Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22478results about "Machine part testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

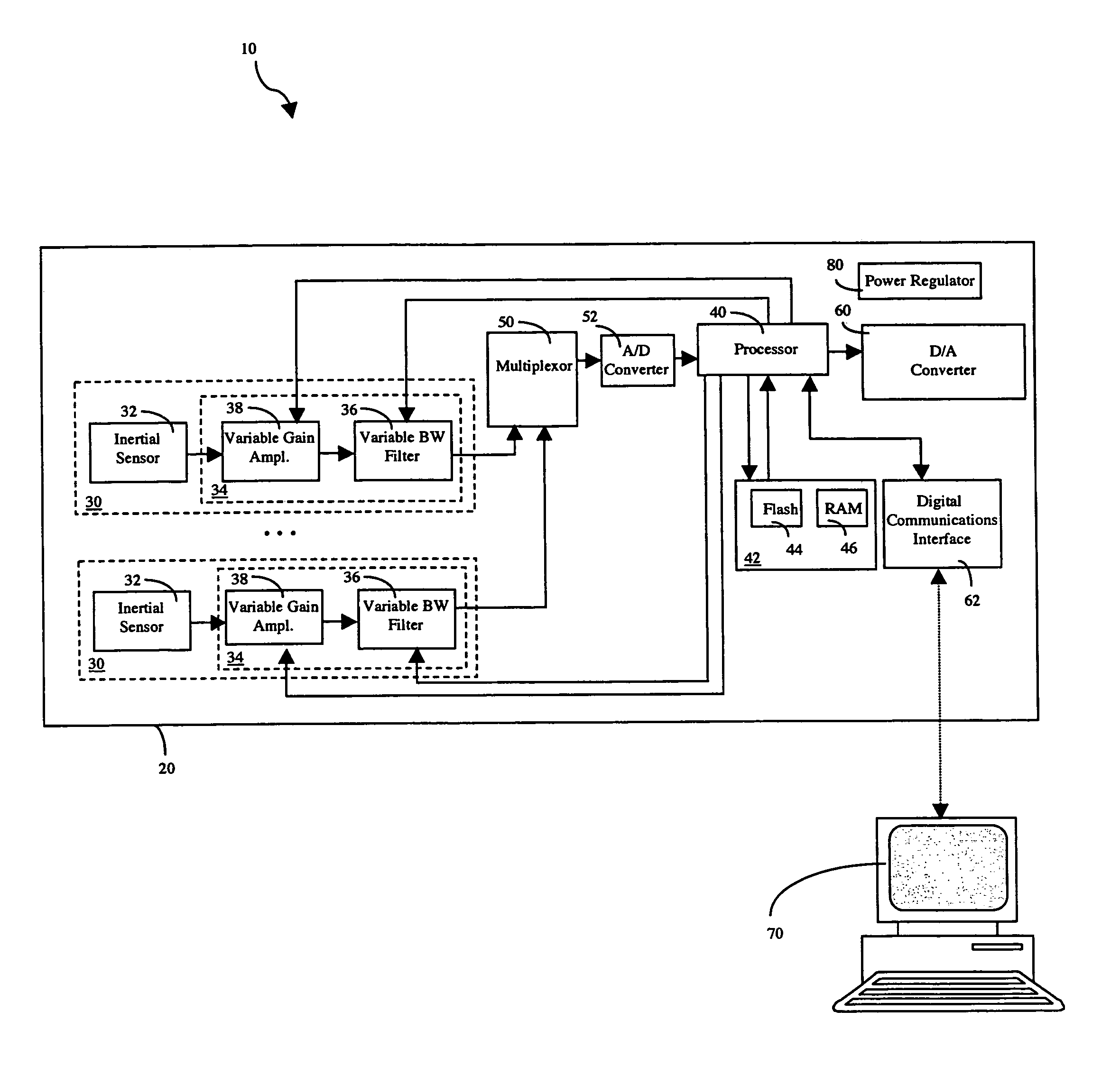

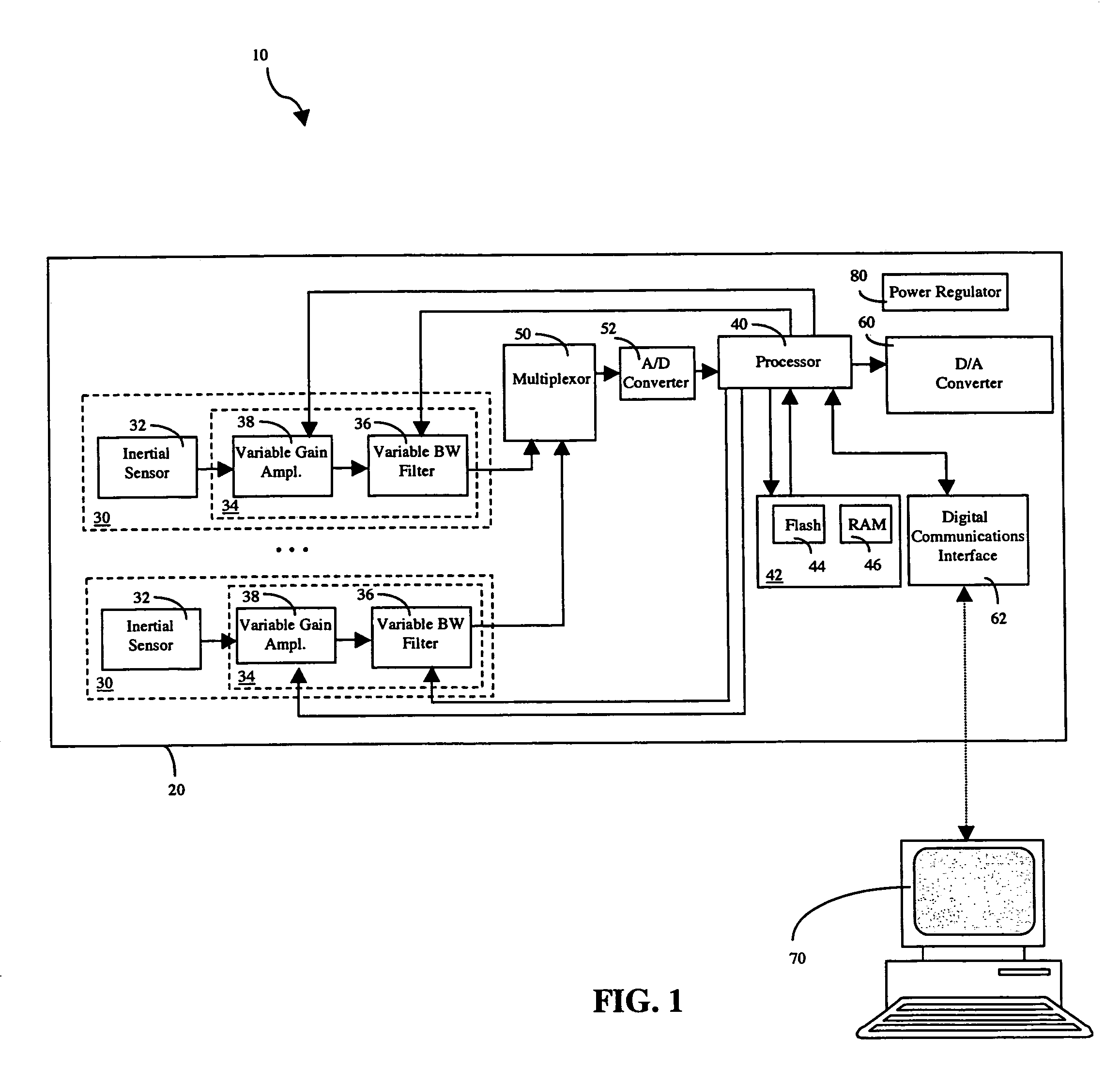

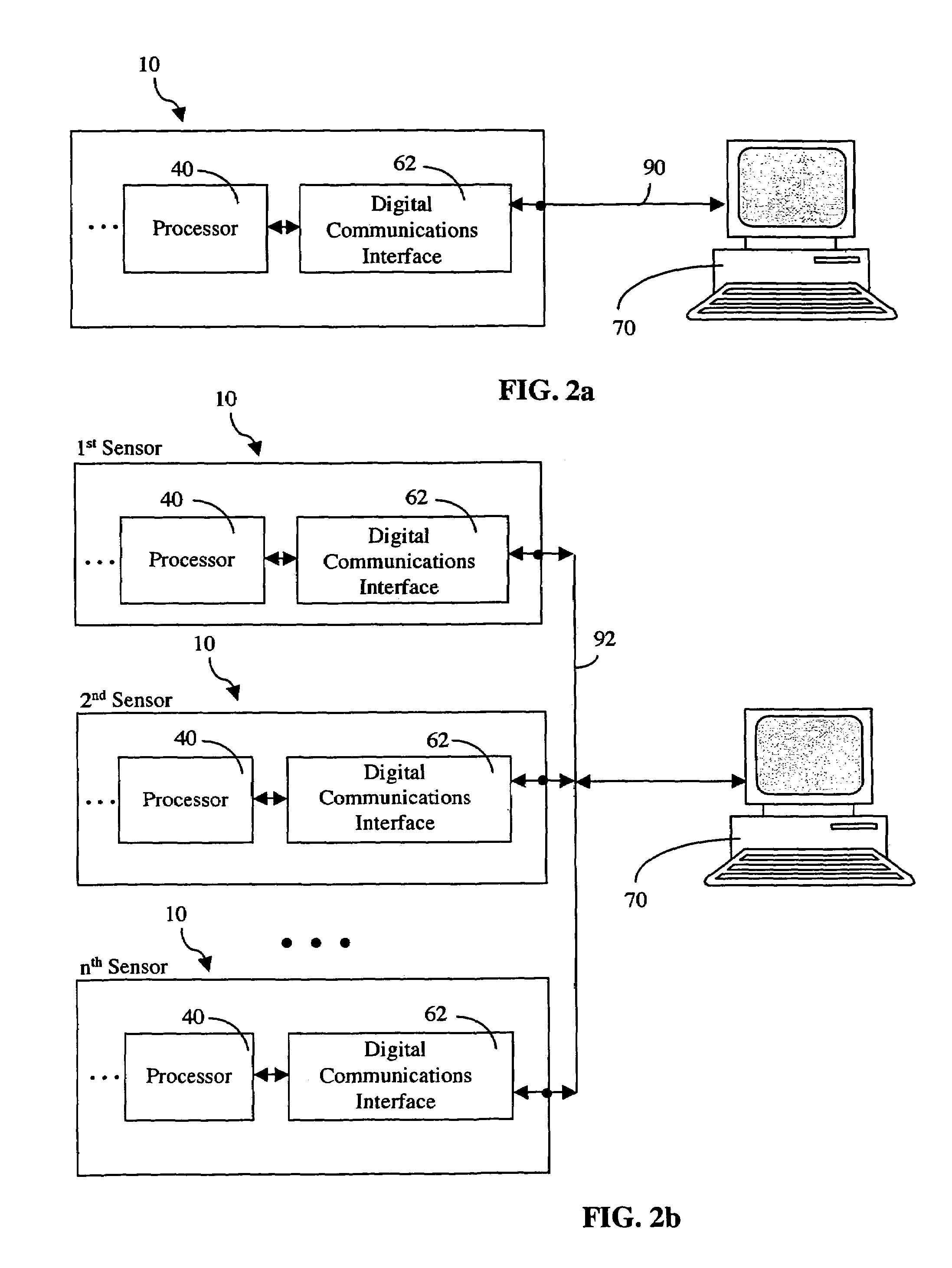

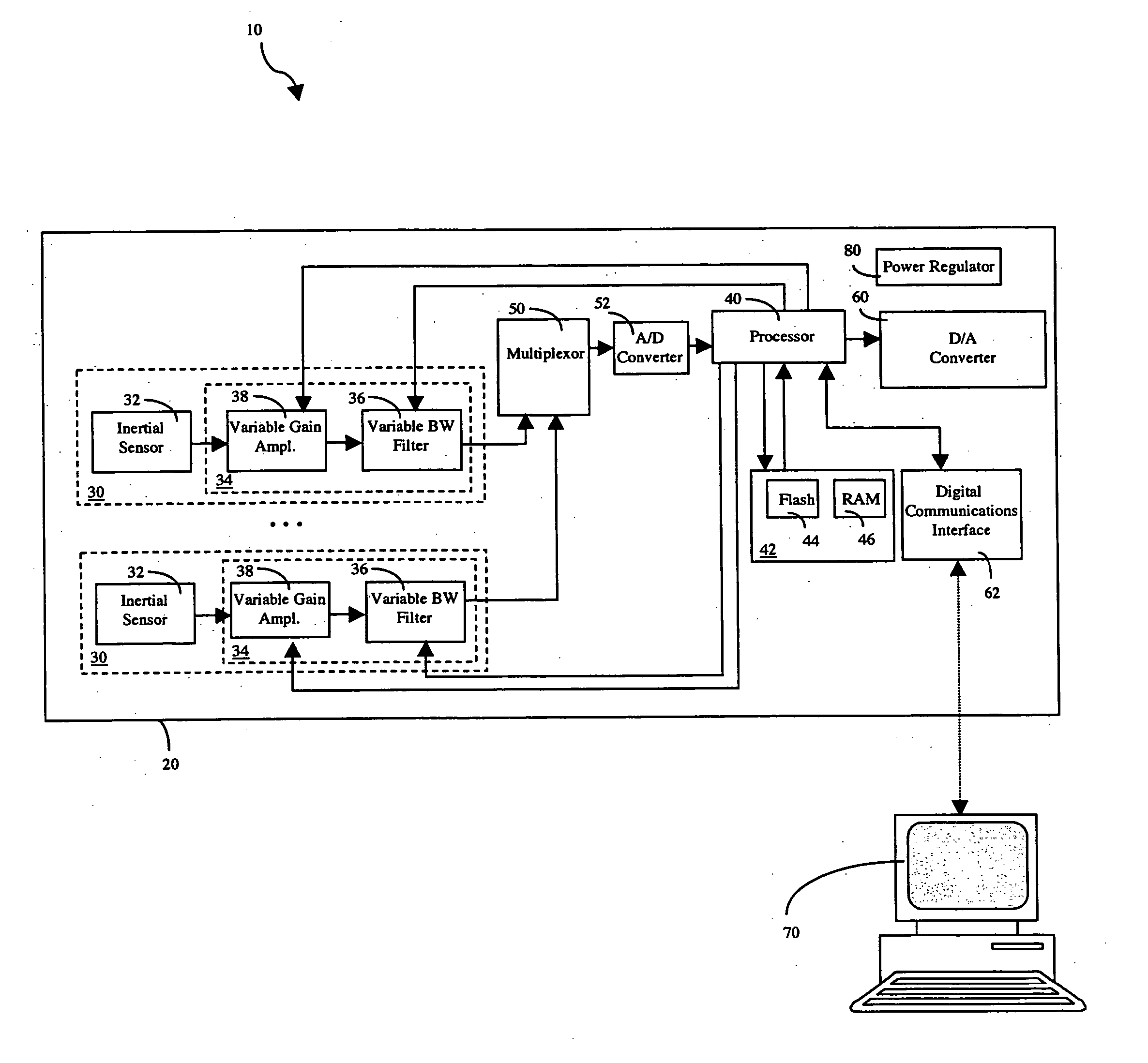

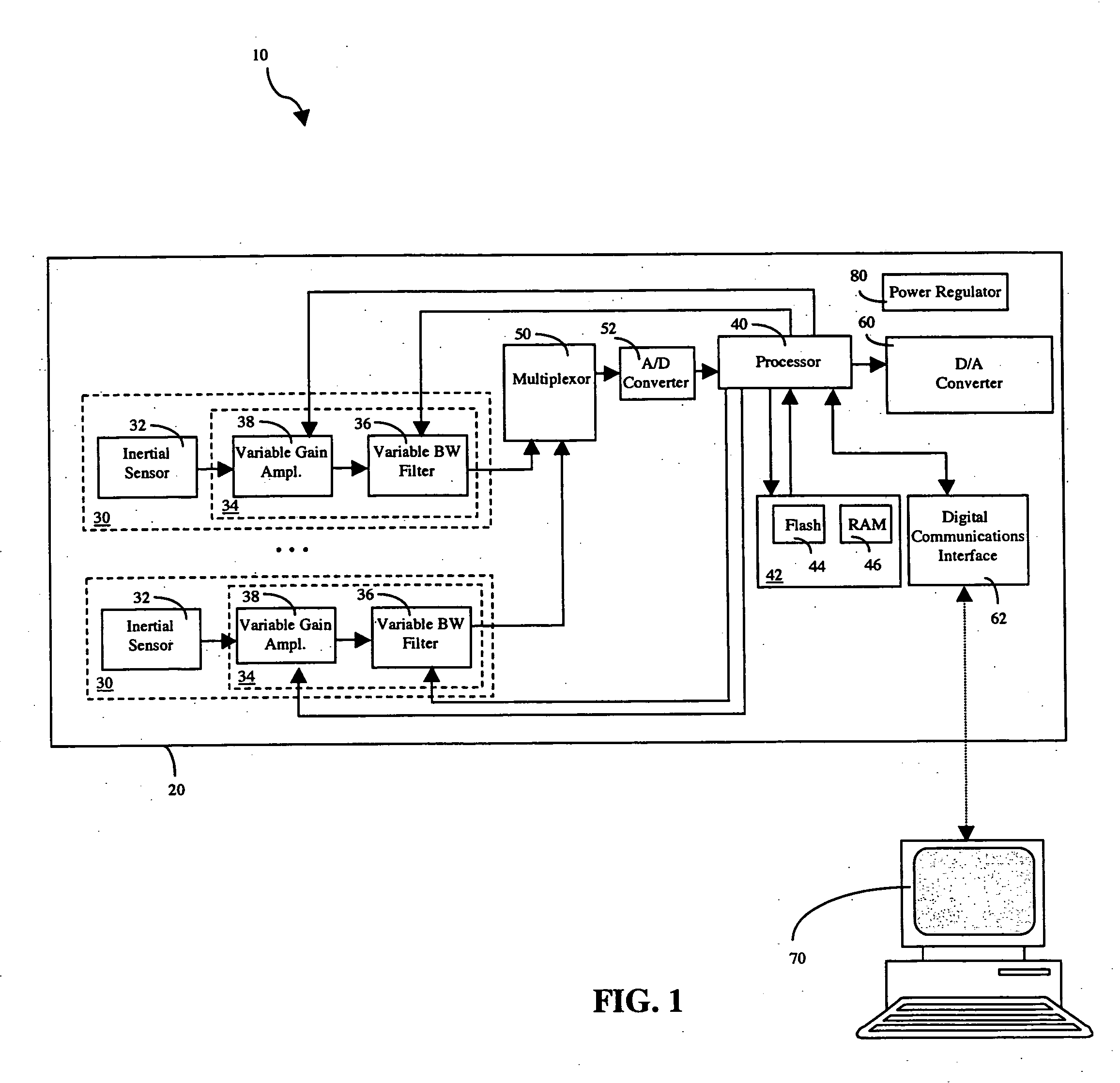

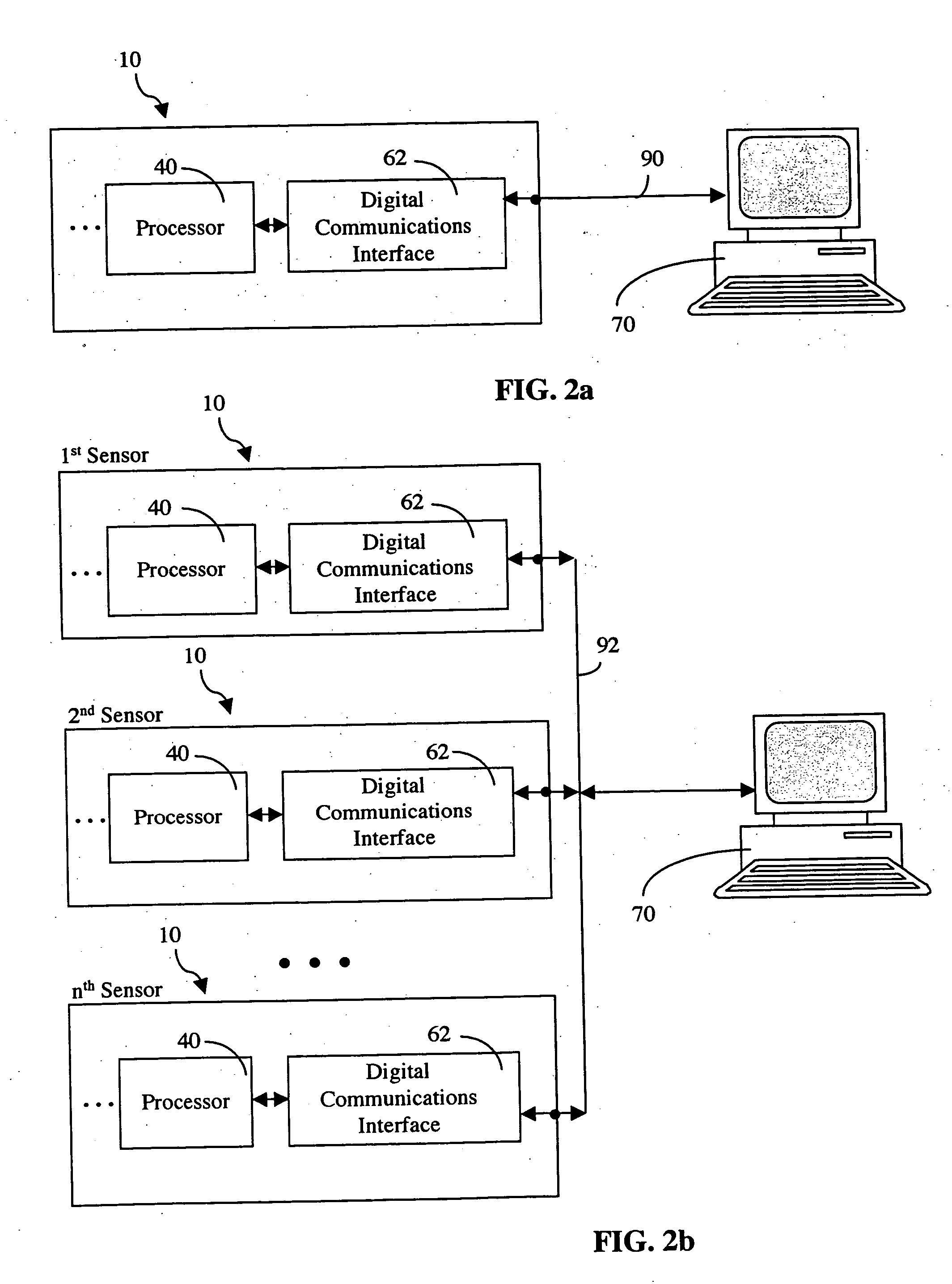

Configurable vibration sensor

InactiveUS7093492B2Vibration measurement in solidsMachine part testingVibration measurementVariable-gain amplifier

A configurable vibration sensor having a sensor circuit, an analog-to-digital converter and a processor is provided. The sensor circuit employs a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

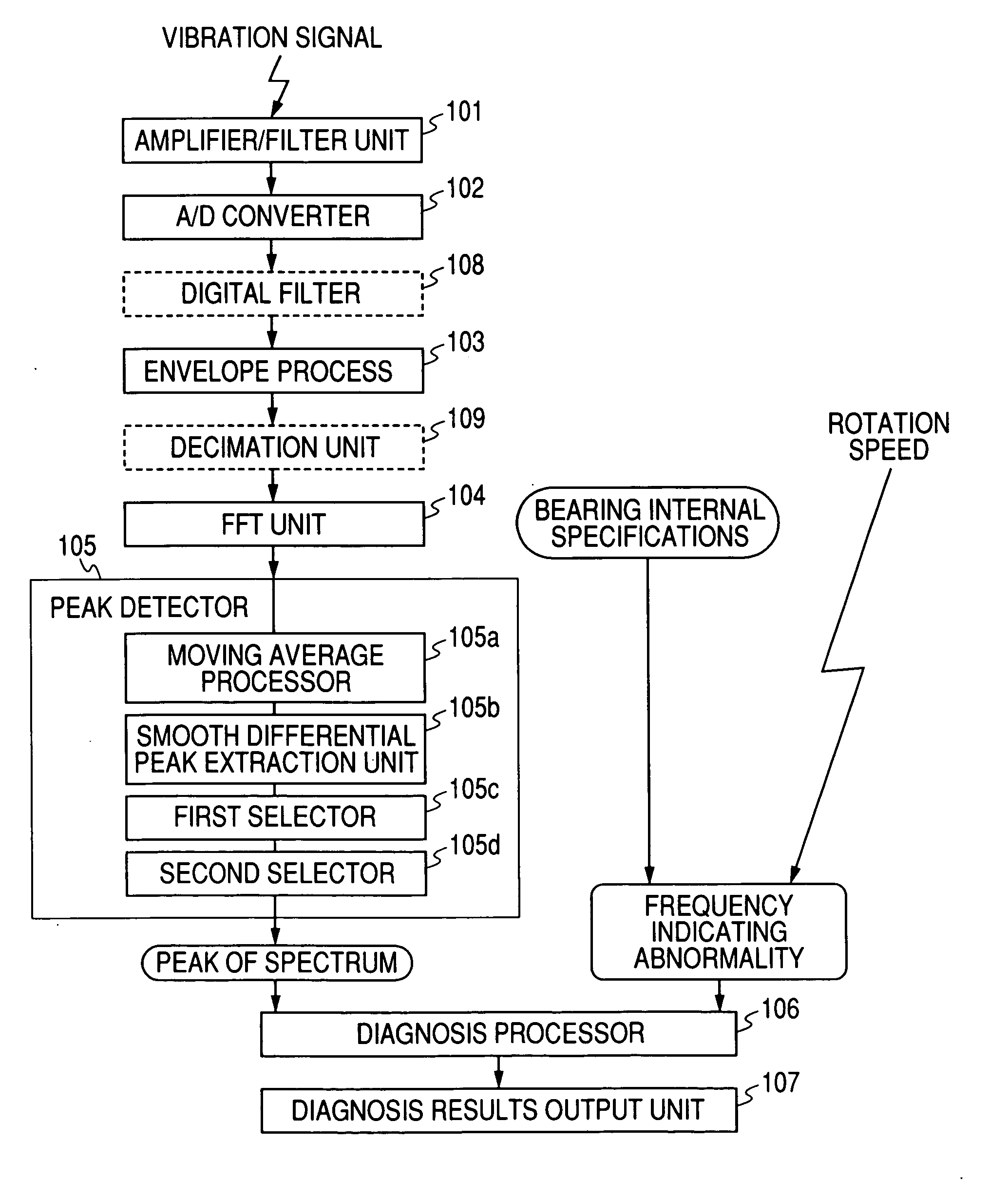

Abnormality Diagnosing System For Mechanical Equipment

ActiveUS20080033695A1Accurate detectionAvoid noisy signalsVibration measurement in solidsMachine part testingDifferential coefficientMoving average

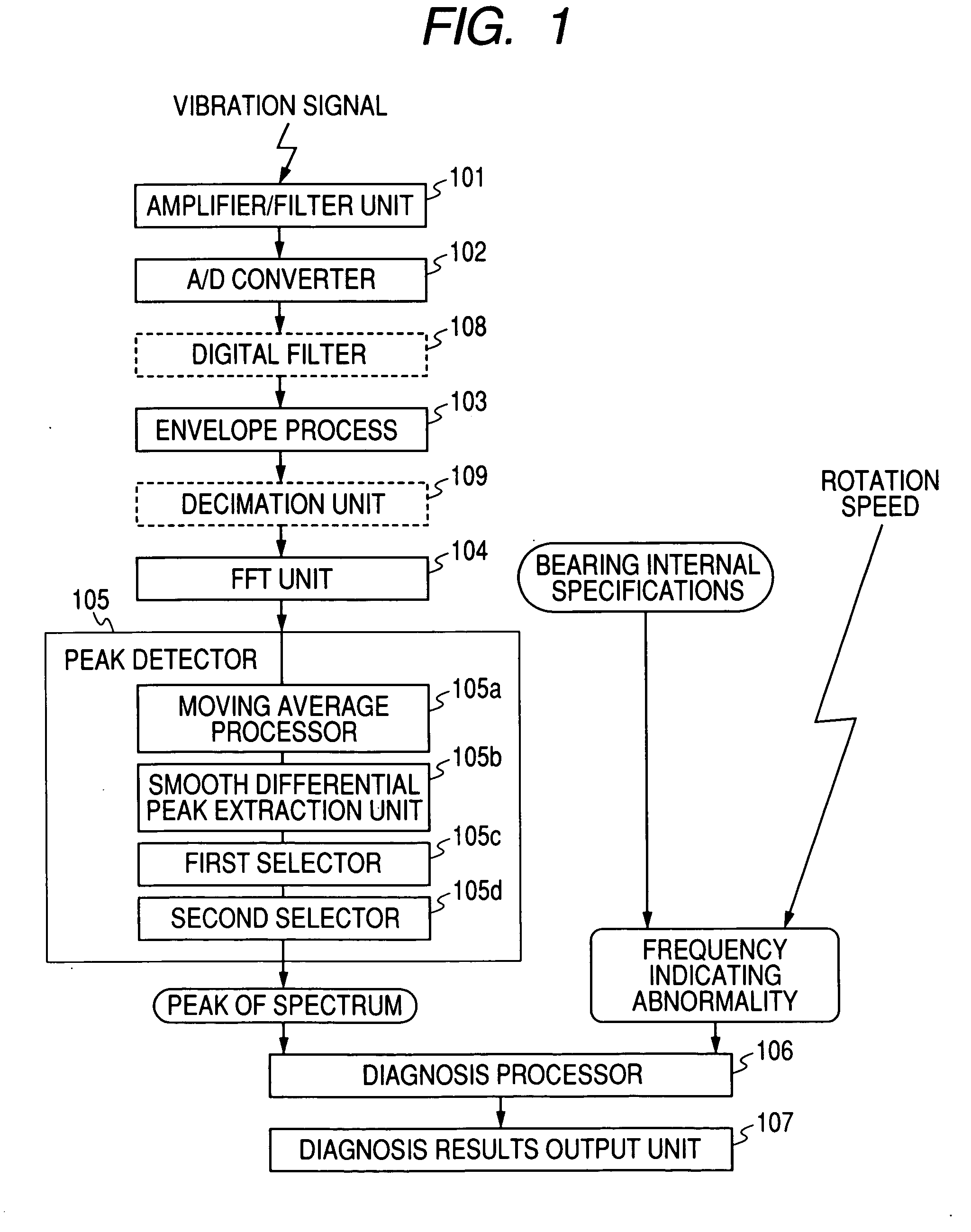

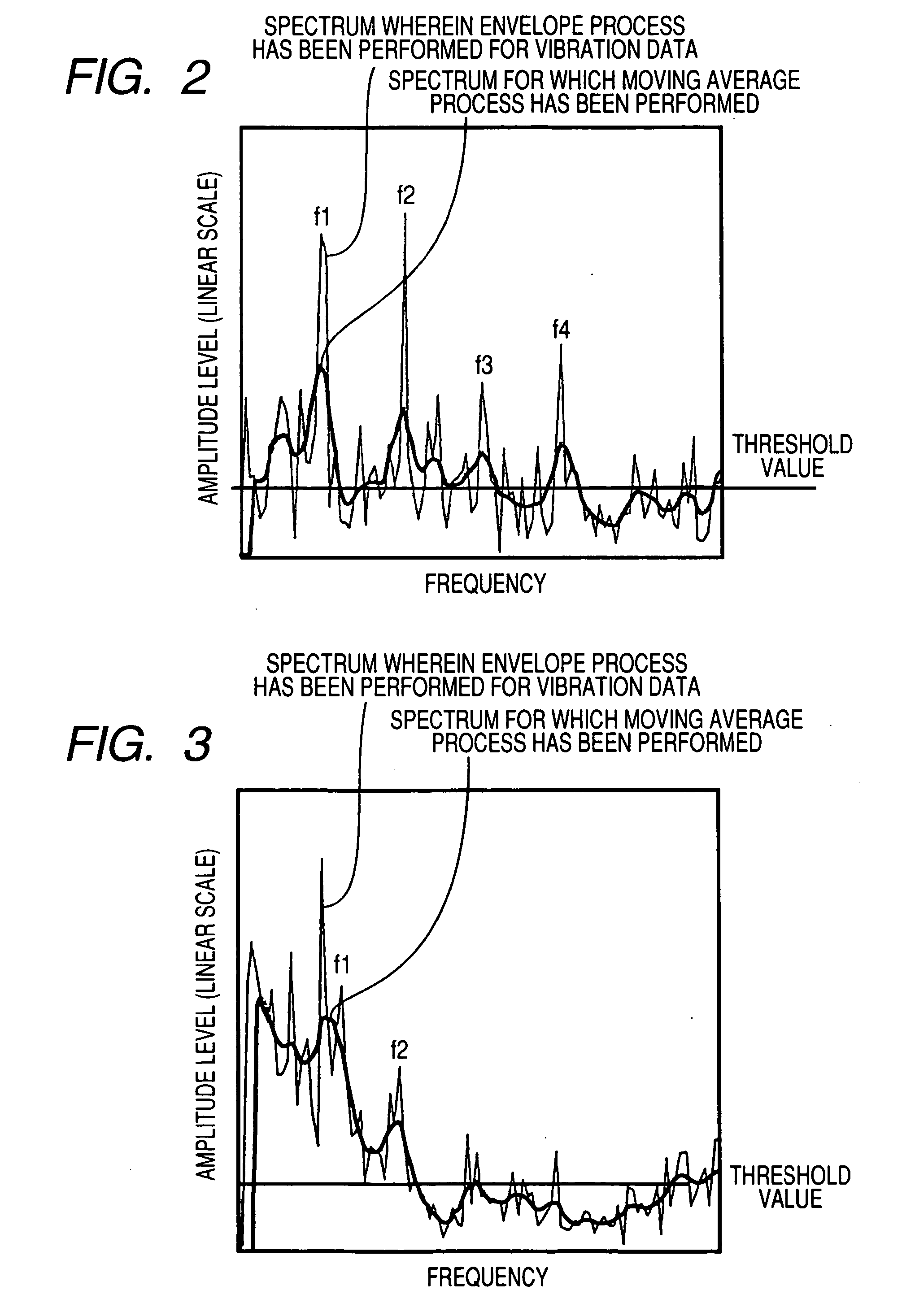

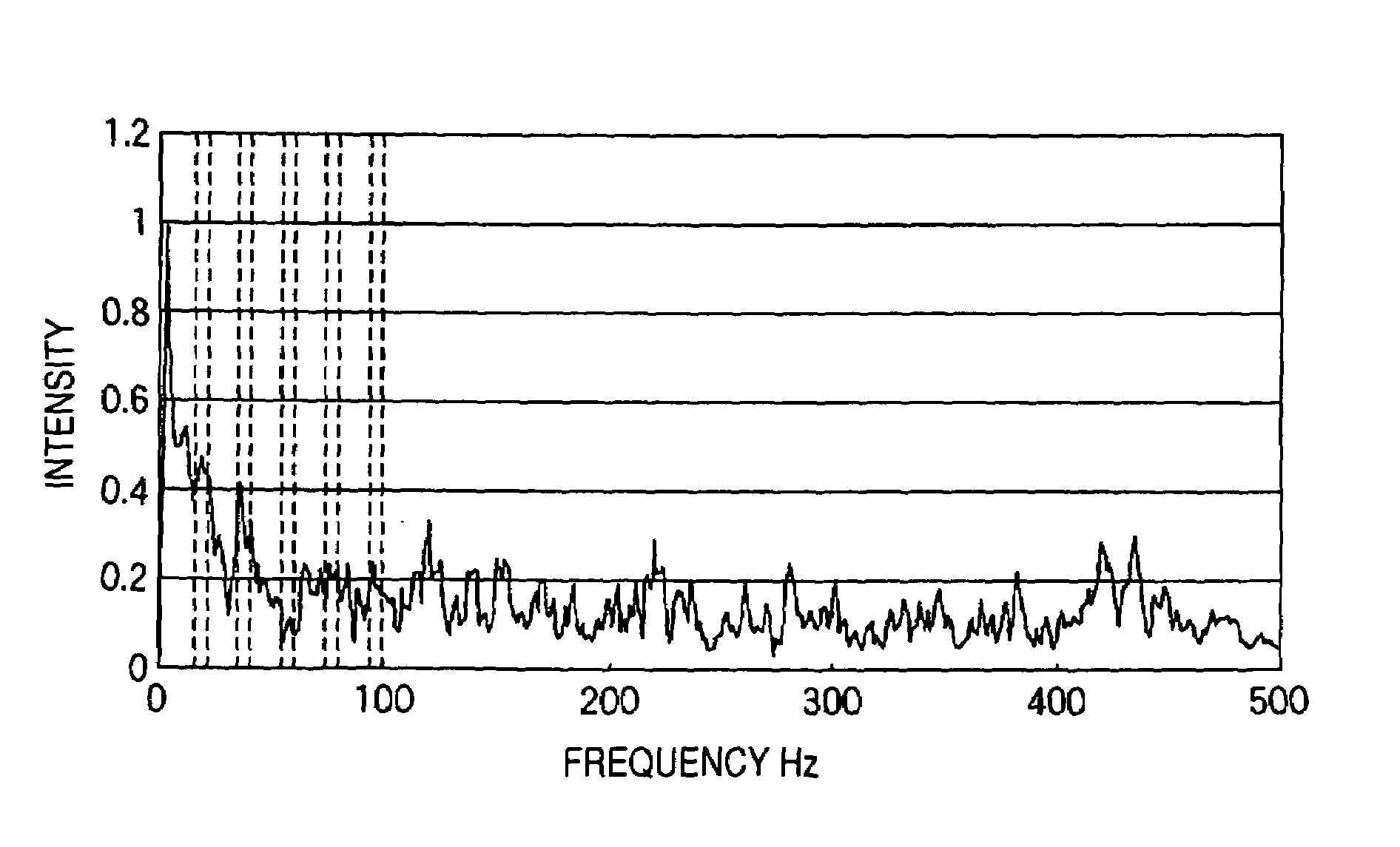

Provided are an envelope processor 103, for obtaining an envelope for a detected signal; a FFT unit 104, for converting the envelope into a frequency spectrum; a peak detector 105, for smoothing the frequency spectrum by calculating a moving average, for further performing smoothing and differentiation for the spectrum, and detecting, as peaks, frequency points at which a sign of a differential coefficient is changed from positive to negative, for extracting peaks having a predetermined threshold value or greater, and for sorting the extracted peaks and detecting upper peaks; and a diagnosis processor T, for diagnosing an abnormality based on the detected peaks.

Owner:NSK LTD

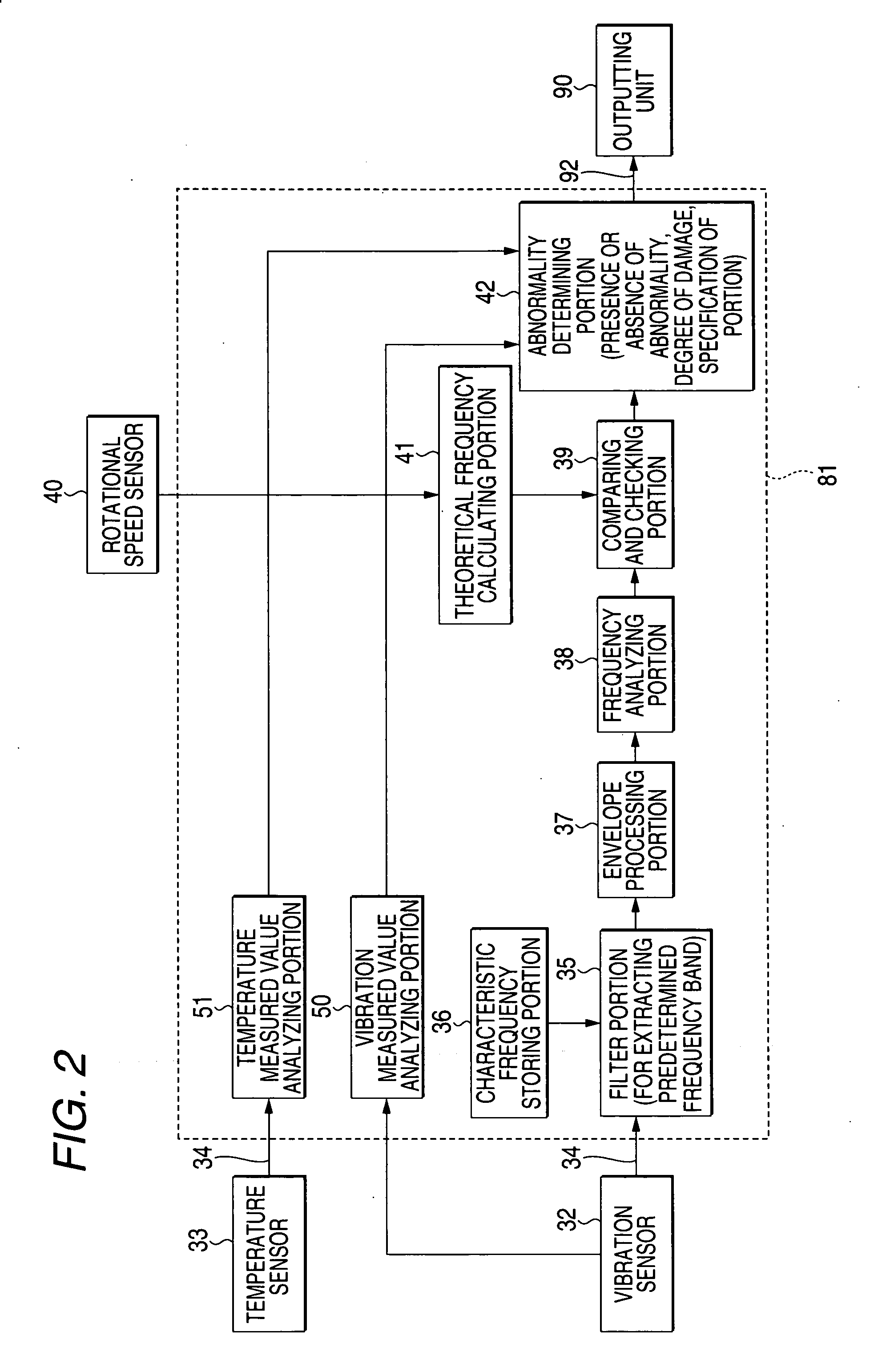

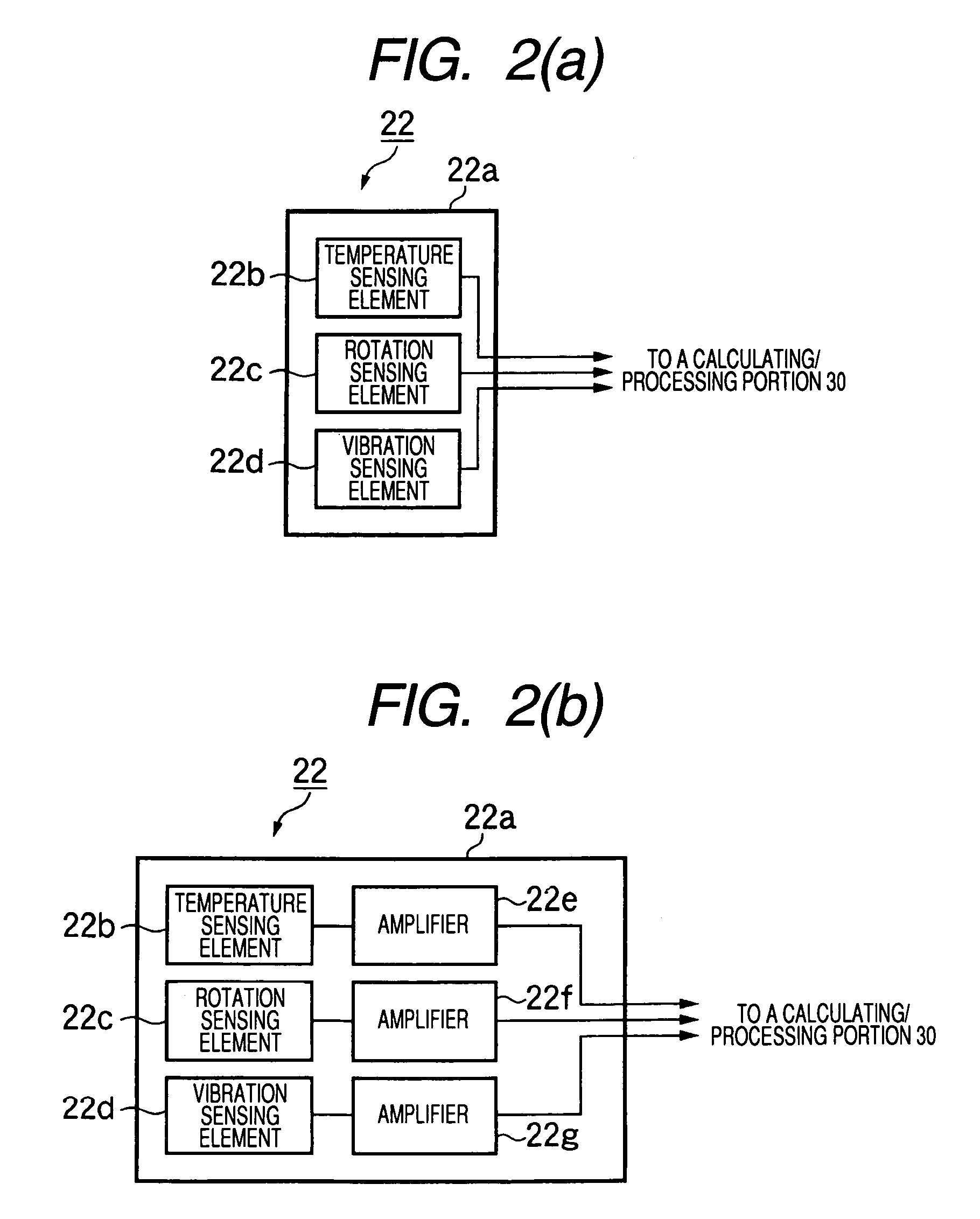

Abnormality Diagnosing Apparatus and Abnormality Diagnosing Method

ActiveUS20080234964A1Improve reliabilityEffective maintenanceVibration measurement in solidsVehicle testingEngineeringSignal processing

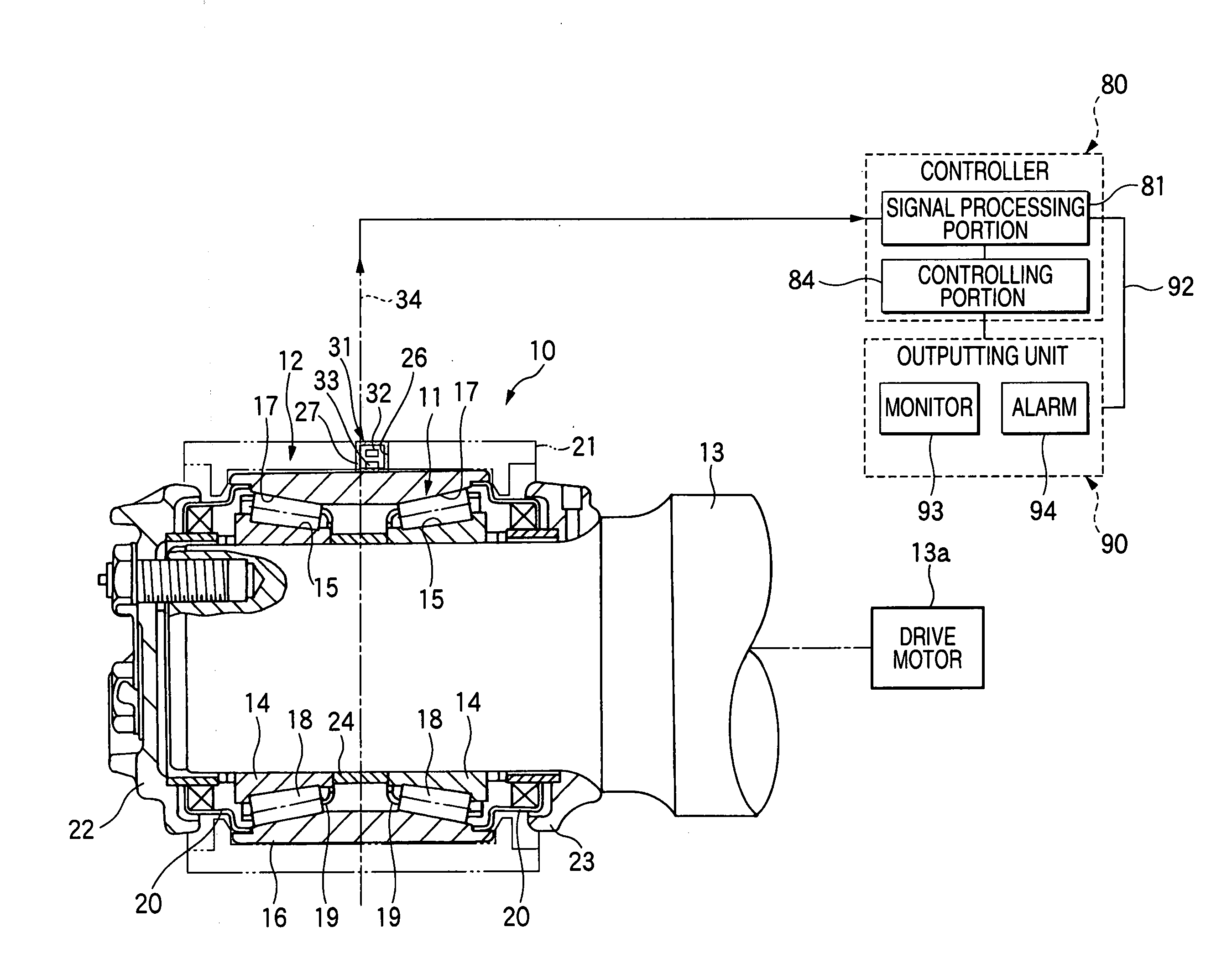

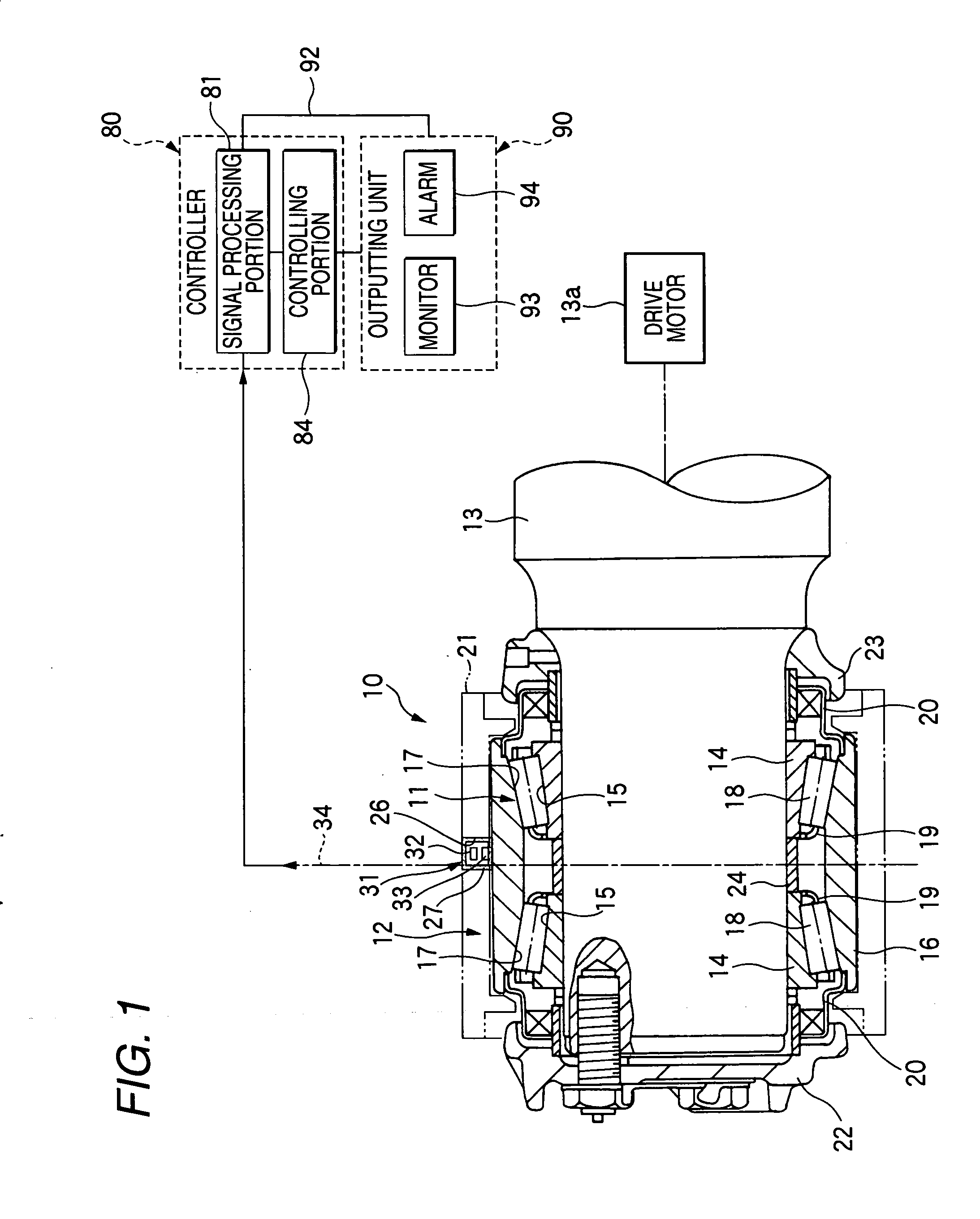

A abnormality diagnosing apparatus used in a machine equipment including a rotating or sliding part relative to a stationary member includes a detecting portion 31 fixed to the rotating or sliding part or the stationary member and including a vibration sensor 32 and a temperature sensor 33, and a signal processing portion 81 for determining a state of the part from a detecting signal outputted by the detecting portion 31. The signal processing portion 81 determines presence or absence of a abnormality, or presence or absence of the abnormality and a degree of a damage of the part based on a combination of a measured result by the vibration sensor 32 and a measured result by the temperature sensor 33.

Owner:NSK LTD

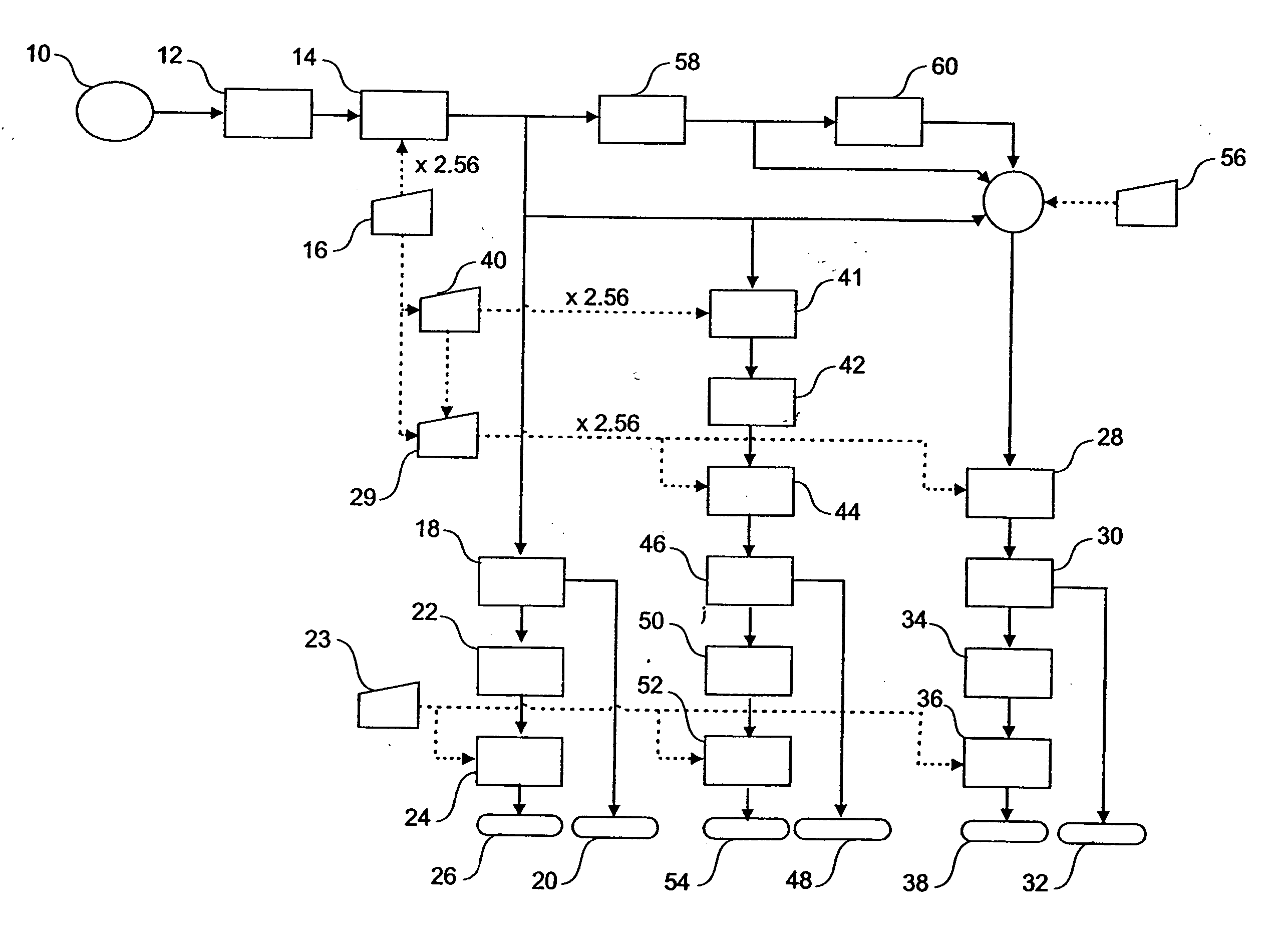

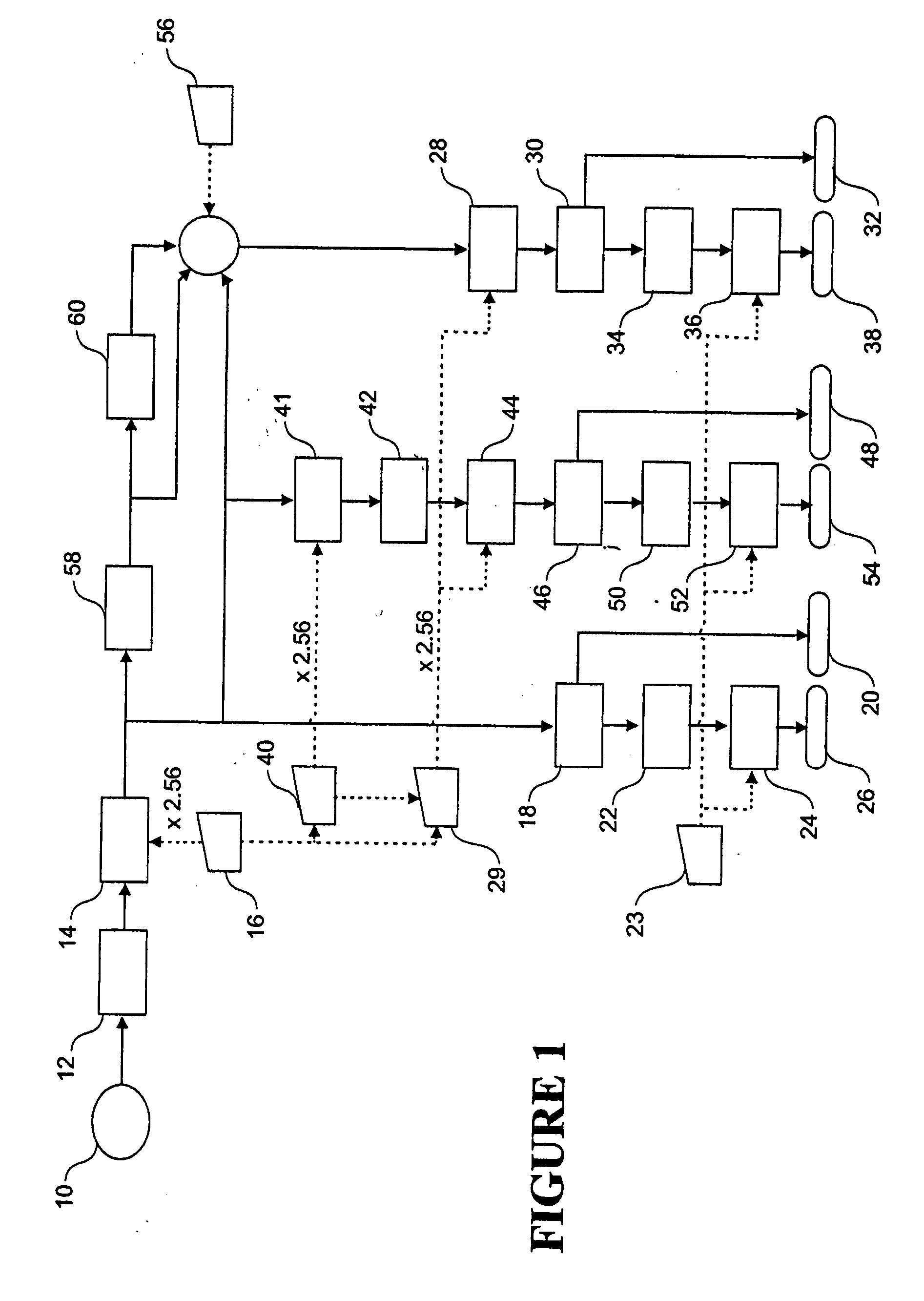

Vibration analysis

ActiveUS20060150738A1Reduce frequencyVibration measurement in solidsMachine part testingElectricityAcoustics

The present invention relates to vibration analysis and in particular, but not limited to, the derivation of multiple types of vibration signals from one vibration signal for vibration analysis. In the preferred method of the invention the vibrations of an object are measured using at least one vibration sensor, wherein the vibration sensor converts vibrations into an electrical vibration signal. The electrical vibration signal is digitised based on a first frequency, wherein the first frequency is selected from a plurality of possible frequency values. A first type of vibration signal is derived from the digitised vibration signal. A second type of vibration signal is then derived from the digitised vibration signal based on a second frequency. The second frequency is rationally determined from, and lower than, the value selected for the first frequency. The invention also provides apparatus for deriving multiple types of vibration signals from one measured vibration signal for vibration analysis.

Owner:MANTHEY DIANE MANT

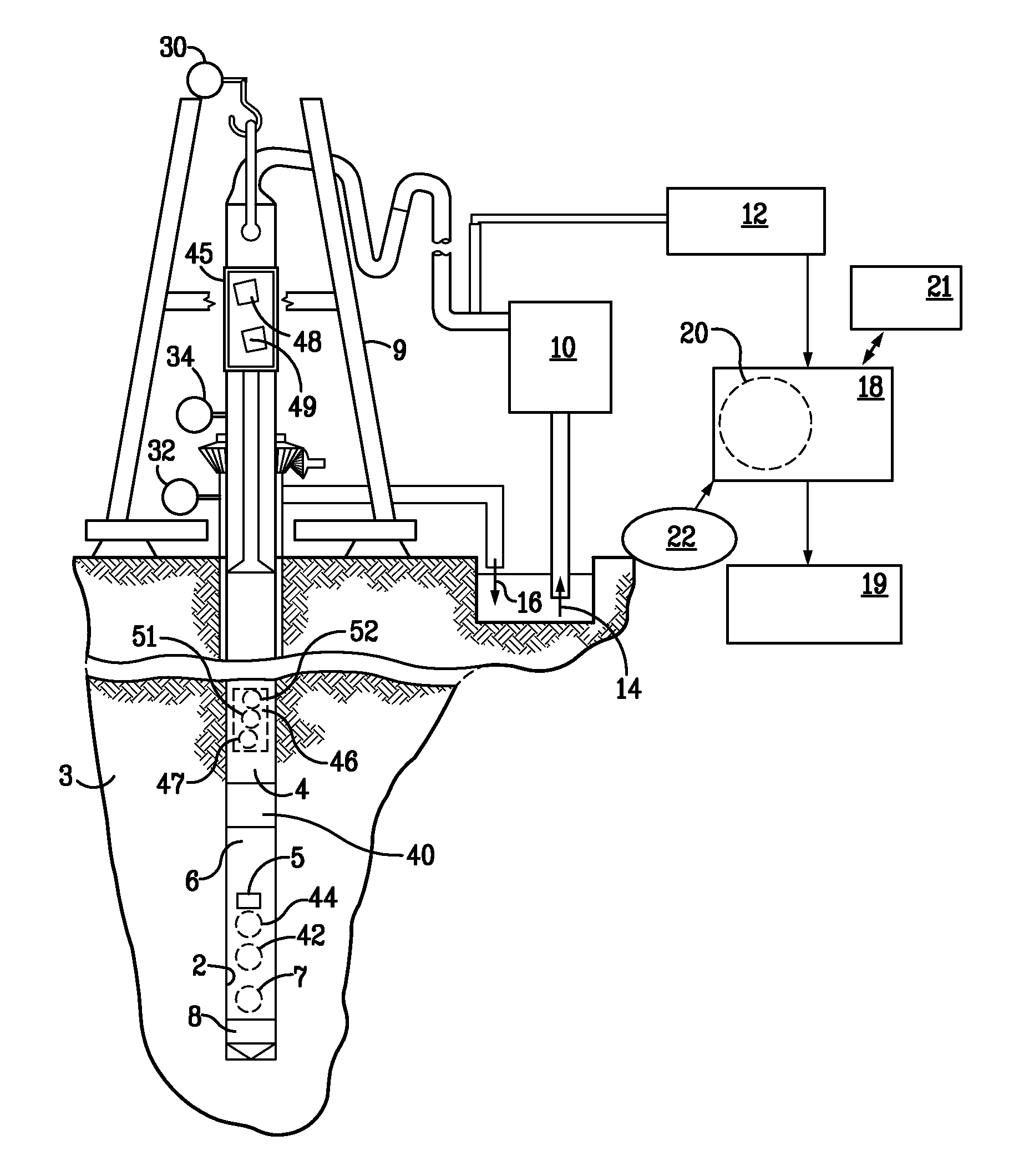

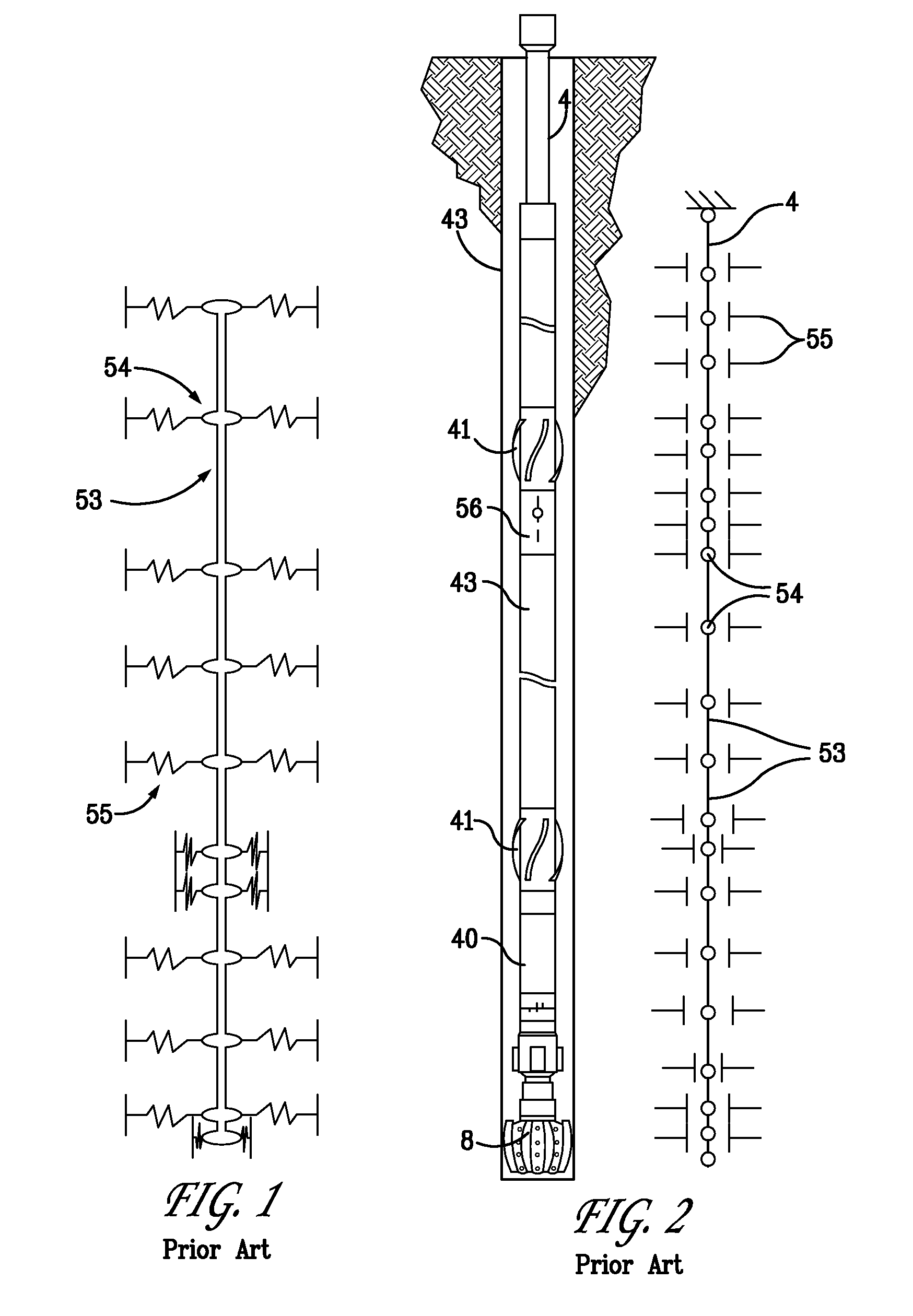

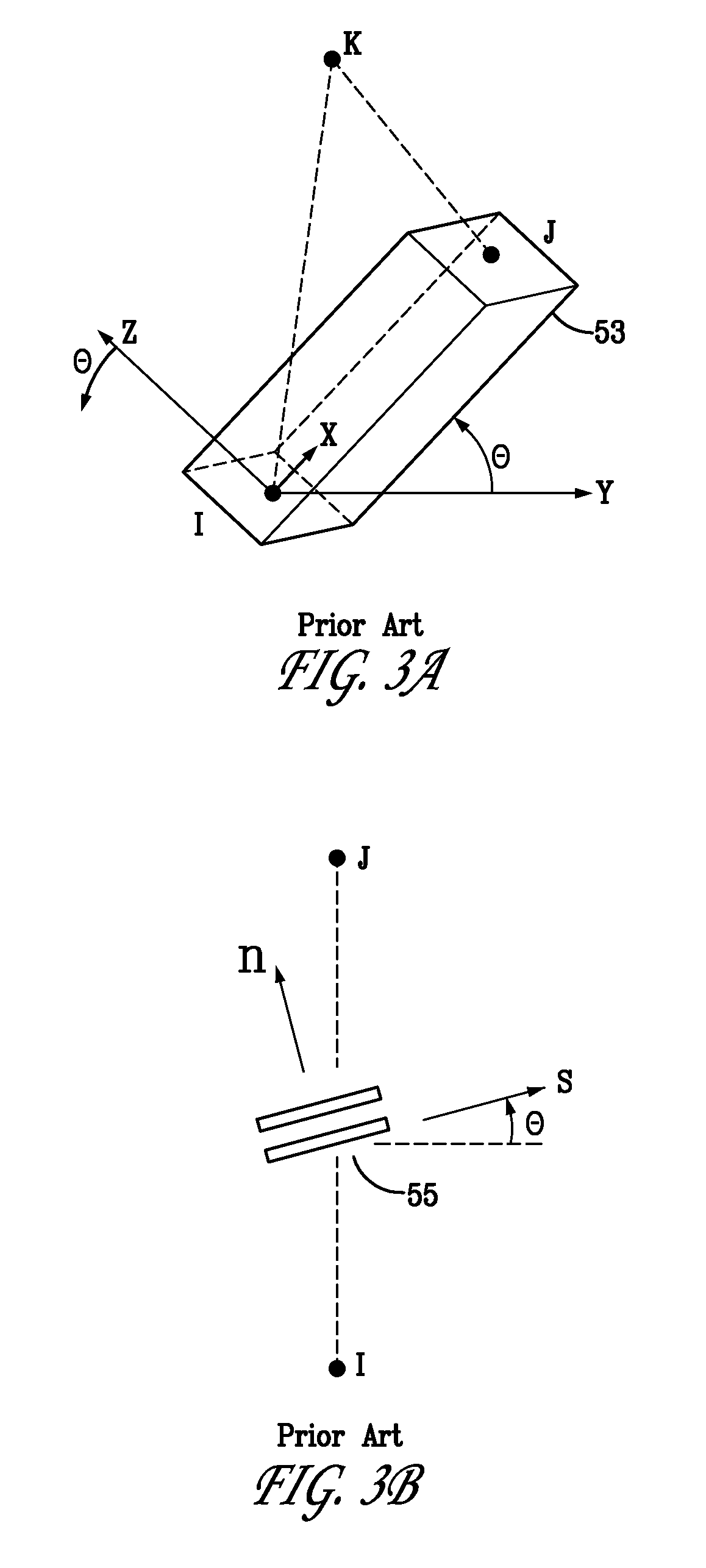

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20110186353A1Reduce the differenceVibration measurement in solidsMachine part testingFinite element techniqueResonance

A system and method for monitoring underground drilling in which vibration is monitored by creating a model of the drill string using finite element techniques or finite difference techniques and (i) predicting vibration by inputting real time values of operating parameters into the model, and then adjusting the model to agree with measured vibration data, (ii) predicting the weight on bit and drill string and mud motor speeds at which resonance will occur, as well as when stick-slip will occur, so that the operator can avoid operating regimes that will result in high vibration, (iii) determining vibration and torque levels along the length of the drill string based on the measured vibration and torque at one or more locations, (iv) determining the remaining life of critical components of the drill string based on the history of the vibration to which the components have been subjected, and (v) determining the optimum drilling parameters that will avoid excessive vibration of the drill string.

Owner:APS TECH

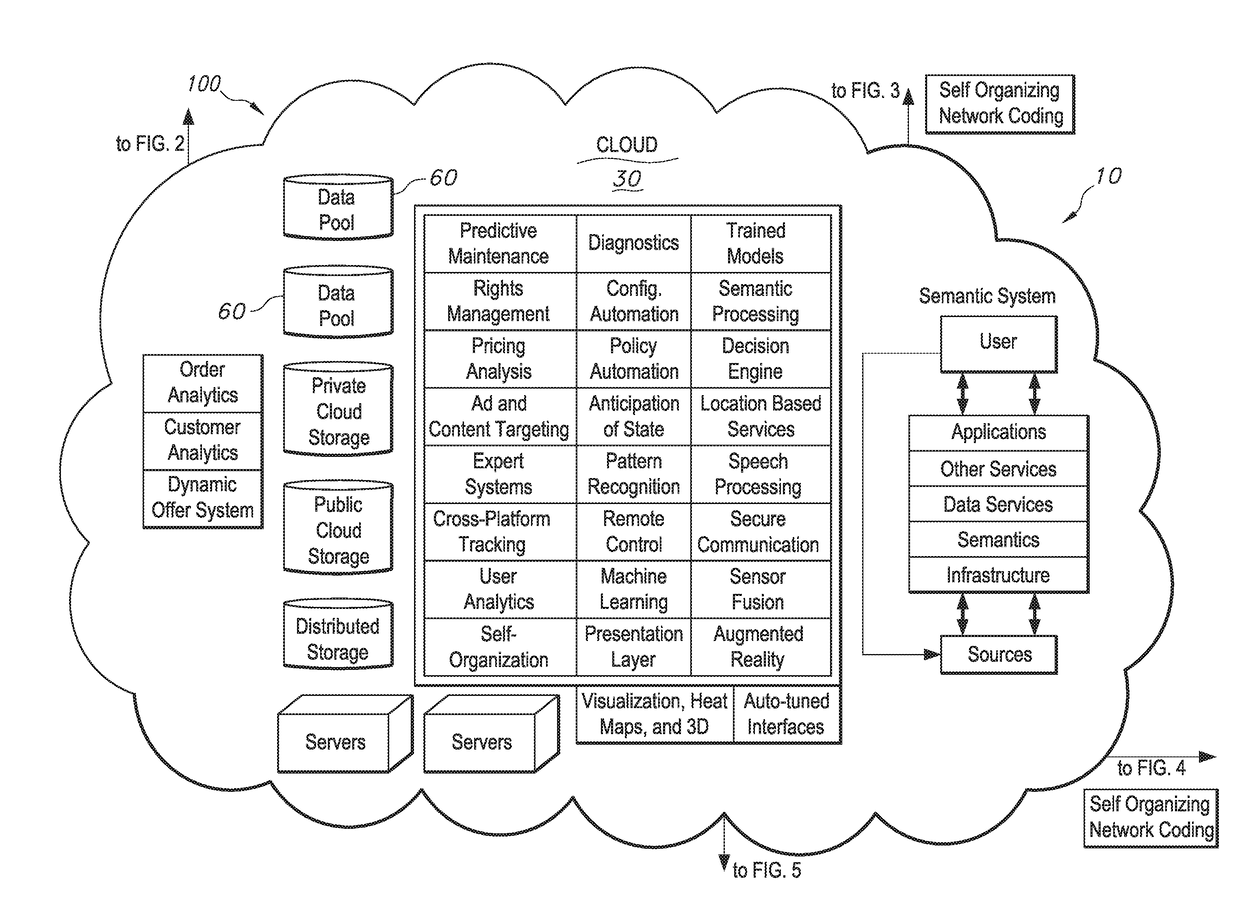

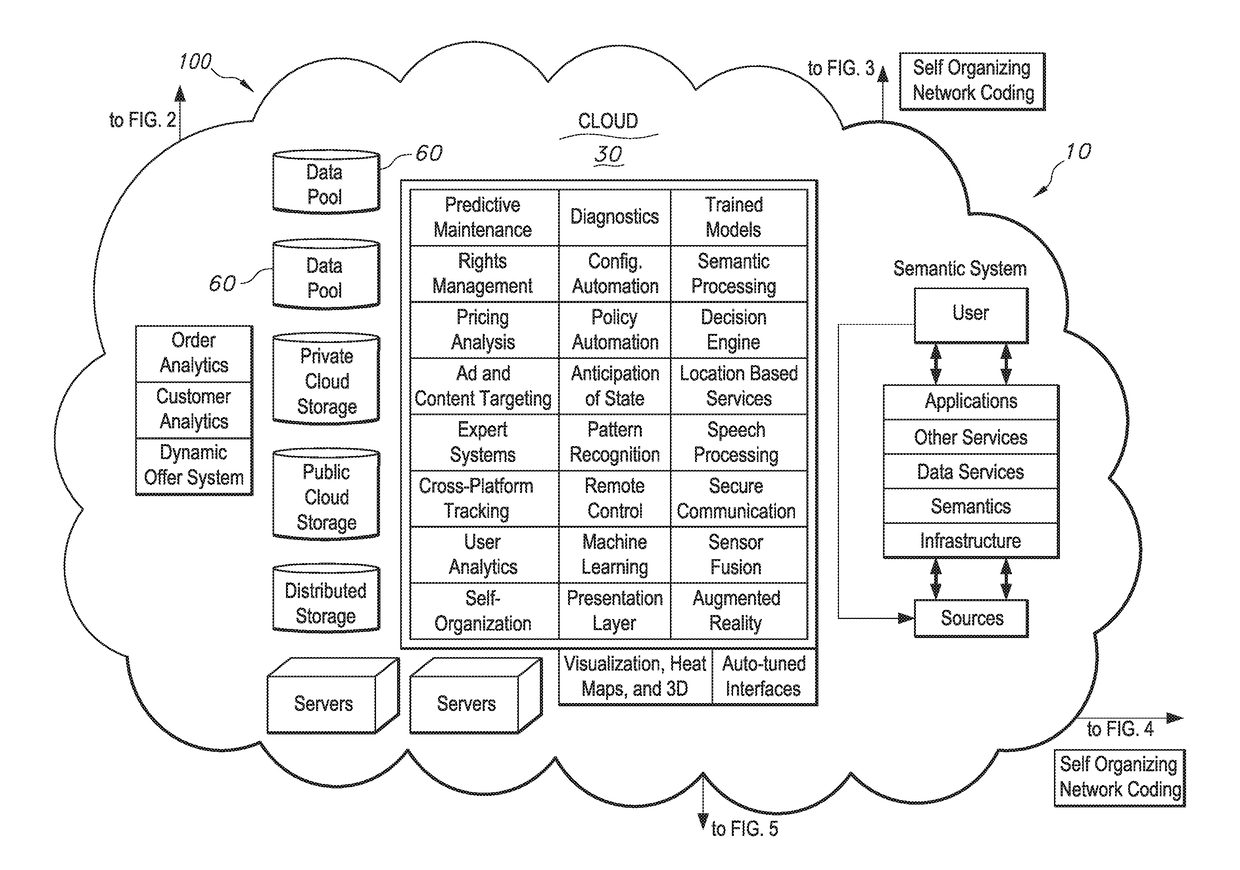

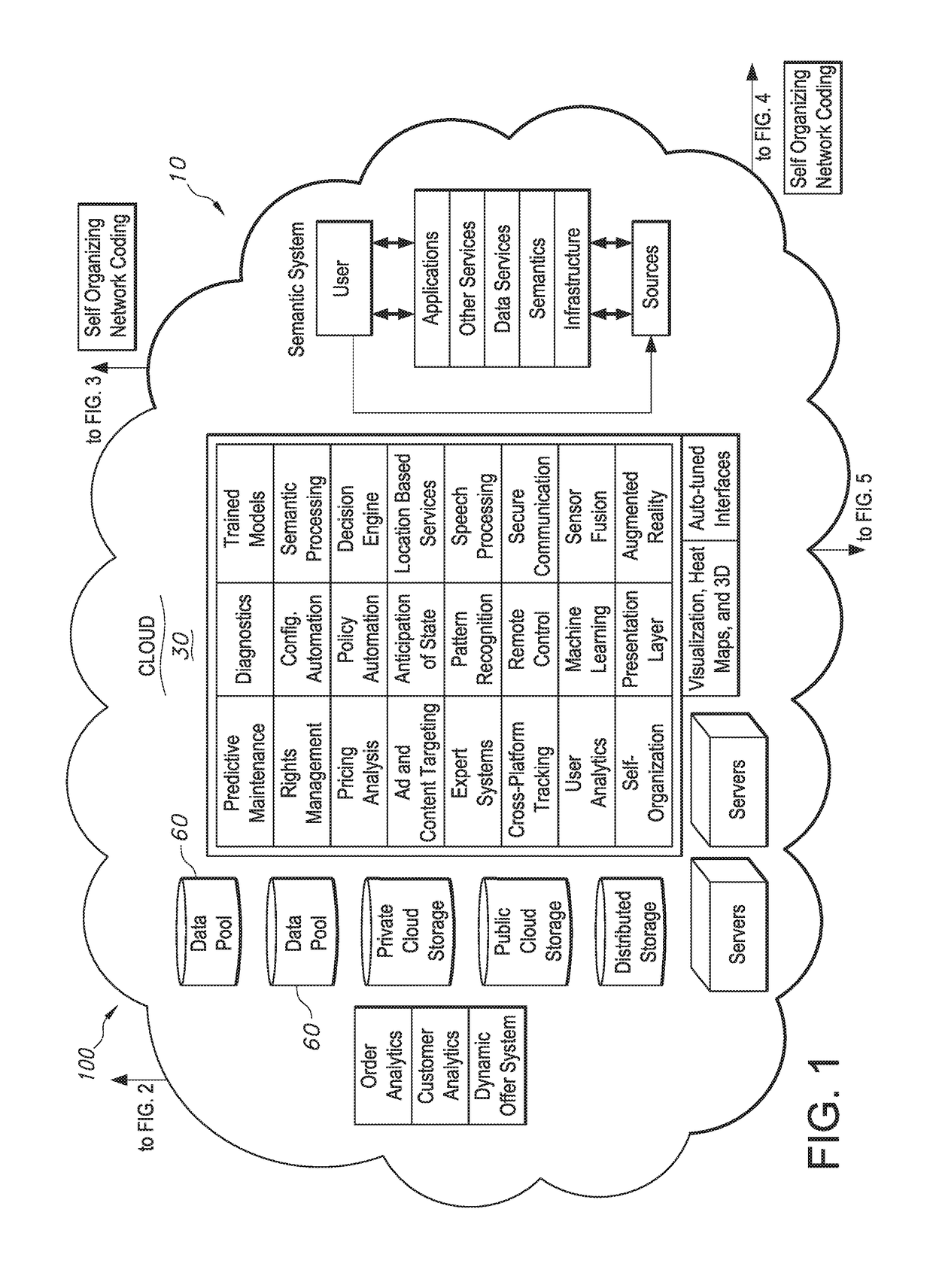

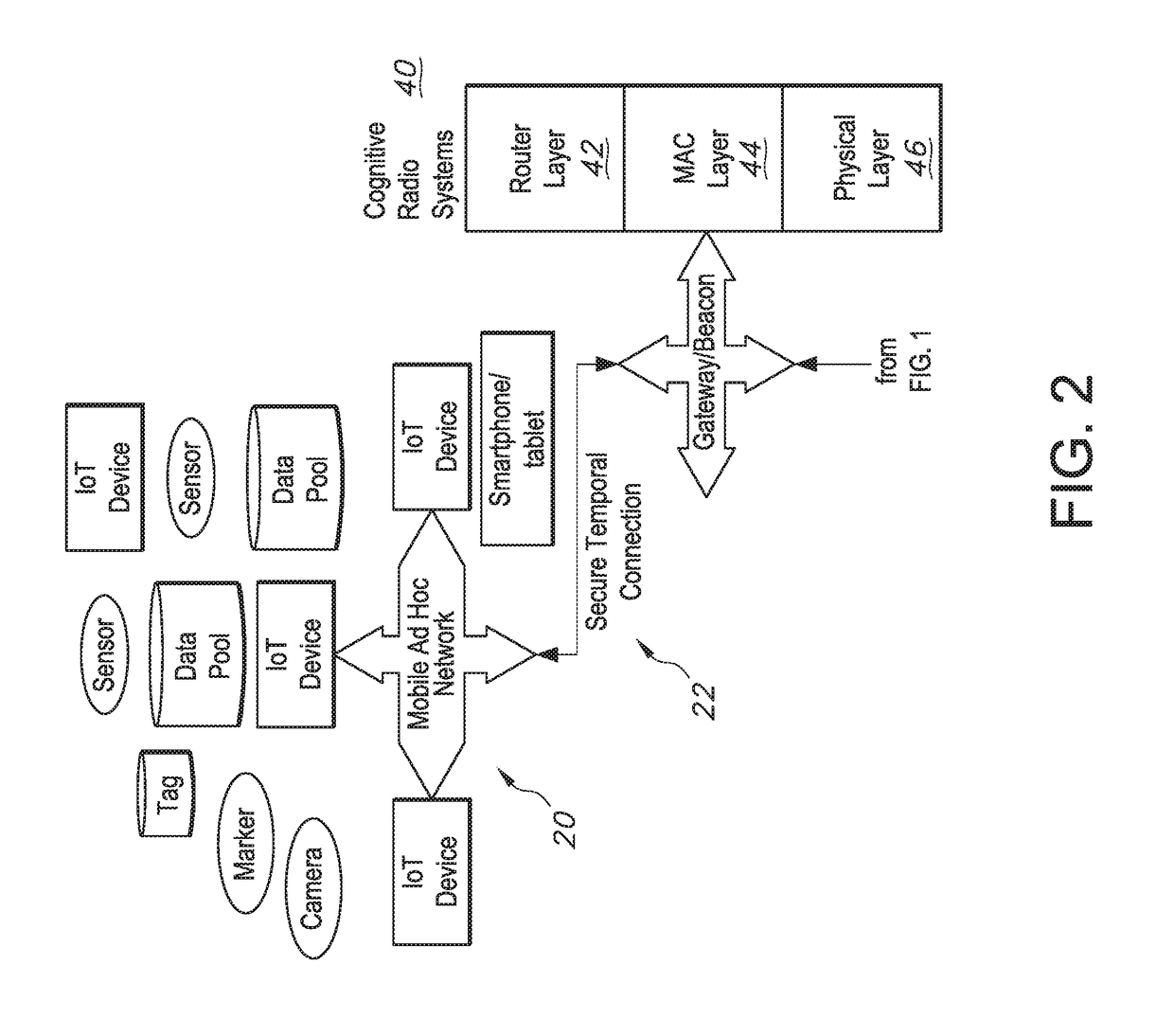

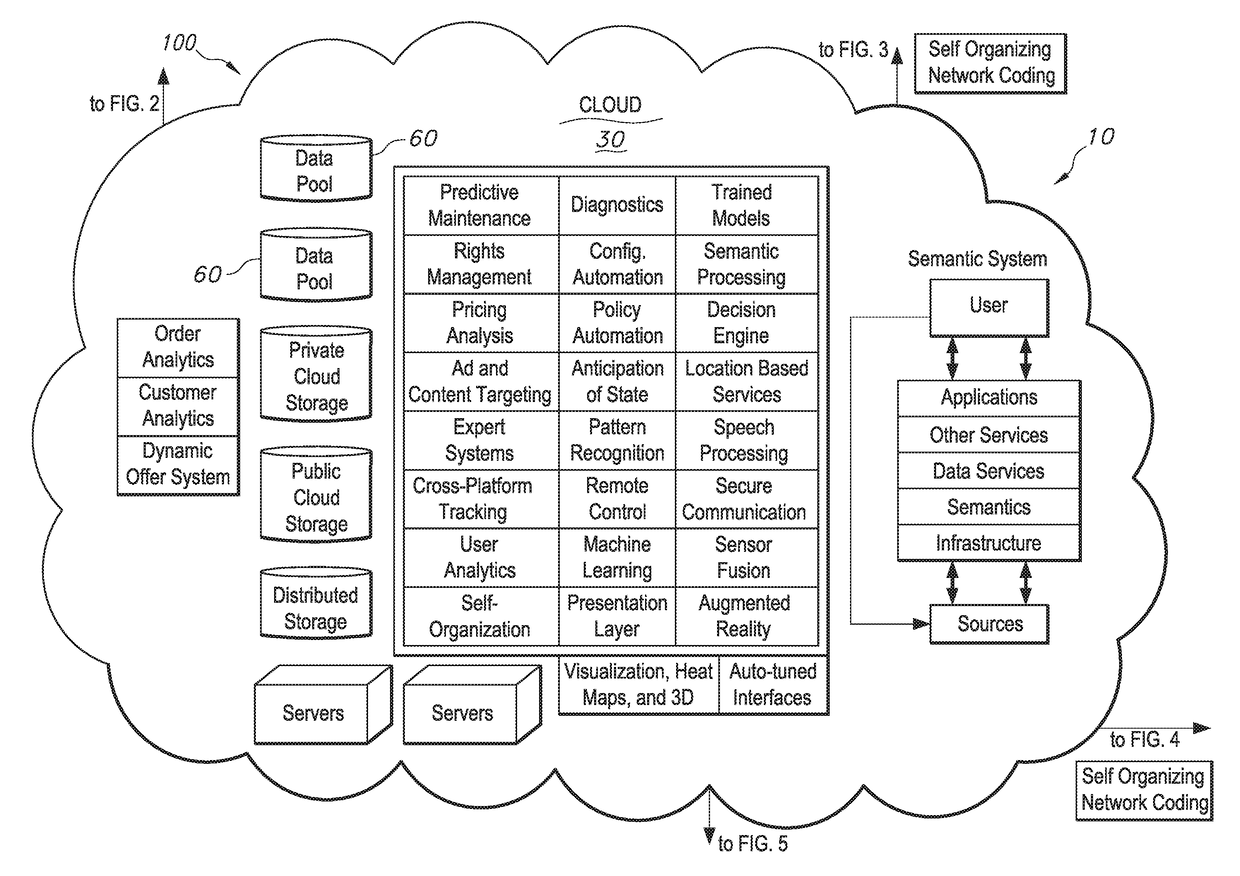

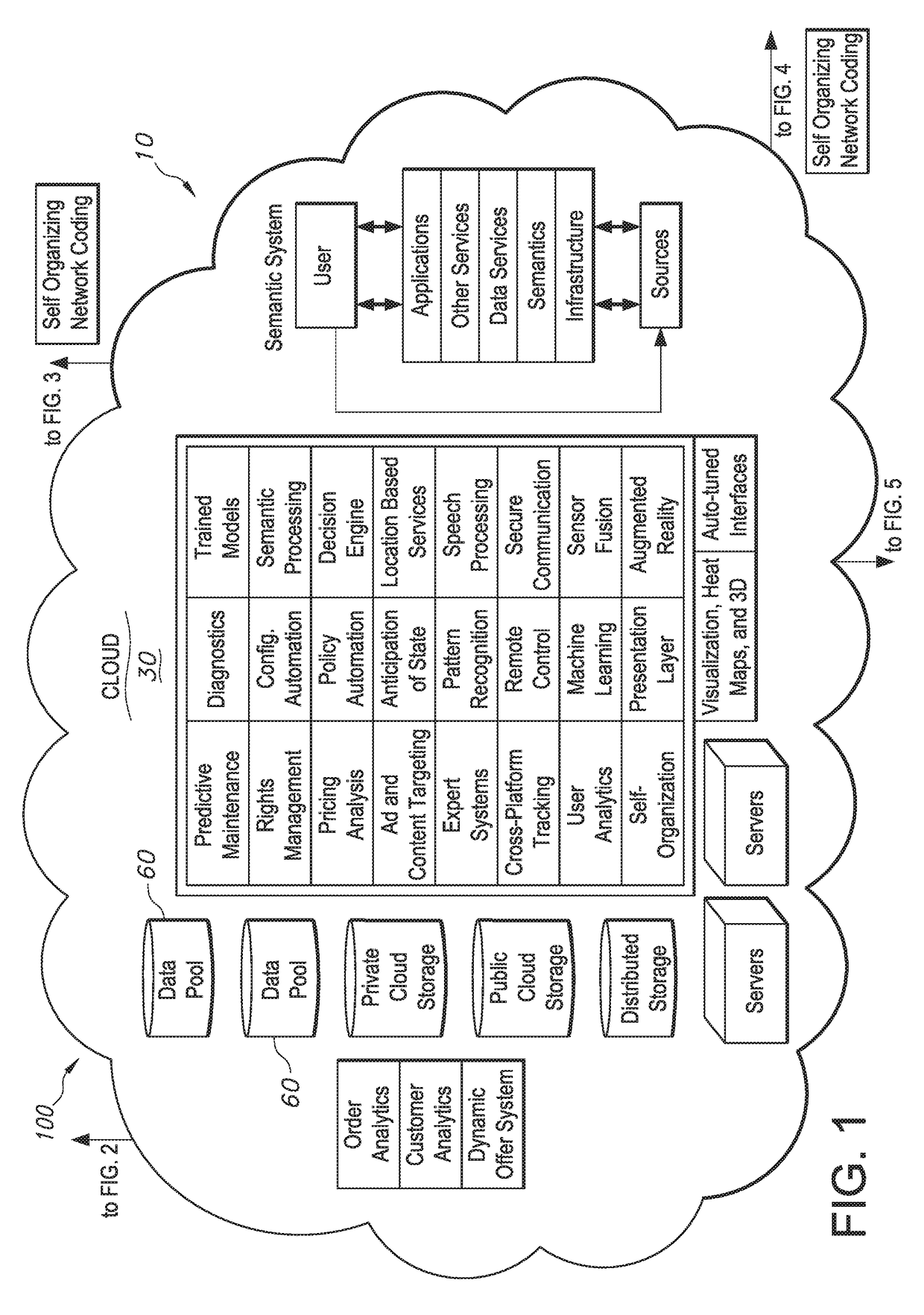

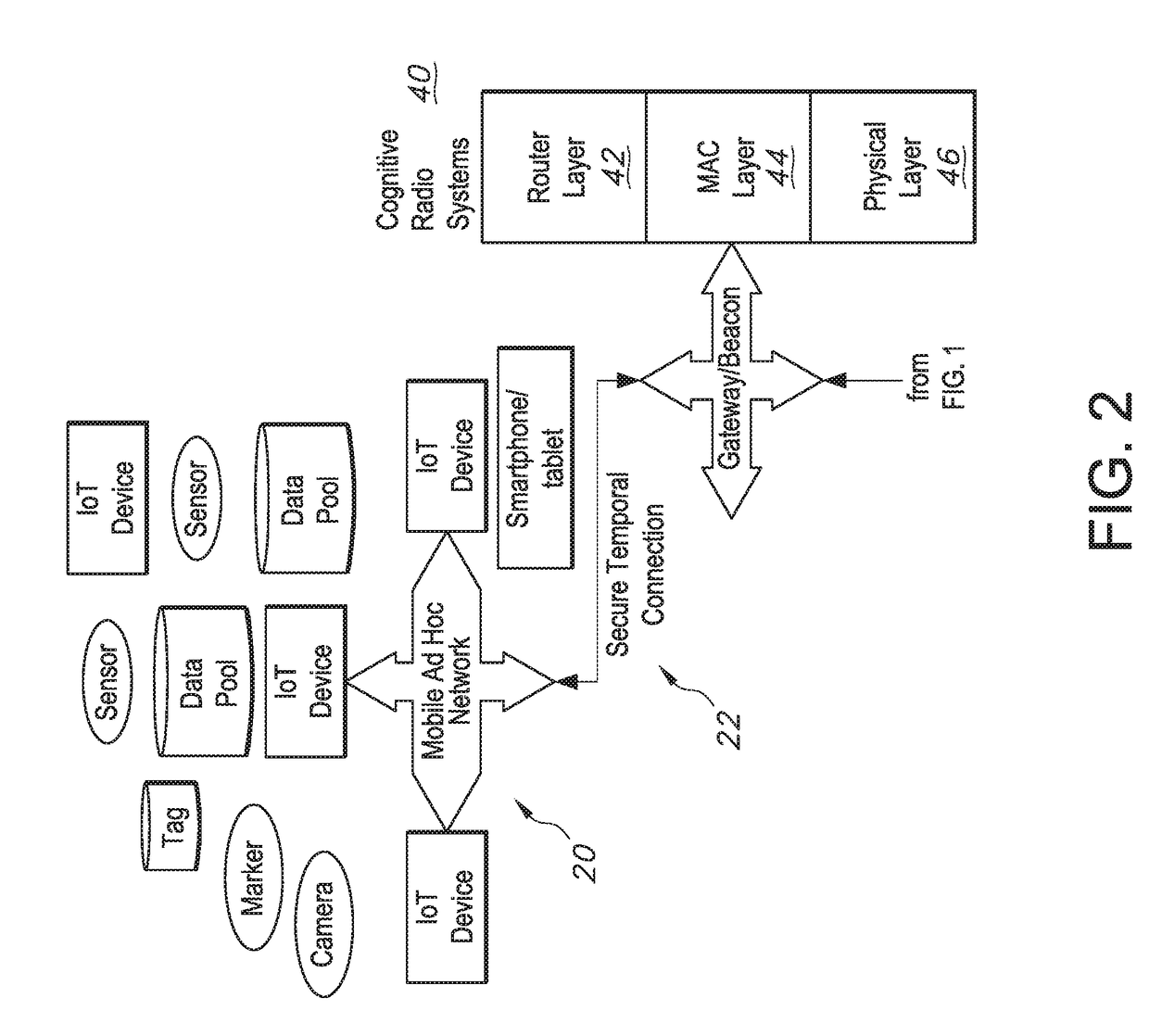

Methods and systems for the industrial internet of things

ActiveUS20180188704A1Improve signal-to-noise ratioLow sampling rateVibration measurement in solidsMachine part testingData streamData acquisition

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The local data collection system includes multiple multiplexing units and multiple data acquisition units receiving multiple data streams from multiple machines in the industrial environment. The local data collection system includes distributed complex programmable hardware device (CPLD) chips each dedicated to a data bus for logic control of the multiple multiplexing units and the multiple data acquisition units that receive the multiple data streams from the multiple machines in the industrial environment. The local data collection system is configured to manage data collection bands.

Owner:STRONG FORCE IOT

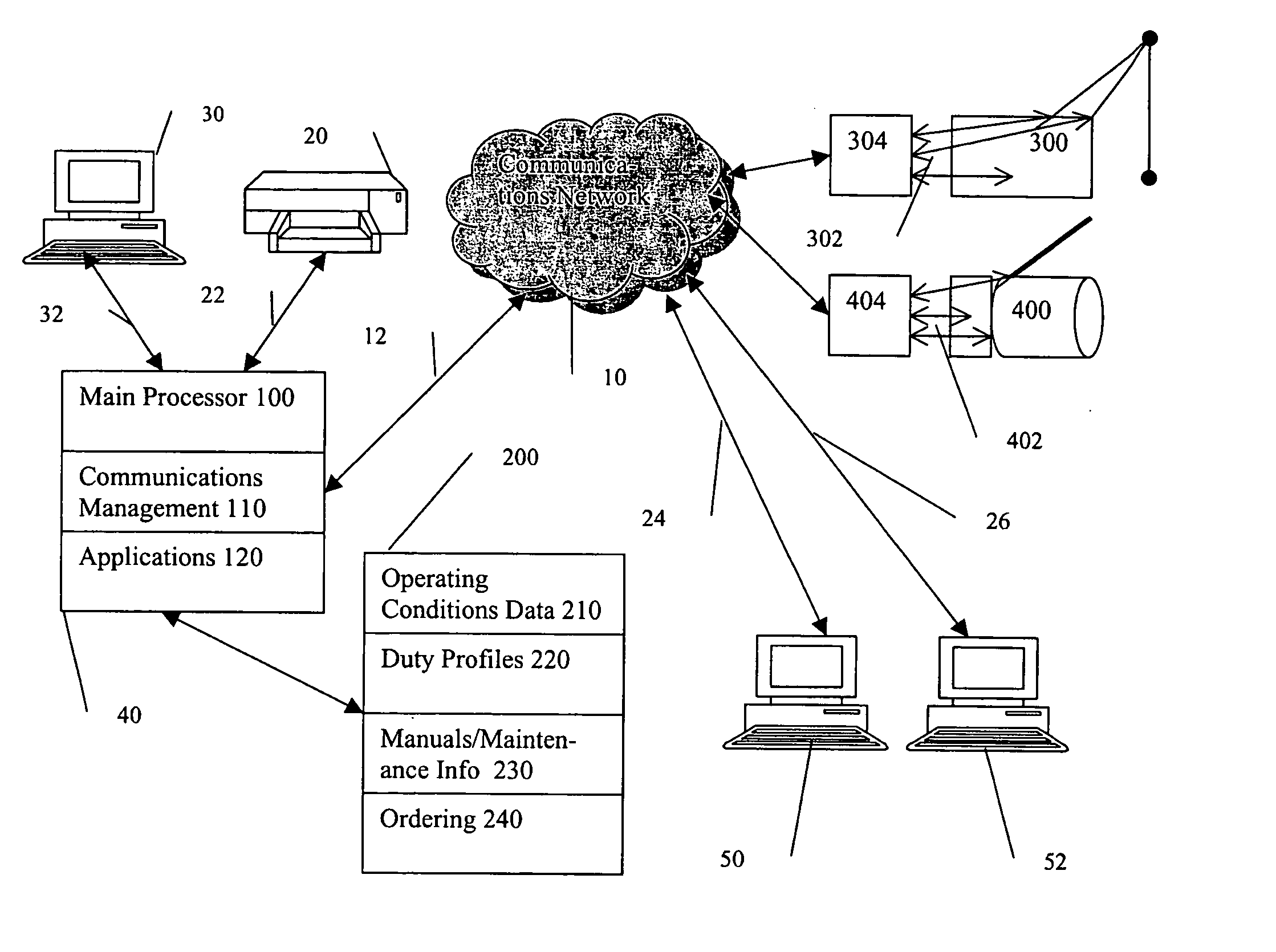

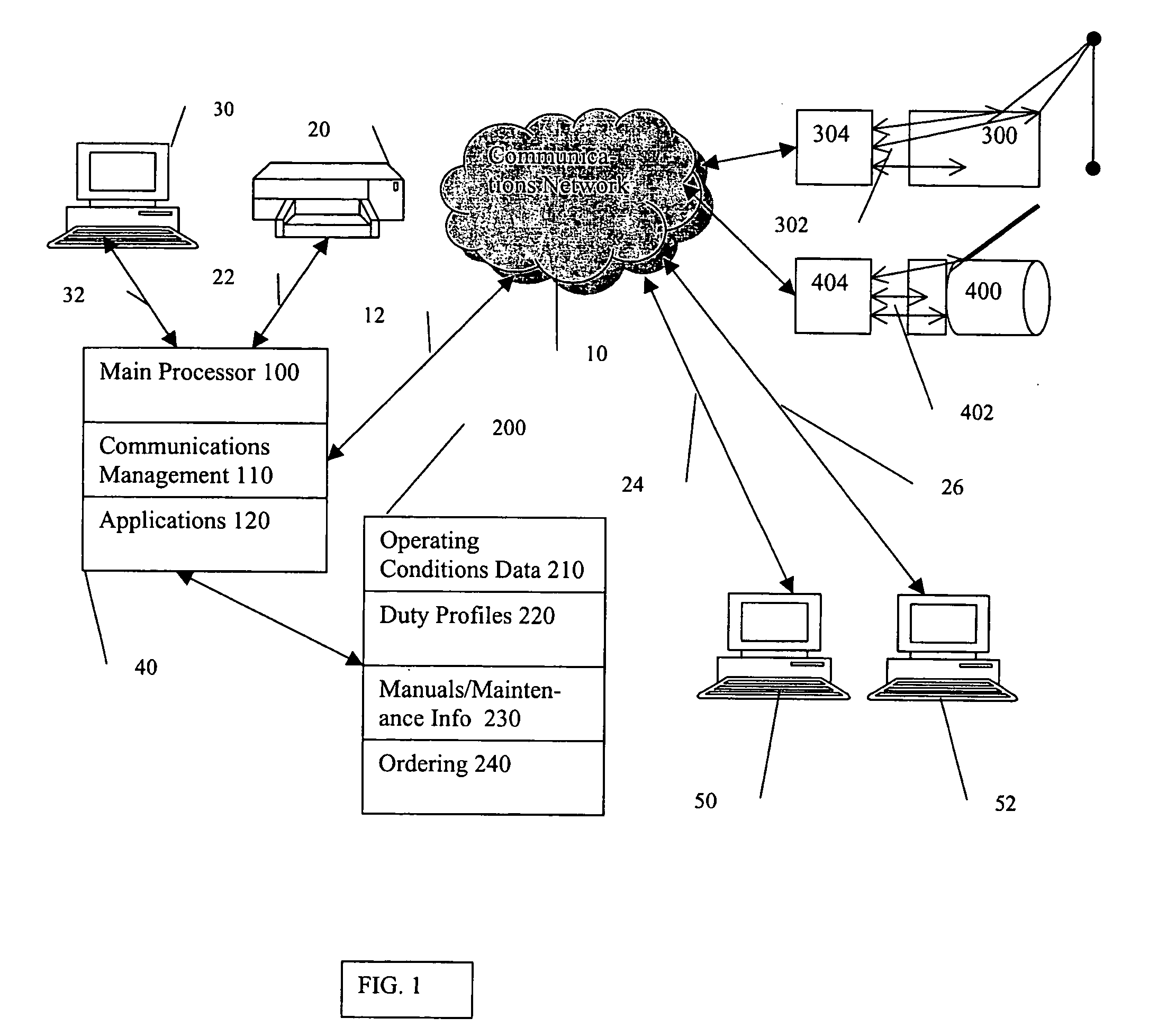

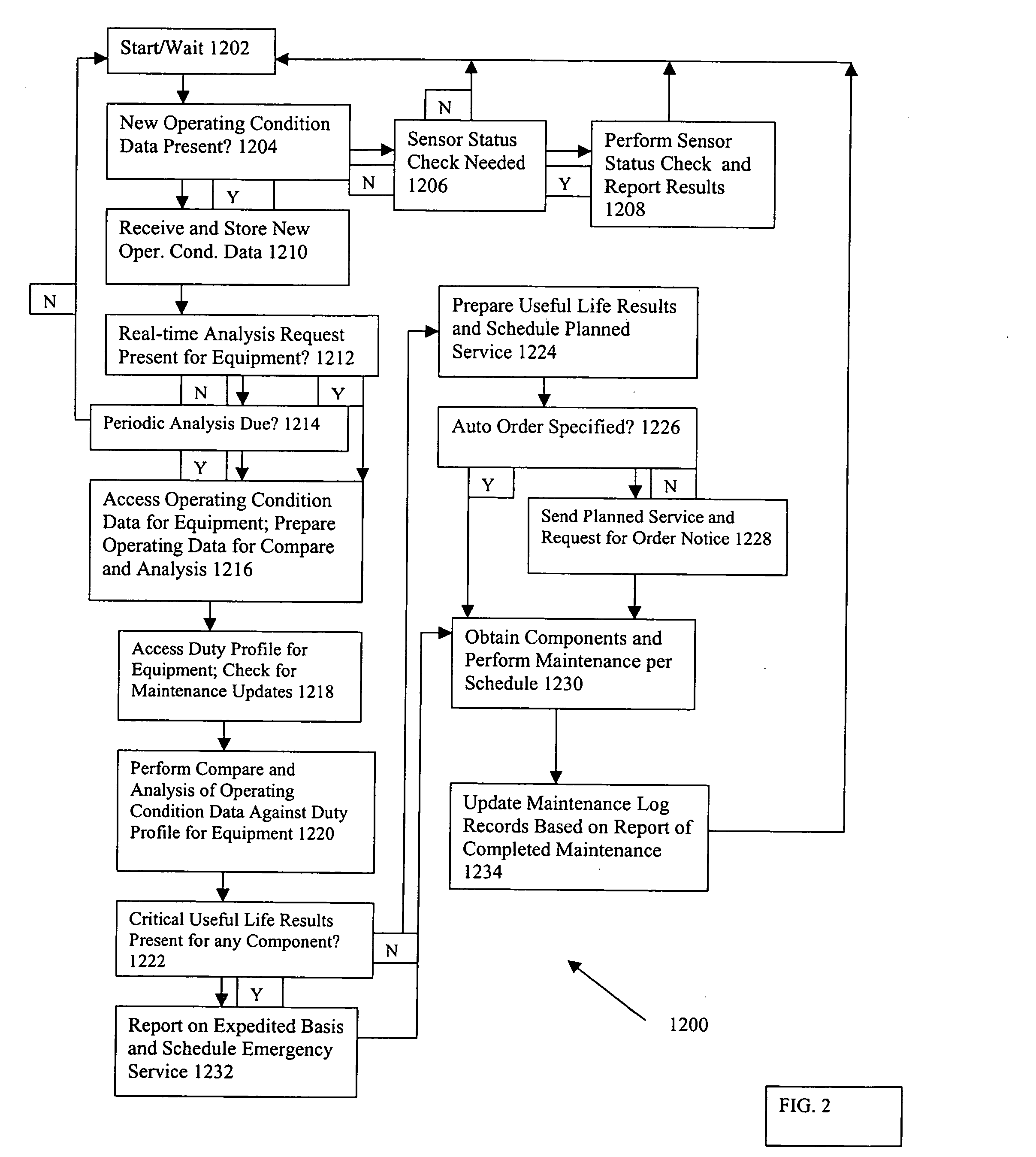

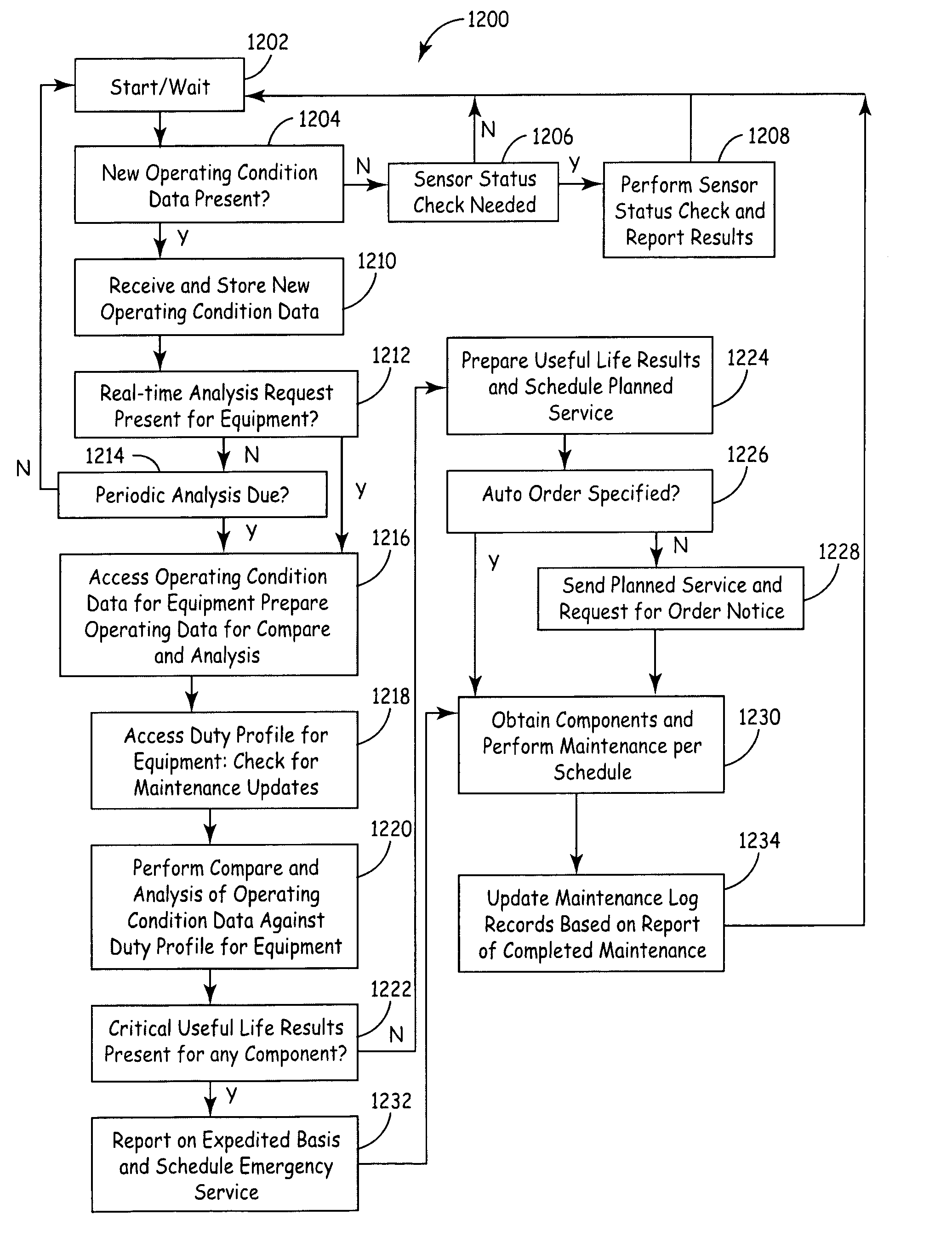

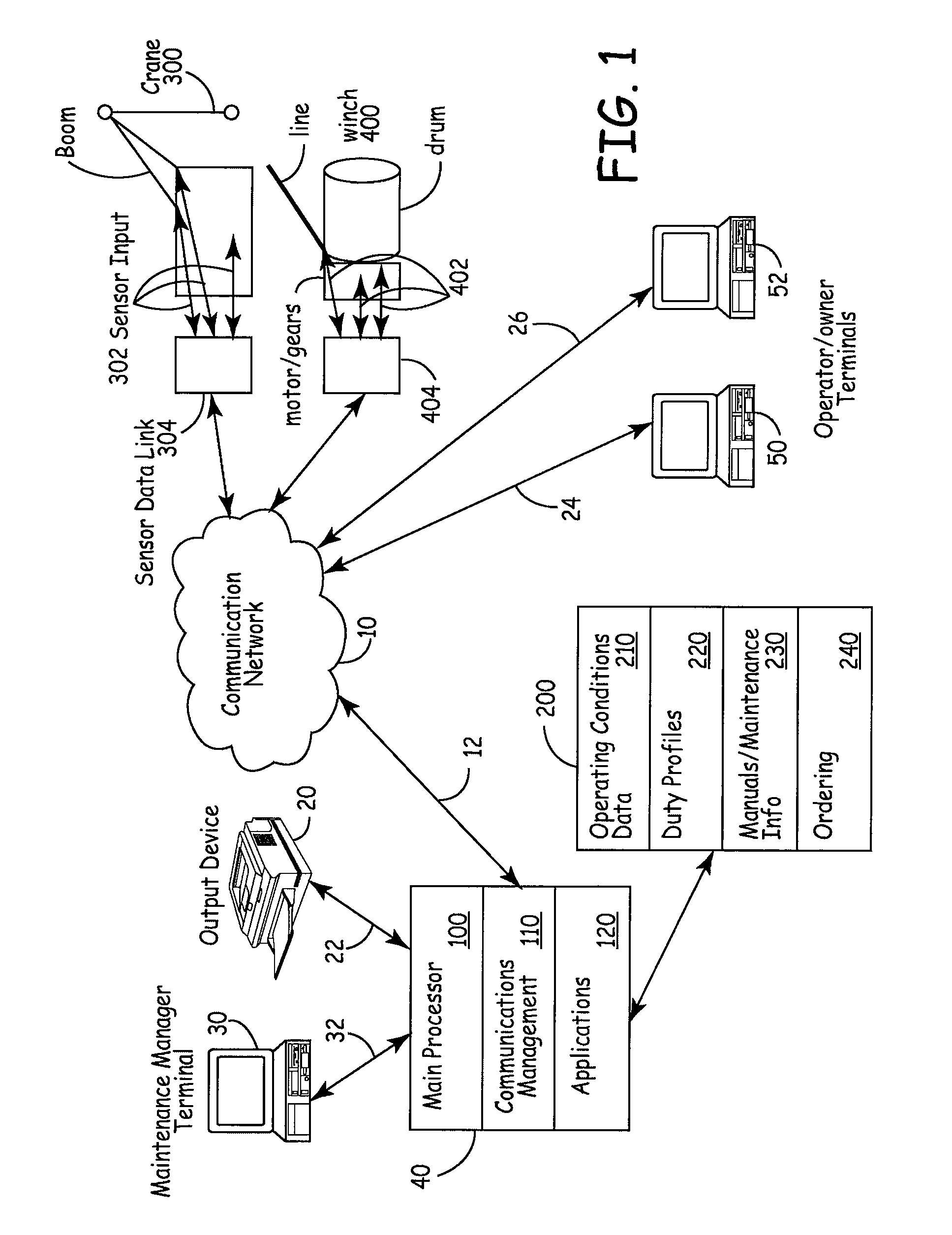

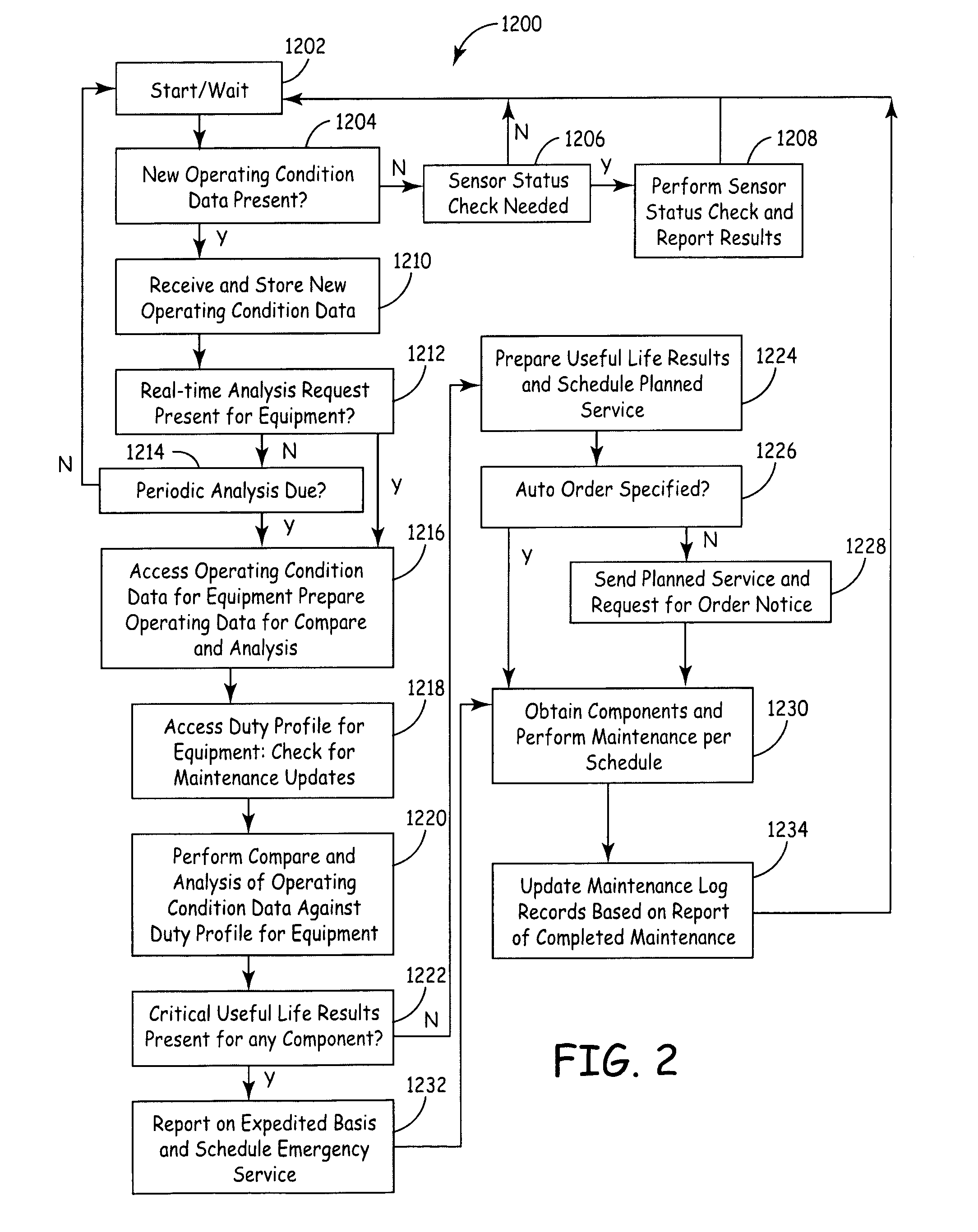

Equipment component monitoring and replacement management system

ActiveUS20050143956A1Improve performanceGood interpretationPlug gaugesMachine part testingComputer scienceOperant conditioning

A system for managing replacement components for equipment having a plurality of components each with a limited useful life has a computer with a processor. The system includes a computer program module for defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the plurality of components and specified operating conditions assumed to be experienced by the involved components during the execution of each of the usage cases. There are also a computer program module for determining a theoretical useful life for each component involved in a duty profile, the theoretical useful life being based on component useful life data under the specified operating conditions; and sensors for determining and monitoring the occurrence of equipment operation corresponding to a usage case and measuring the actual operating conditions experienced in the operation and the number of such operations. A further computer program module computes an adjusted theoretical useful life for a component that has experienced one or more operations, based on a comparison of actual operating conditions to operating conditions assumed to be experienced in the operation of the usage case.

Owner:HYDRALIFT AMCLYDE INC

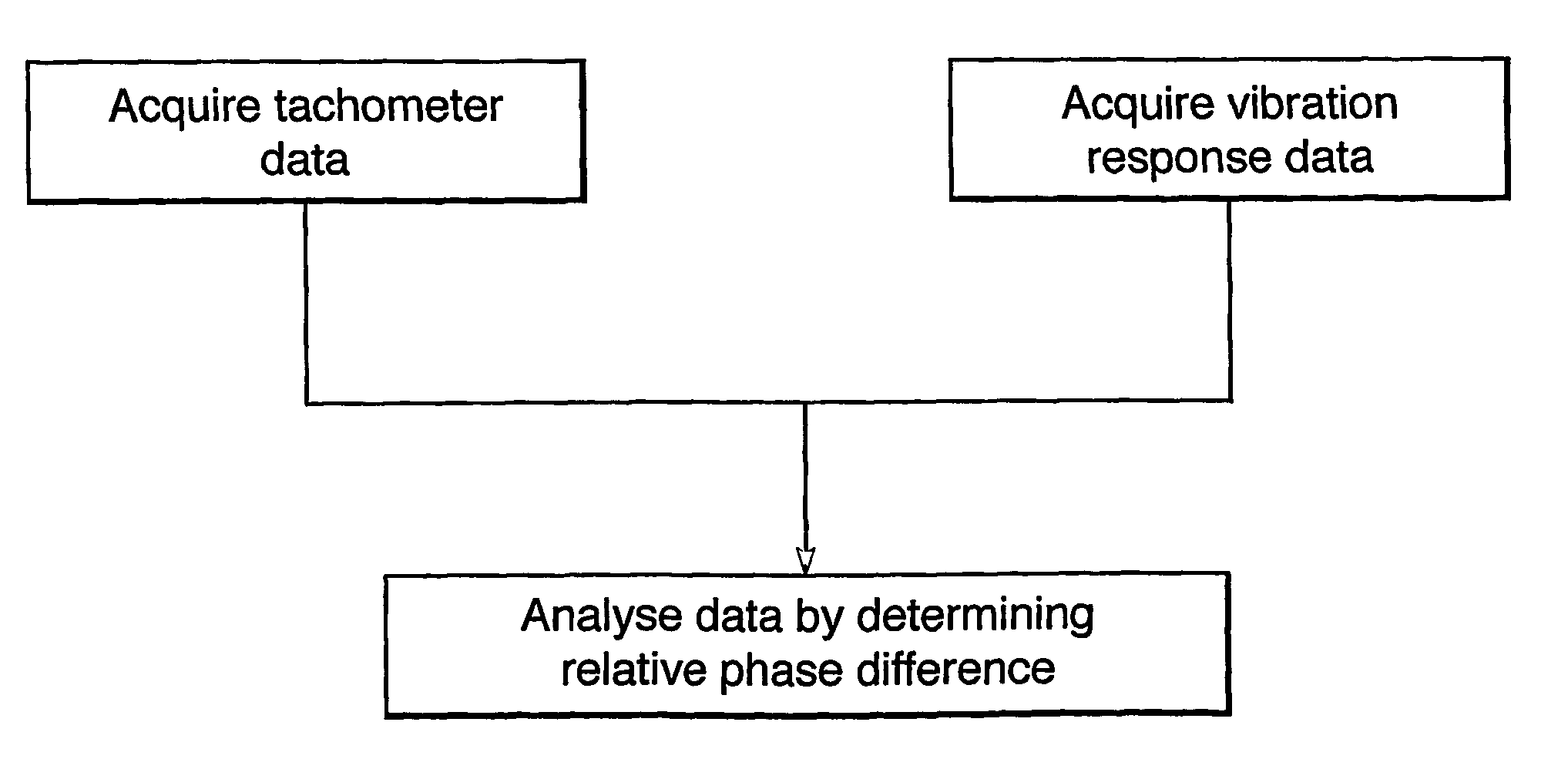

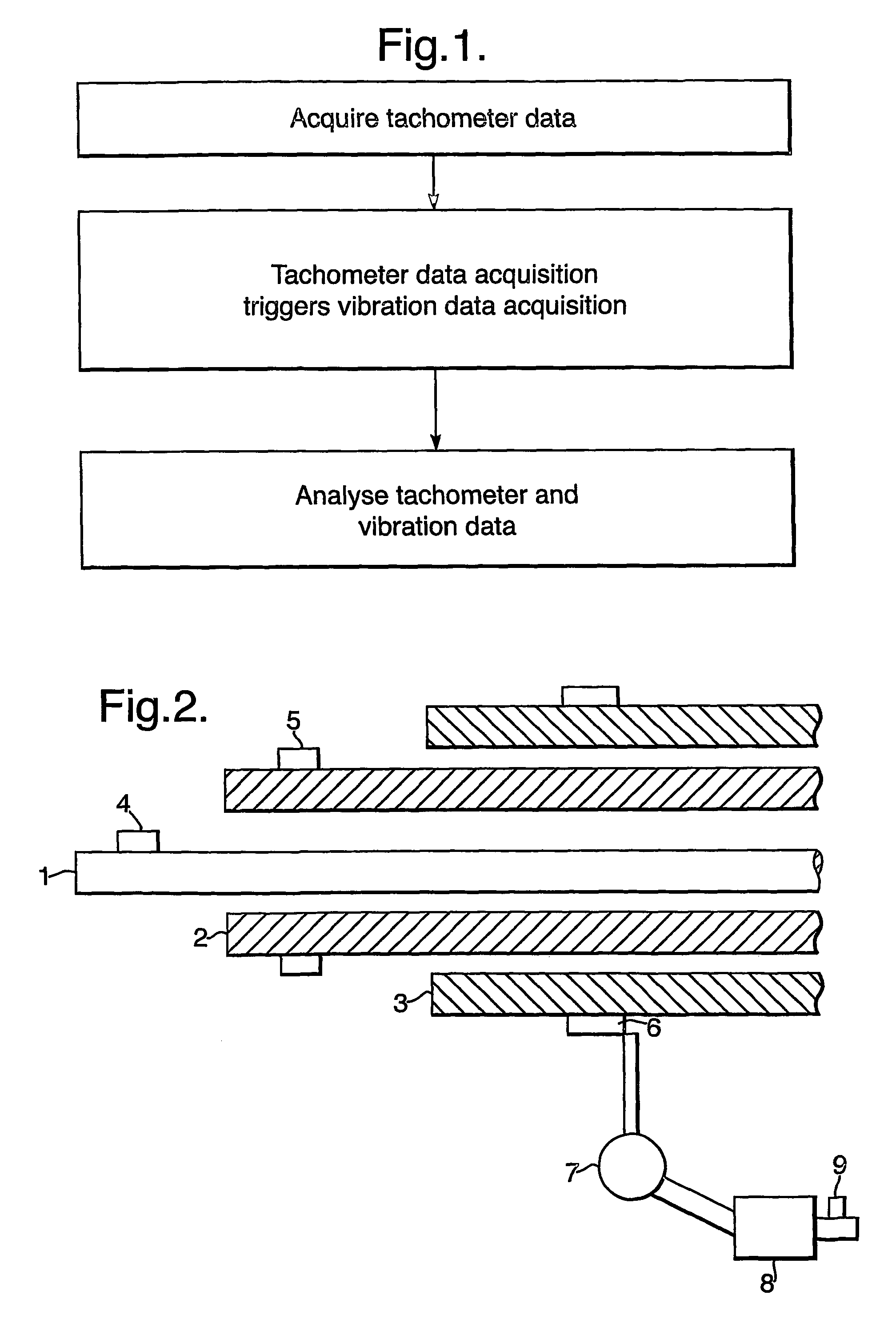

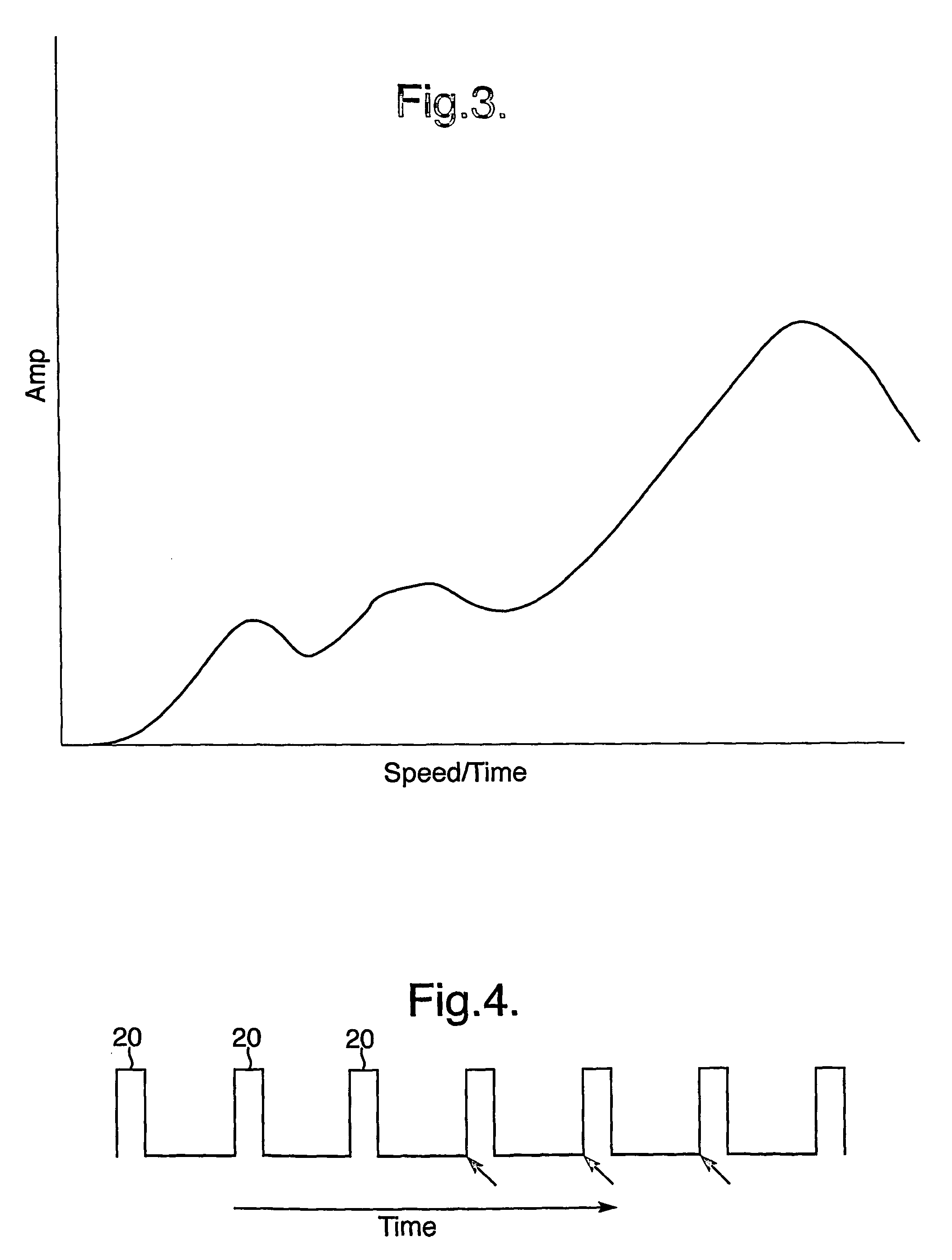

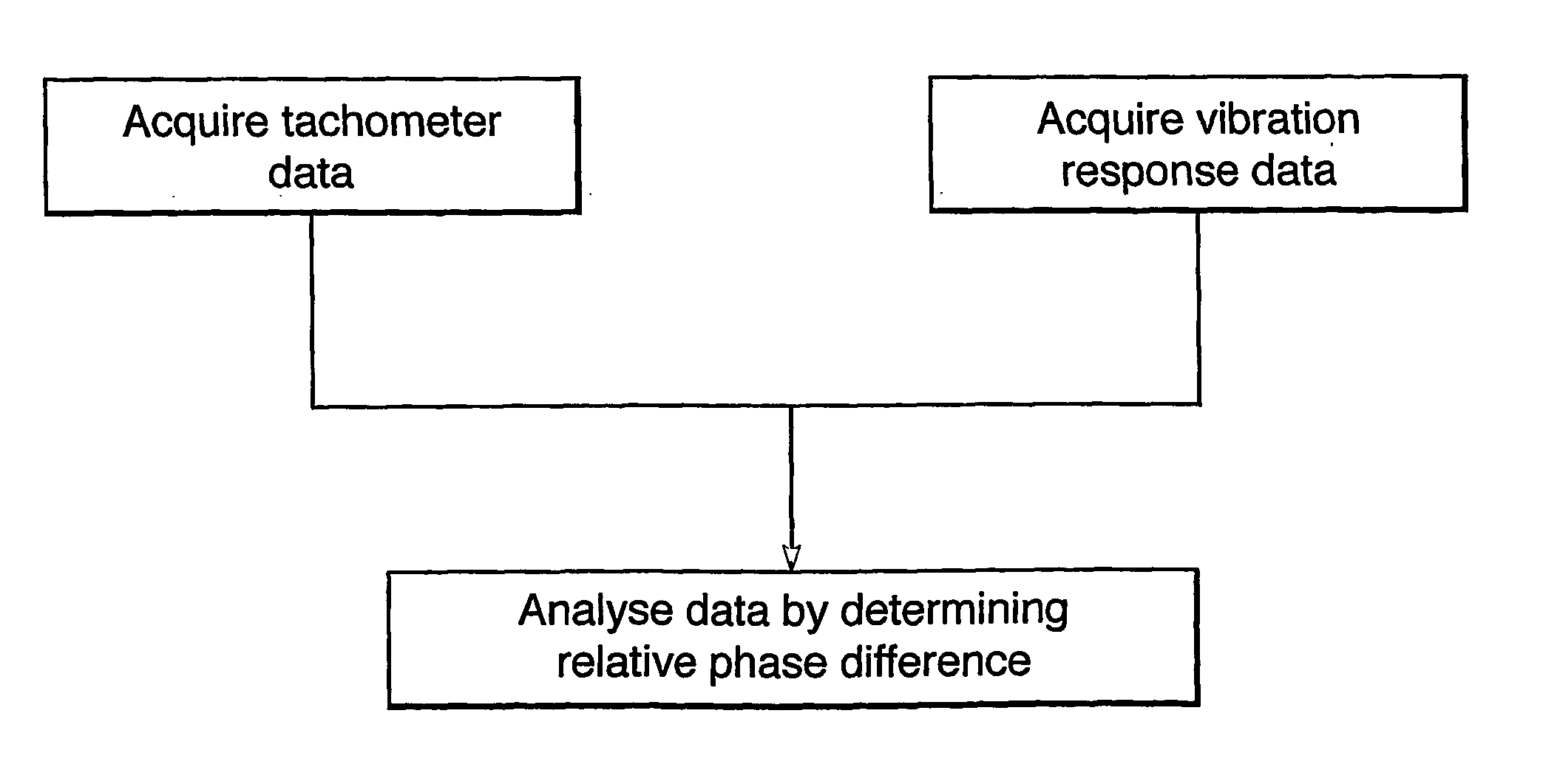

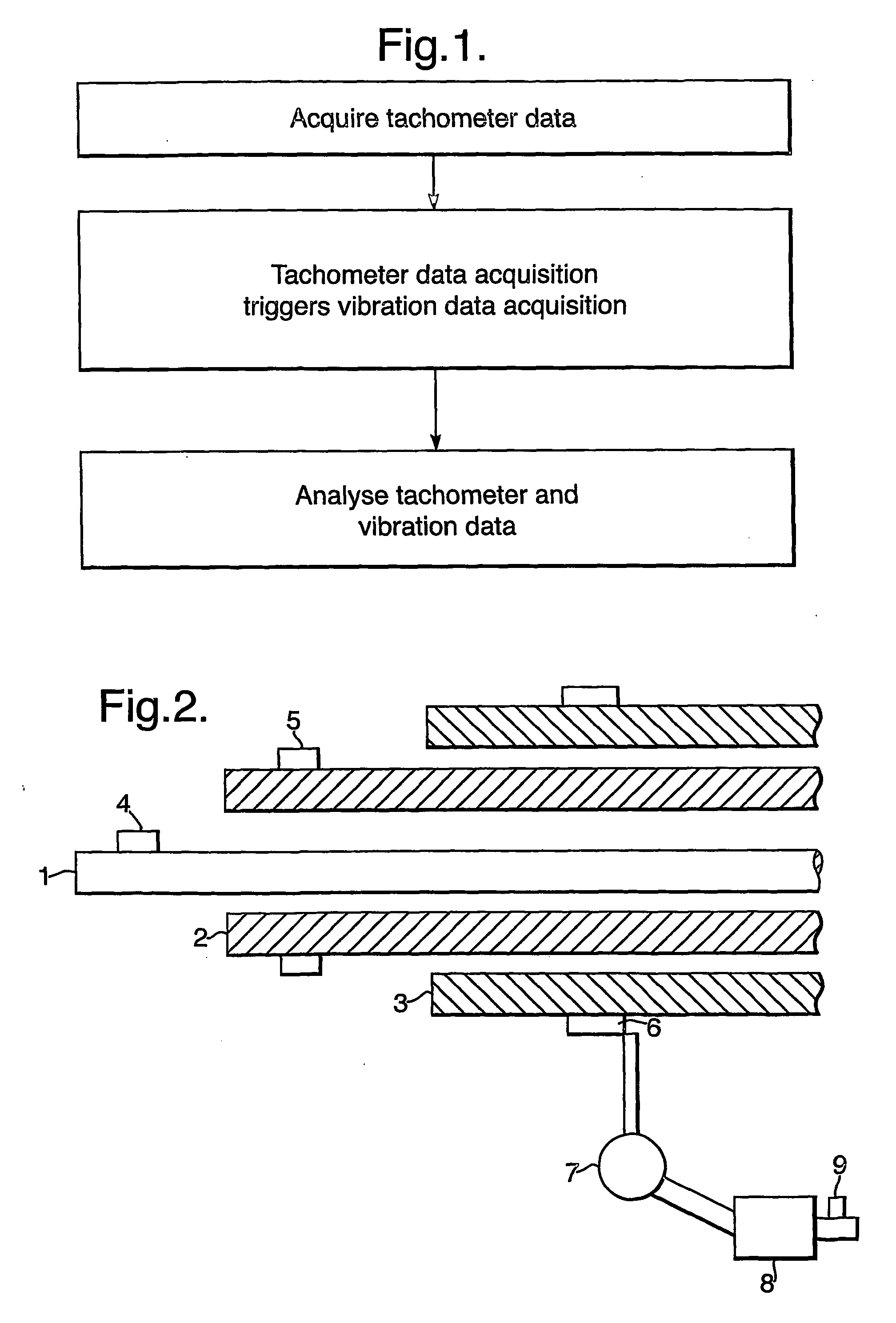

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

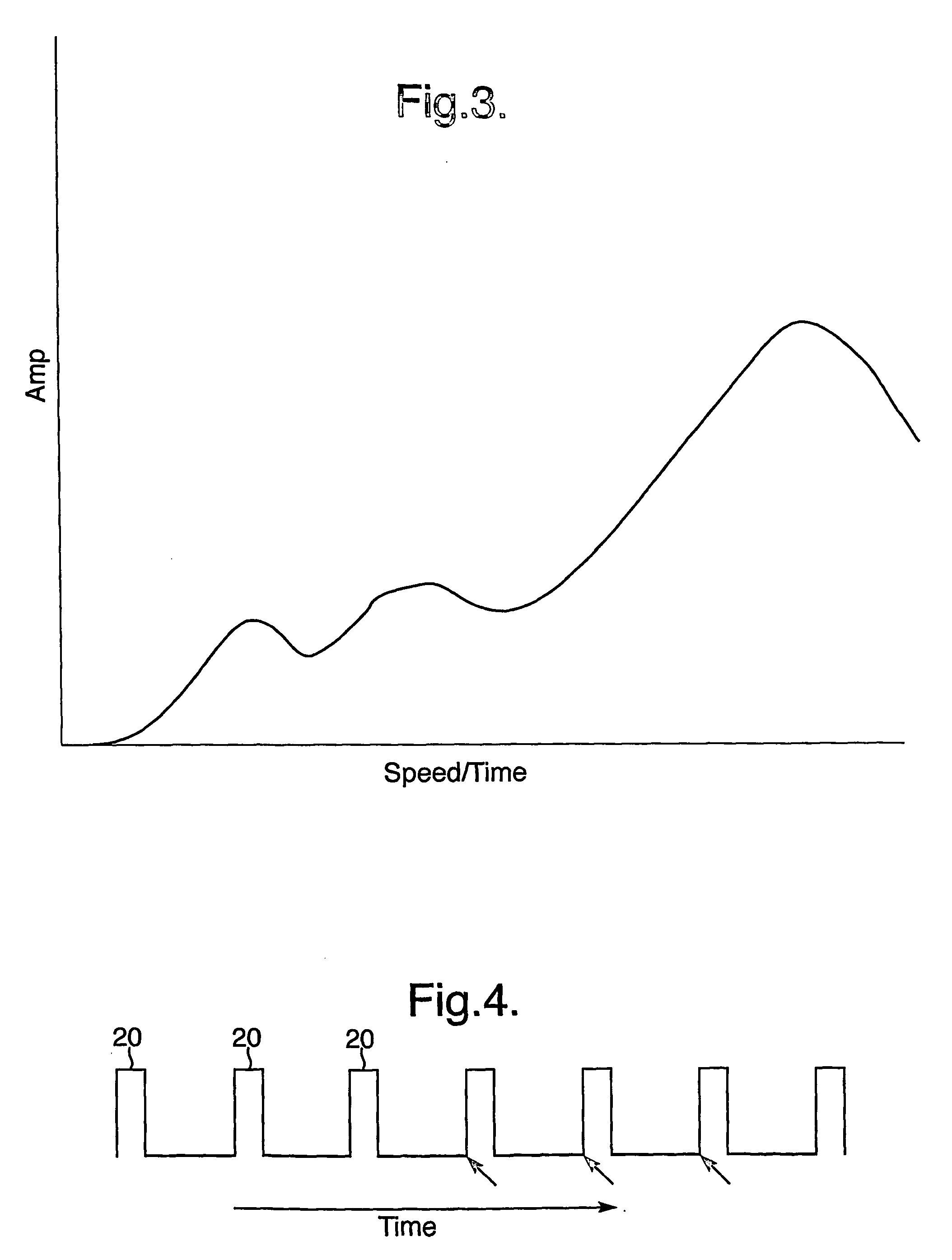

ActiveUS7640802B2Avoid problemsEasy to getVibration measurement in solidsVehicle testingForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behavior of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

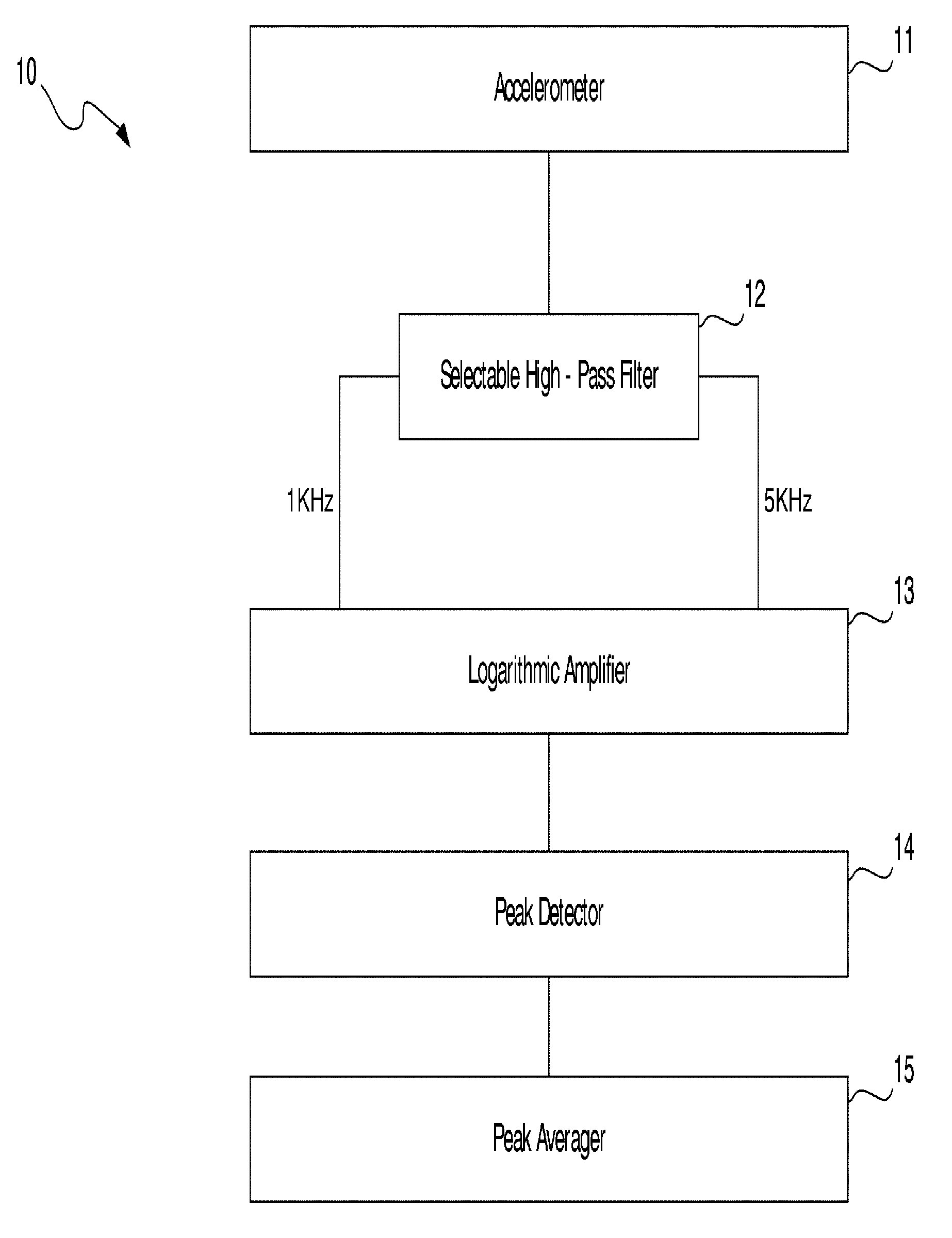

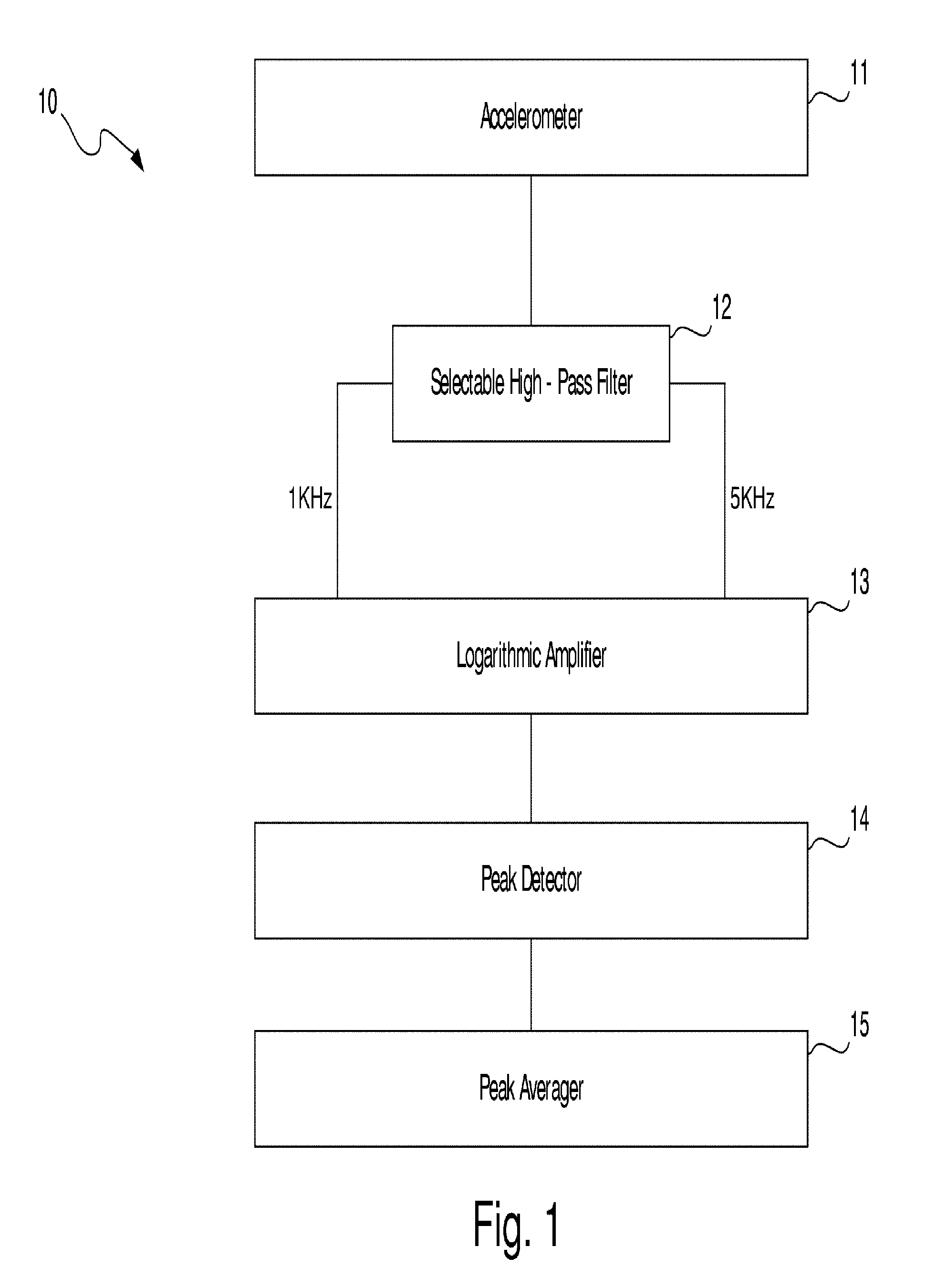

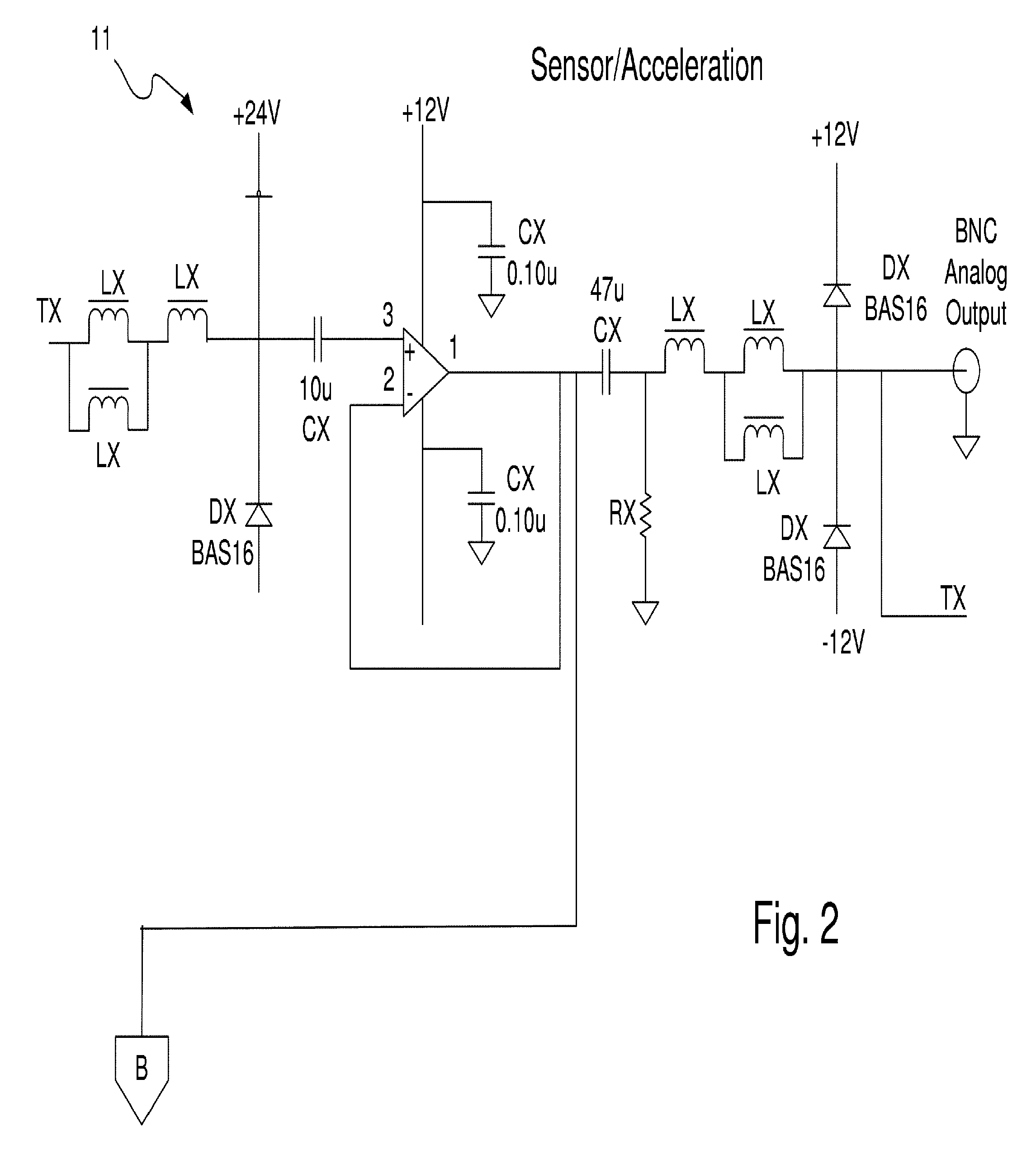

Method and apparatus for vibration sensing and analysis

InactiveUS20050011266A1Readily apparentVibration measurement in solidsMachine part testingPeak valueAcoustics

A method and apparatus for sensing and measuring stress waves. The method comprises the steps of: a.) sensing motion, where the motion comprises a stress wave component and a vibration component; b.) separating the stress wave component from the vibration component with a high pass filter to create a signal proportional to the stress wave; c.) amplifying the signal to create an amplified signal; d.) processing the amplified signal with a sample and hold peak detector over a predetermined interval of time to determine peaks of the amplified signal over said predetermined period of time; e.) creating an output signal proportional to the determined peaks of the amplified signal; and, f.) repeating steps d.) and e.). The invention also includes an apparatus for implementing the method of the invention.

Owner:PCB PIEZOTRONICS IMI SENSORS +1

Methods and systems for the industrial internet of things

ActiveUS20180188714A1Reduce sampling rate outputMinimize anti-aliasing filter requirementVibration measurement in solidsMachine part testingIndustrial InternetMultiple input

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The crosspoint switch includes a third input that is configured with a continuously monitored alarm having a pre-determined trigger condition when the third input is unassigned to any of the multiple outputs.

Owner:STRONG FORCE IOT

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS20070006636A1Avoid problemsEasy to getVehicle testingVibration measurement in solidsForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behaviour of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

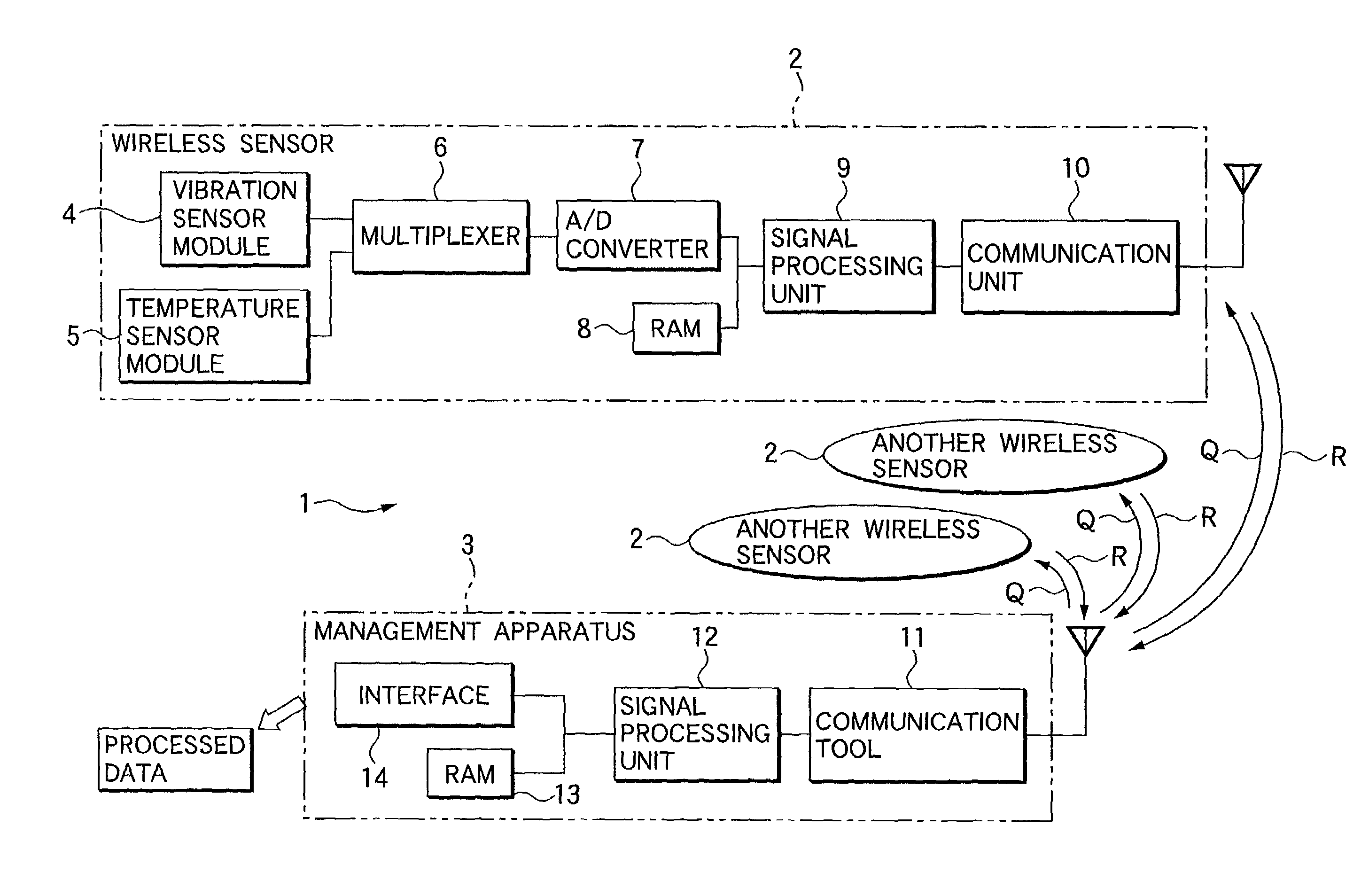

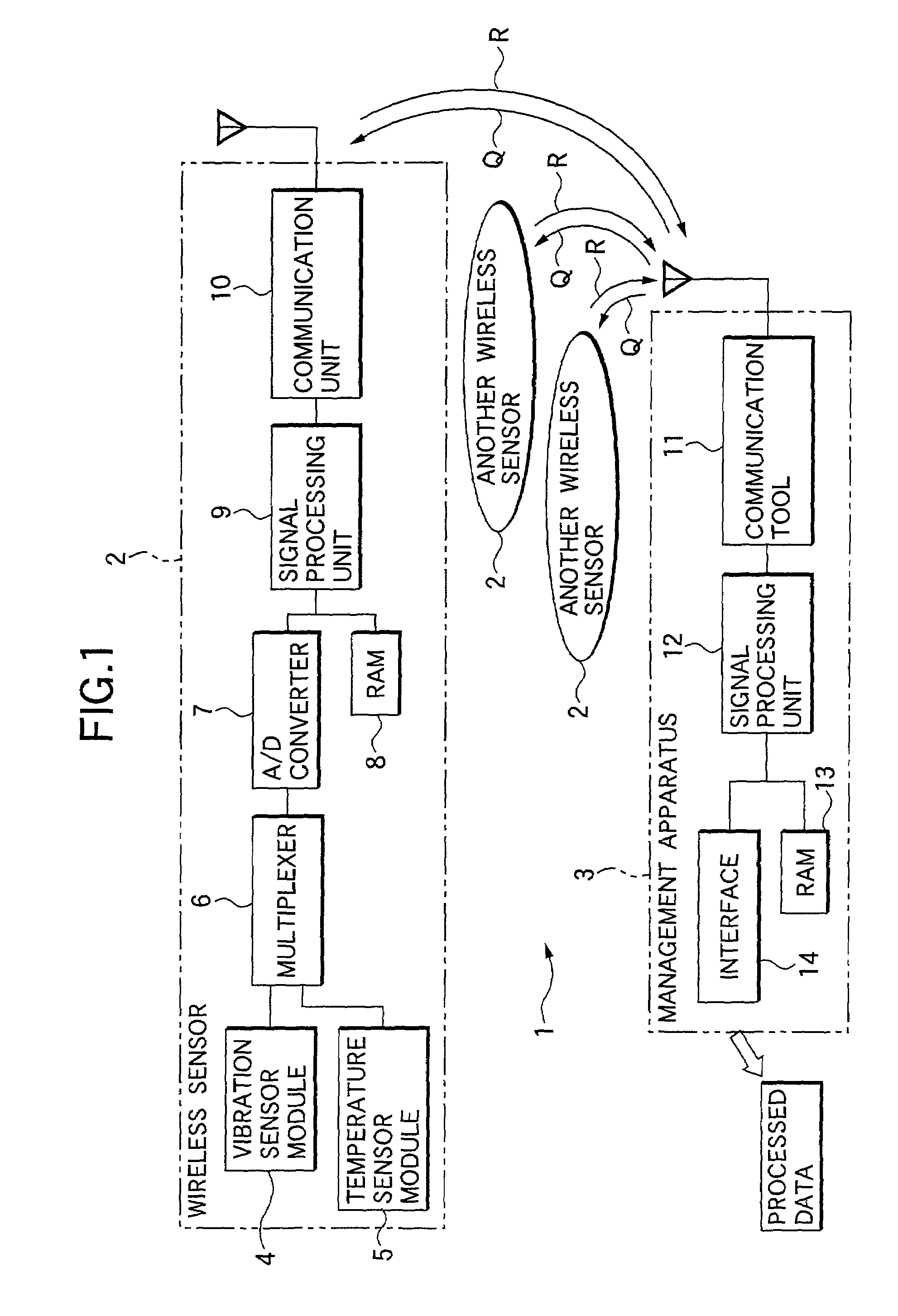

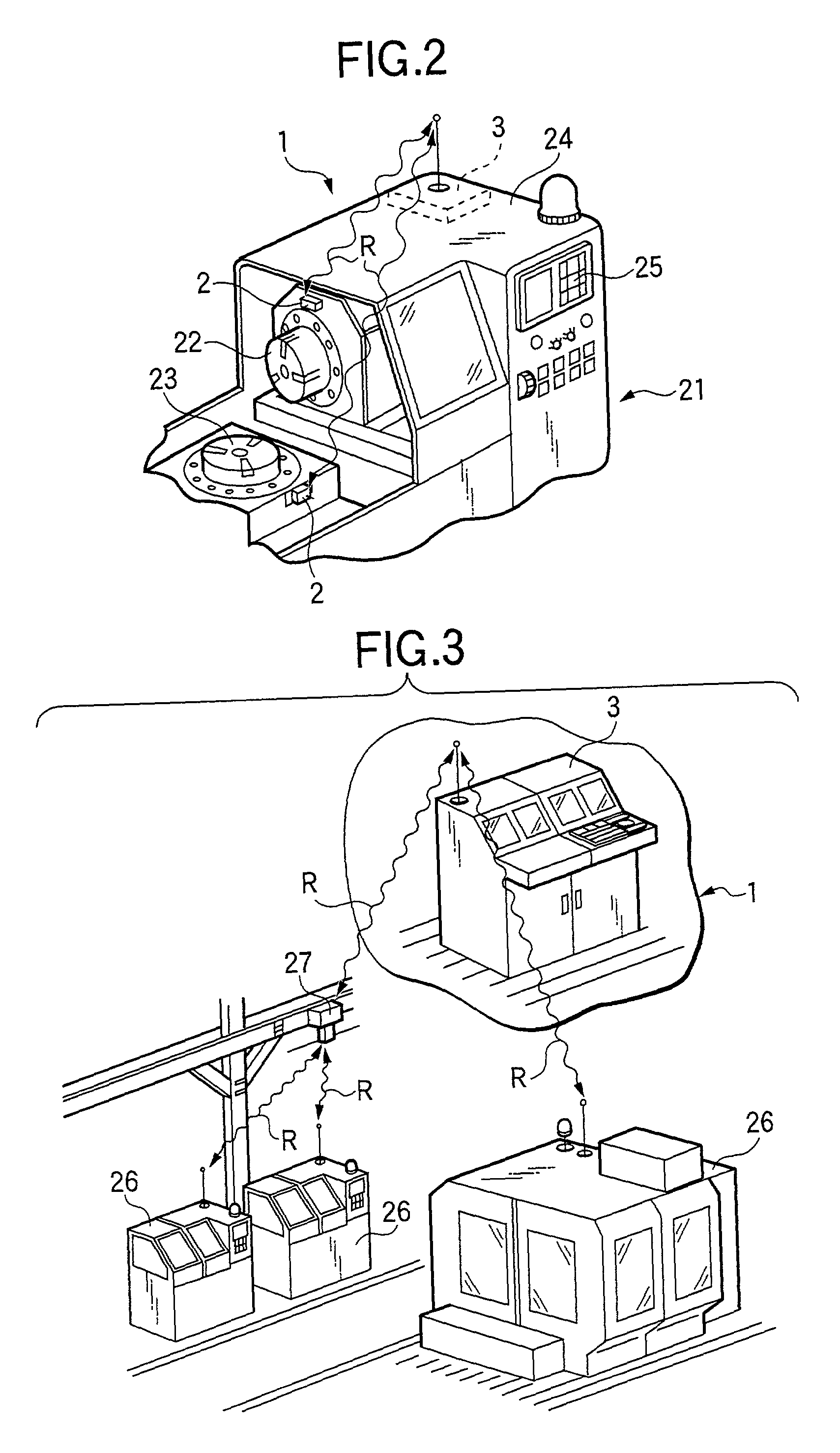

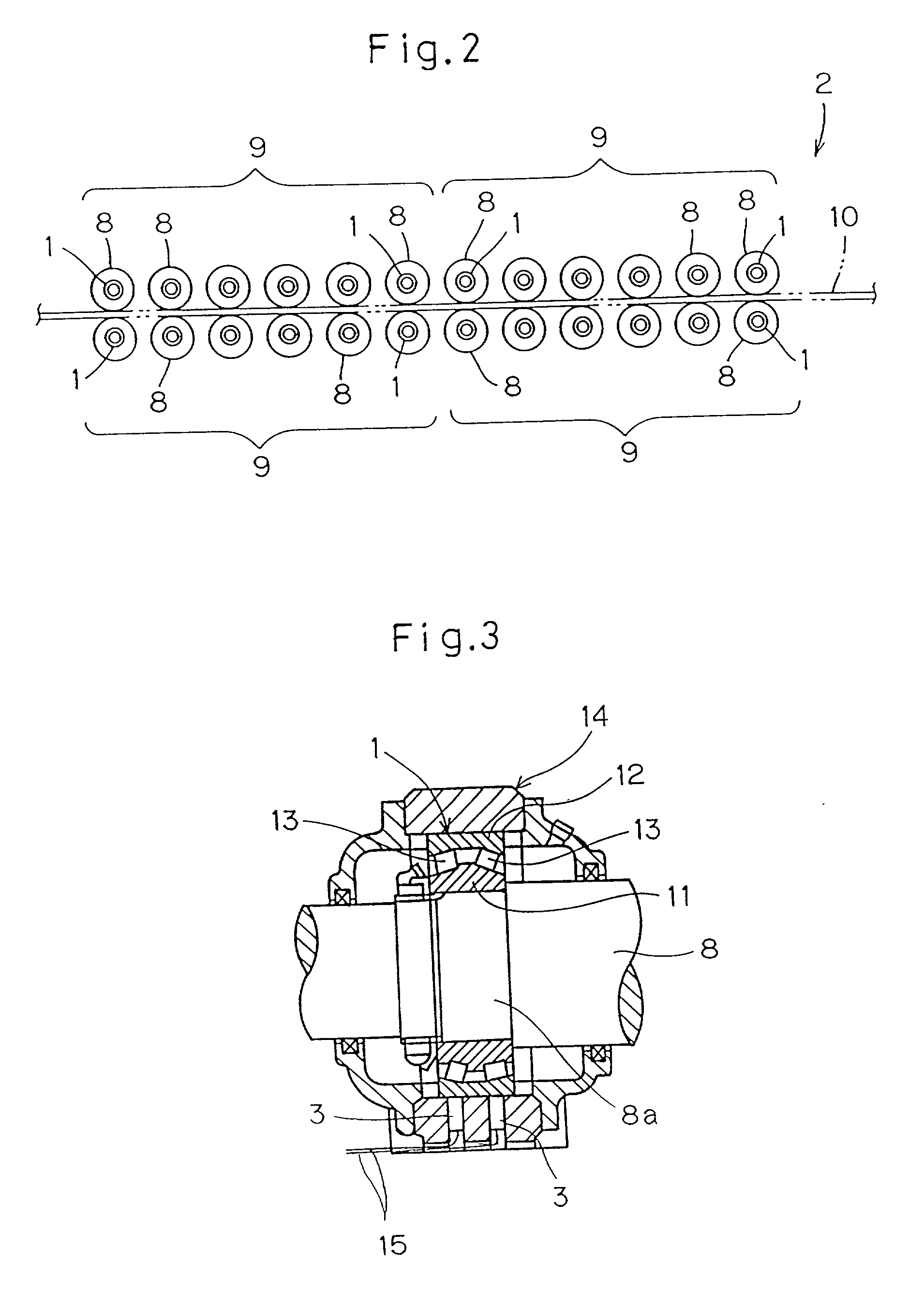

Wireless sensor, rolling bearing with sensor, management apparatus and monitoring system

InactiveUS7034711B2Improve accuracyCondition can be detectedVibration measurement in solidsMachine part testingLine sensorCommunication unit

The wireless sensor adds identification information peculiar to respective sensor modules to detection data of vibration, temperature, and so on, detected by the sensor modules respectively. The wireless sensor transmits the detection data with the identification information as a signal through a communication unit by radio waves. On the other hand, the management apparatus receiving the signal classifies and files the detection data on the basis of the identification information included in the signal. Then, the monitoring system is designed to make the management apparatus manage a plurality of wireless sensors attached to movable shafts of processing machines or the like.

Owner:NSK LTD

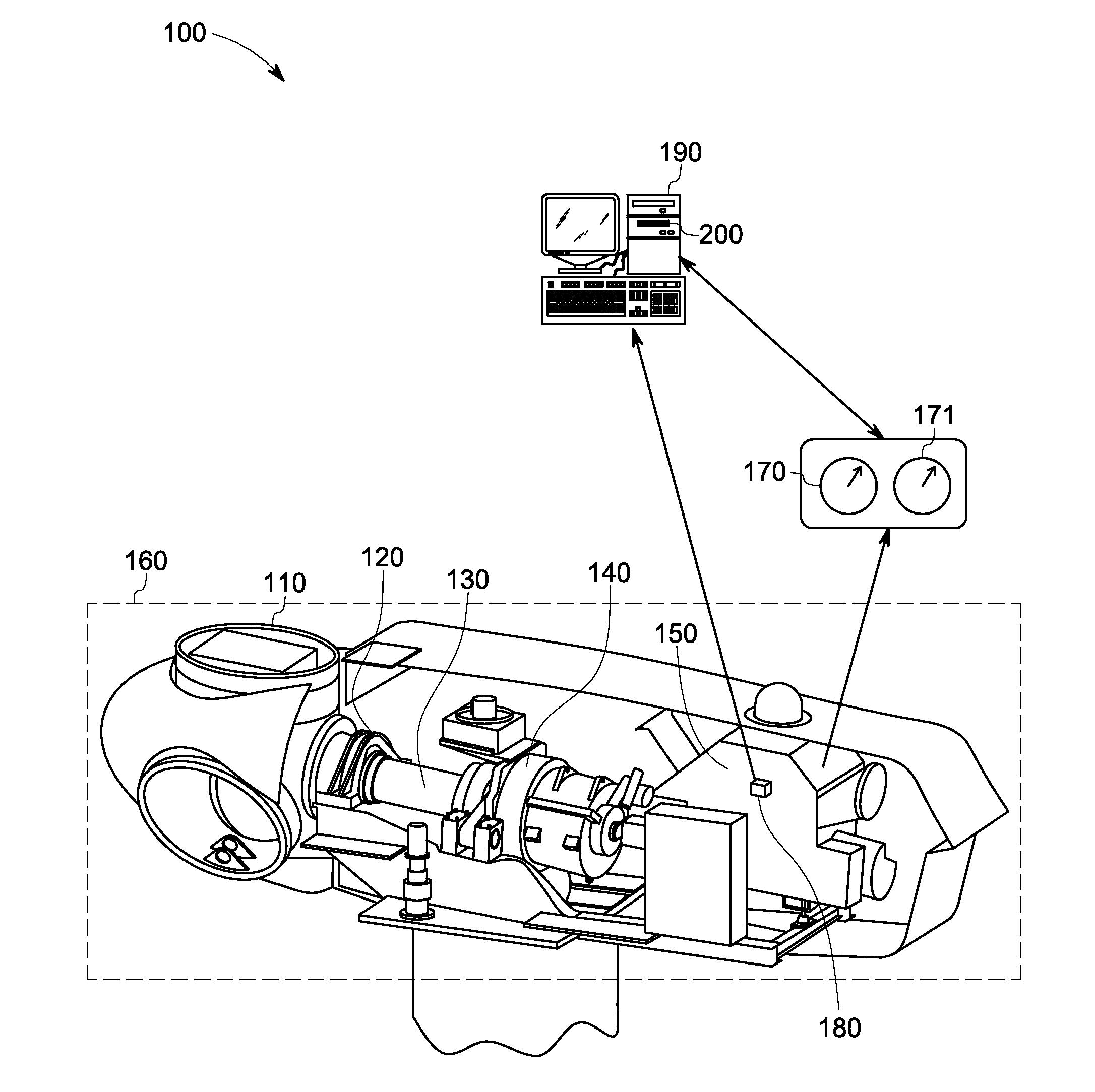

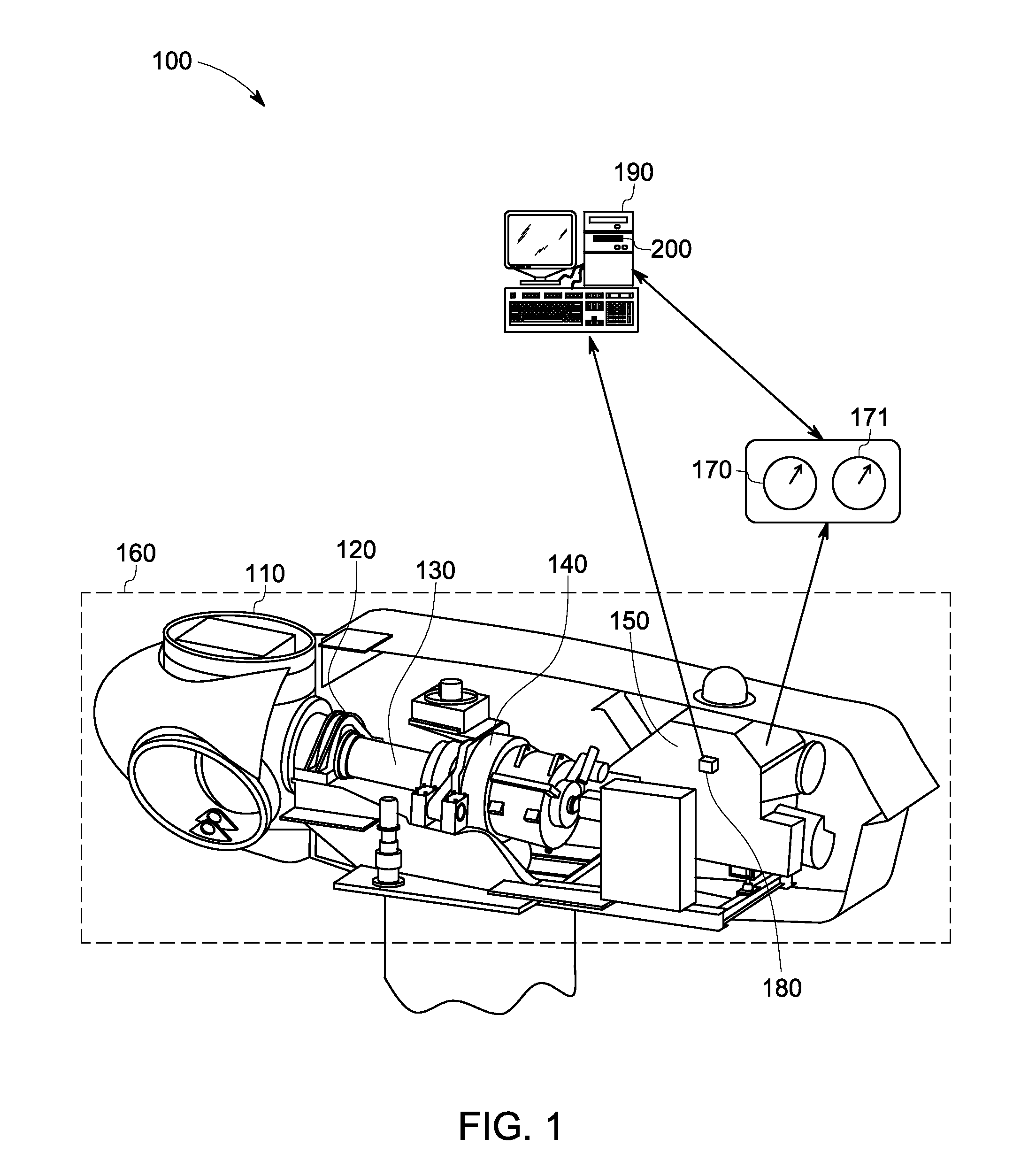

Configurable vibration sensor

InactiveUS20050204820A1Vibration measurement in solidsMachine part testingVibration measurementAudio power amplifier

A configurable vibration sensor comprising a sensor circuit, an analog-to-digital converter and a processor, where each sensor circuit comprises a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

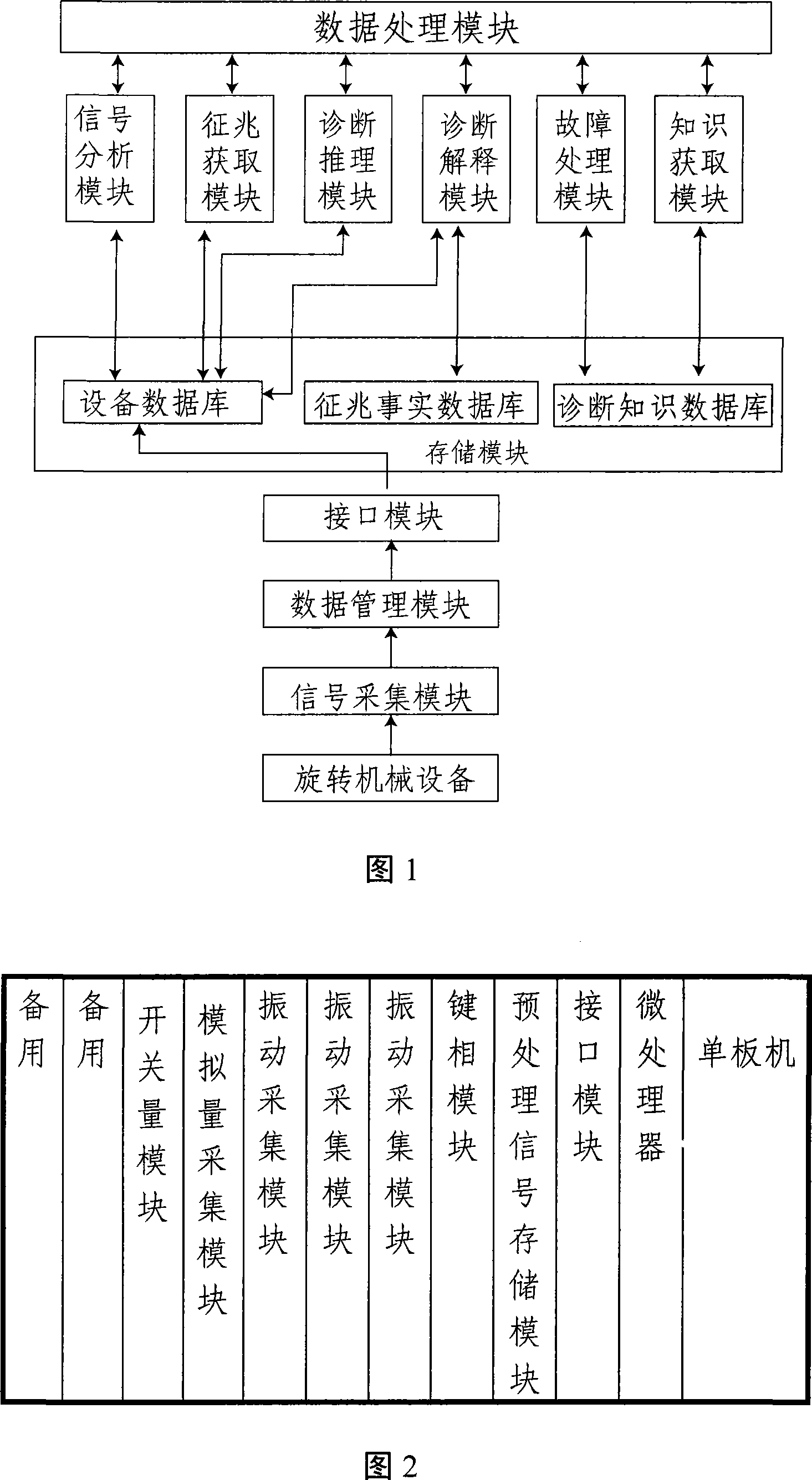

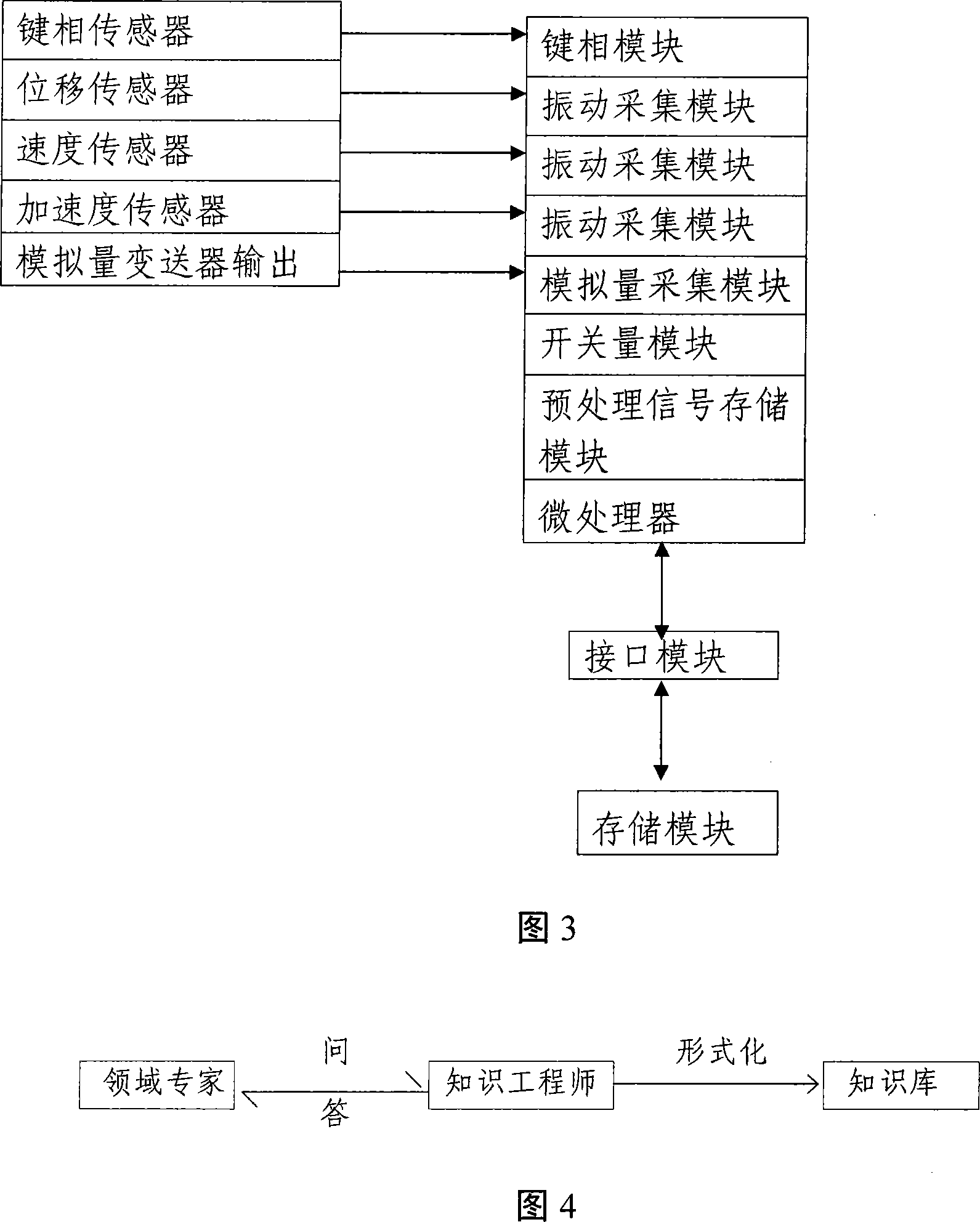

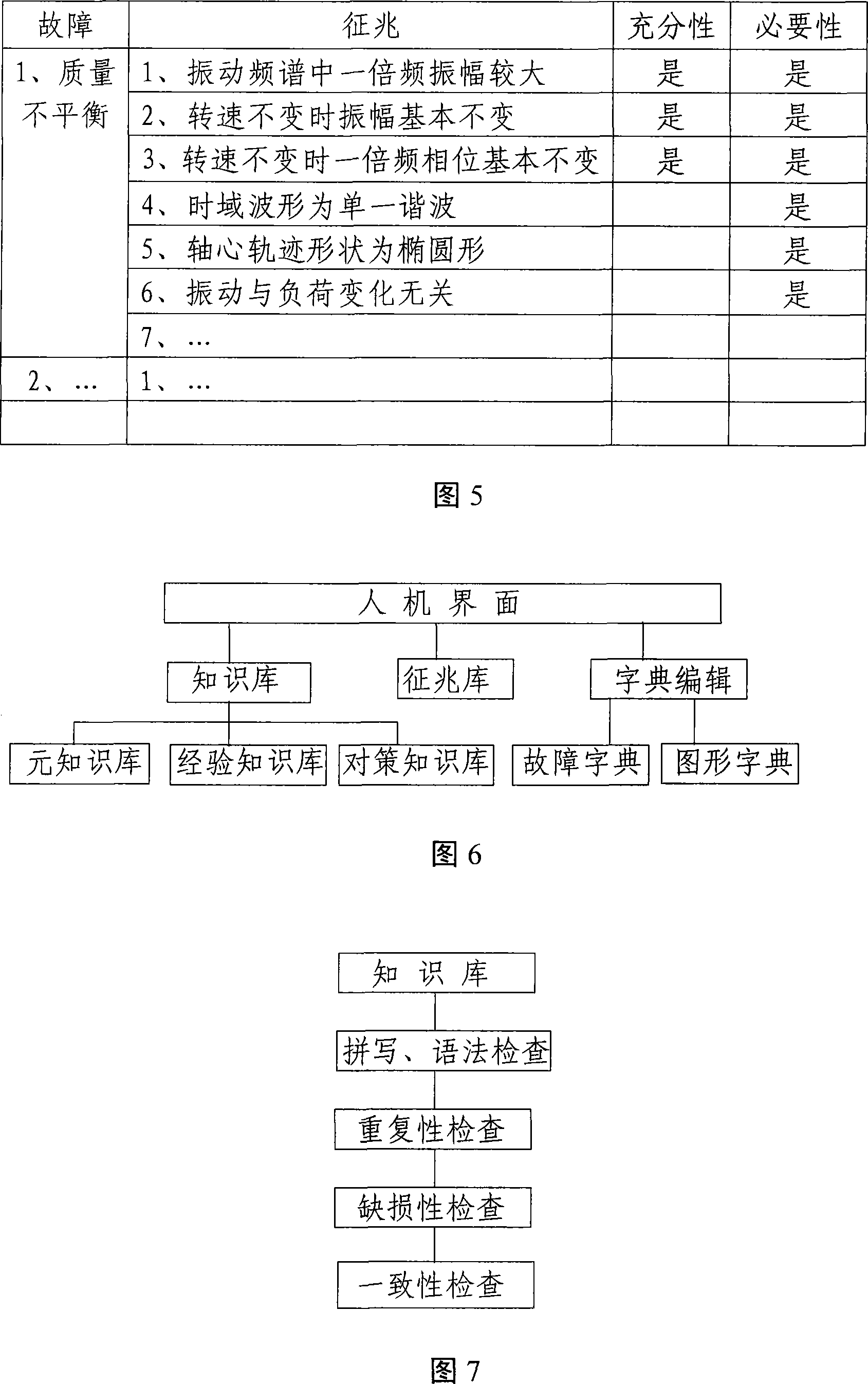

Rotating machinery vibrating failure diagnosis device and method

InactiveCN101135601AImprove reliabilityFriendly man-machine interfaceMachine part testingVibration testingHuman–machine interfaceData pre-processing

The method comprises: using a sensor to collect the characteristic signals; the collected signals about each kind of running state are sent to the data processing module; after processed, the signals are sent to the computer system; said computer system comprises a device database, a symptom event database, a diagnosis knowledge database; a device database and signal analysis module, a symptom acquiring module, a diagnostic reasoning module, and a diagnosis explaining module; the software of the data processing module makes data exchange; the symptom event database exchanges data with the diagnostic module, data processing module; the diagnostic knowledge exchanges the data with the failure processing module, knowledge acquiring module and data processing module.

Owner:北京英华达电力电子工程科技有限公司

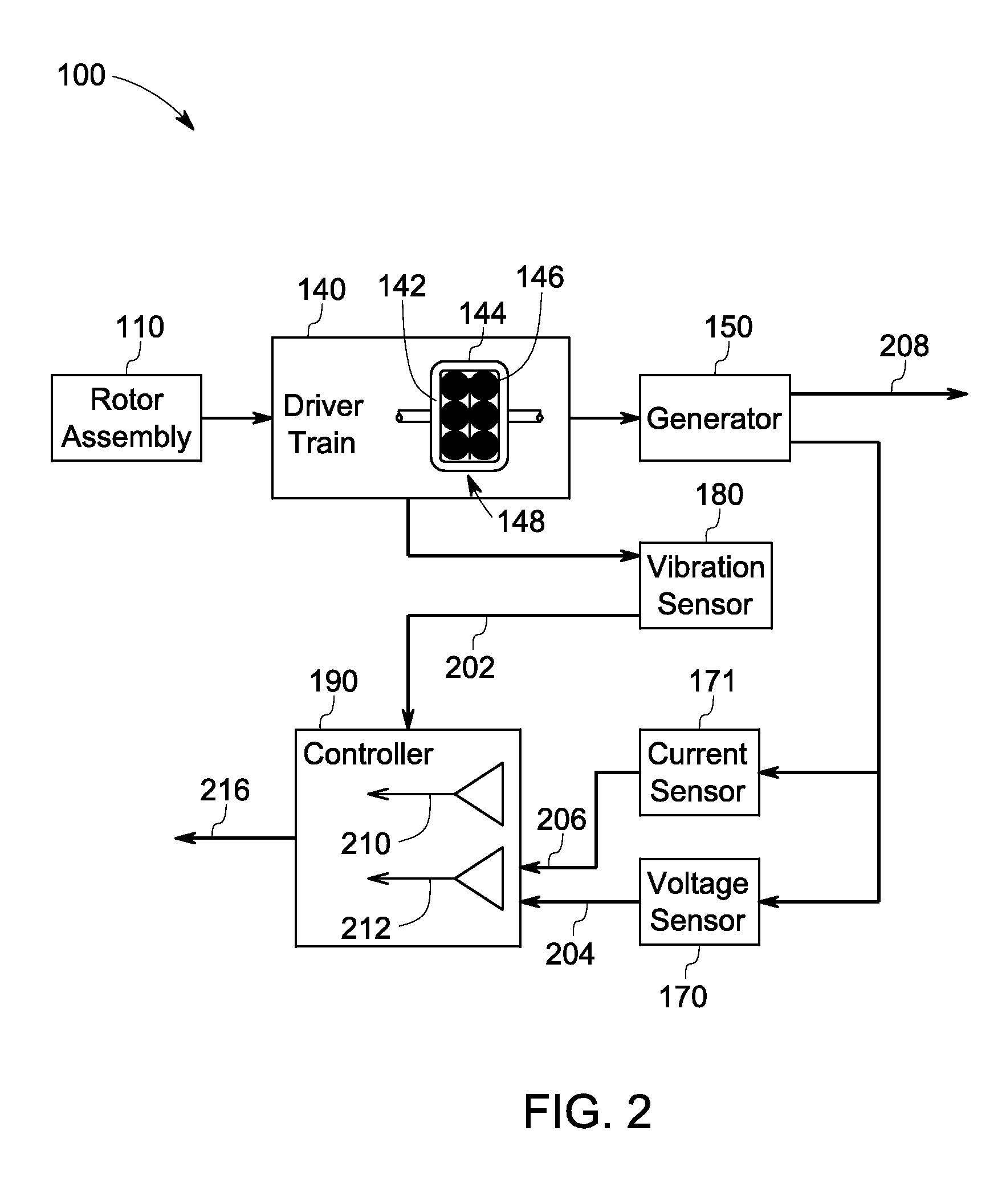

Fault detection system and associated method

ActiveUS20140167810A1Machine part testingDynamo-electric machine testingElectrical devicesCorrelation method

A method implemented using a controller based device includes receiving a measured electrical signal from an electrical device of an electromechanical device and receiving a measured vibration signal from a mechanical device of the electromechanical device, coupled to the electrical device. The method further includes determining a first signal signature based on the measured electrical signal and determining a second signal signature based on the measured vibration signal. The method also includes determining a diagnostic parameter based on the first signal signature and the second signal signature and determining a fault in the mechanical device based on the diagnostic parameter.

Owner:GENERAL ELECTRIC CO

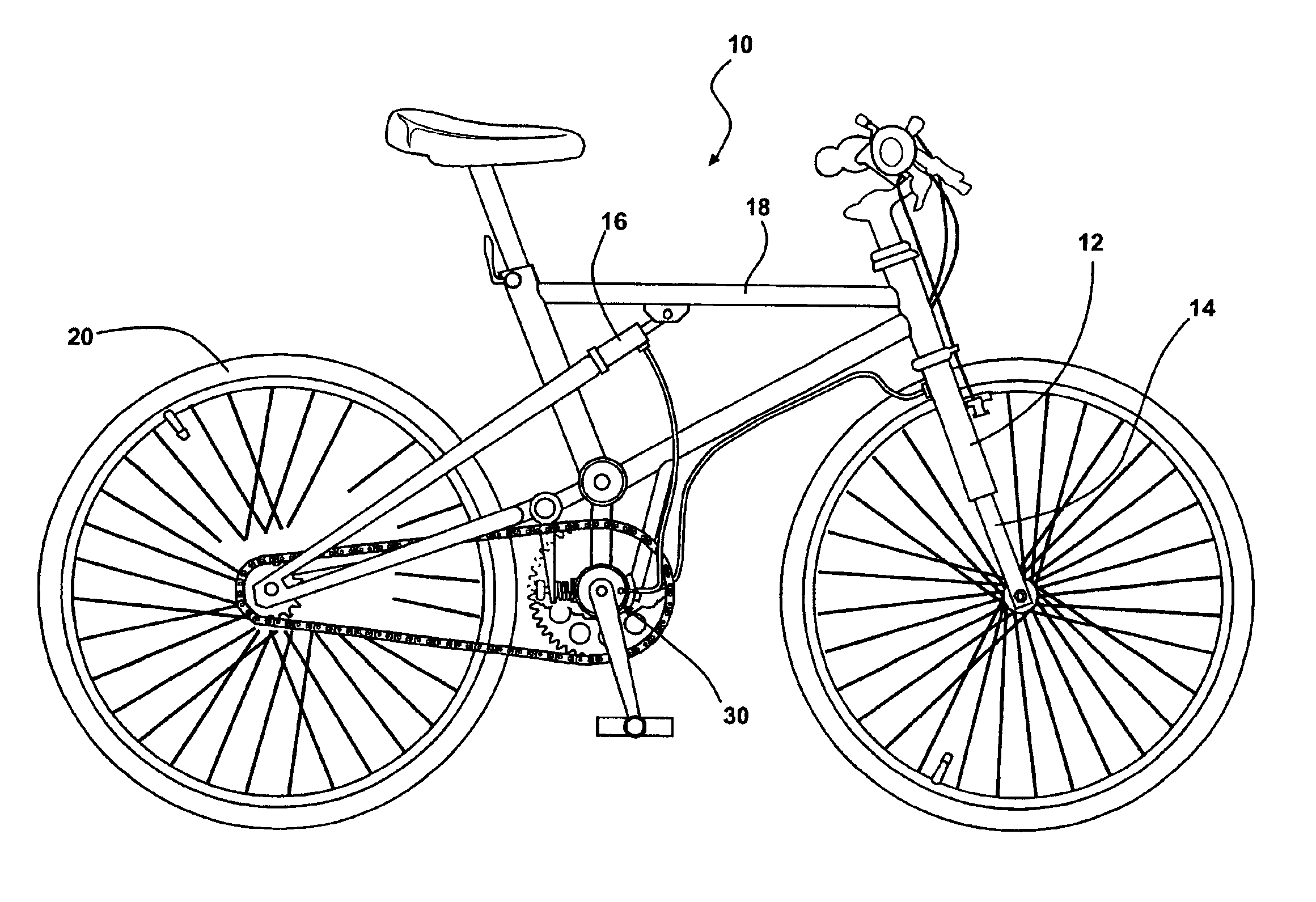

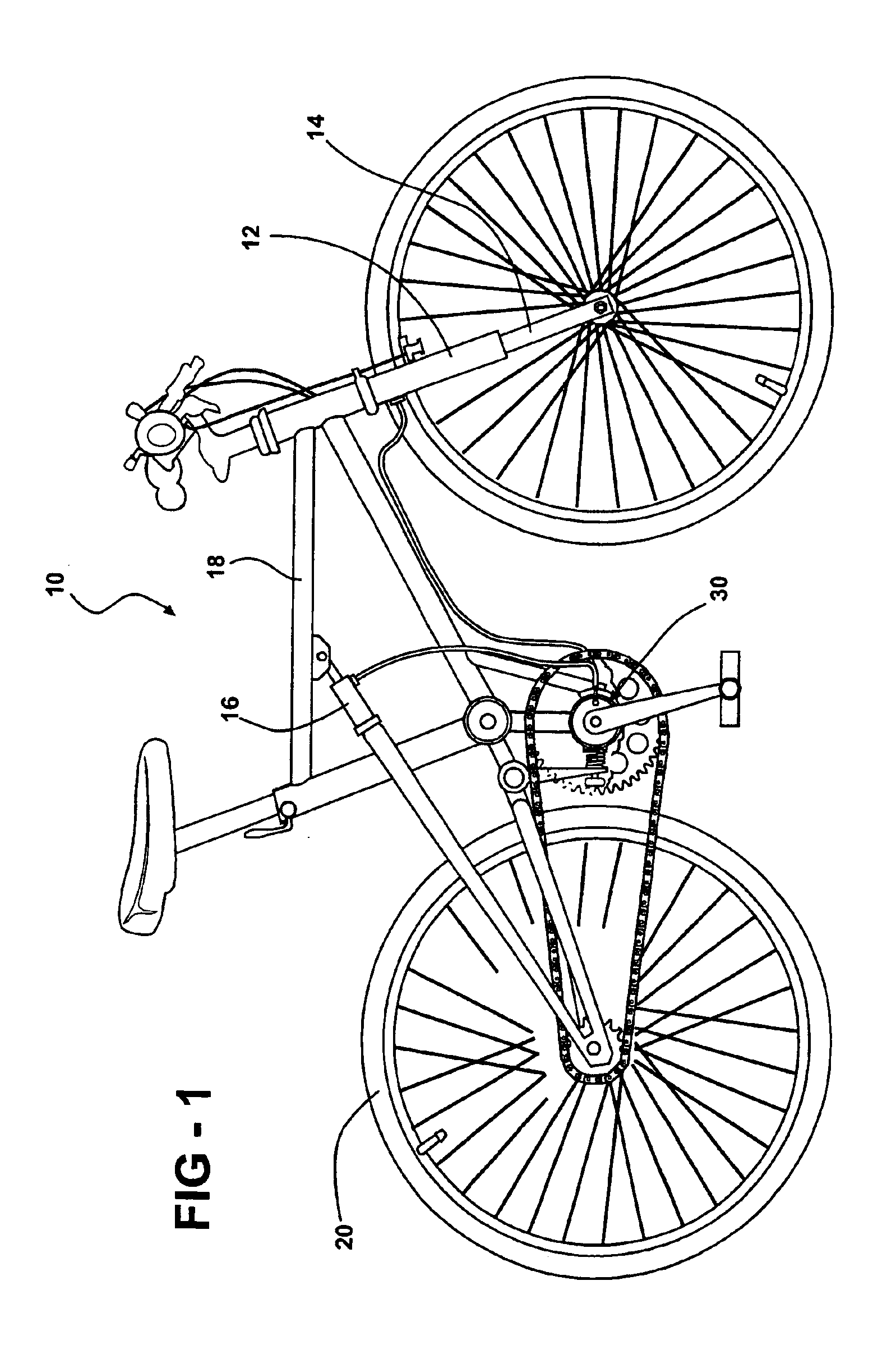

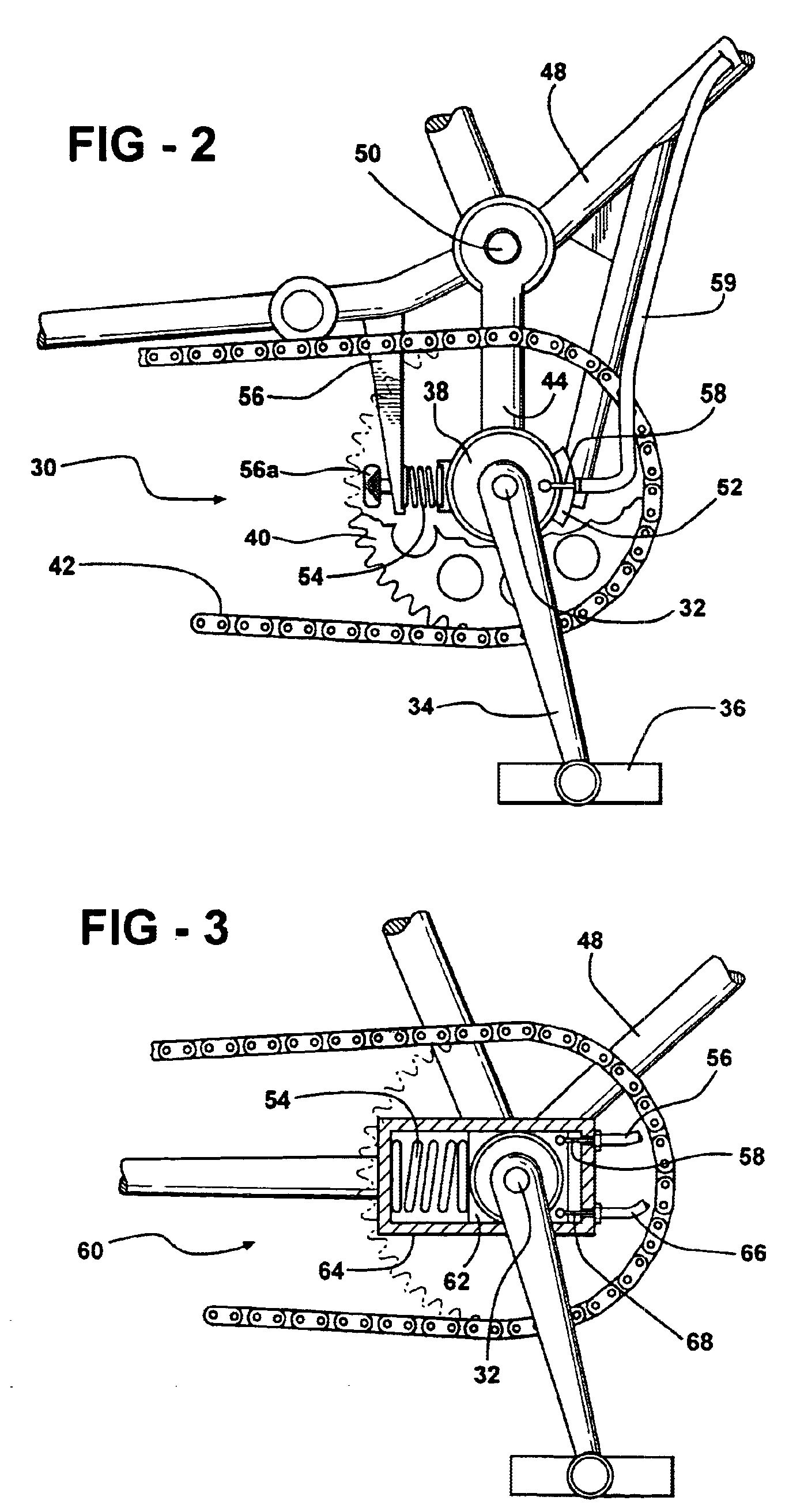

Anti-bob system for cycles

A control system is operable to selectably activate shock damping devices associated with a bicycle so as to eliminate bobbing encountered under extreme pedaling conditions. The system includes a crank axle torque detector which operates to detect a level of torque applied to a crank axle and provide a control signal corresponding to the level of torque. A shock damping device is coupled to the frame of the cycle, and functions to absorb and dampen mechanical shocks communicated to the frame. The shock damping device includes an activator for controlling its damping function. The activator is operable to receive the control signal from the crank axle torque detector and control the shock damping device in response thereto. The control signal may be an electrical or a mechanical signal.

Owner:THE LARRY D MILLER TRUST LARRY D MILLER & MARY L MILLER TRUSTEES DTD 06 12 98

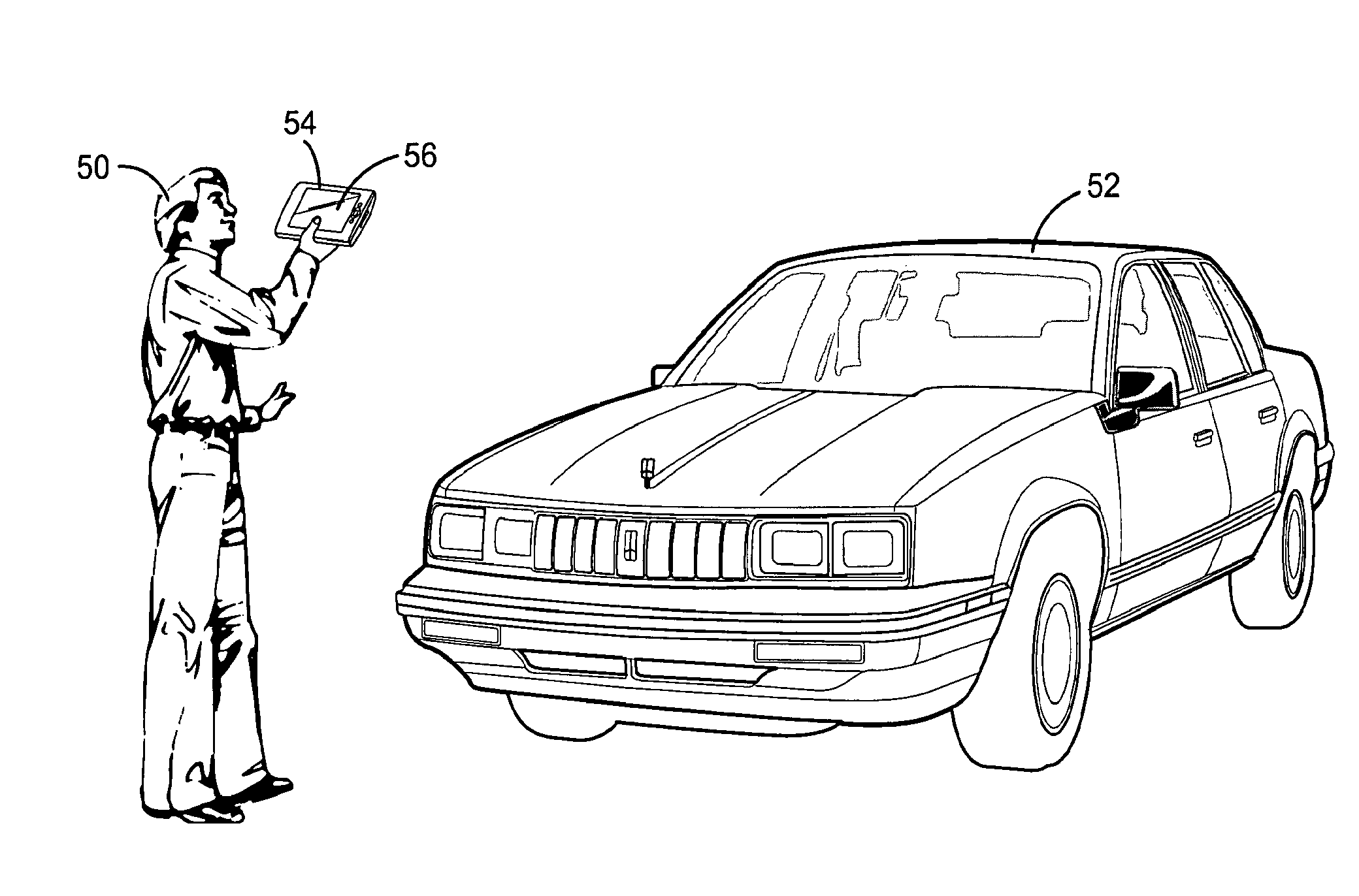

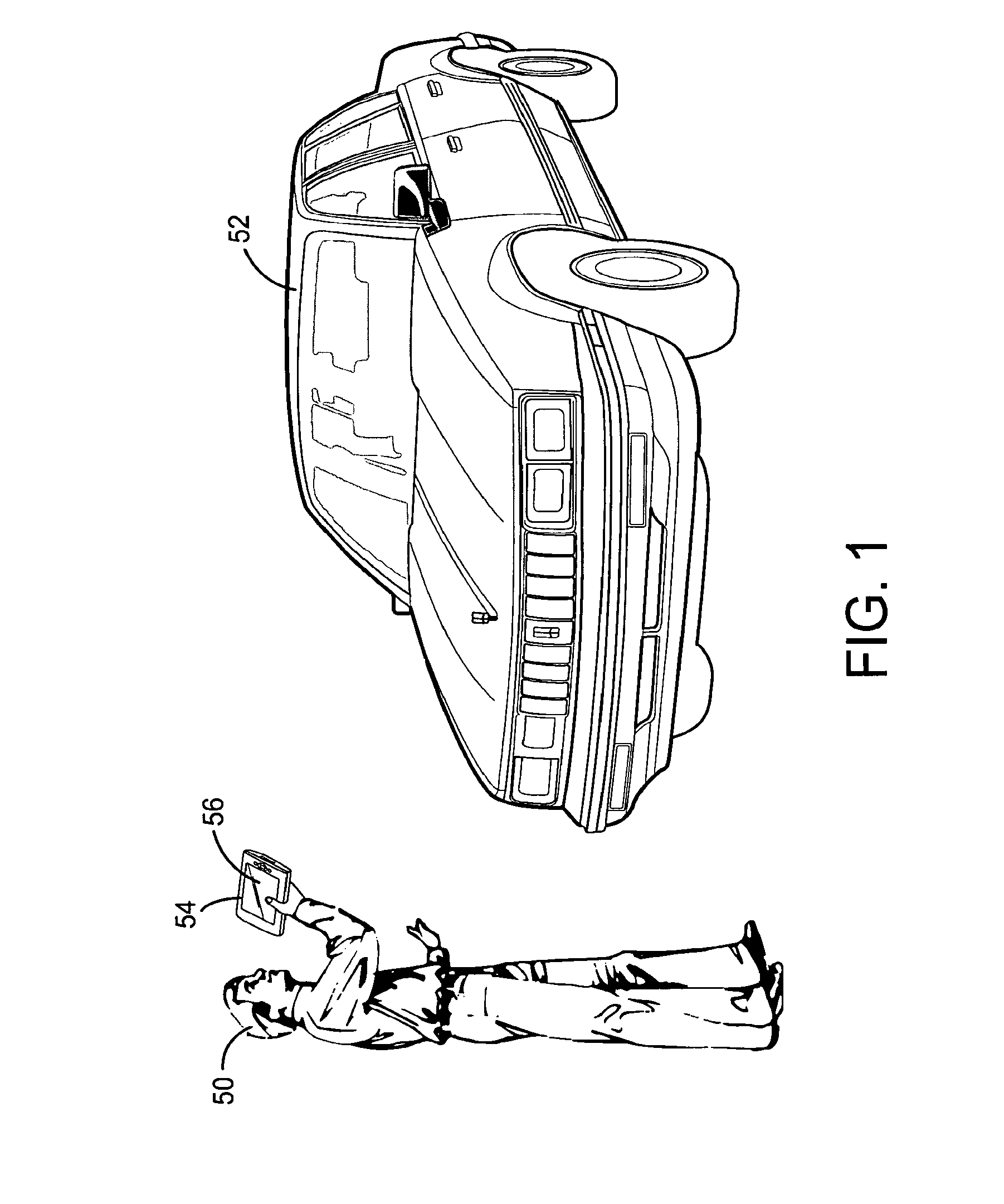

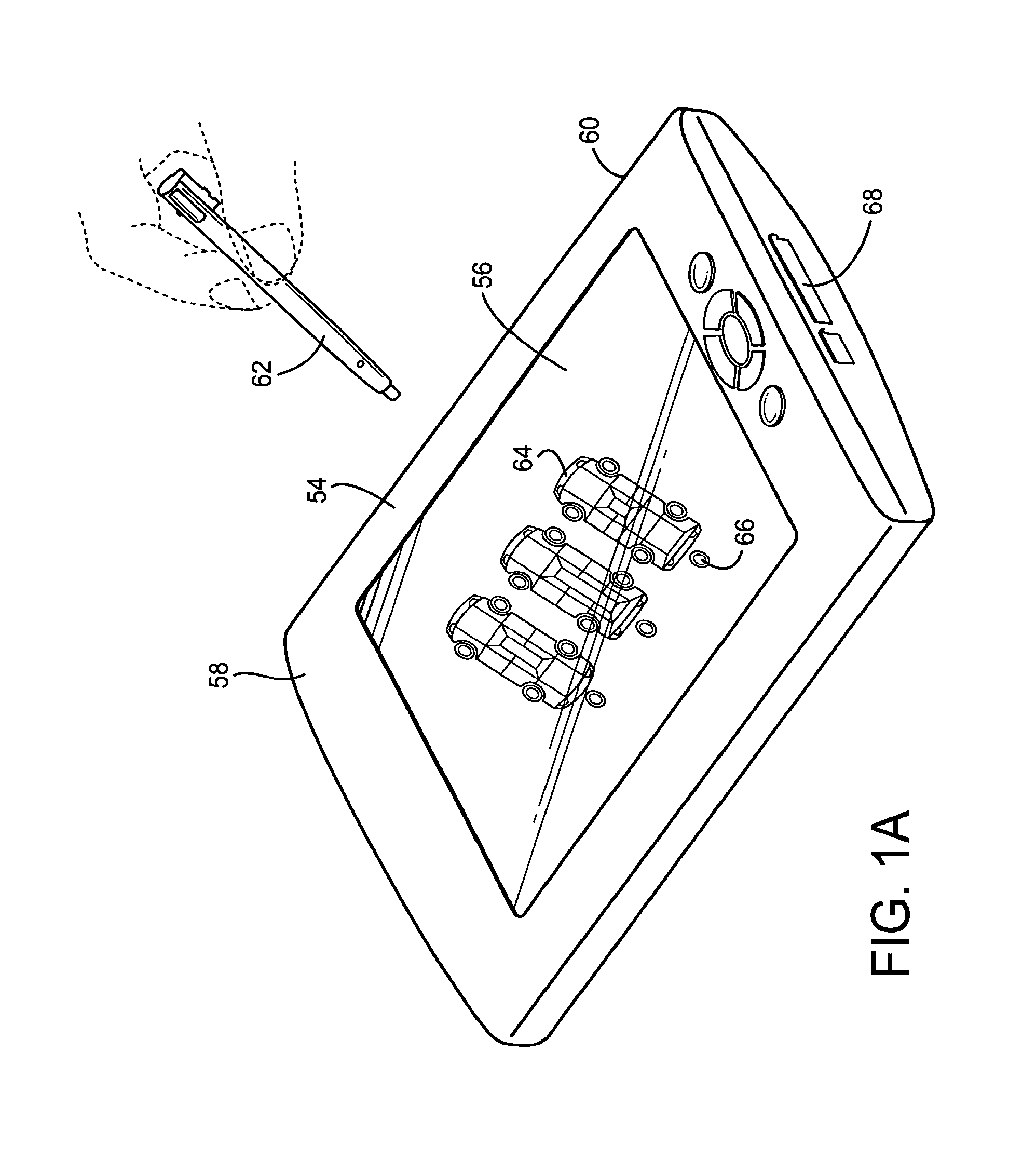

Computer-assisted and/or enabled systems, methods, techniques, services and user interfaces for conducting motor vehicle and other inspections

A computer-assisted inspection system provides customized workflow based on different types of inspections and other factors. The system can provide different rules that can be activated in response to valuation / pricing, rule-based validation and automatic grading. Features include flat car part picking, easy to use, inspectors can be geographically separated, and system is installable over the internet to provide efficient installation to far-flung install sites.

Owner:MANHEIM INVESTMENTS

Health monitoring method for cable system in cable structure

InactiveCN101319962AMonitor and evaluate health statusReduce distortionMachine part testingTension measurementEngineeringLinearity

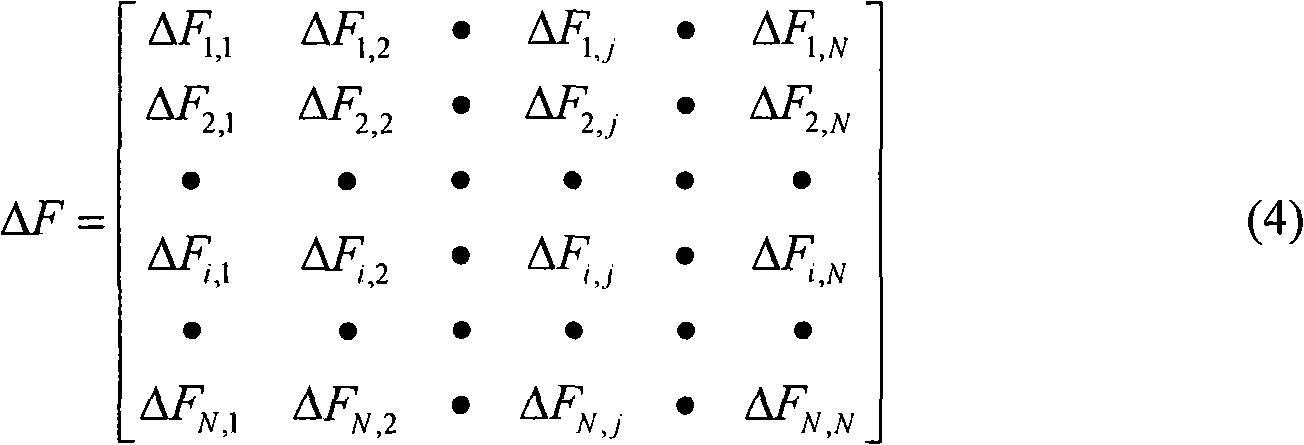

The invention relates to a health monitoring method used for a cable system in a cable structure which carries out a plurality of mechanical calculations based on the mechanical calculation benchmark model of a structure; the calculation times are equal to the quantities of the cables. In each calculation, one cable is supposed to have unit damage; the result for each calculation forms vector for calculating a current cable force; a cable force change vector is obtained by using the vector for calculating the current cable force to subtract an initial cable force vector; all the cable force change vectors form a cable force change identity matrix. The noninferior solution of the current damage vector of the cable can be fast calculated by utilizing proper arithmetic such as multi-target optimizing arithmetic according to the approximating linear relation of the current cable force vector (formed by all the current cable forces that are actually detected), the cable force change identity matrix, a unit damage scalar and the current cable damage vector (formed by all the current damage quantities), thus being capable of more accurately confirming the position and the damage degree of the damaged cable.

Owner:SOUTHEAST UNIV

Method, system, and device for optimizing a vehicle's suspension

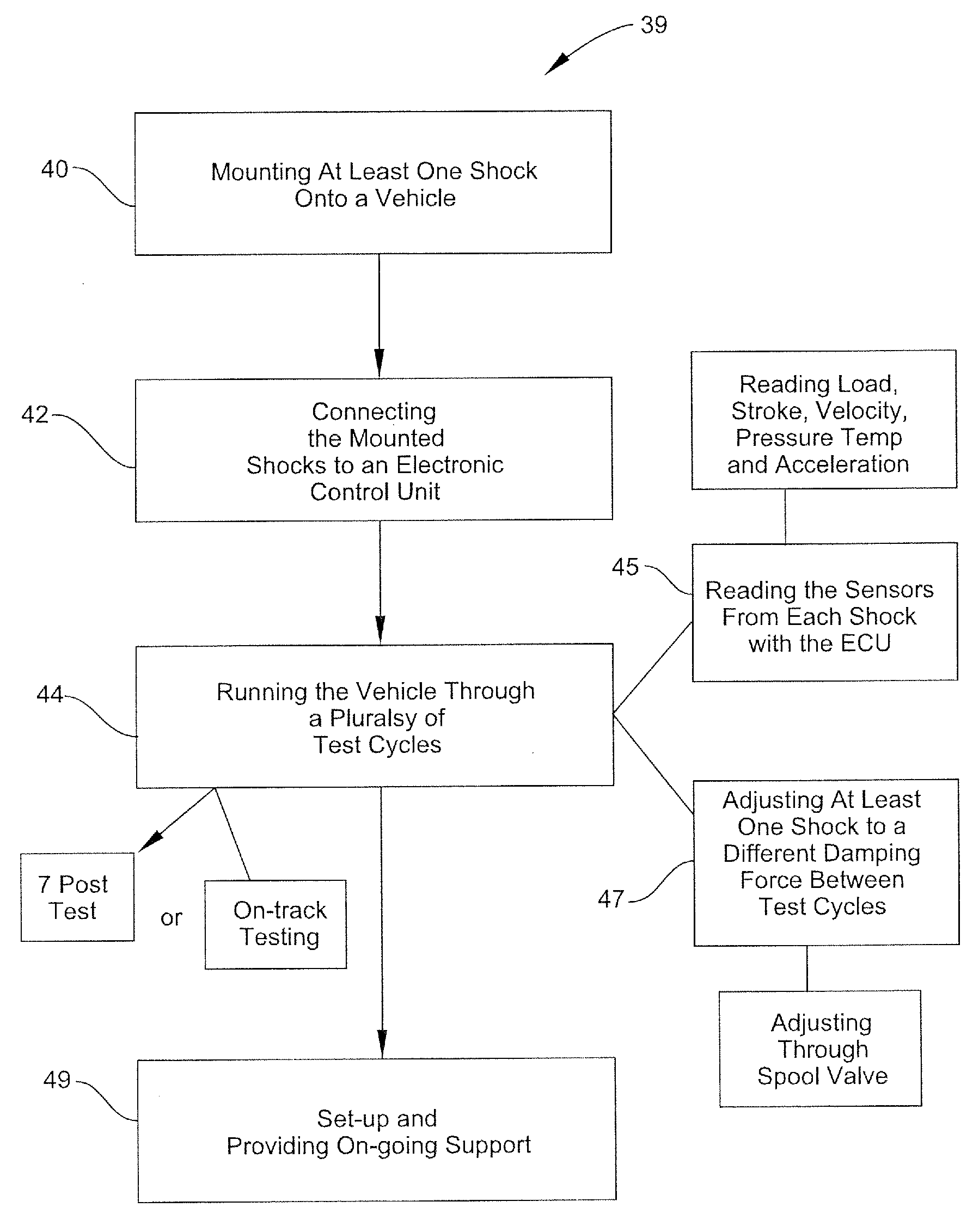

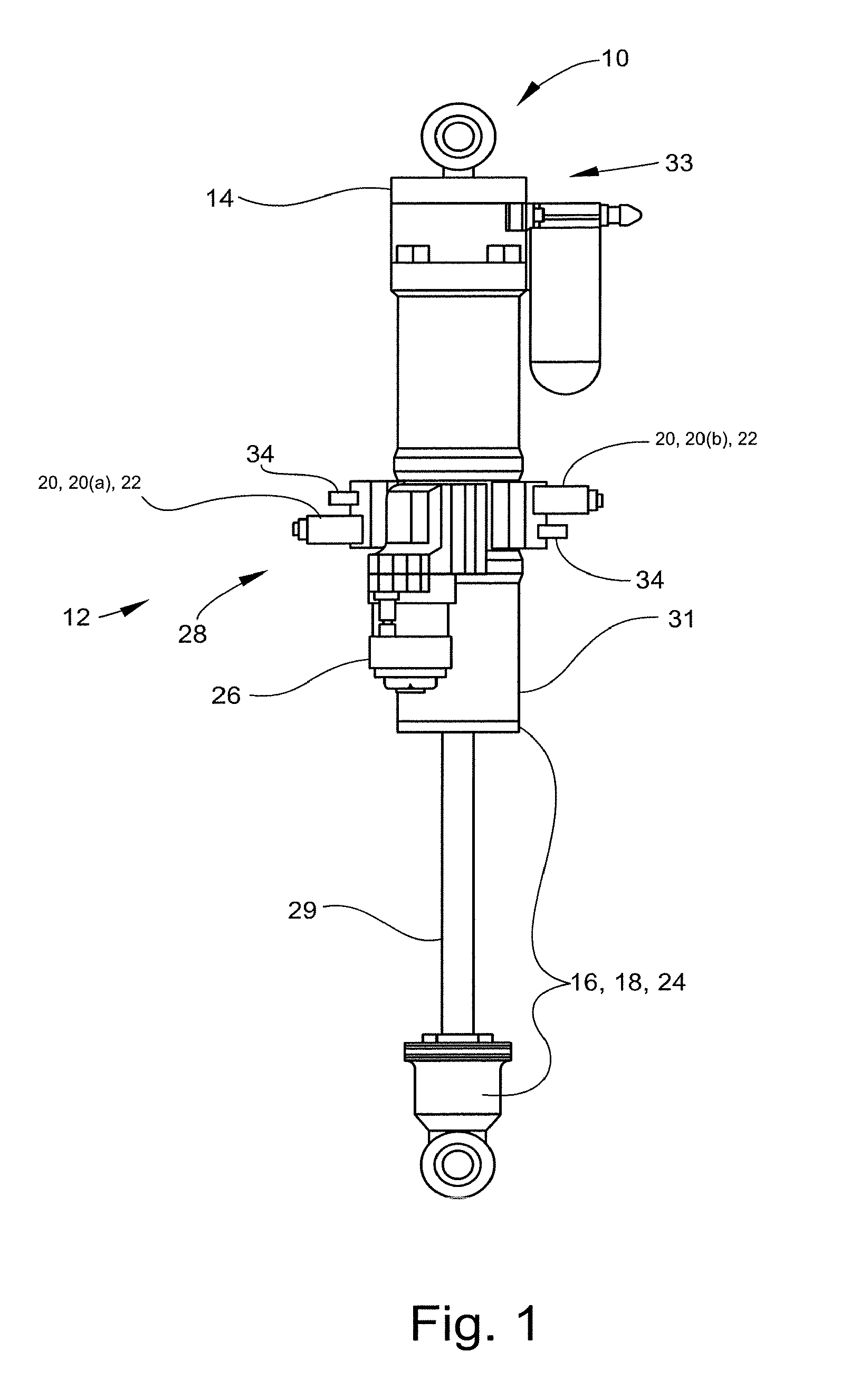

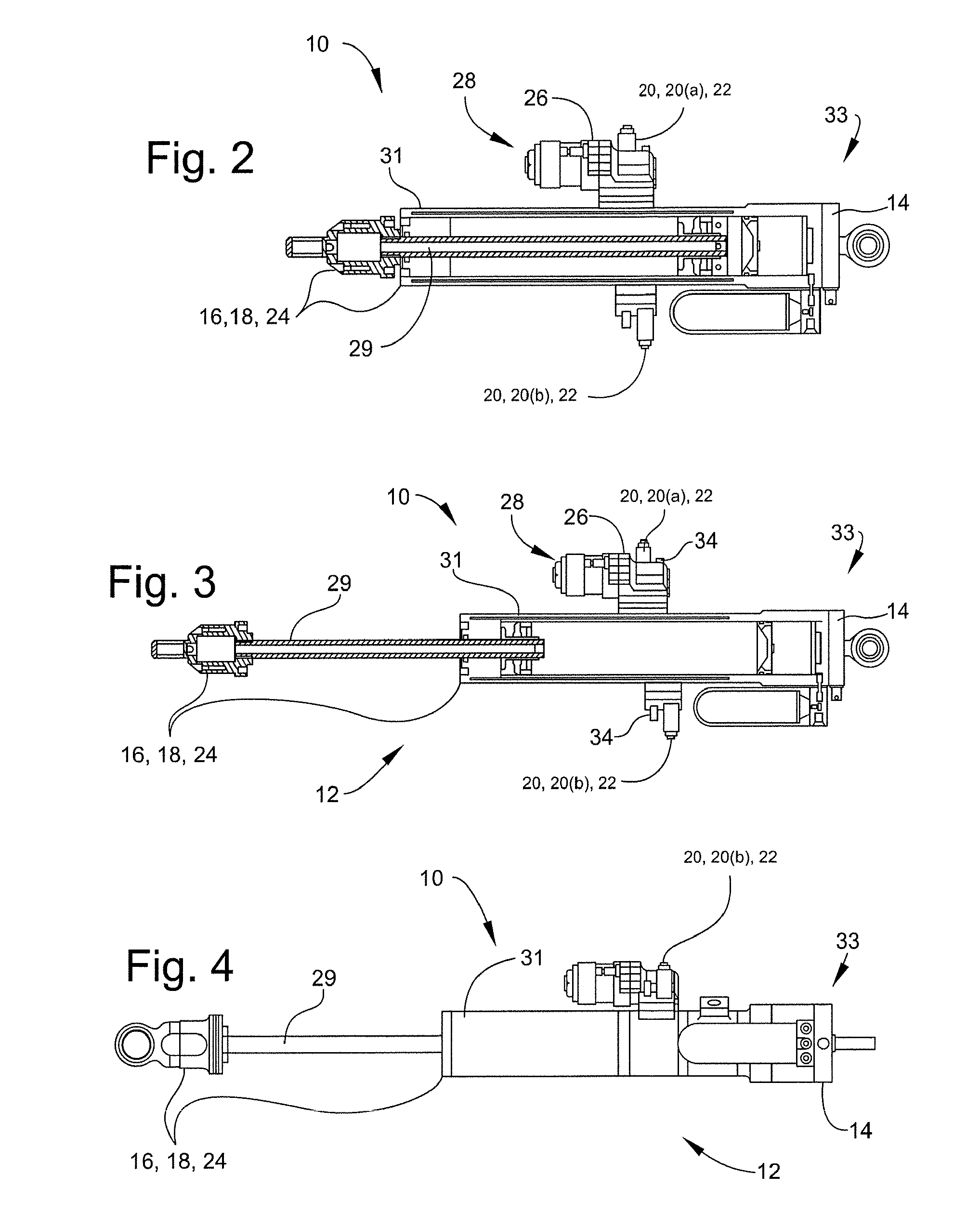

A method, system, and device for optimizing a vehicle's suspension includes: mounting at least one modified passive shock with a plurality of sensors onto a vehicle, where the shock is adjustable for a plurality of damping forces; connecting the shock to an electronic control unit being for adjusting the damping forces of the shock and reading the plurality of sensors; and running the vehicle through a plurality of test cycles where the electronic control unit reading the plurality of sensors during each test cycle and adjusting the shock to a different damping force between each test cycle, where the adjusted shock emulating the damping forces of multiple standard passive shocks.

Owner:ARNOTT T&P HLDG LLC

Equipment component monitoring and replacement management system

A computer system for managing replacement components for equipment having a plurality of components, each component having a limited useful life, has a computer program module defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the components and specified operating conditions for the involved components during execution of the usage cases. A further program module determines a theoretical useful life for each component involved in a duty profile, based on component useful life data under specified operating conditions; and sensors determine and monitor the occurrence of equipment operation corresponding to a usage case and measur actual operating conditions and number of operations. A further program module computes an adjusted theoretical useful life for a component experiencing operations, based on a comparison of actual operating conditions to those assumed for the usage case.

Owner:HYDRALIFT AMCLYDE INC

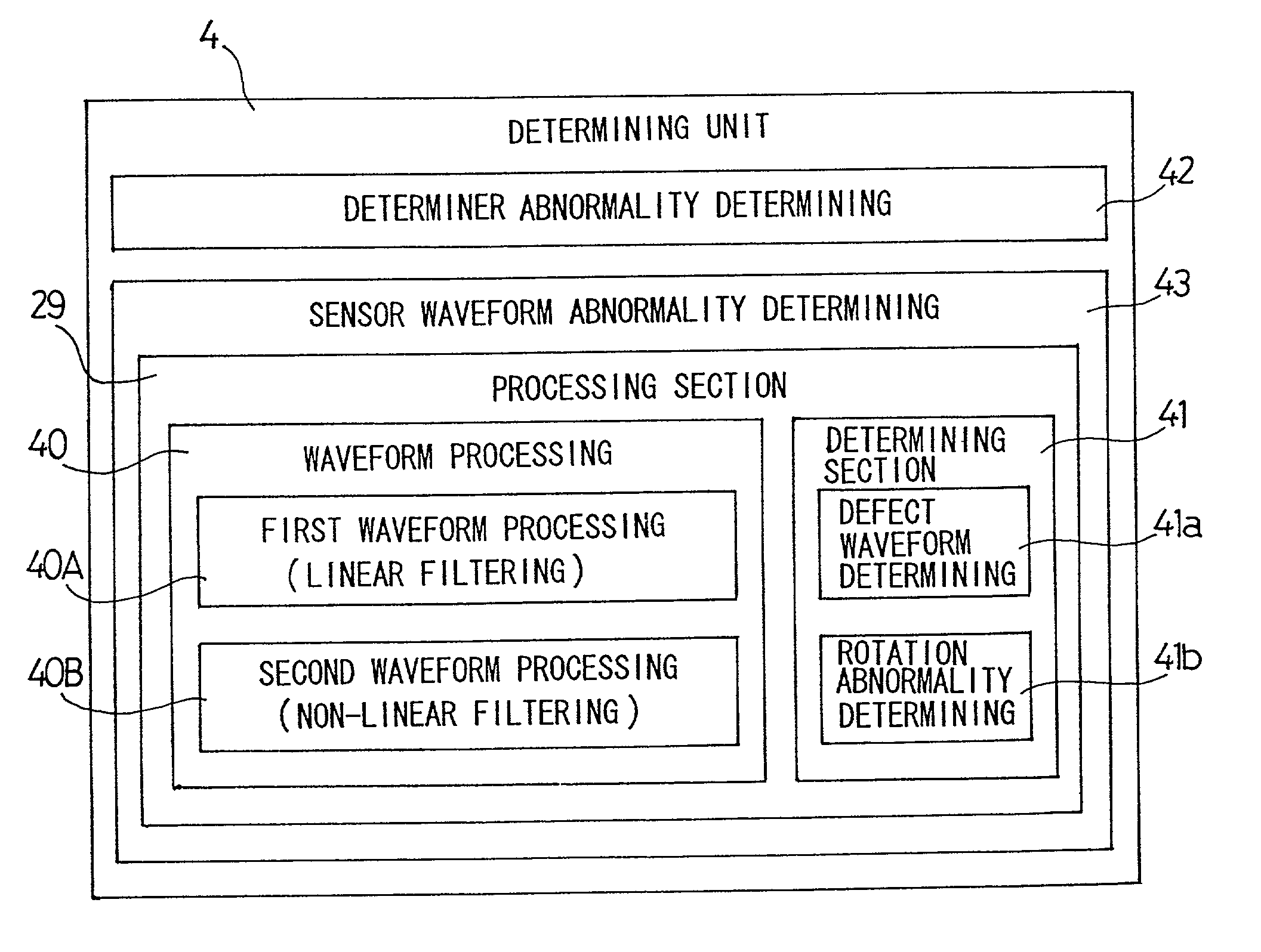

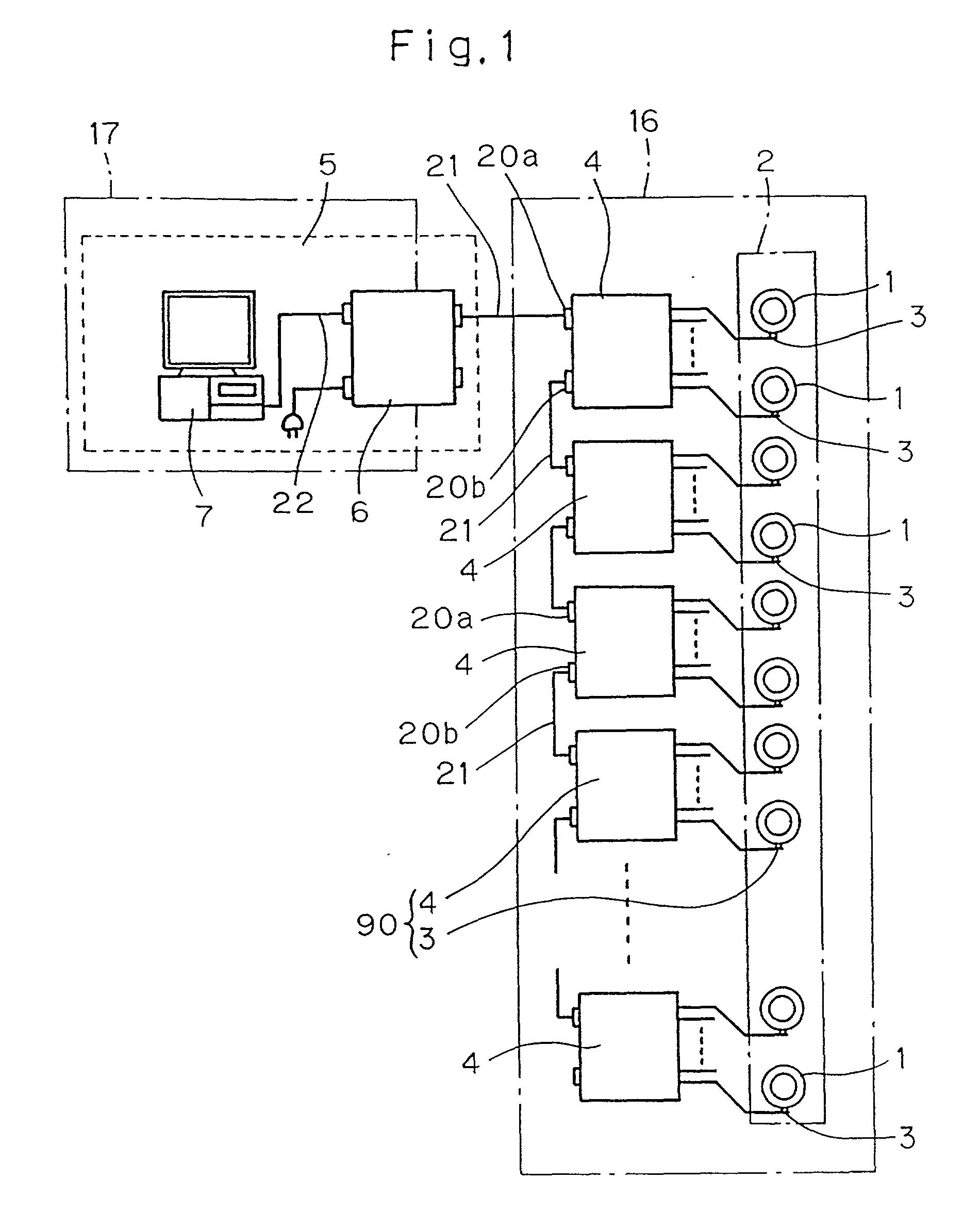

Machine component monitoring, diagnosing and selling system

InactiveUS20020013635A1Quick checkTime spanMachine part testingNuclear monitoringMonitoring statusEngineering

A system for monitoring statuses such as presence or absence of abnormality and lifetime of a machine component such as, for example, a bearing having rolling elements includes a plurality of determining units 4 each connected with a plurality of sensors 3, and a control means 5 connected with the determining units 4. Each sensor is disposed on the machine component 1 of the associated rolling bearing for detecting an influence signal resulting from passage of the rolling element induced in the machine component 1. Each determining unit 4 determines according a process set-up condition the presence or absence of an abnormality, lifetime and others of the machine component 1 associated with the sensor 3 in reference to an output signal from such sensor 3. The control means 5 collects a result of determination performed by each determining unit 4. In this way, with a simplified structure, monitoring can be achieved at a low cost, precisely and efficiently.

Owner:NTN CORP

Methods and systems for the industrial internet of things

ActiveUS20180210425A1Improve signal-to-noise ratioLow sampling rateVibration measurement in solidsMachine part testingData acquisitionEngineering

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The crosspoint switch includes a third input that is configured with a continuously monitored alarm having a pre-determined trigger condition when the third input is unassigned to any of the multiple outputs. The local data collection system is configured to manage data collection bands.

Owner:STRONG FORCE IOT

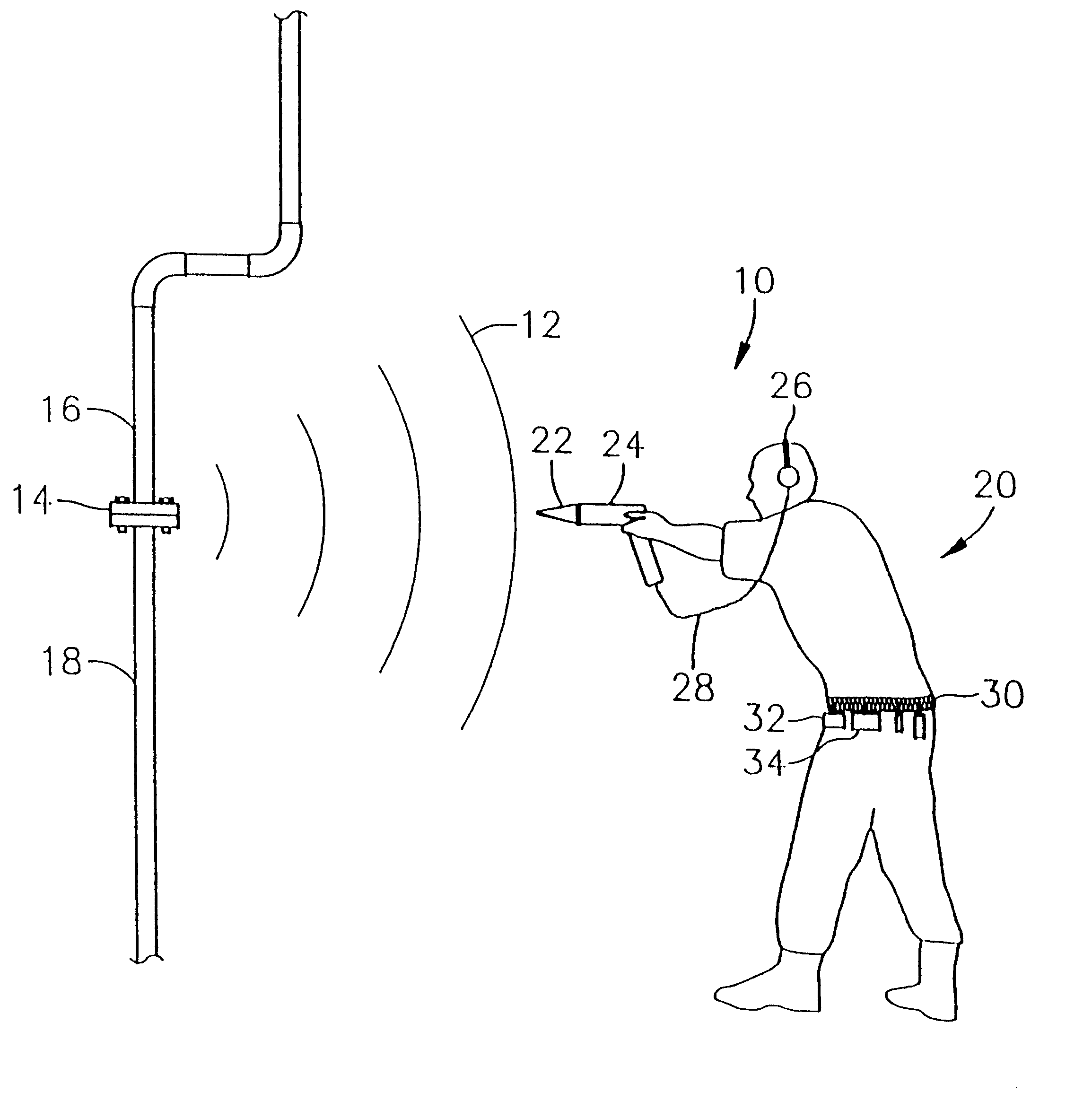

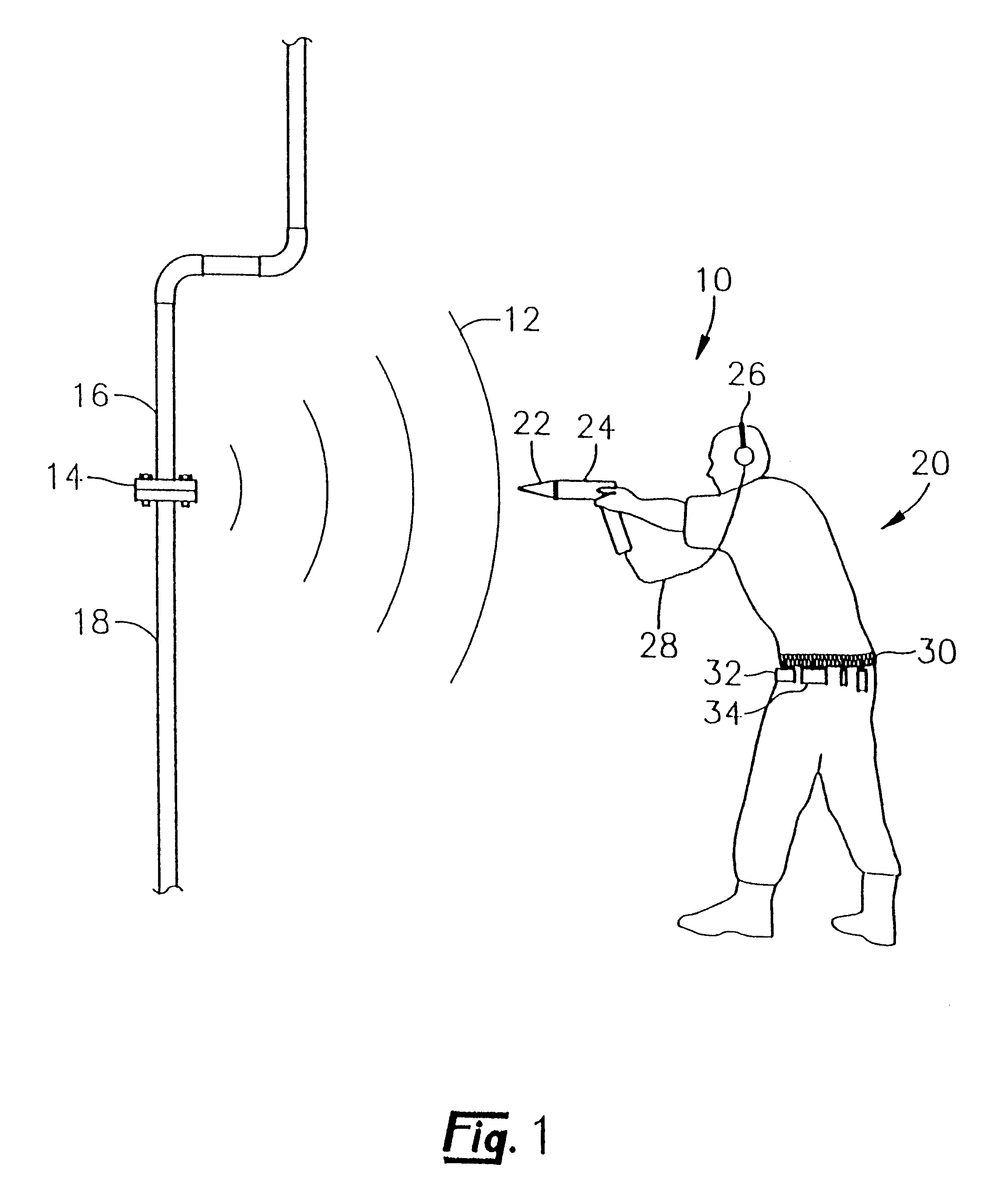

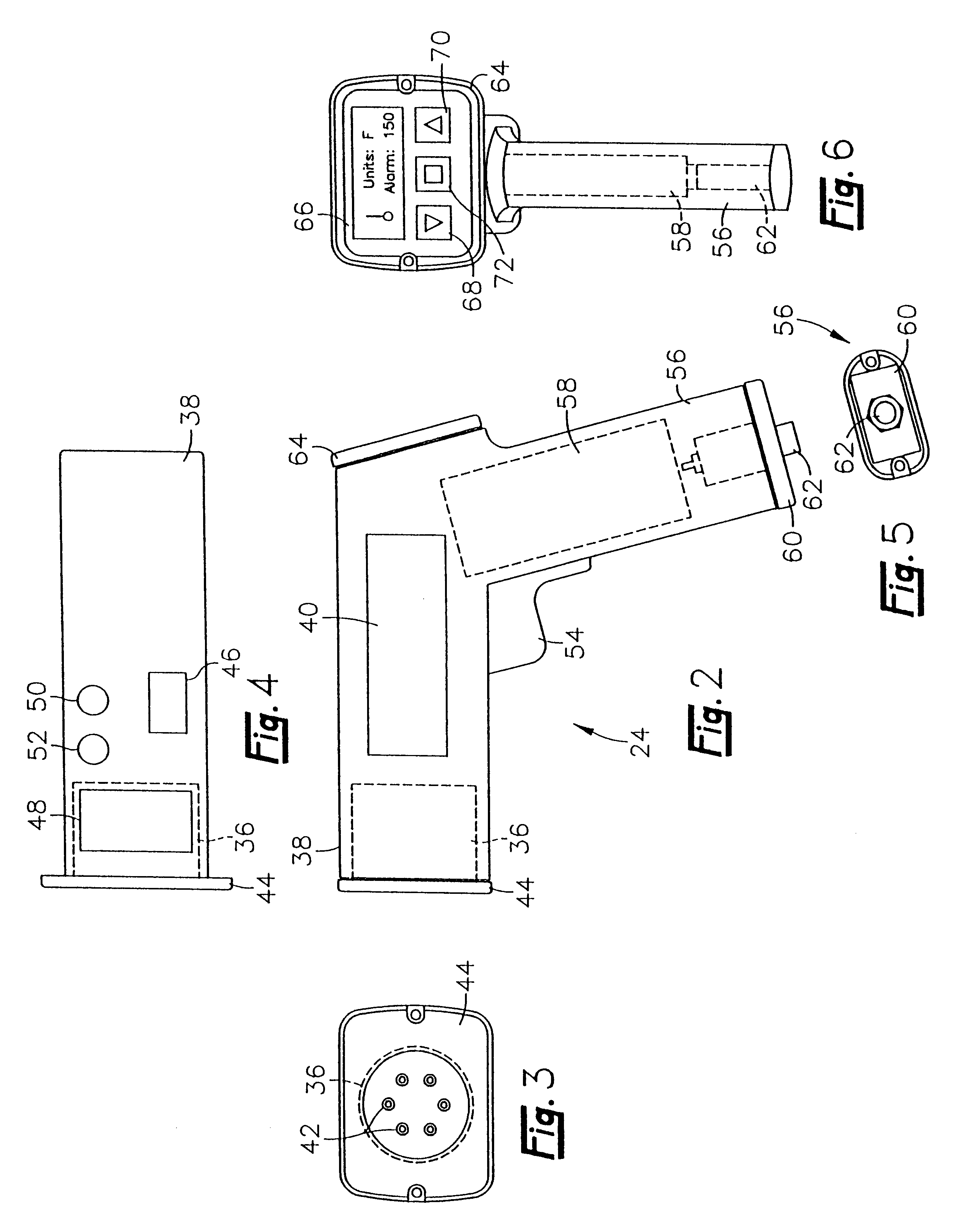

Multiple sensor ultrasonic monitoring device

InactiveUS6220098B1High thermal and ultrasonic conductivityMinimize intrinsic thermal time constantVibration measurement in solidsMachine part testingHand heldMultiple sensor

An ultrasonic monitoring apparatus is provided for use by an operator in detecting ultrasonic vibrations and sound waves. The ultrasonic monitoring apparatus consists of a hand held device with a sensor socket that allows a variety of different types of sensors to be interchangeably installed in the hand held device. These sensors include both contact and airborne ultrasonic sensors as well as a combination temperature and ultrasonic sensor that allows the operator to simultaneously monitor the surface temperature of an object and the ultrasonic vibrations produced by the object. Identification information corresponding to the type of sensor is encoded on the individual sensors. The identification information is read by an identification circuit located in the hand held device. This identification information allows the hand held device to configure itself to operate with the type of sensor installed in the socket.

Owner:COMPUTATIONAL SYST

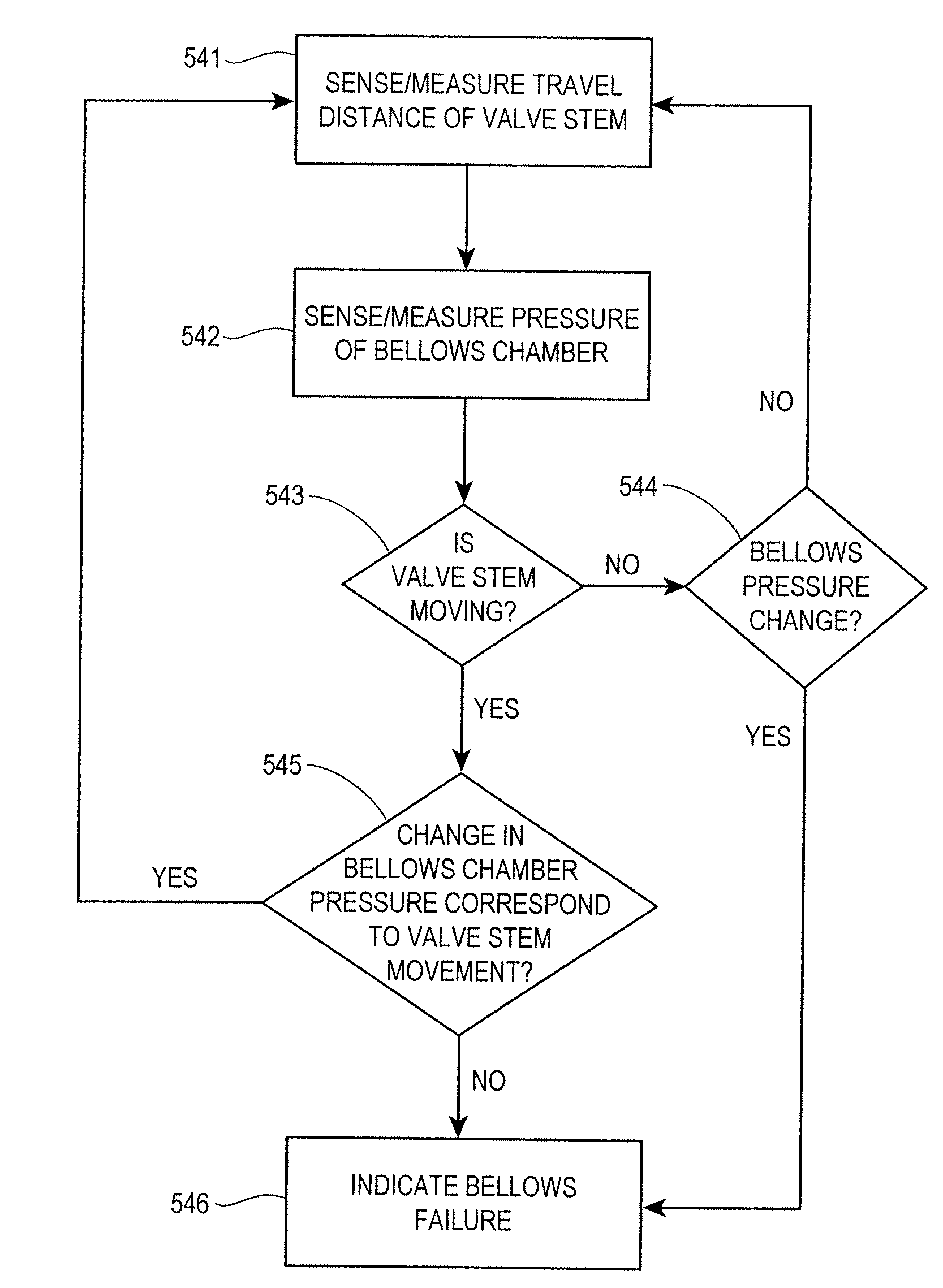

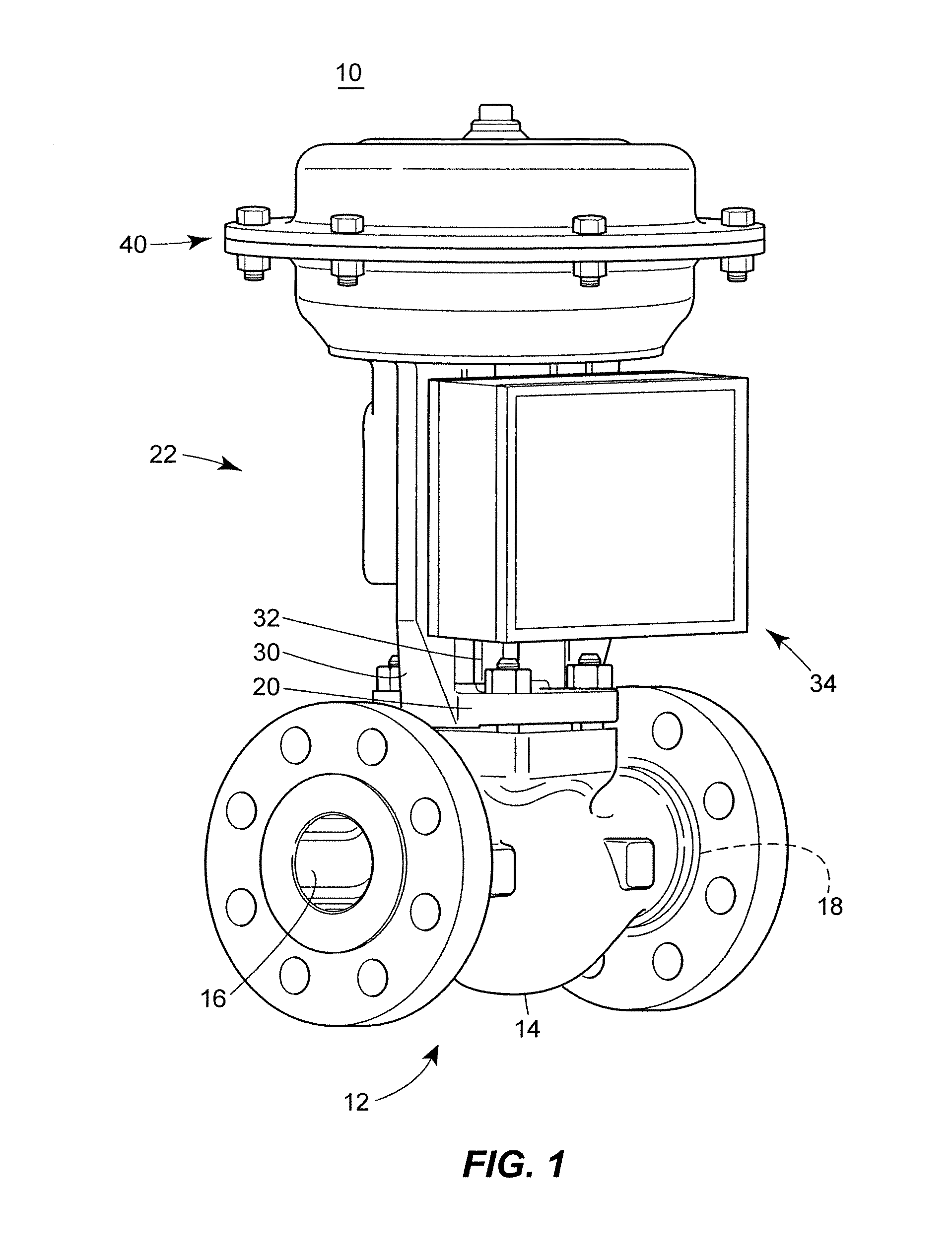

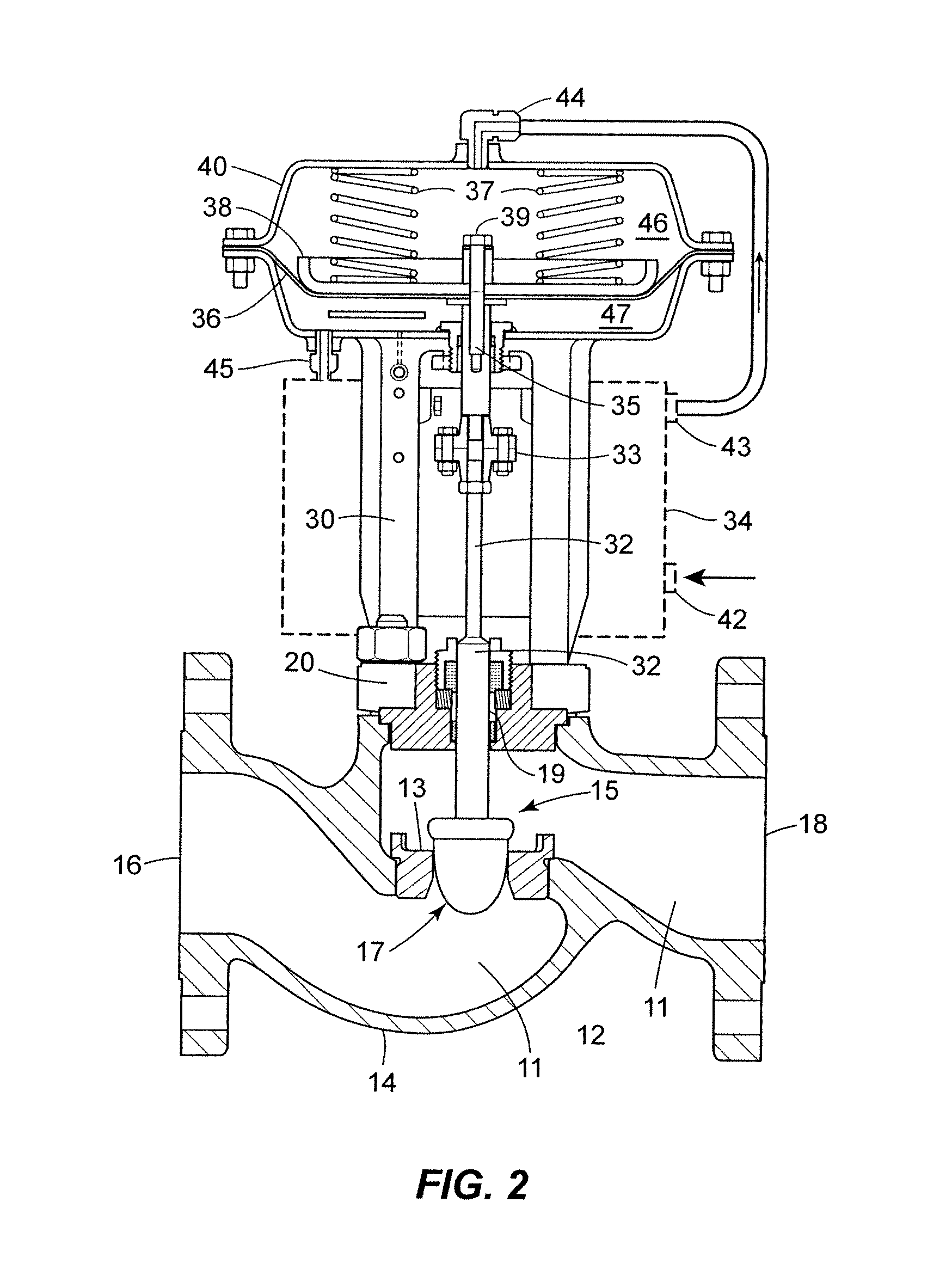

Diagnostic method for detecting control valve component failure

The claimed method and system identifies faults and / or deterioration of components in a process control valve. The system may use different sensor combinations to provide the necessary data to compute irregular component integrity. Alerts may be generated to indicate potential component integrity problems. In particular, the system may detect potential deterioration and / or faults in actuator springs, pneumatic tubing and piping, and bellows seals. The claimed system may be communicatively coupled to a process control network to provide a more elaborate alarm system. Moreover, additional statistical methods may be used to refine the detection accuracy of the system.

Owner:FISHER CONTROLS INT LLC

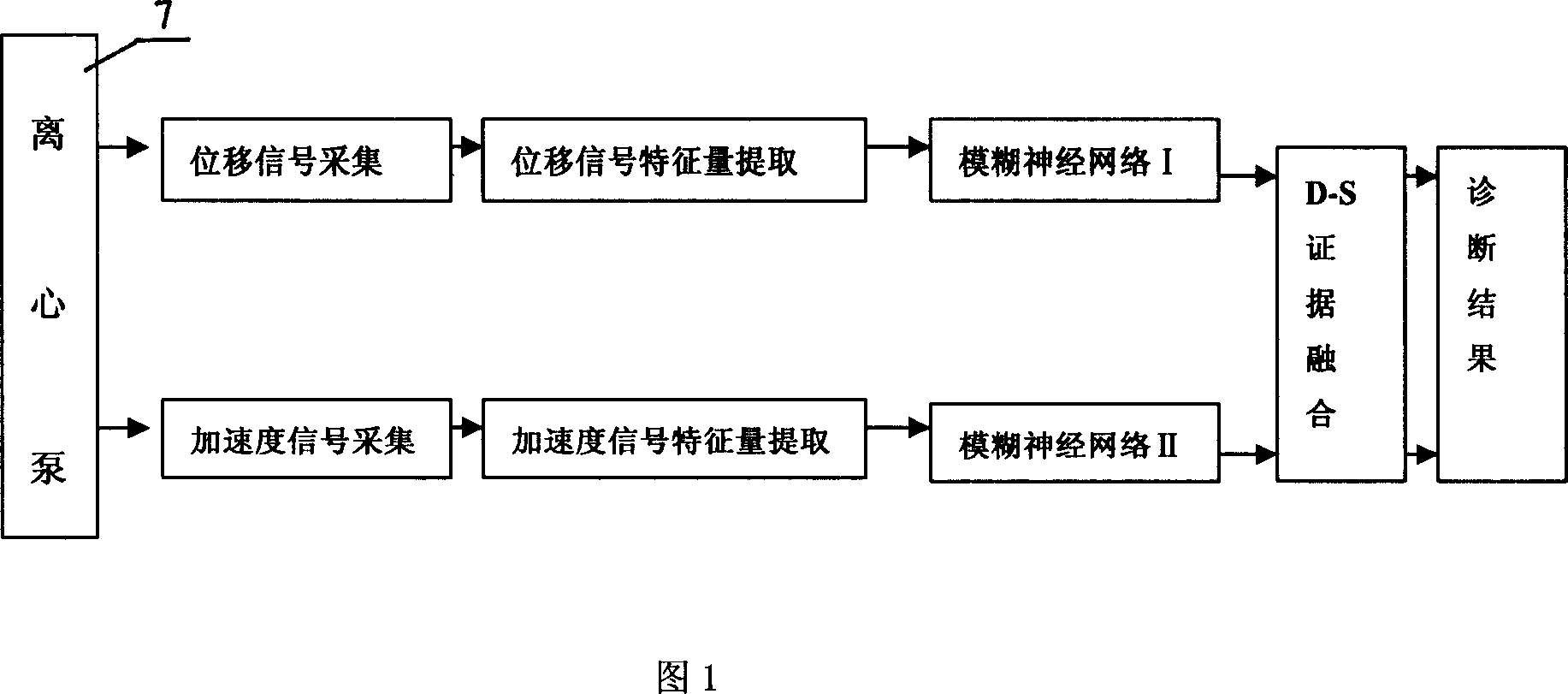

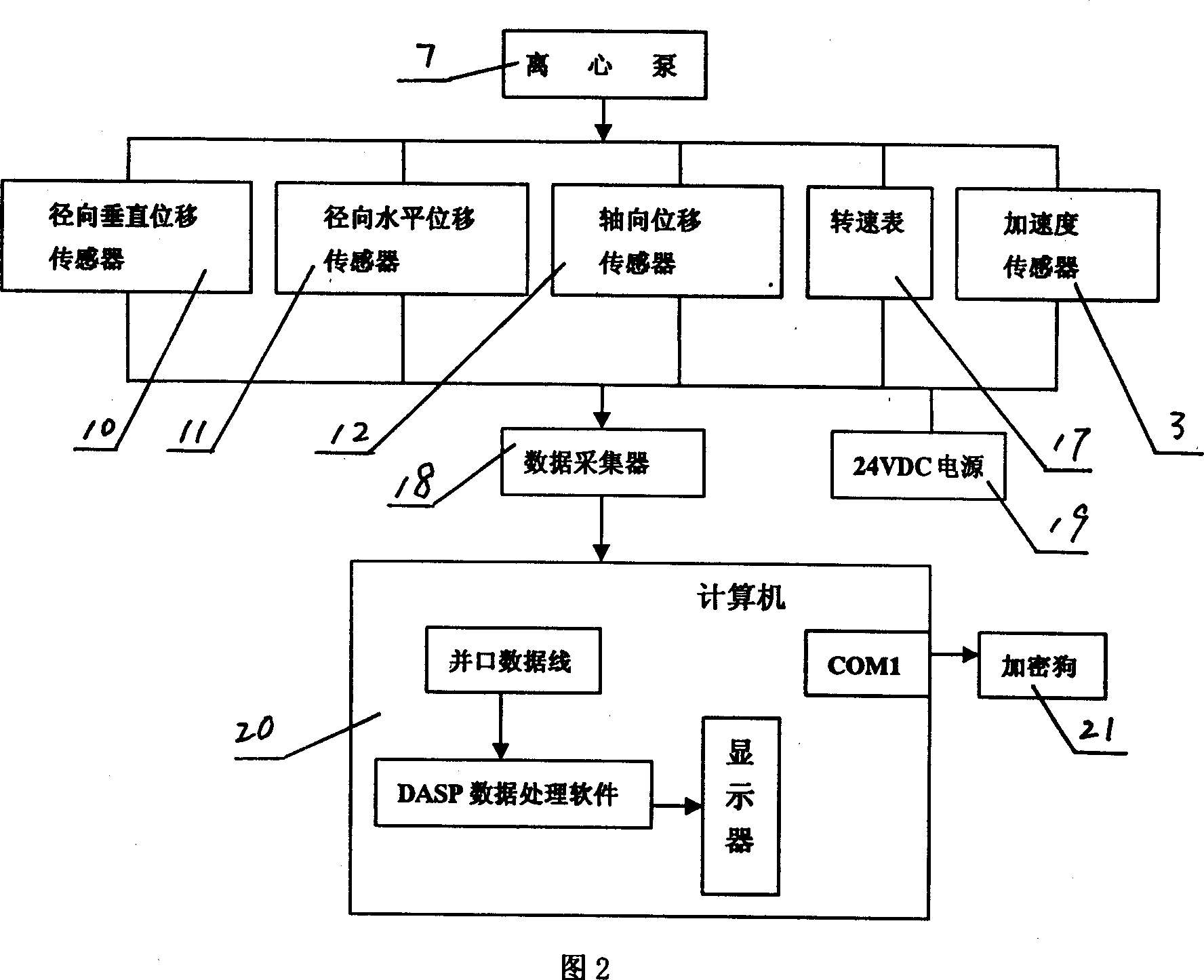

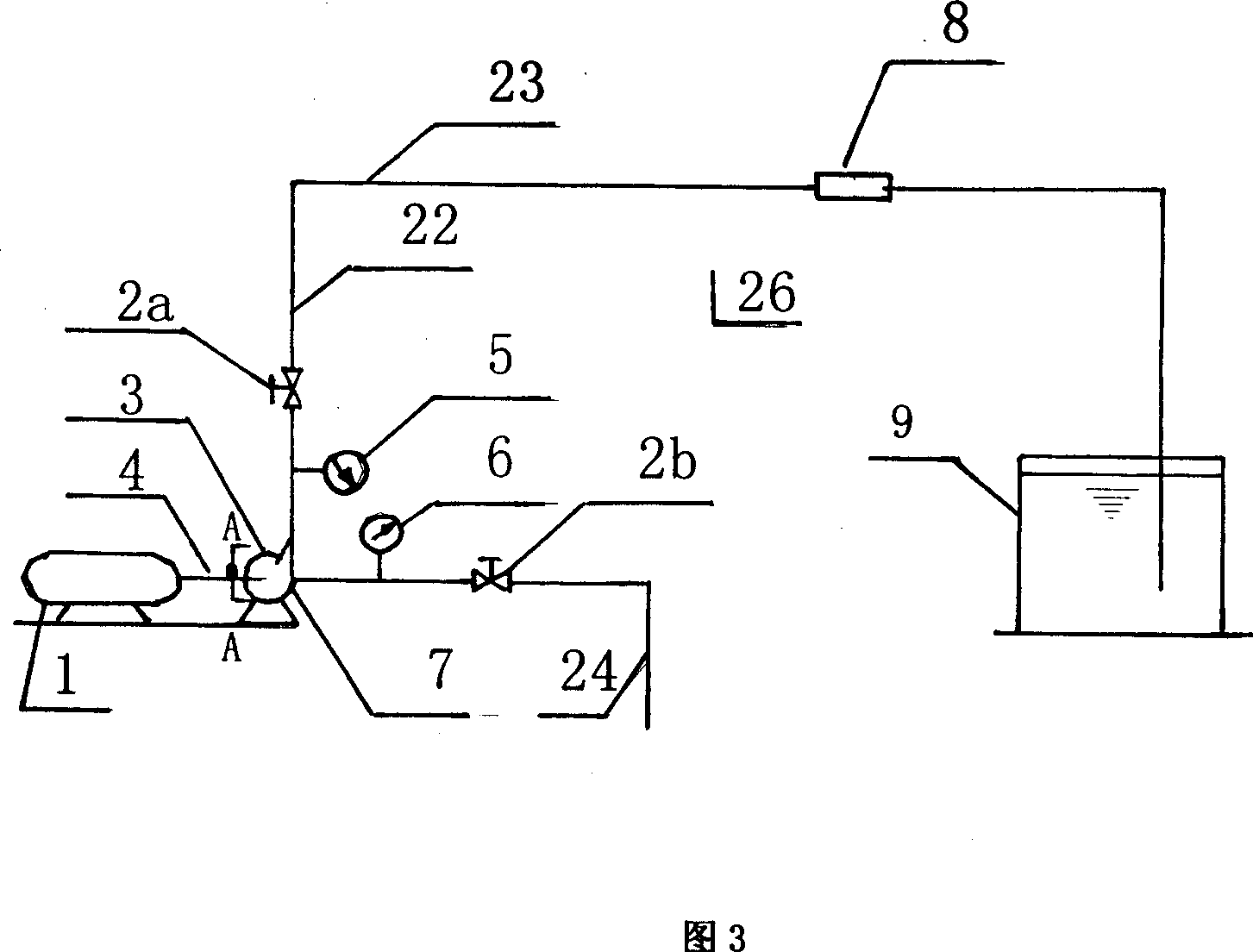

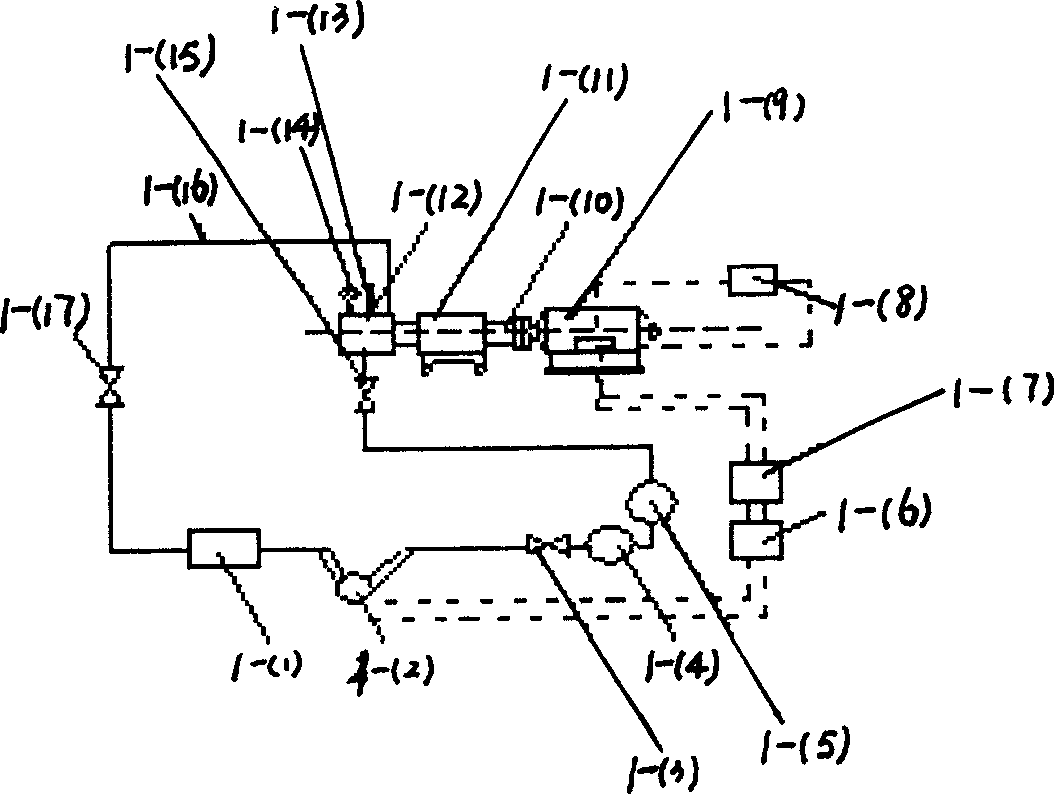

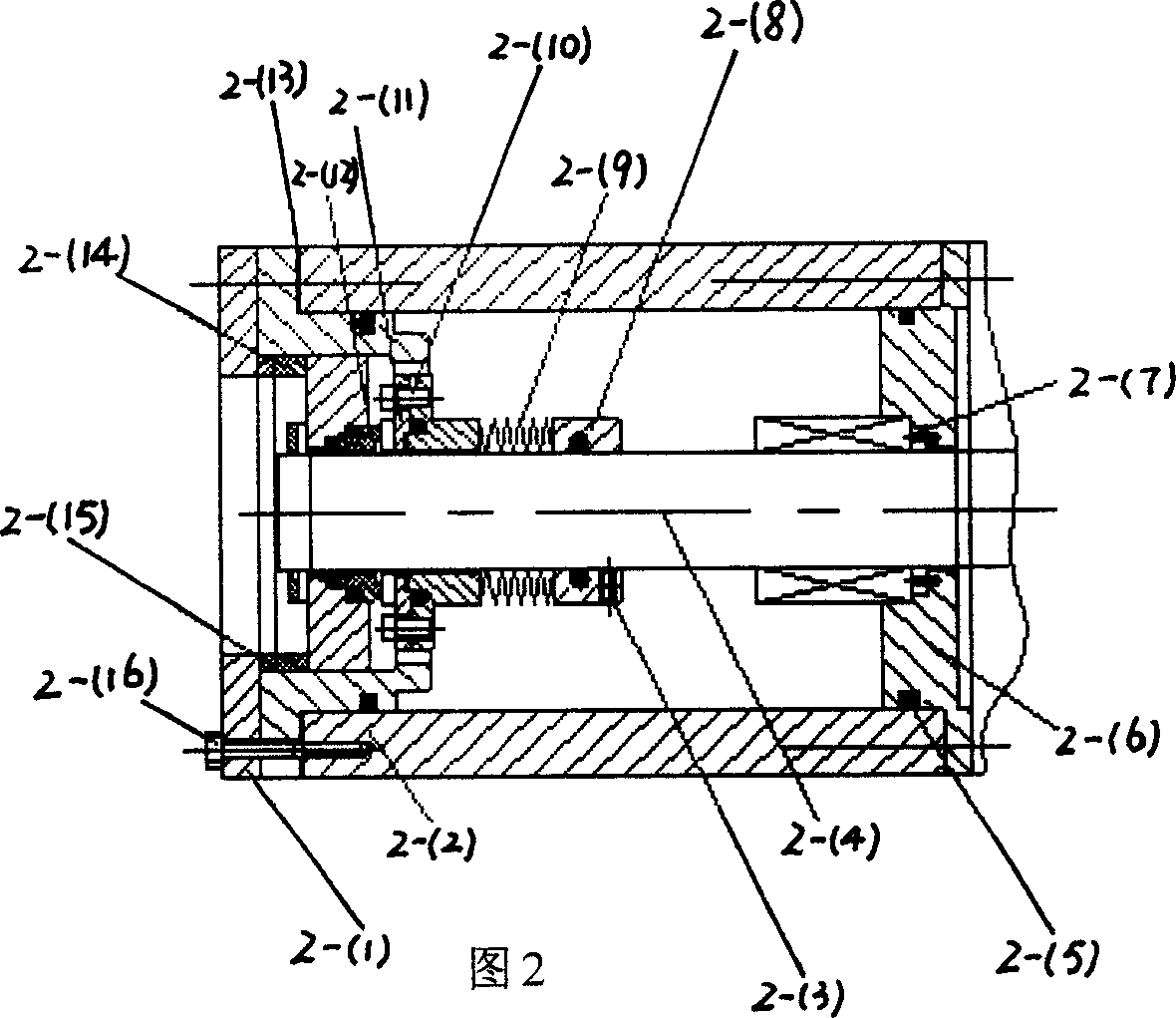

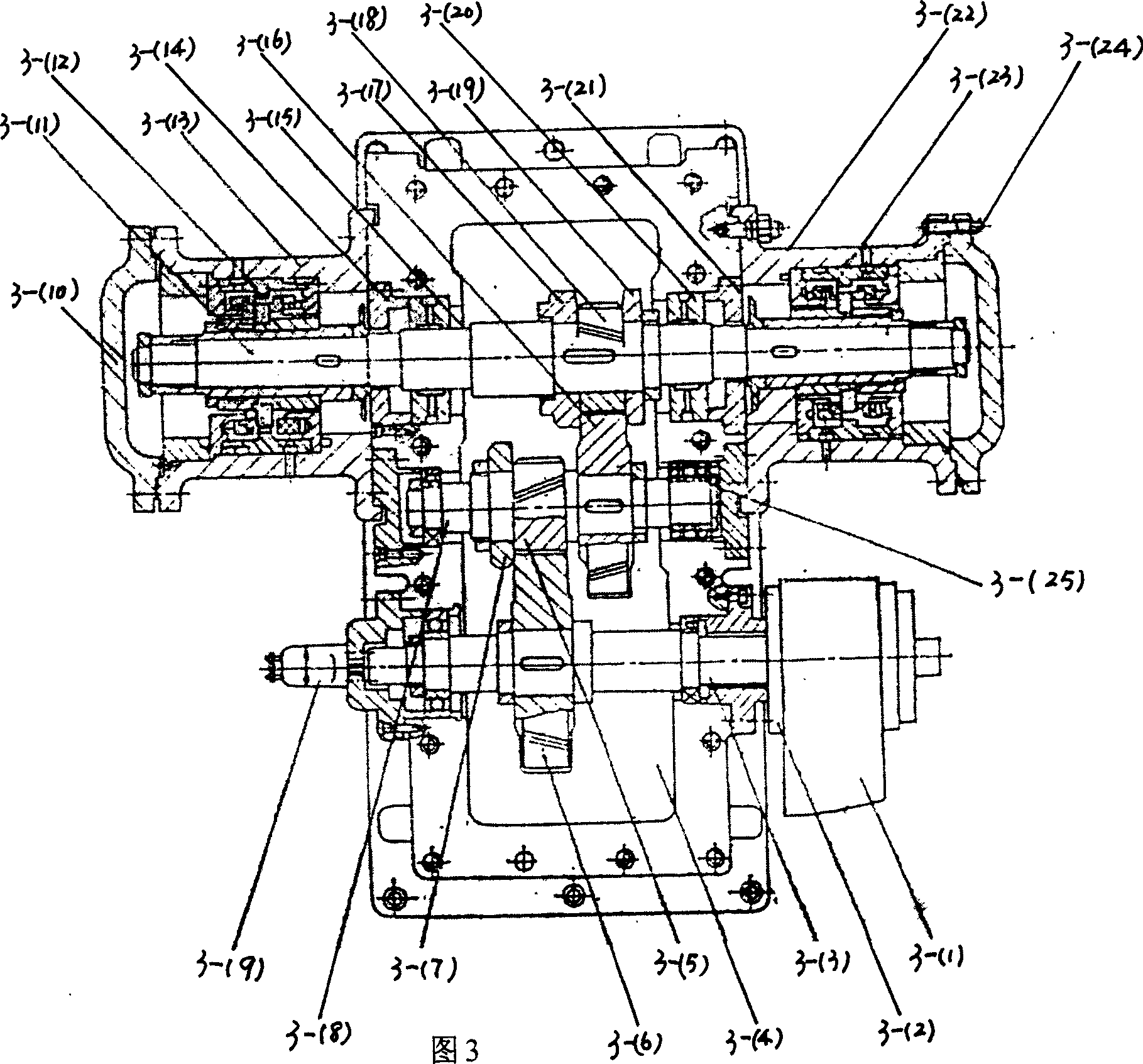

Fusion diagnosing method of centrifugal pump vibration accidents and vibration signals sampling device

InactiveCN1920511AImplementing a normal status signalComprehensive signal acquisitionMachine part testingPump testingEngineeringNormal state

The invention relates to an eccentric pump vibration accidence fusion diagnose method and relative vibration signal collector, wherein said invention is characterized in that: it uses the eccentric pump vibration signal collector to collect the normal state, the quantity imbalance, asymmetry rotate and loose base of eccentric pump; uses wavelet decomposition and reconstruction to extract the character of vibration signal; and inputs the character vectors into sub fuzzy neural networks I and II; to be treated and replace the relation factor matched with sensor signal function; the whole fuzzy neural network comprises data fuzzy layer, input layer, hidden layer and output layer; uses D-S theory to obtain the fused signal function distribution, realize the fusion diagnose on normal state, quantity imbalance, asymmetry rotate and loose base. The invention has simple structure and high effect.

Owner:NORTHEAST DIANLI UNIVERSITY

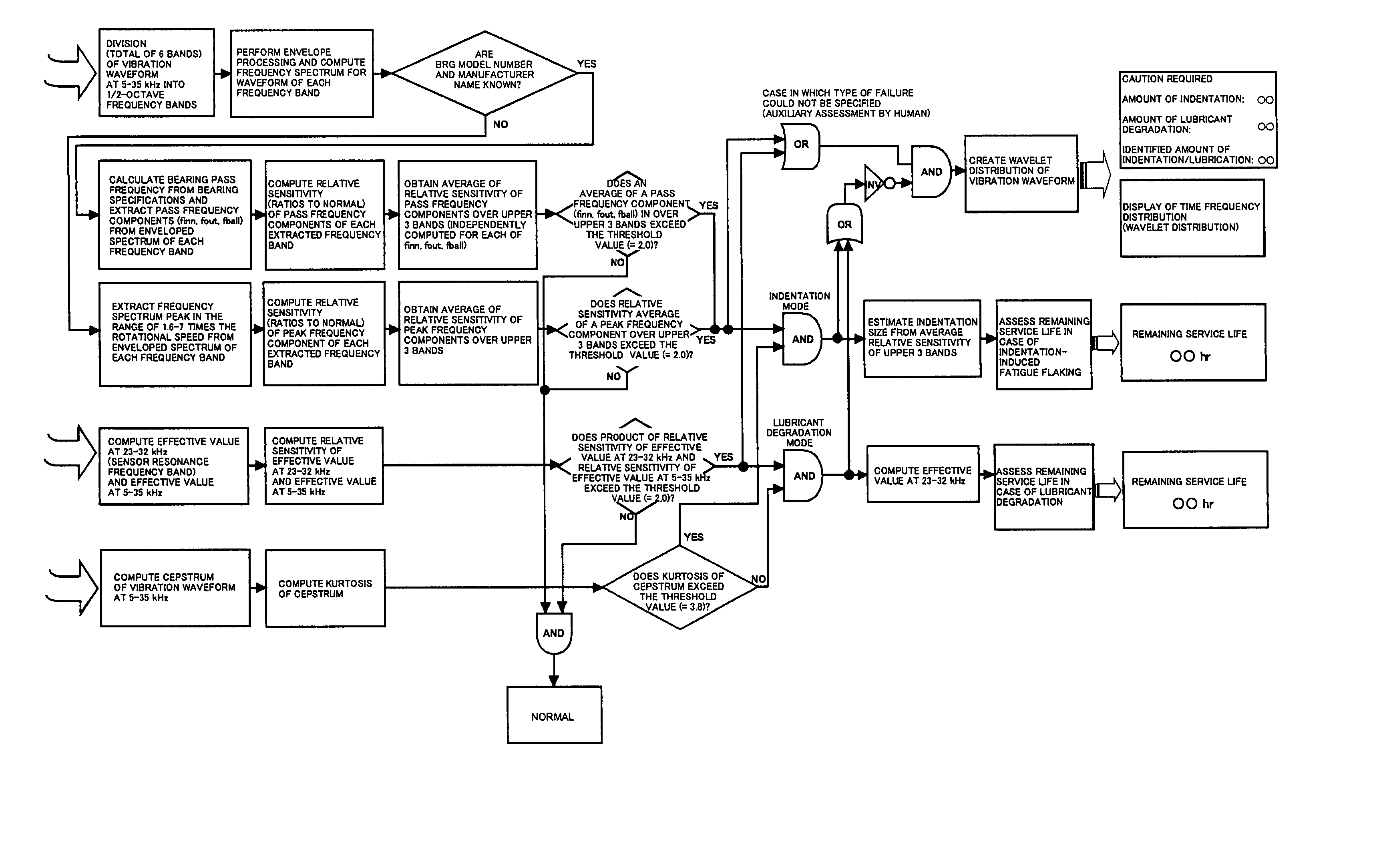

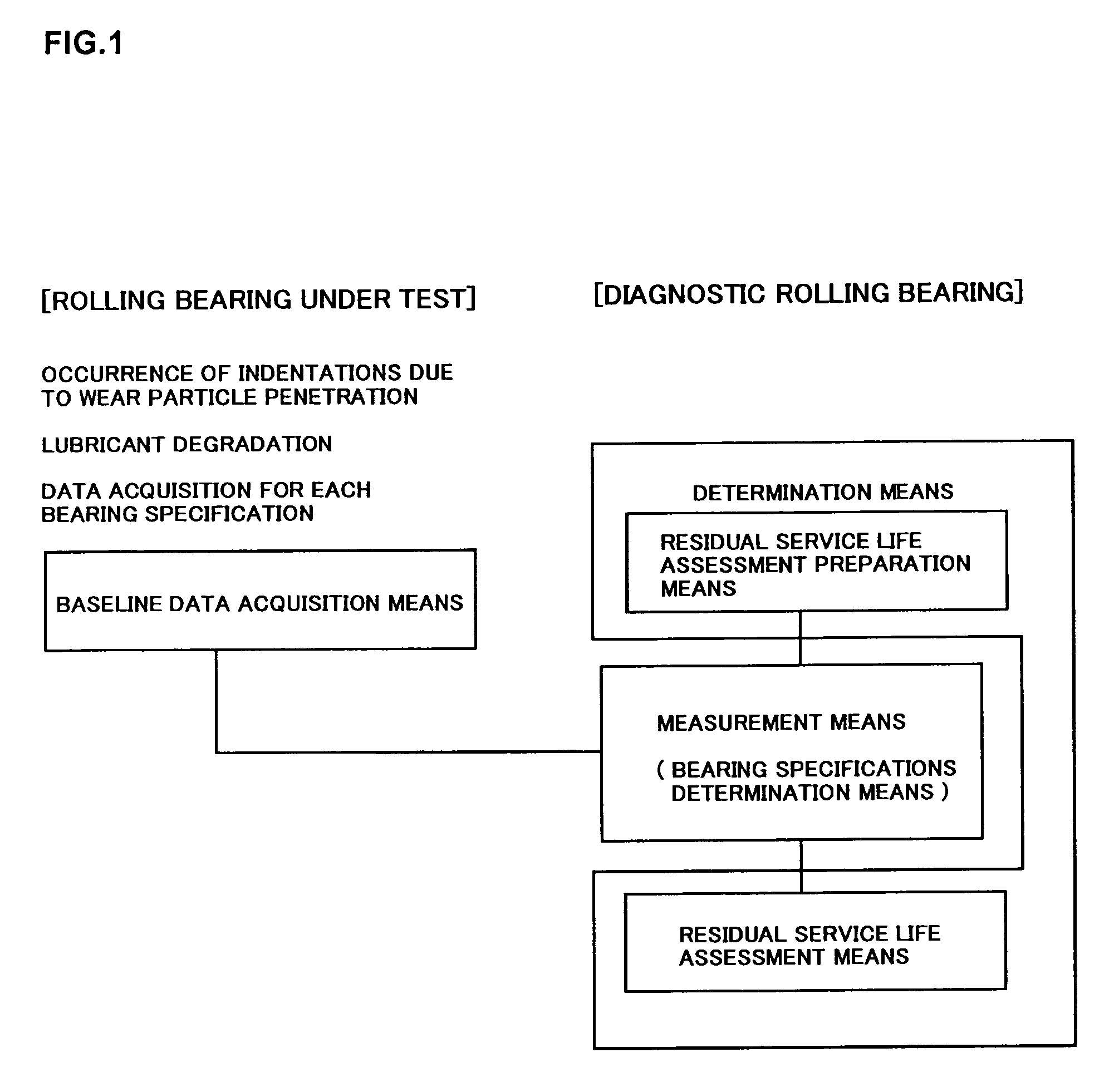

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

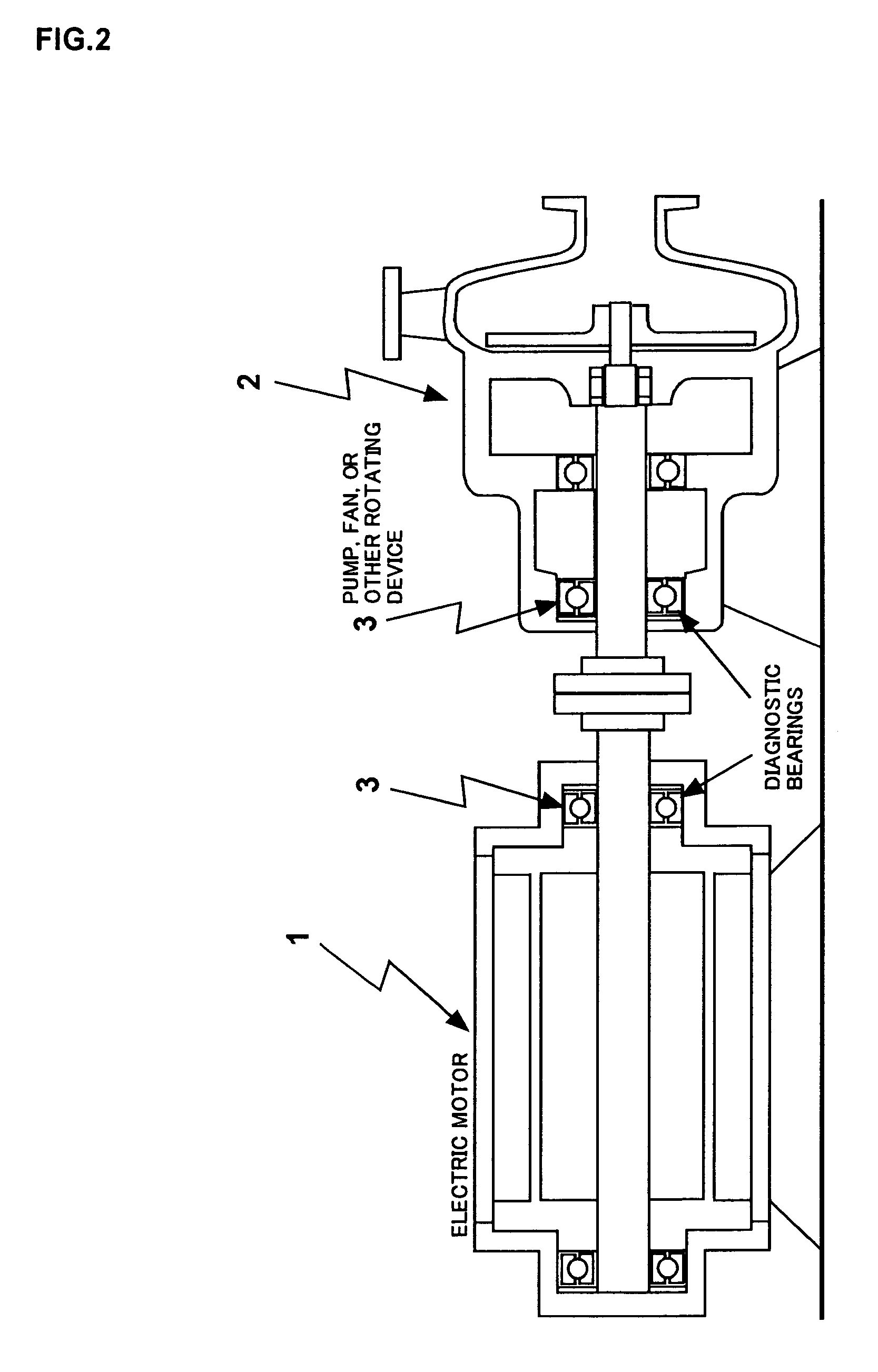

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

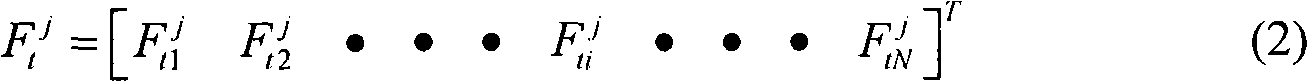

Method and apparatus for in-situ detection and isolation of aircraft engine faults

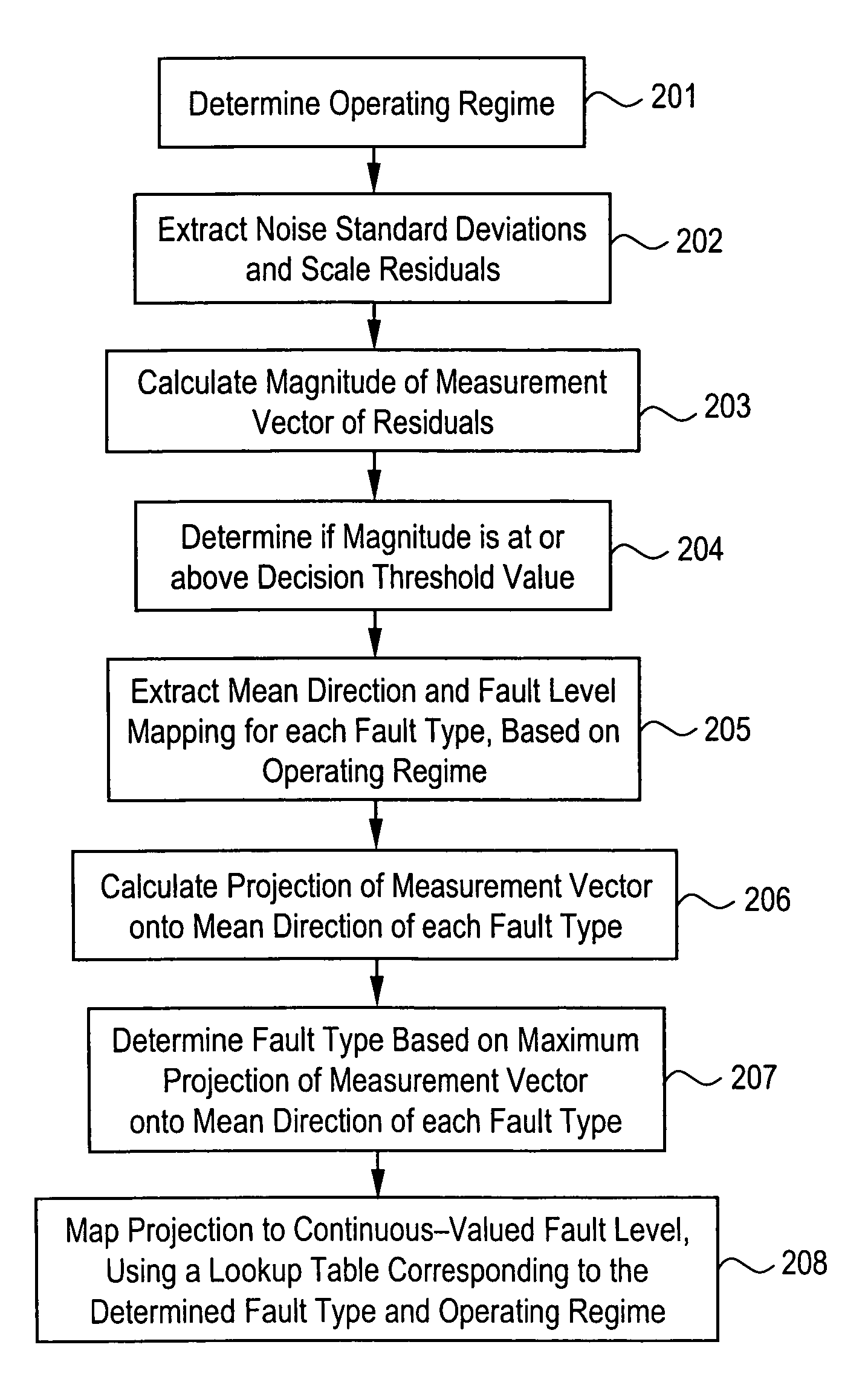

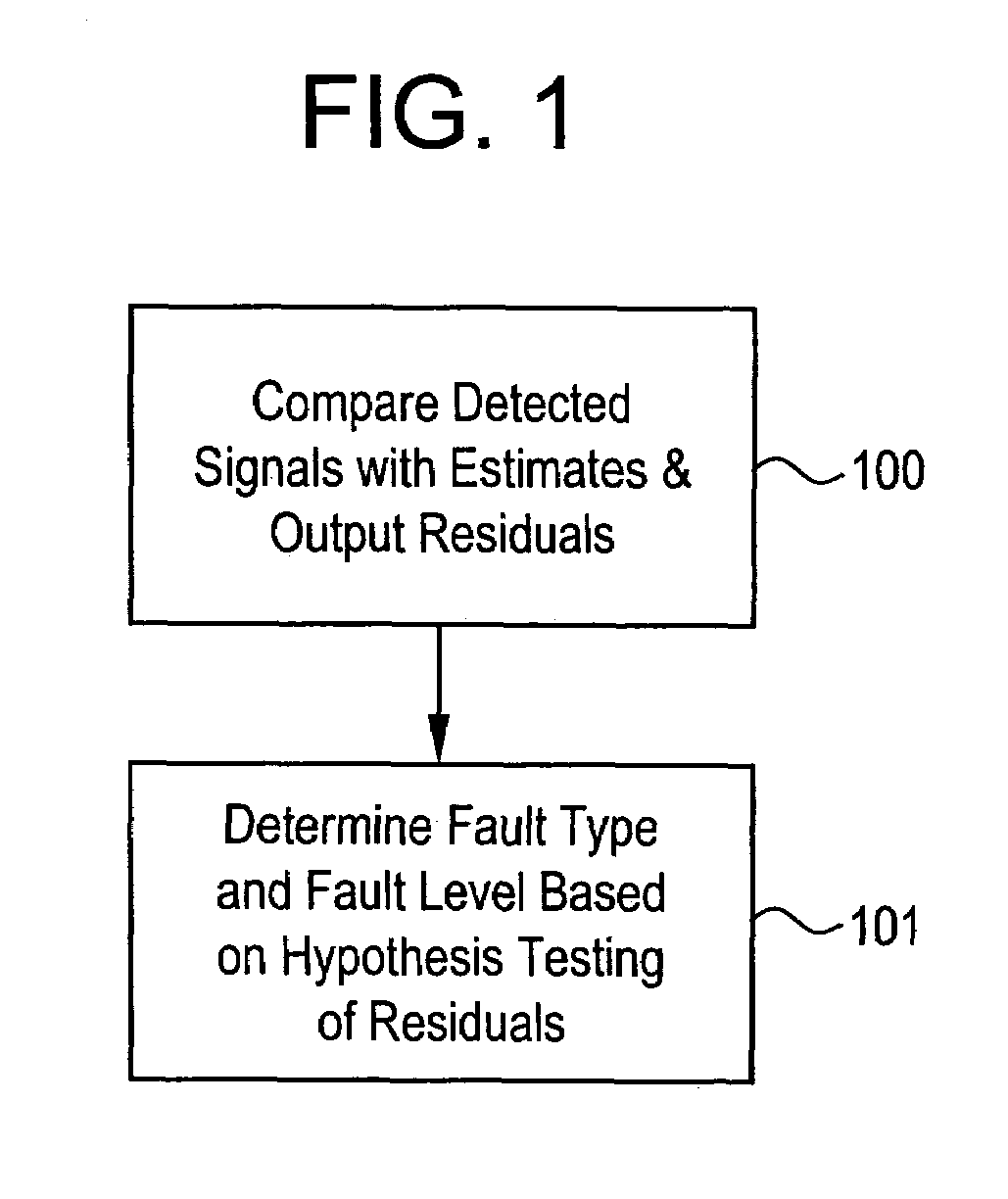

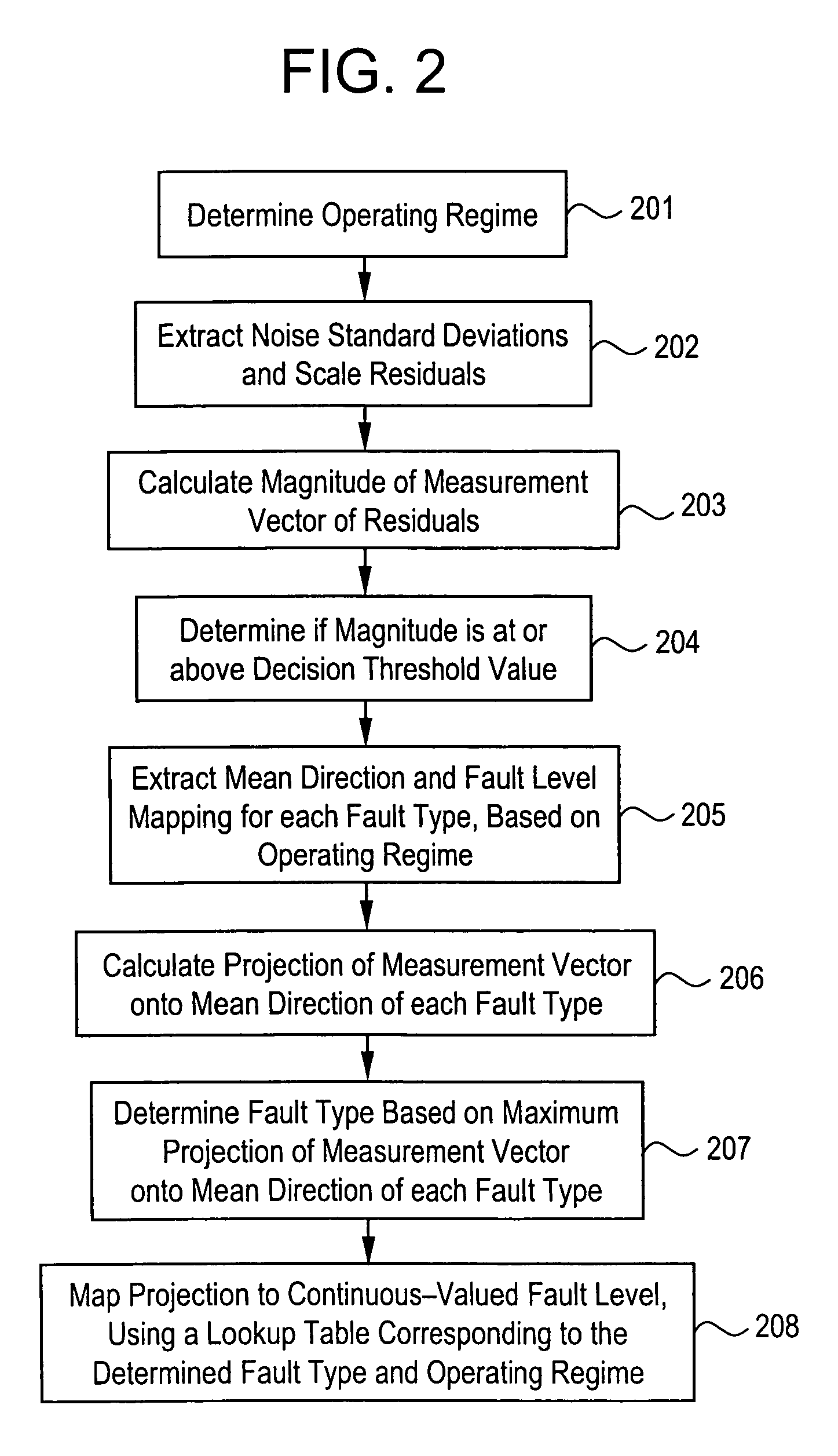

A method for performing a fault estimation based on residuals of detected signals includes determining an operating regime based on a plurality of parameters, extracting predetermined noise standard deviations of the residuals corresponding to the operating regime and scaling the residuals, calculating a magnitude of a measurement vector of the scaled residuals and comparing the magnitude to a decision threshold value, extracting an average, or mean direction and a fault level mapping for each of a plurality of fault types, based on the operating regime, calculating a projection of the measurement vector onto the average direction of each of the plurality of fault types, determining a fault type based on which projection is maximum, and mapping the projection to a continuous-valued fault level using a lookup table.

Owner:GENERAL ELECTRIC CO

Multi-parameter controllable high-rotating speed mechanical sealing performance tester

InactiveCN1825083AEasy to controlReduce stressMachine part testingHydrodynamic testingControl systemData acquisition

The invention relates to a mechanism sealing controllable testing device that includes sealing system, driving system, end face specific pressure loading and servo feed back system, end face attrition torque and end face specific pressure testing system, film thickness testing system, leakage testing system, static loop temperature feedback system, medium temperature and pressure measuring system, experiment medium pressurizing recycling system, data collection and control system. The invention has wide application range, and would be researched under different conditions.

Owner:NANJING COLLEGE OF CHEM TECH

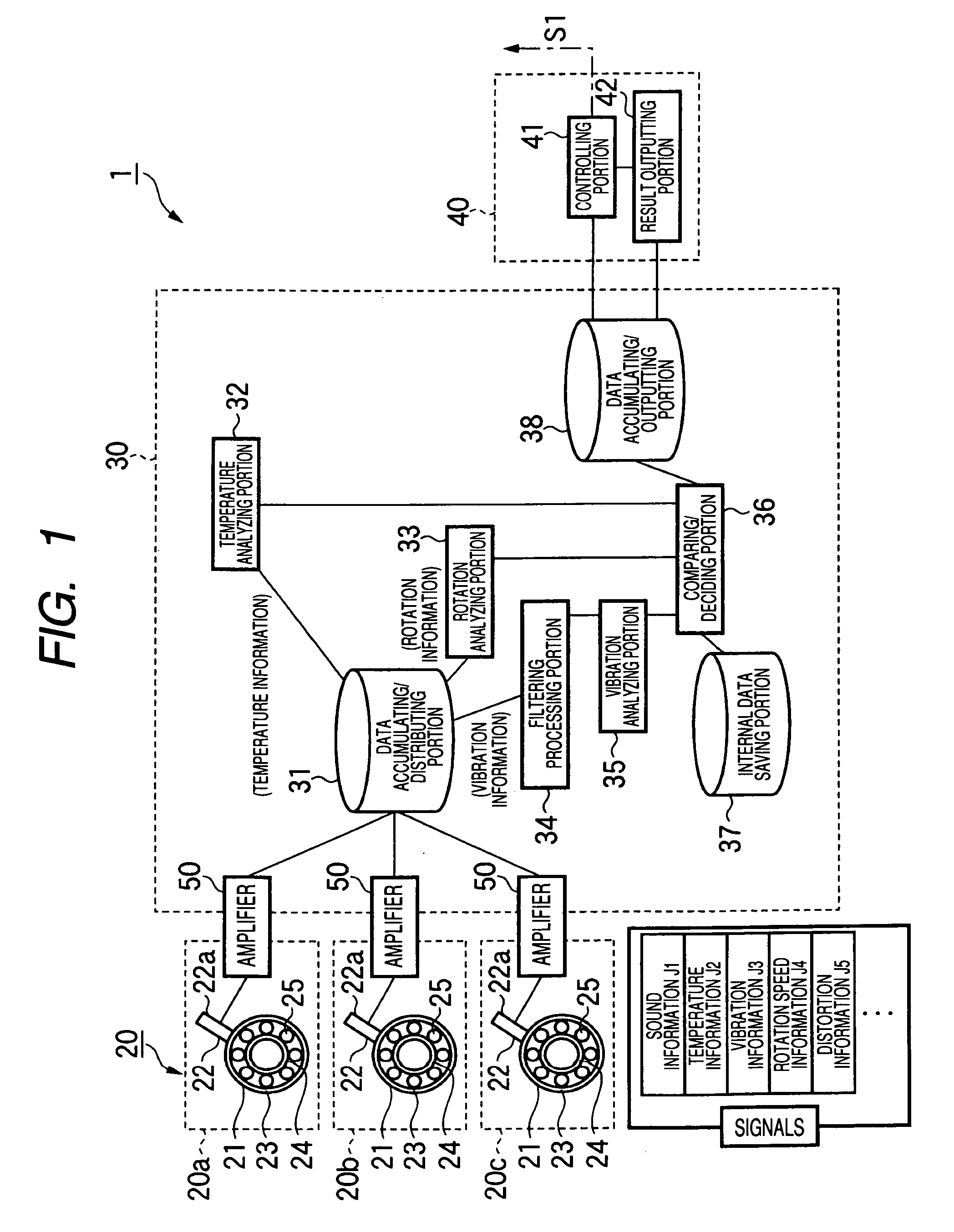

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

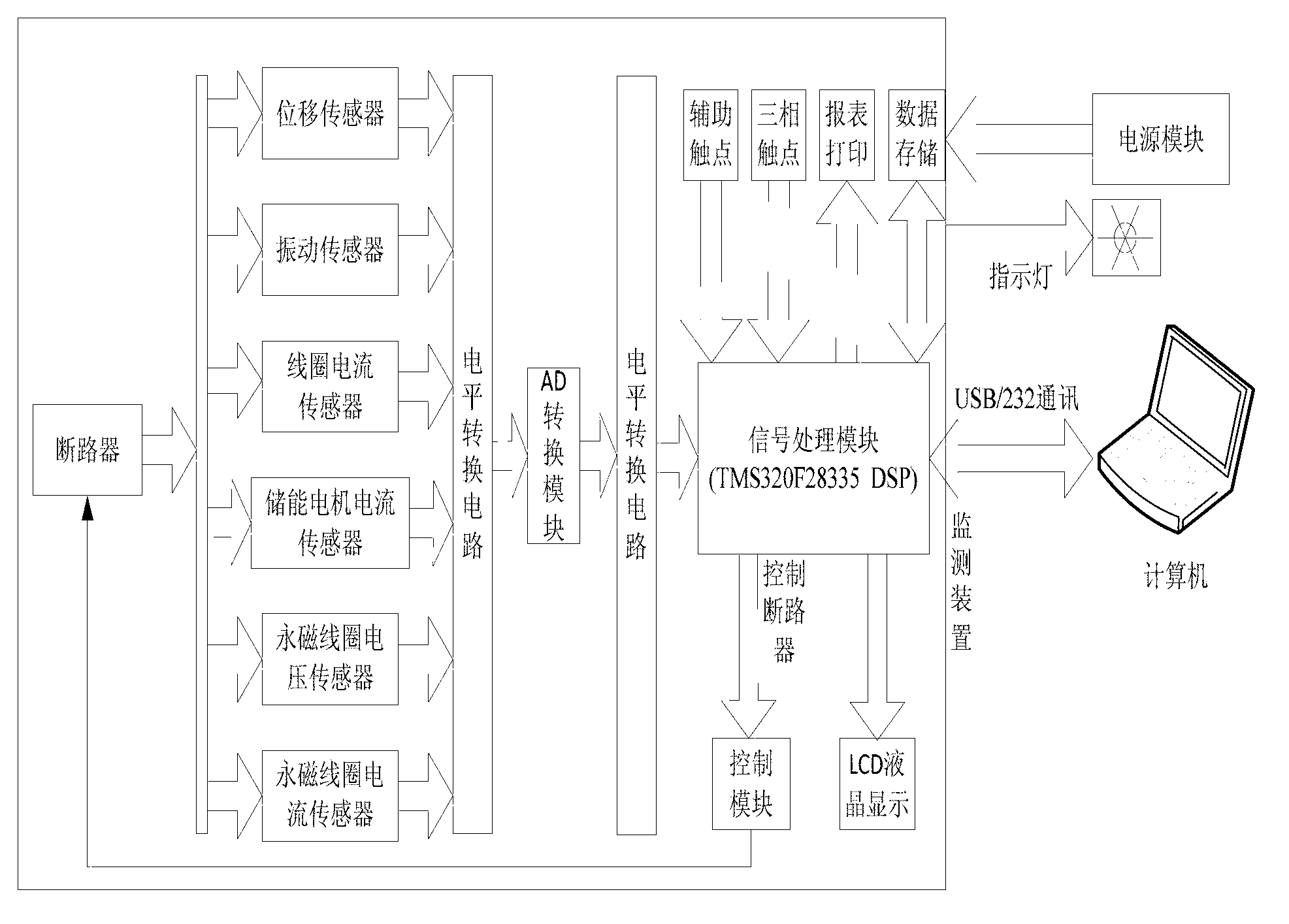

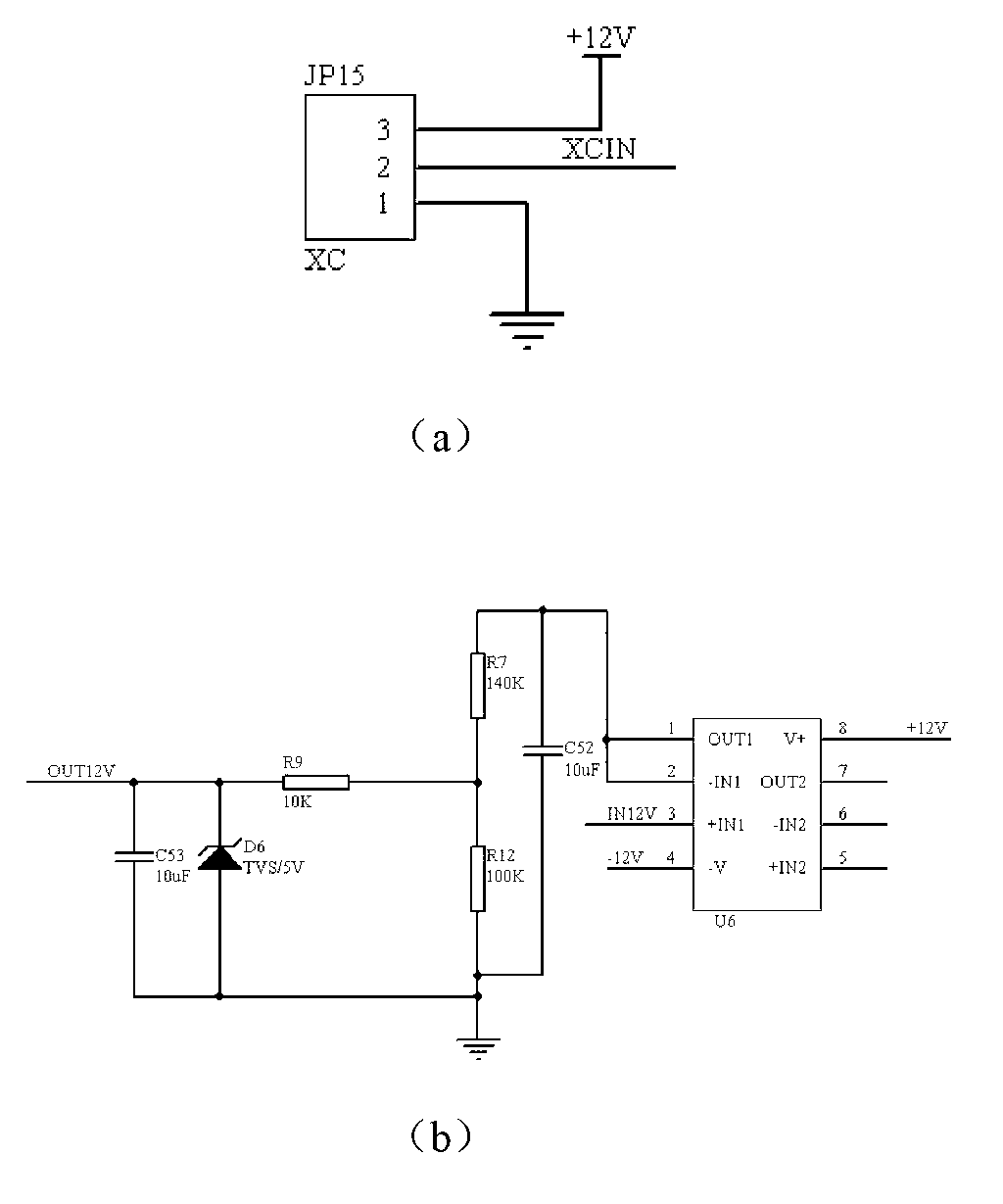

Device for detection of mechanical characteristics and diagnosis of faults of high-voltage circuit breaker

InactiveCN103323770ASimple structureEasy to useMachine part testingCircuit interrupters testingComputer moduleEngineering

The invention discloses a device for detection of mechanical characteristics and diagnosis of faults of a high-voltage circuit breaker, and relates to a switch device in the technical field of electric power. The device for detection of the mechanical characteristics and diagnosis of the faults of the high-voltage circuit breaker comprises a power module, an AD conversion module, a USB / RS232 communication module, a computer, a signal processing module, a control module, a collection module and a USB / RS232 communication module. The device for detection of the mechanical characteristics and diagnosis of the faults of the high-voltage circuit breaker integrates a plurality of paths of collection signals which comprise a loop current of an energy storage motor of the high-voltage circuit breaker of a spring operating mechanism, a coil current of a switch-on releaser, a coil current of a switch-off releaser, vibration signals of the high-voltage breaker, and information content of the angular displacement and the speed of rotation of a main shaft, local information of the mechanical characteristic state of the high-voltage circuit breaker is obtained by collecting information content with different forms, analysis is carried out on the local information through the signal processing module of the device, and the local information is combined, superposed and deduced to generate judgment information of the mechanical characteristics of the high-voltage circuit breaker. The device for detection of the mechanical characteristics and diagnosis of the faults of the high-voltage circuit breaker is simple in structure, convenient to use and stable in monitoring.

Owner:STATE GRID CORP OF CHINA +2

Popular searches

Subsonic/sonic/ultrasonic wave measurement Material analysis using acoustic emission techniques Response signal detection Processing detected response signal Static/dynamic balance measurement Using electrical means Indication of measured values Material analysis by transmitting radiation Frequency analysis Level indicators

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com