Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "Hypophosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

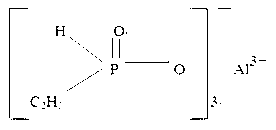

The hypophosphite ion is H₂PO₂−, hypophosphorous acid minus one hydrogen ion. Hypophosphites are the compounds containing this ion, with phosphorus in oxidation state +1, or similar covalent ones. Two hydrogens are attached directly to the phosphorus atom. The IUPAC name for the same ion is phosphinate. This is virtually not used for hypophosphite ion itself, with both hydrogens remaining, but for substituted ions. For example, "dimethylphosphinate" ion would be (CH₃)₂PO₂−. Hypophosphites can be made by heating white phosphorus in warm aqueous alkali: P₄ + 3 OH− + 3 H₂O → 3 H₂PO₂− + PH₃ Hypophosphites are reducing agents: H₂PO₂− +3OH− → HPO₃2− + 2H₂O + 2e⁻ Hypophosphites are used in electroless nickel plating as the reducing agent to deposit for example Ni metal from Ni salts. The hypophosphite ion is thermodynamically unstable, and disproportionates on heating to phosphine gas and phosphate salts: 2 H₂PO₂− → PH₃ + HPO₄2−

Metal-containing compounds

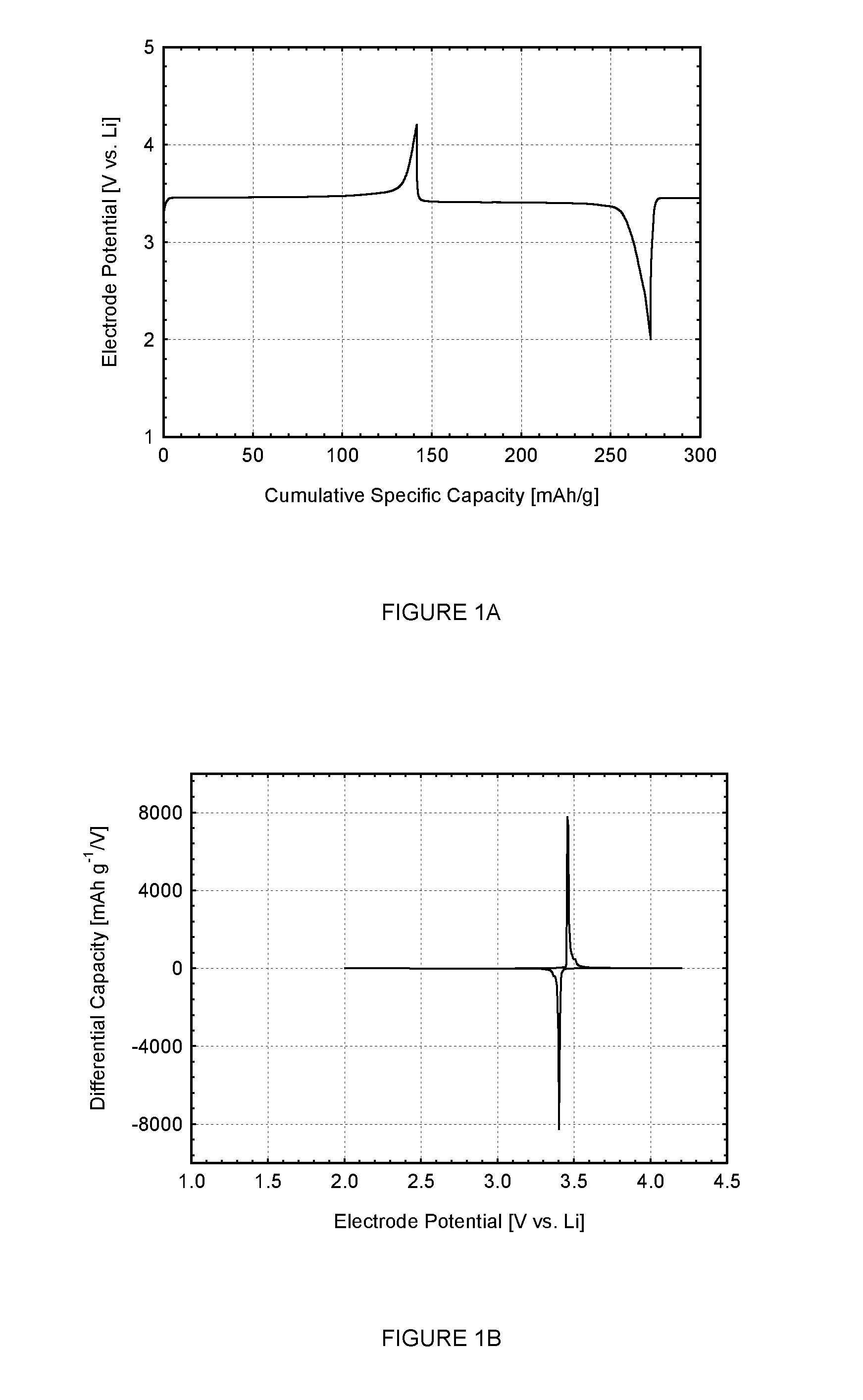

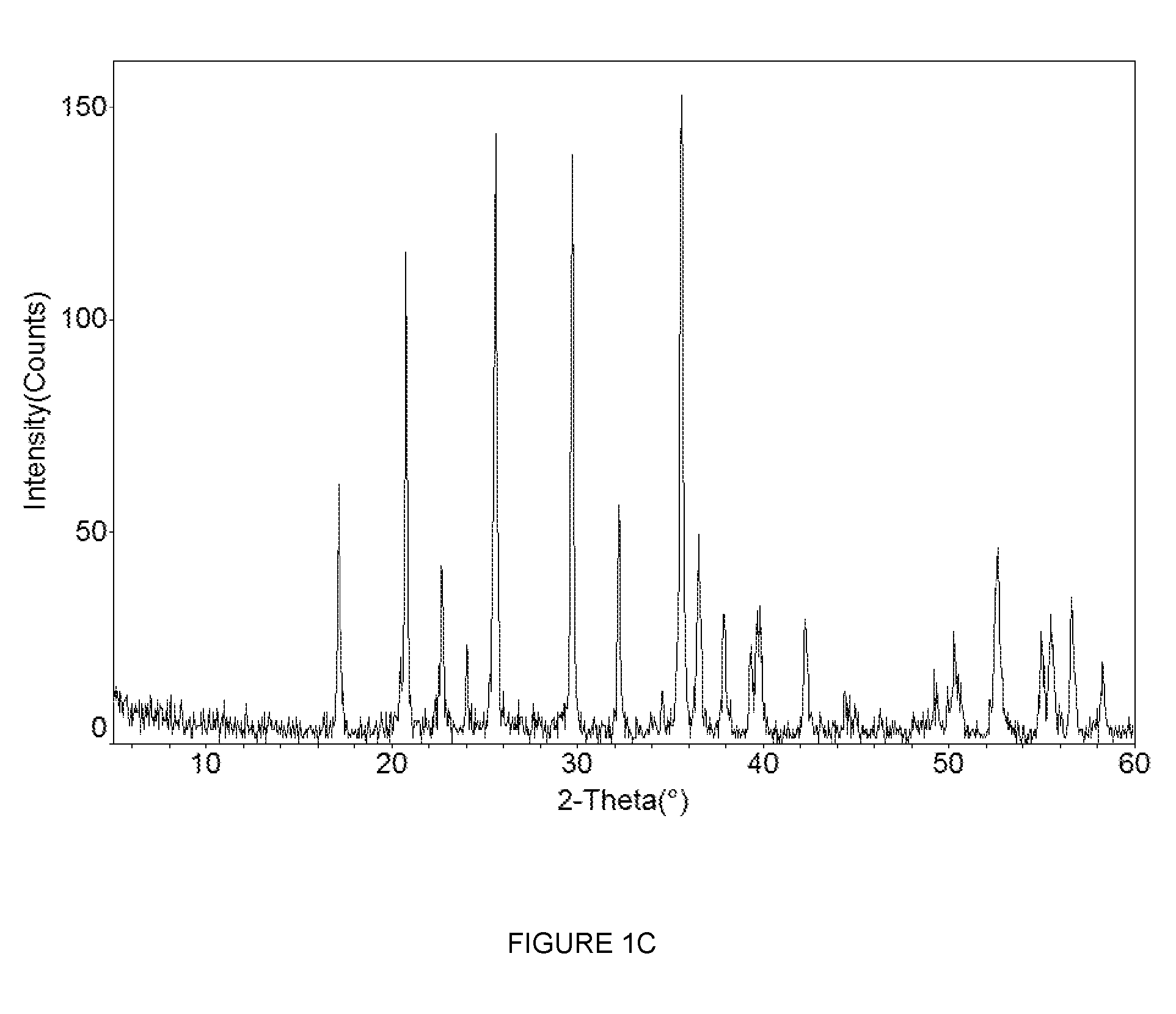

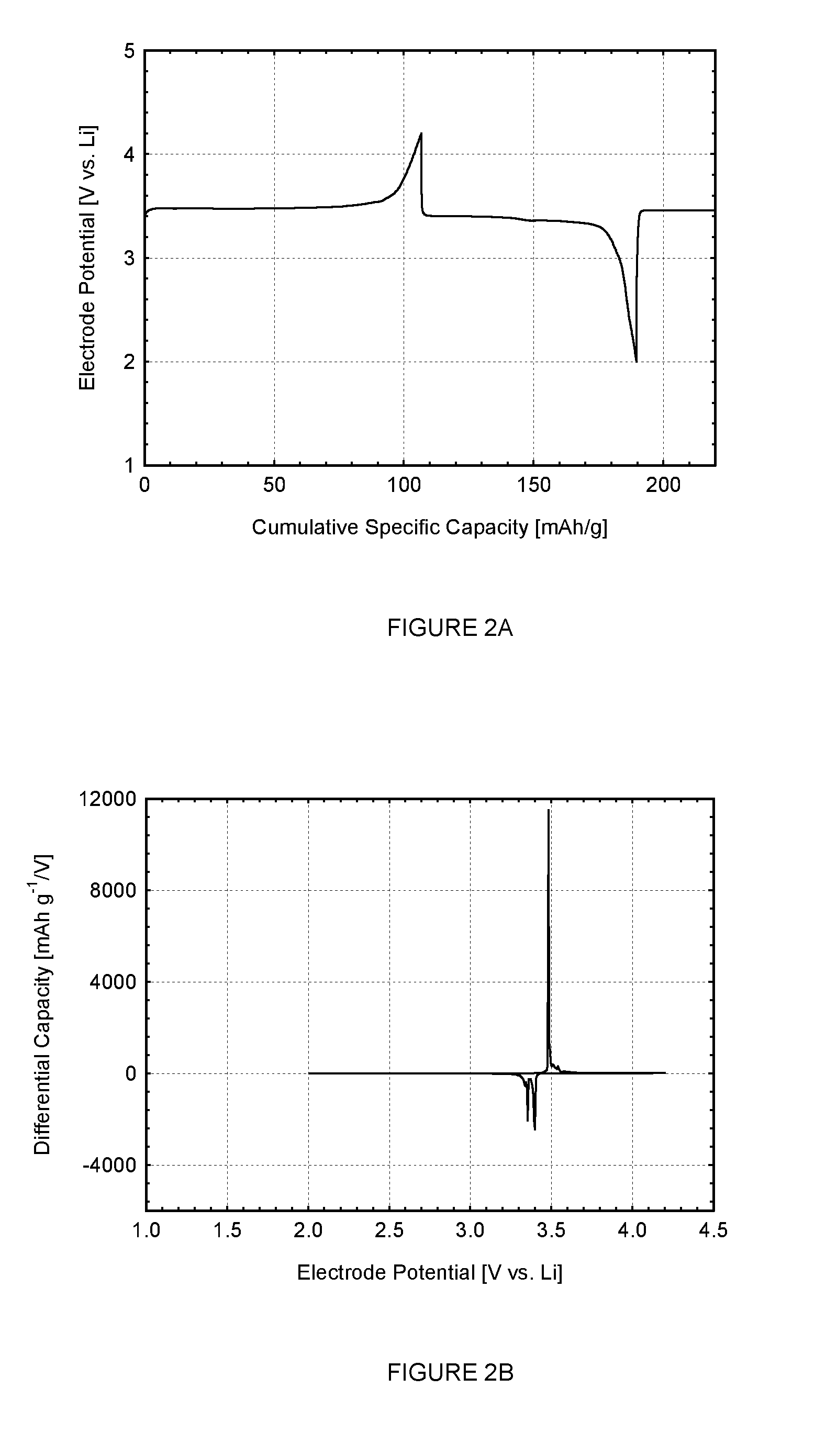

The invention relates to a novel solid state process for the preparation of metal-containing compounds comprising the steps i) forming a reaction mixture comprising one or more metal-containing precursor compounds and optionally one or more non-metal-containing reactants, and ii) using one or more hypophosphite-containing materials as a reducing agent; wherein one or more of the hypophosphite-containing materials is used as an agent to reduce one or more of the metal-containing precursor compounds; and further wherein the process is performed in the absence of an oxidizing atmosphere. Materials made by such a process are useful, for example, as electrode materials in alkali metal-ion battery applications.

Owner:LITHIUM WERKS TECH BV

Stripping and cleaning compositions for microelectronics

InactiveUS20060154839A1Short cleaning timeReduce the temperatureCationic surface-active compoundsOrganic detergent compounding agentsOrganic solventQuaternary ammonium ions

Aqueous, silicate free, cleaning compositions of about pH 9 or below and method of using the cleaning compositions for cleaning microelectronic substrates, which compositions are able to essentially completely clean such substrates and produce essentially no metal corrosion of the metal elements of such substrates. The aqueous cleaning compositions of this invention have (a) water, (b) at least one of ammonium and quaternary ammonium ions and (c) at least one of hypophosphite (H2PO2−) and / or phosphite (HPO32−) ions. The cleaning compositions also may contain fluoride ions. Optionally, the composition may contain other components such as organic solvents, oxidizing agent, surfactants, corrosion inhibitors and metal complexing agents.

Owner:AVANTOR PERFORMANCE MATERIALS LLC

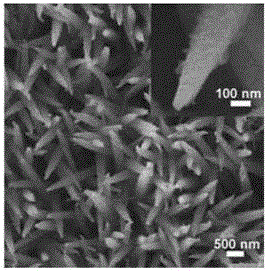

Preparation method for NiCoP nanowire electro-catalytic electrode

InactiveCN105951123AAvoid introducingSimple preparation processMaterial nanotechnologyElectrode shape/formsNanowireReactive material

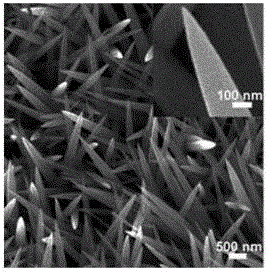

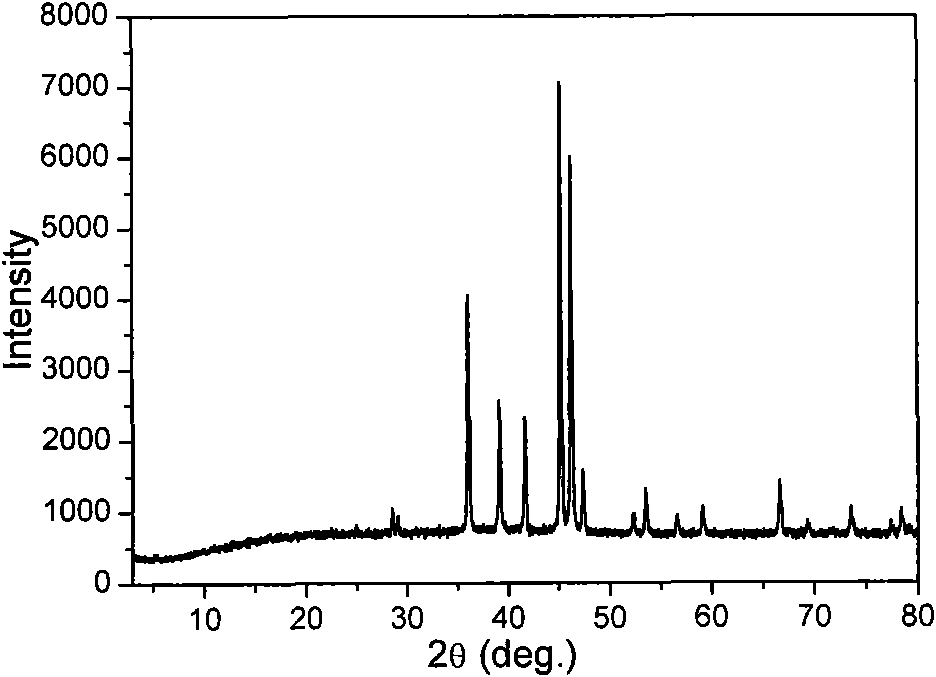

The invention discloses a preparation method for a NiCoP nanowire electro-catalytic electrode. A NiCo salt nanowire is adopted as a phosphorization precursor, hypophosphite is used as a phosphorus source, and the phosphorization process of the NiCo salt nanowire is achieved by controlling the annealing technique in a stored program control tube type annealing furnace. The diameter of the NiCoP nanowire obtained through the method is 140 nanometers, the length of the obtained NiCoP nanowire is about 3.2 micrometers, and the surface of the nanowire is roughly and evenly grown on a 3D netty foamed nickel substrate, so that the specific surface area and the electric conductivity of an electro-catalytic material are effectively improved, and the electro-catalytic hydrogen evolution performance and stability of an electrode material are improved. The electro-catalytic hydrogen production performance of the electrode is tested in 1M of a KOH electrolyte, the overpotential under the electric current density of 10 mA / cm<2> is 109 mV, and the Tafel slope is 88.5 mV / dec, so that the material has the superior electro-catalytic hydrogen production performance compared with common electro-catalytic hydrogen evolution materials. Meanwhile, the preparation technique is simple, the equipment requirement is conventional, reactive materials are abundant, price is low, and the electrode is environmentally friendly.

Owner:HUBEI UNIV

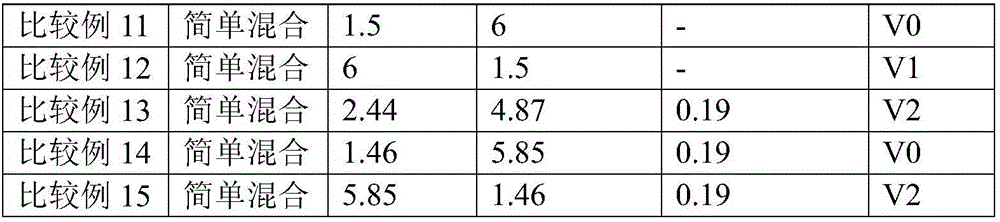

Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a halogen-free flame retardant glass-fiber reinforced polypropylene composite material, which comprises the following components in weight percentage: 33-59% of polypropylene resin, 15-35% of compound flame retardant, 20-30% of glass fiber, 3-10% of compatibilizing agent, 0.4-2.5% of coupling agent and 1-3% of thermal stabilizer; the compound flame retardant is prepared by mixing and compounding a main flame retardant and an auxiliary flame retardant with a mass ratio of 41-79: 21-59; the main flame retardant is one or a mixture of melamine polyphosphate, melamine phosphate and melamine cyanurate; and the auxiliary flame retardant is one or a mixture of inorganic hypophosphite, diethyl hypophosphite and diphenyl hypophosphite. The polypropylene material is good in fire retardant performance and high in fire retardant efficiency; because ammonium polyphosphate component is excluded, the polypropylene material has the advantages of non-hydroplaning in processing, no release of ammonia gas and less water in bracing.

Owner:苏州安鸿泰新材料有限公司

Polyamide composition

ActiveUS20060142443A1Aluminium compoundsPlastic/resin/waxes insulatorsPhosphorous acidPhosphoric Acid Esters

A polyamide composition has (a) a polyamide, (b) at least one phosphorus compound selected from the group consisting of phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites, phosphoric esters, and phosphorous esters, and (c) a soluble metal aluminate compound represented by the general formula (M2O)x(Al2O3)y (wherein X+Y=1 and M is a Group 1 metal of the Periodic Table), wherein the molar ratio of polyvalent metal to monovalent metal in the composition (polyvalent metal / monovalent metal) is from 0.25 to 1.0.

Owner:ASAHI KASEI CHEM CORP

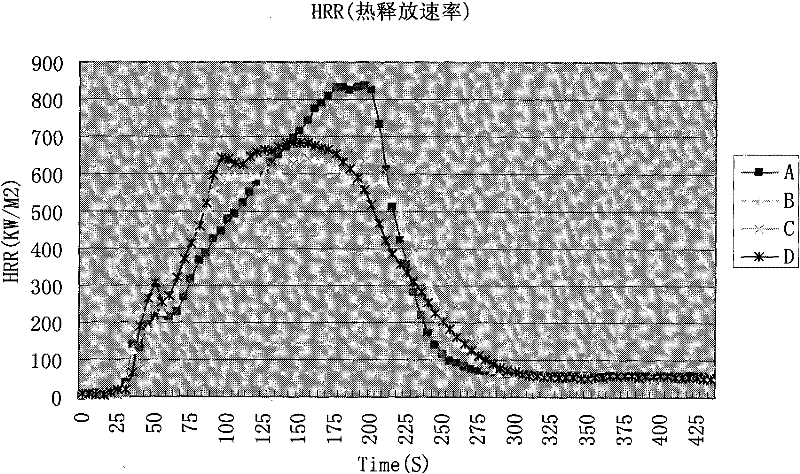

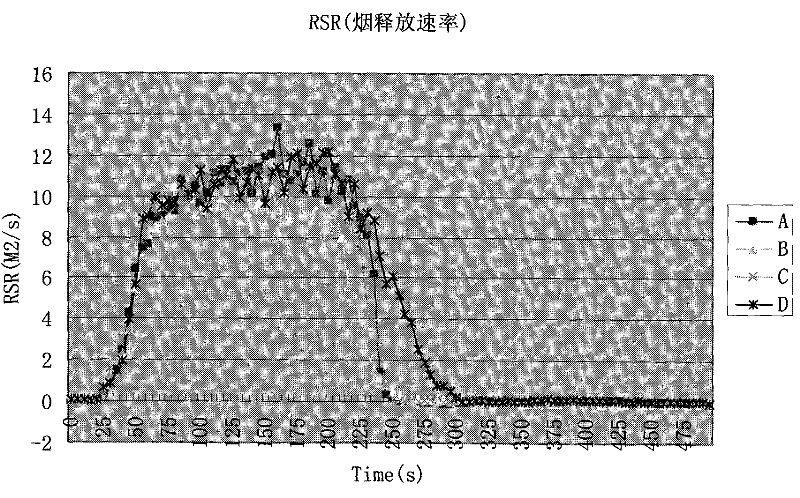

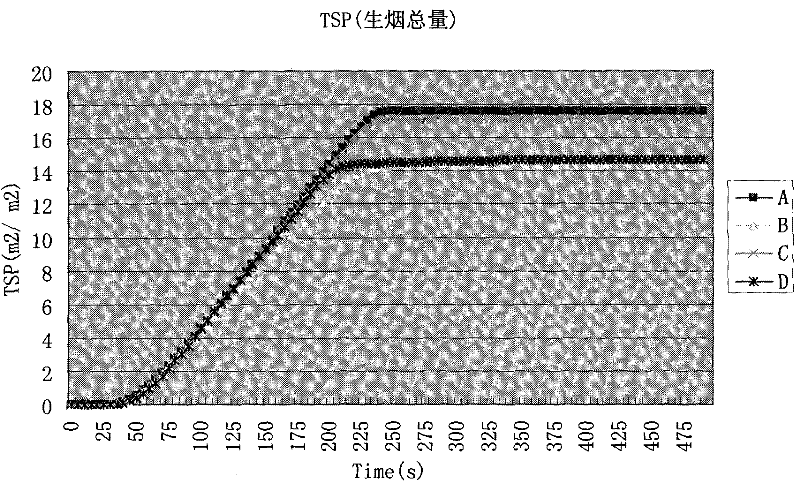

Low-heat low-smoke flame retardant and application thereof in preparing flame-retardant master batch

The invention relates to a low-heat low-smoke flame retardant and application thereof in preparing a flame-retardant master batch. The low-heat low-smoke flame retardant comprises the following components in percentage by weight: 40-70% of hypophosphite, 20-50% of melamine compound, 0.1-10% of nano inorganic substance and 5-15% of assistant. The low-heat low-smoke flame retardant can be used for preparing a flame-retardant master batch. Compared with the prior art, the invention can effectively reduce the heat release rate, smoke release rate and total smoke generation quantity, thereby performing active functions of postponing the propagation of flame, reducing the rate of burning released substances and increasing the escape probability.

Owner:上海安凸塑料添加剂有限公司

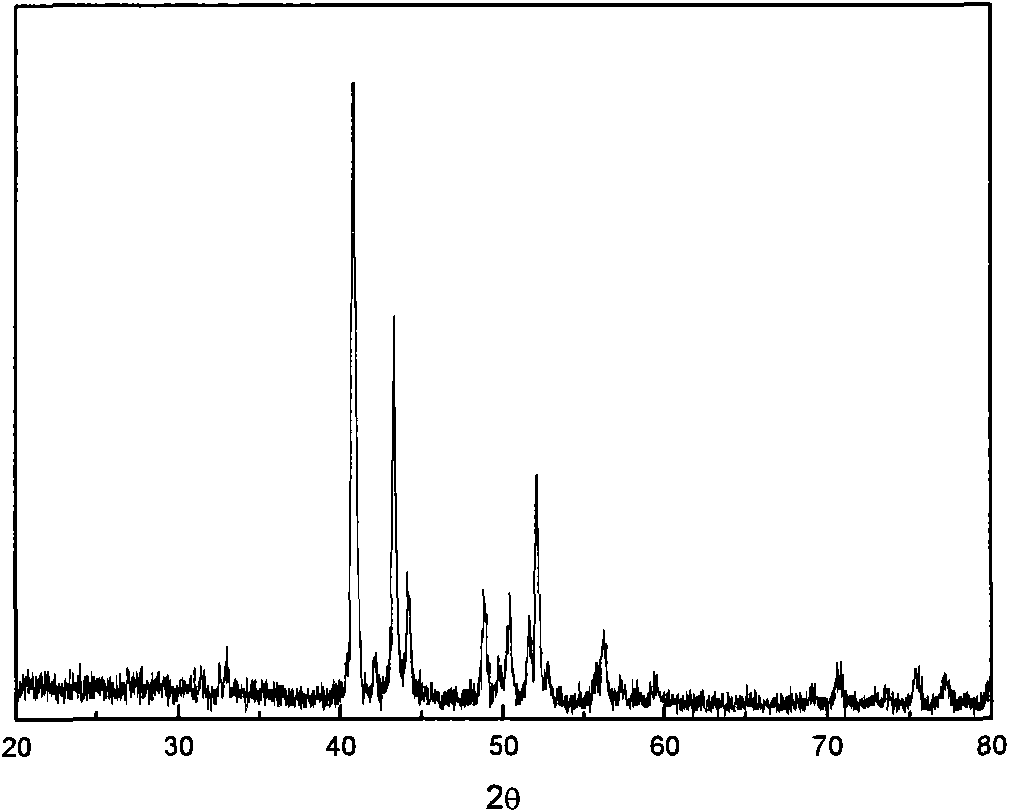

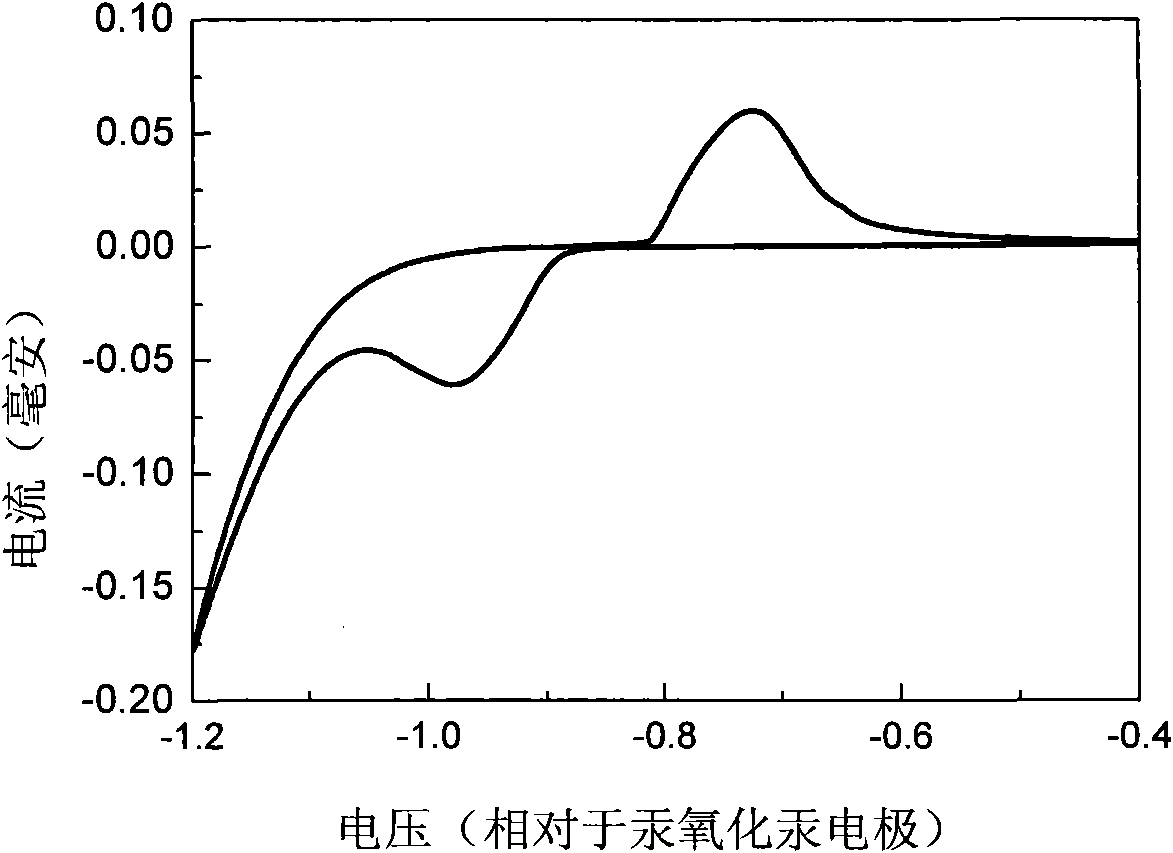

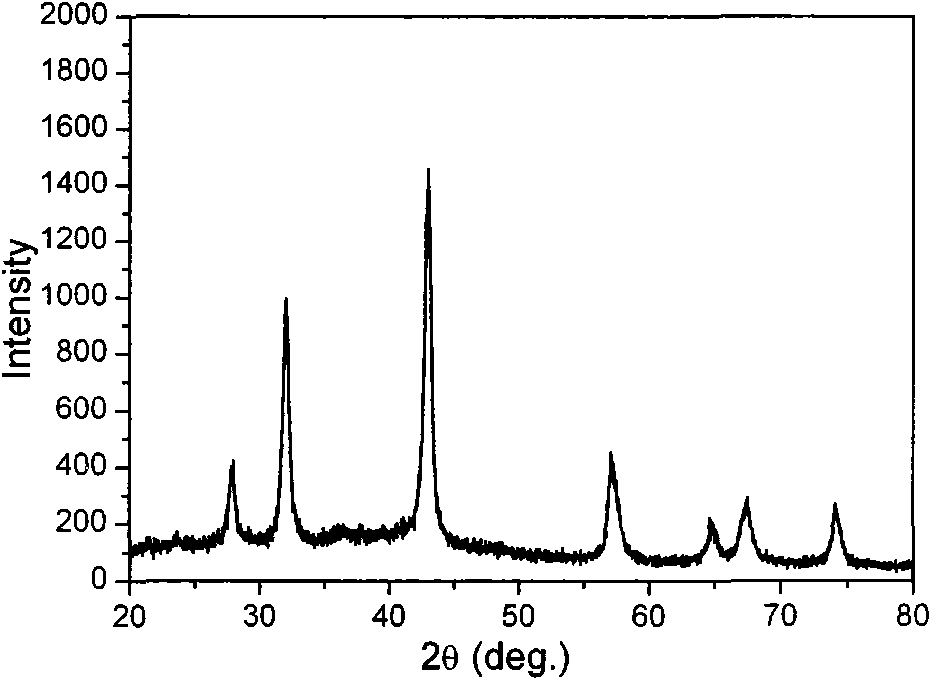

Preparation method and application of transition metal phosphide Co2P

The invention relates to a preparation method of transition metal phosphide Co2P, which includes the following steps that: (1) cobalt salt and hypophosphite as mixing precursors are dissolved in deionized water, and are stirred until the cobalt salt and the hypophosphite are completely dissolved; (2) the produced precursor solution is dried; (3) the dried precursor powder is loaded into a tube furnace, and is calcined under the argon atmosphere; (4) the precursor powder is cooled to the room temperature, the produced product is washed by deionized water and then dried under vacuum, and thereby the transition metal phosphide Co2P is produced. The invention has the following advantages that: the sources of the main materials needed by preparation are rich, the prices are low, and therefore the cost is low; the technique is simple, steps, such as high temperature and high pressure and temperature programming, are not needed, consequently, the preparation flow is simplified, and energy consumption is reduced; in the process of preparation, the environment cannot be polluted, and therefore the invention is suitable for mass production; and when being used for simulating the nickel-metal hydride battery, the prepared product can show good electrochemical invertibility.

Owner:NANKAI UNIV

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172668AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: organic solvent-water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, organic solvent-water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, the reaction period is short, obtained monoalkyl / dialkyl phosphinate can be precisely controlled, a total yield is high, and product purity is high. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:GUANGZHOU KINGSKY MATERIAL

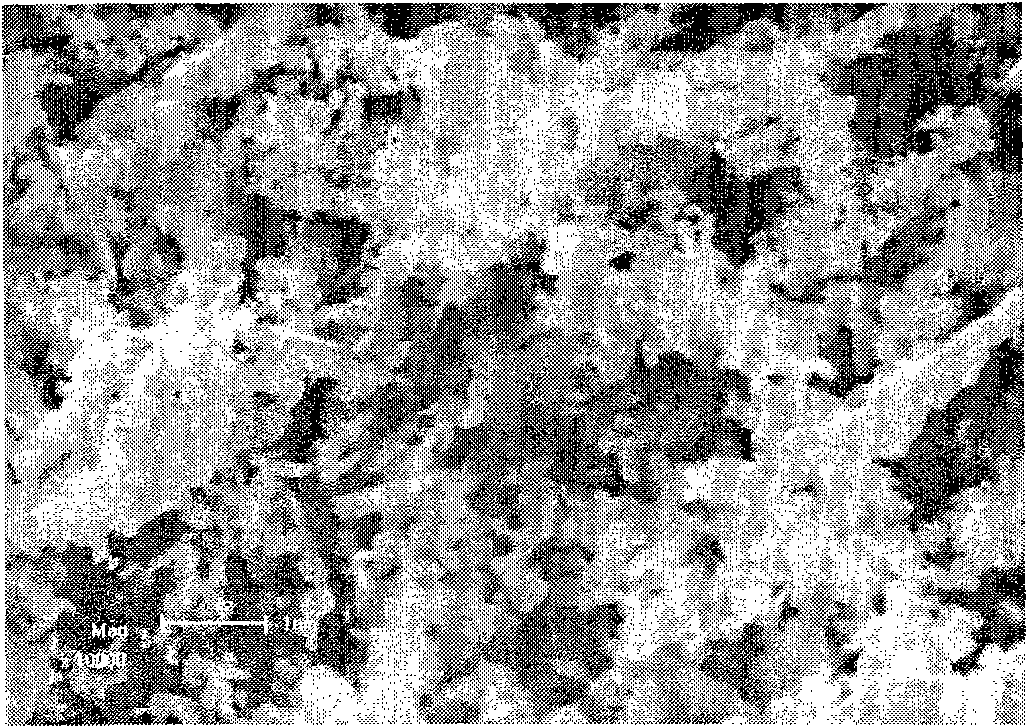

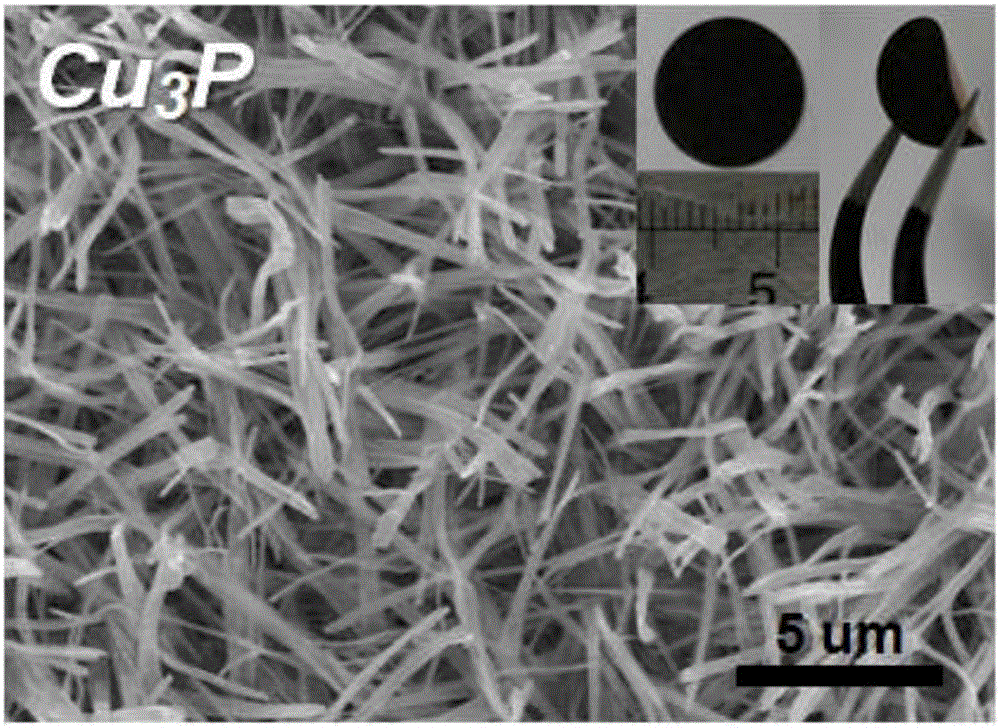

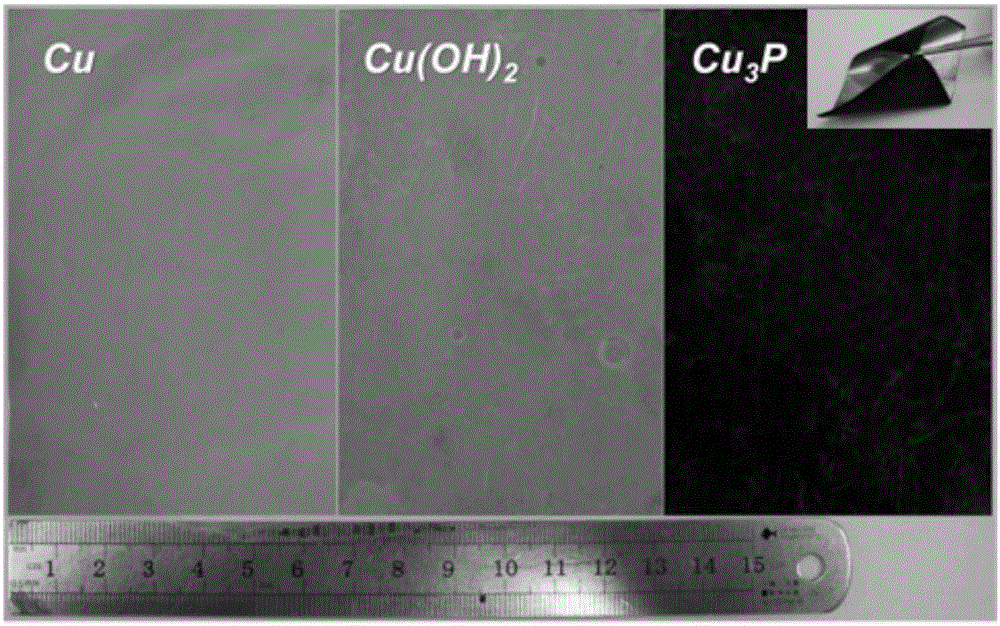

Preparation method of Cu3P nanowire negative electrode, Cu3P nanowire negative electrode prepared by method and application of Cu3P nanowire negative electrode

ActiveCN105845932ALow costThe process steps are simpleCell electrodesSecondary cellsNanowireElectrical battery

The invention relates to a preparation method of a Cu3P nanowire negative electrode, the Cu3P nanowire negative electrode prepared by the method and an application of the Cu3P nanowire negative electrode. The method comprises the following steps: (a) immersing one surface of a copper foil into a mixed water solution of persulfate and hydroxide for reaction, and forming a copper hydroxide nanowire in one side surface of the copper foil; and (b) putting excessive hypophosphite into the middle part of a tube furnace, putting the copper foil formed with the copper hydroxide nanowire in one side surface into the downstream part, discharging air in the tube furnace by an inert gas, then heating the air and reacting a generated hydrogen phosphide gas and the copper foil formed with the copper hydroxide nanowire in one side surface under a low-temperature condition to obtain a Cu3P nanowire negative electrode material in in-situ, unilateral and massive growth on the basis of a copper foil base. The material can be directly used as the negative electrode material for sodium-ion half-batteries and all-batteries. The processing steps are simple; the cost is relatively low; and enlarged production and large-scale promotion are facilitated.

Owner:SUZHOU UNIV

Microencapsulated red phosphorus, and preparation method and application thereof

ActiveCN106009045AHigh degree of albinismImprove heat resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsHeat resistanceMolecular materials

The invention provides microencapsulated red phosphorus, and a preparation method and application thereof. The microencapsulated red phosphorus is prepared from red phosphorus and a coating layer outside the red phosphorus; the microencapsulated red phosphorus is characterized in that the coating layer is a coating layer I containing inorganic hypophosphite, optionally, a coating layer II containing an organic compound also wraps the outside of the coating layer I. The microencapsulated red phosphorus provided by the invention is used as a flame retardant, the whitening degree is high, the heat resistance is good, the water absorption is low, the compatibility with high polymer materials is better, and the influence on mechanical performance of the high molecular materials due to the adding of the flame retardant can be reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing encapsulated red phosphorus

ActiveCN102010618AReduce dosageImprove stabilityPigment treatment with non-polymer organic compoundsPhosphateOrganic group

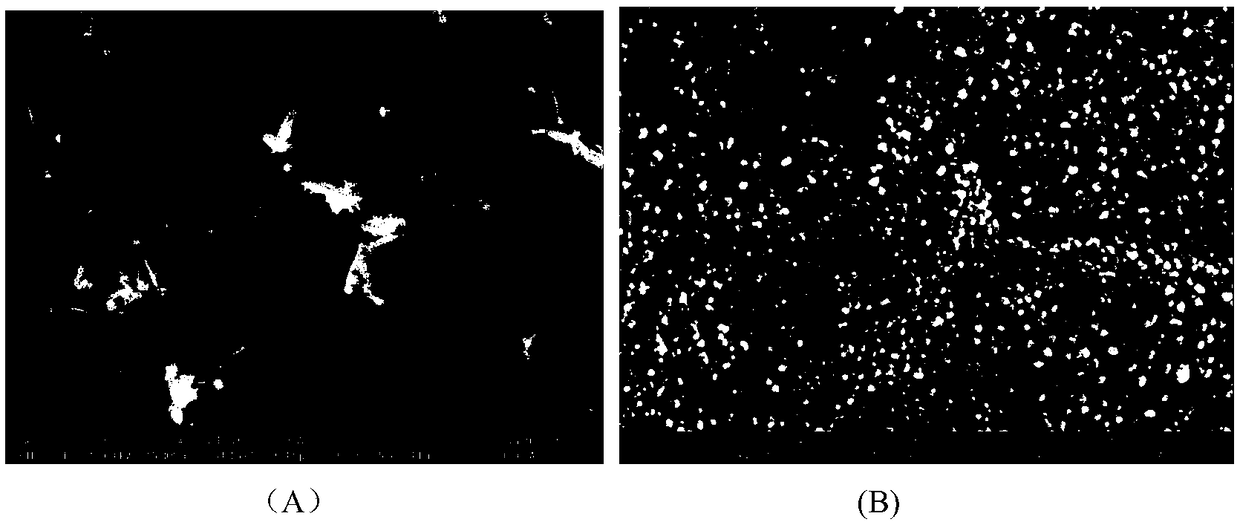

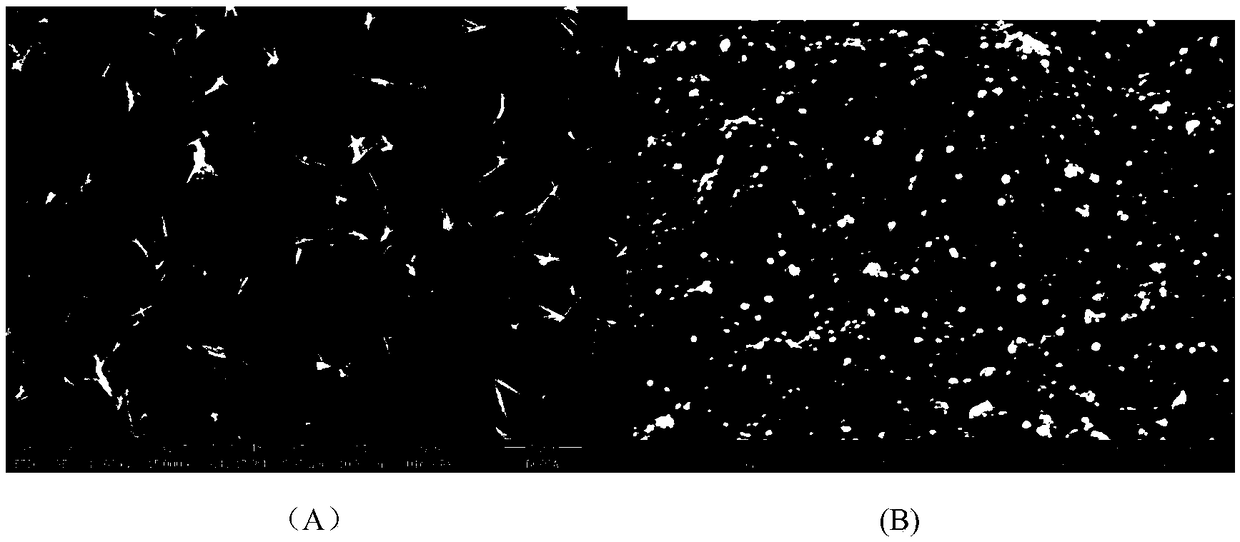

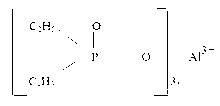

The invention discloses a method for preparing encapsulated red phosphorus. The method comprises the following steps of: mixing red phosphorus powder and hypophosphite with two organic groups to prepare water suspension, wherein the molecular formula of the hypophosphite with two organic groups is (R1R2PO2)nM; adjusting the pH value of the solution to be 3 to 5 by using acid solution, raising the temperature to 50 to 60 DEG C, adjusting the pH value until the solution is neutral by using aqueous alkali; and continuously stirring for 0.5 to 2 hours, cooling and suction-filtering, washing with water, and performing vacuum drying to obtain the encapsulated red phosphorus product. In the method for preparing the encapsulated red phosphorus, the hypophosphite with two organic groups is directly added into the suspension of red phosphorus, the hypophosphite with two organic groups is deposited on the surfaces of the red phosphorus particles directly by adjusting the pH value of the solution, good stabilization effect can be used by using a small amount of a stabilizing agent, the phosphorus content of the product can be kept as much as possible, and the double effect of stabilizing and inflaming retarding can be achieved, so that an ideal and stable encapsulated red phosphorus product can be obtained.

Owner:TONGCHENG SHINDE NEW MATERIALS

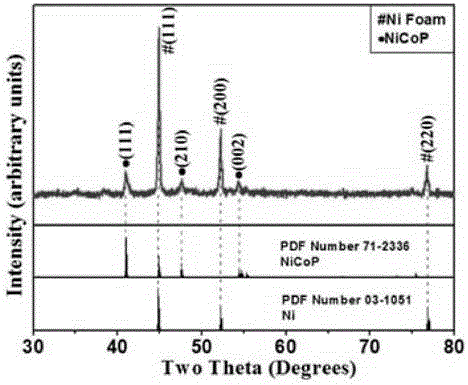

High-efficiency difunctional water decomposition electrocatalyst NiCoP and preparation method thereof

ActiveCN108654658AImprove efficiencyPhysical/chemical process catalystsElectrodesPtru catalystChemical composition

The invention discloses a high-efficiency difunctional water decomposition electrocatalyst NiCoP and a preparation method thereof, and belongs to the technical field of preparation of energy conversion materials. The preparation method comprises the following steps: firstly, obtaining a Ni / Co precursor with a high-activity surface area and proper chemical composition, and on such basis, phosphating the precursor by taking hypophosphite as a phosphorus source. Studies find that the catalyst provided by the invention has high-efficiency difunctional electrocatalytic activity; under an alkaline condition, overpotentials (10mA cm<-2>) thereof required for hydrogen production and oxygen production are 27mV and 144mV respectively, and the performance thereof exceeds that of most reported difunctional electrocatalysts; moreover, a preparation technology provided by the invention is simple, raw materials are rich and cheap, and the catalyst provided by the invention can replace expensive and scarce precious metal-based catalyst to promote commercial application of electrochemical total water decomposition.

Owner:BEIJING UNIV OF TECH

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172670AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, hypophosphite is directly adopted as a raw material, and the monoalkyl / dialkyl phosphinate is obtained with a one-step method. The reaction period is short, a total yield is high, product purity is high, process flow is simple, no organic solvent or other solvent is adopted, and no subsequent processing is needed. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:ZHUHAI WANTONG CHEM

Composite photocatalyst MxP/indium zinc sulfide as well as preparation method and application thereof

ActiveCN108620105AImprove separation efficiencyHigh catalytic activityCatalyst activation/preparationHydrogen productionInorganic saltsIndium

The invention discloses a composite photocatalyst MxP / indium zinc sulfide as well as a preparation method and the application thereof. The composite photocatalyst is prepared by compounding sulfide indium zinc (ZnIn2S4) with an amorphous alloy (MxP); a non-precious metal inorganic salt and hypophosphite solution is fully mixed with the ZnIn2S4; in an inert atmosphere, the zero-valent phosphorus and non-noble metal M are co-deposited on the surface of the ZnIn2S4 to form an amorphous alloy MxP under illumination by utilizing the visible-light response characteristics of the ZnIn2S4. Compared with the ZnIn2S4, the prepared MxP / ZnIn2S4 composite material has the characteristic that the activity of prepared MxP / ZnIn2S4 composite material for producing hydrogen by visible light catalyzed decomposition of water is significantly improved. The method disclosed the invention has the advantages of no need of introducing a reducing agent, low cost, environment friendliness, simplicity, feasibility and easiness in large scale popularization.

Owner:FUZHOU UNIV

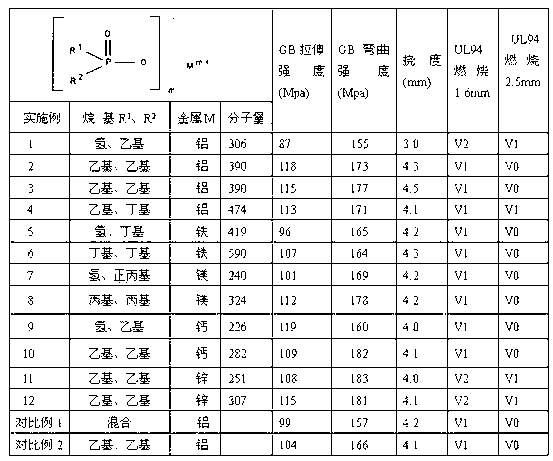

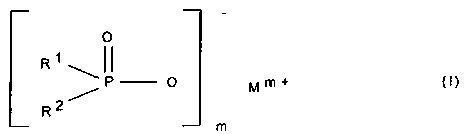

Alkyl phosphinate polymer and preparation method and application thereof

The invention relates to an alkyl phosphinate polymer and a preparation method and application thereof. The method comprises the following steps of: filling a mixture of hypophosphorous acid or phosphinate and water or acetic acid into a pressure reactor with a jacket; when the mixture is heated to between 70 and 110 DEG C, adding alkyne into the pressure reactor through a pressure-reducing valvetill the mixture in the pressure reactor is saturated; uniformly adding aqueous solution of free radical initiator into the obtained mixture with continuous stirring till reaching the required alkynequantity, and then switching the alkyne into olefin; adding the olefin into the pressure reactor through the pressure-reducing valve till the mixture in the pressure reactor is saturated, uniformly adding a catalyst into the mixture, reacting the mixture for 8 to 12 hours, reducing the pressure of the pressure reactor, and cooling the mixture to 80 DEG C; and adding a metal compound into the pressure reactor to perform reaction, centrifuging the obtained solid, washing the solid by using water, and drying the solid in vacuum to obtain the alkyl phosphinate polymer. The invention also relates to the application of the alkyl phosphinate polymer serving as a flame retardant, a flame retardant composition and a flame-retardant polymer molding composition.

Owner:SHANGHAI HUIHAI CHEM TECH

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172669AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsPhosphatePhosphoric acid

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: an organic solvent is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, an organic solvent is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, hypophosphite is directly adopted as a raw material, and the monoalkyl / dialkyl phosphinate is obtained with a one-step method. The reaction period is short, obtained monoalkyl / dialkyl phosphinate can be precisely controlled, a total yield is high, and process floe is simple. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:ZHUHAI WANTONG CHEM

Preparation method of copper phosphide (Cu3P) catalyst with hypophosphite by prosoma pyrolytic process

InactiveCN101574663ALow pricePrice securityCatalyst activation/preparationPhosphidesCopperHigh pressure

The invention provides a new method for preparing a catalyst of supported copper phosphide or non-supported copper phosphide (Cu3P) by the prosoma pyrolytic process of hypophosphite. The invention is characterized in that: the process adopted is simple; complicated steps such as high temperature, high pressure and temperature programming are not necessary; and the supported copper phosphide or non-supported copper phosphide can be prepared only under normal pressure by the pyrolytic process. The materials are low in cost and safe and the cost of equipment is low. Therefore, the method is very suitable for large-scale production. Copper phosphide can improve the clinkering performance of 316L stainless steel and can serve as a reinforcing agent in the production of high speed steel (HSS) composite materials. Due to the good performances of circulation and reversibility, copper phosphide can serve as the potential electrode material for cathode of the lithium ion battery.

Owner:NANKAI UNIV

New method for preparing molybdenum phosphide by reducing molybdenum trioxide precursor

InactiveCN101658796ALow pricePrice securityMolecular sieve catalystsCatalyst activation/preparationShielding gasProduct gas

The invention provides a new method for preparing molybdenum phosphide by reducing the precursor of molybdenum trioxide by utilizing the phosphine generated by hypophosphite in thermal decomposition.The method comprises the steps of: adopting ammonium molybdate as a, roasting the Mo source to obtain molybdenum trioxide, and then by dipping the molybdenum trioxide in solution, and obtaining the precursor; and synthesizing loaded and unloaded molybdenum phosphide by simple thermal decomposition of the precursor at low temperature. The method is characterized in that the adopted process is simple, the preparation temperature of the molybdenum phosphide is low, the production period is short, and the preparing process needs no flowing protective gas and complex steps such as temperature raising of program and the like except simple thermal treatment at constant pressure; the used raw materials are safe and low in cost, and equipment has low cost; and due to the better HDS and HDN activity, the catalyst can be widely used in the hydrotreating of oils.

Owner:NANKAI UNIV

Small particle size hypophosphite telomers of unsaturated carboxylic acids

ActiveUS20130122299A1Faster and more efficientlyDecrease in esterification yieldSynthetic resin layered productsCellulosic plastic layered productsPhosphateSuperplasticizer

The present invention provides compositions comprising particles or agglomerates of one or more phosphorus oxide telomer or cotelomer ((co)telomer) of one or more unsaturated carboxylic acids or anhydrides having a mean average particle size of from 2 μm to 1 mm, preferably from 5 to 500 μm, preferably, comprising at least one carboxylic acid anhydride group. In addition, the present invention provides methods comprising aqueous solution addition polymerizing a monomer mixture of one or more unsaturated carboxylic acid in the presence of a phosphorus oxide acid or salt compound, drying the resulting copolymer at a temperature of from 120 to 230° C. and reducing its particle size to make a phosphorus oxide (co)telomer particle or agglomerate; the methods may further comprise reacting the (co)telomer particle or agglomerate with one or more polyether polyol, alkyl polyether polyol, polyether amine or alkyl polyether amine, with heating, to form a comb polymer useful, e.g. as a superplasticizer or dispersant.

Owner:ROHM & HAAS CO

Microencapsulated inorganic hypophosphite flame retardant and preparation method thereof

ActiveCN103992512AImprove performanceEasy to processMicroballoon preparationMicrocapsule preparationSpontaneous combustionPolymer science

The invention relates to a microencapsulated inorganic hypophosphite flame retardant and a preparation method thereof. A capsule wall material of the microencapsulated inorganic hypophosphite flame retardant is a triazine ring containing crosslinked polymer. In order to solve the problem in the prior art that inorganic hypophosphite flame retardants are liable to combust spontaneously, the microencapsulated inorganic hypophosphite flame retardant is obtained by wrapping the surface of inorganic hypophosphite with the triazine ring containing crosslinked polymer as the capsule wall material through the microencapsulation technology. The microencapsulated inorganic hypophosphite flame retardant has the advantages of higher thermal stability, difficulty in spontaneous combustion, higher flame retardance efficiency, better compatibility with polymer matrices and the like. Besides, the preparation method is simple in process, is easy to operate and is suitable for industrial production.

Owner:苏州安鸿泰新材料有限公司

Method for quickly synthesizing diethyl hypophosphite at low pressure, and diethyl hypophosphite product and application of product

ActiveCN103951699AMild process conditionsReduce equipment investmentGroup 5/15 element organic compoundsIsobutyl alcoholButanol

The invention discloses a method for quickly synthesizing diethyl hypophosphite at low pressure. The method comprises the following steps: firstly mixing soluble hypophosphite with water to obtain a soluble hypophosphite water solution with concentration of 10-15wt%, wherein the soluble hypophosphite is selected from at least one of sodium hypophosphite, potassium hypophosphite and ammonium hypophosphite; adding butyl alcohol to the prepared soluble hypophosphite water solution, adjusting the pH value to be 2-3, then adding a water-soluble initiator, continuously filling ethylene and reacting at 90-110 DEG C and 0.1-0.5MPa for 1-3 hours, thus preparing diethyl hypophosphite, wherein the butyl alcohol is selected from at least one of n-butyl alcohol, isobutyl alcohol, sec-butyl alcohol and tert-butyl alcohol; the mass ratio of the butyl alcohol to the soluble hypophosphite water solution is (1.5-5):100. The method has the advantages that the process conditions are mild; the equipment investment is low; the method is safe to operate; the synthetic efficiency is obviously improved.

Owner:江苏利思德新材料股份有限公司 +1

Flame retardant polymer compositions

The instant invention relates to polymer compositions comprising a calcium hypophosphite, an aluminium inorganic salt and an additive improving the flame retardant properties of the composition other than the hypophosphite salts.

Owner:RHODIA OPERATIONS SAS

Treatment method of chemical nickel plating waste liquid

InactiveCN111170527AReduce doseEasy to operateWater contaminantsWaste water treatment from metallurgical processPhosphite saltO-Phosphoric Acid

The invention discloses a treatment method of chemical nickel-plating waste liquid. The treatment method comprises the following steps: S1, nickel precipitation: adding a precipitant into the chemicalnickel-plating waste liquid to precipitate nickel, and filtering and separating the nickel; S2, oxidization: oxidizing hypophosphite and phosphite into orthophosphate by adopting an iron-carbon micro-electrolysis oxidation method,wherein the nickel ions are reduced into elemental nickel through iron, and the Fe<2+> is generated at the same time, then adding hydrogen peroxide to oxidize the Fe<2+>in the waste liquid is oxidized into Fe<3+>, and oxidize the hypophosphite and phosphite into orthophosphate, wherein the Fe<3+> and orthophosphate form an iron phosphate precipitate. The method hasthe advantages that nickel and phosphorus in the chemical nickel plating waste liquid can be separated through one-step treatment, so that the waste liquid reaches the national emission standard, andthe treatment method is simple and low in cost.

Owner:中冶一局环境科技有限公司

Method for applying a metal layer to a light metal surface

A process for applying a metal layer to surfaces of light metals is proposed, in which iron is electrolytically deposited on the surfaces from a deposition bath containing Fe(II) compounds using dimensionally stable anodes insoluble in the deposition bath. The process is especially suitable for coating cylinder faces of internal combustion engines and of rotationally symmetrical parts with layers having very high wear resistance, especially of valves, nozzles and other parts of high-pressure injection systems for motor vehicle engines. In addition, the present invention pertains to nanocrystalline iron-phosphorus layers, which can be formed preferably by depositing iron in the presence of compounds containing orthophosphite and / or hypophosphite. These layers also have good corrosion resistance besides the good wear resistance.

Owner:ATOTECH DEUT GMBH

Slag-based road grouting material and preparation method thereof

InactiveCN111807769AAvoid stockpilingDoes not consume resourcesCeramic shaping apparatusCement productionSlagPhosphate

The invention provides a slag-based road grouting material and a preparation method thereof. The slurry is stable, the precipitation and separation phenomena are avoided, and the compressive strengthof each age, the fluidity at different time and the expansion rate meet the standard requirements. The slag-based road grouting material comprises a cementing material and an additive, the cementing material comprises the following raw materials: 50-70 parts of slag powder, 6-10 parts of desulfurized gypsum, 5-9 parts of a special alkaline activator for slag, and 20-30 parts of fly ash, and the additive is prepared from the following raw materials in parts by weight: 0.3-0.4 parts of a hypophosphite modified polycarboxylate superplasticizer, 0.1-0.2 parts of a retarder, 0.5-0.6 parts of an expanding agent, and 0.04-0.06 parts of an antifoaming agent.

Owner:山东华迪建筑科技有限公司 +1

Resin composition and uses of the same

InactiveUS20170260365A1Synthetic resin layered productsElectrical equipmentDielectric lossHypophosphite

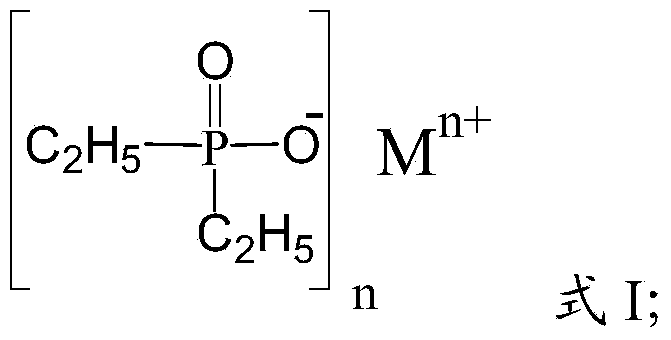

A resin composition, comprising the following components:(a) a thermal-curable resin system, which has a dielectric loss (DO of not higher than 0.006 at 10 GHz; and(b) a metal hypophosphite of formula (I),wherein a, R, and Ma+ are as defined in the specification, and wherein the amount of the metal hypophosphite (b) is 1 wt % to 30 wt % based on the total weight of the resin system (a) and the metal hypophosphite (b).

Owner:TAIWAN POWDER TECH CO LTD

Molybdenum phosphide (MoP) prepared by hypophosphite precursor thermal decomposition method

InactiveCN101623647ALow pricePrice securityCatalyst activation/preparationPhosphidesThermal decomposition methodHigh pressure

The invention provides a novel method for preparing loaded or unloaded molybdenum phosphide (MoP) by hypophosphite precursor thermal decomposition, the invention is characterized in that the process adopted is simple; complicated procedures like high temperature, high pressure, temperature programming and the like are not needed; loaded and unloaded molybdenum phosphide (MoP) can be prepared by simple heat treatment under normal pressure; the used raw materials are low in price and safe and the needed device is low in cost, thus being applicable to industrial production; the catalyst can be widely used in hydrotreating of oils, due to good HDS and HDN activities thereof.

Owner:NANKAI UNIV

Polyamide composition

ActiveUS7491763B2Aluminium compoundsPlastic/resin/waxes insulatorsPhosphoric Acid EstersPhosphorous acid

A polyamide composition has (a) a polyamide, (b) at least one phosphorus compound selected from the group consisting of phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites, phosphoric esters, and phosphorous esters, and (c) a soluble metal aluminate compound represented by the general formula (M2O)x(Al2O3)y (wherein X+Y=1 and M is a Group 1 metal of the Periodic Table), wherein the molar ratio of polyvalent metal to monovalent metal in the composition (polyvalent metal / monovalent metal) is from 0.25 to 1.0.

Owner:ASAHI KASEI CHEM CORP

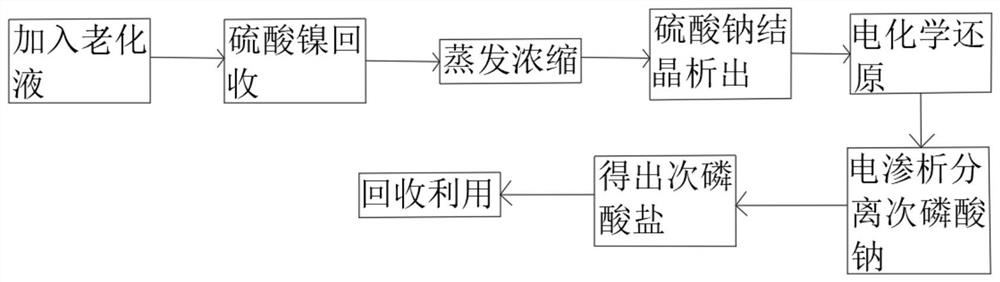

Chemical nickel plating aging liquid reduction regeneration method

PendingCN113026003ALarge exchange capacityLow nickel content in effluentLiquid/solution decomposition chemical coatingProcess efficiency improvementPhosphite saltPhosphate

The invention discloses a chemical nickel plating aging liquid reduction regeneration method. The method comprises the following operation steps that firstly, a recyclable chelating agent is adopted for adsorbing nickel ions in aging liquid, then sulfuric acid is used for desorption, nickel sulfate is prepared and can be returned to a chemical nickel plating production line to be used, then an evaporation concentration process is carried out, sodium sulfate crystals are crystallized and separated, the remaining liquid is subjected to an electrodialysis and electrochemical reduction combined method, phosphite is reduced into hypophosphite, and then the hypophosphite is recycled to the chemical nickel plating production line. According to the method, the comprehensive resource utilization technology is adopted for treating the chemical nickel plating aging liquid, nickel sulfate can be recycled from the aging liquid, hypophosphite can be recycled, resources can be thoroughly utilized, few chemical agents are added, the treatment cost is low, and better use prospects can be brought.

Owner:德星化工(苏州)有限公司

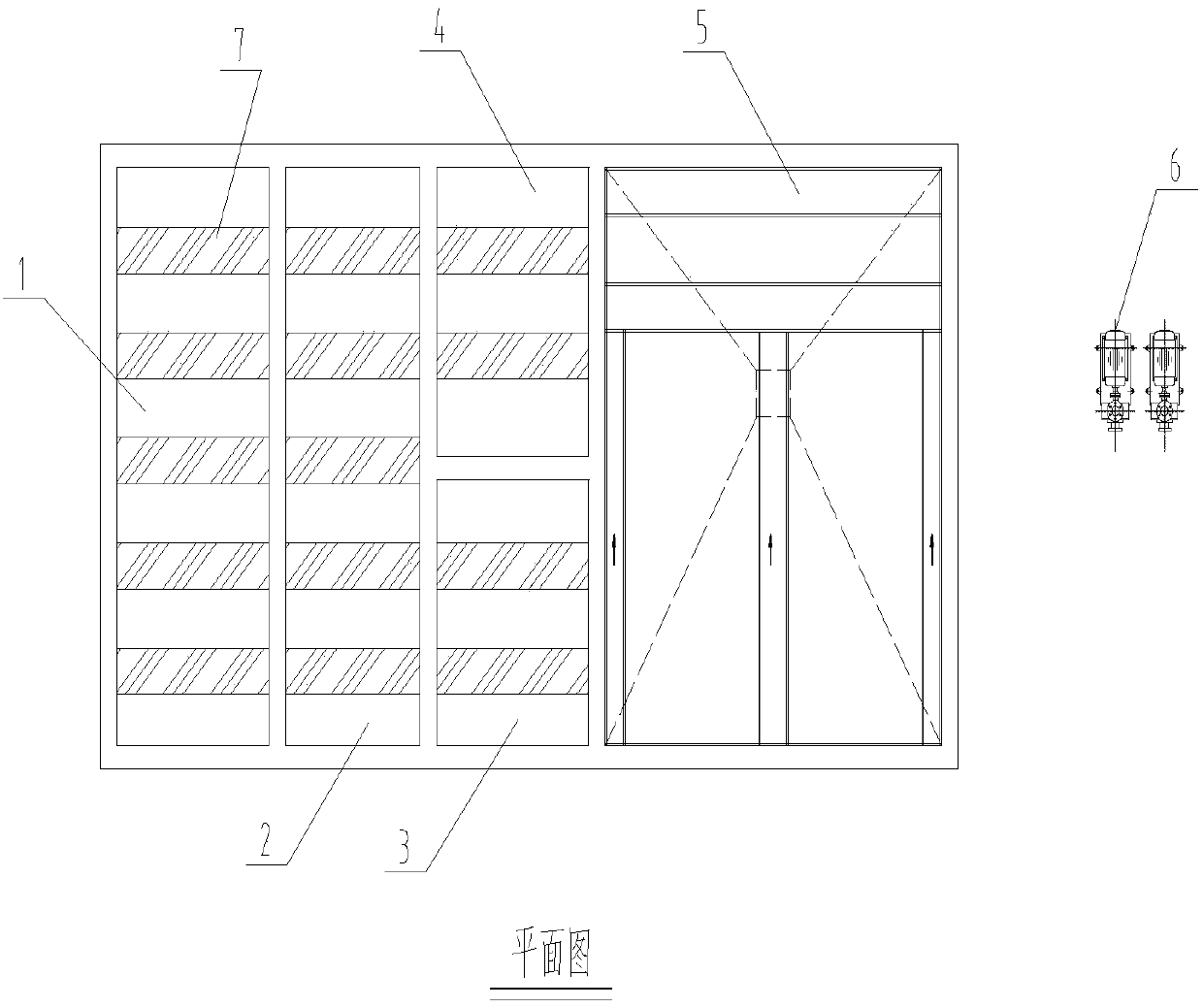

Equipment for treating wastewater with hypophosphite and phosphite

PendingCN107804933AImprove mixing efficiencyReduce consumptionWater treatment compoundsWater contaminantsPhosphite saltPhosphate

The invention discloses equipment for treating wastewater with hypophosphite and phosphate. The equipment consists of a mixing reaction system and a precipitation system, wherein the mixing reaction system is used for feeding a Fenton chemical and a coagulant, used for oxidizing hypophosphite and phosphate pollutants and used for generating calcium orthophosphate suspended solids which can be conveniently precipitated and removed later, and is composed of a first Fenton reaction tank, a second Fenton reaction tank, a coagu-flocculation reaction tank, a flocculation reaction tank and folding plates; the precipitation system is used for separating the calcium orthophosphate suspended solids through gravity, used for removing total phosphorus pollutants, used for backflowing a part of sludgeto the first Fenton reaction tank and is composed of a settling tank and a sludge backflow pump; the folding plates (7) are respectively arranged inside the first Fenton reaction tank (1), the secondFenton reaction tank (2), the coagu-flocculation reaction tank (3) and the flocculation reaction tank (4).

Owner:广州益方田园环保股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com