Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17936results about "Control devices for conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Article transport device

InactiveUS20070034477A1Small and simpleSemiconductor/solid-state device manufacturingControl devices for conveyorsSolid of revolution

Owner:DAIFUKU CO LTD

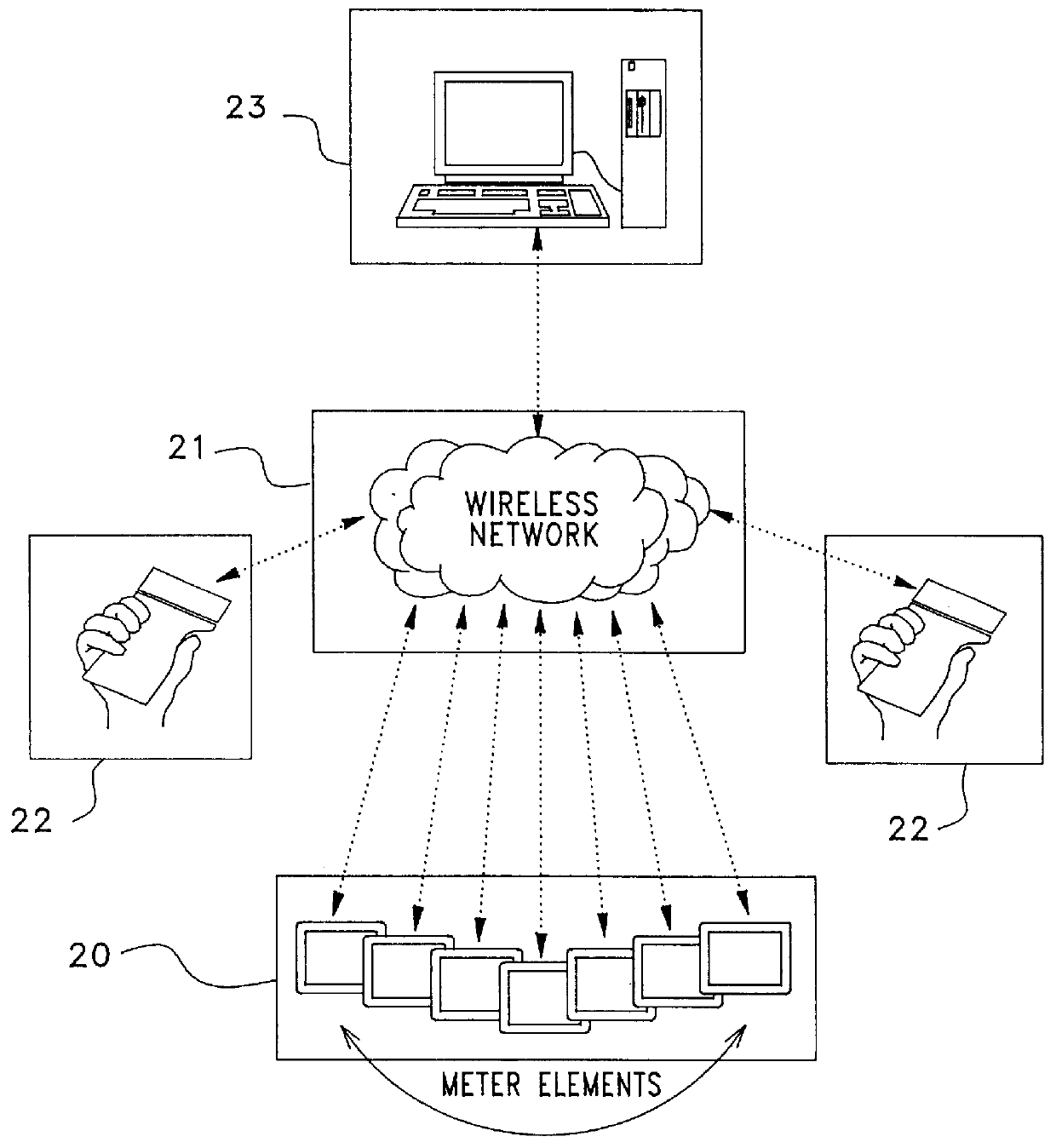

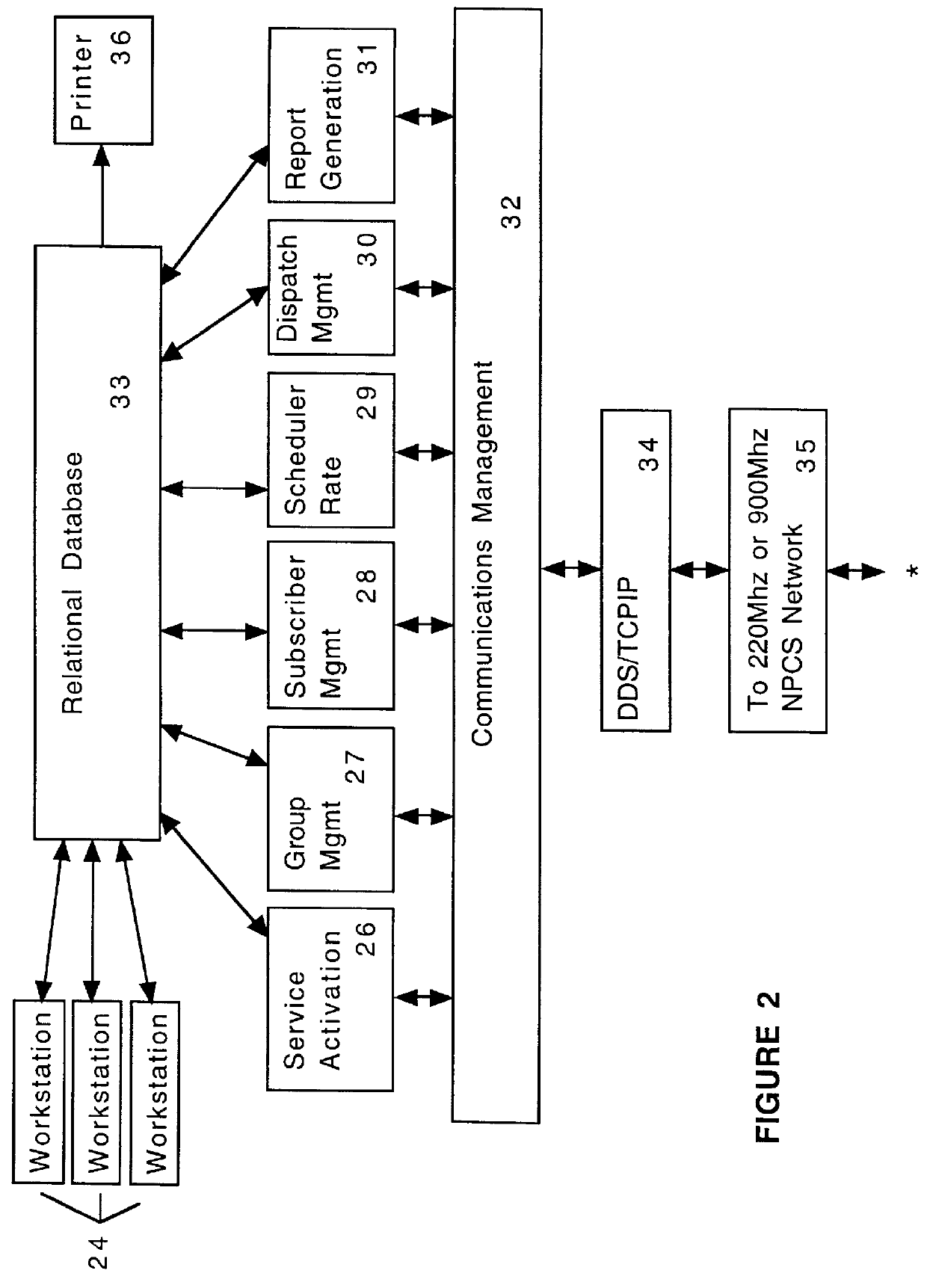

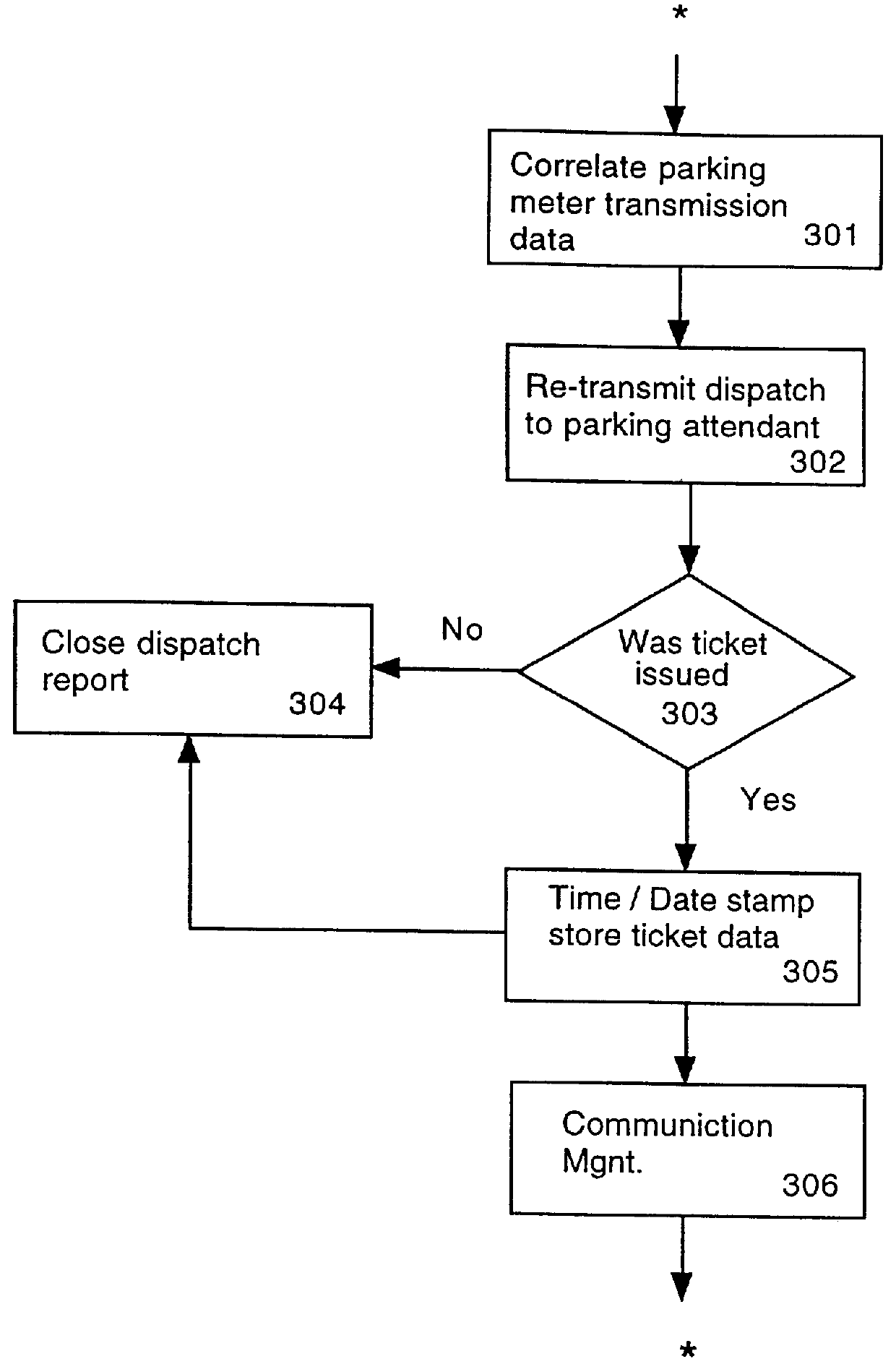

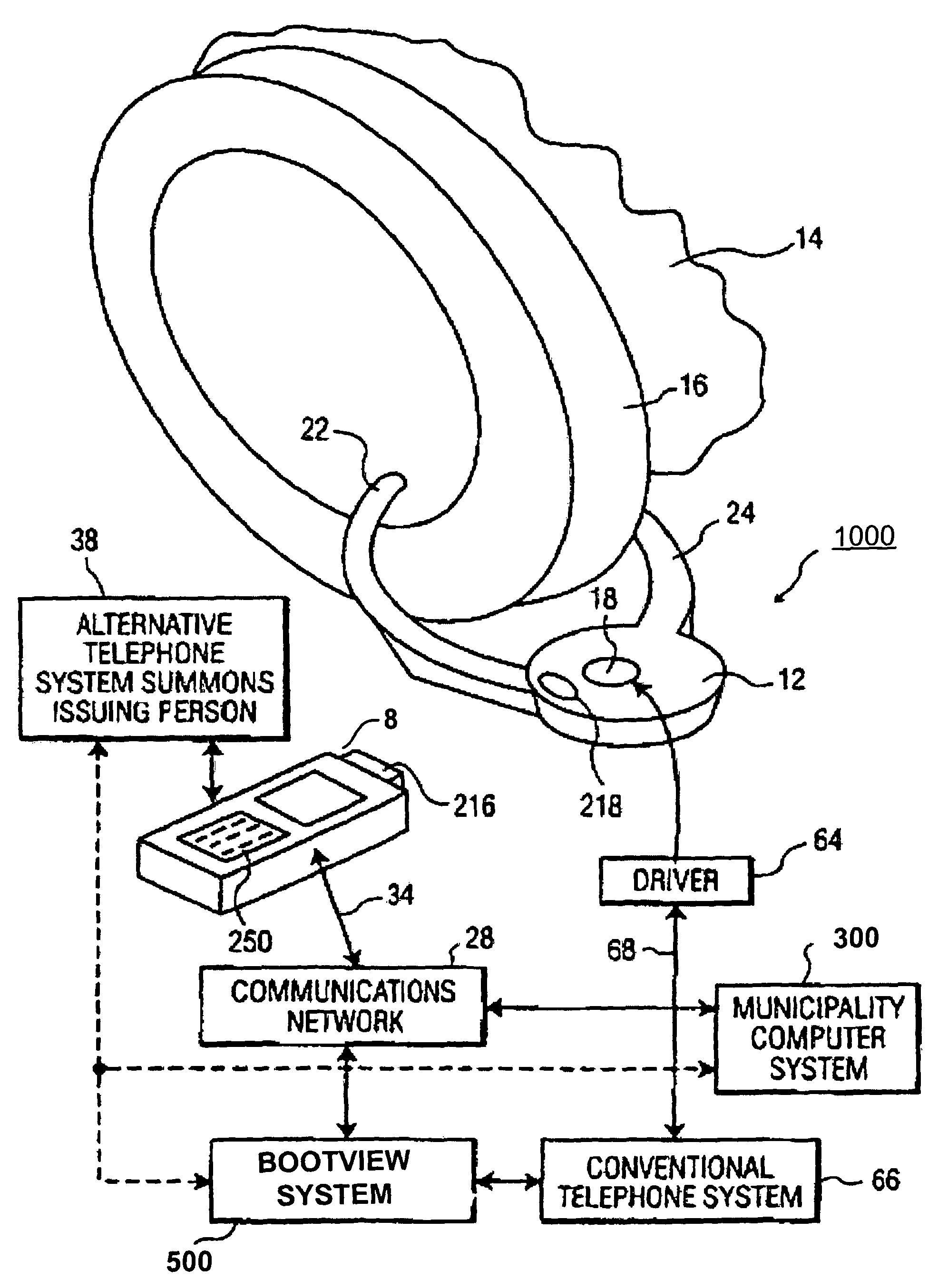

Integrated parking meter system

InactiveUS6037880ASave livesIncrease incomeElectric signal transmission systemsTicket-issuing apparatusParking spaceExact location

An integrated parking meter system automates the issuance of parking citations. Each parking meter will be equipped with a sonar range finder, mercury type switch and a two way radio that communicates via N-PCS to a host computer back at the control center. When a meter runs out of money it checks to see if a vehicle is present in the parking space. If it is, the meter notifies the host computer that there is a car illegally parked in the space. The host computer correlates the information to identify the exact location of the violator. The host computer then sends this information via wireless network to the parking meter attendants' personal communicator. The parking attendant proceeds to the violator and issues the citation. Included within this technology is the capability to remotely change the rate structure of any or all electronic parking meters. A meter diagnostic feature alerts repair personnel to specific malfunctioning meters. The meter may also set the time remaining on the meter to zero whenever a car leaves the adjacent space.

Owner:MANION JEFFREY CHARLES

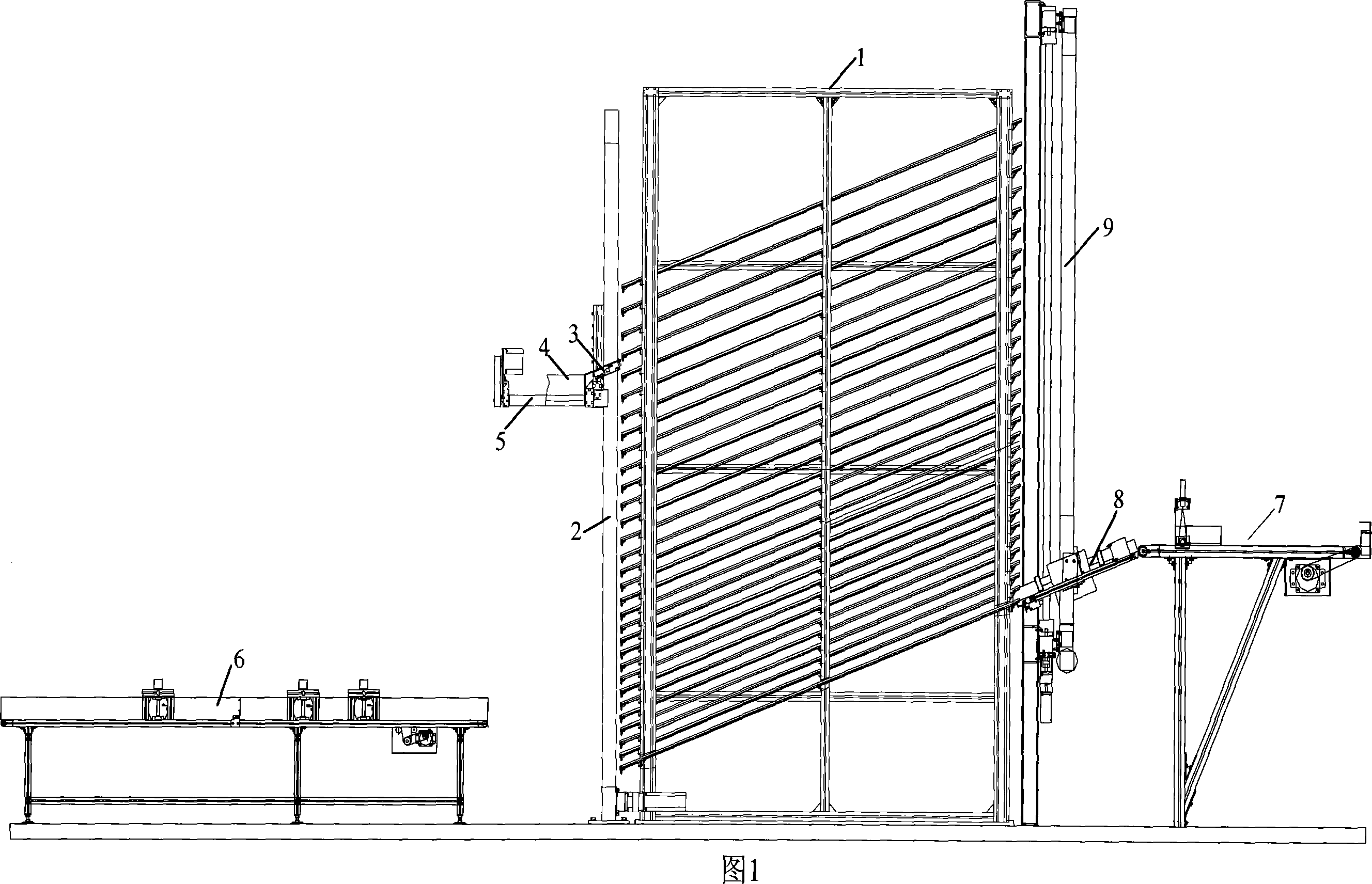

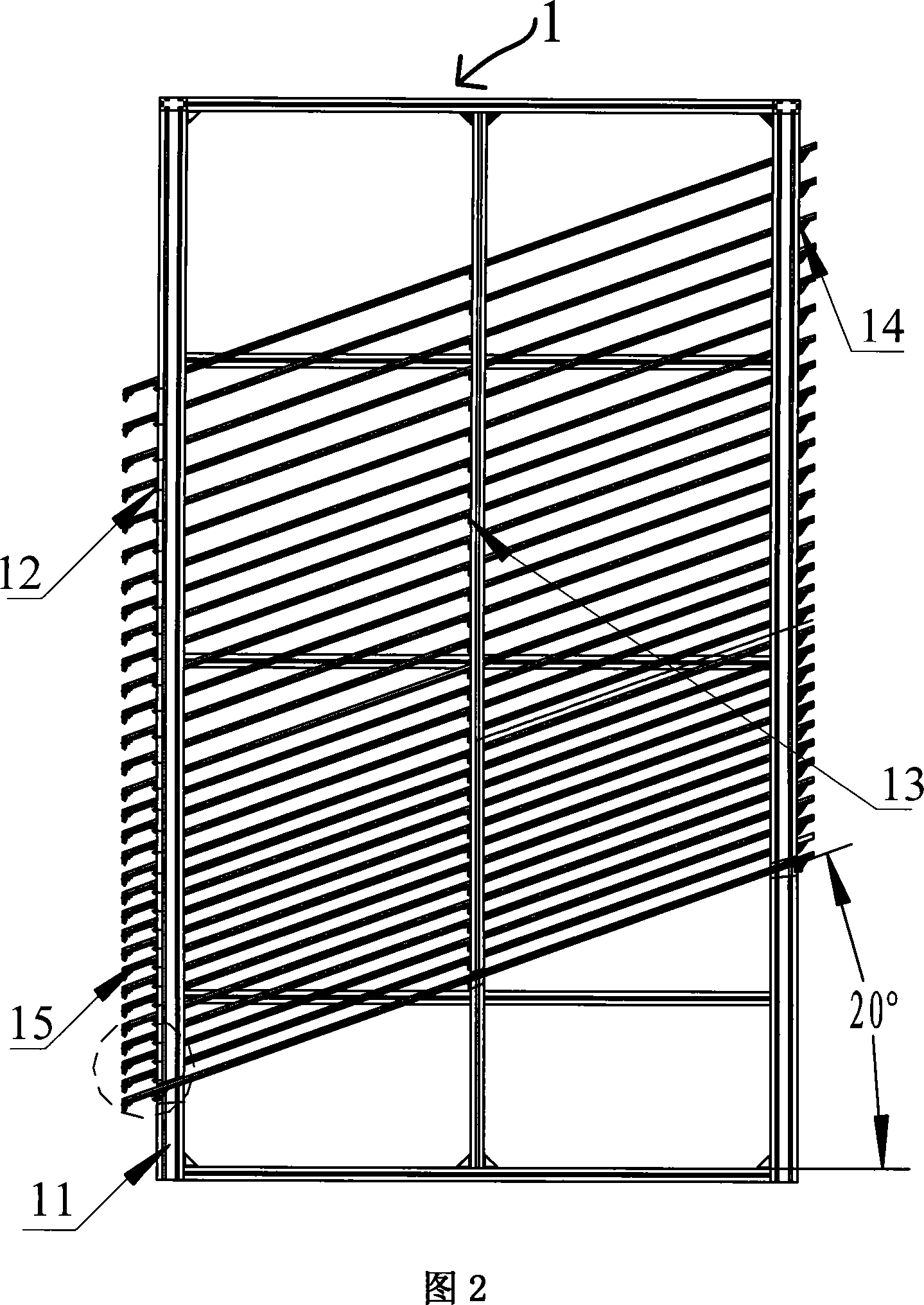

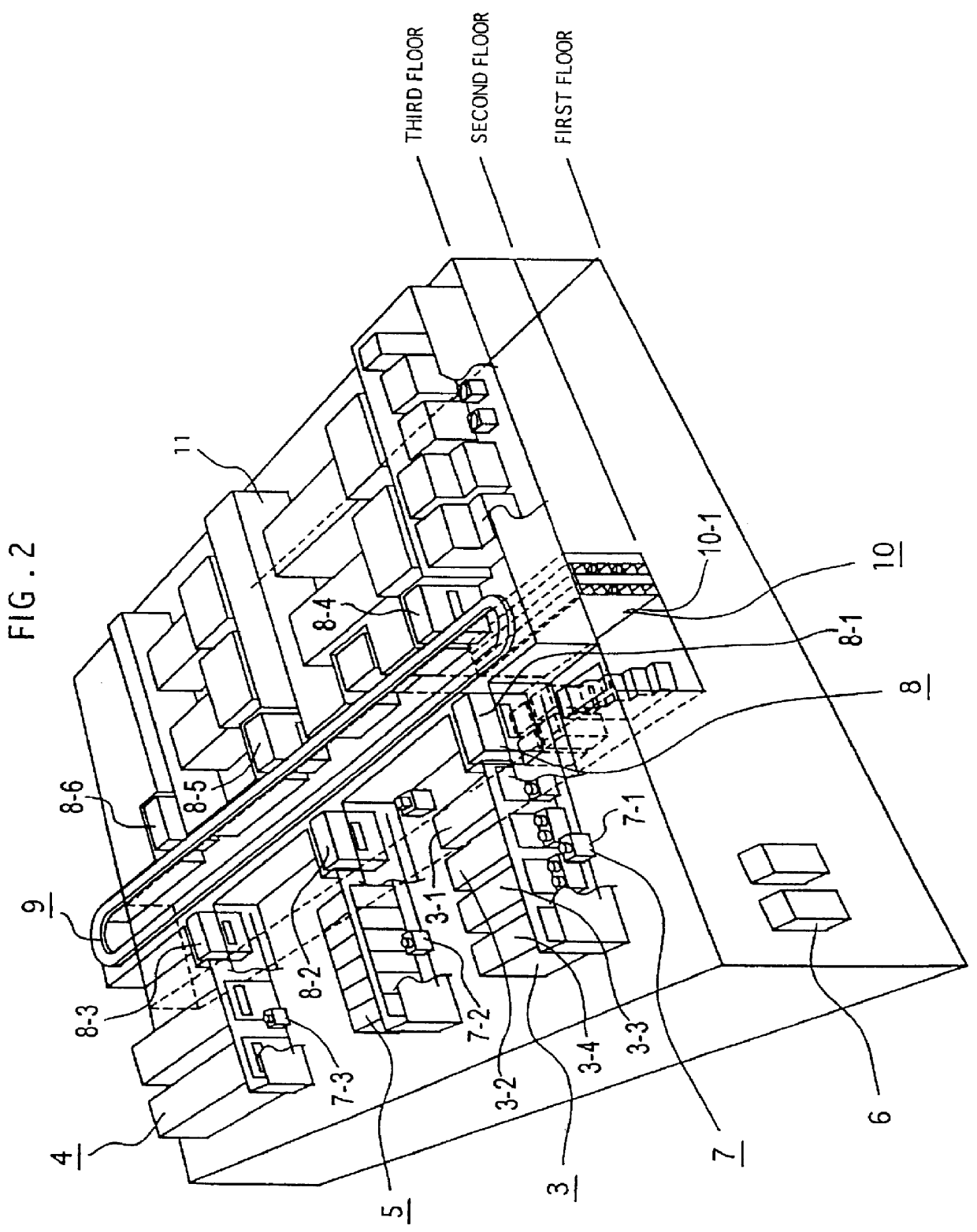

Automatization hospital pharmacy

ActiveCN101214107AImprove storage densityImprove distribution efficiencyShow cabinetsProgramme-controlled manipulatorSemi automaticCartesian coordinate robot

The invention provides an automatic pharmacy, including a slope type medicine storing cabinet, a medicine distributing device, a sorting device, a medication applying device and a control management system. A U-shaped groove of a slope medicine storing holder is fixed to a supporting beam and forms a dip of 20 degrees with the horizontal plane. The medicine distributing device includes an elevator and a medicine output mechanism. A low end medicine outlet port of the U-shaped groove of the slope medicine storing holder is butted with a medicine inlet port of a U-shaped medicine storing groove of the medicine output mechanism. The medicine outlet is connected with a conveyer belt in a way of transiting through a retaining door to form a medicine distributing channel. The medicine outlet end of the medicine distributing device is equipped with the sorting device. A sorting channel is connected with the medicine distributing channel. The medicine outlet port of a medication applying transporting mechanism is butted with a medicine inlet port of a U-shaped groove of a medication applying manipulator which is installed on a Cartesian-coordinate robot. The medicine outlet port of the U-shaped groove of the medication applying manipulator is butted with a high end medicine inlet port of the U-shaped groove of the slope medicine storing holder to form the medication applying channel. Therefore, the functions of semi-automatic batch recharging of boxed medicine, medicine box dense storage and management, automatic medicine distribution according to a prescription and medicine sorting to the determined windows, etc. can be realized.

Owner:SUZHOU IRON TECH

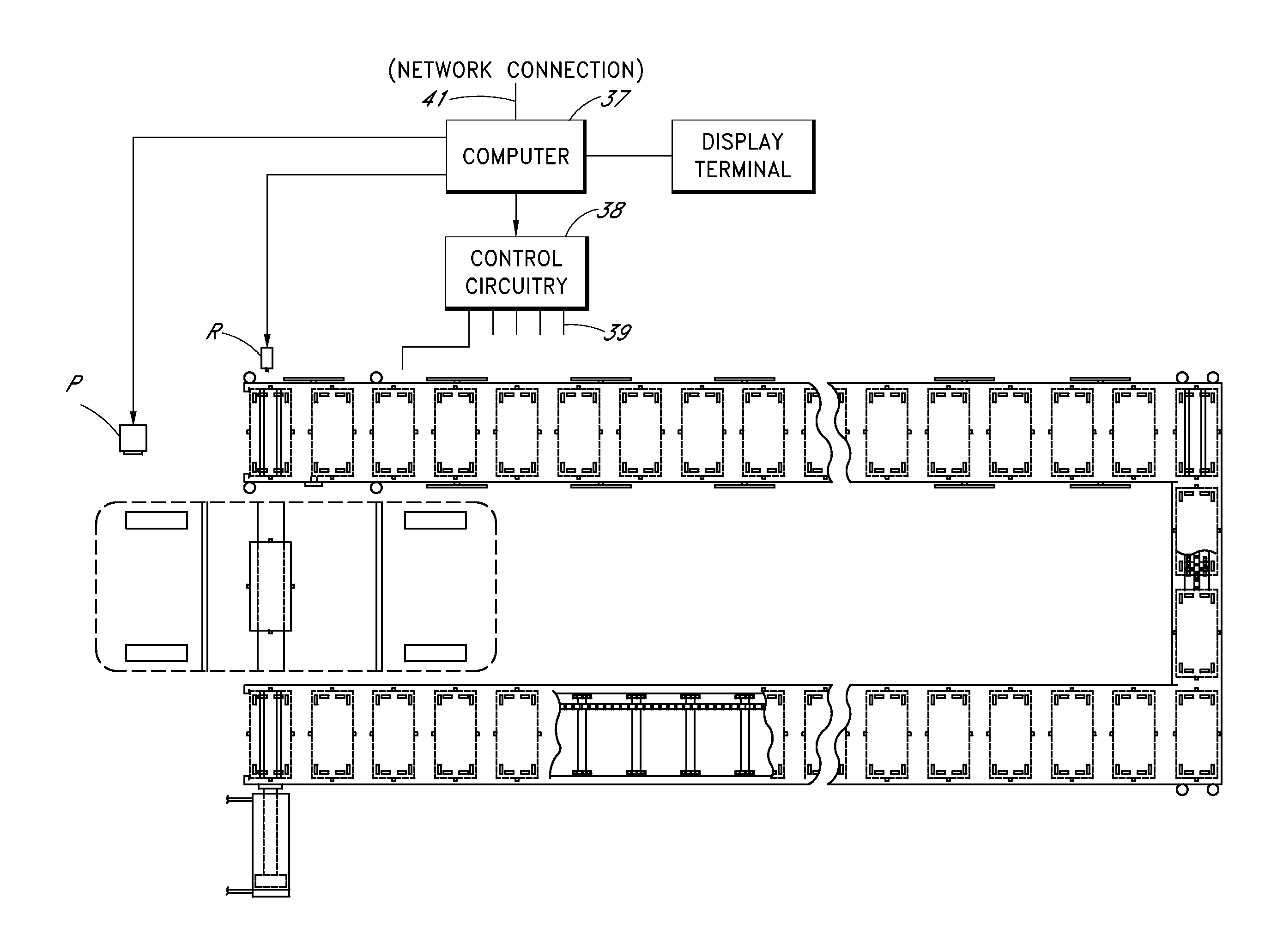

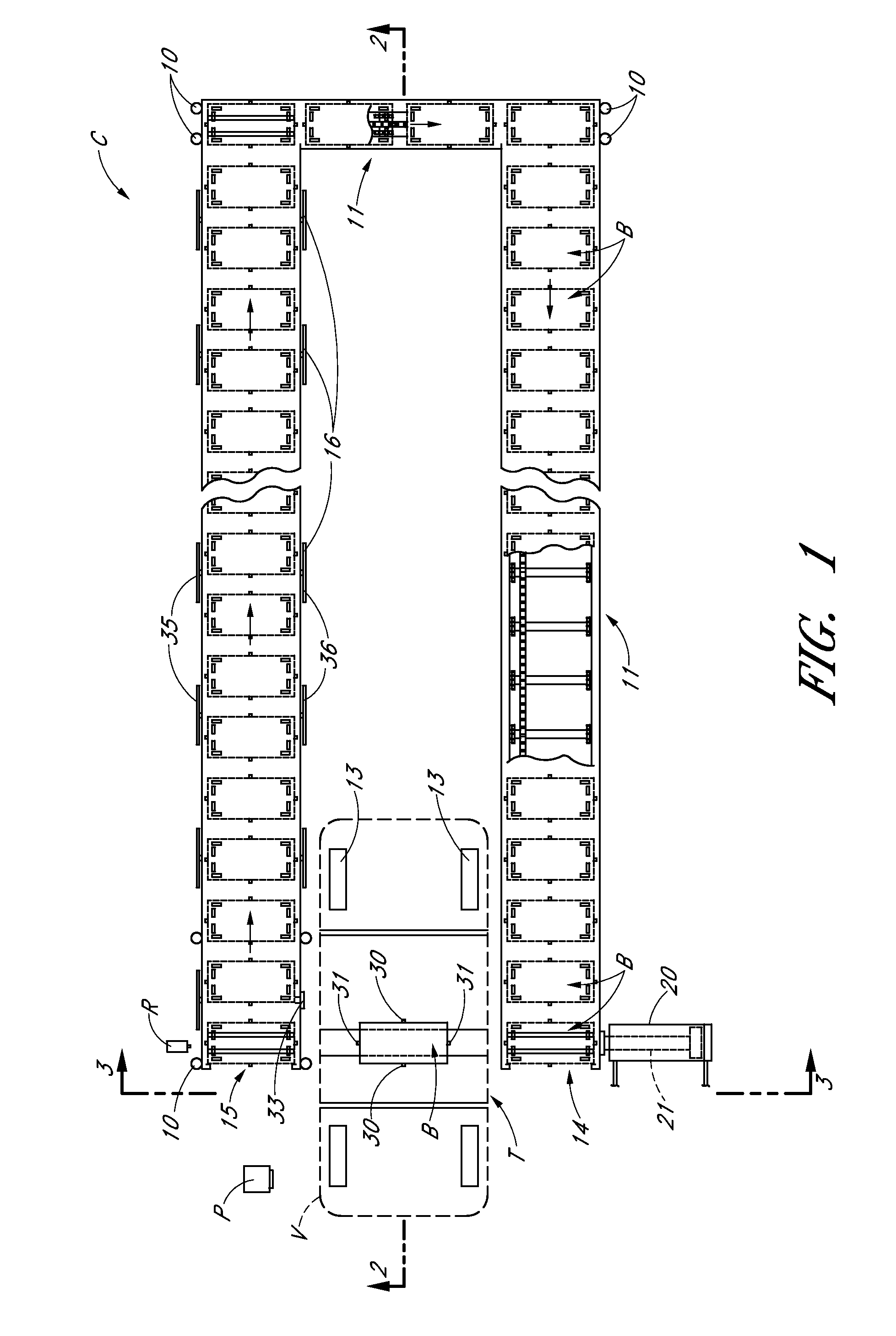

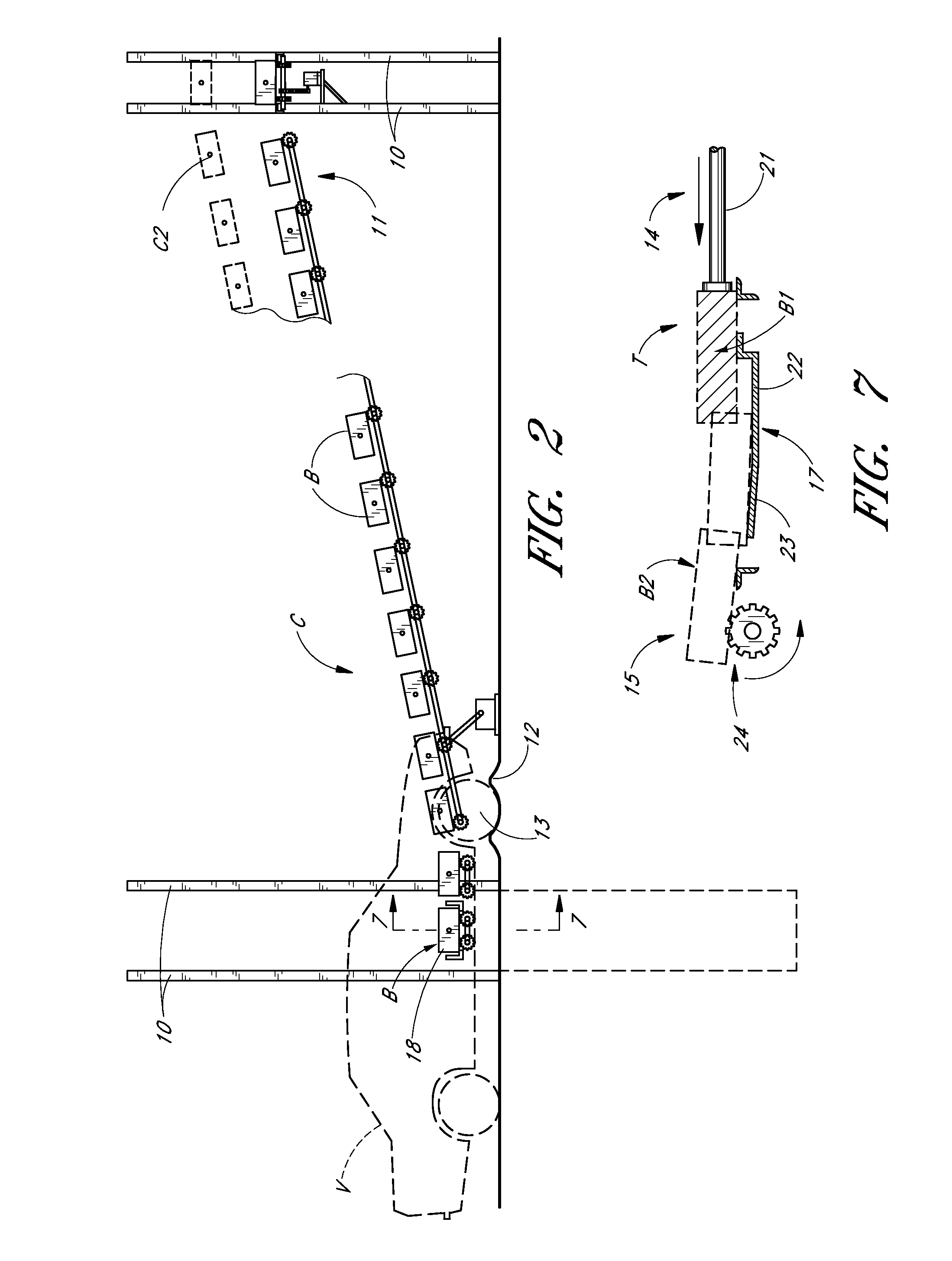

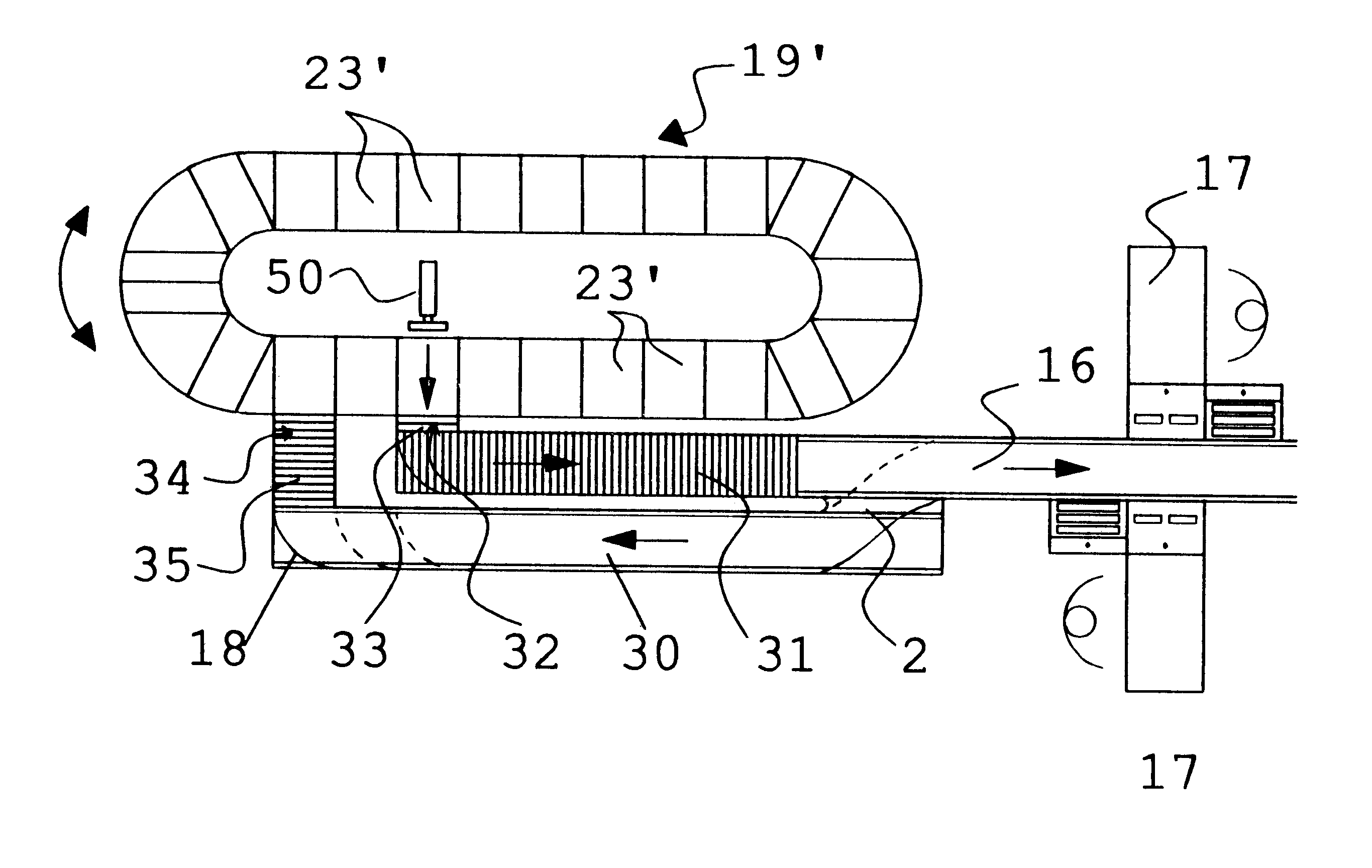

Battery charging and transfer system for electrically powered vehicles

InactiveUS20120316671A1Digital data processing detailsMobile unit charging stationsElectrical batteryTransfer system

A battery transfer and charging system for electric vehicles is described. A station removes one or more spent batteries of electric vehicles having multiple batteries. The receiving system includes an engagement device for engaging with engagement structures of the batteries, in order to assist the removal of spent batteries. Spent batteries removed from vehicles may be tested and charged as they progress through the system in an assembly-line fashion. Following recharge, batteries may be transferred to the displacement station for installation within later vehicles. Batteries which cannot adequately be recharged can be automatically removed from the system.

Owner:UNLIMITED RANGE ELECTRIC CAR SYST

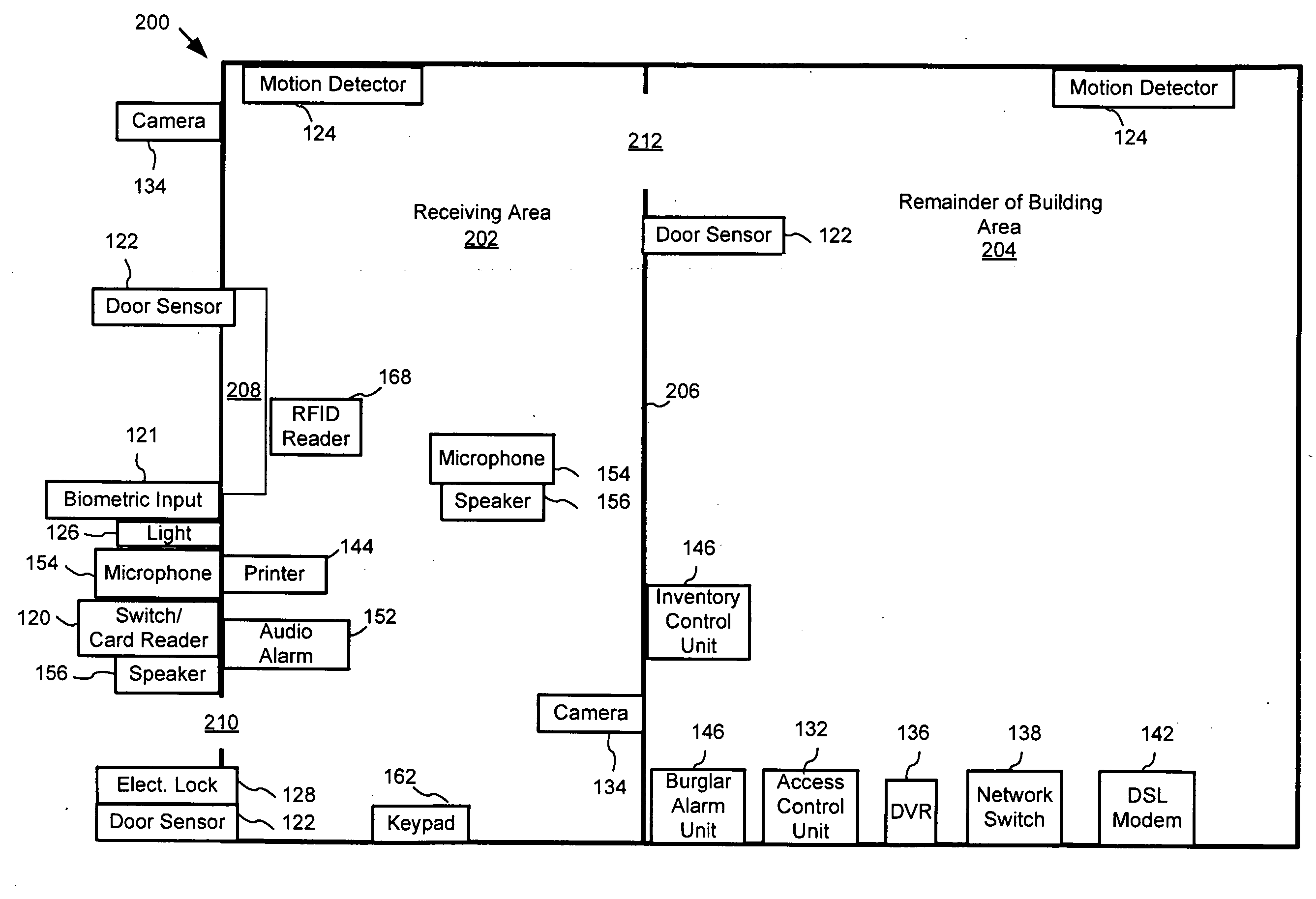

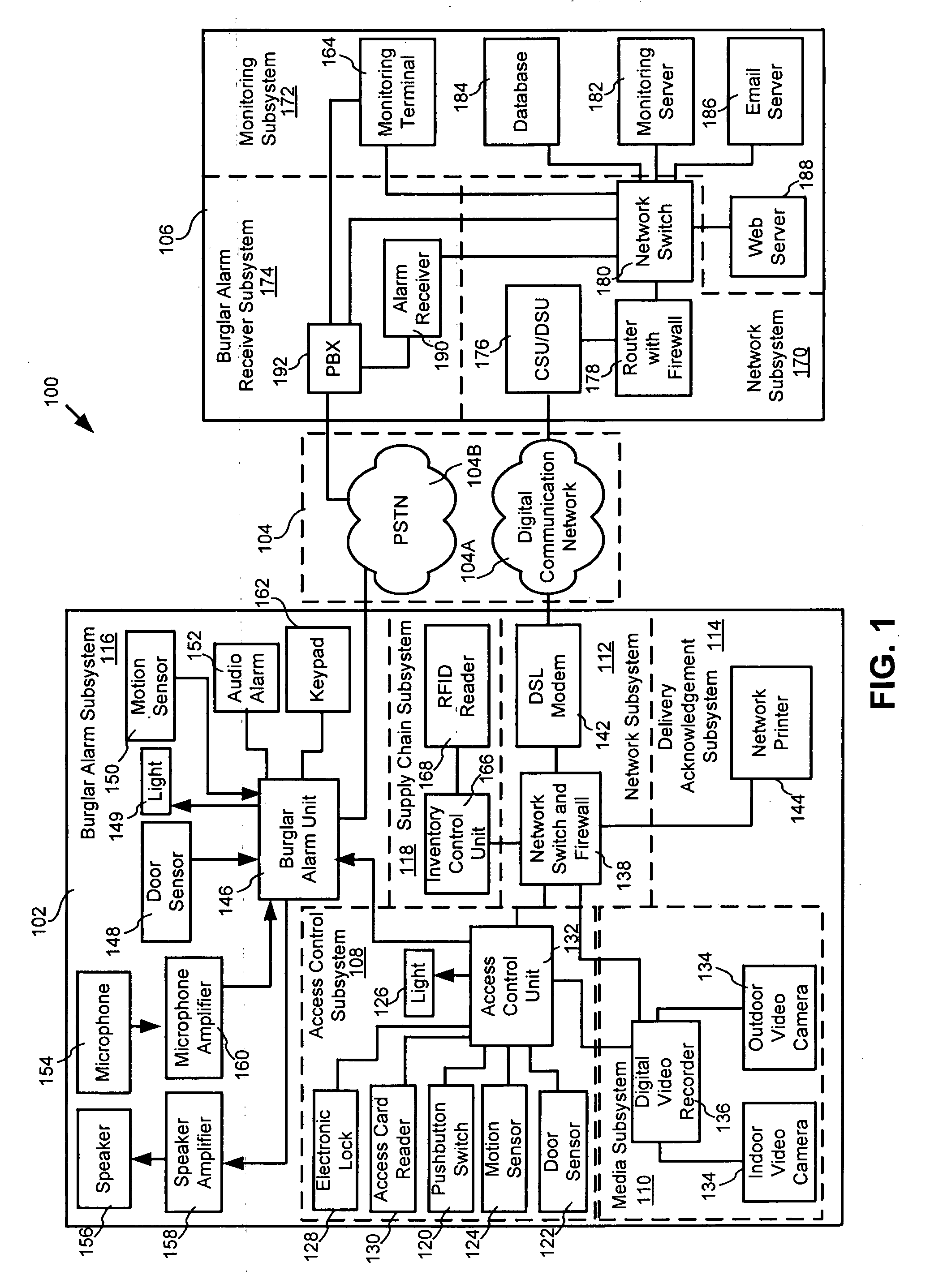

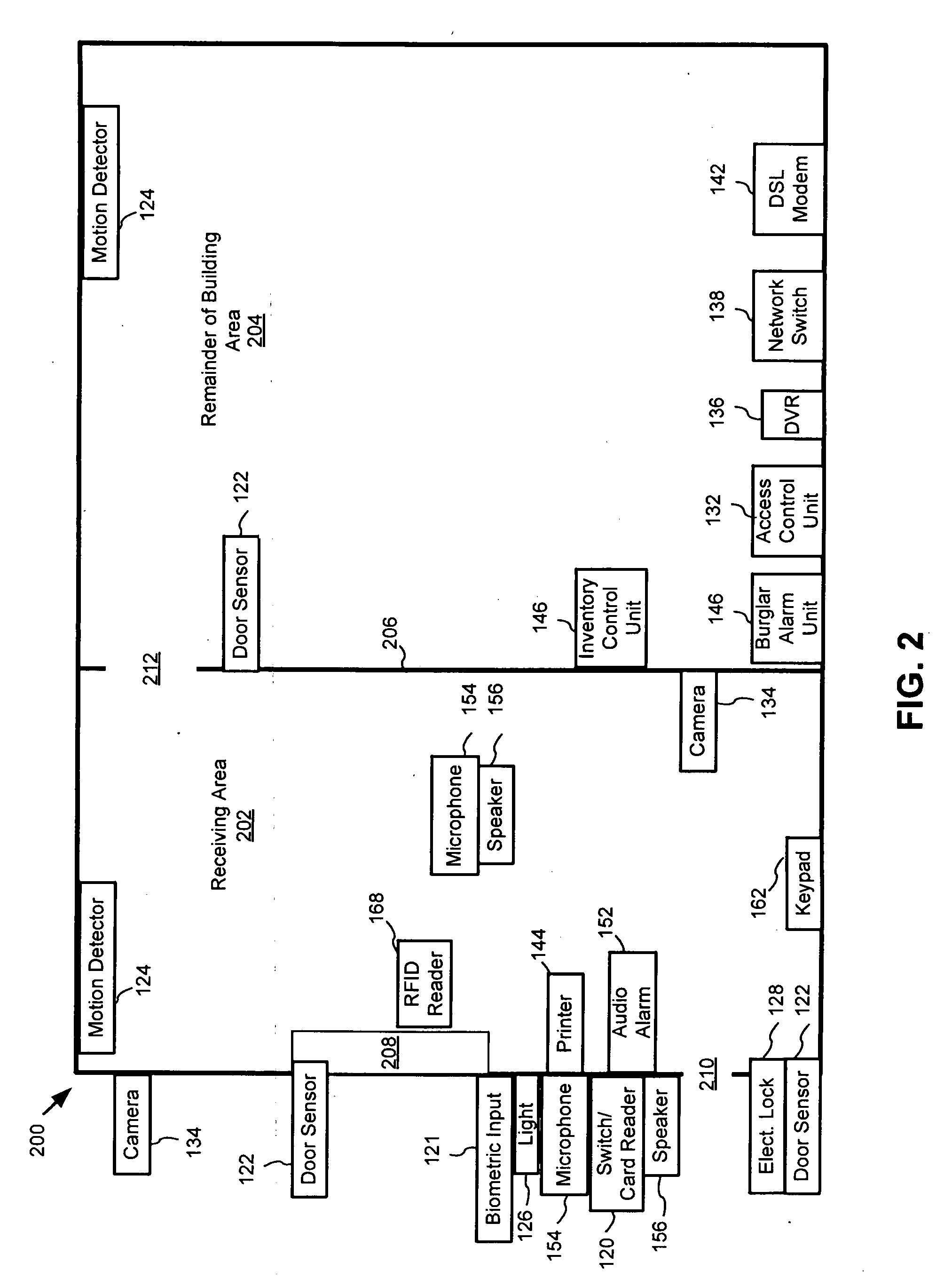

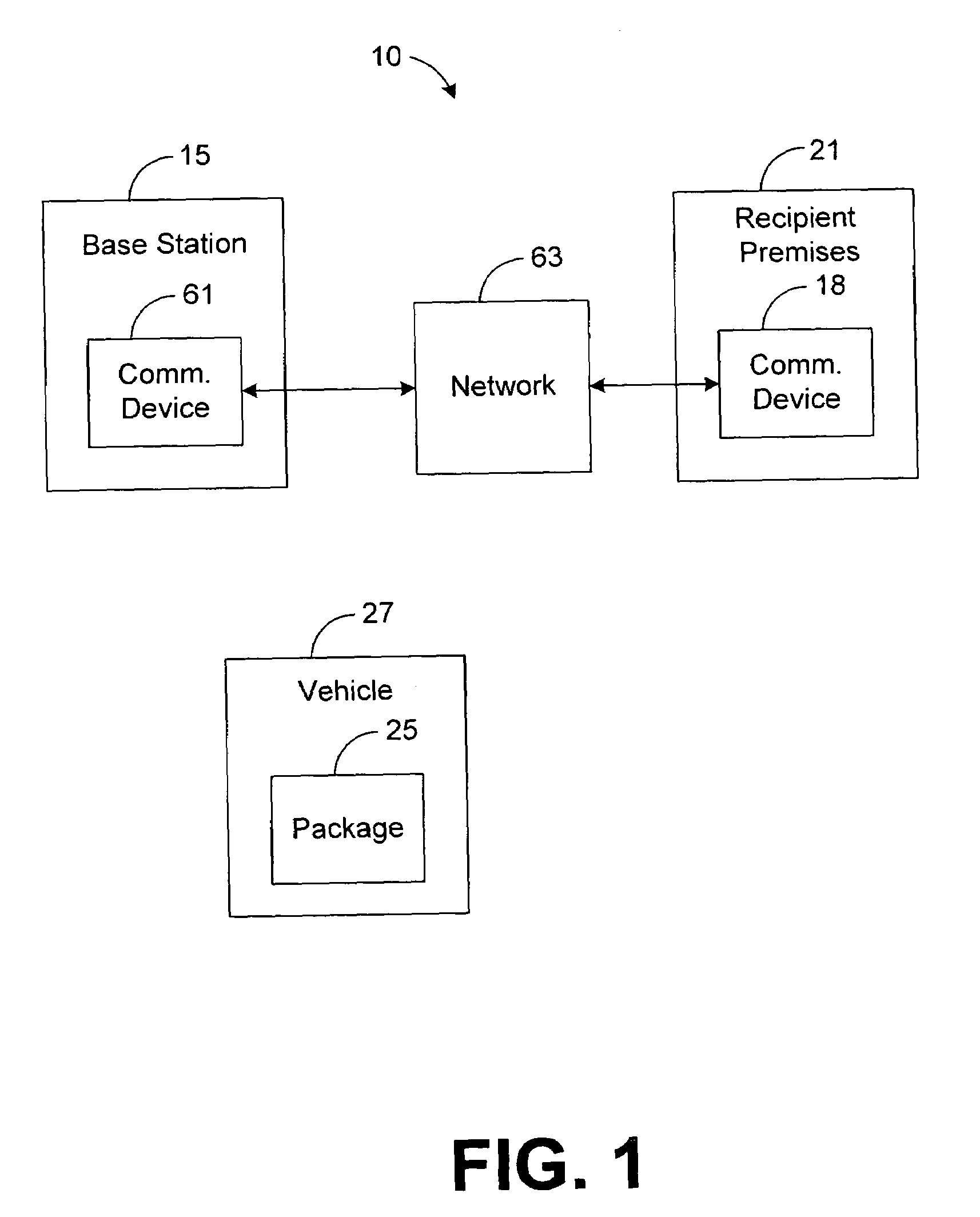

System and method for remotely attended delivery

A method and system for remotely monitoring deliveries, the method and system include detecting an arrival of a delivery at an access point and notifying a monitoring center of the arrival of the delivery at the access point. The method and system include verifying at least one verification detail, which correlates to the delivery, and sending a configuration signal from the monitoring center to the access point, which has instructions for controlling an entrance at the access point. The method and system can further include sending a second configuration signal from the monitoring center to the access point, which has instructions for controlling an entrance at the access point upon completion of the delivery. The method and system can further include sending an indication signal from the monitoring center to the access point, which has instructions for controlling an indicator at the access point.

Owner:ADT SECURITY SERVICES INC

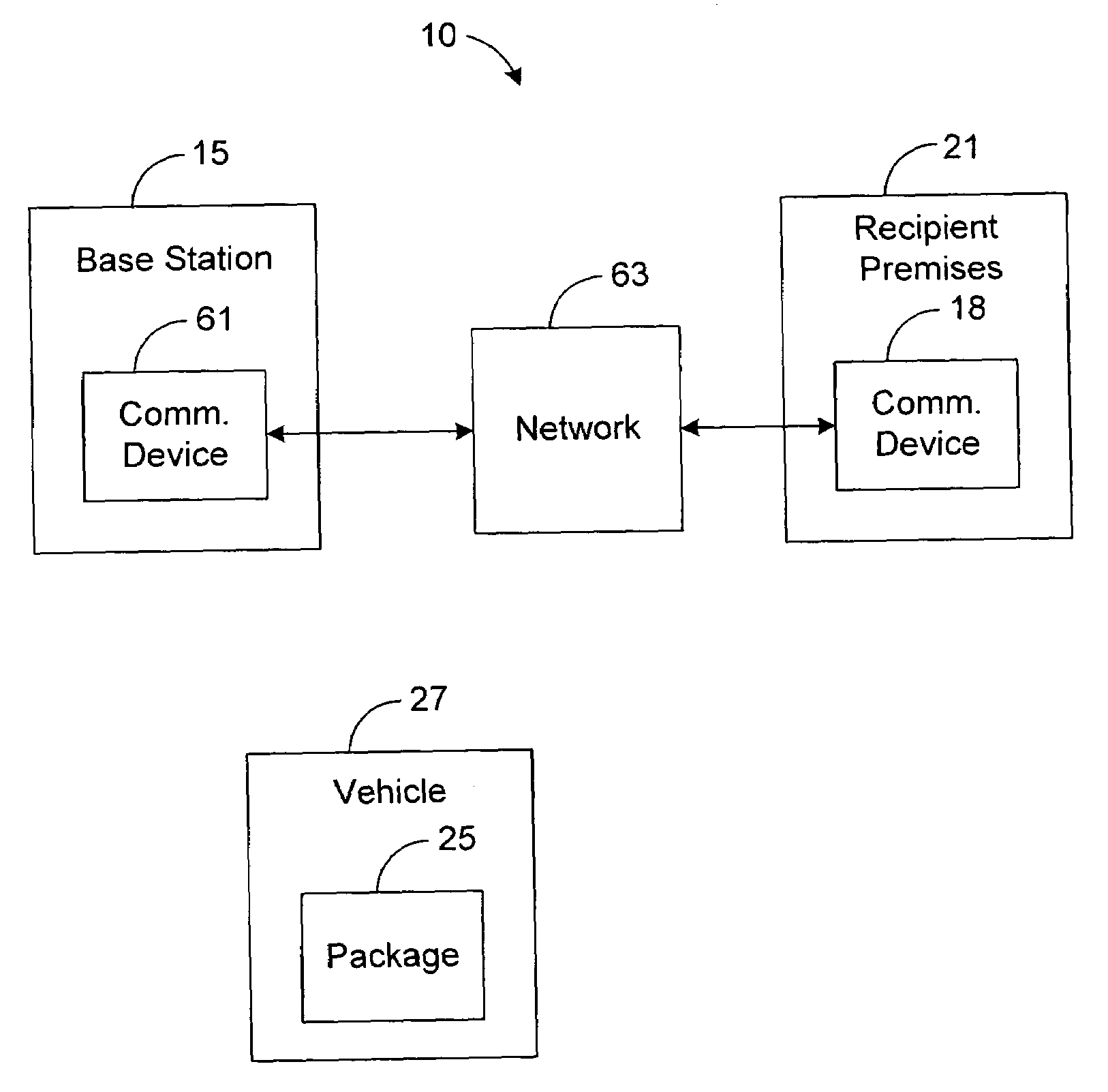

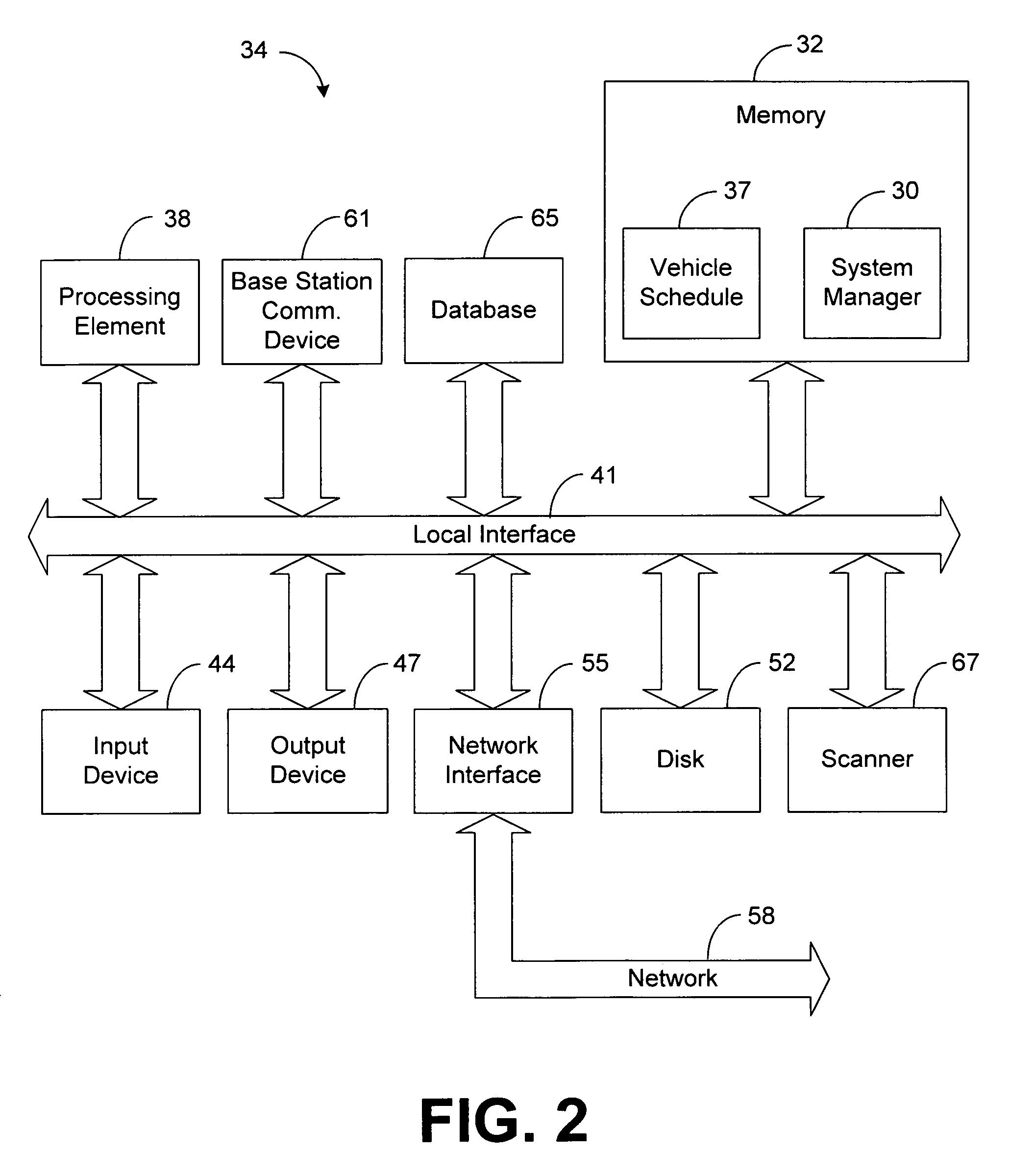

Package delivery notification system and method

InactiveUS6975998B1Accurately notifiedOvercomes inadequacy and deficiencyInstruments for road network navigationWrappersNotification ReceiverSystems management

A package delivery notification system reports impending package deliveries and precisely notifies recipients of when to expect the deliveries. The package delivery notification system utilizes memory, a communications device, and a system manager. Package data identifying a package that is to be delivered to a recipient is stored in the memory. The package data indicates that the recipient is to receive the package and indicates the expected time that the package is to be delivered. When the package is assigned to a vehicle that will deliver the package to a premises of the recipient, the system manager transmits, via the communications device, a notification message to the recipient. The notification message preferably indicates the approximate time that the package is expected to arrive.

Owner:INNOVATION LICENSING SERVICE LLC

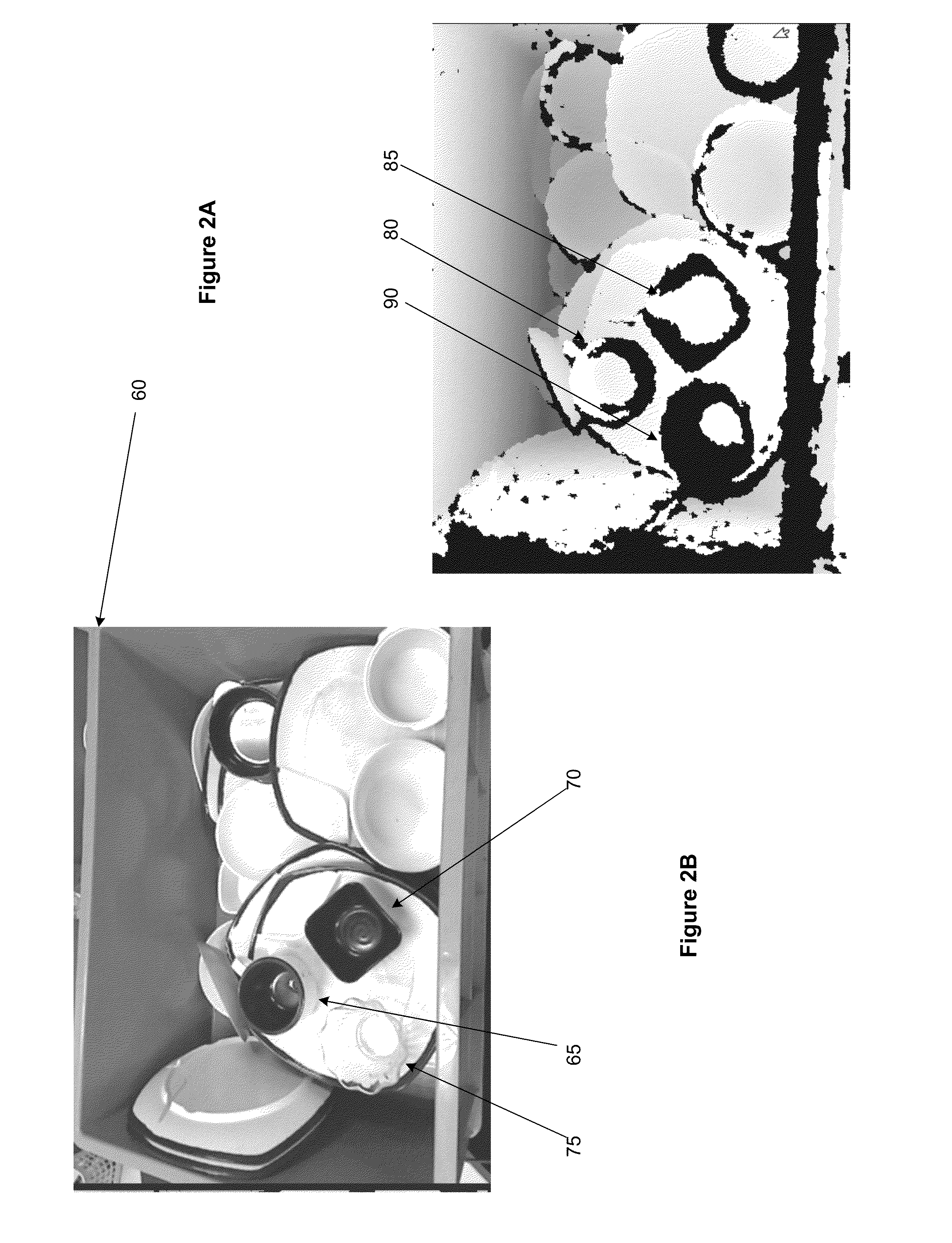

Material handling system and method

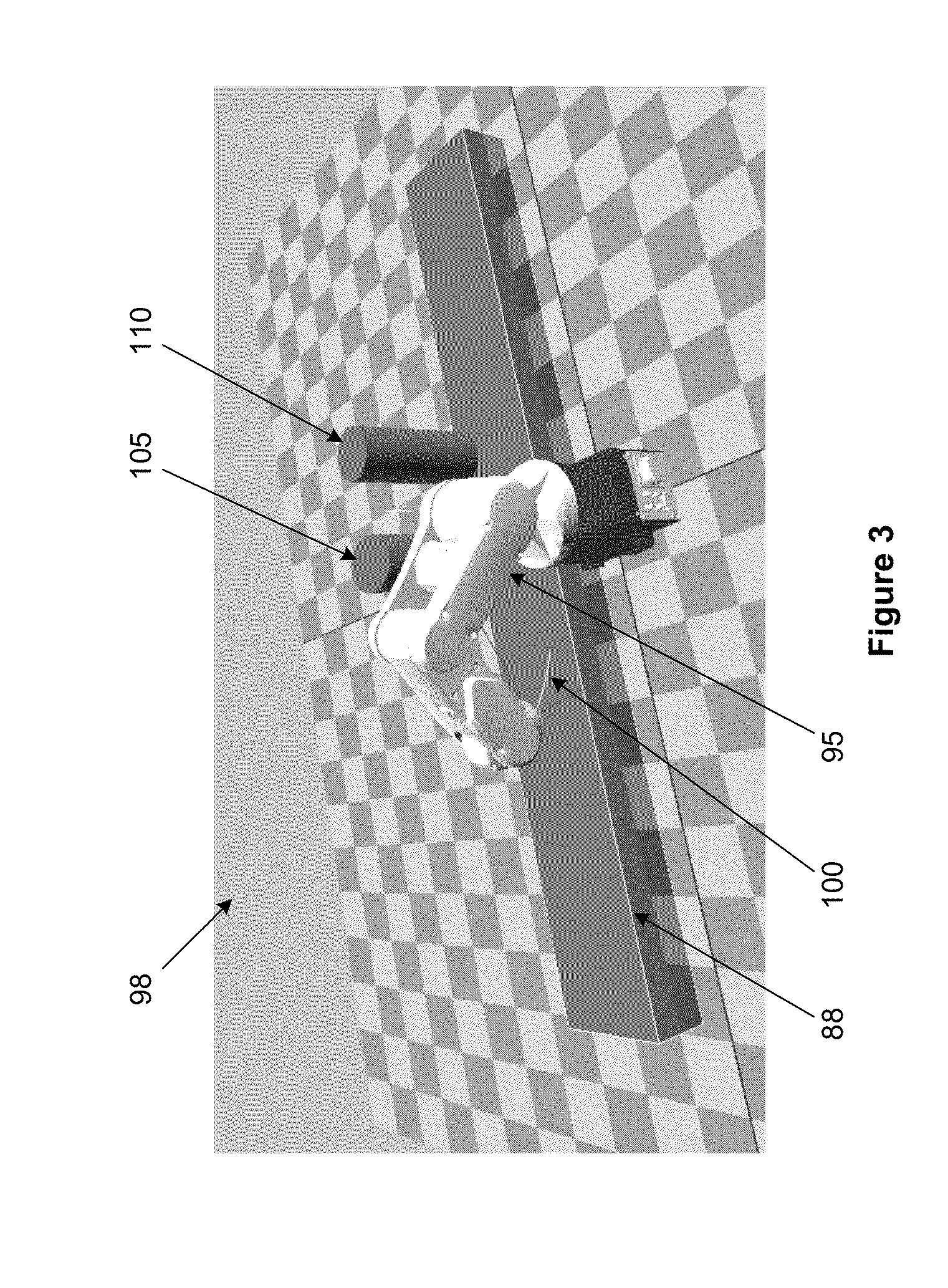

ActiveUS20150081090A1Reduce margin of errorIncrease speedProgramme controlImage enhancementHandling systemMaterial handling

A material handling system comprising: a platform for receiving a plurality of articles; a plurality of sorting bins, each bin in corresponding to an article type; an object recognition system for identifying an article on the platform and categorizing said article by specific article type; said 3D object recognition system including a 3D detector for detecting said article and a database containing data on characteristics of article types; an article engagement assembly for engaging and delivering said article to said corresponding sorting bin; wherein the object recognition system is arranged to identify the article based upon the data within said database and instructs the article engagement assembly to engage and place the article in said sorting bin.

Owner:JCS ECHIGO PTE

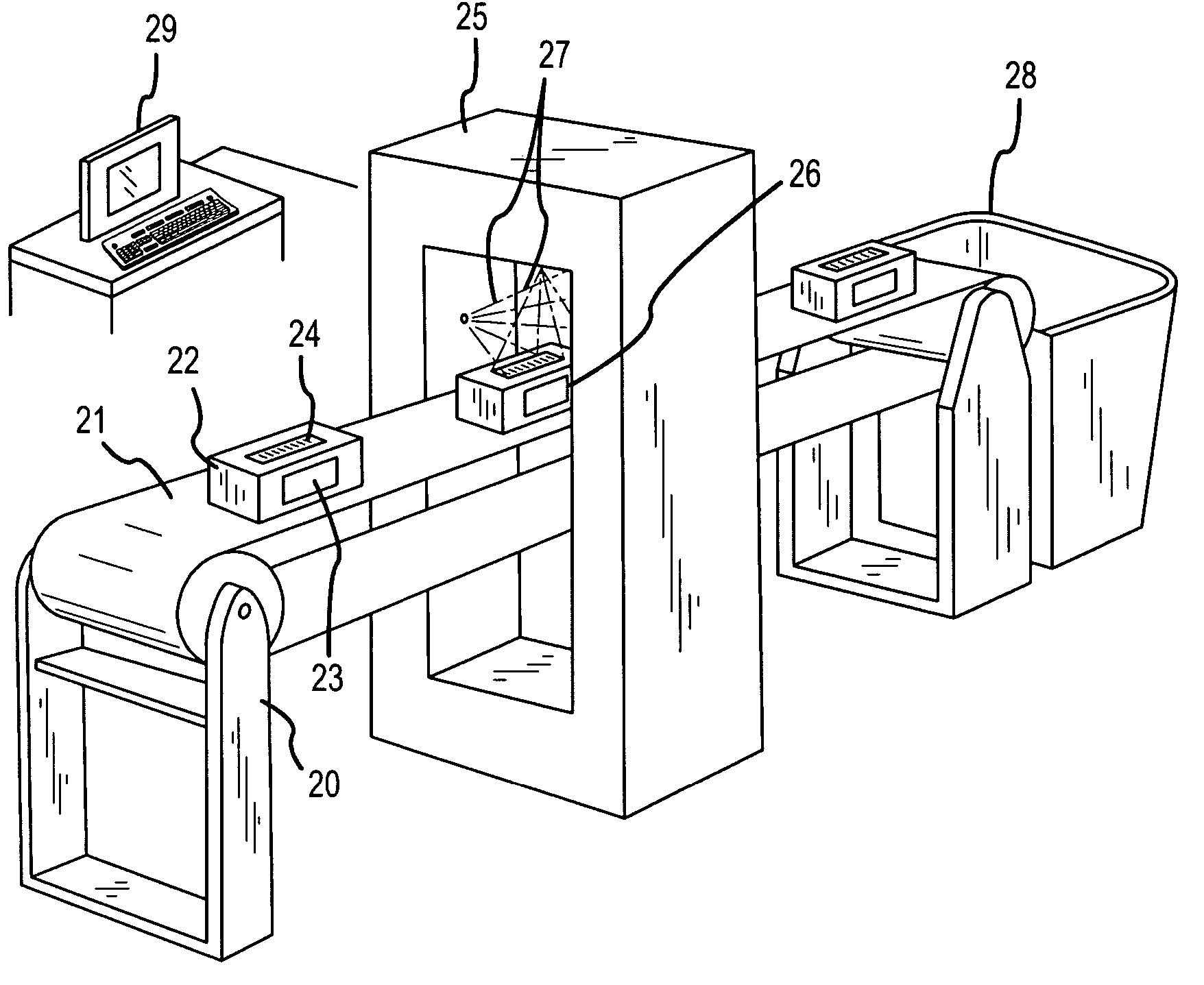

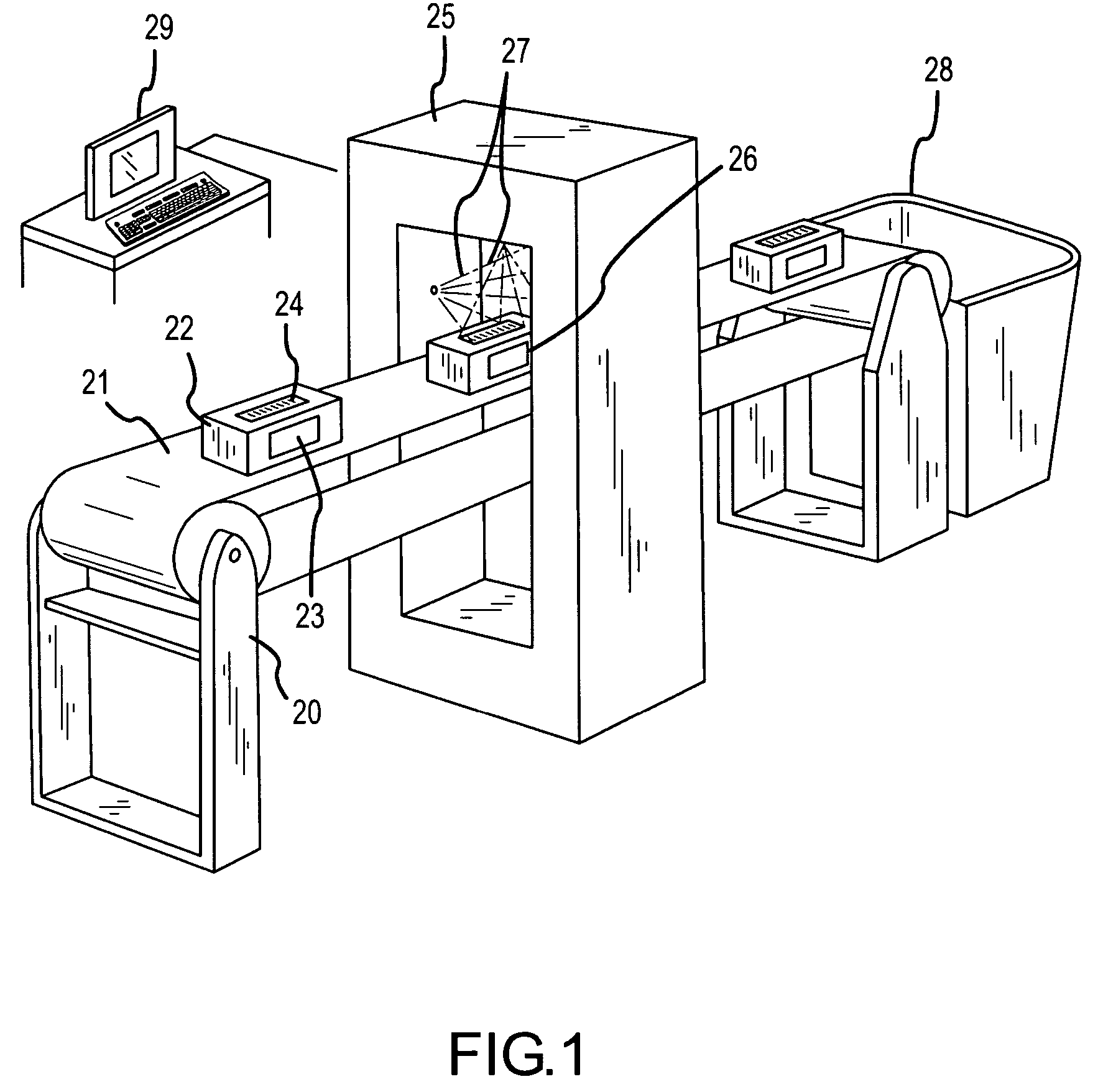

Method and apparatus for preparing an item with an RFID tag

ActiveUS7218231B2Control devices for conveyorsCo-operative working arrangementsComputer hardwareBarcode

An automated reading system for associating an RFID tag and product information includes a conveyor belt for moving a product having an RFID tag and a bar code. The system also includes an RFID scanner and a bar code scanner for reading information on the product as it travels down the conveyor belt. A collecting device is used for receiving the product, and a computer having a database is used for recording the association between the RFID tag and the product information.

Owner:OMNICELL

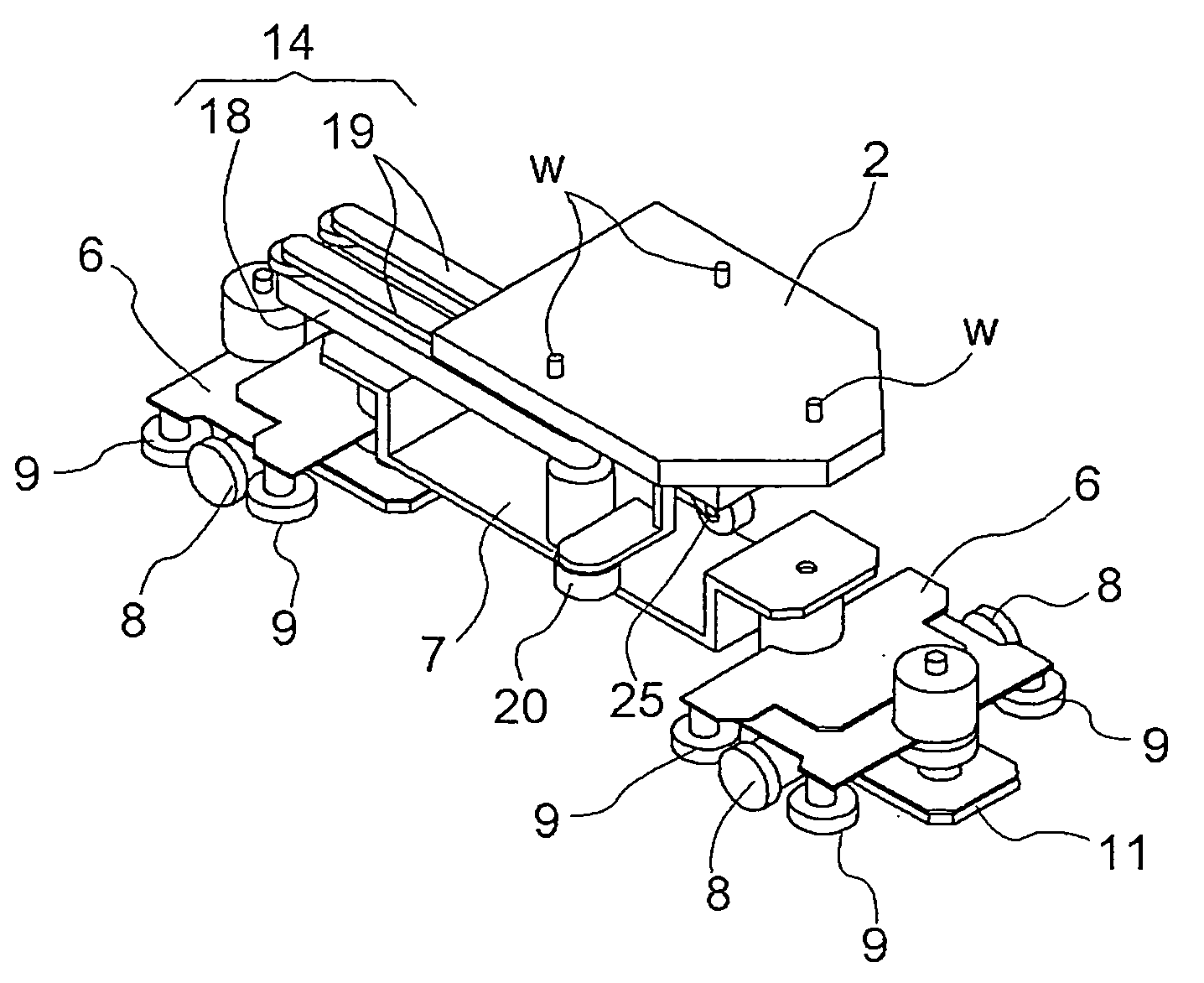

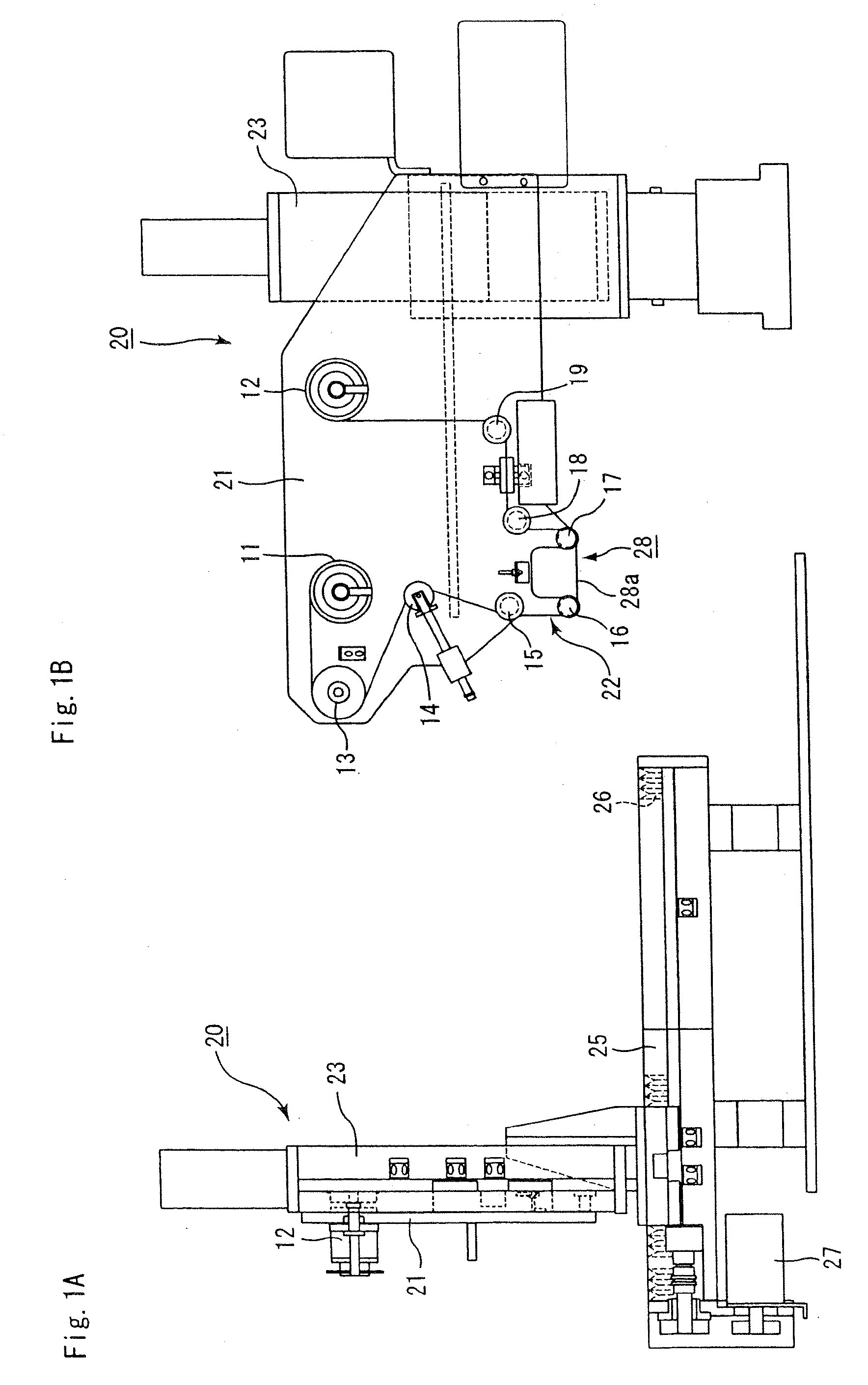

Method and apparatus for controlling semiconductor wafer fabrication equipment based on a remaining process time applicable to the processors

InactiveUS6134482ASemiconductor/solid-state device manufacturingCharge manipulationSemiconductor wafer fabricationSemiconductor

Semiconductor wafer fabrication equipment comprising a selecting device for selecting semiconductor wafers destined to a processor on the basis of a remaining process time applicable to that processor in the equipment, a transporting device for transporting the selected semiconductor wafers to the processor, another selecting device for selecting a processor or a storage device constituting a transport destination to which to transport processed semiconductor wafers, and another transporting device for transporting the semiconductor wafers to the destination processor or storage device in accordance with a transport control changeover code read from the processors and storage devices of the equipment.

Owner:MITSUBISHI ELECTRIC CORP

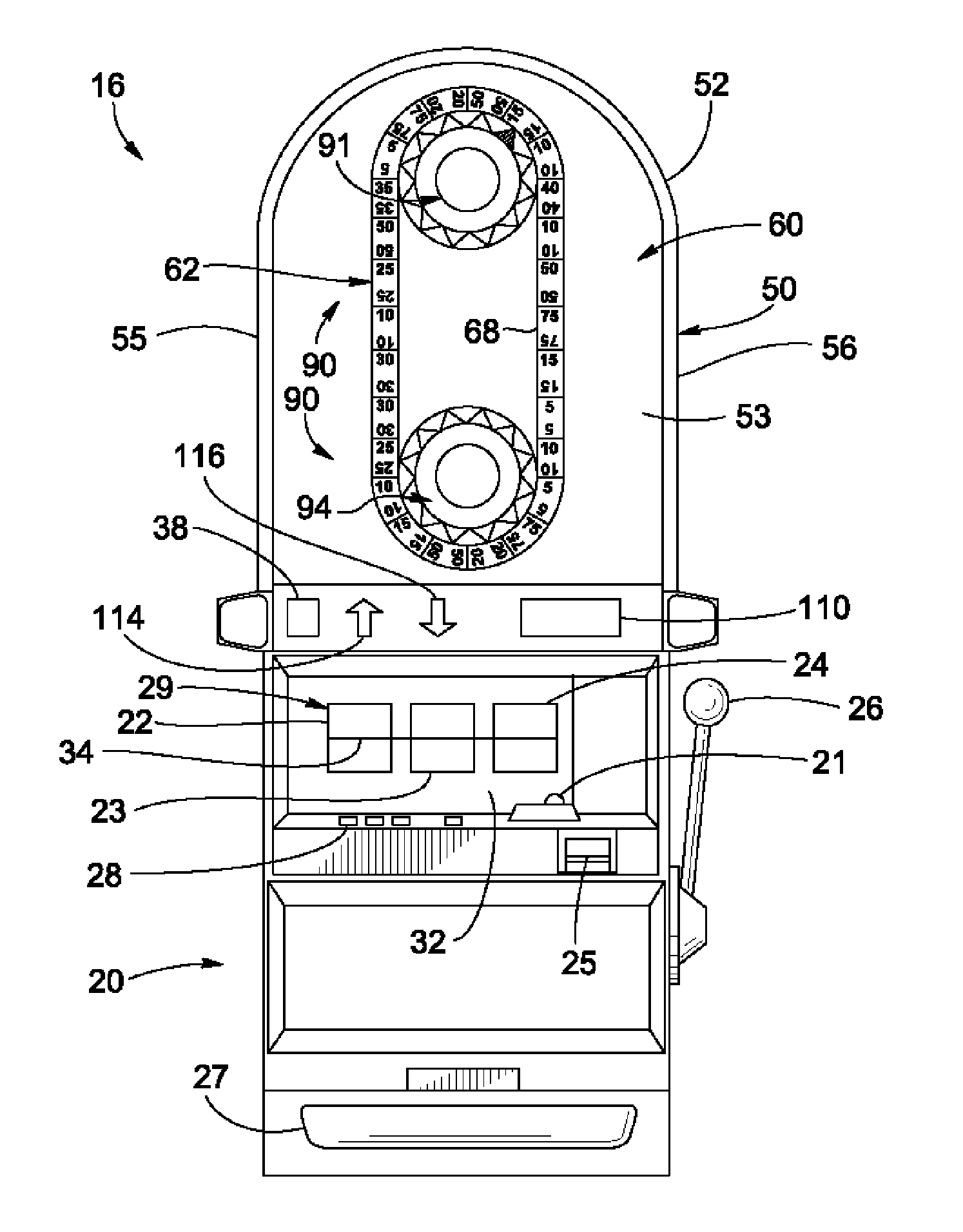

Gaming device with indicators and methods of use

A gaming device is disclosed that includes a housing and a display device associated with the housing. The display device displays several indicia. A positioning mechanism is configured to move the display device. Several indicators are associated with the display device. A controller is in communication with the positioning mechanism and the indicators. The controller determines a game outcome and directs movement of the display device. The controller can illuminate at least one of the indicators in order to display the game outcome.

Owner:IGT

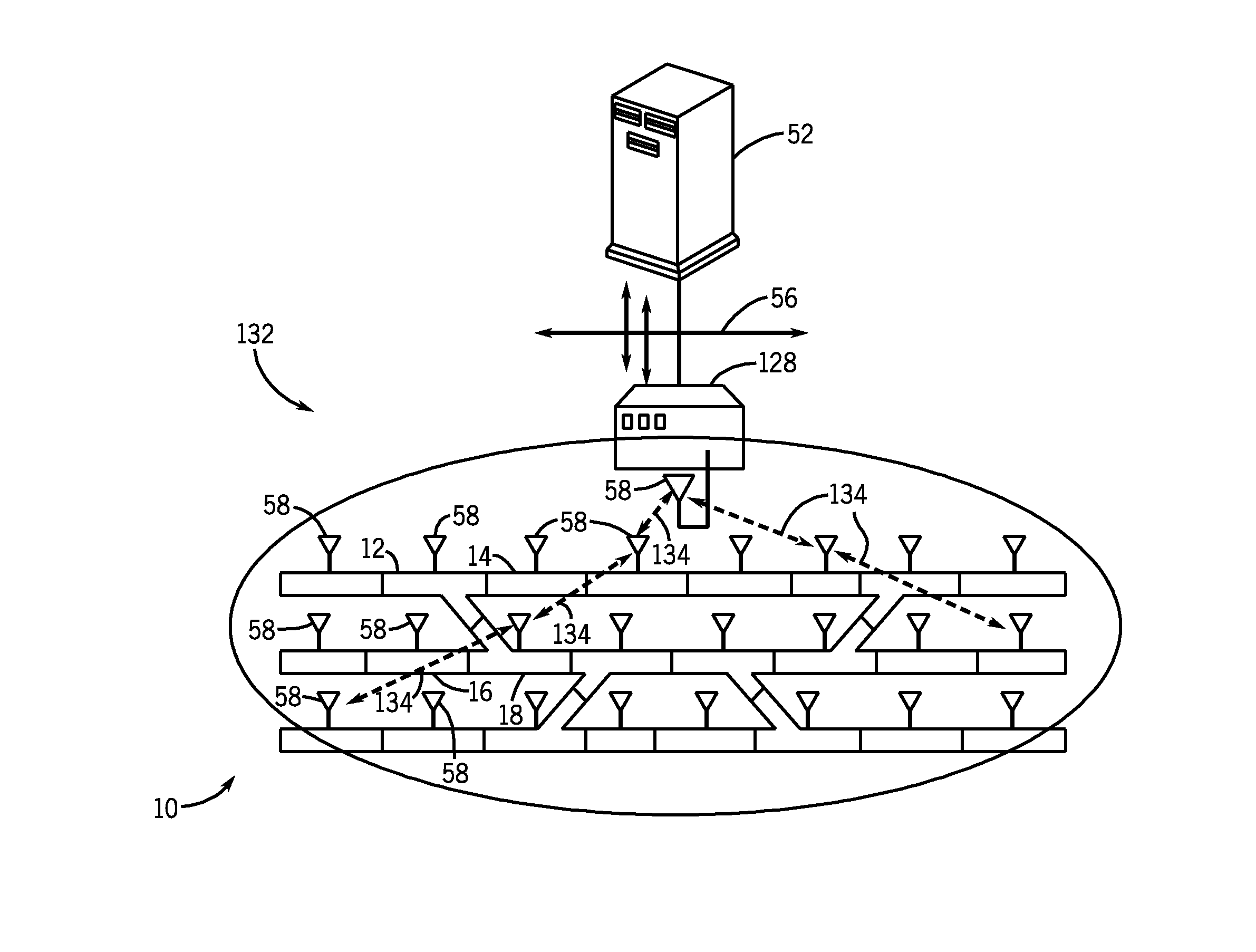

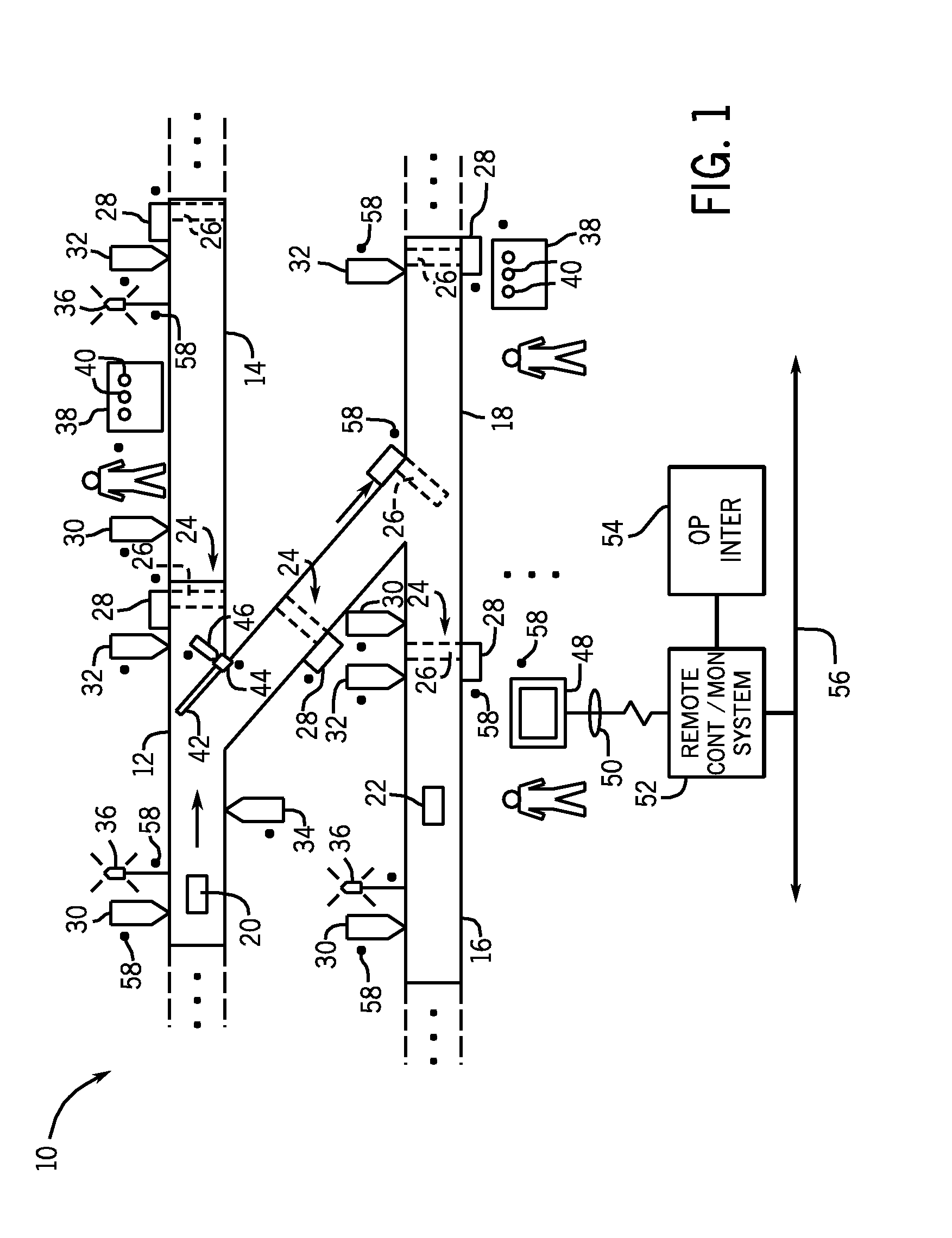

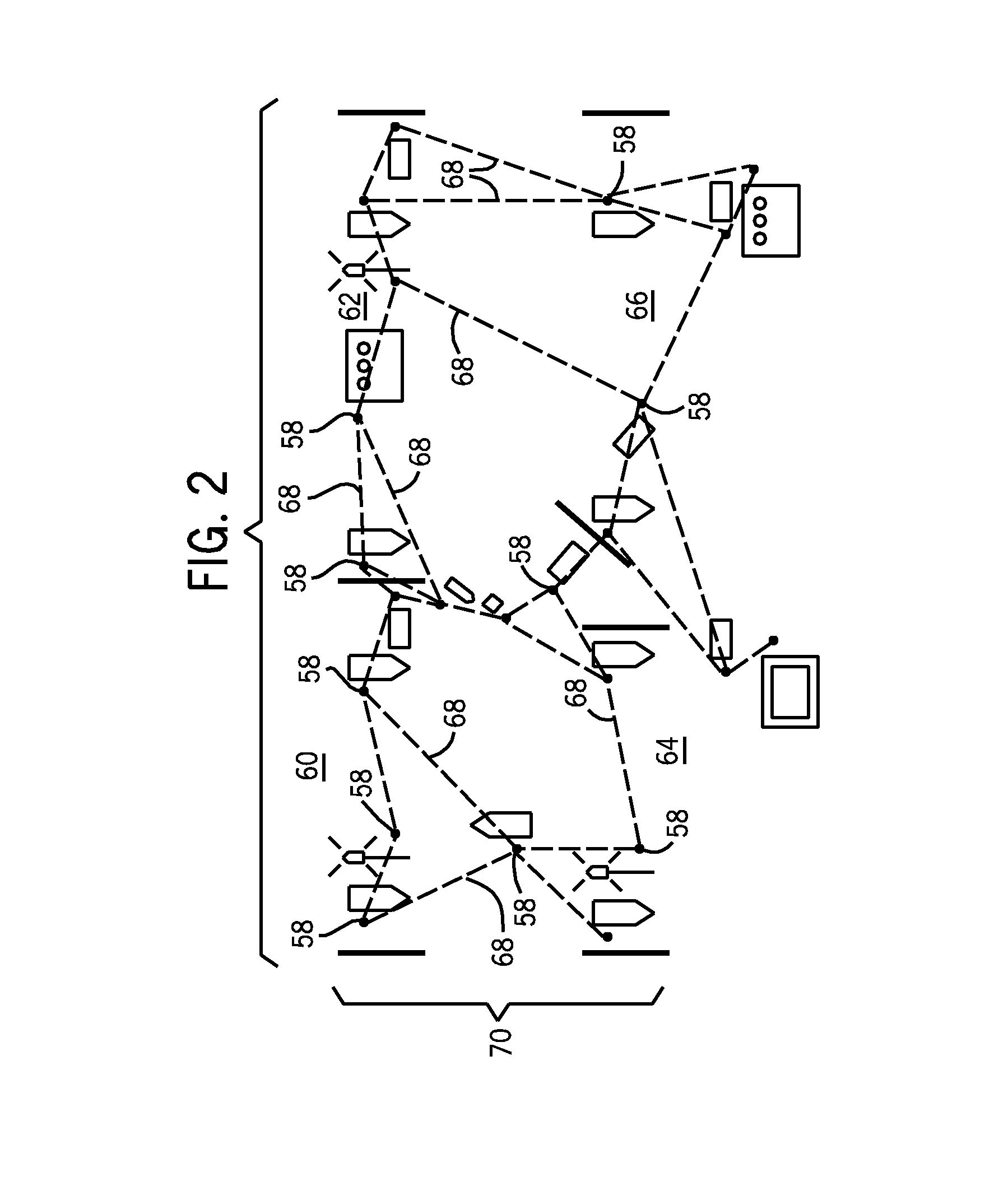

Modular wireless conveyor interconnection method and system

ActiveUS20090084657A1Control devices for conveyorsMultiple digital computer combinationsElectrical batteryComputer module

A modular conveyor system is disclosed in which components of each conveyor module is designed for wireless mesh communication. The communications may be within a module or between modules. Certain of the components may be powered by battery, such that the components may be completely wireless. The network may be entirely self-configuring such that the modules may be assembled and the network established in a straightforward manner.

Owner:ROCKWELL AUTOMATION TECH

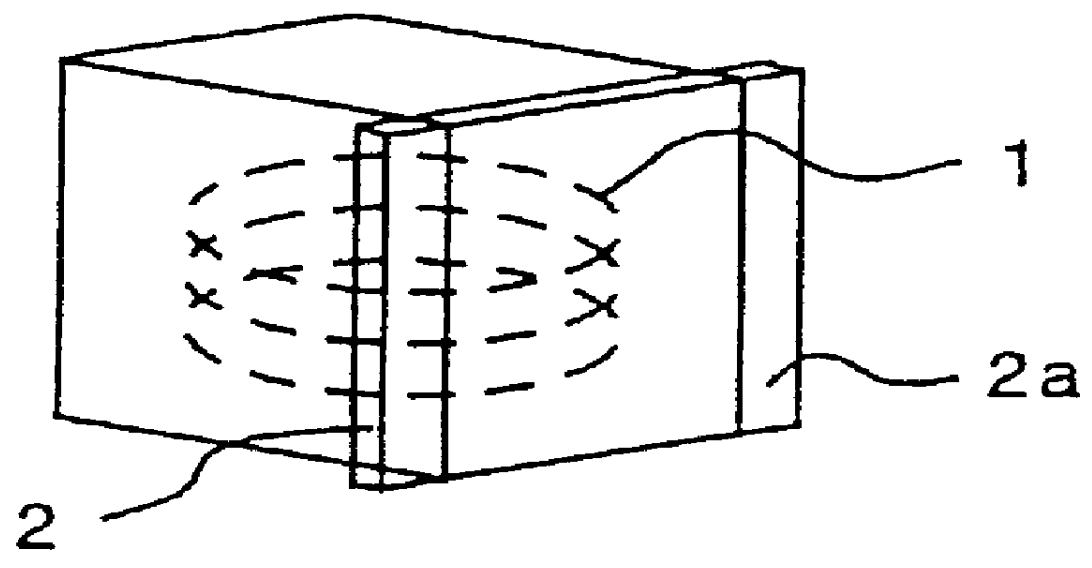

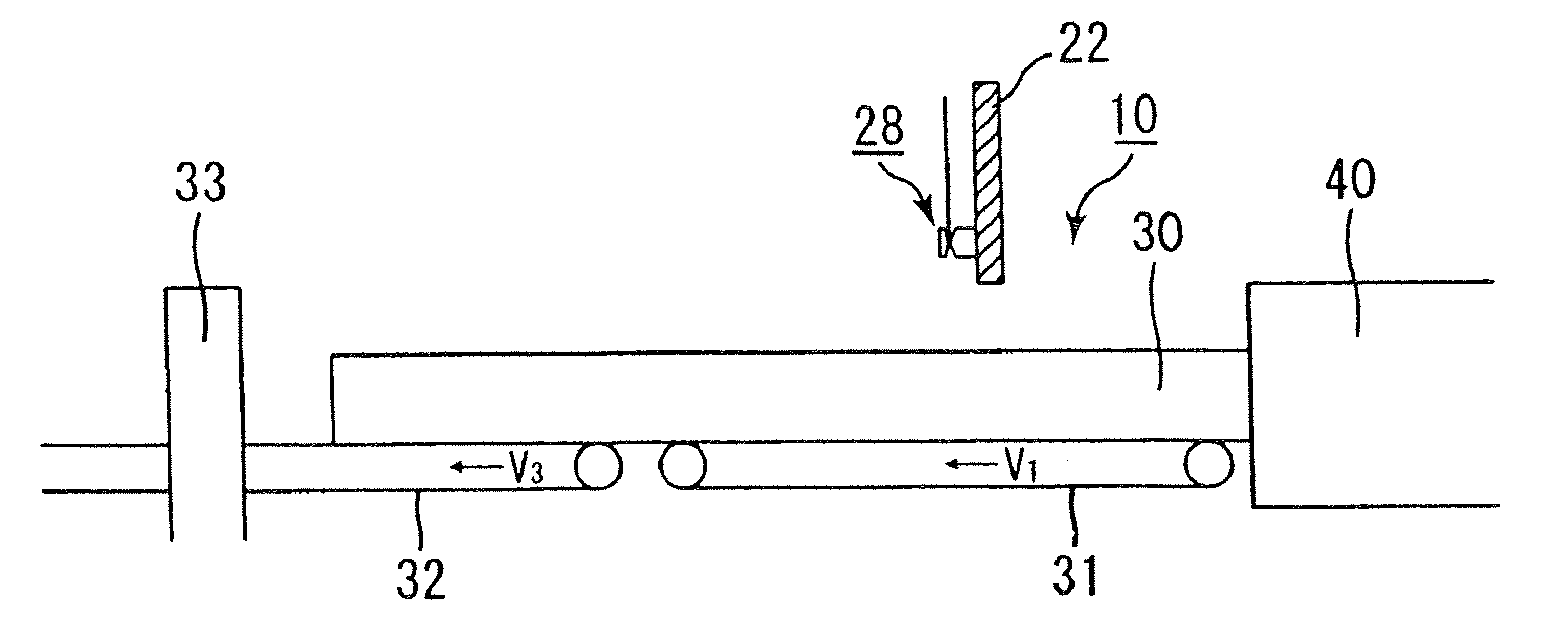

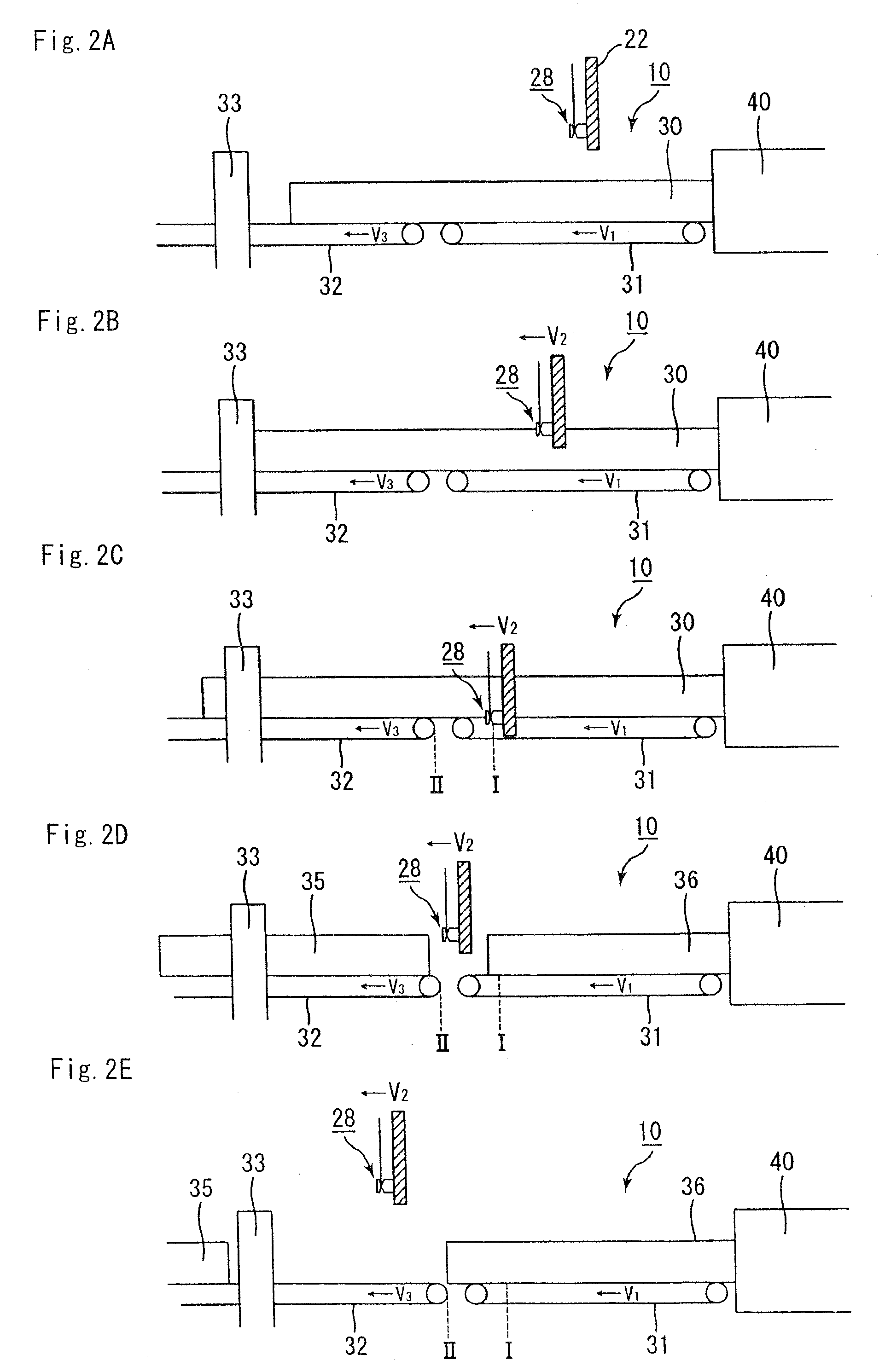

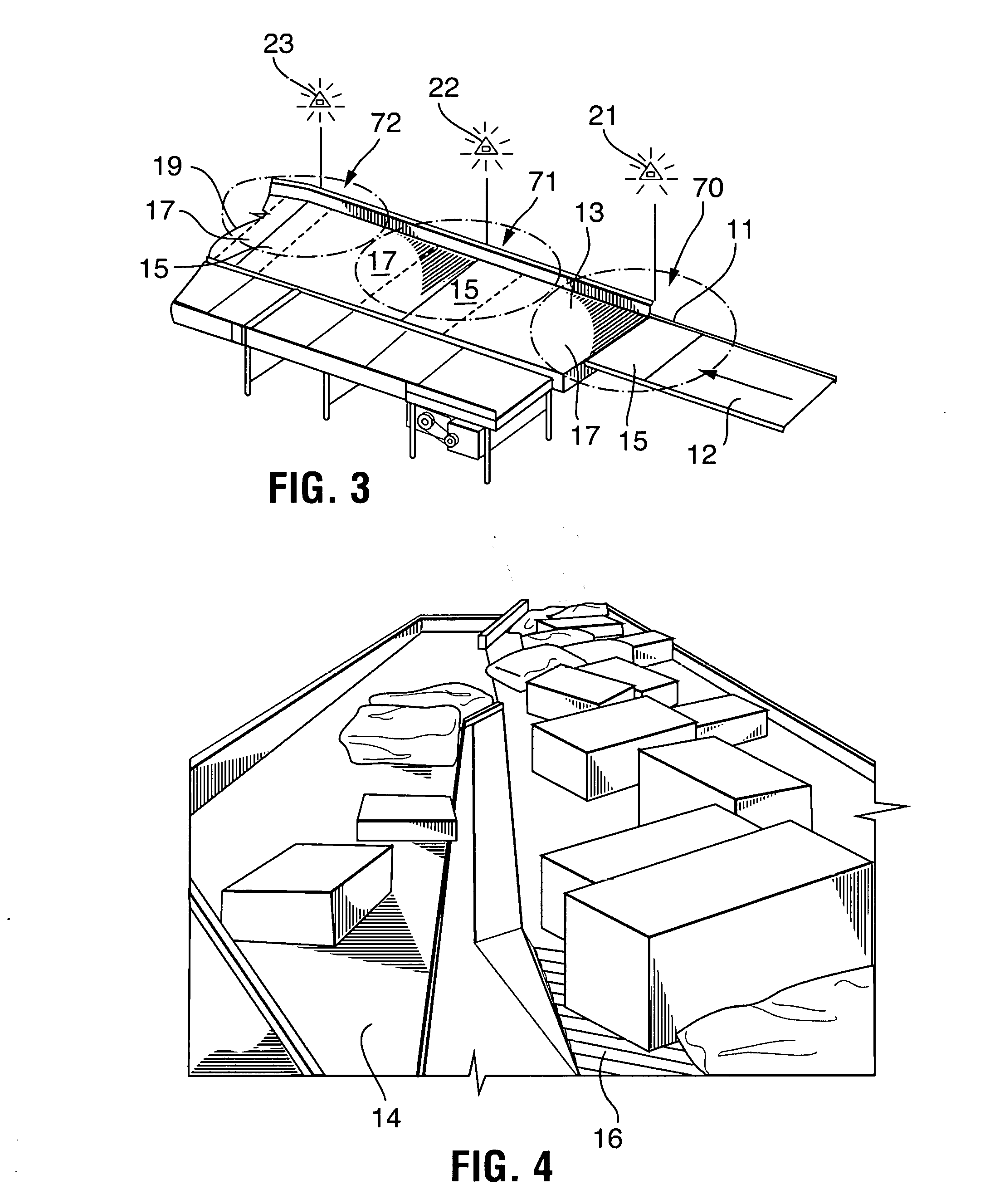

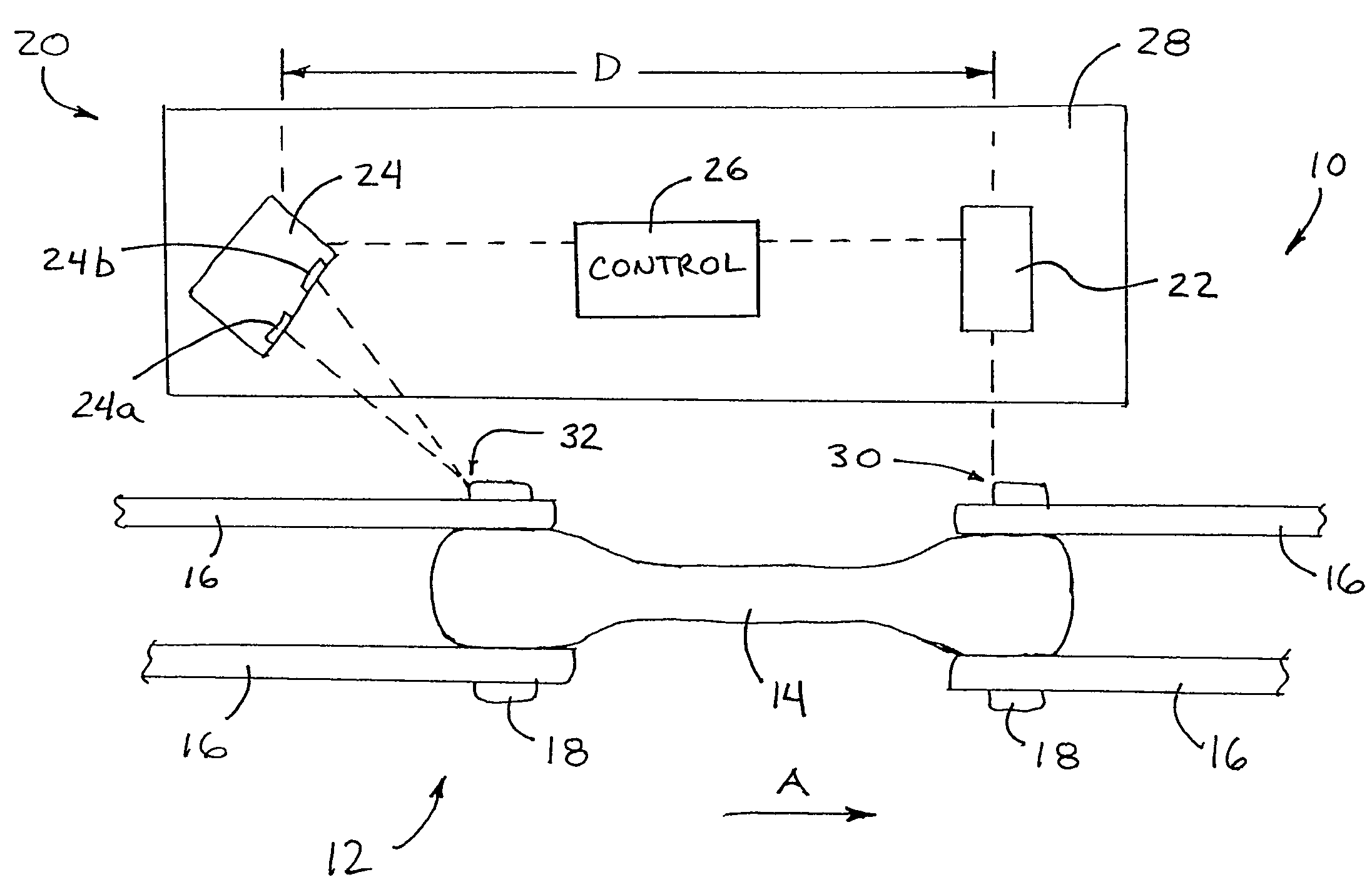

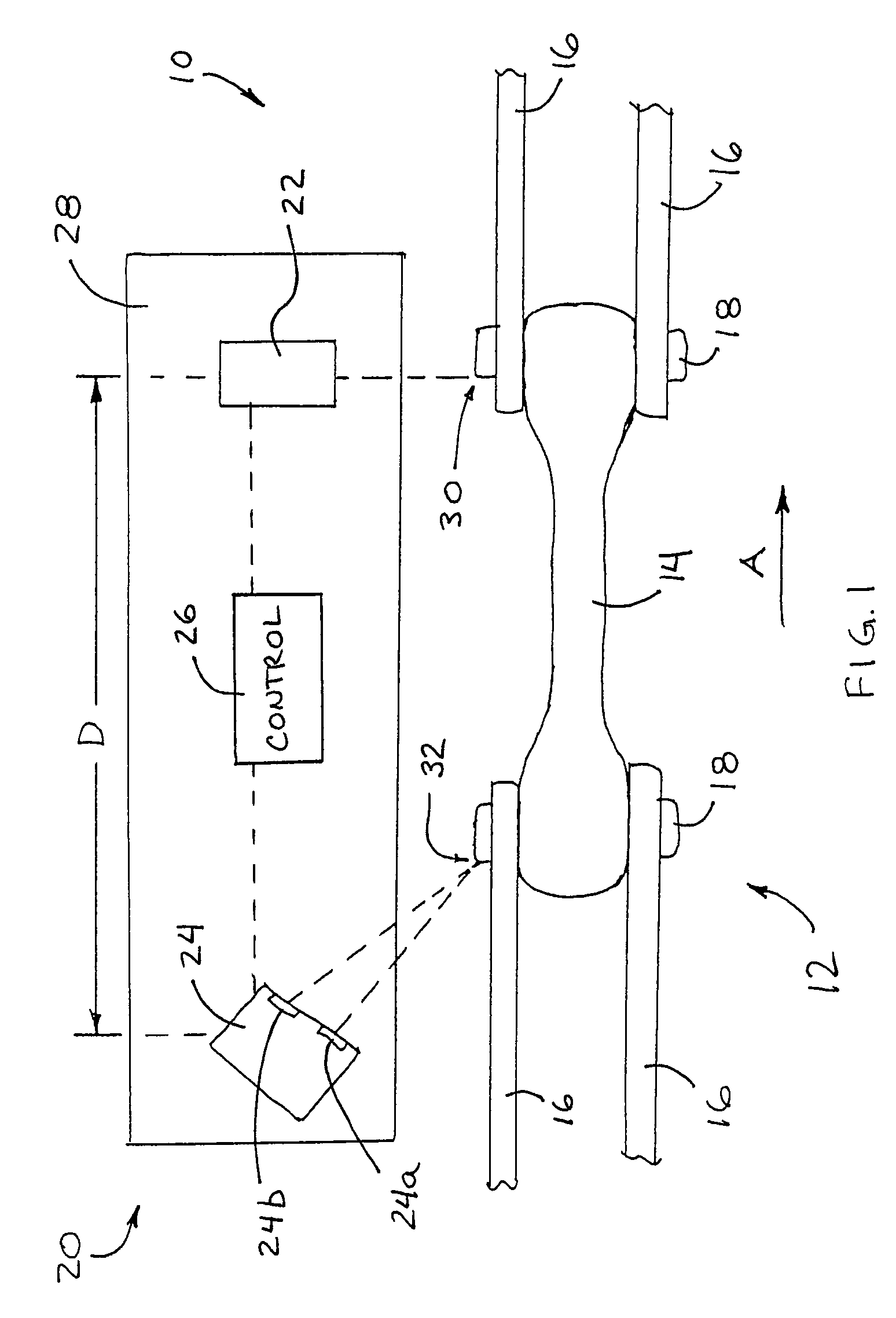

Molded body cutting apparatus, method for cutting ceramic molded body and method manufacturing honeycomb structured body

A molded body cutting apparatus according to the present invention comprising a first conveyer member that conveys an extrusion-molded pillar-shaped ceramic molded body a cutting member that moves in a direction parallel to a movement direction of the above mentioned first conveyer member while moving also in a vertical direction, and cuts the above mentioned ceramic molded body to a predetermined length by passing through the interior of the above mentioned ceramic molded body and a second conveyer member that conveys a cut ceramic molded body cut to a predetermined length by the above mentioned cutting member, wherein a conveyance speed of the above mentioned first conveyer member and a movement speed of the above mentioned cutting member in the above mentioned parallel direction are almost the same, before the above mentioned ceramic molded body is cut, and each of the conveyance speed of the above mentioned first conveyer member, the movement speed of the above mentioned cutting member in the above mentioned parallel direction, and a conveyance speed of the above mentioned second conveyer member becomes faster toward the latter, after the above mentioned ceramic molded body is cut.

Owner:IBIDEN CO LTD

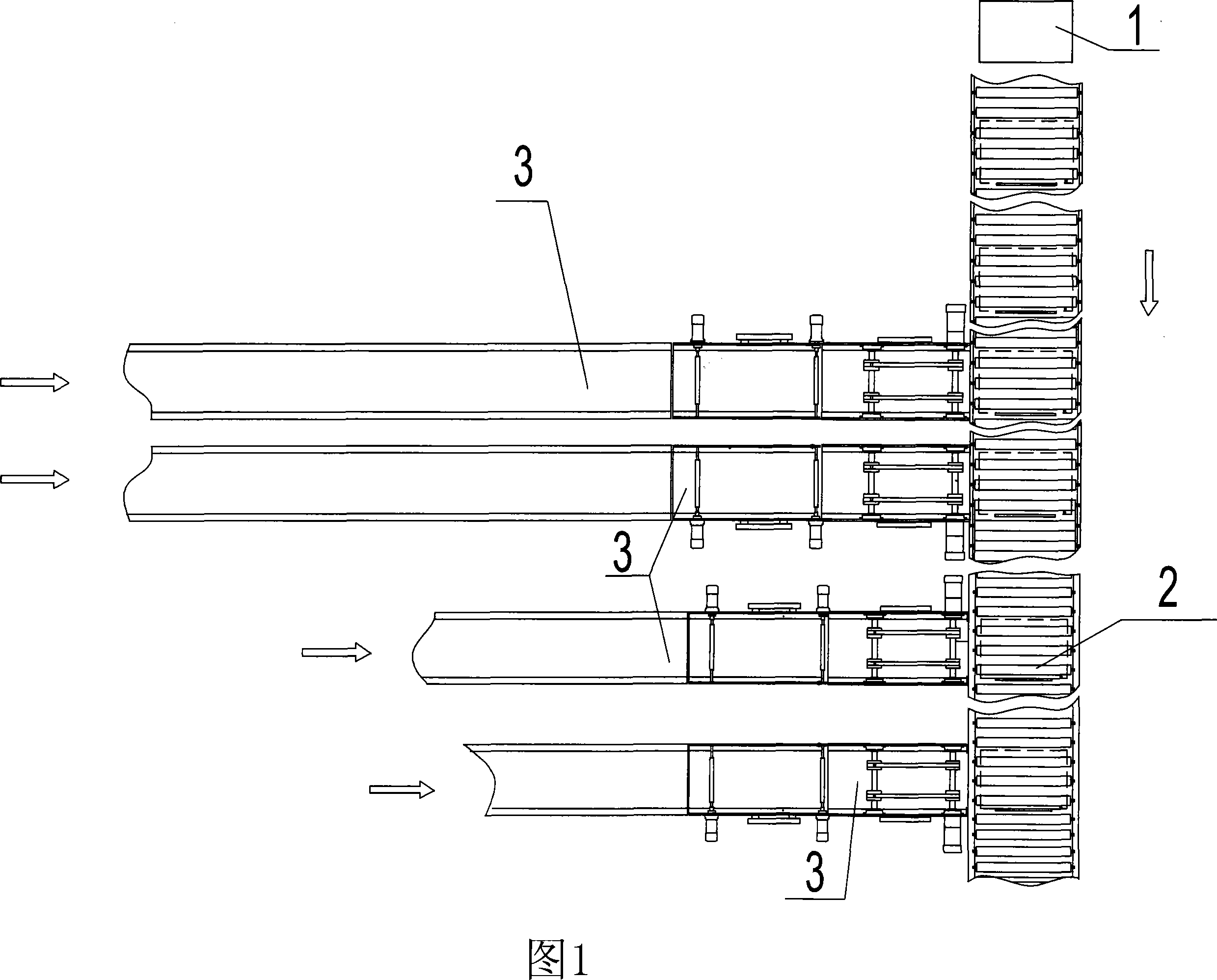

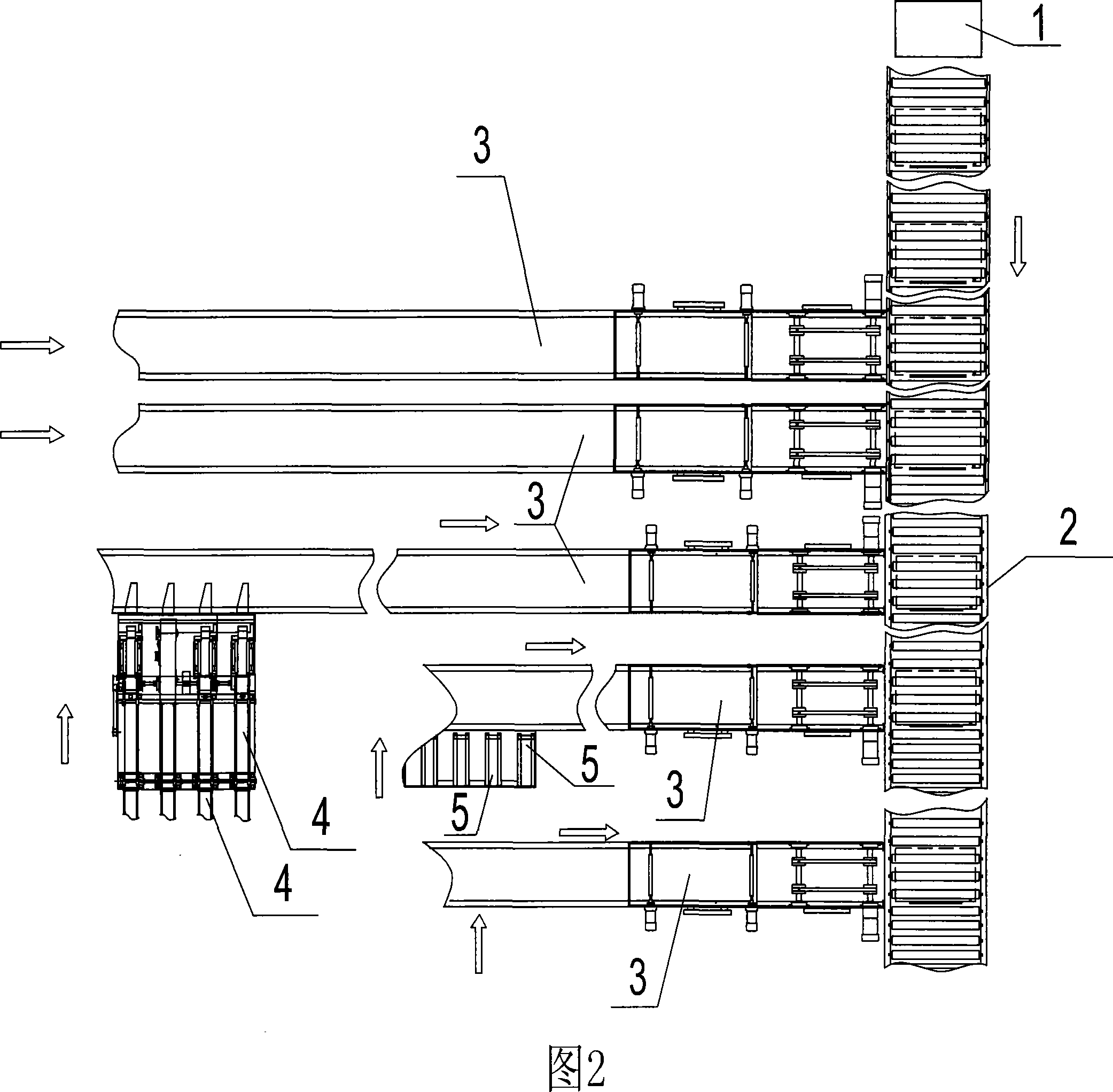

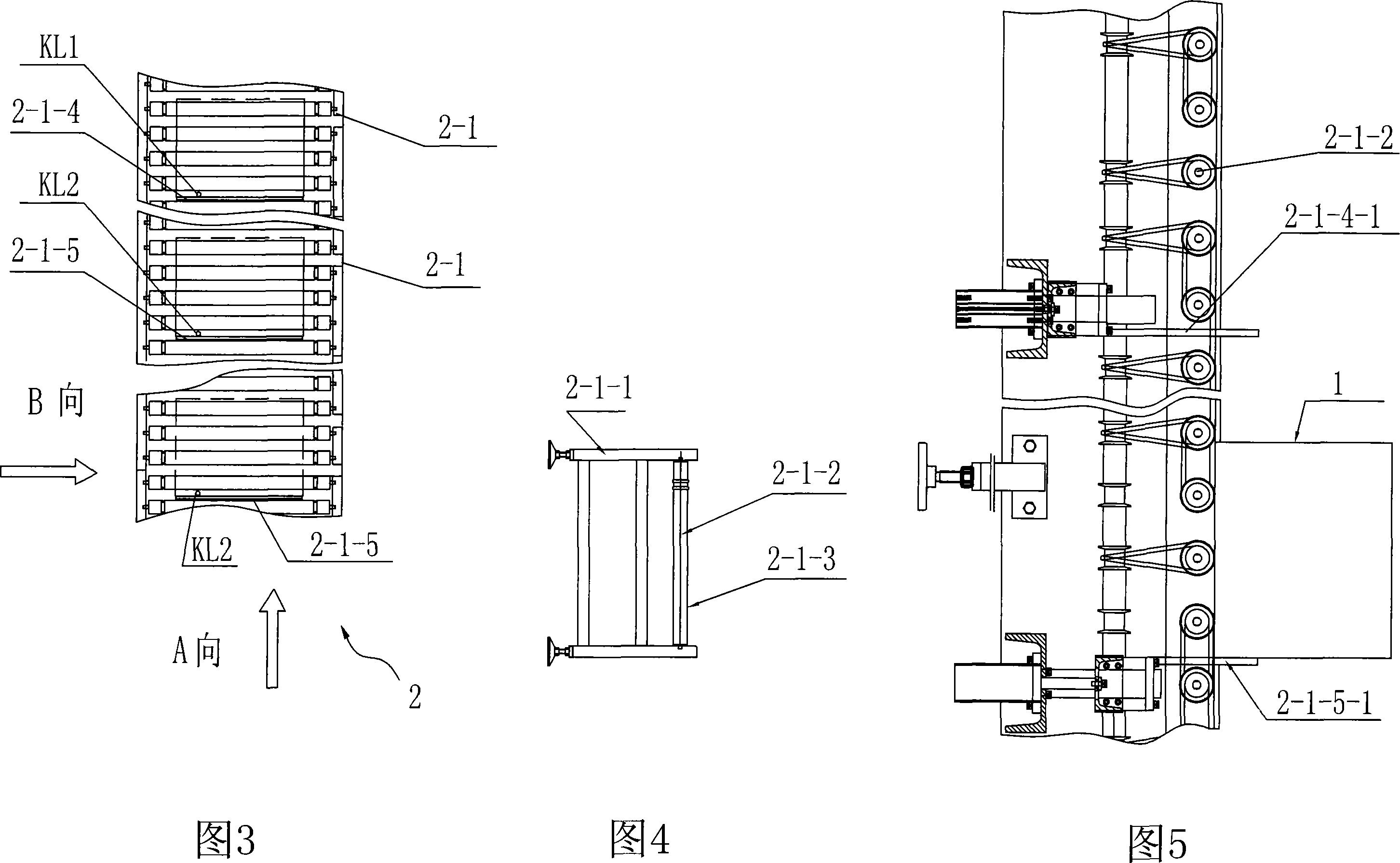

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

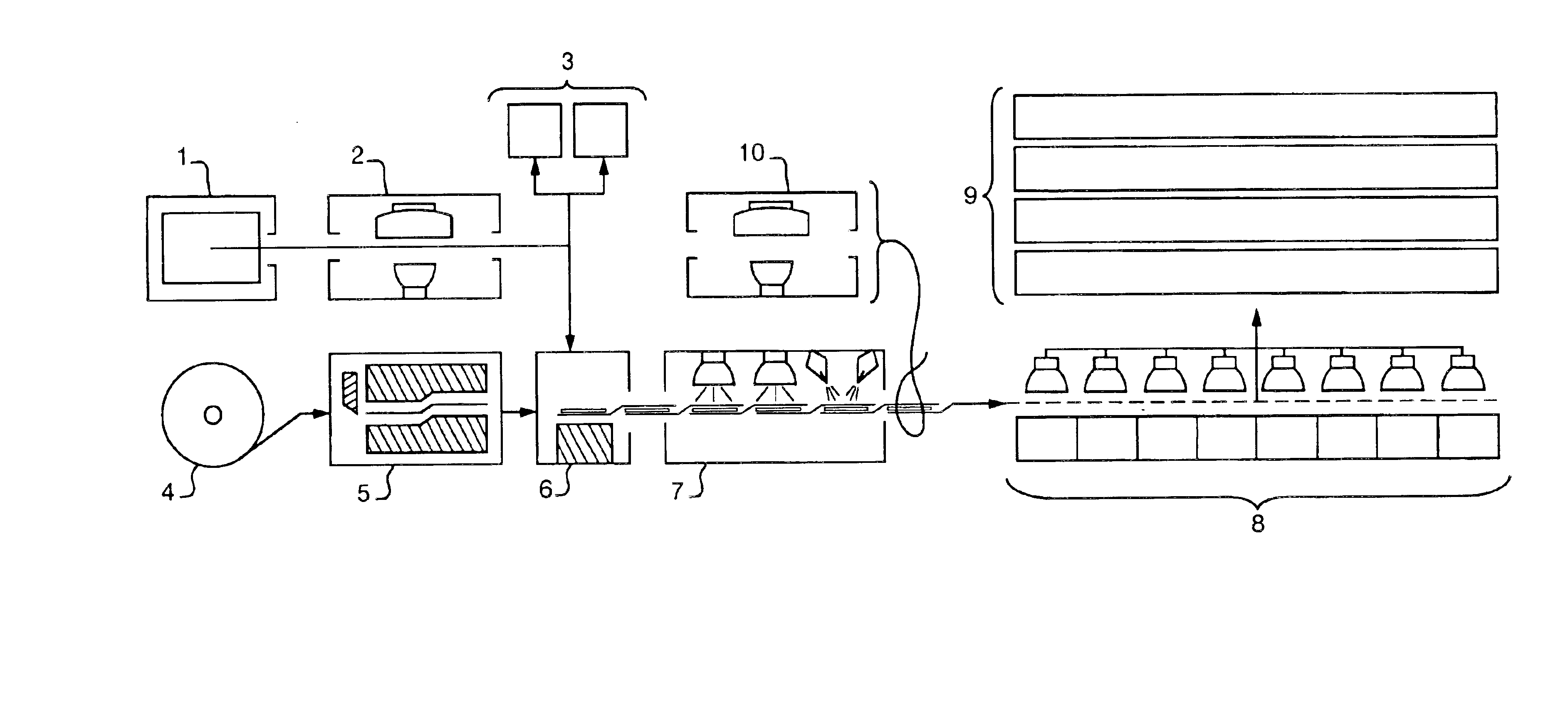

Solar cell stringing machine

Owner:GTAT CORPORATION

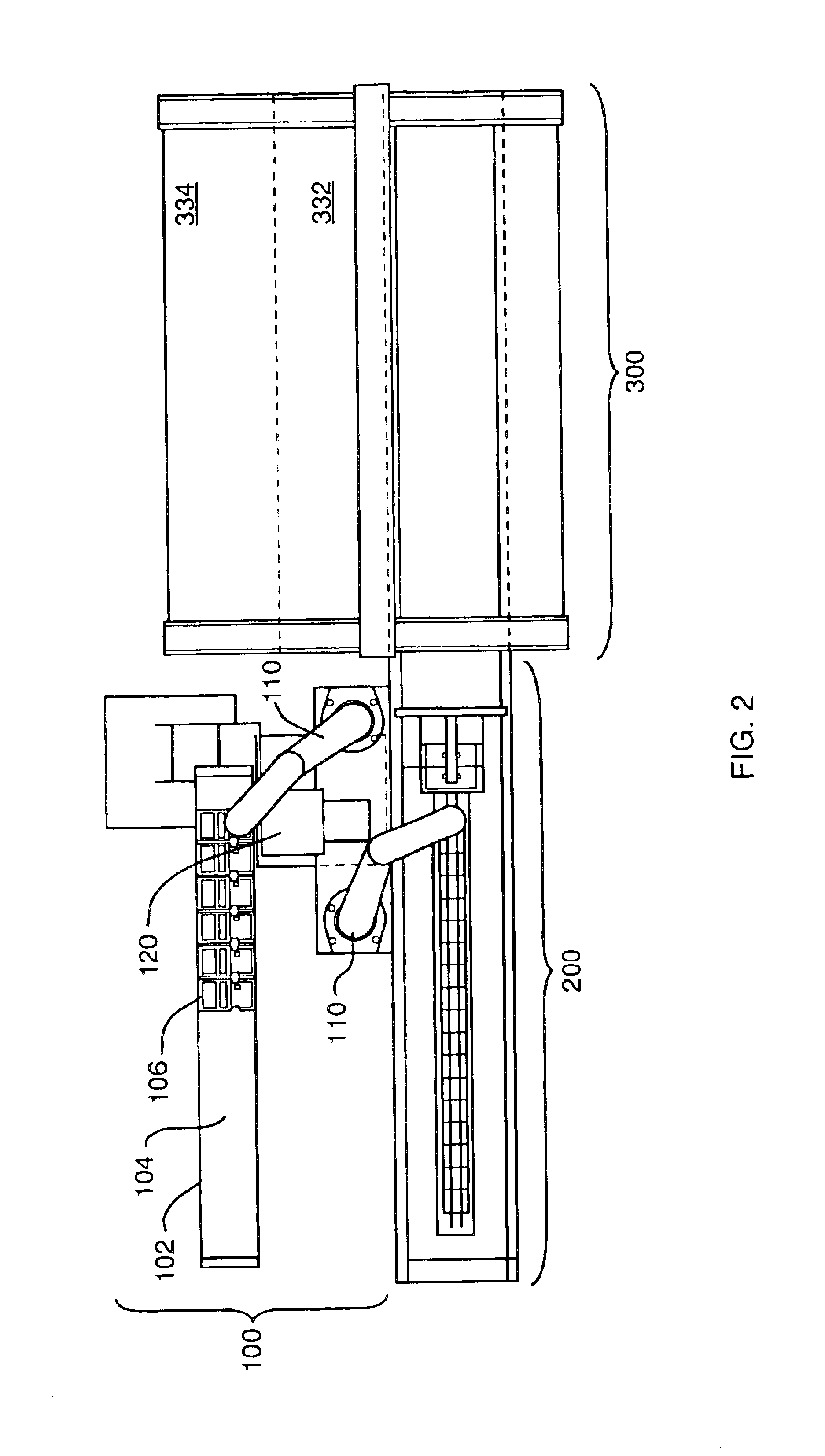

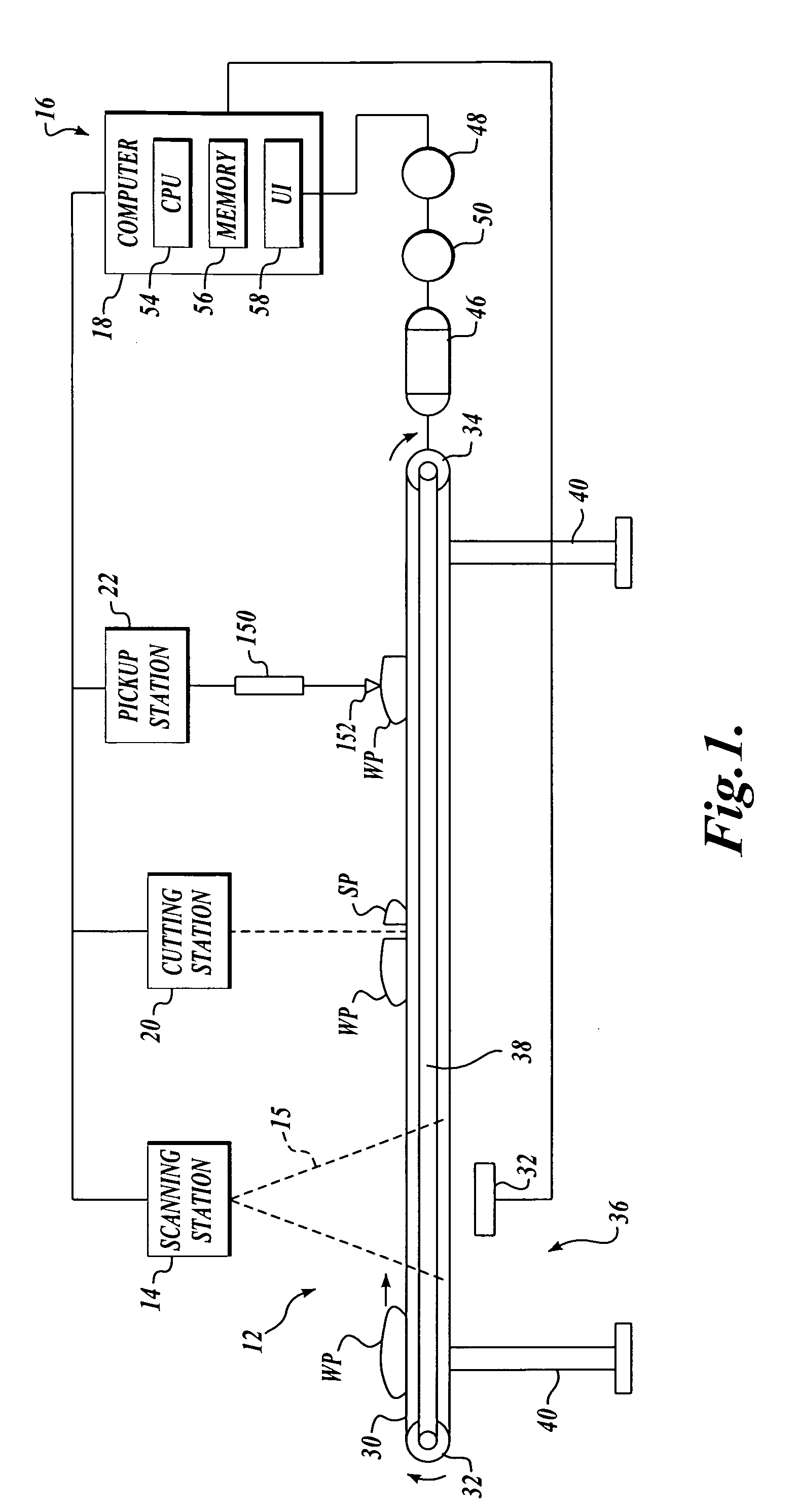

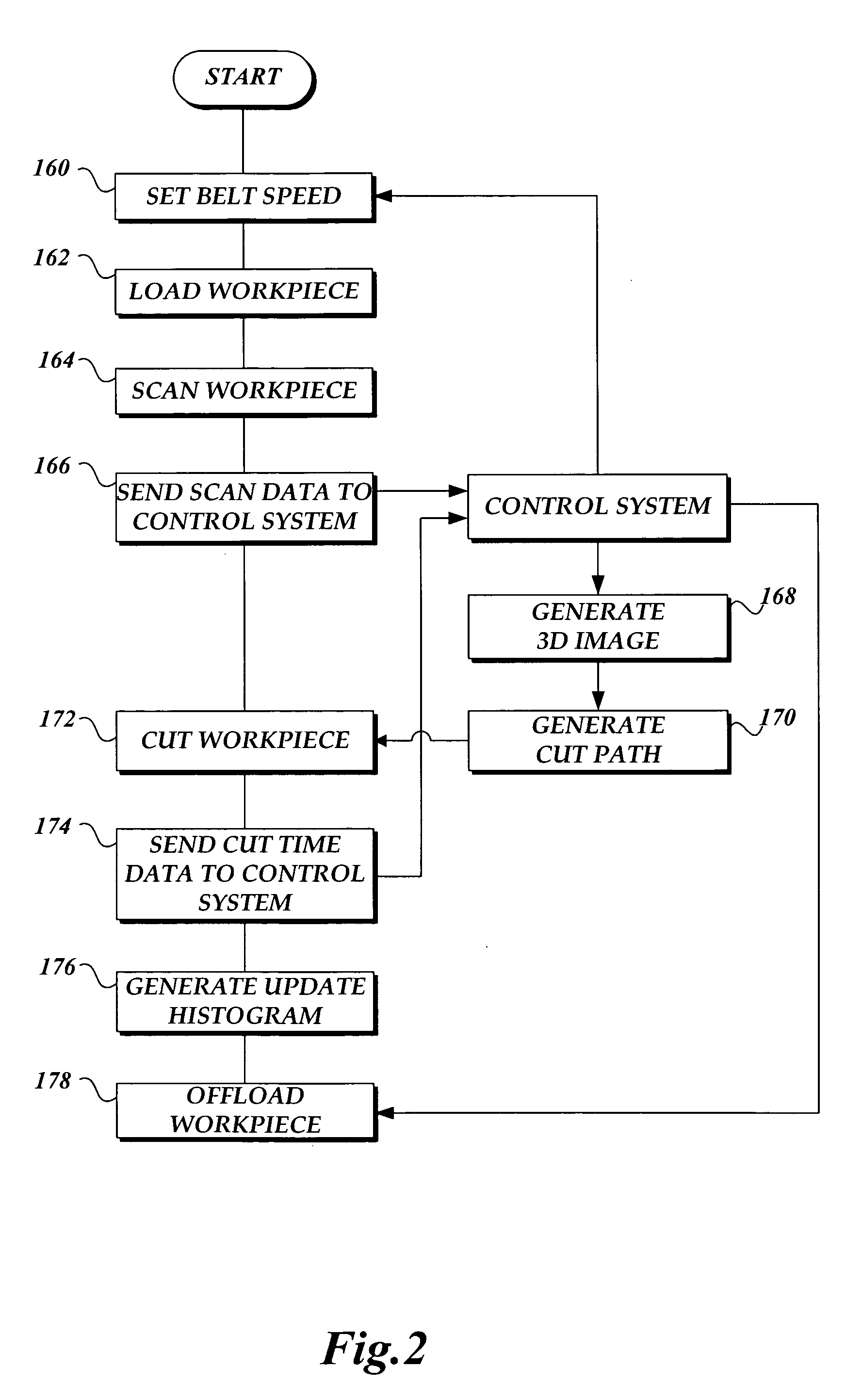

Apparatus and method for portioning using automatic workpiece conveyance speed control

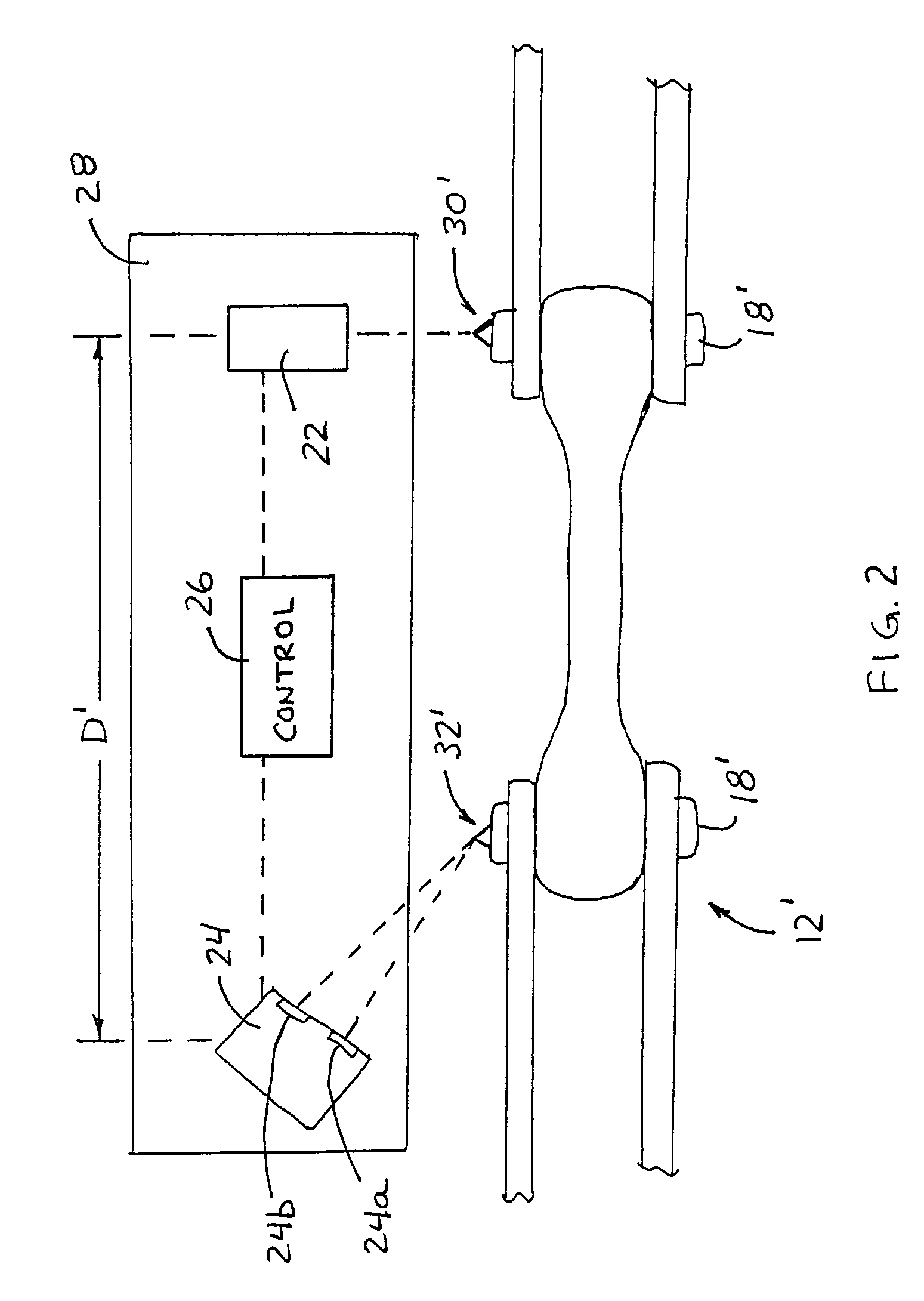

A portioning apparatus (10) includes a powered conveyor (12) for carrying workpieces (WP) past a scanning station (14) and past a cutting station (20). Information from the scanning station pertaining to physical parameters of the workpiece is transmitted to a control system (16) which then determines an optimal cutting strategy for the workpiece, which strategy is implemented at the cutting station (20). The length of time required to portion the workpiece is also determined, and this information is used to ascertain whether the speed of the conveyor (12) is optimal or should be changed.

Owner:JOHN BEAN TECH CORP

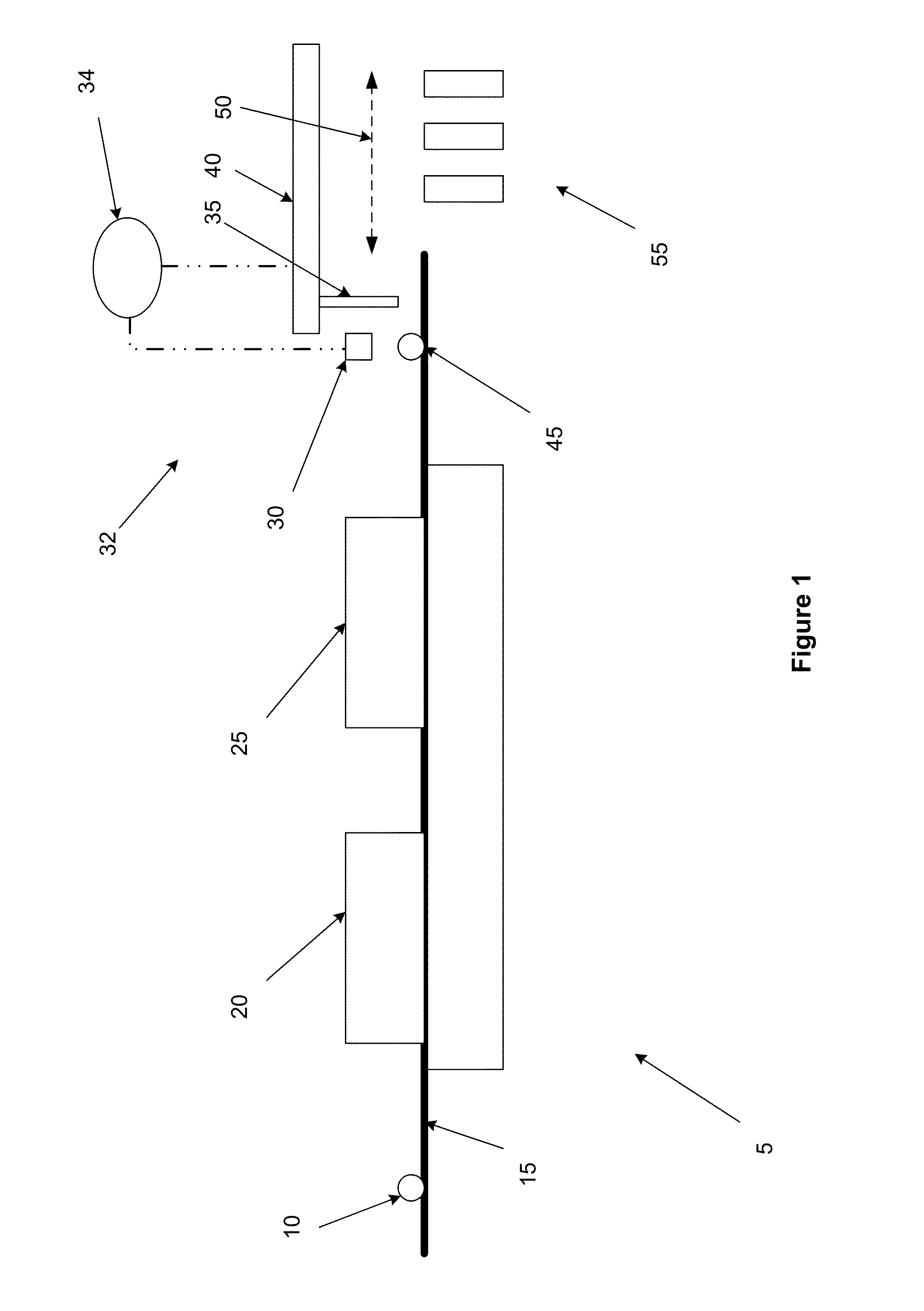

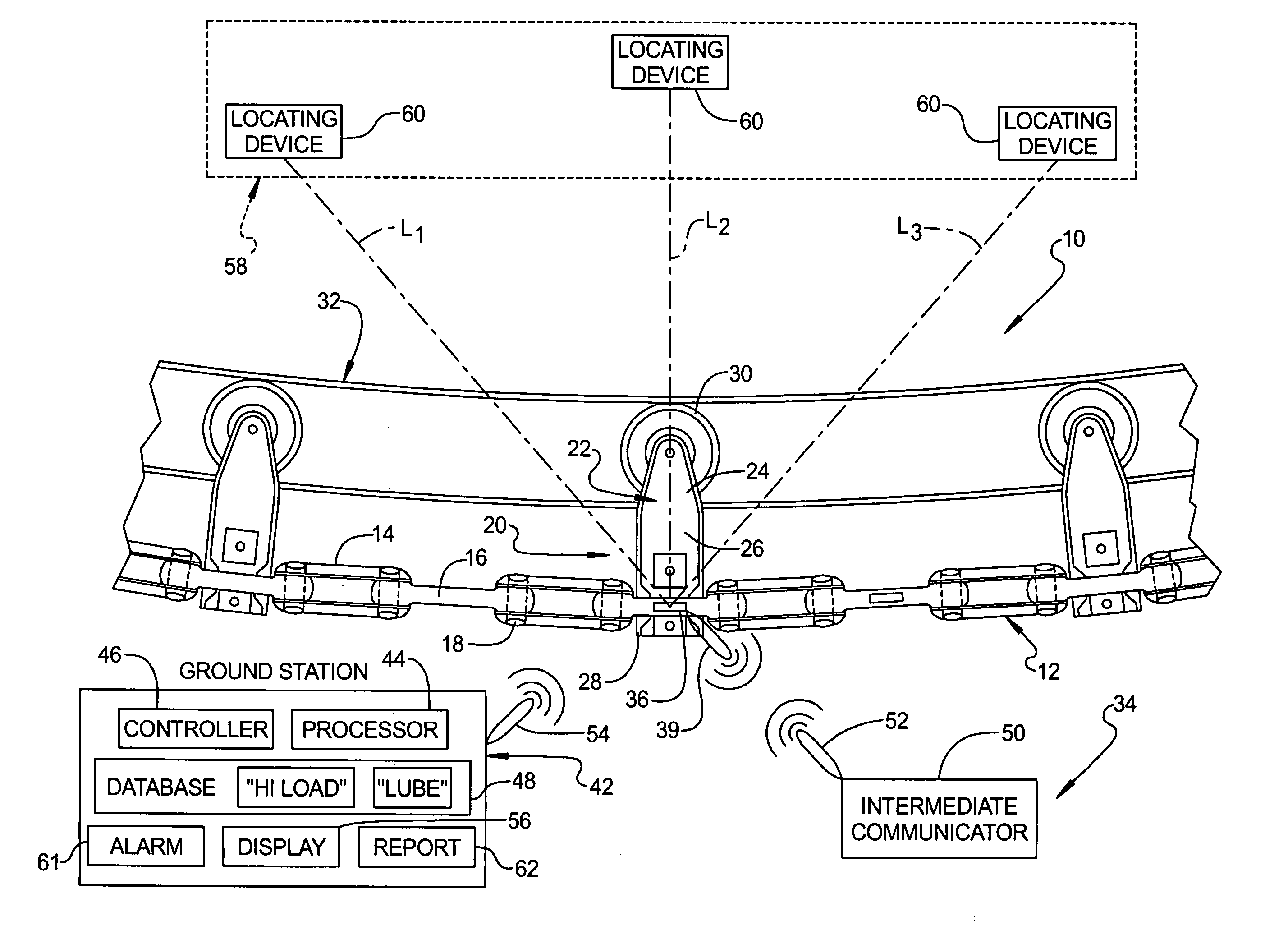

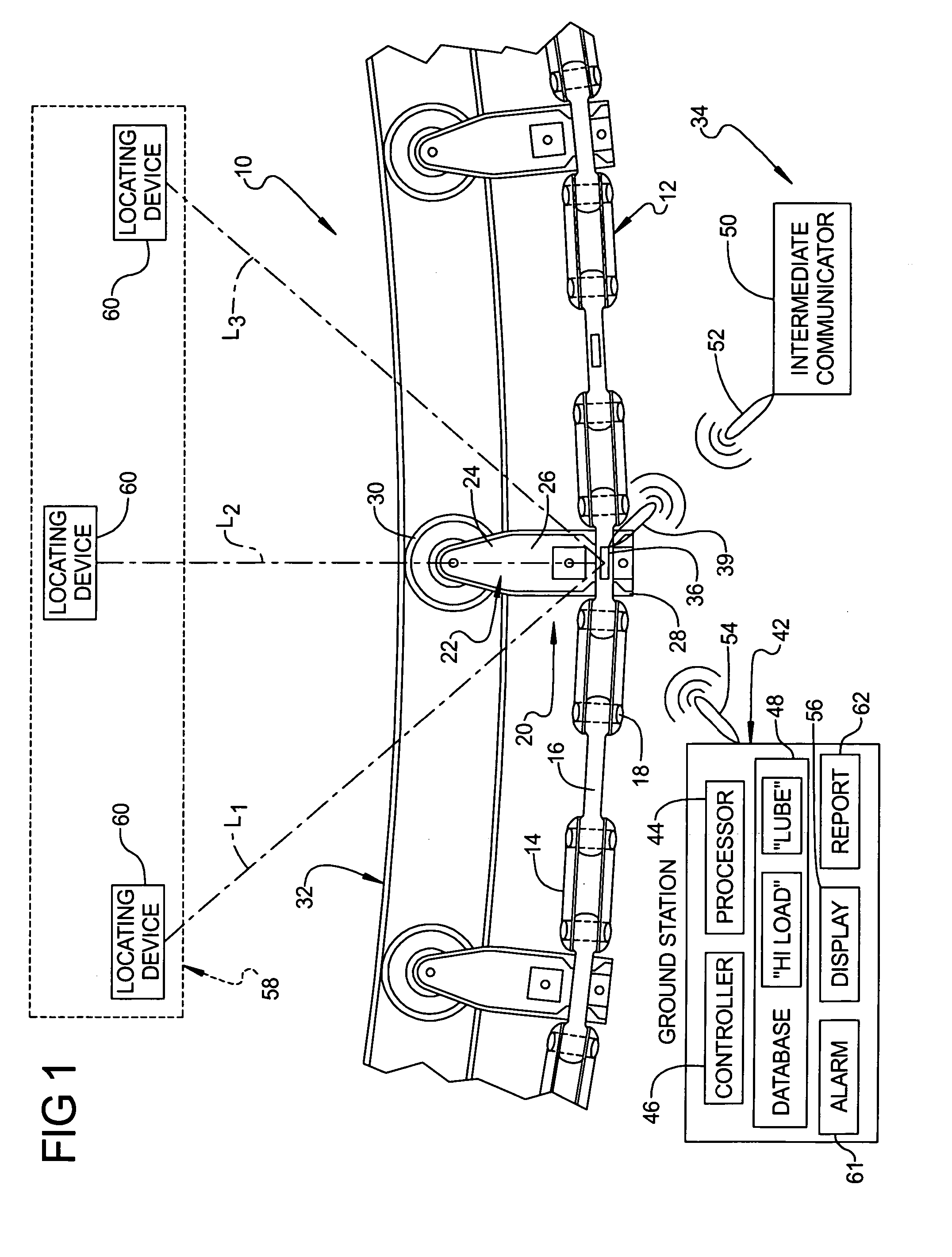

Conveyor diagnostic system having local positioning system

A conveyor diagnostic system for monitoring loading of a conveyor line assembly including at least one sensor component coupled to the conveyor line assembly. The sensor component is adapted for detecting loading of the conveyor line assembly and is further adapted for generating and transmitting a signal that is correlative of the loading of the conveyor line assembly. The conveyor diagnostic system also includes a ground station adapted to receive and process the signal that is correlative of the loading of the conveyor line assembly. Furthermore, the conveyor diagnostic system includes a local positioning system that is adapted for detecting the location of the sensor component in relation to a reference point. A method of using the conveyor diagnostic system is also disclosed.

Owner:FCA US

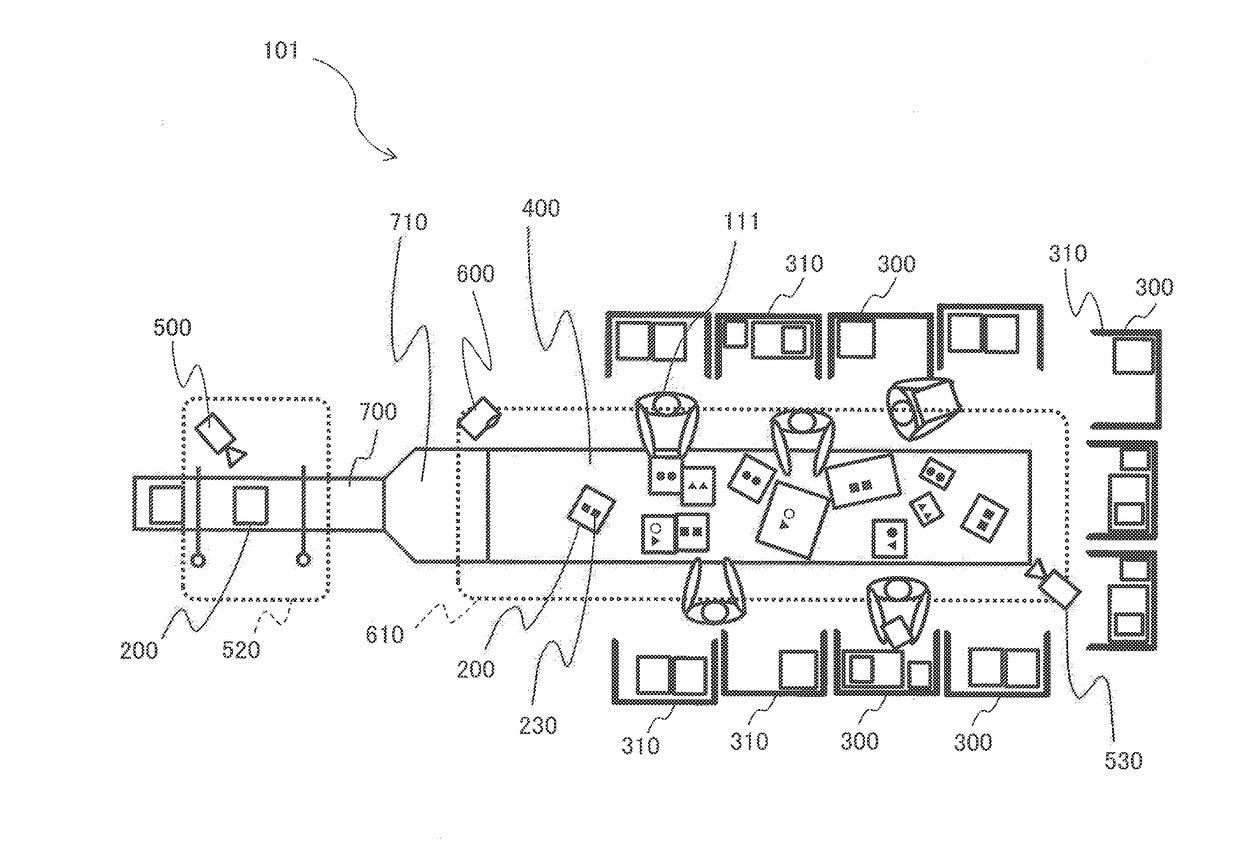

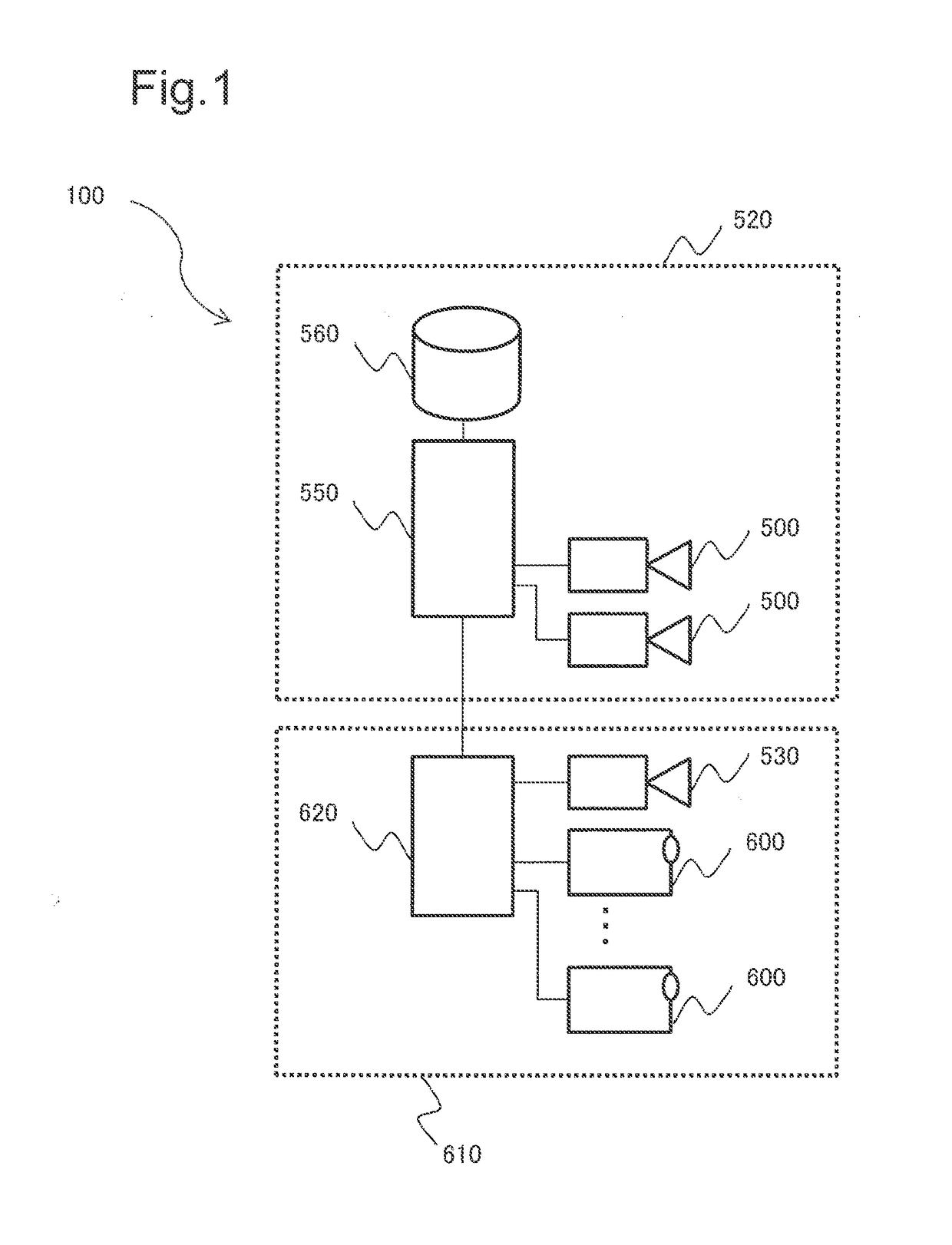

Information processing device, information processing system, distribution system, information processing method, and program storage medium

InactiveUS20170066597A1Improve accuracyImprove efficiencyConveyorsComputer controlInformation processingDistribution system

In order to achieve improved work efficiency and reduced work errors, this information processing device is provided with an acquisition unit, a detection unit, and a report control unit. The acquisition unit acquires information used in work to be executed on a work object from a document attached to the work object. The detection unit detects the whereabouts of the work object. On the basis of a rule that is data in which the information used in the work and work contents utilizing the information are associated with each other, the report control unit detects the work contents for the work object. Further, the report control unit reports the work contents by controlling a report device for reporting the work contents.

Owner:NEC CORP

Vision based conveyor package flow management system

ActiveUS20160221762A1Improve efficiencyMaximize packing densityConveyorsControl devices for conveyorsIndividual itemEntry point

A camera based vision system that recognizes and maximizes belt area utilization. A plurality of cameras are positioned at flow entry points of feed conveyors and at the singulator. The control algorithm recognizes individual items area, the rate at which individual objects are passing, and the area utilization of the collector belt. The video camera and computer based conveyor package management system monitor and control the number and size of the packages present on the infeed conveyors, collector conveyor, singulator conveyor and sorting conveyor in a package handling system wherein the camera data is used to measure the available area or space on the conveyors to maintain a desired density of packages on selected conveyor(s). The conveyor speed is controlled as a function of occupancy on a collector or just prior to a singulator or receiver.

Owner:FIVES INTRALOGISTICS SA

System for the automatic loading and/or unloading of products

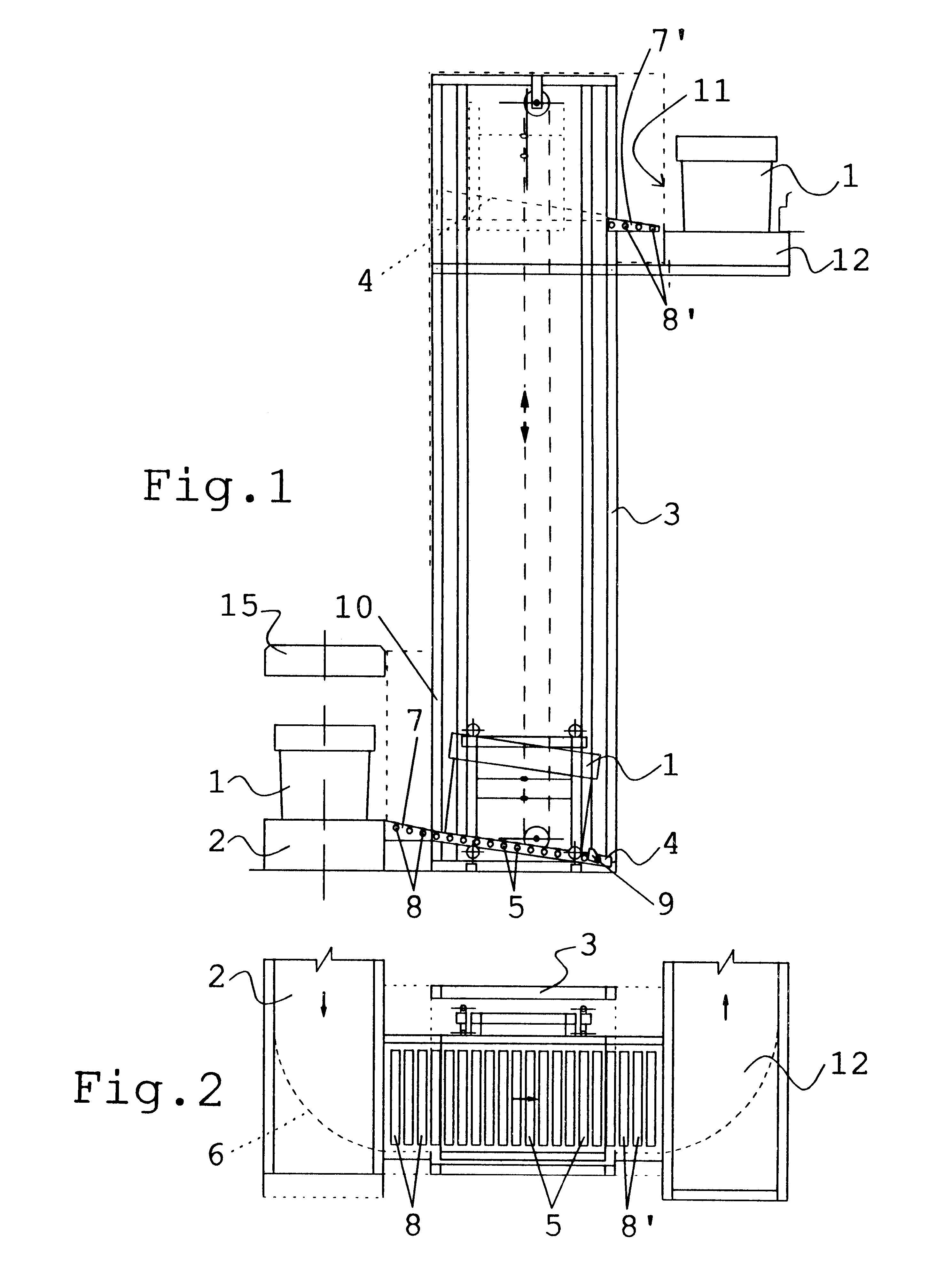

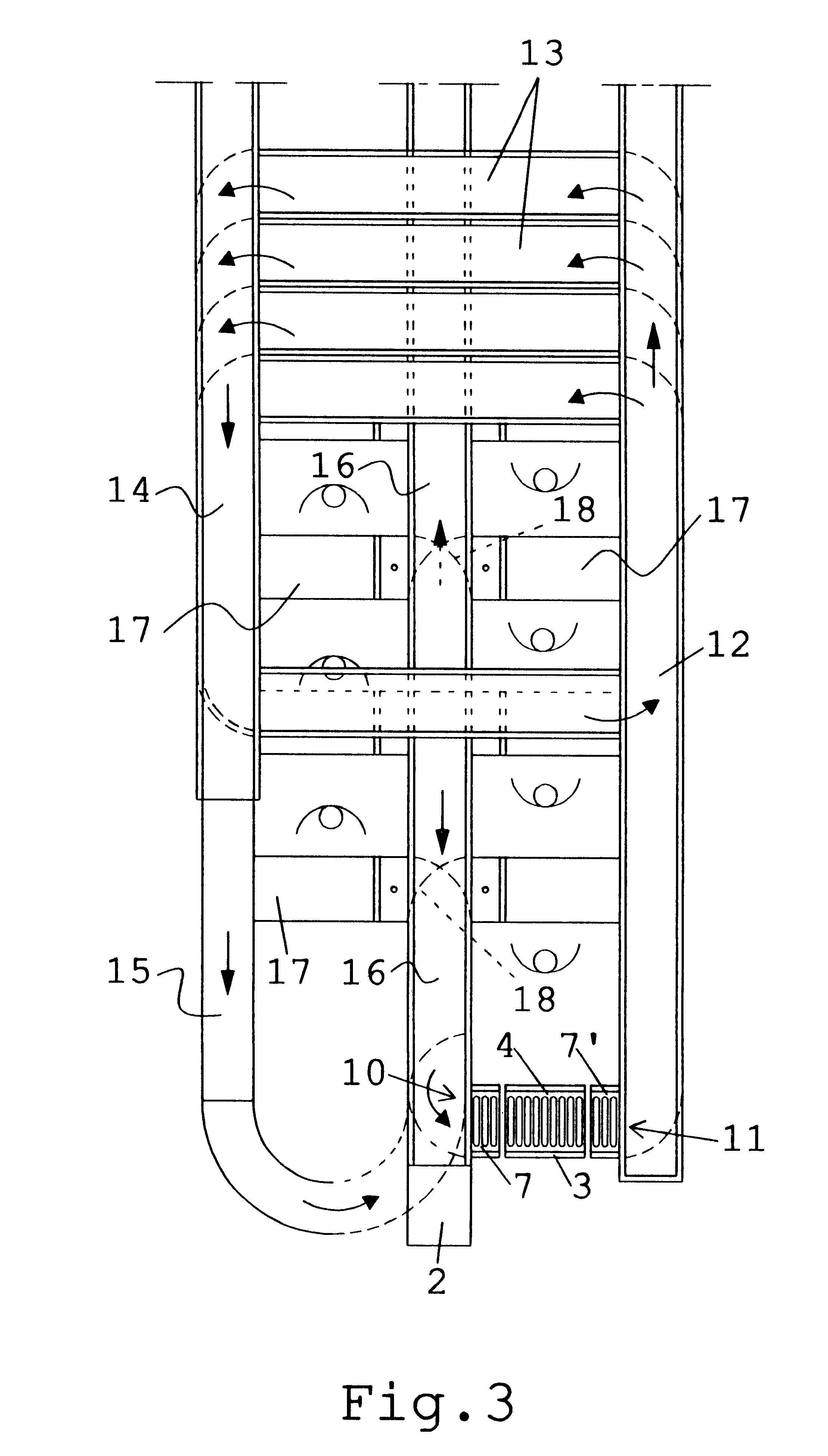

InactiveUS6357985B1Halve the operating timesControl devices for conveyorsCharge manipulationClassical mechanicsEngineering

A system for the automatic loading and / or unloading of products comprises a store (13, 19) with shelves inclined and provided with a mobile transversal blocking means (9, 12), and at least one traveling lift (3) provided with mobile bearing tops (4), also inclined and provided with at least one mobile transversal blocking means (9, 12). Said inclined shelves and bearing tops (4) are provided with transversal, parallel, idle and inclined rollers (5) whereon a product or a product container (1) can slide by gravity when the blocking means is lowered.

Owner:ANZANI +1

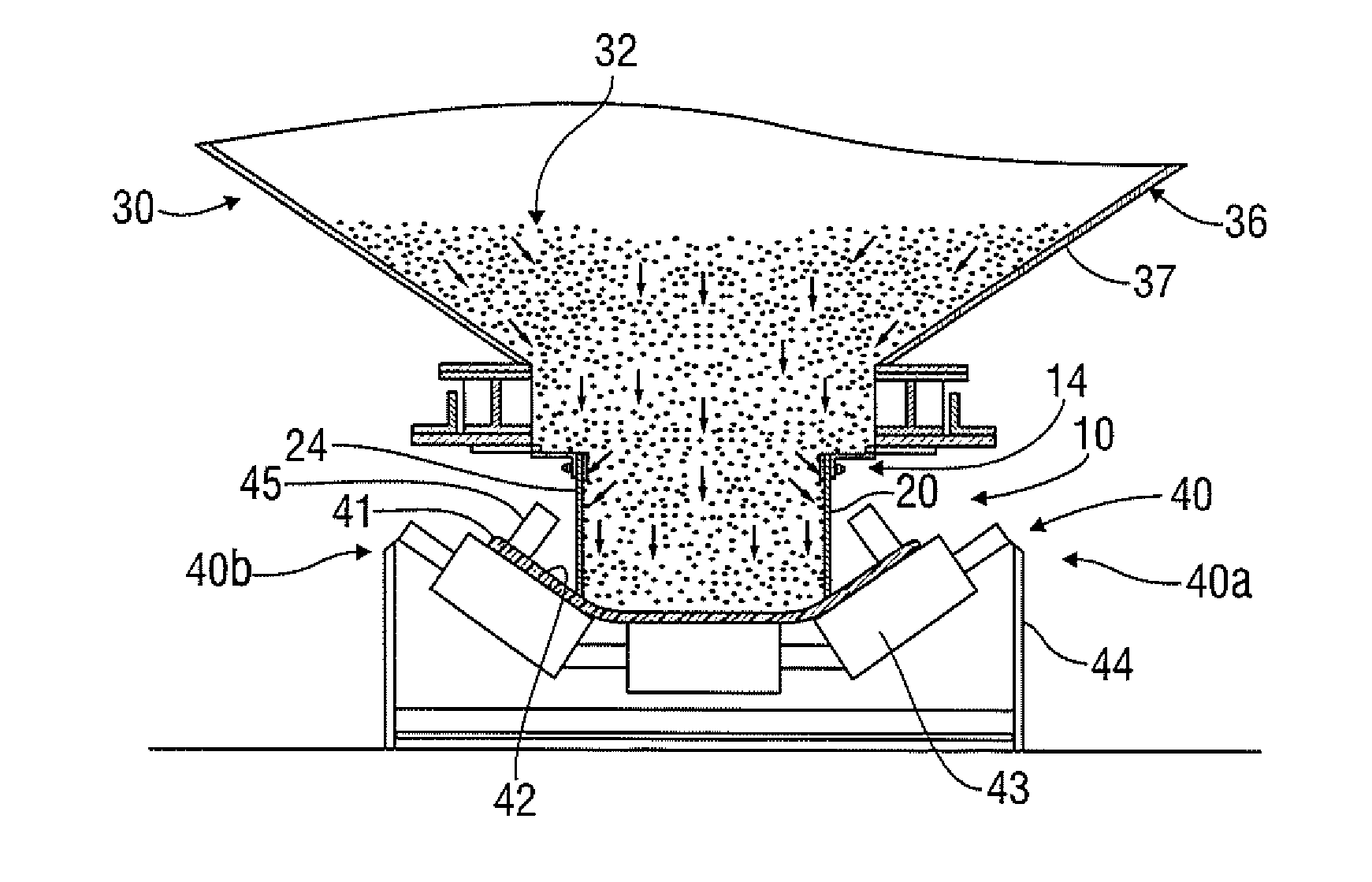

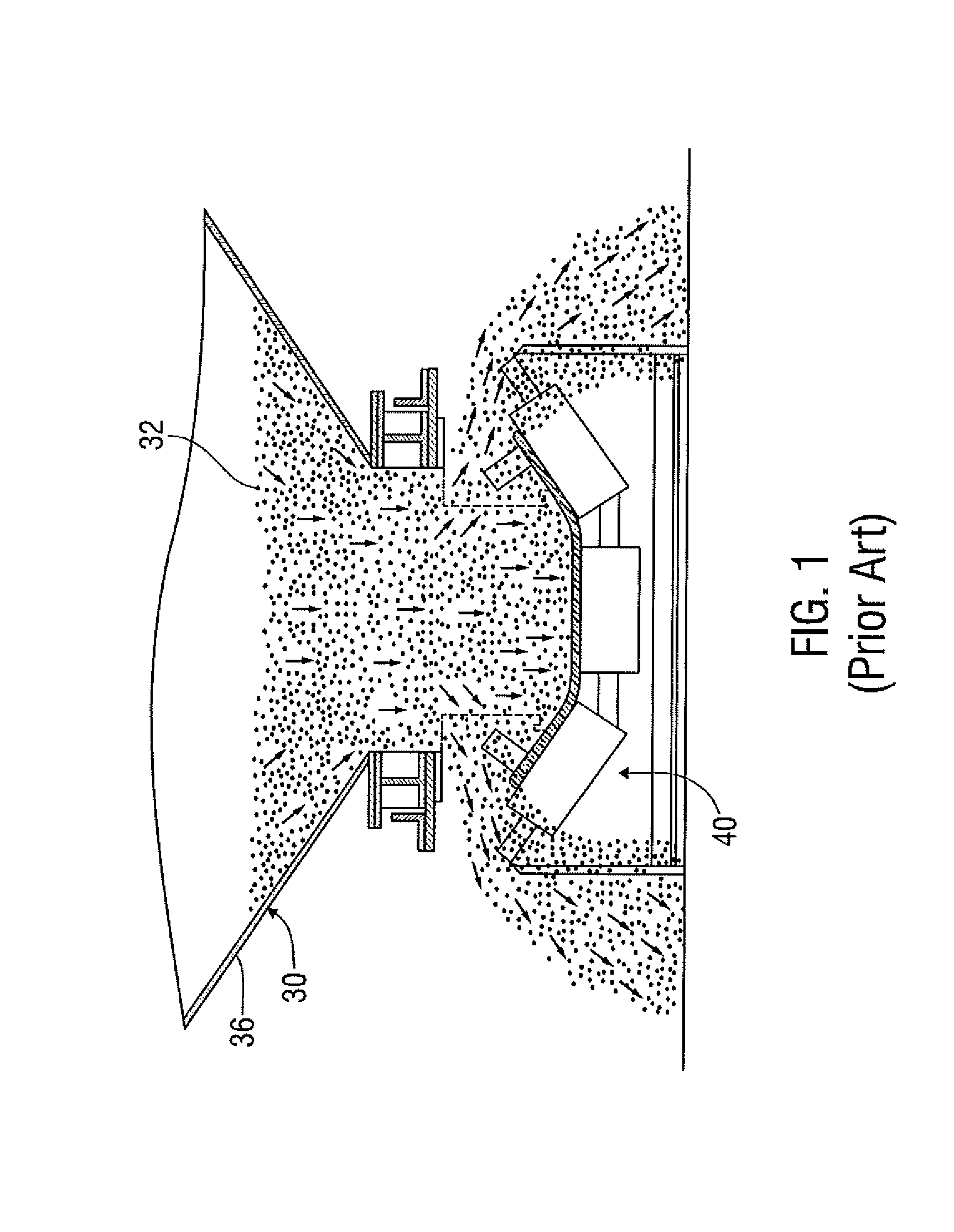

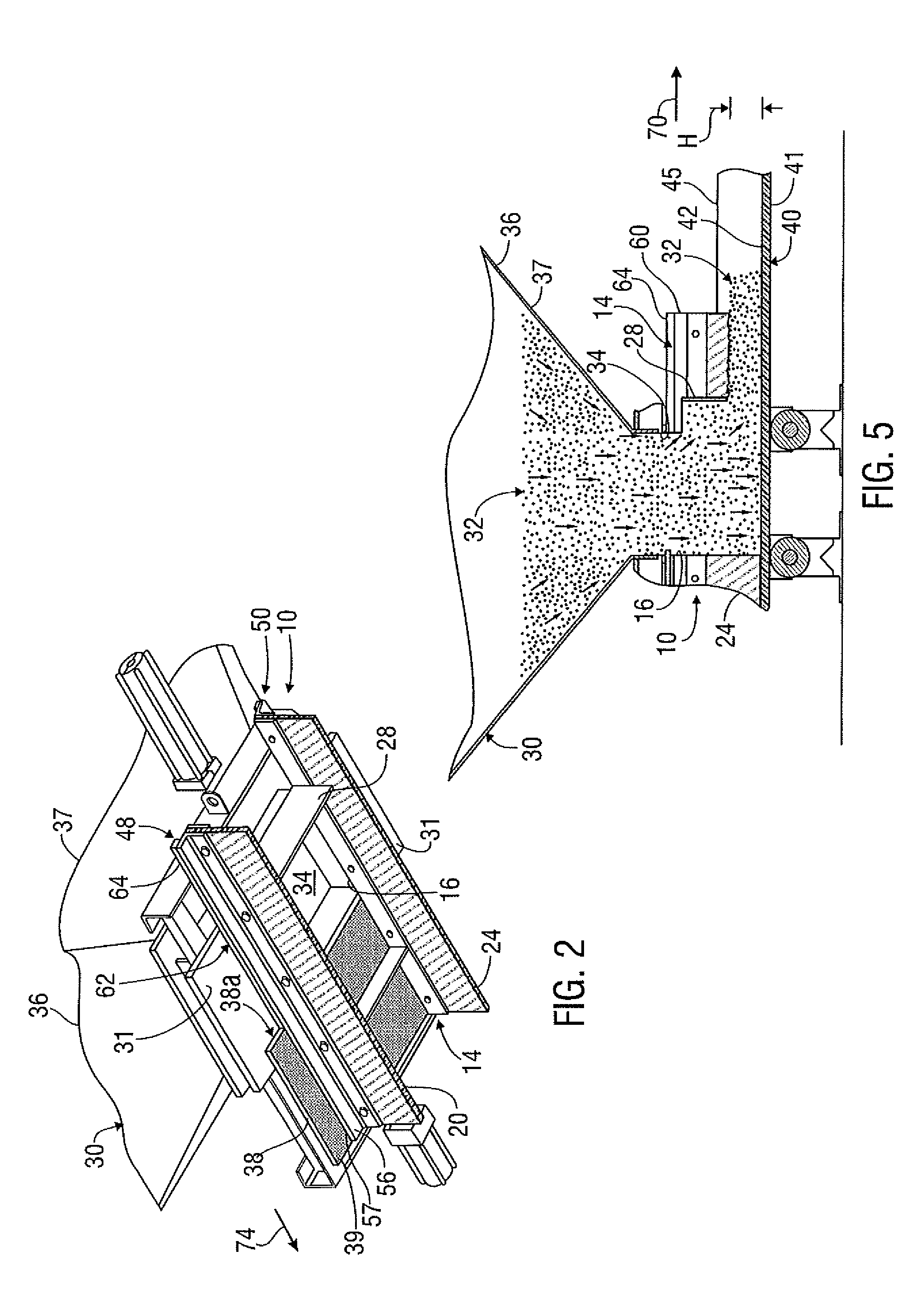

Apparatus and Methods for Assisting in Controlling Material Delivered on a Conveyor

ActiveUS20140044507A1Control devices for conveyorsWeighing apparatus for continuous material flowElectronic controllerConveyor belt

Method of controlling the amount of material delivered by conveyor belt includes measuring the speed of the conveyor belt or a drive pulley that drives the conveyor belt. A weighing device weighs material dispensed onto the conveyor belt from at least one material dispenser. Based at least in part upon such speed and weight measurements, an electronic controller maintains or changes the speed of the conveyor belt by dictating the output of at least one motor that drives the drive pulley.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

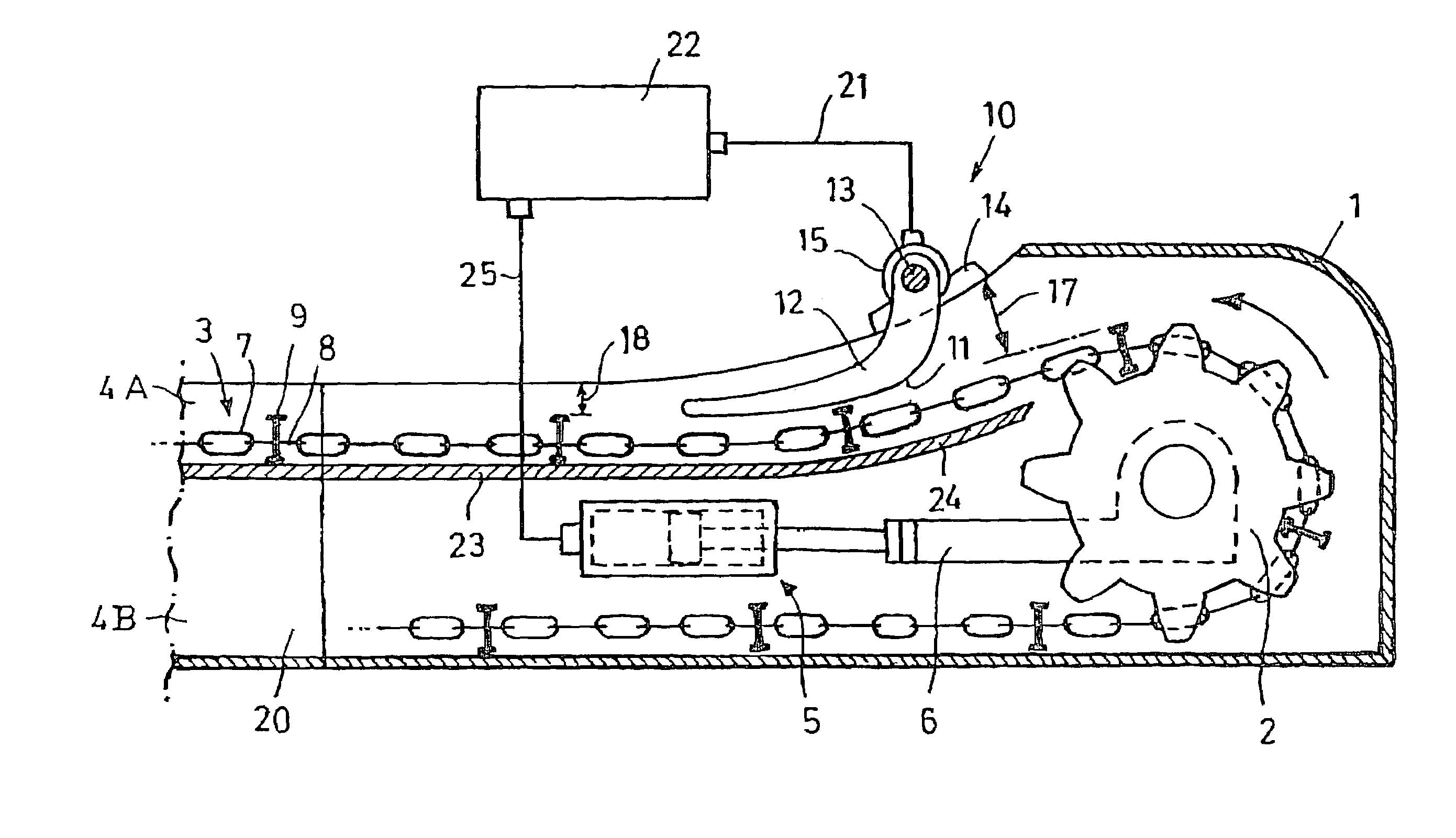

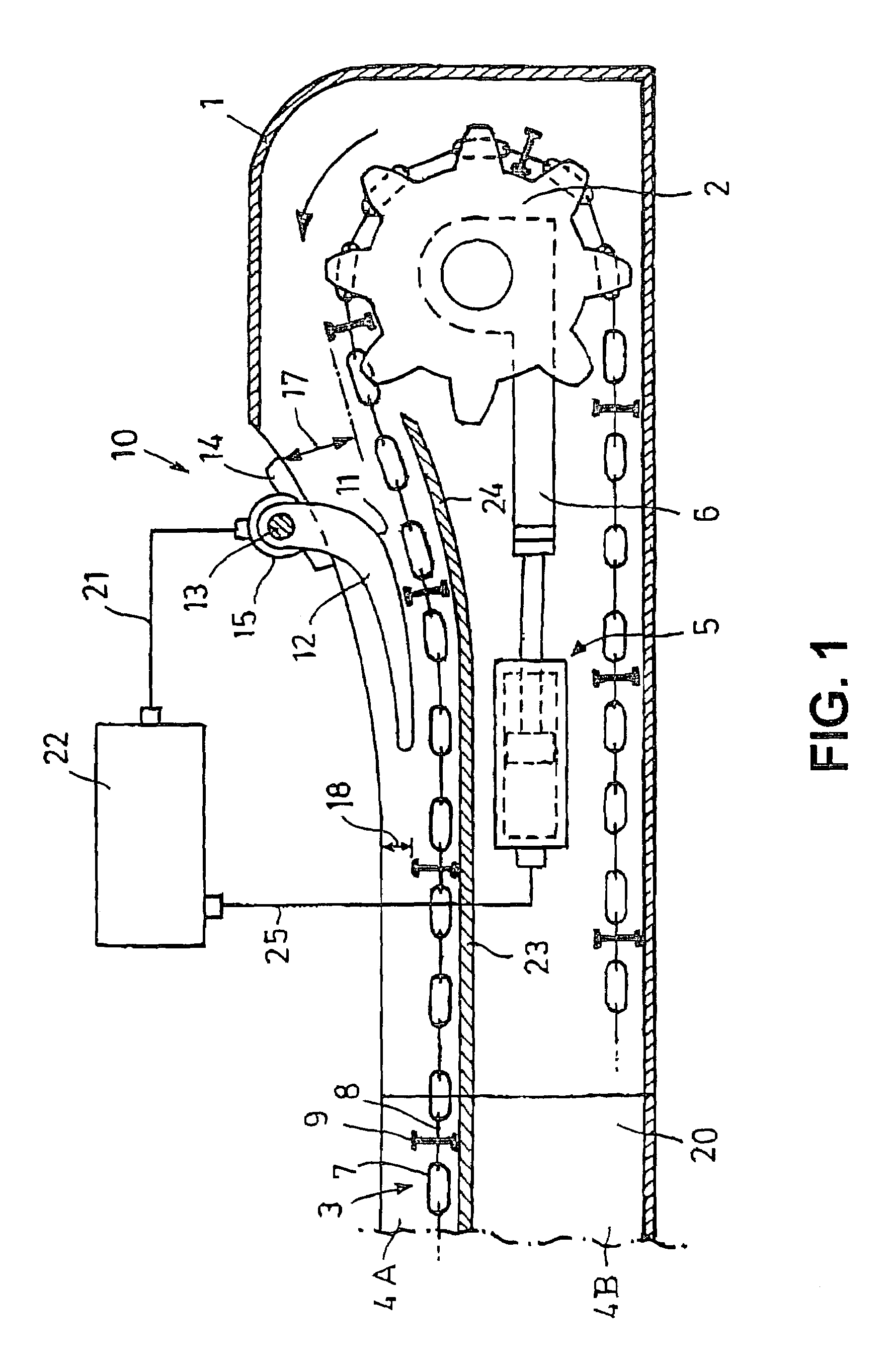

Device for detecting the tension of scraper chains

InactiveUS7117989B2Not easy to wearEasy to replaceConveyorsControl devices for conveyorsEngineeringChain conveyor

A device for detection and adjustment of the tension of a scraper chain of a chain conveyor, in particular of a face conveyor, having a tensionable return station, on which a spoked chainwheel to reverse the scraper chain, having chain links and scrapers attached thereto, is supported between the bottom race and the top race. The devices including a sensor which determines the tension of the scraper chain at the return station and the sensor having a swivellable sensor body coupled with a shaft encoder. The sensor body being in the top race and in contact with the upper face of the scraper chain in a measurement zone with provision being made in the measuring zone for vertical play for the run of the scrapers and / or the chain links.

Owner:DBT

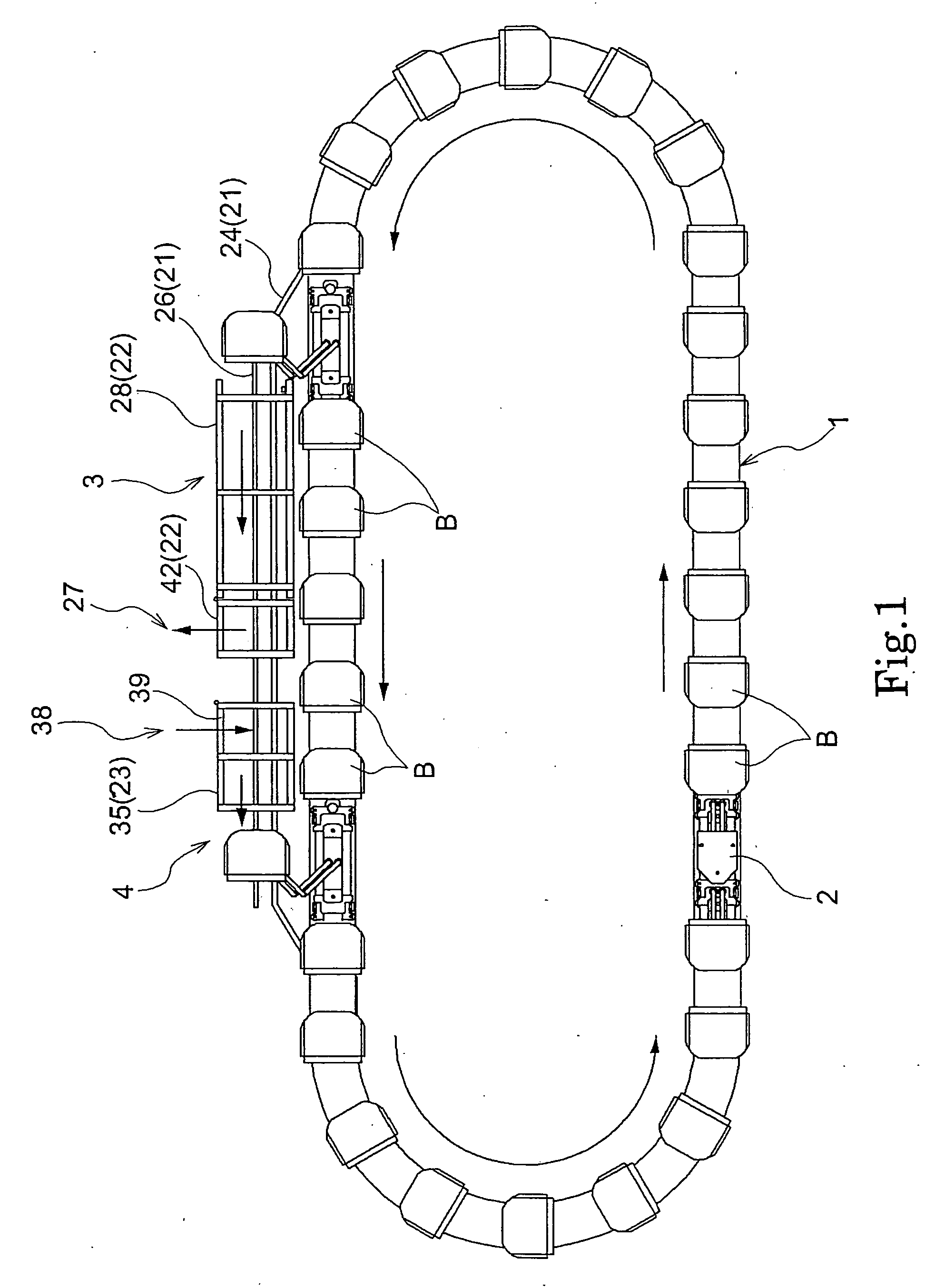

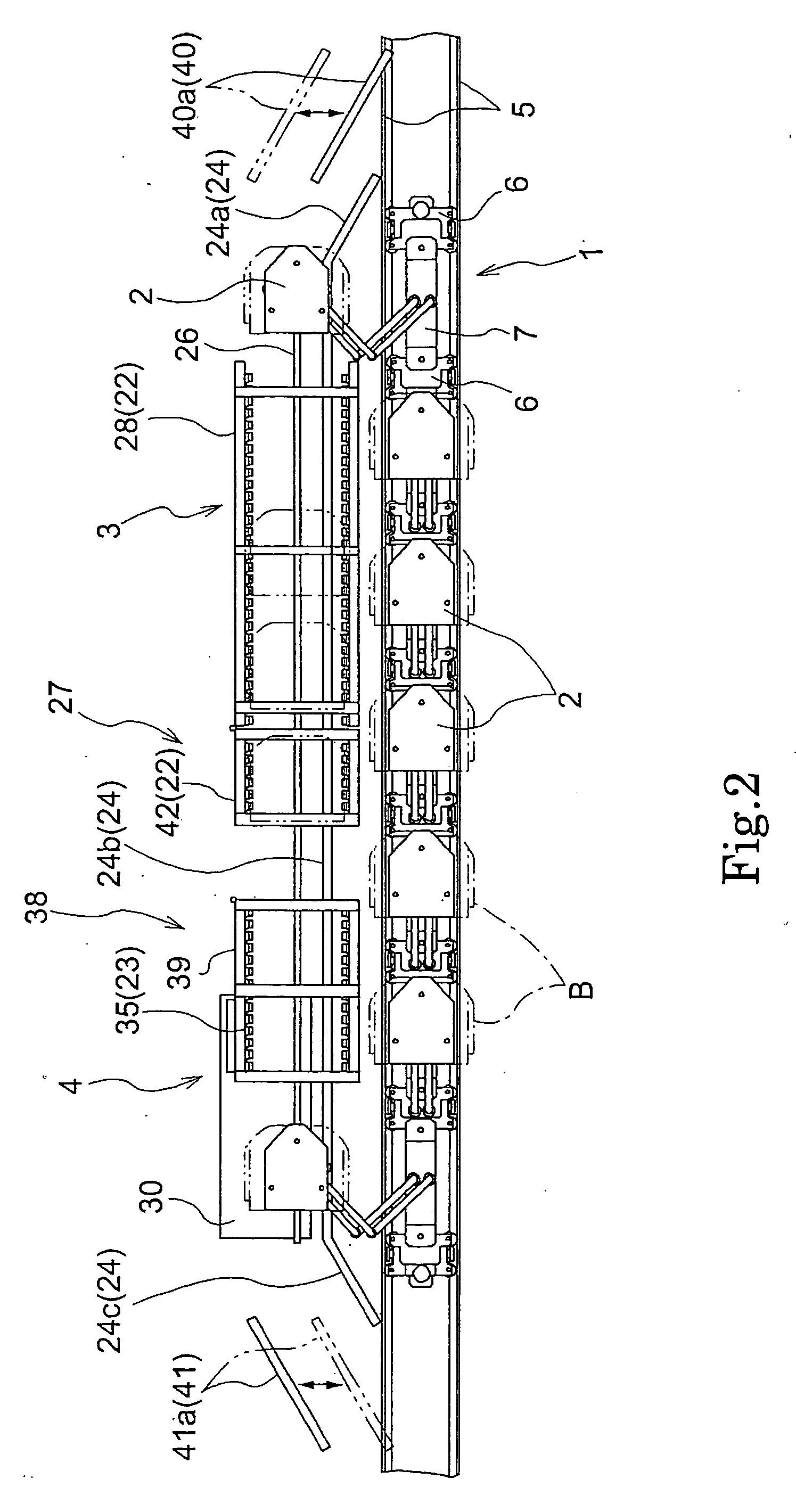

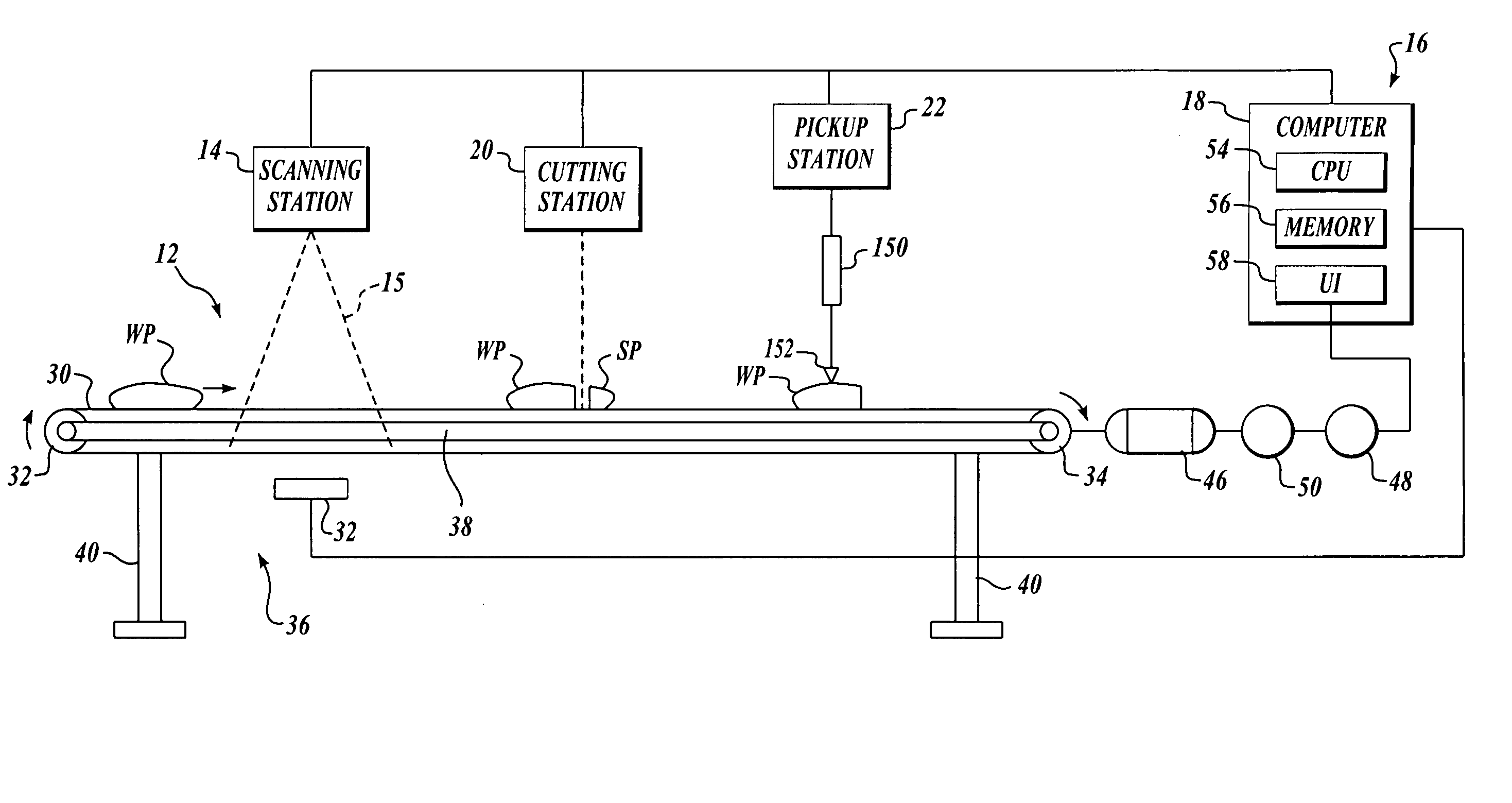

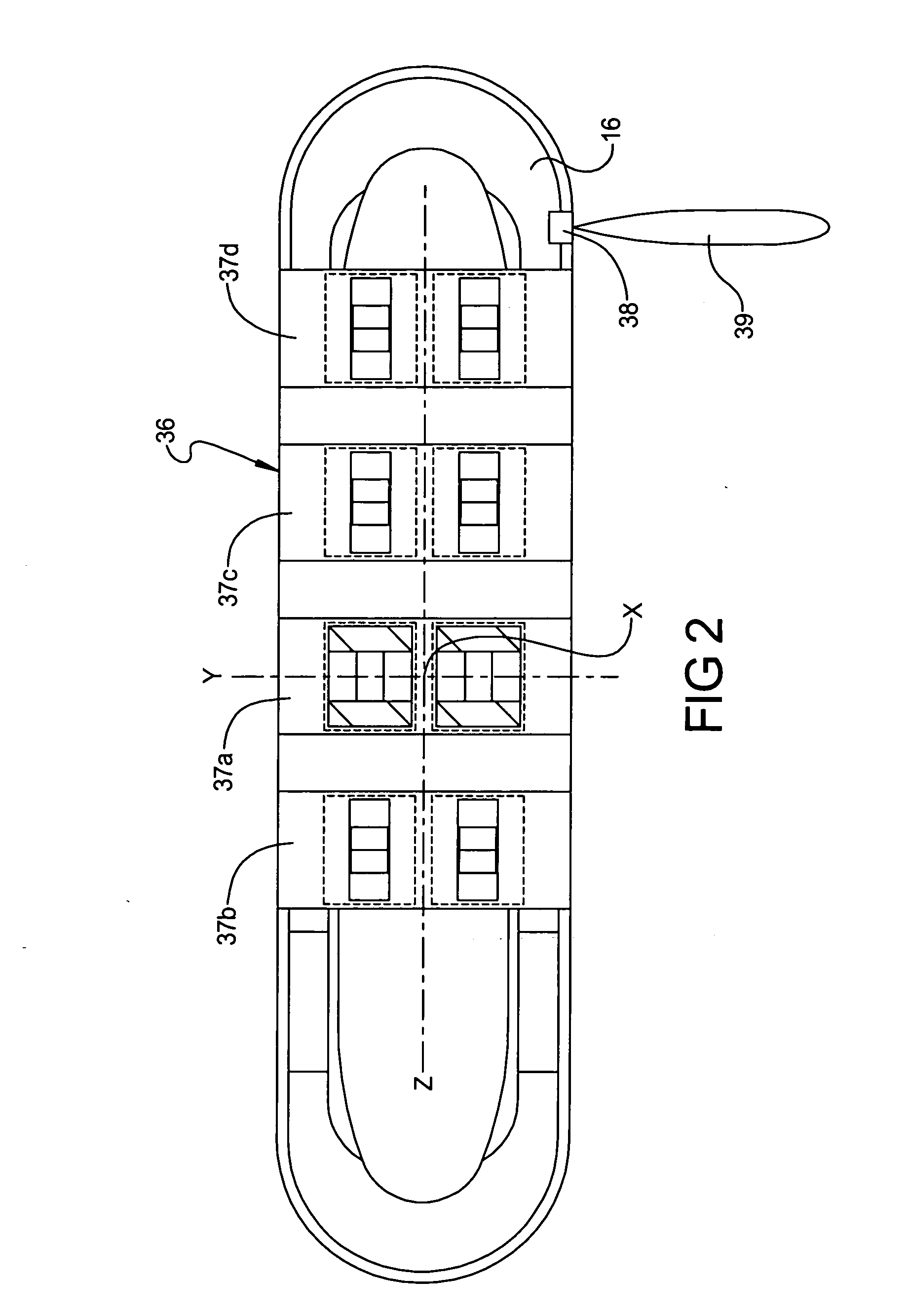

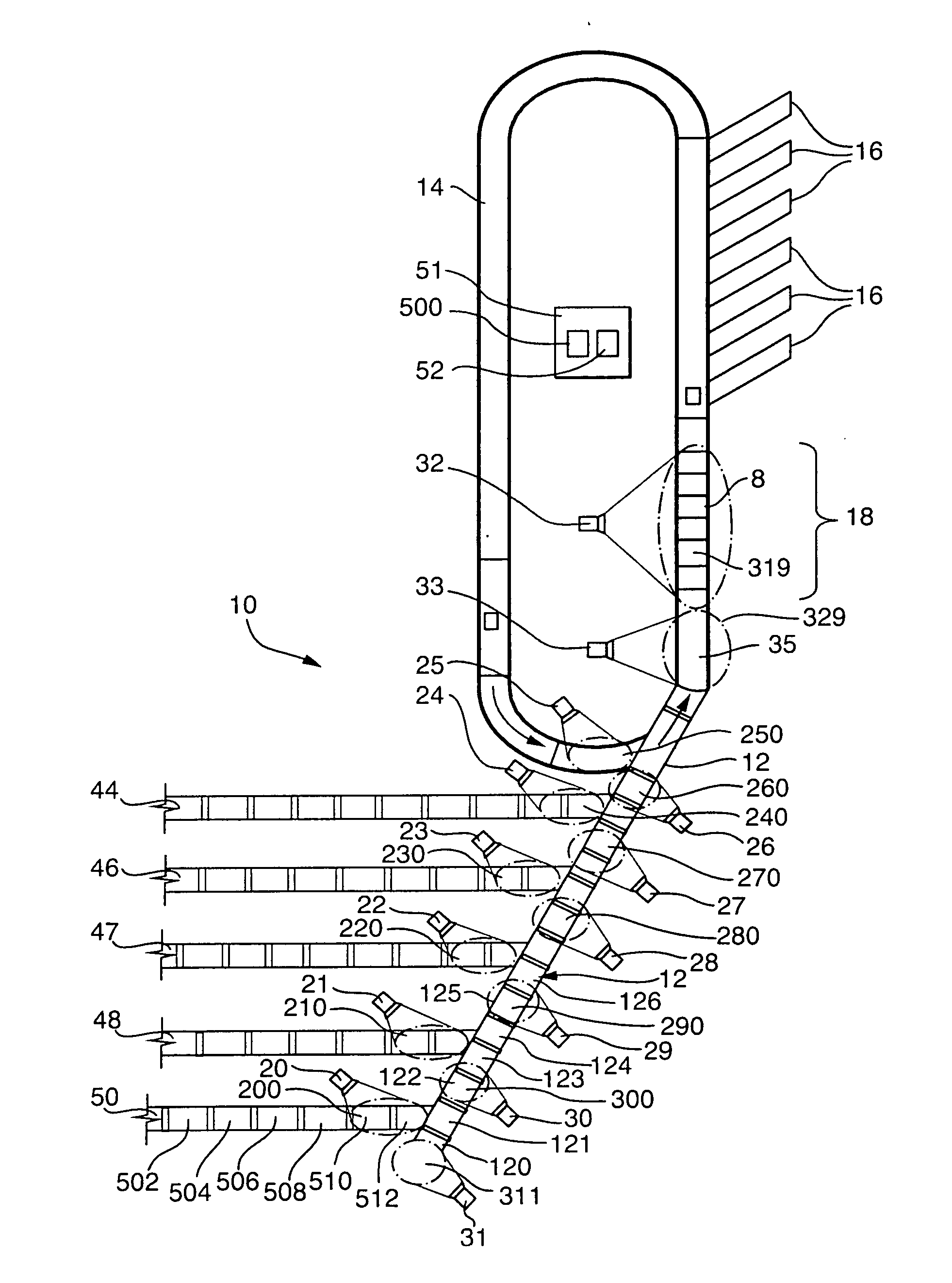

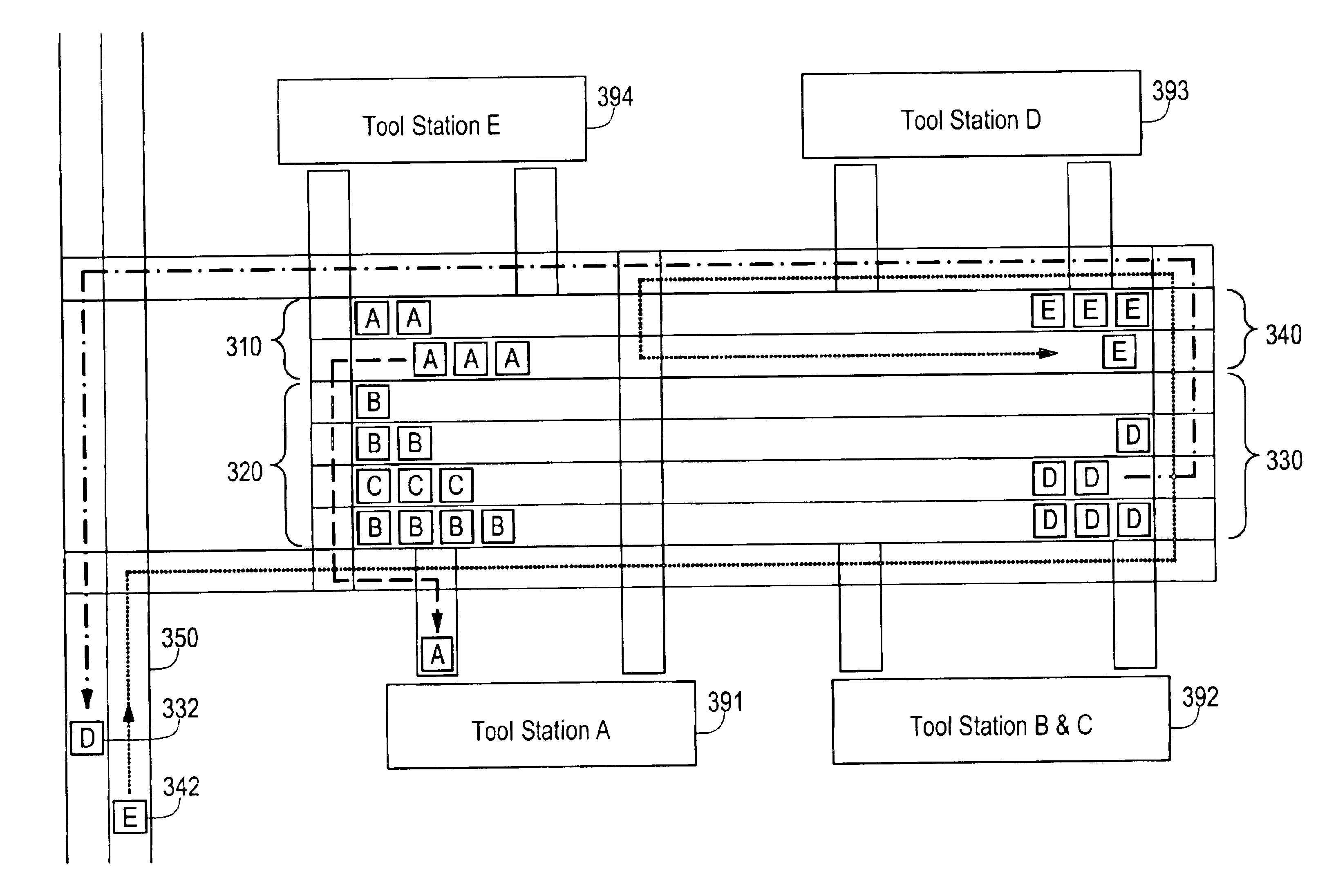

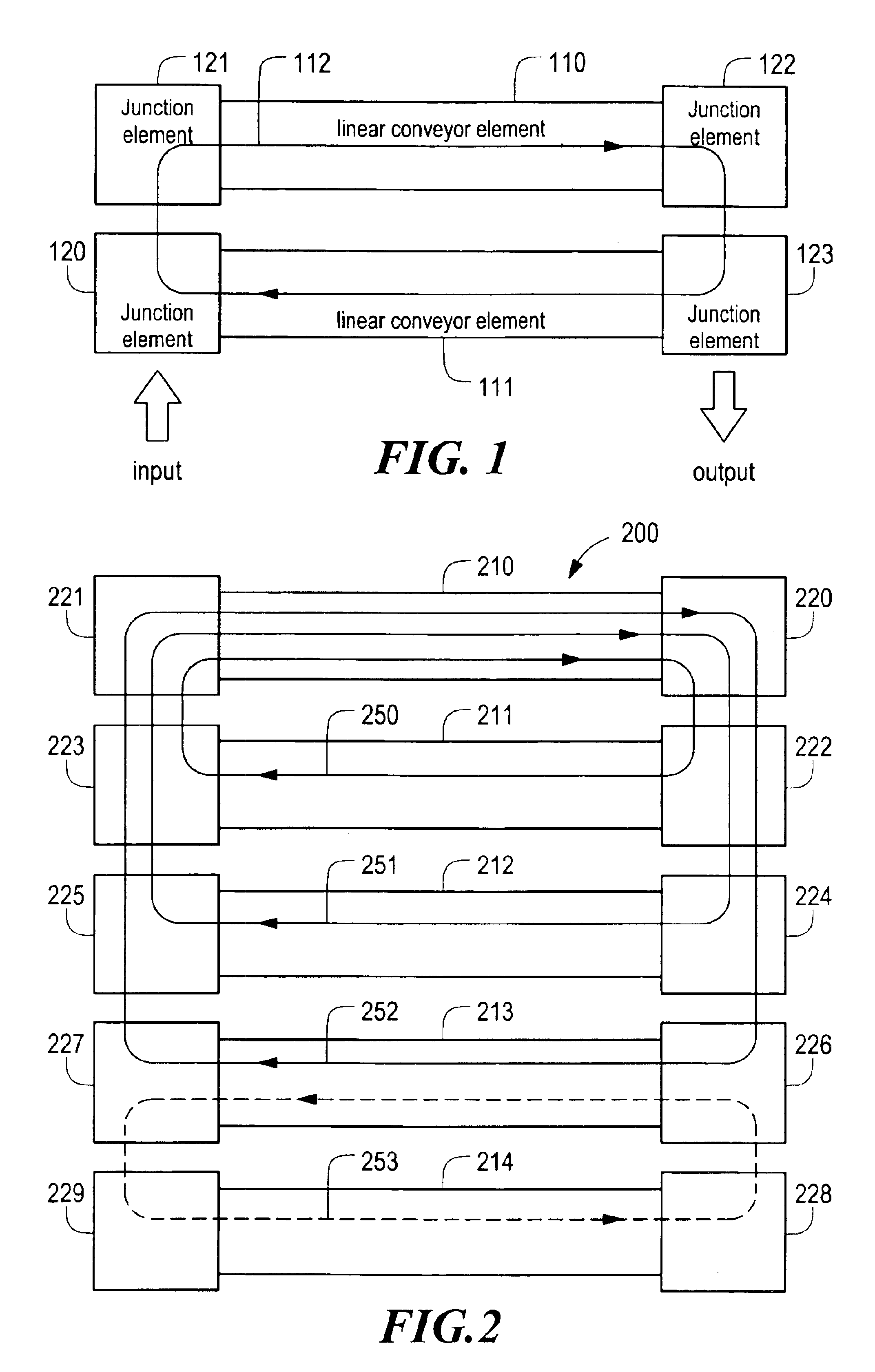

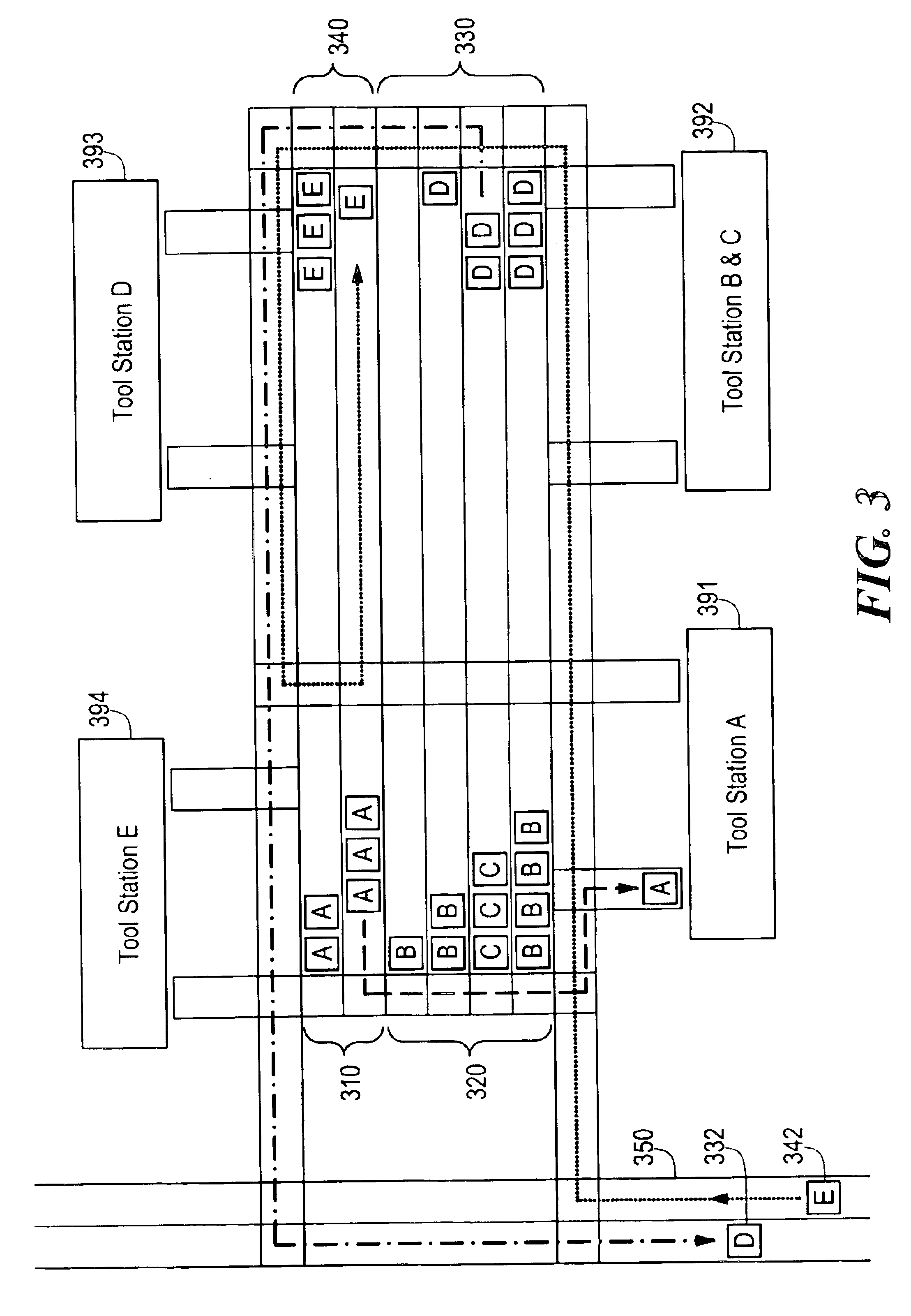

Conveyorized storage and transportation system

InactiveUS6854583B1OptimizationAvoid normal workDigital data processing detailsSemiconductor/solid-state device manufacturingModularityMechanical engineering

A configurable storage system particularly suited for use with clean environment conveyors is disclosed. The storage system includes modular conveyor track elements which may be provided as one way paths which, when provided with plural transfer elements with respect to a conveyor highway, enable the rotation of a workpiece from a storage matrix to a transfer path and back to the storage matrix.

Owner:MIDDLESEX GEN INDS MESNE

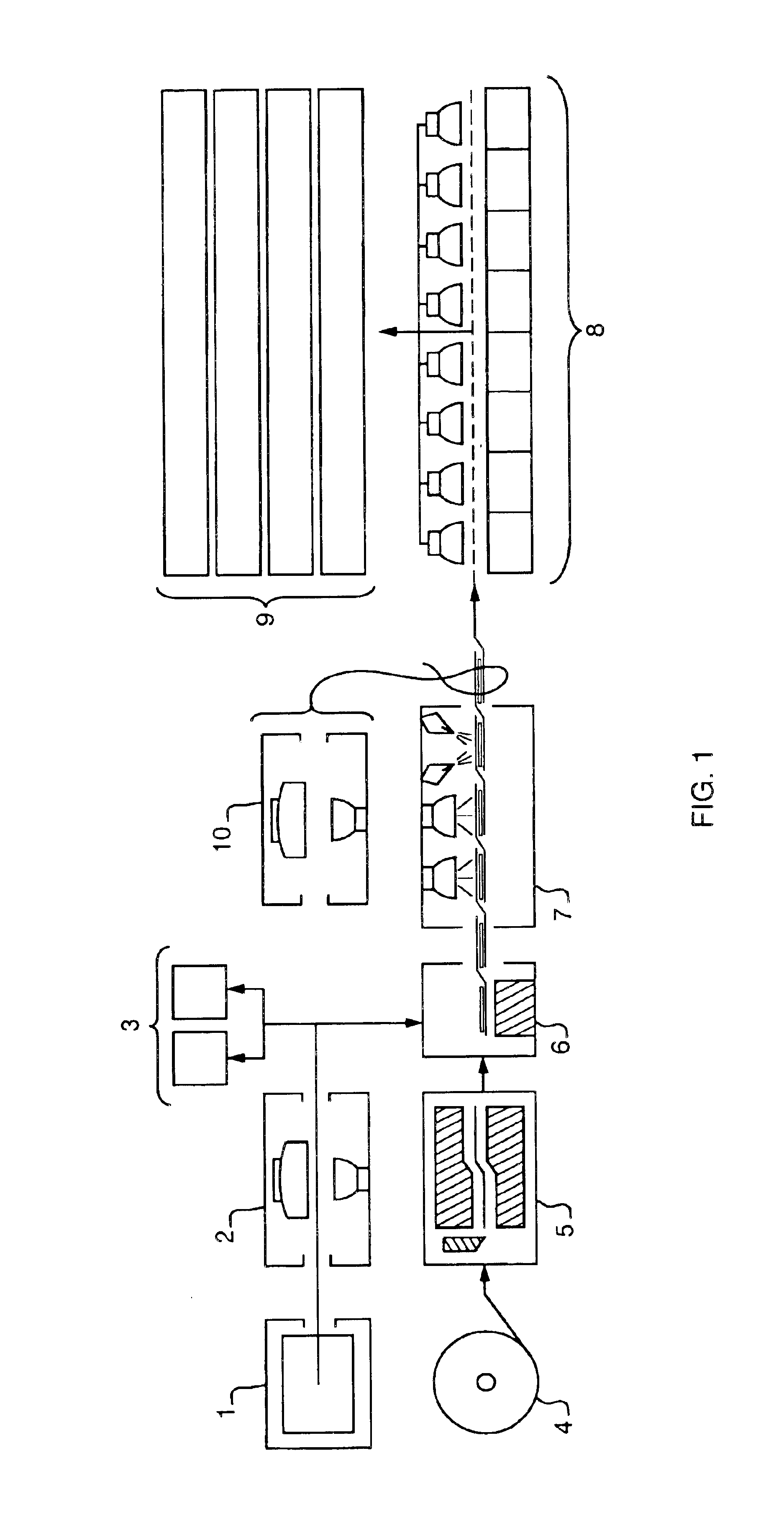

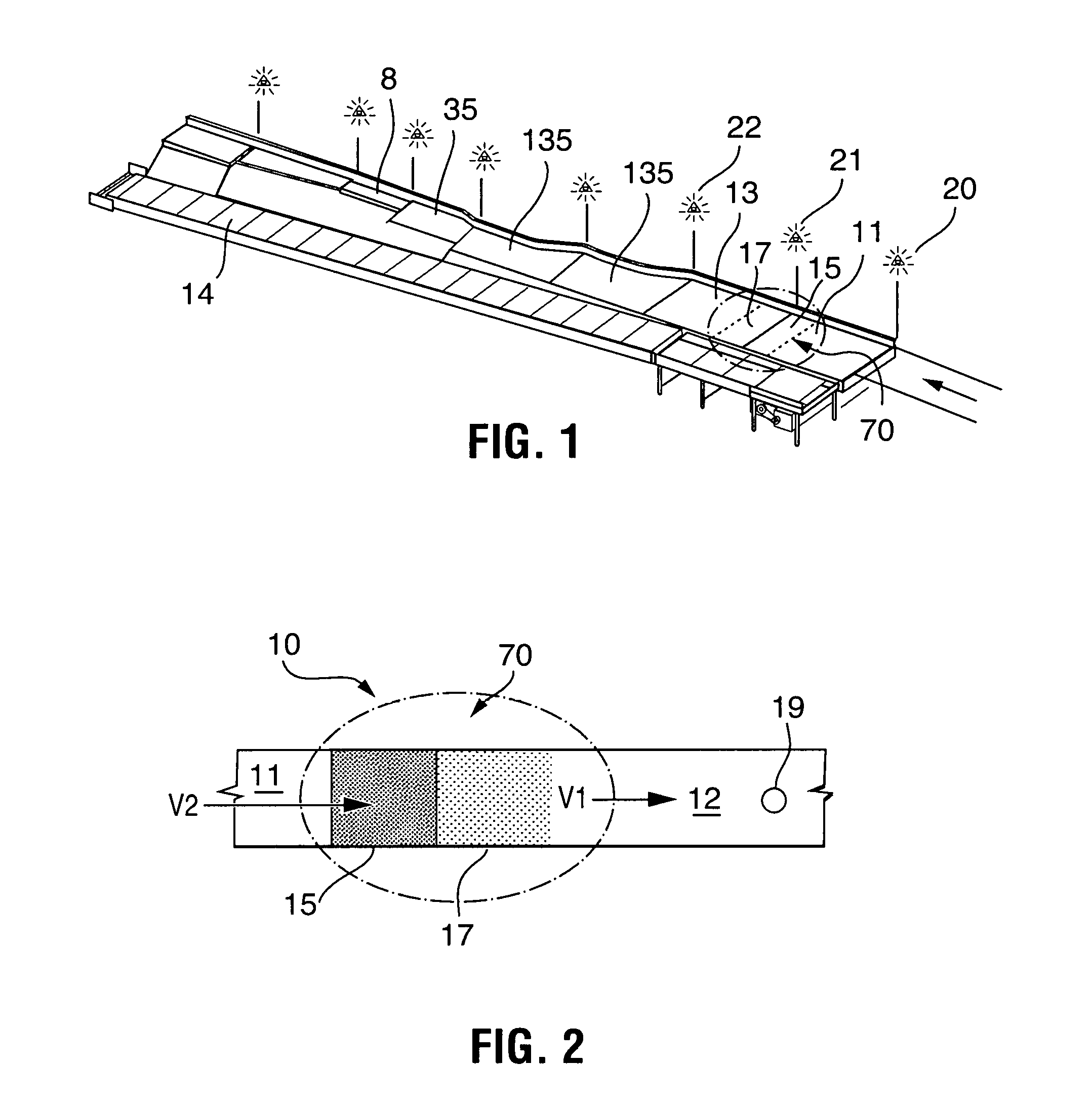

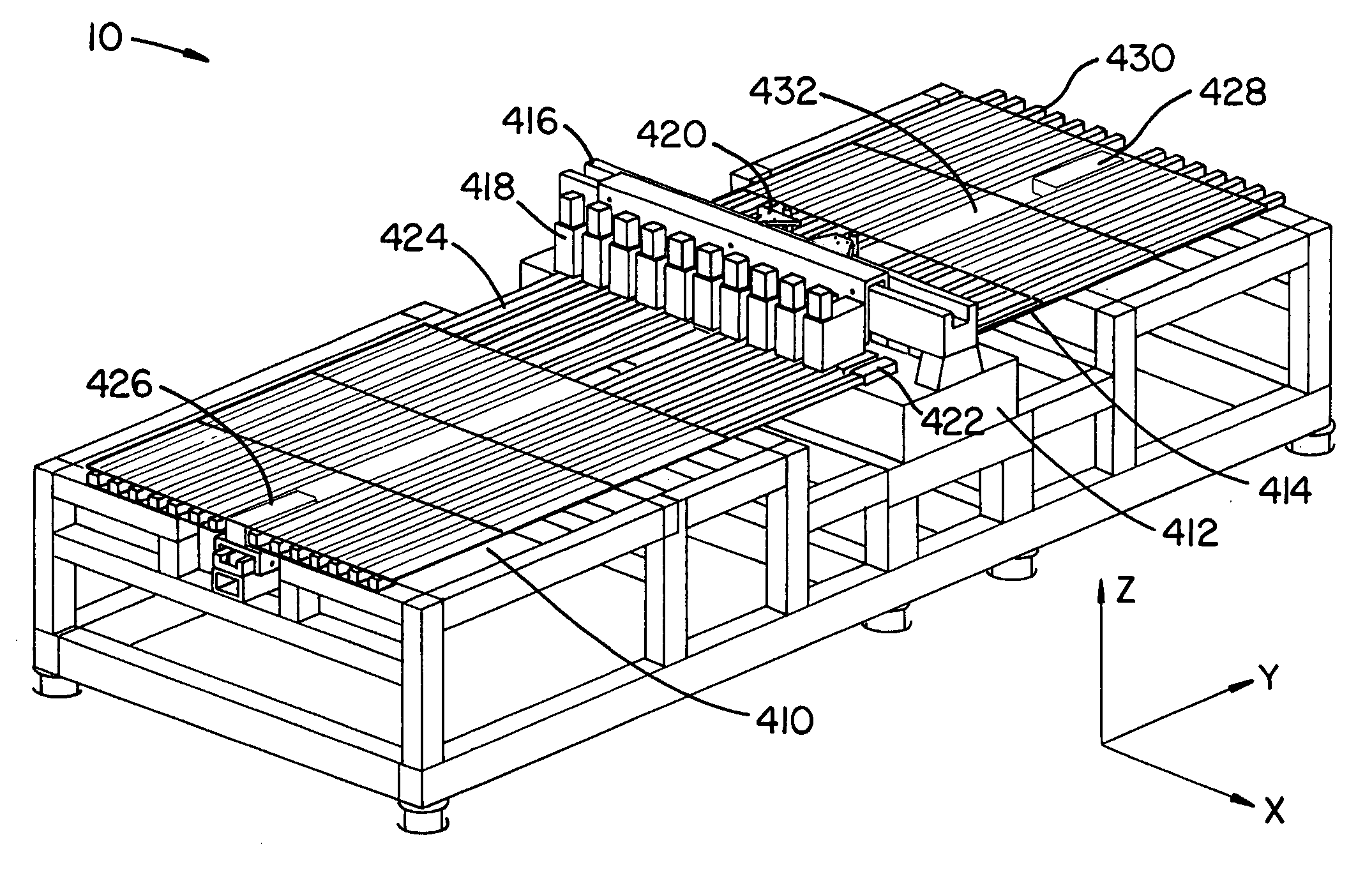

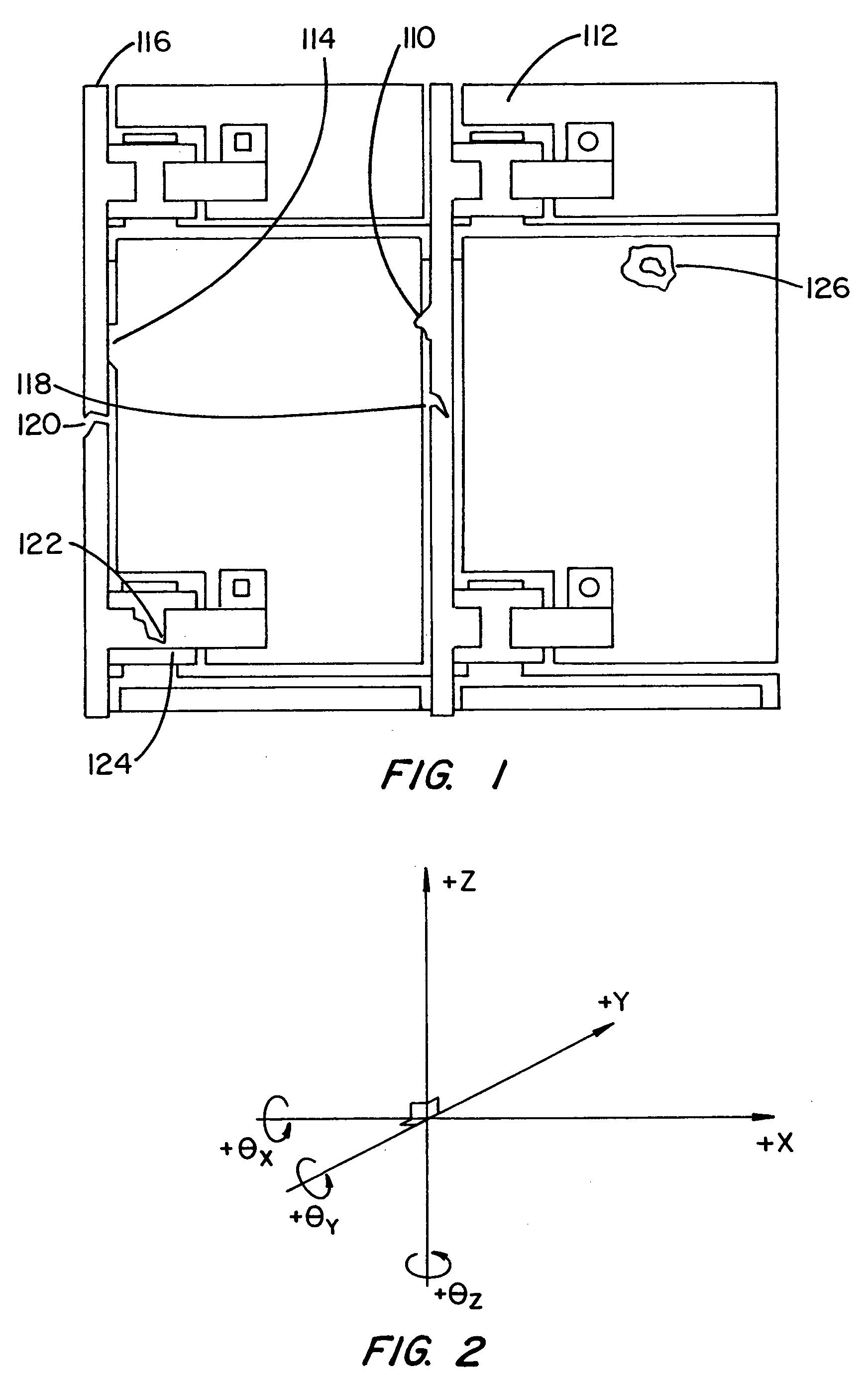

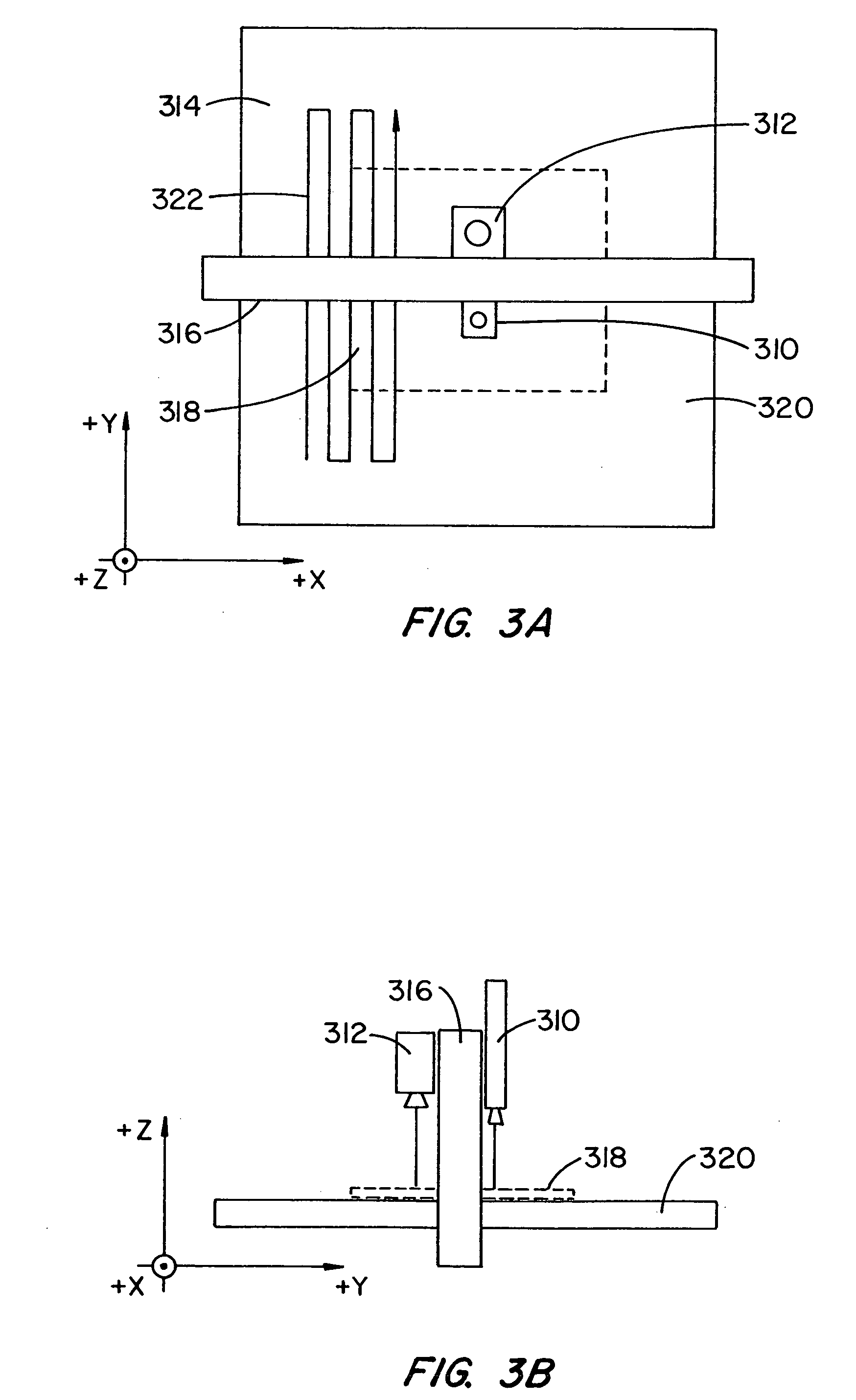

High precision gas bearing split-axis stage for transport and constraint of large flat flexible media during processing

ActiveUS20050040338A1Reduces system inspection tact timeTact time can be reducedConveyorsSemiconductor/solid-state device manufacturingFlat glassPorous medium

A modular split-axis stage is used to inspect and / or repair large flat glass media suitable for LCD / TFT applications. Low-precision air table sections are detachably mounted to a centrally located, high-precision granite inspection / repair section. Glass media held by a vacuum contact is transported on air cushions from the up-web air table to the central inspection / repair section. Vacuum nozzles integrated with porous medium pads precisely control the height of the flexible media above the central section during inspection or repair. Embodiments includes structures in which the media is either stationary or moving during inspection / repair. A first media can be loaded / unloaded while a second media is undergoing inspection or repair in a pipelined operational mode.

Owner:ORBOTECH LTD

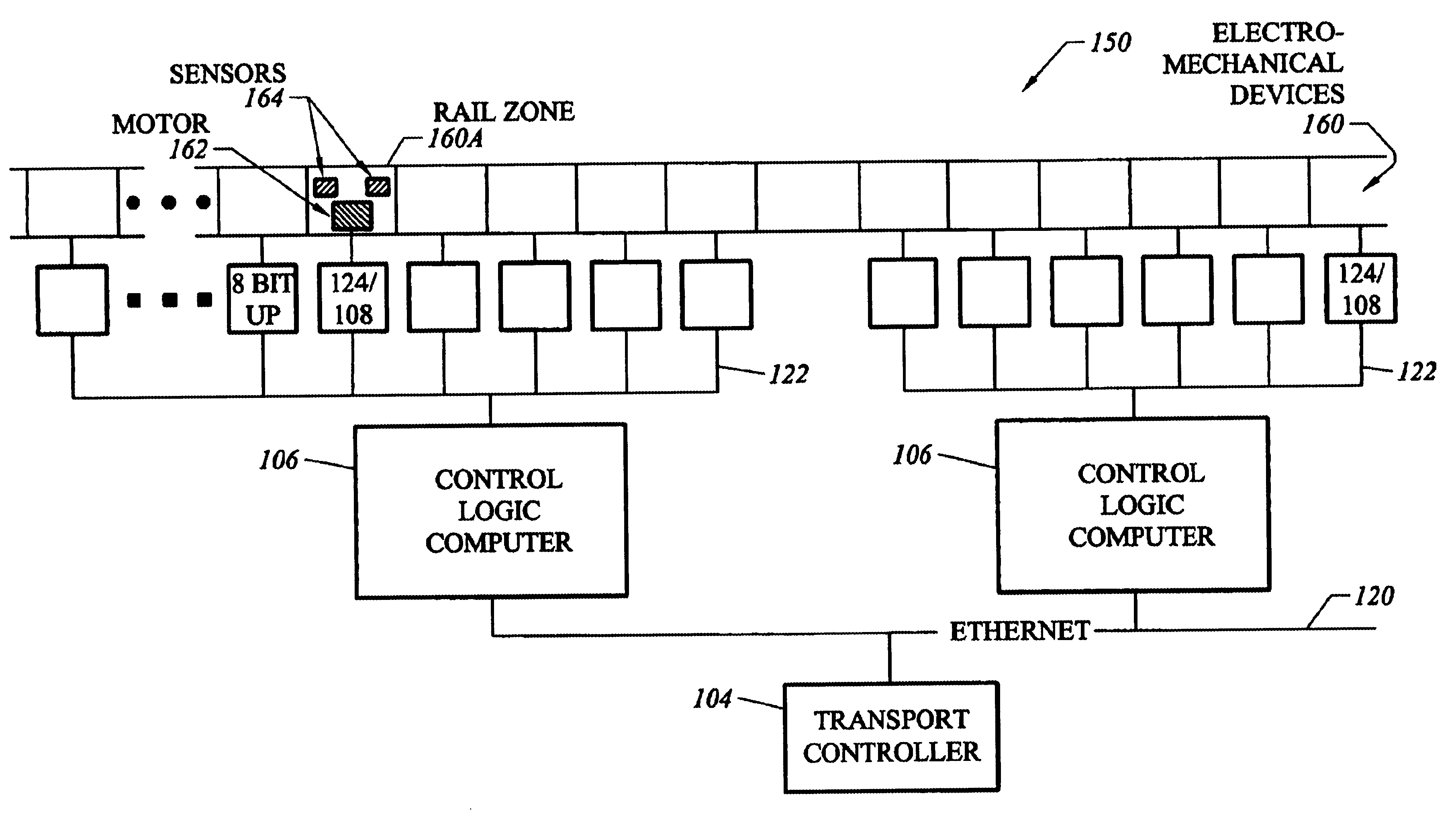

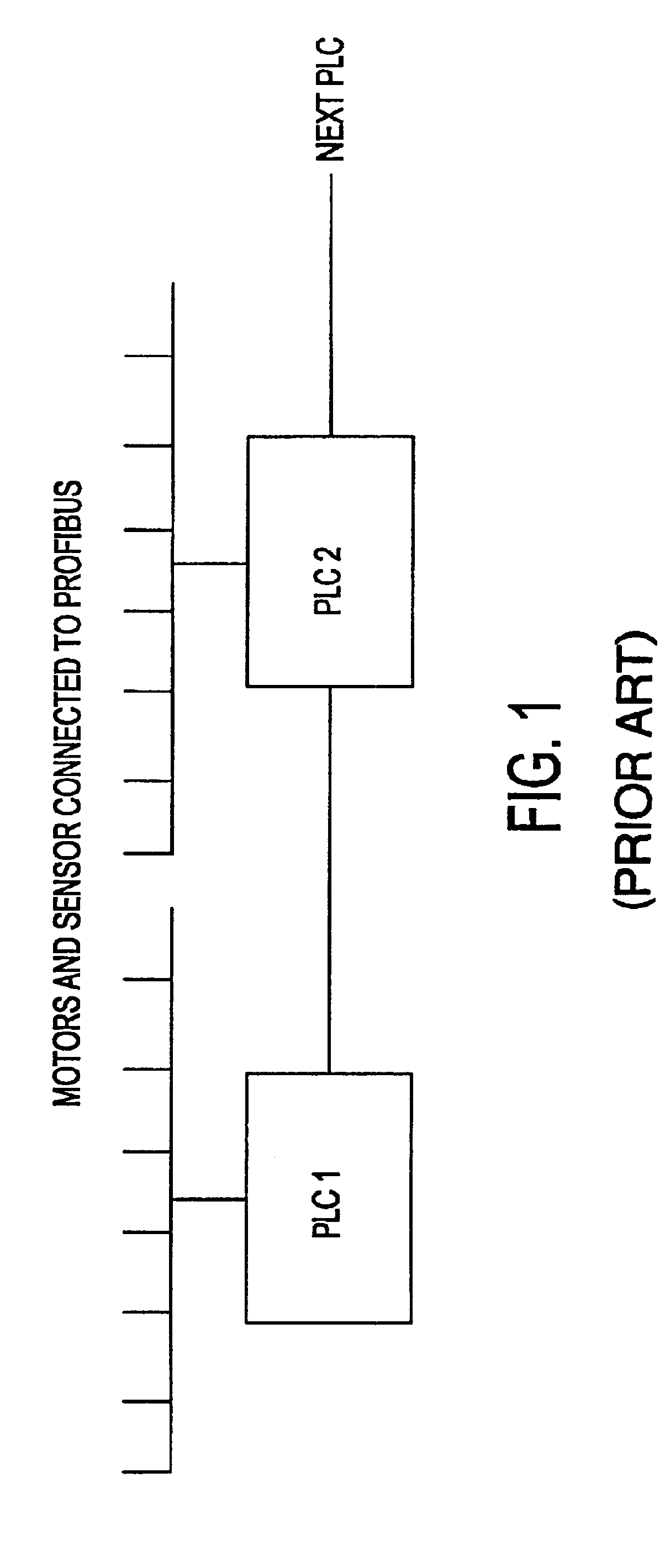

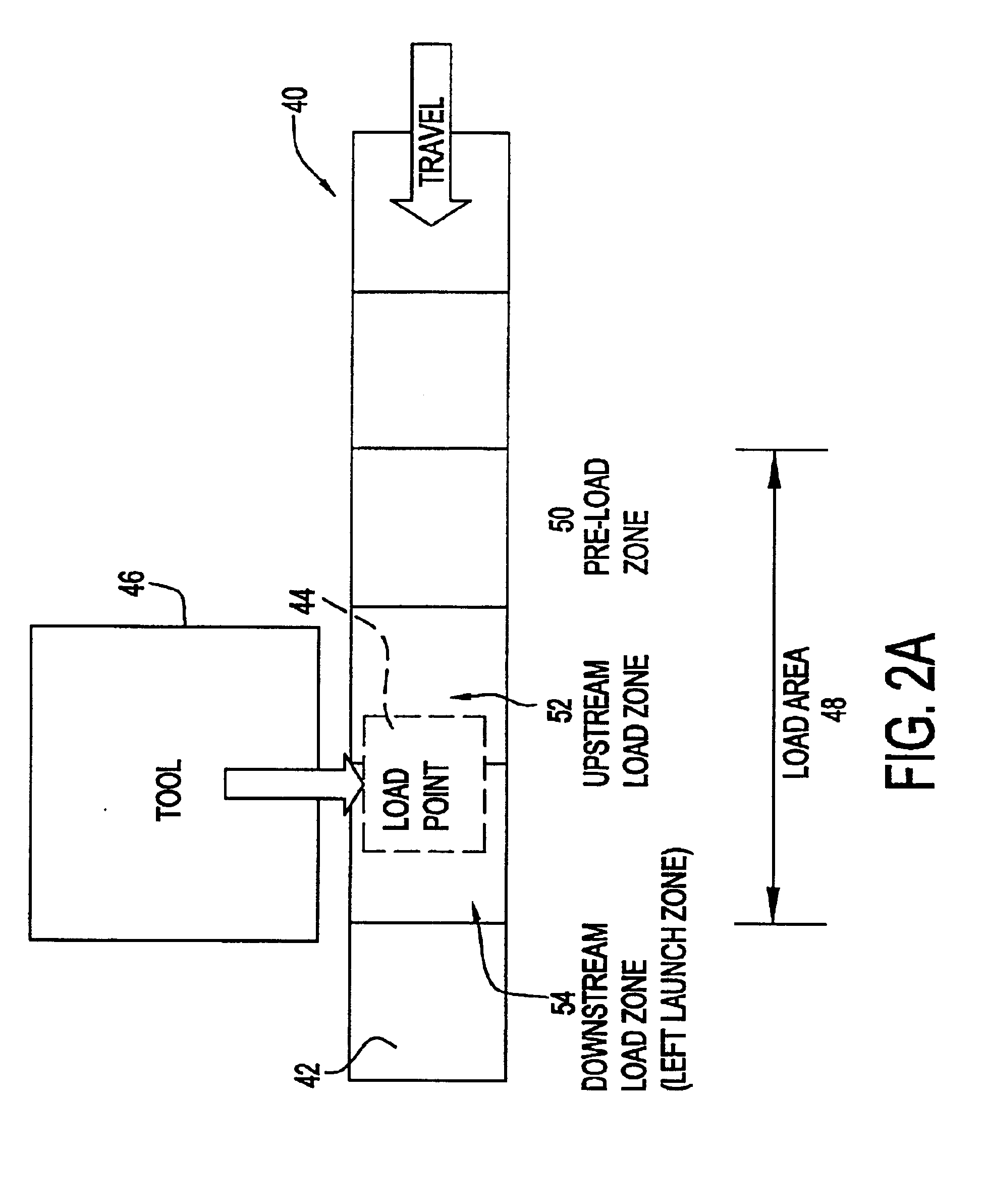

Distributed control system architecture and method for a material transport system

InactiveUS6853876B2Computer controlDigital data processing detailsTransport systemDistributed control system

An automated transport system for use in a material handling system. The automated transport system employs a distributed control system including a top level controller (transport controller), a plurality of second-level controllers (control logic computers) and a plurality of third-level controllers (intelligent drivers). The transport controller (TC) receives material commands from a conventional material control system (MCS). The TC breaks the command into sub-commands directing selected control logic computers (CLCs) to acquire, move to a destination or otherwise interact with a particular container designated by the MCS command. The transport controller selects the CLCs based on the transport system topology, the content of the MCS command and knowledge of which regions of the transport system are controlled by respective CLCs. Each CLC implements the sub-commands by issuing to the intelligent drivers low level control commands to accelerate, elevate, rotate, load or unload the container. Each intelligent driver directly controls one of the electromechanical devices that compose the transport system hardware in accordance with these low level commands. The electromechanical devices can include rail sections (zones), directors, elevators, load port transfer devices and tag readers.

Owner:MURATA MASCH LTD

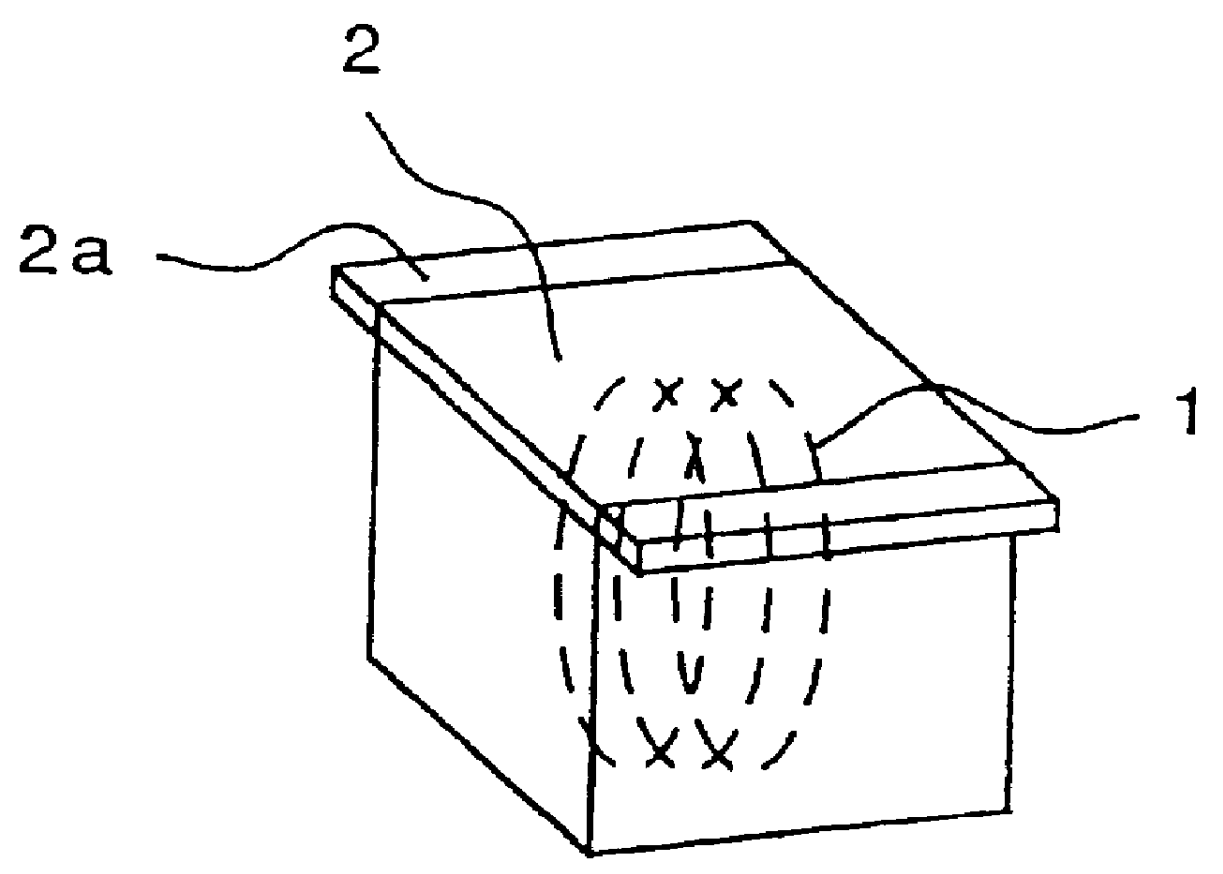

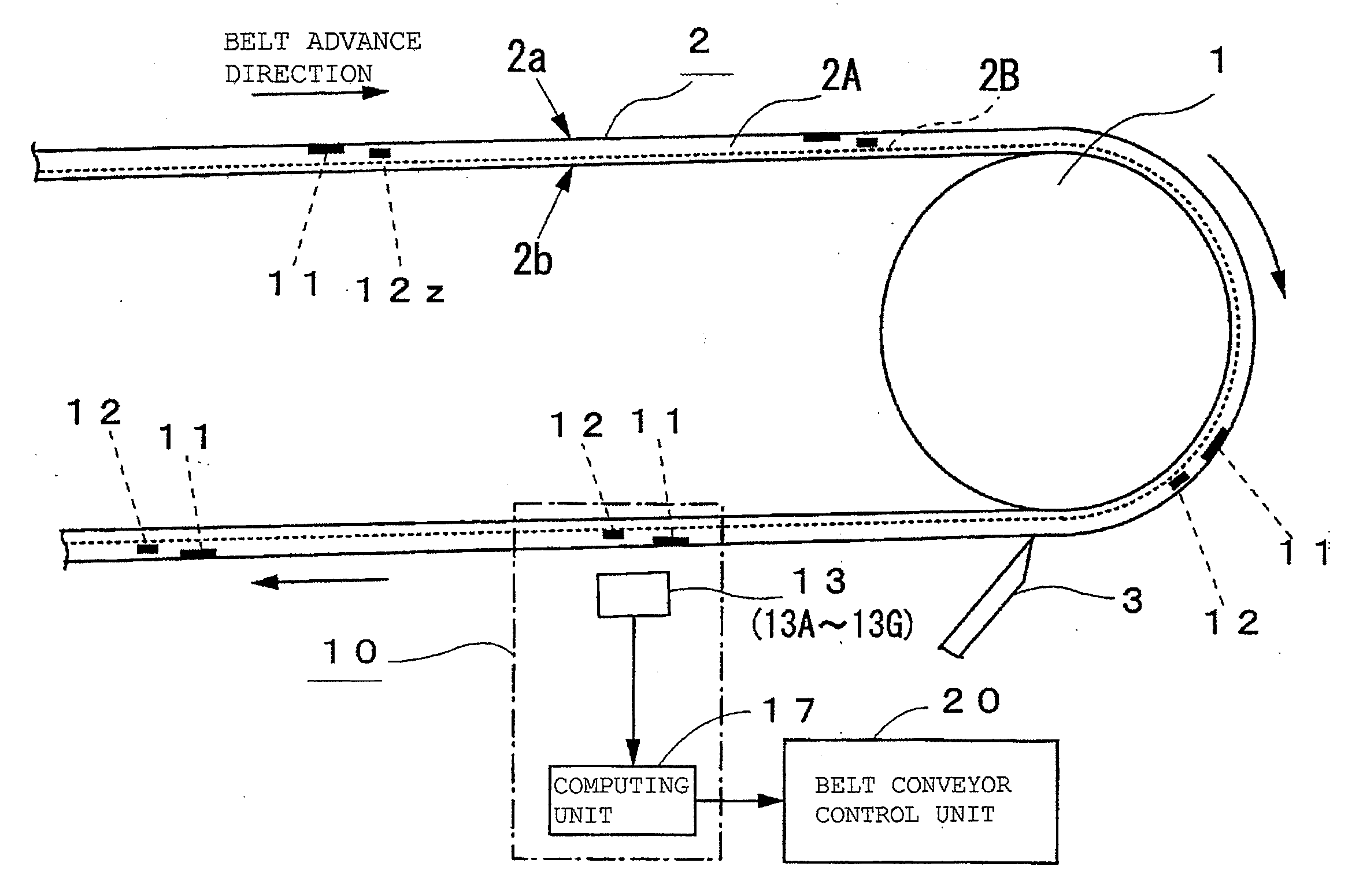

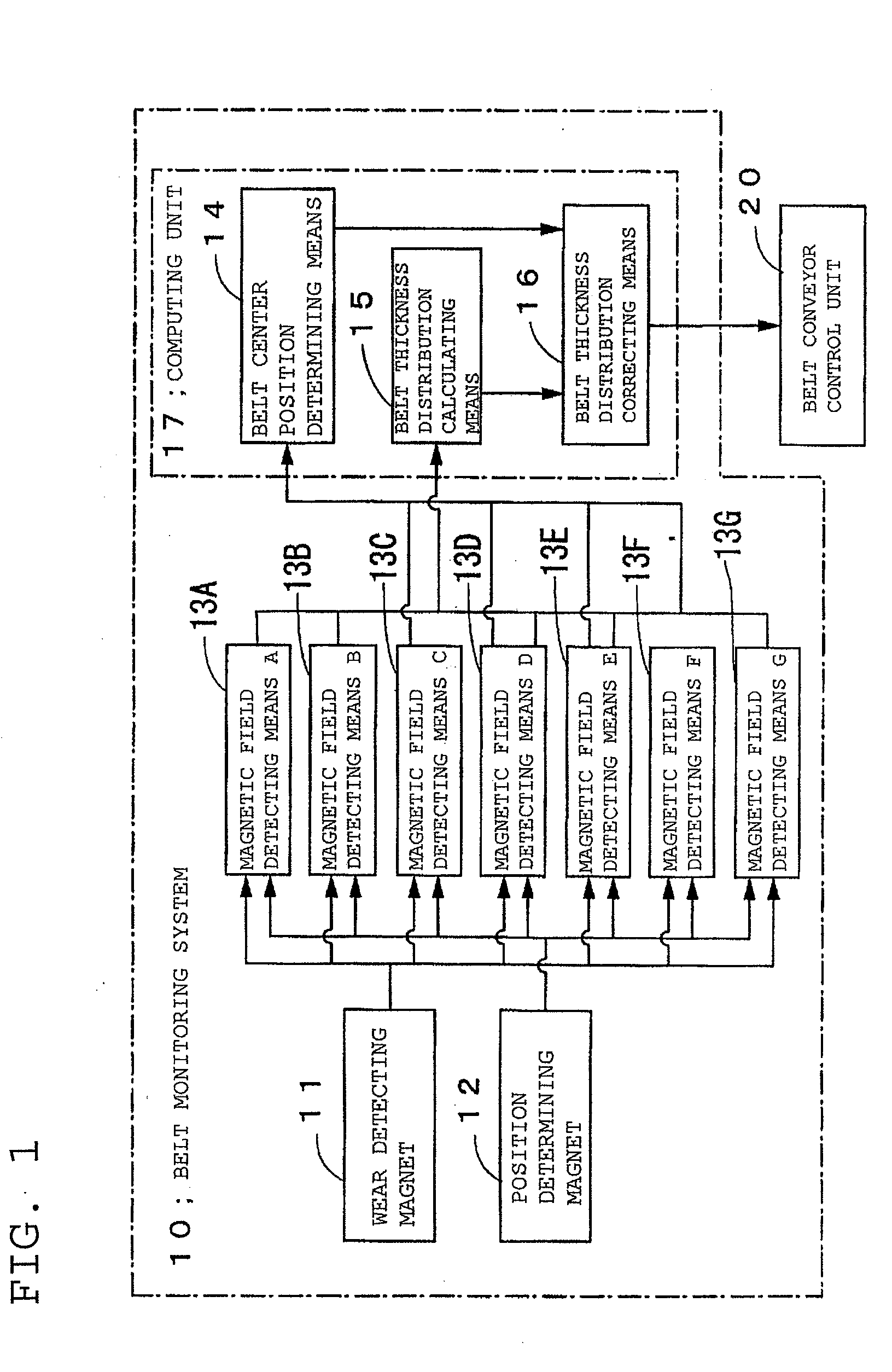

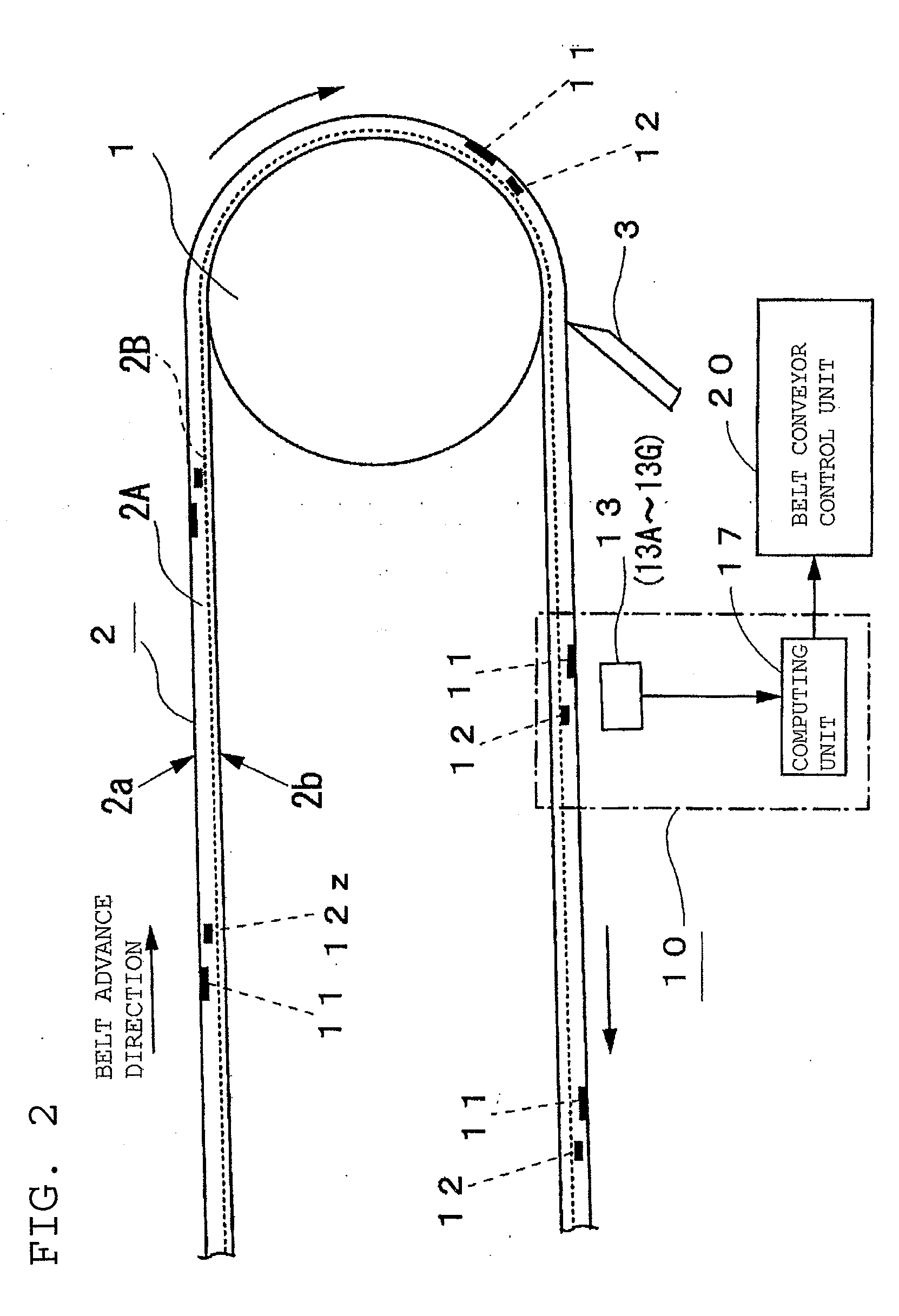

Belt monitoring system

ActiveUS20110050213A1Improve accuracyImprove monitoring accuracyControl devices for conveyorsMagnetic property measurementsMonitoring systemEngineering

A belt monitoring system which can accurately monitor the condition of a conveyor belt by correcting it for the effect of belt deviation. Wear detecting magnets (11), which are rubber magnets spanning the entire belt width, are embedded at intervals along the circumferential direction of the conveyor belt (2). Also, position determining magnets (12, 12z) are embedded in positions a predetermined distance apart from the wear detecting magnets (11). In addition, a plurality of magnetic field detecting means (13: 13A-13G) for detecting the magnetic fields from the magnets (11, 12, 12z), which are arranged at predetermined intervals in the width direction of the conveyor belt (2), are disposed in a position spaced apart from the surface of the conveyor belt (2). The state of deviation of the conveyor belt (2) is detected based on the output signals from the position determining magnets (12, 12z) detected by the magnetic field detection means (13), and then the belt thickness distribution of the conveyor belt (2) in the width direction is corrected based on the detected state of belt deviation.

Owner:BRIDGESTONE CORP

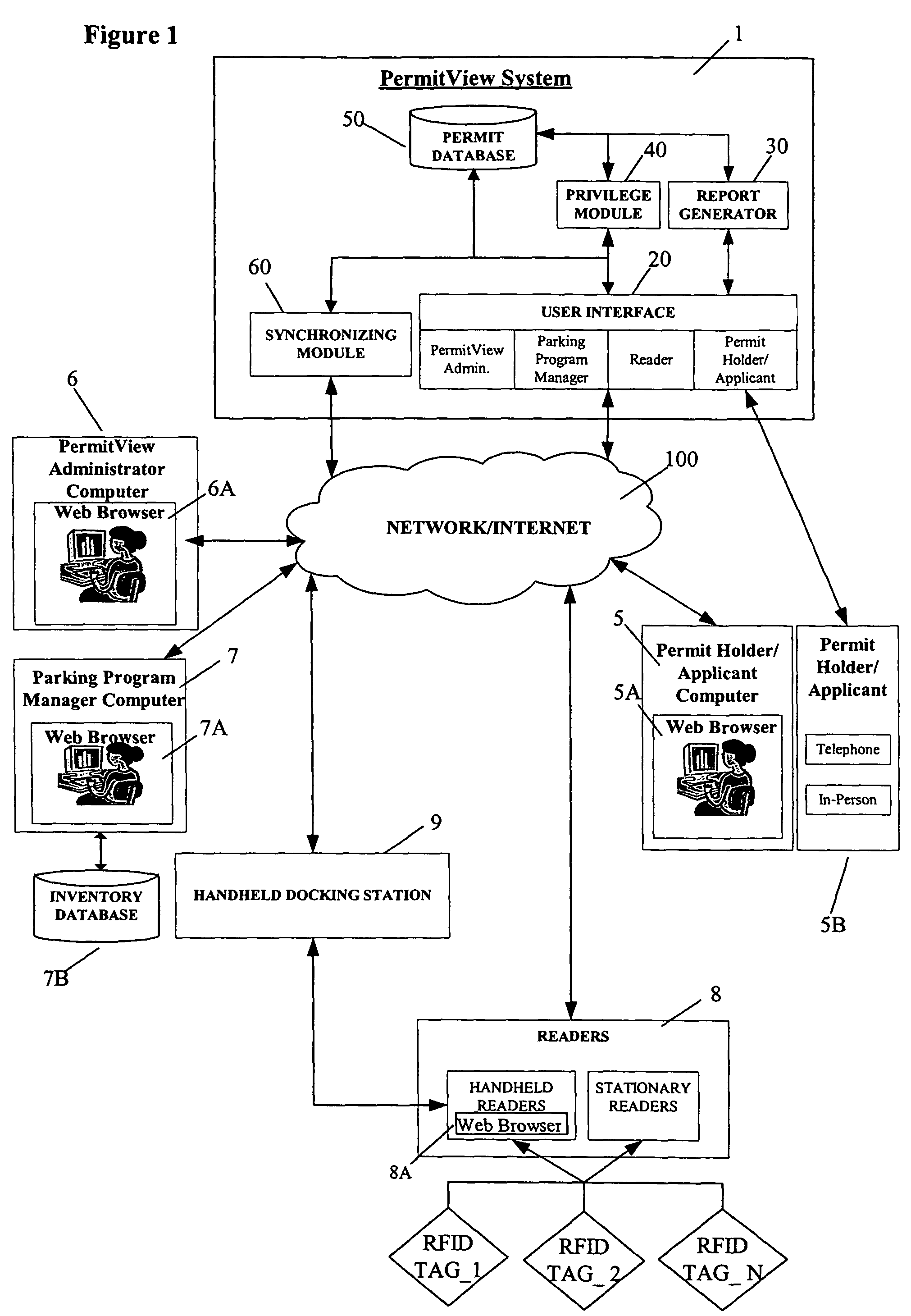

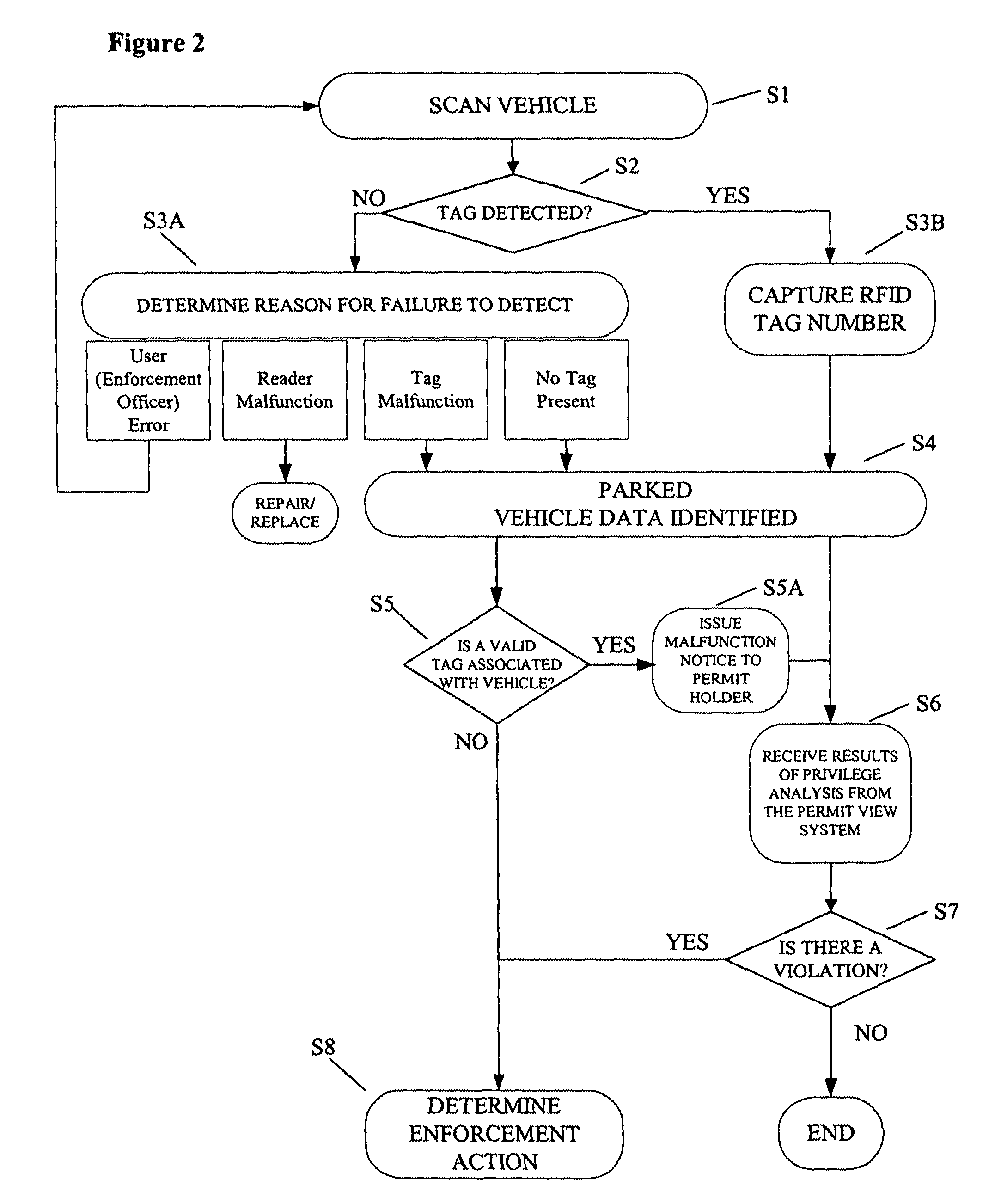

Parking environment management system and method

ActiveUS7950570B2Improve performanceEffective enforcementAnti-theft cycle devicesDetection of traffic movementProgram managementEnvironmental management system

A system and method for managing a permit-based parking environment governed by a parking program. The permit-based parking environment includes a number of parking permits each including a unique RFID tag and tag number. One or more RFID readers are used to scan the vehicles parked in the parking environment to determine if a RFID tag is associated with the parked vehicle. The results of the scan along with information related to the parked vehicle are provided to a permit management system to determine if the vehicle is parked within the scope of privileges pre-defined for that vehicle, pursuant to the parking program governing the parking environment. The permit management system stores, manages, and monitors data related to the permits controlled under the parking program.

Owner:IPT

Chain wear monitoring device

A conveyor system and method of measuring chain wear includes first and second sensing devices positioned at a conveyor line or path and directed toward a conveyor chain that is movable along the conveyor path. The first sensing device senses the presence of a first chain portion of the conveyor chain at a predetermined location as the conveyor chain moves along the conveyor line. The second sensing device senses a second chain portion of the conveyor chain as the conveyor chain moves along the conveyor line. The second sensing device is operable to sense a location of or distance to the second chain portion or may capture an image of the second portion. A controller is operable to determine a degree of wear of a section of chain extending between the first and second chain portions in response to the second sensing device.

Owner:FROST TECH

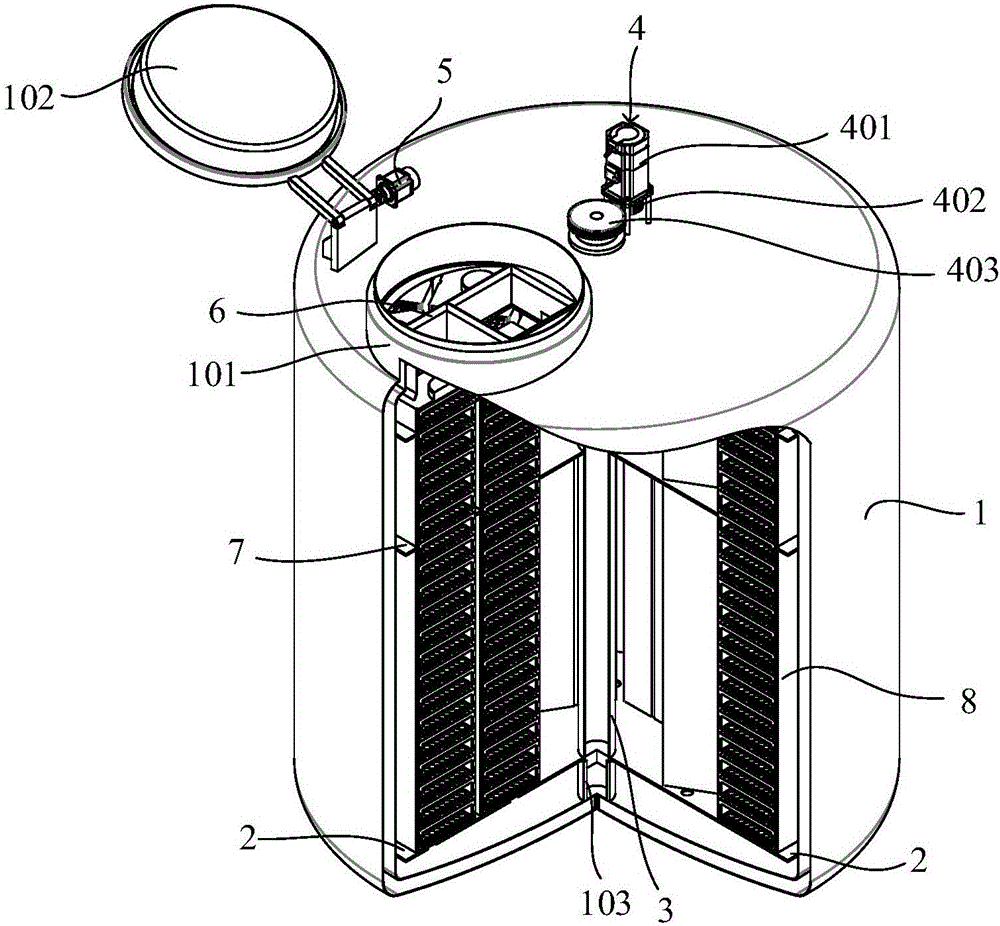

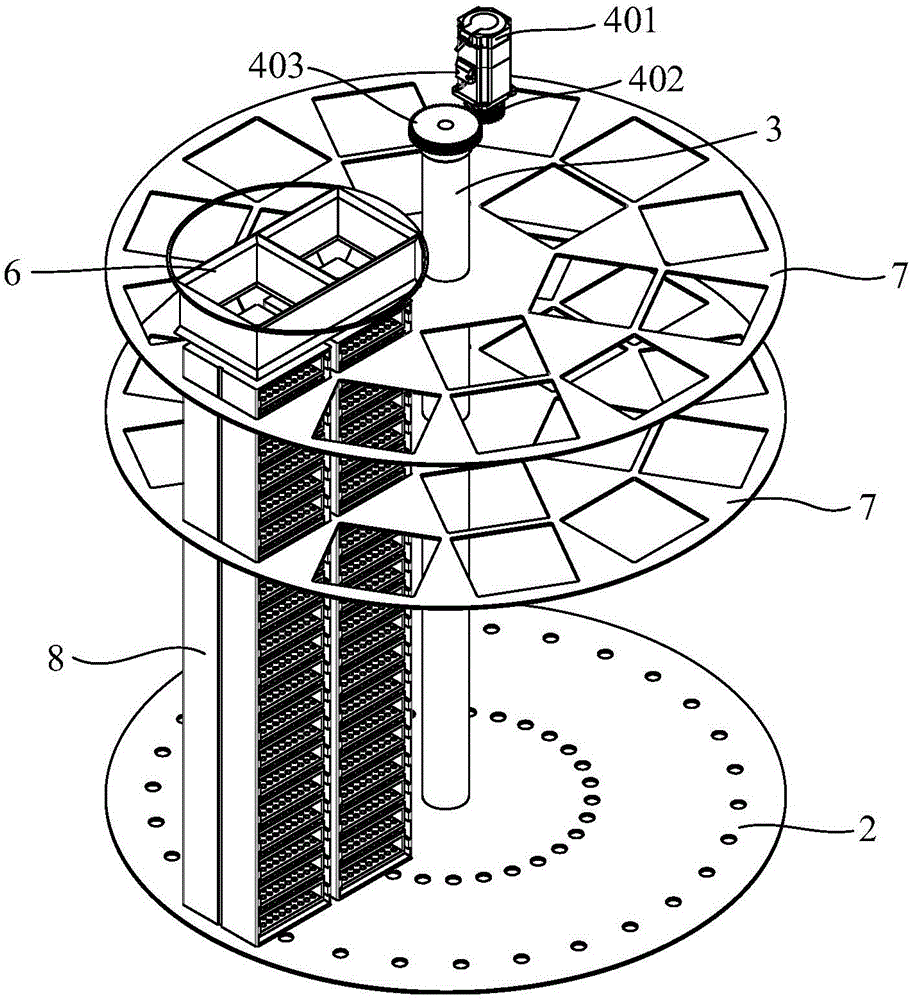

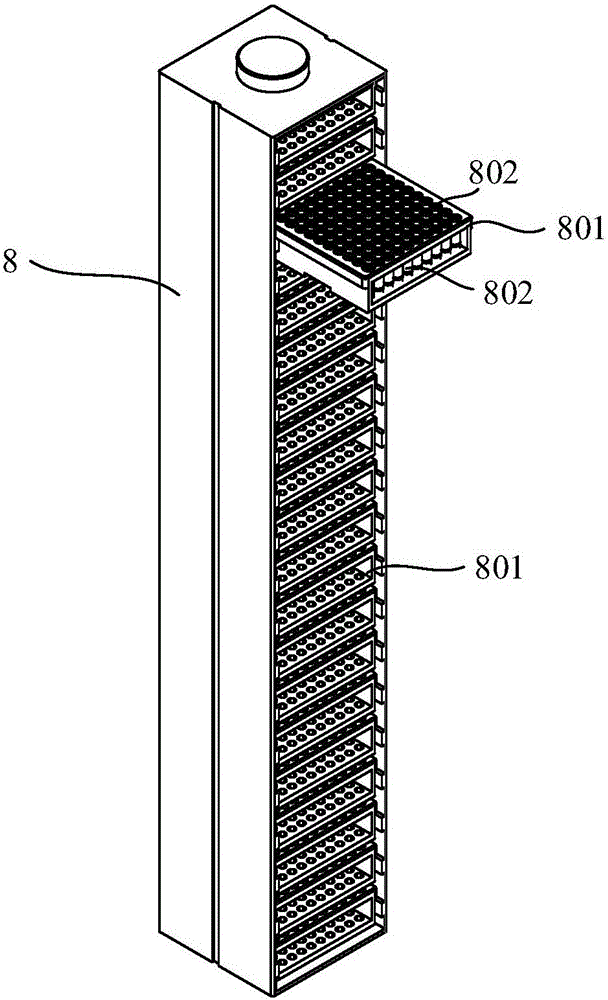

Liquid nitrogen cylinder, cryogenic vial storing and fetching device and liquid nitrogen cylinder storing and fetching system

ActiveCN105857937AReduce error rateAvoid safety hazardsLarge containersControl devices for conveyorsEngineeringLiquid nitrogen

The invention discloses a liquid nitrogen cylinder, a cryogenic vial storing and fetching device and a liquid nitrogen cylinder storing and fetching system. The liquid nitrogen cylinder comprises a cylinder body, wherein the cylinder body is provided with a sealed opening; the liquid nitrogen cylinder further comprises a bracket tray; the bracket tray is arranged in the cylinder body; the bracket tray is used for bearing cryogenic baskets; a central shaft is vertical to the bracket tray and is fixedly connected with the bracket tray; a driving component is electrically connected with the central shaft; the driving component is used for driving the central shaft to rotate; and the central shaft is used for driving the cryogenic baskets to rotate through the bracket tray and conveying the cryogenic baskets to the opening. By adopting the liquid nitrogen cylinder, the error rate of manual cryogenic vial selecting is reduced; and meanwhile, safety hazards for operation personnel during a manual bracket tray rotation process are avoided. By adopting the cryogenic vial storing and fetching device, the process for selecting a single target cryogenic vial for biological samples is realized; and during the whole selecting process, the cryogenic vials are all in a liquid nitrogen environment, so that non-target cryogenic vials are prevented from being exposed at environment temperature. The liquid nitrogen cylinder storing and fetching system is applicable to vial picking work for large biological sample banks.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

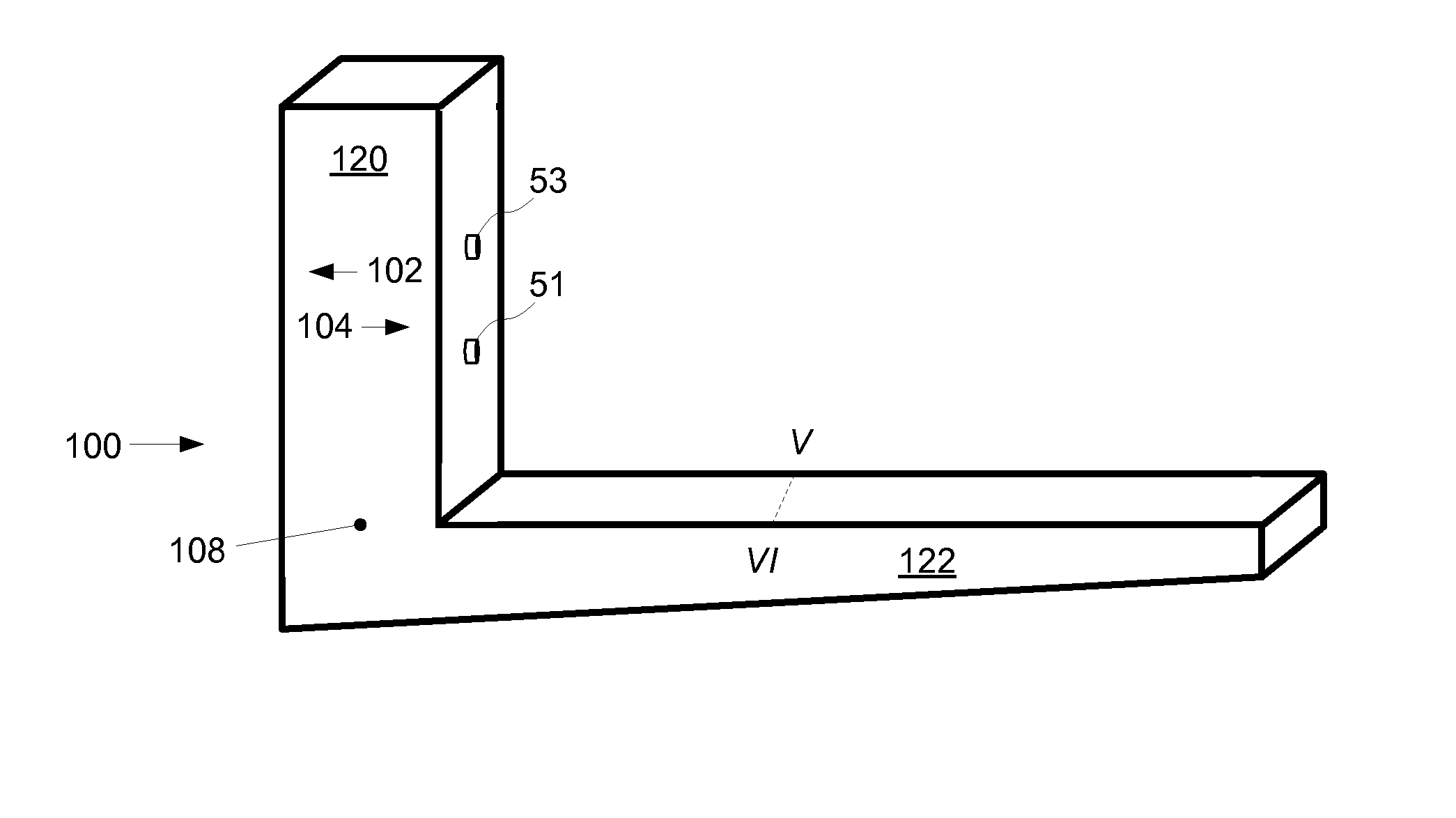

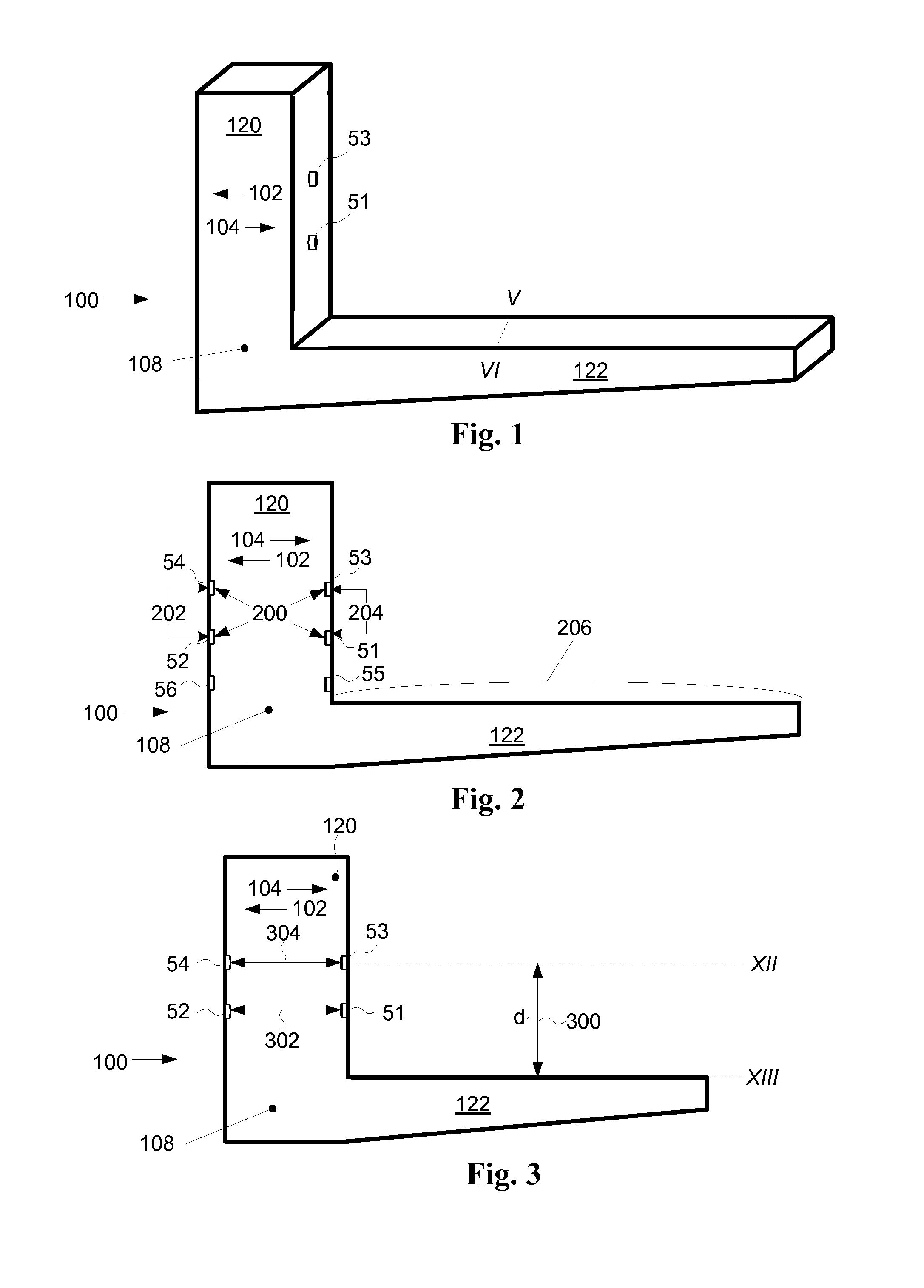

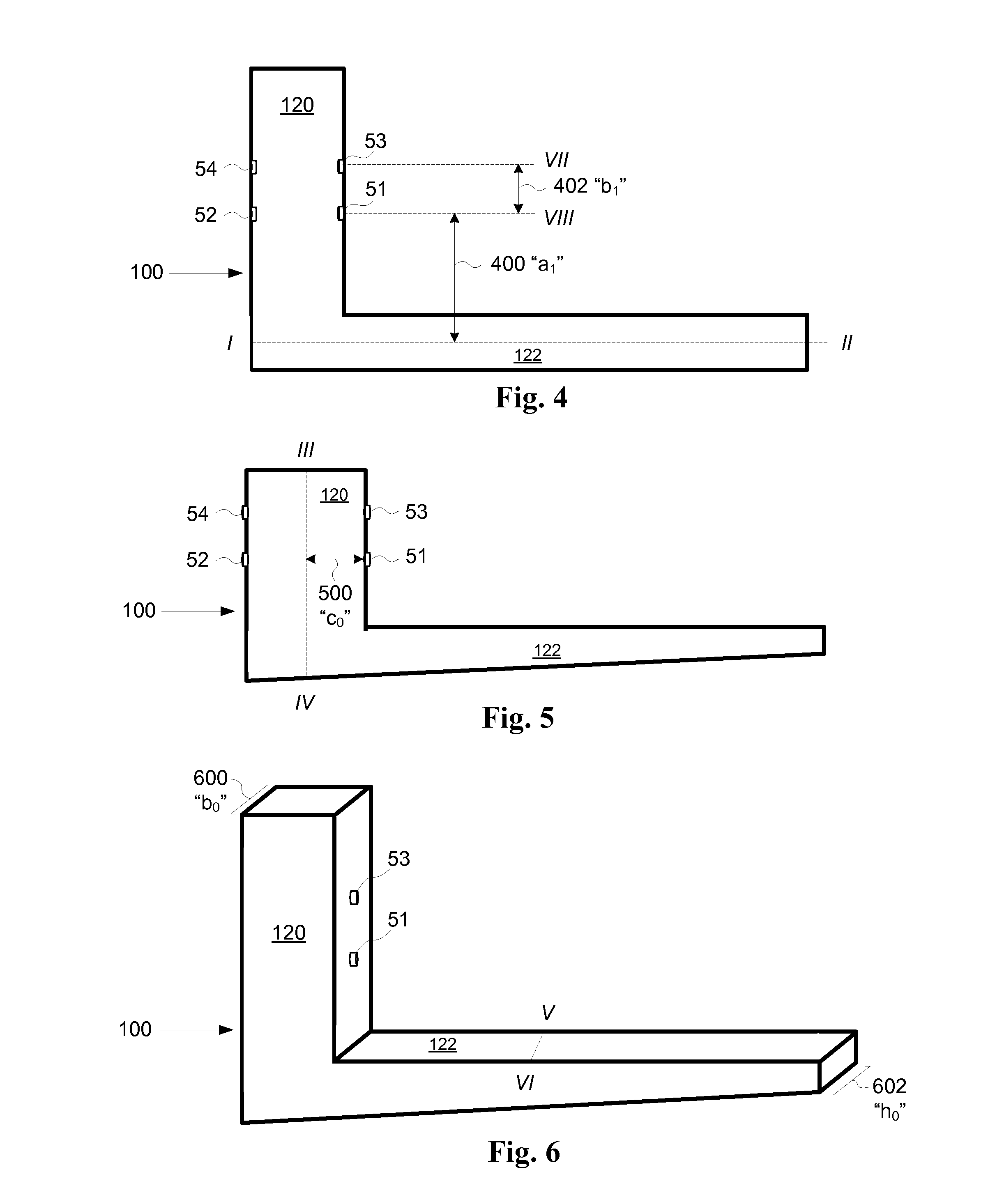

System and method to measure force or location on an l-beam

InactiveUS20160187186A1Improve accuracyAvoid problemsSafety devices for lifting equipmentsConveyorsEngineeringProduct image

Force and location sensing systems and methods are disclosed. A method comprises bending a L-beam at an initially unknown location on a force-supporting portion of the L-beam, the L-beam substantially having a tension side and a compression side, measuring a first local stress at a first location on the tension side, measuring a second local stress at a second location on the tension side, measuring a third local stress at a third location on the compression side, and measuring a fourth local stress at a fourth location on the compression side. A weight-sensing storage system capable of tracking removed items is disclosed with a product image captured via a camera, a plurality of sensors on an L-beam, a first signal from the plurality of sensors indicating a first state prior to change of the product image, and a second signal indicating lower strain on the L-beam than the first signal.

Owner:COLEMAN NATE J +1

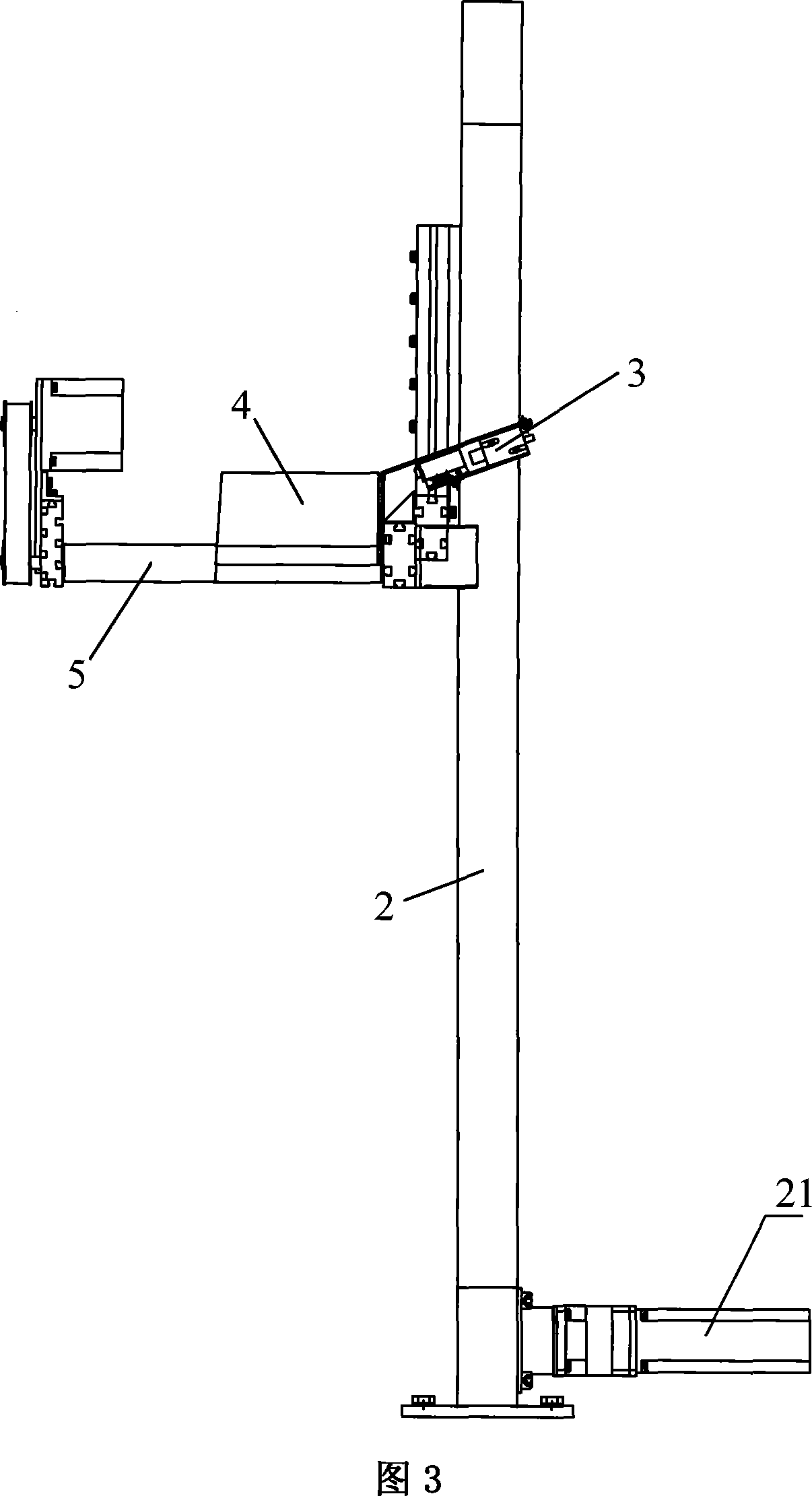

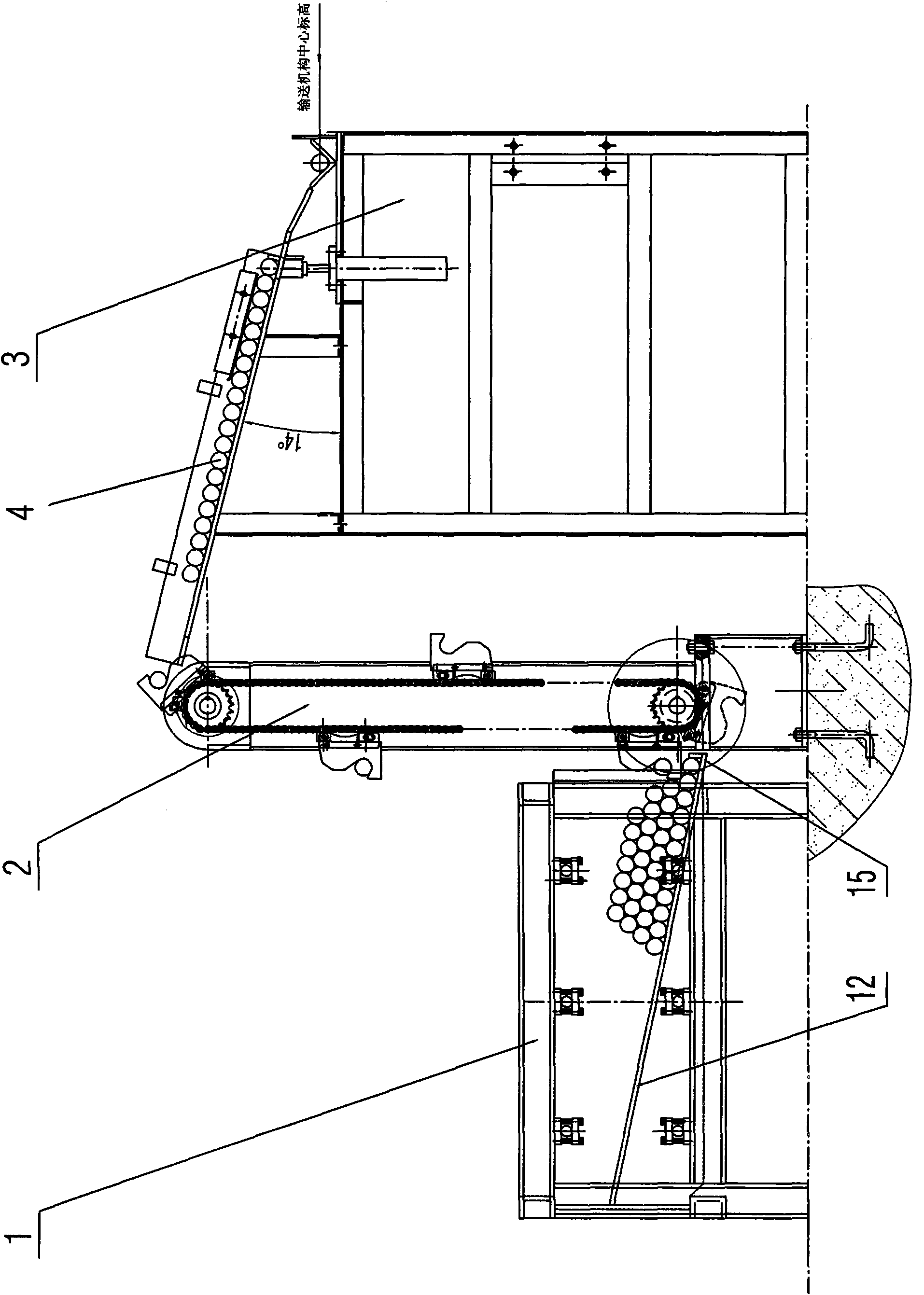

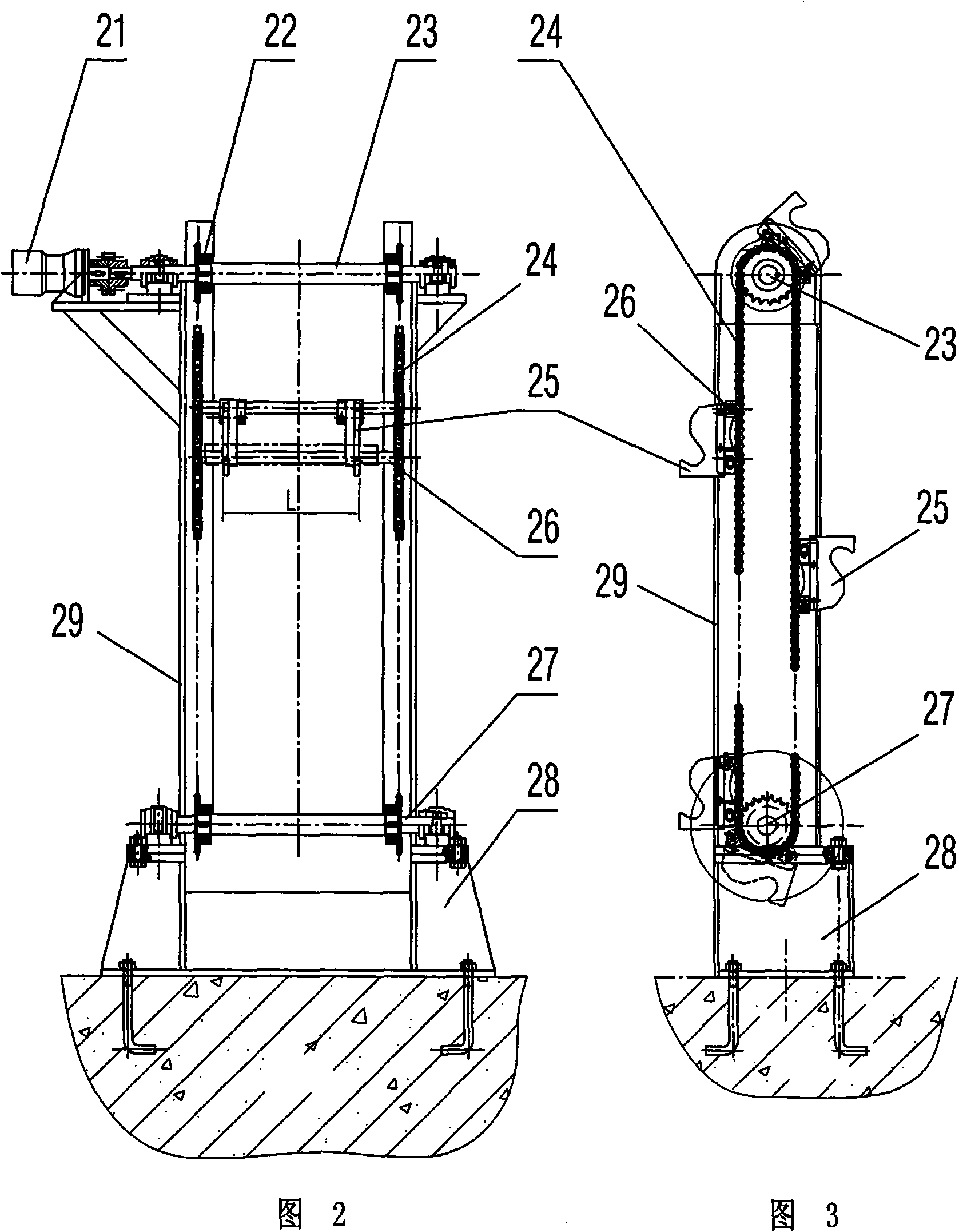

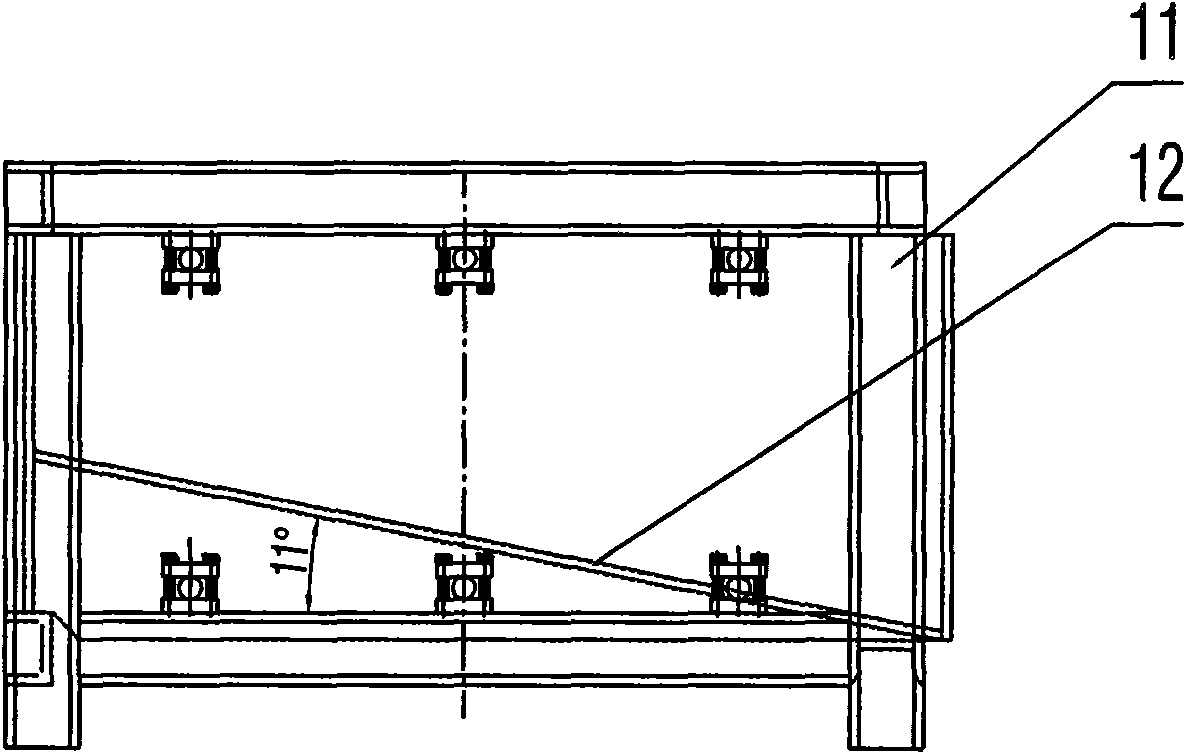

Automatic lifting mechanism for round metal rod

ActiveCN101628658AGuarantee normal productionReduce labor intensityConveyorsControl devices for conveyorsEngineeringAutomation

The invention relates to an automatic lifting feeding and discharging mechanism for a round metal rod, in particular to an automatic lifting mechanism for a round metal rod. According to the technical scheme provided for the mechanism in the invention, a discharge opening of a feed box is connected with a feed end of a lifting feeding machine and a discharge end of the lifting feeding machine is connected with a feed opening of a feeding and discharging machine; in the feed box, an inclined bottom plate of the feed box is arranged on the lower part of the feed box body, the lower end of the inclined bottom plate of the feed box is positioned at the discharge opening of the feed box, and a group of side plate fixing rods are respectively arranged on both the upper part and the lower part of the feed box; the inner ends of the side plate fixing rods are connected with a side regulating plate and the outer ends extend out of a side face of the feed box; and the side regulating plate is positioned on both sides of the inclined bottom plate of the feed box. The mechanism adopts an integrated mechanical, electric and hydraulic automatic lifting mechanism for the round metal rod and has the advantages of high production efficiency, high degree of automation, steady production process and safe reliability.

Owner:王洪军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com