Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2067results about "Heads using thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

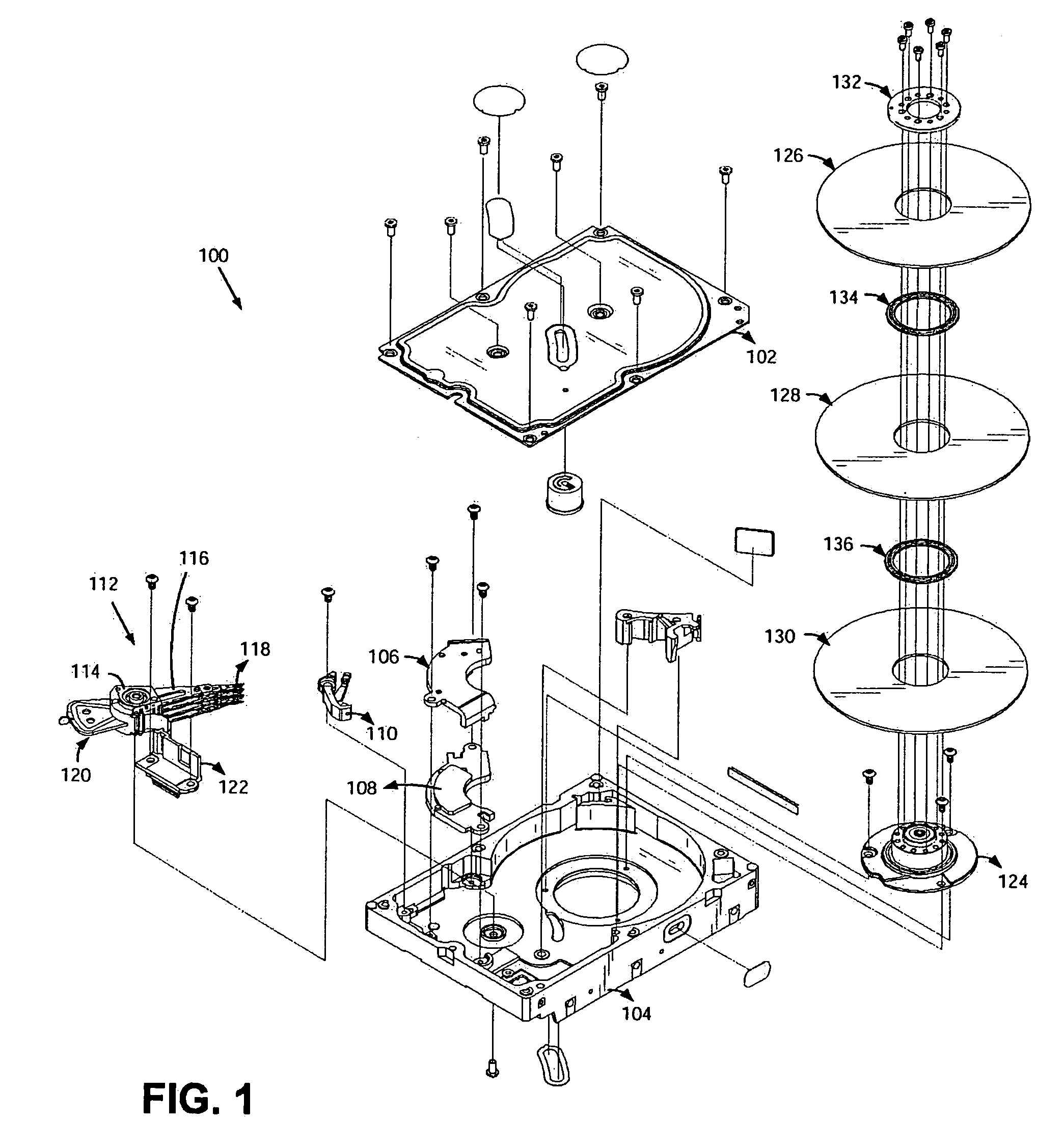

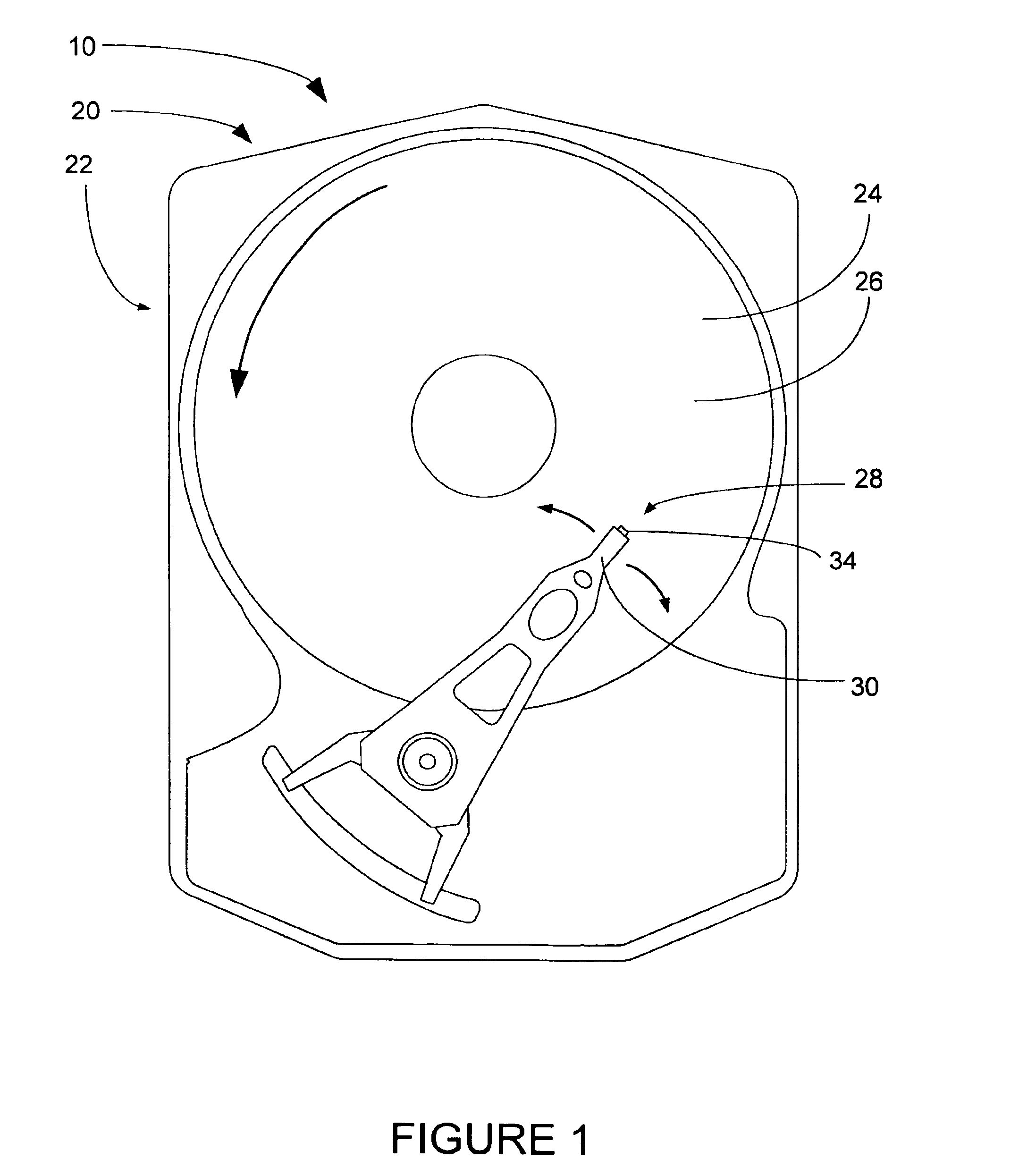

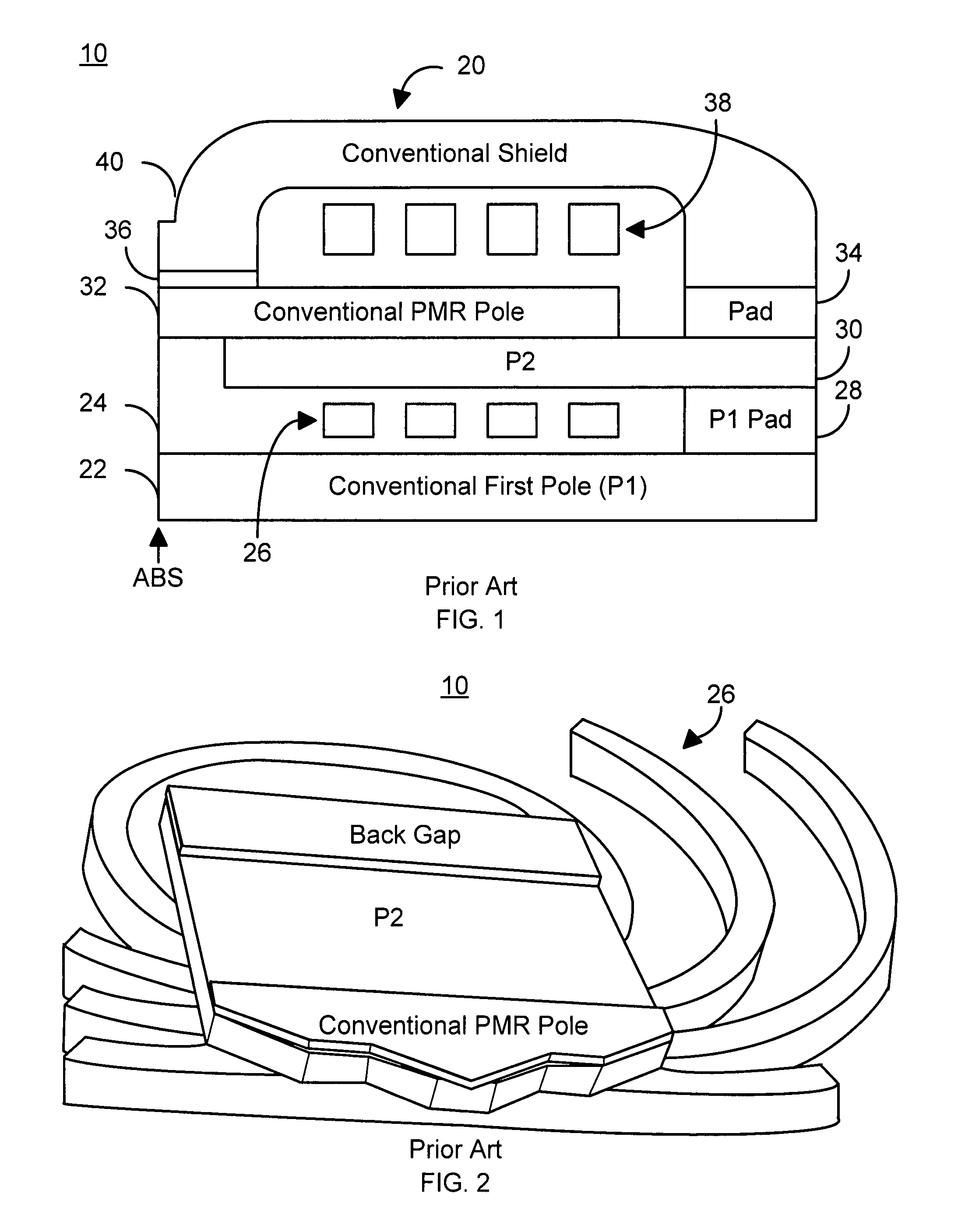

Perpendicular magnetic recording head with nonmagnetic write gap greater than twice side shield gap distance

InactiveUS6954340B2Improve writer efficiencyHigh gradientConstruction of head windingsManufacture head surfaceLeading edgeEngineering

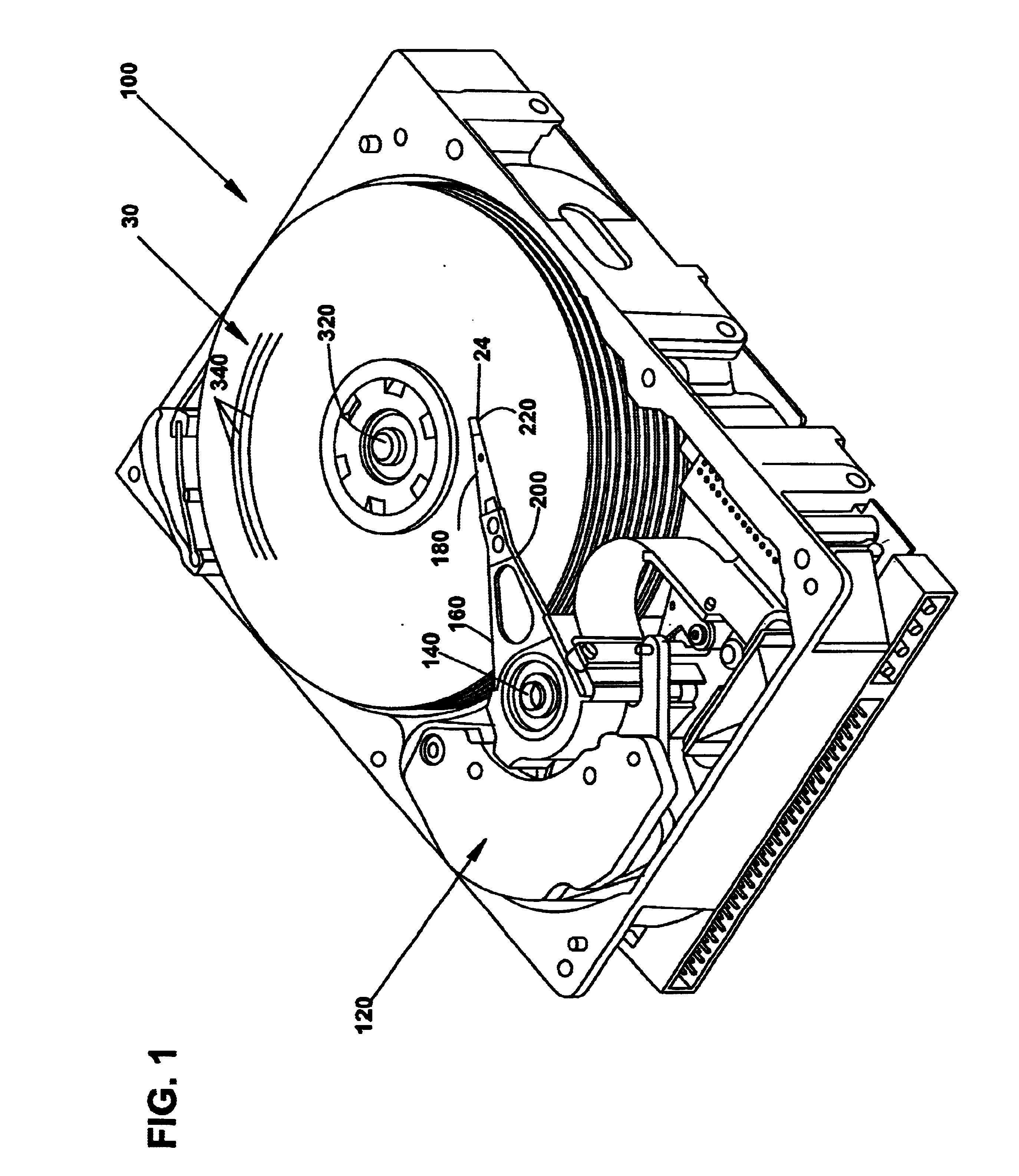

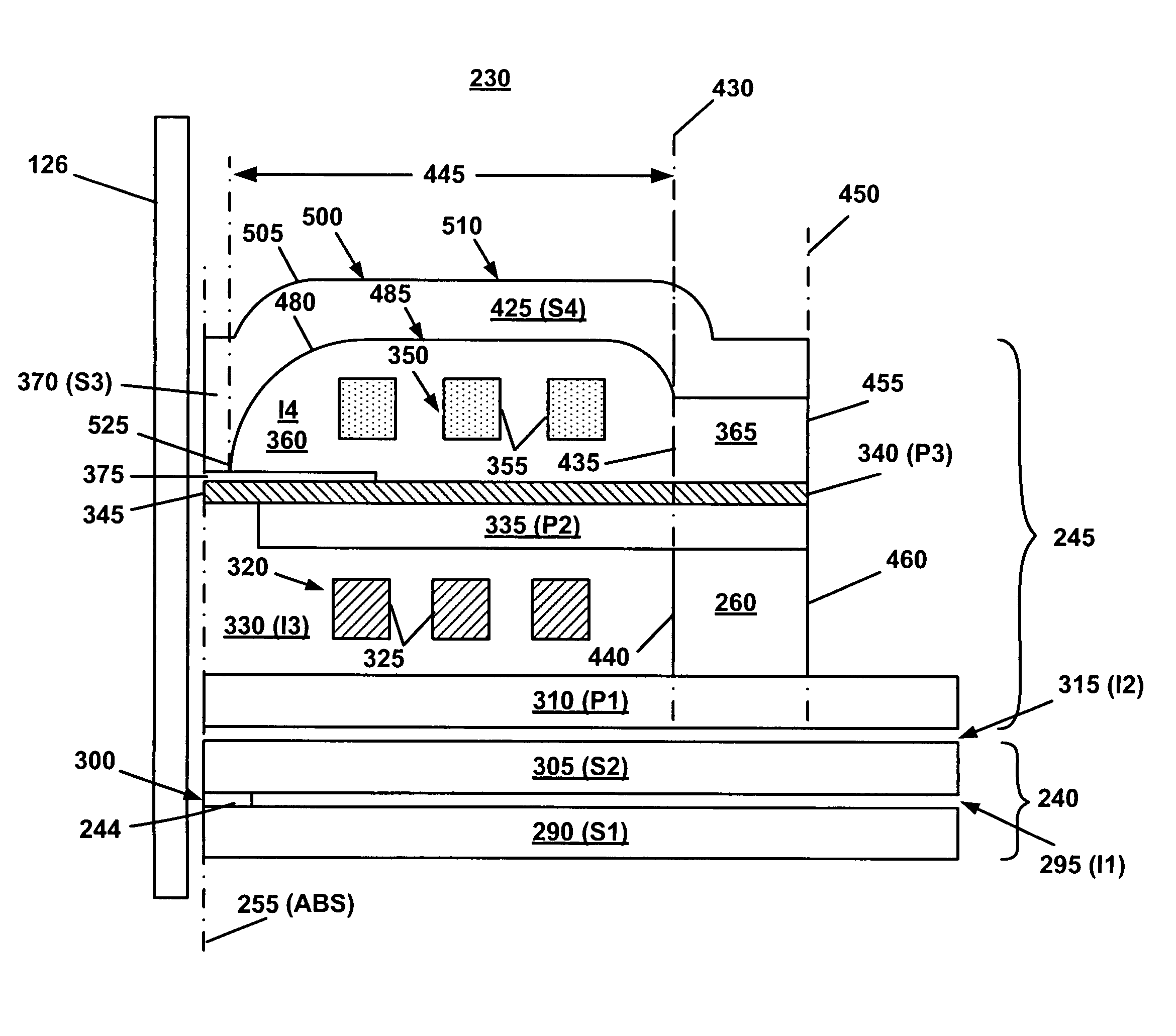

A magnetic head for perpendicular recording on double layer media with suppressed side writing and controlled write width is disclosed. The present invention reduces the problem of side writing and controls the write width of the writing element by providing a writing element with a trailing edge sized dimensionally larger than the leading edge, side shields, and specifically spaced writing gaps placed at various distances between the write element and the side shields, return poles, and the main pole.

Owner:SEAGATE TECH LLC

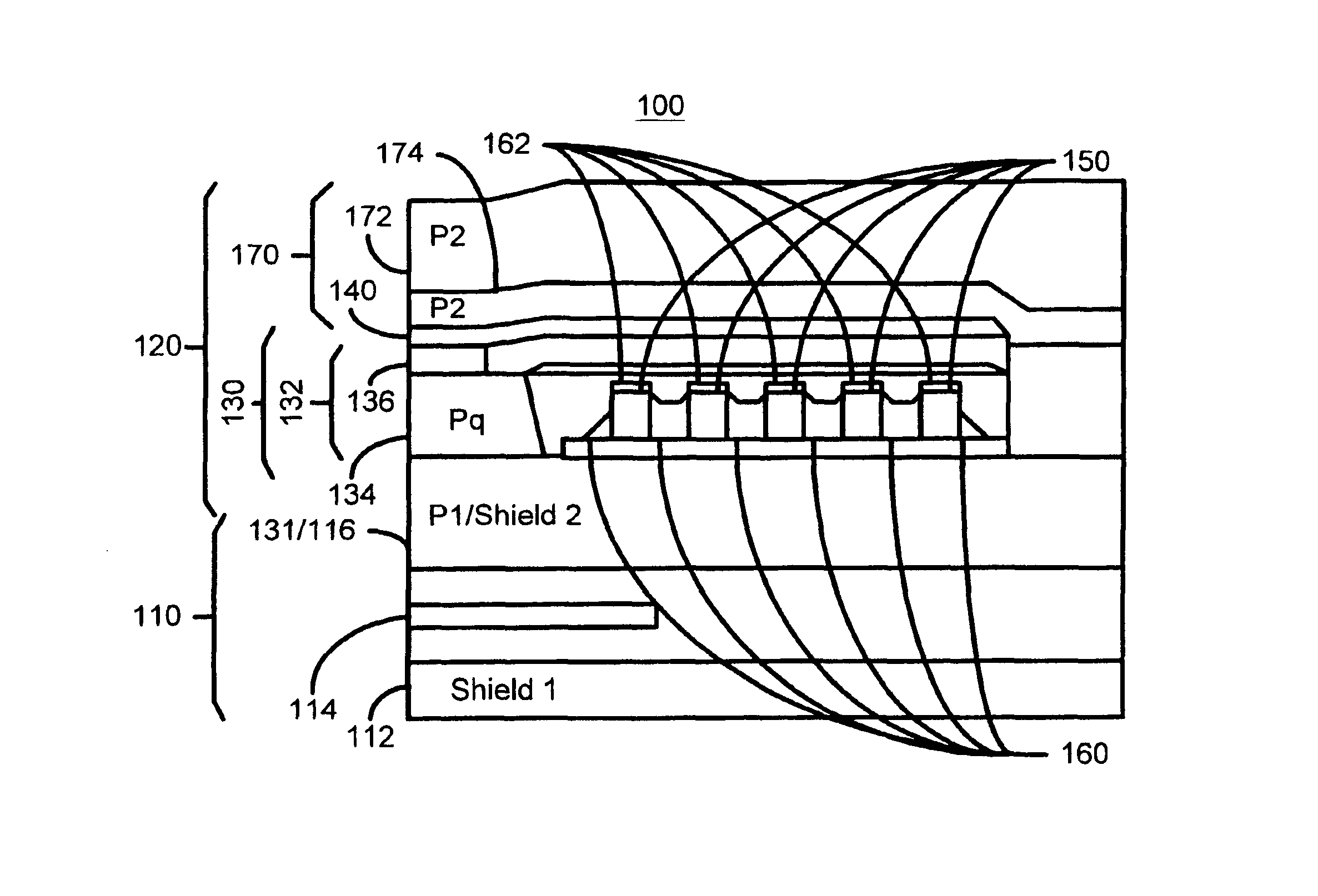

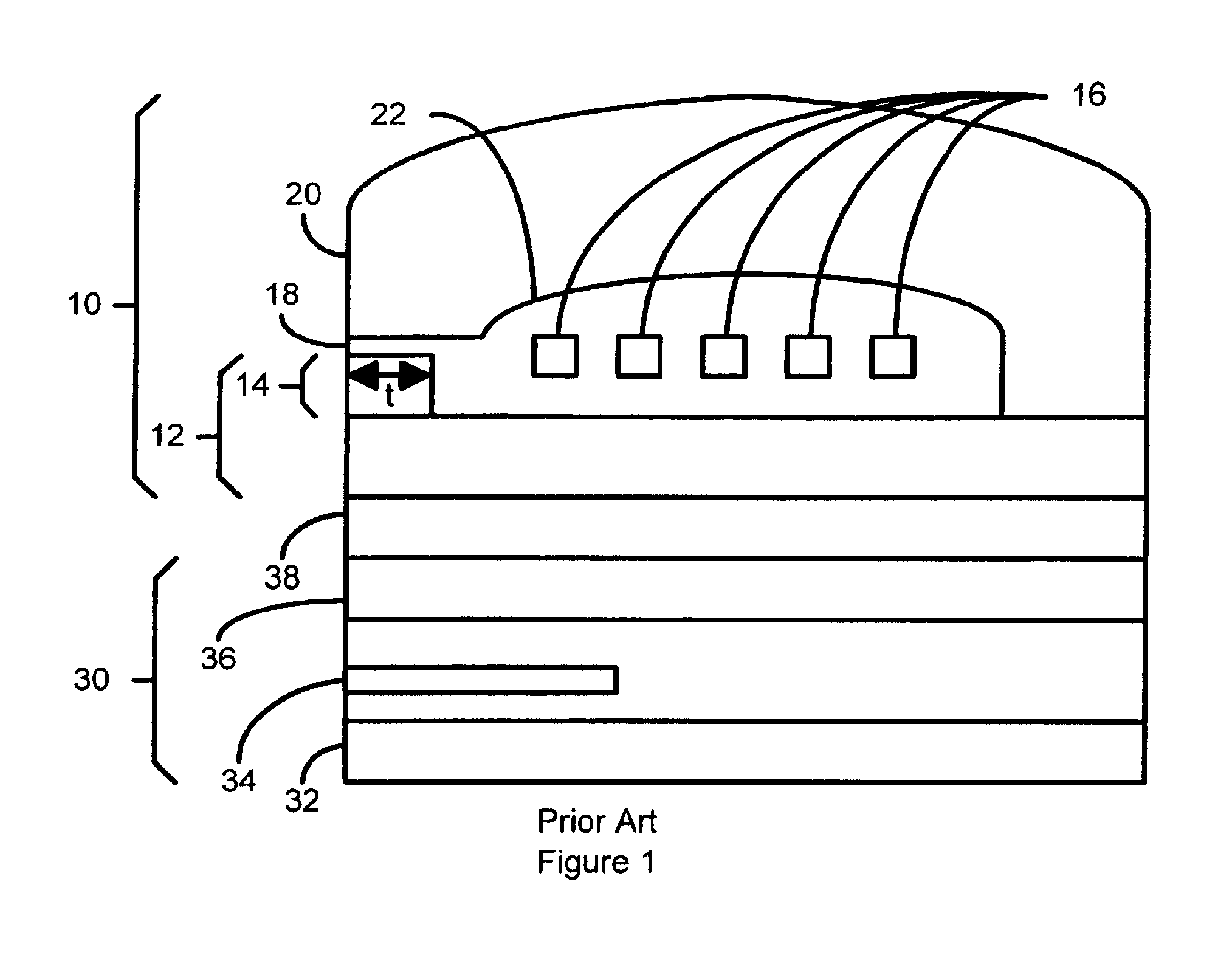

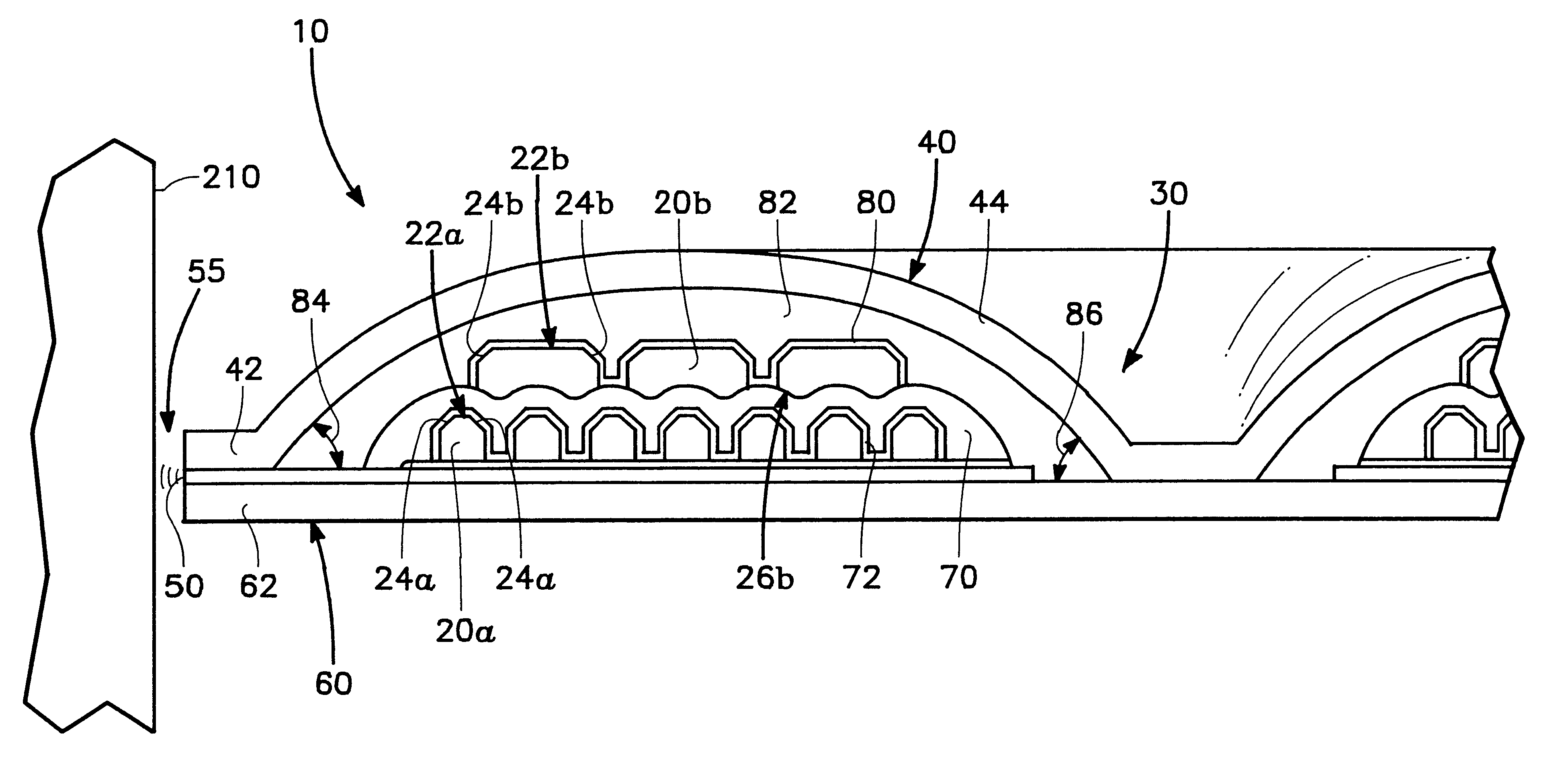

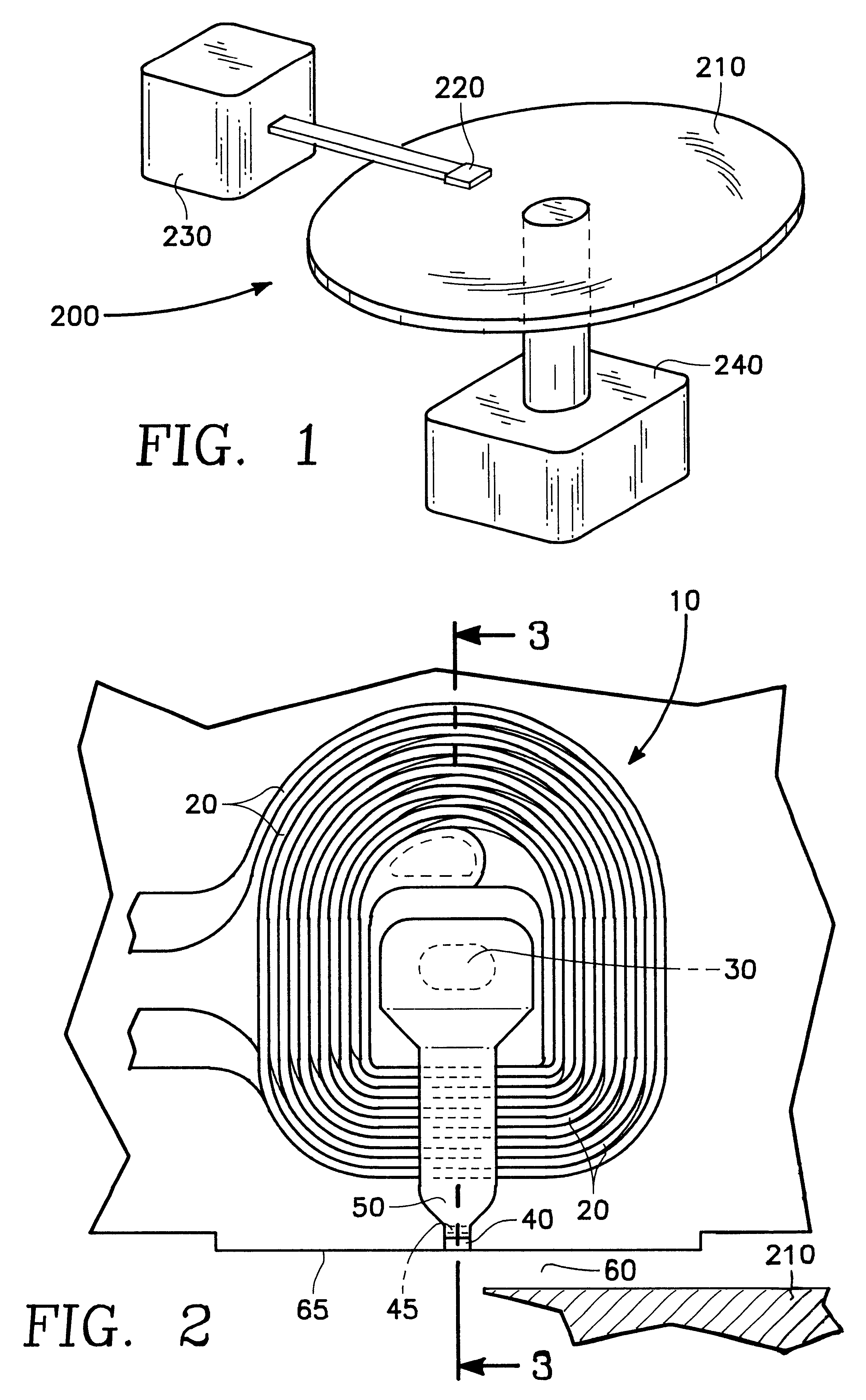

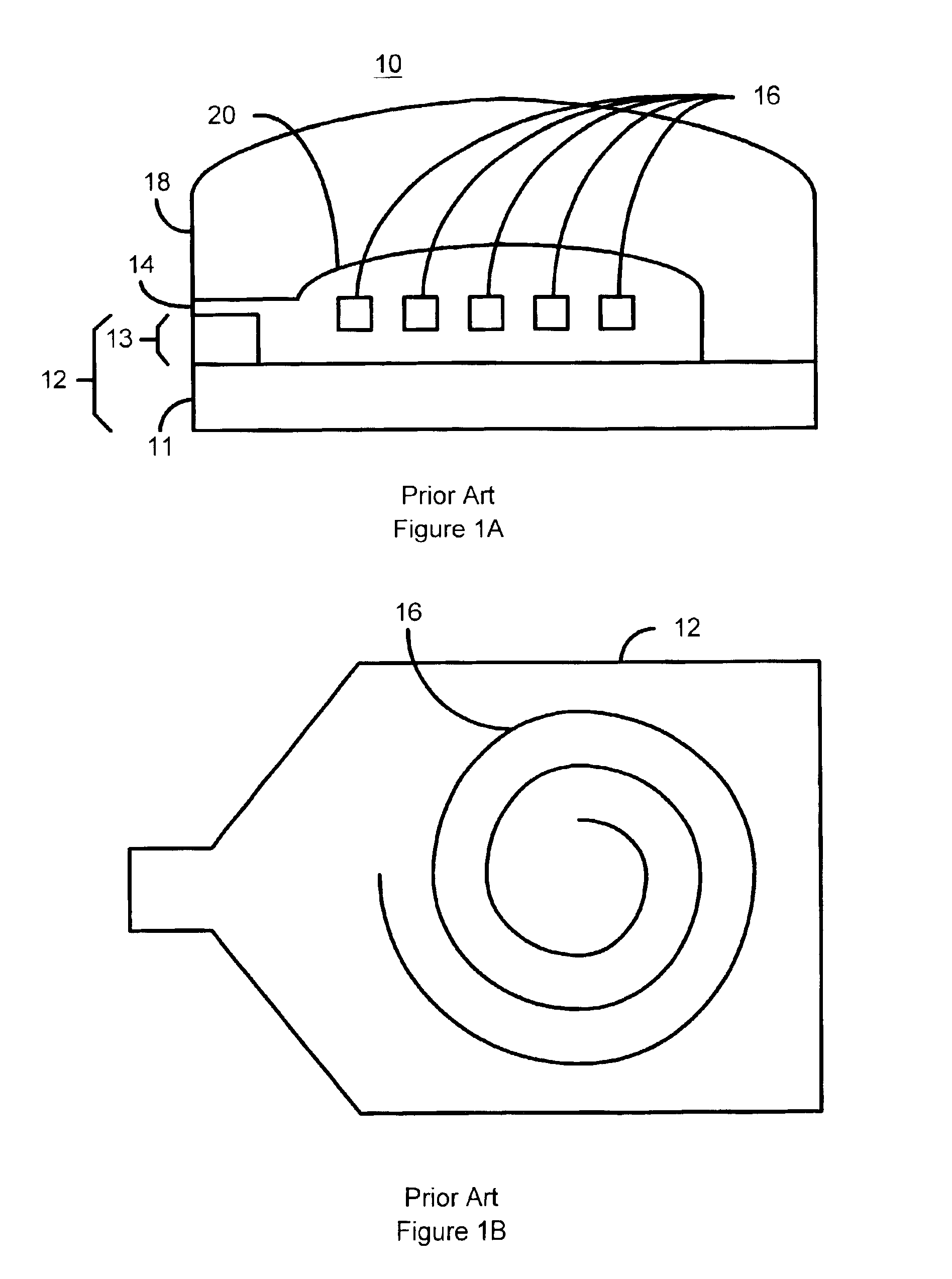

Thin film write head with interlaced coil winding and method of fabrication

InactiveUS6466401B1Increase working frequencySeparationConstruction of head windingsHeads using thin filmsResistConductive materials

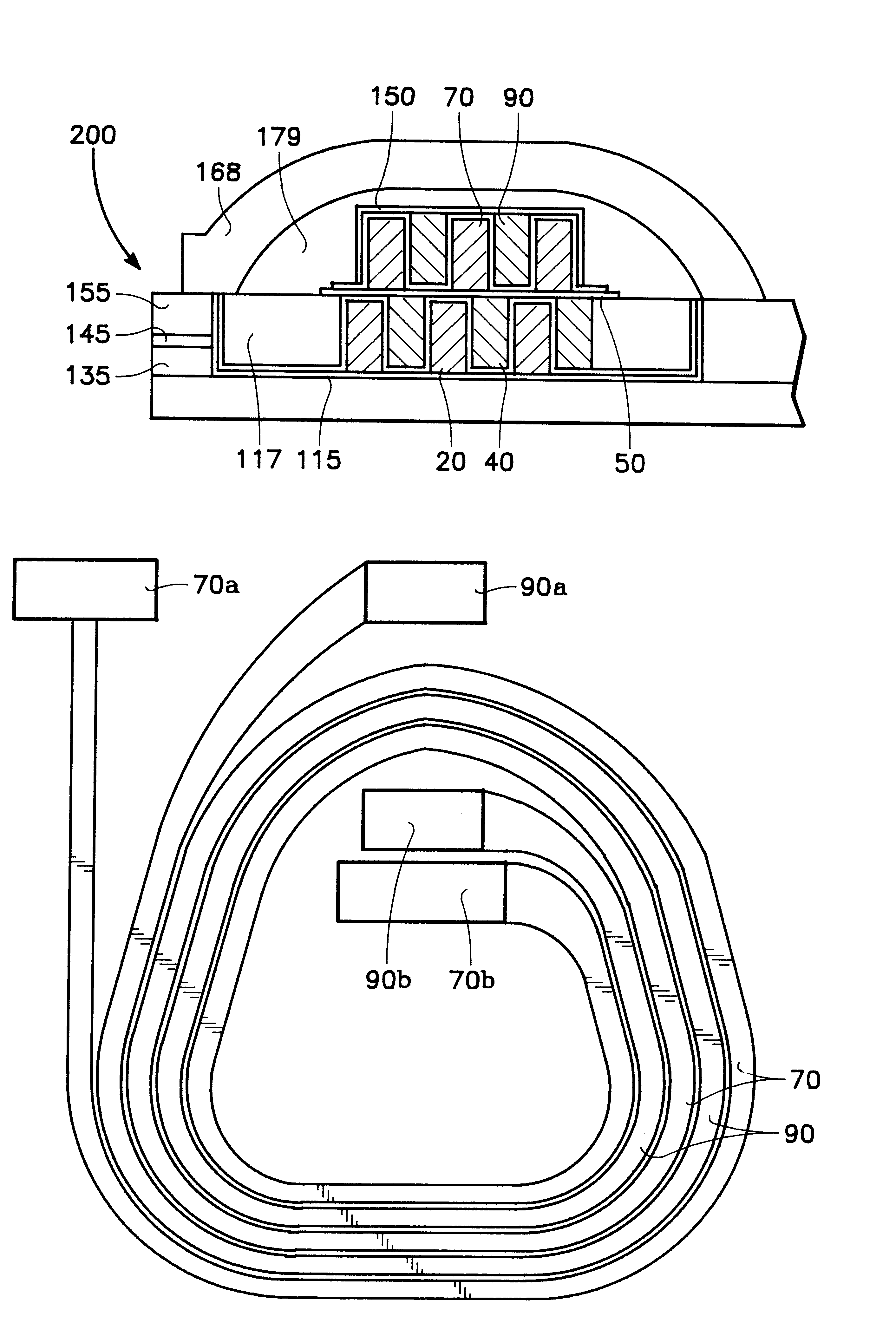

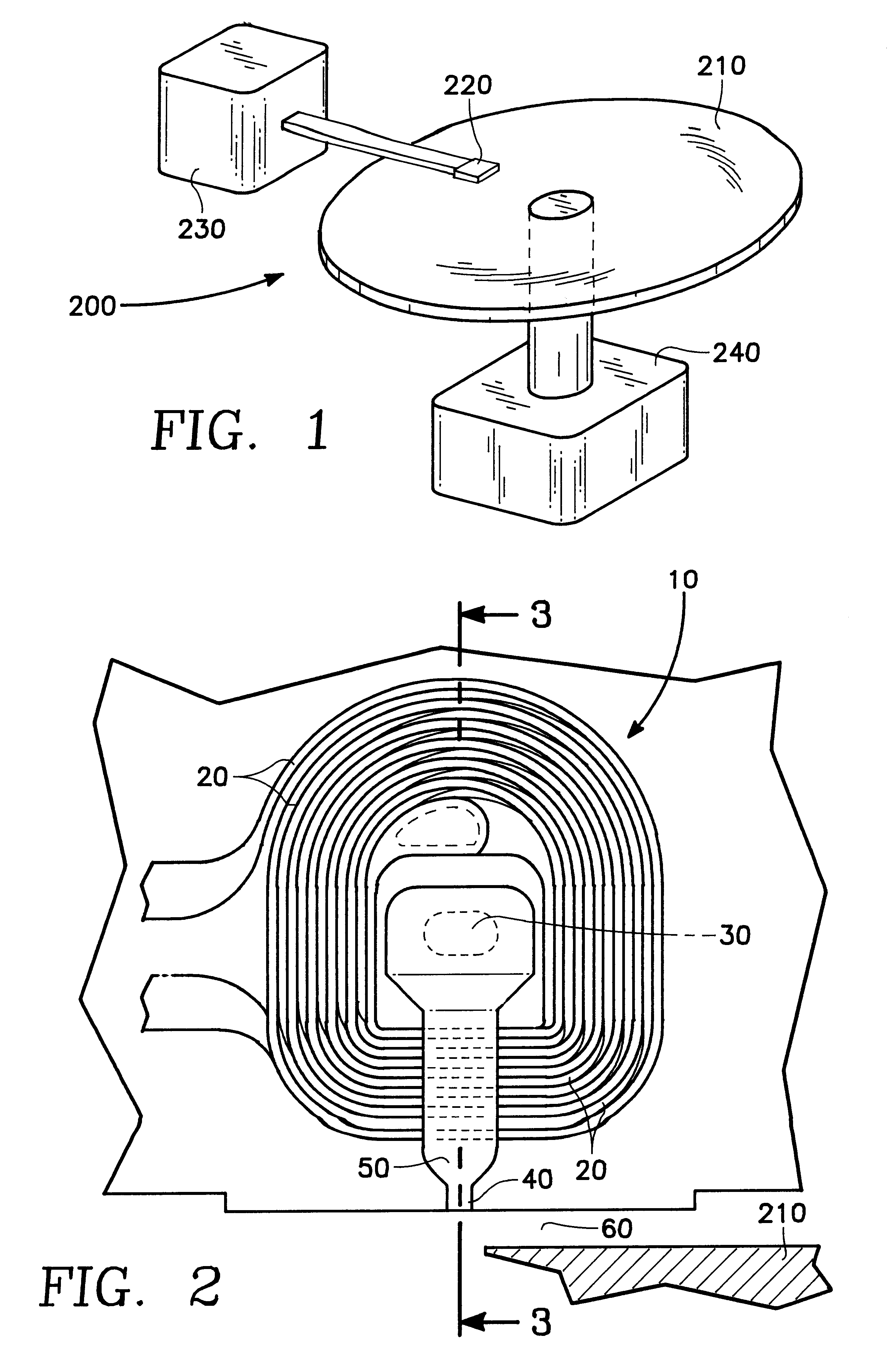

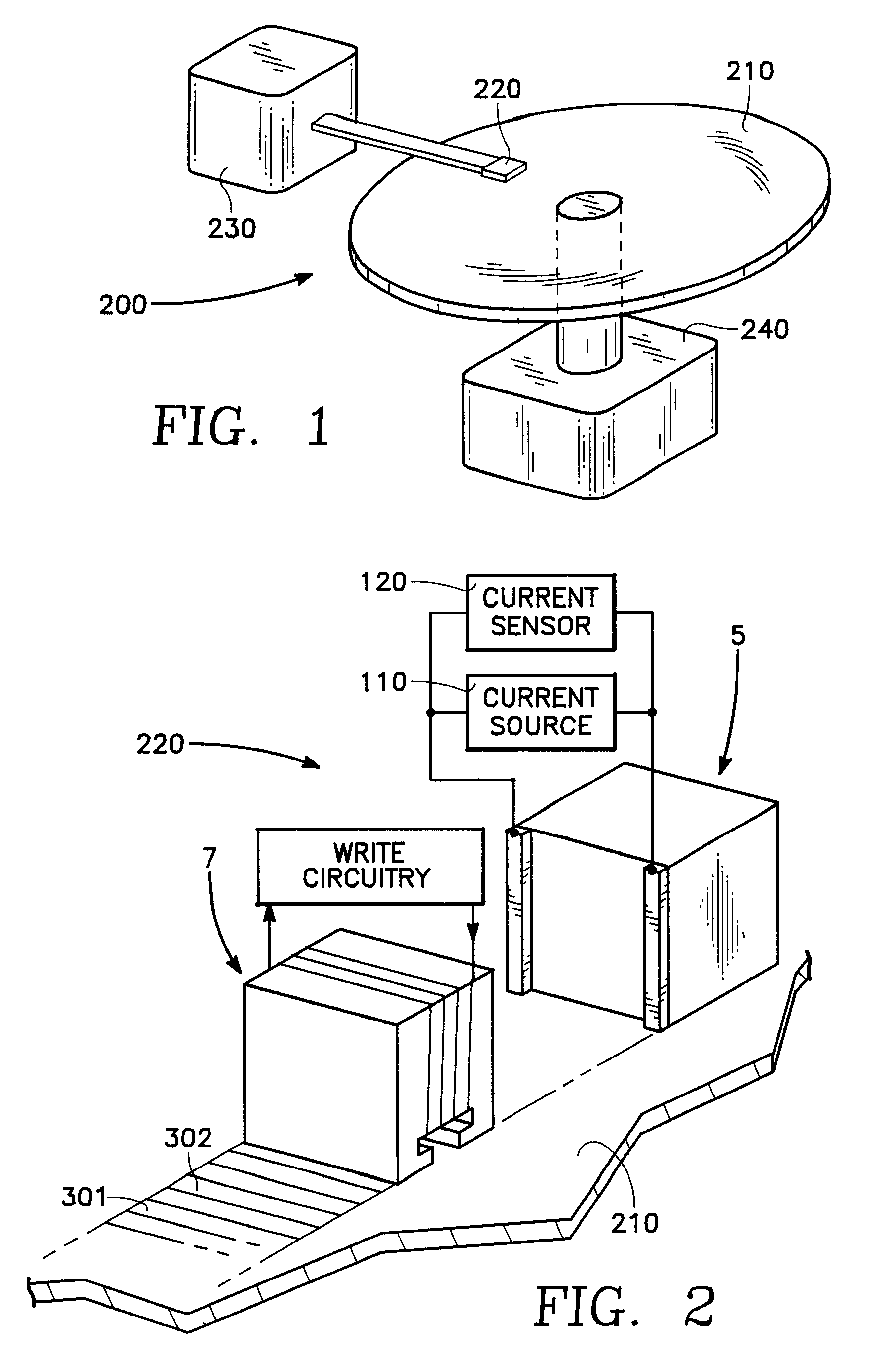

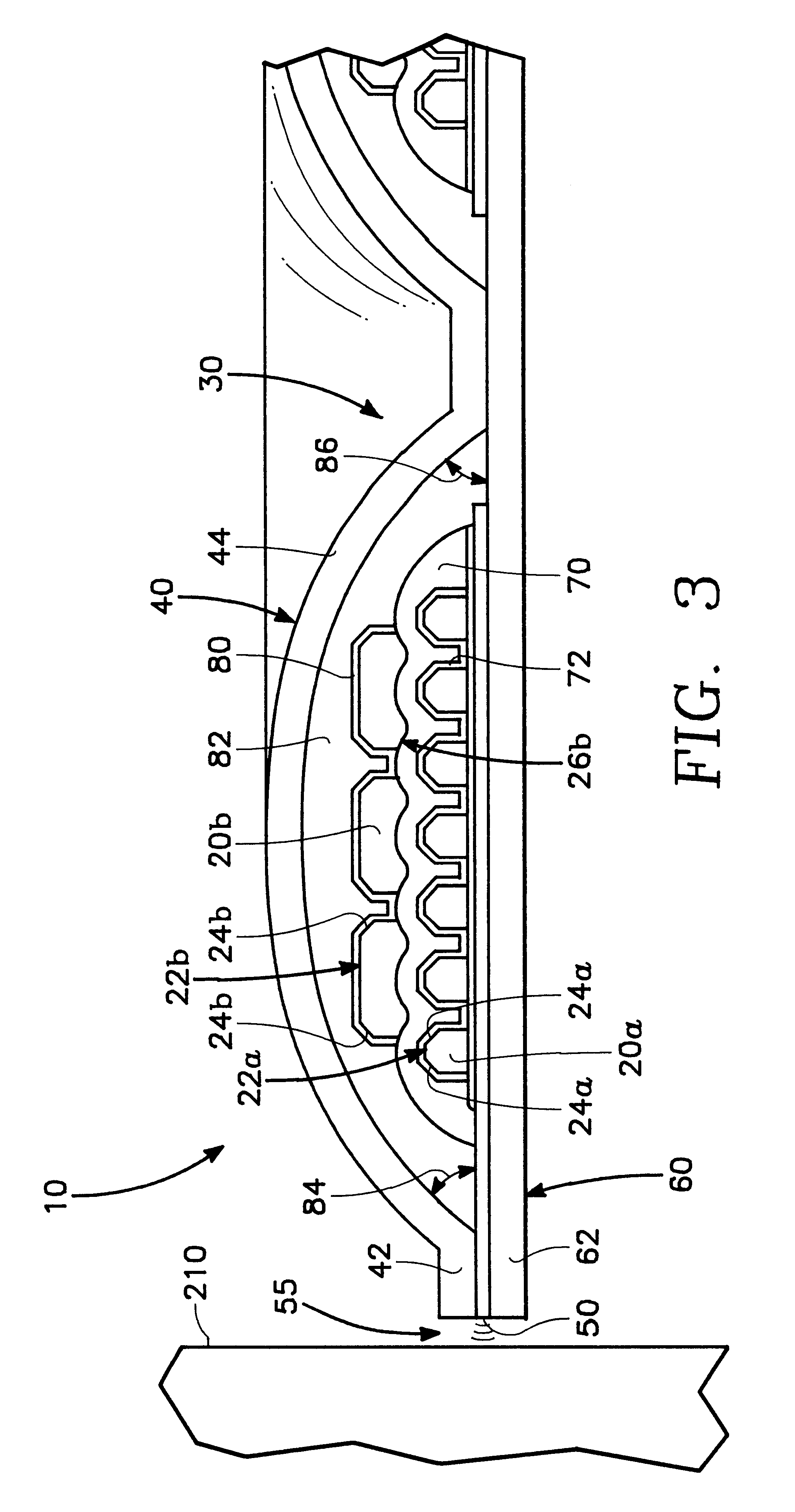

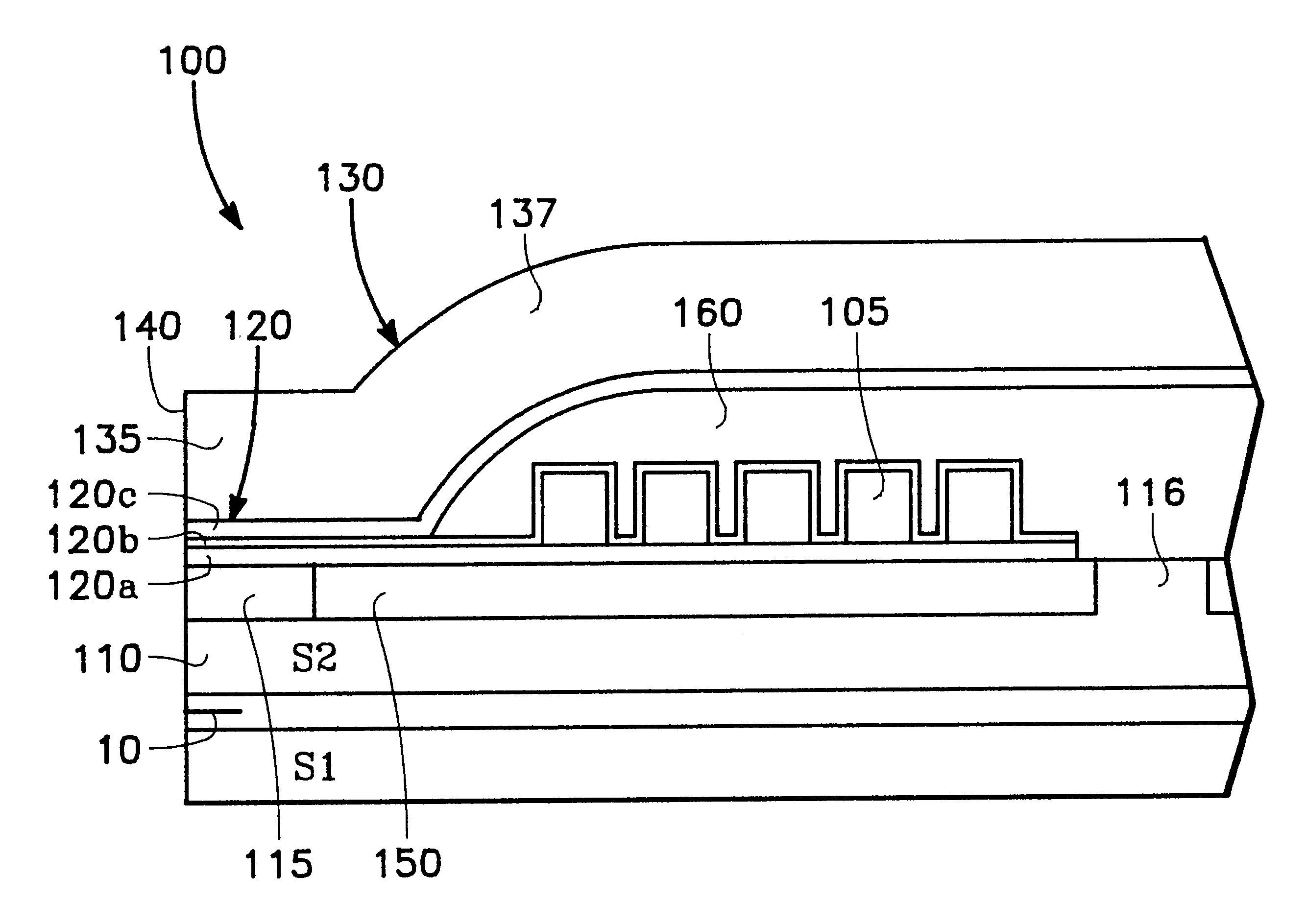

The preferred embodiment of the present invention provides a write head having an interlaced conductor coil winding and method of fabrication. The interlaced winding of the present invention may have alternating turns of a first and a second coil. In the preferred embodiment, the side walls of successive coil turns are separated by an ultra thin inorganic insulation which defines the distance between successive turns of the first and second coil. In one method of fabrication, a conductive seed layer is deposited on a generally planar insulative surface, a resist mask is formed on the seed layer, and a conductive material deposited on the exposed seed layer to form the turns of the first coil. The masked portions of the seed layer are removed, after resist mask removal, to electrically isolate the turns of the first coil. The inorganic insulation may be formed in a layer conformal with the first coil. The second coil is formed between the turns of the first coil. A seed layer and mask may be used to facilitate second coil deposition. Etching, or planarization, may be used to electrically isolate the turns of the second coil. A capping layer may be formed over any exposed conductor material to insulate the winding from an upper pole structure or other overlying structure. Embodiments of the present invention may have multiple layers of conductor winding having some conventional, or all interlaced coil structure.

Owner:WESTERN DIGITAL TECH INC

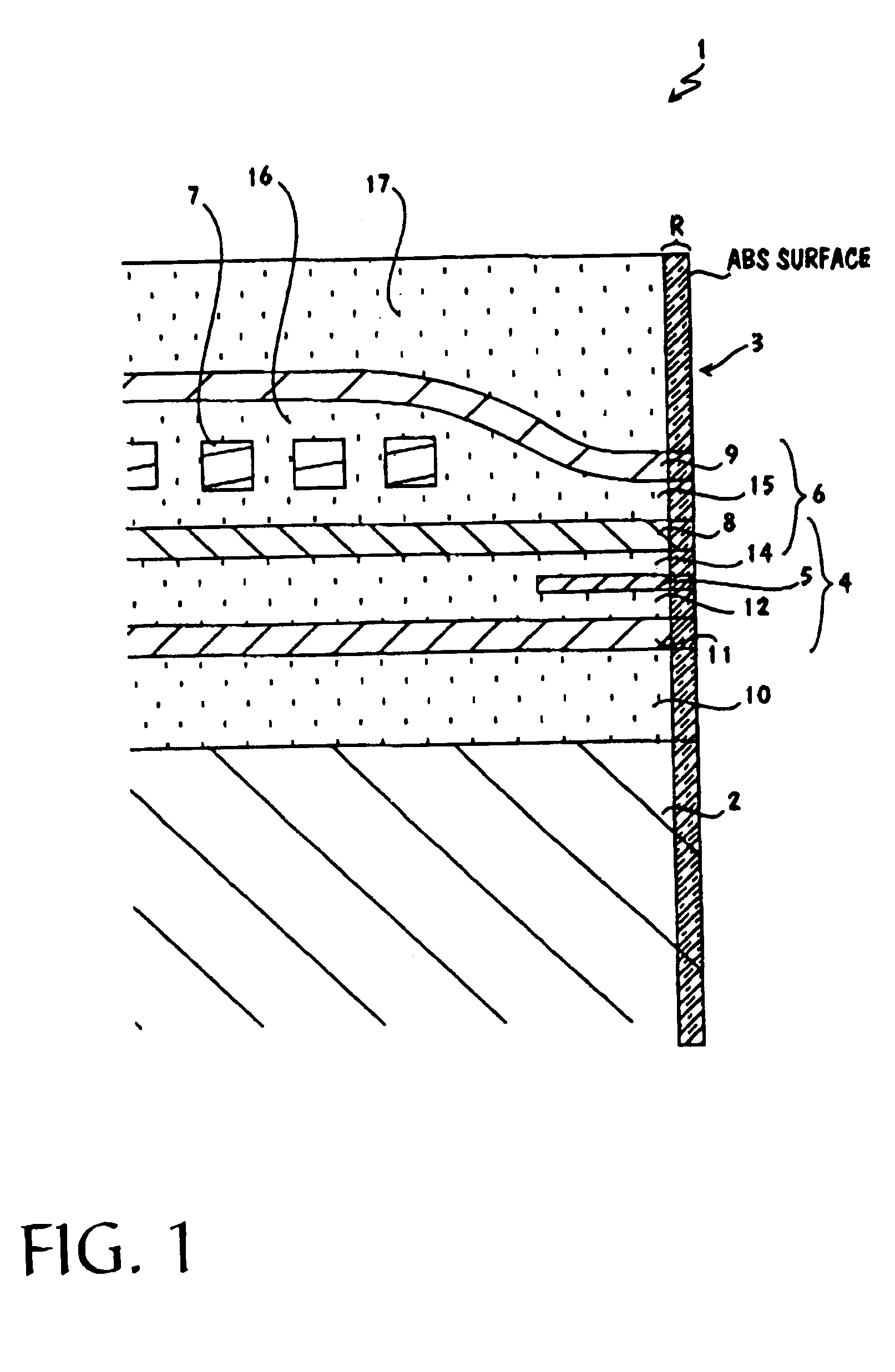

Thin film write head with improved laminated flux carrying structure and method of fabrication

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

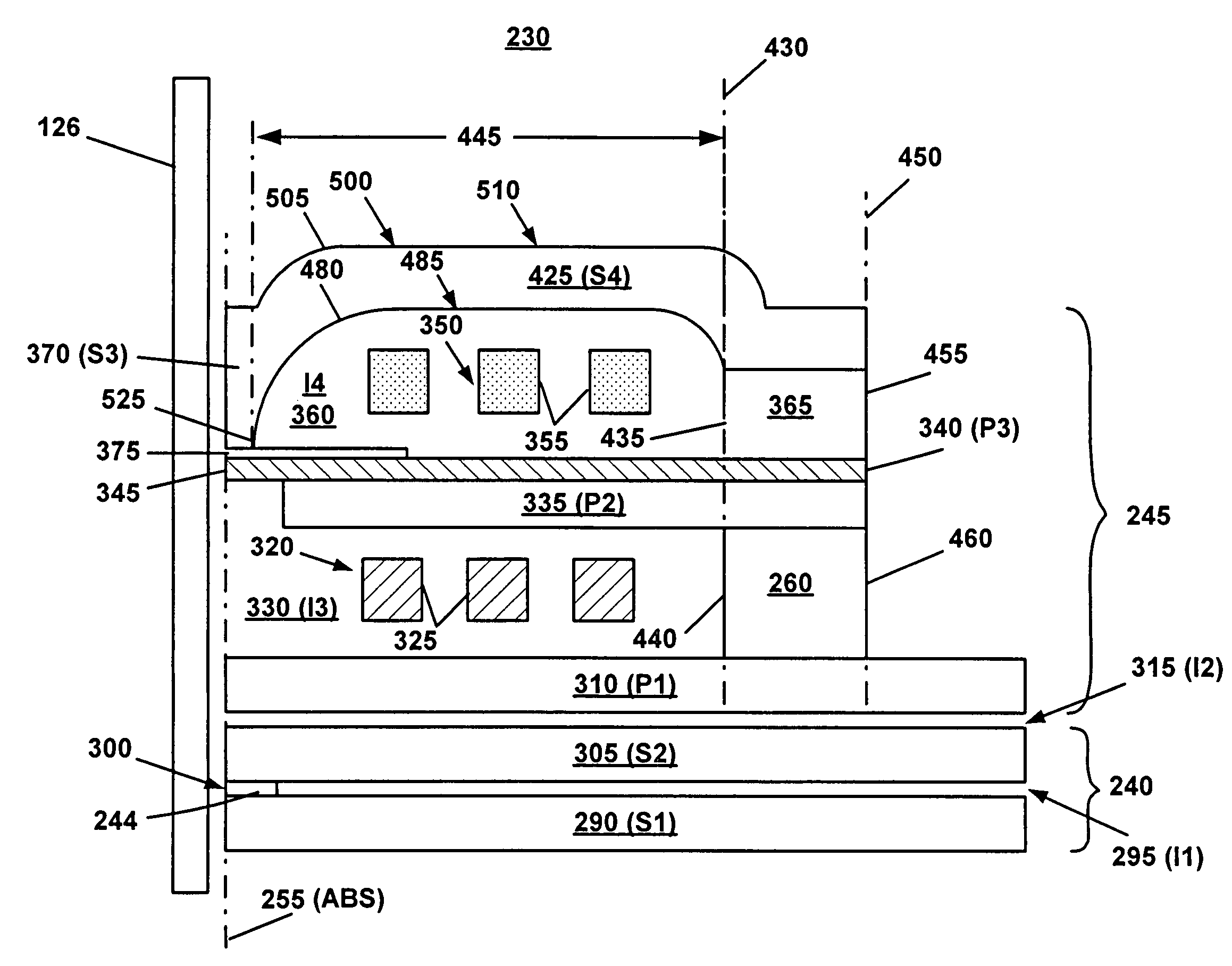

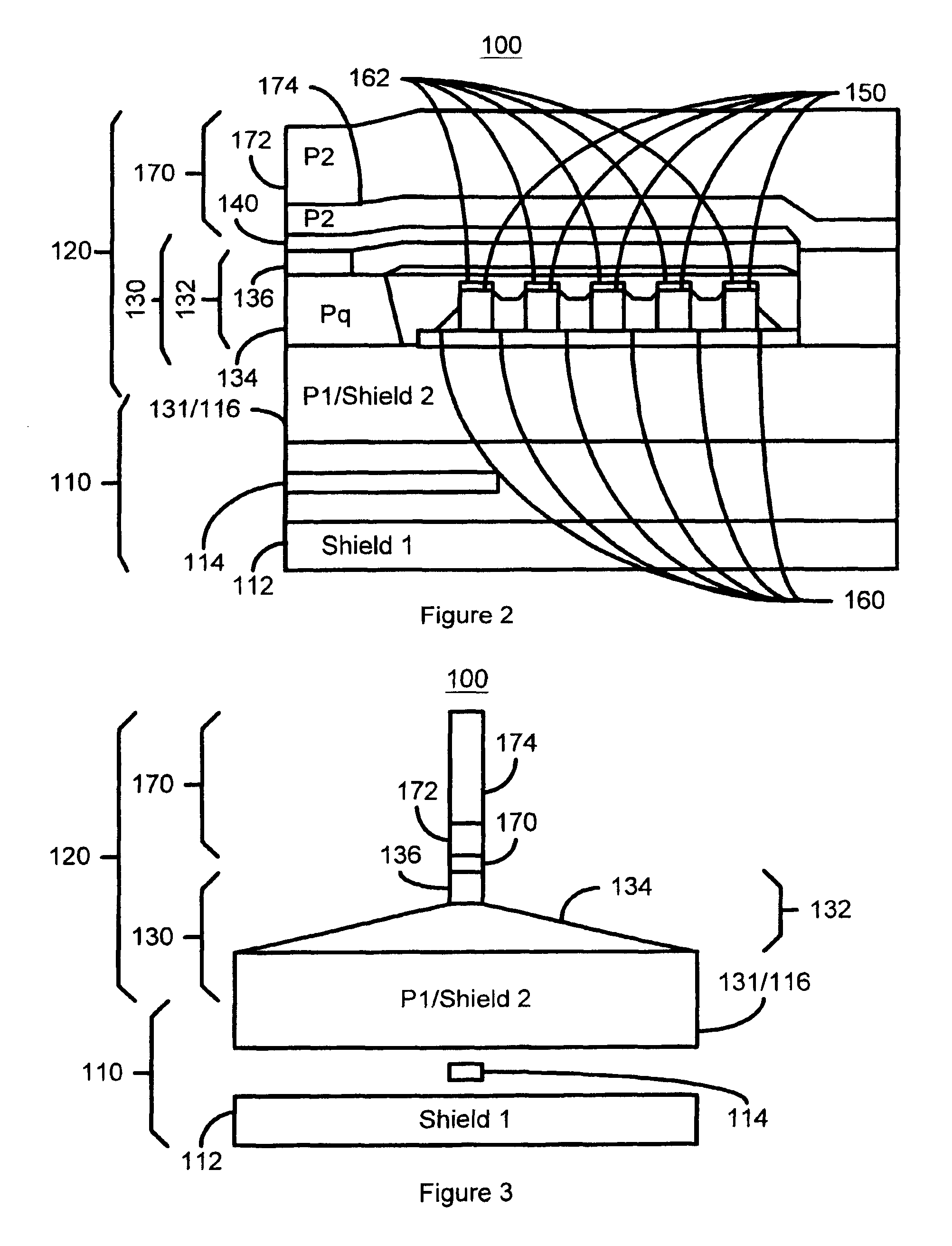

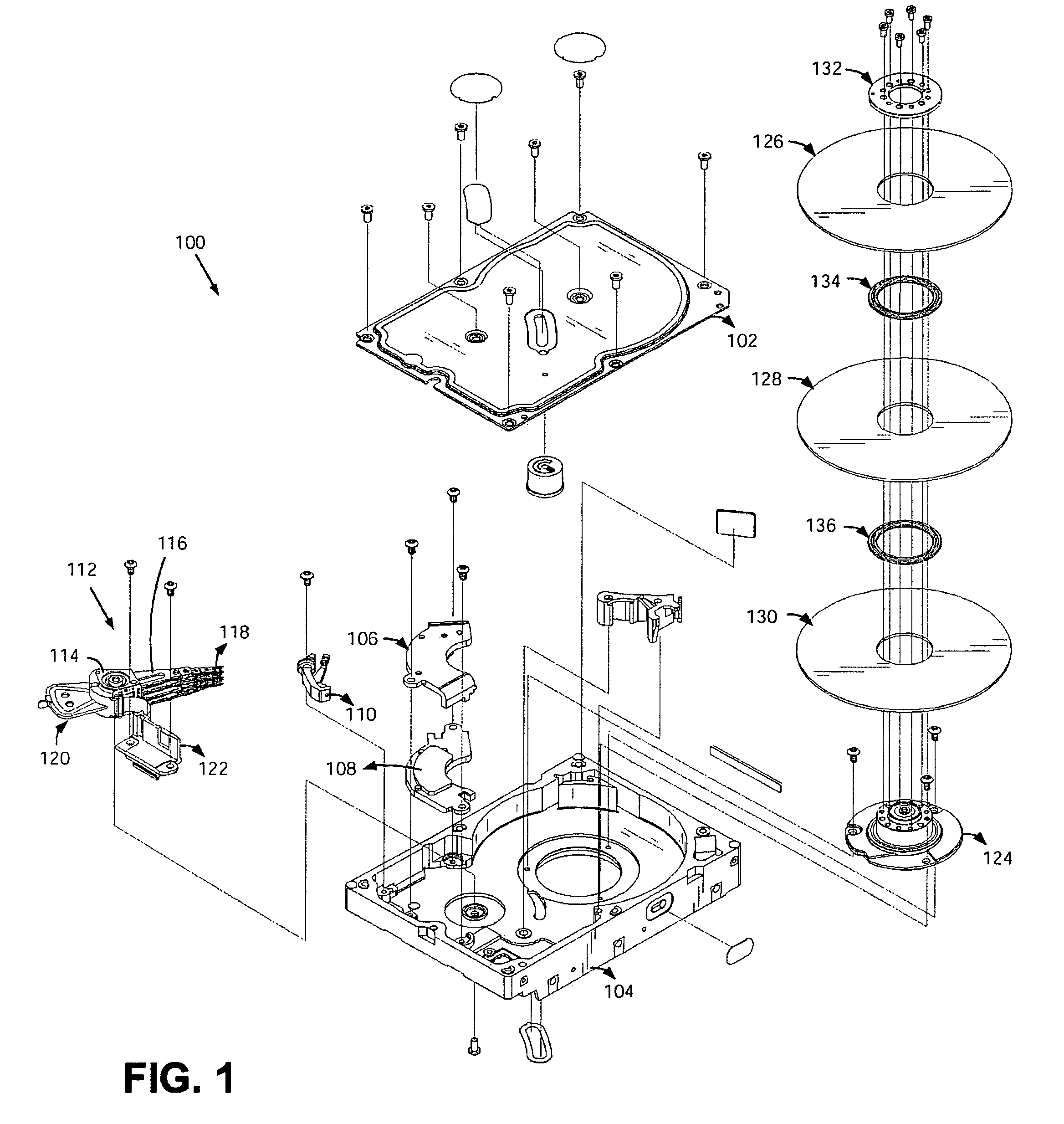

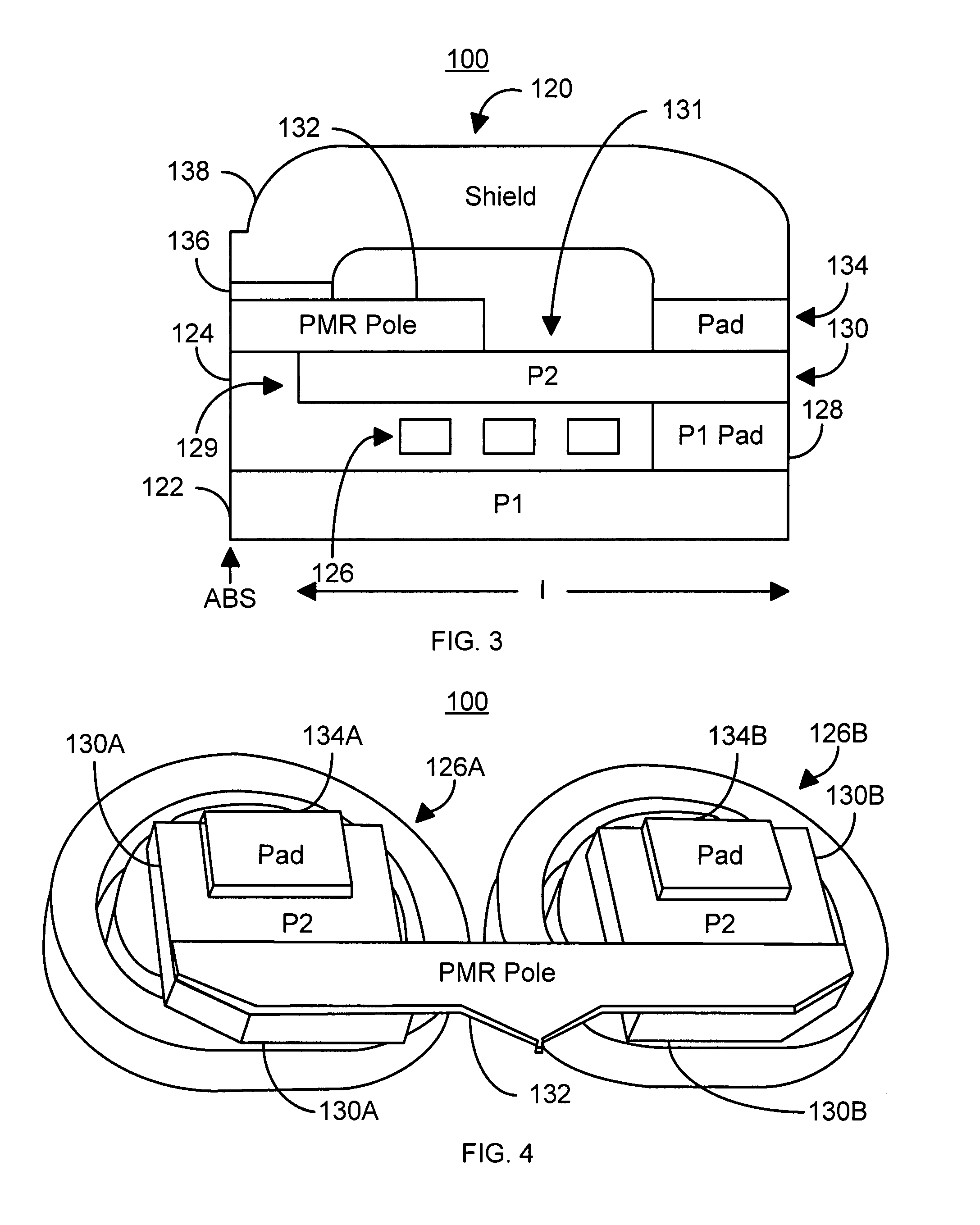

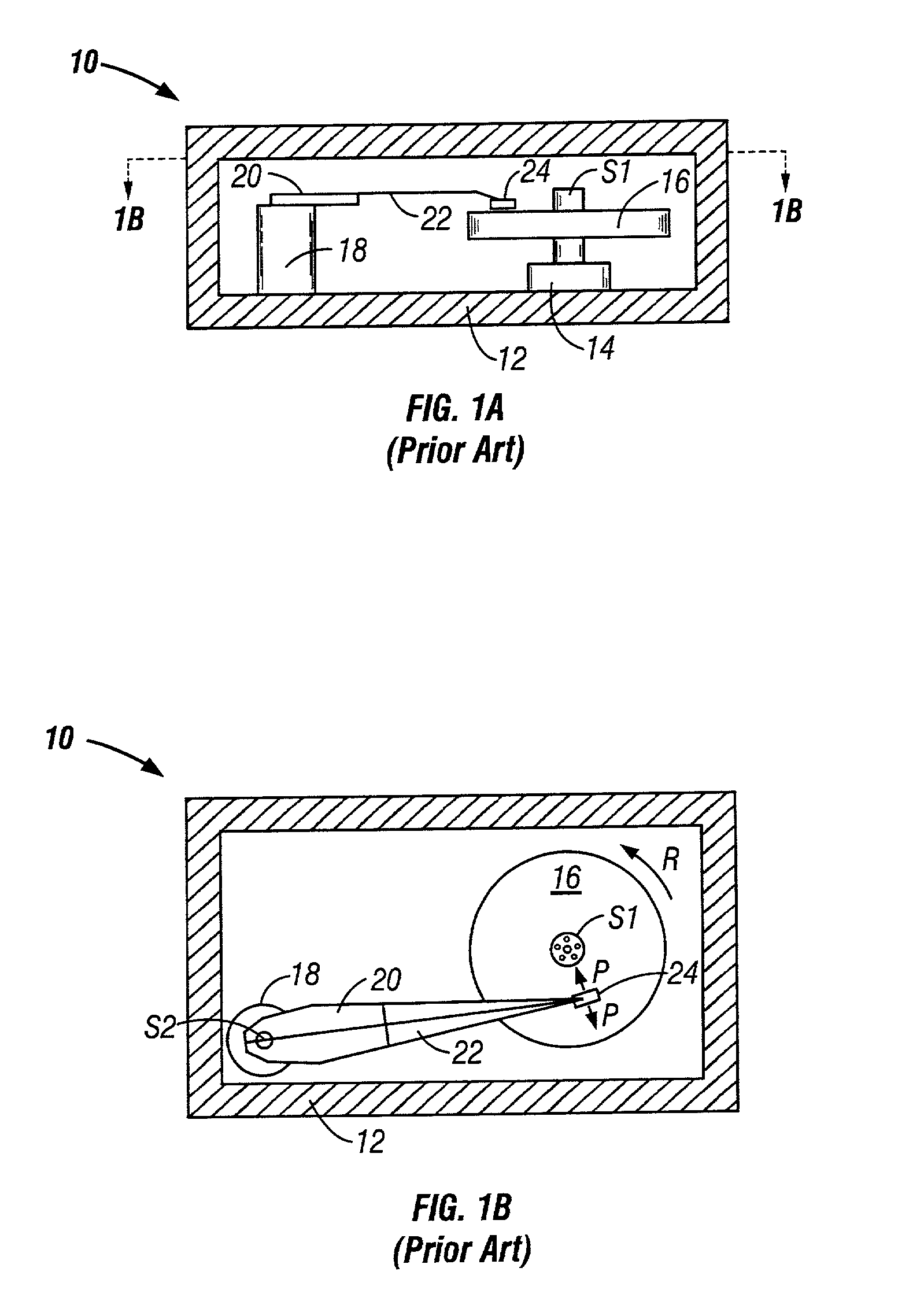

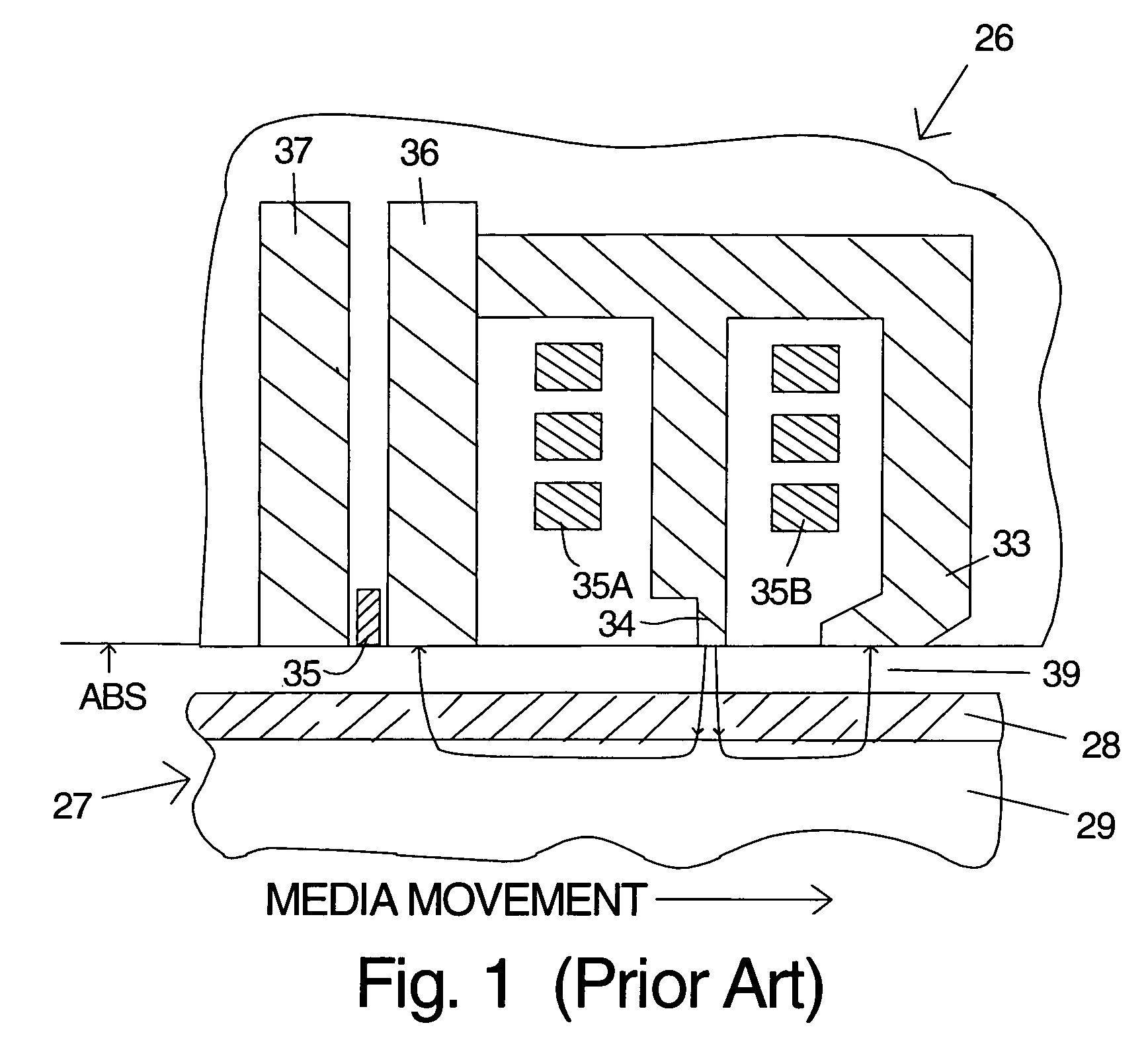

Shielded pole magnetic head for perpendicular recording

A read / write head for use in a perpendicular magnetic recording head in a data storage system. The read / write head includes a write section that is comprised of a first pole layer, a second pole layer, a third pole layer, and a shield layer. The third pole layer defines a write pole tip, and the third pole layer and the shield layer are separated from each other to define a write gap therebetween. At least part of the shield layer has a generally uniform width, and wherein the write pole tip defines a track width that is substantially equal to the uniform width of the shield layer. According to one embodiment the entire shield layer has a generally uniform width that is substantially equal to the track width. According to another embodiment, the shield layer includes a lower section and an upper section, wherein the lower section has a generally uniform width along its entire length, and wherein the upper section is wider than the lower section.

Owner:WESTERN DIGITAL TECH INC

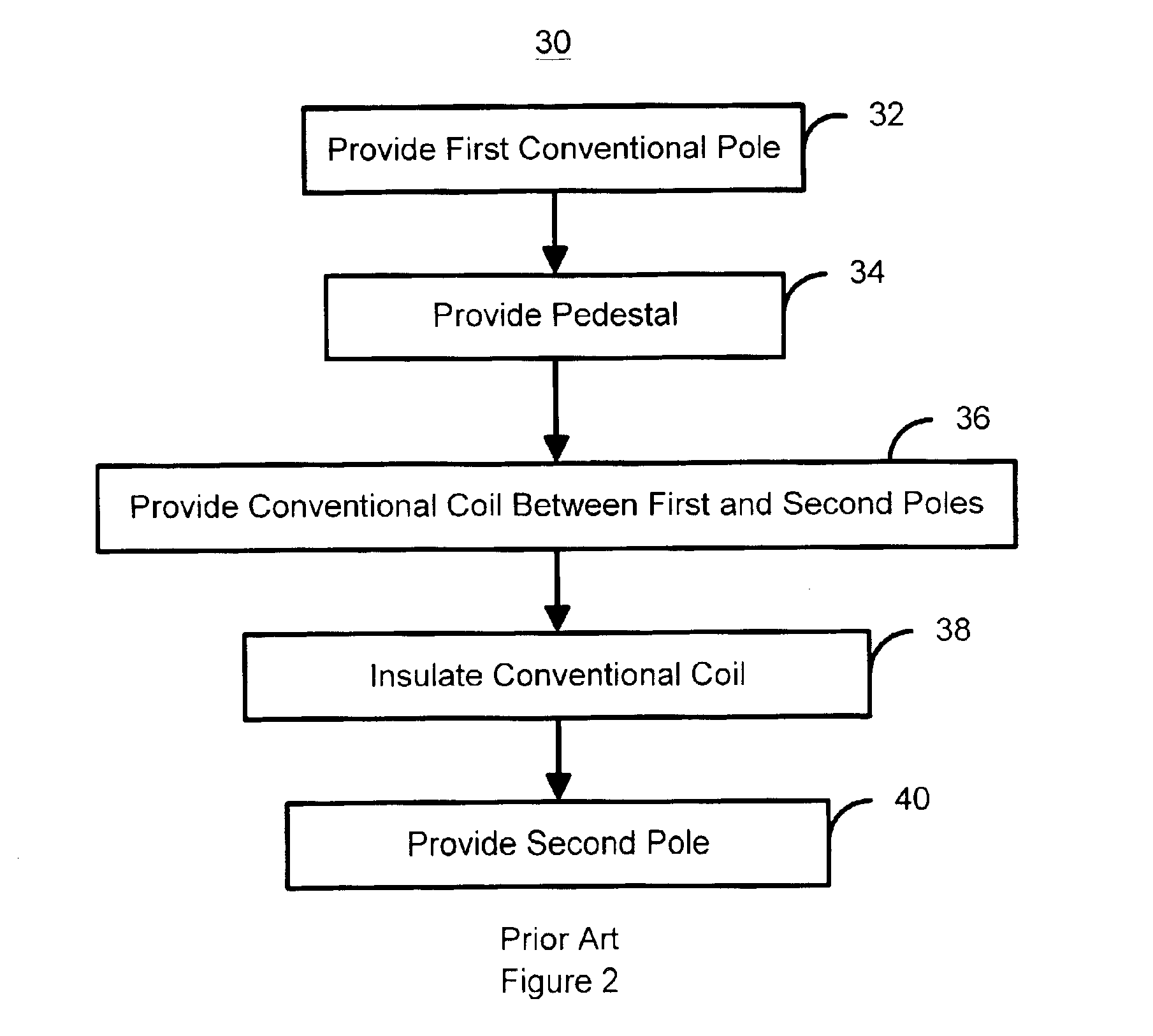

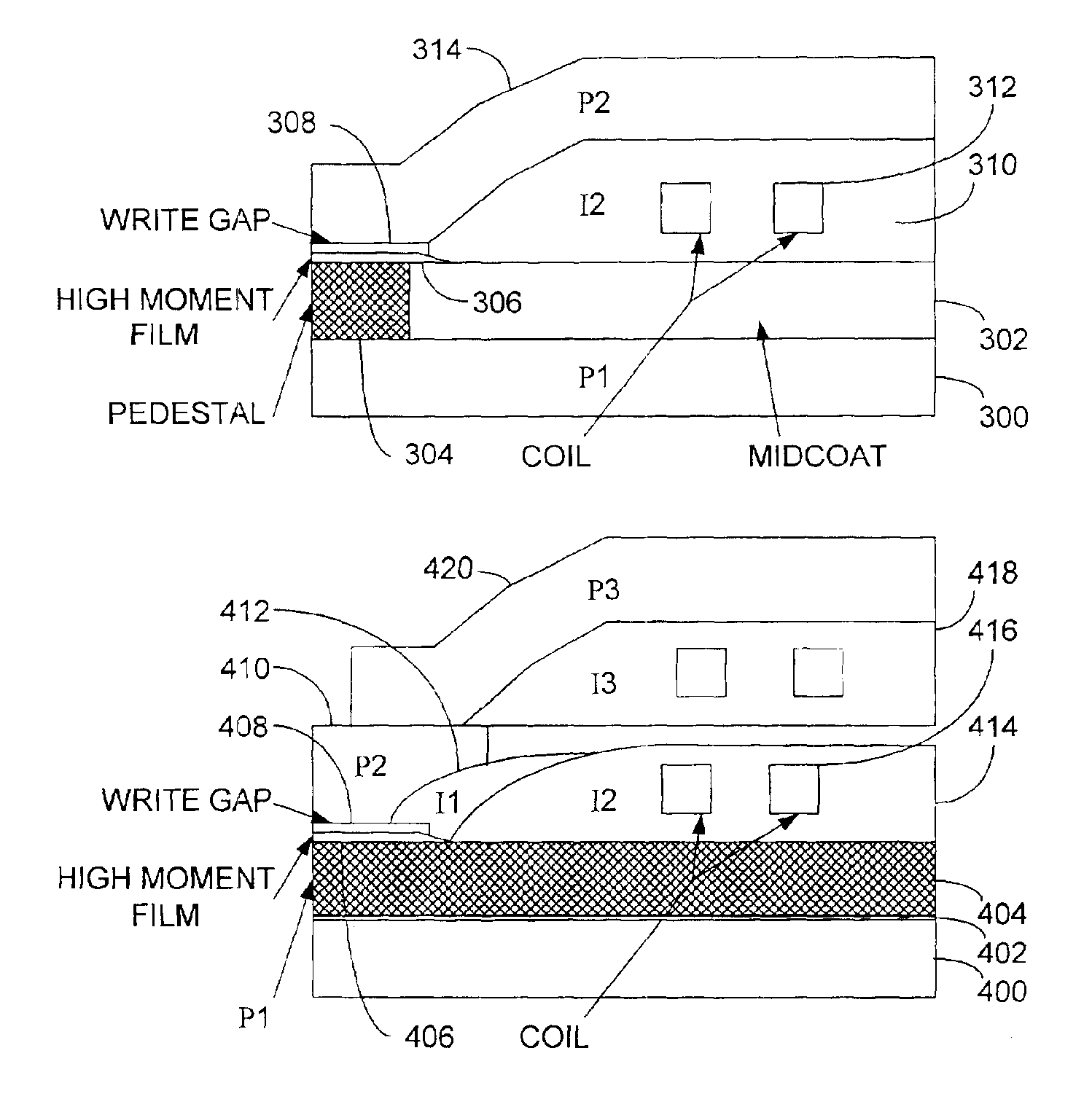

Writer with a hot seed zero throat and substantially flat top pole

InactiveUS6912106B1High-density recordingConstruction of head windingsHeads using thin filmsThroatEngineering

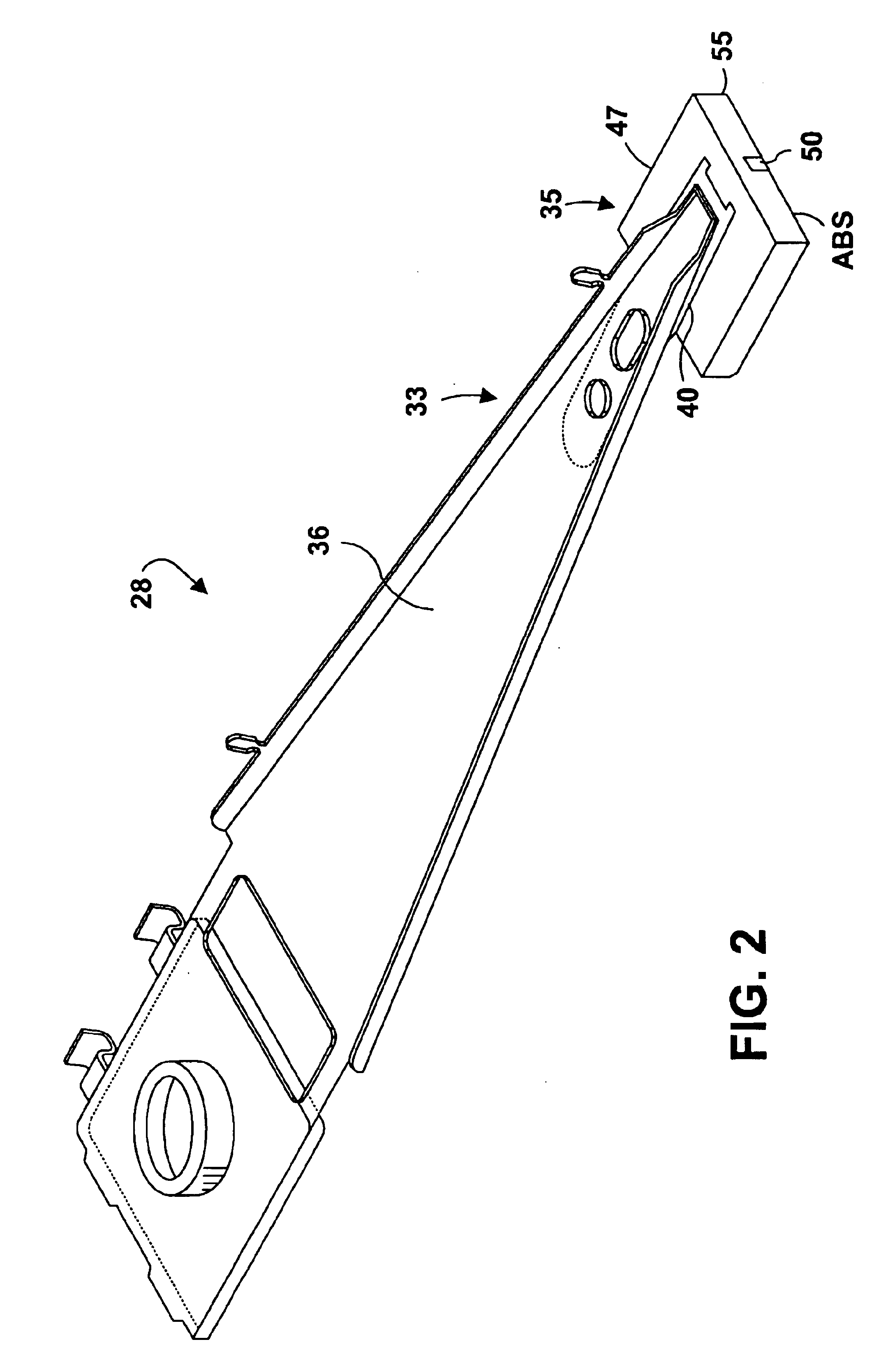

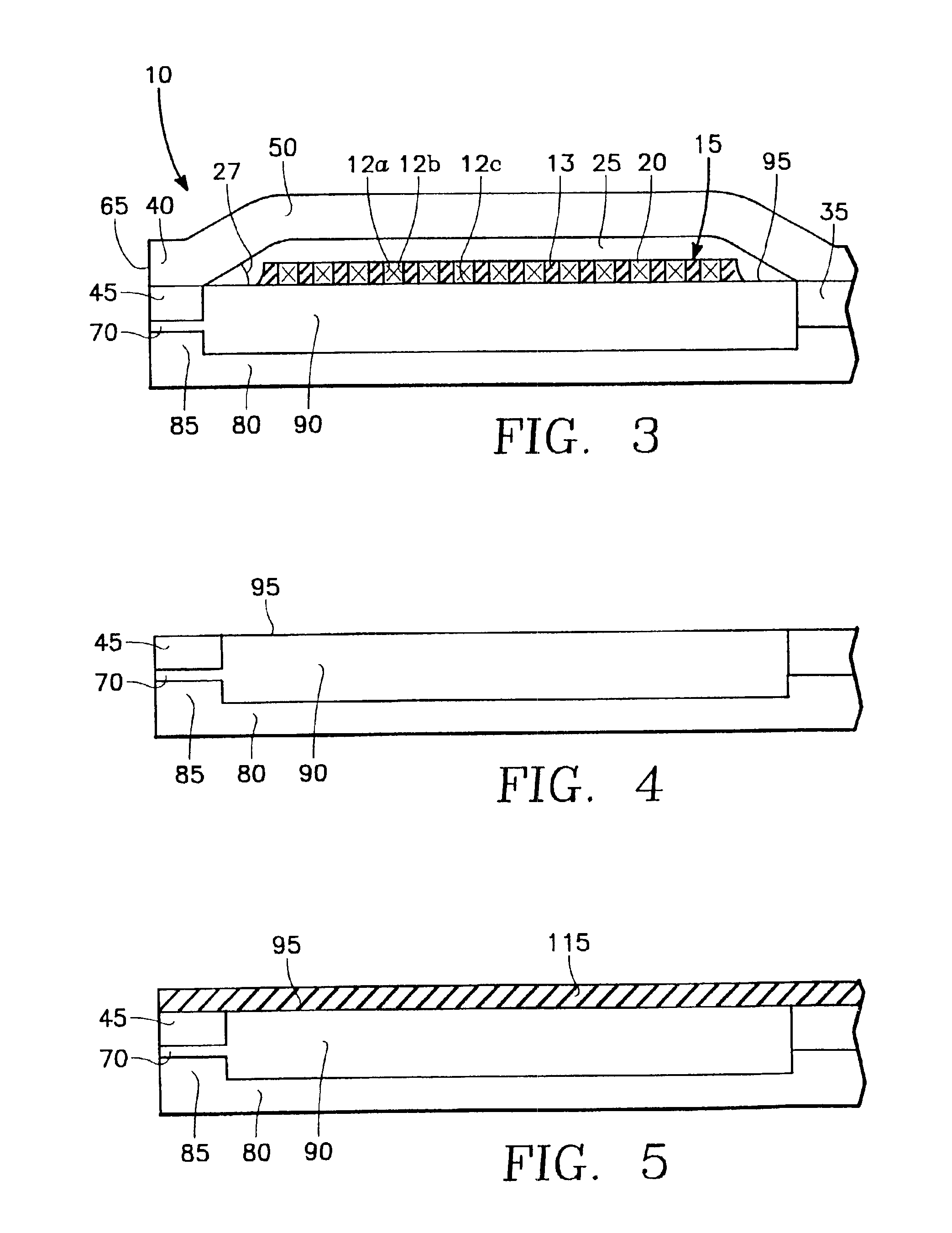

A method and system for providing a recording head is disclosed. The method and system include providing a first pole, a second pole, a write gap and at least one coil. The write cap separates the first pole from the second pole. The coil(s) include a plurality of turns and is between the first and second poles. The first pole includes a pedestal that has a first portion and a second portion. The first portion includes a high moment electroplated material. The second portion includes a hot seed layer that has a high moment sputtered material. The second portion of the first pole is adjacent to the write gap.

Owner:WESTERN DIGITAL TECH INC

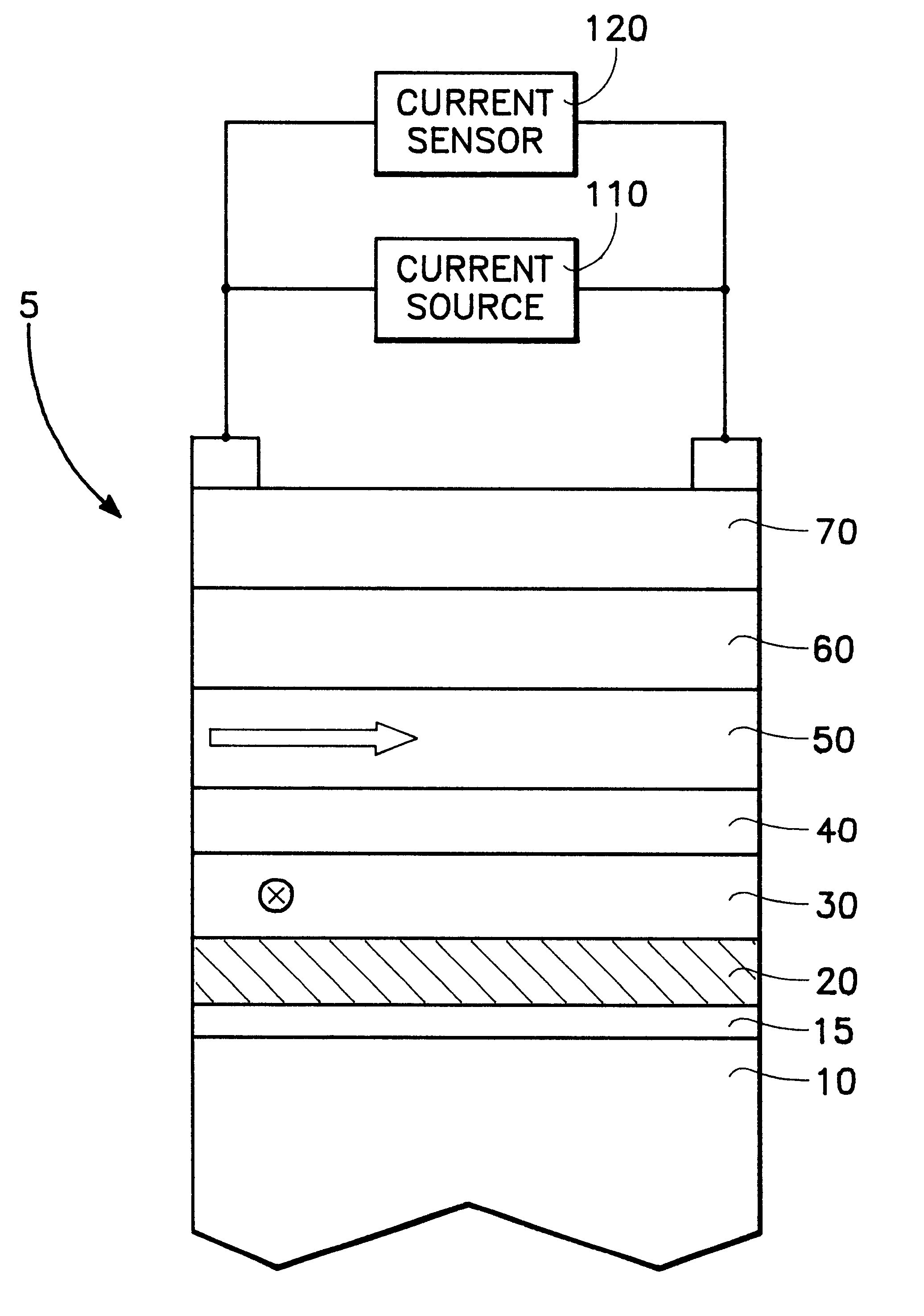

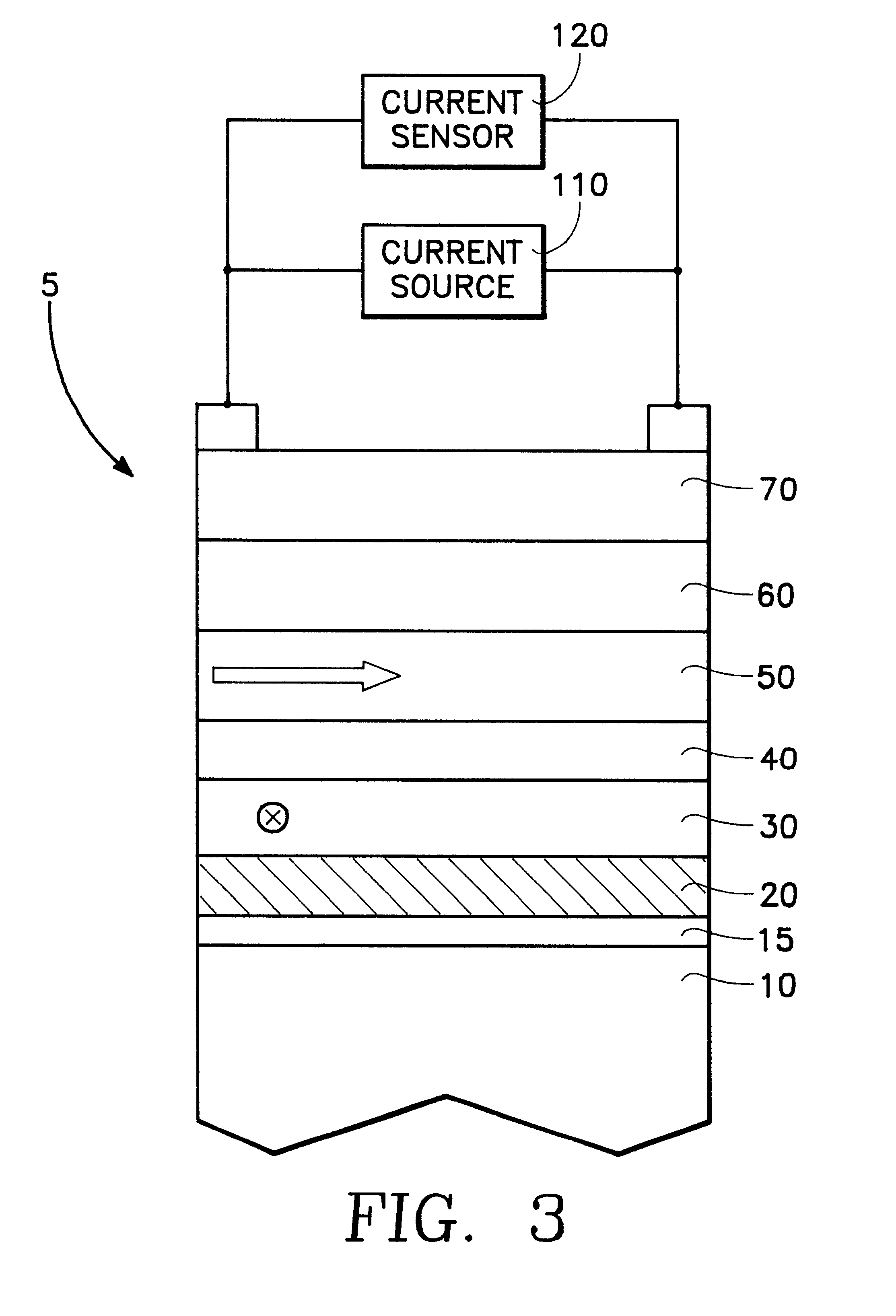

Spin valve device with improved thermal stability

The present invention provides spin valve with a magnetic compensation field which couples to the pinned layer and counteracts sensing current induced magnetic field. The spin valve sensor of the present invention may be formed having a structure comprising: a free layer, a first spacer layer, a pinned layer, a pinning layer, a second spacer layer, and a compensation layer. The compensation layer may be formed of ferromagnetic material with its magnetization set so that the compensation field oriented in a reinforcing relationship with the magnetization of the pinned layer. Current through the compensation layer and the spacer layer may add to the compensation field. The spacer layer may be formed of a nonmagnetic material of sufficient thickness to prevent interaction between the pinning layer and the compensation layer while providing a sufficiently small distance to allow sufficient magnetic coupling to the pinned layer. The present invention may be used to improve thermal stability and reduce Barkhausen noise while not impacting output symmetry.

Owner:WESTERN DIGITAL TECH INC

Method for manufacturing a shielded pole magnetic head for perpendicular recording

ActiveUS7337530B1Electrical transducersHeads using thin filmsEngineeringElectrical and Electronics engineering

A method of making a perpendicular magnetic recording head for use in a data storage device includes forming a first pole layer, a second pole layer, a third pole layer, and a shield layer of a write section. The first pole layer, second pole layer, third pole layer, and shield layer are formed without using a chemical mechanical polishing process. The method next includes concurrently trimming the shield layer and a write pole that is defined by the third pole layer to a predetermined track width. In the trimming step, the shield layer is used as a mask for the write pole.

Owner:WESTERN DIGITAL TECH INC

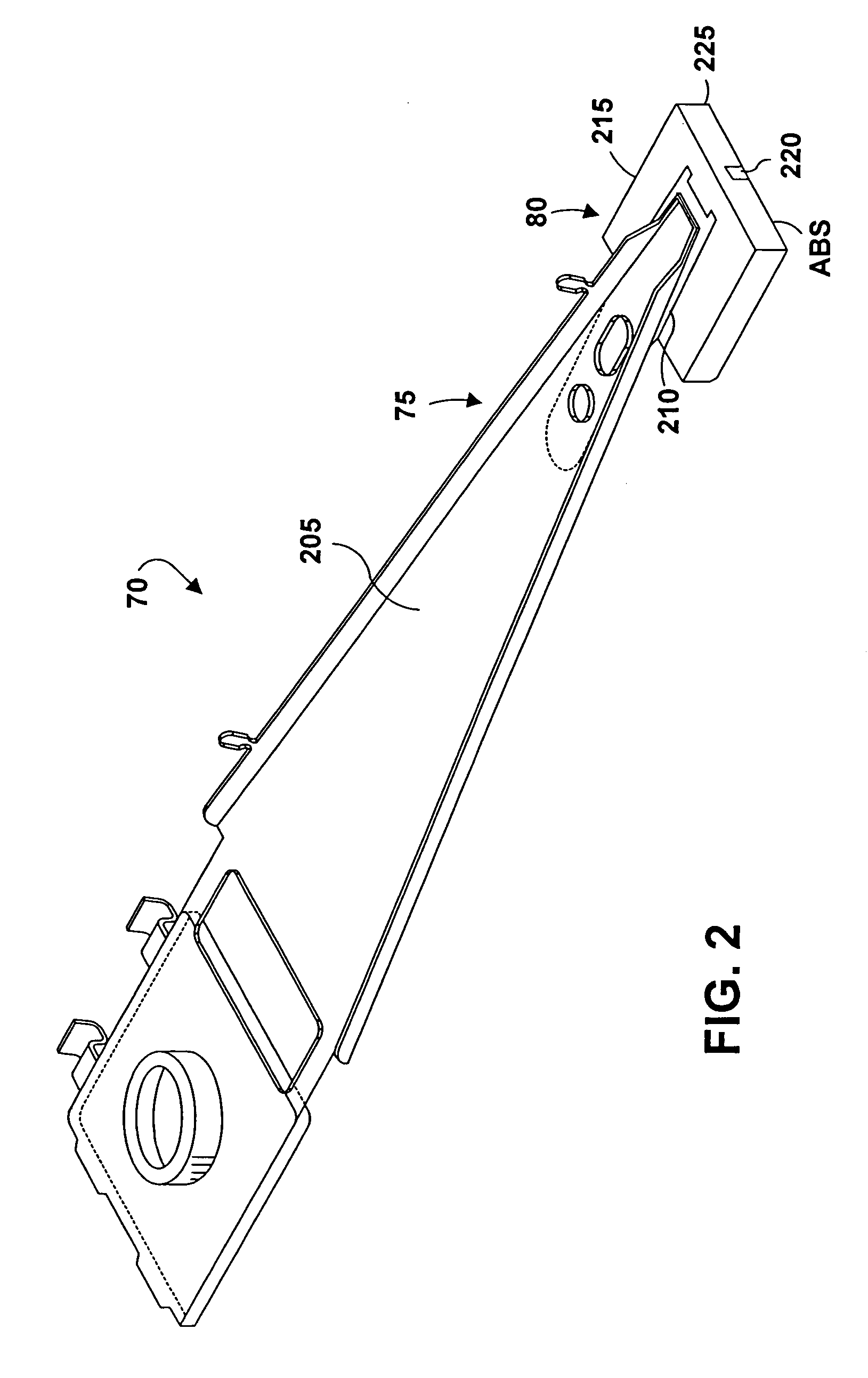

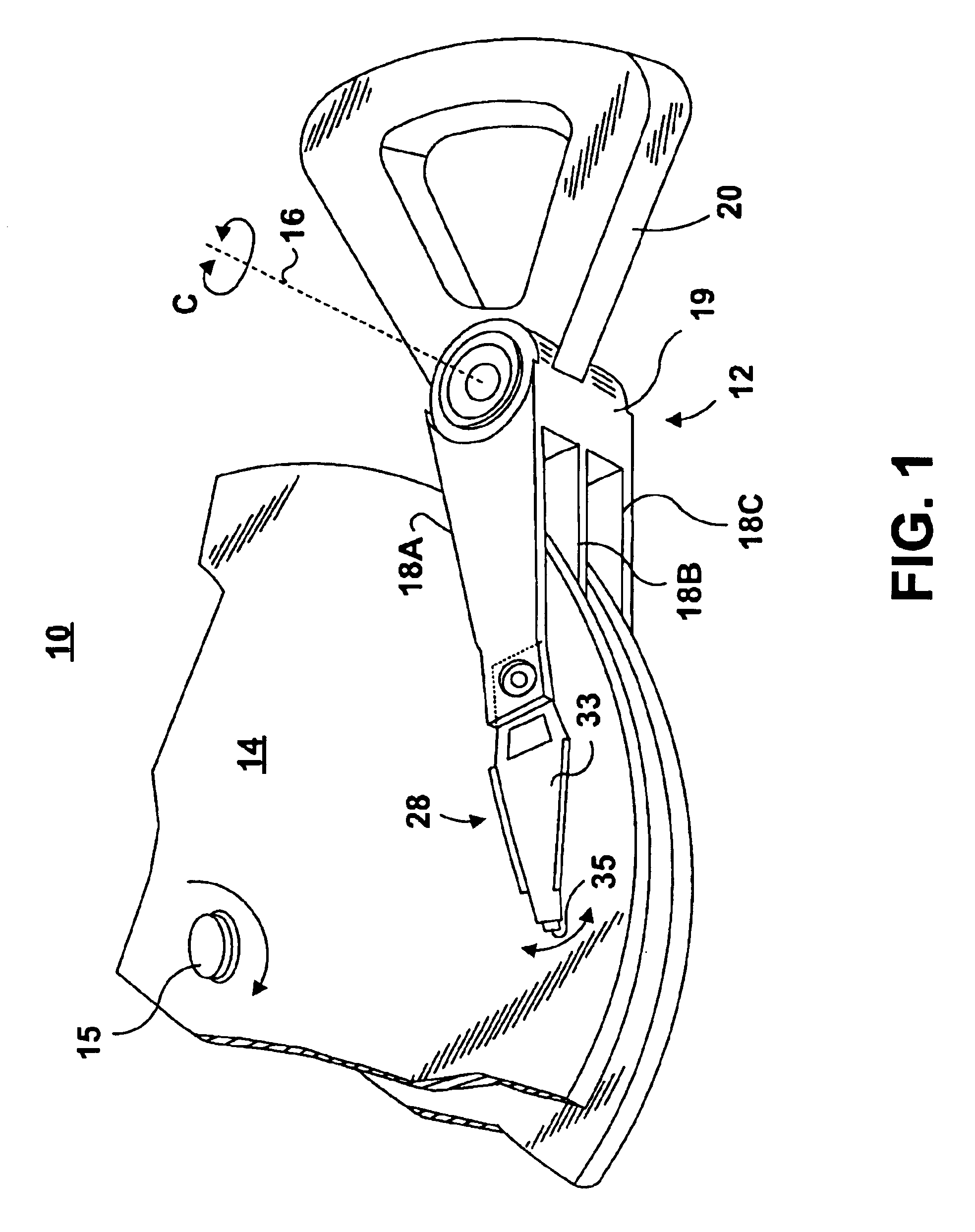

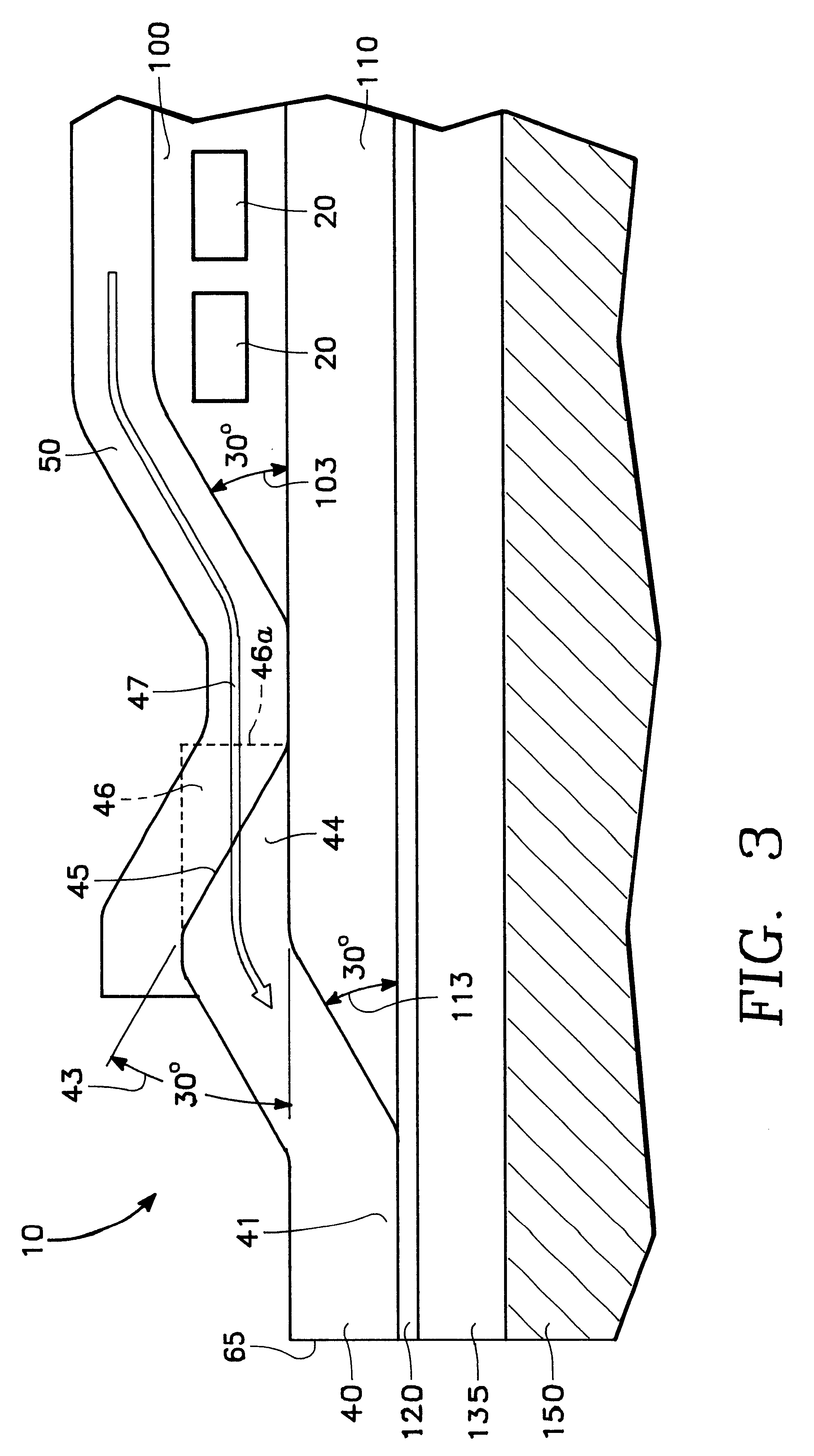

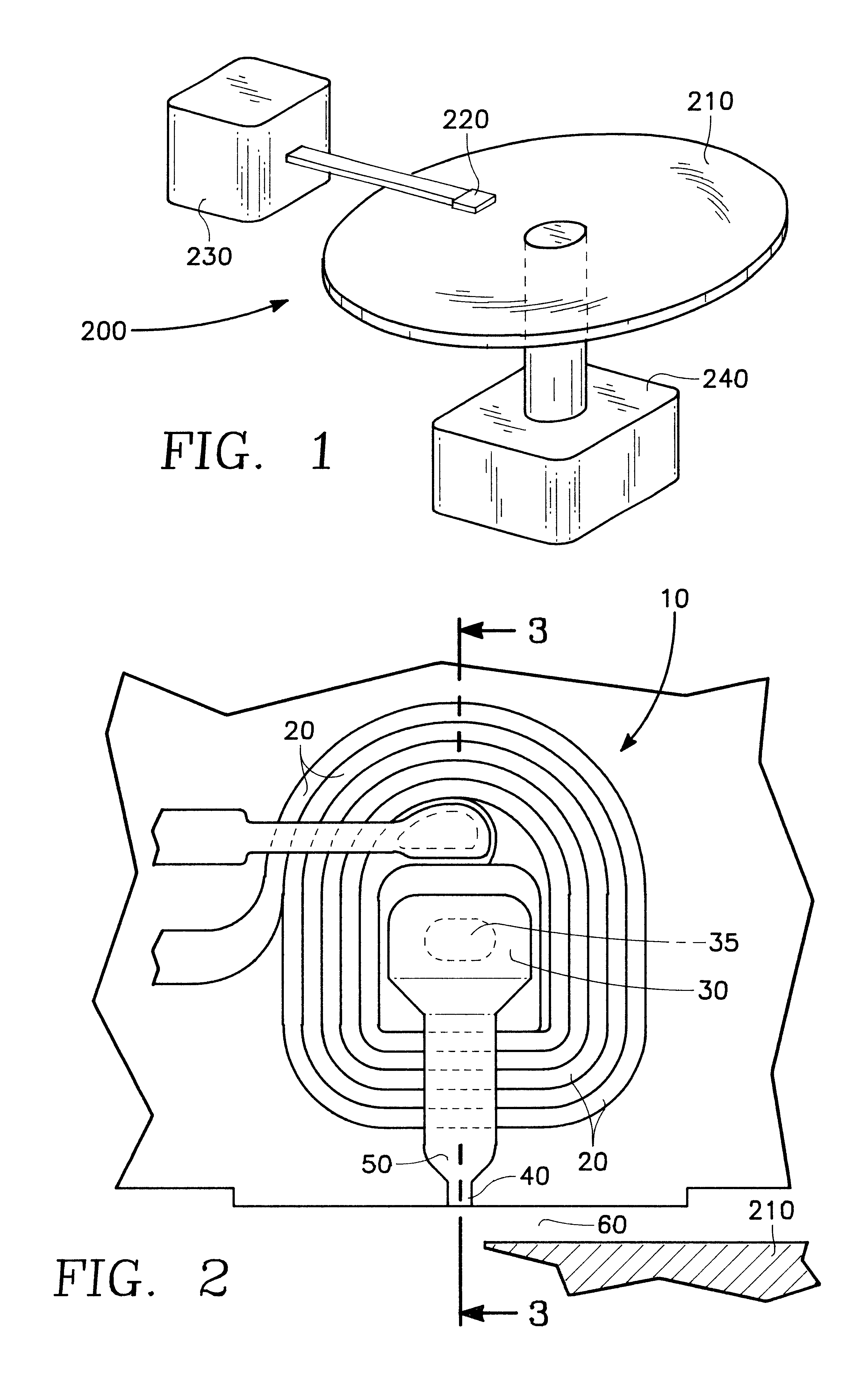

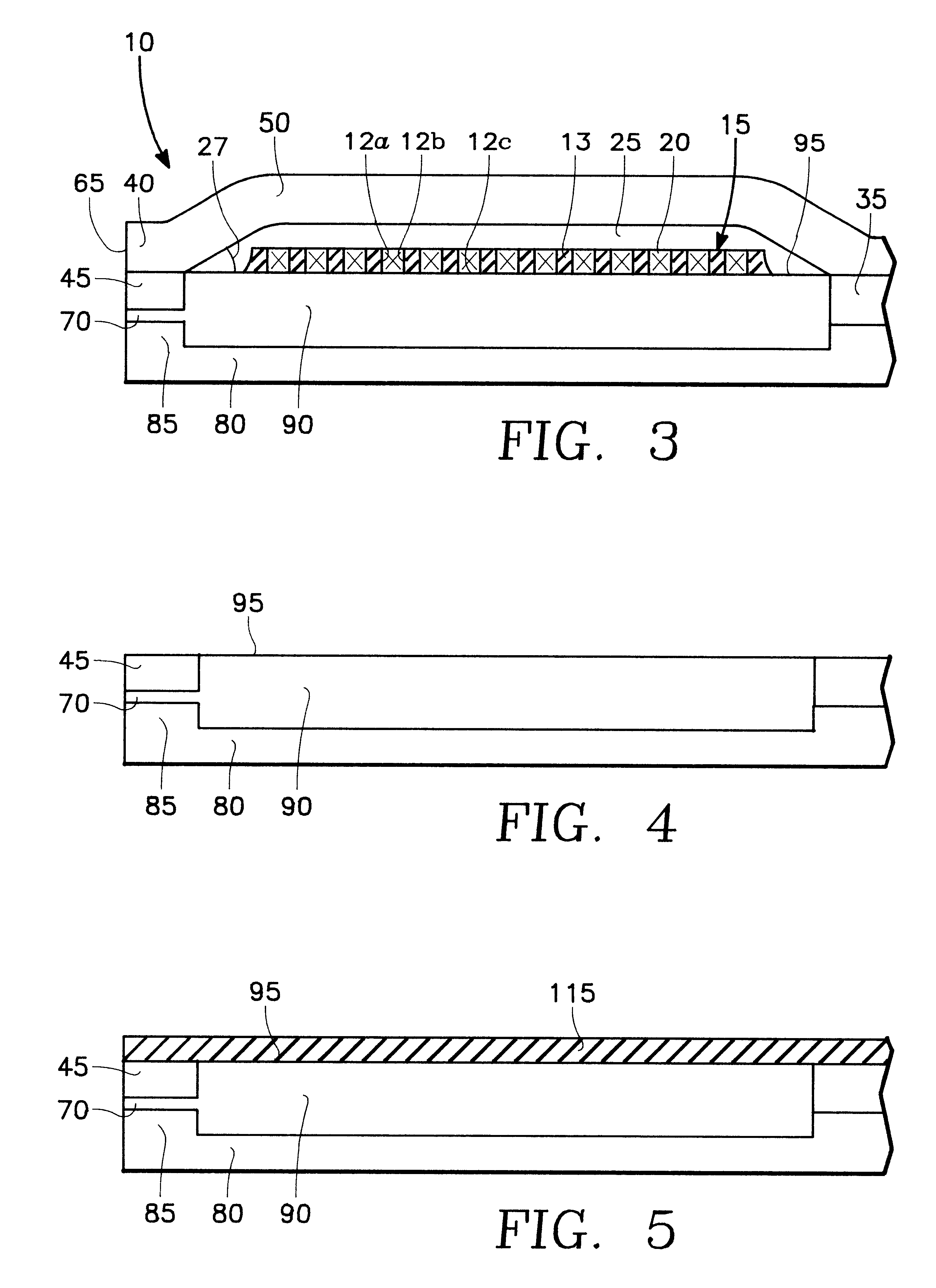

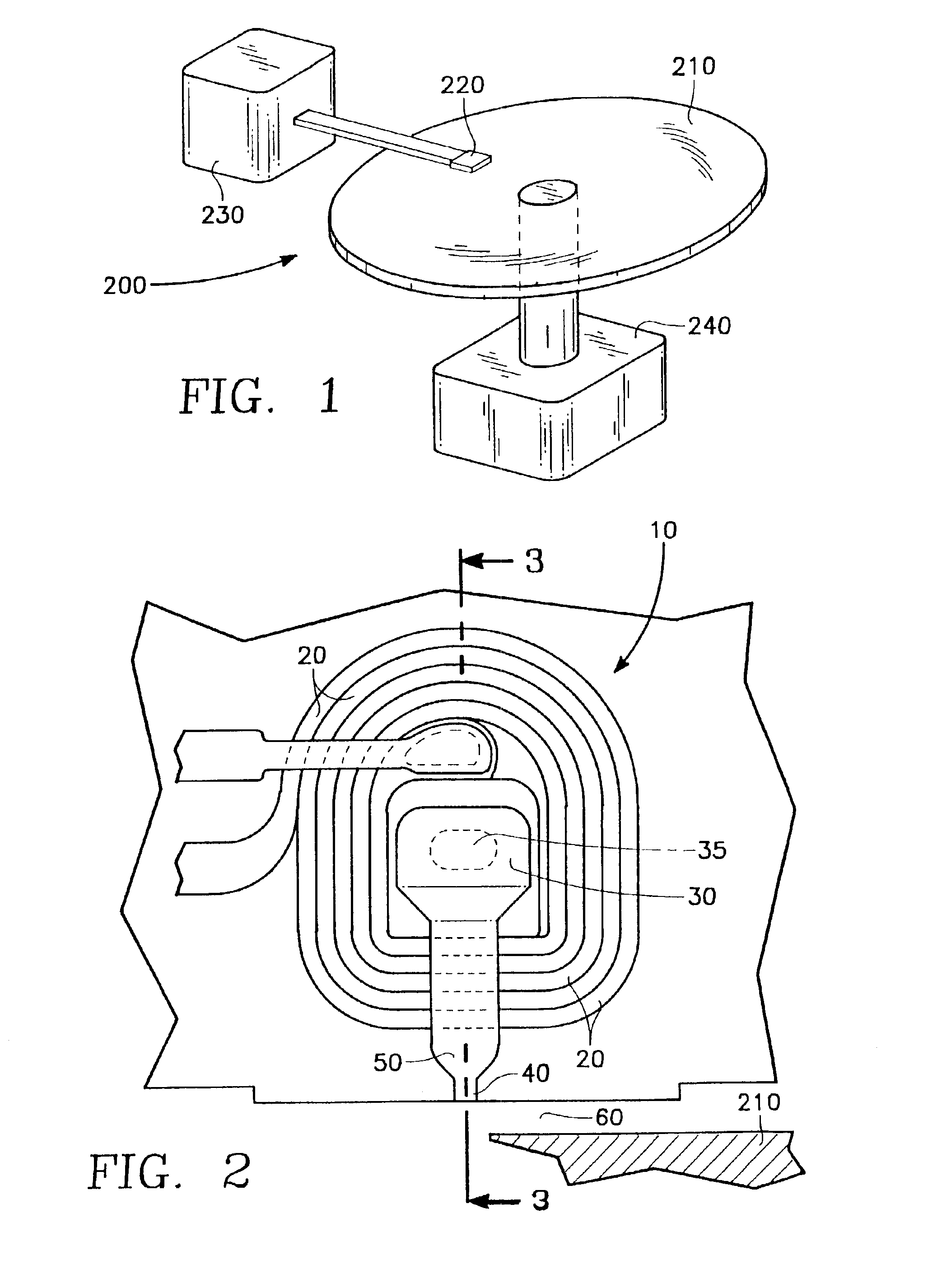

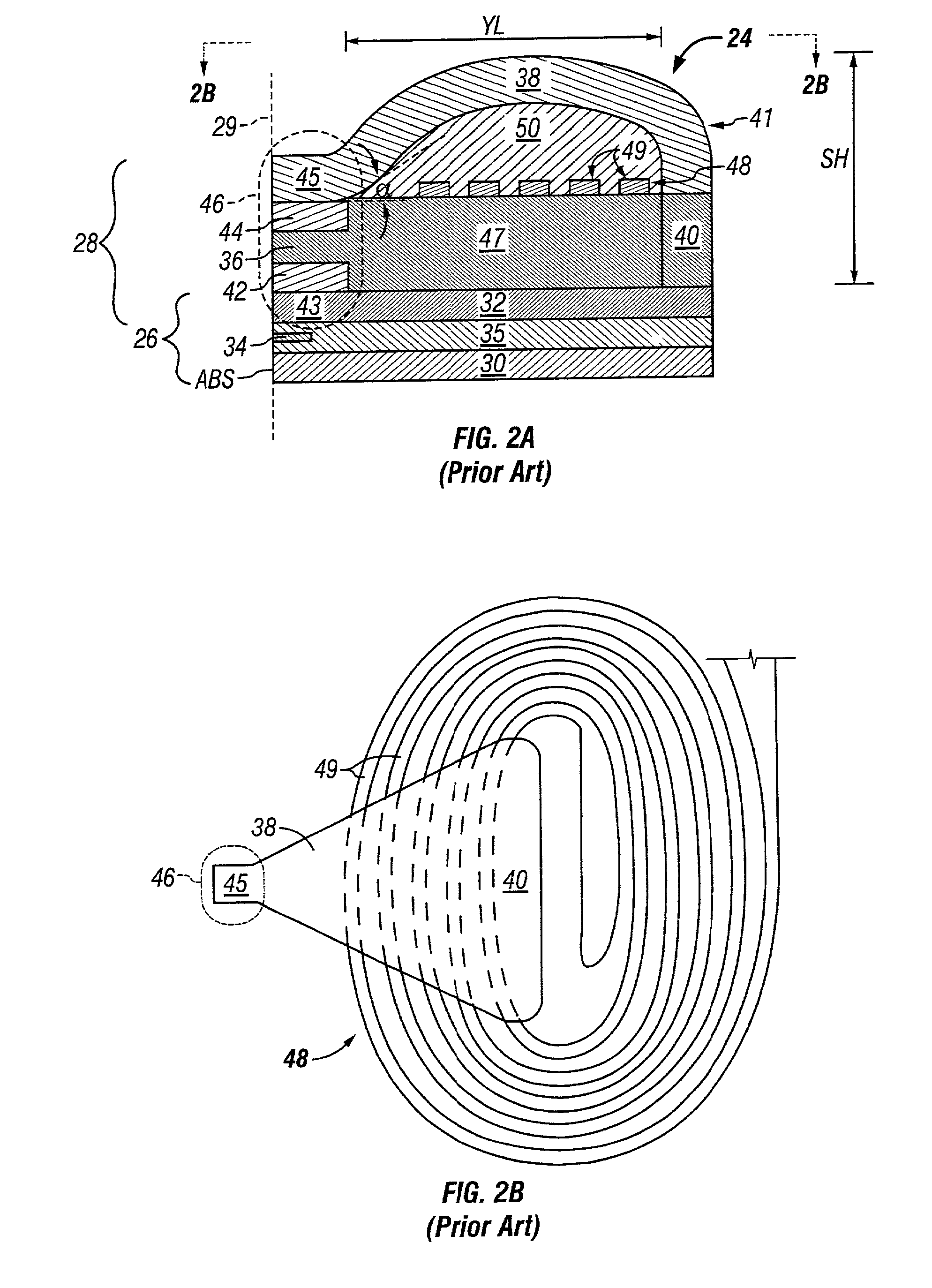

Inductive writer with flat top pole and pedestal defined zero throat

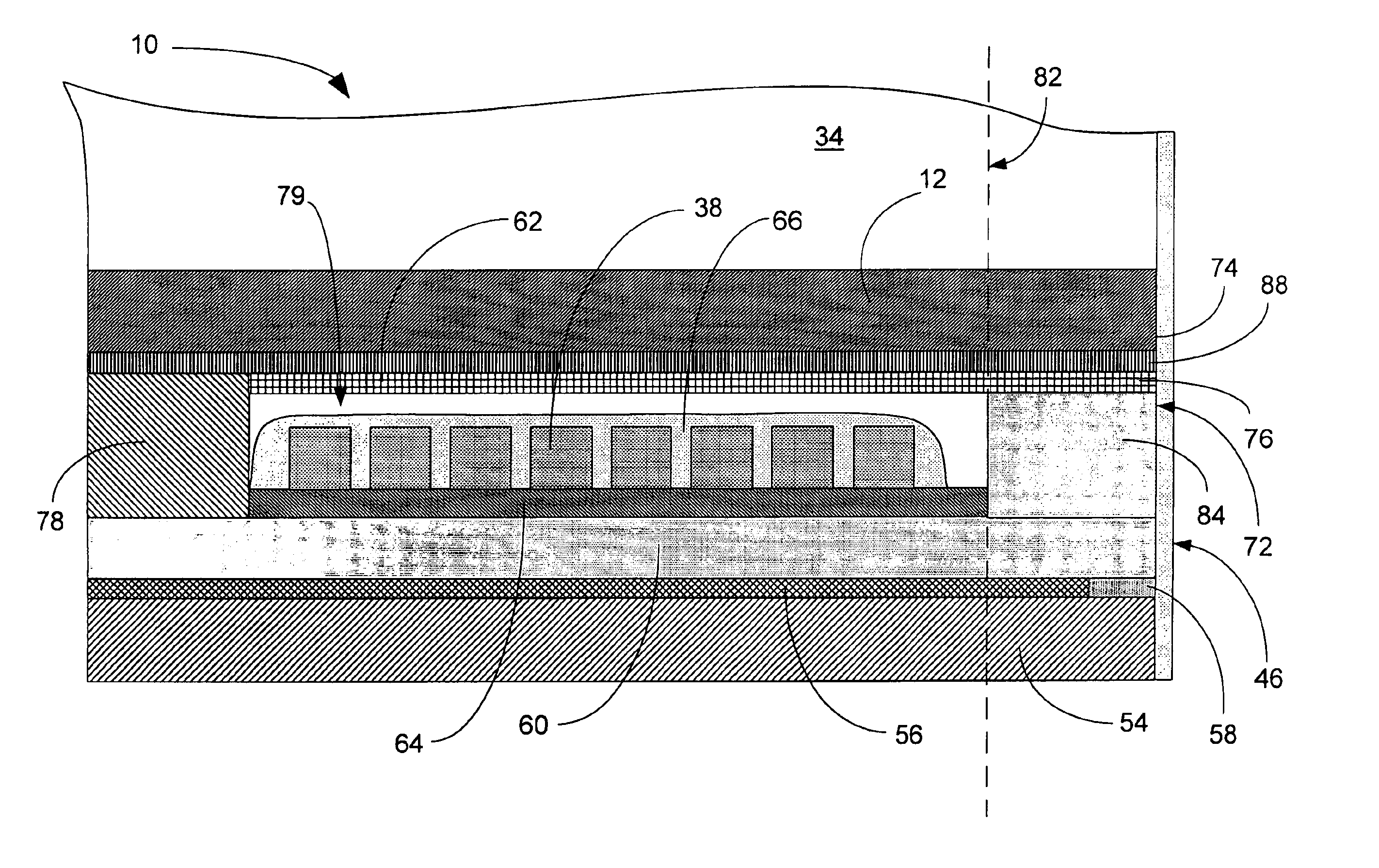

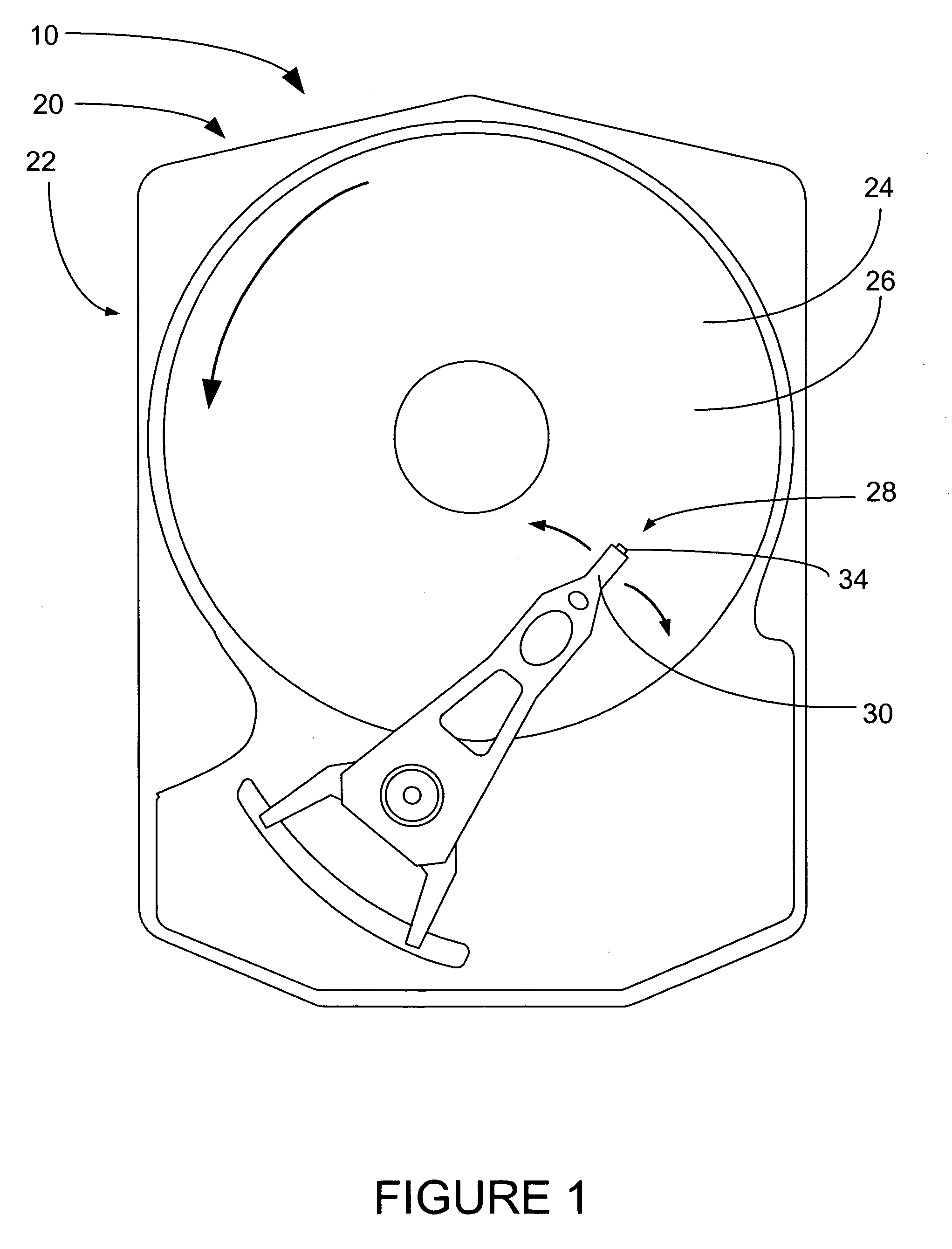

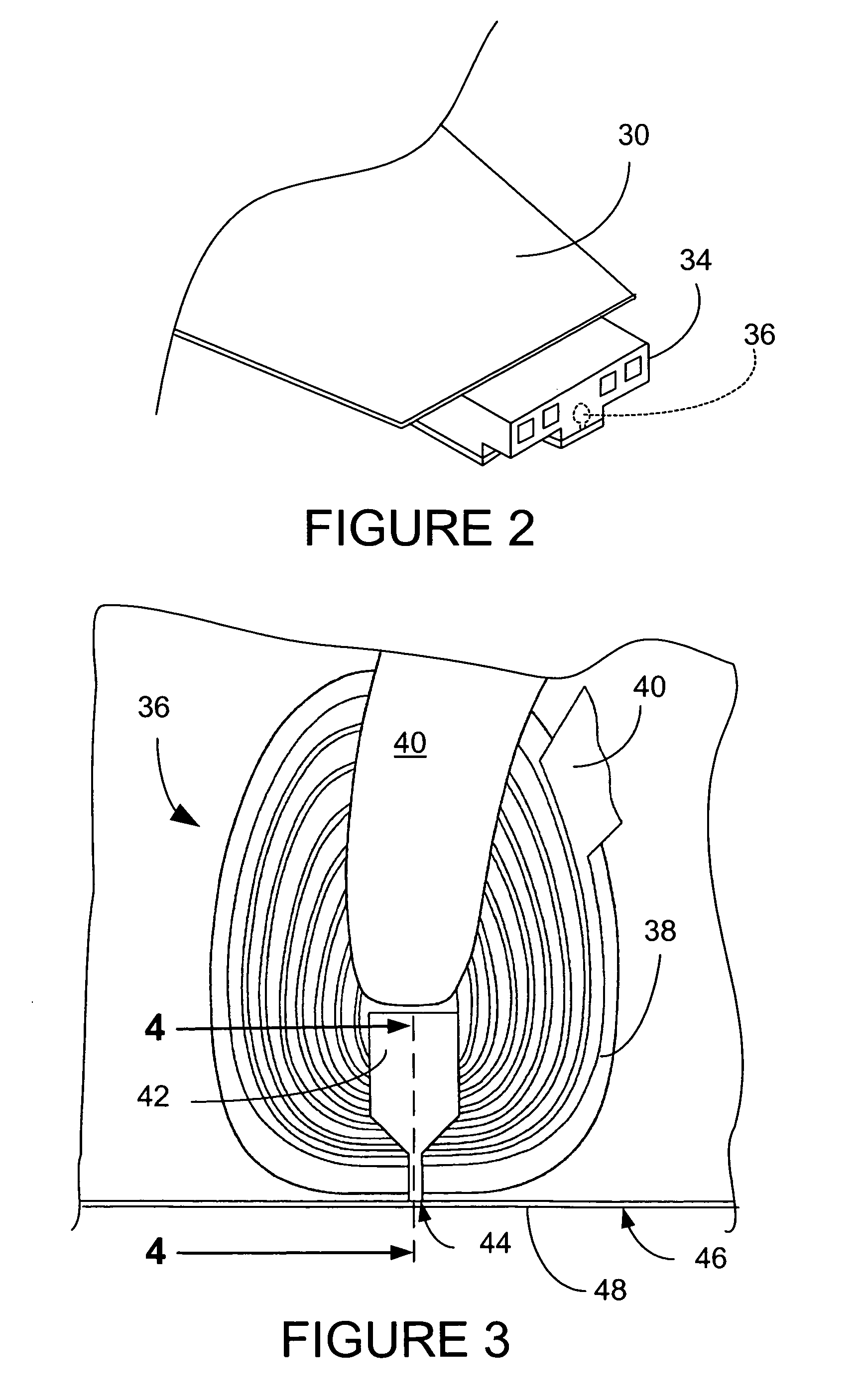

InactiveUS6870712B2Critical dimensions are more easily controlledEasy to controlElectrical transducersHeads using thin filmsEngineeringElectrical and Electronics engineering

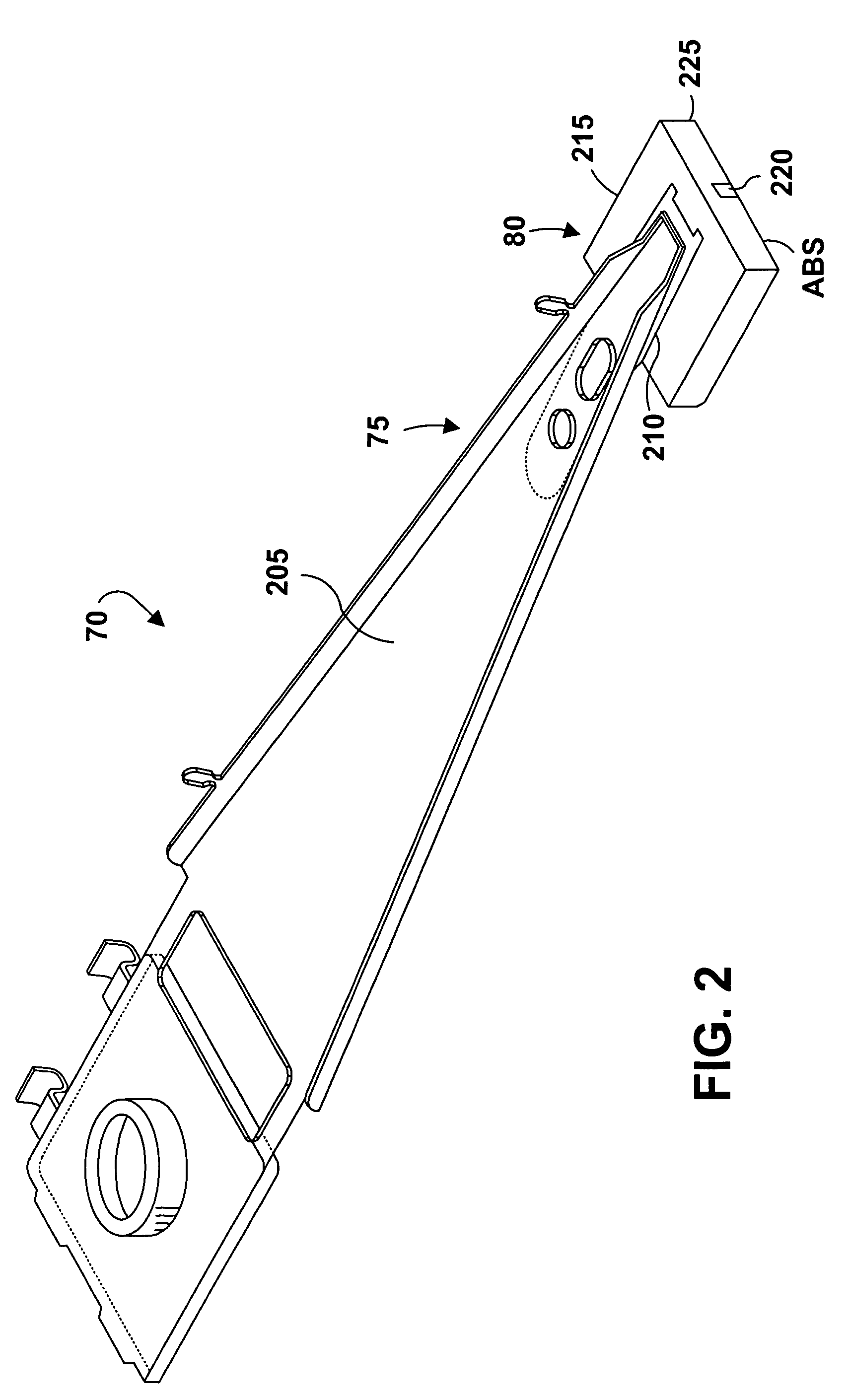

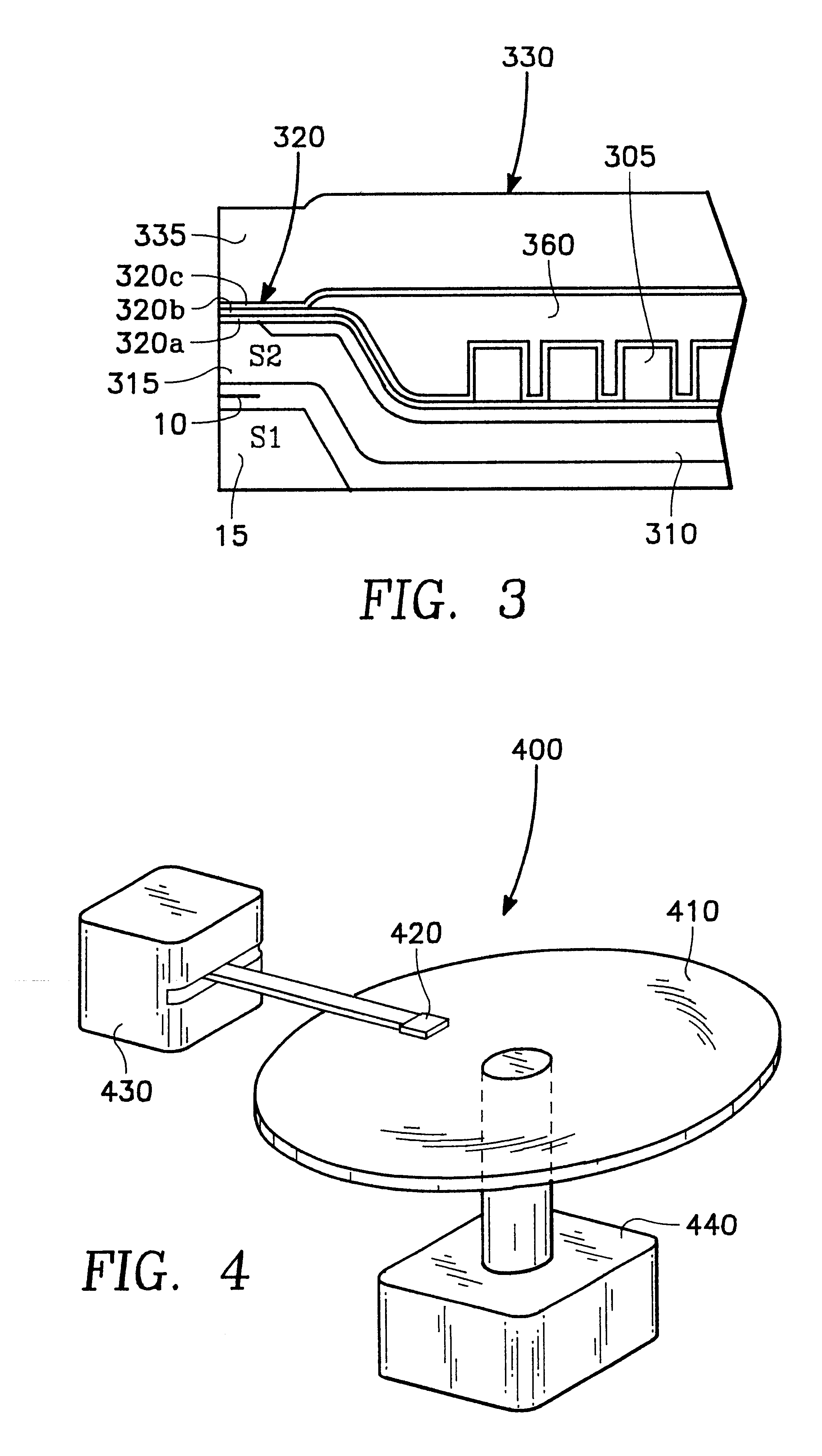

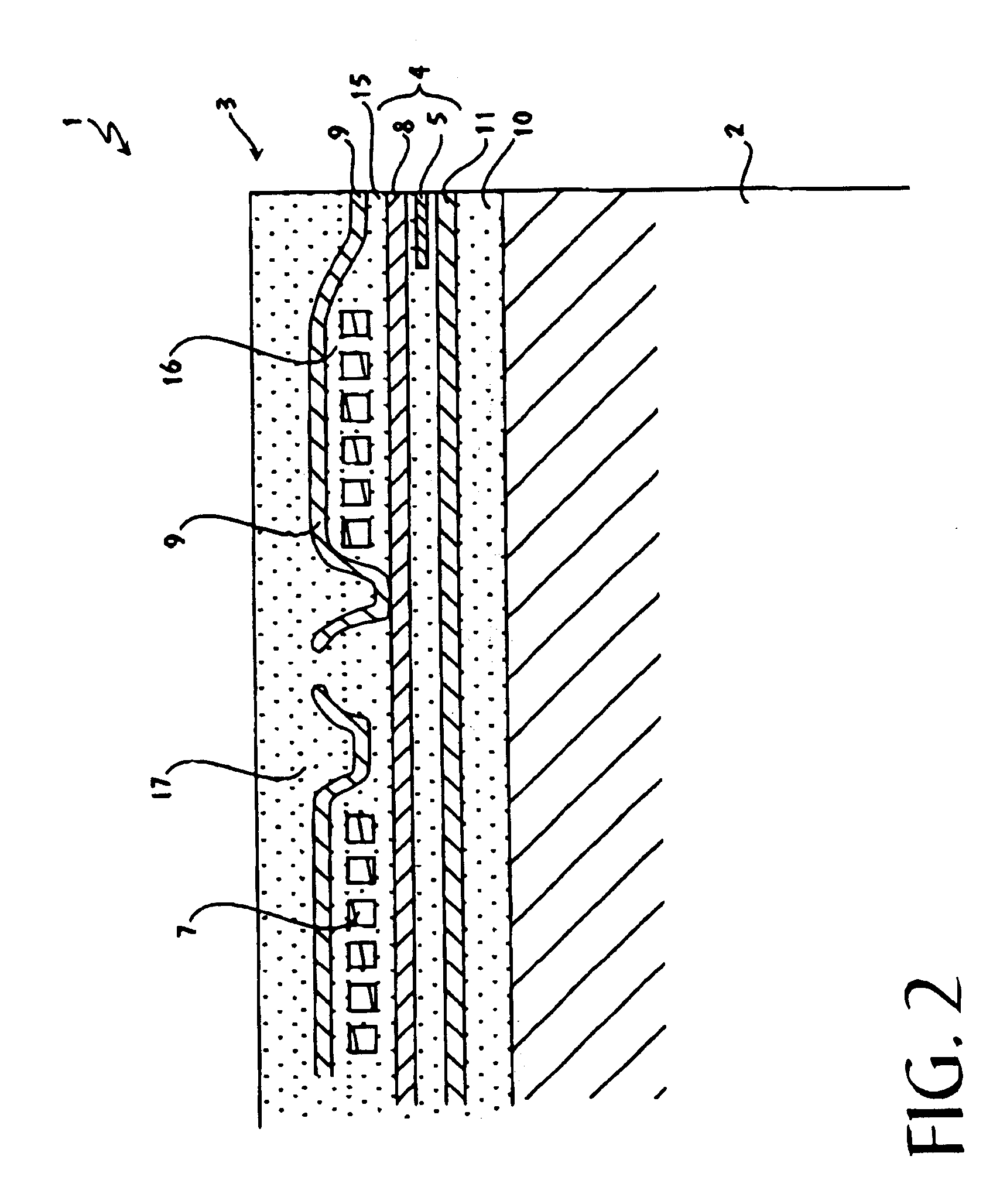

A disk drive write head (10) having a bottom pole (60), a first insulation layer (64) formed on the bottom pole (60), a coil (38) formed on the first insulation layer (64), a second insulation layer (66) formed on the coil (38), a write gap layer (76) formed on the second insulation layer (66), and a top pole (12) formed on the write gap layer (76), where the top pole (12) is substantially flat.A second embodiment (100) is described which is produced by a damascene process.

Owner:WESTERN DIGITAL TECH INC

Low resistance coil structure for high speed writer

InactiveUS6333830B2Lower coil resistanceReduce dissipationConstruction of head windingsHeads using thin filmsElectrical conductorLower pole

The present invention provides a thin film write head having an upper and lower pole structures and conductor turns forming a winding for generating magnetic flux. The conductor is formed with a non-planar top surface. The winding of the present invention may be formed of lower and upper turns. The upper turns may be formed with a non-planar top surface, a non-planar bottom surface, or both. It is preferred that the bottom surface of the upper conductor turns be coherent with the non-planar top surface of the lower conductor turns. The non-planar top surface may be formed by removing corners formed during deposition between a generally planar top surface and abutting side walls. The corners may be removed by ion milling to form the non-planar top surface. The conductor may be copper with the non-planar top surface having sloping facets. The thin film write head of the present invention may be utilized to provide an improved data storage and retrieval apparatus. The preferred embodiment provides reduced coil resistance thereby reducing Johnson Thermal Noise and power dissipation. It also allows for reduced yoke length and reduced stack height while providing low apex angles to expand and improve yoke material deposition thereby improving head response and operational frequency.

Owner:WESTERN DIGITAL TECH INC

Write head having a recessed, magnetic adjunct pole formed atop a main pole, and method of making the same

InactiveUS6906894B2Enhanced magnetic write fieldEliminate the problemConstruction of head windingsElectrical transducersSputteringEngineering

A read / write head and method of making the same are used in a data storage system, such as a disk drive, for perpendicular magnetic recording of data. The head employs a two-layer pole design with a main pole made of sputtered high moment magnetic material, and an adjunct pole made of electroplated soft magnetic film. The main pole is used to write data onto the medium, and is formed over the write coil. The adjunct pole is substantially recessed from the air bearing surface and is formed over the main pole. The present head design significantly enhances the magnetic write field, and substantially reduces side-writing that result in accidental erasure of data in adjacent tracks on the magnetic recording medium.

Owner:WESTERN DIGITAL TECH INC

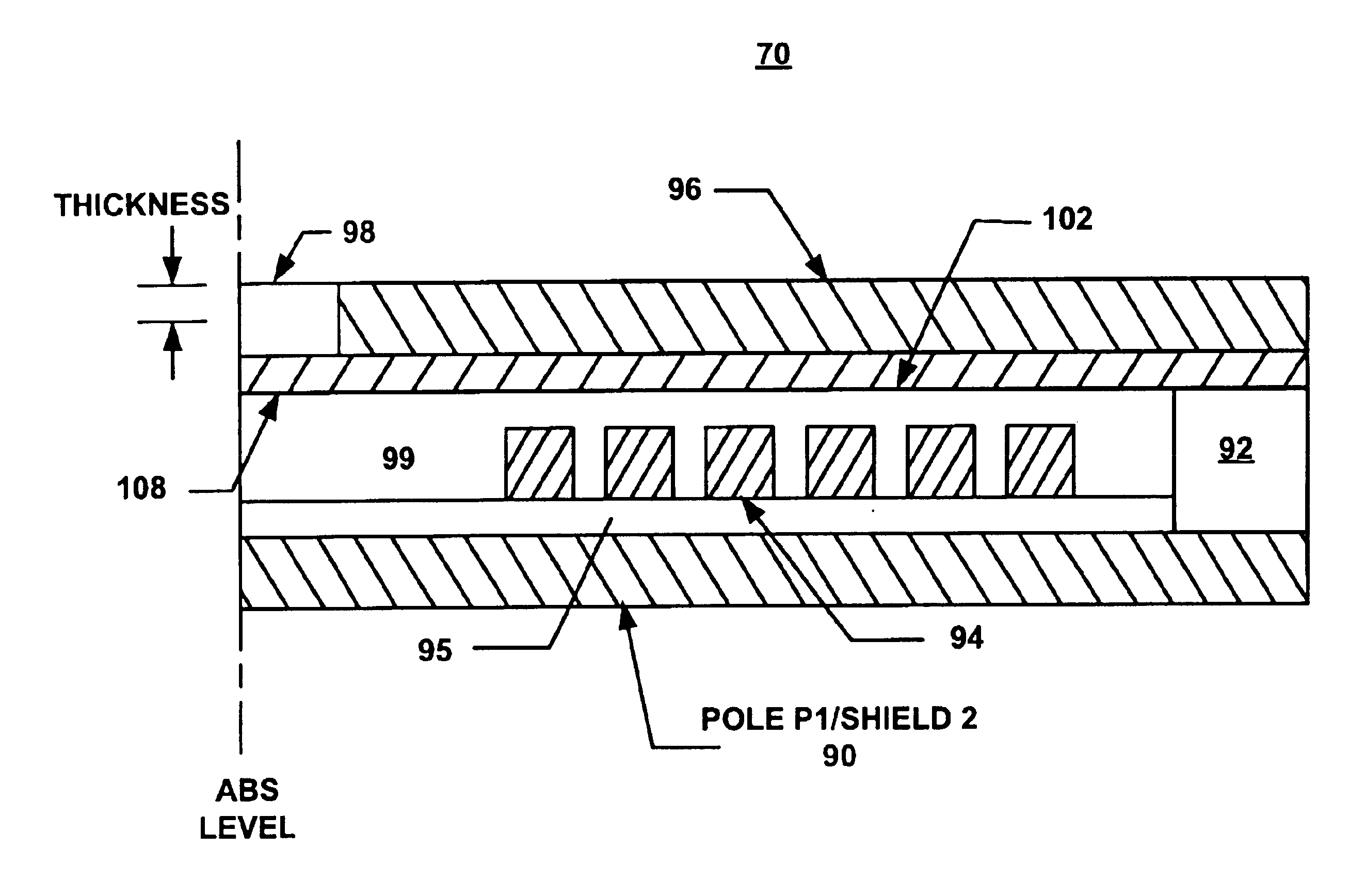

Thin film writer with multiplayer write gap

InactiveUS6724569B1Easy to controlControl performanceConstruction of head windingsManufacture head surfaceElectrical conductorLower pole

Embodiments in accordance with the thin film write head of the present invention have a lower pole structure, an upper pole structure, and a multilayer write gap extending from an air bearing surface between the upper and lower pole structures. In preferred embodiments, the write gap comprises at least two of: (a) a first layer covering a lower pole tip portion of the lower pole structure, (b) a second layer covering turns of a semiconductor winding, or (c) a third layer covering a winding insulation stack. In more preferred embodiments, the write gap is formed of the first, the second, and the third write gap layers. An advantage of a write head with a multilayer write gap is that it allows better control of write gap thickness. As such, loss of write gap thickness can be compensated for by deposition of the second write gap layers, or by deposition of the third write gap layer. Some embodiments have one or more additional advantages in providing increased corrosion prevention, improving the integrity of conductor insulation, and / or improving the top pole magnetic material characteristics.

Owner:WESTERN DIGITAL TECH INC

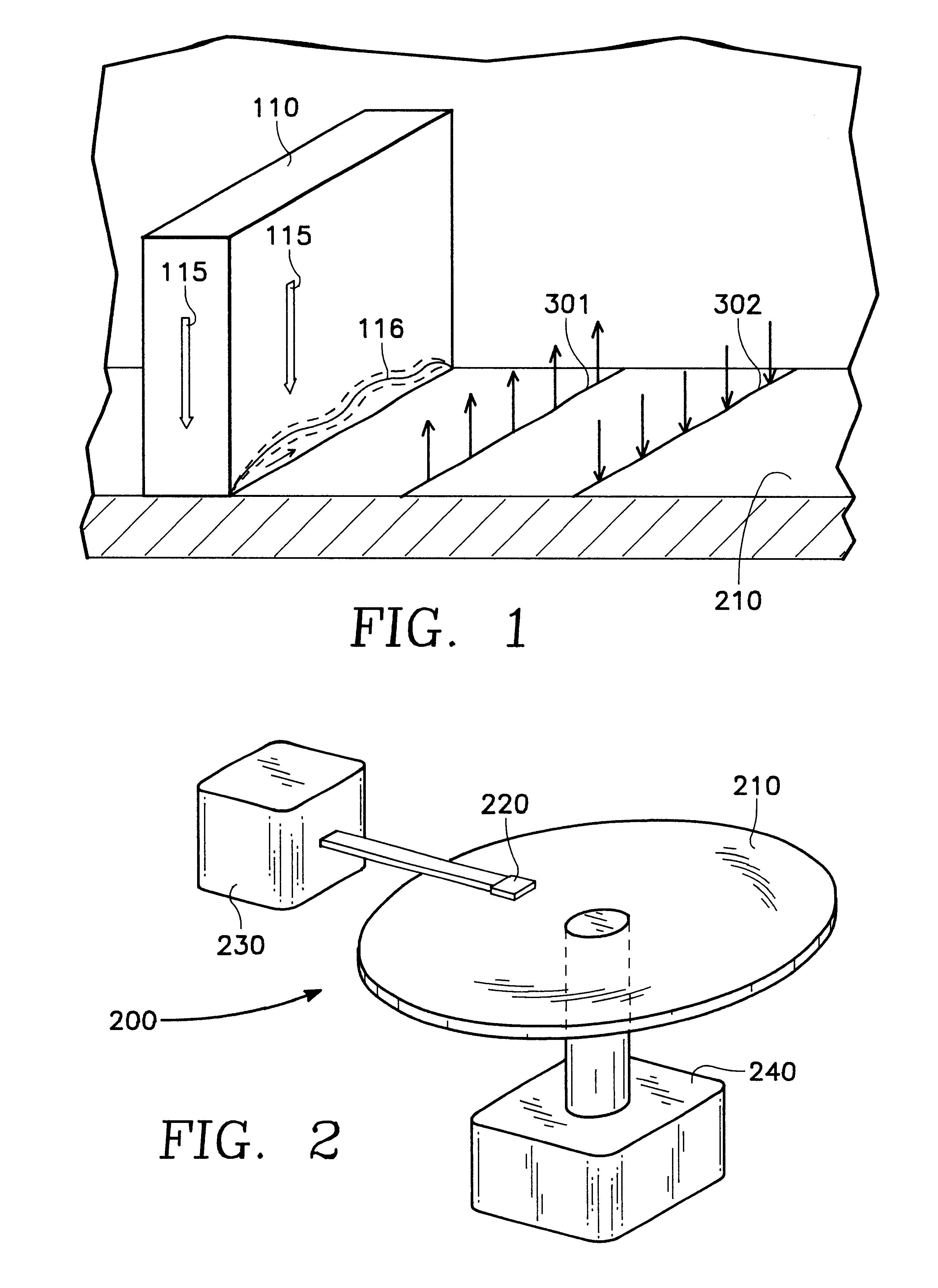

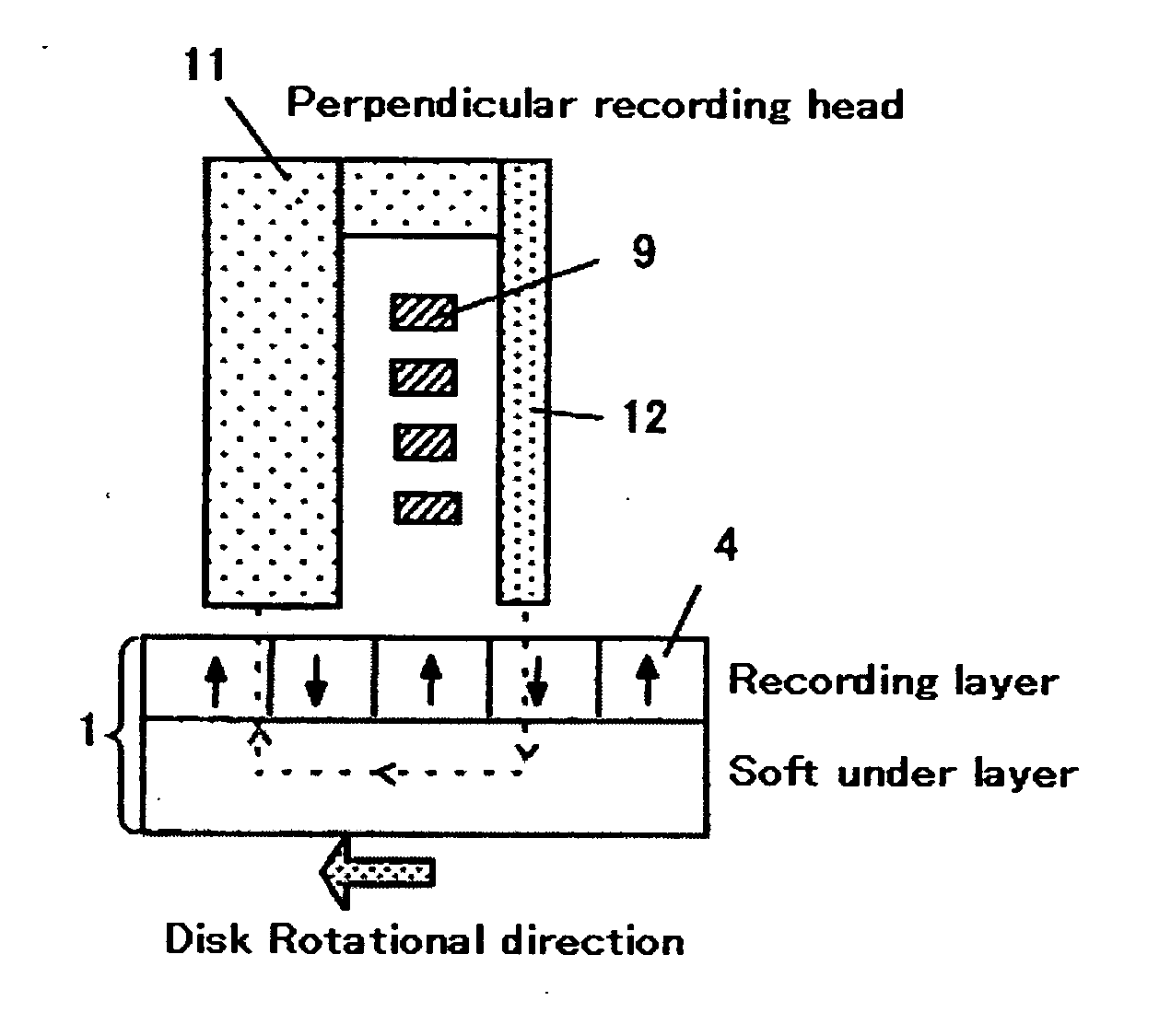

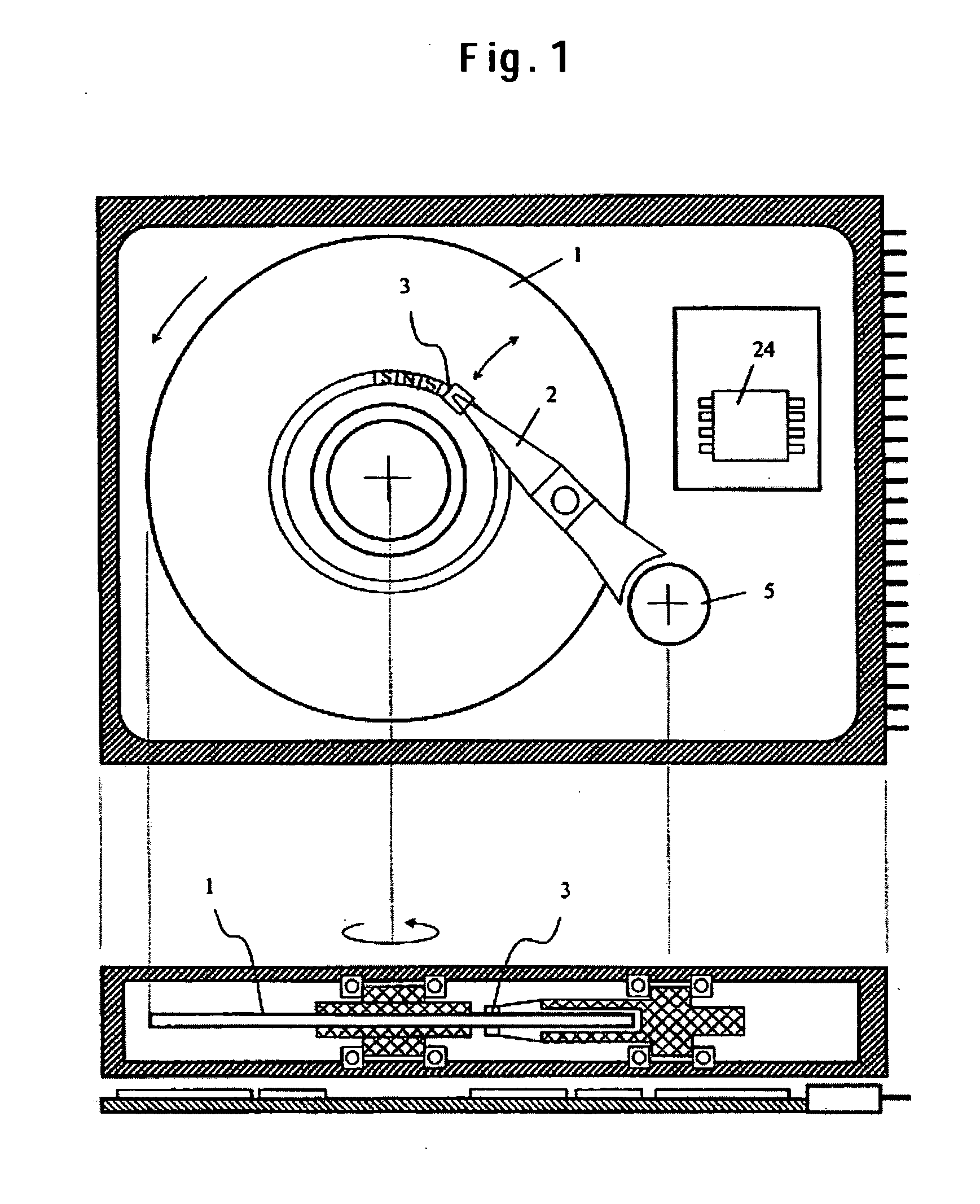

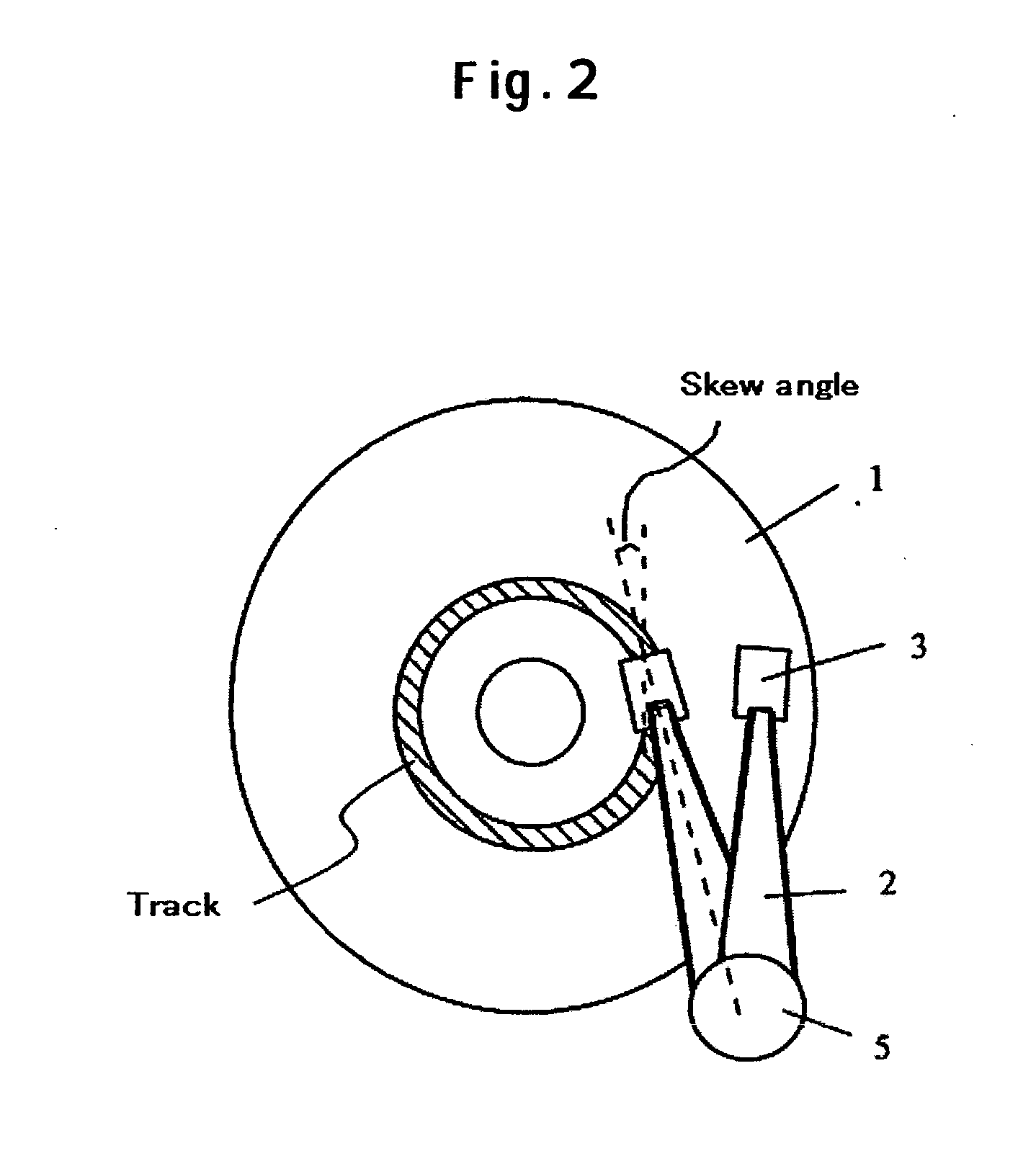

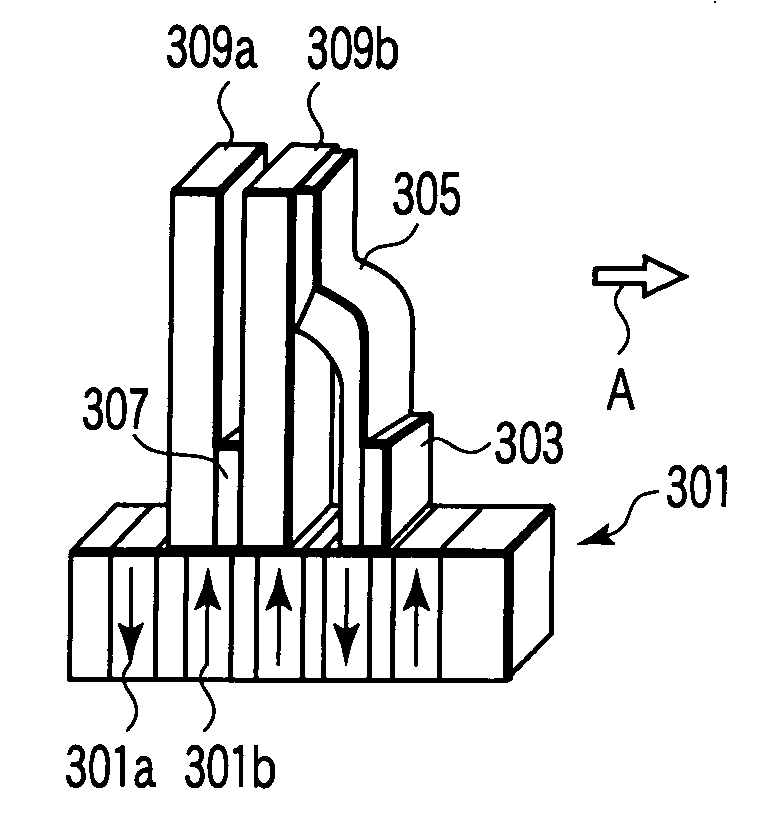

Magnetic recording head for perpendicular recording, fabrication process, and magnetic disk storage apparatus mounting the magnetic head

InactiveUS20050141137A1Improving recording magnetic field gradientIncreasing the thicknessManufacture head surfaceHeads using thin filmsMagnetic field gradientMagnetic media

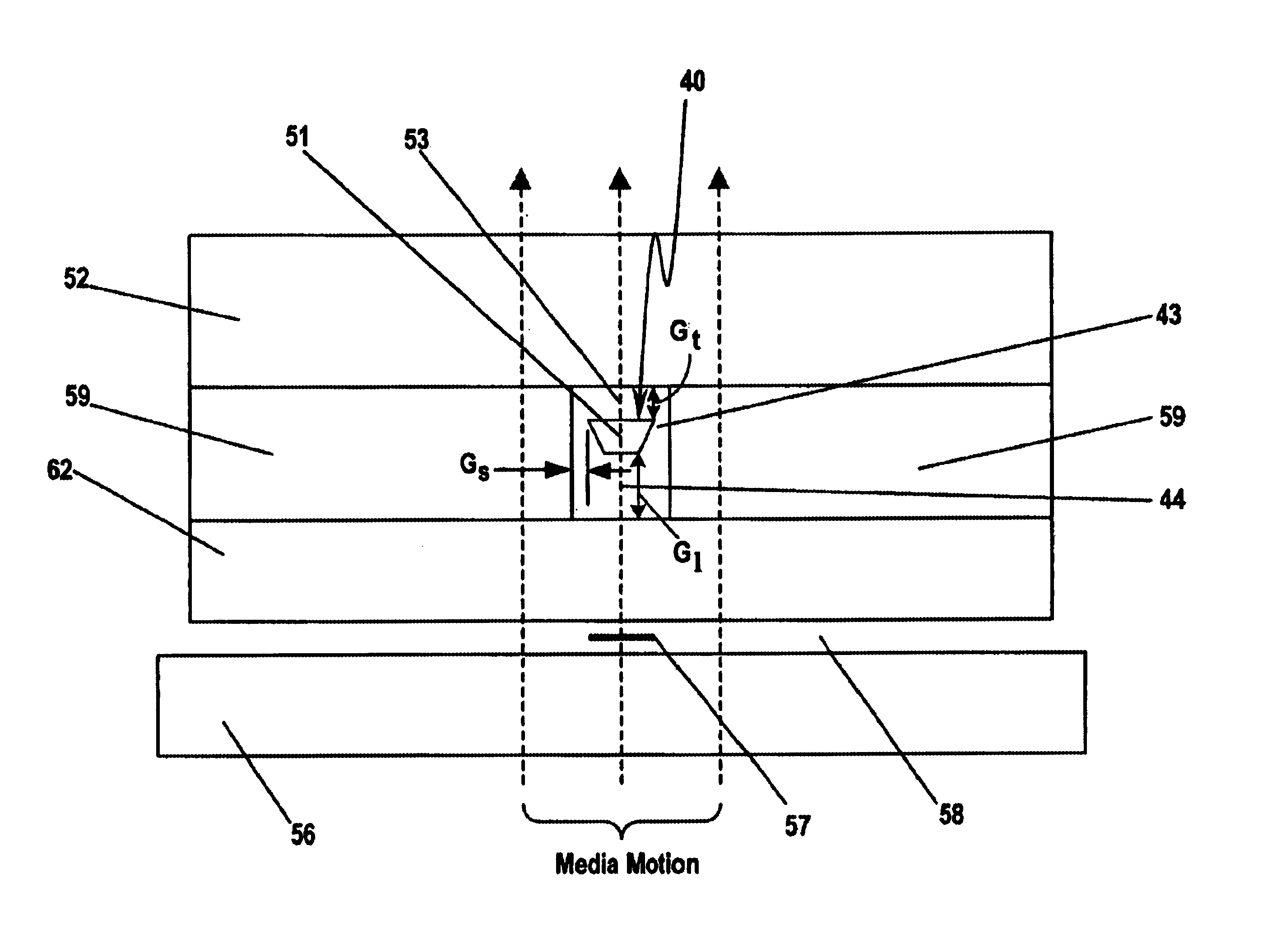

Embodiments of the invention provide a perpendicular magnetic writing head with a suppressed effective track width to be written on a magnetic medium while increasing writing magnetic field gradient. In one embodiment a trailing side shield is disposed by way of a gap film to a main pole of a perpendicular writing magnetic head. A gap distance (Gt) on a trailing side of the main pole and a gap distance (Gs) on a lateral side of the main pole is defined as Gt<Gt, and a thickness (Gd) from an air bearing surface of the shield is made equal to or less than a throat height. Alternatively, the thickness of Gd on the side of the main pole is reduced to less than that on the trailing side of the main pole. Further, for preventing defoliation of the shield upon fabrication of the air bearing surface, a thickness for a portion away from the main pole is increased.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

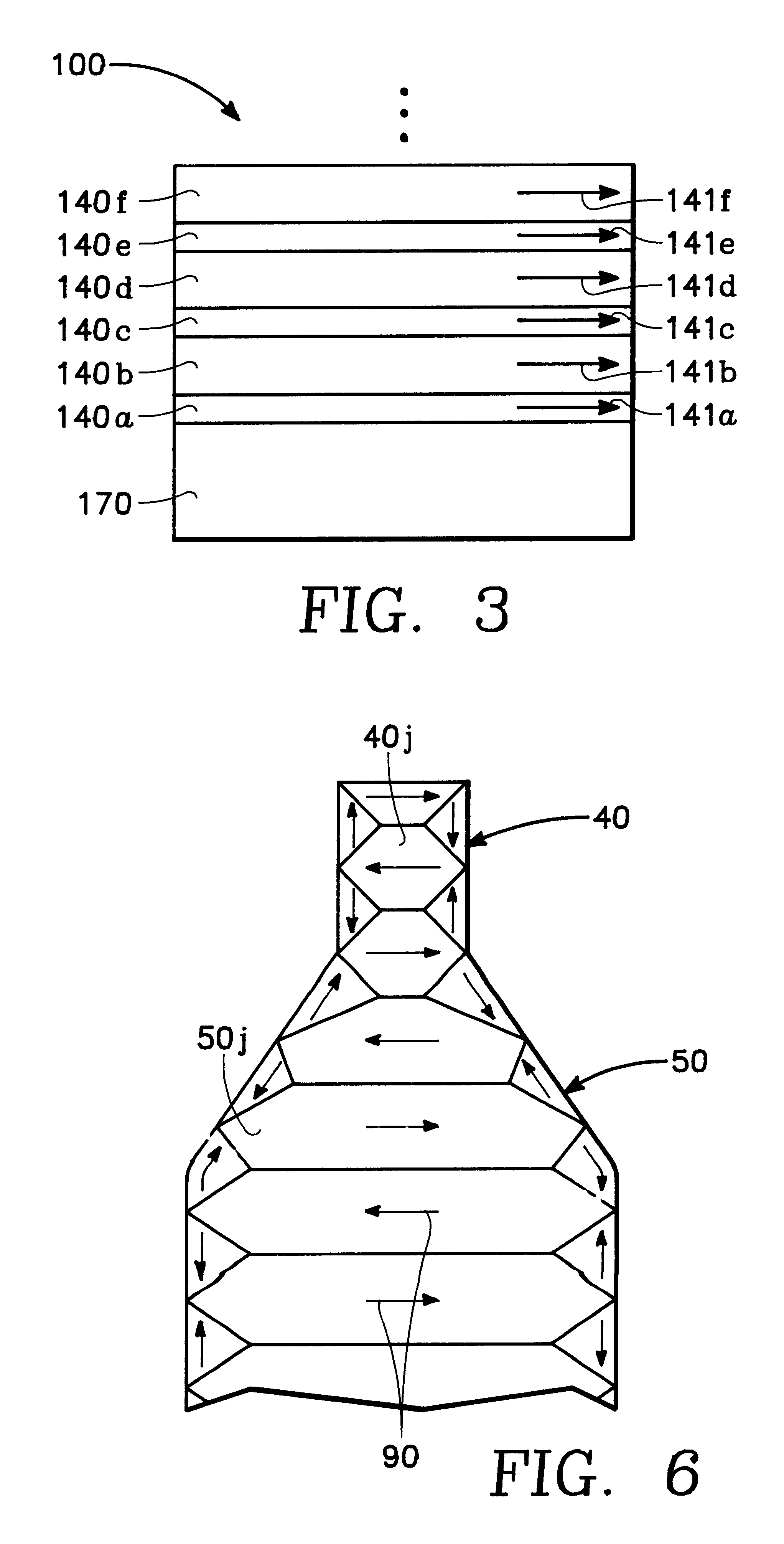

Double winding twin coil for thin-film head writer

InactiveUS6861937B1Small yoke lengthImprove reliabilityConstruction of head windingsManufacture head surfaceElectricityCopper

An enhanced inductive coil design for use in data storage magnetic disk drives with areal density over 35 Gb / in2, features a double wound twin coil that is able to achieve a yoke length of 15 μm or less by reducing the insulation spacing between the two coils. The coil further presents improved reliability by reducing the possibility of occurrence of electrical shorting. The coil is made by forming two interleafing conductors on the same layer with a demesne process. A tri-level process is implemented in the layout of the first conductor to ensure that the coil width and spacing are uniform and even, in order for the second conductor to be wound therebetween. A conformal dielectric layer of approximately 0.1 to 0.2 μm in thickness is deposited between the two conductors and serves as insulation. The two conductors are formed by a copper seed layer plating process that eliminates potential damage to the conductors during production.

Owner:WESTERN DIGITAL TECH INC

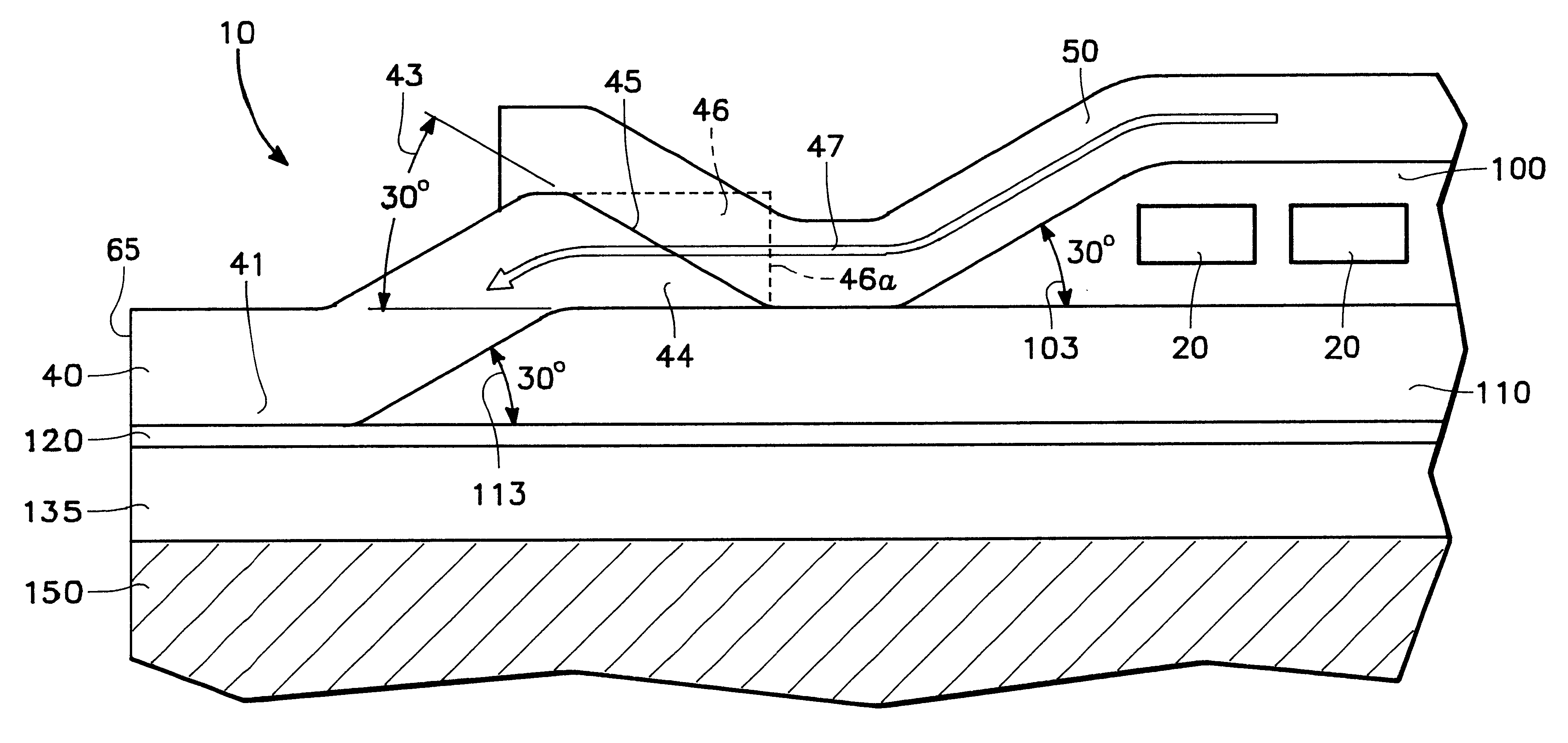

Thin film write head with improved yoke to pole stitch

InactiveUS6490125B1Improve magnetic propertiesWithout sacrificing yoke material property and flux flowConstruction of head windingsHeads using thin filmsAir bearing surfaceEngineering

The present invention provides an write head having an improved upper pole tip-to-yoke stitch. The upper pole tip is formed having an open faced sloping surface at an end of the pole tip distal from an air bearing surface. Preferably the angle of the sloping surface is about 30 degrees. The sloping surface provides a shallow angle for depositing the yoke material over which improves the magnetic properties of the yoke material, particularly in the case of sputtered high moment magnetic materials, and improves the flux flow path through the yoke. As such, the present invention allows conductor coils to be located closer to the air bearing surface without sacrificing yoke material properties and flux flow. The upper pole tip may have a back portion which is formed over an insulation layer located between a write gap layer and a conductor layer. Preferably the insulation layer and the conductor layer or layers are formed having sloping edges with shallow angles of about 30 degrees. An advantage of the present invention is that it allows the yoke and the yoke-to-pole tip stitch to be recessed from the air bearing surface, if desired, to prevent the yoke or yoke-to-pole stitch from inadvertently writing to the media.

Owner:WESTERN DIGITAL TECH INC

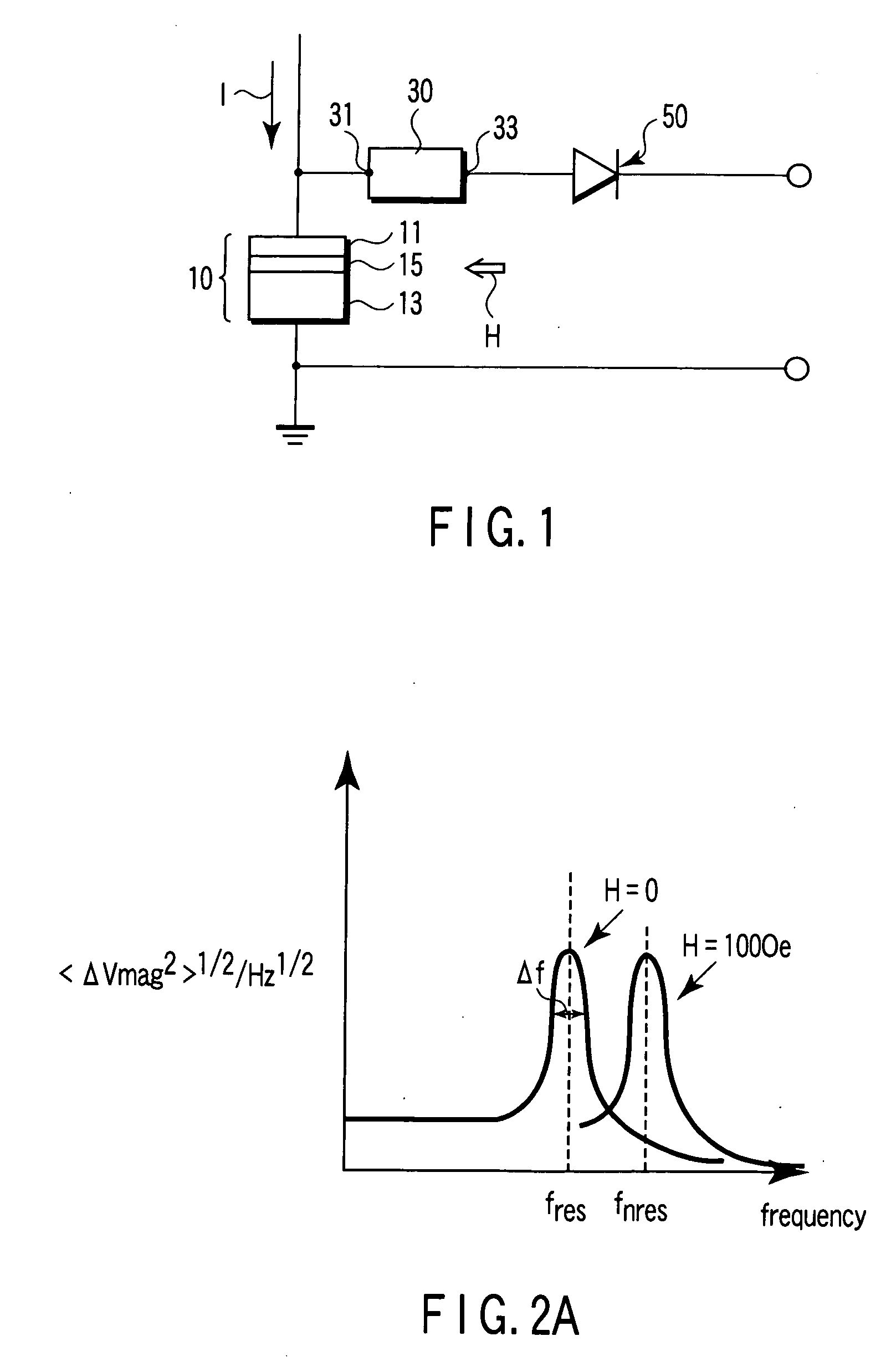

Magnetic sensor, magnetic field sensing method, semagnetic recording head, and magnetic memory device

ActiveUS20050219771A1Modification of read/write signalsNanomagnetismFrequency filteringMagnetization

A magnetic sensor includes a magnetoresistance element having a peak of a thermal fluctuation strength of magnetization under a magnetic field having a certain frequency, a frequency filter connected to the magnetoresistance element and having its transmittance decreased or increased in substantially the frequency of the magnetic field to output a signal corresponding substantially to the peak of the thermal fluctuation strength of magnetization, and a detector connected to the frequency filter to detect the magnetic field based on the signal of the frequency filter.

Owner:KK TOSHIBA

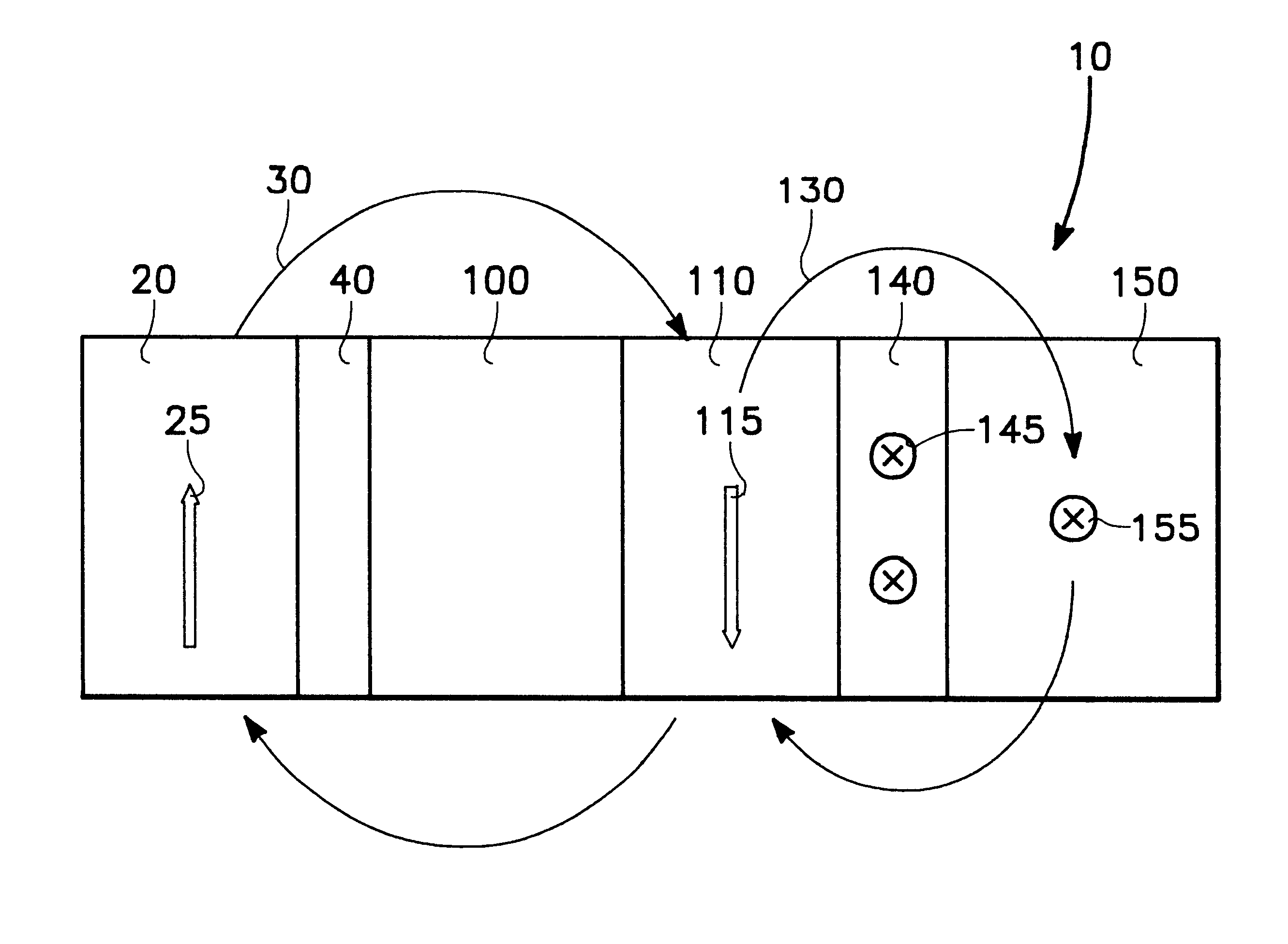

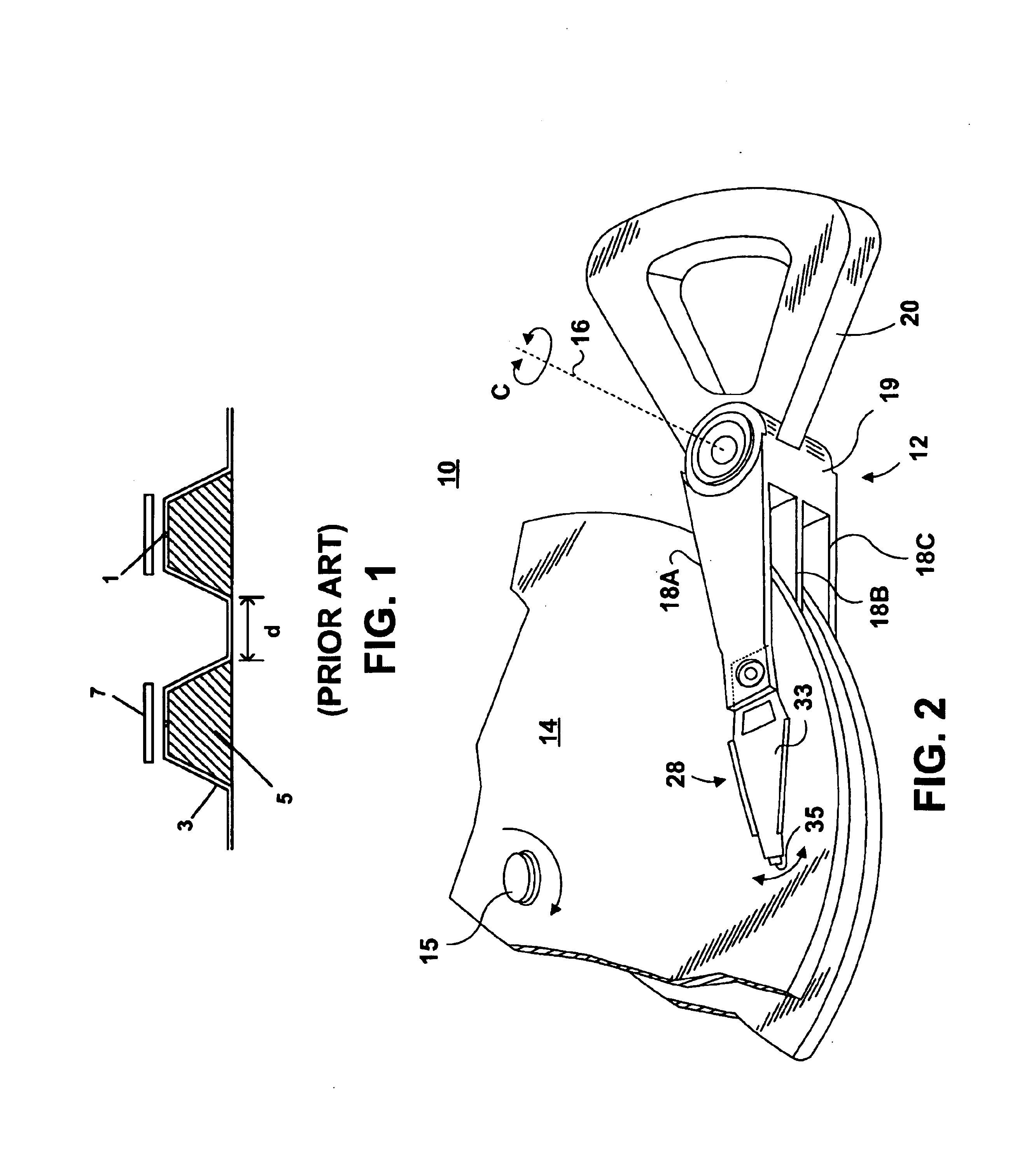

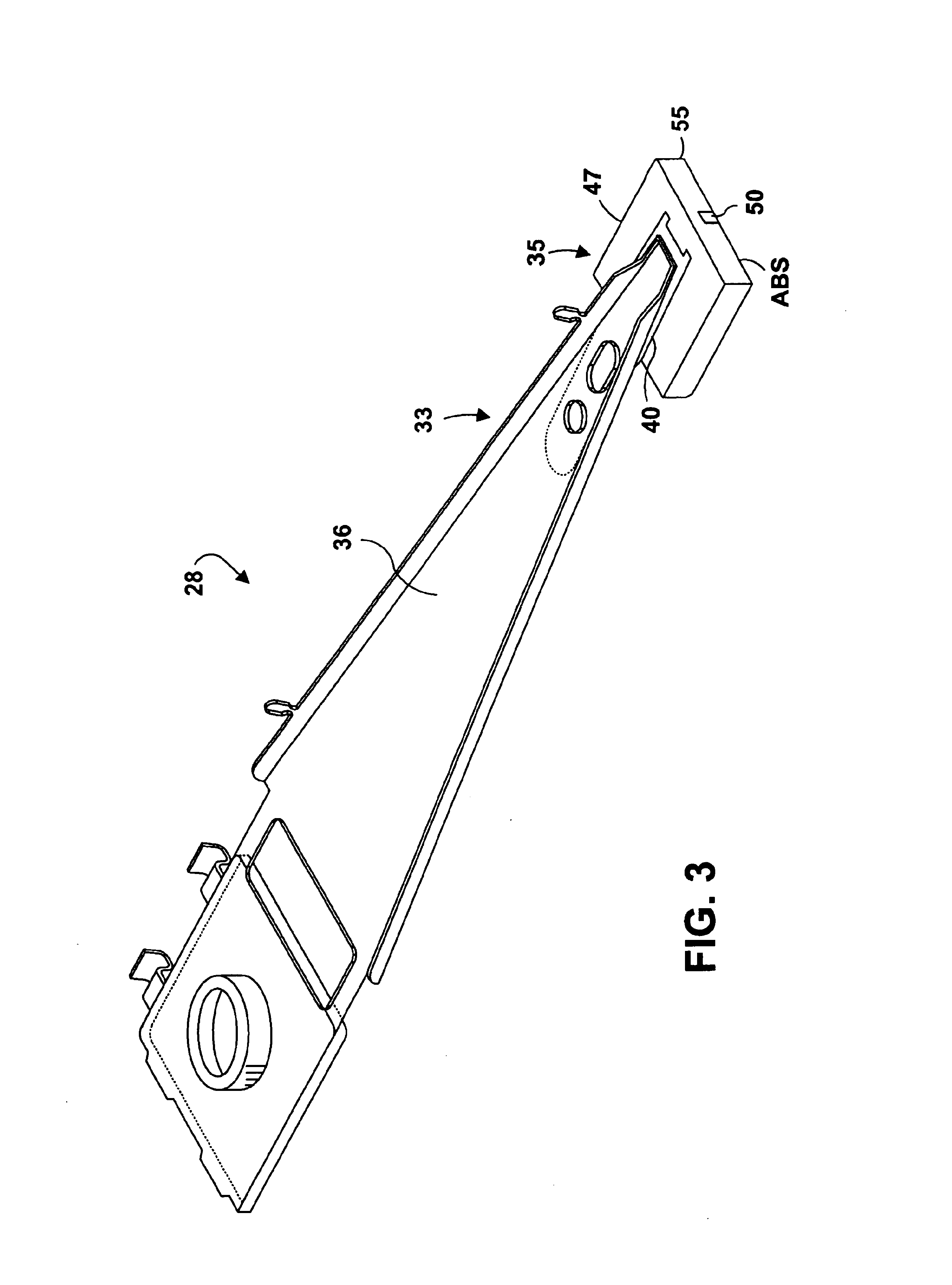

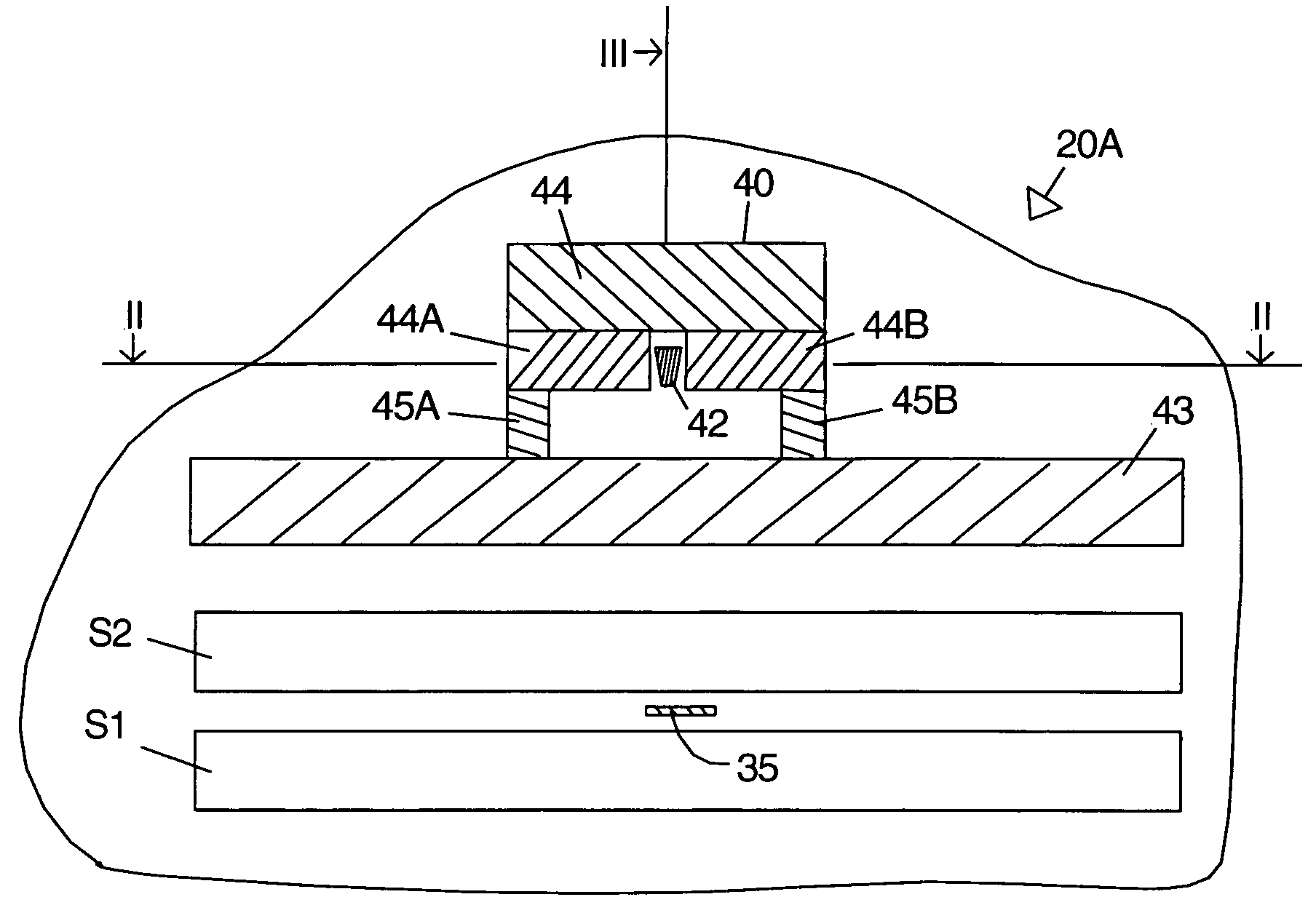

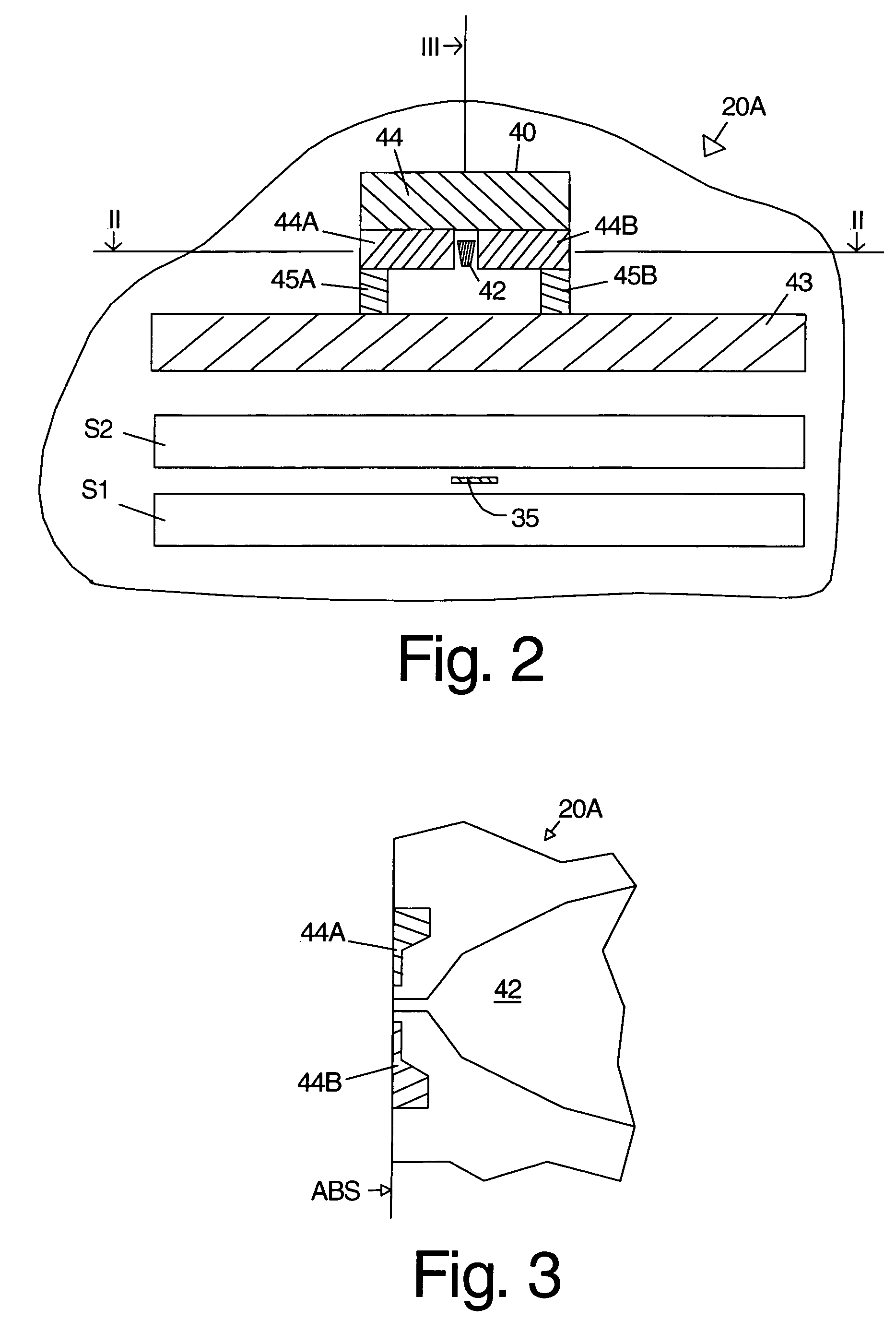

Head for perpendicular recording with reduced erasure

ActiveUS20050128637A1Reduced erasure fieldReducing erasure fieldHeads using thin filmsRecord information storageEngineeringPerpendicular media

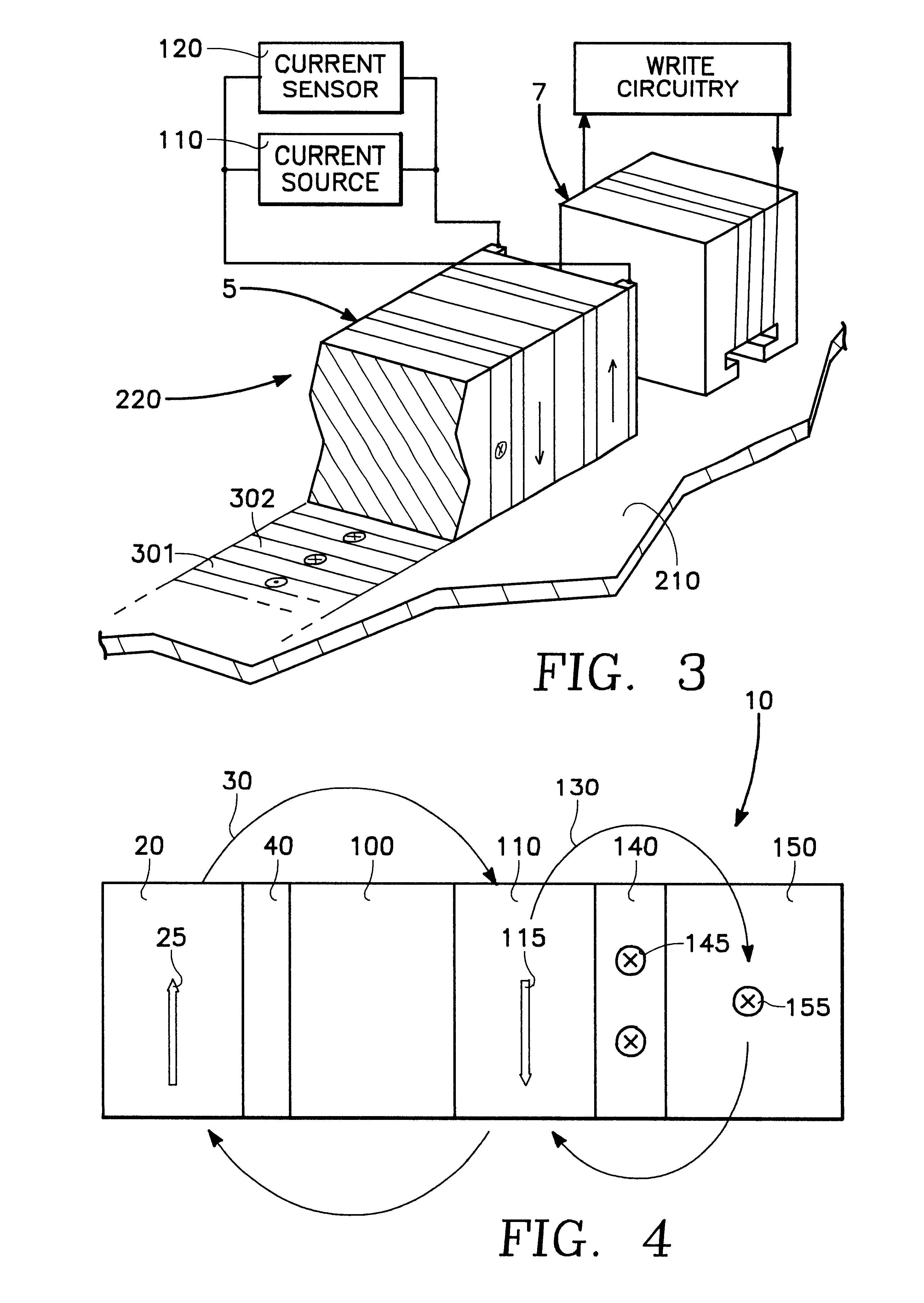

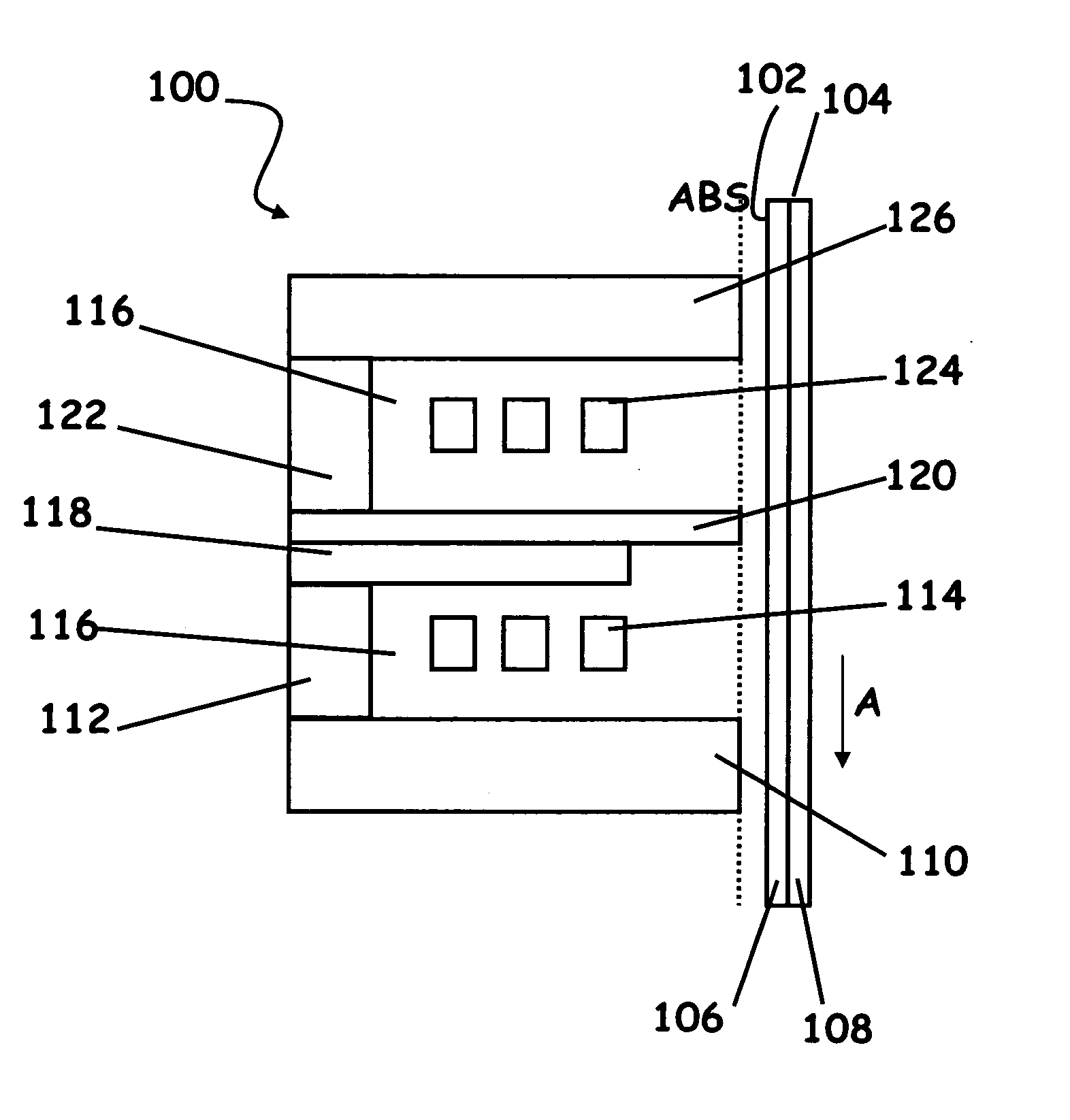

A perpendicular writer of the present invention comprises a main pole connected to two return poles and further includes one or more shorting shields thereby reducing erasure field on double layer perpendicular media. The perpendicular writer may include side shorting shields connecting the first and second return poles thereby modifying the crosstrack field gradient. Additionally, the perpendicular writer may include a top shorting shield modifying the downtrack gradient and may additionally include a bottom shorting shield for further reduction of erasure fields. The distance between the main pole and the shorting shields may be modified to customize the write field gradient.

Owner:SEAGATE TECH LLC

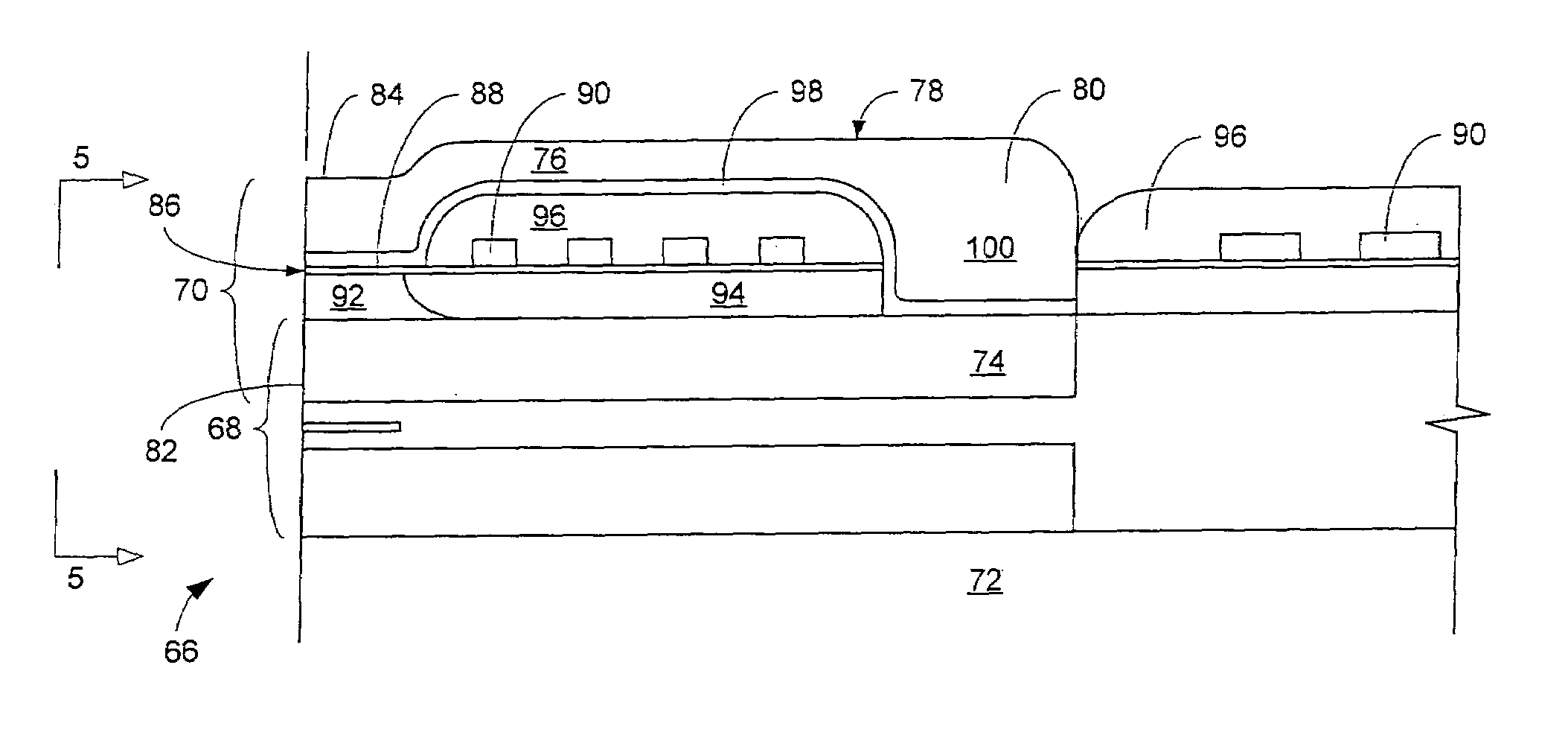

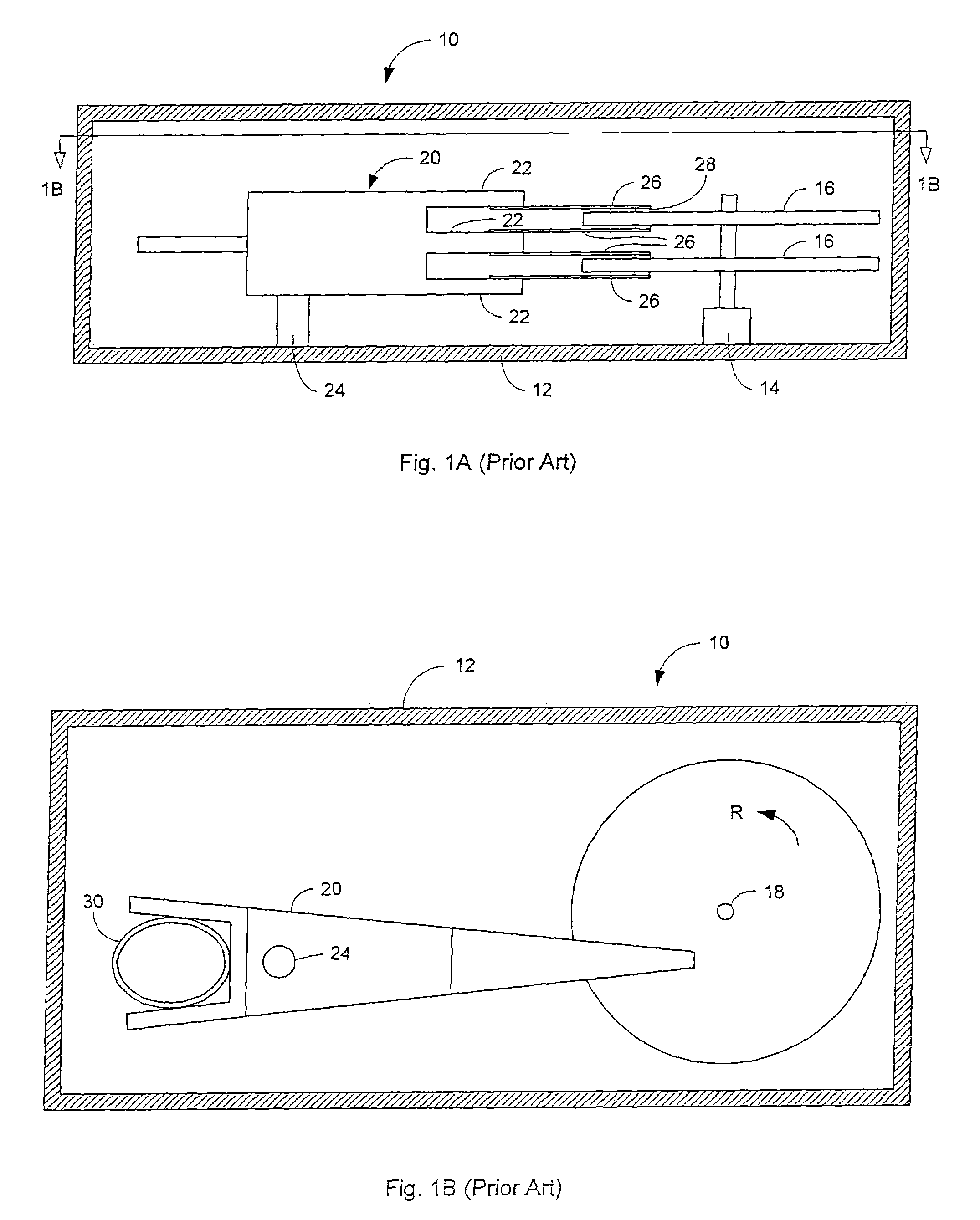

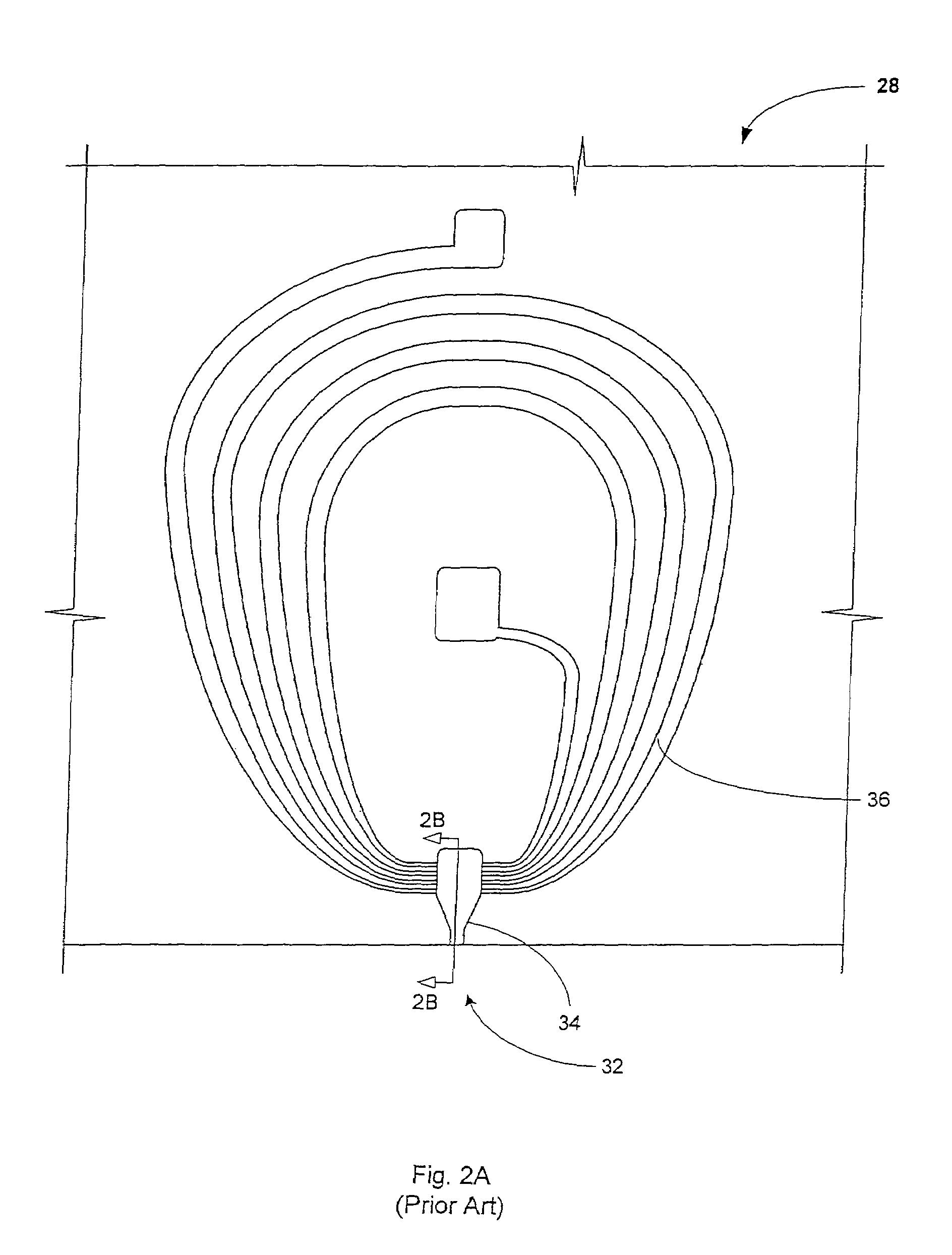

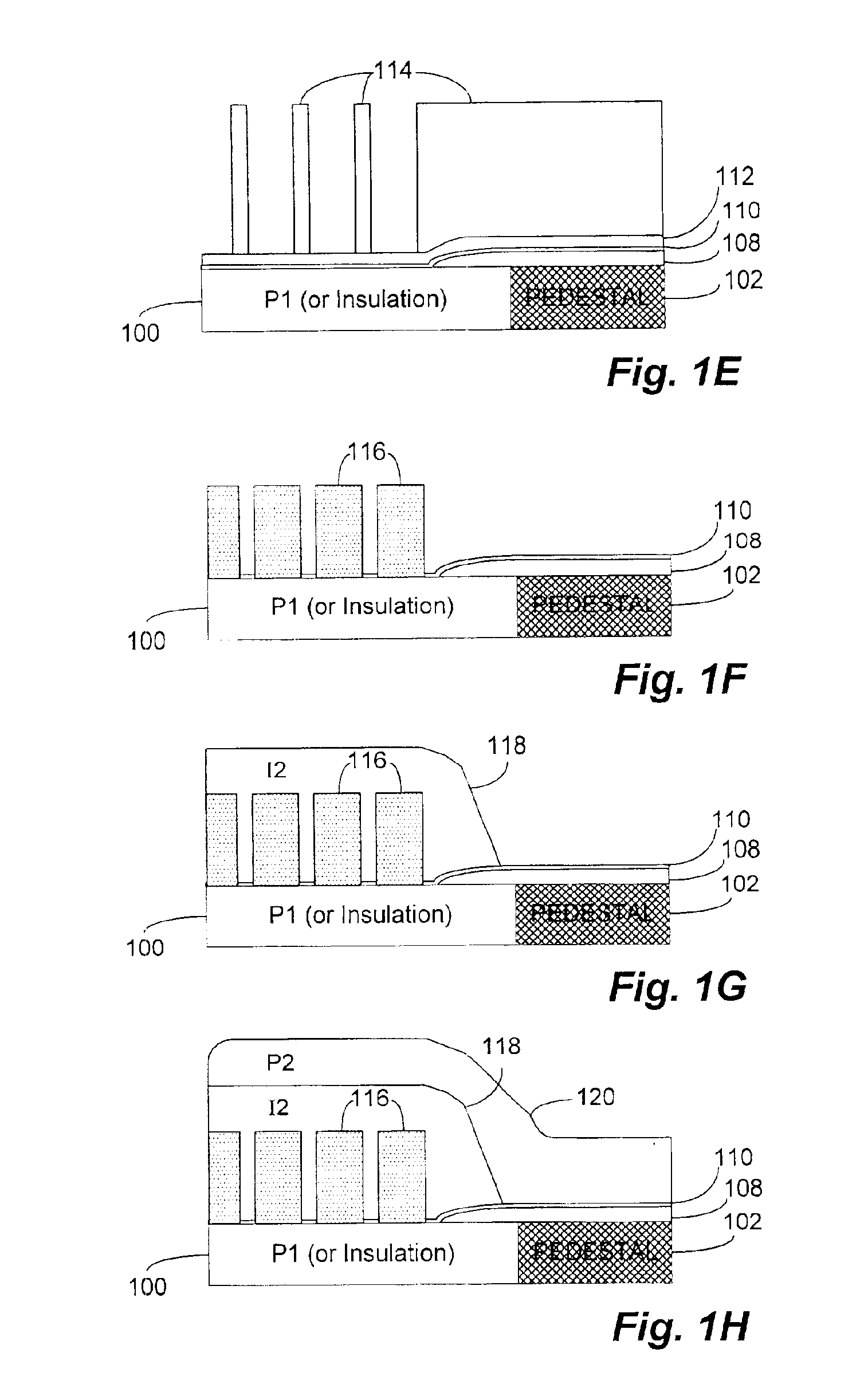

Ultra-short yoke and ultra-low stack height writer and method of fabrication

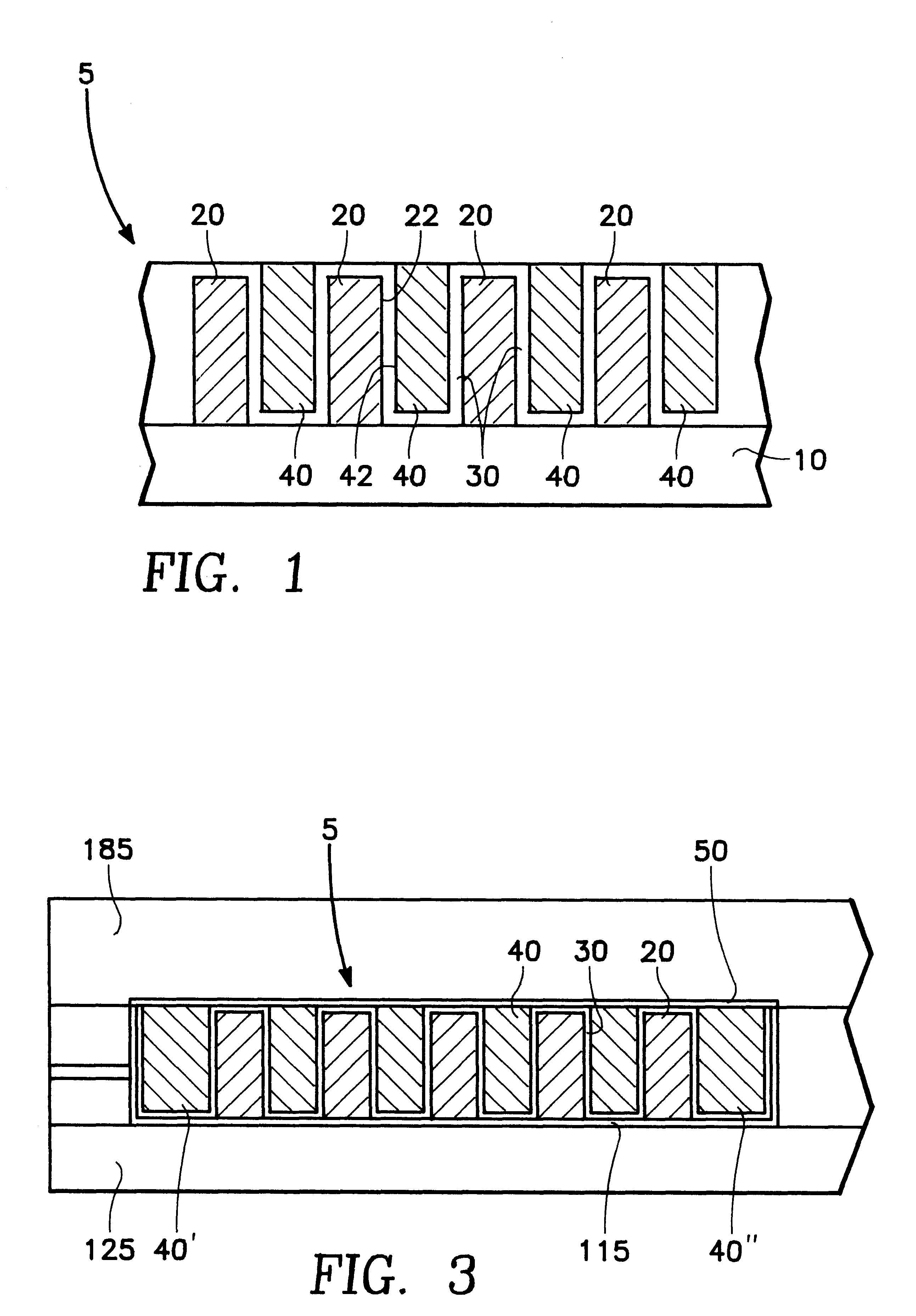

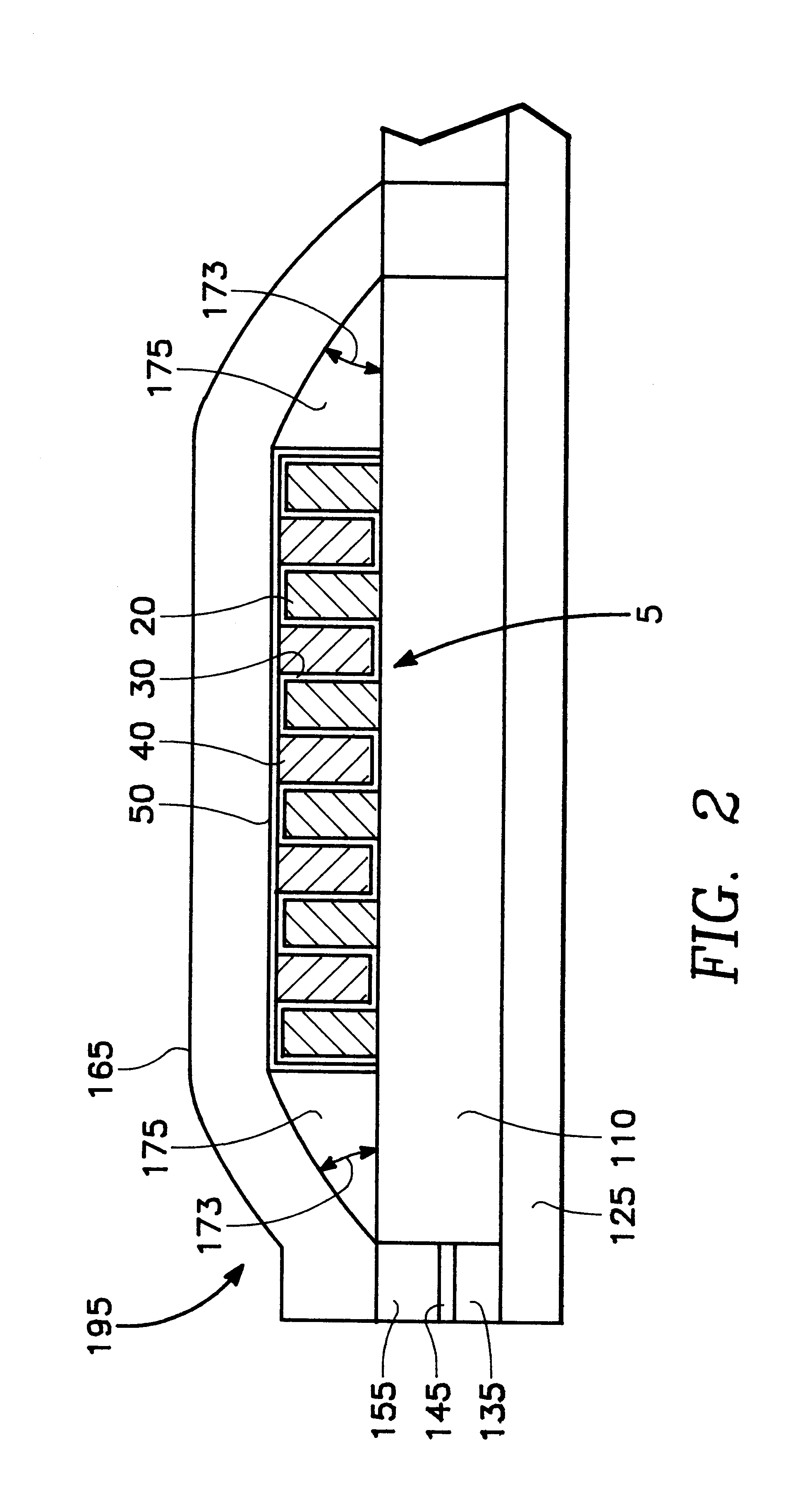

InactiveUS6765756B1Reduce the overall heightShorten the lengthConstruction of head windingsHeads using thin filmsResistElectrical conductor

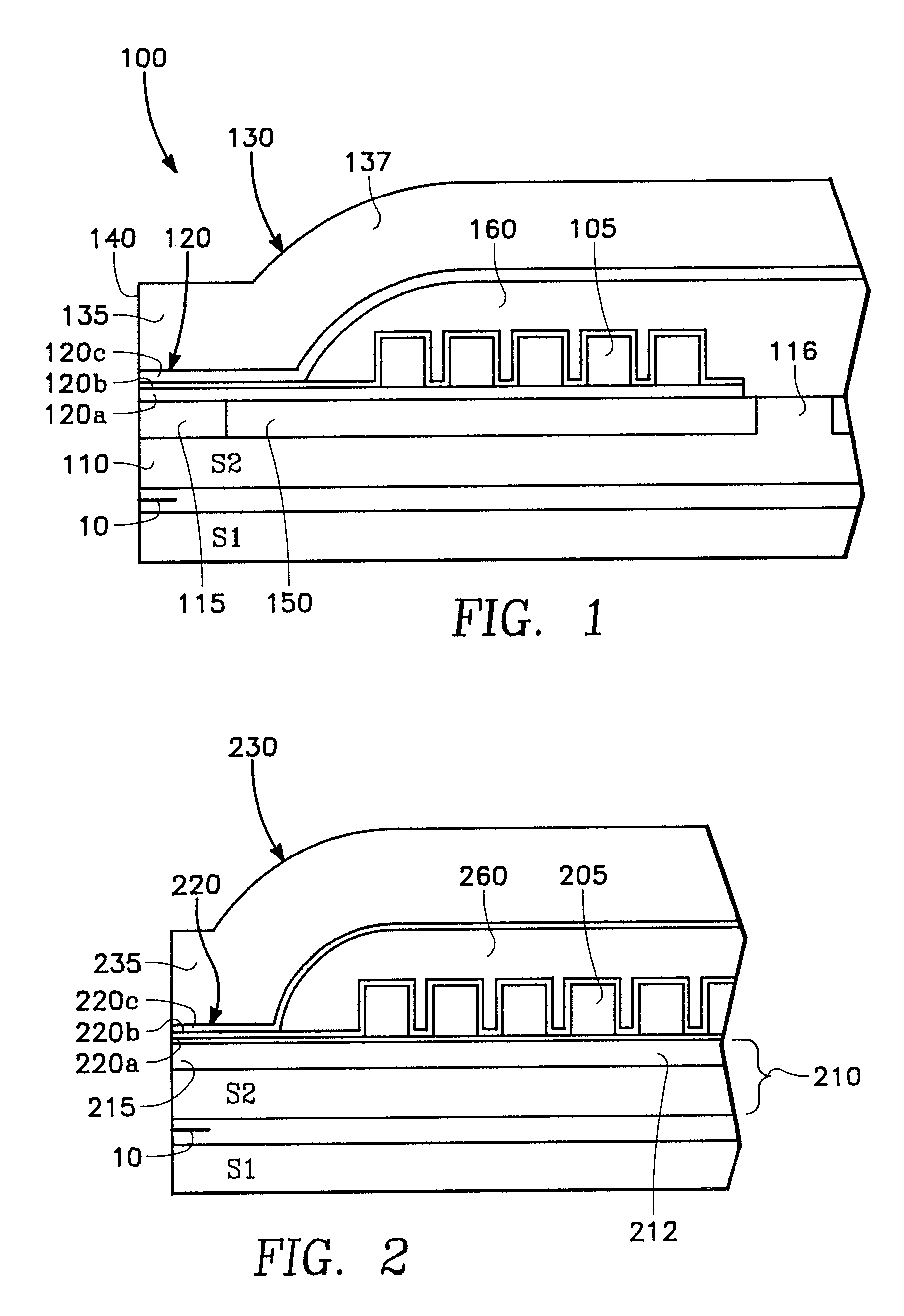

The present invention provides an improved thin film write head and method of fabrication capable of providing an ultra-short yoke and / or an ultra-low conductor winding stack. The present invention reduces yoke length and stack height by forming the conductor winding in a trench etched from an insulation layer, preferably formed of an inorganic insulation material. A thin resist mask is used to define the width of the trench while the etch process defines the depth. Preferably, the insulation layer is formed on a different inorganic insulation material to control the etch process, thus, the conductor winding may be formed on the underlying layer. The conductor winding preferably is formed by depositing conductor material so that it fills the trench and then planarizing, such as by chemical mechanical polish, to remove conductor material deposited outside the trench. An organic insulation layer, such as cured photoresist, may be deposited on the planarized surface of the conductor winding to insulate it from an overlying yoke. This overlying organic insulation layer may also define the apex angle of the head. The present invention may have multiple layers of conductor winding. The subsequent layers of conductor may be formed similar to the first layer, or may be formed with conventional photoresist processes and structures. The present invention may utilize any known pole structure or material.

Owner:WESTERN DIGITAL TECH INC

Ultra-short yoke and ultra-low stack height writer and method of fabrication

InactiveUS6954332B1Height of stackReduce the overall heightConstruction of head windingsManufacture head surfaceResistElectrical conductor

The present invention provides an improved thin film write head and method of fabrication capable of providing an ultra-short yoke and / or an ultra-low conductor winding stack. The present invention reduces yoke length and stack height by forming the conductor winding in a trench etched from an insulation layer, preferably formed of an inorganic insulation material. A thin resist mask is used to define the width of the trench while the etch process defines the depth. Preferably, the insulation layer is formed on a different inorganic insulation material to control the etch process, thus, the conductor winding may be formed on the underlying layer. The conductor winding preferably is formed by depositing conductor material so that it fills the trench and then planarizing, such as by chemical mechanical polish, to remove conductor material deposited outside the trench. An organic insulation layer, such as cured photoresist, may be deposited on the planarized surface of the conductor winding to insulate it from an overlying yoke. This overlying organic insulation layer may also define the apex angle of the head. The present invention may have multiple layers of conductor winding. The subsequent layers of conductor may be formed similar to the first layer, or may be formed with conventional photoresist processes and structures. The present invention may utilize any known pole structure or material.

Owner:WESTERN DIGITAL TECH INC

Coil inductive writer having a low inductance and short yoke length

InactiveUS6940688B2Improve efficiencyIncrease speedConstruction of head windingsHeads using thin filmsLow inductanceElectrical and Electronics engineering

A method and system for providing a thin film recording head are disclosed. The method and system include providing a first pole, providing a second pole and providing a write gap separating the first pole from the second pole. The method and system further include providing at least one coil having a plurality of turns. A portion of each of the plurality of turns is between the first and the second pole. The plurality of turns wind around the second pole.

Owner:WESTERN DIGITAL TECH INC

Method for making high speed, high areal density inductive write structure

InactiveUS7007372B1Excellent magnetic propertiesIncrease coverageDecorative surface effectsVacuum evaporation coatingMagnetic mediaMagnetic poles

An inductive write element is disclosed for use in a magnetic data recording system. The write element provides increased data rate and data density capabilities through improved magnetic flux flow through the element. The write element includes a magnetic yoke constructed of first and second magnetic poles. The first pole includes a pedestal constructed of a high magnetic moment (high Bsat) material, which is preferably FeRhN nanocrystalline films with lamination layers of CoZrCr. The second pole includes a thin inner layer of high Bsat material (also preferably FeRhN nanocrystalline films with lamination layers of CoZrCr), the remainder being constructed of a magnetic material capable of being electroplated, such as a Ni—Fe alloy. An electrically conductive coil passes through the yoke between the first and second poles to induce a magnetic flux in the yoke when an electrical current is caused to flow through the coil. Magnetic flux in the yoke produces a fringing field at a write gap whereby a signal can be imparted onto a magnetic medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

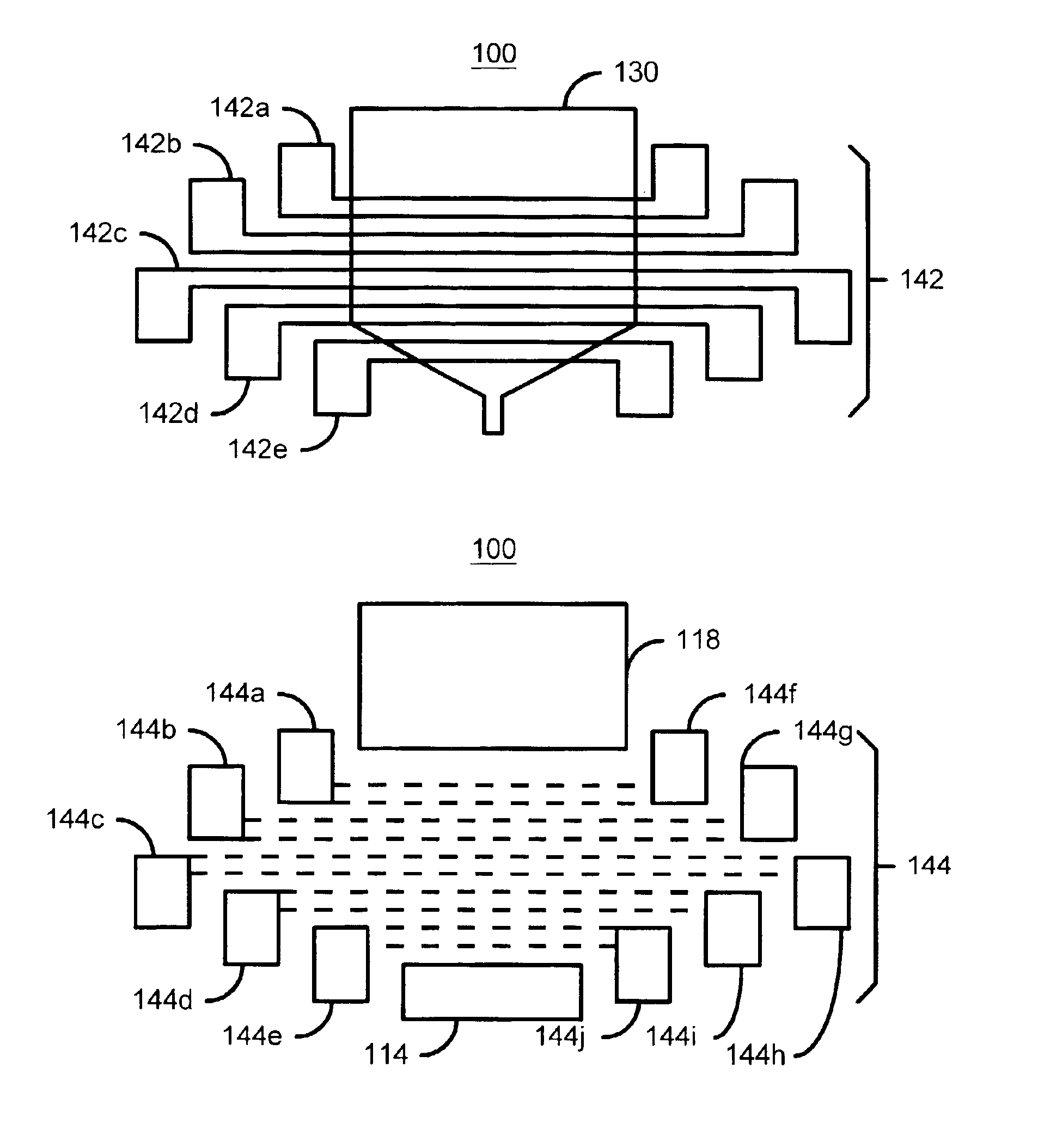

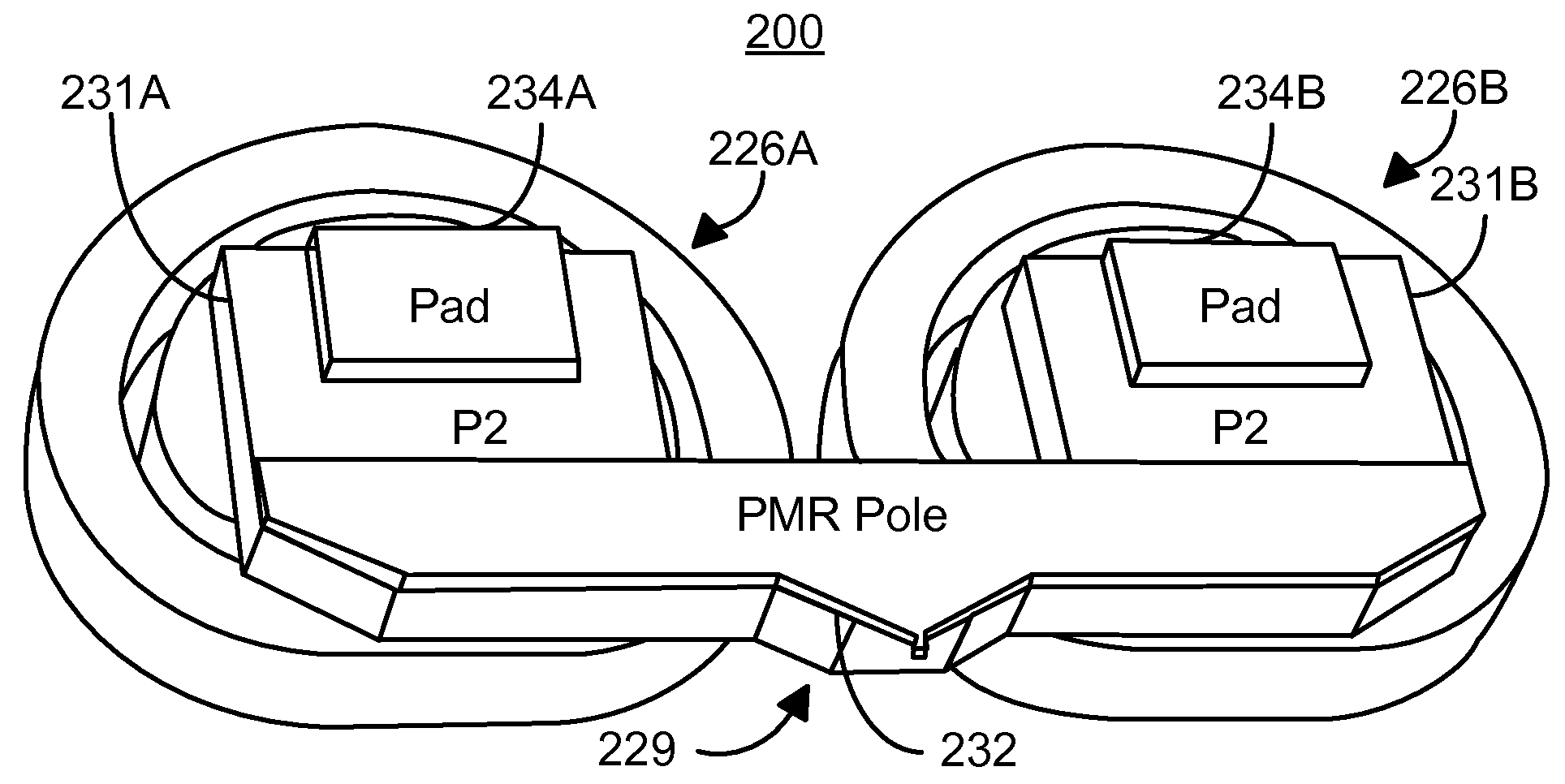

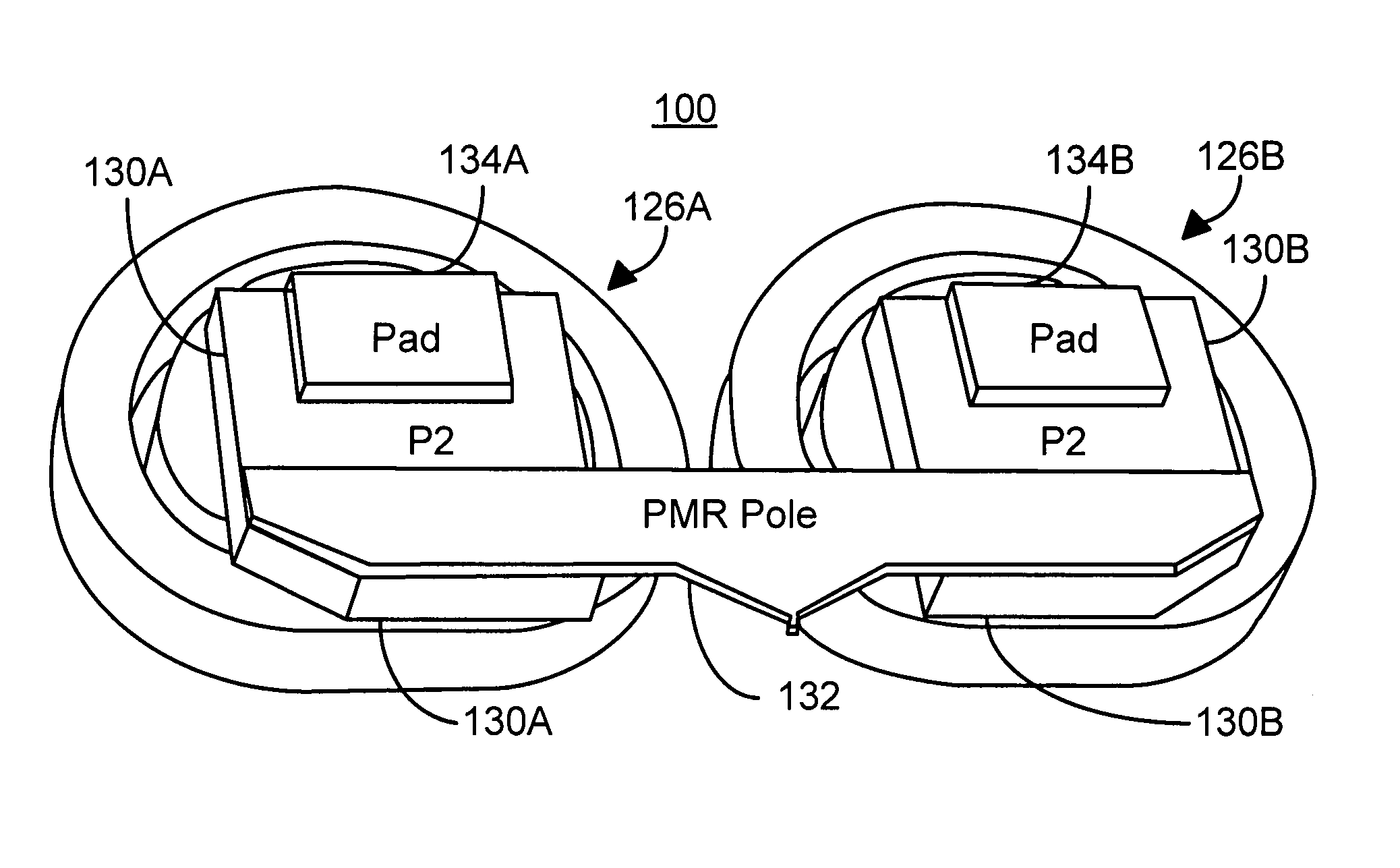

Magnetic writer having a split yoke

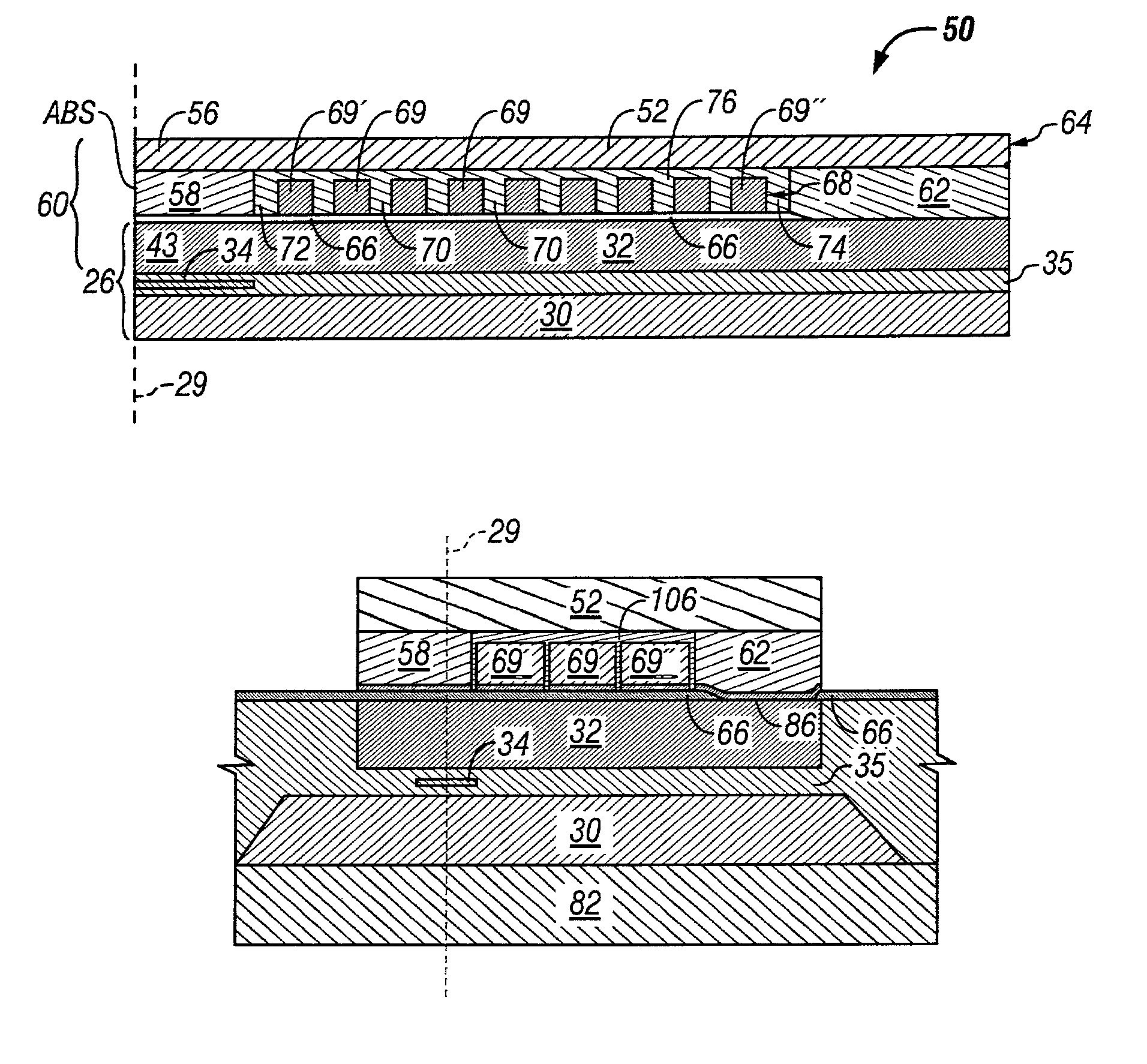

InactiveUS8537495B1Heads using thin filmsRecord information storageMagnetic transducersElectrical and Electronics engineering

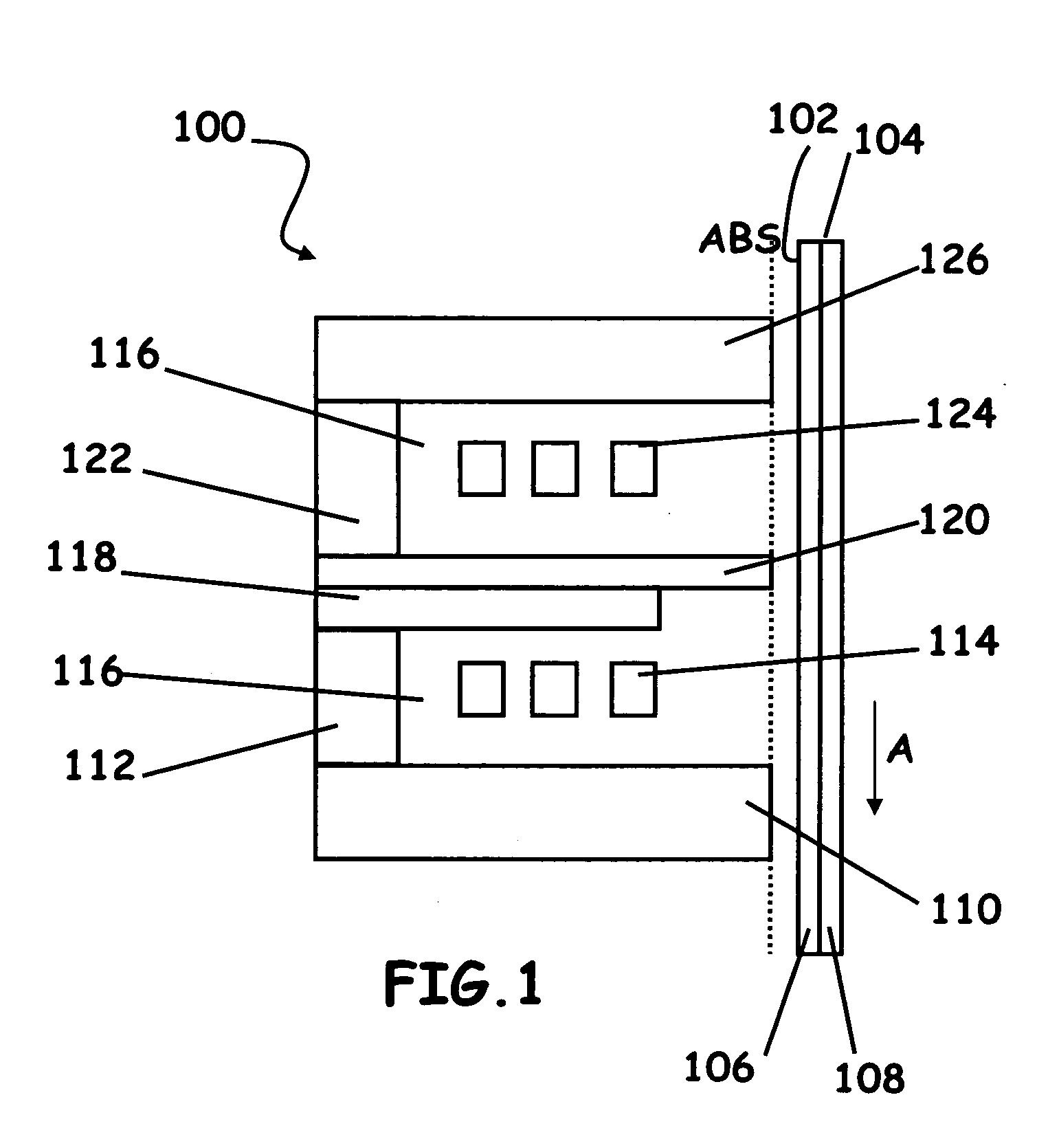

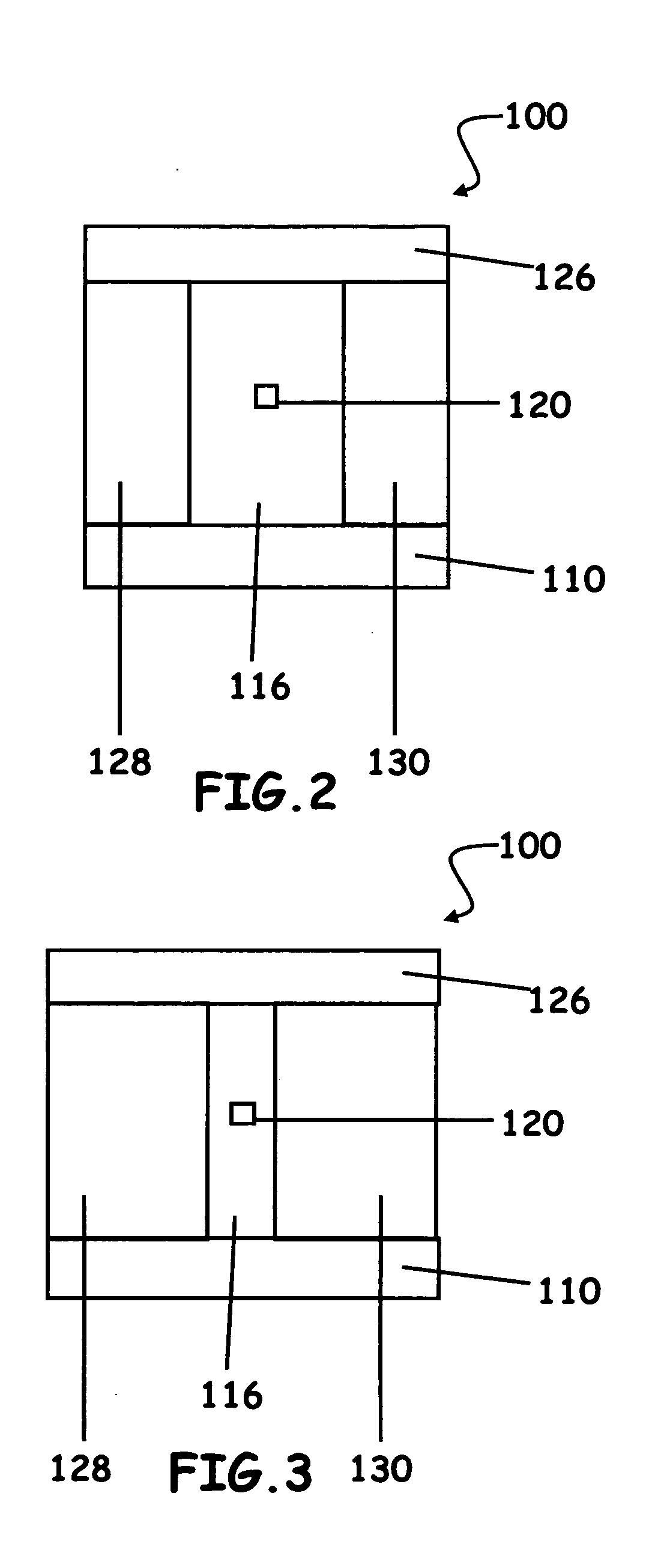

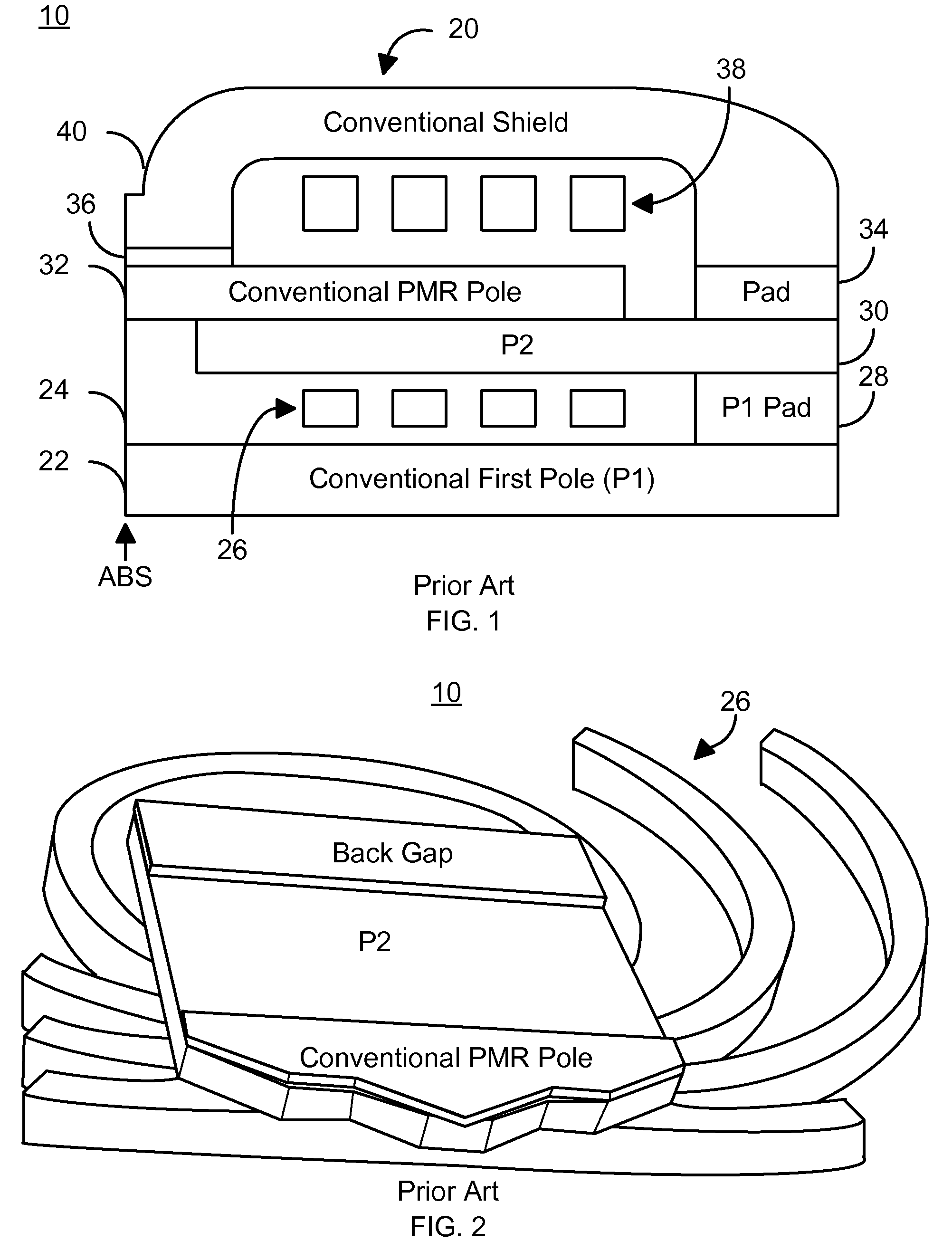

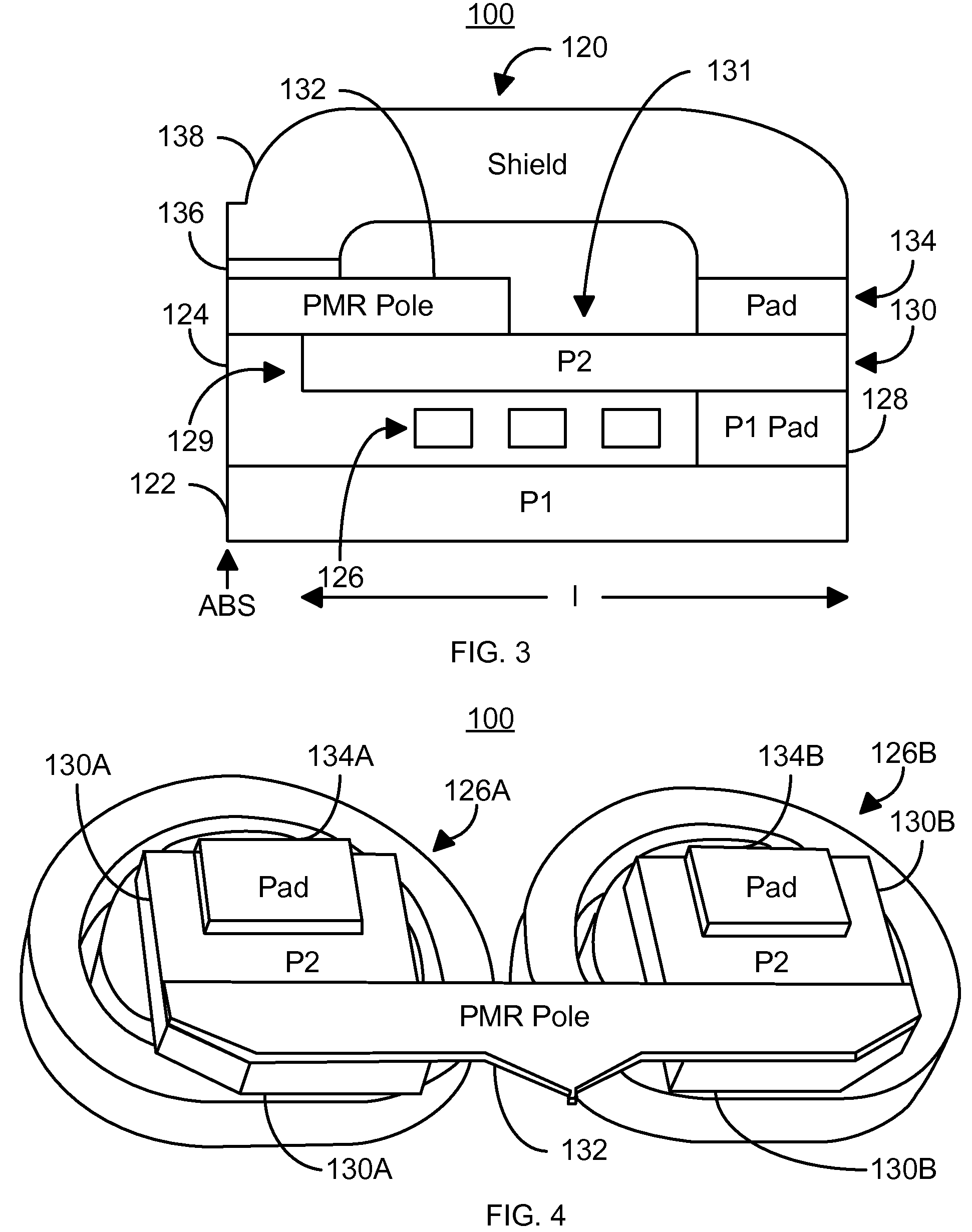

A method and system for providing a magnetic transducer are described. The magnetic transducer includes a first pole, a write gap, a second pole, a first coil, and a second coil. The first pole has a front portion on which at least a portion of the write gap resides. The second pole includes a split yoke that includes a first portion and a second portion. At least a portion of the first coil resides between the first portion of the split yoke and the first pole. At least a portion of the second coil resides between the second portion of the split yoke and the first pole.

Owner:WESTERN DIGITAL TECH INC

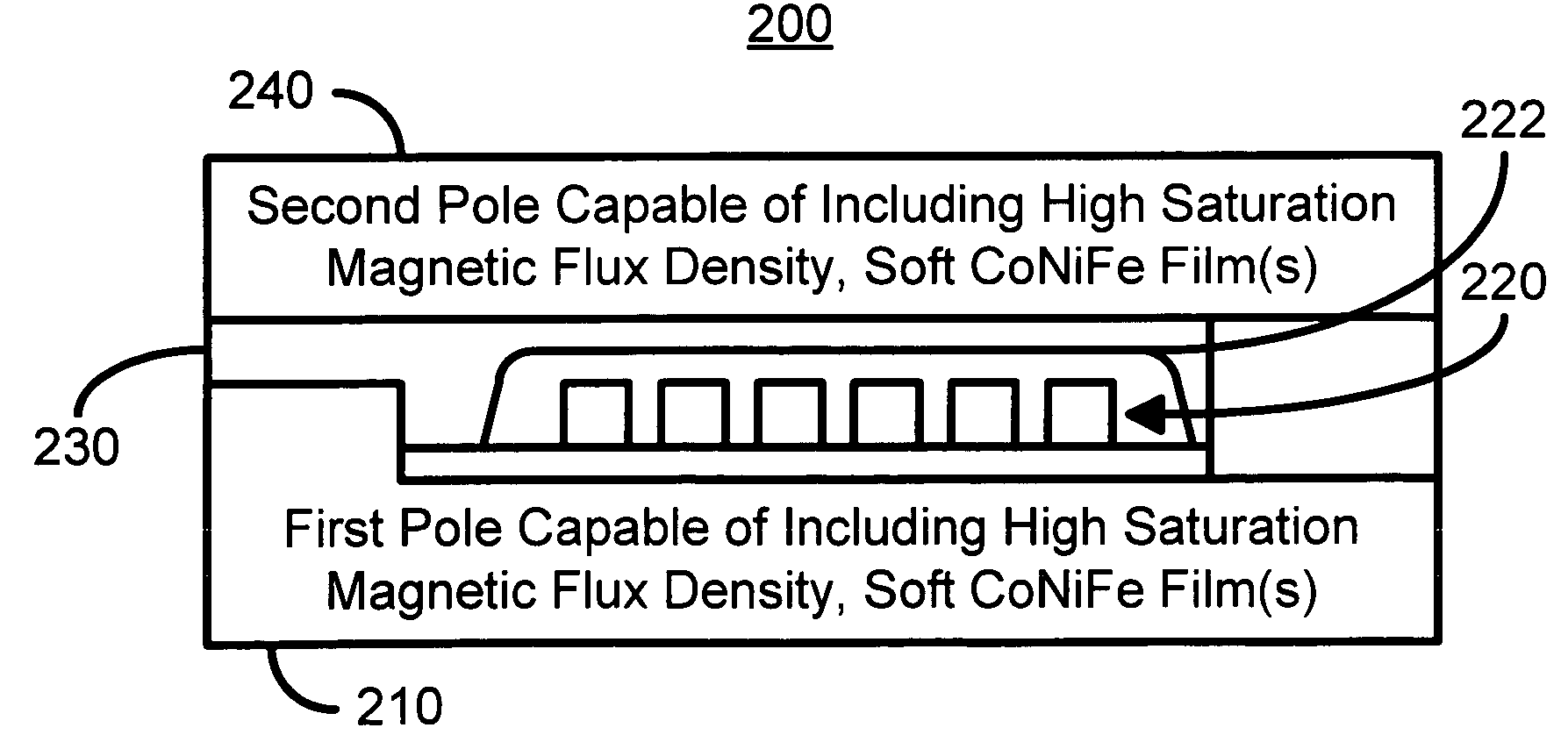

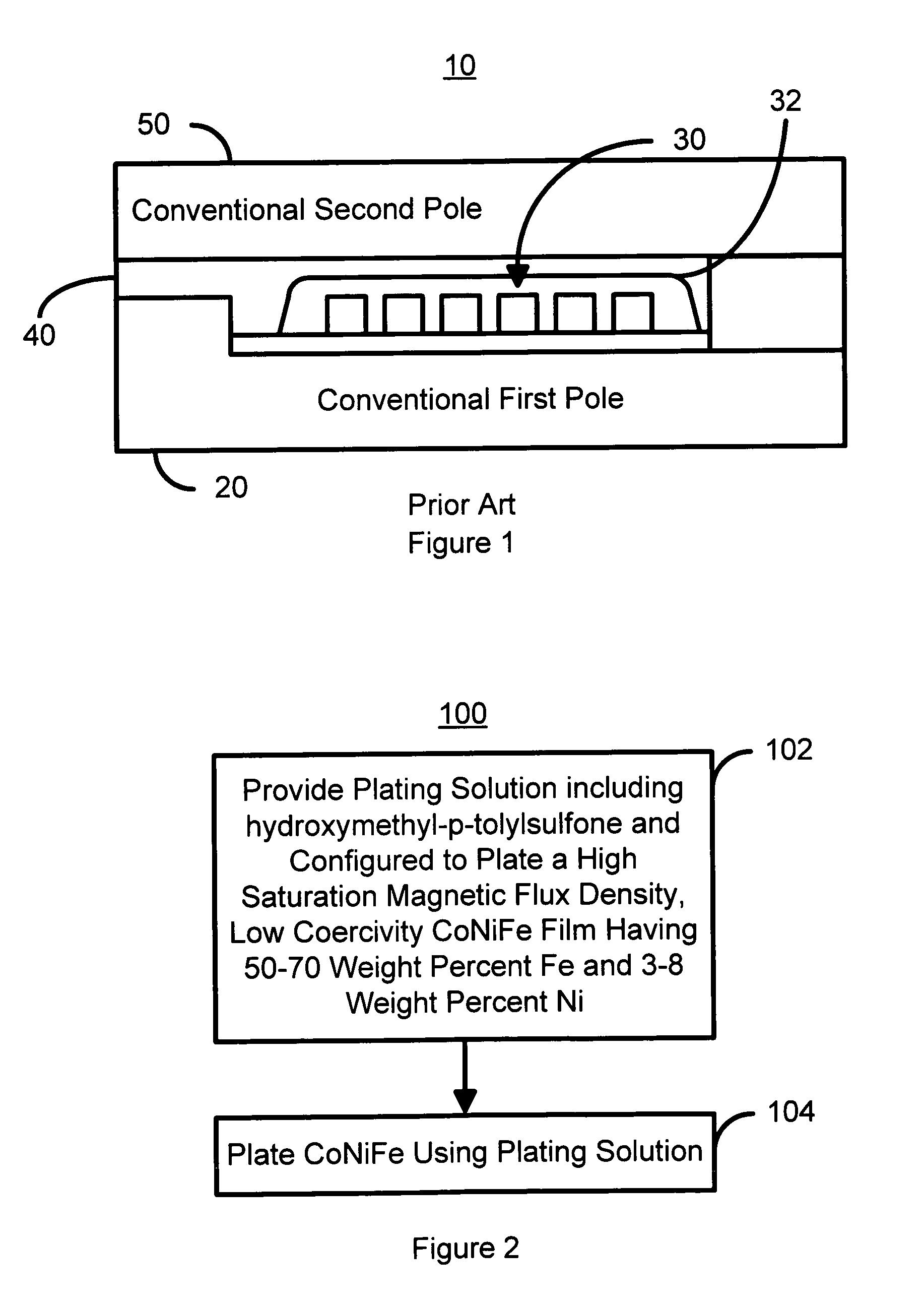

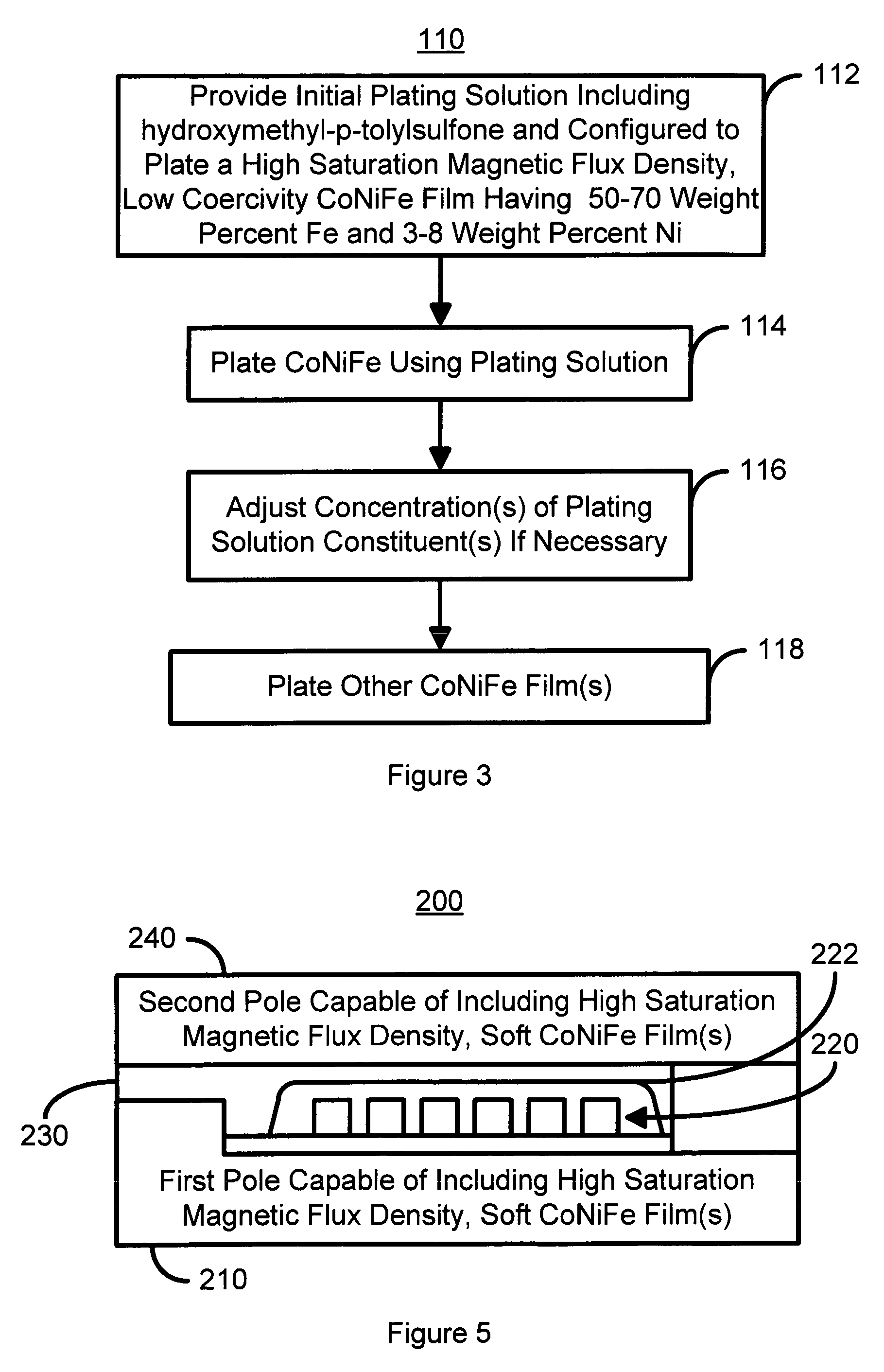

Magnetic recording head with high saturation magnetic flux density CoNiFe thin film composition

InactiveUS7333295B1Suitable for useHigh saturationHeads using thin filmsRecord information storageElectroplatingMagnetism

A method and system for plating CoNiFe is disclosed. The method and system include providing a plating solution including hydroxymethyl-p-tolylsulfone and plating the CoNiFe film on a substrate in the plating solution. The plating solution is configured to provide a CoNiFe film having a high saturation magnetic flux density and having a composition of 50-70 weight percent of Fe and 3-8 weight percent of Ni. In another aspect, the method and system include plating at least a portion of a first and / or second pole of a write head using the plating solution including hydroxymethyl-p-tolylsulfone and configured to plate the CoNiFe film having a high saturation magnetic flux density and a composition of 50-70 weight percent of Fe and 3-8 weight percent of Ni.

Owner:WESTERN DIGITAL TECH INC

Magnetic writer having a split yoke

A method and system for providing a magnetic transducer are described. The magnetic transducer includes a first pole, a write gap, a second pole, a first coil, and a second coil. The first pole has a front portion on which at least a portion of the write gap resides. The second pole includes a split yoke that includes a first portion and a second portion. At least a portion of the first coil resides between the first portion of the split yoke and the first pole. At least a portion of the second coil resides between the second portion of the split yoke and the first pole.

Owner:WESTERN DIGITAL TECH INC

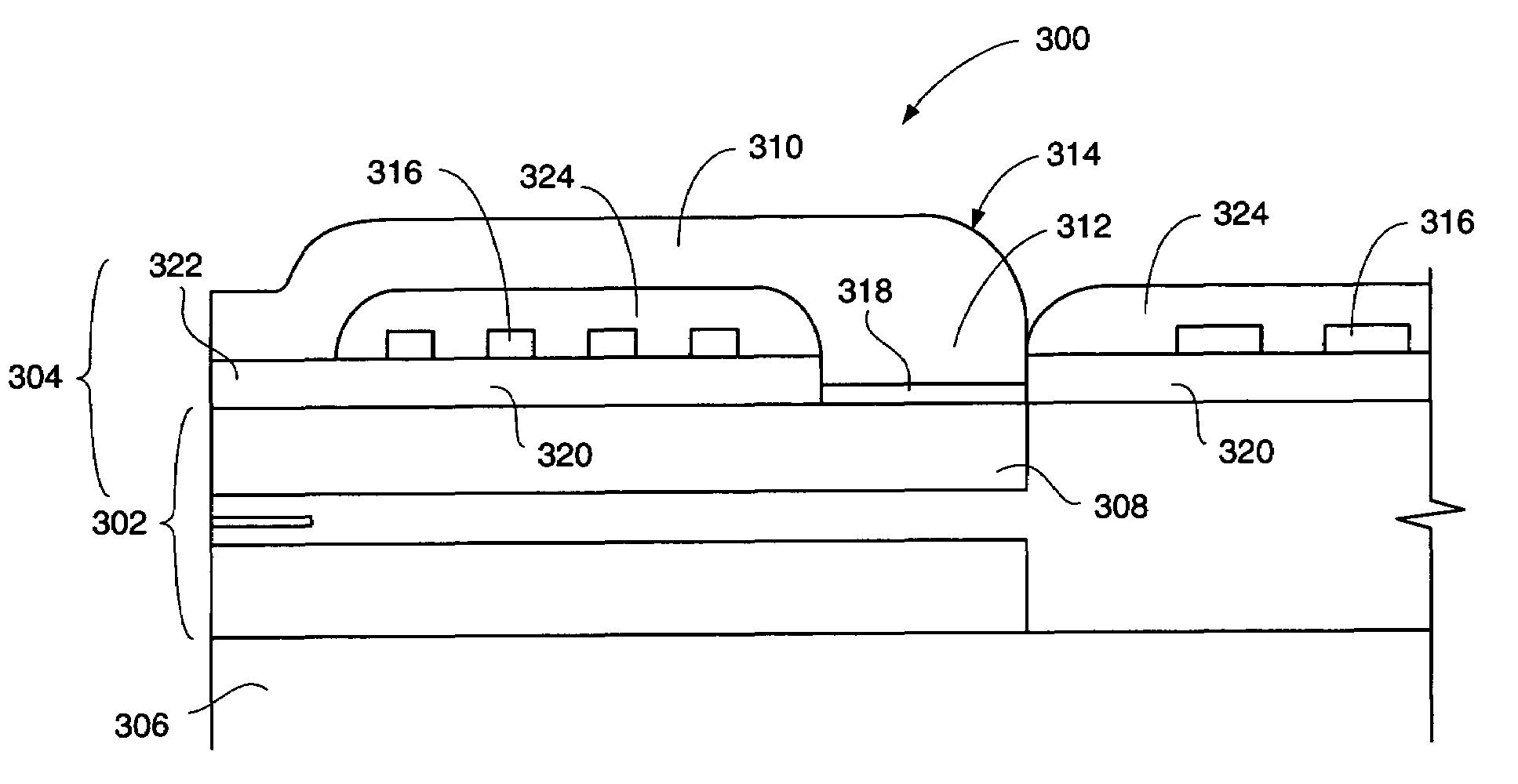

Compact MR write structure

InactiveUS6894877B1Less spaceCompact structureConstruction of head windingsManufacture head surfaceEngineeringBackplane

A compact write element includes a conductive shield layer, an insulating write gap layer, a pole pedestal, a coil, and a conductive pole layer, and, in some embodiments also includes a backgap. The pole pedestal and the coil, and, in some embodiments the backgap, constitute a self-aligned array of components that may be formed in a single masking operation to allow for very tight tolerances between the components for a shorter yoke length. The pole layer is substantially flat and parallel to the conductive shield layer, providing for a shorter stack height. Also, a compact MR read / write head includes such a write element and a magnetic data storage and retrieval system includes the compact MR read / write head having such a write element.

Owner:WESTERN DIGITAL TECH INC

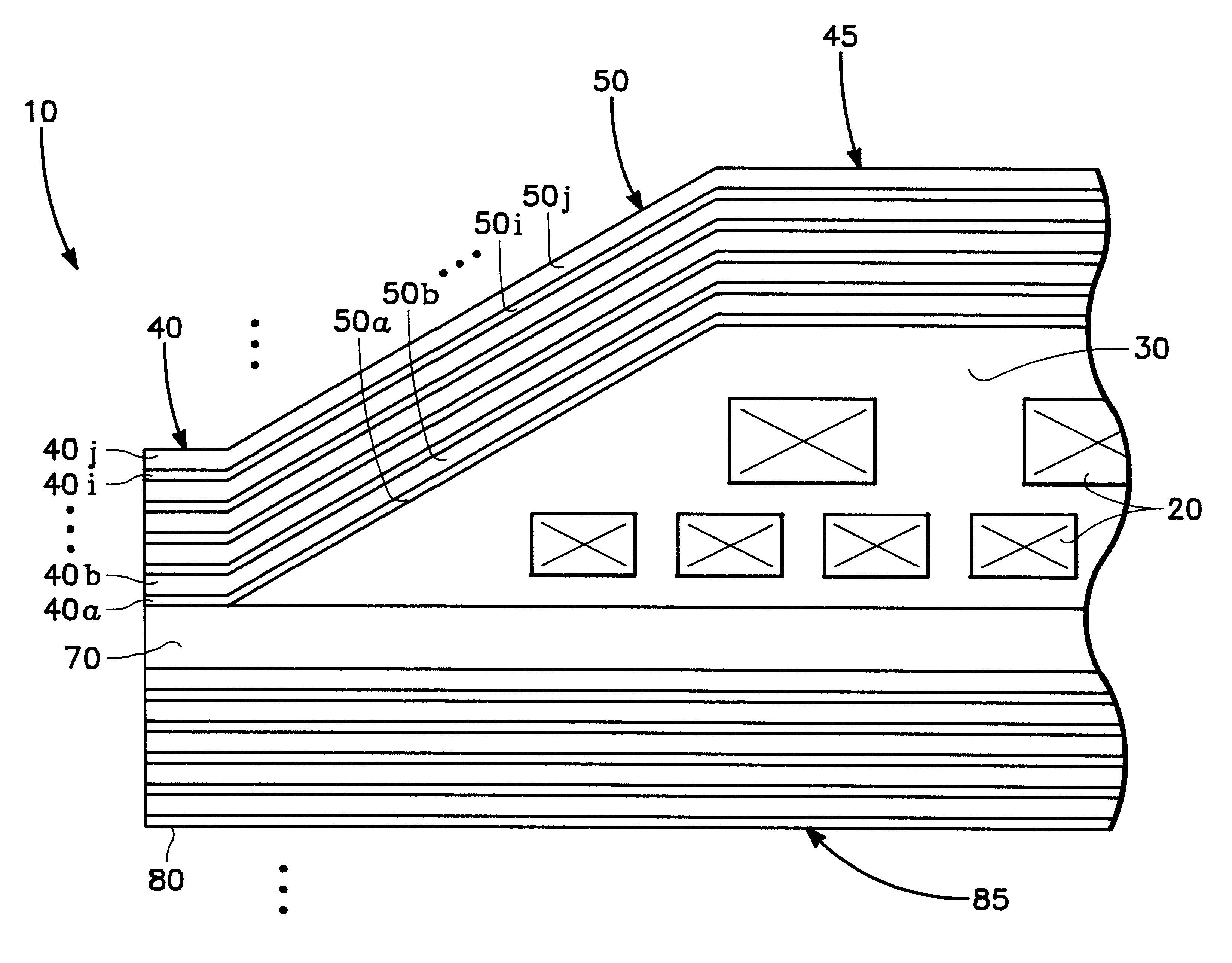

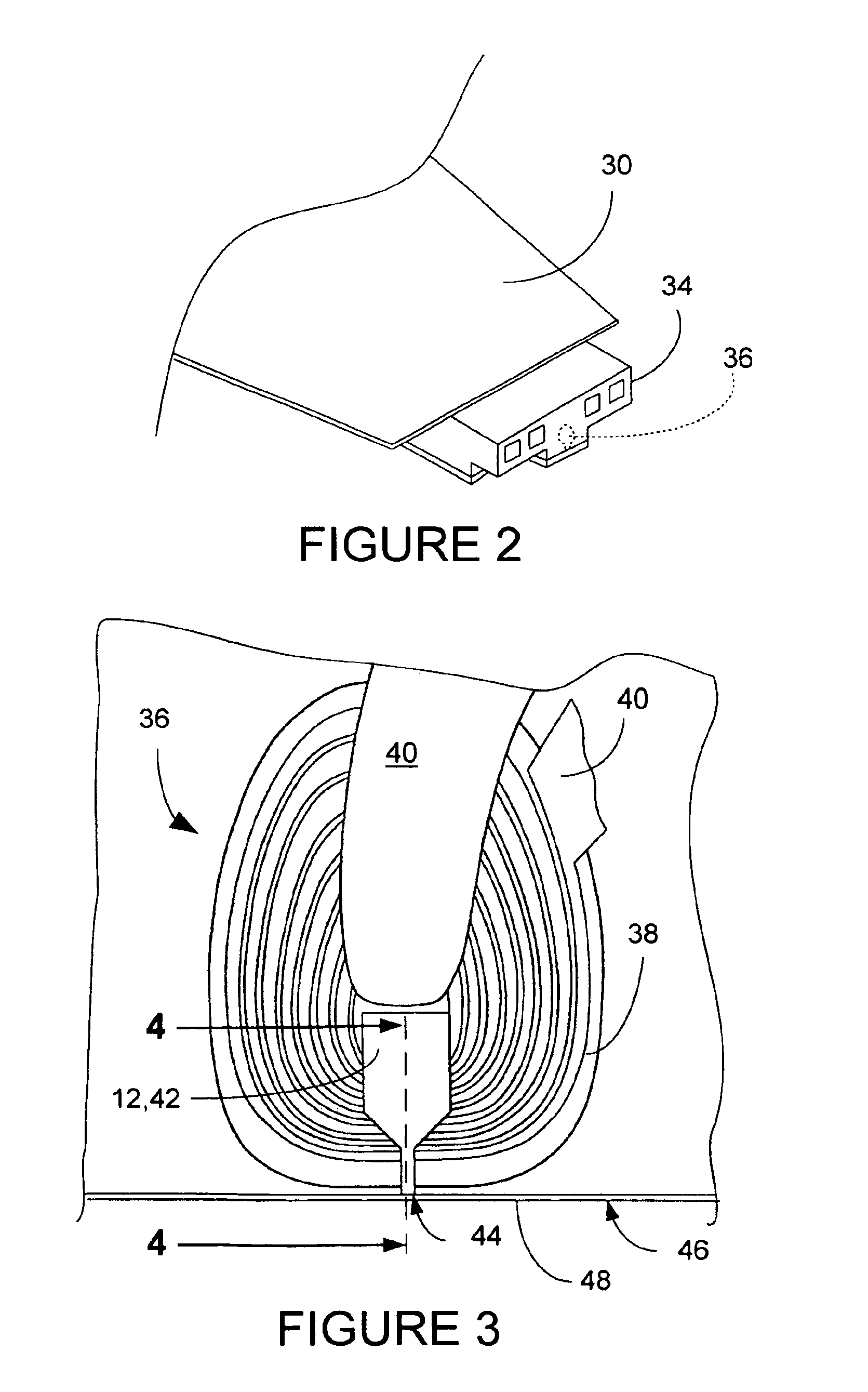

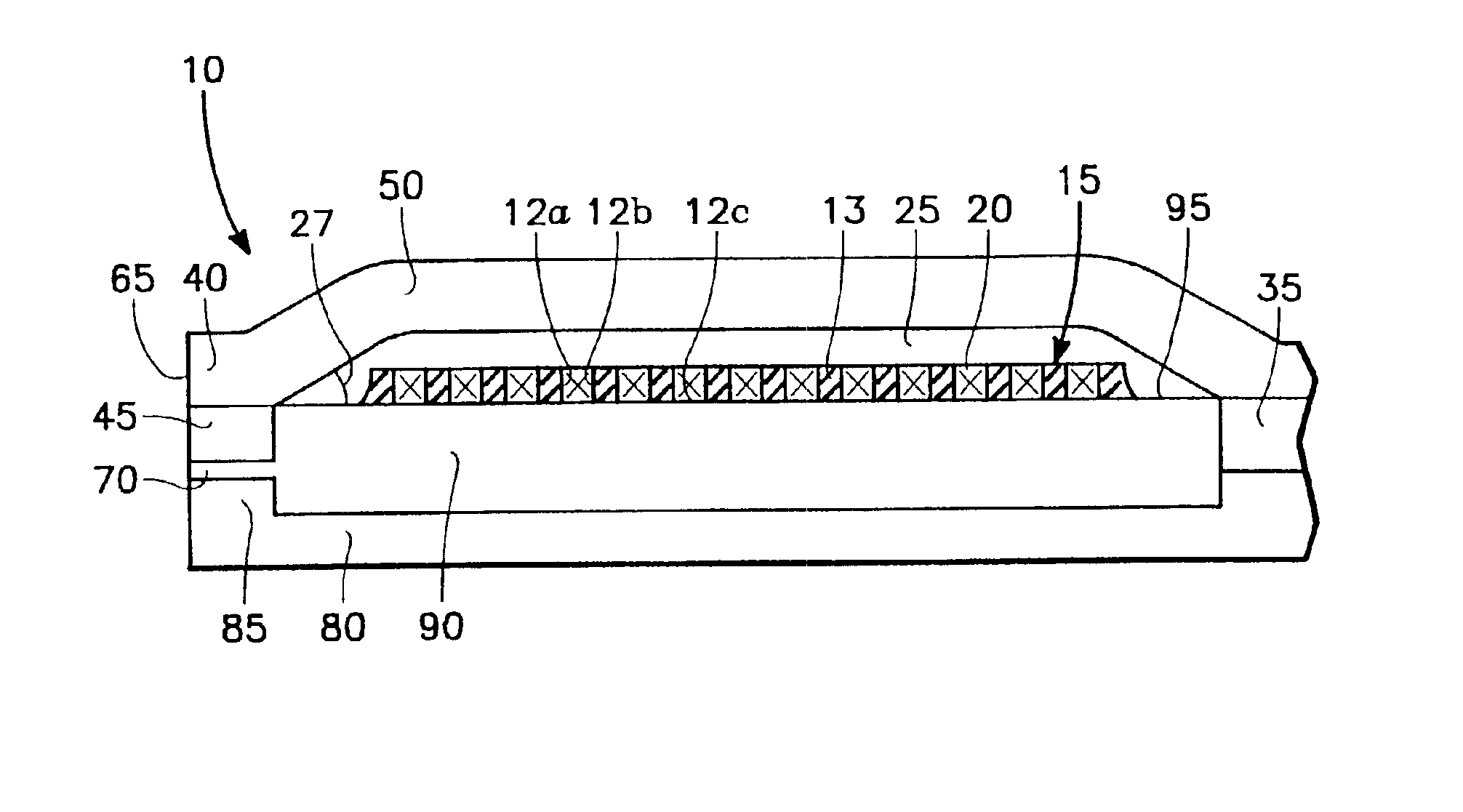

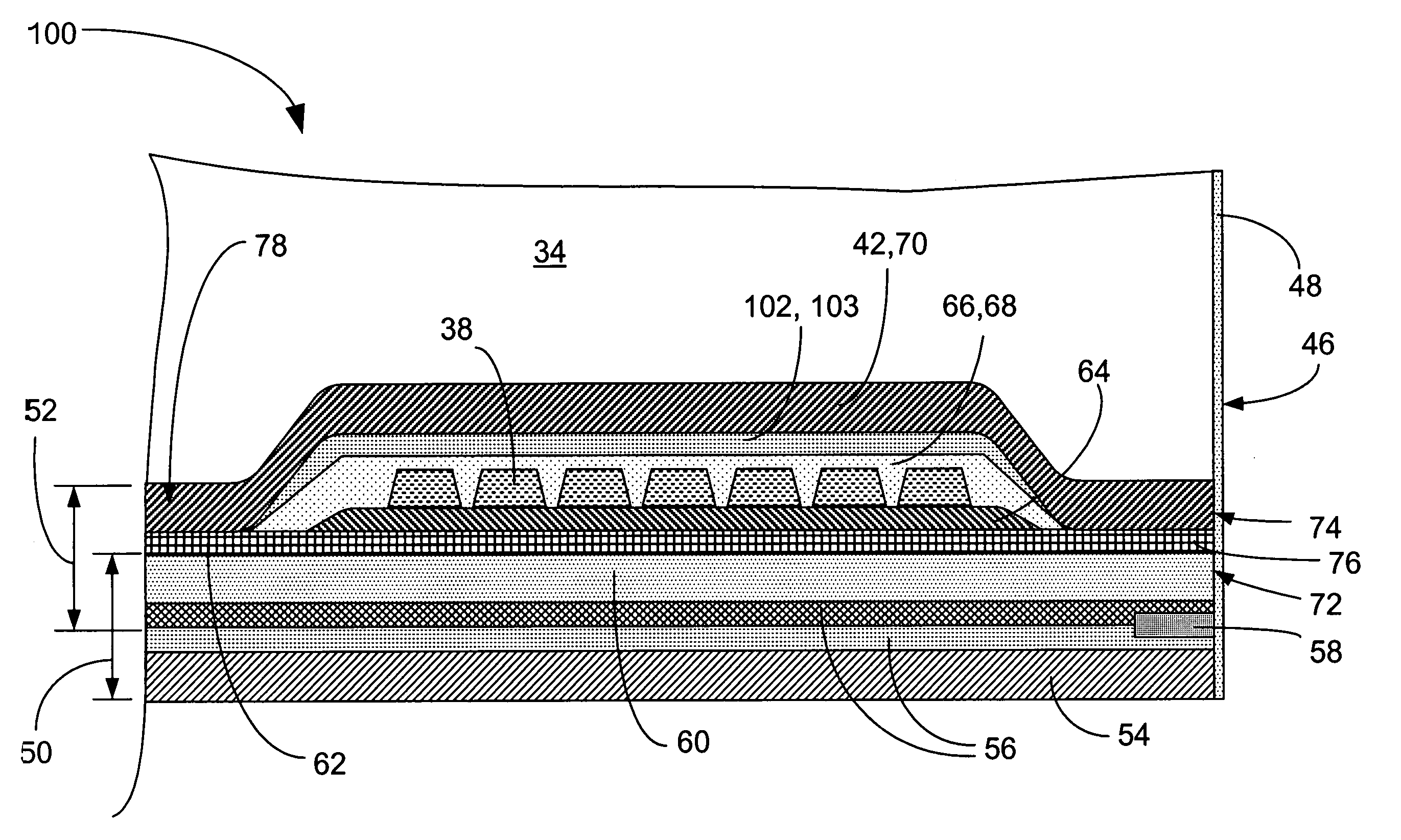

Insulation layer structure for inductive write heads and method of fabrication

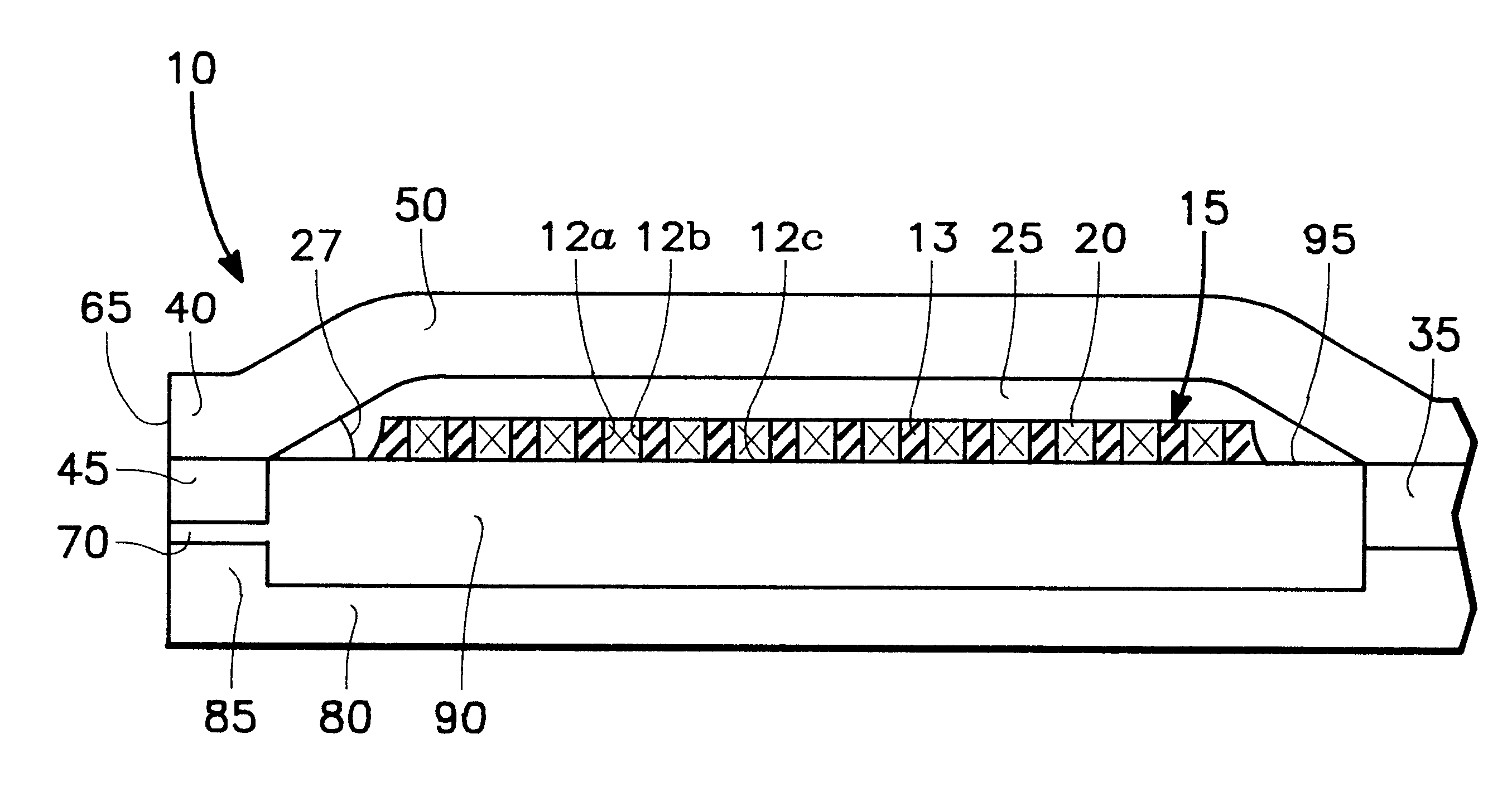

InactiveUS6958885B1Avoid crackingImprove film propertiesConstruction of head windingsElectrical transducersResistInsulation layer

A computer disk drive (22) having a write head (52) which includes a coil (38), a photoresist insulation layer (66) formed on the coil (38), and an insulation shell layer (102) which is formed on the photoresist insulation layer (66). In the first preferred embodiment (100), the top pole (42) of the write head (52) is formed on the insulation shell layer (102).In the second preferred embodiment (200), the disk drive write gap (76) is formed on the insulation shell layer (102) and the top pole (42) of the write head (52) is formed on the write gap (76).The insulation shell layers (102) in both embodiments are preferably made of dielectric materials (103).Methods of fabrication for these embodiments are also disclosed.

Owner:WESTERN DIGITAL TECH INC

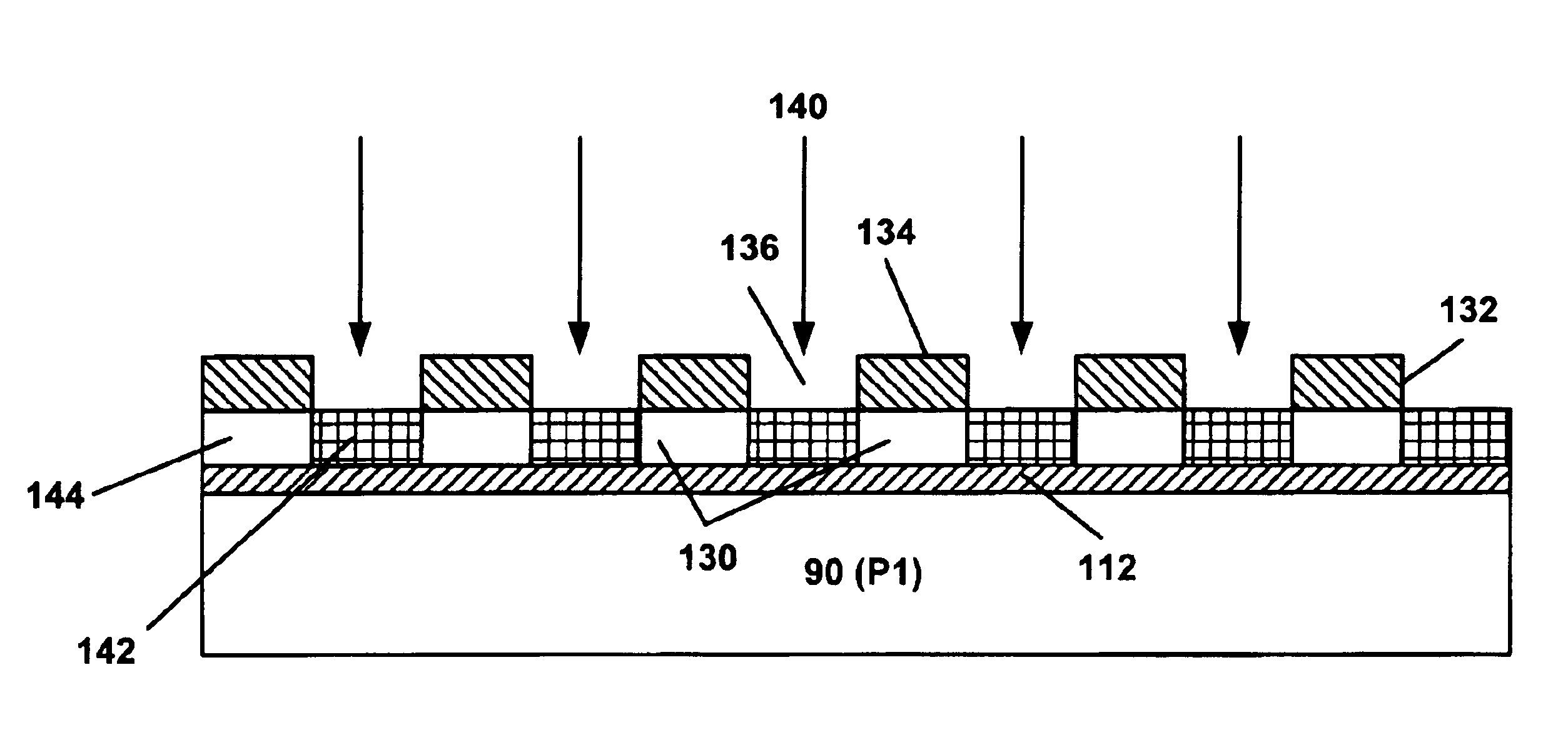

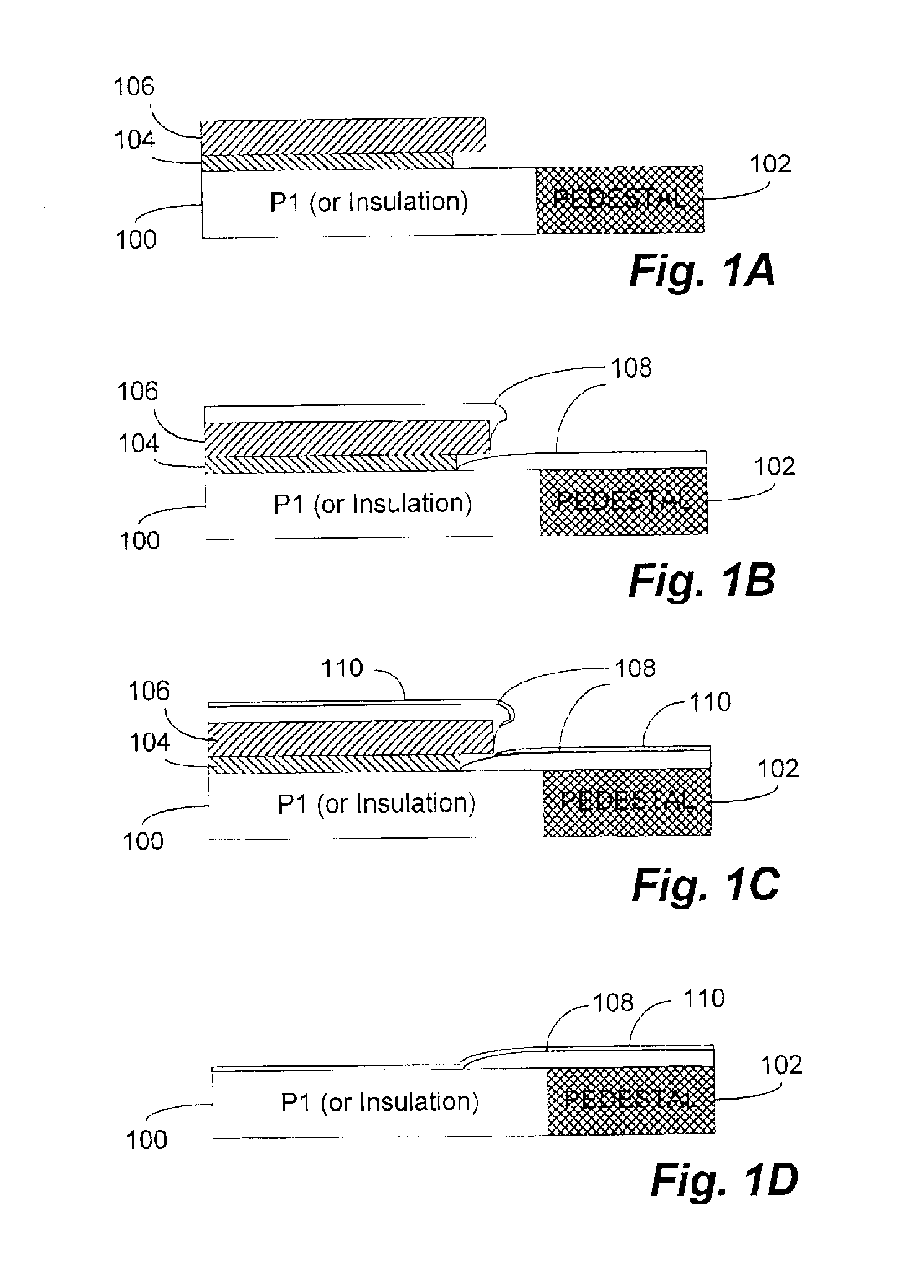

Write head with high moment film layer having tapered portion extending beyond write gap layer

InactiveUS6873494B2Prevent oxidationAvoid corrosionConstruction of head windingsNanomagnetismResistMagnetic storage

An inductive write head structure incorporating a high moment film in conjunction with at least one pole (e.g., the bottom pole) for use with magnetic storage media and a process for producing the same in which a lift-off photoresist mask is used prior to the deposition of the high moment sputtered film. Following the lift-off process, the high moment film remains on the bottom pole (“P1”) pedestal (in the case of a PDZT type write head) or on the P1 itself (in the case of a Stitched Pole write head). The edge of the lift-off sputtered film is then covered by cured photoresist insulation which is placed at a distance away from the air bearing surface (“ABS”). The coverage of insulation at the edge of the sputtered film is desirable in order to avoid forming a topographic step which may have undesired consequences in the subsequent top pole formation processes.

Owner:WESTERN DIGITAL TECH INC

Inductive write head having high magnetic moment poles and low magnetic moment thin layer in the back gap, and methods for making

InactiveUS6989962B1Avoid corrosionNegligible effectHeads using thin filmsRecord information storageMagnetic polesThin layer

The present invention provides a write element for use in magnetic data recording system such as a computer disk drive. The write head utilizes the advantageous properties of high magnetic moments while overcoming the corrosion problems engendered by such materials. The write element includes a magnetic yoke constructed of first and second magnetic poles joined to one another at a back gap. While the majority of the poles are constructed of a high magnetic moment material a layer of relatively low magnetic moment material is provided on the first pole at the back gap portion of the first pole. The relatively low magnetic moment material prevents corrosion of the first pole during subsequent manufacturing of the write head. An electrically conductive coil passes through the magnetic yoke and is insulated there from. By passing an electrical current through the electrical coil, a magnetic flux is generated in the yoke. This magnetic flux then generates a magnetic fringing field in at a write gap of the yoke. The fringing field imparts magnetic data onto a recording medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

Head for perpendicular magnetic recording with a shield structure connected to the return pole piece

An embodiment of the invention is a head for perpendicular recording that has a trailing shield and side shields that are connected to the return pole piece by two studs of ferromagnetic material. The studs extend parallel to the track direction and are located a sufficient distance away from the main pole piece to reduce the flux flow from the main pole piece to the studs. Optionally the studs can be recessed behind the air-bearing surface. The preferred embodiment of the invention is a magnetic transducer with separated read and write heads for perpendicular recording.

Owner:WESTERN DIGITAL TECH INC

Method of manufacturing a magnetic head device

InactiveUS7114241B2Electrical transducersManufacture head surfaceSubject matterElectrical and Electronics engineering

A method of manufacturing a magnetic head device includes forming a thin film magnetic head element over a substrate, the thin film magnetic head element including a magnetoresistance (MR) element. The substrate is cut such that the MR element is exposed on a side surface of the substrate. The side surface is then polished. Afterward, a magnetically degenerated layer is removed from the thin film magnetic head element along the side surface. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:WESTERN DIGITAL TECH INC

Popular searches

Manufacture of flux-sensitive heads Shielding heads Heads for perpendicular magnetisations Heads with metal sheet cores Substrate/intermediate layers Spin-exchange-coupled multilayers Magnetic field measurement using galvano-magnetic devices Recording on magnetic disks Disk carriers Protective measures for recording heads

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

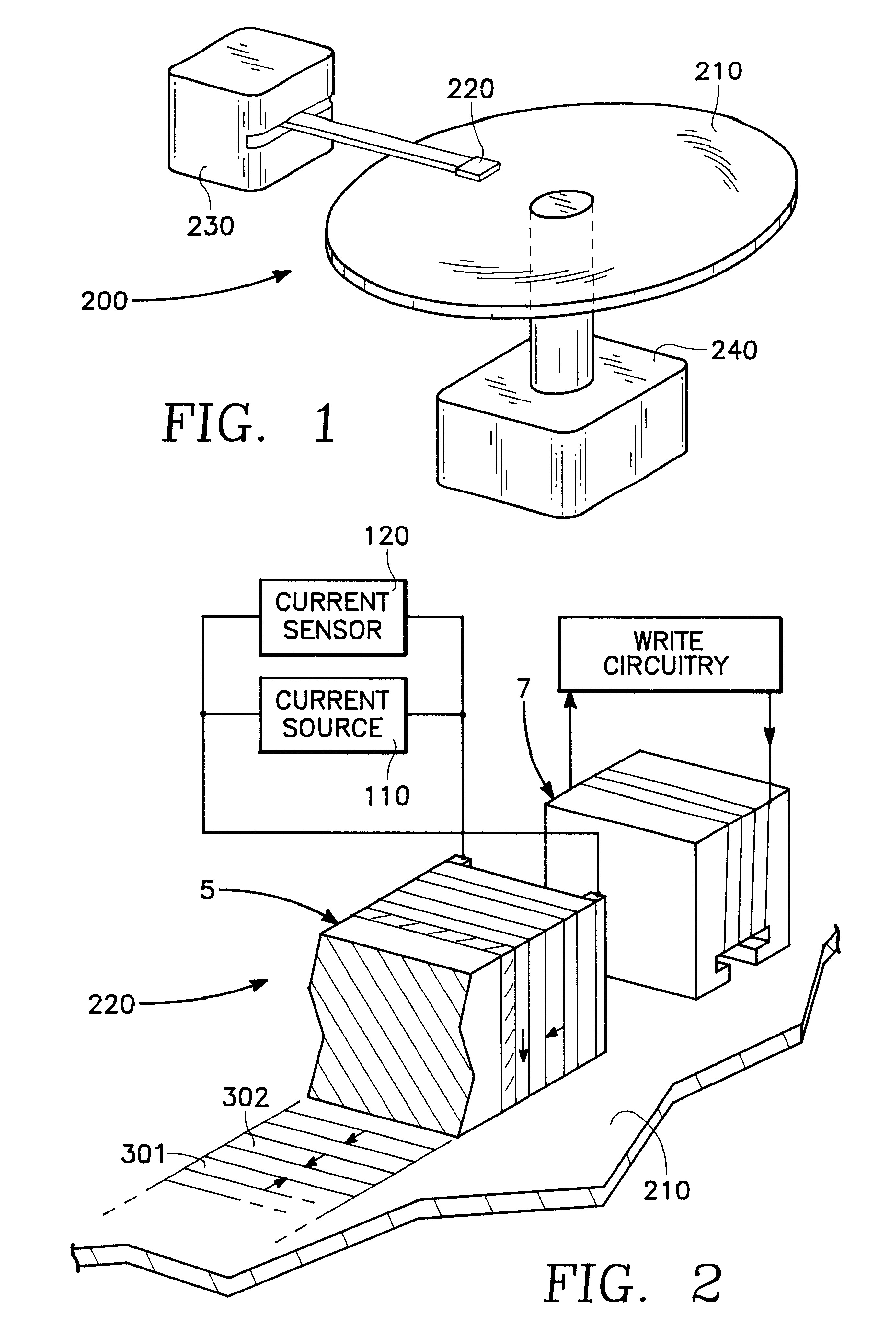

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com