Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7564 results about "Muffle furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A muffle furnace or muffle oven (sometimes retort furnace in historical usage) is a furnace in which the subject material is isolated from the fuel and all of the products of combustion, including gases and flying ash. After the development of high-temperature heating elements and widespread electrification in developed countries, new muffle furnaces quickly moved to electric designs.

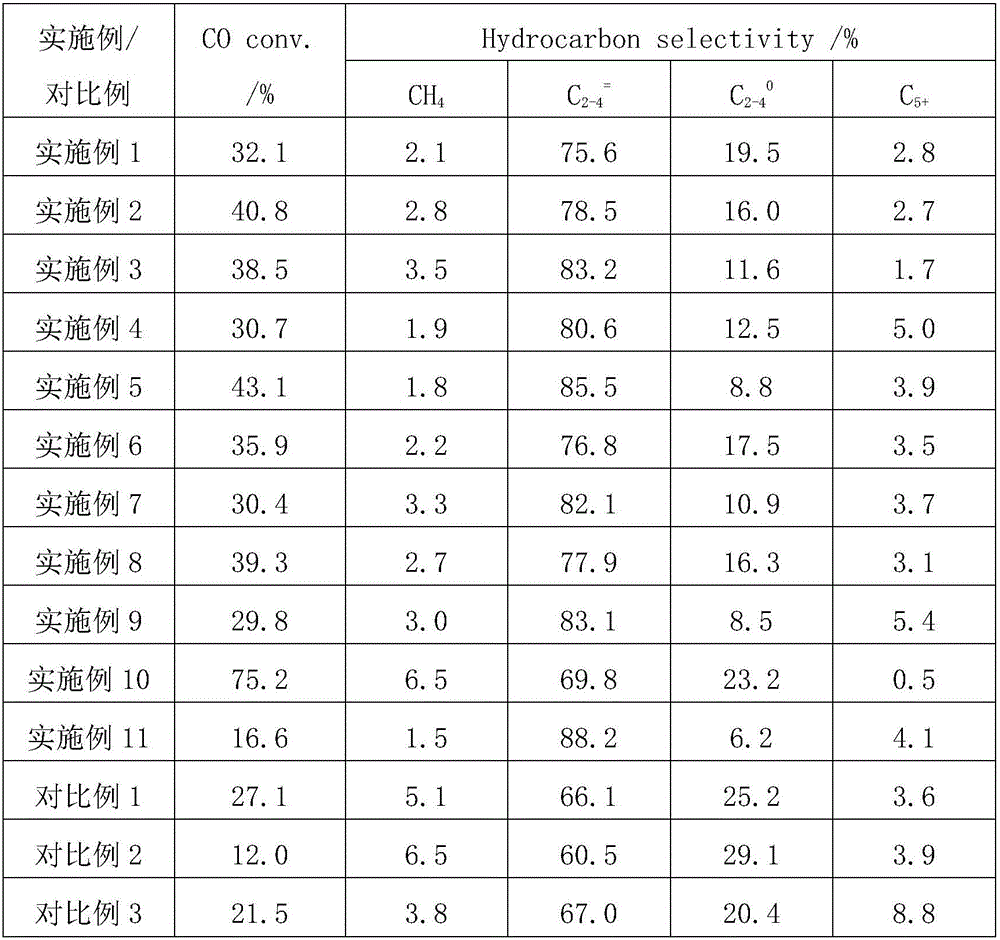

Catalyst for preparing low-carbon olefins by one-step conversion of synthetic gas and preparation method thereof

ActiveCN106345514AImprove catalytic performanceImprove connectivityMolecular sieve catalystsSyngasMolecular sieve

A catalyst for preparing low-carbon olefins by one-step conversion of synthetic gas and a preparation method thereof relate to catalysts; the catalyst is made from 20-60% of a zirconium-based solid solution,30-70% of a double-micropore zeolite molecular sieve and 0.1-10% of metal oxides; the preparation method comprises: adding salt compounds of at least one element from IA, IIIA, VIIB, IB, IIB and the like into deionized water or alcohol to obtain solution A having a mass concentration of 0.1-15%; adding the zirconium-based solid solution into the solution A, heating, drying by distillation, and drying to obtain solid powder; adding the solid powder and the double-micropore zeolite molecular sieve into ethylene glycol, ultrasonically dispersing, and moving a filtered and washed sample to a vacuum drying box, drying at 50-100 DEG C for 2-24 h, calcining in a muffle furnace, and tableting obtained solid sample to obtain the catalyst.

Owner:XIAMEN UNIV

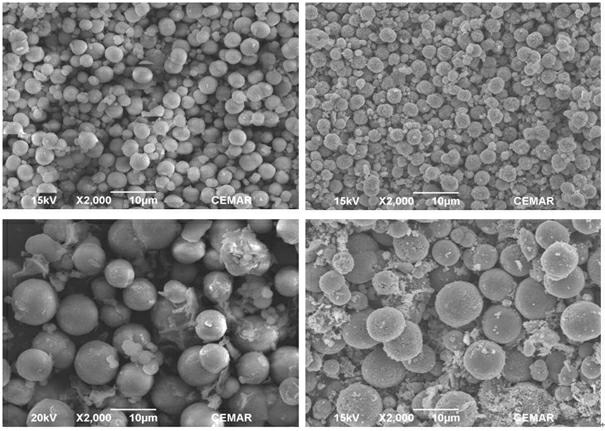

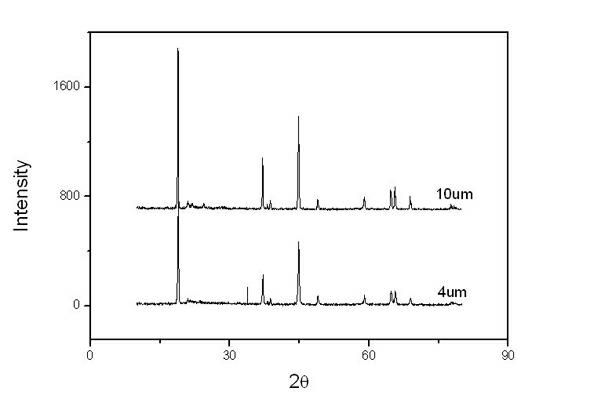

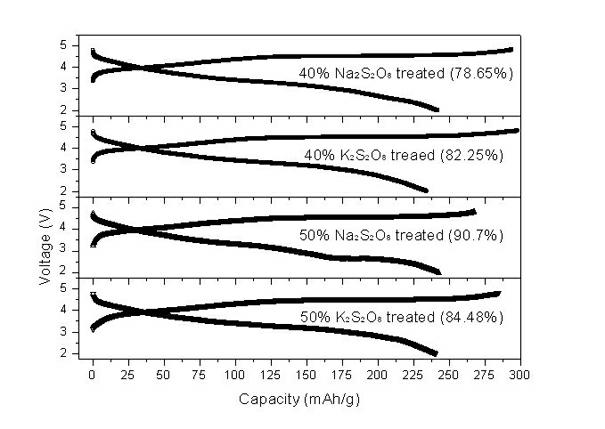

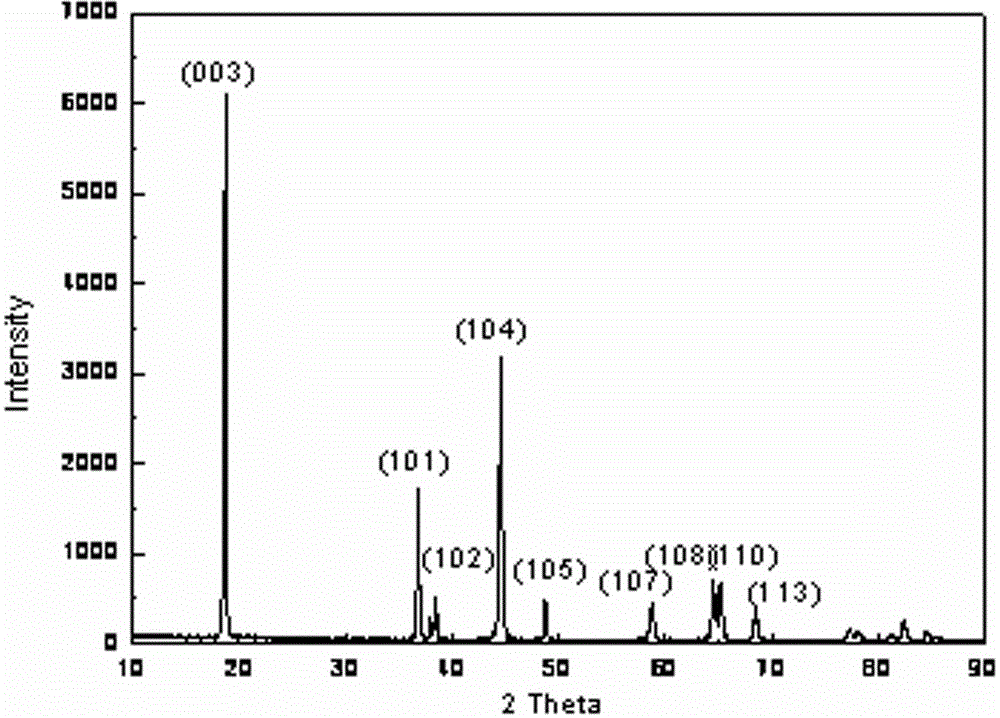

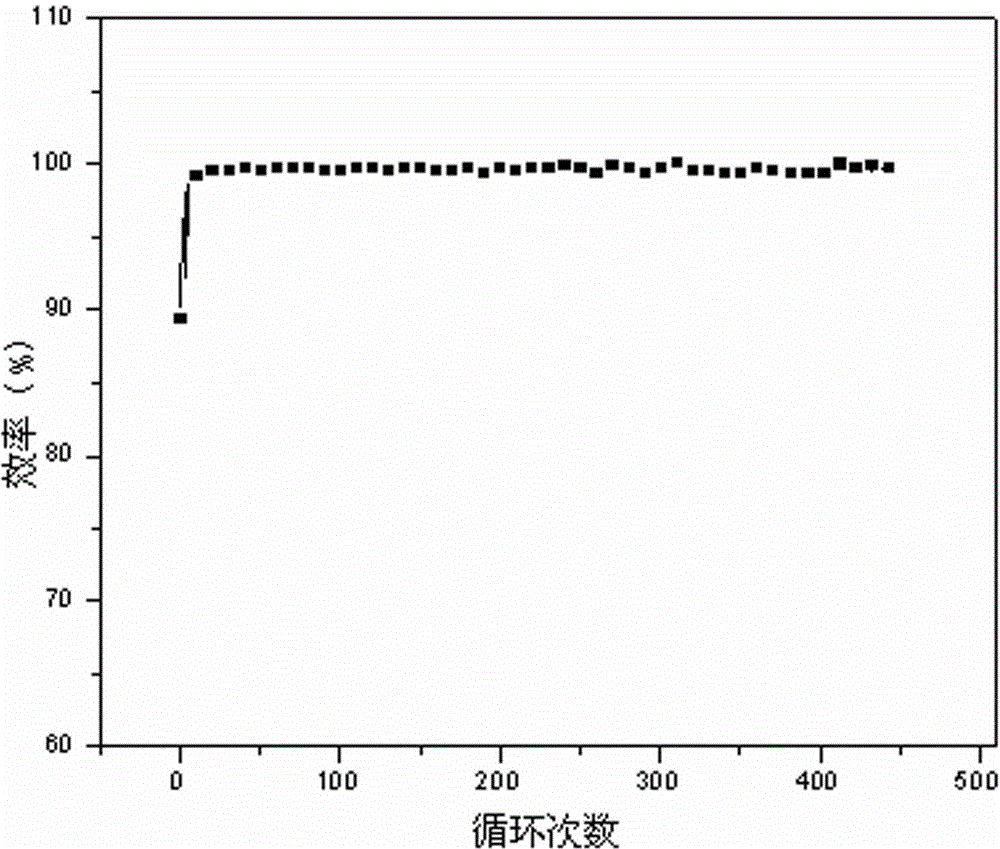

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Method for preparing low density silica aerogel under normal pressure

InactiveCN103435055AShorten the production cycleIncrease productivitySilicaEnergy inputTrimethylsilyl chlorideSilicic acid

The present invention discloses a method for preparing low density silica aerogel under normal pressure. The method comprises: mixing tetraethoxysilane, water and ethanol according to a volume ratio of 1:0.5-19:1-29, adding an acid to adjust the pH value to 3-4, carrying out catalysis hydrolysis, adding an alkali to adjust the pH value to 6-6.5, carrying out catalysis gelating for 8-10 min to obtain a wet gel, aging the wet gel for 6-36 h at a room temperature, adding n-hexane to carry out solvent replacement for 6-36 h, immersing in a trimethylchlorosilane and n-hexane mixed solution to carry out hydrophobic modification for 12-15 h, adopting a n-hexane washing solution to remove the modification solution, placing into a muffle furnace to heat to a temperature of 30-250 DEG C, drying, and finally cooling to a room temperature to obtain the silica aerogel. Test results show that the density of the SiO2 aerogel is 50-80 kg / m<3> and is significantly lower than the density of the SiO2 aerogel prepared under the normal pressure dry condition in most of the public reports.

Owner:ZHEJIANG UNIV OF TECH

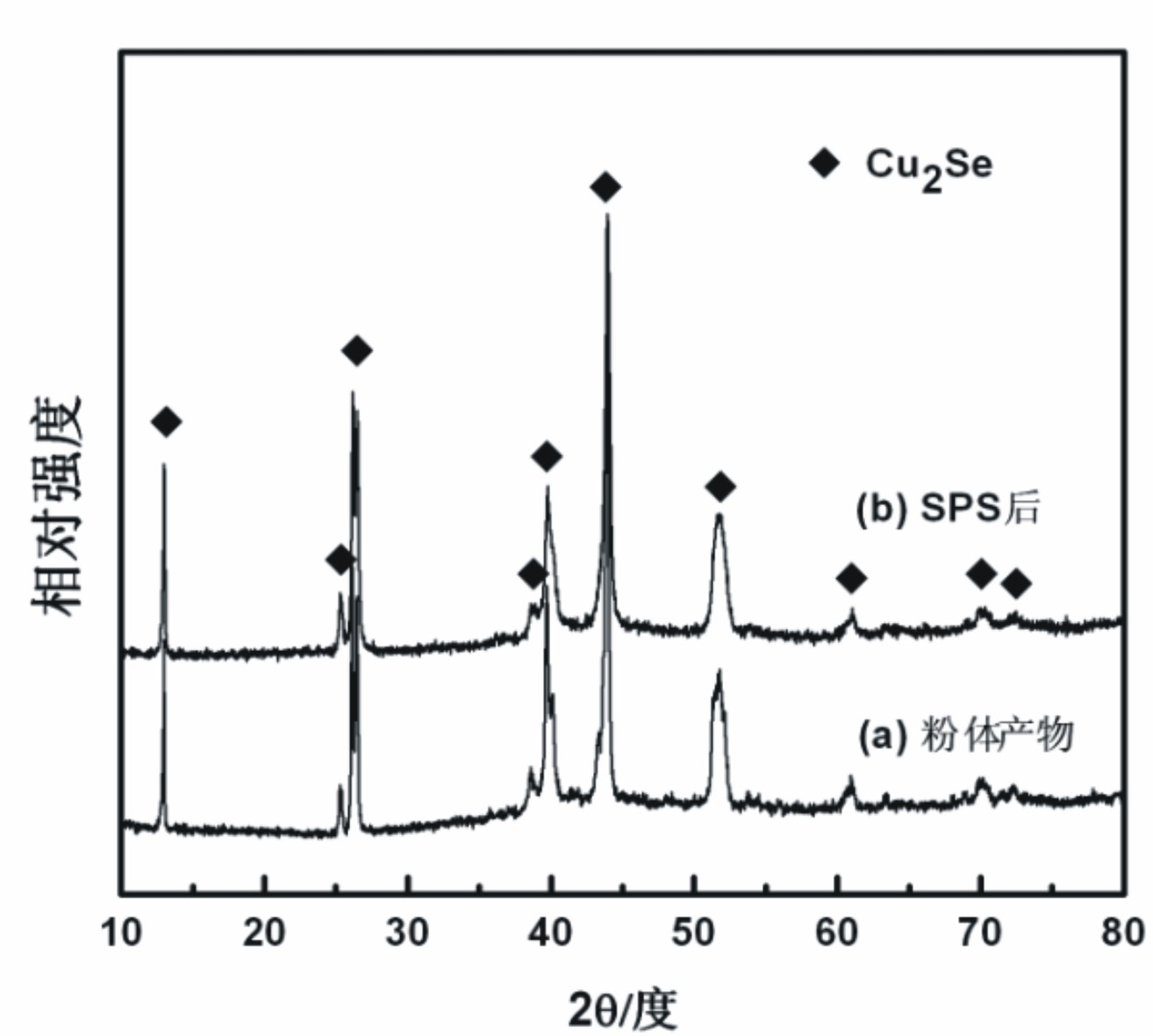

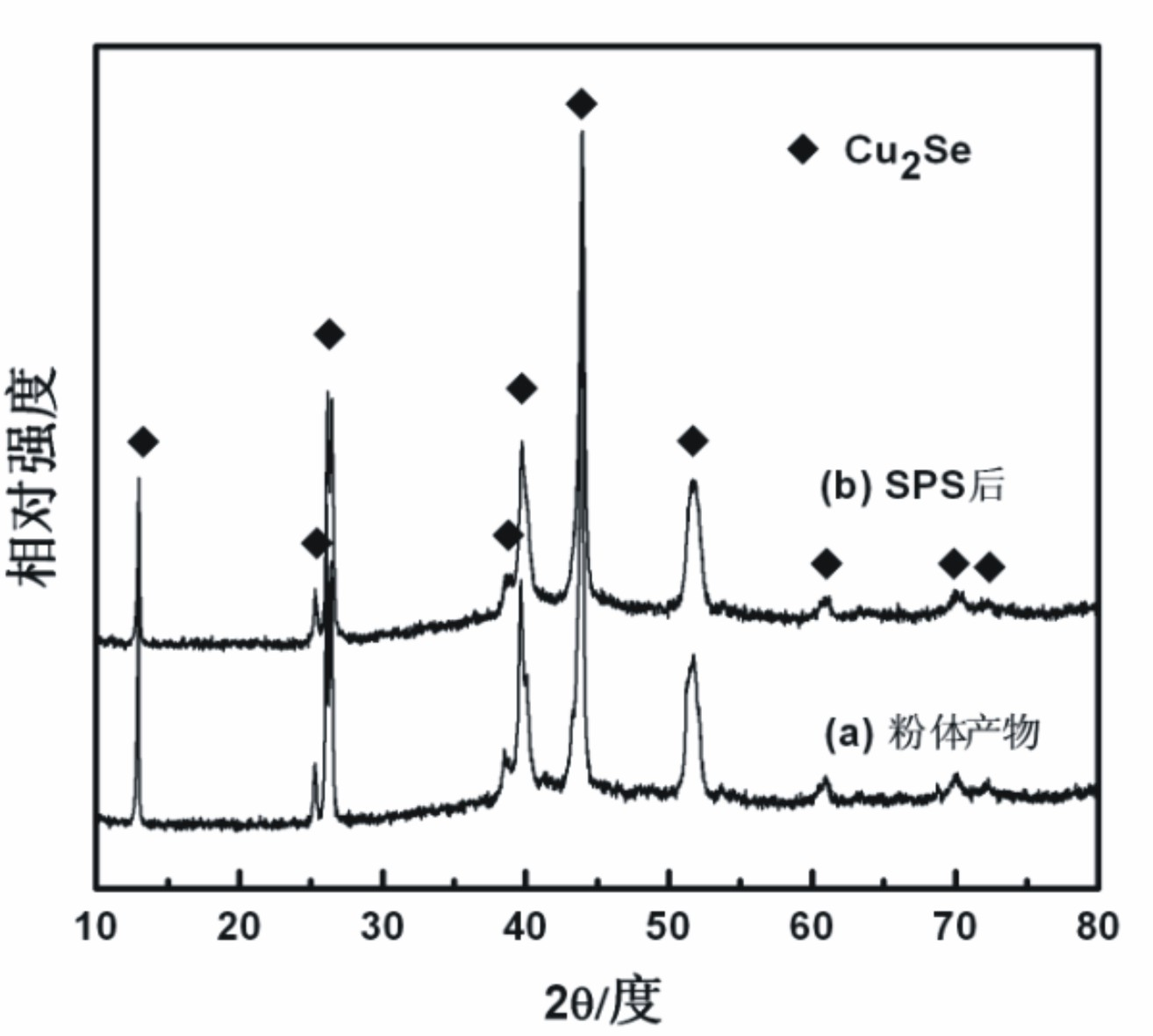

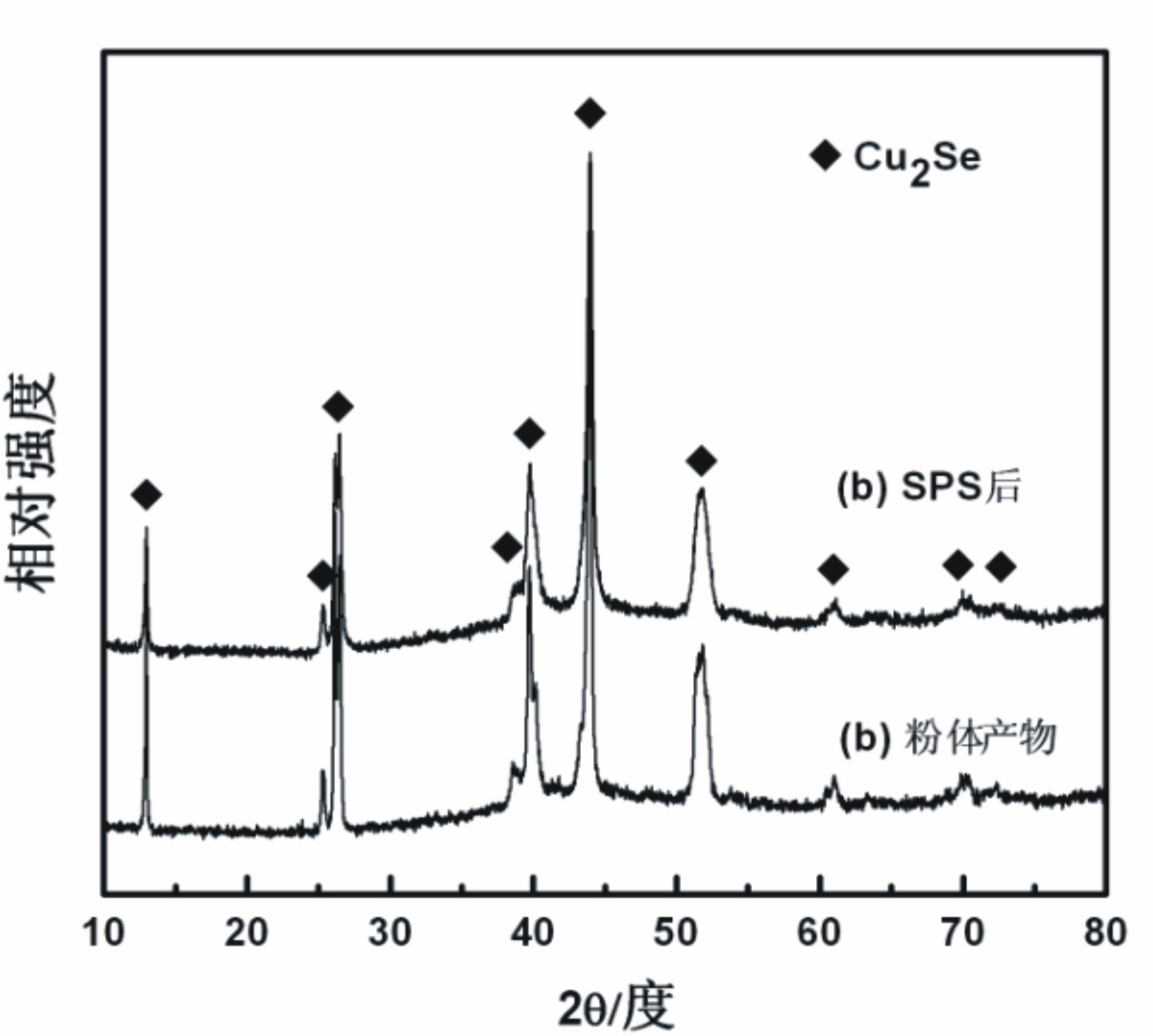

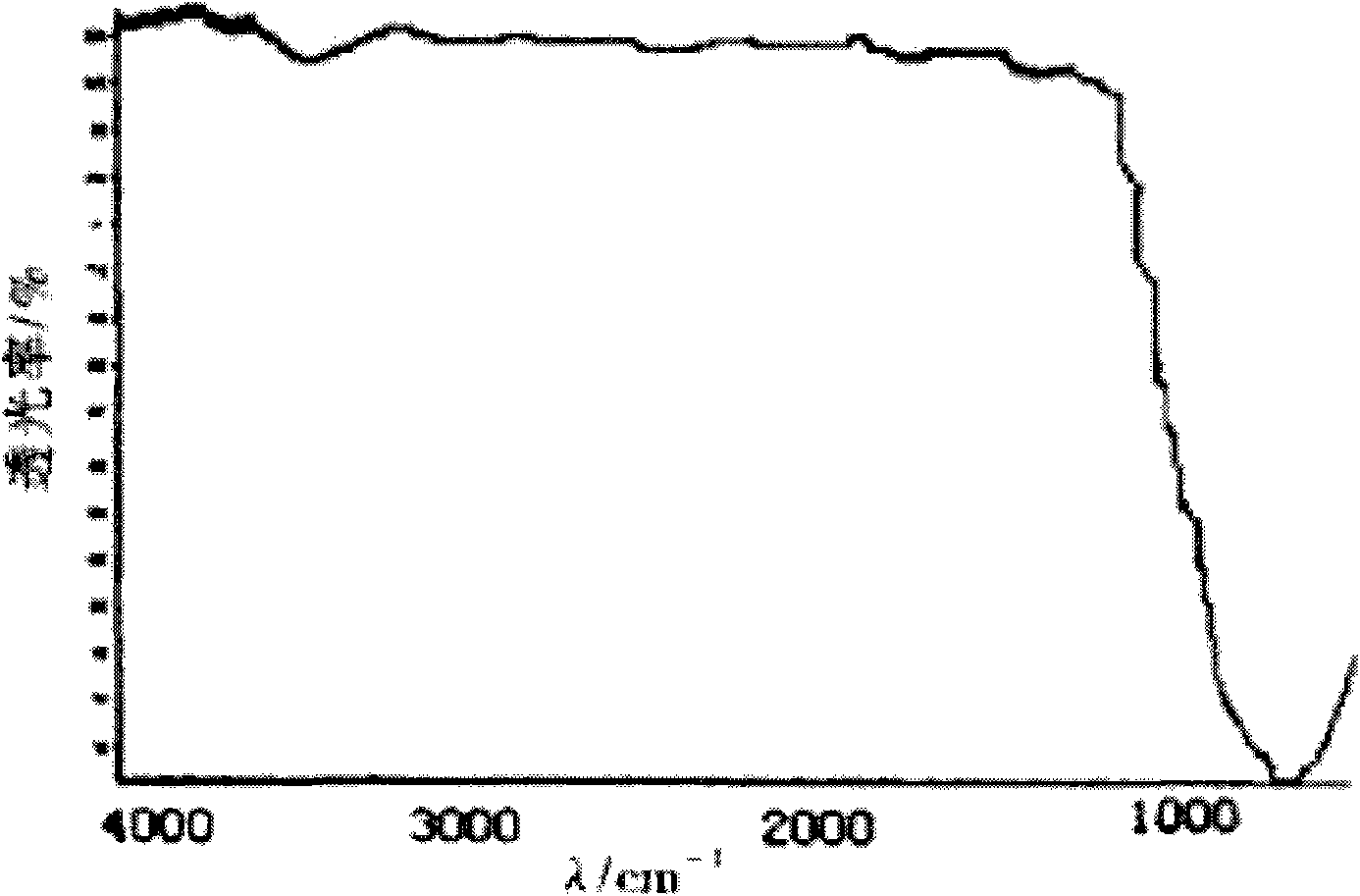

Method for preparing Cu2Se thermoelectric material by low-temperature solid-phase reaction

InactiveCN102674270ALow costControl compositionChemical industryBinary selenium/tellurium compoundsThermoelectric materialsMuffle furnace

The invention relates to a method for preparing a Cu2Se thermoelectric material. The method for preparing the Cu2Se thermoelectric material by the low-temperature solid-phase reaction is characterized by comprising the following step: 1) weighing Cu powder and Se powder according to the molar ratio of 2:1 and mixing the Cu powder and the Se powder uniformly to obtain mixed powder, wherein the Cu powder and the Se powder serve as raw materials; 2) pressing the mixed powder into a block body by using tablet press, placing the block body into a graphite crucible, vacuumizing, sealing into a quartz glass tube, placing into a muffle furnace, performing solid-phase reaction at the temperature of between 650 and 750 DEG C for 12 to 24 hours, and grinding the obtained product into powder; and 3) performing spark plasma sintering on the powder obtained in the step 2) to obtain a compact block body, namely the Cu2Se thermoelectric material. By the method, the raw materials have low cost; the reaction temperature is low; energy is saved; and the materials are fed according to the stoichiometric ratio of the Cu2Se, so the product composition can be controlled precisely; and the repeatability is high.

Owner:WUHAN UNIV OF TECH

Preparation method of high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane

InactiveCN101603245AGood flexibilityBend freelyFilament/thread formingNon-woven fabricsElectrospinningSolvent

The invention provides a preparation method of high elasticity super hydrophobic high temperature silicon dioxide fibrous membrane. The invention is characterized in that the method includes the following steps: template polymer is stirred in solvent at 60 DEG C to obtain template solution with mass concentration of 5-30%; organic silicon or nano silicon dioxide are mixed with water and inorganic acid at normal temperature to obtain silicon source solution; the template solution and the silicon source solution are mixed to be uniform at normal temperature to obtain electro spun solution; the electro spun solution is subject to electrostatic spinning at normal temperature to obtain composite fibrous membrane; the compound fibrous membrane is placed into a muffle furnace to be forged, so as to obtain a nano silicon dioxide fibrous membrane; the nano silicon dioxide fibrous membrane is placed into organic silicon hydrocarbon compound solution to be soaked for 6-30h and then is dried in vacuum, thus obtaining the high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane. The material is antifouling and self-cleaning under high temperature high pressure severe environment.

Owner:DONGHUA UNIV

Method for recovering lead from lead paste of waste lead-acid battery

InactiveCN101613803AReduce handling difficultiesSimple processProcess efficiency improvementMuffle furnaceChloride sodium

The invention relates to a method for recovering lead from lead plaster of waste lead-acid battery, belonging to the recovery treatment technology of the waste lead-acid battery. The method comprises the following steps: carrying out crushing, sorting and rinsing on the waste lead-acid battery by using a special crusher, respectively and independently recovering and utilizing lead or lead alloy grid plate and organic matters, mixing electrolyte, washing liquor and lead paste, placing the mixture into muffle furnace for roasting; carrying out chloridizing leaching on the roasted sand in leachate consisting of sodium chloride, calcium chloride and hydrochloric acid; after chloridizing leaching, carrying out press-filtering, carrying out concentrated treatment on the filter residue, carrying out sharp quenching on the filter liquor to room temperature and standing; after the precipitation is finished, carrying out filtration, returning chloridizing leaching to the filtrate, and obtaining filter residue which is the final product, namely lead chloride. The method is characterized by simple and easy technique, more common and cheaper materials used and equipment, cycle use for chloridizing leaching solution and having no pollution.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of load type metal compound catalyst used for water treatment

ActiveCN101579623ALow costWide variety of sourcesWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereLayer thickness

The invention relates to a preparation method of a load type metal compound catalyst used for water treatment, in particular to a catalyst comprising a metal oxide and metal salt. The method comprises the following steps: a porous inorganic material carrier, metal salt, a dispersant, a stabilizing agent and a accelerant which are treated are added into an organic solvent and stirred to form a load type catalyst before-preparation body mixture, the load type catalyst before-preparation body mixture stands for 1 to 9 days under a sealed condition until the load of the catalyst is completed, a steady load type catalyst before-preparation body is prepared, put in a baking oven for baking, moved into a muffle furnace and heated to 300 DEG C to 600 DEG C under air atmosphere at the speed of 2 DEG C / min to 6 DEG C / min, the temperature is kept for 1 to 8 hours, and finally, the load type metal compound catalyst used for water treatment, which forms a fixed catalyst layer with the layer thickness of 15nm to 28mum on the surface of the carrier, is prepared. The method has lower cost, little loss of raw materials in the preparation technology process and simple preparation technology, and is suitable for industrial mass production.

Owner:内蒙古海驰创新中心有限公司

Preparation method of ceramic granules

InactiveCN102060562ALow water absorptionHigh compressive strengthCeramicwareSpherical granuleDiiron Trioxide

The invention relates to a preparation method of ceramic granules, which comprises the following steps: drying and crushing coal ash, kaolin, ferric oxide and basic magnesium carbonate into powder after wet grinding; carrying out the biscuit firing treatment on the powder to prepare biscuit-firing granules after spherical granules are prepared; preparing microcrystal glass powder by utilizing an Li-Al-Si system; pouring the prepared microcrystal glass powder into a granulator to be stirred; preparing the biscuit-firing granules packaged by the microcrystal glass powder after the surface of the biscuit-firing granules is completely packaged by the microcrystal glass powder; placing the biscuit-firing granules packaged by the microcrystal glass powder into the granulator; adding the powder;preparing the ceramic granules to be treated through the biscuit firing after the biscuit-firing granules packaged by the microcrystal glass powder are completely packaged by the powder; and preparing the ceramic granules after the ceramic granules to be treated through the biscuit firing are placed into a muffle furnace to be sintered and crushed. In the invention, a packaging method is adopted to prepare the ceramic granules, the inner layer of the prepared ceramic granules is completely packaged by the glass powder, and the gas of the inner layer is prevented from discharging in the sintering course so that the inner layer is in a loose porous structure, thereby greatly reducing the water absorption rate of the ceramic granules and decreasing the specific gravity.

Owner:SHAANXI UNIV OF SCI & TECH +1

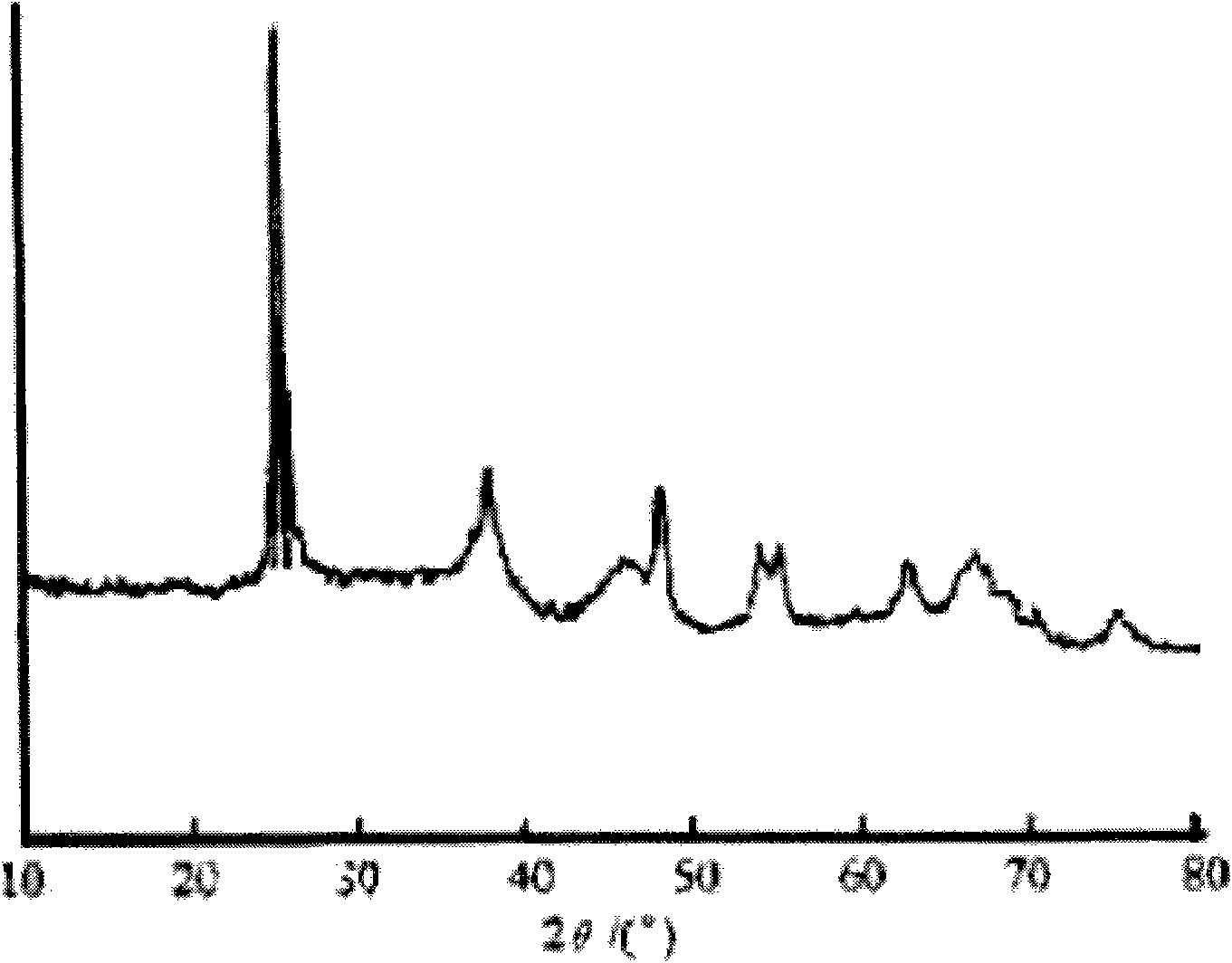

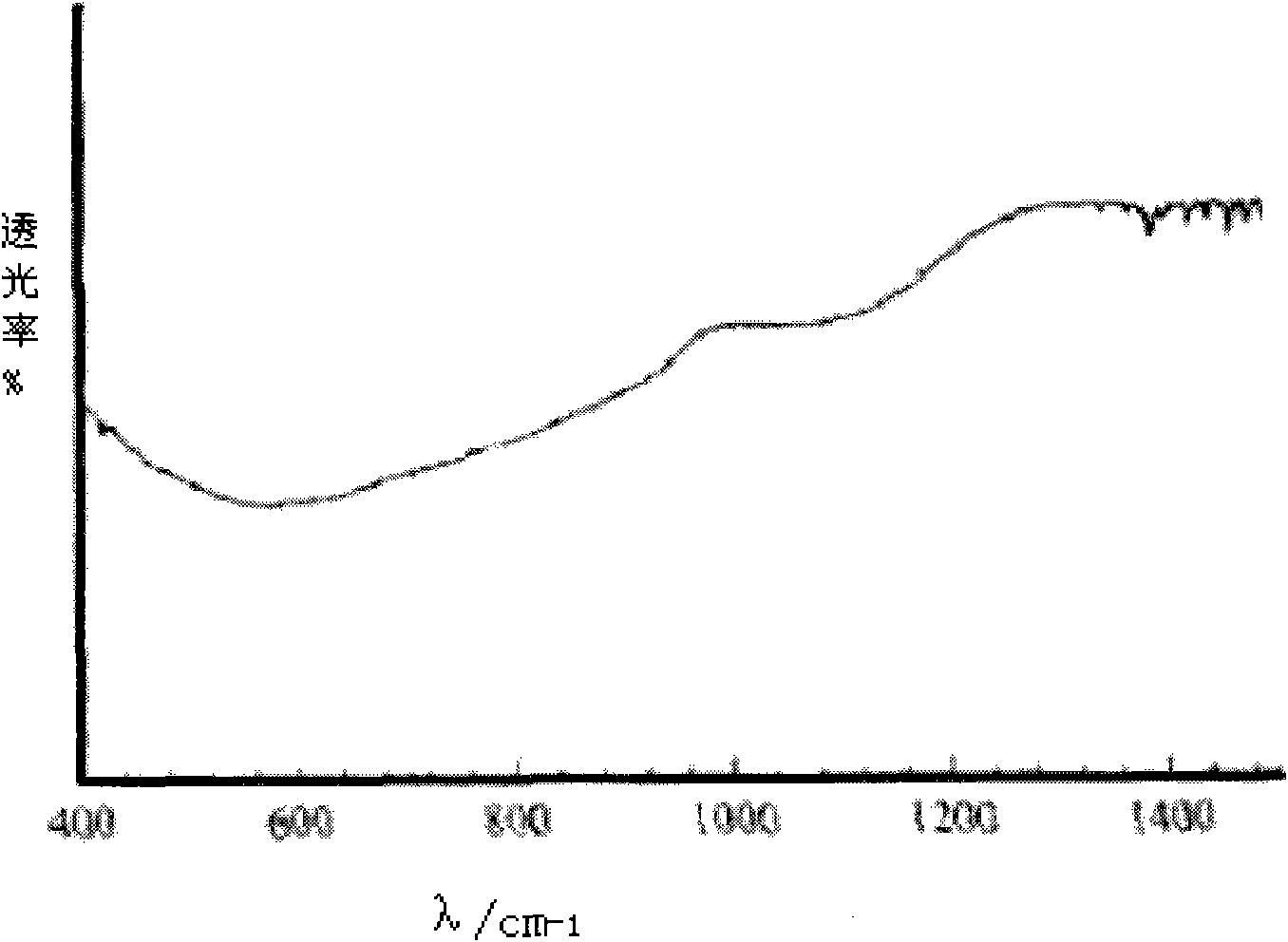

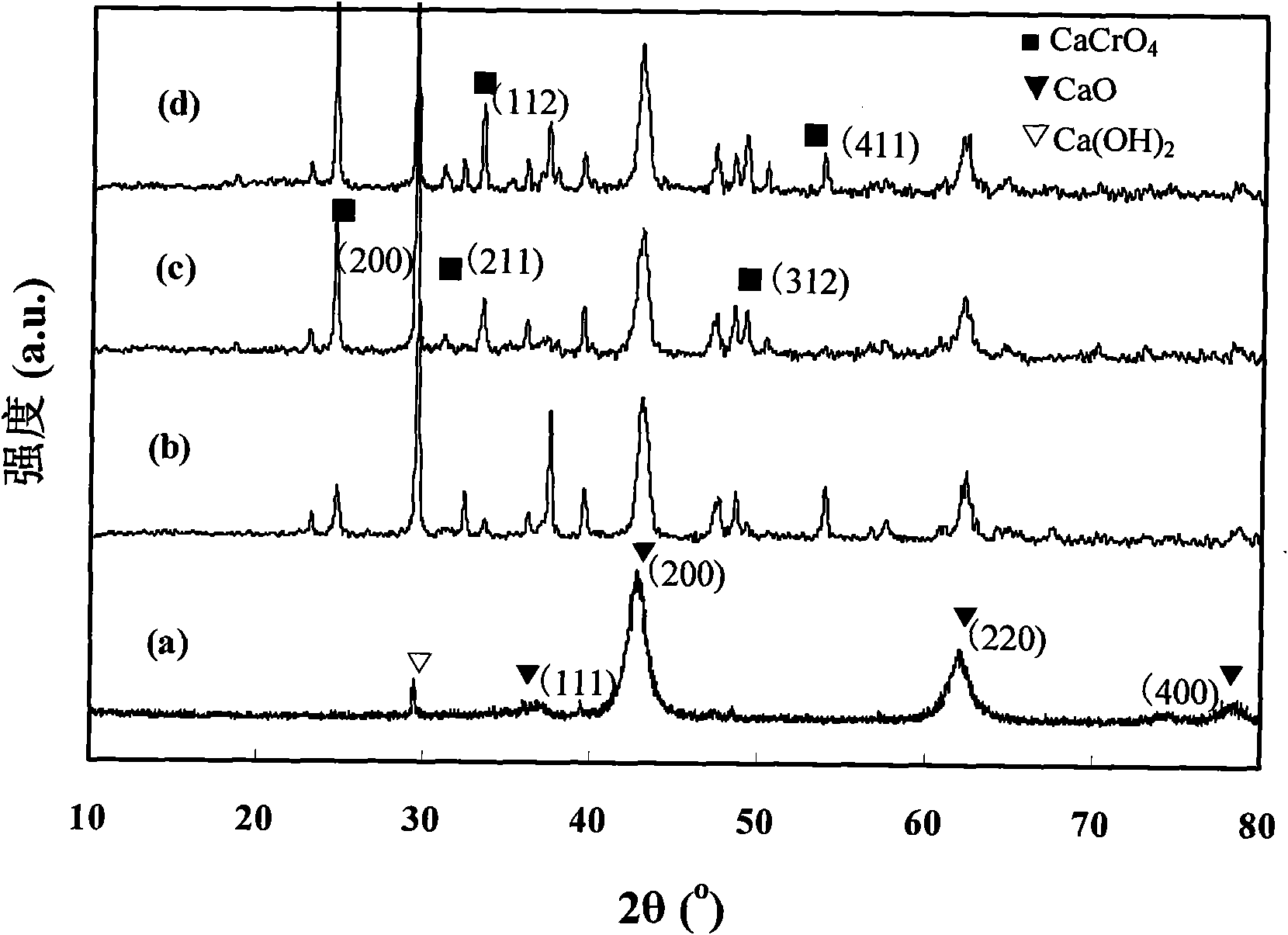

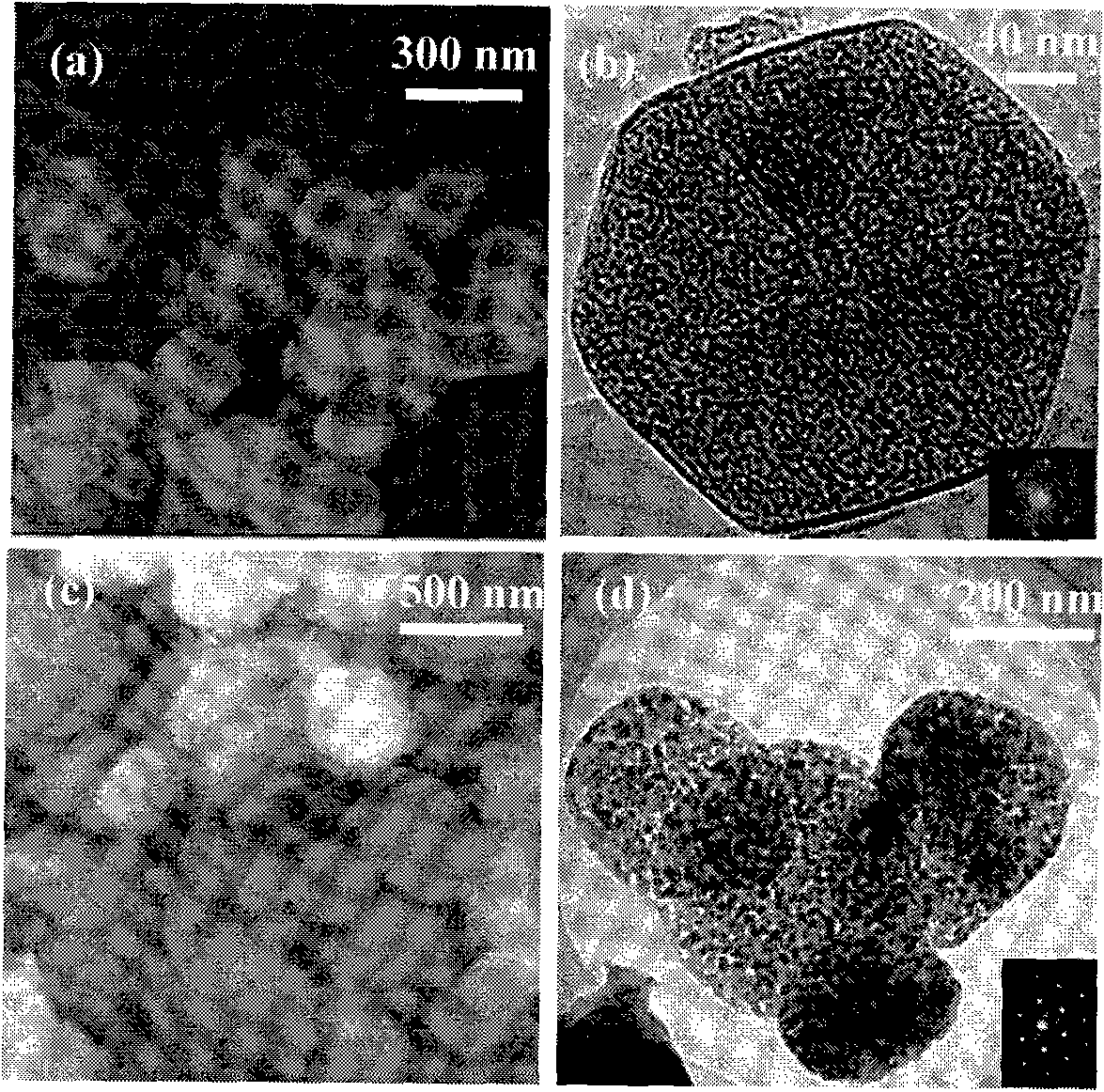

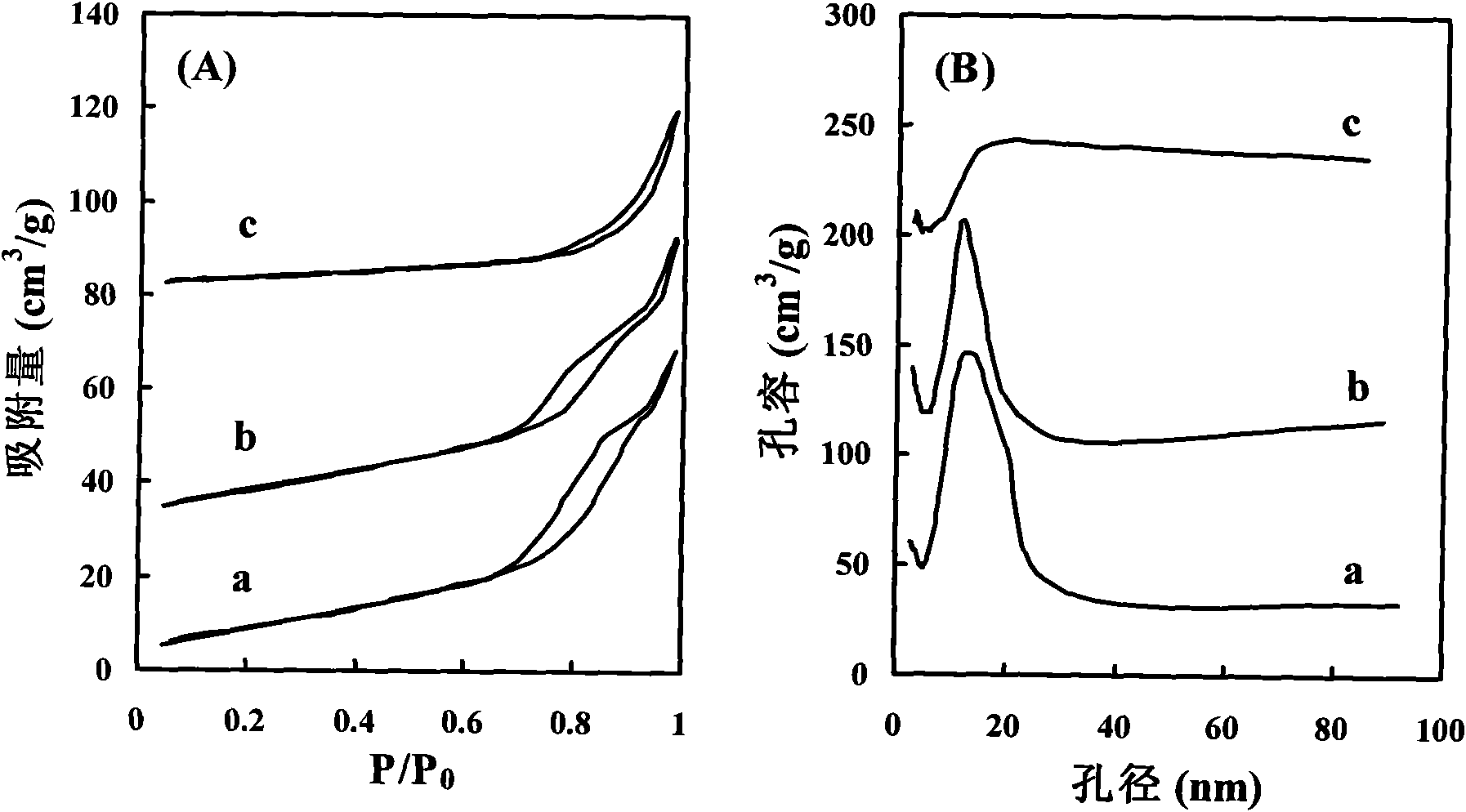

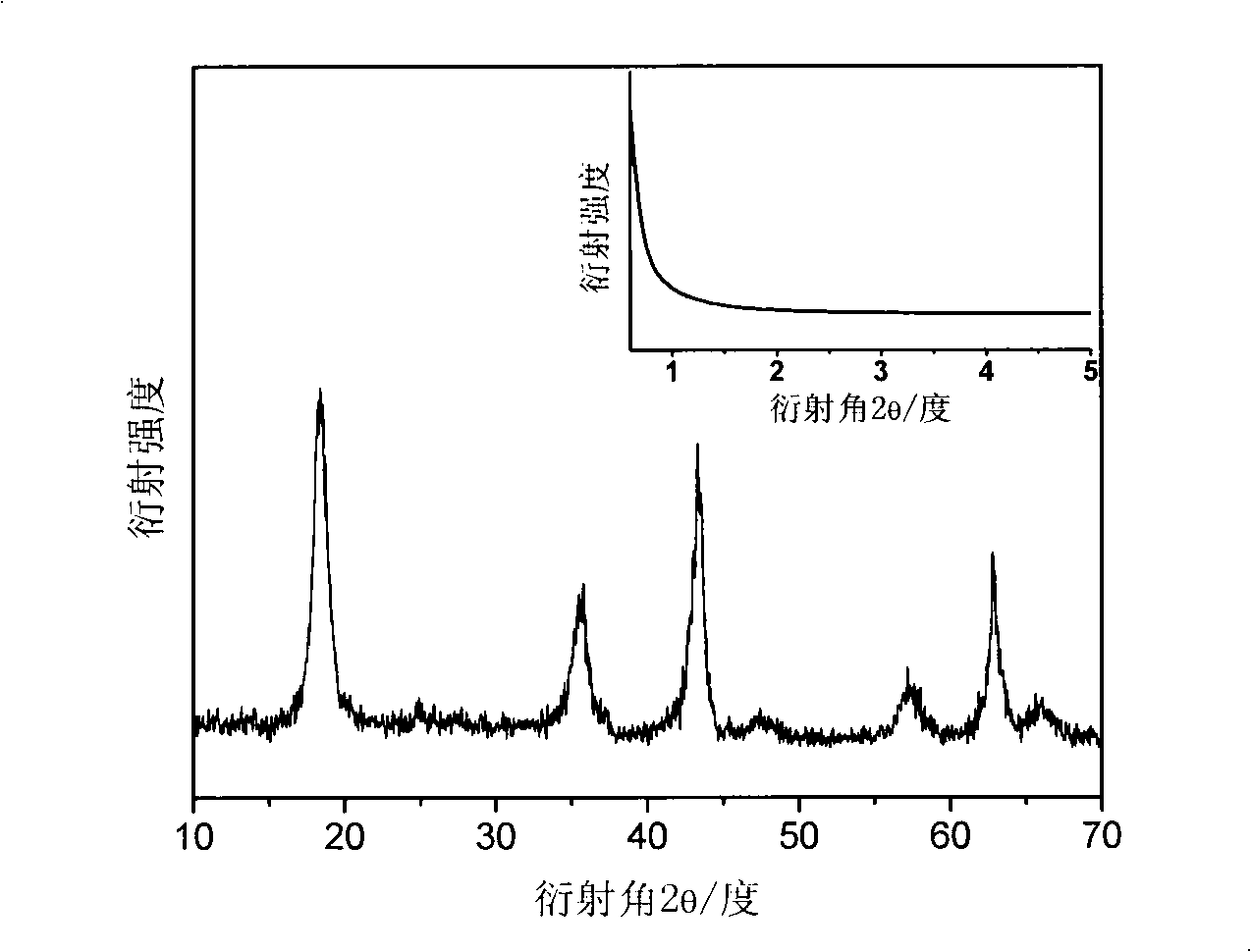

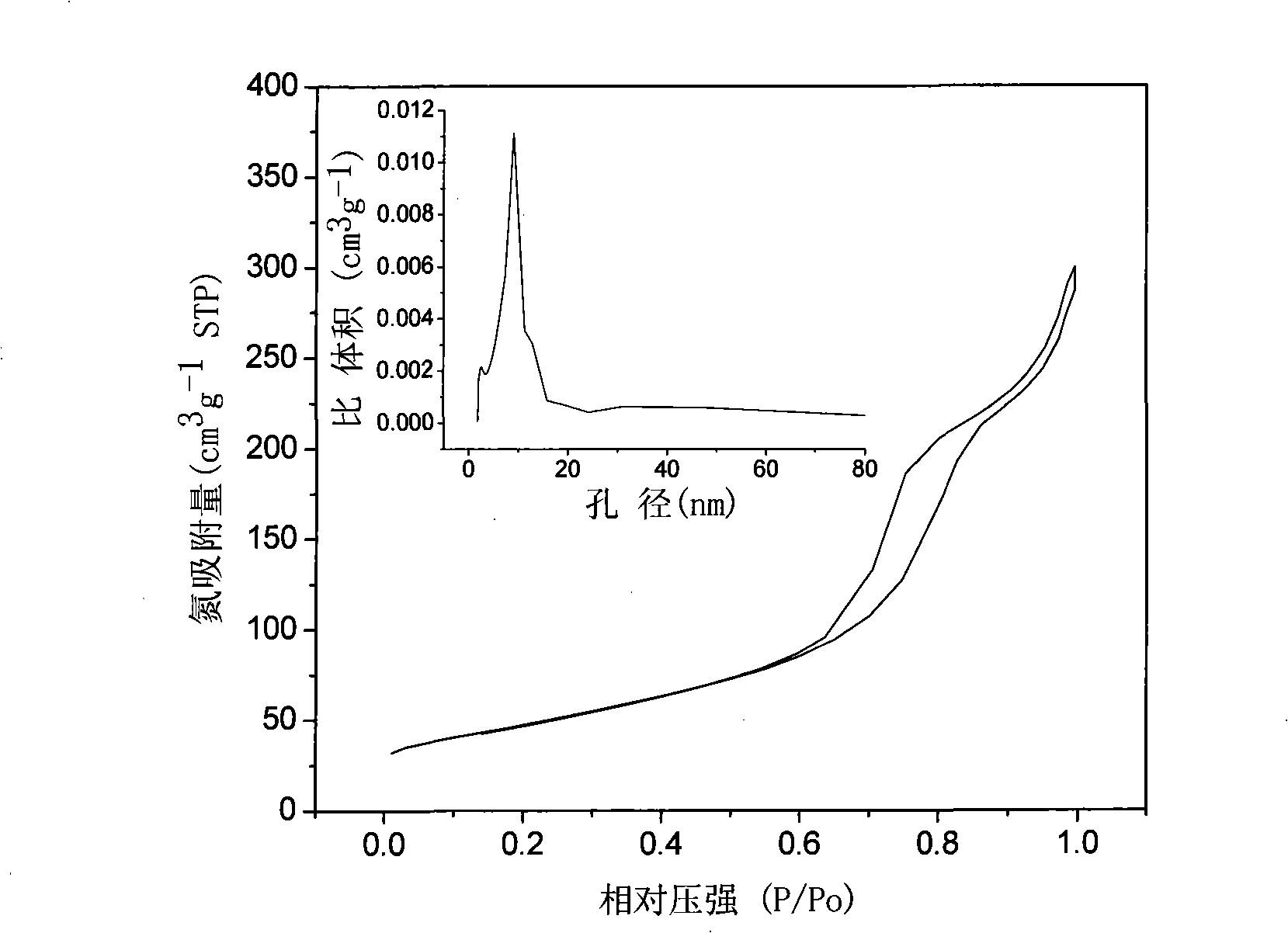

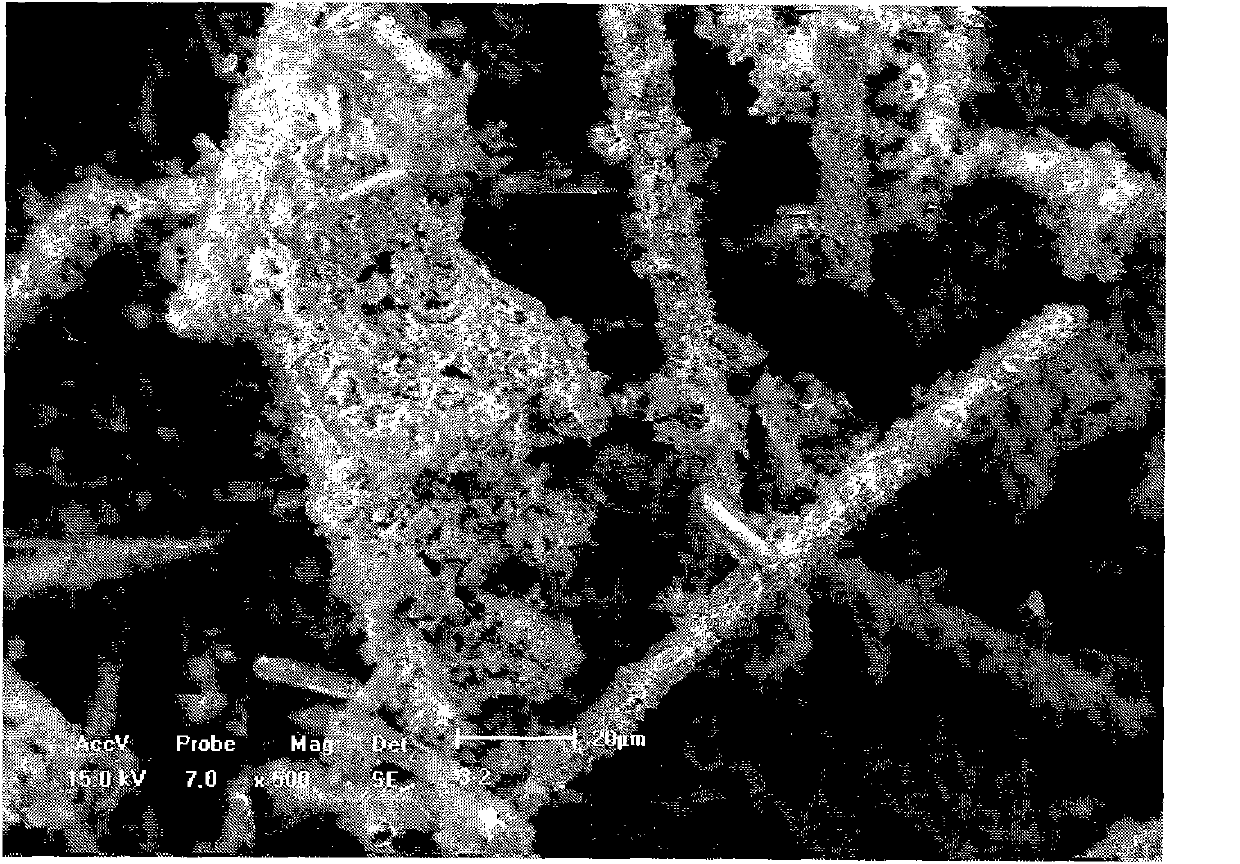

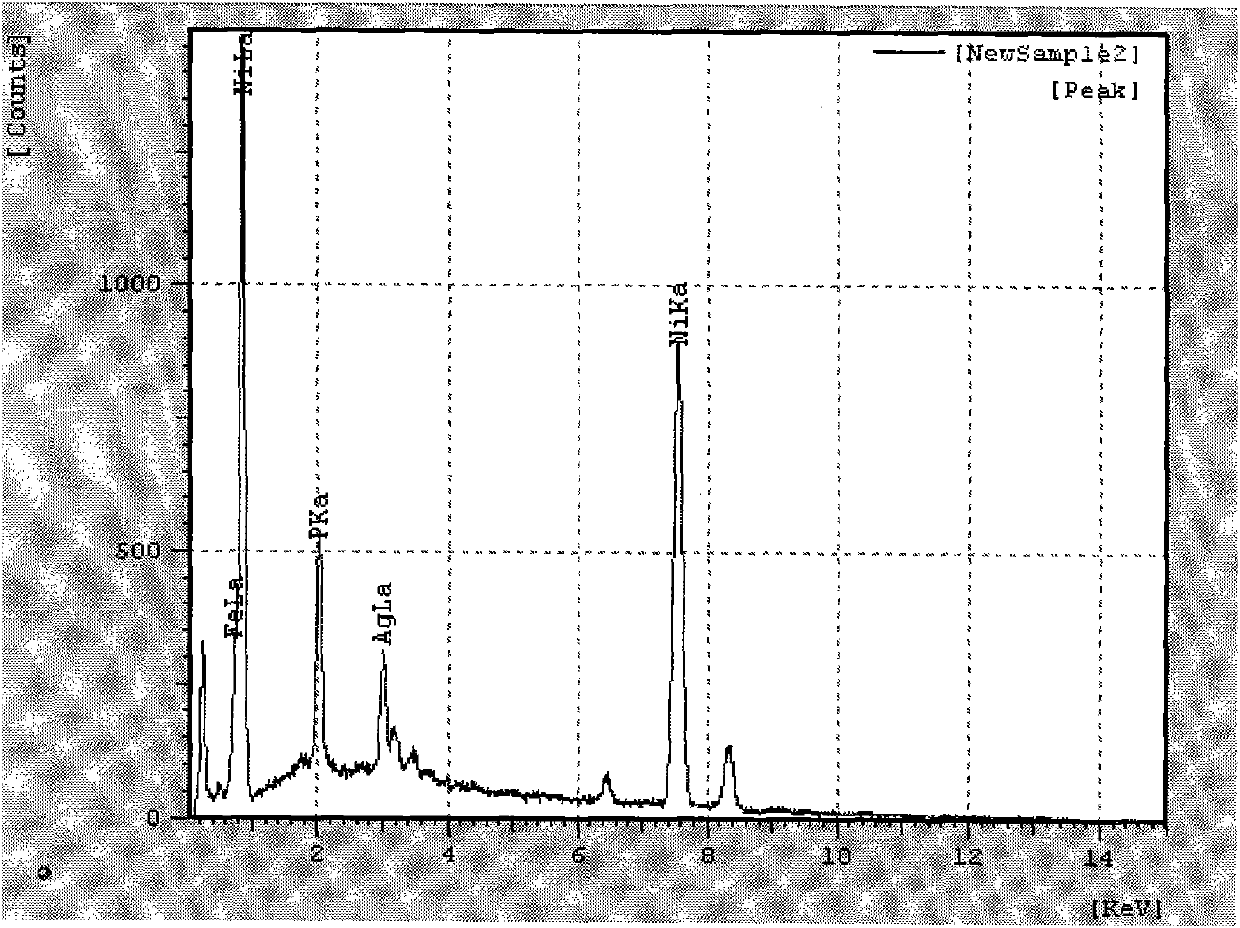

Efficient CrOx/mesoporous CaO catalyst for preparing isobutene by oxidative dehydrogenation of iso-butane and preparation method thereof

InactiveCN101618319AGood oxidation-reduction performanceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereActive component

The invention discloses an efficient CrOx / mesoporous CaO catalyst for preparing isobutene by oxidative dehydrogenation of iso-butane and a preparation method thereof, and belongs to the field of catalysis. The prior catalyst for preparing the isobutene by the oxidative dehydrogenation of the iso-butane has the problems of low isobutene selectivity and the like. The catalyst provided by the invention uses mesoporous CaO as a carrier and uses CrOx as an active component, wherein x is 1 to 3; and the loading capacity of the CrOx active component is 4 to 12 percent in percentage by mass of Cr2O3. The preparation method comprises the following steps: dissolving soluble chromium salt into anhydrous ethanol, then adding the solution into the mesoporous CaO carrier, stirring the mixture evenly, and drying the mixture for 12 hours at 120 DEG C to obtain white solid powder; and heating the white solid powder to 550 DEG C at the rate of 1 DEG C per minute in air atmosphere in a muffle furnace, and firing the heated white solid powder for 3 hours at constant temperature to obtain the CrOx / mesoporous CaO catalyst. The CrOx / mesoporous CaO catalyst prepared by the method has high isobutene selectivity and high activity, and the preparation method has low cost and simple and convenient operation.

Owner:BEIJING UNIV OF TECH

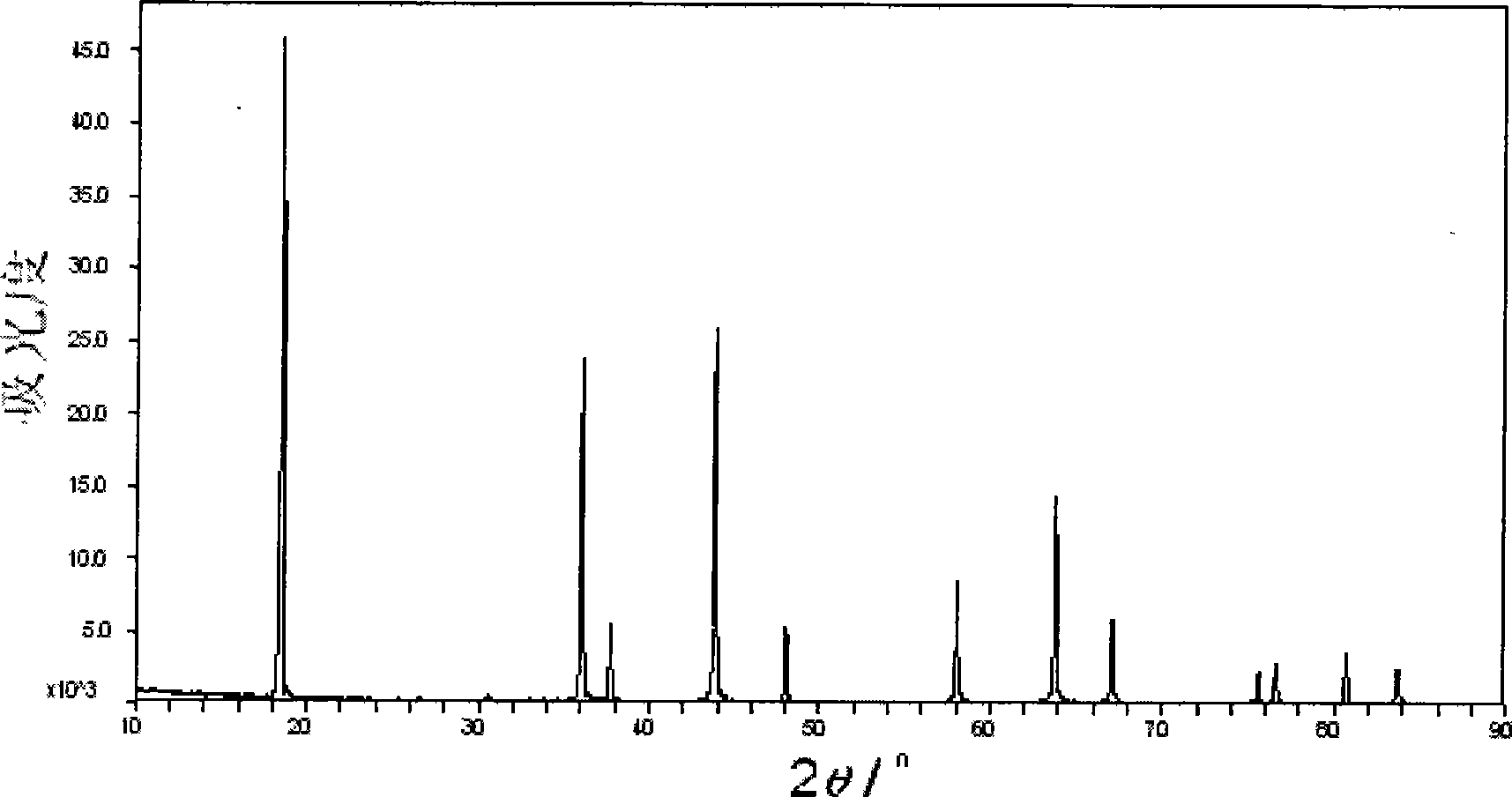

Method for recovering and preparing lithium cobaltate from waste lithium ionic cell

ActiveCN101383442ASimultaneous recyclingLow priceLithium compoundsWaste accumulators reclaimingCobaltMuffle furnace

The invention discloses a method for reclaiming and preparing lithium cobalt oxide from waste lithium ion batteries. The method is characterized in that the waste lithium batteries are disassembled and the shells are removed to select positive plates with the anode made of lithium cobalt oxide; the positive plates are crushed and screened to obtain minus sieve containing waste lithium cobalt oxide as the main component; in a constant-temperature resistance furnace, caking agent and conductive agent acetylene black in the minus sieve are removed in high temperature, sodium hydroxide is adopted to remove aluminum, and filtering, washing and drying are performed to obtain inactive lithium cobalt oxide containing little impurity; the content of lithium and cobalt is detected in the inactive lithium, then lithium carbonate with proper proportion is mixed in, at last, active lithium cobalt oxide battery material is synthesized by high-temperature agglomeration in a muffle furnace. Through the application of the method, the coefficient of recovery of cobalt in waste lithium ion batteries can reach more than 95.0 percent, and the coefficient of recovery of lithium can reach more than 97.0 percent.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

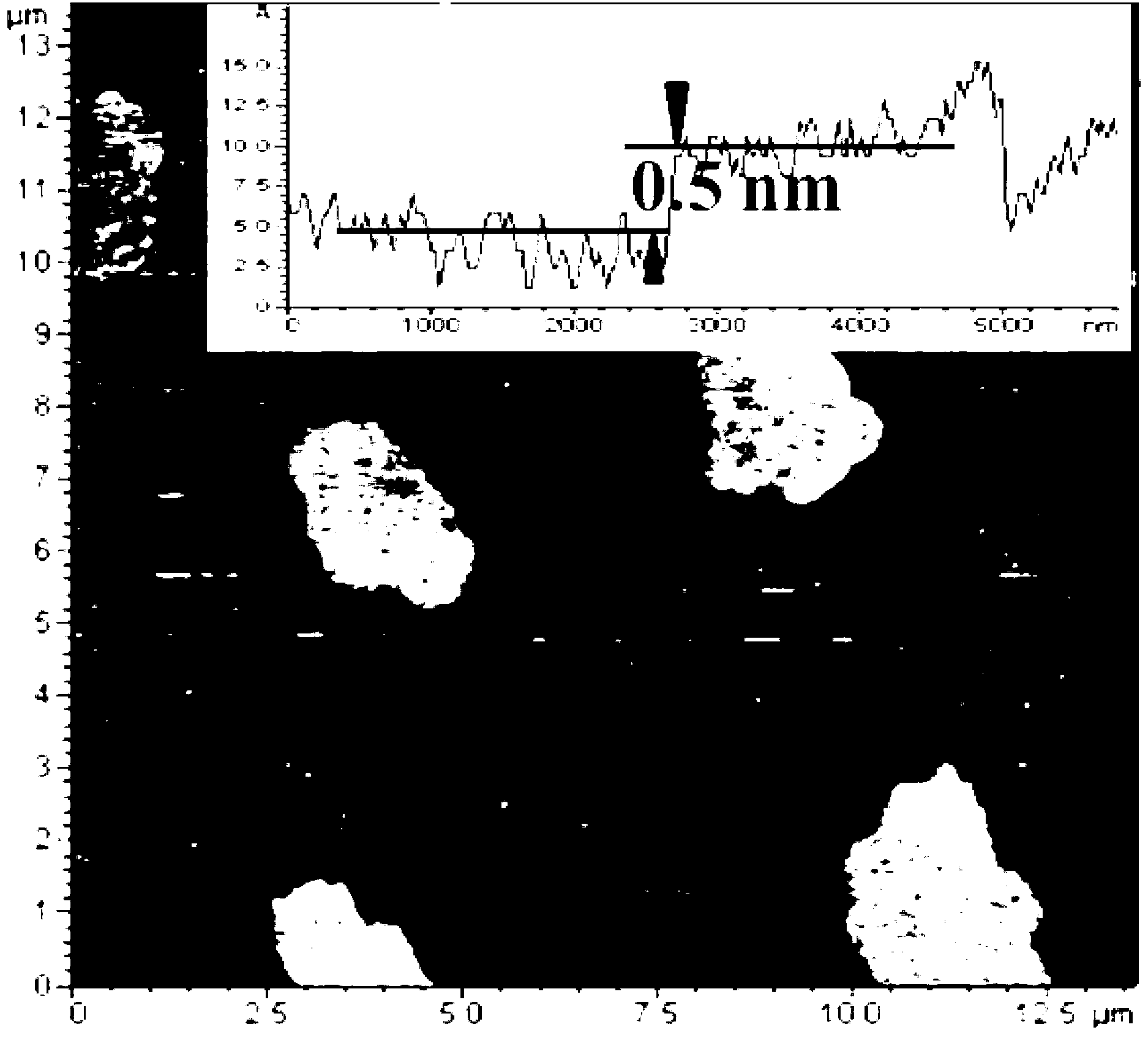

Method for preparing graphite phase carbon nitride material with monatomic layer structure

ActiveCN103232458AEasy to prepareExperimental results have little effectOrganic chemistryMaterials preparationPolymer science

The invention belongs to the field of material preparation and relates to a method for preparing a graphite phase carbon nitride (g-C3N4) material with a monatomic layer structure. The method is characterized in that the prepared g-C3N4 with the monatomic layer structure has the thickness of less than 0.6 nm. The method comprises the following steps of: placing a triazine unit-containing compound serving as a raw material into a muffle furnace, calcining at 400 to 750 DEG C and naturally cooling; porphyrizing the obtained sample and calcining at 400 to 800 DEG C; and ultrasonically stripping the sample which is subjected to secondary calcination into a polar solvent which is a dispersing agent to finally obtain the g-C3N4 with the monatomic layer structure. The method has the advantages that the preparation method is simple; the test result is slightly influenced by human factors in a preparation process; expensive equipment and chemical reagents are not needed in the preparation process; the prepared g-C3N4 with the monatomic layer has large specific surface area and can provide more active sites for catalytic reaction; and the prepared g-C3N4 with the monatomic layer structure is uniform in size and thickness distribution and high in purity.

Owner:DALIAN UNIV OF TECH

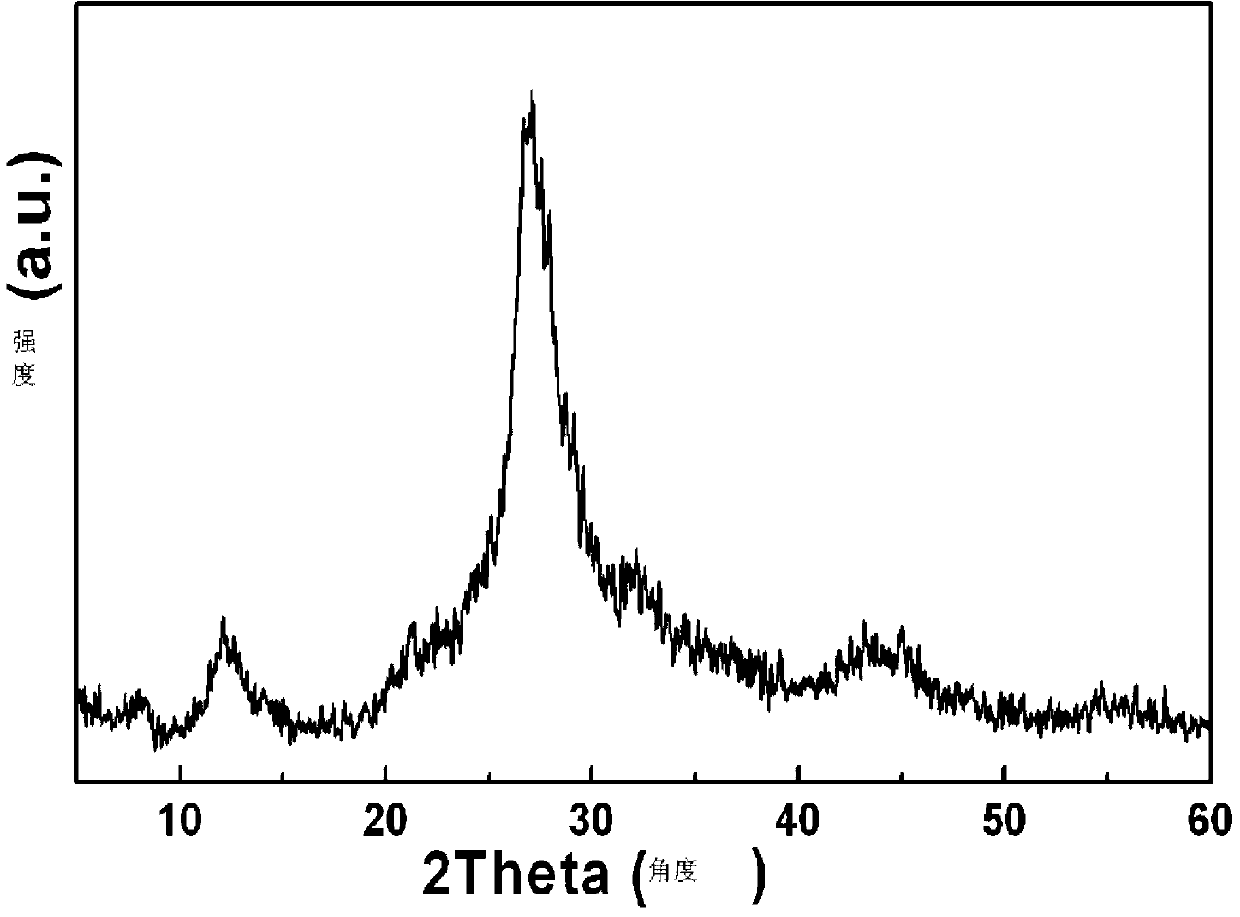

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

InactiveCN102992282AEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

The invention discloses a mesoporous C3N4 photocatalytic material prepared by using a molten salt method and a preparing method thereof. The method comprises the following steps that water-soluble low-melting-point molten salt is fully mixed with melamine, small molten salt drops are used as a blocked layer under the melting temperature of the molten salt, C3N4 grows in a way of being coated with the small drops, and the molten salt is recycled by water washing after reaction, so as to obtain the C3N4 photocatalytic material. The C3N4 photocatalytic material is in a wormlike mesoporous structure, the mesoporous size is within 3.8+ / -1nm, and the forming mechanism of the mesoporous C3N4 photocatalytic material is that the small molten salt drops are used as the growth blocked layer. When the material is prepared, water-soluble low-melting-point chloride salt is used as the molten salt and is fully mixed with melamine to obtain a mixture, the mixture is subjected to the heat treatment in a muffle furnace for 1-5h under the temperature being 400-680 DEG C to obtain samples, and the samples after the heat treatment are washed by water to recycle the molten salt, so as to obtain the mesoporous C3N4 photocatalytic material. In the whole process, a template is not introduced, and the operation is easy and feasible, so that the large-scale industrial production can be realized easily.

Owner:NANJING UNIV

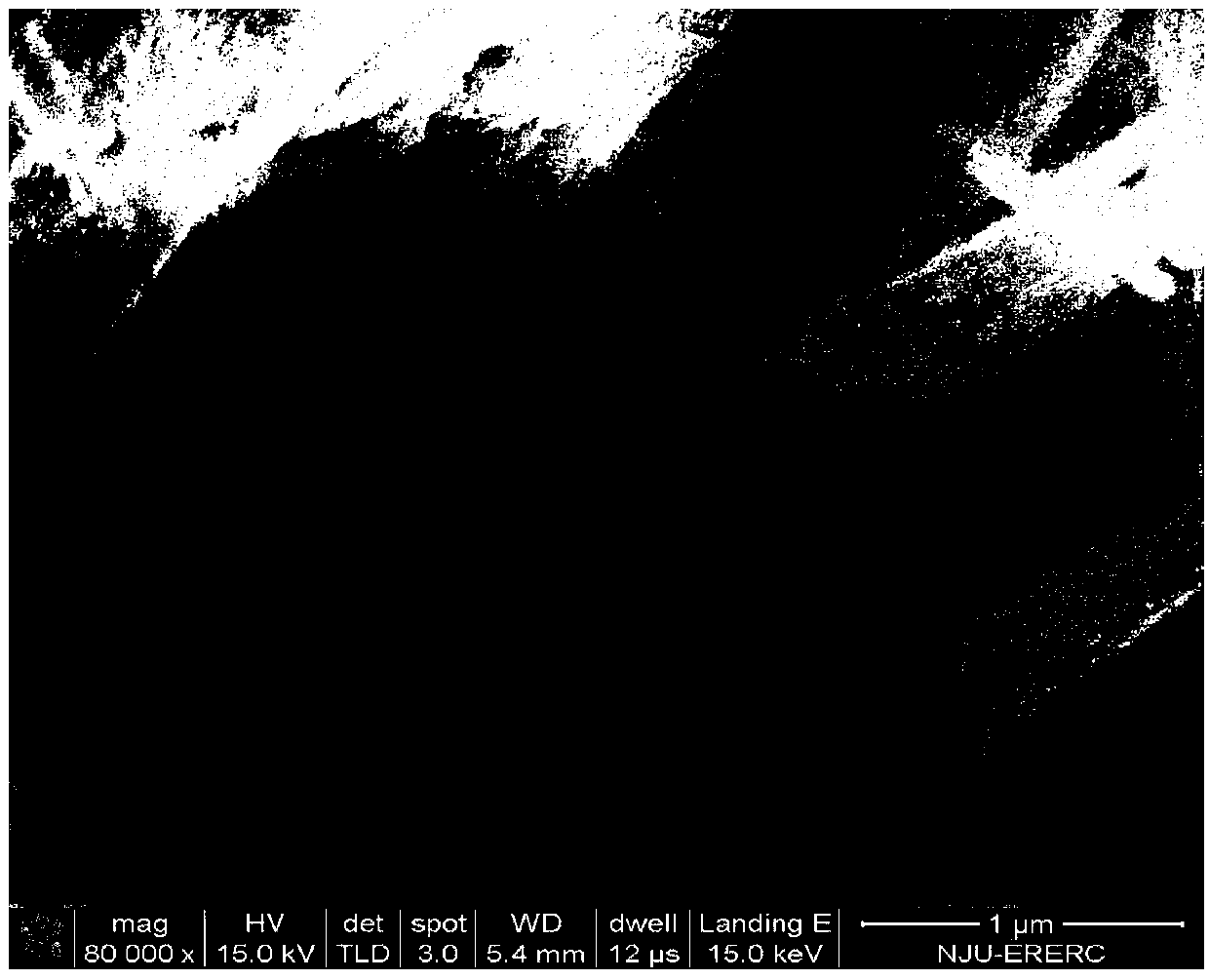

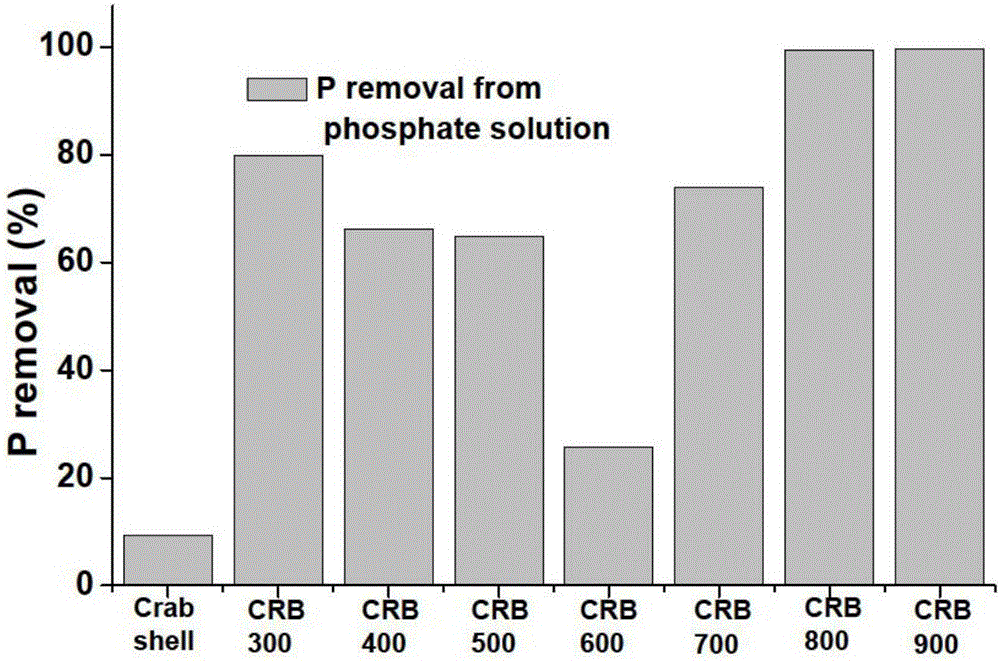

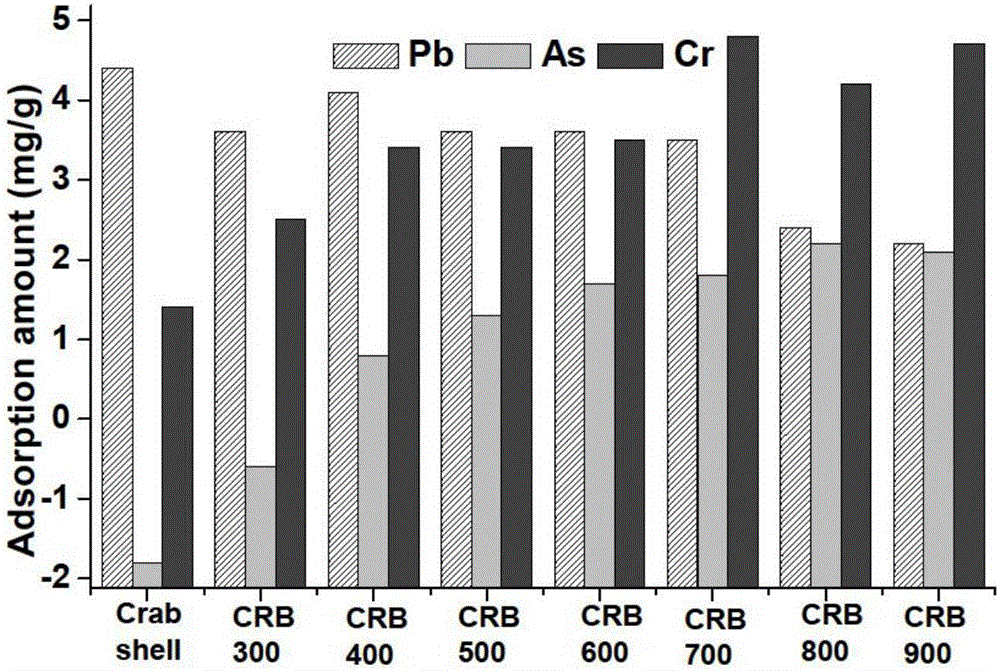

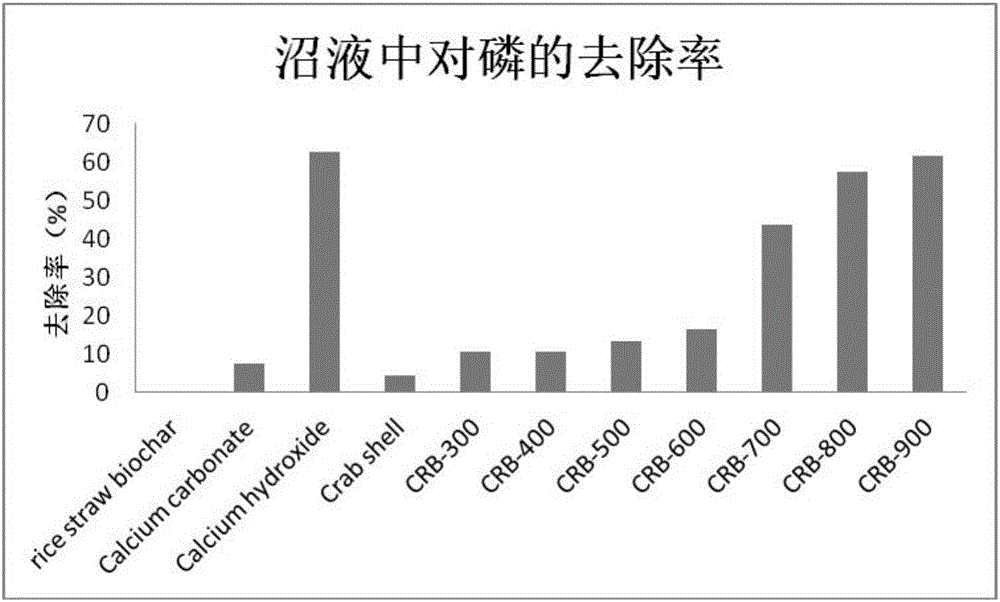

Efficient phosphorus and heavy metal removal biochar, and preparation method and application thereof

ActiveCN105771899AGood phosphorus removal effectImprove clearanceOther chemical processesWater contaminantsNitrogenOxygen

The invention provides a method for preparing efficient phosphorus removal biochar by shellfish waste. The method includes: (1), washing and drying shrimp and crab shells for standby application; (2), putting products obtained in the step (1) in a muffle furnace, and pyrolyzing the products at the high temperature of 300-900 DEG C under the nitrogen condition or oxygen limiting condition for 0.5-3 hours to obtain the biobar. The shrimp and crab shells include at least one of crab shells, shrimp shells or lobster shells. The obtained biochar has excellent phosphorus adsorption effect, and adsorbing capacity of the biochar to the phosphorus can reach 180mg / g; the obtained biochar also has excellent heavy metal removal capability; modification of the obtained biochar is not needed, preparation process is simple, raw materials are easy to obtain and cheap, and the biochar has quite broad market application prospect.

Owner:BIOGAS SCI RES INST MIN OF AGRI

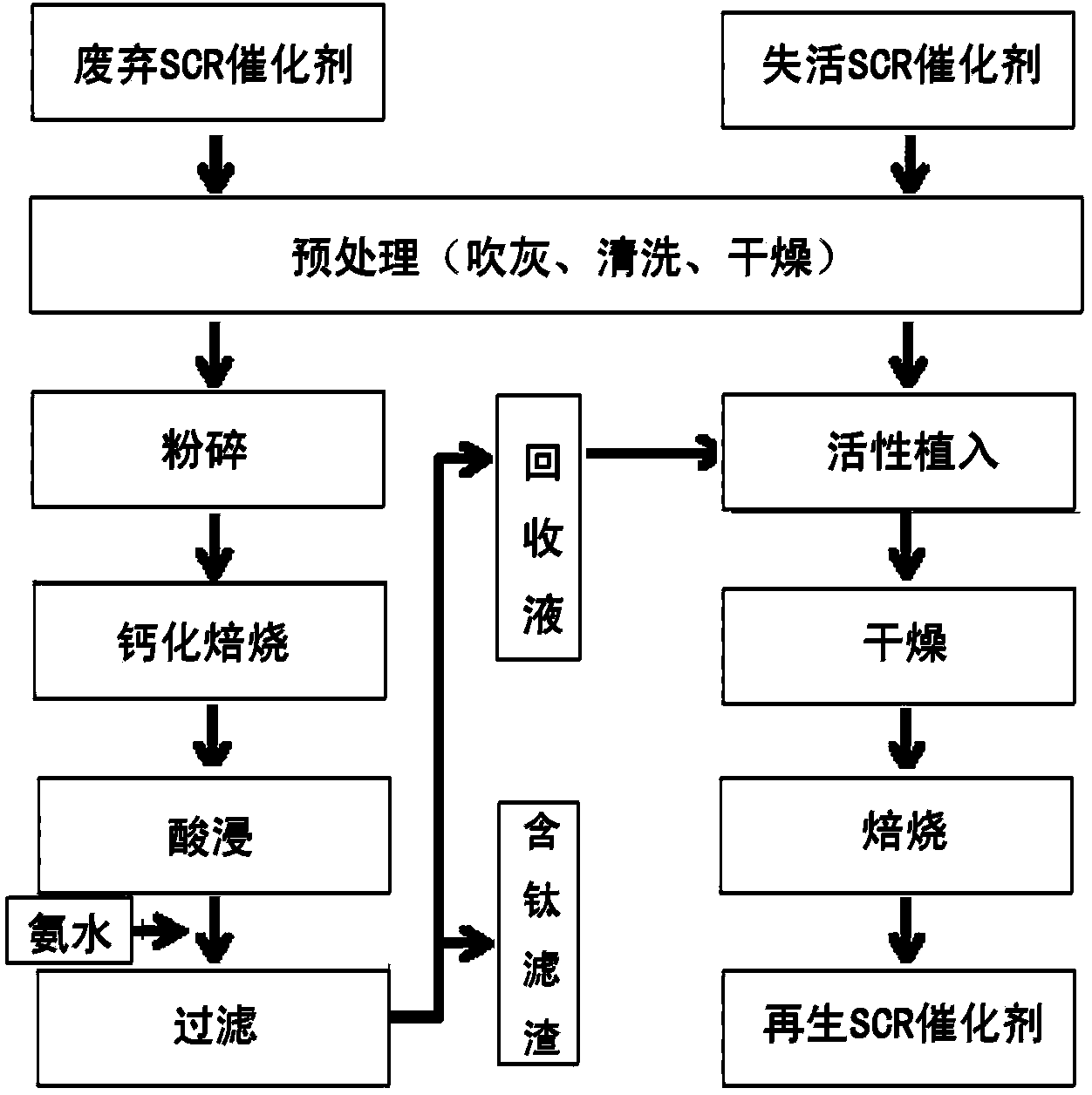

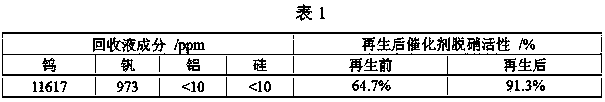

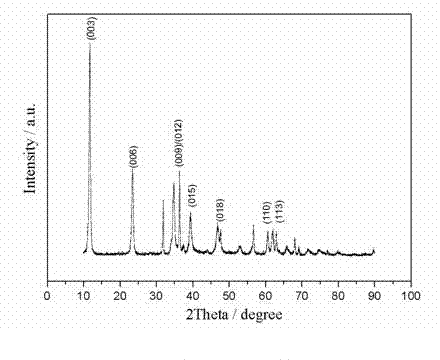

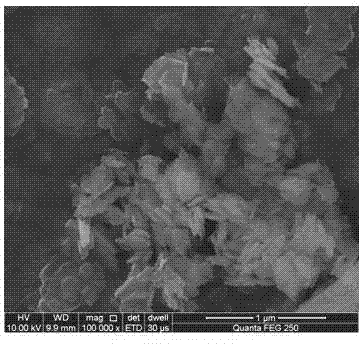

Method for regenerating denitration catalyst by utilizing waste SCR (Selective Catalytic Reduction) catalyst recovery liquid

ActiveCN103846112AShort processing cycleIncrease productivityCatalyst regeneration/reactivationCatalyst activation/preparationAmmonium hydroxideTitanium

The invention discloses a method for regenerating a denitration catalyst by utilizing a waste SCR (Selective Catalytic Reduction) catalyst recovery liquid. The method comprises the following steps: after soot blowing, cleaning and drying pretreatment on a waste SCR catalyst, smashing the waste SCR catalyst into powder; evenly mixing the powder with calcium carbonate to obtain a mixture; roasting the mixture to obtain a roasted material; re-smashing the roasted material to obtain a re-smashed material and adding the re-smashed material into a dilute sulphuric acid solution; adjusting the value of pH to 8-11 by ammonium hydroxide; filtering for separating out titanium-containing residues and thus obtaining a recovery liquid; after soot blowing, cleaning and drying pretreatment on an inactivated SCR catalyst block body, soaking the block body in the recovery liquid; drying the block body; roasting the block body in a muffle furnace with the temperature of 400-600 DEG C, thereby obtaining the regenerated SCR catalyst with denitration activity being recovered. The method organically integrates catalyst recovery and regeneration technologies. The precious metal components of the waste SCR catalyst are fully utilized, the problem of vanadium, tungsten or molybdenum separation-purification is avoided, the recovery and regeneration technology process is shortened, and the treatment expenditure of the waste SCR denitration catalyst is lowered.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

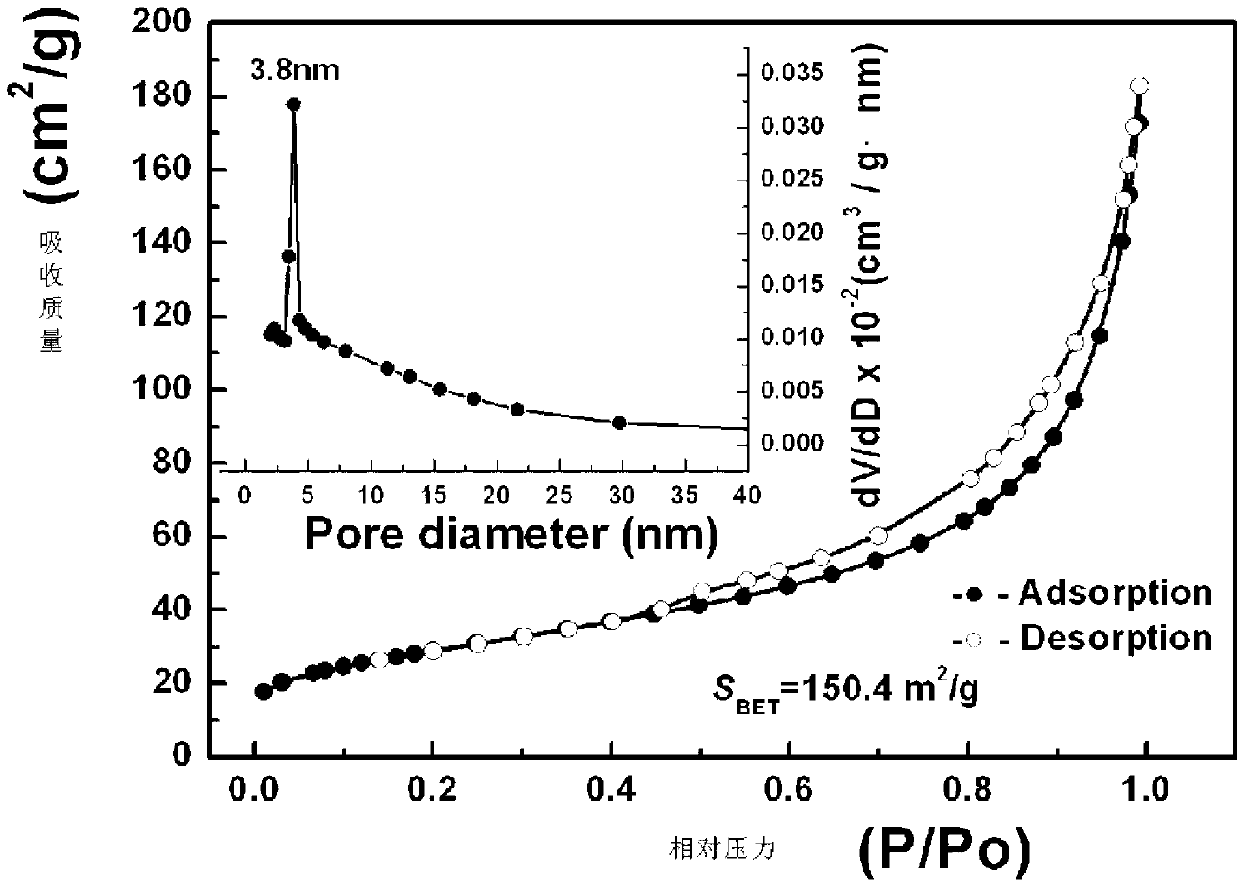

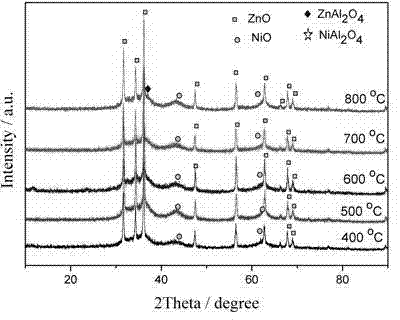

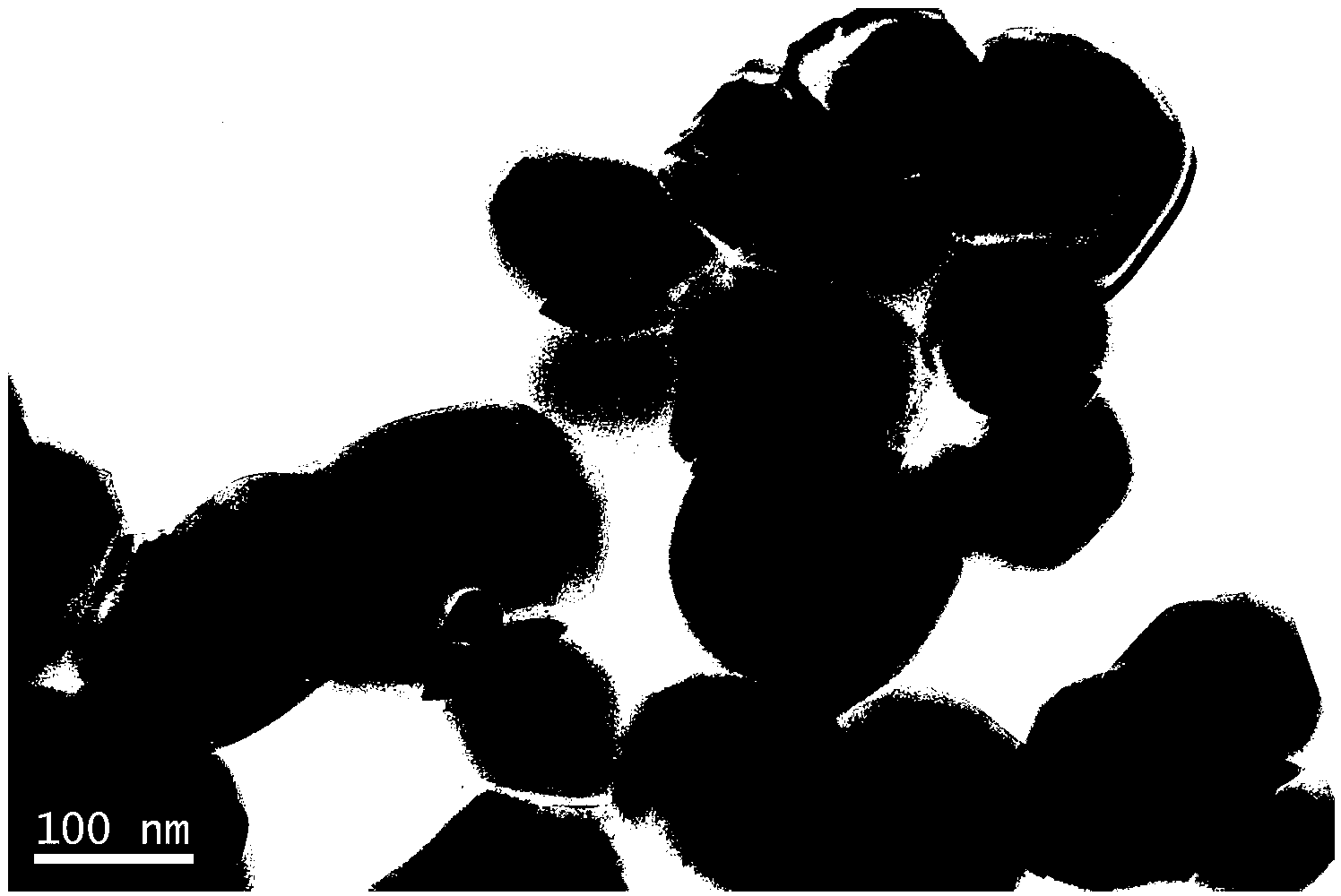

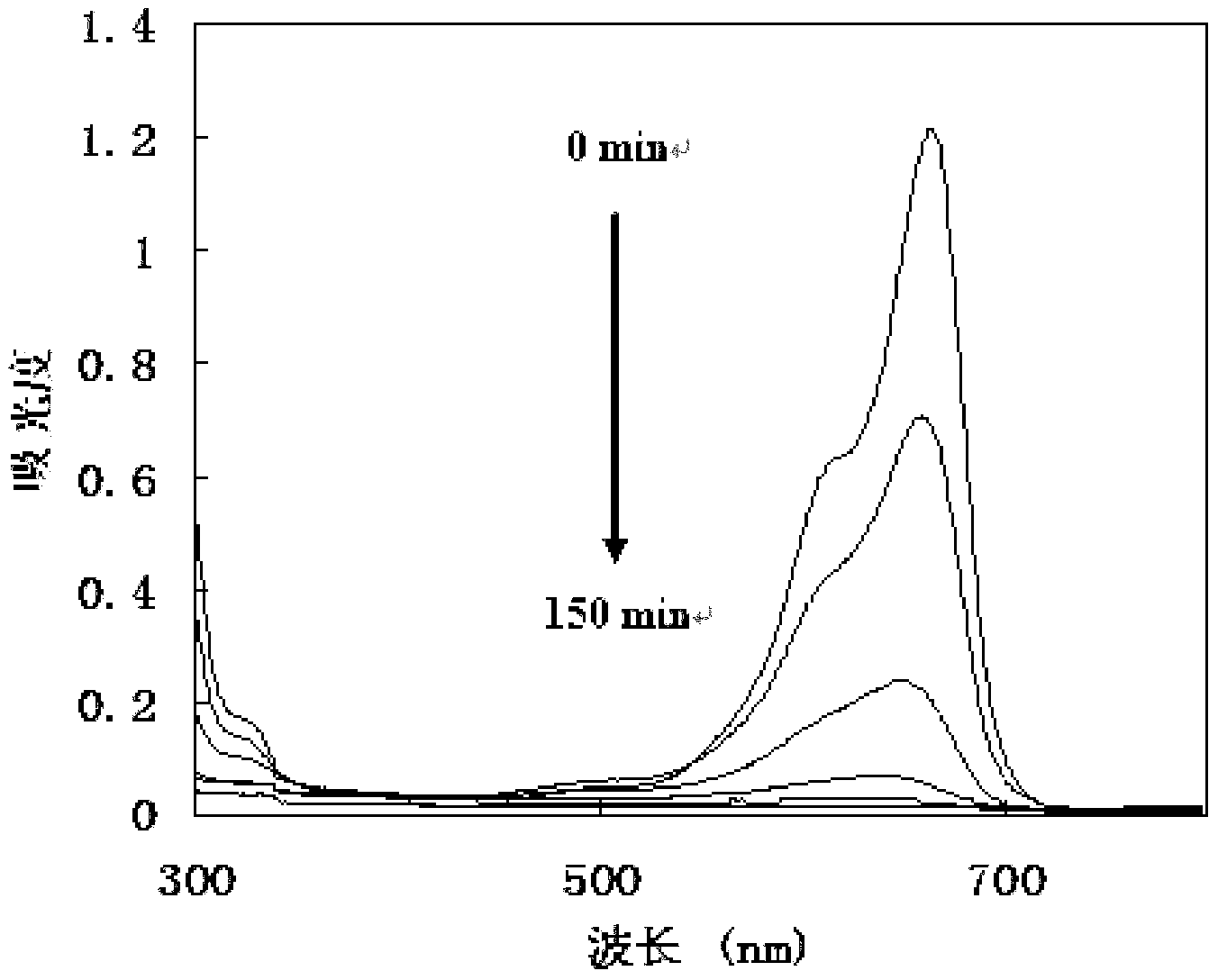

Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

The invention discloses a gahnitem, zinc oxide and nickel zinc nano-composite photocatalytic material which has a high specific surface area and a mesoporous structure and is prepared by roasting at high temperature by taking ternary hydrotalcite as a precursor. The material is used for the adsorption and the degradation of organic pollutants. The photocatalytic material is prepared by taking zinc nitrate, nickel nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and the like as raw materials; preparing the raw materials into salt solutions and alkali solutions respectively; mixing the solutions by using a constant-flow pump at the temperature of 80 DEGC with magnetic stirring, transferring the mixed solution into a hydrothermal reaction kettle; performing hydrothermal treatment at 130 to 180 DEG C; performing suction filtration, washing and drying to the precursor; roasting the precursor in Muffle furnace for 2 to 6 hours at the temperature of 400 to 600 DEG C to obtain the product, wherein the specific surface area is greater than 150 m<2>.g<-1>. The photocatalyst disclosed by the invention has regular shape, large specific surface area, and super-high capacity for adsorbing and degrading organics, and can be reused; the raw materials for preparing the composite photocatalyst are abundant, the cost is low, and the process is simple.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

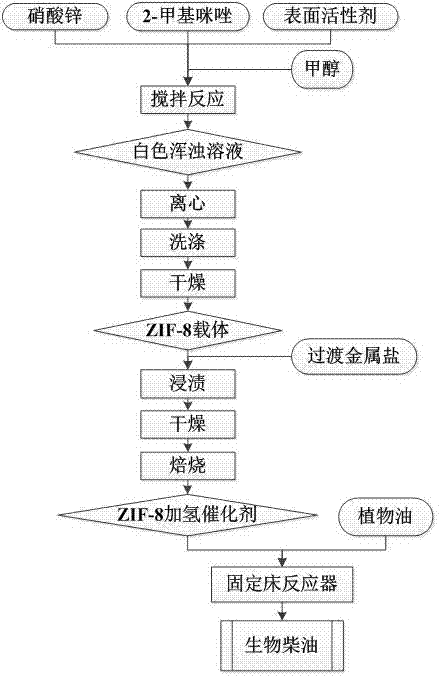

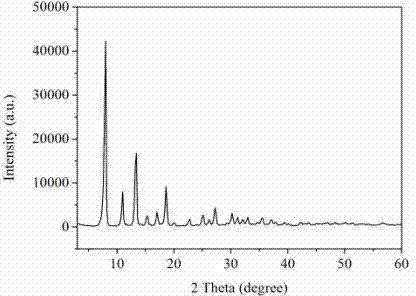

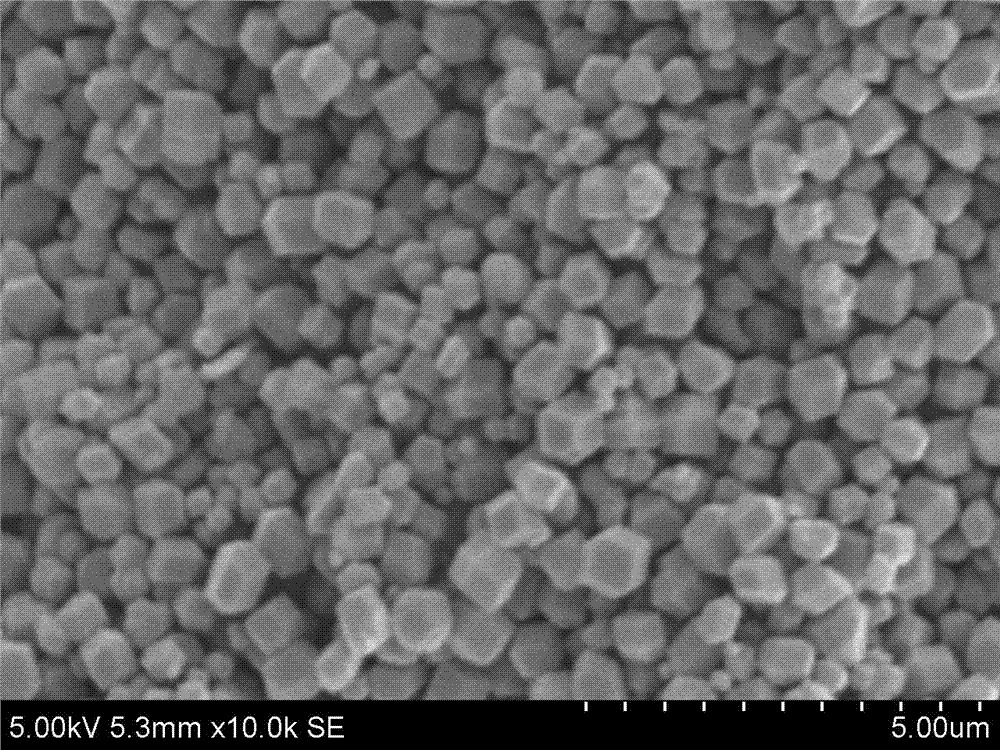

ZIF-8 material-based hydrogenation catalyst and synthetic method thereof

InactiveCN104772165ARaw materials are cheap and easy to getEfficient preparation processOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionBiodieselPtru catalyst

The invention relates to a ZIF-8 material-based hydrogenation catalyst and a synthetic method thereof. The synthetic method particularly comprises the following steps: (1) dissolving zinc nitrate, 2-methylimidazole and a surface active agent with methanol, carrying out stirring reaction for 1-6h at 20-60 DEG C, and standing for 10-18h to obtain a turbid solution; (2) carrying out centrifugal treatment on the turbid solution, placing sediments in a drying oven to be dried to obtain a ZIF-8 carrier after washing with methanol; and (3) dissolving transition metal salt with water, dipping the ZIF-8 carrier into the dissolved transition metal salt, and roasting in a muffle furnace to obtain the ZIF-8 material based hydrogenation catalyst. The hydrogenation catalyst can be used for preparing biodiesel; the biodiesel preparation method comprises the steps of placing the ZIF-8 material based hydrogenation catalyst into a fixed bed reactor to be reduced, and introducing vegetable oil into the reactor for hydrocracking reaction at 300-400 DEG C under the conditions that the hydrogen partial pressure is 2-4MPa, the air speed is 0.9-3.6h<-1> so as to obtain the biodiesel finally. The catalytic efficiency of the synthesized ZIF-8 material based hydrogenation catalyst is improved by dozens of times compared with the catalytic efficiency of a traditional aluminum oxide catalyst.

Owner:BEIJING FORESTRY UNIVERSITY

Method for preparing nano alumina fiber film material

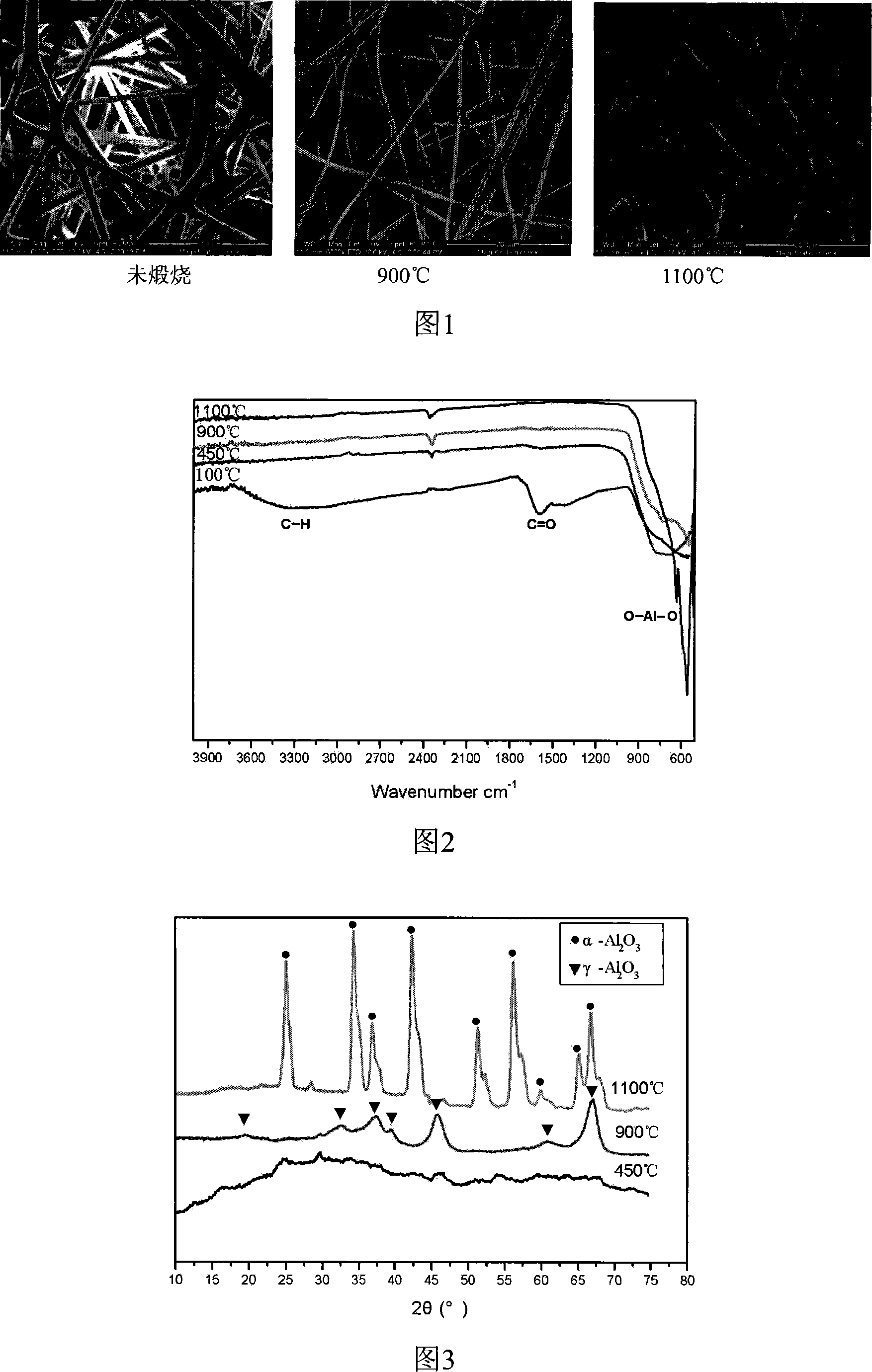

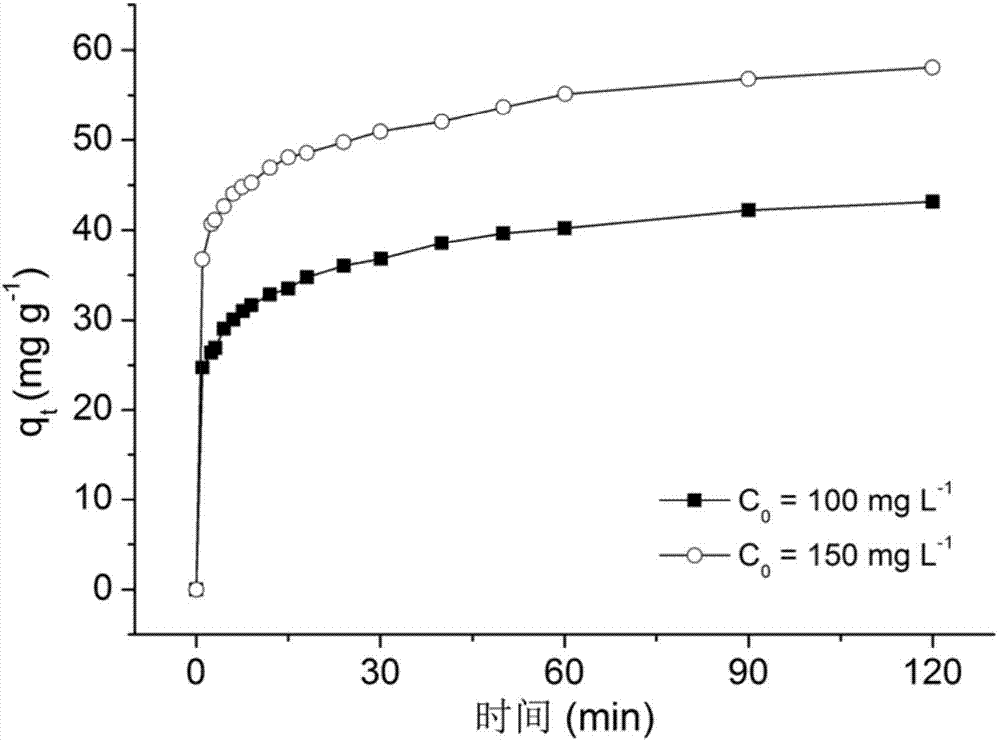

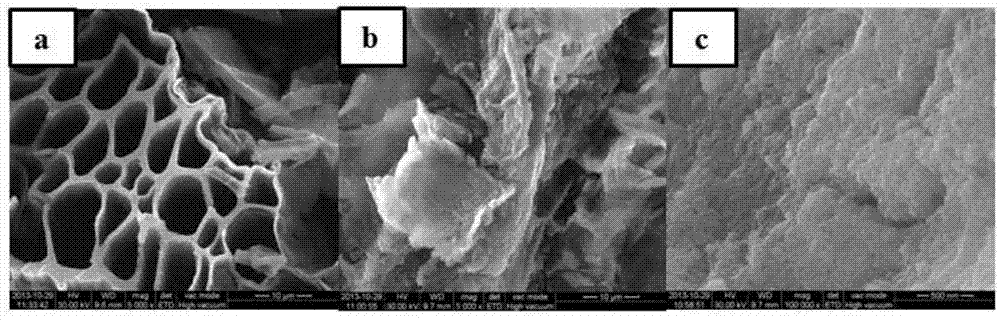

The invention relates to a technology of preparing nano alumina fiber membrane material by electrostatic spinning, comprising: 1. the configuration of sol gel electrostatic spinning liquid. Pouring polyvinyl pyrrolidone into ethanol solvent and stirring thereof with high speed until completely dissolved; getting the polyvinyl pyrrolidone ethanol solution with the concentration of 5-8wt%, then, mixing the solution with the aluminum chloride solution with the concentration of 10-30wt%, wherein, the weight ratio between the polyvinyl pyrrolidone and the aluminum chloride is 3:1-1:1, stirring for one hour. 2. Electrostatic spinning. The prepared sol gel spinning liquid is injected into the electrostatic spinning device and electrostaticly spinning thereof is injected into aluminum chloride / polyvinyl pyrrolidone nano fiber membrane under the voltage of 25-35kv, the extrusion speed of 1-10ml / min and the reception distance of 10-20cm. 3. calcining. At last putting the prepared aluminum chloride / polyvinyl pyrrolidone nano fiber membrane into a muffle furnace and raising the temperature to 450-1100 DEG C with the speed of 50 DEG C / h, calcining for five hours and getting amorphous, Gamma type or Alpha type aluminum oxide fiber membrane. The nano aluminum oxide fiber membrane made by the invention is a catalyst and the carrier material of the catalyst and high temperature resistance filtration material with high specific surface area, good thermal stability and excellent mechanical properties. Furthermore, the material can be widely applied in fields such as the insulating materials and reinforced composites of space shuttle and high temperature boiler.

Owner:TIANJIN POLYTECHNIC UNIV

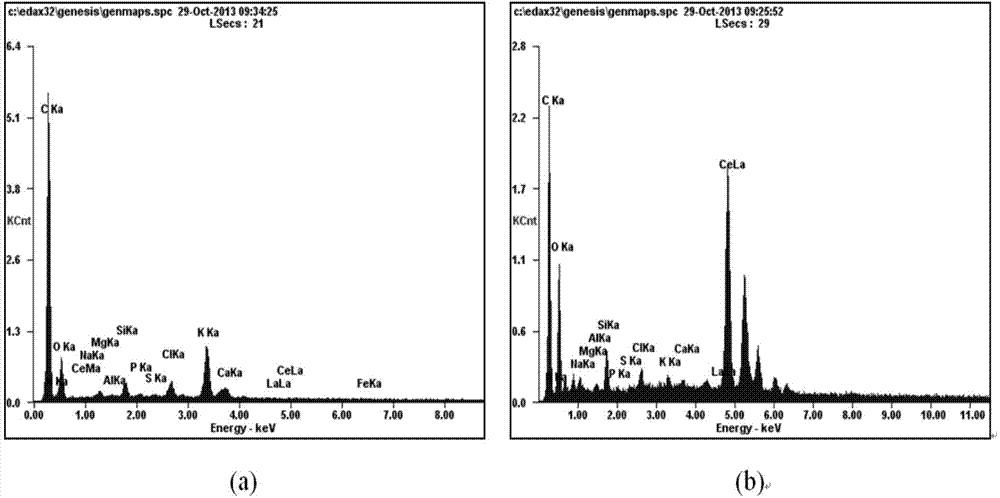

Improved charcoal-based phosphorous removal adsorbent and preparation method thereof

ActiveCN103877937AImprove adsorption capacityEfficient removalOther chemical processesWater/sewage treatment by sorptionRare-earth elementSorbent

The invention discloses an improved charcoal-based phosphorous removal adsorbent and a preparation method of the improved charcoal-based phosphorous removal adsorbent. The method comprises the following steps: loading light rare earth elements to charcoal under optimized conditions, and preparing a high-efficiency environment-friendly charcoal-based phosphorous removal adsorbent; impregnating the cleaned and dried plant powder by using a cerium chloride solution with a certain concentration, and regulating a mass ratio of the original material of charcoal to Ce element to be 5-15 percent; adding an alkaline solution to control the pH value of the system to be more than 10, stirring, washing by using ethanol, centrifuging and drying; putting the prepared material into a muffle furnace, performing temperature programming and pyrolysis under anoxic conditions through the sealing measure, and controlling the pyrolysis temperature and pyrolysis time; washing the material by using distilled water after the pyrolysis is ended and cooling is performed, centrifuging, drying, screening, and obtaining the final product. The phosphorous removal adsorbent prepared in the invention has excellent adsorptive property on phosphate radical, the adsorptive property can reach 77.52mg / g, and a charcoal-based material which is environment-friendly and excellent in adsorptive property is provided for adsorbing and purifying phosphorous-containing wastewater.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

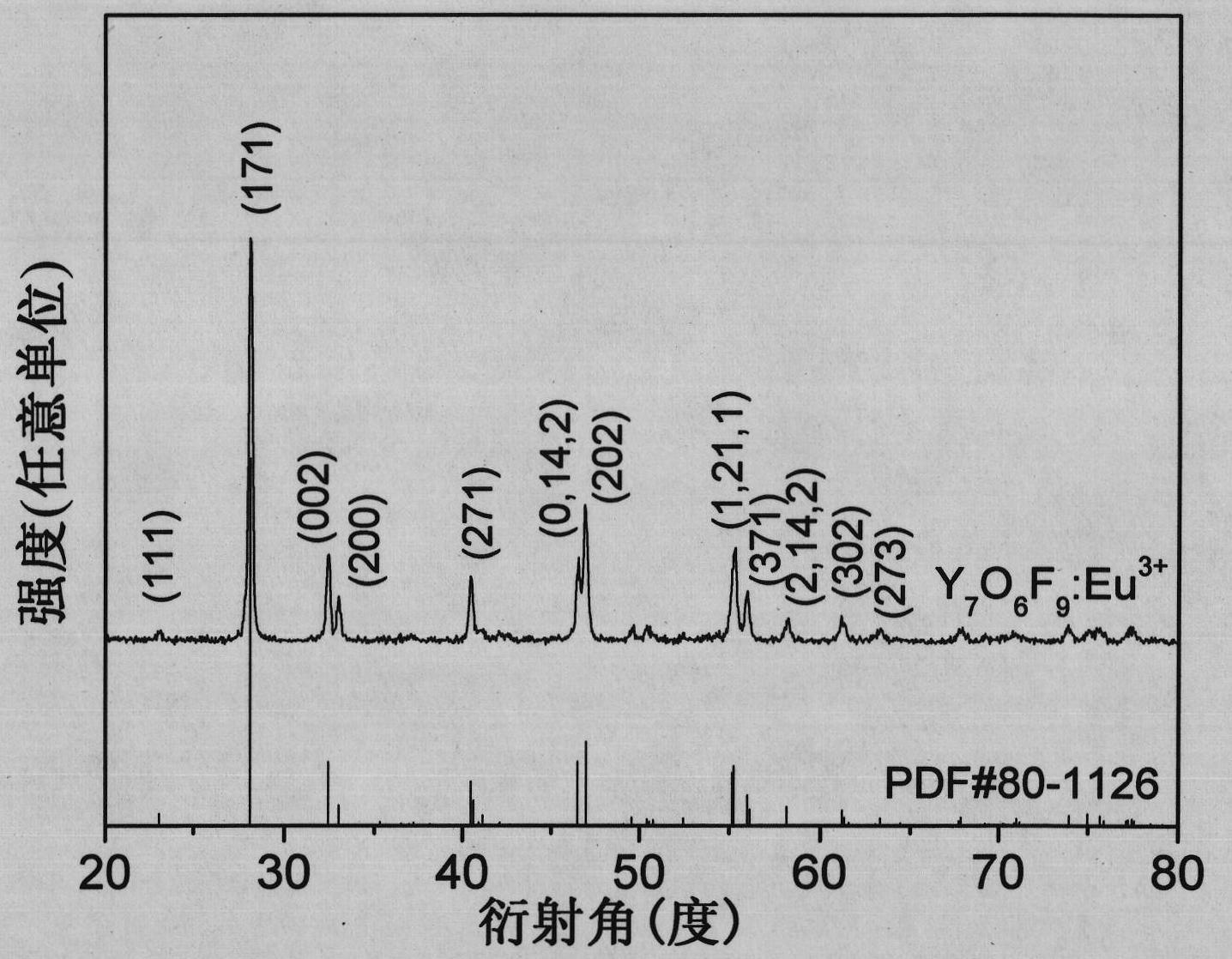

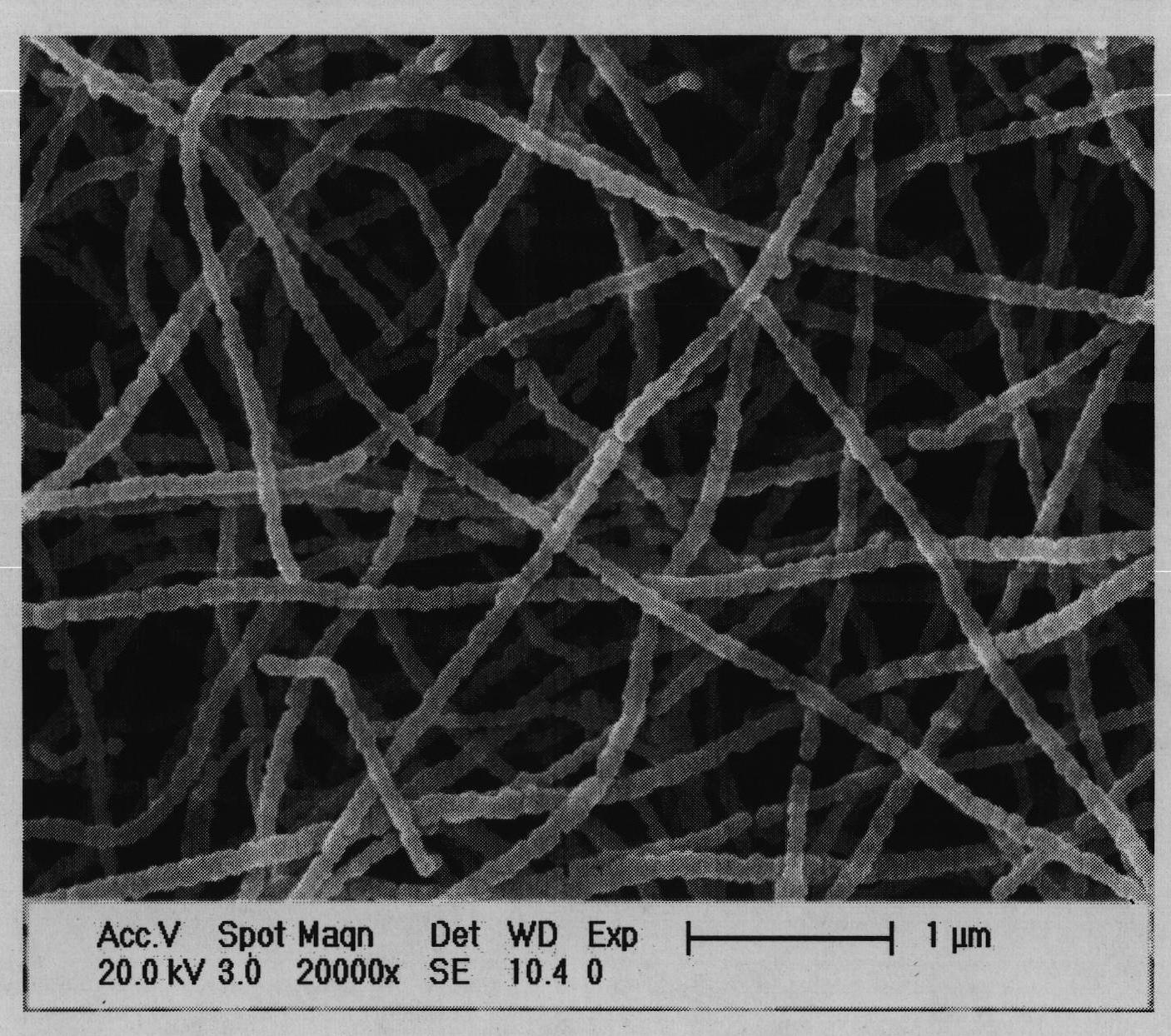

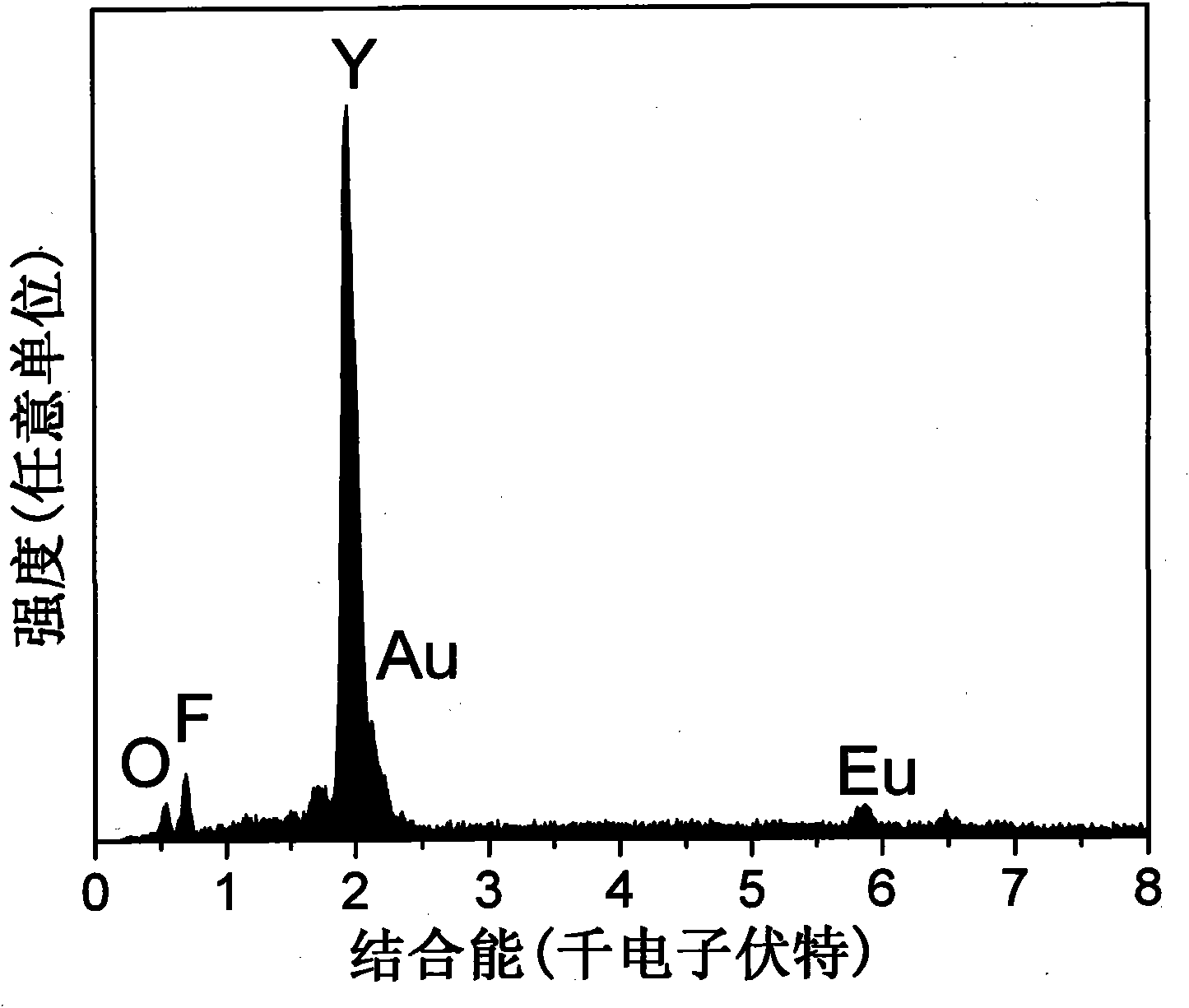

Europium-doped Y7O6F9 nano fiber and preparation method thereof

The invention relates to a europium-doped Y7O6F9 nano fiber and a preparation method thereof, belonging to the technical field of the preparation of nano materials. A rare earth fluoride / rare earth oxyfluoride composite nano fiber is prepared by the traditional electrostatic spinning technology. The preparation method provided by the invention comprises the following three steps: (1) preparation of a Y2O3:5%Eu<3+> nano fiber: preparing a PVP / [Y(NO3)3+Eu(NO3)3] composite nano fiber by adopting the electrostatic spinning technology, and then, carrying out heat treatment to obtain the Y2O3:5%Eu<3+> nano fiber; (2) preparation of a YF3:5%Eu<3+> nano fiber: fluorinating the Y2O3:5%Eu<3+> nano fiber by a double-crucible method to obtain the YF3:5%Eu<3+> nano fiber, wherein the fluorinating reagent is ammonium bifluoride; and (3) preparation of a Y7O6F9:5%Eu<3+> nano fiber: placing the YF3:5%Eu<3+> nano fiber in a muffle furnace, heating at 580 DEG C under the air atmosphere for 9 hours to obtain the Y7O6F9:5%Eu<3+> nano fiber, wherein the diameter is 181-241 nm, and the length is greater than 300 mu m. The europium-doped Y7O6F9 nano fiber is a novel important red nano fluorescent material having wide application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

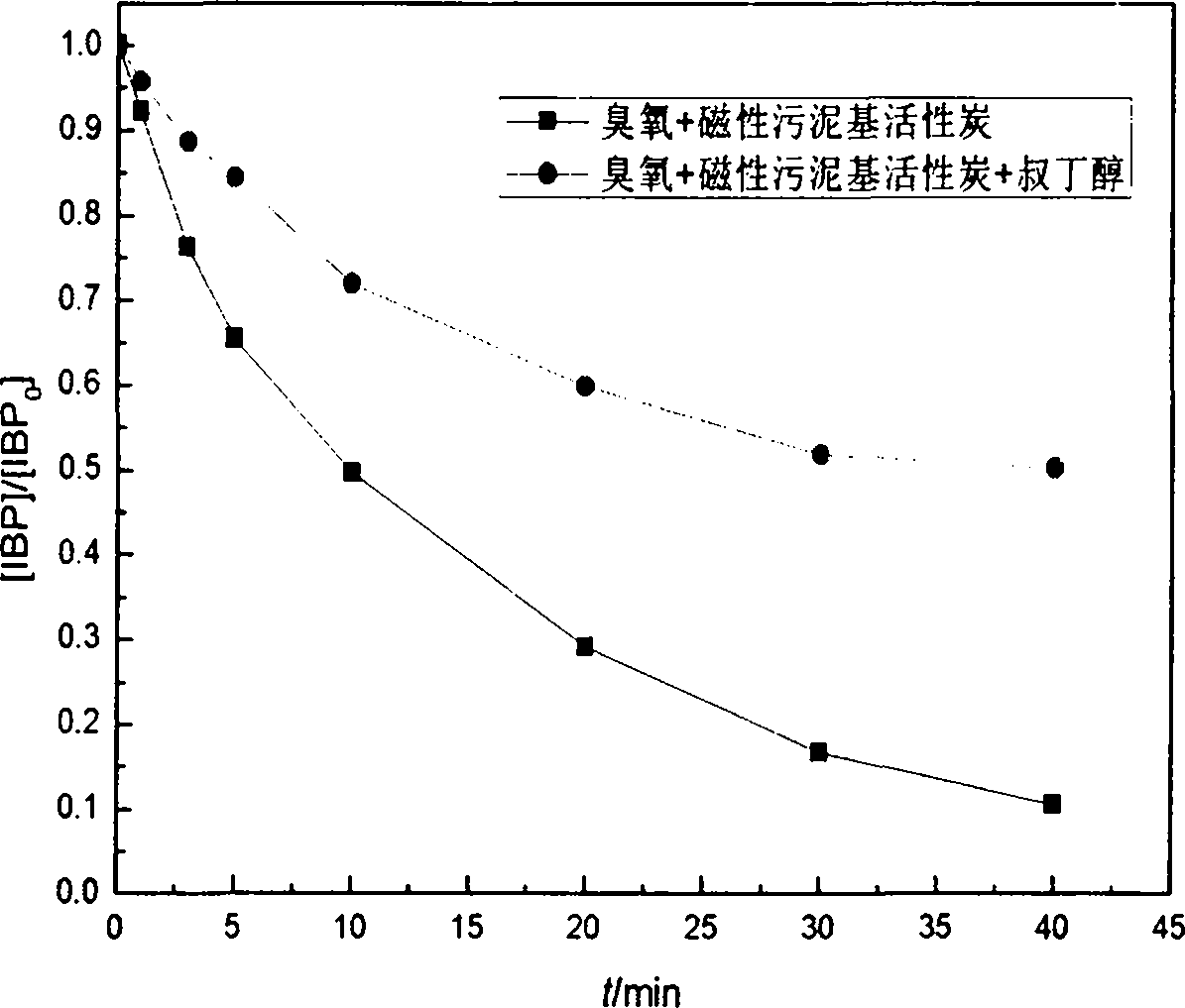

Method for manufacturing magnetic sludge-based active carbon

InactiveCN103406094ASolve environmental problems caused by improper disposalLow running costSludge treatmentOther chemical processesSludgeCatalytic oxidation

The invention discloses a method for manufacturing magnetic sludge-based active carbon by taking redundant sludge in an urban sewage treatment plant as main raw materials and aims to solve the problem that existing active carbon catalysts are difficult to be recycled. The method comprises the steps of immersing the dried redundant sludge in a ferric chloride and ferrous chloride mixing solution activation agent for activating for 24 hours, dripping ammonia water, putting the mixture into a drying box with the temperature of 105 DEG C for drying, carbonizing and activating the mixture in a muffle furnace, cleaning the mixture with distilled water, grinding and screening products, and performing magnetic separation to obtain the magnetic sludge-based active carbon. The magnetic sludge-based active carbon manufactured by the method is very convenient to separate and recycle and is extremely high in catalytic oxidation capacity and heavy metal adsorption capacity.

Owner:BEIJING FORESTRY UNIVERSITY

Bamboo charcoal-based microelectrolysis porous ceramsite filler and preparing method thereof

ActiveCN104003483AReduce consumptionPromote micro-electrolysis effectWater/sewage treatmentPtru catalystIron powder

The invention provides bamboo charcoal-based microelectrolysis porous ceramsite filler and the preparing method thereof. According to the filler, iron serves as the anode, carbon serves as the cathode, and the cathode carbon is made from bamboo powder. According to the preparing process, activation and carbonization of bamboo powder are integrated, bamboo powder also plays a role in partial pore forming, the filler is of a porous honeycomb ball-shaped structure, the grain size is 1 mm - 15 mm, water absorption is 20% - 45%, and the specific surface area is 30 m<2> / g - 60 m<2> / g; iron powder, bamboo powder, clay, activating agents, catalysts, pore-forming agents and binding agents are mixed evenly to form a ball, the ball is placed in a muffle furnace to be roasted, nitrogen is introduced into the muffle furnace for protection, the temperature is increased to 150 DEG C - 250 DEG C, pre-activation and pre-carbonization are conducted for 30 min - 60 min, then the temperature is increased continuously to 500 DEG C - 800 DEG C, heat preservation is conducted for 1 h - 3 h, then the temperature is naturally reduced to the indoor temperature, and finally the bamboo charcoal-based microelectrolysis porous ceramsite filler is obtained. According to the bamboo charcoal-based microelectrolysis porous ceramsite filler and the preparing method thereof, raw materials are environmentally friendly and easy to obtain, the preparing technology is simple, the filler has a good effect in sewage treatment and is suitable for heavy metal and dye sewage treatment, and the problems such as poor recycling property of traditional filler can be solved.

Owner:FUZHOU UNIV

Regular iron-carbon micro-electrolysis filler and preparation method thereof

InactiveCN101817574AGood processing effectPrevent compactionWater contaminantsWater/sewage treatmentElectrolysisSewage treatment

The invention discloses a regular iron-carbon micro-electrolysis filler and a preparation method thereof, belonging to the technical field of sewage treatment. The filler comprises the following components by weight percent: 50 to 80 percent of scrap iron with the diameter is 0.1 to 1 mm , 5-17 percent of powdery active carbon with the diameter of less than 0.1 mm and 15-35 percent of clay with diameter of less than 0.15 mm. The preparation method of the iron-carbon micro-electrolysis filler comprises the following steps of: a, uniformly mixing the filler according to the weight percentages; b, adding water to make the mixture into granular filler with the diameter of 3 to 10 mm; c, putting the filler into an oven and drying at 30 to 50 DEG C; d, moving the filler into a muffle furnace and baking for 2 to 4 hours at 250 to 600 DEG C in an oxygen-isolated condition; and e, cooling after the filler is baked to obtain the regular iron-carbon micro-electrolysis filler. The invention prevents hardening and passivation of the iron-carbon micro-electrolysis filler, is easy to fill and has advantages of good sewage treatment effect, low cost and easy preparation.

Owner:JILIN UNIV

Silver-based flux-cored wire and manufacturing method thereof

ActiveCN102513726ASatisfy soldering temperature matchingNot easy to absorb moistureWelding/cutting media/materialsSoldering mediaLiquid stateInlet valve

Provided are a silver-based flux-cored wire and a manufacturing method thereof. The manufacturing method of the silver-based flux-cored wire includes the following steps: 1 placing soldering flux powder in a soldering flux jar, heating up to 580-600 DEG C, and smelting soldering flux to liquid state for use; 2 smelting proportioned silver, copper and zinc to be cast to bars, then turning the cast bars to remove scale, and cutting the cast bars to ingots for use; 3 enabling a flux-cored wire extrusion device to be heated to 520-530 DEG C; 4 placing the ingots in a muffle furnace for preheating with the preheating temperature at 560-580 DEG C; 5 placing the preheated ingots in a mould drum of the flux-cored wire extrusion device, starting a press of the flux-cored wire extrusion device to extrude an extrusion rod into an upper mould drum, and enabling alloy to be extruded into a material leading cone, enter an upper mould, a mould core and a lower mould through split-flow and then form a hollow pipe; and 6 opening an air inlet valve of the soldering flux jar, pressurizing, and enabling the liquid-state soldering flux in the soldering flux jar to be pressed into a feeding port to enter the mould core and be injected to the alloy hollow pipe to be solidified after heat dissipation. Thus, the silver-based flux-cored wire is produced. Compared with the prior art, the silver-based flux-cored wire and the manufacturing method thereof have the advantages of being simple in soldering process, high in production efficiency, low in cost, easy in controlling use level of soldering flux accurately, capable of meeting the requirement for alloy welding temperature matching, easy in cleaning after welding, good in welding performance, not prone to moisture absorption of solder wires, and long in storage time of solder wires.

Owner:FOSHAN CITY YIHONG WELDING CO LTD

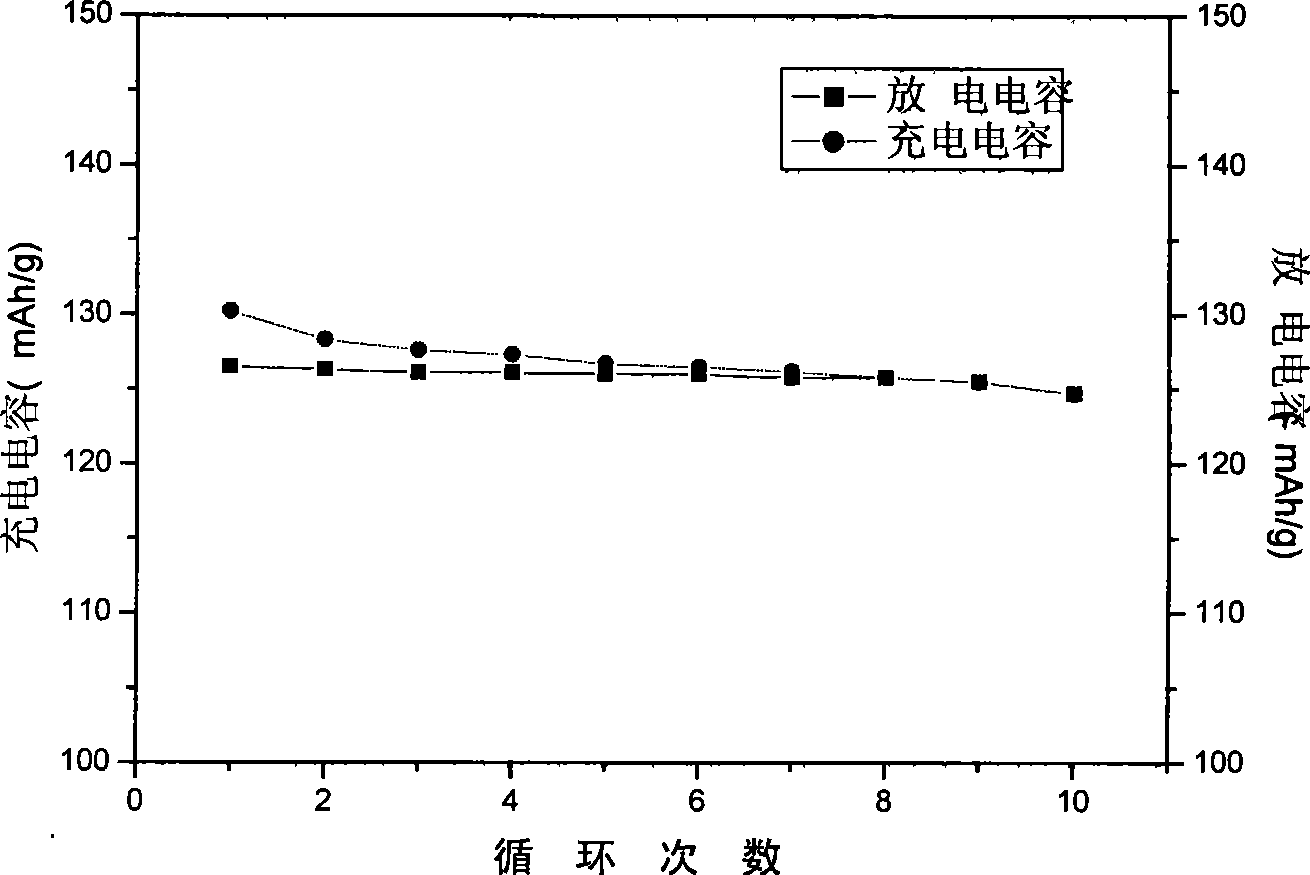

Method for preparing lithium titanate cathode material of lithium ion battery

InactiveCN101409341AExcellent high rate charge and discharge performanceElectrode manufacturing processesHigh rateLithium hydroxide

The invention discloses a preparation method of a lithium titanate cathode material for a lithium ion battery. Titanium dioxide colloid is taken as an initial raw material; the titanium dioxide colloid and lithium hydroxide are added to a mixture of water and ethanol while stirring, then the obtained solution is transferred to a hydrothermal reaction kettle for hydrothermal ion exchange reaction at 150-200 DEG C for 10-18h, the reacted solution is naturally cooled to room temperature, then filtered to obtain white precipitate; the obtained precipitate is placed in a muffle furnace with the temperature of 350-600 DEG C for 1-3h heat treatment to obtain the lithium titanate cathode material used in the lithium ion battery. The lithium titanate cathode material which is used in the lithium ion battery and synthesized by the method has stable discharge specific capacity of 125mAh / g at the rate of 20C (3.5A / g), and has good high-rate charge and discharge performance.

Owner:SHANGHAI JIAO TONG UNIV +1

Pyromellitic dianhydride catalyst and preparation method thereof

InactiveCN102008971ASolve the problem of selectivityPhysical/chemical process catalystsOrganic chemistryAlkali metal oxideSlurry

The invention provides a pyromellitic dianhydride catalyst and a preparation method thereof, relates to a catalyst and the preparation method and solves the problems of low catalyst yield and low selectivity of the conventional gaseous oxidation method for preparing pyromellitic dianhydride. The catalyst consists of an active ingredients and a carrier, wherein the active ingredients consist of V2O5, TiO2, P2O5, Sb2O3 and alkali metal oxides. The method comprises the following steps of: 1, weighing; 2, adding an antimony source and a vanadium source into oxalic acid solution with stirring to obtain vanadyl oxalate solution; 3, adding a phosphorus source, the antimony source and alkali metal salt into the vanadyl oxalate solution, uniformly mixing, then adding a titanium source, adding polyvinyl acetate emulsion and then pulping and grinding to obtain size; and 4, adding the carrier into a revolving drum of spray painting equipment, heating and spraying the size on the carrier, putting into a Muffle furnace to carry out air purge and cooling to obtain the catalyst. The catalyst is used for catalysis and preparation of pyromellitic dianhydride.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

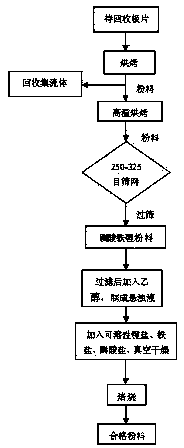

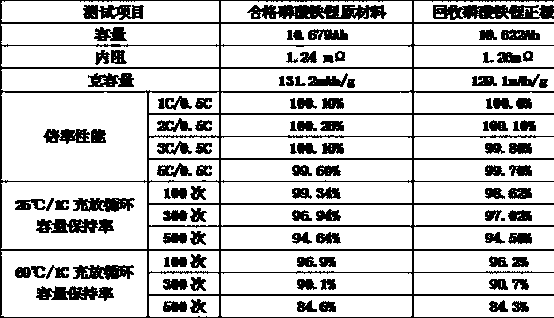

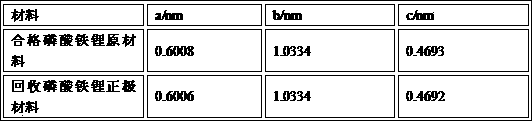

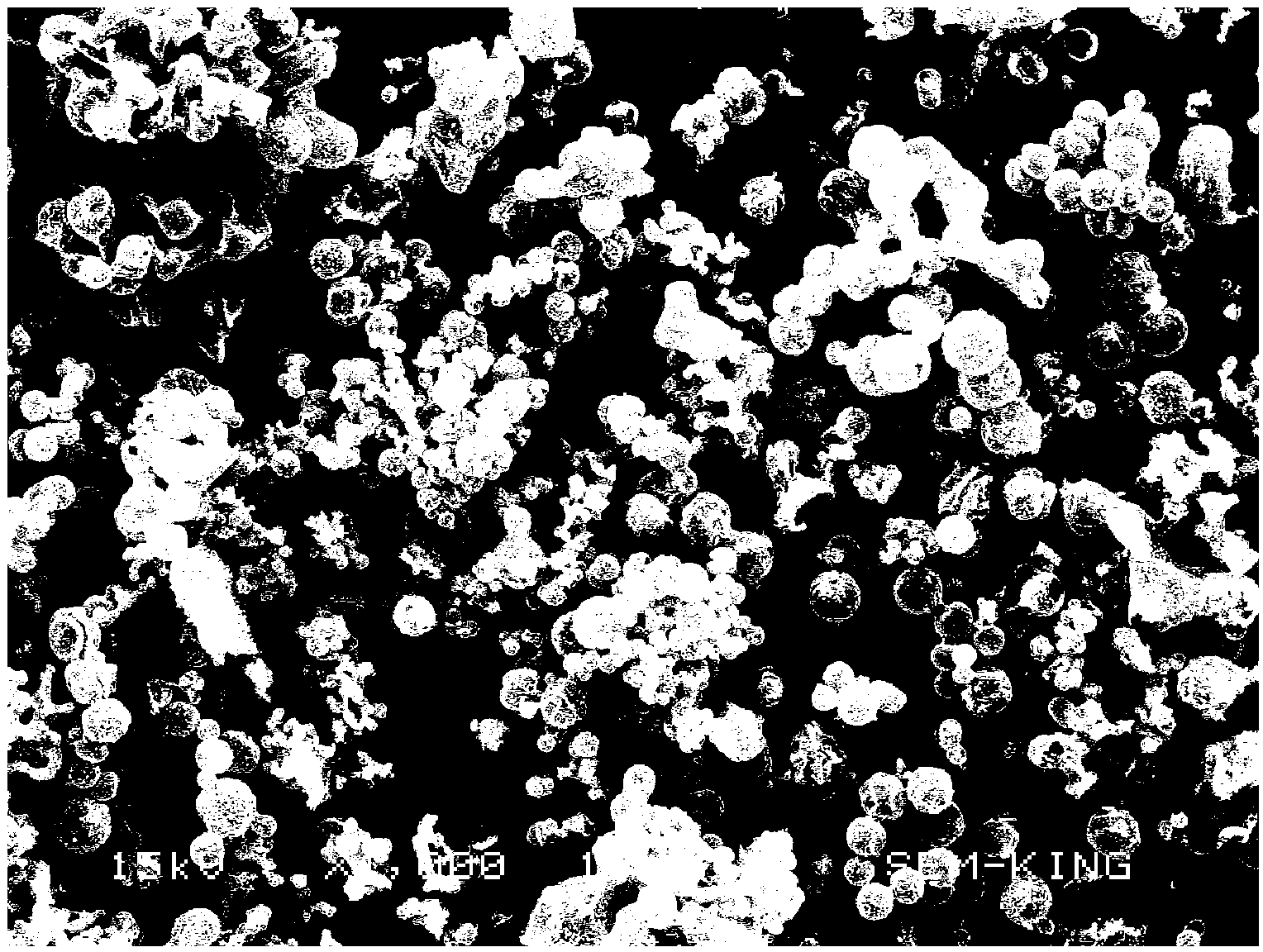

Method for recycling lithium iron phosphate wastes in manufacturing link of lithium iron phosphate batteries

ActiveCN104362408AImprove electrochemical performanceHigh reuse rateWaste accumulators reclaimingBattery recyclingDecompositionLithium-ion battery

The invention discloses a method for recycling lithium iron phosphate wastes in the manufacturing link of lithium iron phosphate batteries and relates to lithium ion batteries. The recycling method is characterized by comprising the following steps: after a pole piece to be recycled is put into a muffle furnace, baking is performed for 2-3h at the temperature of 400-600 DEG C, the decomposition of a binder fails, and an active material lithium iron phosphate and conductive agent powder completely fall off from a current collector aluminum foil; after the powder is put in the muffle furnace, baking is performed for 4-6h at the temperature of 650-800 DEG C, sieving is performed to obtain lithium iron phosphate power; filtering is performed, the lithium iron phosphate power is washed with deionized water, and an ethanol wetting agent after washing is added to obtain turbid liquid; soluble lithium salt, molysite and phosphate are proportionally mixed into an ethanol solution, the mixed solution is added into the turbid liquid for mixing, and vacuum drying is performed at the temperature of 120-140 DEG C; roasting is performed for 3-6h at the temperature of 650-850 DEG C in an inert gas atmosphere to obtain acceptable materials. The method has the advantages of being good in electrochemical performance of recycled materials, high in reuse rate and low in cost.

Owner:SHANDONG SACRED SUN POWER SOURCES

Preparation method and application of zinc oxide visible-light-induced photocatalyst sensitized by squarylium cyanine

InactiveCN103071535AEfficient degradationImprove photocatalytic activityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsCarbon compositesMicrosphere

The invention relates to a preparation method of a zinc oxide visible-light-induced photocatalyst sensitized by squarylium cyanine. The preparation method comprises the following steps: dissolving Zn(Ac)22H2O and glucose into deionized water; carrying out ultrasonic processing to form a settled solution; after transferring the solution into a liner of a polytetrafluoroethylene autoclave, performing hydrothermal reaction for 12 to 24 hours at a temperature of 140 to 180 DEG C; after cooling to room temperature, carrying out centrifugal washing on the obtained black powder respectively with the deionized water and absolute ethyl alcohol; drying at a temperature of 60 DEG C to obtain a zinc oxide and carbon composite precursor; placing the precursor into a muffle furnace to calcine for 3 hours at a temperature of 400 to 600 DEG C, so as to obtain zinc oxide microspheres; mixing the zinc oxide microspheres and the squarylium cyanine as well as an organic solvent; at a temperature of 30 to 60 DEG C, carrying out ultrasonic processing on the mixture for 0.5 to 2 hours; then removing the organic solvent under the condition of pressure reduction; and finally, drying the obtained solid at a temperature of 60 DEG C. The zinc oxide visible-light-induced photocatalyst sensitized by the squarylium cyanine can be used for photocatalysis processing on organic pollutants in air, soil and sewage.

Owner:常州浩瀚万康纳米材料有限公司

Wet-method preparation process of ternary positive material for lithium ion battery

The invention provides a wet-method preparation process of a ternary positive material for a lithium ion battery. The synthesis process of a ternary precursor comprises the steps of: adding complexing agent ammonia water, an aqueous solution of metal nickel-cobalt-manganese ions, and a precipitating agent aqueous solution of sodium hydroxide into a reaction kettle to prepare the liquid-phase ternary precursor under the condition of protection gas; and the synthesis process of the ternary material comprises the steps of: carrying out preliminary-stage sintering in a muffle furnace after ball grinding, mixing, smashing and fast drying the ternary precursor and lithium salt, secondarily introducing of the lithium salt into the materials according to a proportion after the preliminary-stage sintering, and carrying out secondary sintering in the muffle furnace after mixing the materials, so as to obtain the nickel-cobalt-manganese acid lithium ternary positive material. The method provided by the invention is simple in preparation process, the particle size of the prepared nickel-cobalt-manganese acid lithium ternary positive material ranges from 0.5 to 10 microns, the prepared nickel-cobalt-manganese acid lithium ternary positive material is controllable and can be uniformly distributed, and the nickel-cobalt-manganese acid lithium ternary positive material has an excellent electrochemical performance.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

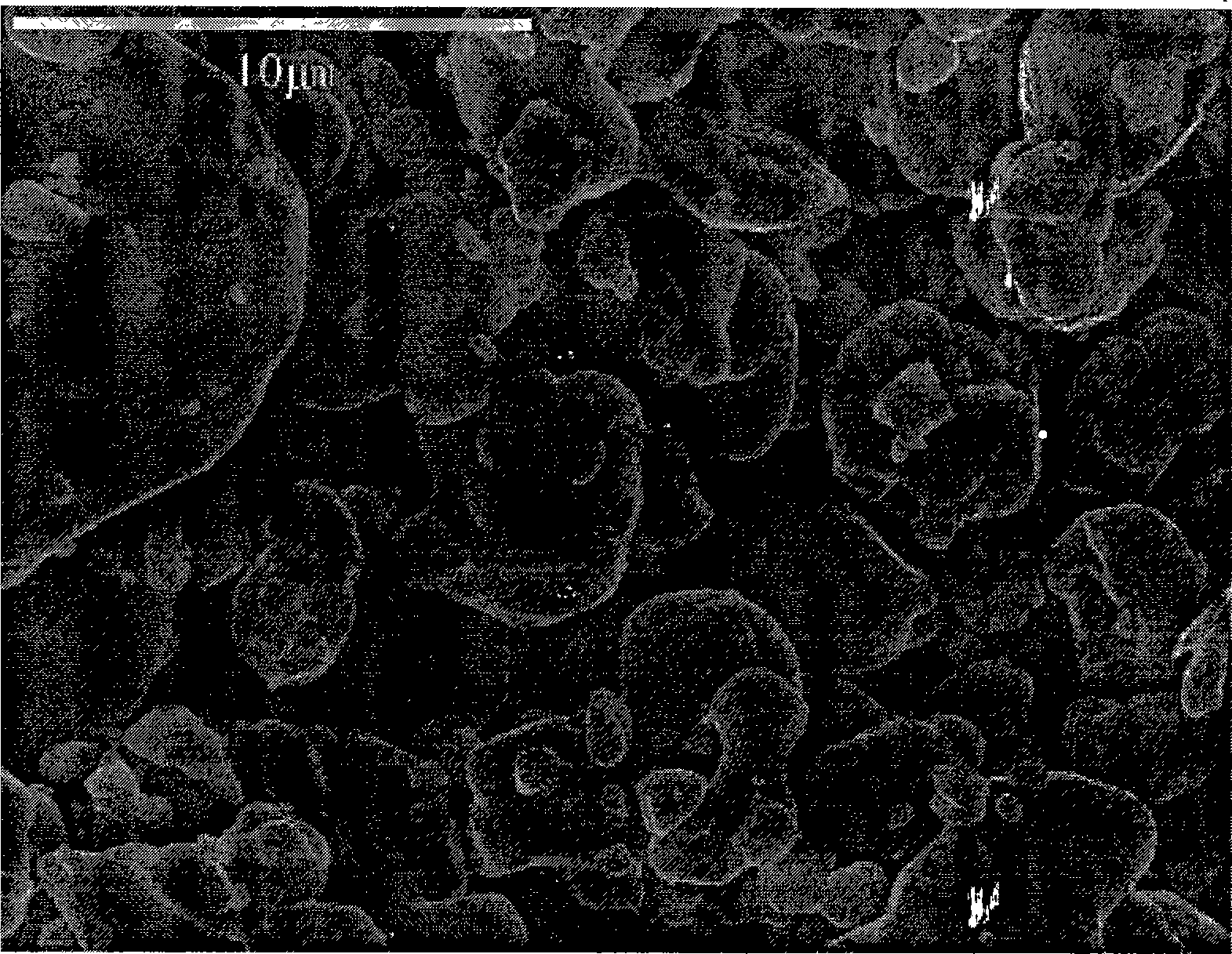

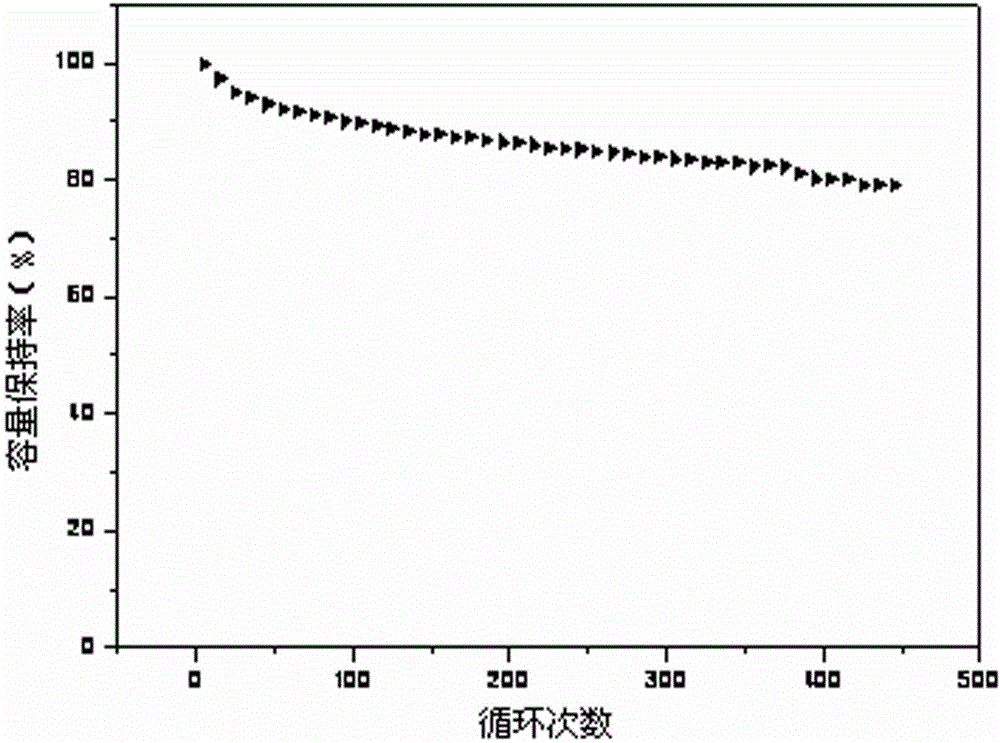

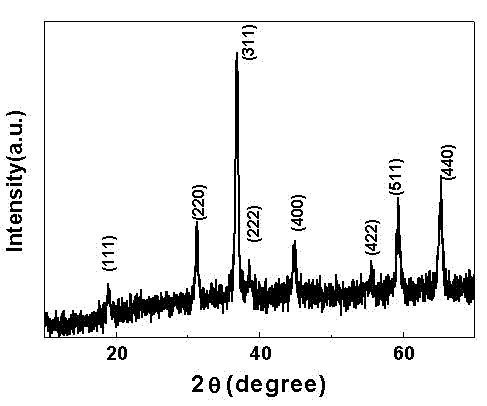

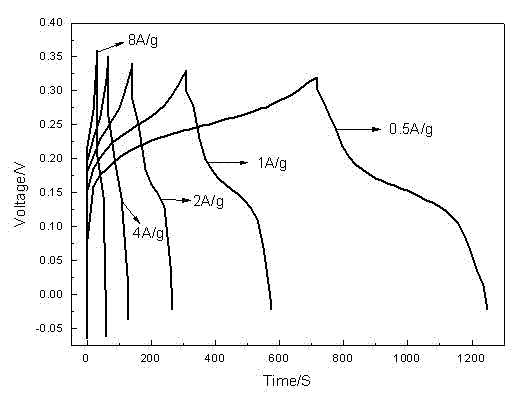

Co3O4 nanometer material for supercapacitor and preparation method thereof

InactiveCN102531070AImprove stabilityUniform particle size distributionNanotechnologyCobalt oxides/hydroxidesElectrolytic agentGlycol synthesis

The invention discloses a Co3O4 nanometer material for a supercapacitor and a preparation method thereof. The method comprises the following steps: on the basis of using cobalt nitrate as a raw material and a mixture of ethylene glycol and water as a solvent, adding a defined amount of glucose, placing the mixture in an autoclave to react at 120-200 DEG C for 10-25 hours, performing suction filtering, drying at 80 DEG C, calcining in a muffle furnace at 300 DEG C to obtain Co3O4 sea urchin-shaped conjoined spheres which have the diameter of 7-15mu m and are of a three-dimensional hierarchical structure. The Co3O4 nanometer material and the preparation method have the characteristics that the operation method is simple, the yield is high, and the product has the three-dimensional hierarchical structure and superior electrochemical performance. The prepared Co3O4 spheres with the three-dimensional hierarchical structure have the characteristics that the stability is higher, the particle size distribution is uniform, the dispersibility is good, the spheres are difficult in agglomeration and pores with the three-dimensional structure are beneficial to the diffusion of the electrolyte, thus the material can be widely applied in the fields of catalysis, lithium batteries and supercapacitors.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com