Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2752 results about "Pentoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentoxide may refer to: Antimony pentoxide, Sb₂O₅ Arsenic pentoxide, As₂O₅ Carbon pentoxide, CO₅ Dinitrogen pentoxide, N₂O₅ Iodine pentoxide, I₂O₅ Niobium pentoxide, Nb₂O₅ Phosphorus pentoxide, P₄O₁₀ Tantalum pentoxide, Ta₂O₅ Tungsten pentoxide, W₁₈O₄₉

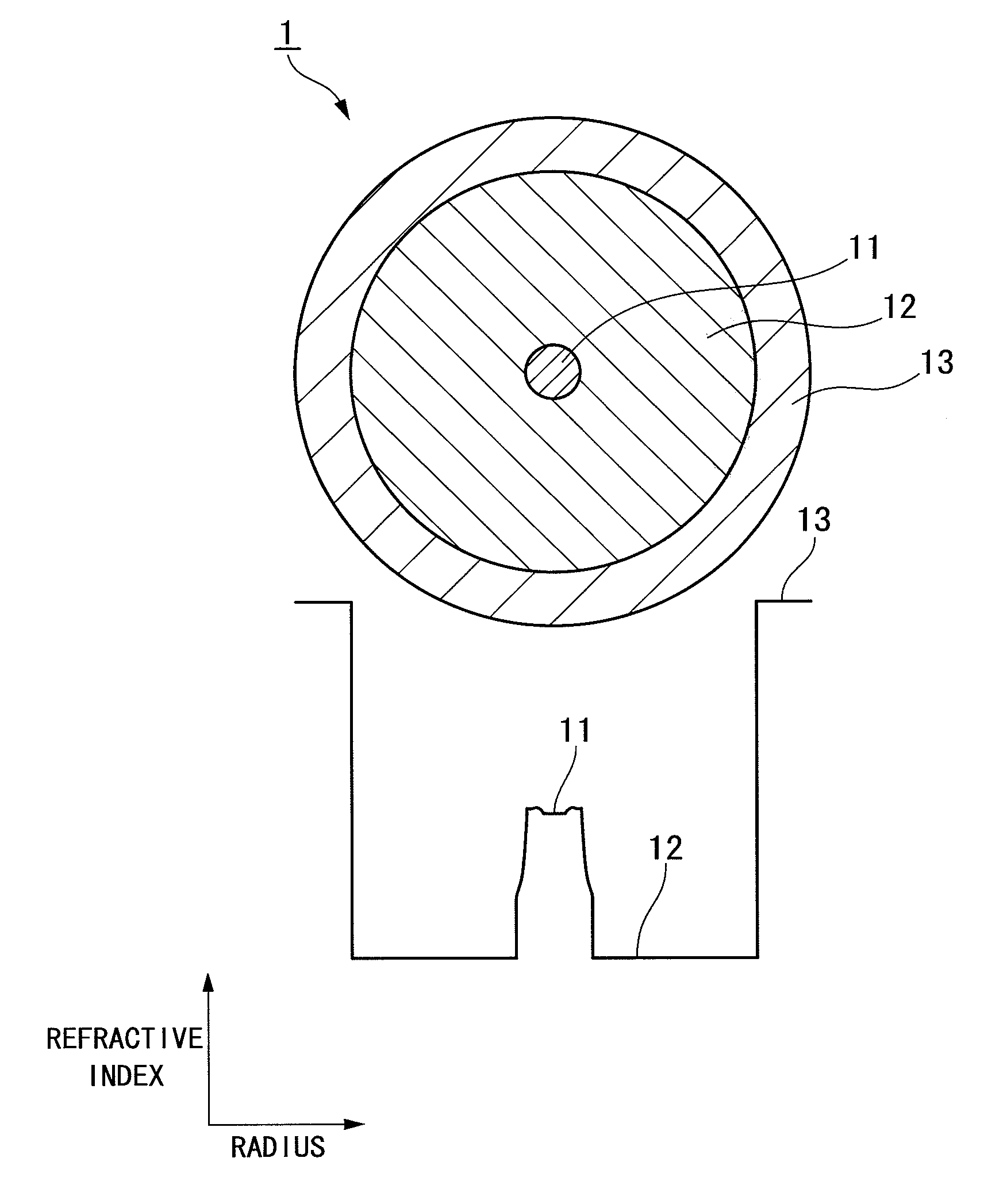

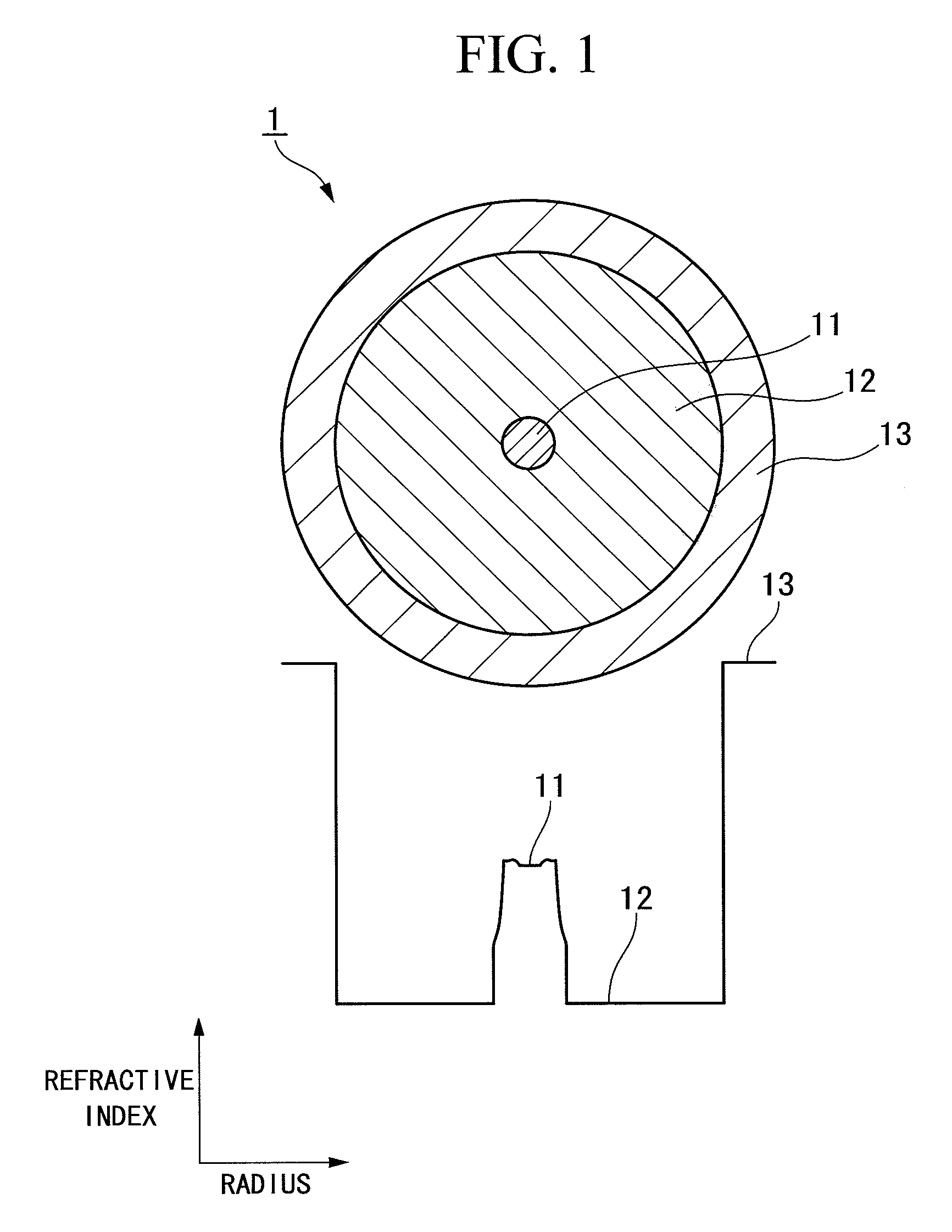

Ytterbium-doped optical fiber, fiber laser, and fiber amplifier

ActiveUS8363313B2Avoid small quantitiesSuperior optical amplificationLaser using scattering effectsOptical fibre with polarisationYTTERBIUM OXIDEDiphosphorus

An ytterbium-doped optical fiber of the present invention includes: a core which contains ytterbium, aluminum, and phosphorus and does not contain germanium; and a cladding which surrounds this core. The ytterbium concentration in the core in terms of ytterbium oxide is 0.09 to 0.68 mole percent. The molar ratio between the phosphorus concentration in the core in terms of diphosphorus pentoxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 30. The molar ratio between the aluminum concentration in the core in terms of aluminum oxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 32. The molar ratio between the above aluminum concentration in terms of aluminum oxide and the above phosphorus concentration in terms of diphosphorus pentoxide is 1 to 2.5.

Owner:FUJIKURA LTD

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

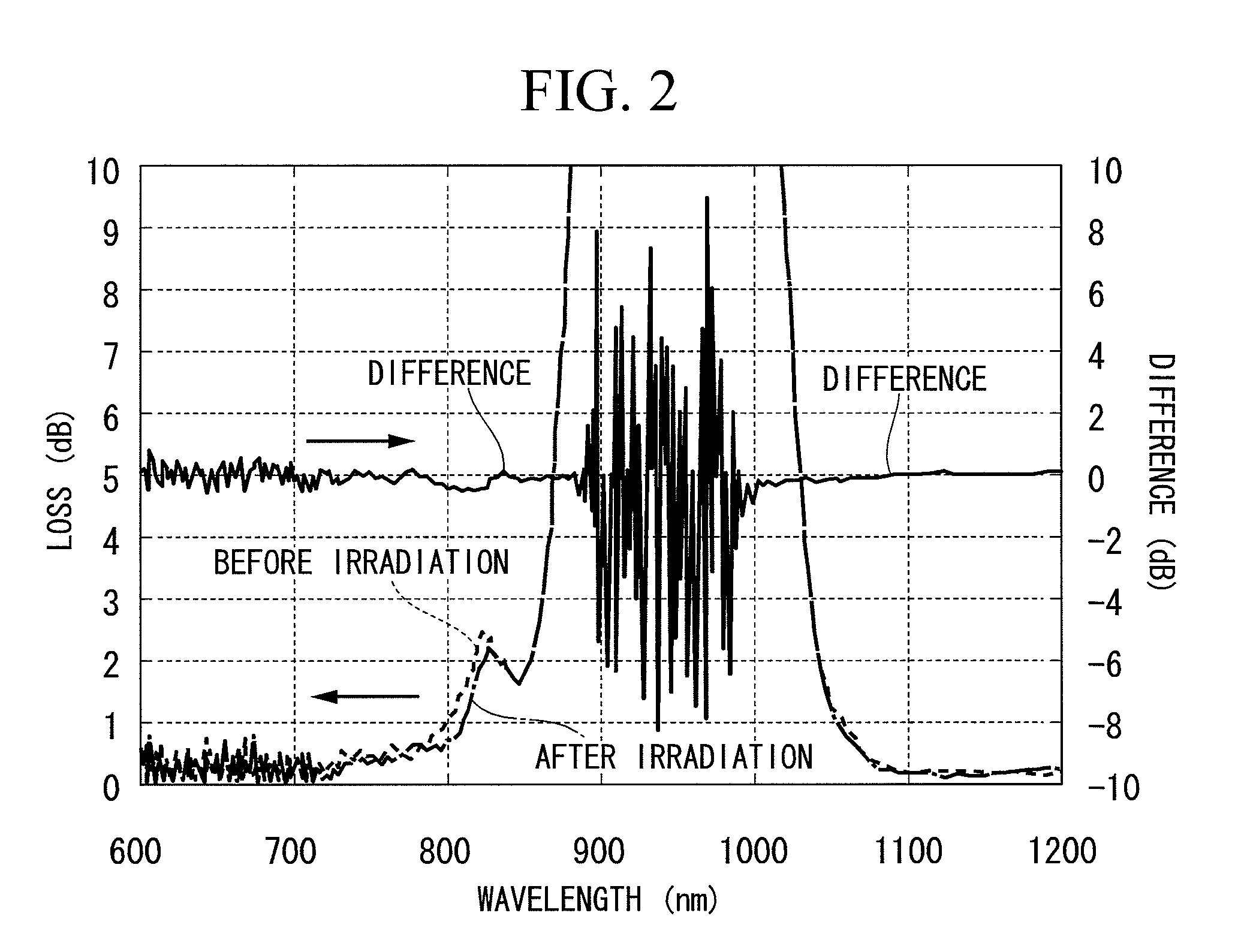

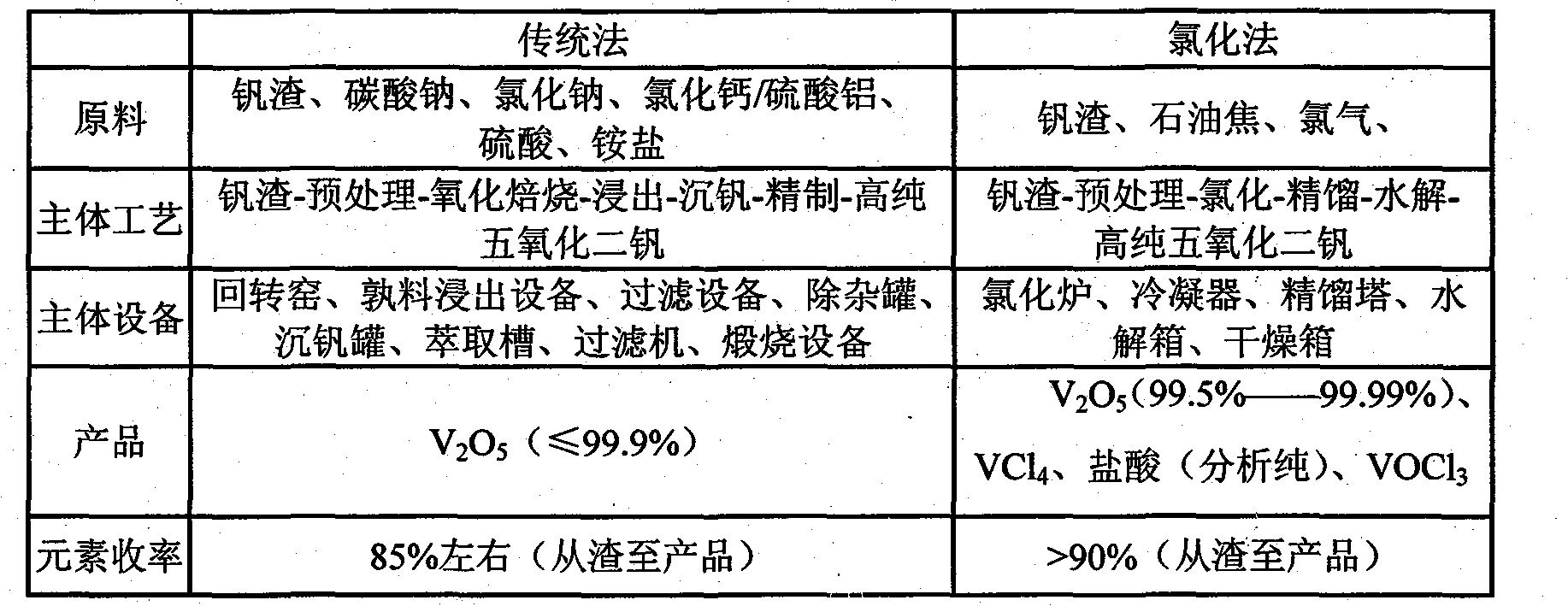

Method for producing high-purity vanadium pentoxide by chlorination

The invention discloses a novel method for extracting and converting a substance containing vanadium into high-purity vanadium pentoxide by chlorination. The high-purity vanadium pentoxide process comprises batching, chlorination, dedusting, condensation, rectification, hydrolysis, filtering, drying and postprocessing. Raw materials comprise the substance containing vanadium and a carbon elementary substance and the weight ratio of the substance containing vanadium to the carbon elementary substance is 1: (0.05-0.25). The raw materials are evenly mixed, dried and put in a reactor and the high-purity vanadium pentoxide is obtained through successive chlorination, hydrolysis, postprocessing and the like. The novel method for producing high-purity vanadium pentoxide instead of a traditional method reduces industrial harmful waste water produced during a traditional hydrometallurgy process, and cyclic utilization of chlorine is achieved after the chlorine is processed. The whole production process is easy in process and basically free of produced wastes, and has certain economic benefit and social benefit. The purity of the vanadium pentoxide powder obtained by the method is 99.5%-99.99%.

Owner:刘艳梅

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

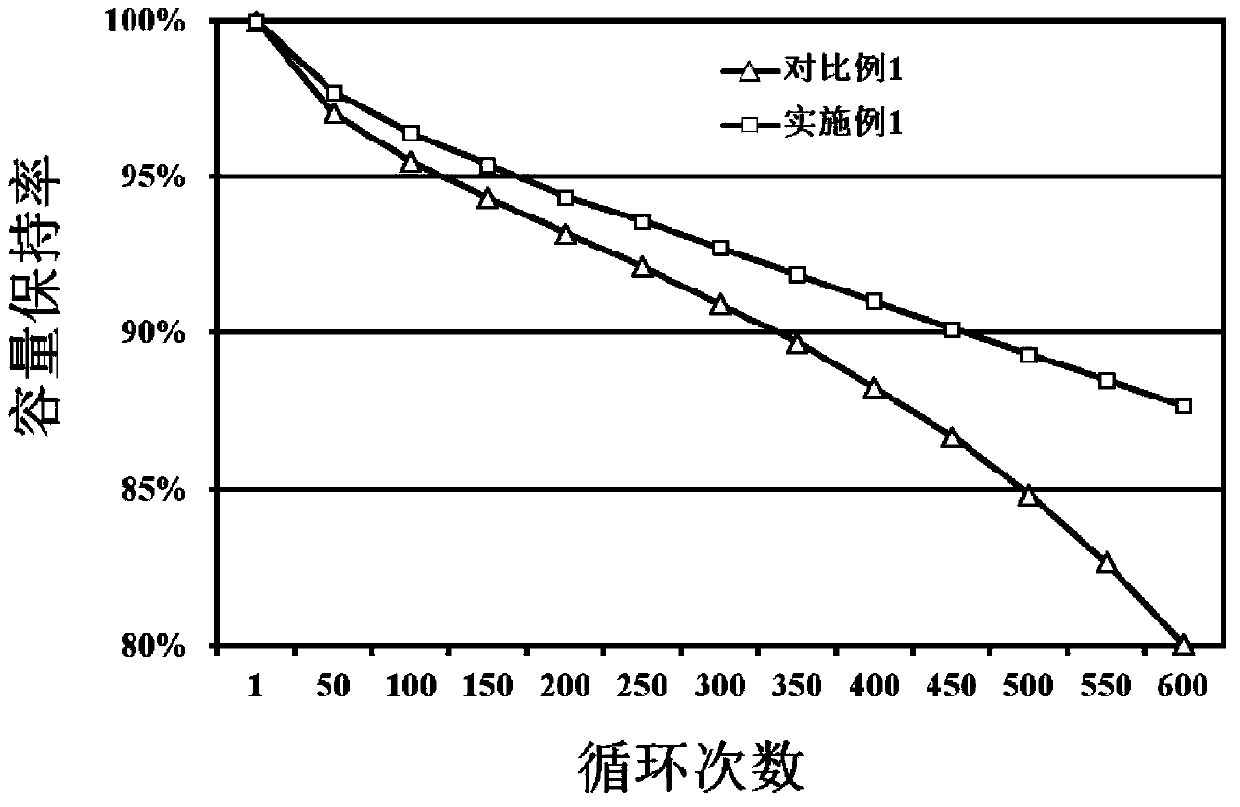

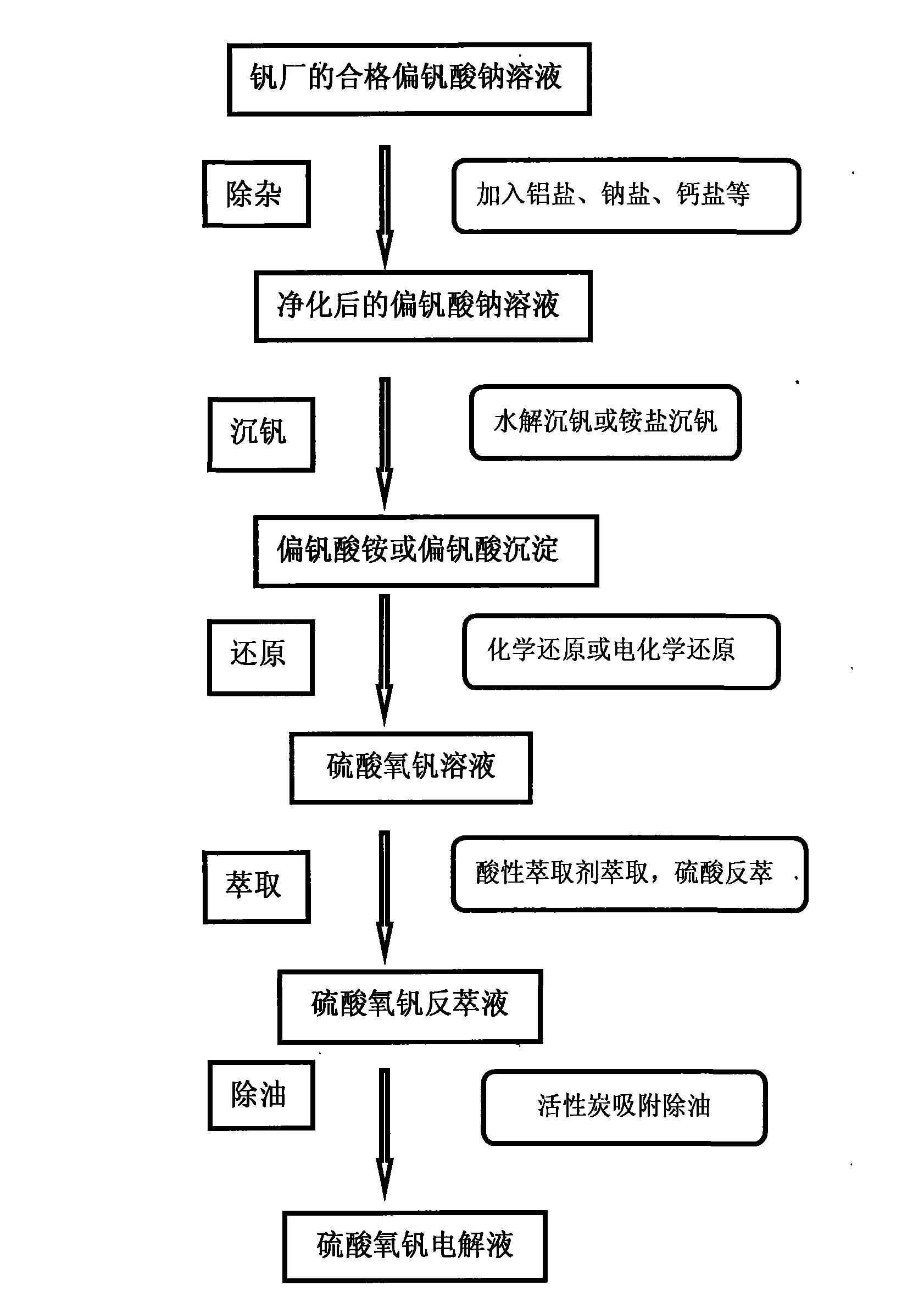

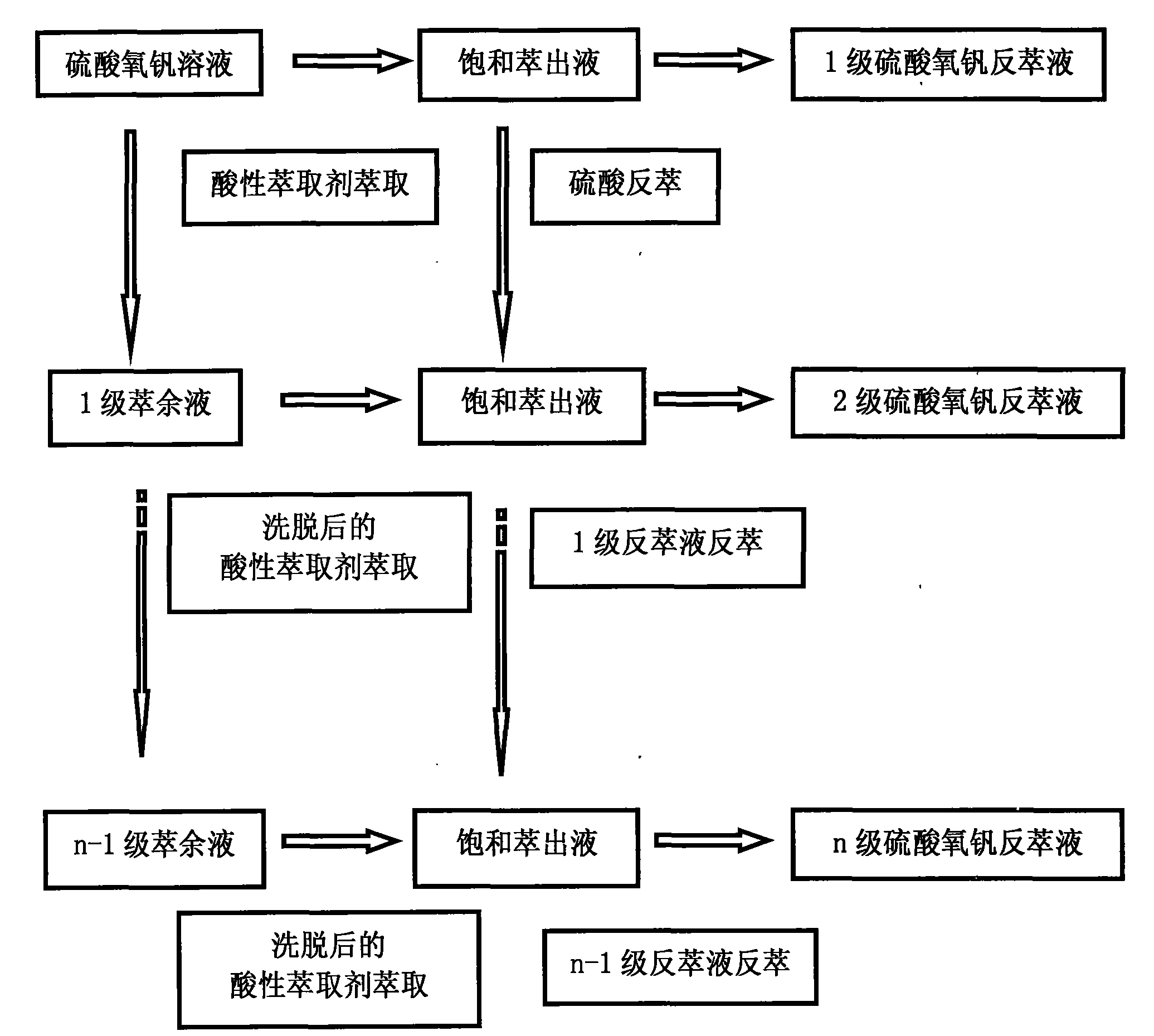

Preparation method of vanadium battery electrolyte solution with high purity and high concentration

InactiveCN103515642AHigh purityIncrease concentrationRegenerative fuel cellsHigh concentrationVanadyl sulfate

The invention relates to a preparation method of a vanadium battery electrolyte solution with high purity and high concentration. The vanadium battery electrolyte solution is different from a traditional vanadium electrolyte solution with vanadium pentoxide as raw material; through the method, a qualified vanadium solution produced by a vanadium factory is adopted as raw material, steps of removing impurities, precipitating vanadium, reducing, extracting and removing oil are carried out, after carrying out processes of four-step impurity removal and one-step reduction, the impurities in the electrolyte solution are effectively removed, and the all-vanadium solution flow battery vanadyl sulfate electrolyte solution with high purity and high concentration and with the concentration of 1-4 M is obtained. The method adopts the initial vanadium solution as the raw material, has the advantages of low cost, simple preparing procedures, and mild reaction conditions, allows the obtained electrolyte solution product to have high purity, and is suitable for application in an all-vanadium solution flow battery.

Owner:NO 63971 TROOPS PLA

Method for preparing high purity vanadium pentoxide through using ammonium metavanadate

The invention which relates to a method for preparing high purity vanadium pentoxide through using ammonium metavanadate belongs to the wet metallurgy field. The method comprises the following steps: heating and dissolving crude ammonium metavanadate in water, adjusting the pH value to 8-10 with an alkali after dissolving, adding an impurity removing agent to remove impurities, filtering to obtain a sodium metavanadate solution, adding ammonia water or an ammonium salt to the sodium metavanadate solution to precipitate to obtain an ammonium metavanadate precipitate, dehydrating the ammonium metavanadate precipitate, carrying out water washing on the precipitate through using a dilute ammonium salt solution, dehydrating after the wash washing, and roasting to obtain the high purity vanadium pentoxide. Vanadium pentoxide produced through adopting the method of the invention has the advantages of high purity and less impurities, and completely satisfies production requirements of high-end products; and the method of the invention has the advantages of short process flow, simple equipment, low cost and high benefit, and is suitable for the large-scale industrial production.

Owner:崇阳县恒通工贸有限公司

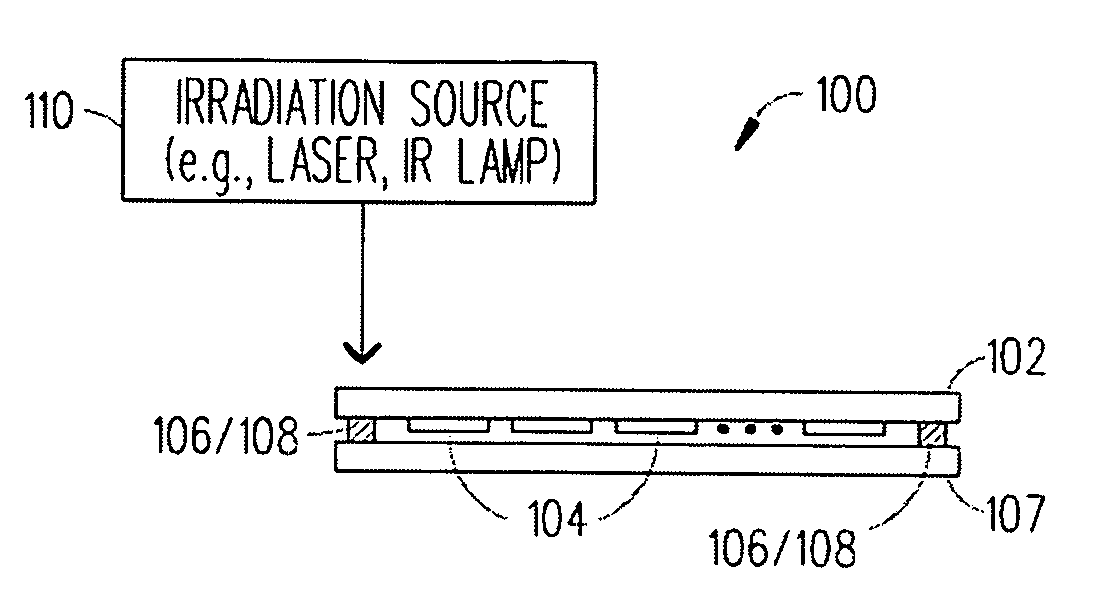

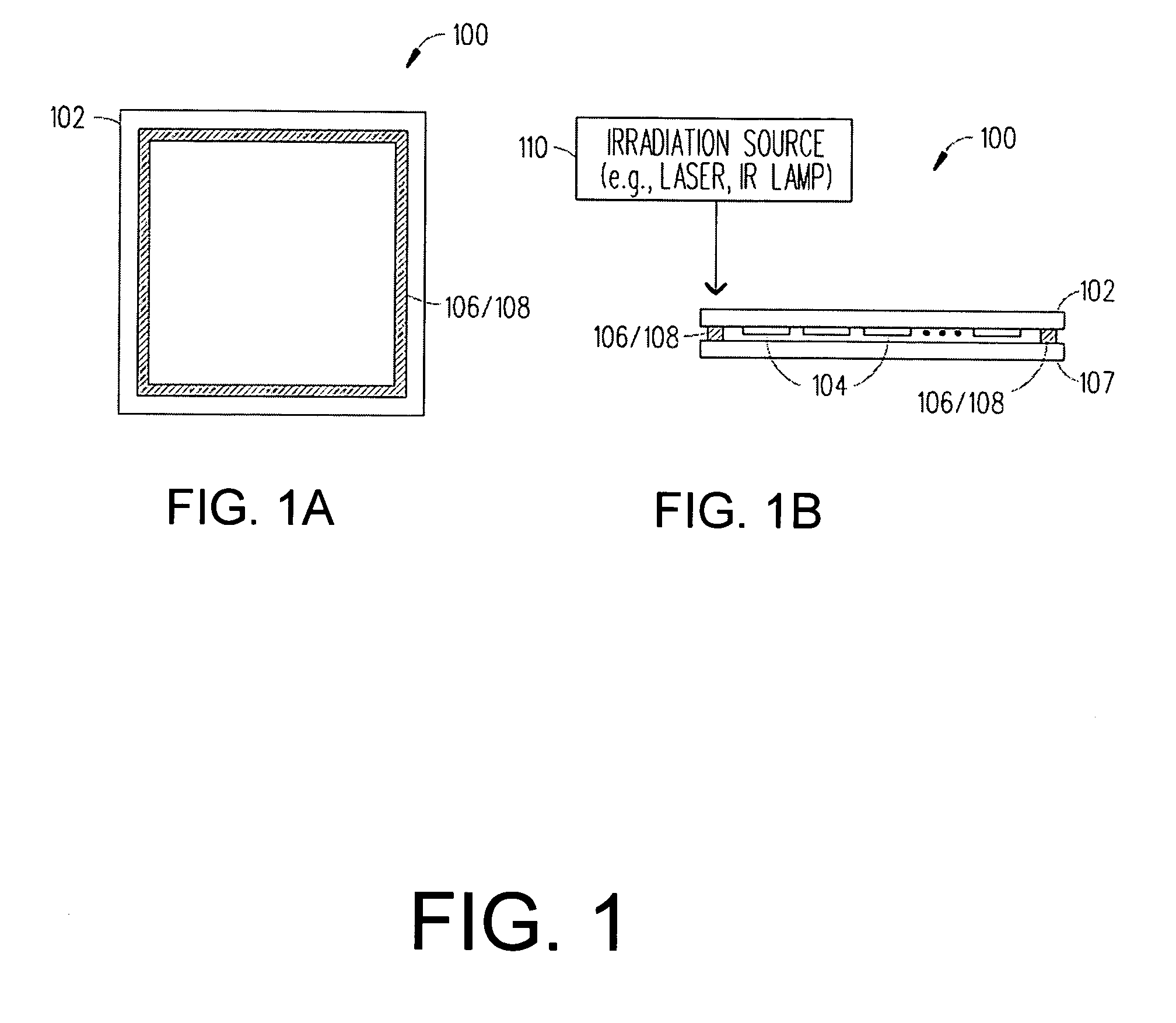

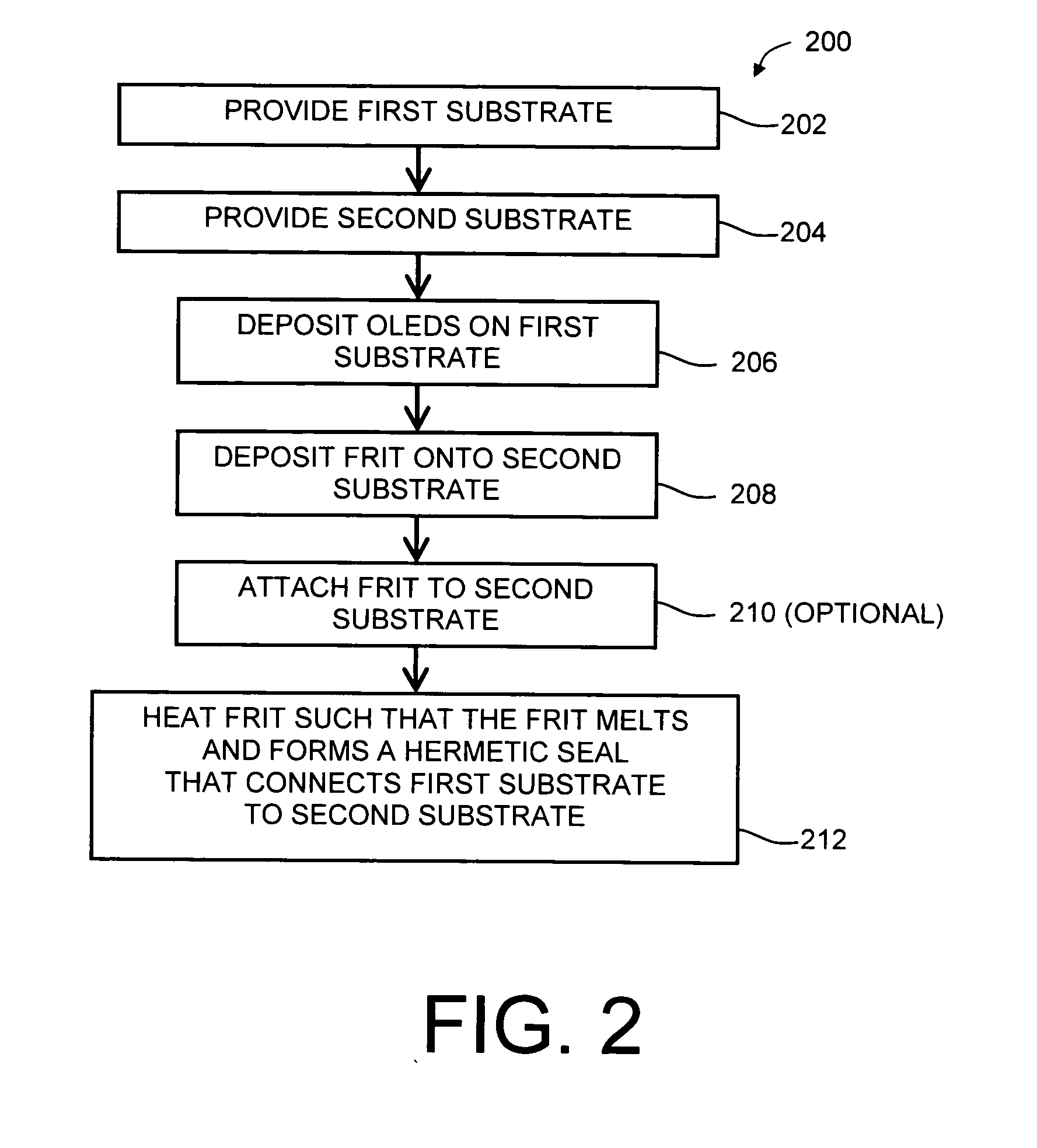

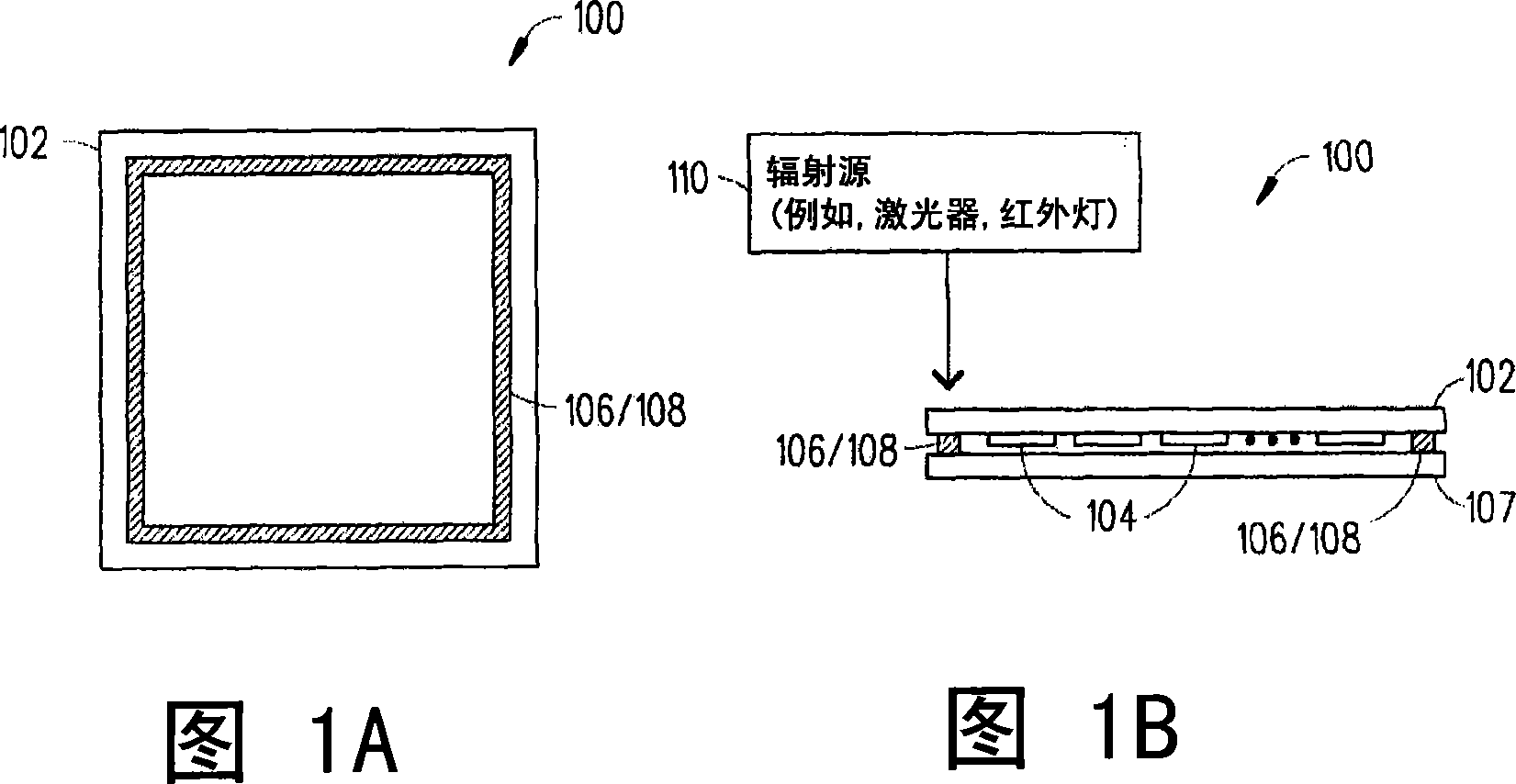

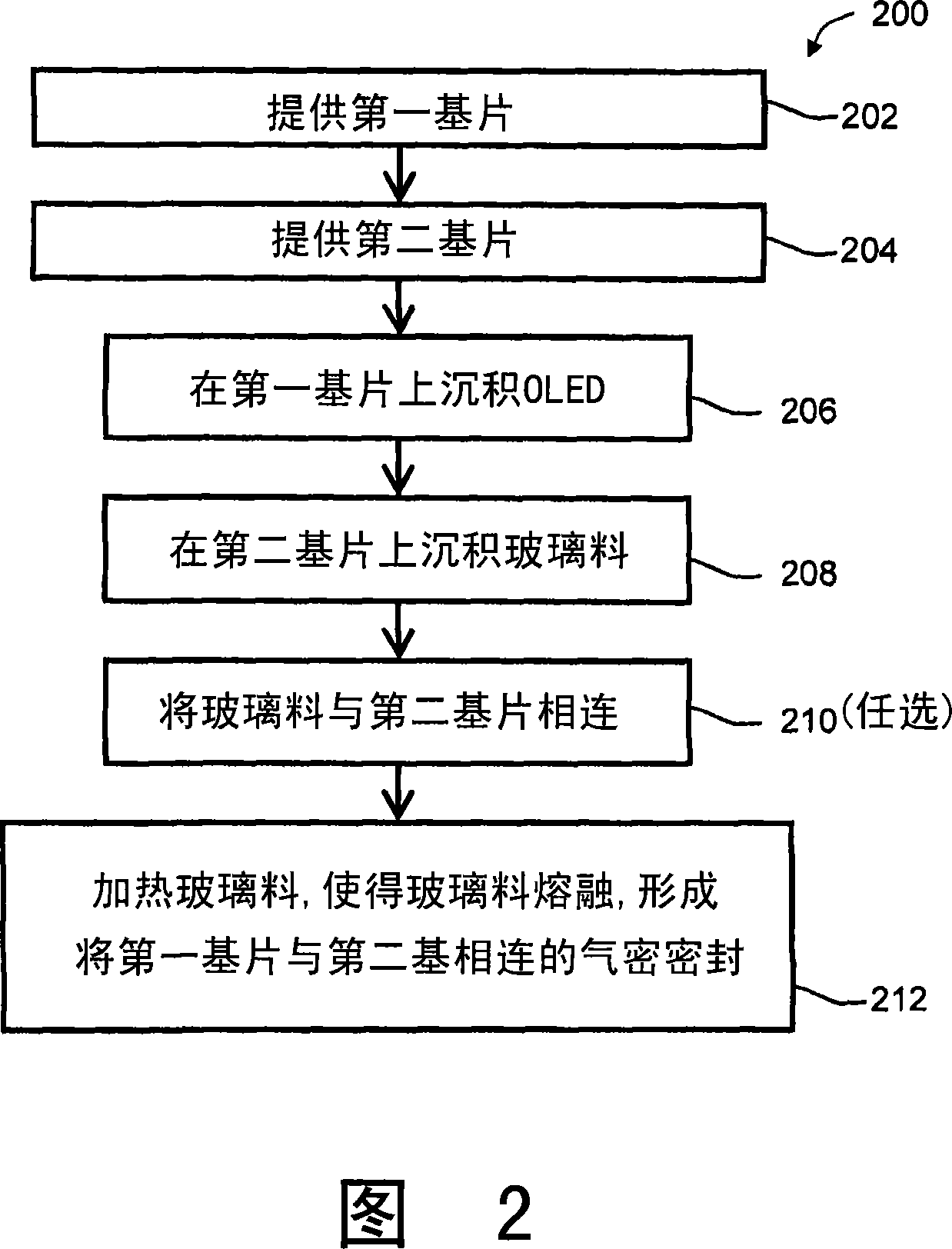

Boro-silicate glass frits for hermetic sealing of light emitting device displays

InactiveUS20080124558A1Problem be addressLamination ancillary operationsSolid-state devicesFritSilicate glass

A frit composition useful for sealing a light emitting device is disclosed. The frit composition comprises a glass portion comprising a base component and at least one absorbing component. The glass portion of the frit comprises silica, boron oxide, optionally alumina, and (a) cupric oxide and / or a (b) combination of ferric oxide, vanadium pentoxide, and optionally titanium dioxide. Also disclosed is an article comprising a substrate and a frit, and a glass package comprising two substrates and a frit positioned between the substrates. A method for manufacturing a hermetically sealed glass package comprising the deposition of a glass frit and heating of the glass frit to form a hermetic seal is also disclosed.

Owner:CORNING INC

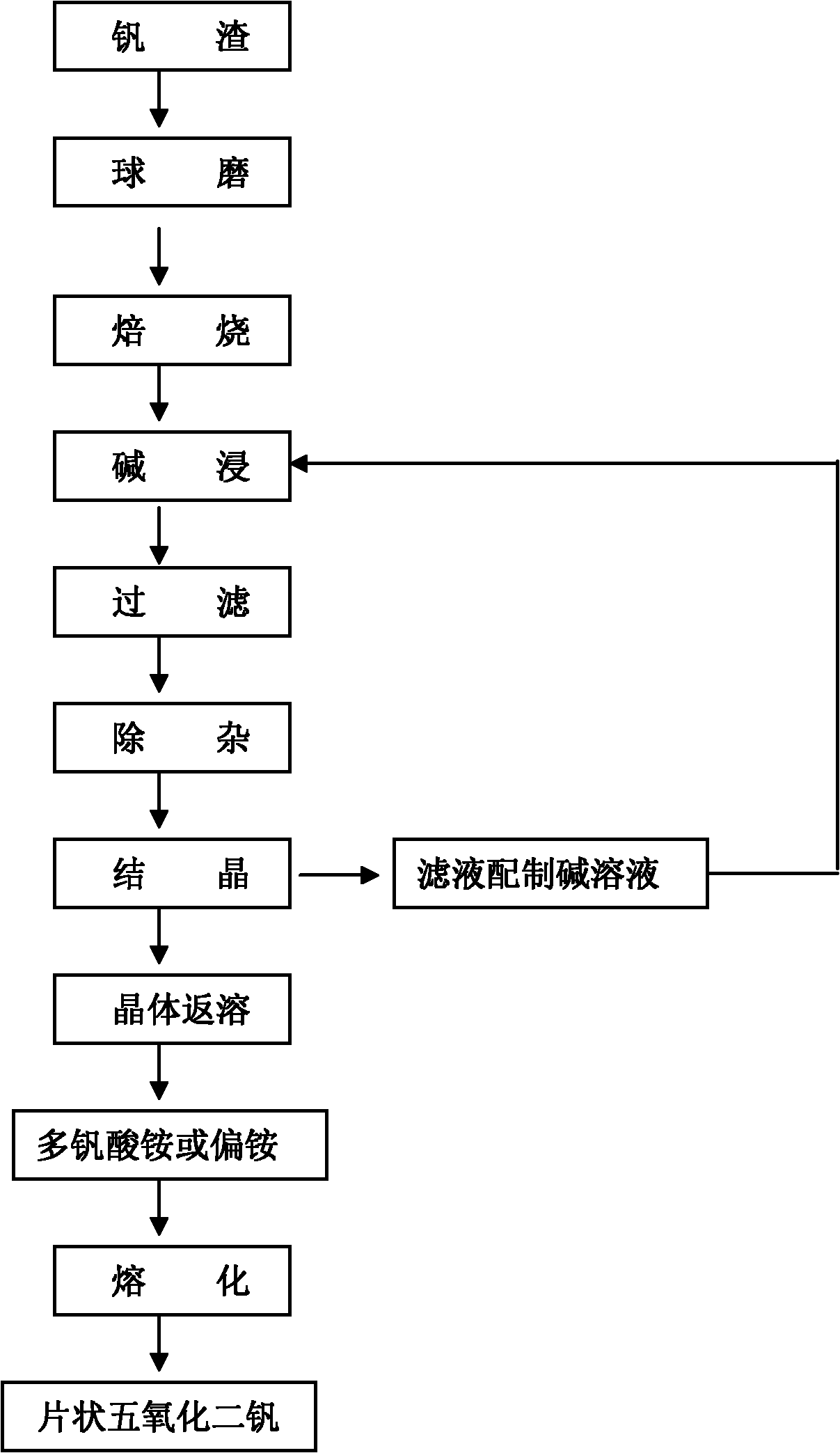

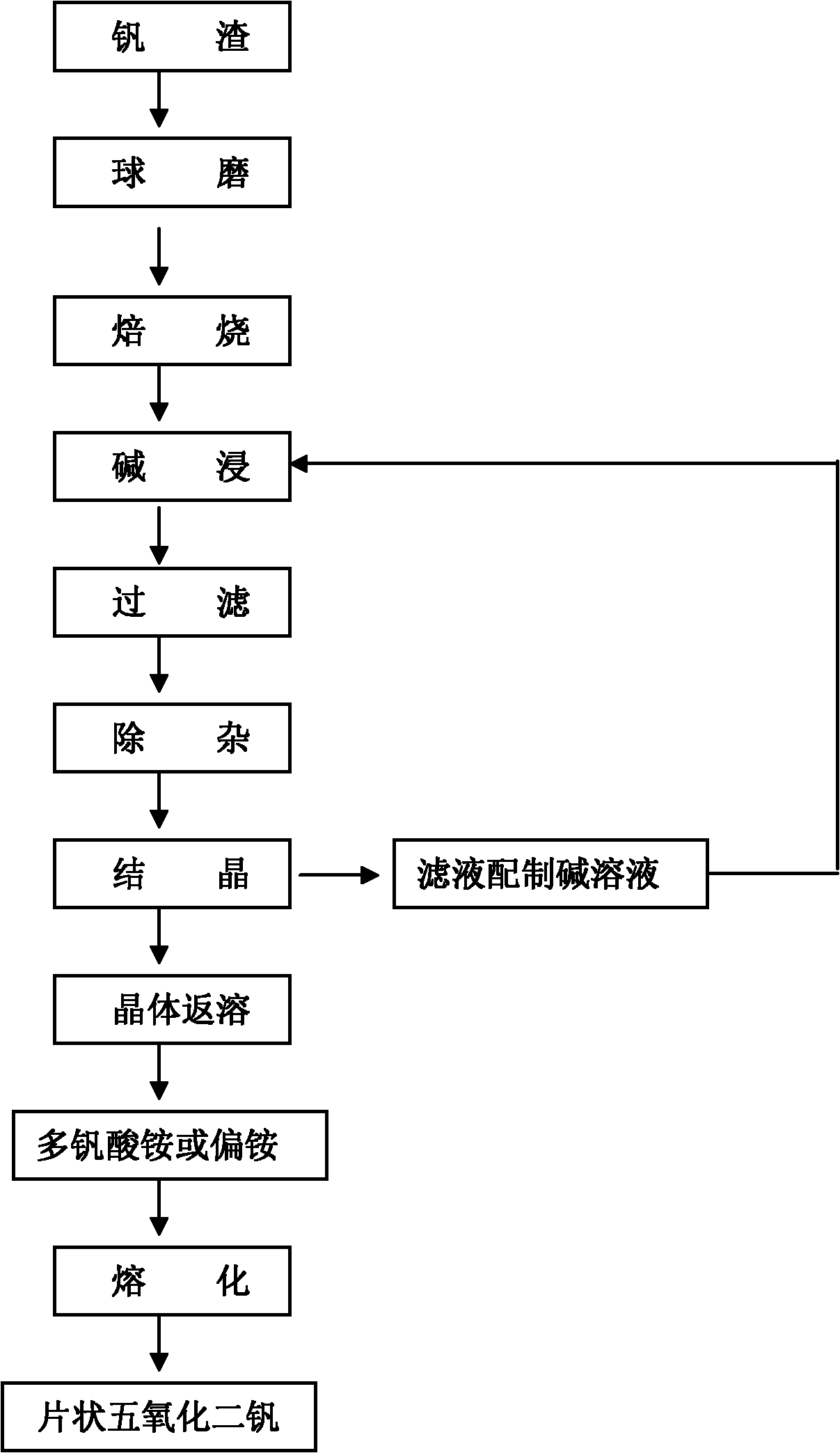

Method for extracting vanadium pentoxide from vanadium slag

InactiveCN101899582AReduce pollutionHigh extraction rateProcess efficiency improvementSlagAmmonium metavanadate

The invention relates to a method for extracting vanadium pentoxide from vanadium slag, belonging to the field of vanadium metallurgy. In order to solve the technical problem, the invention provides a method for extracting vanadium pentoxide from vanadium slag with less environment pollution. The method comprises the following steps of: a. smashing the vanadium slag, and removing metal iron to obtain the refined vanadium slag; b. baking the refined vanadium slag at 800-1000 DEG C to obtain grog; c. adding the grog into alkali liquor for leaching, and filtering with hot to obtain vanadium-containing solution and tailings; d. removing impurity in the vanadium-containing solution, reducing the temperature of the impurity-removed and vanadium-containing solution to be less than 35 DEG C, crystallizing and filtering to obtain Na3VO4.5-12H2O crystalloid and filtering mother liquor thereof; and e. dissolving the Na3VO4.5-12H2O crystalloid by adding water, treating with an acid ammonium salt precipitation method to obtain ammonium poly-vanadate or ammonium metavanadate, and dehydrating, deaminizing and melting the ammonium poly-vanadate or the ammonium metavanadate to obtain the vanadium pentoxide.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Preparation method of high-purity vanadium pentoxide

ActiveCN103194603AAffect the washing effectHigh purityProcess efficiency improvementVanadateImpurity

The invention discloses a preparation method of high-purity vanadium pentoxide. The method comprises the following steps of: a, grinding a vanadium-containing raw material, and removing iron; b, performing sodium roasting on the raw material treated in the step a, and leaching to obtain the vanadium-containing solution; c, removing cation impurities and anion impurities from the vanadium-containing solution obtained in the step b, and filtering to obtain the purified vanadium-containing solution; d, adding ammonium sulfate into the purified vanadium-containing solution to perform molybdenum precipitation treatment, filtering, washing and removing impurities to obtain vanadate precipitate; and e, pulping and filtering the vanadate precipitate, washing, further removing impurities in the vanadate precipitate, drying and roasting to obtain a vanadium pentoxide product. By virtue of the strict and effective impurity removal treatment, the purity of the vanadium pentoxide product can be increased, and can be over 99 percent.

Owner:攀枝花市阳润科技有限公司

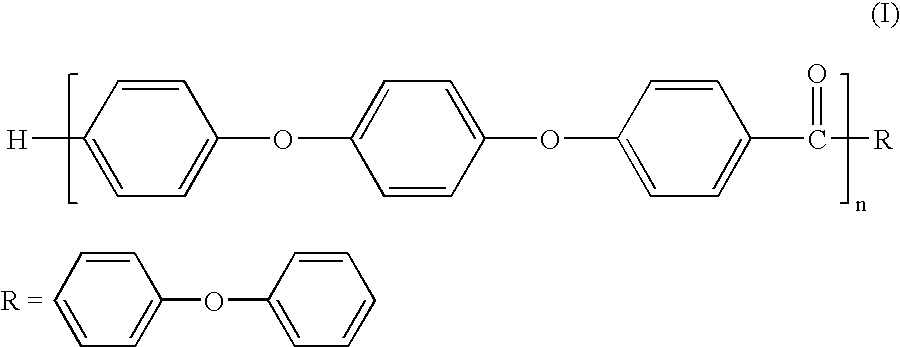

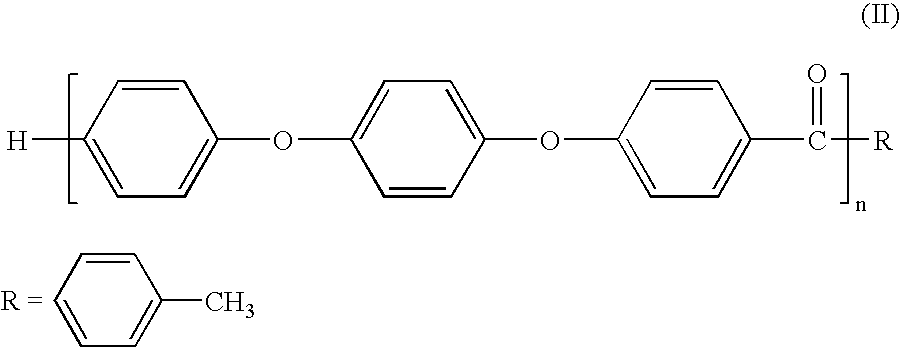

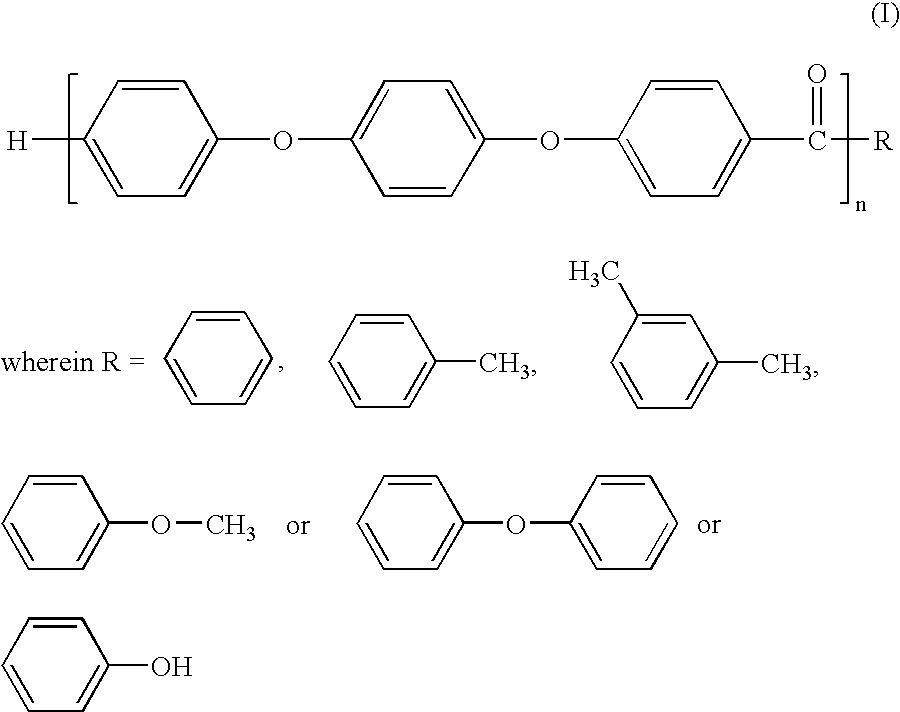

Melt processible polyether ether ketone polymer

InactiveUS6881816B2Easy to processReduce the temperatureChemical recyclingMethane sulfonic acidEnd-group

A melt processible Polyether Ether Ketone (PEEK) polymer with novel end-group structure is synthesized electrophilically using Methane Sulfonic Acid containing Methane Sulfonic Anhydride or Phosphorous Pentoxide. The product so obtained shows controlled structure with elimination of reactive end group like —COOH and is therefore melt processible by conventional techniques and exhibits high thermal and mechanical properties making it useful high temperature engineering and specialty plastics. It can be extruded into a rod, film and can also be molded into commercially useful products.

Owner:GHARDA CHEM LTD

Preparation method of high-purity vanadium pentoxide

InactiveCN102923775AEfficient removalReduce pollutionVanadium oxidesMetal impuritiesAmmonium metavanadate

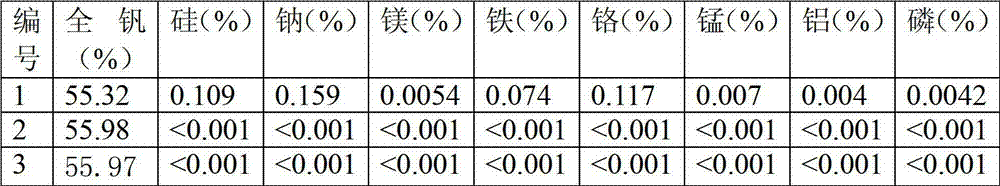

The invention discloses a preparation method of high-purity vanadium pentoxide. The preparation method comprises the following steps of: returning and dissolving coarse vanadium in aqueous alkali, and filtering the solution to remove metal impurities, which are subjected to precipitation reaction with the aqueous alkali, in the coarse vanadium, thus obtaining a primary returned solution; slowly pouring the primary returned solution into a sulfuric acid solution, adjusting the pH value of the solution to be 1.0-2.0 to obtain a liquid-solid mixture, and performing solid-liquid separation on the liquid-solid mixture; filtering and washing precipitates obtained from the solid-liquid separation of the mixture, and returning and dissolving the mixture into the aqueous alkali, thus obtaining a secondary returned solution; adding ammonium sulfate into the secondary returned solution for precipitating vanadium, and filtering the solution to obtain ammonium metavanadate; and processing the ammonium metavanadate to obtain the high-purity vanadium pentoxide. The preparation method adopting multiple stages of returned dissolving can be used for effectively removing the metal canon impurities of the vanadium pentoxide, and further obtaining the high-purity vanadium pentoxide with the metal canon impurity contents of less than 0.001% and the vanadium pentoxide content of 99.99%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

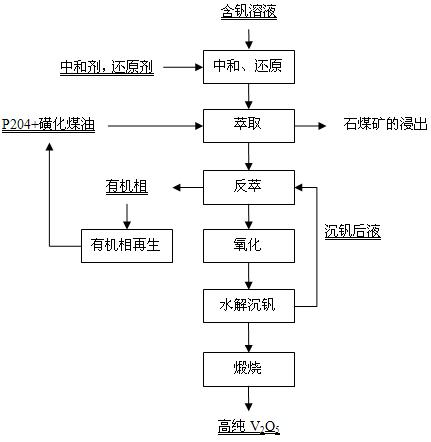

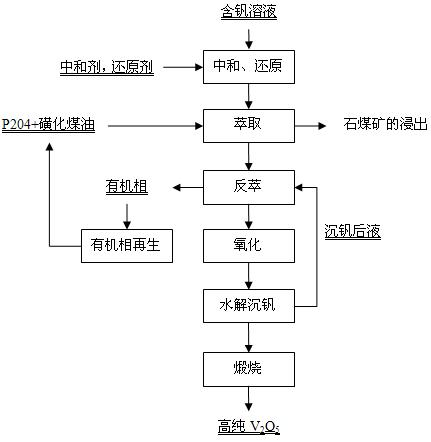

Method for preparing vanadium pentoxide from sulfuric acid leach liquor of stone coal vanadium ore

The invention relates to a method for preparing vanadium pentoxide from sulfuric acid leach liquor of stone coal vanadium ore, particularly a method for preparing high-purity vanadium pentoxide from sulfuric acid leach liquor of low-impurity-content stone coal vanadium ore. The method is characterized by sequentially comprising the following steps: (1) extracting leach liquor, which is obtained by leaching stone coal vanadium ore with sulfuric acid, to remove impurities; (2) carrying out back extraction on sulfuric acid to carry an organic phase; (3) oxidizing the back extraction liquor; (4) carrying out hydrolysis to precipitate vanadium; and (5) calcining the vanadium precipitate slag to obtain the vanadium pentoxide. Compared with the traditional technique, by using oxydol, persulfuric acid and the like as oxidants in the oxidation process, the method provided by the invention can avoid introducing other impurity cations, thereby ensuring the purity of the product vanadium pentoxide. Compared with the traditional ammonium-salt vanadium-precipitation technique, the method provided by the invention saves the alkali consumption required by neutralization. The purity of the prepared vanadium pentoxide is up to 99.9%, and the recovery rate of vanadium is up to above 98%; and meanwhile, the invention can implement no pollution and cyclic utilization of the back extraction agent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Low-vanadium denitration catalyst and preparation method and application thereof

ActiveCN101590404AReduce dosageReduce pollutionDispersed particle separationCatalyst activation/preparationReaction temperatureFixed bed

The invention relates to a low-vanadium denitration catalyst and a preparation method and application thereof, and belongs to the technical fields of environmental materials, environmental catalysis and environmental protection. The catalyst is prepared by a co-immersion method by adopting anatase titanium dioxide as a carrier, vanadium pentoxide as a main active component and tungstic oxide and cerium oxide as minor active components. Moreover, the low-vanadium denitration catalyst is characterized in that the catalyst reduces both the dosage of highly toxic vanadium and cost, and also has a conversion rate of NOx higher than 90 percent within a temperature range from 200 to 450 DEG C. The method provided for reducing nitrogen oxide comprises the following steps: putting the catalyst in a fixed bed reactor and controlling the reaction temperature between 200 and 500 DEG C; and taking NH3 as a reducing agent and controlling air speed at 28,000h and total gas flow at 300ml / min. The low-vanadium denitration catalyst still maintains high conversion rate of NOx in the presence of water and sulfur dioxide, and is suitable for treating NOx in exhaust gases discharged from thermal power plants, smelting plants, oil plants, and the like.

Owner:TSINGHUA UNIV

Method for preparing vanadium pentoxide

InactiveCN1843938AMeet the needs of domestic chemical productionVanadium oxidesCalcium hydroxideSodium aluminate

The invention relates to a method for preparing vanadic anhydride. It comprises following steps: employing ammonium vanadate, vanadic anhydride of technical grade or waste catalyst discharged in sulfuric acid preparation process; treating with ammonium hydroxide, sulfuric acid and ammonium chloride, washing with water; getting fine active vanadic anhydride; removing foreign matter with ammonium hydroxide, calcium hydroxide, sodium aluminate, sodium silicate, sulfuric acid and ammonium chloride; washing with water again; drying; calcing at 670 Deg. C and getting high-purity vanadic anhydride. The invention is characterized in that it makes use of current material to prepare chemical materials urgently needed by industrial production, and saves a large amount of foreigh exchange.

Owner:宿素满

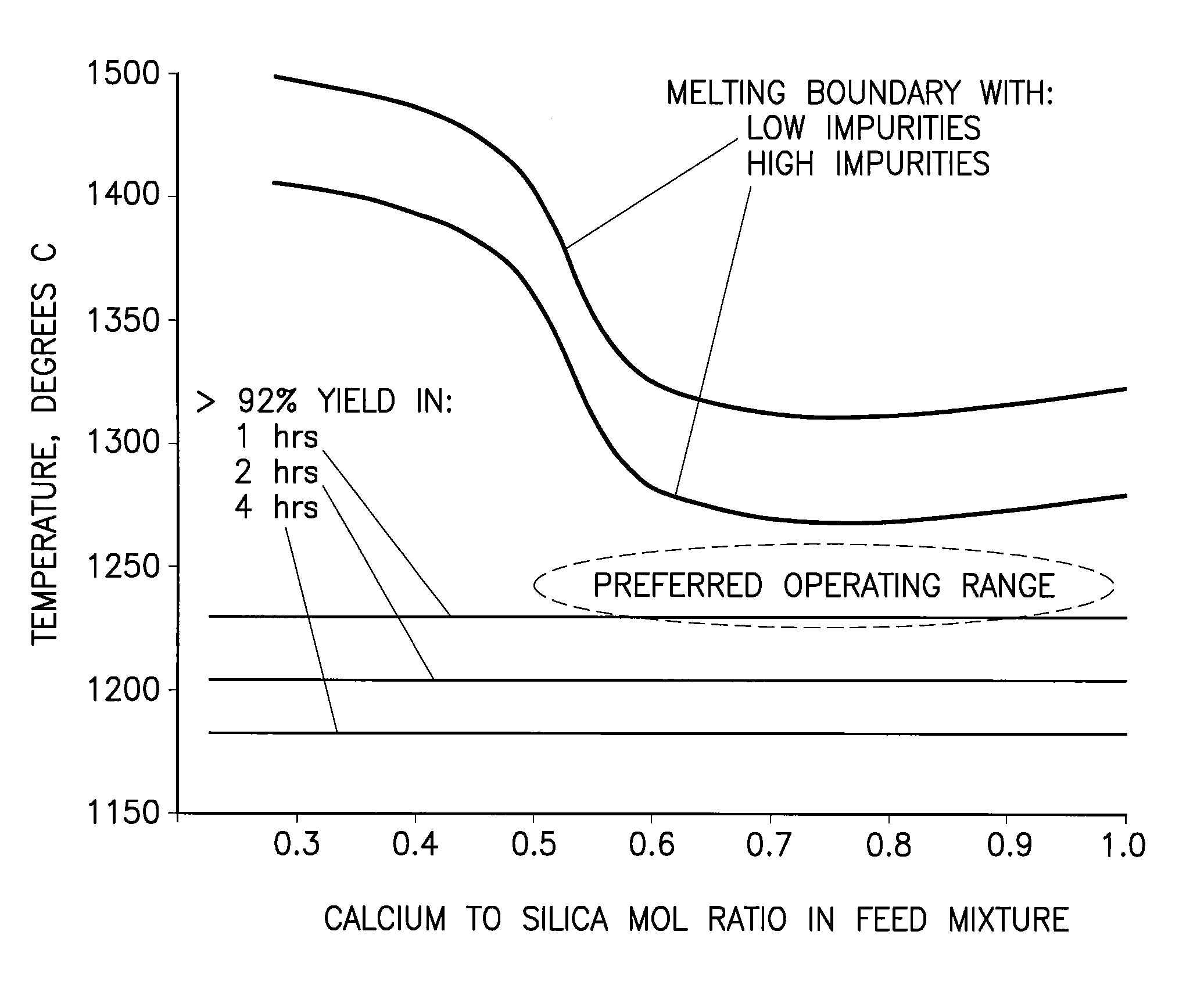

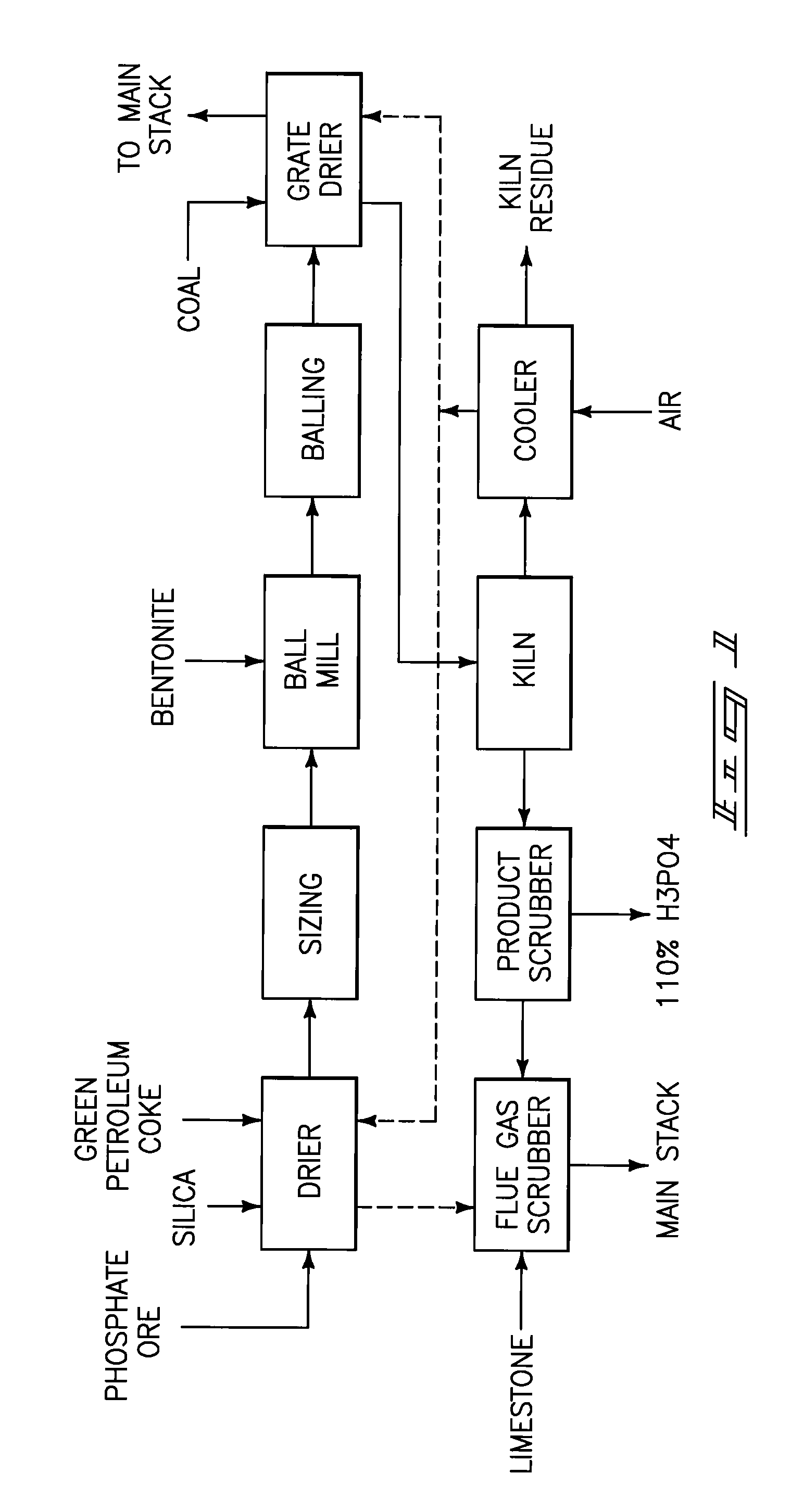

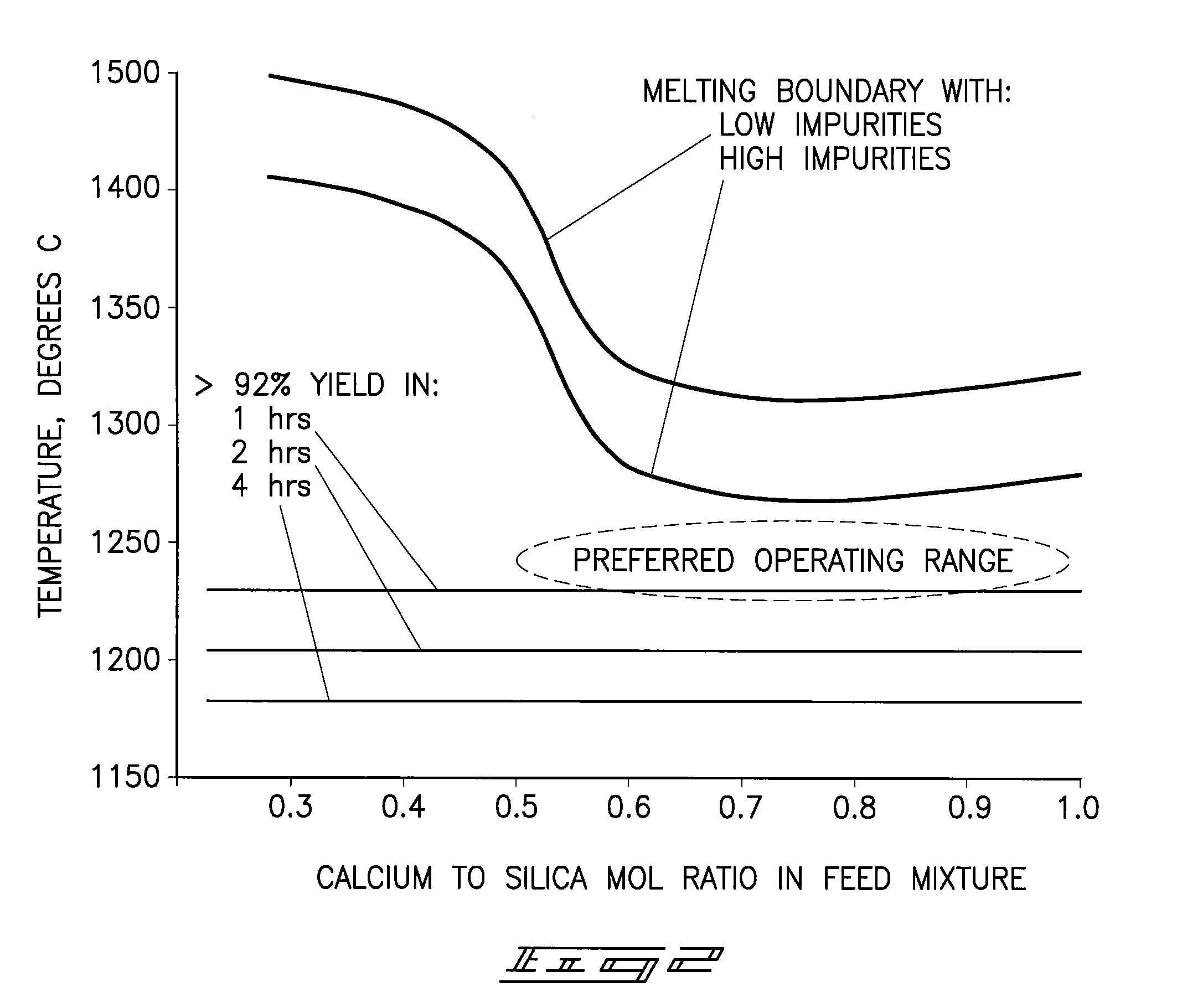

Phosphorous pentoxide producing methods

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of from 0.5 to 1.0 and maintaining a bed temperature at or above 1260° C. along a portion of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS INC

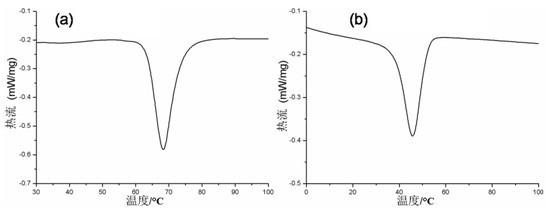

Preparation method for vanadium dioxide and doped powder thereof

The invention discloses a preparation method for vanadium dioxide and doped powder thereof. The method comprises the following steps: 1, weighing vanadium pentoxide, hydrogen peroxide and distilled water, preparing the materials into a V<5+>-containing complex aqueous solution; 2, adding a reducing agent, a surfactant and a dopant to the complex aqueous solution, and stirring to form a clear solution; 3, transferring the resulting solution from the step 2 to a hydrothermal reaction kettle, and carrying out a reaction for 1-168 hours at a temperature of 140-220 DEG C to obtain the doped powderof the VO2(B); 4, placing the resulting doped powder of the VO2(B) from the step 3 in high pure argon atmosphere or nitrogen atmosphere, and annealing for 10-720 minutes at the temperature of 400-700DEG C to obtain the doped powder of the VO2(M). The method of the present invention has characteristics of low cost, simple process and easy control, and is suitable for the large-scale industrial production. With the method of the present invention, the doping of the VO2 powder material can be realized, and the doped atoms can be uniformly dispersed in the VO2.

Owner:张家港楚人新材料科技有限公司

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

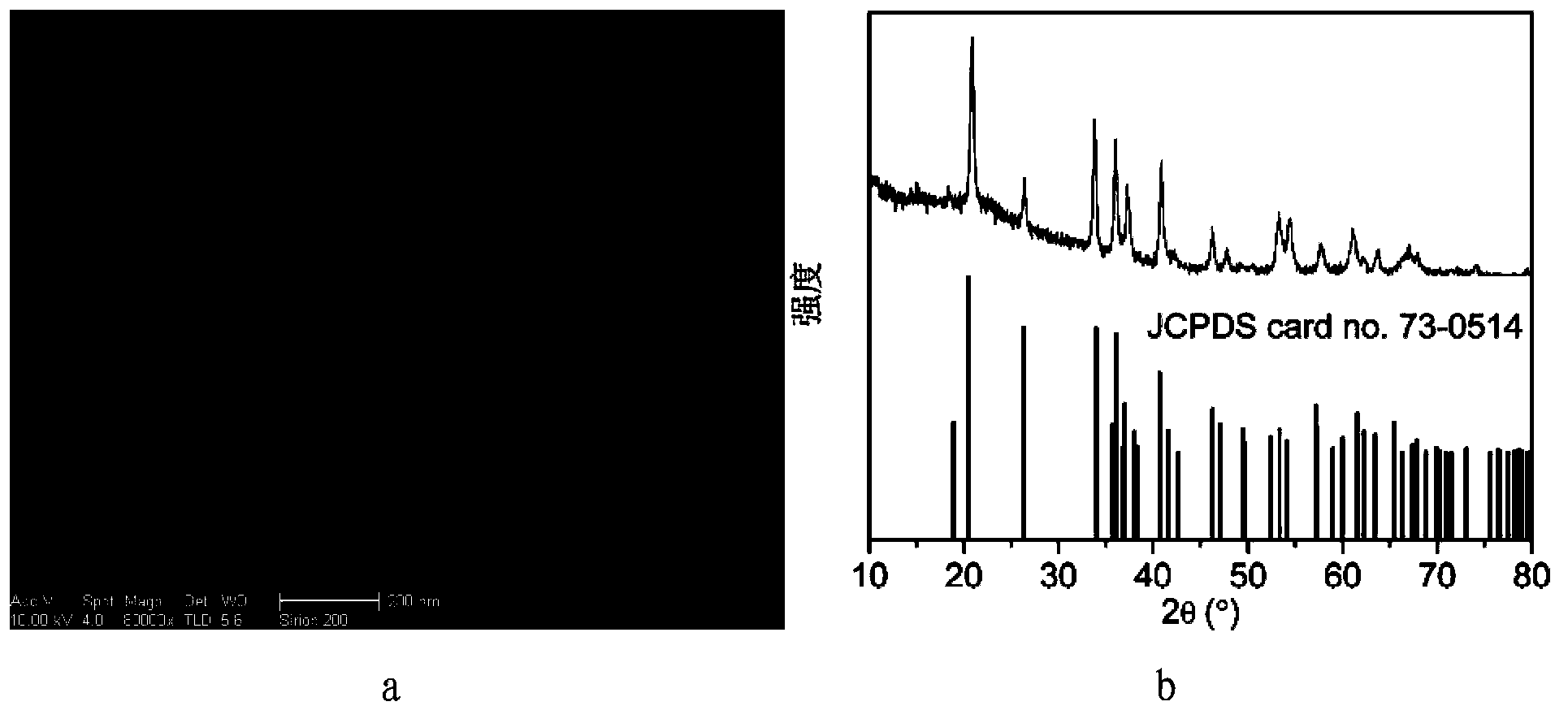

Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

InactiveCN104071843AGood phase change propertiesExcellent infrared control performanceMaterial nanotechnologyVanadium oxidesVanadium dioxideDispersity

The invention discloses a preparation method of monodispersed M-phase vanadium dioxide nanoparticles. The preparation method comprises the following steps: mixing vanadium pentoxide, oxalate dihydrate and water according to a molar ratio of (1-2.5) : 1 : (500-800) to obtain mixed liquid, adding 4%-6% of a surfactant based on the volume of the mixed liquid into the mixed liquid, and stirring for at least 2 hours to obtain a precursor solution; reacting the precursor solution in a sealed state at 200-260 DEG C for at least 1 day to obtain reaction liquid; performing solid-liquid separation and washing on the reaction liquid in sequence to obtain orthogonal vanadium dioxide powder; annealing the orthogonal vanadium dioxide powder in a nitrogen atmosphere at 300-600 DEG C for 0.5 hour to obtain the monodispersed M-phase vanadium dioxide nanoparticles with particle sizes of 60nm-80nm. The preparation method has the advantages of environmental protection and no temperature gradient control during annealing, and can be widely used for preparing the M-phase vanadium dioxide nanoparticles with very good dispersity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-toughness enamel glaze

InactiveCN108658462AImprove toughnessOvercome the defect of porcelain crackLithium oxideSilicon dioxide

The invention discloses high-toughness enamel glaze. The enamel glaze is prepared from the following components in parts by weight: 40-50 parts of silicon dioxide, 15-25 parts of titanium dioxide, 5-15 parts of potassium oxide, 10-20 parts of sodium oxide, 1-5 parts of lithium oxide, 2-4 parts of calcium fluoride, 6-12 parts of vanadium pentoxide, 1-3 parts of tungsten carbide and 5-10 parts of aluminum oxide and zirconium dioxide. According to the enamel glaze, by means of the composition, the toughness of the enamel glaze can be greatly improved, meanwhile, the defect that ceramic cracks arecaused due to collision can be overcome, and therefore, the enamel glaze has a wide application prospect.

Owner:沙冰娟

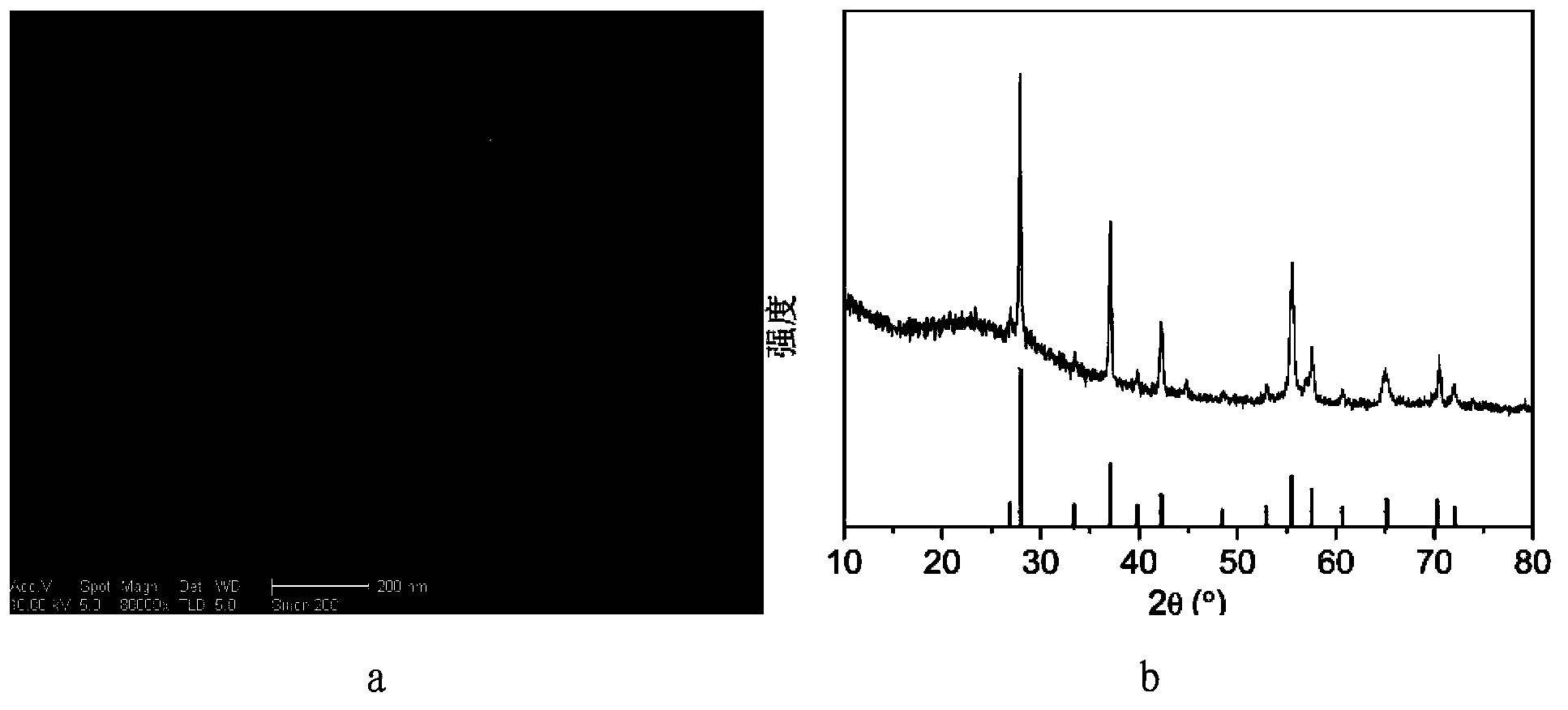

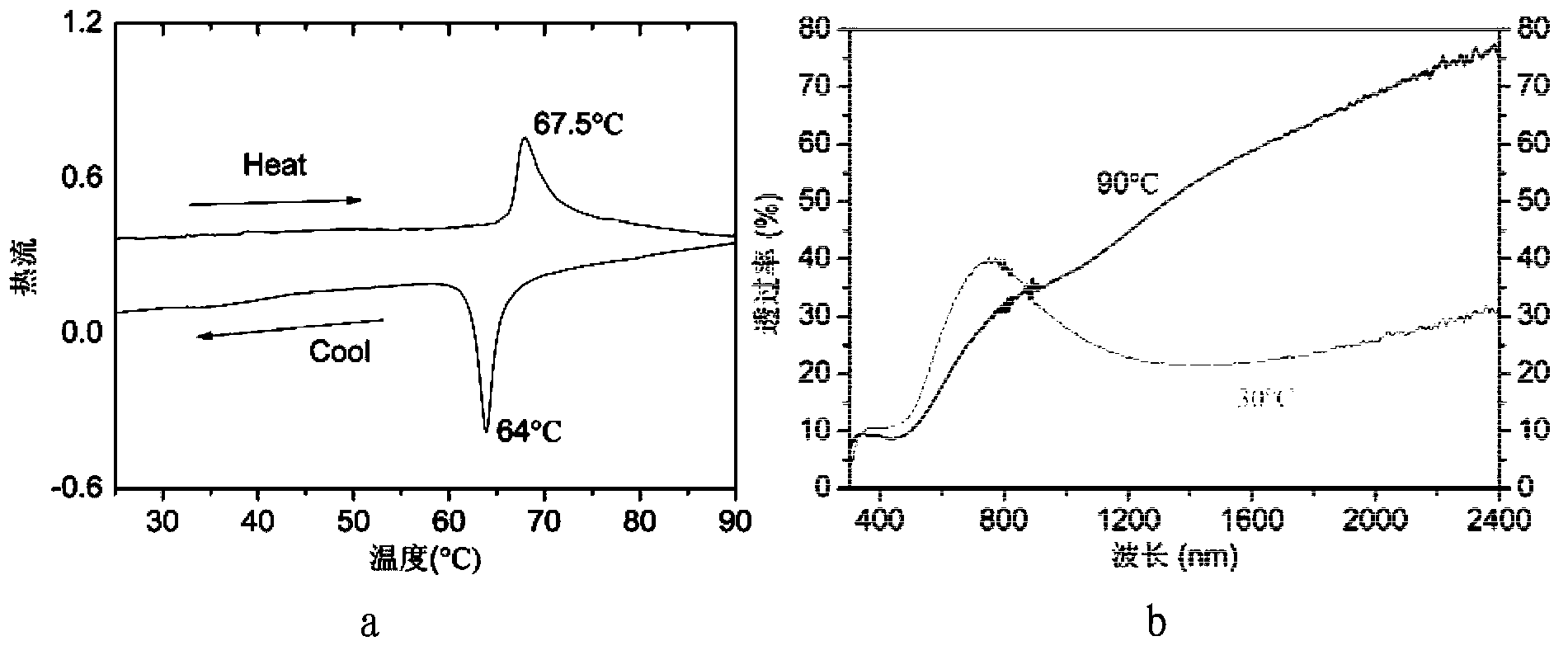

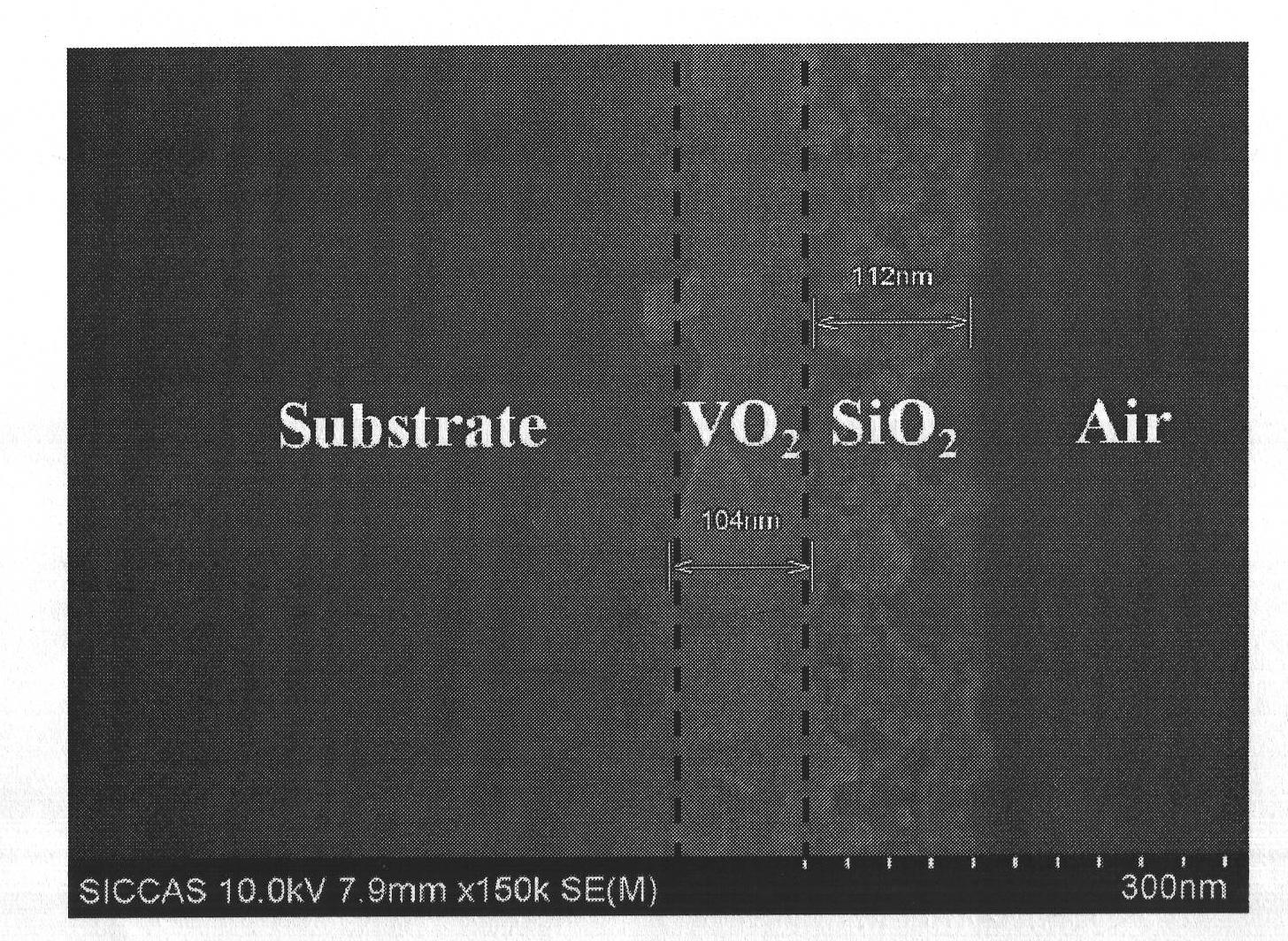

Intelligent temperature-control vanadium dioxide composite multifunctional thin film and preparation method thereof

ActiveCN102241482AImprove the transmittance in the visible light regionImprove transmittanceVanadium dioxideChemical solution

The invention relates to an intelligent temperature-control vanadium dioxide nano composite multifunctional thin film and a preparation method thereof, and is characterized in that the nano composite thin film is VO2 / SiO2, VO2 / ZnO, VO2 / ZrO2 or VO2 / TiO2. The composite thin film consists of nano particles, wherein the size of the nano particles is kept between 10 and 500 nanometers, and the thickness of the composite thin film is 50 to 3,000 nanometers. In the invention, a wet chemical solution process is adopted, vanadium pentoxide (V2O5) powder serving as a precursor is uniformly dispersed and dissolved in a weakly reducing organic solvent to form a VOx thin film (x is more than 2.0 and less than 2.5), and the vanadium dioxide (VO2) thin film is formed by post treatment; and the nano composite thin film is prepared by a sol-gel technique. The VO2 nano composite thin film system based on co-doping and interface synergetic effect has high visible light transmittance, high infrared thermosensitive property, hydrophilic and photocatalytic functions and other functions, and a bright prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

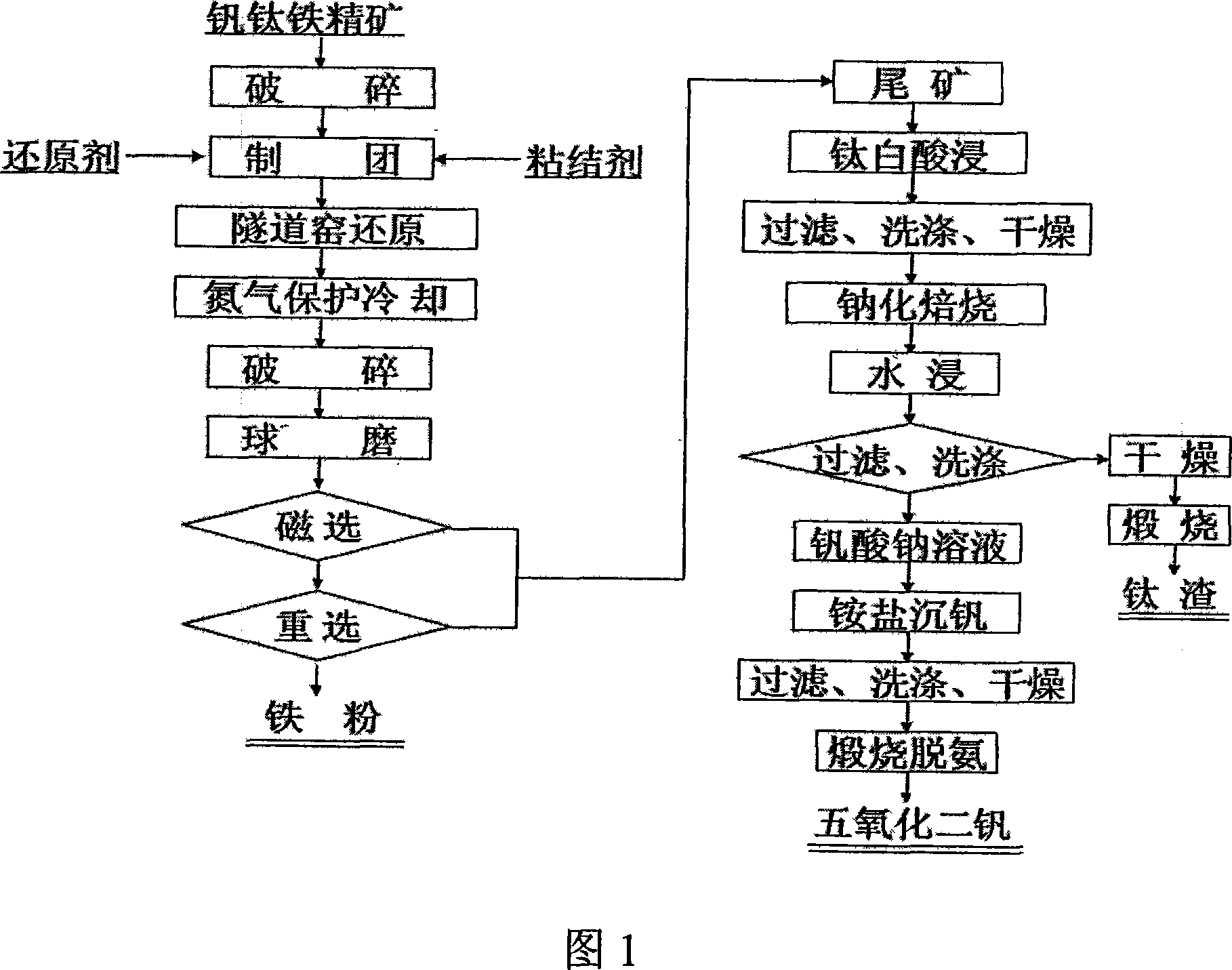

Method for comprehensive utilization of V-Ti-bearing iron ore concentrate by using tunnel kiln reduction-grinding - separation

InactiveCN101113488AAvoid defects such as loopsHigh yieldProcess efficiency improvementTunnel kilnResource utilization

The invention relates to an iron powder production method by using a tunnel kiln to reduce concentrate pellets containing carbon vanadium ferrotitanium with titanium slag and vanadium pentoxide as combined products. Concentrate pellets are made from vanadium-titanium iron concentrate through crashing and damp milling. The iron powder and tailings are obtained by putting the concentrate pellets into the tunnel kiln to be reduced, crashing, wet-grinding, magnetic separation and gravity separation. The tailings are soaked with titania waste acid to eliminate remnants magnesium and iron. Then the tailings are filtrated and dried to obtain a new material. And then the new material is added with sodium salt to do salt roast and then to be soaked by water, then titanium slag and sodium vanadate are obtained respectively after the water soaking. At last, the vanadium pentoxide is obtained by ammonium vanadate precipitating and calcination deaminase to the sodium vanadate liquid. The invention eliminates the disadvantage of high energy consumption by electric furnace smelting and bad separating effect of vanadium and titanium, difficult control of vanadium and titanium trend and low yield rate of extracting vanadium and titanium through converter blowing iron molten, etc. The invention has the advantages of high yield rate of vanadium, titanium and iron and high resources utilization rate and explores a novel practical way for comprehensive utilization of vanadium, titanium and iron concentrate ore.

Owner:攀枝花锐龙冶化材料开发有限公司

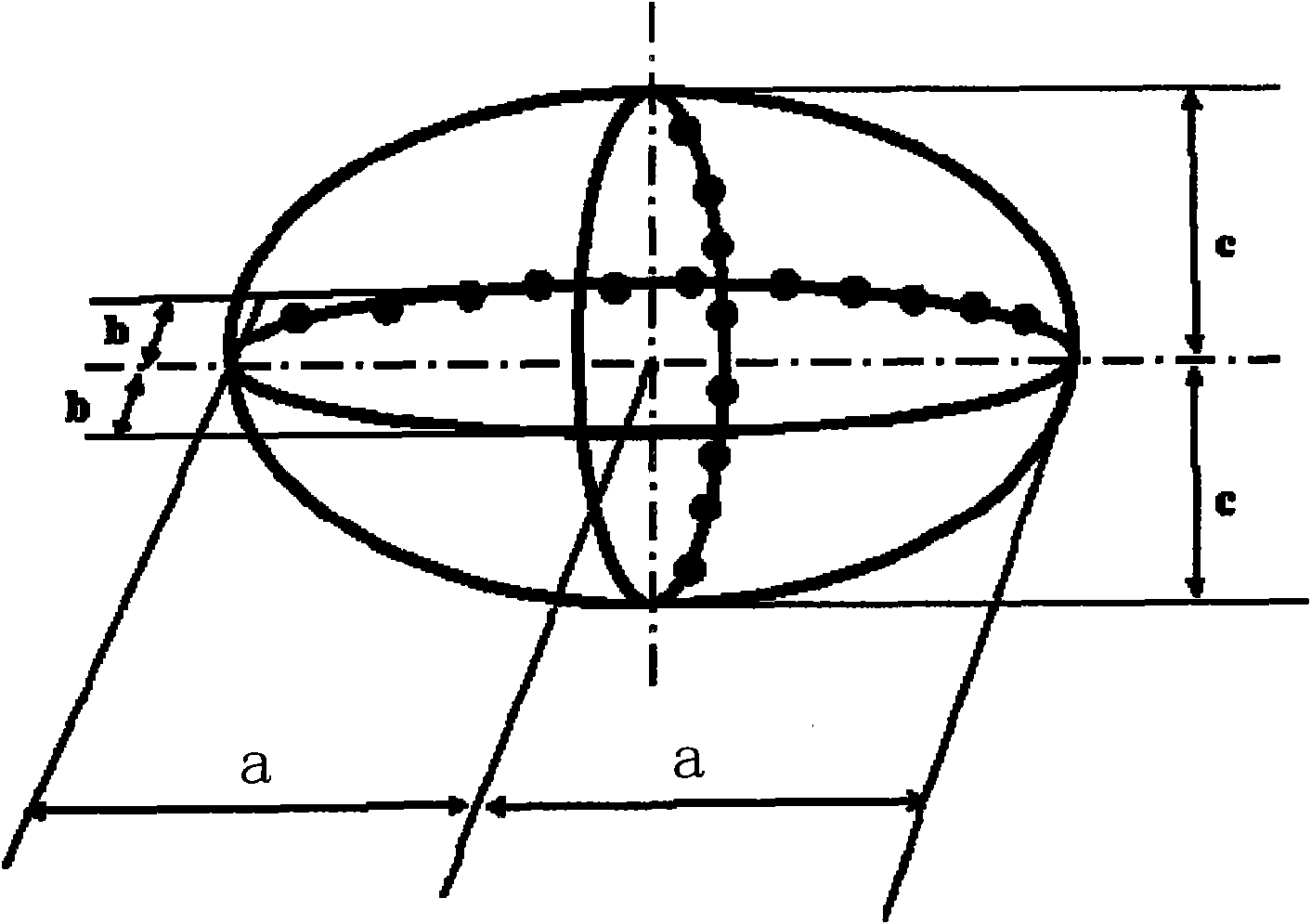

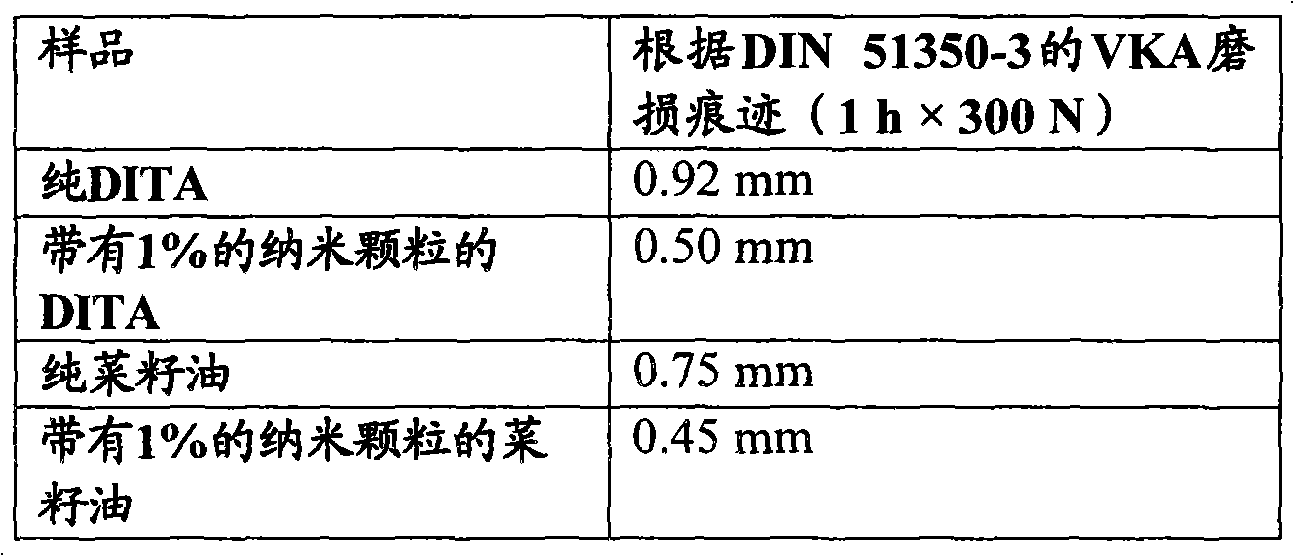

Additive for lubricant for improving the tribologic properties, a method for its production and application

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

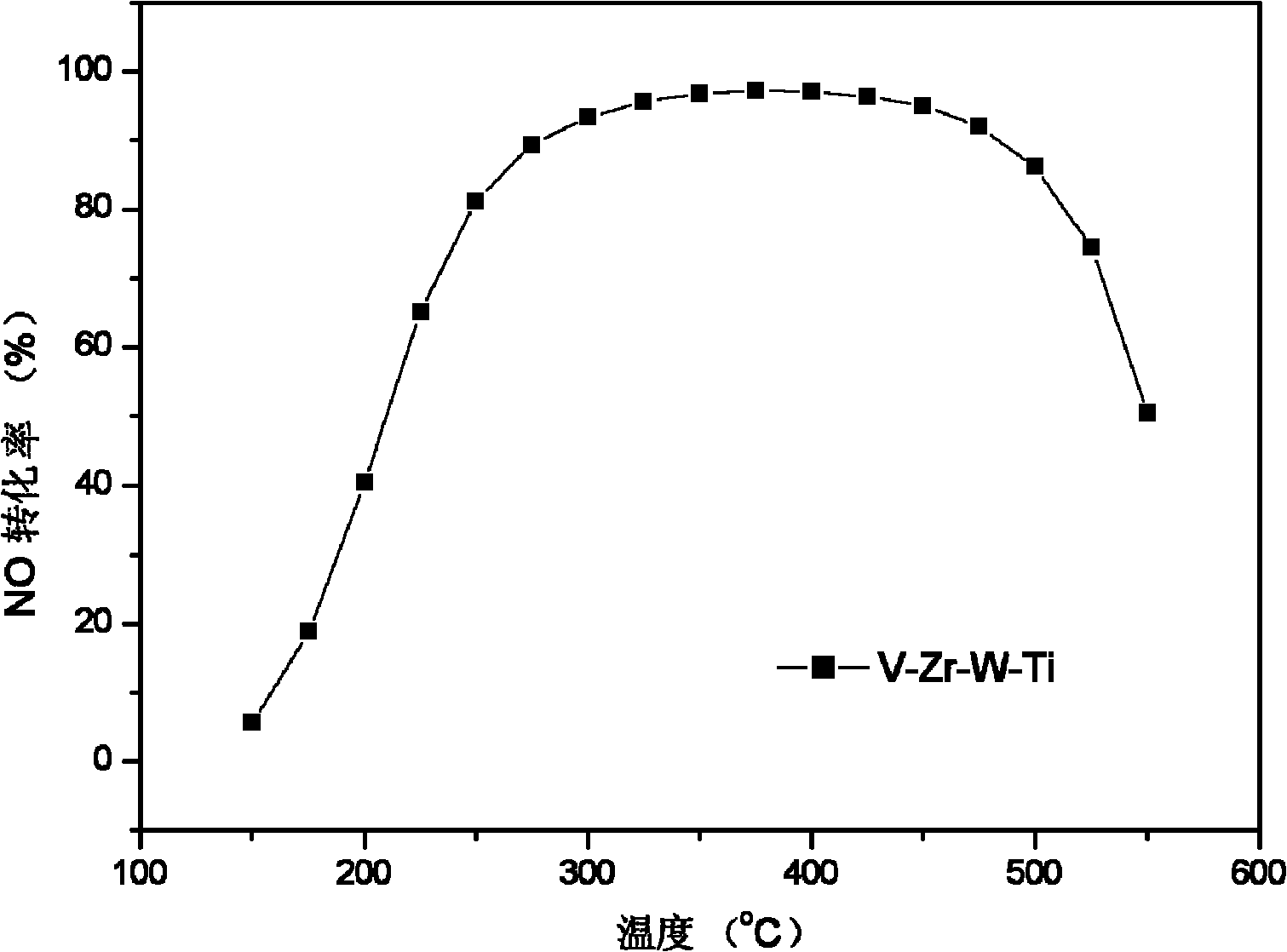

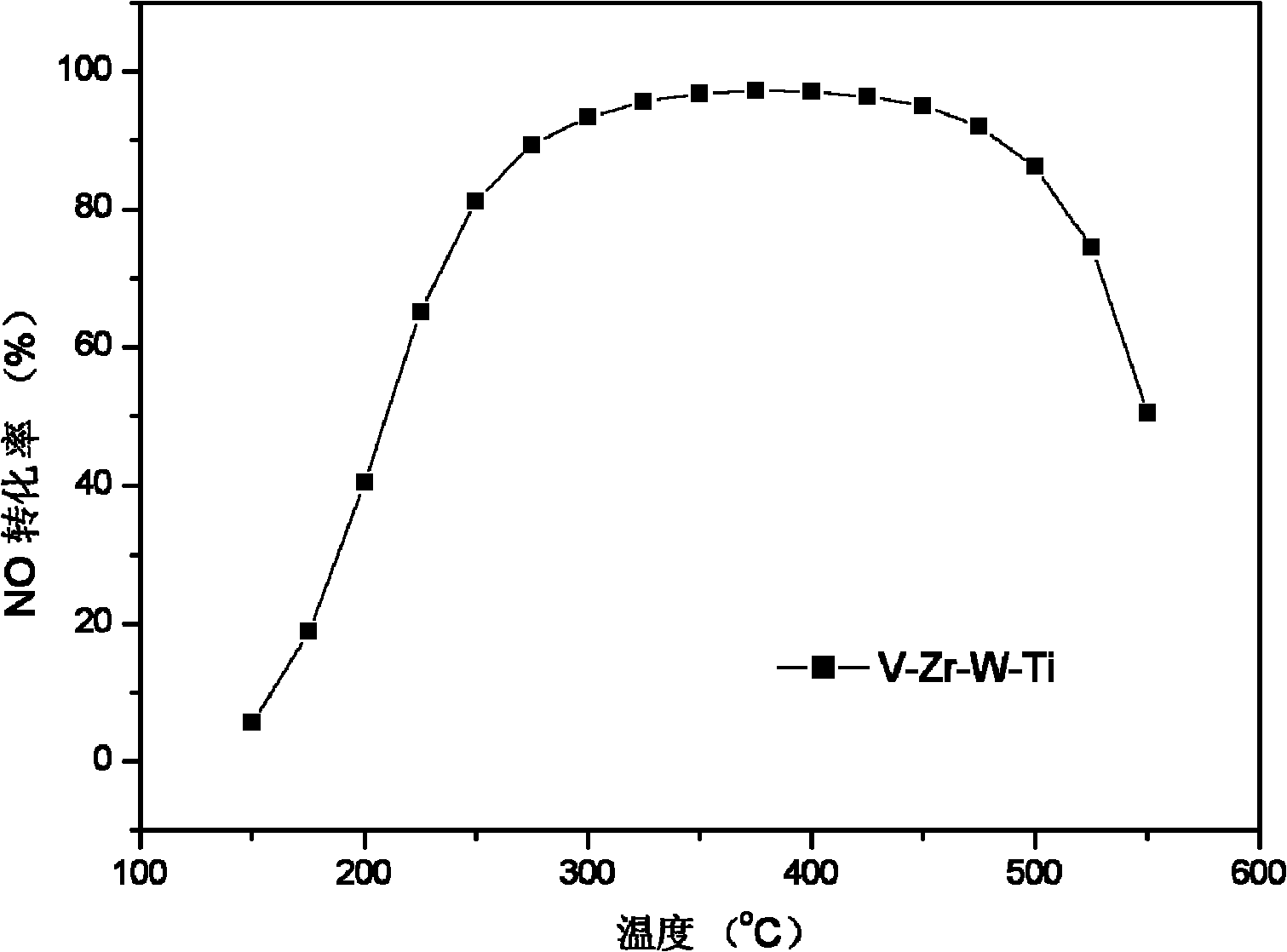

Selective catalyst for removing oxynitrides from tail gases of diesel vehicles and preparation method thereof

InactiveCN101912775AImprove smoothnessSatisfy and attain purifyingInternal combustion piston enginesDispersed particle separationWater vaporCordierite

The invention discloses a selective catalyst for removing oxynitrides from tail gases of diesel vehicles and a preparation method thereof. Cordierite honeycomb ceramic serves as a carrier, and the oxides of vanadium, zirconium, tungsten and titanium form a catalytic active site. The preparation method comprises the following steps of: sequentially dissolving vanadium pentoxide, a zircon salt, tungsten trioxide and titanium dioxide into the aqueous solution of oxalic acid, adding a bonder into the mixed solution to prepare pulp, impregnating the cordierite honeycomb ceramic in the pulp, drying the cordierite honeycomb ceramic for 1 to 3 hours at 100 to 150 DEG C, and roasting the cordierite honeycomb ceramic for 2 to 4 hours at 450 to 550 DEG C. In the invention, the preparation method is improved, and a powder catalyst is improved into a honeycomb selective catalytic reduction (SCR) catalyst applied to the removal of the oxynitrides from the tail gases of the diesel vehicles, so the high-efficiency catalytic removal of the oxynitrides can be realized at the temperature of 205 to 515 DEG C; and in the presence of steam or SO2, the activity of the catalyst is kept over 80 percent.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Method for recycling vanadium pentoxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN104195342ASolve pollutionAchieve separationProcess efficiency improvementEconomic benefitsOxidizing agent

The invention belongs to the field of non-ferrous metal recycling, and in particular relates to a method for separating and recycling vanadium pentoxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst according to a reduction acid leaching method. The method provided by the invention comprises the following steps: firstly, reducing pentavalent vanadium in the catalyst by using a reducing agent in an acidic solution to tetravalent vanadium which is more soluble, then oxidizing the tetravalent vanadium in the acidic solution to the pentavalent vanadium by using an antioxidant, fully hydrolyzing the pentavalent vanadium under certain conditions for precipitation by adjusting the pH value of the solution, collecting the precipitation, roasting the precipitation and then obtaining the vanadium pentoxide with high purity. The method disclosed by the invention is simple in process, higher in operability, and suitable for large-scale production. The recovery rate of the vanadium pentoxide can be ensured to reach above 95%, and the purity of the obtained vanadium pentoxide is high (higher than 98%), so that the vanadium pentoxide can be directly used for preparing raw materials of the SCR denitration catalyst; the method disclosed by the invention can not only turn wastes into useful resources, and harm into benefits, but also solve a series of potential environmental pollution problems to bring considerable economic benefits and environmental benefits.

Owner:无锡华骏宏科技有限公司

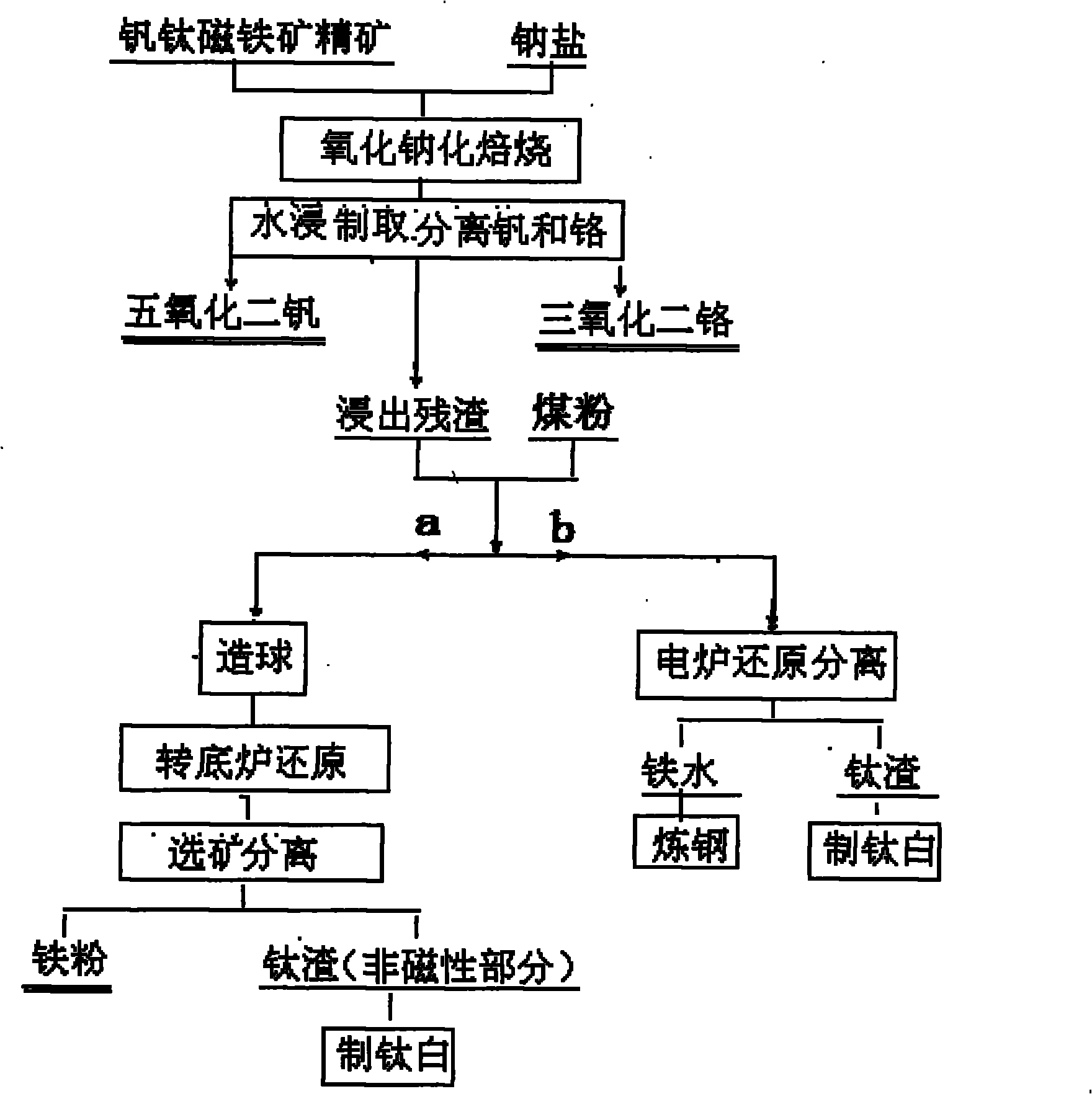

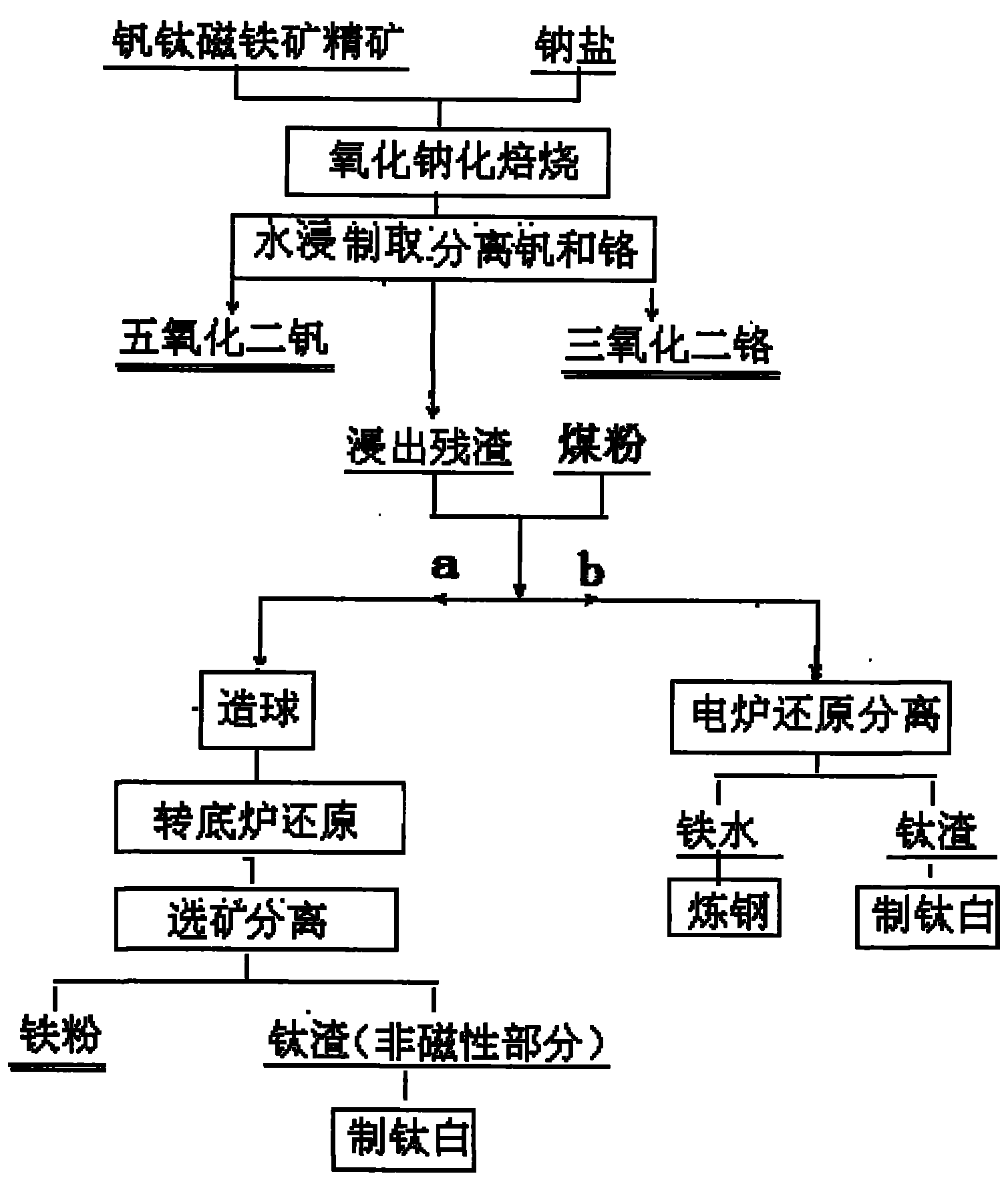

Method for recycling vanadium, chromium, titanium and iron from vanadium-titanium magnetite ore

ActiveCN102061397AHigh recovery rateSimple processProcess efficiency improvementSteelmakingMagnetite

The invention discloses a method for recycling valuable elements from vanadium-titanium magnetite ore, which comprises the following steps of: crushing the ore or concentrate, adding sodium salt, performing oxidizing roasting, converting vanadium and chromium into water-soluble sodium vanadate and sodium chromate, performing water leaching in solution, and separating the vanadium and chromium from the solution to obtain vanadium pentoxide and chromium sesquioxide products; and adding coal dust into the leached residue for pelletizing, reducing in a rotary hearth furnace, magnetically separating iron and titanium, using the obtained magnetic iron powder as a raw material for powder metallurgy or steelmaking, and using a nonmagnetic product containing more than 50 percent of TiO2 as a raw material for extracting the titanium; or reducing iron from the leached residue in an electric furnace, using the obtained molten iron as a raw material for steelmaking and using electric furnace slag containing more than 50 percent of TiO2 as a raw material for extracting the titanium. The method is short in process flow and economical; and the recovery rate of the vanadium, chromium, titanium and iron is high.

Owner:SICHUAN LOMON MINING & METALLURGY +1

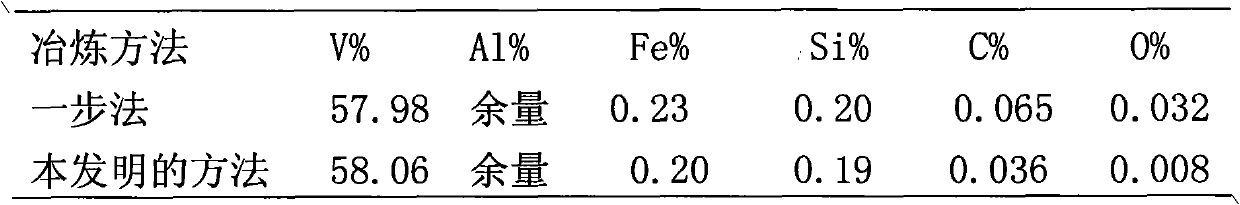

Method for preparing vanadium-aluminum alloy

InactiveCN101906546ASolving the melting puzzleImprove appearance qualityIntermediate frequencyTitanium alloy

The invention discloses a method for preparing a vanadium-aluminum alloy and relates to a method for preparing a vanadium-aluminum intermediate alloy for producing a titanium alloy. The method is characterized by comprising the following steps of: firstly, with aluminum as a reducing agent, reducing vanadium pentoxide to prepare a vanadium-aluminum alloy in one step by adopting a metallothermic reduction method; secondly, crushing and drying the vanadium-aluminum alloy prepared in one step; and adding aluminum in the dried vanadium-aluminum alloy prepared in one step and refining in a second step in a vacuum intermediate-frequency induction furnace to obtain a final product of the vanadium-aluminum alloy. In the method, by taking the aluminum as the reducing agent in the metallothermic reduction method (one-step method) and reserving a small part of aluminum during smelting of the vanadium-aluminum alloy and adding the aluminum in the refining of the vacuum intermediate-frequency induction furnace, the problem that the vanadium-aluminum alloy is molten in the vacuum intermediate-frequency induction furnace can be effectively solved. In addition, compared with the one-step method for preparing the alloy, the appearance quality, the consistency, impurity components, the uniformity and other aspects of the alloy are superior and the aim of refining can be achieved. Meanwhile, when being used for refining the vanadium-aluminum alloy, the process can be used for completely molting the alloy at the lower feeding power and has remarkable the energy-saving effect.

Owner:CHENGDE TIANDA VANADIUM IND

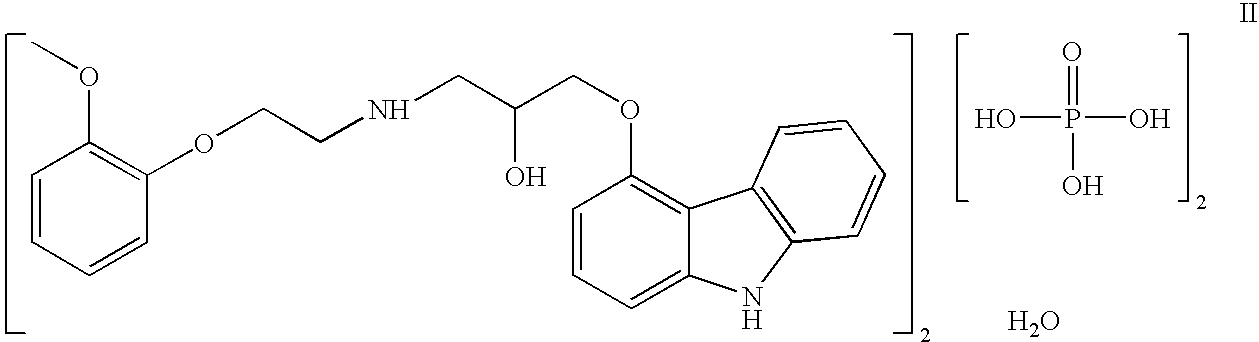

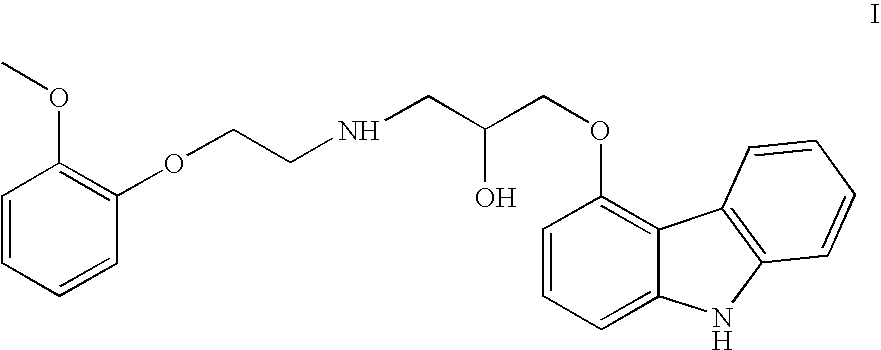

Efficient process for production of carvedilol phosphate

InactiveUS7777053B2High purityHigh yieldOrganic chemistryDipotassium hydrogen phosphateCarvedilol Phosphate

A novel cost effective process for the synthesis of phosphate salts of 1-(9H-carbazol-4yloxy)-3-[[2-(2-methoxyphenoxy)ethyl]amino]-propan-2-ol, (carvedilol phosphate) of formula (II) with high yields and purity is disclosed. More particularly, the invention discloses a process for preparation of crystalline phosphate salts of carvedilol using various phosphate forming reagents such as phosphorous pentoxide, polyphosphoric acid, dipotassium hydrogen phosphate, ammonium dihydrogen ortho phosphate, and sodium dihydrogen ortho phosphate in solvents selected from Acetonitrile, acetone and tetrahydrofuran. The solvents used to prepare solvates of carvedilol dihydrogen phosphate are methanol, ethanol and isopropyl alcohol.

Owner:WANBURY

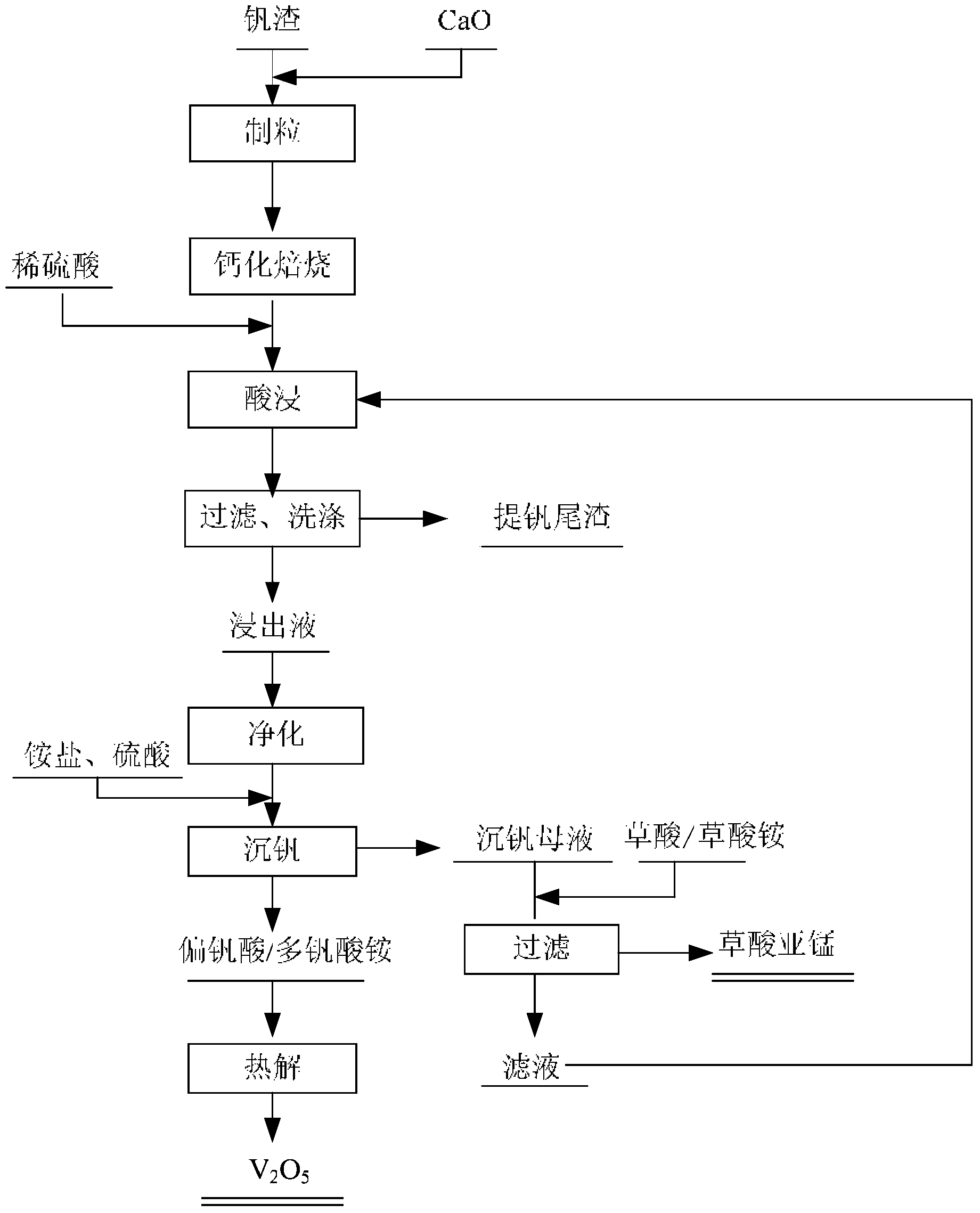

Method for clean production of vanadium pentoxide

ActiveCN104357660AHigh extraction rateNo pollution in the processProcess efficiency improvementTotal recoveryVanadium oxide

The invention discloses a method for the clean production of vanadium pentoxide, and belongs to the field of production of vanadium oxide. The method comprises the steps of raw material pretreatment, roasting, diluted acid leaching, vanadium liquid purification, vanadium precipitation, pyrolysis, recovery of Mn in residual vanadium precipitation liquid and the like. According to the method, the discharge of the residual vanadium precipitation liquid is avoided, and vanadium extraction tailings do not contain Na and K, and can be returned to a blast furnace or directly reduced to realize the comprehensive recycling of resources; the total recovery rate of vanadium is higher than that of a conventional sodium salt roasting-water leaching vanadium extraction process in the industry, the V2O5 content of a product is higher than 98 percent, the production cost is lower than that of a process for the sodium treatment vanadium extraction preparation of vanadium pentoxide, and meanwhile, the residual vanadium precipitation liquid can be completely recycled, and the vanadium extraction tailings can be secondarily and comprehensively utilized.

Owner:NORTHEASTERN UNIV

Boro-silicate glass frits for hermetic sealing of light emitting device displays

A frit composition useful for sealing a light emitting device is disclosed. The frit composition comprises a glass portion comprising a base component and at least one absorbing component. The glass portion of the frit comprises silica, boron oxide, optionally alumina, and (a) cupric oxide and / or a (b) combination of ferric oxide, vanadium pentoxide, and optionally titanium dioxide. Also disclosed is an article comprising a substrate and a frit, and a glass package comprising two substrates and a frit positioned between the substrates. A method for manufacturing a hermetically sealed glass package comprising the deposition of a glass frit and heating of the glass frit to form a hermetic seal is also disclosed.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com