Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

802 results about "Saturation (magnetic)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seen in some magnetic materials, saturation is the state reached when an increase in applied external magnetic field H cannot increase the magnetization of the material further, so the total magnetic flux density B more or less levels off. (It continues to increase very slowly due to the vacuum permeability.) Saturation is a characteristic of ferromagnetic and ferrimagnetic materials, such as iron, nickel, cobalt and their alloys.

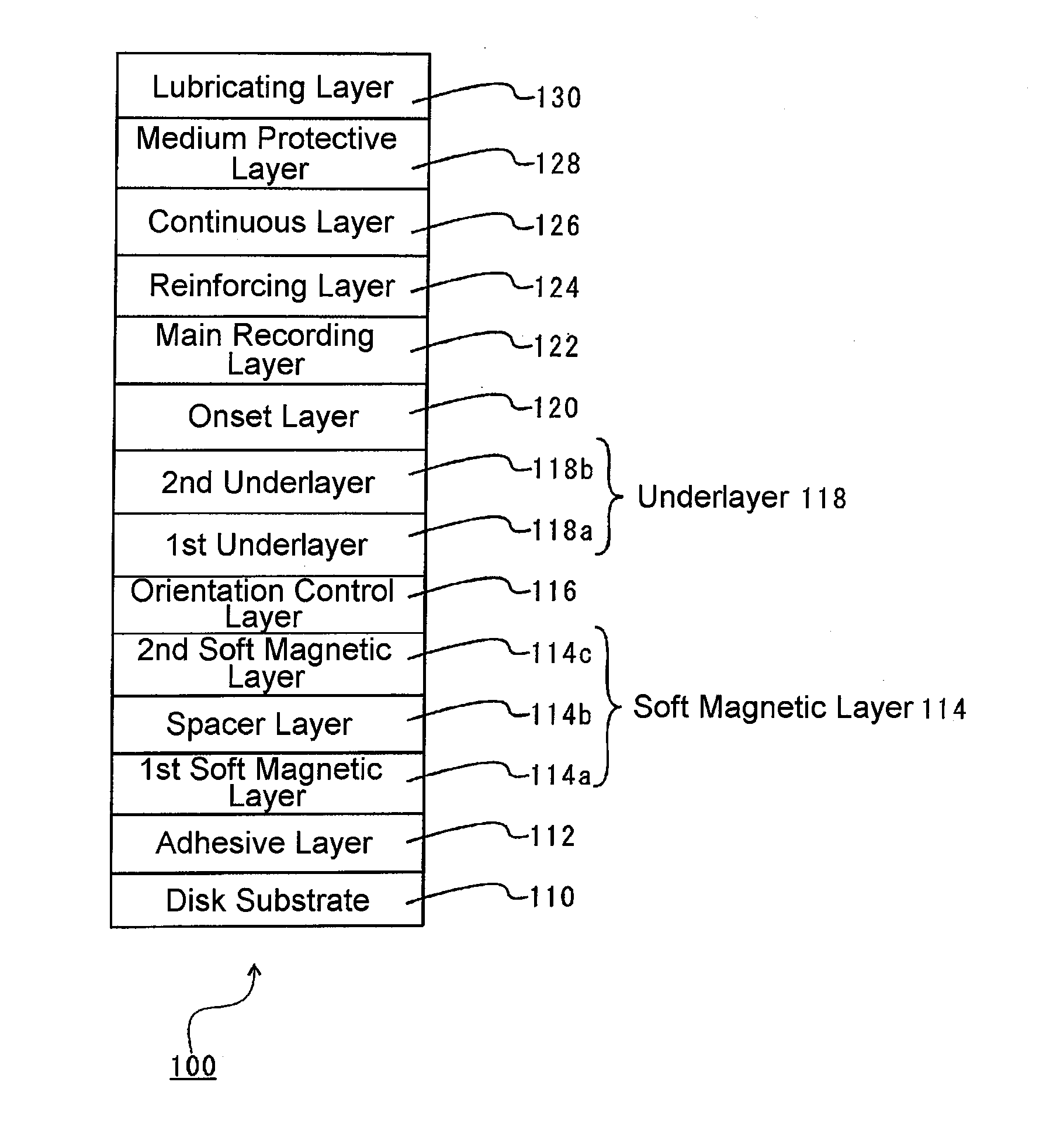

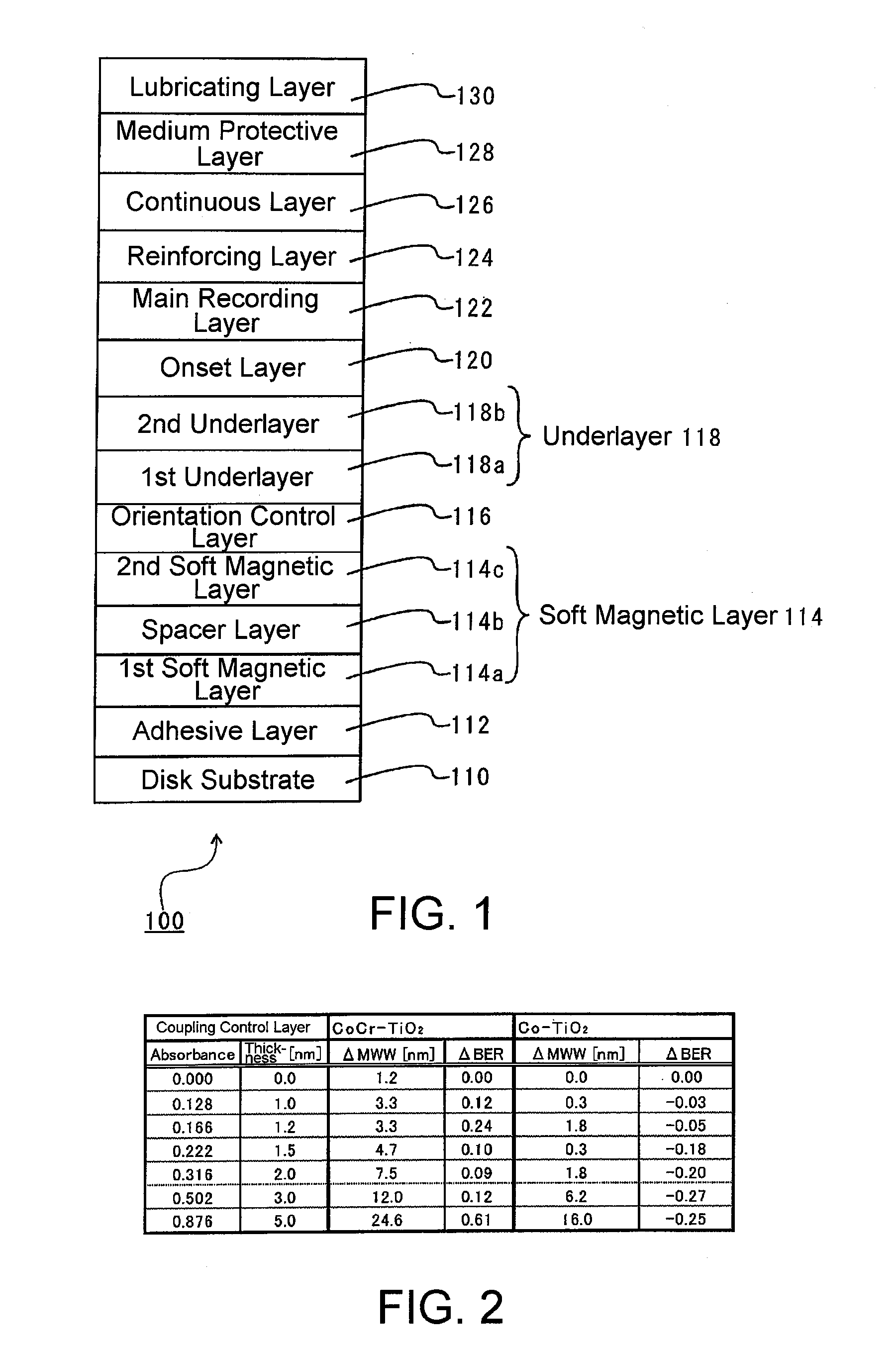

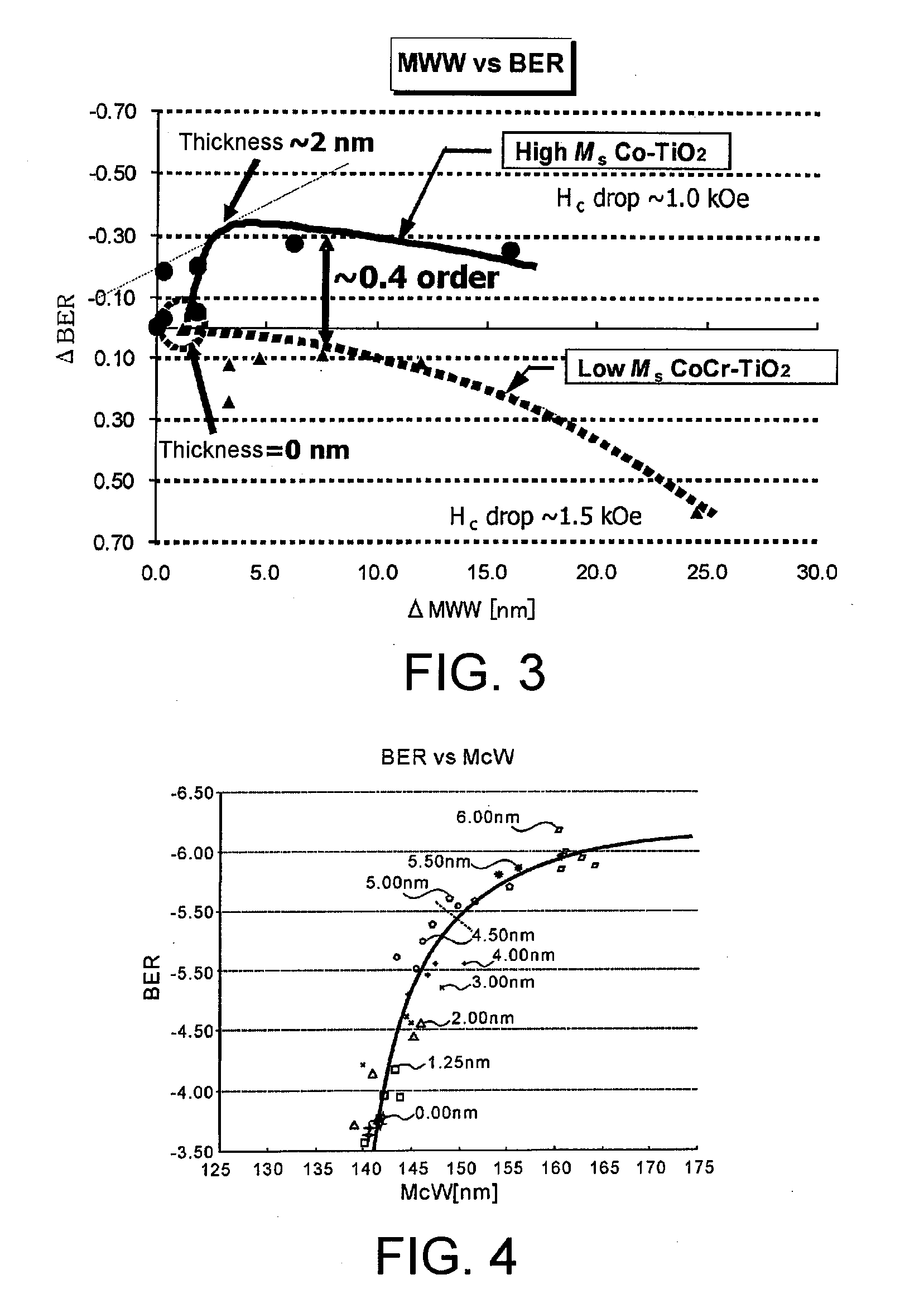

Perpendicular magnetic recording medium and perpendicular magnetic recording medium manufacturing method

ActiveUS20100190035A1Improve signal-to-noise ratioReduce write fringingRecord information storageCoatingsMagnetizationRecording layer

[Problems] To provide a reinforcing layer between a main recording layer and a continuous layer so as to improve the S / N ratio of a magnetic recording medium and reduce the write fringing effect by the new configuration.[Means for Solving Problems] A perpendicular magnetic recording medium (100) includes a substrate (110), and a main recording layer (122), a reinforcing layer (124), and a continuous layer (126) which are overlaid in this order on the substrate. The reinforcing layer (124) has a granular structure. The saturation magnetization Ms of the reinforcing layer (124) is higher than the saturation magnetization of the main recording layer (122).

Owner:WESTERN DIGITAL TECH INC

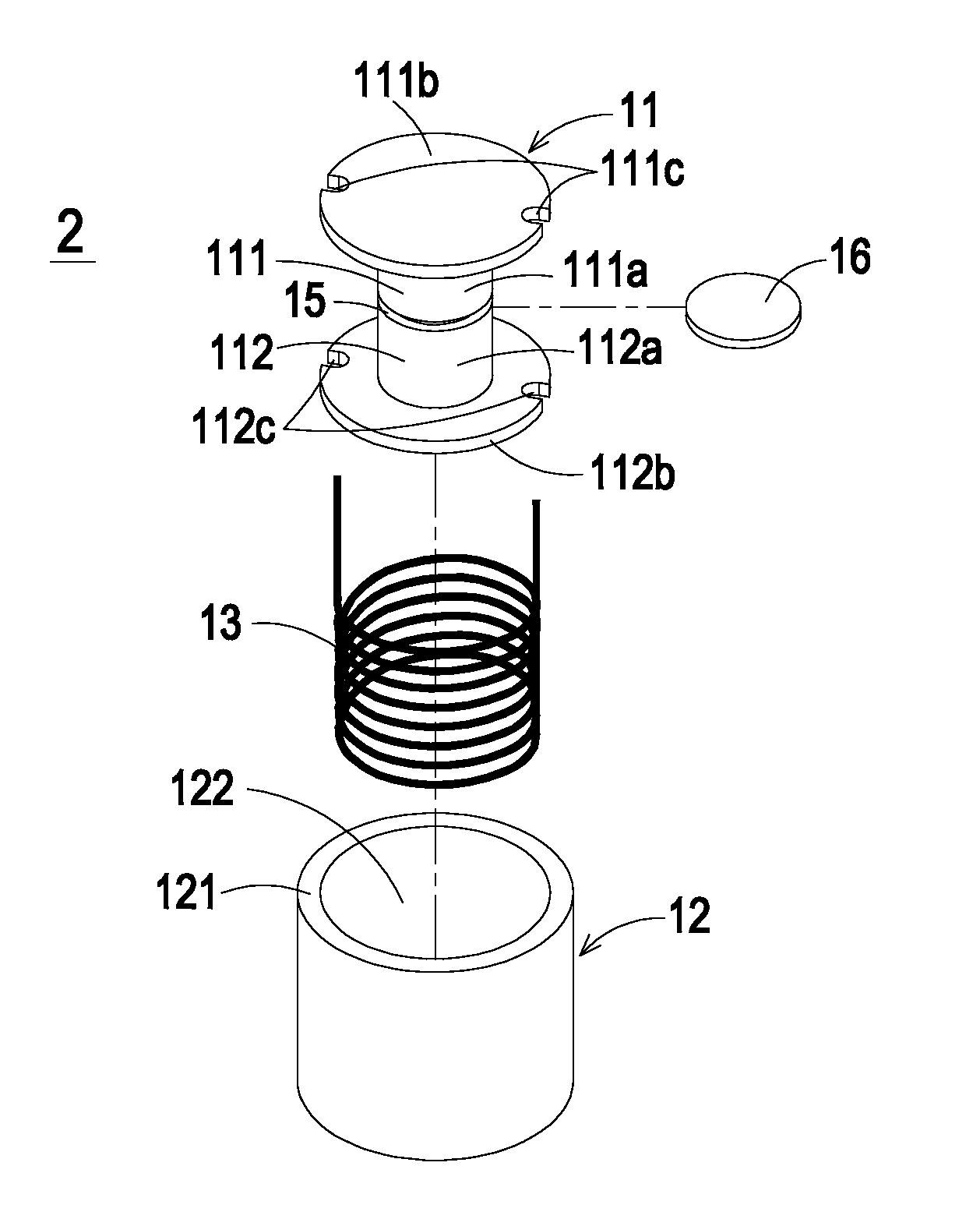

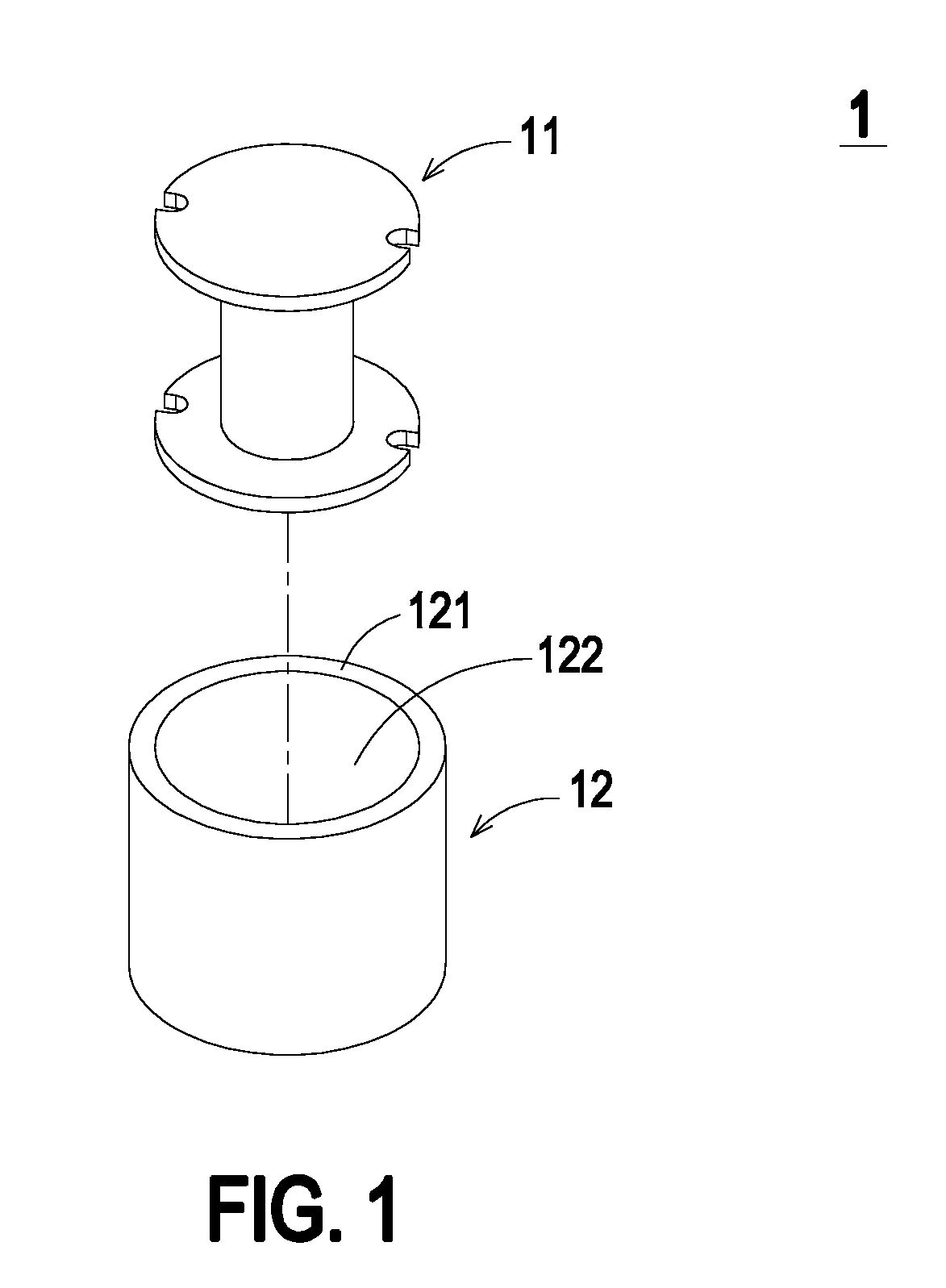

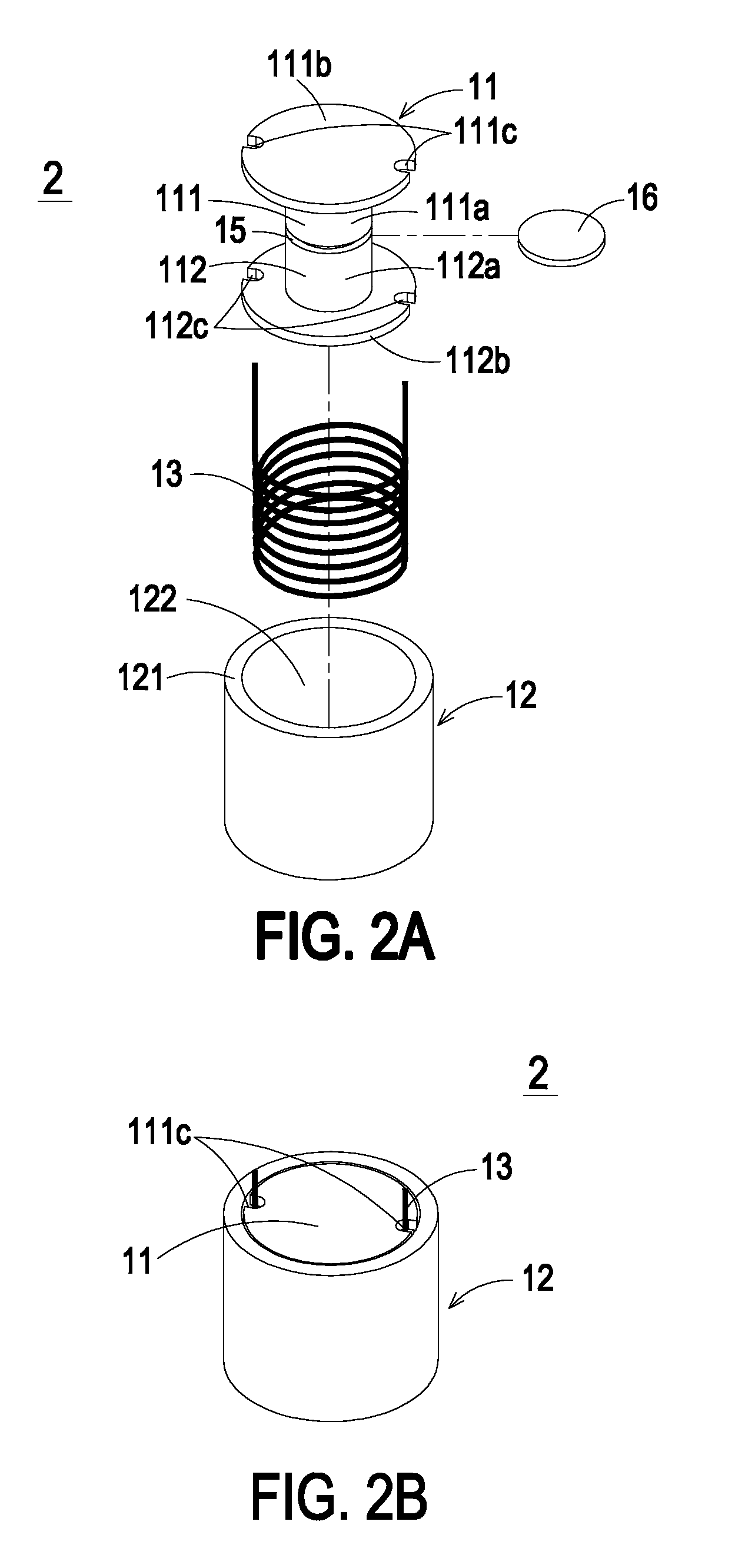

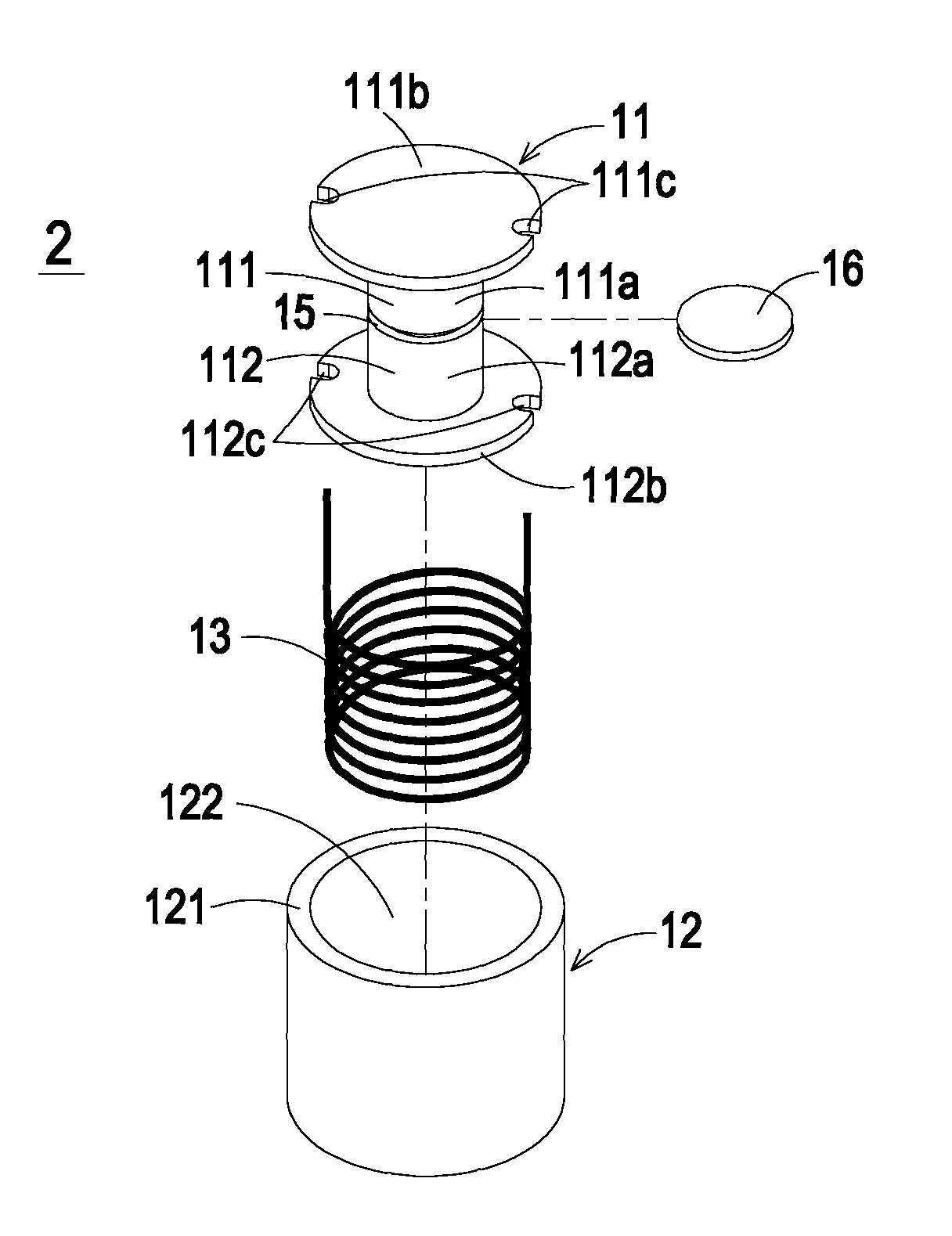

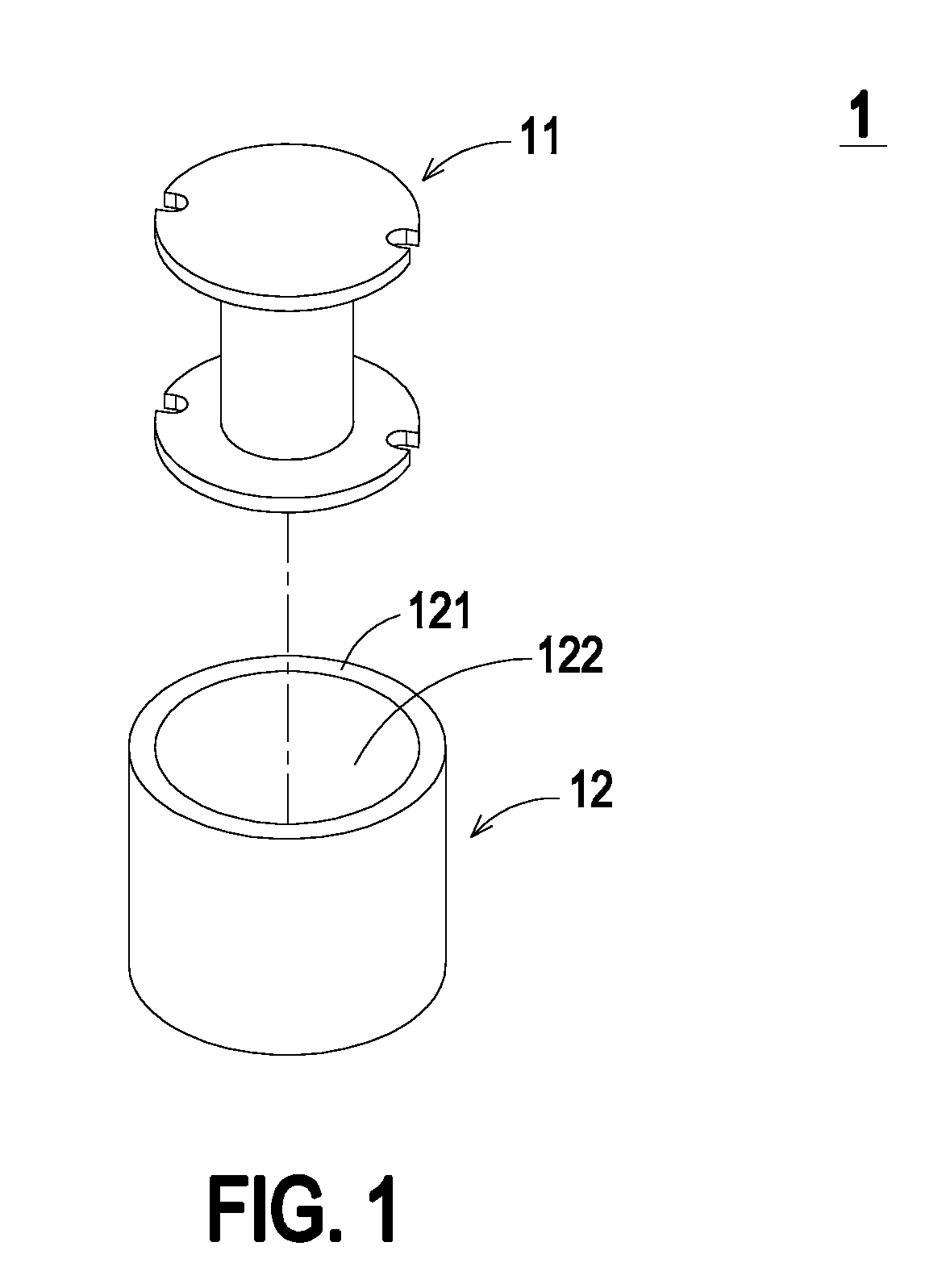

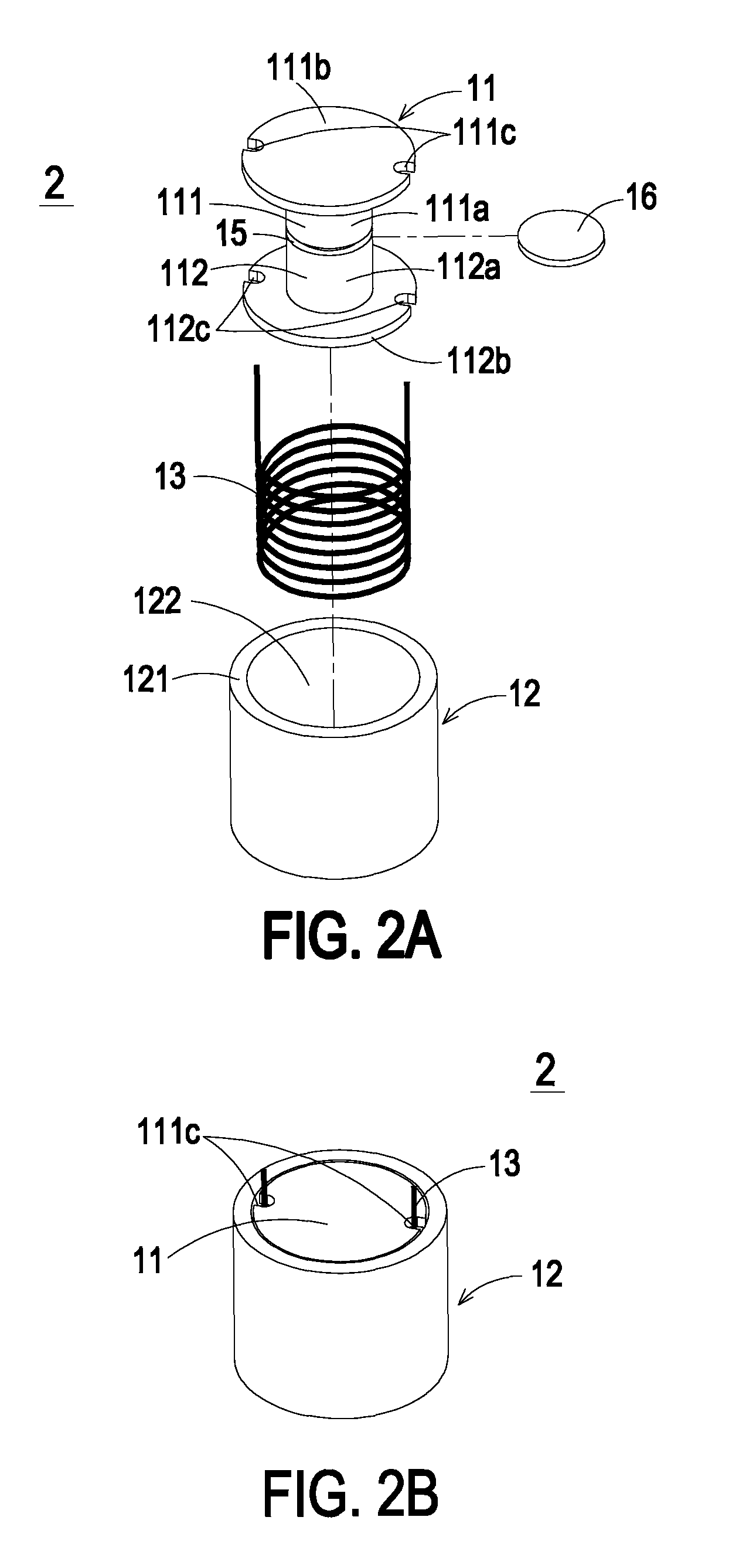

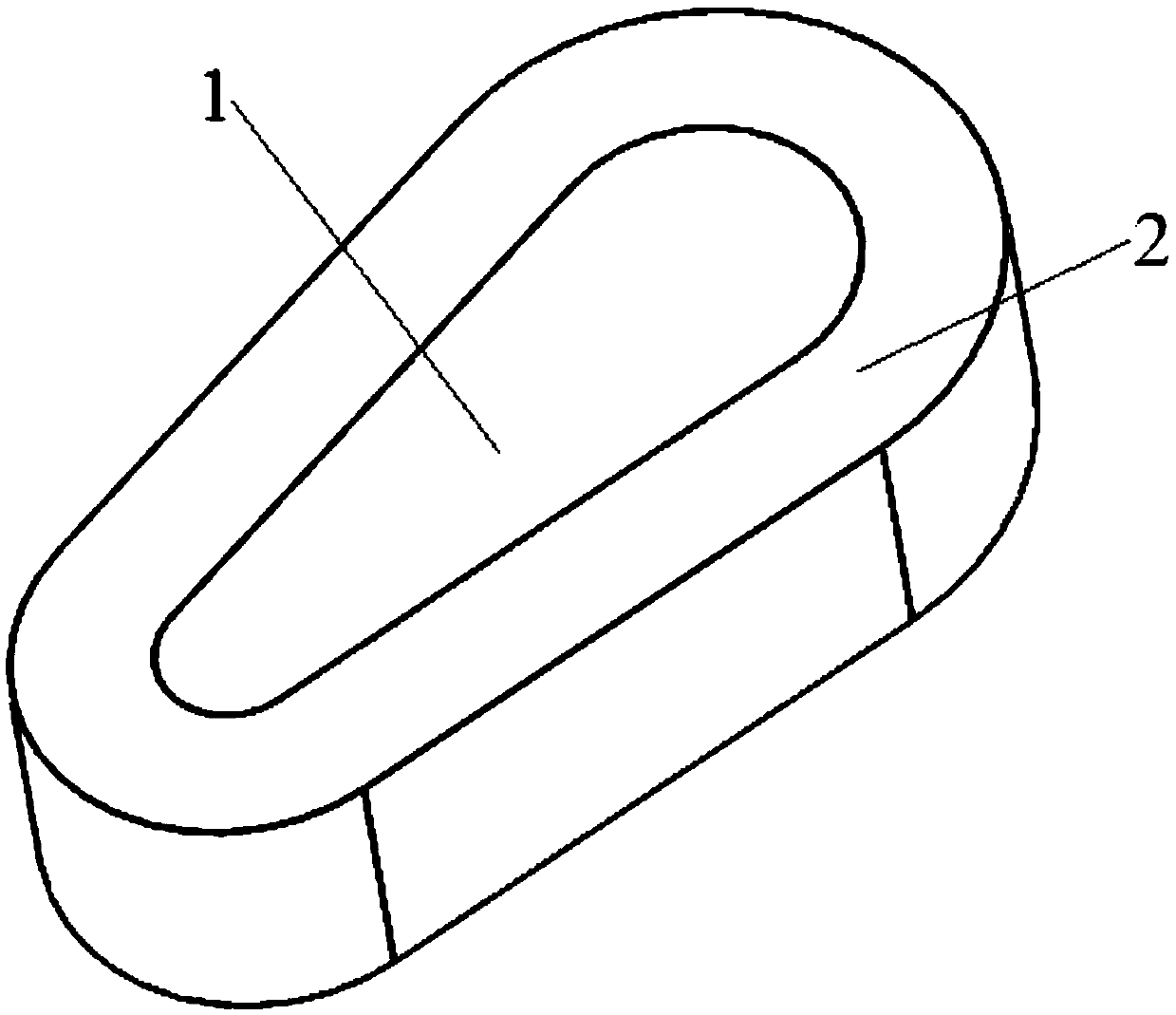

Composite magnetic core assembly, magnetic element and fabricating method thereof

InactiveUS20110121935A1Efficient in operationReduce cost and volumeInorganic material magnetismTransformers/inductances magnetic coresMagnetic coreLow permeability

A composite magnetic core assembly includes an inner magnetic core and an outer magnetic core. The inner magnetic core is made of a high saturation flux density and low permeability material. The outer magnetic core is made of a low saturation flux density and high permeability material. The outer magnetic core includes a ring-shaped wall and a receptacle. The inner magnetic core is accommodated within the receptacle.

Owner:DELTA ELECTRONICS INC

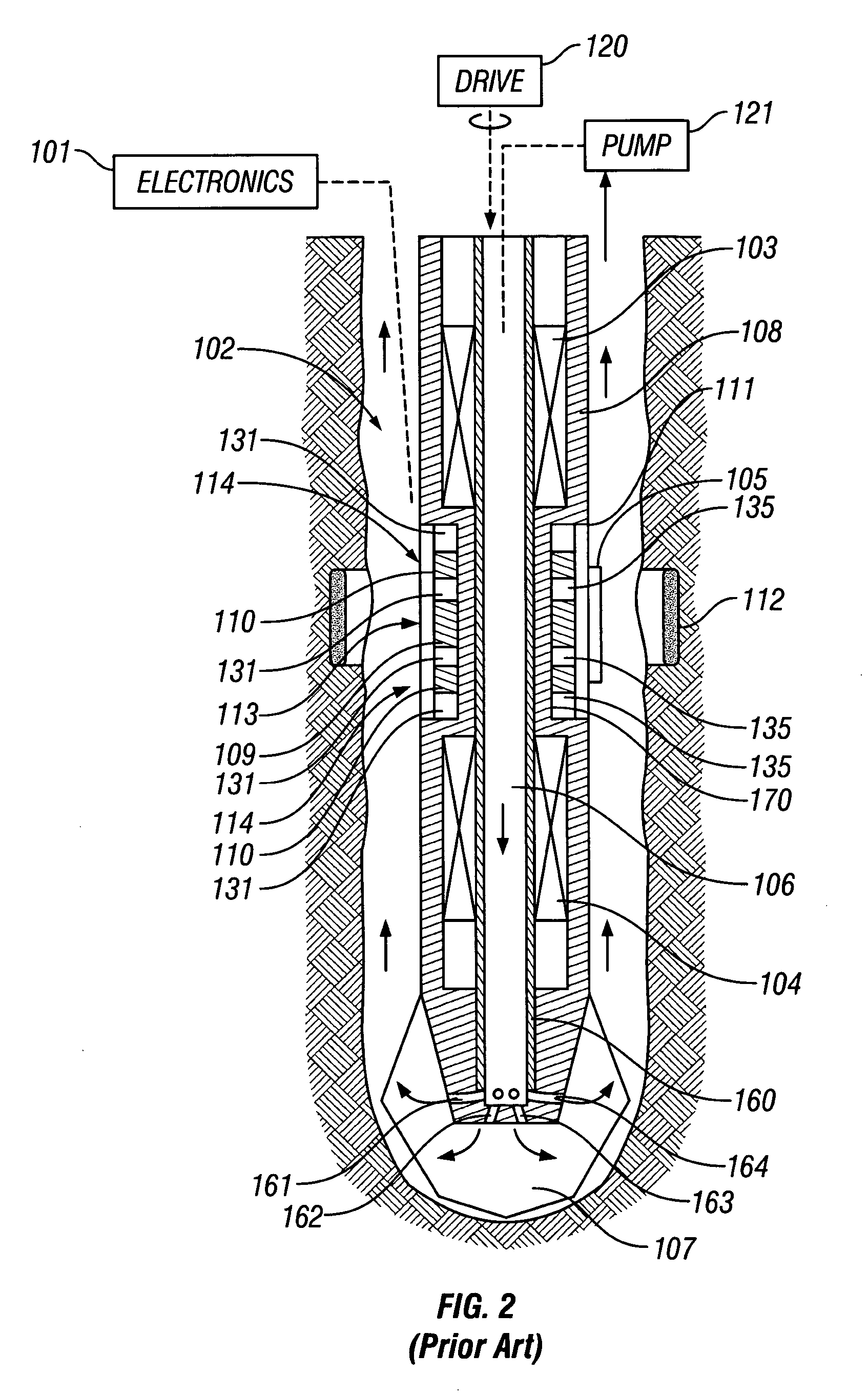

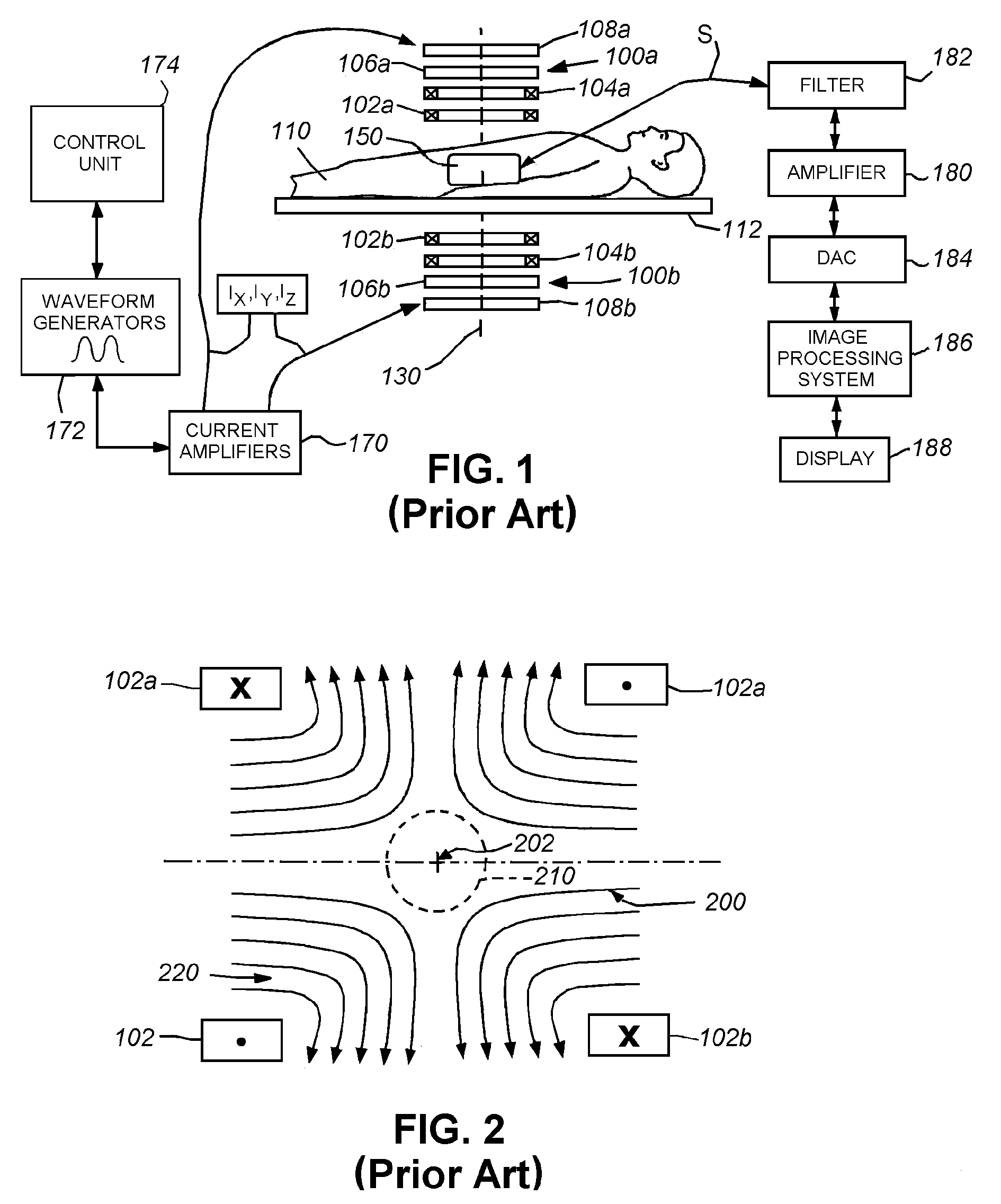

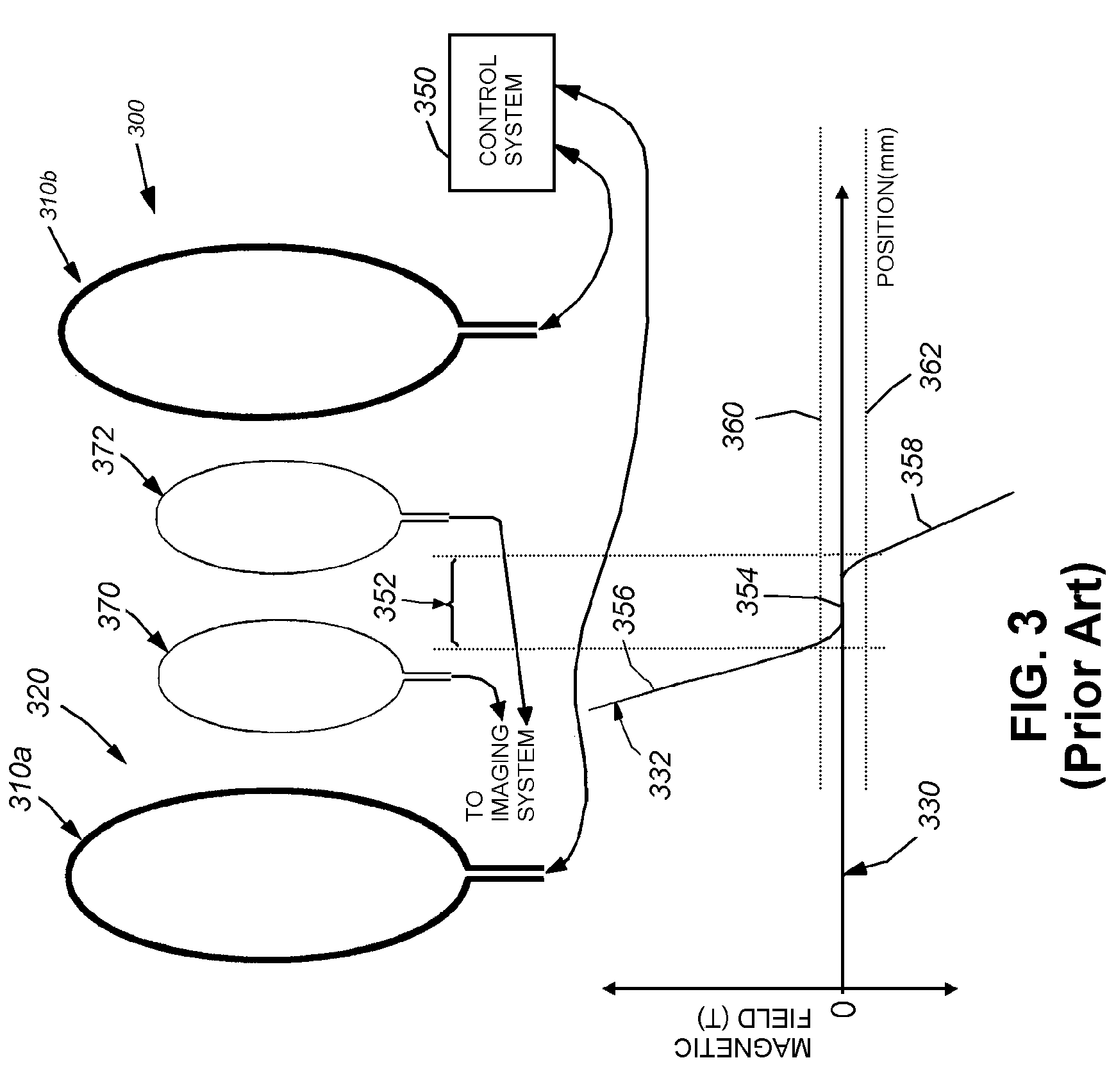

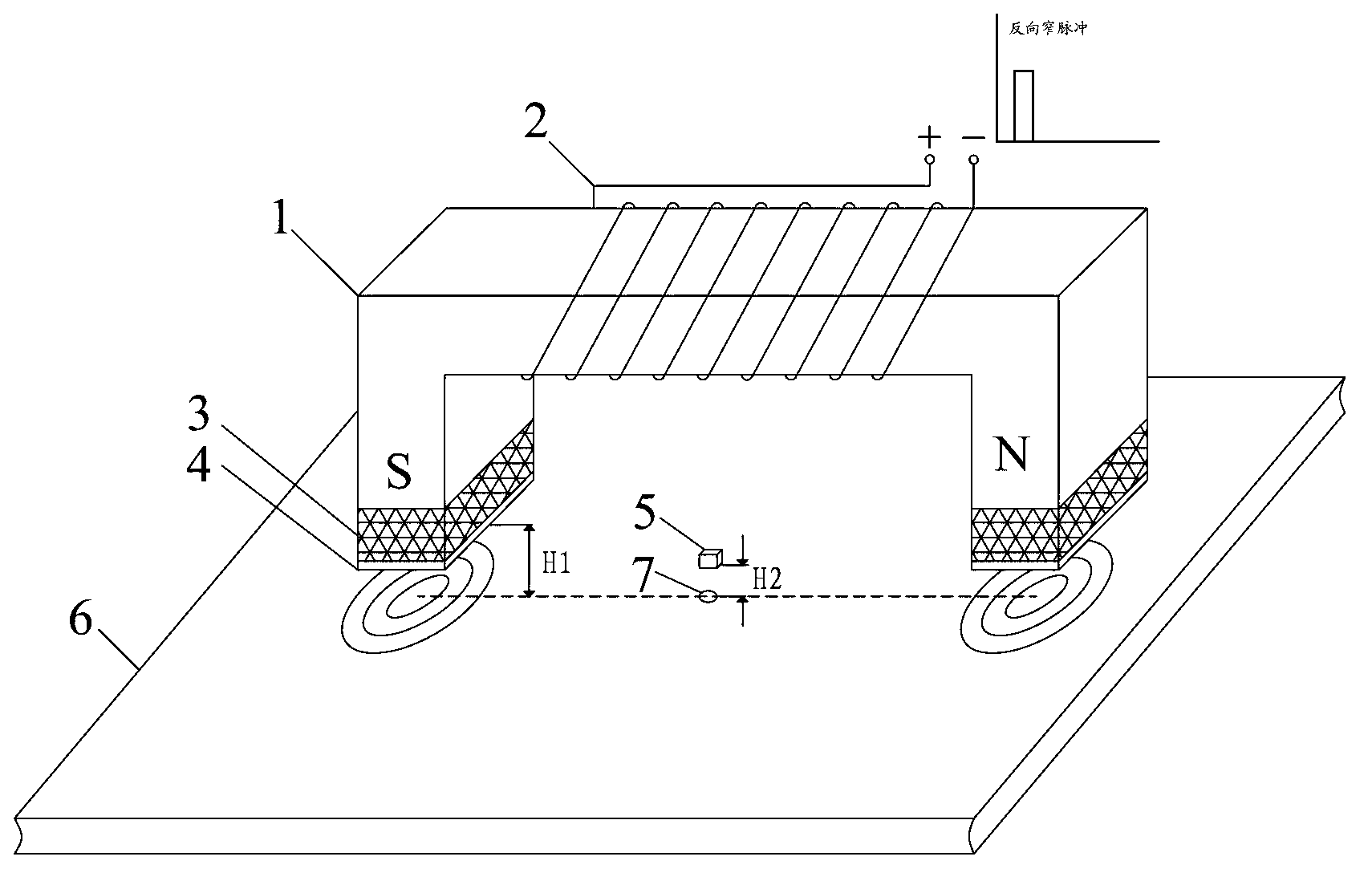

Reduction of motion artifacts in NMR

ActiveUS20050248342A1Different sensitivityElectric/magnetic detection for well-loggingDetection using electron/nuclear magnetic resonanceMagnetic fluxMotion artifacts

NMR spin echo signals, acquired on a MWD logging tool, are susceptible to errors magnetic flux density has a gradient and the magnet on the logging tool is moving relative to the earth. The errors can be corrected by having the excitation pulse cover a smaller or a larger volume than the refocusing pulses. Correction may also be made by selective saturation, or by echo averaging.

Owner:BAKER HUGHES INC

Intergrated magnetic component

ActiveUS20110063065A1Low costImprove efficiencyTransformers/inductances coils/windings/connectionsApparatus with intermediate ac conversionNuclear engineeringCore component

A magnetic component, with a first and a second U / UR core (U1, U2) assembled to a first O-shaped core assembly, wherein an U / UR core has—according to its shape—a first post and a second post with free ends on one side and a leg connecting the first post and the second post on their other side, wherein the first and the second U / UR core (U1, U2) are assembled with their free ends abutting each other to form the first O-shaped core assembly. The free ends of a third U / UR core (U3) are abutting the outside of the first O-shaped core assembly on one side and that the free ends of a fourth U / UR core (U4) are abutting the outside of the first O-shaped core assembly on an opposite side. In another embodiment, the leg of a third U / UR core (U3) is abutting the outside of the first O-shaped core assembly, wherein the ends of a fourth U / UR core (U4) are abutting the ends of the third U / UR core (U3). In a further embodiment, the ends of a third U / UR core (U3) are abutting the outside of the first O-shaped core assembly. At least one winding is wound directly on the first, the second, the third, and / or the fourth U / UR core (U1, U2, U3, U4). The core structure can either be fully composed of high permeability low saturation cores with air gaps or be composite comprising low permeability high saturation cores and high permeability low saturation cores with no air gaps.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD +1

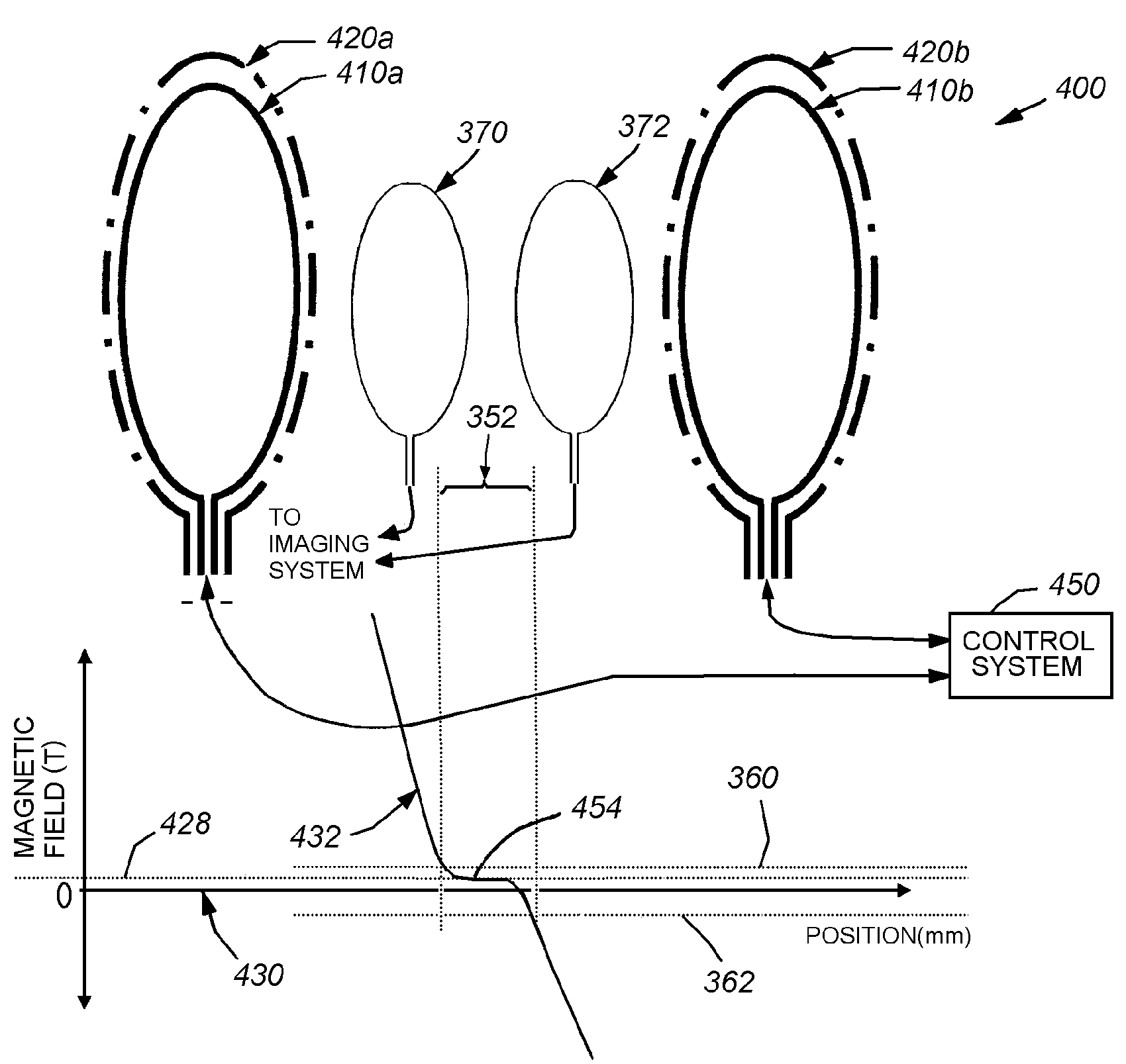

System and method for use of nanoparticles in imaging and temperature measurement

ActiveUS20090115415A1Improve rendering capabilitiesHigh sensitivityNanomagnetismMagnetic property measurementsBinding energyMagnetic particle imaging

This invention provides a system and method that improves the sensitivity and localization capabilities of Magnetic Particle Imaging (MPI) by using combinations of time-varying and static magnetic fields. Combinations of magnetic fields can be used to distribute the signals coming from the magnetic particles among the harmonics and other frequencies in specific ways to improve sensitivity and to provide localization information to speed up or improve the signal-to-noise ratio (SNR) of imaging and / or eliminate the need for saturation fields currently used in MPI. In various embodiments, coils can be provided to extend the sub-saturation region in which nanoparticles reside; to provide a static field offset to bring nanoparticles nearer to saturation; to introduce even and odd harmonics that can be observed; and / or to introduce combinations of frequencies for more-defined observation of signals from nanoparticles. Further embodiments provide for reading of the signal produced by cyclically saturated magnetic nanoparticles in a sample so as to provide a measurement of the temperature of those nanoparticles. The spectral distribution of the signal generated provides estimates of the temperature of the nanoparticles. Related factors may also be estimated—binding energies of the nanoparticles, phase changes, bound fraction of the particles or stiffness of the materials in which the nanoparticles are imbedded.

Owner:DARTMOUTH HITCHCOCK CLINIC

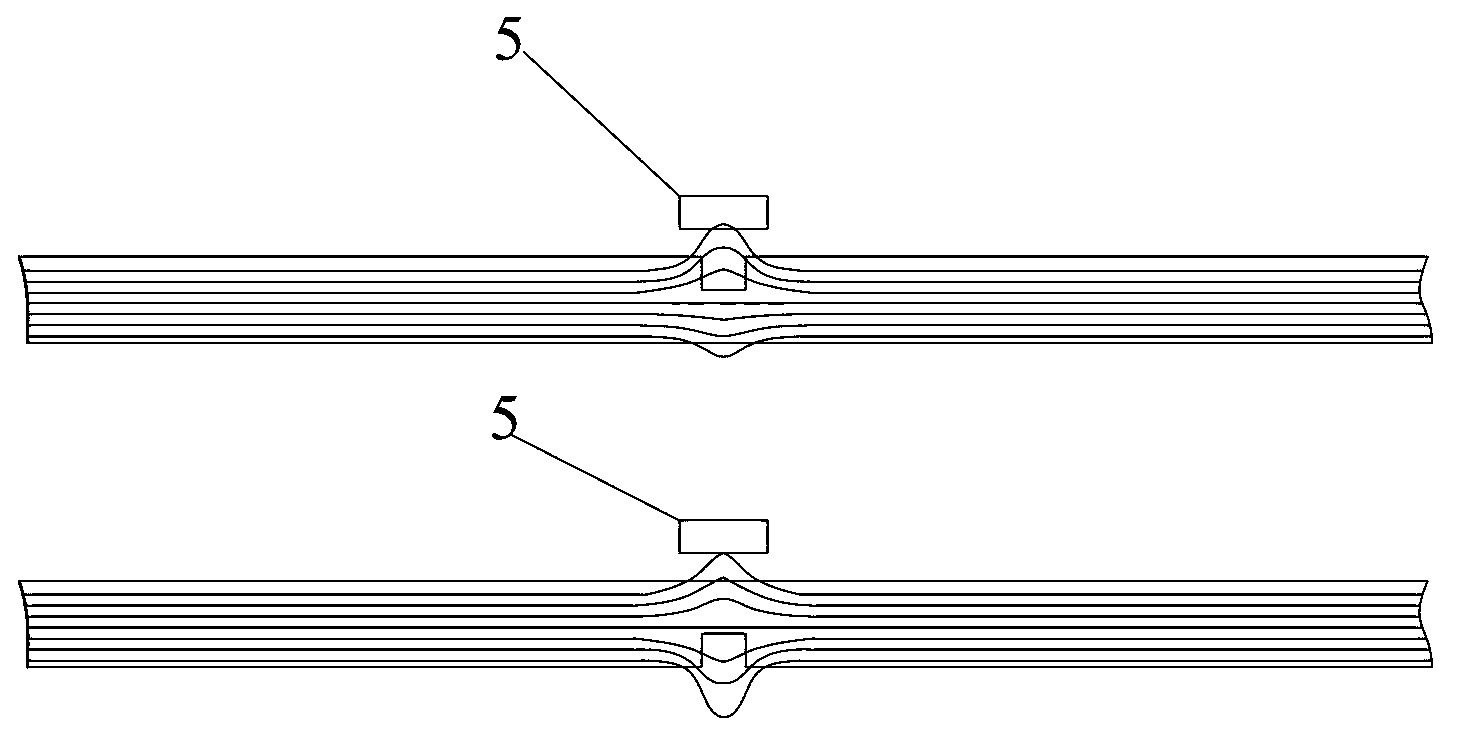

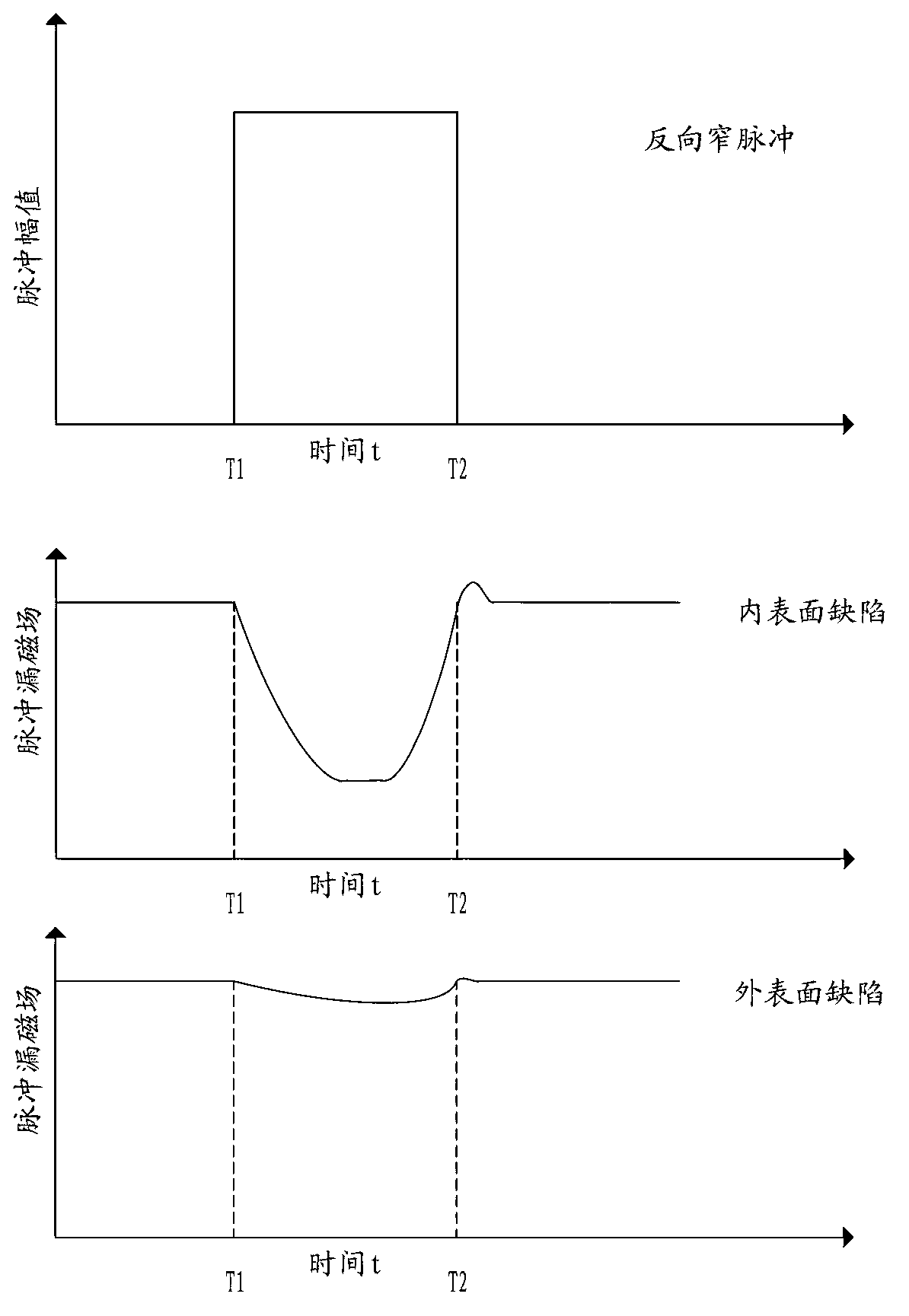

Permanent magnet and pulsed eddy current composite magnetic flux leakage detection method

InactiveCN103175891ASimple hardware structureSimple processing capacityMaterial magnetic variablesHardware structureMagnetization

The invention relates to a permanent-magnet and pulsed-eddy-current composite magnetic flux leakage detection method. With the method provided by the invention, defects on inner and outer surfaces can be effectively identified. The method belongs to the field of nondestructive test. With the effect of a permanent magnet, a ferromagnetic material requiring detection is magnetization into a local saturation state; if a detected magnetic flux leakage signal is larger than a preset intensity threshold B1, the ferromagnetic material has a defect; a reverse narrow pulse signal is applied to a excitation coil, such that the excitation coil generates a pulsed magnetic field, and pulsed eddy current is formed on the inner surface of the ferromagnetic material below two poles of a U-shaped magnetic yoke; at the time, if a detected leakage field intensity pulsation value is larger than a preset pulsation threshold B2, the defect is positioned on the inner surface of the ferromagnetic material; otherwise, the defect is positioned on the outer surface of the ferromagnetic material. The method provided by the invention has the advantages of simple hardware structure, low energy consumption, and convenient and fast signal processing.

Owner:XIAMEN UNIV

Ferrite composite magnetic powder core and preparing method thereof

InactiveCN103426584AOvercome the disadvantage of reduced magnetic performanceImprove permeabilityInorganic material magnetismInductances/transformers/magnets manufactureAdhesivePhosphoric acid

The invention relates to a ferrite composite magnetic powder core and a preparing method thereof. According to the technical scheme, a hydrothermal method is used for preparing nano nickel zinc ferrite particles with even particle sizes, the nano nickel zinc ferrite particles are used as insulation media to coat magnetically soft alloy powder which is passivated by phosphoric acid, an inorganic adhesive is added, and a novel nickel zinc ferrite composite magnetic powder core is prepared after compression and heat treatment. The ferrite composite magnetic powder core and the preparing method thereof have the advantages that first, due to the fact that the ferrite is used as the insulation coating agent of the magnetically soft alloy powder, the defect that the magnetic performance of a substrate is lowered due to the fact that traditional nonmagnetic substances are used as the coating agent is overcome, and high magnetic conductivity and saturation magnetization can be achieved; second, the hydrothermal method is used for preparing the ferrite, and controllable nano particles with even sizes can be prepared conveniently; third, inorganic materials are used as the coating agent, and magnetic powder devices can be prevented from losing efficacy when being used at a high temperature.

Owner:CHINA JILIANG UNIV

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

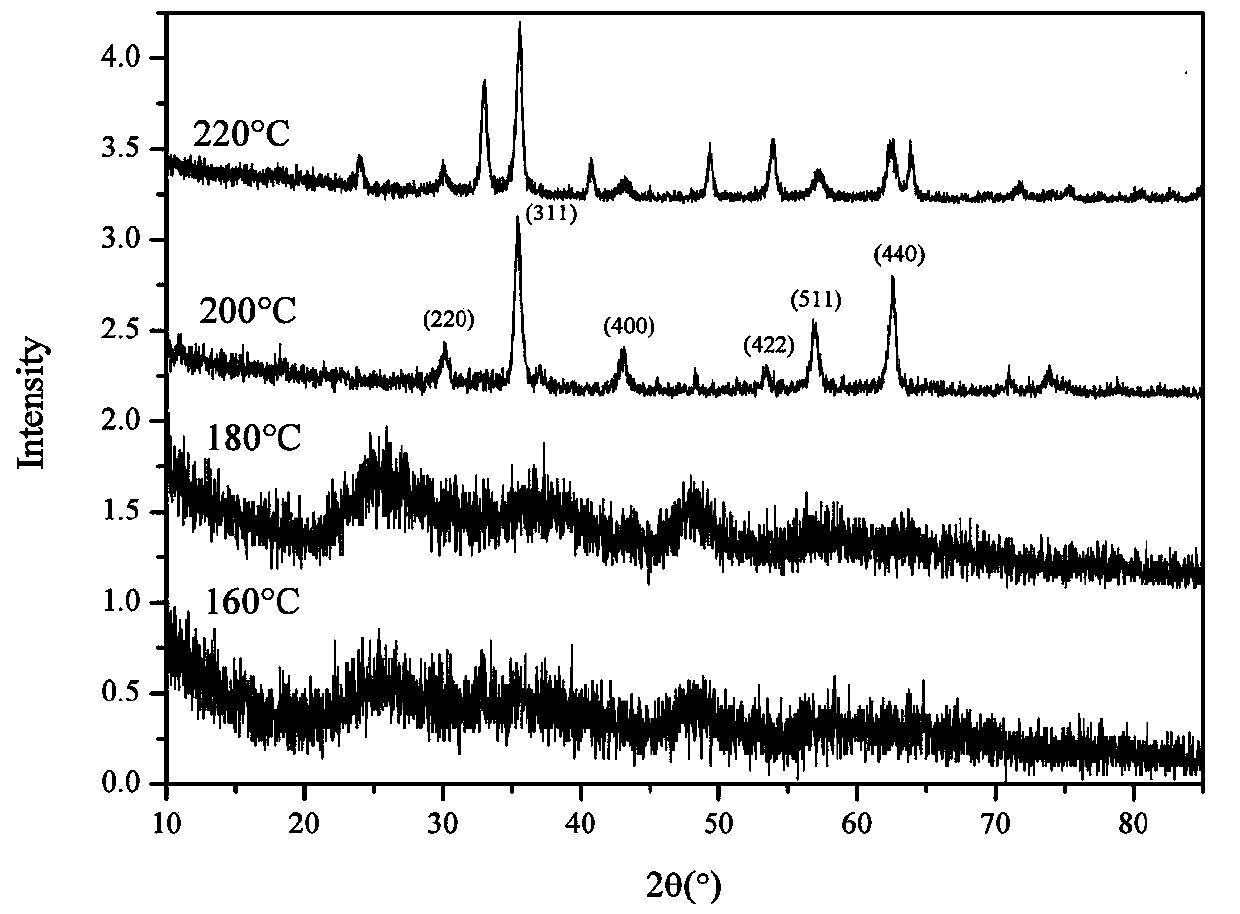

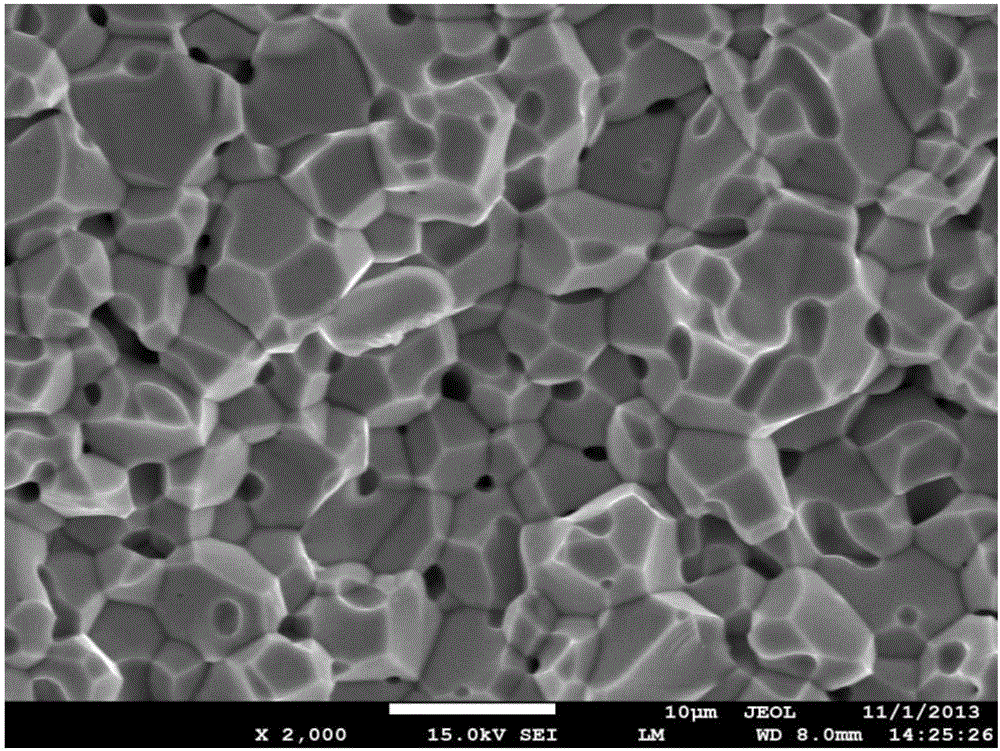

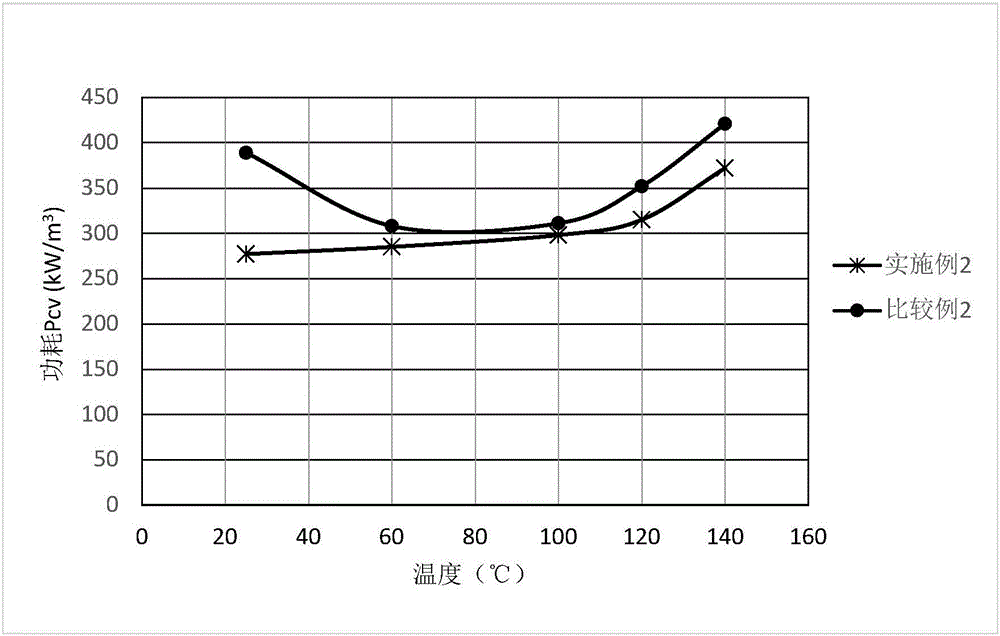

Ni-free MnZn ferrite magnetic core with double characteristics and manufacture method

ActiveCN103496963AOvercome the inability to take into account multiple featuresImprove performanceFerrite (magnet)Condensed matter physics

The invention provides a Ni-free MnZn ferrite magnetic core with double characteristics and a manufacture method thereof, wherein the double characteristics mean high temperature and high Bs, and wide temperature and low loss. The ferrite magnetic core comprises main components and auxiliary components. The main components comprise: 53 mol%-54 mol% of Fe2O3, 39 mol%-42 mol% of MnO and 4 mol%-7 mol% of ZnO; and the auxiliary components comprise: Co2O3 or CoO or Co3O4 as a first auxiliary component, SiO2 and CaCO3 as a second auxiliary, and a third auxiliary component which is one or more selected from MoO3, TiO2, SnO2, Nb2O5, V2O5, Sm2O3 and ZrO2. The provided MnZn ferrite magnetic core with double characteristics has unit volume loss Pcv (100kHz, 200mT) less than 350 kW / m<3> at the temperature of 25 DEG C to 120 DEG C, lowest loss of 300 kW / m<3> at the temperature of about 90 DEG C, and saturation magnetic flux density up to 450 mT at the temperature of 100 DEG C.

Owner:江门安磁电子有限公司

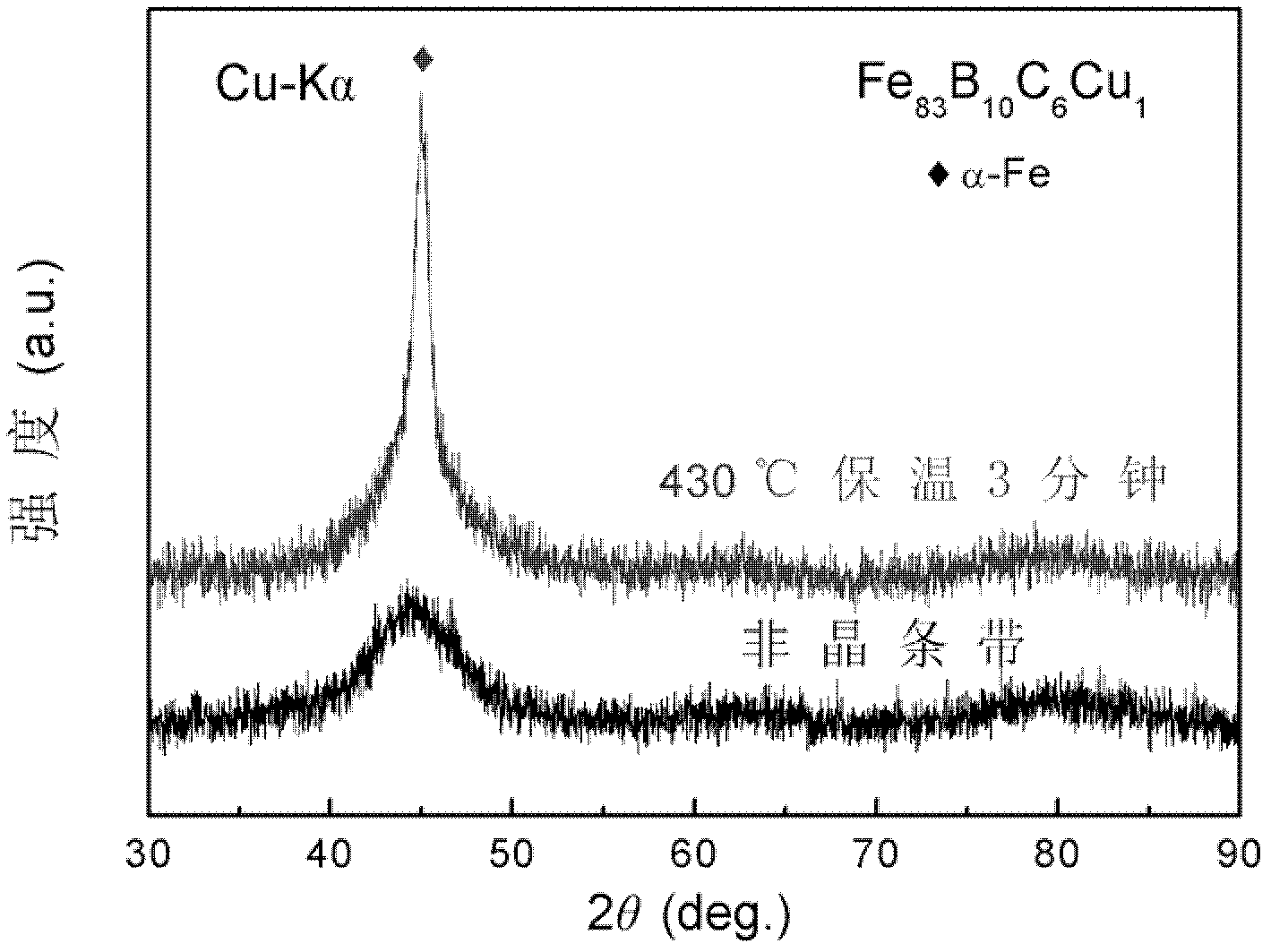

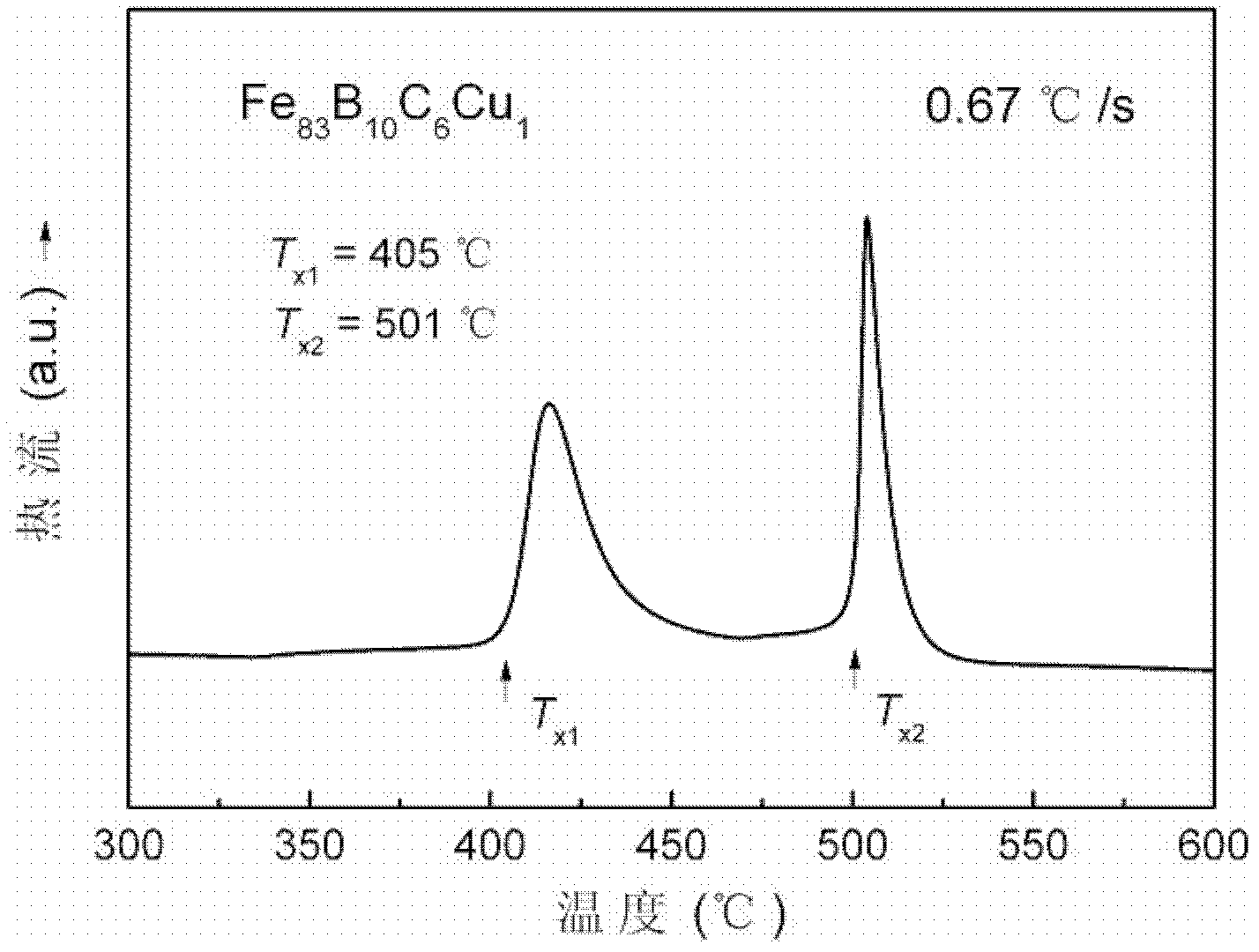

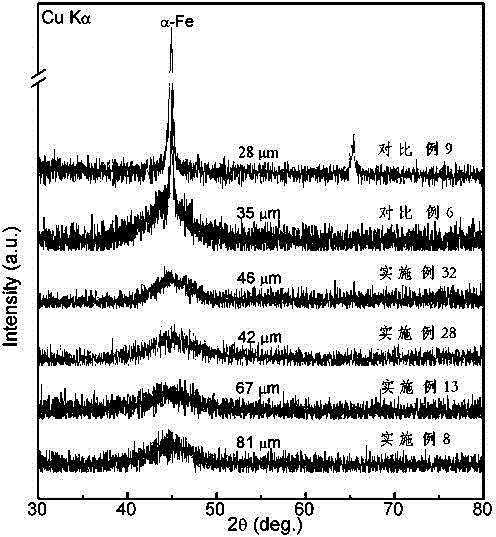

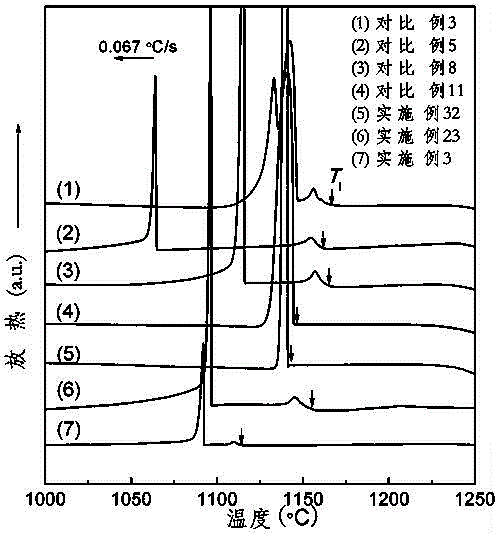

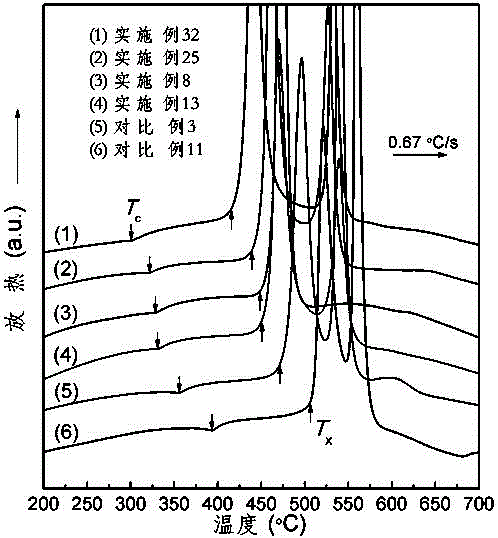

Iron-based nanocrystalline soft magnetic alloy with high saturation magnetic induction and low cost

ActiveCN102304669AHigh saturation magnetic inductionLow coercivityMagnetic materialsProcessing costAmorphous matrix

The invention relates to an iron-based nanocrystalline soft magnetic alloy. The alloy is characterized in that: the alloy meets the following relation in composition: FeaBbCcMdCue, wherein M represents one or more of Si, Al, Cr and Mn, the subscripts a, b, c, d and e represent the atom percents of the corresponding elements of the alloy respectively and meet the following conditions: 78<=a<=88, 4<=b<=16, 3<=c<=10, 0<=d<=8, 0.3<=e<=1.5 and a+b+c+d+e=100. The iron-based nanocrystalline alloy consists of an amorphous matrix phase and a nanocrystalline phase. The alloy is obviously characterized in that: the alloy has excellent soft magnetic performances such as high saturation magnetic induction, low coercivity, low loss and the like; and the alloy does not contain precious metal elements and volatile elements, thereby reducing the processing cost of the raw materials and bringing convenience to popularization and application. The invention also relates to a preparation method of the alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

Composite magnetic powder core and preparation method thereof

InactiveCN103426580AEasy to manufactureUniform sizeInductances/transformers/magnets manufactureMagnetic materialsNanoparticleNickel-zinc ferrite

The invention relates to a composite magnetic powder core and a preparation method of the composite magnetic powder core. According to the technical scheme, nanometer ferrite particles with even size are prepared on the surface of soft magnetic alloy powder through a hydrothermal method in a root-positioning mode, and a novel ferrite composite magnetic powder core is prepared through the pressing and thermal processing technology. The composite magnetic powder core and the manufacturing method of the composite magnetic powder core have the advantages that due to the fact that manganese zinc ferrite and nickel zinc ferrite are prepared through a hydrothermal method and a root position method, nanometer particles with controllable and even size can be prepared conveniently; the ferrite can be used as an insulated coating agent of the soft magnetic alloy powder, the defect that magnetic performance of a substrate is reduced when traditional nonmagnetic substances are used as the coating agent are overcome, and high magnetic conductivity and saturation magnetization strength can be obtained.

Owner:CHINA JILIANG UNIV

High saturation induction density iron-based nanocrystalline magnetically soft alloy material and preparation method thereof

InactiveCN102808140AHigh saturation magnetic inductionLow costMagnetic materialsIngotThermal treatment

The invention relates to a high saturation induction density iron-based nanocrystalline magnetically soft alloy material and a preparation method thereof. According to the scheme provided by the invention, the alloy material consists of the following chemical components in percentage by atom: 72.5-76.5 percent of Fe, 9-12 percent of Si, 9-9.6 percent of B, 0.8-1.2 percent of Cu, 0.3-0.5 percent of Co, 1.5-2 percent of Mo, 0.8-1.5 percent of Cr, 1-2 percent of P, 0.002-0.06 percent of Y and other inevitable impurities. The preparation method of the alloy material comprises the following steps of: preparing the chemical components according to the percentage by atom, mixing uniformly, and smelting and casting in vacuum to obtain a master alloy ingot; remelting the master alloy ingot, and spraying into an amorphous belt material with a single roll melt-spinning method; and performing thermal treatment to obtain the high saturation induction density iron-based nanocrystalline magnetically soft alloy material. The method has the characteristics of low production cost and easiness in realizing a thermal treatment process; and the product has high saturation induction density, low coercive force and a wide application range, and is particularly suitable for the fields of transformers and mutual inductors.

Owner:WUHAN UNIV OF SCI & TECH

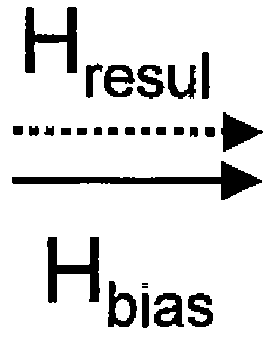

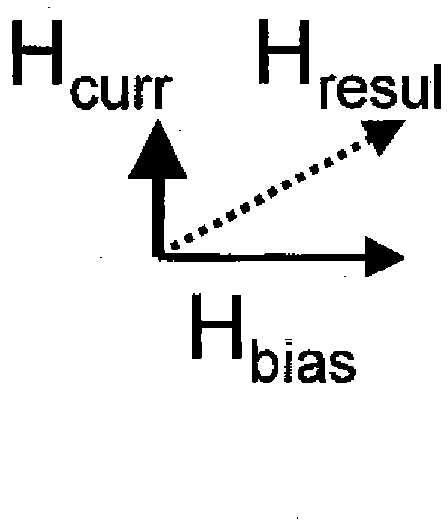

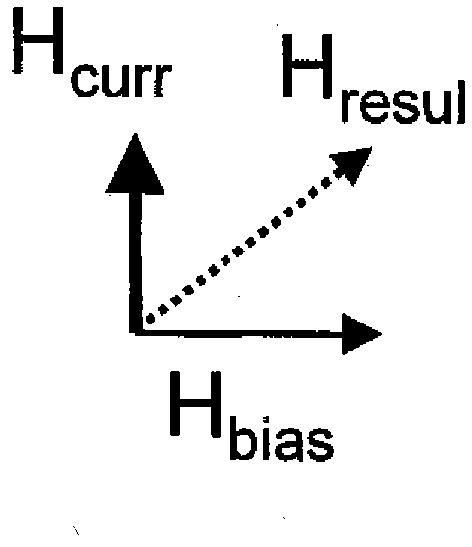

Magnetoresistive sensor arrangement for current measurement

A sensor unit for the measurement of a current in a conductor (1) comprising at least one magnetoresistive sensor (5, 6) located at a radial distance from the outer surface of the conductor (1) is disclosed, wherein the conductor (1) has a circular cross-section, and wherein it comprises at least one auxiliary coil (7) for the generation of a bias magnetic field (Hbias) to the magnetoresistive sensor (5, 6) strong enough for inducing magnetic saturation in the magnetoresistive sensor (5, 6) continuously during the whole current measurement process. Further the use of such a sensor and a method for measuring the current in the conductor using such a sensor unit are disclosed.

Owner:ABB (SCHWEIZ) AG

Fe-based amorphous alloy with high saturation magnetic induction intensity and strong amorphous forming ability

ActiveCN105088107AStrong Amorphous Formation AbilityStrong magnetismFurnace typesMagnetic materialsPlanar flowQuenching

The invention relates to a Fe-based amorphous alloy. The percentage content of Fe atoms in the Fe-based amorphous alloy ranges from 81.8 to 84.3, and the Fe-based amorphous alloy has a saturation magnetic induction intensity being larger than or equal to 1.61 T, and / or a coercive force being less than or equal to 5 A / m. The formula of the Fe-based amorphous alloy is FeSiB<c>P<d>C<e>M<f>, wherein M is one or more inevitable impurity elements in the raw materials; a, b, c, d, e and f respectively represent the atom percentage contents of all the corresponding components; and the sum of a, b, c, d, e and f is 100. The Fe-based amorphous alloy has the advantages of high saturation magnetic induction intensity and other good magnetic properties on the premise of meeting the requirement of strong amorphous forming ability for preparation of wide-width strips through planar flow casting and rapid quenching. The maximal thickness of an alloy wide-width strip sample reaches 81 [mu]m. In addition, the alloy does not contain nonmagnetic metallic elements, is suitable for being produced by industrial-purity raw materials, is simple in preparation method, and has the advantage of low manufacturing cost. The alloy strip sample has very good ductility before and after heat treatment, and can be folded by 180 degrees without fracture when reaching the optimal magnetic property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

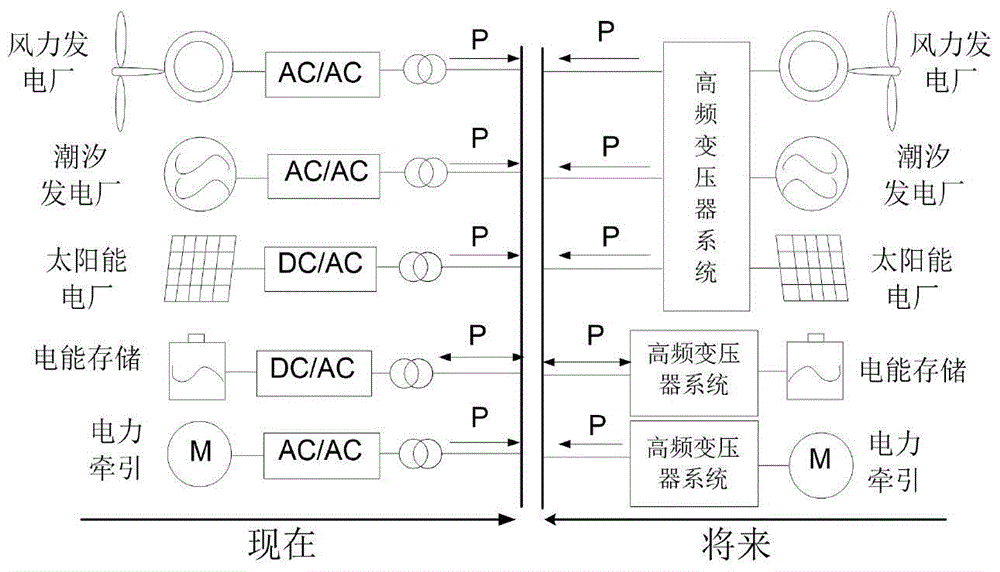

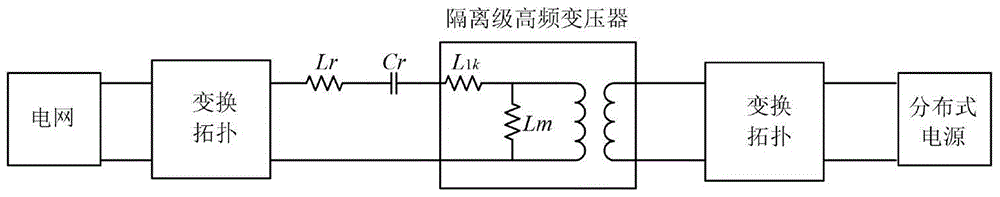

Control method for inductance parameter of high-frequency transformer body

InactiveCN105742047AAccurate control of inductance parametersAccurate control of inductance parameter valuesInductances/transformers/magnets manufactureInformaticsMagnetic coreEngineering

The invention provides a control method for an inductance parameter of a high-frequency transformer body. The control method comprises excitation inductance control and leakage inductance control of a high-frequency transformer; the rated voltage and the work frequency of the high-frequency transformer are known under the condition that the magnetic core structure and dimension are determined; the excitation inductance control method comprises the following steps: selecting a magnetic core material according to different magnetic core material magnetization characteristics and different saturation flux densities; controlling the work flux density to be Bm; and controlling an air-gap length to be lg under the condition of an open air gap of the magnetic core; and the leakage inductance control method comprises the following steps: controlling the number of turns of single-layer windings in primary and secondary windings; controlling the interlayer thickness of the primary winding, the interlayer thickness of the secondary winding and the thickness between the primary winding and the secondary winding; and changing the arrangement mode of the primary winding and the secondary winding in a separating manner, a sandwich manner and a complete coordinated transposition manner. The control method provided by the invention is used for controlling the inductance parameter, so that resonance on conversion topologies at two sides of the high-frequency transformer is achieved; and the voltage quality is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

Power type nickel-zinc ferrite material and preparation method thereof

ActiveCN106587977AThe preparation method is simple and easyEasy to operateInorganic material magnetismNickel-zinc ferriteZinc

The invention discloses a power type nickel-zinc ferrite material. The power type nickel-zinc ferrite material is prepared from a main material and an auxiliary material. The main material is prepared from, by molar percentage, 48-53 mol% of Fe2O3, 18-23 mol% of NiO, 20-25 mol% of ZnO and 6-8 mol% of CuO. The auxiliary material is selected from at least one of MnO, SiO2, Bi2O3, TiO2, V2O5, Co2O3, Cr2O3, MoO3, ZrO2, Nb2O5 and WO3. The power type nickel-zinc ferrite material has high magnetic conductivity, ultrahigh saturation flux density, ultralow power loss and high high-temperature-resisting soldering tin temperature, and the application range of the nickel-zinc ferrite material can be widened. The invention further provides a preparation method of the power type nickel-zinc ferrite material. The preparation method is simple in step, high in operability and suitable for industrial production.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

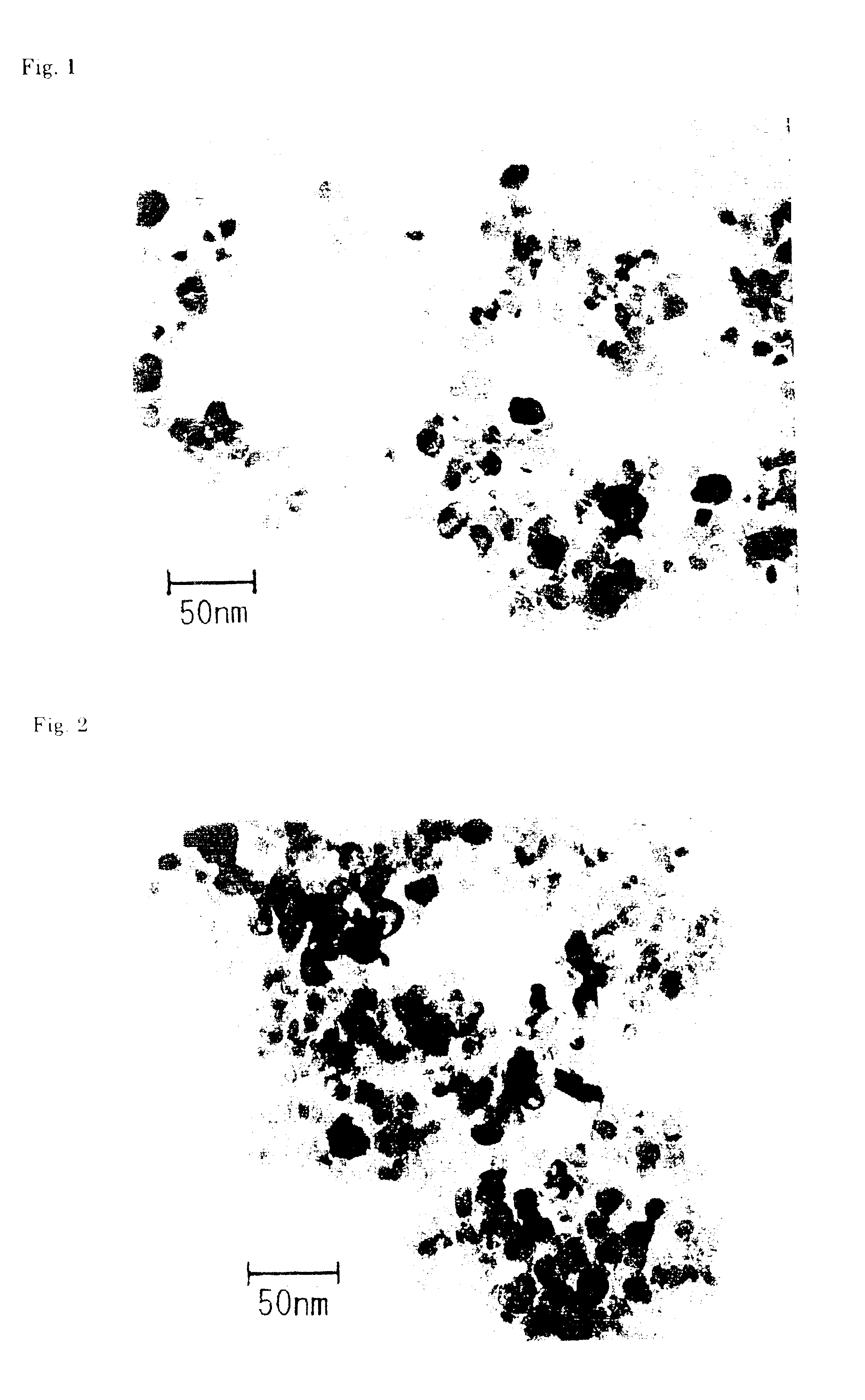

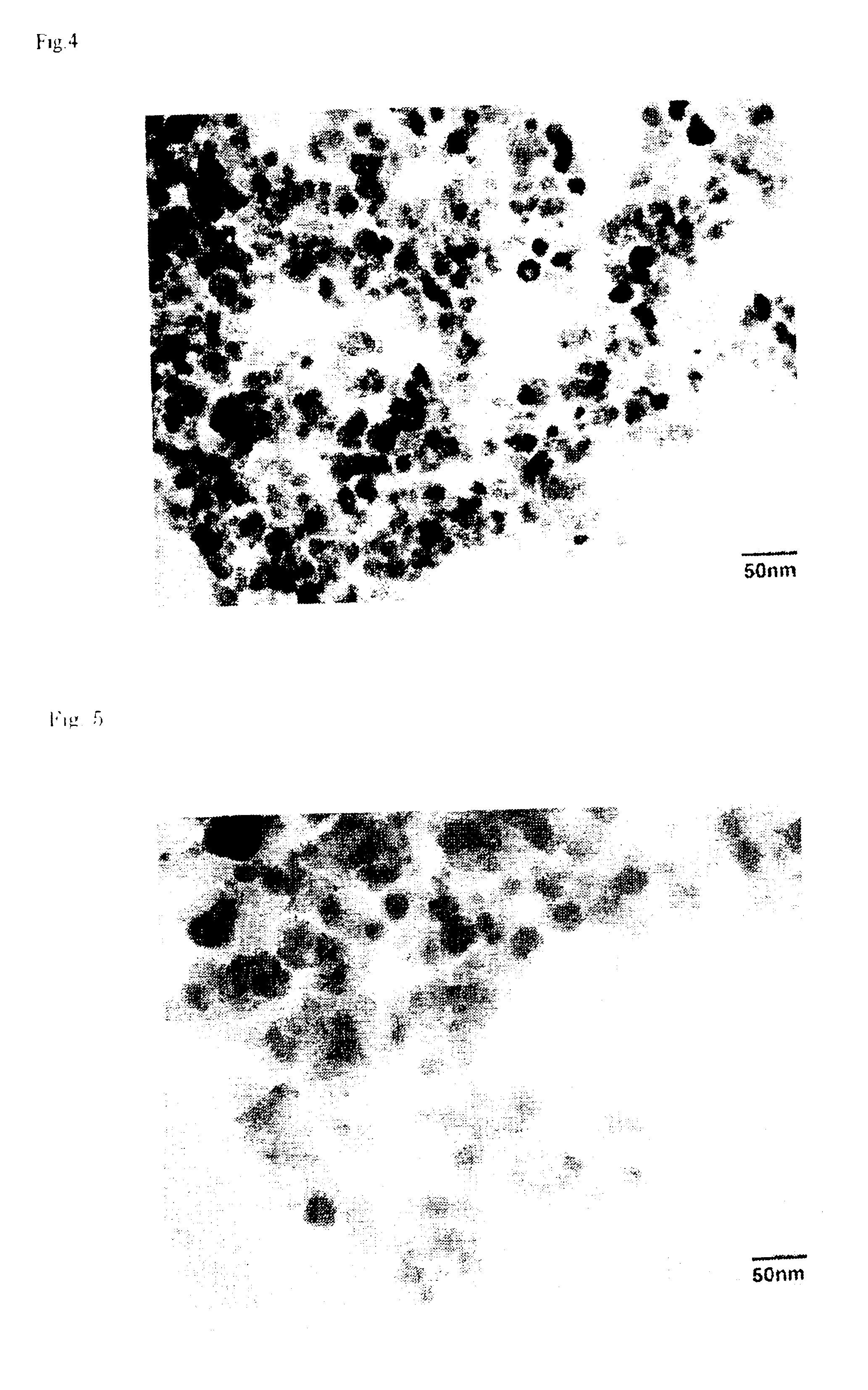

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

InactiveUS6964811B2Recording characteristicImprove recording effectMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 uWb / g.

Owner:FUJIFILM CORP

Magnetic clay material and preparation method thereof

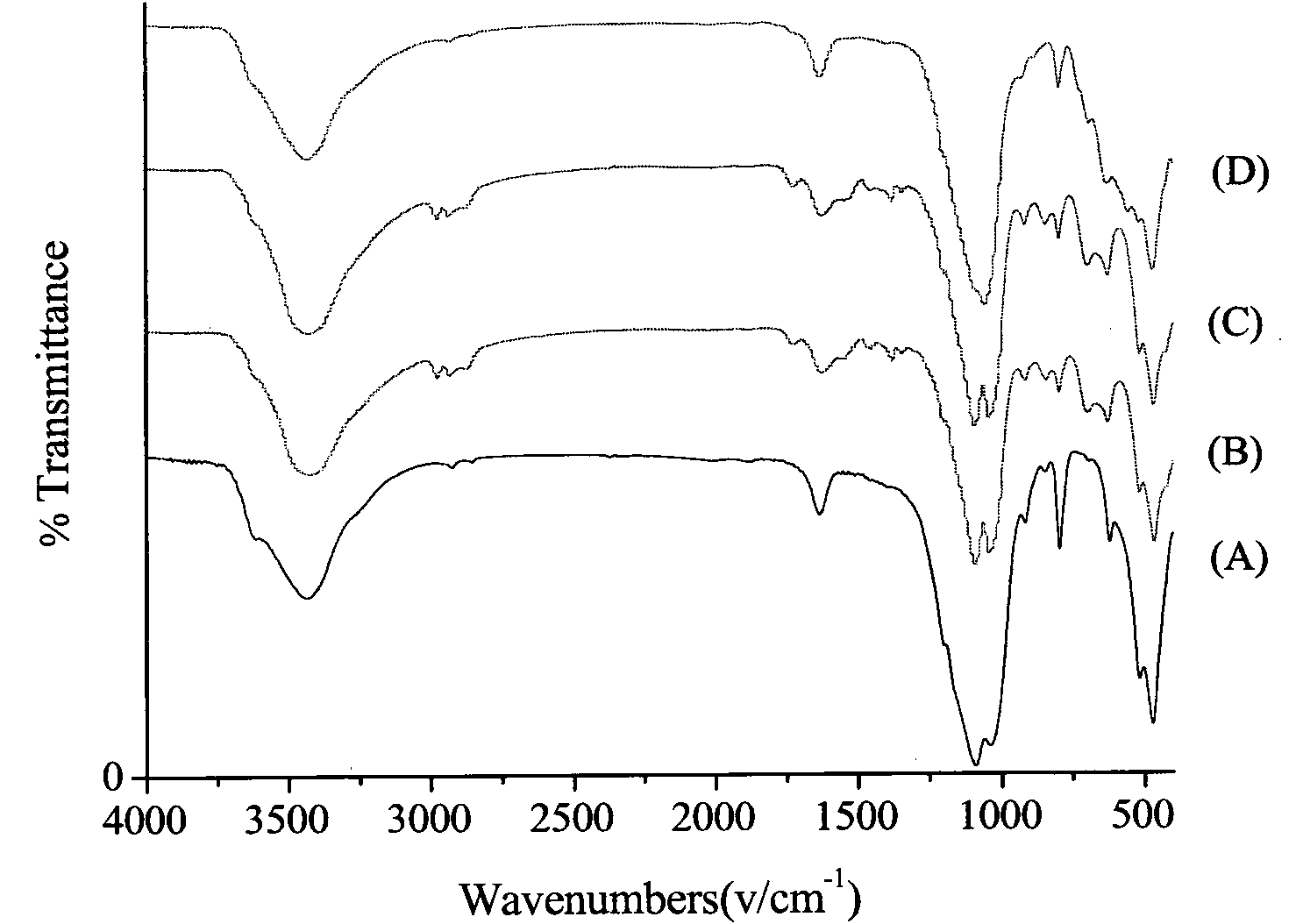

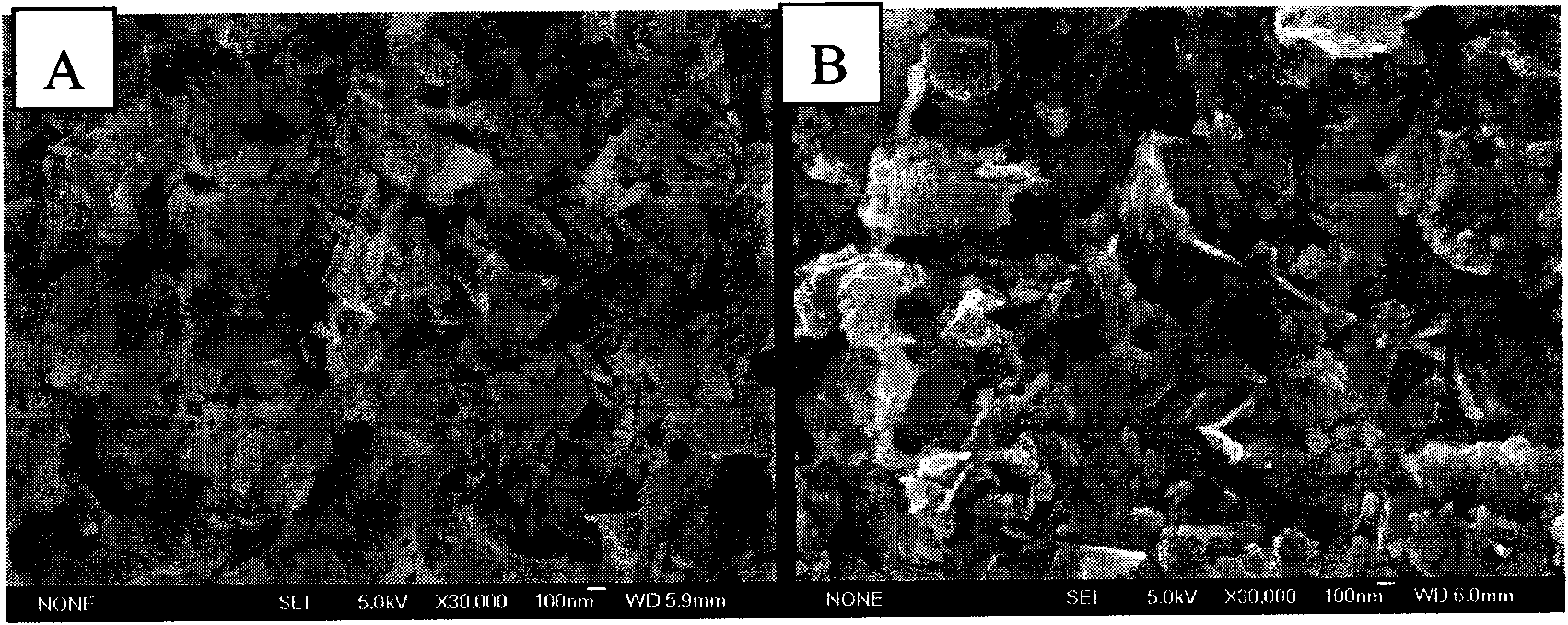

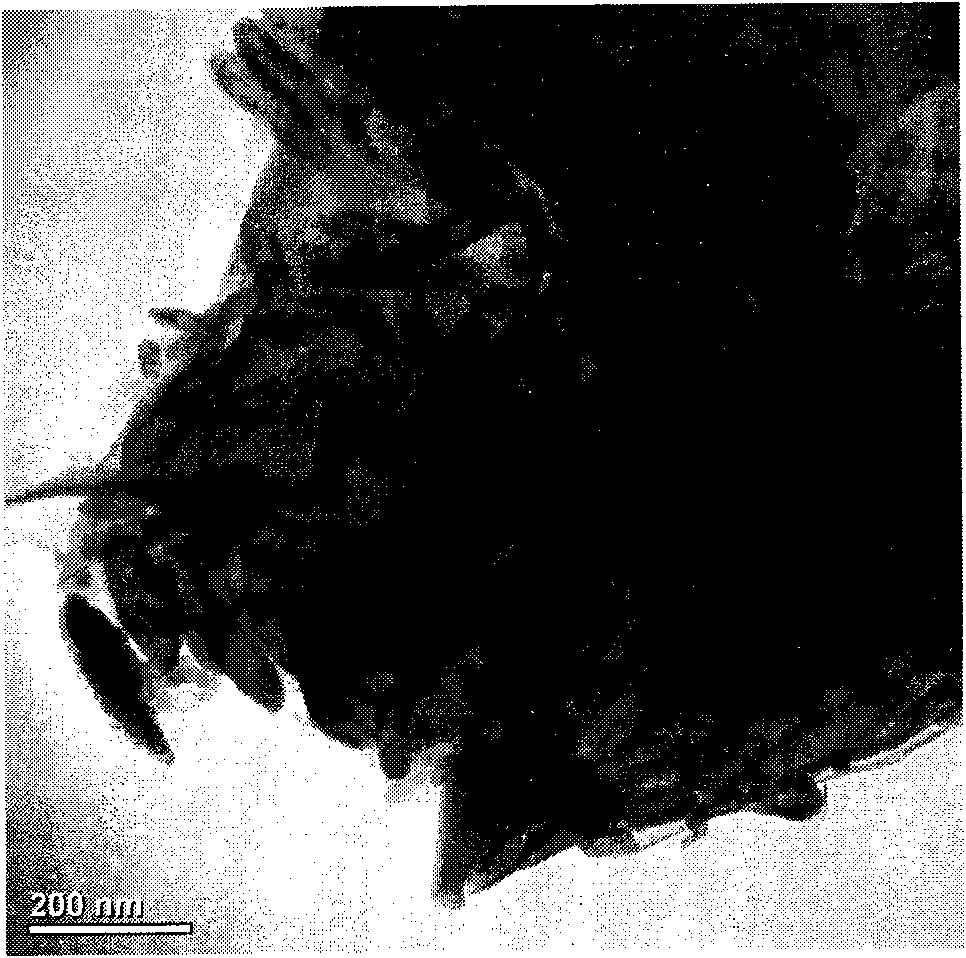

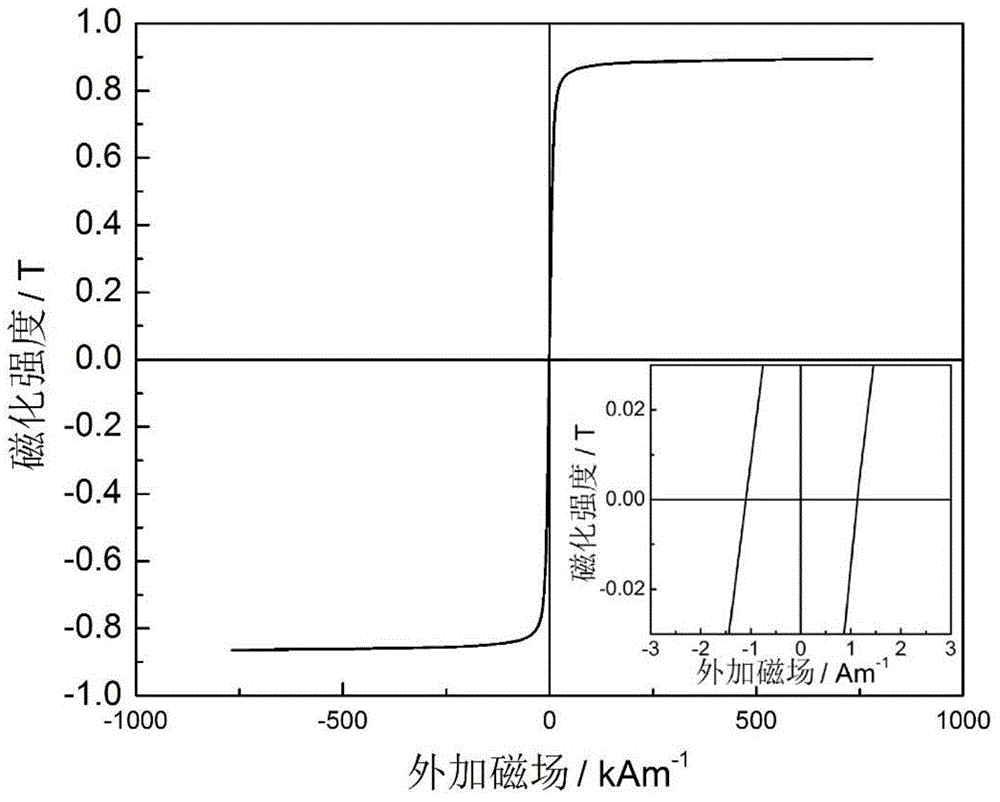

InactiveCN102063988AImprove adsorption capacityImprove featuresOther chemical processesMagnetic materialsAcetic acidMontmorillonite

The invention relates to a magnetic clay material and a preparation method thereof. The magnetic clay material is a superparamagnetc material formed by loading nano-iron oxide particles (gamma-Fe2O3) on the clay surface. In the preparation process, the surfactant is used as a template agent, the immobilization process of hydrated hydraferro on the surface of montmorillonite clay is regulated, and fumigating with acetic acid and thermal treatment are performed to obtain the superparamagnetc clay material. The micelle formed by the surfactant is synergic with the immobilization of the hydrated hydraferro on the clay surface, the load capacity is increased, and thus the magnetic saturation strength of the magnetic clay is enhanced. The magnetic clay material provided by the invention not only has the characteristics of large adsorption capacity and strong adsorption ability, but also can realize the aim of enhanced separation in the using process of material by using external magnetic field, and solve the problem of secondary pollution as the clay material is difficult to separate and recycle.

Owner:BEIJING UNIV OF CHEM TECH

Soft-magnetic high-entropy block amorphous alloy FeCoNiMB and preparation method thereof

ActiveCN104878324AEnhanced Amorphous Formation AbilityImprove thermal stabilityMagnetic materialsMagnetizationIngot

The invention provides a soft-magnetic high-entropy block amorphous alloy FeCoNiMB. M represents at least one of P, C and Si elements, and typical compositions include Fe25Co25Ni25Si7.5B17.5, Fe25Co25Ni25Si10B15, Fe25Co25Ni25P5C4Si6B10, Fe25Co25Ni25P12C8B5 and Fe25Co25Ni25P10C10B5. The saturation magnetization of the alloy is 0.80-0.87T, coercivity is 1.1-3.4A / m, and effective magnetic conductivity under 1kHz is 12500-19800. The invention further provides a preparation method of the soft-magnetic high-entropy block amorphous alloy. The preparation method includes preparing a master alloy ingot through arc melting or induction melting, and preparing an amorphous band and an amorphous bar by single-roll melt-spinning and copper-mold casting respectively. The technical blank in preparation of the soft-magnetic high-entropy block amorphous alloy is filled up, and the provided alloy has an application prospect of serving as a soft-magnetic functional device.

Owner:DALIAN UNIV OF TECH

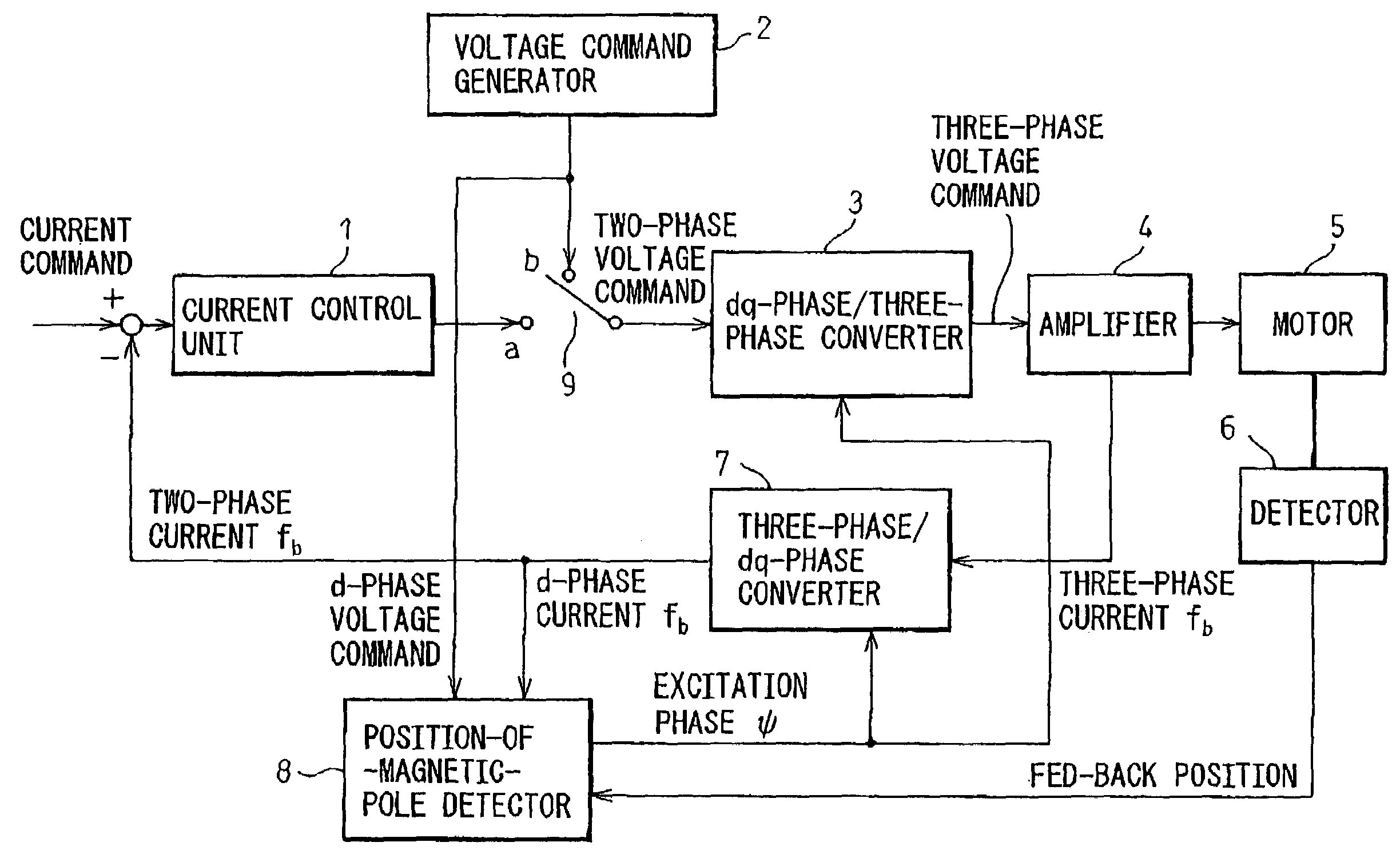

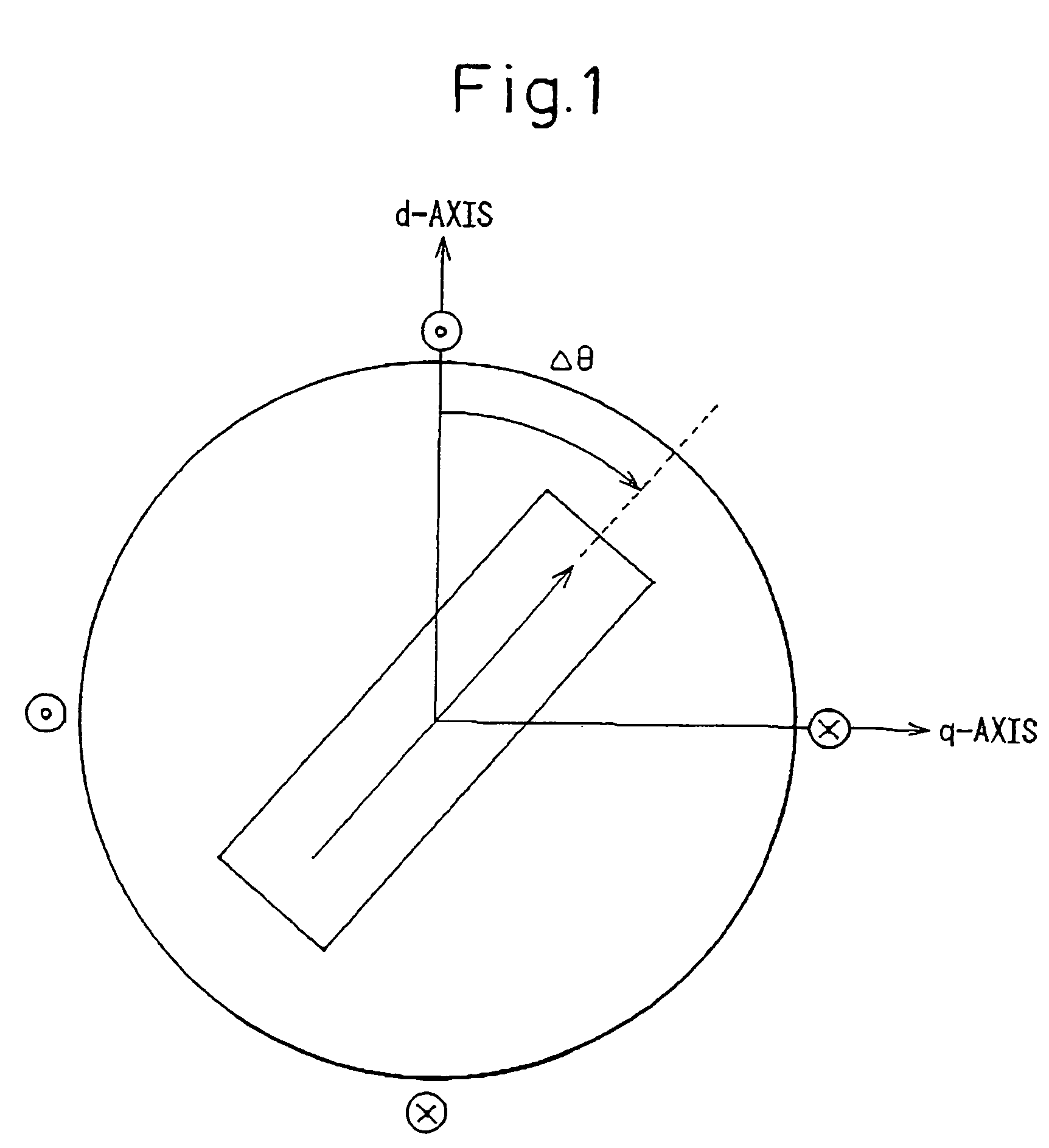

Position-of-magnetic-pole detecting device and method

ActiveUS7071651B2Readily and accurately detectingCorrect deviationAC motor controlVector control systemsElectric machineMagnetic poles

A high-frequency voltage whose amplitude is small is applied as a d-phase command voltage, and an excitation phase is changed to a predetermined degree at predetermined intervals, whereby a motor is driven. As the d-phase command voltage has the small amplitude and high frequency, the rotor of the motor does not rotate. A d-phase feed back current is detected, and the product of a derivative of the d-phase feed back current by the high-frequency voltage command is calculated. A high-frequency component is removed from the product. An excitation phase (direction of a magnetic flux) associated with a deviation of 0 or π from the position of a magnetic flux and also associated with a peak value assumed by the product having the high-frequency component removed therefrom is detected. A plurality of thus detected excitation phases is averaged in order to determine the direction of a magnetic flux. The excitation phase associated with one of two peak values assumed by the product is adopted on a fixed basis. Positive and negative rectangular waves having a magnitude causing magnetic saturation are applied as d-phase voltage commands. The polarity of a magnetic pole is determined based on positive and negative d-phase feed back currents. As the direction of a magnetic flux and the polarity thereof are detected separately from each other, the position of a magnetic pole can be detected accurately and reliably.

Owner:FANUC LTD

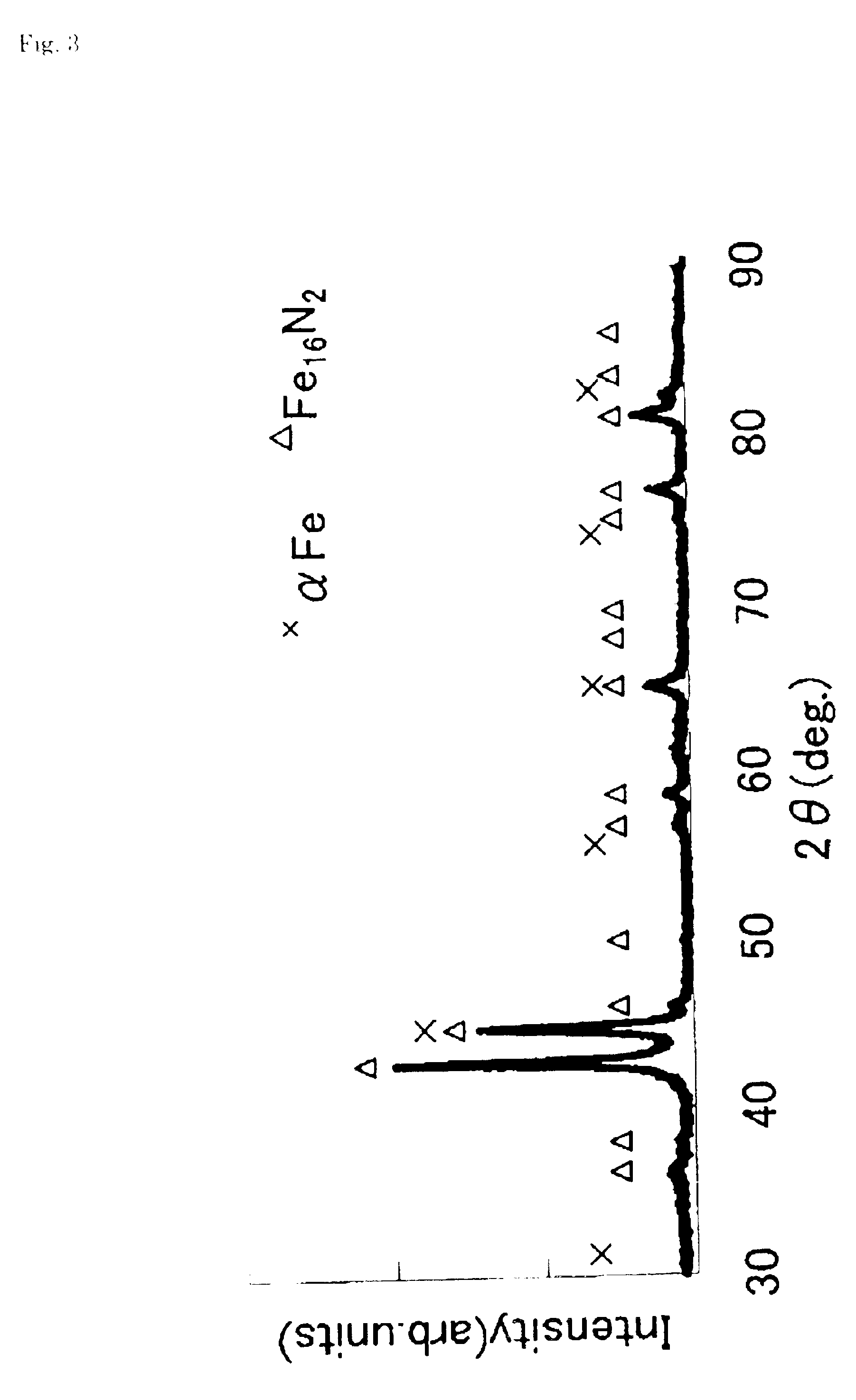

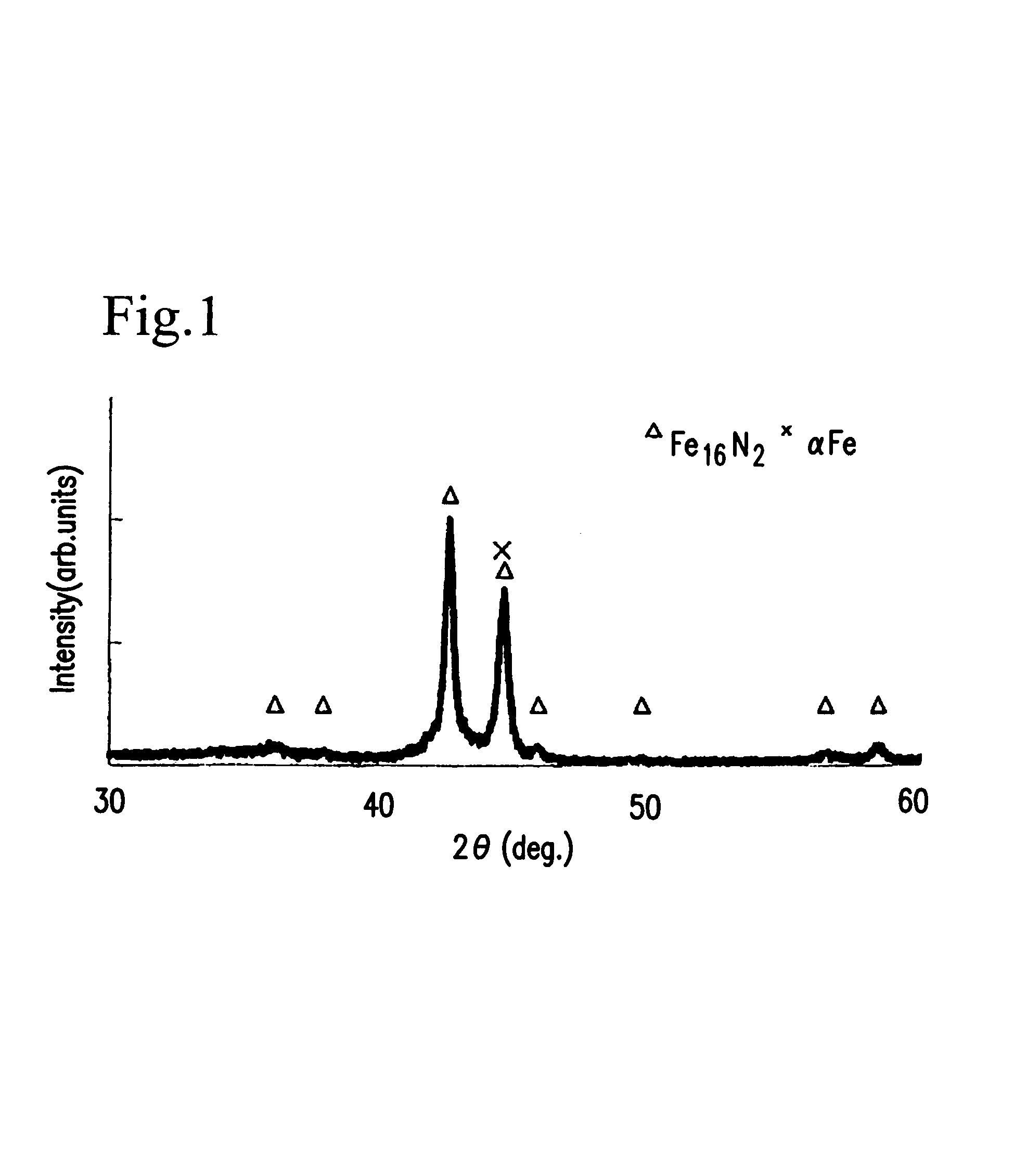

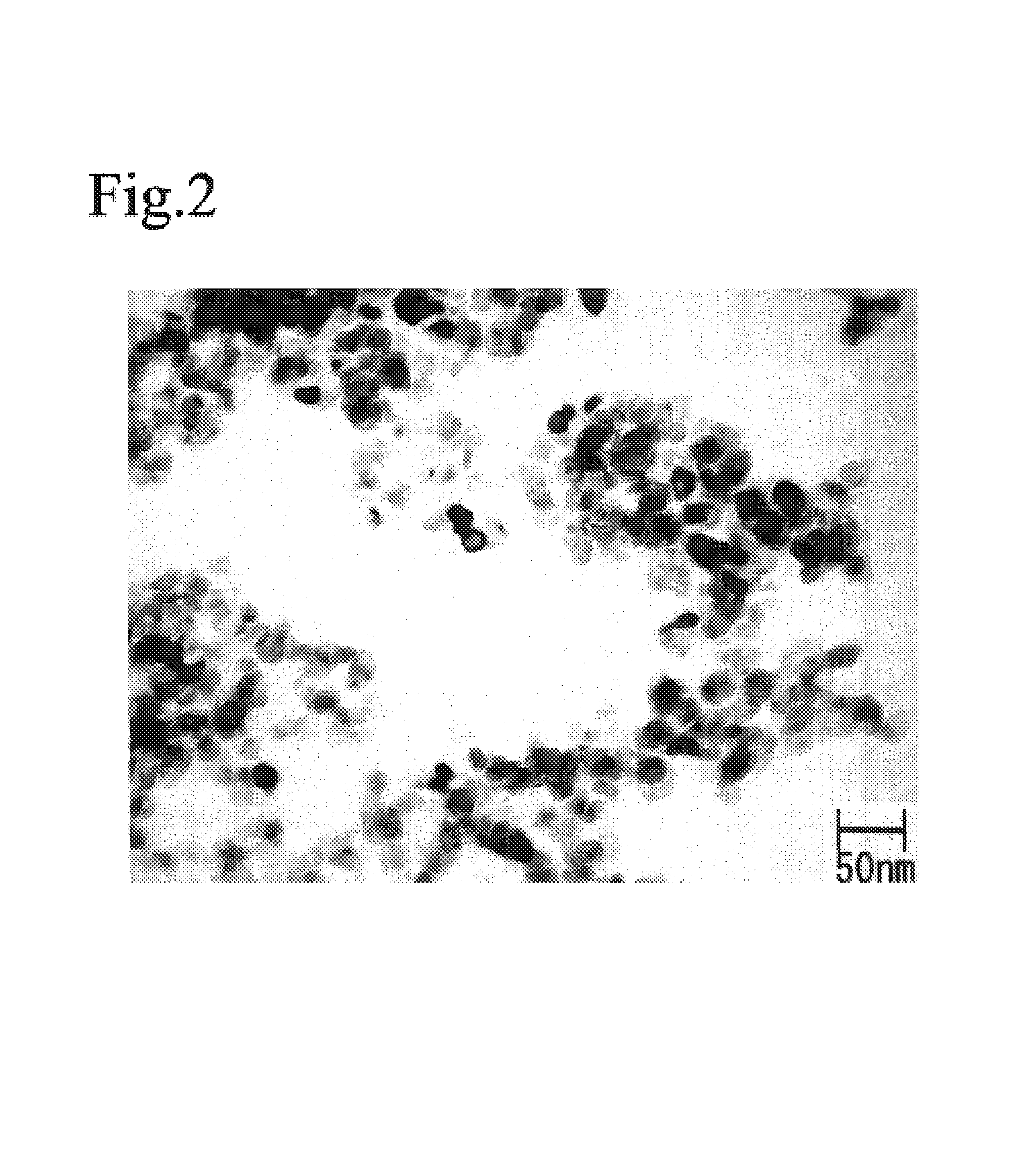

Magnetic recording medium containing particles with a core containing a Fe16N2 phase

ActiveUS7238439B2Increase productionExcellent short wavelength recording propertyMaterials with ironBase layers for recording layersRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a nonmagnetic support and a magnetic layer formed on the support and containing a magnetic powder and a binder, wherein said magnetic powder comprises substantially spherical or ellipsoidal particles and at least one element selected from the group consisting of rare earth elements, silicon and aluminum, and has a Fe16N2 phase, an average particle size of 5 to 30 nm and an axis ratio (a ratio of a major axis to a minor axis) of 1 to 2. This magnetic recording medium achieves a high output and has excellent short wavelength recording properties, since it uses a magnetic powder having a very small particle size and has a very high coercive force and a saturation magnetization suitable for high density recording.

Owner:FUJIFILM CORP

Composite magnetic core assembly, magnetic element and fabricating method thereof

InactiveUS8487733B2Easy to operateShorten production timeInorganic material magnetismTransformers/inductances magnetic coresCondensed matter physicsMaterials science

Owner:DELTA ELECTRONICS INC

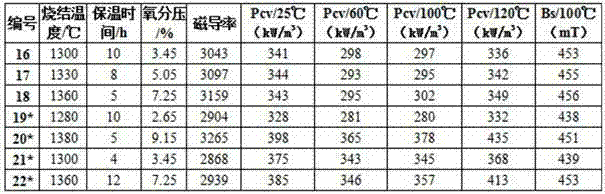

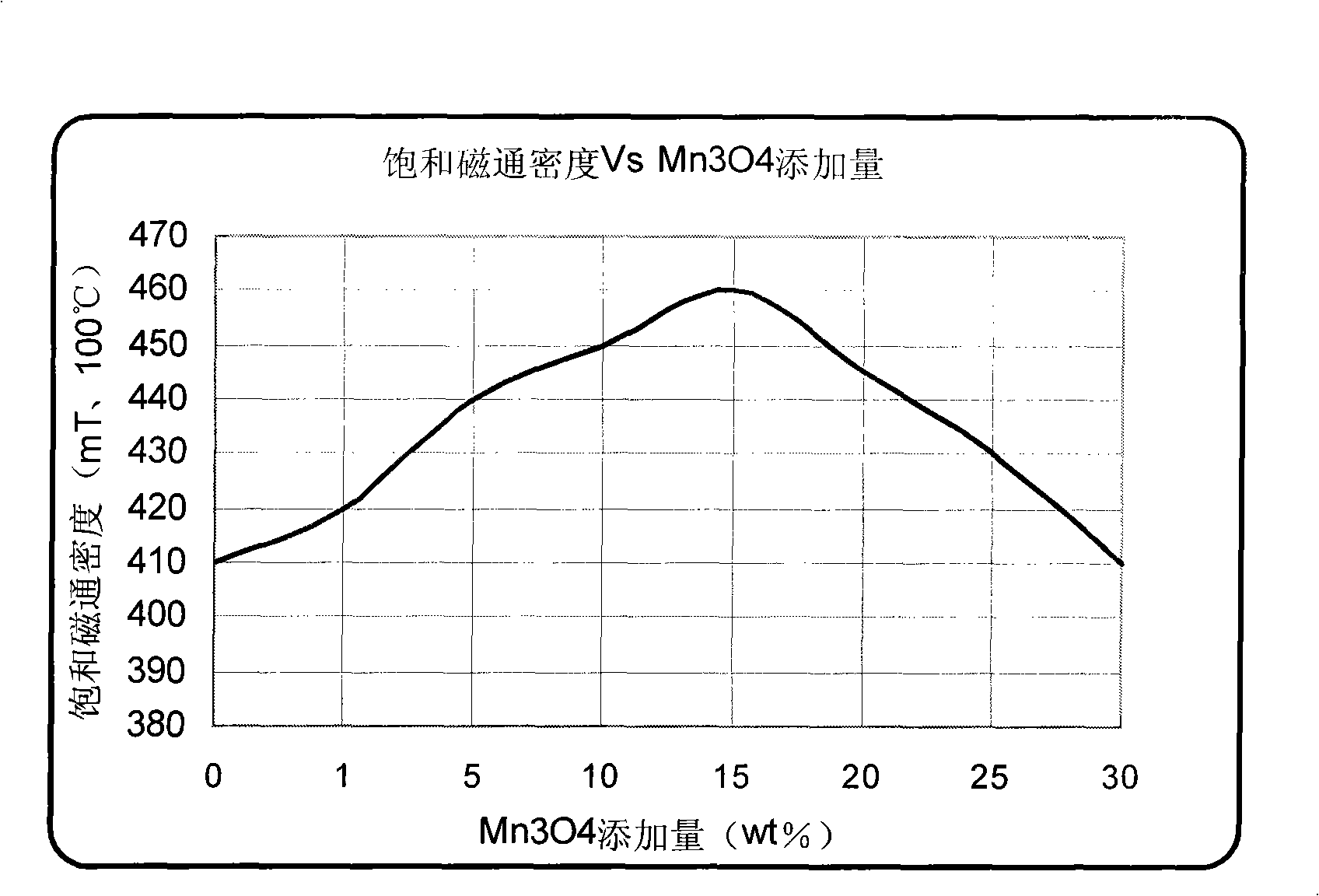

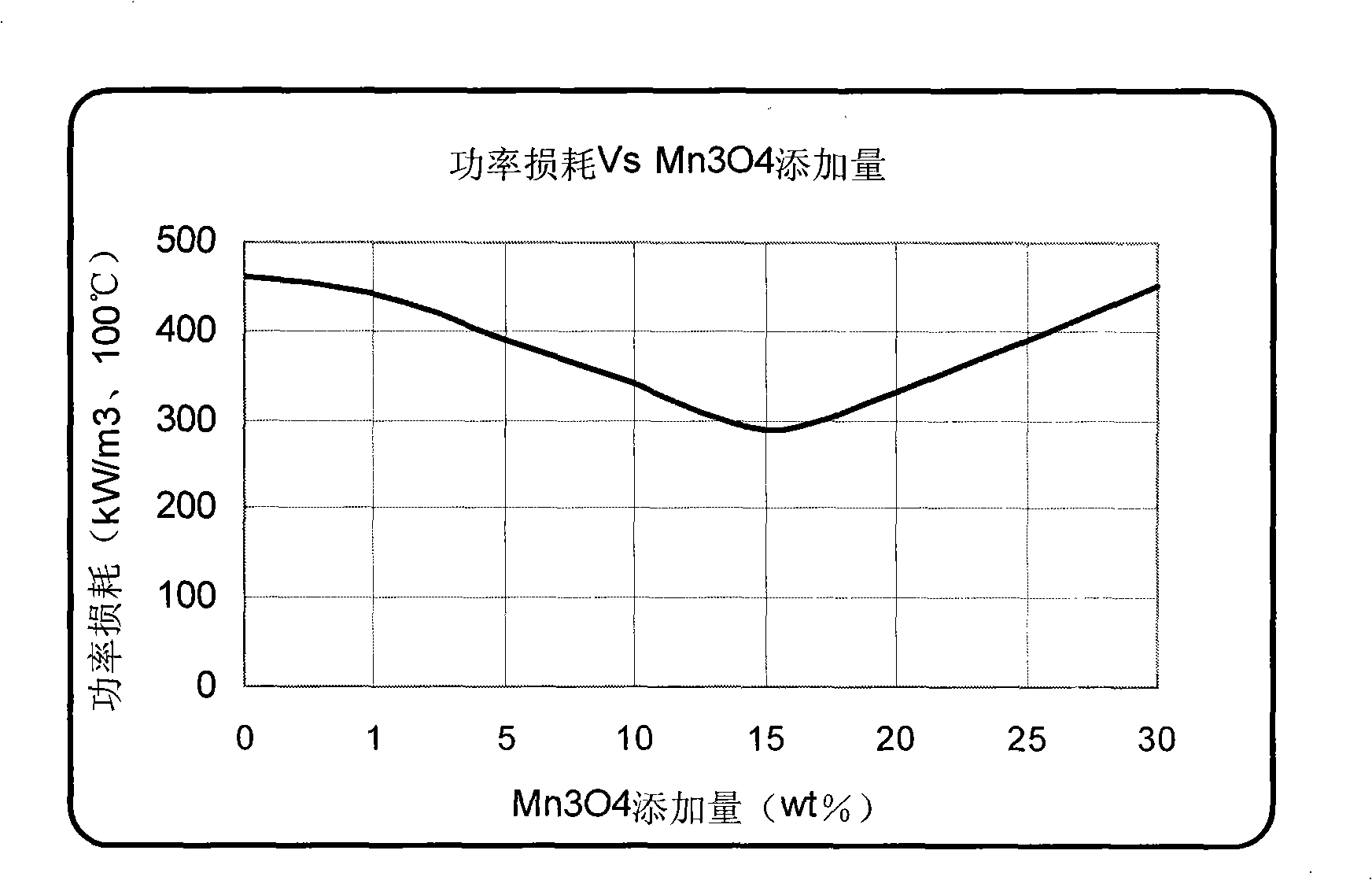

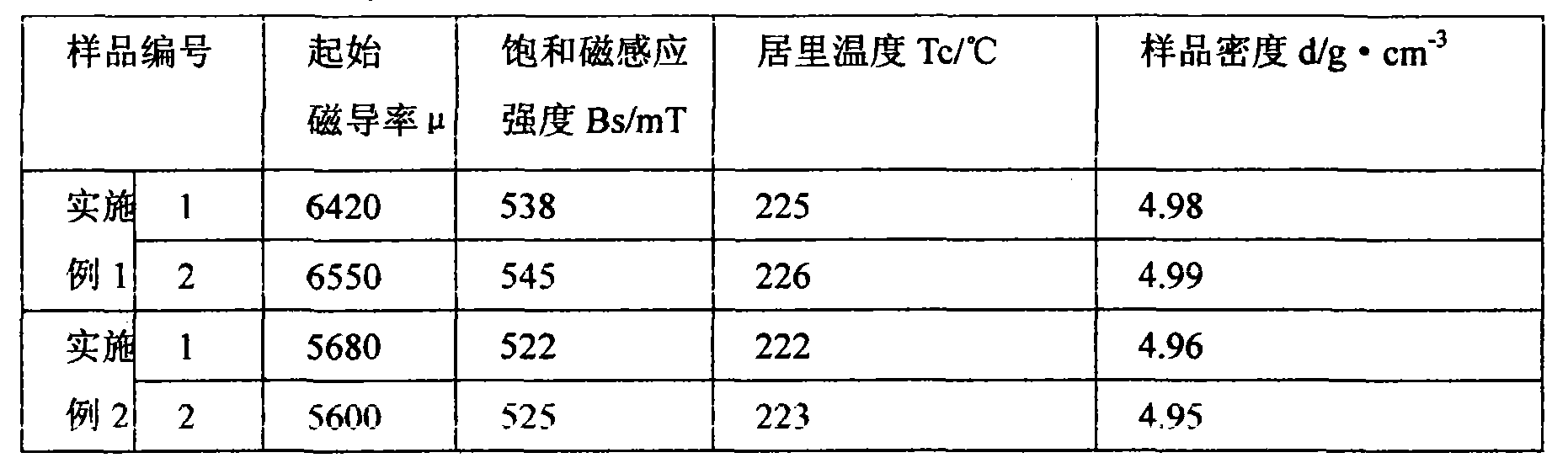

Manganese-zinc ferrite material of high performance and power, and manufacturing method therefor

ActiveCN101290827AGrain refinementReduce power lossInorganic material magnetismManganeseCurie temperature

The invention discloses a manganese-zinc ferrite material and a manufacturing method thereof. The material synchronously has high saturation flux density (Bs), lower power consumption (Pcv) and high Curie temperature (Tc) under the state of lower temperature and high temperature; the method solves the technical problem that three performances, namely the high saturation flux density, the high Curie temperature and the lower power consumption of the prior soft magnetic power ferrite material fail to be consistently realized in one material. The main compositions adopted by the invention are Fe2O3, Mn3O4 and ZnO; the manufacturing process successively has stages such as material mixing of the main compositions, initial crushing, preburning, additive adding, secondary crushing, pelleting and so on; and the main innovation of the method is that: additive added in the four stage contains a large quantity of Mn3O4, the preferred amount of the Mn3O4 is between 1 and 20wt percent, and the best amount is between 13 and 18wt percent. The material is applied in electronic assemblies and whole machines, and can improve direct current bias ability of the electronic assemblies and reduce power consumption of the whole machines.

Owner:TDG HLDG CO LTD

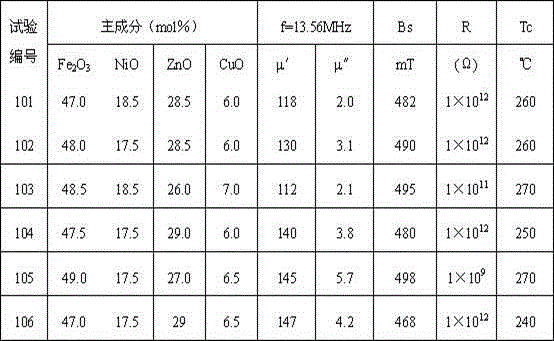

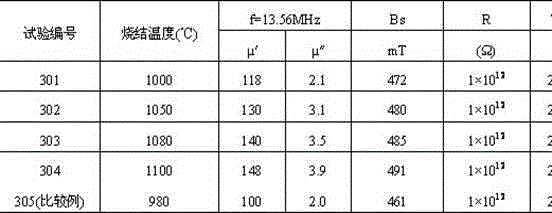

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

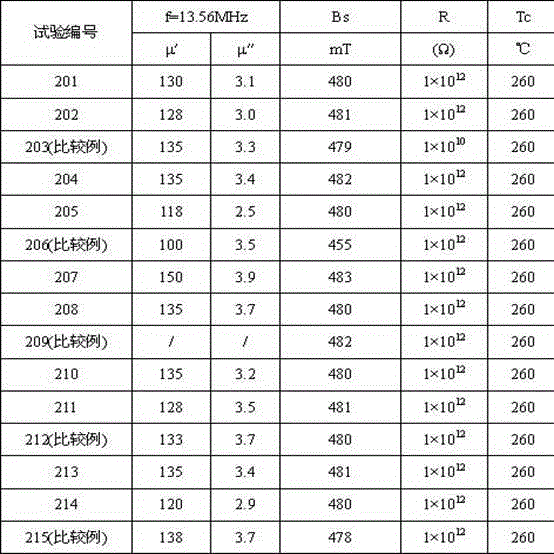

The invention belongs to the field of soft-magnetic ferrite materials. The objective of the invention is to provide a soft-magnetic nickel-copper-zinc ferrite material and a preparation method thereof. The material provided by the invention comprises major components and minor components. The major components comprise the following raw materials in mole percentage: 47.0-49.0mol% of Fe2O3, 17.5-18.5mol% of NiO, 26.0-29mol% of ZnO and 6.0-7.0mol% of CuO. The minor components comprise, based on the total weight of the major components, 0.1-0.40% of MnO, 0.1-0.5% of Bi2O3 and 0.3-0.5% of Co2O3. Under a high frequency of 13.56 MHz, the material provided by the invention has the characteristics of high magnetic conductivity ([mu]' is approximately equal to 130), low complex magnetic permeability [mu]''(namely low loss), high resistivity, high Curie temperature, high saturation magnetic induction density Bs, and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

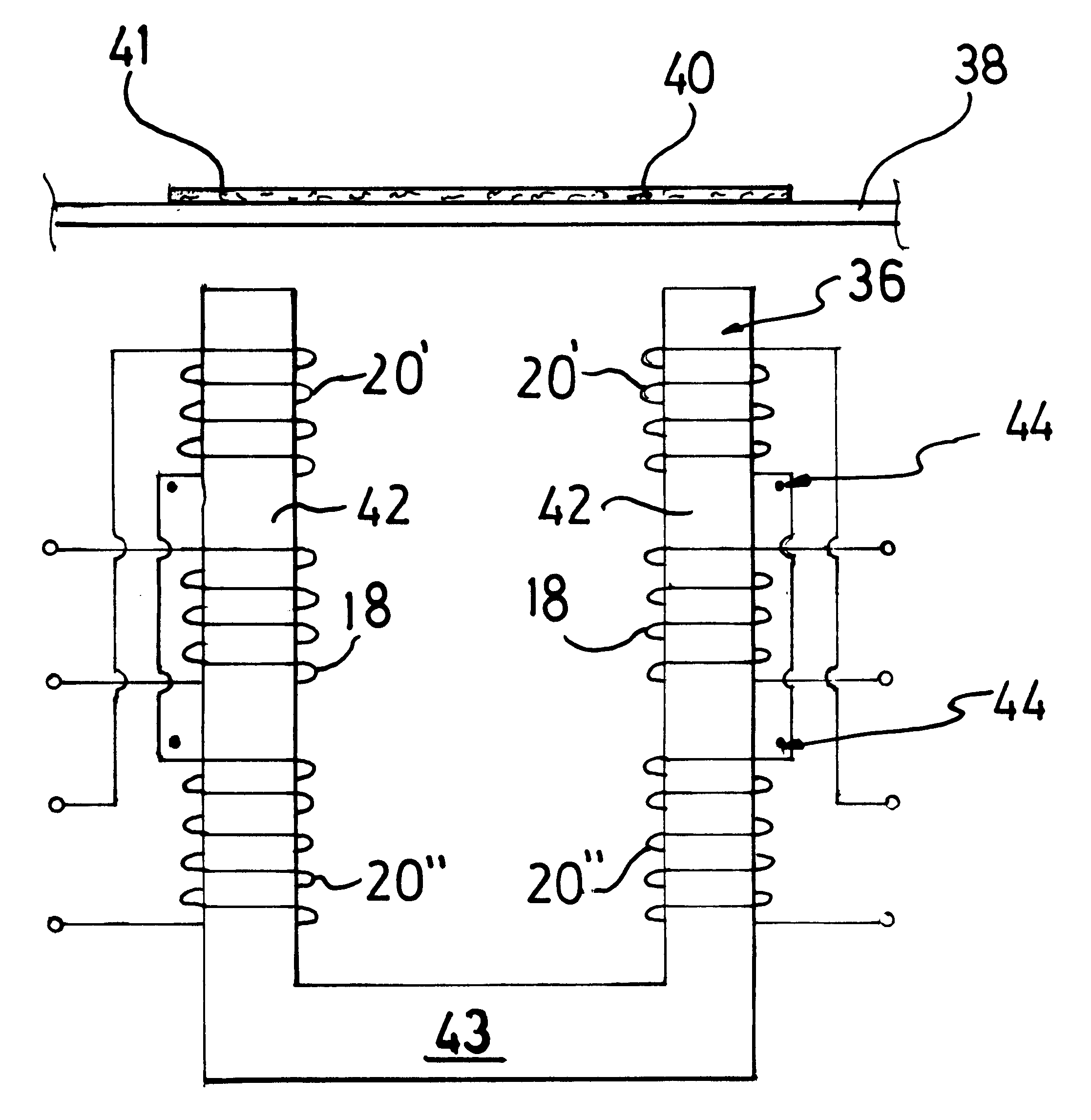

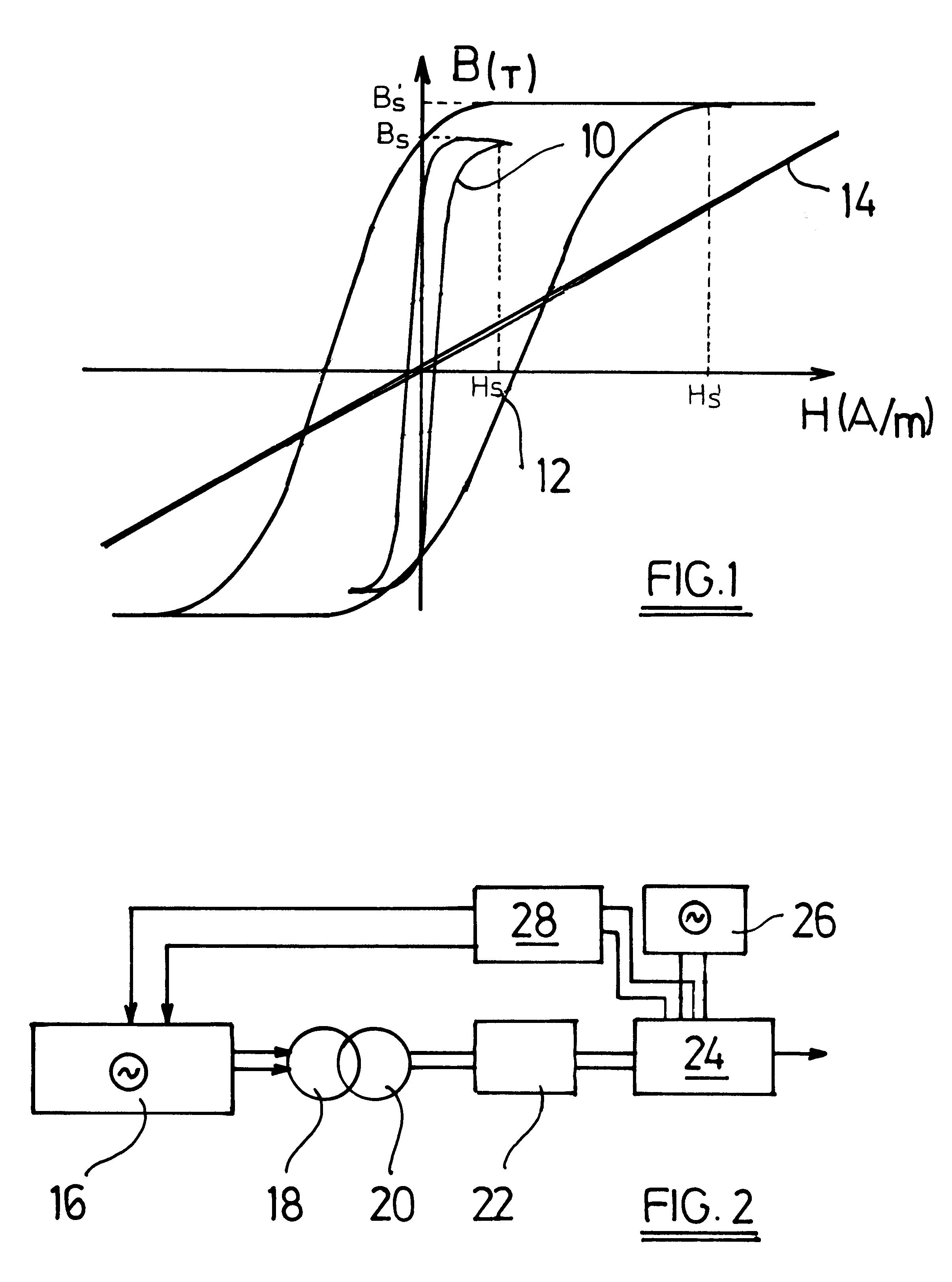

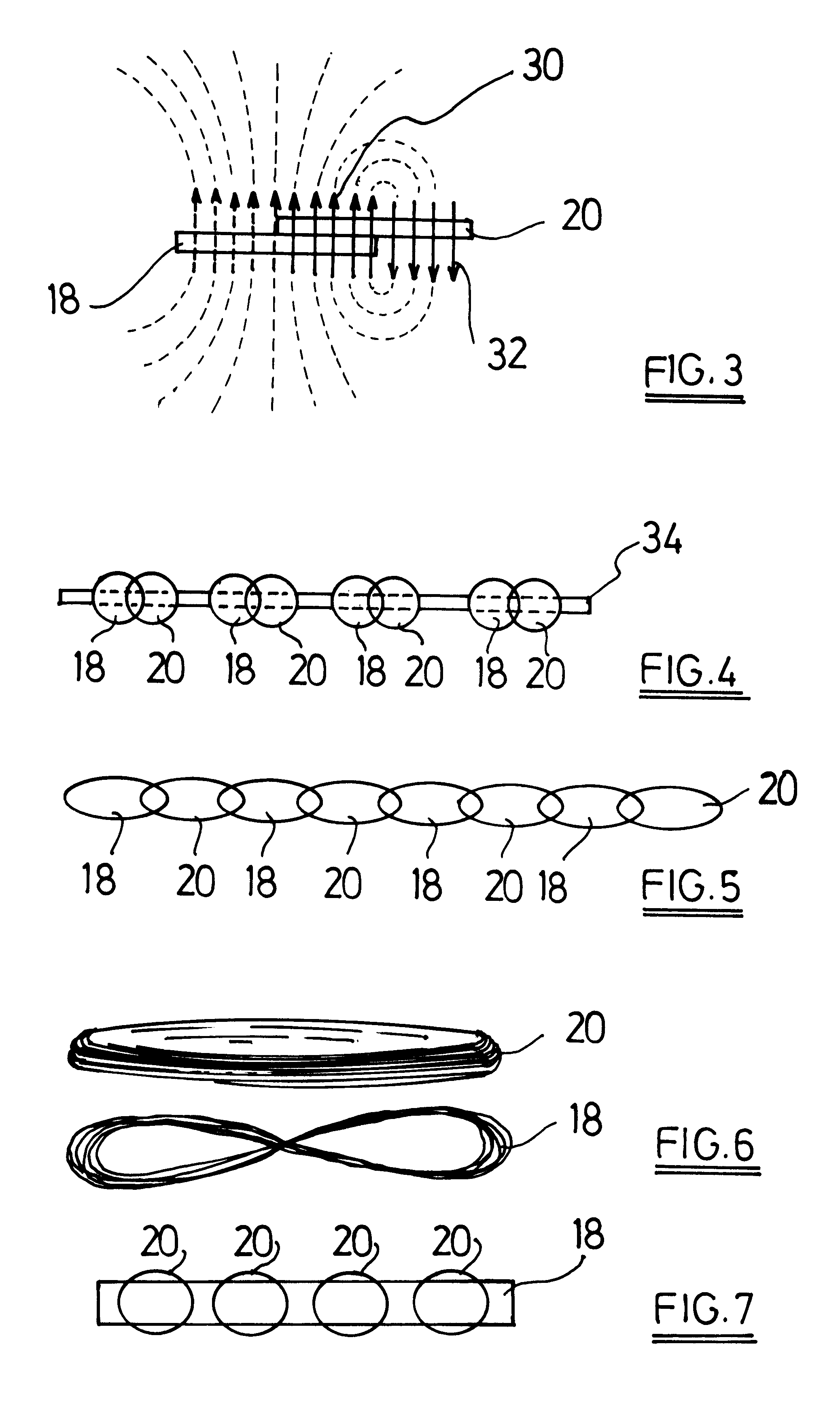

Magnetic detector for security document

InactiveUS6257488B1Avoid disadvantagesImprove discriminationPaper-money testing devicesSensing record carriersMicrometerHarmonic

Apparatus for detecting the presence of magnetic elongated particles in a substrate, the base material of the substrate having magnetic properties substantially differing from the corresponding magnetic properties of the elongated particles. The elongated particles have such a long and thin form that their demagnetization factor N is smaller than {fraction (1 / 250)}, they have a diameter smaller than 30 micrometer, and they a magnetic saturation field greater than 100 A / m. Apparatus includes an emitter which emits an electromagnetic source signal of one or more particular base frequencies to the substrate (e.g., so that any magnetic elongated particles present go into a non-linear part of a B-H curve for at least part of cycle of the source signal). Apparatus also includes a detector that detects an electromagnetic detection signal emanating from the substrate for examining the detection signal for the presence of particular higher harmonics of the base frequencies or of any linear combination of the base frequencies or of the harmonics, particular higher harmonics being indicative of the presence of the magnetic elongated particles.

Owner:NV BEKAERT SA

Manganese zinc ferrite of high magnetic conductivity high saturation magnetic flux density high Curie temperature

InactiveCN101388269AImprove performance indicatorsHigh performance index High magnetic permeability HighInorganic material magnetismMagnetic fluxCurie temperature

The invention relates to a MnZn ferrite material with high magnetic permeability, high magnetic flux density and high curie temperature, wherein the ferrite material comprises principal component Fe2O3, ZnO, MnO and adding auxiliary components, the main component formulation is that: Fe2O3 is 48-55 mol%, ZnO is 8-16mol%, and MnO is 30-39mol%. The auxiliary components comprise CoO and Bi2O3, and the adding total amount of the auxiliary components is 0.03-0.40 percent of the principal component total amount. CoO:0.005-0.15wt%, Bi2O3:0.008-0.25wt%, one or more of CaO, In2O3, WO3 and MoO3 are added, and CaO:0.008-0.15wt%, In2O3:0.008-0.10wt%, WO3:0.008-0.10wt%, and MoO3:0.005-0.15wt%.

Owner:SHANDONG ZHONGRUI ELECTRONICS

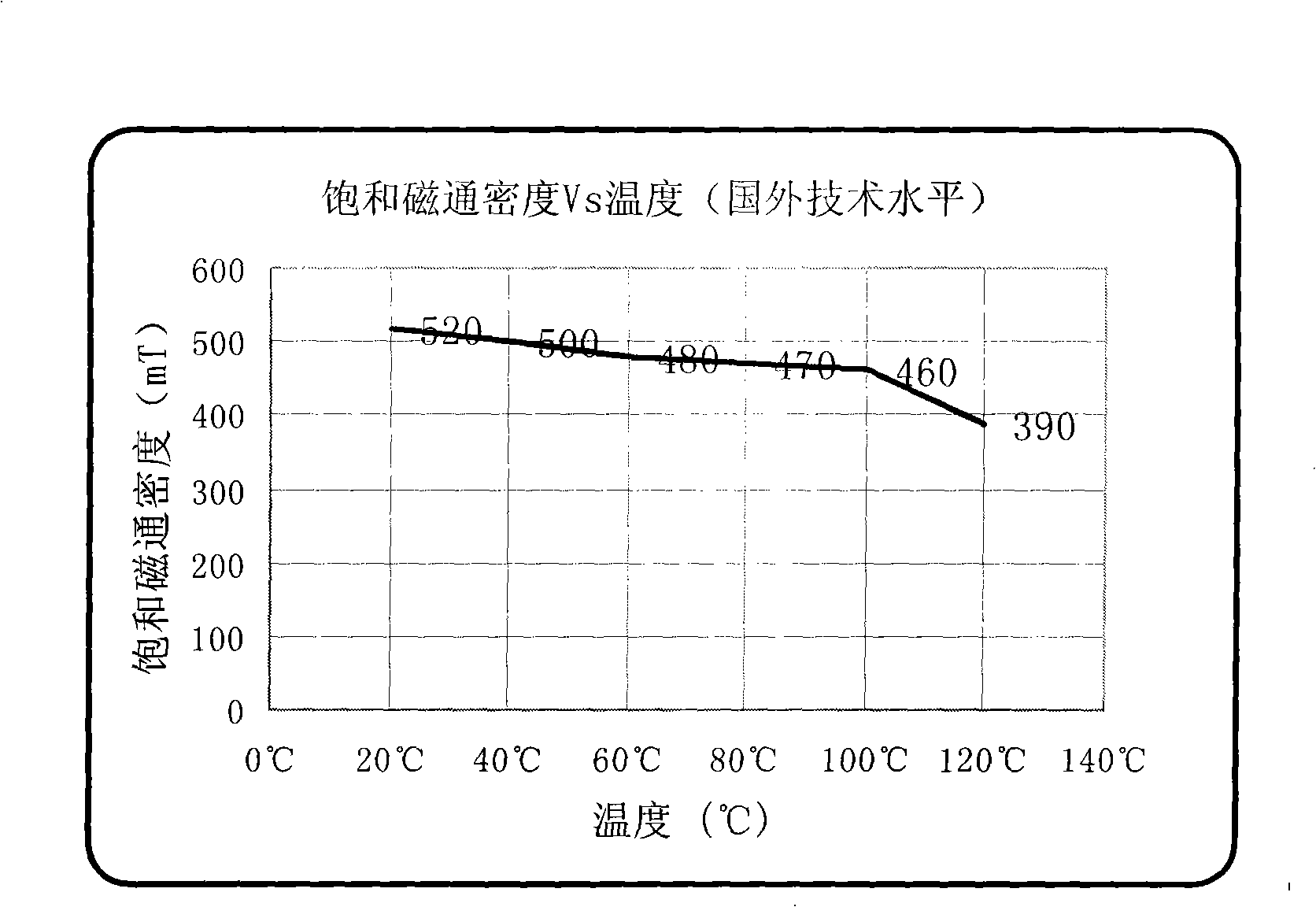

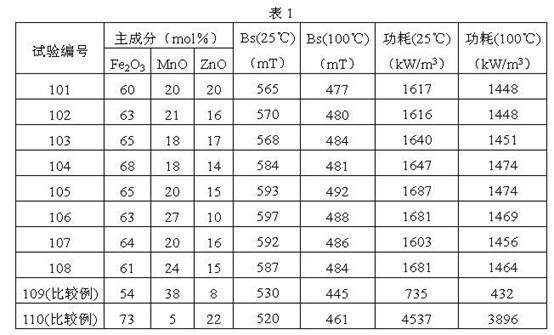

High-saturation-flux-density MnZn ferrite material and preparation method thereof

The invention belongs to the field of soft-magnetic MnZn ferrite materials, and particularly relates to a high-saturation-flux-density MnZn ferrite material which comprises major components and minor components, wherein on the basis of oxides, the major components comprise 60-68 mol% of Fe2O3, 10-20 mol% of ZnO and the balance of MnO; and on the basis of the total weight of the major components, the minor components comprise 50-200 ppm of SiO2, 200-1500 ppm CaCO3, 50-500 ppm of ZrO2, 50-500 ppm of Nb2O5 and 50-500 ppm of V2O5. The invention also provides a preparation method of the ferrite material. The invention overcomes the defect that the existing soft-magnetic ferrite material can not combine low loss and high saturation flux density; the saturation flux density of the provided ferrite core is higher than 560mT at 25 DEG C, and higher than 460mT at 100 DEG C; and the volume loss is less than 1800kW / m<3> at 25 DEG C, and less than 1600kW / m<3> at 100 DEG C.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Low-remanence nanocrystalline magnetic core and preparation method thereof

ActiveCN107256793AAvoid direct contactImprove high temperature stabilityInorganic material magnetismInductances/transformers/magnets manufactureRemanenceWater cooling

The invention relates to the technical field of high frequency inverter power supplies, in particular to a low-remanence nanocrystalline magnetic core and a preparation method thereof. The preparation method includes the following steps: performing vacuum isothermal annealing on a Fe-Ni based nanocrystalline ribbon prepared by the single roller melt rotation rapid quenching method, and water-cooling the Fe-Ni based nanocrystalline ribbon to the indoor temperature; crushing the Fe-Ni based nanocrystalline ribbon into nanocrystalline metallic powder, performing ball-milling and shaping on the nanocrystalline metallic powder, screening the powder into first powder and second powder; evenly mixing the processed first powder and the processed second powder, pressing the mixed powder into a magnetic core; putting the formed magnetic core in a vacuum annealing furnace to perform heat treatment; performing heat treatment again; and performing glue dipping and curing treatment on the nanocrystalline magnetic core. The preparation method is simple in process, and is low in production cost; the acquired magnetic core finished product has high saturation flux density, low a loss value, low coercivity, low remanence, and high temperature resistance, is excellent in comprehensive performance, will not be damaged, and is improved in reliability.

Owner:DONGGUAN DAZHONG ELECTRONICS

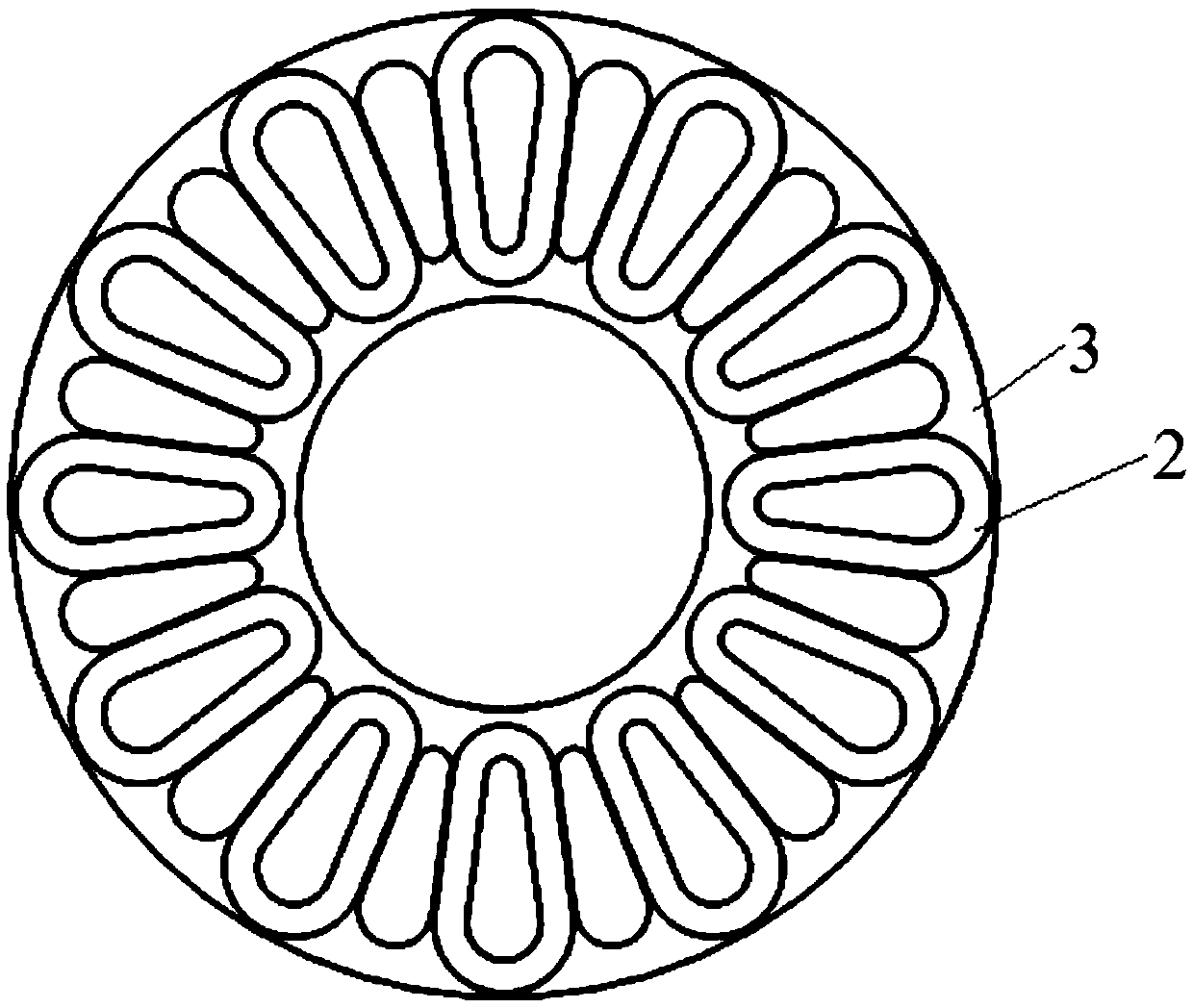

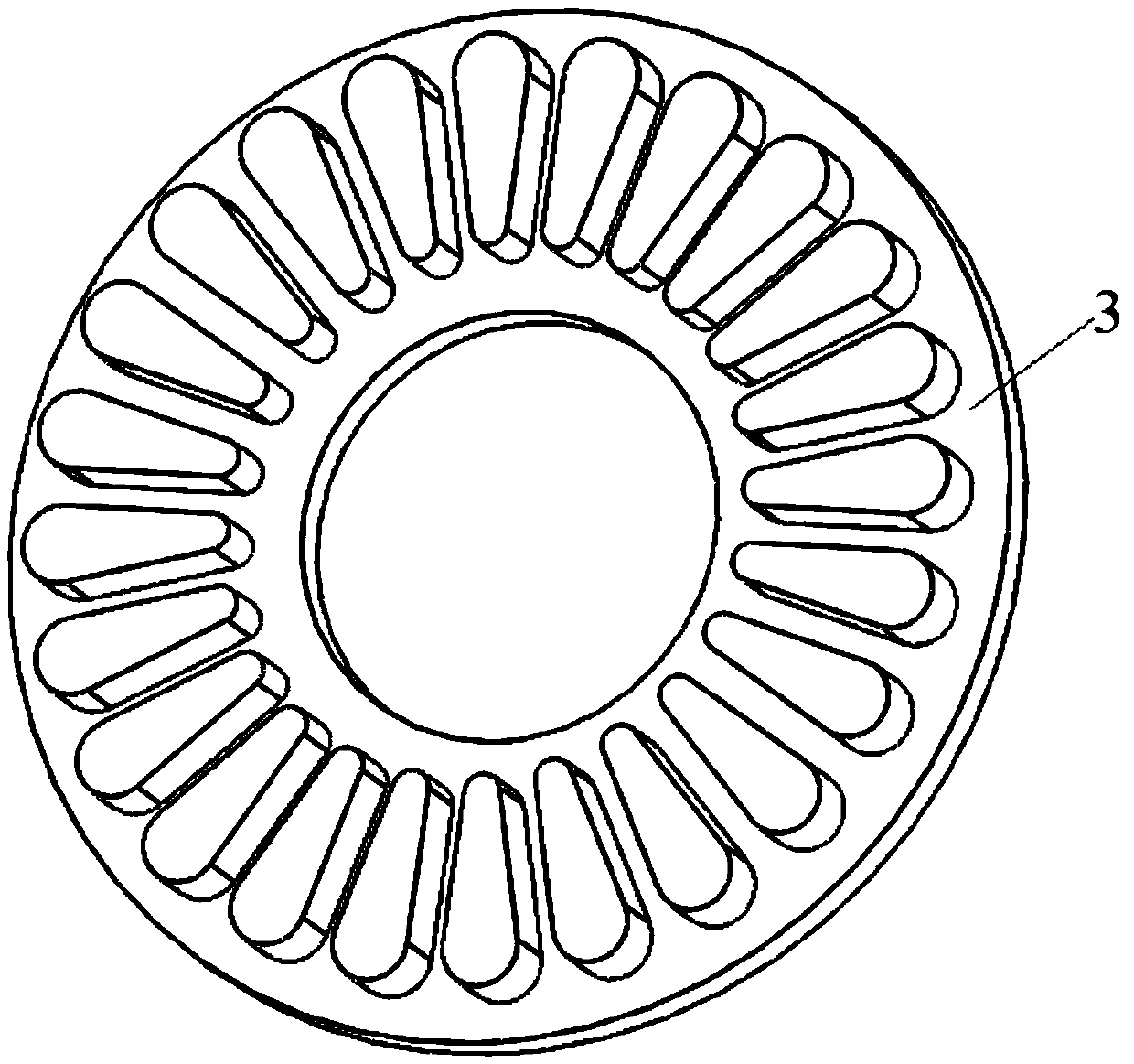

Axial flux motor applying soft magnetic powder core with high saturation induction density

ActiveCN105375655AIncrease output powerMagnetic circuit characterised by magnetic materialsElectric machineUltimate tensile strength

The invention relates to an axial flux motor applying soft magnetic powder core with high saturation induction density, specifically, the soft magnetic powder core with the high saturation induction density is applied to a composite permanent magnet and / or an iron core. Compared with the prior art, when the soft magnetic powder core with the high saturation induction density is applied to the composite permanent magnet or the high-power iron core, a higher excitation magnetic field can be used under the same iron core material so as to excite stronger excitation flux density of a stator due to the high saturation induction density; and the maximum excitation flux density is obviously higher than that of the conventional amorphous iron core and the relatively new iron-coreless stator according to theoretical calculations and tests. Therefore, the motor is higher in the output power.

Owner:TONGJI UNIV

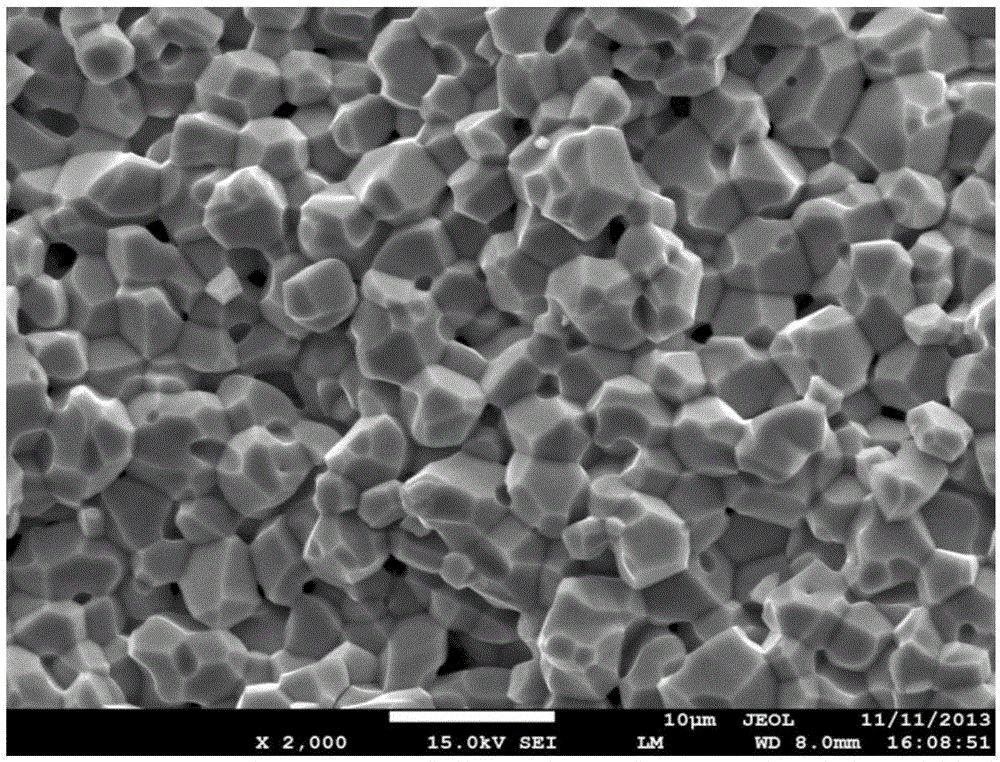

Manganese zinc ferrite material with wide temperature and low power as well as preparation method thereof

ActiveCN106396661AReduce hysteresis lossReduce eddy current lossInorganic material magnetismSodium bicarbonateMetallurgy

The invention relates to a manganese zinc ferrite material with wide temperature and low power. The material comprises main components and auxiliary components; the main components comprise the following components in percentages by mol: 52.7-53.5mol% of Fe2O3, 8.6-9.6mol% of ZnO, and the balance being MnO; based on the total weight of the main components, the auxiliary components comprise the following components in percentages by weight: 0.03-0.04% of CaCO3, 0.02-0.03% of Nb2O5, 0.4-0.5% of Co2O3, 0.05-0.15% of SnO2, and 0.0074-0.022% of NaO2 (NaO2 is added in the form of sodium bicarbonate). Insulation treatment for controlling atmosphere is carried out at 1200 DEG C in the sintering cooling stage. The ferrite material has low power consumption in the temperature range of 25-140 DEG C, and at the same time, the material has high saturation magnetic flux density and high magnetic permeability.

Owner:马鞍山新康达磁业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com