Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

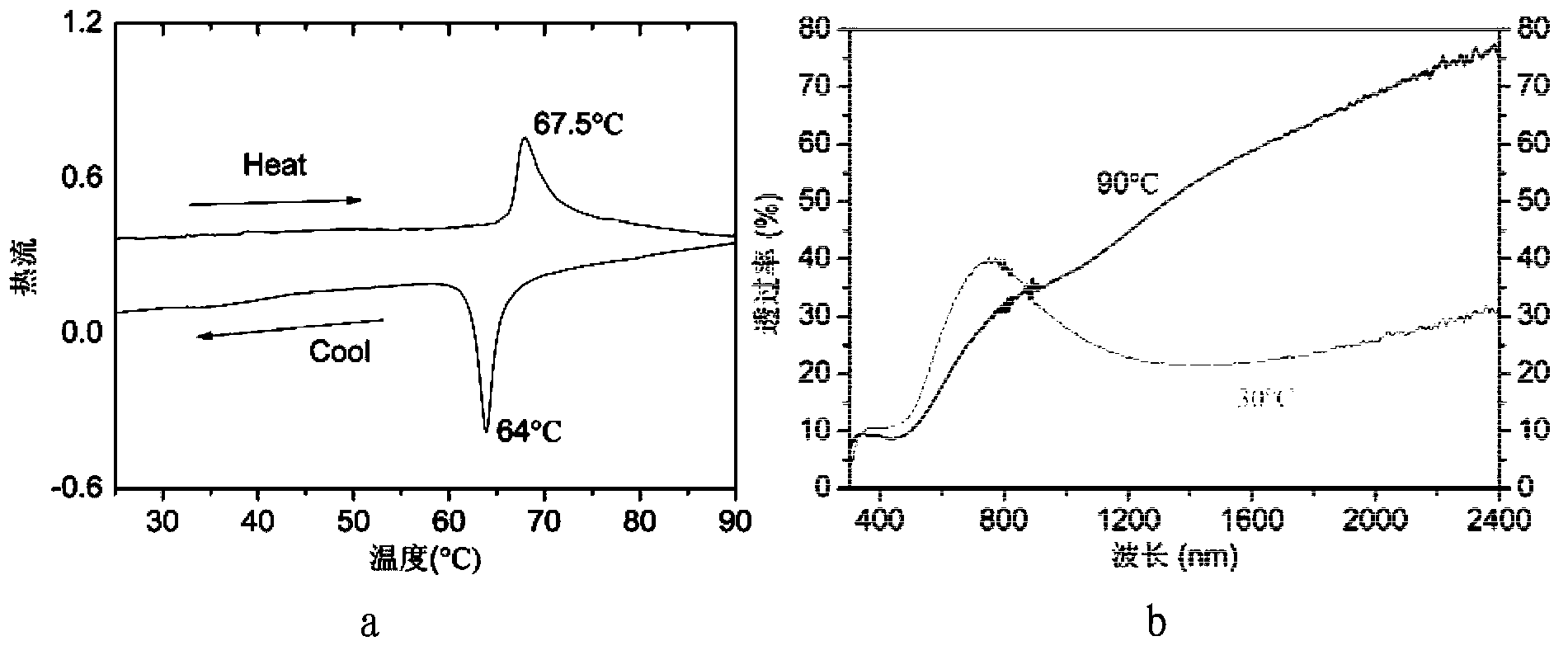

A vanadium dioxide nano, vanadium dioxide technology, applied in the field of nanoparticle preparation, can solve the problems of difficulty in reducing production costs, increasing preparation complexity, large amount of oxalic acid, etc., to achieve good phase transition characteristics, excellent infrared control performance, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete steps of preparation are:

[0020] In step 1, vanadium pentoxide, oxalic acid dihydrate and water are mixed in a molar ratio of 1:1:500; wherein, the water is deionized water to obtain a mixed liquid. Then add a surfactant to the mixed solution and stir for 2 hours, wherein the added amount of the surfactant is 4% of the volume of the mixed solution, and the surfactant is polyethylene glycol to obtain a precursor solution.

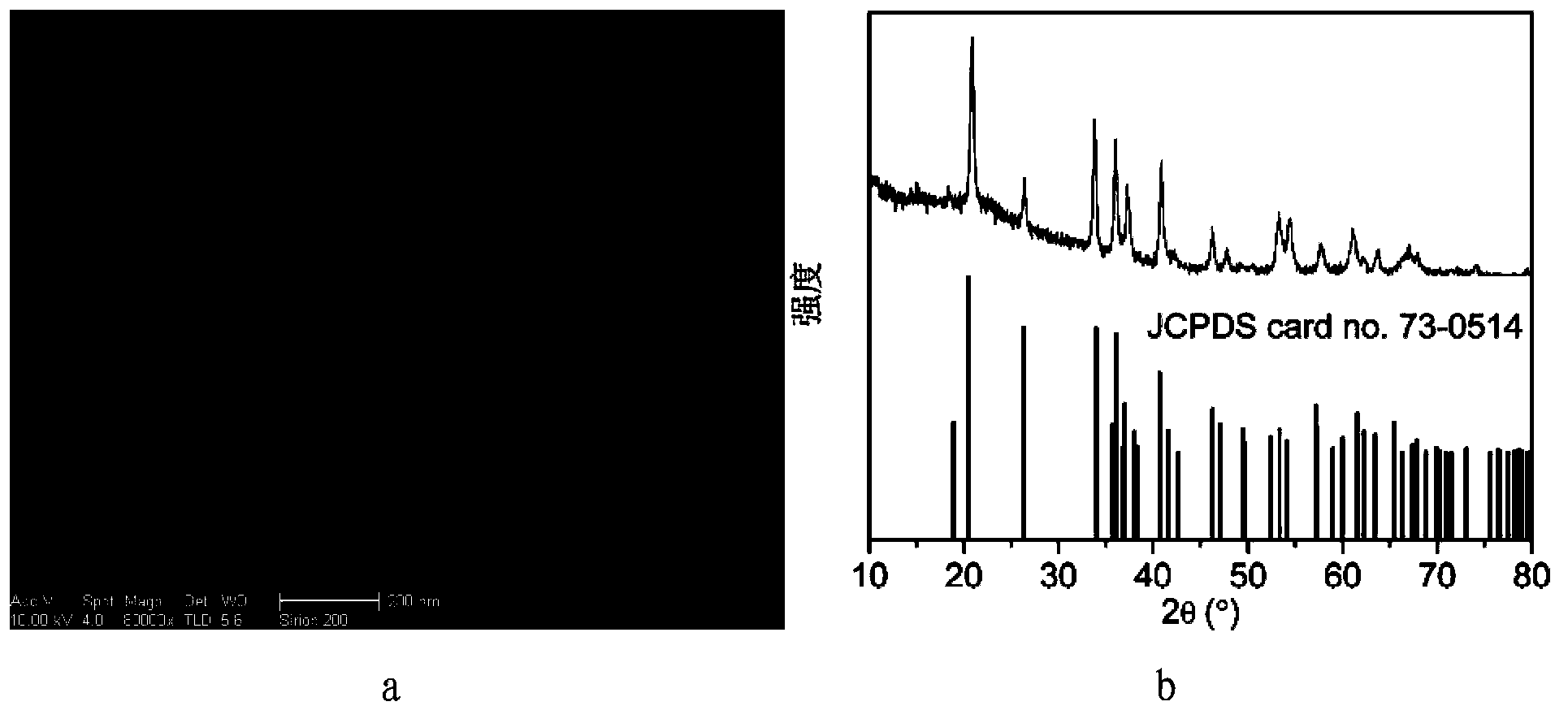

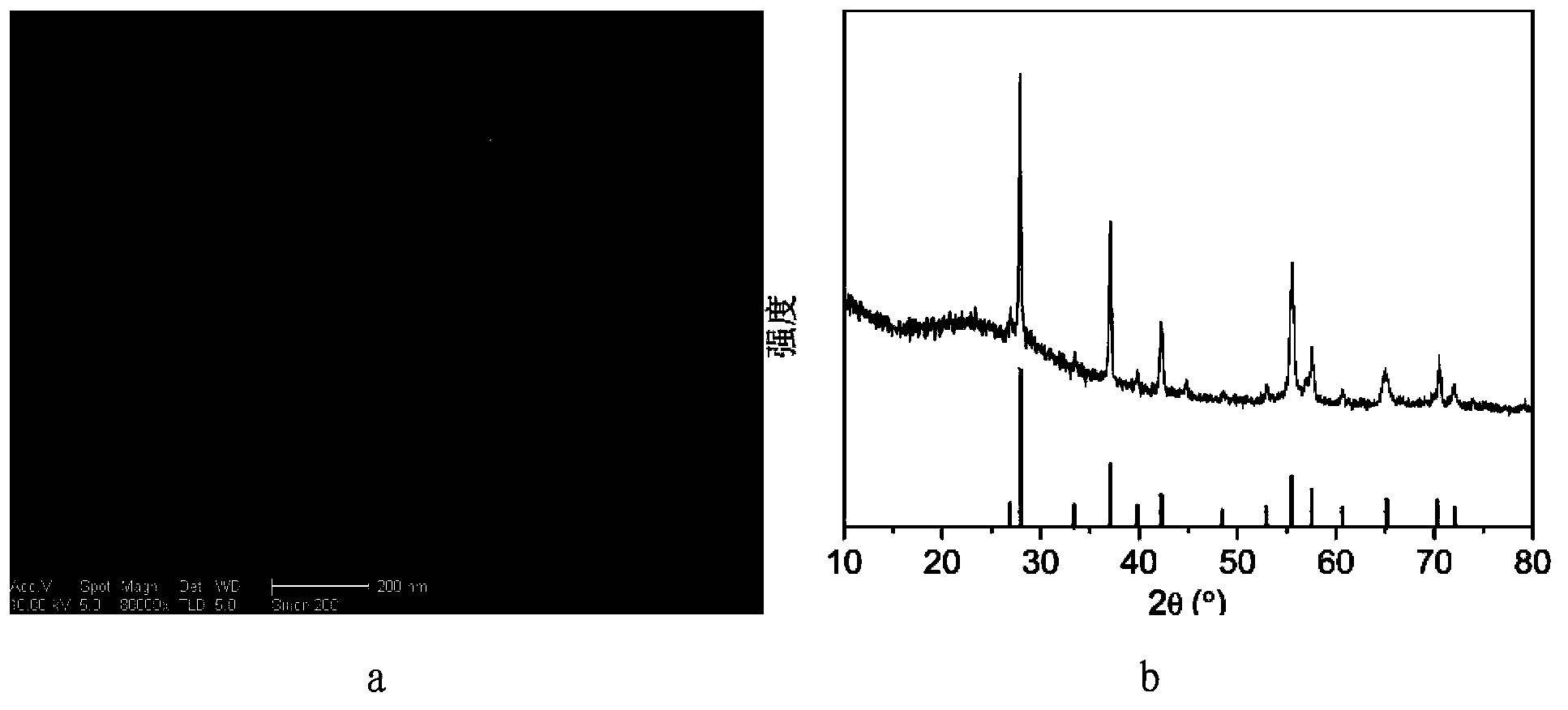

[0021] In step 2, first place the precursor solution in an airtight state, and react at a temperature of 200°C for 5 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation and washing in sequence; wherein, the solid-liquid separation is centrifugation, and the speed of centrifugation is 10000r / min, and the washing process is obtained after centrifugation with deionized water and ethanol respectively. The solid matter is washed 3 times, and the approximate figure 1 as shown in a, and as ...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] In step 1, vanadium pentoxide, oxalic acid dihydrate and water are mixed in a molar ratio of 1.4:1:580; wherein, the water is deionized water to obtain a mixed solution. Then add a surfactant to the mixed solution and stir for 2.5 hours, wherein the added amount of the surfactant is 4.5% of the volume of the mixed solution, and the surfactant is polyethylene glycol to obtain a precursor solution.

[0026] Step 2, first place the precursor solution in a closed state, and react at a temperature of 215° C. for 4 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation and washing in sequence; wherein, the solid-liquid separation is centrifugation, and the speed of centrifugation is 11000r / min, and the washing process is obtained after centrifugation with deionized water and ethanol respectively. The solid matter is washed 3 times, and the approximate figure 1 as shown in a, and ...

Embodiment 3

[0029] The concrete steps of preparation are:

[0030]In step 1, vanadium pentoxide, oxalic acid dihydrate and water are mixed in a molar ratio of 1.8:1:650; wherein, the water is deionized water to obtain a mixed solution. Then add a surfactant to the mixed liquid and then stir for 3 hours, wherein the added amount of the surfactant is 5% of the volume of the mixed liquid, and the surfactant is polyethylene glycol to obtain a precursor solution.

[0031] Step 2, first place the precursor solution in a closed state, and react at a temperature of 230° C. for 3 days to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation and washing in sequence; wherein, the solid-liquid separation is centrifugation, and the speed of centrifugation is 12000r / min, and the washing process is obtained after centrifugation with deionized water and ethanol respectively. The solid matter is cleaned 3 times to obtain such as figure 1 as shown in a, and as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com