Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17963results about "Nanotechnology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

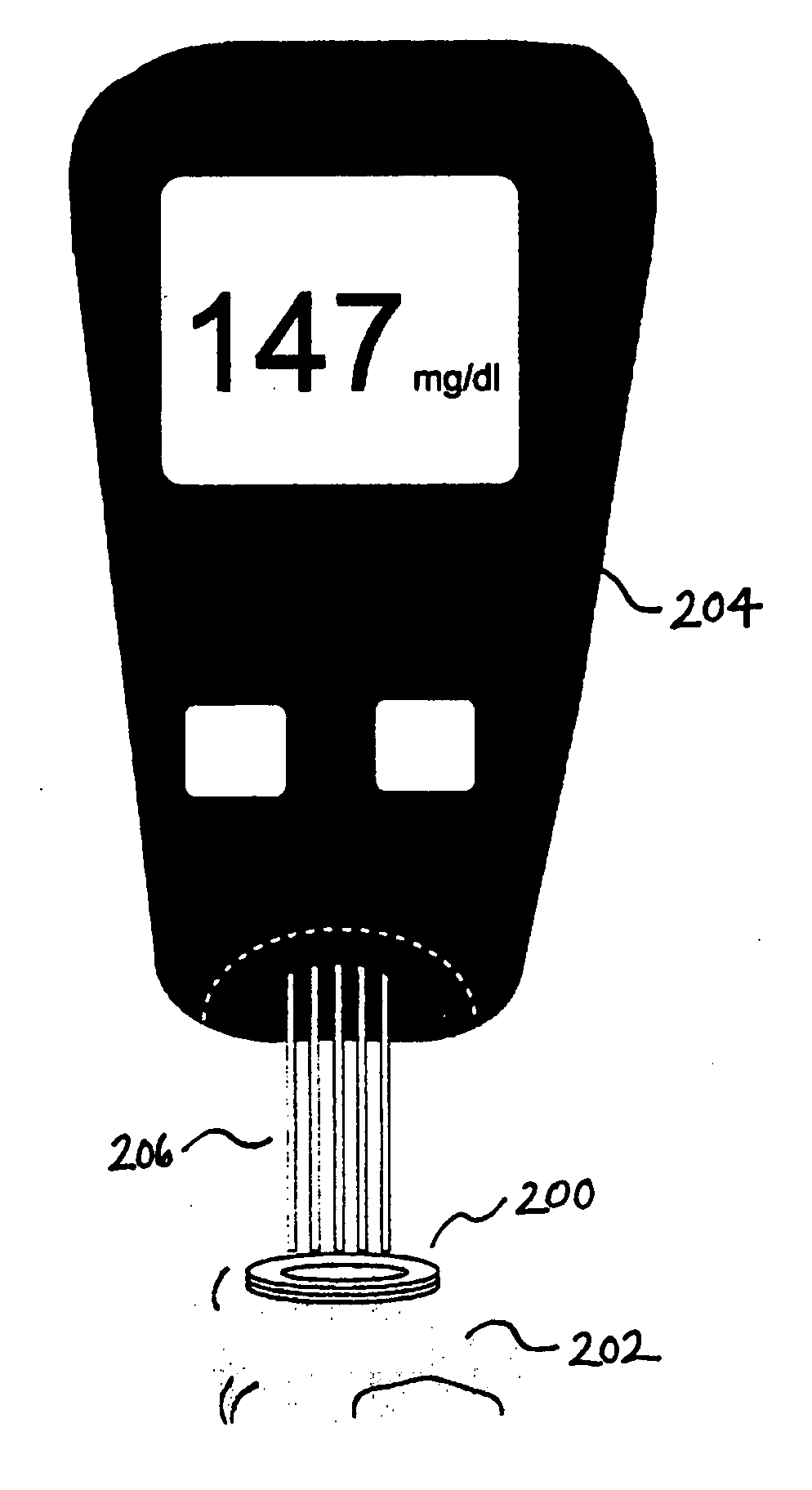

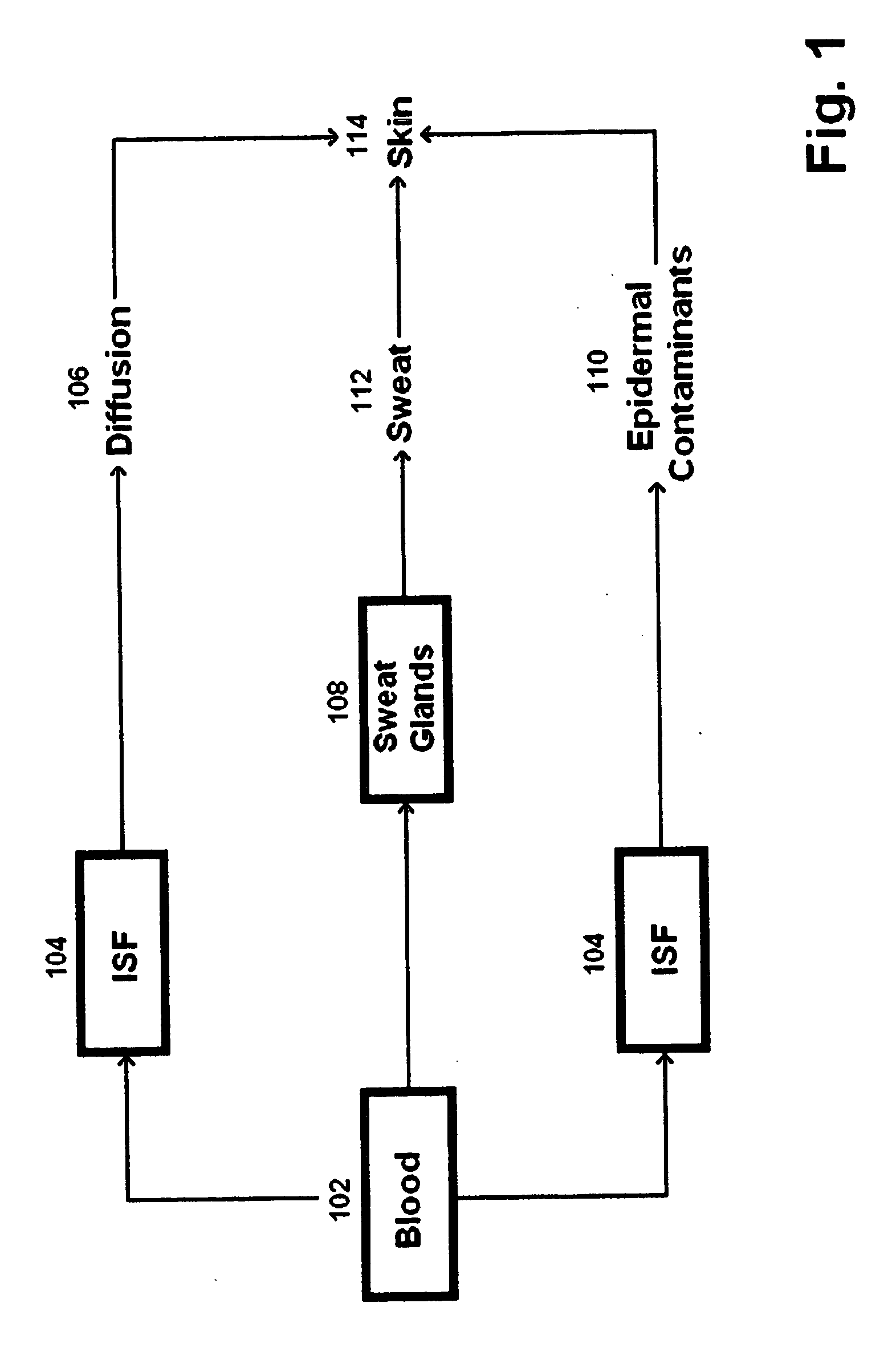

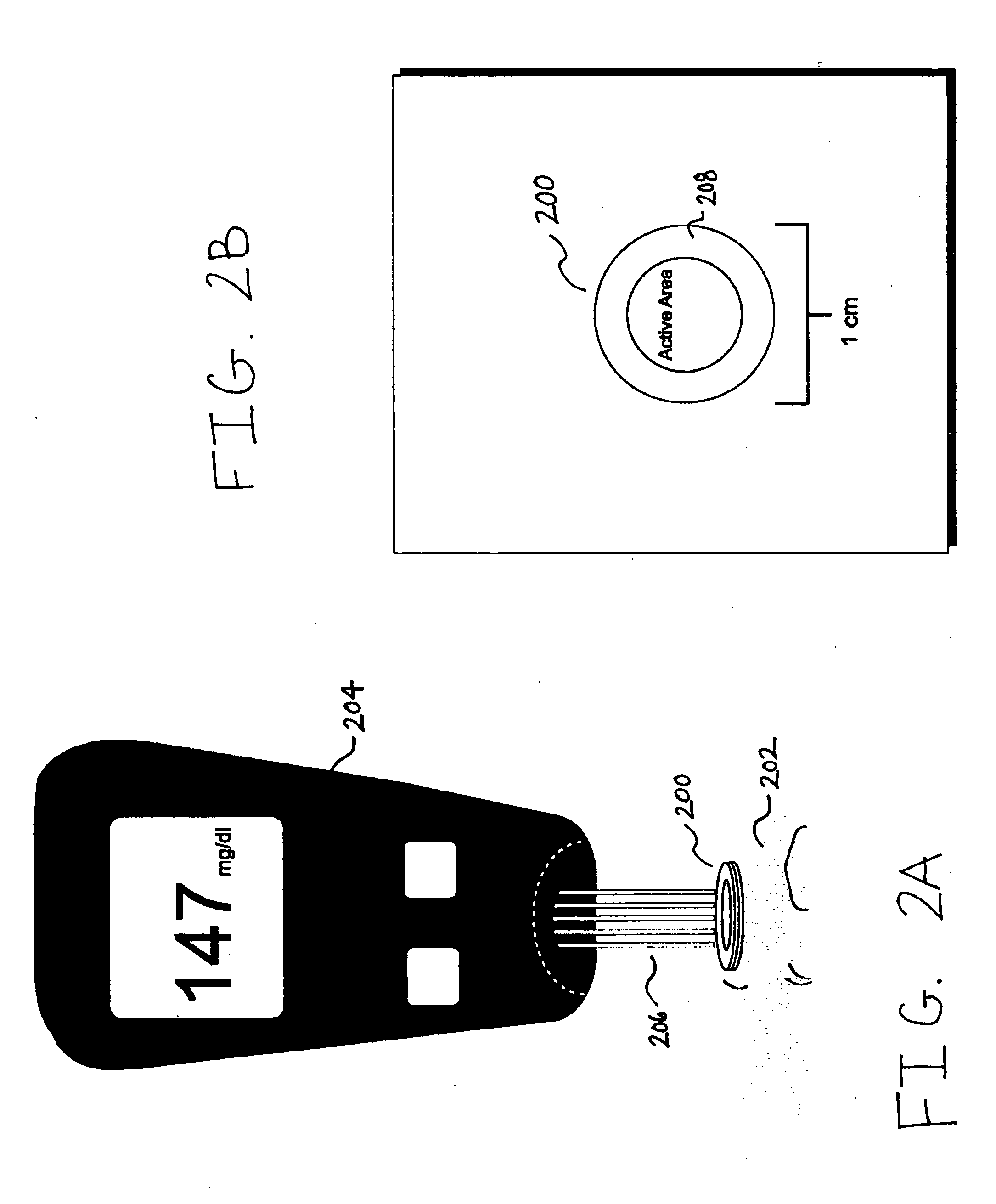

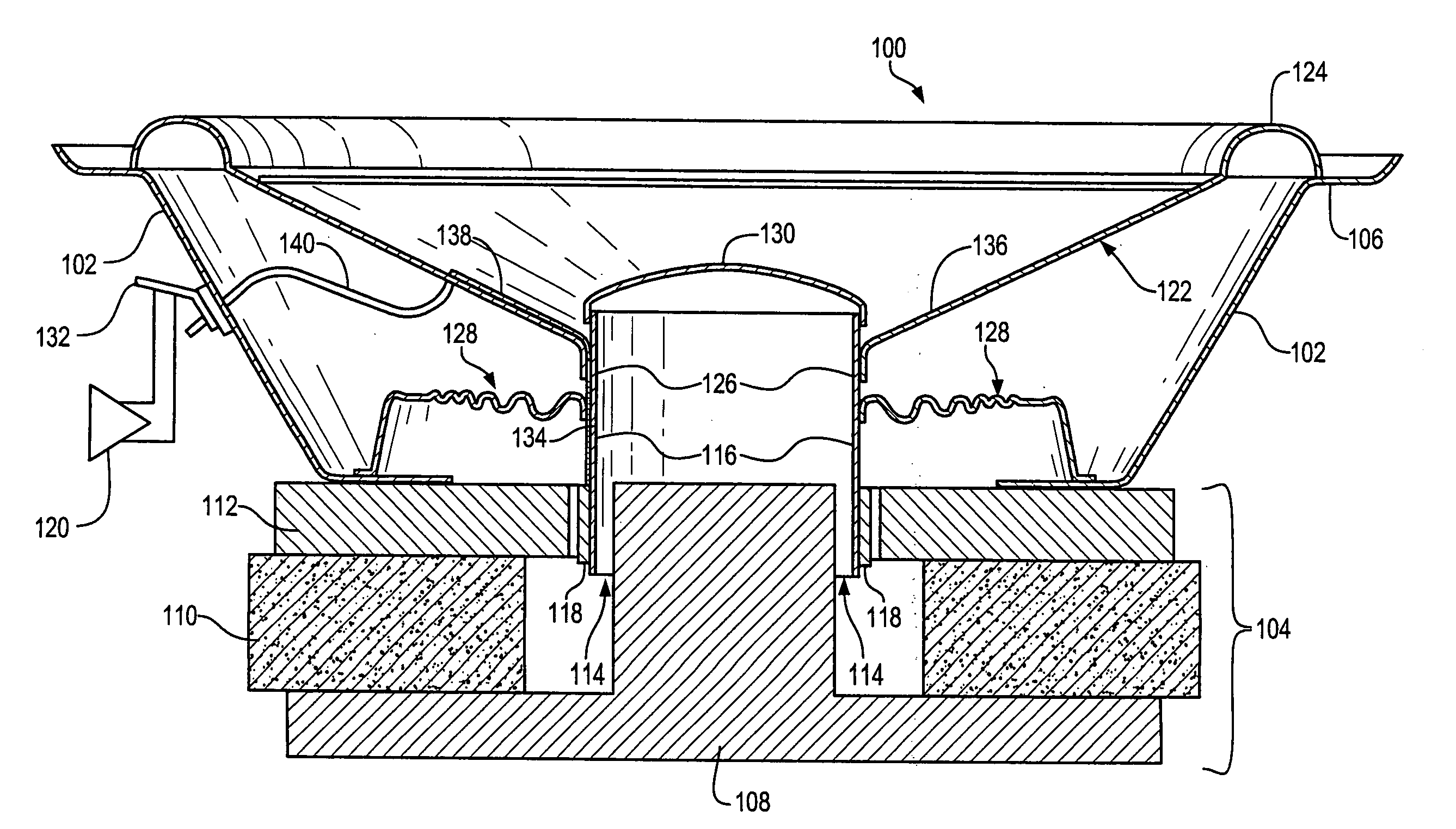

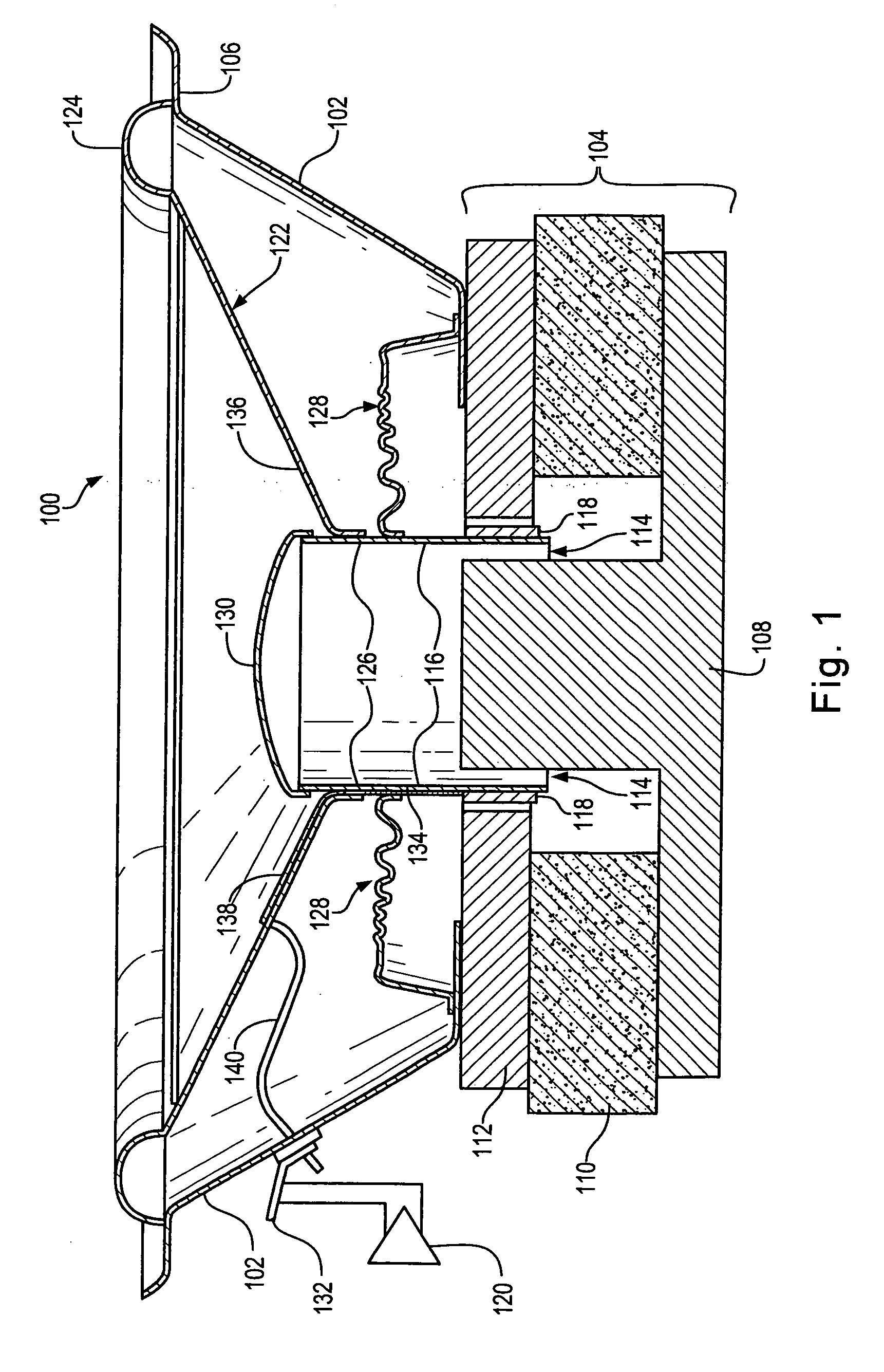

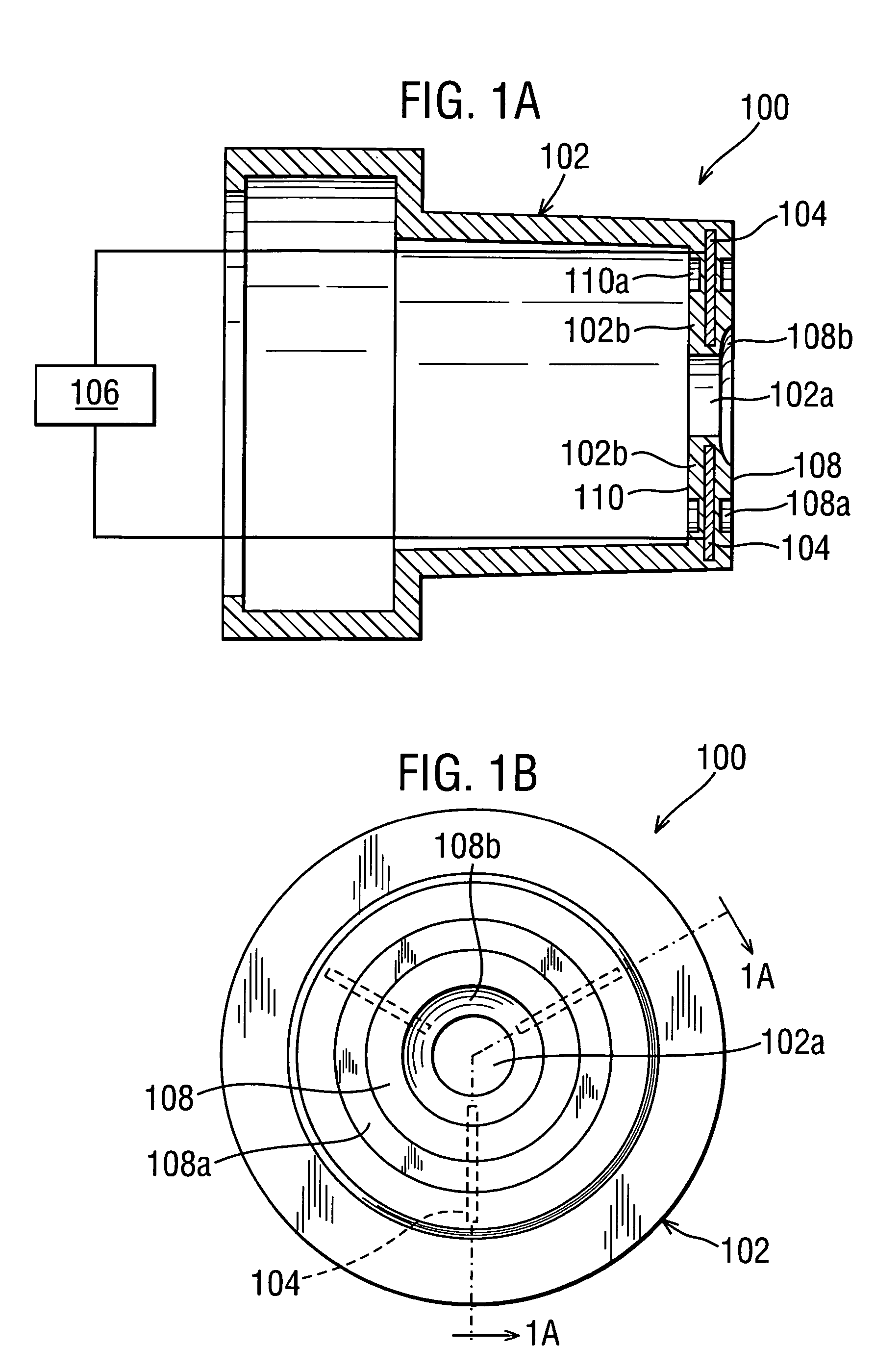

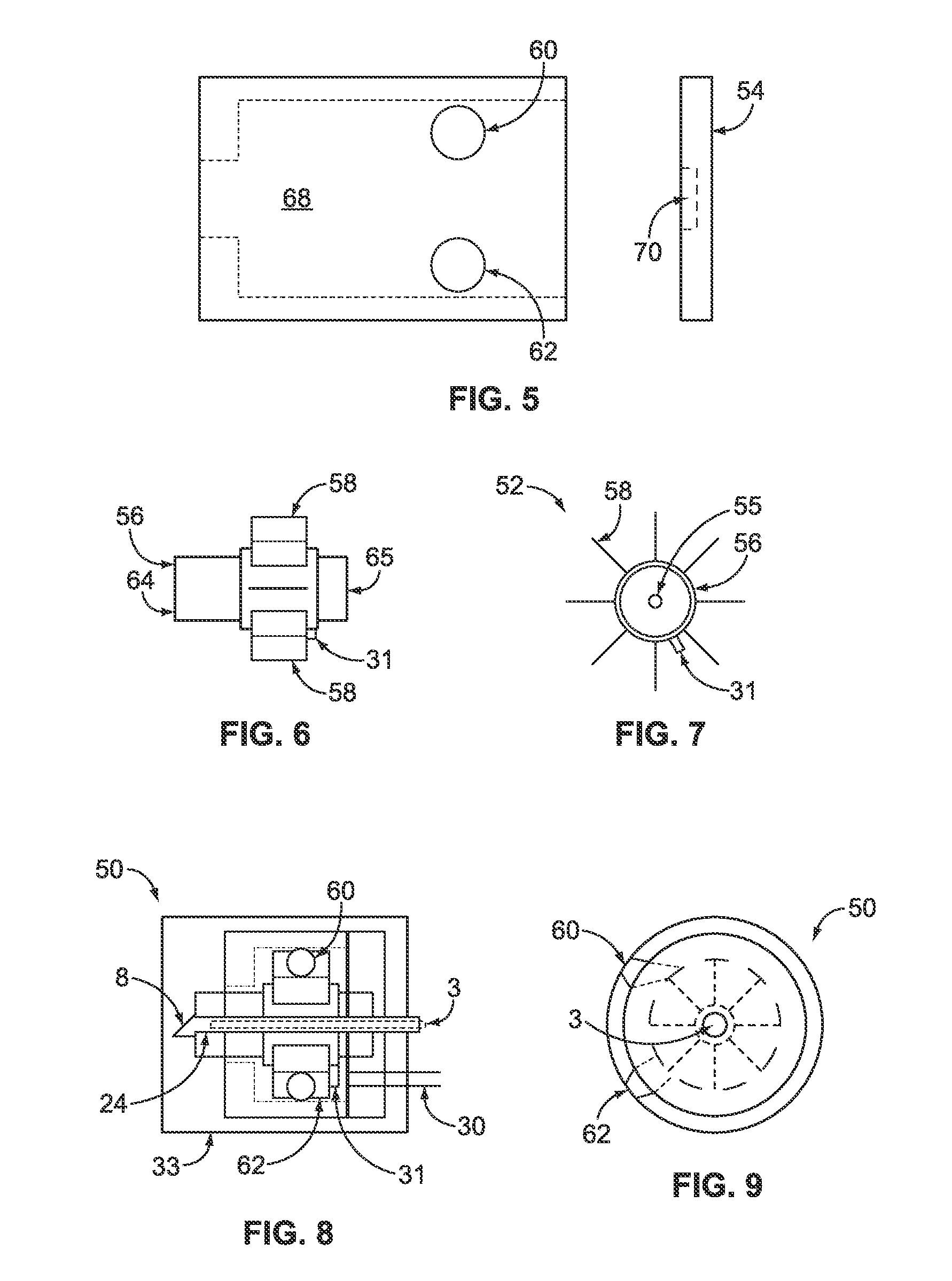

Devices, methods, and kits for non-invasive glucose measurement

InactiveUS20060004271A1Minimize impactMicrobiological testing/measurementSurgeryMeasurement deviceDisplay device

Described are devices, methods, and kits for non-invasively measuring glucose. In general, the devices comprise skin patches for placement on a skin surface and measurement devices for measuring glucose collected in the patches. The patches may include an adhesive material, a collection layer, an interface layer, and a sweat-permeable membrane. The sweat-permeable membrane is configured to act as a barrier to epidermal contaminants and glucose brought to the skin surface via diffusion. In this way, non-correlatable skin surface glucose will not be measured. The patches may further include components to induce a local sweat response. The measurement device typically includes a display, a processor, and a measurement mechanism. The methods typically include the steps of wiping the skin surface with a wipe containing at least one solvent for removing glucose, placing a patch on a skin surface, and measuring glucose collected in the patch. Kits comprising the patch and measurement device are also described.

Owner:VIVOMEDICAL INC

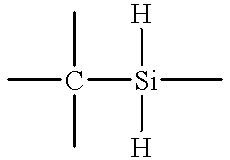

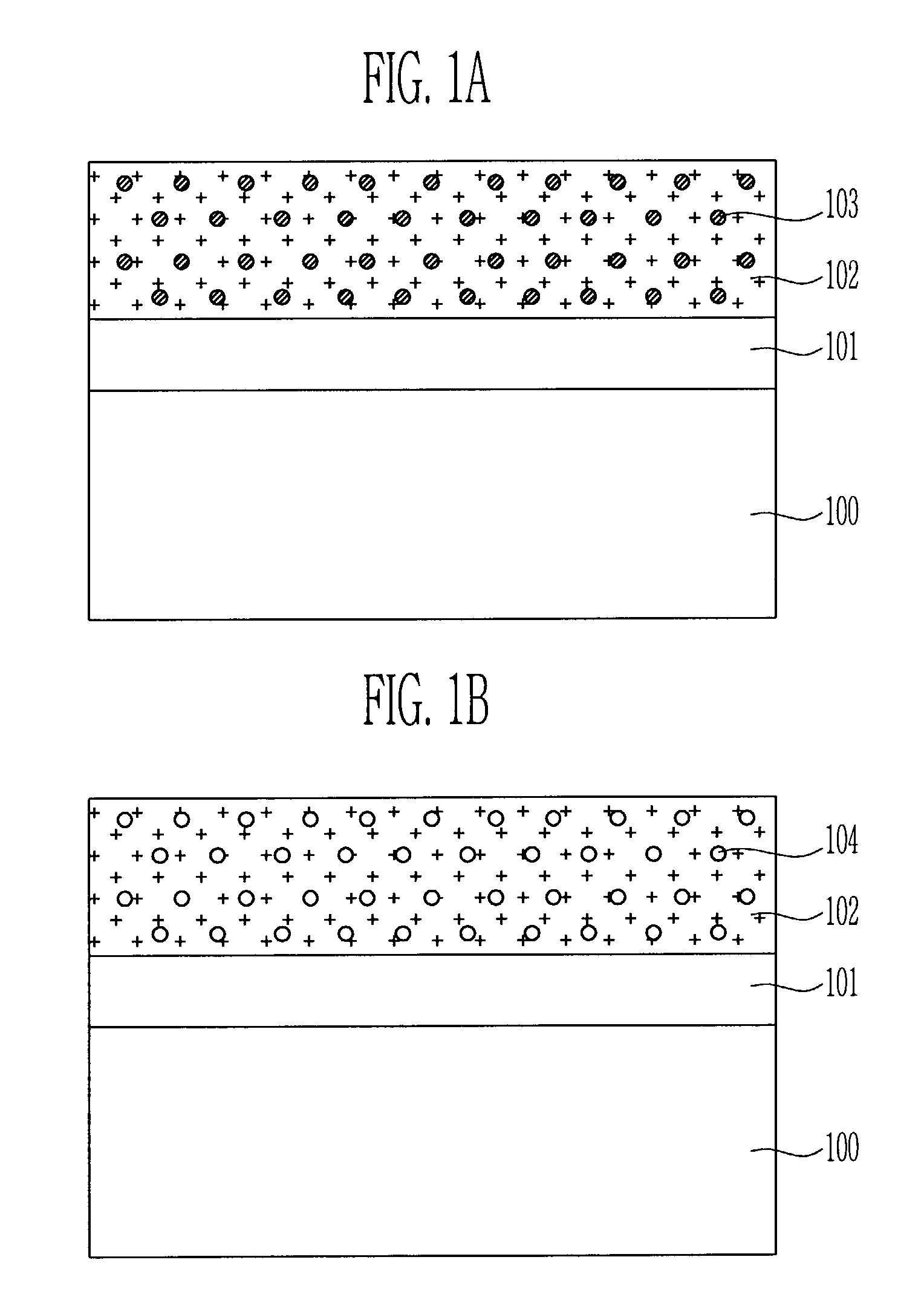

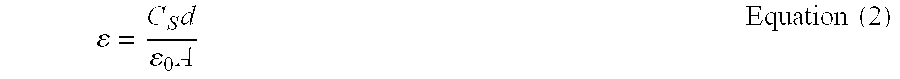

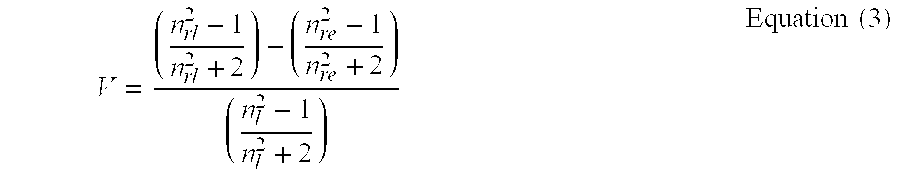

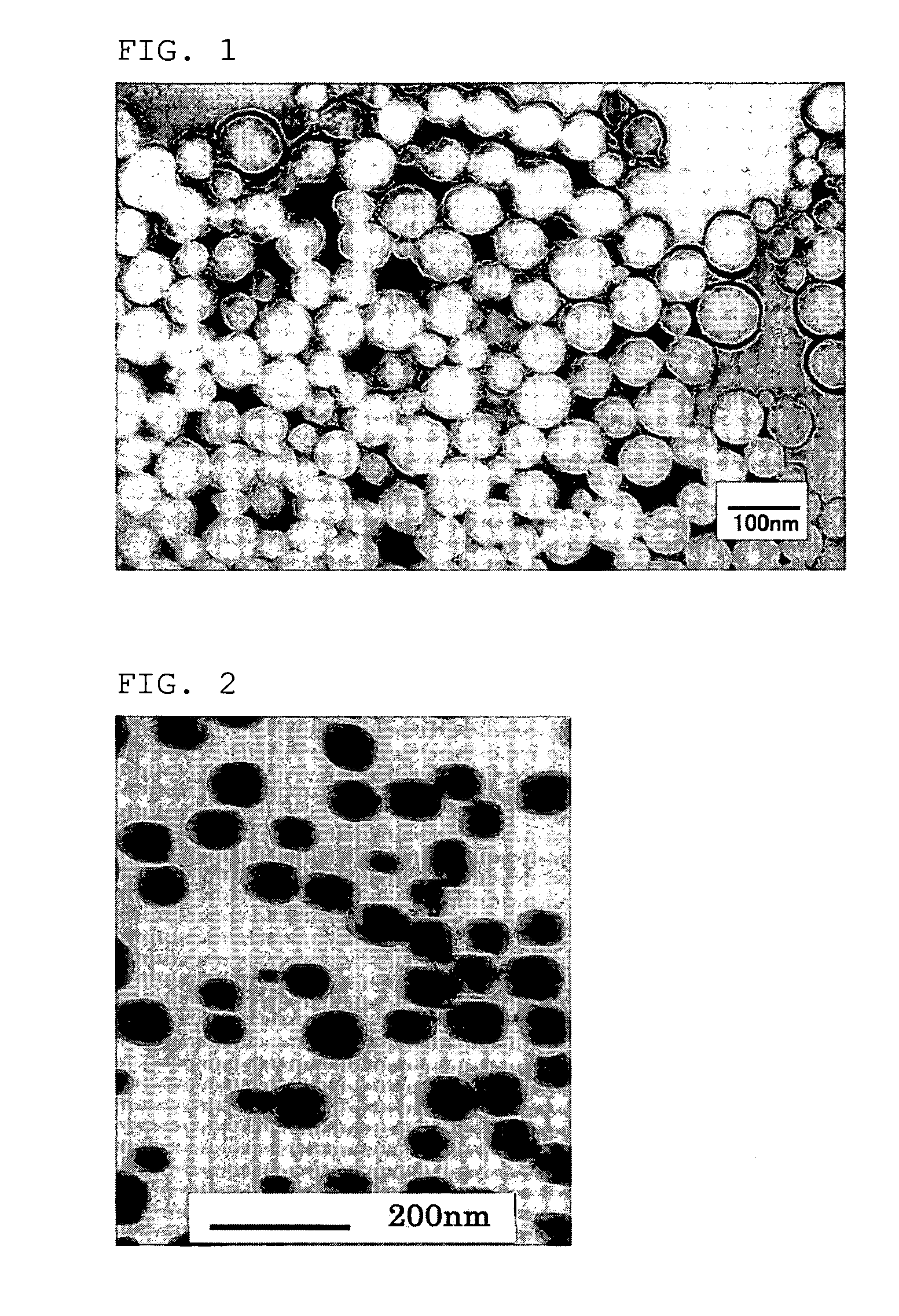

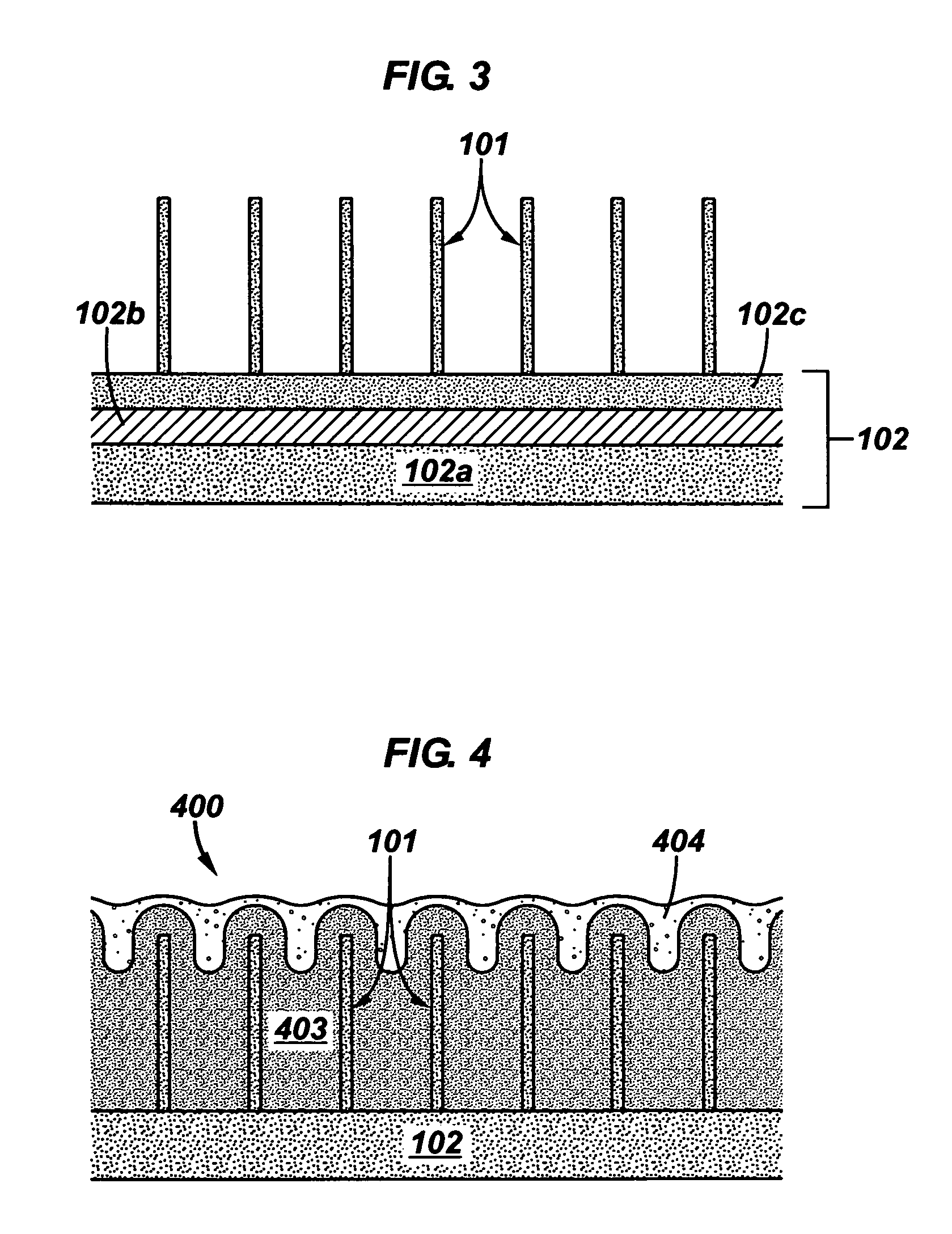

CVD nanoporous silica low dielectric constant films

InactiveUS6171945B1Semiconductor/solid-state device detailsSolid-state devicesSilicon oxideGradual increase

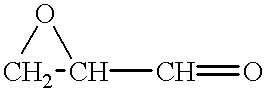

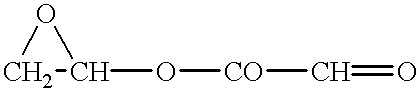

A method and apparatus for depositing nano-porous low dielectric constant films by reaction of a silicon hydride containing compound or mixture optionally having thermally labile organic groups with a peroxide compound on the surface of a substrate. The deposited silicon oxide based film is annealed to form dispersed microscopic voids that remain in a nano-porous silicon oxide based film having a foam structure. The nano-porous silicon oxide based films are useful for filling gaps between metal lines with or without liner or cap layers. The nano-porous silicon oxide based films may also be used as an intermetal dielectric layer for fabricating dual damascene structures. Preferred nano-porous silicon oxide based films are produced by reaction of 1,3,5-trisilanacyclohexane, bis(formyloxysilano)methane, or bis(glyoxylylsilano)methane and hydrogen peroxide followed by a cure / anneal that includes a gradual increase in temperature.

Owner:APPLIED MATERIALS INC

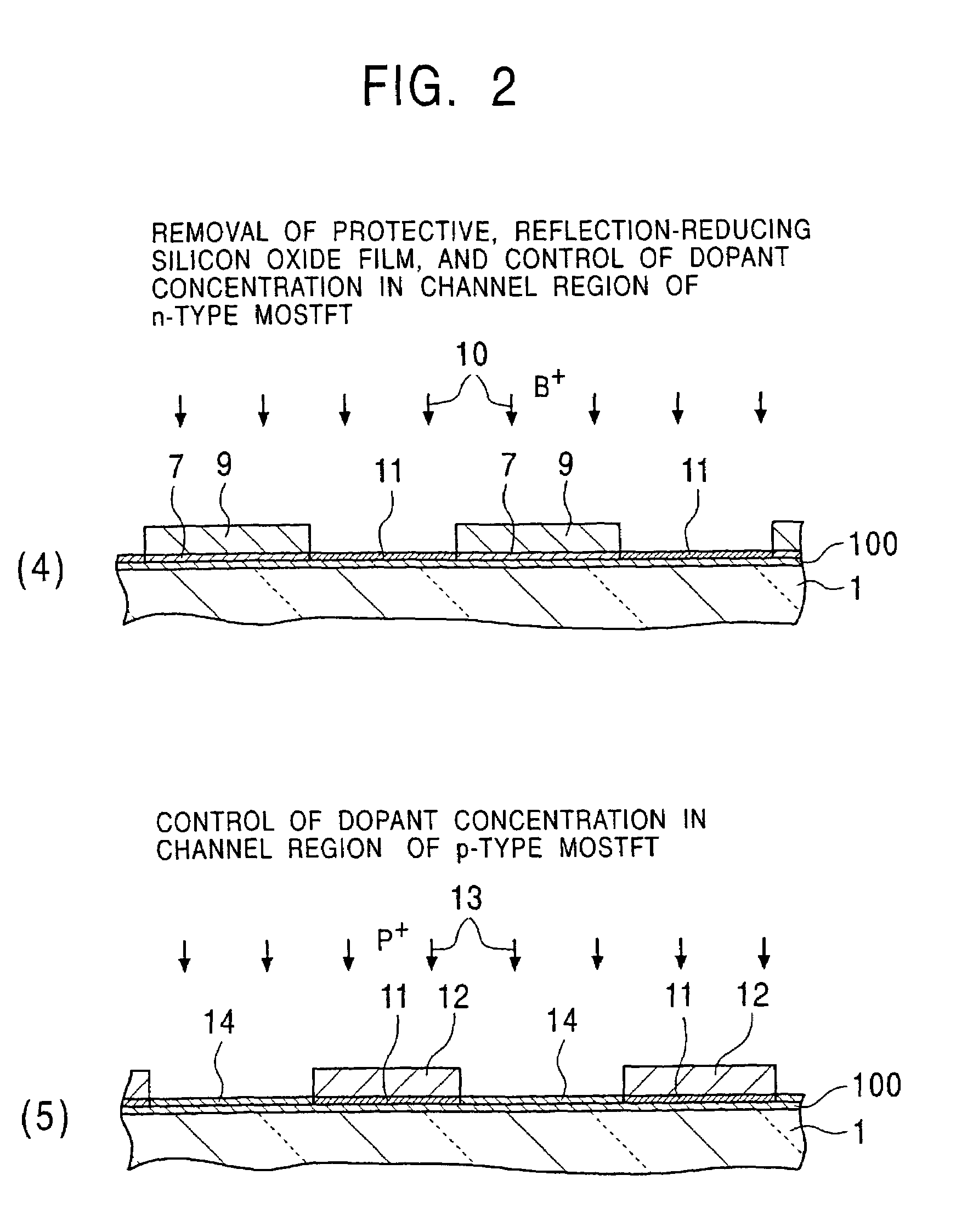

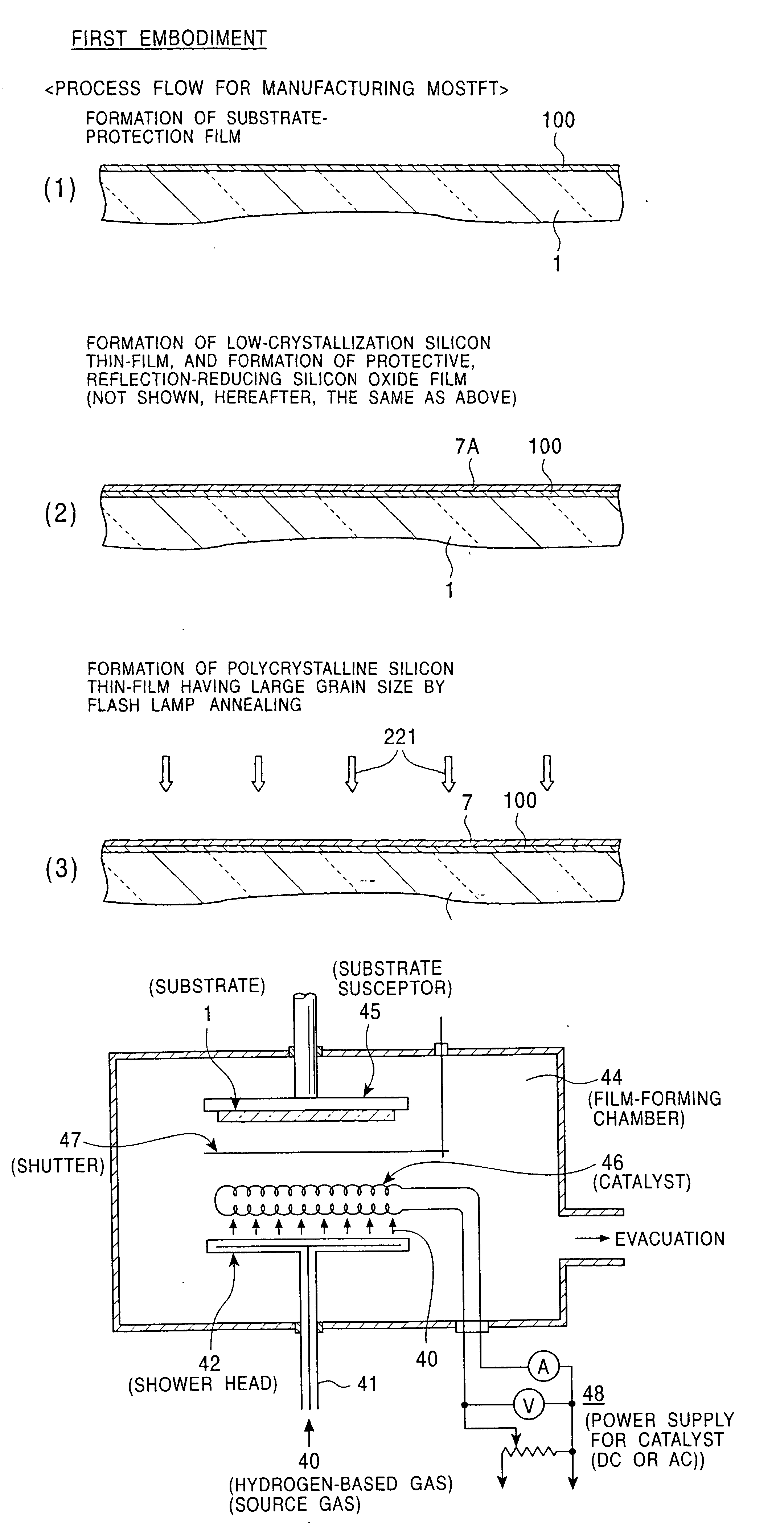

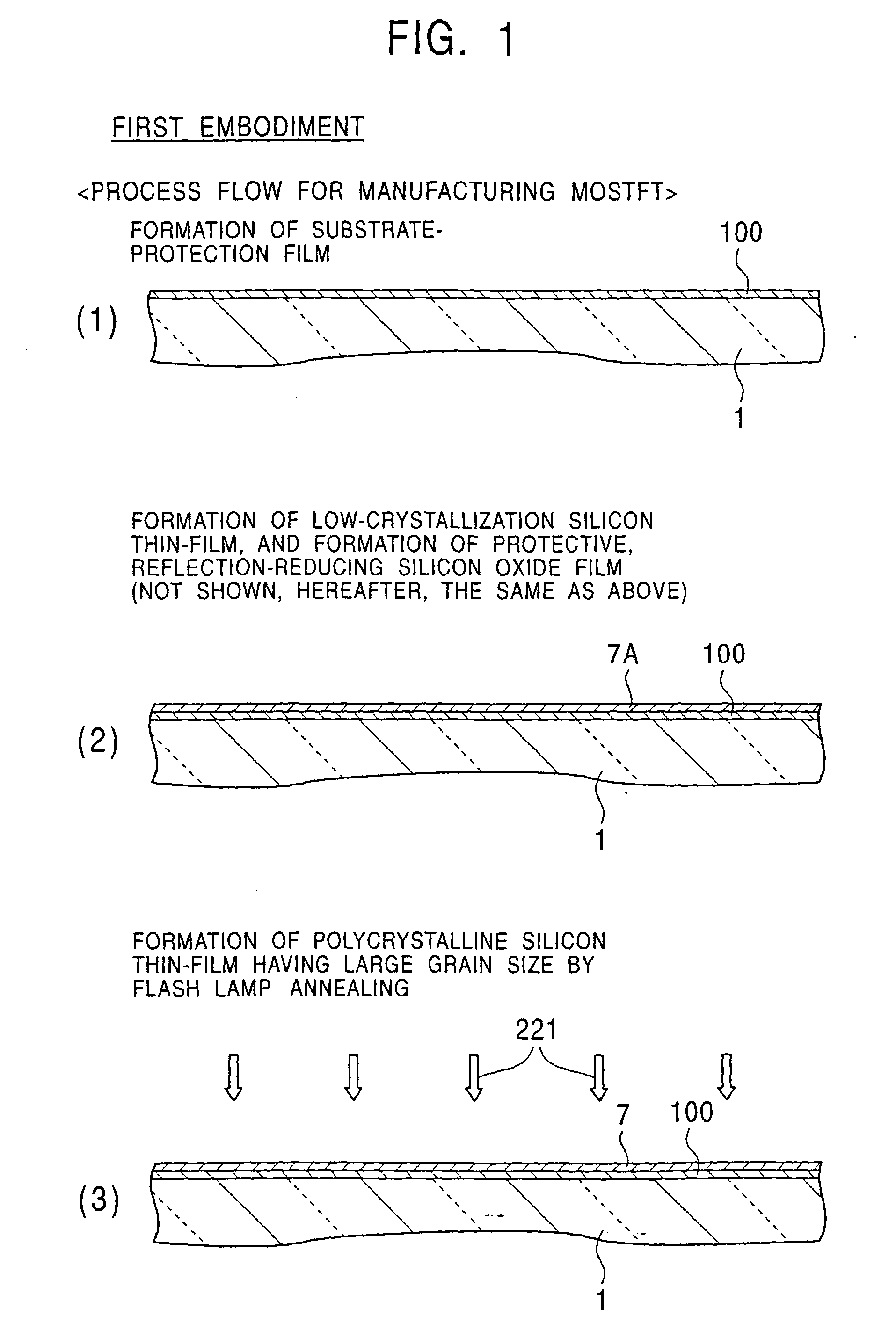

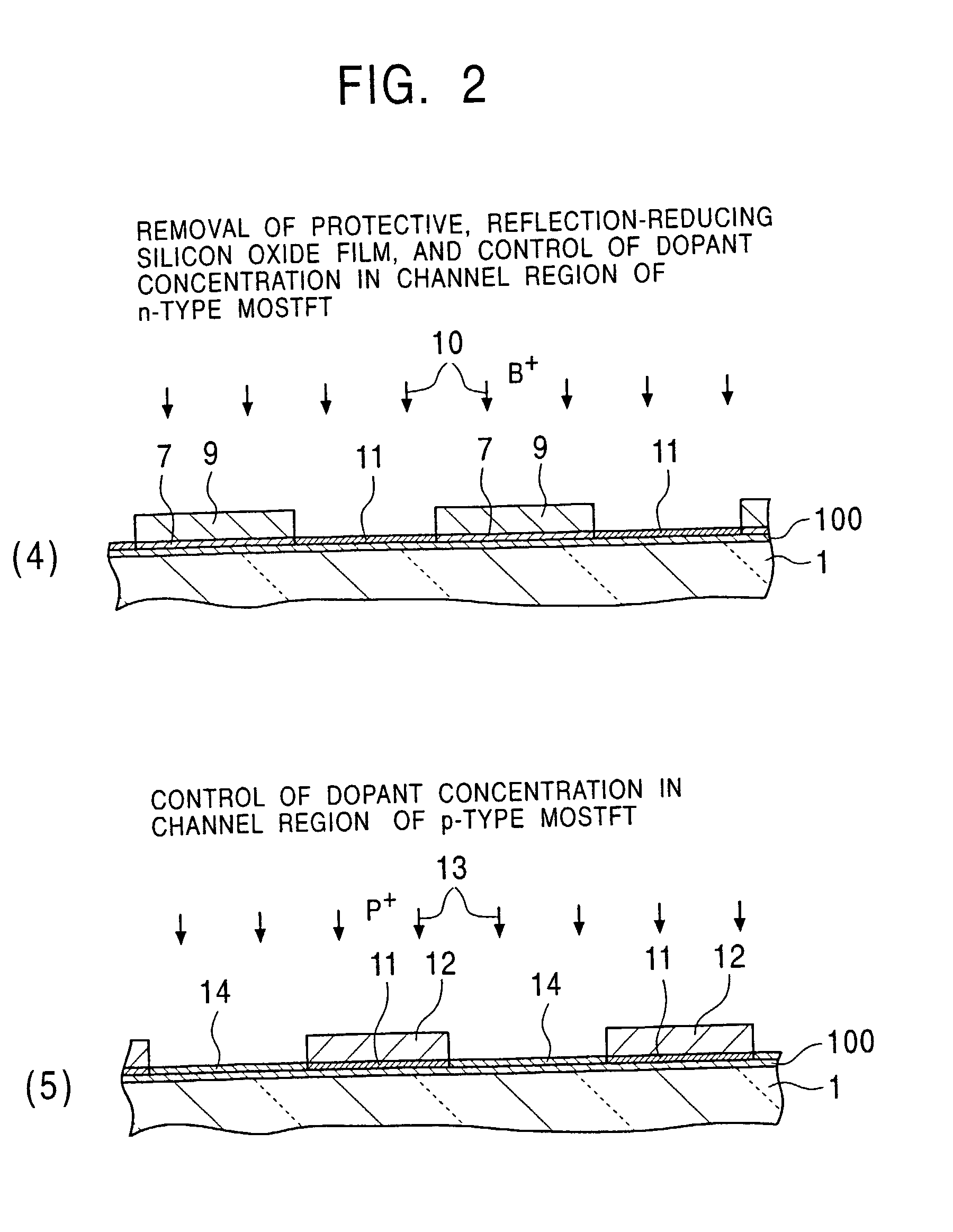

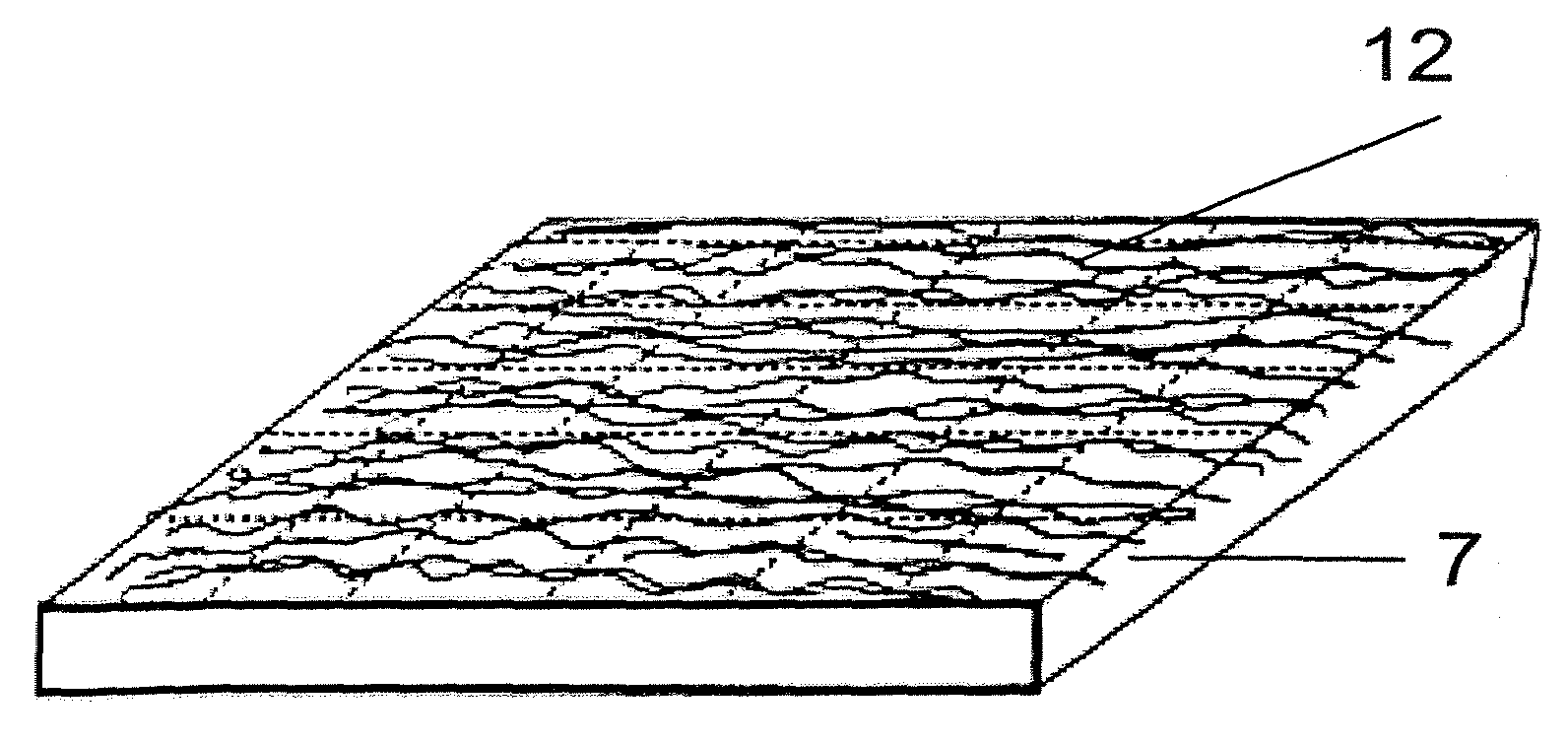

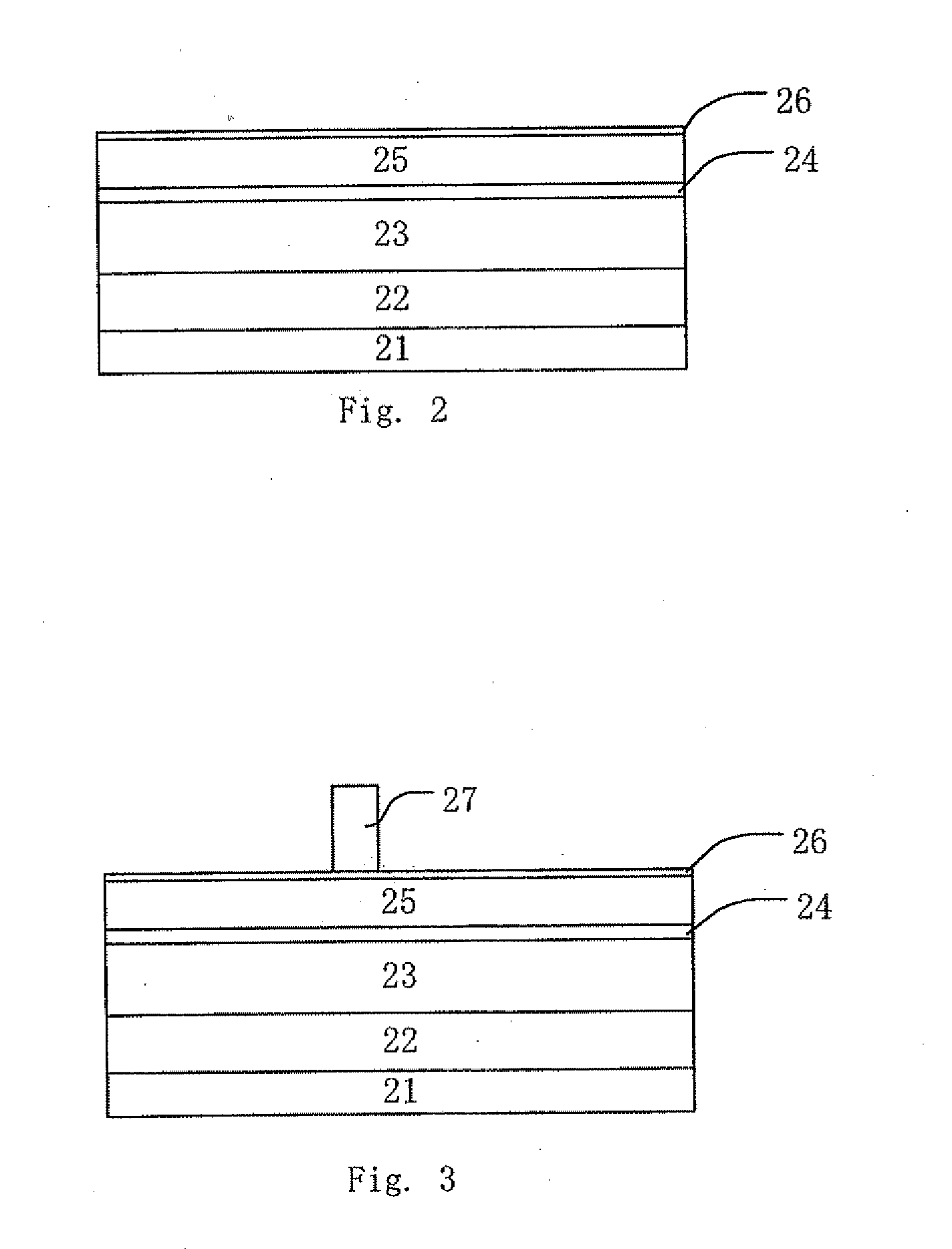

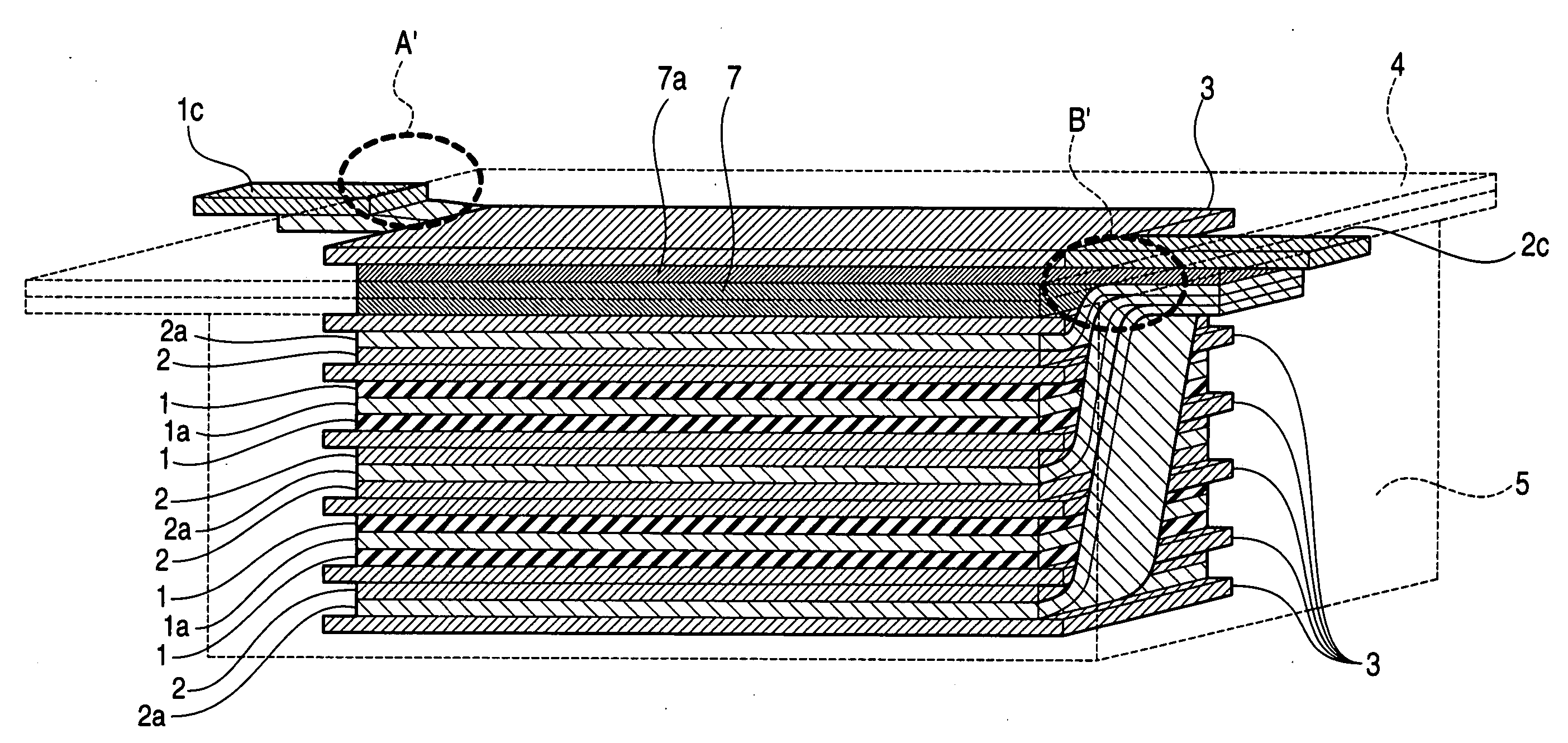

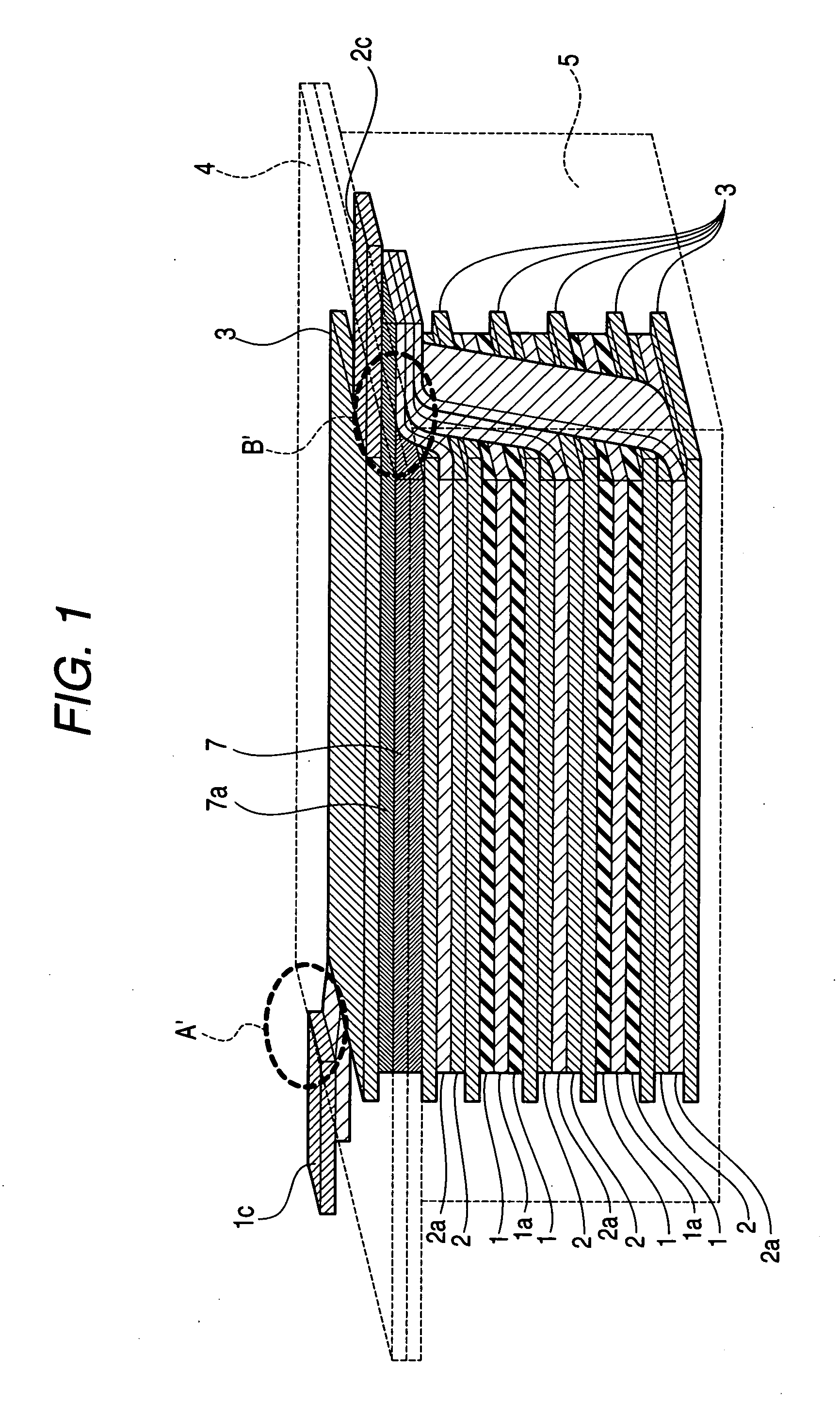

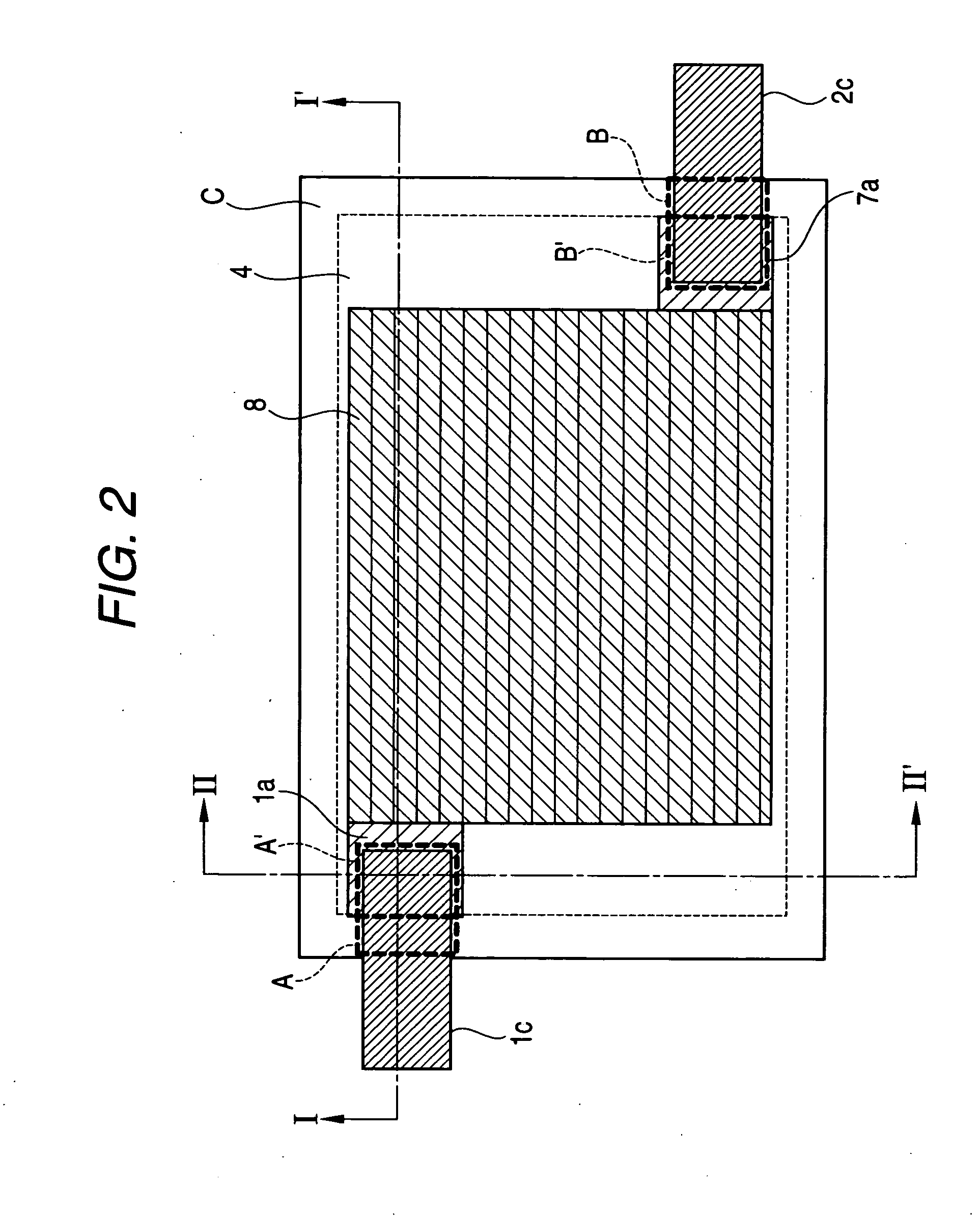

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

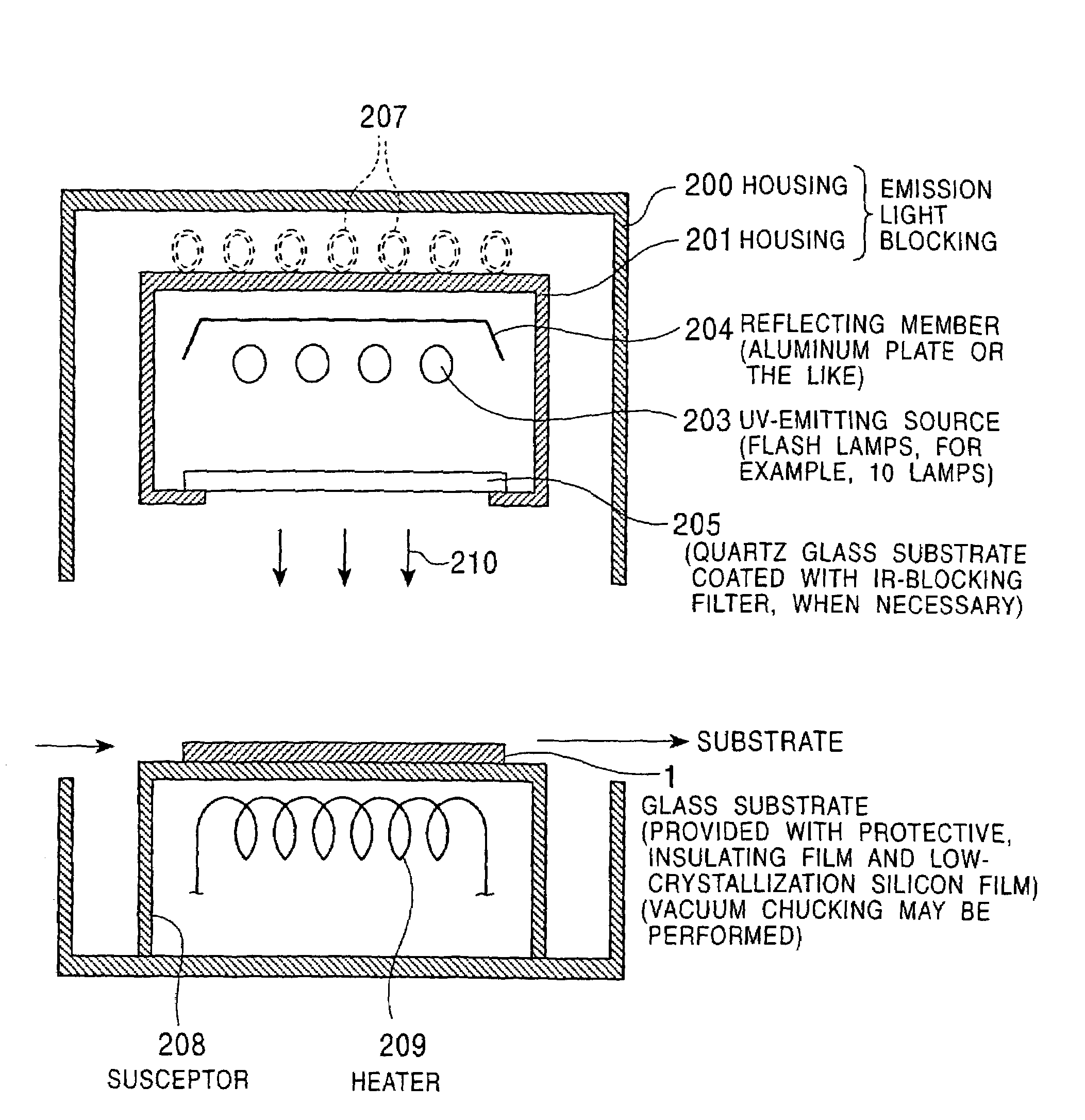

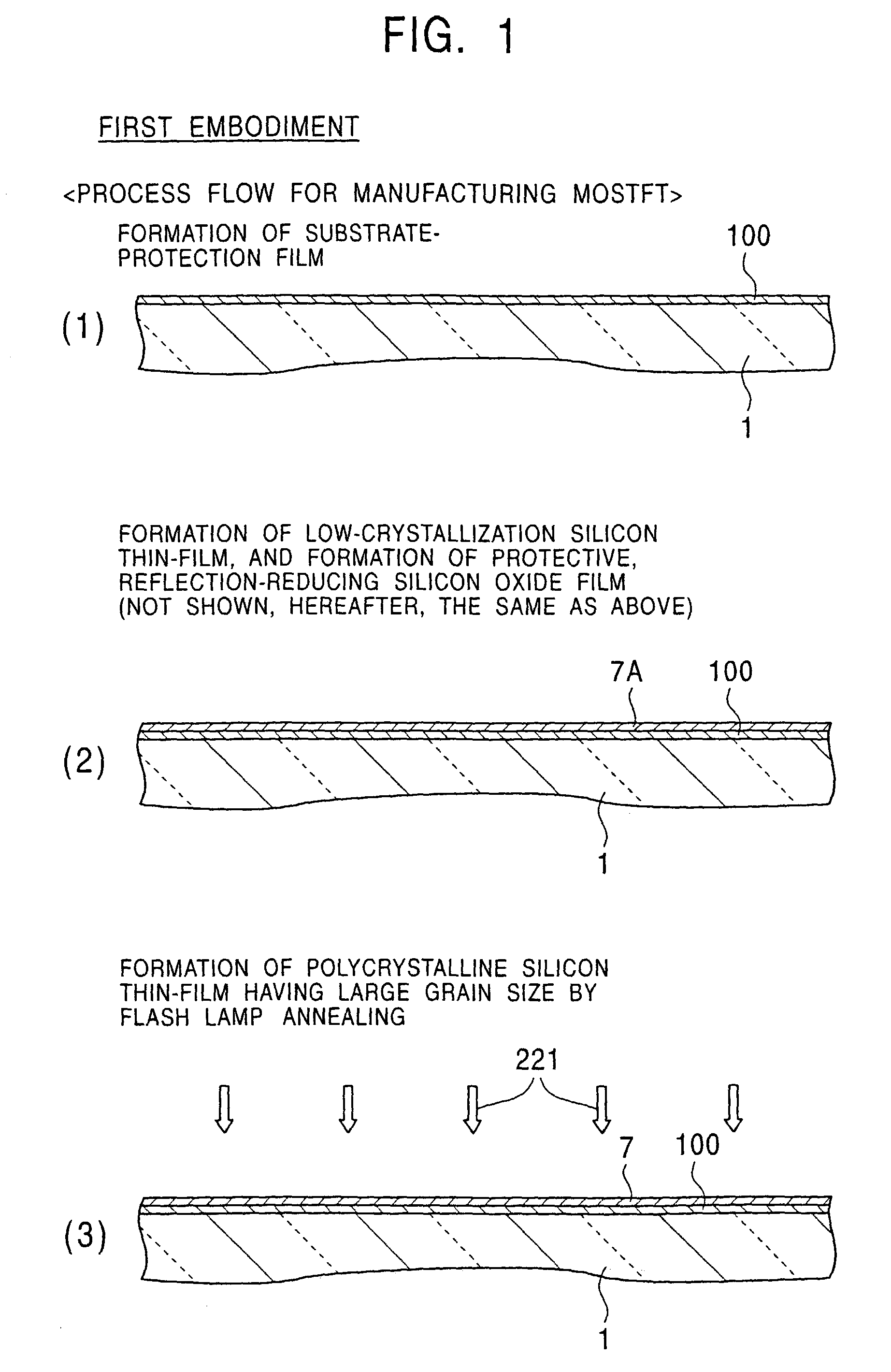

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

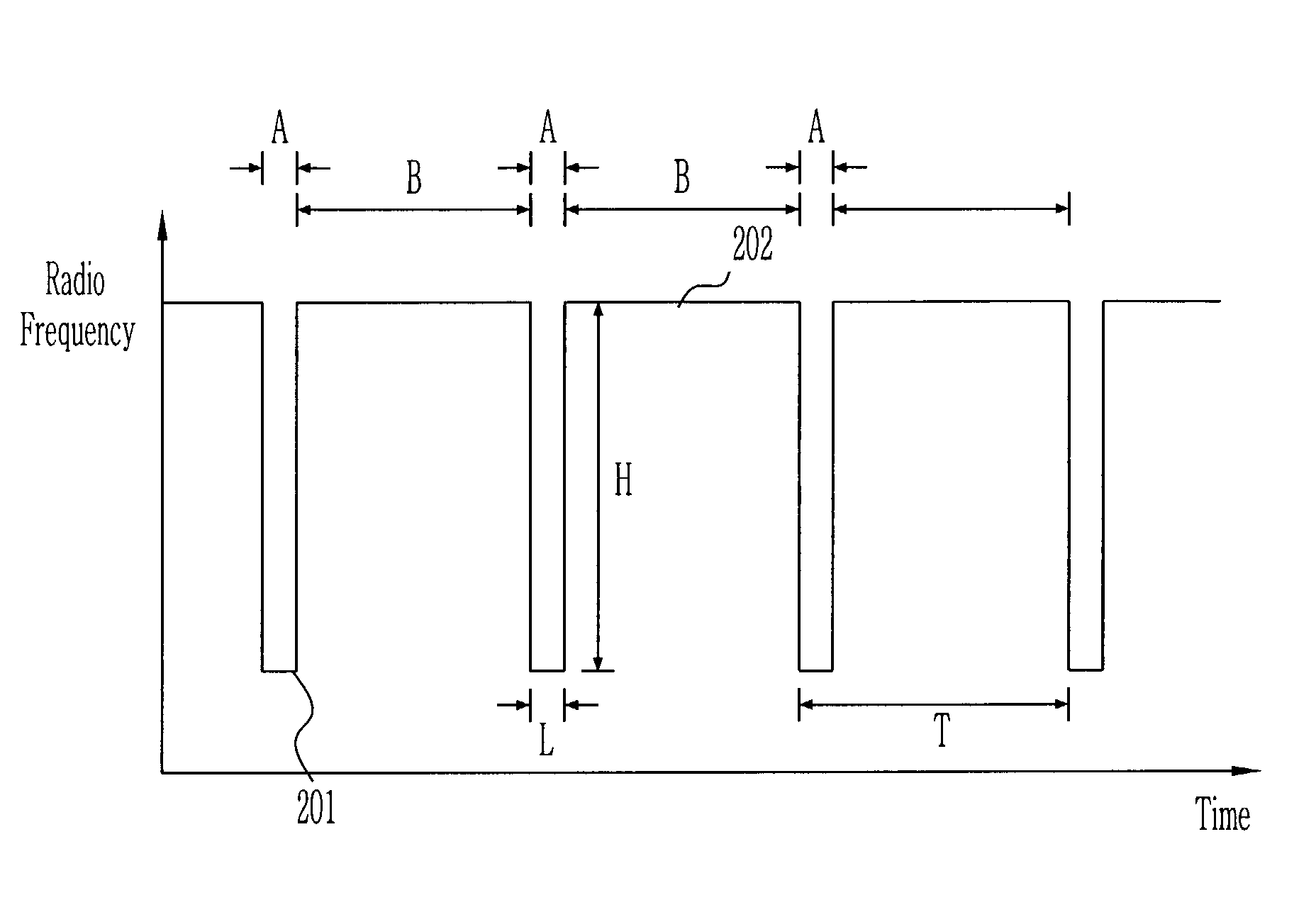

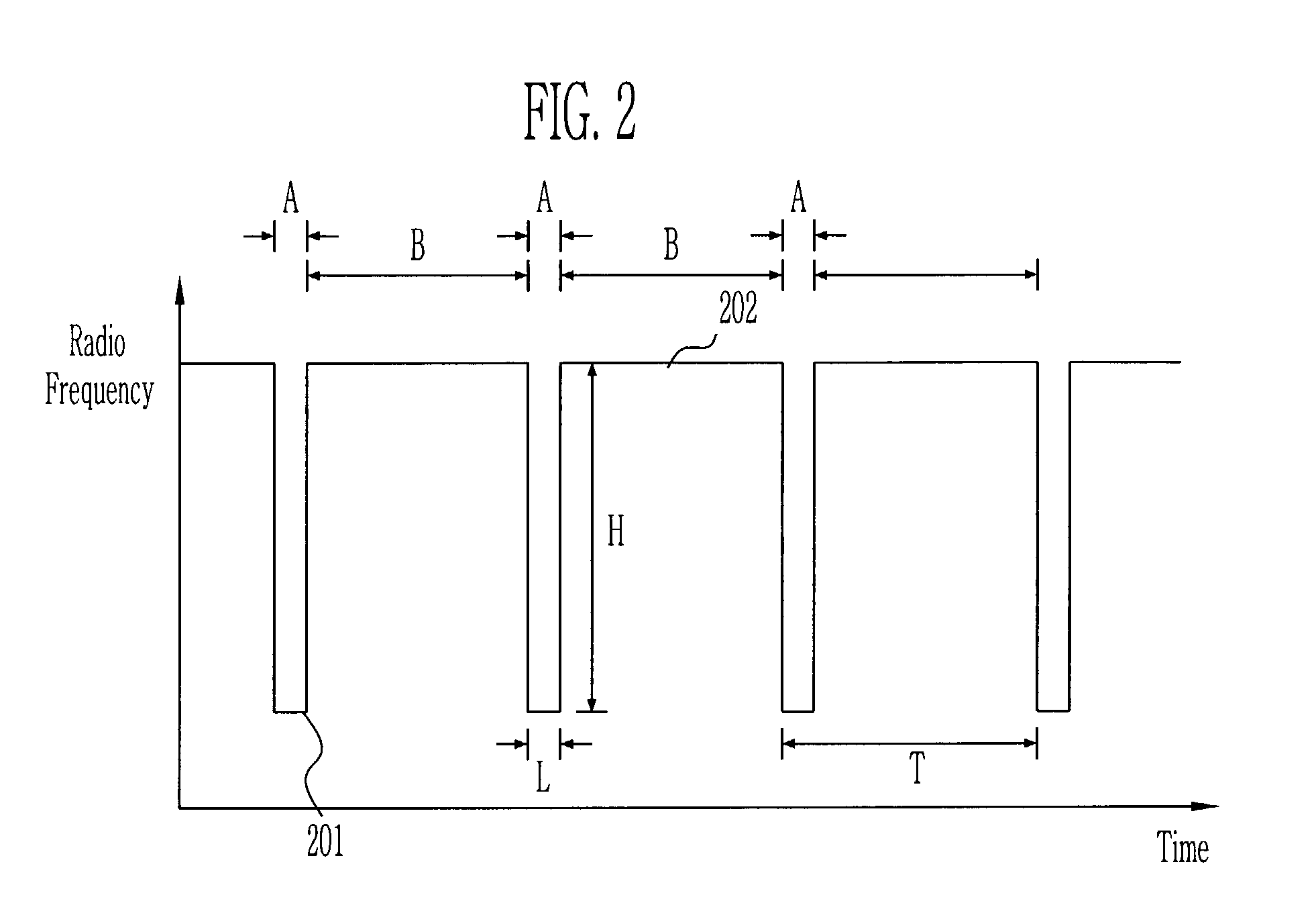

Method of forming insulating layer in semiconductor device

The present invention relates to a method of forming an insulating film in a semiconductor device. After a mixed gas of alkyl silane gas and N2O gas is supplied into the deposition equipment, a radio frequency power including a short pulse wave for causing incomplete reaction upon a gas phase reaction is applied to generate nano particle. The nano particle is then reacted to oxygen radical to form the insulating film including a plurality of nano voids. A low-dielectric insulating film that can be applied to the nano technology even in the existing LECVD equipment is formed.

Owner:SK HYNIX INC

Method for Removal of Carbon From An Organosilicate Material

Described herein is a method for removing at least a portion of the carbon-containing species within an organosilicate (OSG) film by treating the OSG film with a chemical, such as but not limited to an oxidizer, exposing the OSG film to an energy source comprising ultraviolet light, or treating the OSG film with a chemical and exposing the OSG film to an energy source.

Owner:VERSUM MATERIALS US LLC

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

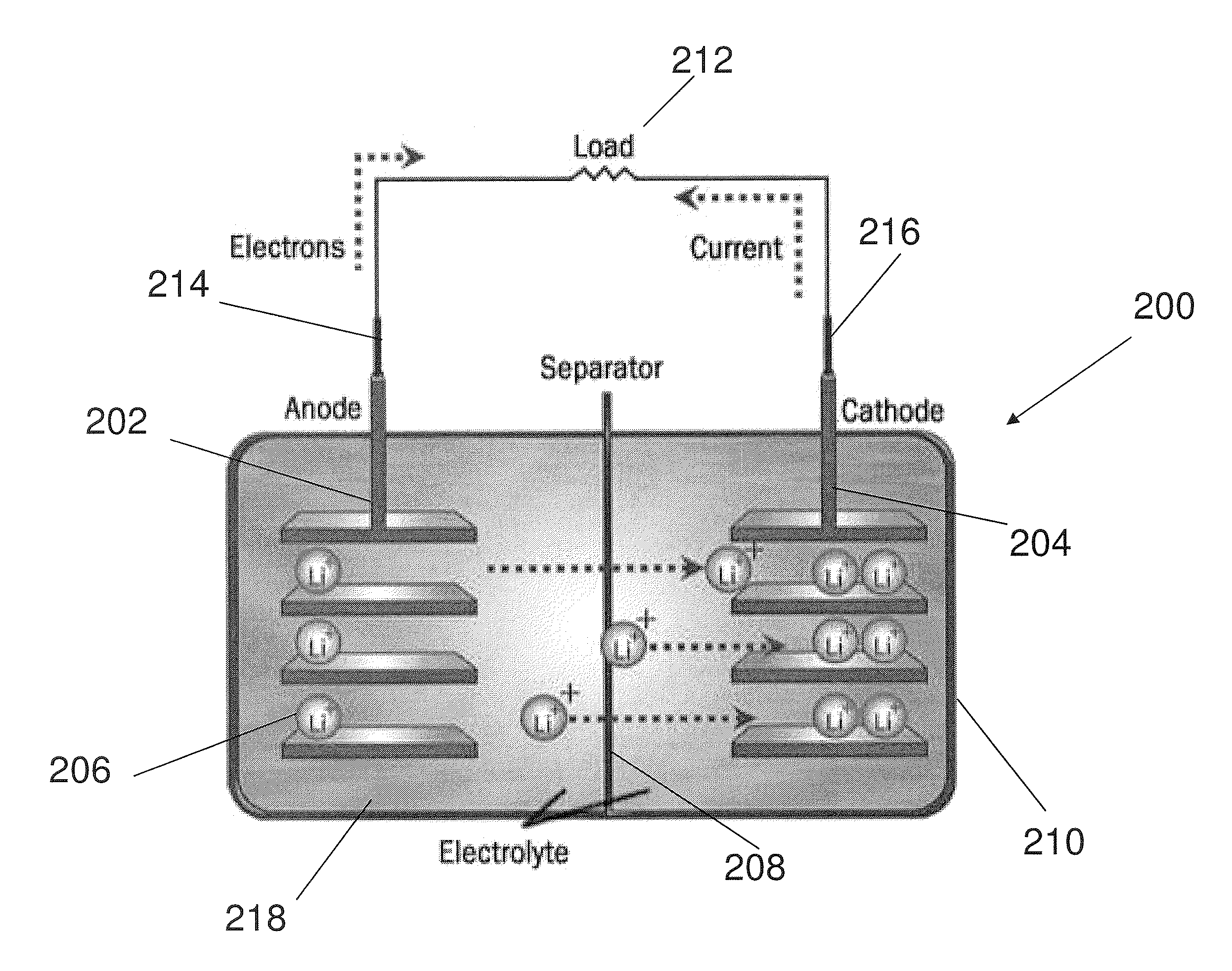

Nanostructured Materials for Battery Applications

The present invention relates to nanostructured materials (including nanowires) for use in batteries. Exemplary materials include carbon-comprising, Si-based nanostructures, nanostructured materials disposed on carbon-based substrates, and nanostructures comprising nanoscale scaffolds. The present invention also provides methods of preparing battery electrodes, and batteries, using the nanostructured materials.

Owner:ONED MATERIAL INC

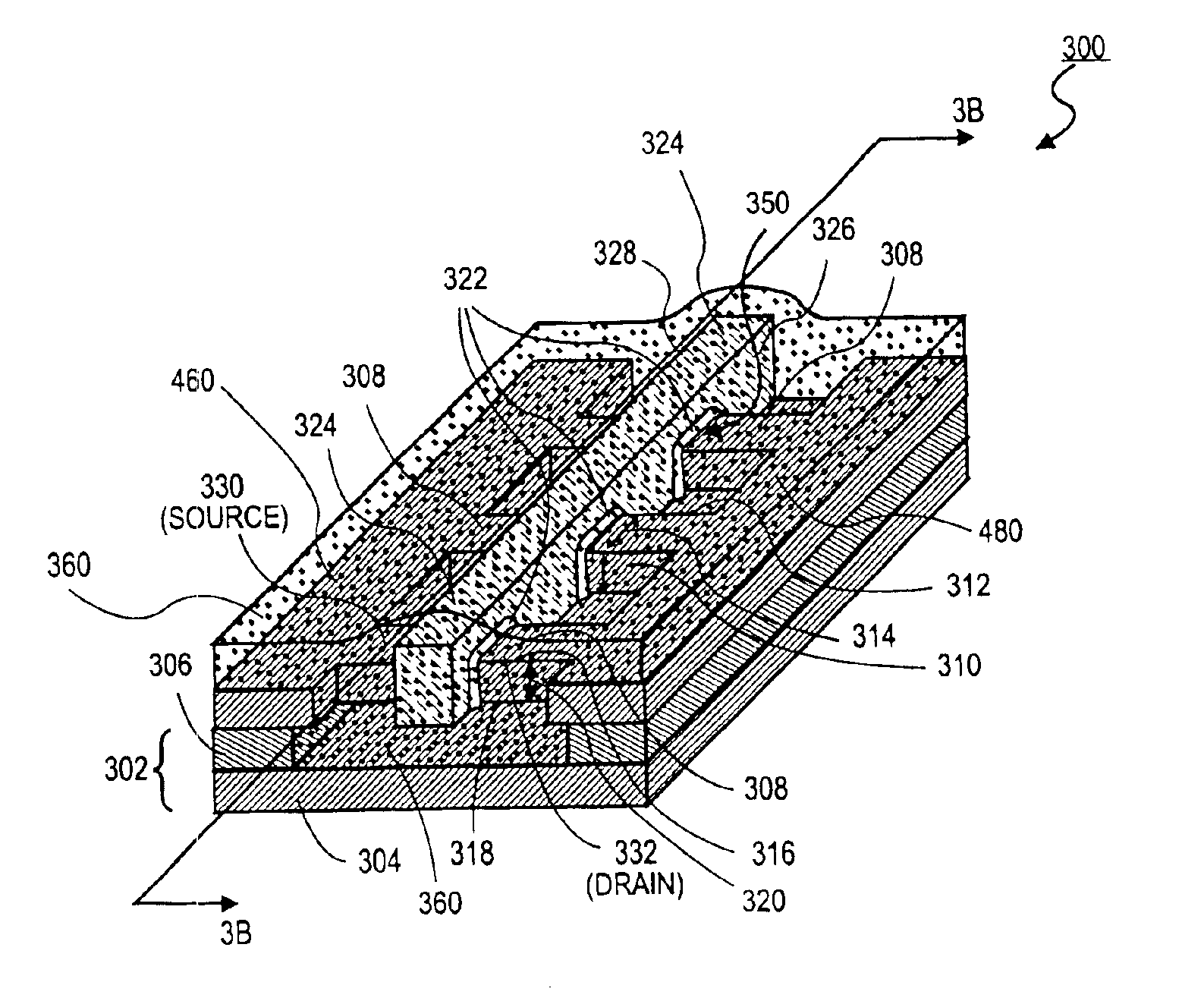

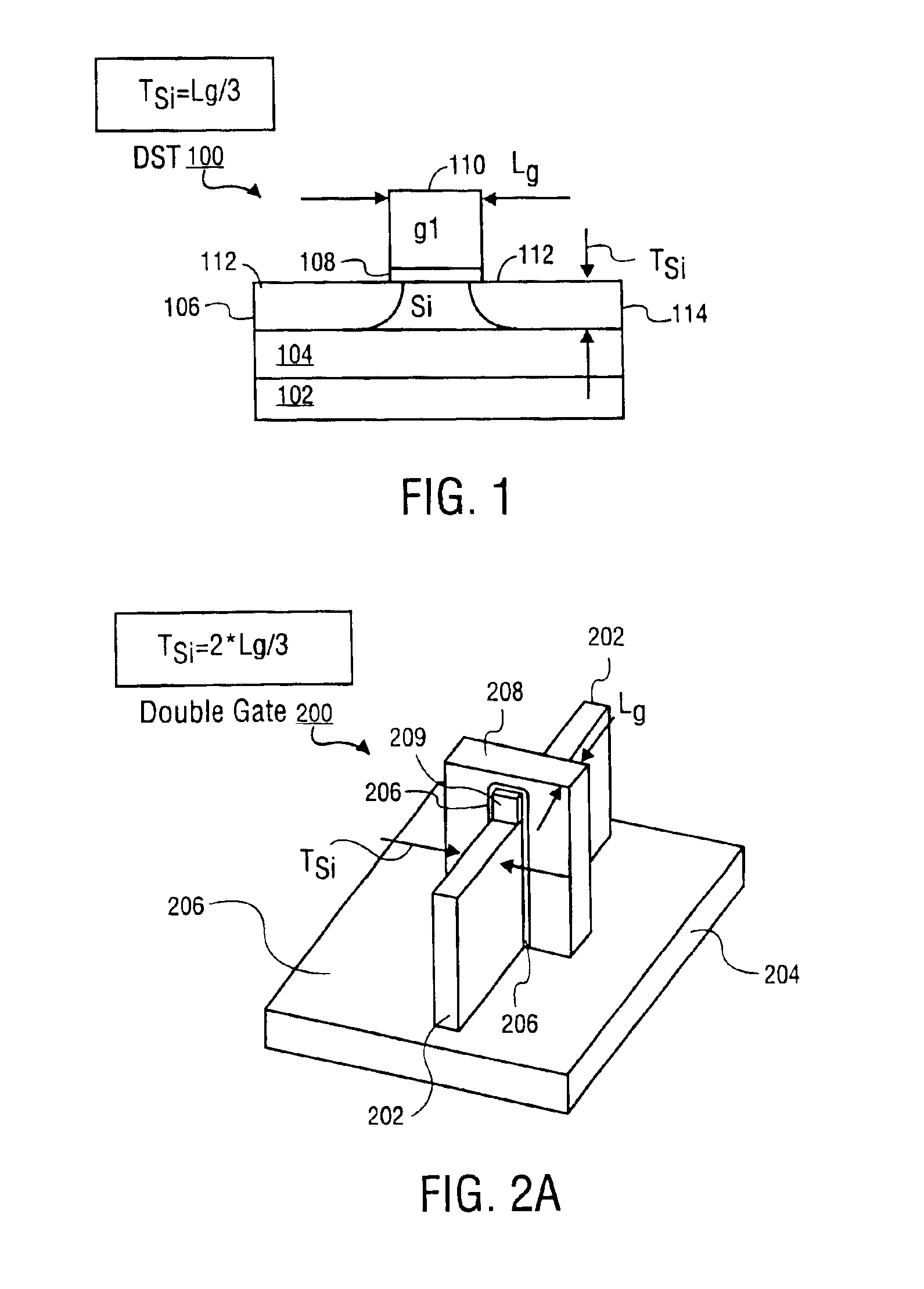

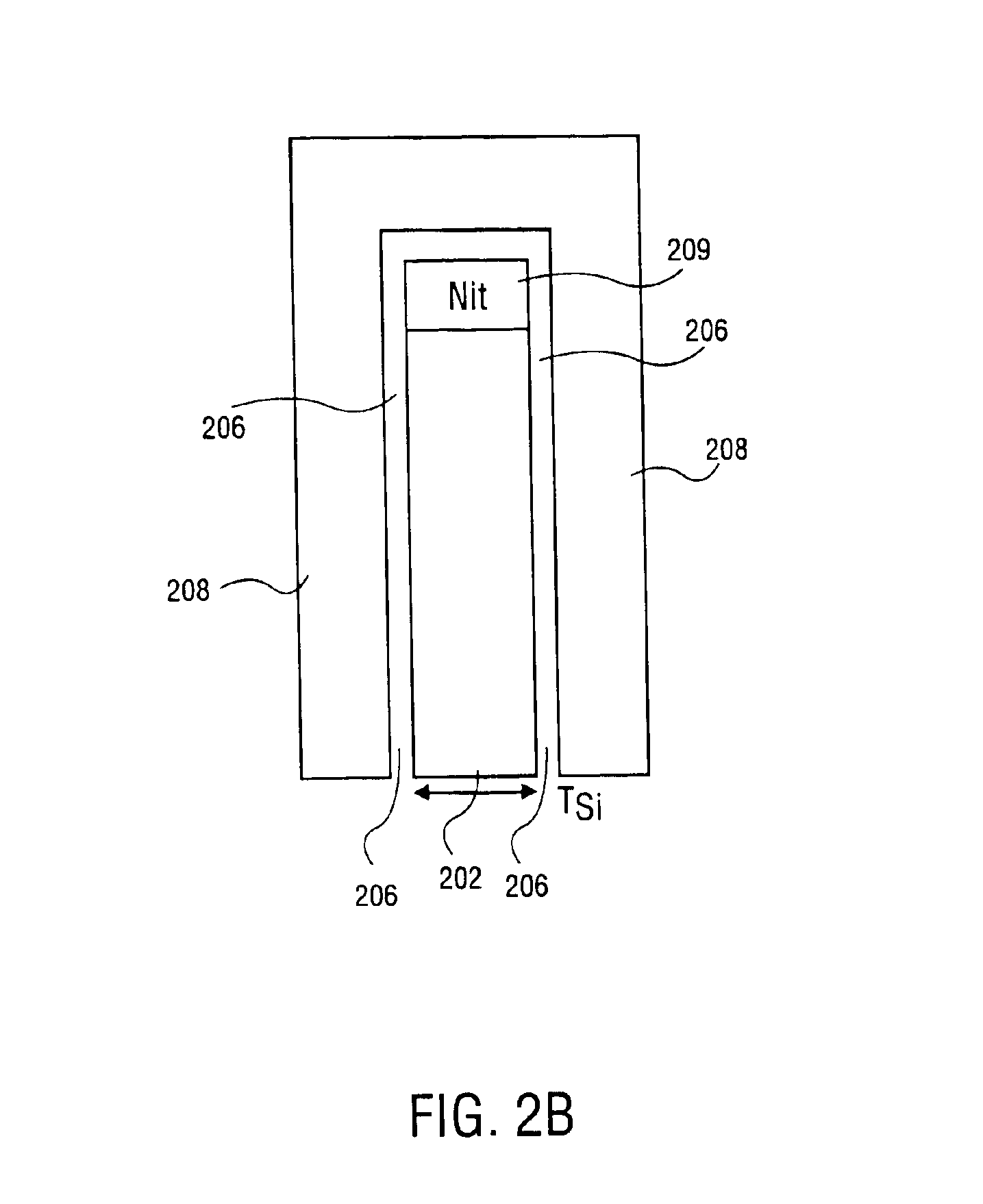

Nonplanar device with stress incorporation layer and method of fabrication

InactiveUS6909151B2Improve performanceHigh carrier mobilityTransistorSolid-state devicesGate dielectricSemiconductor

A semiconductor device comprising a semiconductor body having a top surface and laterally opposite sidewalls is formed on an insulating substrate. A gate dielectric layer is formed on the top surface of the semiconductor body and on the laterally opposite sidewalls of the semiconductor body. A gate electrode is formed on the gate dielectric on the top surface of the semiconductor body and is formed adjacent to the gate dielectric on the laterally opposite sidewalls of the semiconductor body. A thin film is then formed adjacent to the semiconductor body wherein the thin film produces a stress in the semiconductor body.

Owner:INTEL CORP

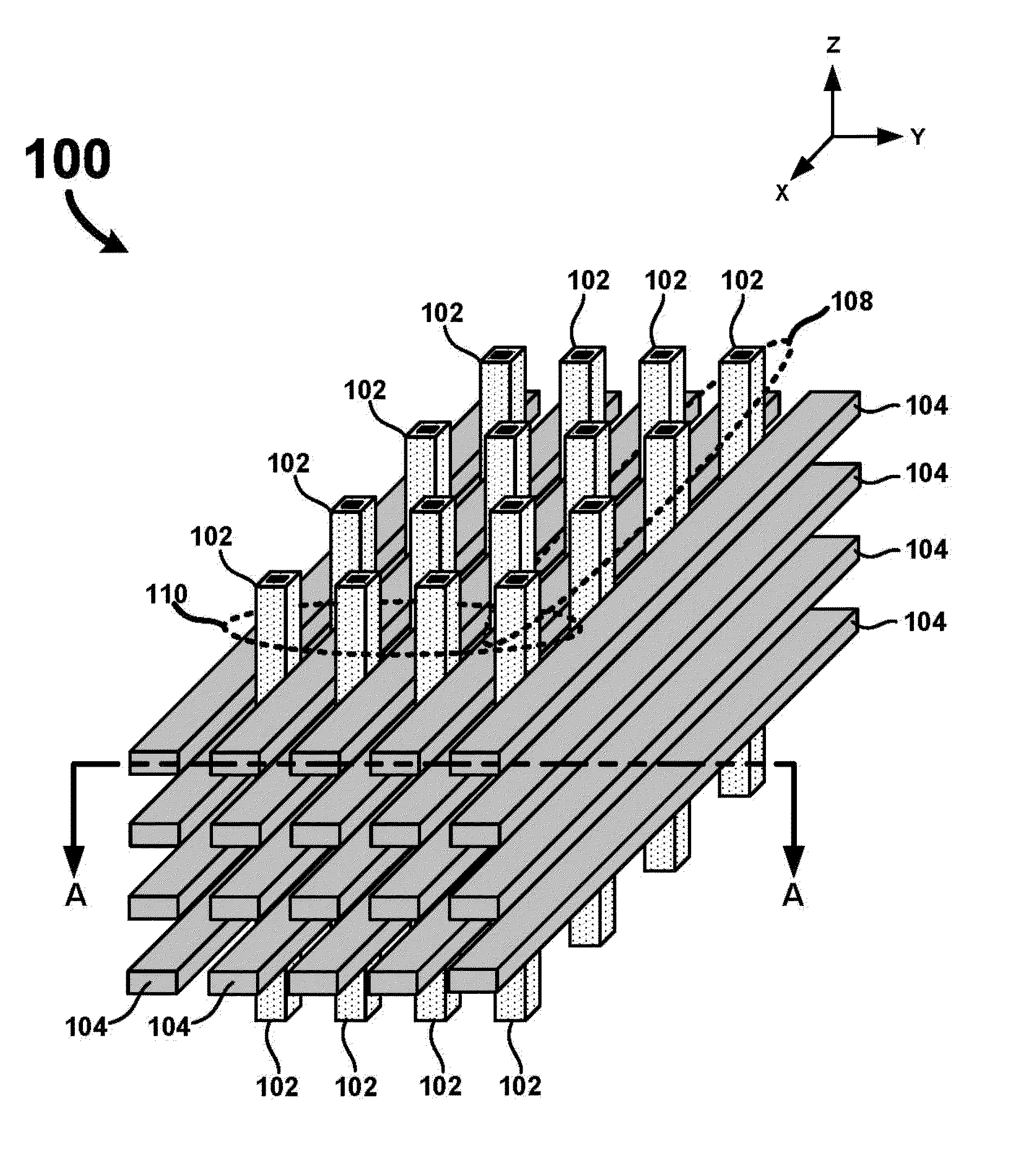

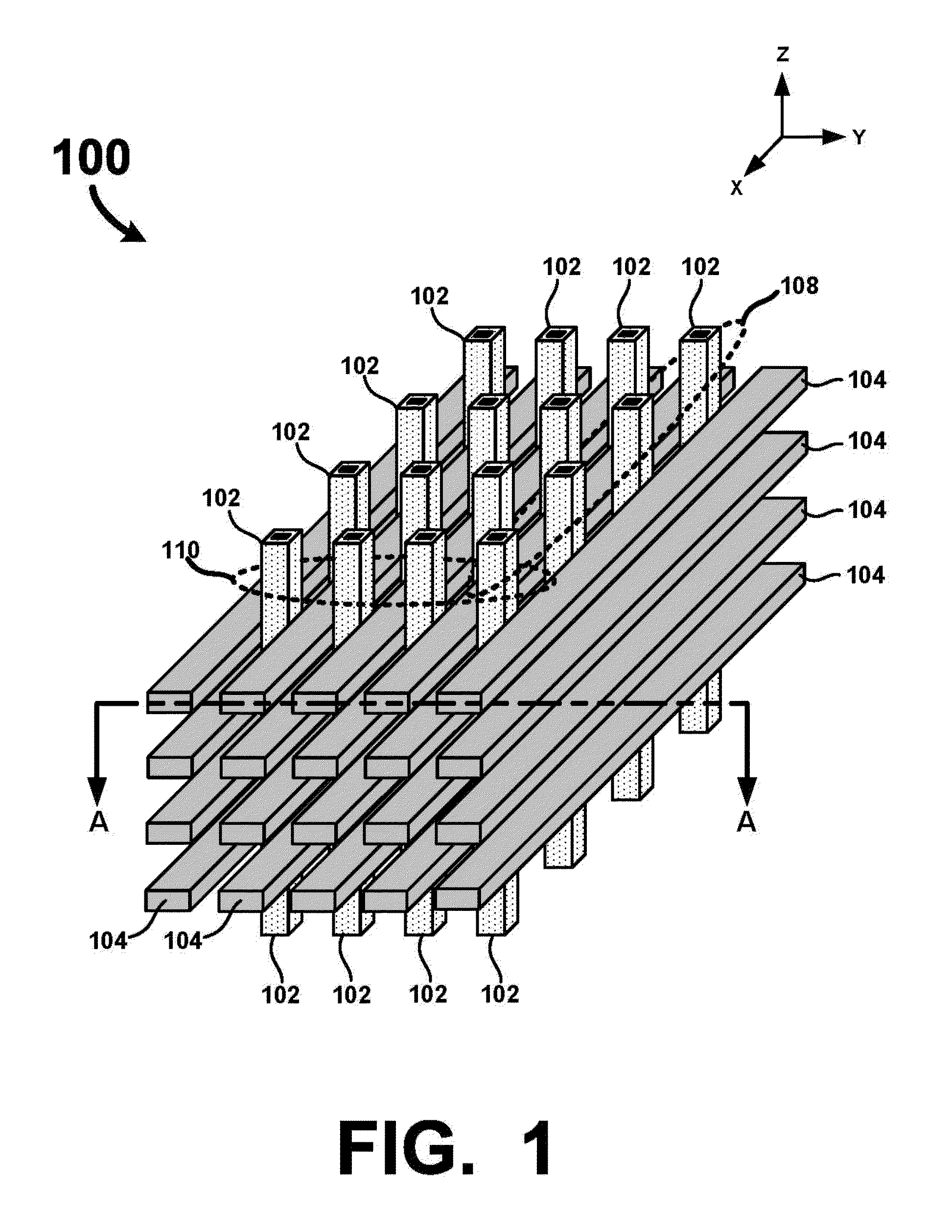

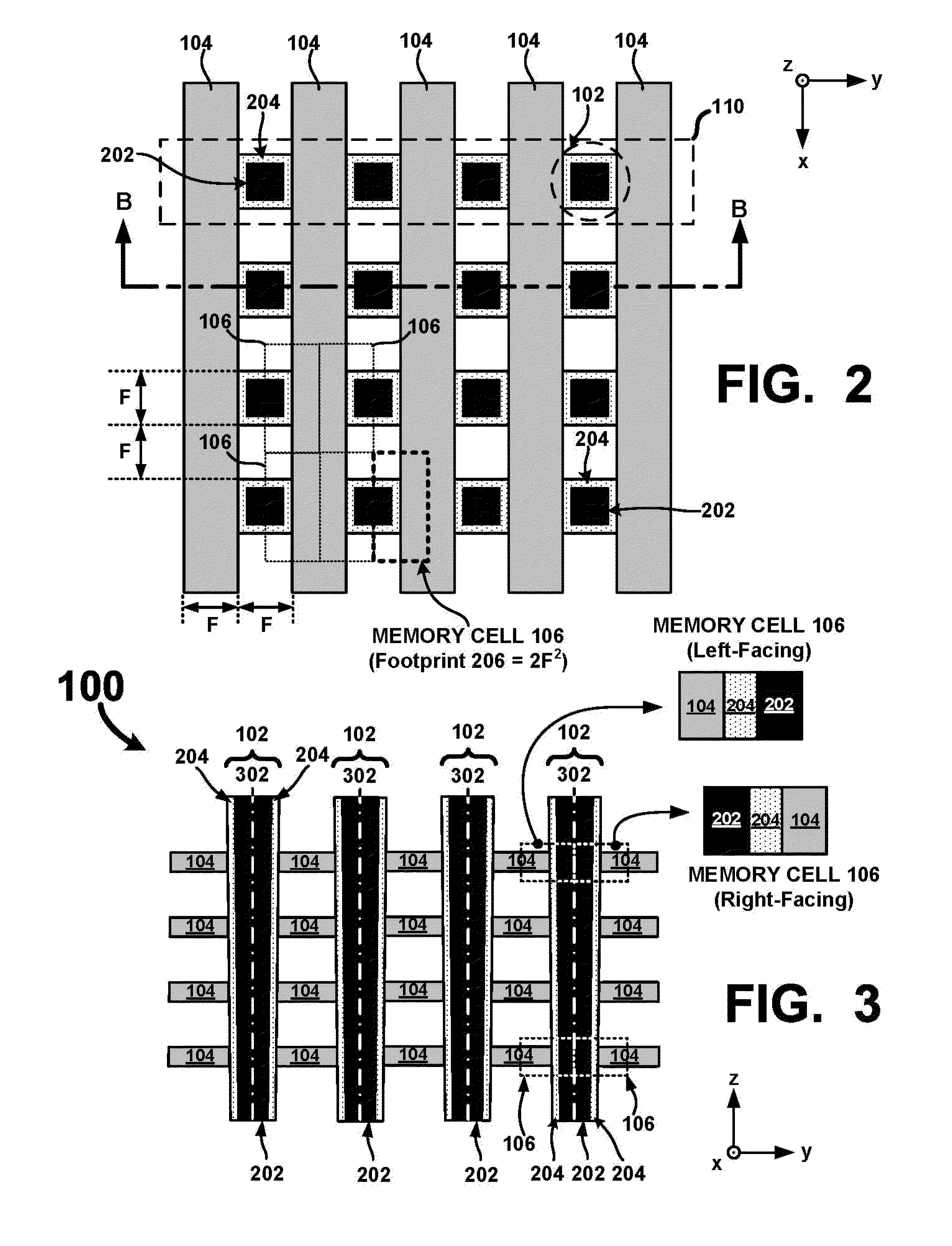

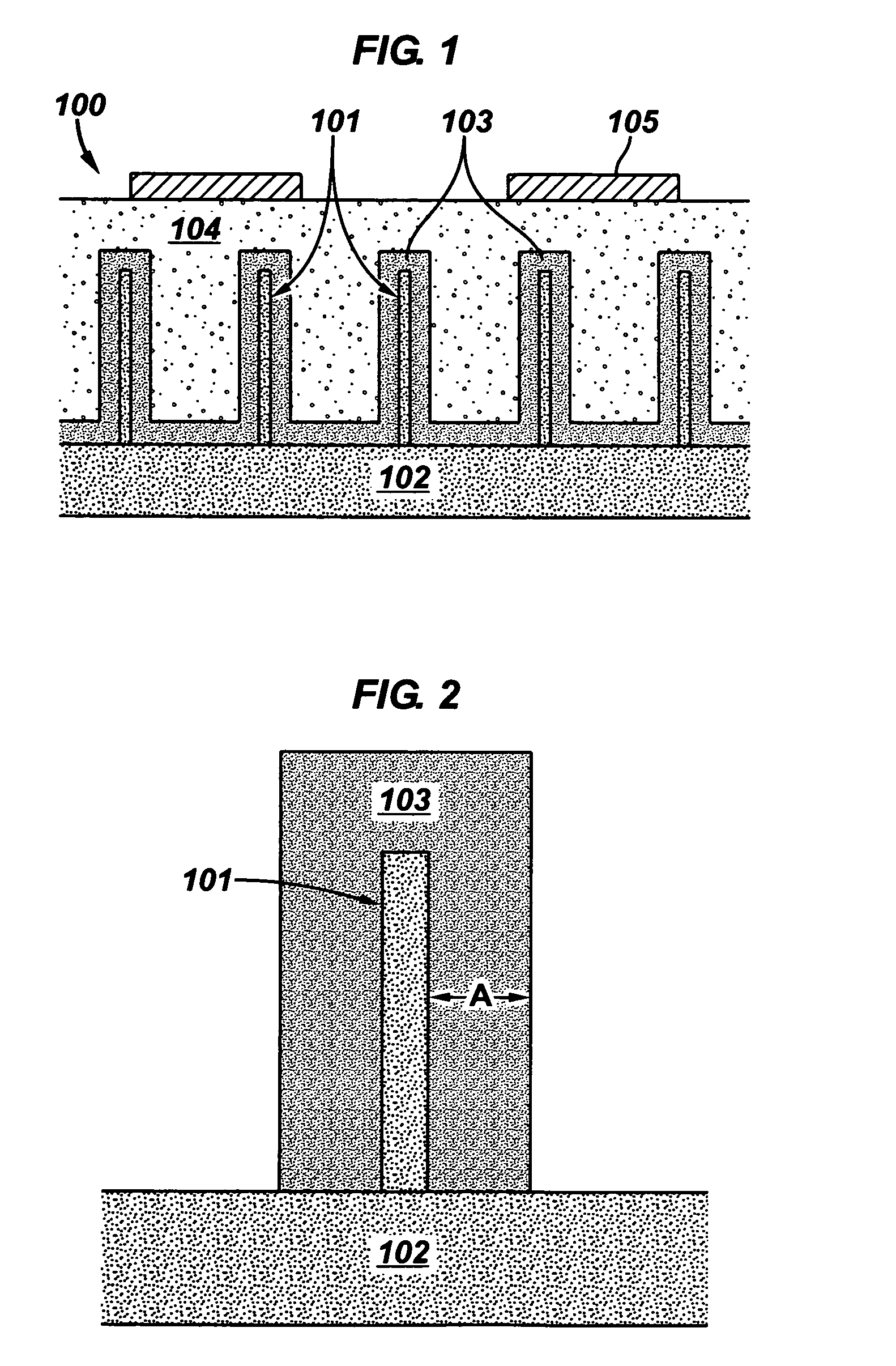

Vertical Cross Point Arrays For Ultra High Density Memory Applications

An ultra-high-density vertical cross-point array comprises a plurality of horizontal line layers having horizontal lines interleaved with a plurality of vertical lines arranged in rows and columns. The vertical lines are interleaved with the horizontal lines such that a row of vertical lines is positioned between each consecutive pair of horizontal lines in each horizontal line layer. Each vertical line comprises a center conductor surrounded by a single or multi-layered memory film. Accordingly, when interleaved with the horizontal lines, two-terminal memory cells are integrally formed between the center conductor of each vertical line and each crossing horizontal line. By configuring the vertical and horizontal lines so that a row of vertical lines is positioned between each consecutive pair of horizontal lines, a unit memory cell footprint of just 2F2 may be realized.

Owner:UNITY SEMICON

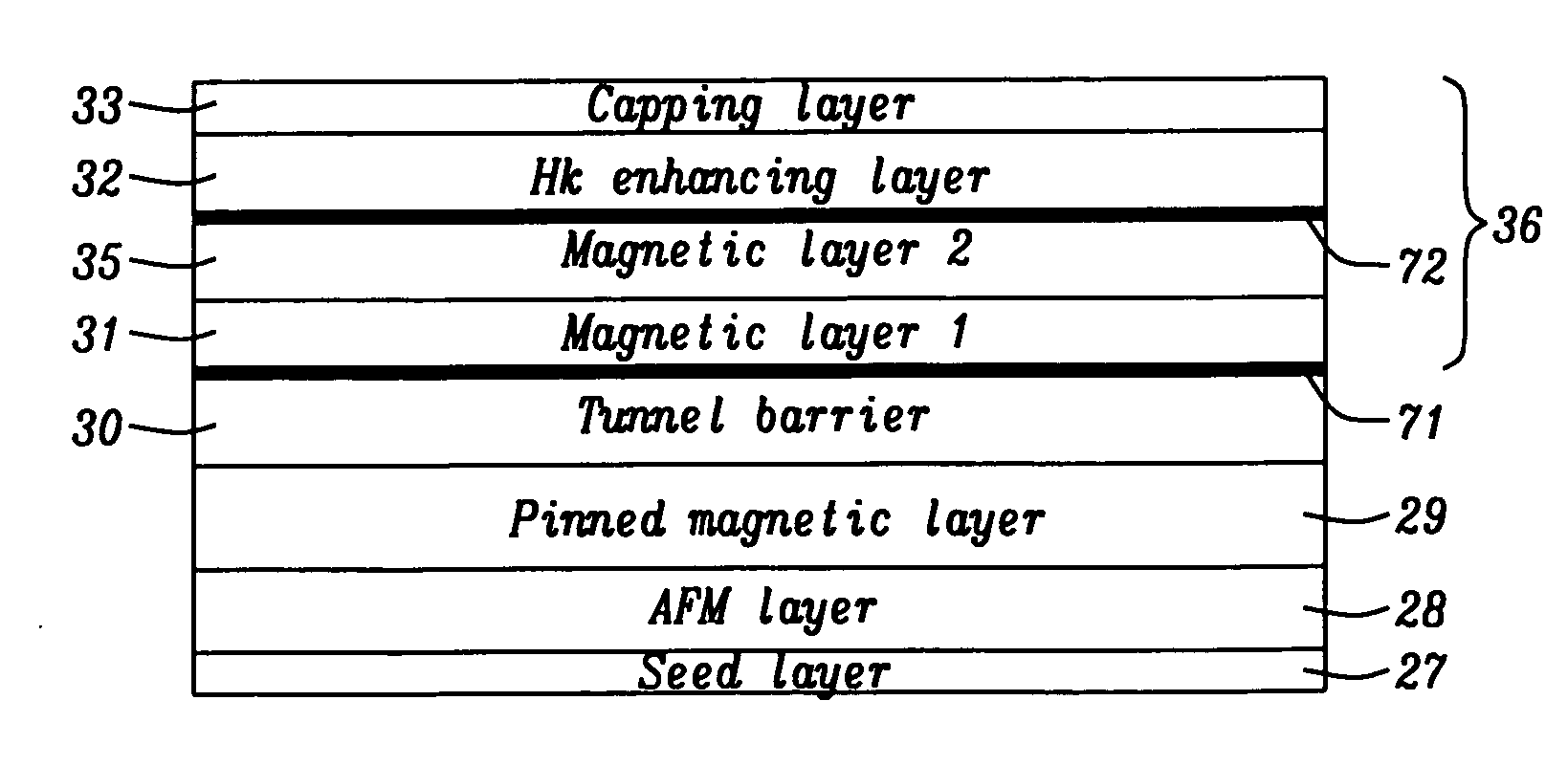

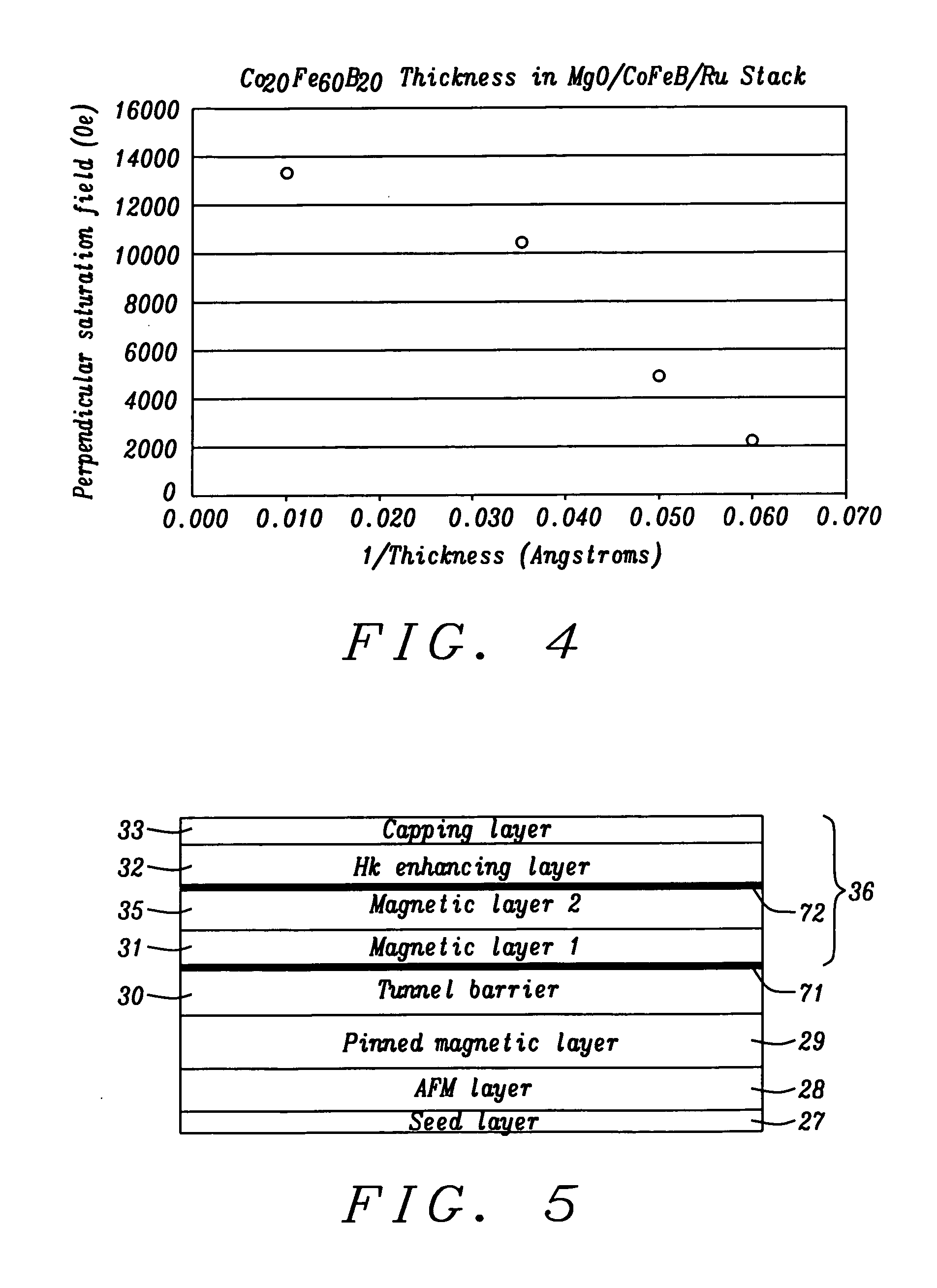

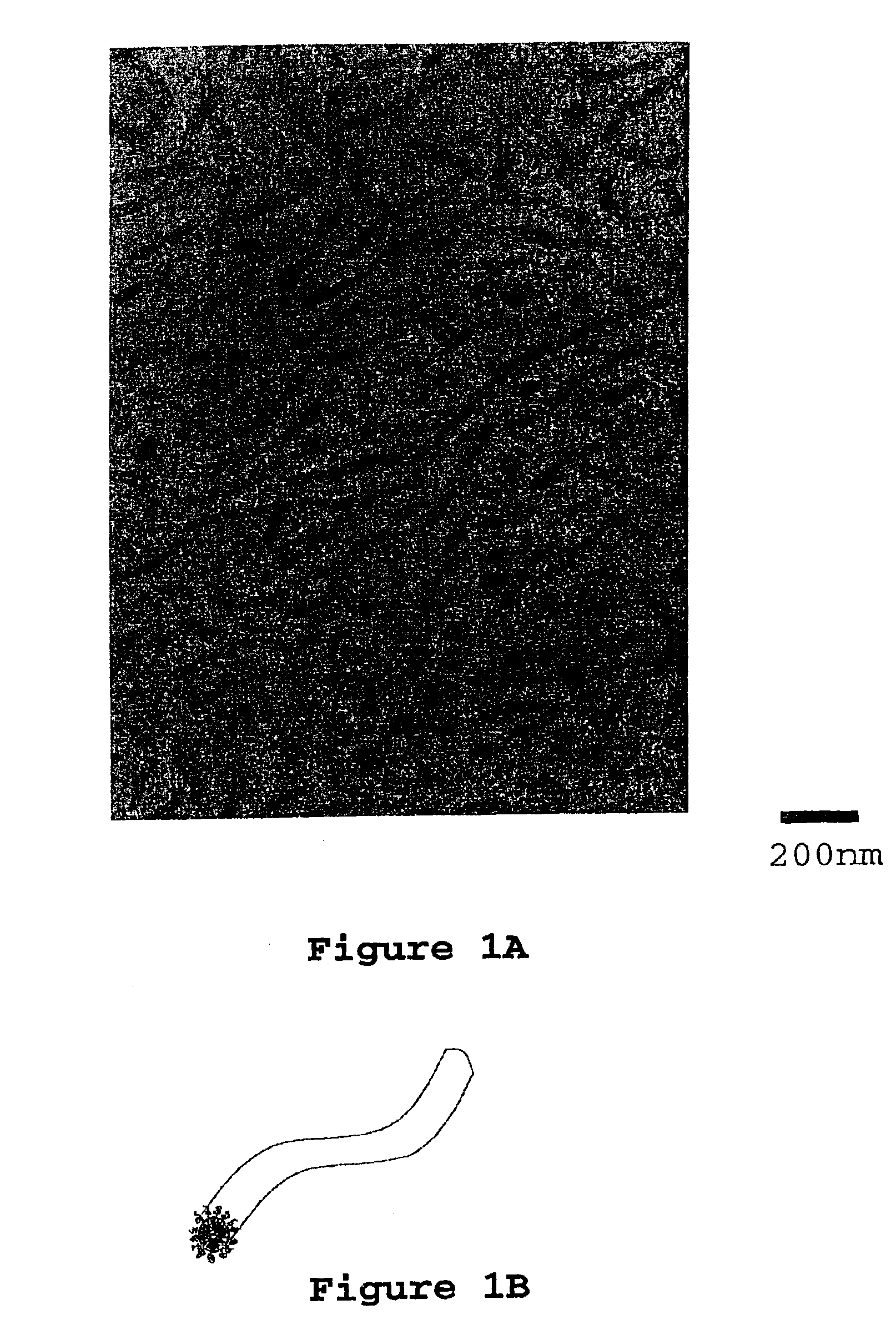

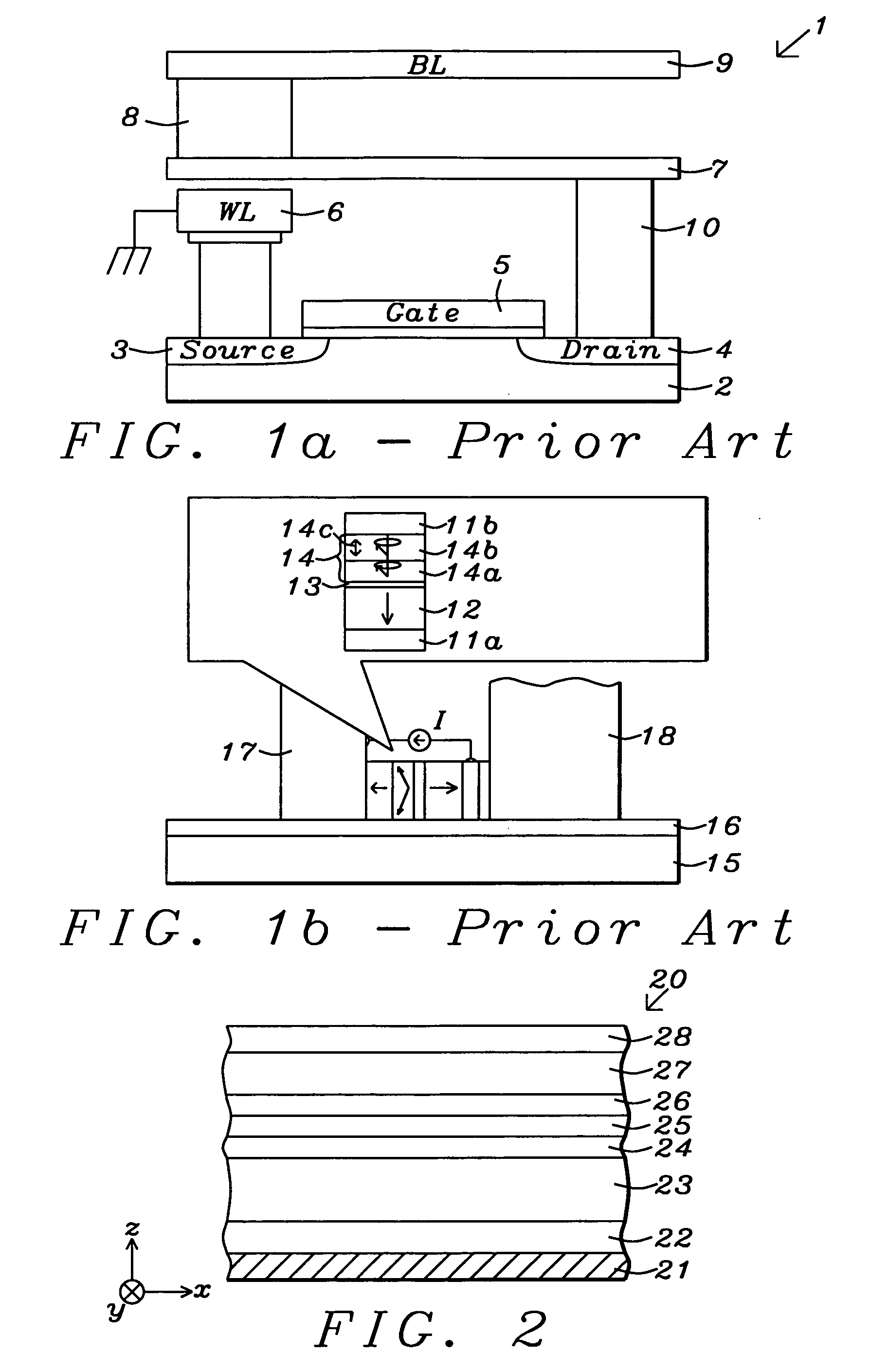

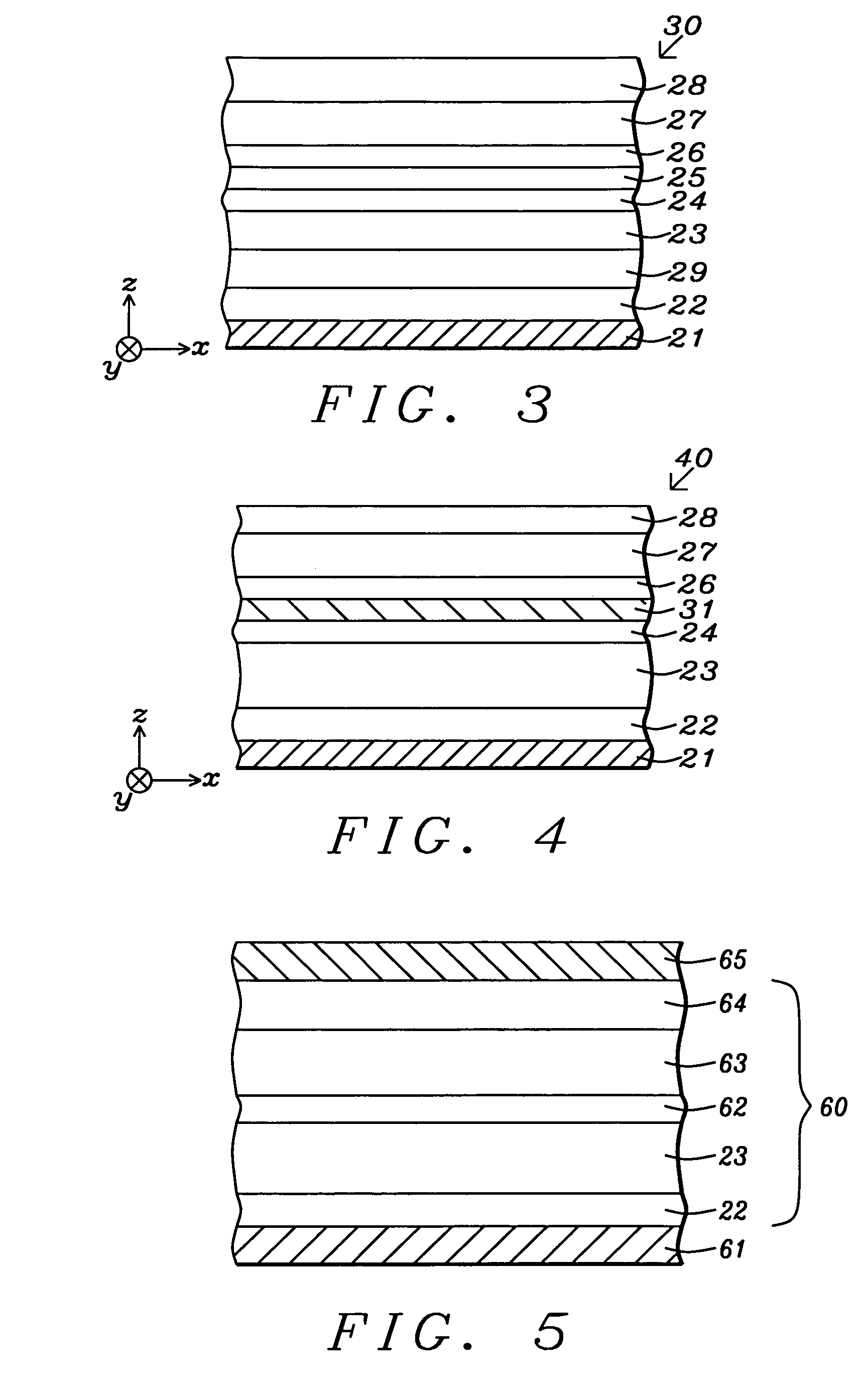

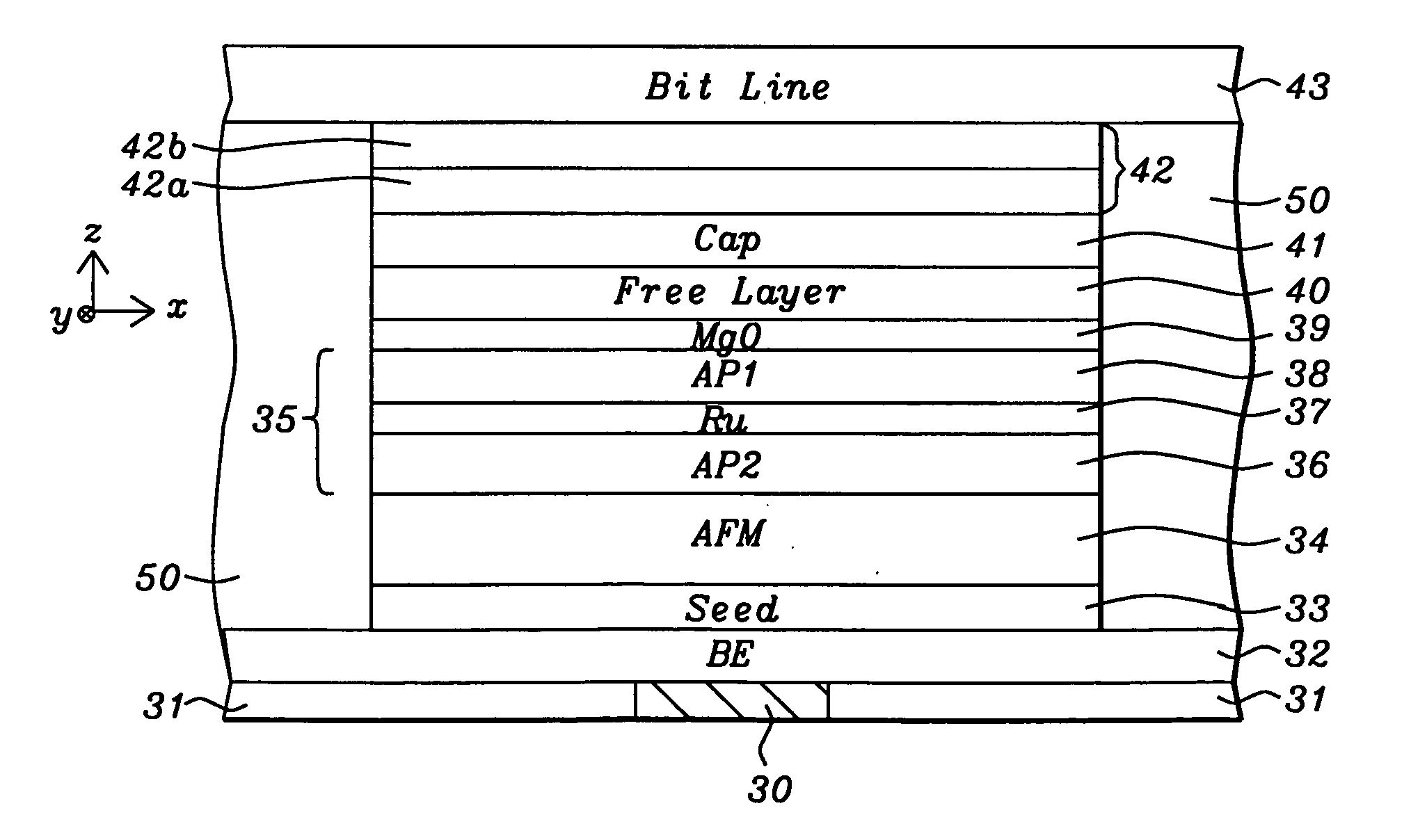

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS20120205758A1Without degrading thermal stability and MR ratioEnhanced interfacial perpendicular anisotropyMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

Curable flame retardant epoxy compositions

InactiveUS6887574B2Improve fracture resistanceModulus is reducedSynthetic resin layered productsPrinted circuit aspectsEpoxyHigh fracture

A curable flame retardant epoxy resin composition including (a) at least one flame retardant epoxy resin; (b) at least one amphiphilic block copolymer; and (c) a curing agent. Such components are present in the curable composition in the appropriate amounts and ratios such that, upon curing, the block copolymer self-assembles into a nano structure morphology, such as a worm-like micelle morphology. The resulting cured product made from the composition of the present invention has a remarkably increased high fracture resistance; and allows the use of flame retardant epoxies in applications where fracture resistance is an issue.

Owner:RGT UNIV OF MINNESOTA

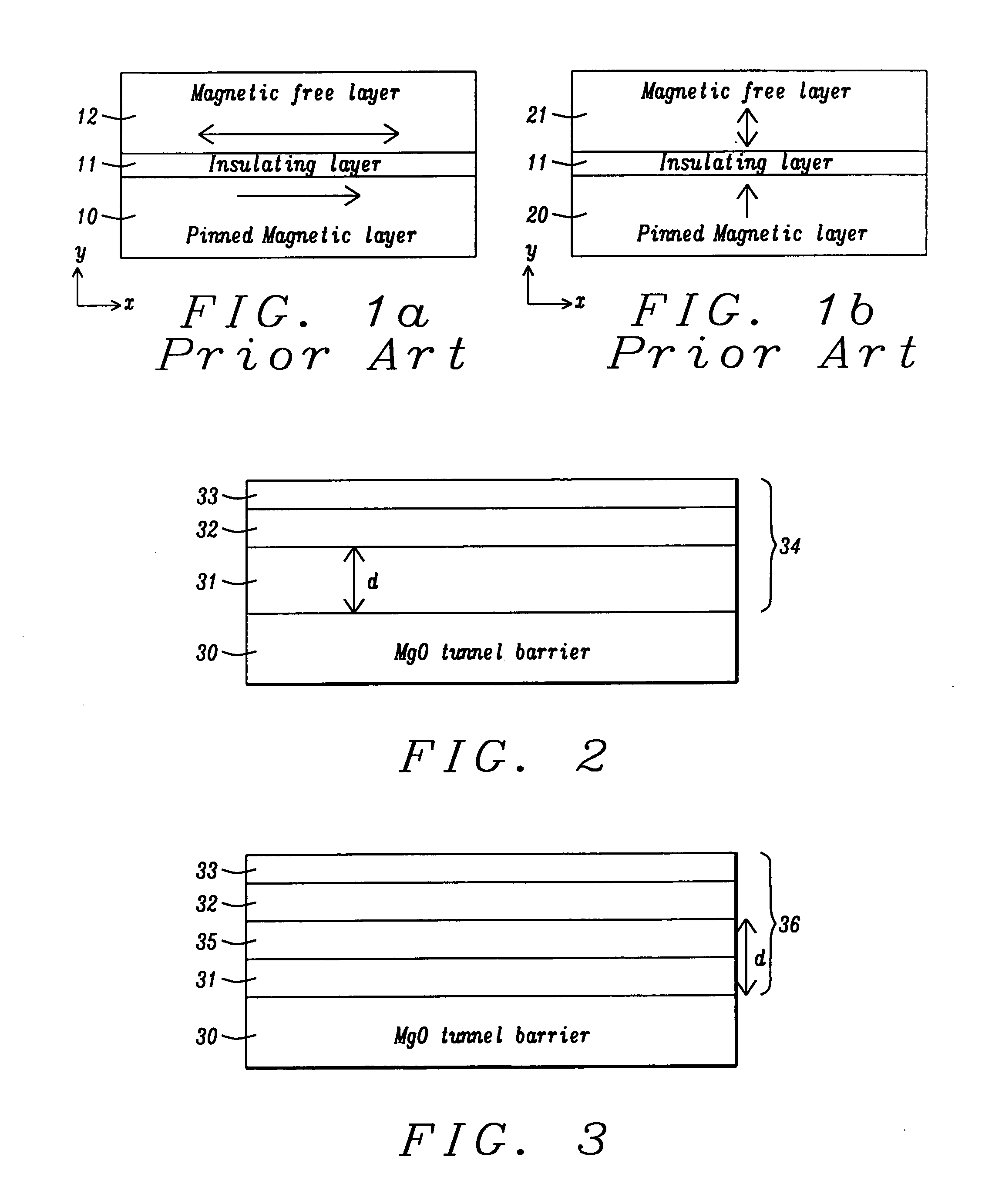

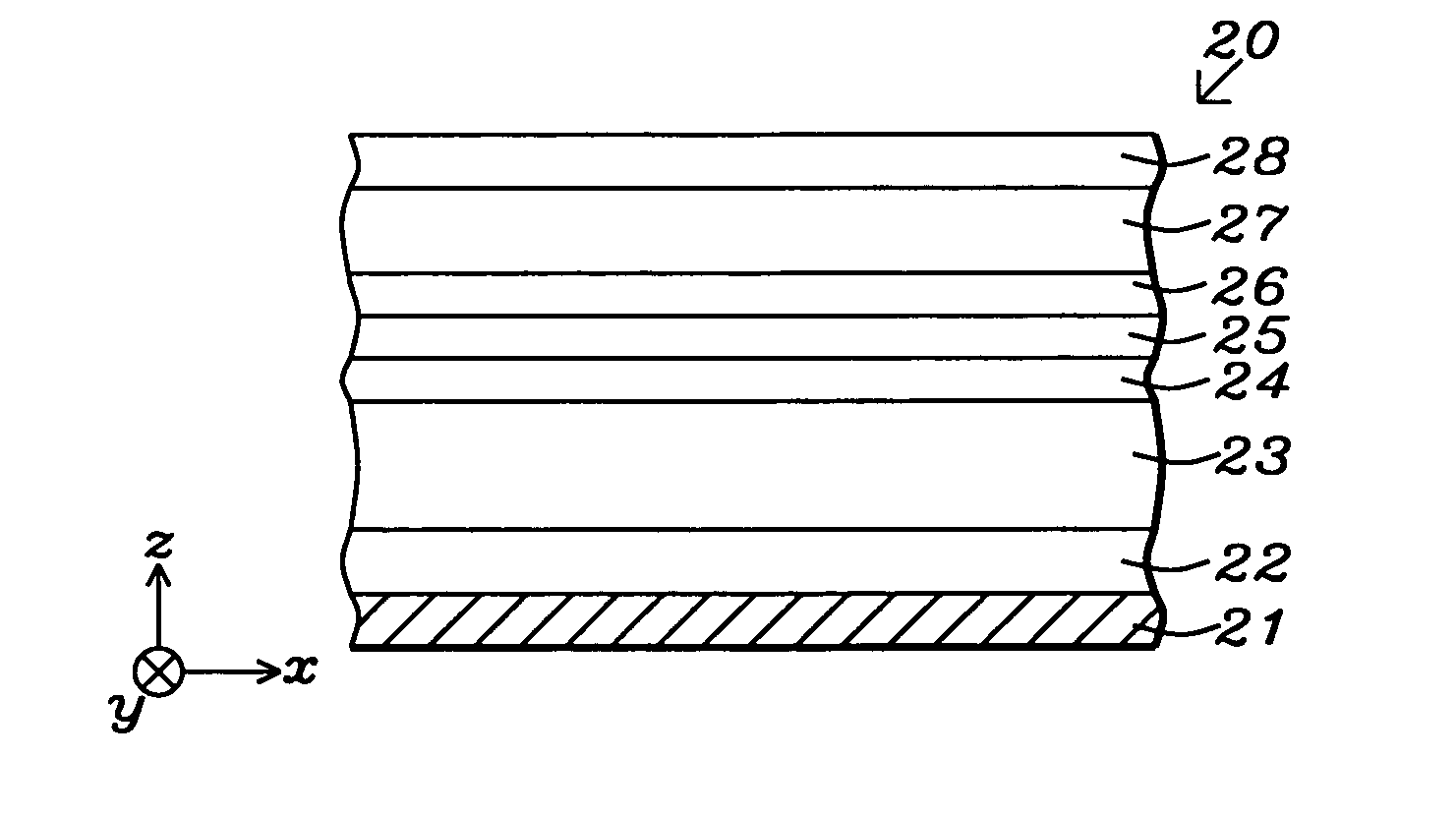

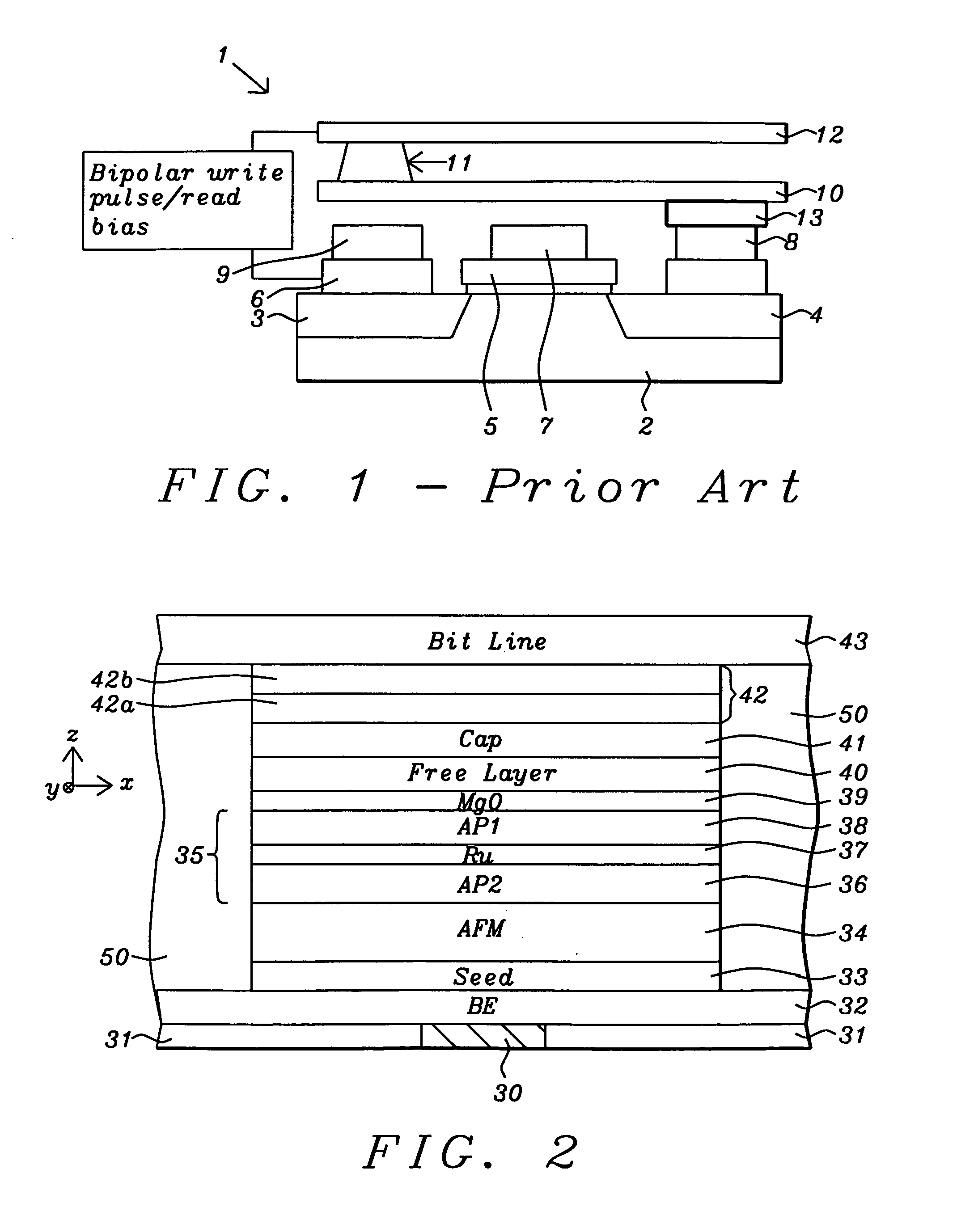

MTJ incorporating CoFe/Ni multilayer film with perpendicular magnetic anisotropy for MRAM application

ActiveUS20110096443A1Minimize impinging ion energyMaximize PMA propertyMagnetic measurementsVacuum evaporation coatingSpin transferSpin valve

A MTJ for a spintronic device is disclosed and includes a thin composite seed layer made of at least Ta and a metal layer having fcc(111) or hcp(001) texture as in Ta / Ti / Cu to enhance perpendicular magnetic anisotropy (PMA) in an overlying laminated layer with a (CoFe / Ni)X, (Co / NiFe)X, (Co / NiCo)X, (CoFe / NiFe)X, or (CoFe / NiCo)X composition where x is from 5 to 30. In one embodiment, a CPP-TMR spin valve has one or both of a laminated free layer and laminated reference layer with the aforementioned compositions. The MTJ includes an interfacial layer made of CoFeB, CoFeB / CoFe, or CoFe / CoFeB between each laminated structure and the tunnel barrier. The laminated layers are deposited by a low power and high Ar pressure process to avoid damaging interfaces between adjoining layers. Annealing occurs at 220° C. to 400° C. A laminated layer with high PMA may also be included in one or more layers of a spin transfer oscillator.

Owner:TAIWAN SEMICON MFG CO LTD

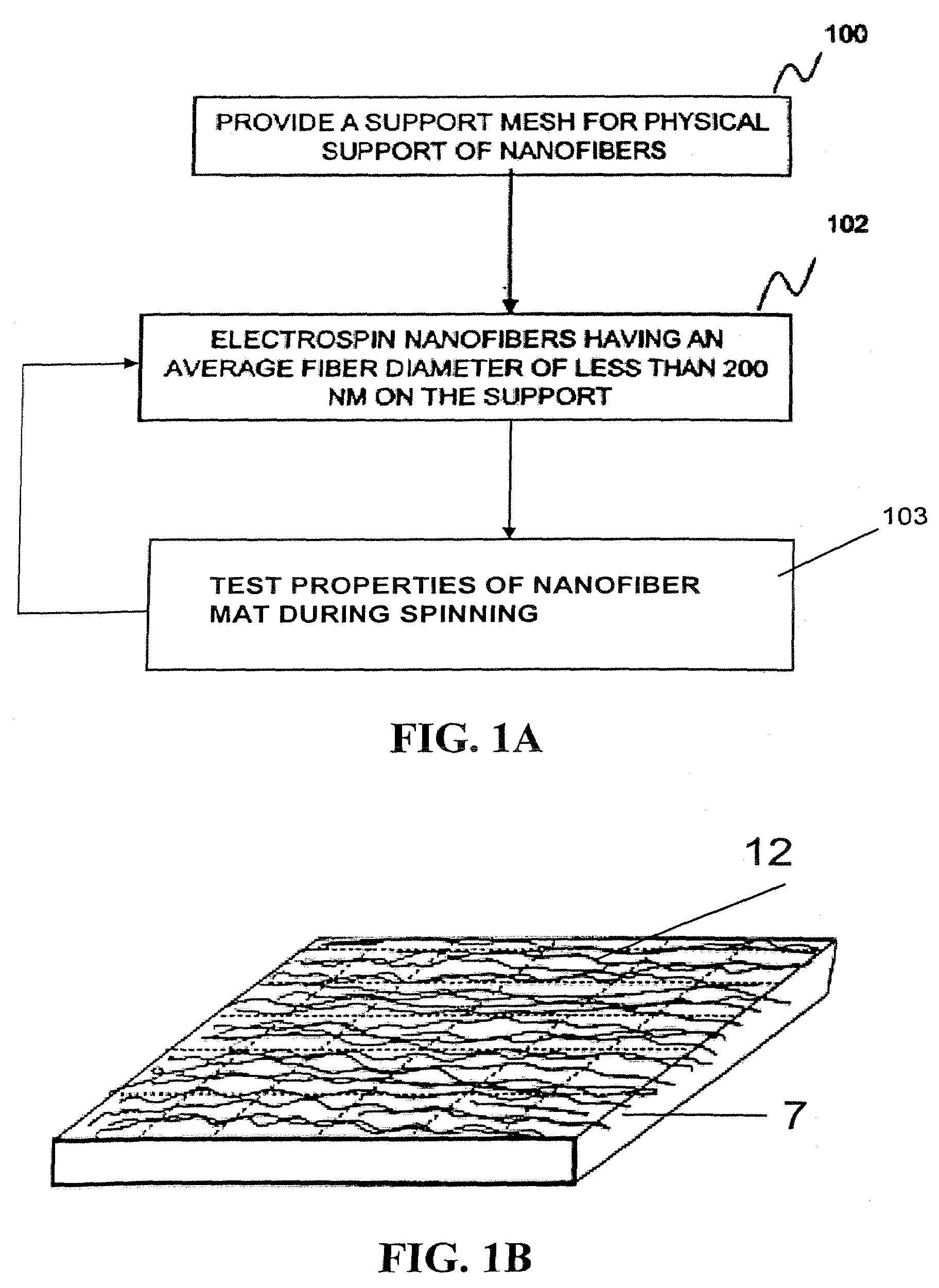

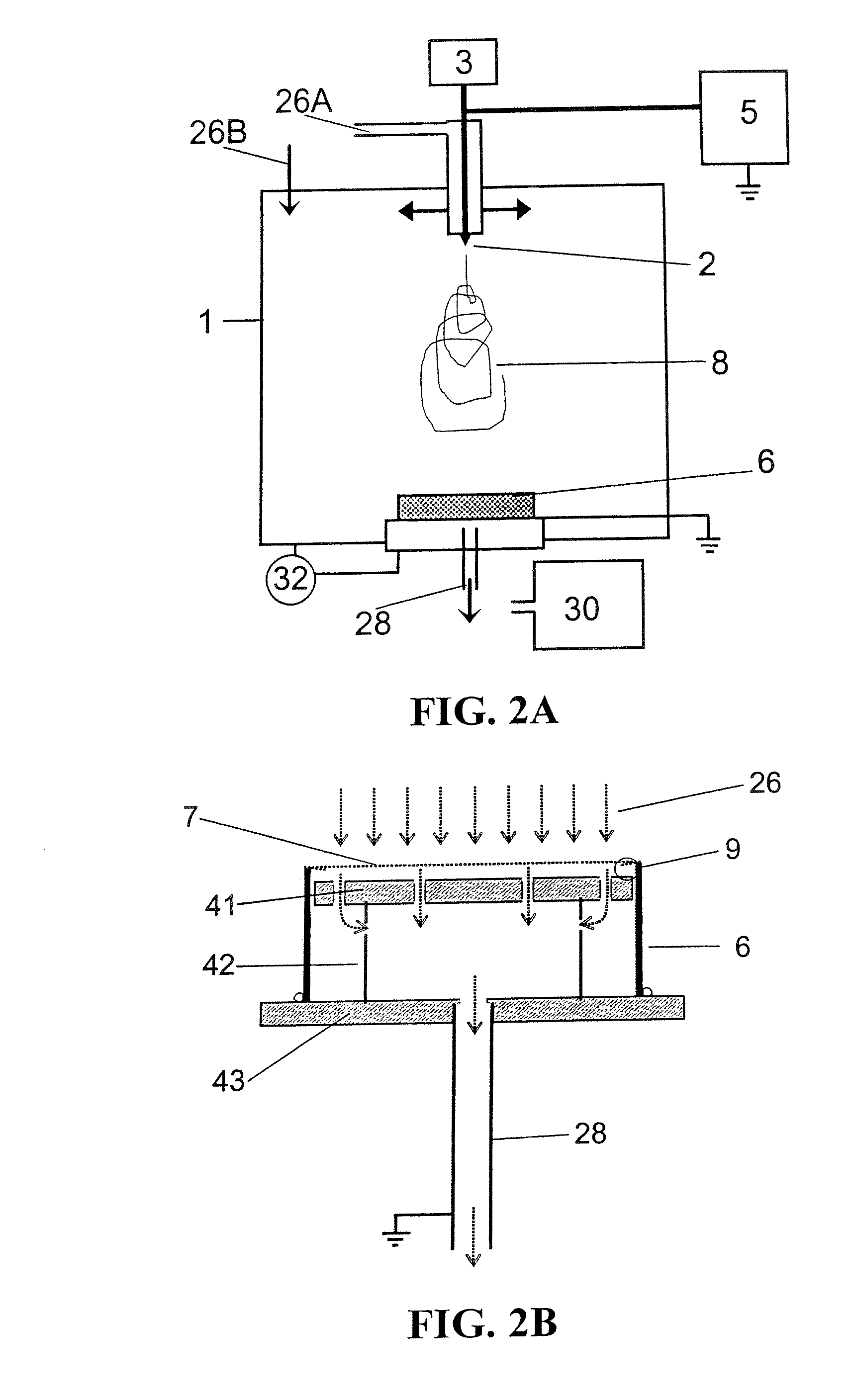

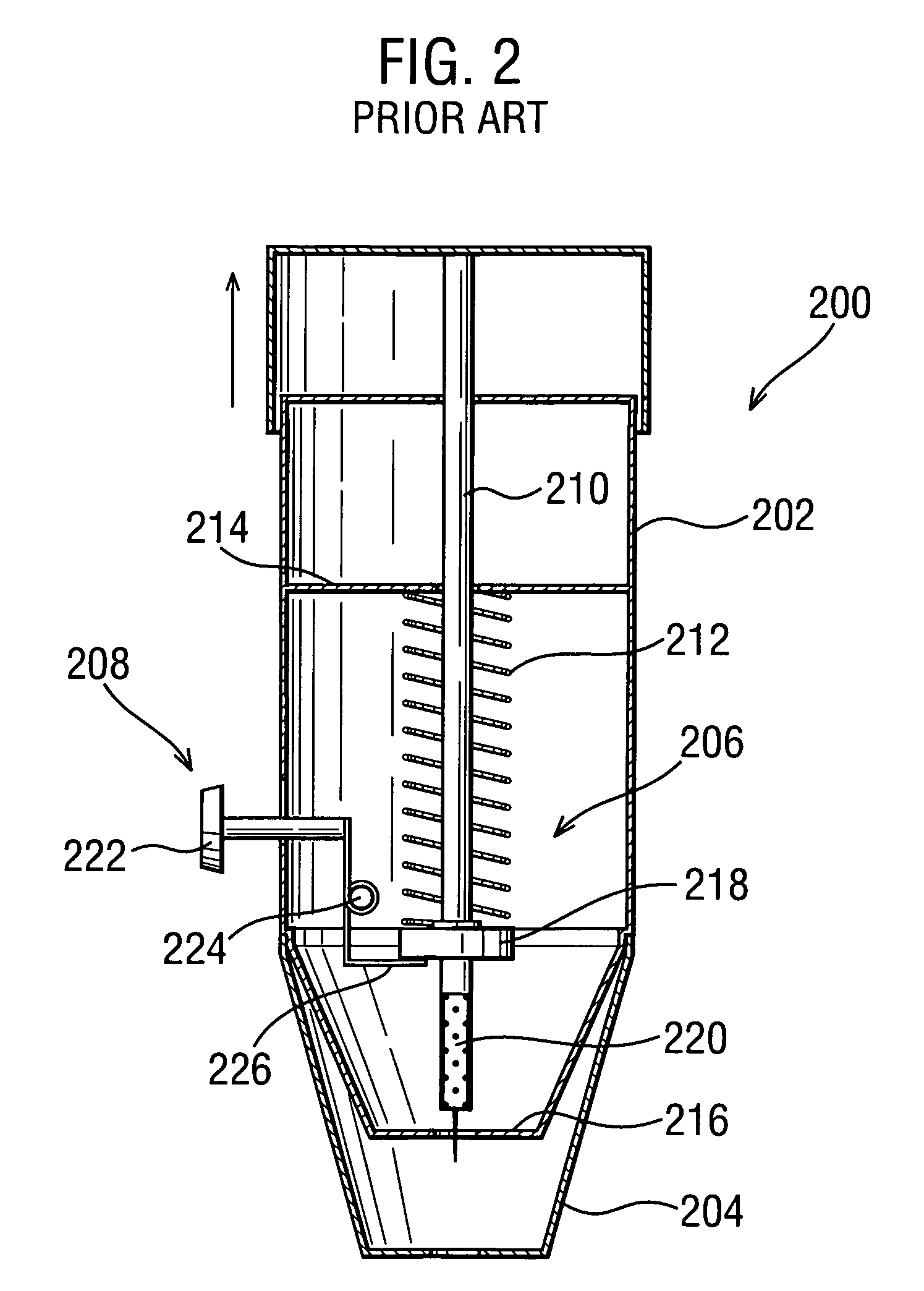

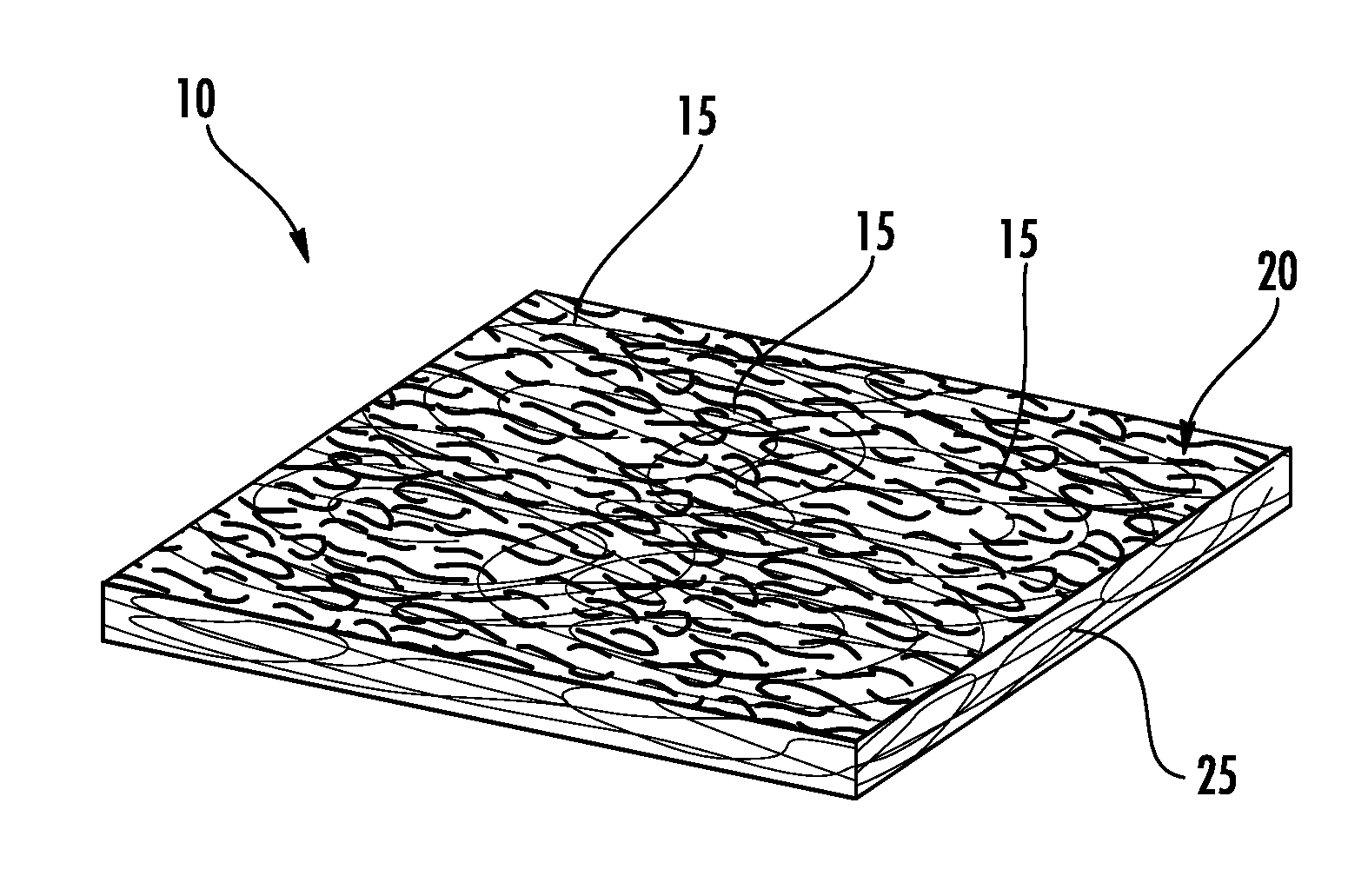

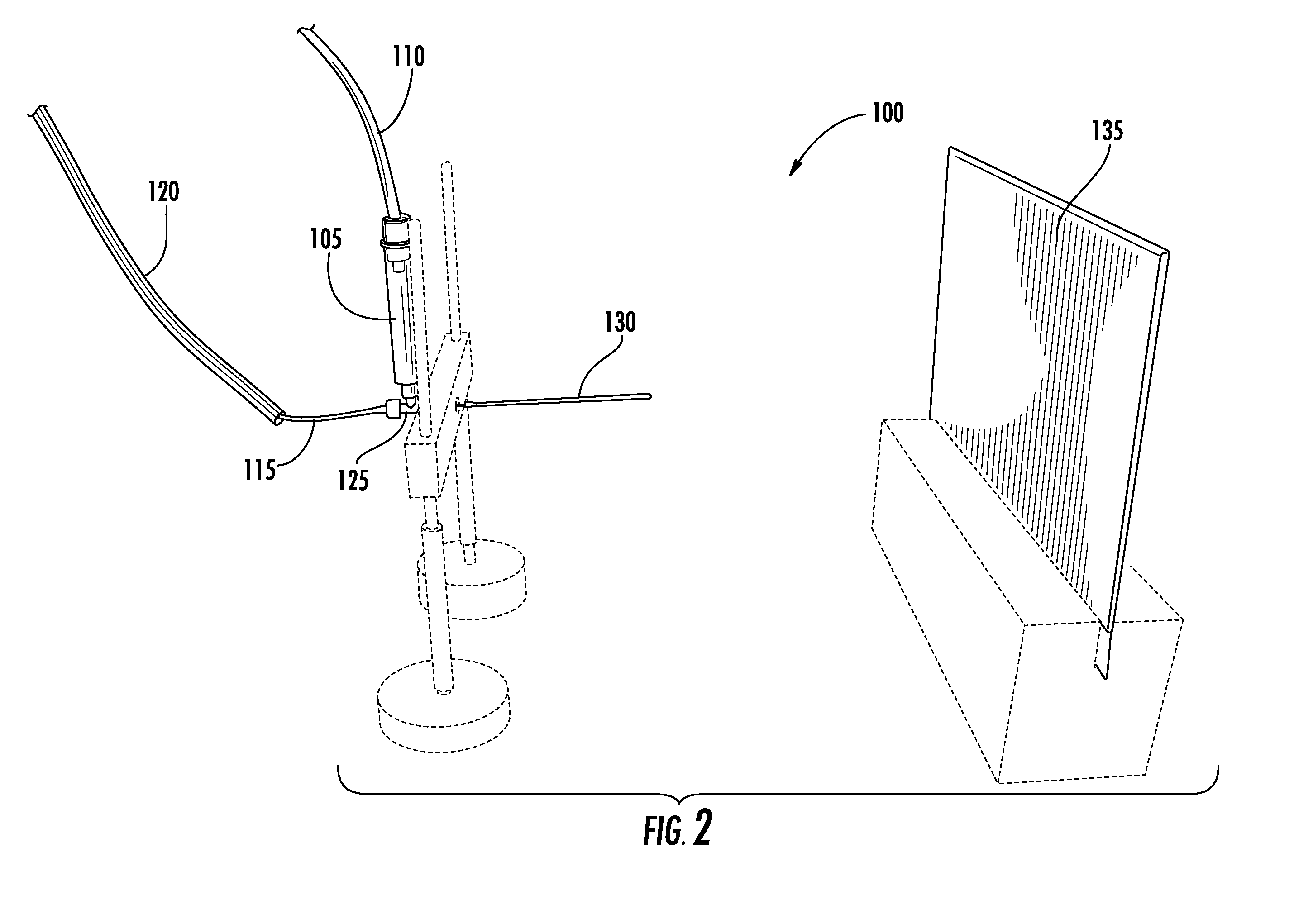

Particle filter system incorporating nanofibers

ActiveUS20080110342A1Electric discharge heatingFilament/thread formingElectric field modulationFiber

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

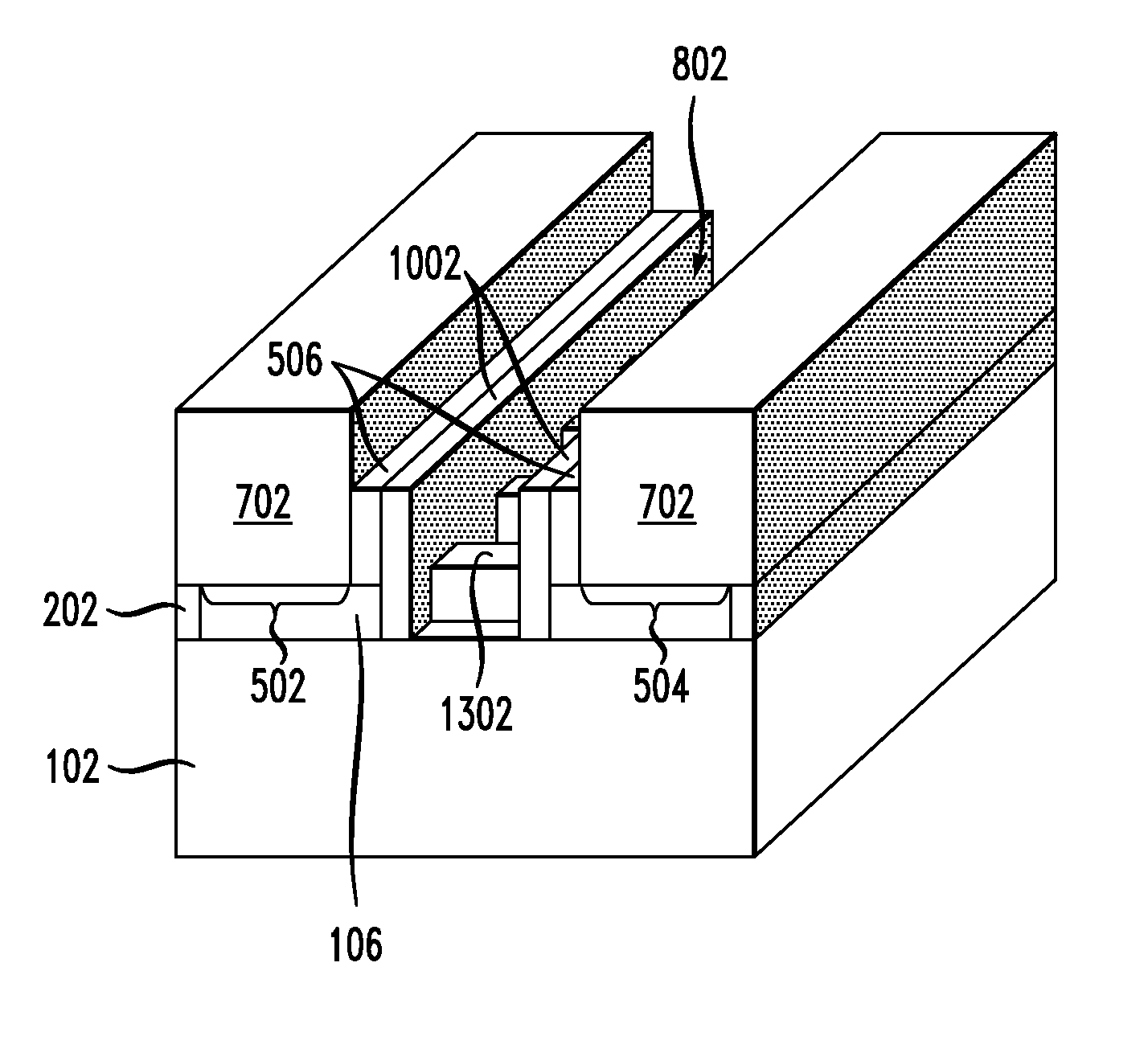

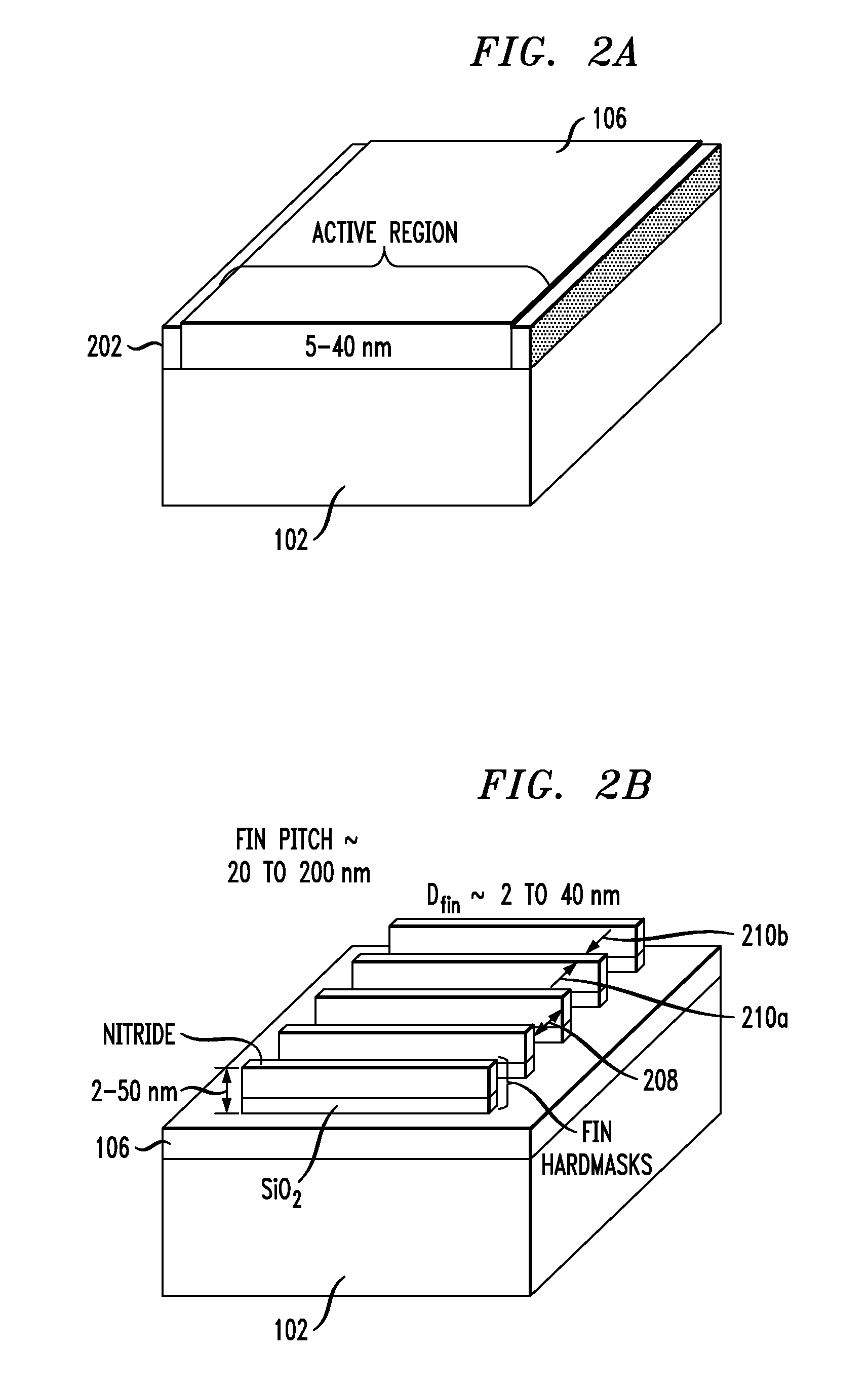

Fin-Last Replacement Metal Gate FinFET

InactiveUS20120313170A1Solid-state devicesSemiconductor/solid-state device manufacturingDopantEngineering

FinFET devices and methods for the fabrication thereof are provided. In one aspect, a method for fabricating a FET device includes the following steps. A wafer is provided having an active layer on an insulator. A plurality of fin hardmasks are patterned on the active layer. A dummy gate is placed over a central portion of the fin hardmasks. One or more doping agents are implanted into source and drain regions of the device. A dielectric filler layer is deposited around the dummy gate. The dummy gate is removed to form a trench in the dielectric filler layer. The fin hardmasks are used to etch a plurality of fins in the active layer within the trench. The doping agents are activated. A replacement gate is formed in the trench, wherein the step of activating the doping agents is performed before the step of forming the replacement gate.

Owner:AURIGA INNOVATIONS INC

White Light Devices Using Non-polar or Semipolar Gallium Containing Materials and Phosphors

ActiveUS20120187371A1Easy to implementLighting techniqueSolid-state devicesNanotechnologyPhosphorGallium

A packaged optical device includes a substrate having a surface region with light emitting diode devices fabricated on a semipolar or nonpolar GaN substrate. The LEDs emit polarized light and are characterized by an overlapped electron wave function and a hole wave function. Phosphors within the package are excited by the polarized light and, in response, emit electromagnetic radiation of a second wavelength.

Owner:SLT TECH

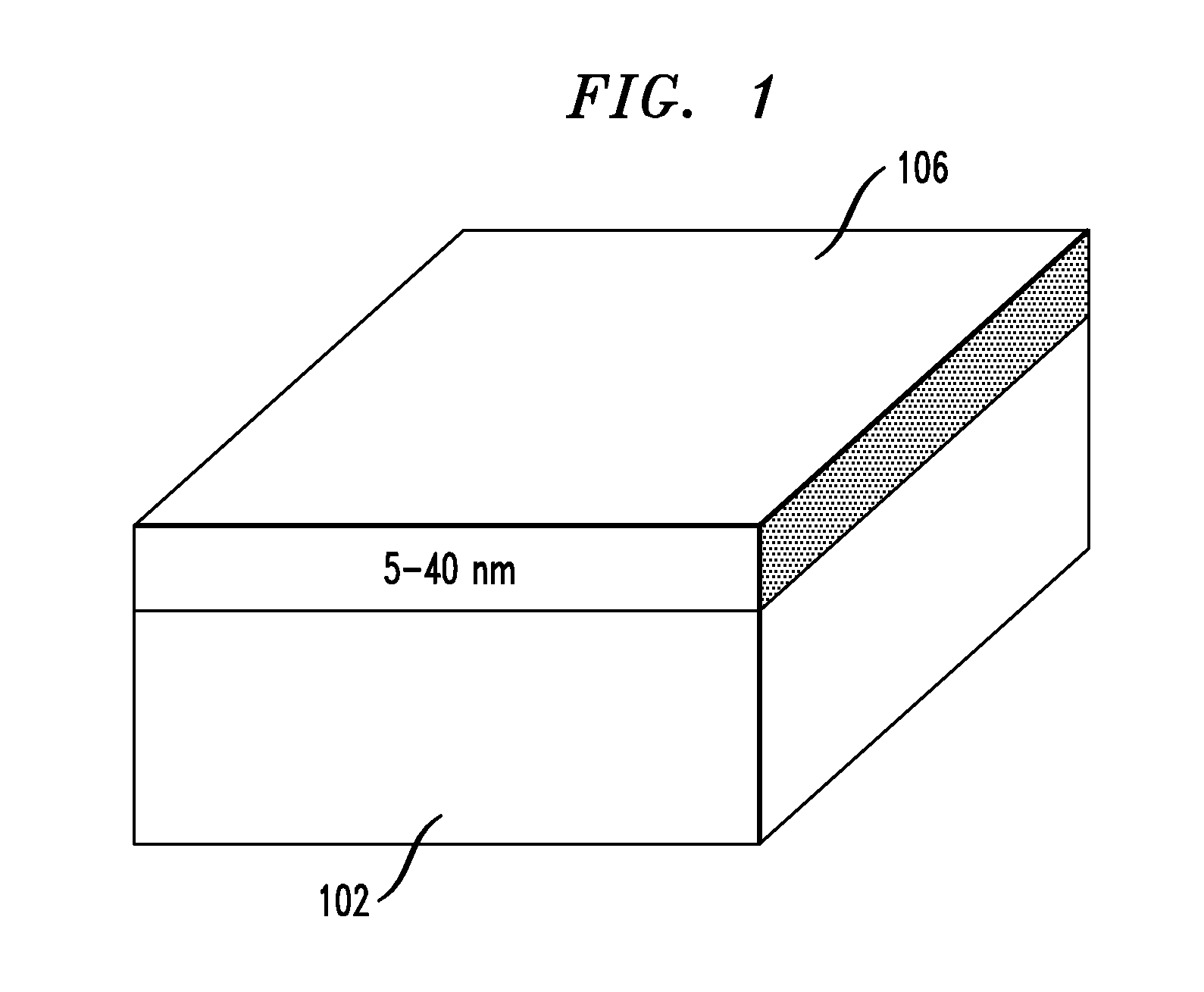

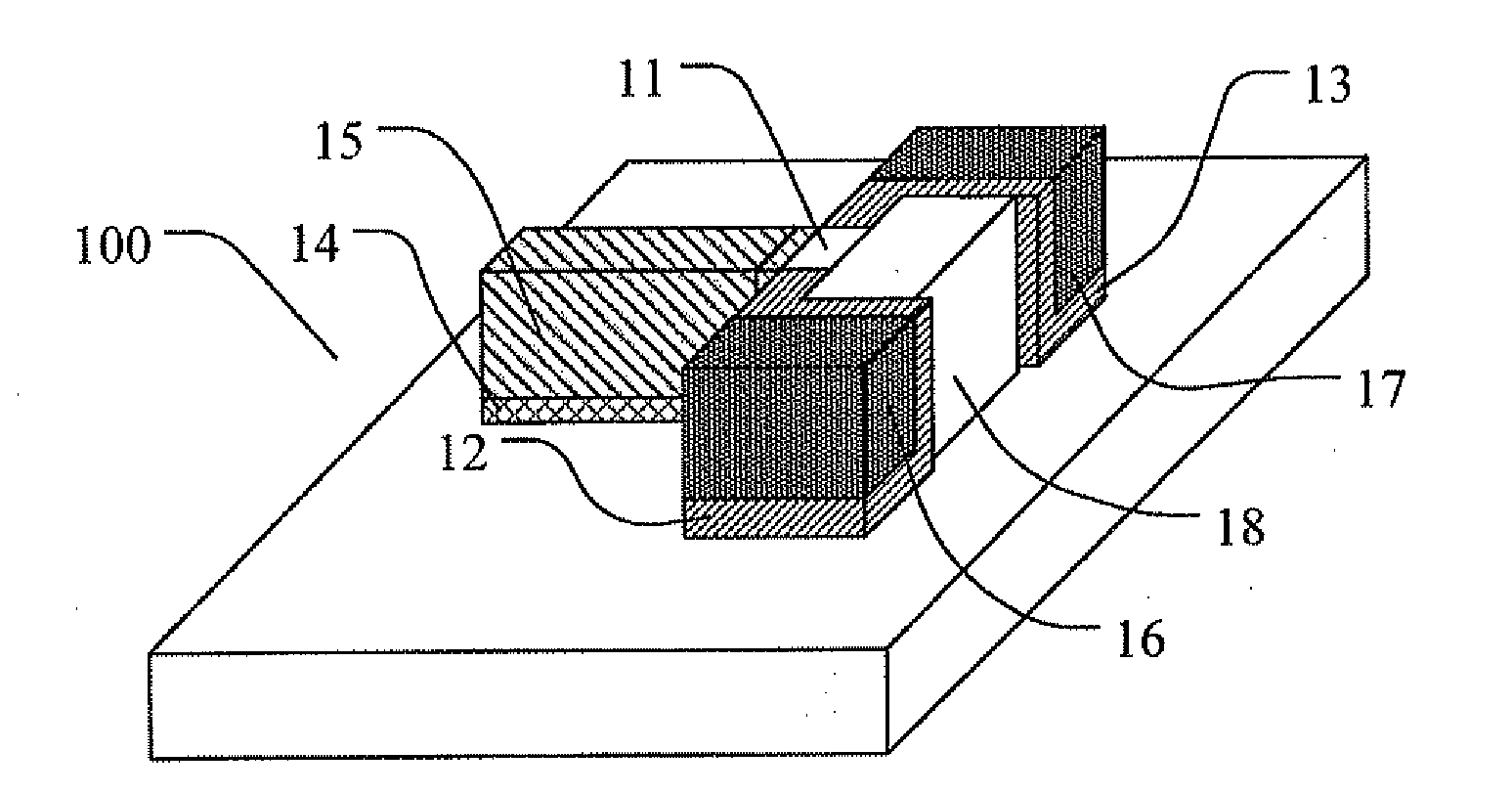

Semiconductor device and method for manufacturing the same

ActiveUS20110193164A1Reduce parasitic capacitanceLarge thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceGate dielectric

The present application discloses a semiconductor device formed on a SOI substrate which comprises a buried insulating layer and a semiconductor layer on the buried insulating layer and a method for manufacturing the same, wherein a fin of semiconductive material having two opposing sides perpendicular to a main surface of the SOI substrate is provided in the semiconductor layer, said semiconductor device comprising: a source region and a drain region provided at two ends of the fin respectively; a channel region provided at a central portion of the fin; and a stack of gate dielectric and gate conductor provided at one side of the fin, where the gate conductor is isolated from the channel region by the gate dielectric, wherein the gate conductor extends away from the one side of the fin in a direction parallel to the main surface of the SOI substrate. The semiconductor device has an improved short channel effect and a reduced parasitic capacitance and resistance, which contributes to an improved electrical property and facilitates scaling down of the transistor.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

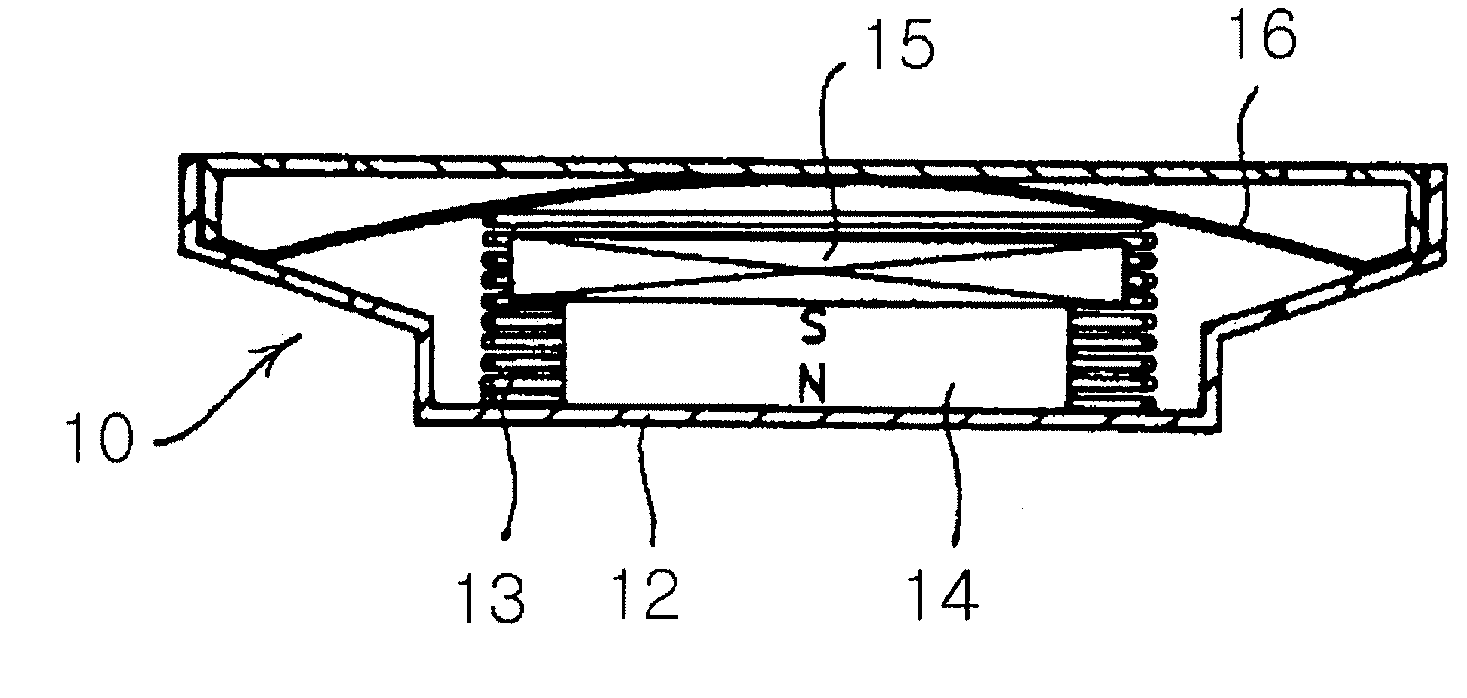

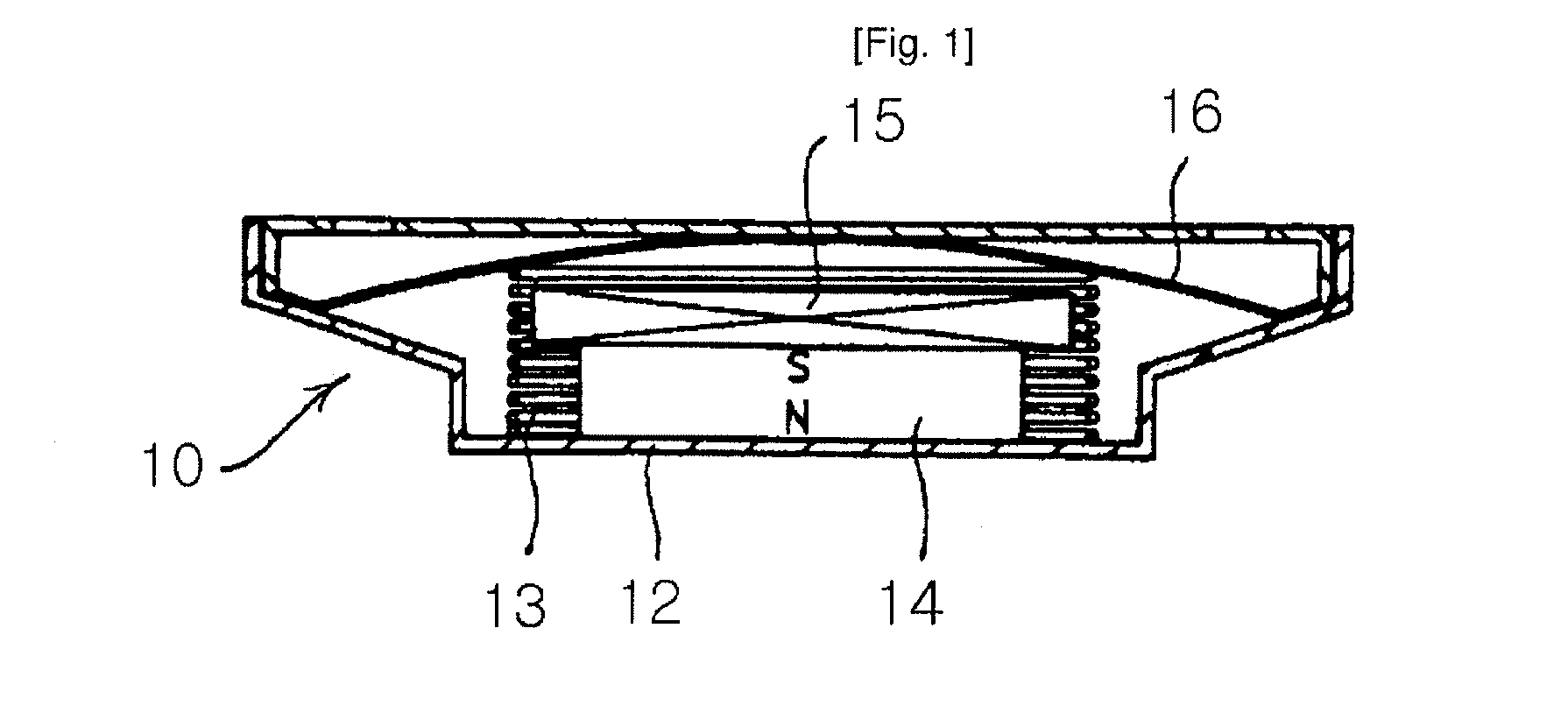

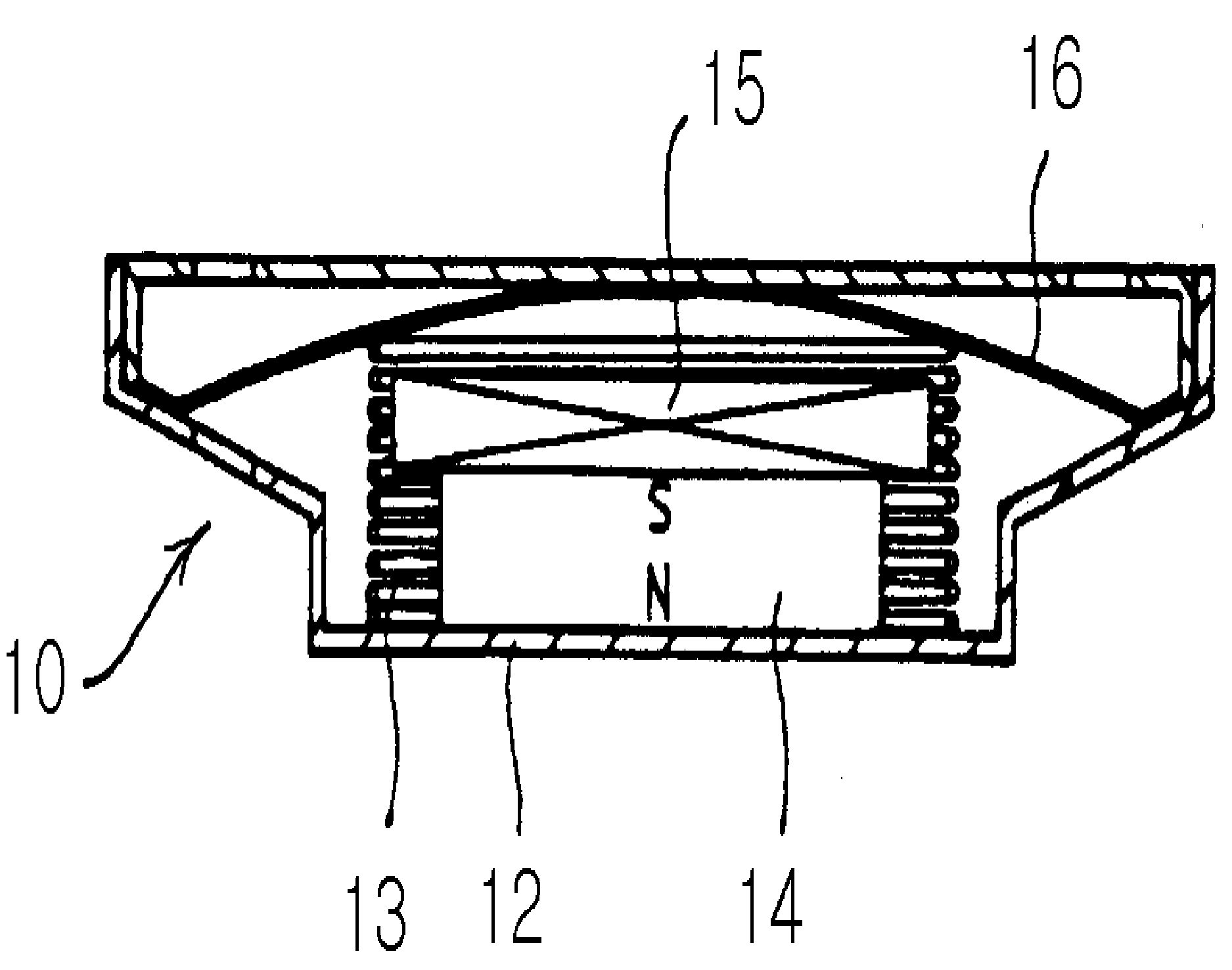

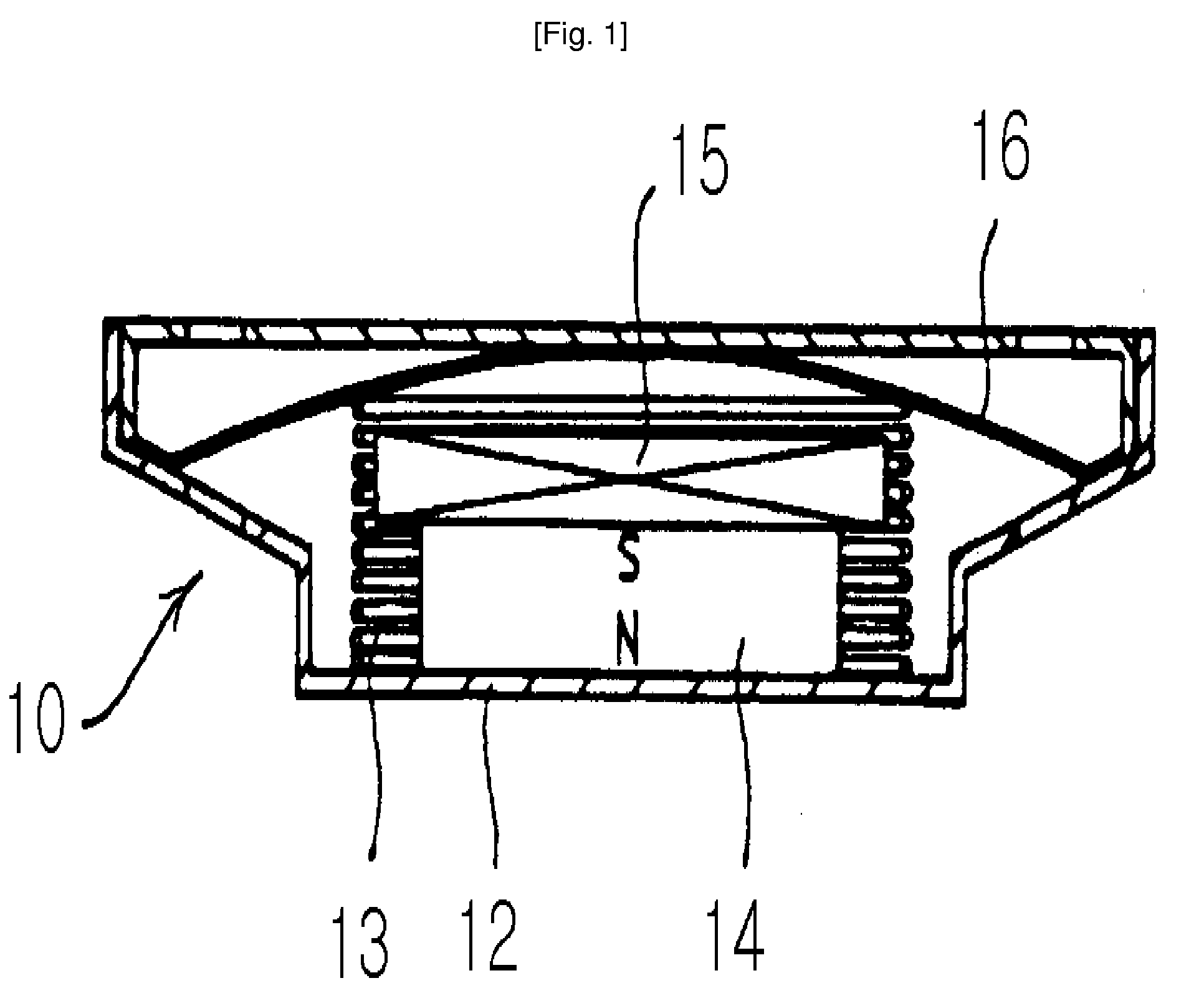

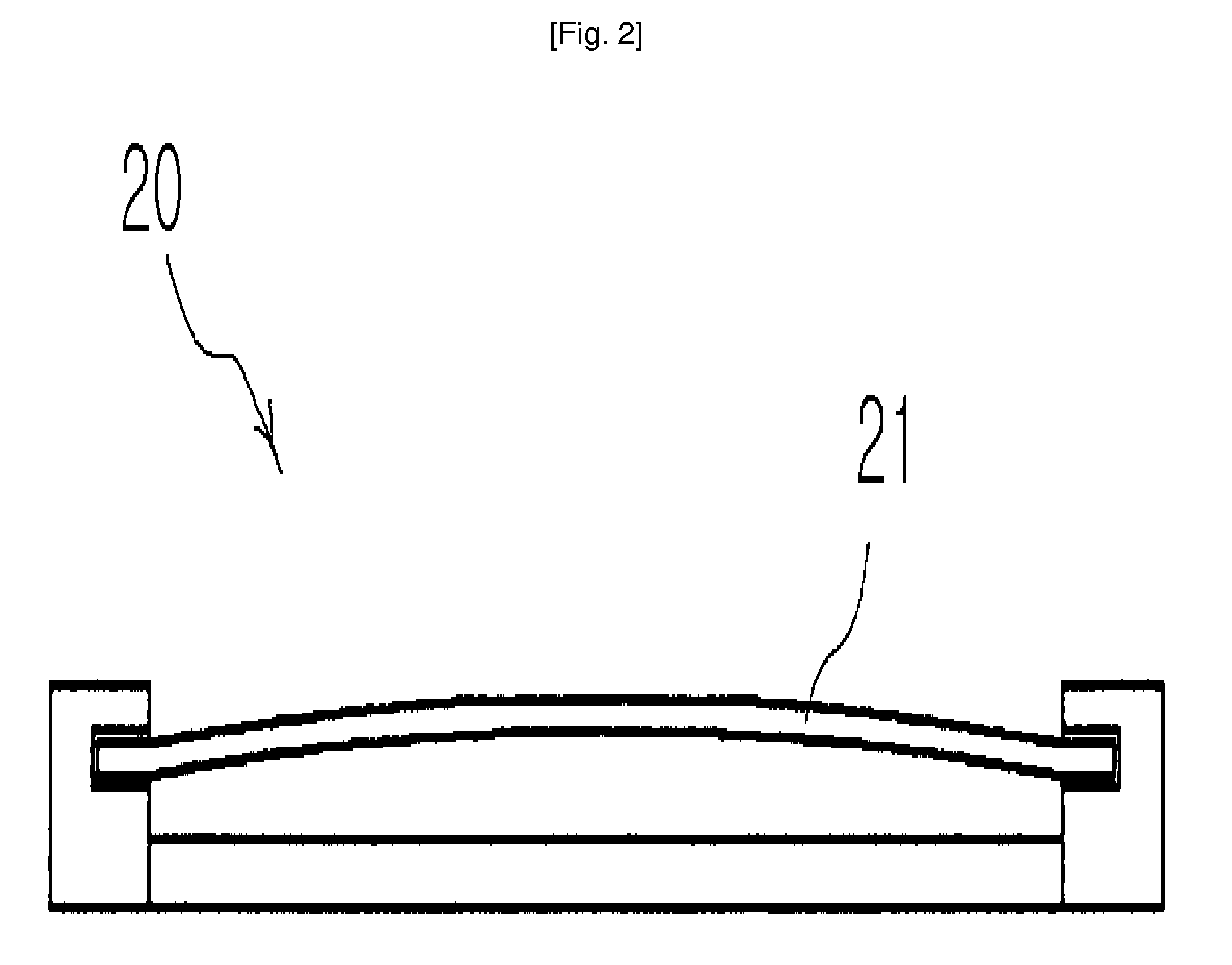

Acoustic Diaphragm and Speaker Having the Same

InactiveUS20080260188A1Good physical propertiesImprove sound qualityFibre diaphragmsPolymeric diaphragmsFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as major materials. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss and strength, it can effectively achieve superior sound quality and high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

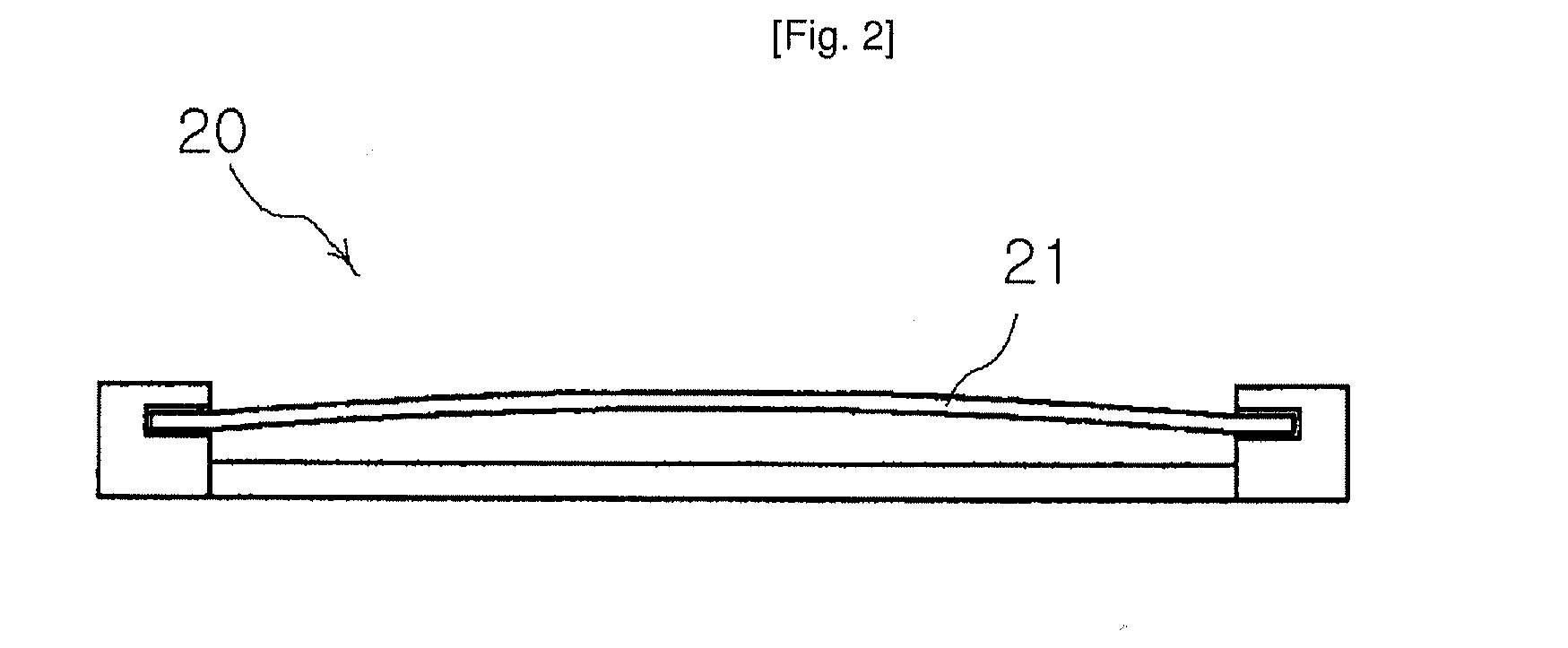

Loudspeaker plastic cone body

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

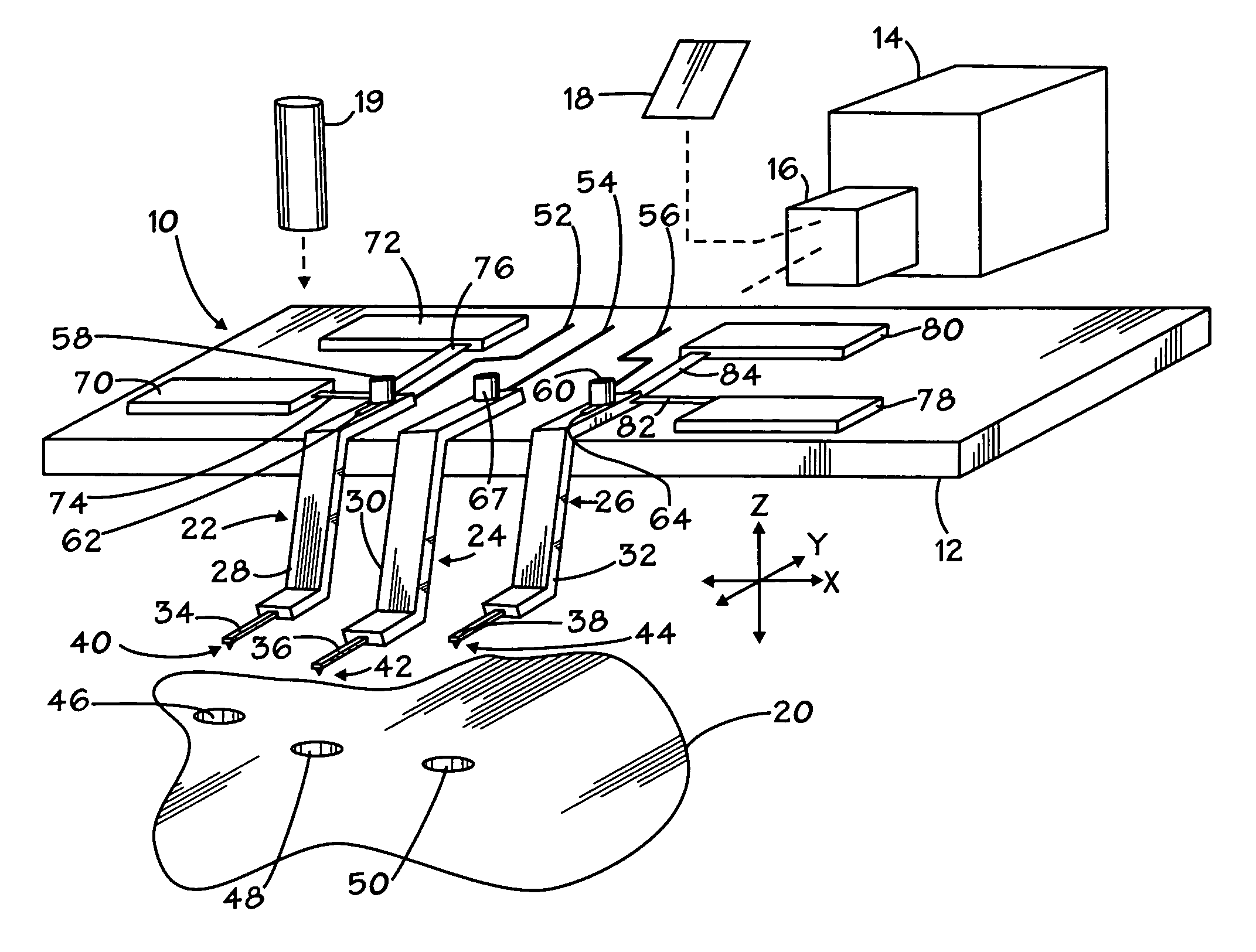

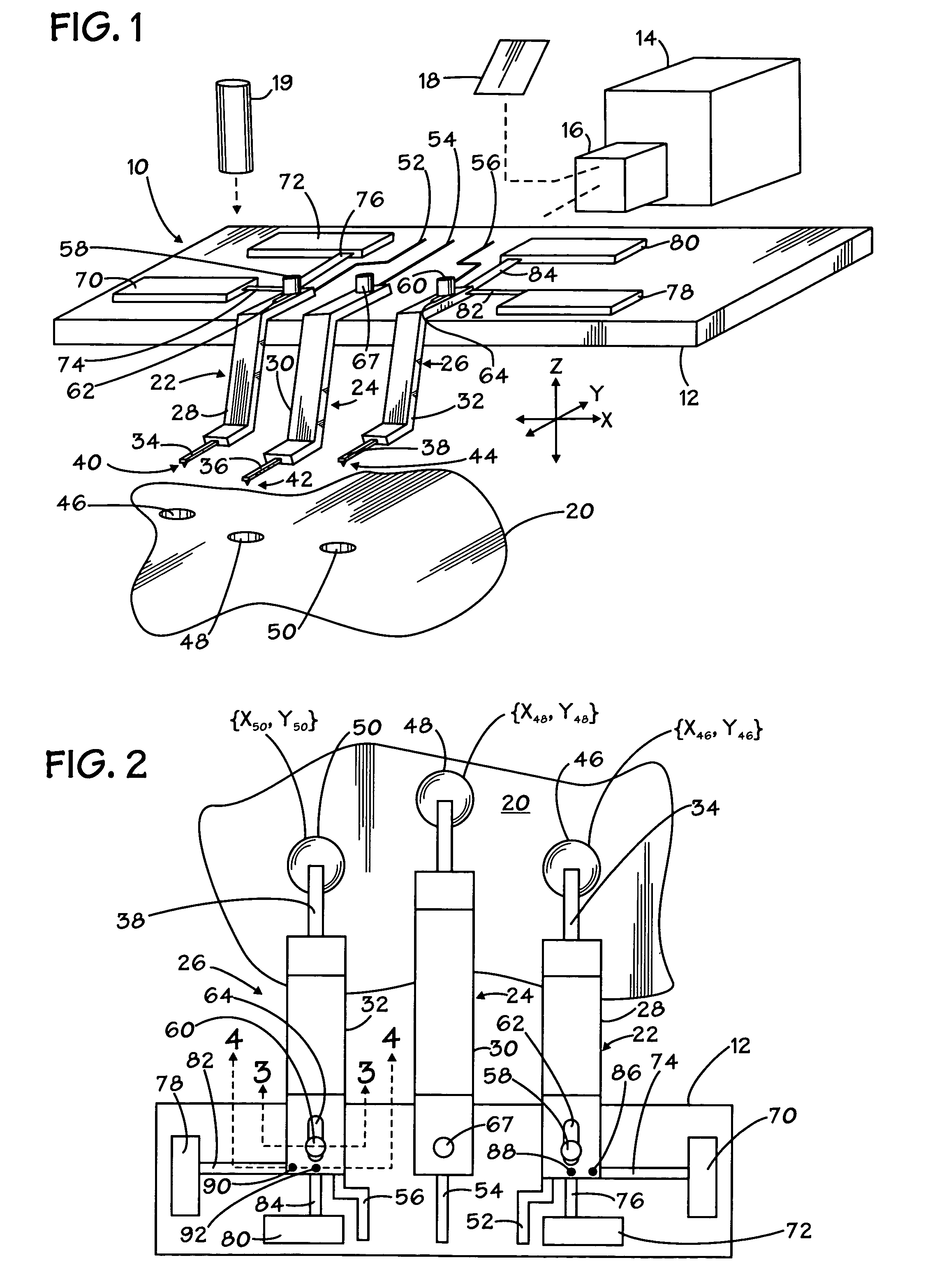

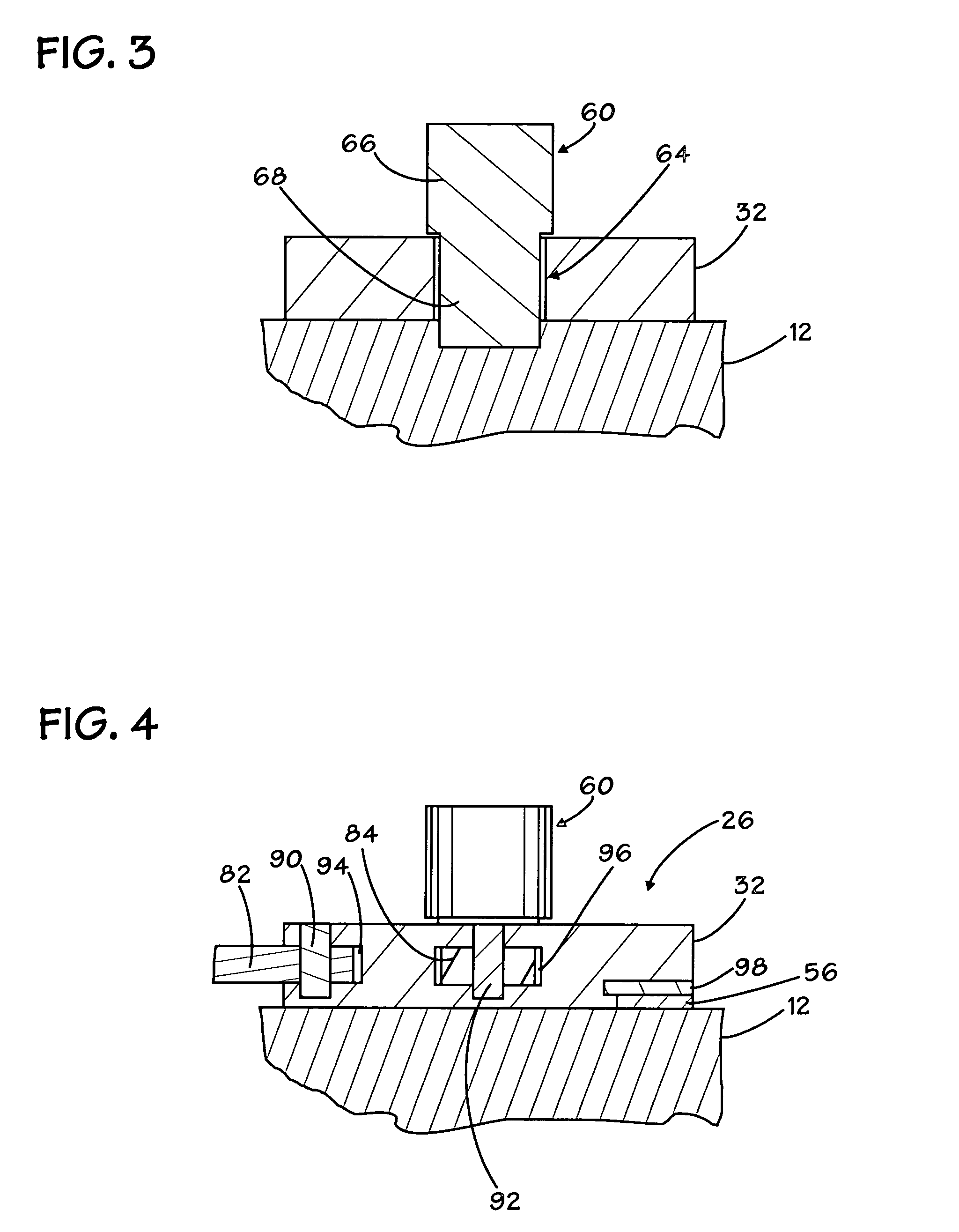

Dynamically adjustable probe tips

ActiveUS7022976B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansEngineeringActuator

Various probe systems and probes are provided. In one aspect, a probe is provided that includes a base and a first member coupled to the base. The first member has a first tip for probing a circuit device. A first actuator is coupled to the first member for moving the first member relative to the base. Electrical and / or topographical probing is possible.

Owner:GLOBALFOUNDRIES US INC

Acoustic Diaphragm and Speakers Having the Same

InactiveUS20090045005A1Good physical propertiesImprove sound qualityPiezoelectric/electrostrictive transducersNanotechnologyFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as reinforcing agents. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm or coated on the surface of the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss, strength and density, it can effectively achieve superior sound quality and a high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

Actuation system for a bodily fluid extraction device and associated methods

ActiveUS7169116B2Reduce painLess discomfortOperating means/releasing devices for valvesVacuum evaporation coatingEngineeringBody fluid

An actuation system for a bodily fluid extraction device includes a detector cap, at least one vibration sensor connected to the detector cap, and at least one signal processing unit in communication with the vibration sensor. In addition, the signal processing unit is configured to receive an output signal from the vibration sensor, analyze the received output signal, and to send an actuation signal to the bodily fluid extraction device based on the analysis of the received output signal.

Owner:CILAG GMBH INT +1

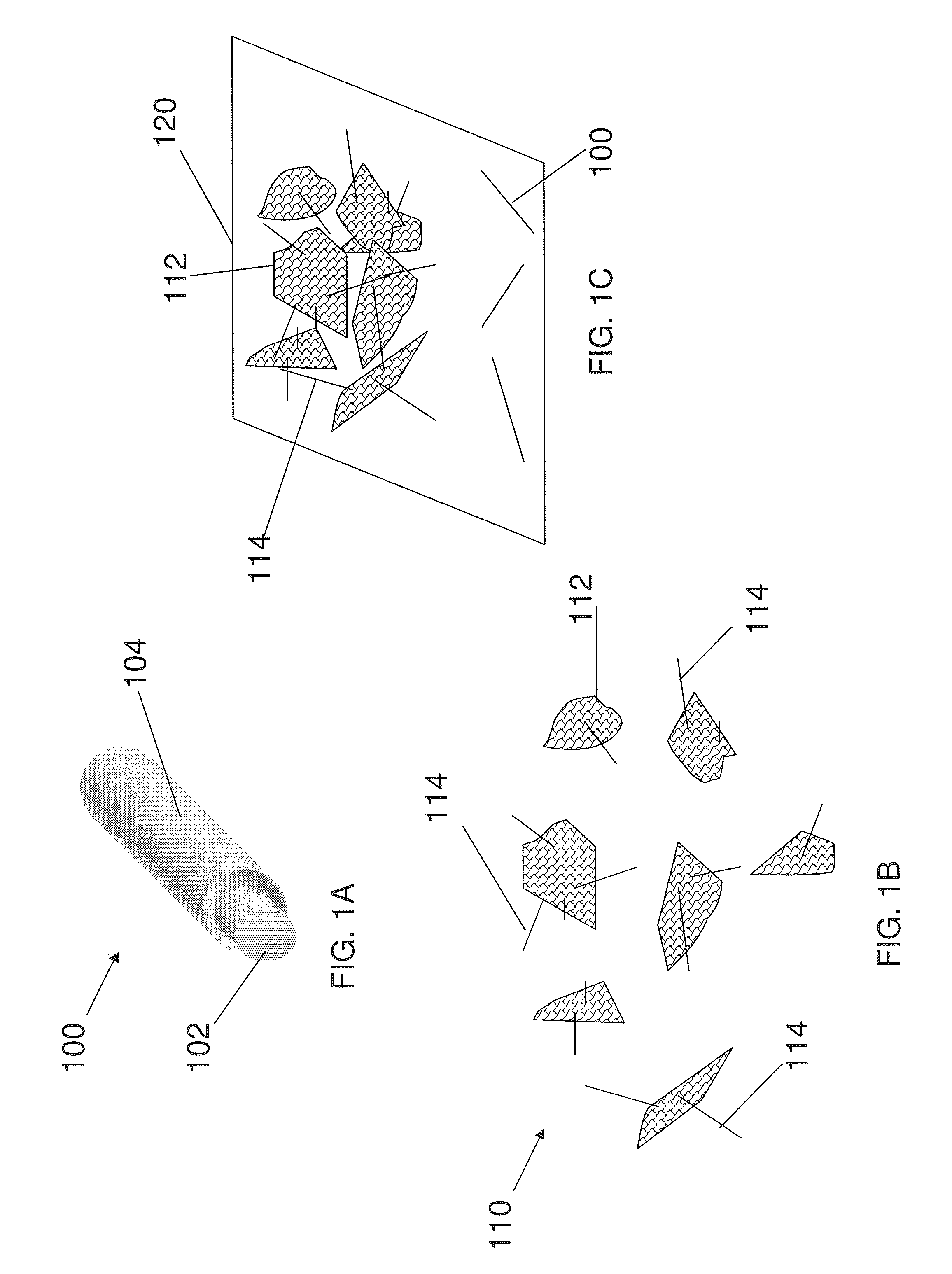

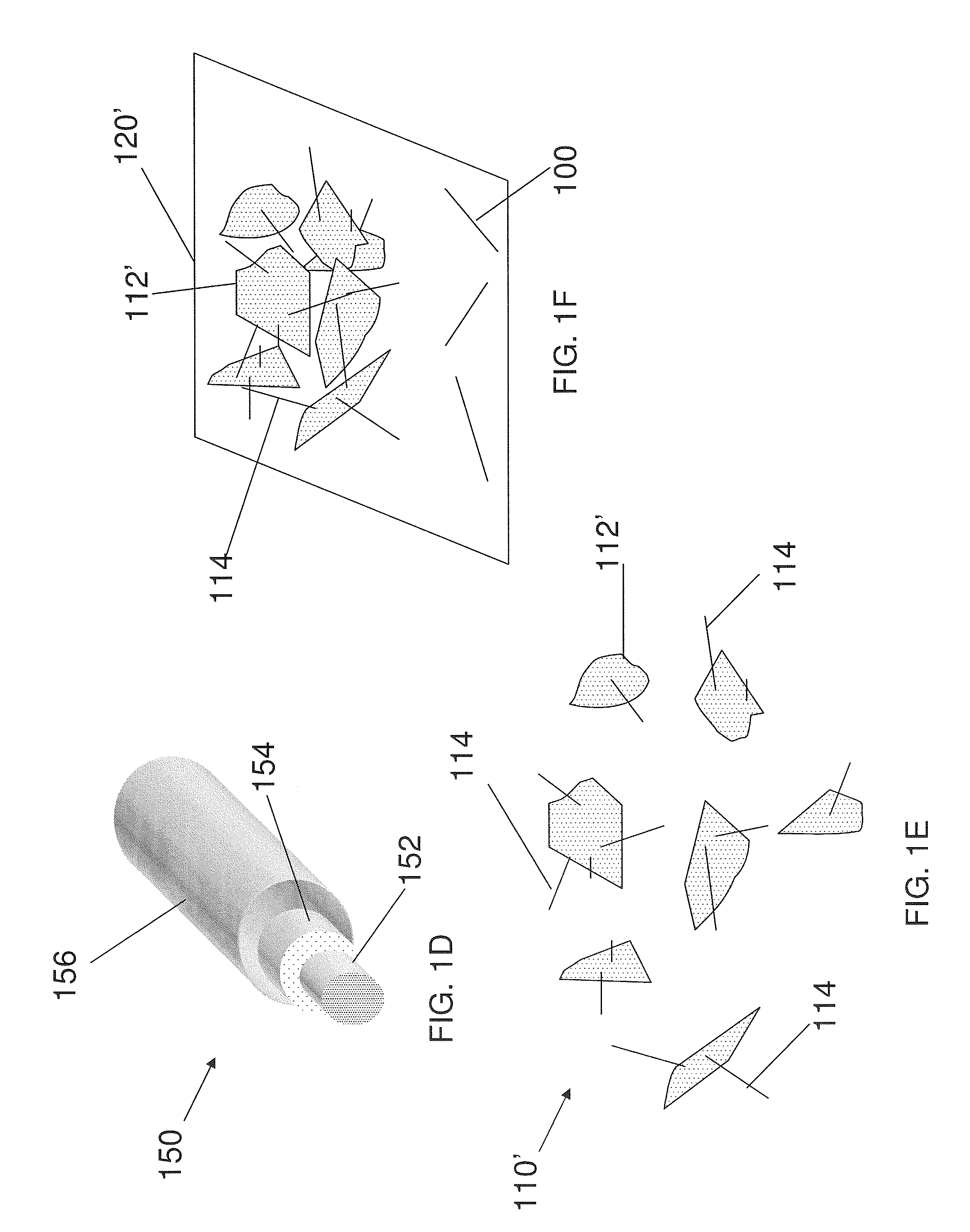

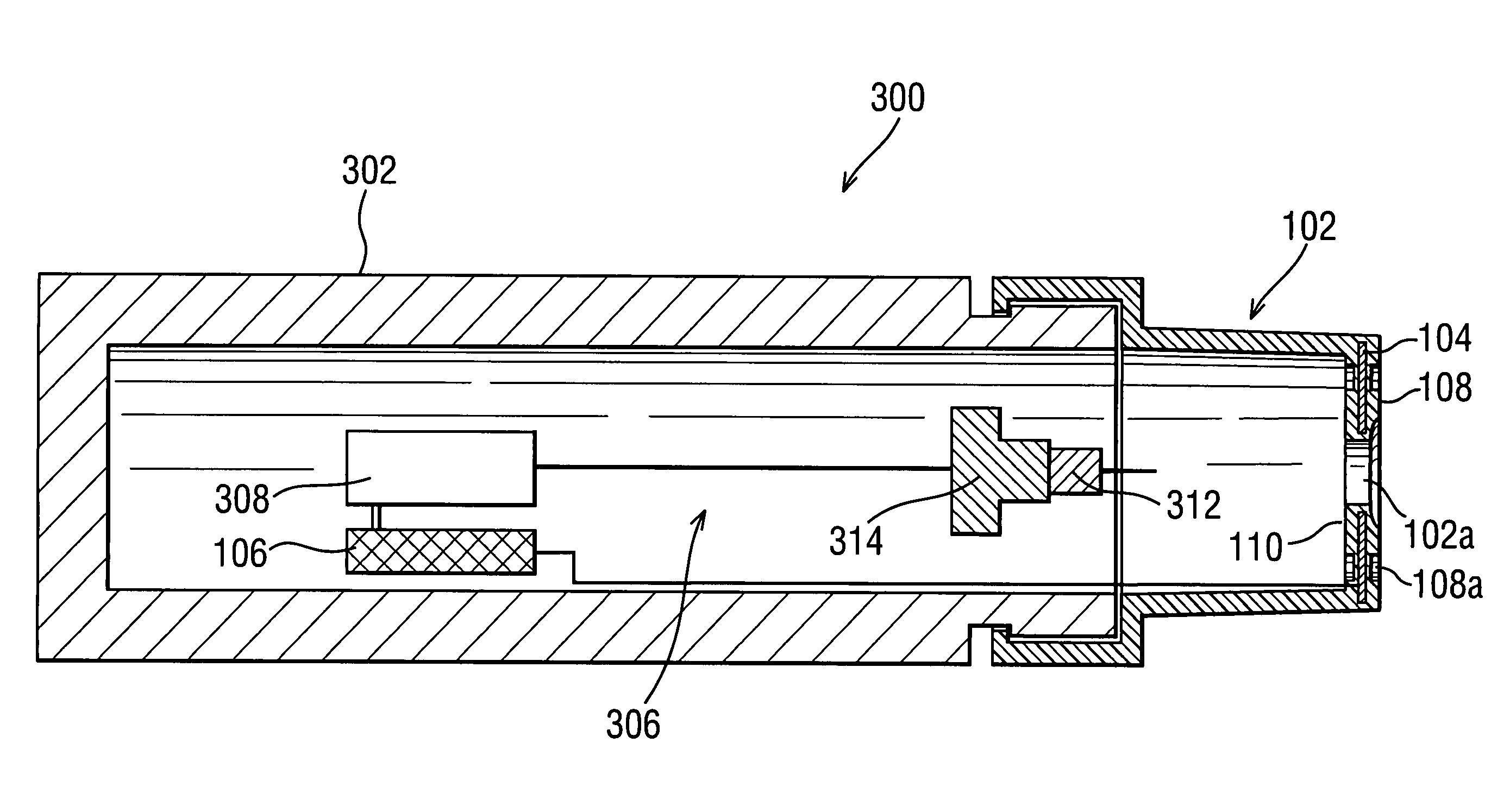

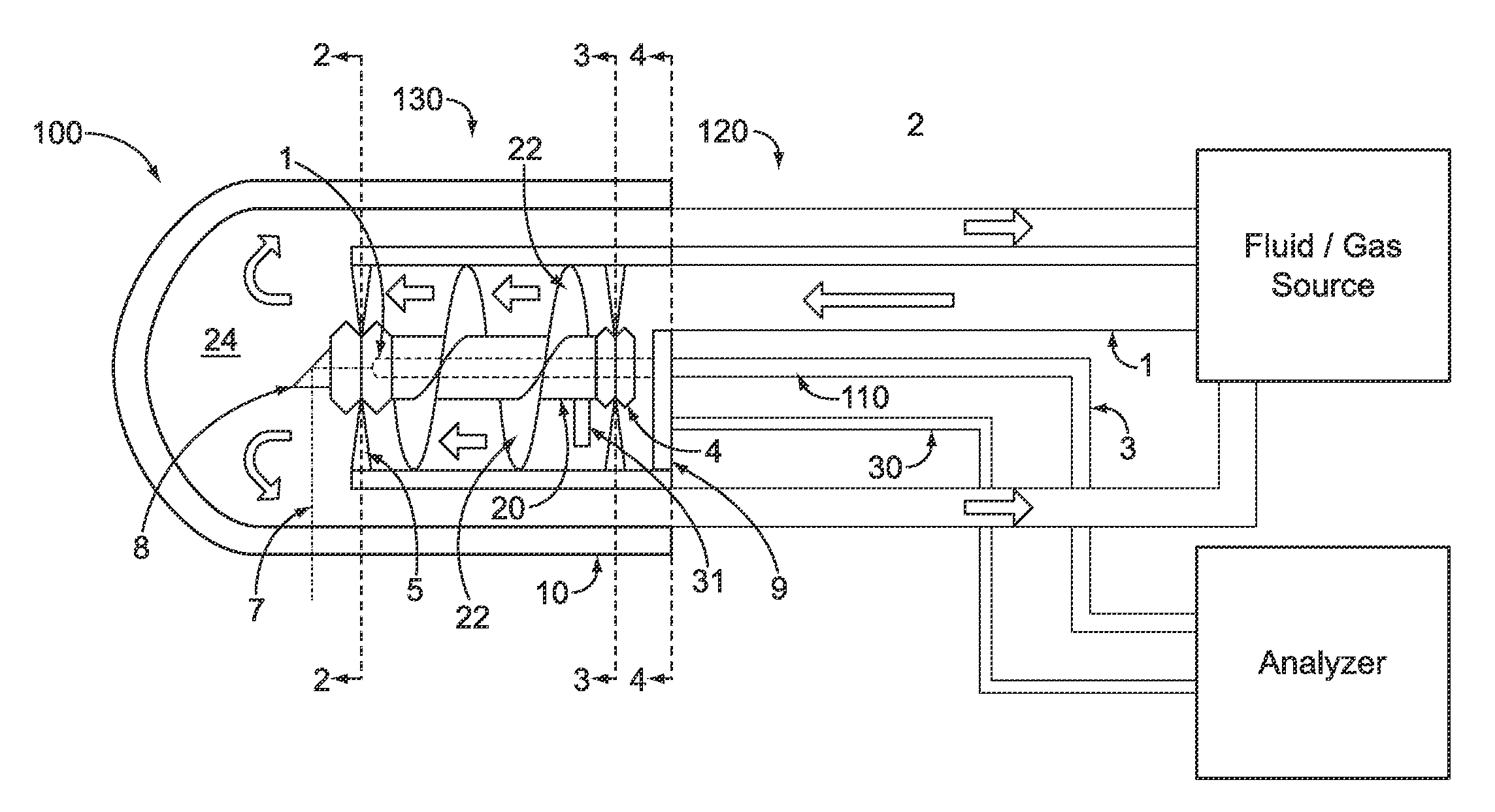

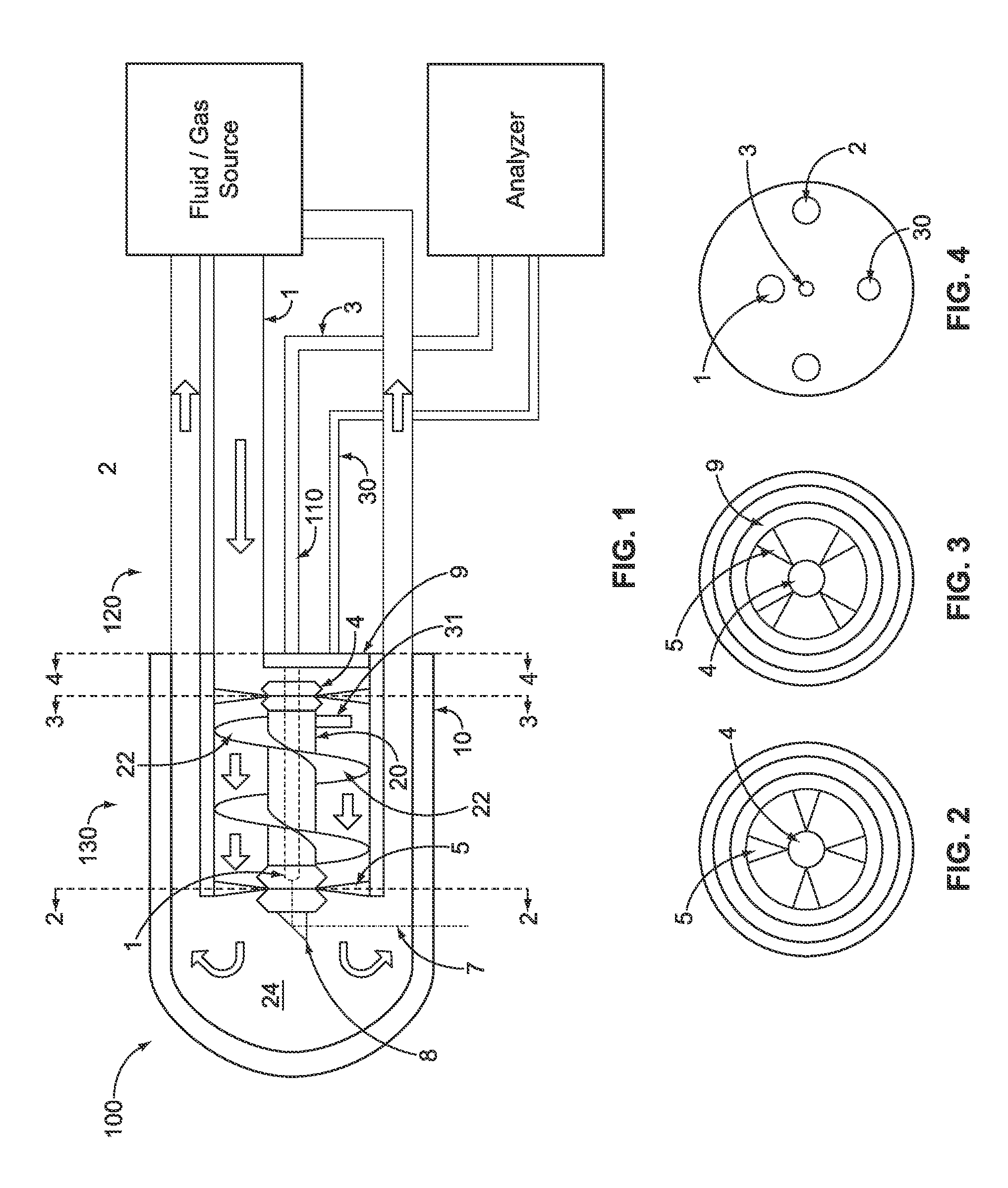

Catheter imaging probe and method

A catheter imaging probe for a patient. The probe includes a conduit through which energy is transmitted. The probe includes a first portion through which the conduit extends. The probe includes a second portion which rotates relative to the conduit to redirect the energy from the conduit. A method for imaging a patient. The method includes the steps of inserting a catheter into the patient. There is the step of rotating a second portion of the catheter relative to a conduit extending through a first portion of the catheter, which redirects the energy transmitted through the conduit to the patient and receives the energy reflected back to the second portion from the patient and redirects the reflected energy to the conduit.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Organic electrolyte capacitor

ActiveUS20070002523A1Improve conductivityLower internal resistanceLiquid electrolytic capacitorsFinal product manufactureLithiumElectrolysis

There is provided an organic electrolyte capacitor having electrodes on current collectors that have holes penetrating the front and rear surfaces, in which electrode materials formed an the through-holes of the current collectors seldom fall off and high energy density and high power density can be obtained. The organic electrolyte capacitor includes positive electrodes, negative electrodes and an electrolyte capable of transferring lithium ions, in which the positive electrodes contain a substance capable of carrying lithium ions and / or anions reversibly as a positive electrode active material, the negative electrodes contain a substance capable of carrying lithium ions as a negative electrode active material, the positive and negative electrodes possess the positive or negative electrode active material layers on an electrode substrate that has conductive layers made of conductive materials on current collectors, which have through-holes, and the negative electrodes carry lithium electrochemically.

Owner:SUBARU CORP

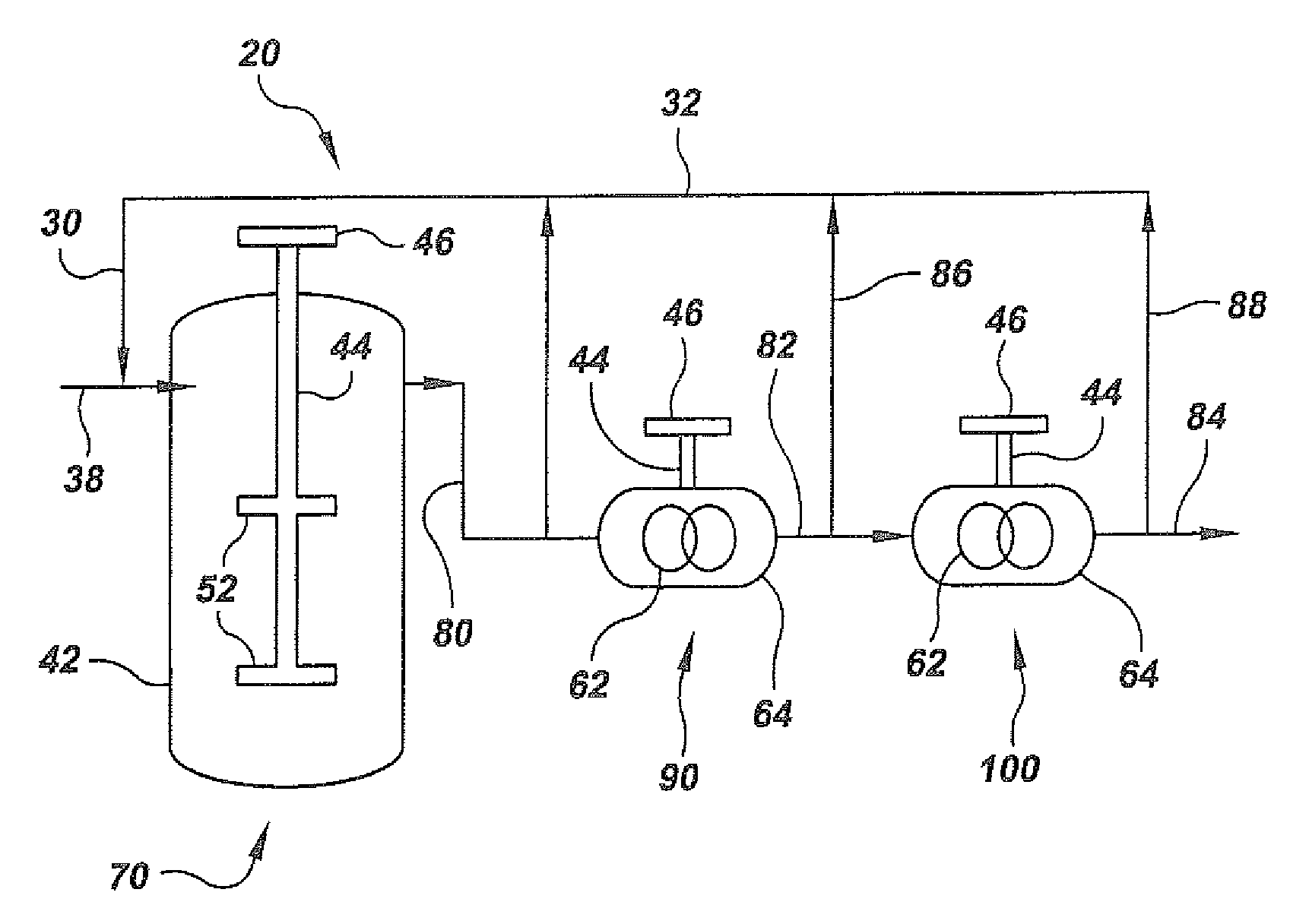

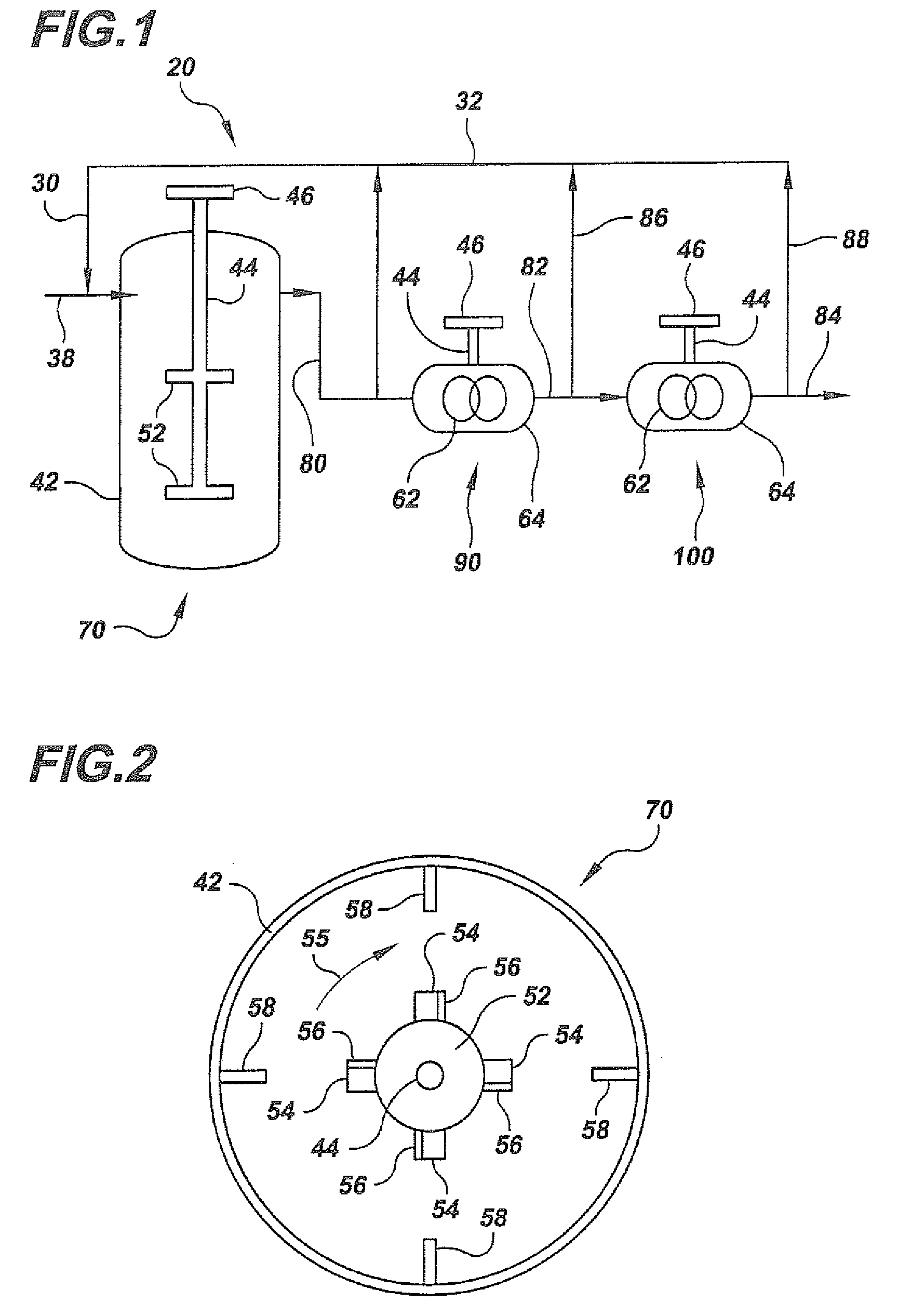

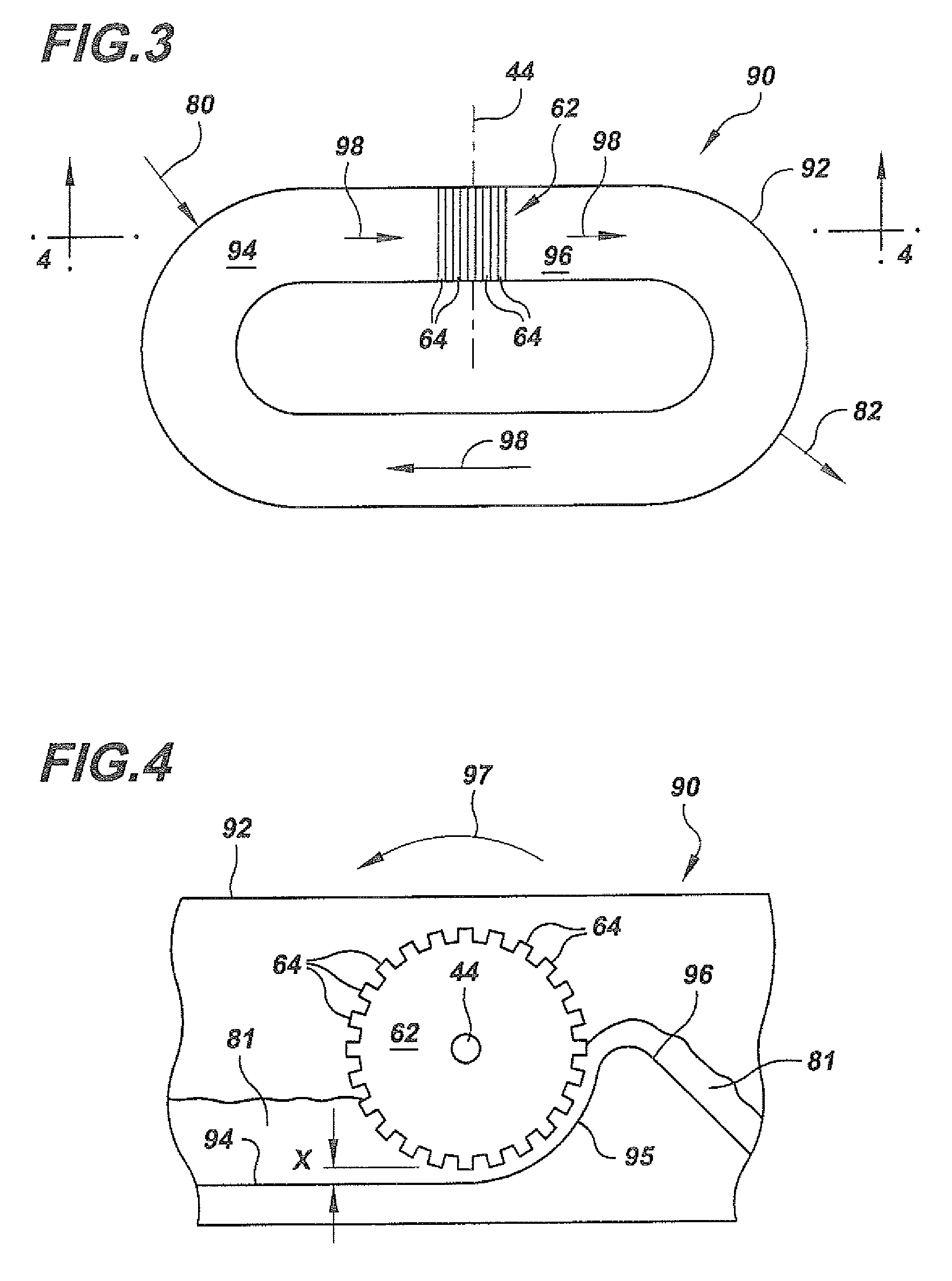

Process for producing nanofibers

ActiveUS20080057307A1Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberNanofiber

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

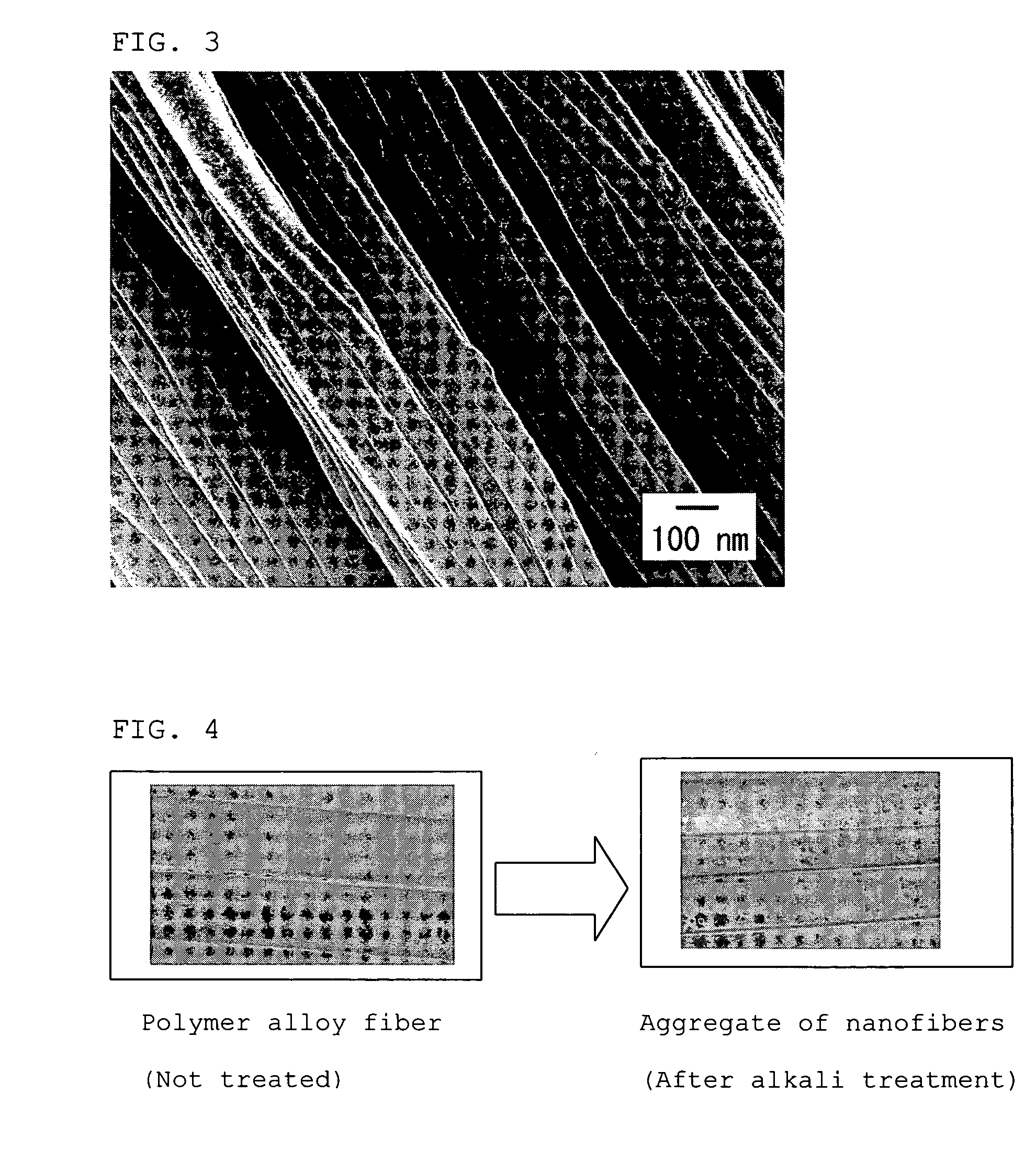

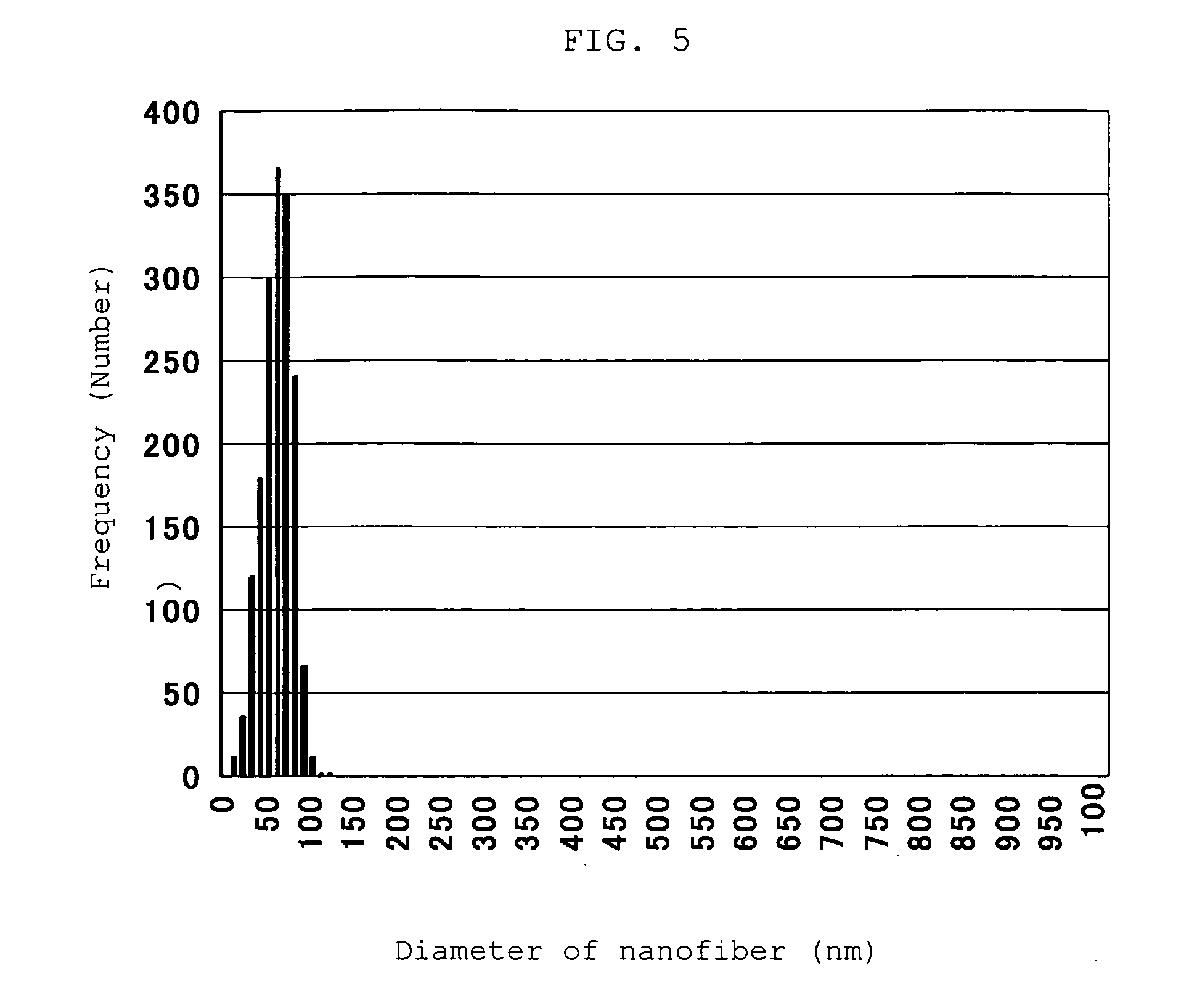

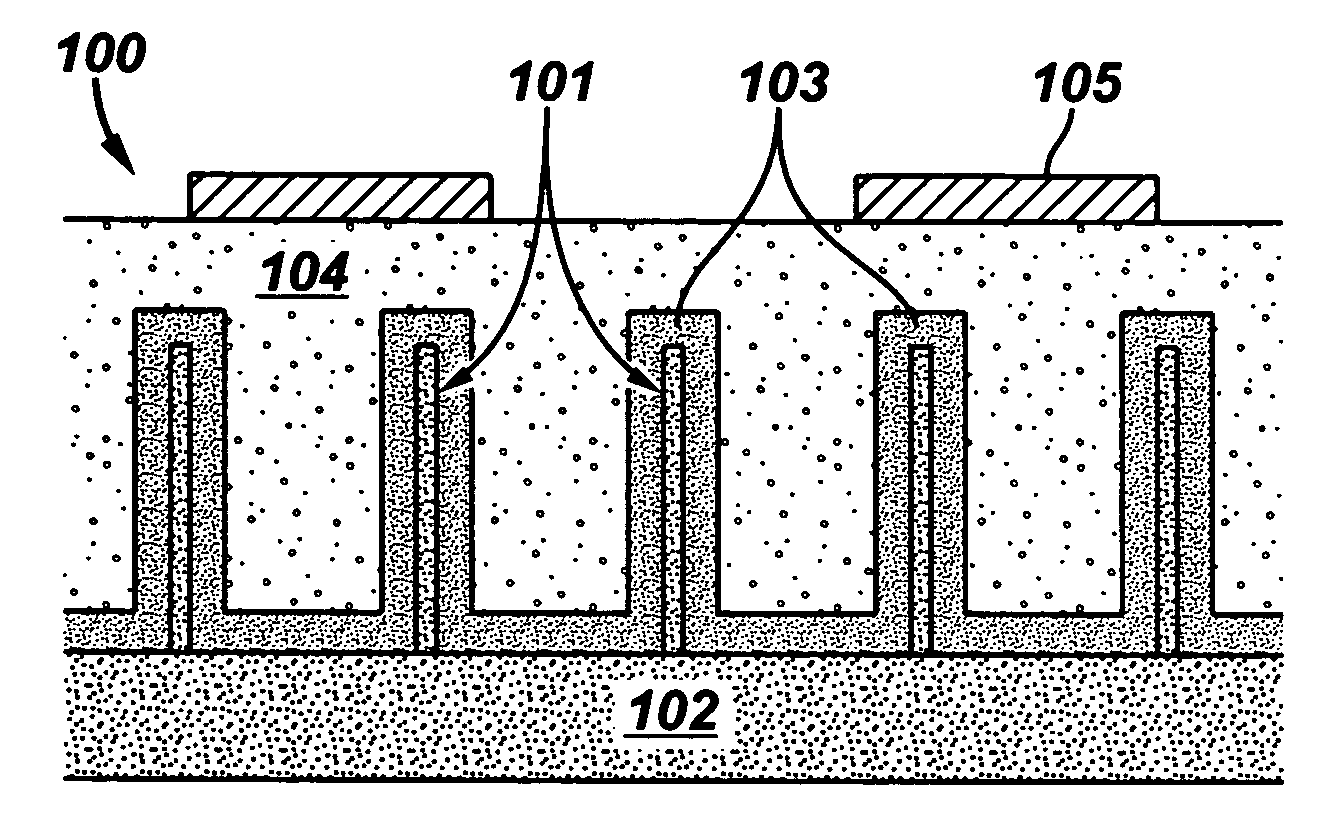

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveUS20060057350A1Less spreadingWide applicationSynthetic resin layered productsFilament/thread formingPolymer sciencePolymer alloy

The present invention provides an aggregate of nanofibers having less spread of single fiber fineness values that can be used in wide applications without limitation to the shape and the kind of the polymer, and a method for manufacturing the same. The present invention is an aggregate of nanofibers made of a thermoplastic polymer having single fiber fineness by number average in a range from 1×10−7 to 2×10−4 dtex and single fibers of 60% or more in fineness ratio have single fiber fineness in a range from 1×10−7 to 2×10−4 dtex.

Owner:TORAY IND INC

Graded hybrid amorphous silicon nanowire solar cells

InactiveUS20080135089A1Raise VocIncrease IscPV power plantsSemiconductor/solid-state device manufacturingAmorphous siliconSilicon nanowires

In some embodiments, the present invention is directed to compositionally-graded hybrid nanostructure-based photovoltaic devices comprising elongated semiconductor nanostructures and an amorphous semiconductor single layer with continuous gradation of doping concentration across its thickness from substantially intrinsic to substantially conductive. In other embodiments, the present invention is directed to methods of making such photovoltaic devices, as well as to applications which utilize such devices (e.g., solar cell modules).

Owner:GENERAL ELECTRIC CO

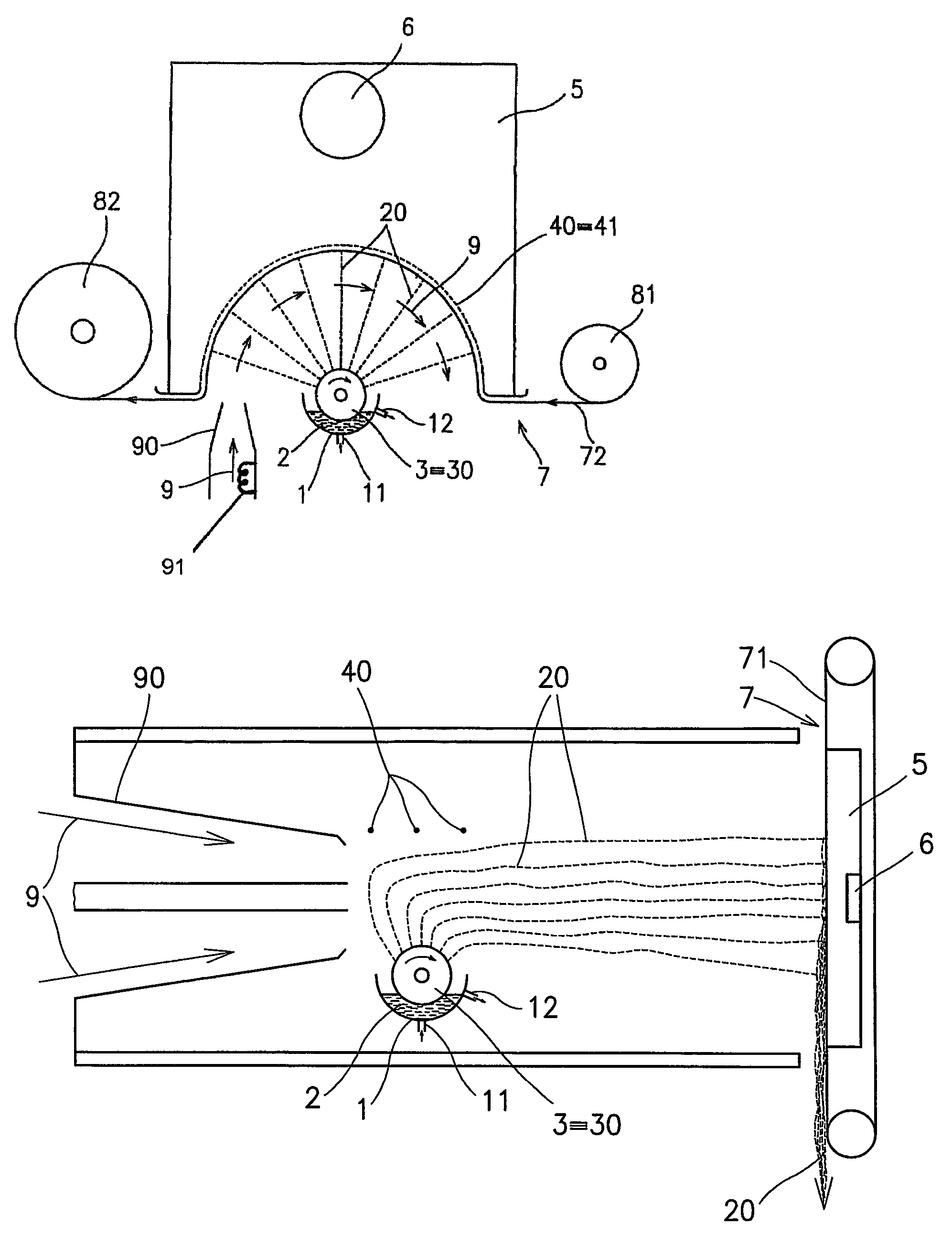

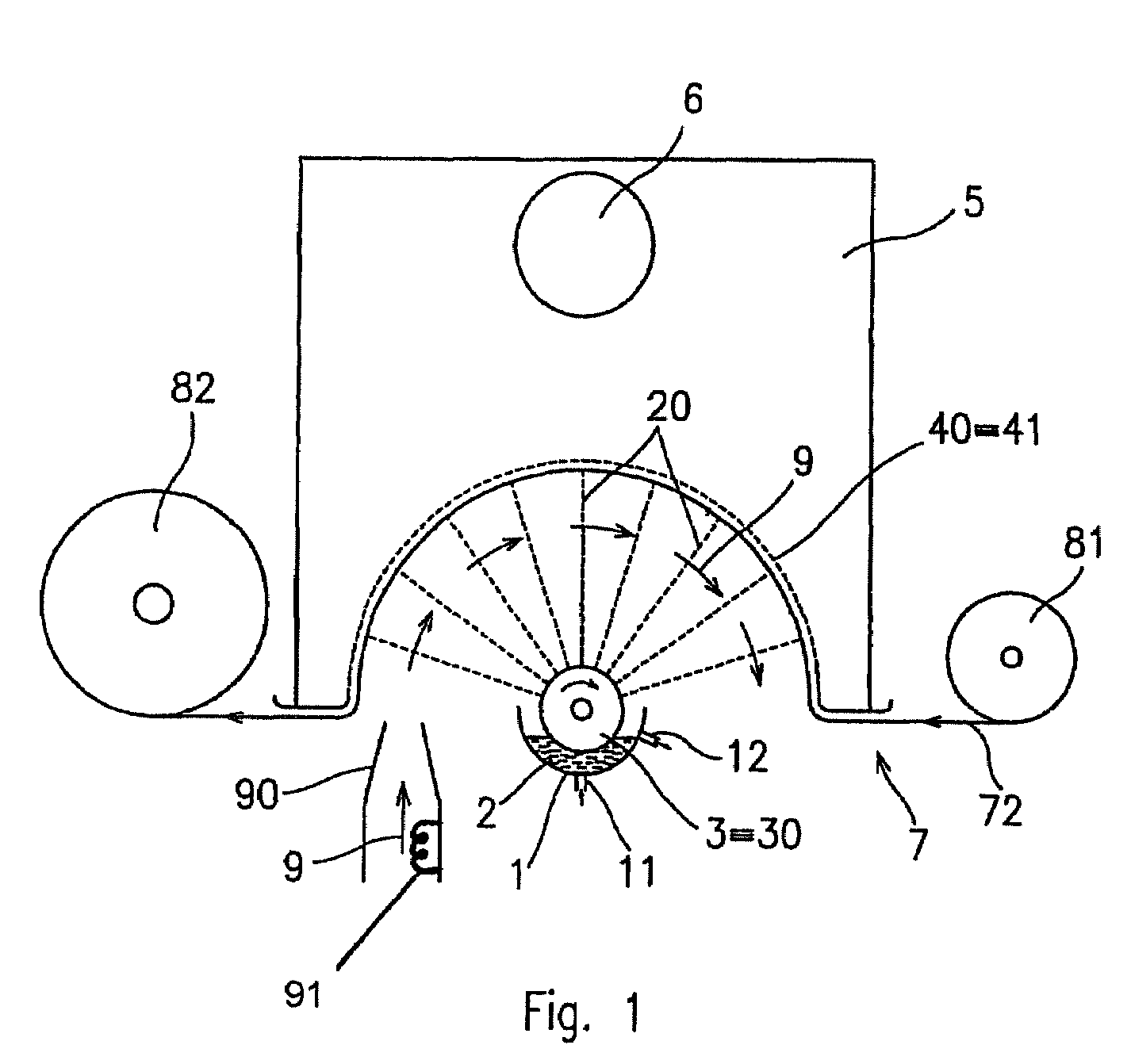

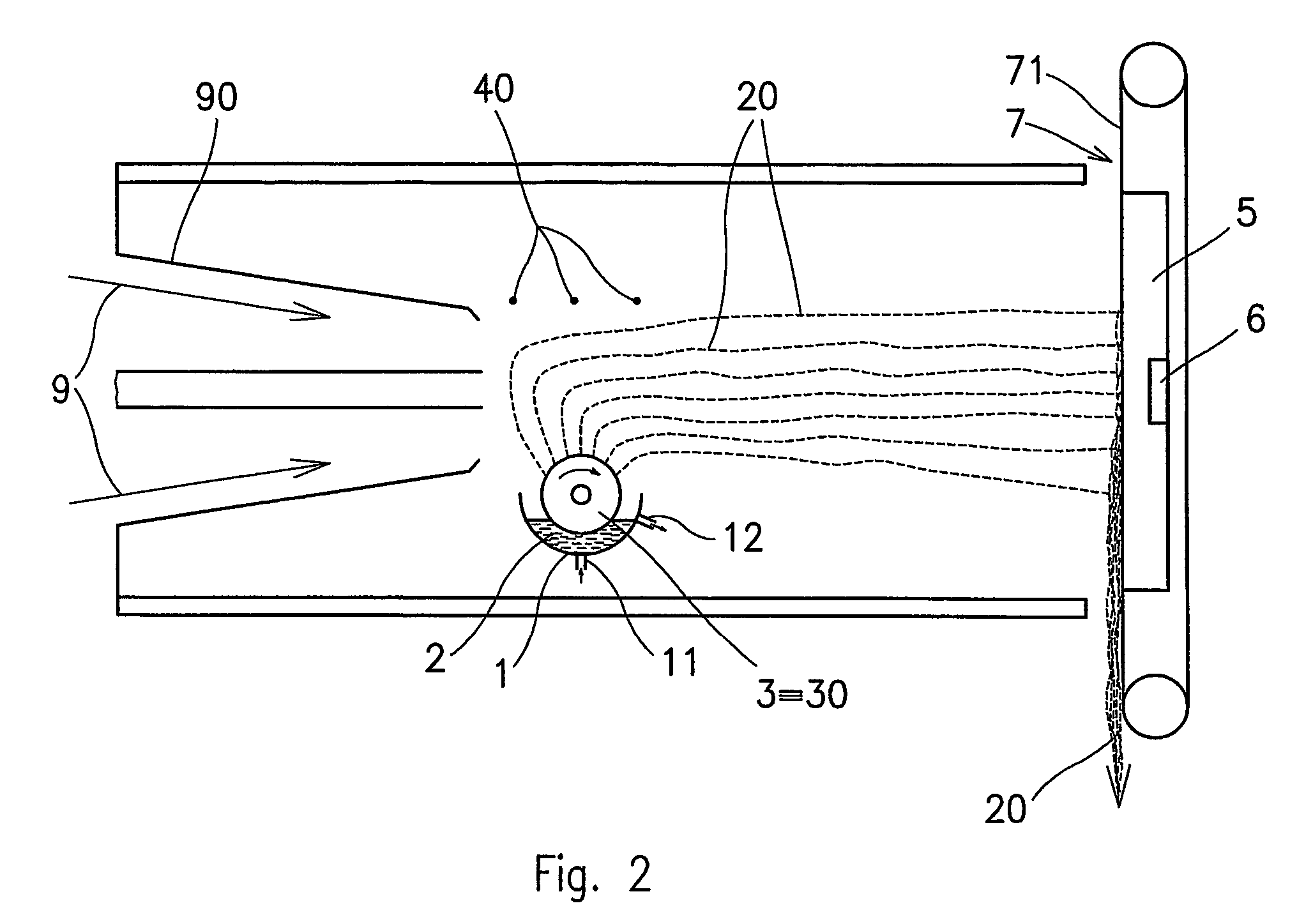

Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

ActiveUS7585437B2High quality and uniformity of layerSpinnerette packsNanotechnologyPotential differenceElectrospinning

A method of nanofibers production from a polymer solution uses electrostatic spinning in an electric field created by a potential difference between a charged electrode and a counter electrode. The polymer solution for spinning is supplied into the electric field using the surface of a rotating charged electrode. On a part of the circumference of the charged electrode near to the counter electrode, a spinning surface is created for attaining a high spinning capacity. In a device for carrying out the method, the charged electrode is pivoted and part of its circumference is immersed in the polymer solution. The free part of the circumference of the charged electrode is positioned opposite the counter electrode.

Owner:TECHNICKA UNIVEZITA V LIBERCI

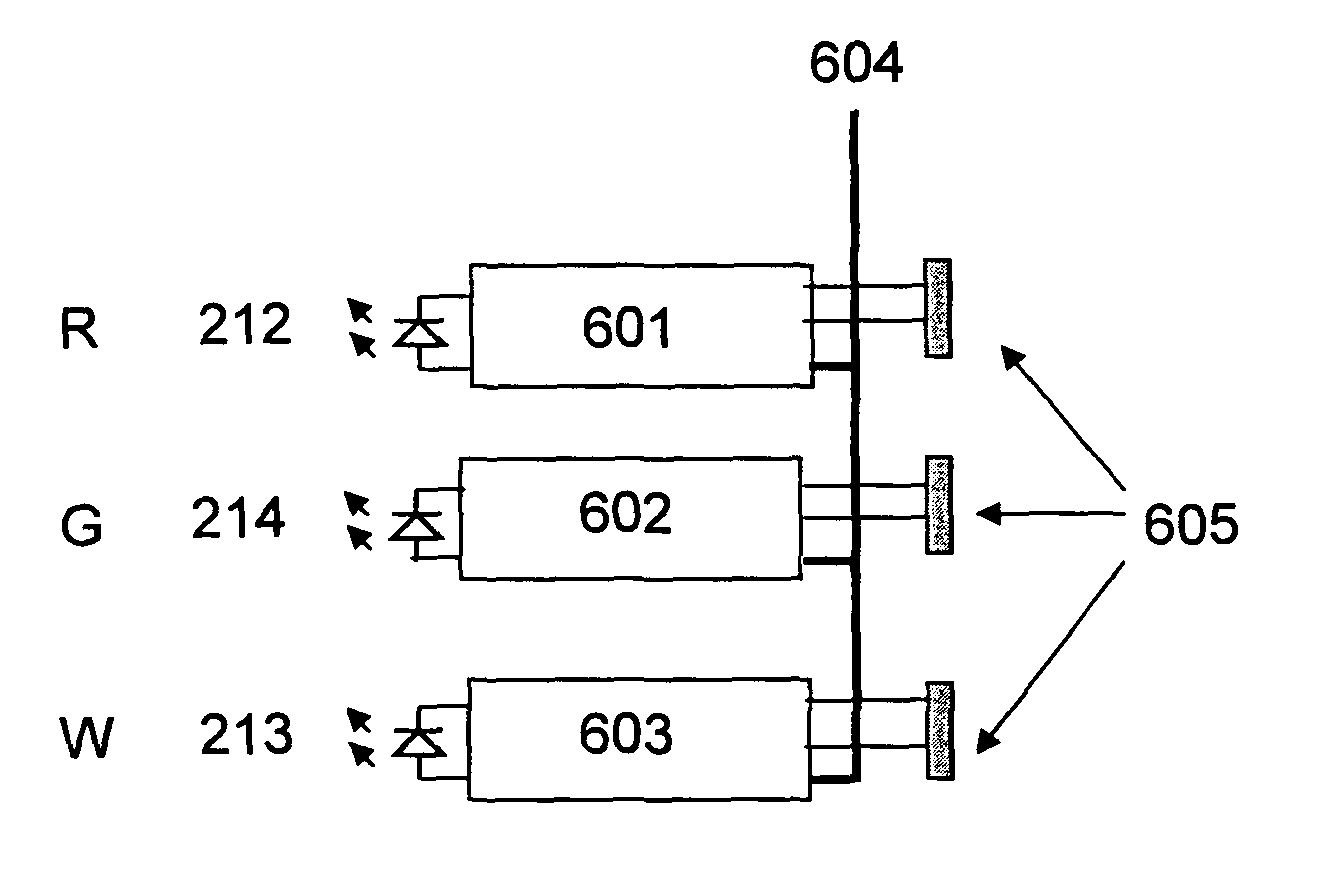

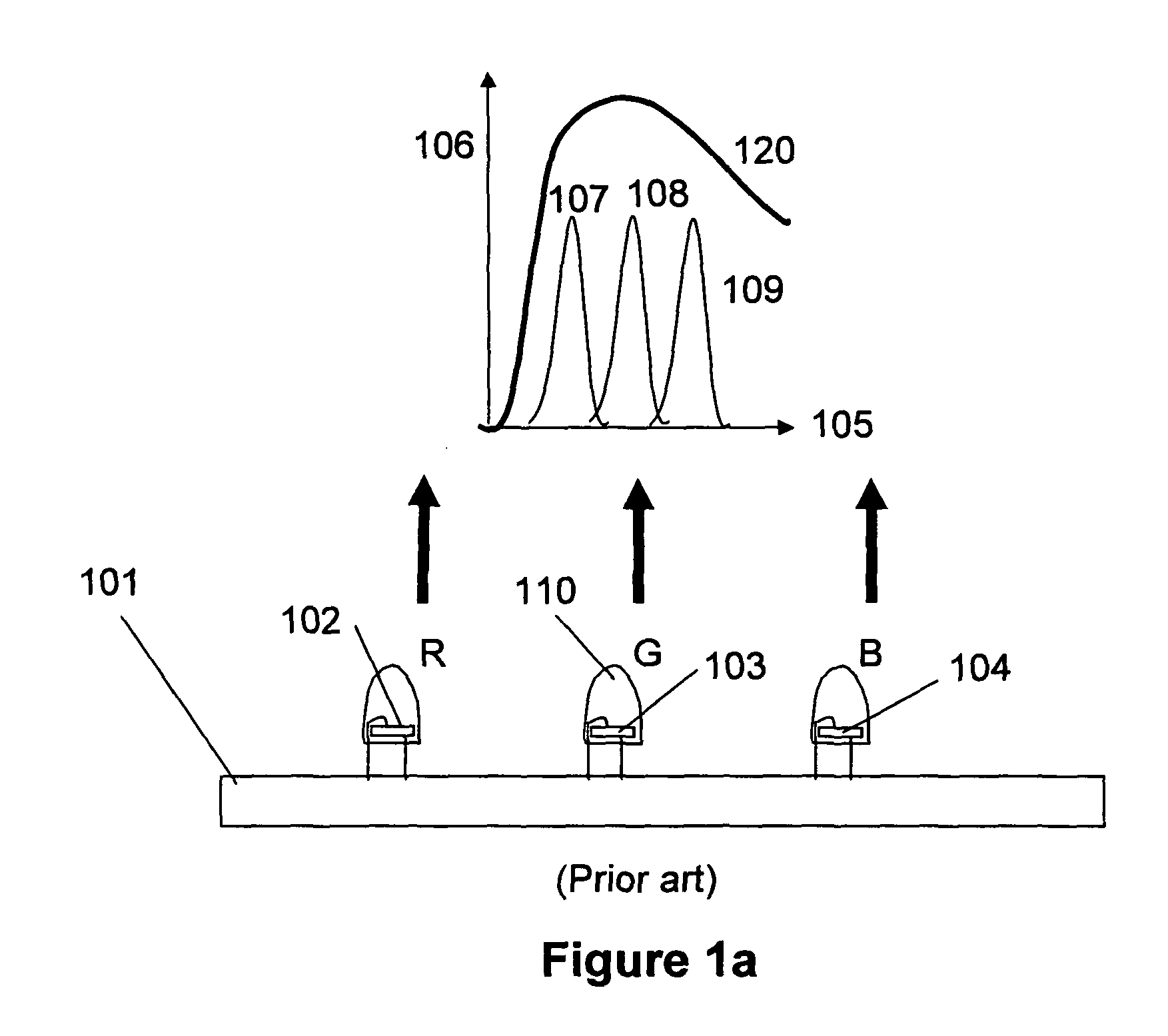

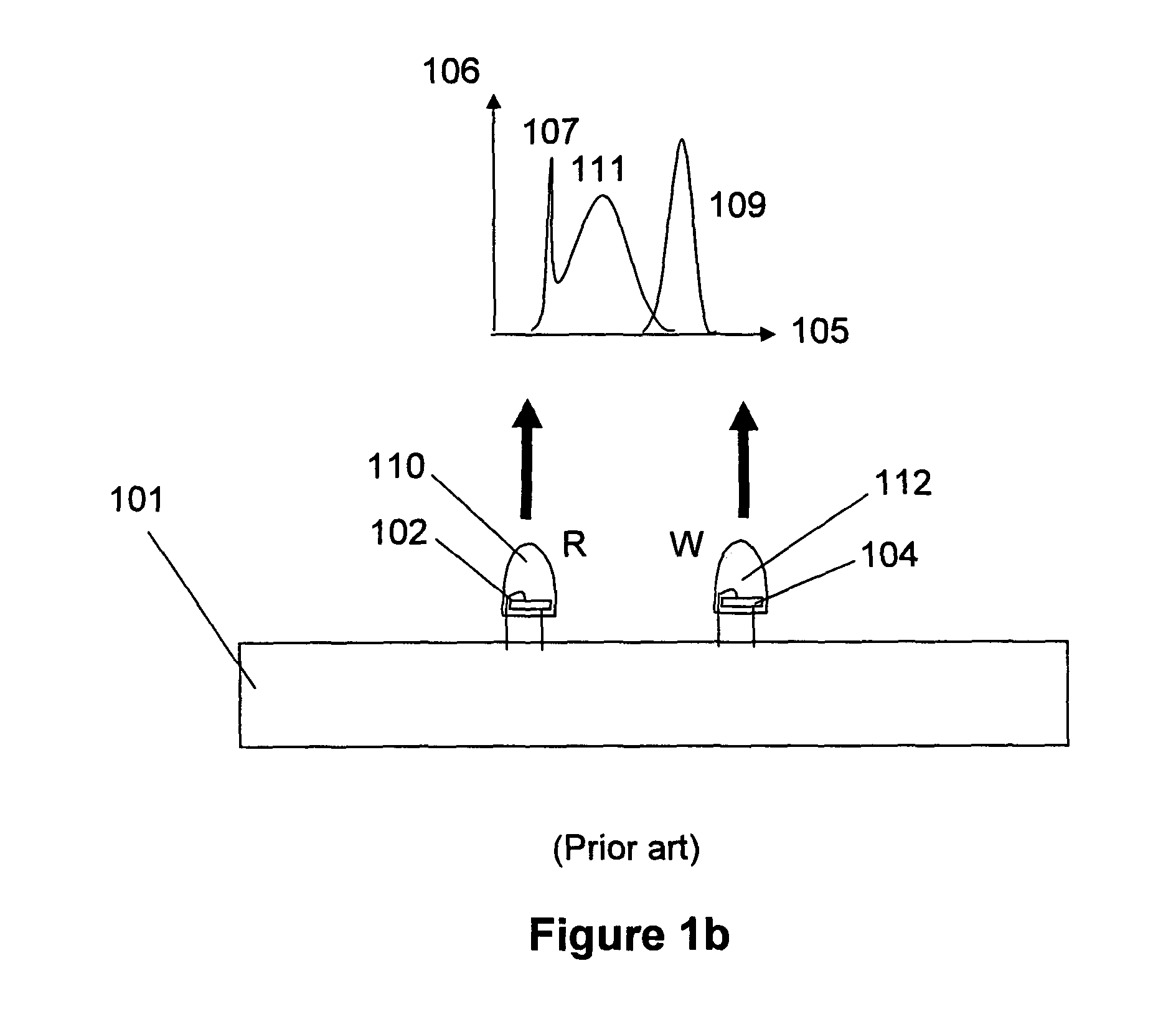

Tunable colour LED module

InactiveUS20110133654A1Low costUniform chromaticity propertyElectroluminescent light sourcesSolid-state devicesControl systemBiological activation

A tunable colour LED module comprises at least two sub-modules, each comprising an LED (104), a wavelength converting element (WCE) (201, 112, 203) and a reflector cup. The total light emitted by the module comprises light generated from each LED and WCE and the module is configured to emit a total light having a predefined colour chromaticity when activation properties of the LEDs are managed appropriately. The total light may have a broad white emission spectrum (106). The module combines the benefits of a low cost with uniform chromaticity properties in the far field, and offers long and controlled lifetime at the same time as flexibility and intelligence of tunable colour chromaticity, Colour Rendering Index (CRI) and intensity, either at manufacture or in an end user lighting application. A controlled LED module system comprises a control system for the managing activation properties of the LEDs in the sub-modules. Also described is a method of manufacture.

Owner:PHOTONSTAR LED

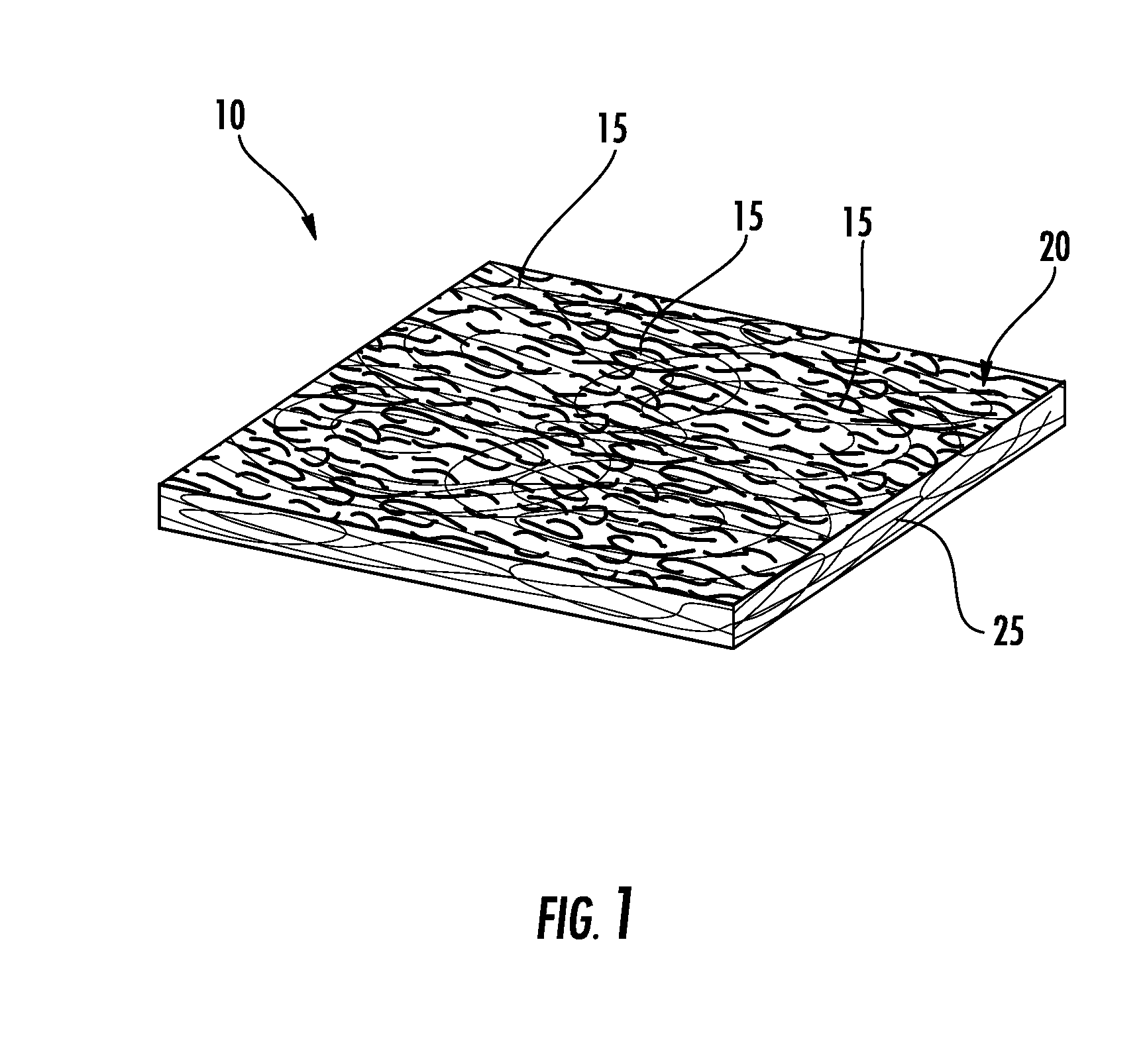

Methods of Applying Skin Wellness Agents to a Nonwoven Web Through Electrospinning Nanofibers

Generally, the present invention is directed to, in one embodiment, a method for forming a composite nonwoven web configured to deliver skin wellness agents to the skin of a user. According to the method, an aqueous system of a hydrophilic polymer and a skin wellness agent is formed. The aqueous system is then electrospun onto a surface of a nonwoven web containing synthetic fibers. The resulting nanofibers have an average diameter of from about 50 nanometers to about 5000 nanometers, such as from about 200 nanometers to about 700 nanometers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Structure and method for enhancing interfacial perpendicular anisotropy in CoFe(B)/MgO/CoFe(B) Magnetic Tunnel Junctions

ActiveUS20120135273A1Magnetic materials for record carriersVacuum evaporation coatingSwitched currentPerpendicular anisotropy

A STT-RAM MTJ is disclosed with a MgO tunnel barrier formed by natural oxidation process. A Co10Fe70B20 / NCC / Co10Fe70B20, Co10Fe70B20 / NCC / Co10Fe70B20 / NCC, or Co10Fe70B20 / NCC / Co10Fe70B20 / NCC / Co10Fe70B20 free layer configuration where NCC is a nanocurrent channel layer made of Fe(20%)-SiO2 is used to minimize Jc0 while enabling higher thermal stability, write voltage, read voltage, Ho, and Hc values that satisfy 64 Mb design requirements. The NCC layer is about 10 Angstroms thick to match the minimum Fe(Si) grain diameter size. The MTJ is annealed with a temperature of about 330° C. to maintain a high magnetoresistive ratio while maximizing Hk⊥(interfacial) for the free layer thereby reducing Heff and lowering the switching current. The Co10Fe70B20 layers are sputter deposited with a low pressure process with a power of about 15 Watts and an Ar flow rate of 40 standard cubic centimeters per minute to lower Heff for the free layer.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com