Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1362 results about "Molybdenum trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum trioxide is chemical compound with the formula MoO₃. This compound is produced on the largest scale of any molybdenum compound. It is an intermediate in the production of molybdenum metal. It is also an important industrial catalyst. Molybdenum trioxide occurs as the rare mineral molybdite.

Organic devices, organic electroluminescent devices and organic solar cells

ActiveUS20060008740A1Reduce harmLower barrier heightElectric discharge tubesElectroluminescent light sourcesOrganic solar cellSimple Organic Compounds

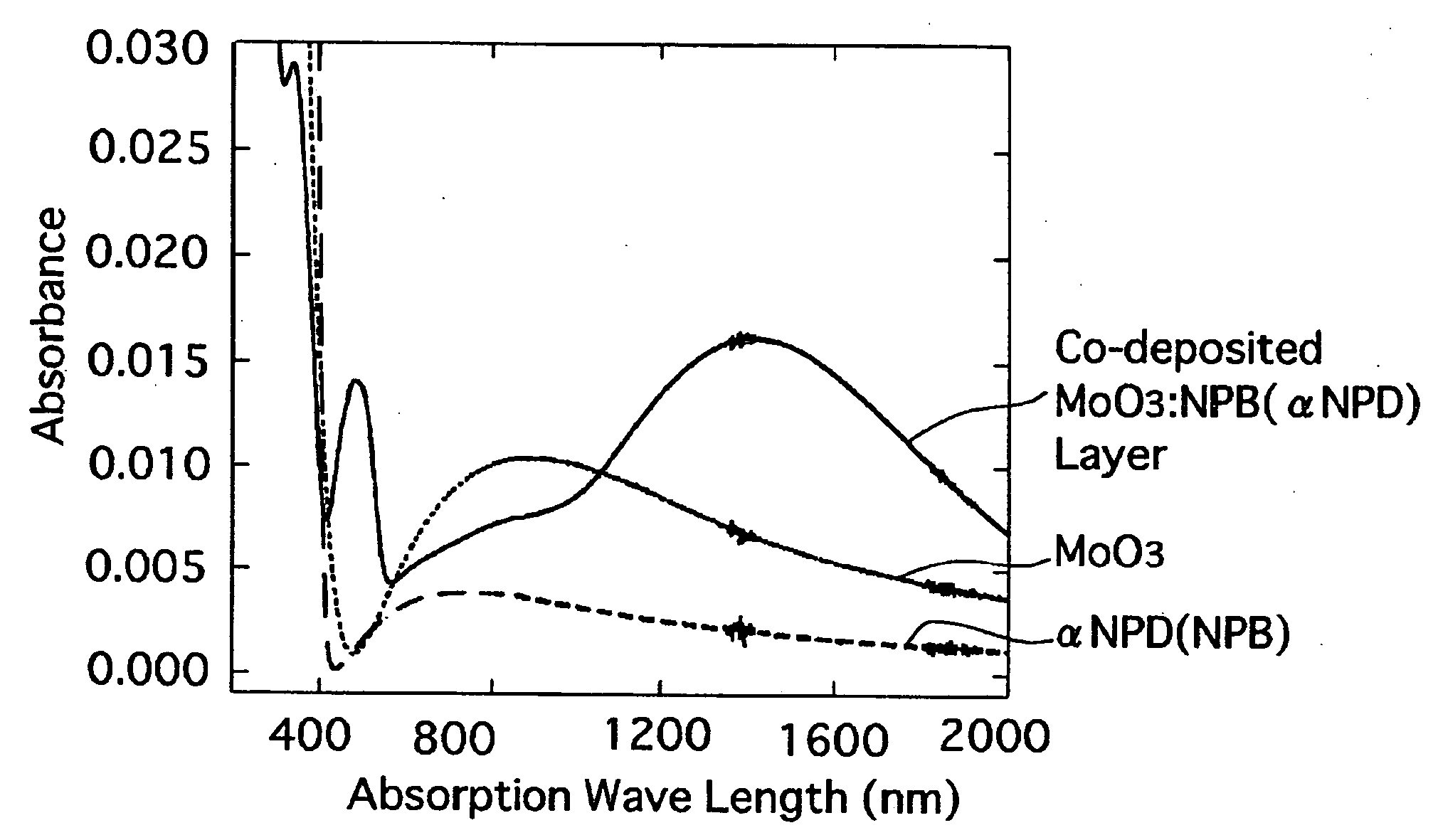

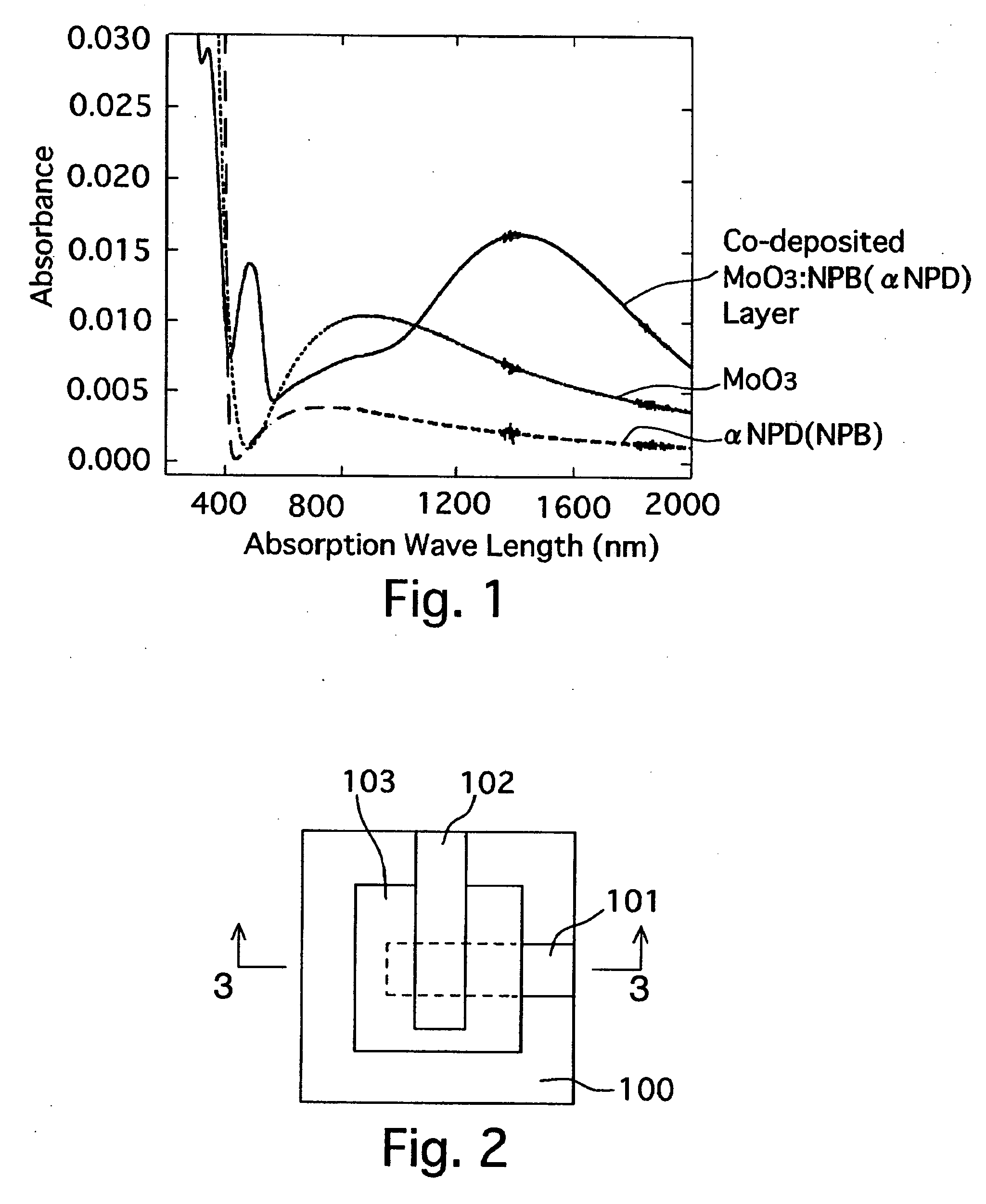

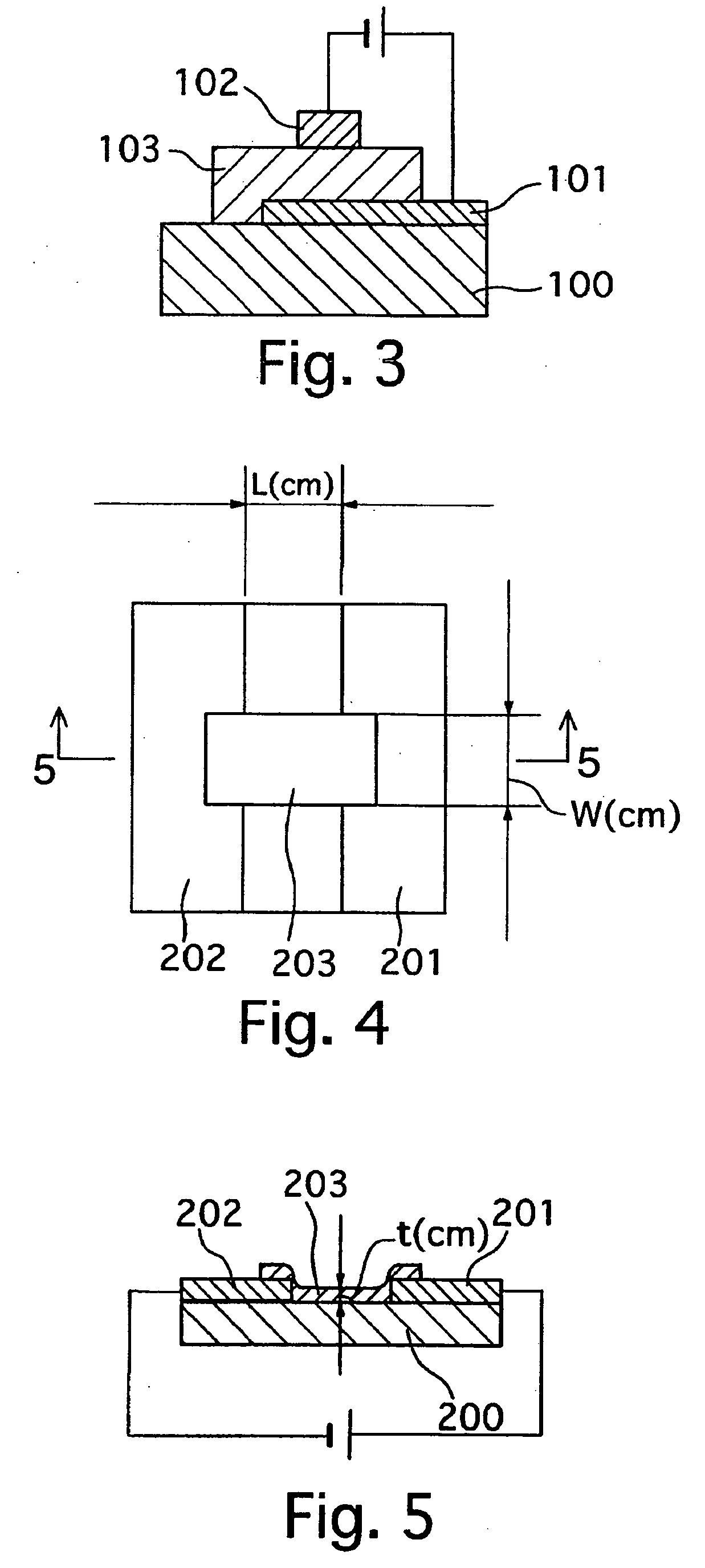

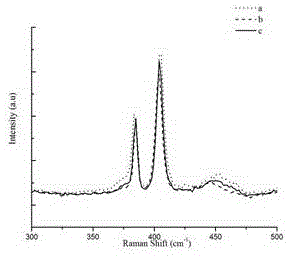

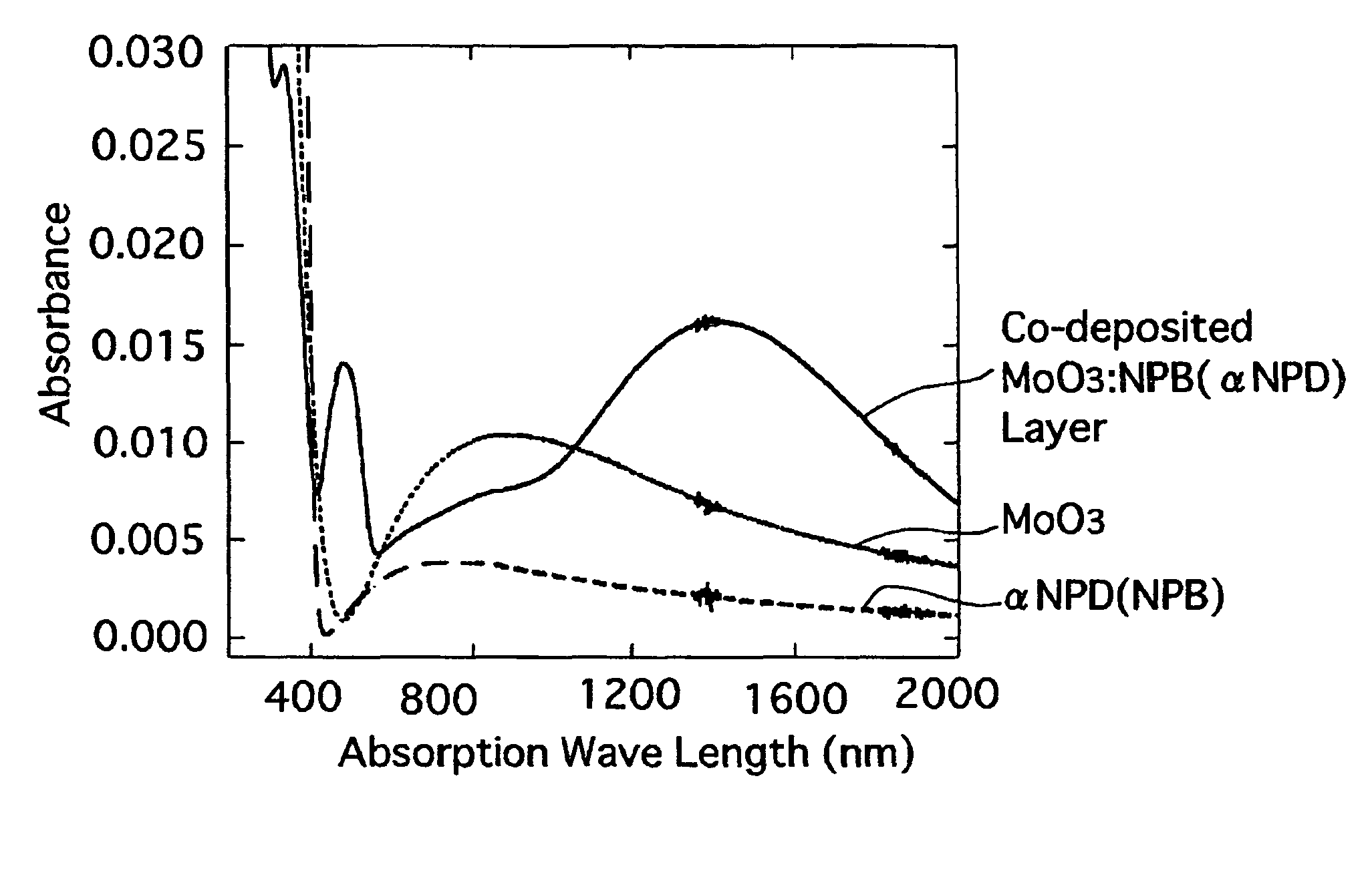

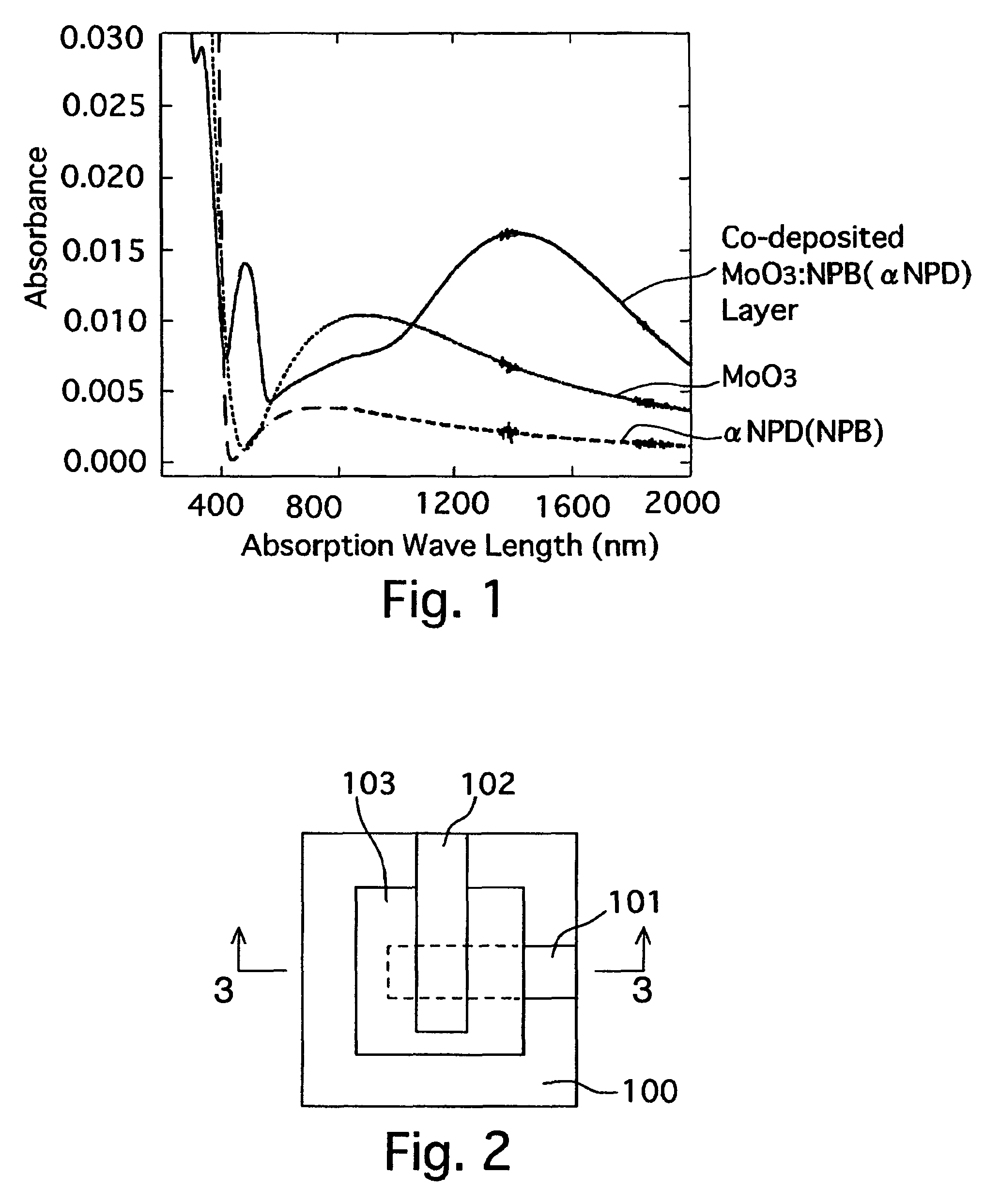

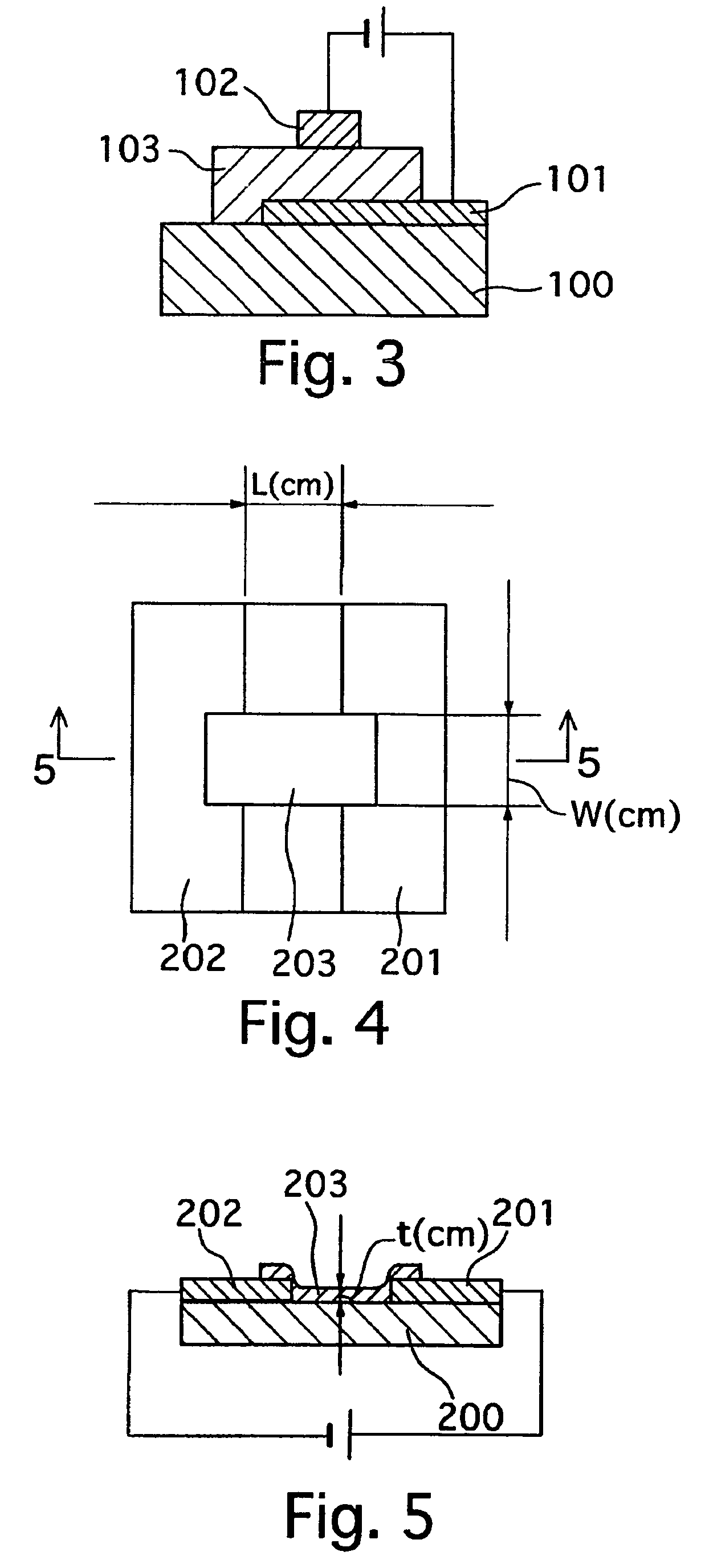

An organic device, including an organic compound having charge-transporting ability (i.e., transporting holes and / or electrons) and / or including organic light emissive molecules capable of emitting at least one of fluorescent light or phosphorescent light, has a charge transfer complex-contained layer including a charge transfer complex formed upon contact of an organic hole-transporting compound and molybdenum trioxide via a manner of lamination or mixing thereof, so that the organic hole-transporting compound is in a state of radical cation (i.e., positively charged species) in the charge transfer complex-contained layer.

Owner:MITSUBISHI HEAVY IND LTD +1

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

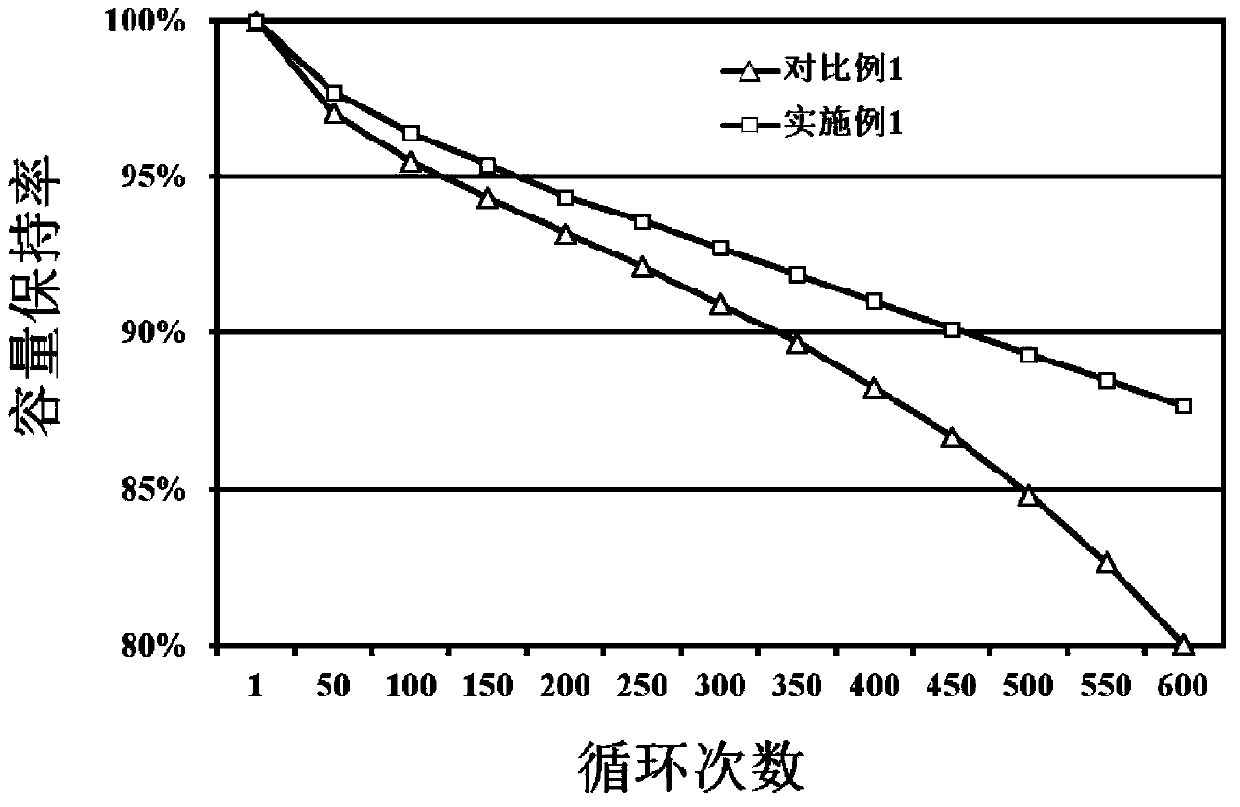

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

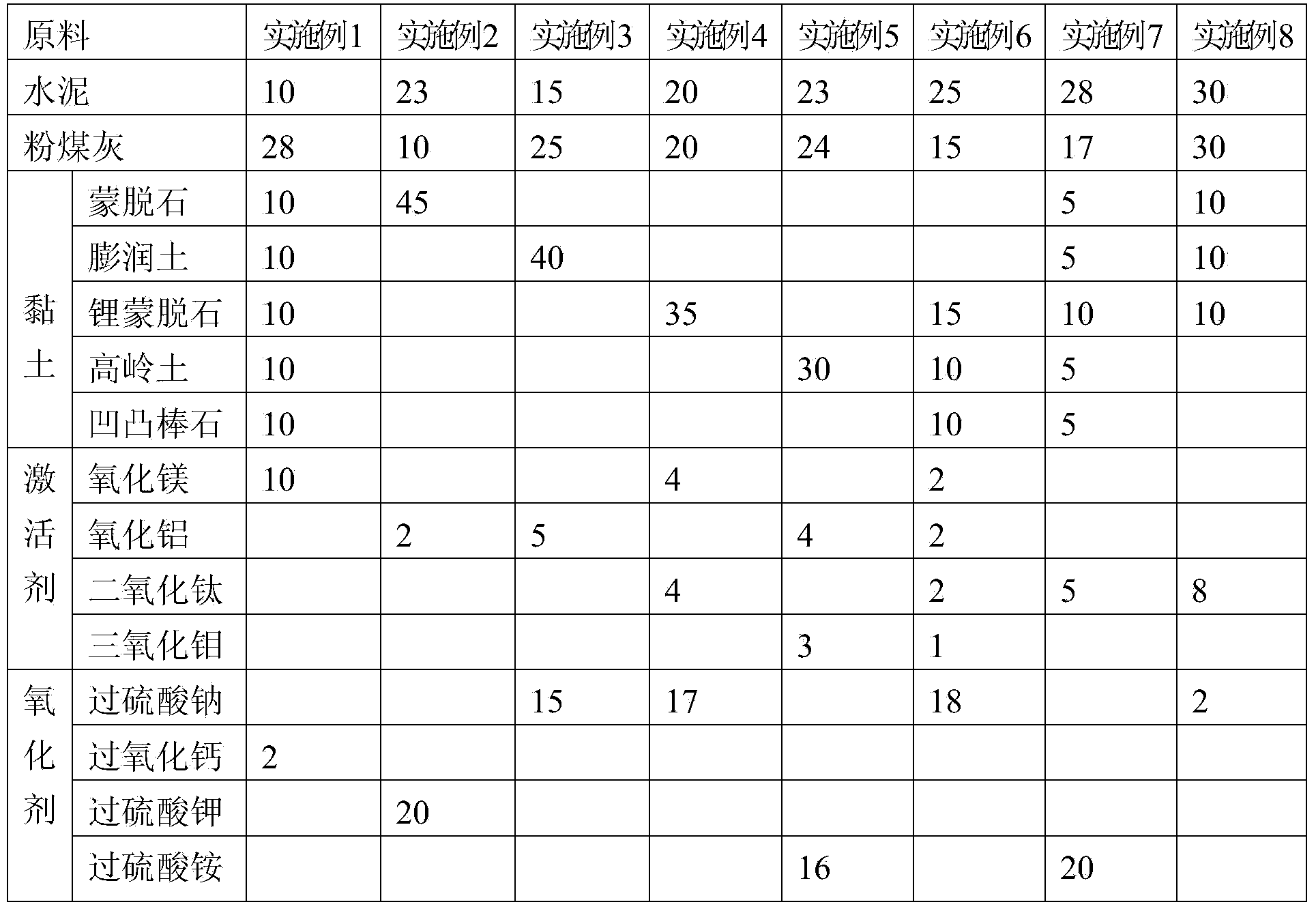

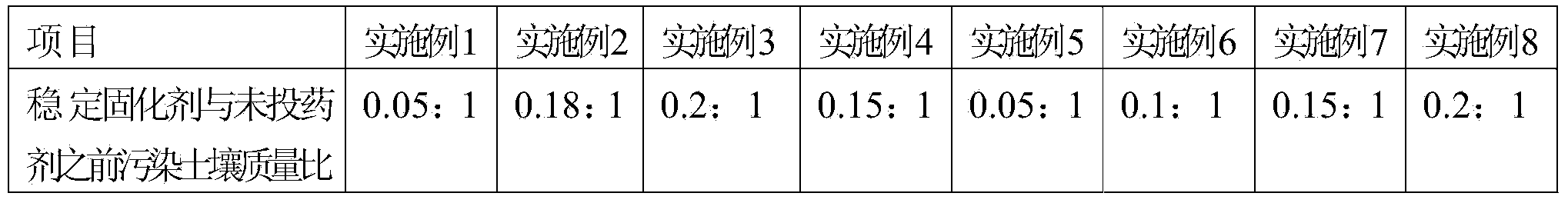

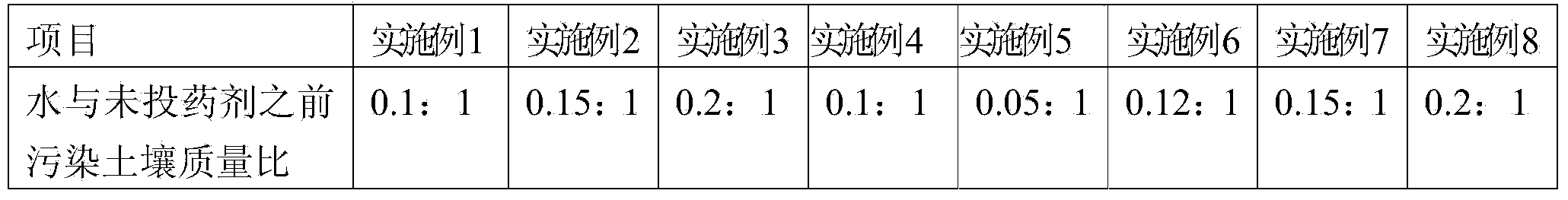

Stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil and using method of curing agent

ActiveCN103881727AImprove repair effectBioeffectiveAgriculture tools and machinesContaminated soil reclamationPotassium persulfateCoal

The invention relates to a stable curing agent of repairing heavy metal and toxic organic matter combined polluted soil. The stable curing agent comprises the following raw materials in percentage by weight: 10-30% of cement, 10-30% of coal ash, 20-50% of clays, 2-10% of an activating agent and 2-20% of an oxidizing agent, wherein the activating agent is a composition of one or more than two of magnesium oxide, aluminum oxide, titanium dioxide or molybdenum trioxide, and the oxidizing agent is a composition of one or more than two of sodium persulfate, calcium peroxide, potassium persulfate and ammonium persulfate. The raw materials are put into a grinder to be uniformly grinded and mixed to prepare the stable curing agent with the specific surface area of 400-800 / kg. The stable curing agent provided by the invention has the characteristics of low cost, good soil repairing effect and simplicity in construction.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

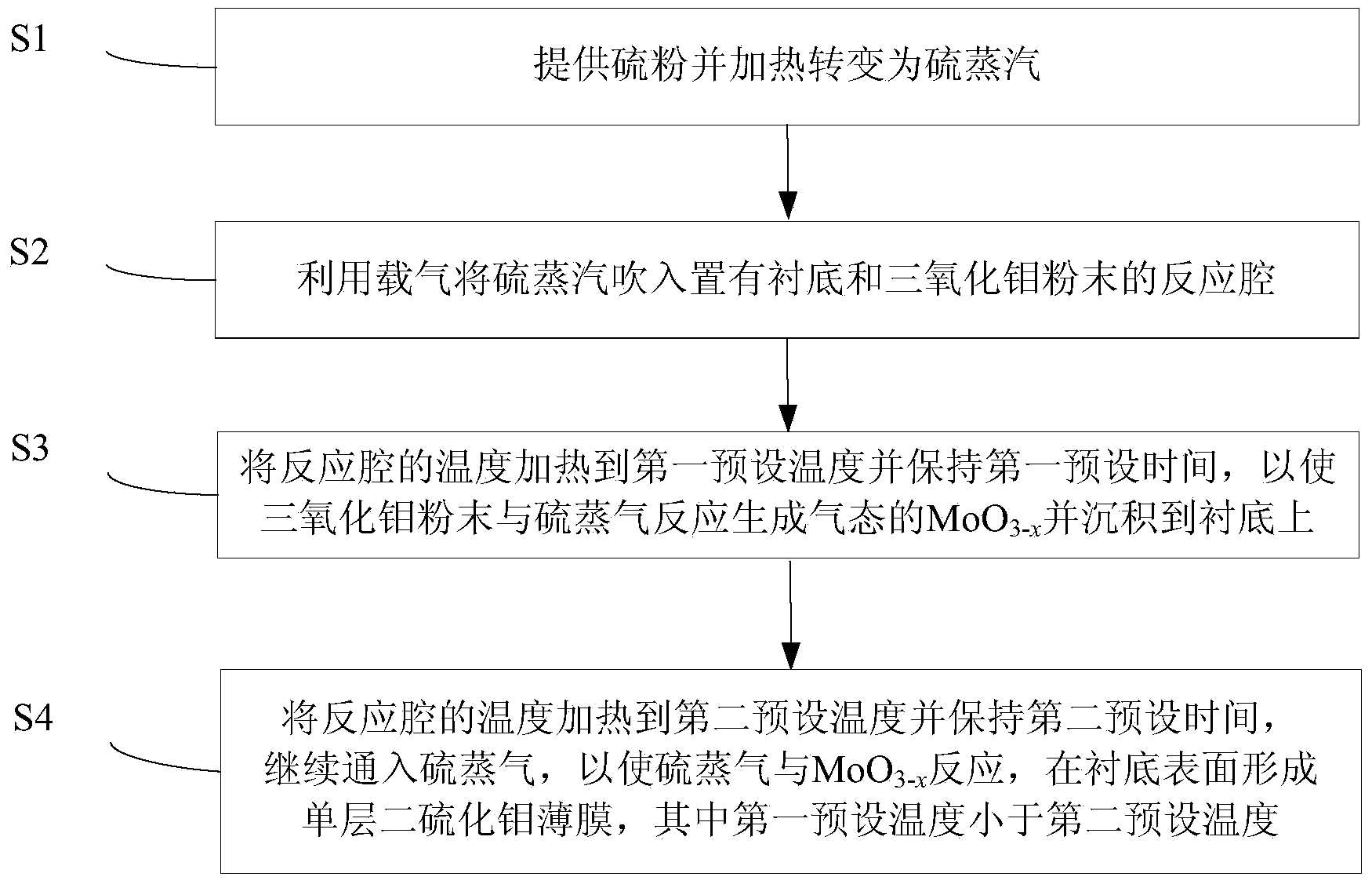

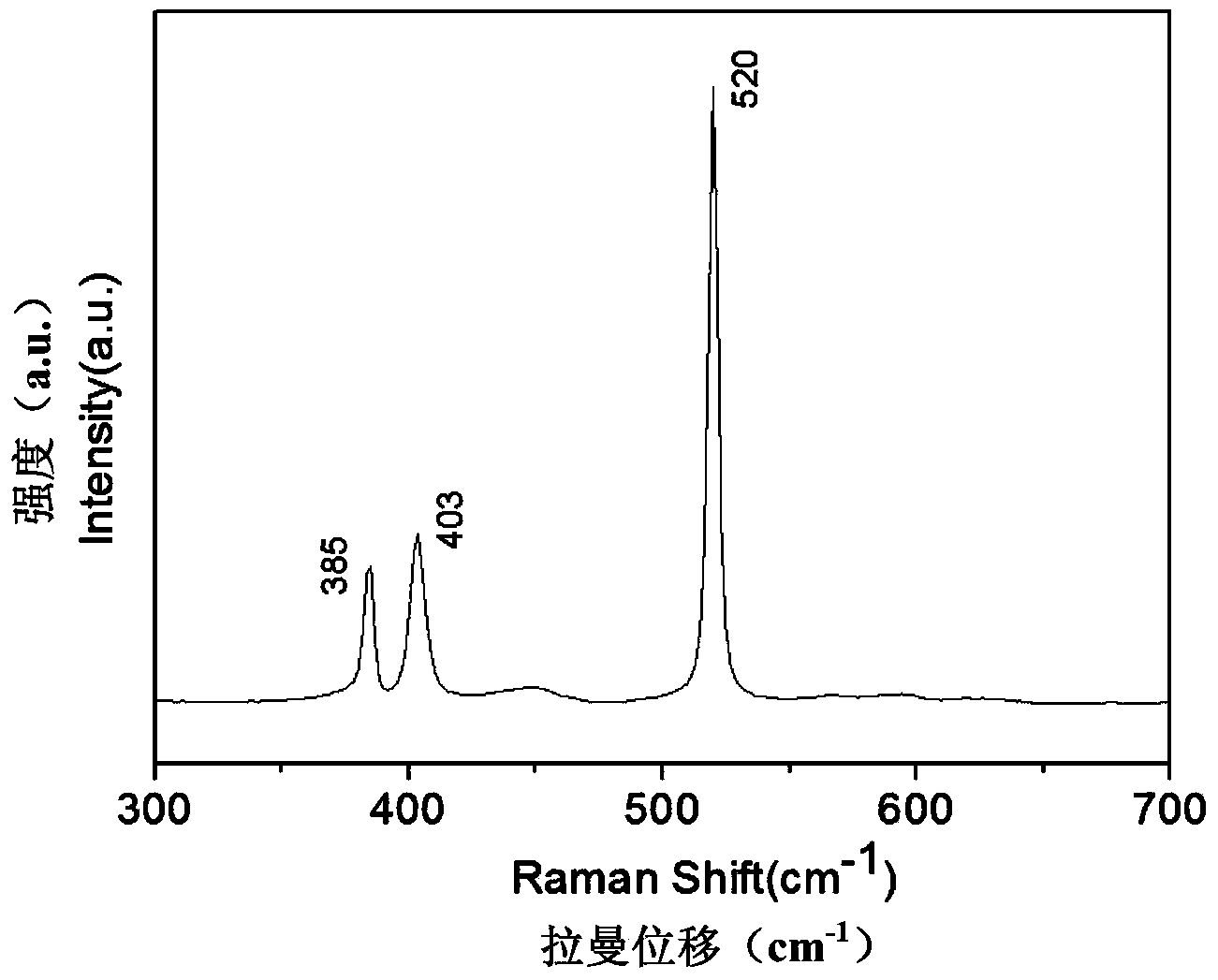

Method for preparing single-layer molybdenum disulfide film

ActiveCN103757602AThe number of layers is controllableChemical vapor deposition coatingSulfurMolybdenum trioxide

The invention discloses a method for preparing a single-layer molybdenum disulfide film. The method comprises the following steps: providing powdered sulfur and heating and transferring the powdered sulfur to sulfur vapor; blowing the sulfur vapor into a reaction cavity filled with a substrate and molybdenum trioxide powder by utilizing carrier gas; heating the temperature of the reaction cavity to a first preset temperature, and keeping the temperature for a first preset time, so that the molybdenum trioxide and the sulfur vapor are reacted to generate MoO3-x in a gas state to be deposited on the substrate, and x is more than 0 and less than or equal to 1; heating the temperature of the reaction cavity to a second preset temperature, keeping the temperature for a second preset time, continuously introducing the sulfur vapor, so that the sulfur vapor is reacted with the MoO3-x, and forming the single-layer molybdenum disulfide film on the surface of the substrate, wherein the first preset temperature is lower than the second preset temperature. According to the method, the large-area single-layer molybdenum disulfide film with controllable layers can be obtained through a two-step reaction method.

Owner:TSINGHUA UNIV

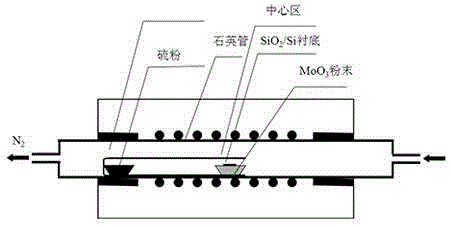

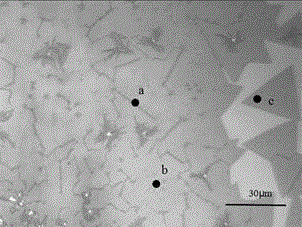

Preparation method for a large-area single-layer or few-layer molybdenum disulfide film

The invention discloses a preparation method for a large-area single-layer or few-layer molybdenum disulfide film. The main steps of the preparation method are as follows: firstly, sulfur powder and molybdenum trioxide powder are placed in two quartz boats respectively, a substrate is placed on the quartz boat loaded with molybdenum trioxide powder, and the obverse surface faces downwards; secondly, the two quartz boats loaded with sulfur powder and molybdenum trioxide powder are placed at a bottom end and an orifice of a quartz test tube respectively; thirdly, the above quartz test tube is placed in a tubular furnace, the bottom end and the orifice of the test tube are located at the edge area and the central area of the tubular furnace respectively; fourthly, protection gas argon or nitrogen is inputted into the tubular furnace, a normal pressure is kept until the experiment is over; fifthly, the tubular furnace is heated at a certain heating speed, thus the edge area and the central area of the tubular furnace are in proper temperatures respectively, the temperatures are kept for some time, sulfur powder sublimates and reacts with gas phase molybdenum trioxide, and a large-area single-layer or few-layer molybdenum disulfide film is generated on the substrate; sixthly, the tubular furnace is cooled to the room temperature, and the preparation process is finished. The method is slightly affected by air flow, the repetition rate is high, preparation of high-quality large-area single-layer or few-layer molybdenum disulfide film can be achieved at a normal pressure.

Owner:XIANGTAN UNIV

Organic devices, organic electroluminescent devices and organic solar cells

ActiveUS8101857B2Lower barrier heightSolid-state devicesSemiconductor/solid-state device manufacturingOrganic devicesOrganic solar cell

An organic device, including an organic compound having charge-transporting ability (i.e., transporting holes and / or electrons) and / or including organic light emissive molecules capable of emitting at least one of fluorescent light or phosphorescent light, has a charge transfer complex-contained layer including a charge transfer complex formed upon contact of an organic hole-transporting compound and molybdenum trioxide via a manner of lamination or mixing thereof, so that the organic hole-transporting compound is in a state of radical cation (i.e., positively charged species) in the charge transfer complex-contained layer.

Owner:MITSUBISHI HEAVY IND LTD +1

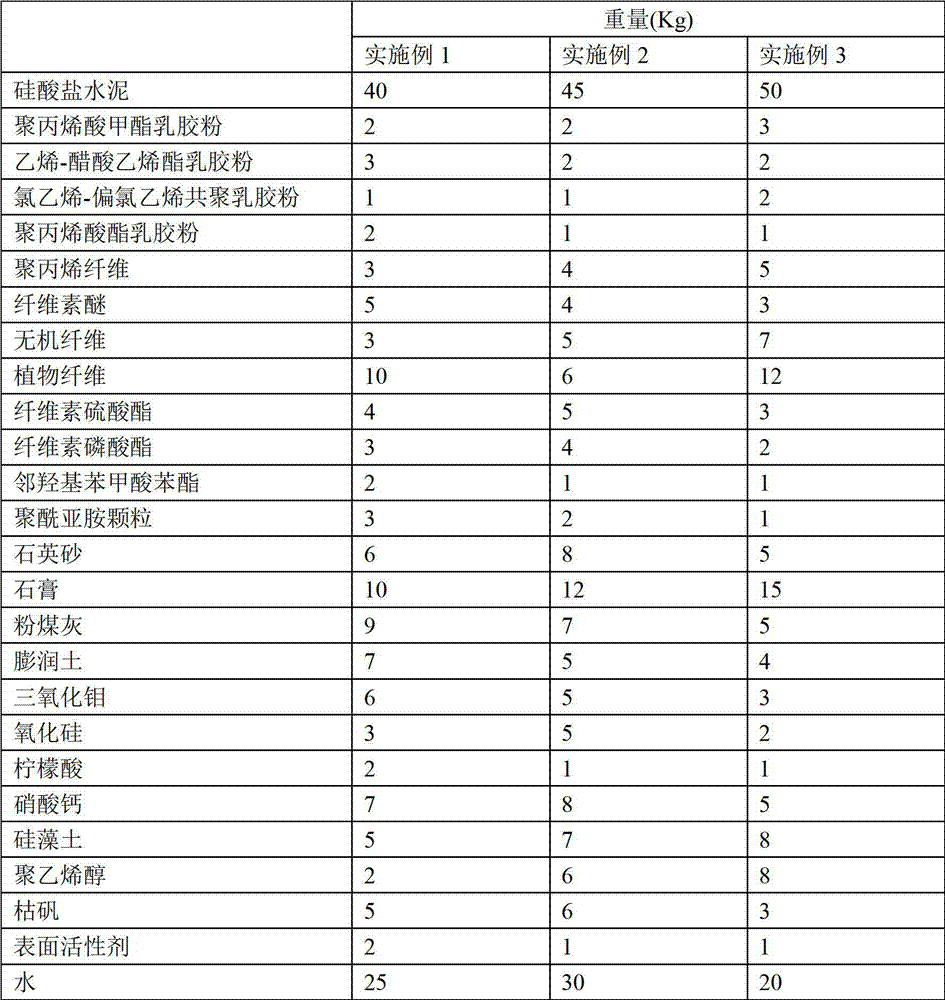

Corrosion-resistant polymer waterproof mortar

The invention provides a corrosion-resistant polymer waterproof mortar, which comprises the following components by weight: 40-50 parts of portland cement, 2-3 parts of polymethyl acrylate latex powder, 2-3 parts of ethylene-vinyl acetate latex powder, 1-2 parts of vinyl chloride-vinylidene chloride copolymerized latex powder, 1-2 parts of polyacrylate latex powder, 3-5 parts of polypropylene fibers, 3-5 parts of cellulose ether, 3-7 parts of inorganic fibers, 6-12 parts of plant fibers, 3-5 parts of cellulose sulfate, 2-4 parts of cellulose phosphate, 1-2 parts of phenyl salicylate, 1-3 parts of polyimide particles, 5-8 parts of quartz sand, 10-15 parts of gypsum, 5-9 parts of fly ash, 4-7 parts of bentonite, 3-6 parts of molybdenum trioxide, 2-5 parts of silicon oxide, 1-2 parts of citric acid, 5-8 parts of calcium nitrate, 5-8 parts of diatomite, 2-8 parts of polyvinyl alcohol, 3-6 parts of dried alum, 1-2 parts of a surfactant, and 20-30 parts of water.

Owner:WUJIANG TIANYUAN PLASTIC

Method for preparing submicron molybdenum powder

The invention discloses a method for preparing submicron molybdenum powder, which comprises the following steps that: ammonium molybdate or molybdenum trioxide are put in a mechanical crusher to be crushed into fine-particle raw materials, and the fine particle raw materials are put in a material boat; the fine-particle raw materials in the material boat are subjected to the primary hydrogen reduction in a reduction temperature region in a primary reduction furnace, and the product of the primary hydrogen reduction is molybdenum dioxide; then the material boat filled with the molybdenum dioxide is directly pushed into a secondary reduction furnace, the molybdenum dioxide in the material boat is subjected to the secondary hydrogen reduction in a reduction temperature region in the secondary reduction furnace, and the product of the secondary hydrogen reduction in the material boat is molybdenum powder; and finally, the sub-micron molybdenum powder can be obtained by sieving with a 160-mesh screen. The method for preparing the submicron molybdenum powder adopts the reduction temperature lower than the conventional reduction temperature, and short temperature region used in the reduction process, thereby reducing cost; and the average Fisher particle size of the prepared molybdenum powder is small, the specific surface area is large, and the activity is high, thereby being favorable for the follow-up sintering process.

Owner:JINDUICHENG MOLYBDENUM CO LTD

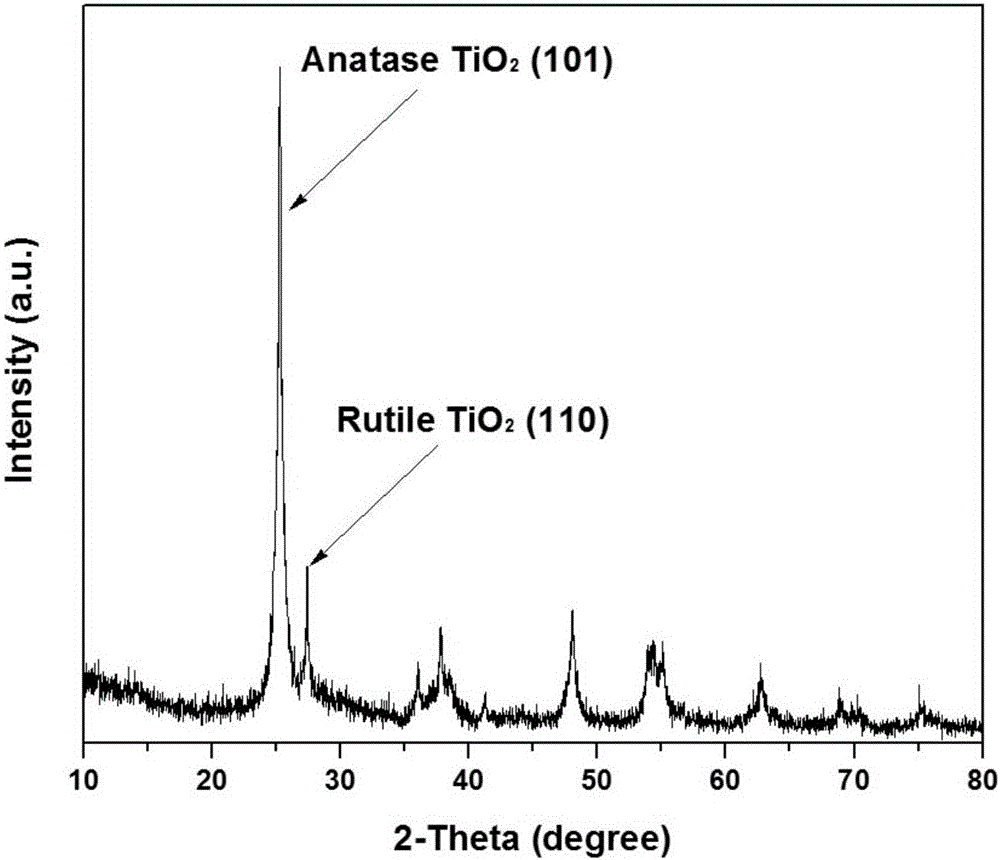

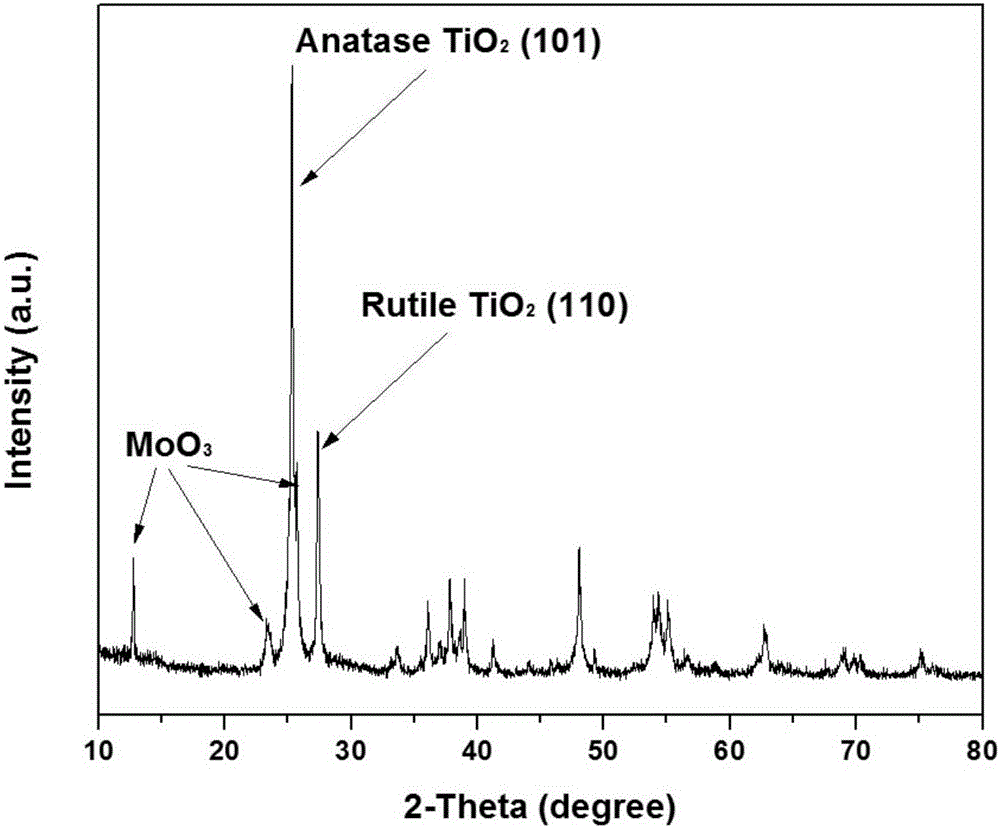

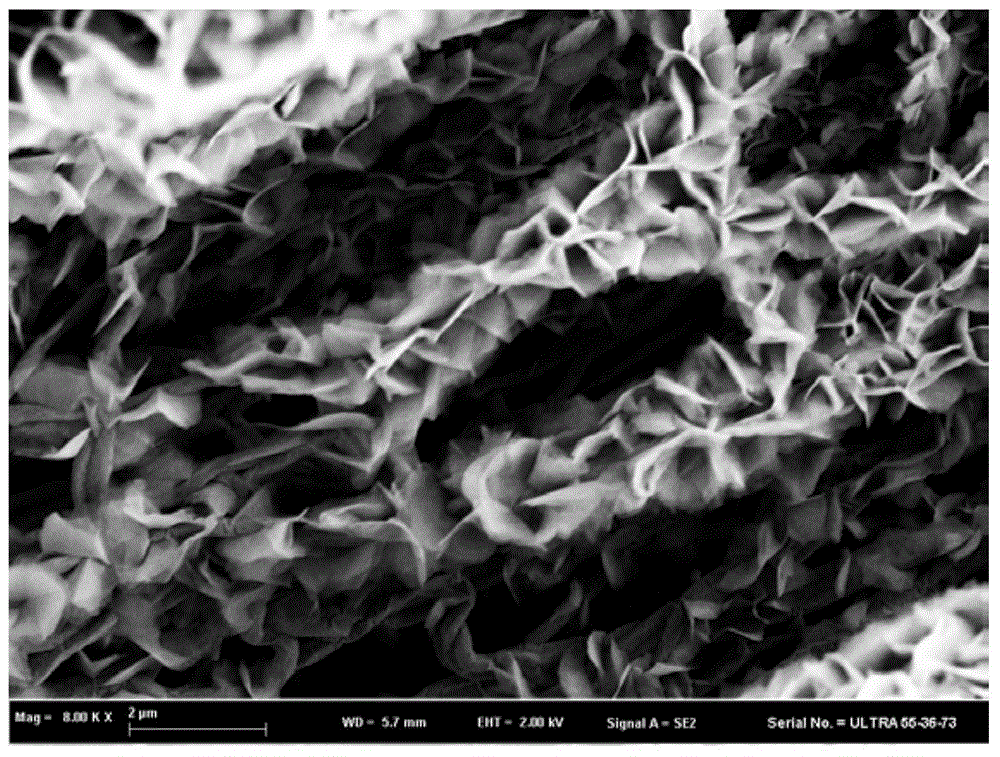

Molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle and preparation method and application thereof

InactiveCN105161700AGood transmission and diffusion effectImprove conductivityMaterial nanotechnologyCell electrodesHigh rateElectrochemistry

The invention relates to a molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle. The surface of a trivalent molybdenum ion doped titanium dioxide nano particle is coated with molybdenum trioxide, titanium dioxide is a mixed phase composed of an anatase phase and a rutile phase, and a sintered interface is arranged among titanium dioxide particles and is of a chain structure. A flame spraying combustion technology is adopted, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle can be rapidly and continuously prepared; a synergistic effect is played to the greatest extent; and the conductivity of TiO2 is improved, an extra lithium insertion space is provided by the TiO2 and MoO3 grown on the surface, the specific capacity is improved, high electrochemical activity and high rate performance of a material are ensured, and the molybdenum trioxide coated molybdenum doped titanium dioxide nano composite particle has excellent rate performance and cyclic stability when applied to the field of an anode material of a lithium ion battery.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Continuous single stage process for the production of molybdenum metal

Molybdenum trioxide or ammonium dimolybdate is reduced to molybdenum metal as it passes through an atmosphere of hydrogen in a multi-zoned thermally profiled rotating tube furnace.

Owner:HARPER INT CORP

Preparation method of molybdenum disulfide/carbon nano-fiber hybrid material

InactiveCN104056642AHigh catalytic activitySimple preparation processPhysical/chemical process catalystsFibre chemical featuresFiberSulfur

The invention relates to a preparation method of a molybdenum disulfide / carbon nano-fiber hybrid material. The method comprises the following steps: putting manganese dioxide, molybdenum trioxide and carbon nano-fibers into three corundum boats abreast respectively; placing the three corundum boats in the middle of a tubular furnace; adding powdered sulfur into another corundum boat, and placing at the upstream part of gas flow; after inert protective gas flow is connected for 30 minutes, raising the temperature of the tubular furnace to 700 DEG C, and raising the temperature of the corundum boat filled with the powdered sulfur to 150 DEG C; and raising the temperature of the tubular furnace to 800-1,300 DEG C after 30 minutes, preserving heat for 5-12 hours, maintaining the temperature of the corundum boat filled with the powdered sulfur at 150 DEG C all the time, and finally cooling to room temperature under the protection of inert protective gas to prepare the molybdenum disulfide / carbon nano-fiber hybrid material. The preparation method has the beneficial effects that a preparation process is simple; the stability and the repeatability are high; the obtained hybrid material is high in catalytic activity.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing nm-class composite rare earth molybdenum material by sol-gal process

The invention discloses an infusible metal material, belonging to compound nanometer material field. Especially relates to a method for using sol-gel method to produce nanometer compound rare earth molybdenum material. The method is, in ammonium molybdate solution, the lemon acid is poured in, and then the rare earth nitrate solution is added into the mixed solution. They are dried in the drying box, and form the dry gel. Then the dry gel is baked in furnace, forms compound of molybdenum trioxide and lanthana or lanthanum hydroxide. Finally, they are reduced for 1.5-2.5 hours under temperature of 400-450deg.C and 800-900deg.C in hydrogen furnace. The reduced compound rare earth lanthana is formed under pressure, and it is heated and baked into shape under high temperature and pressure in hydrogen furnace. The material particle is tiny, the density can reach to 95% of the ideal density, the rare earth oxide exists with nanometer particle, the emitting ability is strong, and it can be used as new negative material.

Owner:XI AN JIAOTONG UNIV

Anti-corrosion copper-based brake material with high friction coefficient and preparation method of anti-corrosion copper-based brake material

The invention discloses an anti-corrosion copper-based brake material with a high friction coefficient. The anti-corrosion copper-based brake material is prepared from the following raw materials in percentage by weight: 34%-79% of copper, 6%-12% of carbon, 2%-6% of titanium, 2%-6% of nickel, 4%-10% of quartz sand, 3%-9% of silicon carbide, 2%-6% of mullite, 0-8% of molybdenum disulfide and 2%-9% of molybdenum trioxide, wherein the materials can be pressurized, sintered and molded in a protective atmosphere in a powder metallurgy manner; the sintering temperature is 800-890 DEG C; the sintering time is 100-200 minutes; and the exerted pressure is 1.9-3MPa. A Cu-Ni-Ti alloy component is adopted as a connecting phase, so that the problem that a common copper-based powder metallurgy brake material is poor in decay resistance in a marine environment is overcome; and the mullite is adopted as a friction phase, so that the problem that a common copper-based brake material is low in dynamic and static friction coefficient is solved.

Owner:贵州新安航空机械有限责任公司

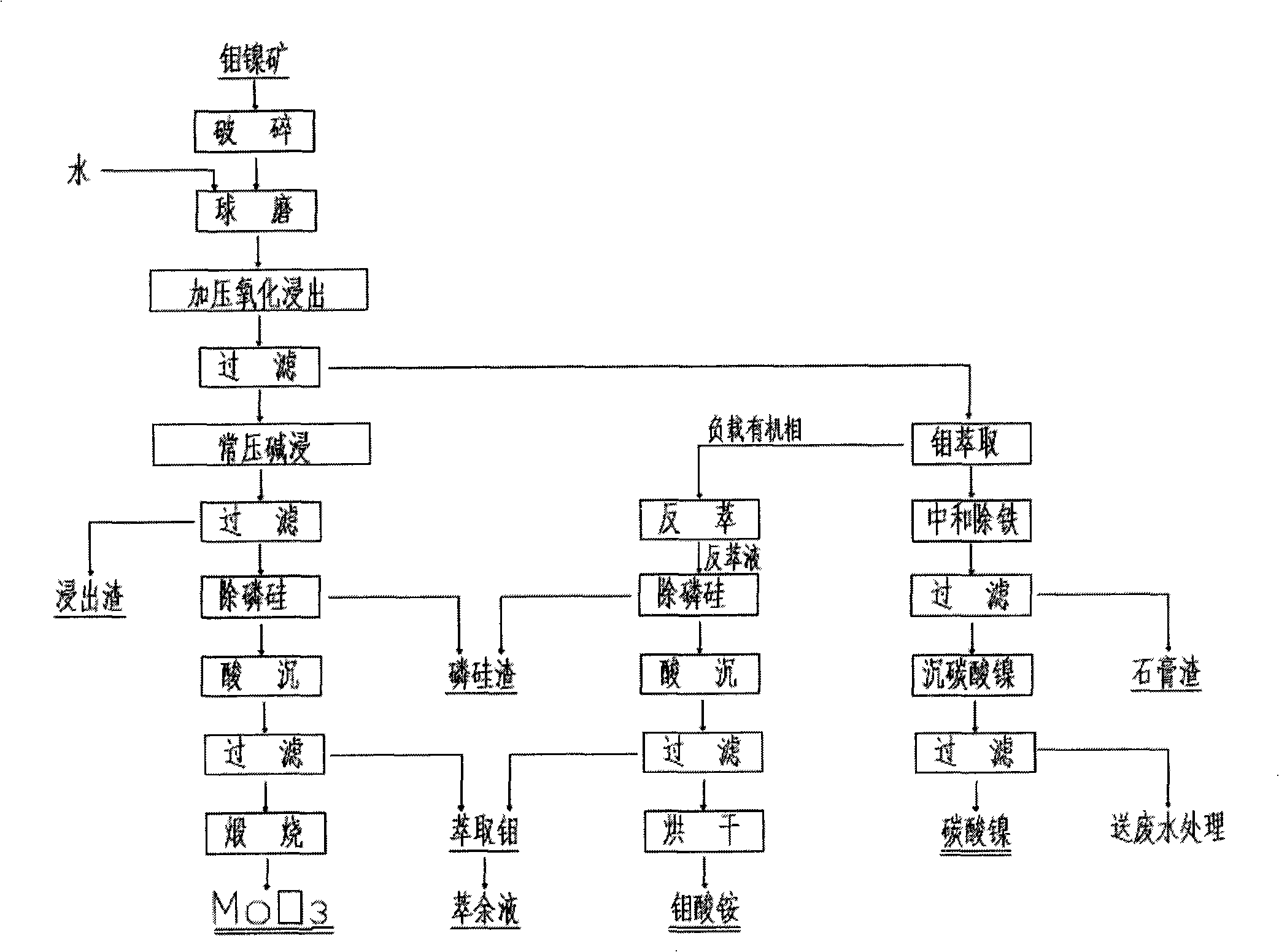

Method for extracting molybdenum and nickel by molybdenum nickel ore whole wet method

ActiveCN101323915AHigh overall yieldReduce processing costsProcess efficiency improvementNickel saltSlag

The invention discloses a method for extracting nickel and molybdenum by a nickel-molybdenum ore all-wet method, relating to the smelting of nonferrous metals by a wet method, in particular to a all-wet method for extracting nickel and molybdenum from nickel-molybdenum ores of black rock series. The method is characterized in that during extraction process, pressure oxidation leaching is carried out to the nickel-molybdenum ores milled, thus obtaining a nickel leaching solution containing nickel and molybdenum and leaching slag containing molybdenum oxides; the leaching solution undergoes extraction for separating nickel and molybdenum, thus producing nickel salt and ammonium molybdate or molybdenum trioxide; alkali steeping in a normal pressure, purification and ammonium molybdate acid deposition are carried out to molybdenum contained in the leaching slag for recycling. The method of the invention has high nickel and molybdenum recycling rate, low production cost and environmentally friendly production process.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

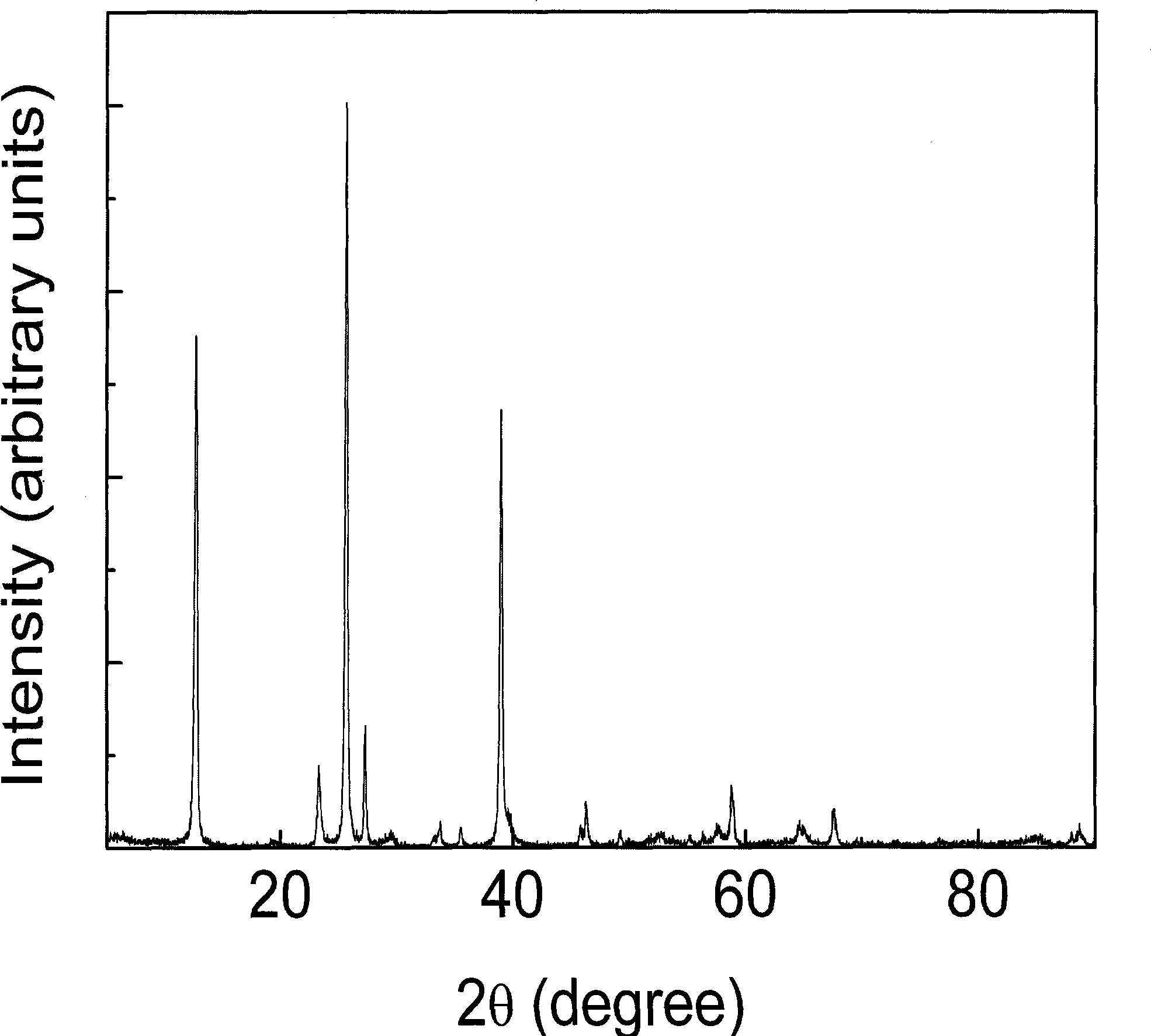

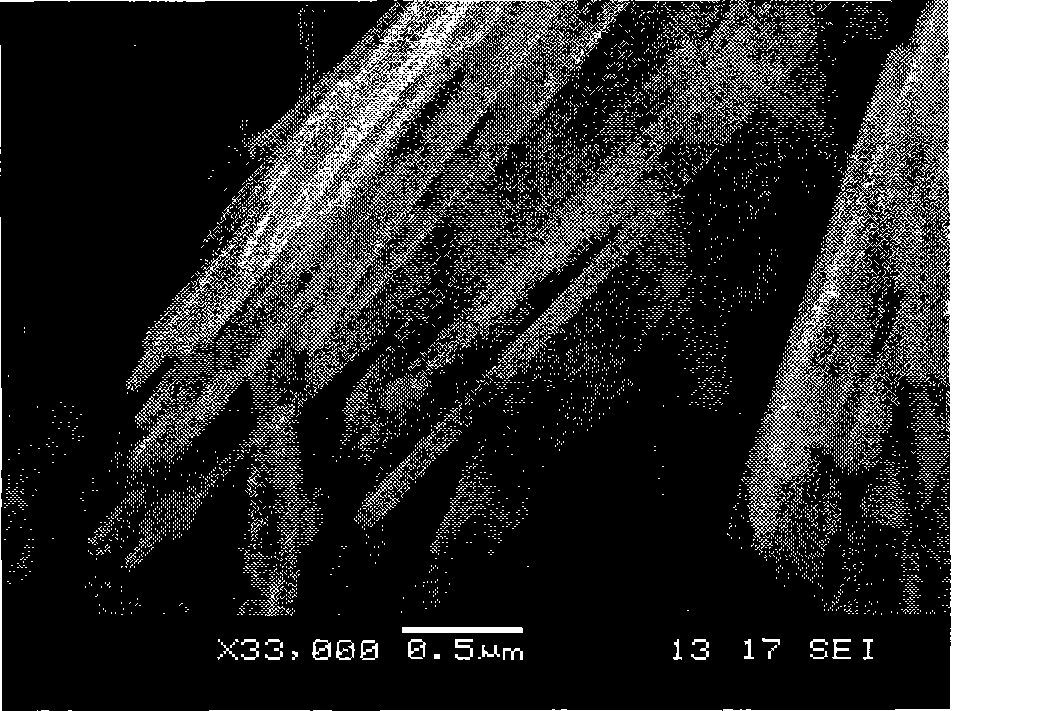

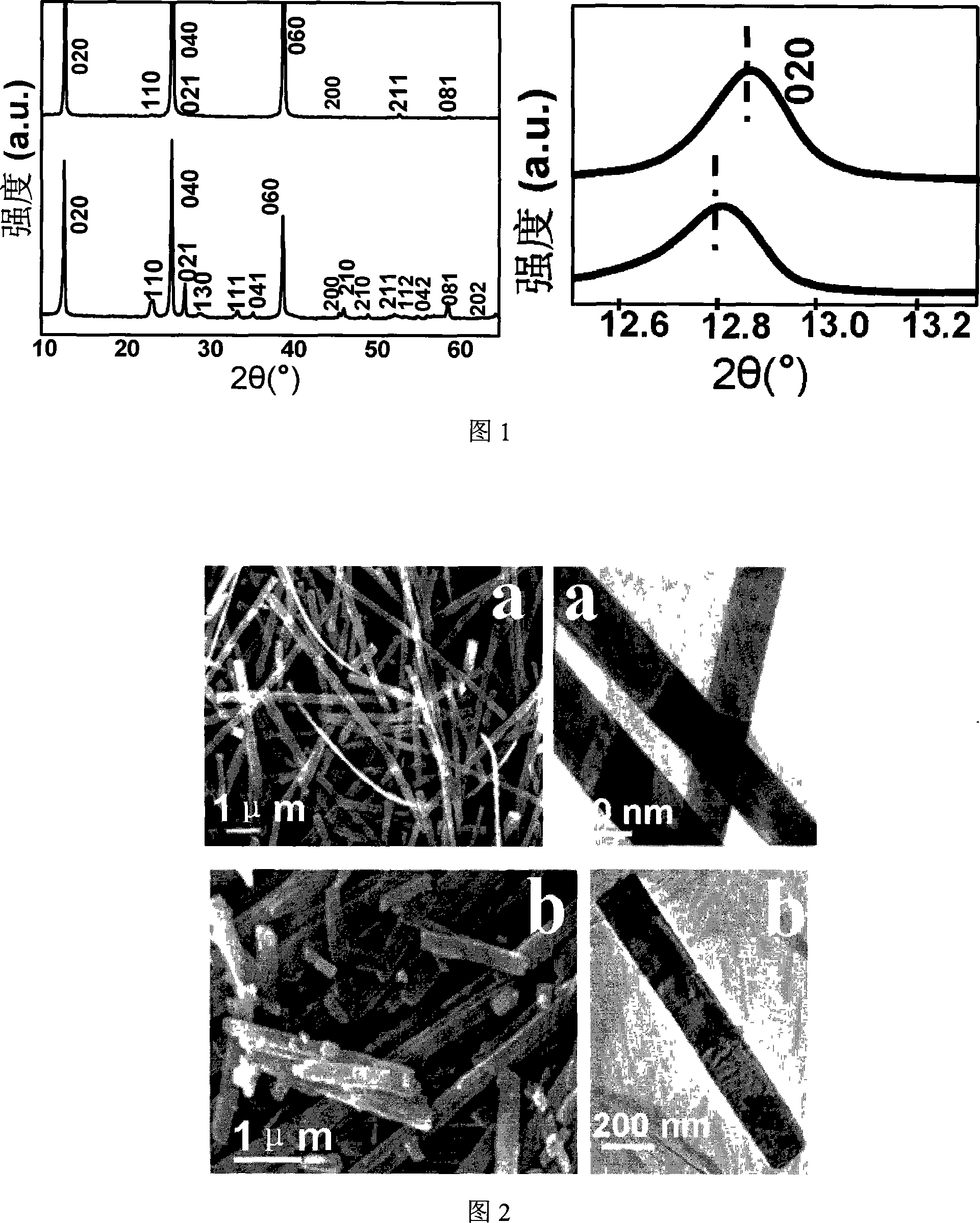

Method for preparing orthorhombic phase molybdenum trioxide nano wire

InactiveCN101423254ASimple reaction conditionsHigh selectivityMolybdenum oxides/hydroxidesEthylenediamineMolybdate

The invention discloses a method for preparing an orthorhombic phase molybdenum trioxide nano wire, which is characterized in that molybdate, molybdic acid or molybdenum trioxide is dissolved in aqueous solution with quadrol concentration of 0.2-6 mol / L to cause the mol ratio of molybdenum atom and quadrol to be 1:1-6; and then strong acid solution with hydrogen ion concentration of 0.5-3.0 mol / L is dropwise added under the condition of stirring till the pH value is within 4 to 5; the solution is unceasingly stirred for 10 to 30 min; then the white precipitation is sucked, filtered, washed and dried to obtain white orthorhombic phase single crystal nano wires with the diameter of 100 to 400 nm and the length of 10-40 Mum. In the method, the raw materials are easily obtained; the needed device is simple; the technique is convenient; the reaction can be finished in an hour in the normal temperature and pressure; the method is safe and easy to be controlled; the productive rate reaches more than 99 percent; the mother solution can be reused; and the method is applicable to large-scale industry production.

Owner:UNIV OF SCI & TECH OF CHINA

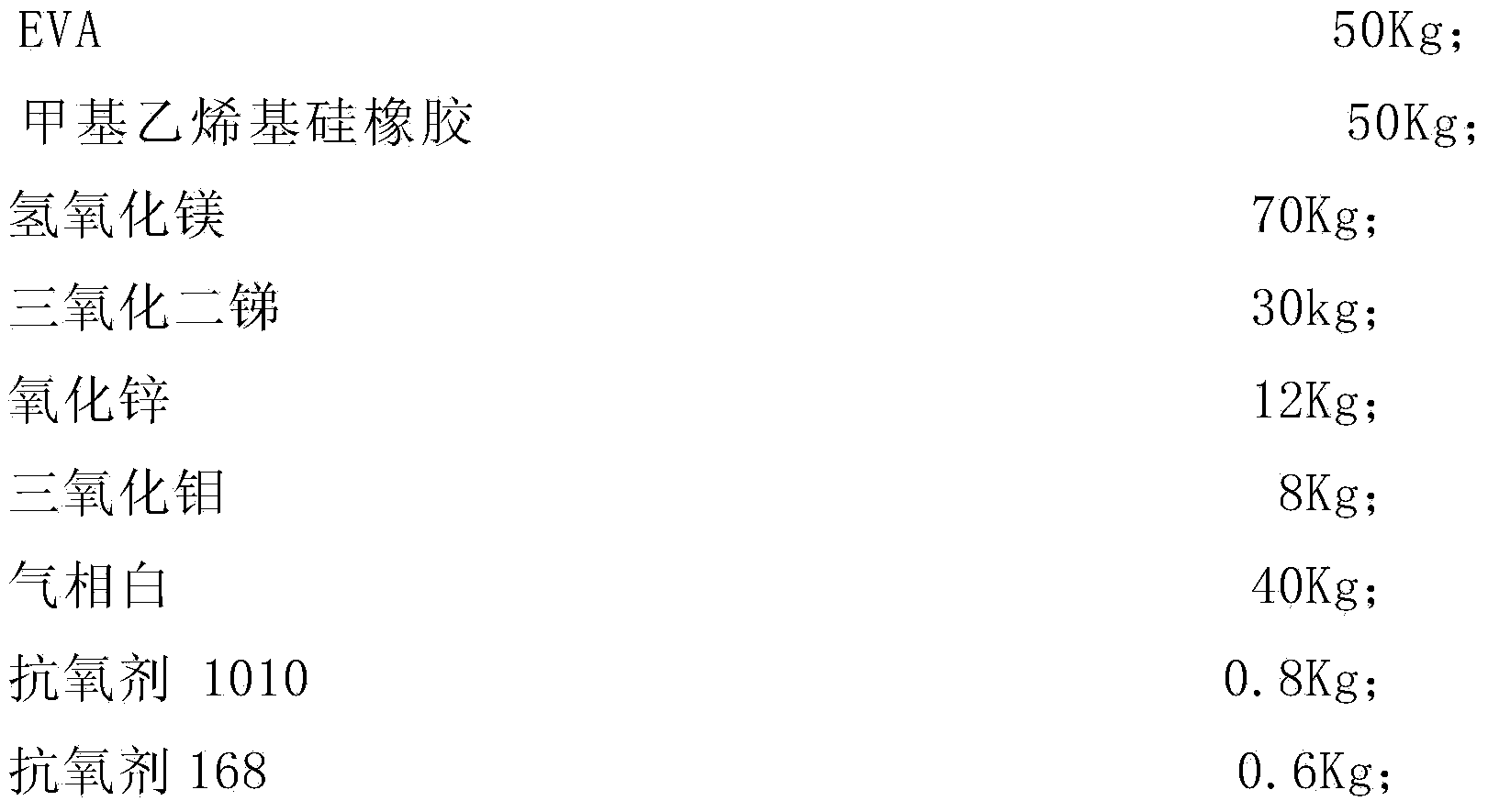

Low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material, preparation method thereof and cable

ActiveCN103627074AGood cold and oil resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesAntioxidantCarvacryl acetate

The invention provides a low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material and a preparation method thereof. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material comprises the following components in parts by weight: 100 parts of basic material, 80-100 parts of flame retardant A, 10-20 parts of flame retardant B, 0.8-2 parts of antioxidant, 0.4-2 parts of lubricant, 0.8-3 parts of coupling agent, 25-40 parts of reinforcing agent and 0.4-0.6 parts of vulcanizing agent, wherein the basic material is a combination of ethylene-vinyl acetate (EVA) and methyl vinyl silicone rubber; the flame retardant A is a combination of magnesium hydroxide and antimony trioxide; the flame retardant B is a combination of zinc oxide and molybdenum trioxide; the antioxidant is a combination of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate), (antioxidant 1010) and tri(2,4-di-tert-butylphenyl) phosphite (antioxidant 168); and the reinforcing agent is fumed silica. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material has the following characteristics of high abrasion resistance, high flame retardance, good oil resistance and chemical corrosion resistance, low temperature resistance, aging resistance, and excellent mechanical properties and the like. The invention further provides the preparation method of the low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material.

Owner:上海至正新材料有限公司

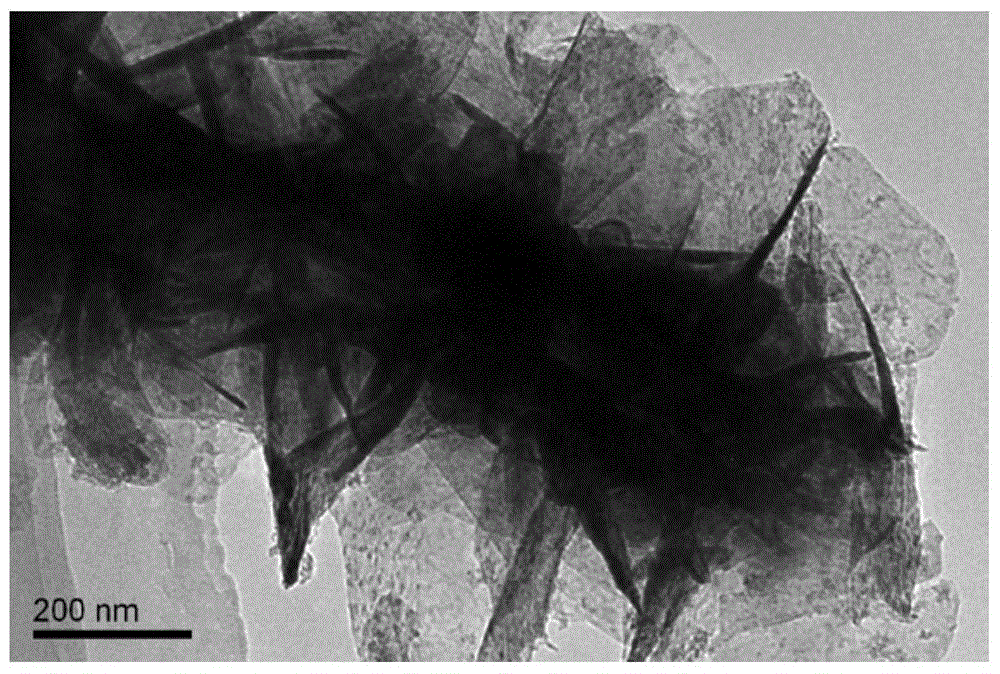

Method for synthesizing rod-like and echinoid molybdena-based nano-material

InactiveCN101412541ALow costUniform scaleNanostructure manufactureMolybdenum oxides/hydroxidesMolybdenum trioxidePeroxide

The invention relates to a quick and efficient non-template agent hydro-thermal synthesizing method. The system can synthesize an alpha-molybdenum trioxide nanometer rod and a high-density echinoid molybdenum oxide based nanometer materials. Molybdenum peroxide acid prepared from molybdenum trioxide and aqueous hydrogen peroxide solution is used as a precursor, is produced into scattered alpha-molybdenum trioxide nanometer rod by hydro-thermal synthesis at a temperature of between 80 and 180 DEG C, and is produced into the peroxide modified molybdenum oxide hydrate by hydro-thermal synthesis at a temperature of between 65 and 75 DEG C. The hydrate is a multiscale structure; a nanometer thin slice, a micron prism and a nanometer rod-shaped structure unit are divergently assembled into a micron-size high-density echinoid structure. The hydrate is roasted to obtain high-density echinoid alpha-molybdenum trioxide. Modulation of the synthesizing condition can realize fine adjustment for appearance of the nanometer rod, the micron-size echinoid structure and the structure unit thereof. The method uses raw materials with low cost, has the advantages of simple technical process, controllable conditions and the like, and can promote research and application of the molybdenum oxide in the fields of sensors, field transmission, electrode materials and so on.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

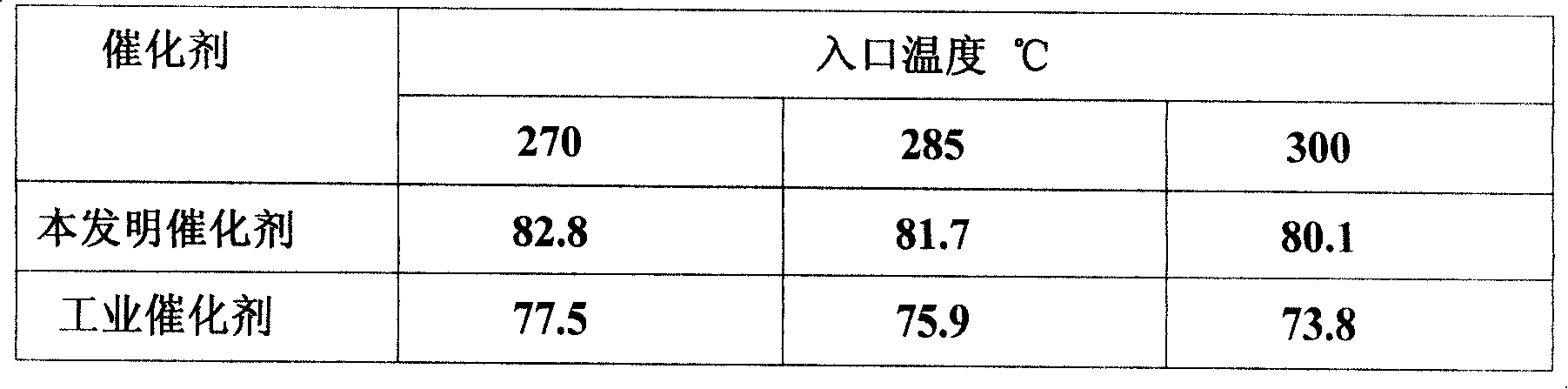

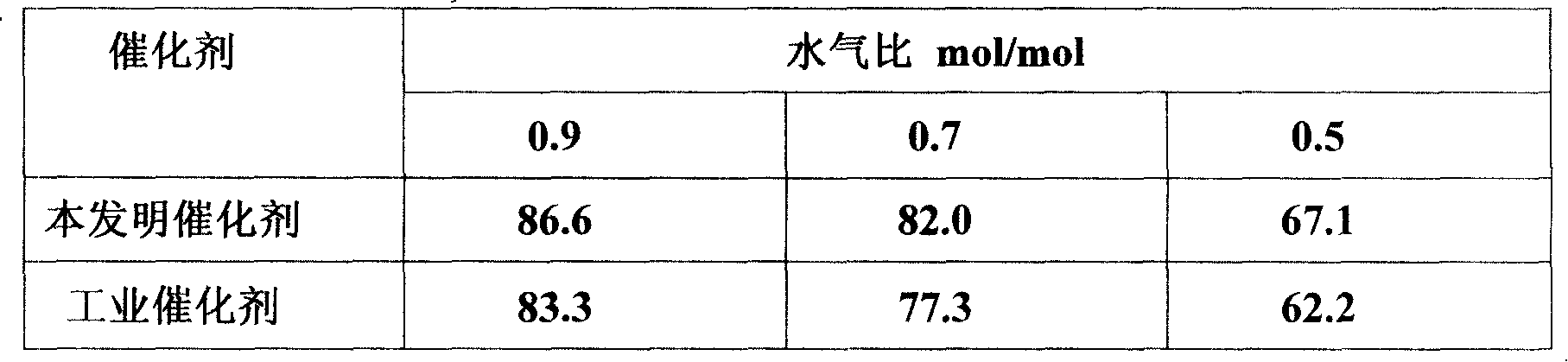

Polynary metal oxide catalyst and preparing process thereof

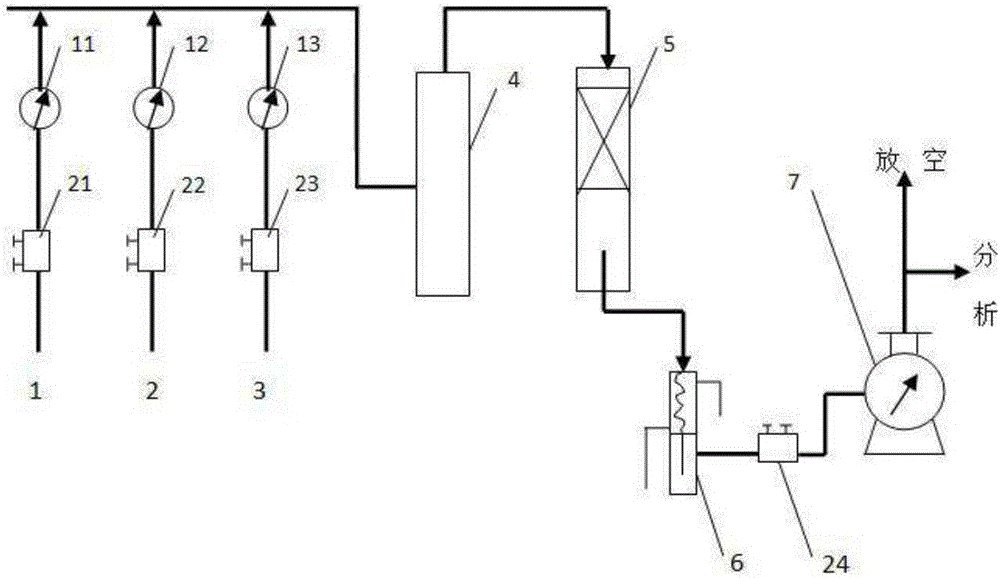

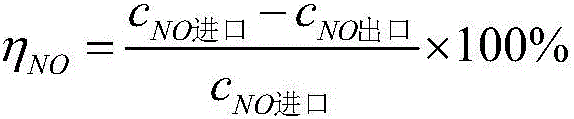

ActiveCN101199933AHigh activityHigh low temperature activityCatalyst carriersCombined combustion mitigationCerium(IV) oxideManganese

The invention discloses a multi-complex-metal-oxides catalyst and the preparation method. The catalyst carrier is multi-complex-metal-oxides solid alkali or surface solid alkali or the precursors of the solid alkali or surface solid alkali. The multi-complex-metal-oxides is complex oxides by combining two or more than two selections from alumina, titania, zirconium dioxide and ceria with one or more than one selections from magnesia, calcium oxide, baryta, potassium oxide and sodium oxide. Active ingredient is composed of cobalt oxides or / and nickel oxide and molybdenum trioxide or / and tungsten trioxide. The additive added to carriers or active components is the oxide of at least one of the following elements: cerium, lanthanum, zinc, zirconium, nickel or manganese. The invention has the advantages of high activity, high activity at low-temperature, high activity stability and wide temperature range of activity; high intensity, high intensity stability and high anti-hydration and anti-pulverization ability, wide water / gas ratio adaptability and wide range for impurity content. The catalyst of the invention is applied to the promotion of dirty water gas shift reaction.

Owner:汤海溶 +2

Process for the manufacture of a bio-release fertiliser of an anionic micro nutrient viz molibdenum

This invention describes a process for the preparation of bio-release molybdenum fertilizers which comprises heating molybdenum trioxide, one or more basic compound(s) of metal(s) selected from magnesium, calcium and sodium, and phosphoric acid till a solid polyphosphate is obtained and finally obtaining the dried powder.

Owner:AGTEC INNOVATIONS

Method for extracting tungsten trioxide and molybdenum trioxide by pretreating tungsten-molybdenum concentrates with concentrated acid

InactiveCN101824533AAchieve separationTake advantage ofProcess efficiency improvementSolubilityEconomic benefits

The invention relates to a method for extracting tungsten trioxide and molybdenum trioxide by pretreating tungsten-molybdenum concentrates with a concentrated acid, which comprises eight flows of pretreatment with the concentrated acid, lixiviation, molybdenum precipitation, the preparation of MoO3 by roasting, ammonia leaching, concentration, cooling for crystallization, and the preparation of WO3 by roasting. The flows have the advantages that: 1, the recovery rate is high, the process is simple, the flows are short, the total recovery rate of molybdenum is between 95 and 98.5 percent, and the total recovery rate of the WO3 is between 96 and 97.5 percent; and 2, the separation of tungsten and the molybdenum is realized, in the process flows, the solubility of the molybdenum and the tungsten in the acid is different, and thus, according to the principle, the tungsten content of the molybdenum trioxide is less than or equal to 0.4 percent, the molybdenum content of leaching residues (tungsten concentrates) is less than or equal to 0.3 percent, so that the separation of the tungsten and the molybdenum is realized. Tungsten-molybdenum concentrate resources are utilized fully, so the method has excellent social and economic benefits.

Owner:范颖

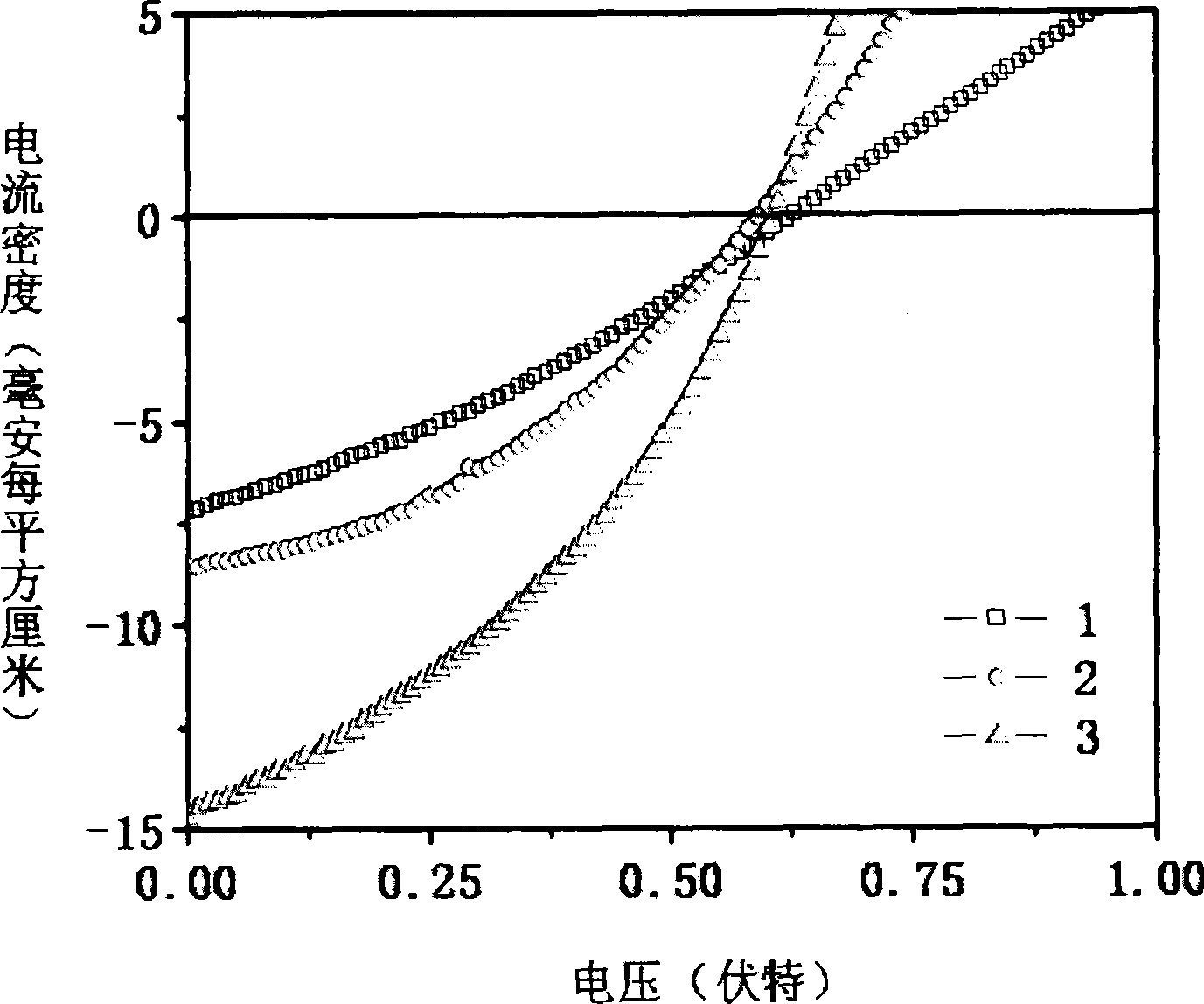

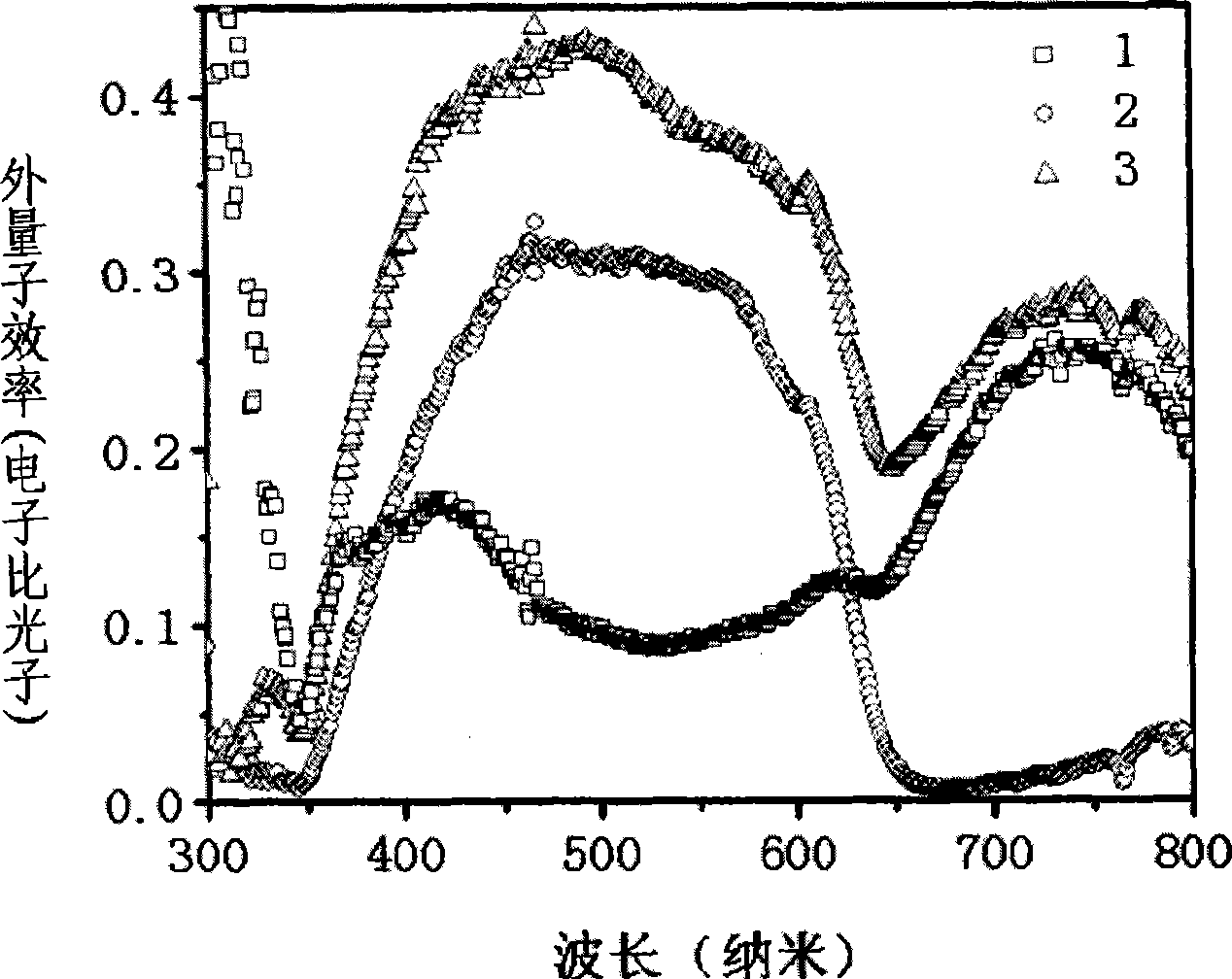

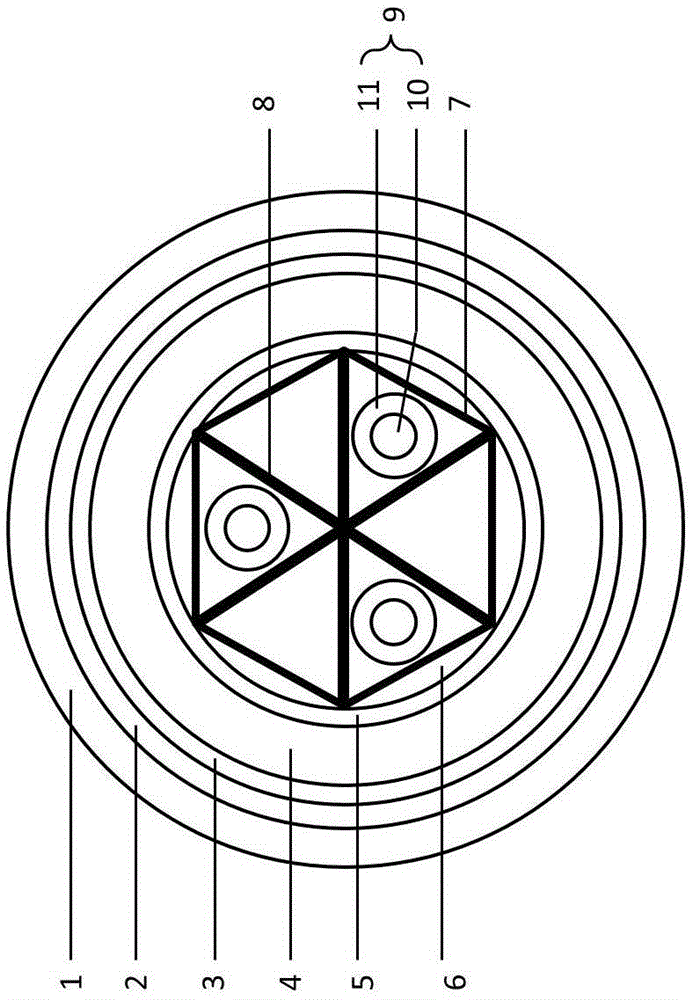

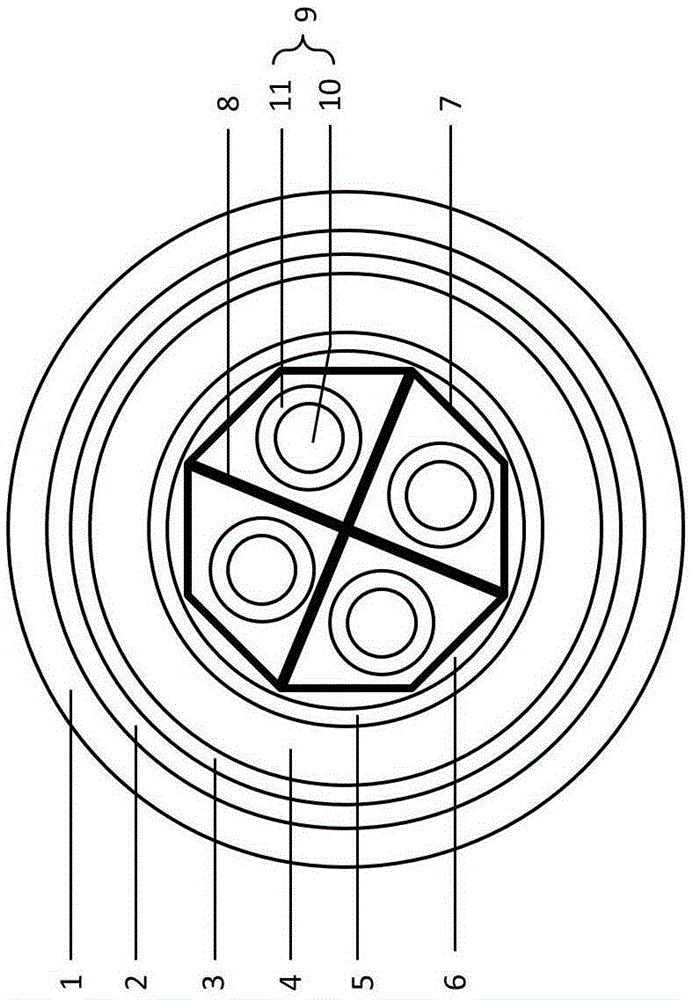

Stacking polymer thin-film solar cell with parallel connection structure

ActiveCN101414663ASolid-state devicesSemiconductor/solid-state device manufacturingTandem cellPolymer thin films

The invention provides a tandem polymer solar cell with a parallel structure. In the solar cell, metals with a high work function such as gold and sliver are taken as a semitransparent anode to extract holes. A p-type metal oxide molybdenum trioxide or tungsten oxide is taken as a hole transport layer at two sides of the anode for connecting an upper sub-cell photosensitive layer and a lower sub-cell photosensitive layer so as to construct a built-in electric field and improve the collection efficiency of a current carrier. The photosensitive layers of an upper sub-cell and a lower sub-cell in the tandem cell are respectively a mixture consisting of a conjugated polymer and a fullerene derivative with different absorption ranges. The two sub-cells are connected in parallel, and short circuit current density of the tandem solar cell is the sum of the short circuit current density of the upper sub-cell and the short circuit current density of the lower sub-cell. By conjugated polymers with the different absorption ranges, the tandem polymer thin film solar cell effectively improves the active sunlight absorption and realizes that the short circuit current is effectively increased to 15 milliampere / square centimeter, thus increasing the maximum energy conversion efficiency of the polymer thin film solar cell to 3.36%.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

A composite material used for a special cable, a preparing method thereof and the special cable

InactiveCN105400131AImprove performanceGuaranteed mechanical propertiesClimate change adaptationInsulated cablesPolymer sciencePoly ether ether ketone

A composite material used for a special cable, a preparing method thereof and the special cable are disclosed. According to the composite material, polyether ether ketone, polyethylene and polyimide are mixed according to a ratio and adopted as a substrate material, ethylene-vinyl acetate copolymer modified geopolymers, molybdenum trioxide and magnesium oxide are processed by a coupling agent and then adopted as a flame retardant additive, dicumyl peroxide is adopted as a crosslinking catalyst, silicon nitride whiskers are adopted as a fortifier, and the composite material is formed by melting and blending. The composite material has good high-temperature resistance and improved flame retardant effects, and can achieve no performance stability decrease under severe working conditions. In addition, the composite material is used for preparing an outer sheath of the special cable, and durability, fire resistance and stability of the special cable are improved.

Owner:YANCHENG KEHENGDA MATERIALS CO LTD

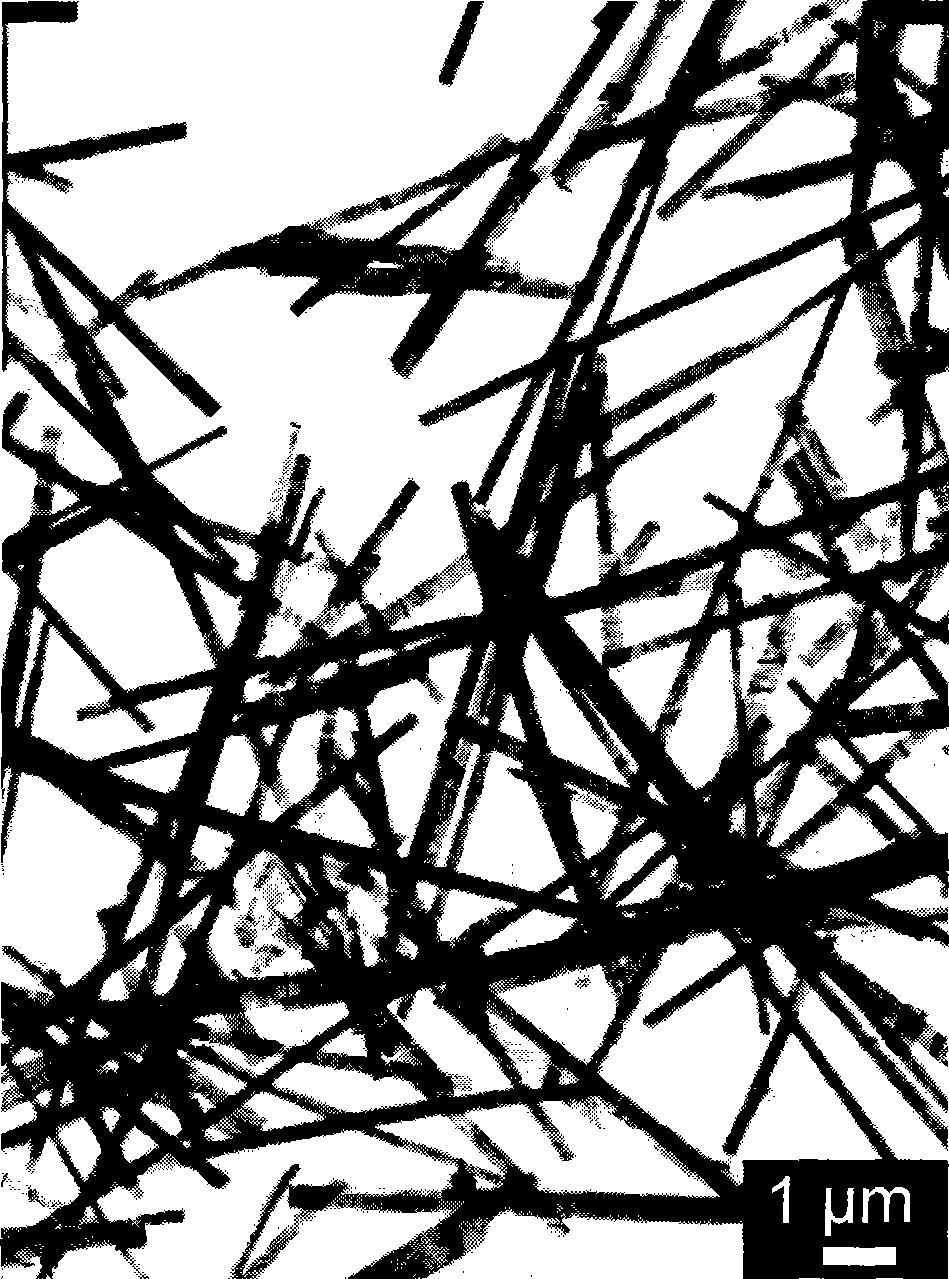

Lithiation molybdenum trioxide nano band electrode material and its lithiation modifying method

ActiveCN101071849AEasy to prepareGood reproducibilityElectrode manufacturing processesActive material electrodesLithiumStructural stability

A lithiated molybdenum trioxide nanometer belt electrode material and its the lithiation modification method, its characteristic is that: put molybdenum trioxide nanometer belt in deionized water to conduct supersonic dispersing, then add lithium salt powder to make the mole ratio of molybdenum element and lithium element be 1: 3 to 1: 10; stir; move the obtained suspension liquid into the stainless reaction pot with poly-tetre-fluro-ethylene substrate to conduct hydrothermo reaction; cool and filter the hydrothermo product and wash the product by deionized water to obtain the molybdenum trioxide nanometer belt.

Owner:武汉经开科创运营有限公司

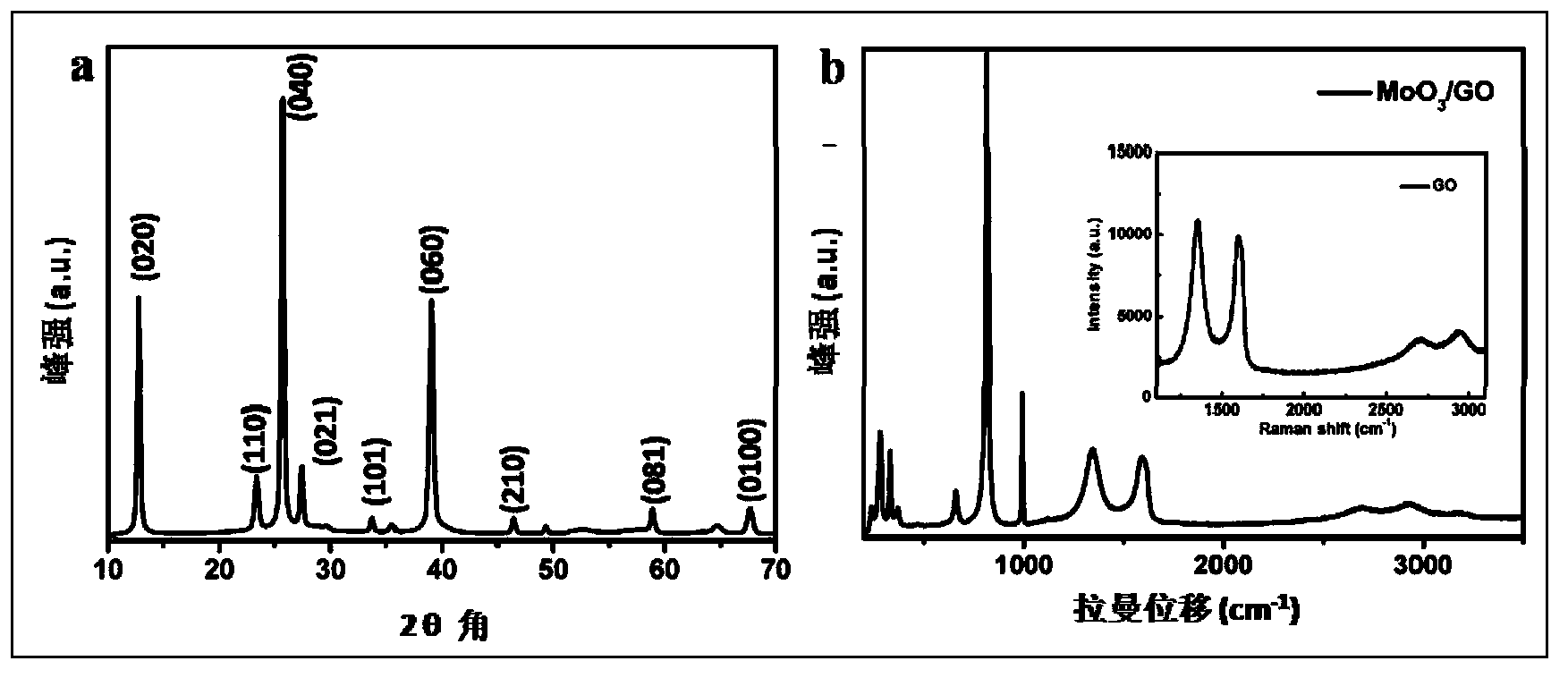

Graphene curled molybdenum trioxide nano-ribbons, and preparation method and application thereof

ActiveCN103413925AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesElectrical batteryLithium-ion battery

The invention relates to graphene curled molybdenum trioxide nano-ribbons, and a preparation method and an application thereof. The nano-ribbons can be used as a lithium ion battery positive electrode material. The method comprises the steps that: (1) a molybdenum sol is prepared, wherein excessive hydrogen peroxide solution is weighed and placed into a beaker; molybdenum powder is slowly added into the hydrogen peroxide, wherein the entire process is carried out under a cold water bath; when the molybdenum powder is completely added, the materials are stirred, such that molybdenum sol is obtained; (2) a graphene dispersion prepared with a Hummer method and the molybdenum sol prepared in the step (1) are weighed and are stirred under water bath; the mixture is transferred to a reaction kettle, and is subjected to a hydrothermal reaction in a thermostat; the material is naturally cooled to room temperature; (3) the product obtained in the step (2) is washed by using anhydrous ethanol, and is dried in a drying oven. The nano-ribbons and the method have the advantages that: when the material is adopted as a lithium ion battery positive electrode material, excellent rate performance, high specific capacity, and good circulation stability are shown. The process is simple and economical.

Owner:WUHAN UNIV OF TECH

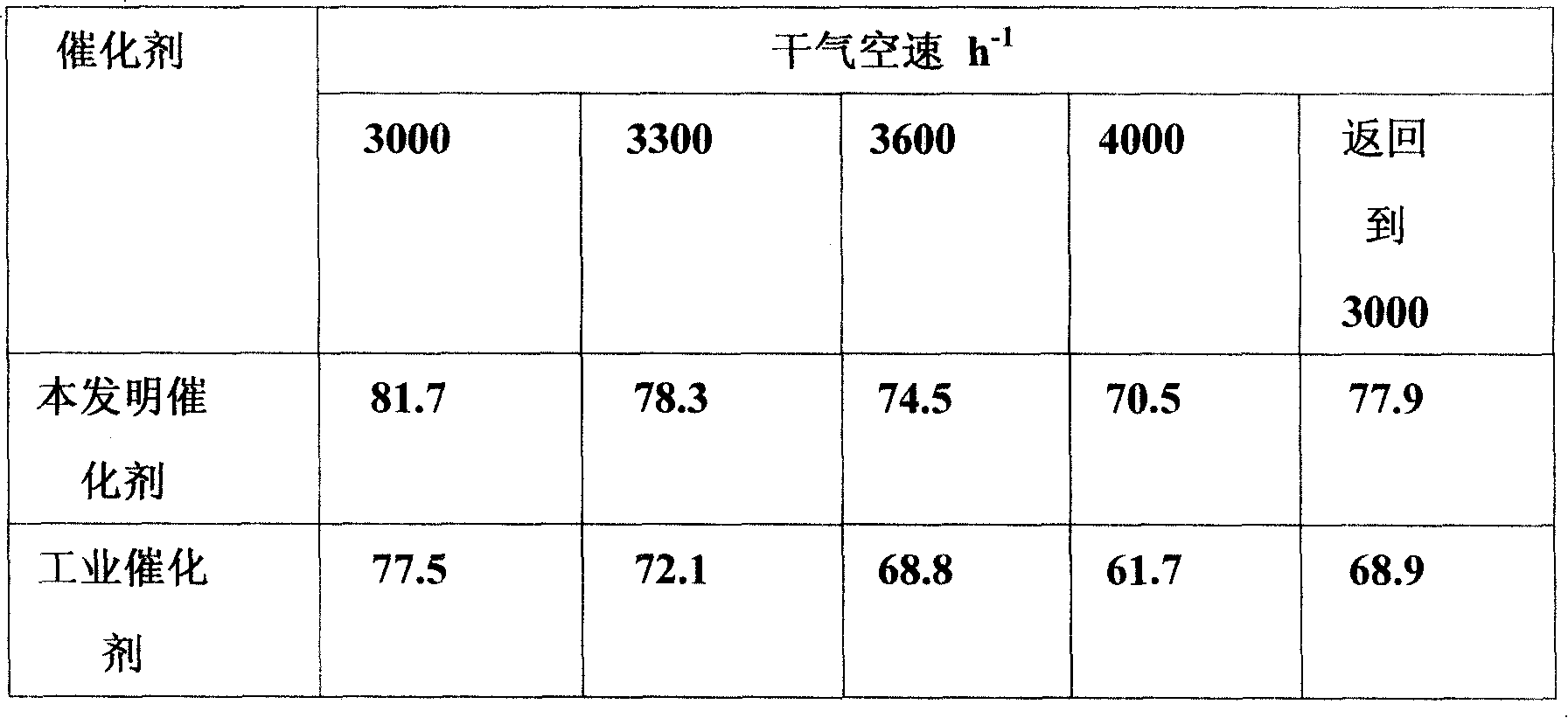

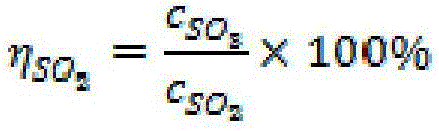

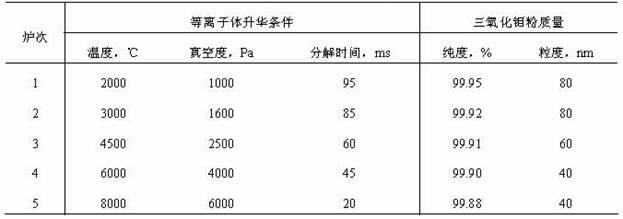

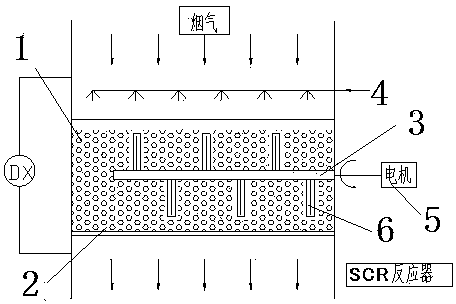

Medium and low temperature denitration catalyst and preparation method thereof

ActiveCN106492791AReduce oxidation activityHigh activityHeterogenous catalyst chemical elementsDispersed particle separationCeriumStearic acid

The invention provides a medium and low temperature denitration catalyst, and belongs to the technical field of denitration catalysts. The catalyst is prepared from ultrafine titanium dioxide, strontium-doped cerium manganese calcium titanium ore type composite oxides, vanadium pentoxide, tungsten trioxide, molybdenum trioxide and stannic oxide; glass fiber is used as an enhancing agent; carboxymethylcellulose and polyoxyethylene are used as bonding agents; stearic acid is used as a lubricating agent. The invention also relates to a preparation method of the medium and low temperature denitration catalyst. The concrete preparation method comprises the steps of preparation of the strontium-doped cerium manganese calcium titanium ore type composite oxides, preparation of carrier materials, preparation of powder catalysts, extrusion forming of honeycomb-shaped catalysts and post treatment of honeycomb-shaped denitration catalysts. The denitration catalyst prepared by the method has the advantages of high denitration efficiency, good sulfur-resistant and waterproof performance, reliable production process and the like in the wide temperature range from 180 DEG C to 350 DEG C; the requirements of oxynitride removal from industrial smoke gas in industries of coking, petrifaction, furnaces and the like can be met; wide application prospects are realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Process for manufacturing molybdenum disulfide thin film through two-step method

ActiveCN105063573AAvoid premature vulcanizationReaction is easy to controlPolycrystalline material growthFrom chemically reactive gasesSulfurGas phase

The invention discloses a process for manufacturing a molybdenum disulfide thin film through a two-step method. The process includes the steps that A, the surface of a substrate is cleaned; B, powdered molybdenum trioxide is weighed and placed in a quartz boat, the quartz boat is placed in a tube furnace, and the substrate is placed at the downstream position of the quartz boat containing the molybdenum trioxide; C, powdered sulfur is weighed, a heat tracing cable is wound around a material bottle and placed outside the tube furnace, and a gas inlet pipe and a gas outlet pipe in the material bottle are connected with a gas inlet pipeline of the tube furnace; D, vacuumizing is conducted, Ar is fed in for heating the tube furnace, and primary deposition is conducted; E, after primary deposition is finished, secondary deposition is conducted; F, the material bottle is heated, and Ar is fed in for conducting sulfuration on the molybdenum trioxide; and G, the material bottle and the tube furnace are naturally cooled to the room temperature, and a sample is taken out to be tested. By the adoption of the process, the situation that molybdenum trioxide is sulfurated in advance due to uncontrollable evaporation time of sulfur in a traditional chemical vapor deposition process is avoided, and the whole reaction process can be more controllable by manufacturing the molybdenum disulfide thin film through the two-step method.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

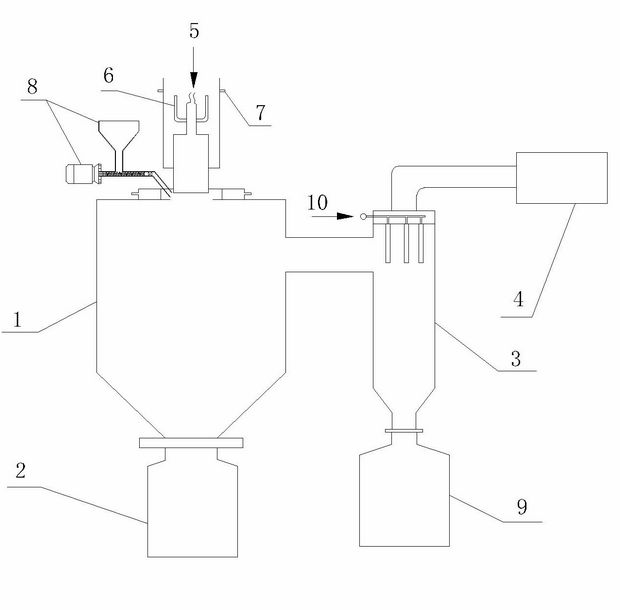

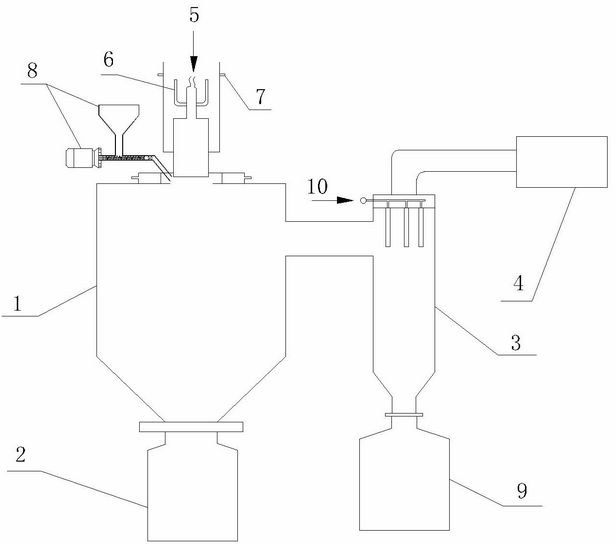

Method for preparing nanometer molybdenum trioxide

InactiveCN102603005AProductive timeFully automatedNanotechnologyMolybdenum oxides/hydroxidesNonferrous metalPhysical chemistry

The invention relates to the technical field of nonferrous metallurgy, in particular to a method for preparing nanometer molybdenum trioxide and using pure molybdenum trioxide as a raw material. The pure molybdenum trioxide is used as the raw material, the nanometer molybdenum trioxide is prepared by means of plasma sublimation, pure molybdenum trioxide powder is fed into a plasma subliming furnace via a feeding device and is sublimed in plasma flow, operation time ranges from 10ms to 100ms, obtained gaseous molybdenum trioxide is in shock cooling by the aid of shock cooling media and collected by a receiving device, the nanometer molybdenum trioxide is obtained, and content of MoO3 is higher than 99.80%. The molybdenum trioxide is prepared by the aid of a plasma sublimation method, the high-purity nanometer molybdenum trioxide with the granularity within 80nm can be obtained in a super-short time period, and automatic and continuous production is truly realized.

Owner:洛阳开拓者投资管理有限公司

Powder metallurgic material for brake pad of high-speed electric multiple unit

InactiveCN101623759AMeet the needs of brakingImprove thermal conductivityFriction liningSilicon dioxideMolybdenum trioxide

The invention relates to a powder metallurgic material for a brake pad of high-speed electric multiple units, which comprises the following components in percentage by weight: 55-70 percent of copper, 2-7 percent of tin, 2-6 percent of zinc, 1-7 percent of iron, 1-5 percent of silicon dioxide, 4-8 percent of molybdenum trioxide, 3-7 percent of aluminium oxide, 6-13 percent of carbon, one or more of 5-9 percent of nickel, 4-7 percent of tungsten and 1-6 percent of lead. The powder metallurgic material for the brake pad of the high-speed electric multiple units has higher friction heat resistance, stable friction coefficients, stronger wearing resistance and better thermophysical stability; meanwhile, the mechanical strength is also markedly improved, and the powder metallurgic material can satisfy a braking requirement when the high-speed electric multiple units run at high speed.

Owner:丁艳

Method for preparing nanometer metallic sulfide

InactiveCN1803632AEasy to prepareWide range of raw materials and cheapMolybdenum sulfidesTungsten compoundsTungstateMetallic sulfide

The invention discloses a preparation method for nano molybdenum disulfide and tungsten sulfide. Wherein, with ammonium molybdate / tungstate hydrate as molybdenum / tungsten source and porous molybdenum trioxide / tungsten oxide as carrier, thermal cracking to original converse into molybdenum trioxide / tungsten oxide crystal in carrier pore channel; in high-temperature cracking furnace of 800-1100Deg, leading H2S gas and H2 gas with 8-20% partial pressure / H2S gas to generate the final product on limit of pore carrier channel.

Owner:唐百仲

Flue gas denitration catalyst

InactiveCN103962124AImprove performanceImprove catalytic performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasHoneycomb

The invention relates to a flue gas denitration catalyst. The catalyst is characterized in that the catalyst comprises 60-90wt% of TiO2 (titanium dioxide), 10-30wt% of an activator and 1-10wt% of an auxiliary agent, the sum of the weight percentages of the above components is 100%, and the activator is one of V2O5 (vanadium pentoxide), V2O5-WO3 (vanadium pentoxide-tungsten trioxide) and or V2O5-MoO3 (vanadium pentoxide-molybdenum trioxide). The material composition and the processing process of the flue gas denitration catalyst like the material composition and the processing process of a honeycomb catalyst, so the flue gas denitration catalyst has excellent performances of the honeycomb catalyst, such as good catalysis effect, larger specific surface area, wear resistance, long service life and good regeneration effect. The flue gas denitration catalyst is much smaller than the honeycomb catalyst monomer, so the flue gas denitration catalyst has the advantages in transportation, installation, maintenance and regeneration. The flue gas denitration catalyst can cooperate with a specific groove to in order to make the running safety of a set using the flue gas denitration catalyst higher than the running safety of a set using the honeycomb catalyst.

Owner:上海达源环境科技工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com