Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

652results about How to "Improve fracture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curable flame retardant epoxy compositions

InactiveUS6887574B2Improve fracture resistanceModulus is reducedSynthetic resin layered productsPrinted circuit aspectsEpoxyHigh fracture

A curable flame retardant epoxy resin composition including (a) at least one flame retardant epoxy resin; (b) at least one amphiphilic block copolymer; and (c) a curing agent. Such components are present in the curable composition in the appropriate amounts and ratios such that, upon curing, the block copolymer self-assembles into a nano structure morphology, such as a worm-like micelle morphology. The resulting cured product made from the composition of the present invention has a remarkably increased high fracture resistance; and allows the use of flame retardant epoxies in applications where fracture resistance is an issue.

Owner:RGT UNIV OF MINNESOTA

Drug formulations

InactiveUS20120202838A1Improve fracture toughnessImprove fracture resistancePowder deliveryBiocideHigh fractureMedicine

In one embodiment, the present invention relates to abuse-deterrent drug formulations comprise a plurality of discrete domains uniformly dispersed in a pharmaceutically acceptable matrix, wherein said domains have high fracture toughness and comprise at least one polymer and at least one abuse-relevant drug. In another embodiment, the present invention relates to a formulation comprising a plurality of discrete mechanically reinforcing particles uniformly dispersed in a pharmaceutically acceptable matrix, wherein said matrix has high fracture toughness and comprises at least one polymer and at least one active agent, at least one abuse-relevant drug or a combination of at least one active agent and at least one abuse-relevant drug.

Owner:ABBVIE INC

Glass substrates and methods of annealing the same

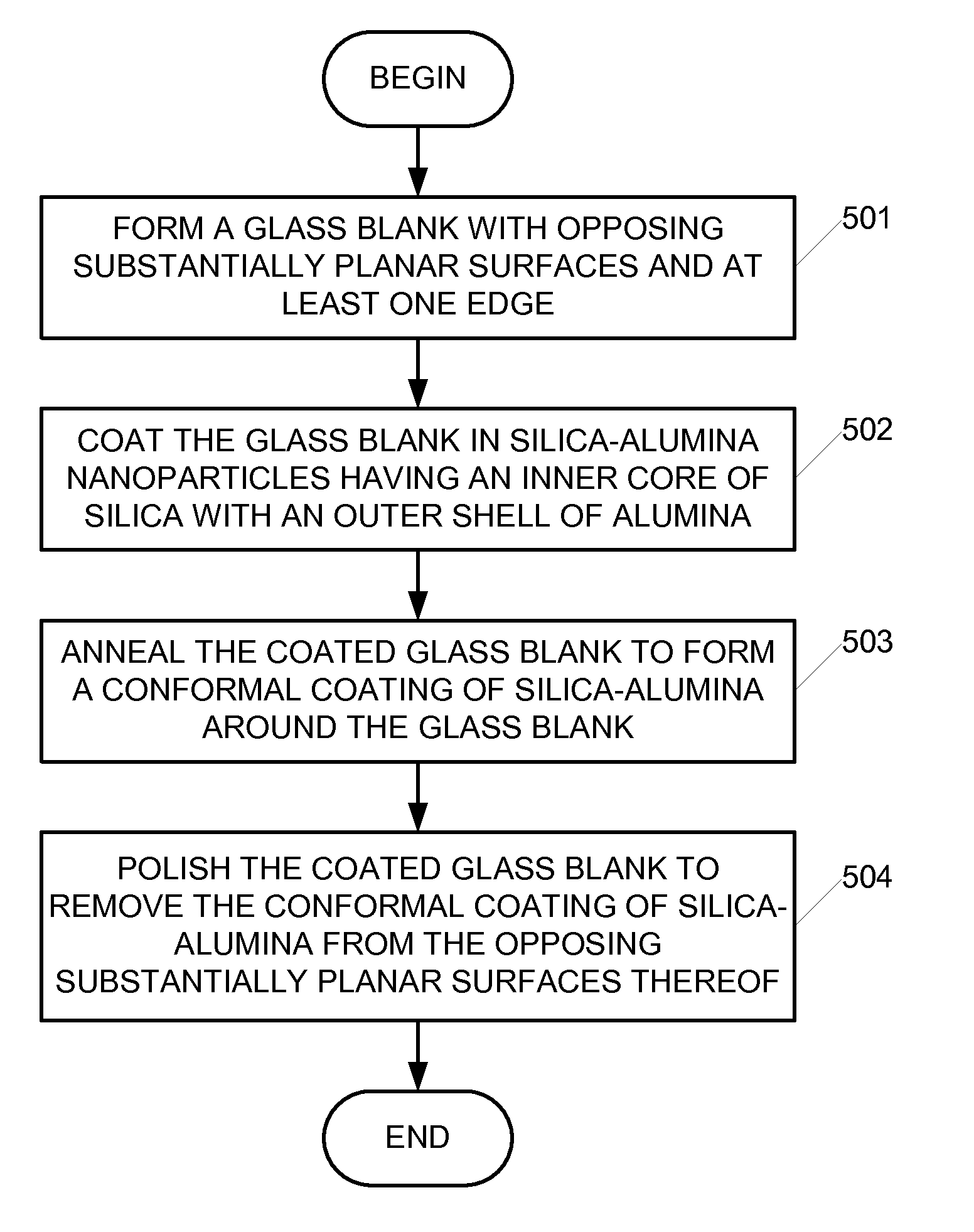

ActiveUS8206789B2Improve fracture resistanceDisc-shaped record carriersMagnetic materials for record carriersNanoparticleConformal coating

A method for forming a glass substrate comprises the steps of forming a glass blank with opposing substantially planar surfaces and at least one edge, coating the glass blank in silica-alumina nanoparticles, the silica-alumina nanoparticles comprising an inner core of silica with an outer shell of alumina, annealing the coated glass blank to form a conformal coating of silica-alumina around the glass blank, and polishing the coated glass blank to remove the conformal coating of silica-alumina from the opposing substantially planar surfaces thereof.

Owner:WESTERN DIGITAL TECH INC

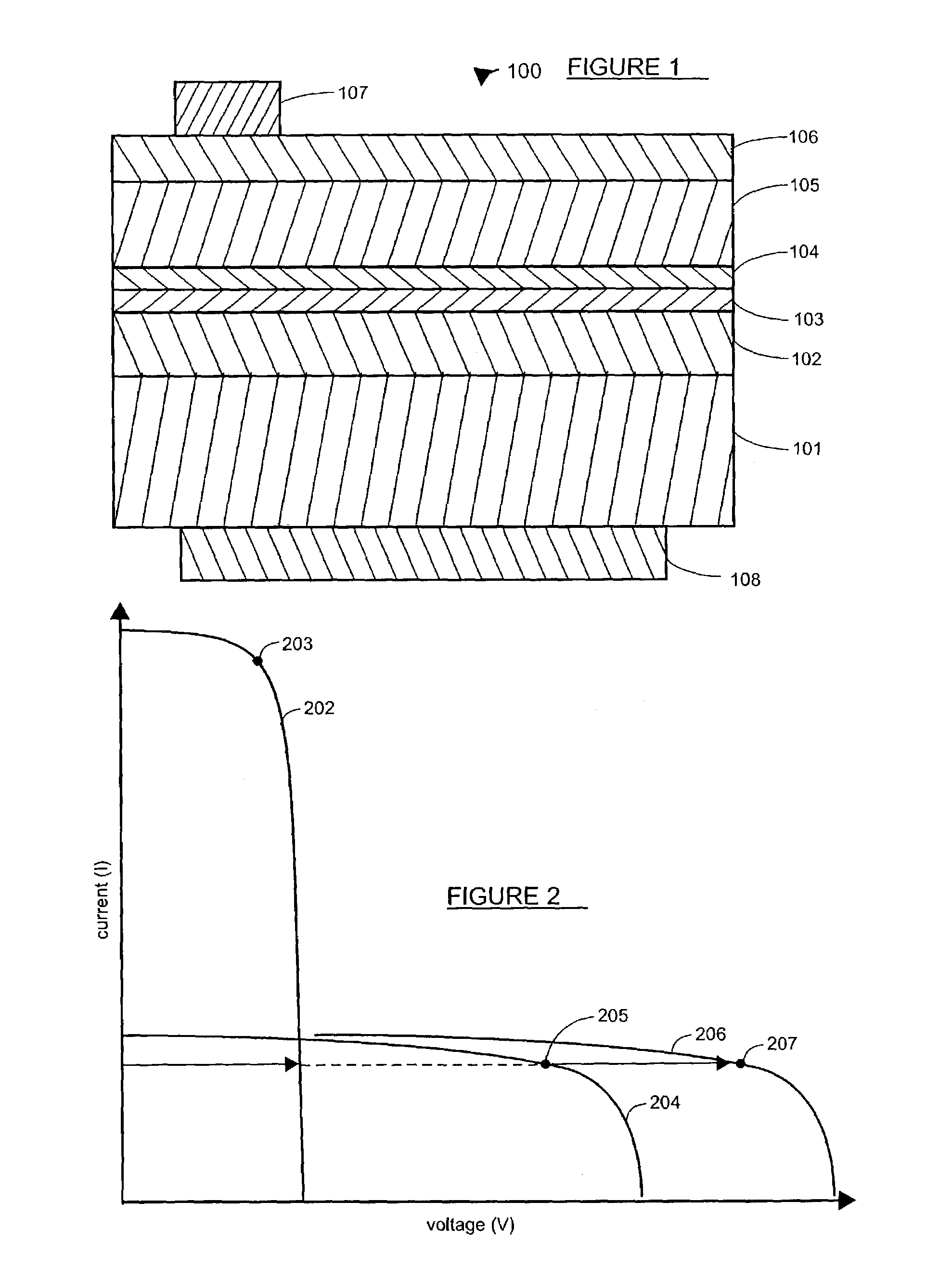

GaP/silicon tandem solar cell with extended temperature range

InactiveUS7148417B1Improve performanceHigh operating temperaturePhotovoltaic energy generationSemiconductor devicesTandem solar cellCrystalline silicon

A two-junction solar cell has a bottom solar cell junction of crystalline silicon, and a top solar cell junction of gallium phosphide. A three (or more) junction solar cell has bottom solar cell junctions of silicon, and a top solar cell junction of gallium phosphide. The resulting solar cells exhibit improved extended temperature operation.

Owner:NASA

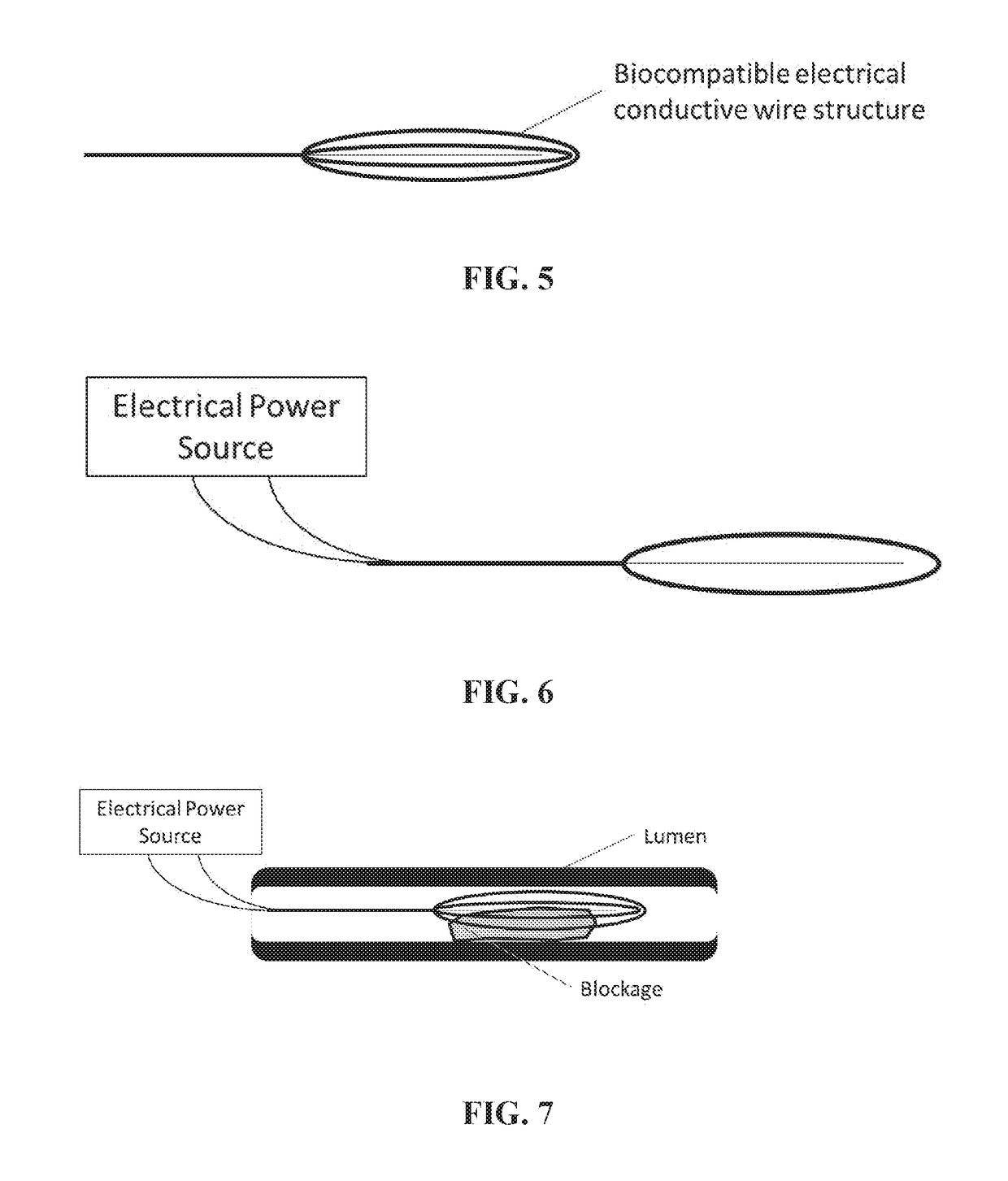

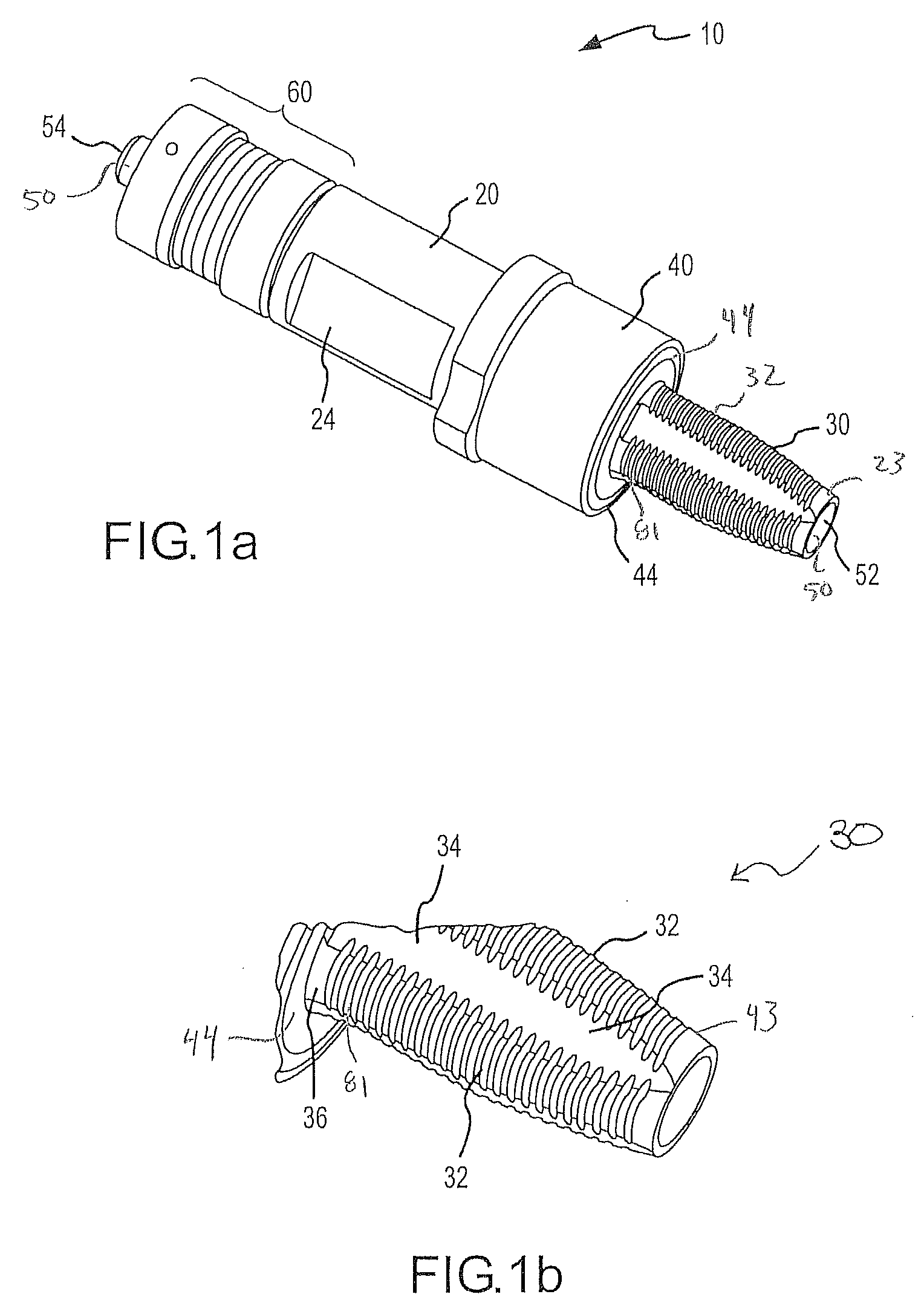

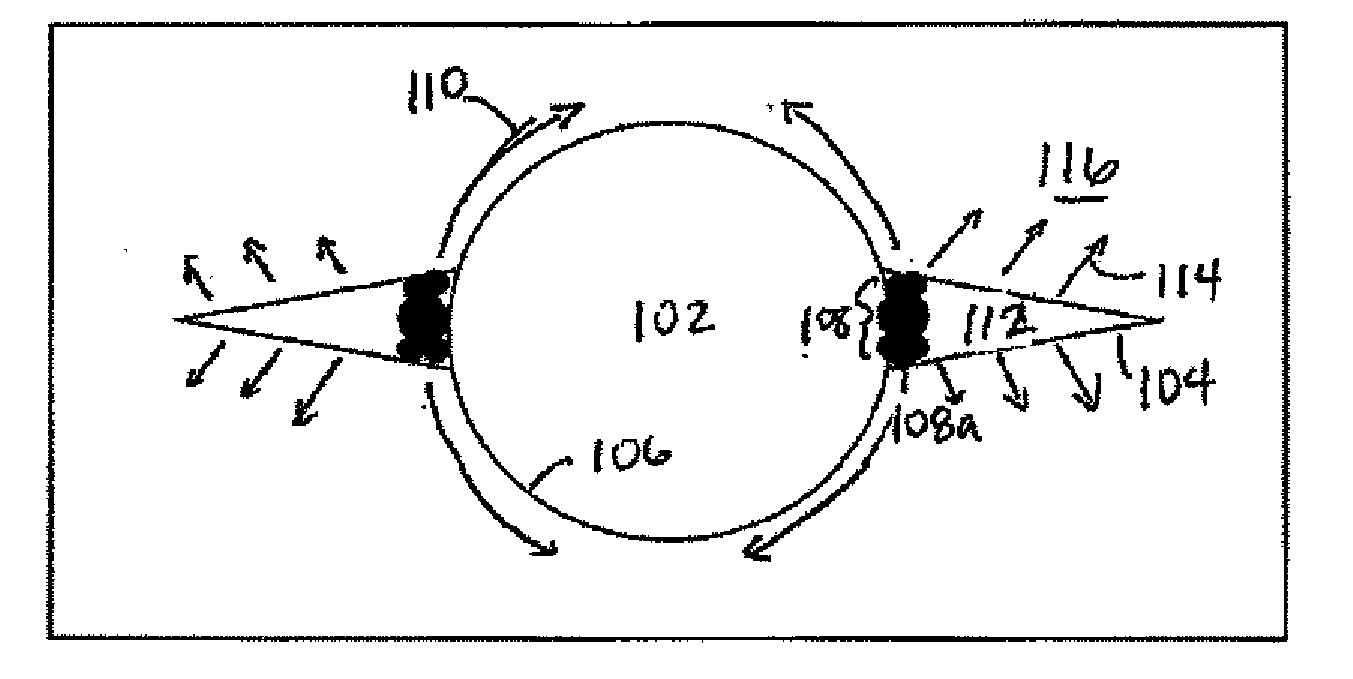

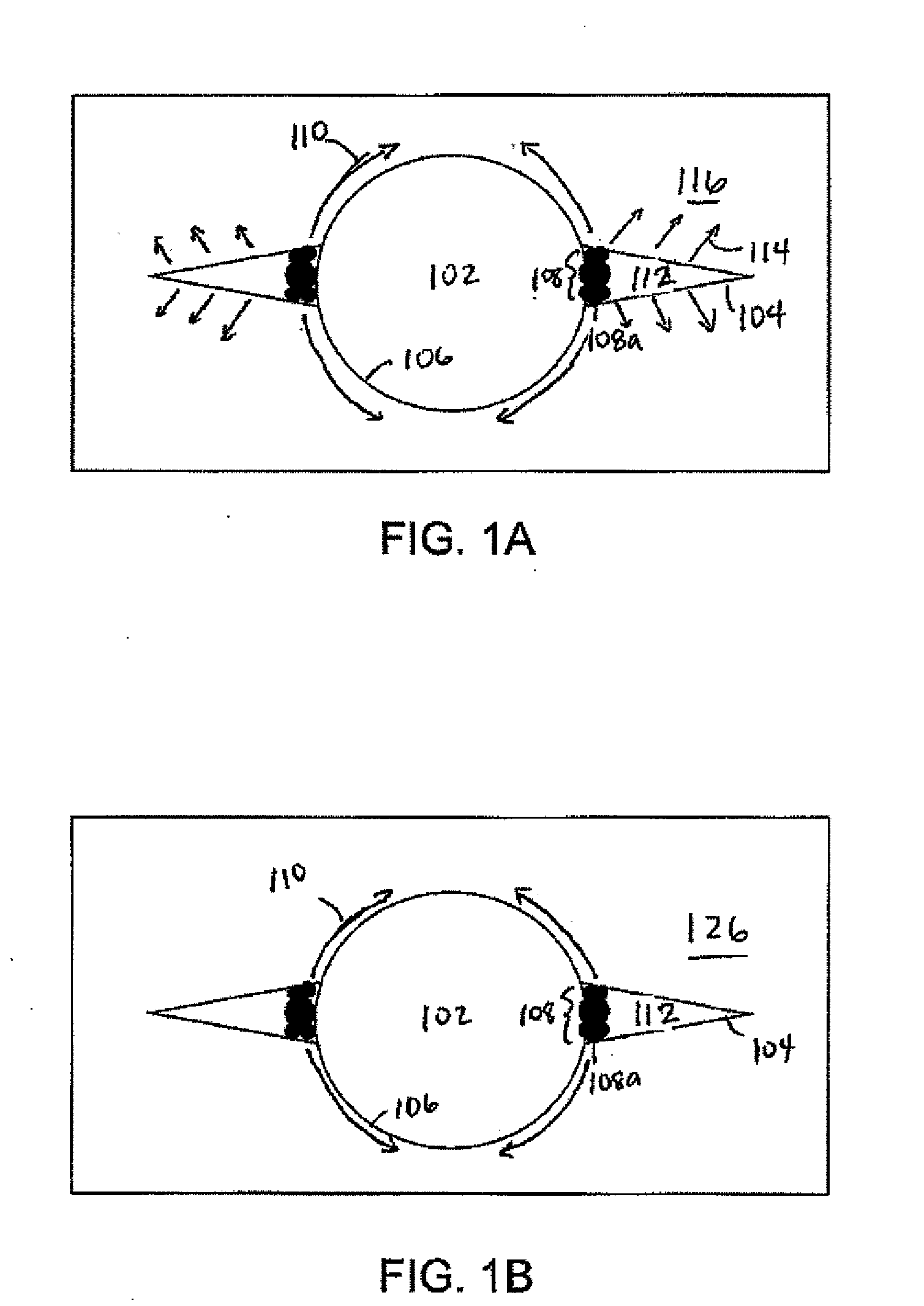

Radio frequency electro-thrombectomy device

ActiveUS20180140354A1Reduce riskImprove adhesionSurgical instruments for heatingCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumen blockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking density and interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage during the removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely captured during the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

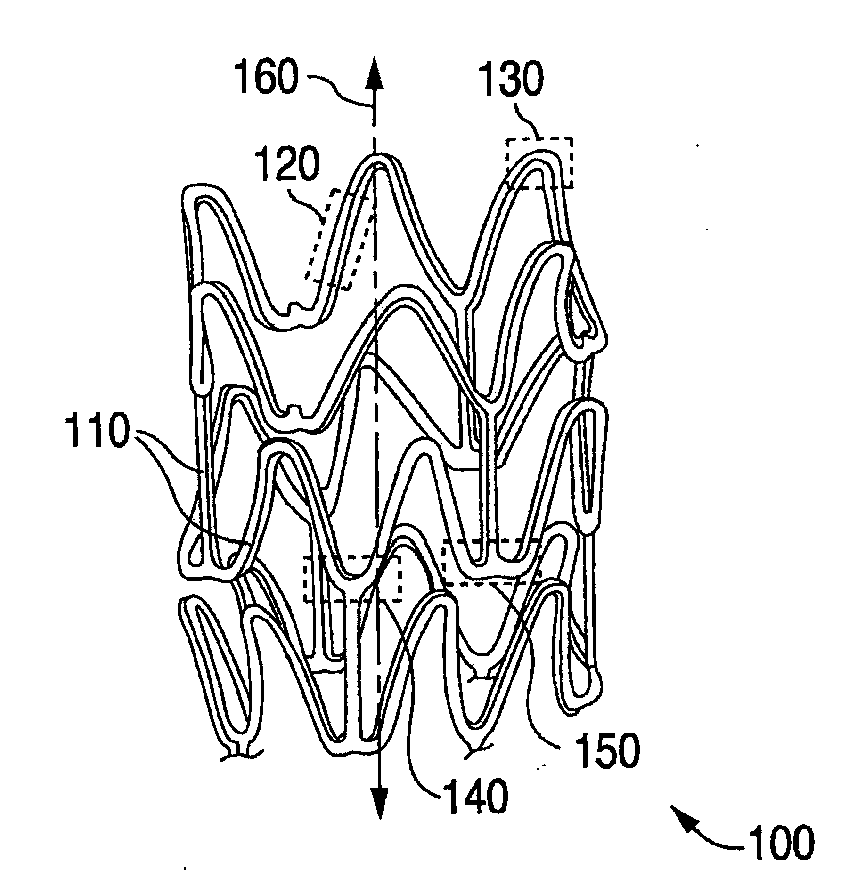

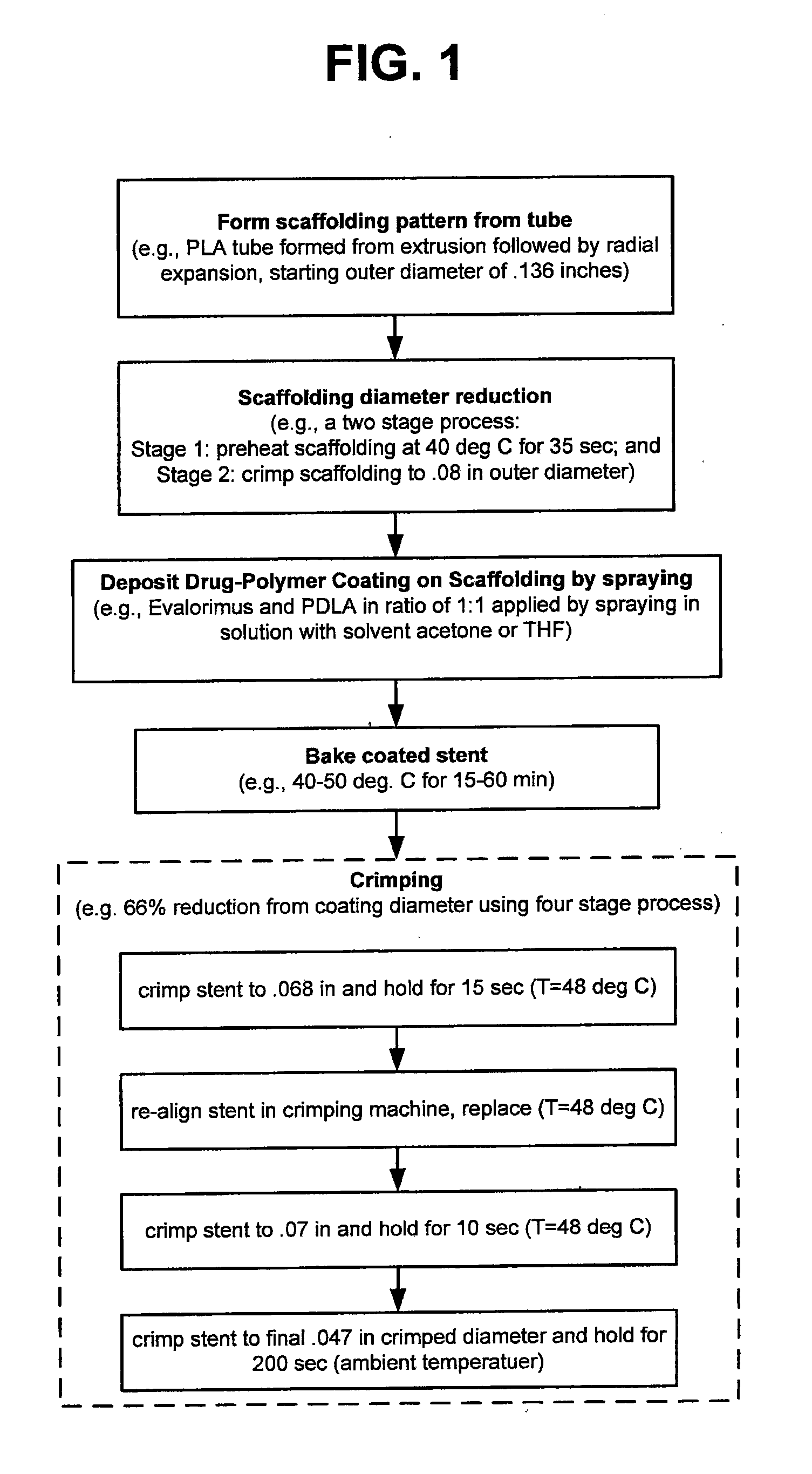

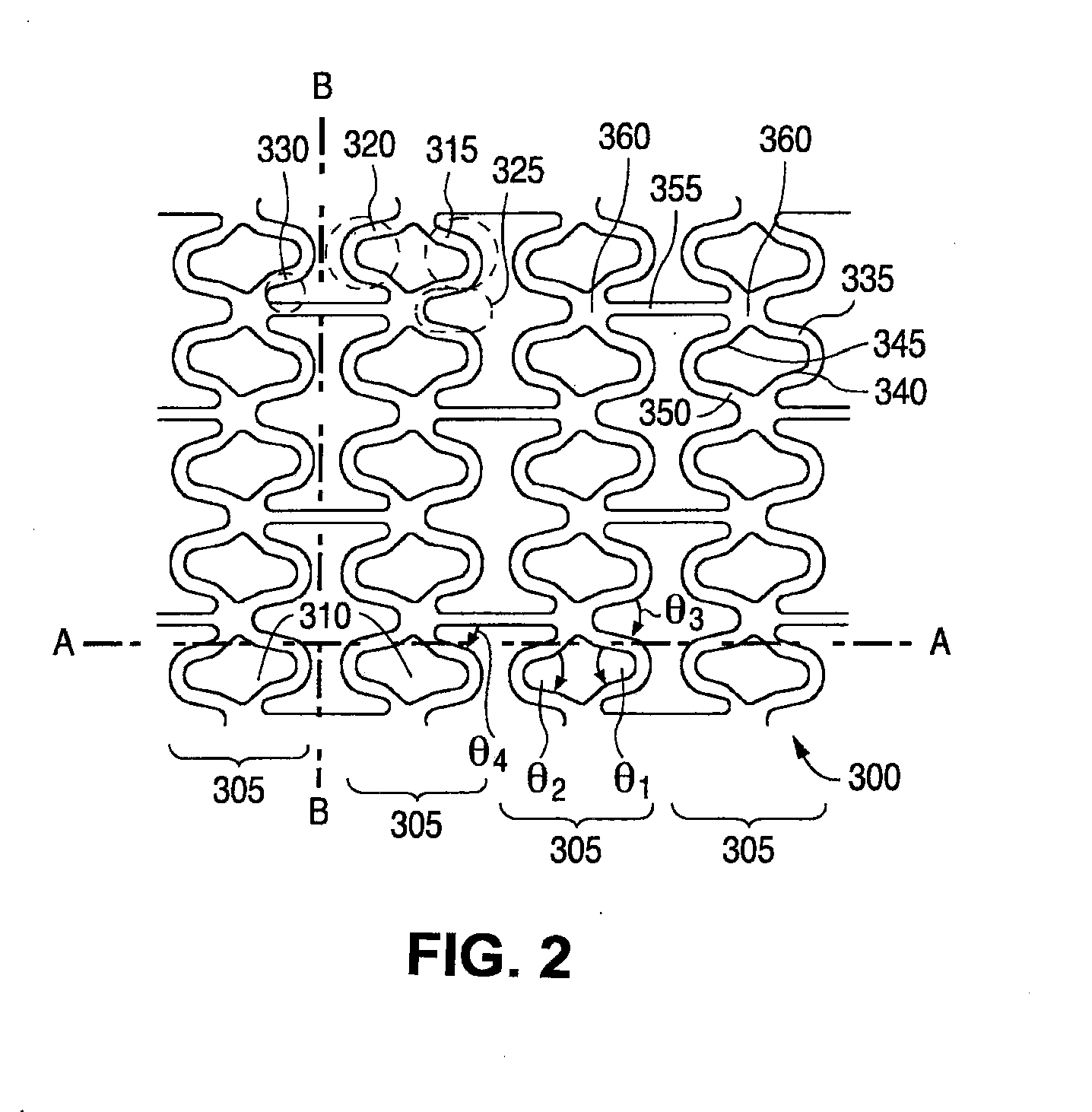

Methods To Increase Fracture Resistance Of A Drug-Eluting Medical Device

InactiveUS20100323091A1Improve fracture resistanceRelieve stress/strainStentsPharmaceutical containersPolymer coatingsMedical device

Owner:ABBOTT CARDIOVASCULAR

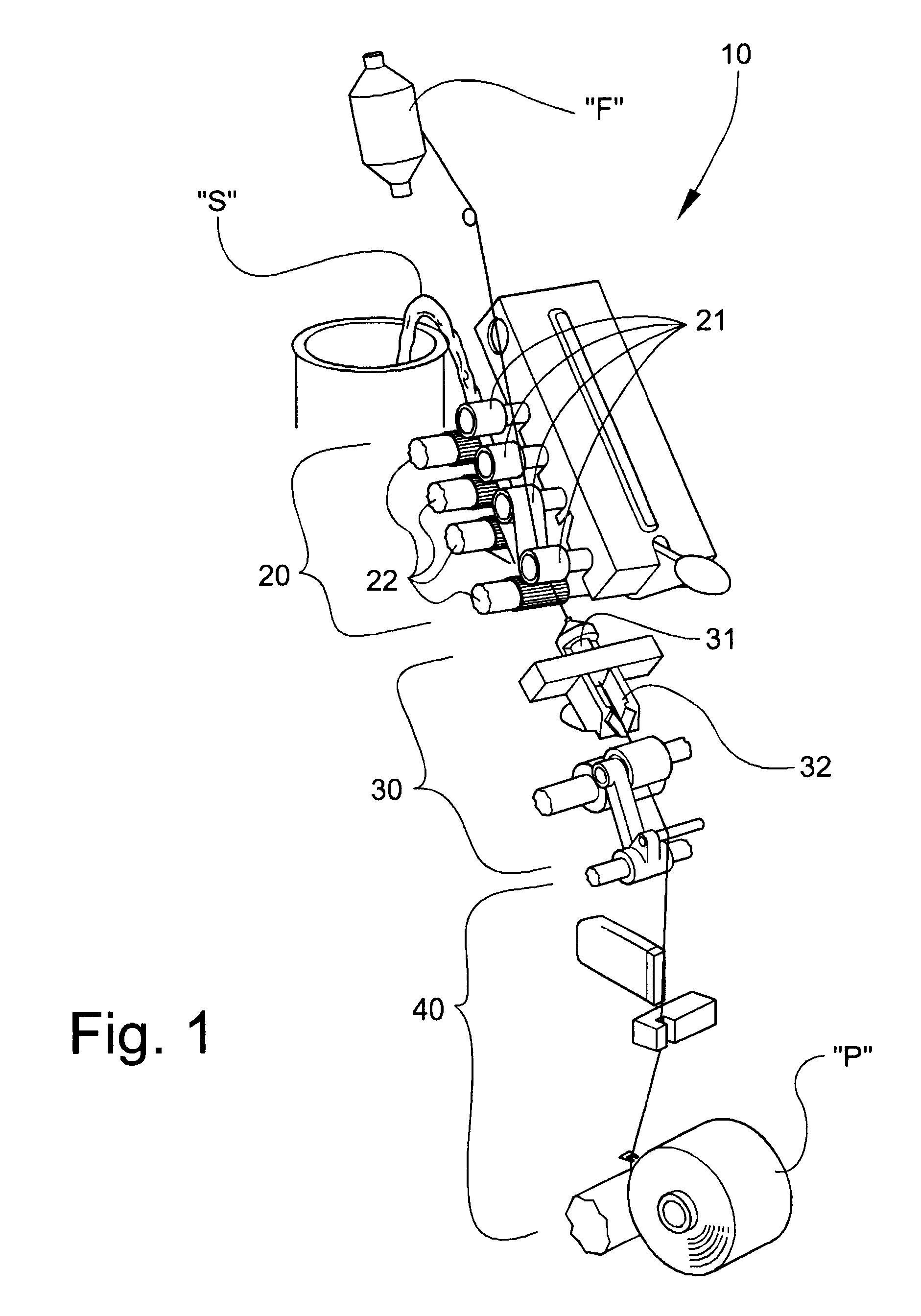

Composite, break-resistant sewing thread and method

InactiveUS6405519B1Improve fracture resistanceReduce tensionDrafting machinesContinuous wound-up machinesFiberYarn

A composite, break-resistant sewing thread having a core of continuous multi-filament, non-stretch high-tenacity synthetic yarn and a cover of drafted staple fibers air-jet twisted around and covering the core for protecting the core from heat and friction during a sewing operation. The yarn is plied.

Owner:BURKE MILLS

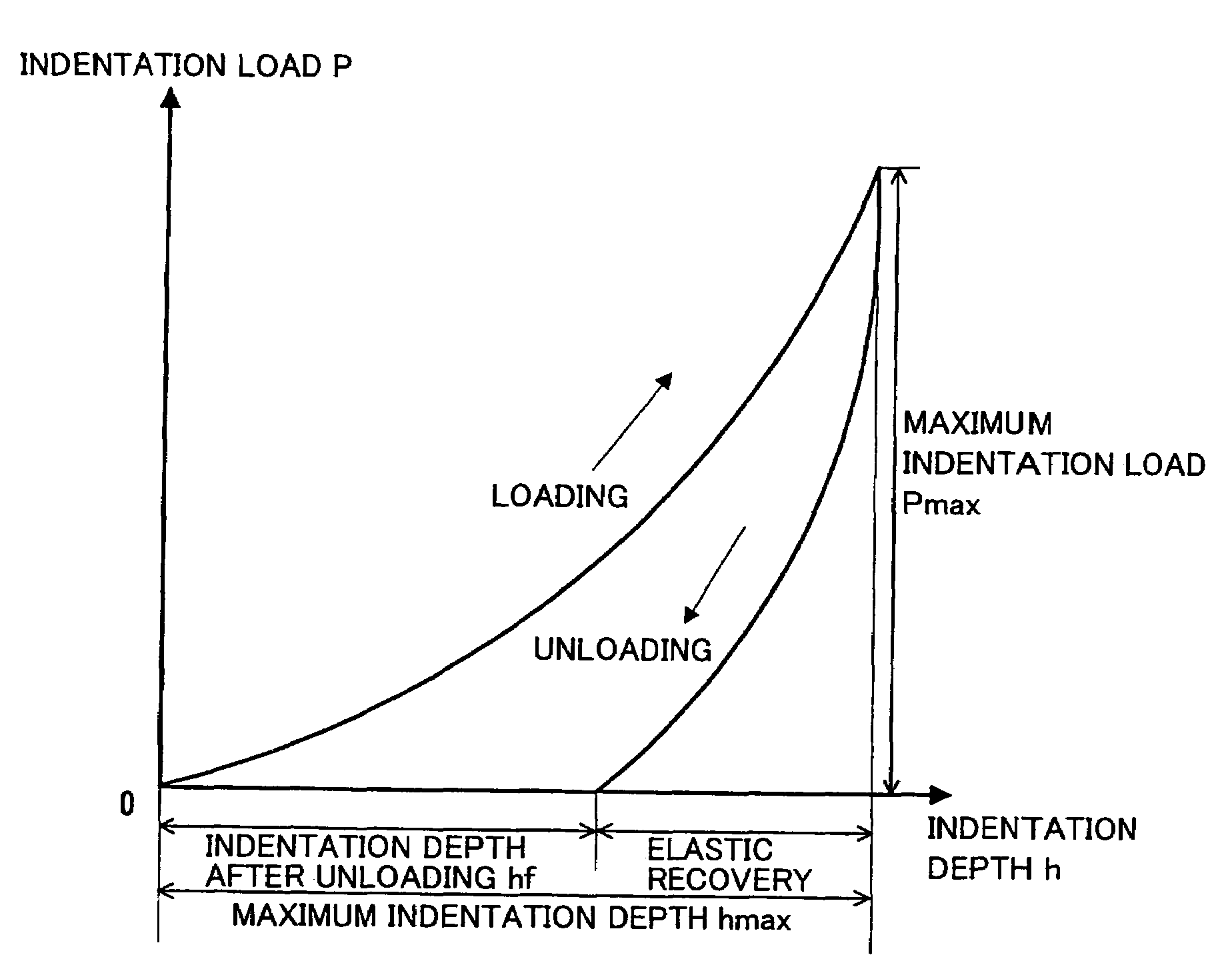

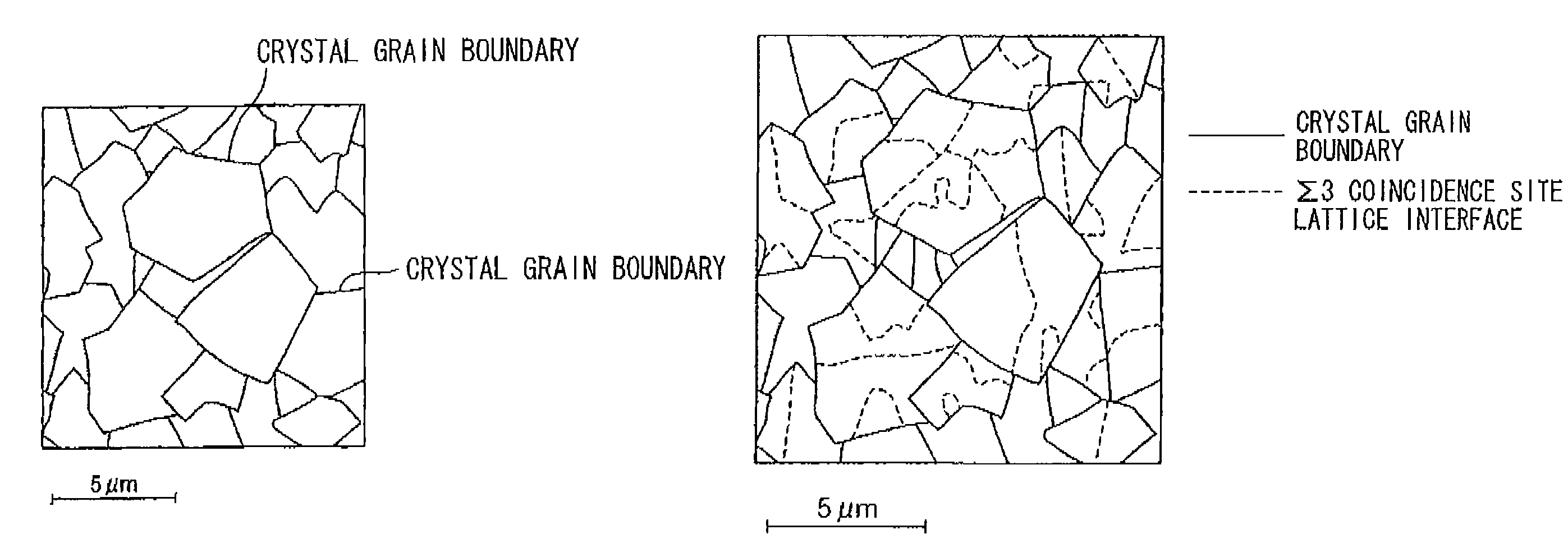

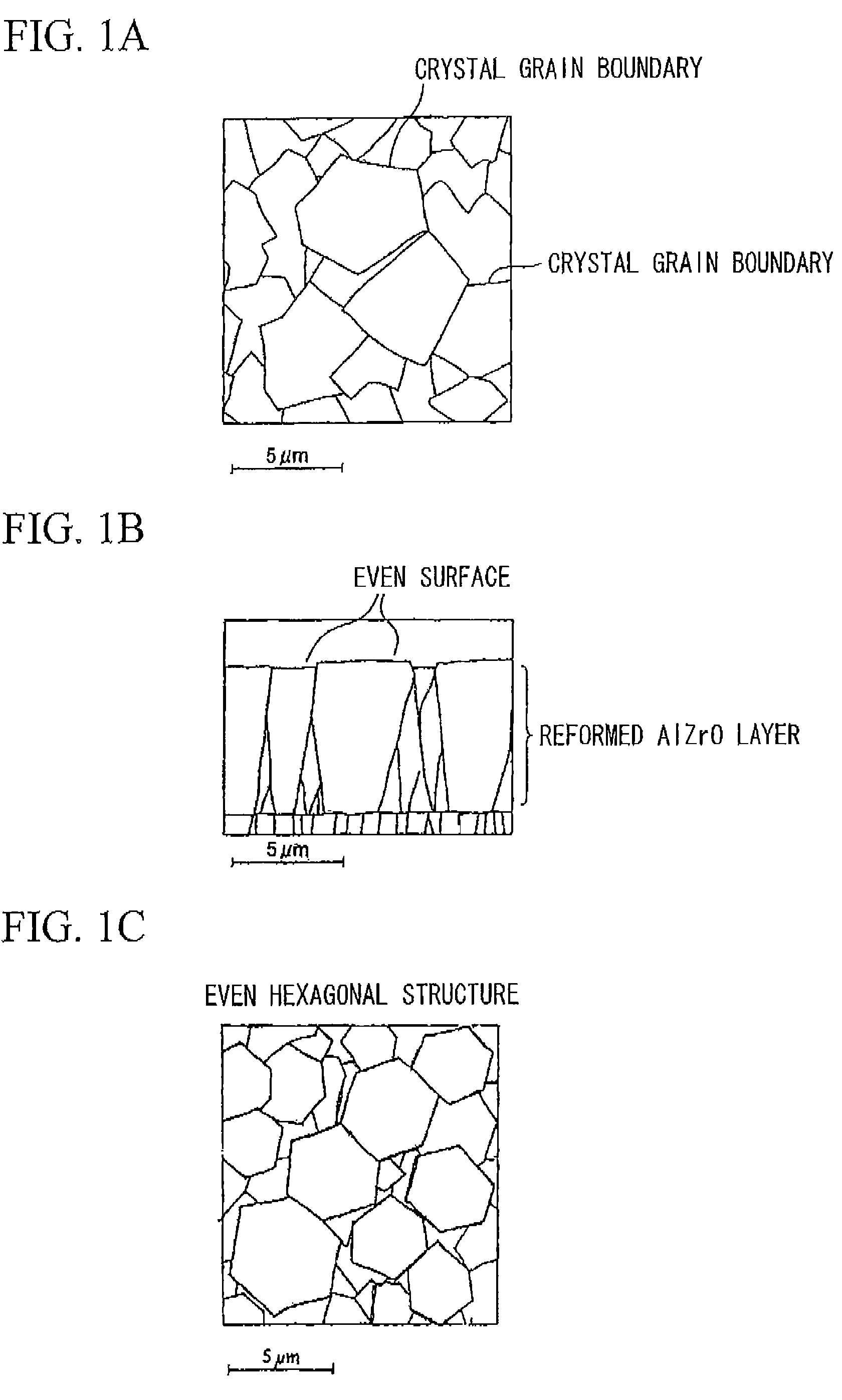

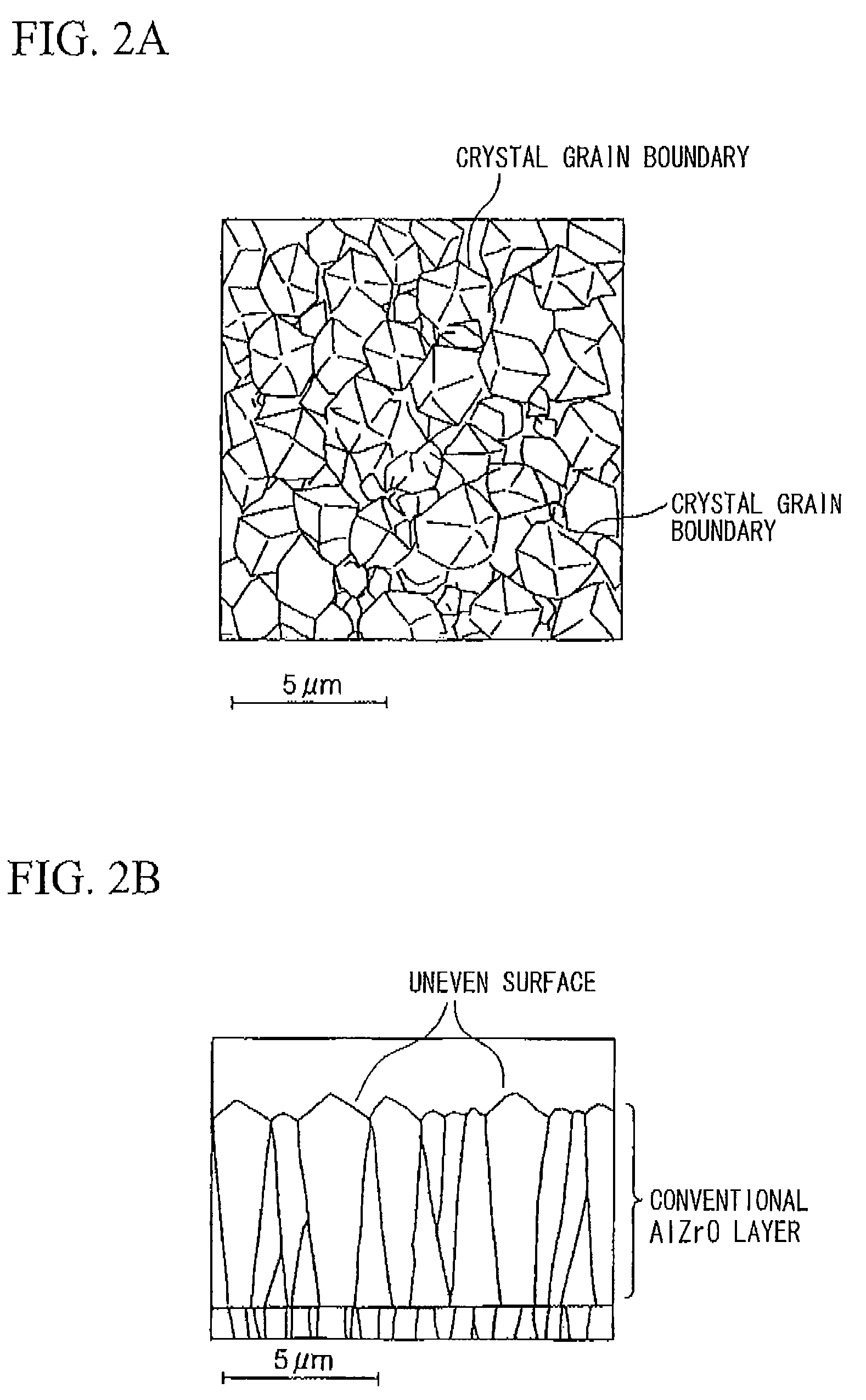

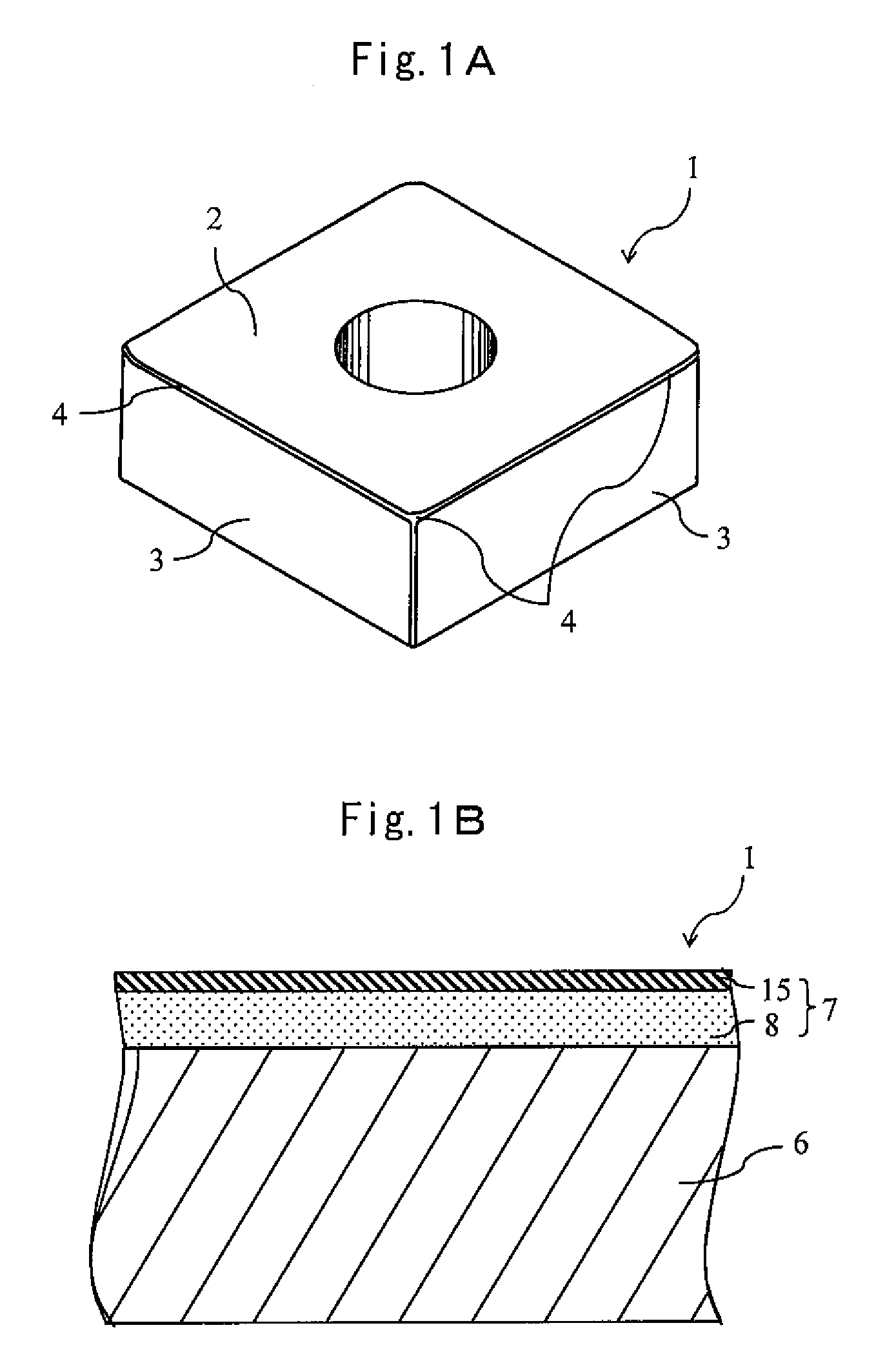

Surface-coated cutting tool

ActiveUS7410707B2Effectively inhibit the baseImprove fracture resistancePigmenting treatmentOther chemical processesHardnessNitrogen oxide

The present invention provides a surface-coated cutting tool comprising a coating film on a base, while the coating film comprises a hard layer constituted of a compound selected from a nitride, a carbonitride, an oxynitride and a carboxynitride of at least one primary element selected from a group consisting of the metals belonging to the groups 4a, 5a and 6a of the periodic table as well as B, Al and Si, and the hard layer satisfies the following: (a) (hmax−hf) / hmax is at least 0.2 and not more than 0.7, assuming that hmax represents the maximum indentation depth and hf represents the indentation depth (dent depth) after unloading in a hardness test according to nanoindentation, (b) the thickness of the hard layer is at least 0.5 μm and not more than 15 μm, and (c) the hardness according to nanoindentation is at least 20 GPa and not more than 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

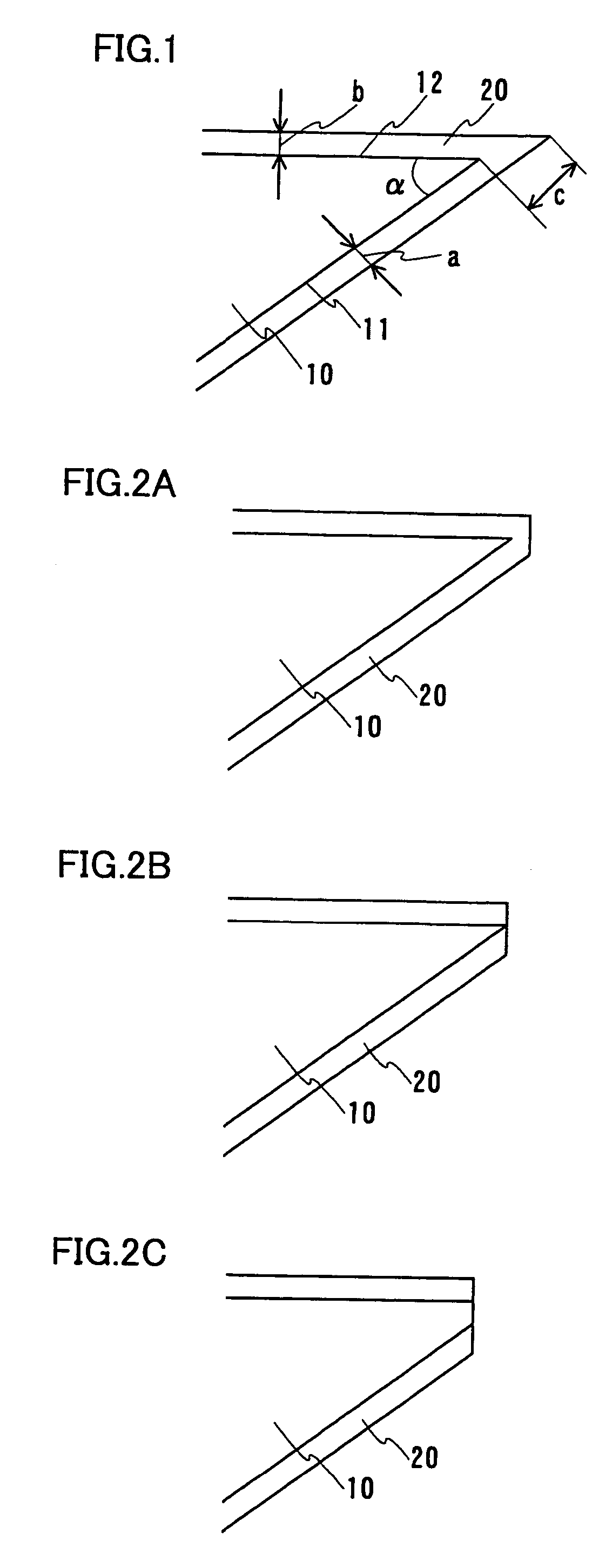

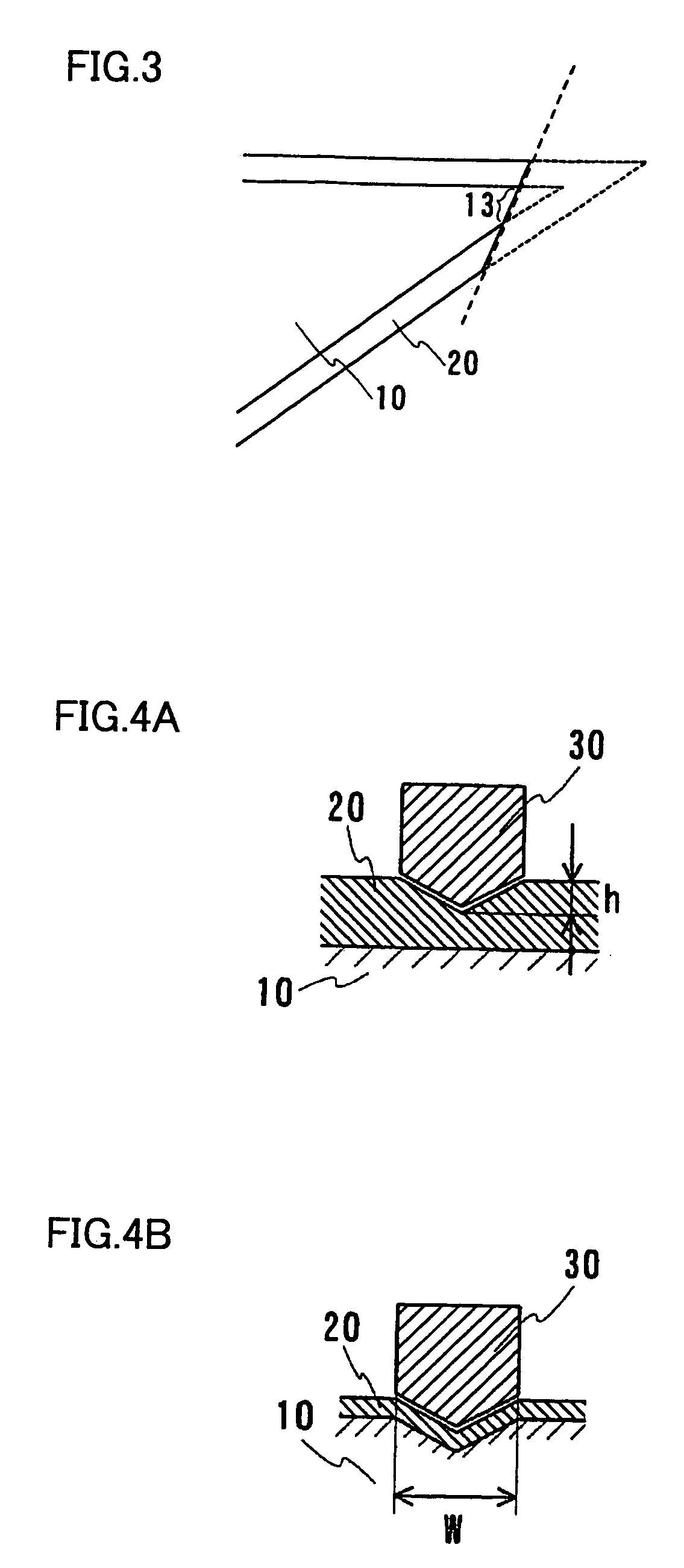

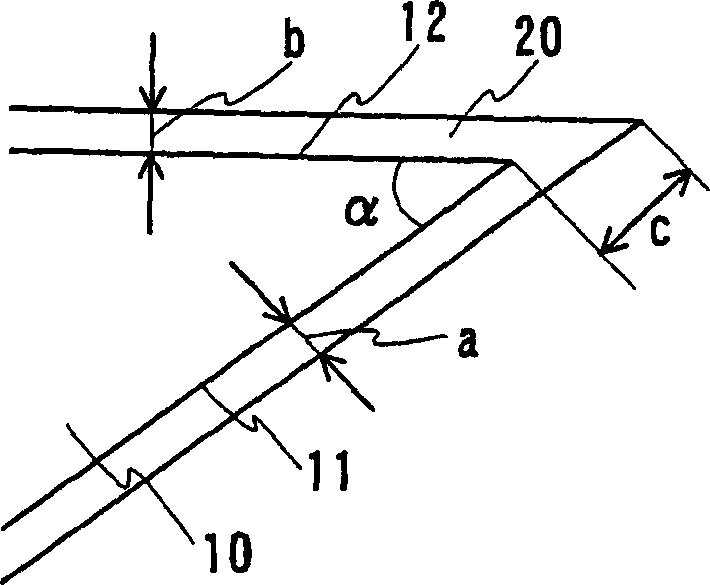

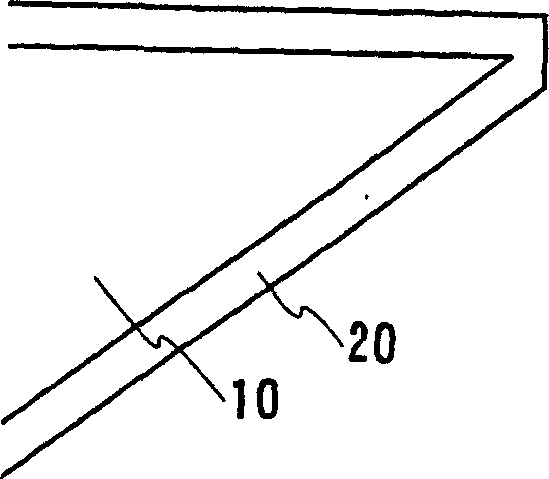

Cutting Insert, Cutting Tool, and Method of Cutting Workpiece Using the Same

ActiveUS20110135407A1Reduce cutting resistanceImprove fracture resistanceTransportation and packagingMilling cuttersEngineeringLower face

A cutting insert of the present invention includes a side face having an upper concave portion which is located between an upper face and a lower face and extends up to the upper face, and a plurality of divided upper cutting edges which are located at the intersection of the upper face and the side face, and are divided by the upper concave portion. Each of these divided upper cutting edges includes a first end and a second end, and is inclined being closer to the lower face from the first end toward the second end. The plurality of divided upper cutting edges include a first divided upper cutting edge and a second divided upper cutting edge adjacent to each other. When viewed from side, the first end of the second divided upper cutting edge is located above the intersection of an extension line of the first divided upper cutting edge, and a line which passes through the first end of the second divided upper cutting edge and is parallel to the central axis of the cutting insert, and is located at the same position as the second end of the first divided upper cutting edge, or located therebelow. A cutting tool including the cutting insert, and a method of cutting a workpiece by using the cutting tool are also provided.

Owner:KYOCERA CORP

Surface-coated cutting tool

ActiveUS20060154108A1Improve wear resistanceChipping resistancePigmenting treatmentOther chemical processesHardnessNanoindentation

The present invention provides a surface-coated cutting tool comprising a coating film on a base, while the coating film comprises a hard layer constituted of a compound selected from a nitride, a carbonitride, an oxynitride and a carboxynitride of at least one primary element selected from a group consisting of the metals belonging to the groups 4a, 5a and 6a of the periodic table as well as B, Al and Si, and the hard layer satisfies the following: (a) (hmax−hf) / hmax is at least 0.2 and not more than 0.7, assuming that hmax represents the maximum indentation depth and hf represents the indentation depth (dent depth) after unloading in a hardness test according to nanoindentation, (b) the thickness of the hard layer is at least 0.5 μm and not more than 15 μm, and (c) the hardness according to nanoindentation is at least 20 GPa and not more than 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Coated cutting tool and method for producing the same

ActiveUS20080057280A1Improve fracture resistanceReduce machining accuracyPigmenting treatmentOther chemical processesX-rayWear resistance

Provided are a coated cutting tool having excellent wear resistance and excellent resistance to chipping as well as excellent fracture resistance such that the coated cutting tool is unlikely to cause backward movement of the tool edge position due to wear or chipping, and a method for producing the same.A coated cutting tool comprising a base material having a surface coated with a coating film, wherein the coating film comprises at least one layer comprised of a TiCN columnar crystal film, wherein the TiCN columnar crystal film has an average grain size of 0.05 to 0.5 μm, as measured in the direction parallel to the surface of the base material, and exhibits an X-ray diffraction pattern having a peak at a diffraction angle 2θ in the range of from 121.5 to 122.6° wherein the peak is ascribed to the (422) crystal facet of the TiCN columnar crystal as measured using CuKα radiation.

Owner:TUNGALOY CORP

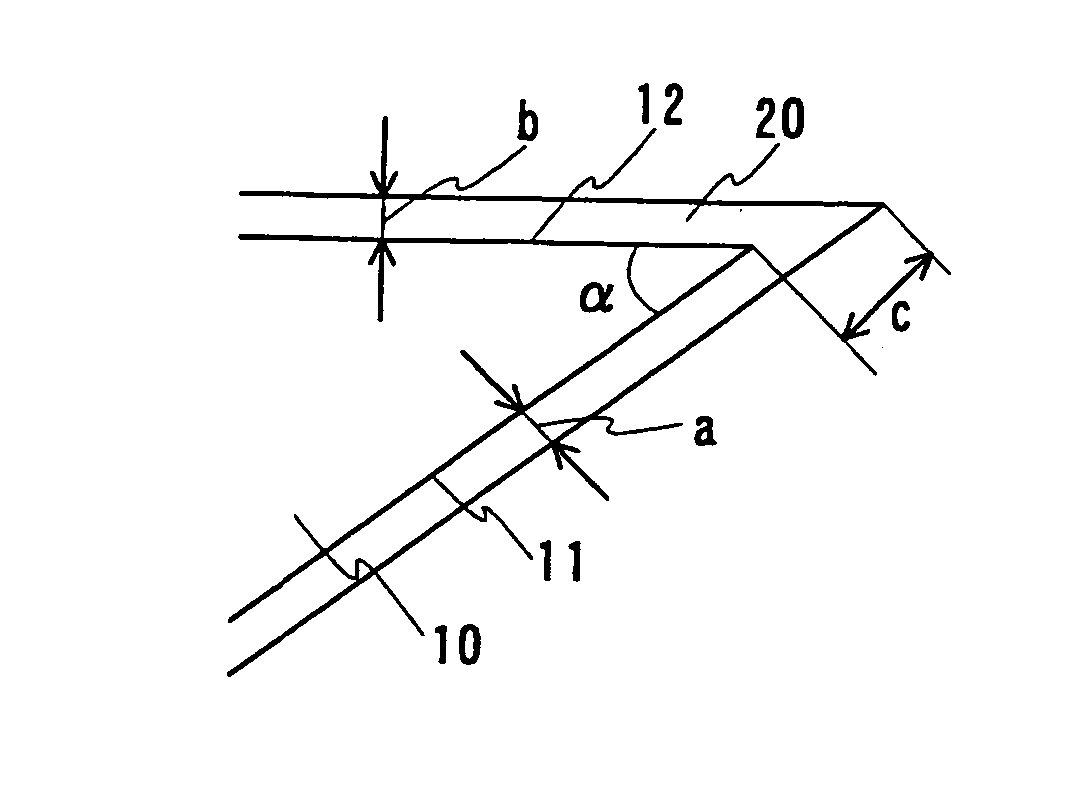

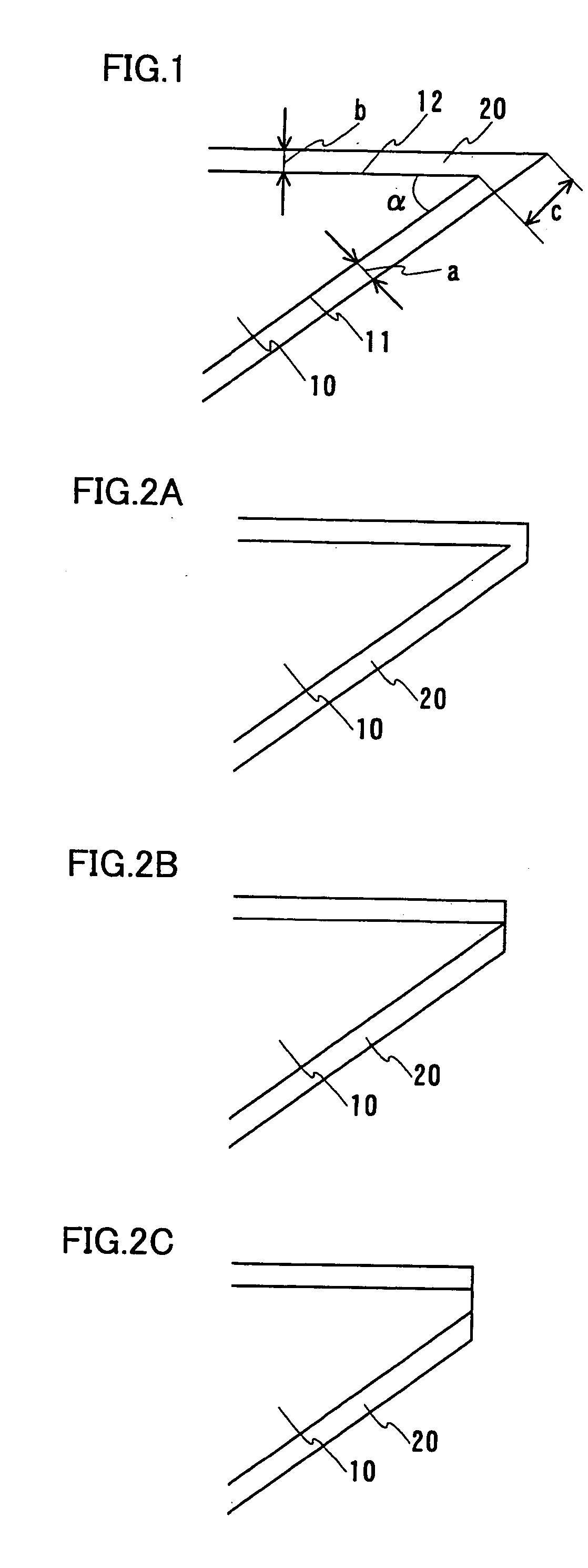

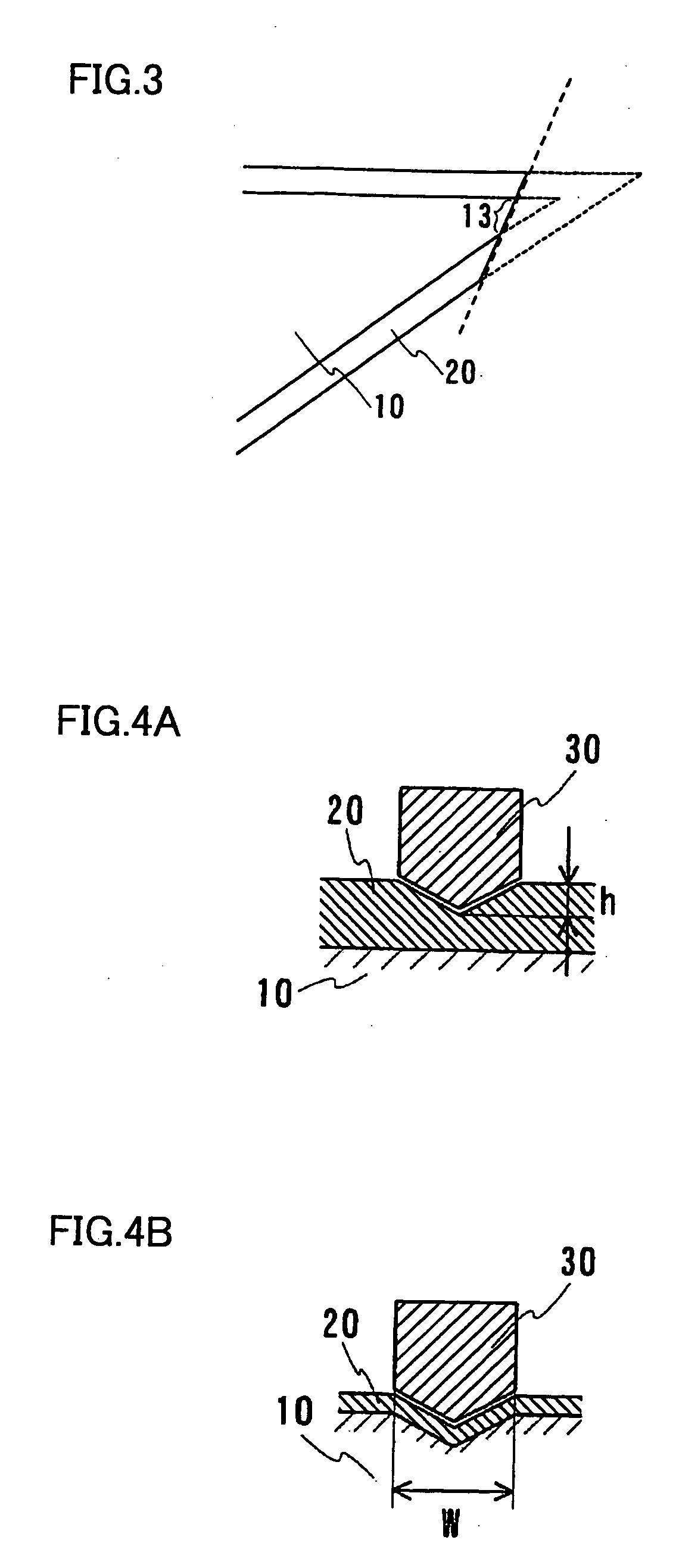

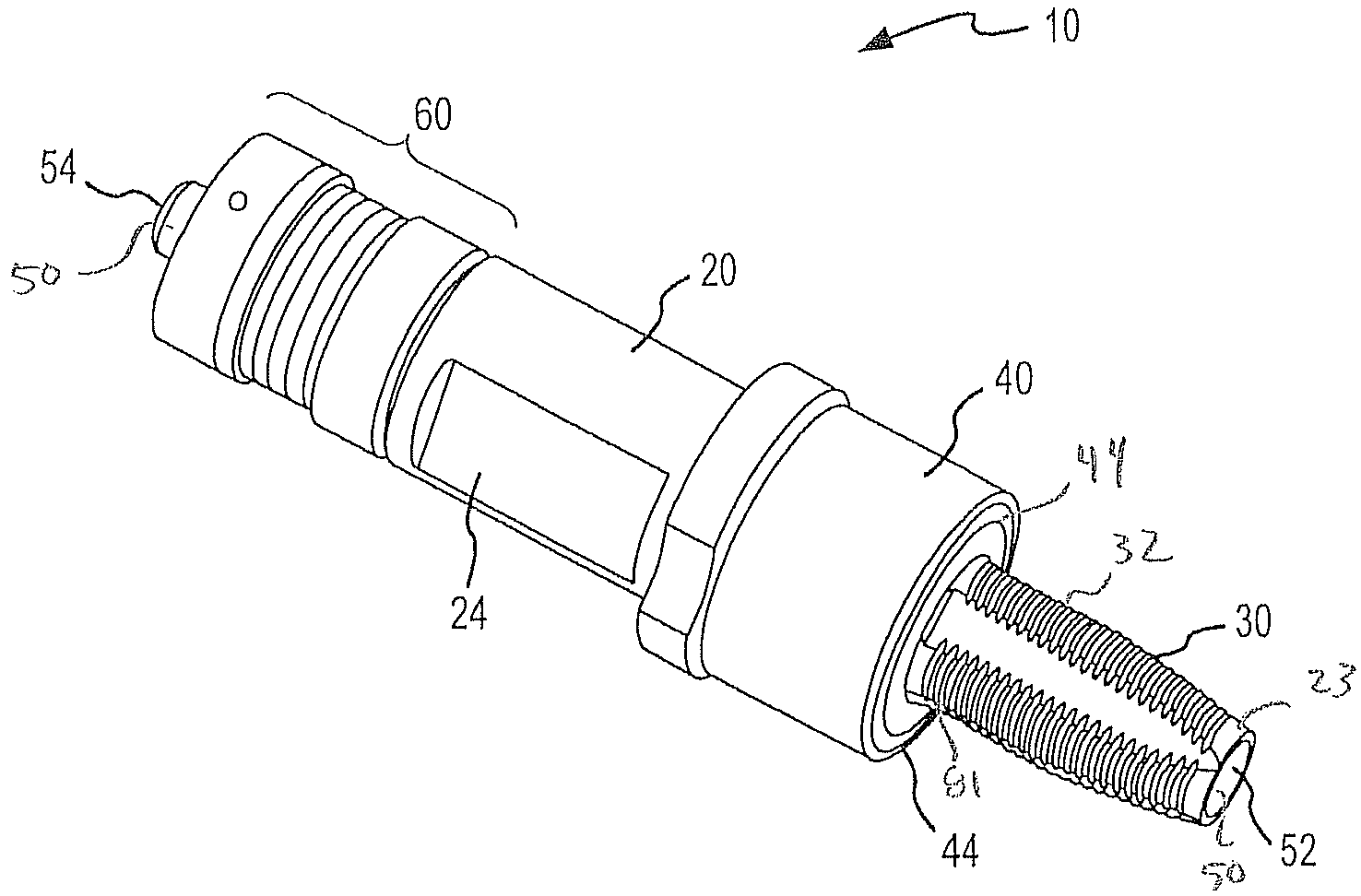

Fracture Resistant Friction Stir Welding Tool

InactiveUS20080217377A1Improve fracture resistanceLow failure rateWelding/cutting auxillary devicesAuxillary welding devicesAxial compressionAxial force

Friction stir welding tool to facilitate stress reduction within the tool that may include a body, a pin, a tension member, and an end assembly, the tension member and end assembly facilitating axial compression of the pin. The tension member may be decoupled from the pin and / or body of the tool via one or more decoupling members. The end assembly may comprise spring members to provide an axial force to the tension member. The pin may include various features to facilitate stress reduction proximal the pin.

Owner:ARCONIC INC

Hydraulic bag concrete using industrial solid wastes

The invention discloses hydraulic moulded bag concrete using industrial solid waste, which is prepared by the processes of mixing crude aggregate, fine aggregate, cementing material, reinforcing fiber and water by stirring, injecting the mixture into a moulded bag, and the like, wherein weight portion and content range of the components comprise the following: 3 to 4 portions of the crude aggregate, 0.5 to 2 portions of the fine aggregate, and 1 portion of the cementing material, and the ratio of the water to the cementing material is 0.35 to 0.85; the reinforcing fiber is an additive, and the adding amount of the reinforcing fiber is 0.1 to 5 percent of the total weight of the cementing material; the crude aggregate is steel slag or tailings; the fine aggregate is tailing sand or coal ash coarse slag or river sand; and the cementing material consists of the steel slag, coal ash, silicate cement clinker, mineral slag, and alkaline excitation agent accounting for 0.1 to 3 percent of the total weight of the components, which are mixed and milled, or is formed by milling each component raw material of the cementing material and then mixing the milled raw materials. The hydraulic moulded bag concrete has the advantages of stronger construction performance, mechanical strength, underwater stability and low cost, and can be widely applied in the fields of processing, construction and the like of bank protection and dike strengthening materials for rivers, lakes and sea.

Owner:ANHUI GUWEITE MATERIAL TECH CO LTD

Spark plug having laminated ground electrode

ActiveUS8217561B2Decreasing in metal fatigue strengthImprove fracture resistanceSparking plugsEngineeringMetal

A spark plug includes: a metal shell having a mounting thread formed with a nominal diameter of M12 or smaller; a ground electrode consisting of a first structural member and at least one ith structural member (i=2, 3, 4, 5) laminated to cover an outer surface thereof, the length of protrusion of the ground electrode from a front end face of the metal shell being 4.5 mm or larger, the ground electrode having a bent portion with a curvature radius of 2.3 mm or smaller; and an electrode tip joined thereto at a position facing the front end of the center electrode and having a protrusion length of 0.5 mm or larger and a cross sectional area of 0.20 to 1.13 mm2. The ground electrode has a total thermal conductivity of 35 W / (m·K) or higher at 20° C.

Owner:NGK SPARK PLUG CO LTD

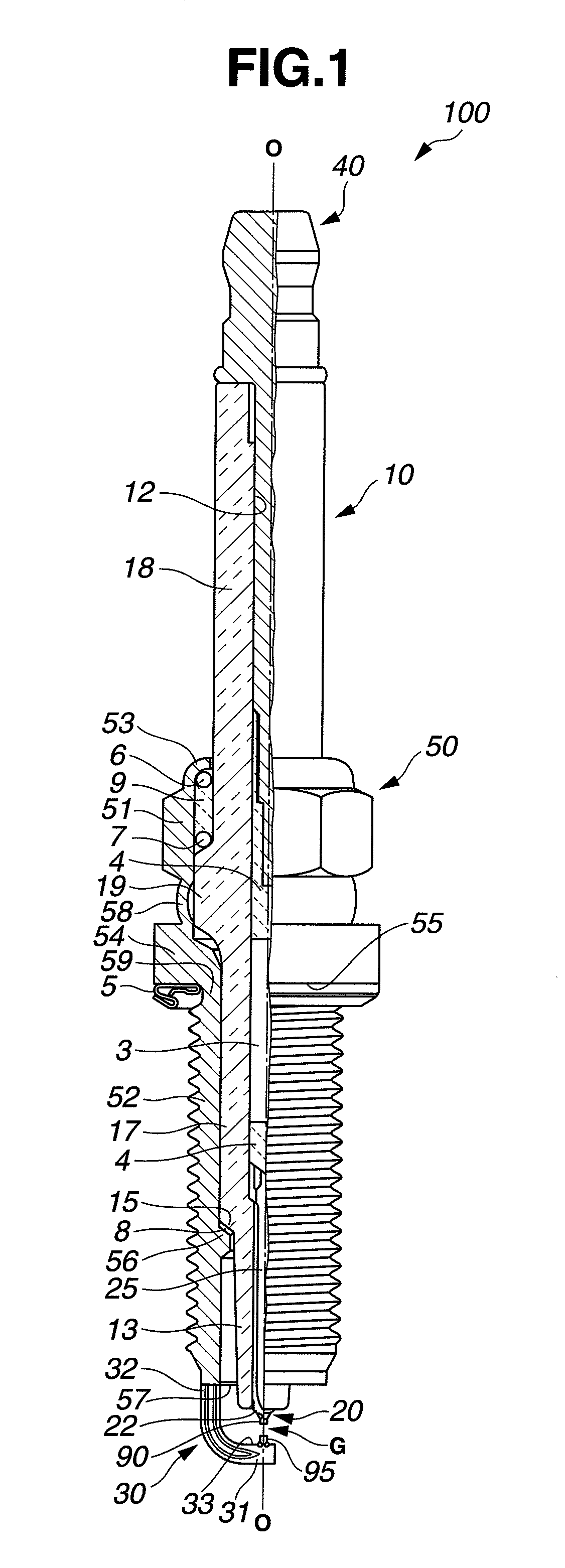

Controlled fracture connections for stents

InactiveUS8961585B2Maintain and improve patencyImprove fracture resistanceStentsBlood vesselsInsertion stentEndoluminal stent

The invention provides for intra-luminal stents, especially stent having controlled fracture connection, as well as, methods of making and using the same. In one embodiment, a stent for implantation into a vessel has a plurality of annular segments collectively forming tubular shape, characterized by at least first and second adjacent annular segments each defined by a plurality of struts and at least one joint interconnecting respective struts of the first and second segments on a non-permanent basis.

Owner:COVIDIEN LP

Surface-coated cutting tool with hard coating layer having excellent abrasion resistance

ActiveUS7597511B2Improve wear resistanceImprove the immunityPigmenting treatmentLayered productsGrain structureWear resistance

Owner:MITSUBISHI MATERIALS CORP

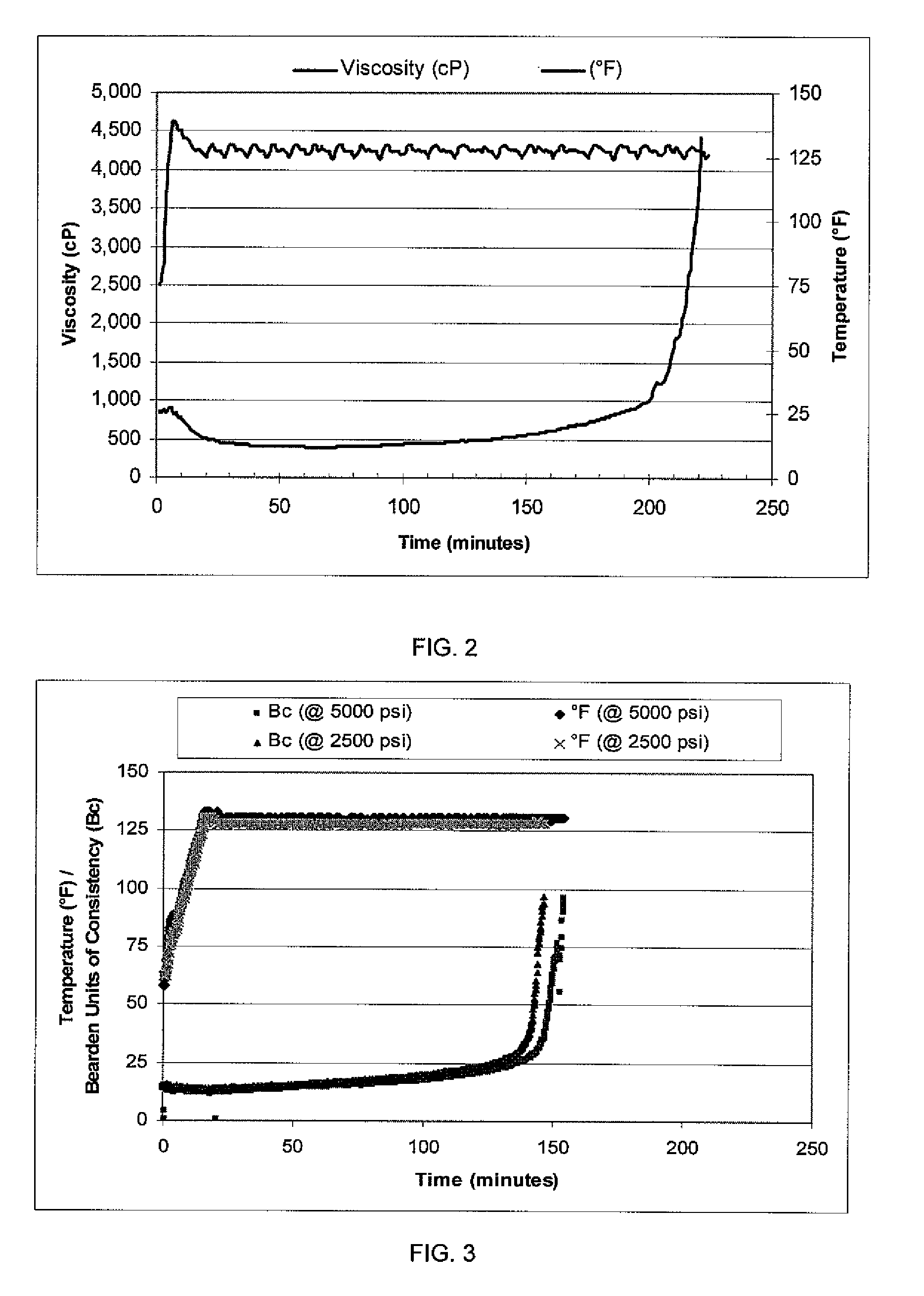

Methods of increasing fracture resistance in low permeability formations

ActiveUS20100282470A1Low resistance goodIncreased formationFluid removalSealing/packingParticulatesCrack resistance

A method of increasing the fracture resistance of a low permeability formation that includes emplacing a wellbore fluid in a wellbore through the low permeability formation, the wellbore fluid comprising: a settable carrier fluid; and a solid particulate bridging material; increasing the pressure in the wellbore such that fractures are formed in the formation; allowing the settable carrier fluid to enter the fractures; bridging and sealing the mouths of the fractures to form a substantially impermeable bridge proximate the mouth of the fractures thereby strengthening the formation; and holding the increased pressure for an amount of time sufficient for setting of the carrier fluid in the fractures is disclosed.

Owner:BP CORP NORTH AMERICA INC +2

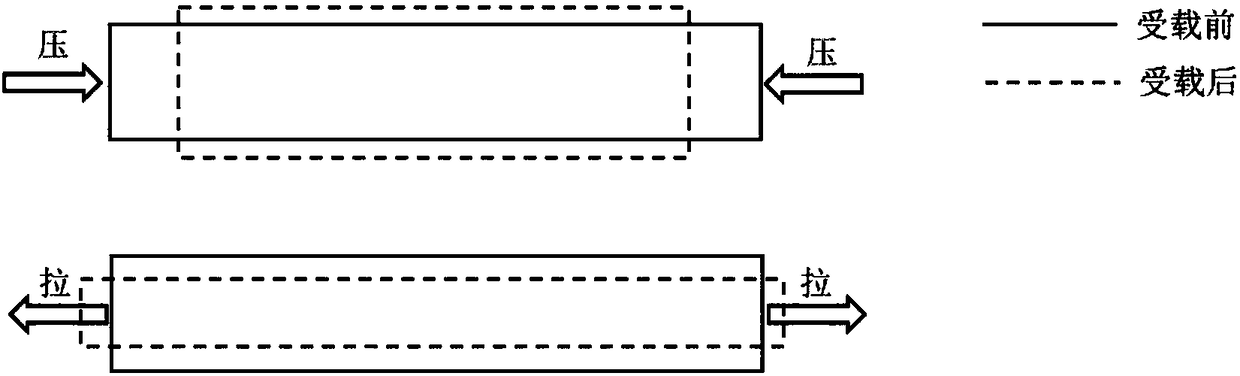

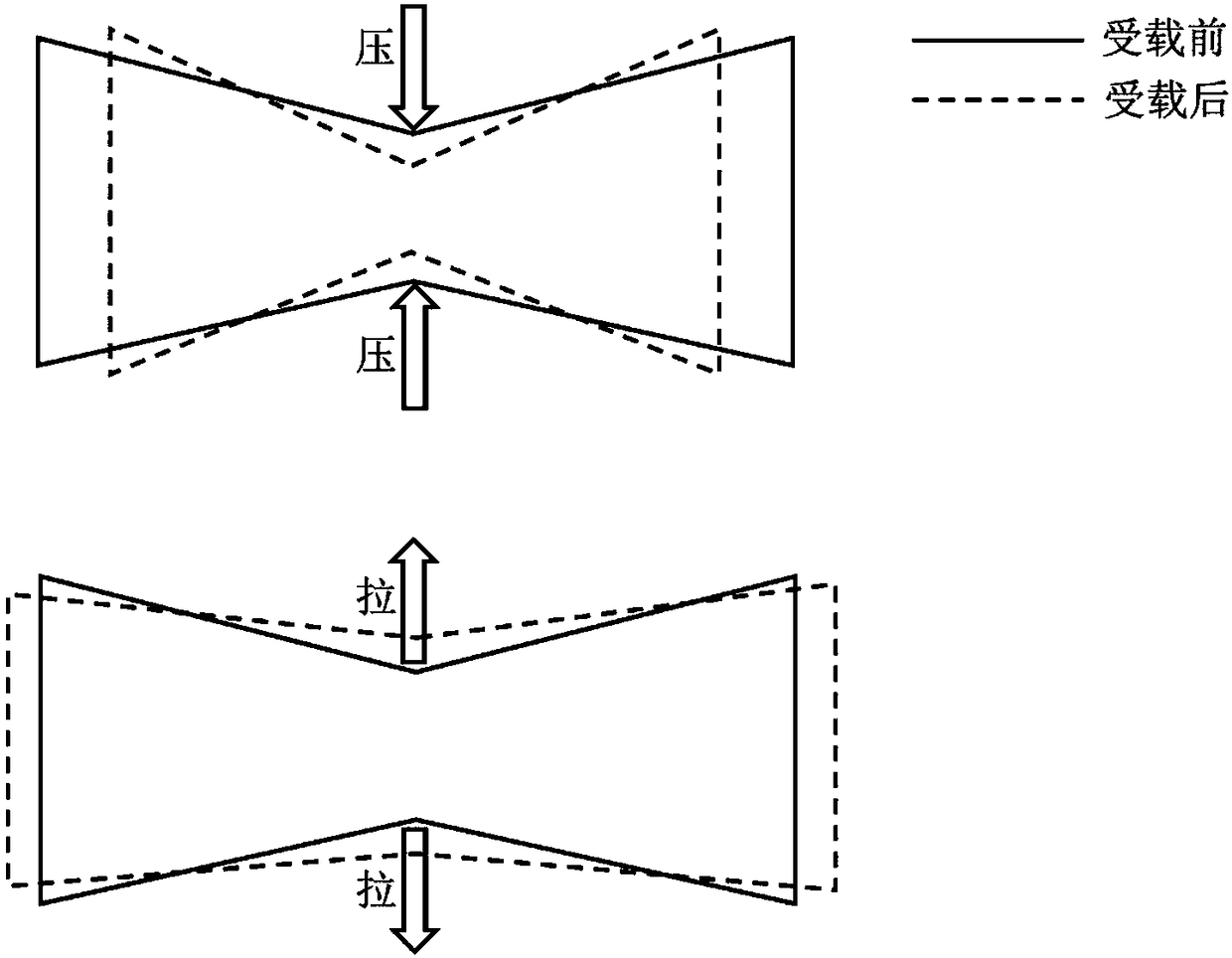

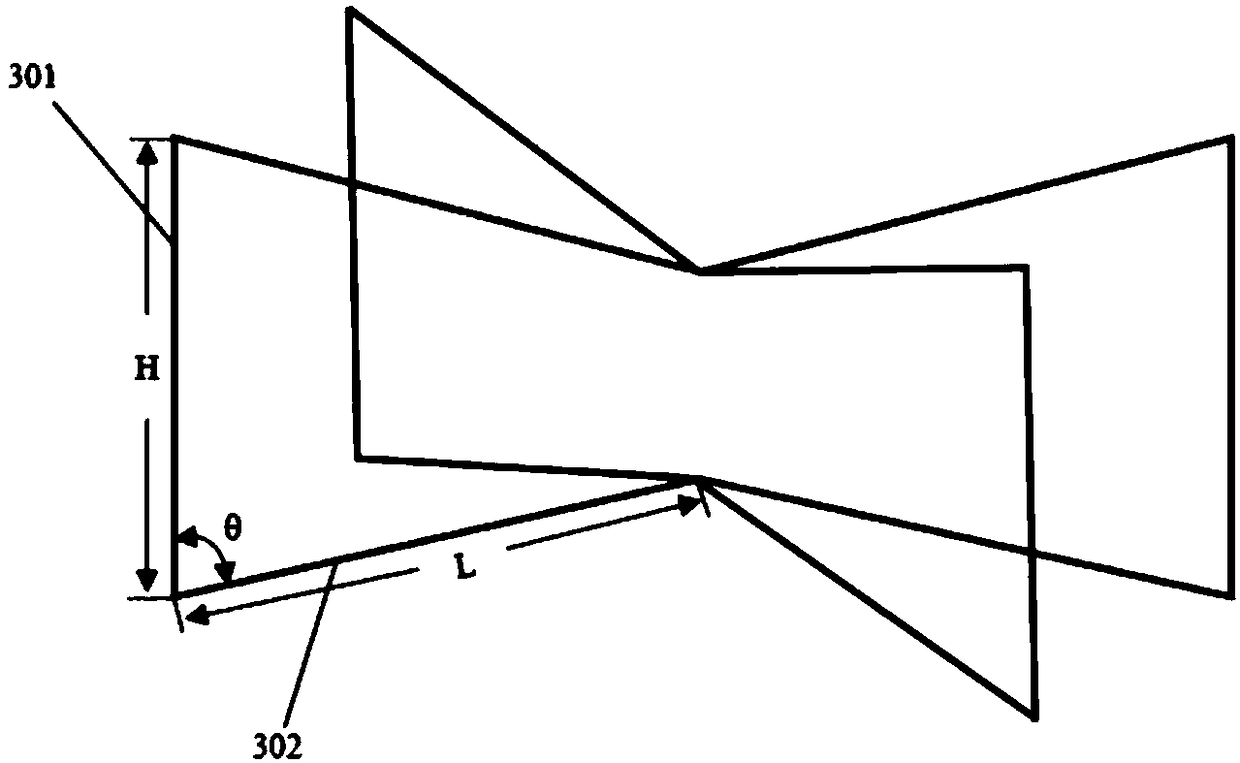

Negative poisson ratio structural component based on inner sunken hexagonal unit

PendingCN108082102AGood resilience toughness and fracture resistanceHigh strengthBumpersSustainable transportationSupporting cellElastic modulus

The invention discloses a negative poisson ratio structural component based on an inner sunken hexagonal multi-cell unit. The negative poisson ratio structural component comprises a plurality of unitcell structures, each of the unit cell structures consists of two inner sunken hexagons, the inner sunken hexagons are in a left-right symmetric dovetail shape, and every two inner sunken hexagons arearranged in an orthogonal mode and intersect at two concave angle apexes to form a complete unit cell structure; the multiple unit cell structures are connected with each other horizontally in both directions by sharing one support cell arm, and are extended in the horizontal direction to form a continuous unit layer; and a plurality of unit layers are connected with each other in the vertical direction by sharing curved ribs to form a multi-layered cross-aligned inner sunken honeycomb-shaped three-dimensional negative poisson ratio structure. According to the negative poisson ratio structural component based on the inner sunken hexagonal multi-cell unit, a significant negative poisson ratio effect is achieved, higher elastic modulus, shear modulus and storage modulus can be generated when loaded, better rebound toughness and fracture resistance are achieved and improved with the enhancement of the negative poisson ratio effect.

Owner:NANJING UNIV OF SCI & TECH

Surface-coated cutting tool

ActiveCN1845808AImprove overall lifespanAvoid chippingTransportation and packagingMilling cuttersHardnessIndentation hardness

A surface-coated cutting tool having a base material and, formed thereon, a coating film, wherein the coating film has a hard layer comprising a compound selected from among a nitride, a carbonitride, a nitroxide and a carbonitroxide of one or more first elements selected from the group consisting of metals belonging to 4a, 5a and 6a Groups of the Periodic Table and B, Al and Si, and wherein the hard layer satisfies the followings: (a) in the nano indentation hardness test, (hmax - hf) / hmax is 0.2 to 0.7, wherein hmax represents the maximum indentation depth, and hf represents the indentation depth after the removal of a load (impression depth), (b) the hard layer has a film thickness of 0.5 to 15 mum, and (c) a hardness according to the nano indentation method is 20 to 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Cutting tool

ActiveUS7811683B2Improve antioxidant capacityImprove fracture resistancePigmenting treatmentVacuum evaporation coatingCarbideWear resistance

A cutting tool having a substrate and a coating layer for coating the surface of the substrate, the coating layer being composed of Ti1−a−b−c−dAlaWbSicMd(CxN1−x), where M is at least one selected from Nb, Mo, Ta, Hf and Y, 0.45≦a≦0.55, 0.01≦b≦0.1, 0.01≦c≦0.05, 0.01≦d≦0.1, and 0≦x≦1. The cutting tool has excellent wear resistance and fracture resistance. The cutting tool may be further provided with a layer composed of at least one selected from carbides, nitrides and carbonitrides of Al and the elements of the groups 4, 5 and 6 of the periodic table.

Owner:KYOCERA CORP

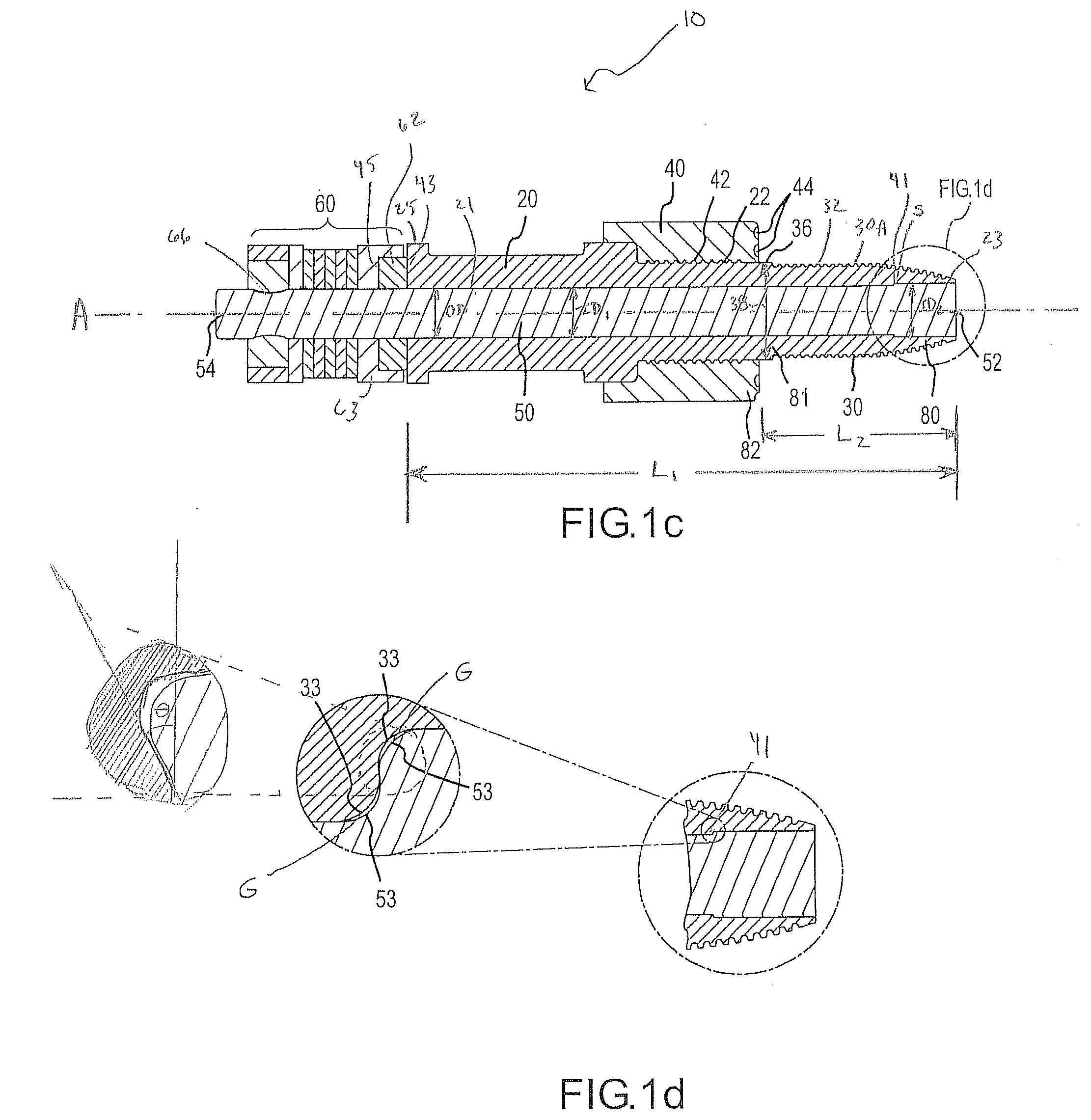

Medical electrical lead

InactiveUS7660635B1Improve fracture resistanceLimited extensibilityTransvascular endocardial electrodesExternal electrodesElectrical conductorEngineering

An implantable lead which has an increased resistance to fracture and has the capability of continued function after fracture of a conductor. The lead is provided with a coiled conductor which may be monofilar or multifilar and which extends along the length of the lead, running from an electrical connector at the proximal end of the lead to an electrode at or near the distal end of the lead. In addition, the lead is provided with a stranded conductor which is electrically coupled to the coiled conductor at point along the lead body located proximal to the point of expected breakage of the coiled conductor and at a point along the lead body located distal to the point of expected breakage. The proximal and distal ends of the stranded conductor in some embodiments are also mechanically coupled to the coiled conductor.

Owner:MEDTRONIC INC

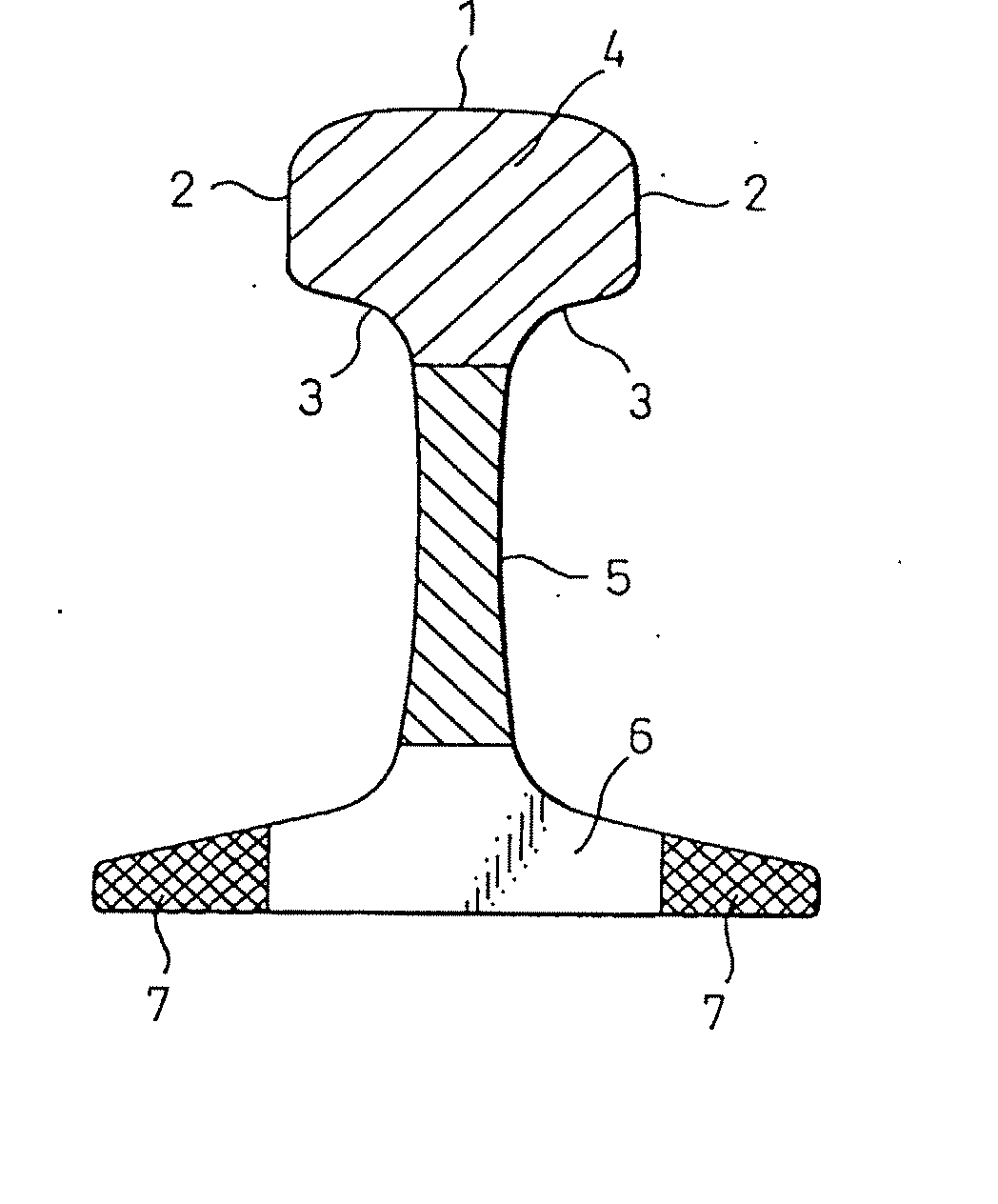

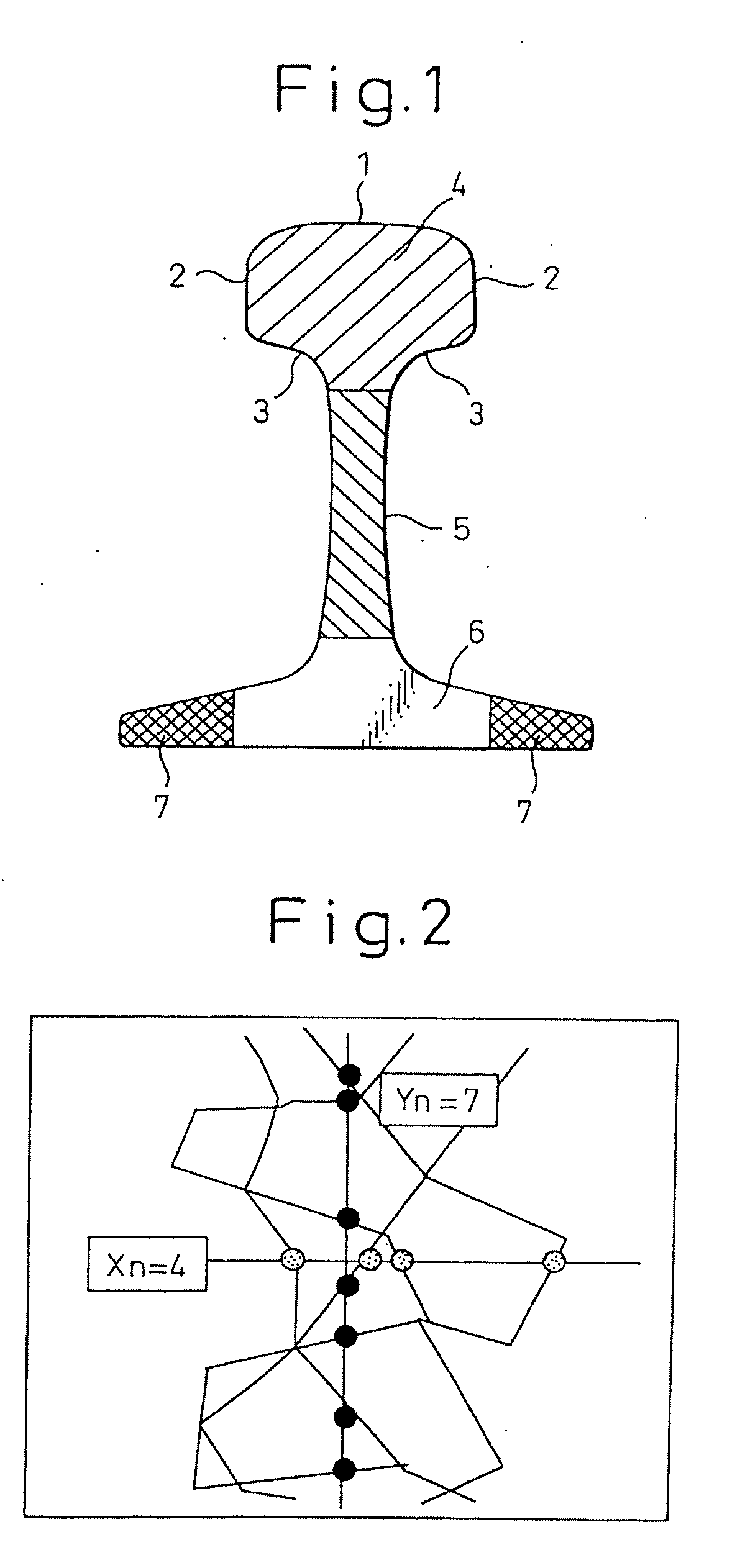

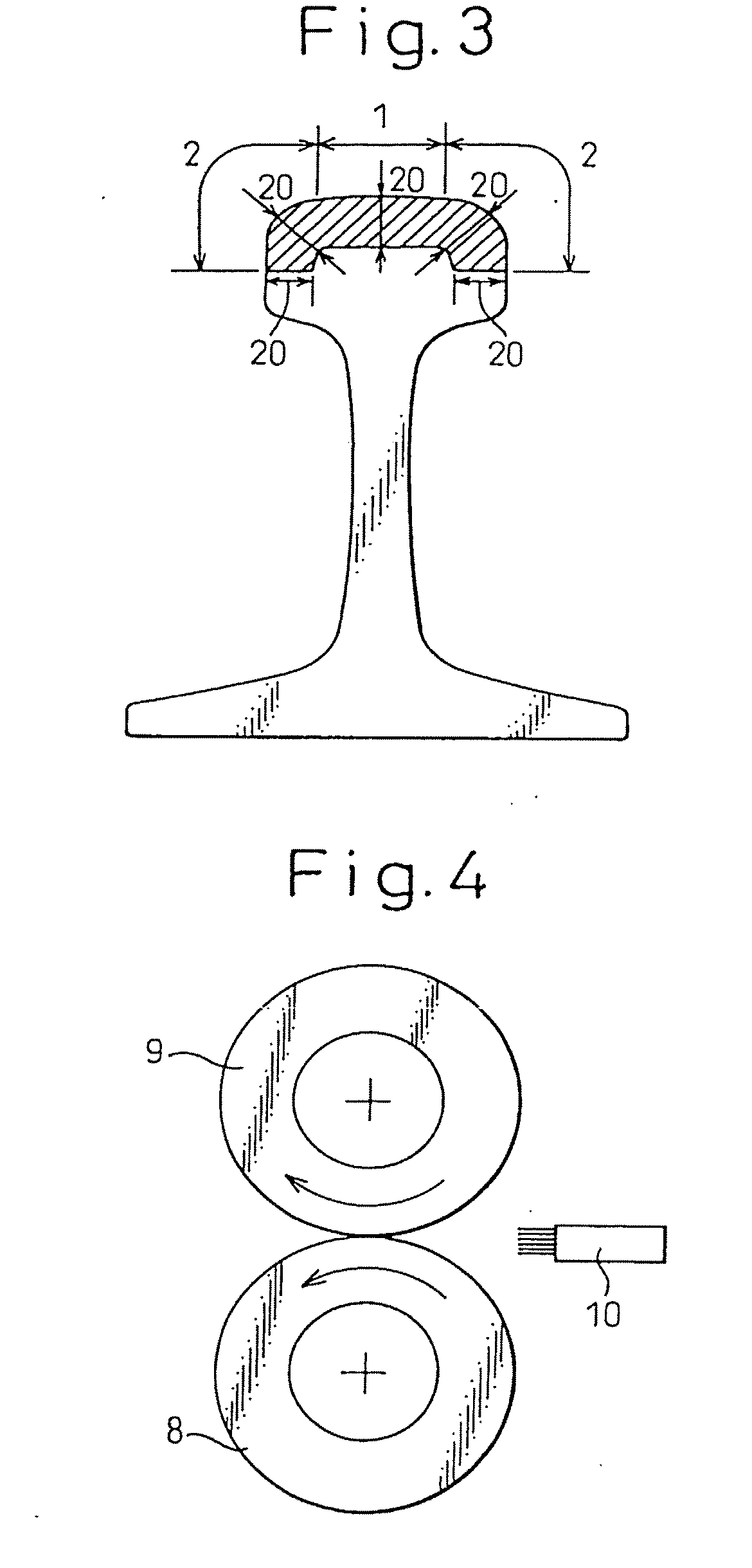

Pearlitic steel rail excellent in wear resistance and ductility and method for producing same

InactiveUS20080011393A1High carbon contentInhibition formationFurnace typesHeat treatment furnacesGranularityPearlite

The present invention is: a pearlitic steel rail excellent in wear resistance and ductility, characterized in that, in a steel rail having pearlite structure containing, in mass, 0.65 to 1.40% C, the number of the pearlite blocks having grain sizes in the range from 1 to 15 μm is 200 or more per 0.2 mm2 of an observation field at least in a part of the region down to a depth of 10 mm from the surface of the corners and top of the head portion; and a method for producing a pearlitic steel rail excellent in wear resistance and ductility, characterized by, in the hot rolling of said steel rail, applying finish rolling so that the temperature of the rail surface may be in the range from 850° C. to 1,000° C. and the sectional area reduction ratio at the final pass may be 6% or more, and then applying accelerated cooling to the head portion of said rail at a cooling rate in the range from 1 to 30° C. / sec. from the austenite temperature range to at least 550° C.

Owner:NIPPON STEEL CORP

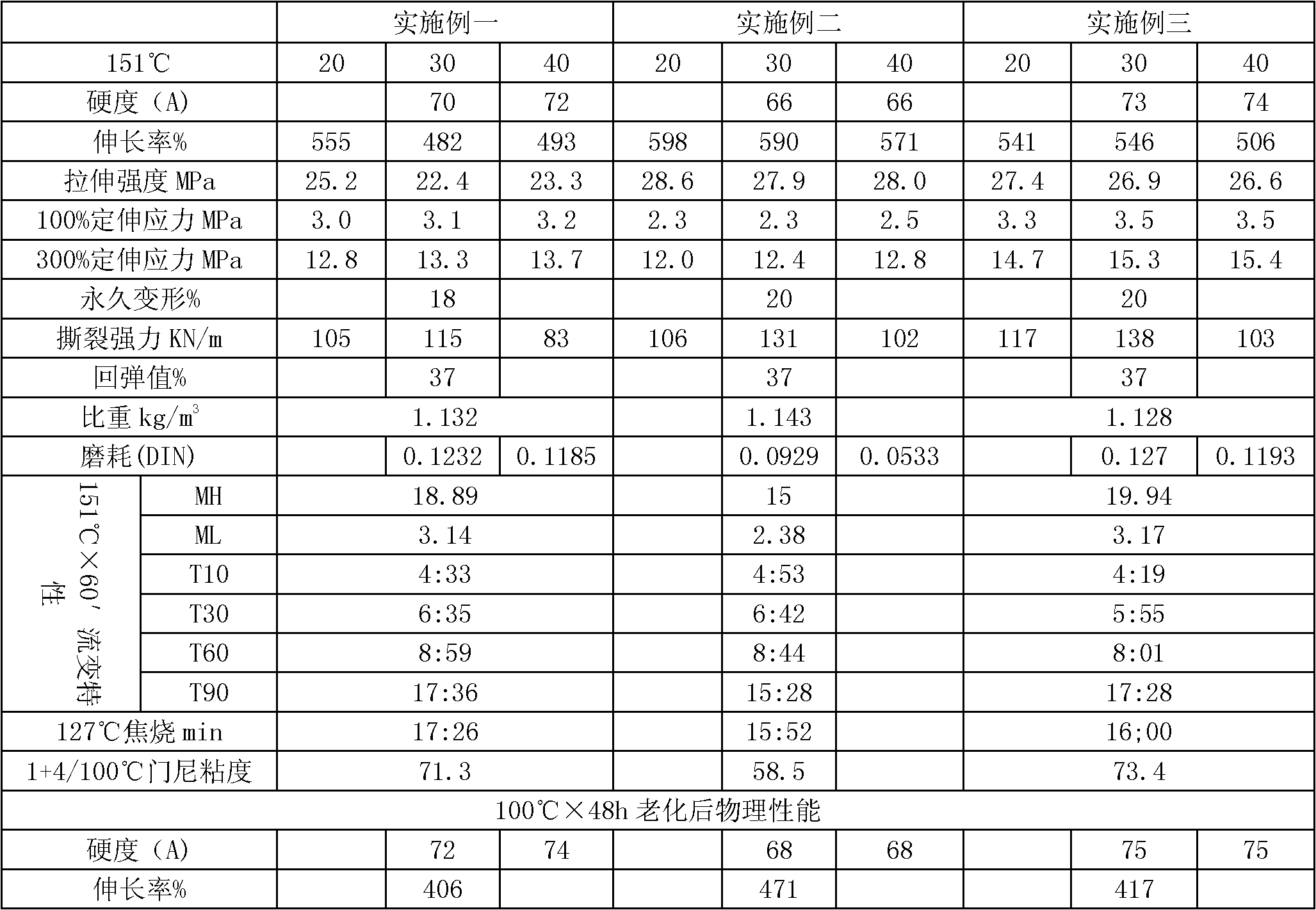

Mine-type all-steel radial truck tire tread rubber and preparation method thereof

InactiveCN102276881AImprove crack resistanceImprove fracture resistanceMicrocrystalline waxCrack resistance

The present invention relates to a kind of preparation method of mine-type all-steel radial truck tire tread rubber, which comprises the following process steps: (1) masticating natural rubber, styrene-butadiene rubber and peptizer in a mixing chamber, and then adding charcoal black, silica, silane coupling agent, zinc oxide, stearic acid, plasticizer and anti-crack resin, continue mixing, then add carbon black for mixing, and finally inject aromatic oil for mixing, and carry out mixing after mixing Glue removal to obtain one section of masterbatch; (2) cooling one section of masterbatch to normal temperature; (3) mixing one section of masterbatch with carbon black, antioxidant A, antioxidant B and microcrystalline wax in the mixing chamber, mixing After refining, carry out debinding to obtain the second-stage masterbatch; (4) cool the second-stage masterbatch to normal temperature; (5) mix the second-stage masterbatch and sulfur, accelerator and anti-scorch agent in the mixing chamber, mix After the rubber is discharged, the finished tread rubber is obtained. The invention can improve the crack resistance, fracture resistance, fatigue resistance and impact resistance of the radial tire tread.

Owner:JIANGSU GENERAL SCI TECH

Rubber composition, rubber composition for tire side use, crosslinked rubber composition and tire

ActiveUS20130324660A1Improve fracture resistanceGood weather resistanceSpecial tyresPolymer scienceWeather resistance

The present invention provides a rubber composition that is used for manufacturing a rubber excellent in weather resistance, fracture resistance and crack growth resistance, and that contains a conjugated diene compound / non-conjugated olefin copolymer, a conjugate diene-based polymer and a non-conjugated diene compound / non-conjugated olefin copolymer, a rubber composition for tire side use using the rubber composition for tire sidewall members, a crosslinked rubber composition obtained by crosslinking the rubber composition, and a tire. The rubber composition includes: (A) a conjugated diene compound / non-conjugated olefin copolymer containing a conjugated diene compound-derived unit by at least 40 mol %; (B) a conjugated diene-based polymer; and (C) a non-conjugated diene compound / non-conjugated olefin copolymer containing an ethylene-propylene-diene rubber.

Owner:BRIDGESTONE CORP

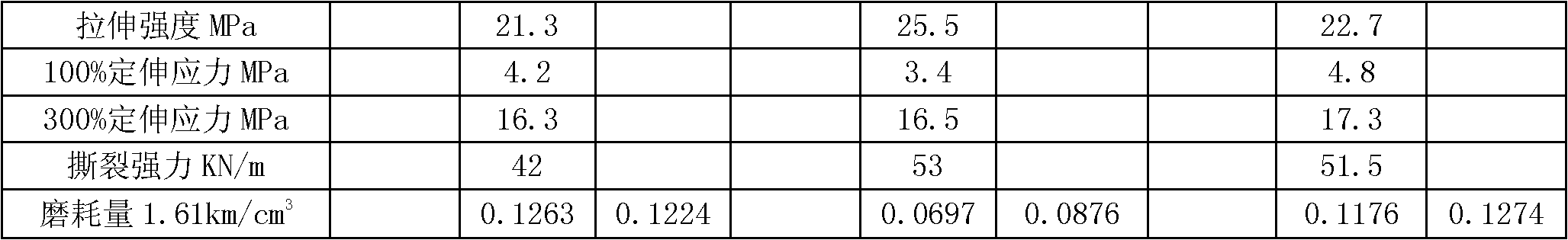

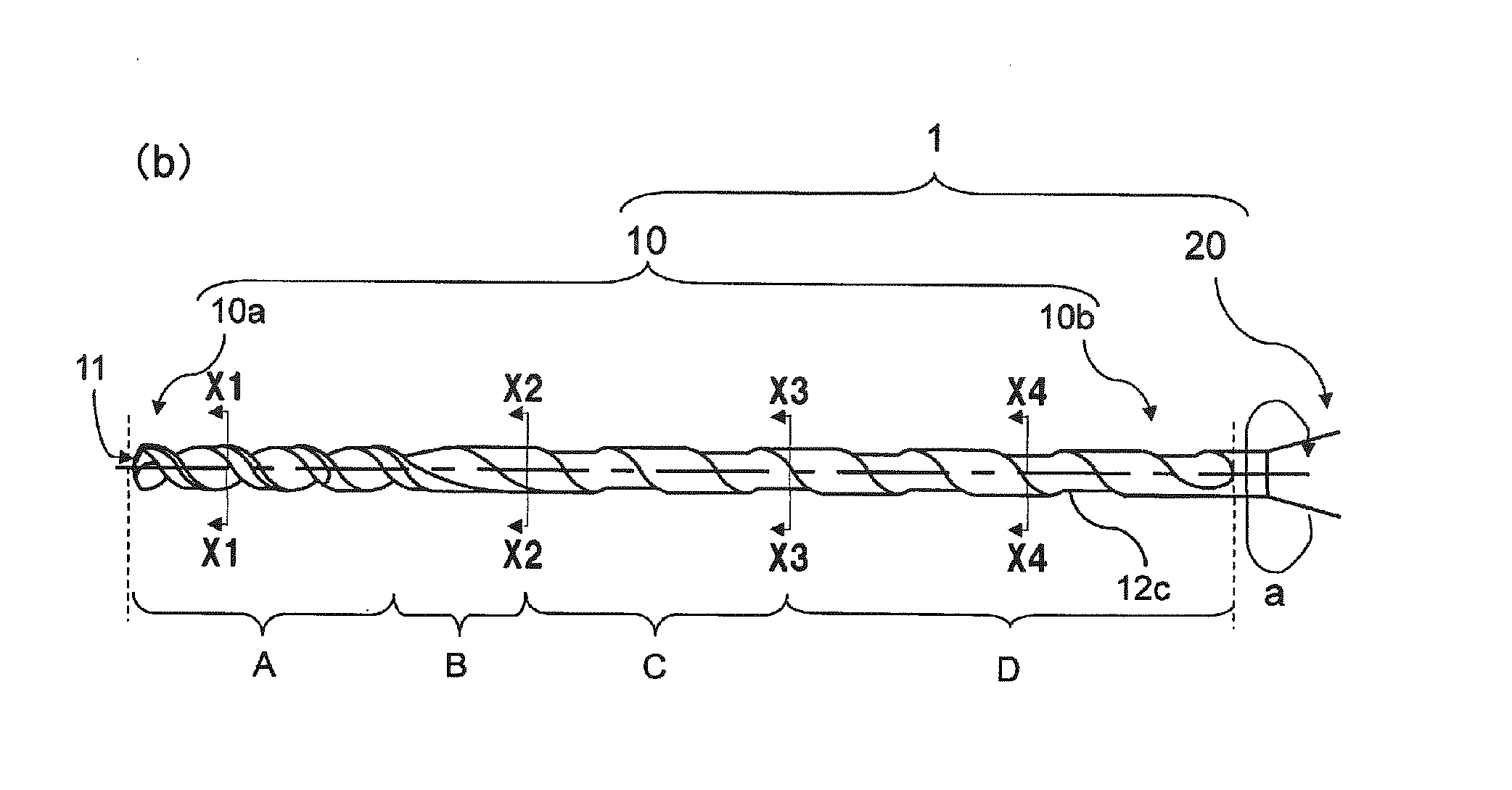

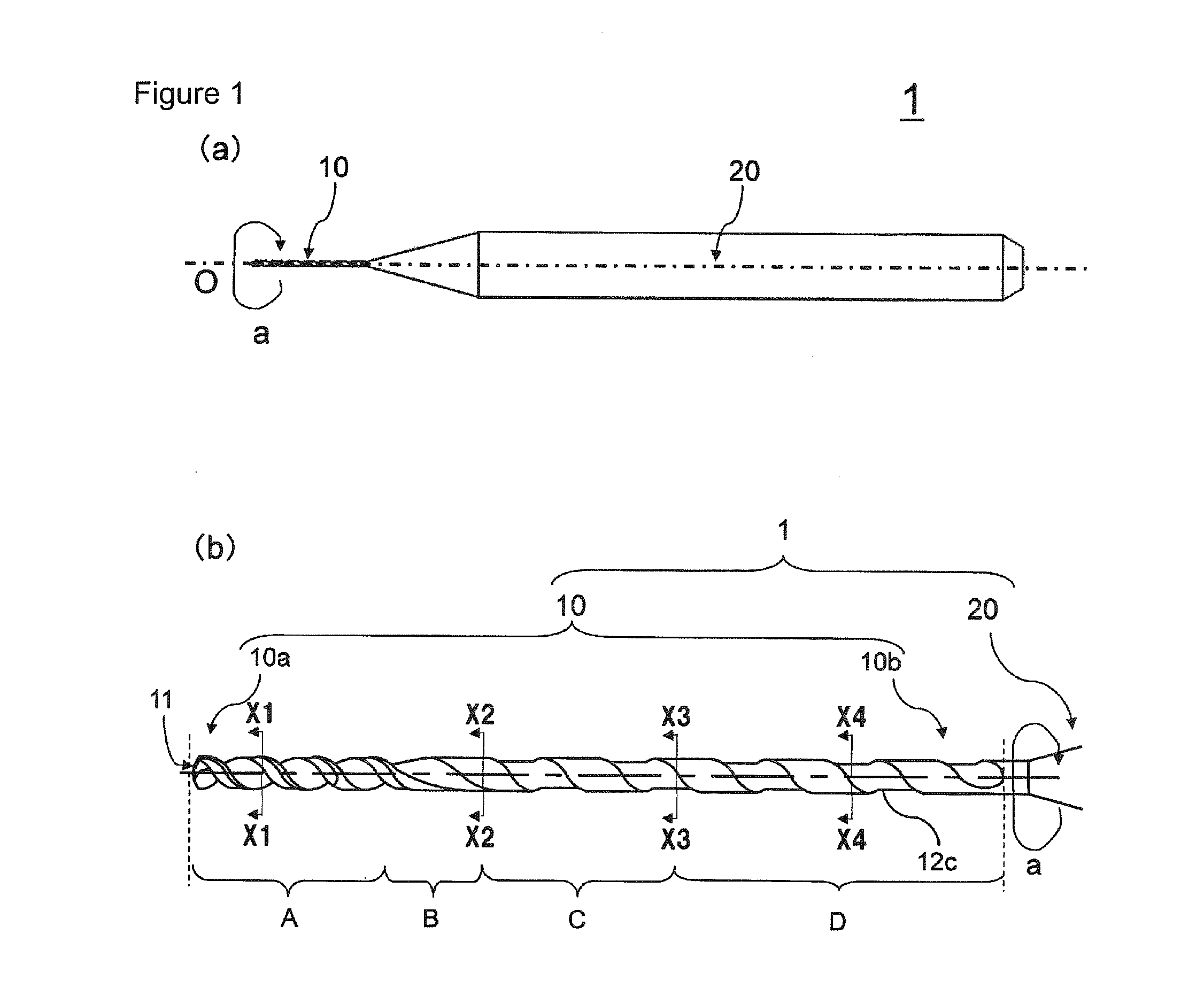

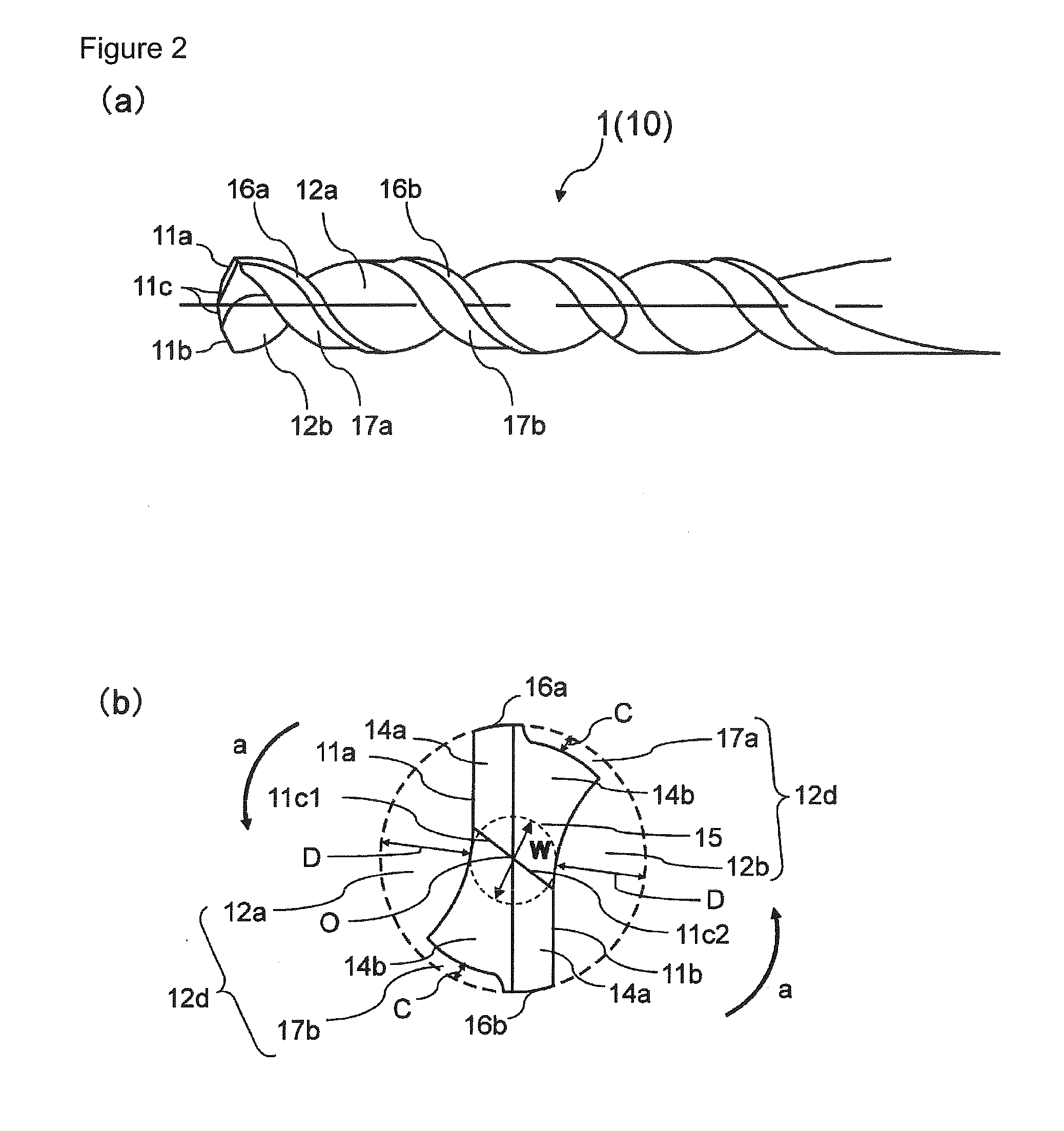

Drill and method of manufacturing machined product using the same

InactiveUS20130170920A1Reduce situationLarge core thicknessWood turning toolsTransportation and packagingFluteDrill bit

A drill according to an embodiment of the present invention includes a body part and a cutting part with a cylinder-like shape. The cutting part includes two cutting edges located separately from each other at a front end portion of the cutting part, two flutes which are continuous with each of the two cutting edges and extend spirally toward a rear end portion of the cutting part, and a clearance which extends spirally from a side of the front end portion to a side of the rear end portion, and is recessed inward in reference to a periphery of the cutting part in a sectional view. The cutting part includes a first joining flute including at least one of the two flutes and the clearance being joined together. The first joining flute includes a bottom surface being outwardly protruding curve-like line in a sectional view. A method of manufacturing a machined product using the drill is also provided.

Owner:KYOCERA CORP

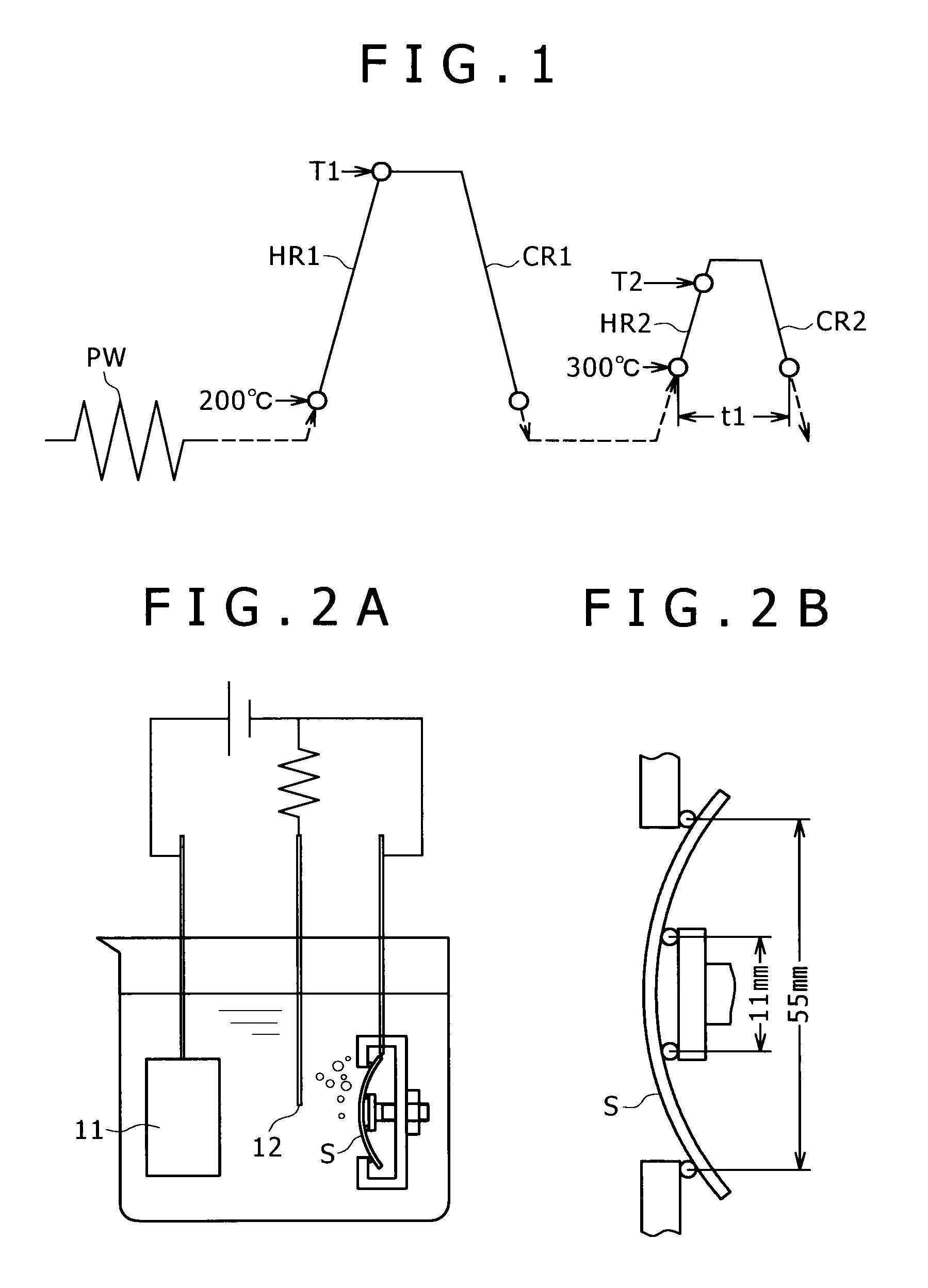

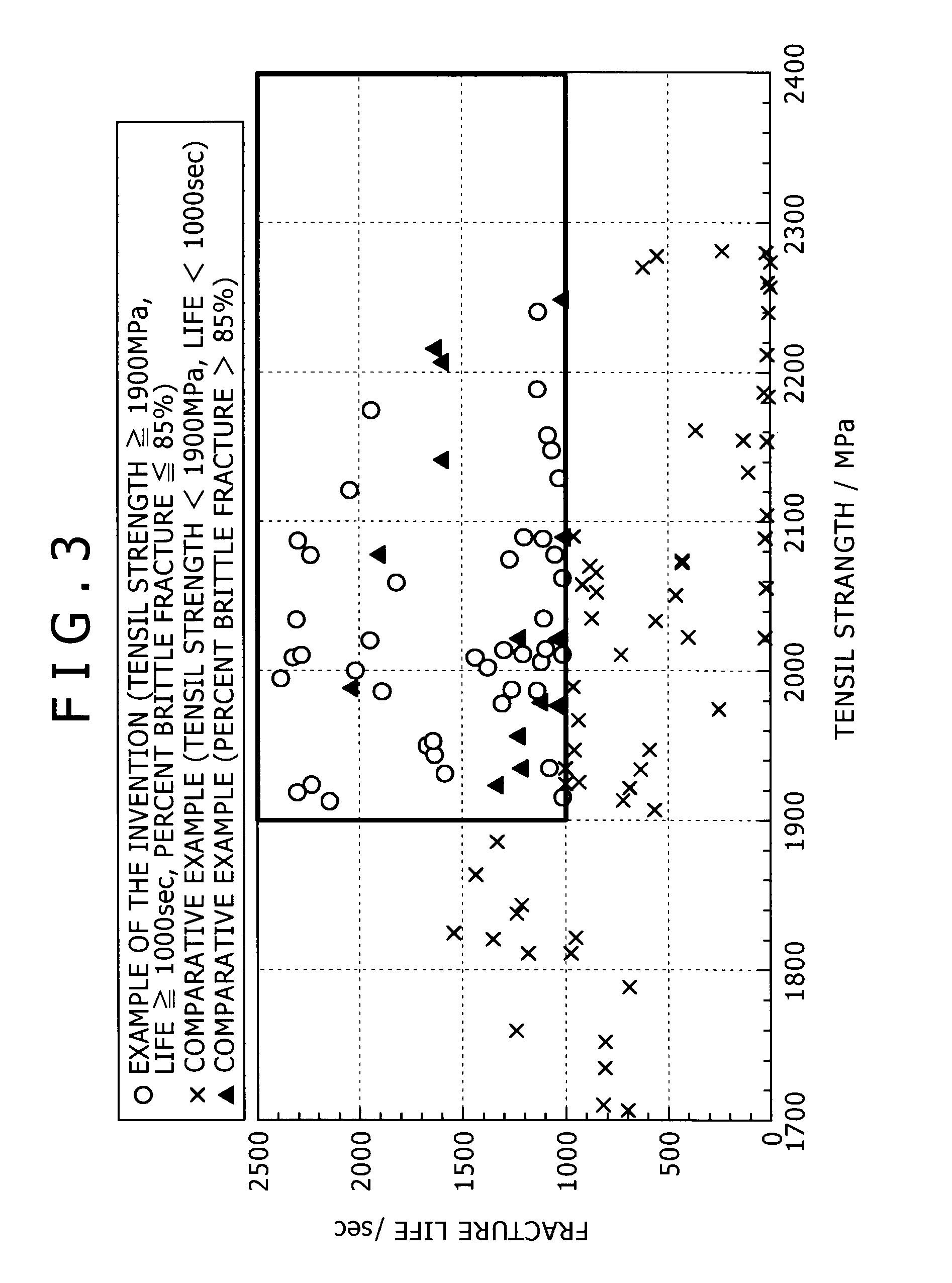

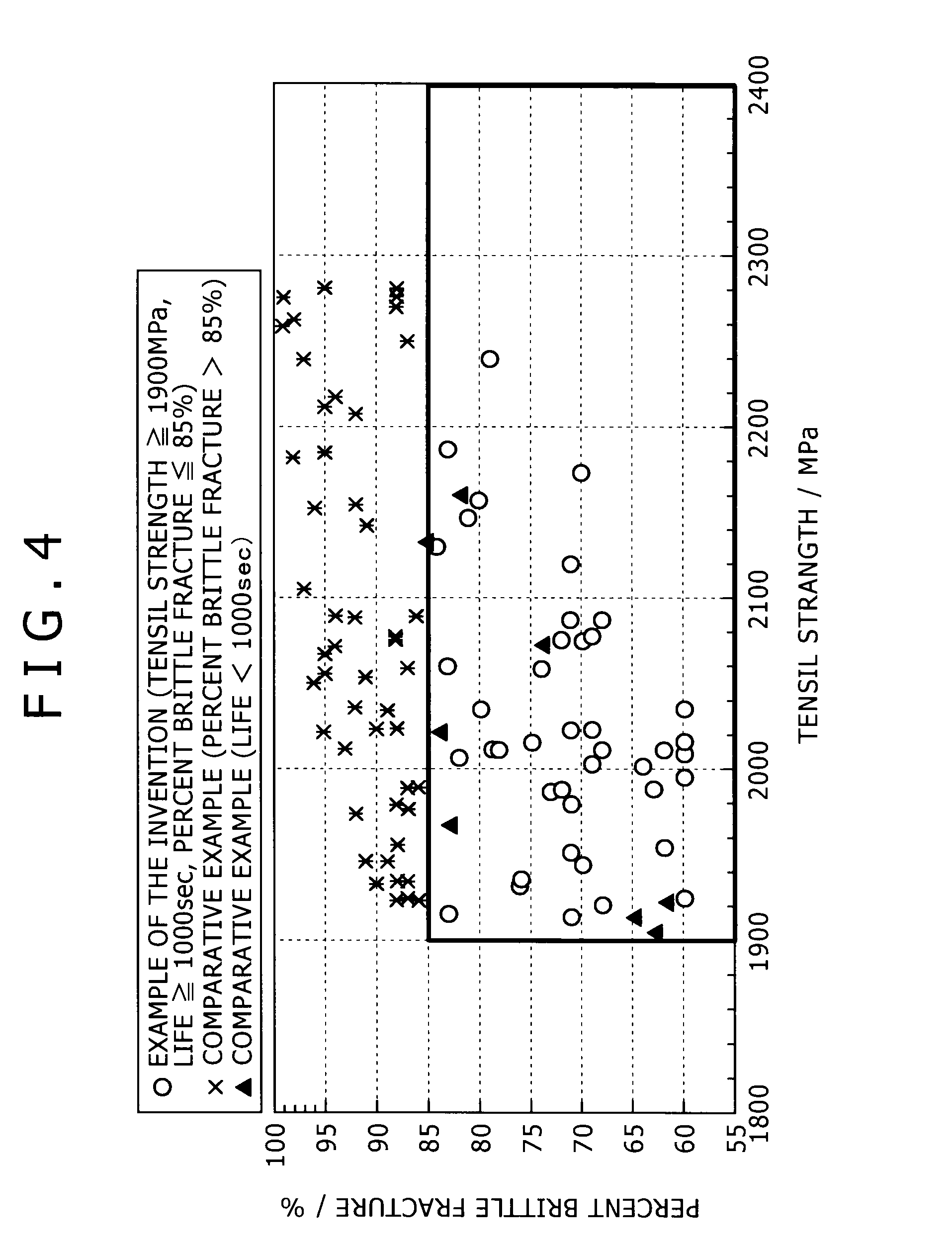

High-strength spring steel excellent in brittle fracture resistance and method for producing same

ActiveUS20100224287A1Stable resistance to fractureEasily manufactureFurnace typesHeat treatment process controlSpring steelHigh intensity

A spring steel having a high strength of 1900 MPa or more and superior in the brittle fracture resistance, as well as a method for manufacturing the same, are provided.The high strength spring steel comprises, as basic components in mass %, C: 0.4-0.6%, Si: 1.4-3.0%, Mn: 0.1-1.0%, Cr: 0.2-2.5%, P: 0.025% or less, S: 0.025% or less, N: 0.006% or less, Al: 0.1% or less, and O: 0.003% or less, the amount of solute C being 0.15% or less, the amount of Cr contained as a Cr-containing precipitate being 0.10% or less, and a TS value represented by the following equation being 24.8% or more, and in point of structure, the pre-austenite grain diameter being 10 μm or smaller, wherein TS=28.5*[C]+4.9*[Si]+0.5*[Mn]+2.5*[Cr]+1.7*[V]+3.7*[Mo] where [X] stands for mass % of element X.

Owner:KOBE STEEL LTD

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

High-carbon steel wire rod with superior drawability and method for production thereof

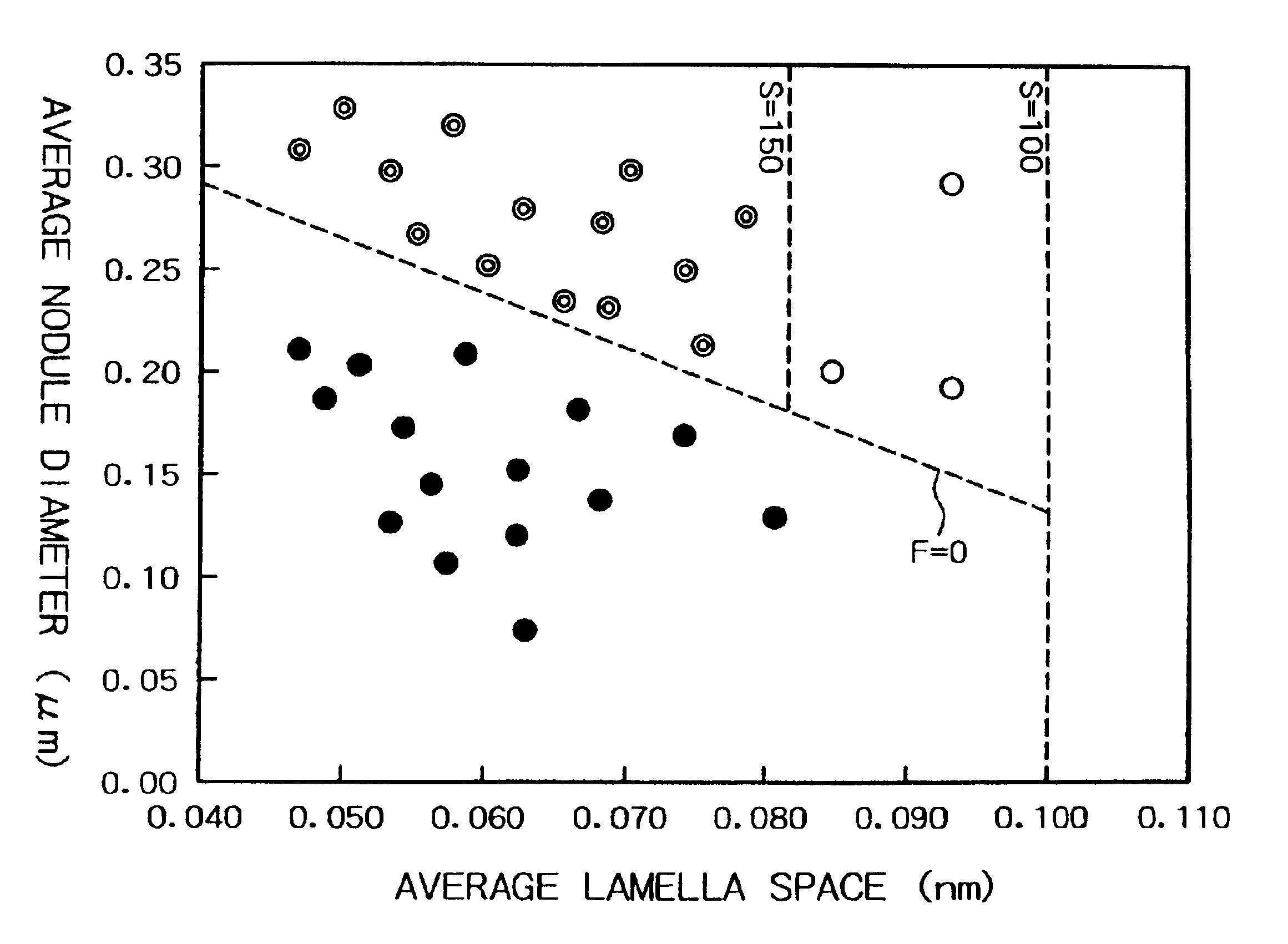

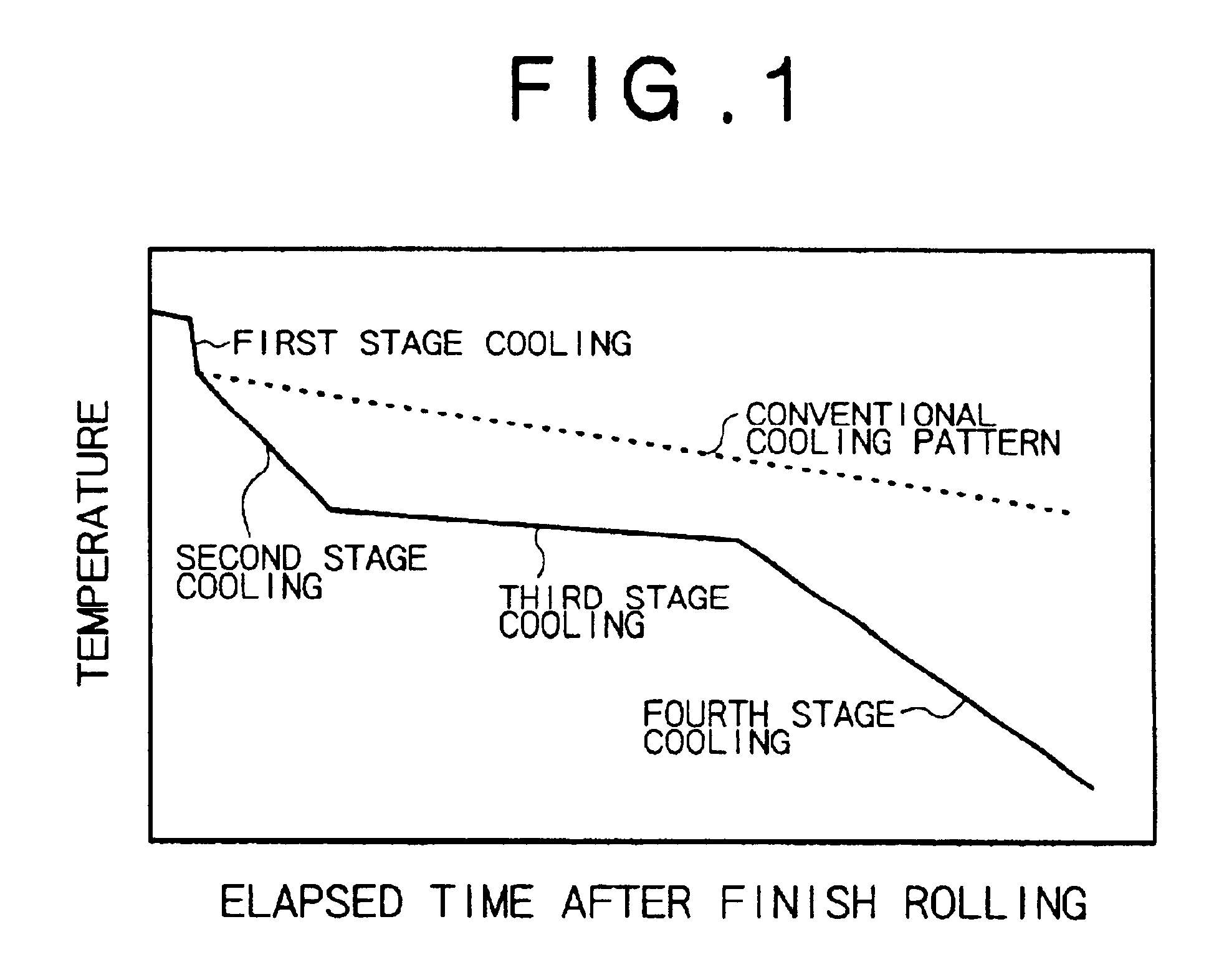

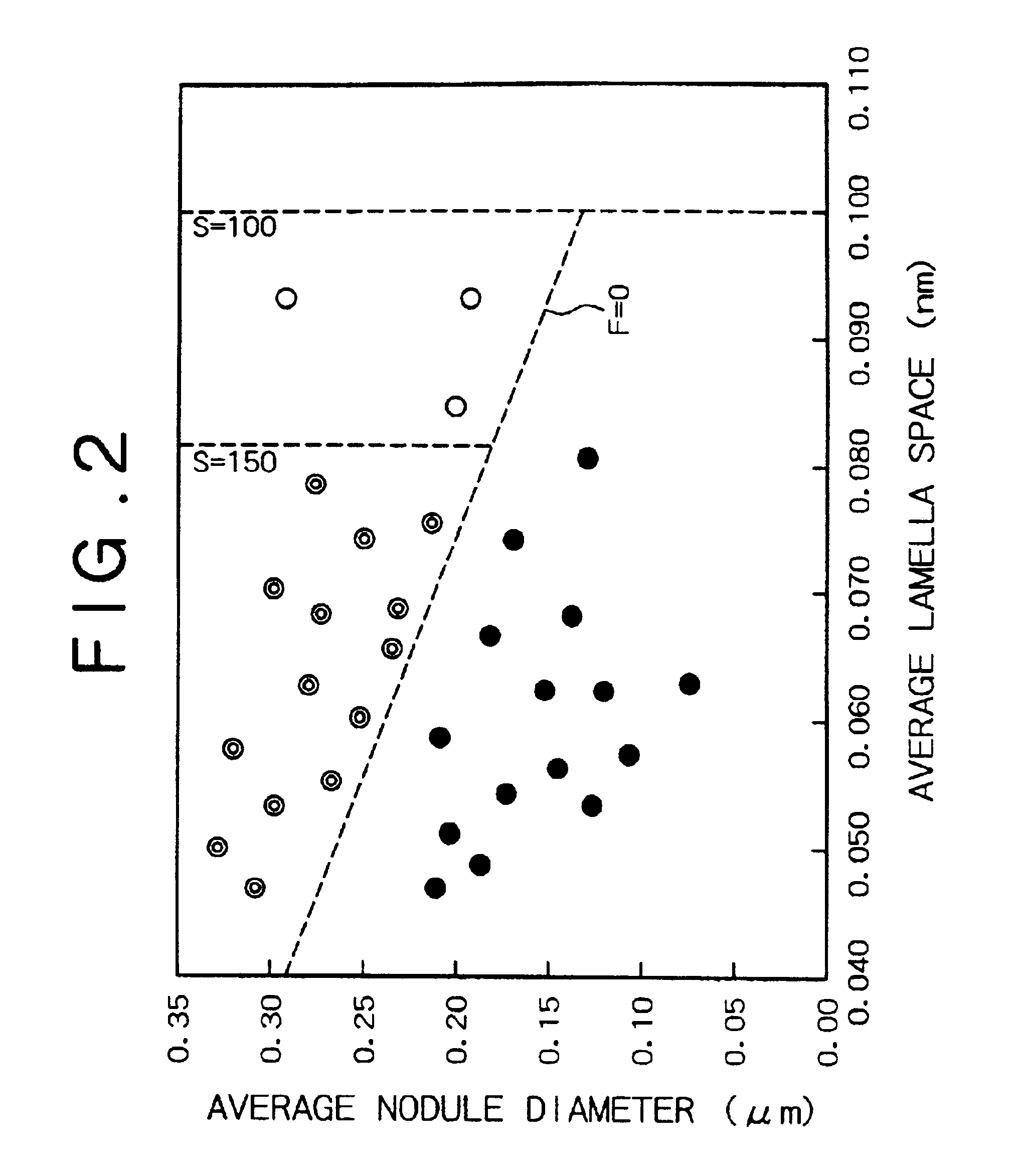

InactiveUS6783609B2Good stretchabilityImprove fracture resistanceFurnace typesHeat treatment furnacesWire rodChemical composition

A high-carbon steel wire rod with superior drawability which has the chemical composition (in mass %) of C: 0.6-1.0%, Si: 0.1-1.5%, Mn: 0.3-0.9%, P: no more than 0.02%, S no more than 0.03%, N: no more than 0.005%, (optional Nb: 0.020-0.050% and V: 0.05-0.20%), with the remainder being Fe and inevitable impurities, and the structure which is characterized in that pearlite accounts for no less than 95 area % and pearlite has an average nodule diameter (P mum) no larger than 30 mum and an average lamella space (S nm) no smaller than 100 nm such that the value of F calculated by the formula below is larger than zero

Owner:KOBE STEEL LTD

Blood processing filter

ActiveUS7641794B2Sufficient strengthHigh pressureOther blood circulation devicesHaemofiltrationWhite blood cellEngineering

A flexible blood filter allowing smooth flow of a liquid and being excellent in separation resistance, pressure resistance and centrifugation resistance. The blood processing filter, includes a first filter element for removing aggregates from blood, a second filter element for removing leukocytes provided in the downstream of the first filter element, and a third filter element having gas permeability of 3 to 40 cc / cm2 / sec per thickness of 1 cm provided between the second filter element and the outlet port. The filter contains a seal zone at a peripheral section which contains five layers including a layer of molten material and layers of molten material mixed with filter element material.

Owner:ASAHI KASEI MEDICAL CO LTD

Coating composition and coated paper

ActiveUS20140050922A1Improve fracture resistanceReduce riskCoatings with pigmentsCellulose coatingsCellulosePigment

A coating composition for forming a paper coat includes nano-fibrillated cellulose, pigment, latex, an auxiliary additive, and water. On a dry weight basis, the nano-fibrillated cellulose is in an amount by weight of 0.02 parts to 10 parts in the total composition, the pigment is in an amount by weight of 75 parts to 95 parts in the total composition, the latex is in an amount by weight of 5 parts to 15 parts in the total composition, and the auxiliary additive is in an amount by weight of 0.35 parts to 10 parts in the total composition.

Owner:GOLD EAST PAPER JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com