Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3205 results about "Nickel alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel alloys are used extensively because of their corrosion resistance, high temperature strength and their special magnetic and thermal expansion properties. The major alloy types that are used are: Iron-Nickel-Chromium alloys.

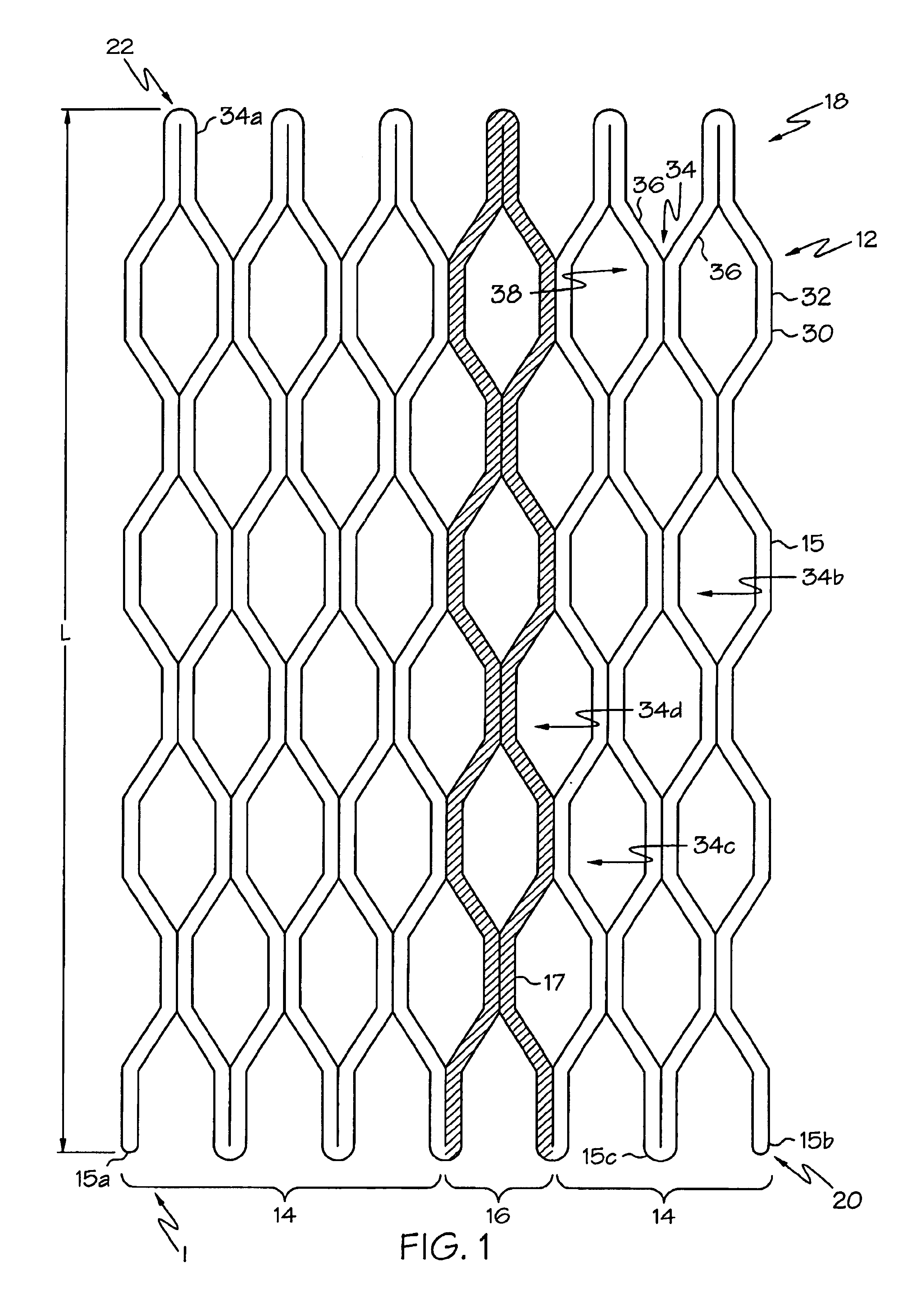

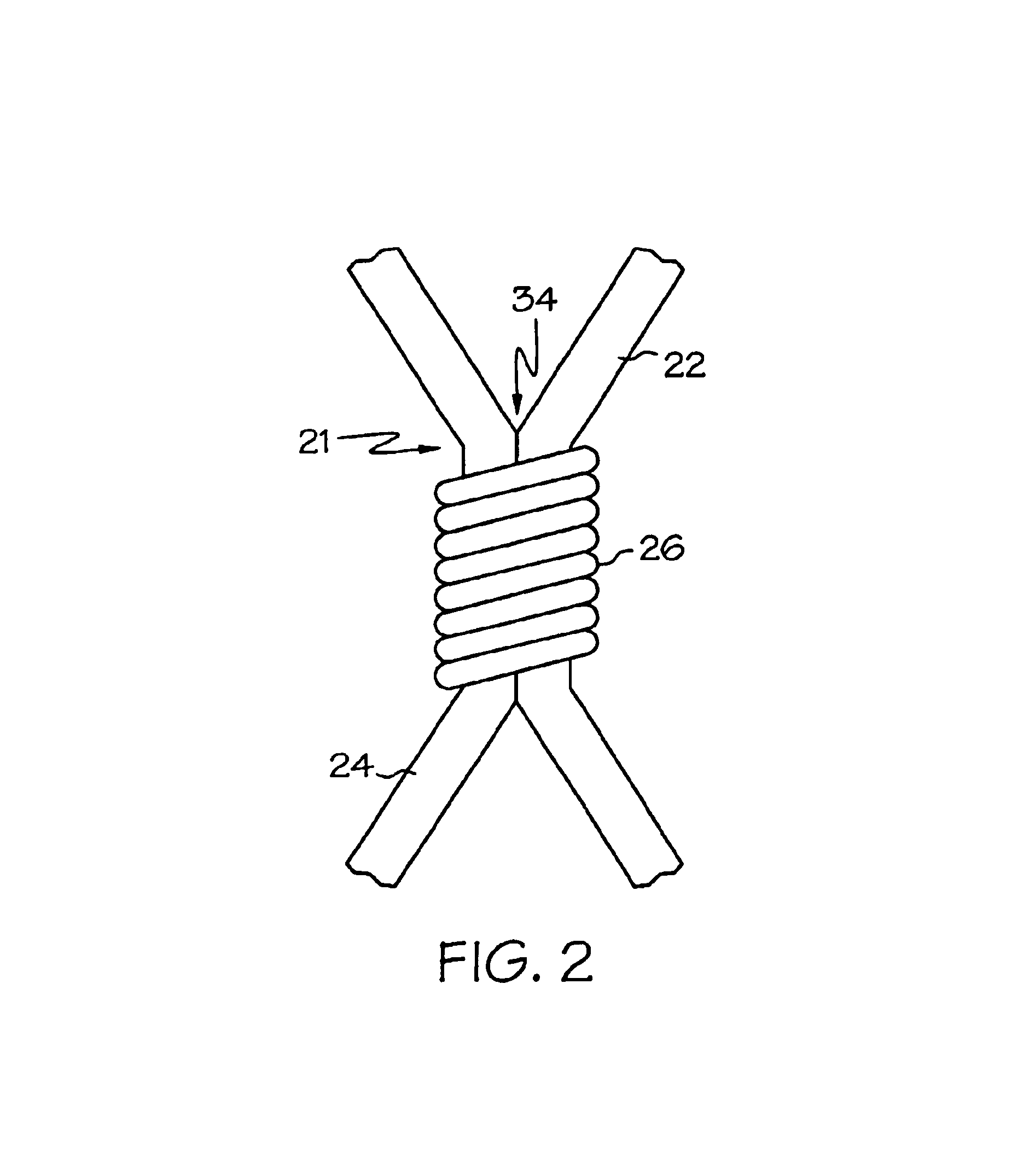

Combination self-expandable, balloon-expandable endoluminal device

An endoluminal device, such as a stent or a vena cava filter, comprising at least one superelastic section and at least one plastically deformable section. The superelastic section may comprise, for example, a superelastic grade of nitinol, whereas the plastically deformable section may comprise, for example, gold, platinum, tantalum, titanium, stainless steel, tungsten, a nickel alloy, a cobalt ally, a titanium alloy, or a combination thereof. Each plastically deformable section may merely comprise a constrained portion of the superelastic section comprising a plastically deformable material, such as gold. The device enables deployment by a method comprising introducing the device into a body lumen with the device radially constrained in a first configuration having a first diameter; allowing the device to self-expand into a second configuration having a second diameter less than or equal to a fully-self-expanded diameter; and then optionally “fine-tuning” the device by forcibly expanding the device into a third configuration having a third diameter in a range between the second diameter and less than or equal to a fully-forcibly-expanded diameter. The superelastic and plastically deformable sections may be tubular sections placed end-to-end, such that the plastically deformable section can be conformed to fit a tapered section of a lumen.

Owner:BOSTON SCI SCIMED INC

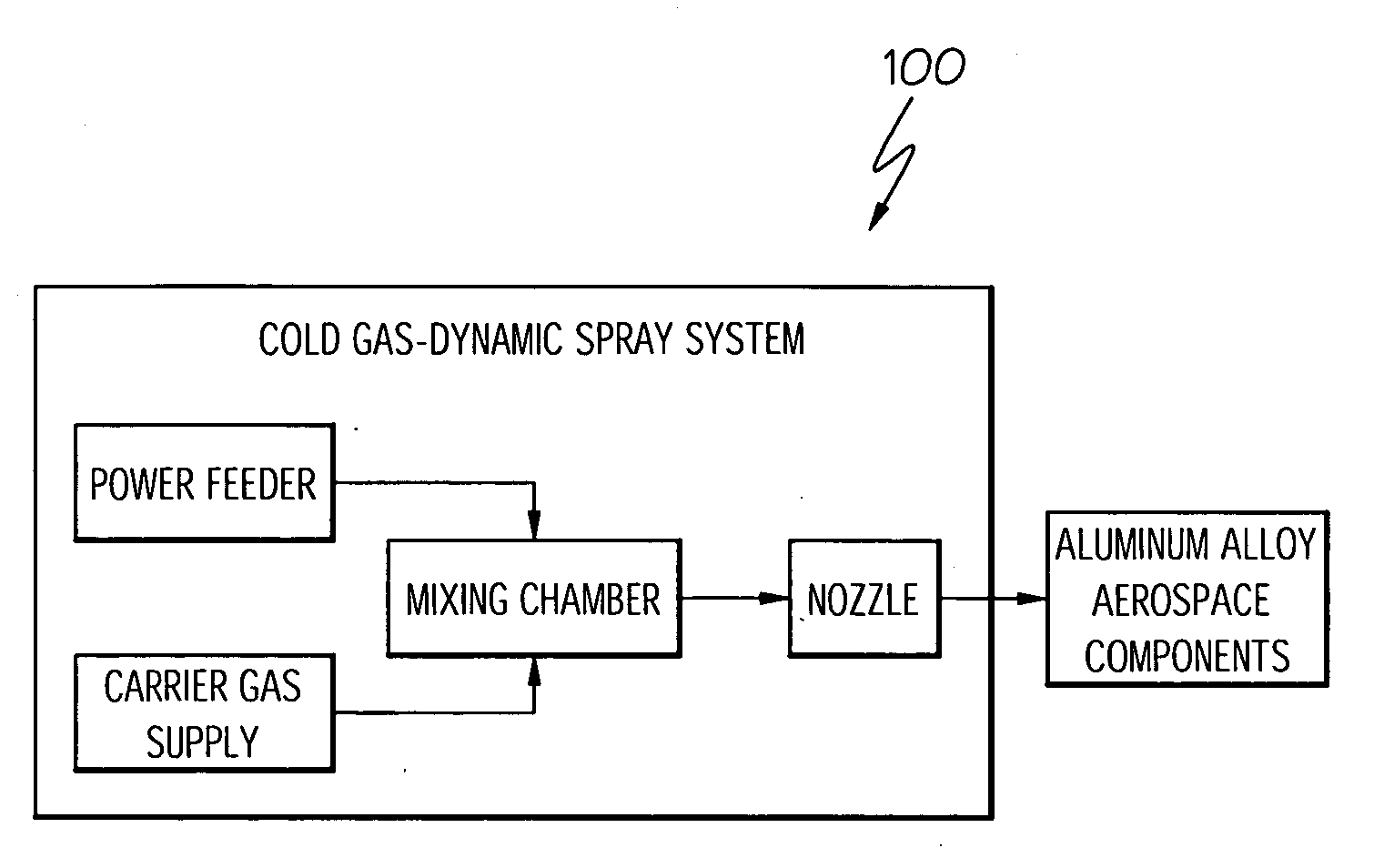

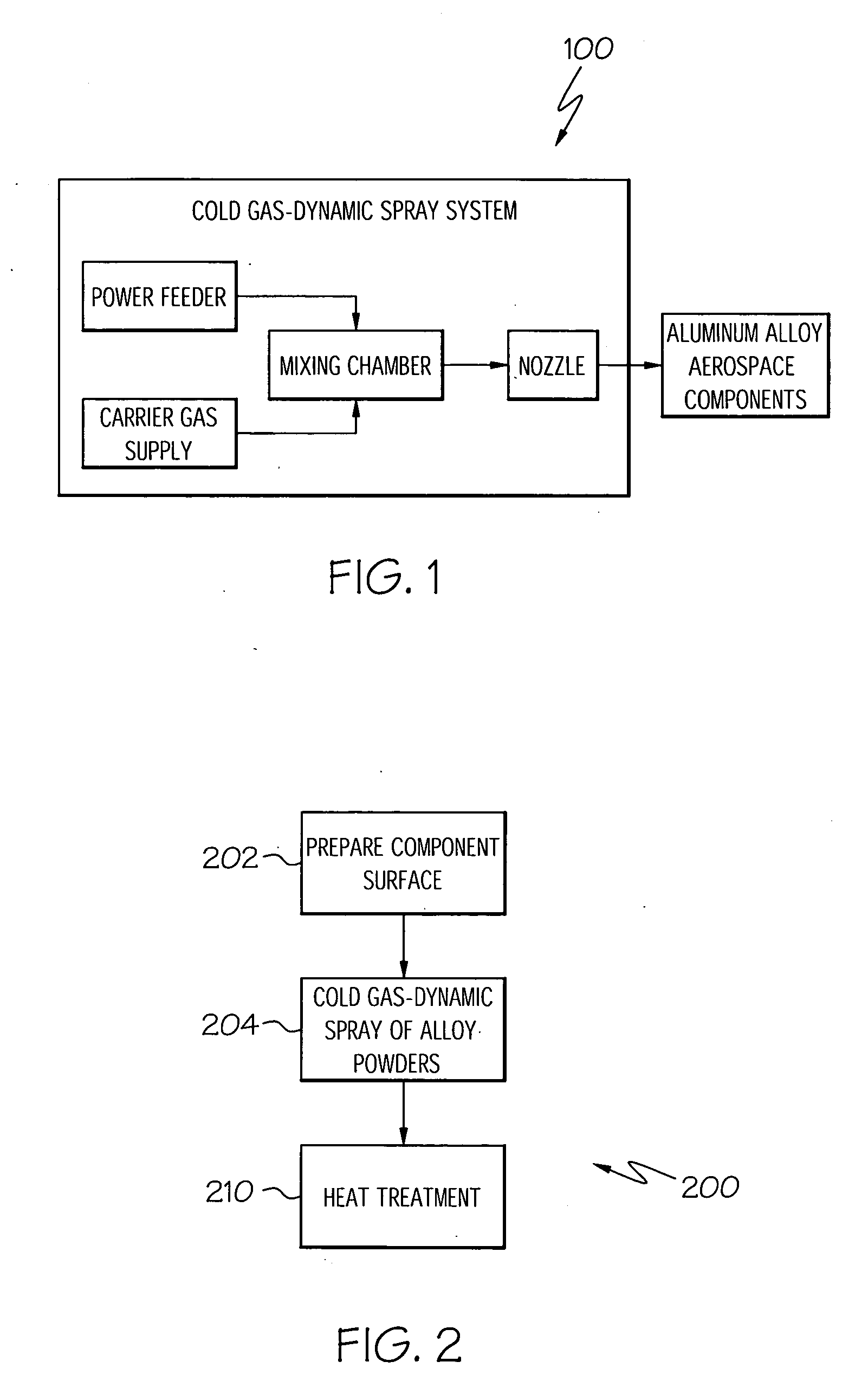

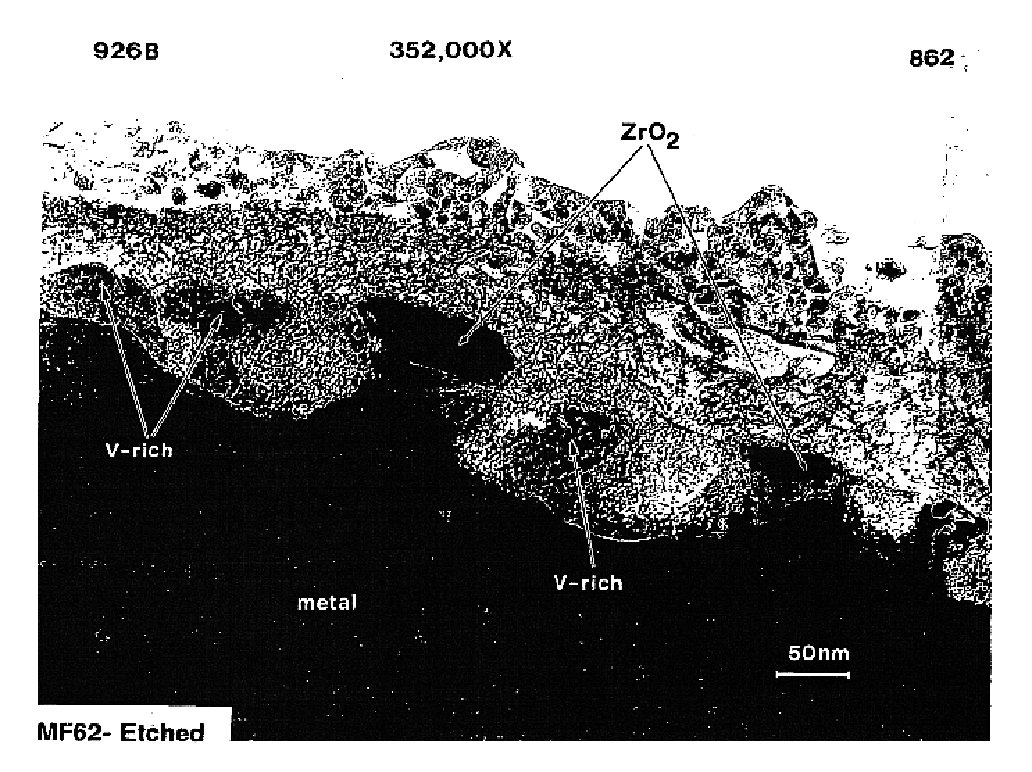

Aluminum articles with wear-resistant coatings and methods for applying the coatings onto the articles

InactiveUS20060093736A1Liquid surface applicatorsSuperimposed coating processWear resistantTitanium alloy

A method for coating a surface of a component formed from aluminum or an alloy thereof includes the step of cold gas-dynamic spraying a powder material on the component surface to form a coating, the powder material comprising at least one alloy from the group consisting of titanium, a titanium alloy, nickel, a nickel alloy, iron, an iron alloy, aluminum, an aluminum alloy, copper, a copper alloy, cobalt, and a cobalt alloy. In one embodiment, the method further includes the step of heat treating the turbine component after the cold gas-dynamic spraying.

Owner:HONEYWELL INT INC

Finely divided metal catalyst and method for making same

InactiveUS6841512B1Facilitating hydrogen consumptionSmall particle sizeReactant parameters controlReversible hydrogen uptakeParticulatesMetal catalyst

An inexpensive, highly catalytic material preferably formed by a leaching process. The catalyst comprises a finely divided metal particulate and a support. The active material may be a nickel and / or nickel nickel alloy particulate having a particle size less than about 100 Angstroms. The support may be one or more metal oxides.

Owner:CHEVRONTEXACO TECH VENTURES

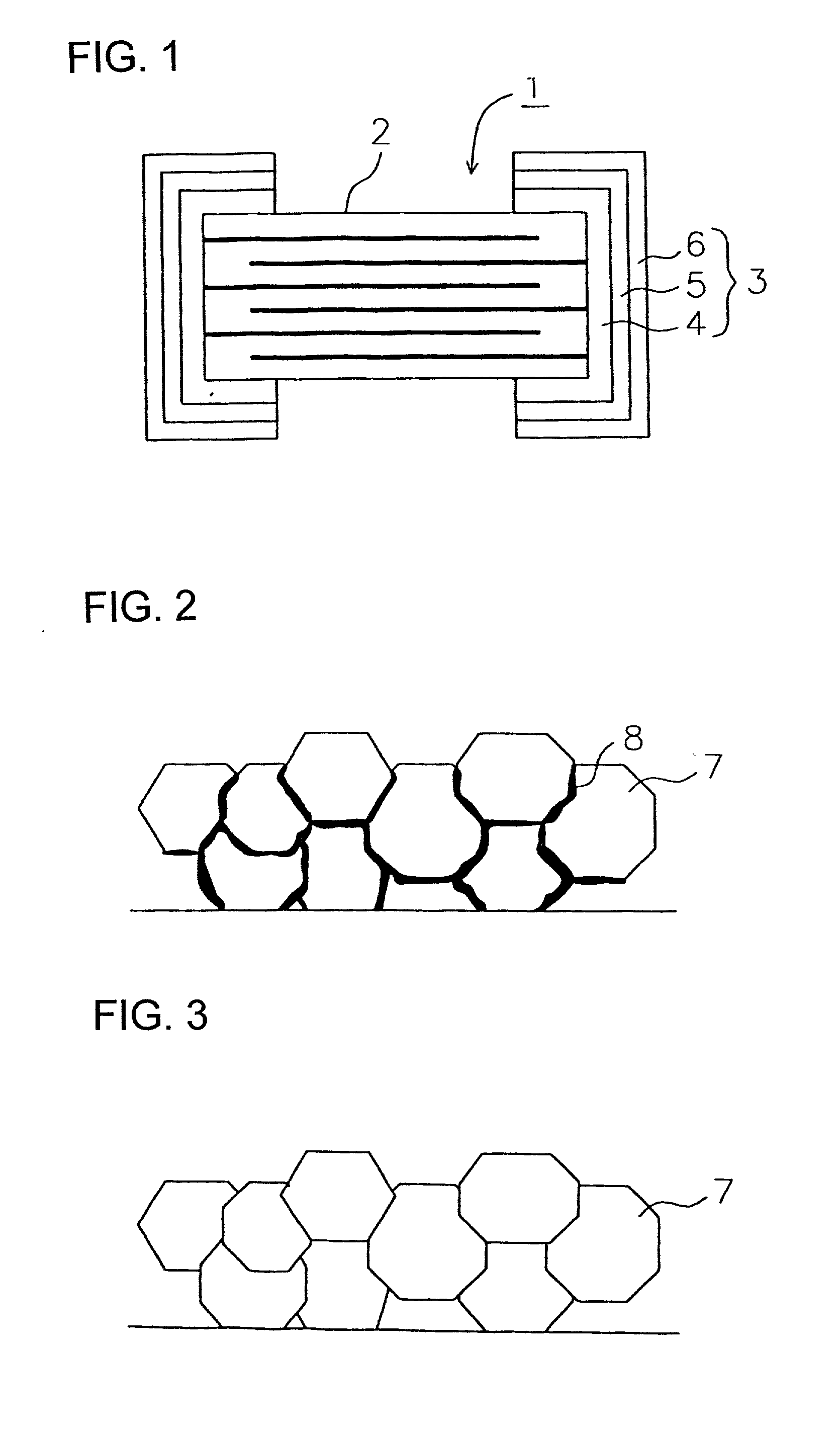

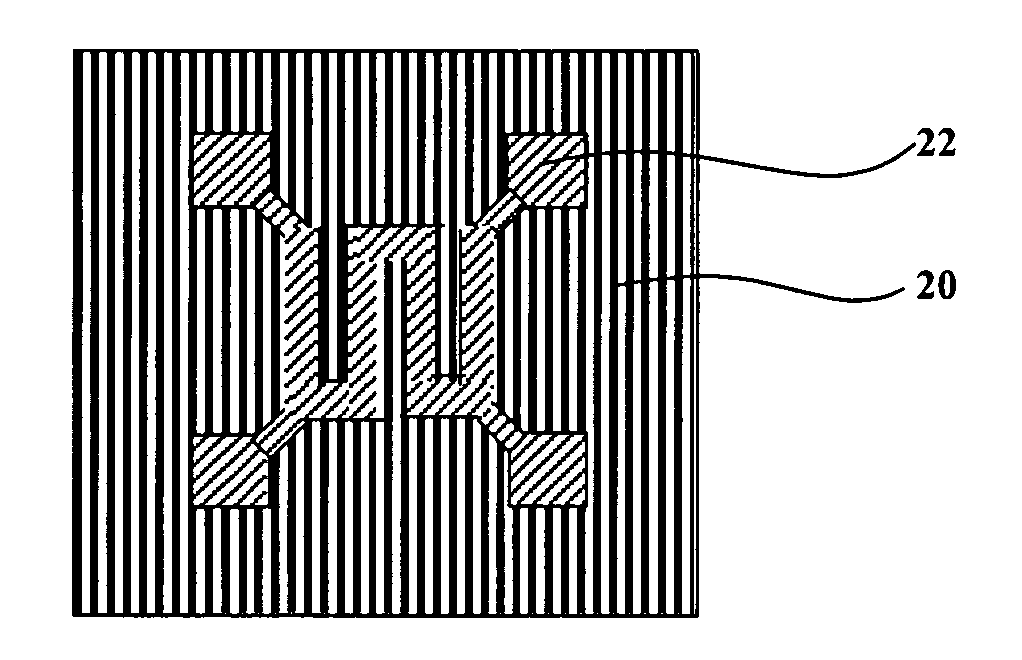

Conductive electrolessly plated powder, its producing method, and conductive material containing the plated powder

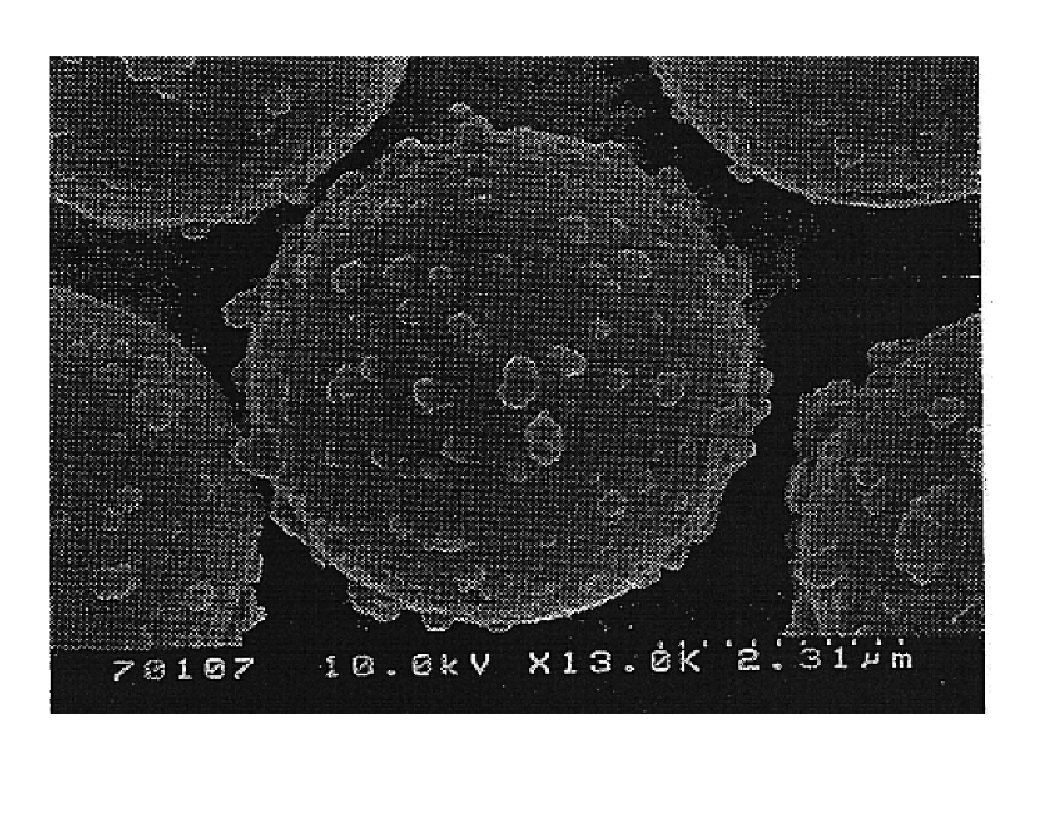

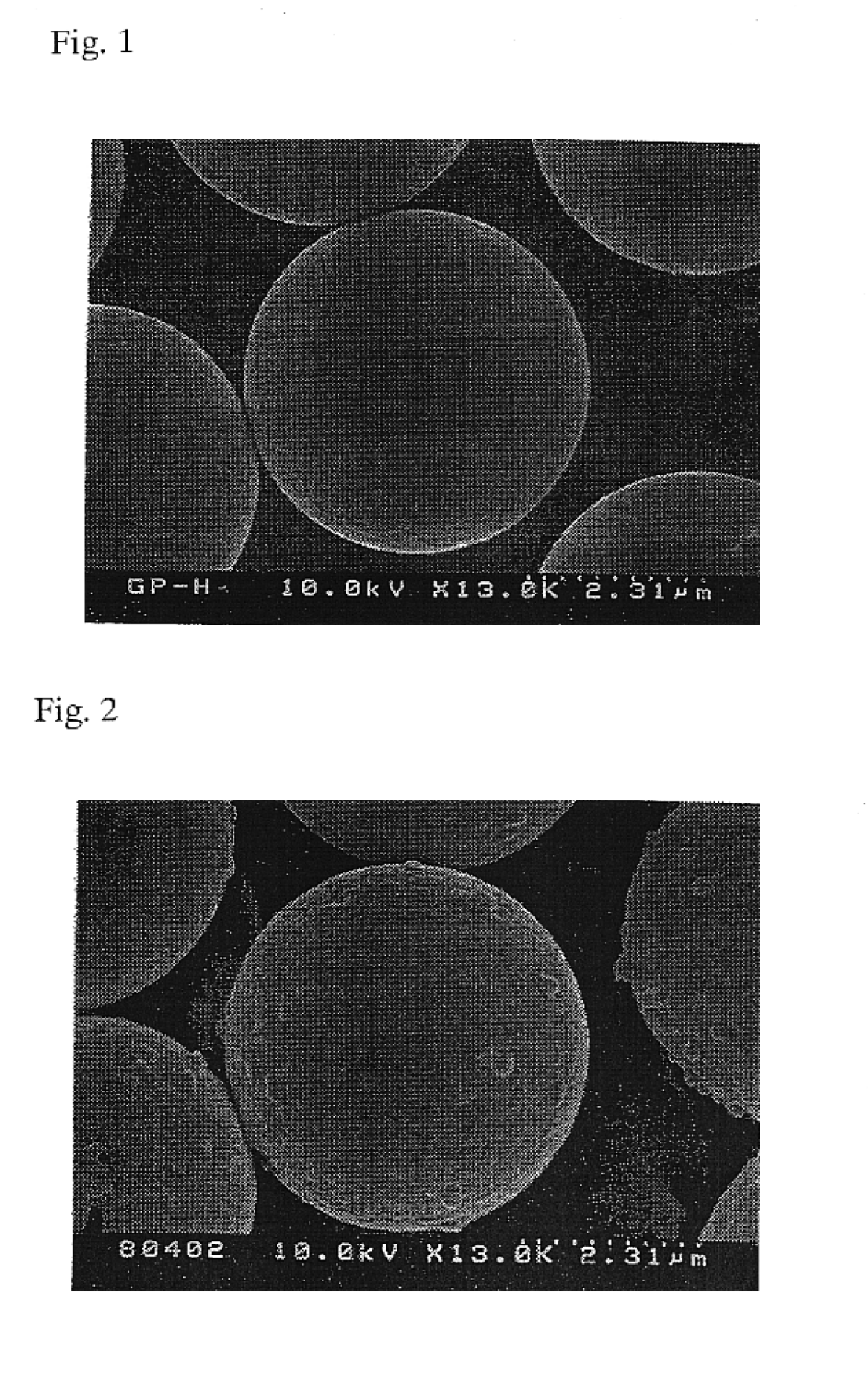

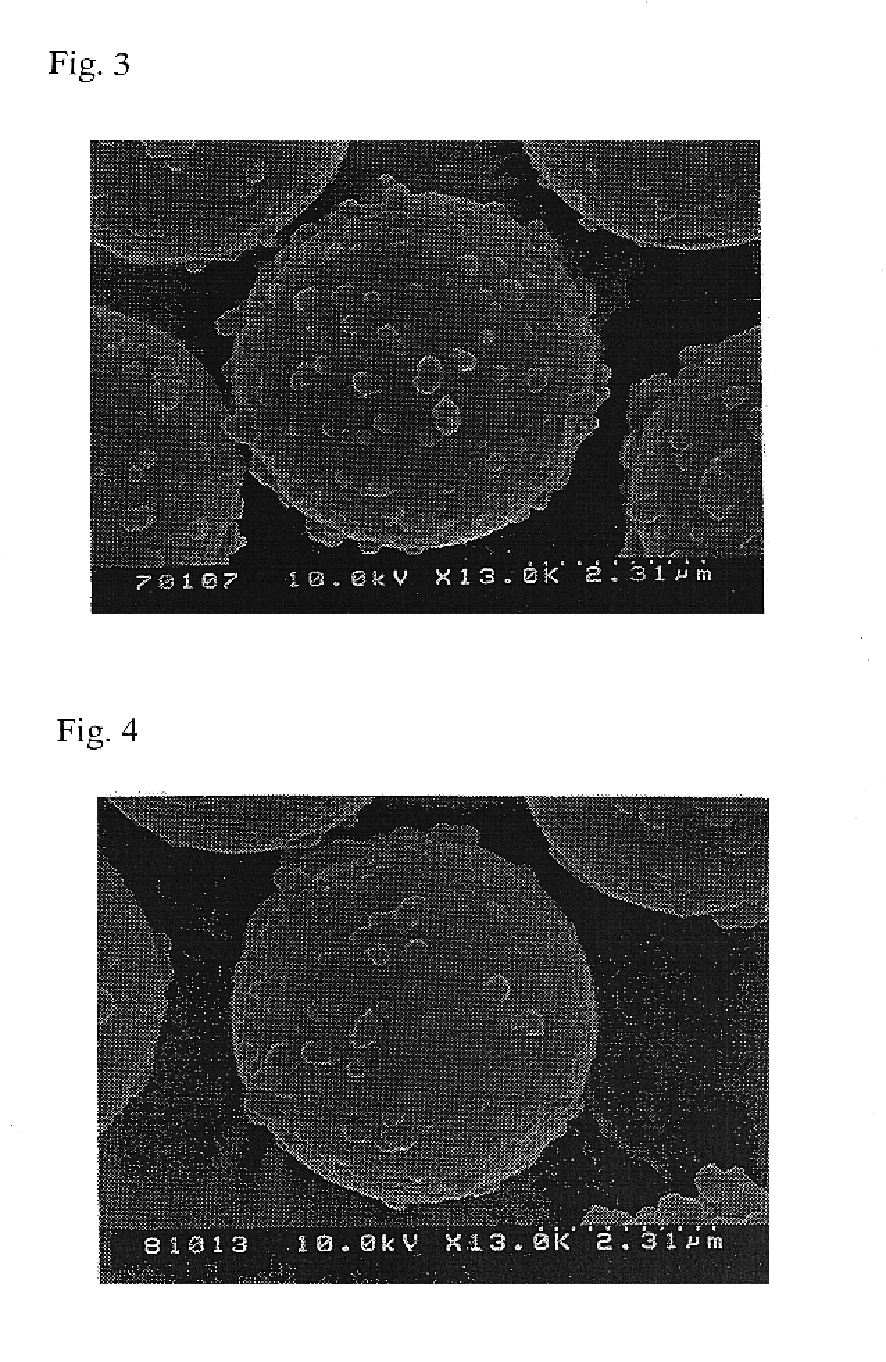

A conductive electrolessly plated powder used, for example, for bonding a small electrode of an electronic device, its producing method, and a conductive material containing the plated powder. Conventionally, there has been known, as conductive powders, metallic powders such as of nickel, carbon powders, and conductive plating powders the resin core particles of which are coated with a metal, e.g., nickel. However, there has been no conductive electrolessly plated powders having a good conductivity with respect to connection between conductive patterns having an oxide coating thereon or between electrodes and no methods for producing such powders industrially. The conductive electrolessly plated powder of the present invention consists of resin spherical core particles the average size of which is 1 to 20 mum and each of which has a nickel or nickel alloy coating formed by electroless plating. The coating includes small projections of 0.05 to 4 mum on its outermost layer and the coating is substantially continuous with the small projections. A method of producing such a powder is also disclosed.

Owner:NIPPON CHECMICAL IND CO LTD

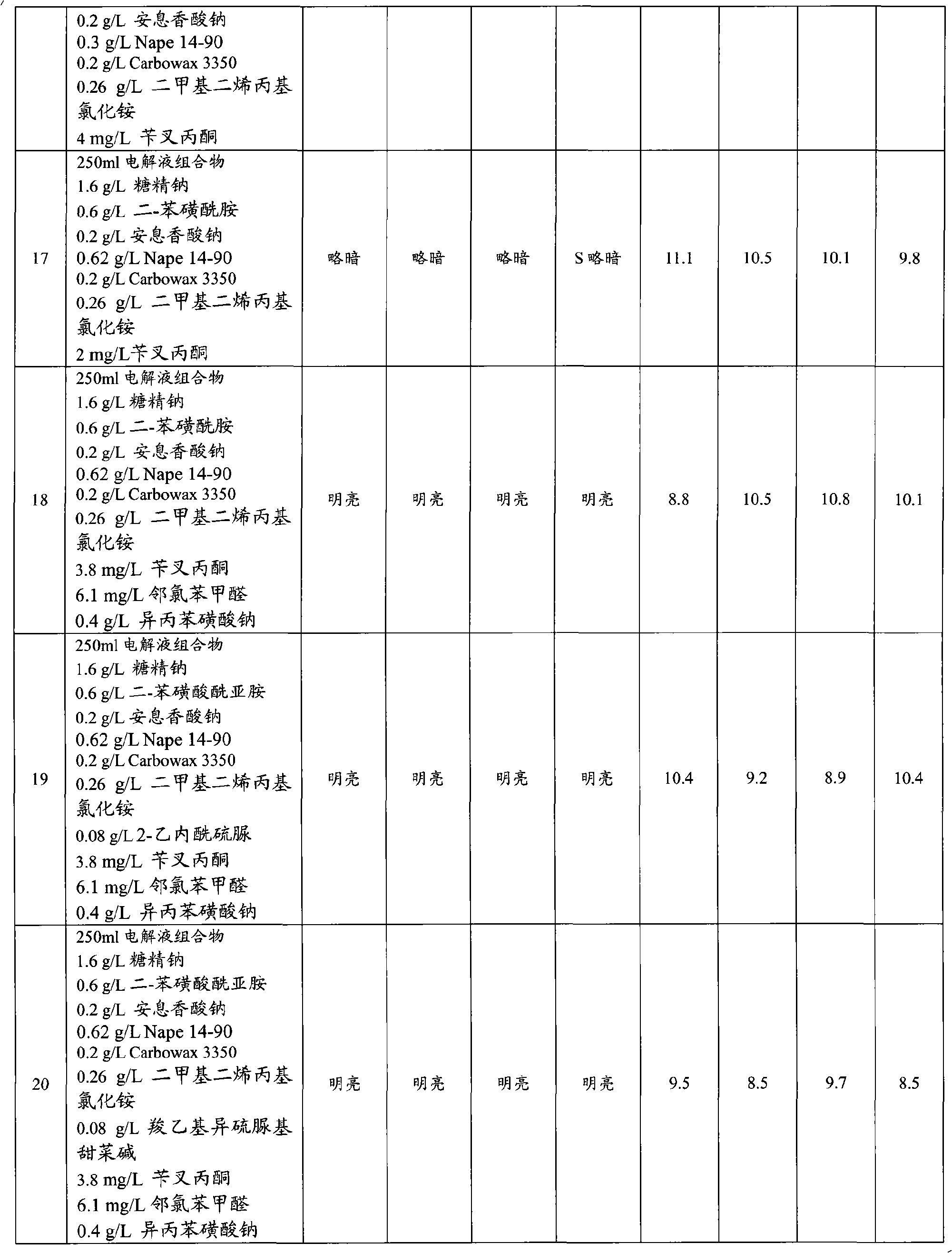

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

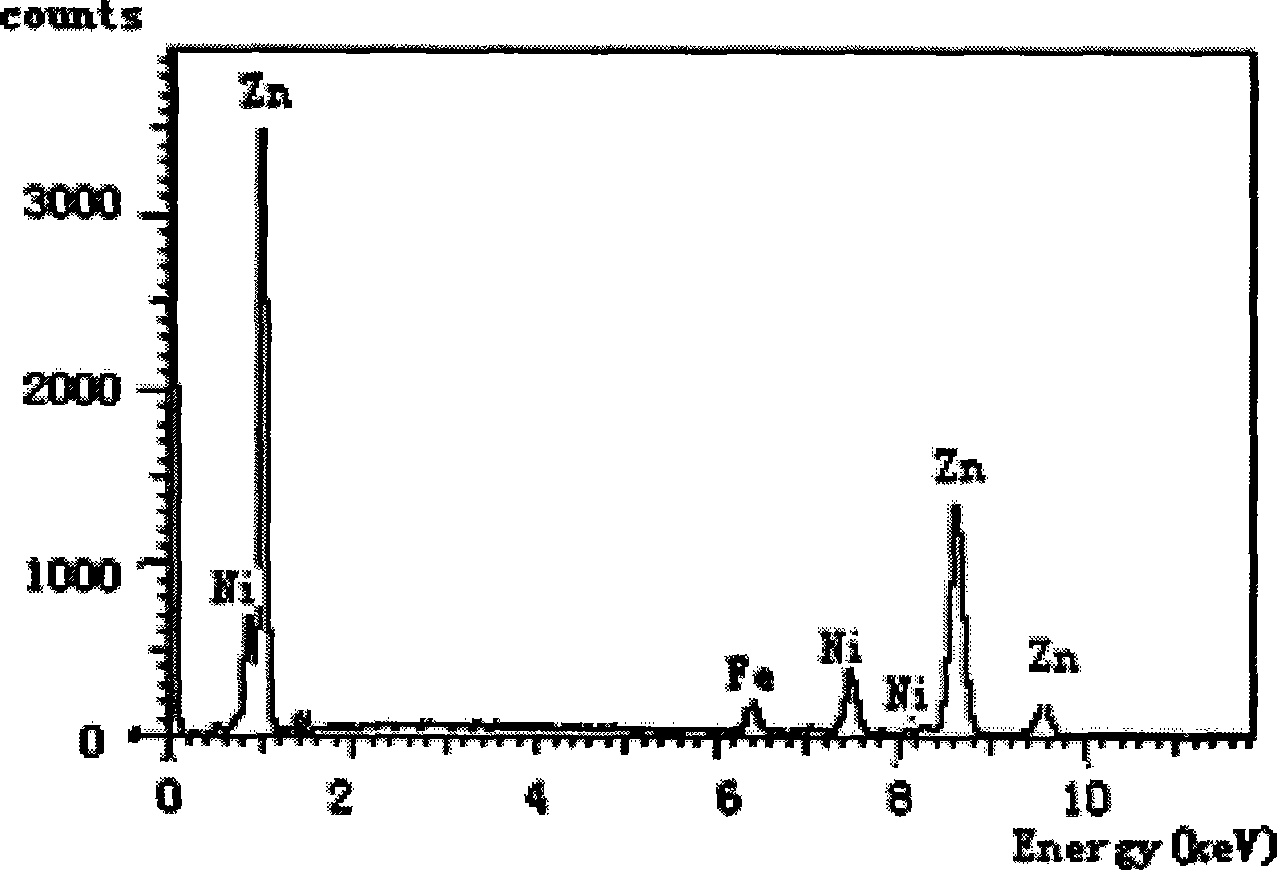

InactiveUS20050133376A1Easy to handleImprove ductilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingZinc ionNickel alloy

The present invention relates to an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:ATOTECH DEUT GMBH

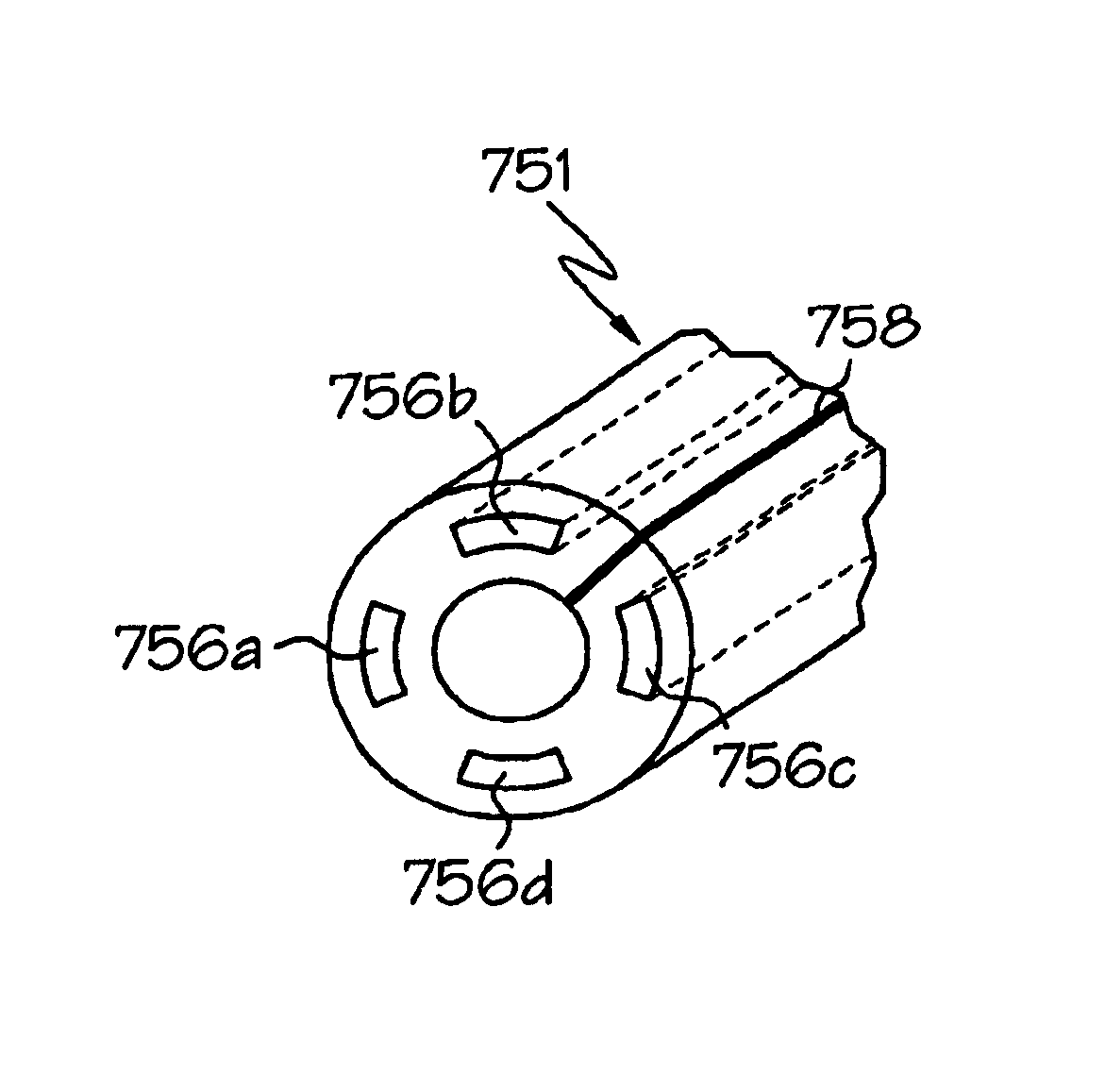

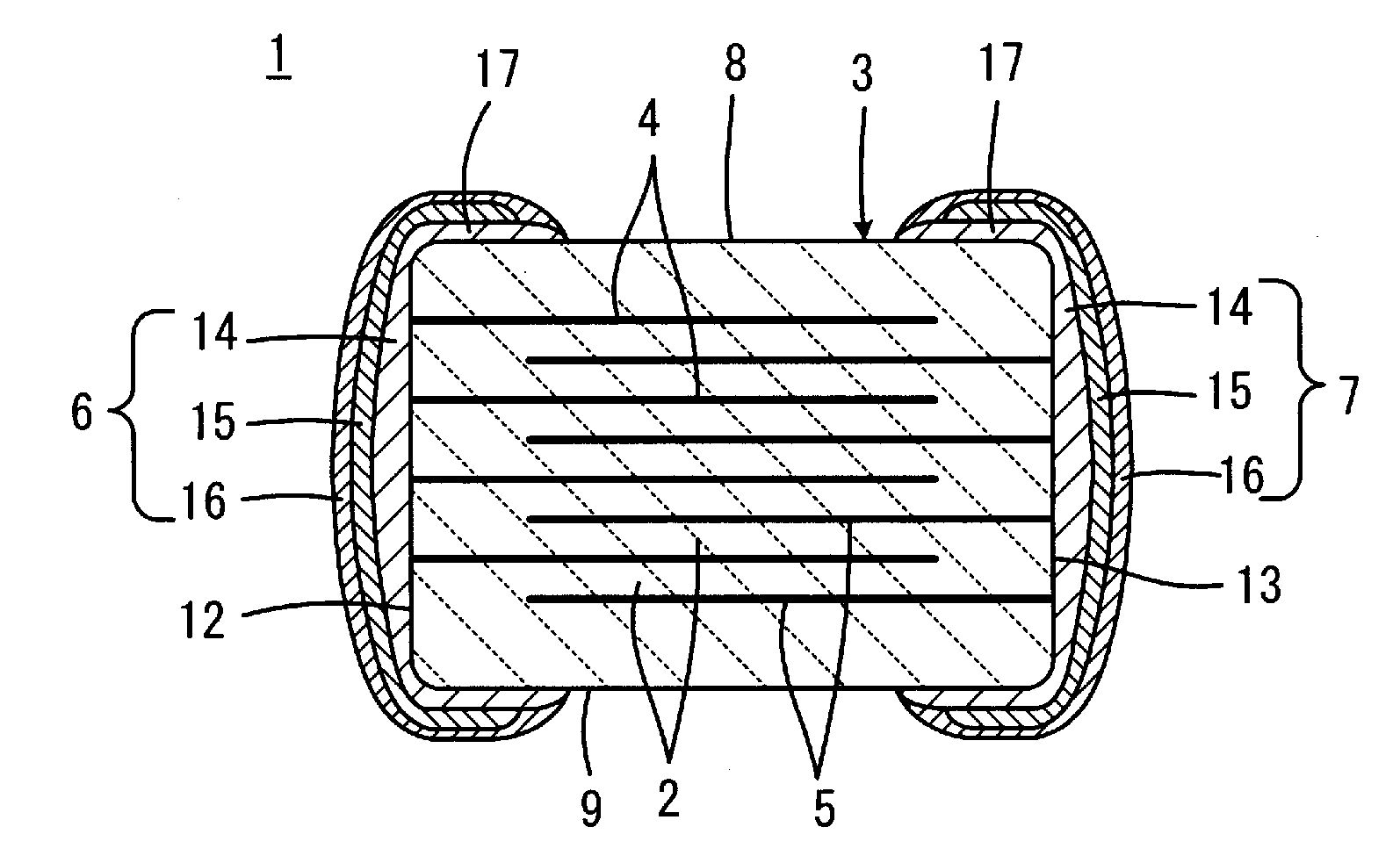

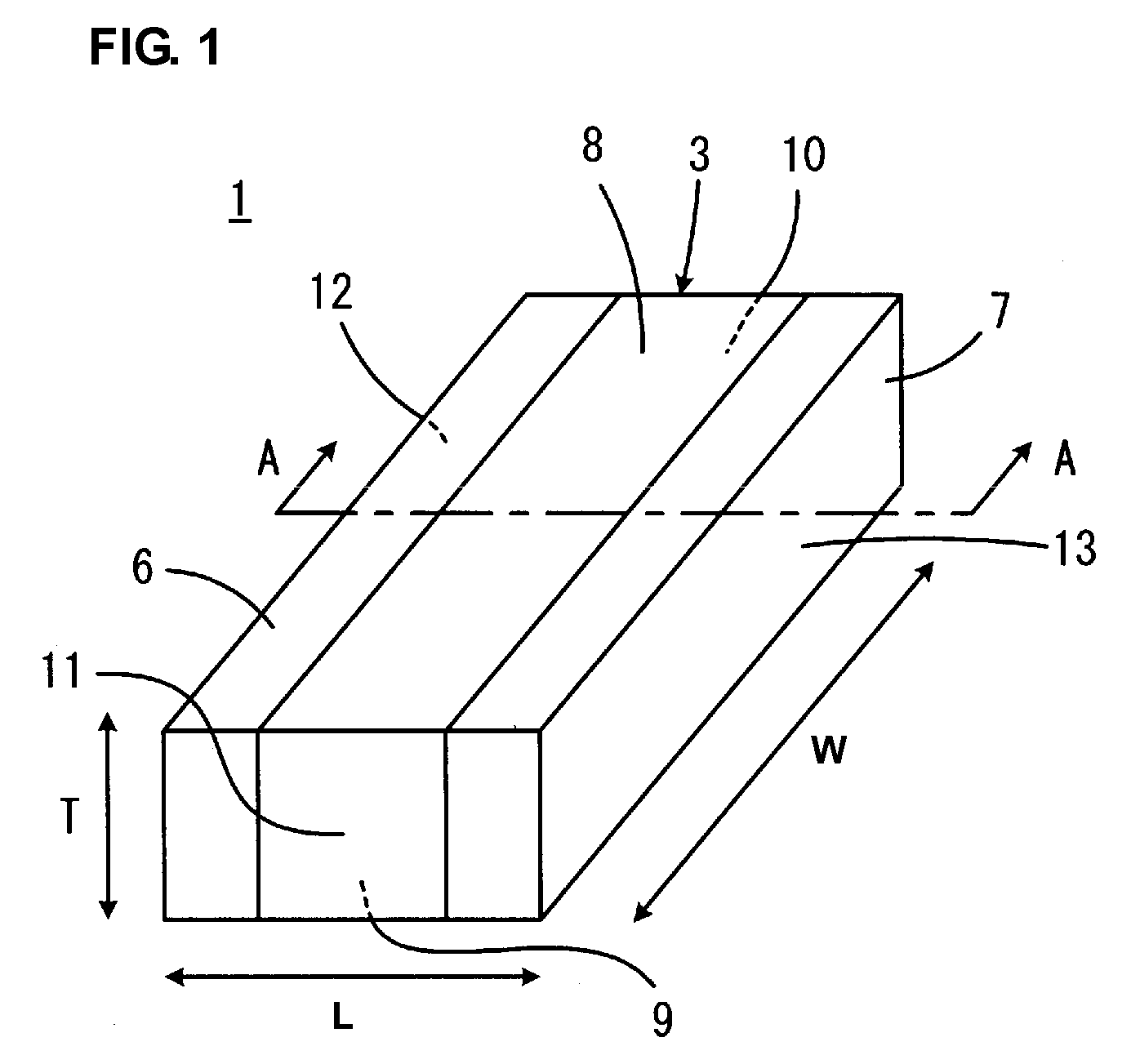

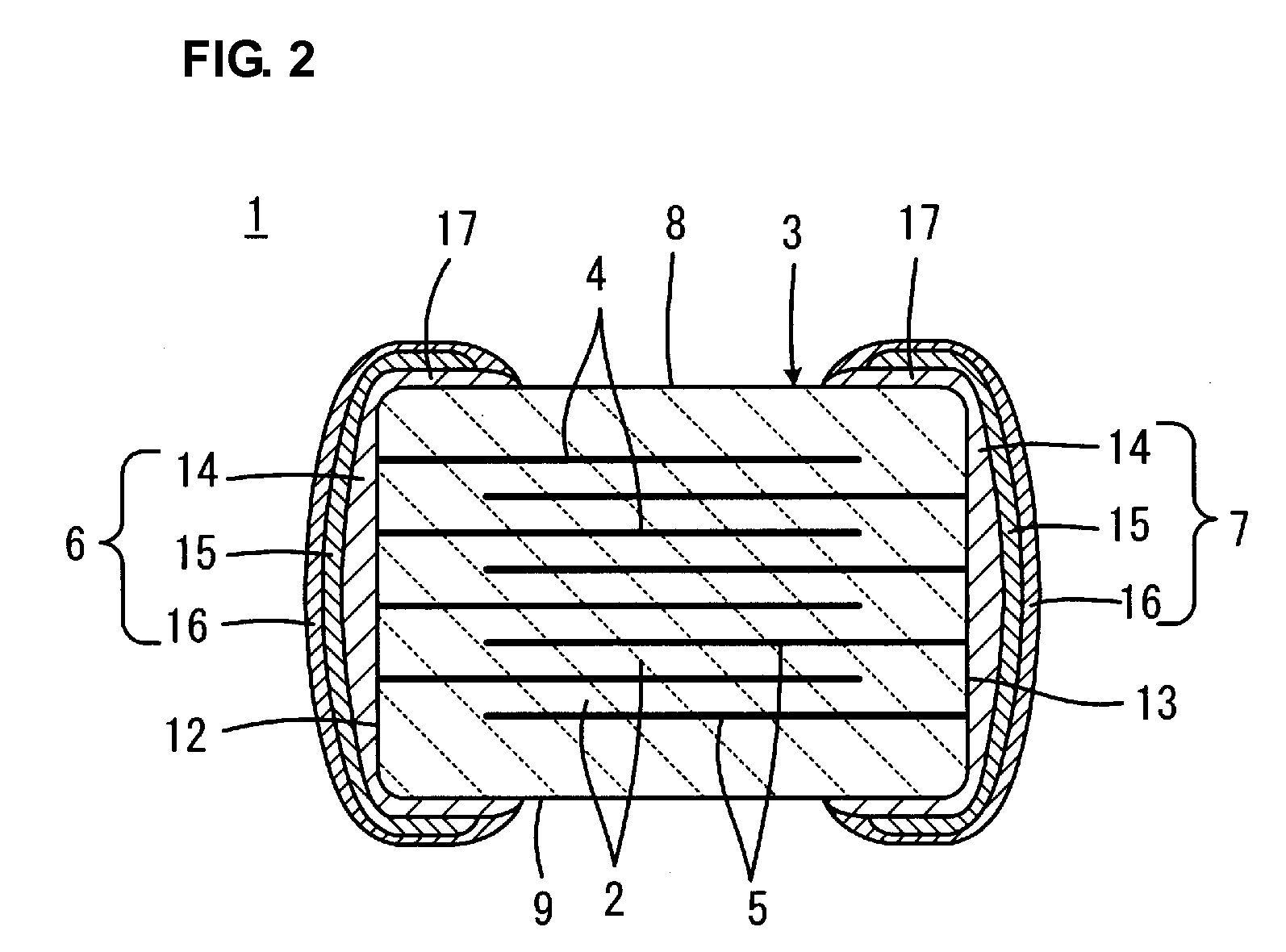

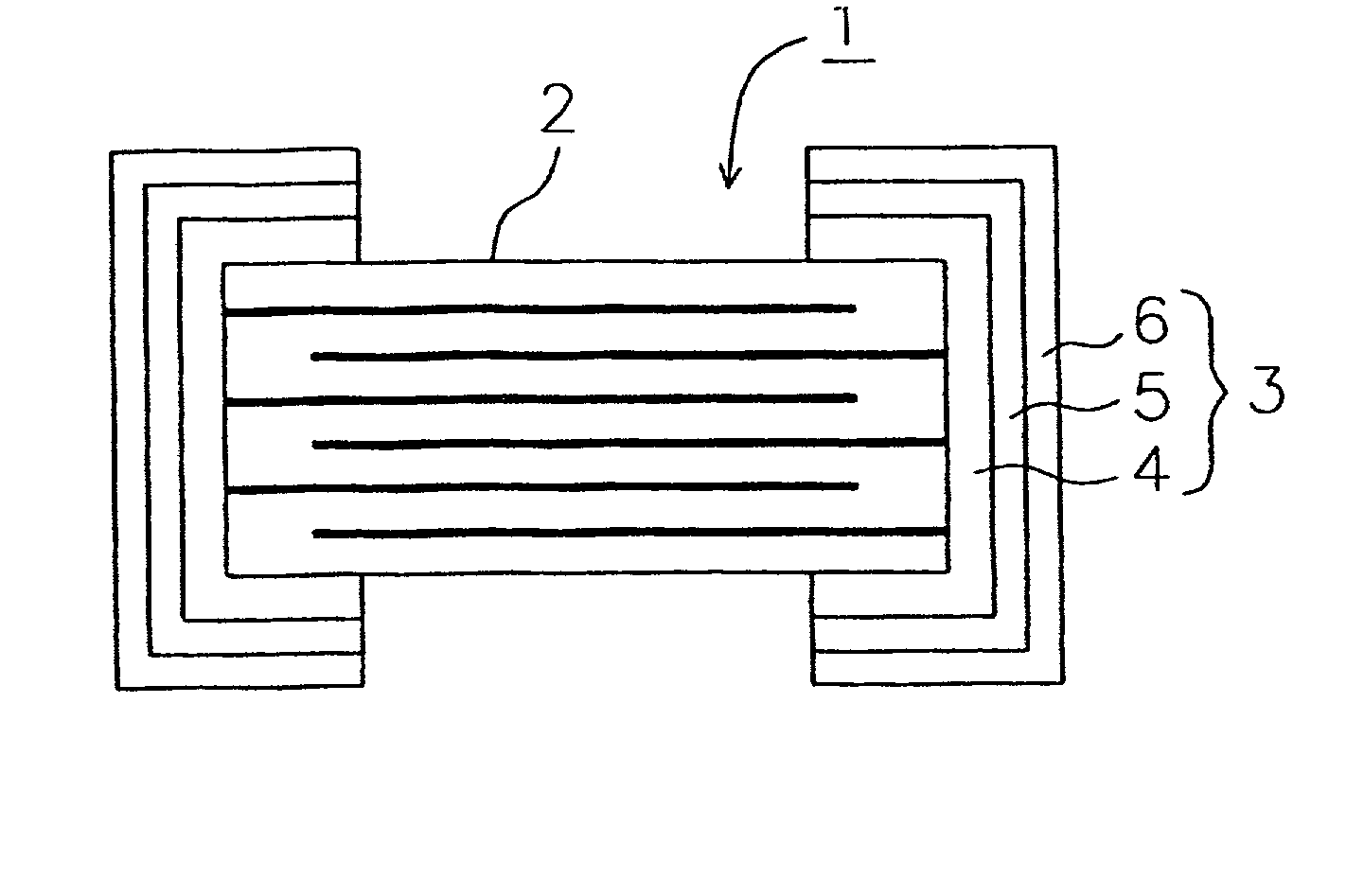

Monolithic ceramic capacitor

ActiveUS20090002920A1Improve installabilityLow reliabilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorOptoelectronics

In an LW-reverse-type monolithic ceramic capacitor including external terminal electrodes each including a resistance component, internal electrodes include nickel or a nickel alloy, and the external terminal electrodes each include a first layer, a second layer provided on the first layer, and a third layer provided on the second layer. The first layer has a wrap-around portion extending from an end surface to principal surfaces and side surfaces of a capacitor main body, and contains a glass component and a compound oxide that reacts with Ni or the Ni alloy. The second layer covers the first layer such that the edge of the wrap-around portion of the first layer remains exposed, and contains a metal. The third layer covers the edge of the wrap-around portion of the first layer and the second layer, and is formed by plating.

Owner:MURATA MFG CO LTD

Electrochemical device

InactiveUS7604717B2Faster, more economically viable and simpler to carry outCellsOptical filtersMinor elementThin layer

The invention relates to an essentially metallic target of a cathodic sputtering device, in particular a magnetic-field-assisted device, the said target mainly comprising nickel alloyed with at least one other minor element in order to reduce or eliminate its ferromagnetism. The invention also relates to the use of the target to manufacture an electrochromic material with anodic colourization as a thin layer based on alloyed nickel oxide.

Owner:SAINT-GOBAIN GLASS FRANCE

Nickel-base alloy for the electro-welding of nickel alloys and steels, welding wire and use

The alloy contains, by weight, less than 0.05% of carbon, from 0.015% to 0.5% of silicon, from 0.4% to 1.4% of manganese, from 28% to 31.5% of chromium, from 8% to 12% of iron, from 2% to 7% of molybdenum, from 0% to 0.75% of aluminium, from 0% to 0.8% of titanium, from 0.6% to 2% in total of niobium and tantalum, the ratio of percentages of niobium plus tantalum and of silicon being at least 4, less than 0.04% of nitrogen, from 0.0008% to 0.0120% of zirconium, from 0.0010% to 0.0100% of boron, less than 0.01% of sulphur, less than 0.020% of phosphorus, less than 0.30% of copper, less than 0.15% of cobalt and less than 0.10% of tungsten, the remainder of the alloy, with the exception of unavoidable impurities of which the total content is at most 0.5%, consisting of nickel. The alloy is used, in particular, for the production of wires for the electro-gas welding of units or components of nuclear reactors and, more particularly, of pressurised water-cooled nuclear reactors.

Owner:FRAMSTOME ANP

Copper foil excellent in laser beam drilling performance and production method therefor

InactiveUS6638642B2Improve drilling effectFine surfaceRadiation applicationsExtrusion containersIndiumCopper foil

Owner:JX NIPPON MINING & METALS CORP

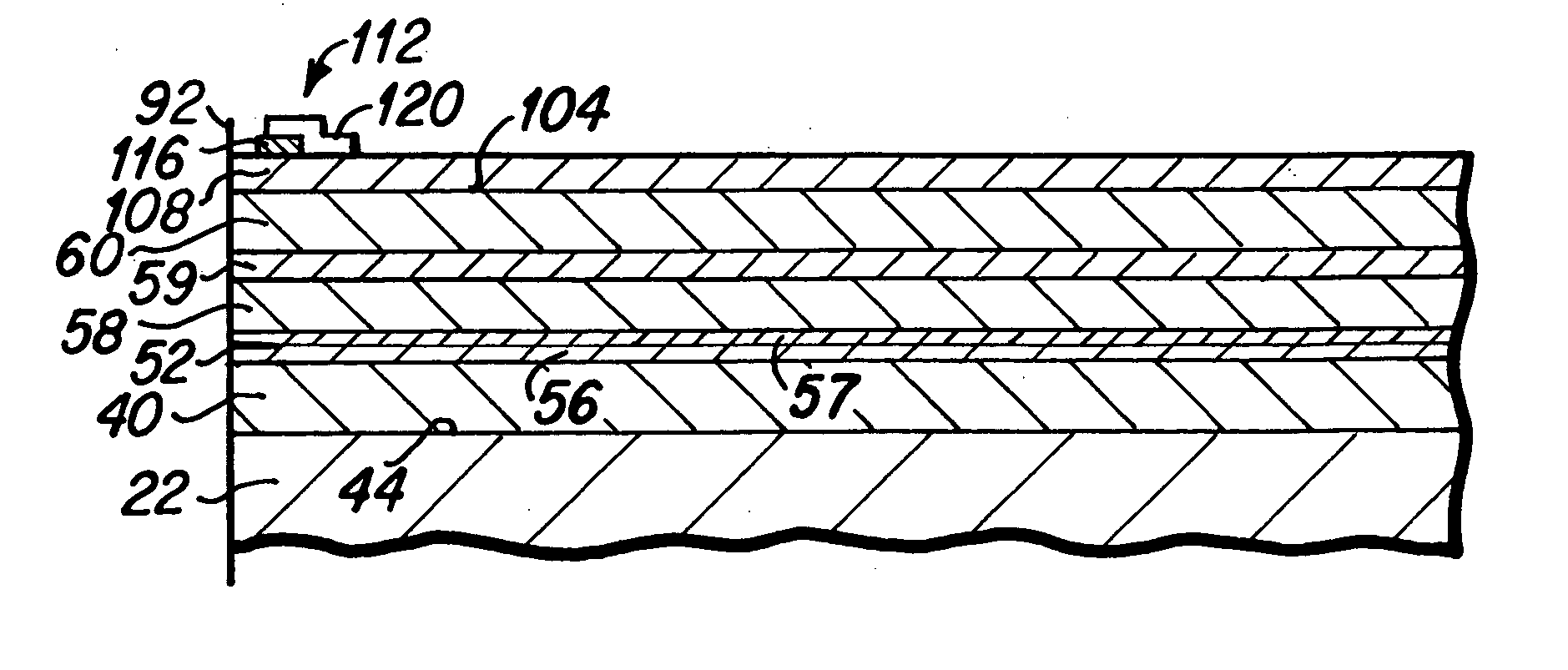

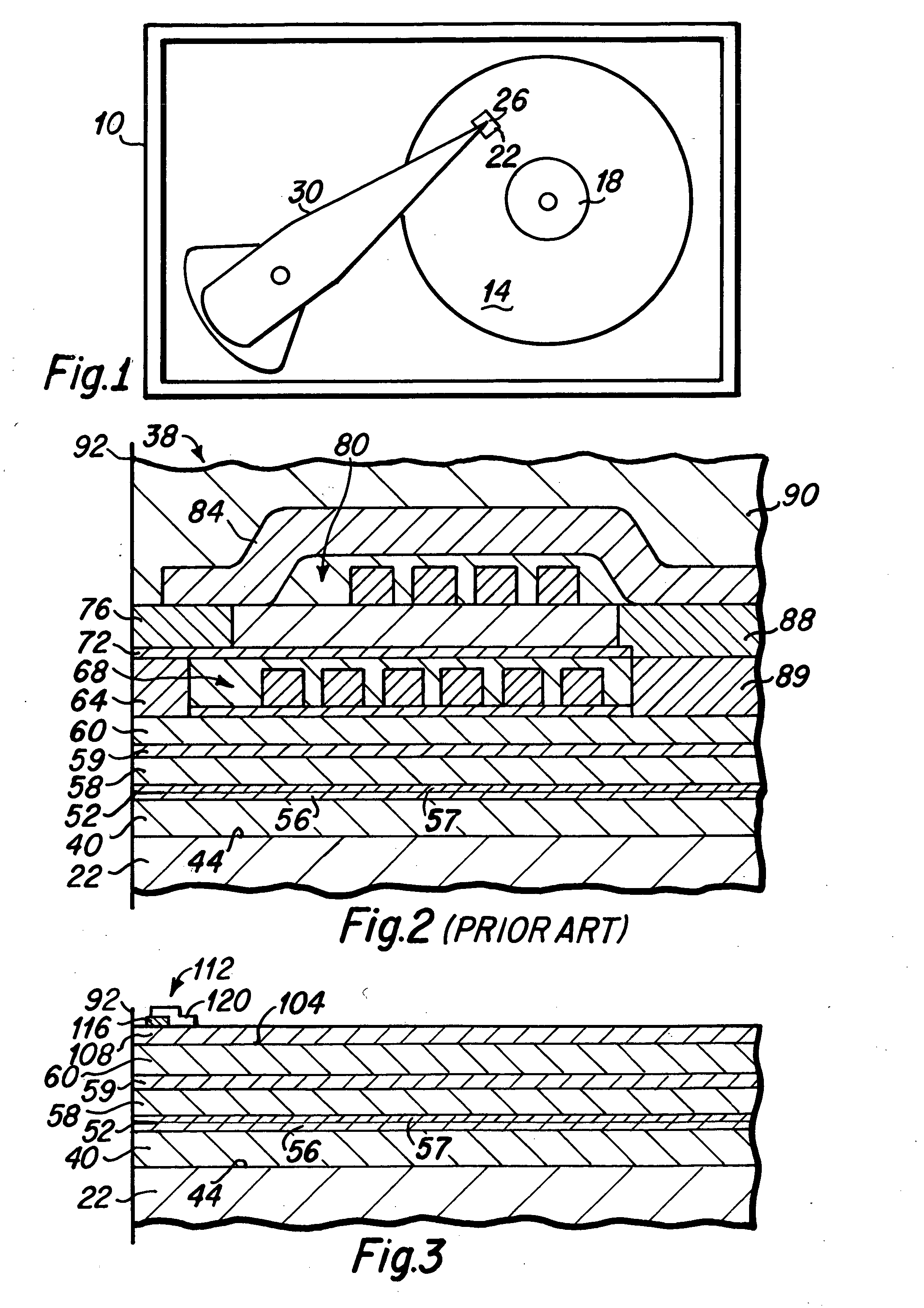

Magnetic head having multilayer heater for thermally assisted write head and method of fabrication thereof

ActiveUS20050024773A1Facilitates writing of dataLower its localized coercivityConstruction of head windingsHeads using thin filmsMetallic materialsEngineering

A magnetic head including a media heating device that is fabricated within the magnetic head structure. The media heating device is fabricated with diffusion barrier layers and / or adhesion layers beneath the heating device layers, between heating device layers and / or above the heating device layers. A diffusion barrier layer prevents the diffusion of the metal materials that comprise the heating device layers into layers that are disposed below and / or above the heating device, and adhesion layer promotes adhesion of the heating device to the magnetic head layers adjacent to the heating device. The diffusion barrier layer may be comprised of tantalum, tantalum nitride, other tantalum alloys, titanium, rhodium and ruthenium, and the adhesion layer may be comprised of tantalum, tantalum nitride, tantalum oxide, other tantalum alloys, titanium, nickel iron, chromium, platinum alloys, nickel alloys and aluminum oxide.

Owner:WESTERN DIGITAL TECH INC

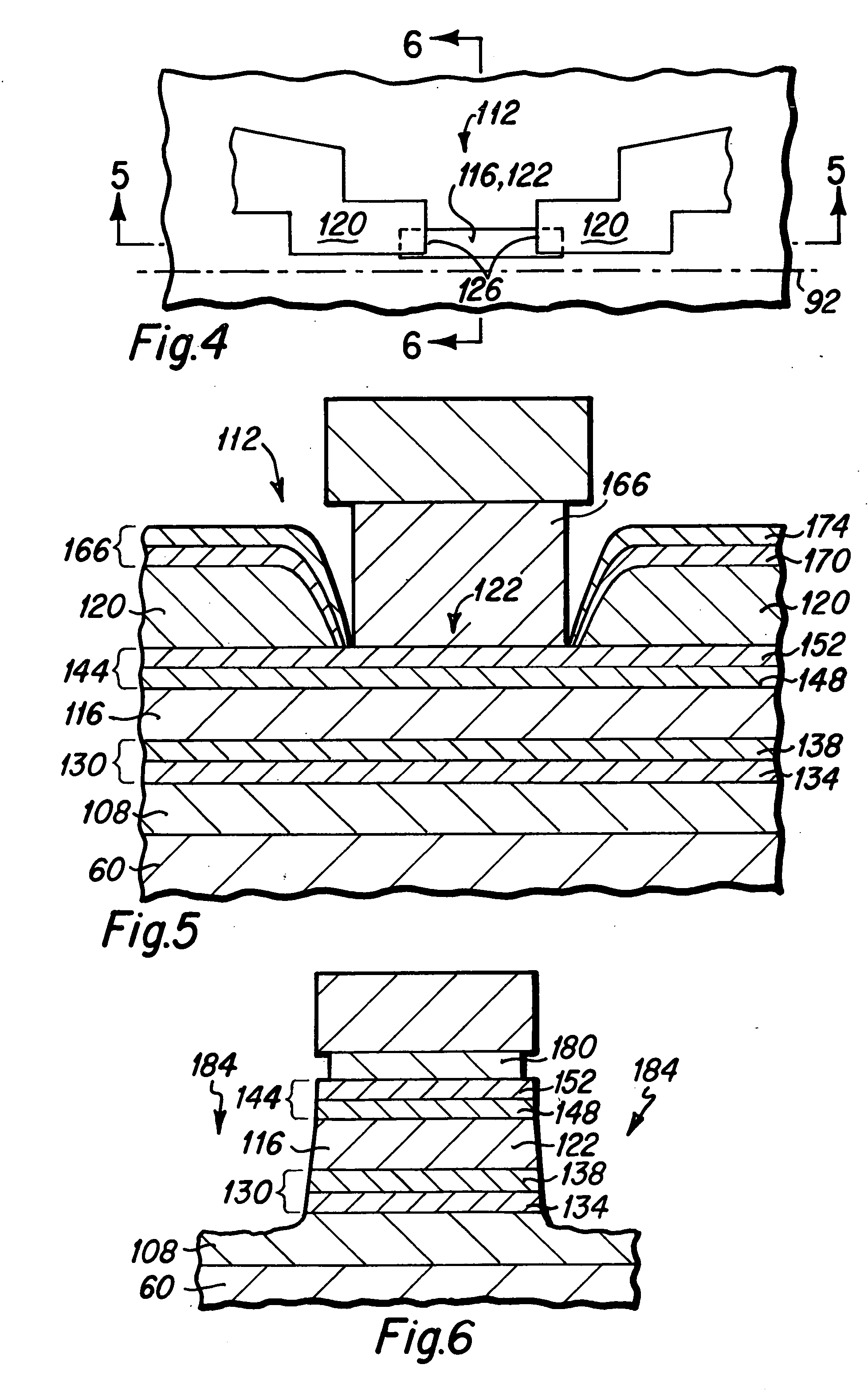

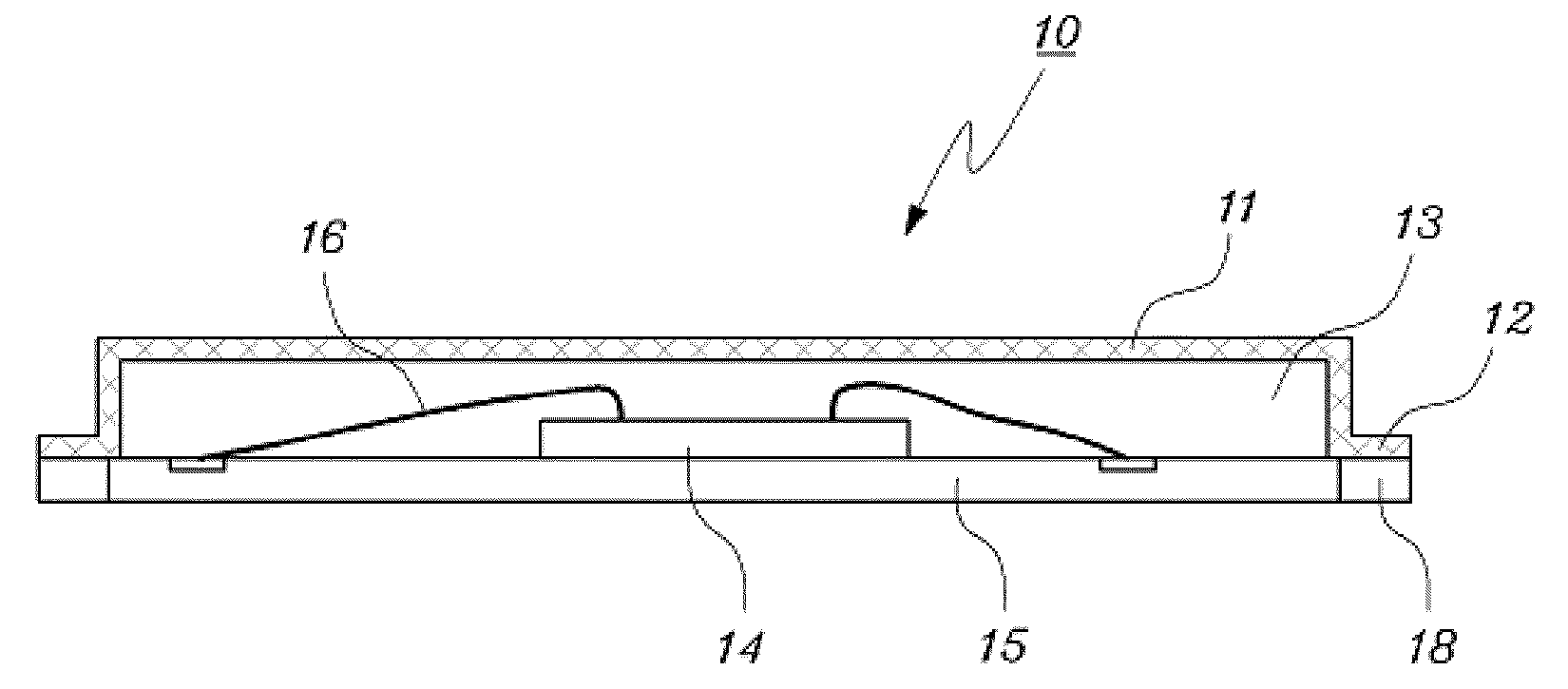

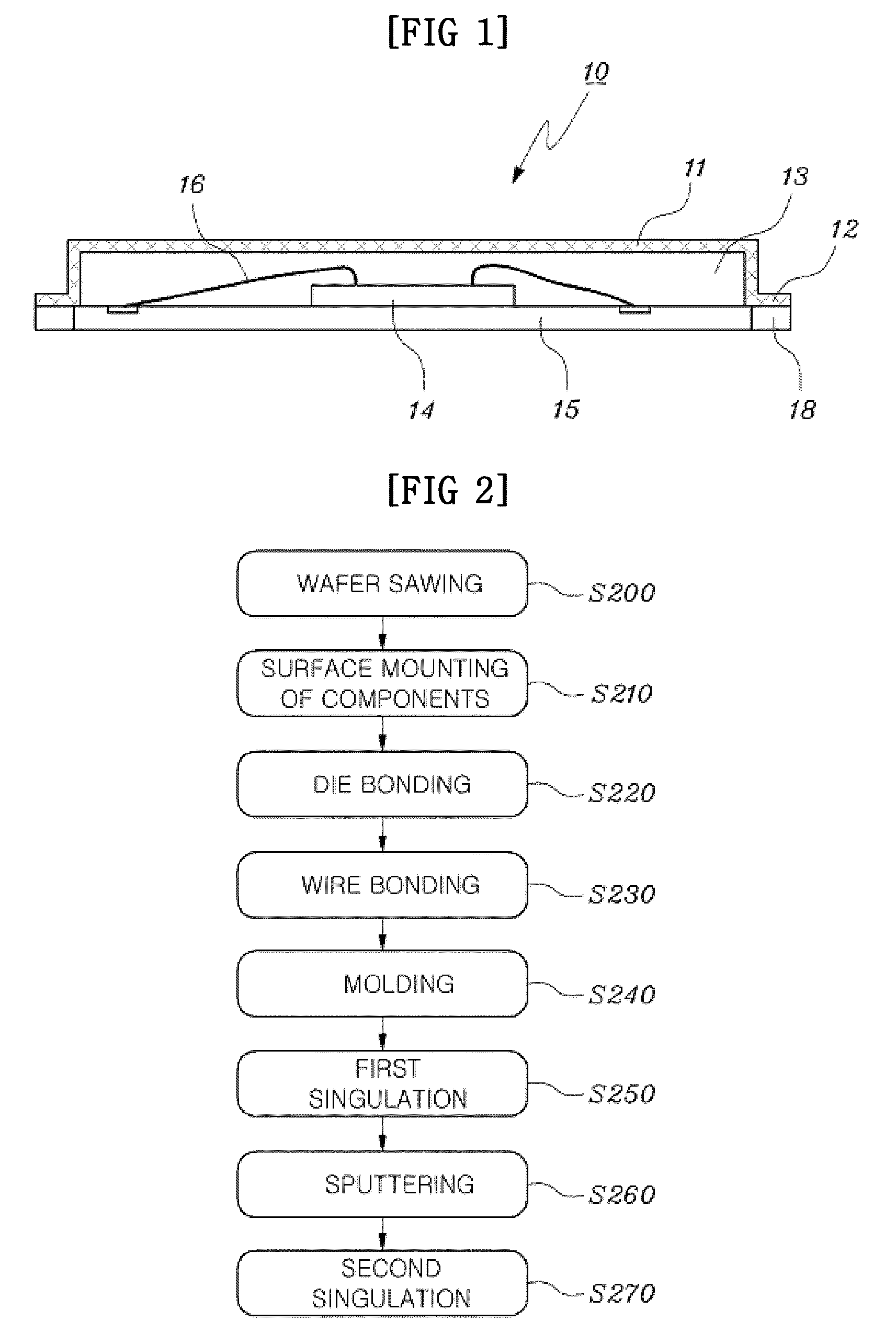

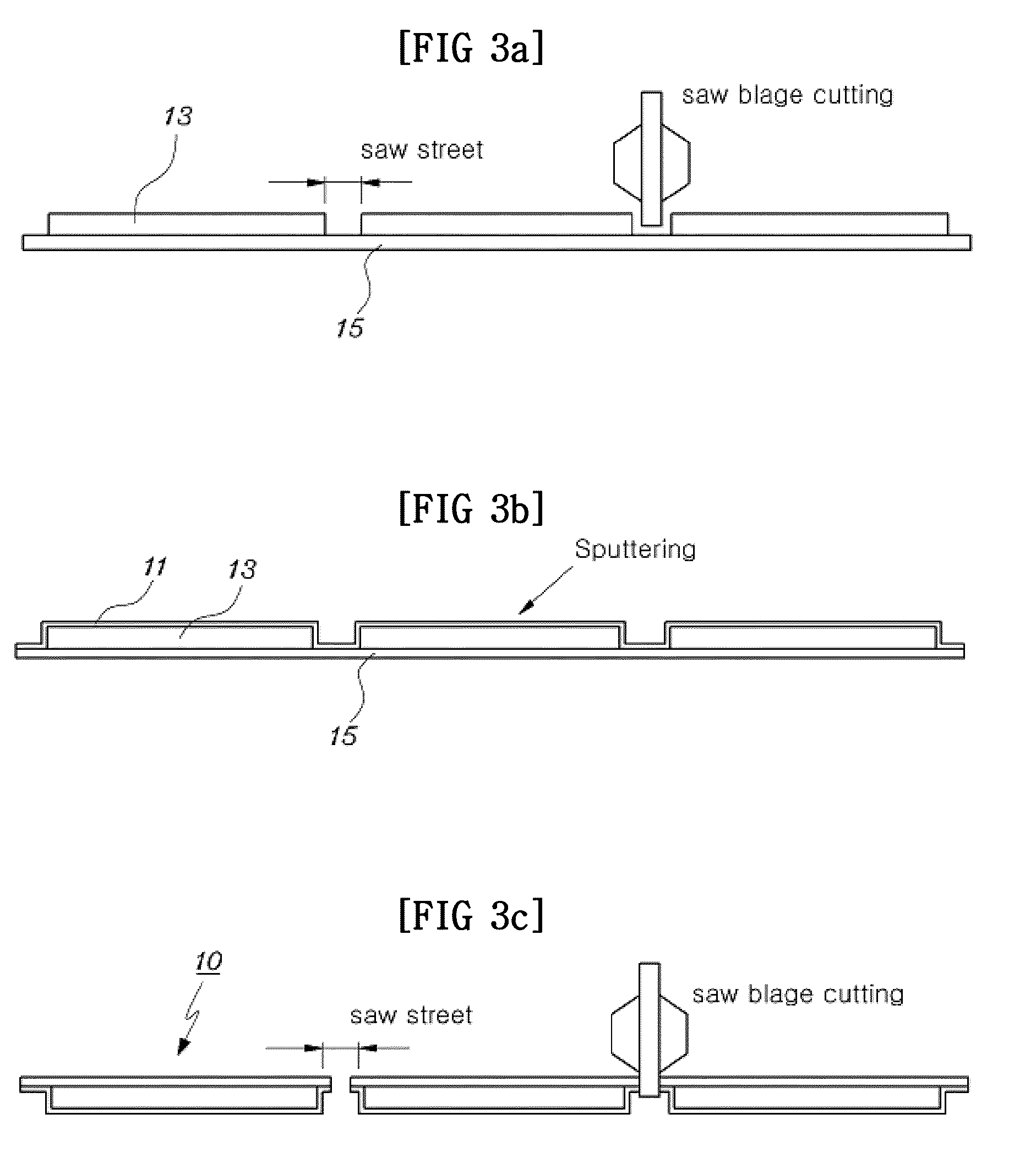

Semiconductor packages having electromagnetic interference-shielding function, manufacturing method thereof and jig

InactiveUS20090294930A1Reduce manufacturing costCellsSemiconductor/solid-state device detailsSputteringElectromagnetic interference

The present invention relates to relates to a semiconductor package having a function of shielding electromagnetic interference (EMI), a manufacturing method thereof and a jig, and more particularly, to such a semiconductor package having an electromagnetic interference (EMI)-shielding function, a manufacturing method thereof and a jig for use in a plasma sputtering, in which a nickel alloy is coated on the surface of a semiconductor package by a sputtering method so as to shield electromagnetic interference (EMI) generated from the semiconductor package.

Owner:YOON JUM CHAE

Method for fabricating semiconductor device

InactiveUS20080124922A1Improve thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSalicideHydrogen

A semiconductor device fabrication method by which the thermal stability of nickel silicide can be improved. Nickel (or a nickel alloy) is formed over a semiconductor substrate on which a gate region, a source region, and a drain region are formed. Dinickel silicide is formed by performing a first annealing step, followed by a selective etching step. By performing a plasma treatment step, plasma which contains hydrogen ions is generated and the hydrogen ions are implanted in the dinickel silicide or the gate region, the source region, and the drain region under the dinickel silicide. The dinickel silicide is phase-transformed into nickel silicide by performing a second annealing step.

Owner:FUJITSU SEMICON LTD

Nickel alloy sputtering target

InactiveUS20060037680A1Improve uniformityImprove plastic processing performanceVacuum evaporation coatingSputtering coatingManufacturing technologyNickel alloy

A nickel alloy sputtering target containing 0.5 to 10 at % of tantalum in nickel, in which inevitable impurities excluding gas components are 100 wtppm or less. Provided is a nickel alloy sputtering target, and the manufacturing technology thereof, enabling the formation of a thermally stable silicide (NiSi) film, unlikely to cause the coagulation of films or excessive formation of silicides, having few generation of particles upon forming the sputtered film, having favorable uniformity and superior in the plastic workability to the target, and which is particularly effective for the manufacture of a gate electrode material (thin film).

Owner:JX NIPPON MINING & METALS CO LTD

Electronic component, method for producing electronic component, and circuit board

InactiveUS20020001712A1Suppress generationEasy to spreadSurface reaction electrolytic coatingVacuum evaporation coatingTin platingNickel alloy

Owner:MURATA MFG CO LTD

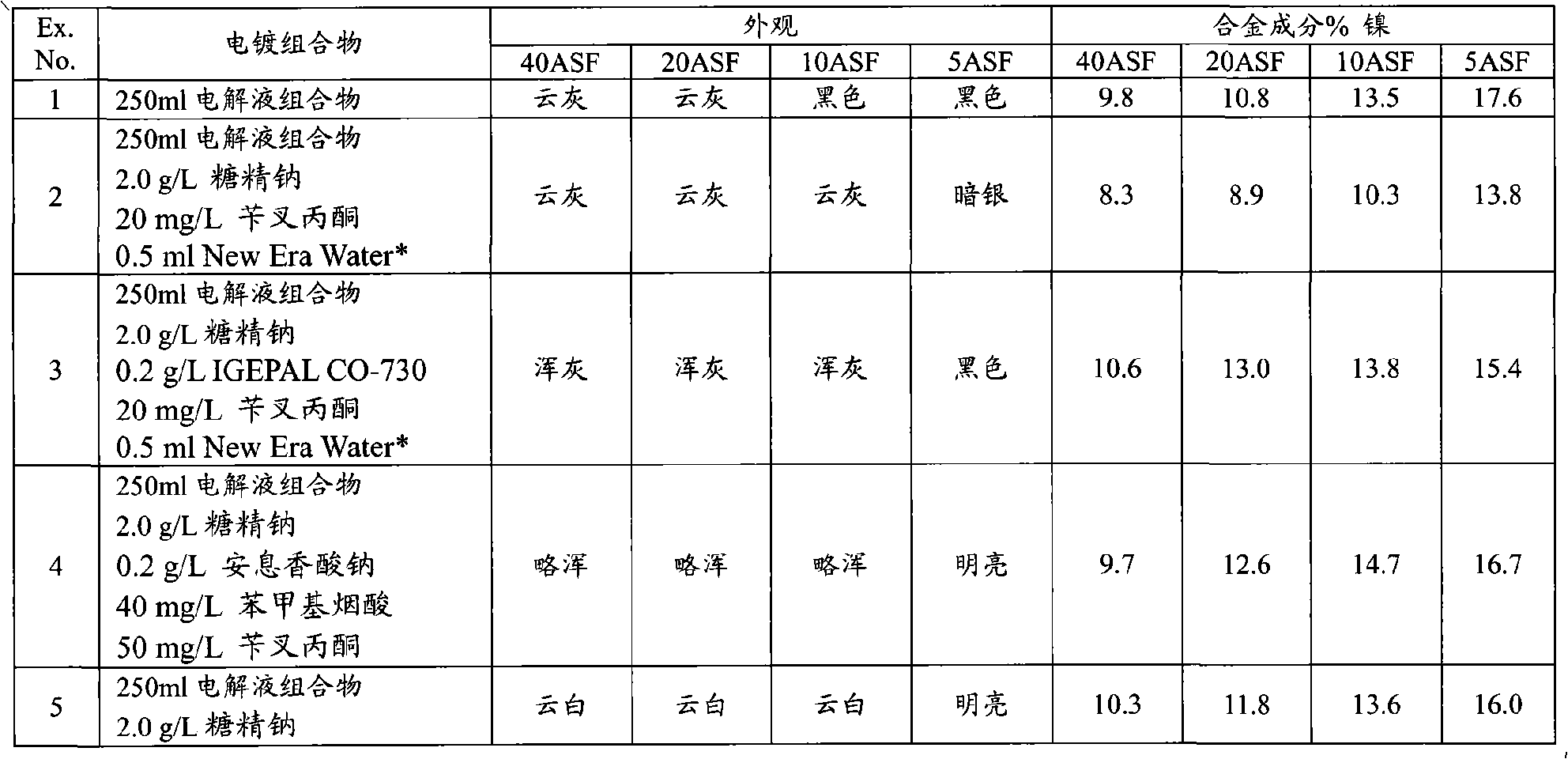

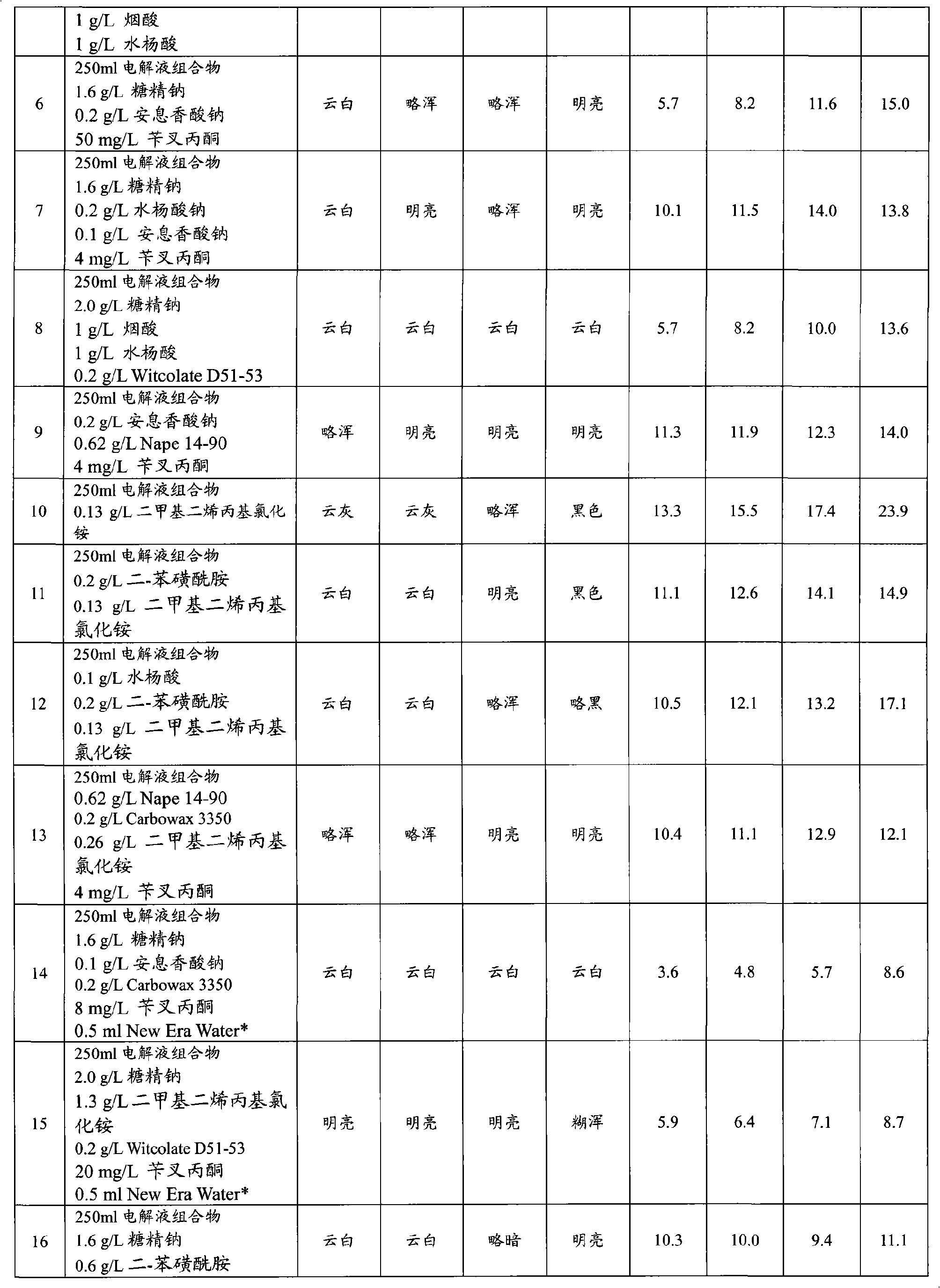

Zinc-nickel alloy electroplating system

The invention provides an aqueous zinc-nickel alloy electroplating composition particularly useful in an electroplating method for depositing a zinc-nickel alloy layer on a substrate, wherein the deposited layer exhibits uniform nickel concentration and good aesthetics across a broad range of current densities. The electroplating composition comprises an electrolyte composition and an organic composition. In one embodiment, the electrolyte composition comprises a zinc ion source, a nickel ion source, a pH buffering agent and at least one additional salt, and the organic composition comprises a Class I nickel brightener, a Class II nickel brightener, an aromatic carboxylic acid, an aldehyde or ketone compound, and a non-ionic or anionic surfactant. The electroplating composition is particularly free of chelators and free ammonium-producing agents.

Owner:PAVCO INC

Method for electroplating double-layer admiro film on Nd-Fe-B magnetic surface

This invention relates to a preparation of electroplating double-deck zinc-nickel alloy coatings on surface of NdfeB magnet, firstly progress treatment before plating; Then pre-plate zinc-nickel alloy; And electroplate zinc-nickel alloy that is high corrosion resistance; At last progress treatment after plating, Its noncorrodibility is well, combination is firm, cost is low, influence toward magnet is small, make it has effect that decreases corroding NdfeB magnet in electroplating process.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Electrochemical fabrication methods with enhanced post deposition processing

InactiveUS20050029225A1Improved post deposition processingDecorative surface effects3D structure electroformingAlcoholNickel alloy

An electrochemical fabrication process for producing three-dimensional structures from a plurality of adhered layers is provided where each layer comprises at least one structural material (e.g. nickel or nickel alloy) and at least one sacrificial material (e.g. copper) that will be etched away from the structural material after the formation of all layers have been completed. An etchant containing chlorite (e.g. Enthone C-38) is combined with a corrosion inhibitor (e.g. sodium nitrate) to prevent pitting of the structural material during removal of the sacrificial material. A simple process for drying the etched structure without the drying process causing surfaces to stick together includes immersion of the structure in water after etching and then immersion in alcohol and then placing the structure in an oven for drying.

Owner:UNIV OF SOUTHERN CALIFORNIA

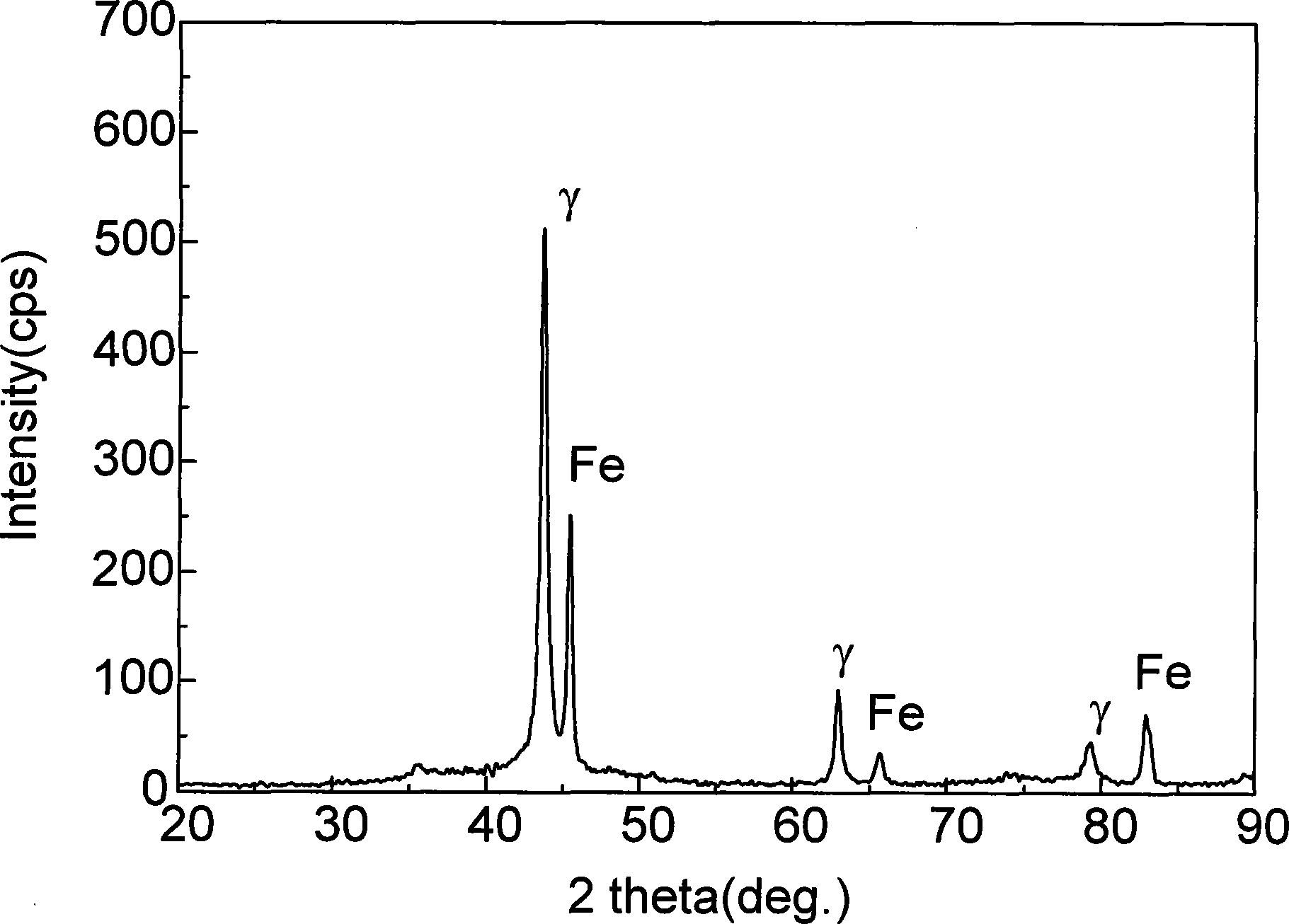

Method for plating zinc-nickel alloy in alkaline electroplate liquid

InactiveCN101240437ASolve the problem of large compositional changesImprove current efficiencyWater basedOrganic solvent

The invention discloses a method for electroplating alkaline Zn-Ni alloy, comprising the steps of: preparing alkali wash and acid wash, preparing electroplating Zn-Ni alloy plating solution, mechanical grinding, degreasing with organic solvent or water-based detergent, alkali washing, acid washing and electroplating. The invention provides a stable electroplating solution formula and complete electroplating process. The coating electroplated by the method is proved to have good flat surface, uniform coating distribution and alloy distribution, the coating is single gamma-phase, the nickel has a content of 10% to 15%; the coating has superior corrosion resistance, red rust appears on the non-passivated Zn-Ni coating after 1500 hours in a neutral salt spray test; compared with general alkali electroplating solution, the coating has high current efficiency, reaching up to 80% to 90%.

Owner:BEIHANG UNIV

Method for preparing copper and nickel alloy seamless copper tube

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

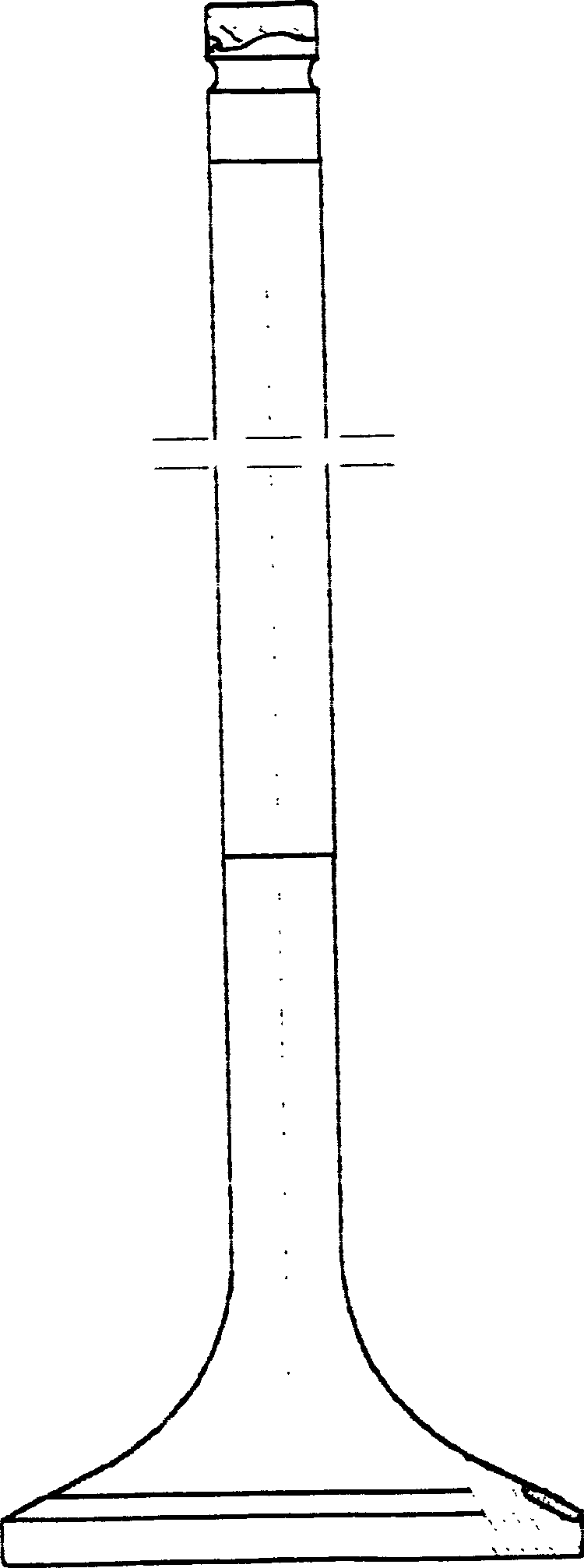

Double-metal exhaust gate for diesel engine of diesel locomotive and its manufacture

InactiveCN1453458AImprove performanceSimple processInternal combustion piston enginesLift valveDiesel locomotiveAlloy

The double-metal exhaust gate for diesel engine of diesel locomotive is manufactured with super Fe-Ni alloy comprising C 0.04-0.15 wt%, Si 0.40-1.20 wt%, Mn 0.50-1.0 wt%, Cr 20.0-24.0, Ni 30.0-40.0 wt%, Ti 2.5-3.0 wt%, Al 0.60-1.20 wt%, Nb 0.40-1.20 wt%, V 0.01-0.20 wt%, W 0.60-0.80 wt%, B 0.01-0.04 wt%, Mg 0.01-0.04 wt%, Ce 0.005-0.08 wt%, Co 0.5-1.0 wt%, Mo 0.15-0.30 wt% and Cu 0.05-0.30 wt% other than Fe. The gate material has good performance and machinability, stable quality and high performance / cost ratio.

Owner:BEIJING TEYE IND & TRADE

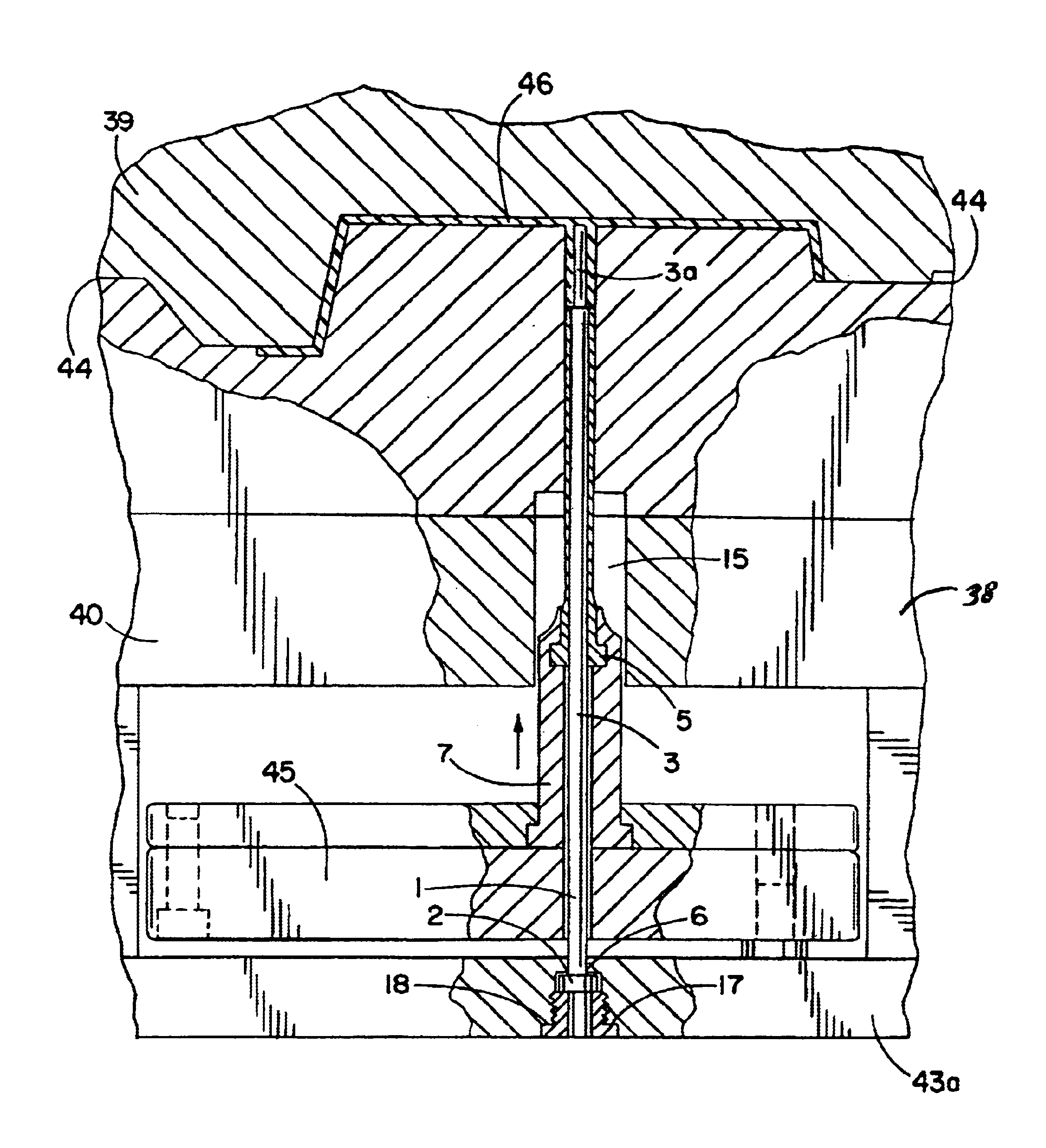

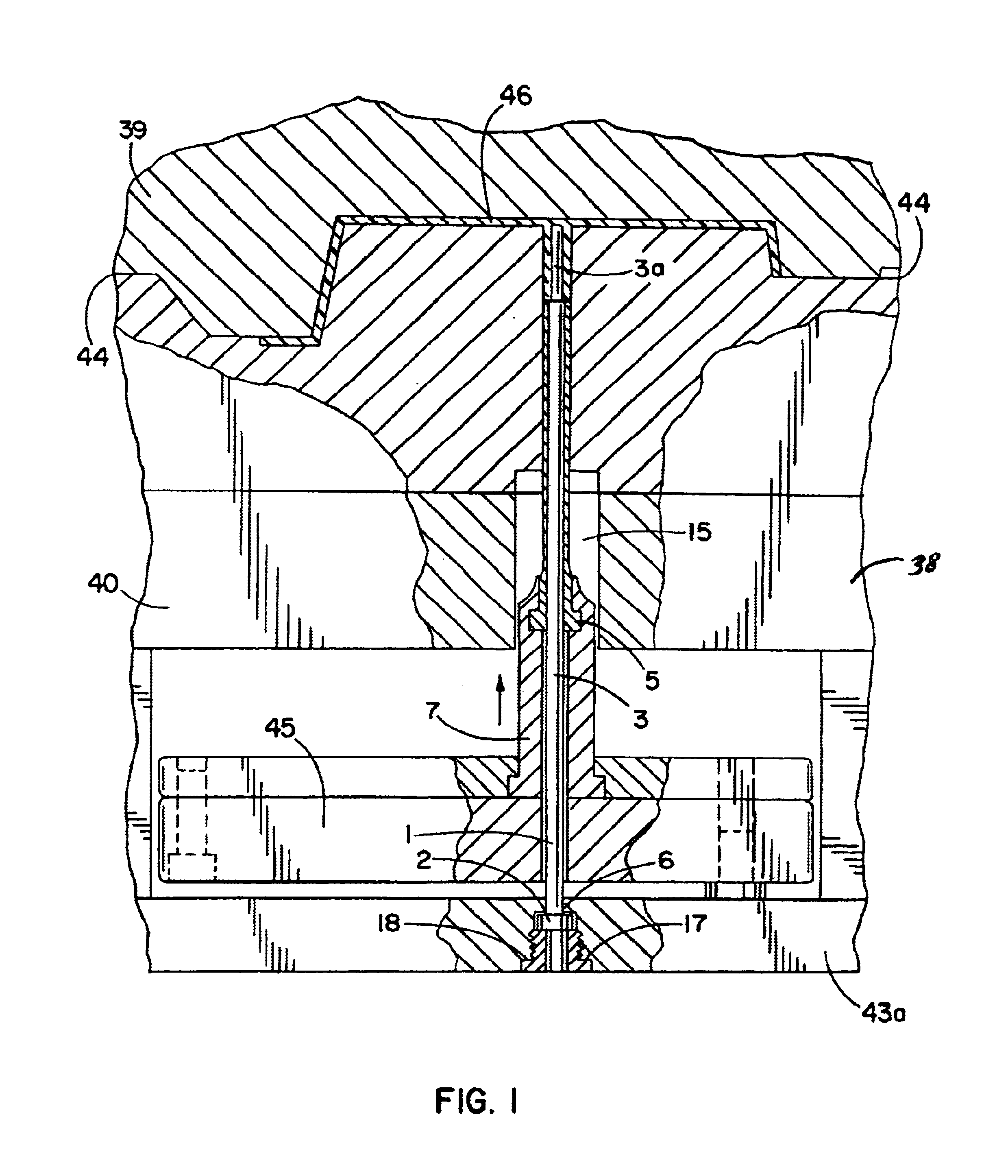

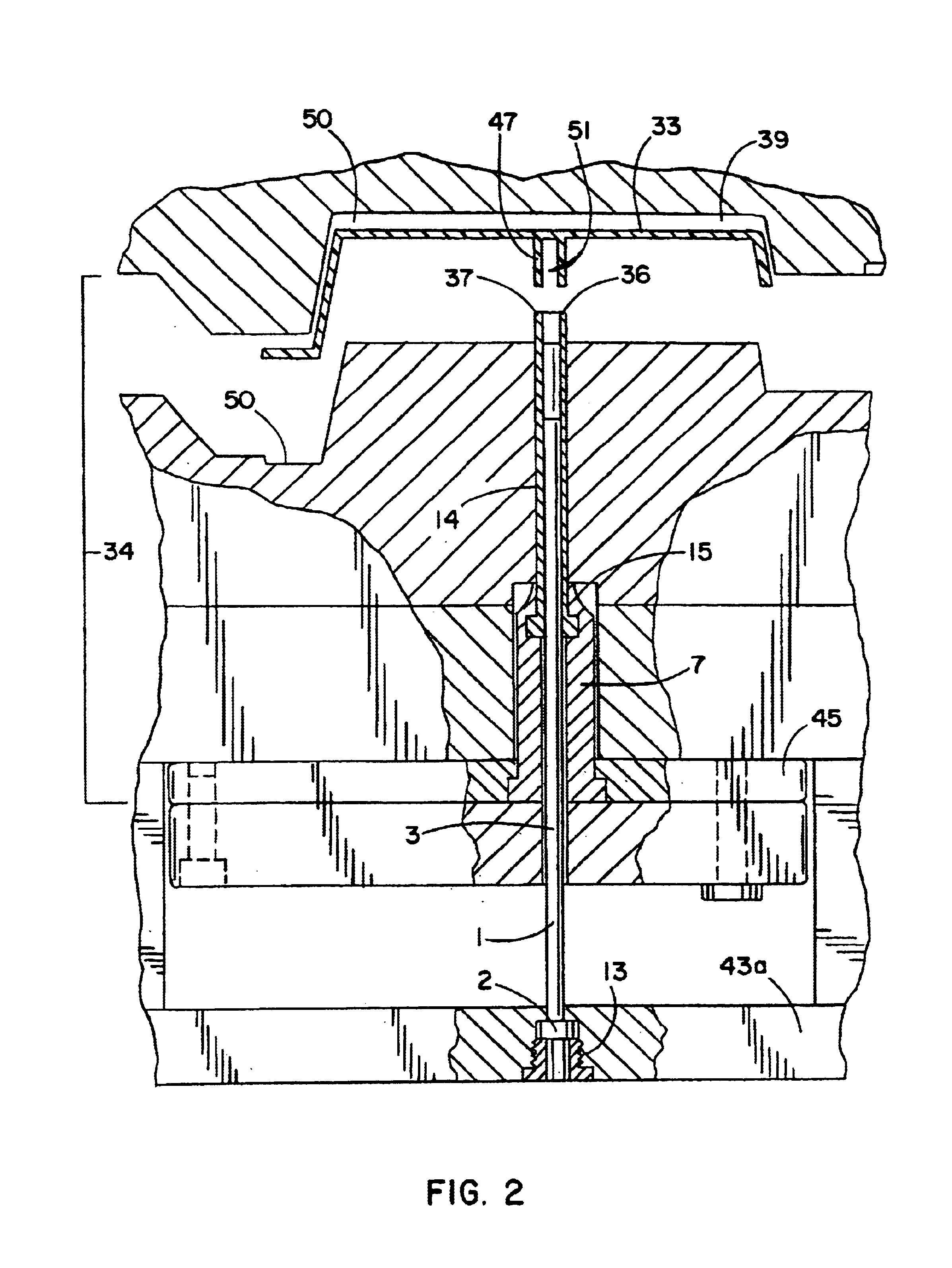

Ejector sleeve for molding a raised aperture in a molded article

The present invention includes an improved ejector sleeve (5) having thinner side-walls than prior sleeves. The sleeves generally include a ring (31) for mounting the sleeve, a central bore (42) for receiving a core pin (1), a tube portion extending from the ring to a tube end portion. The side-walls defining the tube end portion have a thickness of less than forty thousandths, and preferably thirty thousandths of an inch. Preferably, the coated ejector sleeve is provided in which a thin, lubricous coating of nickel, chromium or alloys of chromium or nickel is applied to at least a portion of the sleeve. The coating is applied in thickness of less than 0.0001 inch which improves the wear characteristics of the pins and sleeves as well as allowing the coated pins and sleeves to be stocked and used as nominal thickness parts.

Owner:PROGRESSIVE COMPONENTS INT CORP

Zinc-nickel alloy electroplating system

The invention provides an aqueous zinc-nickel alloy electroplating composition particularly useful in an electroplating method for depositing a zinc- nickel alloy layer on a substrate, wherein the deposited layer exhibits uniform nickel concentration and good aesthetics across a broad range of current densities. The electroplating composition comprises an electrolyte composition and an organic composition. In one embodiment, the electrolyte composition comprises a zinc ion source, a nickel ion source, a pH buffering agent and at least one additional salt, and the organic composition comprises a Class I nickel brightener, a Class II nickel brightener, an aromatic carboxylic acid, an aldehyde or ketone compound, and a non- ionic or anionic surfactant. The electroplating composition is particularly free of chelators and free ammonium-producing agents.

Owner:百富可公司

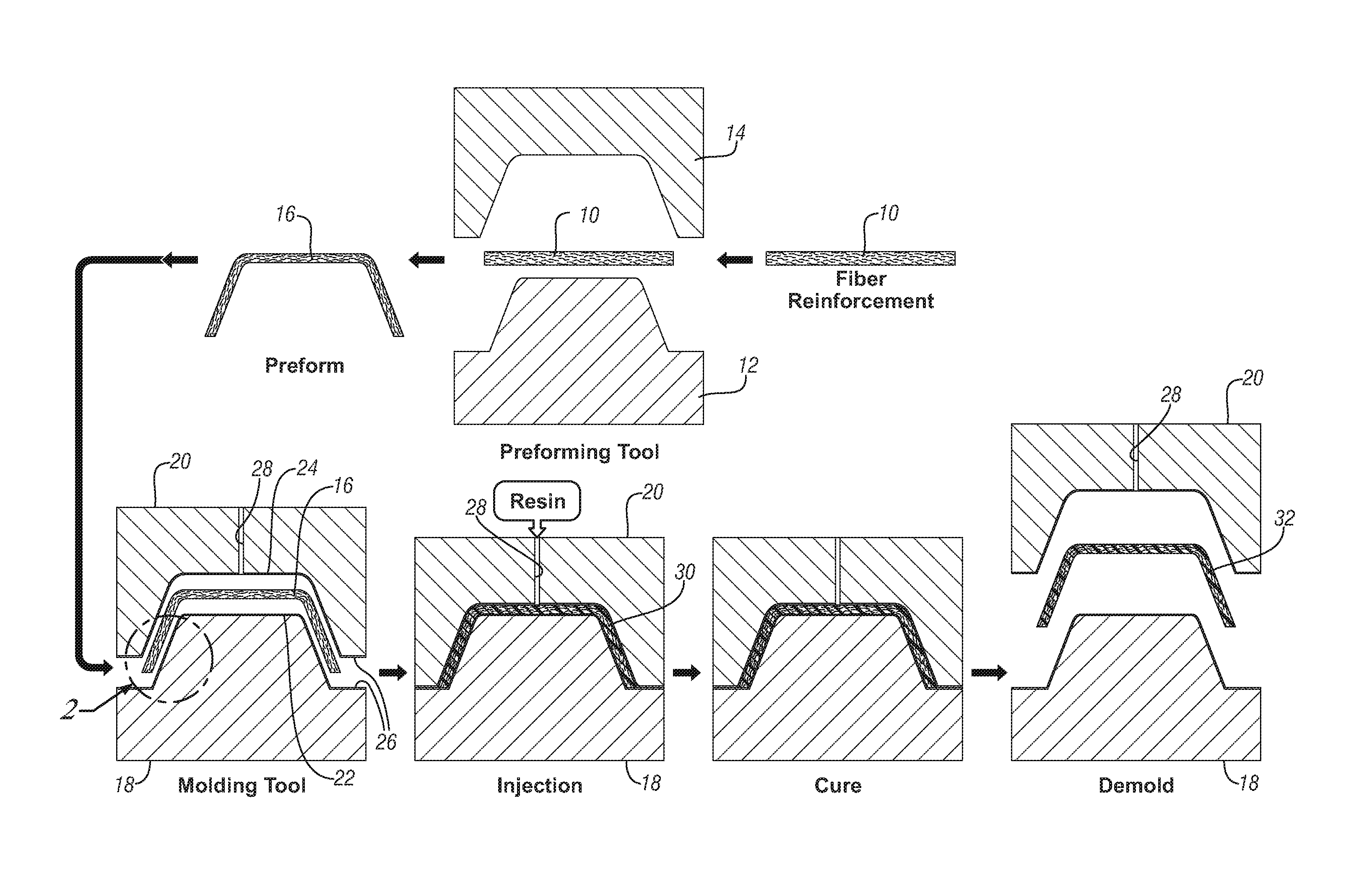

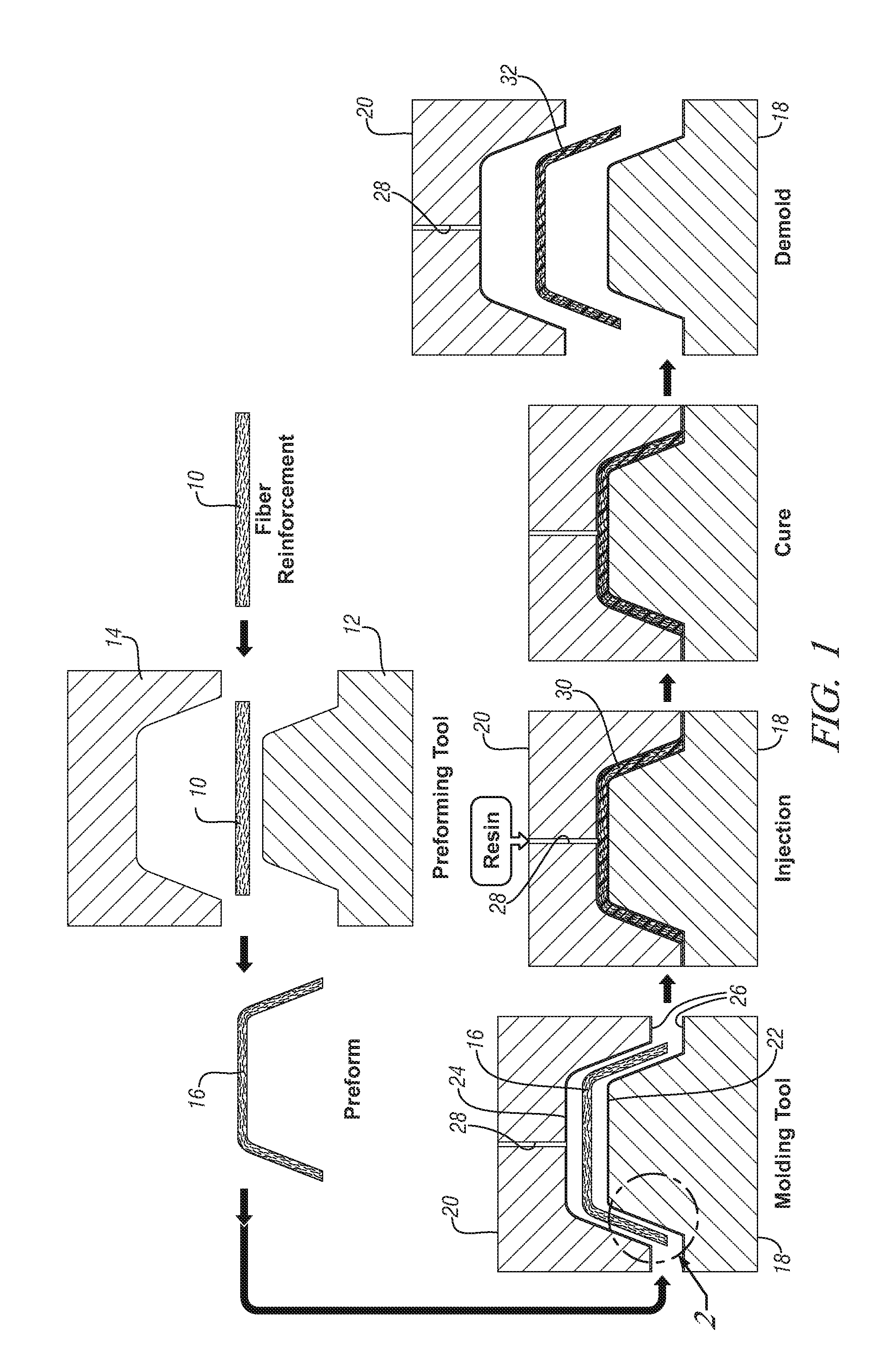

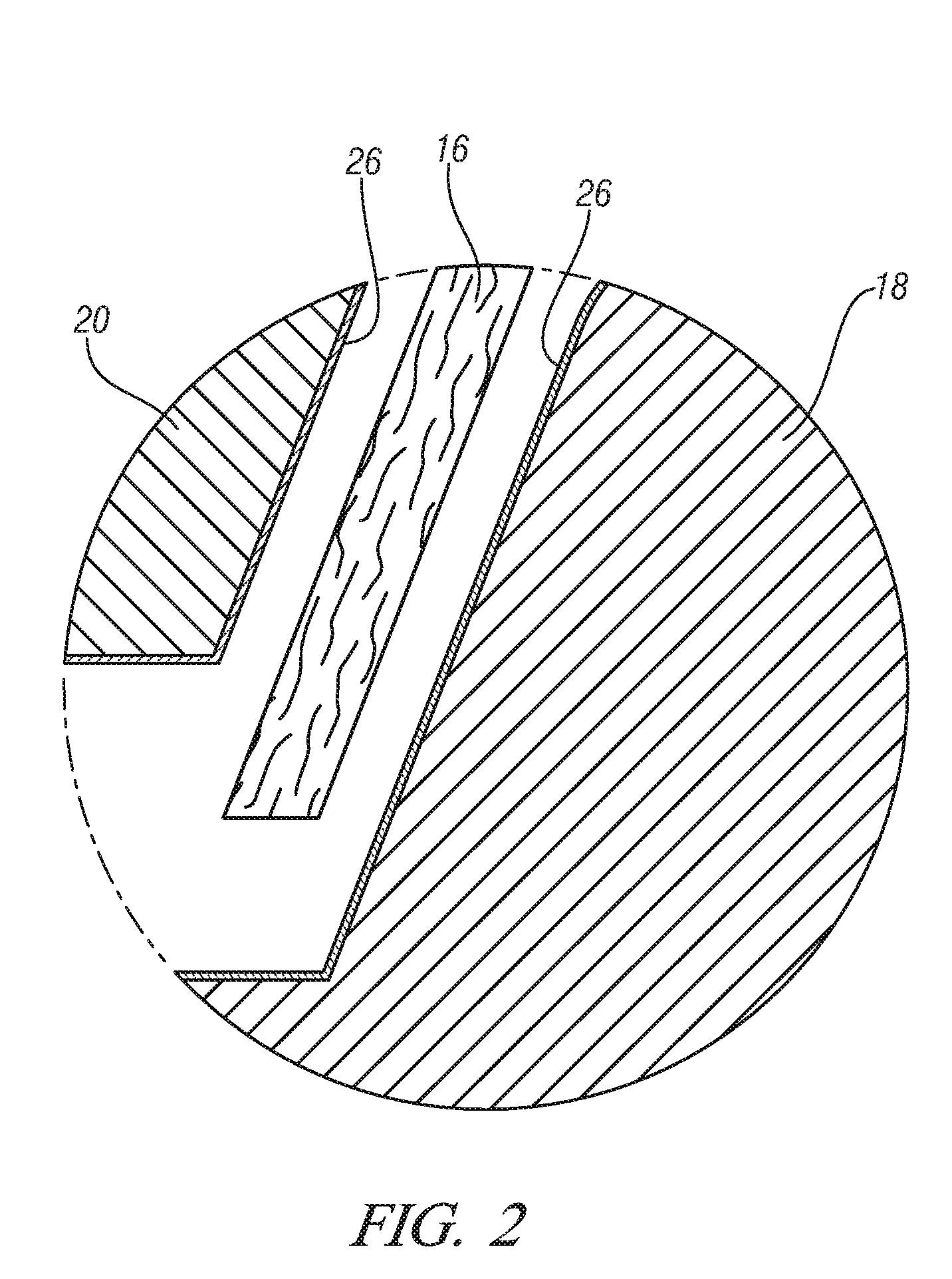

Durable tool for molding of polymer composites

ActiveUS20080241296A1High dimensional accuracyMore durableConfectioneryLaminationCarbon compositesFiber

Mold tooling formed of suitable iron-nickel alloys and provided with a hard electroless nickel coating on the mold cavity surface are useful for high volume production of carbon fiber reinforced, polymer matrix, composites. The iron and nickel alloy provides thermal expansion properties for the molding of dimensionally accurate parts. The nickel alloy coating provides a durable surface, without adversely affecting the expansion properties of the mold, and remains adherent to the base metal during the repeated thermal cycling encountered in high volume production of substantially identical molded carbon composite parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

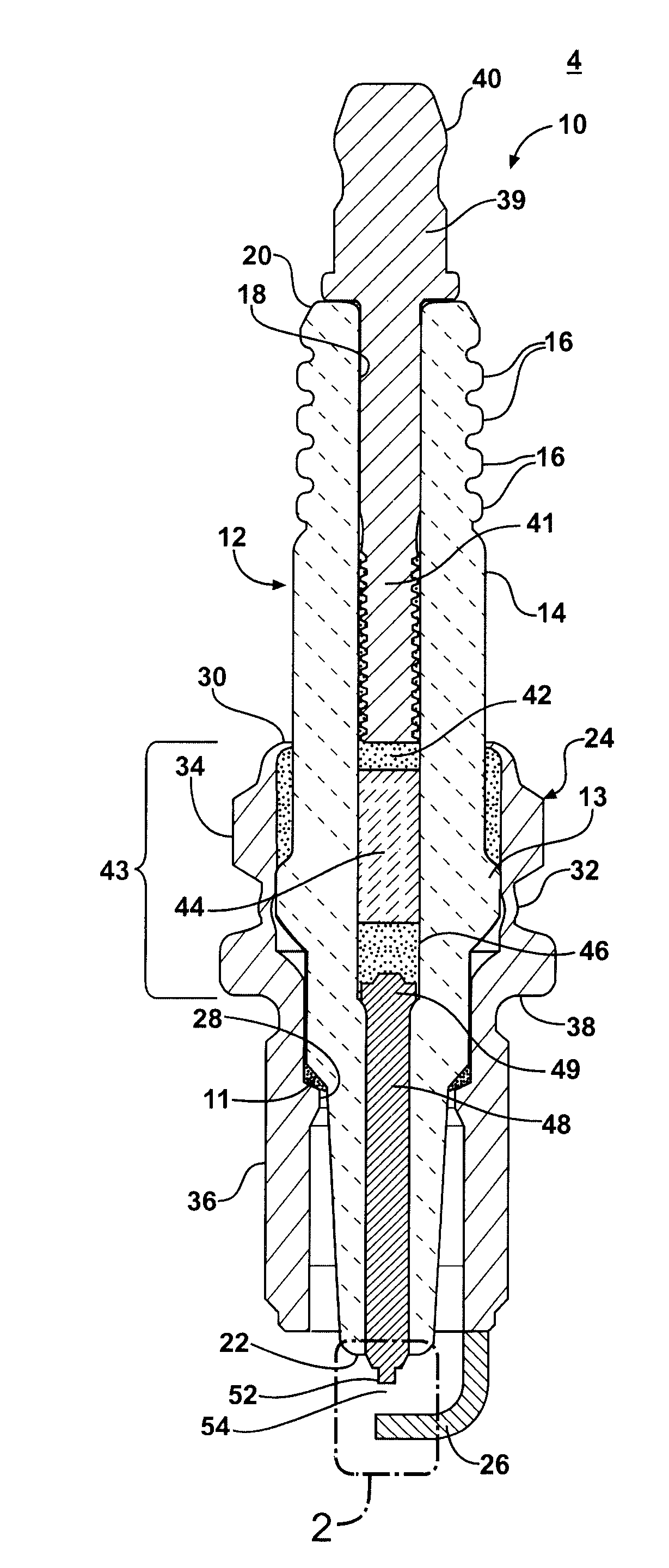

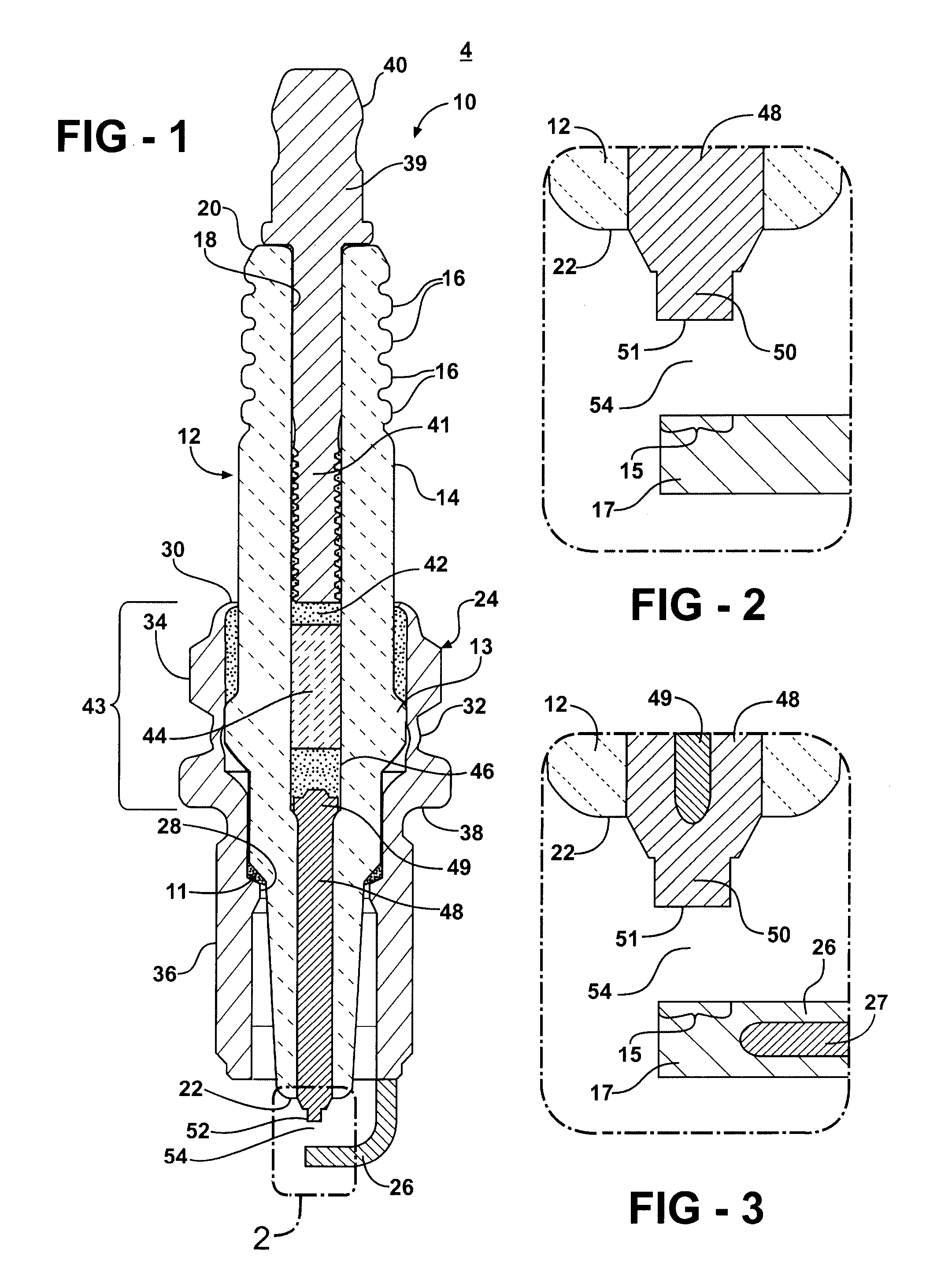

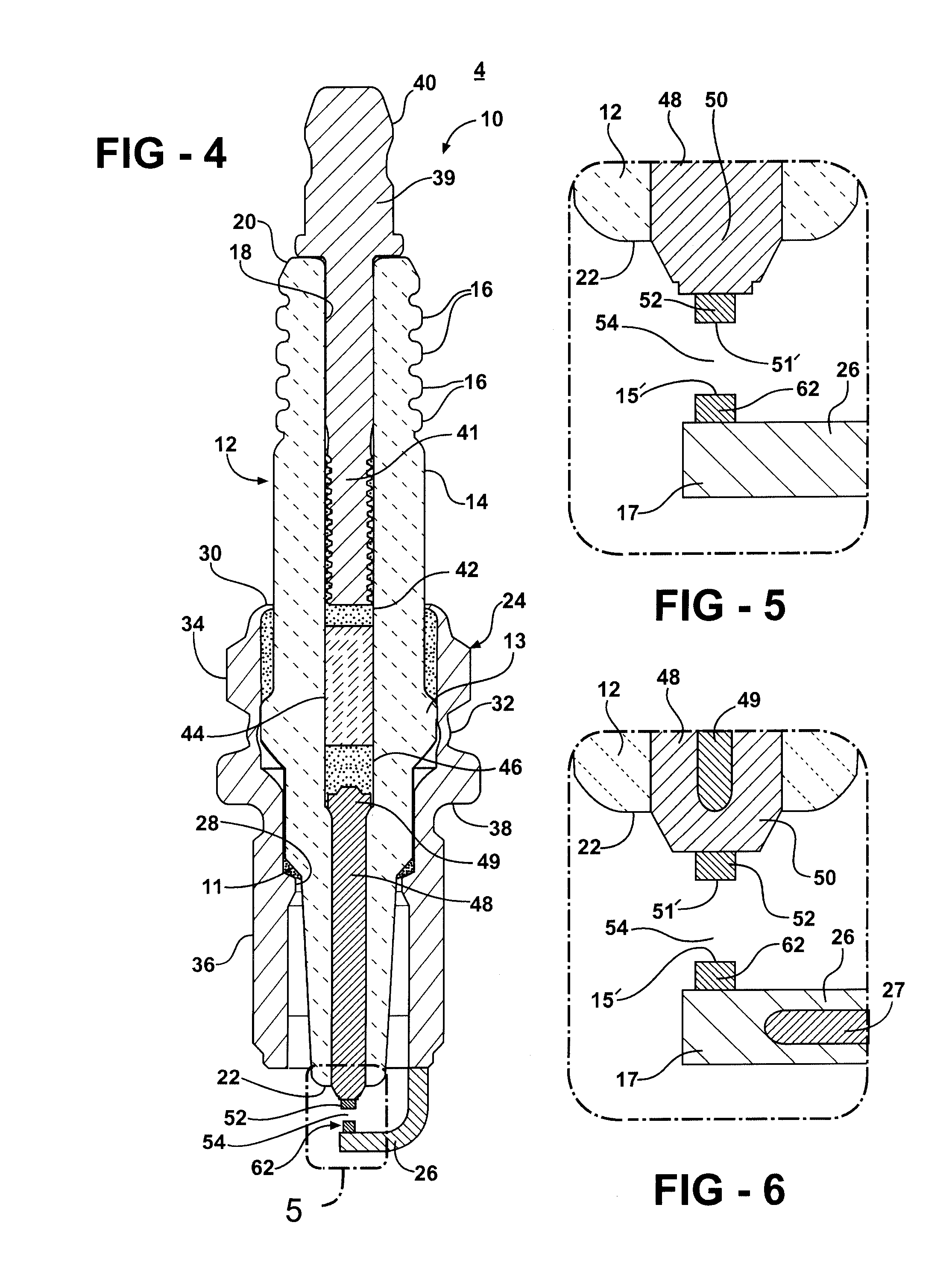

Electrode for an Ignition Device

InactiveUS20080308057A1Improve the immunityGood synergySparking plugsElectric spark ignitersNiobiumManganese

An electrode for an ignition device is made from a dilute nickel alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture and includes at least 90% by weight of nickel; zirconium; boron and at least one element from the group consisting of aluminum, magnesium, silicon, chromium, titanium and manganese. The weight ratio of Zr / B may range from about 0.5 to 150, and may include amounts of, by weight of the alloy, 0.05-0.5% zirconium and 0.001-0.01% boron. The oxidation resistance of the alloy may also be improved by the addition of hafnium to the alloy in an amount that is comparable to the amount of zirconium, which may include an amount of, by weight of the alloy, 0.005-0.2% hafnium. Electrodes of dilute nickel alloys which include aluminum and silicon, as well as those which include chromium, silicon, manganese and titanium, are particularly useful as spark plug electrodes. These electrode alloys of the may also include at least one of cobalt, niobium, vanadium, molybdenum, tungsten, copper, iron, carbon, calcium, phosphorus or sulfur as trace elements, generally with specified maximum amounts. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, center electrode and ground electrode. The center electrode, ground electrode, or both, may be made from the dilute nickel alloy of the invention. These electrodes may also include a core with thermal conductivity greater than that of the dilute nickel alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE

Corrosion-resistance stainless steel electric welding rod used for nuclear power and production method thereof

ActiveCN103008913AStrong corrosion resistanceImprove impact performanceWelding/cutting media/materialsSoldering mediaNuclear powerNickel alloy

The invention discloses a corrosion-resistance stainless steel electric welding rod used for nuclear power and a production method thereof, and relates to a nuclear power product. The corrosion-resistance stainless steel electric welding rod used for the nuclear power consists of a chrome-nickel alloy welding core and a coating covered on the surface of the welding core, wherein the chrome-nickel alloy welding core comprises the following ingredients: less than or equal to 0.01wt% of C, 1.00-2.50wt% of Mn, less than or equal to 0.030wt% of Si, 19.6-21.0wt% of Cr, 9.6-10.6wt% of Ni, less than or equal to 0.20wt% of Mo, less than or equal to 0.10wt% of Co, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of V, less than or equal to 0.035wt% of N, less than or equal to 0.015wt% of S, less than or equal to 0.012wt% of P and the balance of Fe and impurities. Compared with the prior art, the corrosion-resistance stainless steel electric welding rod used for the nuclear power, which is disclosed by the invention, has the advantages of good molten slag liquidity during welding, stable electric arc, big electric arc blowing force, even molten slag coverage, small splashing, excellent slag removal, small welding smoke, light welding line, attractive appearance, moderate welding bead height and good full-position operation performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Nickel-coated free-standing silicon carbide structure for sensing fluoro or halogen species in semiconductor processing systems, and processes of making and using same

InactiveUS20040163444A1High resistivitySmall heat capacityAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationHalogenNickel alloy

A (MEMS)-based gas sensor assembly for detecting a fluorine-containing species in a gas containing same, e.g., an effluent of a semiconductor processing tool undergoing etch cleaning with HF, NF3, etc. Such gas sensor assembly in a preferred embodiment comprises a free-standing silicon carbide support structure having a layer of a gas sensing material, preferably nickel or nickel alloy, coated thereon. Such gas sensor assembly is preferably fabricated by micro-molding techniques employing sacrificial molds that are subsequently removable for forming structure layers.

Owner:ENTEGRIS INC

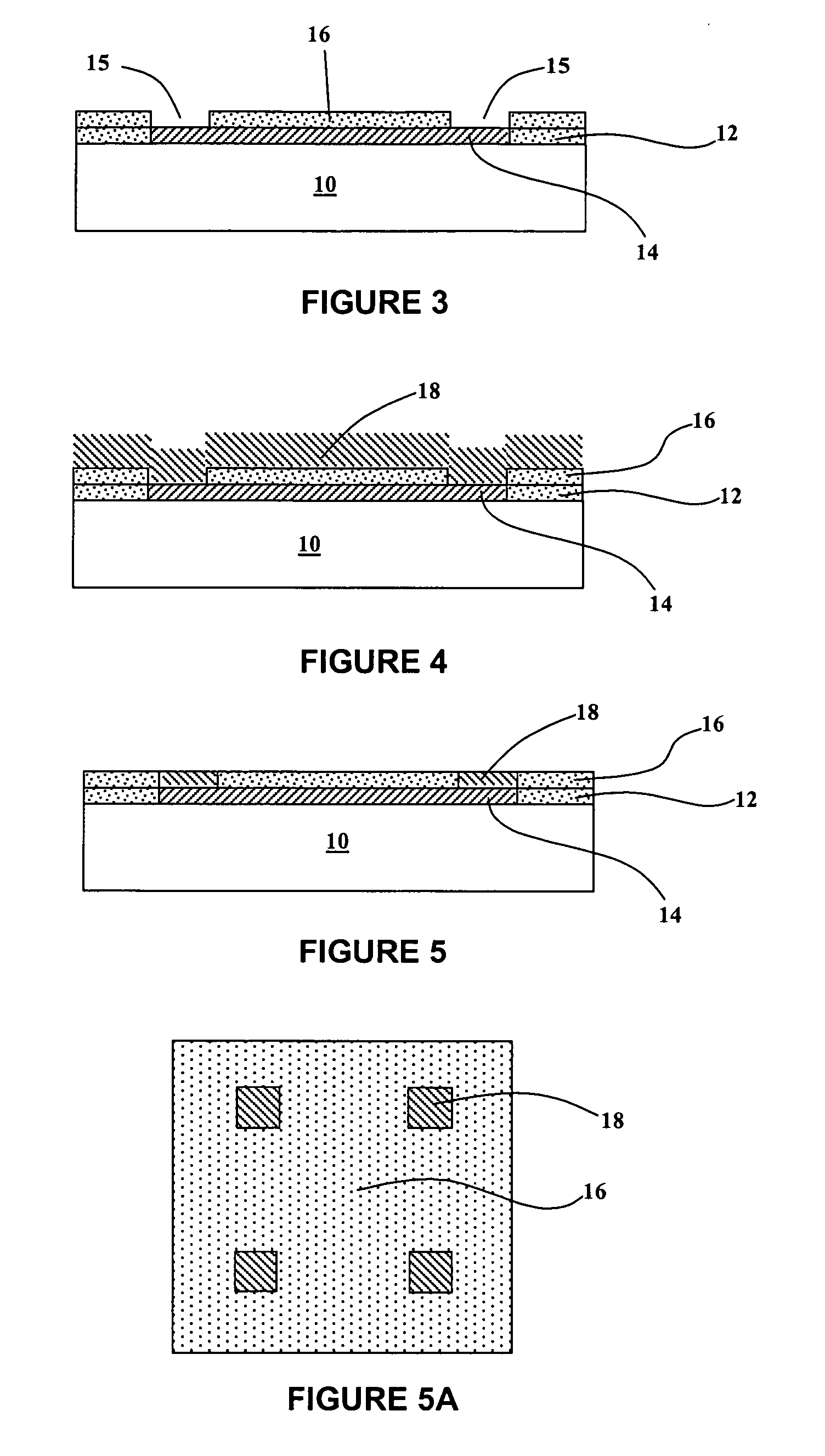

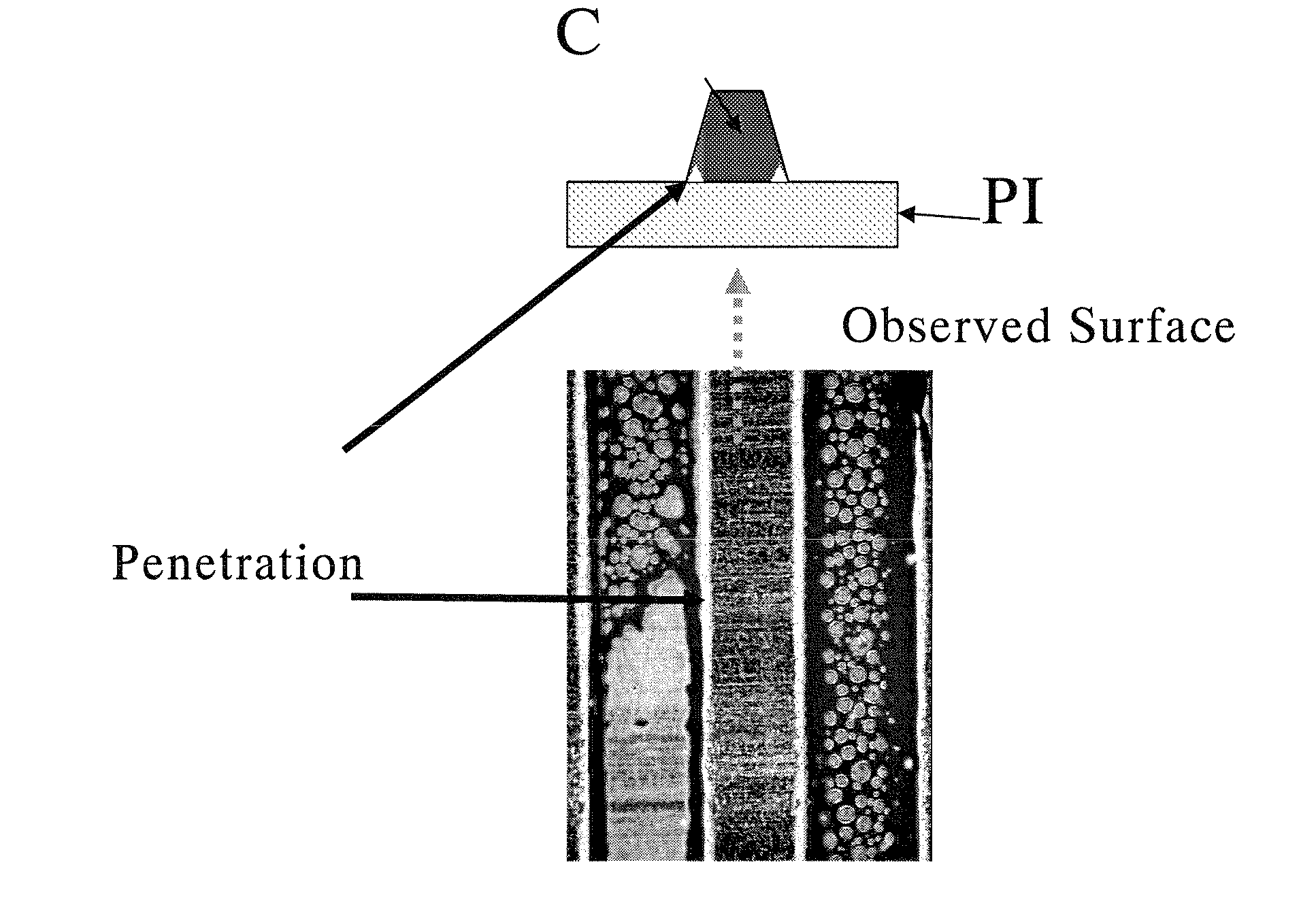

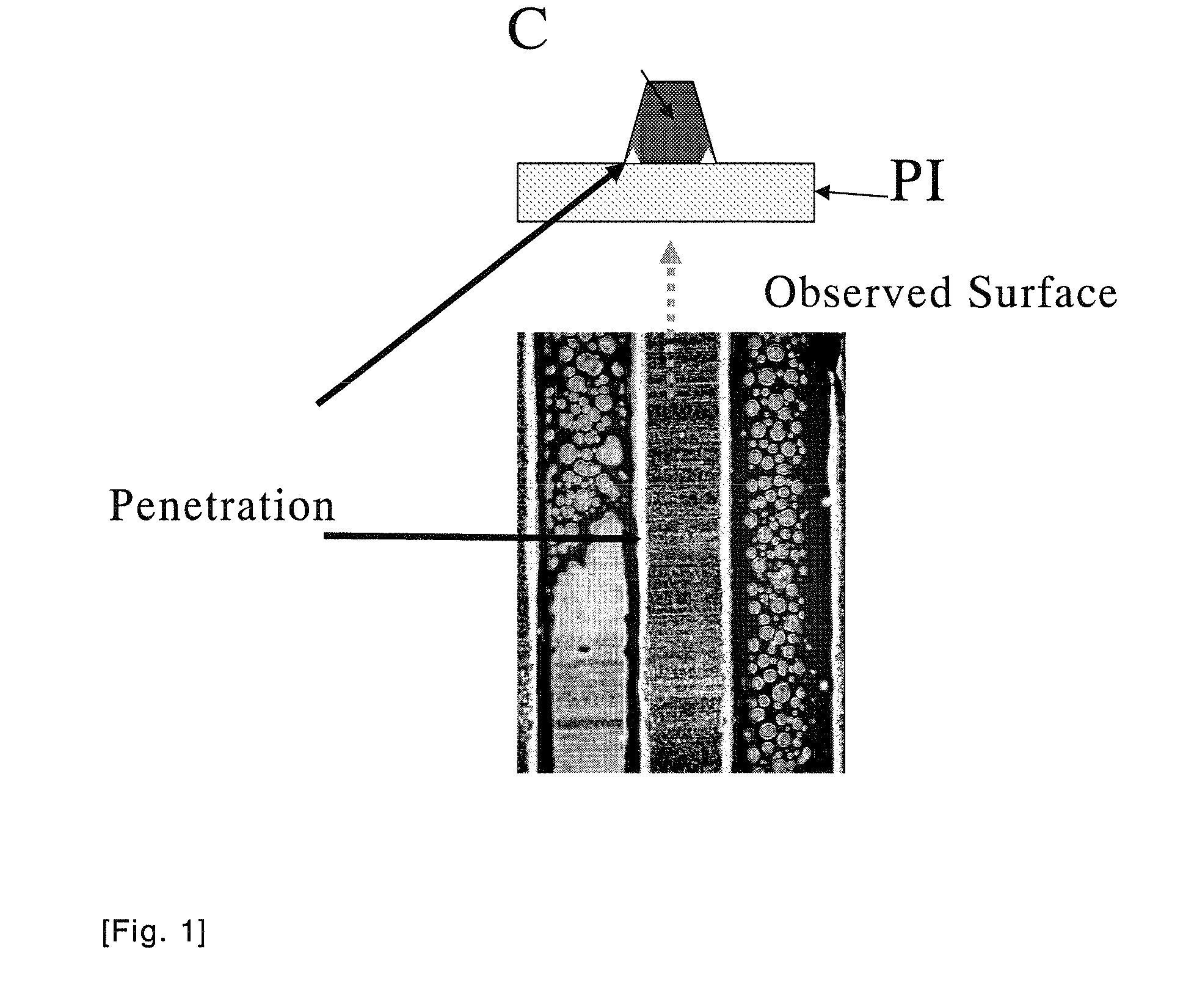

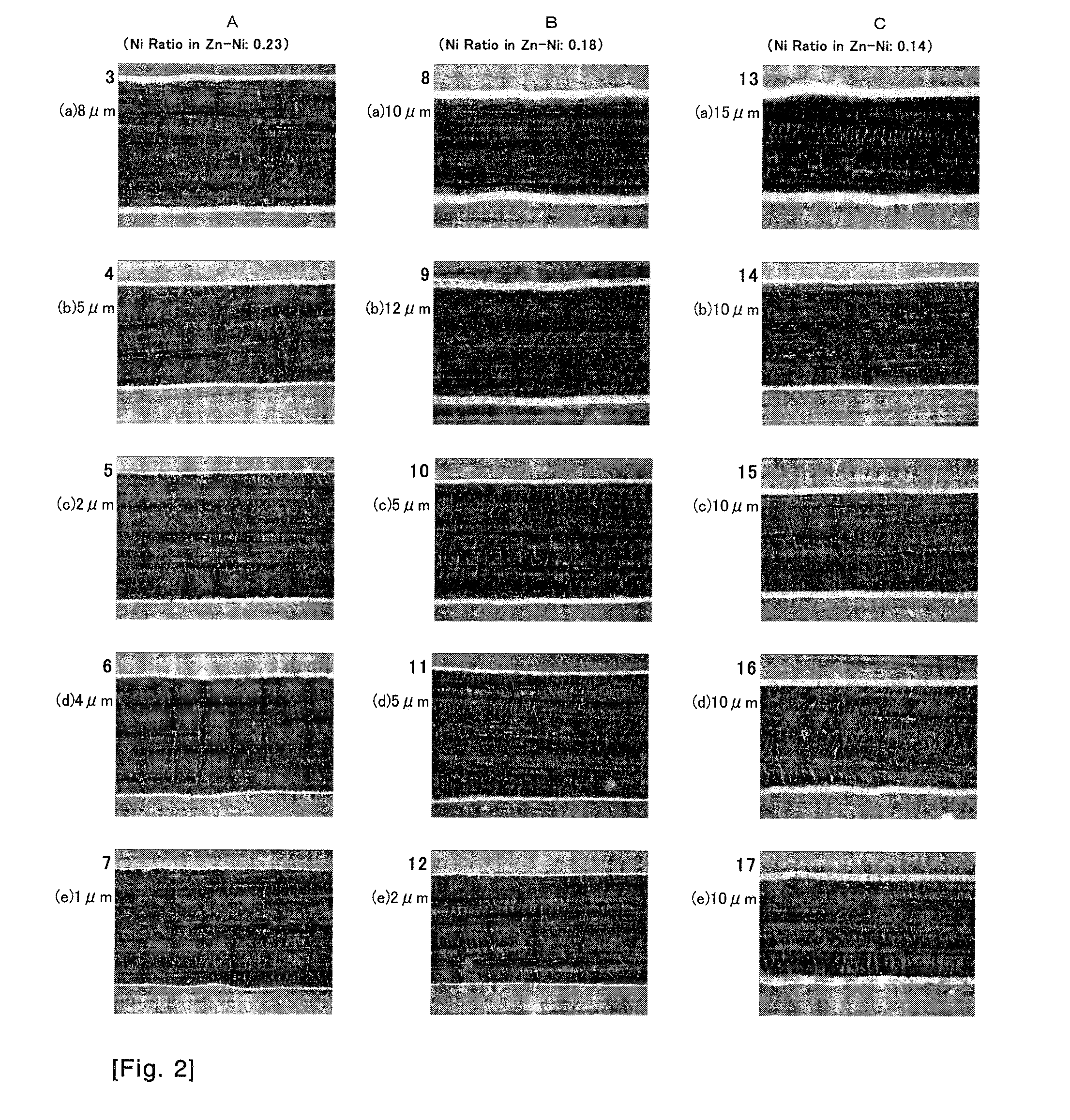

Copper Foil for Printed Circuit and Copper-Clad Laminate

ActiveUS20100212941A1Easy to integrateIncrease temperatureNon-insulated conductorsElectrolytic inorganic material coatingEtchingCopper foil

Provided is a copper foil for printed circuit comprising a roughened layer on a surface of a copper foil by way of copper-cobalt-nickel alloy plating, a cobalt-nickel alloy plated layer formed on the roughened layer, and a zinc-nickel alloy plated layer formed on the cobalt-nickel alloy plated layer, wherein the total amount of the zinc-nickel alloy plated layer is 150 to 500 μg / dm2, the lower limit of the nickel ratio in the alloy layer is 0.16, the upper limit thereof is 0.40, and the nickel content is 50 μg / dm2 or more.With the development of electronic equipment, the miniaturization and high integration of semiconductor devices have advanced further. This tendency has led to a demand for the adoption of a higher temperature in treatment in a production process of printed circuits and has led to heat generation during the use of electronic equipment after the productization. The present invention provides a technique that, even under these circumstances, the adhesive strength between a copper foil and a resin base material does not decrease and the penetration into a circuit edge part can be effectively prevented when performing the soft etching of a copper foil circuit.

Owner:JX NIPPON MINING& METALS CORP

Method for preparing dihydric alcohol from crop straw

InactiveCN103667365ANovel production processNovel processChemical recyclingFermentationCelluloseIon exchange

The invention discloses a method for preparing dihydric alcohol from crop straw. The method comprises steps of steeping raw material crop straw into diluted acid, pretreating for a short time at high temperature, then carrying out refining treatments such as cellulose hydrolyzing, decoloring and filtering, ion exchanging and high efficiently concentrating, so as to prepare straw sugar, in the presence of a special nickel alloy catalyst, continuously hydrocracking the straw sugar under high pressure so as to obtain a mixture of dihydric alcohol and polyhydric alcohols, rectifying the split product at reduced pressure and separating so as to obtain products such as ethylene glycol and propylene glycol. The method has the advantage of unique and novel and advance process; non-grain biomass resource is taken as the raw material, so that the grain risk is thoroughly avoided; the non-grain biomass resource can substitute for non-renewable resources such as petroleum or coal, so that the method has significance to development of circular economy.

Owner:郸城财鑫糖业有限责任公司

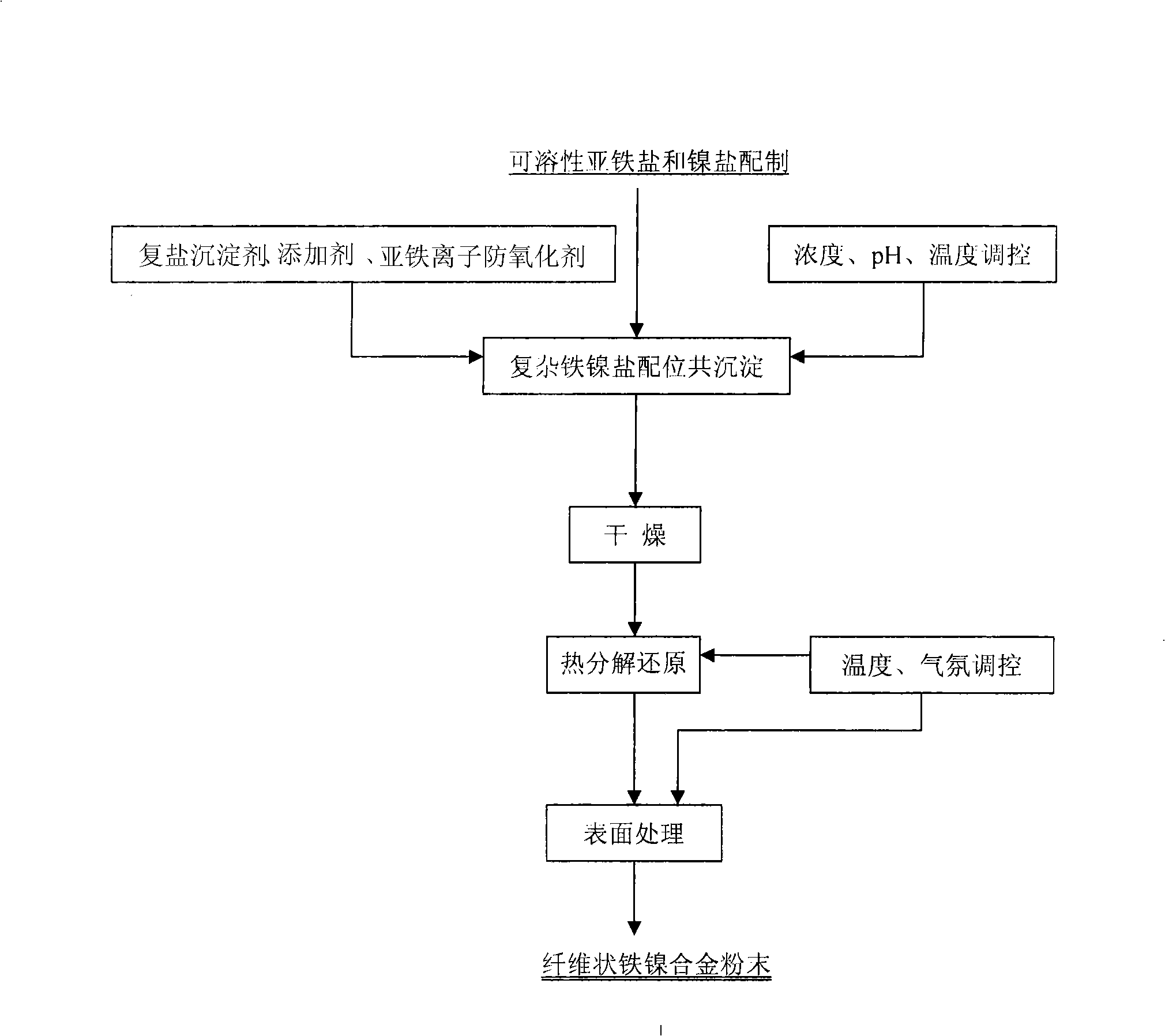

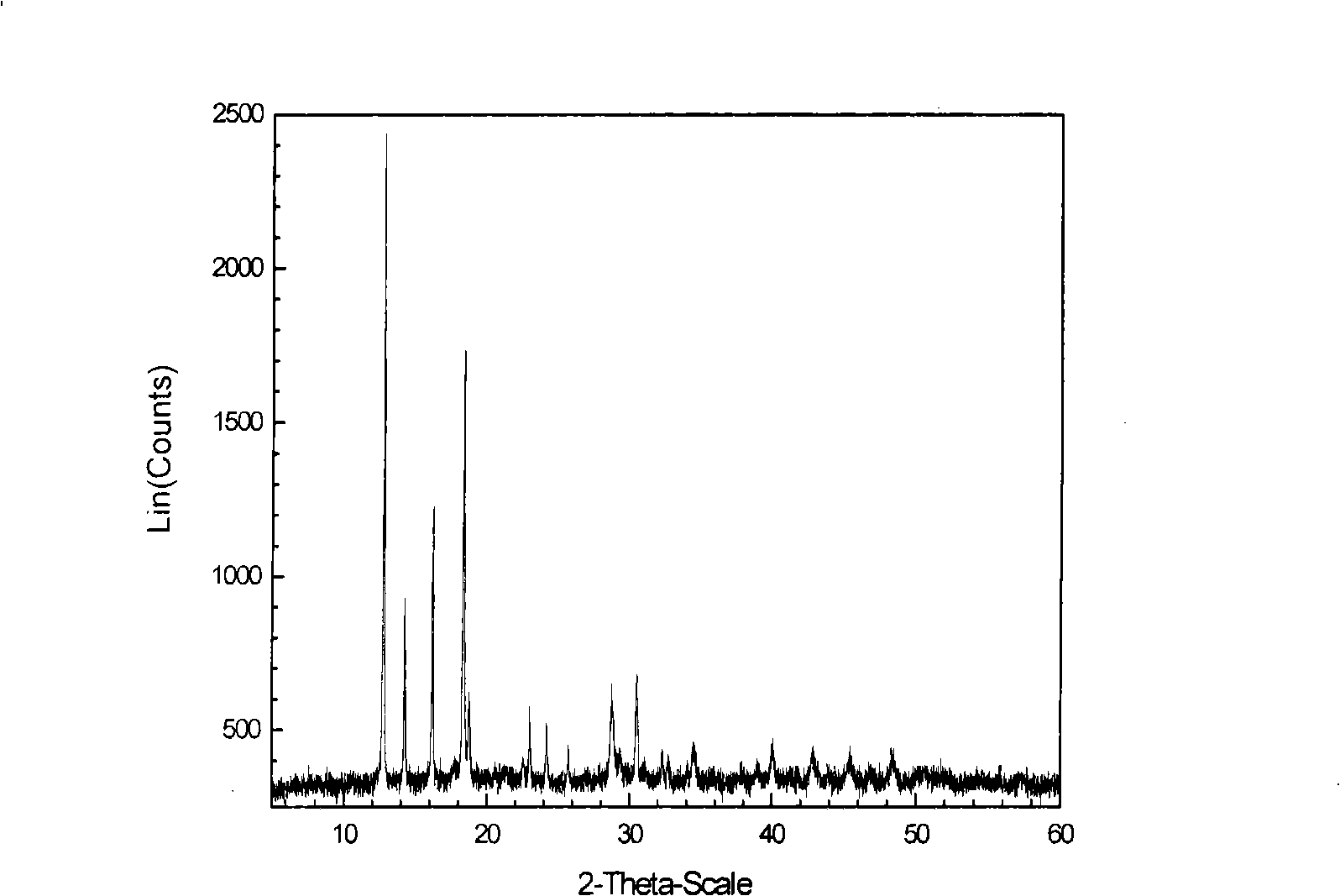

Preparation method of fibrous iron-nickel alloy powder

The invention relates to a preparation technology of a powder functional material, in particular to a preparation method of fibrous iron-nickel alloy powder. A coordinated coprecipitation-thermal decomposition-reduction process is adopted to synthesize a precursor coprecipitate product of the fibrous iron-nickel alloy powder in a Ni<2+>-Fe<2+>-H2NCH2CH2NH2-(H3NCH2CH2NH3)<2+>-SG<n->-C2O4<2->-H2O system at the normal temperature and pressure (SG<n-> stands for Cl<->, SO4<2->, NO3<-> and CH3COO<->), and the precursor is thermally decomposed and reduced under an weak reducing atmosphere to obtain the fibrous iron-nickel alloy powder; anti-oxidation treatment of surface of the fibrous iron-nickel alloy powder is carried out in the same device under the regulation and control of the temperature and atmosphere. The whole preparation process is safe, reliable, nontoxic and pollution-free. The iron-nickel alloy powder produced by the preparation method is fibrous and porous, and has small particle size, large specific surface area; and the iron-nickel alloy powder has strong oxidation resistance, and can meet requirements of a plurality of purposes.

Owner:CENT SOUTH UNIV

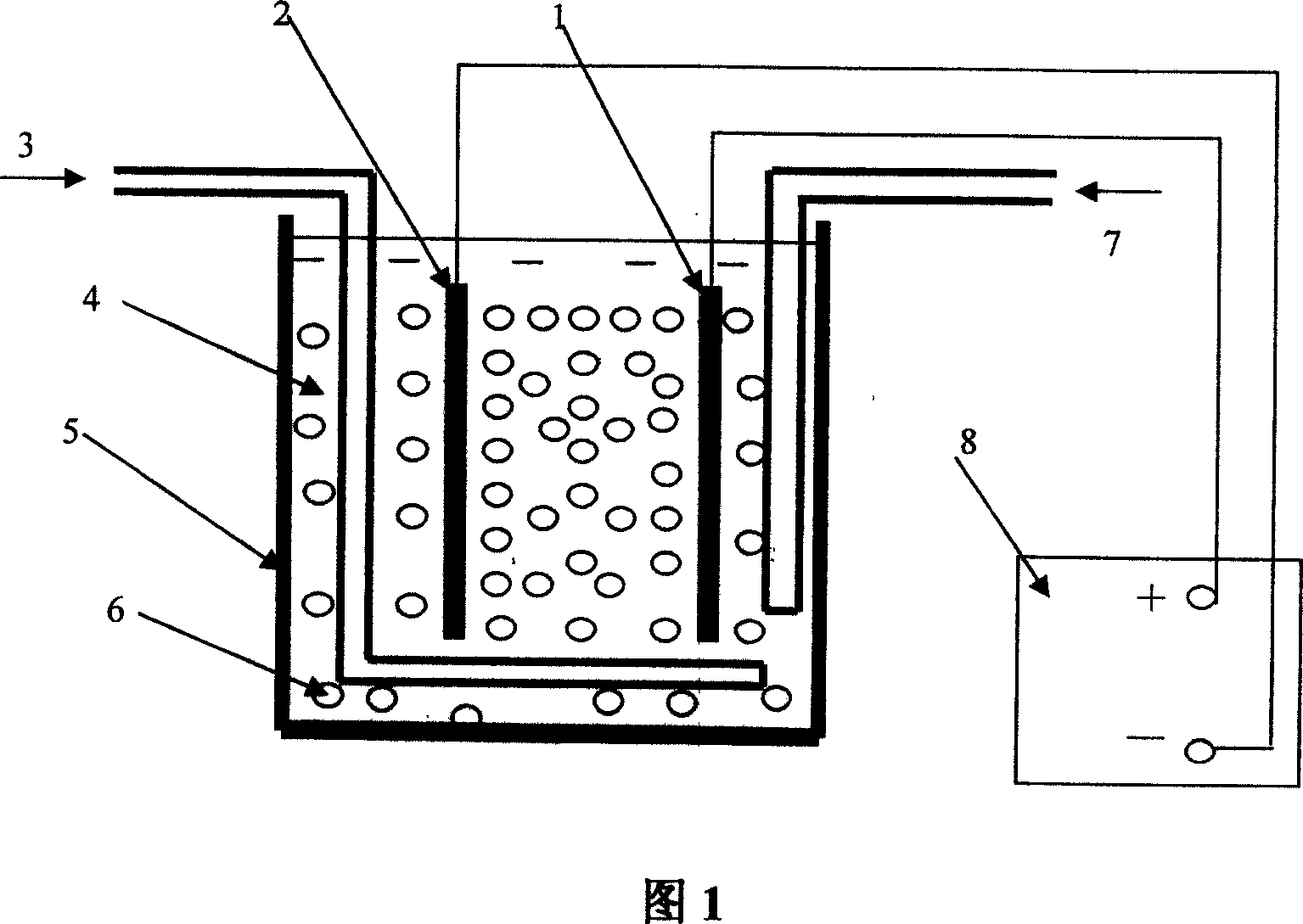

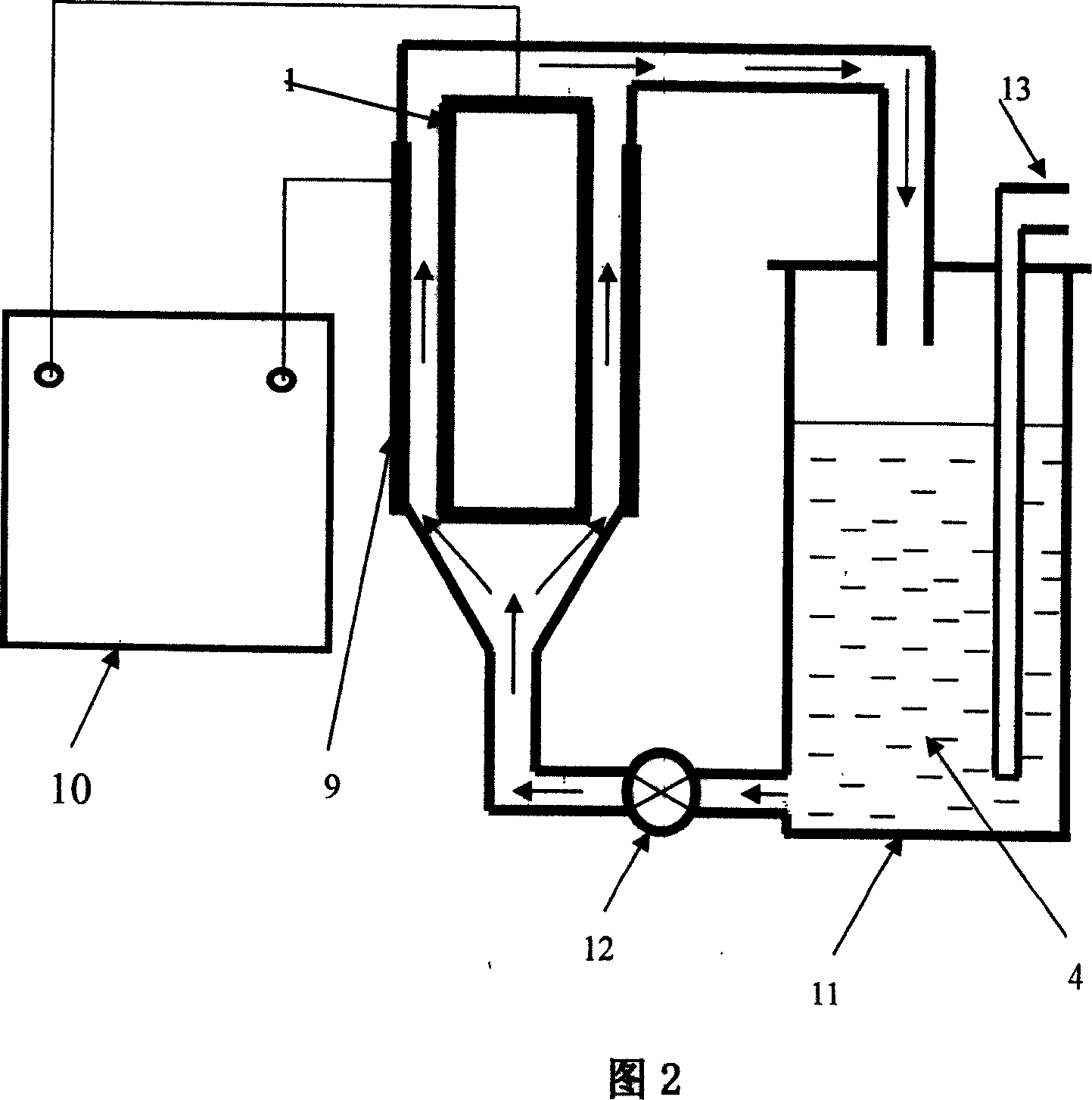

Composite plating coat material for metallurgy conticaster crystallizer, preparation method and apparatus thereof

The invention discloses a composite coating material and preparing method and equipment in the metallurgical conticaster crystallizer, which is composed of nickel-based composite material or nickel alloy composite material, which consists of base metal and large scale of particle or fiber in the base with polyphase structure, wherein the DC composite plating or composite pulse plating equipment is composed of plating power, plating groove, nickel anode or nickel alloy anode, metallurgical conticaster crystallizer, stirring device, liquid circulating device, heating and temperature-controlling device.

Owner:CHENGDU SHENJIA MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com