Co3O4 nanometer material for supercapacitor and preparation method thereof

A technology of cobalt tetroxide and supercapacitor, applied in the direction of cobalt oxide/cobalt hydroxide, nanotechnology, etc., to achieve the effects of excellent cycle performance, not easy to agglomerate, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1g of cobalt nitrate hexahydrate, add 30mL of distilled water and stir to disperse for 10 minutes, measure 10mL of ethylene glycol and add to the above solution, dissolve 0.1g of glucose into the above solution, stir magnetically at room temperature in air for 30 minutes, and the obtained The mixed solution was placed in an autoclave with a polytetrafluoroethylene liner and sealed, kept at a constant temperature of 120°C for 15 hours, the product was washed three times with distilled water and absolute ethanol, and dried in vacuum at 80°C for 12 hours. The dried product was calcined in a muffle furnace at 300° C. for 2 hours to obtain sea urchin-like nanospheres with a three-dimensional hierarchical structure of cobalt tetroxide.

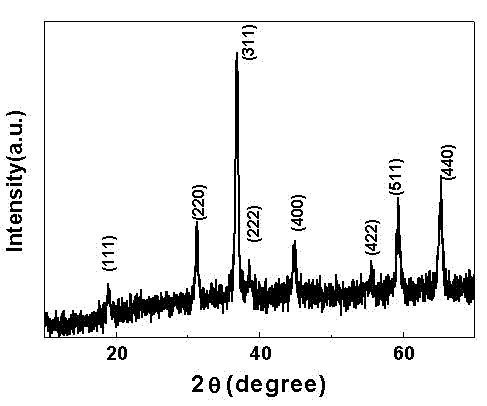

[0022] figure 1 For the XRD spectrum of the nanomaterial obtained in this example, the diffraction peaks in the figure correspond well to the diffraction peaks of tricobalt tetroxide, and the spectra match, which proves that the produc...

Embodiment 2

[0024] Weigh 1g of cobalt nitrate hexahydrate, add 20mL of distilled water and stir to disperse for 10 minutes, measure 20mL of ethylene glycol and add to the above solution, dissolve 0.1g of glucose into the above solution, stir magnetically at room temperature in air for 30 minutes, and the obtained The mixed solution was put into an autoclave with a polytetrafluoroethylene liner and sealed, kept at a constant temperature of 150 °C for 15 hours, the product was washed three times with distilled water and absolute ethanol, and dried in vacuum at 80 °C for 12 h. The dried product was calcined in a muffle furnace at 300° C. for 2 hours to obtain sea urchin-like nanospheres with a three-dimensional hierarchical structure of cobalt tetroxide.

Embodiment 3

[0026] Weigh 1g of cobalt nitrate hexahydrate, add 10mL of distilled water and stir to disperse for 10 minutes, measure 30mL of ethylene glycol and add to the above solution, dissolve 0.1g of glucose into the above solution, stir magnetically at room temperature in air for 30 minutes, and the obtained The mixed solution was placed in an autoclave with a polytetrafluoroethylene liner and sealed, kept at a constant temperature of 200°C for 15 hours, the product was washed three times with distilled water and absolute ethanol, and dried in vacuum at 80°C for 12 hours. The dried product was calcined in a muffle furnace at 250° C. for 2 hours to obtain sea urchin-like nanospheres with a three-dimensional hierarchical structure of cobalt tetroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com