Magnetic clay material and preparation method thereof

A magnetic material and clay technology, applied in the design, preparation and application of magnetic clay materials, can solve the problems of nanoparticle agglomeration, difficult separation and recovery of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

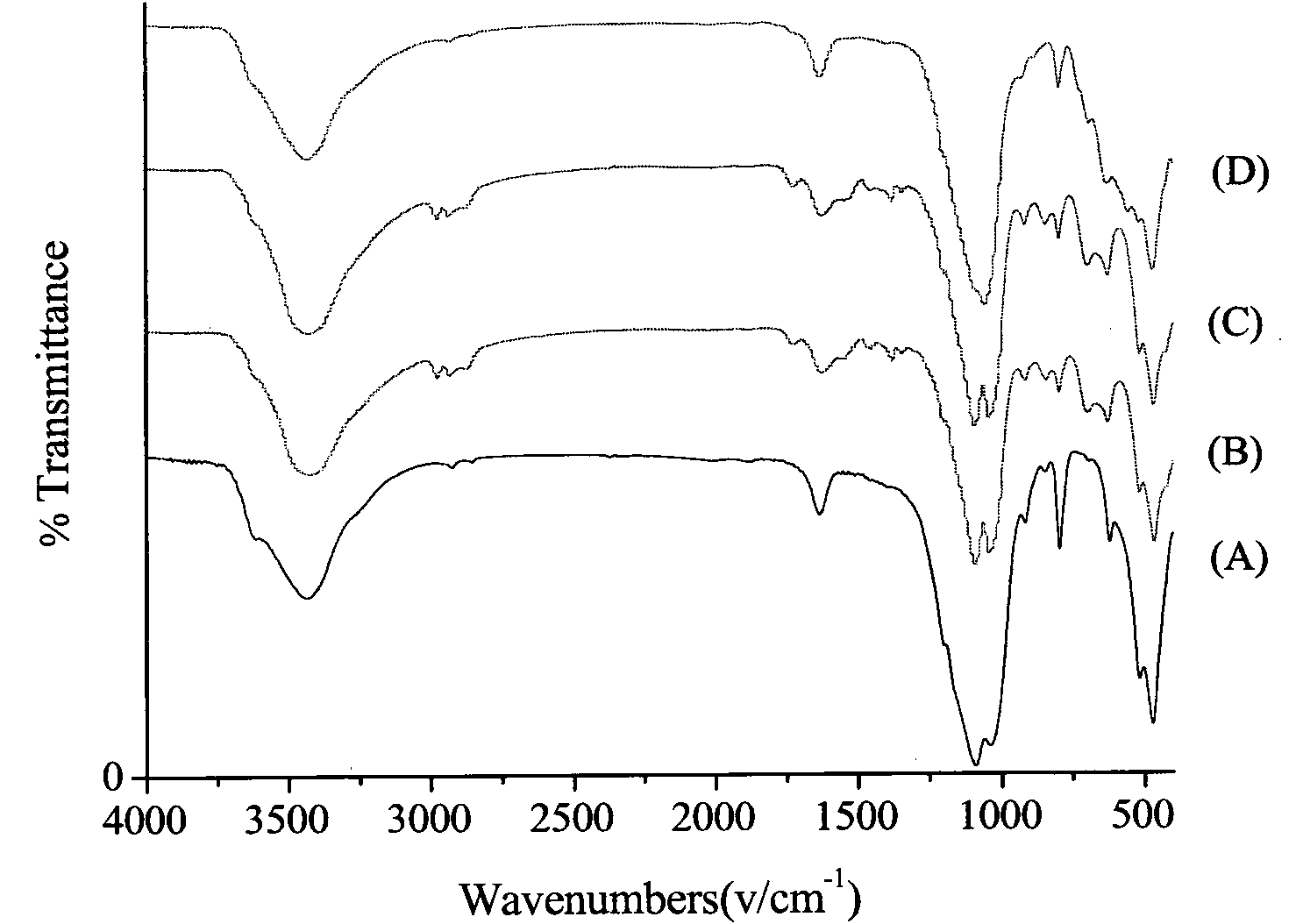

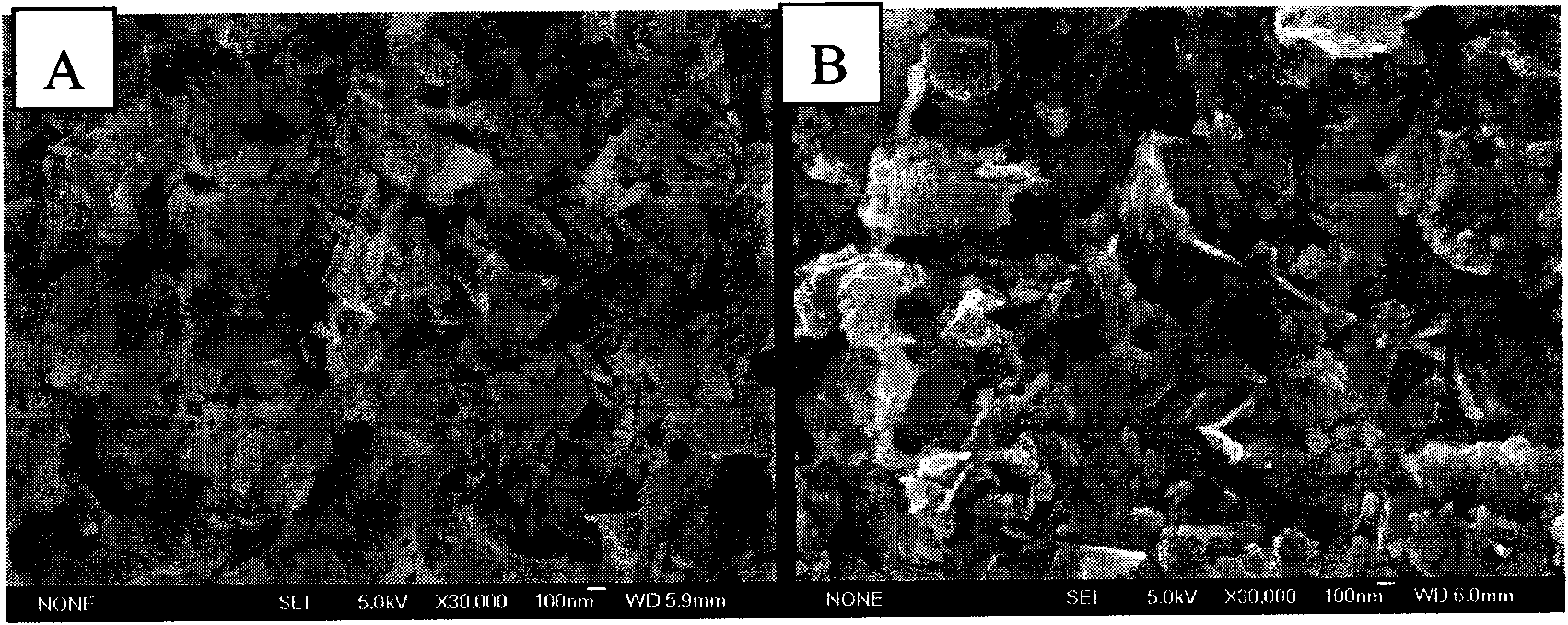

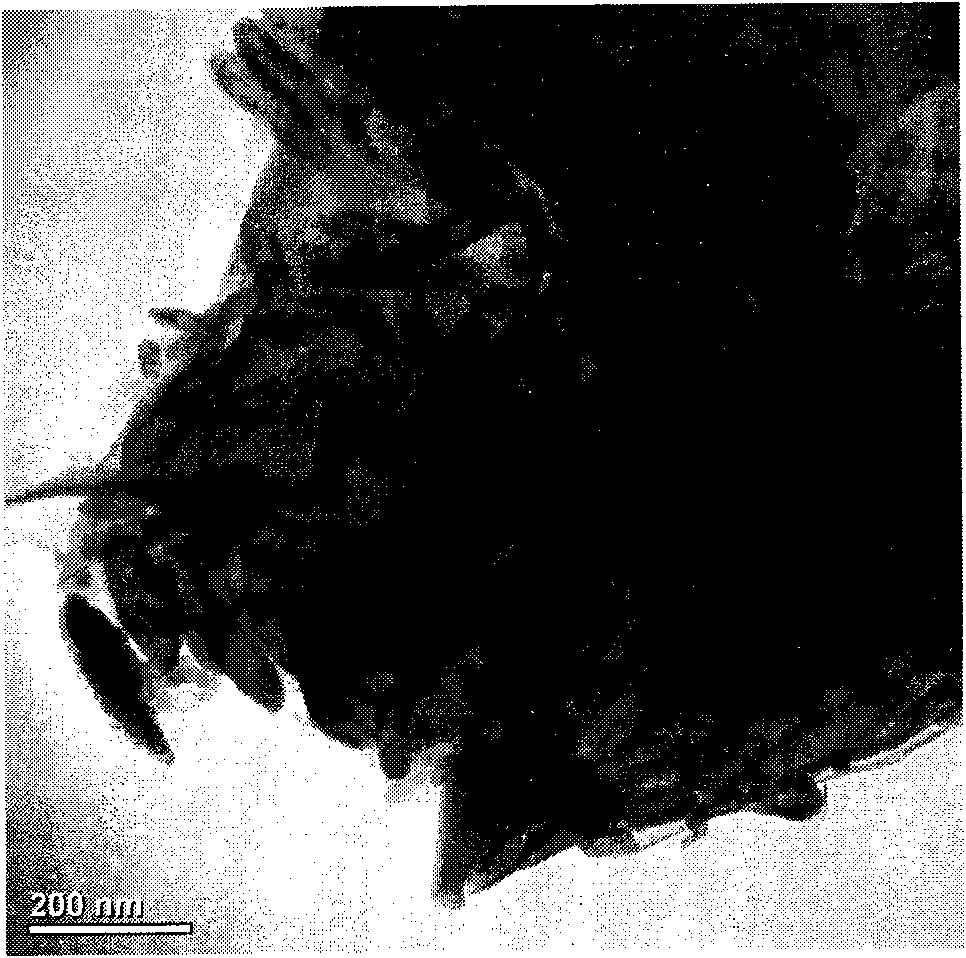

[0026] (1) Na-montmorillonite (Na + -Mt) before use, wash the soluble salts with 50% ethanol solution, magnetically stir for 5 minutes, discard the supernatant after centrifugation, repeat washing and centrifugation for 3 times, dry at 45° C., grind into powder, and 200 meshes.

[0027] (2) Disperse 1.0 g of montmorillonite in 100 ml of deionized water, hydrate for 6 hours, and overnight to make it fully swell.

[0028] (3) Under stirring, add 0.4M iron proppant (10.8g FeCl 3 ·6H 2 O dissolved in 100ml deionized water) was added dropwise into the montmorillonite suspension, and magnetically stirred for 4 hours to obtain ferropillared montmorillonite (Fe-Mt).

[0029] (4) Organic proppant (1.712g D 2000 Dissolve in 100ml of deionized water, then add twice the amount of hydrochloric acid, so that the amino groups at both ends of the polymer form ammonium cations) dropwise added to the iron pillared montmorillonite, stirred in a water bath for 9 hours, to obtain a composite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com