Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2156 results about "Conveyor system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

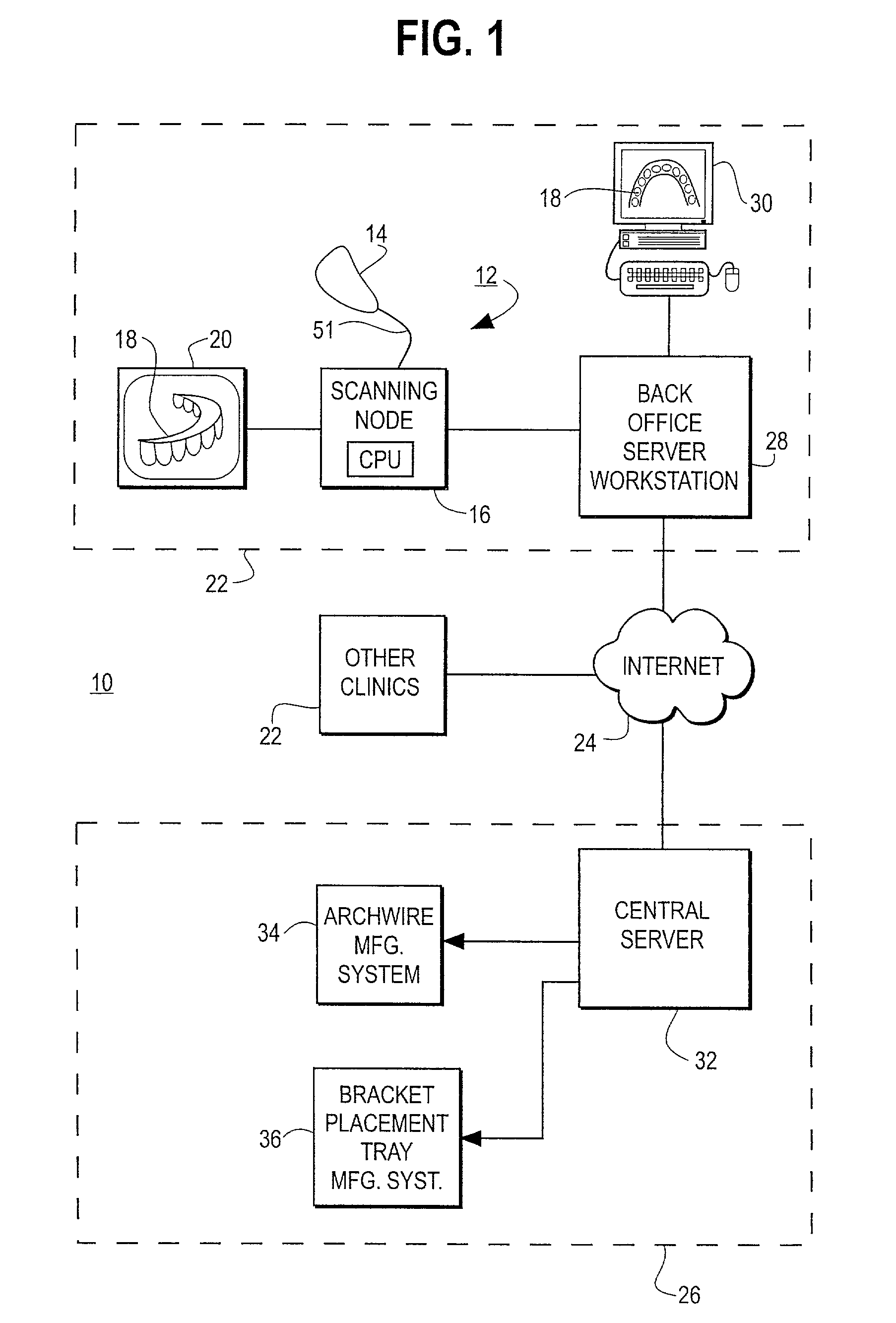

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transportation of heavy or bulky materials. Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors (floor and overhead) as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

Conveyor system

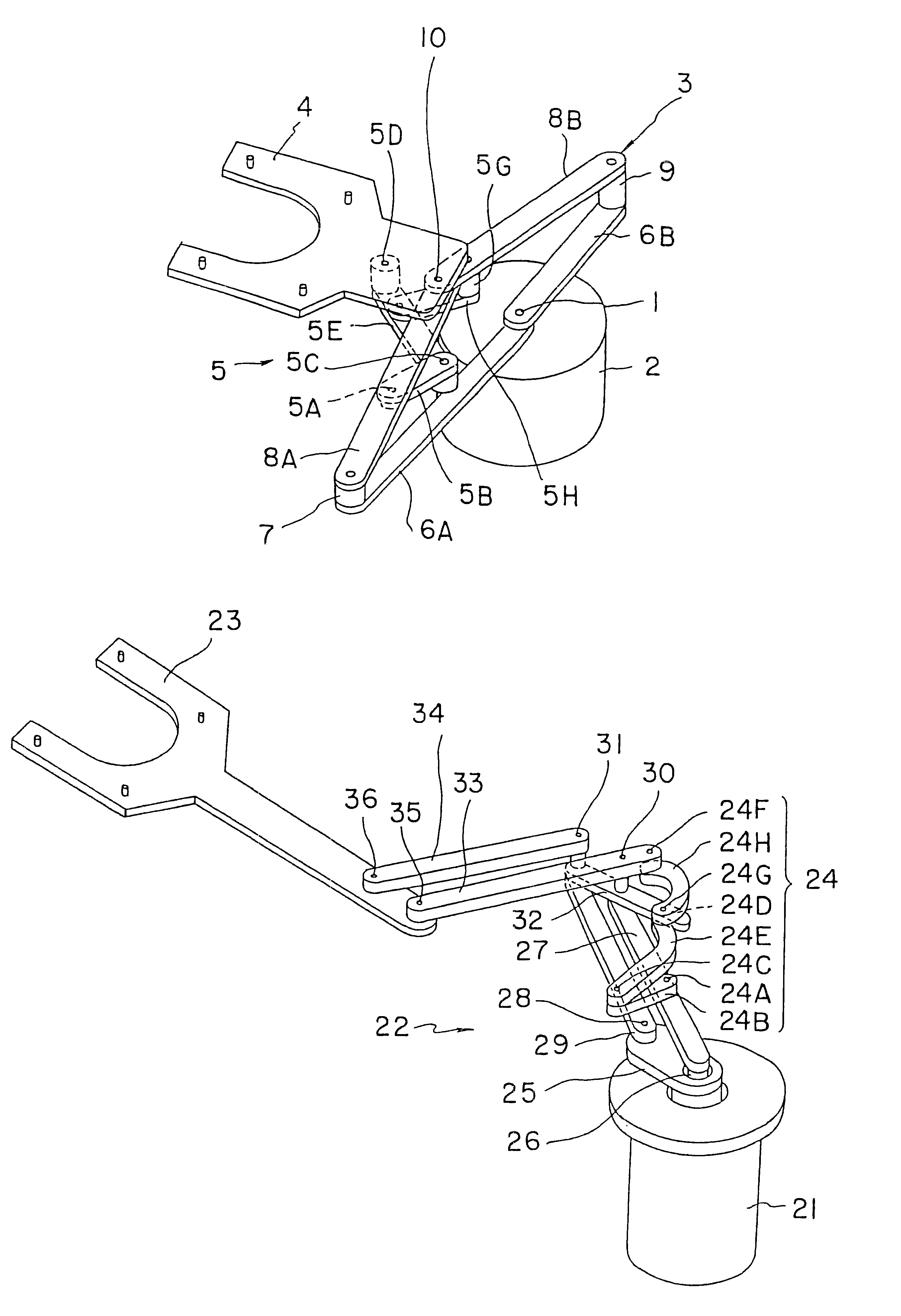

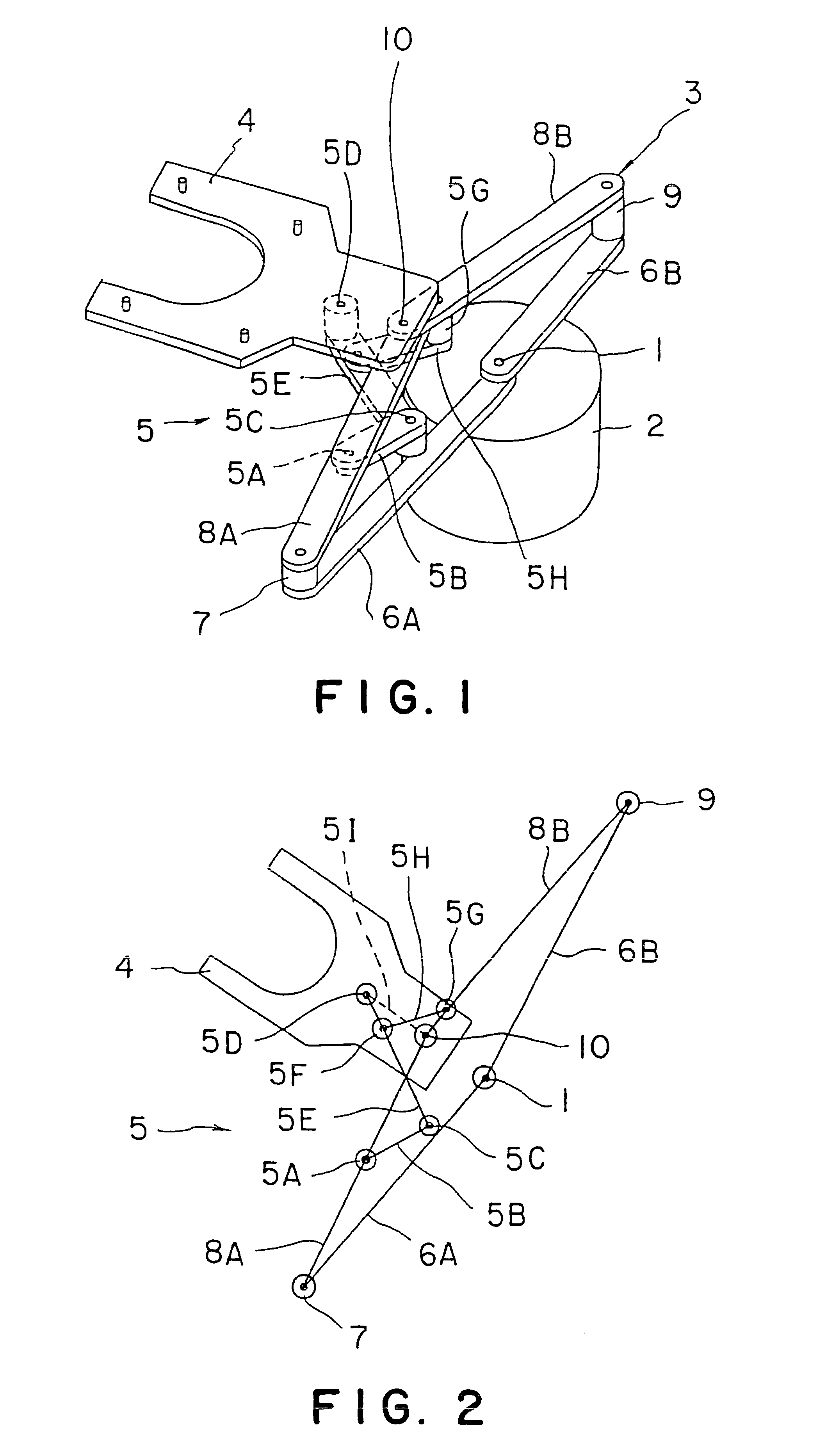

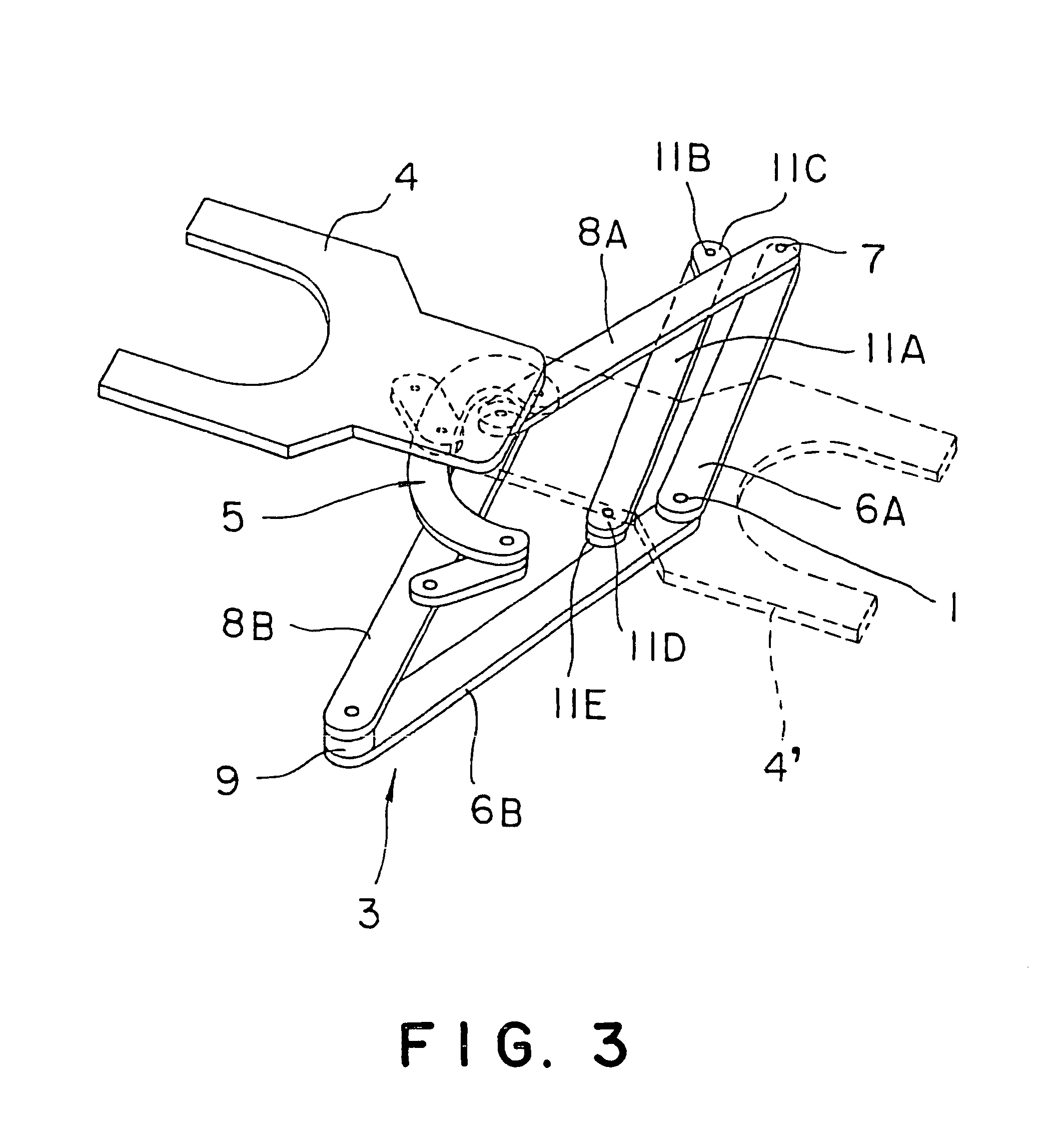

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

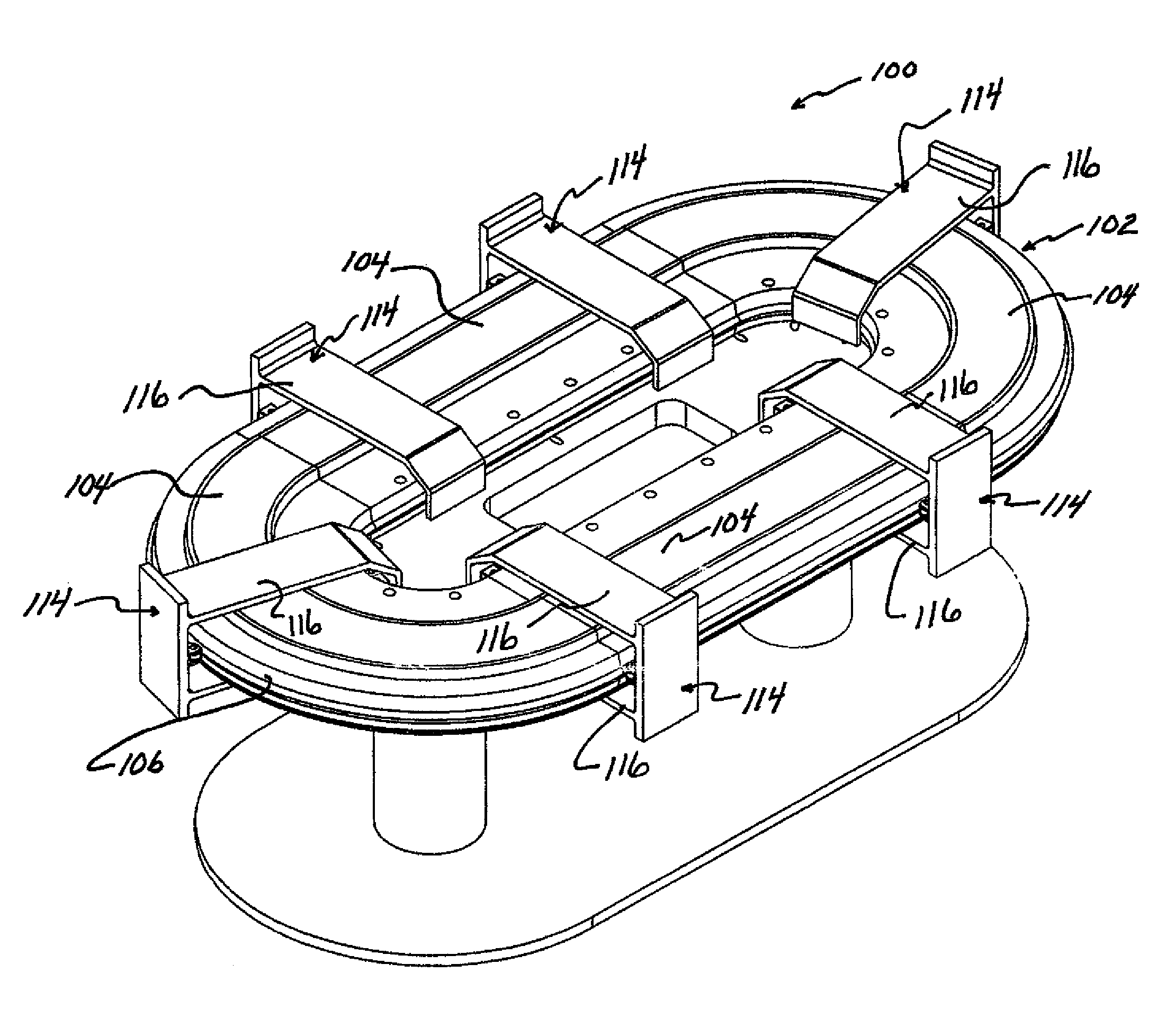

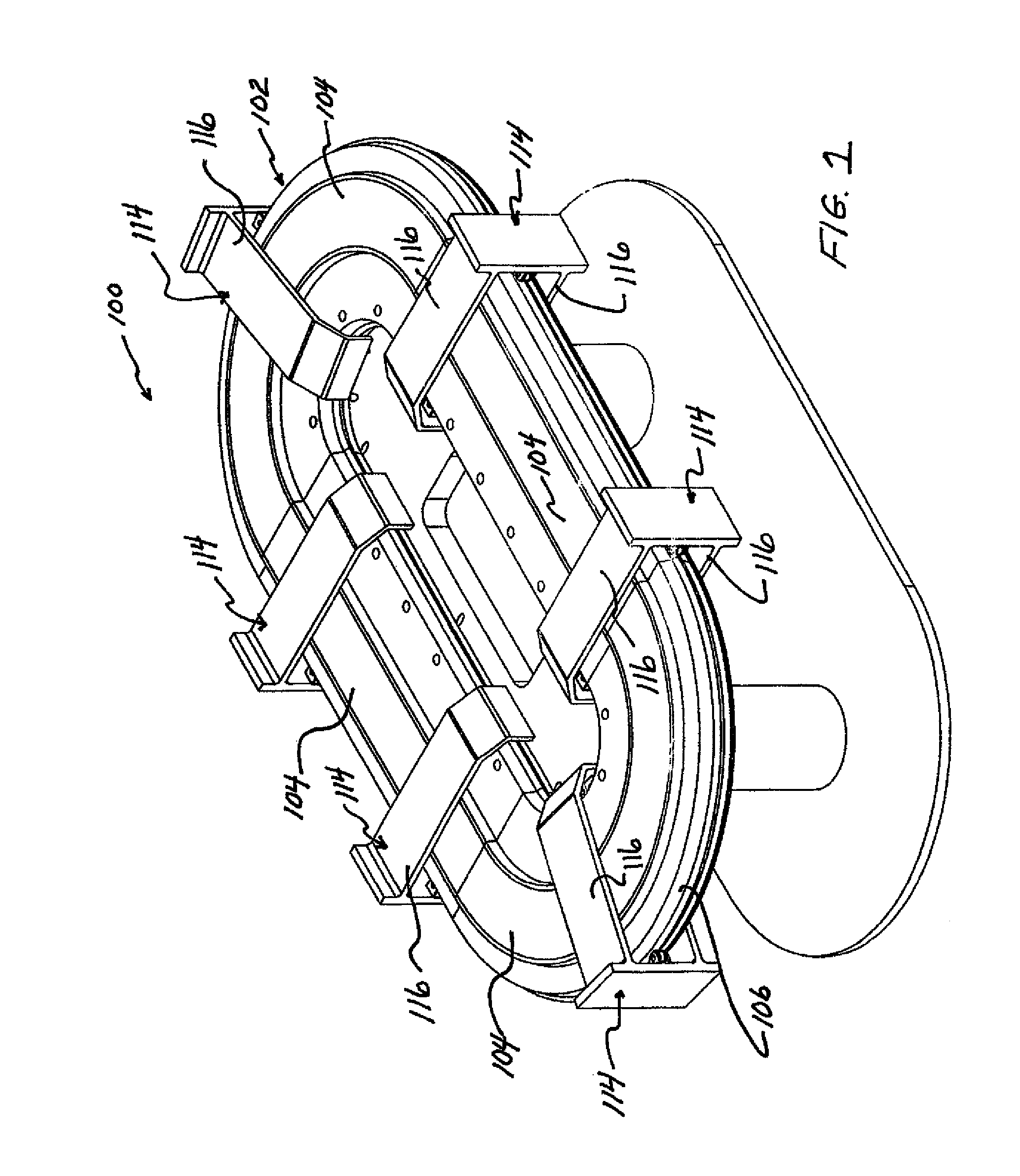

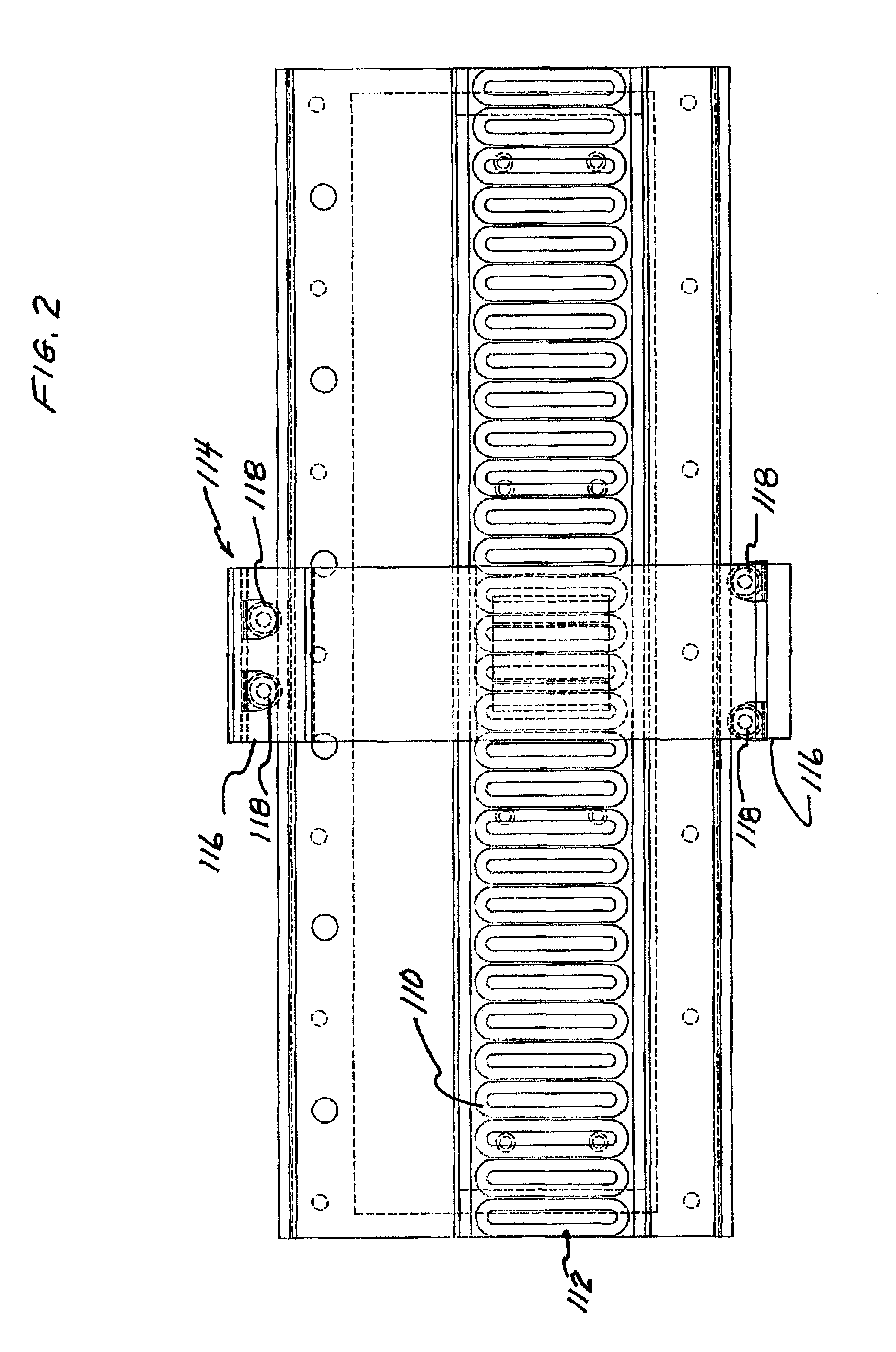

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

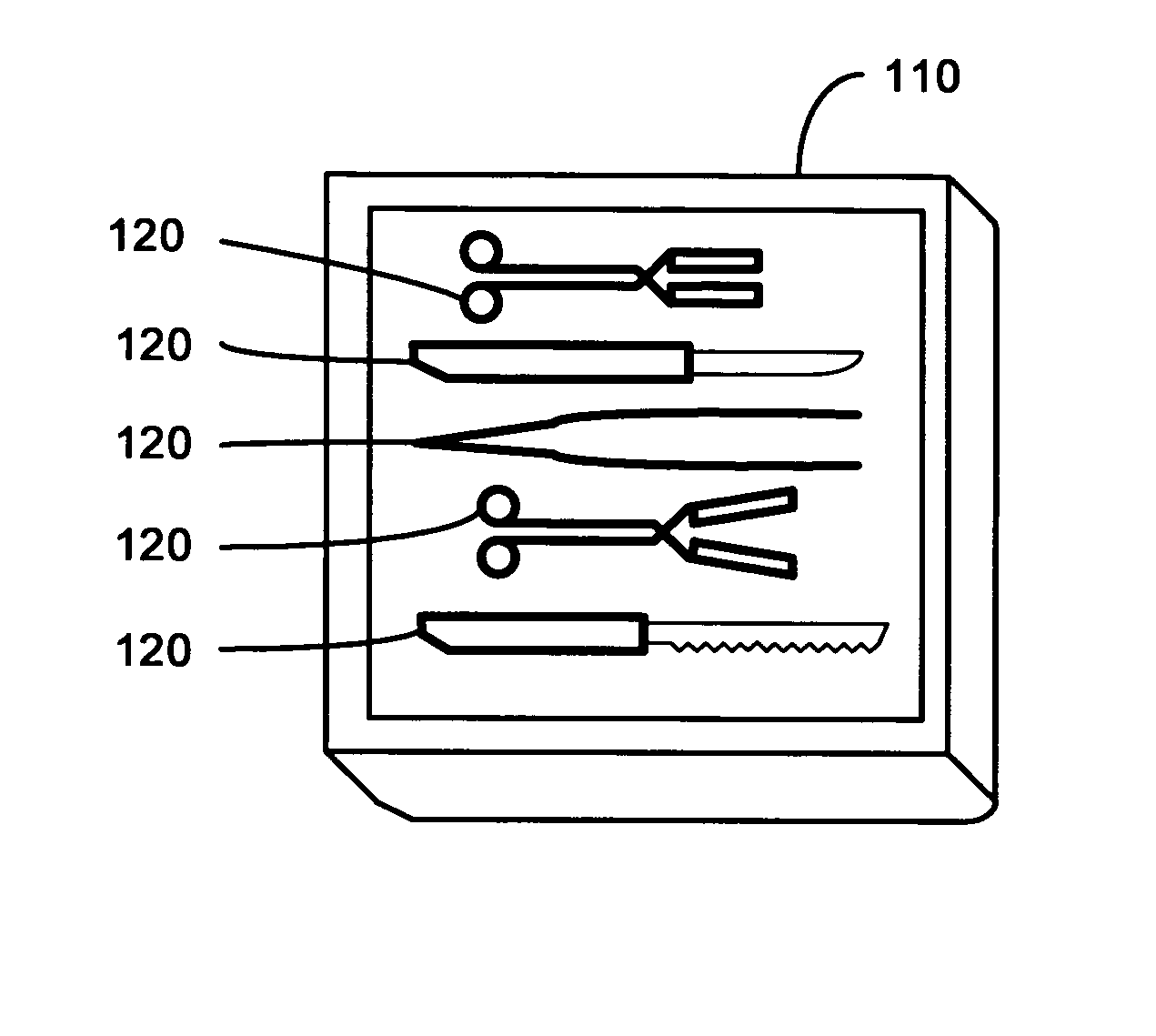

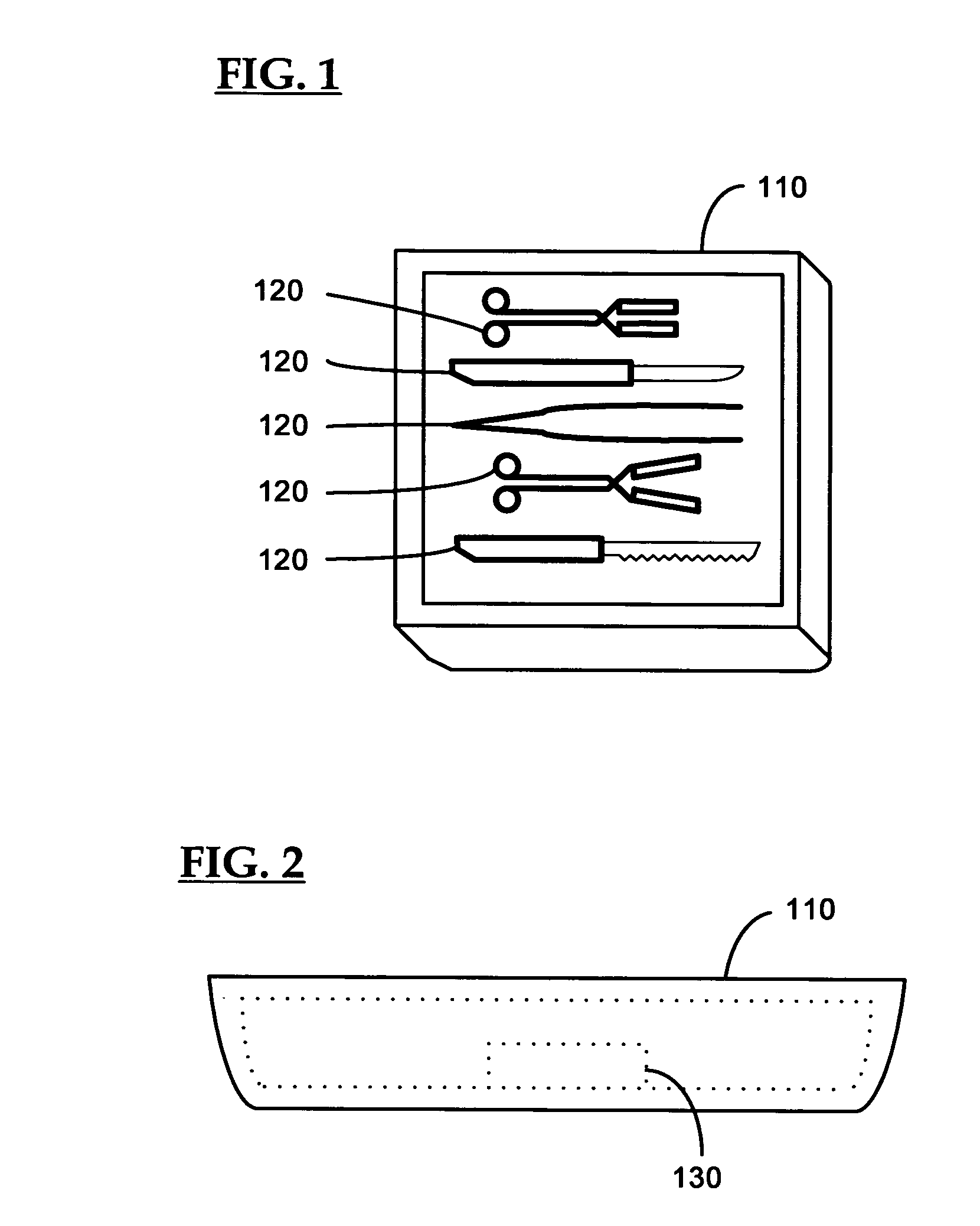

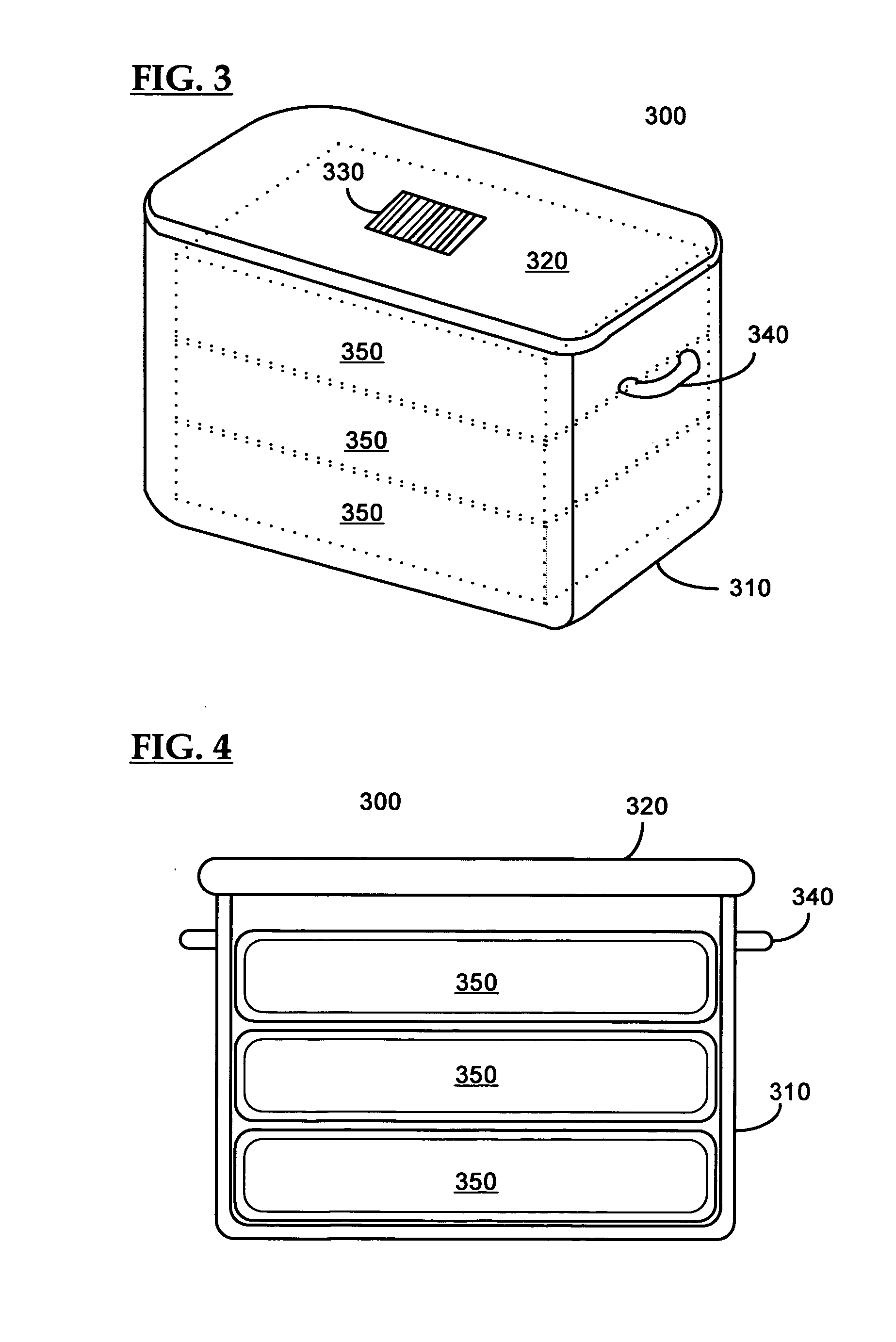

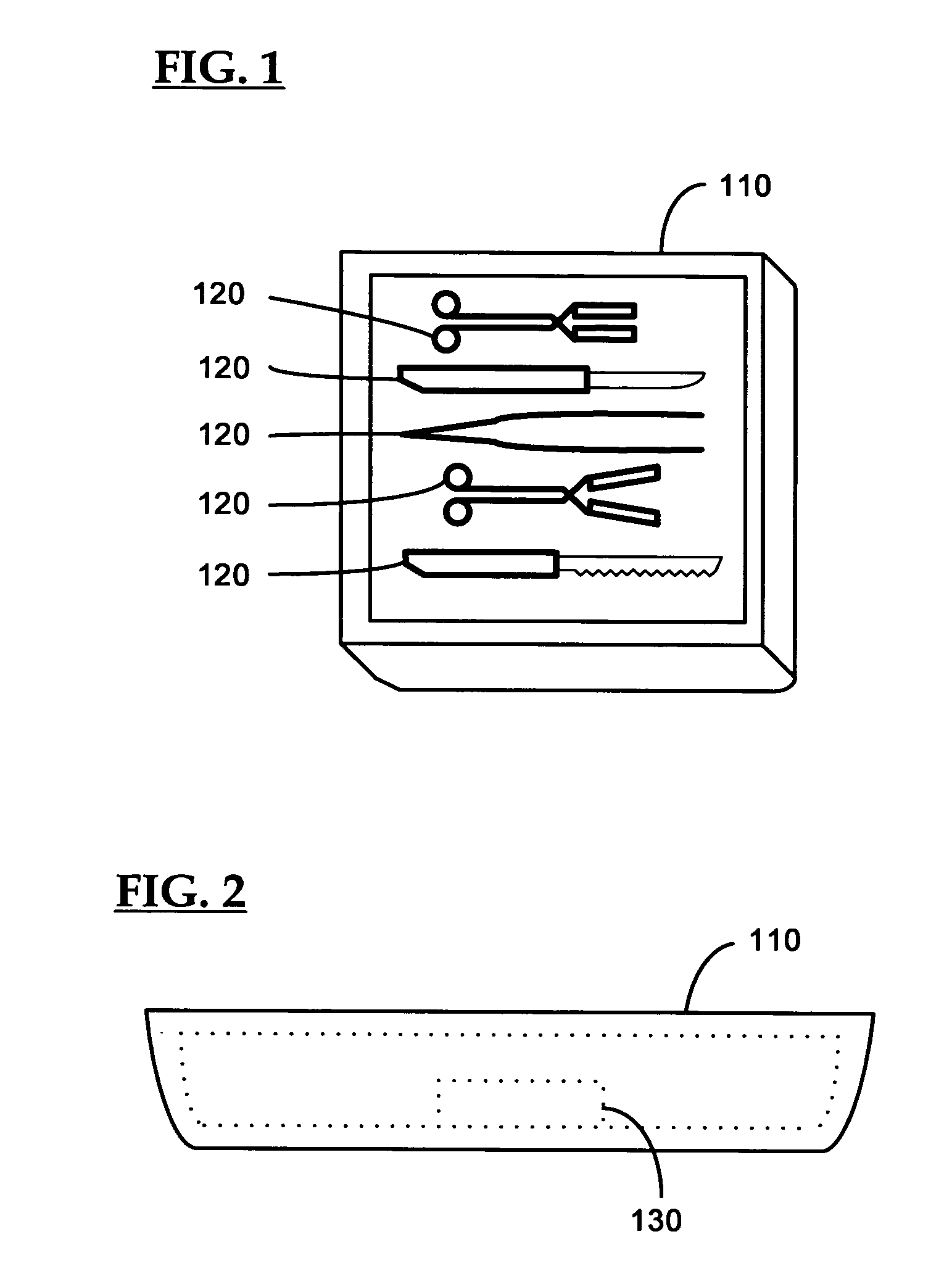

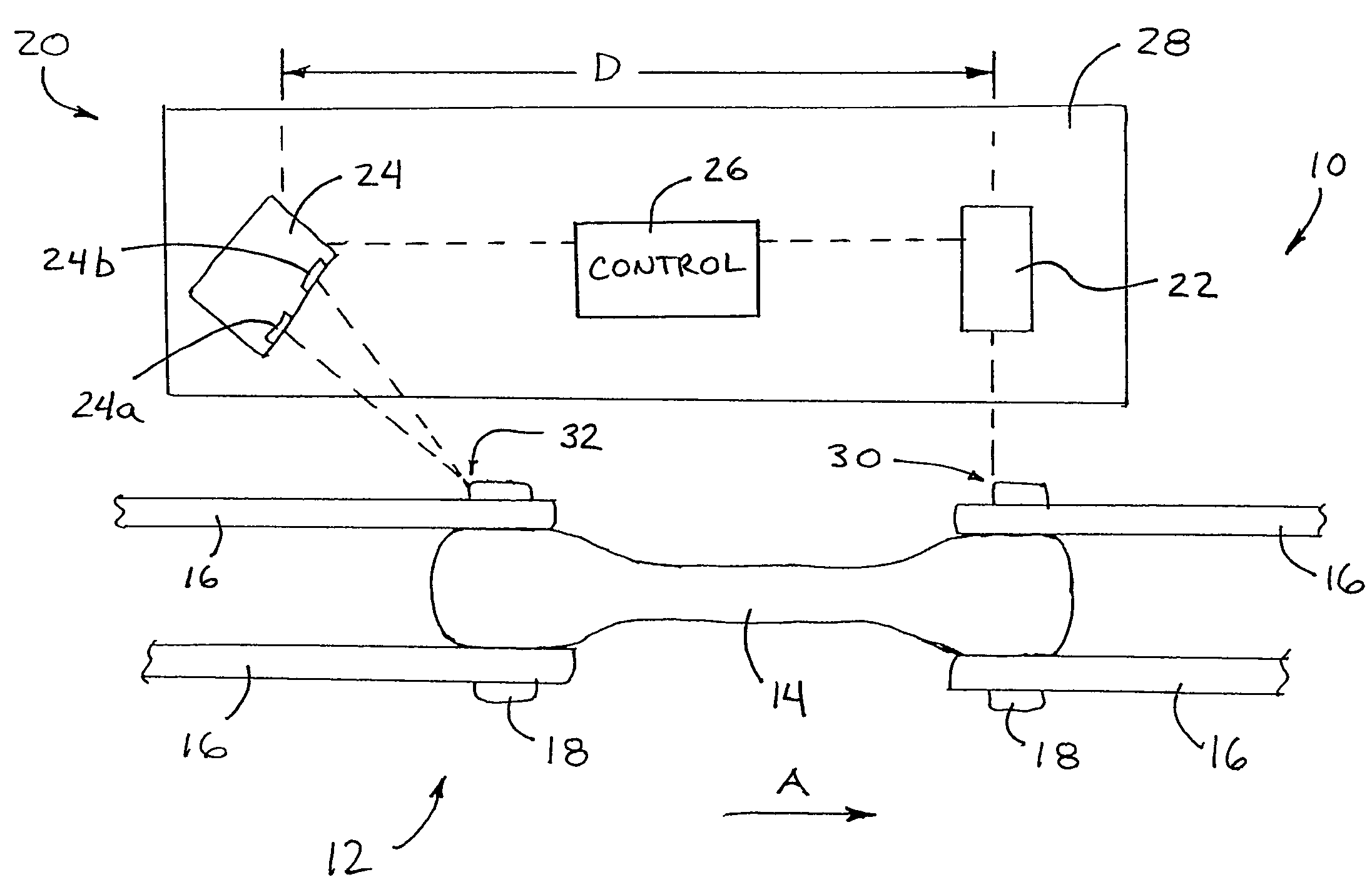

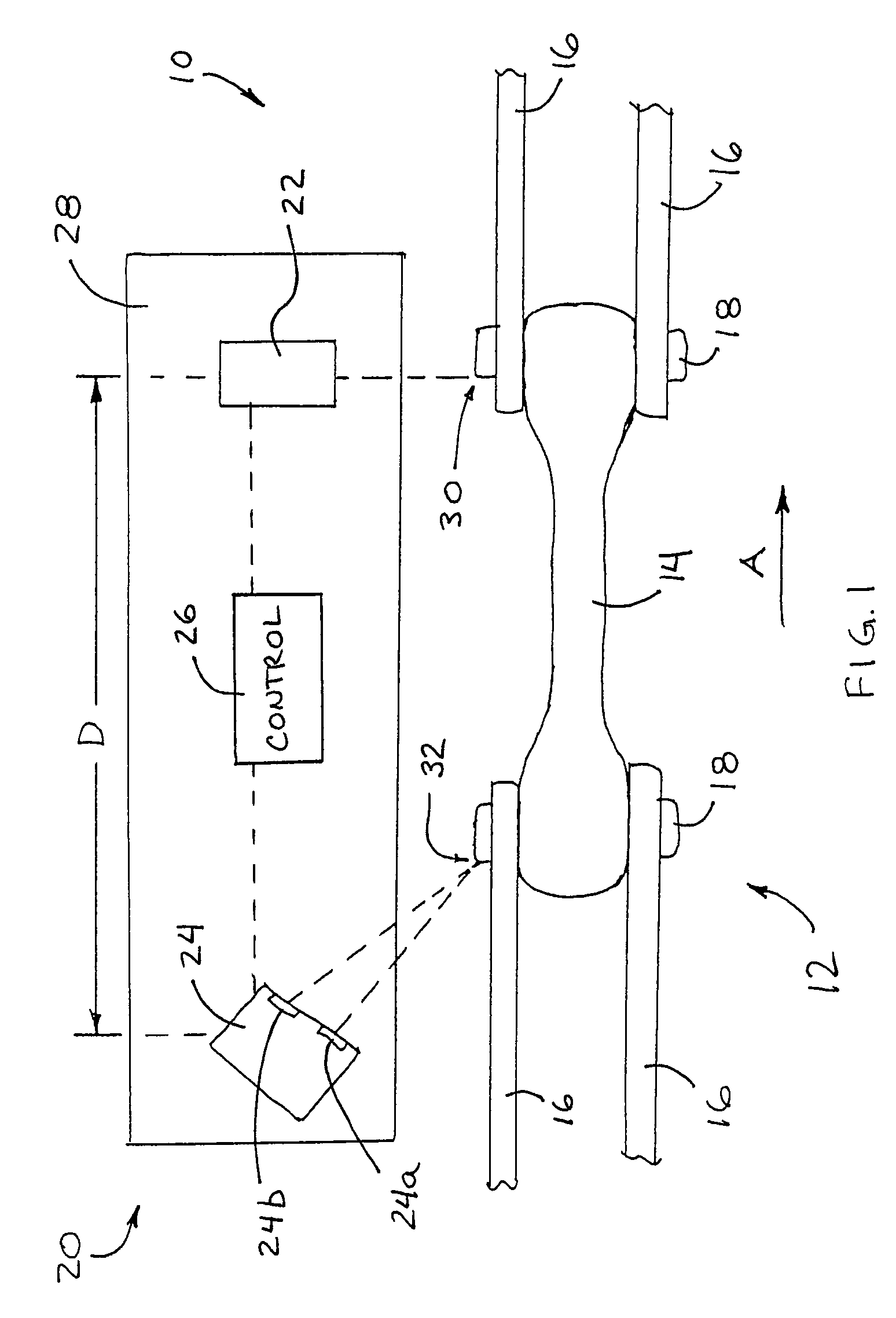

Surgical instrument tray shipping tote identification system and methods of using same

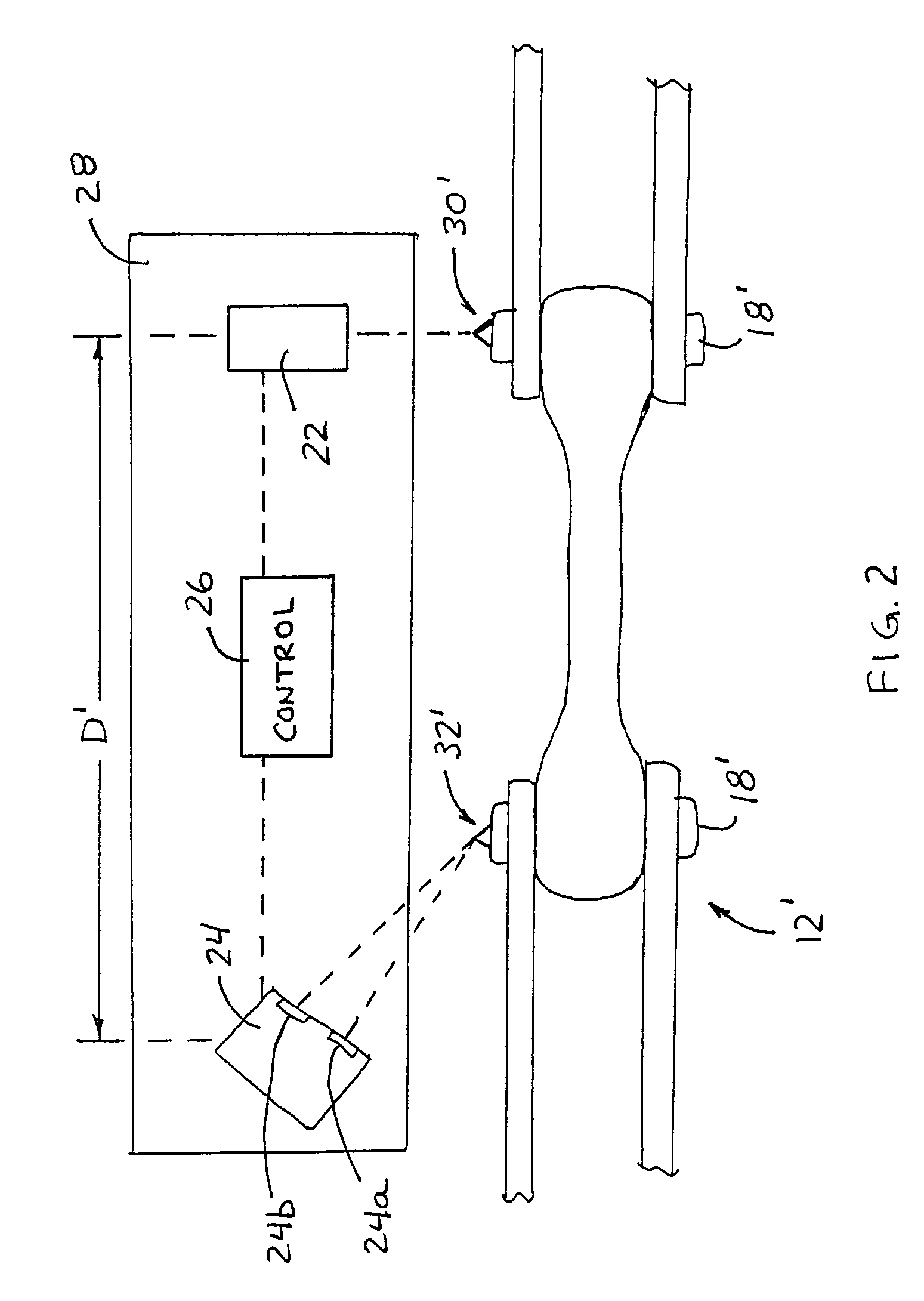

ActiveUS20060109105A1Reduce processing costsAccurate and rapid trackingLogisticsElectric signalling detailsTransceiverBarcode

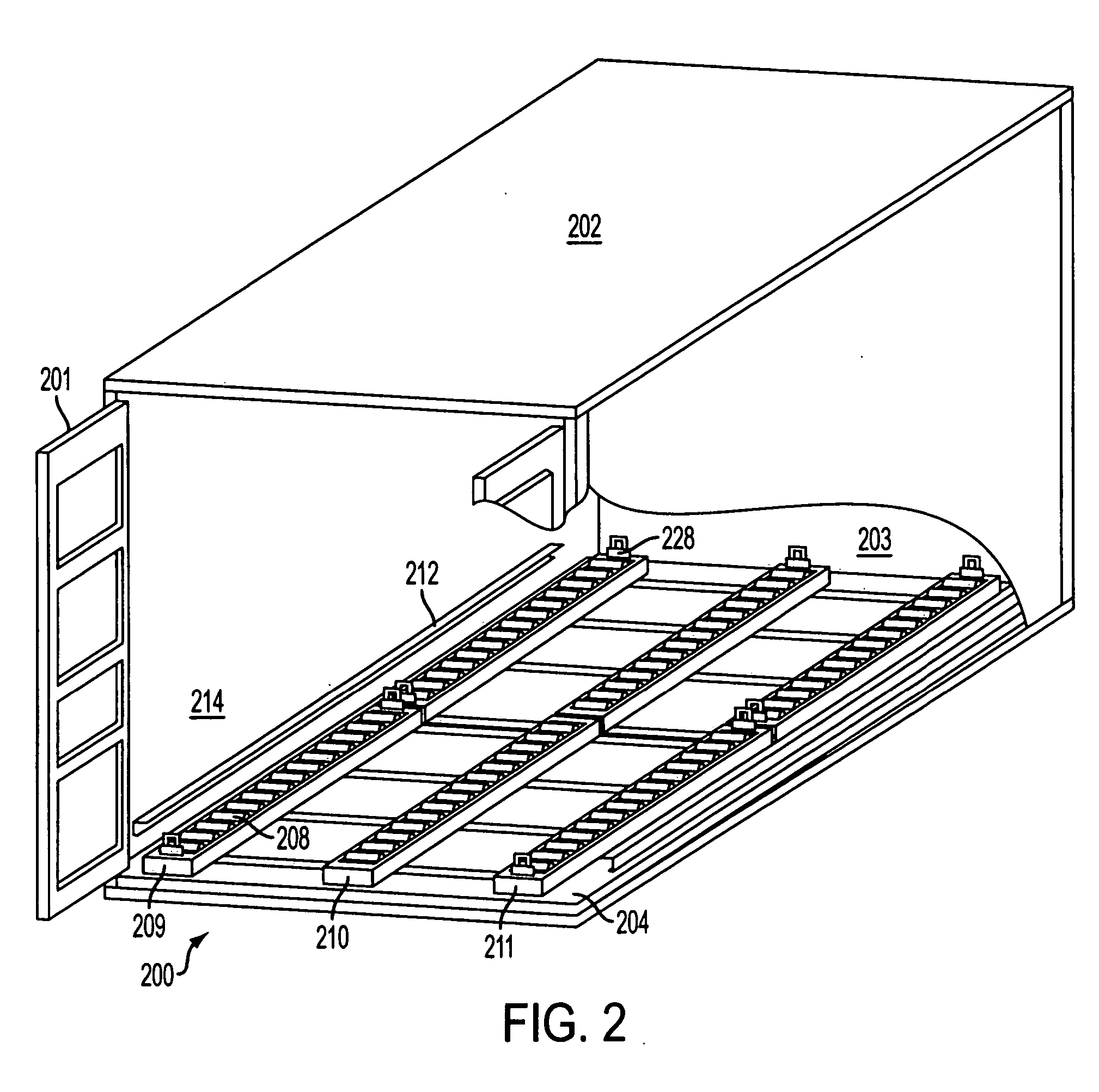

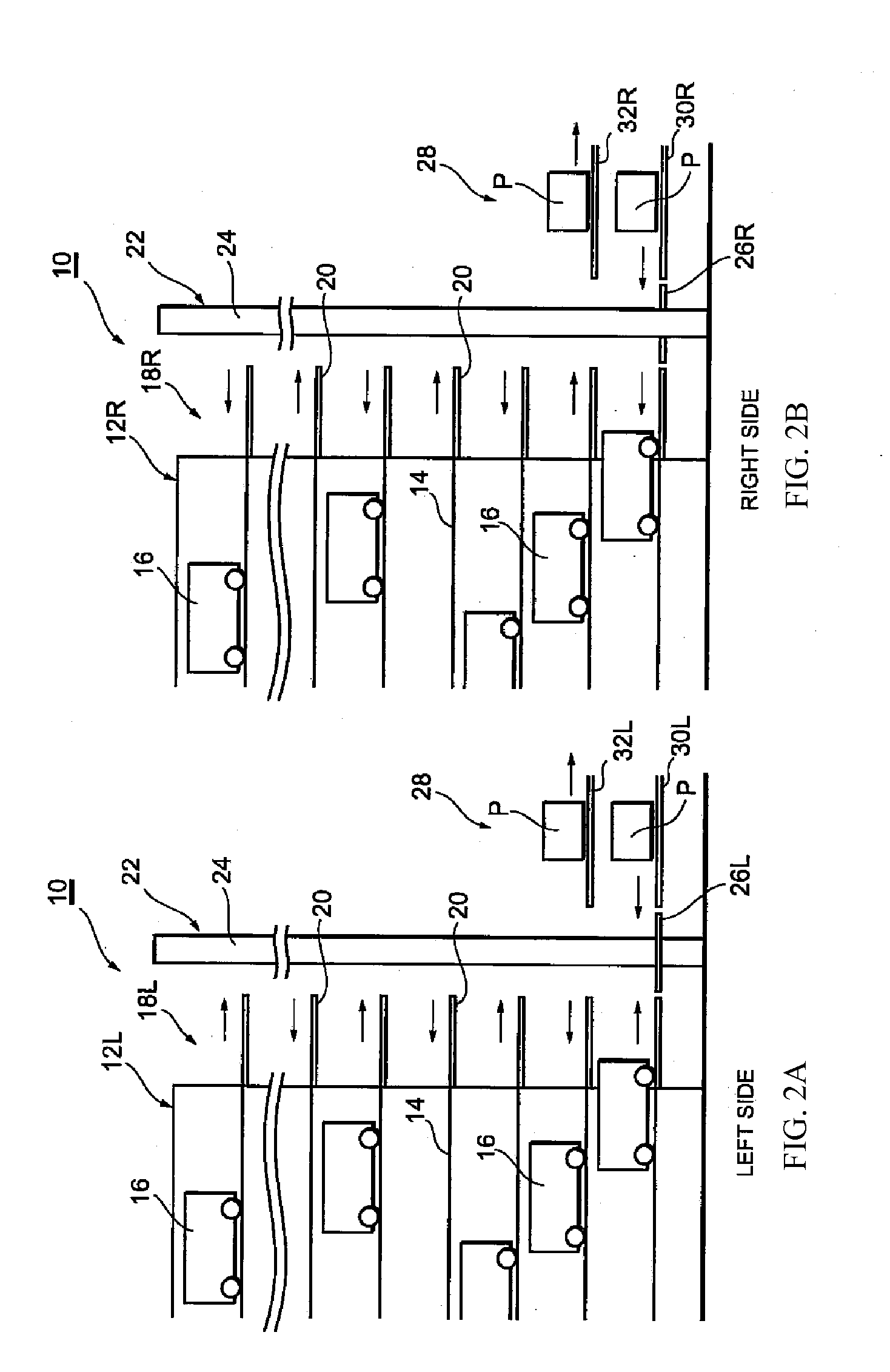

A surgical instrument tray shipping tote identification system is provided. During transit to or from a medical facility, processing center, distribution center or other location, multiple surgical instruments trays are placed in an instrument tray shipping tote. Each instrument tray includes at least one RFID transponder tag storing identification information about that tray. The shipping tote has a bar coded shipping label affixed to one surface generated at the point of origin. When the tote arrives at the distribution center, it is placed on a conveyor system that includes a reading station having an RFID transceiver and a bar code reader. Information read from the RFID transponder tags and the bar code label is transmitted by a controller to an external database to check for any off-nominal status indicators. Once this check is performed, an indication is sent back to the controller and an appropriate indicator on the identification system is activated.

Owner:WARSAW ORTHOPEDIC INC

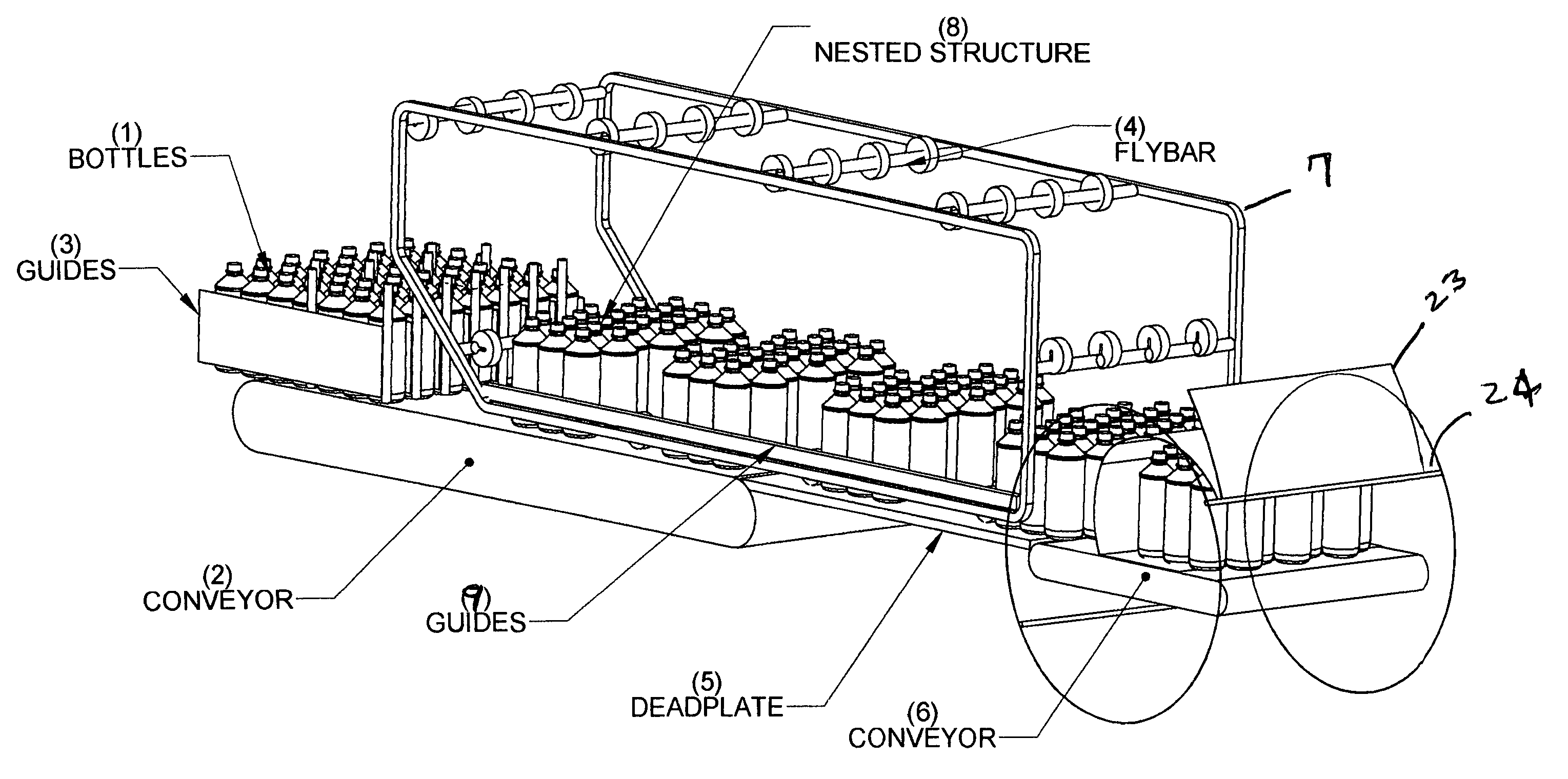

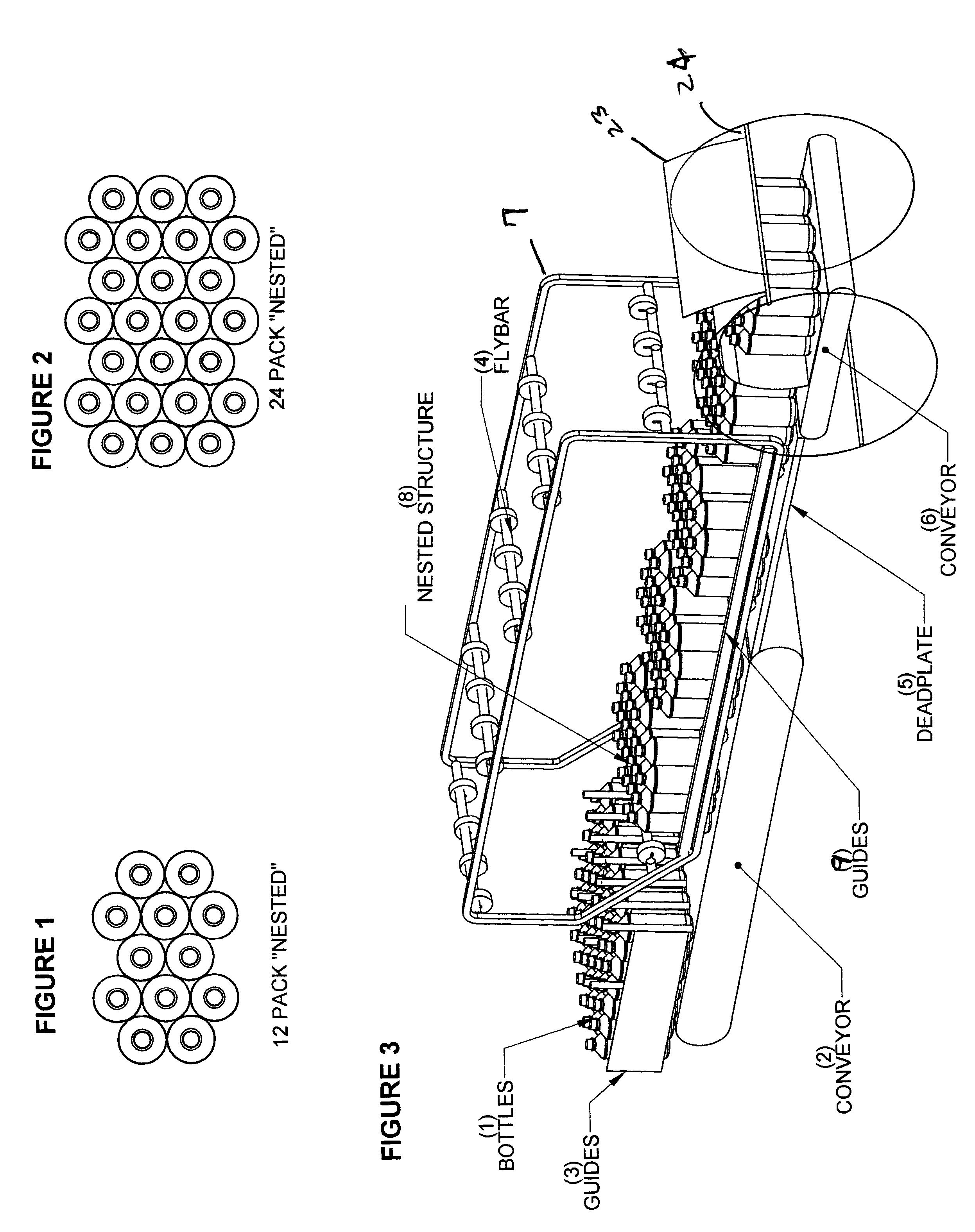

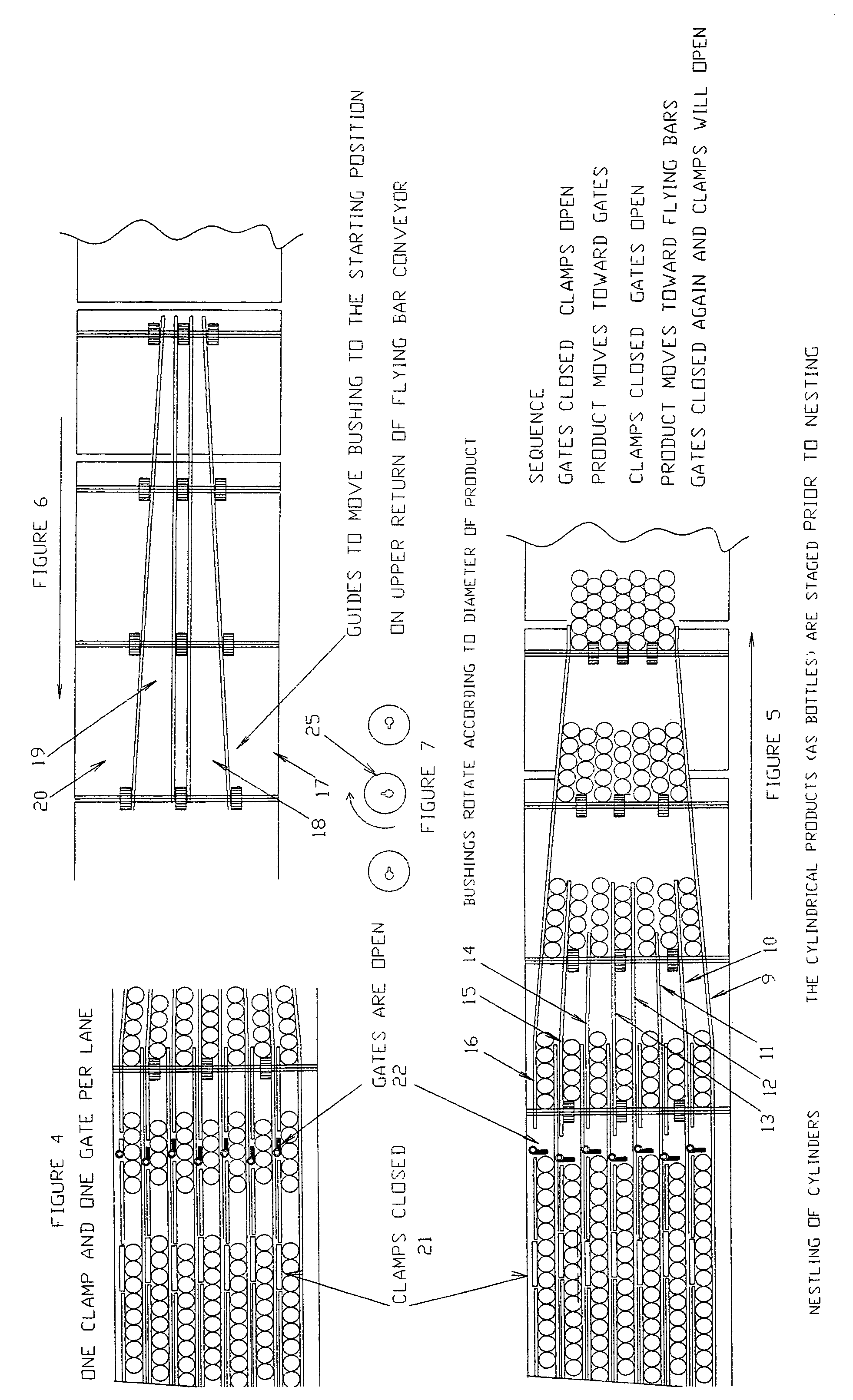

Apparatus for nesting bottles

The objective of this invention is to provide an apparatus for forming a stable arrangement of bottles so they can be moved on an inline conveyor system. This is accomplished by an apparatus for nesting bottles comprising a first conveyor having lanes of bottles, and a second conveyor, wherein a fixed number of bottles from each lane is released from each lane in a staggered arrangement to facilitate nesting of the released bottles and then pushing and guiding the released bottles from the first conveyor onto a second conveyor so that the bottles form a nested bundle.

Owner:CERF ALAIN

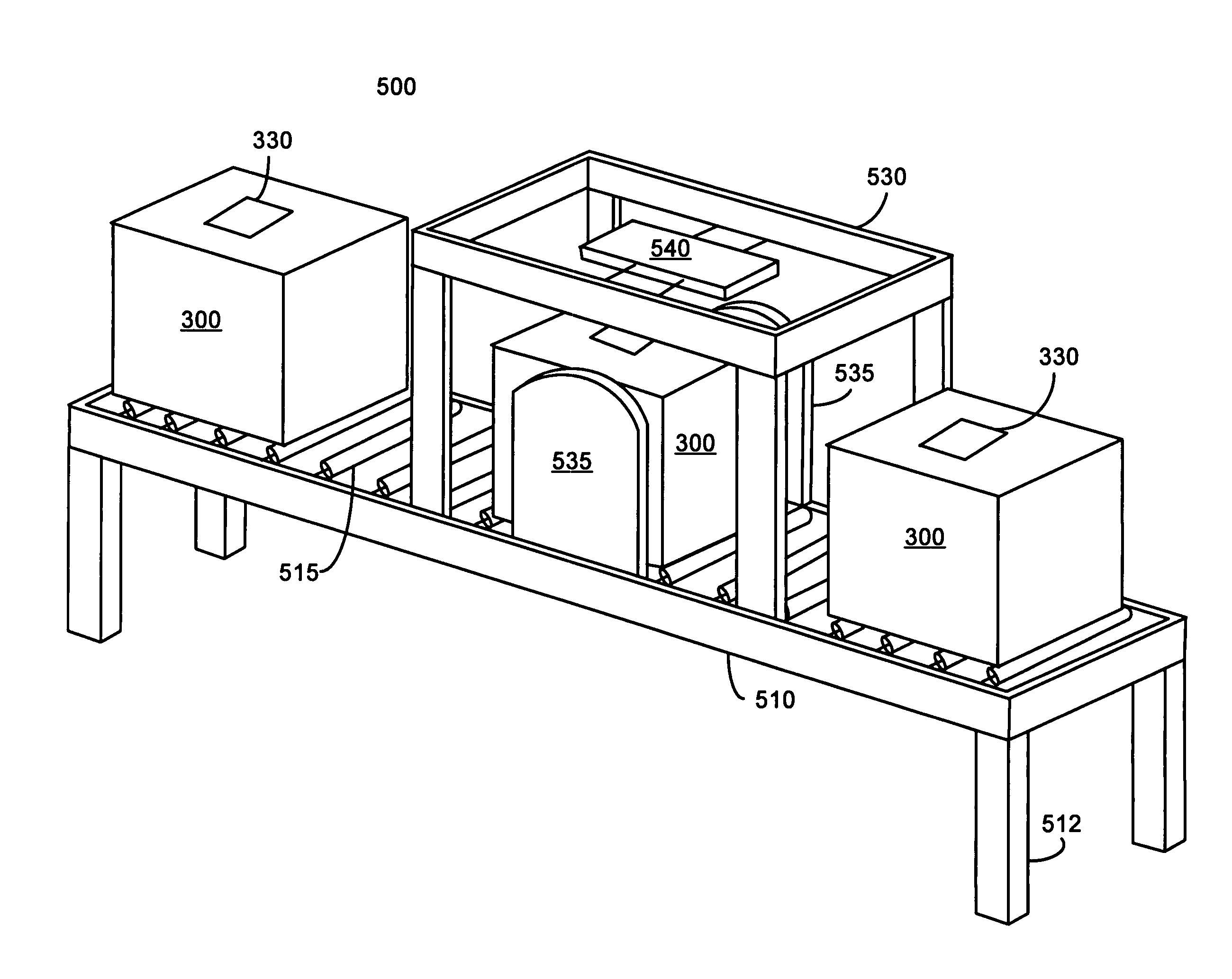

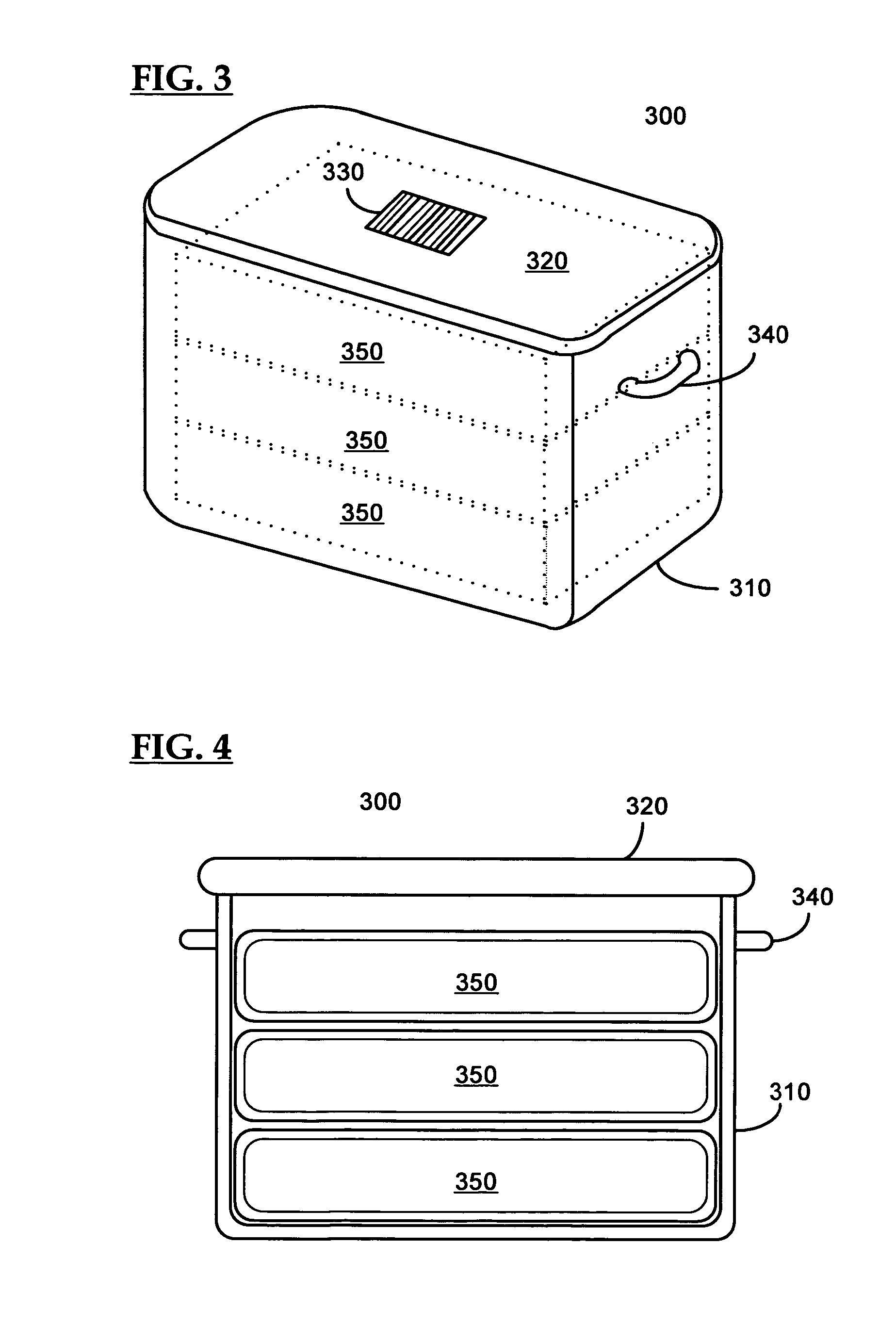

Surgical instrument tray shipping tote identification system and methods of using same

ActiveUS7227469B2Accurate and rapid trackingReduce processing costsLogisticsElectric signalling detailsTransceiverBarcode

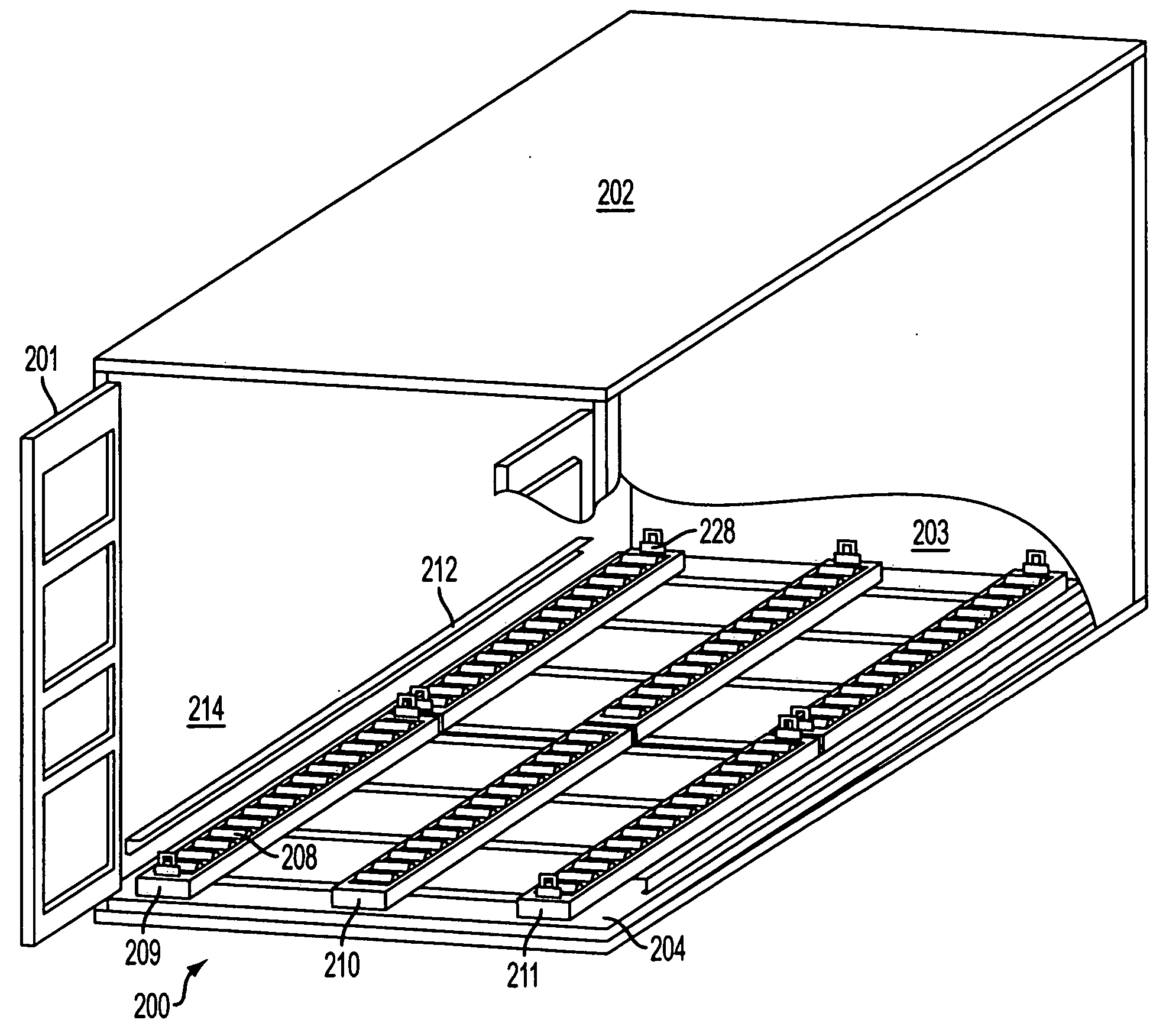

A surgical instrument tray shipping tote identification system is provided. During transit to or from a medical facility, processing center, distribution center or other location, multiple surgical instruments trays are placed in an instrument tray shipping tote. Each instrument tray includes at least one RFID transponder tag storing identification information about that tray. The shipping tote has a bar coded shipping label affixed to one surface generated at the point of origin. When the tote arrives at the distribution center, it is placed on a conveyor system that includes a reading station having an RFID transceiver and a bar code reader. Information read from the RFID transponder tags and the bar code label is transmitted by a controller to an external database to check for any off-nominal status indicators. Once this check is performed, an indication is sent back to the controller and an appropriate indicator on the identification system is activated.

Owner:WARSAW ORTHOPEDIC INC

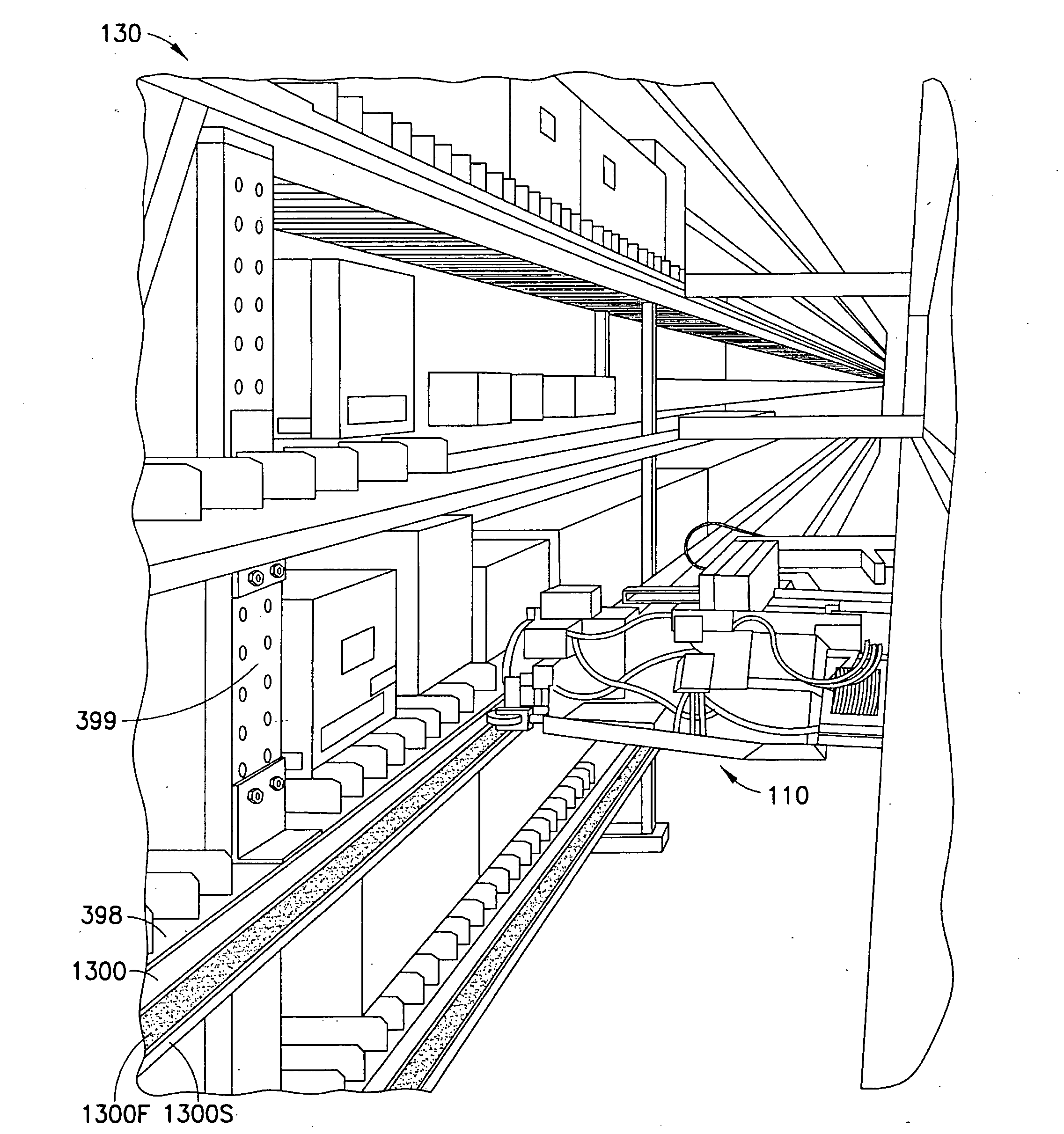

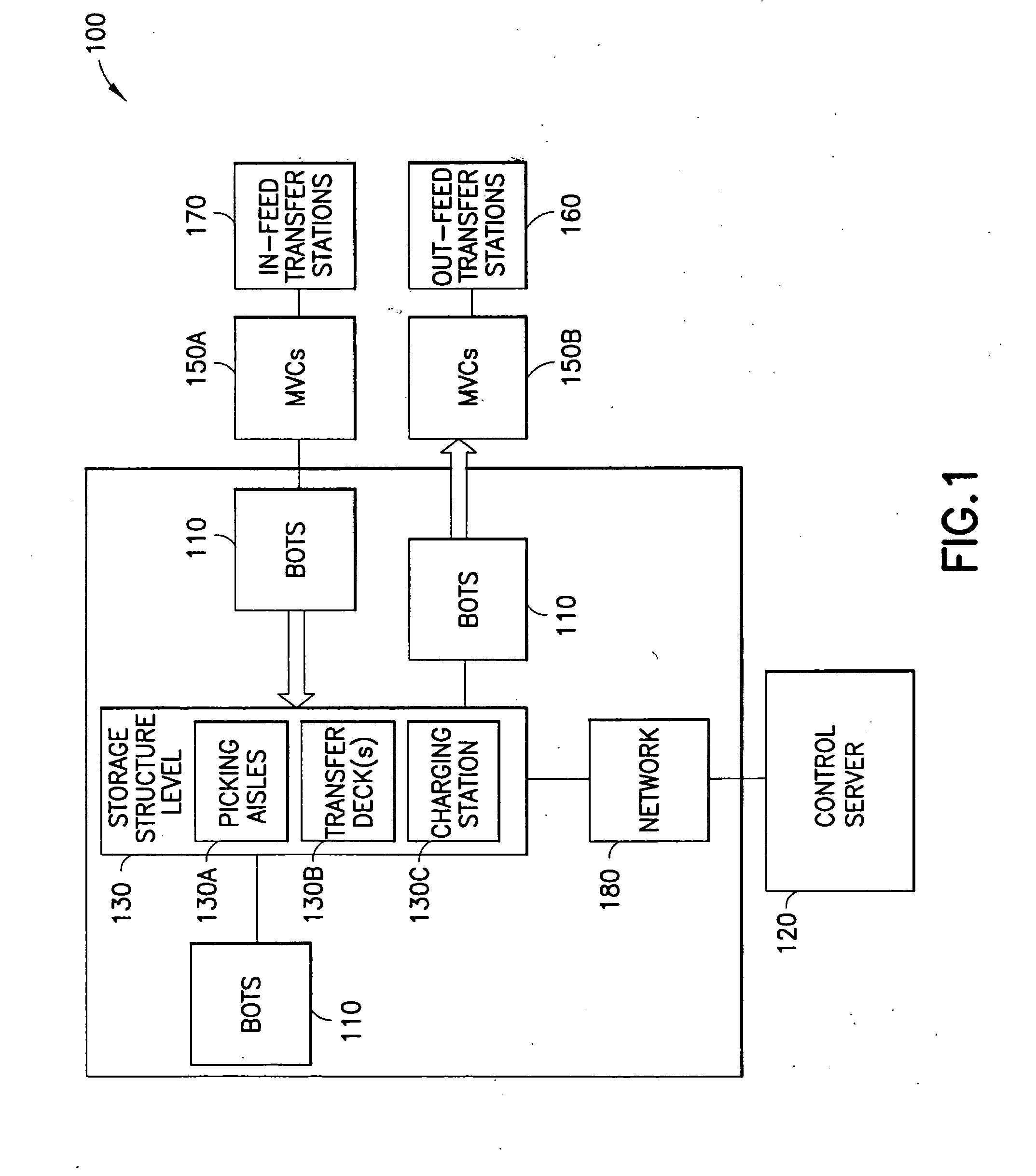

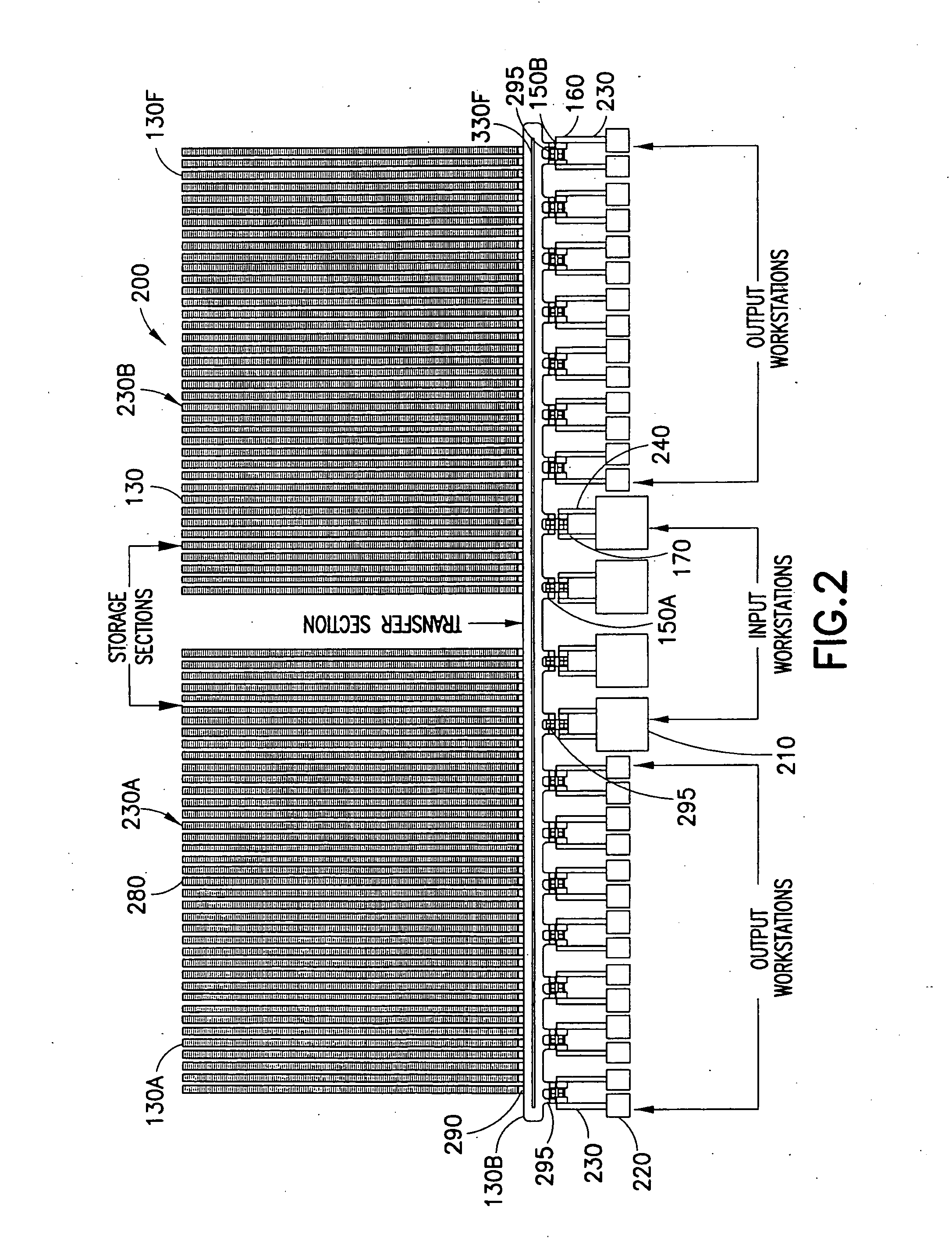

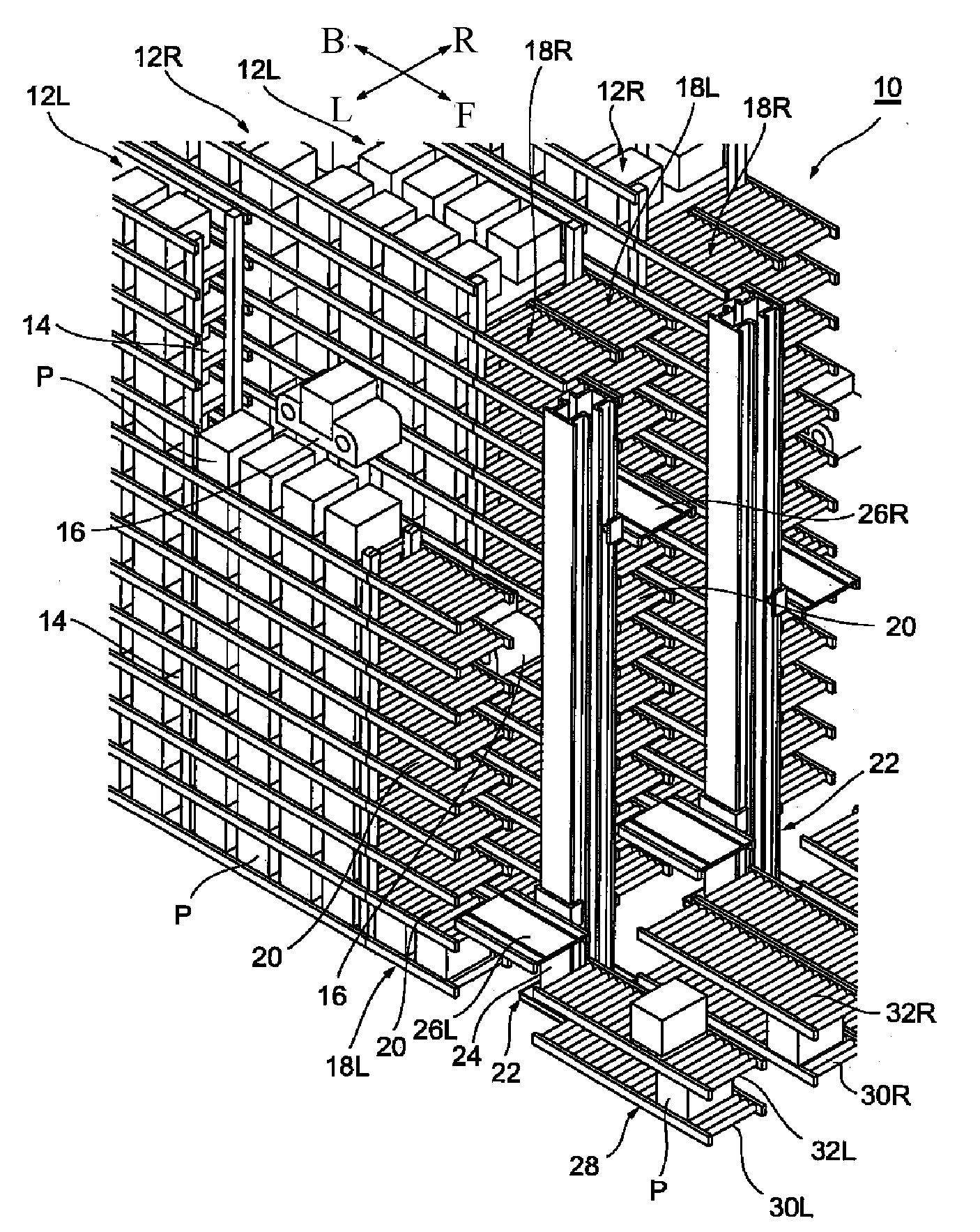

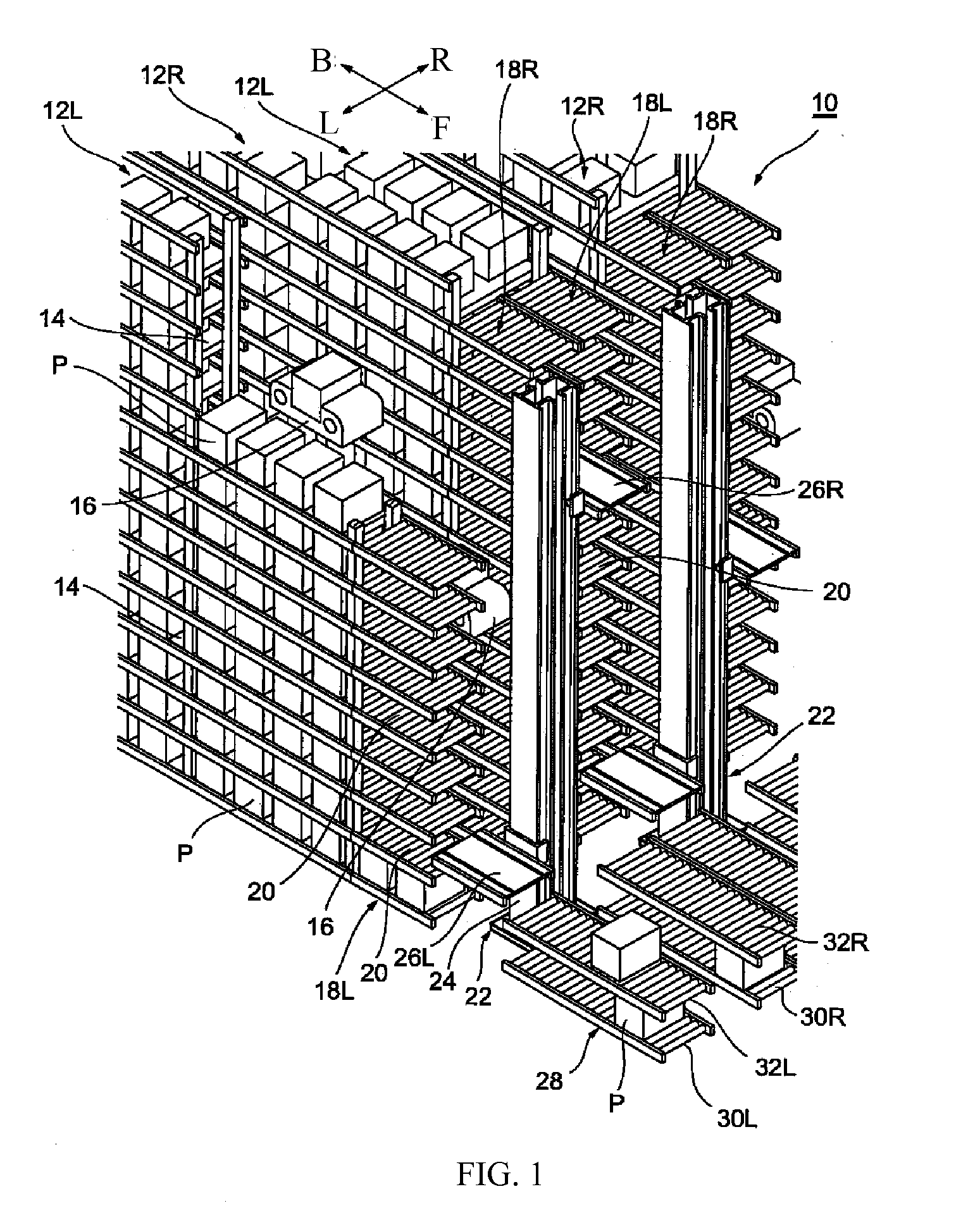

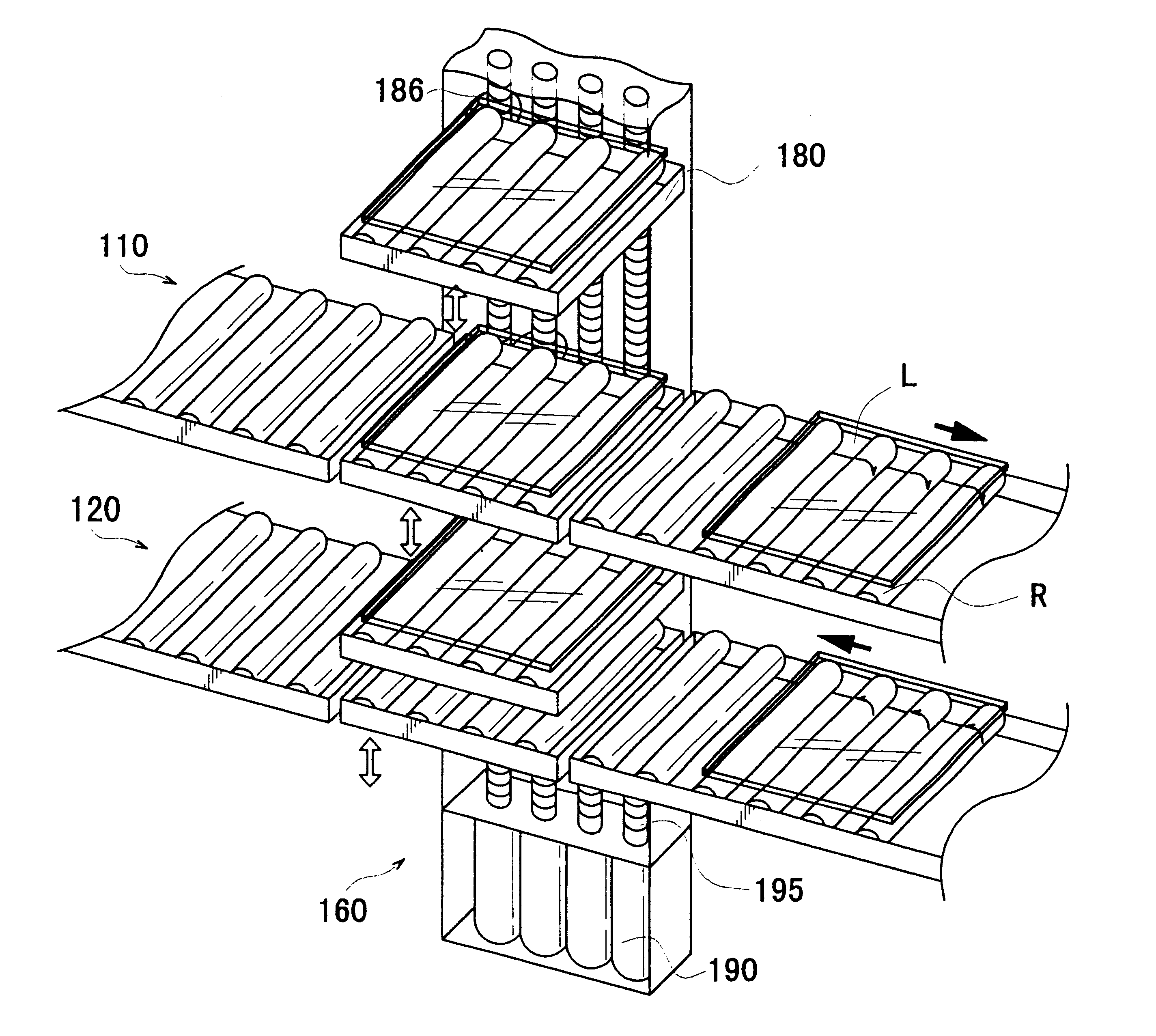

Storage and retrieval system

A storage and retrieval system including a vertical array of storage levels, each storage level having storage locations, a multilevel vertical conveyor system configured to transport the uncontained case units to and from the vertical array of storage levels, each storage level being configured to receive uncontained case units from the multilevel vertical conveyor system, at least one autonomous transport confined to each storage level, the at least one autonomous transport being configured to transport the uncontained case units between respective storage locations and the multilevel vertical conveyor system, and a controller configured to effect operation of the multilevel vertical conveyor system and at least one autonomous transport for assembling orders of uncontained case units of different types without moving bundles of the same uncontained case unit type throughout the storage and retrieval system.

Owner:SYMBOTIC LLC

Battery exchange station

ActiveUS8013571B2Keep for a long timeReduce dependenceRailway vehiclesRefuse receptaclesElectrical batteryElectric vehicle

At the battery exchange station a discharged battery is removed and a charged battery is inserted into an electric vehicle. The battery is inserted and removed along a vertical axis, i.e., into and out of the bottom of the vehicle. The battery exchange system is located in a service bay under the vehicle. A sliding door system creates an opening above the service bay. A vehicle is received over the sliding door system, such that at least one wheel of the vehicle rests on the conveyor system. The door slides in a first direction while allowing the conveyor system to slide in a direction opposite the first direction. The conveyor system also supports the at least one wheel of the vehicle while the door and conveyor slide in opposite directions. The sliding of the door and the sliding of the conveyor system occur at least partially simultaneously.

Owner:CHARGE PEAK

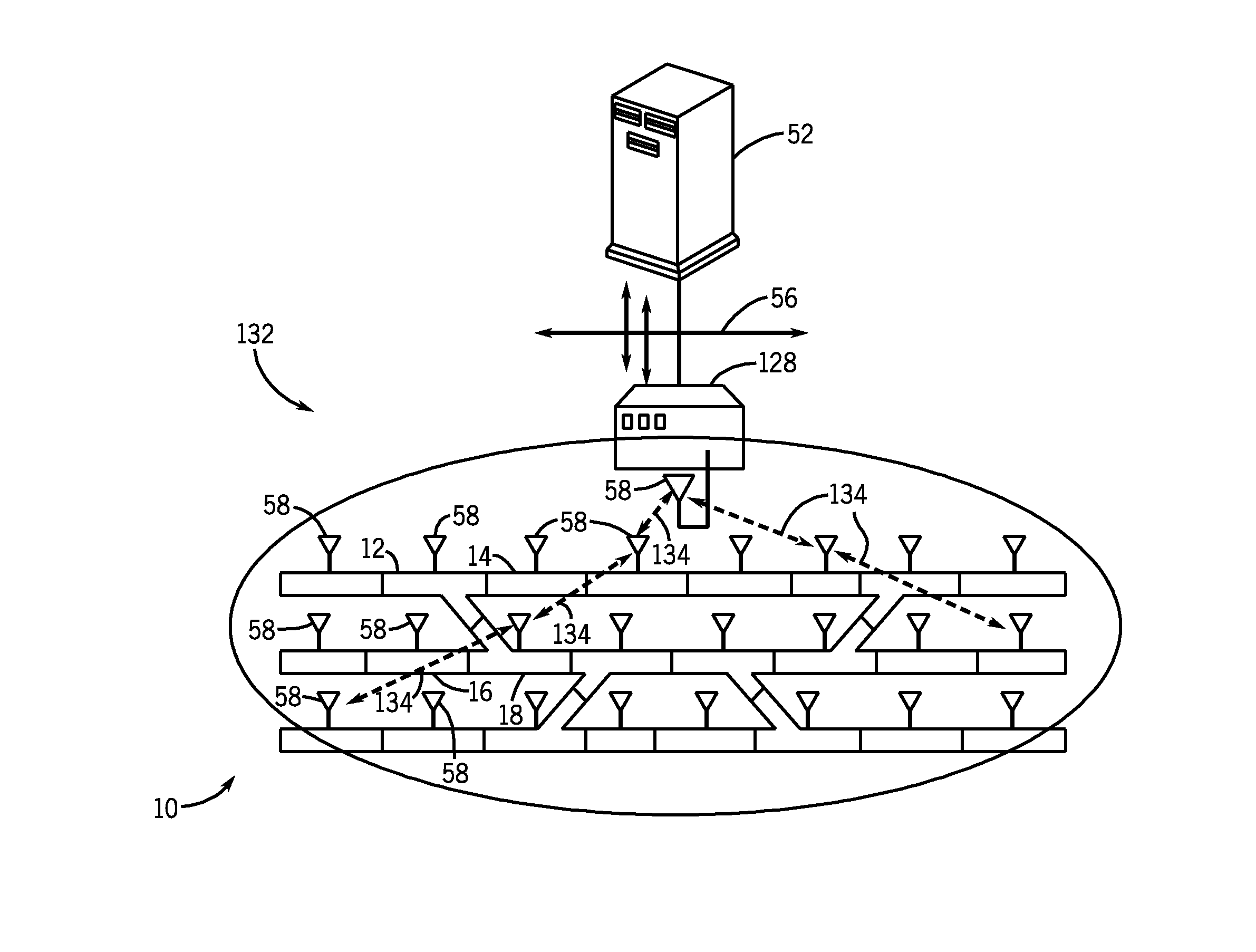

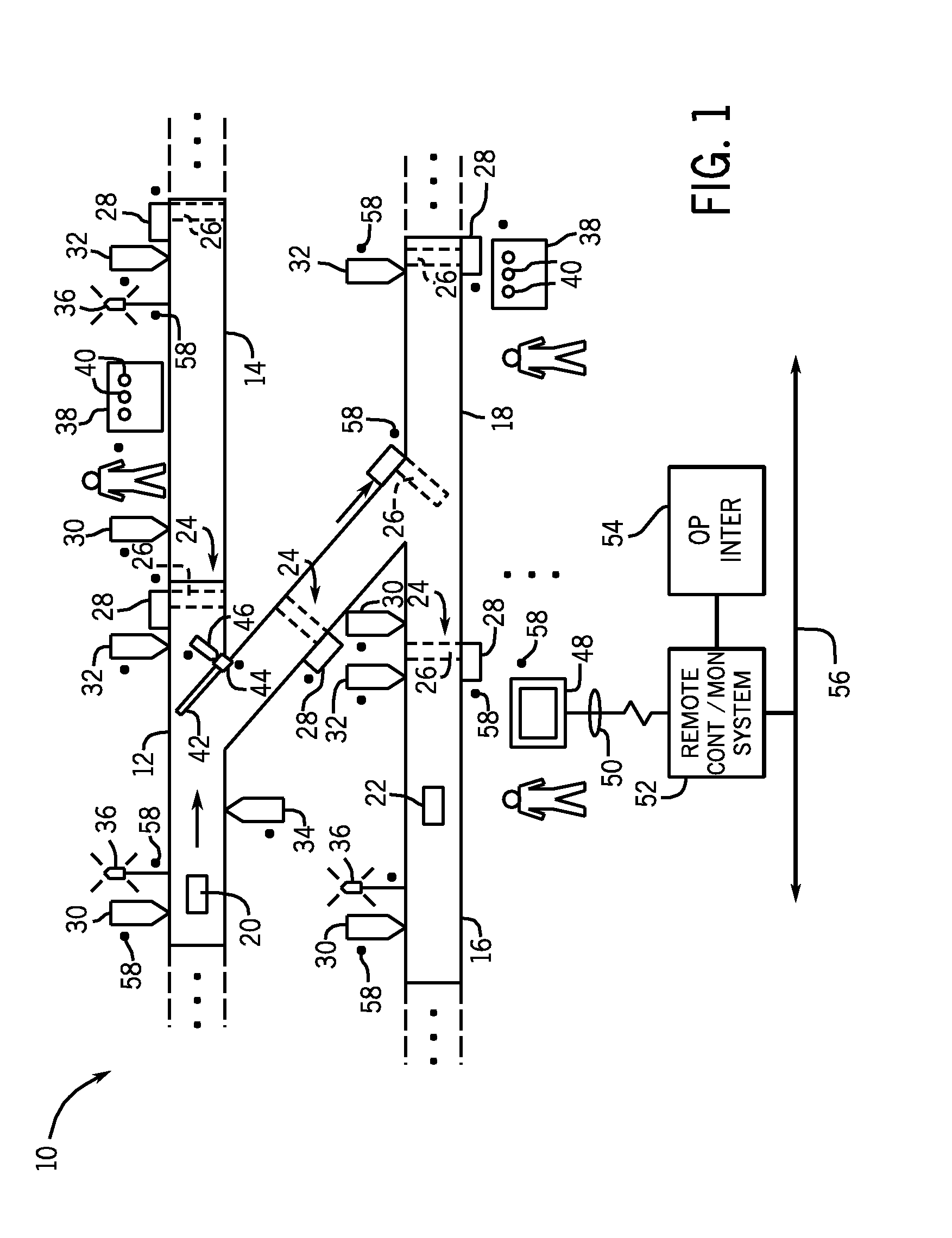

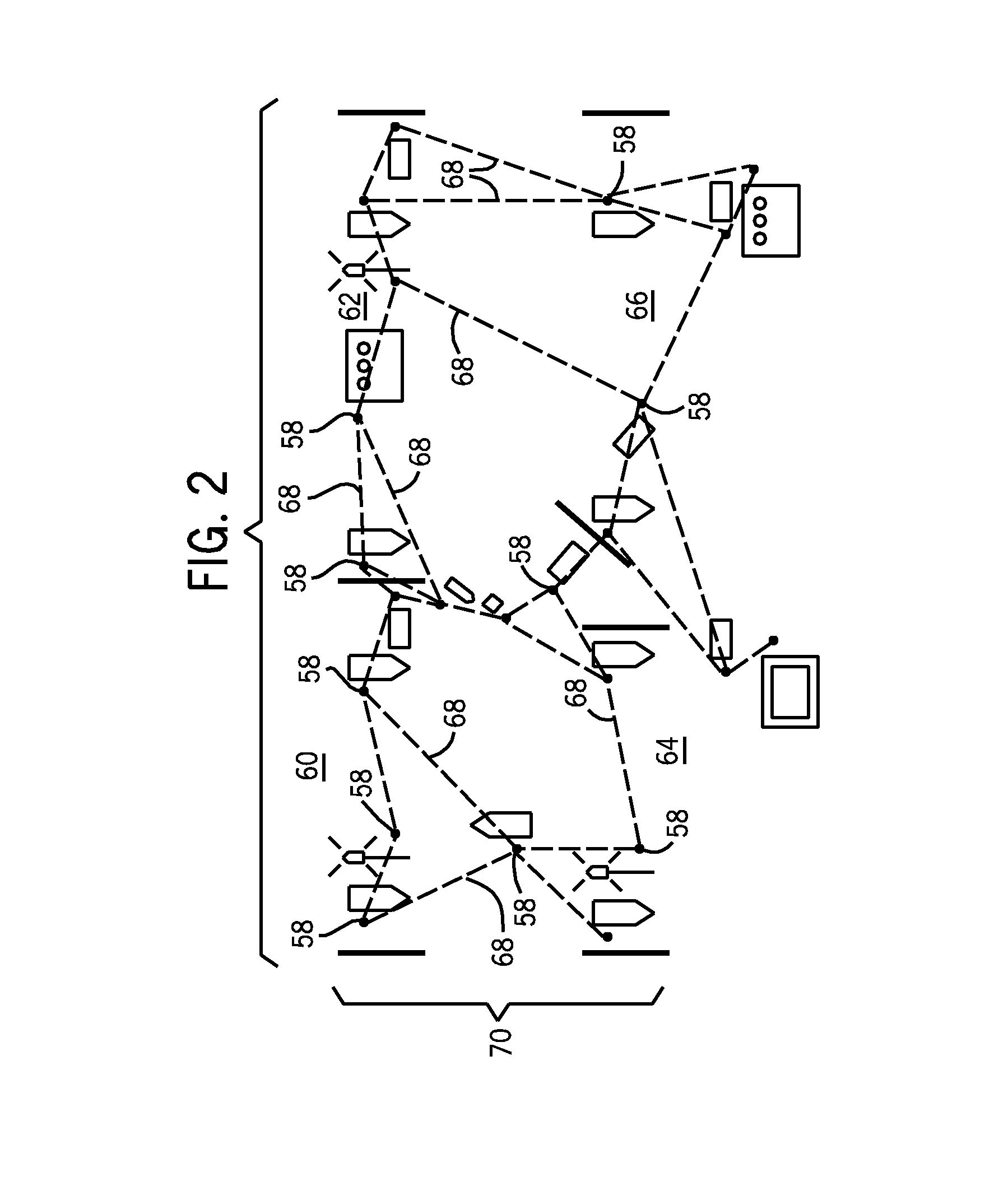

Modular wireless conveyor interconnection method and system

ActiveUS20090084657A1Control devices for conveyorsMultiple digital computer combinationsElectrical batteryComputer module

A modular conveyor system is disclosed in which components of each conveyor module is designed for wireless mesh communication. The communications may be within a module or between modules. Certain of the components may be powered by battery, such that the components may be completely wireless. The network may be entirely self-configuring such that the modules may be assembled and the network established in a straightforward manner.

Owner:ROCKWELL AUTOMATION TECH

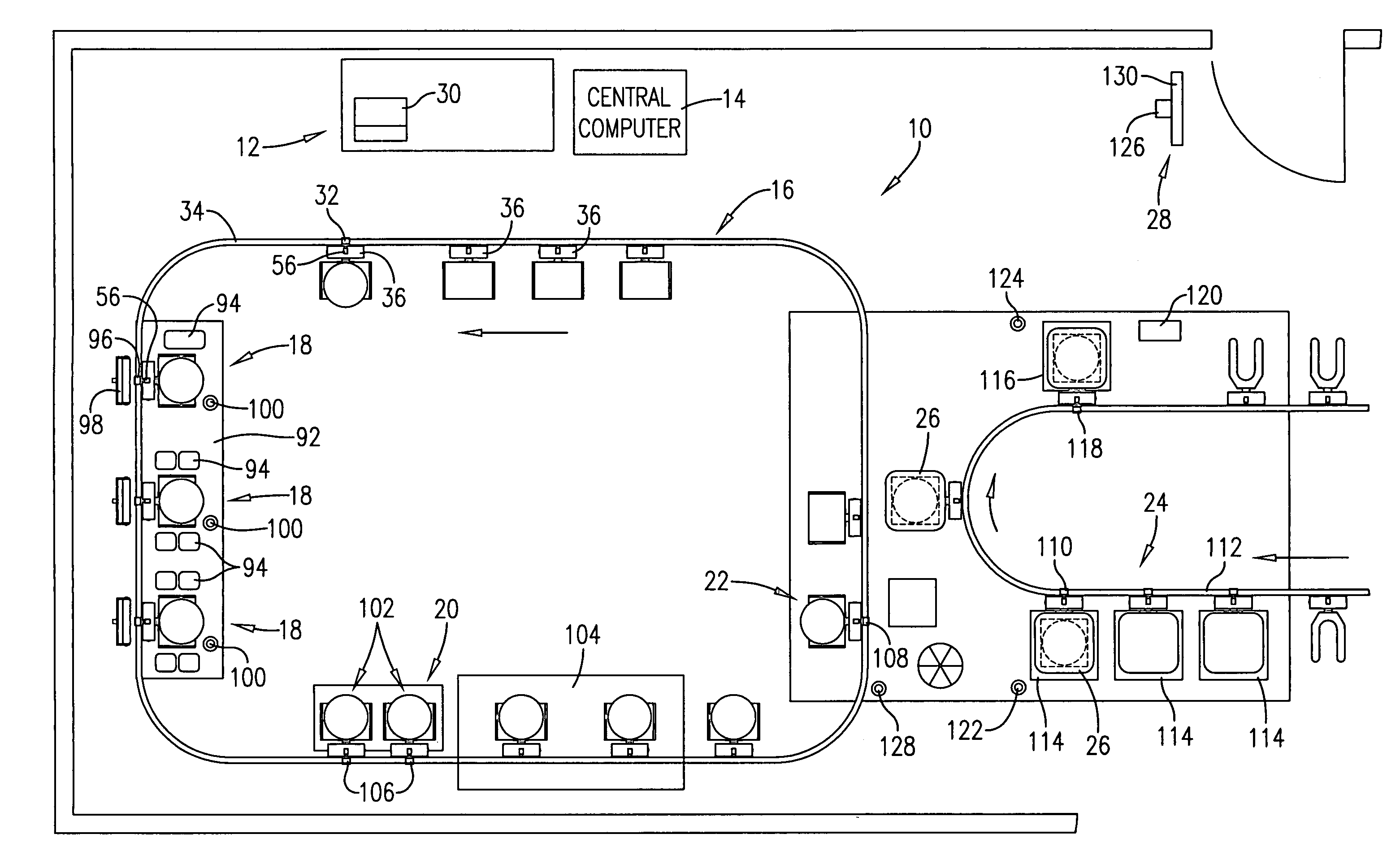

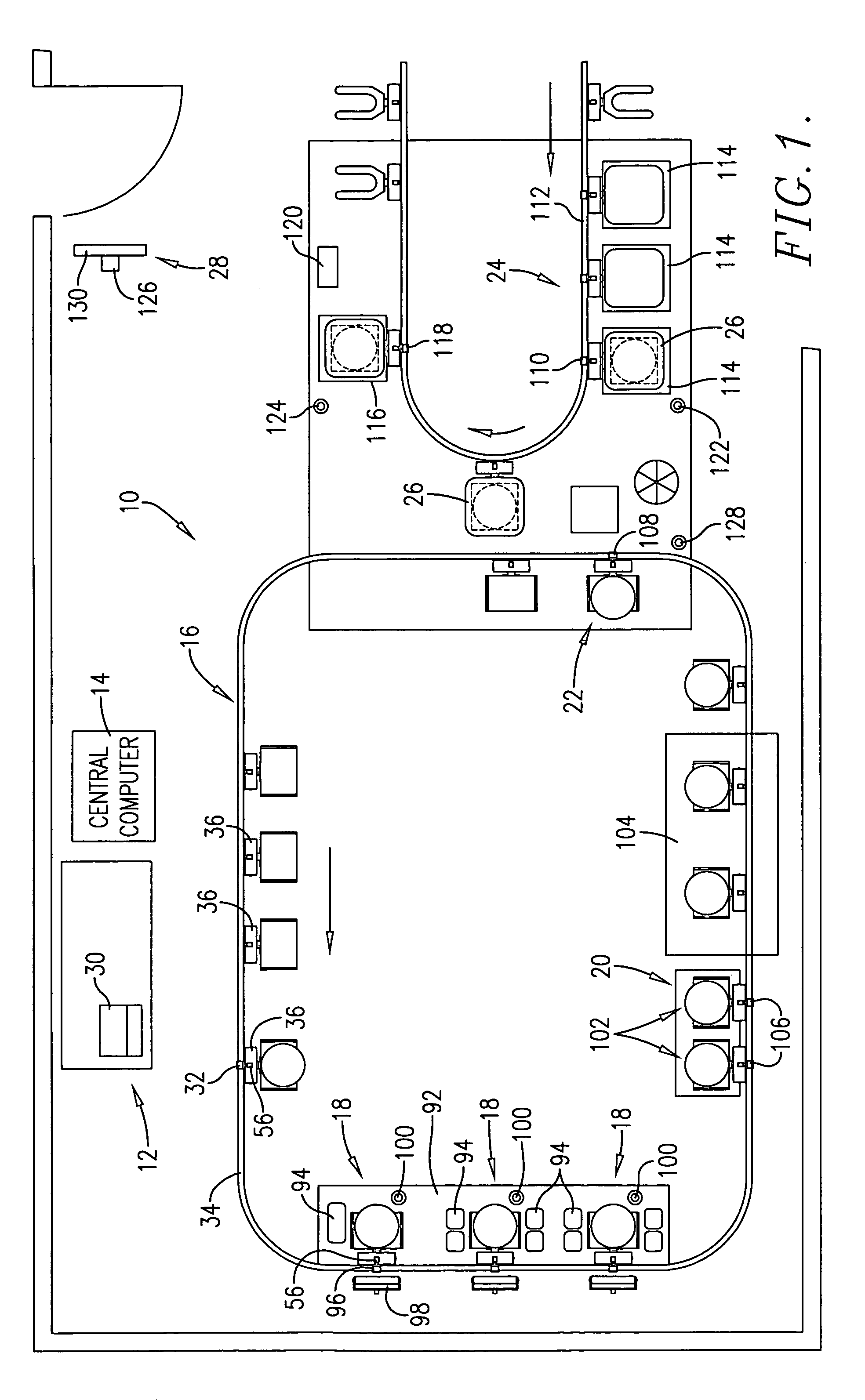

Food preparation system

InactiveUS20050256774A1Reduces and even eliminates human mistakeEfficient solutionLiquid transferring devicesNon-mechanical conveyorsEngineeringDelivery system

A food preparation system and method that partially automates the ordering, preparation, and delivery of food items such as pizza. The food preparation system broadly comprising an ordering or point-of-sale station, a computing device, a conveyor system, at least one food preparation station, at least one heating station, a transfer station, a delivery station including at least one delivery device, and an entry / exit station.

Owner:TSI TECH

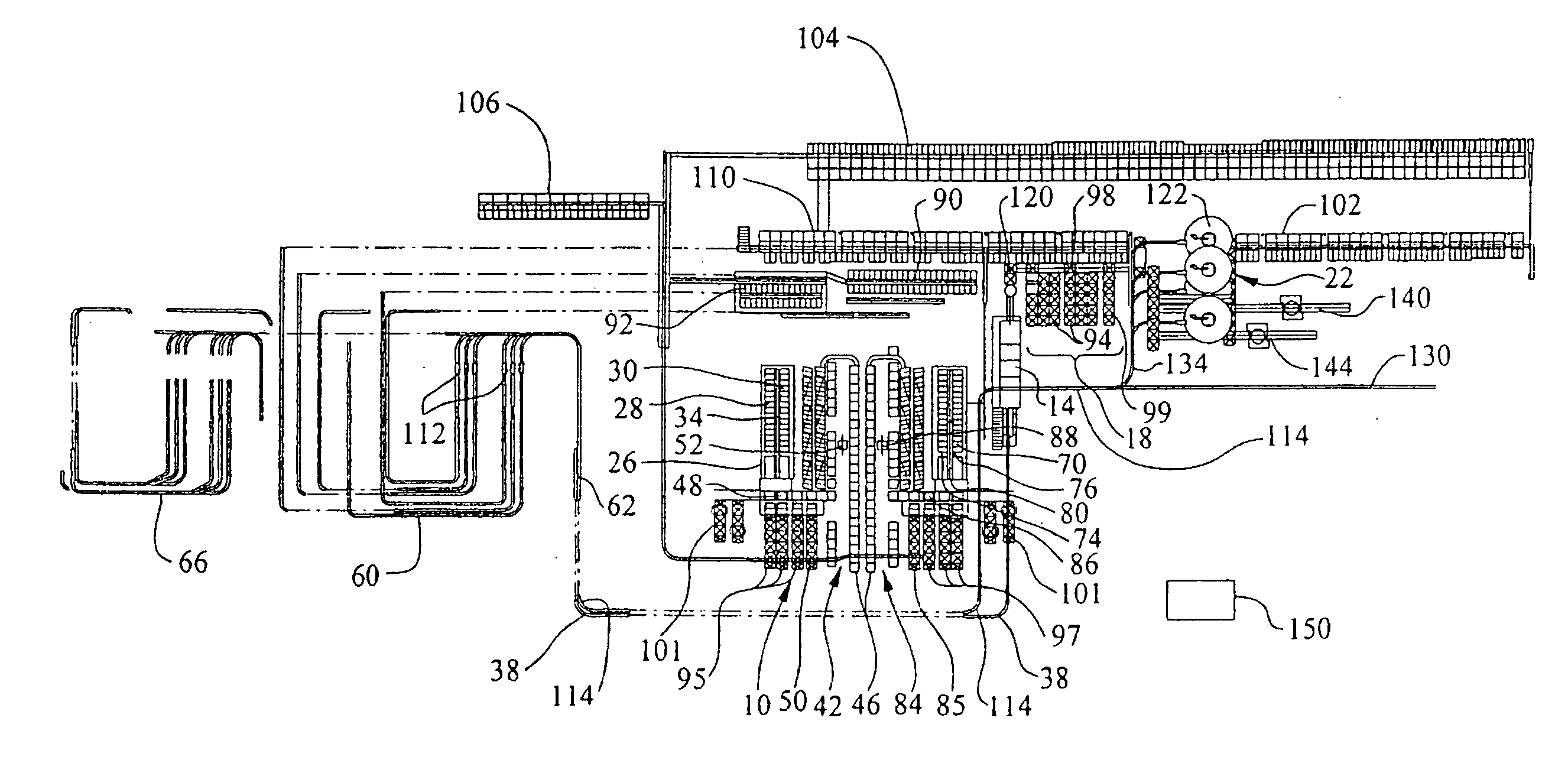

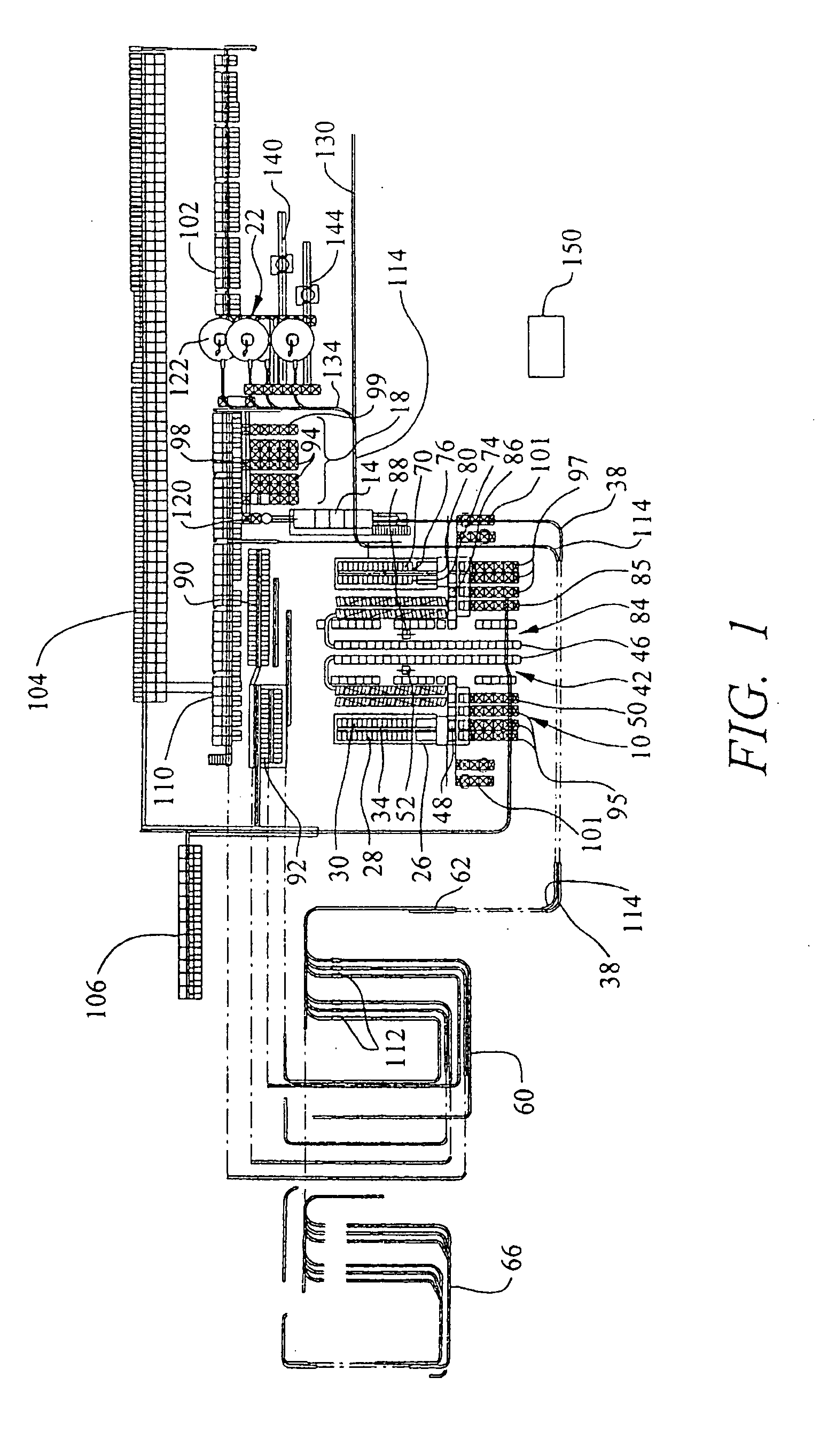

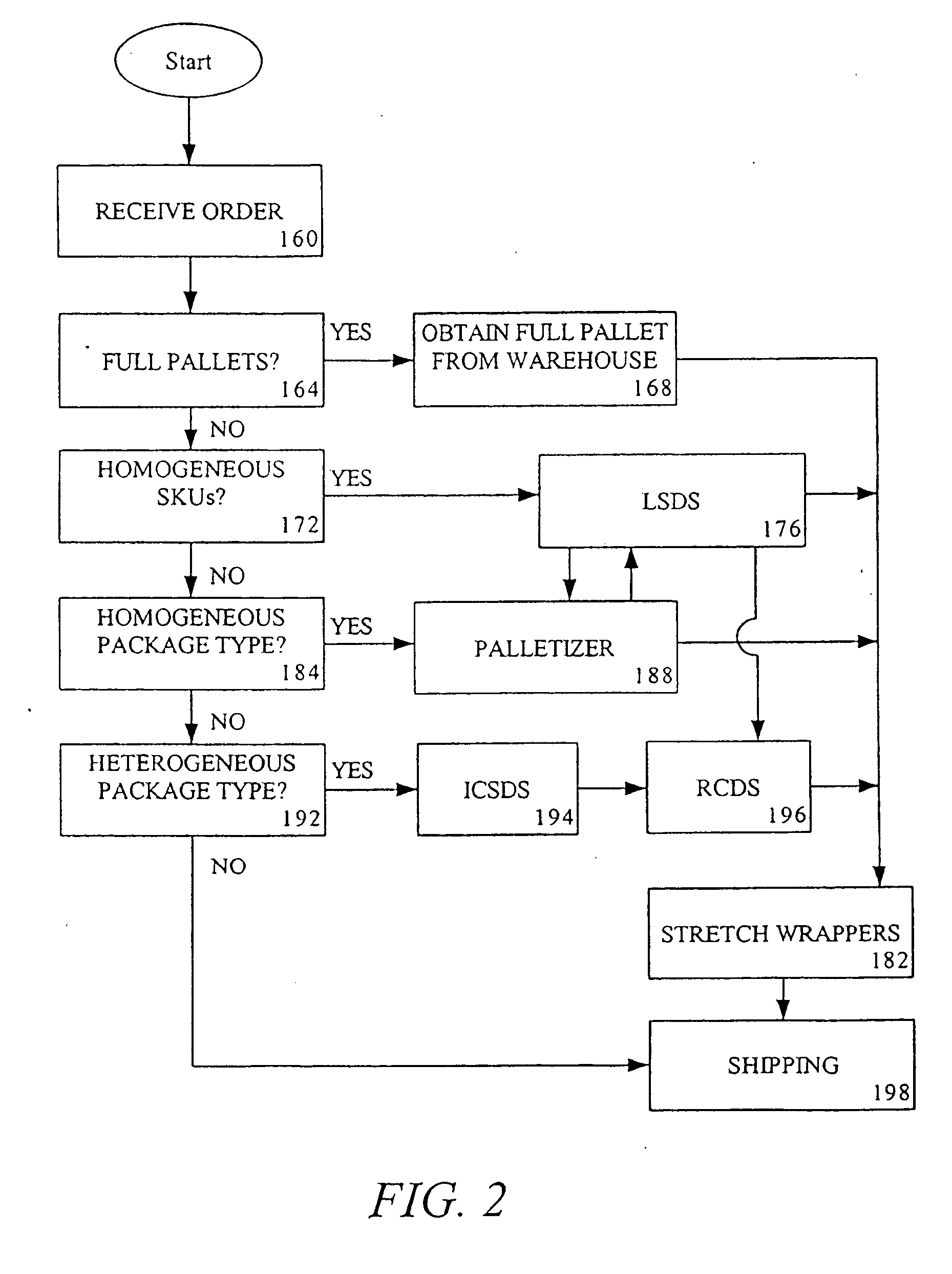

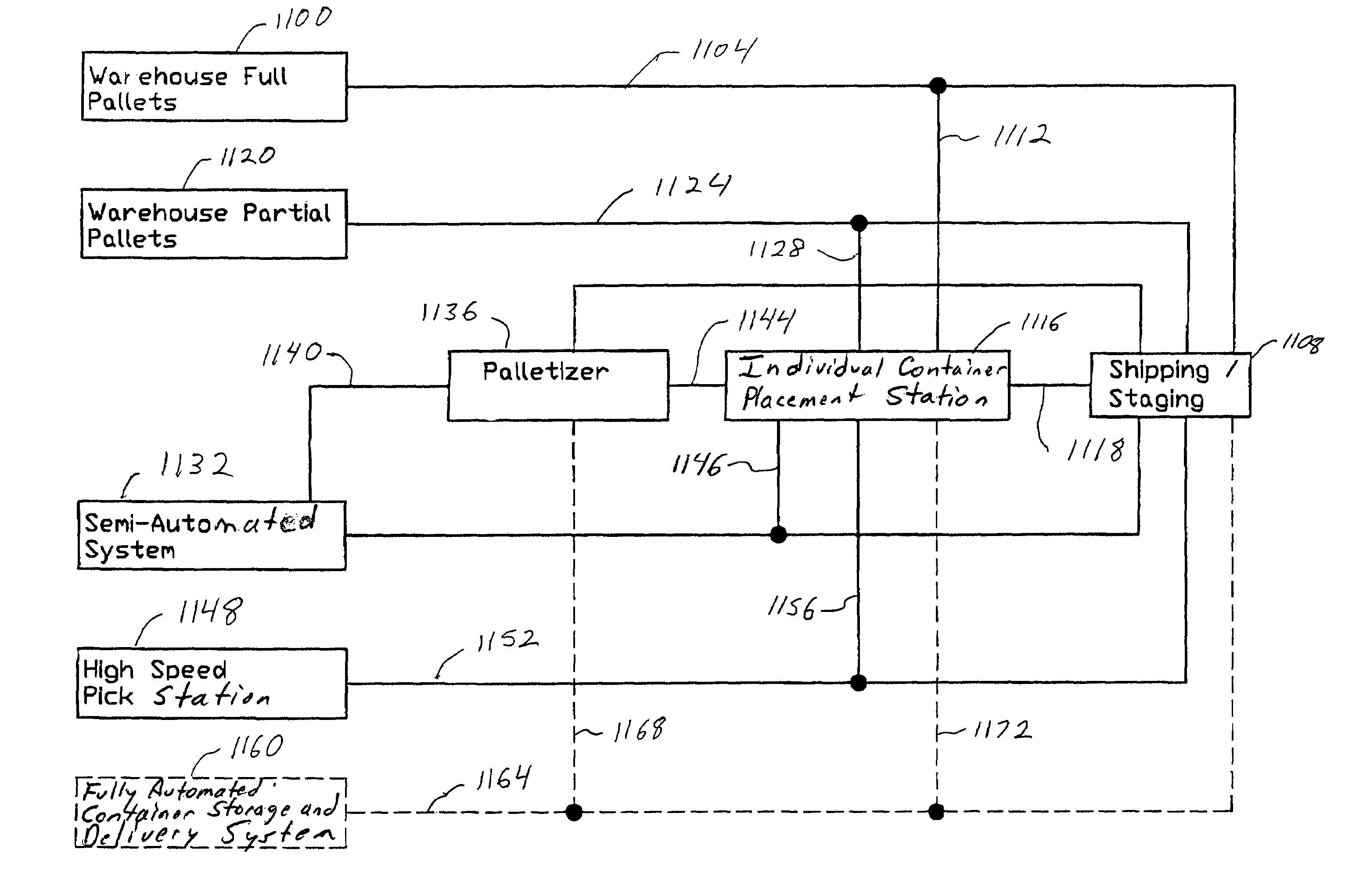

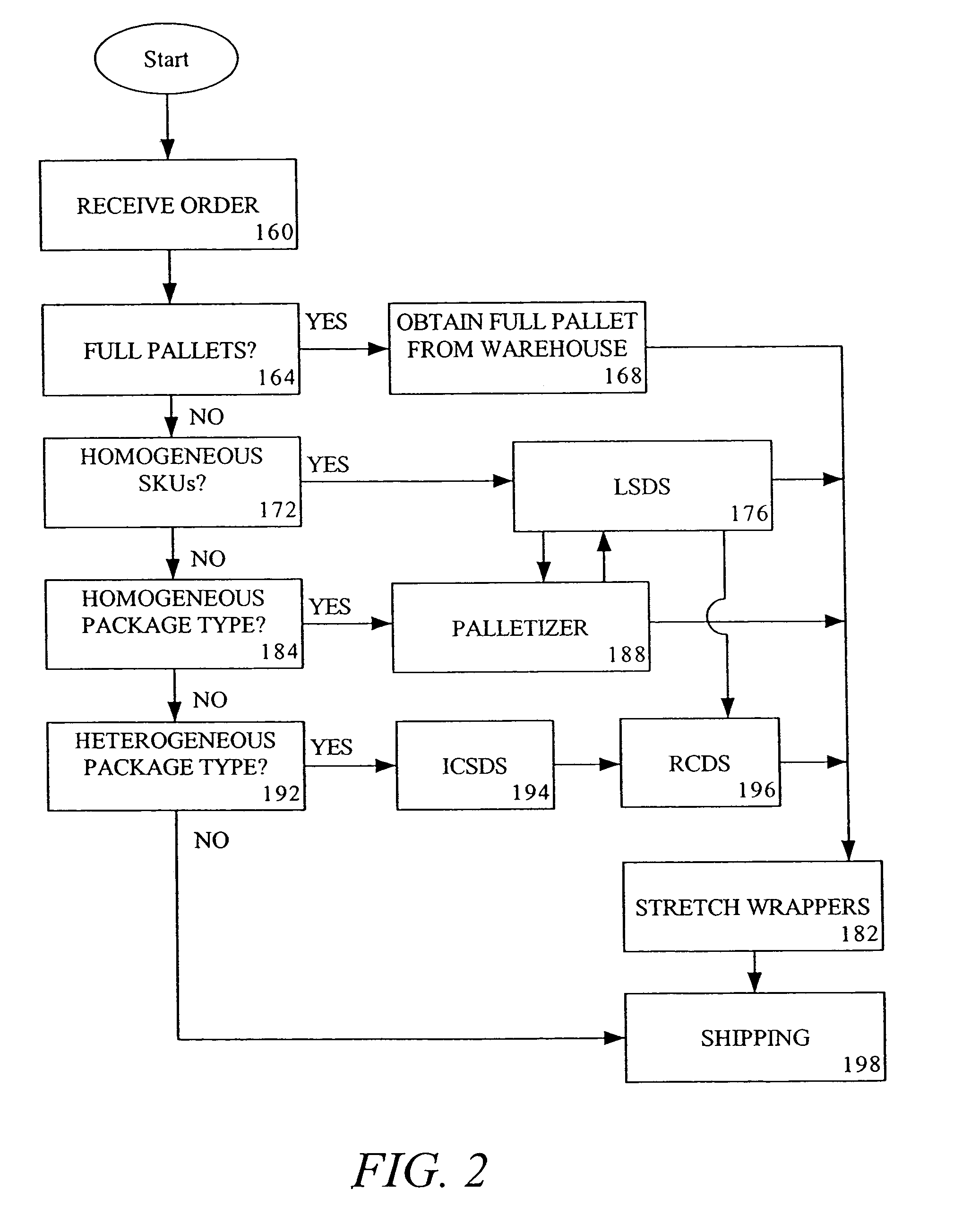

Automated container storage and delivery system

A material storage and delivery system includes an individual container storage and delivery system (ICSDS). A palletizer is provided for placing containers from the ICSDS on a pallet. A layer storage and delivery system (LSDS) places full layers of containers on a pallet. A robotic container delivery system (RCDS) places individual containers on a pallet. A conveyor system conveys containers and pallets between at least two of the ICSDS, the palletizer, the LSDS and the RCDS. A method for storing and delivering containers is also disclosed.

Owner:STINGEL FREDERICK J III +2

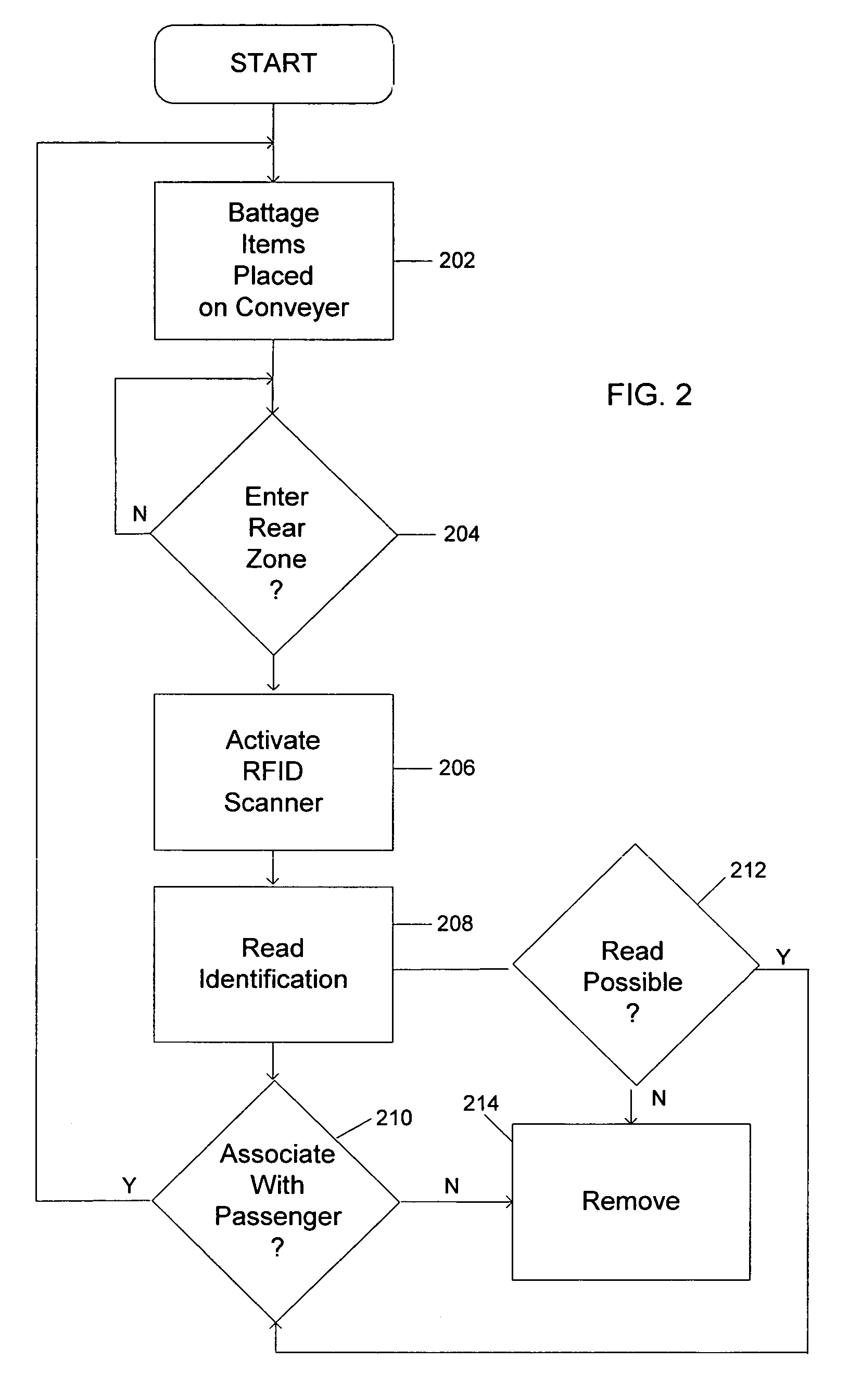

Radio frequency identification for advanced security screening and sortation of baggage

ActiveUS6967579B1Avoid readingMemory record carrier reading problemsBurglar alarm by hand-portable articles removalEnergy absorbingConveyor system

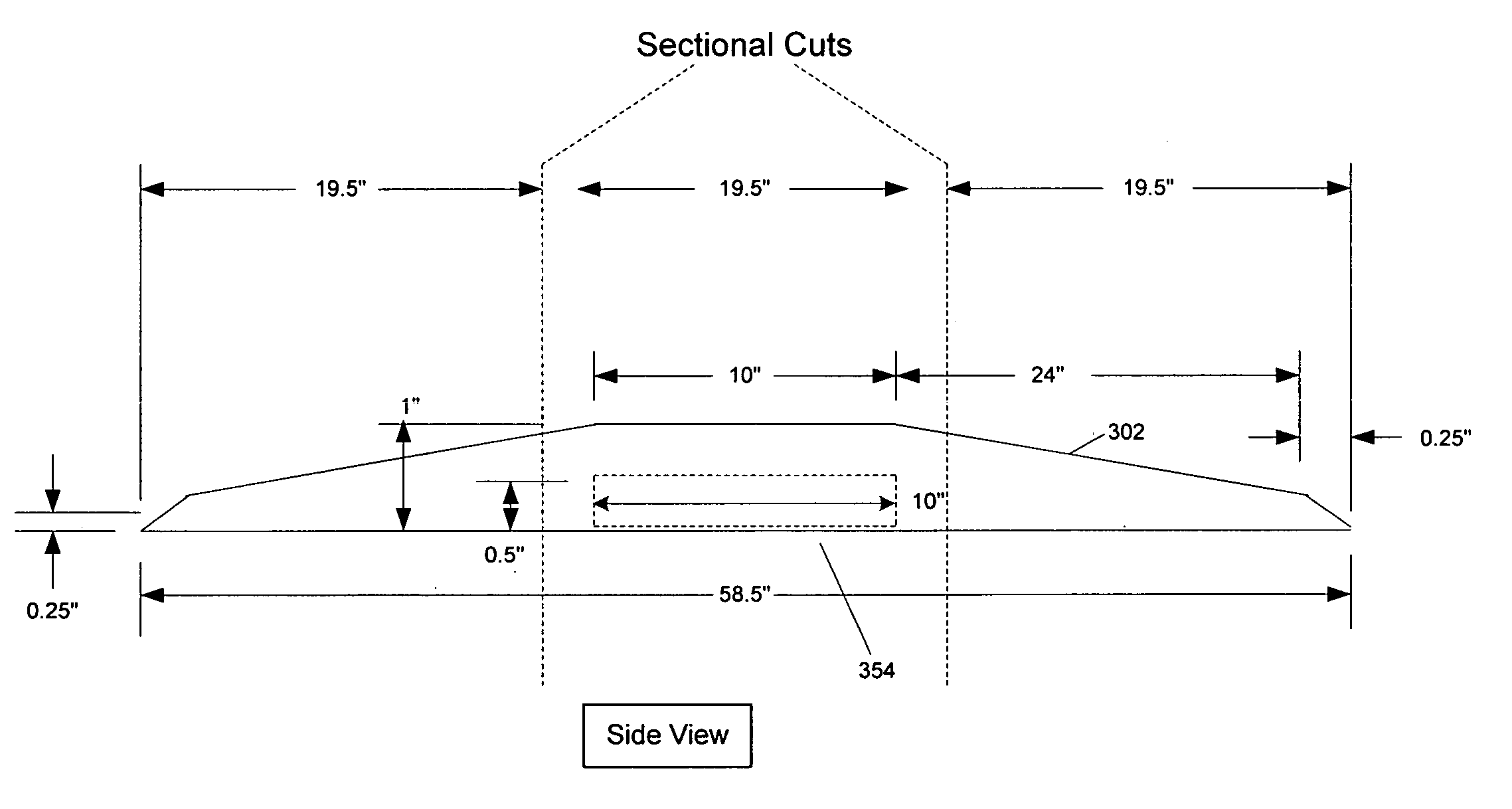

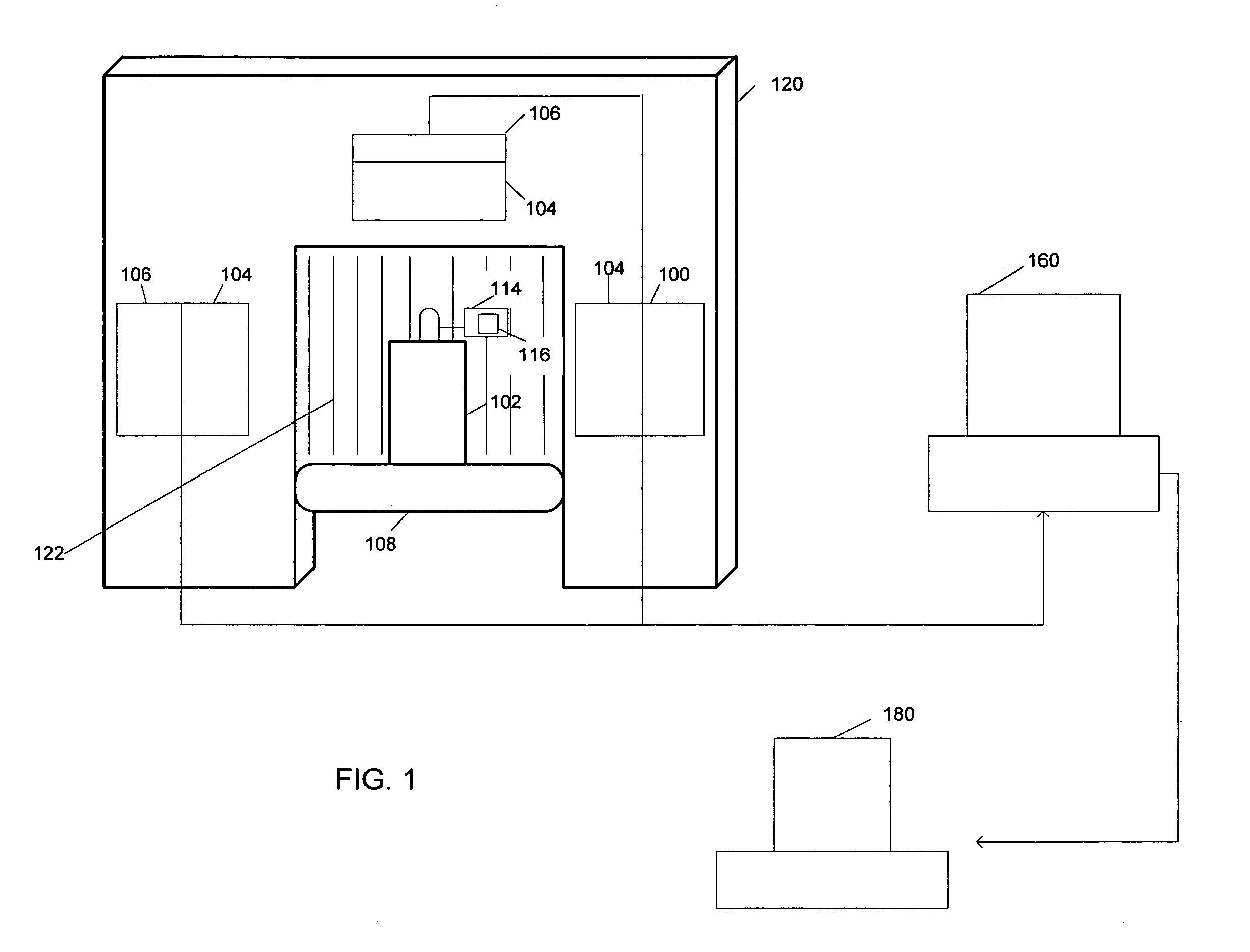

An RFID conveyor system comprises one or more wedges designed to allow an RFID scanner to detect and uniquely identify RFID-tagged baggage as they are conveyed through an antenna array. The RFID conveyor system can also be designed to prevent the reading of previous or subsequent bags by using antennas with highly focused RF read fields in conjunction with RF energy absorbing materials, such as RF curtains, designed to eliminate the identification of any baggage located outside of the “read” area.

Owner:SMARTRAC TECH FLETCHER INC

Cargo roller system for cargo handling

A roller unit that can be used to retrofit a cargo carrying surface makes loading and unloading of the cargo carrying surface easier by transforming the cargo carrying surface to include a conveyor system. The roller unit includes at least two trays in which are mounted rollers, the trays being connected by a crosspiece. The roller unit is designed to be installed on cargo carrying surfaces such as portable platforms, including Flatracks or CROPs, and in cargo containers of any type.

Owner:ENGINEERED SUPPORT SYST INC

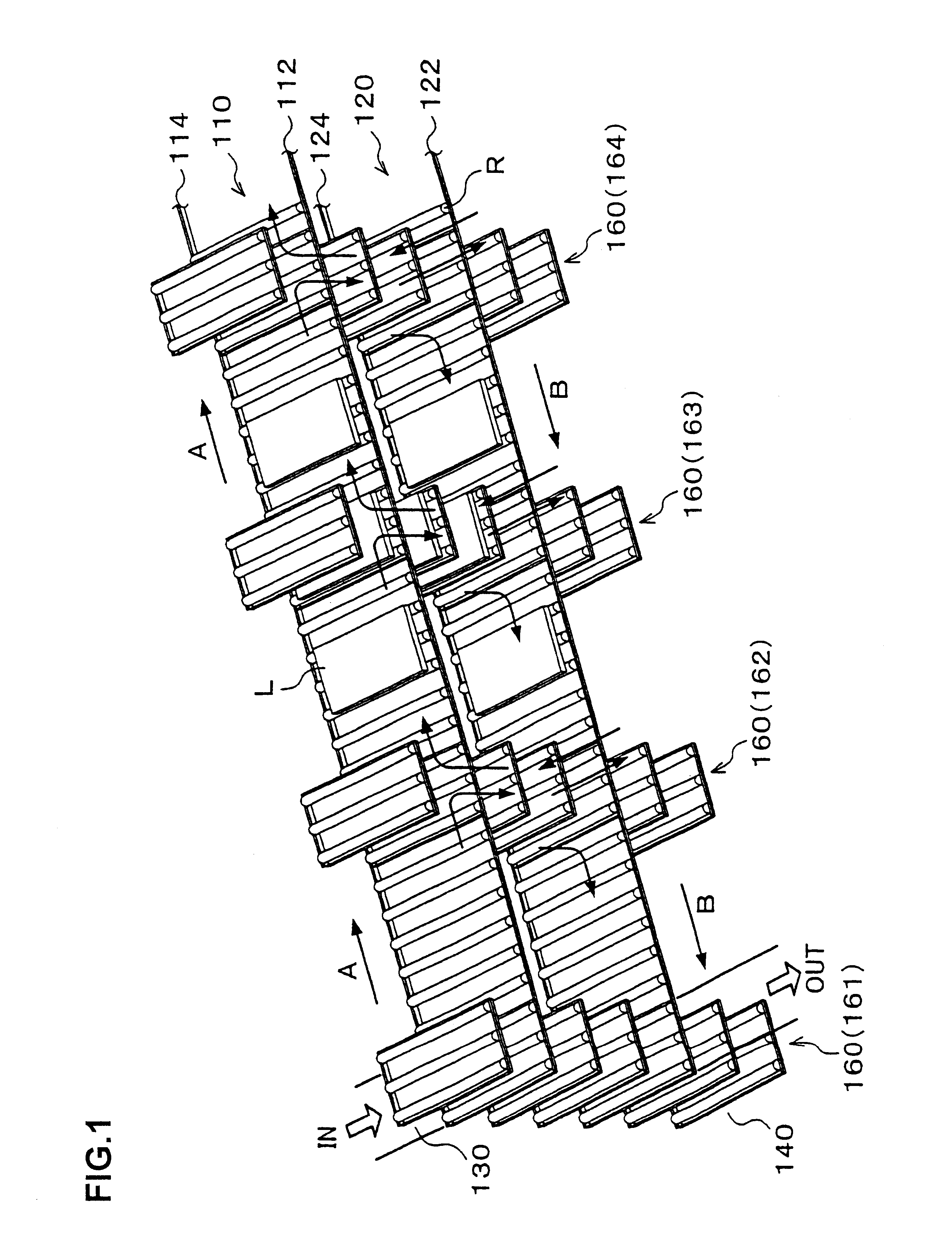

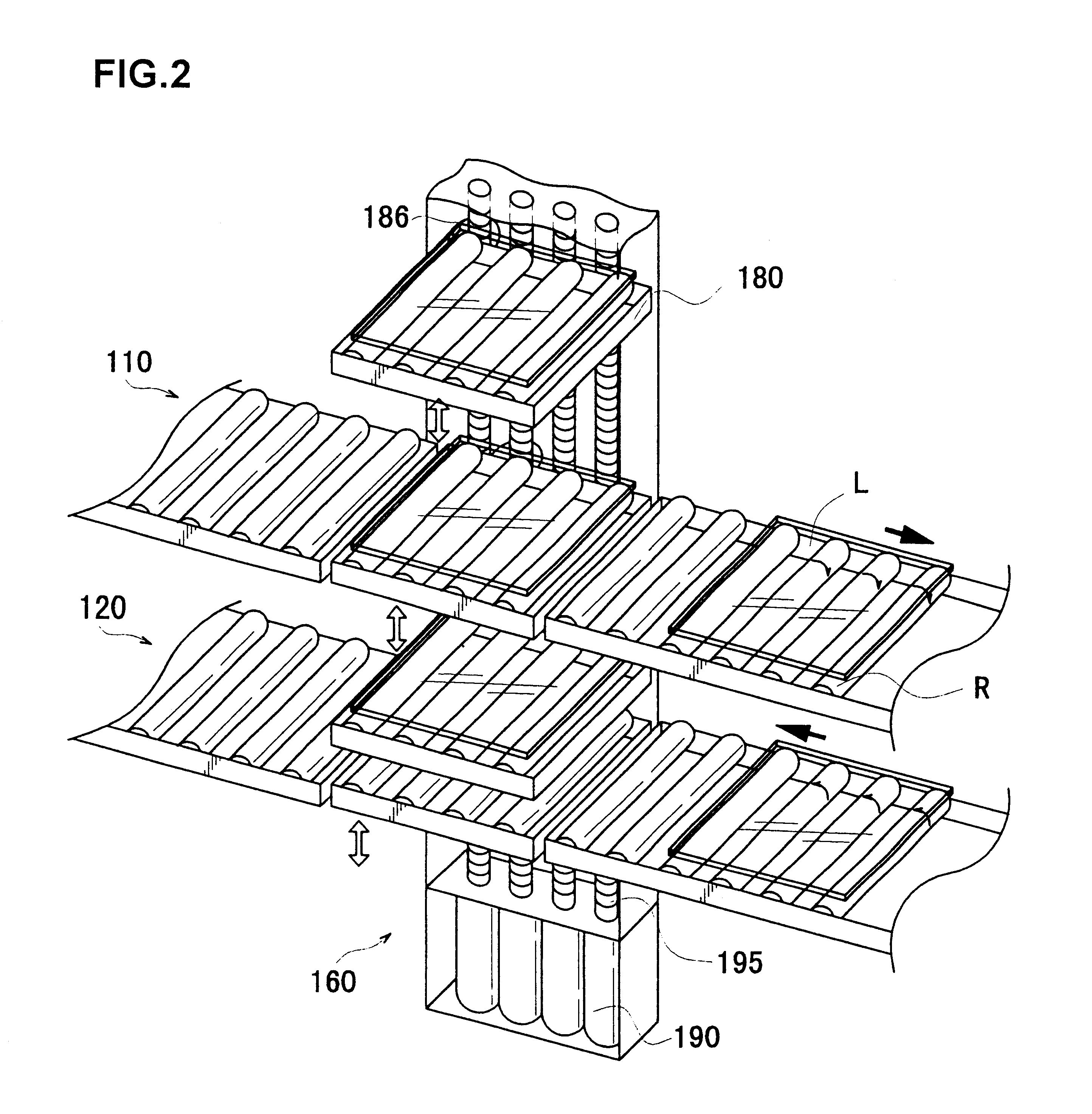

Automated three dimensional warehouse

Provided is a multistory parking garage comprising first and second laminated racks arranged to face each other in parallel, first and second warehousing stations arranged adjacent to one end side of each of those laminated racks and having waiting conveyors of the same number of stages as that of the shelves of the laminated racks, transfer shuttles interposed between the first and second laminated racks and between the first and second warehousing stations, a lifting system having first and second lifts for transferring cargoes to and from standby conveyors in the first and second warehousing stations, and a conveyor system for transferring cargoes to and from the first and second lifts. At the same level, the conveying direction of the standby conveyors of the first warehousing station and the conveying direction of the standby conveyors of the second warehousing station are opposite to each other. The conveying direction of some of the standby conveyors in the first warehousing station is opposite to the conveying direction of the remaining standby conveyors in the first warehousing station.

Owner:DEMATIC ACCOUNTING SERVICES

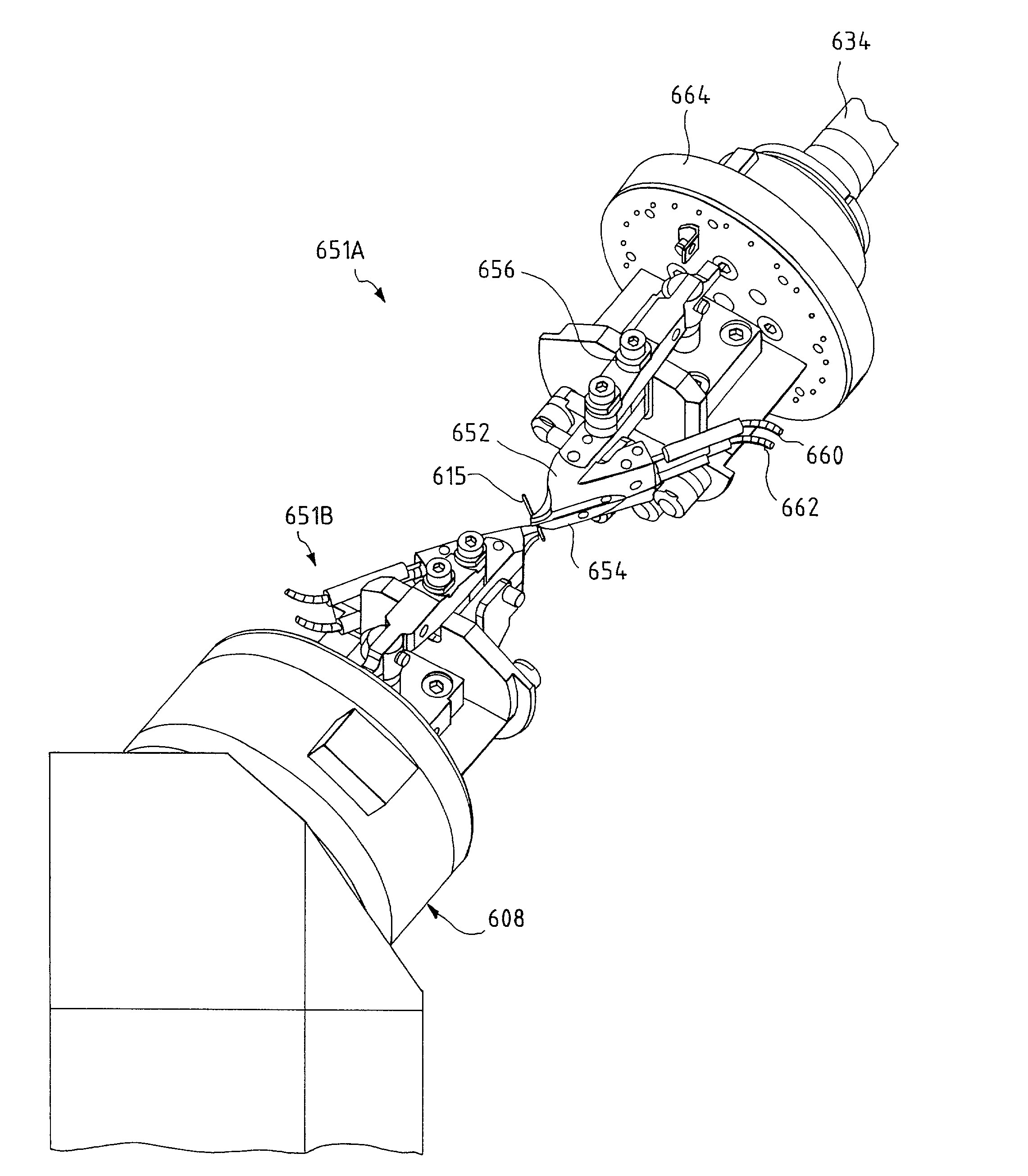

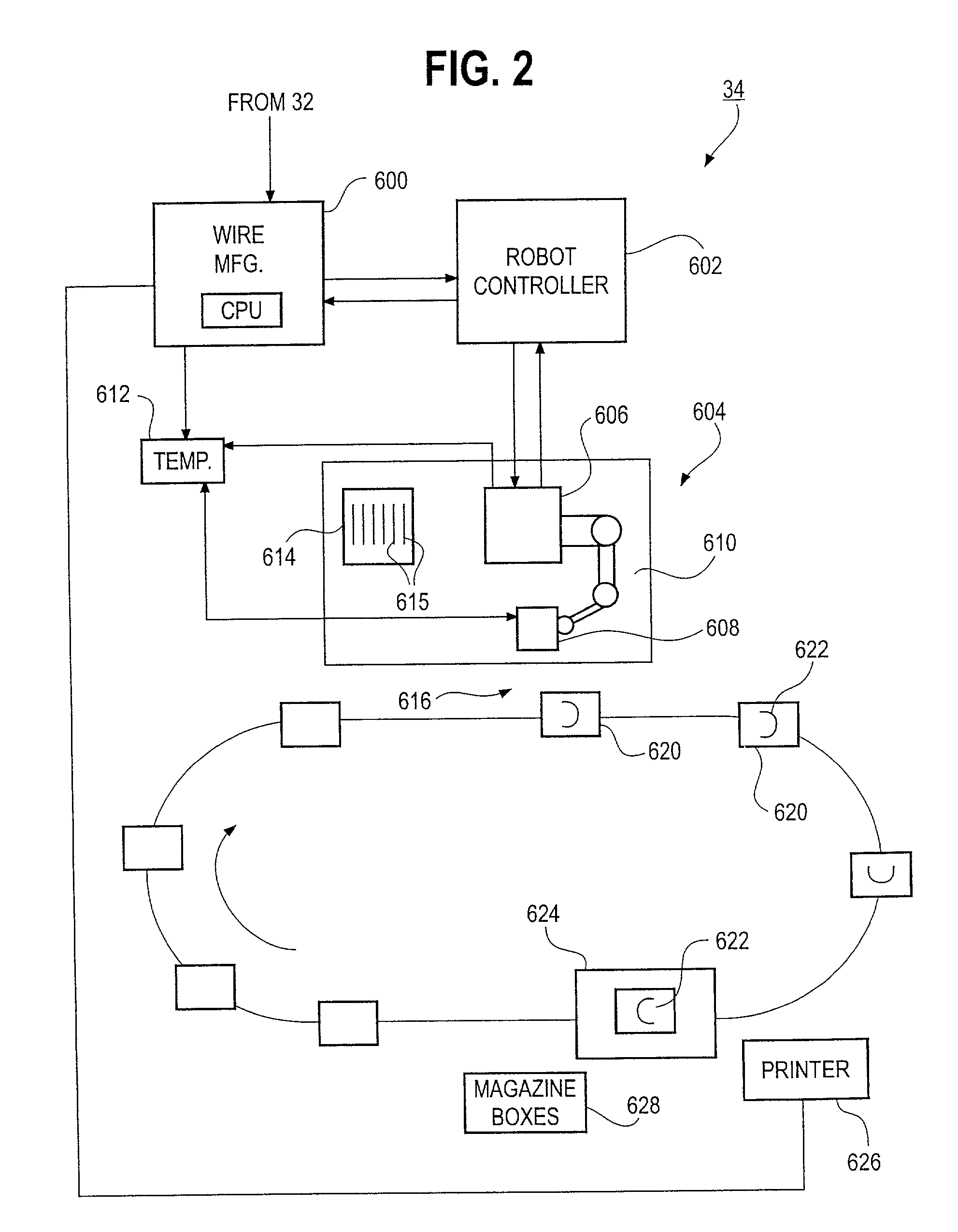

Robot and method for bending orthodontic archwires and other medical devices

A robotic bending apparatus for bending archwires and other types of elongate, bendable medical devices into a desired configuration includes a first gripping tool and a moveable gripping tool. The first gripping tool can be either fixed with respect to a base or table for the robot or positioned at the end of robot am. The moveable gripping tool is mounted to the end of a moveable robot arm having a proximal portion also mounted to the base. The robot preferably comprises a six axis bending robot, in which the distal end of the moveable arm can move relative to the fixed gripping tool about three translational axes and three rotational axes. The gripping tools preferably incorporate force sensors which are used to determine overbends needed to get the desired final shape of the archwire. The robot may also include a resistive heating system in which current flows through the wire while the wire is held in a bent condition to heat the wire and thereby retain the bent shape of the wire. A magazine for holding a plurality of straight archwires needing to be bent and a conveyor system for receiving the wires after the bending process is complete are also described. The robot bending system is able to form archwires with any required second and third order bends quickly and with high precision. As such, it is highly suitable for use in a precision appliance-manufacturing center manufacturing a large number of archwires (or other medical devices or appliances) for a distributed base of clinics.

Owner:ORAMETRIX

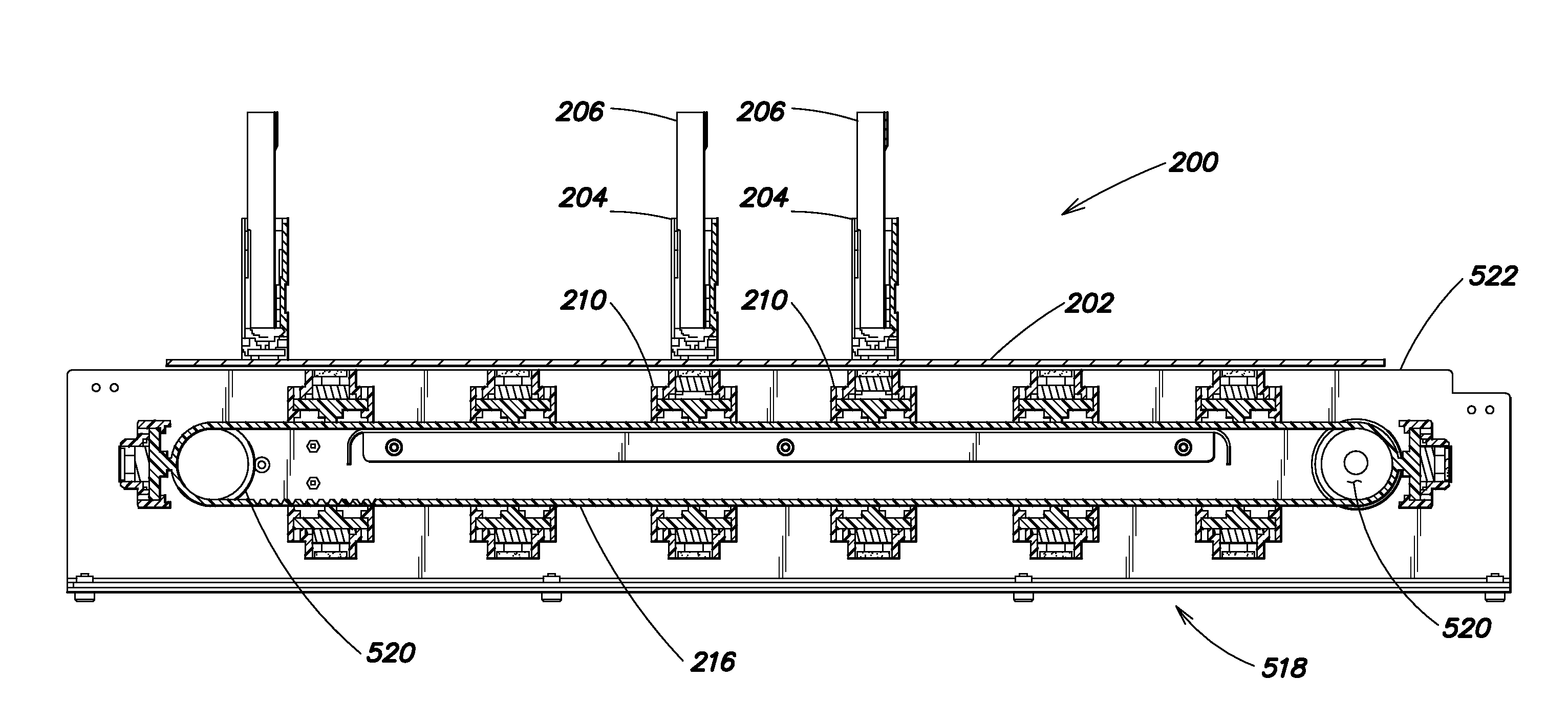

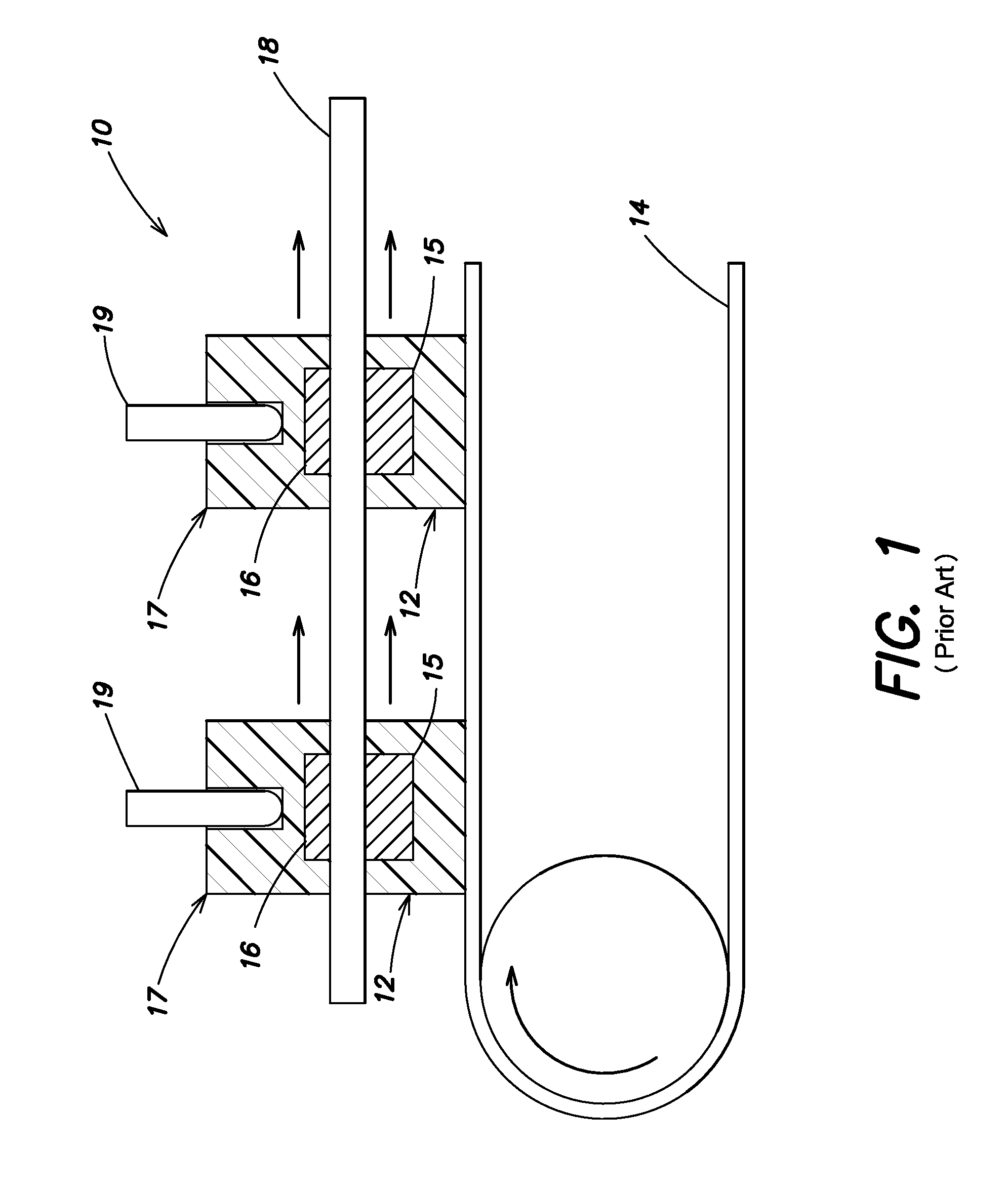

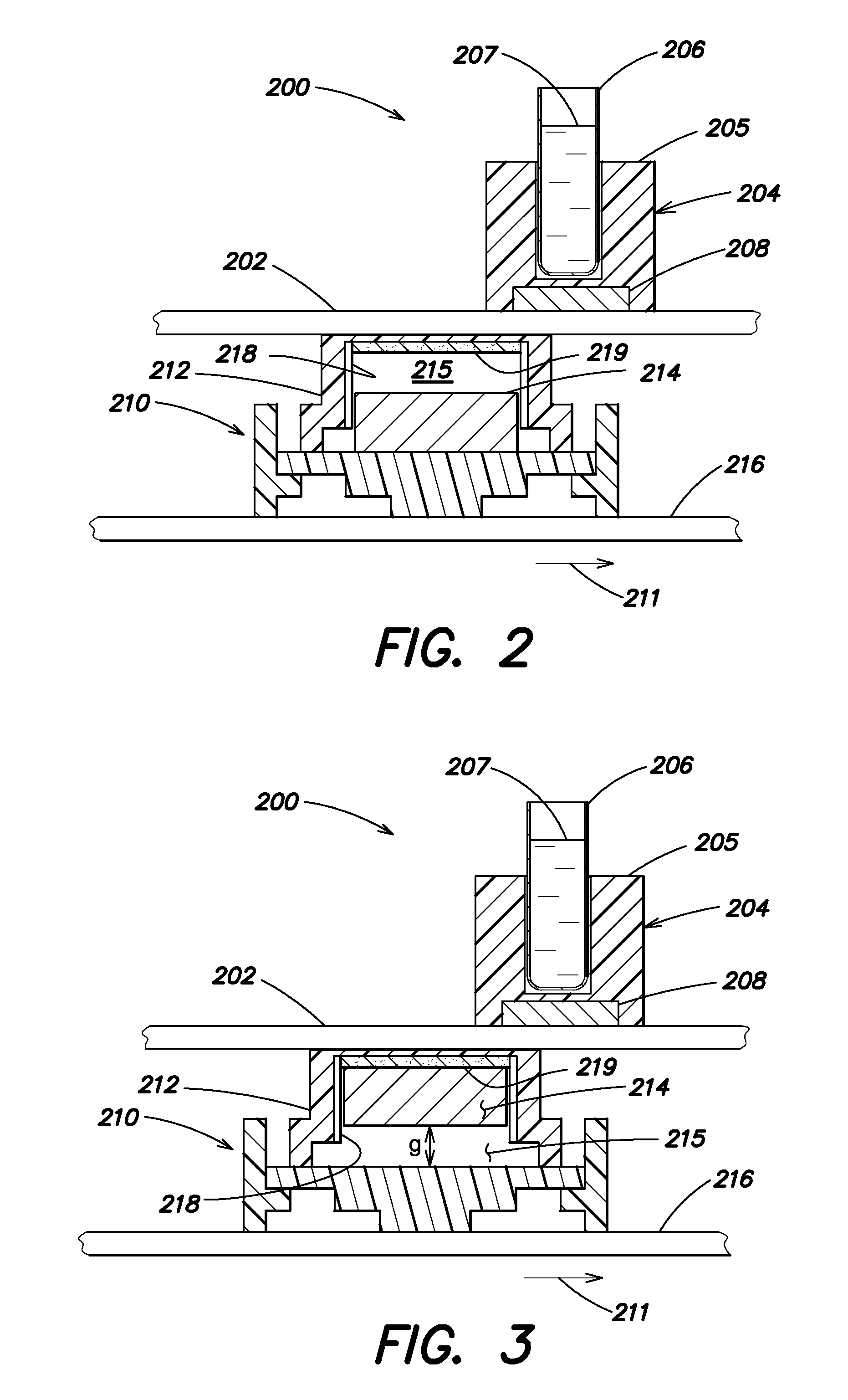

Magnetic Conveyor Systems, Apparatus and Methods Including Moveable Magnet

InactiveUS20120295358A1Easy to optimizeMaterial analysis by optical meansNon-mechanical conveyorsMagnetic tension forceCoupling

Disclosed are magnetic conveyor systems and apparatus having a magnetic coupling with a housing and moveable magnet therein. The moveable magnet is substantially constrained in one dimension and adapted to move in another. The moveable magnet is adapted to magnetically couple with an attracting portion of a sample rack and move the rack along a conveying surface. Ease of transfer of sample racks is provided while minimizing spillage from the open sample containers therein. Method of operating the conveyor system are provided, as are other aspects.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

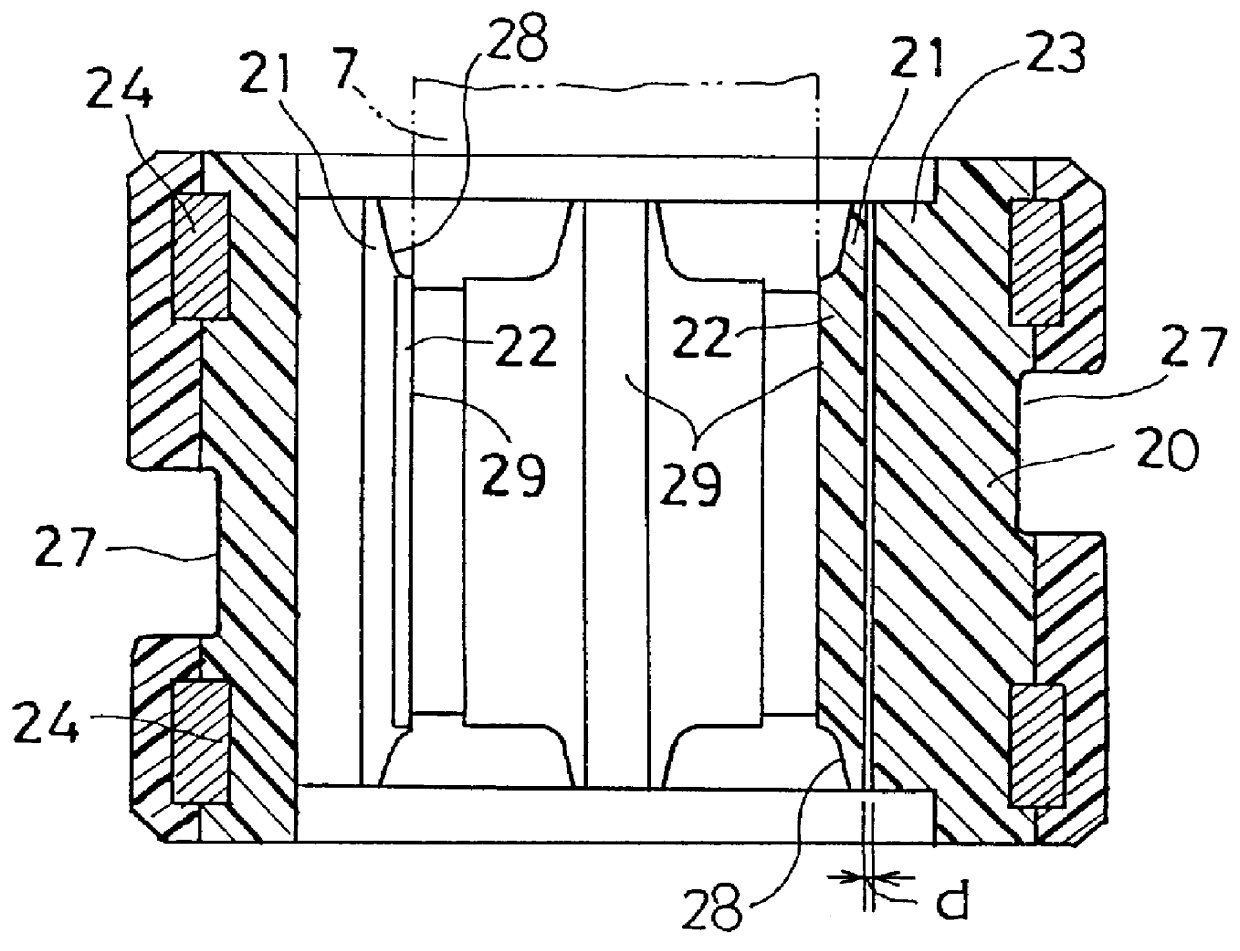

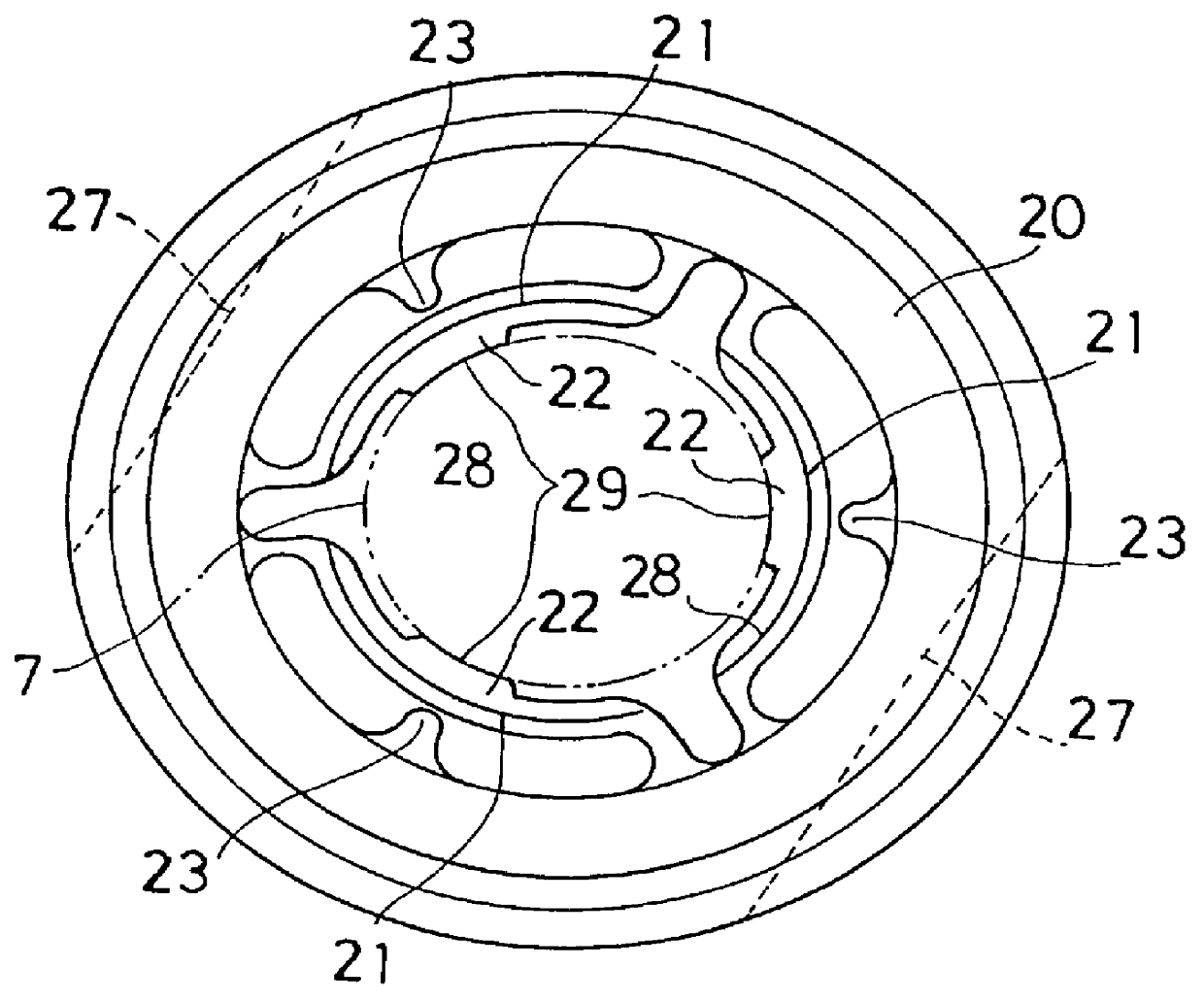

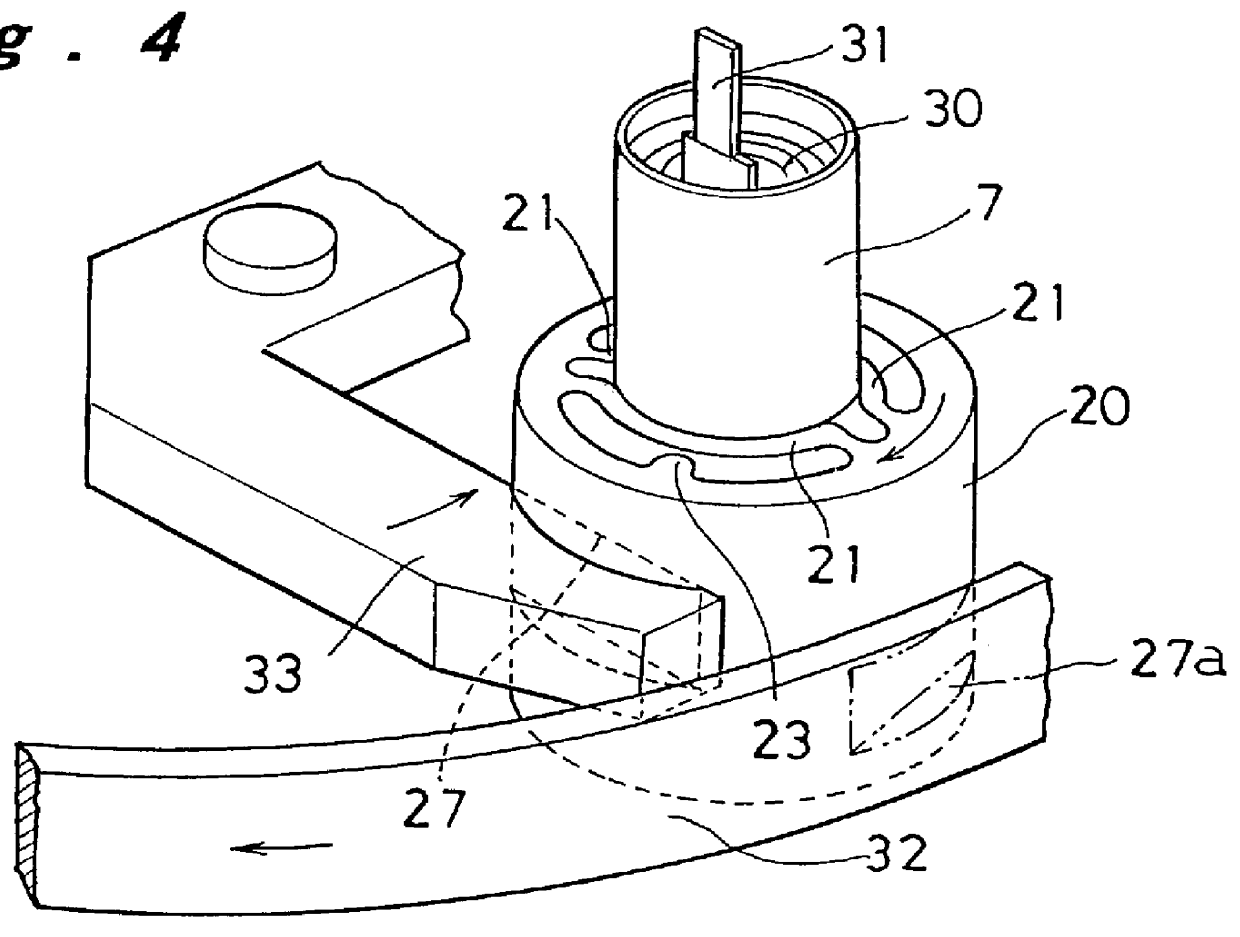

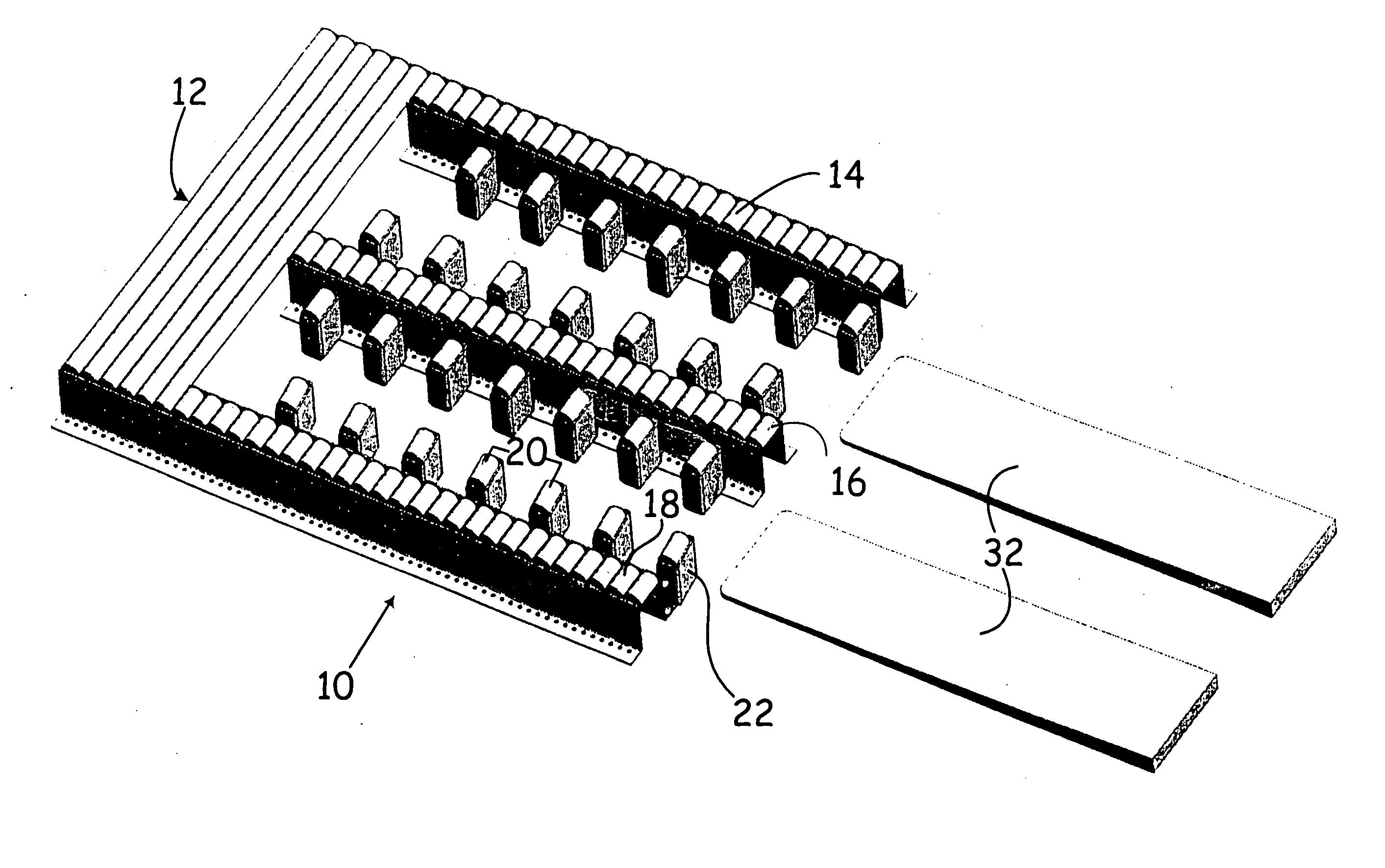

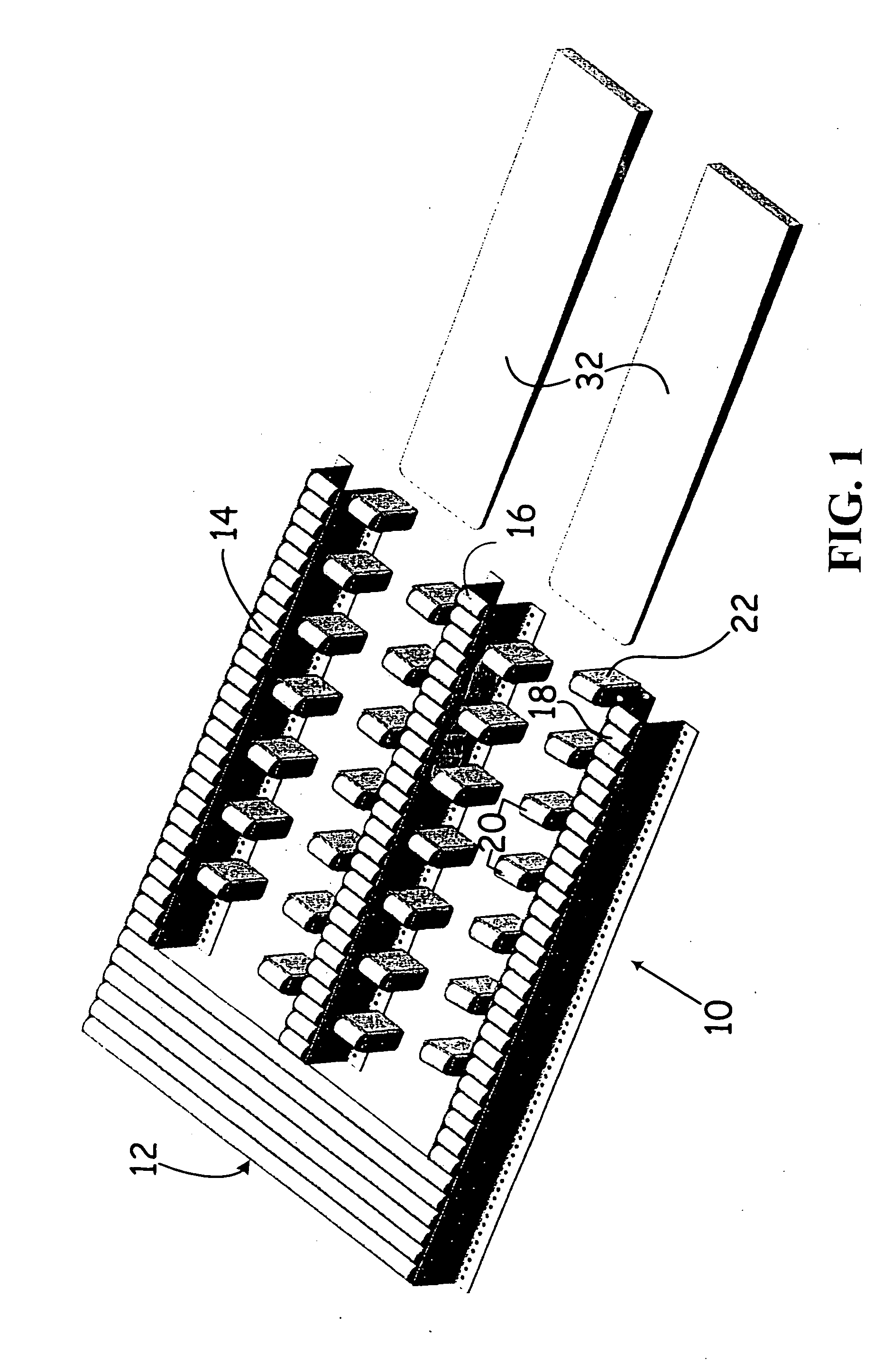

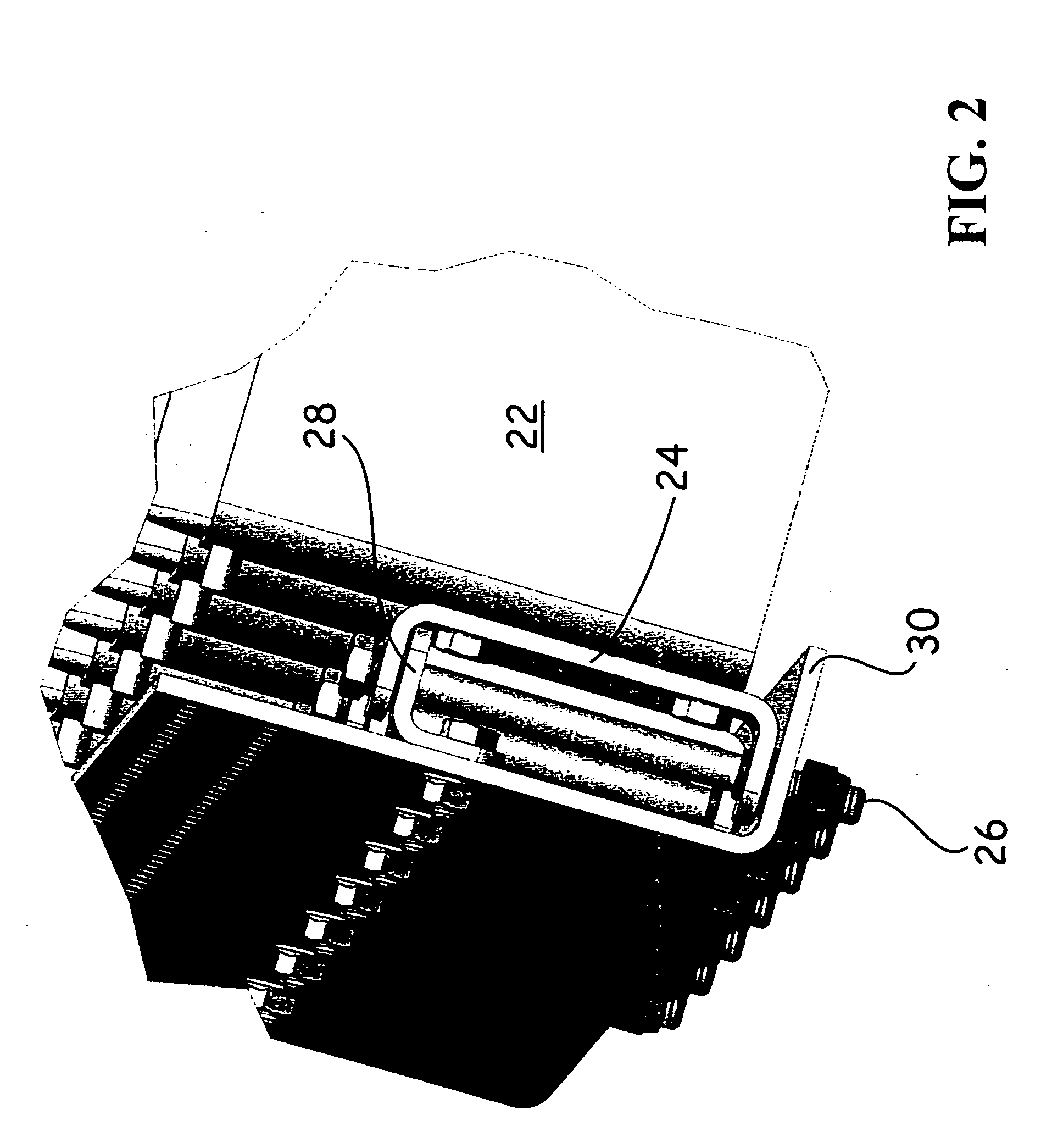

Holder for cylindrical cell in conveyor system

A conveying holder for cylindrical cell is provided which is capable of stably supporting a cylindrical cell irrespective of variation in outer diameter of the cell or impact during transfer. An outer wall member 20 of which inner diameter is greater than the diameter of a cylindrical cell 7 is provided. A plurality of elastic inner wall portions 21 are concentrically arranged to have a distance from the inner side of the outer wall member 20, each elastic inner wall portion joined at both ends to the outer wall member 20. A cell holding portion 22 is provided projecting inwardly from the inner side of each elastic inner wall portion 21 and having a cell holding surface 29 thereof corresponding in shape to the outer side of the cylindrical cell 7. The cell holding surfaces 29 are arranged along a concentric circle which is smaller in diameter than the cylindrical cell 7 so that they can hold the cylindrical cell 7 in-between under pressure.

Owner:PANASONIC CORP

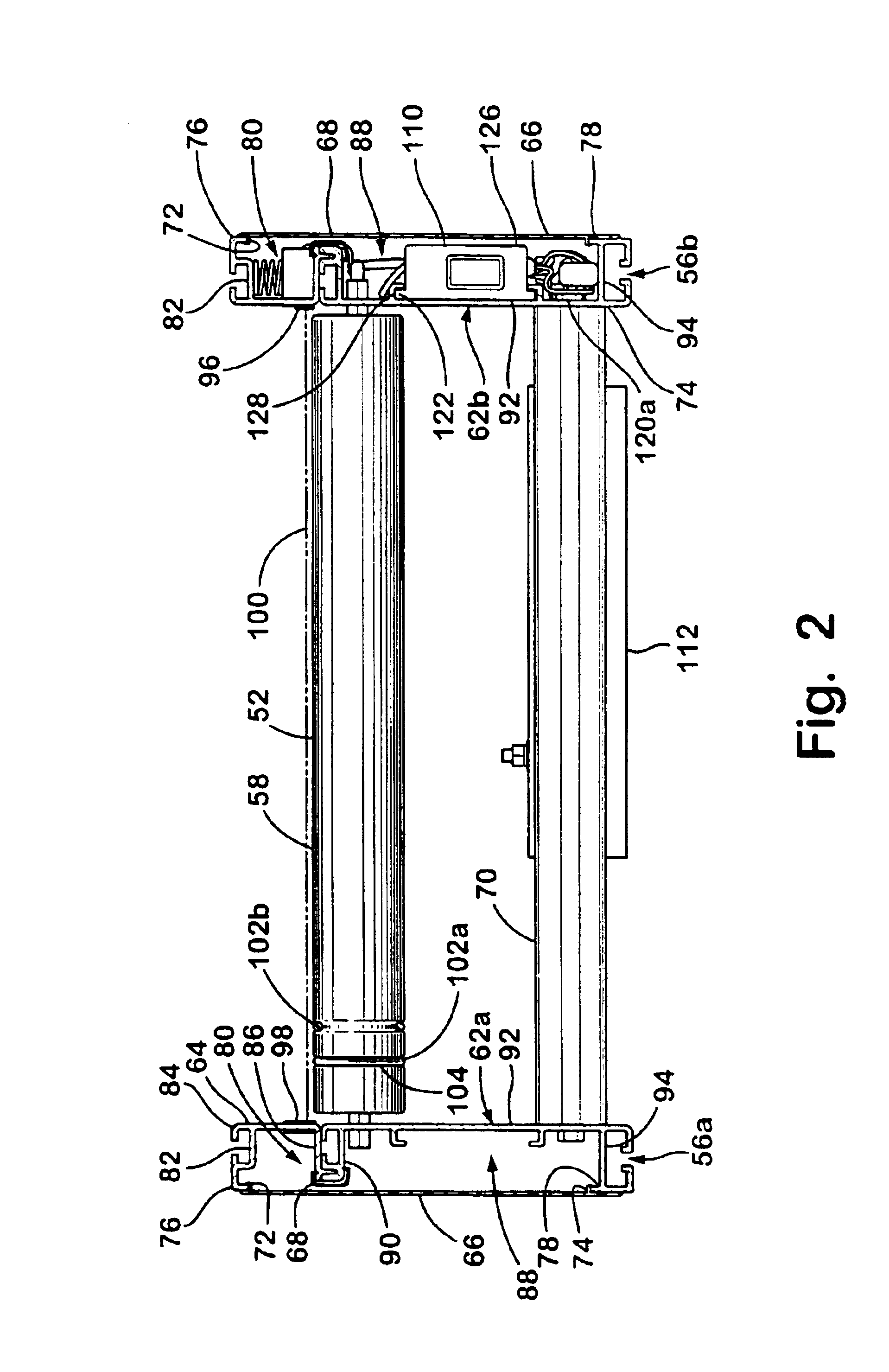

Chain wear monitoring device

A conveyor system and method of measuring chain wear includes first and second sensing devices positioned at a conveyor line or path and directed toward a conveyor chain that is movable along the conveyor path. The first sensing device senses the presence of a first chain portion of the conveyor chain at a predetermined location as the conveyor chain moves along the conveyor line. The second sensing device senses a second chain portion of the conveyor chain as the conveyor chain moves along the conveyor line. The second sensing device is operable to sense a location of or distance to the second chain portion or may capture an image of the second portion. A controller is operable to determine a degree of wear of a section of chain extending between the first and second chain portions in response to the second sensing device.

Owner:FROST TECH

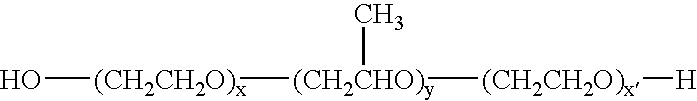

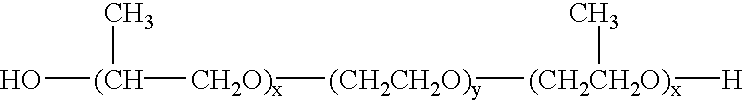

Lubricant for conveyor system

A method of lubricating conveyor tracks or belts is herein described wherein the lubricant composition contains a polyalkylene glycol polymer and a fatty acid; also described are methods of manufacture of such lubricant compositions in both concentrate and diluted form. The compositions may also comprise additional functional ingredients.

Owner:ECOLAB USA INC

Moving crank mechanism

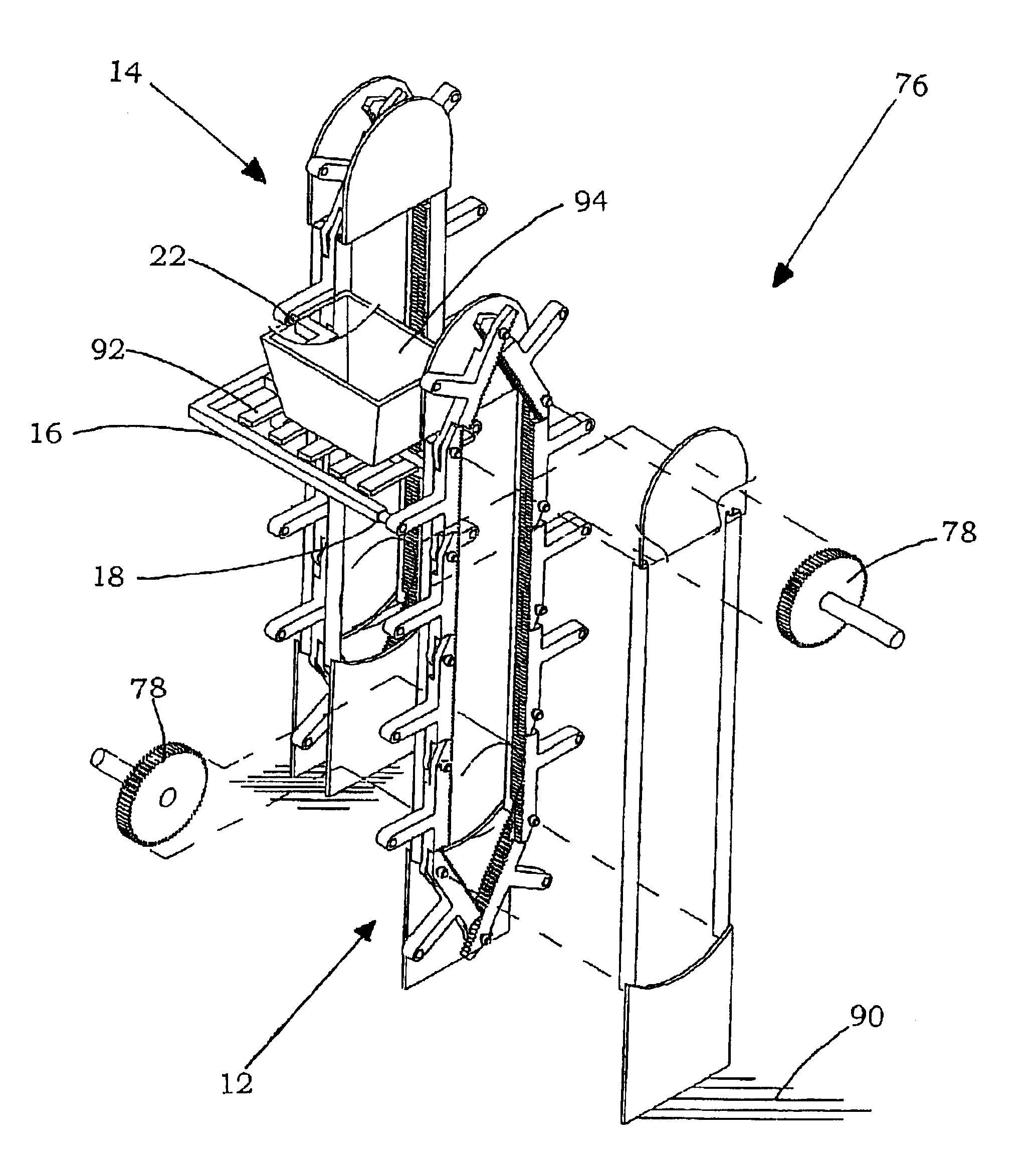

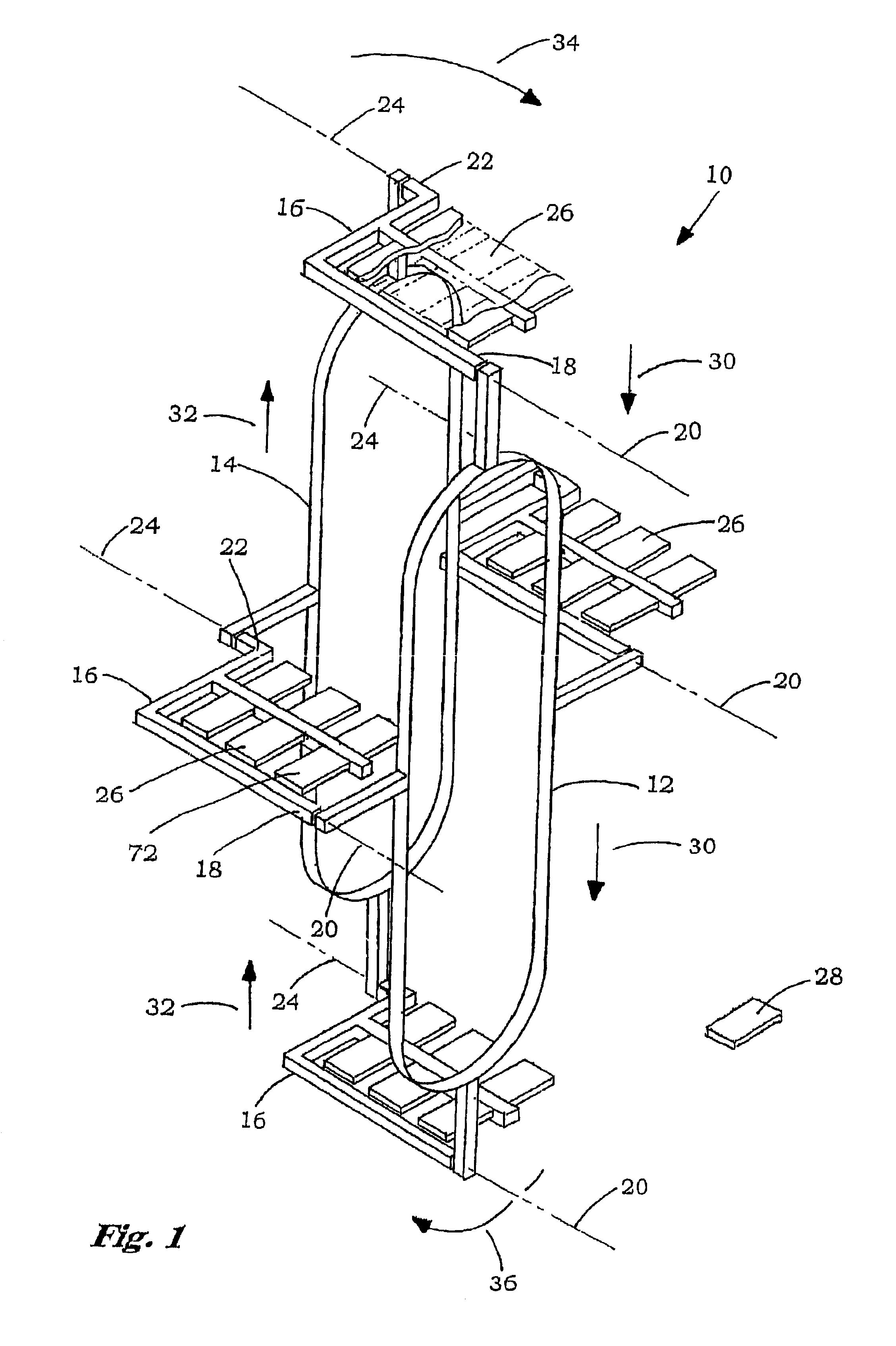

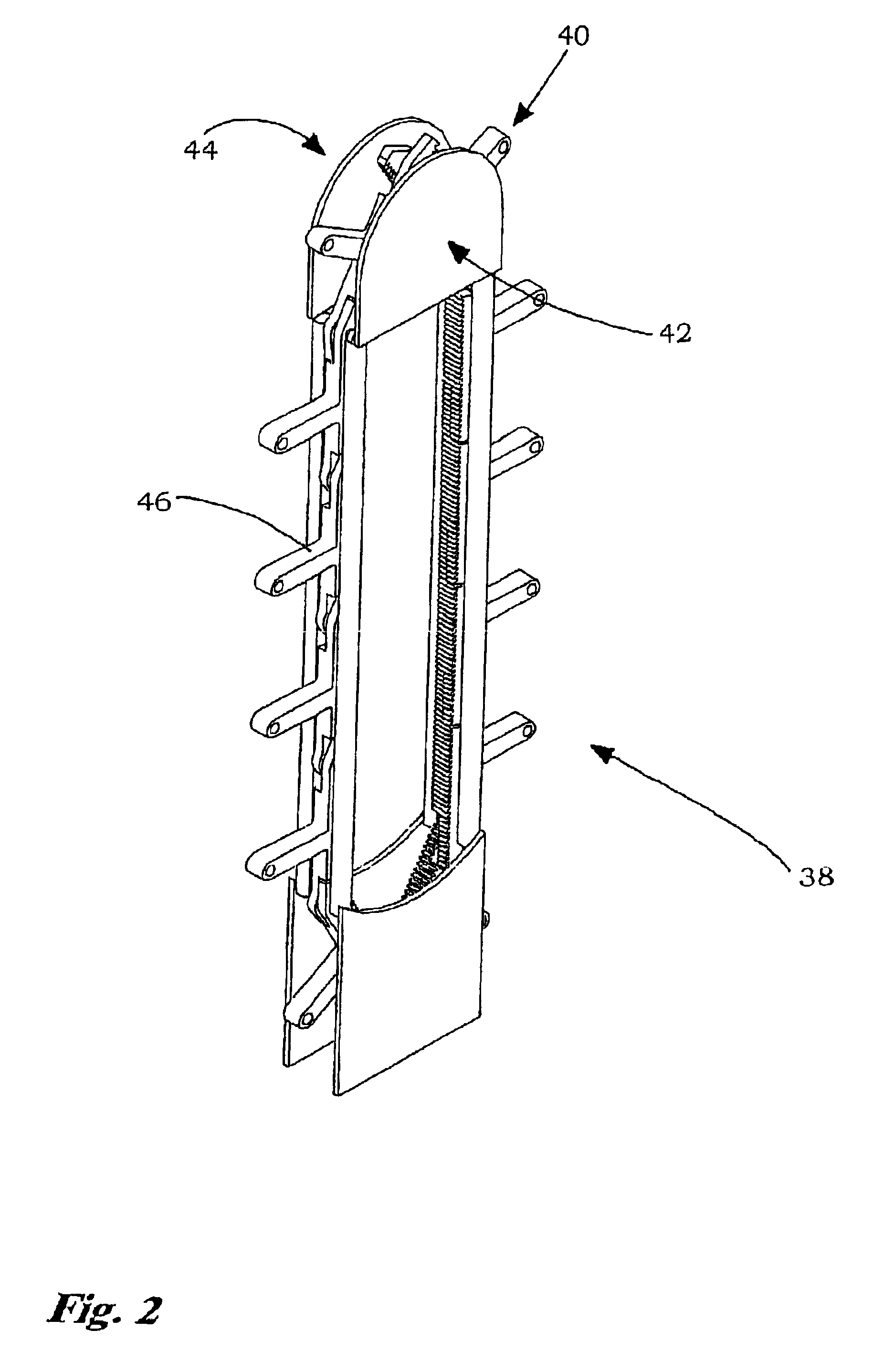

InactiveUS7025191B2Improve efficiencyIncrease flexibilityStorage devicesConveyor partsClosed loopEngineering

A moving crank mechanism that is particularly adapted for use in a conveyor system. A moving crank remains in a substantially parallel position with respect to a fixed reference plane as the crank member is driven by its offset opposed ends along an endless loop. The closed loop vertical lift unit is adapted for use in an automated high-speed storage system. The vertical lift unit is adapted to be used as a primary storage location or as a lift for carrying objects in transit between levels in a storage system. The vertical lift unit includes a plurality of crank members with generally rigidly mounted shelves that are adapted to carry objects continuously and indefinitely as the shelves travel through a vertically oriented closed path. While traveling along the vertically oriented closed path the shelves remain parallel to a fixed horizontal plane so objects can be carried on the shelves while the shelves transition between the up and down reaches of the vertical lift mechanism. The opposed ends of the crank member are journaled in carriage members that are mounted to carry the respective ends of the crank member around the closed loop. The respective ends are carried around the closed loop at about the same rate. The closed loops are offset from one another by the amount of the crank offset. Shelf stabilizing mechanisms can also be employed.

Owner:LICHTI ROBERT D +1

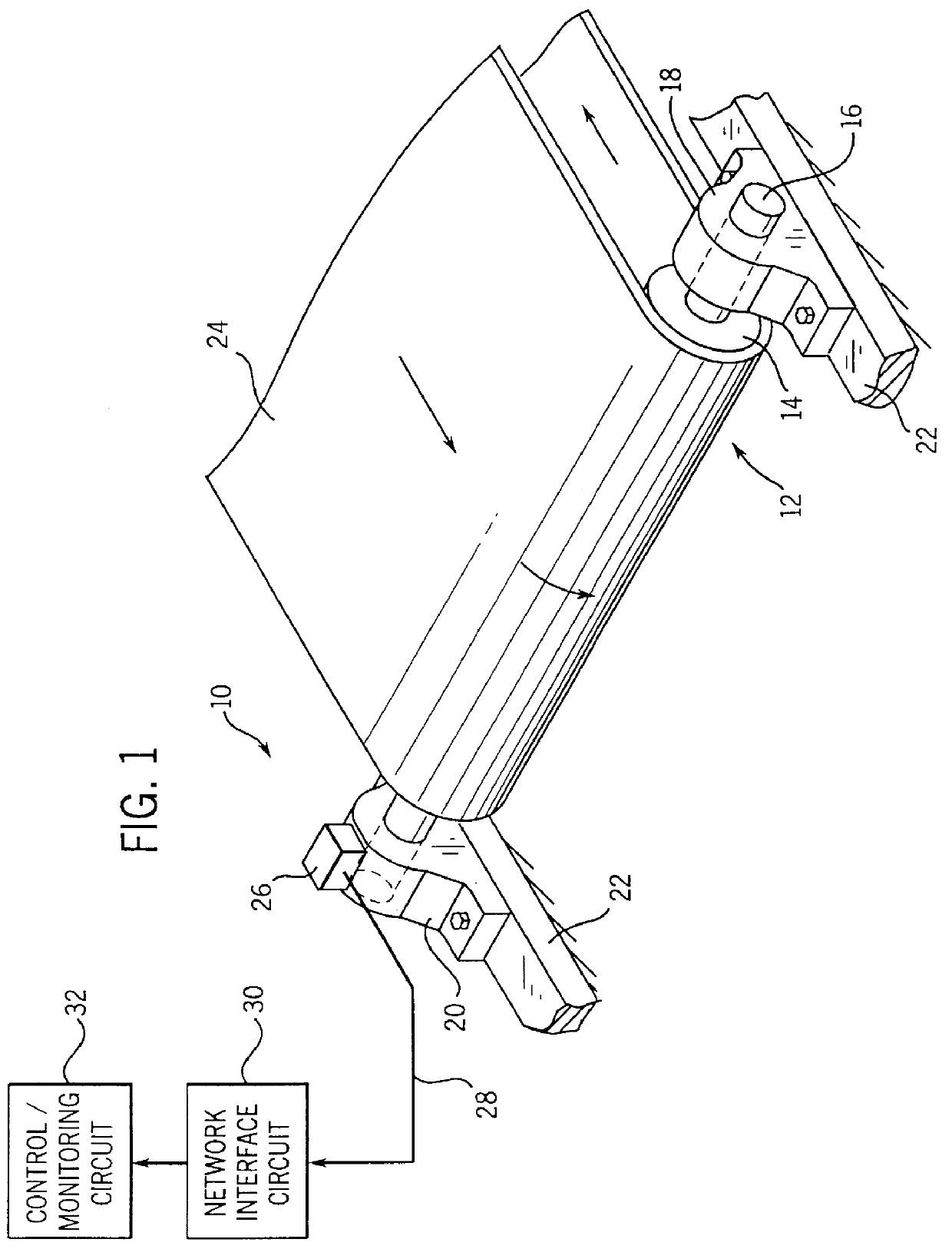

Method and apparatus for identifying defects in a rotating machine system

InactiveUS6116089AVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesAccelerometerEngineering

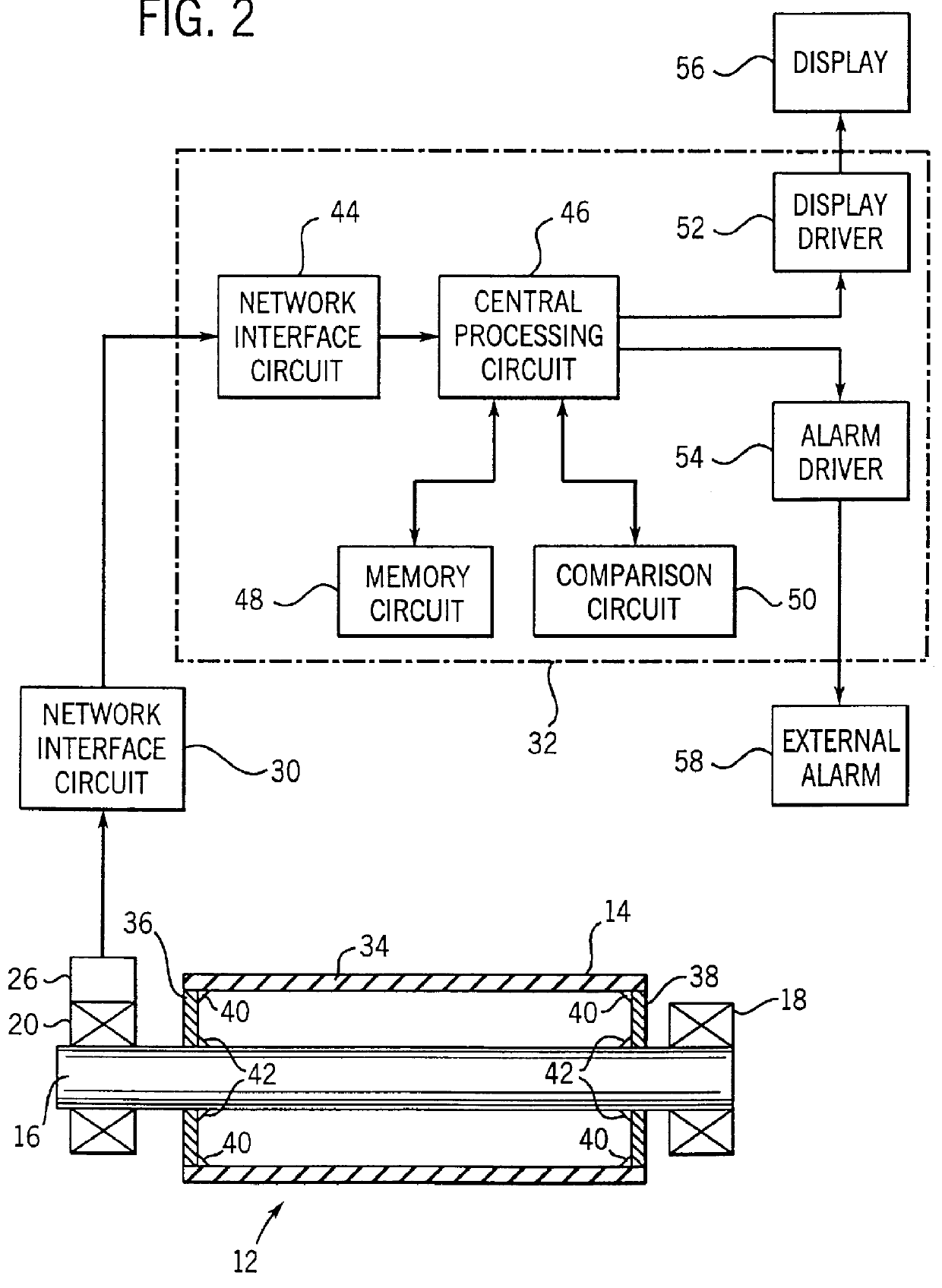

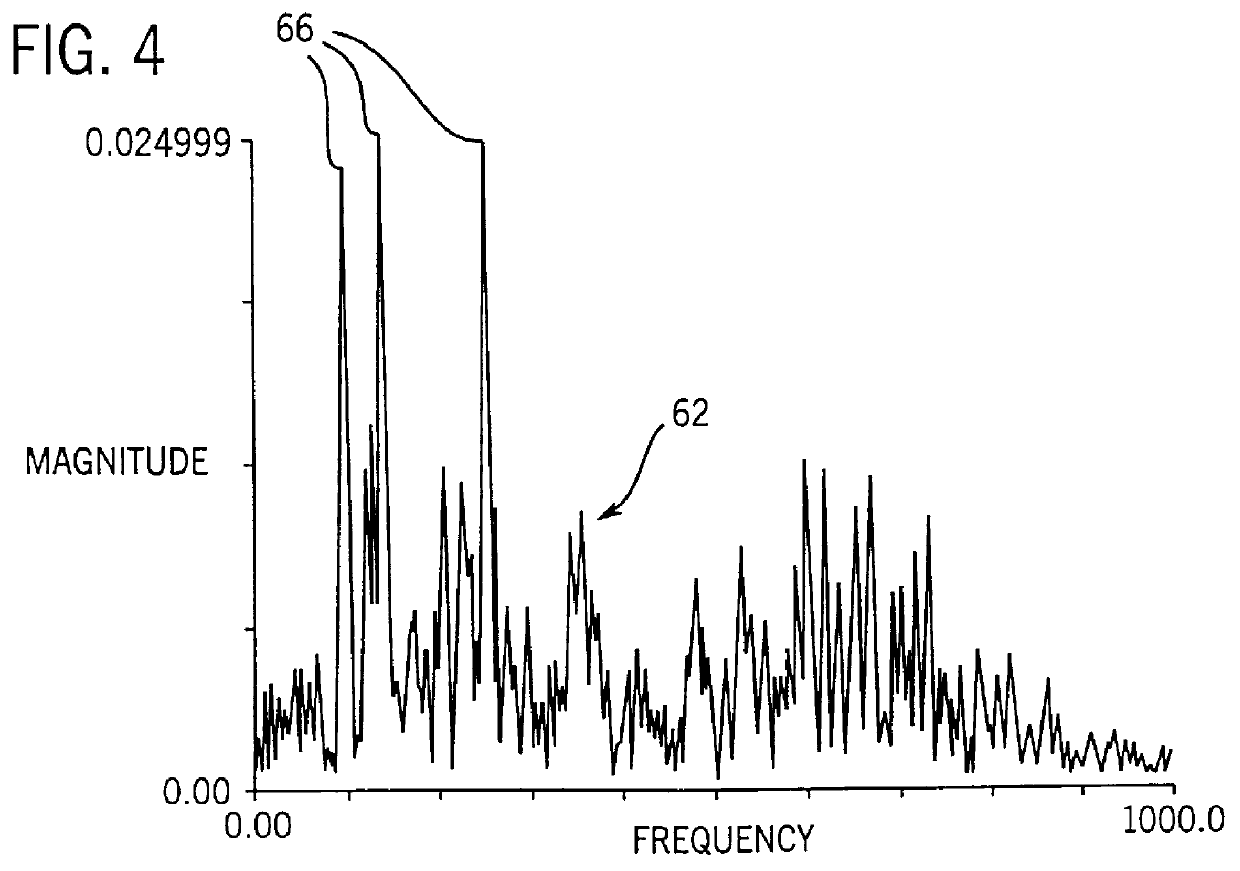

A system for detecting defects in a rotating machine system includes a sensor such as an accelerometer coupled to the machine system for detecting vibrations of a rotating element. Output of the accelerometer is transmitted, preferably via a network data link to a monitoring / control circuit. The monitoring / control circuit analyzes the vibration data to develop a normal vibration profile for the machine system during a normal operating phase. The normal vibration profile is stored in a memory circuit for later reference. During subsequent operation of the machine system, the monitoring / control circuit cyclically analyzes vibration data to develop actual vibration profiles. The actual vibration profiles are compared to the normal vibration profile and, where variations between the profiles exceed preset tolerances, the circuit provides an indication of a malfunction or defect in the machine system. The technique is particularly well suited to conveyor systems such as drum pulleys and the like in which cracks, breaks and other defects can result in unexpected failure and maintenance.

Owner:BALDOR ELECTRIC COMPANY

Automated container storage and delivery system

A container storage and delivery system includes an individual container storage and delivery system. A palletizer is provided for forming a group of containers from the individual container storage and delivery system into a layer or a partial layer, and placing this layer or partial layer onto a pallet. A high speed pick station provides access for manual retrieval of high throughput case types from each storage location. An individual container placement station is also provided for placing individual containers onto a pallet. A conveyor system conveys containers and pallets from the individual container storage and delivery system, the palletizer, the high speed pick station, and the individual container placement station.

Owner:SYST LOGISTICS CORP

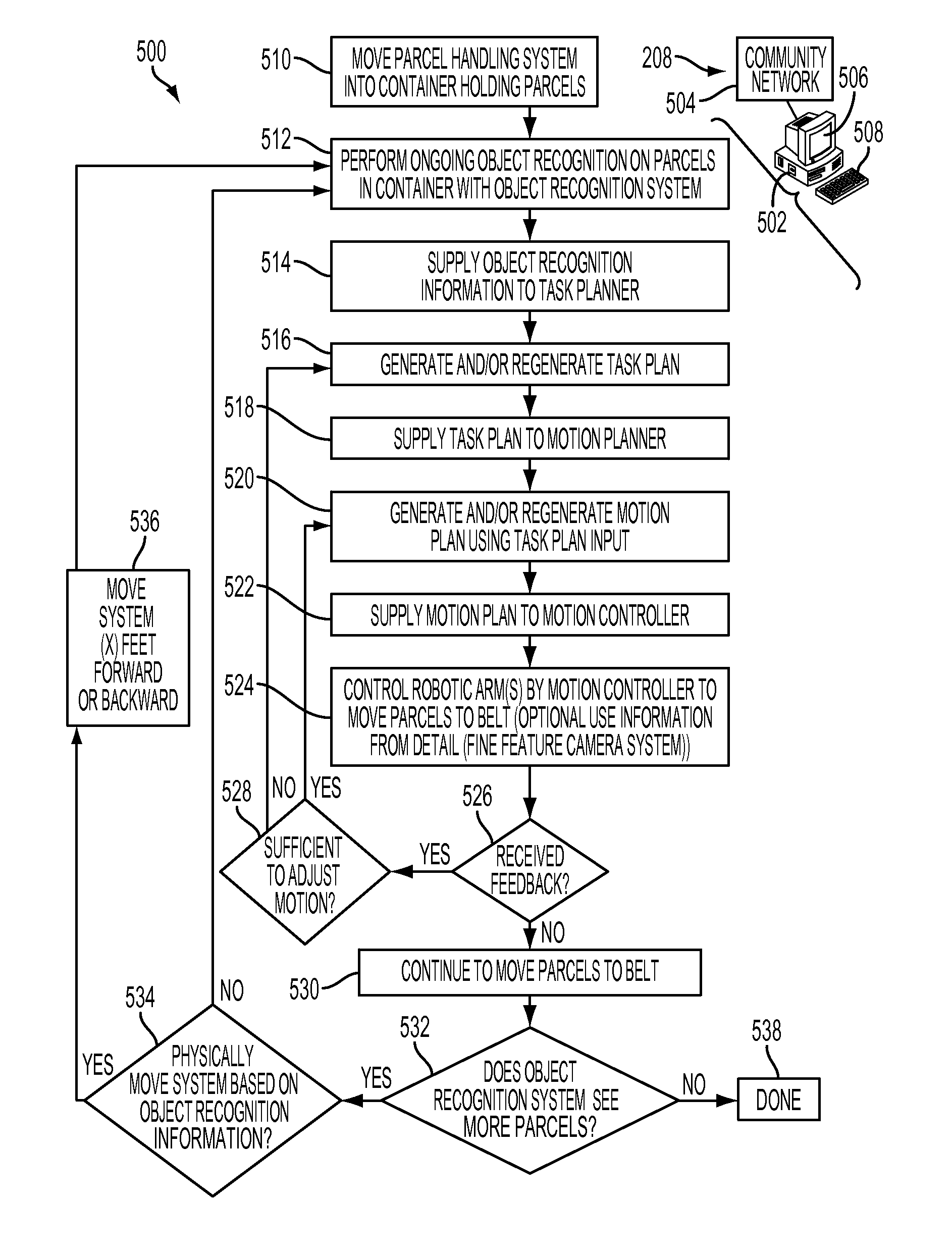

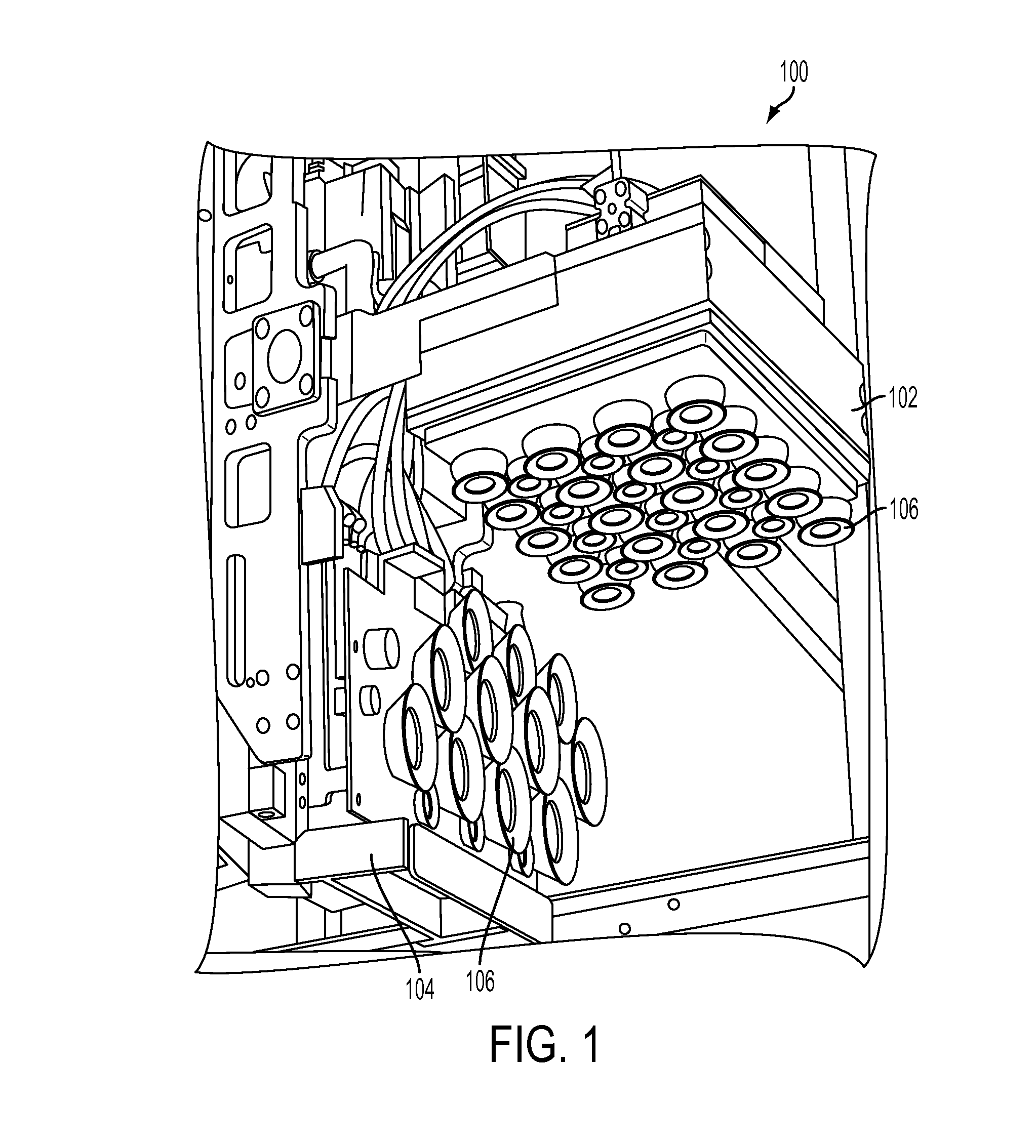

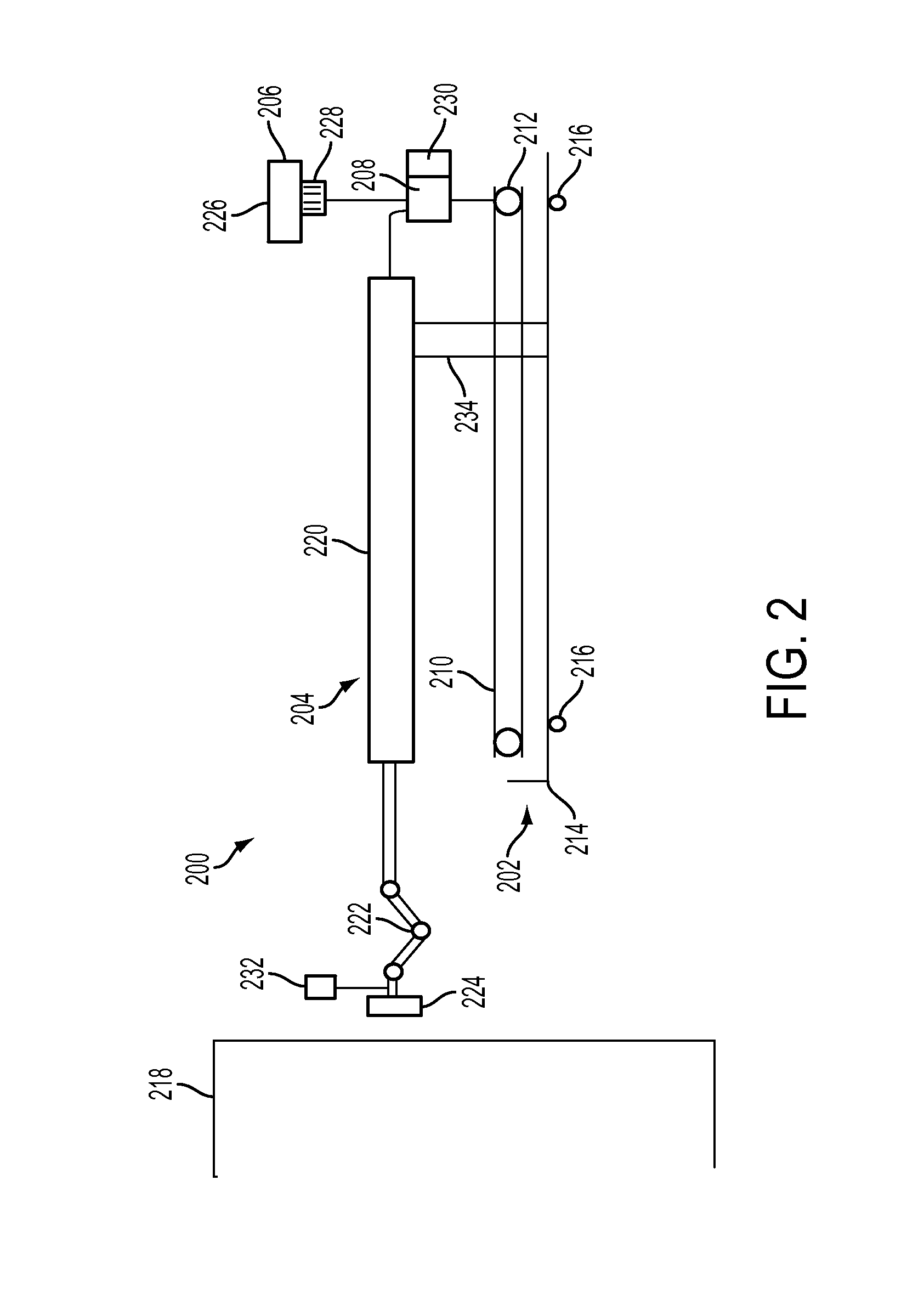

High throughput parcel handling

A high throughput parcel unloading system includes a robotic arm arrangement, including a cluster of robotic arms having grouping mechanisms. A conveyor system is also provided onto which parcels are placed by the robotic arm system. An image recognition system determines the position and arrangement of parcels within a container, and a control system is configured to receive image information from the image recognition system and control operation of the robotic arm system and conveyor system.

Owner:XEROX CORP

Transfer system for conveying LCD glass substrate

Owner:TOKYO ELECTRON LTD

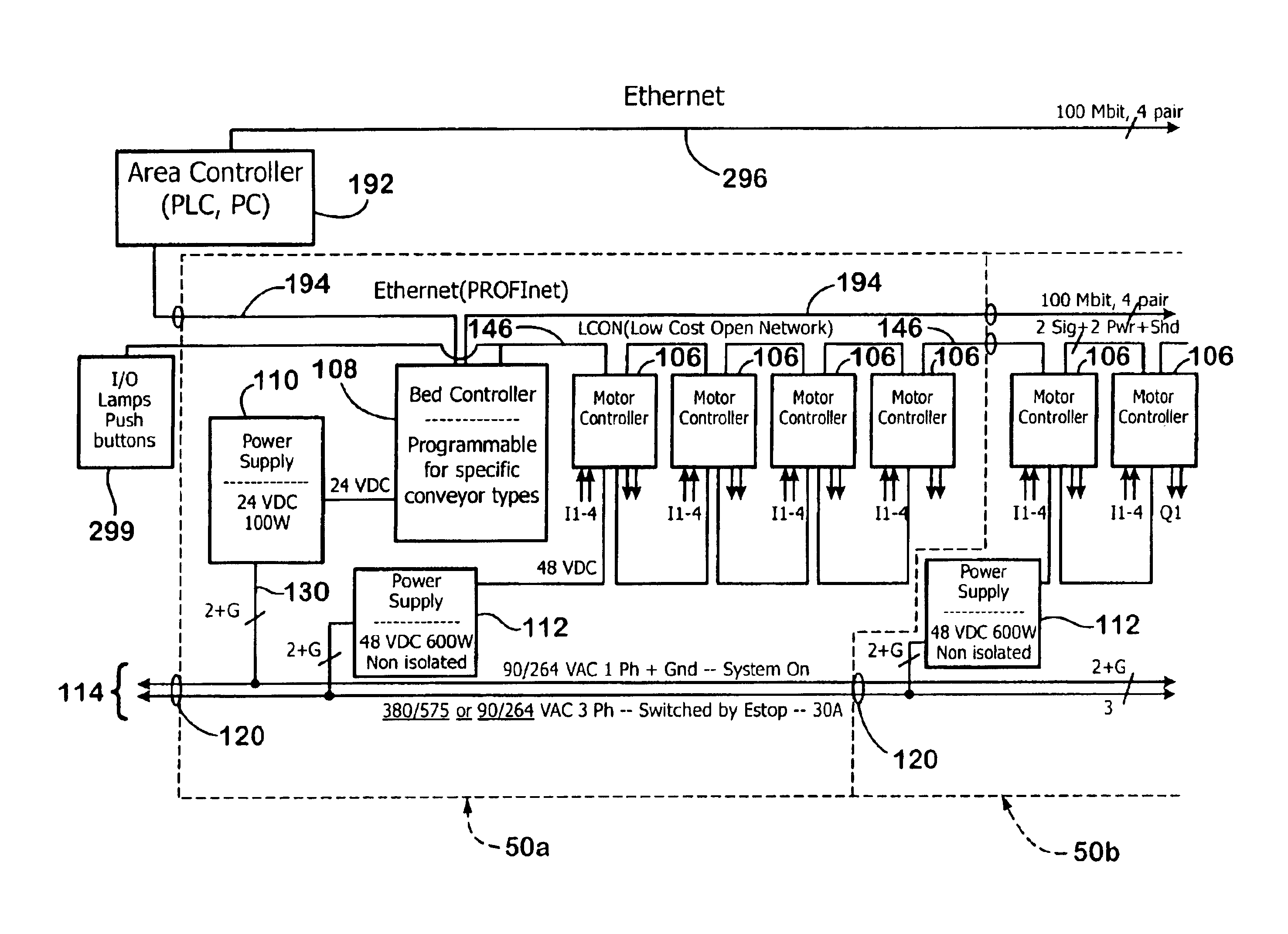

Integrated conveyor bed

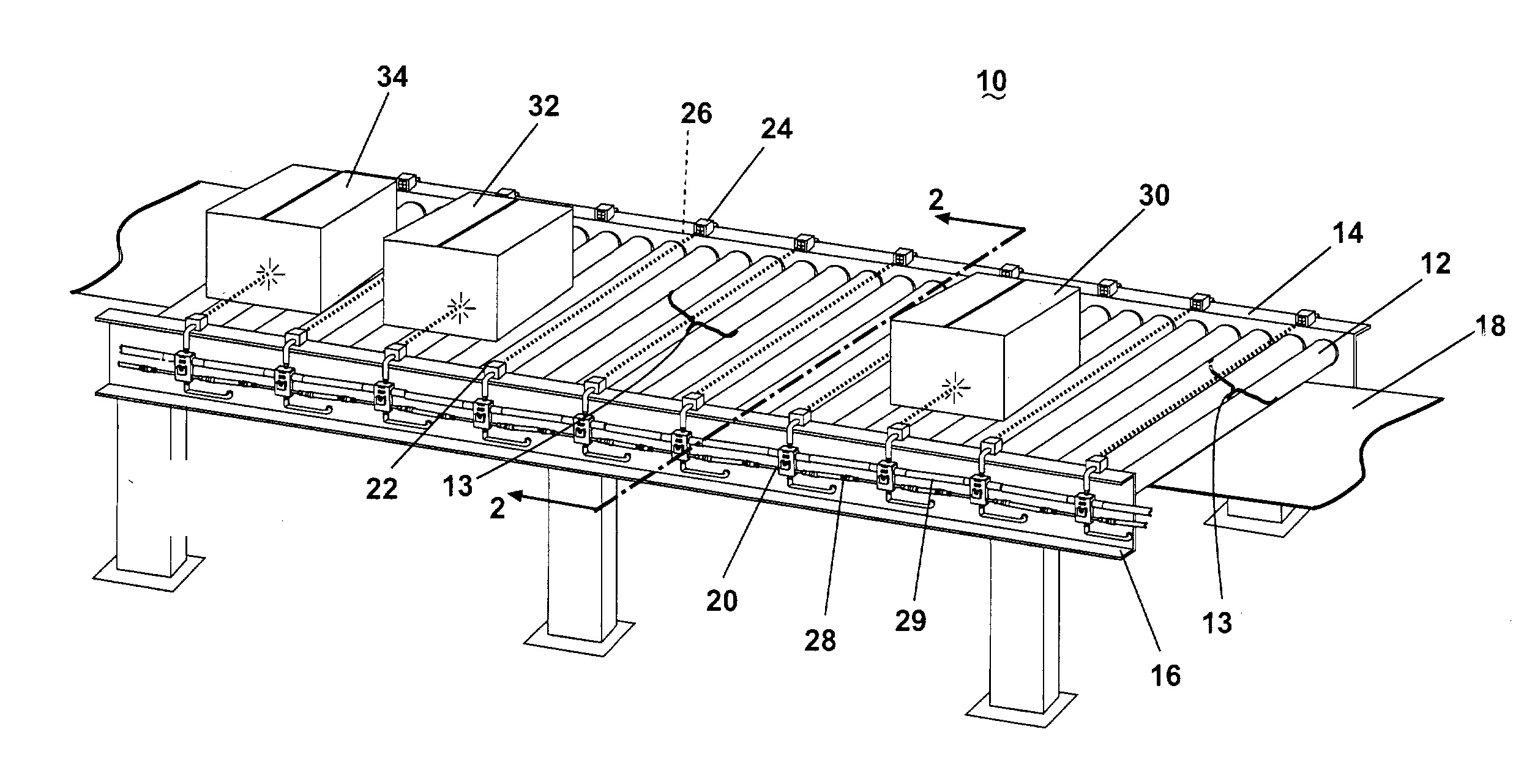

InactiveUS7035714B2Simplifies installation and operation and maintenanceEasy to installDigital data processing detailsControl devices for conveyorsControl theoryElectric motor

A conveyor system, and method of controlling the conveyor system, includes providing a conveying surface, at least one motor propelling the conveying surface and a plurality of lower-level controllers. At least one of the lower-level controllers adapted to control the at least one motor. An upper-level controller is provided in communication with the plurality of lower-level controllers. The upper-level controller is adapted to send communications to the lower-level controllers for controlling the at least one motor. A communications bus is provided that carries the communications between the upper-level controller and the lower-level controllers. The upper-level controller is adapted to automatically assign each lower-level controller a unique communications address. The unique communications address enables the upper-level controller to send messages over the communications bus to individual ones of the lower-level controllers.

Owner:DEMATIC

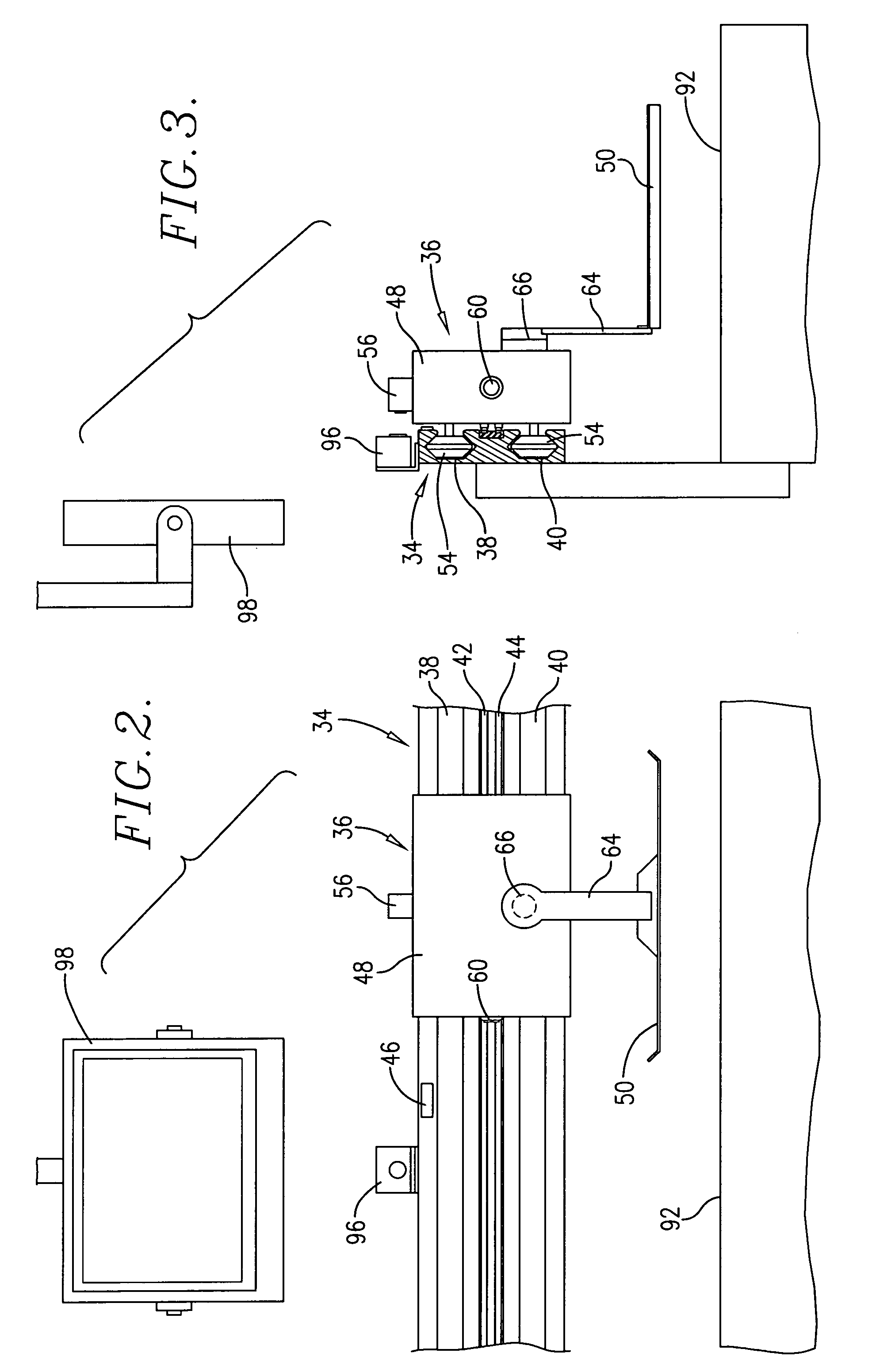

Conveyor system load transfer devices

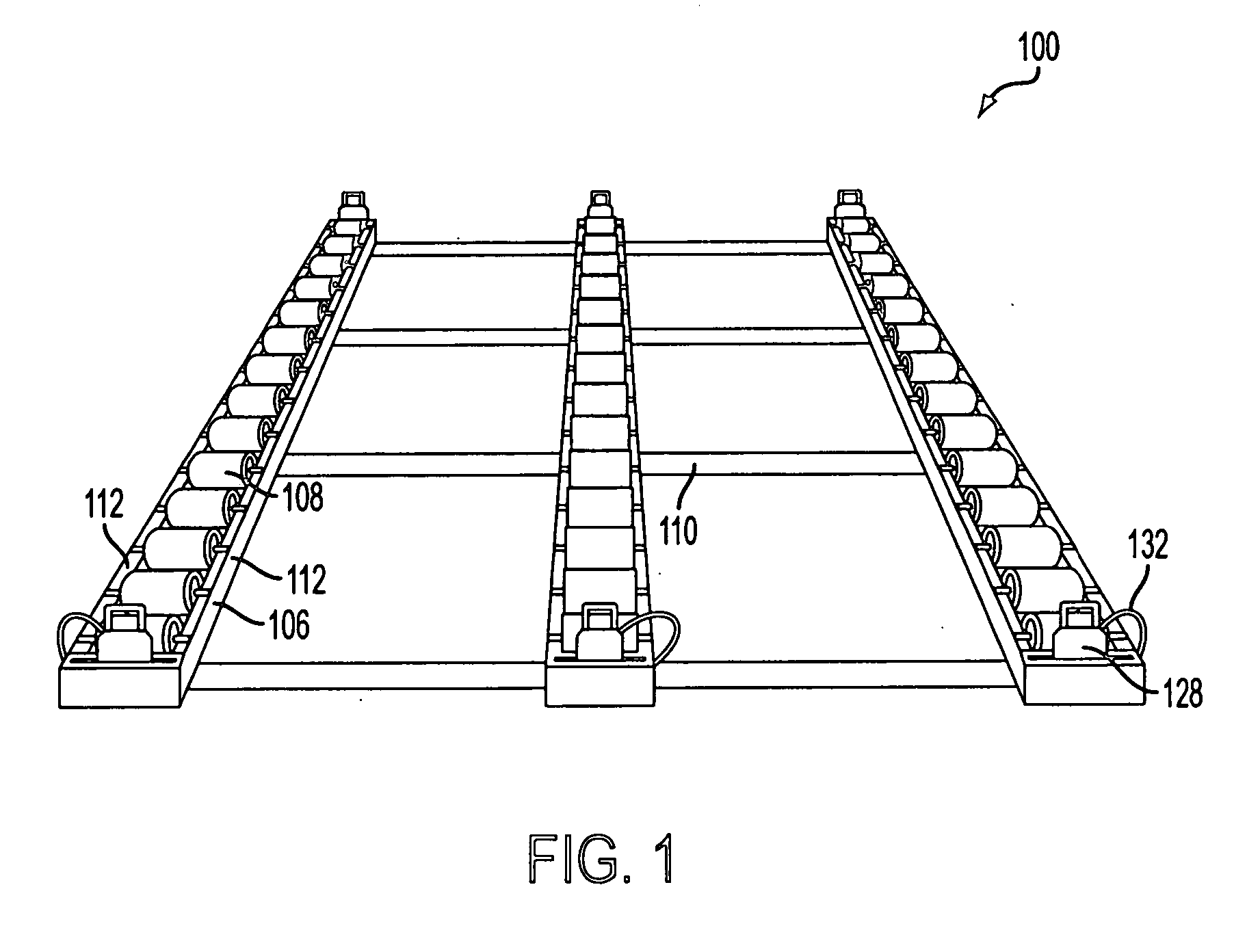

Conveyor systems for storage and movement of goods on pallets and slip sheets. The transfer structures enable slip sheet mounted loads to be transferred to a roller conveyor by providing structures that cooperate with wide platen forks of a lift truck. The structures provide roller contact between a portion of the underside of the slip sheet at all times. In other areas there is alternatively contact between a lift truck platen or additional rollers that cooperate in a manner making it possible to move the slip sheet mounted load from the lift truck to an adjacent conveyor system.

Owner:CREATIVE STORAGE SYST

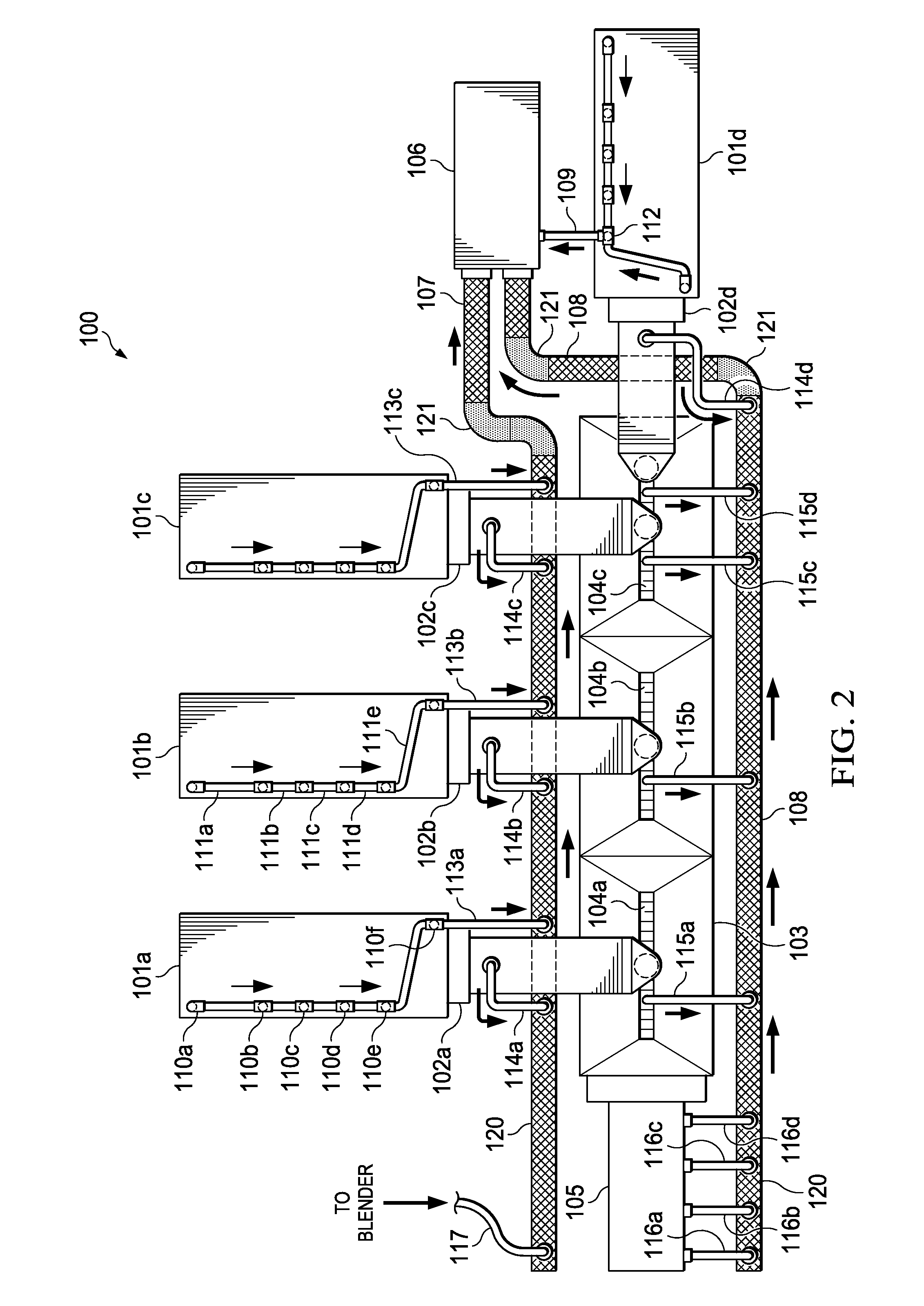

Mobile dry material storage

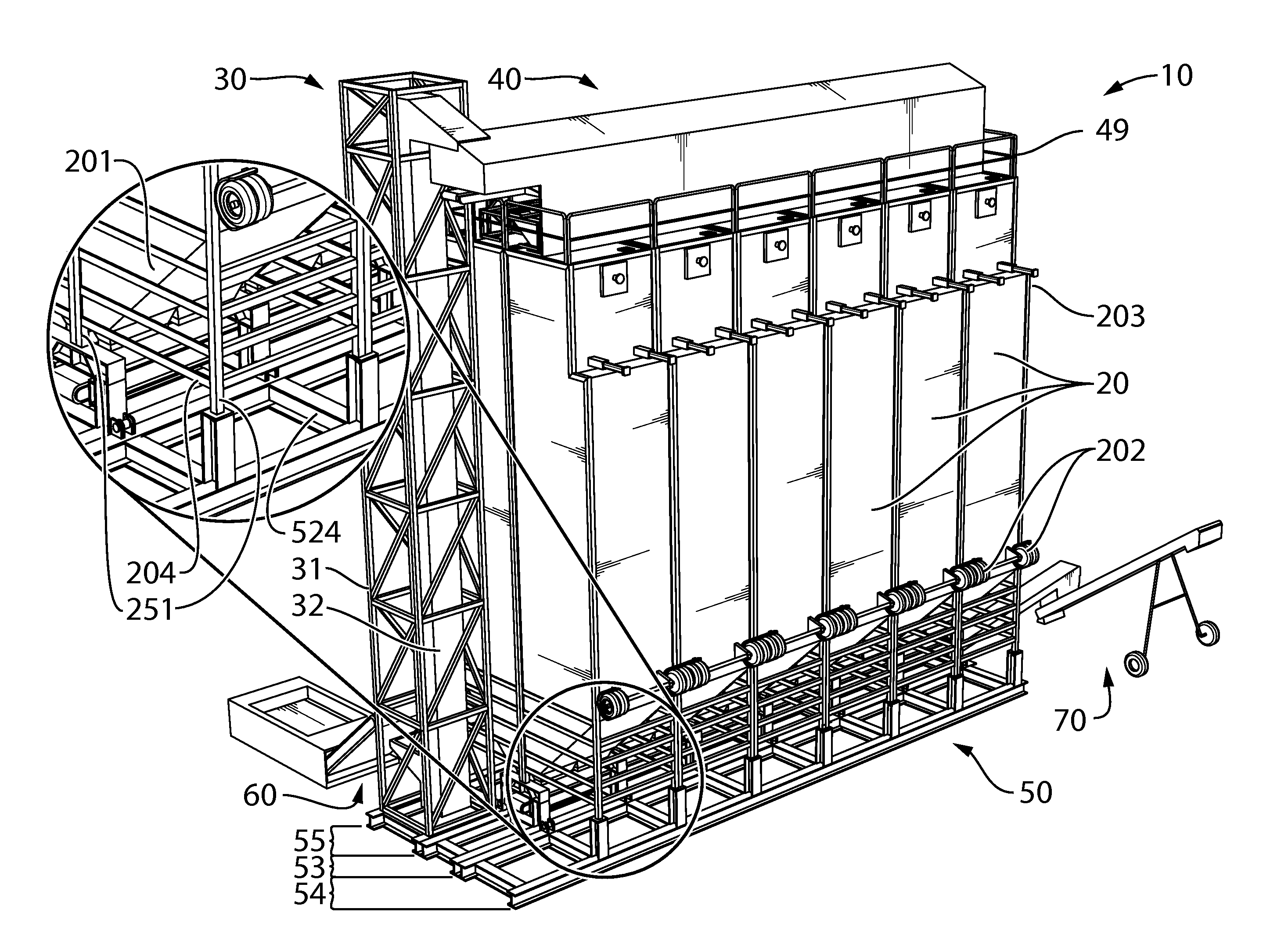

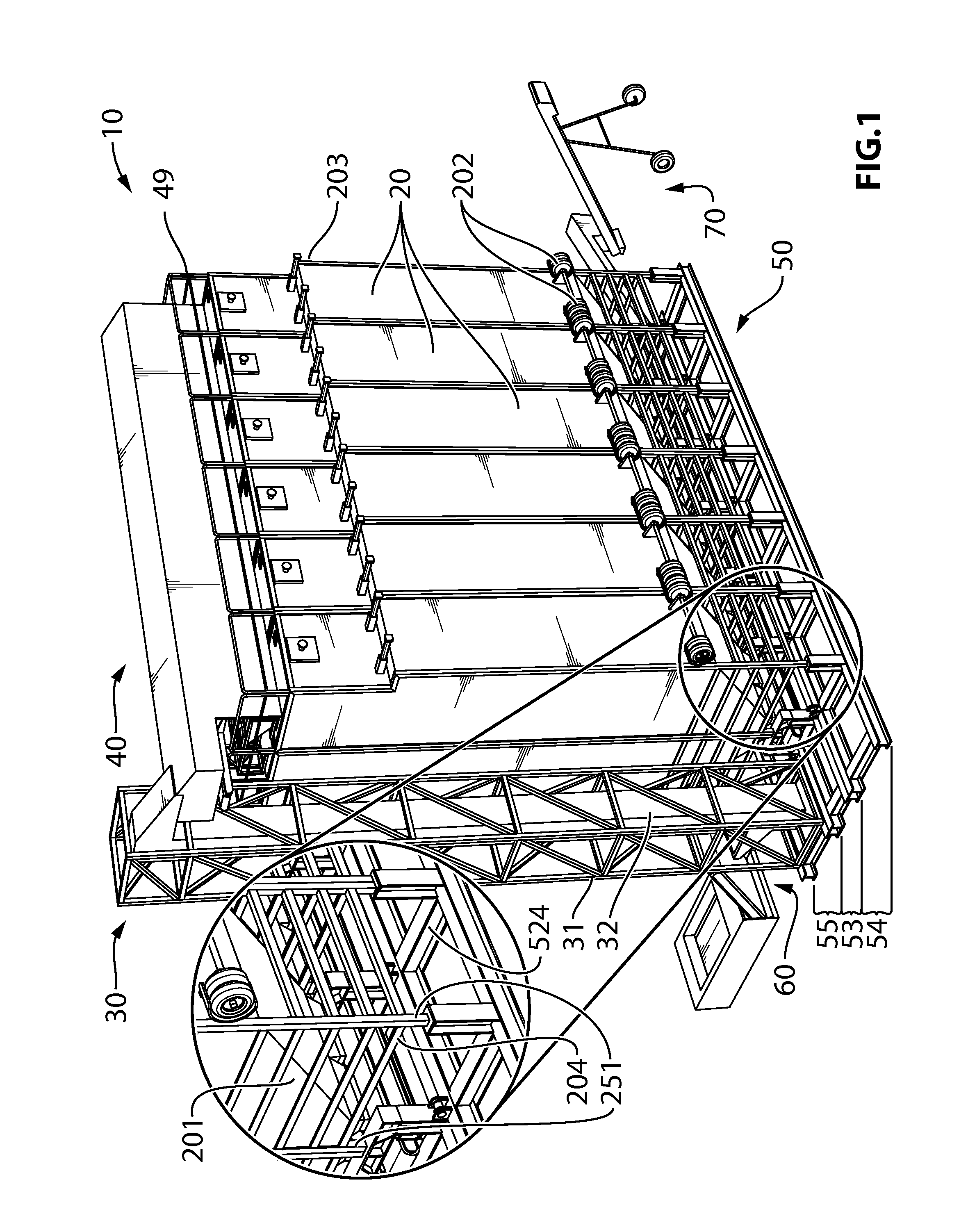

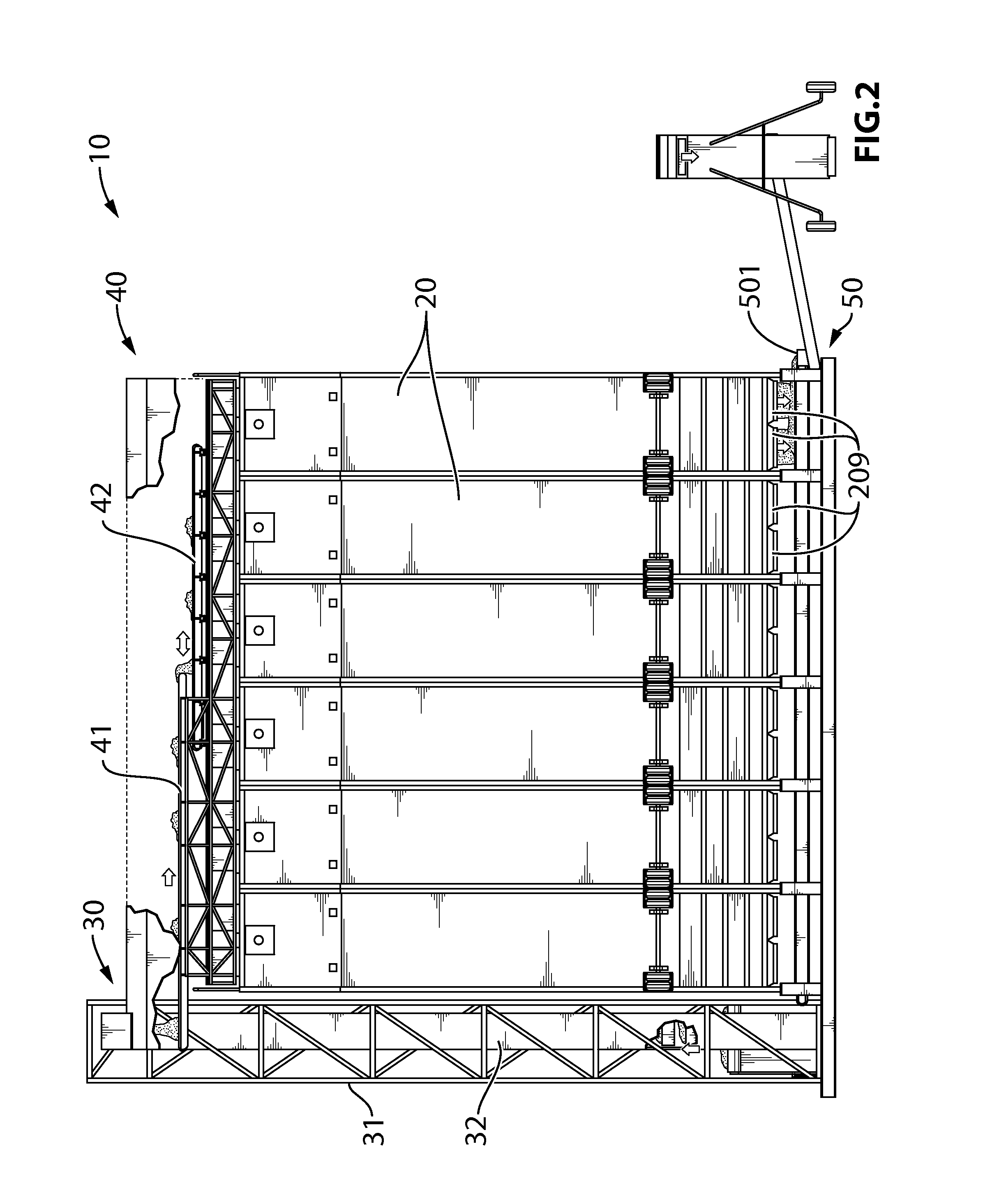

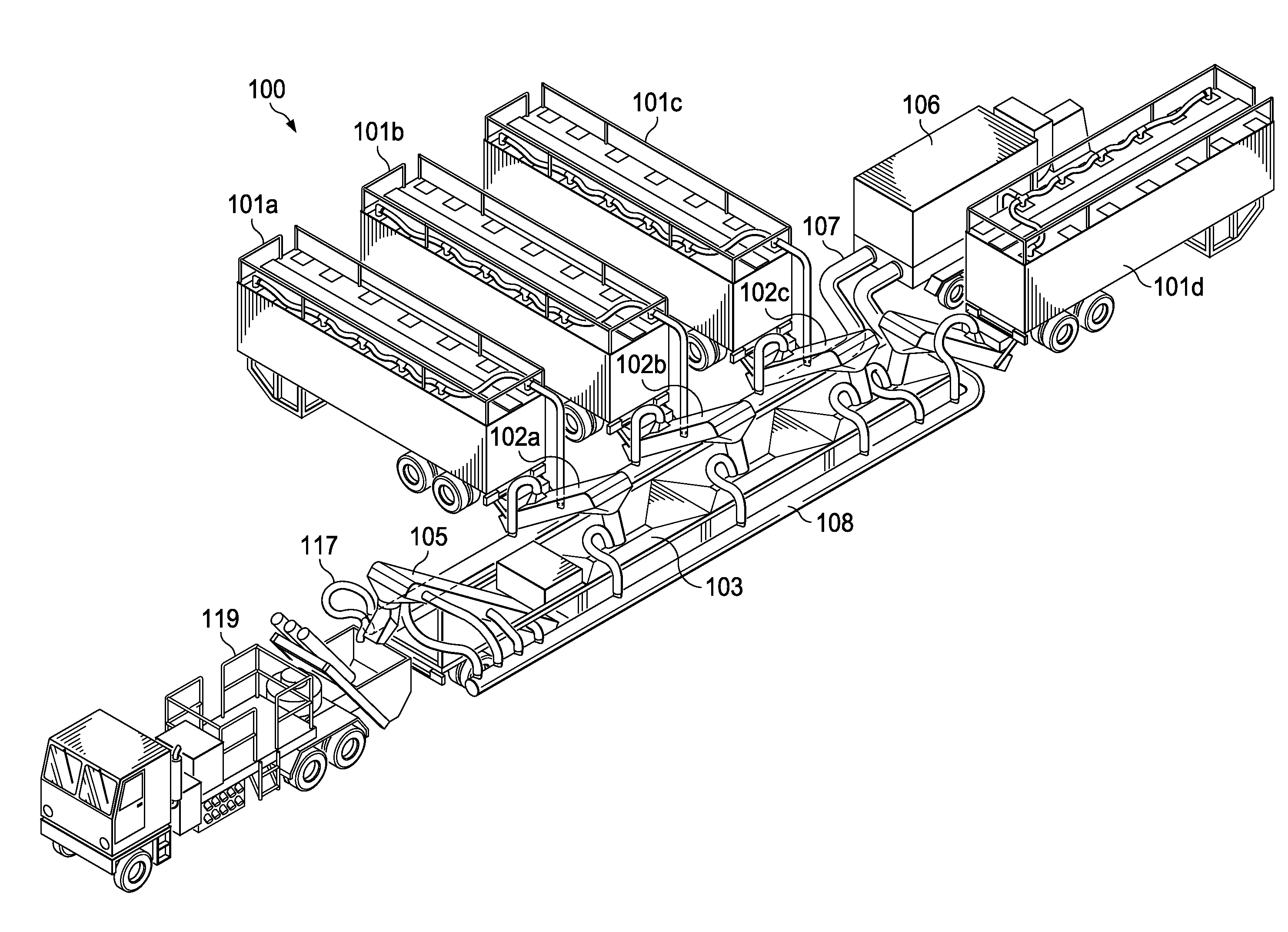

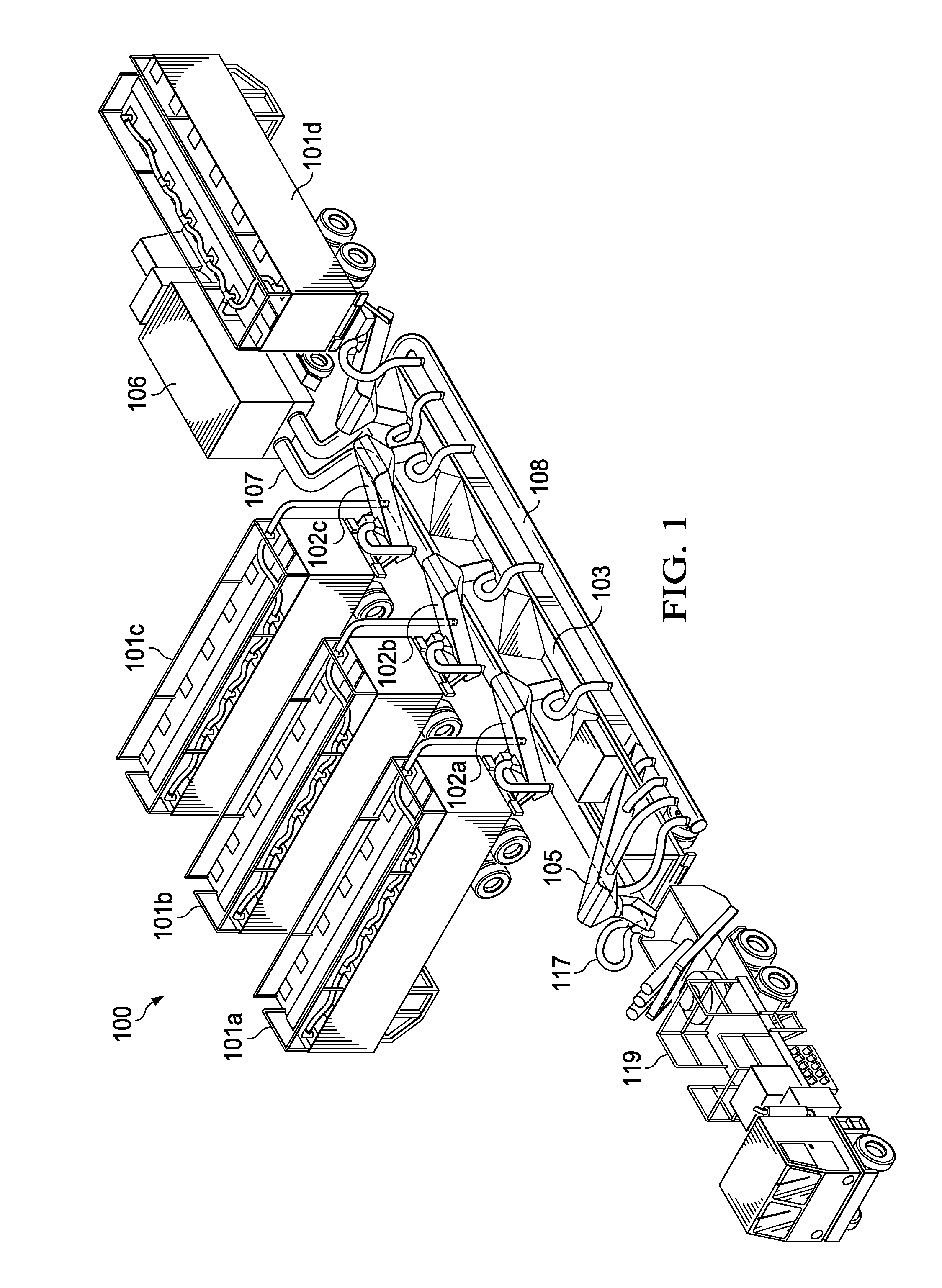

ActiveUS20140377042A1Avoid accidental damageIncrease volumeTractor-trailer combinationsKitchen equipmentWell drillingBucket elevator

A system that can be assembled at a well drilling or other site for storing bulk material such as sand includes a plurality of storage bins configured as trailers, a skid that includes a lower conveyor, a bucket elevator and a top conveyor system. At the site, the bins and the elevator are vertically oriented and stood on the skid, resulting in discharge outlets on the bins becoming positioned over the lower conveyor. The top conveyor is installed on top of the bins. In operation, the elevator lifts the material and discharges it onto the top conveyor system. The top conveyor system discharges the material into the bins for storage. The stored material is controllably discharged from the discharge outlets of the bins onto the lower conveyor from which the material is conveyed to one end of the skid for transport to a new location or directly into a blender.

Owner:SOURCE LOGISTICS LTD O A AMMOS FIELD SOLUTIONS +1

Tubular handling apparatus and method

InactiveUS20030196791A1Safe working environmentMinimize and eliminate needDrilling rodsFluid removalGeneral purpose computerEngineering

A pipe handling system comprising at least one pipe magazine, a pipe conveyor system, and a pipe arm for handling pipes in conjunction with a drill rig for drilling a well bore. The pipe handling system operates to transfer pipe joints from each pipe magazine to a pipe arm via the pipe conveyor system. The pipe arm then moves to transfer each pipe to the drilling rig for connection to drill string. The pipe handling system also operates to remove each pipe from the drill string. The arm engages the pipe to be removed and moves to transfer the pipe to the pipe conveyor system. The pipe conveyor system then transfers the pipes to each pipe magazine. The system is alternatively comprises electronic sensors that measure the location of pipe. The entire system is also alternatively operated with software and a general-purpose computer.

Owner:N I ENERGY DEV

Systems and methods for controlling silica dust during hydraulic fracturing operations

ActiveUS8881749B1Improve flexibility and efficiencyEfficient and flexible systemMechanical cleaningPressure cleaningEngineeringHydraulic fracturing

A system for controlling silica dust generated during the transfer of frac sand from a storage container through a conveyor system includes a system of conduits having a plurality of inlets for collecting silica dust generated at selected points along the conveyor system. An air system pneumatically coupled to the system of conduits generates a negative pressure at each of the inlets to induce the collection of silica dust at the selected points along the conveyor.

Owner:SIERRA DUST CONTROL

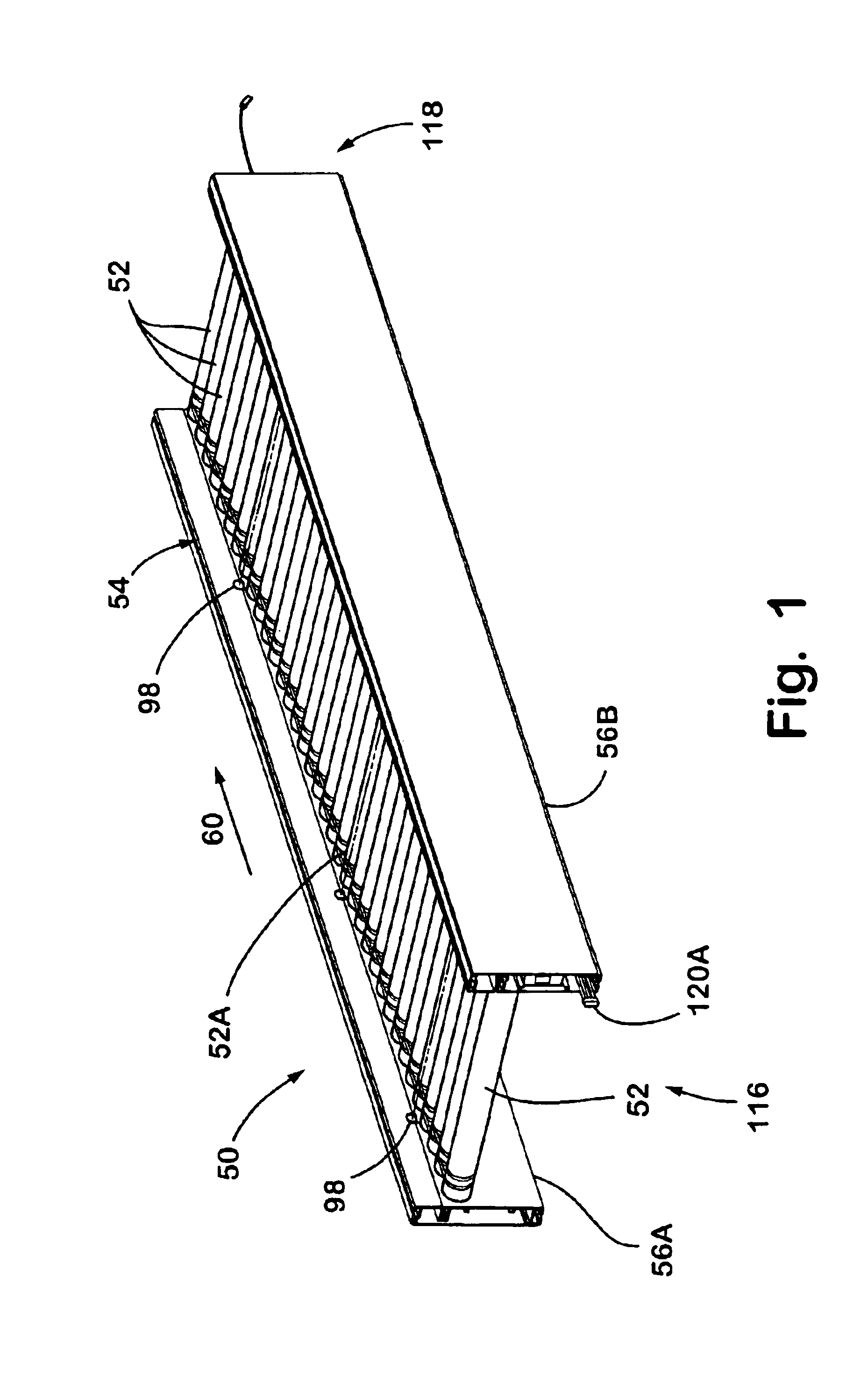

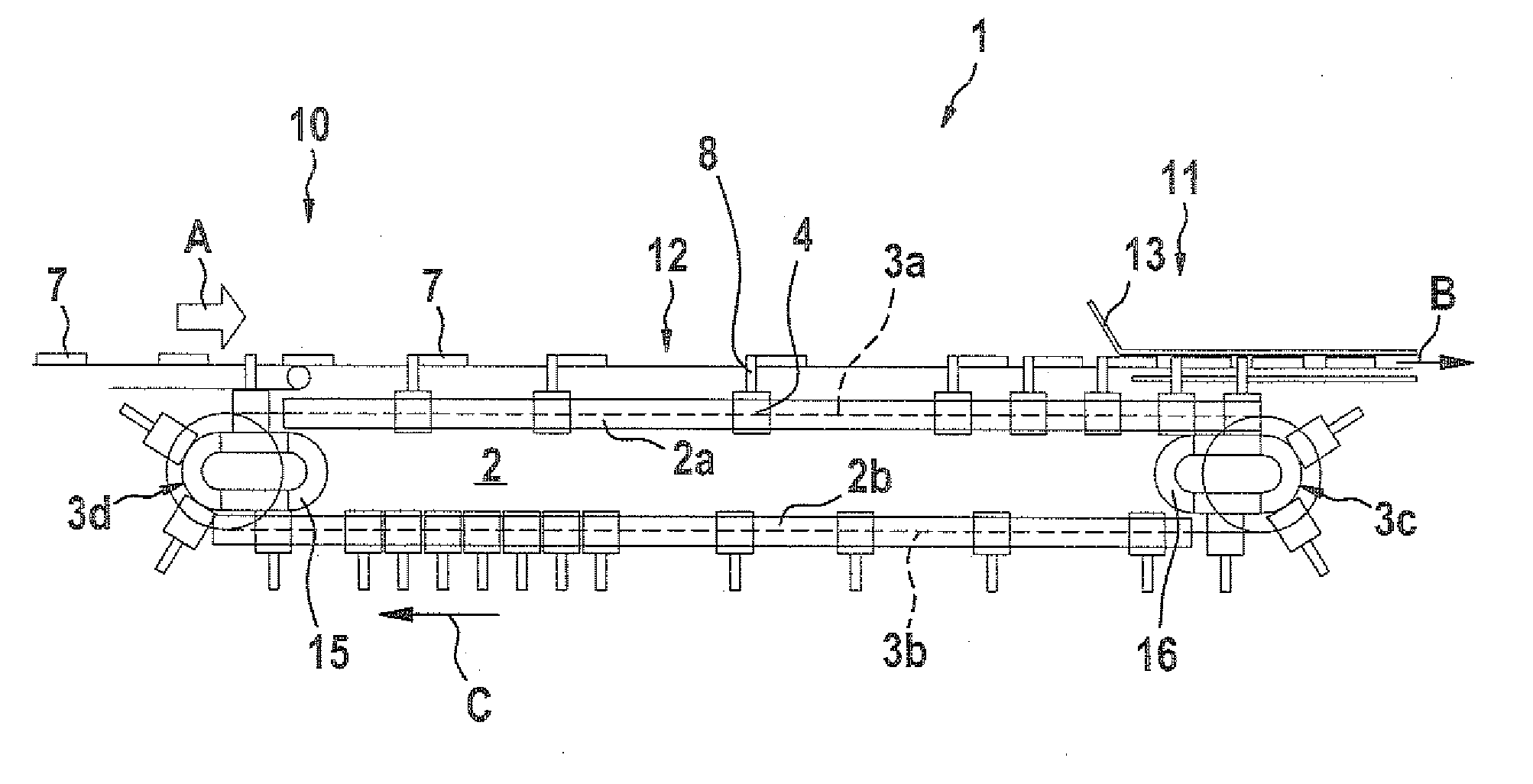

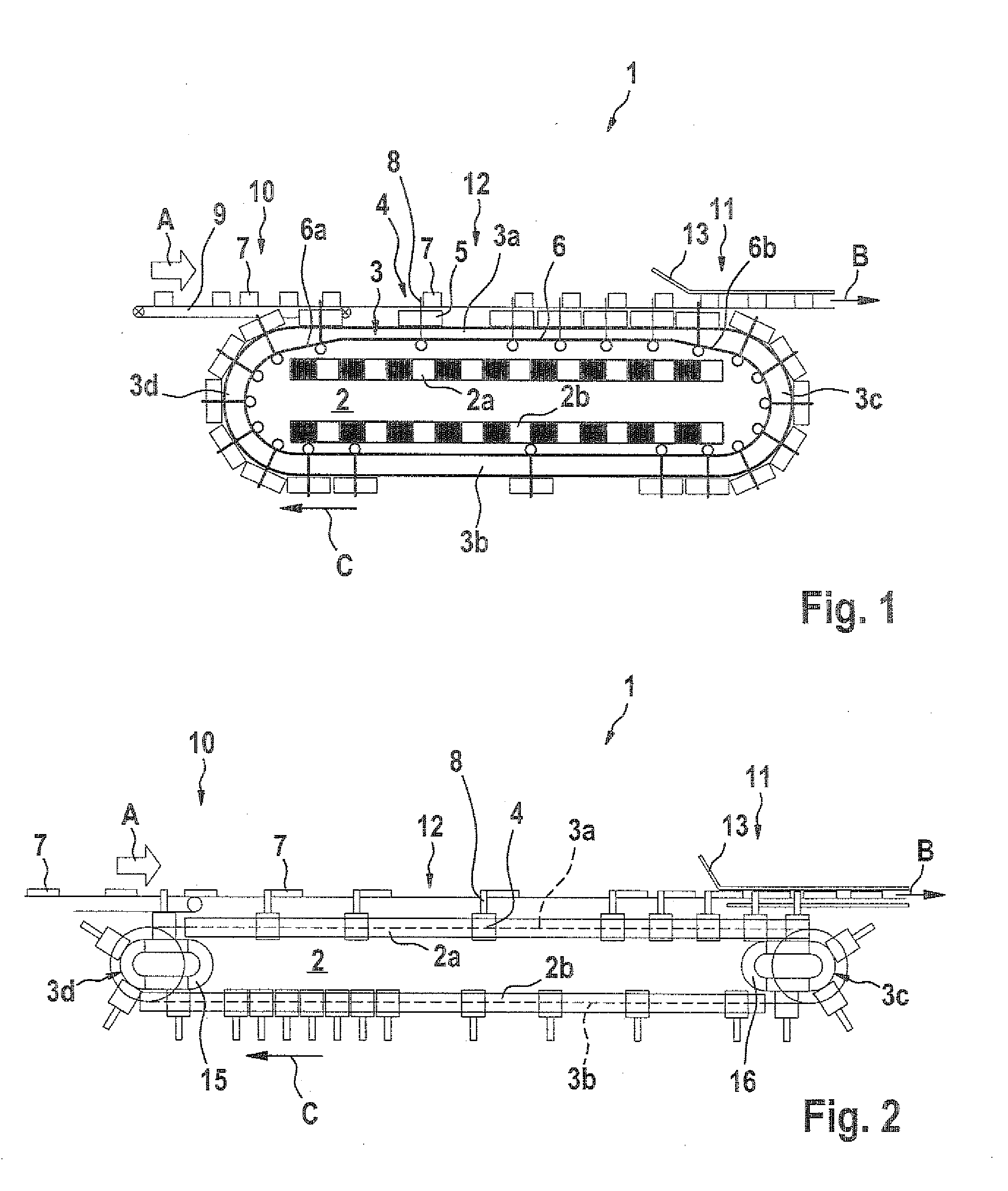

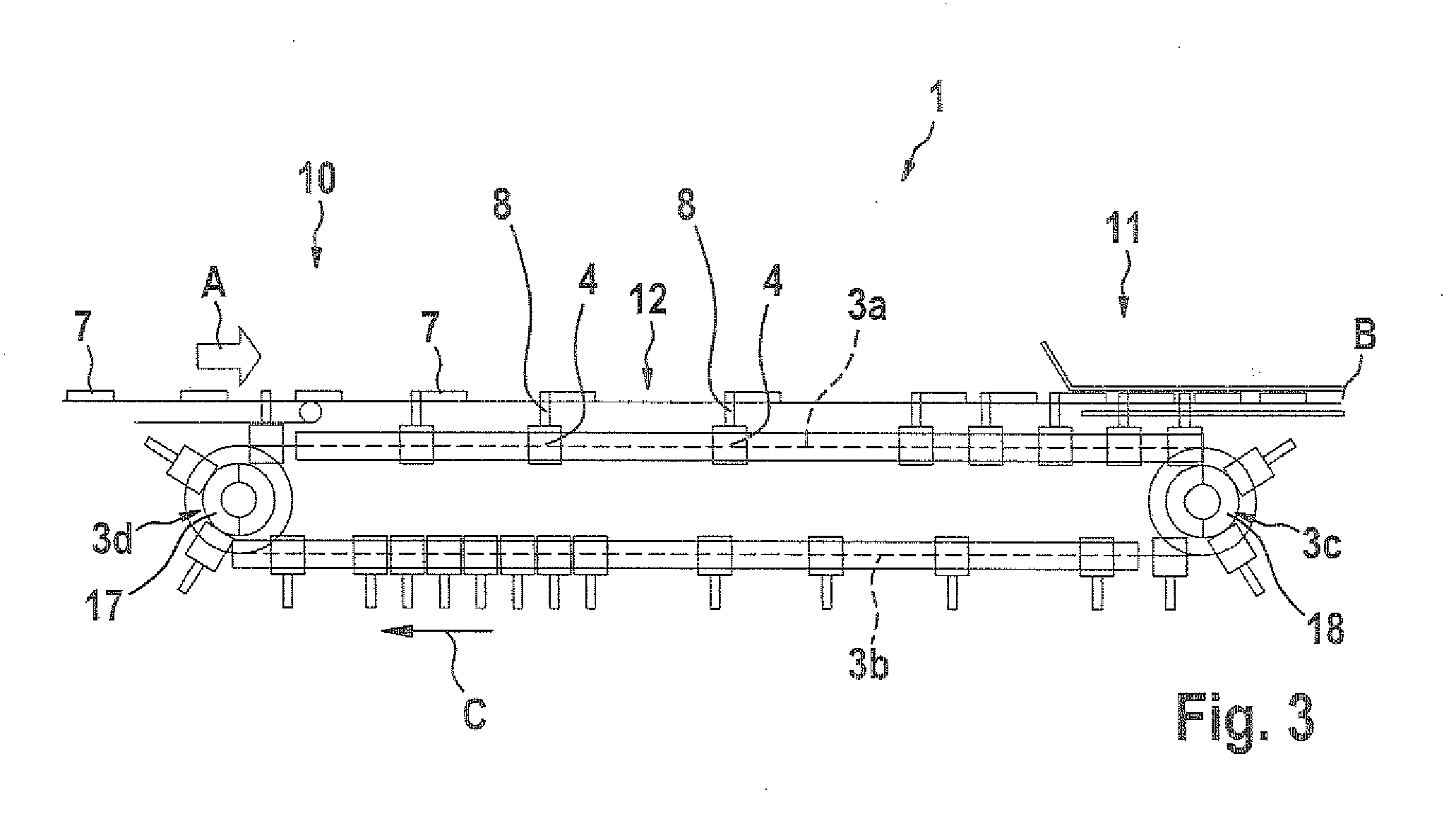

Apparatus and method for transporting products, having a linear drive mechanism

ActiveUS20100084247A1Space minimizationCompact structureNon-mechanical conveyorsConveyor partsLinear driveConveyor system

The invention relates to a transporting apparatus for transporting products, which includes a linear drive mechanism, a continuous conveyor system, having two parallel straight conveyor regions and two curved conveyor regions each connecting one end of the straight conveyor regions, and a plurality of conveyor elements. The conveyor elements extend along the continuous conveyor system and convey the products to be conveyed along at least a portion of the conveyor system while being guided along a guide path. The linear drive mechanism includes a first linear segment and a second linear segment, which are disposed parallel to the straight conveyor regions. The curved conveyor regions of the conveyor system are advantageously embodied as driveless.

Owner:SYNTEGON TECHNOLOGY GMBH

Packaging system and method utilizing intelligent conveyor systems

ActiveUS9008831B1Digital data processing detailsControl devices for conveyorsEngineeringDelivery system

A packaging system and method for receiving articles from a first location, such as a product delivery system, transporting the articles to a second location for unloading the articles such that they are placed in a desired orientation and number of columns, rows, and stacks.

Owner:ROCKWELL AUTOMATION

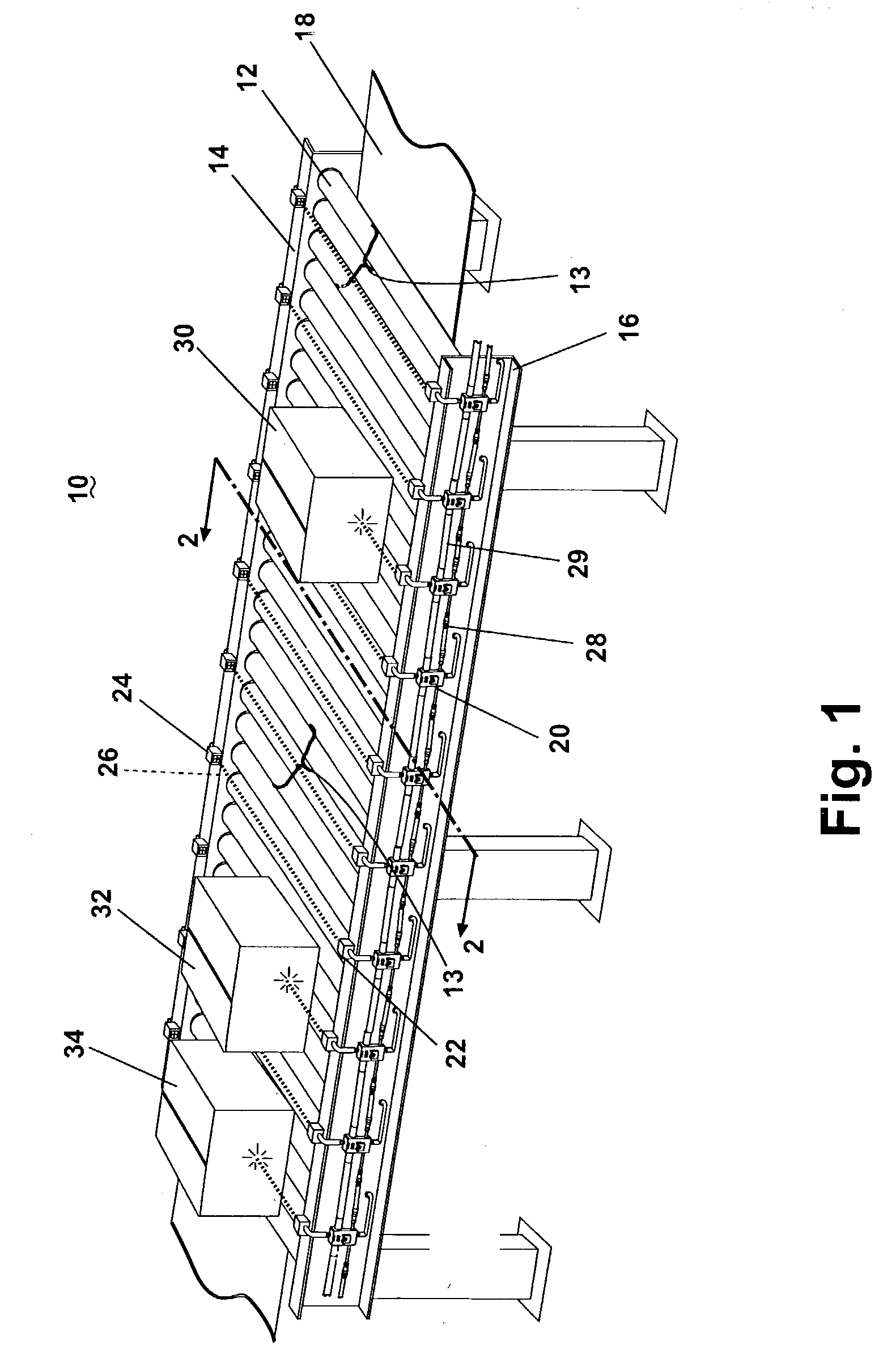

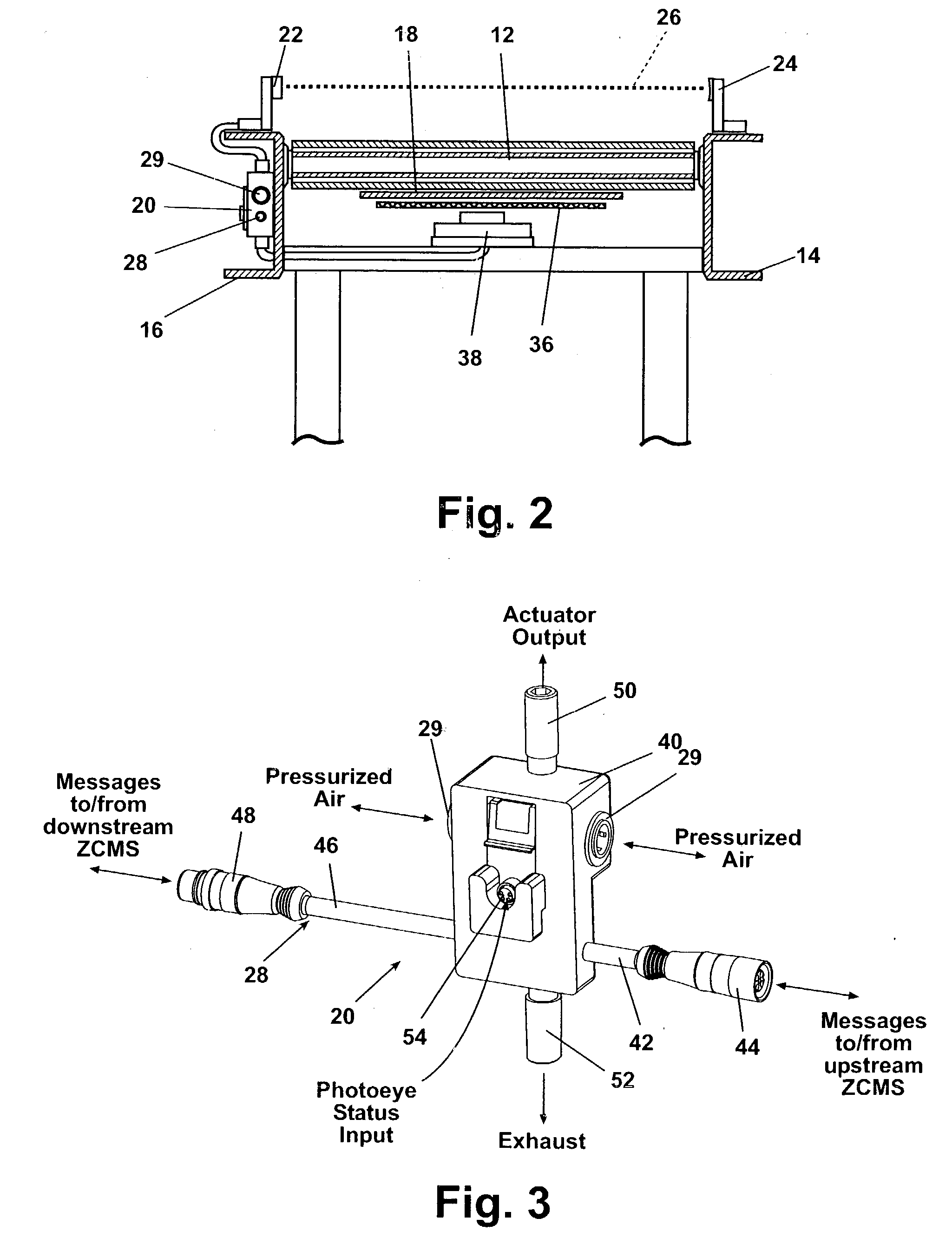

Networkable zone control modules and method and coveyor system incorporating the same

ActiveUS20030168316A1Digital data processing detailsControl devices for conveyorsProcess engineeringConveyor system

A package control conveyor system comprises a plurality of independently-controllable package conveying units each of which comprises a zone control module operably connected to a package sensing device and a package conveying unit for selectively activating and deactivating the package conveying unit, wherein the zone control modules are communicably interconnected upstream and downstream so that each zone control module can selectively activate and deactivate its associated package conveying unit in response to information provided by one or more upstream and / or downstream zone control modules.

Owner:HUMPHREY PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com