Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3249results about How to "Small particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

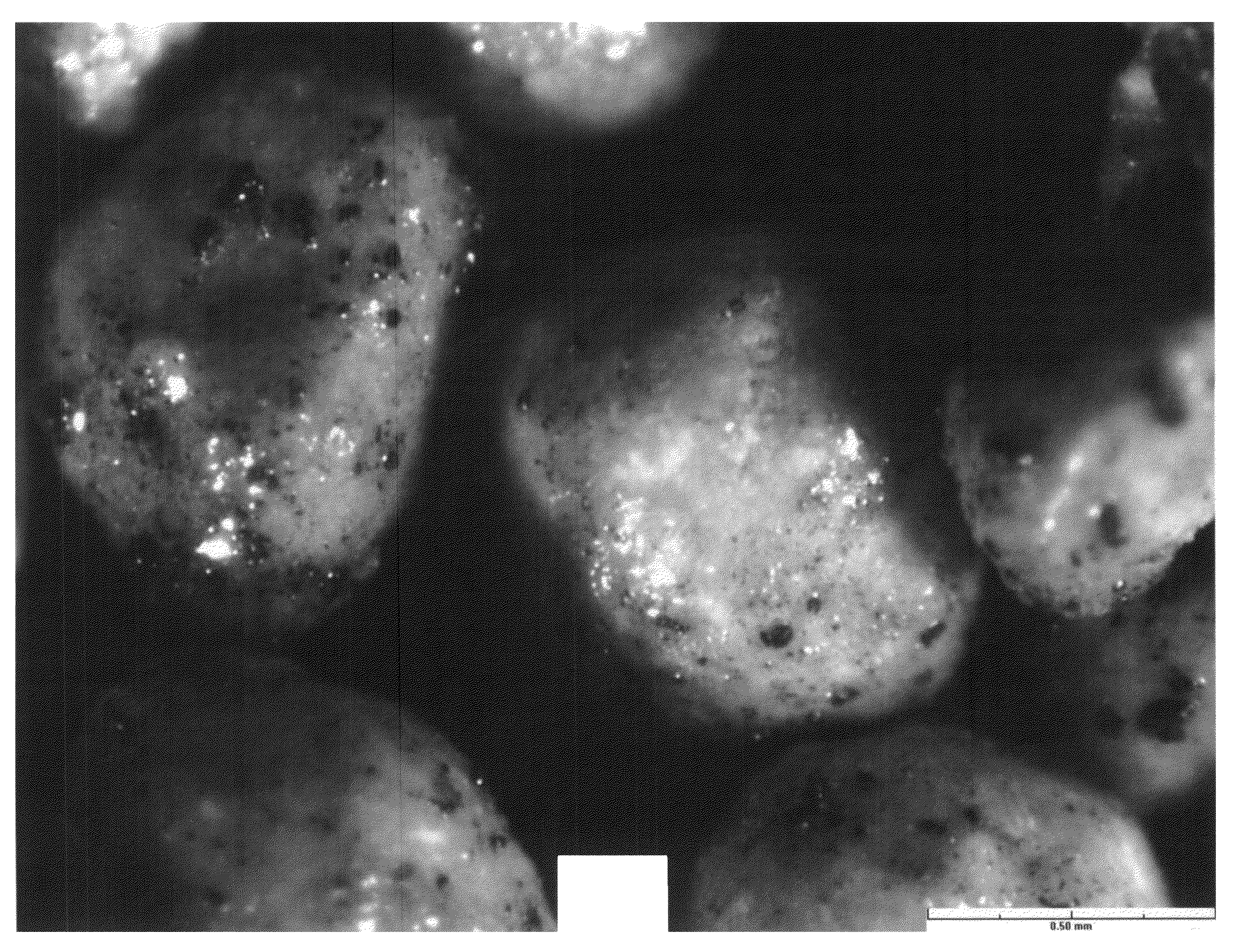

Swellable Dosage Form Comprising Gellan Gum

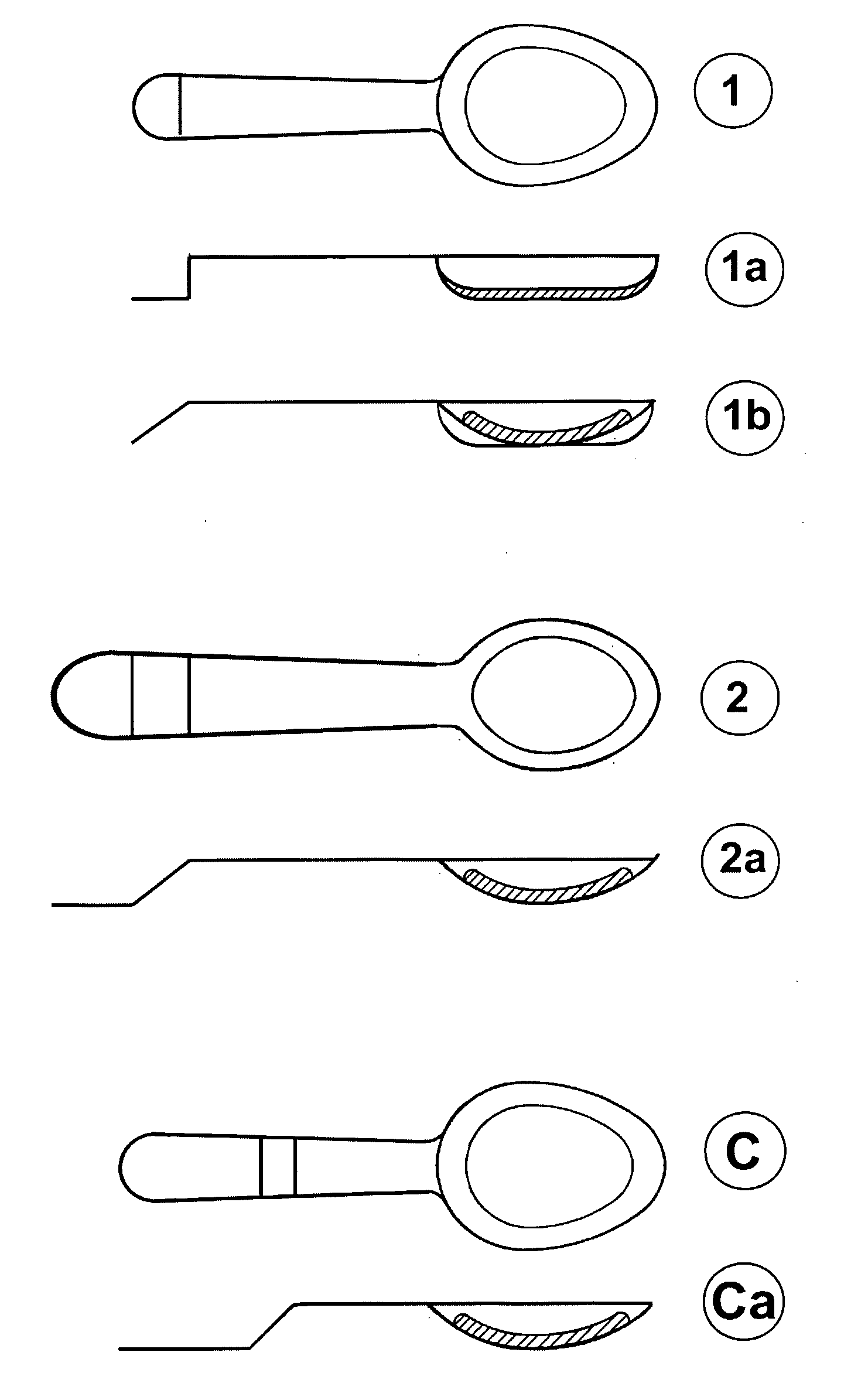

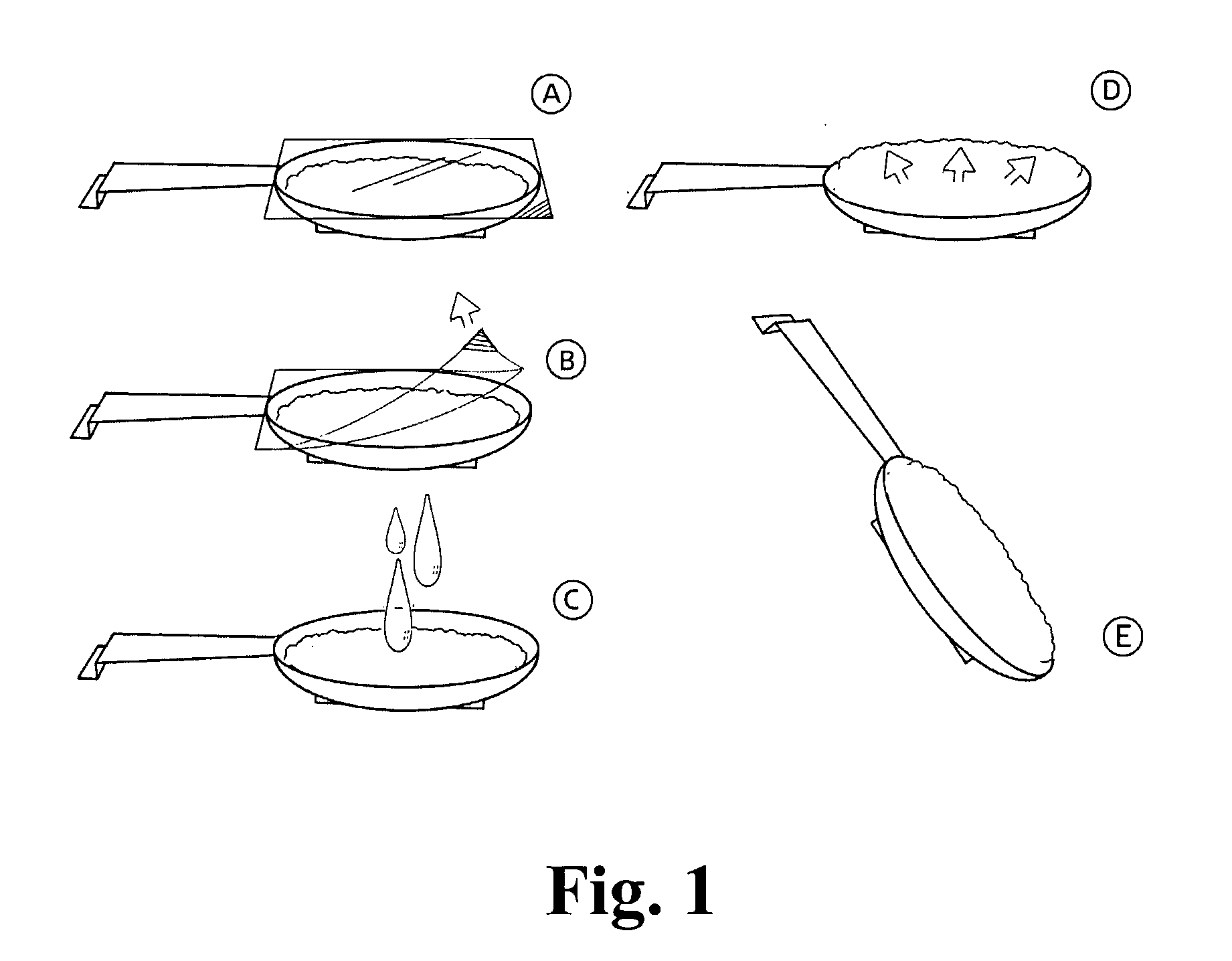

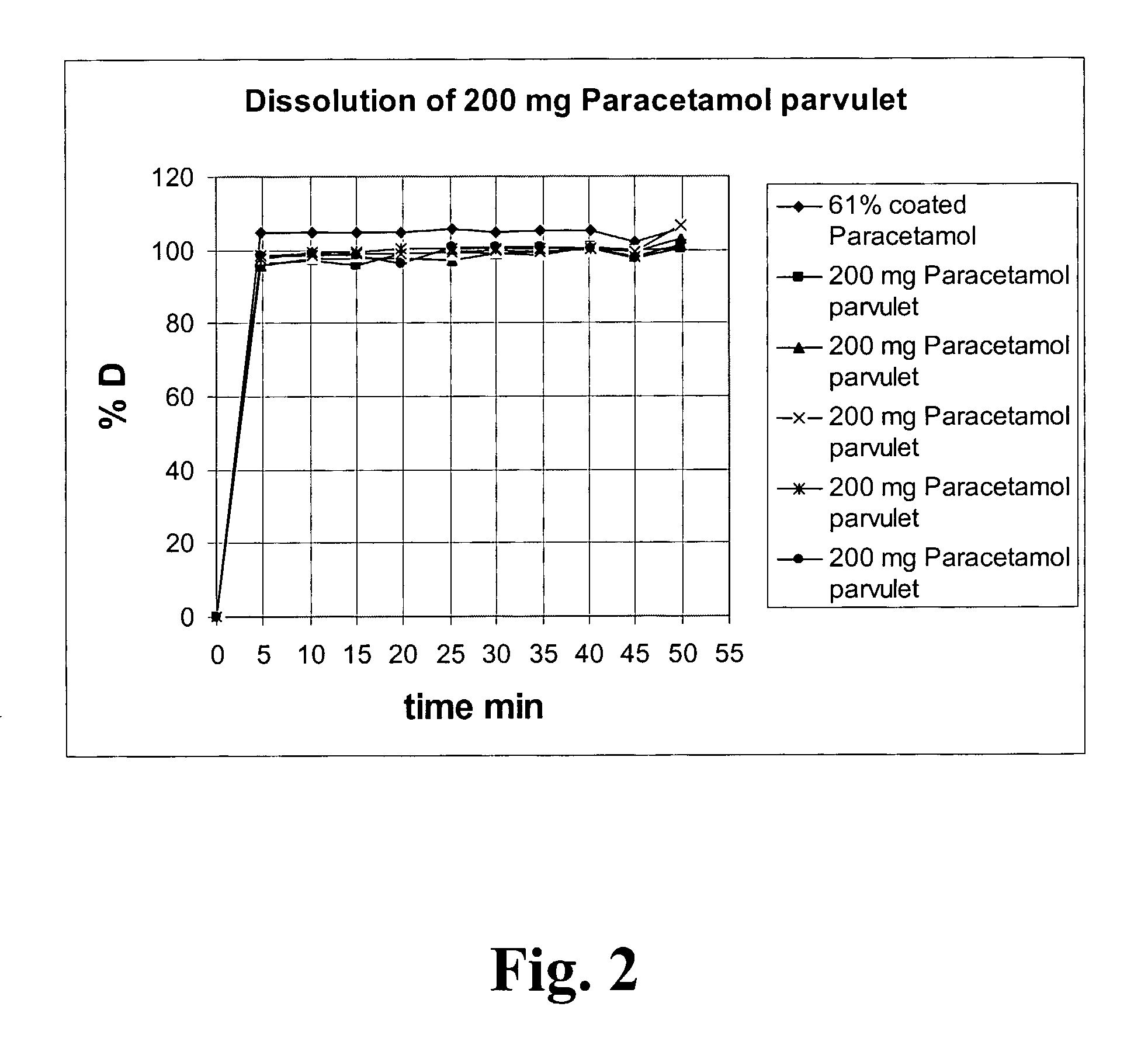

ActiveUS20080299199A1Easily can be orally ingestedIncrease intakeHeavy metal active ingredientsOrganic active ingredientsParticulatesGellan gum

A novel dosage form. The dosage form is presented in particulate form and before oral ingestion the particulate material is subjected to an aqueous medium, whereby it is converted to a semi-solid form by swelling or gelling of one or more of the components, especially of a gellan gum, of the particulate matter. The invention also relates to a vehicle for oral administration of one or more active substances, the vehicle comprising a gellan gum arranged in a configuration allowing optimal water diffusion so that upon addition of a predetermined amount of an aqueous medium, without the necessity of applying shear forces or other mixing forces, within a time period of 5 minutes or less swells and / or gels and the texture of the swelled vehicle being similar to that of a soft pudding and having a viscosity of at least about 10,000 cps as measured by a Brookfield Viscometer with a #4 LV spindle at 6 rpm and at 20-25° C. In one embodiment of the invention, the particulate matter can be moulded into a desired shape or pressed onto a dispensing unit such as a spoon.

Owner:ADARE PHARM INC

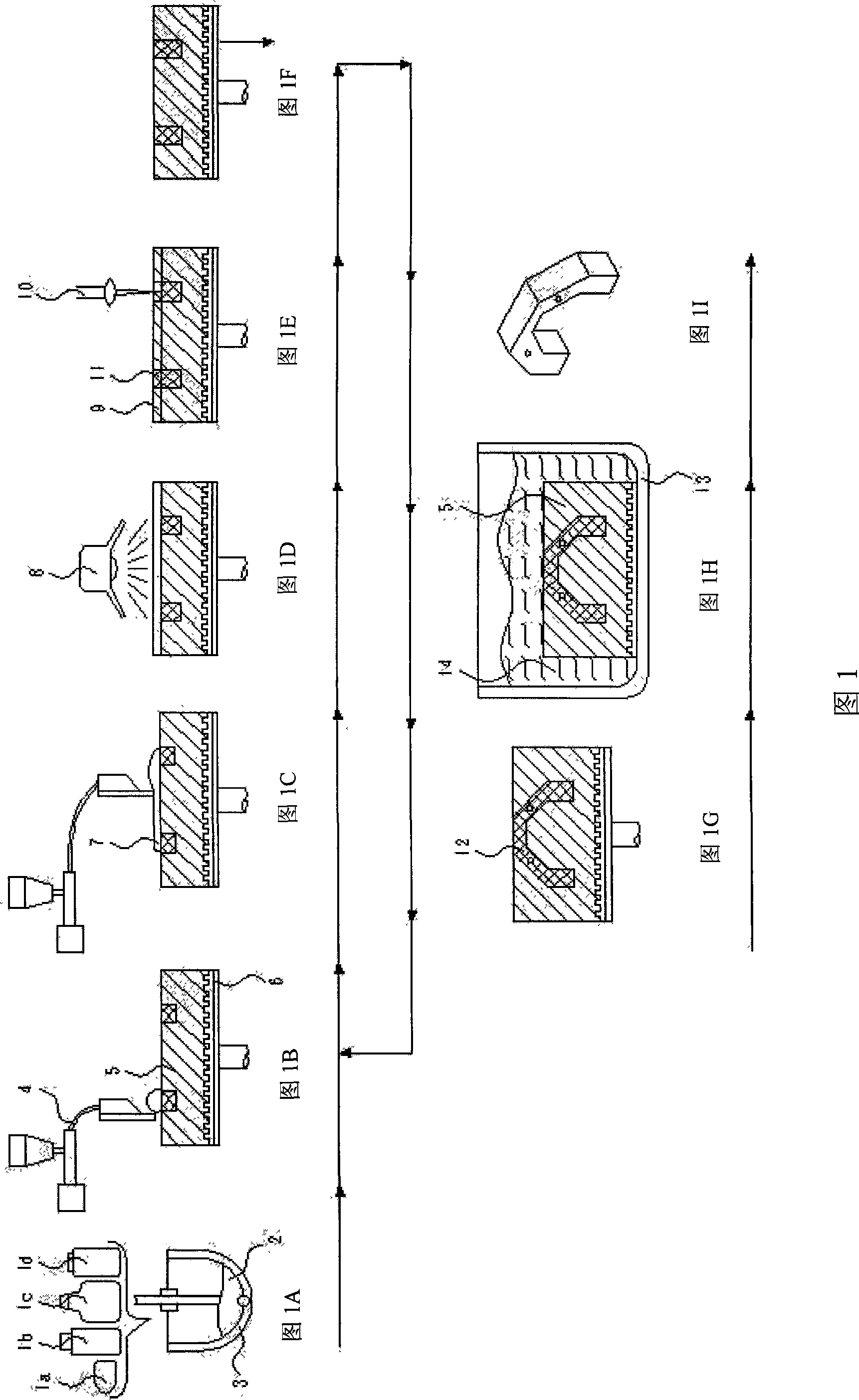

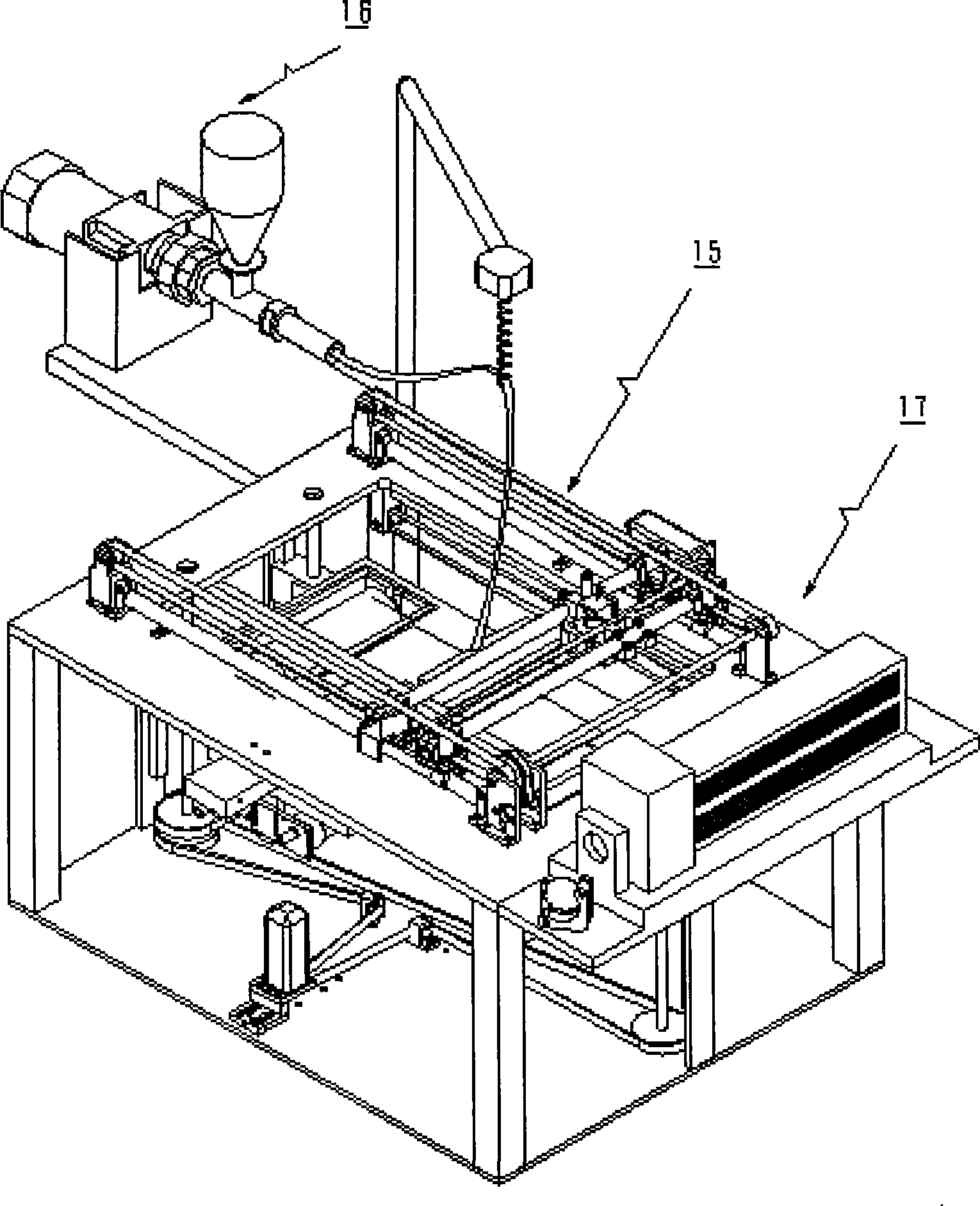

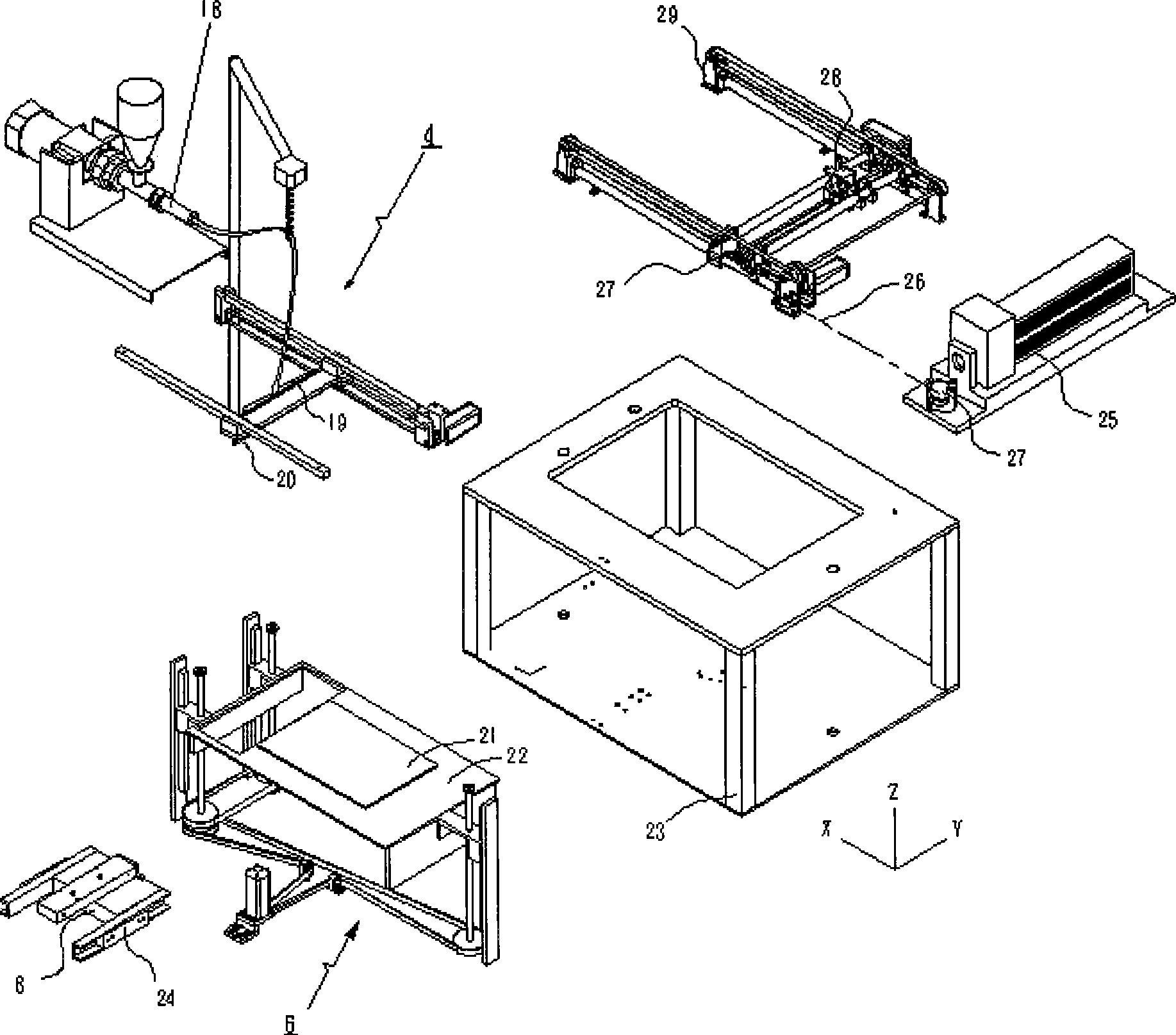

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

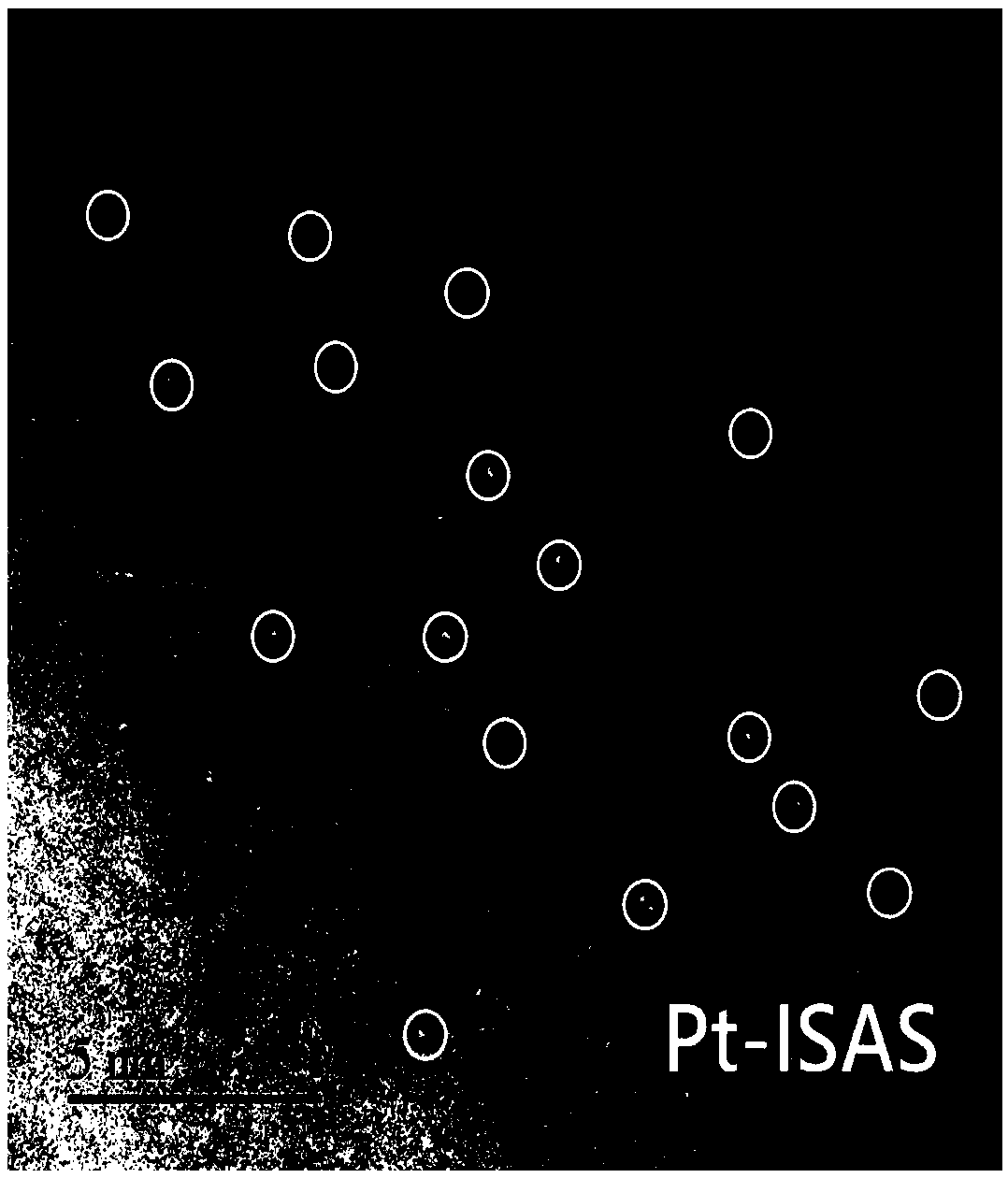

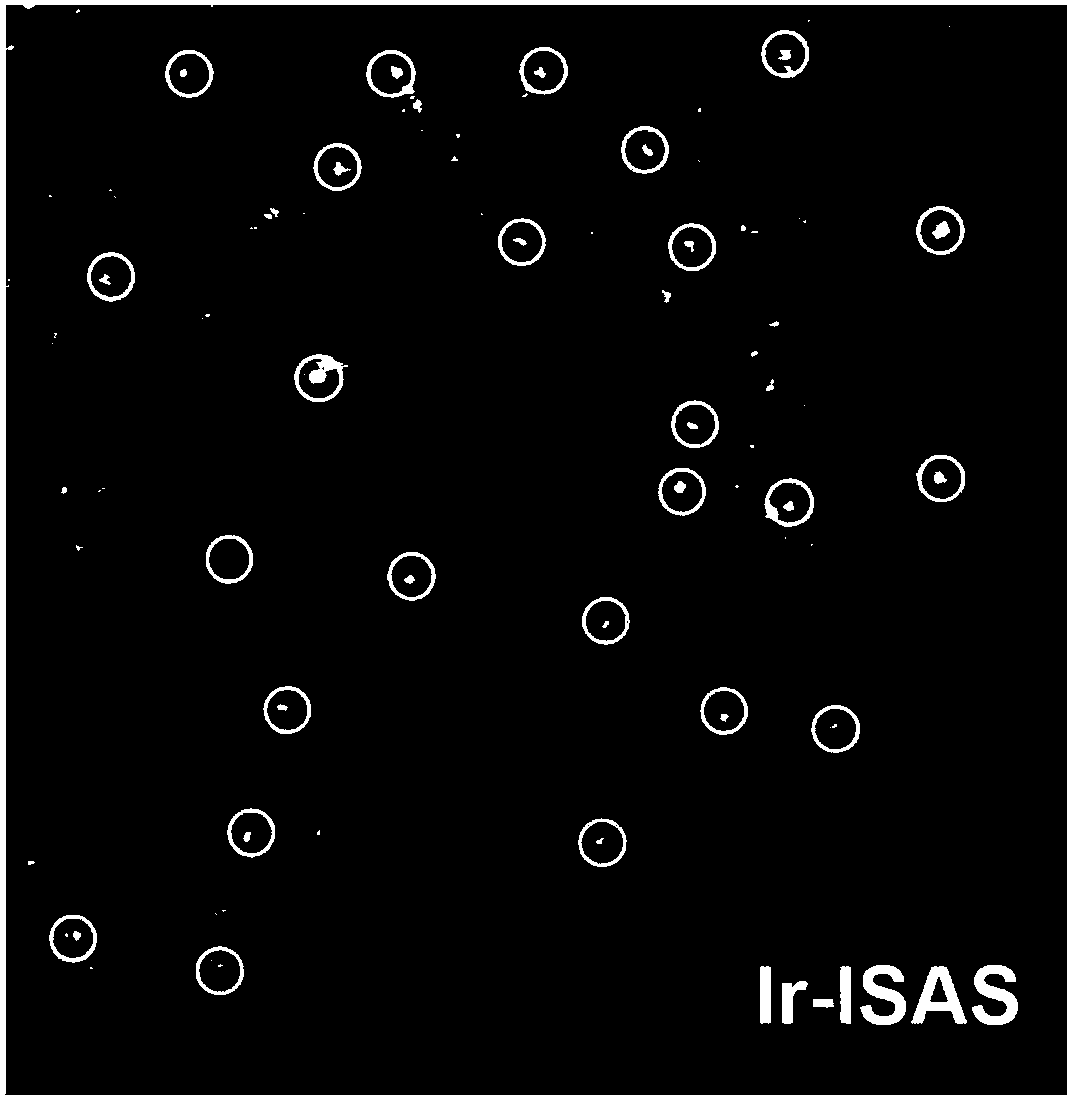

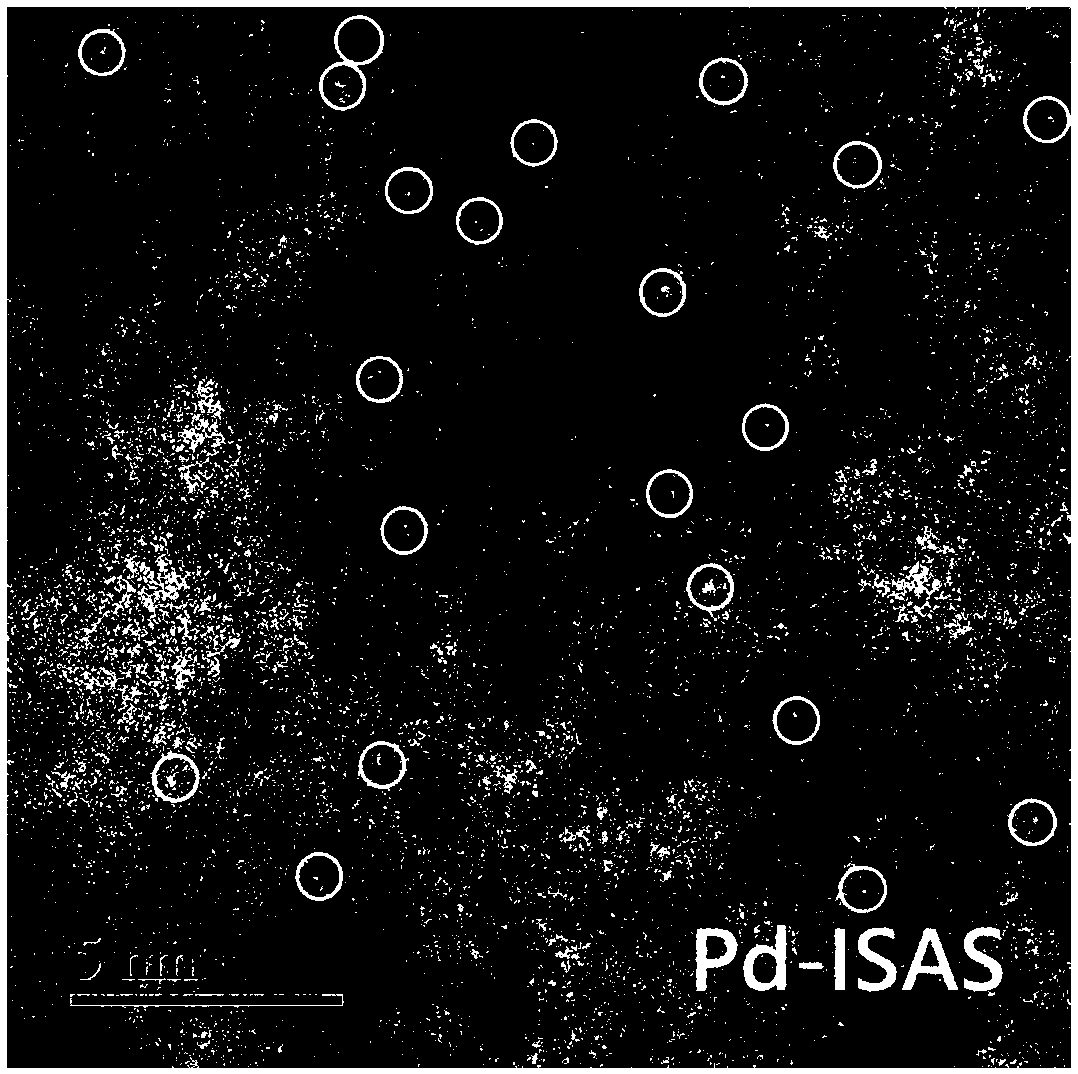

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

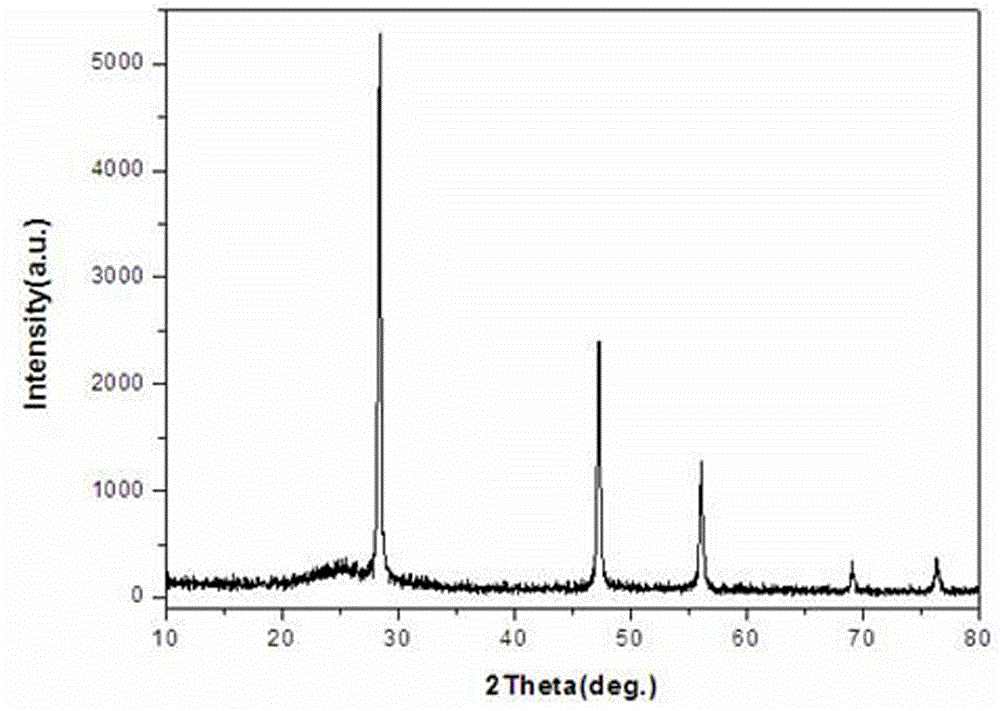

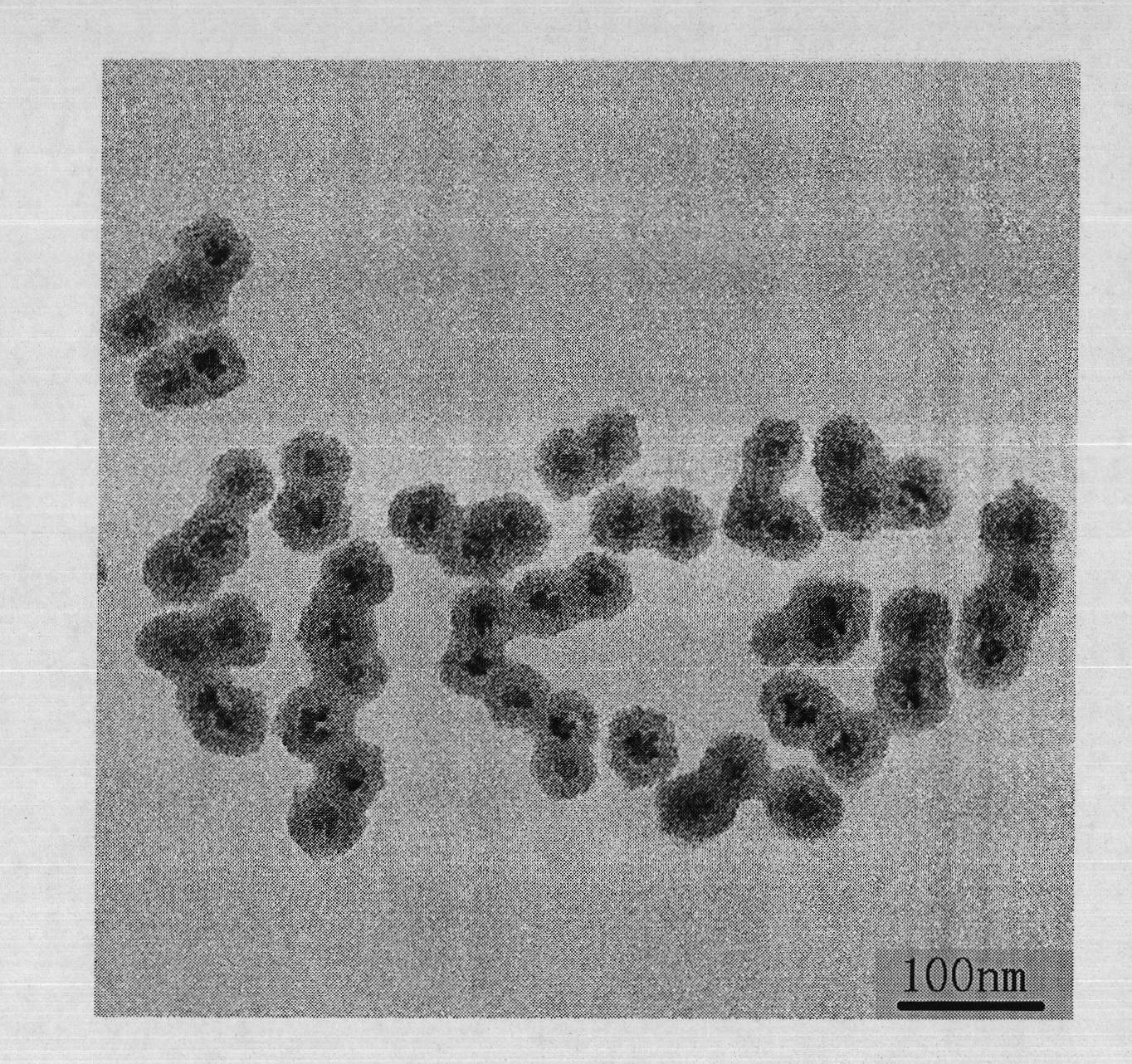

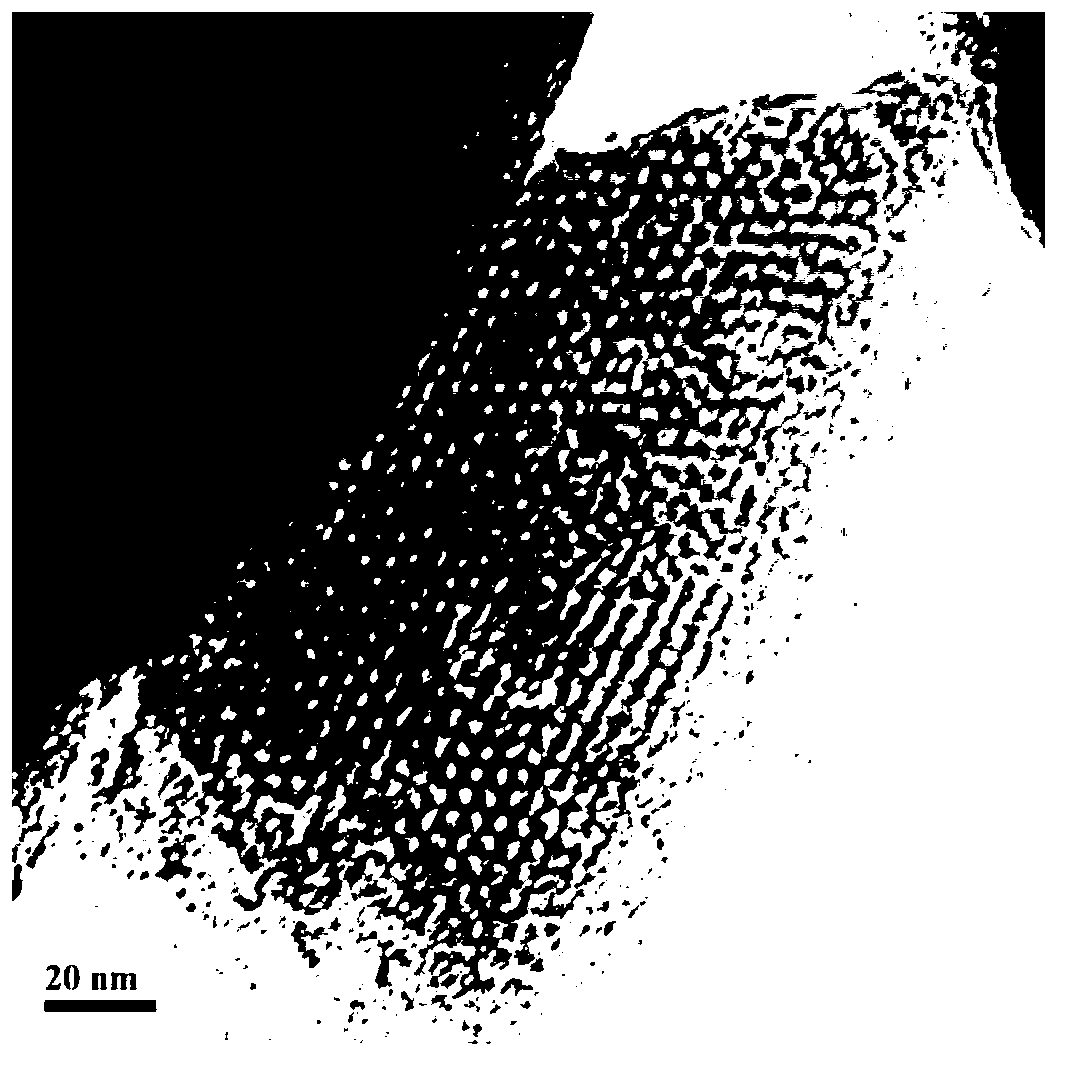

Nanoscale lithium titanate compound and preparation method thereof

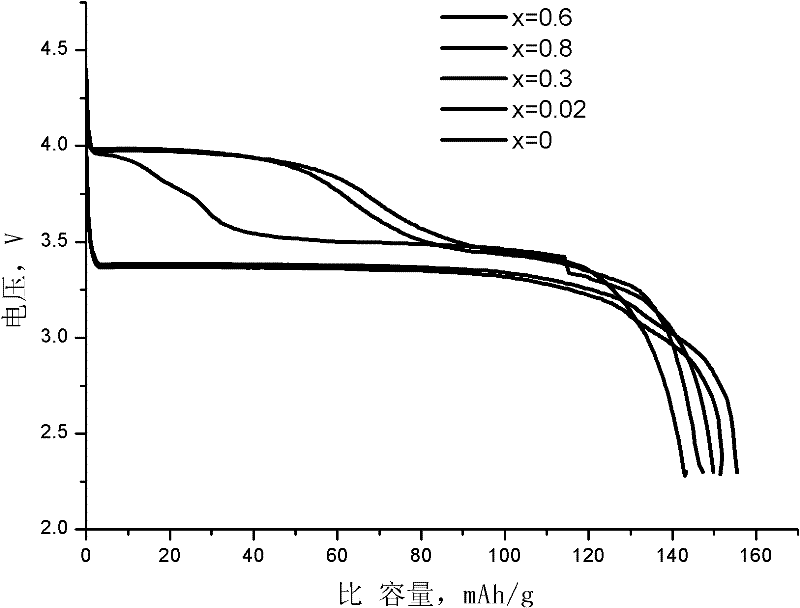

ActiveCN101630732AEnabling molecular-scale mixingHigh purityElectrode manufacturing processesActive material electrodesLithium compoundCharge and discharge

The invention relates to a nanoscale lithium titanate compound and a preparation method thereof. The nanoscale lithium titanate compound is prepared by following steps: a lithium compound, a titanium compound and a doped element compound are mixed according to a molar ratio of 0.75-0.80:1:0:0.05 of Li to Ti to doped elements so as to form a mixture A; the mixture A and a complexing agent are mixed according to a weight ratio of 1:0.1-10 and dissolved in water to form a mixture B; and the mixture B and a carbon nanotube dispersion C are mixed to form the nanoscale lithium titanate compound coated by carbon nanotubes with a nanoscale grain size. The preparation method comprises the following steps: mixing the mixture B and the carbon nanotube dispersion C; heating an obtained mixture in nitrogen at 100-200 DEG C for 1-2 hours to obtain gel; and sintering the obtained gel in inert atmosphere at 500-1,000 DEG C for 5-48 hours to obtain the powdered lithium titanate compound. The lithium titanate compound is nanoscale lithium titanate coated by the carbon nanotubes, has fine and even grain and high purity and has the characteristics of higher charge and discharge capacity, good rate discharge performance, good cycle performance and good safety performance, and the like, thus the lithium titanate compound is an ideal anode material for manufacturing a lithium ion battery.

Owner:SHENZHEN DYNANONIC

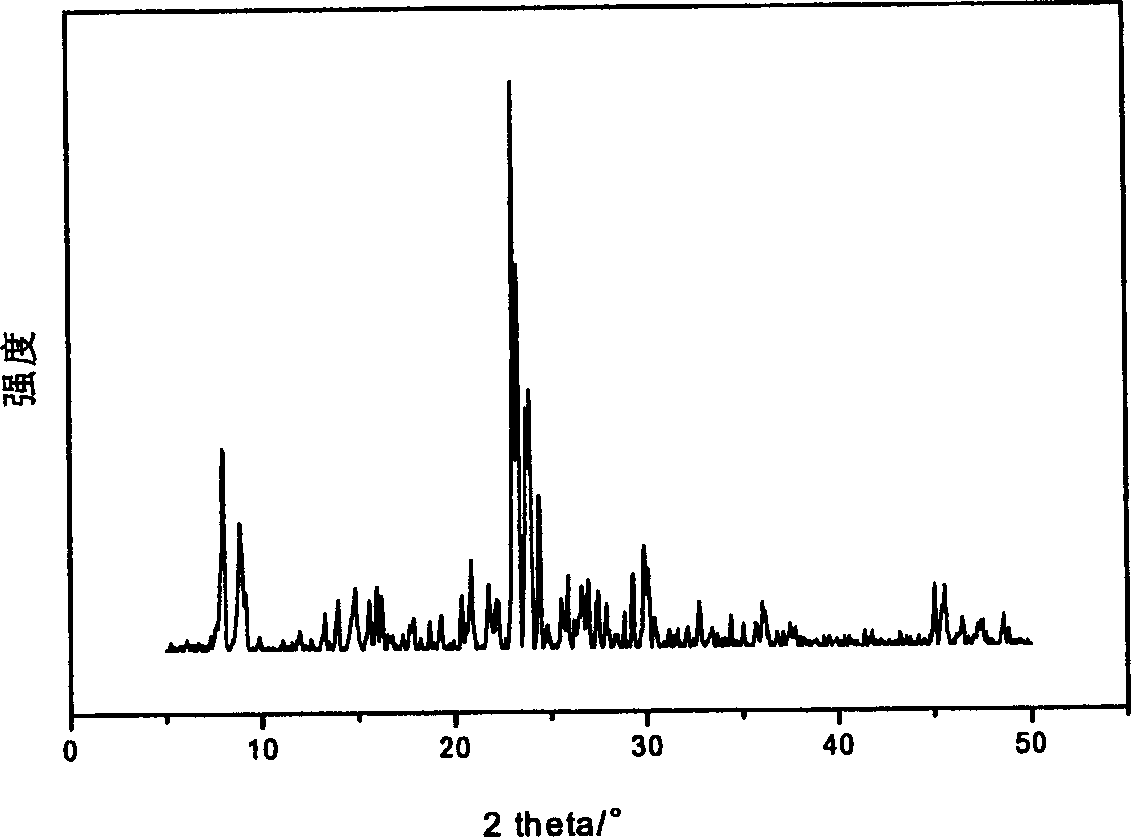

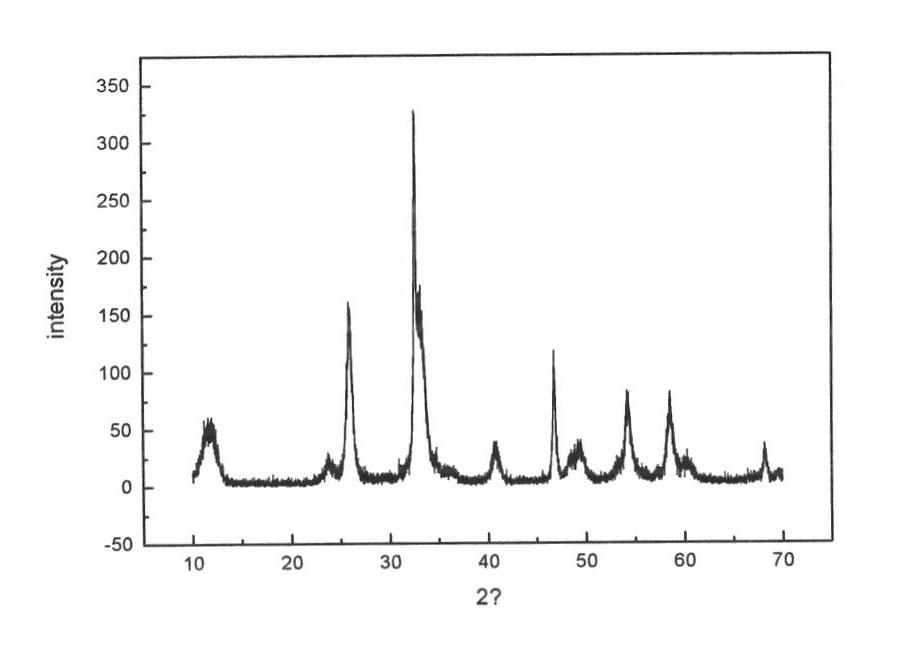

ZSM-5 type molecular sieve and method for preparing the same

ActiveCN1803613AReduce contentPerformance is not affectedMolecular sieve catalystsPentasil aluminosilicate zeolitePearliteZSM-5

The invention provides a preparation method for small-size ZSM-5 molecular sieve. Wherein, using pearlite and montmorillonite as material for aluminum, adding crystal seed for crystallization reaction on hydrothermal condition, and obtaining a small-size product with 5~95% ZSM-5 that can be used to prepare modified ZSM-5 molecular sieve by different post-treatment method or as the active intergradient or carrier for catalyst. This invention cuts the cost more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

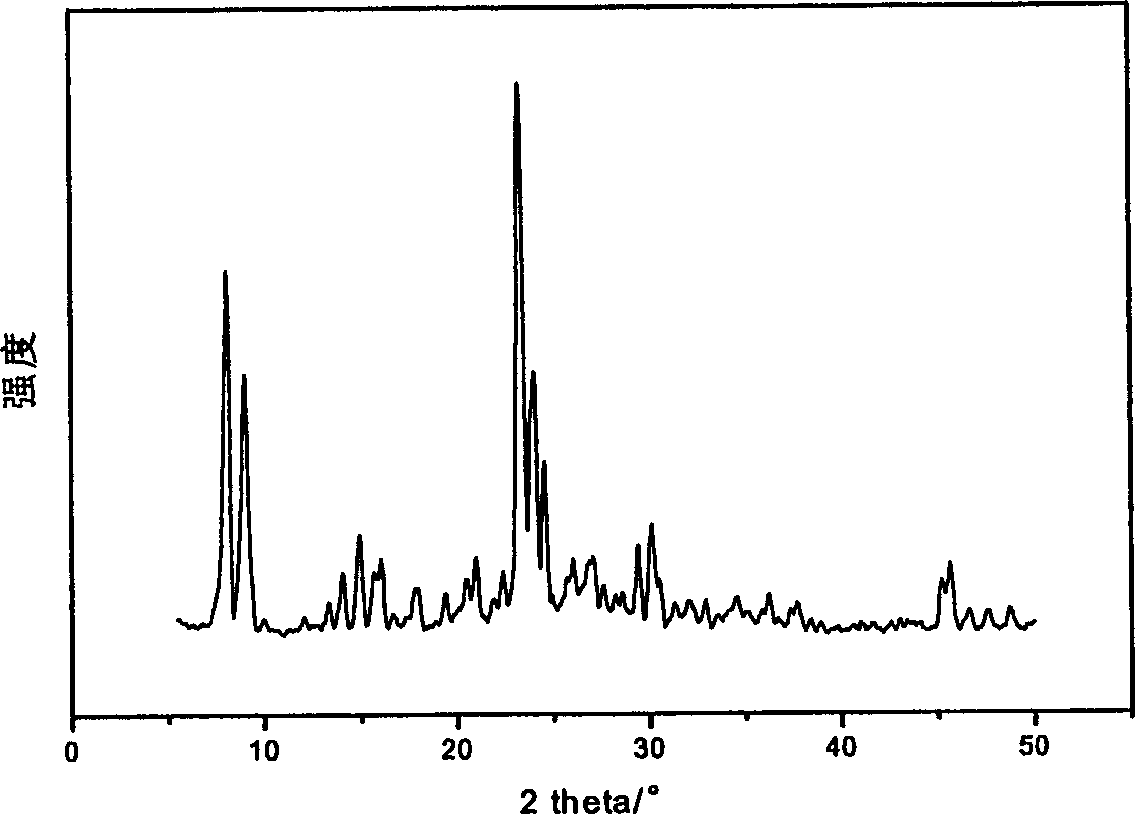

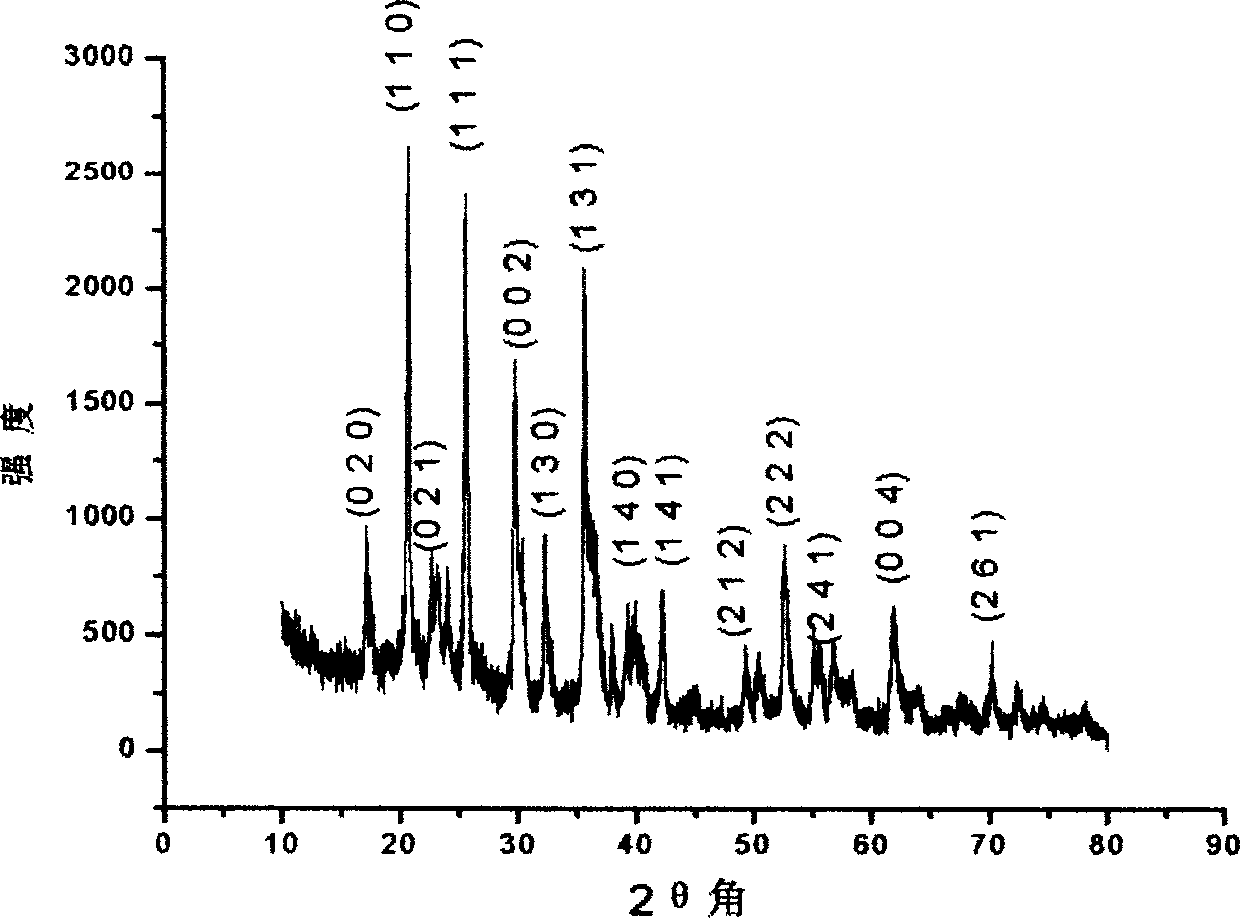

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

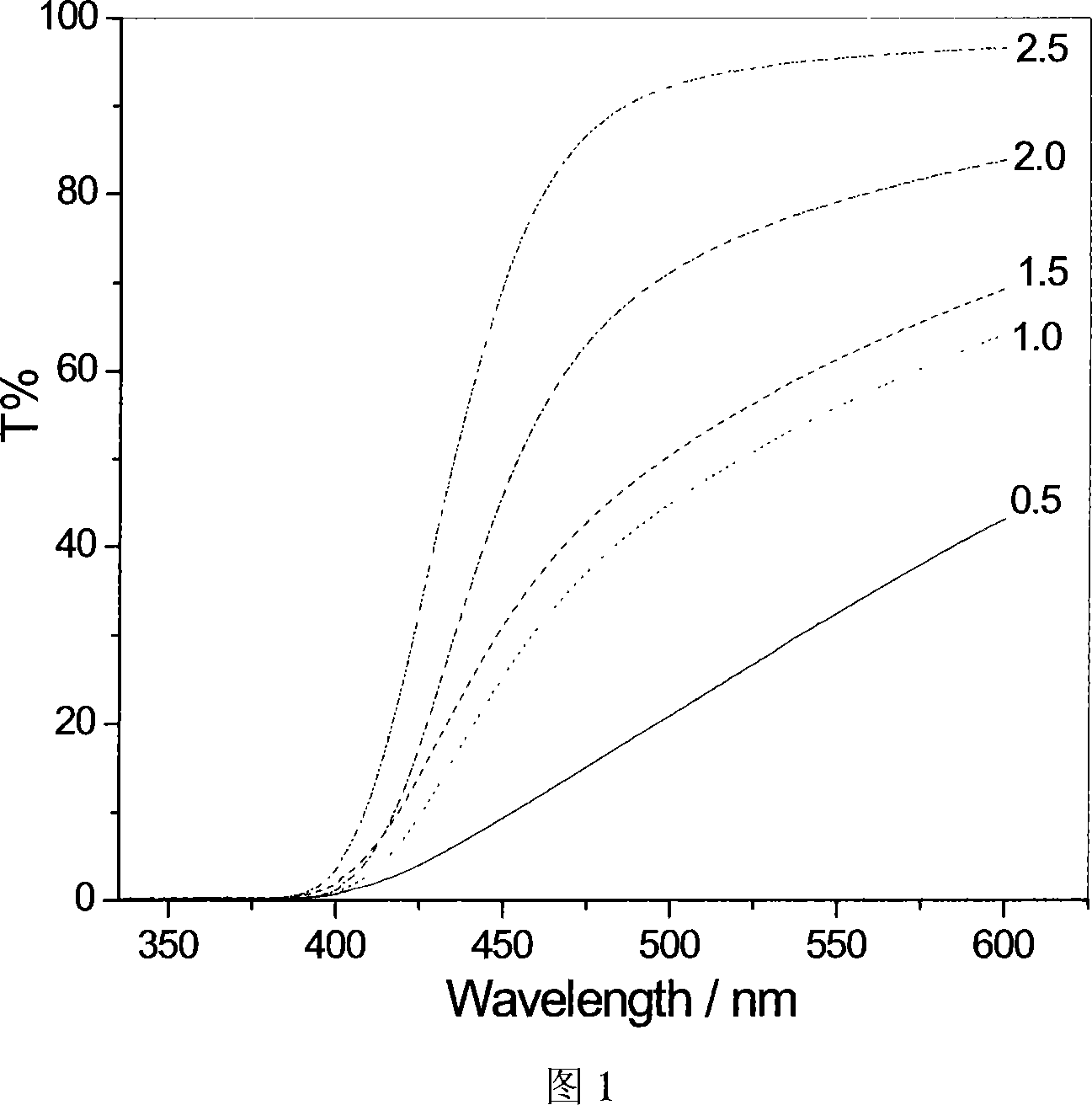

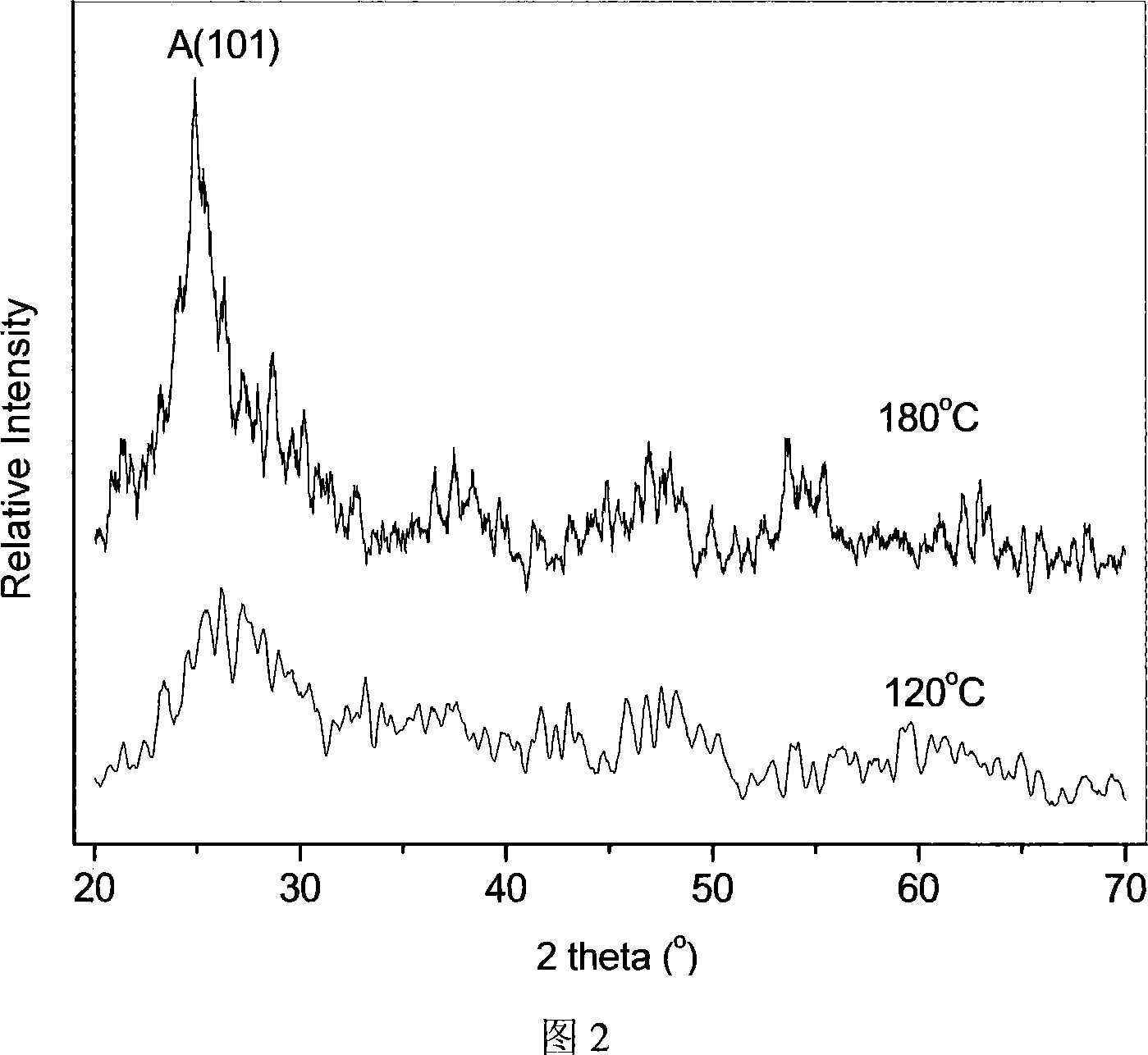

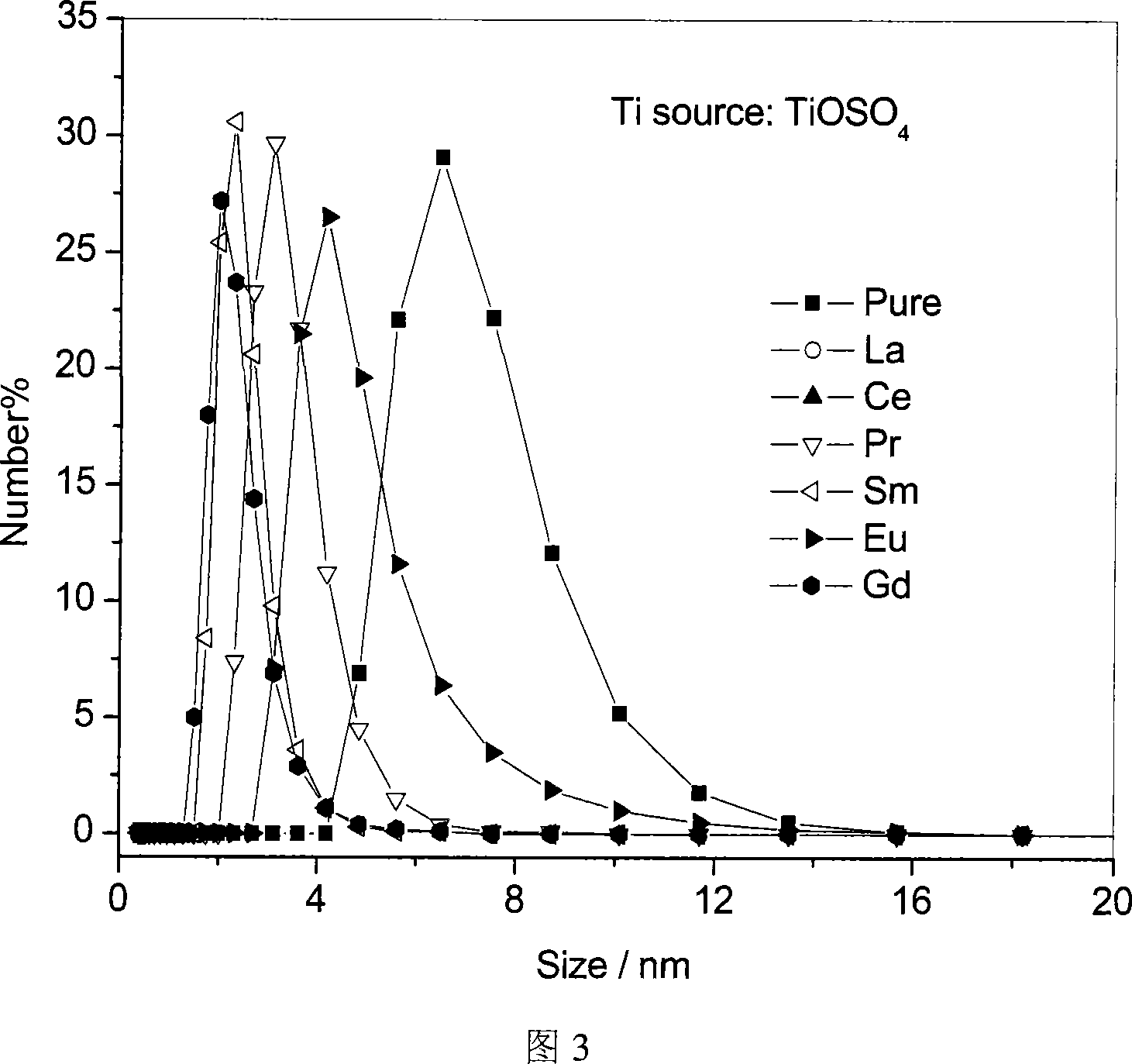

Method for preparing sol of neutral Nano titanium dioxide

This invention discloses a method for preparing neutral titanium dioxide nanosol. The method comprises: (1) preparing amorphous titanium dioxide; (2) dispersing and dissolving amorphous titanium dioxide; (3) performing hydrothermal treatment to obtain neutral titanium dioxide nanosol. The obtained neutral titanium dioxide nanosol (below 10 nm) is transparent and golden, and does not have any odor. Besides, the neutral titanium dioxide nanosol has such advantages as high stability, certain crystallinity, high specific surface area, high adhesiveness, reduced particle sizes after doped with transition metal, and high utility of visible light. The method has such advantages as wide raw materials and easy operation, and is suitable for large-scale production.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Aquosity elastic heat preserving insulating paint and its preparing process

A water-base and elastic heat insulation coating and the preparation method are provided. The invention adopts the elastic pure emulsion and the silicone-acrylate emulsion as the film former and also adopts the materials such as insulating materials and rutile type titanium pigment talc. The preparation process is that water is added with a dispersant, an antifoamer A, a pH regulator with right amount, propylene glycol and titanium pigment in turns under the stirring speed of 500r / min; the rotary speed is adjusted to 1500r / min and the dispersive degree below 25Mum; then an antifoulant, a mildewproof agent, an antifoamer B, silicone-acrylate emulsion, elastic emulsion and a film forming additive are added to stirred for 10min under the rotary speed of 500r / min and then the rotary speed is adjusted to 300r / min, and two third of the insulating materials are added to stir for 20min; at last, the remaining insulating materials are added to stir for 20min under the rotary speed of 300r / min, and the thickeners A, B are added to stir for 15min; the pH value is adjusted to 7.5 to 9 and a preservative is added to stir for 10min to produce the coating of the invention.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Reducing flow-back in well treating materials

ActiveUS7754659B2Ease in attachment and retentionLow costFluid removalFlushingPorous ceramicsMaterials science

A composite proppant having a proppant substrate such as a porous ceramic or silica sand coated with magnetic particles and a method of propping a subterranean formation using a composition consisting essentially of the composite proppant.

Owner:GEORGIA PACIFIC CHEM LLC

Preparation and application method of optical catalysed environment protection type coating

The invention provides a preparation and application method for photocatalysis environmental protection type painting, which relates to construction painting, especially provides a preparation and application method for photocatalysis function painting, which includes steps: mixing titanium-containing organic, water, chelating agent and hydrolysis inhibitor to prepare nano anatase type titanium dioxide water sol; adding metal, oxide or impure titanium dioxide photocatalyst into the titanium dioxide water sol and stirring equably. Using method is coating inorganic isolated layer firstly and coating the photocatalysis painting after drying. Advantages of the invention are: the prepared painting and using technique can be widely used for inner and outer wall surface of building and is harmless to bottom ainting, photocatalysis efficiency is high, cost is low, bonding is firm, transparency is good, preparation is simple, and usage is easy.

Owner:YUNNAN UNIV +1

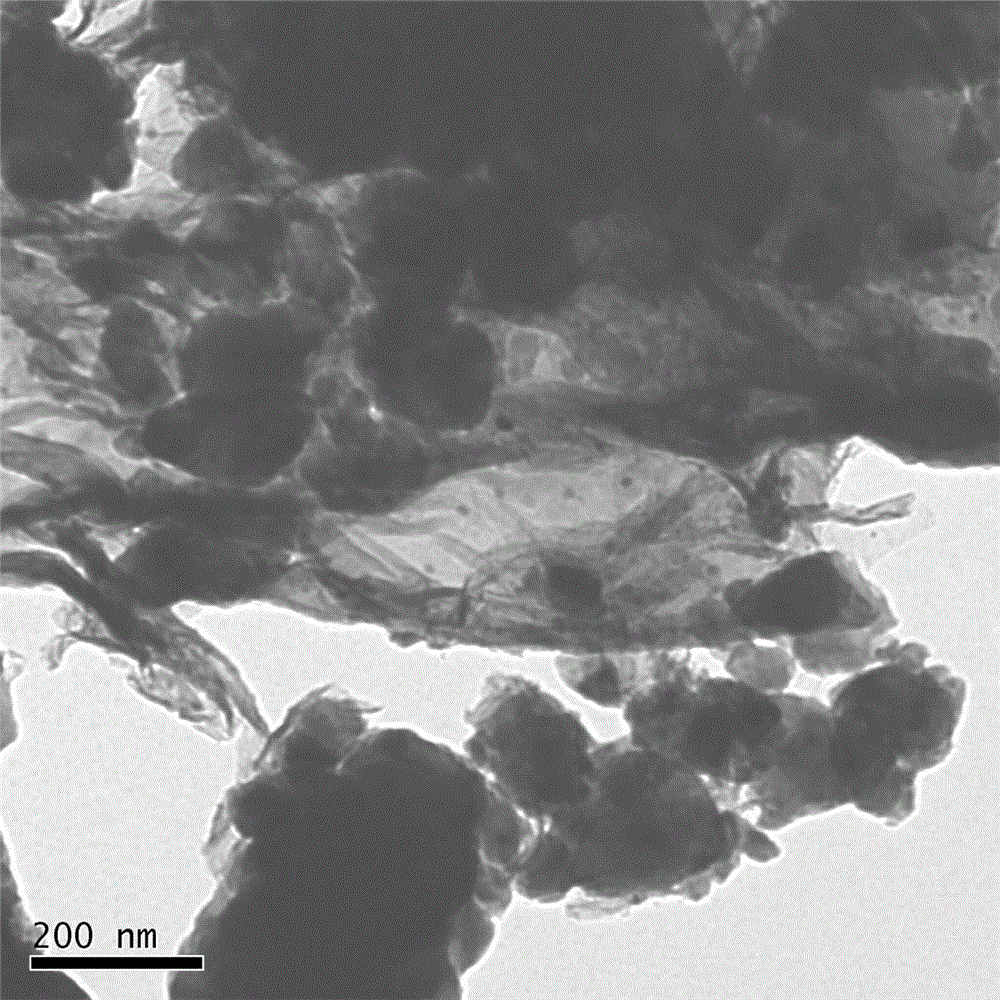

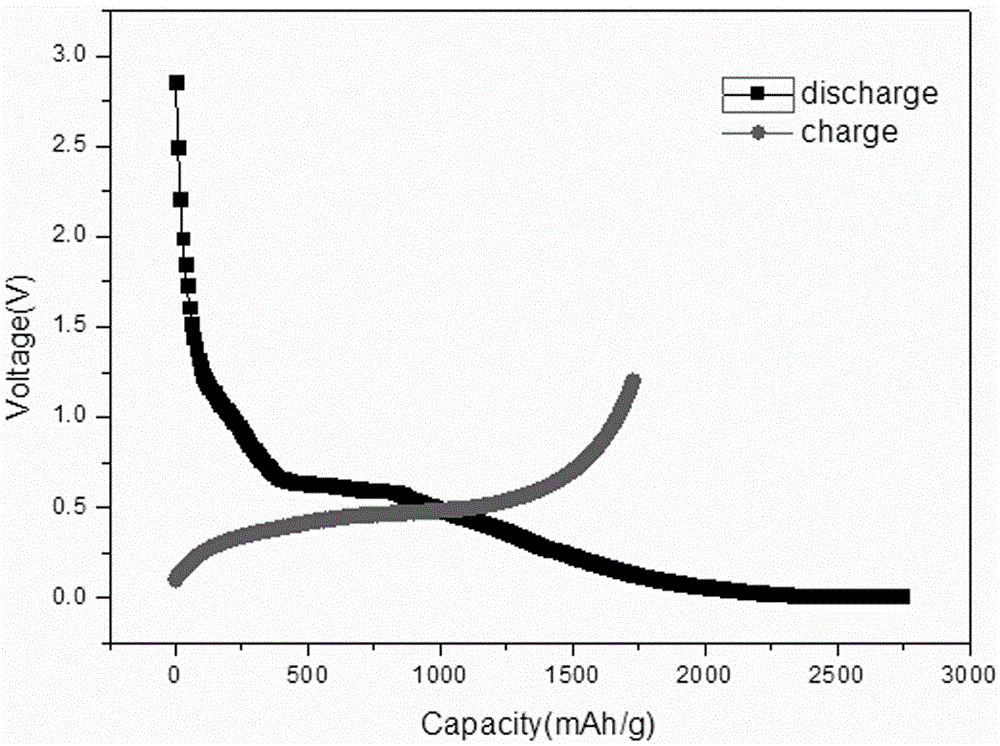

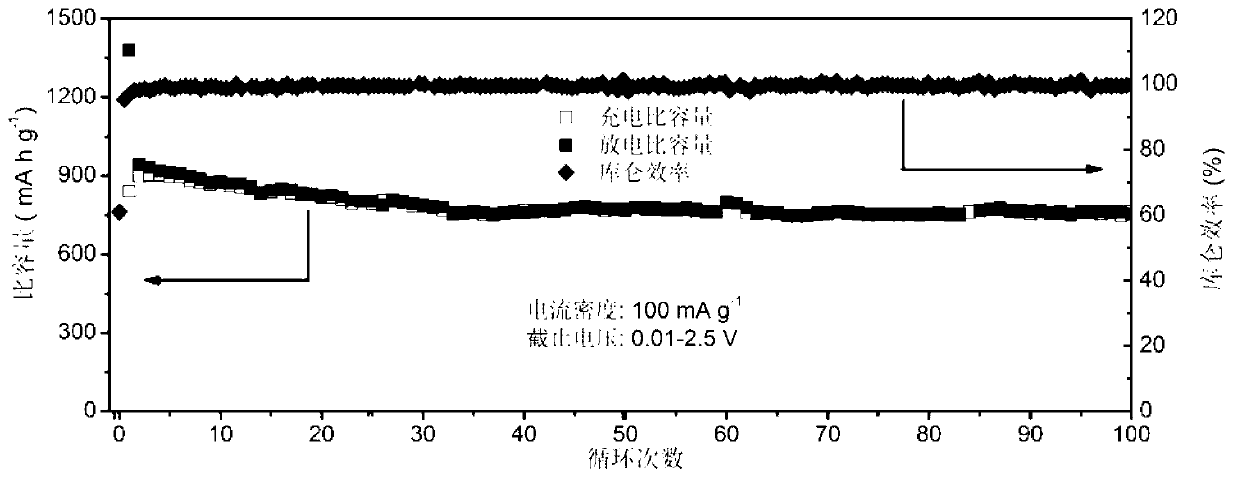

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

Nano-thermite Well Plug

Owner:CONOCOPHILLIPS CO

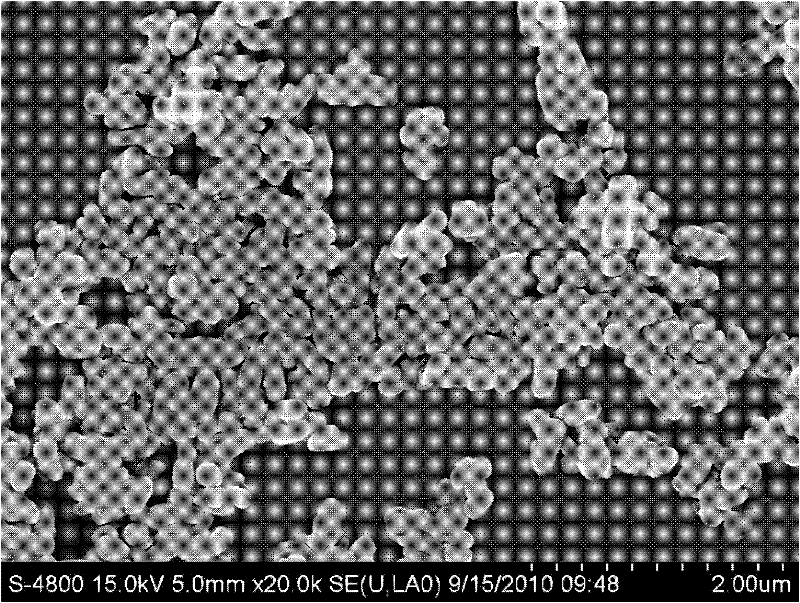

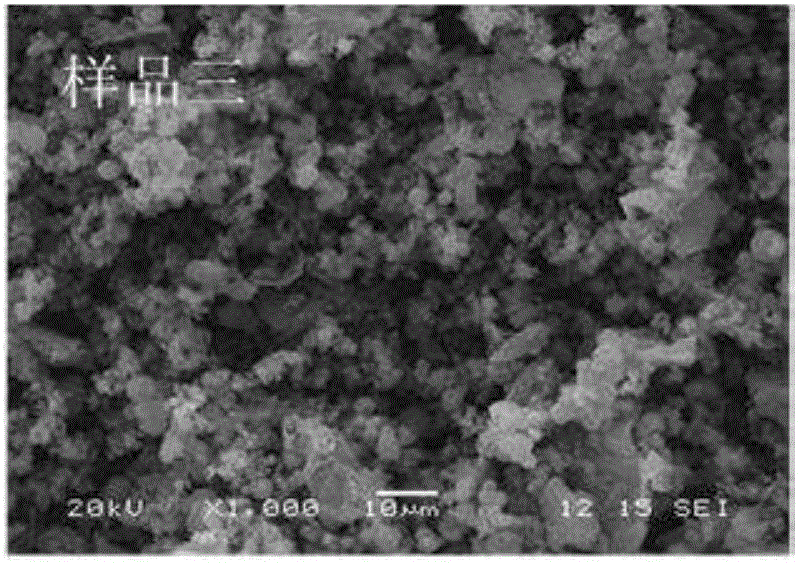

Nano lithium iron phosphate material and preparation method thereof

InactiveCN101546830ASolve the real problemSmall particlesElectrode manufacturing processesChemical/physical/physico-chemical processesChemical compositionLithium iron phosphate

The invention relates to a nano lithium iron phosphate material and a preparation method thereof. A lithium source, an iron source, a phosphate radical source and a doped element compound are dissolved in water solution containing a complexing agent according to a stoichimetric proportion and added with high-conductive carbon nano tubes scattered by assistant to form a cladding material, the obtained solution is sintered in an inert atmosphere furnace, the reaction temperature is between 500 and 900 DEG C, and the reaction time is 3 to 16 hours. The method effectively controls the chemical components, phase components and grain diameters of LiFePO4; and the obtained lithium iron phosphate is the nano lithium iron phosphate clad by the carbon nano tubes, has fine and even grains with high purity, high charge / discharge capacity, good multiplying power performance and good cycle performance, and is an ideal material for manufacturing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

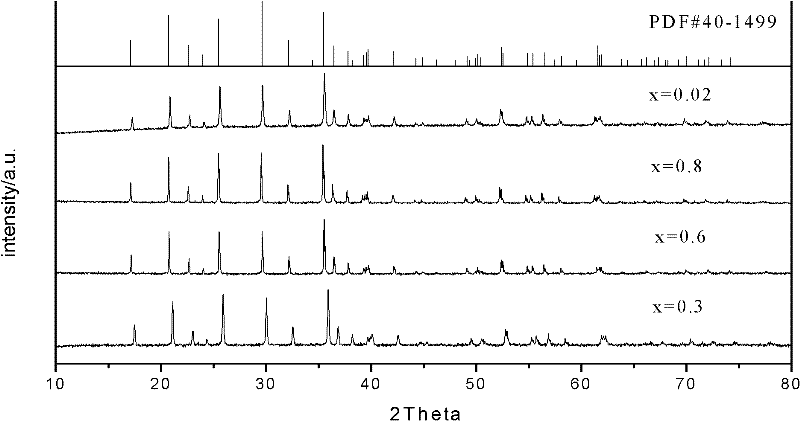

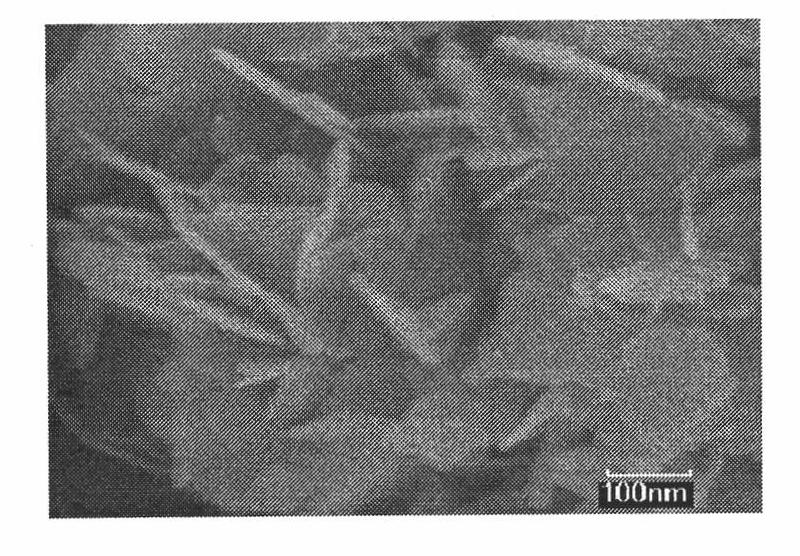

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

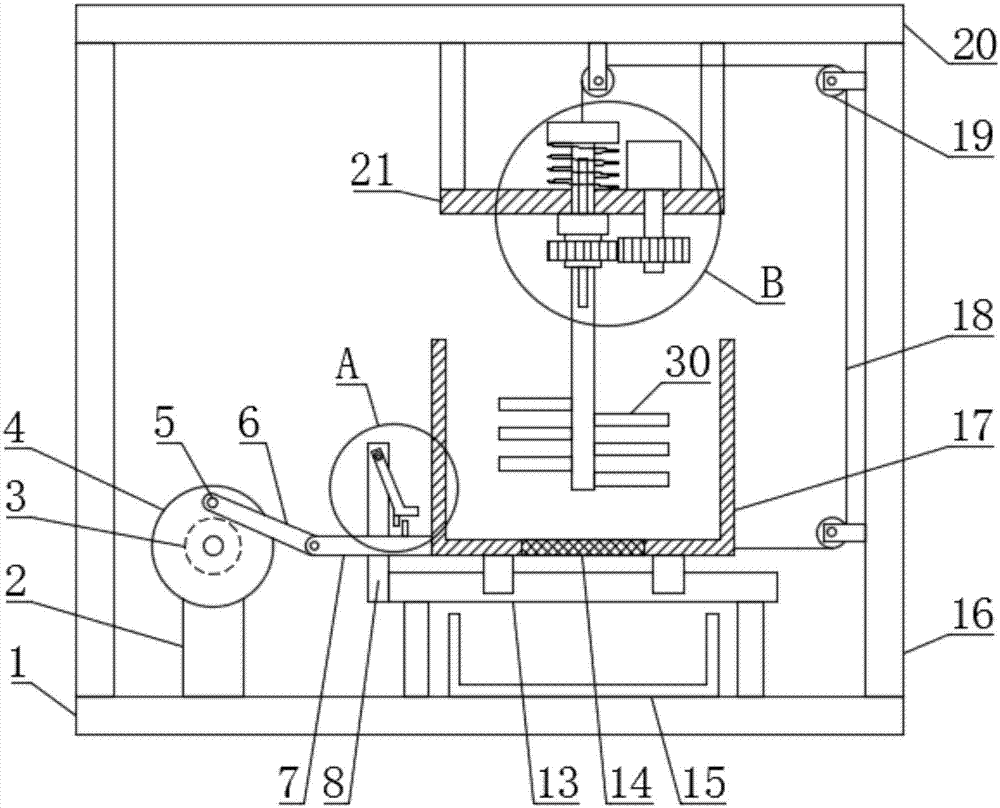

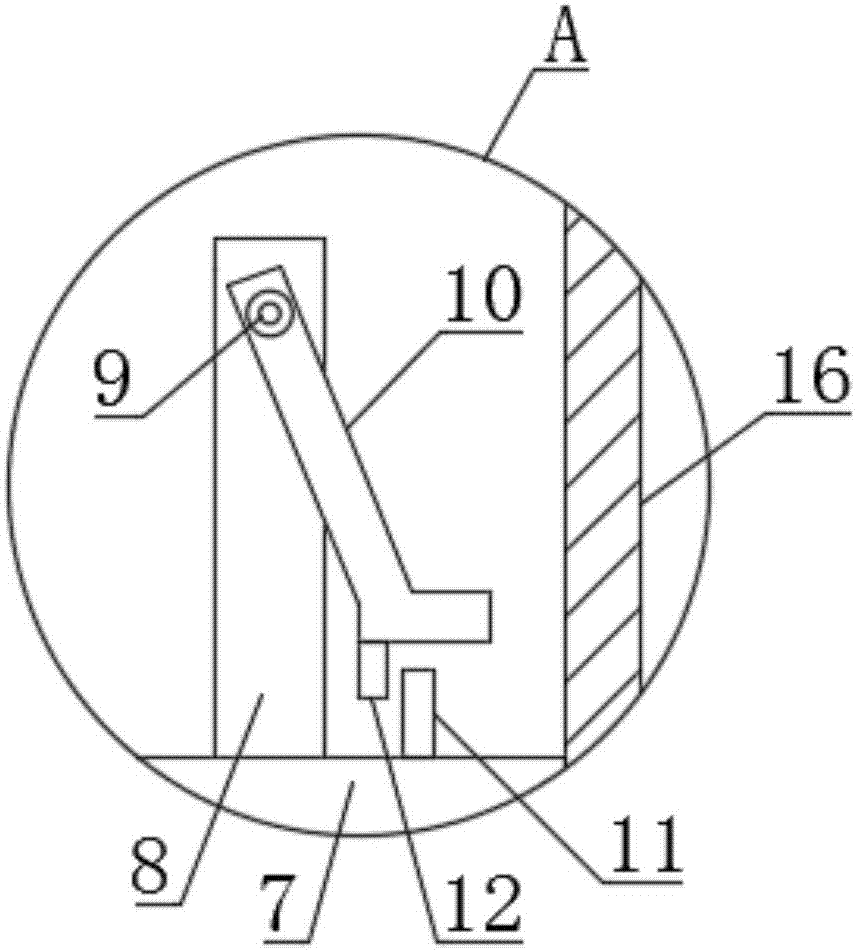

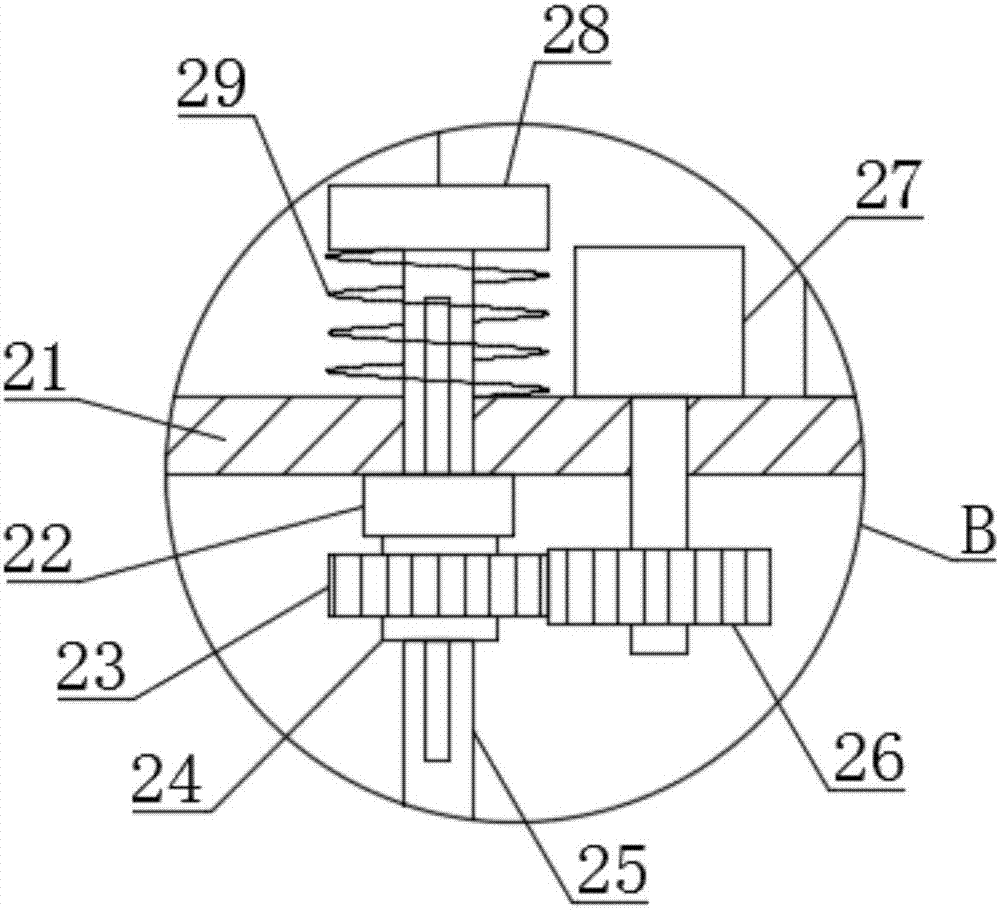

High-efficiency fodder crushing, vibrating and screening device

InactiveCN107486299AExpand the crushing rangeImprove crushing efficiencySievingScreeningElectric machineryMotor shaft

The invention discloses a high-efficiency feed crushing and vibrating screening device, which comprises a base, a slide rail is fixed on the top of the base through a bracket, a crushing box is slidably connected above the slide rail, a screen is arranged at the bottom of the crushing box, and a bottom left corner of the crushing box is connected with a Moving rod; the top of the base is also provided with a fixed seat, the front side wall of the fixed seat is provided with a deceleration motor, the motor shaft at the front end of the deceleration motor is installed with a rotating disc, the top of the front end of the rotating disc is provided with a pin shaft, and the pin shaft is rotatably connected with a connecting rod , the connecting rod is hinged with the moving rod; the left end of the slide rail is fixedly provided with a fixed rod, the top of the front side wall of the fixed rod is hinged with a knocking rod, the bottom of the knocking rod is fixedly provided with a baffle, and the top of the moving rod is provided with a push plate. During the feed grinding process of the present invention, the grinding box moves left and right by rotating the disc, thereby driving the feed to shake; during the grinding process, the knocking rod knocks on the side wall of the grinding box to prevent the feed from sticking to the inner wall of the grinding bucket and avoid screen blockage.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

Method for preparing high-activity silicon collidal sol formed from superfine silicon dioxide particles

InactiveCN101070161AEvenly distributedOvercome the disadvantage of uneven sizeSilicaSilicic acidIon exchange

The invention discloses a kind of preparation method of silica sol of high activity. For this kind of silica sol, the particle is tiny and grain size of it is distributed narrowly. It is characterized in that it takes sodium silicate as raw material, natrium ion is took out using method of exchanging ion and then get active silicic acid solution, prepare silica sol of high activity whose grain size is 6-12 nm, content of silicon dioxide is accounting for 10-30%,content of sodium monoxide is accounting for 0.2-0.3%, and PH value is between 8.5 and 10.5,through controlling proportion, pH value of reaction and heating temperature of active silicic acid solution. Silica sol prepared using this method can satisfy needs of spinning sizing, organic polymerization catalysis and modifying technology. Compared to common ion-exchanging method, preparation method of the invention has advantages of tiny particle, equal granularity, synchronizing dehydration and purification and low energy wasting, and it can control size of particle according to needs of actual utilization.

Owner:LUDONG UNIVERSITY +1

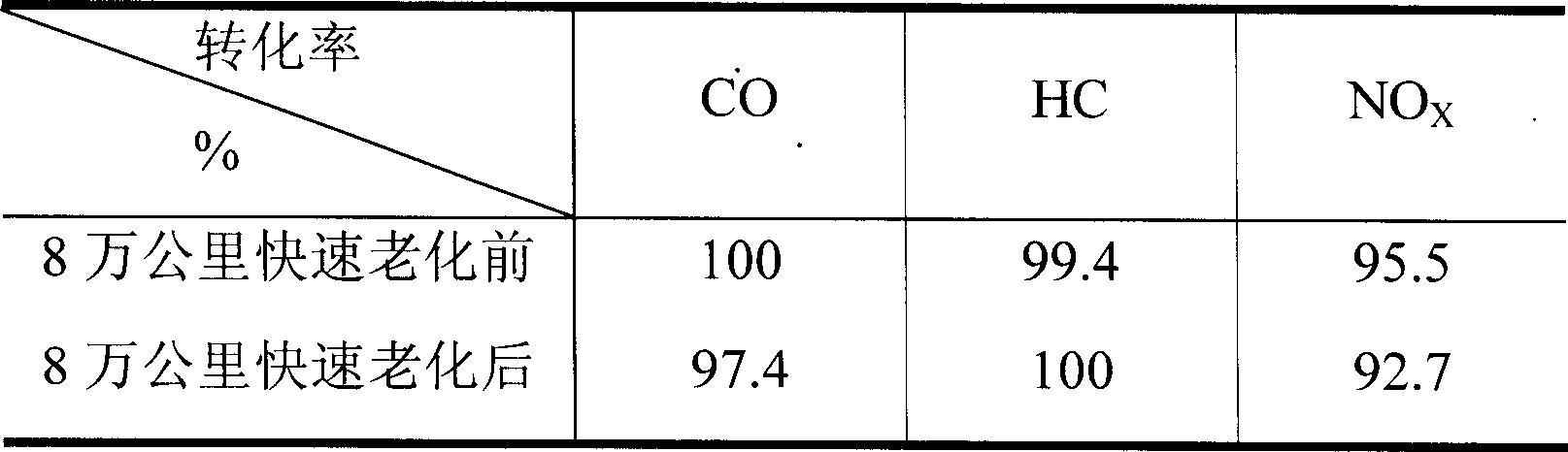

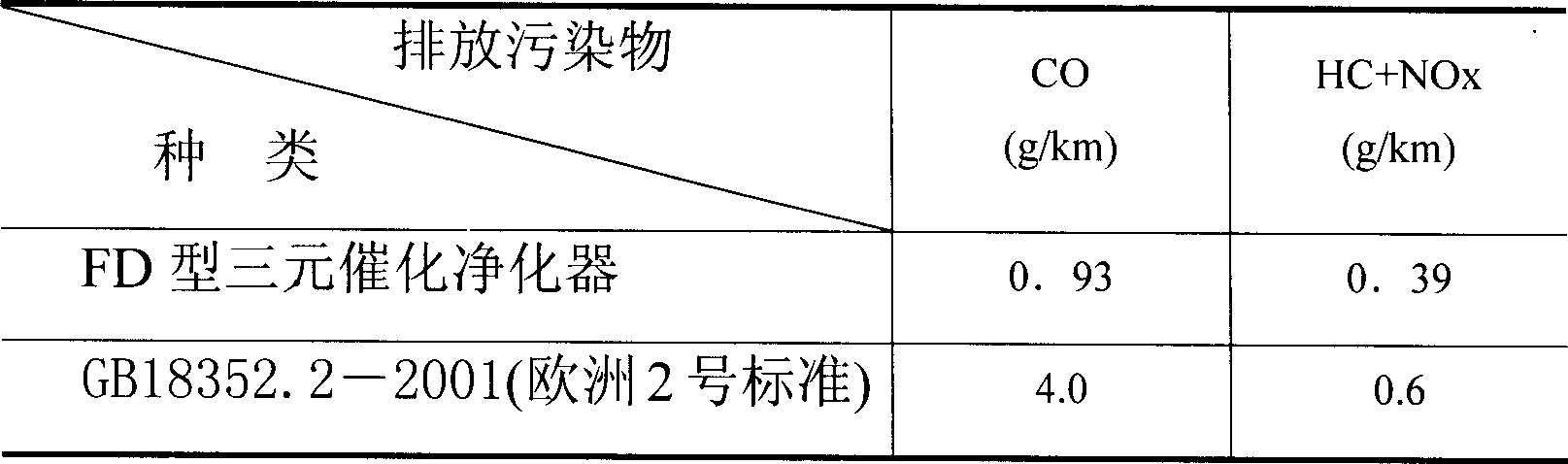

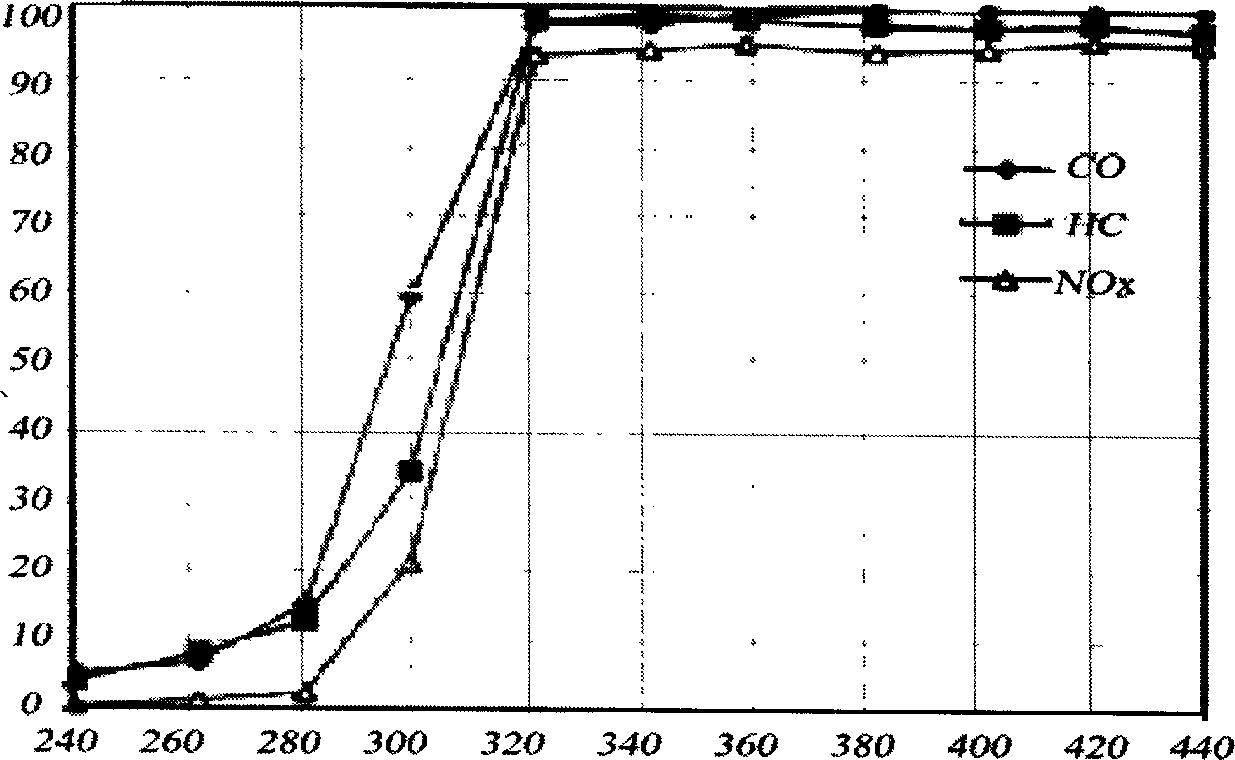

Ternary catalyst for automobile tail gas and its preparation method

InactiveCN1413769AIncrease profitSmall metal particlesCatalyst carriersDispersed particle separationActive componentCordierite

A three-element catalyst for cleaning the tail gas of car features that the cellular cordierite ceramics modified by the RE tailing mixture or transition metal oxide is ued as the first carrier, the internal and external modified alumina coating layers are used as the second carrier, and the noble metal Pt, Rh or Pd is used as its active component.

Owner:FUZHOU UNIV

Biochar prepared from banana peel, preparation method and application thereof

ActiveCN106010601ASmall particlesLarge specific surface areaOther chemical processesWater contaminantsBanana peelEconomic benefits

The invention discloses a method for preparation of biochar from banana peel. The method comprises the steps of: (1) crushing banana peel, then mixing the crushed banana peel with an aqueous solution of an activator, and performing standing; then carrying out washing and drying to obtain a biochar precursor, wherein the activator is at least one of alkali metal hydroxide, lewis acid and peroxide; (2) mixing the biochar precursor with an acid solution, then carrying out hydrothermal charring reaction at 180DEG C-260DEG C, and at the end of the hydrothermal charring reaction, carrying out washing and drying to obtain the biochar. In addition, the invention also comprises the biochar prepared by the method and application of the biochar to adsorption of heavy metals. The method provided by the invention utilizes agricultural production waste to prepare a biochar adsorbent by simple and rapid hydrothermal charring method, turns waste into treasure, makes full use of resources, reduces environmental pollution, has good economic benefits, develops new technology, and is beneficial to industrial production.

Owner:HUNAN AGRICULTURAL UNIV

A preparation method of surface metallized composite material through chemical plating under photocatalysis

InactiveCN101550546APromote reductionImprove plating speed and productivityLiquid/solution decomposition chemical coatingIonPhotocatalysis

The present invention pertains to the technical field of the preparation of surface metallized composite material and relates to a preparation method of surface metallized composite material through chemical plating under photocatalysis, wherein the fibre, plastic, fabric, resin, glass, ceramic, monocrystalline silicon or metal encapsulated with semiconductor nano inorganic powder is used as substrate material, or the semiconductor nano inorganic powder is used as substrate material, the photocatalytic technique integrates the reducer effect in conventional chemical plating, metal is carried on the surface of substrate material effectively, and surface metallized composite material is prepared. The advantage is that it makes use of the feature that semiconductor nano inorganic powder will be excited and generate a large number of electron-cavity pairs under the irradiation of photons of which energy is equal to or greater than band-gap energy, while electrons have a reducing effect and help accelerate the reduction of metal ions, and combines this feature with the reducer effect in conventional chemical plating to raise plating speed and production efficiency, reduce product cost and prepare surface metallized composite material with uniform surface metal layer, tiny metal particles, high quality and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method and application of core-shell structure cobalt-base catalyst of middle distillate for synthesis gas preparation

ActiveCN101804351AUniform particle size distributionGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSyngasNanometre

The invention relates to a core-shell structure cobalt-base catalyst of a middle distillate for synthesis gas preparation, which comprises the following components in percentage by weight: 5 to 30 percent of cobalt and 70 to 95 percent of silica. The catalyst has the following physical properties: the specific surface area is 200 to 1400m<2> / g, the pore volume is 0.5 to 1.3cm<3> / g, the average pore size is 2.0 to 18nm, the cobalt crystallite dimension is 12 to 25nm, and the particle size of the core-shell structure cobalt-base catalyst is less than 100nm, and cobaltosic oxide nano particles are coated in a mesoporous silicon shell to form a core-shell structure. The invention has the advantages of simple operation, high yield, high activity and high selectivity of the middle distillate.

Owner:中科潞安能源技术有限公司

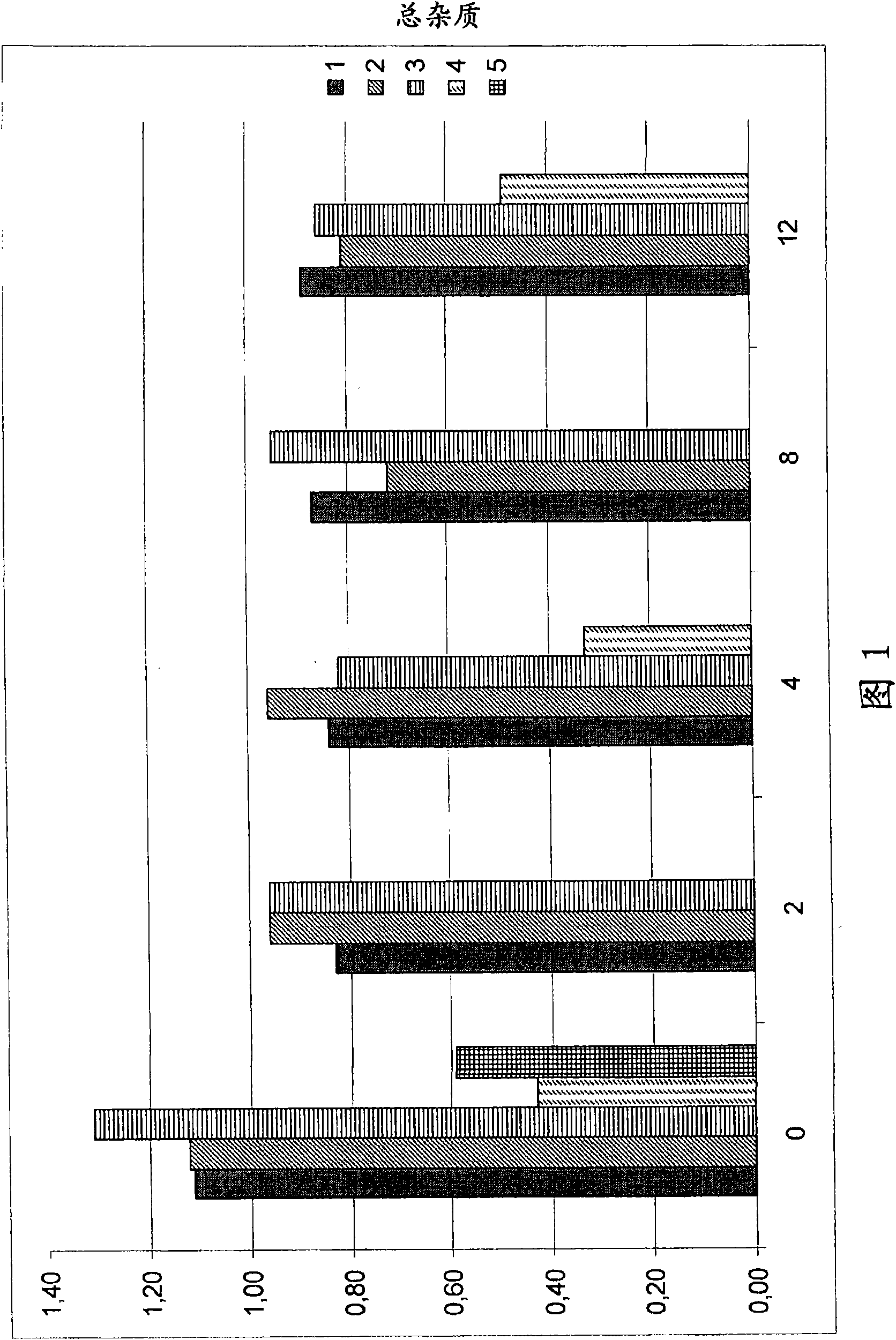

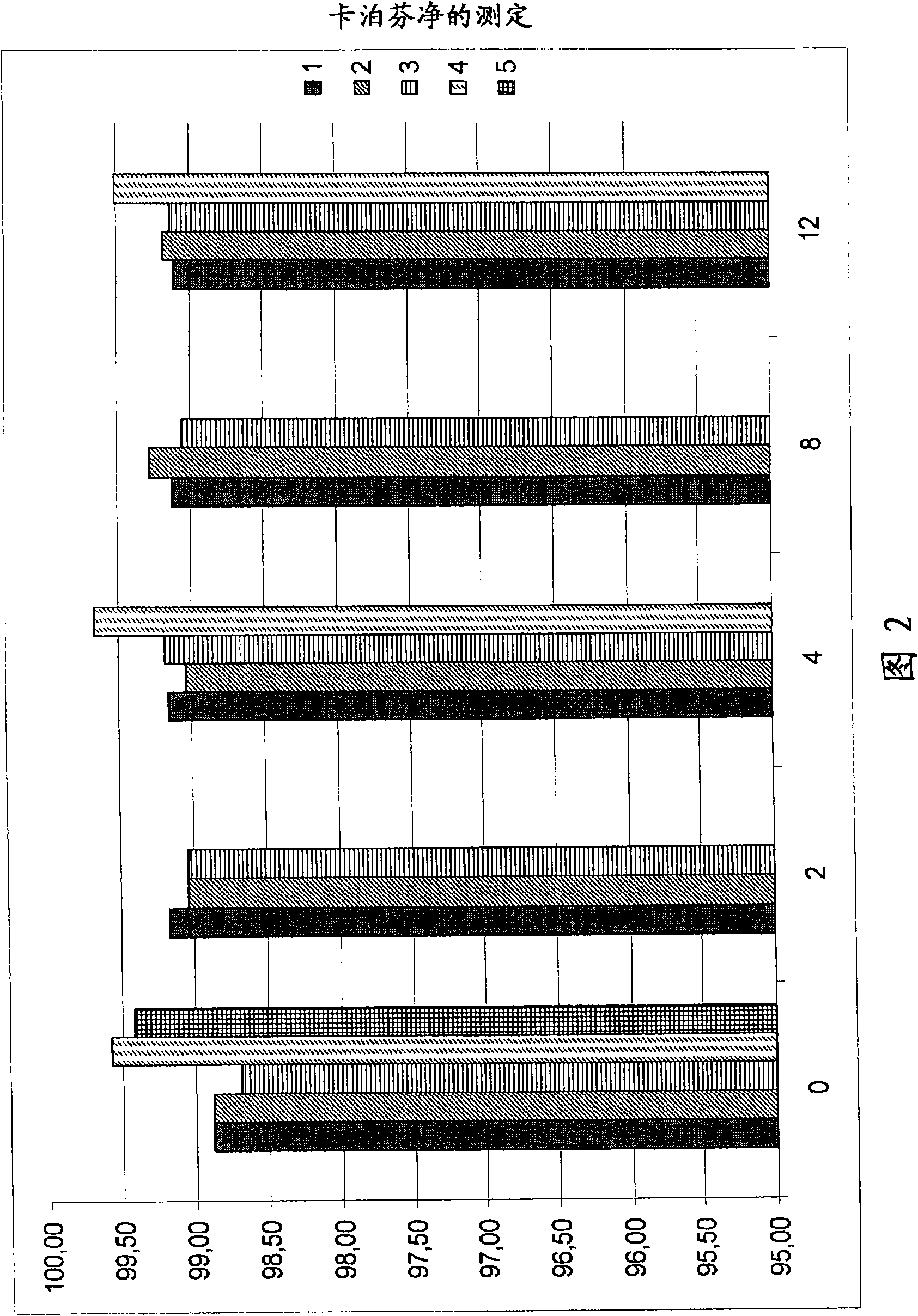

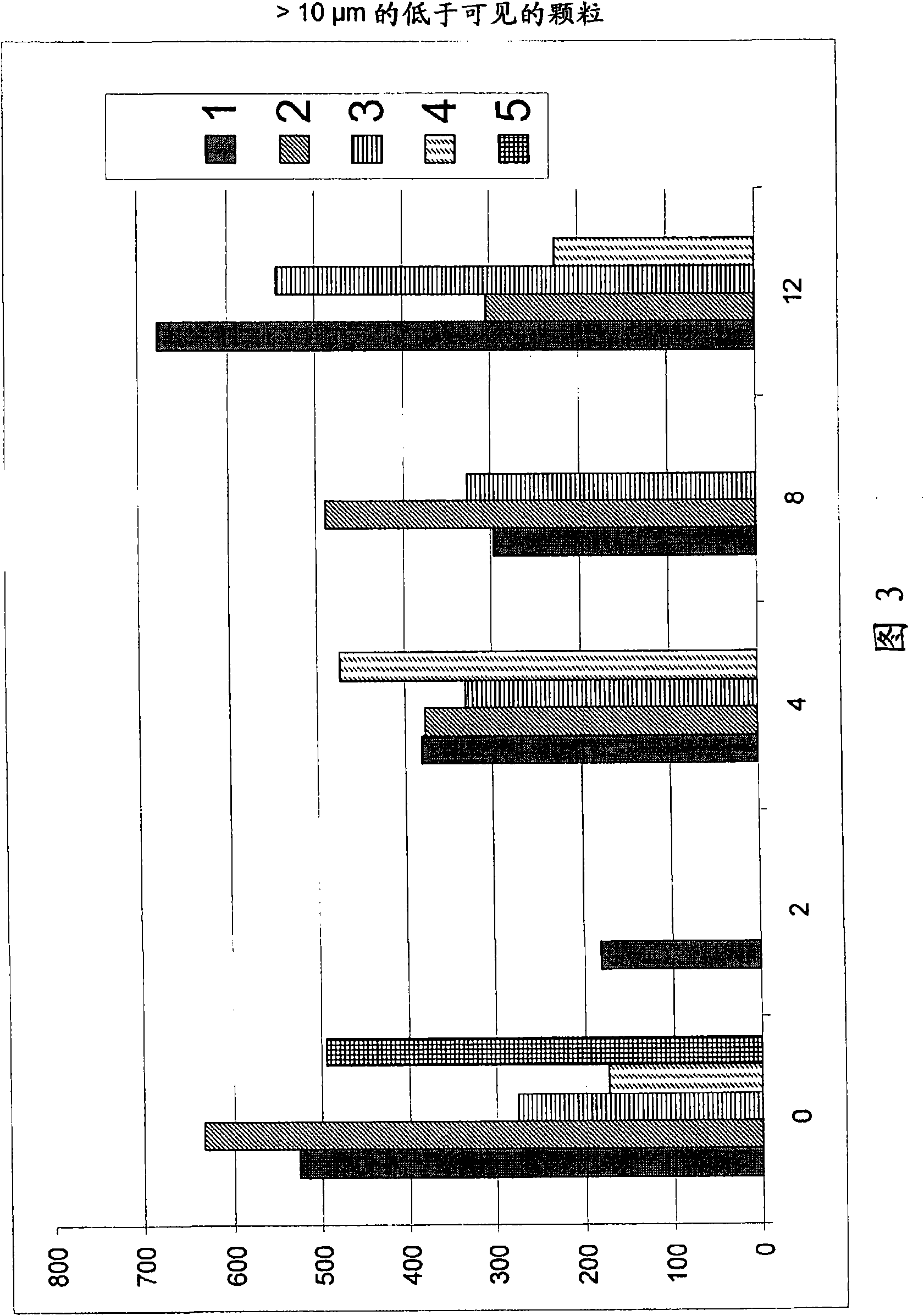

Caspofungin formulations

The present invention relates to pharmaceutical compositions comprising a pharmaceutically acceptable salt of caspofungin as active ingredient being useful for the prevention and / or treatment of fungal infections. Said compositions additionally comprise specific bulking agents and small amounts or no amounts of an additional pH modifier and may be in a liquid or solid form, e.g. may be lyophilized compositions. Said compositions show good stability and reduced amounts of sub-visible particulate matter formed in solutions which are reconstituted from the lyophilized product.

Owner:SANDOZ AG

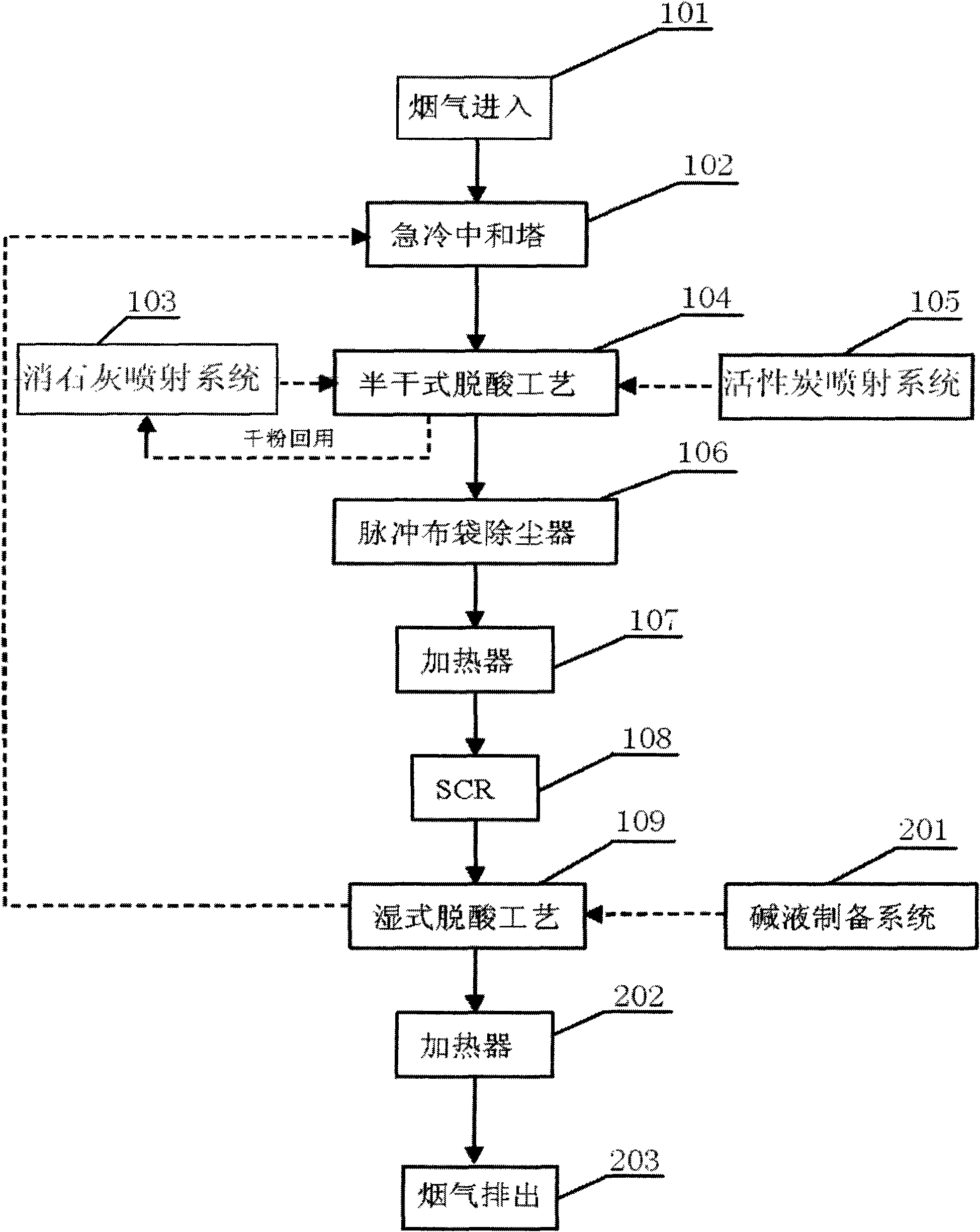

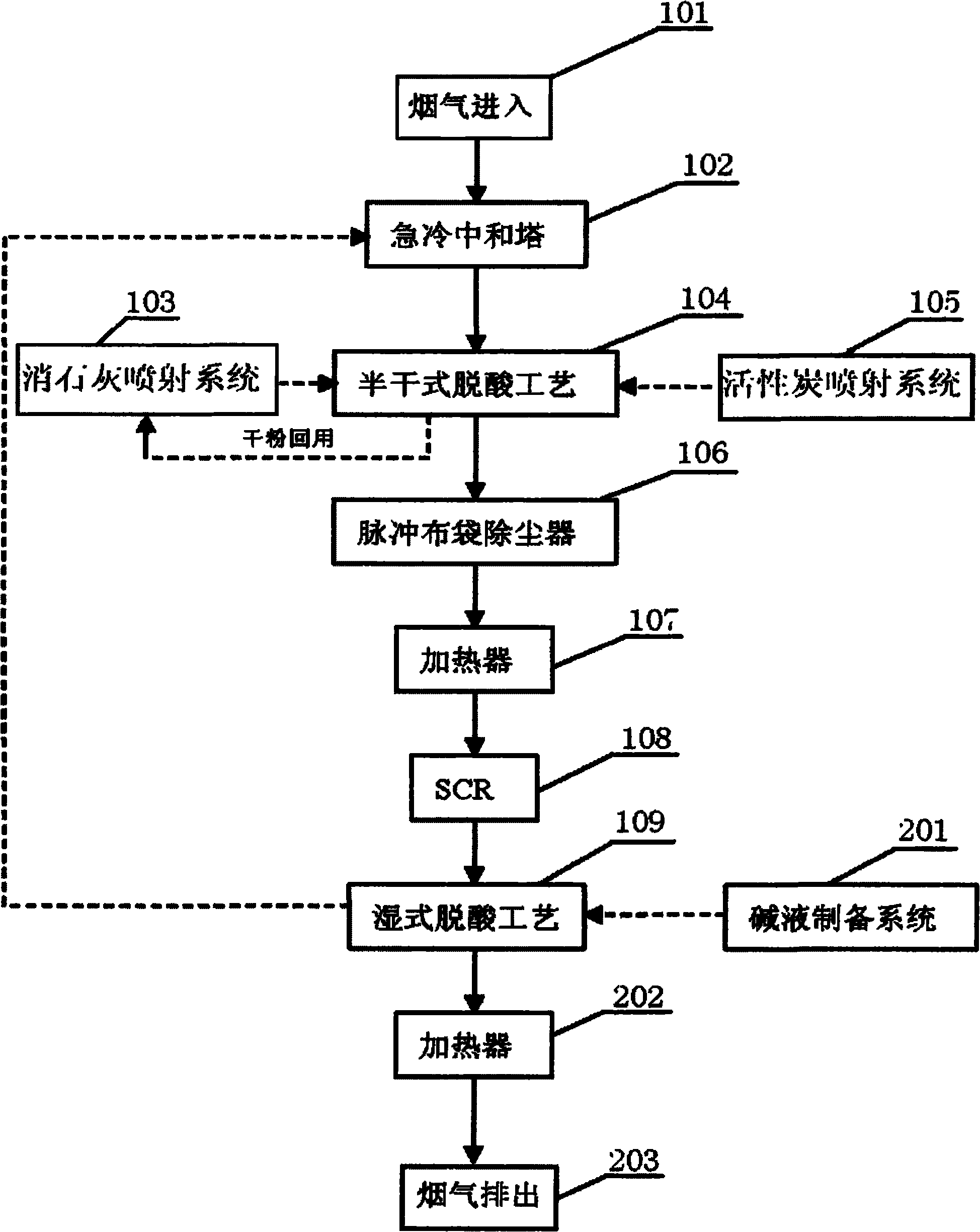

Smoke processing technology

InactiveCN101797472AAvoid corrosionEasy to handleDispersed particle separationAdditive ingredientProduct gas

The invention discloses smoke processing technology, which belongs to the technical filed of environment protection. The smoke processing technology at least comprises the following steps: a. smoke cooling: introducing smoke into a quench tower to be cooled; b. half-dry deacidification: introducing cooled smoke into an absorber provided with an alkaline material injection device; c. dust removal: introducing the smoke processed by the second step into a bag type dust remover; d. denitration: introducing the smoke processed by the third step into a denitration device provided with an ammonia spraying device; e. wet type deacidification: introducing the smoke processed by the fourth step into a wet type absorption tower provided with an alkaline liquid spraying device, wherein the alkaline material in the second step is a mixture of active slaked lime and active carbon. The invention has high purification efficiency on acid gas, saves the technical area, and saves the cost. Proper adjustment can also be carried out according to the actual smoke ingredients and the technical requirements, the flexibility is high, and the applicable range is wide.

Owner:上海蓝鸟环境科技发展有限公司

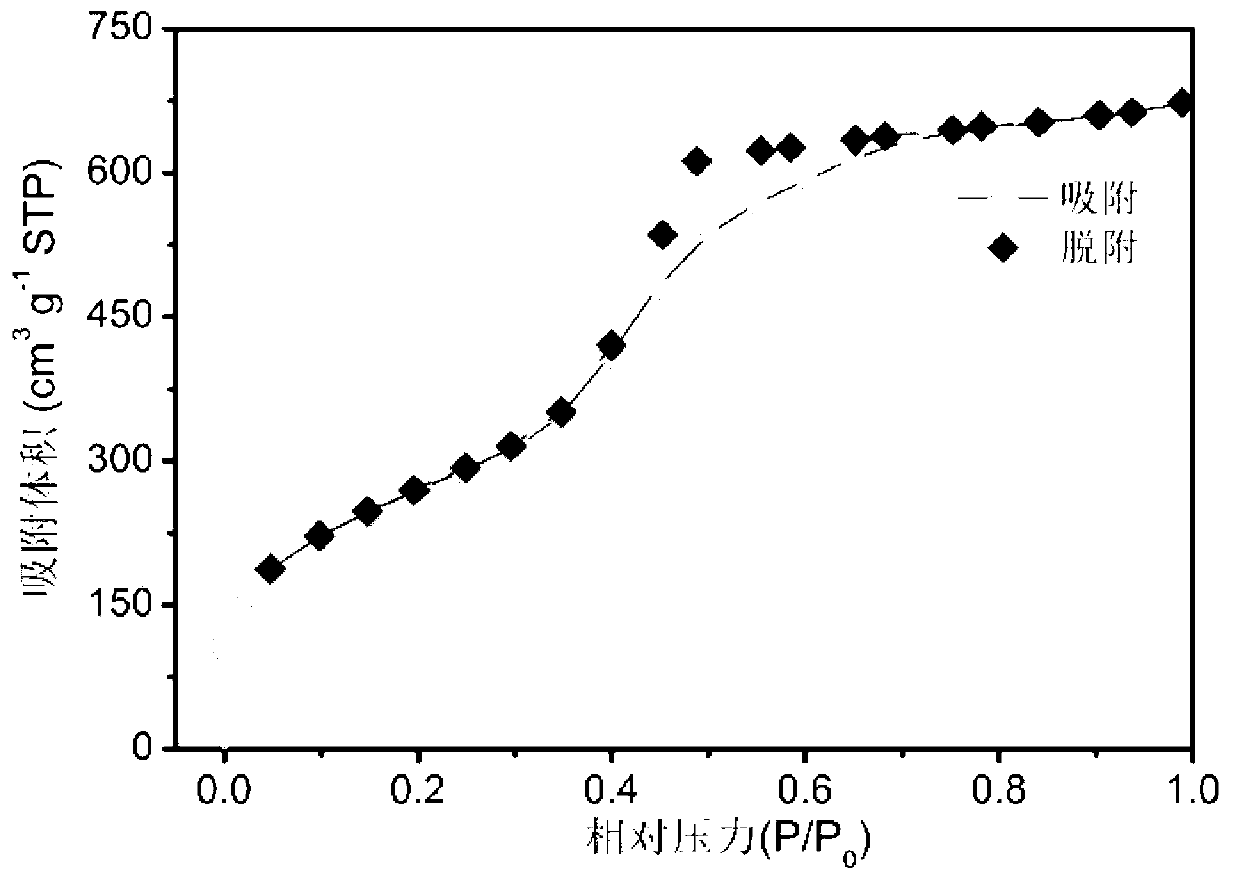

Preparation method of mesoporous SiOx/C composite negative material of lithium-ion battery

ActiveCN103280560ASmall particlesUniform particle sizeCell electrodesMesoporous silicaSurface-active agents

The invention discloses a preparation method of a mesoporous SiOx / C composite negative material of a lithium-ion battery, and belongs to the fields of new materials and electrochemistry. The preparation method comprises the following steps of: taking polyvinylpyrrolidone as an auxiliary template agent, taking an organic surface active agent as a template agent and organic silicon as a silicon source, obtaining mesoporous silica precursor by hydrothermal treatment, adding a carbon source, and preparing SiOx / C composite negative material with a mesoporous structure by carbothermic reduction reaction occurring in the process of high-temperature thermal treatment. The preparation method disclosed by the invention has the advantages that the specific capacity of the material is high, the structure is novel, and simultaneously the cycling stability is good; the yield is high; and the prepared SiOx / C composite material is fine in particle, uniform in particle size and component distribution, high in specific capacity and good in cycling stability, is an ideal composite negative material of the lithium-ion battery, and can be widely applied in the fields such as various portable electronic equipment, electric vehicles and aerospace.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

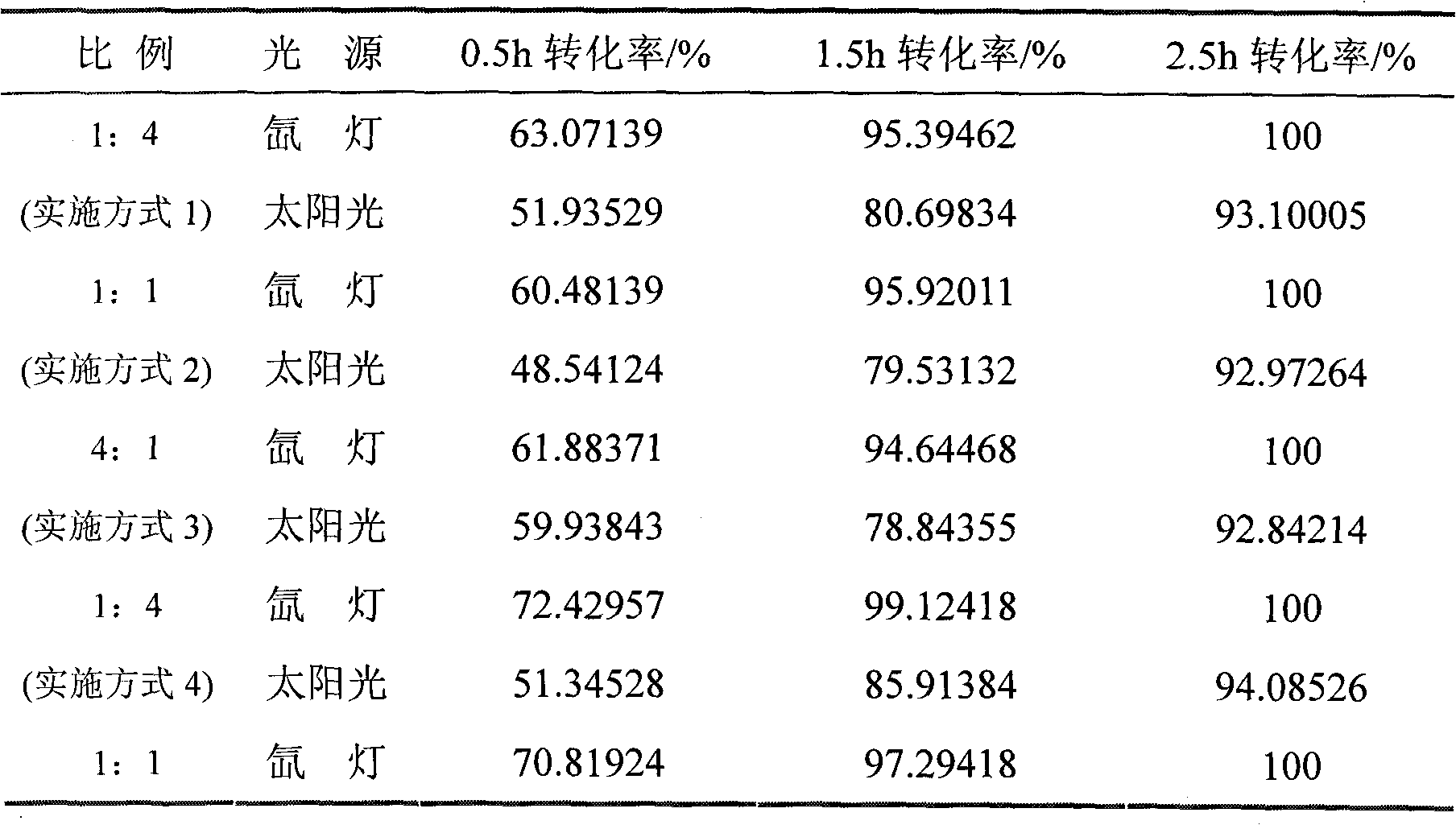

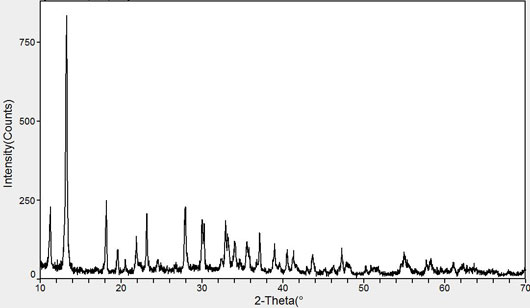

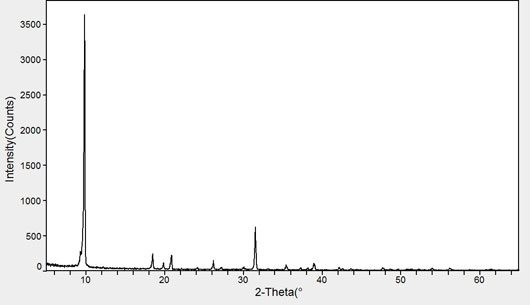

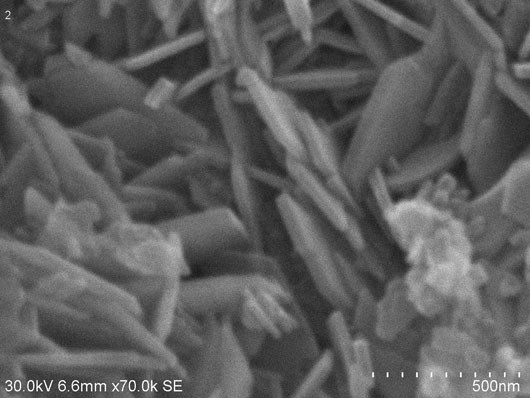

Preparation and application methods of BiOBr/BiOCl compound photocatalyst

InactiveCN102068998AMake up for gap width defectsEasy to preparePhysical/chemical process catalystsWater/sewage treatment by irradiationCompound (substance)Trace Amounts

The invention relates to preparation and application of a BiOBr / BiOCl compound photocatalyst, belonging to the technical field of photocatalysis water treatment in environmental chemical engineering. In the invention, the preparation method comprises the following steps: hydrolyzing BiCl3 and BiBr3 which are used as raw materials, precipitating, carrying out solid-liquid separation, drying and the like to obtain the BiOBr / BiOCl compound photocatalyst. The BiOBr / BiOCl compound photocatalyst can be used for degrading organic substances in water, and especially for treating trace amounts of toxic and harmful nondegradable organic substances in water. The BiOBr / BiOCl compound photocatalyst prepared by the invention has the advantages of simple technique, low cost, high photocatalysis activityand the like, is safe to operate, and has wide industrial application prospects.

Owner:TAIYUAN UNIV OF TECH

Preparation method of superfine nanometer lithium iron phosphate electrode material and application thereof

InactiveCN102674291AImprove electrochemical performanceIncrease capacityCell electrodesNanotechnologyLithium iron phosphatePhosphate

The invention discloses a preparation method of a superfine nanometer lithium iron phosphate electrode material, comprising the following steps of: firstly, taking an iron source compound and a phosphorus source compound as raw materials to obtain nanometer ferrous phosphate as a precursor; and secondly, using the ferrous phosphate and the lithium source compound to prepare the superfine nano lithium iron phosphate electrode material. The preparation method of ferrous phosphate, disclosed by the invention, has a simple production process; the obtained nanometer ferrous phosphate can be used for preparing the high-purity superfine nanometer lithium iron phosphate; and the ferrous valence state is not changed when the ferrous phosphate is used for preparing the lithium iron phosphate, thus, no carbon source compound or reducing agent needs to to be added to change the iron valence state, and then the carbon-coated lithium iron phosphate or non-carbon-coated lithium iron phosphate can be directly prepared. The nanometer lithium iron phosphate manufactured by the nanometer ferrous phosphate precursor has excellent performance, good discharge capacity and voltage platform performance under high capability and high multiplying power, and long cycle life.

Owner:GUANGXI NUOFANG ENERGY STORAGE TECH

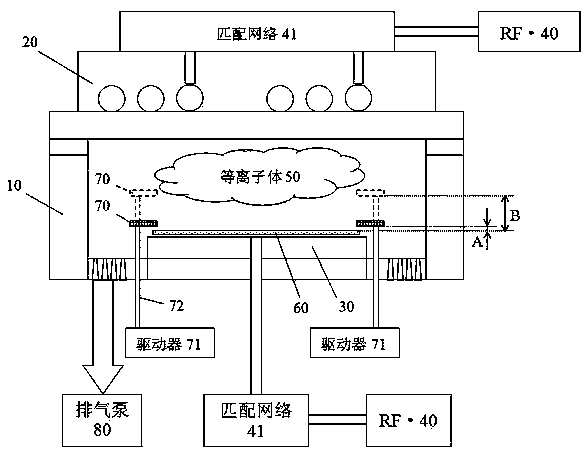

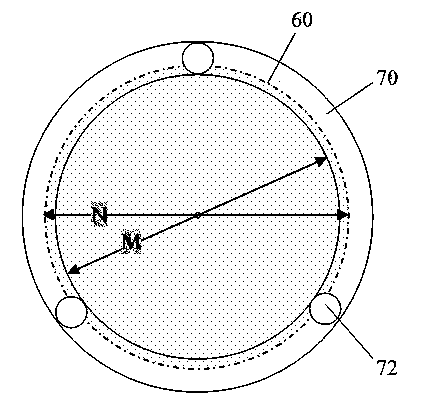

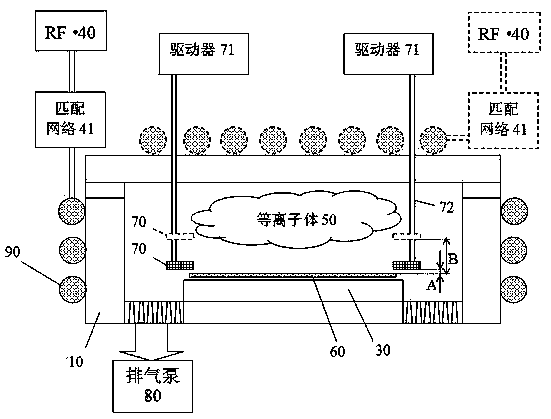

Wafer edge protection ring and method for reducing particles at wafer edge

ActiveCN103730318ASmall particlesQuality assuranceElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProtection ring

The invention relates to a wafer edge protection ring and a method for reducing particles at a wafer edge. The protection ring is located in a reaction cavity of a plasma processing device, the protection ring can cover the wafer edge in the process that a wafer is processed so that processing byproducts including polymers can be borne, and the protection ring can move in the process that the wafer is released and take the collected polymers off the wafer. The wafer edge protection ring is simple in structure, convenient to control and capable of effectively reducing the particles at the wafer edge and guarantees quality of a chip on the wafer edge.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

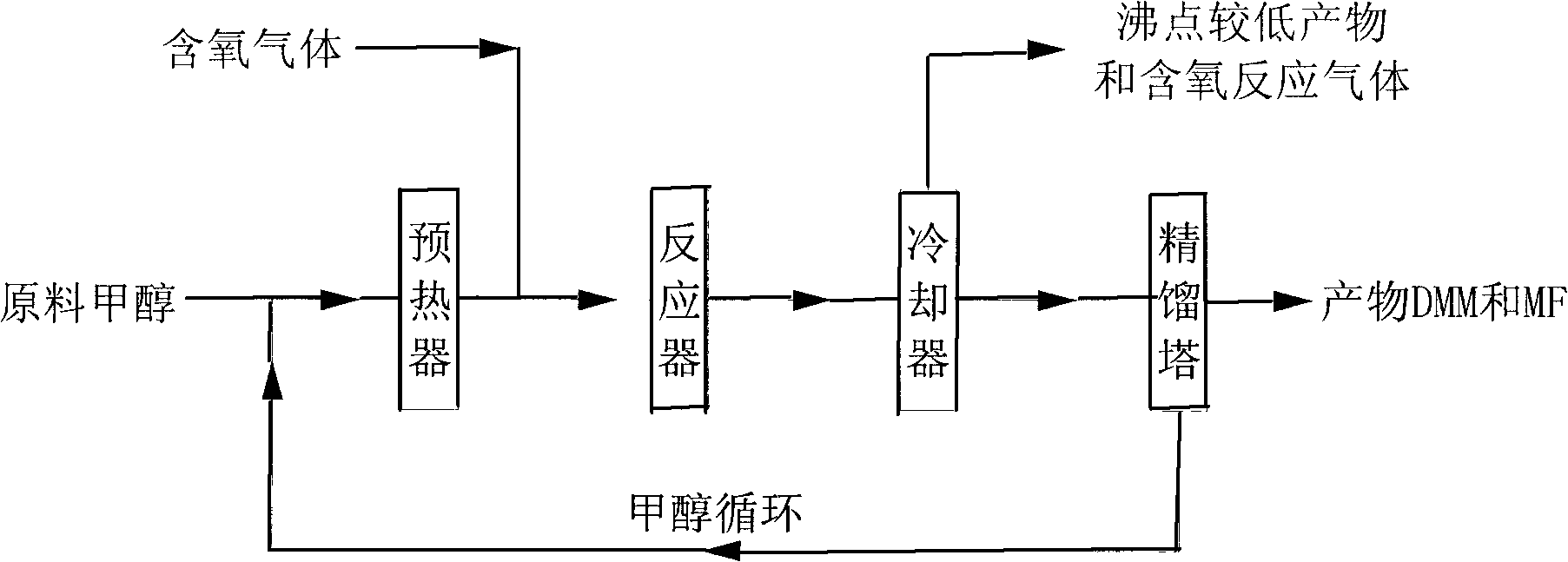

Metallic catalyst for synthesizing dimethoxym ethane and methyl formate and production method thereof and use

InactiveCN101327444ALarge specific surface areaSmall particlesMolecular sieve catalystsOrganic compound preparationFormate EstersTitanium

The present invention relates to a metal catalyst synthesizing methylal and methyl formate. In weight percentage of the metal catalyst, the content of vanadium is calculated by the weight of V2O5; the content of titanium is calculated by the weight of TiO2; the weight proportion of the V2O5 and the TiO2 in the catalyst is 5 to 70 to 30 to 95; the V2O5 and the TiO2 take 20 percent to 100 percent of the catalyst in weight percentage; the content of accessory ingredient is calculated by the content of the oxide of the accessory ingredient and takes 0wt percent to 2.0wt percent of the catalyst in weight percentage; support takes 0wt percent to 78wt percent of catalyst in weight percentage. The catalyst has the advantages of high methanol conversion rate, the high selectivity of the methylal and the methyl formate, the good stability of the catalyst and long life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

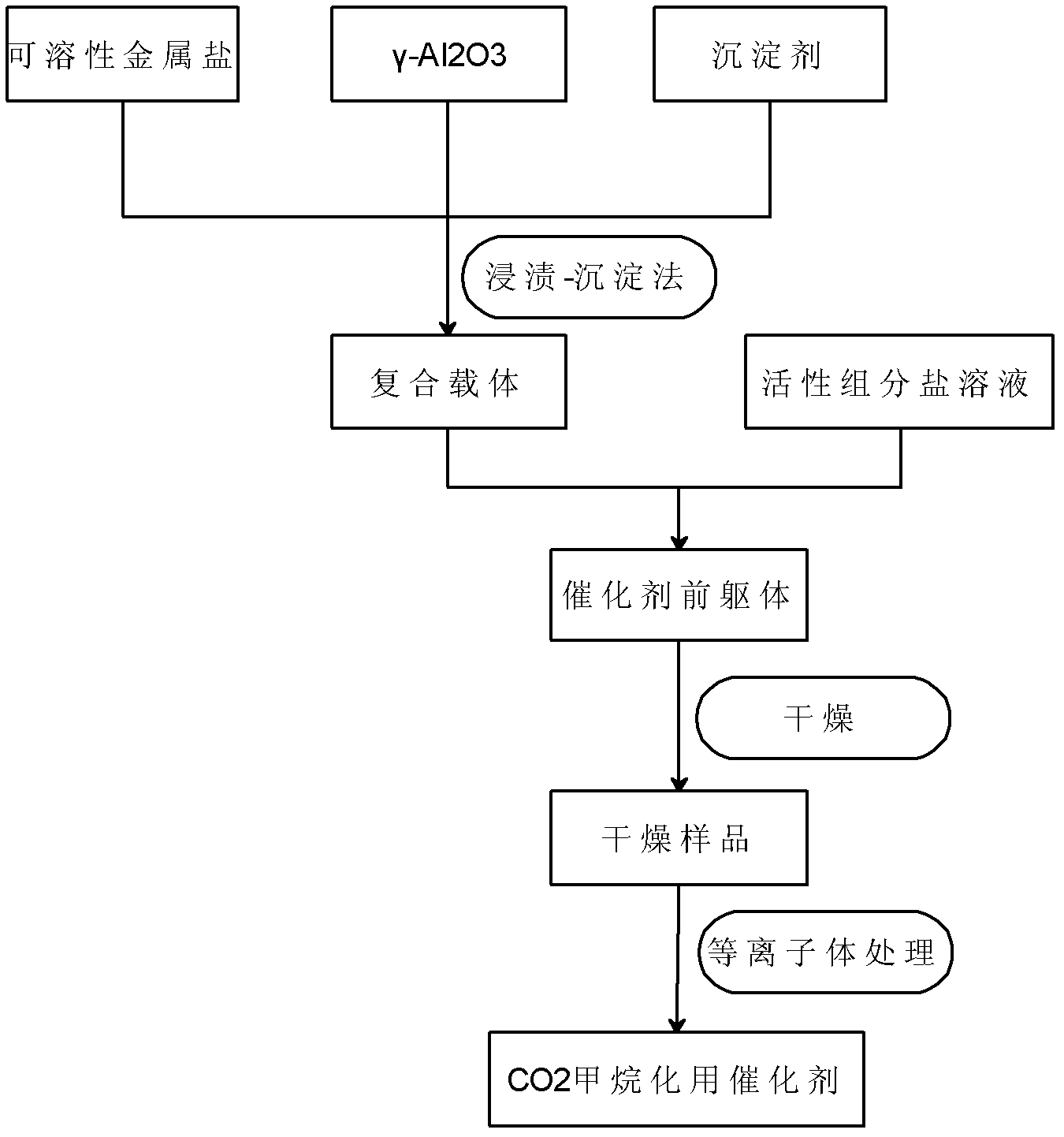

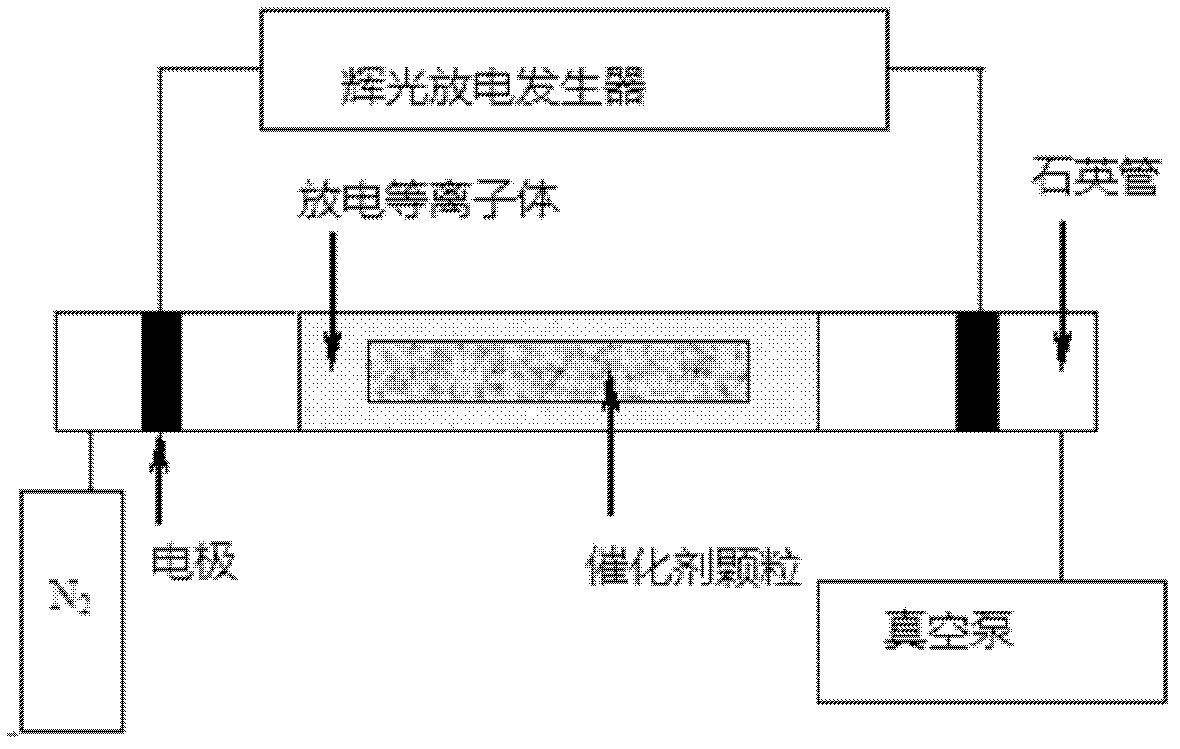

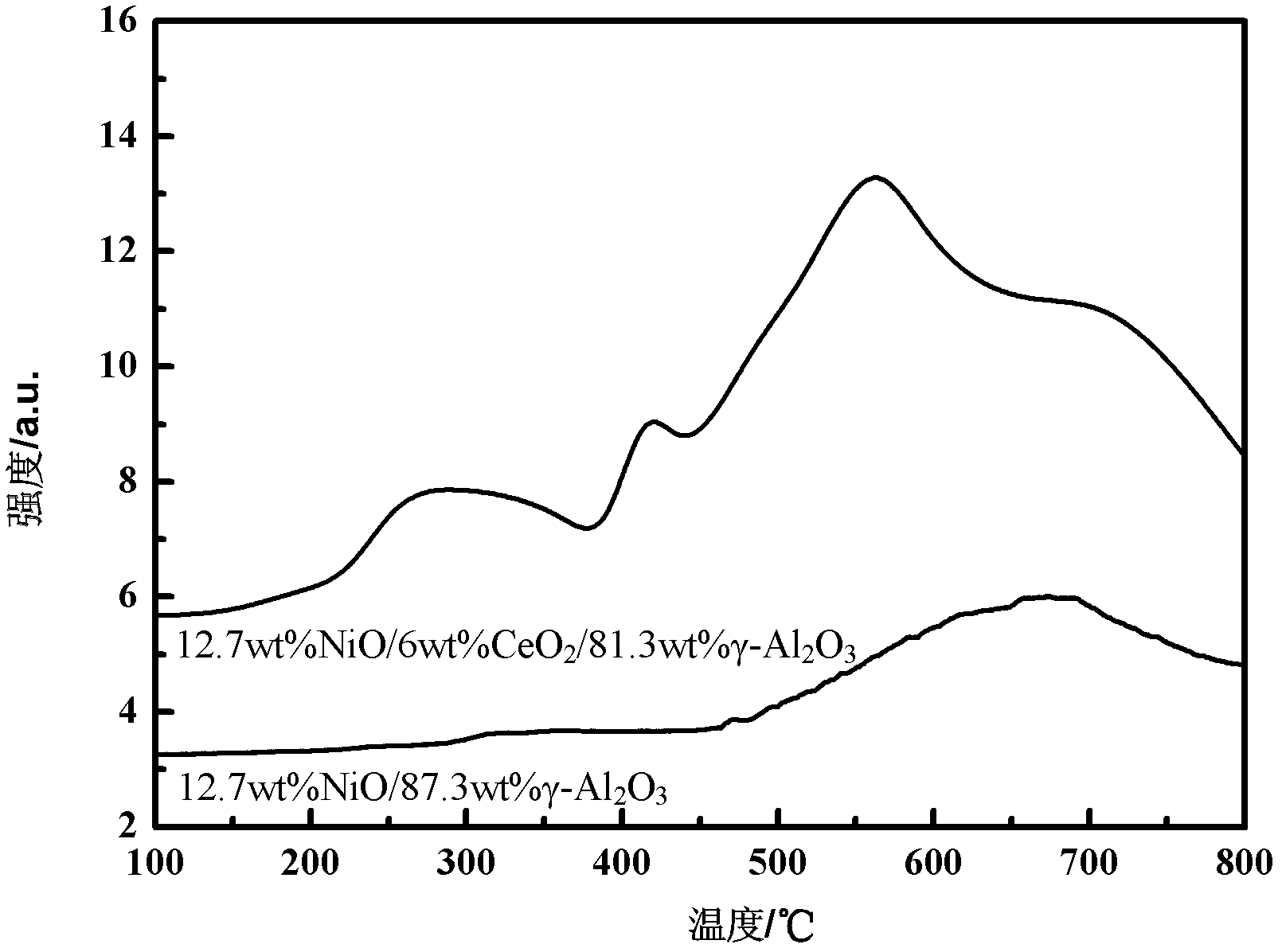

Catalyst for carbon dioxide methanation and preparation method thereof

InactiveCN102600854ASmall particle sizeEvenly dispersedHydrocarbon from carbon oxidesCatalyst activation/preparationChemistryWater soluble

The invention discloses a catalyst for carbon dioxide methanation and a preparation method of the catalyst, belonging to the technical field of carbon dioxide methanation. The catalyst for carbon dioxide methanation is composed of a composite carrier and an active ingredient at a ratio of 84-90wt%:10-16wt%, wherein the composite carrier is composed of gamma-Al2O3 and water soluble metal oxide at a mass ratio of 77-86:2-10; and the active ingredient is Ni which exists in the catalyst in a form of NiO. The catalyst is high in activity, low in cost and better in stability, and can be used for carbon dioxide methanation reaction under normal pressure condition.

Owner:SICHUAN UNIV

Preparation method of non-supported high-activity hydrogenation catalyst

ActiveCN103861609AHigh specific surface areaLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentAluminiumFixed bed

The invention relates to a preparation method of a non-supported high-activity hydrogenation catalyst. The preparation method of the non-supported high-activity hydrogenation catalyst is characterized by comprising the following steps: preparing an acid solution A containing at least one group VIII metal compound and at least one group VIB metal compound, and an alkali solution B containing at least one silicon source or aluminium source, slowly mixing the two solutions into a sedimentation reactor, carrying out co-precipitation reaction to obtain slurry under the conditions that temperature is 20-120 DEG C and pH value is 7-12, and carrying out ageing, suction filtration, washing, drying, moulding and roasting on the slurry, so that a catalyst with high catalytic performance for hydrogenation reaction of a fixed bed is obtained. The prepared non-supported hydrogenation catalyst has large specific surface area, high pore volume and high hydrogenation activity; meanwhile, the preparation method of the non-supported high-activity hydrogenation catalyst is simple, reaction conditions are mild, and operation is easy and stable, so that the preparation method of the non-supported high-activity hydrogenation catalyst is applicable to industrial batch-type production.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

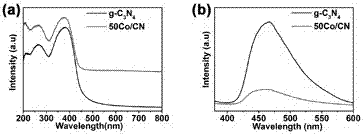

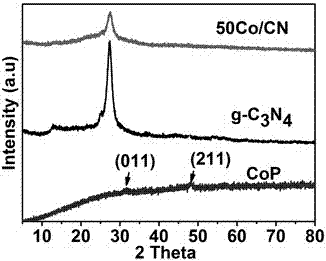

Preparation and application of composite CoP/g-C3N4 photocatalyst

InactiveCN107126971ASmall particlesInhibition releasePhysical/chemical process catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesNanoparticleCarbon nitride

The invention provides a method for in-situ growth of CoP nanoparticles on a g-C3N4 surface and application. The method is mainly characterized in that in-situ growth of Co(OH)2 on carbon nitride is performed according to an in-situ loading method, and then sodium hypophosphite is decomposed under the protection of an inert atmosphere to release PH3 gas to generate CoP. By adoption of the method, the CoP nanoparticles can be uniformly loaded on carbon nitride, and a composite CoP / g-C3N4 photocatalyst is obtained finally. Easiness in raw material acquisition and simplicity in operation are realized, and the composite photocatalyst is innovatively applied to photocatalysis production of hydrogen peroxide; as an auxiliary catalyst, CoP is capable of enhancing visible light absorbability, and owing to the metalloid property of CoP, quick separation of electrons and holes can be realized, and absorbed light can be used more efficiently, and finally catalysis activity of carbon nitride being a main catalyst in photocatalysis production of hydrogen peroxide is effectively improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com