Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256results about How to "Correct deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

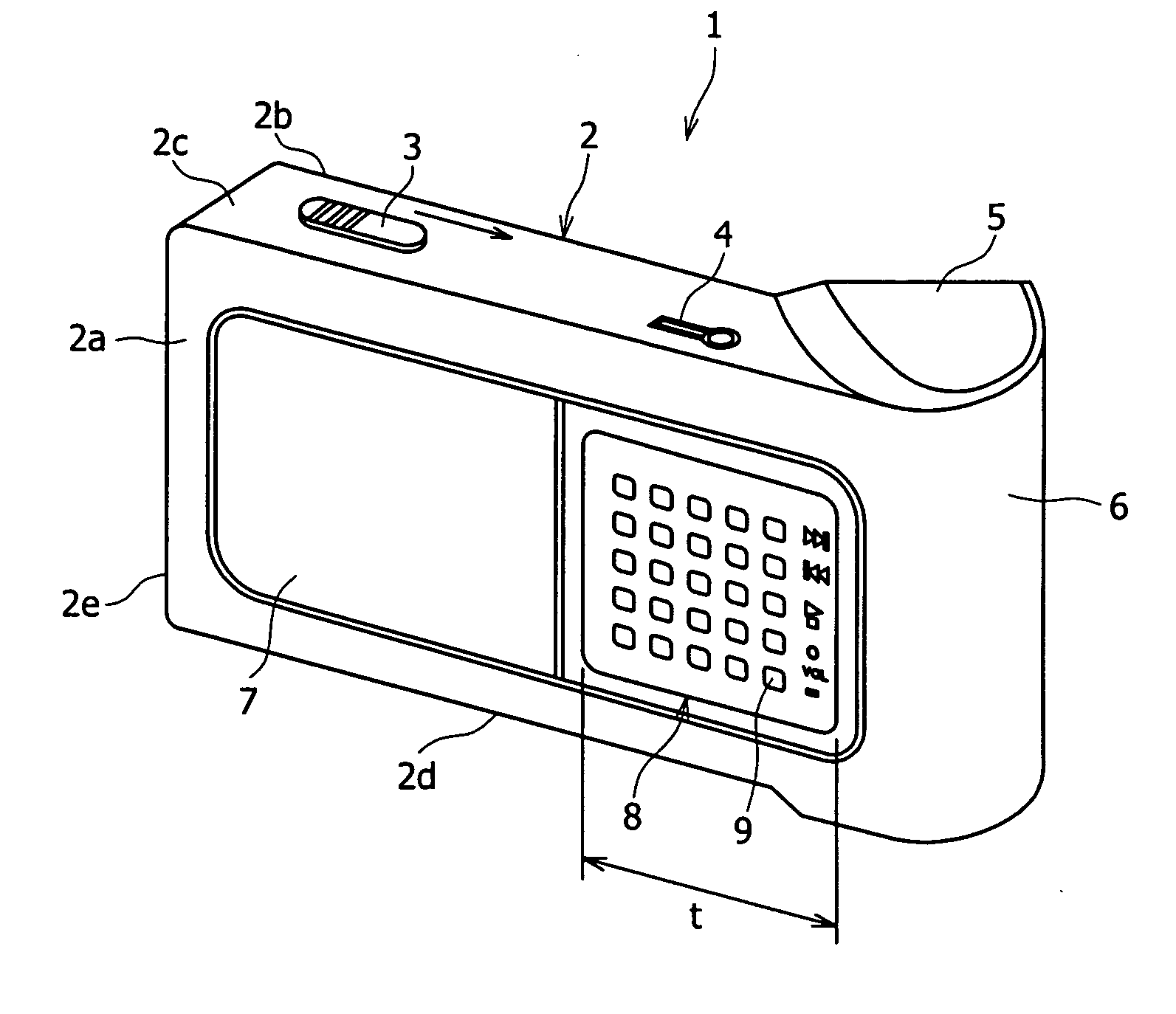

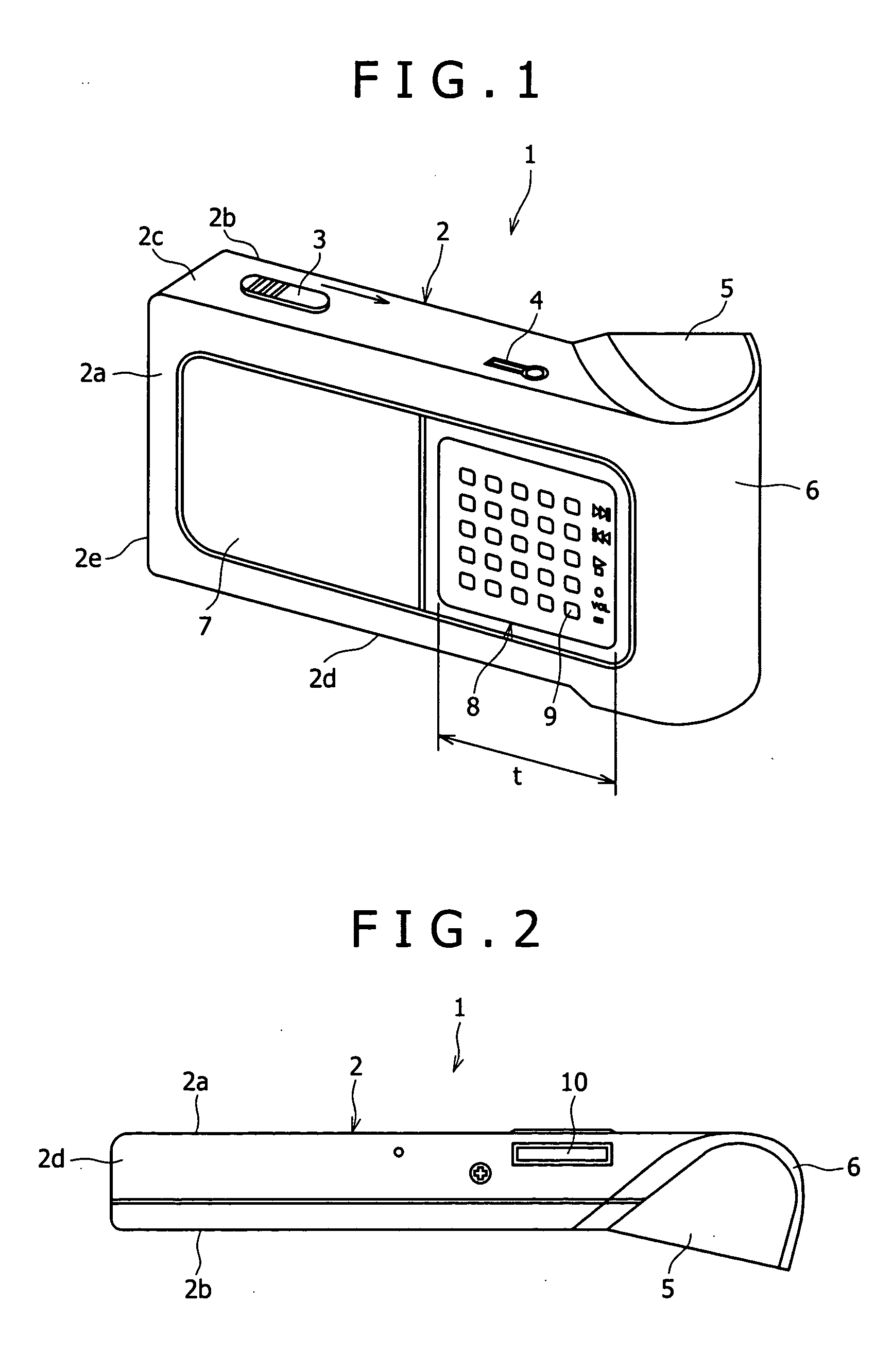

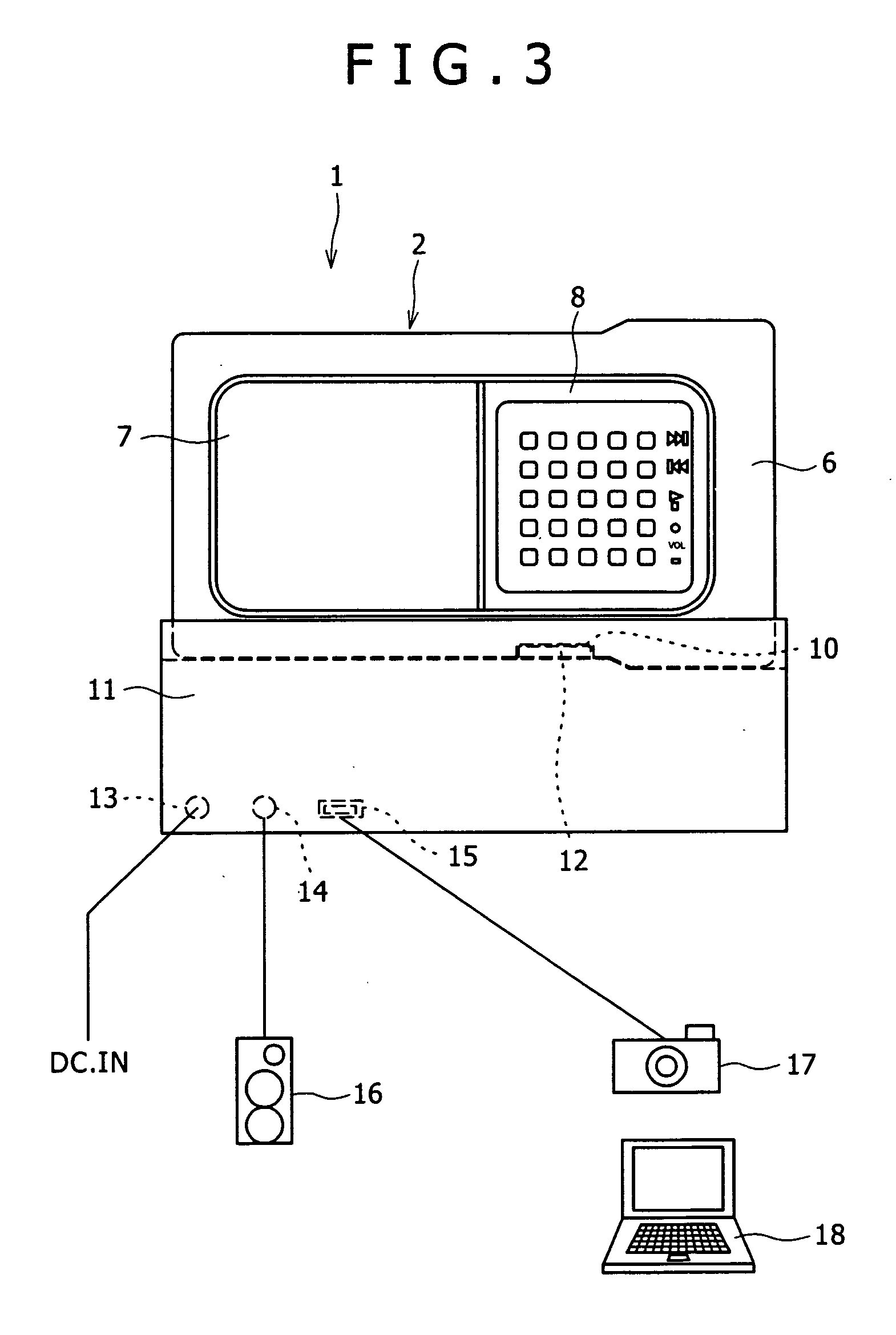

Portable electronic device, method of controlling input operation, and program for controlling input operation

ActiveUS20050270276A1Accurate correctionReduce the amount of processingInput/output for user-computer interactionCathode-ray tube indicatorsHuman–computer interactionElectronic equipment

Owner:SONY CORP

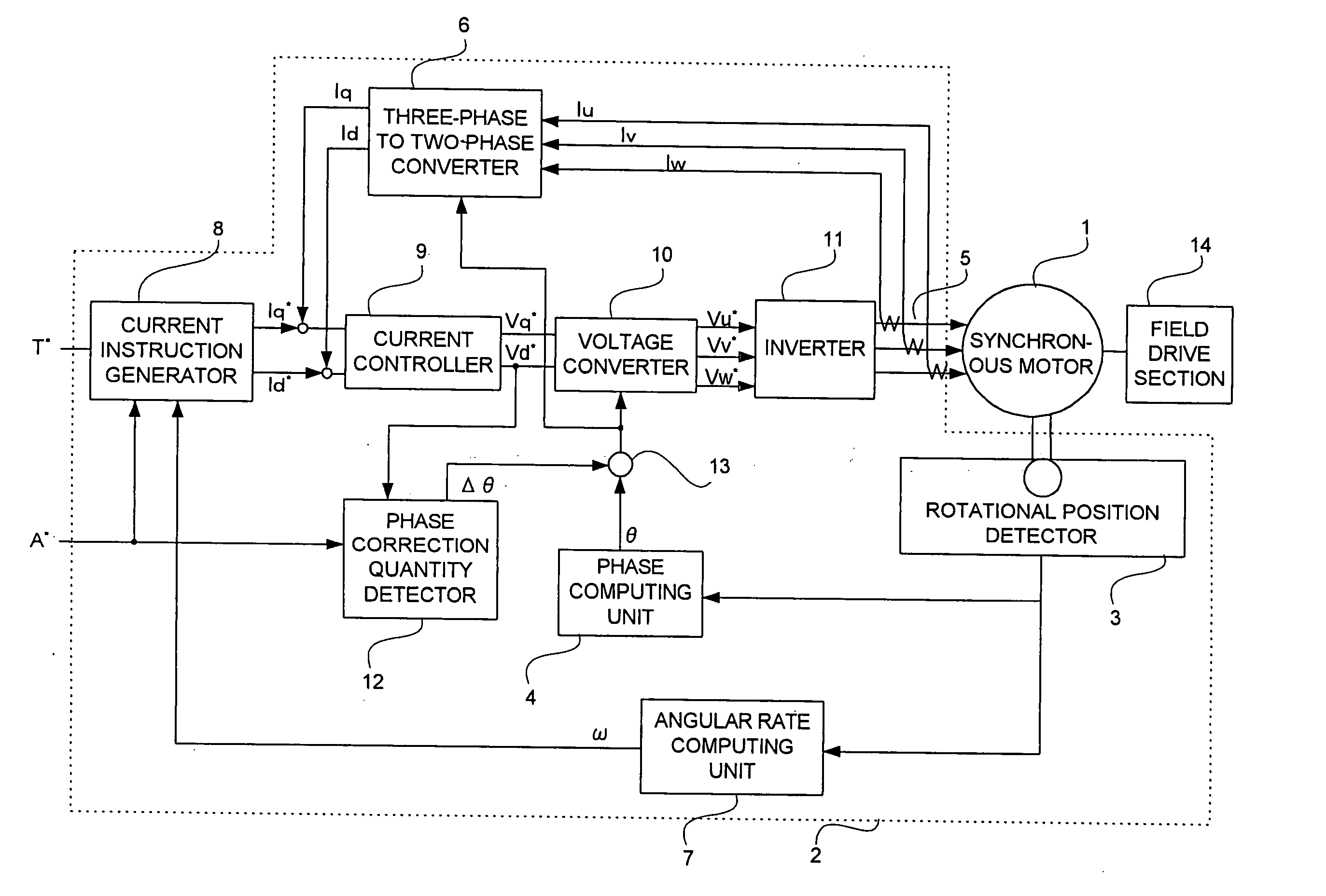

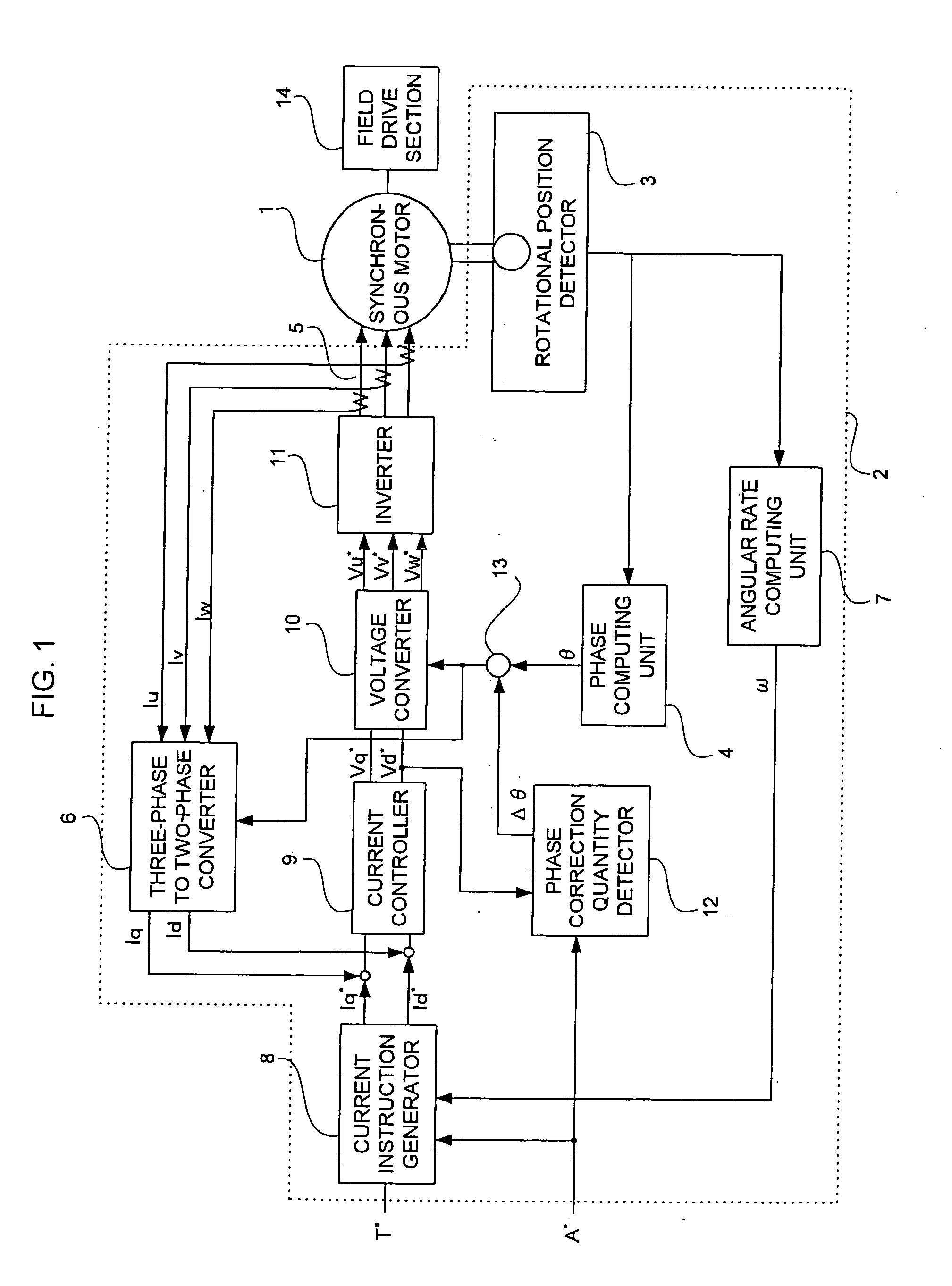

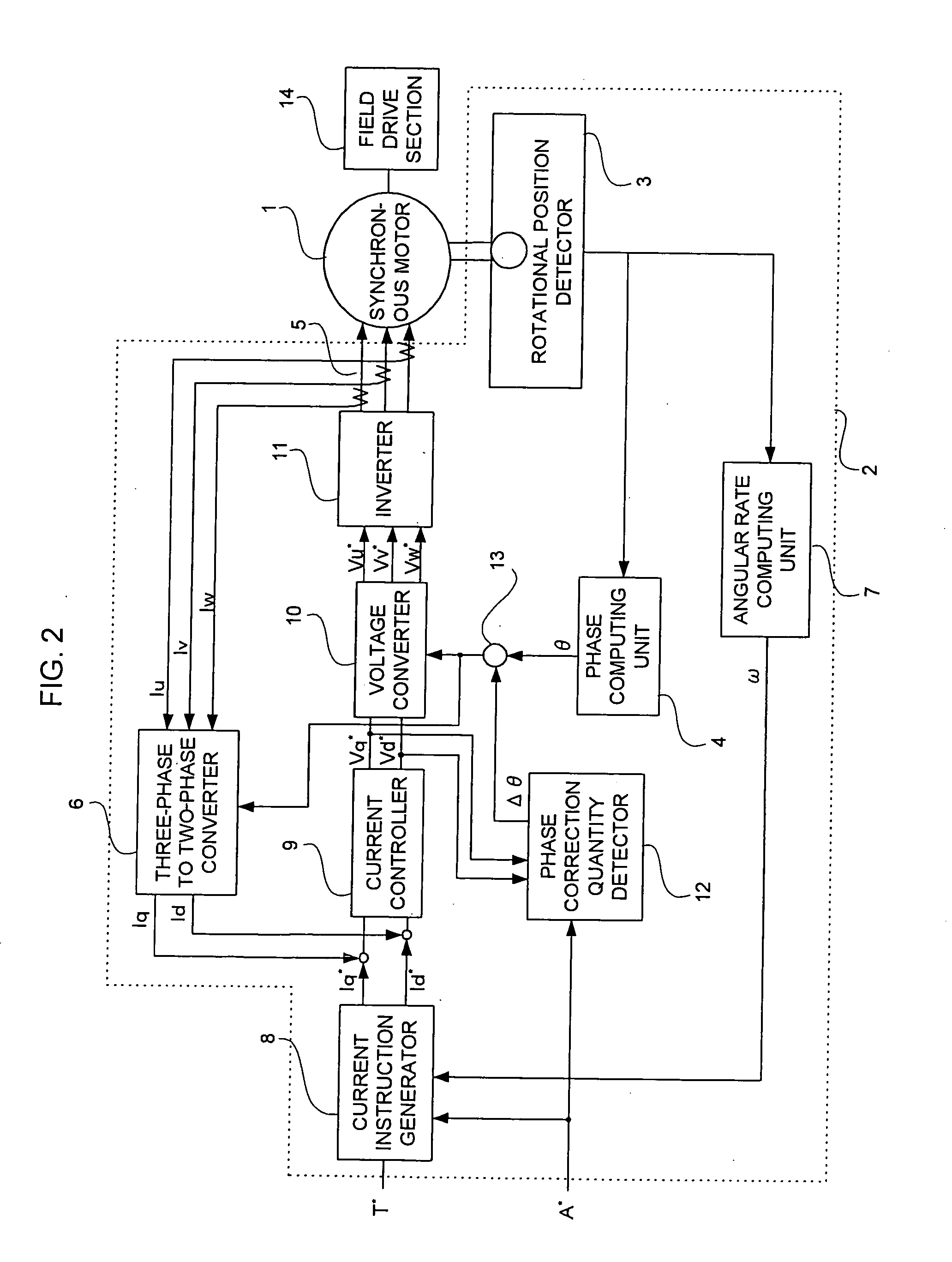

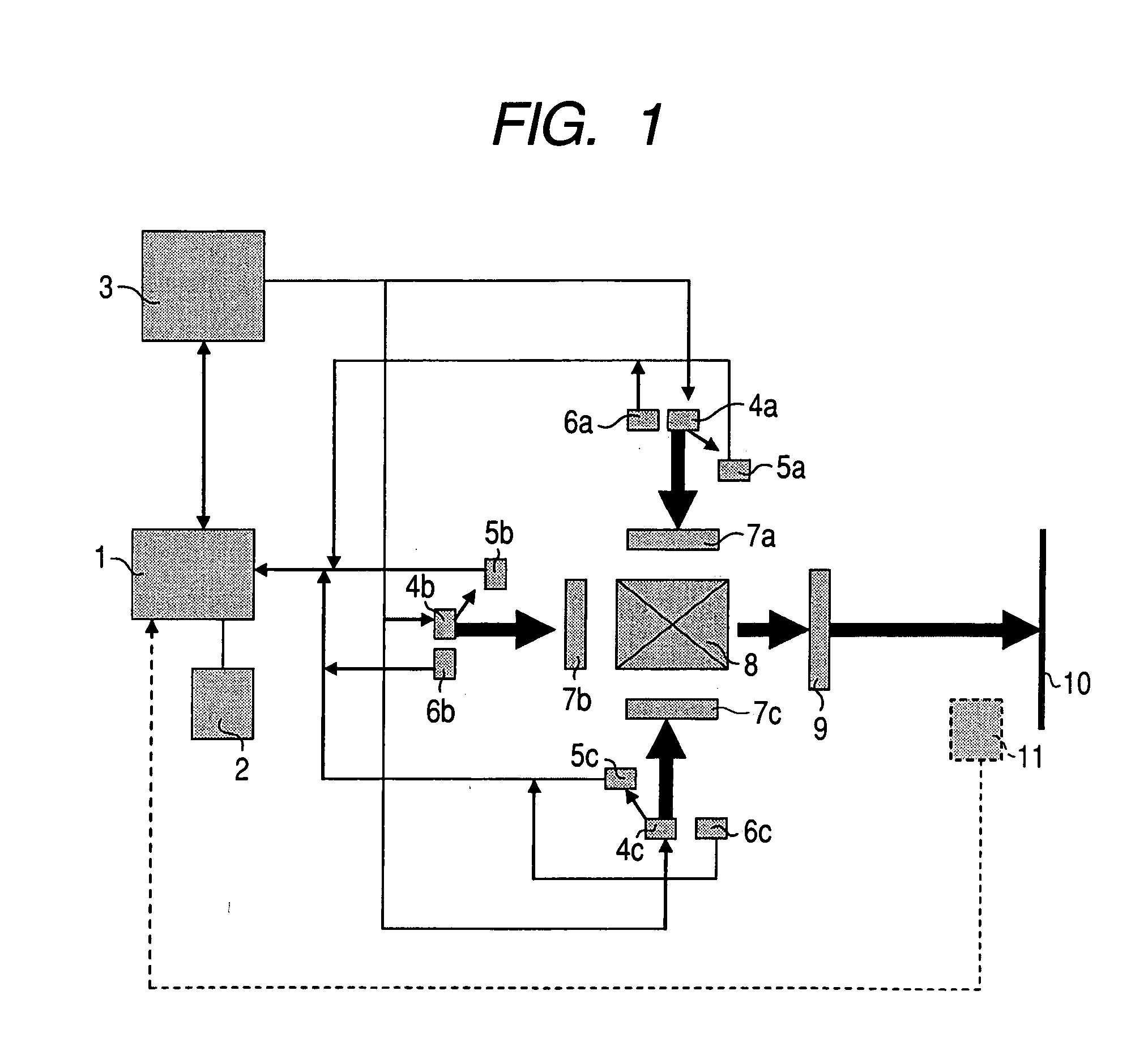

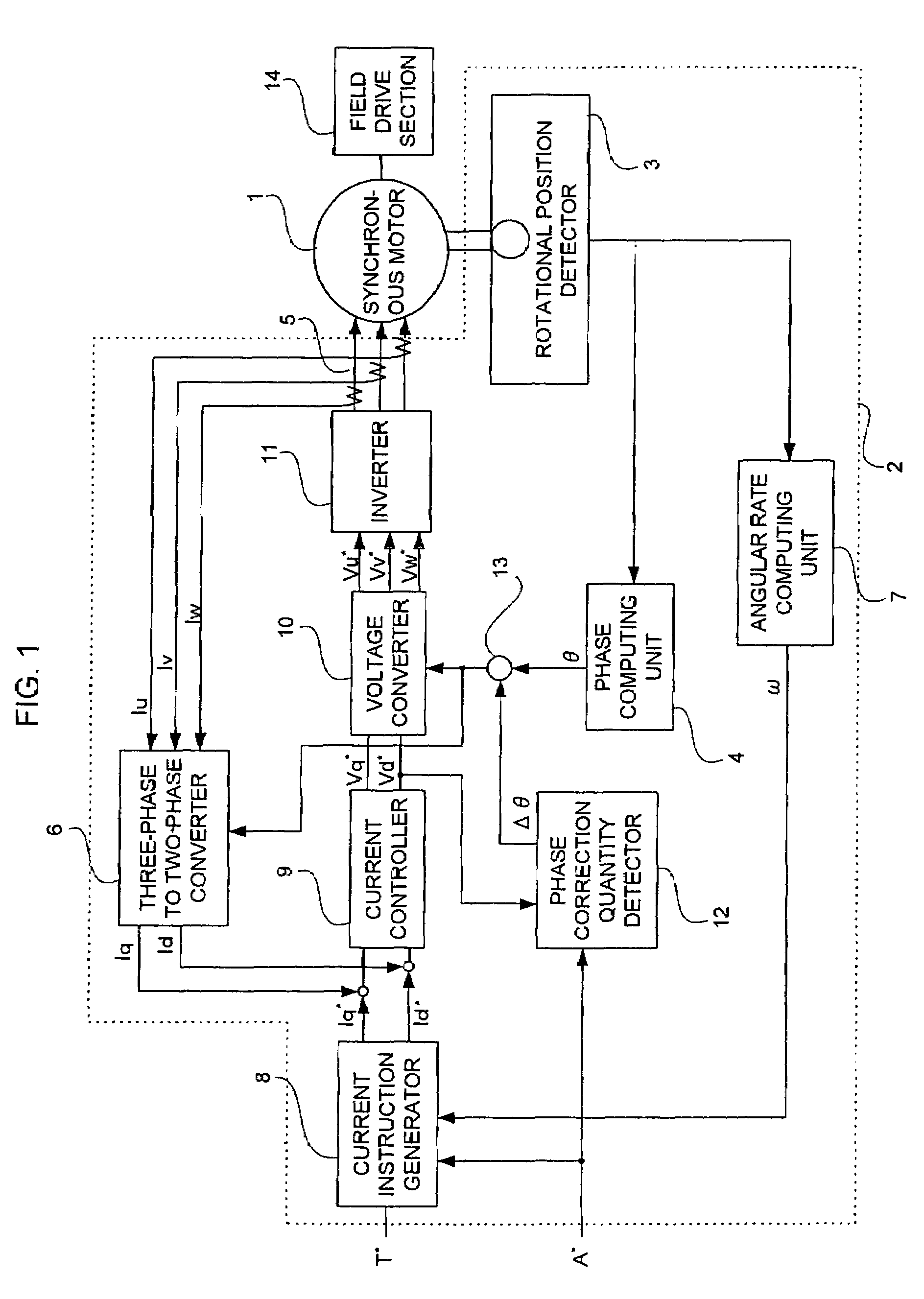

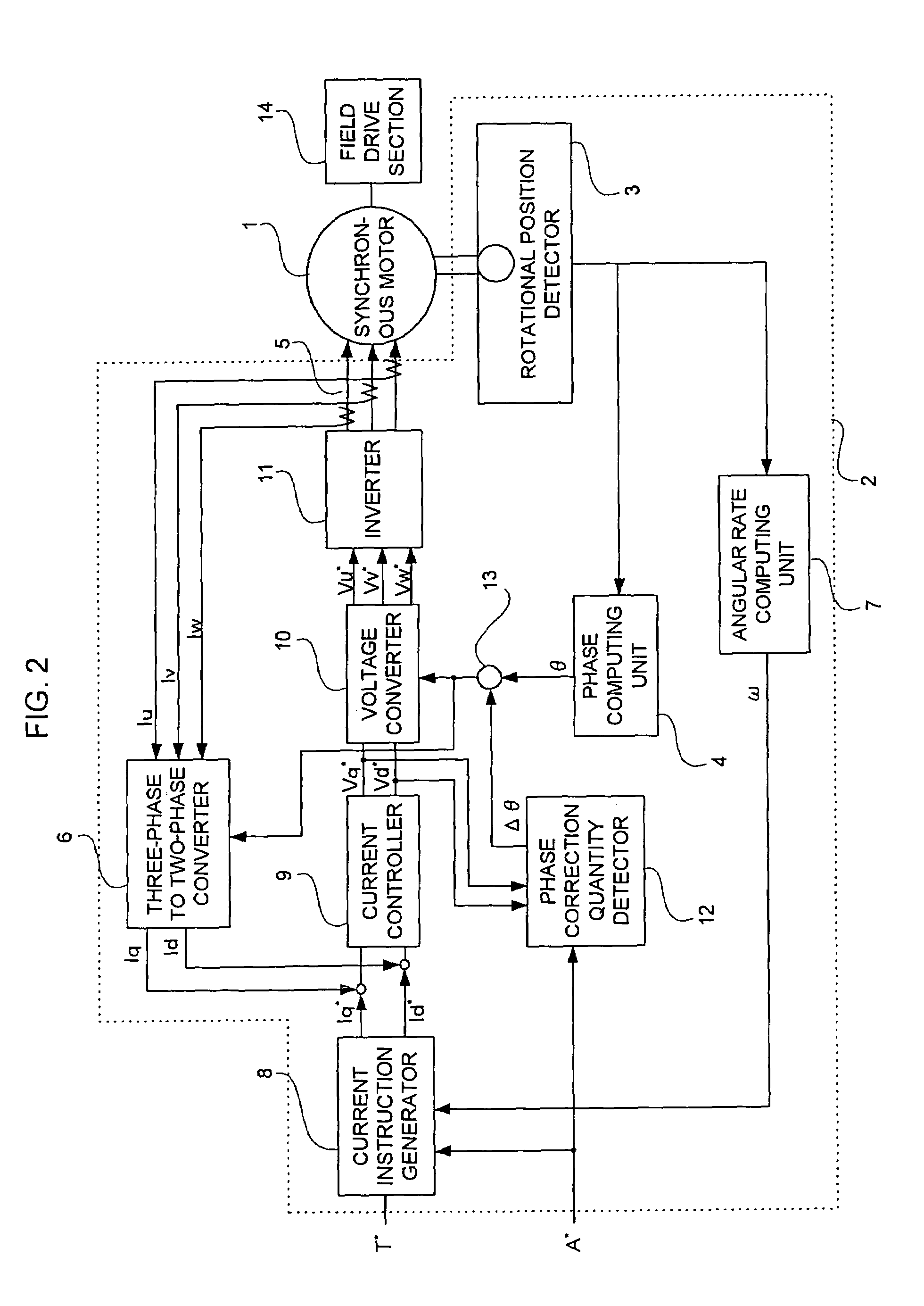

Synchronous motor control device and method of correcting deviation in rotational position of synchronous motor

ActiveUS20050104551A1Correct deviationAC motor controlDC motor speed/torque controlPhase correctionVoltage converter

In a synchronous motor control device that corrects a deviation in rotational position which is related to a rotational position detector for a synchronous motor on which vector-control is performed, the synchronous motor control device includes: a current instruction generator that disables a torque instruction to set d-axis and q-axis current instructions as zero when a phase correction instruction is inputted; a current controller that outputs d-axis and q-axis voltage instructions based on the d-axis and q-axis current instructions; a phase correction quantity detector for determining the amount of offset in which the d-axis voltage instruction becomes zero when the phase correction instruction is inputted and the d-axis voltage instruction is not zero; an adder for adding a rotor positional angle and the amount of offset; and a voltage converter for determining three-phase voltage instructions based on the additional value, the d-axis and q-axis voltage instructions.

Owner:MITSUBISHI ELECTRIC CORP

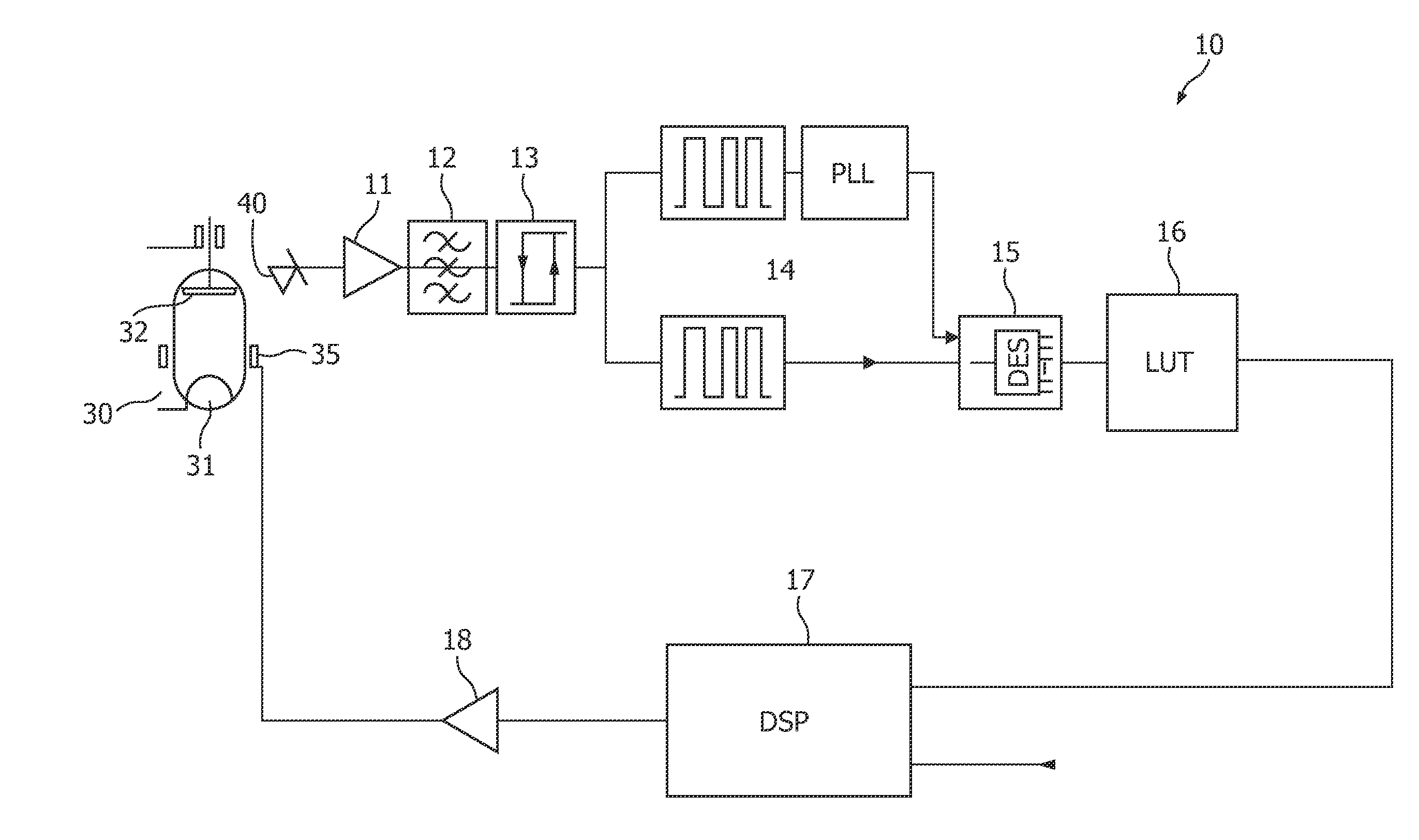

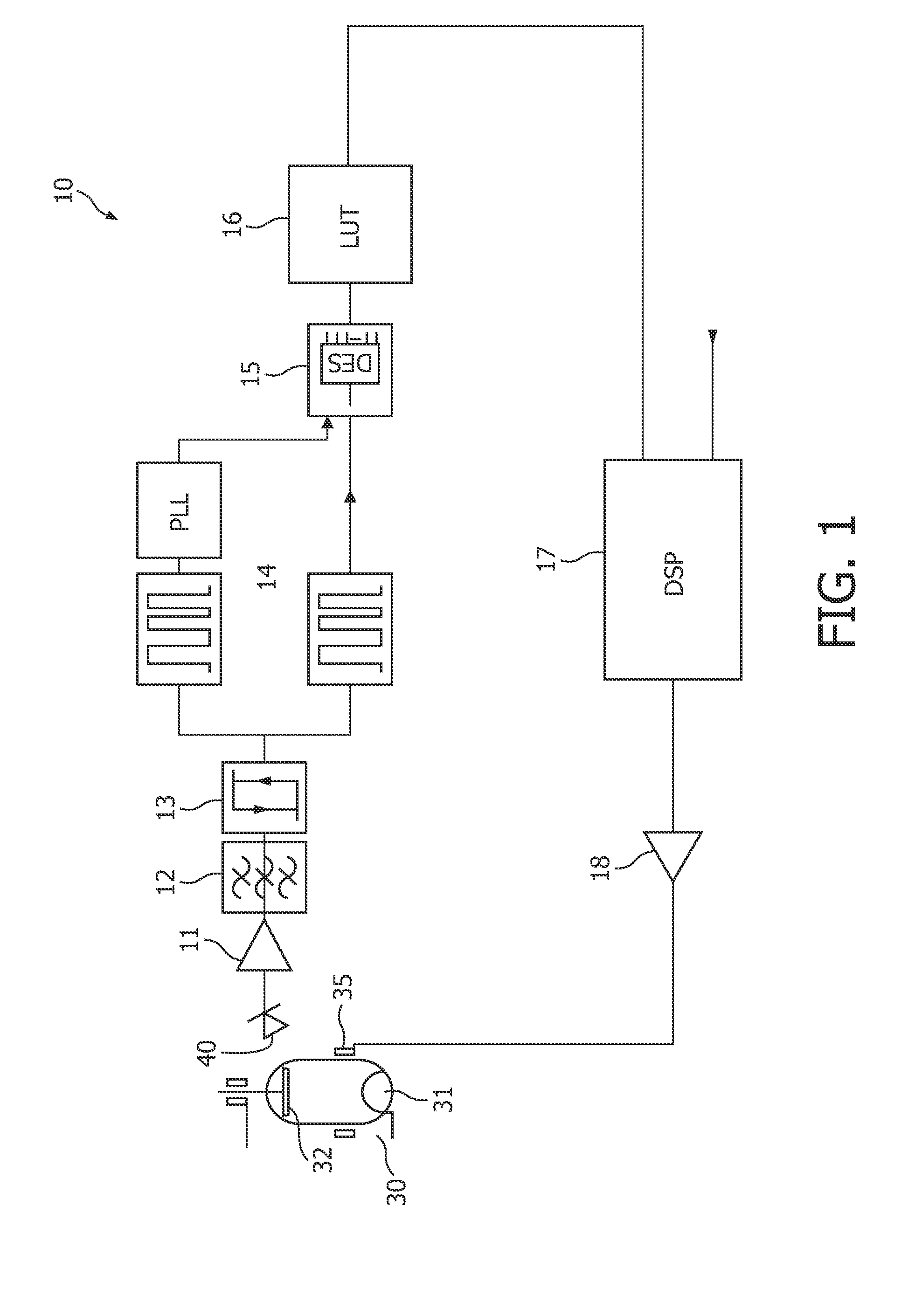

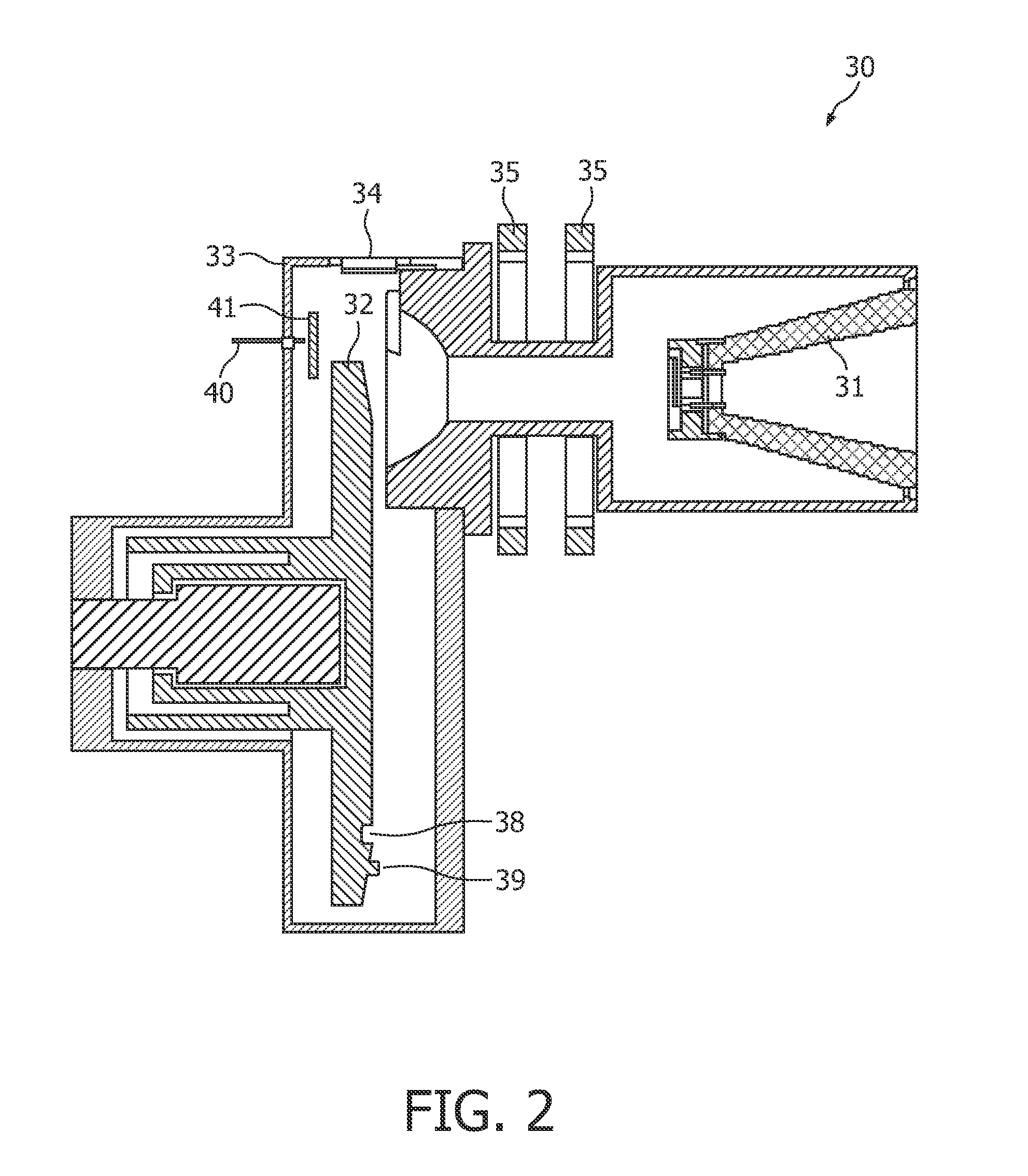

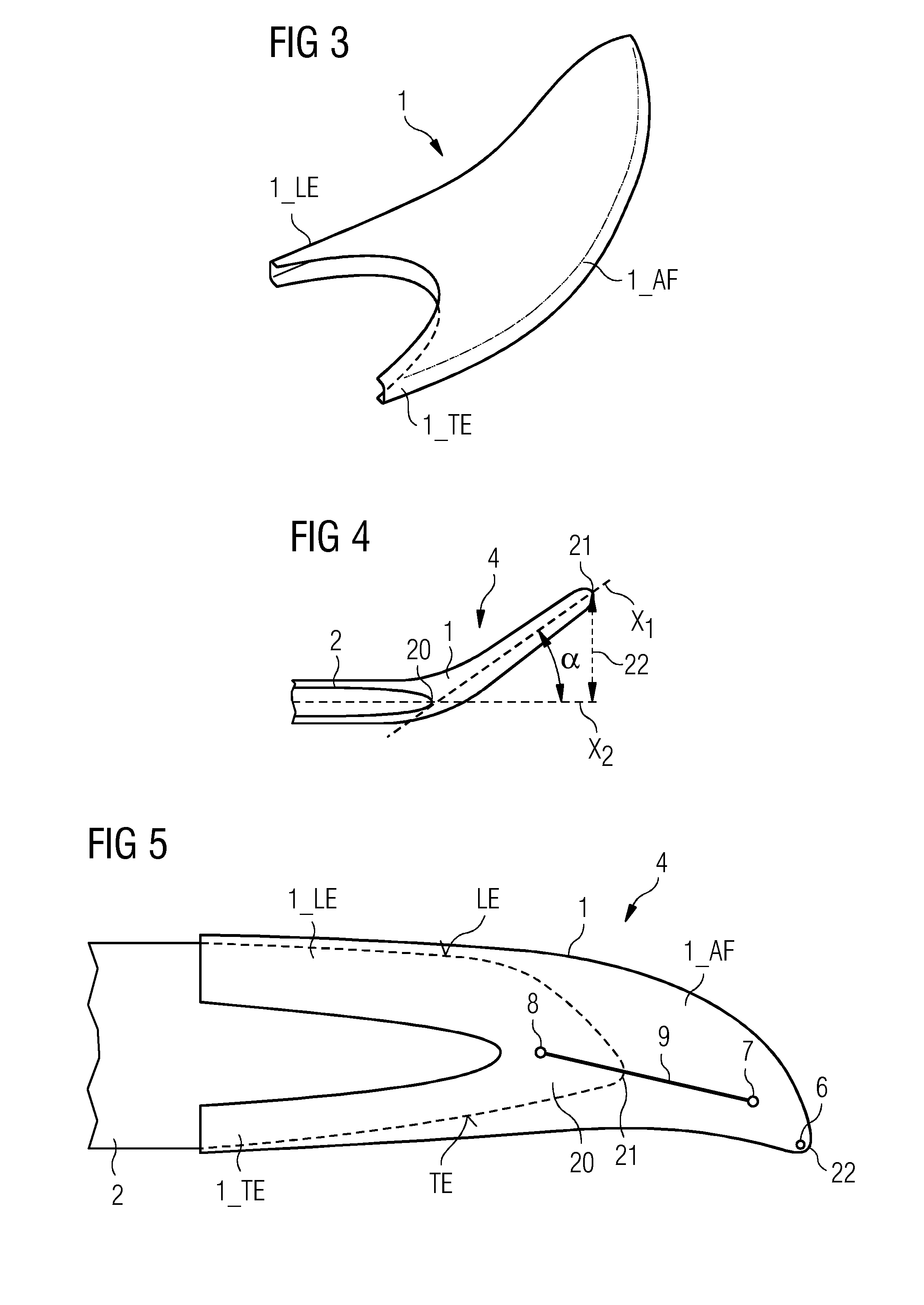

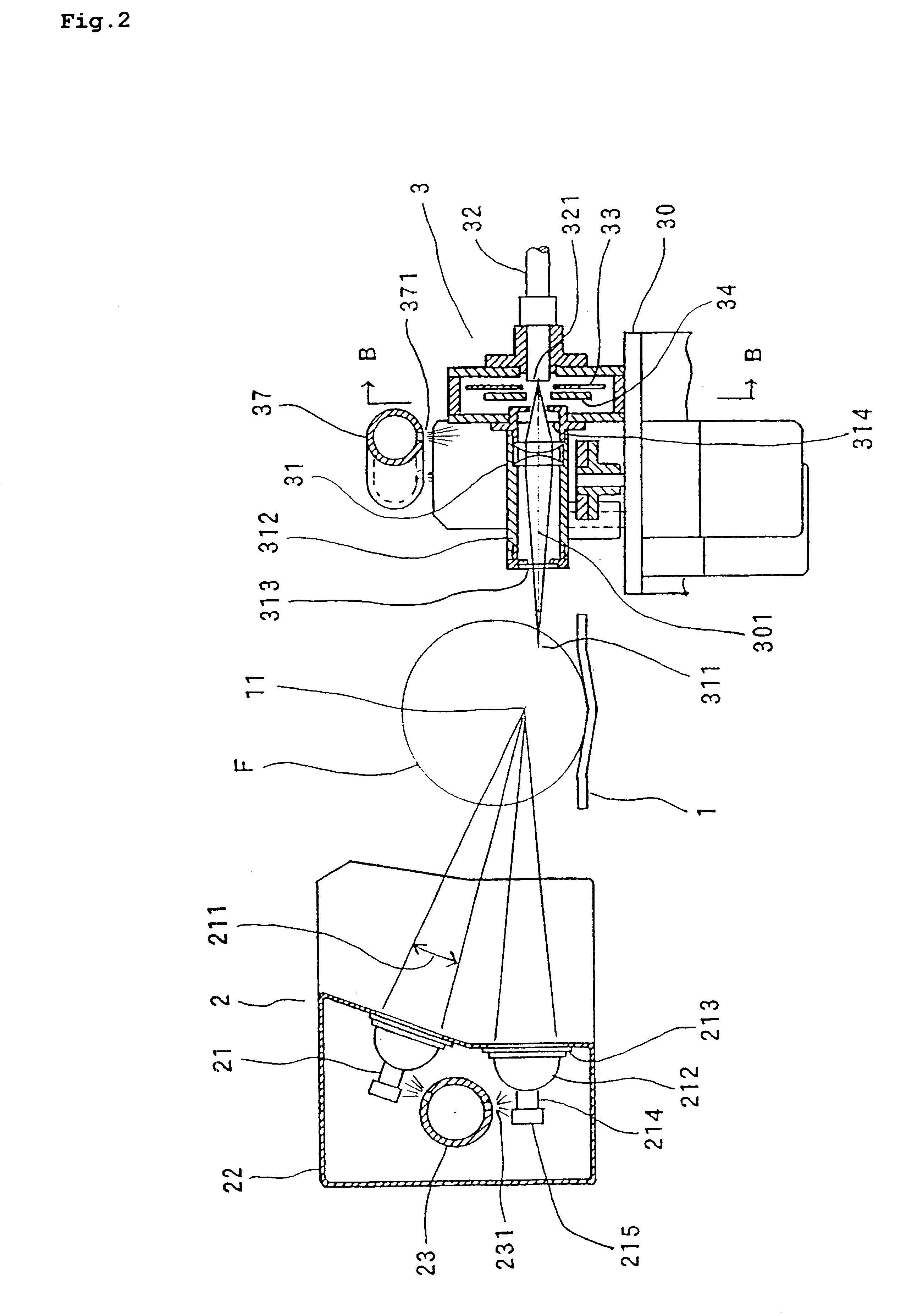

Device and method for x-ray tube focal spot size and position control

InactiveUS20100020938A1Easy to controlEasy to operateCathode ray concentrating/focusing/directingX-ray apparatusControl signalParameter control

A device and method for X-ray tube focal spot parameter control, wherein stray electrons are detected in an X-ray tube. The detected electrons lead to a signal having a characteristic pattern. The characteristic pattern may be evaluated, and based on the evaluation a controlling signal may be outputted so that a fast and exact controlling of the operating parameters of an X-ray tube may be carried out based on the detected stray electrons.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

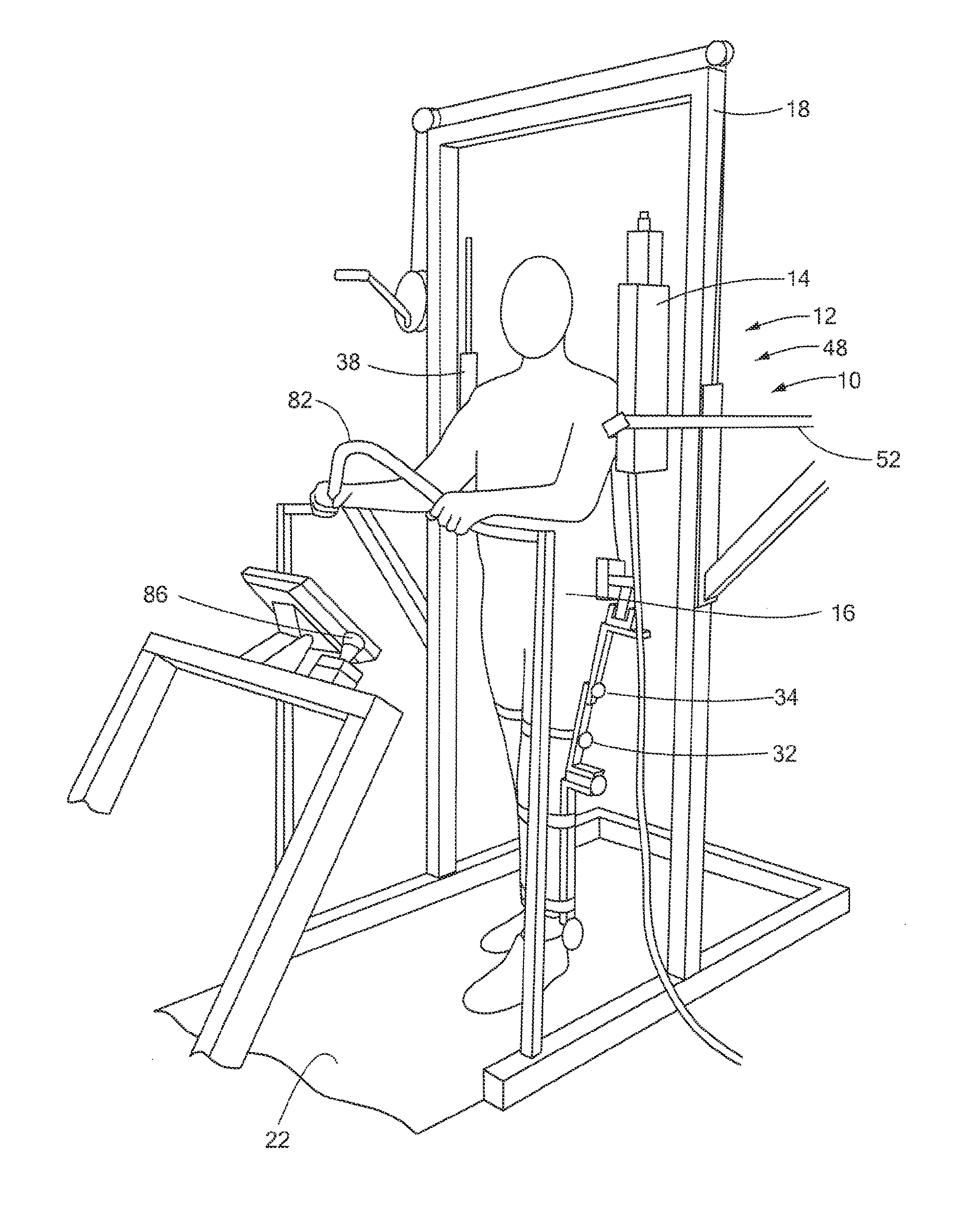

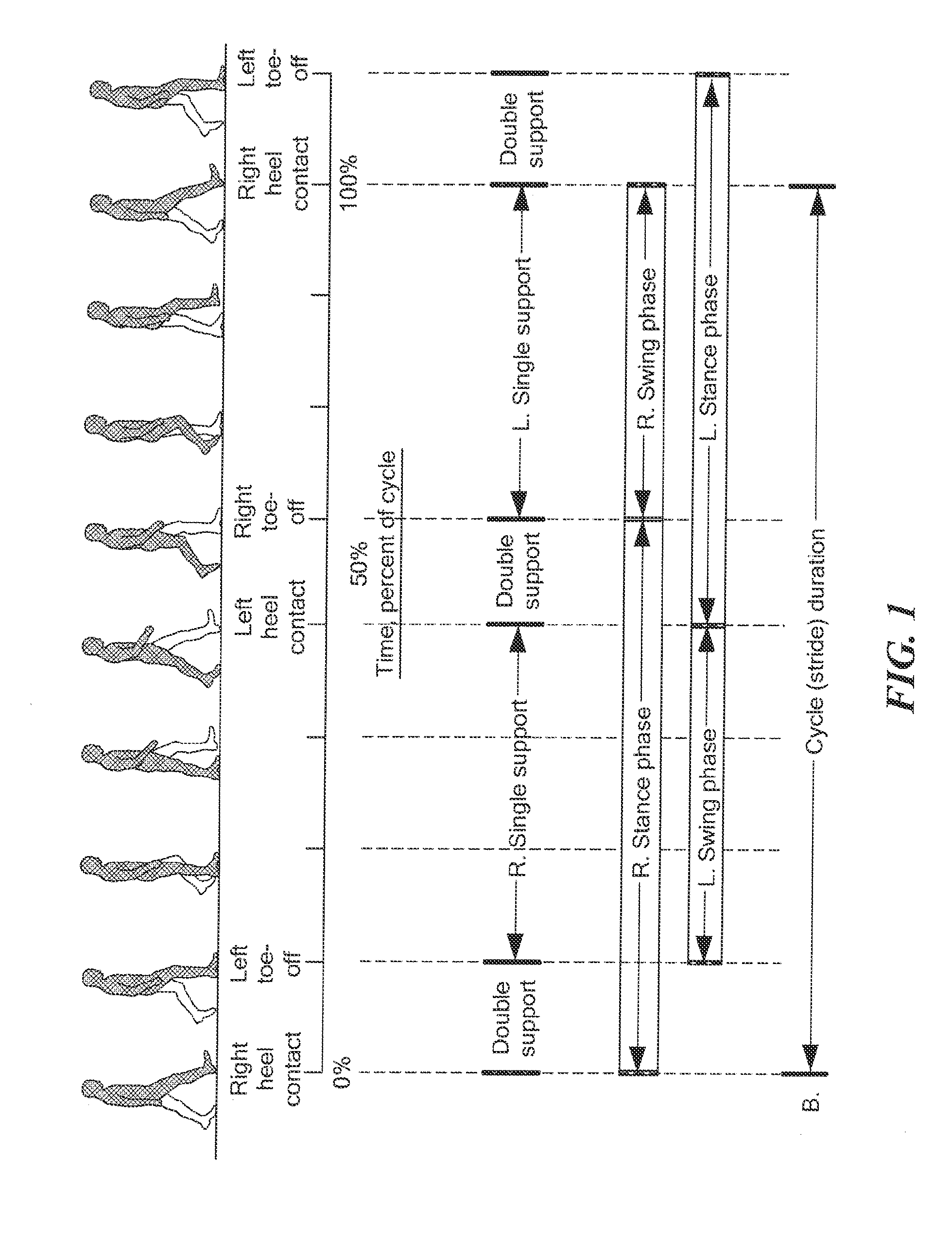

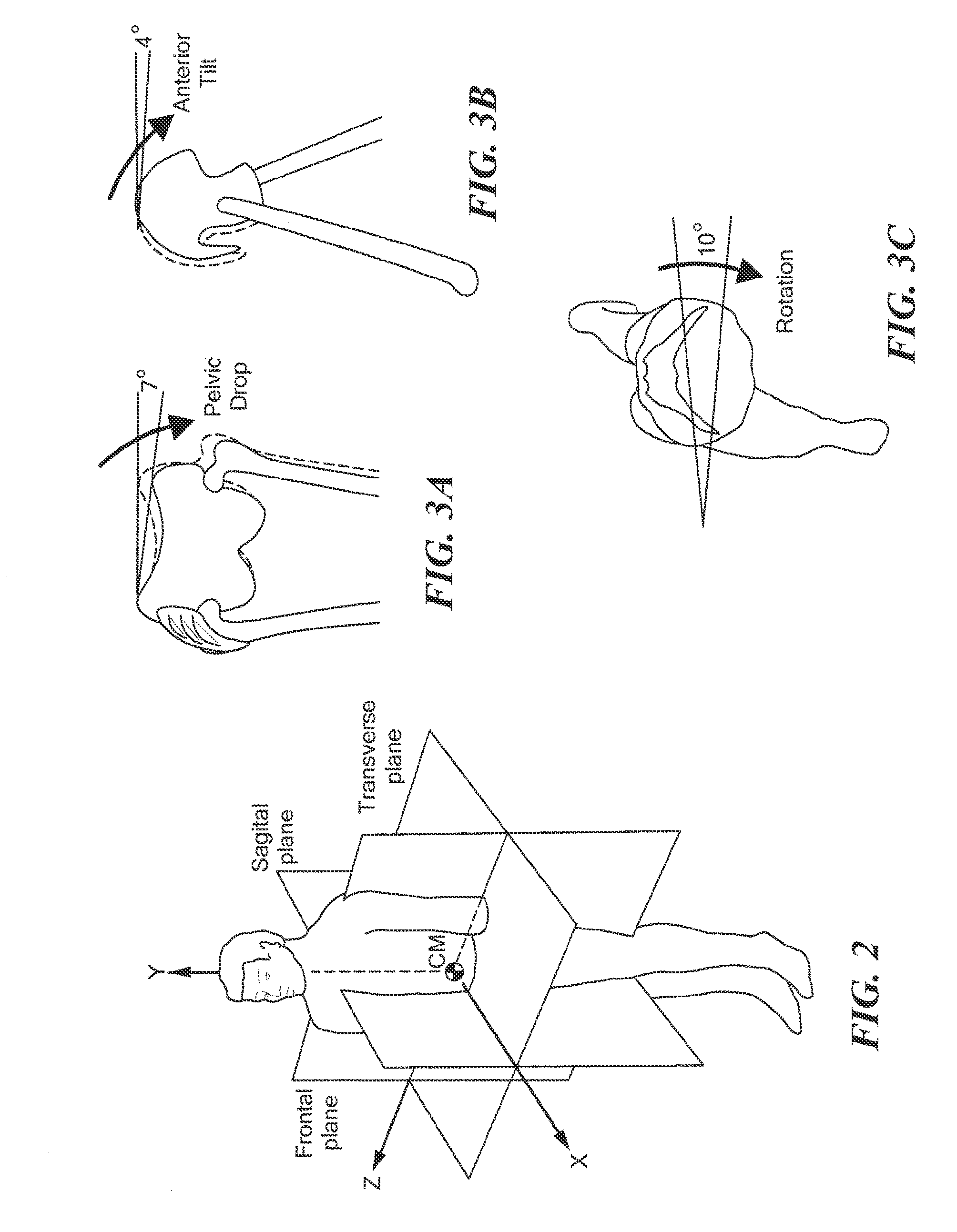

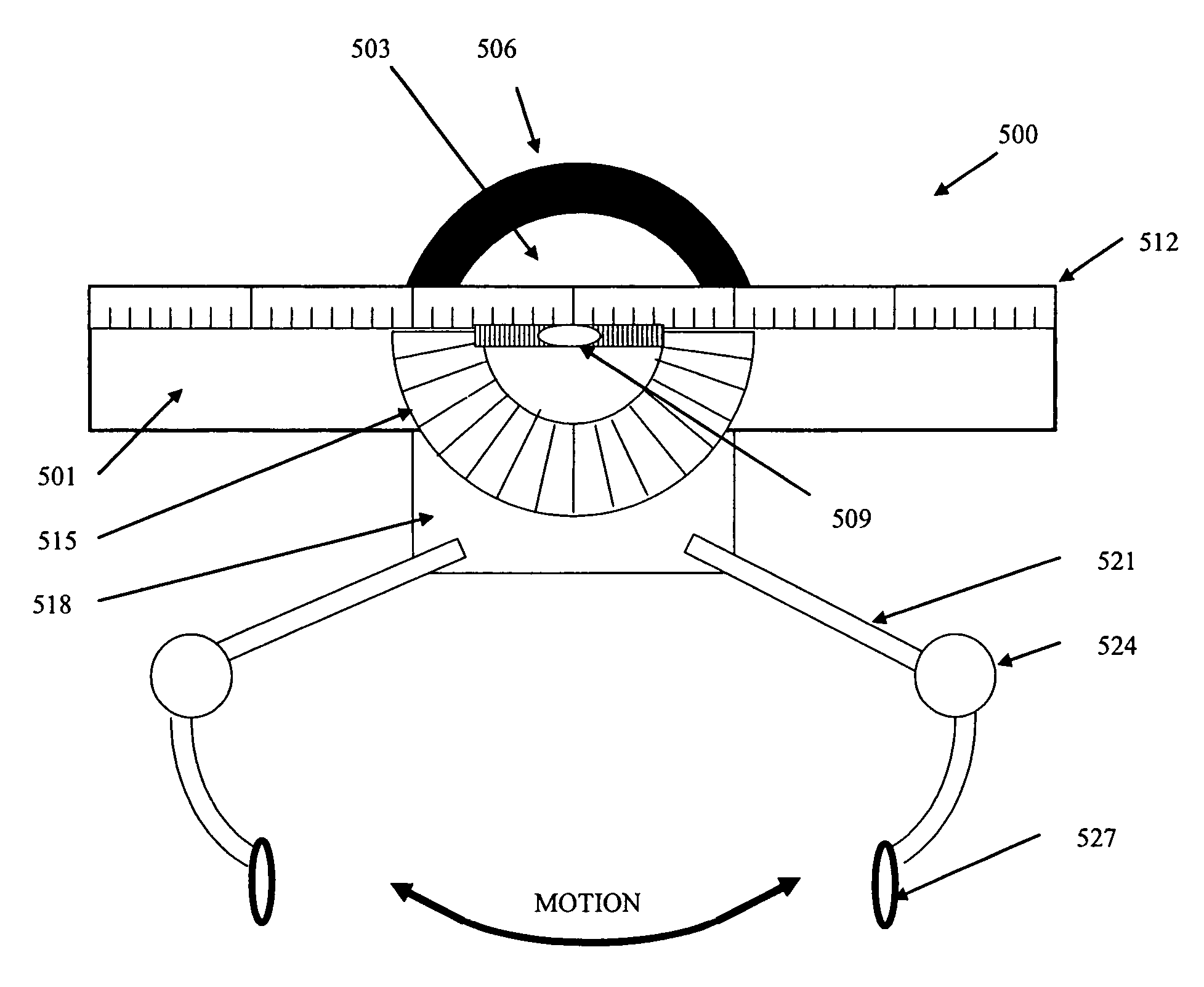

Robotic gait rehabilitation training system with orthopedic lower body exoskeleton for torque transfer to control rotation of pelvis during gait

InactiveUS20140213951A1Facilitates robotic gaitGood torque transmissionDiagnosticsChiropractic devicesRoboticsControl system

A robotic gait rehabilitation (RGR) training system is provided to address secondary gait deviations such as hip-hiking. An actuation assembly follows the natural motions of a user's pelvis, while applying corrective moments to pelvic obliquity. A human-robot interface (HRI), in the form of a lower body exoskeleton, is provided to improve the transfer of corrective moments to the pelvis. The system includes an impedance control system incorporating backdrivability that is able to modulate the forces applied onto the body depending on the patient's efforts. Various protocols for use of the system are provided.

Owner:SPAULDING REHABILITATION HOSPITAL CORP +1

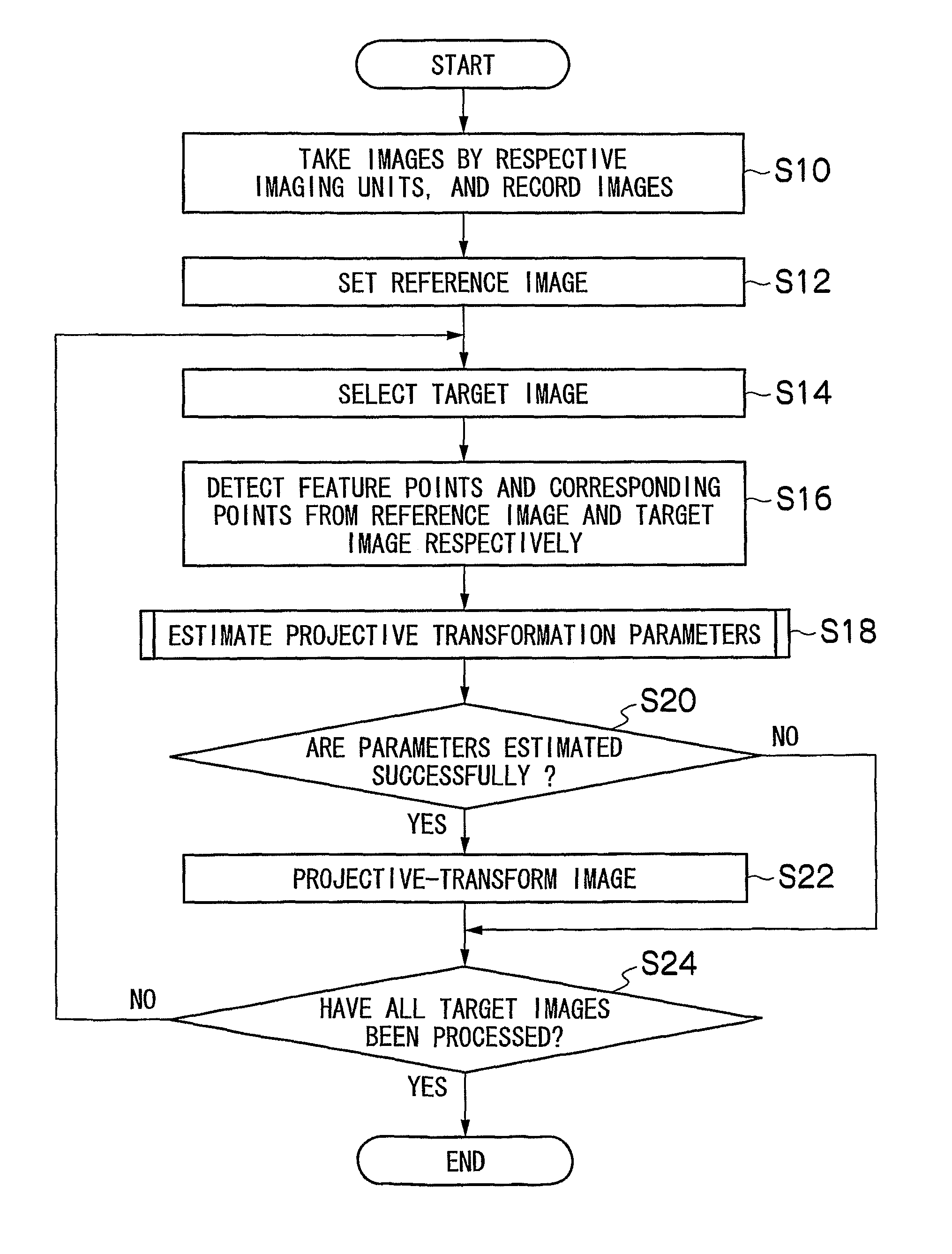

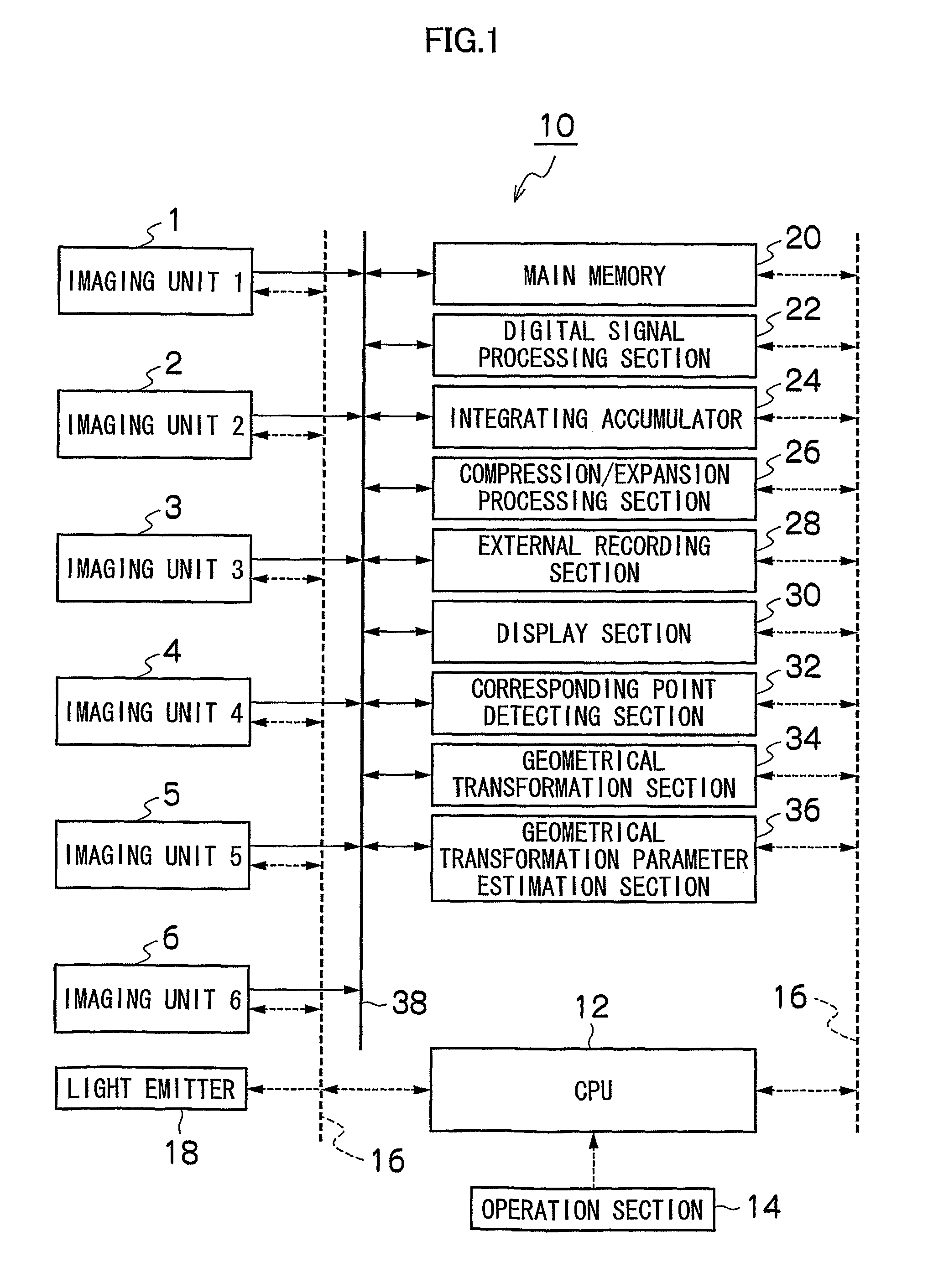

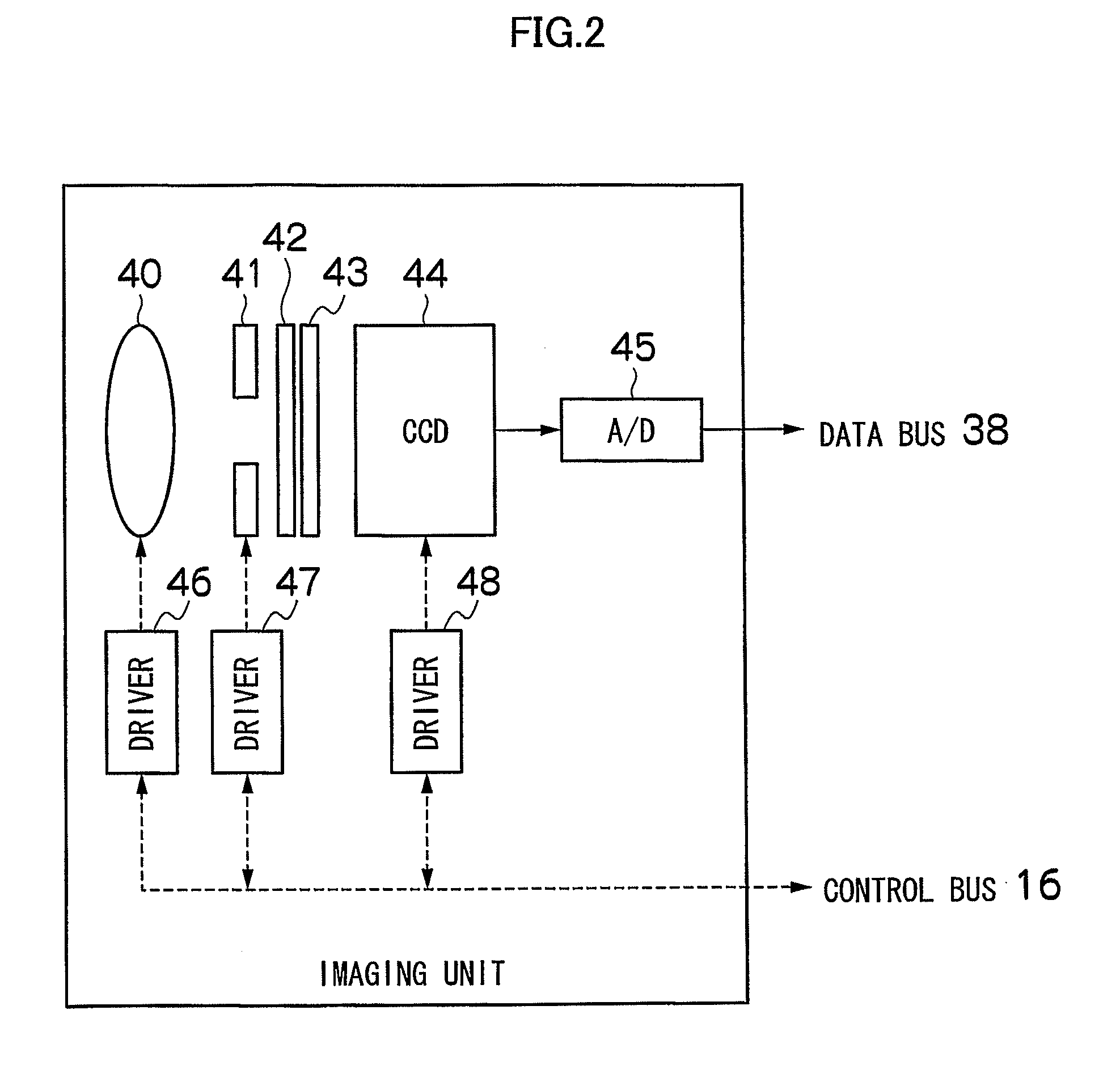

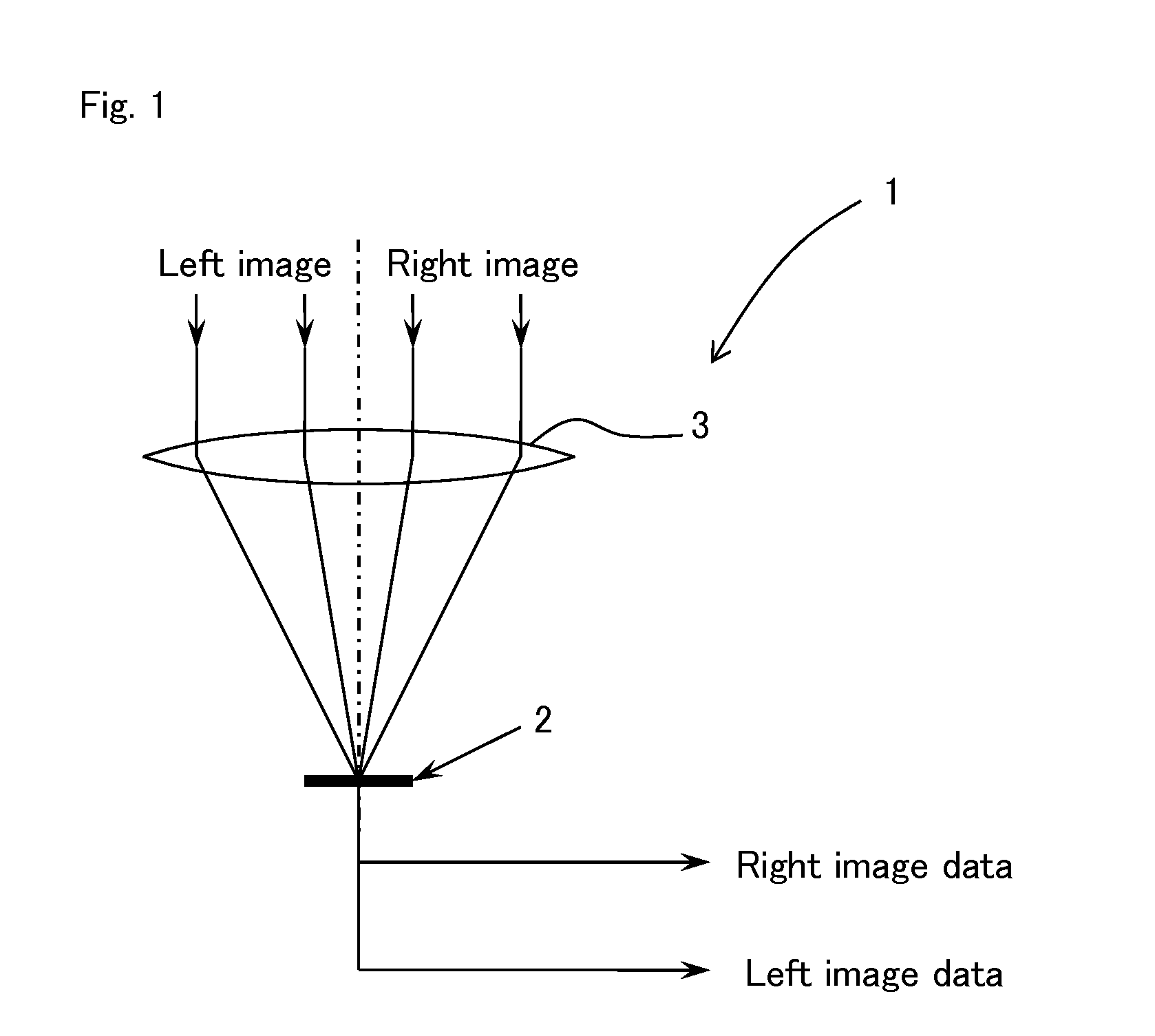

Stereoscopic image processing device, method, recording medium and stereoscopic imaging apparatus

An apparatus (10) includes a device for acquiring a plurality of images of an identical subject taken from a plurality of viewpoints; a device for selecting a prescribed image as a reference image, selecting an image other than the reference image as a target image from among the images, and detecting feature points from the reference image and corresponding points from the target image to generate pairs of the feature point and corresponding point, wherein feature of the feature point and the corresponding point in the same pair are substantially identical; a device for estimating geometrical transformation parameters for geometrically-transforming the target image such that y-coordinate values of the feature point and the corresponding point included in the same pair are substantially identical, wherein y-direction is orthogonal to a parallax direction of the viewpoints; and a device for geometrically-transforming the target image based on the parameters.

Owner:FUJIFILM CORP

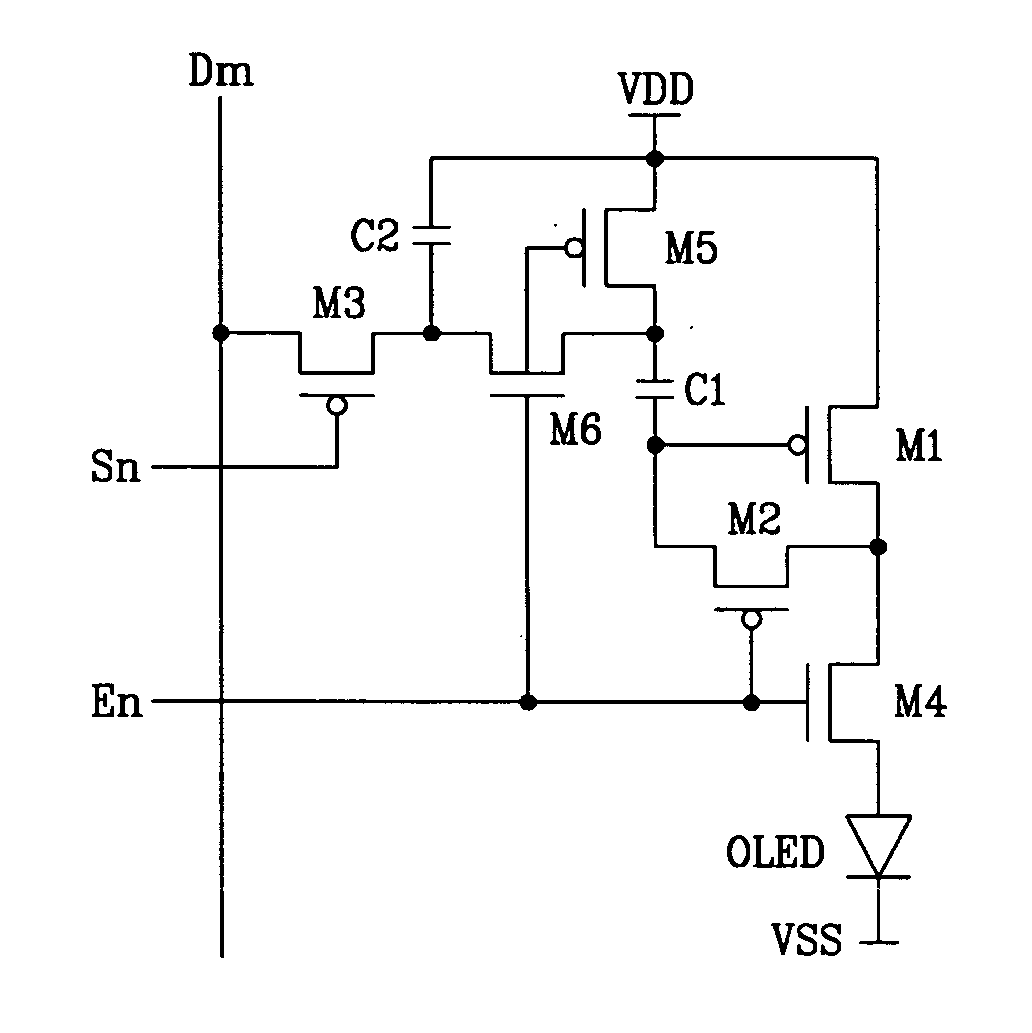

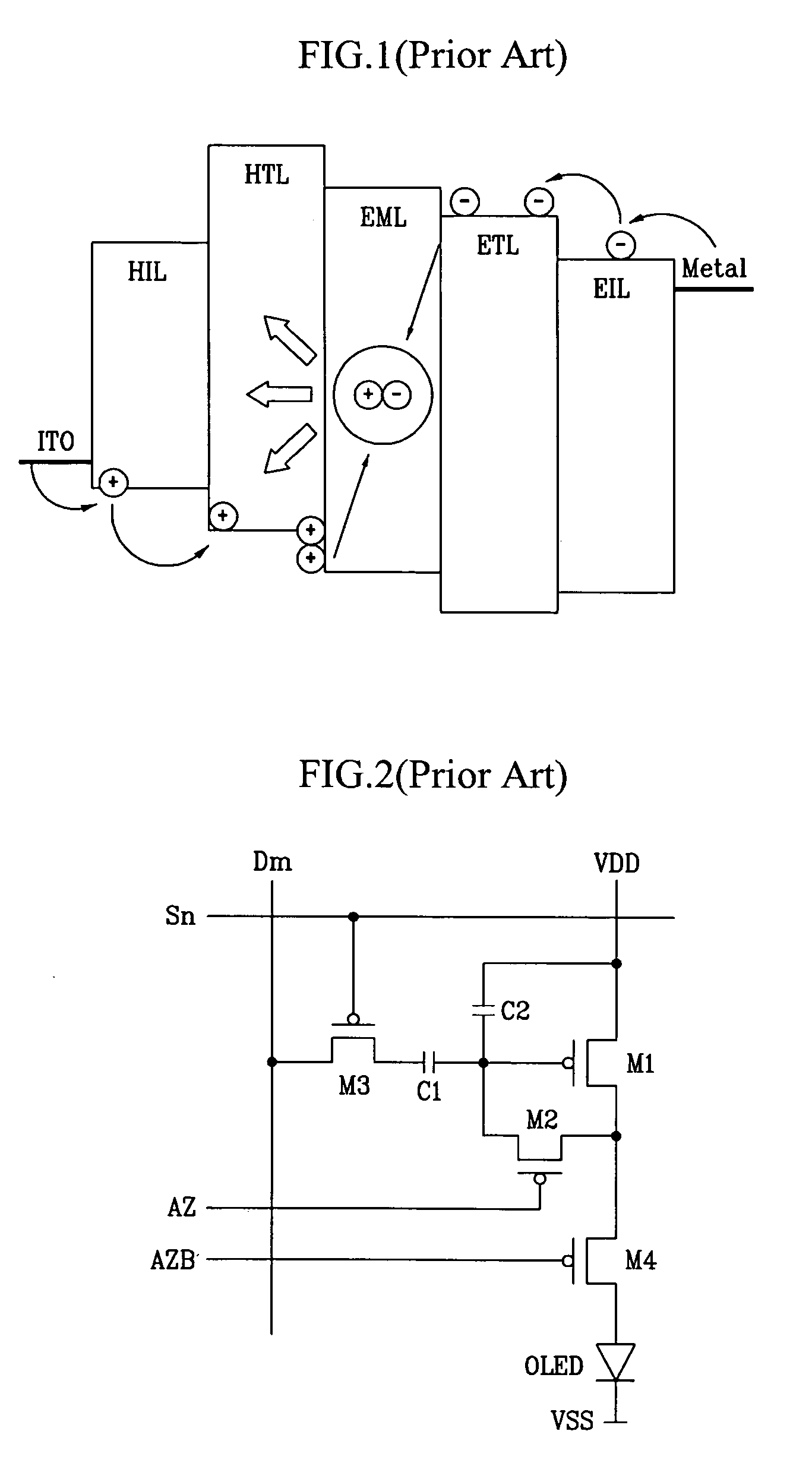

Image display device and driving method thereof

ActiveUS20050140605A1Increase the aperture ratioSimple processTelevision system detailsStatic indicating devicesCapacitanceElectric force

An image display device comprises a pixel circuit including a display element; a first transistor for controlling a current output to a third electrode according to a voltage applied between the first and second electrodes; a first switch for diode-connecting the first transistor in response to a select signal; a first capacitor; a second switch for coupling a first electrode of the first capacitor to a power in response to the select signal; a second capacitor; a third switch for transmitting the data voltage to a second electrode of the second capacitor in response to the select signal; and a fourth switch for intercepting the first electrode of the first capacitor and the second electrode of the second capacitor in response to the select signal.

Owner:SAMSUNG DISPLAY CO LTD

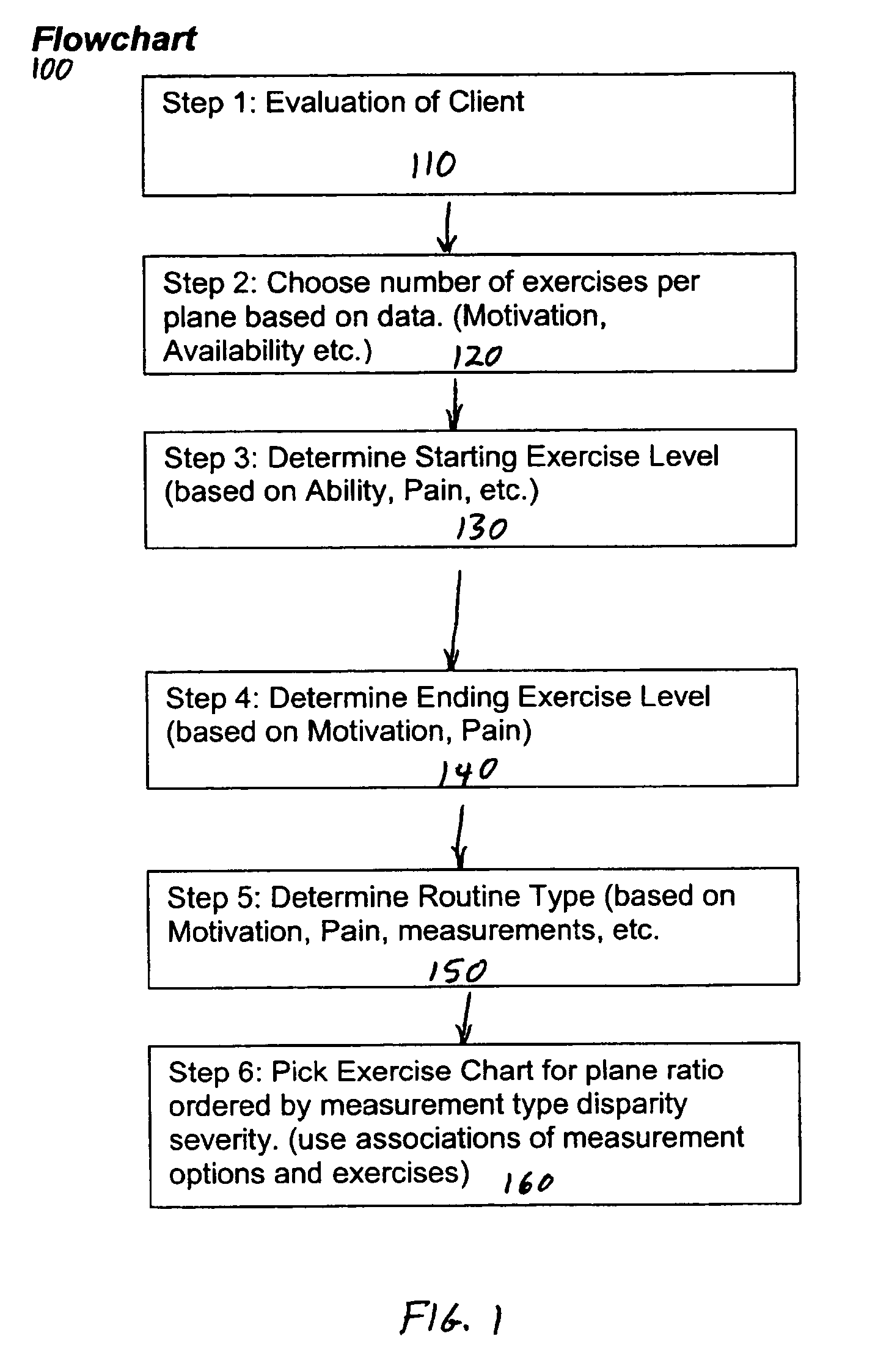

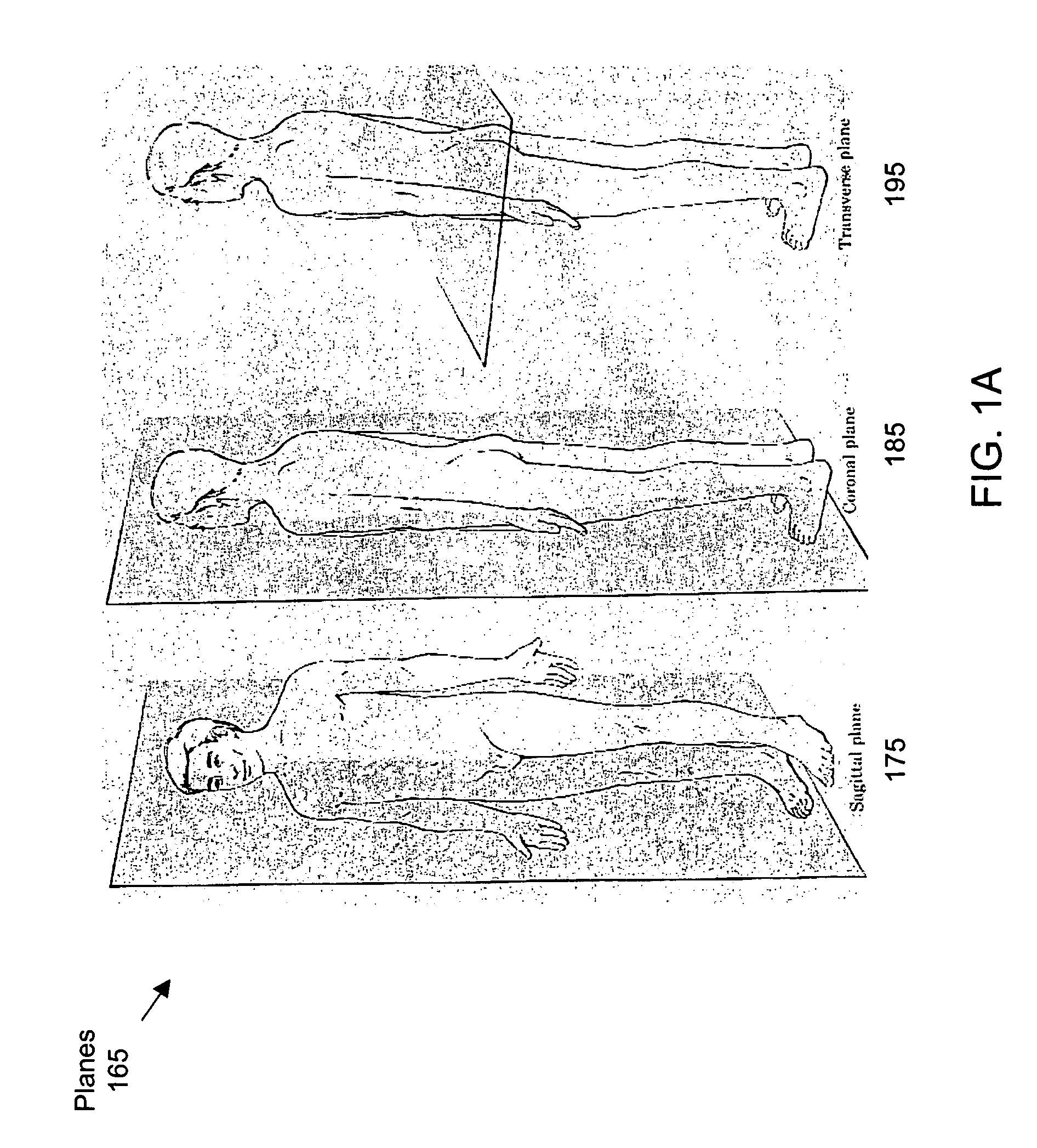

Posture realignment system

InactiveUS7335167B1Improve athletic performanceReduce practitioner errorWave based measurement systemsSurgerySoftware systemPhysiologic Factors

A software system and apparatus for the collection of various measurements of the human body representing deviations from an ideal posture in several planes of motion relative to the body. A specially designed apparatus enables the correct measurements, while the software component performs an analysis of the measurements and recommends an exercise routine based on the severity of the deviations with respect to the planes of motion. The routine can be adjusted based on the flexibility and motivation of the patient as well as on the type of symptoms being experienced by the person. Additionally, physiologic factors are taken into account, such as the person's age and weight. The exercise routine is provided via a computer display, via email or via a web page available on the Internet, utilizing textual descriptions and visual and audio aids to describe the exercises.

Owner:SYMMETRY FOR HEALTH

Method and system for ascertaining the position and orientation of a camera relative to a real object

ActiveUS20100239121A1Low rangeImprove accuracyImage enhancementImage analysisComputer graphics (images)Sensor system

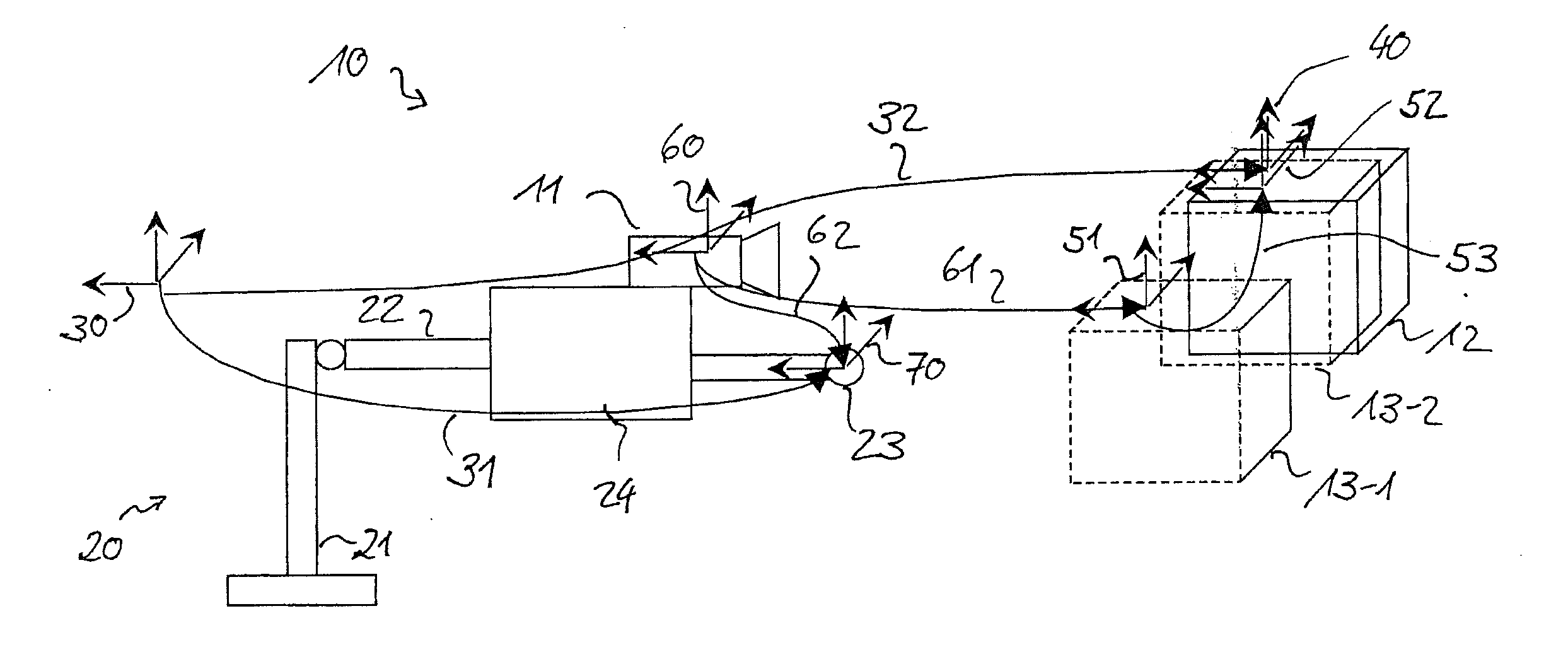

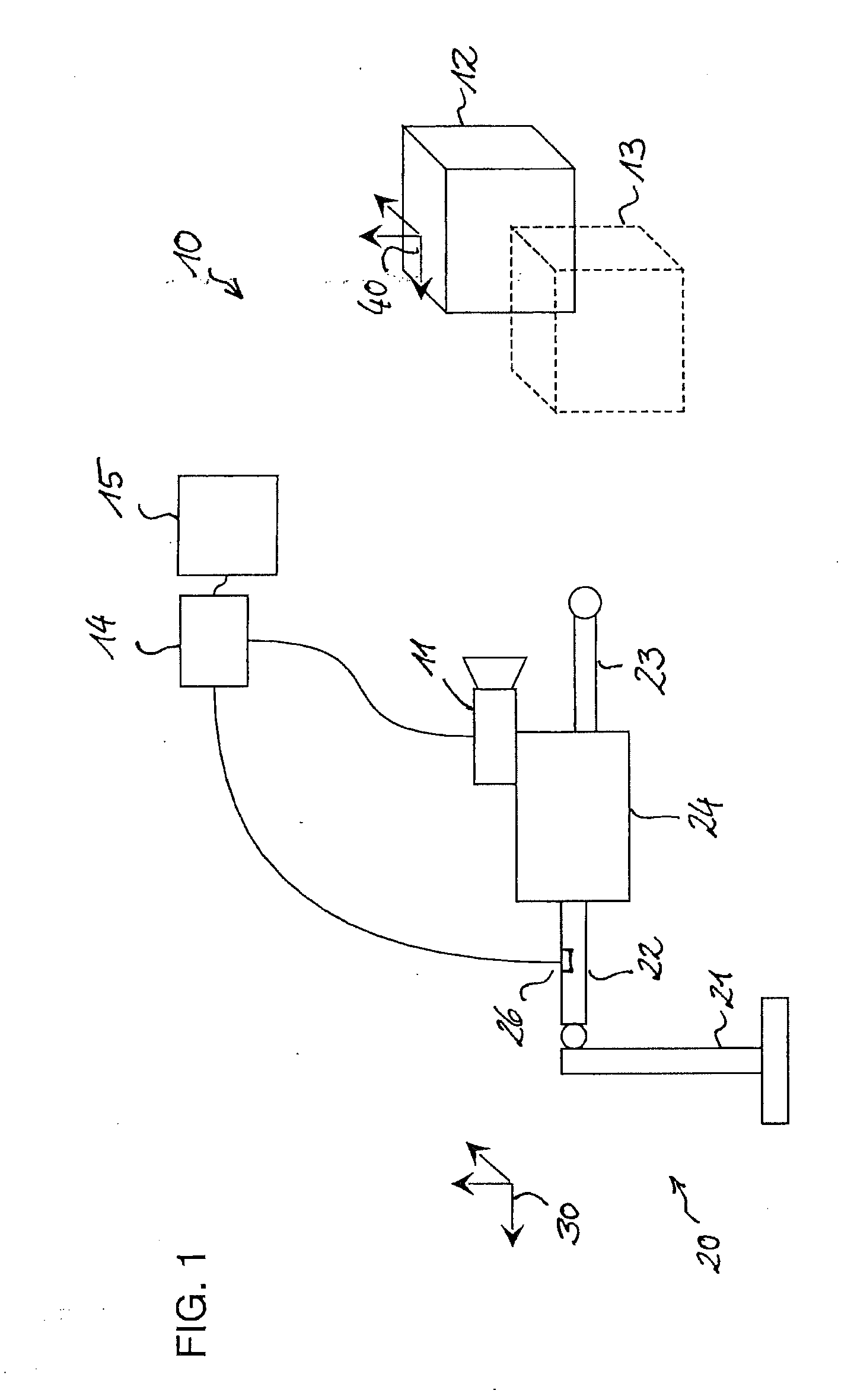

The invention relates to a method for ascertaining the position and orientation of a camera (11) relative to a real object (12) for use in merging a virtual data model (13) with an image generated by the camera (11), said image comprising at least one part of the real object (12). The method comprises the following steps: disposing the camera (11) on a movable part (22) of a sensor system (20) which is coupleable to at least one probe (23) which is suitable to come in contact with at least one part of the real object (12), positioning the movable part (22) of the sensor system, with the camera (11) applied, in such a manner that the image is generatable by the camera, and generating position data (31) of the sensor system (20) with respect to the real object (12), and determining the position and orientation of the camera (11) on the basis of the position data (31, 32) of the sensor system (20).

Owner:APPLE INC

Display apparatus and illumination apparatus, and light emitting element and semiconductor device

InactiveUS20180040665A1Reduce image qualityReduce the impactPlanar light sourcesLight source combinationsPower semiconductor deviceLength wave

A display apparatus according to one embodiment of the disclosure includes pixels in a plurality. The pixels are two-dimensionally disposed, and the pixels each include light emitting elements of at least a first primary color. The pixels each or pixel groups each include, as the light emitting elements of the first primary color, a first light emitting element and a second light emitting element that have peak wavelengths of light emission in different wavelength bands from each other. The pixel groups each include two or more adjacent ones of the pixels.

Owner:SONY SEMICON SOLUTIONS CORP

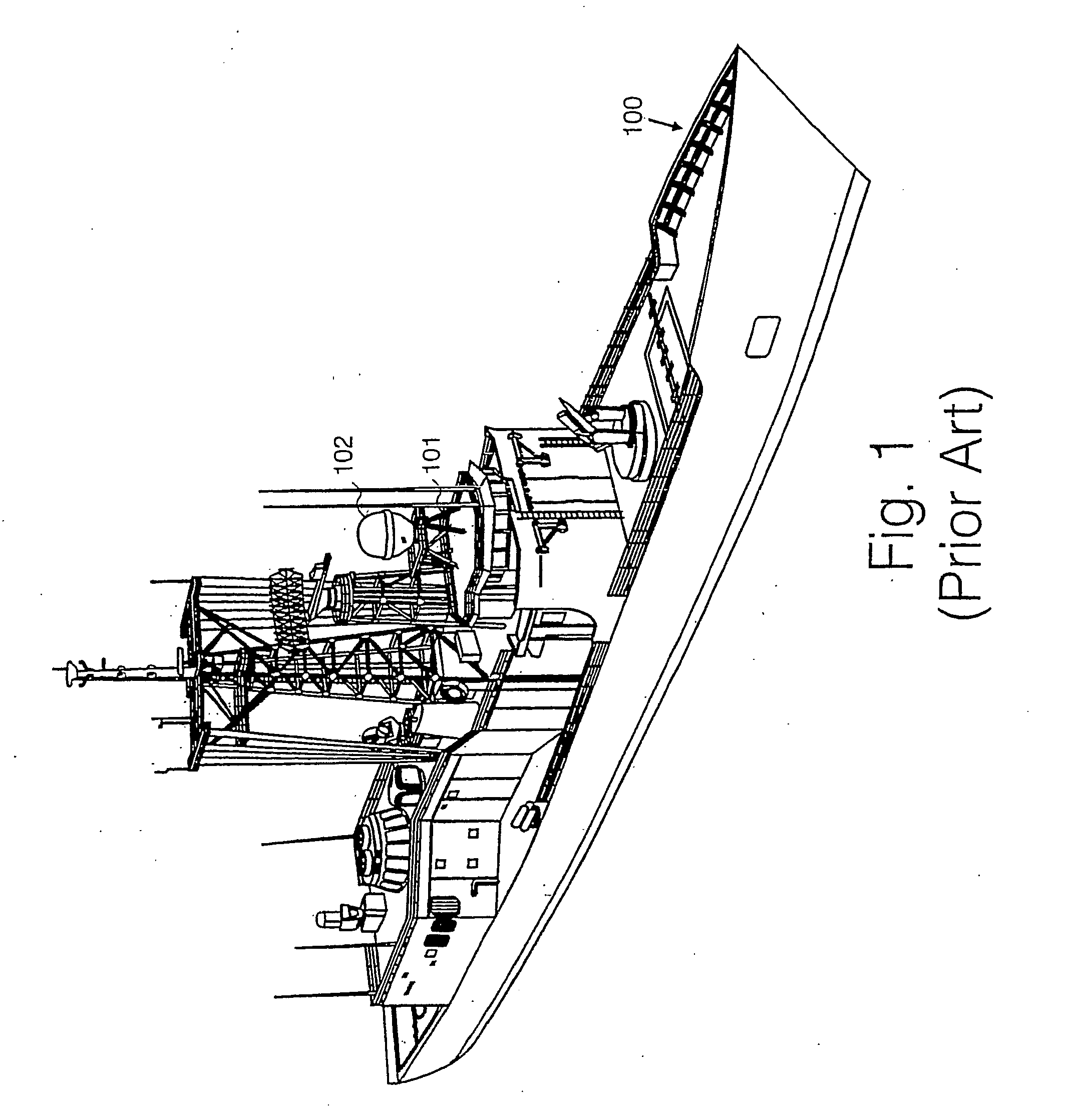

Rudderless unmanned ship capable of automatically sailing

ActiveCN103303452AReduce usageSimple structurePropulsion power plantsPropulsive elementsTerrainCommunication unit

The invention relates to the technical field of unmanned remote control measurement, and provides a rudderless unmanned ship capable of automatically sailing, which comprises a ship body, pontoons on the two sides, a communication unit, a navigation and positioning unit, a measuring unit, a power and driving unit, a ship body gesture measuring unit, an industrial personal computer, and a battery providing a working power supply for the other parts. According to the invention, the advancement, backing and turning of the unmanned ship can be realized through controlling the turning and speed difference of the power equipment mounted on the two sides of the ship body; the unmanned ship can complete planned sailing lines to perform measuring tasks such as underwater terrain plotting, flow velocity and flow rate measurement, and close-range photogrammetry; the automatic voyage of the unmanned ship at the rudderless state can be realized; the flexibility of the unmanned ship is improved; and the measuring working efficiency is greatly improved and the cost is reduced.

Owner:WUHAN CHUHANG SURVEYING SCI&TECH

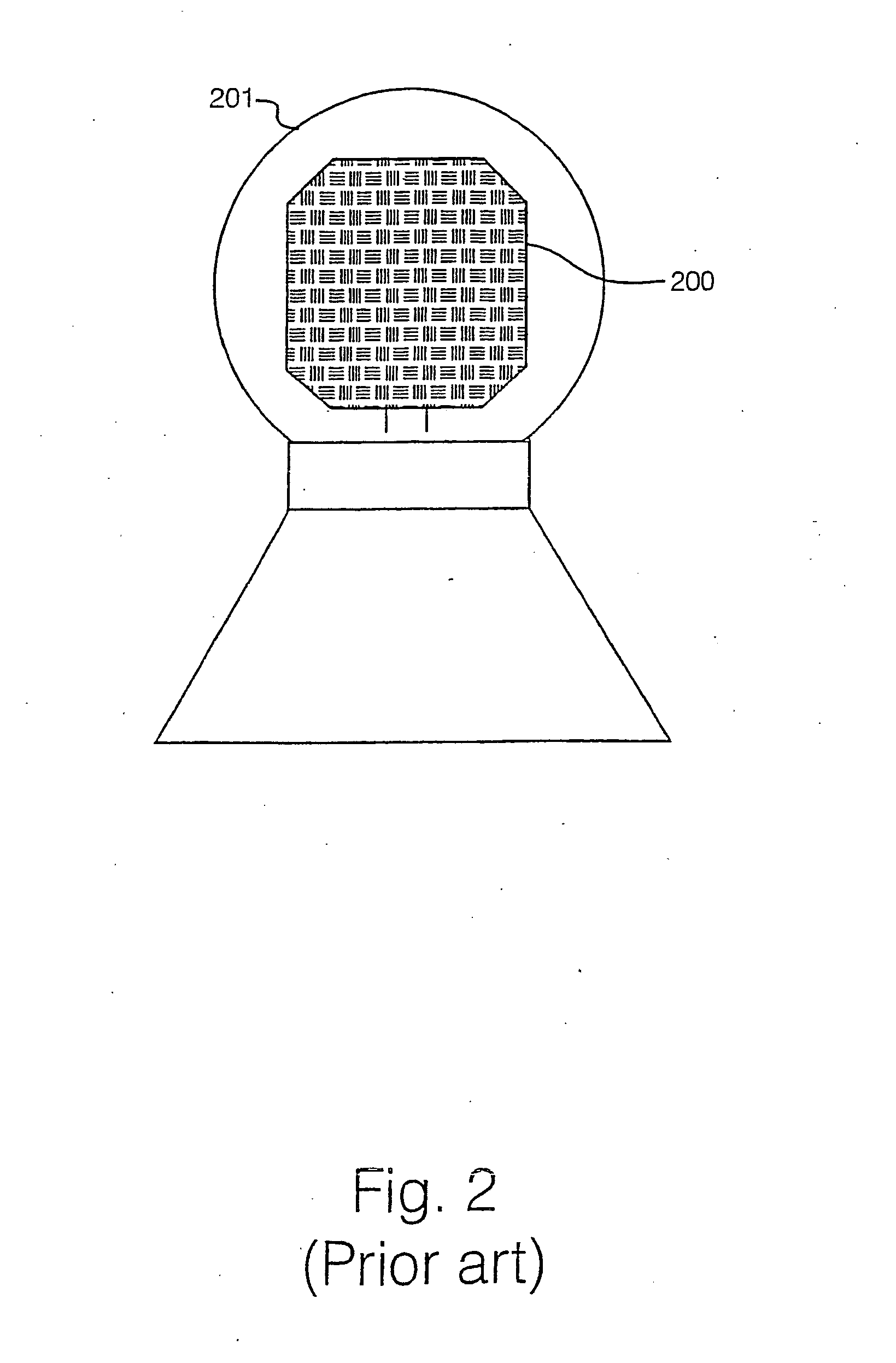

System and method for the measurement of optical distortions

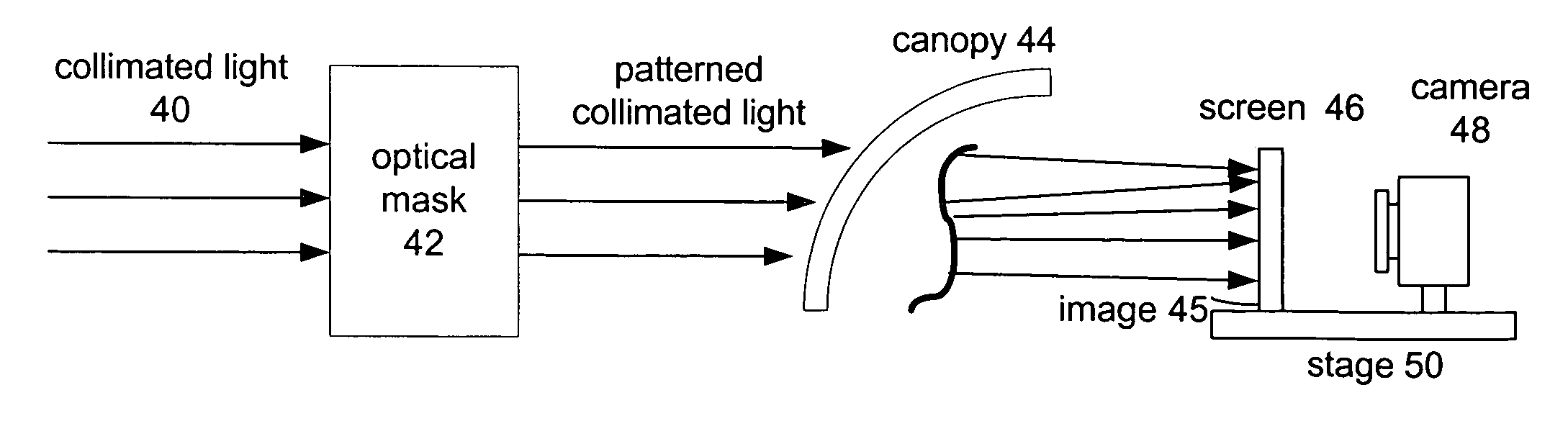

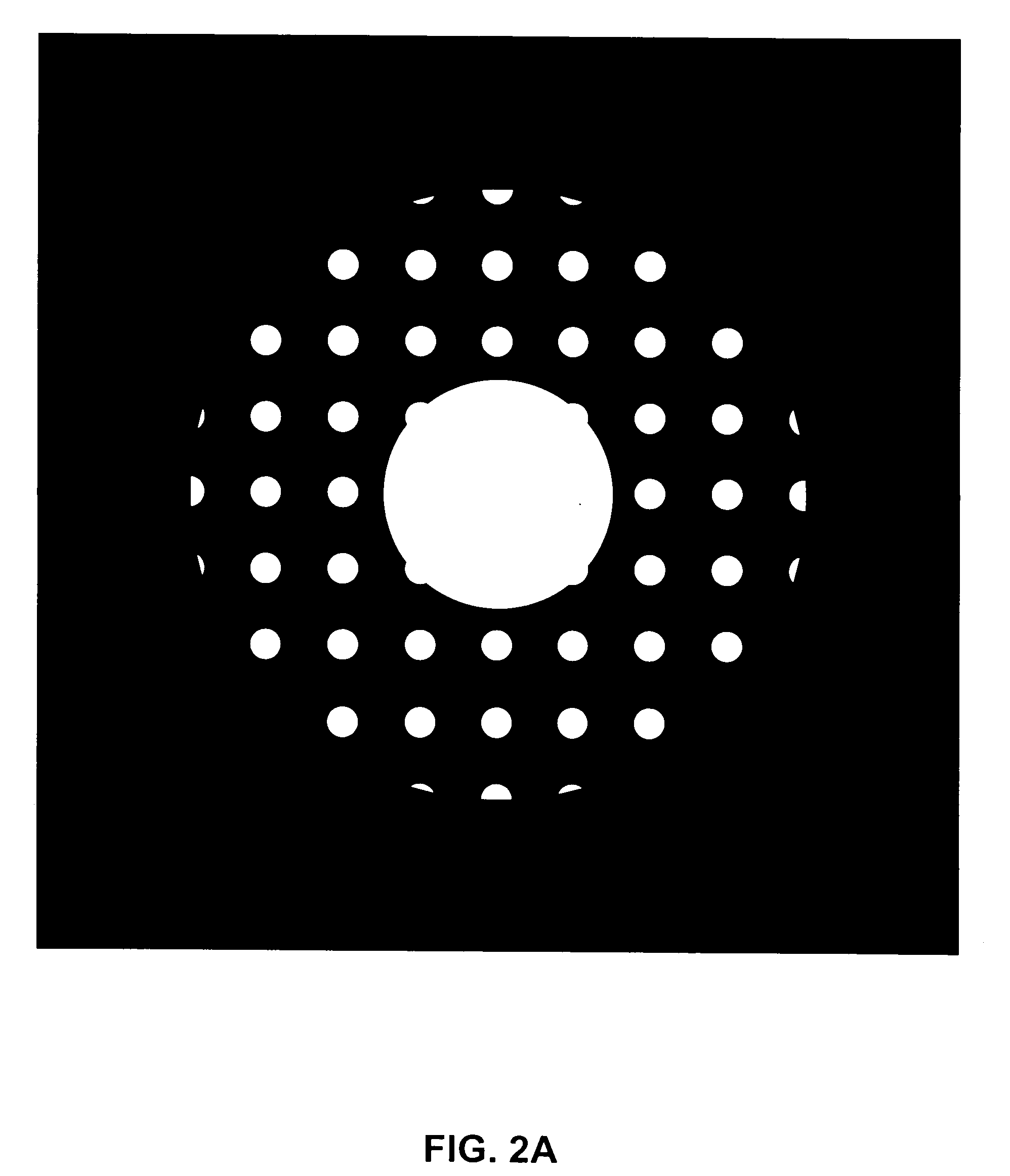

InactiveUS20050219522A1Improve accuracyIncrease speedOptically investigating flaws/contaminationUsing optical meansLight beamOptical distortion

An apparatus measures optical deviations caused by an aircraft canopy. In this apparatus, a light source generates a beam of light. A collimator, optically coupled to the light source, then collimates the beam of light. An optical assembly patterns the collimated beam of light into a patterned array of subaperture beams, which is directed onto an imaging screen. The patterned collimated beam of light produces images, which are electronically imaged and recorded to memory. An undistorted image results when the aircraft canopy is not placed in a path of the patterned collimated beam of light. However, a distorted image results when the aircraft canopy is placed in a path of the patterned collimated beam of light and distorts the patterned collimated beam of light. A processing unit compares the distorted image to the undistorted image to determine the optical distortions caused by the aircraft canopy.

Owner:LOCKHEED MARTIN CORP

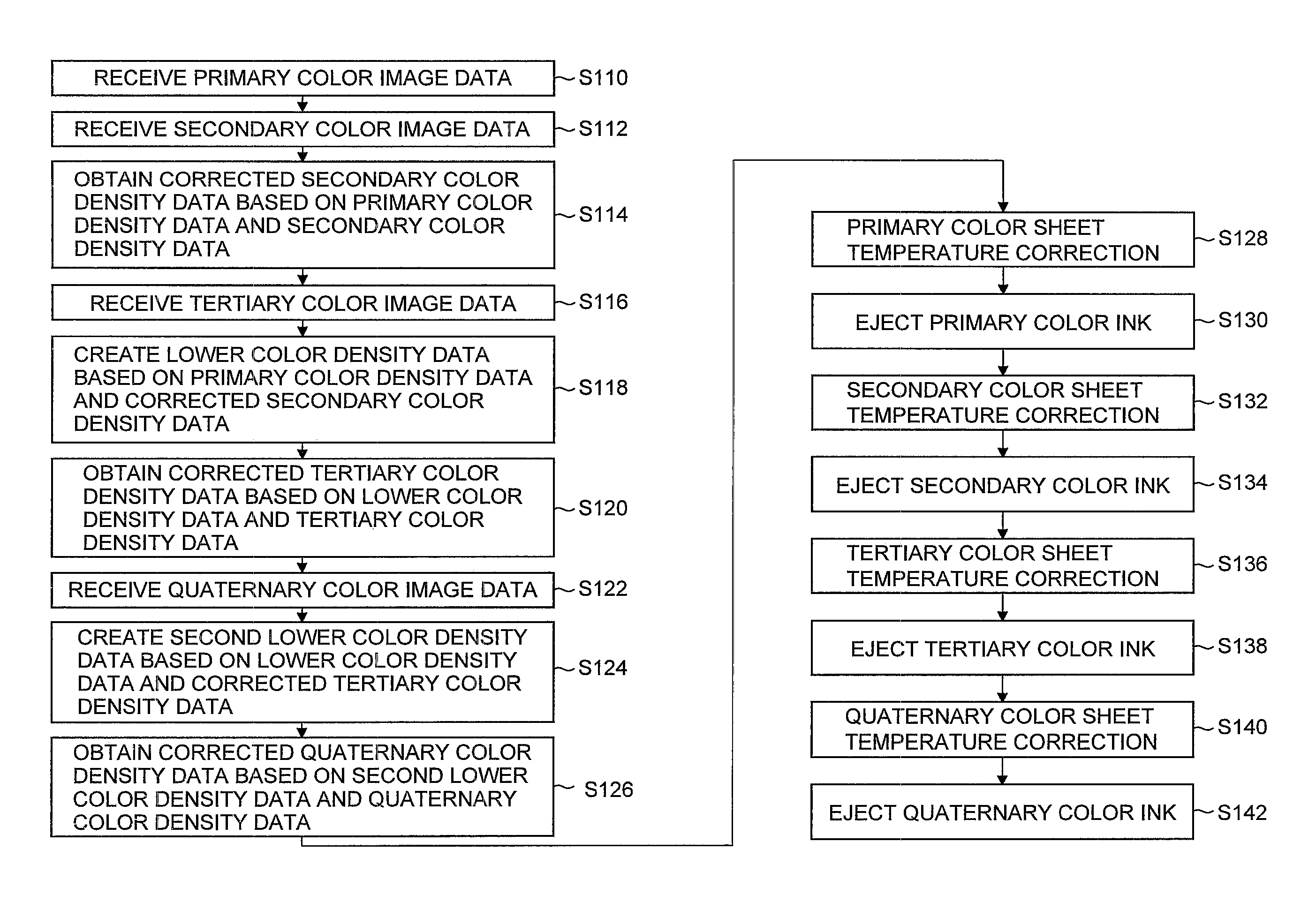

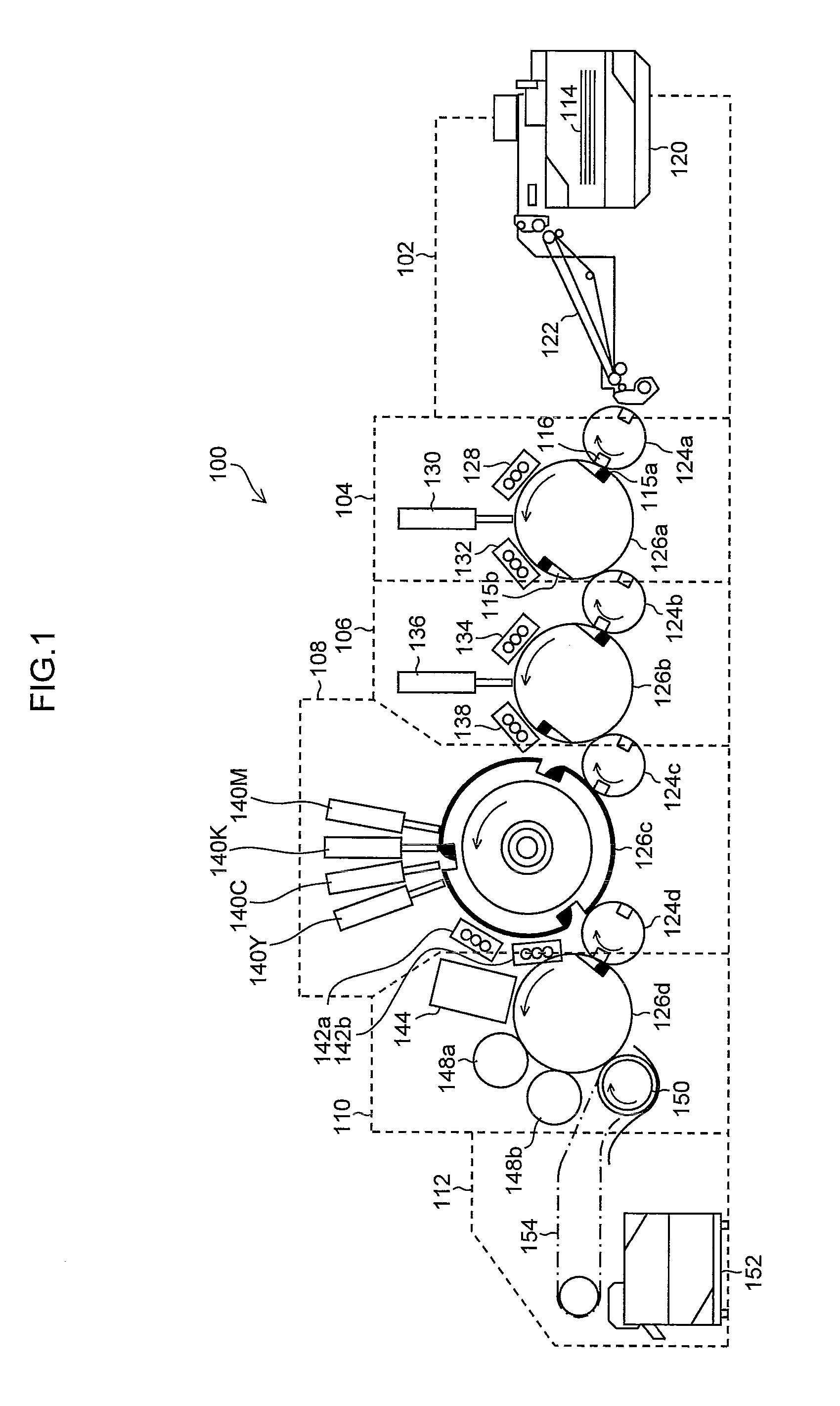

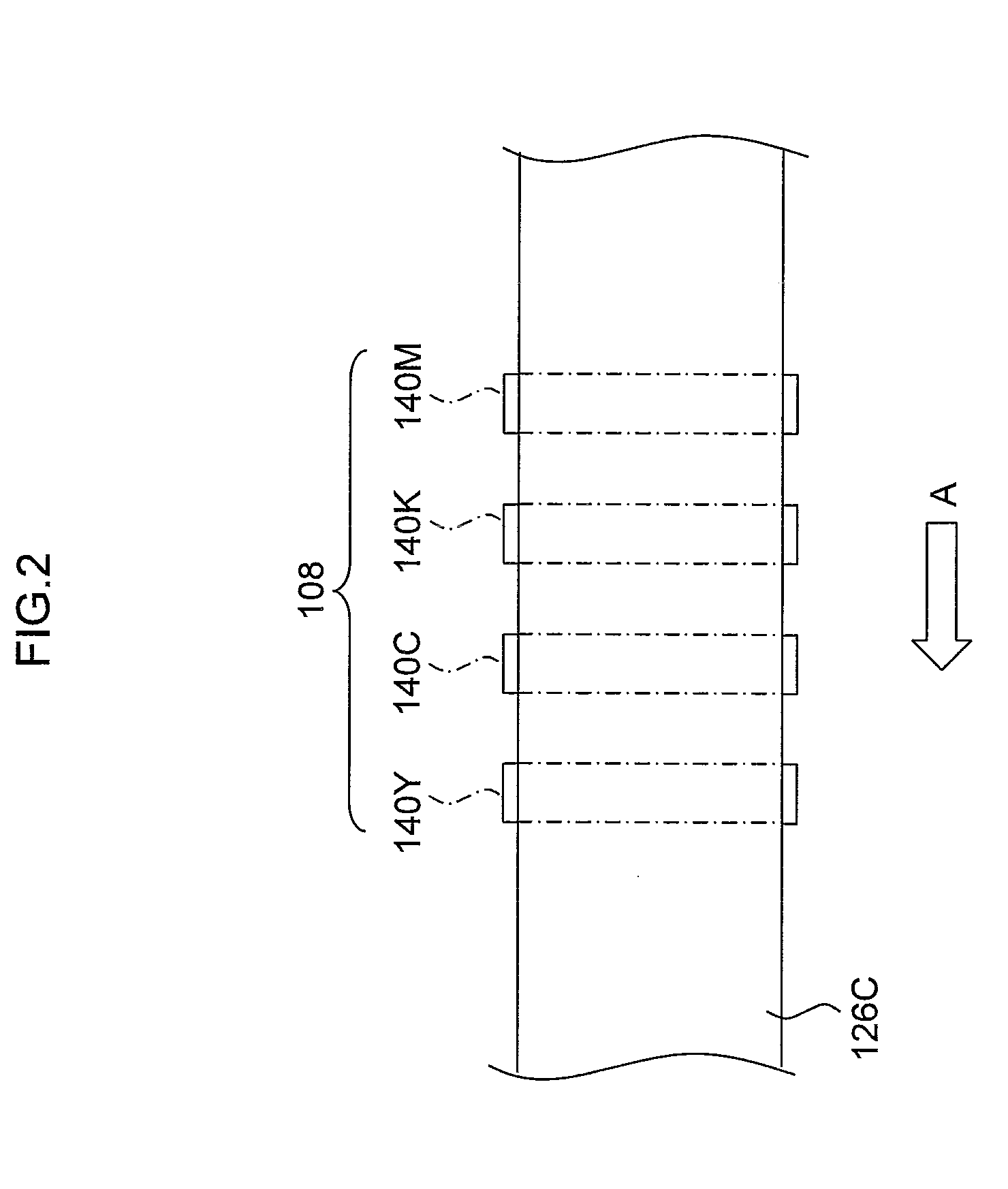

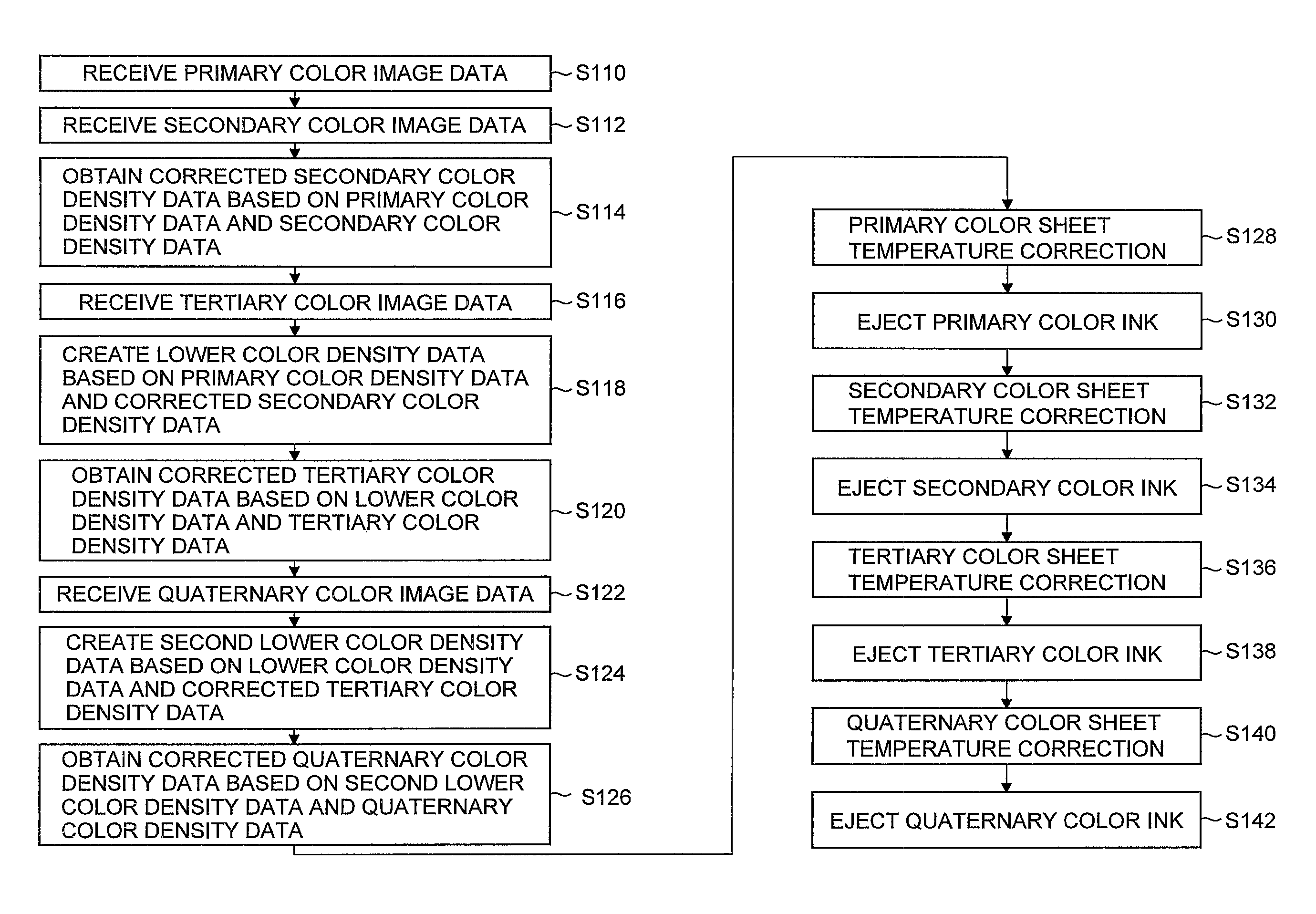

Inkjet recording apparatus, color correction method and computer-readable medium

ActiveUS8310721B2Good reproducibilityHigh quality imagingImage enhancementDigitally marking record carriersColor correctionData acquisition

An inkjet recording apparatus includes: a treatment liquid deposition device which deposits a treatment liquid insolubilizing or aggregating inks of a plurality of colors, onto a recording medium; a recording head which has a plurality of nozzles ejecting the inks onto the recording medium on which the treatment liquid has been deposited; a data acquisition device which acquires density data of an image with respect to each color, the density data corresponding to the plurality of colors; a higher-order color correction device which corrects the density data, wherein when the inks of different colors are ejected in ejection order so that a preceding ink ejected precedingly to form a lower layer and a subsequent ink ejected subsequently to form an upper layer overlap each other, the higher-order color correction device corrects the density data for a nozzle ejecting the subsequent ink according to the density data for a nozzle ejecting the preceding ink; and an ejection controller which controls ejection of the inks from the recording head according to the density data that the higher-order color correction device has corrected in such a manner that the image is formed on the recording medium.

Owner:FUJIFILM CORP

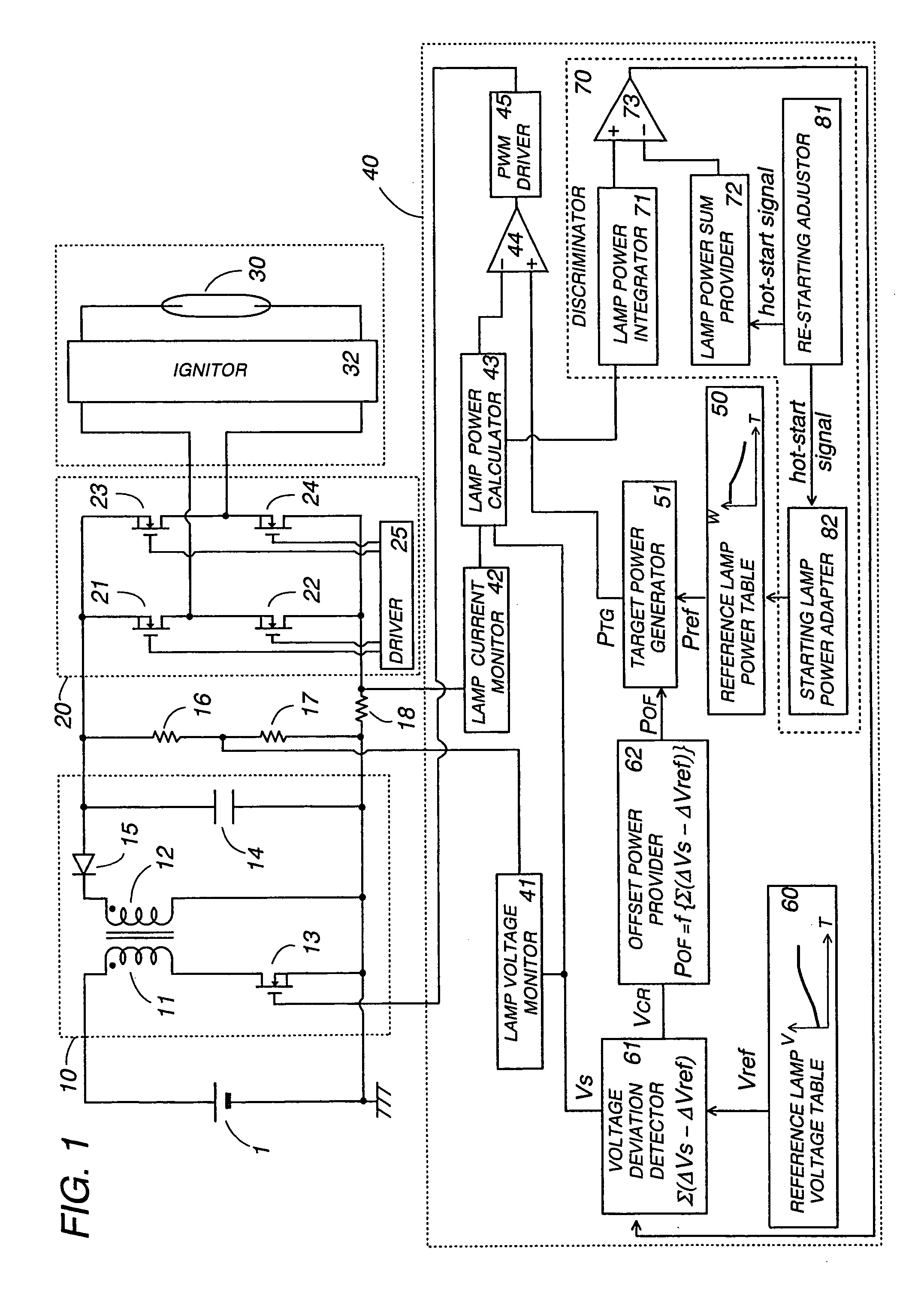

Electronic ballast for a discharge lamp

ActiveUS7002305B2Reduce downtimeCorrect deviationElectrical apparatusElectric light circuit arrangementTemporal changeElectric light

An electronic ballast for a discharge lamp has a controller that increase luminous flux of the lamp to a stabilized level in a constant time irrespective of possible variations in lamp characteristic. The controller utilizes a reference lamp power table and a reference lamp voltage table respectively defining a reference lamp power and a reference voltage varying with time. The controller includes a voltage deviation detector that gives a voltage correction index indicating a voltage deviation between the reference voltage and a monitored lamp voltage. The voltage correction index is processed at an offset provider that gives an offset power. A target power generator is included to correct the reference lamp power in view of the offset power, thereby generating a target lamp power which is constantly updated and is supplied to the lamp.

Owner:MATSUSHITA ELECTRIC WORKS LTD

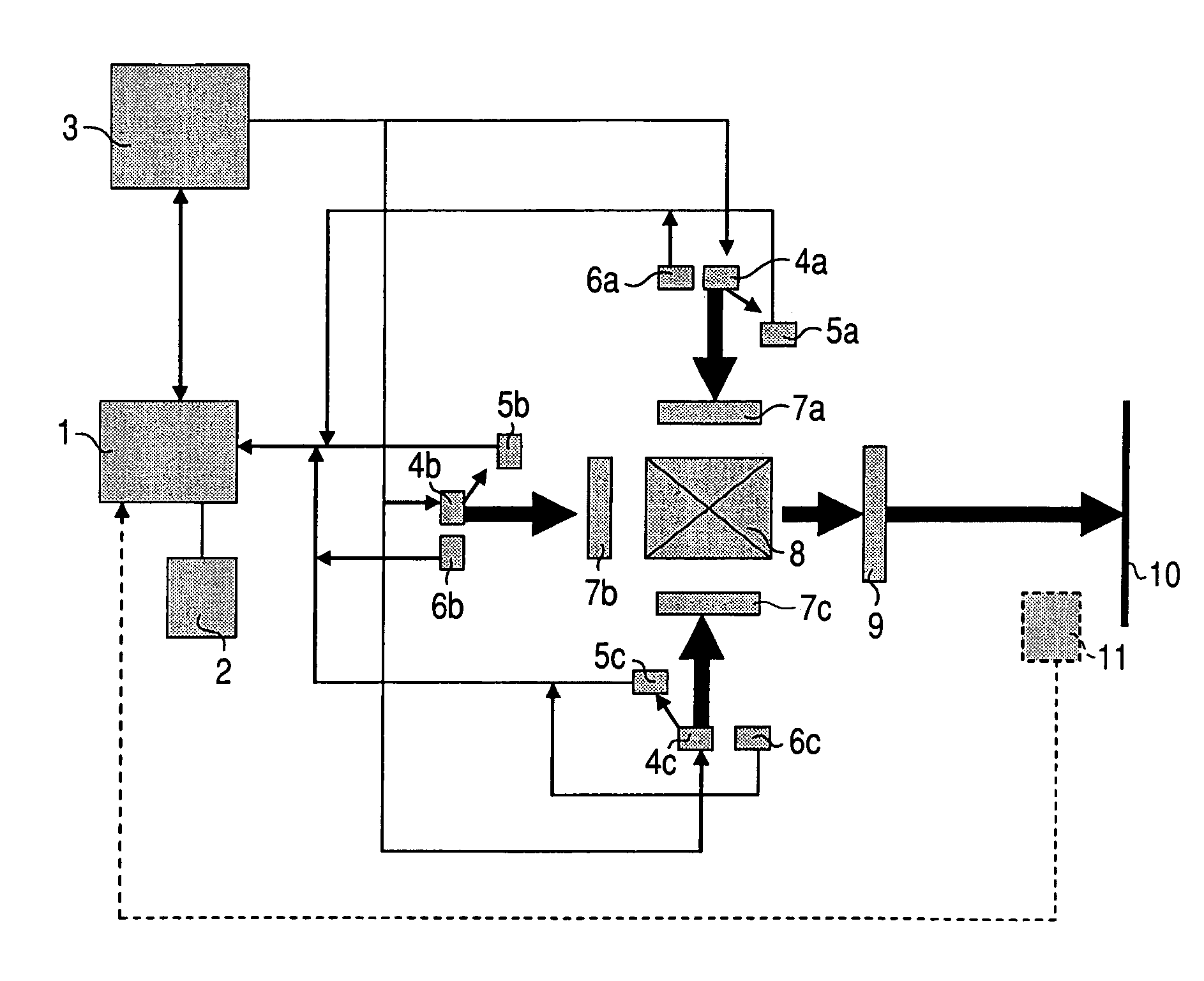

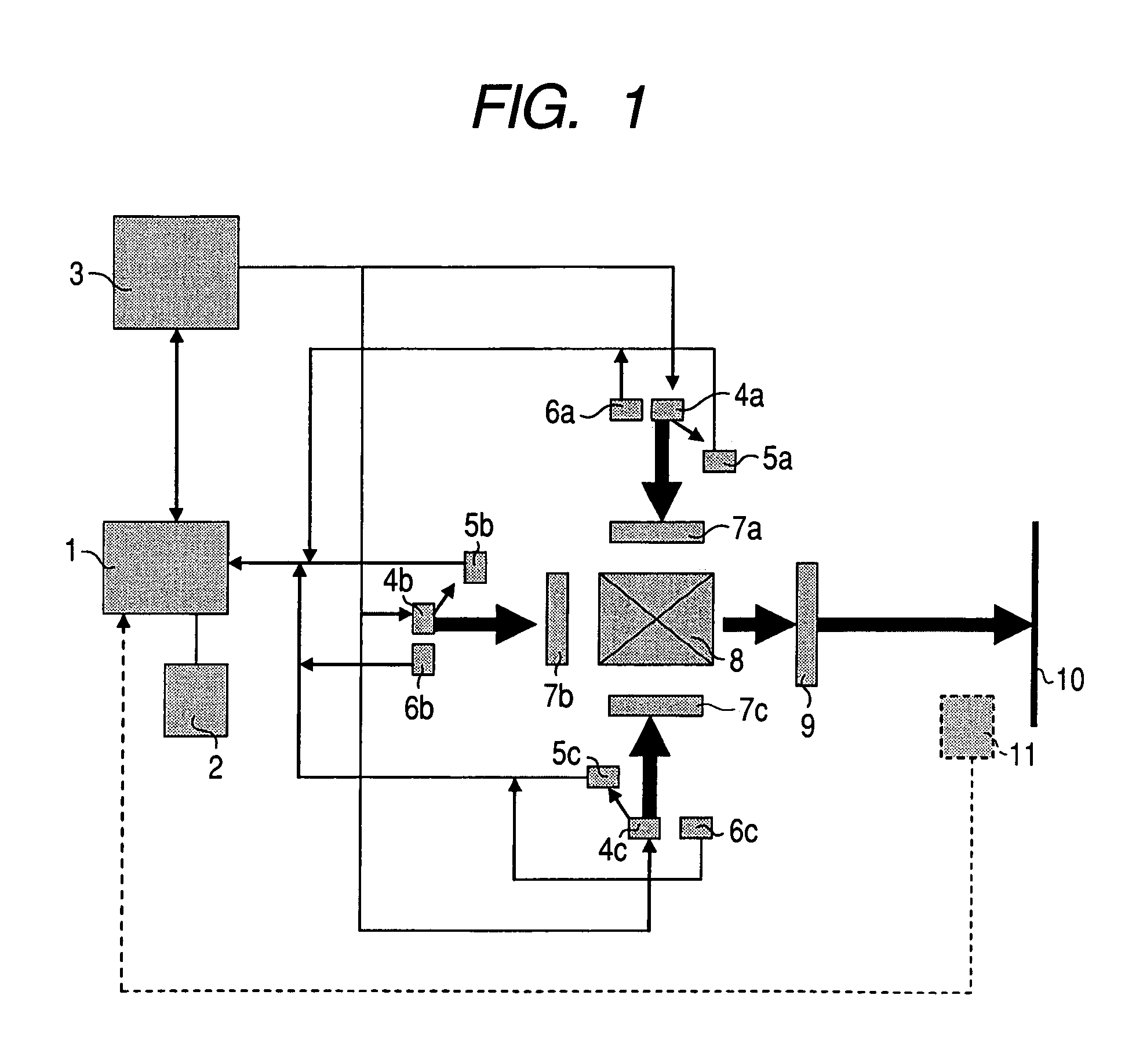

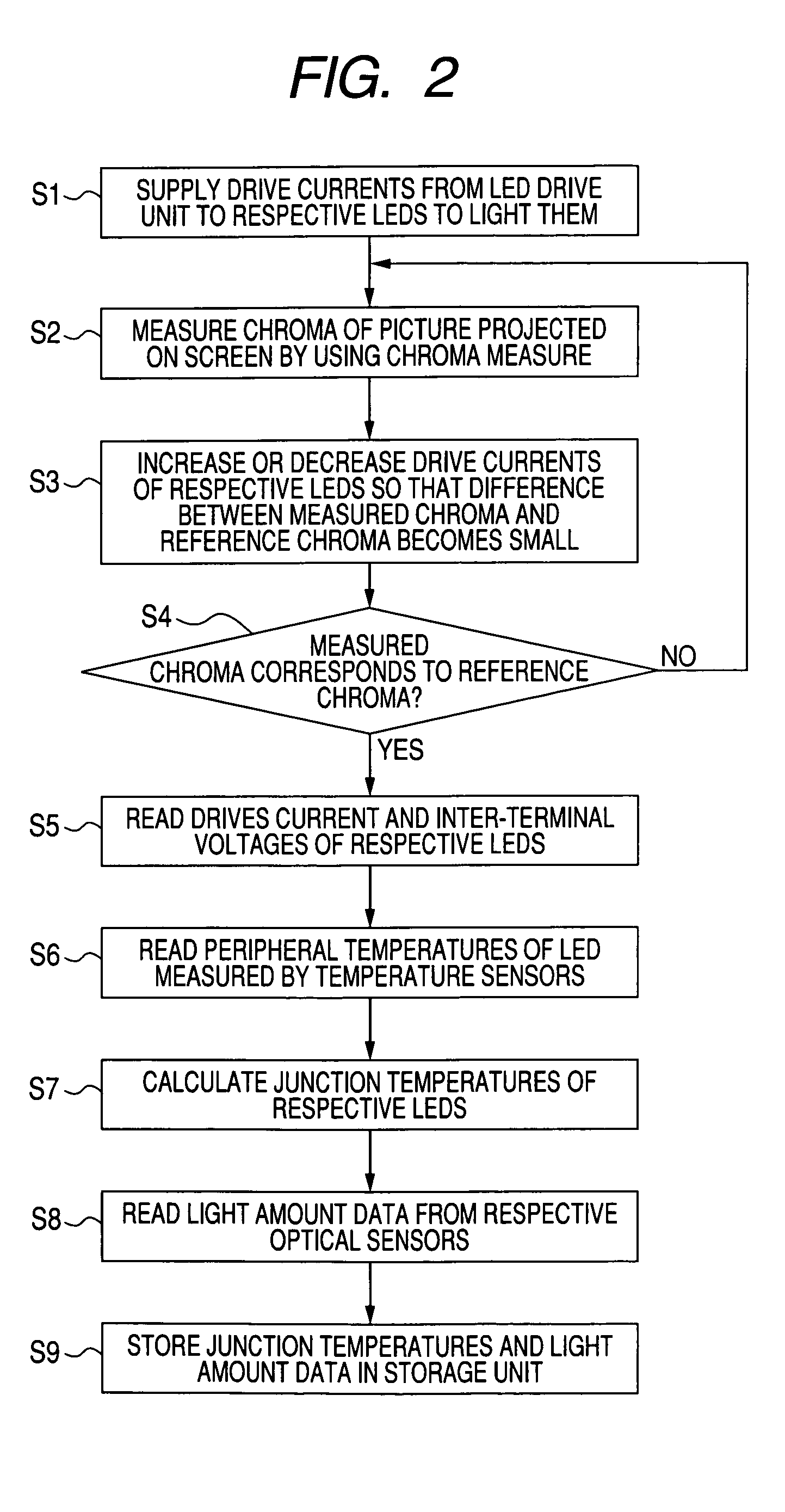

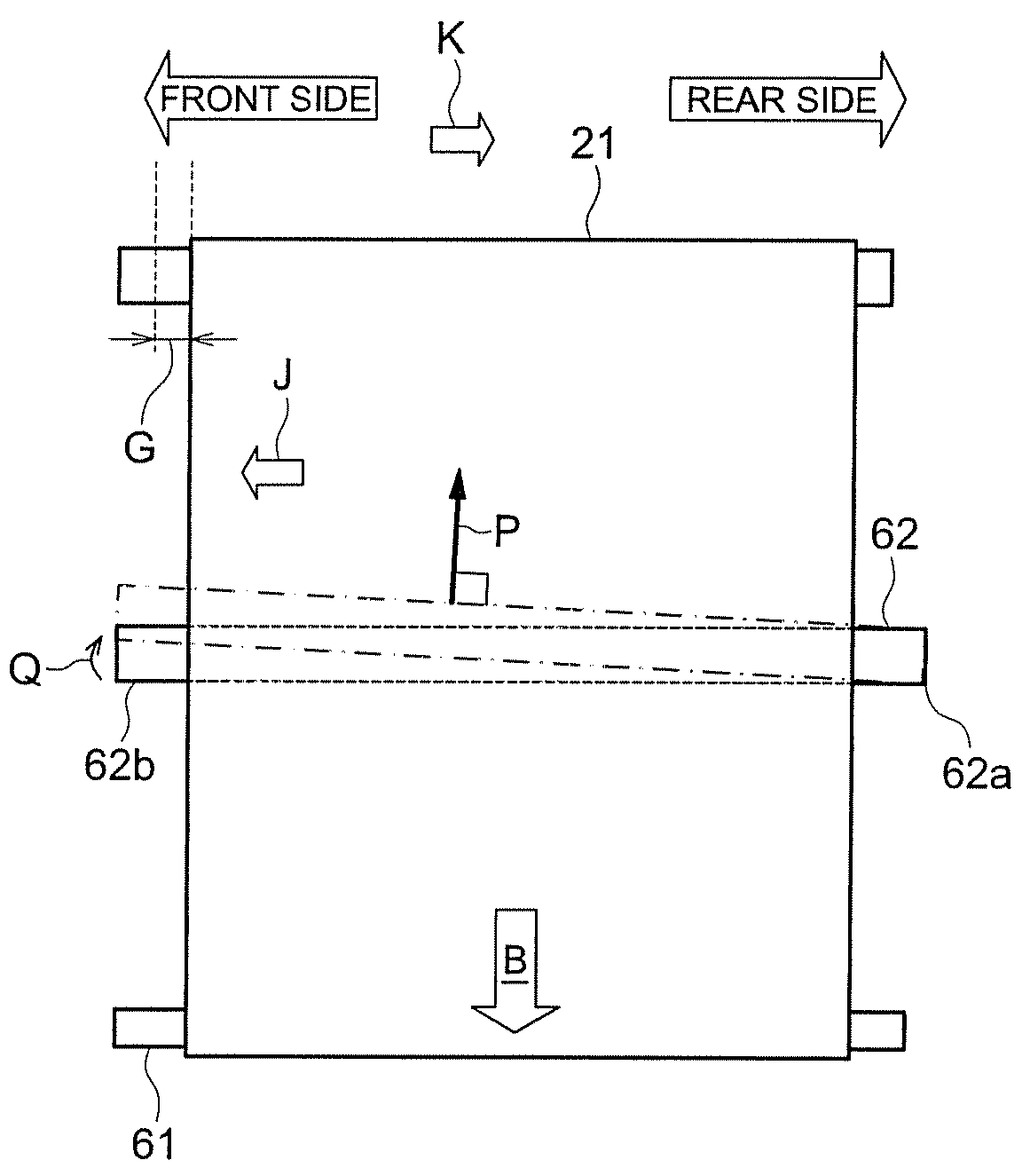

Illumination device and display device

InactiveUS20090206236A1Appropriate settingAppropriately maintain color balancePhotometry using reference valueElectroluminescent light sourcesDriving currentJunction temperature

An illumination device includes: a light emitting element to be a light source; a light amount detecting means for detecting the amount of light emitted by the light emitting element; a light emitting element drive means for controlling drive current supplied to the light emitting element so that the difference between the light mount detected by the light amount detecting means and a light amount target value becomes small; a junction temperature detecting means for calculating junction temperature of the light emitting element; and a setting means for setting the light amount target value in accordance with the junction temperature detected by the junction temperature detecting means.

Owner:SONY CORP

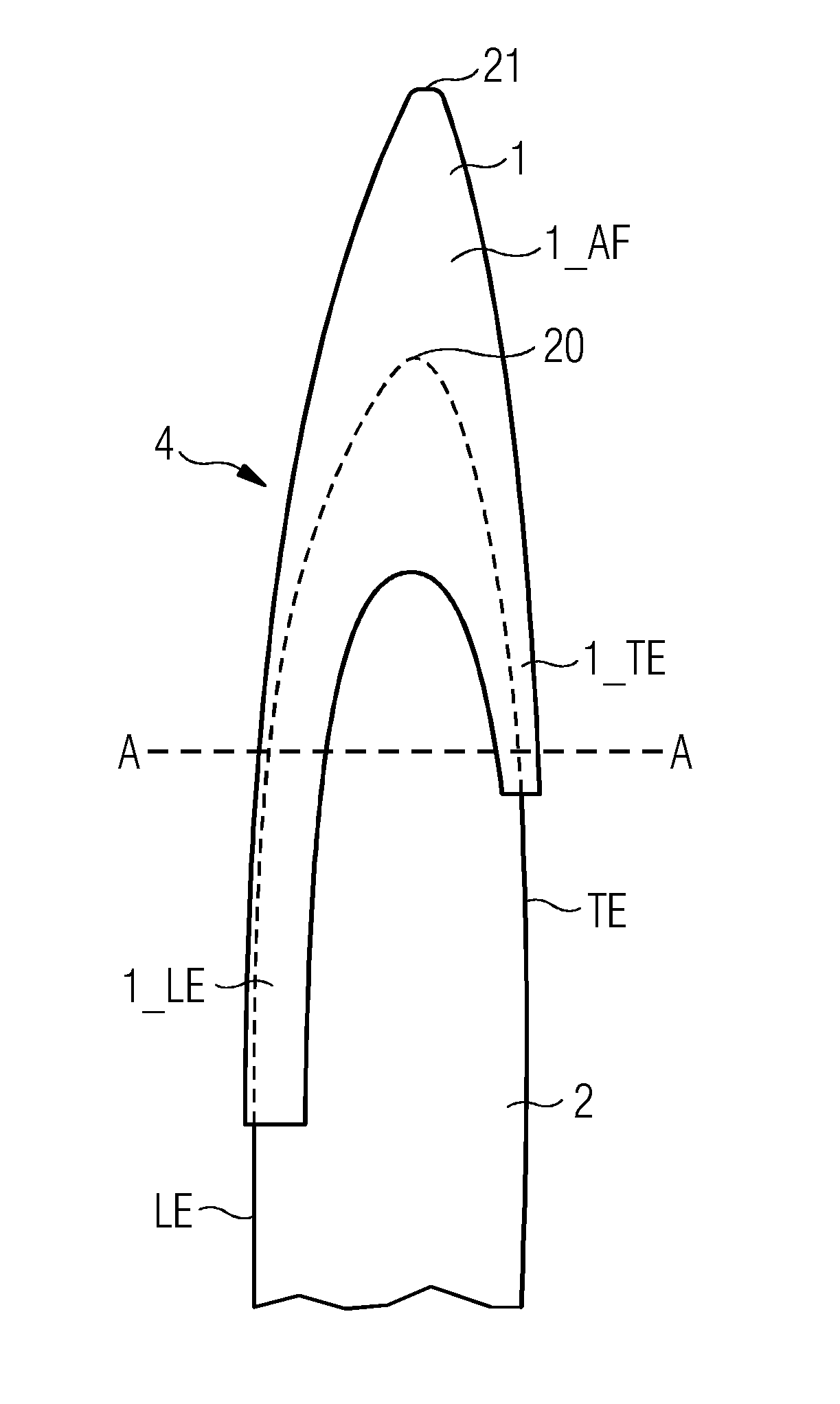

Rotor blade extension

InactiveUS20160177915A1Favorable increase in rotor areaMaintain tip deflectionEngine manufactureFinal product manufactureLeading edgeTrailing edge

A rotor blade extension for mounting over a tip of a wind turbine rotor blade, including an airfoil extension portion) configured to extend a length of the rotor blade, a leading edge portion configured to cover a profile of the leading edge of the rotor blade, and a trailing edge portion configured to cover a profile of the trailing edge of the rotor blade, is provided. A wind turbine including a number of rotor blades and a rotor blade extension mounted to each rotor blade is also provided.

Owner:SIEMENS AG

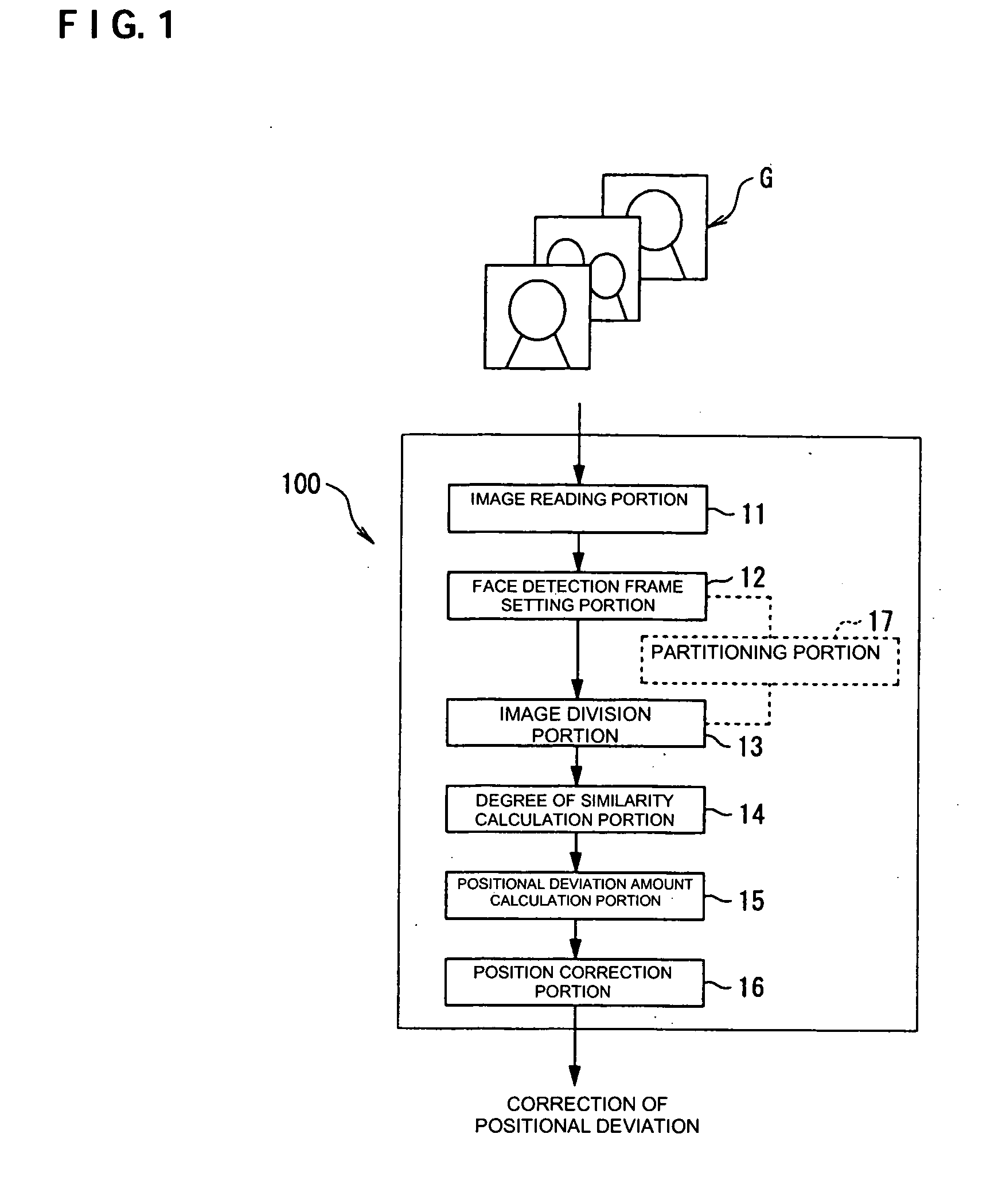

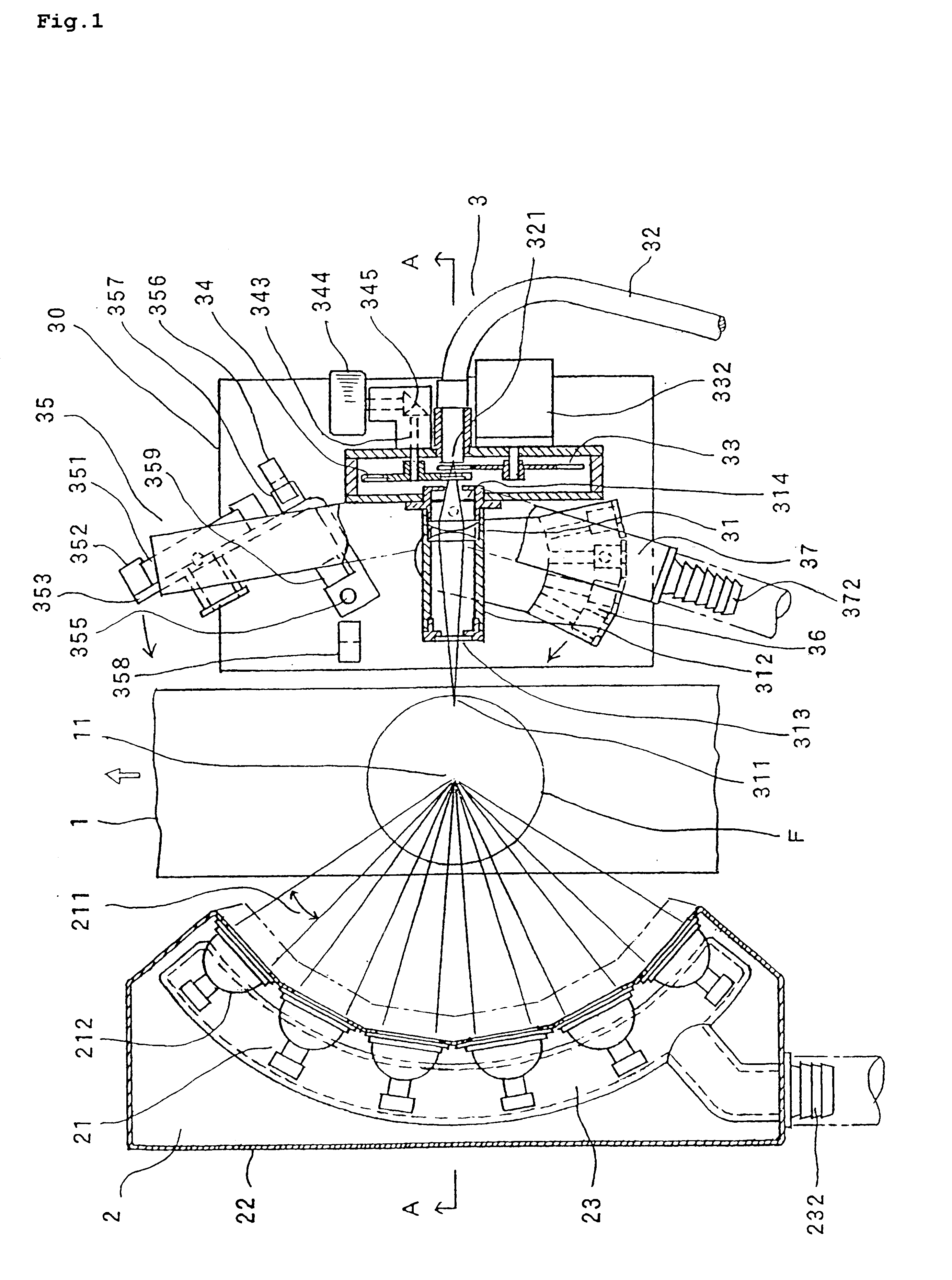

Method of correcting deviation of detection position for human face, correction system, and correction program

InactiveUS20050180612A1Correct deviationRealized more economically and easilyImage analysisCharacter and pattern recognitionFace detectionDegree of similarity

A method of correcting the deviation of a position at which a human face is detected using a face detection frame F. An image G within the detection frame F is divided left and right along the portion of the center axis C. The degree of similarity of mirror-symmetrical relationship between the image portions G-1 and G-2 obtained by the division is calculated. An amount of positional deviation d that maximizes the degree of similarity and its direction are found. The frame F is moved a distance corresponding to the amount of positional deviation d in the direction. Thus, the deviation of the detection position due to the detection frame F can be corrected by a quick and simple method.

Owner:SEIKO EPSON CORP

Illumination device and display device

InactiveUS7888623B2Correct deviationAppropriate settingPhotometry using reference valueElectroluminescent light sourcesDriving currentDisplay device

Owner:SONY CORP

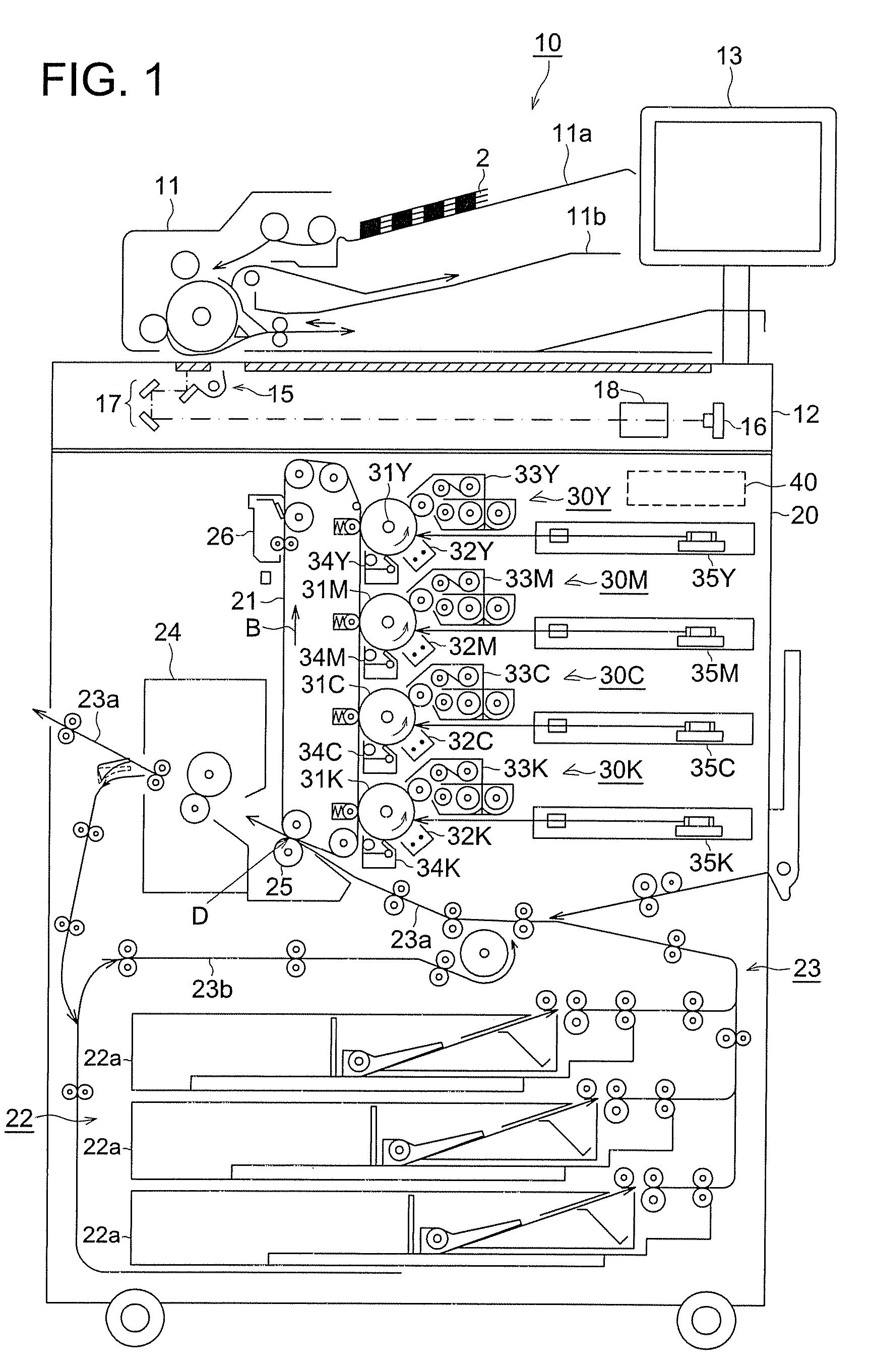

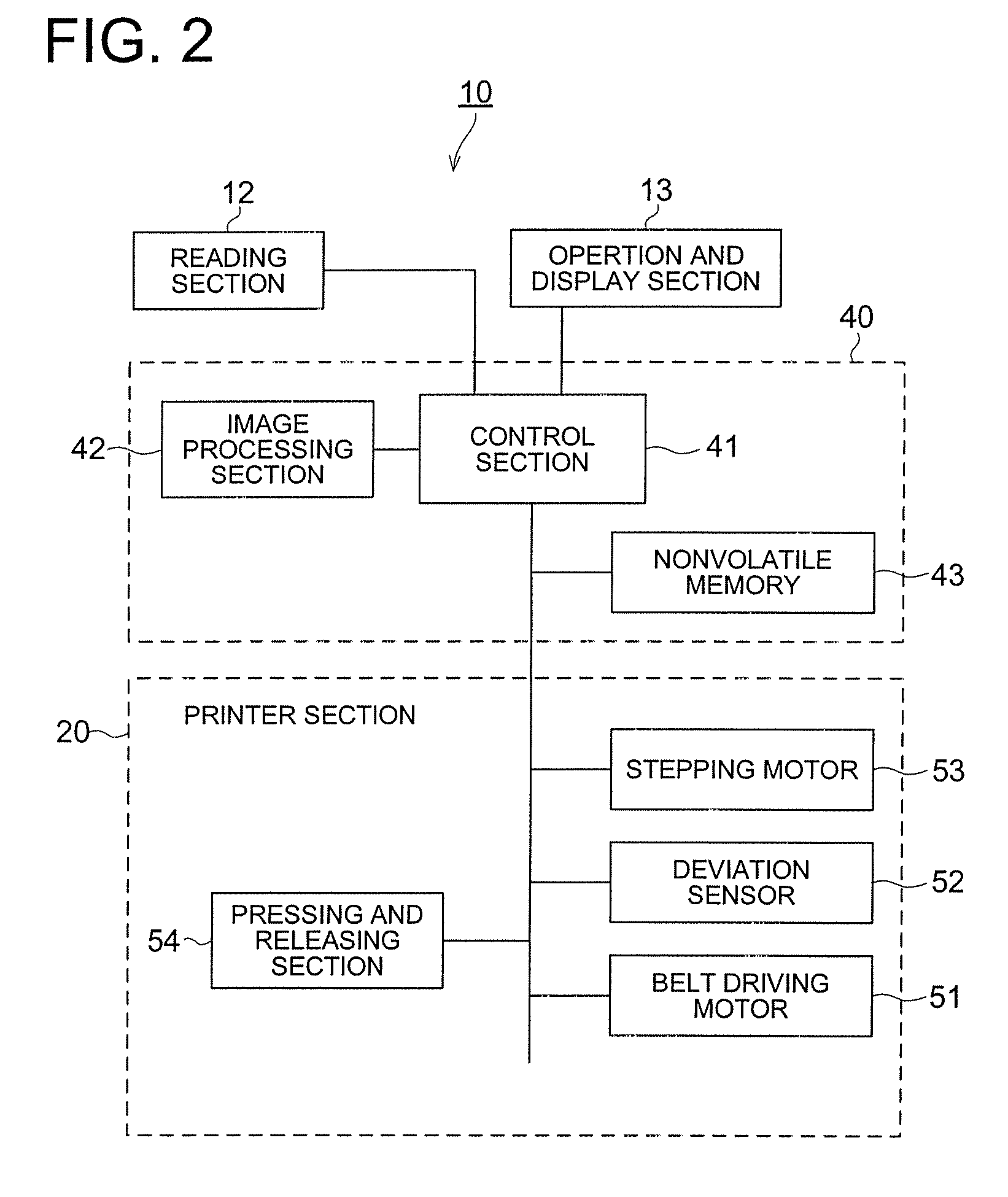

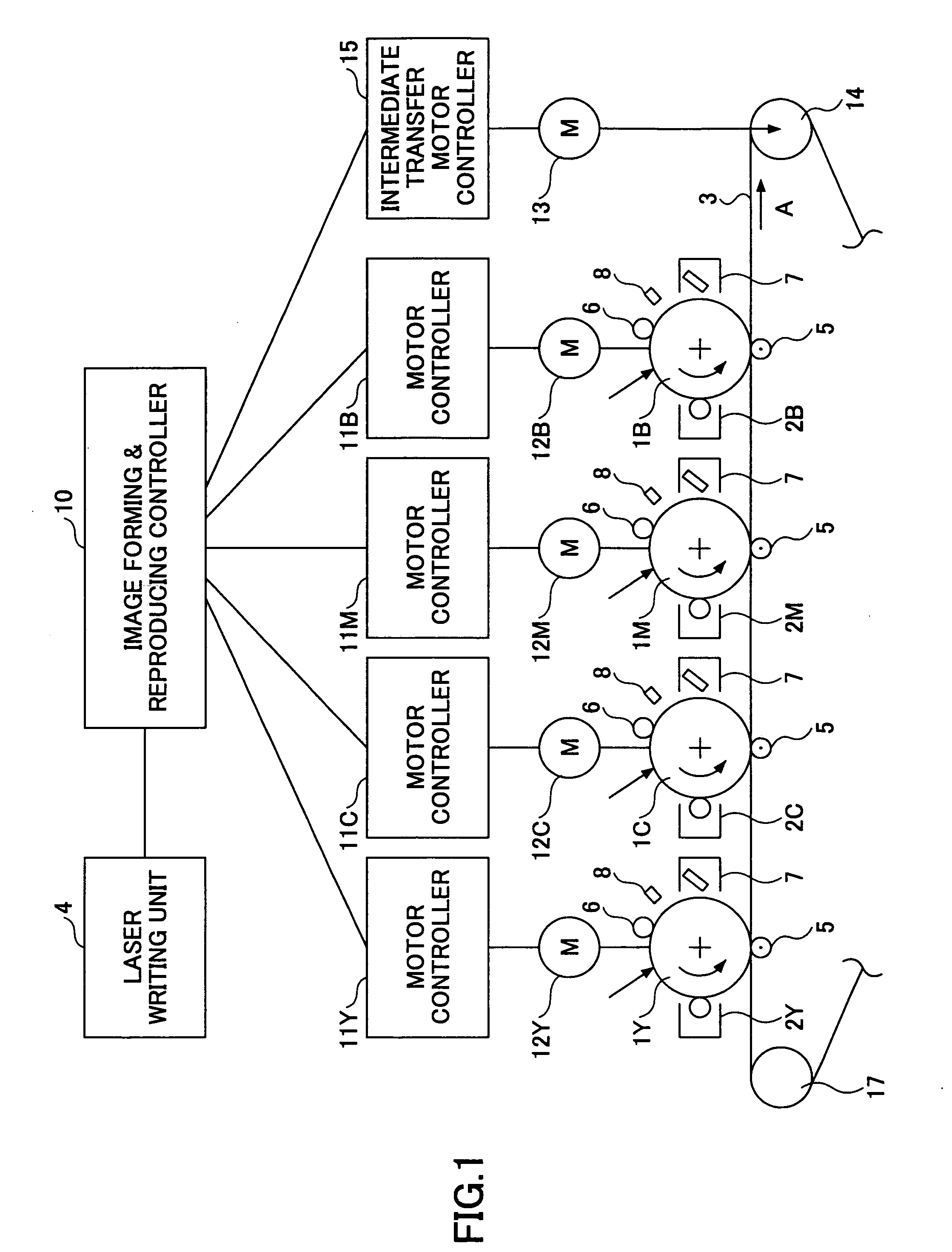

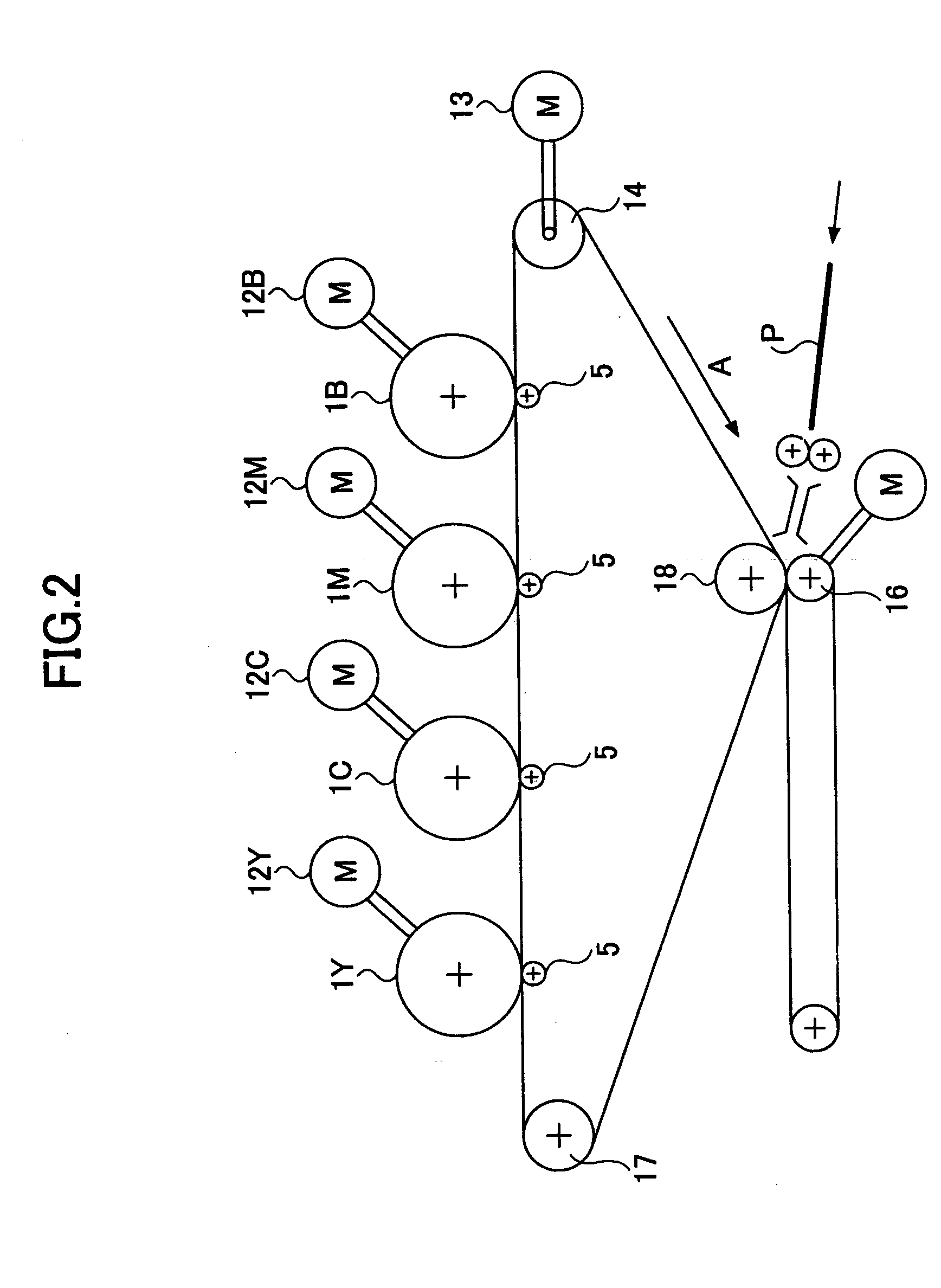

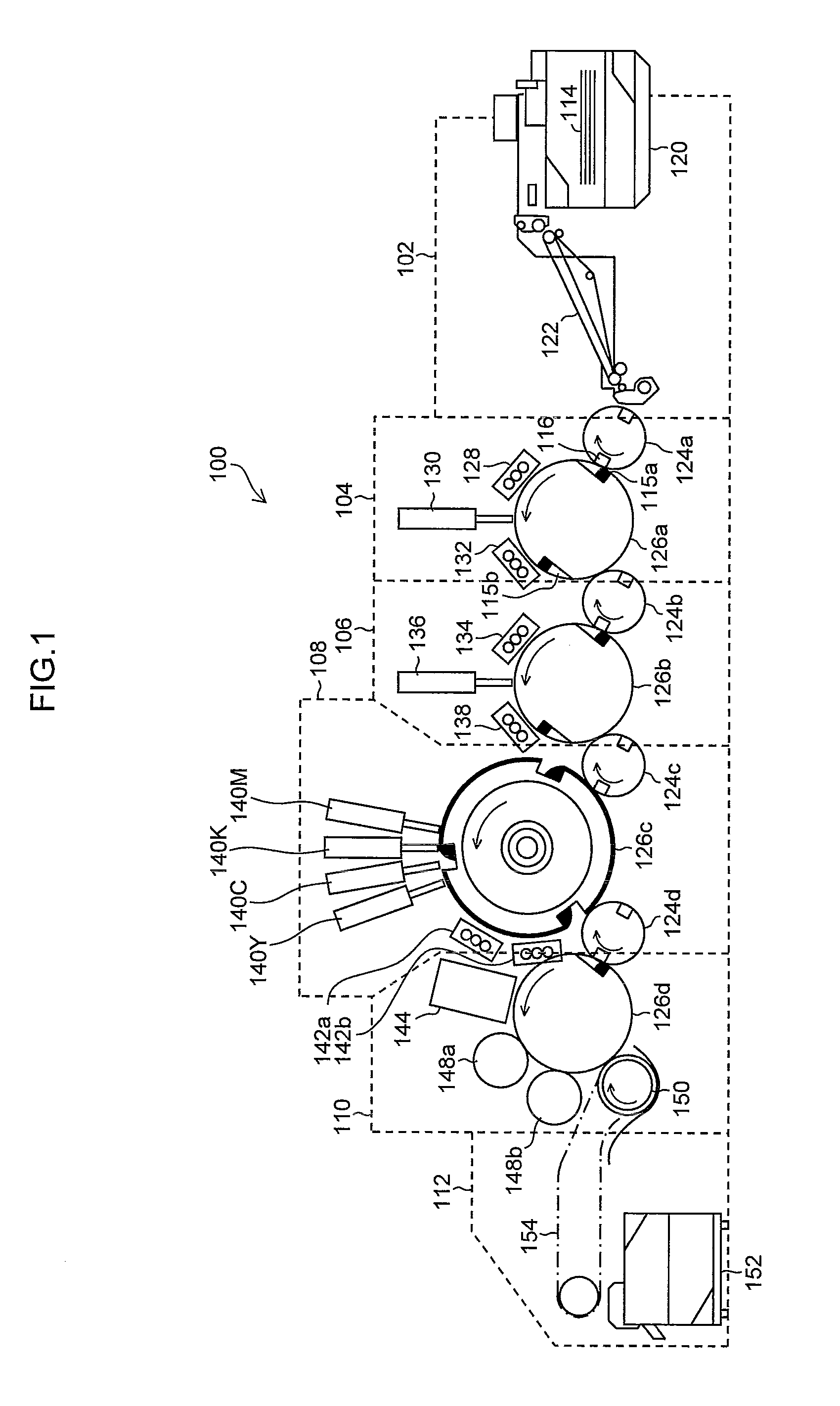

Image forming apparatus

Owner:KONICA MINOLTA BUSINESS TECH INC

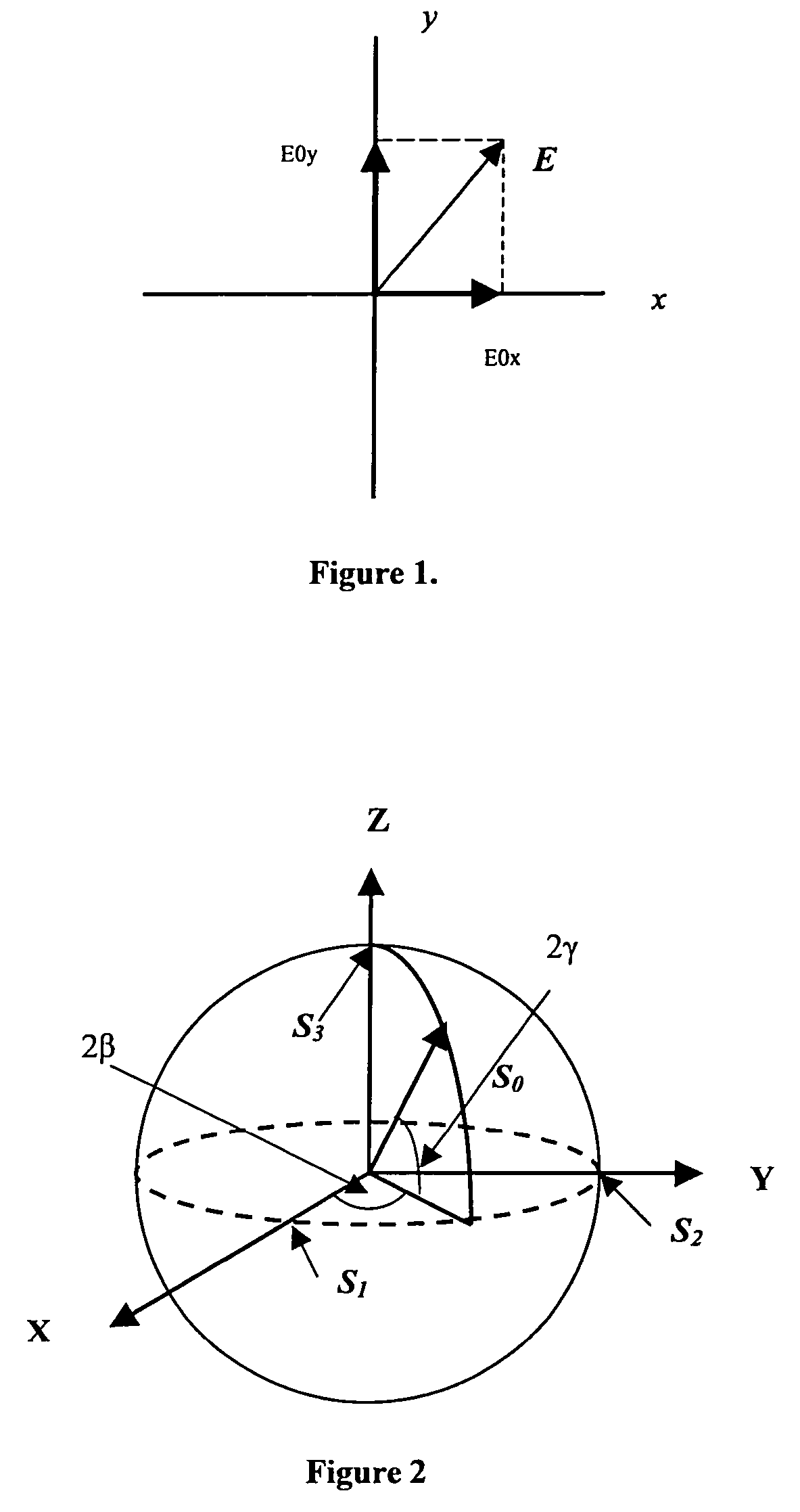

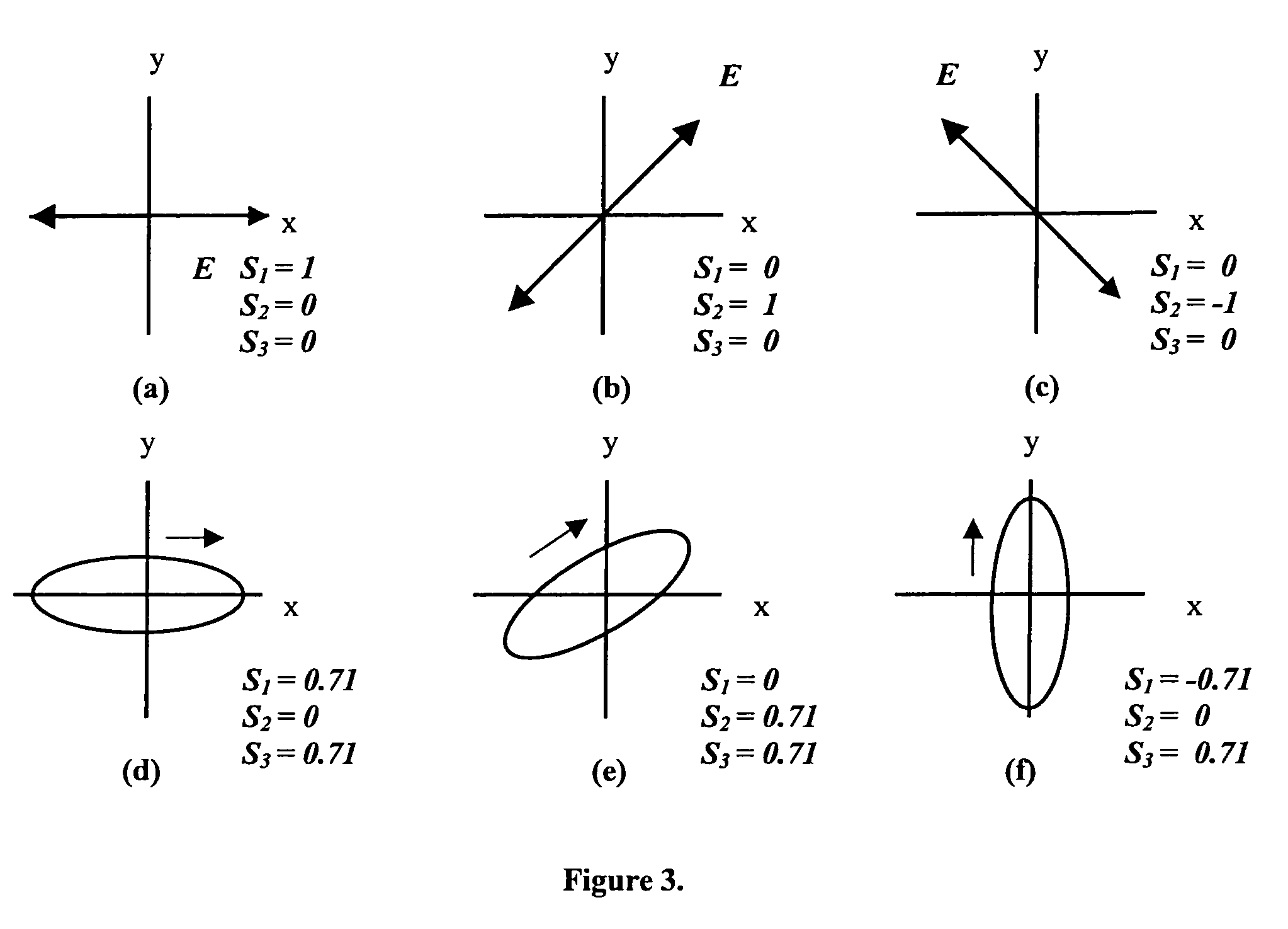

Method for polarization-based intrusion monitoring in fiberoptic links

InactiveUS20060072922A1Improve physical safetyImprove securityTransmission monitoringElectromagnetic transmission optical aspectsLight beamLight signal

A fiber optic communication system including a fiber optic link, a transmitter system and a receiver system. The transmitter system includes a laser source producing a light beam, and a polarization controller receiving the light beam and providing an expected pattern of changing states of polarization to the light beam to output light signals into the fiber optic link to cause the expected pattern of changing states of polarization to be transmitted along the fiber optic link. The receiver system is provided with a polarization analyzer, and a light detector. The light detector receives the light signals transmitted by the transmitter, and forwards data indicative of the light signals to the polarization analyzer. The polarization analyzer analyzing the data with an inverse polarization reference frame and generates an alert based on deviations of the data from the expected pattern of changing states of polarization.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Ship motion predictor

There is disclosed a predictive filter for predicting the future position of a look direction of a rotating directional antenna mounted on a vessel. Prediction of a look direction of the antenna at any instant is made from input of ship's compass data including roll data, pitch data and heading data, as well as data describing a rotational position of the antenna, output from an antenna synchro device. Smoothing of the digital roll, pitch and heading data and antenna position data is followed by application of a moving time window, filter which removes any offset from the data within of the moving time window to produce data having a zero mean. The zero mean data is input into an auto-regression algorithm, the output of which is combined with mean roll, pitch, heading, position and antenna velocity data to obtain predicted positions of the antenna relative to the vessel, and a predicted motion of the vessel. The combined vessel motion prediction and antenna position and velocity prediction can be used to establish a predictive future look direction of the antenna for a period of between 0.1 and 5 seconds into the future.

Owner:BAE SYSTEMS PLC

Image forming and reproducing apparatus, and image transferring method

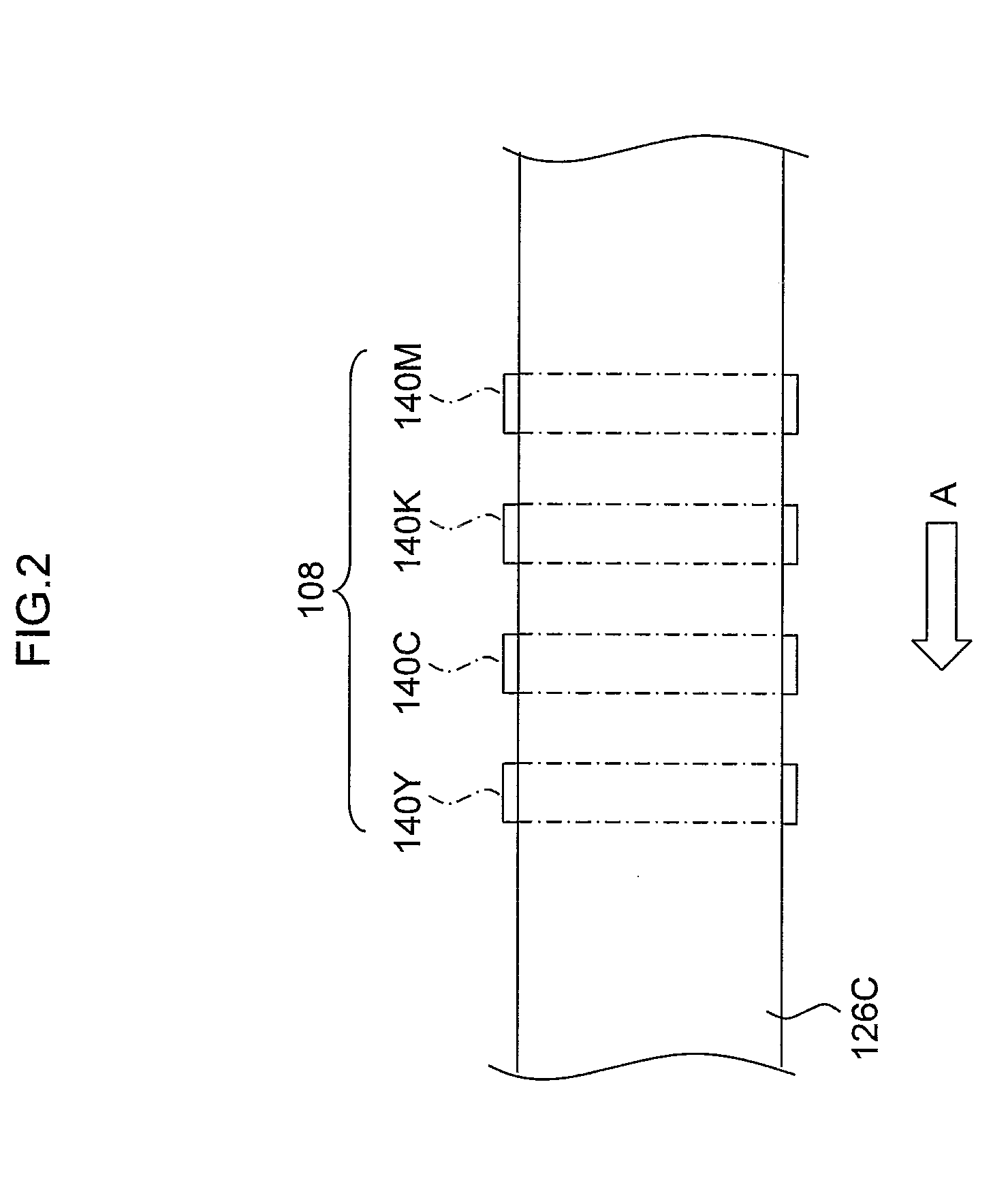

InactiveUS20060002745A1Improve calibration accuracyShorten the timeElectrographic process apparatusImage formationEngineering

An image forming and reproducing apparatus is configured to transfer images formed on multiple rotatable image carriers (1Y, 1C, 1M, and 1B) onto a transfer member (3) at associated transfer positions (P1-P4). The apparatus includes a rotation speed controller that controls the rotation speeds of the image carriers such that times required for the images formed at exposure positions of the image carriers to reach the associated transfer positions agree with each other among the image carriers when superposing the images one on the other on the transfer member.

Owner:RICOH KK

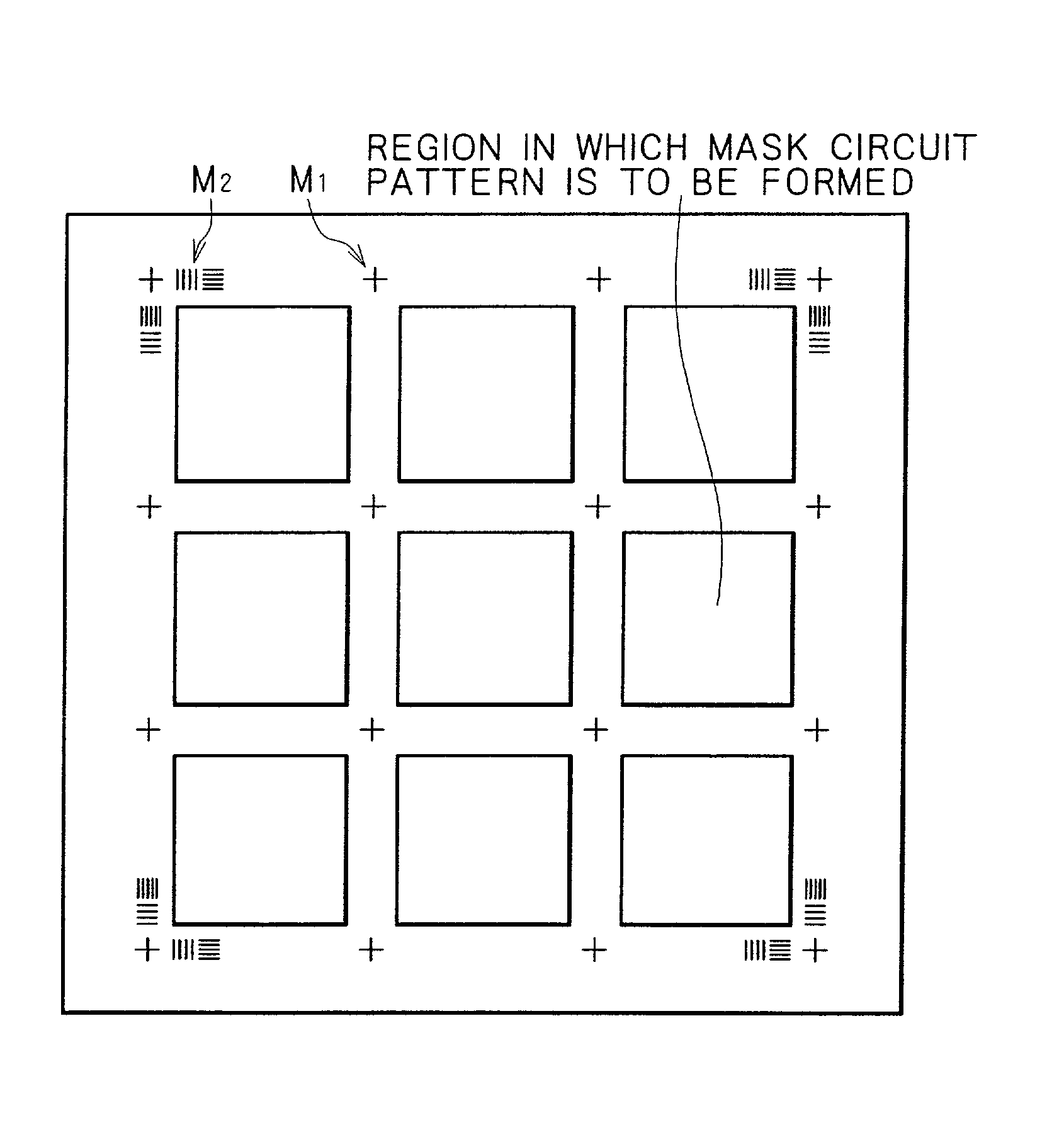

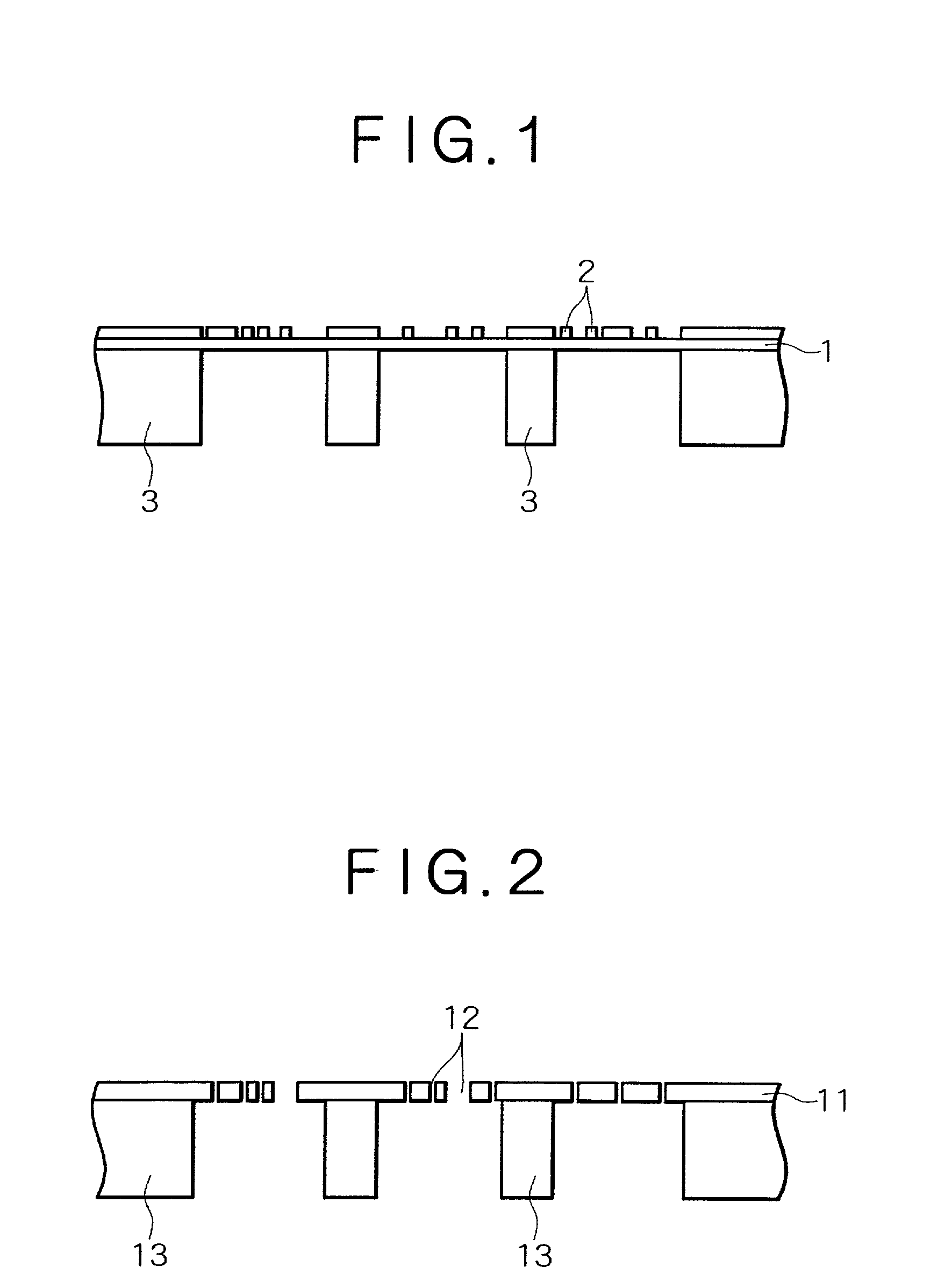

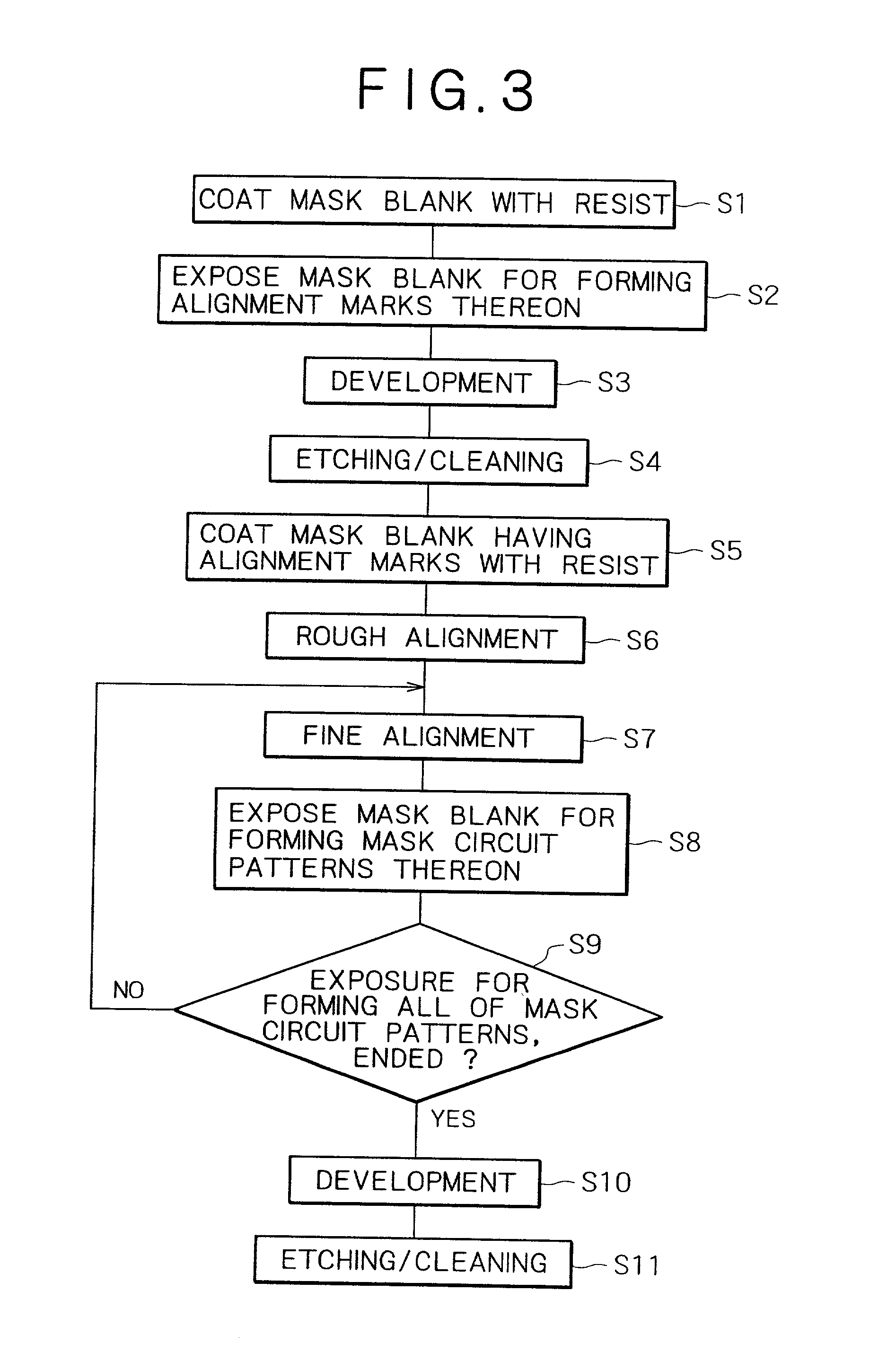

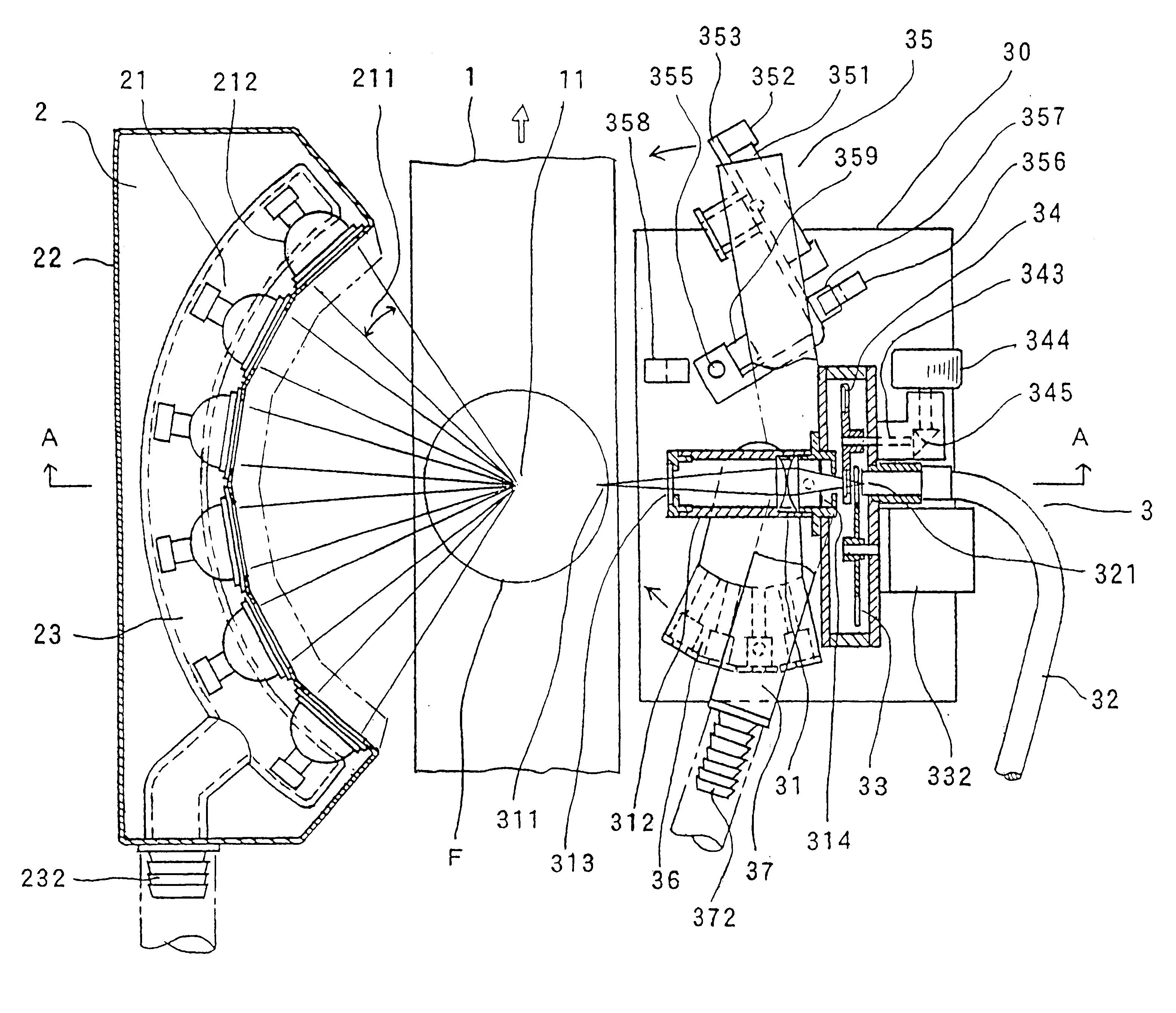

Mask-making member and its production method, mask and its making method, exposure process, and fabrication method of semiconductor device

InactiveUS20020130425A1Made preciselyLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A mask blank has a plurality of pattern formation regions in which mask circuit patterns are to be formed, and a supporting region in which any mask circuit pattern is not to be formed. The supporting region is provided for holding the plurality of pattern formation regions while separating the plurality of pattern formation regions from each other. The supporting region has first and second alignment marks. Exposure of a mask made from the mask blank for forming mask circuit patterns thereon is performed on the basis of the first alignment marks, and exposure of a substrate for forming circuit patterns thereon is performed on the basis of the second alignment marks. With this configuration, a mask used for charged particle beam reduction-and-division transfer exposure can be highly accurately produced at a low cost, and exposure of a substrate can be highly accurately performed by using the mask.

Owner:SONY CORP

Side multiple-lamp type on-line inside quality inspecting device

InactiveUS6657722B1Reduce errorsReduce lightRadiation pyrometrySpectrum investigationLight beamCalibration curve

An object of inside-quality inspection being conveyed on a conveyer is irradiated sideways with beams of light from projection lamps concentratedly. A photodetecting device detects light transmitted through the object irrespective of the size and thickness of the skin of the object without being influenced by extraneous light. A white-level calibrating device is provided to the photodetecting means. The projection lamps project and concentrate their beams of light onto one side of the object in an inspection position at different angles from different positions diagonally distributed from the oblique front to the oblique back. Fractions of light transmitted through the object and emerging from the other side of the object are condensed by a condenser lens A shutter for opening / closing the optical path is provided between a light receiving window of the condenser lens and a light-inputting face of an optical fiber for directing light to a spectrometer. The shutter is operated when the inspection center of the object passes the inspection position. A white-level calibrating plate is moved to a position in front of the light receiving window and moved back so as to perform calibration. The deviation of the calibration curve is corrected by placing a quality reference material in the same position and moving it back.

Owner:KAJITSUHIHAKAIHINSHITSUKENKYUJO

Inkjet recording apparatus, color correction method and computer-readable medium

ActiveUS20100079524A1Correct deviationImprove color reproducibilityImage enhancementDigitally marking record carriersData acquisitionImage formation

An inkjet recording apparatus includes: a treatment liquid deposition device which deposits a treatment liquid insolubilizing or aggregating inks of a plurality of colors, onto a recording medium; a recording head which has a plurality of nozzles ejecting the inks onto the recording medium on which the treatment liquid has been deposited; a data acquisition device which acquires density data of an image with respect to each color, the density data corresponding to the plurality of colors; a higher-order color correction device which corrects the density data, wherein when the inks of different colors are ejected in ejection order so that a preceding ink ejected precedingly to form a lower layer and a subsequent ink ejected subsequently to form an upper layer overlap each other, the higher-order color correction device corrects the density data for a nozzle ejecting the subsequent ink according to the density data for a nozzle ejecting the preceding ink; and an ejection controller which controls ejection of the inks from the recording head according to the density data that the higher-order color correction device has corrected in such a manner that the image is formed on the recording medium.

Owner:FUJIFILM CORP

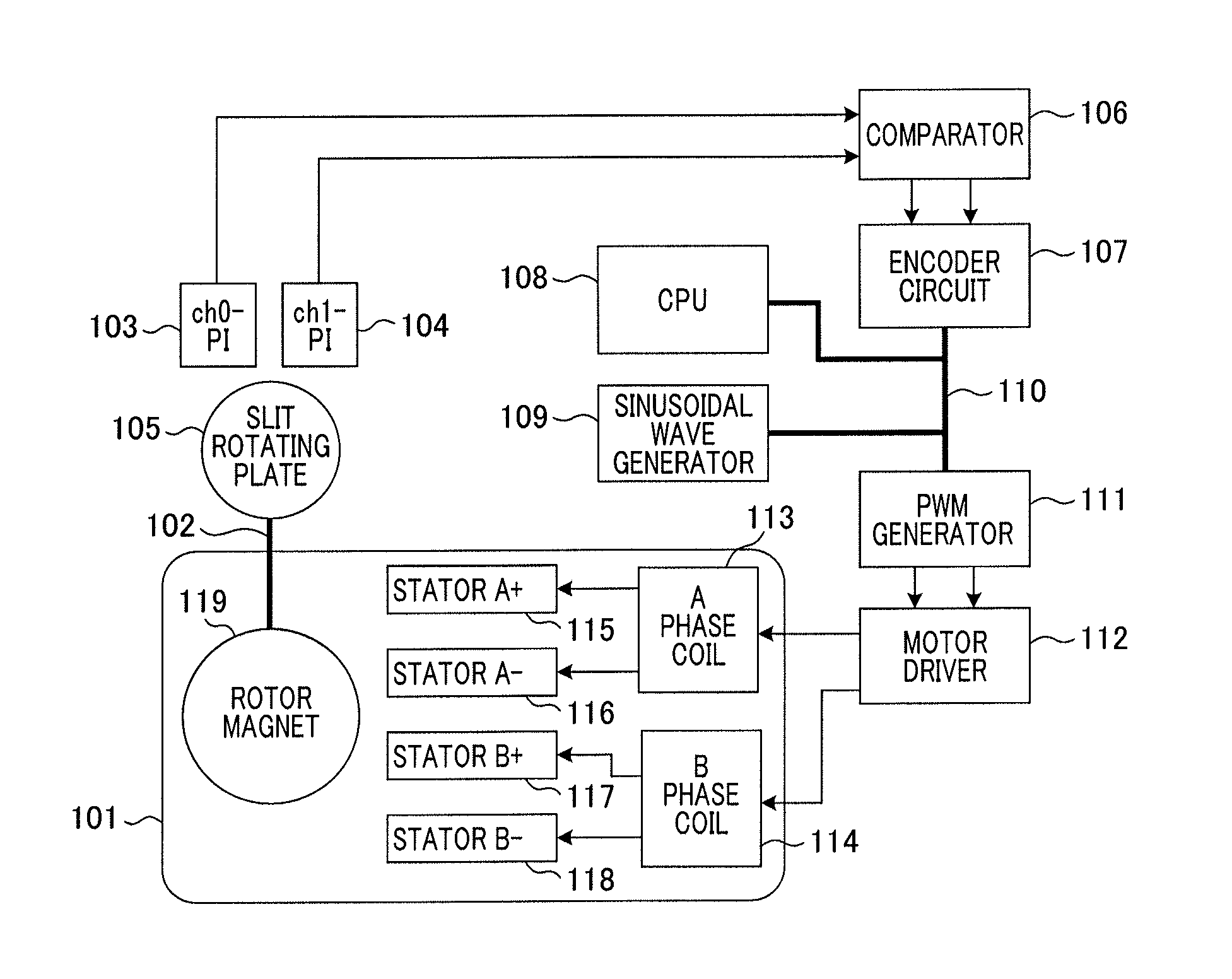

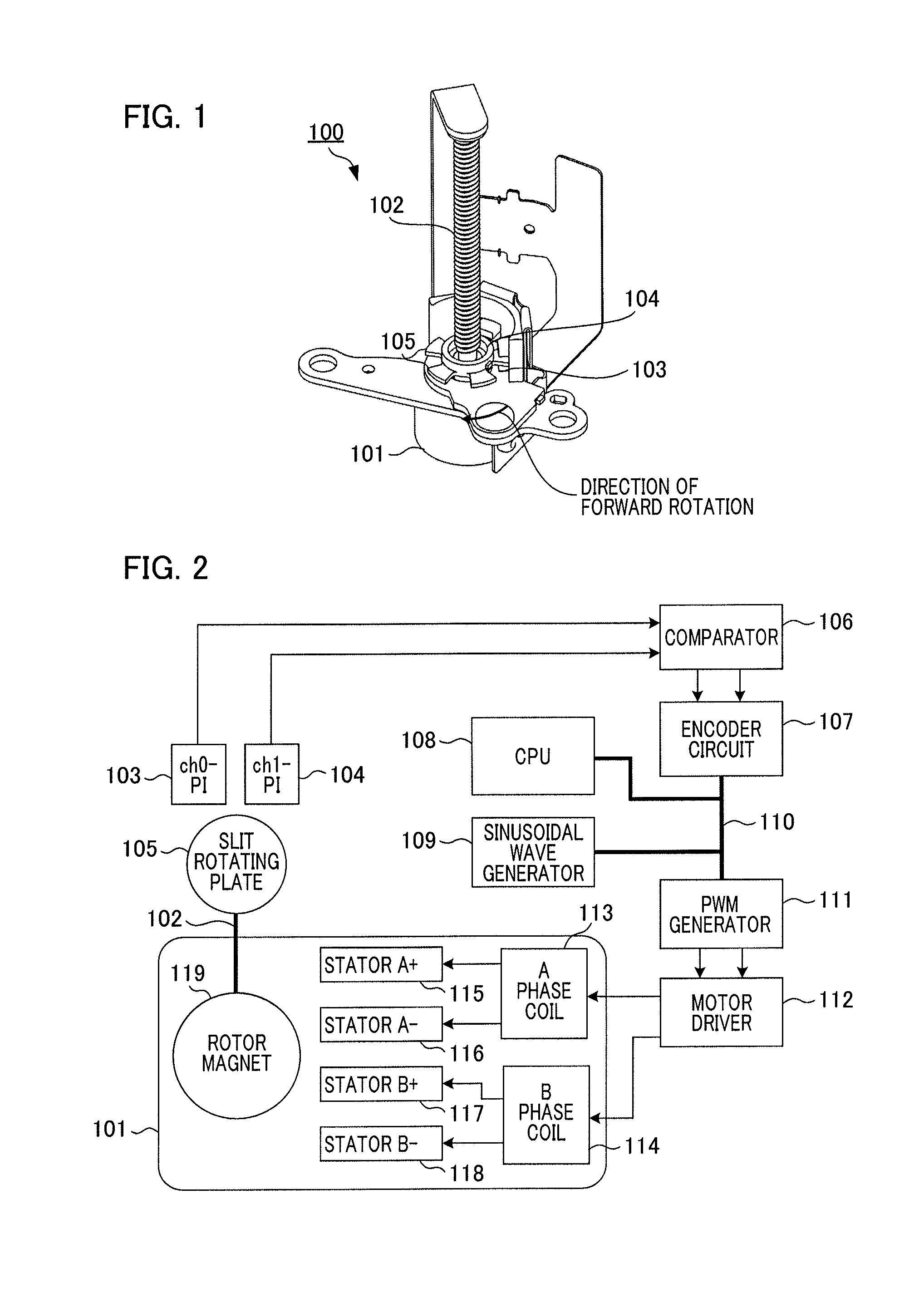

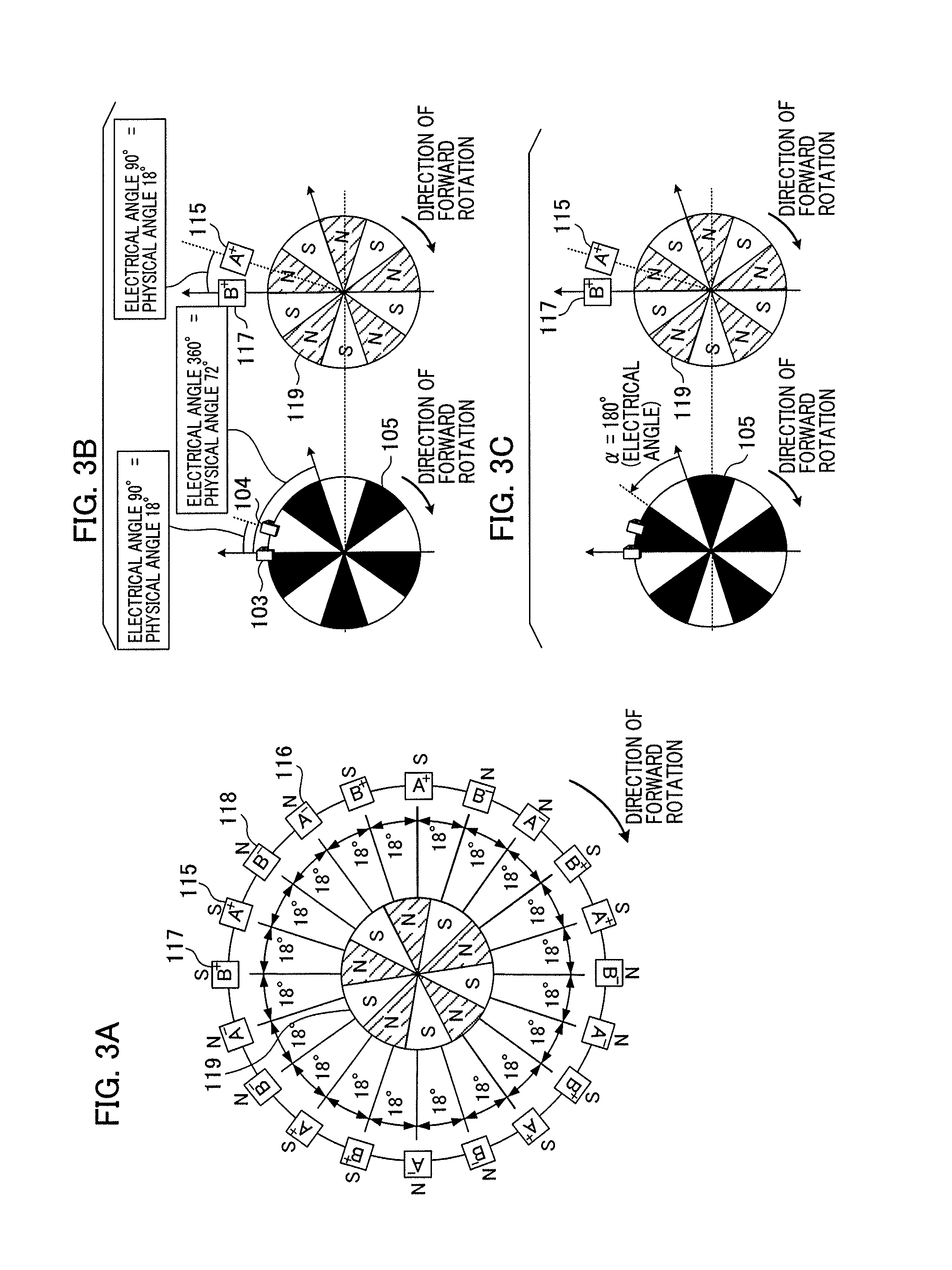

Motor control apparatus and motor control method

ActiveUS20140035496A1Simply and quickly adjustsQuickly reachMotor/generator/converter stoppersAC motor controlDriving currentElectric machine

A motor control apparatus applying a sinusoidal drive waveform to a motor and including a position detection unit outputting a signal according to a motor shaft's position; and a control unit: acquiring a phase value of the motor's drive waveform when a signal is output by the position detection unit, changing a cycle of the drive waveform by measuring time from a previously output signal to a presently output signal, comparing the phases of the drive waveform and the motor shaft, and controlling to change to a cycle at which a phase value of the drive waveform matches a target phase value when a travel time corresponding to a phase value for adjustment has elapsed from a present time when a phase value of the drive waveform presently acquired differs from a target phase value acquired when the motor's drive current and drive voltage are in a designated phase relationship.

Owner:CANON KK

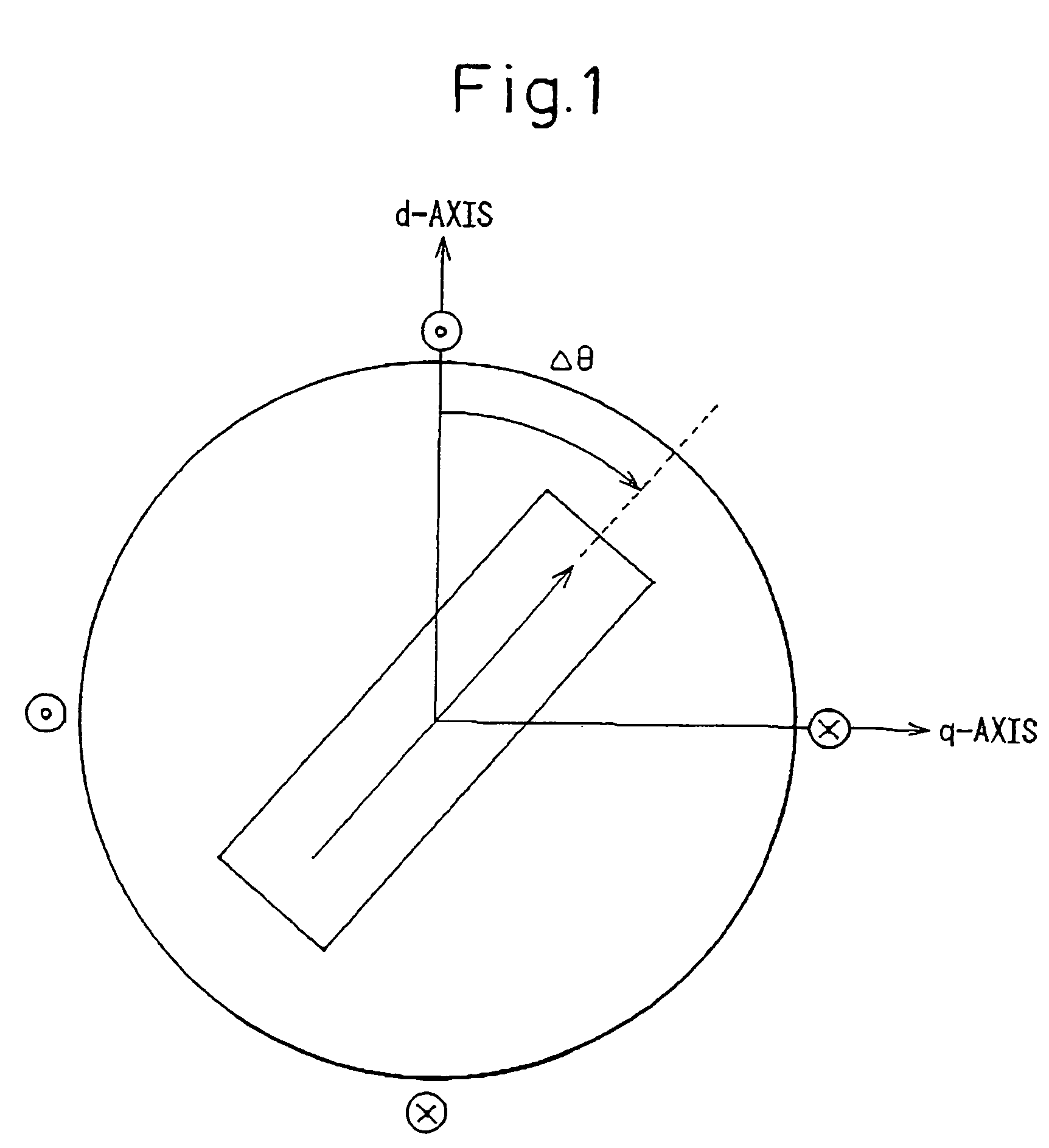

Synchronous motor control device and method of correcting deviation in rotational position of synchronous motor

ActiveUS6940250B2Correct deviationSynchronous motors startersAC motor controlVoltage converterPhase correction

In a synchronous motor control device that corrects a deviation in rotational position which is related to a rotational position detector for a synchronous motor on which vector-control is performed, the synchronous motor control device includes: a current instruction generator that disables a torque instruction to set d-axis and q-axis current instructions as zero when a phase correction instruction is inputted; a current controller that outputs d-axis and q-axis voltage instructions based on the d-axis and q-axis current instructions; a phase correction quantity detector for determining the amount of offset in which the d-axis voltage instruction becomes zero when the phase correction instruction is inputted and the d-axis voltage instruction is not zero; an adder for adding a rotor positional angle and the amount of offset; and a voltage converter for determining three-phase voltage instructions based on the additional value, the d-axis and q-axis voltage instructions.

Owner:MITSUBISHI ELECTRIC CORP

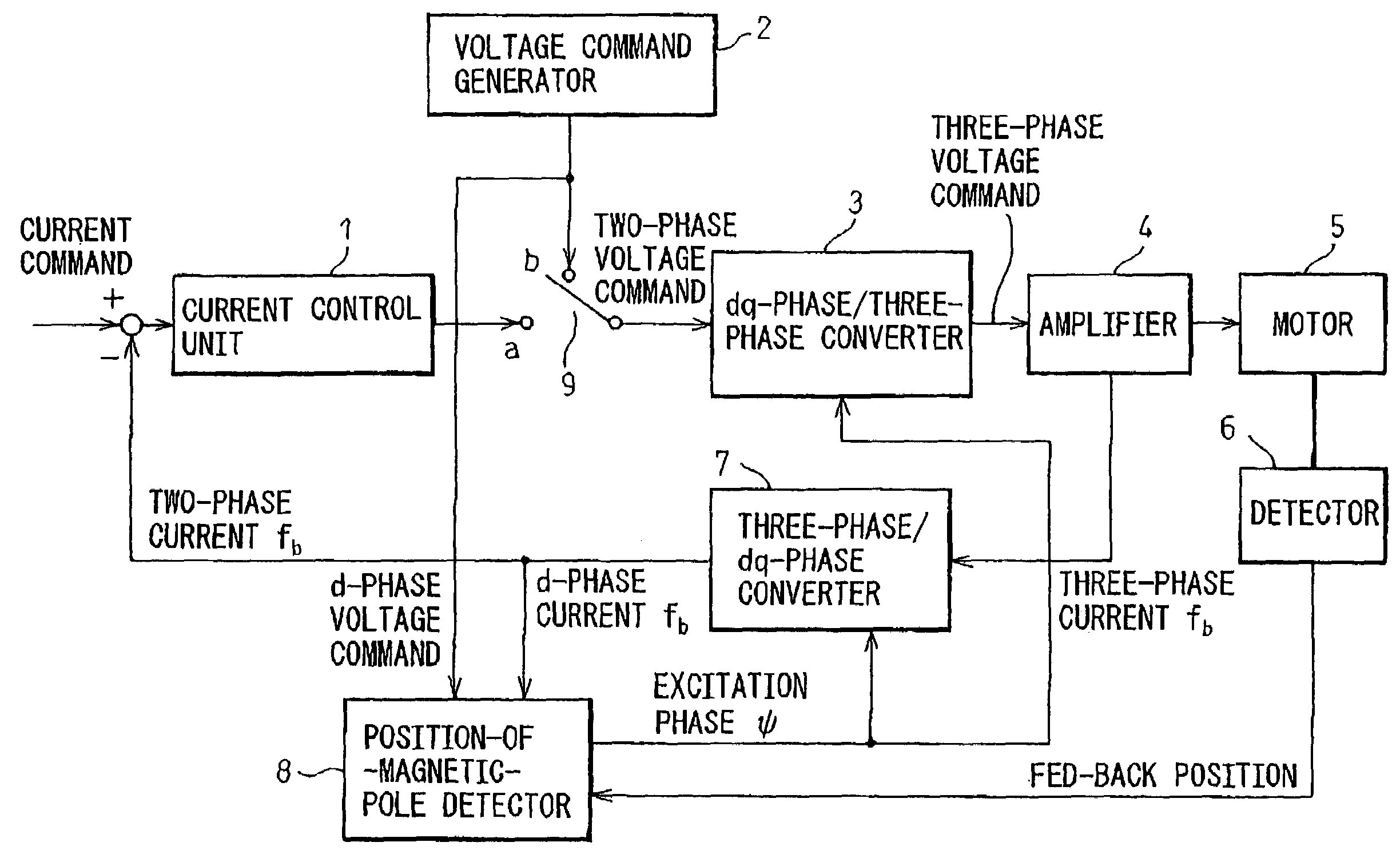

Position-of-magnetic-pole detecting device and method

ActiveUS7071651B2Readily and accurately detectingCorrect deviationAC motor controlVector control systemsElectric machineMagnetic poles

A high-frequency voltage whose amplitude is small is applied as a d-phase command voltage, and an excitation phase is changed to a predetermined degree at predetermined intervals, whereby a motor is driven. As the d-phase command voltage has the small amplitude and high frequency, the rotor of the motor does not rotate. A d-phase feed back current is detected, and the product of a derivative of the d-phase feed back current by the high-frequency voltage command is calculated. A high-frequency component is removed from the product. An excitation phase (direction of a magnetic flux) associated with a deviation of 0 or π from the position of a magnetic flux and also associated with a peak value assumed by the product having the high-frequency component removed therefrom is detected. A plurality of thus detected excitation phases is averaged in order to determine the direction of a magnetic flux. The excitation phase associated with one of two peak values assumed by the product is adopted on a fixed basis. Positive and negative rectangular waves having a magnitude causing magnetic saturation are applied as d-phase voltage commands. The polarity of a magnetic pole is determined based on positive and negative d-phase feed back currents. As the direction of a magnetic flux and the polarity thereof are detected separately from each other, the position of a magnetic pole can be detected accurately and reliably.

Owner:FANUC LTD

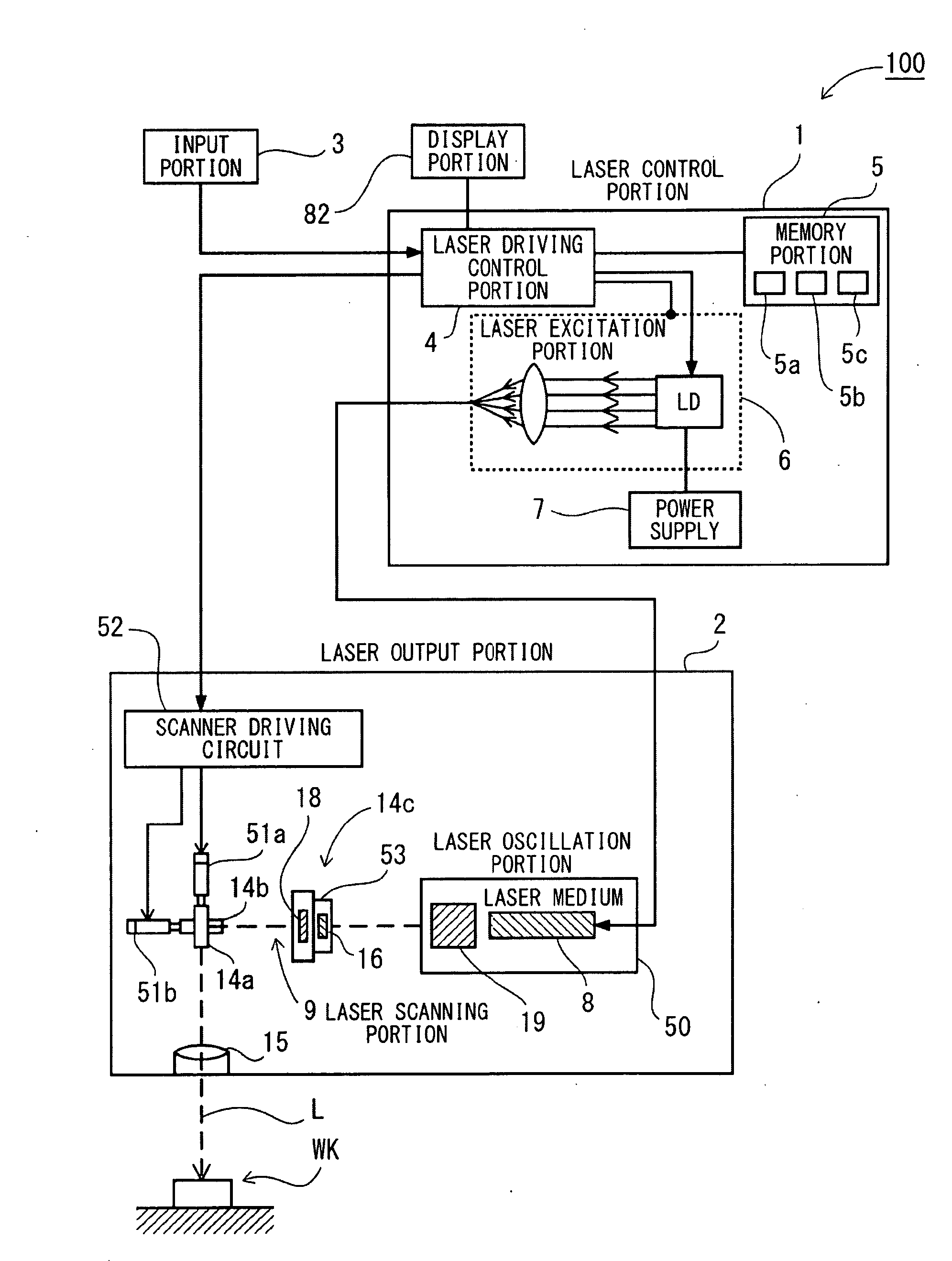

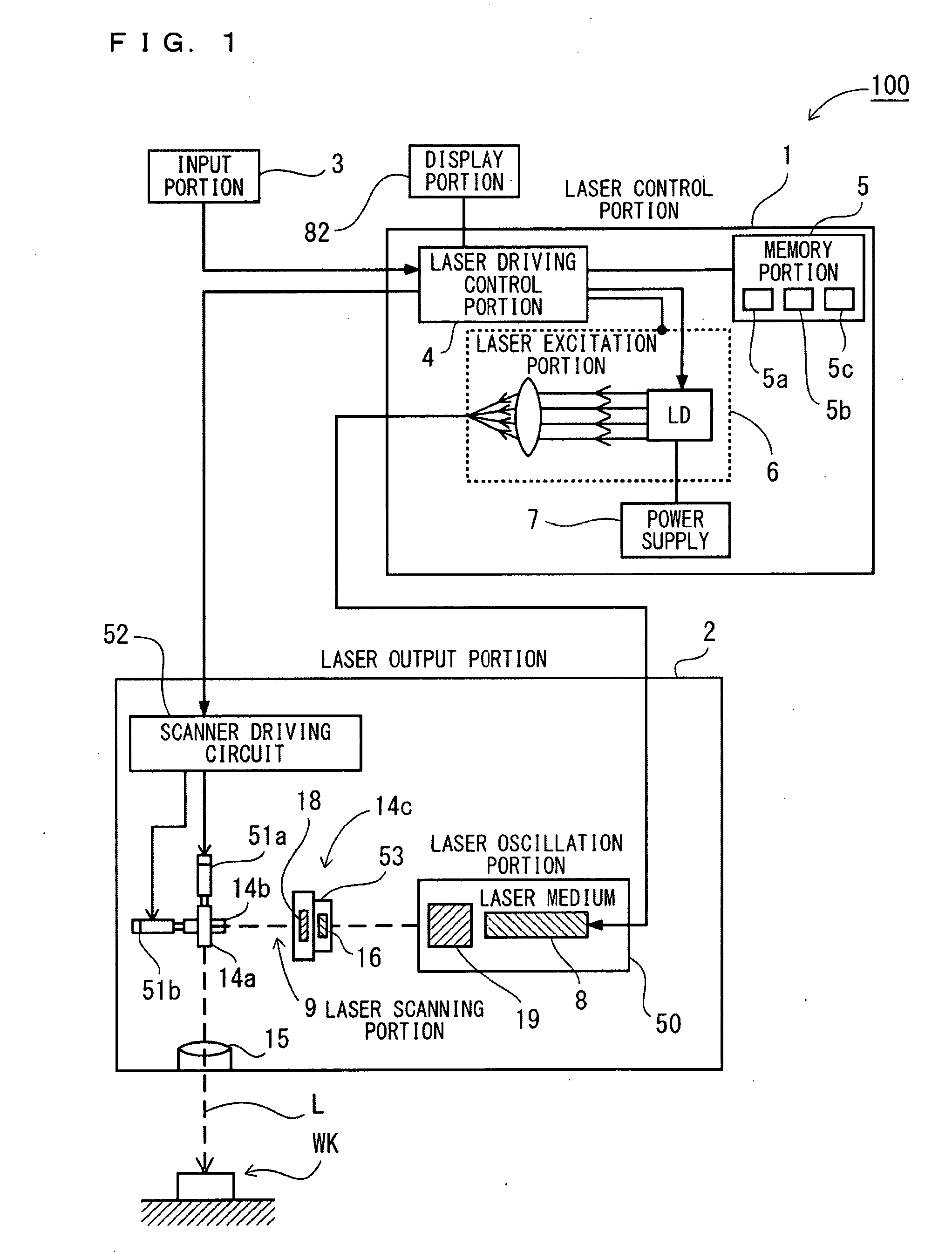

Laser Processing Apparatus, Laser Processing Method, and Method For Making Settings For Laser Processing Apparatus

InactiveUS20090154504A1Eliminate operationIntuitive effectLaser detailsPrintingLaser processingOptical axis

It is an object to enable easily adjusting a focus position for coping with thermal lens effects. There is provided a laser-light scanning portion including a Z-axis scanner capable of adjusting the focus position of laser light in the direction of the optical axis, an X-axis scanner and a Y-axis scanner. Further, there are provided a laser driving control portion for controlling a laser oscillation portion and the laser-light scanning portion, a processing-condition setting portion for setting a laser-light outputting condition and a processing pattern as processing conditions for processing in a desired processing pattern, and an amount-of-correction identification section for identifying, as an amount of focus-position correction, the deviation of the focus position in the direction of the optical axis which is caused by thermal lens effects induced based on the laser-light outputting condition set by the processing-condition setting portion. During irradiation of the laser light, the laser driving control portion scans the laser light, in such a way as to add the amount of focus-position correction identified by the amount-of-correction identification section to the processing condition set by the processing-condition setting portion.

Owner:KEYENCE

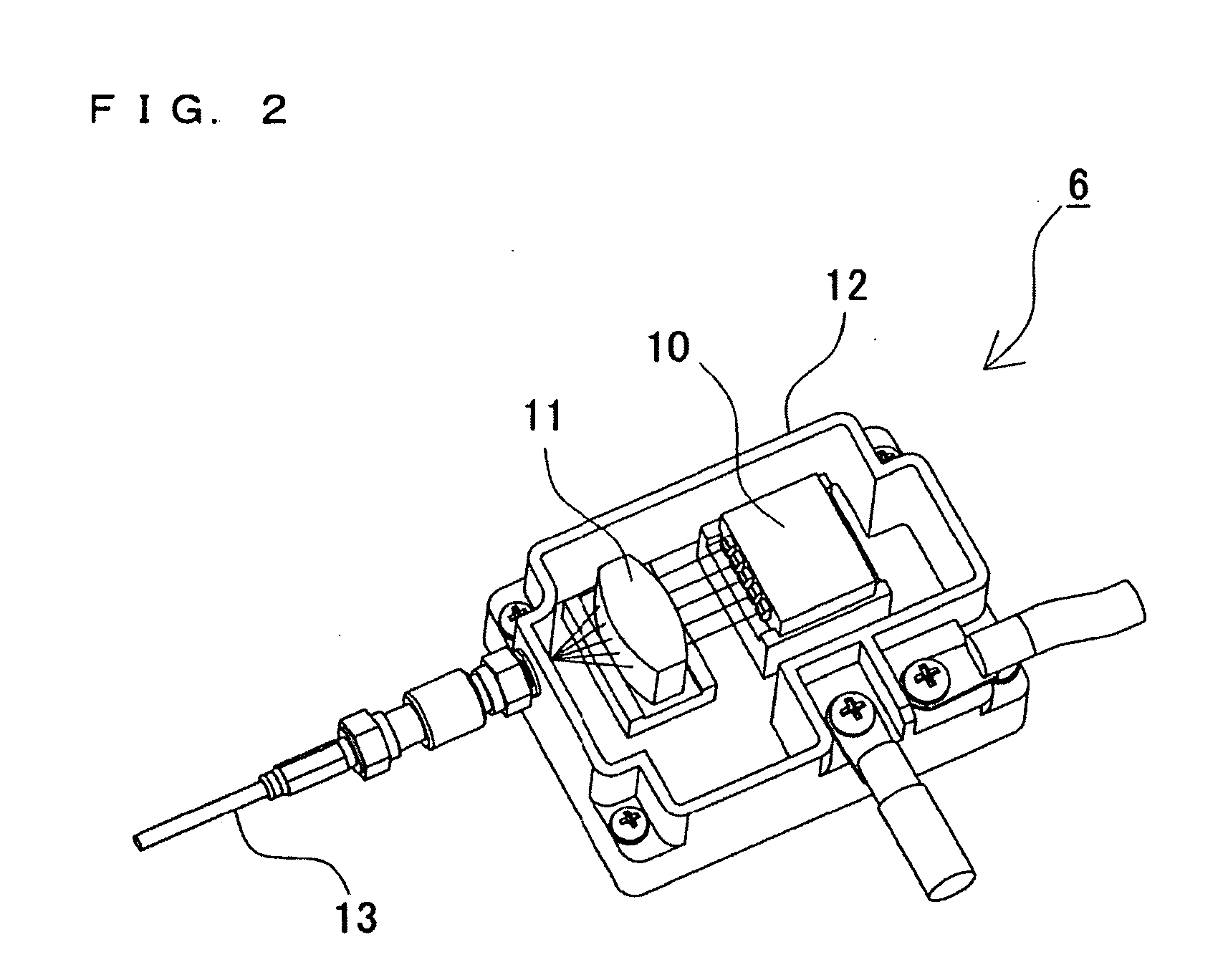

Imaging device and electronic information instrument

ActiveUS20140368618A1Correct deviationSolid-state devicesStereoscopic photographyElectronic informationStereo image

A means for correcting tilts and positional deviations from a stereo image is rendered unnecessary. The present invention has a solid-state imaging element 2 on which a plurality of light receiving sections for photoelectrically converting and imaging an image light from a subject are arranged in a matrix pattern and a lens means 3 with a single focal point on an imaging surface of the solid-state imaging element 2. The present invention is configured to simultaneously or chronologically expose and image each imaging light from a subject entering different positions of the lens means 3 as a plurality of images in a plurality of imaging regions for each predetermined imaging regions of the solid-state imaging element 2.

Owner:SHARP KK

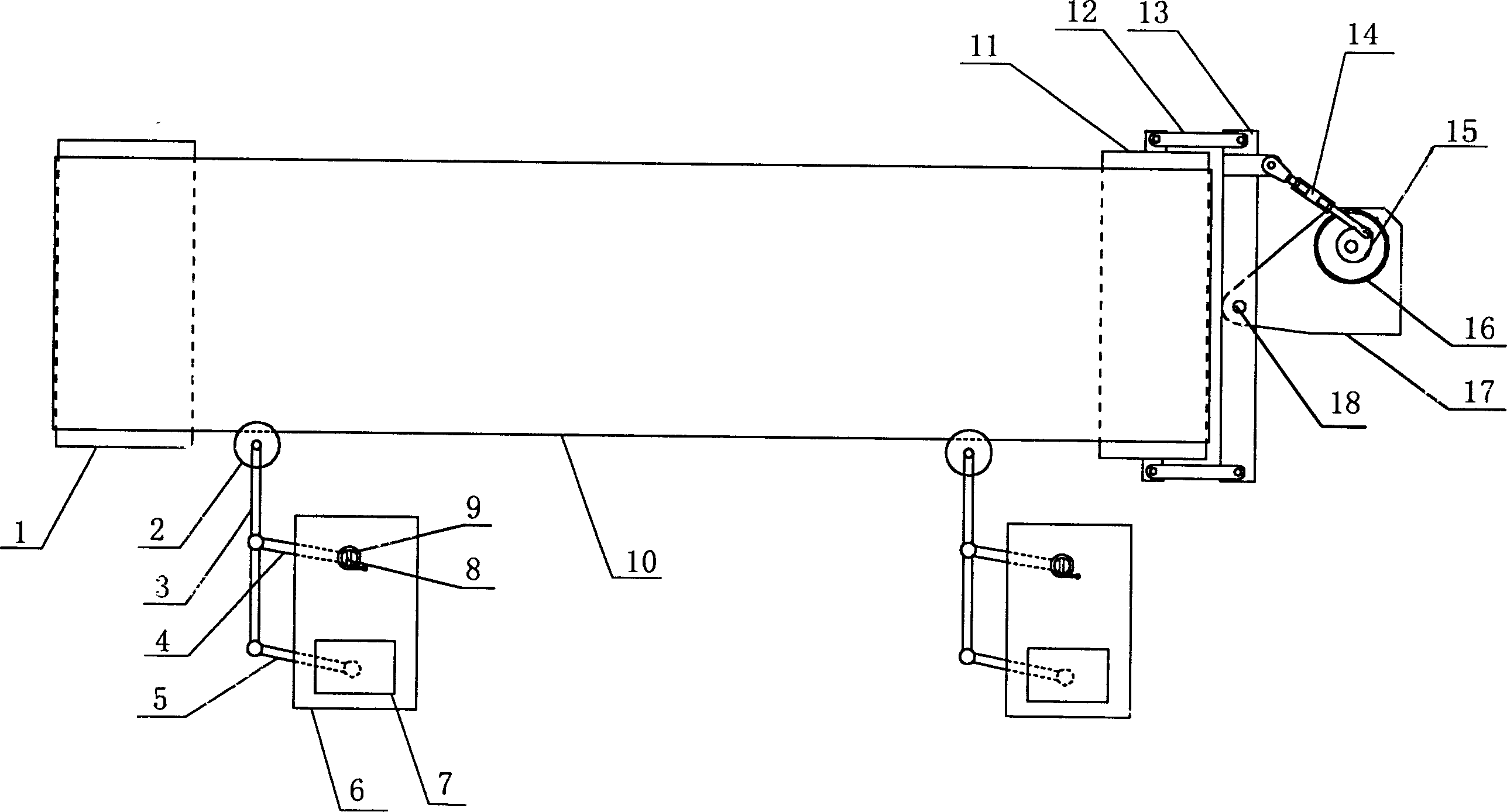

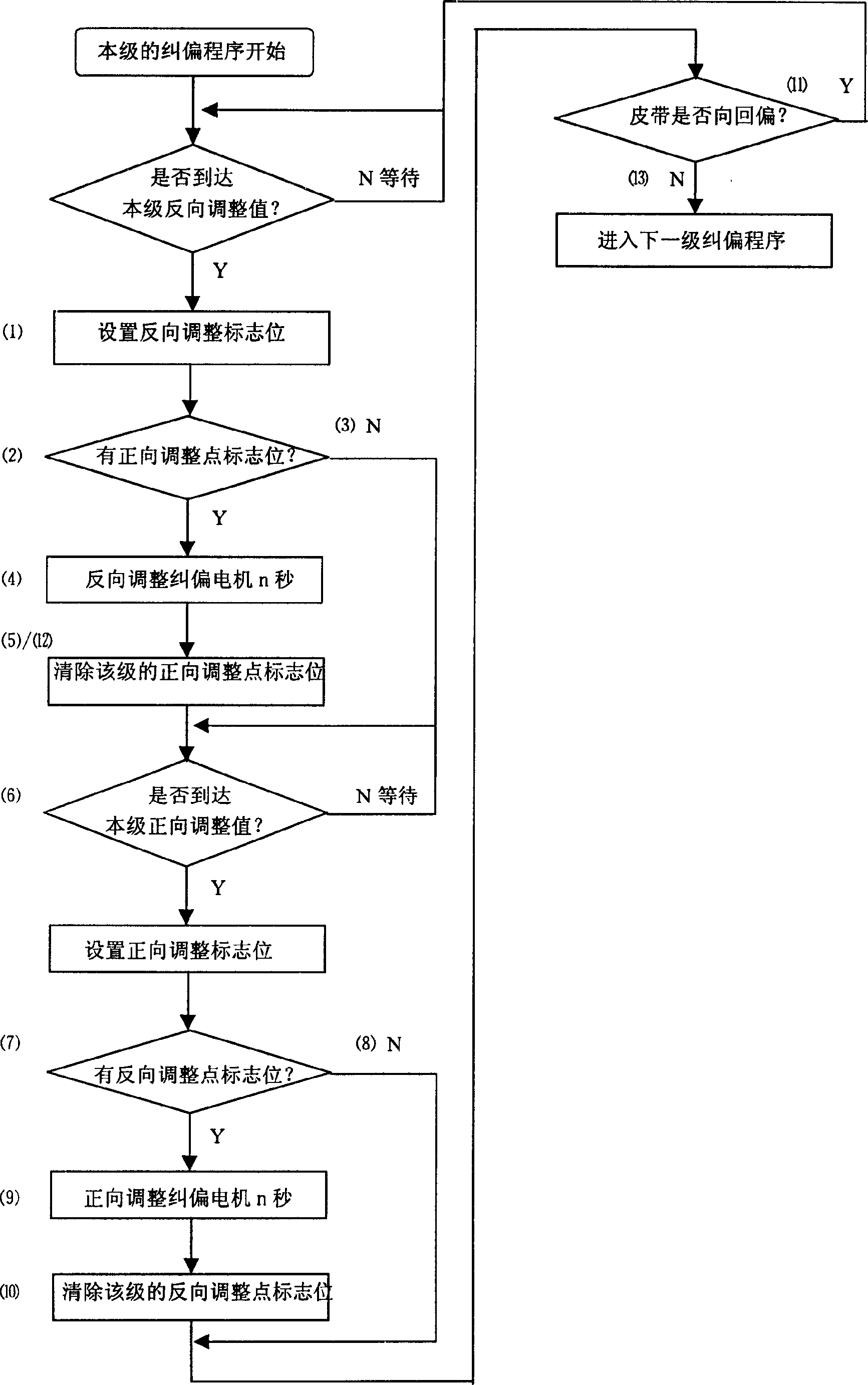

Automatic error correcting system of short leather belt and its method

InactiveCN1597469ACorrection method is reasonable and feasibleCorrection accuracyConveyorsControl devices for conveyorsSystem structureLeather belt

This invention relates to a system and a method for calibrating short belt against a correct position. A system consists of a four-bar-linkage, a motor a cam, which is hinged with a push rod, and a position monitor. The four-bar-linkage is used as an actuator. The motor drives the cam to actuate the four-bar-linkage via the push rod hinged with the cam. The push rod is respectively hinged with the cam and a movable rod of the four-bar-linkage as its both ends. The position monitor is equipped with a detecting lever. A roller is elastically pressed to contact with an edge of the belt. The method is carried out by: feeding the detected position signals into computer system, outputting a calibrating signal to the motor and to change the tension forces on both edges of the conveying belt via the cam mechanism and actuator. It is simple and reliable.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com