Flue gas denitration catalyst

A denitrification catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of large smoke resistance, wear resistance, and poor reproducibility , poor operating performance of the unit, etc., to achieve good regeneration effect, long service life and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

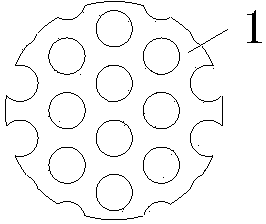

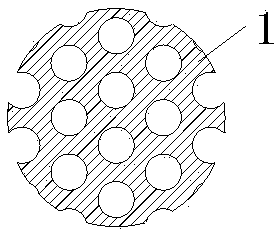

[0023] The flue gas denitrification catalyst uses 80% titanium dioxide as the carrier, 10% vanadium pentoxide as the main active ingredient, and additionally adds 10% WO (tungsten oxide) or 10% MoO 3 (Molybdenum trioxide) etc. are extruded into balls as catalyst auxiliary components, dried and sintered. Such as figure 2 As shown, the appearance of the catalytic material is as figure 2 As shown, the whole is spherical. The holes are evenly arranged inside the ball, the holes are cylindrical, the diameter is 15-60mm, the hole diameter is 5-12mm, the spacing can be adjusted according to the working conditions, and the specific surface area is about 300-600 m 2 / m 3 .

Embodiment 2

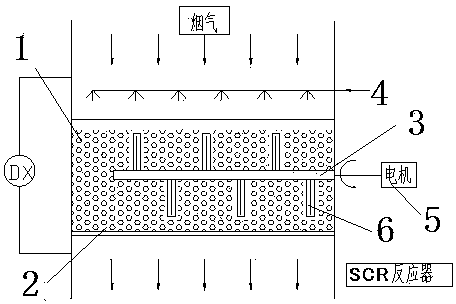

[0025] The flue gas denitrification catalyst uses 60% titanium dioxide as the carrier, 30% vanadium pentoxide as the main active ingredient, and additionally adds 10% WO (tungsten oxide) or 10% MoO 3 (Molybdenum trioxide) is extruded into a spherical shape as a catalyst auxiliary component, dried and sintered. The flue gas denitrification catalyst of the present invention is arranged in the tank that stirrer is arranged, as figure 1 shown. The flue gas passes through the tank from top to bottom, and the flue gas fully contacts and reacts with the catalyst material in the tank. When the pressure difference in and out of the notch reaches a certain value, the motor will start the stirring device to drive the catalytic material to stir, and at the same time perform steam purge to remove the ash attached to the surface of the catalyst pellets. The number of layers and height of the catalyst can be flexibly selected according to the specific denitration process.

[0026] When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com