Preparation method of vanadium battery electrolyte solution with high purity and high concentration

A high-concentration, high-purity technology, applied in the direction of regenerative fuel cells, etc., can solve the problems of high impurity content and inclusions in vanadium electrolyte, and achieve the effect of reducing production costs and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

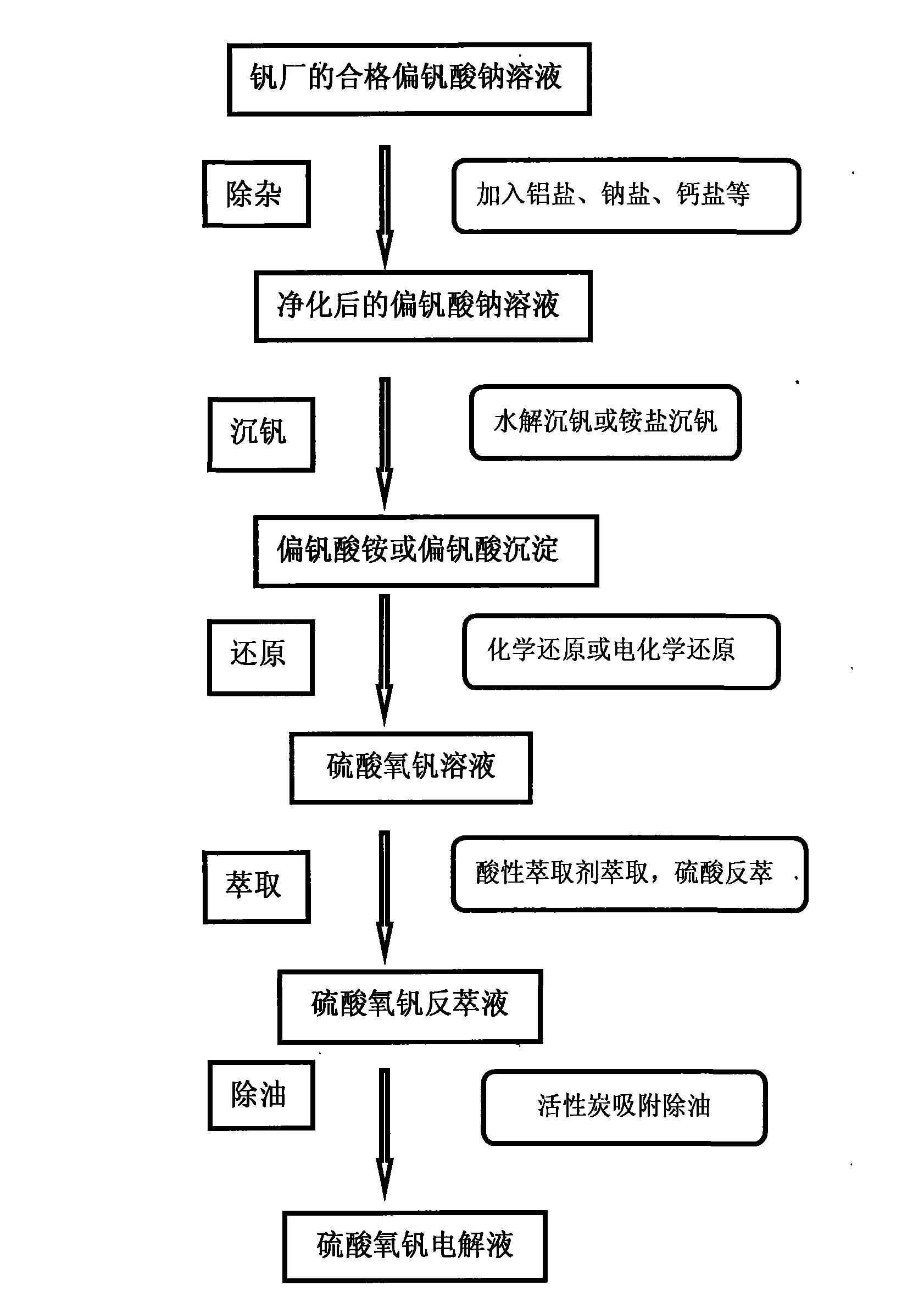

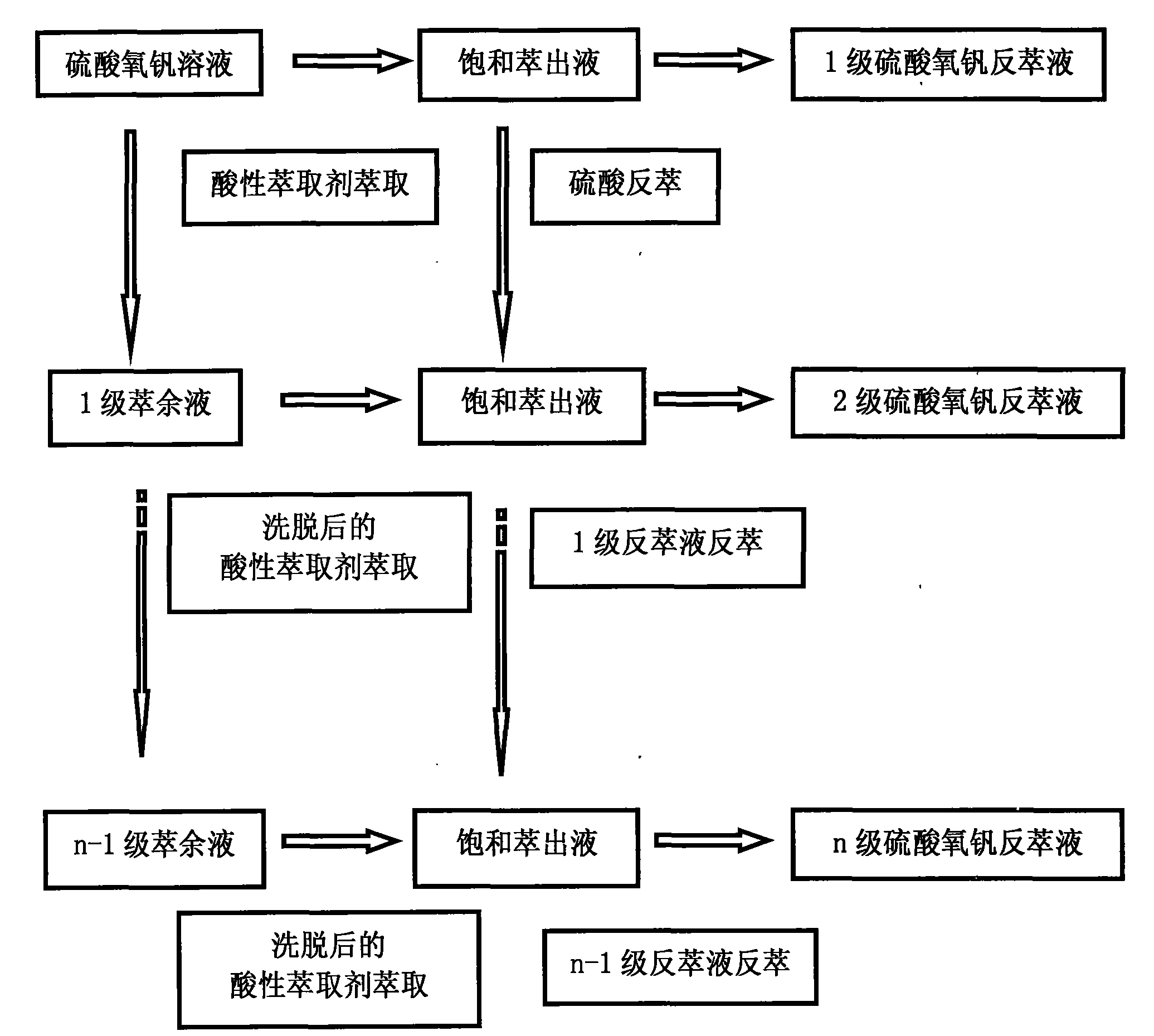

Method used

Image

Examples

example 1

[0020] In 10 liters of standard pentavalent vanadium stock solution, the vanadium concentration is 0.4M, other impurities include silicate, chromate, and phosphate, and cations include iron, calcium, magnesium, and manganese ions.

[0021] 1. Remove impurities

[0022] Silicon removal: Take 10 liters of the stock solution, adjust the pH of the stock solution to 9, add aluminum sulfate (according to the ratio of Si:Al=1:1.2), and keep the pH of the stock solution at 9 during stirring for 2 hours. After standing for 12 h, the precipitate was filtered.

[0023] Calcium removal: add sodium carbonate (according to Ca:CO 3 2- =1:1 ratio), adjust the pH of the filtrate to 11, heat to 100 degrees and then cool slowly, let stand for 12h, and filter the precipitate.

[0024] 2. Ammonia precipitation (basic ammonia precipitation after acidic ammonia precipitation)

[0025] Acidic ammonia precipitation: take out 10 liters of the stock solution after removing impurities, adjust the aci...

example 2

[0034] In 10 liters of standard pentavalent vanadium stock solution, the concentration of vanadium is 0.6M, other impurities include silicate, chromate, and phosphate, and cations include iron, calcium, magnesium, and manganese.

[0035] 1. Remove impurities

[0036] Silicon removal: Take 10 liters of the stock solution, adjust the pH of the stock solution to 9, add aluminum sulfate (according to the ratio of Si:Al=1:1.2), and keep the pH of the stock solution at 9 during stirring for 2 hours. After standing for 12 h, the precipitate was filtered.

[0037] Calcium removal: add sodium carbonate (according to Ca:CO 3 2- =1:1 ratio), adjust the pH of the filtrate to 11, heat to 100 degrees and then cool slowly, let stand for 12h, and filter the precipitate.

[0038] 2. Ammonia precipitation (basic ammonia precipitation after acidic ammonia precipitation)

[0039] Acidic ammonia precipitation: take out 10 liters of the stock solution after removing impurities, adjust the acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com