film; and through taking the graphene film as a deposition carrier, preparing a three-dimensional porous film for the graphene / porous nickel oxide composite super capacitor by using a chemical bath film-coating method. The porous composite thin film prepared by the method has the advantages of good mechanical capacity and super-capacitance property, high-discharge specific capacitance, high-ratio charge-discharge properties, high cycle life and the like, and has wide application prospects in the fields such as electric automobiles, communication, consumer electronics, signal control and the like.

Owner:ZHEJIANG UNIV

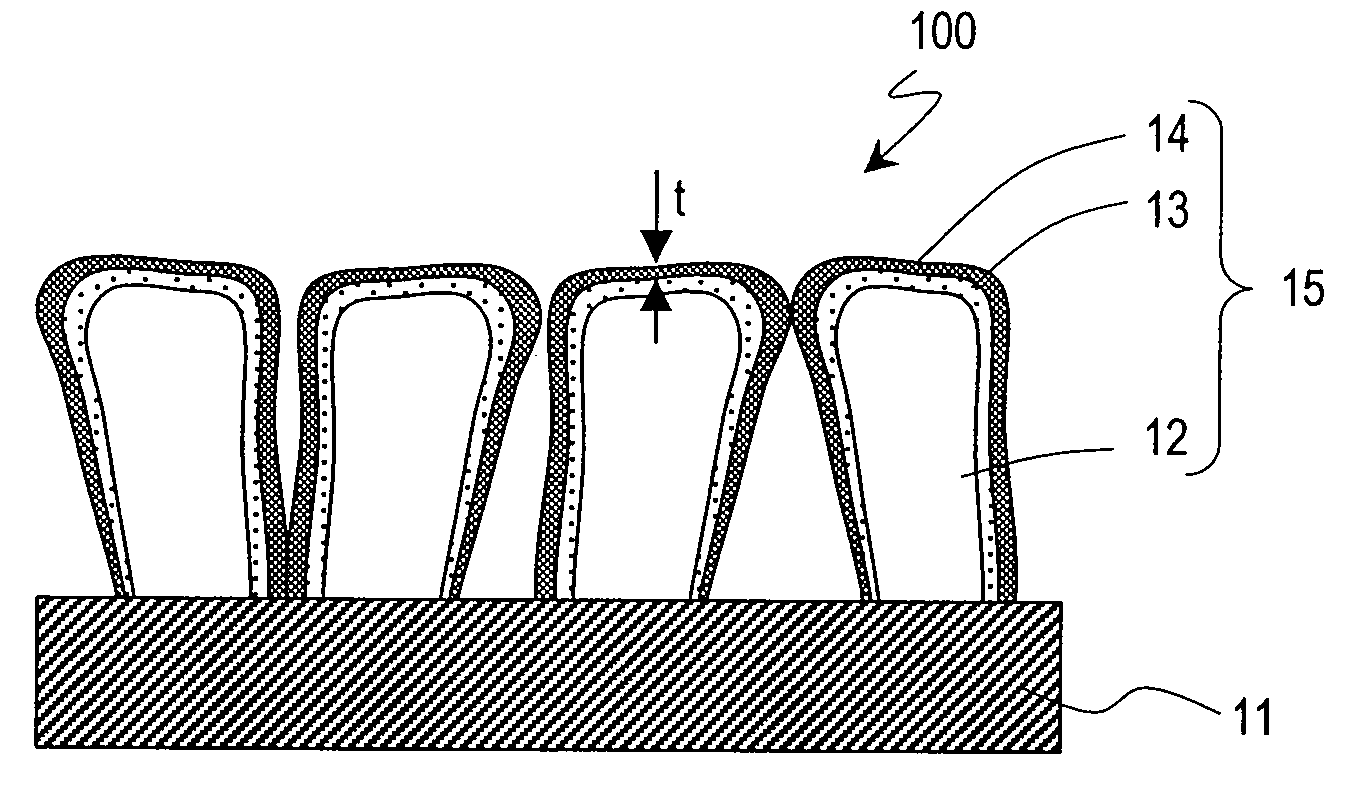

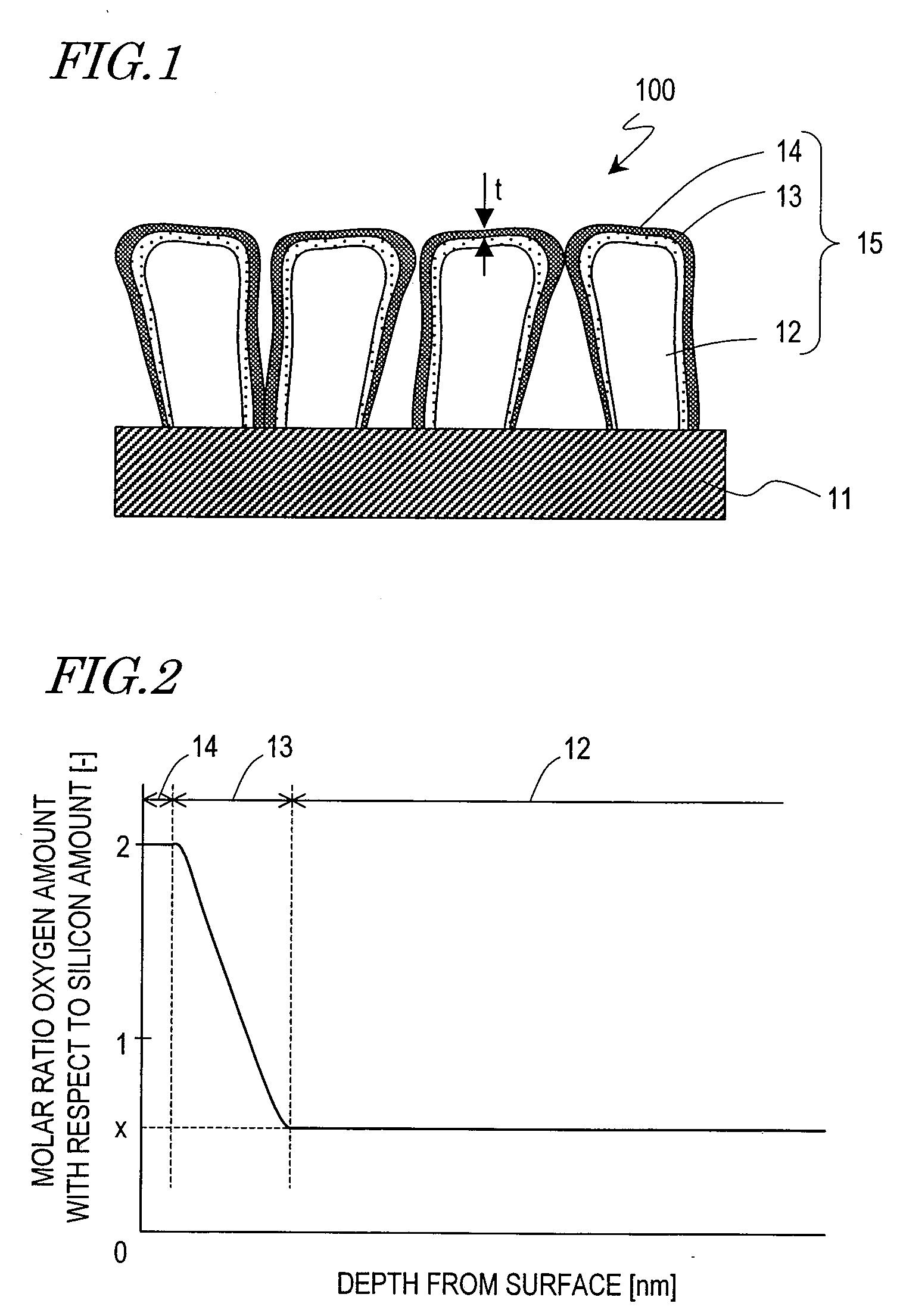

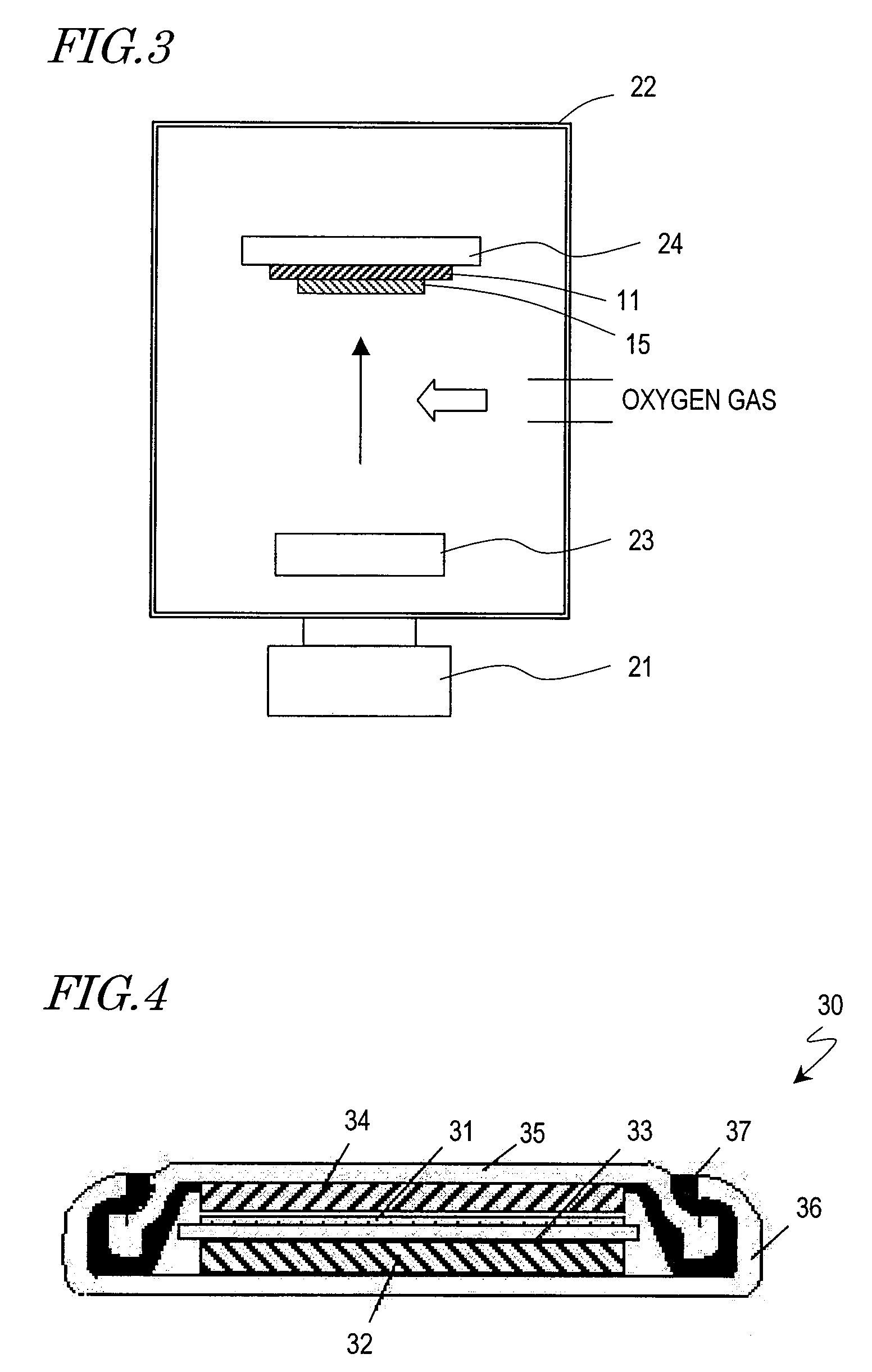

Negative electrode for lithium secondary battery, method for producing same, and lithium secondary battery comprising such negative electrode for lithium secondary battery

ActiveUS20090117472A1Improve charge and discharge cycle characteristicsHigh charge and discharge capacityElectrode manufacturing processesElectrode carriers/collectorsLithiumChemical composition

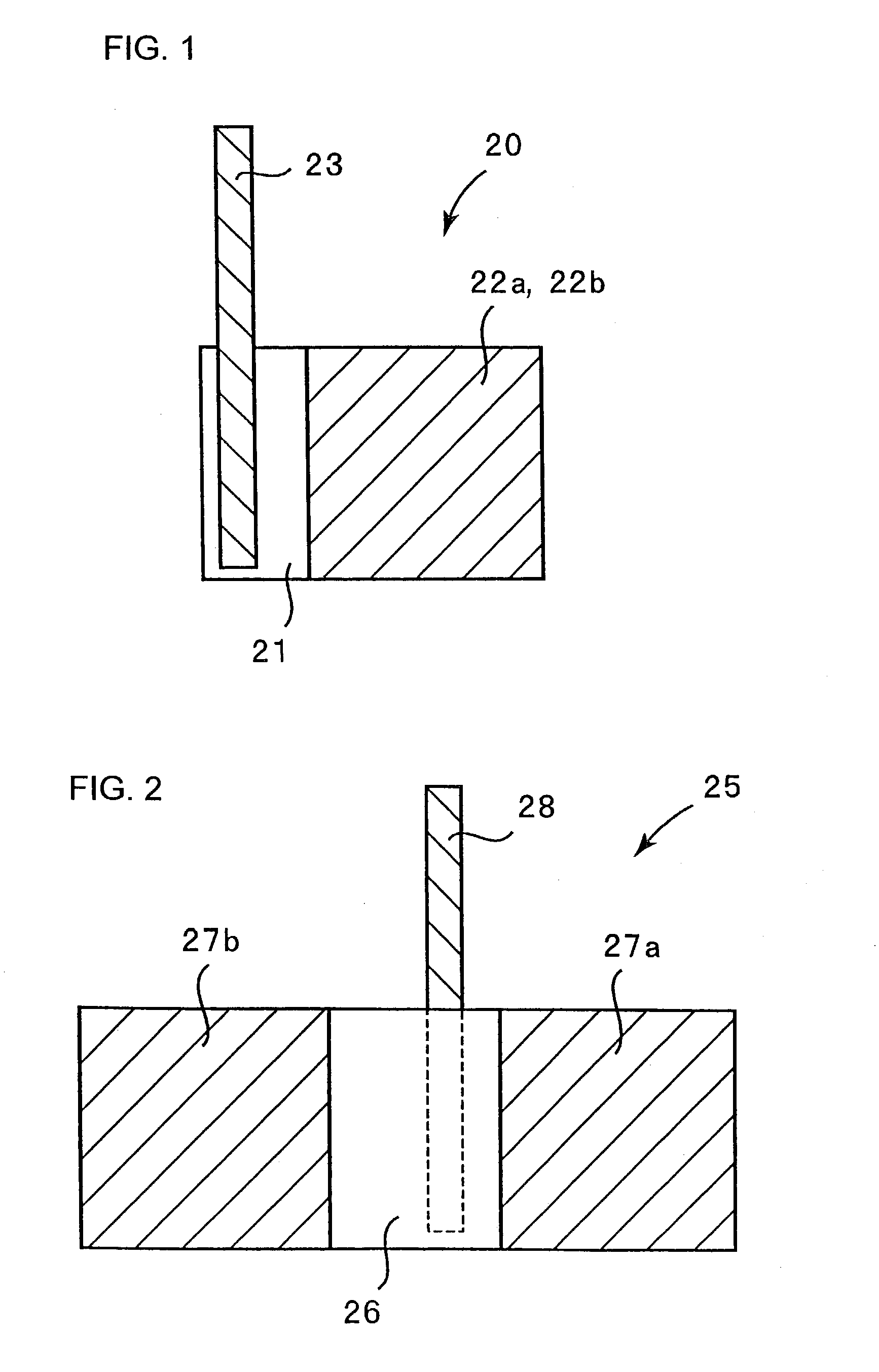

A negative electrode 100 for a lithium secondary battery includes: a current collector 11; a negative-electrode active material body 12 supported by the current collector 11, the negative-electrode active material body 12 having a chemical composition represented as SiOx (0.1≦x≦1.2); and a covering layer 14 formed on the negative-electrode active material body 12, the covering layer 14 having a chemical composition composed of silicon dioxide. The covering layer 12 has a thickness which is greater than 1 nm and no more than 10 nm.

Owner:PANASONIC CORP

Anode material vanadium lithium phosphate and preparation method thereof

ActiveCN101186290ASmall and evenly dispersedAvoid reunionCell electrodesPhosphorus compoundsOrganic compoundMaterials science

The invention discloses a cathode material Li3V2 (PO4)3) and a preparation method thereof. The technical problem that is needed to be solved is to improve the electrochemical properties of Li3V2 (PO4)3) and reduce production cost. The Li3V2 (PO4)3) matrix of the invention is coated with an inhibitory coating containing 1-3wt. percent of carbon material. The material with 0.5-30Mum of particle size, 5-25m<2> / g of surface area and 1.1-1.6g / ml of tap density has the microscopic characteristics of being spherical, approximately spherical, diamond, conical, flake, and / or massive. The preparation method comprises: liquid phase mixing reaction, preparation of former body, pretreatment, roasting, coating with organic compounds that can be carbonized and carbonizing treatment. Compared with the prior art, the cathode material Li3V2 (PO4)3) synthesized by secondary molding of liquid and solid combined nano-particle has high percentage between the product output and raw material input quality, comparatively high charging and discharging capacity, excellent cycle stability, simple preparation technique, little discharge of pollutant and low production cost.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

Composite positive electrode material with core-shell structure for lithium ion batteries and preparing method thereof

InactiveUS20120264018A1Promote circulationImprove conductivityMaterial nanotechnologySecondary cellsHigh rateLithium iron phosphate

A composite positive electrode material with a core-shell structure for a lithium ion battery consists of a core active material and a shell active material. The core active material is a lithium iron phosphate or a lithium manganate, and the shell active material is a composite lithium iron phosphate with carbon. The carbon is one or more of carbon nanotube, superfine conductive carbon black and amorphous carbon material. The composite positive electrode material includes from 65% to 99% core active material and from 1% to 35% shell active material, based on the total weight of the composite positive electrode material. The composite positive electrode material has stable property and excellent electrochemistry performance. The lithium ion battery made with the material has higher charge-discharge capacity, excellent cycle performance. It can be charged quickly and discharged at high rate. A preparing method for the composite positive electrode material is also provided.

Owner:SHENZHEN DYNANONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com