Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

621 results about "Calendering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calendering of textiles is a finishing process used to smooth, coat, or thin a material. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens.

Thermoplastic olefinic compositions

Thermoplastic olefinic compositions comprising (a) at least one ethylene / α-olefin polymer having a PRR between 8 and 70 and (b) at least one polypropylene polymer and an (a) / (b) weight ratio of greater than 50 / less than 50 to 90 / 10. The compositions are used in extrusion, calendering, blow molding, foaming and thermoforming processes to make a variety of articles, such as automotive instrument panel skins.

Owner:DOW GLOBAL TECH LLC

100% synthetic nonwoven wipes

InactiveUS20050133174A1Easy to processGood cross-directional strengthNon-fibrous pulp additionOrganic detergent compounding agentsPolyolefinPunching

The present invention relates to wipes comprising at least one layer of a 100% synthetic nonwoven web. The wipes may be provided as a single layer of nonwoven web, or may be provided in a laminate material, such as one comprising spunlaid-meltblown-spunlaid (SMS) webs. The 100% synthetic nonwoven webs of the present invention may be made via a process comprising a fiber laying step selected from the group consisting of spunlaying, meltblowing, carding, airlaying, wetlaying and combinations thereof. The 100% synthetic nonwoven webs of the present invention may be made via a process comprising a fiber bonding step selected from the group consisting of hydroentanglement, cold calendering, hot calendering, air thru bonding, chemical bonding, needle punching and combinations thereof. The nonwoven webs may also comprise one or more polyolefins. In one embodiment of the present invention, the nonwoven webs may be spunlaid and HET.

Owner:THE PROCTER & GAMBLE COMPANY

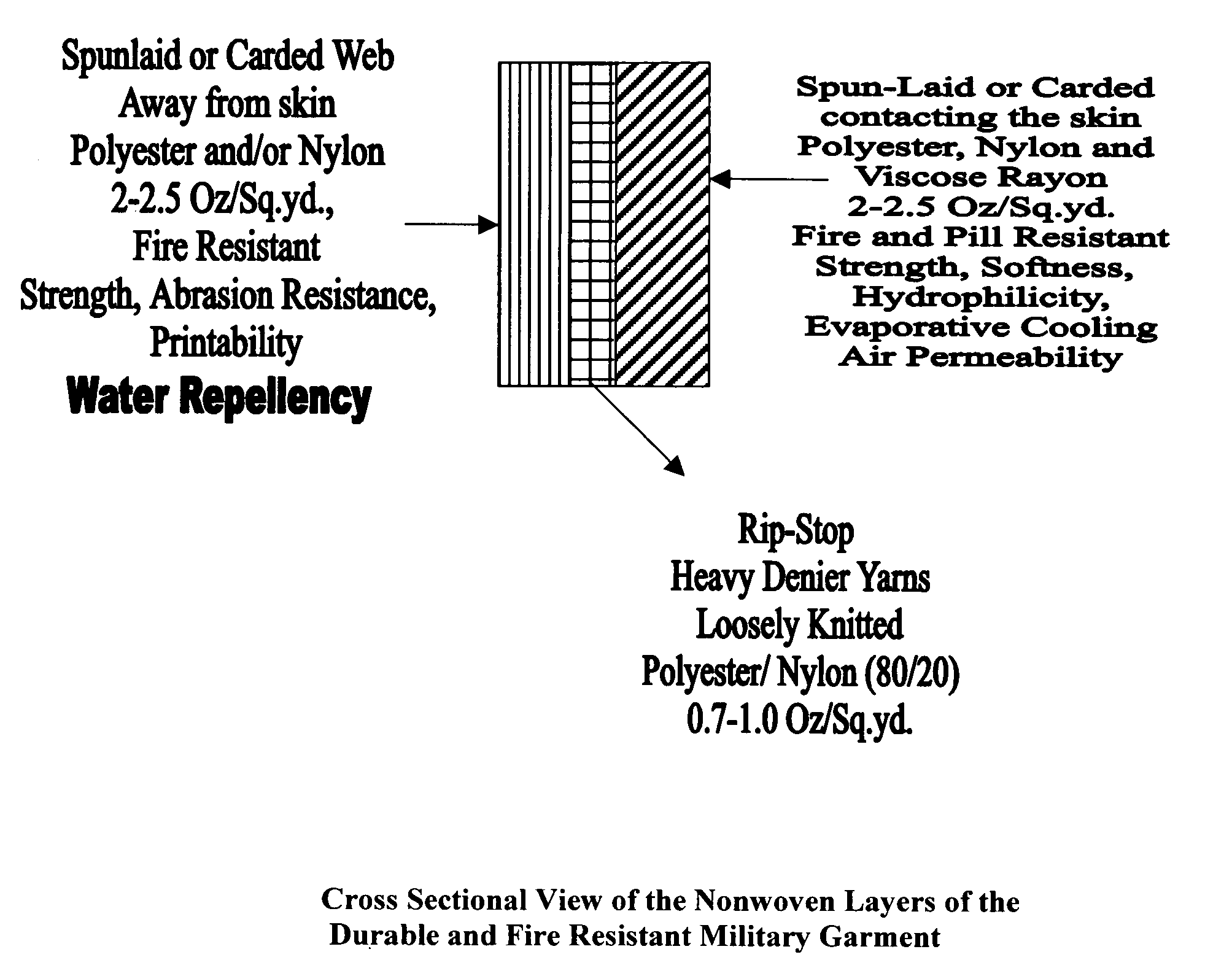

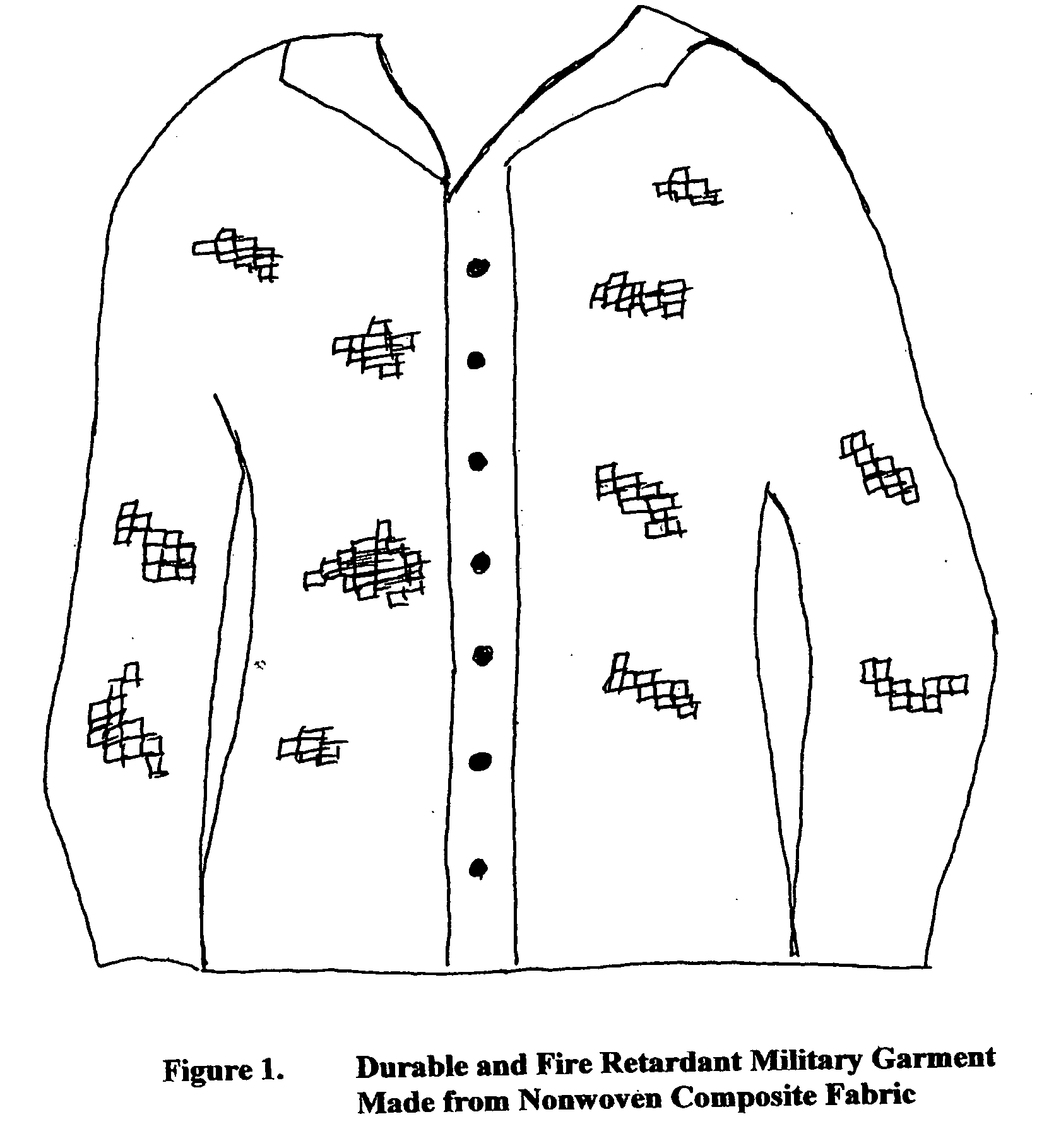

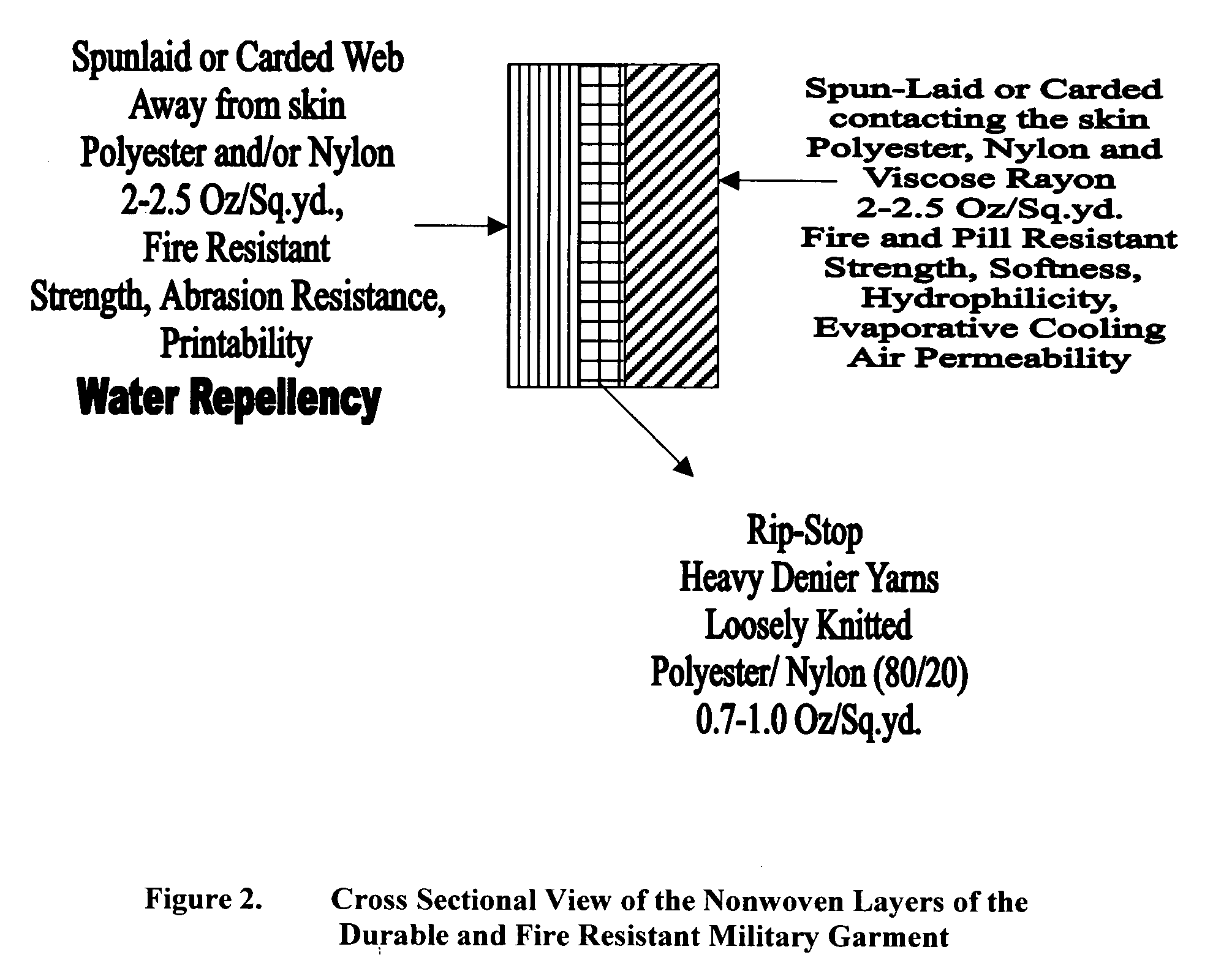

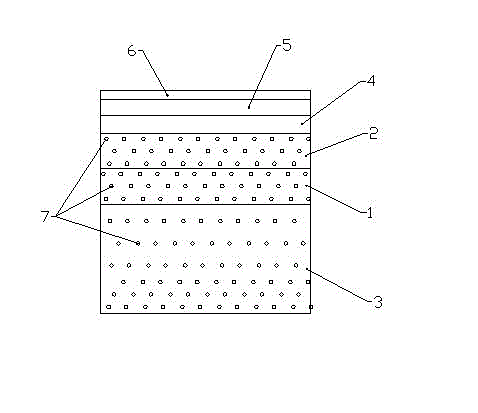

Durable and fire resistant nonwoven composite fabric based military combat uniform garment

InactiveUS20060035555A1Durable/wash resistant fire retardant chemicalImprove wear resistanceProtective equipmentLayered productsPunchingMilitary Uniforms

The present invention is directed to the design and manufacture of a durable, fire resistant, comfortable and economical nonwoven composite fabric based garment, which meets the stringent requirements of military combat uniform clothing. The nonwoven based garment is designed to replace the traditional woven textile fabric used in the military and outdoor sporting garments today. The novel garment of the current invention is constructed using a unique nonwoven composite fabric that exhibits mechanical, physical, durability and comfort characteristics similar to or better than that of the current woven military uniform fabric. In particular, the present invention contemplates the nonwoven composite fabric used to make the garment is prepared by combining at least two separate fire resistant nonwoven webs forming the inside and outside layers of the garment. An optional rip-stop element such as a loosely knitted fabric may be sandwiched between the two nonwoven webs to improve the tear resistance of the entire garment. Hydroentangling or needle-punching processes and subsequent thermal calendering / embossing techniques combine the individual nonwoven webs of the garment before dyeing, printing and finishing with traditional textile chemicals to form a composite fabric for stitching to make the garment.

Owner:NARAYANAN VASANTHAKUMAR +2

Adhesive tape for outdoor use

InactiveUS20030113534A1Improve initial viscosityReduce adhesionThin material handlingPressure sensitive film/foil adhesivesUltravioletChemistry

Transparent, UV and heat resistant adhesive compositions and associated methods of manufacturing using such compositions are provided. Exemplary methods of use include the utilization of the provided adhesive compositions as part of tape to be used outdoors where UV exposure is high. The present invention also provides a simple one-pass calendering process whereby the UV resistant adhesive compositions may be formed and extruded directly onto tape backing.

Owner:SCAPA NORTH AMERICA

Preparation method of flexible anisotropy bonding rare earth permanent magnet material

InactiveCN101800106AAbundant resourcesReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureMagnetizationRare earth

The invention discloses a preparation method of flexible anisotropy bonding rare earth permanent magnet material, belonging to the field of magnetic materials. The material is prepared by combining the two-step approach accompanying temperature magnetic field orientation technology of which the calendaring process and the accompanying temperature magnetic field orientation process are separated. A certain quantity of anisotropy magnetic powder which is performed with surface treatment by the processing agent in advance, binder and processing agent are evenly mixed; the mixed material is calendered into flaky flexible bonding magnetic body by the calendaring technology; then, the flaky flexible bonding magnetic body is cut into parts which are heated at certain temperature under the condition of heat preservation for certain time, after that, the obtained product is put into an orientation magnetic field for accompanying temperature magnetic field orientation; and the direction of the orientation magnetic field is parallel to the plane normal direction of the flaky flexible bonding magnetic body. In the preparation technology, magnetic powder can overcome the constraint of a bonding system and rotates under the action of magnetic field force to ensure that the direction of easy magnetization of the magnetic powder generally points to the orientation direction, and the magnetic property of prepared flexible anisotropy bonding rare earth permanent magnet material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

Weaving process of hemp textile product

InactiveCN101838876AHigh degree of automationEasy windingFabric breaking/softeningBiochemical fibre treatmentYarnEngineering

The invention discloses a weaving process of a hemp textile product, which comprises the process steps of winding, warping and weaving. Blended yarns bended by hemp fibers and cotton fibers are weaved by warps and wefts in the process, wherein the rotary speed of a grooved drum is 600 plus or minus 5r / min, and the ratio of hemp fibers to cotton fibers is 35:65. The process also comprises processing steps of refining, singeing, softening, drying and calendering. The hemp textile product produced by the invention has less filoplume, biodegradability, and excellent moisture absorbance and sweat release properties, keeps the natural antimicrobial and health-care functions of hemp, has good soft and comfortable properties, excellent ultraviolet resistance, radiation resistance and antibacterial properties, excellent high-temperature resistance and unique odor absorption and waste discharging properties; and the hemp textile product feels soft and comfortable compared with other hemp products, and is a new-generation environment-protection product.

Owner:SUNVIM GROUP

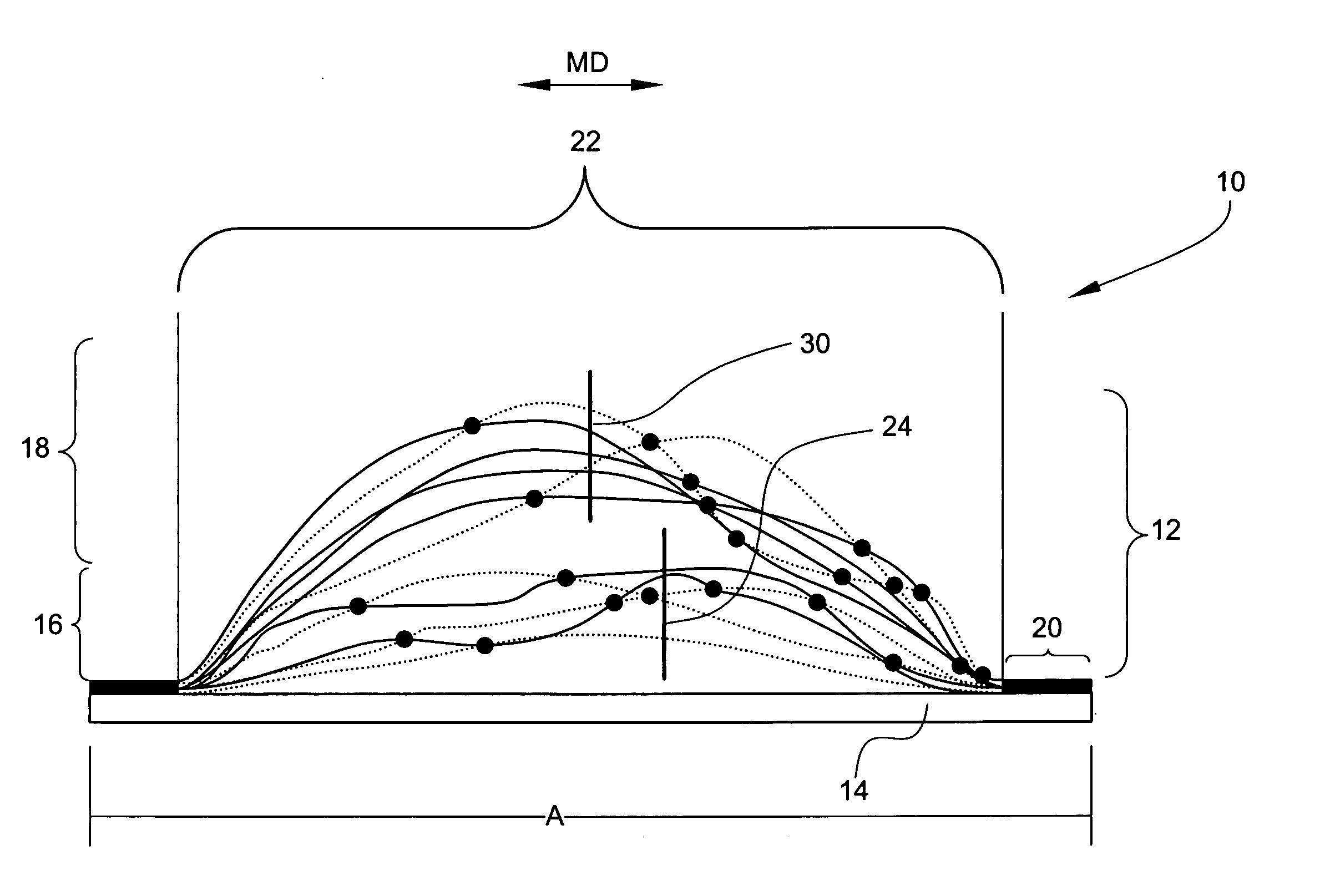

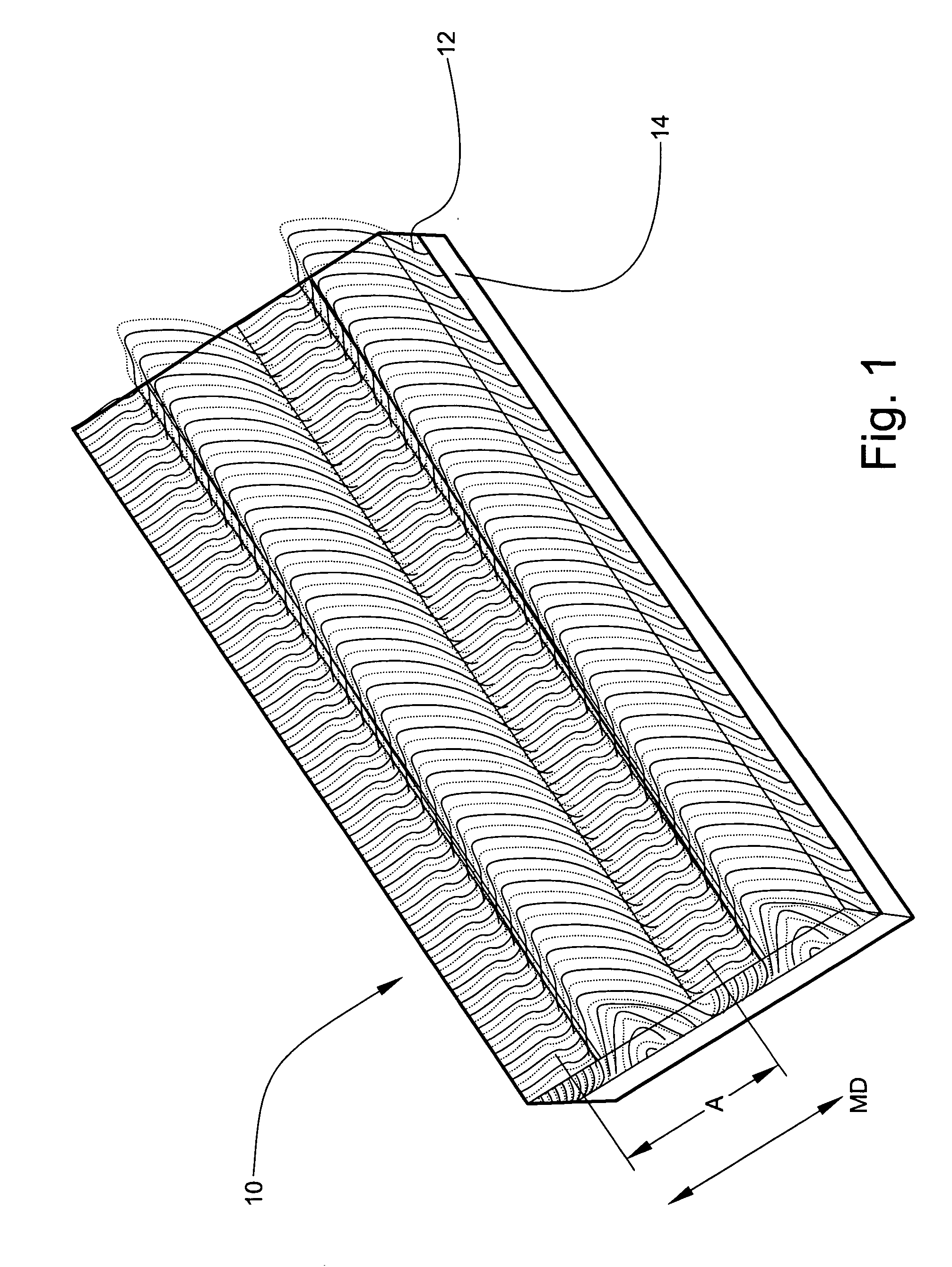

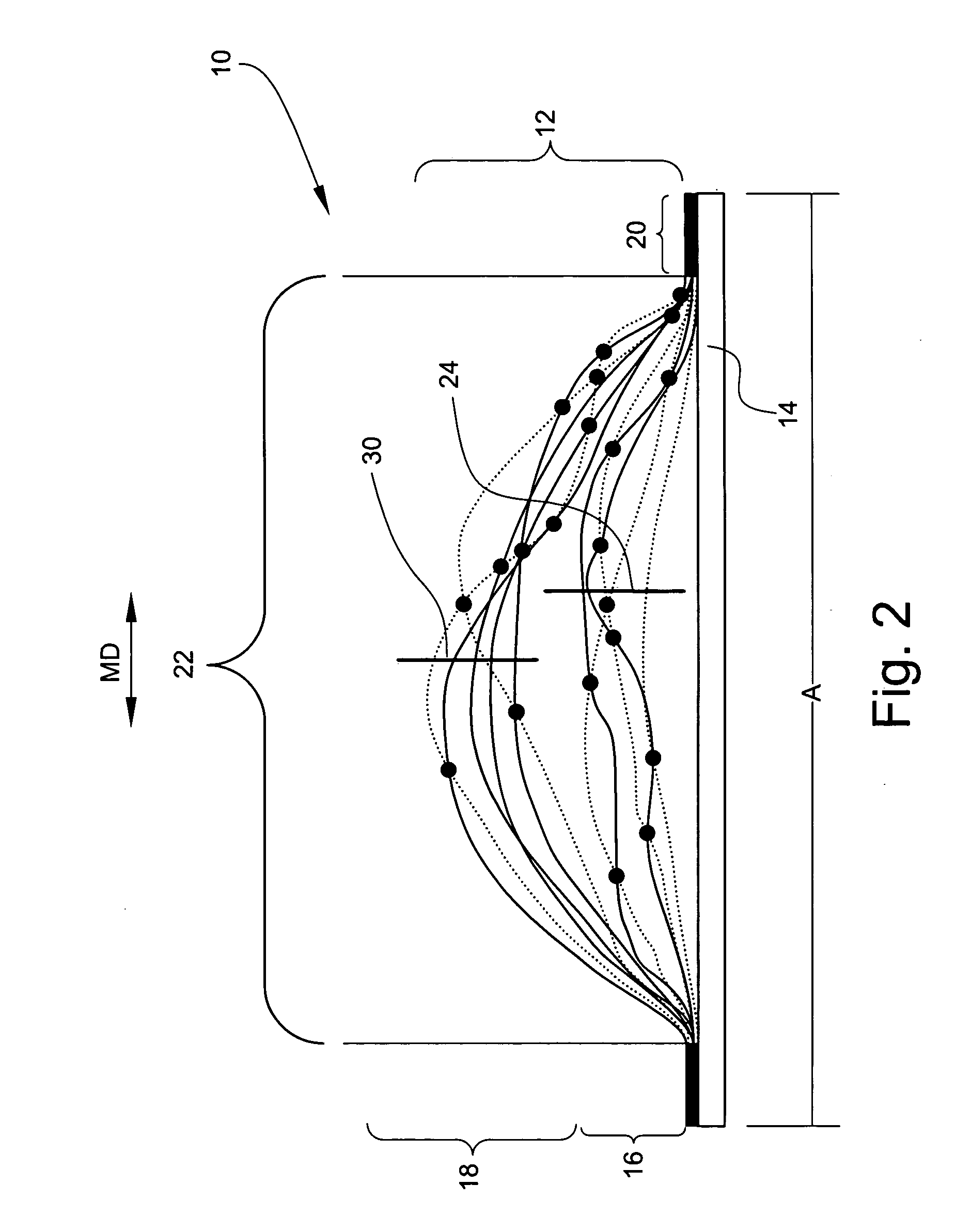

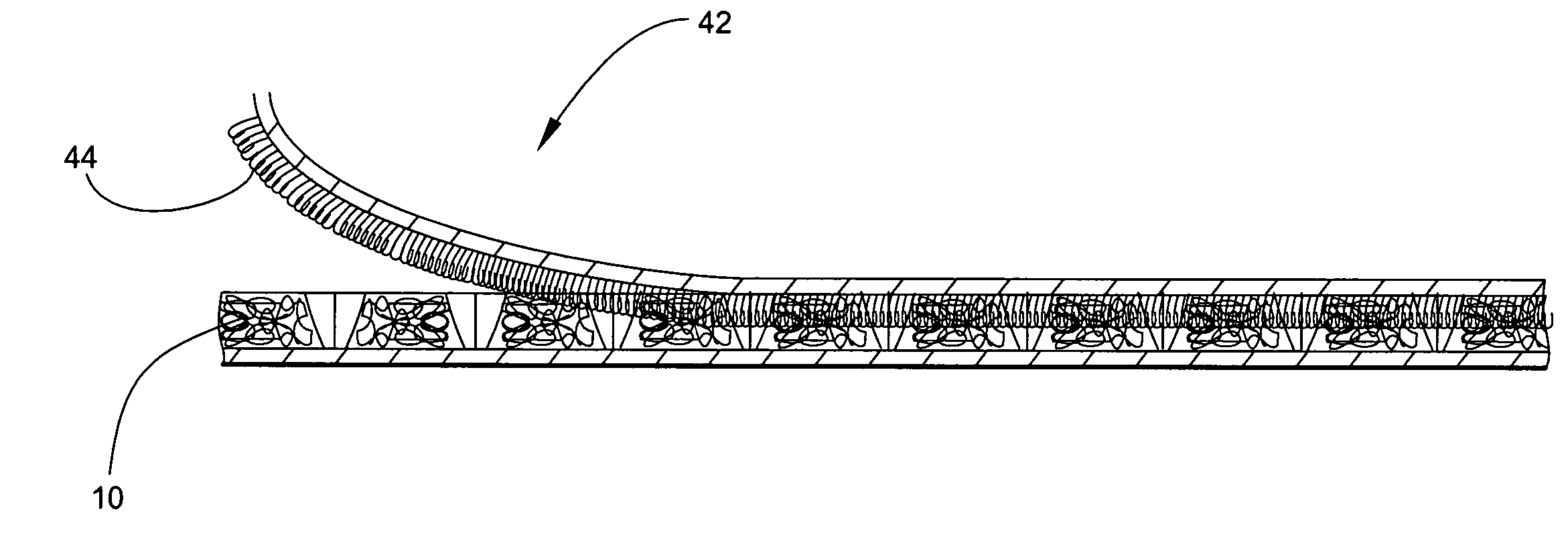

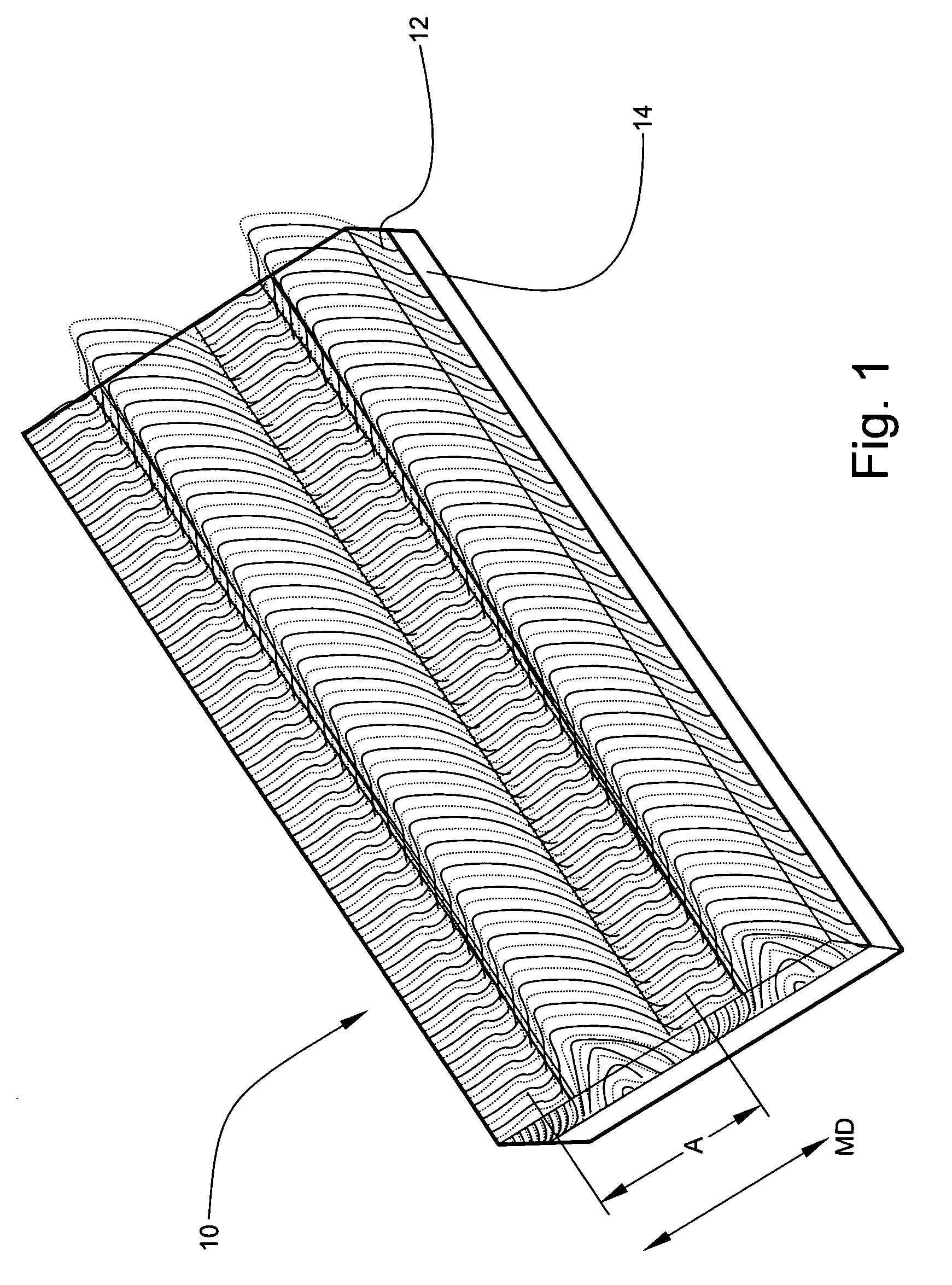

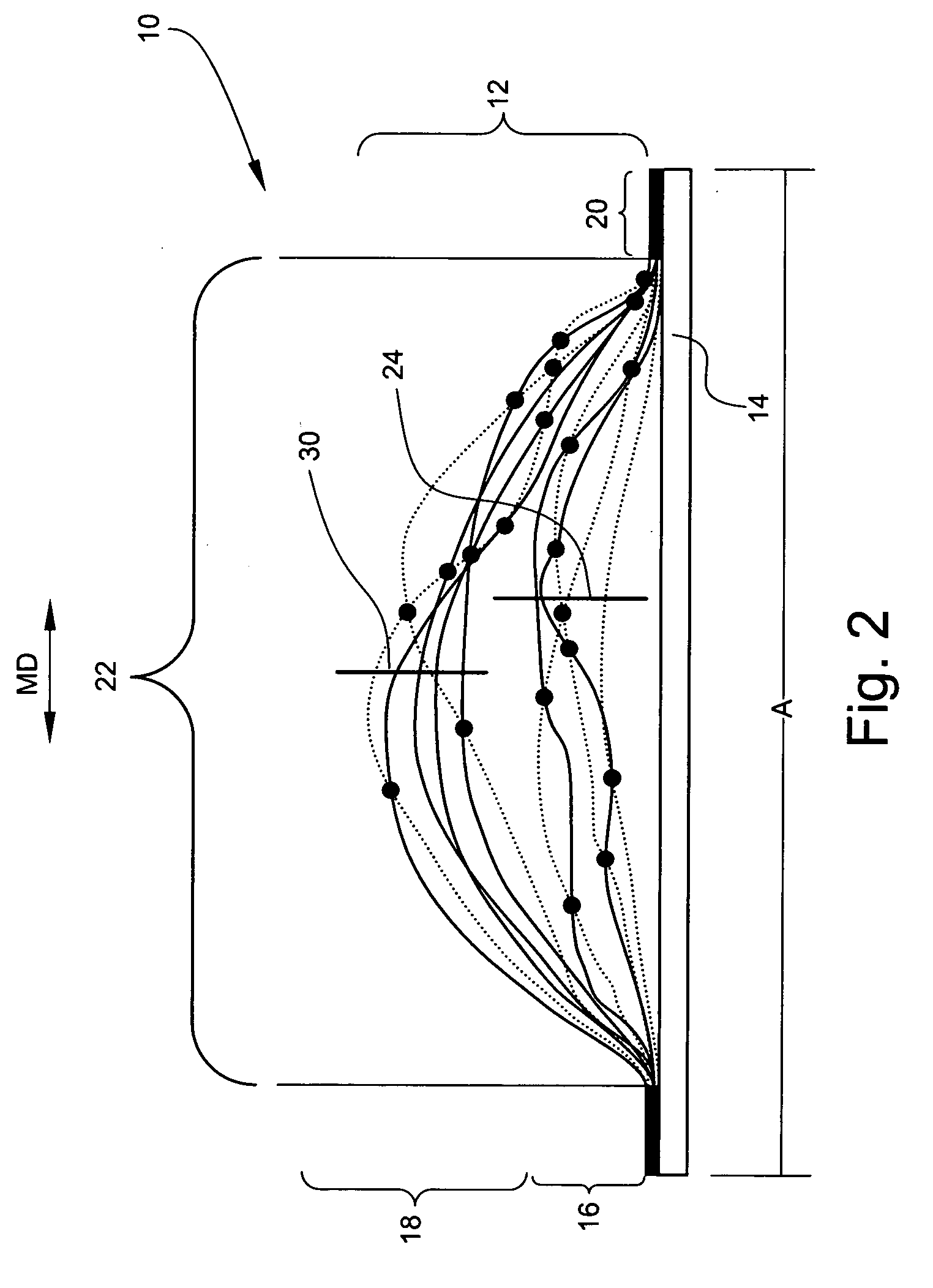

Hook and loop fastener device

The instant invention is a hook and loop fastener device. According to the instant invention, the hook and loop fastener device includes a loop component. The loop component includes a binder-free non-woven material having a bottom layer and a top layer. The bottom layer includes a first bicomponent fiber and a first monocomponent fiber. The first bicomponent fiber comprises the majority of the bottom layer based on total weight of the bottom layer, and the first monocomponent fiber comprises the balance thereof. The top layer includes a second bicomponent fiber, and a second monocomponent fiber. The second monocomponent fiber comprises the majority of the top layer based on total weight of the top layer, and the second bicomponent layer comprises the balance thereof. The bottom layer and the top layer may further include interfiber bonding to form the binder-free non-woven material. The non-woven material may further be island bonded via hot-roll calendering thereby forming a bonded area and a non-bonded area. Additionally, the loop component may include a backing layer bonded to the non-woven material.

Owner:APLIX SA

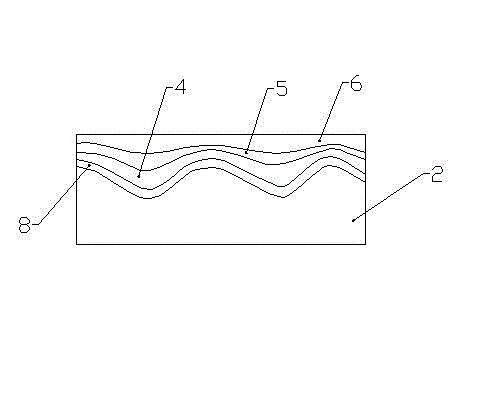

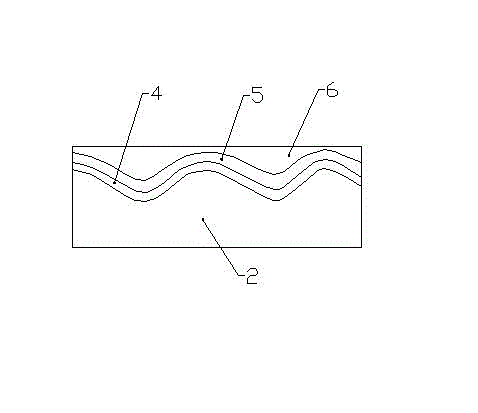

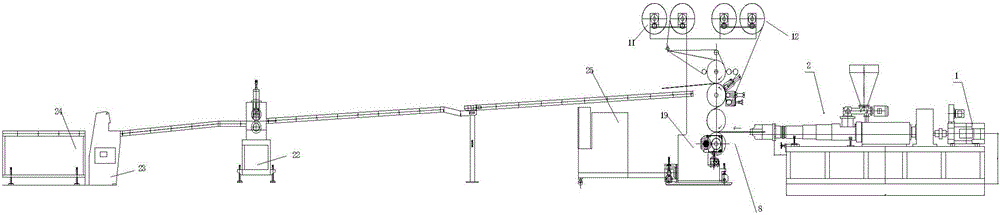

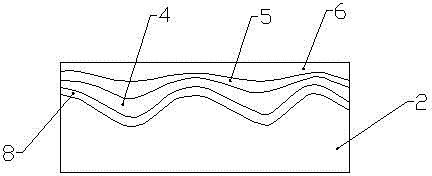

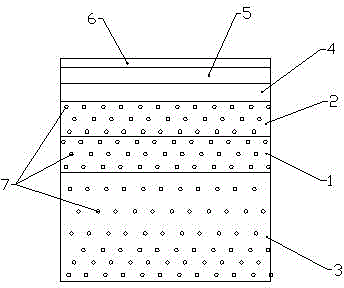

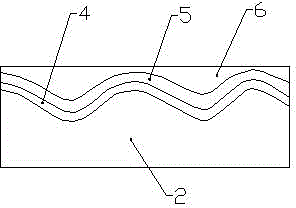

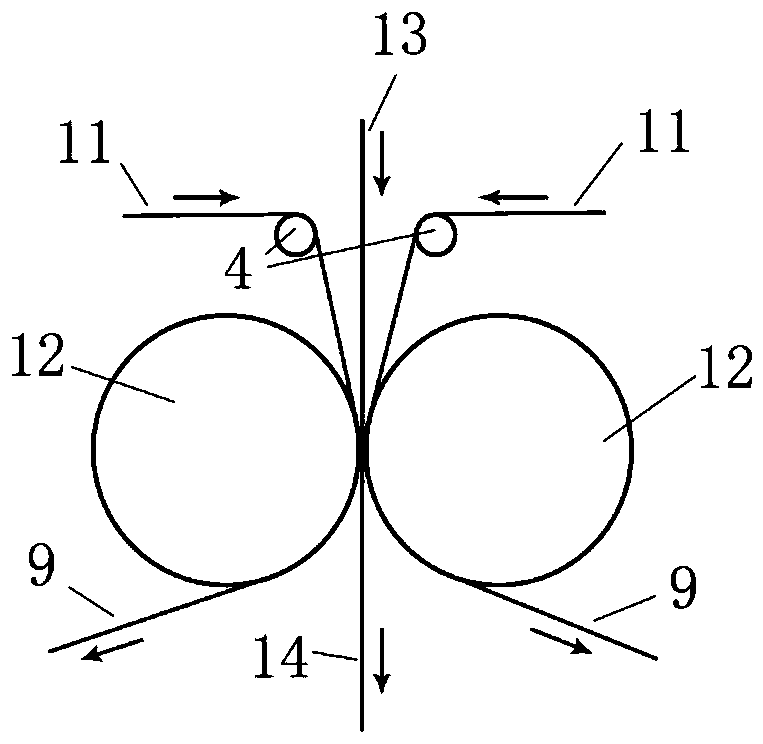

Four-roll calendering and draping production device for PVC plastic floor surface film attachment

ActiveCN105711226AImprove bindingEasy to produceLamination ancillary operationsLaminationEngineeringCalendering

The invention discloses a four-roll calendering and draping production device for PVC plastic floor surface film attachment. The four-roll calendering and draping production device comprises a four-roll calender, a wear-proof film unwinding mechanism, a printing film unwinding mechanism, a wear-proof film attaching mechanism, a printing film attaching mechanism and a guide-out mechanism. The printing film unwinding mechanism and the wear-proof film unwinding mechanism are installed on the two sides of the top end of the four-roll calender respectively. The wear-proof film attaching mechanism, the printing film attaching mechanism and the guide-out mechanism are sequentially arranged on the right side of a shading roll from top to bottom. The wear-proof film attaching mechanism is obliquely arranged on the right side of the shading roll. The printing film attaching mechanism and the guide-out mechanism are parallelly arranged on the right side of the shading roll. According to the four-roll calendering and draping production device, a vertical design is adopted, and a lower mirror roll and an upper mirror roll are used for determination of thickness; air is evenly extruded and exhausted by means of false attachment of a first guide-out roll in the printing film attaching mechanism, a PVC bottom board, a printing film and a wear-proof film can be more easily bound firmly, and production becomes convenient, simple and stable.

Owner:WUXI BOYU PLASTIC MACHINERY

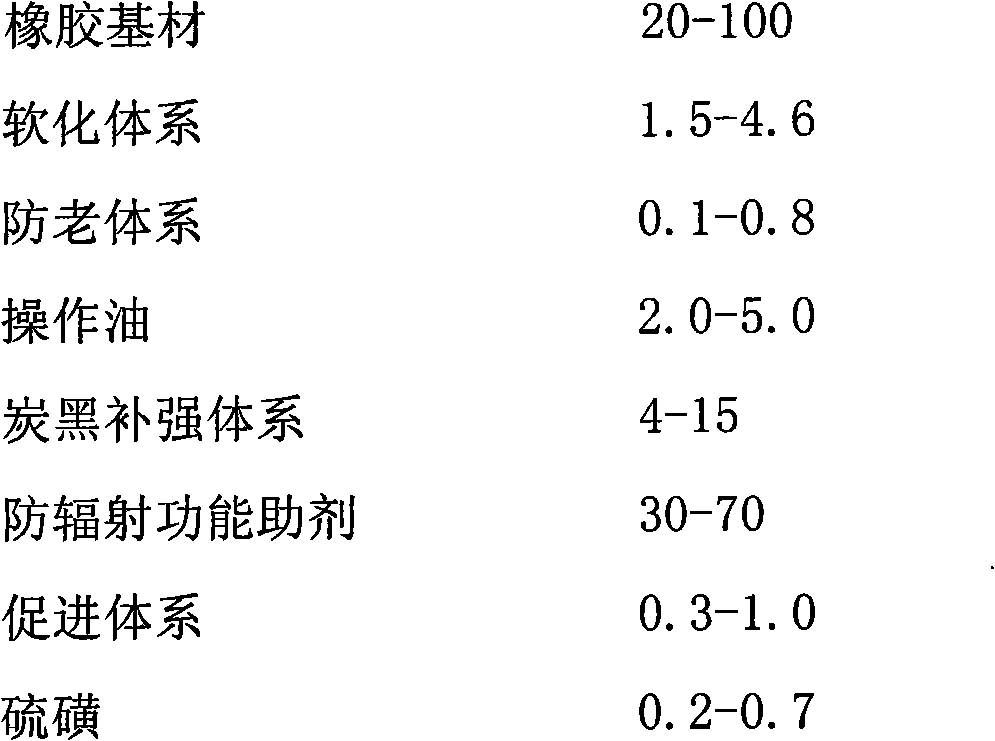

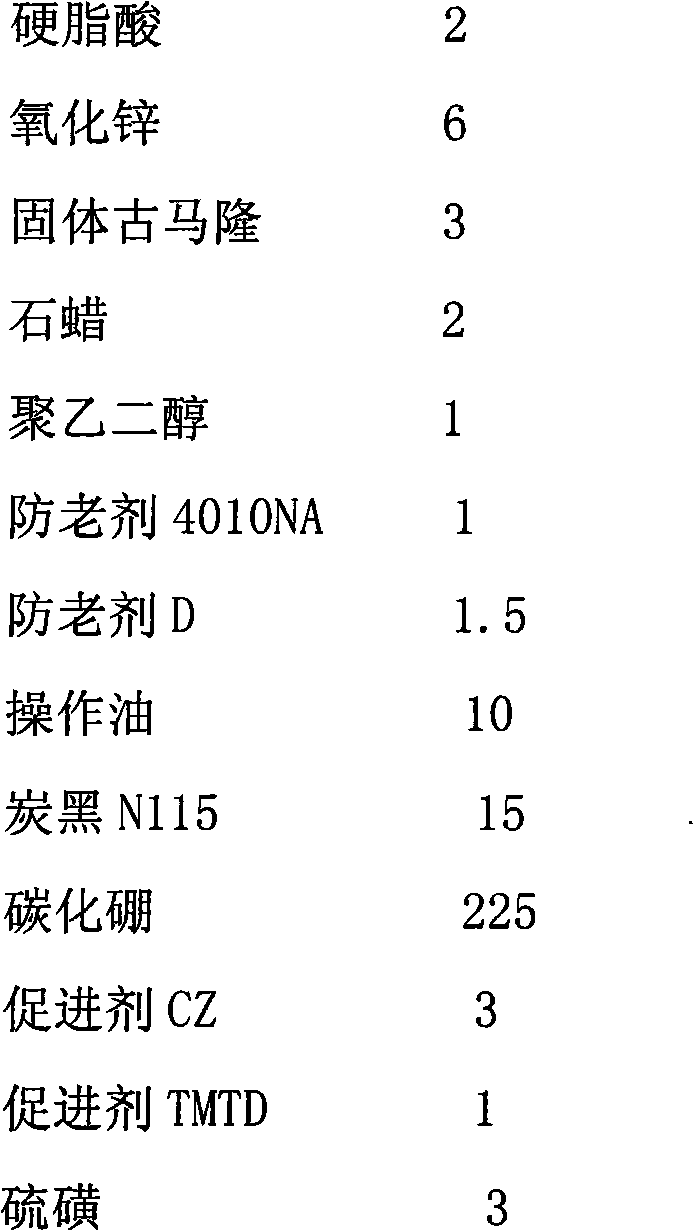

Anti-thermal neutron radiation shielding material and preparation method thereof

ActiveCN102708937AImprove mechanical propertiesAchieve the purpose of the inventionShieldingNeutron radiationRadiation resistance

The invention discloses an anti-thermal neutron radiation shielding material and a preparation method thereof. The anti-thermal neutron radiation shielding material is prepared by the following steps of: using rubber with radiation resistance as a matrix material; adding an anti-radiation additive which can shield thermal neutrons, a reinforced carbon black assistant and a processing assistant; and performing technical processes of a, mixing the rubber matrix, b, rolling and pre-forming the rubber matrix, c, vulcanizing and forming the rubber matrix, and the like to prepare the material. The anti-thermal neutron radiation shielding material provided by the invention has the shielding performance for the thermal neutrons, further, is good in flexibility, can be attached to the appearances of devices or apparatuses, and can be applied to surface protection of detectors such as a neutron diffraction spectrometer and the like and neutron protection of special curves.

Owner:北京富迪创业科技有限公司

Coated craft paper and production method thereof

ActiveCN102912691AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentPulp and paper industry

The invention discloses coated craft paper and a production method thereof. The coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: manufacturing paper through a paper layer by taking the UKP pulp, the non-deinked waste paper pulp or the mixture of the UKP pulp and the non-deinked waste paper pulp as the pulp to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

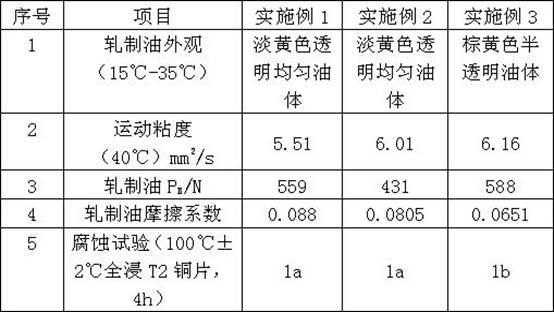

Calendaring copper foil rolled oil and preparation method thereof

ActiveCN102660357AHigh surface finishLong anti-corrosion periodAdditivesPolyethylene glycolCopper foil

The invention relates to the technical field of lubricating agents, in particular to calendaring copper foil rolled oil and a preparation method thereof. The calendaring copper foil rolled oil is used for lubricating in the cold-rolled process of calendaring copper foil. The preparation method is characterized by comprising the following steps of: adding N5 engine oil, butyl stearate, dodecanol, nitrogen-containing borate, fatty alcohol polyethylene glycol phosphate, petroleum sodium sulfonate and benzotriazole into a reaction kettle of which the rotation speed is 80 to 120 revolutions / minute sequentially, heating and stirring; and when the temperature is 80 DEG C, keeping the temperature, stirring continuously for 30 minutes, stopping heating, and stirring continuously to room temperature to obtain uniform and transparent oil, namely the required rolled oil. The minimum rolling thickness of the calendaring copper foil lubricated by the rolled oil is 25 micrometers, so that the calendaring copper foil is high in surface smoothness, long in anti-corrosion period and high in annealing detergency.

Owner:UNIV OF SCI & TECH BEIJING

Production method for base wallpaper

InactiveCN102978995AImprove performanceImprove resource utilizationReinforcing agents additionPaper/cardboardPolyesterFiber

The invention relates to papermaking technology and especially to a production method for base wallpaper. The production method for base wallpaper comprises the following steps: A, mixing chemically bleached needle wood pulp, chemically bleached bamboo fiber pulp, polyester fiber pulp and bleached recycled pulp to obtain pulp I; B, adding an inorganic filling material and a chemical auxiliary agent for batching to form base paper pulp; C, subjecting the base paper pulp to paper making and drying with a fourdrinier; D, mixing the chemically bleached needle wood pulp and the polyester fiber pulp to obtain pulp II; E, adding the inorganic filling material and the chemical auxiliary agent for batching to form surface paper pulp; F, subjecting the surface paper pulp to paper making and drying with the fourdrinier; G, coating a layer of a paper binder on semi-finished base paper, applying semi-finished surface paper on the layer of the paper binder and carrying out compacting; and H, dipping semi-finished composite paper in mixed liquor of a surface conditioning agent and latex, subjecting a surface coating to drying and gelling and carrying out surface mechanical calendering and reeling.

Owner:福建希源纸业有限公司

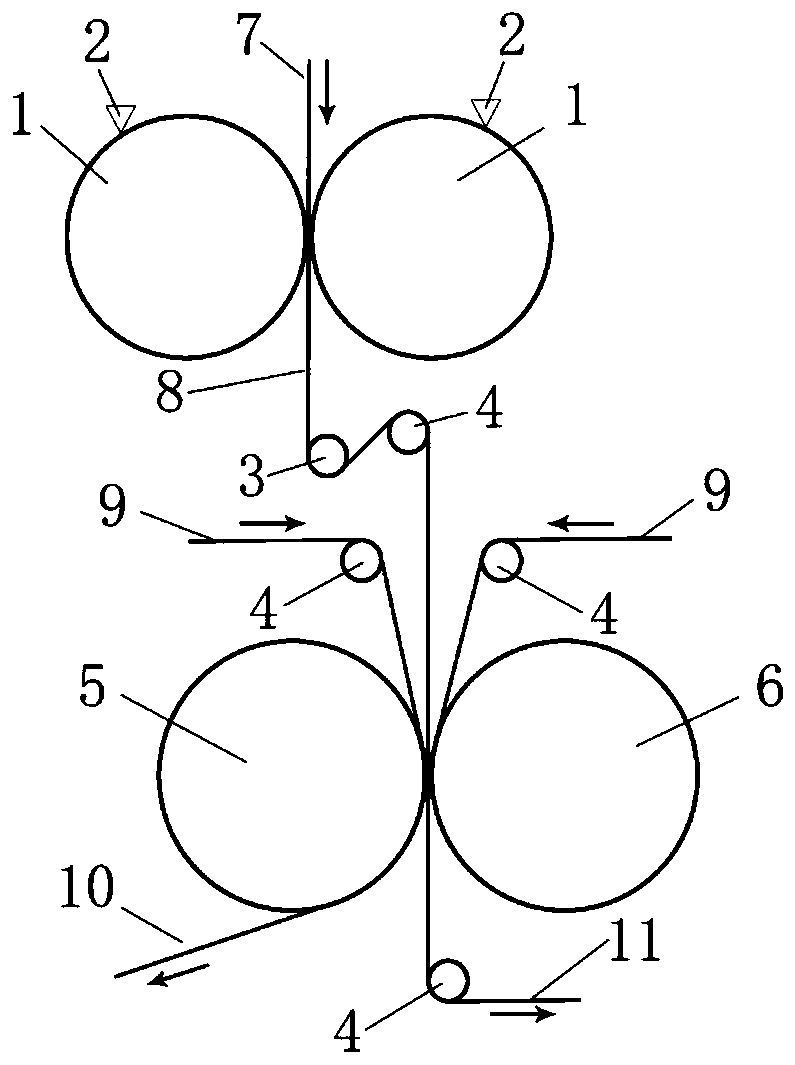

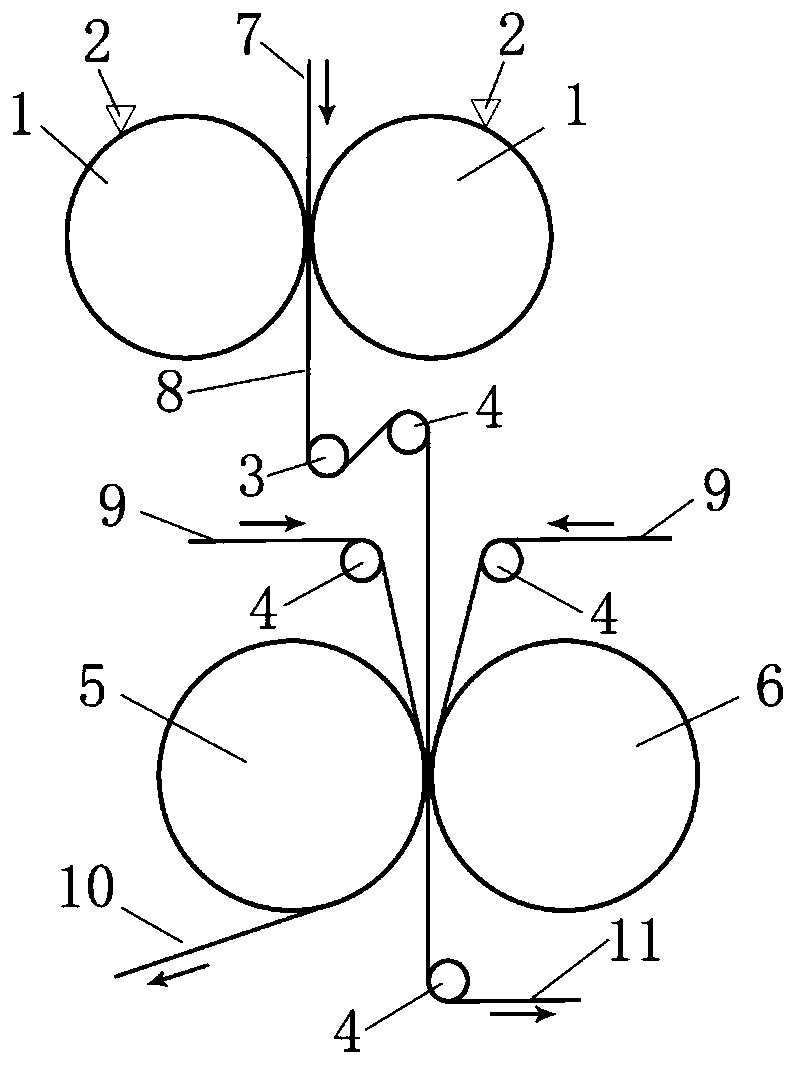

Graded calendering molding method of prelithiation anode

ActiveCN110010844ASuitable for large-scale productionReduce thickness requirementsElectrode rolling/calenderingLithiumFOIL method

The invention discloses a graded calendering molding method of a prelithiation anode. The graded calendering molding method comprises the steps that: a graded calendering lithium foil method is employed, the primary calendering of a lithium strip at pre-pressing rollers is completed, release films are introduced between main pressing rollers to assist in the secondary calendering of the lithium strip to form a lithium foil, and finally, on the release films attached at the fast roller sides of the main pressing rollers, the prelithiation anode is prepared through rolling of composite rollers and recombination of a negative pole piece under the transfer printing effect of the release films so that the large-scale production of the prelithiation anode is achieved, the production is low and the graded calendering molding method is safe and reliable.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

Production method for polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process

ActiveCN104213398AOxygen bleachingTo achieve the purpose of cost reductionMercerising of indefinite length fabricsSingeingDisperse dyeOxygen

The invention a printing and dyeing method, and especially relates to a production method for a polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, mercerizing, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, designing a dyeing formula, carrying out jar dyeing on the cloth sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The production method for the polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process has obvious energy saving and emission reduction effects, and the handle elasticity, the color fullness and various quality indexes of fabrics obtained in the invention can meet requirements of different clients.

Owner:ZHEJIANG HANGMIN STOCK

High-performance magnetic rubber and its preparation method

A high-property magnetic rubber is prepared from composite permanent-magnet powder (90-97 mass%), rubber (2-9.8), assistant (0.1-0.5) and coupling agent (0.1-0.5) through pulverizing, coating, pugging, calendering and heat treating. Said composite permanent-magnet powder is composed of ferrite-type permanent-magnet, alloy-temp one, and epoxy resin. Its advantages are high magnetic property, better flexibility and high elongate percentage (40-150%).

Owner:BGRIMM TECH CO LTD

Surface flame-retardant wood-plastic composite material plate and preparation thereof

InactiveCN101486267AReasonable designSimple structureSynthetic resin layered productsFiberMagnesium Sulfate whiskers

The invention relates to a surface flame retarded wood plastic composite plate and a method for preparing the same, which relates to a composite material, an environment-friendly material and a method for preparing the same. The composite material is applicable to making the following products: floor boards, shelf boards, and the like for means of transportation such as automobiles, planes, and the like in the field of transportation; road slabs, fences, wallboards, aisle guard bars, and the like in the field of construction; and outdoor desks and chairs, office partition boards, storage boxes, flower boxes, adjustable shelves, beach chairs, and the like in the furniture industry. The surface flame retarded wood plastic composite plate consists of two layers of crystal whisker modified plastic layers and plant fiber reinforced plastic layers, wherein the plant fiber reinforced plastic layers are arranged between the two layers of the crystal whisker modified plastic layers through die stamping. The crystal whisker modified plastic layers are made from modified basic magnesium sulfate whiskers, plastic particles, and the like through mixed calendering. The plant fiber reinforced plastic layers are made from plastic particles and plant fibers through mixed calendering.

Owner:NANJING FORESTRY UNIV

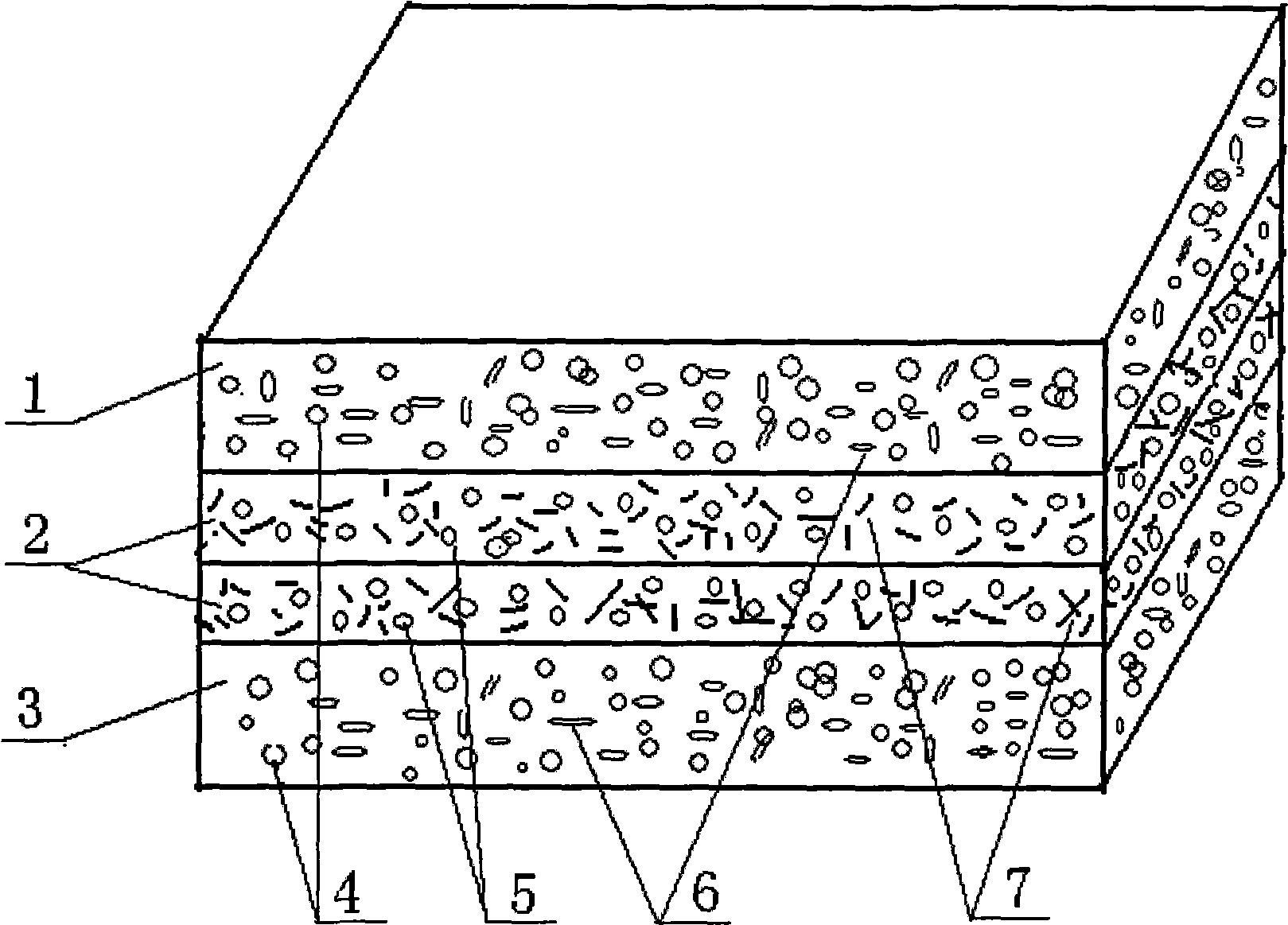

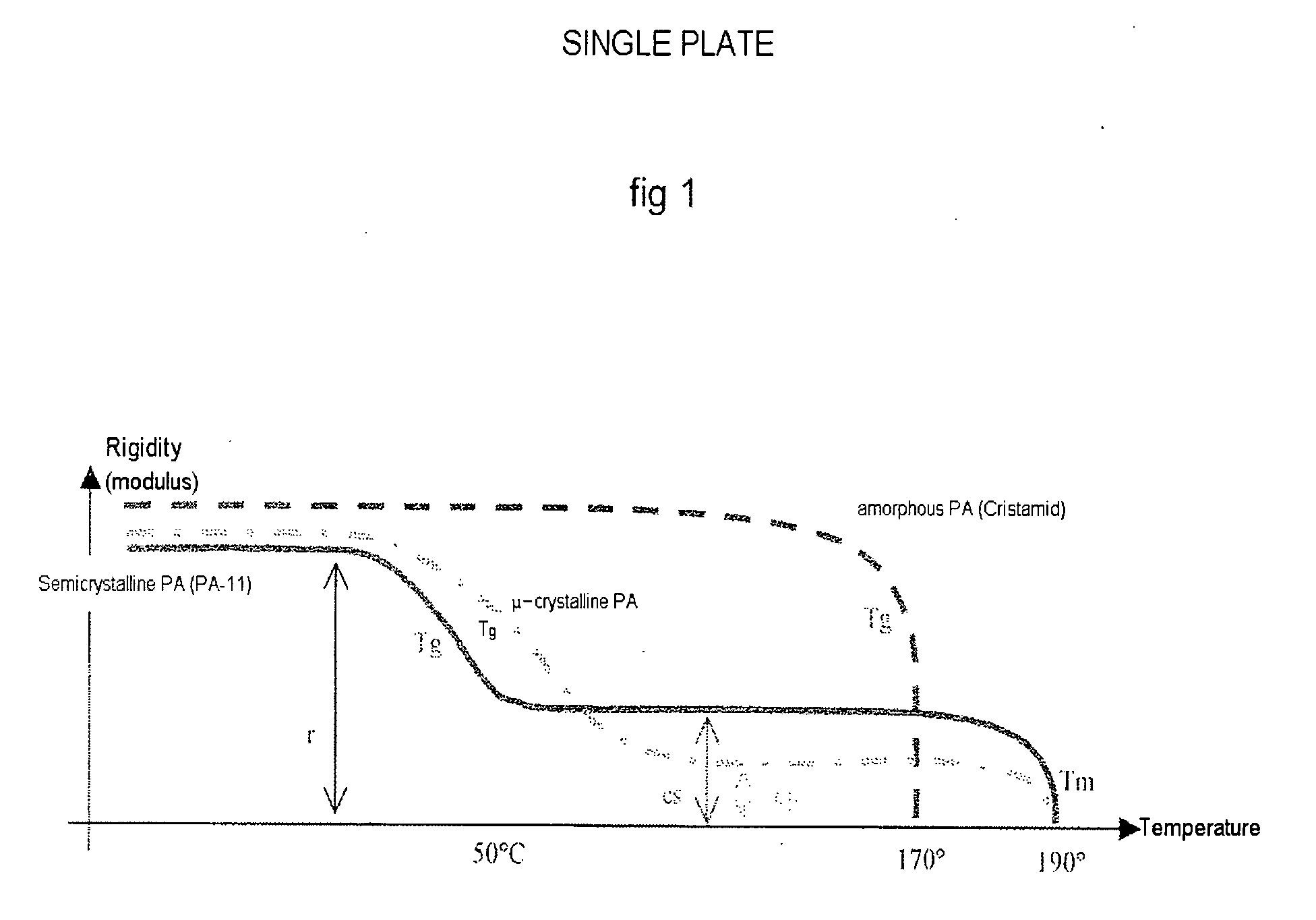

Use of a microcrystalline polyamide to obtain a particular surface finish

InactiveUS20060030692A1Improve performanceGood chemical resistanceSynthetic resin layered productsLaminationPolyamideInjection moulding

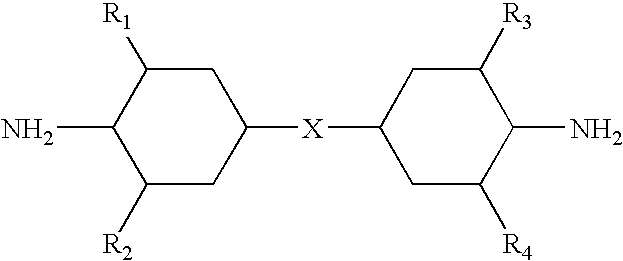

The present invention relates to the use of a microcrystalline polyamide for obtaining an object having all or part of its outer surface formed from this microcrystalline polyamide and having a particular surface finish, in which: the manufacture of the object comprises steps carried out hot between the Tg (glass transition temperature) and the Tm (melting point) of this microcrystalline polyamide; the transparency of the microcrystalline polyamide is such that the light transmission at 560 nm on a polished object 1 mm in thickness is greater than 80%, advantageously greater than 88%, the transparency being measured on the object obtained by standard processing methods, such as injection moulding and sheet extrusion / calendering. Advantageously, the microcrystalline polyamide is such that its degree of crystallinity is greater than 10% and less than 30% (1st DSC heating according to ISO 11357 at 40° C. / min) and the enthalpy of melting is greater than 25 J / g and less than 75 J / g (1st DSC heating according to ISO 11357 at 40° C. / min). Preferably, it such that its Tg (glass transition temperature) is between 40° C. and 90° C. and its Tm (melting point) is between 150° C. and 200° C. Advantageously, it results from the chain-linking of monomers such that 50% or more, by weight, of these monomers are ≧C9 monomers (i.e. having a number of carbon atoms equal to 9 or higher).

Owner:ARKEMA FRANCE SA

Hook and loop fastener device

The instant invention is a hook and loop fastener device. According to the instant invention, the hook and loop fastener device includes a loop component. The loop component includes a binder-free non-woven material having a bottom layer and a top layer. The bottom layer includes a first bicomponent fiber and a first monocomponent fiber. The first bicomponent fiber comprises the majority of the bottom layer based on total weight of the bottom layer, and the first monocomponent fiber comprises the balance thereof. The top layer includes a second bicomponent fiber, and a second monocomponent fiber. The second monocomponent fiber comprises the majority of the top layer based on total weight of the top layer, and the second bicomponent layer comprises the balance thereof. The bottom layer and the top layer may further include interfiber bonding to form the binder-free non-woven material. The non-woven material may further be island bonded via hot-roll calendering thereby forming a bonded area and a non-bonded area. Additionally, the loop component may include a backing layer bonded to the non-woven material.

Owner:APLIX SA

Melt extrusion-casting/calendering molded polyvinyl alcohol membrane and production method thereof

InactiveCN106189008ALower melt processing temperatureReduce processing temperatureFlat articlesProcedure AgentsPolyethylene glycol

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through casting or calendering molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 25 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 95 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. A production method of the polyvinyl alcohol membrane has the advantages of simple process, less device investment, small occupied area, and formation of normal-temperature and medium-temperature water-soluble membranes through melt extrusion casting / calendering. The method is mainly used for producing single-layer membranes which are applied to the fields of hydrographics transfer printing base membranes, printing paper hot melt adhesive membranes, agricultural membranes and other medium-and-high end products.

Owner:CHINA PETROCHEMICAL CORP +2

Method for manufacturing easy-to-clean artificial leather

ActiveCN102851994AGood anti-pollutionAchieve cleaning effectPattern makingSynthetic resin layered productsPolyvinyl chlorideSolvent

The invention discloses a method for manufacturing easy-to-clean artificial leather. The method comprises stirring 100 parts of a polyvinyl chloride resin, 30-50 parts of a plasticizer, 30-50 parts of a filler, 0.5-1 part of a lubricant, 2-5 parts of a heat-resistant stabilizer, 3-5 parts of a pigment, 30-50 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent, or 100 parts of a polyurethane resin, 10-50 parts of a solvent, 10-50 parts of a filler, 3-5 parts of a pigment, 1-5 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent in a high-speed dispersing mixer at 120-130 DEG C for 150-250 s, mixing, milling, calendering, base bonding or coating to form a semifinished product, and performing surface treatment and hot pressing on the semifinished product. The surface of the product manufactured by the inventive method has excellent anti-contamination effects, and contaminants on the surface of the manufactured product can be cleaned by wiping through common base cloth, without destroying the surface effects of the product.

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

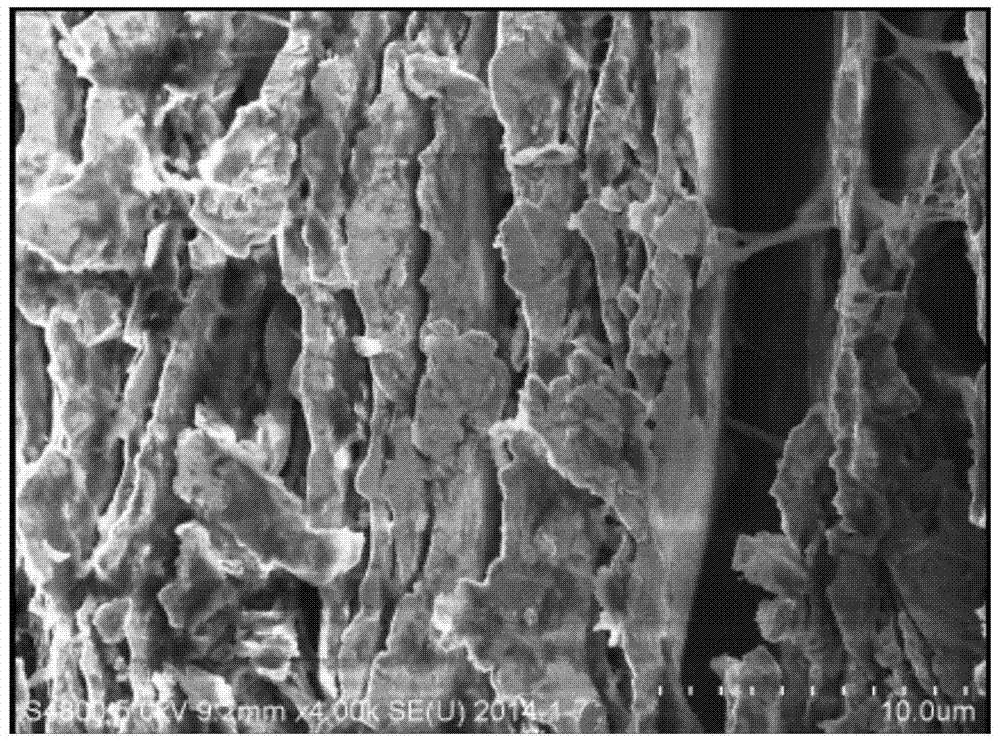

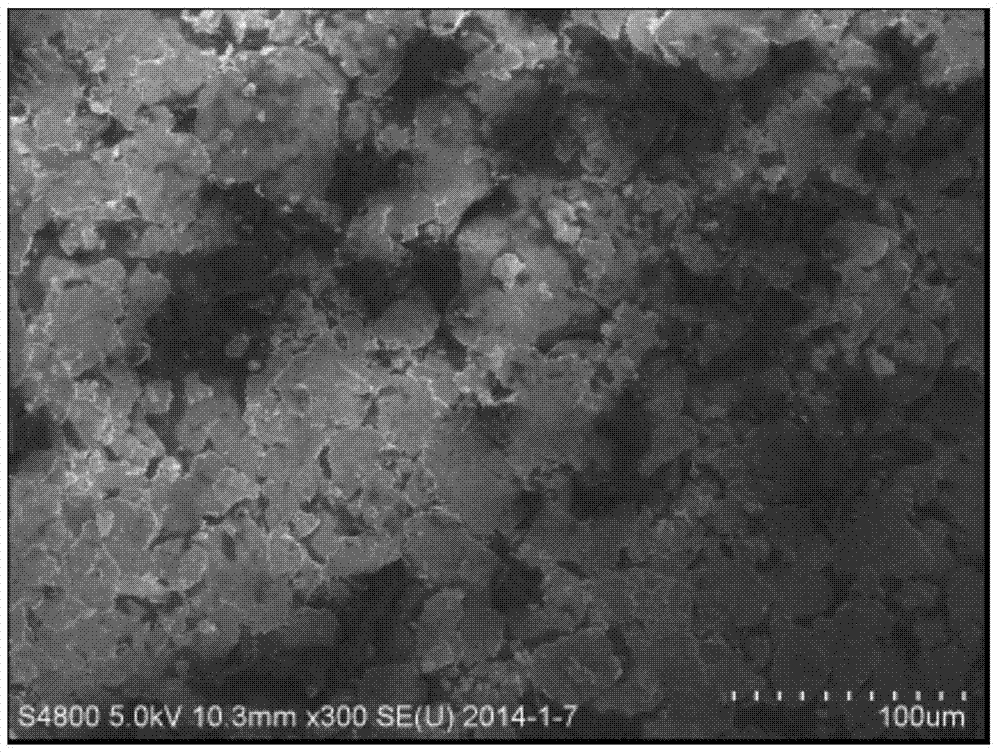

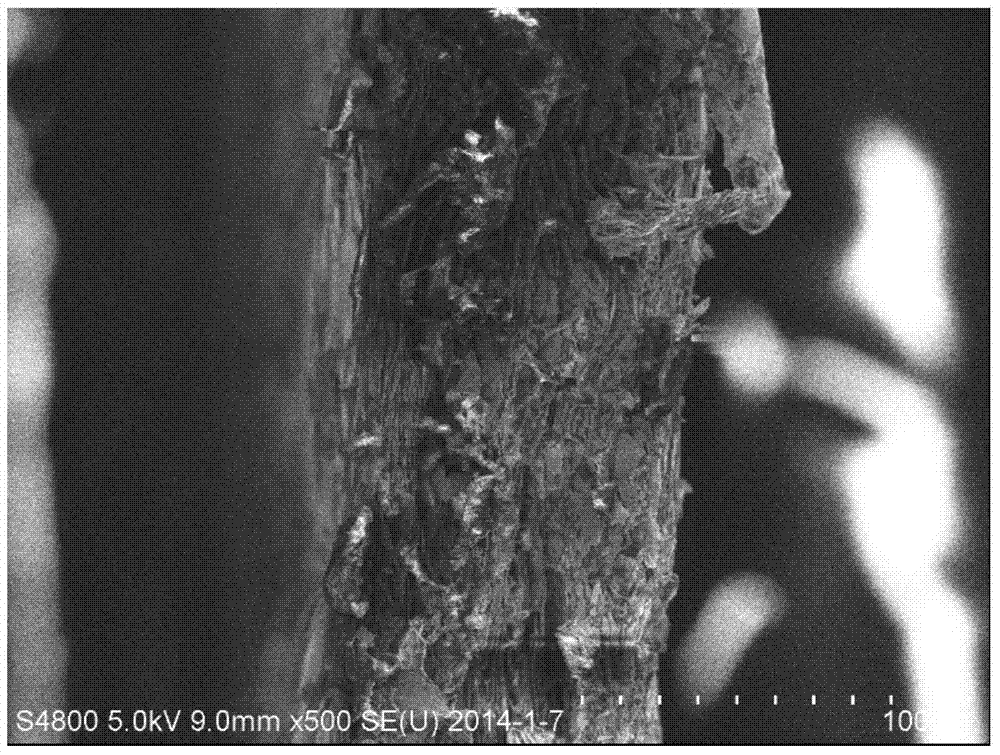

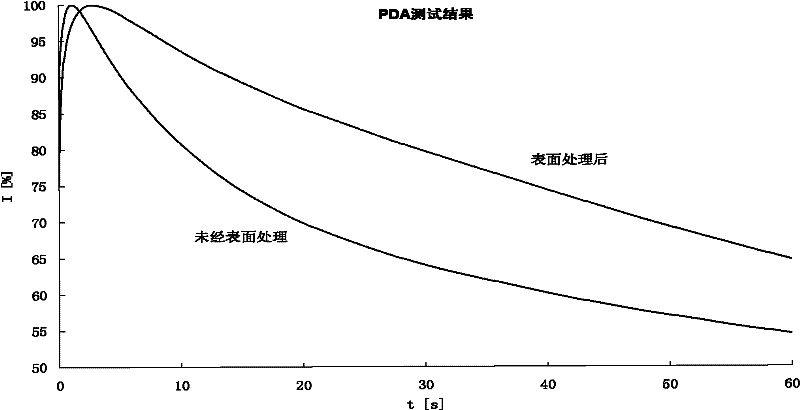

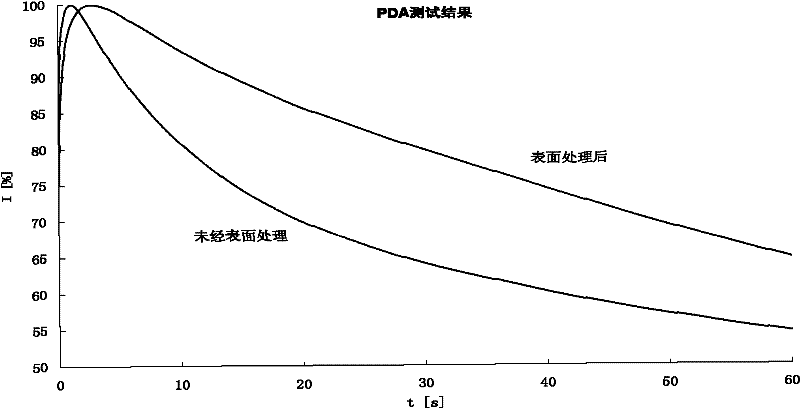

Method for surface treating calender copper foil of printing circuit board

InactiveCN101074484AFast degreasingGood degreasing effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilNickel alloy

A method for treating calendaring copper foil surface of printing circuit board is carried out by pre-treating by weak alkali mixed oil remover with Na2CO3, Na3PO4 and Na2SiO3, primary coarse treating, electroplating copper by electroplating liquid containing copper ion, H2SO4 and arsenic ion, clad treating by barrier, zinc-nickel alloy clad treating, passivating and electroplating chromium clad treating to obtain final product. It has better combination with printing base plate and corrosion resistance.

Owner:SHANGHAI UNIV

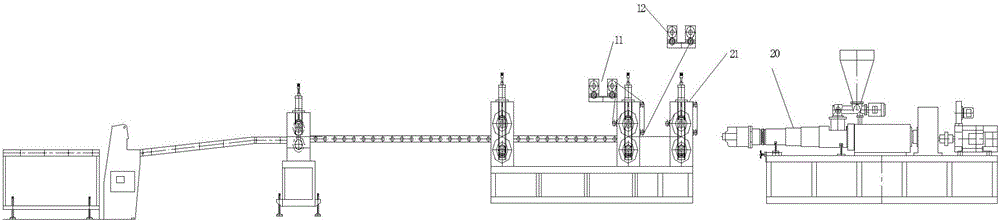

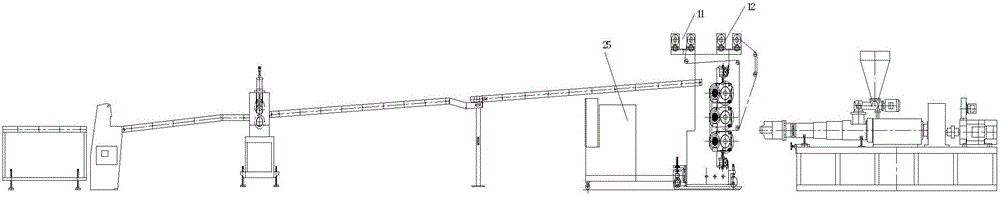

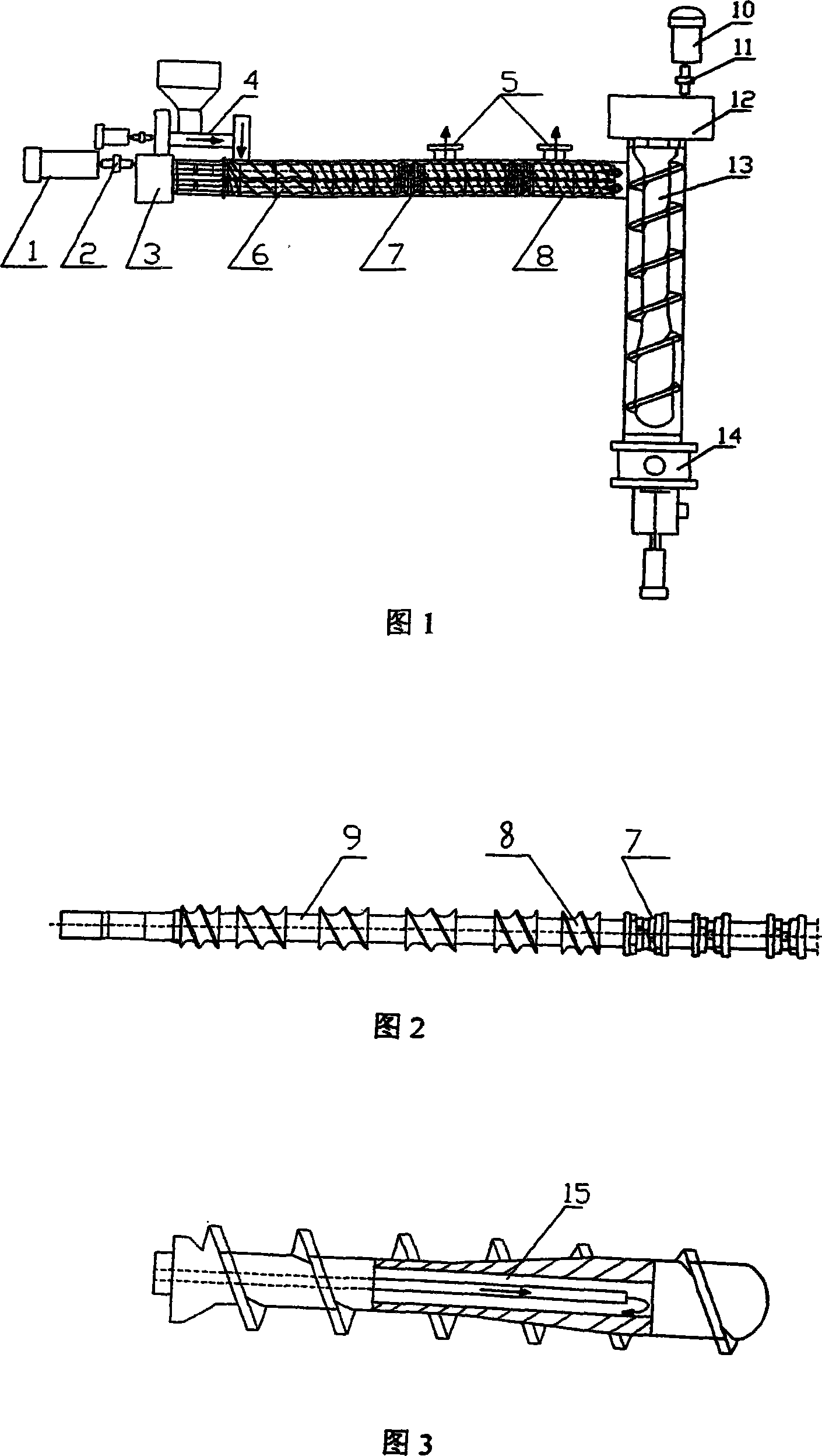

Non-woven fabrics composite economy master batch and its producing method and device

The invention relates to a non-woven composite economical masterbatch and its production method and equipment. The masterbatch formula is: 12-18 parts of polypropylene resin with a melting index of 60-90, and polypropylene with a melting index of 3-30 Resin 6-10, nano-scale activated calcium carbonate 55-65, polyethylene wax 8-10, composite antioxidant 0.5-0.7, zinc stearate 1.5-2.5, titanate 1.5-2.5, white oil 1.5-2, Rutile titanium dioxide 1.5-2; the masterbatch production method is as follows: the raw materials are fully mixed and sent to the twin-screw extruder, and then sent to the single-screw extruder, and the finished non-woven fabric is obtained through melt extrusion, pelletizing and screening; The production equipment used is a stepped screw extruder, including a first-stage twin-screw extruder and a second-stage single-screw extruder, and the two extruders are arranged in a "T" shape. The present invention uses nano-scale active calcium carbonate to partially replace the PP material for non-woven fabrics, and adds the present invention to the raw material PP used for non-woven fabrics, which can greatly reduce the cost of materials under the premise of ensuring continuous fibers by melt-blowing and calendering, and Can save a lot of energy.

Owner:胡国川

Method for processing fine-count flax/cotton blended knitted fabric

ActiveCN101748595AStrong and goodSoft and smooth feelBiochemical fibre treatmentHeating/cooling textile fabricsYarnEngineering

The invention discloses a method for processing fine-count flax / cotton blended knitted fabric, which is characterized in that: processes such as demineralization, high-temperature boiling and soft finishing of yarn are added prior to a conventional weaving process, and the processes of mercerization, biological enzyme treatment, fabric soft finishing, calendering and shape forming are added in a dyeing and finishing process. The method has the following advantage that: the fine-count flax / cotton blended knitted fabric processed by the method has relatively higher strength, is hardly damaged in the weaving process and has soft and smooth hand feel, bright and clean fabric surface, luster, shape-preserving property, comfortableness and stiffness.

Owner:浙江盛泰服装集团股份有限公司

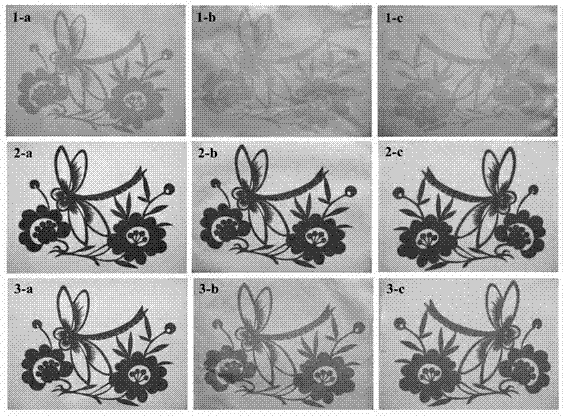

Dry-type transfer-printed textile and preparation method thereof

ActiveCN103774469AIncrease contentDoes not increase viscosityDyeing processWater dispersibleEnergy conservation

The invention relates to a dry-type transfer-printed textile and a preparation method of the dry-type transfer-printed textile. The method comprises the following steps: uniformly dispersing a water-dispersible hot melt adhesive into water so as to form a suspension; adding a printing thickener so as to regulate the viscosity of the suspension; adding printing auxiliaries such as acid, alkali and a hygroscopic agent according to the used dye, so as to prepare printing paste; coating a paper sheet or s film by use of the printing paste; drying and calendering, so as to obtain a paper sheet or film with the coating surface; performing printing treatment on the paper sheet or the film by use of a dye, so as to prepare transfer paper or a transfer film; hot-pressing and laminating the transfer paper or transfer film and a to-be-printed textile; performing color fixing, then stripping off the transfer paper or transfer film, and washing and sizing the textile after the color fixing, so as to obtain the printed textile. According to the printing method provided by the invention, wetting treatment of the textile is omitted, and transfer printing can be directly performed on the dry textile or a garment, so that the definition of printed patterns and the transfer stability of the dye are ensured; meanwhile, the operation sequence is simplified, emission of waste water of the printing and dyeing industry can be reduced, and the preparation method is beneficial to energy conservation and environment protection.

Owner:KAISHENG TEXTILE

Wave-absorbing material and preparation method thereof

ActiveCN103881245AImprove permeabilityExcellent electromagnetic wave absorption performanceElastomerMagnetic poles

The invention provides a wave-absorbing material and a preparation method thereof. The wave-absorbing material is prepared from the following raw materials in parts by mass: 5-15 parts of thermosetting elastomer, 60-80 parts of flaky wave-absorbing agent, 0.1-2 parts of curing agent, 0.1-0.5 part of accelerator and 20-30 parts of solvent. The preparation method comprises the following steps: (1) dissolving a matrix; (2) mixing the matrix with the wave-absorbing agent; (3) scraping the base material; and (4) flattening the surface by a double-roller calender, and passing through a tunnel furnace to perform high-temperature curing, thereby obtaining the product. The method prevents the calendering from crushing the flaky wave-absorbing agent, and maintains the completeness of the flaky wave-absorbing agent particles. The magnetic poles are added to well orient the flaky wave-absorbing agent, thereby avoiding unordered arrangement of the particles in the high-polymer matrix due to calendering. The wave-absorbing material has the advantages of very high magnetic permeability and favorable electromagnetic wave absorption property, and can be prepared into a material of which the minimum thickness is 0.03mm.

Owner:重庆市鸿富诚电子新材料有限公司

Base paper for thermal transfer

InactiveCN102212984ASolve the problem of low bulk and high wood fiber consumptionSolve the problem of high consumptionSpecial paperWater-repelling agents additionFiberFibrillation

The invention discloses base paper for thermal transfer. The base paper is prepared from 100% of chemical pulp through pulping, papermaking, drying and curling. The base paper is characterized in that in the pulping step, 50-100% of bleached chemical staple fibers and 0-50% of bleached chemical long fibers are used and undergo pulp dispersion, pulp cleaning and defibrination to achieve fibrillation in the defibrination process; when chemicals are added, 0-20kg / ton paper of alkyl ketene dimmer, 0-2kg / ton paper of alkenyl succinic anhydrides and 70-500kg / ton paper of filler are added to the wet part and other functional auxiliaries are added according to the conventional quantity demanded; 0-20kg / ton paper of surface sizing agent is added to surface sizing starch; and the front calendering pressure and the rear calendering pressure are 10-30kg / cm in the curling process. The base paper has the advantages of higher bulk, suitability for various dye sublimation ink, no crease despite large width of transfer, good transfer effect, bright pattern colors after transfer and the like.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Method for improving porosity rate of two-way stretching polytetrafluoroethylene micropore thin film

The invention relates to the technical field of thin films, and particularly provides a method for improving the porosity rate of a two-way stretching polytetrafluoroethylene micropore thin film. The method comprises the following steps: (1) mixing materials: uniformly mixing polytetrafluoroethylene resin powder and liquid lubricating oil according to the weight ratio of 1:(0.2-0.28), performing still standing for 10-16 h at the temperature of 40-80 DEG C, so as to form a polytetrafluoroethylene material; (2) compaction and calendering: compacting the polytetrafluoroethylene material into cylindrical blank at the temperature of 30-50 DEG C, squeezing the blank into rod-like material through a compactor at the temperature of 40-60 DEG C, and then calendering into a polytetrafluoroethylene baseband through a calender at the temperature of 40-60 DEG C; (3) longitudinal stretching and water vapor treatment: conducting longitudinal stretching on the polytetrafluoroethylene baseband at 180-300 DEG C, and then conducting water vapor treatment for 0.5-5 min, so as to obtain a defatted baseband; (4) transversal stretching and heat shaping: conducting transversal stretching on the defatted baseband at 180-210 DEG C, then conducting sintering shaping at 250-380 DEG C with the sintering time of 20-80 s, so as to obtain the heat-shaped thin film. According to the method, the porosity rate can reach up to 86-92%, the process is simple, and the cost is low.

Owner:ZHEJIANG LUCKING ENVIRONMENTAL PROTECTION CO LTD

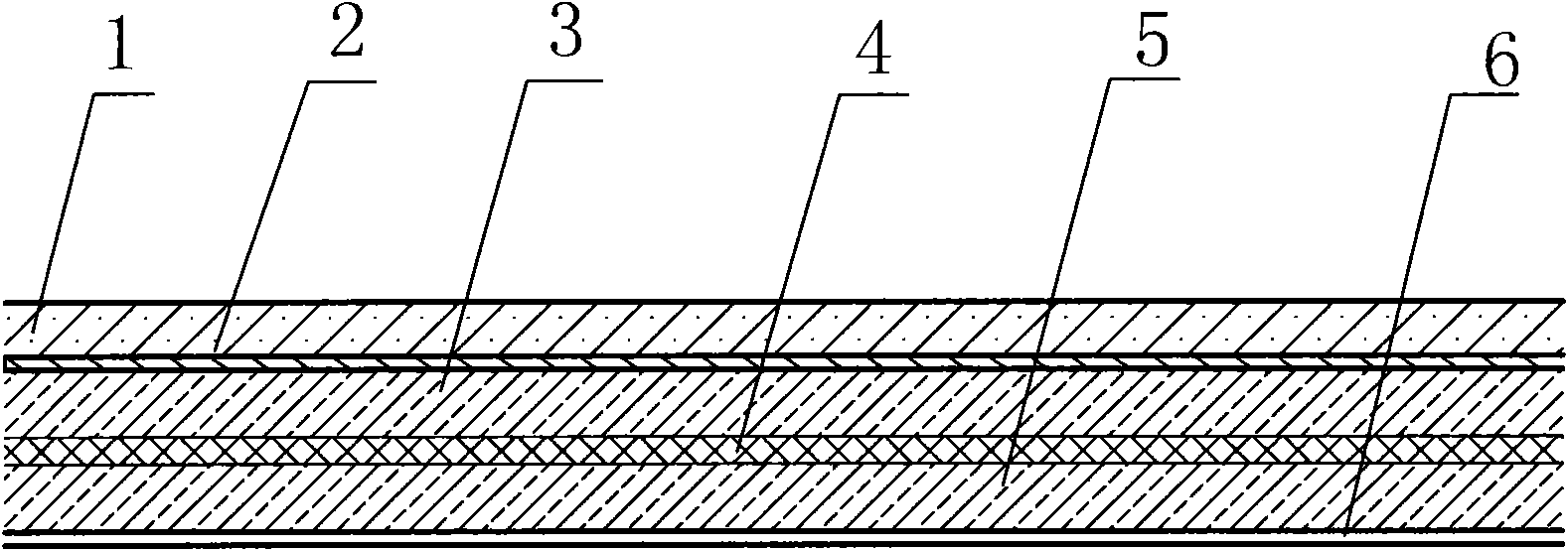

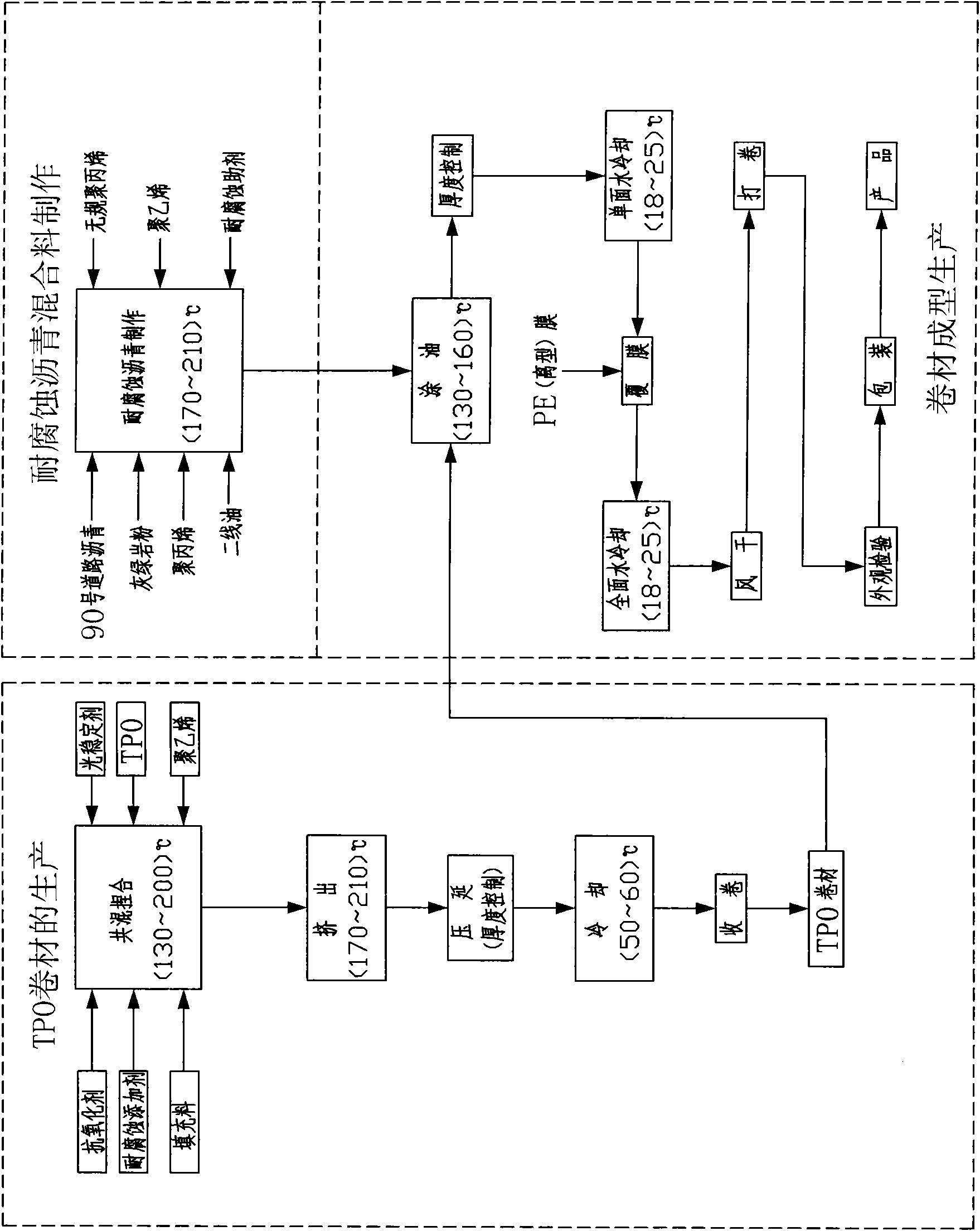

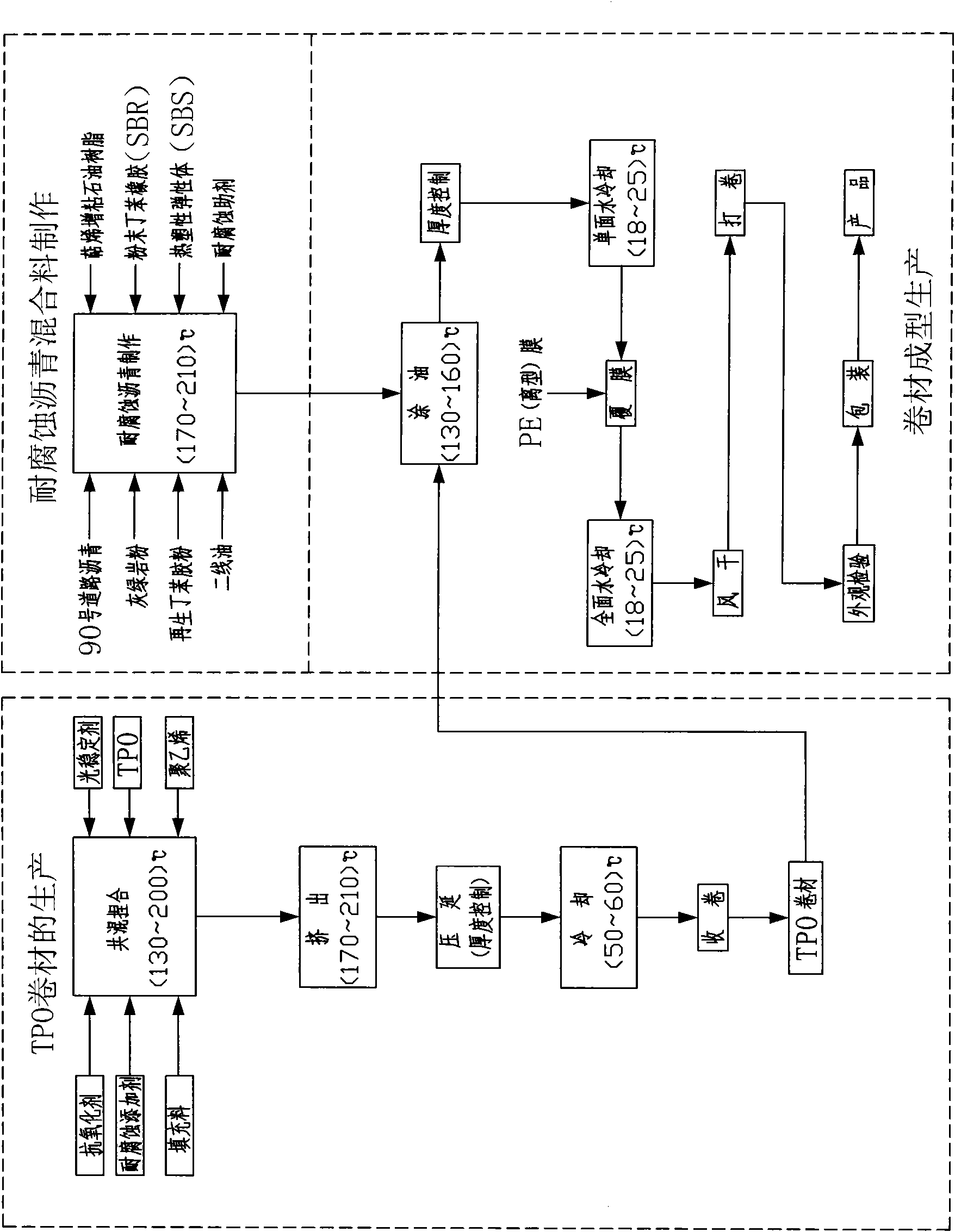

Anticorrosive TPO modified asphalt composite waterproof coiled material and preparation method thereof

ActiveCN102121277AImprove corrosion resistanceOutstanding long-term resistance to acid, alkali and salt corrosionUnderground chambersRoof covering using flexible materialsTectorial membranePolyester

The invention discloses an anticorrosive thermoplastic polyolefin (TPO) modified asphalt composite waterproof coiled material. The coiled material has a multilayer laminar structure formed by compounding and solidifying a TPO material layer, an adhesive isolation layer, an upper anticorrosive asphalt layer, a polyester filament non-woven fabric, a lower anticorrosive asphalt layer and a protective film layer, with a thickness of 2 to 5mm. A manufacturing method for the coiled material comprises the following steps of: conventionally manufacturing the TPO material layer, preparing an anticorrosive asphalt mixture constructed by a hot melting method and a normal temperature self-adhesive method, selecting the anticorrosive asphalt mixture according to the technical requirements, spreading the polyester filament non-woven fabric on a production line and guiding the polyester filament non-woven fabric into an immersion trough to immerse non-woven fabric in the anticorrosive asphalt mixture, and performing double-roll calendering and film coating, cooling, airing and coiling on the non-woven fabric and the TPO coiled material to form a finished product. The upper and lower layers of anticorrosive modified asphalt are wrapped on the polyester filament non-woven fabric, so the coiled material has predominant long-term acid, alkali and salt corrosion resistance; and No.90 road asphalt is used as a raw material, so the cost is low, and the preparation method is simple and scientific.

Owner:TANGSHAN DESHENG WATERPROOF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com