Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174results about How to "High tear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oilfield ultrahigh-pressure acid-resistant rubber seal material and preparation method thereof

ActiveCN103396591AOvercome leaksOvercoming extrusion edge tearing phenomenonOther chemical processesPolymer scienceAntioxidant

An oilfield ultrahigh-pressure acid-resistant rubber seal material comprises, by weight, 85-65 parts of hydrogenated butadiene-acrylonitrile rubber, 15-35 parts of butadiene-acrylonitrile rubber, 5-7 parts of zinc oxide, 1-4 parts of stearic acid, 1-2 parts of an antioxidant, 50-65 parts of nanometer carbon black, 15-25 parts of white carbon black, 5-10 parts of a phenolic resin, 5-10 parts of a softener, 3-6 parts of a peroxide vulcanizing agent, 6-8 parts of a vulcanizing aid, 1-3 parts of sulfur, and 2-4 parts of a promoter, wherein the sum of the weight parts of the hydrogenated butadiene-acrylonitrile rubber and the butadiene-acrylonitrile rubber is 100. A seal ring made through adopting the rubber seal material can satisfy the seal of oilfield high-pressure acid-resistant liquid (hydrochloric acid or hydrofluoric acid) pipelines, and overcomes the leakage and torn edge extrusion phenomena of seal members under a high hydraulic pressure.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Production technology of medical fabric

ActiveCN107299540ASoft touchImprove tear resistanceMedical preparationsCoatingsEngineeringResin coating

The invention discloses a production technology of a medical fabric. The technology comprises the following steps of grey fabric weaving, desizing, drying, splashing and sizing, calendering treatment, and coating of a double-sided coating, wherein the calendered surface of the fabric is coated with a PU resin coating with water pressure resistance; the PU resin coating is divided into a PU polyether two-component base material and a PU one-component fabric for separate coating; after the calendered surface is coated, the fabric is dried through high-temperature oven until being rolled up, and the other side of the fabric is coated with an organic silicone coating, and high-temperature drying is carried out to obtain the medical fabric. The tissue style characteristics of the woven fabric are integrated, and coating finishing is carried out on the front and reverse sides of the fabric, so that the fabric has the characteristics of being waterproof, easy to decontaminate and high in tenacity, and the production technology is suitable for the medical fabric.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

High-intensity low-gramweight embossing casting film and manufacture method thereof

An embossing and casting film with high intensity and low gram weight consists of a first flexible outer layer and a second flexible outer layer; wherein, a rigid bracing layer is arranged between the first flexible outer layer and the second flexible outer layer, and is respectively connected with the first flexible outer layer and the second flexible outer layer in an attaching way. The thickness of the rigid bracing layer is 1.3-1.8 times of that of the first flexible outer layer or the second flexible outer layer. The method for manufacturing the embossing and casting film with high intensity and low gram weight comprises the steps that a three-layer co-extrusion casting machine is used for extruding polyethylene material according to the structure of the first flexible outer layer-the rigid bracing layer-the second flexible outer layer. The invention promotes the intensity and the tenacity of the casting film with low gram weight by utilizing the flexible outer layers, provides good hand feeling, enhances the effects of heat seal and printing with other materials, and improves the stiffness and the rigidity of the casting film with low gram weight by utilizing the rigid bracing layer. Therefore, the technical problems of poor mechanical intensity and easiness producing of crease of the casting film with low gram weight in the prior art are solved.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

Easy open envelope

InactiveUS20030015581A1Easy to startHigh tear performanceEnvelopesPaper/cardboardAerospace engineering

Owner:ENVELOPE PROD GROUP

Filled polystyrene tear back container lids

The invention relates to tear-back thermoformed high impact polystyrene lids having from at least 10% to about 15% of filler and the specified configuration of the tear-back portion. In particular, the tear back lid comprises a tear back portion defined by two sets of tear back indentations and a left and a right notch cut into a skirt defined by the outer diameter of the lid. The combination of the filler amount and tear-back configuration allows an improved tearability for the filled polystyrene lids.

Owner:GPCP IP HLDG LLC

Nano material modified rubber V strip

The invention provides a modified rubber V belt made of nano-material, which comprises rubber matrix, vulcanizing agent, accelerators, stearic acid, antioxidant, softener and carbon black, and comprises further nano-zinc oxide and nano-calcium carbonate. The product is made with 2.5 to 10 portions of the nano-zinc oxide and 5 to 50 portions of nano-calcium carbonate on the basis of 100 portions of rubber matrix. Mechanical property, wear resistance, compression set and tearing property of the rubber can be improved obviously and the performance of the finished product is improved with indirect zinc oxide being replaced by the nano-zinc oxide, soft semi reinforcing carbon black being replaced by the nano-calcium carbonate.

Owner:SANLUX

High polymer self-adhesive glue film waterproof roll adopting pre-laid stick side up construction method and production method of roll

InactiveCN104354432AAchieve full stickinessSolve the problem of failureSynthetic resin layered productsChemical reactionTear resistance

The invention discloses a high polymer self-adhesive glue film waterproof roll adopting a pre-laid stick side up construction method and a production method of the roll. The high polymer self-adhesive glue film waterproof roll comprises a main high polymer waterproof layer, a self-adhesive glue layer, an anti-sticking layer and a PET film overlapped edge layer, the high polymer self-adhesive glue film waterproof roll has the service life of 70 years above, and has the tensile strength of 750N / 50mm above; the nail rod tear resistance is 500N above, the peel strength between the roll and post-pouring concrete is 2.5N / 50mm, and the peel strength between rolls is 2.5N / 50mm. According to the waterproof roll disclosed by the invention, the self-adhesive glue layer and the post-pouring concrete can be subjected to a chemical reaction to be cured to form an integrated body, so that full adhesion between the main waterproof layer and the structural concrete can be realized, and the problem of seepage and channeling of underground water or failure of the main waterproof layer caused by foundation settlement can be effectively solved.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

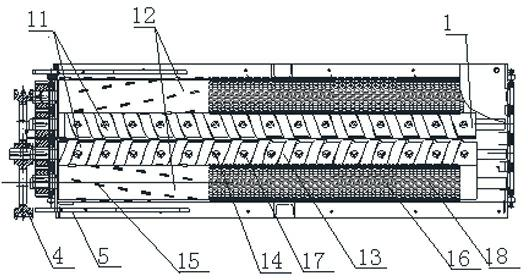

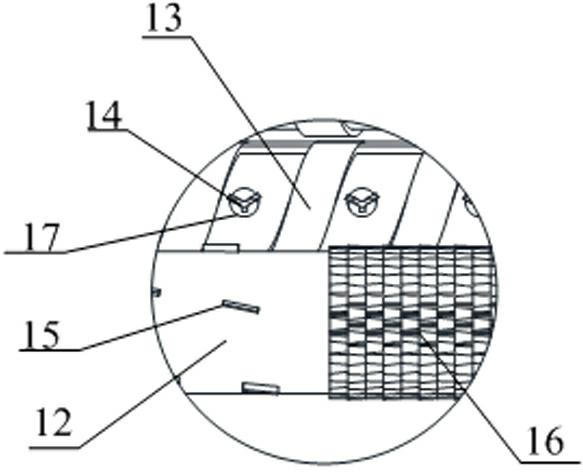

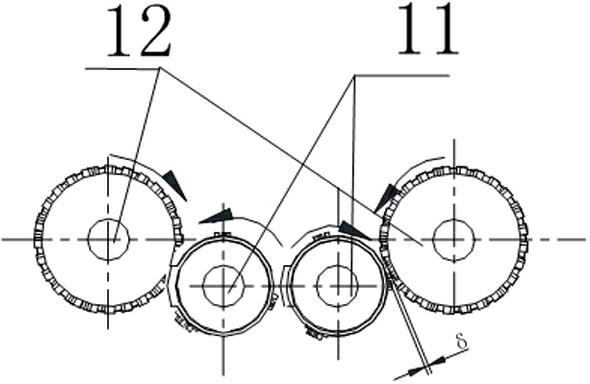

Roller type crushing device

InactiveCN101011673AIncrease contact areaReduce energy consumptionGrain treatmentsEngineeringEnergy consumption

The rolling crusher comprises at least a set of main shaft, each comprising at least two main shafts in parallel position, crushing roll on the main shaft with several convexes and concaves in wave like distribution, with the adjacent convex and concave of two crushing roller matching with each other with gaps between them. The crushed material goes through the gap between the crushing rollers with pressing and tearing. It has low noise, high output, low energy consumption, feasible for the crushing of food and forage.

Owner:JIANGSU MUYANG GRP CO LTD

Waterstop of nano material modified rubber

InactiveCN1597830AImprove stress resistanceImprove aging resistanceOther chemical processesPolymer scienceSulfur

The invention relates to a nano-material modified rubber water-stop belt, composed of a belt body and a central hole in the belt body, and containing in weight share: natural rubber 100 shares, nano-zinc oxide 2-3 shares, stearic acid 2-3 shares, accelerant CZ 1-1.5 share; sulfur 1.5-2 shares, antiageing agent D 1-2 shares, antiageing agent 4010NA 1-2 shares, carbon black N330 25-30 shares and nano-calcium carbonate 25-30 shares. It is increasing compression deformation-resisting and age-resisting property, prolonging its service life and simultaneously improving its dynamic property, strengthening its wearability and tearing strength and reducing the cost.

Owner:李树奎

Aluminium hydroxide flame retardant adhesive and preparation method thereof

The invention discloses an aluminium hydroxide flame retardant adhesive and a preparation method thereof, and belongs to the field of flame retardant materials. The aluminium hydroxide flame retardant adhesive comprises the following components in parts by mass: 40 parts of a chloroprene rubber adhesive, 60 parts of natural rubber, 2 to 5 parts of an anti-aging agent RD, 7 to 15 parts of phenolic resin 12687, 1 to 6 parts of stearic acid, 4 to 10 parts of magnesium oxide, 10 to 30 parts of argil, 10 to 30 parts of carbon black, 20 to 25 parts of aluminium hydroxide, 8 to 14 parts of paraffin oil, 1 to 3 parts of an accelerant M, 1 to 3 parts of an accelerant DM, and 2 to 4 parts of sulphur. Aluminium hydroxide is processed in a plastication starting stage by using a two-stage plastication way. The aluminium hydroxide flame retardant adhesive provided by the invention has a good flame retardant efficiency, the escape of combustible gases can be prevented by using aluminium hydroxide, the formation of soot is avoided, a better flame retardant and smoke suppression effect is played, the tensile strength is high, the stretch rate is good, the production process is simple, and the manufacturing cost and the manufacturing difficulty are lowered.

Owner:MAANSHAN TIANXIN ROLL IND

Easy open envelope

InactiveUS20020130169A1Easy to startHigh tear performanceEnvelopesPaper/cardboardSoftware engineeringMechanical engineering

Owner:ENVELOPE PROD GROUP

High-strength high-breathability polrvinyl chloride (PVC) preservative film

InactiveCN101948592AGood moisture permeabilityHigh mechanical strengthFruit and vegetables preservationZinc compoundsPolyvinyl chloride

The invention relates to a high-strength high-breathability polrvinyl chloride preservative film which comprises the following components in parts by weight: 100 parts of PVC resin (SG-4 type), 4-6 parts of calcium-zinc compound stabilizing agent, 0.5-1 part of stearic acid, 25-30 parts of dioctyl phthalate (DOP), 20-25 parts of 1,2-propylene glycol adipate, 2-5 parts of nano scale silicon dioxide (SiO2), 1-3 parts of silane coupling agent, 2-5 parts of nano scale calcium carbonate (CaCO3) and 1-3 parts of titanate coupling agent. The components are prepared into a film with a certain thickness through the working procedures of mediating, extruding, blow molding, and the like, and the film is used for retaining the freshness of agricultural products. The preservative film has the main technical characteristics that the tensile strength and the elongation at break of the preservative film are 10-30 percent higher than that of ordinary preservative films, the breathability rate is improved by 10-20 percent, and the preservative film has better packability to the agricultural products and good breathability and can effectively prevent frosting.

Owner:天津市食品加工工程中心

High-efficiency and low-breakage corn ear peeling device

InactiveCN102274771AImprove grip and tear abilityIncrease contact areaGrain huskingGrain polishingWaxy cornMetal strips

The invention relates to agricultural machinery, in particular to a peeling mechanism for removing bracteal leaves from fresh corn ears, in particular to a device for efficiently peeling corn ears at a low smashing rate. The device comprises a feeding hopper, a discharging hopper, a transmission system and a frame, wherein the frame is provided with an engine base; the engine base is provided with a peeling roller device; the peeling roller device comprises at least two pairs of peeling rollers which are meshed in parallel with each other; the peeling rollers consist of fixed peeling rollers and floating peeling rollers; the surface of each fixed peeling roller is provided with metal strip-shaped spiral bumps and inverted V-shaped bracteal leaf cutting teeth; the floating peeling roller close to one side of the feeding hopper is provided with rasp bar-shaped peeling teeth; and the other side is provided with rubber trapezoidal peeling teeth. The device is particularly suitable for fresh corns (such as fruit corns, waxy corns and sweet corns) with high moisture and tight bracteal leaves, fodder corns, corn seeds and the like, and has a good peeling effect, high efficiency and low smashing rate.

Owner:GANSU AGRI UNIV

Brominated butyl/chlorinated butyl rubber composition and preparation method thereof

The invention relates to a brominated butyl / chlorinated butyl rubber composition for gas masks. The composition comprises the following components in parts by weight: 100 parts of rubber matrix, 50-60 parts of carbon black N220, 5 parts of zinc oxide, 0.1-0.5 part of sulfur, 1 part of stearic acid, 1-4 parts of plasticizer (paraffin oil: DOP (dioctyl phthalate): DBP (dibutyl phthalate) is 2: 1: 1), 2 parts of promoter, 1 part of anti-aging agent and 0.5 part of anti-scorching agent, wherein the rubber matrix is composed of brominated butyl rubber and chlorinated butyl rubber. As for vulcanized rubber prepared by using the brominated butyl / chlorinated butyl rubber composition, the tensile strength is 18.50MPa, the elongation at fracture is 539%, the 300% stretching strength is 9.30MPa, the tearing strength is 39.45kN.m<-1>, the Shore hardness is 54, the tension set is 10%, and the brittleness temperature is -50 DEG C; and after the vulcanized rubber is aged in hot air (70 DEG C * 72h), the tensile strength is 17.91MPa, the elongation at fracture is 569%, the aging coefficient achieves 100%, the sustainable time of resisting mustard gas of the vulcanized rubber is greater than 3600min, and the comprehensive performances of the vulcanized rubber can completely meet the performance requirements of cover body materials of the gas masks.

Owner:NANJING UNIV OF SCI & TECH

Foamed shoe sole material and preparation method thereof

The invention relates to a foamed shoe sole material and a preparation method thereof. The shoe sole material comprises, by weight, 100 parts of rubber body, 35-45 parts of filler, 25-35 parts of operating oil, 1-4 parts of accelerant, 0.5-1 part of stearic acid, 3-7 parts of zinc oxide, 25-50 parts of white carbon black, 20-30 parts of modified kaolin, 2-5 parts of silane coupling agent, 1-5 parts of inorganic nano crystal whisker, 0.5-3 parts of 4,4-oxybis(benzenesulfonyl hydrazide), 0.3-1.5 parts of paraffin, 5-8 parts of polyethylene glycol, 1-3 parts of styrenated phenol, 1-3 parts of phenolic resin and 1.5-4 parts of sulfur. The foamed shoe sole material has more uniform foaming holes, the weight of a shoe sole is reduced, and meanwhile, the shoe sole material has relatively high wear resistance. The foamed shoe sole material is high in abrasion and light, and can be conveniently used for preparing mountaineering shoe soles and tennis shoe soles.

Owner:GUANGZHOU WEIZHEN CHEM TECH CO LTD

Anti-siphon non-woven fabric and manufacturing method thereof

InactiveCN106048893AStrong tear performanceGood bending performanceLiquid/gas/vapor removalNon-woven fabricsPolyesterWoven fabric

The invention discloses an anti-siphon non-woven fabric and manufacturing method thereof. Raw materials of the anti-siphon non-woven fabric includes the following components in parts by weight: 50 to 70 parts of polyester fiber and 30 to 50 parts of low-melting cotton, wherein the polyester fiber includes two dimensions of 16D*51mm and 6D*51mm, and the dimension of the low-melting cotton is 4D*51mm. Common polyester fiber and low-melting cotton are subjected mixed opening according to proportion, then enter a carding machine to be carded to form a web, are then subjected to lapping stacking through a lapping machine, are then subjected to high-speed needle punching interweaving, and are then subjected to hot-pressing shaping, thereby obtaining a base fabric, and the base fabric is put in a soaking pool of a waterproof blending agent to be soaked and are dried, thereby obtaining the anti-siphon non-woven fabric. The anti-siphon non-woven fabric has the characteristics of high tension and tear resistance, good bending performance and good waterproof effect, and satisfies requirements of outdoor equipment products.

Owner:ENPING YIMA ENTERPRISE

Method for improving strength of wastepaper fibers based on nanometer microcrystalline cellulose

InactiveCN105113320AImprove tensile strengthHigh burst resistancePaper/cardboardInorganic compound additionFiberUltimate tensile strength

The invention relates to a method for improving the strength of wastepaper fibers based on nanometer microcrystalline cellulose. The method comprises the following steps: preparing the nanometer microcrystalline cellulose and a wastepaper pulp; taking a certain amount of the pulp, adding a proper amount of water, sequentially adding calcium carbonate, a cationic polyacrylamide solution and a nanometer microcrystalline cellulose suspension, and defibering in a GBJ-A fiber standard dissociator; shaping the defibered pulp in the shaping position of a ZQJ1-B-II paper handsheet former to obtain wet paper; and transferring the wet paper to a position between two dry cloths, carrying out a squeezing technology to remove a certain amount of water, and carrying out vacuum drying at 105DEG C for 15min to obtain dry paper. The method has the advantages of simple process, no need of arrangement of any devices, and easy operation control, and is of great guiding significance to efficient application of wastepaper fibers and enterprise production adopting wastepaper as a raw material.

Owner:ZHEJIANG SCI-TECH UNIV

Equipment for manufacturing easy-tear type thin plastic film

Owner:ZHEJIANG GOLDSTONE PACKING

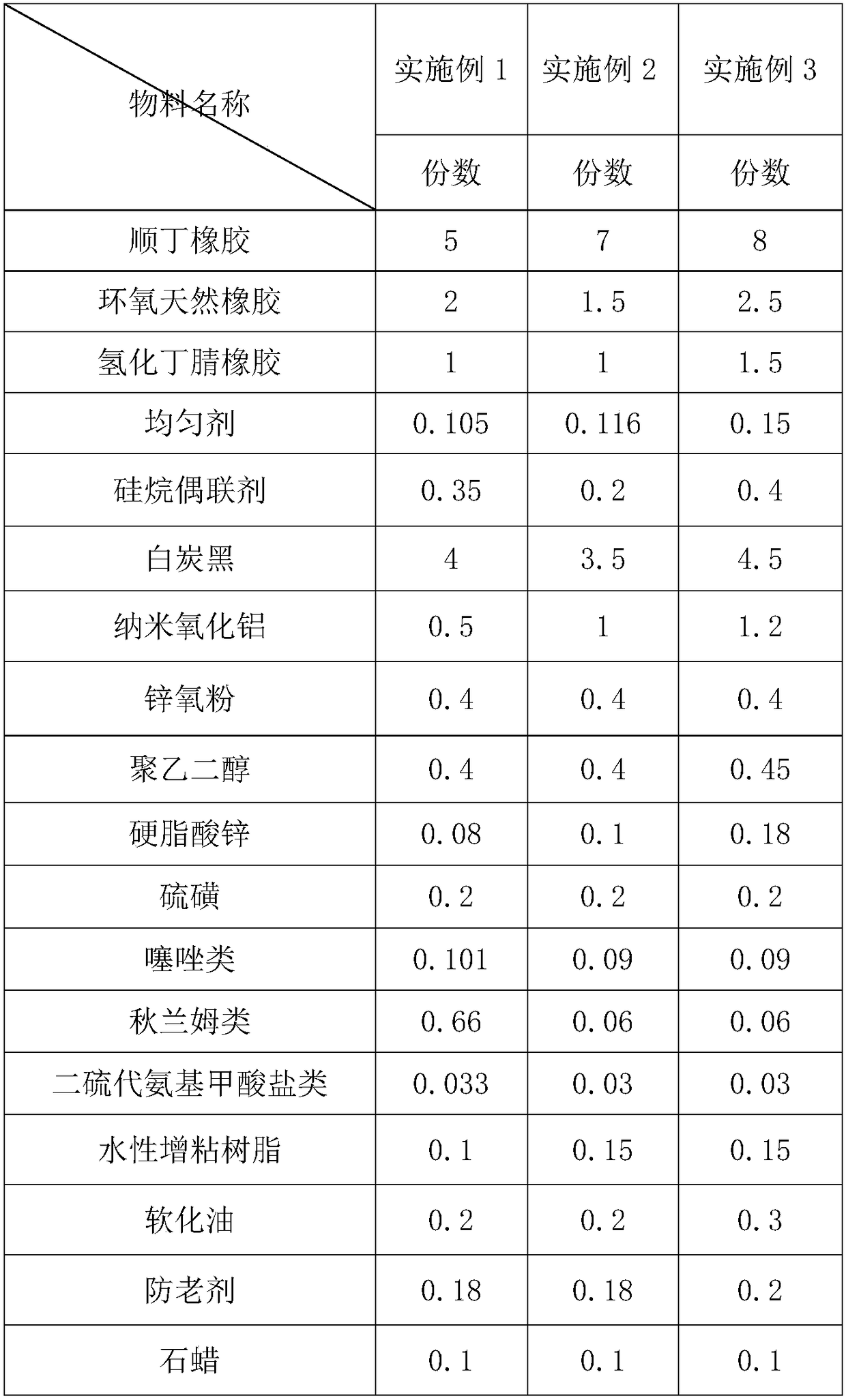

Wear-resistant rubber for sports shoe soles and preparation method thereof

The invention discloses wear-resistant rubber for sports shoe soles. The wear-resistant rubber for the sports shoe soles comprises the following components in parts by mass: 50-80 parts of butadiene rubber, 10-30 parts of epoxy natural rubber, 5-20 parts of hydrogenated butadiene-acrylonitrile rubber, 1-2 parts of a homogenizing agent, 2-5 parts of a silane coupling agent, 25-65 parts of a reinforcing agent, 2-5 parts of zinc oxide powder, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 1.5-2 parts of a vulcanizing agent, 1.6-2.1 parts of an accelerator, 0.5-2 parts of a tackifier, 2-5 parts of a softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the wear-resistant rubber for the sports shoe soles. Wear-resistant rubber shoe soles for the sports shoe soles, prepared according to the technical scheme adopted by the invention, have super wear resistance which is incomparable with that of ordinary rubber soles, and have many properties such as good weather resistance and folding resistance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

High-performance natural rubber/butadiene styrene rubber composite material

The invention discloses a high-performance natural rubber / styrene-butadiene rubber composite material. The raw materials include: natural rubber, styrene-butadiene rubber, rare-earth isoprene rubber, zinc oxide, stearic acid, sulfur, benzoyl peroxide, and an accelerator CZ, accelerator DM, accelerator NOBS, antioxidant, light calcium carbonate, magnesium oxide, calcium hydroxide, graphene oxide, bamboo charcoal powder, aluminum silicate, diatomaceous earth, sodium montmorillonite, benzyl triphenyl Phosphorous chloride, polyethylene glycol. The high-performance natural rubber / styrene-butadiene rubber composite material proposed by the invention has high strength, good heat resistance and wear resistance, can meet the use requirements of various fields, and has a long service life.

Owner:合肥市再德高分子材料有限公司

Tread rubber compound with low rolling resistance and high wear resistance and preparation method thereof

ActiveCN107312218AReduce cohesionGood dispersionSpecial tyresRolling resistance optimizationWaxButadiene-styrene rubber

The invention discloses a tread rubber compound with low rolling resistance and high wear resistance and a preparation method thereof. The compound comprises the following raw materials: 20 parts of natural rubber, 25 parts of butadiene rubber, 75 parts of styrene-butadiene rubber, 70 parts of carbon black, 8 parts of an environmentally-friendly peptizing agent, 0.5 part of stearic acid, 2.5 parts of zinc oxide, 2 parts of an antioxidant 4010NA, 1.5 parts of protective wax, 1 part of tackifying resin, 2 parts of aramid staple fibers, 2 parts of a binder, 1.5 parts of sulfur, 1.4 parts of an accelerant CZ, 1 part of ginger fibers and 2 parts of potato fibers. After the potato fibers are added, a three-dimensional fibrous network structure of the potato fibers binds the ginger fibers firmly, so that the performance of rubber products is overall enhanced, the ginger fibers are wrapped with the potato fibers, so that active free radicals of the potato fibers can promote the binding with a rubber base body; the use of waste facilitates the environmental protection.

Owner:QINGDAO UNIV OF SCI & TECH

Blend rubber of silicone rubber and ethylene propylene diene monomer, and preparation method thereof

The invention belongs to the field of organic silicon materials, and particularly relates to blended rubber of silicone rubber and ethylene propylene diene monomer, and a preparation method thereof. The blend rubber of the silicone rubber and the ethylene propylene diene monomer is prepared from the following raw materials: raw methyl vinyl silicone rubber, raw ethylene propylene diene monomer, fumed silica, hydroxyl silicone oil, hexamethyl disilazane, dimethyldimethoxysilane, a silane coupling agent, methyl-terminated hydrogen-containing silicone oil, distilled water, zinc oxide, cerium oxide, calcium stearate, an accelerator, dicumyl peroxide, sulfur and auxiliary cross-linking agent. The silicone rubber and the ethylene propylene diene monomer in the blend rubber are good in compatibility, and the blend rubber has good mechanical properties and certain aging resistance.

Owner:SHANDONG UNIV +1

Styrene butadiene rubber with novel styrene incorporation

InactiveUS20120010356A1Improve braking performanceImprove grip performanceSpecial tyresRolling resistance optimizationRolling resistanceButadiene-styrene rubber

The present invention relates to improved compositions of SSBR rubber. The improved compositions exhibit sufficient or improved balance of characteristics such as rolling resistance, HBU, abrasion, grip, and / or tear. The compositions may be made in an efficient, cost-effective manner.

Owner:TRINSEO EURO GMBH

Antimicrobial and mildew resistant preservative film and preparation method thereof

The invention provides an antimicrobial and mildew resistant preservative film and a preparation method thereof. The preservative film comprises the following raw materials in percentage by weight: 30-65% of a polymer, 3.5-12% of a natural antibacterial agent, 1.5-3% of sand sagebrush seed oil, 1.5-3% of cuttlefish bone, and 1.5-3% of glyceryl monooleate; the raw materials are subjected to various processing means to prepare the preservative film, and the prepared preservative film is bright, transparent, soft, thin and light, not only has excellent mechanical strength, ageing-resistant performance, good stretchability and tearing property, but also has the effects of being broad in antifungal spectrum, uniform in distribution, highly efficient, durable and safe, effectively inhibits the growth and reproduction of various malignant bacteria, fungi and mould, and at the same time, shows better barrier property, gas permeability, moisture-penetrability and gas replaceability, and automatically and persistently emits far infrared rays, so as to achieve the functions of purifying the environment, eliminating peculiar smell, self-cleaning and resisting mildew; besides, the preservative film provided by the invention can be directly used for storing various food, prolonging the preservation time, and has a broad application prospect.

Owner:陆思烨

Preparation method of wet strength agent for papermaking

InactiveCN106638144AHigh strengthHigh tear performanceReinforcing agents additionPaper/cardboardCellulosePhosphoric acid

The invention relates to a preparation method of a wet strength agent for papermaking and belongs to the technical field of preparation of wet strength agents. Chitosan is subjected to swelling treatment with anhydrous ethanol firstly and then modified with maleic anhydride and phosphoric acid, and modified chitosan is obtained; modified chitosan reacts with isocyanate, and a chitosan polymer is obtained; hydroxyl and amino in the chitosan polymer can form hydrogen bonds with cellulose in paper and can perform bridging and film formation among cellulose to enhance the wet strength and the tearing strength of paper; then, methyl benzene sulfonic chloride and other substances are utilized to modify hydroxypropyl guar gum, and modified guar gum is obtained; finally, modified guar gum is mixed with a chitosan polymer concentrated solution and other substances for ageing, and the wet strength agent for papermaking is obtained. The wet strength agent solves the problem that a conventional wet strength agent cannot improve the wet strength and the tear resistance of paper, improves the wet strength and the tear resistance of paper greatly, and can realize expanded production.

Owner:梅庆波

High-strength low temperature resistant cable sheath material

InactiveCN103992581AEasy to useLower embrittlement temperaturePlastic/resin/waxes insulatorsInsulated cablesMethacrylateAntioxidant

The invention discloses a high-strength low temperature resistant cable sheath material which is prepared as follows: putting polyvinyl chloride, unitary ethylene propylene rubber, rubber and ethylene-propylene-diene monomer rubber into a plasticator for plastication; melting and mixing acrylic acid grafted high density polyethylene and bentonite in a flowing deformation instrument to obtain a second material, sending a first material and the second material into a mixing machine to mix evenly, when the temperature is increased to 80-85 DEG C, sequentially adding an antioxidant, N, N '-ethylene distearic amide, zinc stearate, microencapsulated red phosphorus and white carbon black, when the temperature is increased to 125-132 DEG C, adding gamma-aminopropyltrimethoxysilane, triallyl cyanurate and zinc methacrylate, mixing, then extrusion-molding and cutting to obtain the high-strength low temperature resistant cable sheath material. The high-strength low temperature resistant cable sheath material is excellent in low temperature resistant performance, high in mechanical strength and thermal deformation temperature, and good in thermal stability.

Owner:JINYUAN ELECTRIC GRP

Method for preparing polyurethane-modified organosilicon double-component room-curing elastomer adhesive

ActiveCN105018015AEasy to operateShorten the production cycleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerAdhesive

The invention discloses a method for preparing a polyurethane-modified organosilicon double-component room-curing elastomer adhesive, which comprises the following steps: (1) uniformly mixing hydroxypropyl-terminated silicone oil and glycerol, and dehydrating to obtain a hydroxyl-terminated (-OH) component; (2) reacting aromatic polyisocyanate, the hydroxyl-terminated (-OH) component and dibutyltin dilaurate to obtain a component A; (3) adding vapor-phase silica white, carbon black and talcum powder into the container filled with hydroxy silicone oil and dihydroxy polysiloxane, adding a catalyst, adding 3-aminopropyl triethoxy silane, finally adding a defoaming agent, uniformly mixing, and drying to obtain a component B; and (4) uniformly mixing the component A and component B in a mass ratio of 12:(23.5-24), and curing at room temperature for 4-5 hours. The elastomer adhesive prepared by the method has the advantages of favorable tear resistance, excellent high / low temperature resistance and excellent binding property. The preparation method is easy to operate and accessible in raw materials, and lowers the preparation cost.

Owner:道一高分子聚合物(宁波)有限公司

Hybrid Janus nano-particles obtained through polymer grafting modification as well as preparation method and application thereof

ActiveCN104610573AImprove the mixing effectGood dispersionPigment treatment with macromolecular organic compoundsDispersityRubber material

The invention belongs to the field of rubber and plastic filler and particularly relates to polystyrene / silicon dioxide organic-inorganic hybrid Janus nano-particles grafted with polymers on the surface by utilizing a plurality of chemical reactions as well as a preparation method and an application thereof. According to the preparation method of the hybrid Janus nano-particles obtained through polymer grafting modification, the single spherical surface or dual spherical surfaces of the Janus nano-particles comprising polystyrene spheres and silicon dioxide spheres which are connected through chemical bonds are grafted with the polymers, wherein the dual spherical surfaces are grafted with the same or different polymers; after a rubber material is filled with the polystyrene / silicon dioxide organic-inorganic hybrid Janus nano-particles grafted with polymers, the dispersity is good, the stress at definite elongation and the general storage modulus of the rubber material are increased, the abrasive resistance, tearing resistance, strength and elongation at break are all obviously improved. Especially for different rubber blended systems, the Janus nano-particles grafted with different rubber molecules can remarkably improve the mixing effect of different rubbers, so that the general property of multi-element rubber can be given a full play.

Owner:QINGDAO UNIV OF SCI & TECH

Easily- tearable film

InactiveUS20010006736A1Better easy-tearabilityHigh tear performanceSynthetic resin layered productsDomestic containersPolymer scienceThin membrane

The present invention provides a film comprising a layer formed of a resin composition including (a) an olefine-based resin having a solubility parameter (SP value) of from 8.45 to 8.70 and containing therein no repeat unit derived from an aromatic vinyl compound [component (A)] and (b) a thermoplastic resin having a glass transition temperature of more than 50° C. and being made up of a repeat unit different than that of component (A) [component (B)] wherein the resin composition contains from 10 to 1800 parts by weight of component (A) based on 100 parts by weight of component (B), and the like, said film showing an improved easy-tearability, especially better linear tearability.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com