Insulated phase-change heat conducting material and preparation method thereof

A technology of heat-conducting materials and insulating phases, applied in the field of insulating phase-change heat-conducting materials and their preparation, can solve problems affecting product performance, poor thermal conductivity, weakened electrical conductivity, etc., and achieve good phase change characteristics, good thermal conductivity, and good insulation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

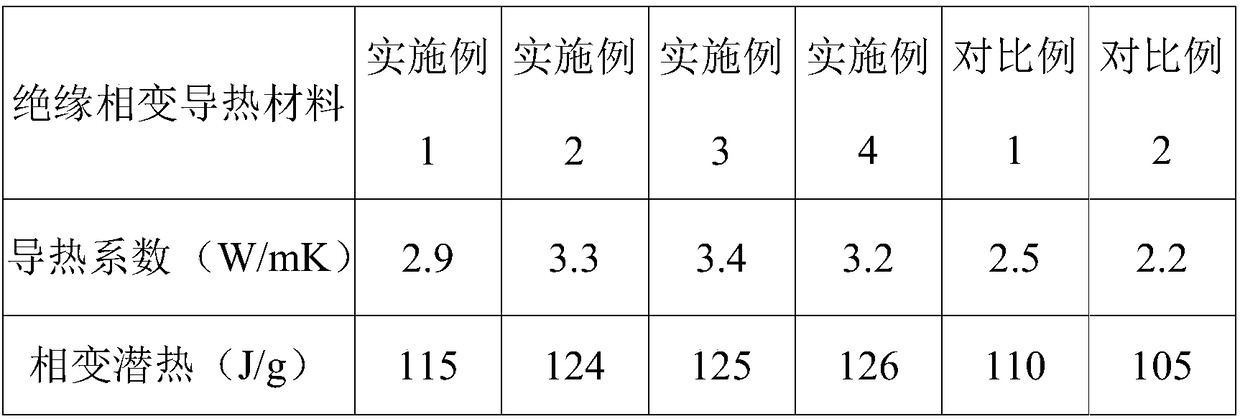

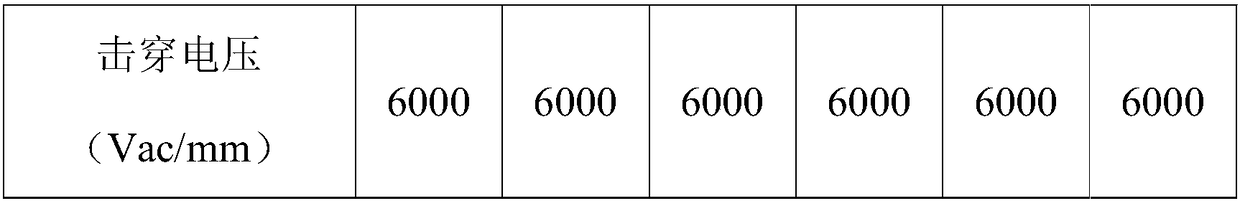

Examples

Embodiment 1

[0026] S1. Preparation of three-dimensional network expanded boron nitride:

[0027] Take 5g of boron oxide and 1g of expanded graphite dissolved in 75ml of methanol solution, and carry out magnetic stirring and mixing for 1h, put the stirred viscous mixed solution in an oven and dry at a temperature of 90°C to obtain a mixture B of boride and expanded graphite. The obtained mixture B was flattened in a graphite crucible and put into a tube furnace. Under the flow rate of 100mL / min N2, the temperature of the tube furnace was raised to 400°C at a rate of 10°C / min and kept for 1h, and at a rate of 5°C / min The temperature was raised to 800°C at a rate of 5°C / min and kept at 2h, and the rate of 5°C / min was heated to 1400°C for 2.5h and then cooled to room temperature with the furnace. After the reaction was completed, the obtained product was placed in a muffle furnace, and kept at 750°C for 5 hours to remove excess carbon, and finally obtained a white powder with a specific surfa...

Embodiment 2

[0033] S1. Preparation of three-dimensional network expanded boron nitride:

[0034] Take 5g of boron oxide and 1g of expanded graphite dissolved in 75ml of methanol solution, and carry out magnetic stirring and mixing for 1h, put the stirred viscous mixed solution in an oven and dry at a temperature of 90°C to obtain a mixture B of boride and expanded graphite. The obtained mixture B was flattened in a graphite crucible and put into a tube furnace. Under the flow rate of 100mL / min N2, the temperature of the tube furnace was raised to 400°C at a rate of 10°C / min and kept for 1h, and at a rate of 5°C / min The temperature was raised to 800°C at a rate of 5°C / min and kept at 2h, and the rate of 5°C / min was heated to 1400°C for 2.5h and then cooled to room temperature with the furnace. After the reaction was completed, the obtained product was placed in a muffle furnace, and kept at 750°C for 5 hours to remove excess carbon, and finally obtained a white powder with a specific surfa...

Embodiment 3

[0042] S1. Preparation of three-dimensional network expanded boron nitride:

[0043] Take 5g of boron oxide and 1g of expanded graphite dissolved in 75ml of methanol solution, and carry out magnetic stirring and mixing for 1h, put the stirred viscous mixed solution in an oven and dry at a temperature of 90°C to obtain a mixture B of boride and expanded graphite. The obtained mixture B was flattened in a graphite crucible and put into a tube furnace. Under the flow rate of 100mL / min N2, the temperature of the tube furnace was raised to 400°C at a rate of 10°C / min and kept for 1h, and at a rate of 5°C / min The temperature was raised to 800°C at a rate of 5°C / min and kept at 2h, and the rate of 5°C / min was heated to 1400°C for 2.5h and then cooled to room temperature with the furnace. After the reaction was completed, the obtained product was placed in a muffle furnace, and kept at 750°C for 5 hours to remove excess carbon, and finally obtained a white powder with a specific surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com