Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Finite element technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

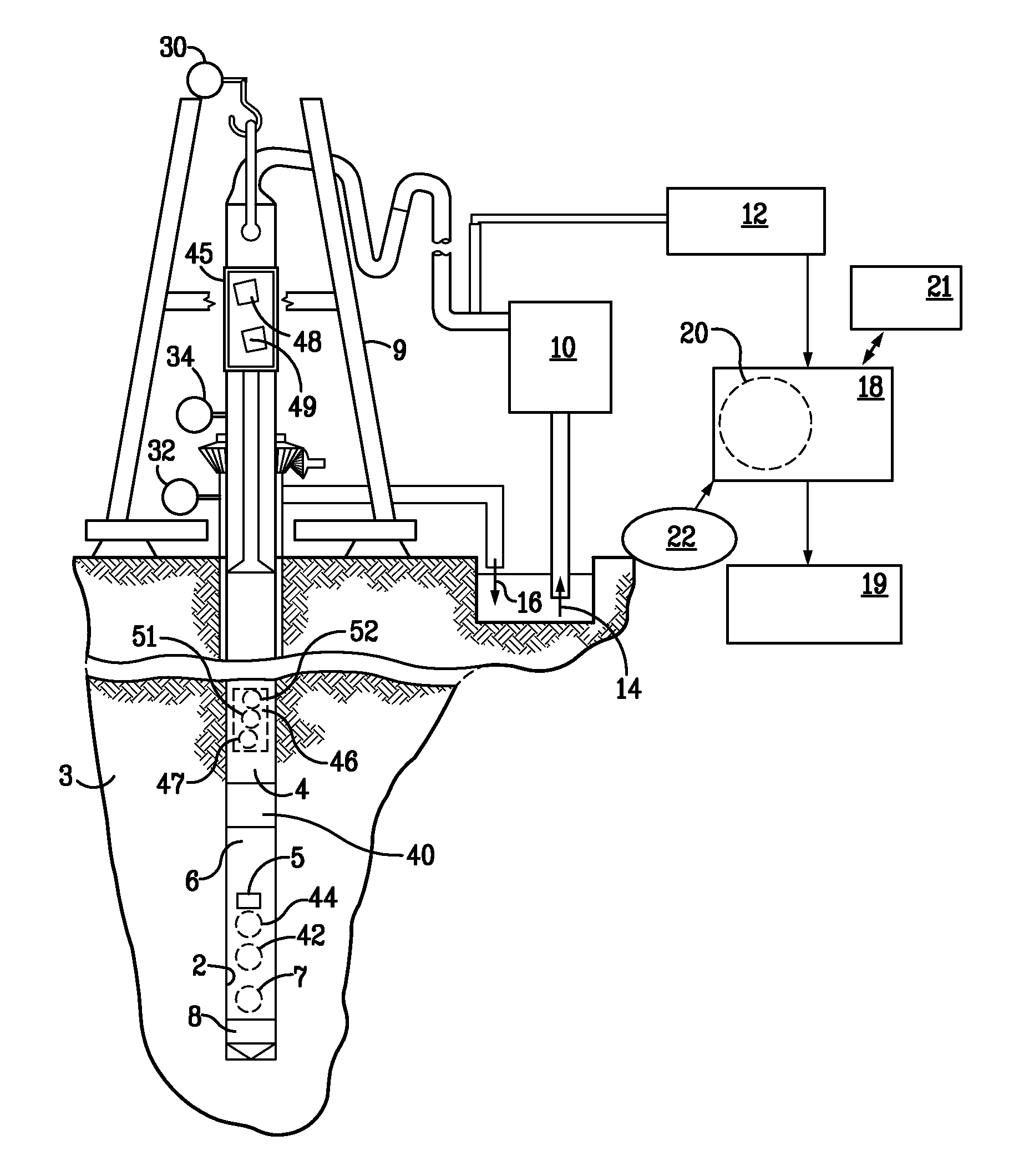

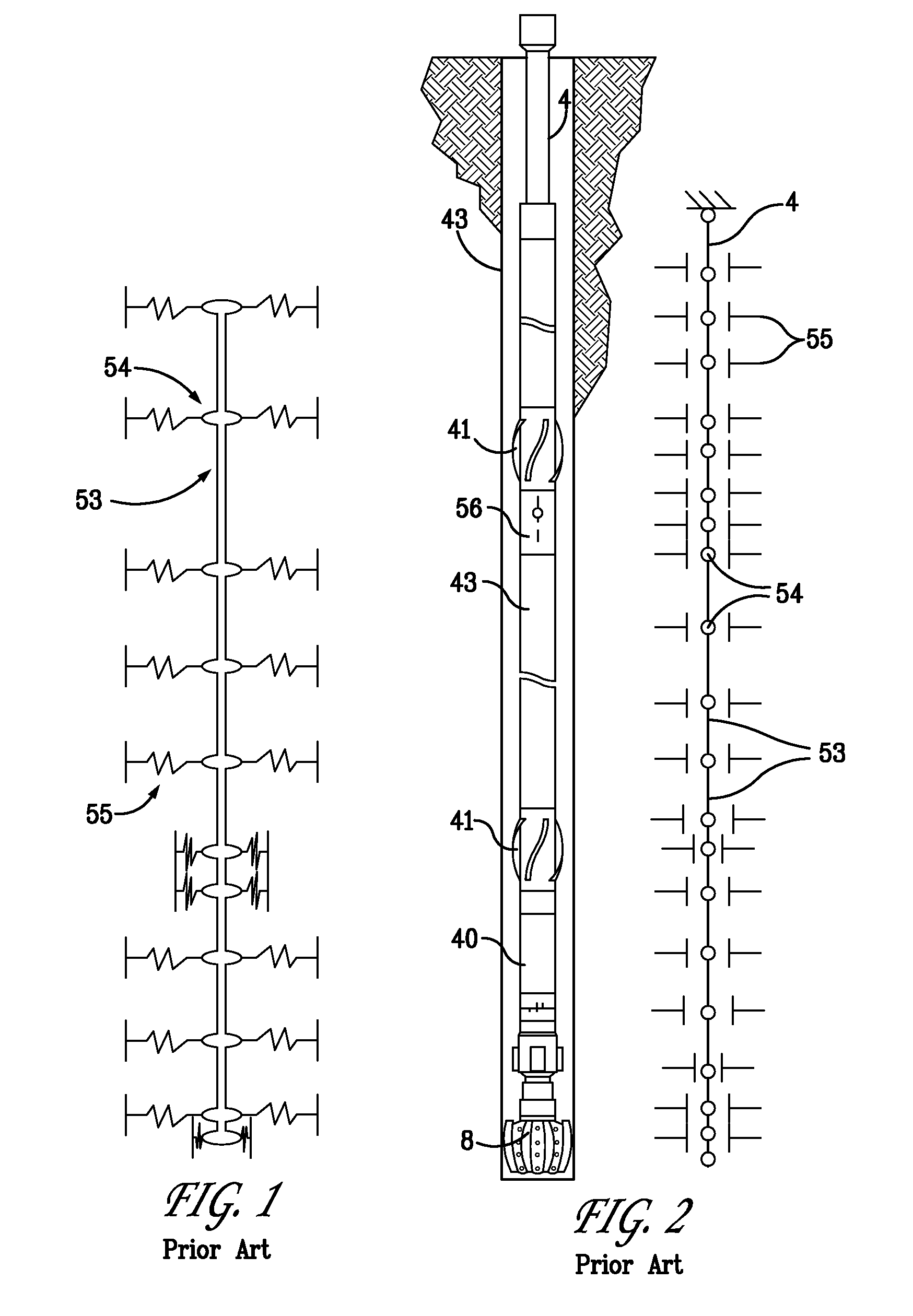

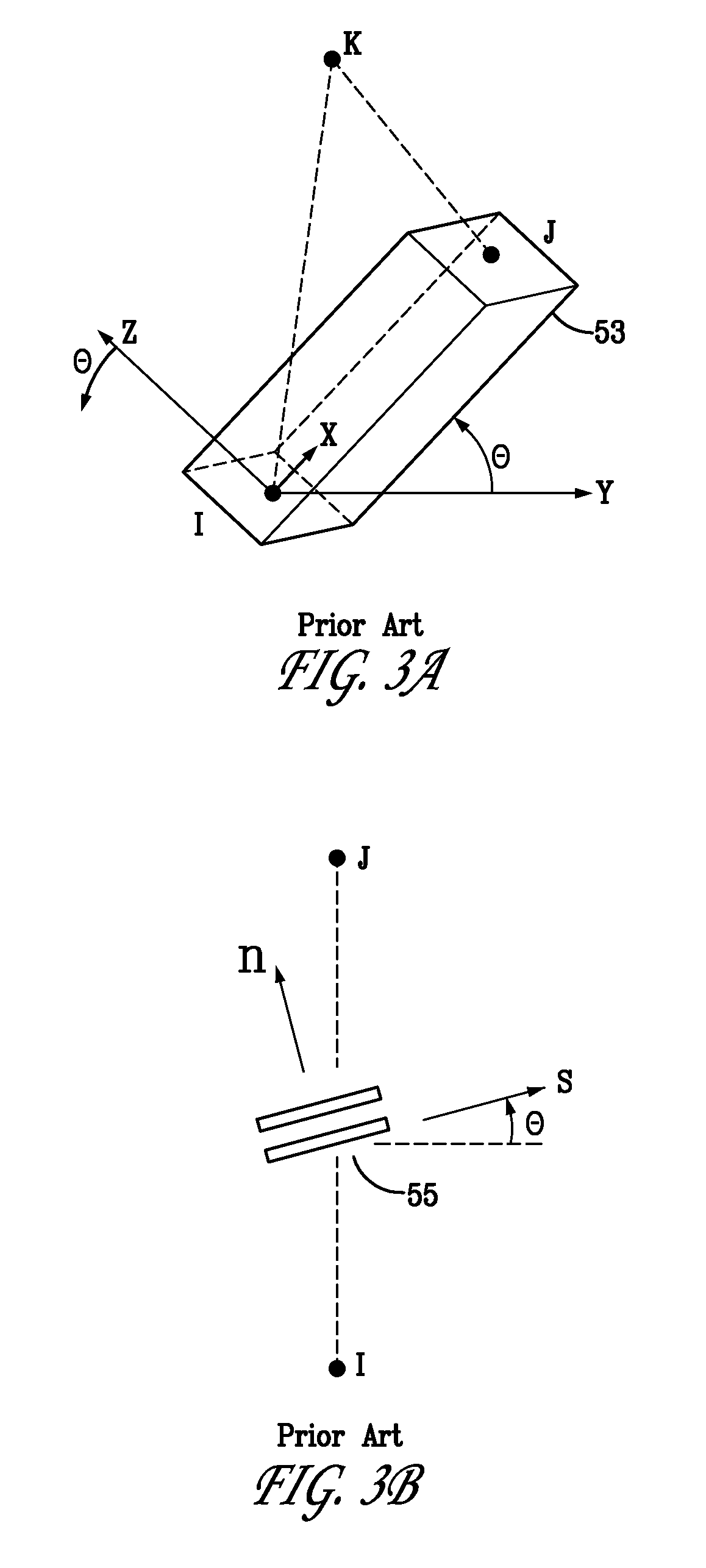

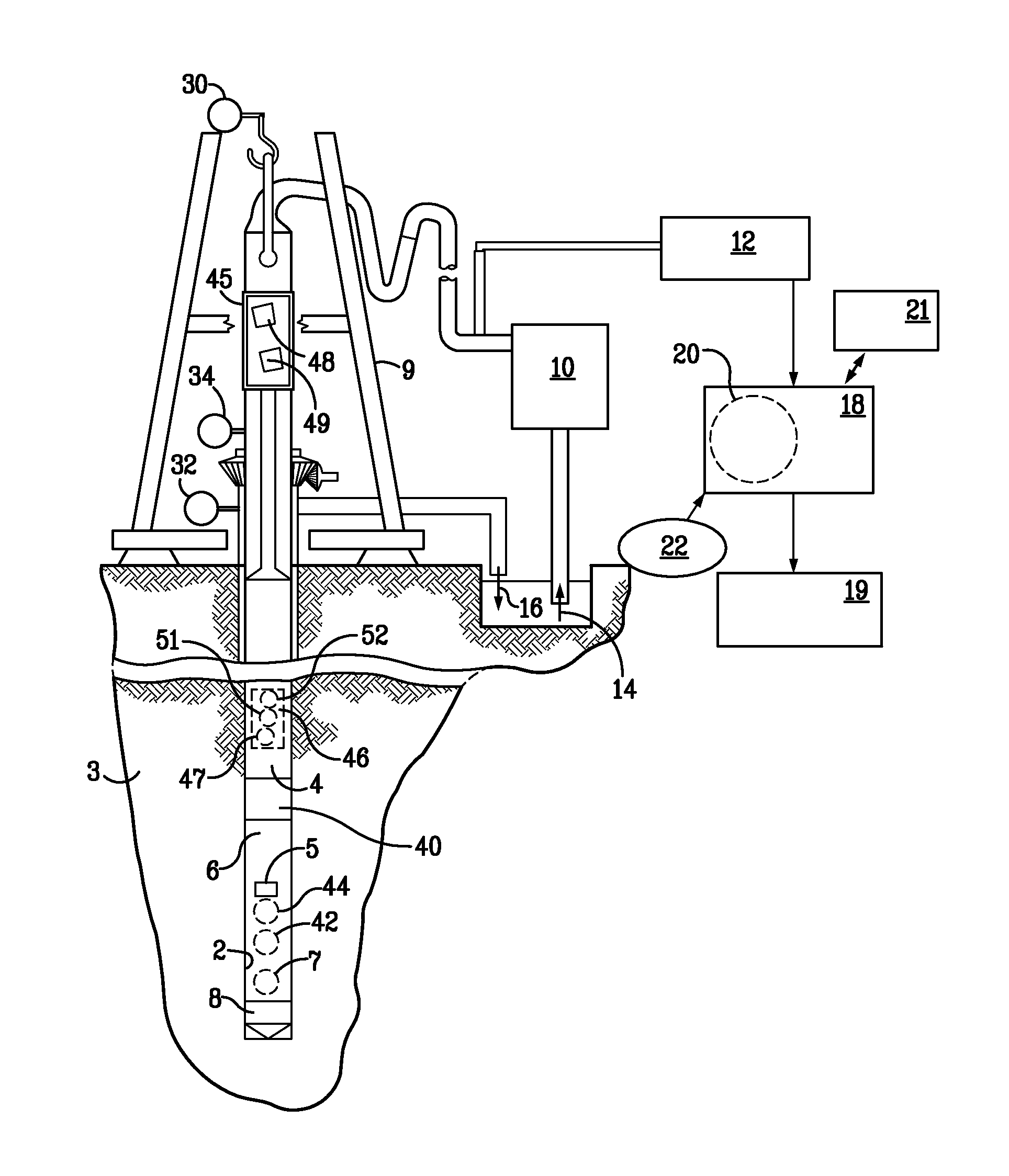

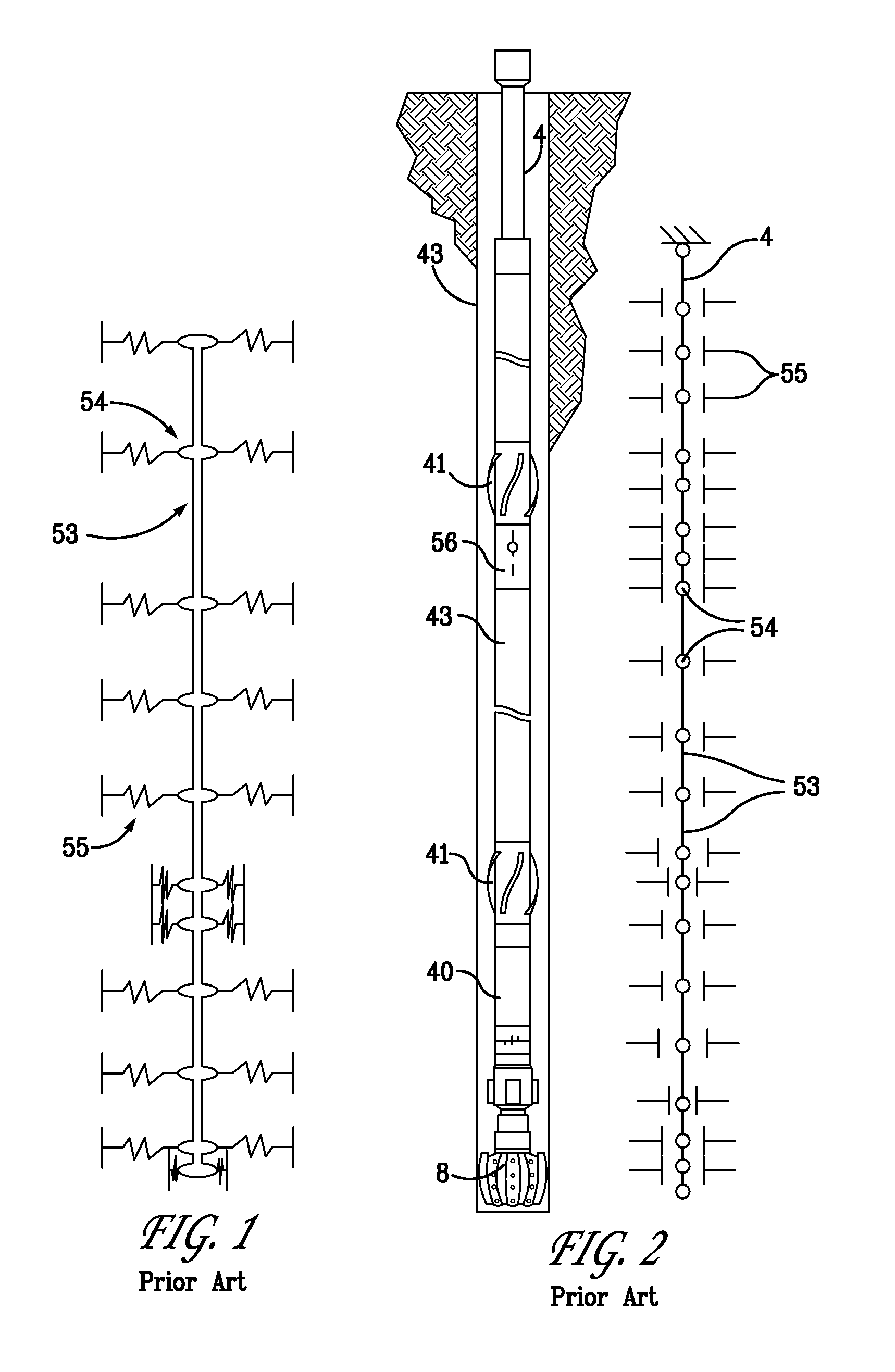

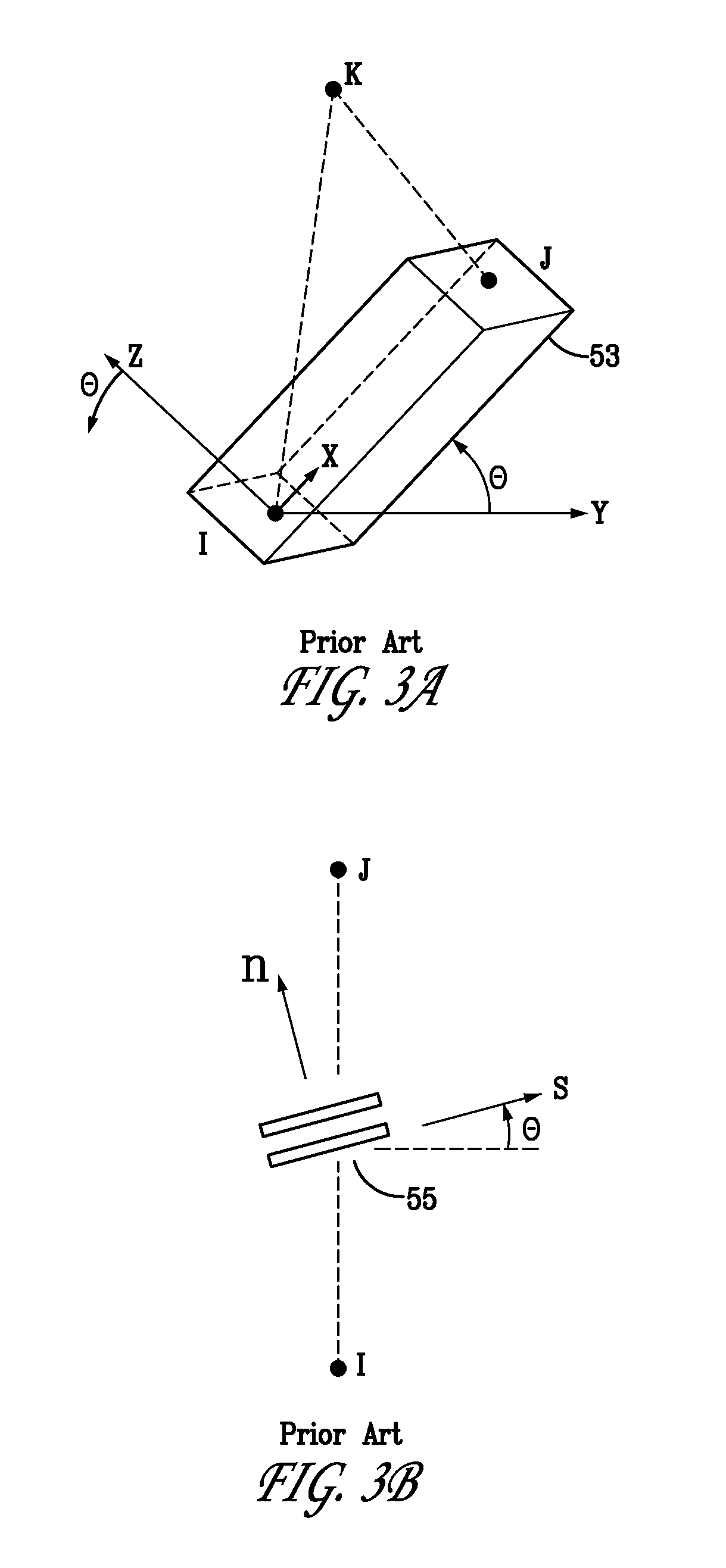

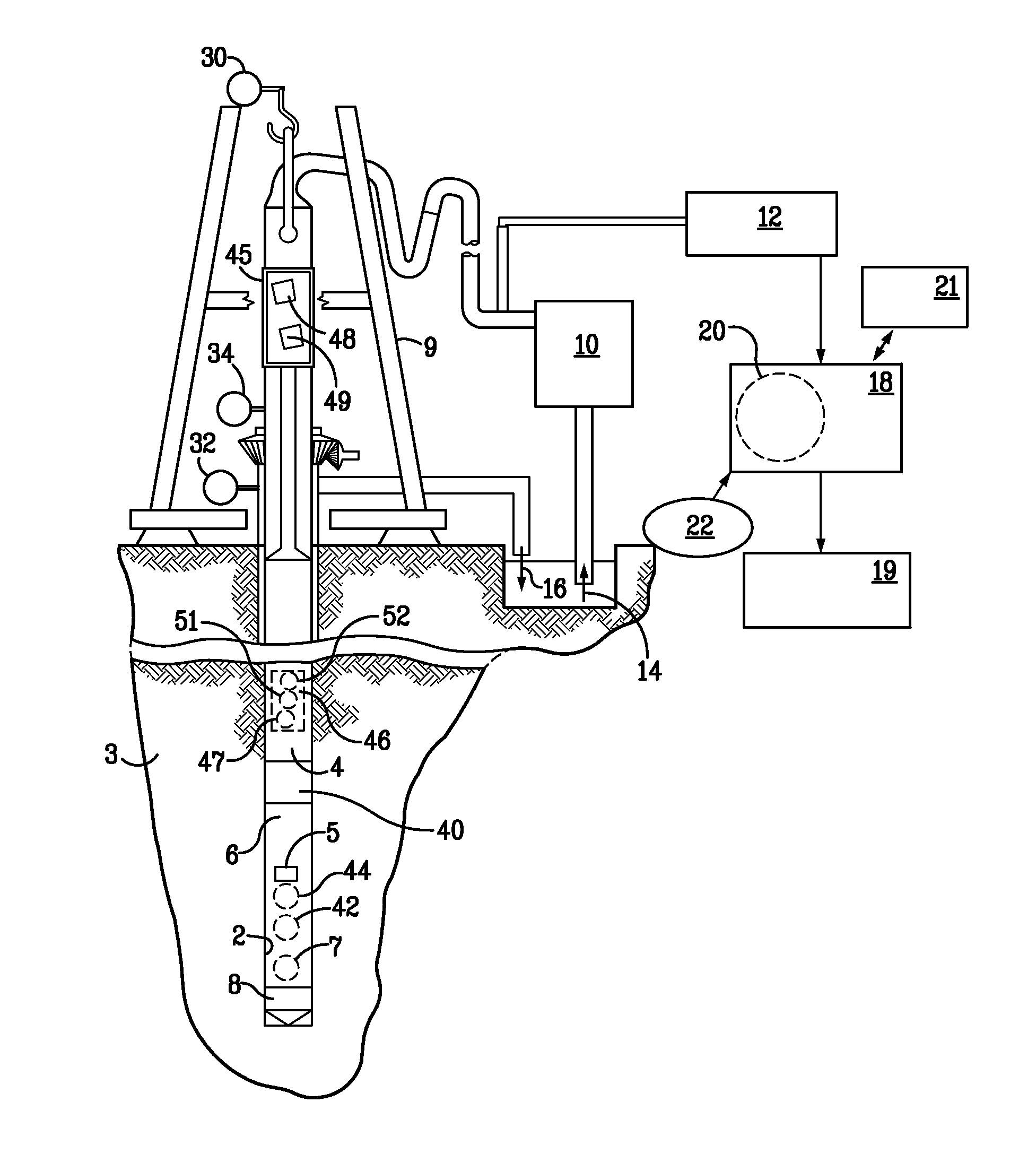

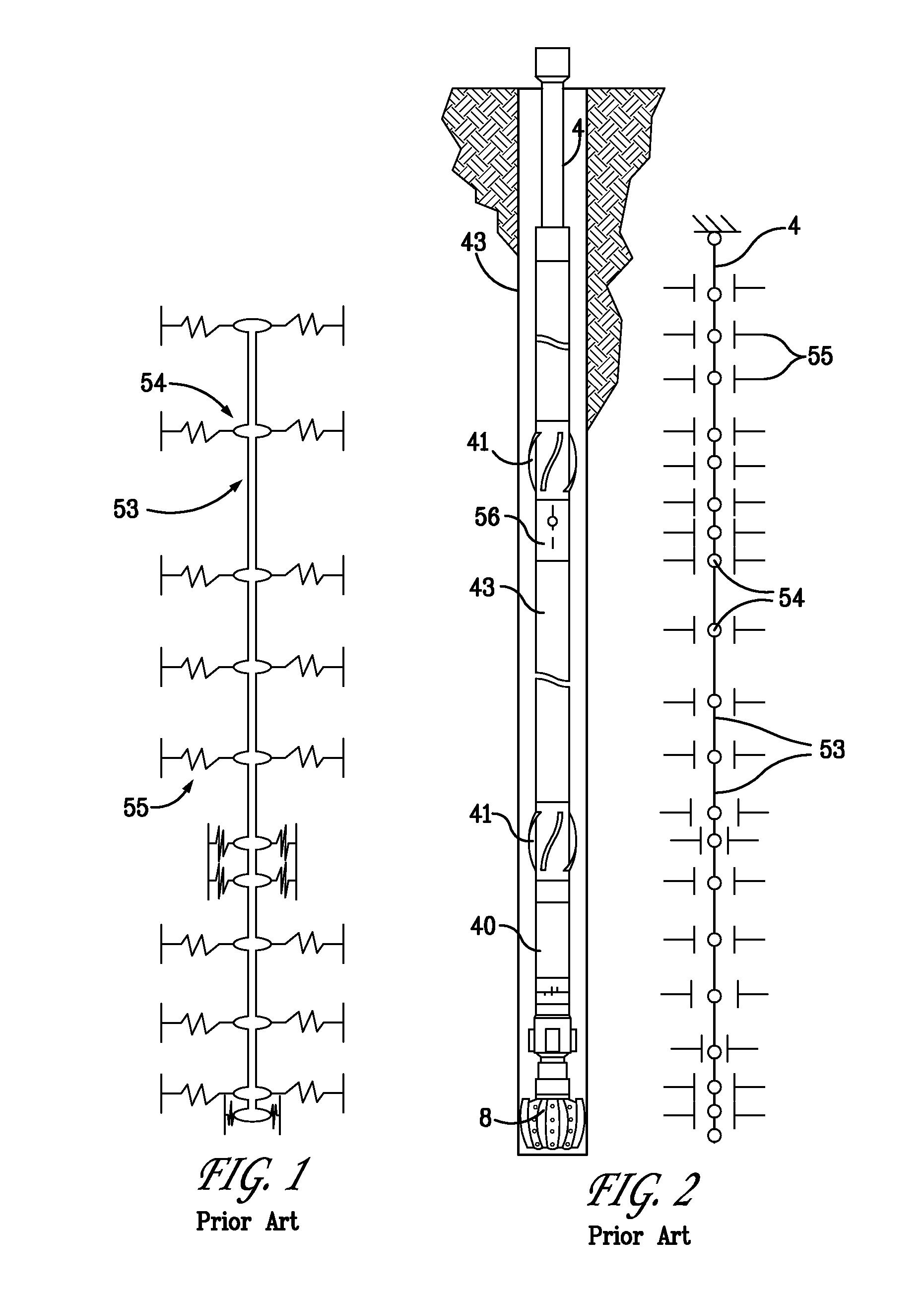

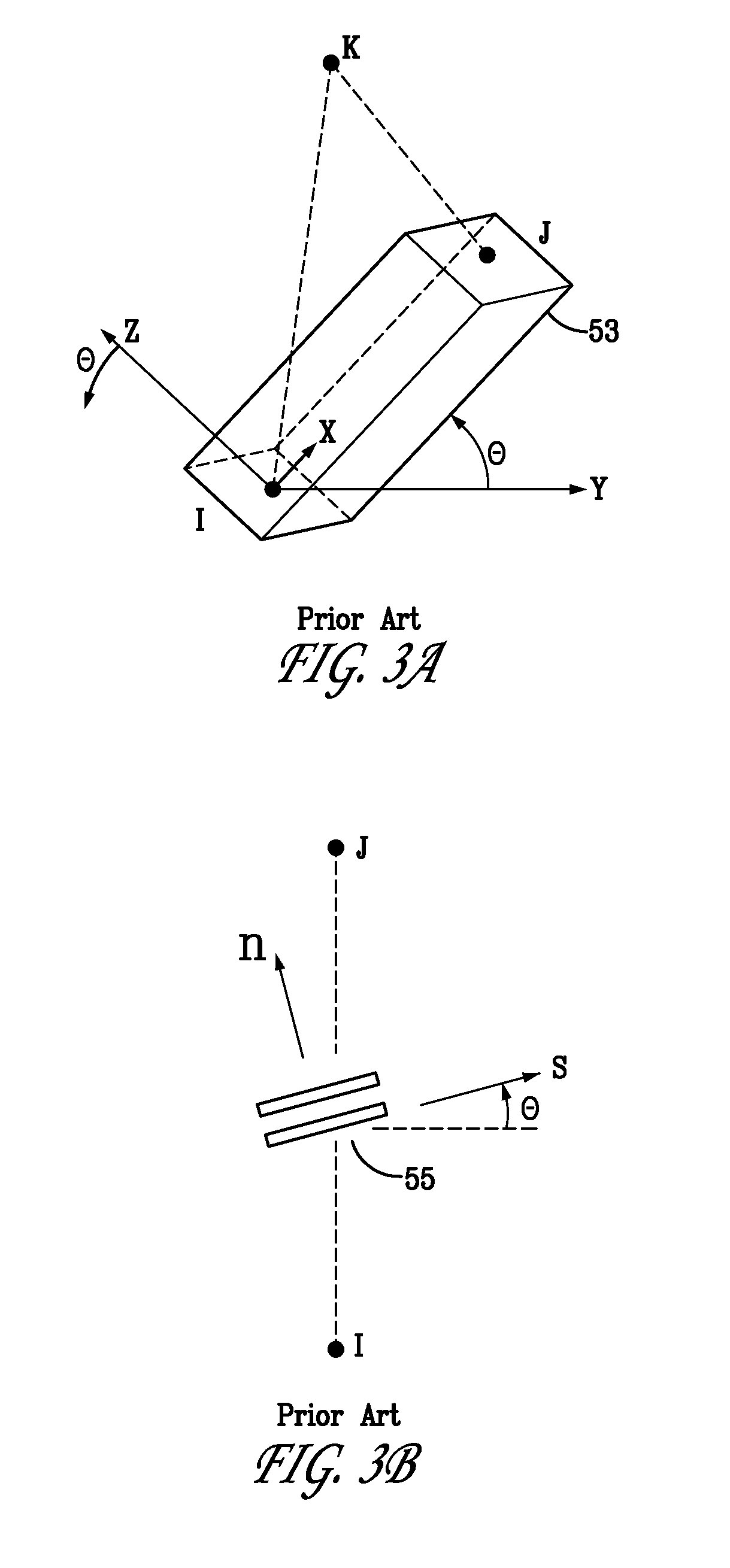

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20110186353A1Reduce the differenceVibration measurement in solidsMachine part testingFinite element techniqueResonance

A system and method for monitoring underground drilling in which vibration is monitored by creating a model of the drill string using finite element techniques or finite difference techniques and (i) predicting vibration by inputting real time values of operating parameters into the model, and then adjusting the model to agree with measured vibration data, (ii) predicting the weight on bit and drill string and mud motor speeds at which resonance will occur, as well as when stick-slip will occur, so that the operator can avoid operating regimes that will result in high vibration, (iii) determining vibration and torque levels along the length of the drill string based on the measured vibration and torque at one or more locations, (iv) determining the remaining life of critical components of the drill string based on the history of the vibration to which the components have been subjected, and (v) determining the optimum drilling parameters that will avoid excessive vibration of the drill string.

Owner:APS TECH

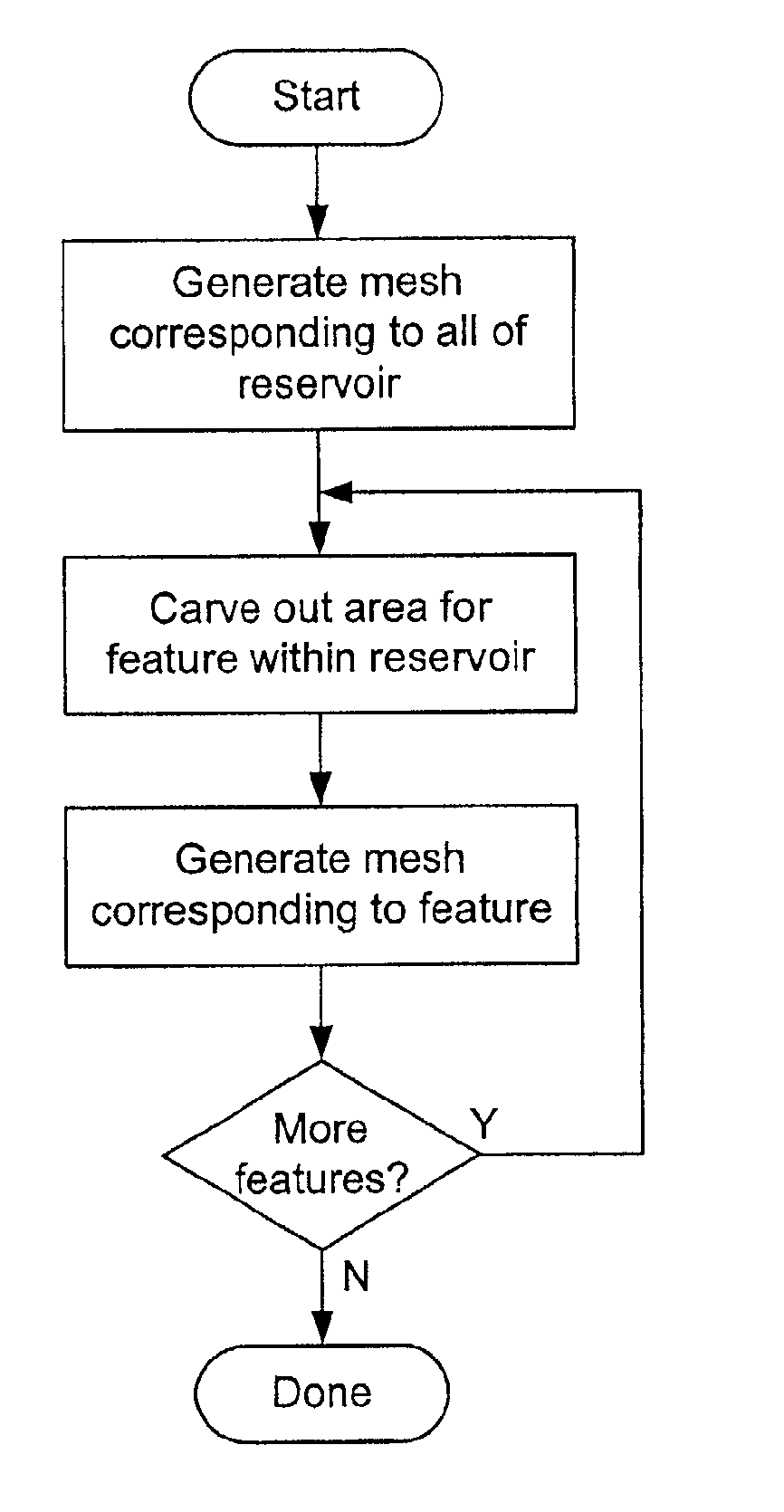

Feature modeling in a finite element model

ActiveUS6941255B2Accurate representationSmall amount of calculationGeometric CADComputation using non-contact making devicesFinite element techniqueElement model

A method for simulating a physical system using finite element techniques, wherein two or more distinct models corresponding to distinct regions within the modeled system are solved, each with a corresponding evaluator. Nodes which lie on the boundaries between the models may have different values corresponding to the different models. When a particular model is solved, the evaluator for that model is used to obtain the appropriate values for each of these common nodes. In one embodiment, a first model is defined, then a region corresponding to a particular feature within the system is carved out of it. A finite element model corresponding to the feature is then inserted into the region. The finite elements may be adapted to share nodes on the boundaries between them.

Owner:LANDMARK GRAPHICS

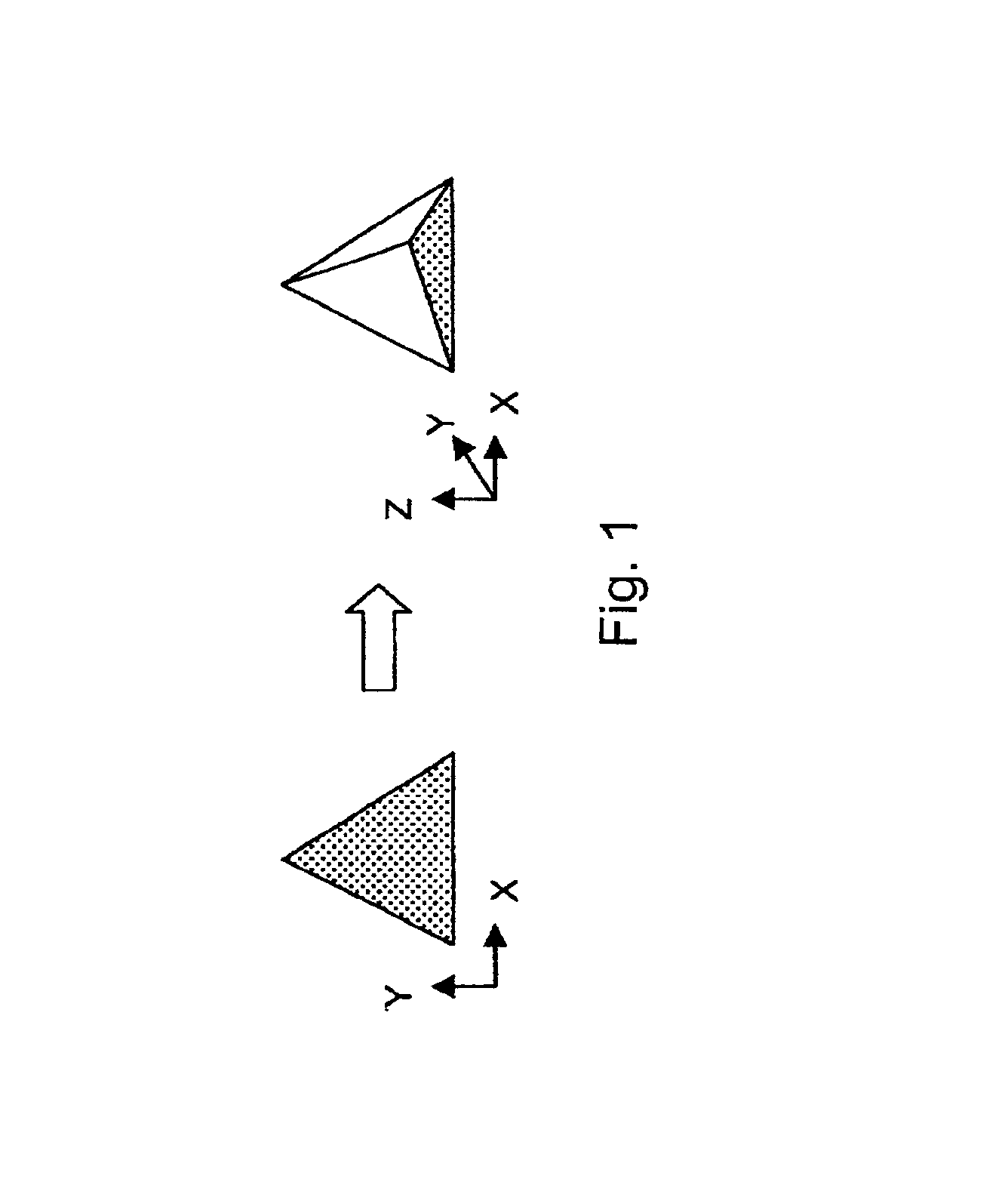

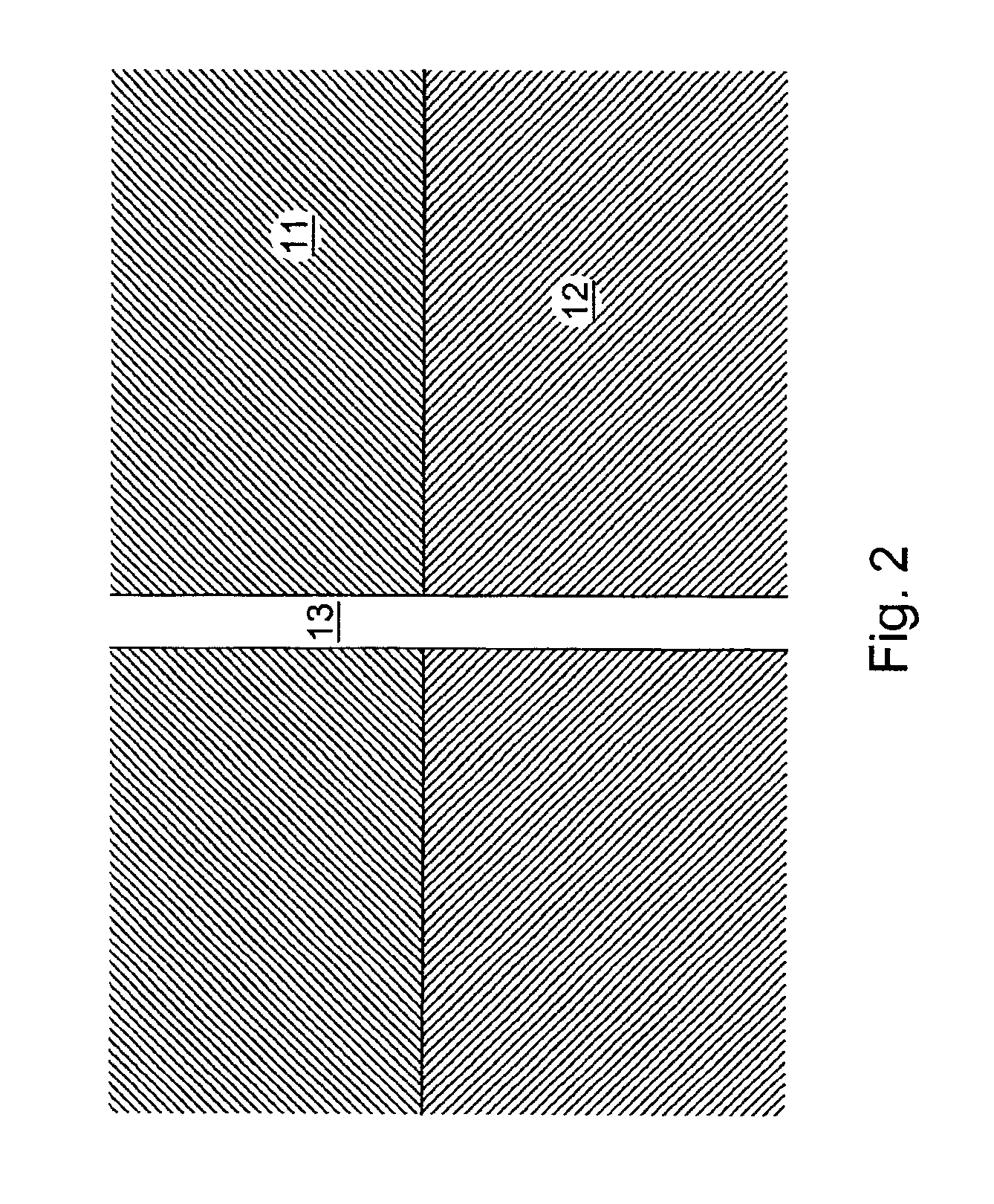

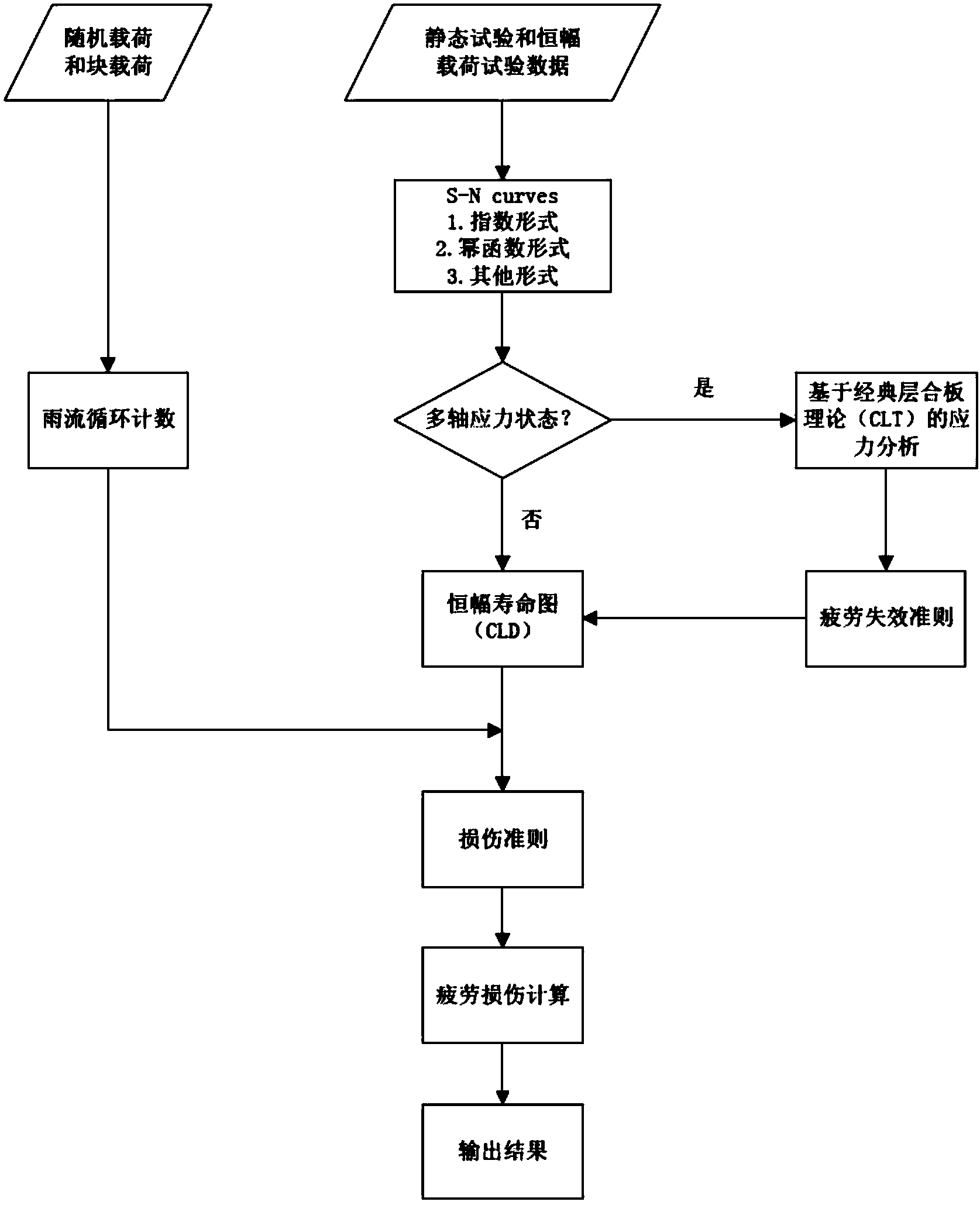

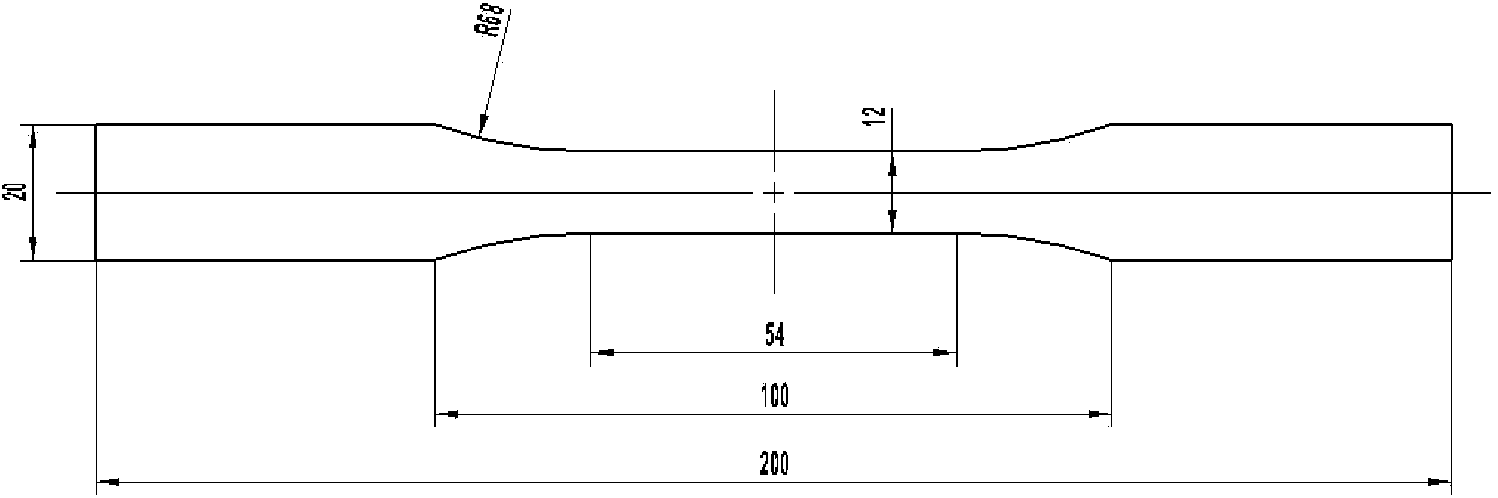

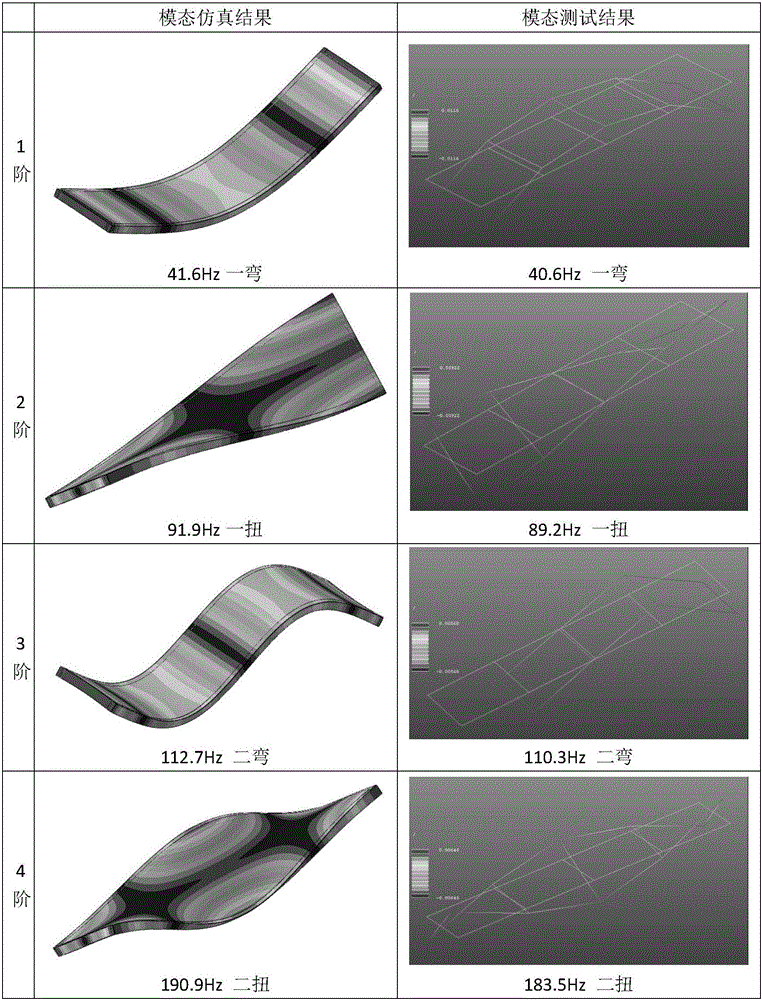

Carbon fiber composite material fatigue life estimating method based on stress ratio influences

InactiveCN103942441AAccurate lifeAccurate Damage AssessmentSpecial data processing applicationsStrength propertiesFinite element techniqueDispersity

The invention belongs to the technical field of composite materials, and discloses a carbon fiber composite material fatigue life estimating method based on stress ratio influences. Structural response calculation is carried out by means of a finite element technology. A finite element model is based on a classical laminate plate theory, and a umat subprogram taking tension and compression asymmetry into consideration is built. By carrying out constant-amplitude fatigue tests under different stress ratios, an equation of an influence mechanism of average stress on prediction of the service life of a carbon fiber composite material structure is built and is popularized to a block load and a spectrum load. A service life estimating model built through the method is based on the classical laminate plate theory and takes influences of the average stress and a variable-amplitude load into consideration, dispersity of a prediction result is little, accuracy is high, theoretical guidance is provided for reliability design of parts made of carbon fiber composite materials, and the technical problems that existing carbon fiber composite material structure fatigue life is only estimated through a test method, and accordingly cost is high and consumed time is long are solved.

Owner:SHANGHAI JIAO TONG UNIV

Structure fatigue life calculation method based on non-linear cumulative damage theory

InactiveCN104833536AHigh precisionSimple calculationStructural/machines measurementFinite element techniqueCalculation methods

A structure fatigue life calculation method based on the non-linear cumulative damage theory comprises the following steps: firstly, performing a stress analysis on a metal structure through the finite element technology and determining a large-stress-value area as a dangerous area, secondly, determining initial damage of the structure according to a served age and surface quality detection of the structure, thirdly, measuring a stress spectrum of the structure in a certain period through a stress detector, fourthly, calculating cumulative damage of the structure under the stress spectrum through the non-linear cumulative damage theory, and fifthly, calculating a fatigue life of the metal structure through the cumulative damage. According to the method, the multi-stage load loading sequence and an influence of the size of a load on the cumulative damage are taken into account, and precision of the fatigue life is higher than the precision of a fatigue life calculated according to the linear cumulative damage theory. The method only needs a small amount of material performance data such as a cyclic stress-strain curve and a constant-amplitude strain life curve, calculation is simple, and the method is suitable for engineering applications.

Owner:DALIAN UNIV OF TECH +4

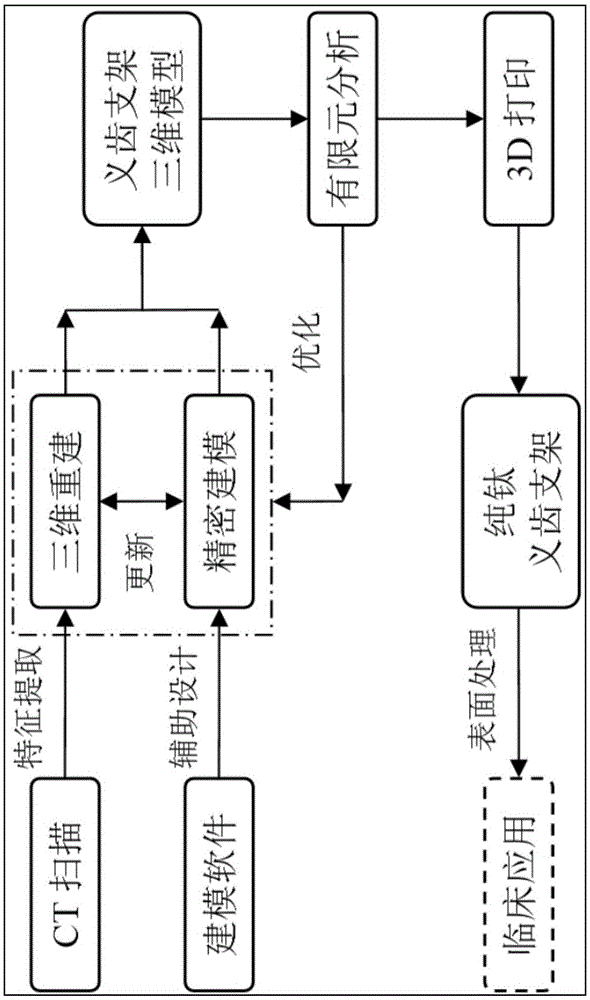

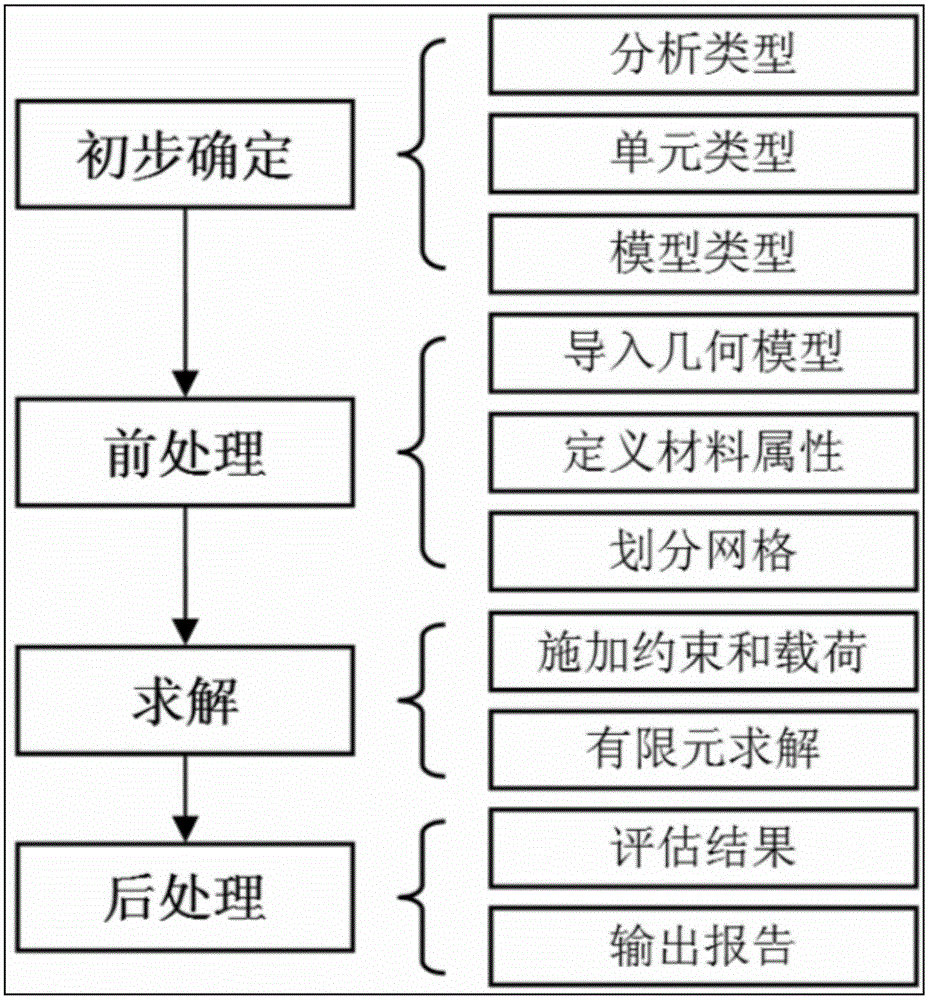

Method for preparing false tooth support through 3D printing laser stereo-lithography technology

InactiveCN104999078AGuaranteed comfortGuaranteed service lifeAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionFinite element technique

The invention discloses a method for preparing a false tooth support through a 3D printing laser stereo-lithography technology. According to the method for preparing the false tooth support through the 3D printing laser stereo-lithography technology, the individual false tooth support most suitable for a patient is printed through the 3D printing laser stereo-lithography technology; the comfort level and the service life of the false tooth support are ensured by means of a finite element technology; the operation difficulty of a physician is lowered; the manufacturing cost is reduced; the manufacturing period is shortened. The surface of the false tooth support is processed through an anodizing and / or electrochemical deposition method so that the surface of the false tooth support can have more excellent synosteosis features and biology activity, osteoblast growth and surface calcification are facilitated, and the satisfaction of the patient is improved. The method is suitable for the field of medical devices.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Allowance-free numerical-control method for aircraft skin

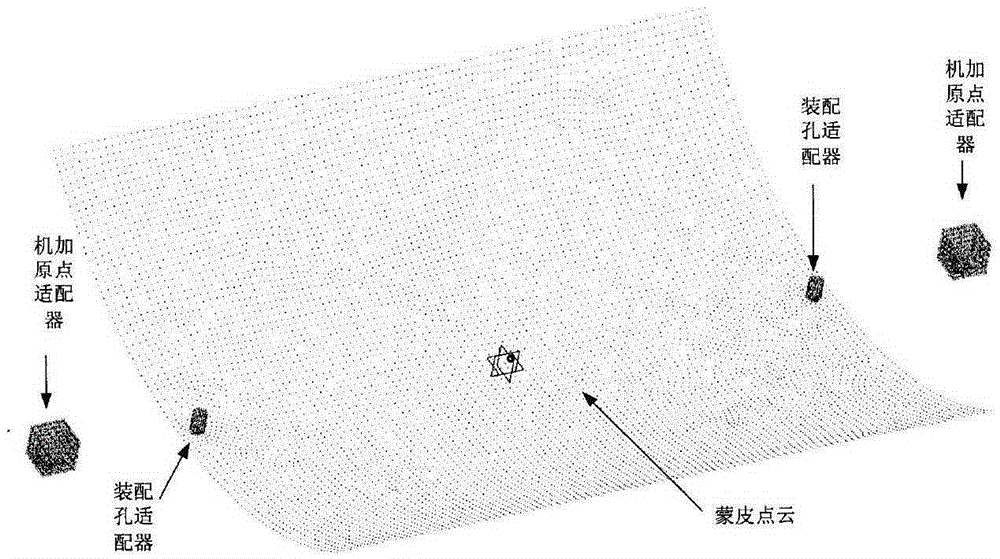

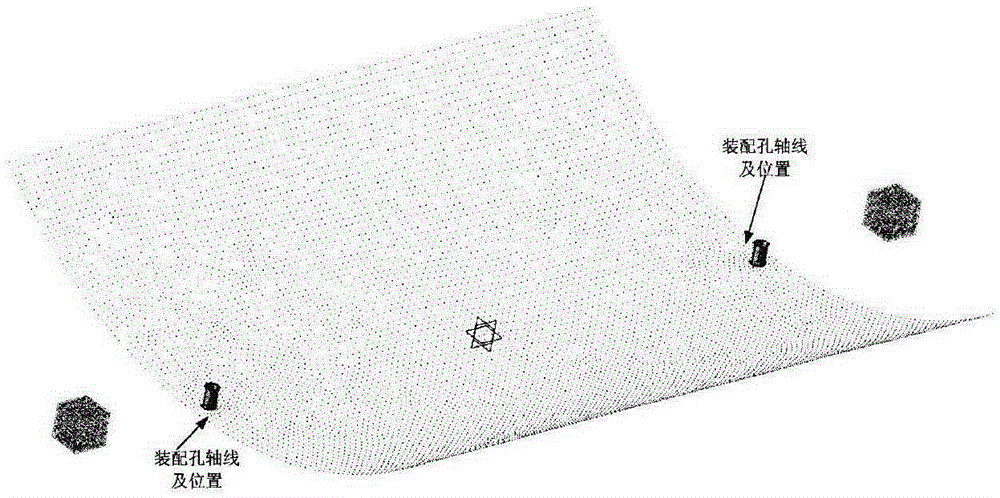

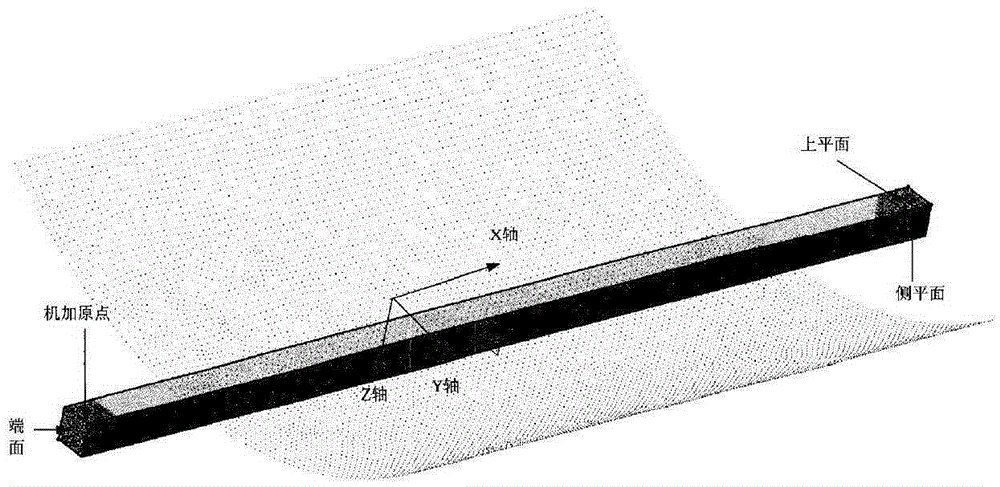

ActiveCN105269049AEliminate the effects ofLow positioning accuracy requirementsMilling equipment detailsNumerical controlFinite element technique

The invention discloses an allowance-free numerical-control method for an aircraft skin. The skin is clamped through three-dimensional scanning to obtain the actual pose and the shape point cloud of the skin; a machining original point adapter and an assembling hole adapter are additionally arranged on a flexible tool to obtain point cloud data of the machining original point adapter and the assembling hole adapter; the assembling hole pose and a tool original point coordinate system are fitted out through a point cloud fitting technique; a theoretical digital-analog milling boundary is mapped to a skin point cloud face through a finite element technology to serve as a milling boundary; and the machining original point coordinate system serves as a machining original point, and the milling boundary serves as a machining path to write numerical-control machining programs. According to the allowance-free numerical-control method, a numerical-control machine tool is utilized to establish an actual machining original point with the machining original point adapter to carry out machining. The allowance-free numerical-control method is not high in requirement for locating accuracy of all clamping point, so that the producing cost of the flexible toll can be greatly simplified.

Owner:SHENYANG AIRCRAFT CORP

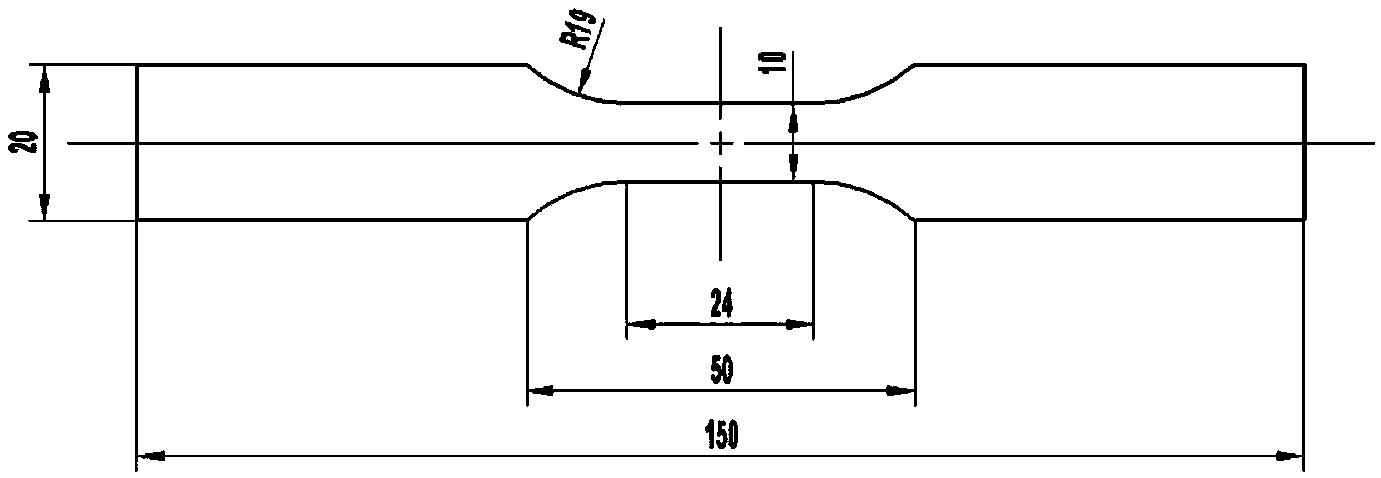

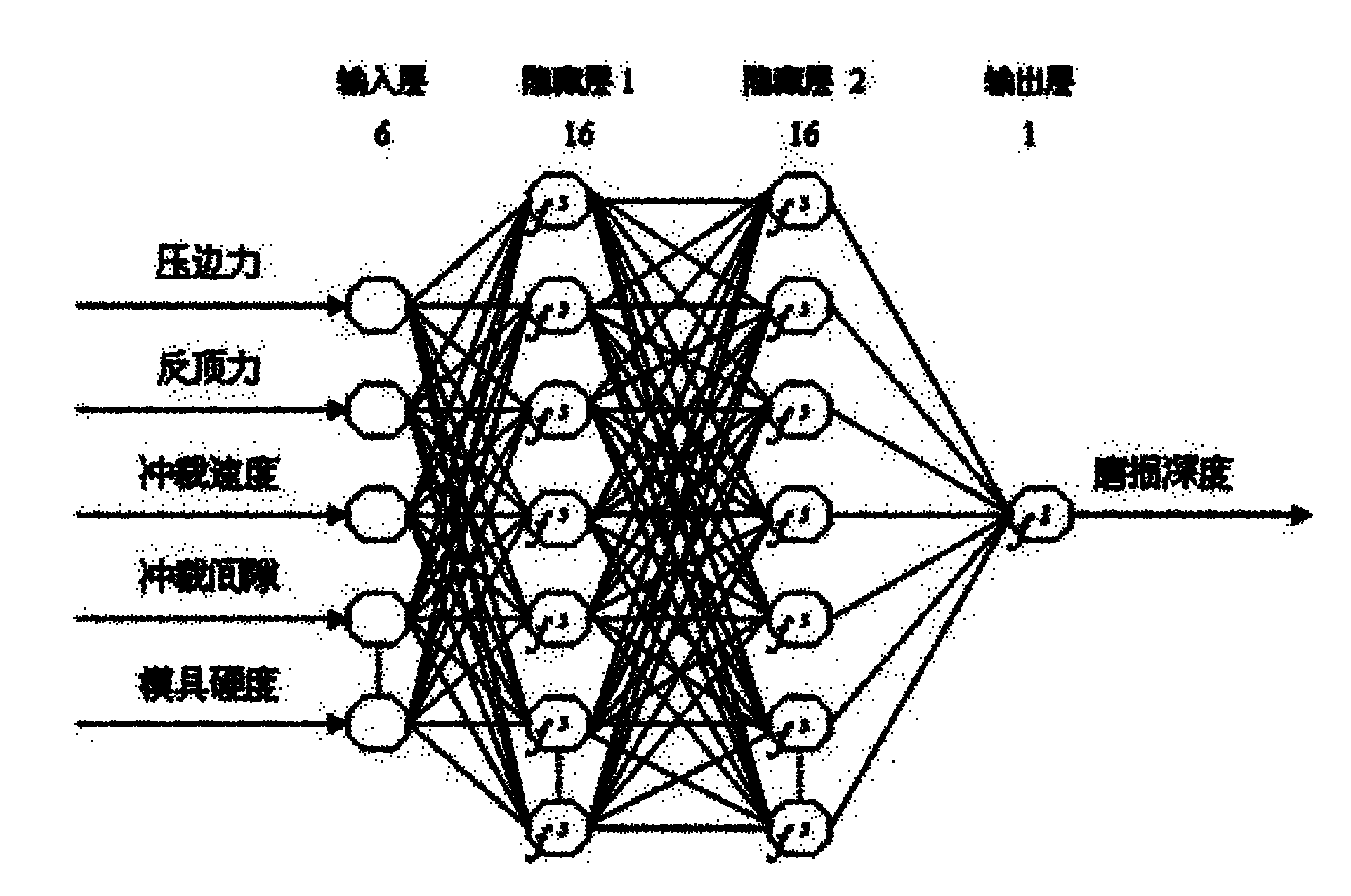

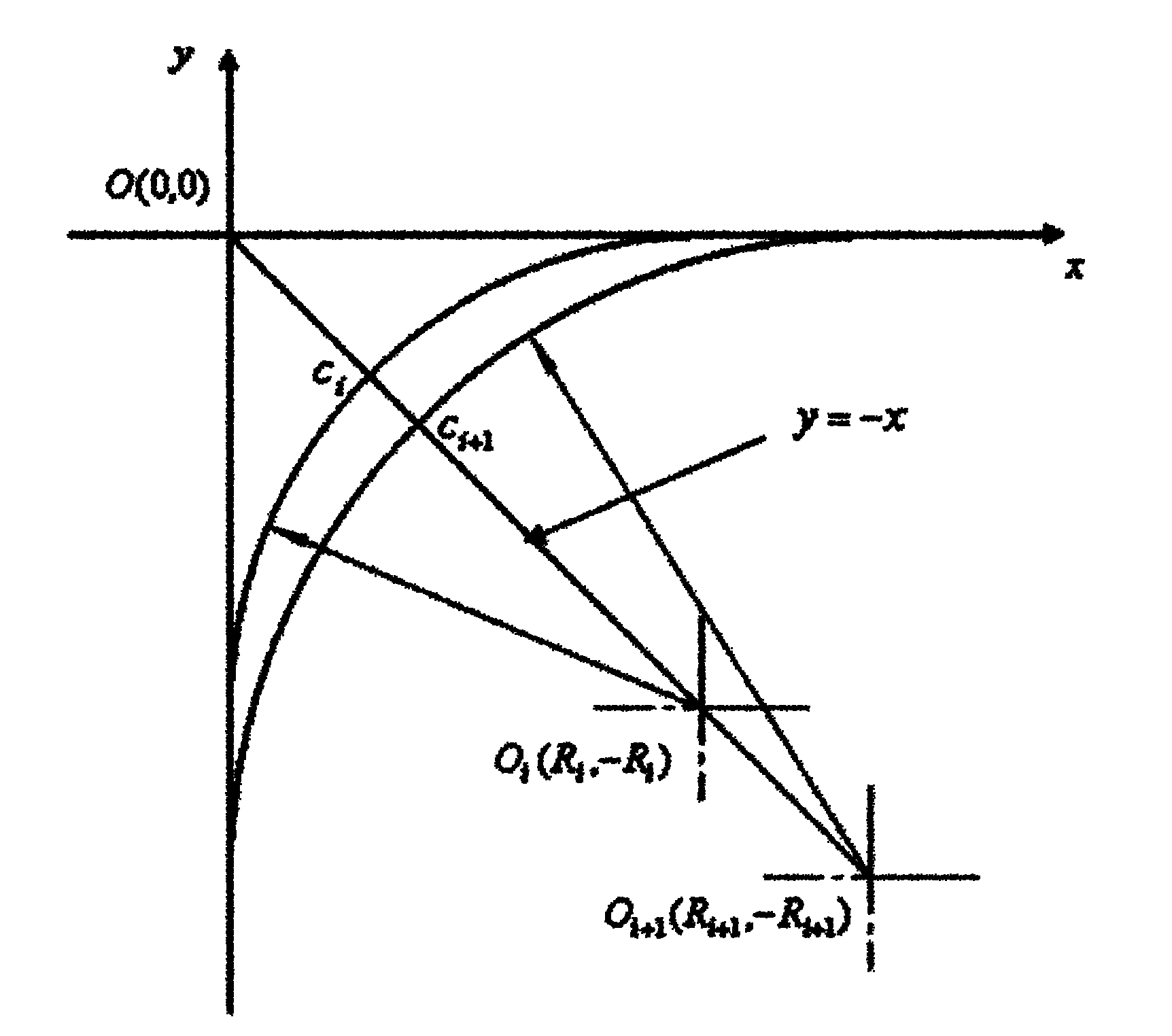

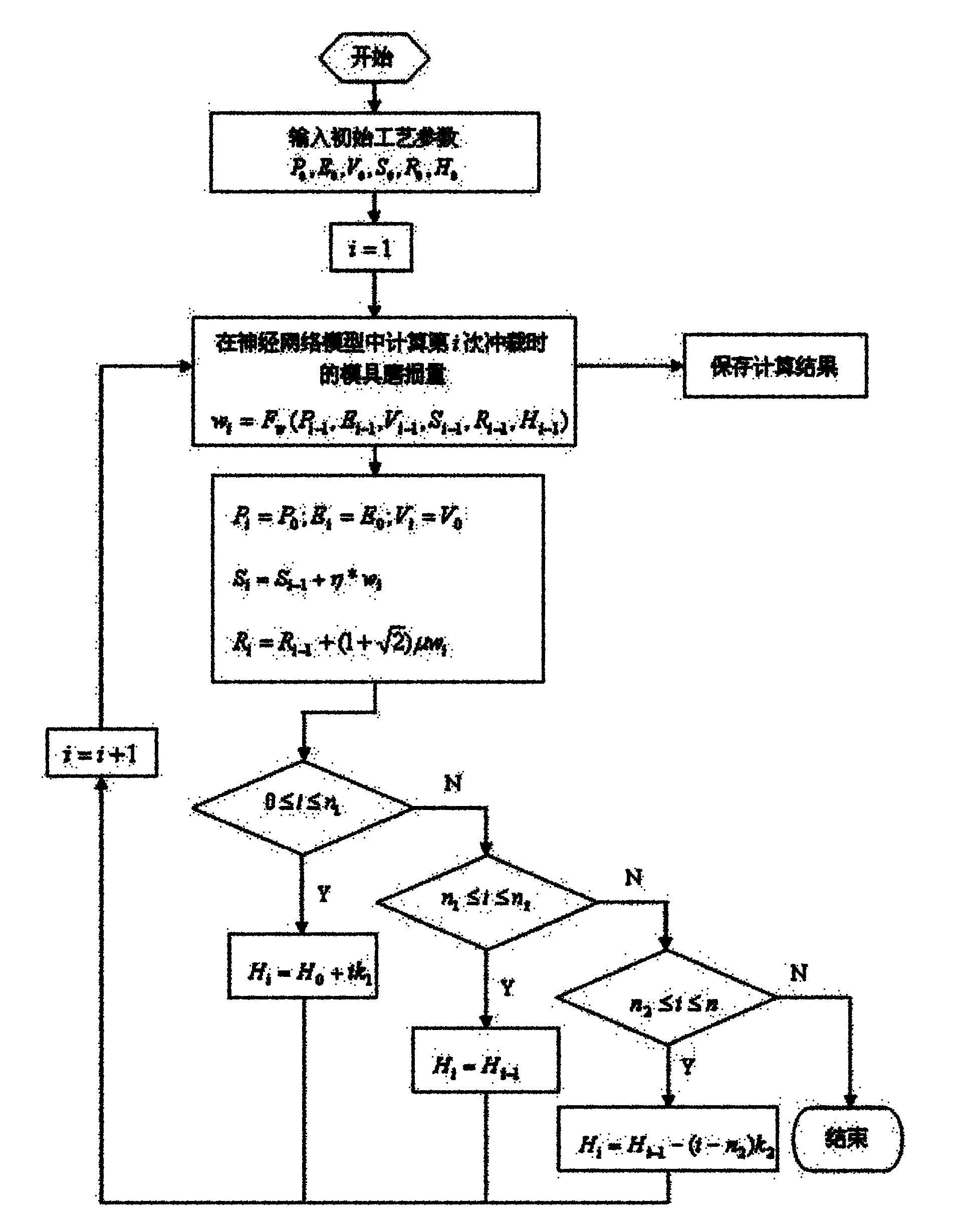

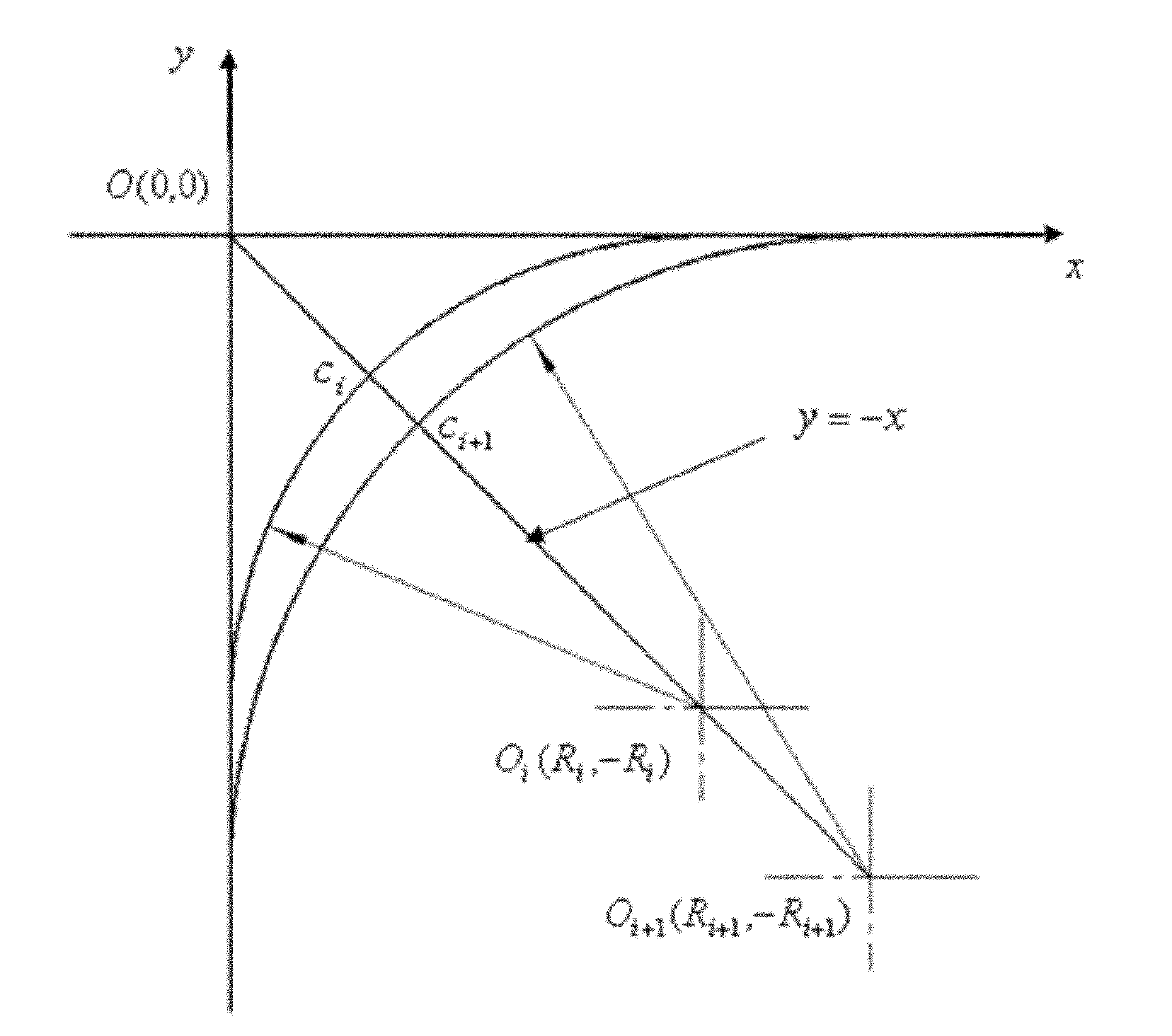

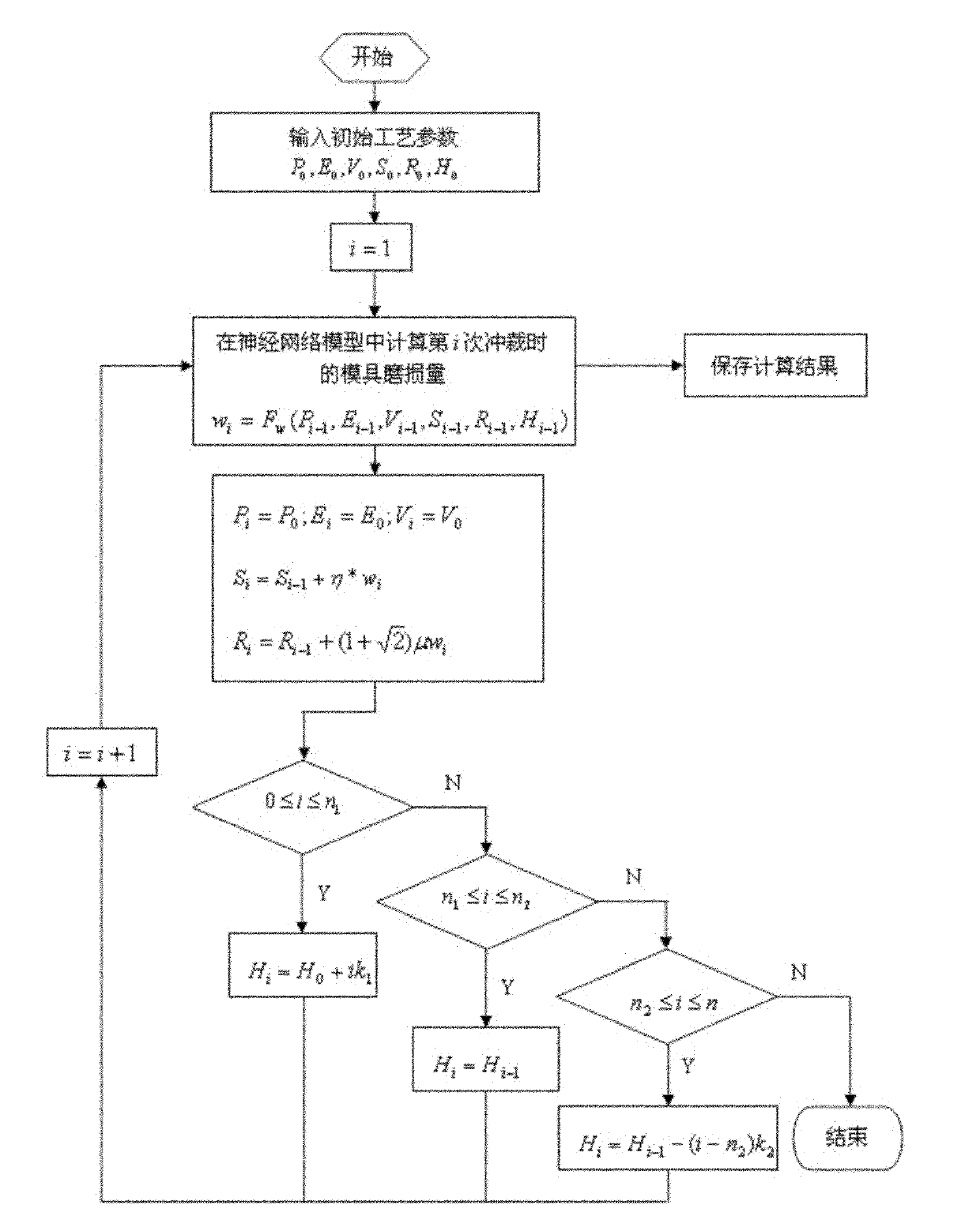

Wear prediction method for fine blanking dies based on finite-element technique and artificial neural network

ActiveCN102103646AImprove forecast accuracyQuick responseBiological neural network modelsSpecial data processing applicationsFinite element techniqueElement analysis

The invention relates to the technical field of fine blanking, in particular relates to a wear prediction method for fine blanking dies based on a finite-element technique and an artificial neural network. The method provided by the invention comprises the following steps: building a finite-element analysis model, namely, simulating a fine blanking process on a finite-element analysis and calculation platform, and calculating the wear extent of a fine blanking die in the fine blanking process by using an Archard wear model; building a neural network model, namely, training a designed neural network model by using a finite-element analysis result guided by an orthogonal experimental design so as to obtain a functional relation between the wear extent of the fine blanking die and fine blanking parameters; obtaining the fine blanking parameters, namely, obtaining the functional relations between the fine blanking parameters and the wear extent, blanking time, and the like of the fine blanking die according to geometrical relationships and production practices; and building and simulating a fine blanking wear prediction model. The method provided by the invention has the advantages of high prediction precision, fast response speed and strong operability.

Owner:武汉客车制造股份有限公司

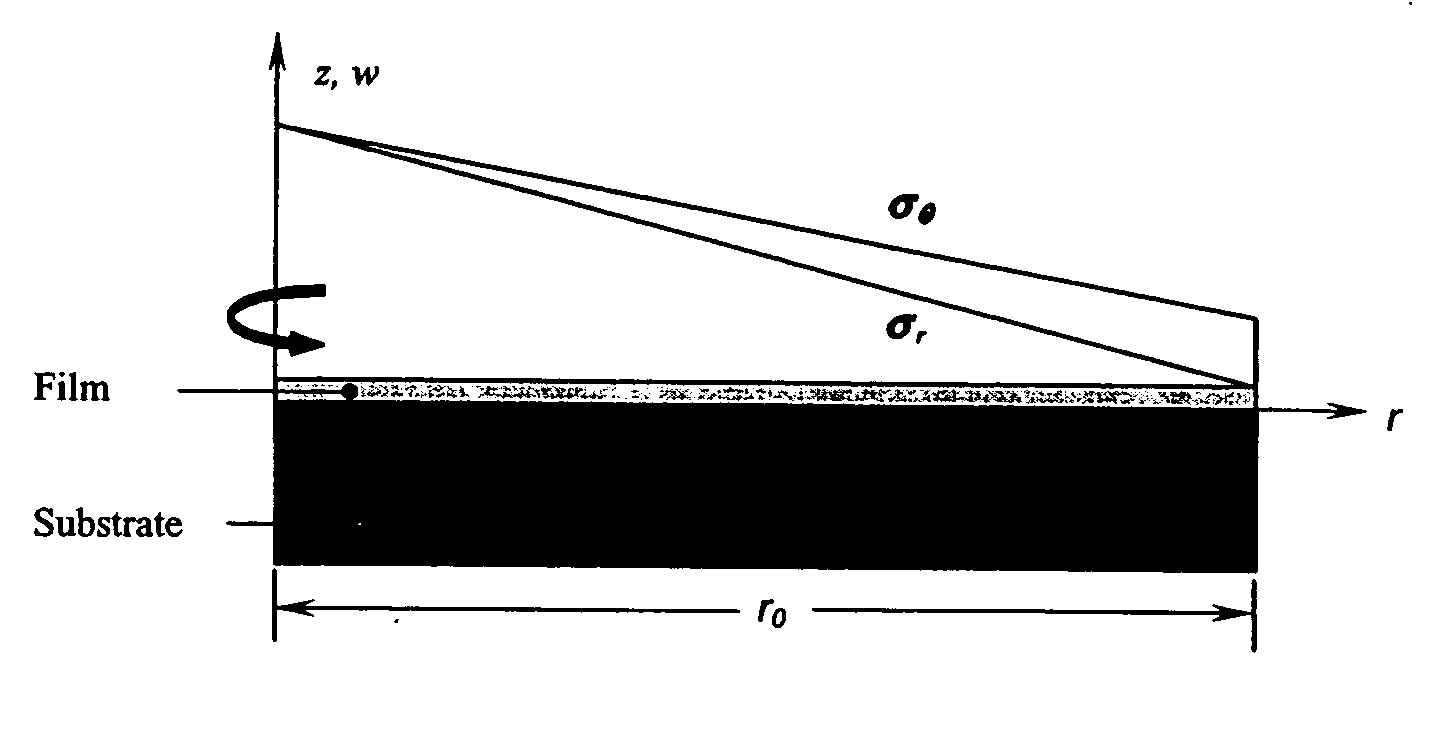

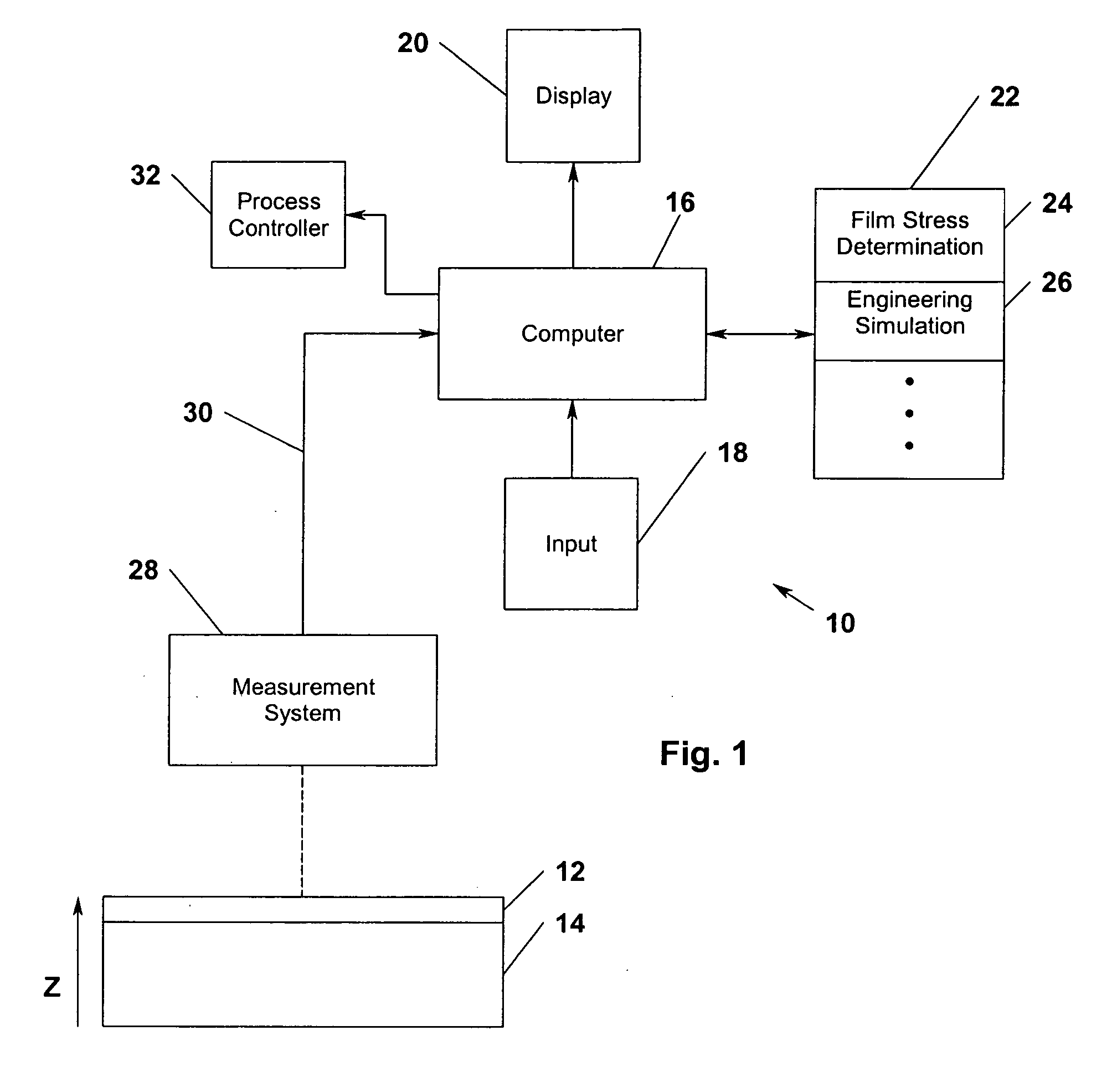

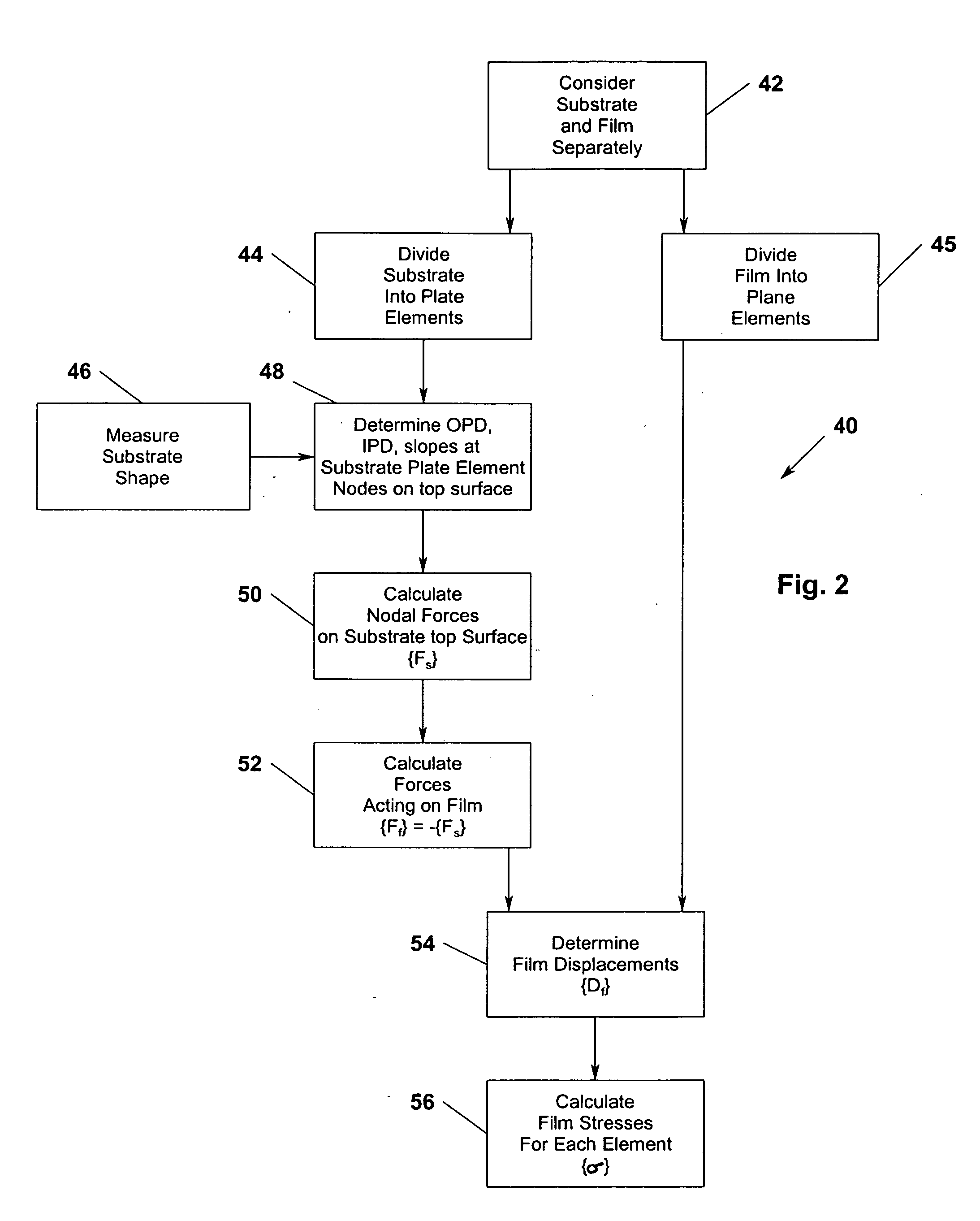

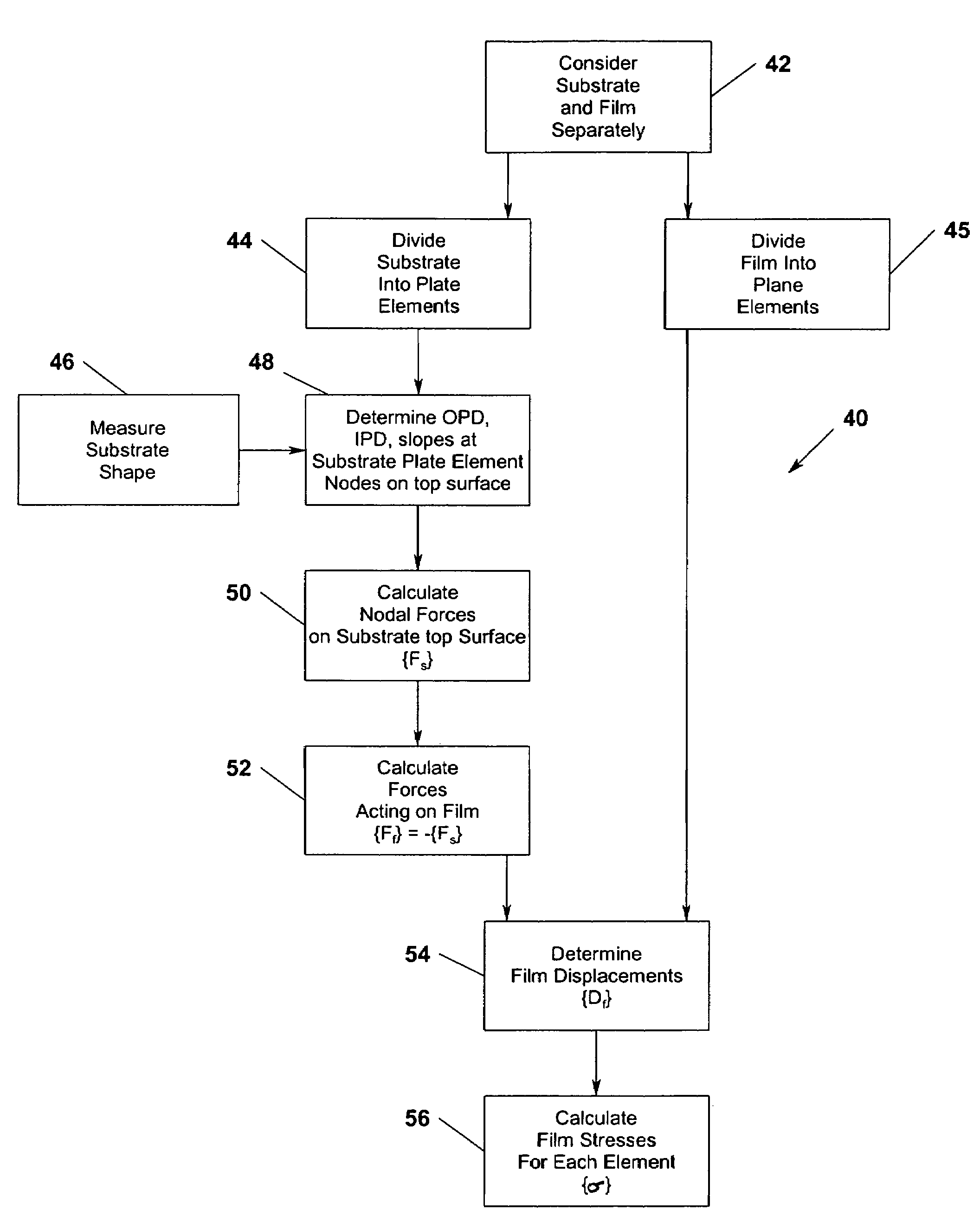

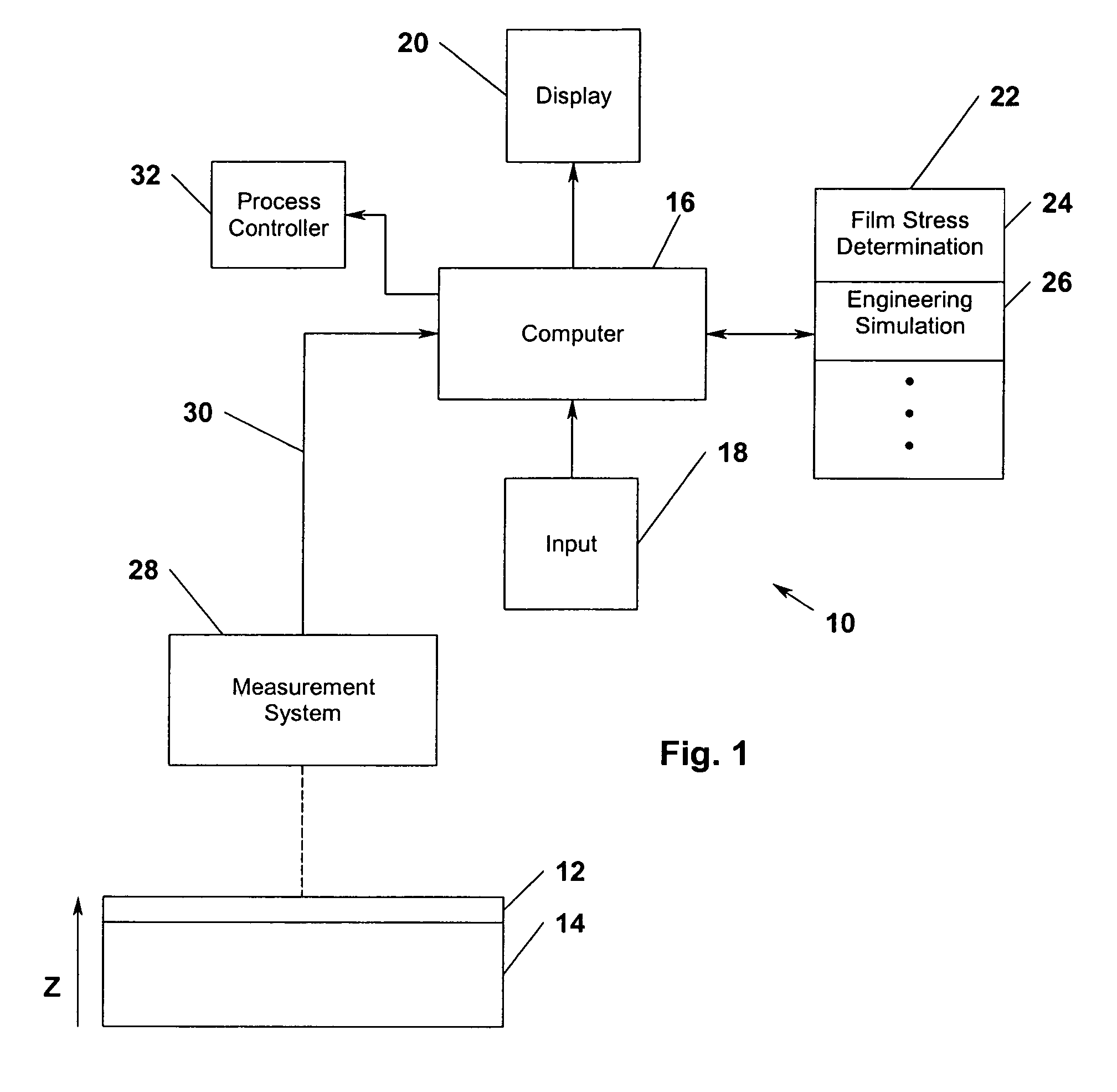

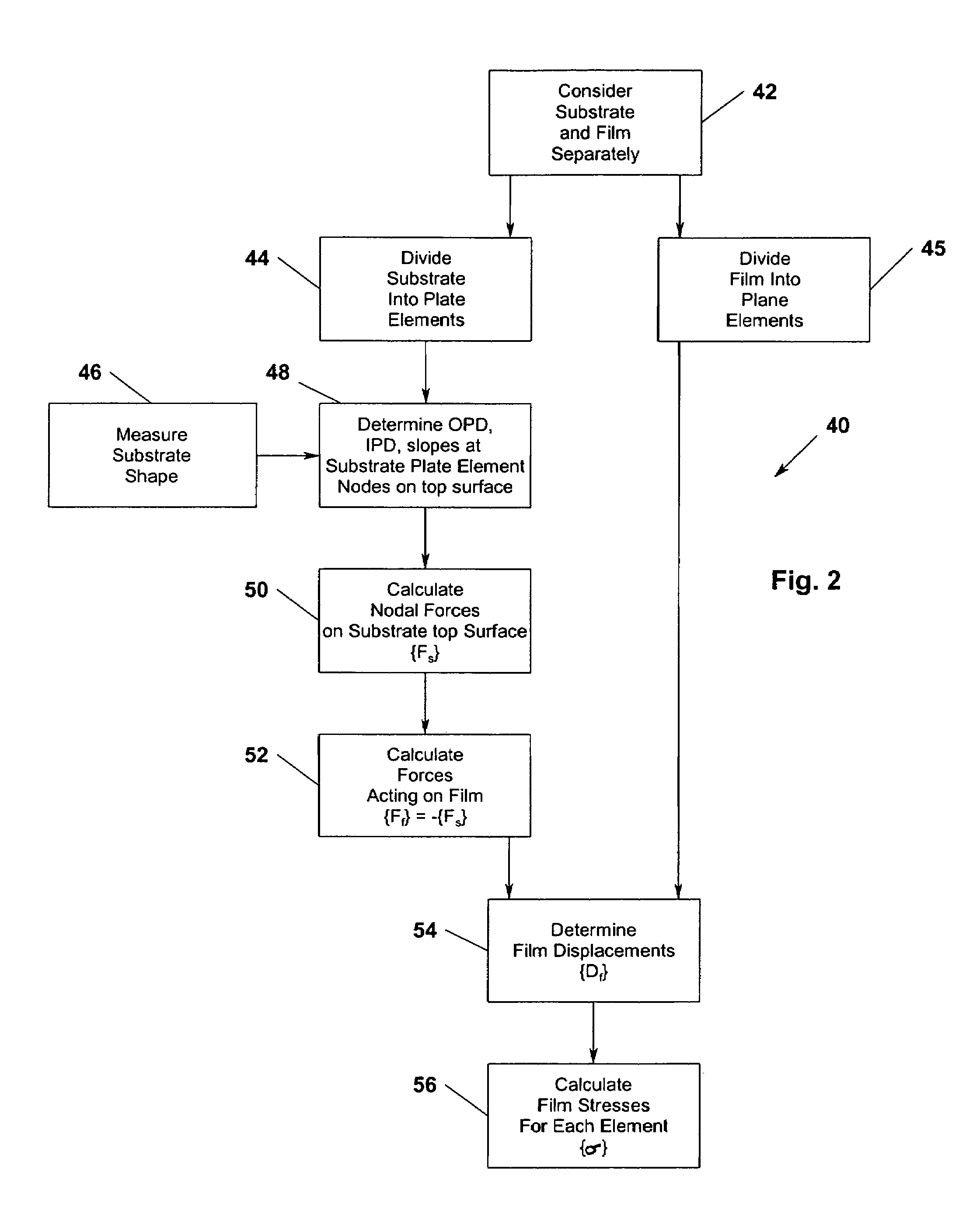

Determining film stress from substrate shape using finite element procedures

ActiveUS20060123919A1Accurately determine film stressFlow propertiesForce measurementFinite element techniqueNODAL

A method for determining the stresses in a film applied to a substrate from measured substrate shape. The substrate is first analyzed using finite element techniques to obtain nodal forces at the surface of the substrate to which the film is applied, based on measured distortion data of the substrate surface. The film is then analyzed to calculate the film stresses from the applied nodal forces using finite element techniques. The invention may be applied to determine stresses in thin films applied to a variety of substrates, including those used for micro-electronic (e.g., integrated circuit) and micro-mechanical devices and / or for the lithography masks or other optical / projection systems used to fabricate such devices.

Owner:WISCONSIN ALUMNI RES FOUND

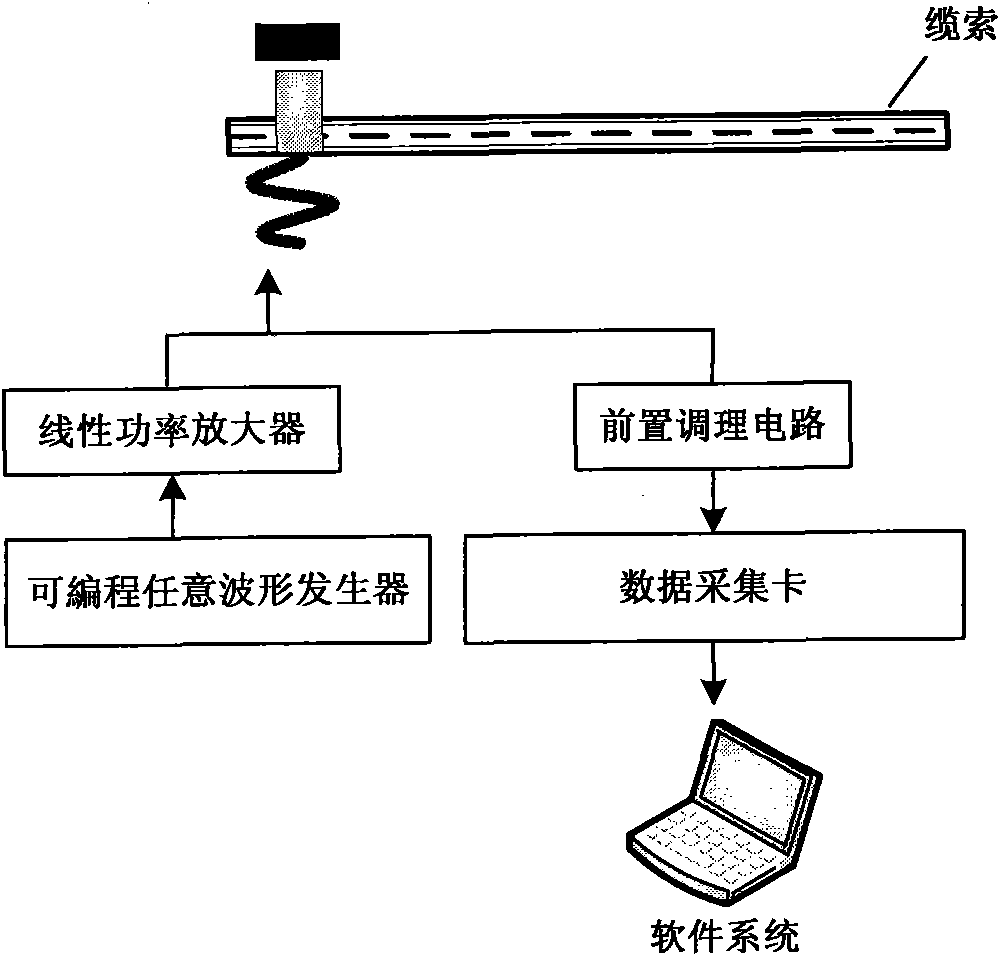

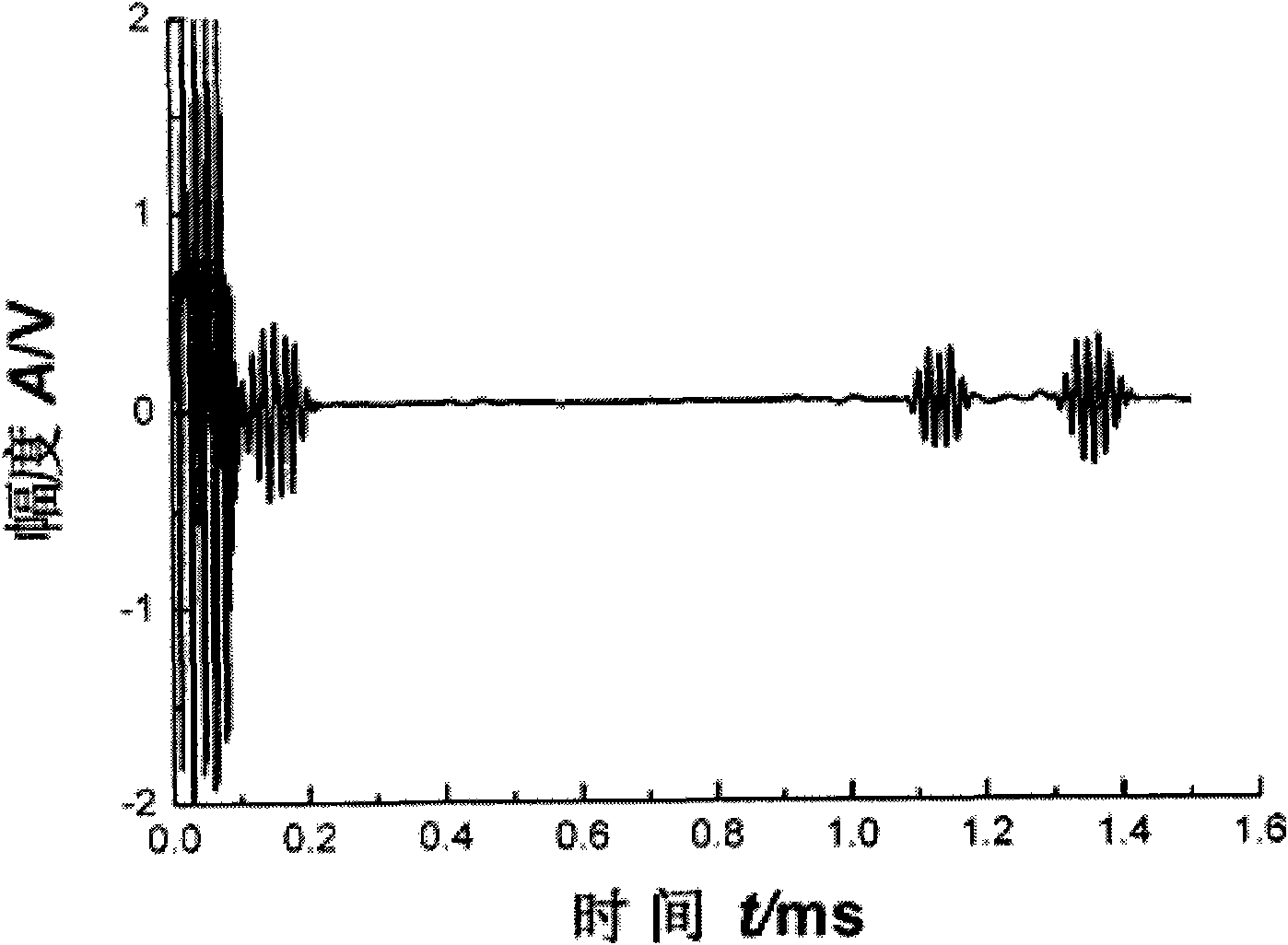

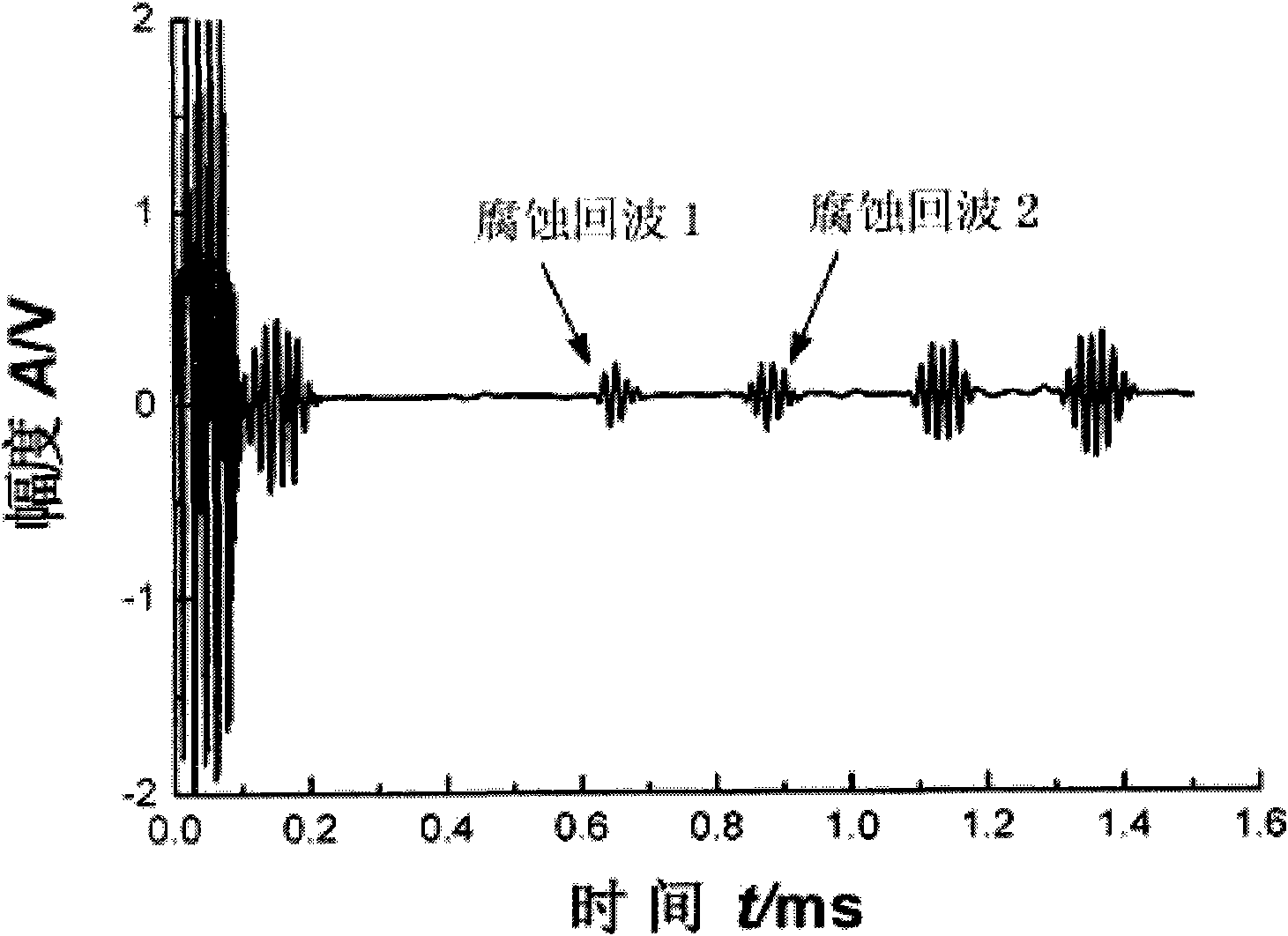

Method for judging and positioning bridge cable corrosion

ActiveCN101943681AReduce calculation errorsAvoid Linear DistortionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesFinite element techniqueNeural network analysis

The invention discloses a method for judging and positioning bridge cable corrosion. The method comprises the following steps of: arranging a sensor on a cable to be detected, acquiring an actual measured signal by using the sensor and reading the signal into a laptop by using a data acquisition card; establishing a fine numerical model for the cable corrosion judgment by adopting the finite element technology according to geometric dimension, material characteristics and excitation signal conditions of the cable, initializing the numerical model, analyzing and calculating to obtain a simulation response signal, and providing a standard comparison signal for the actual measured signal; using the actual measured signal as a judgment signal of the cable corrosion, and comparing the judgment signal and the standard comparison signal and analyzing the judgment signal by adopting a neural network analysis method, if the damage does not exceed a threshold value, judging that the cable is not corroded, otherwise alarming and positioning the corroded part; generating a recording report and recording a local database. The method for judging and positioning the bridge cable corrosion has the advantages of high resolution, high judging precision and no influence on normal use of the cable.

Owner:ZHEJIANG UNIV

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20130098683A1Vibration measurement in solidsProgramme controlFinite element techniqueResonance

A system and method for monitoring underground drilling in which vibration is monitored by creating a model of the drill string using finite element techniques or finite difference techniques and (i) predicting vibration by inputting real time values of operating parameters into the model, and then adjusting the model to agree with measured vibration data, (ii) predicting the weight on bit and drill string and mud motor speeds at which resonance will occur, as well as when stick-slip will occur, so that the operator can avoid operating regimes that will result in high vibration, (iii) determining vibration and torque levels along the length of the drill string based on the measured vibration and torque at one or more locations, (iv) determining the remaining life of critical components of the drill string based on the history of the vibration to which the components have been subjected, and (v) determining the optimum drilling parameters that will avoid excessive vibration of the drill string.

Owner:APS TECH

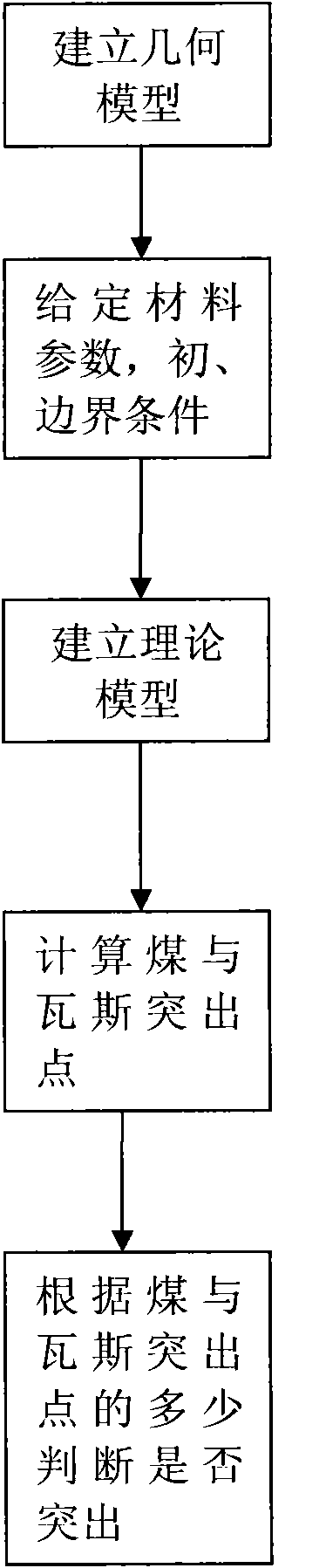

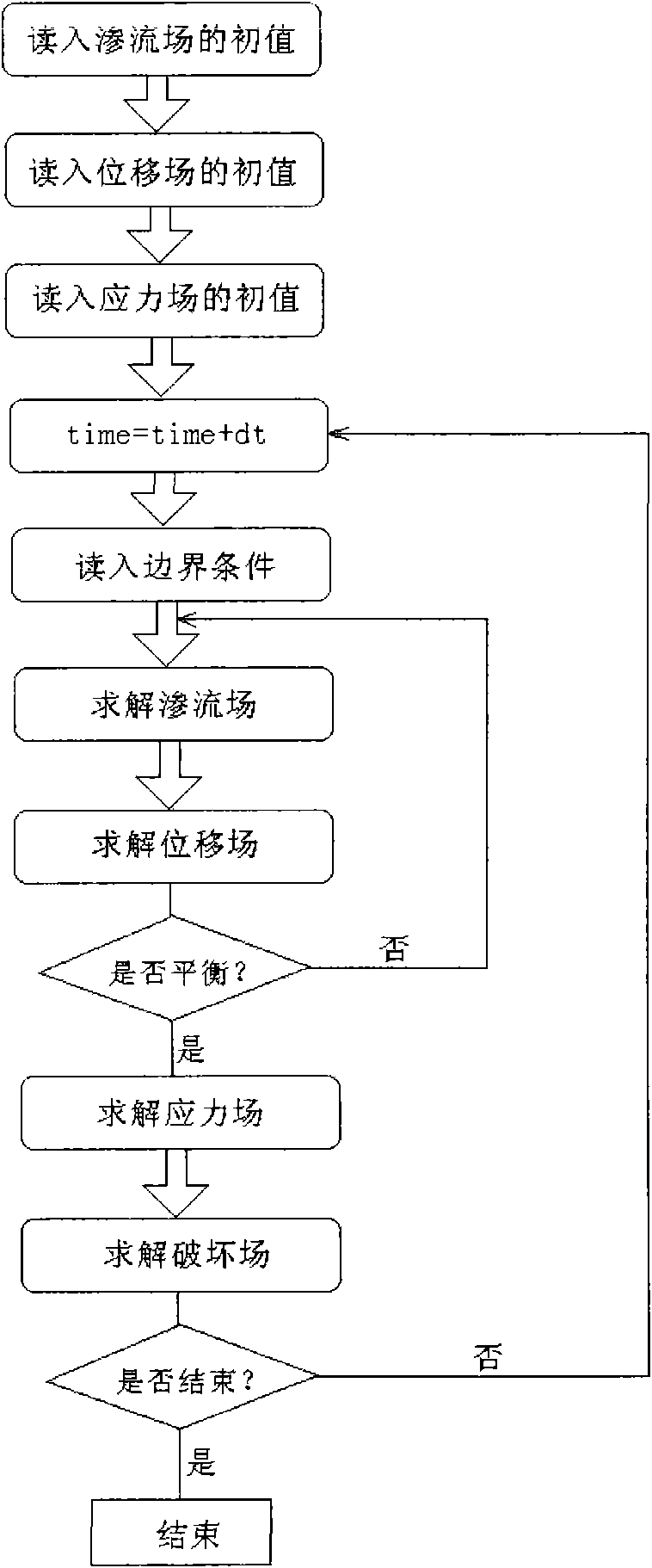

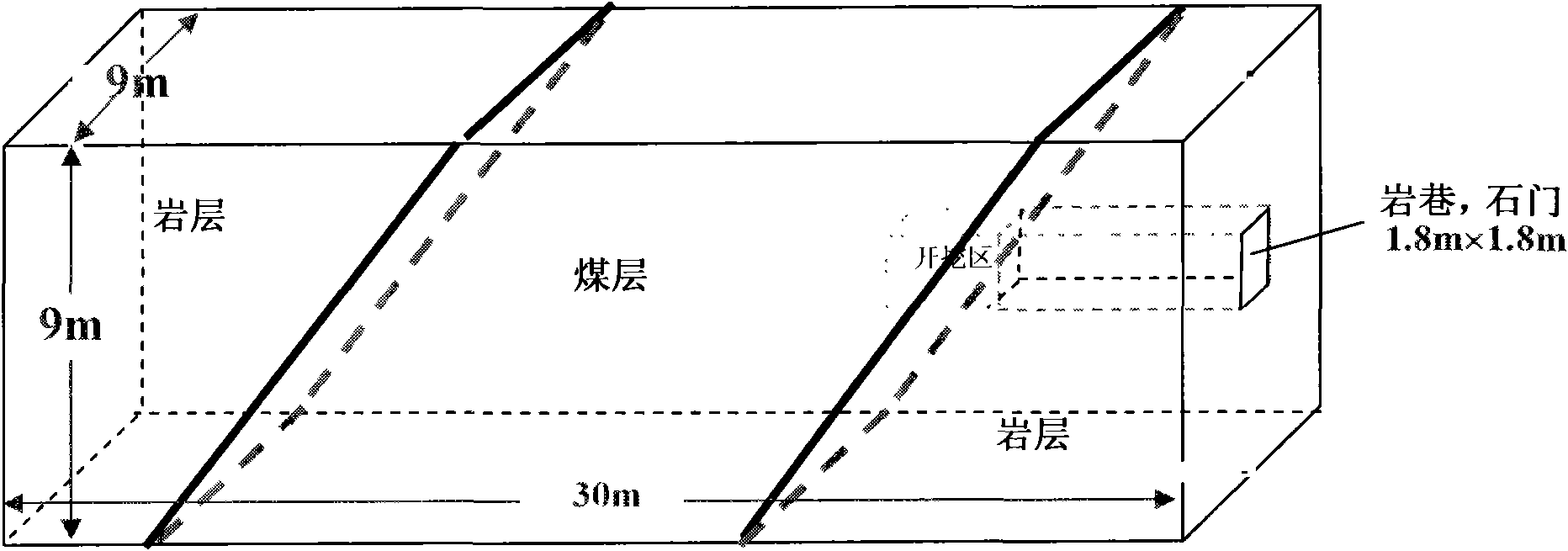

Coal and gas outburst forecasting method

InactiveCN101787898AEasy to operateReduce engineering costsMining devicesGas removalFinite element techniqueCloud atlas

The invention discloses a coal and gas outburst forecasting method which comprises the following steps that: (1) a geometric model is built; (2) material parameters, initial values and boundary conditions of an area to be tested are given; (3) a theoretical model is built; (4) the material parameters, the initial values and the boundary conditions are substituted into the theoretical model to calculate the coal and gas outbursts in the area to be tested; (5) the coal and gas outbursts calculated in step (4) is marked to generate a cloud atlas; and (6) according to the number of the coal and gas outburst marks of the area to be tested in the cloud atlas, whether the area has coal and gas outbursts is judged. The coal and gas outburst forecasting method of the invention first builds the theoretical model for judging the outbursts, and then adopts a finite element technique to calculate, to realize the forecasting of the coal and gas outbursts. The forecasting method of the invention is based on the complete theoretical model, realizes the coal and gas outburst forecasting by numerical calculation, is easy to operate in actual situations, and can greatly reduce the engineering cost.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

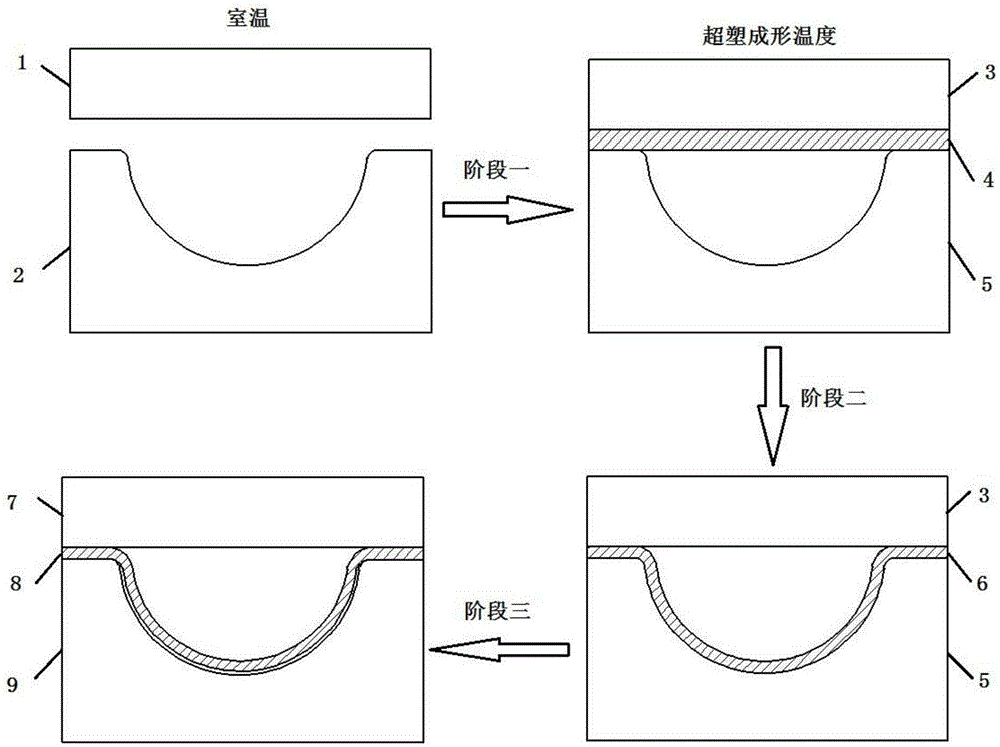

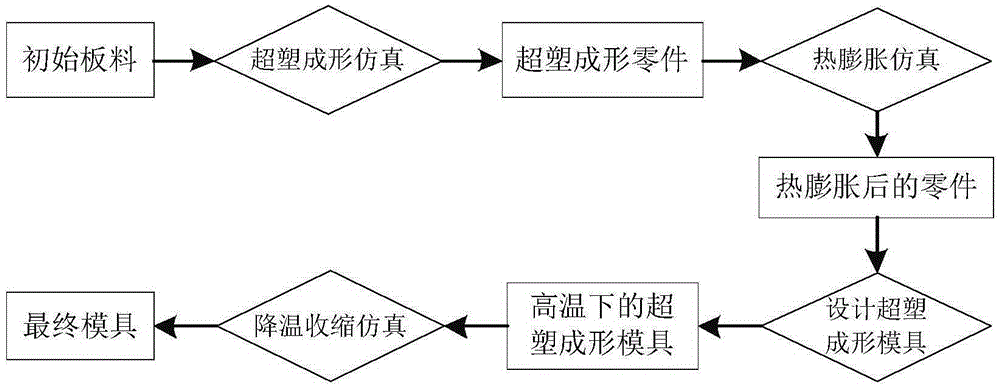

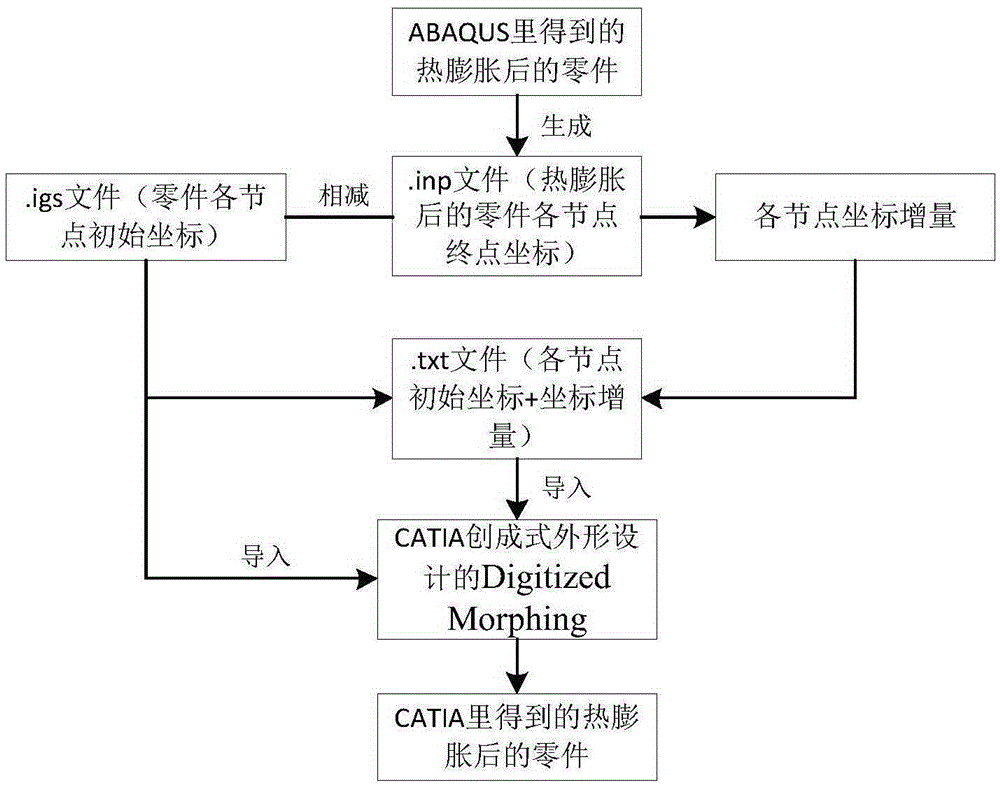

Superplastic forming mold design method based on finite element technique with consideration of thermal expansion

ActiveCN105335568AHigh forming precisionSolve the problem of forming errorSpecial data processing applications3D modellingFinite element techniqueEconomic benefits

The invention discloses a superplastic forming mold design method based on a finite element technique with consideration of thermal expansion. The superplastic forming mold design method comprises the following four main steps: I, performing superplastic forming simulation in finite simulation software, and calculating so as to obtain a superplastic formed component; II, by utilizing the thermal expansion property of a component material, performing thermal expansion simulation independently on the superplastic formed component obtained in the step I; III, leading out the outline of the component after thermal expansion in the step II, and according to the leading result, designing a surface and a corresponding three-dimensional overall model of the superplastic forming mold in three-dimensional modeling software; and IV, by utilizing the thermal expansion property of the mold material, performing cooling shrinkage simulation on the superplastic forming mold obtained in the step III at high temperature in the finite simulation software, thereby obtaining a final mold. By adopting the superplastic forming mold design method, forming precision of the superplastic formed component is greatly improved, and direct economic benefits are brought to mold design methods and component manufacturing.

Owner:BEIHANG UNIV

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20130092438A1Programme controlVibration measurement in solidsFinite element techniqueResonance

Owner:APS TECH

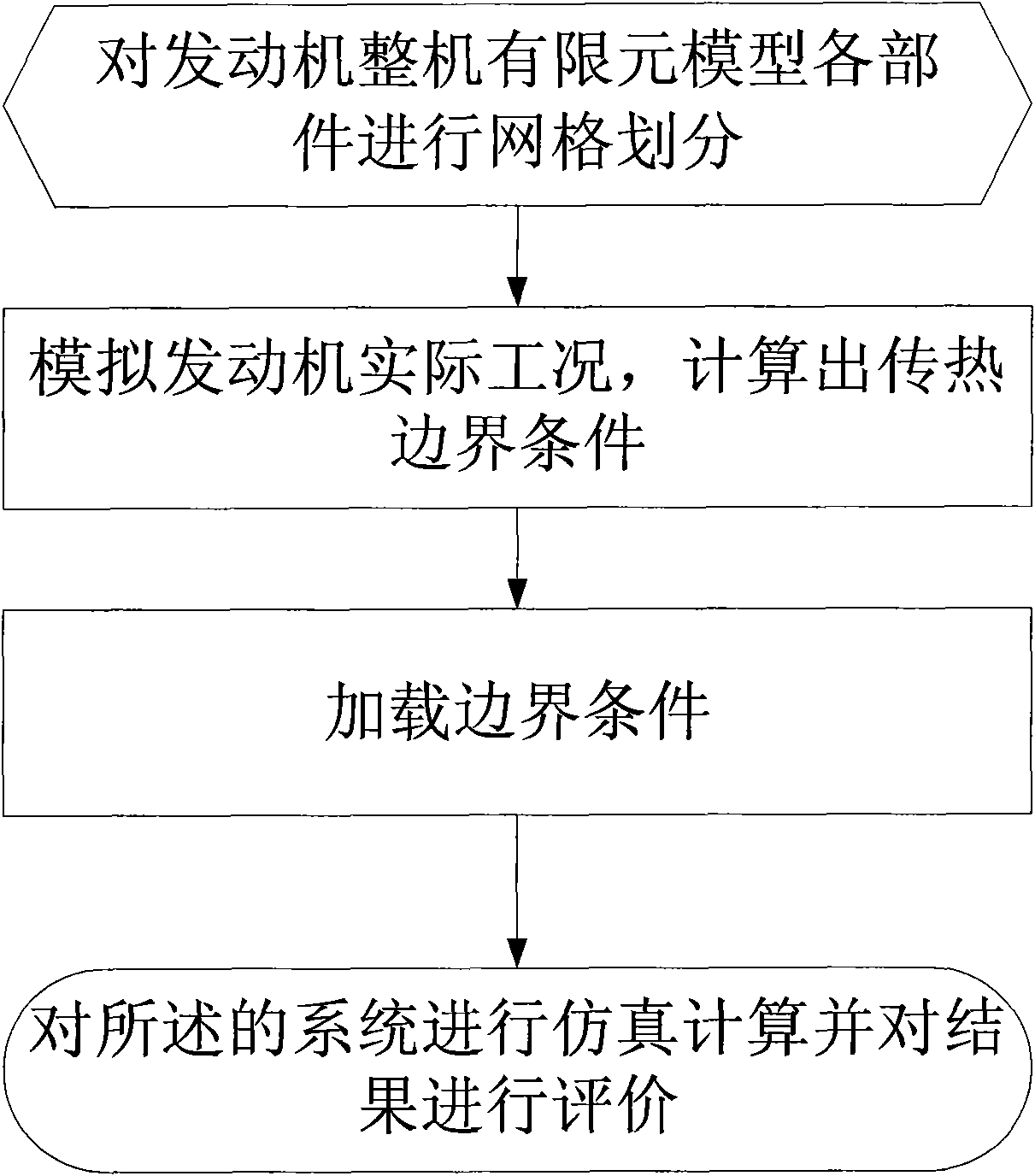

Engine coupling analytical method

InactiveCN101593228AImprove development efficiencyReduce testing costsSpecial data processing applicationsFinite element techniqueElement model

The invention fully discloses an engine coupling analytical method, which uses finite element technology to calculate a temperature field, thermal stress, mechanical stress, fatigue and the like of a complete machine of an engine and to establish a set of checking methods and procedures so as to better guide the engine product design and evaluate the reasonableness of the whole structure to improve accordingly. The method comprises the following steps of: carrying out grid partition on components of a finite element model of the complete machine of the engine; simulating an actual working condition of the engine; calculating a heat transmission boundary condition; and loading the boundary condition to carry out simulation calculation on a system and evaluate the result. The development cycle of products is greatly shortened by using the technical proposal. Various performances of the actual working condition of the engine can be simulated in a virtual environment before trial-produce of samples. The method improves the development efficiency, saves a great amount of testing cost and points out the direction for the structure design of the complete machine of the engine.

Owner:CHERY AUTOMOBILE CO LTD

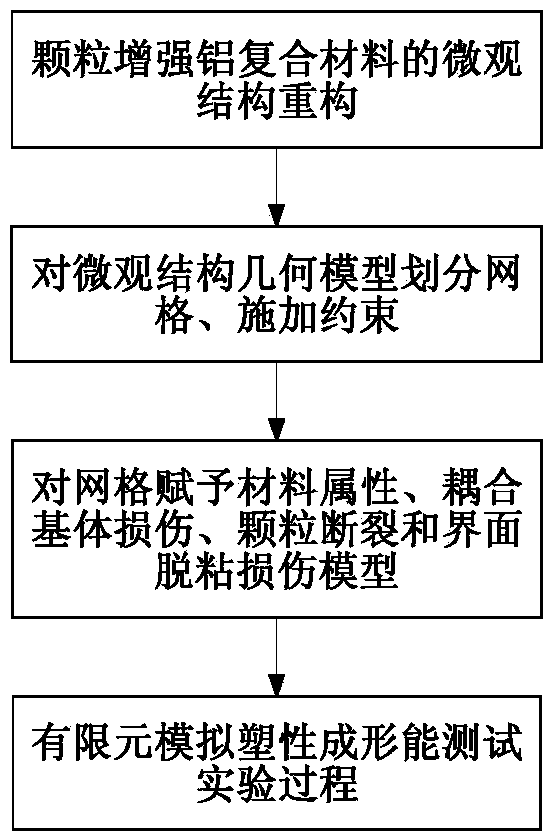

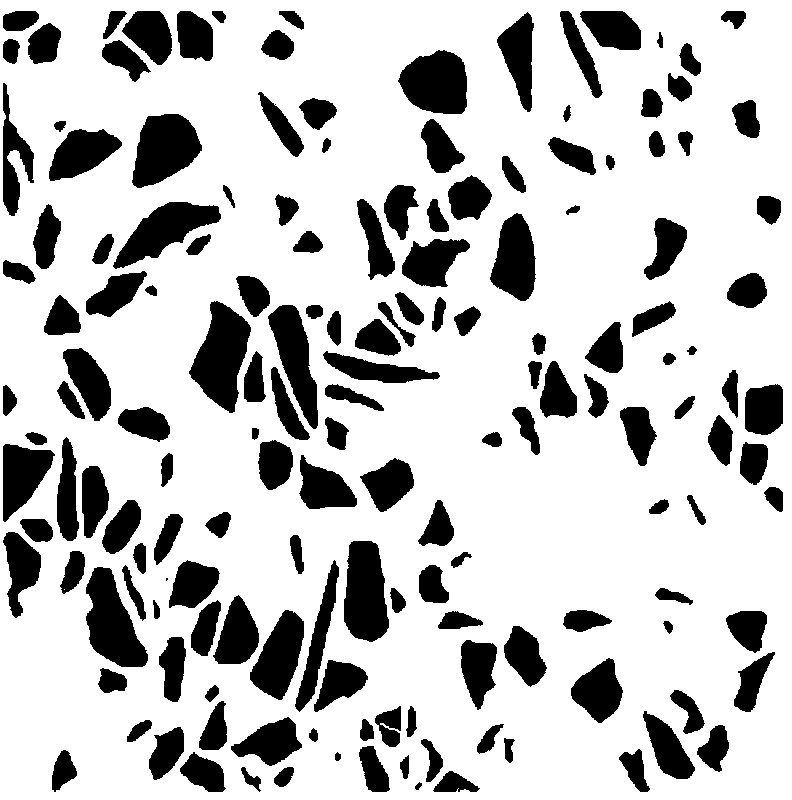

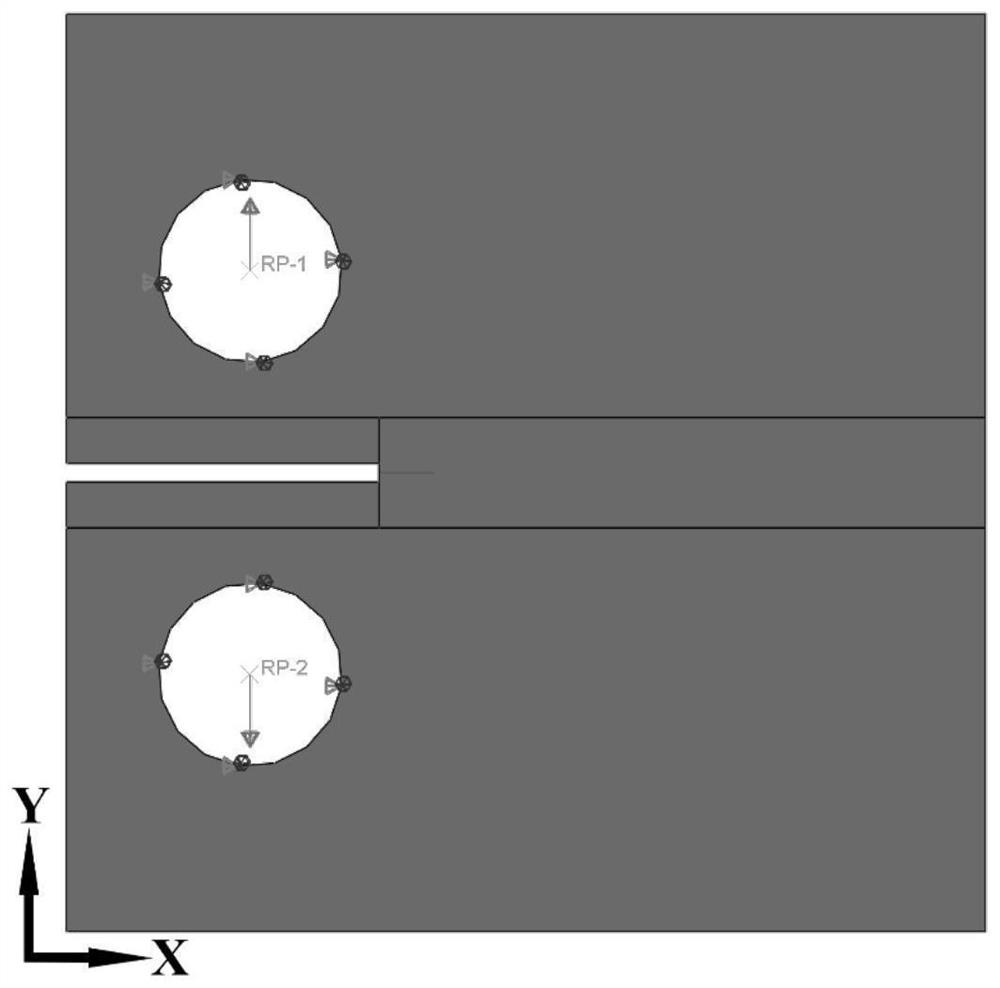

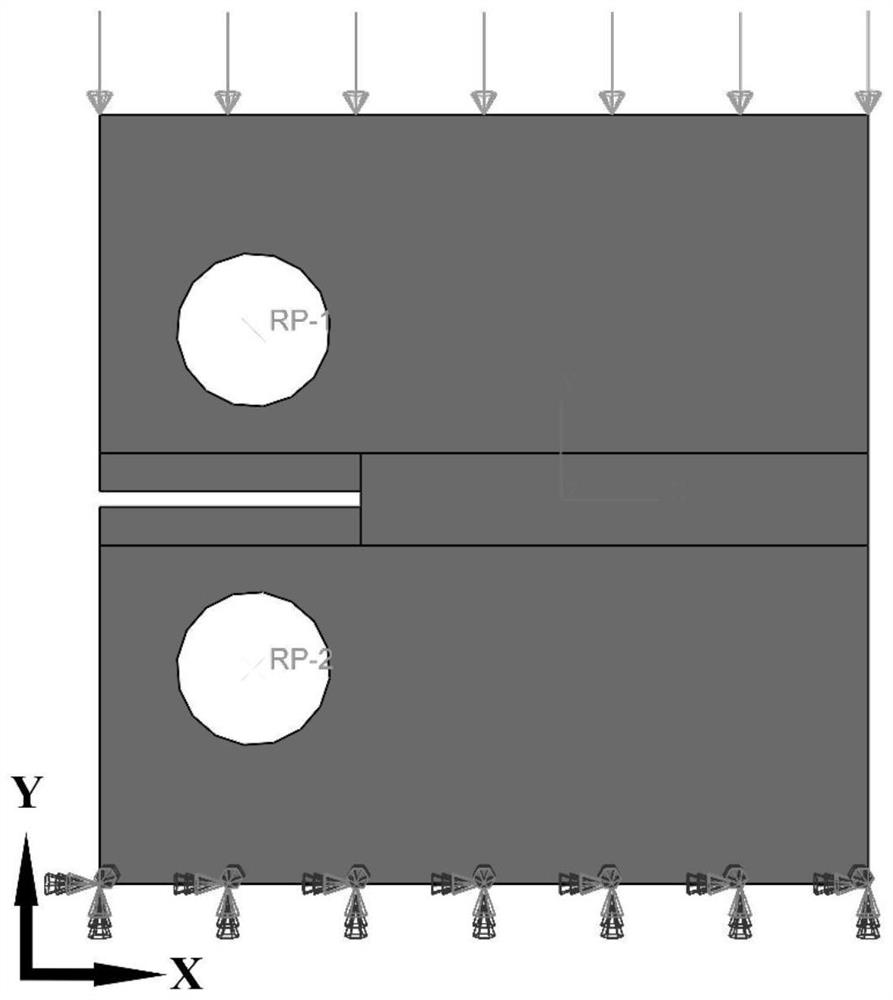

Virtual test method of plastic forming property of particle reinforced aluminum matrix composite

InactiveCN103593541AHigh cost of plastic formabilityReduce typesSpecial data processing applicationsMatrix damageFinite element technique

The invention belongs to the field of composite plastic forming, and particularly provides a virtual test method of the plastic forming property of a particle reinforced aluminum matrix composite. The method includes the steps that (1) geometric reconstruction is conducted on a microstructure of the particle reinforced aluminum matrix composite; (2) meshes of a geometric model, established in the step (1), of the microstructure are divided through an object-oriented finite element technology, and the model is restricted; (3) in finite element software, material attributes are given to the meshes in the step (2), and a matrix damage model, a particle breakage damage model and an interface debond damage model are coupled; (4) the plastic forming property test experimental process is simulated in finite element simulation software, and then plastic forming property indexes of the composite are acquired. According to the method, the plastic forming property of the particle reinforced aluminum matrix composite can be accurately and virtually predicted, experimental test cost of the plastic forming property of the composite can be lowered, operation is easy to conduct, and convenience is brought for technical staff to use.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

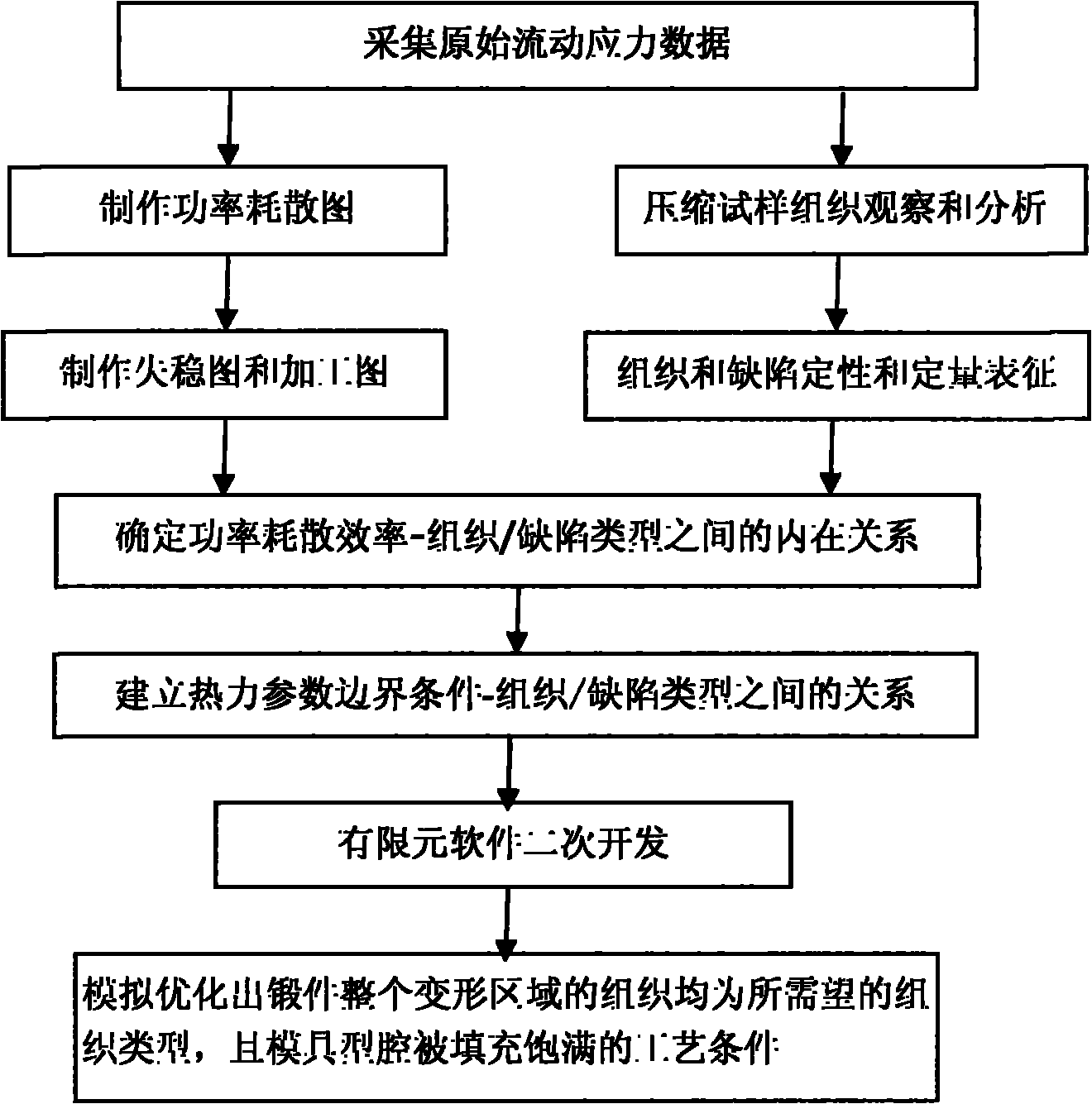

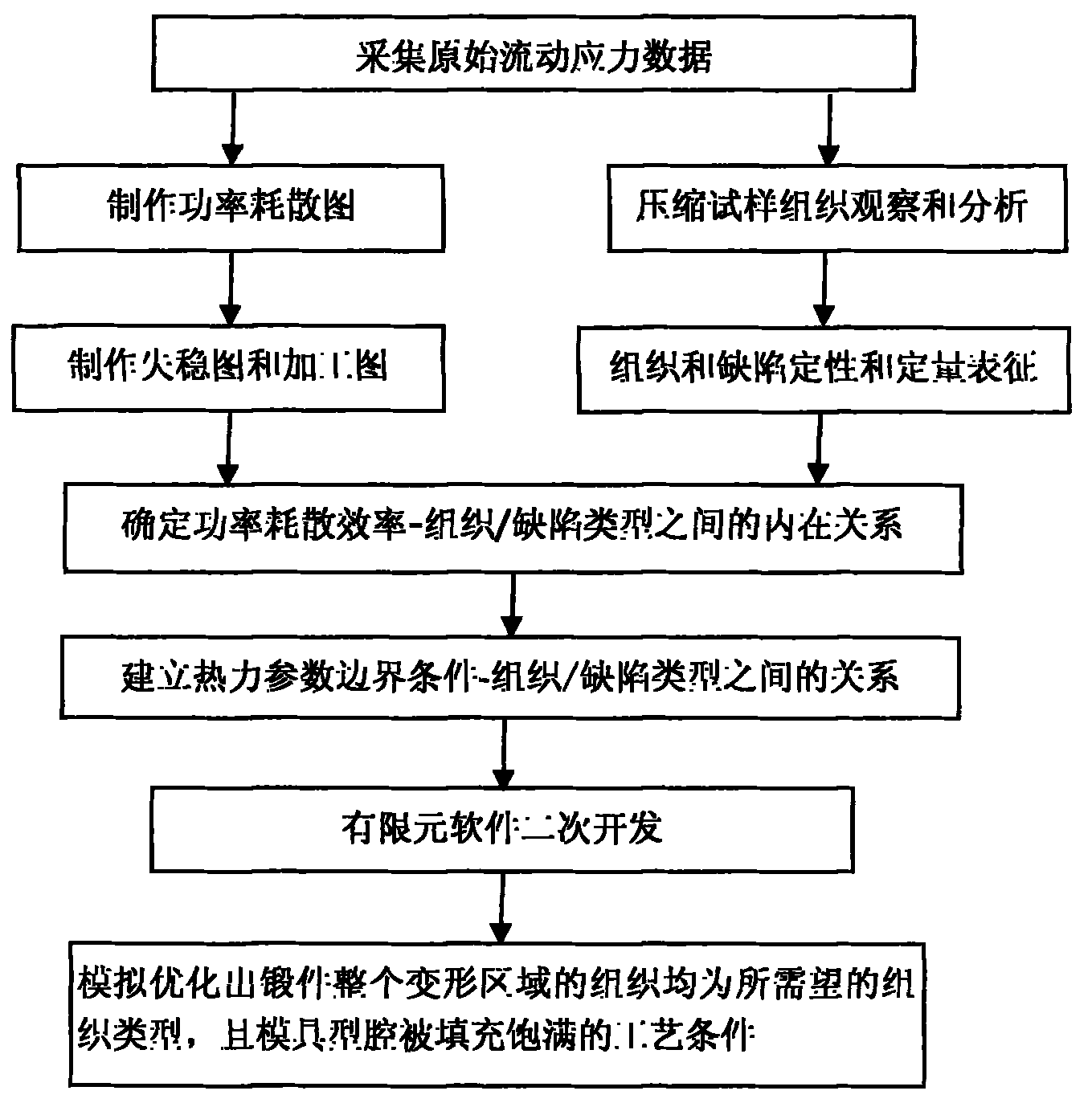

Method for optimizing metal accurate forging process conditions based on finite element technology and operation drawing technology

InactiveCN101833598AOptimizing the Process Conditions of Precision ForgingSpecial data processing applicationsFlow stressFinite element technique

The invention relates to a method for optimizing metal accurate forging process conditions based on finite element technology and operation drawing technology, which is characterized by comprising the following steps of: (1) acquiring initial flow stress data; (2) producing a power dissipation drawing; (3) producing an instability drawing; (4) producing an operation drawing; (5) carrying out qualitative and quantitative characterization of tissues and defects; (6) determining power dissipation efficiency, namely a relation between tissue / defect types; (7) establishing a thermal parameter final condition, namely a relation between the tissue / defect types; (8) leading the thermal parameter final condition, namely the relation between the tissue / defect types, into a finite element model; and (9) carrying out simulation optimization on the accurate forging process conditions. The method has the advantage of comprehensively giving play to the process condition optimizing function of the finite element technology in the aspect of 'accurate shape control' and the deformation thermal parameter optimizing function of the operation drawing technology in the aspect of 'accurate performance control' by effectively combining the finite element technology with the operation drawing technology so as to optimize the metal accurate forging process conditions.

Owner:NANCHANG HANGKONG UNIVERSITY

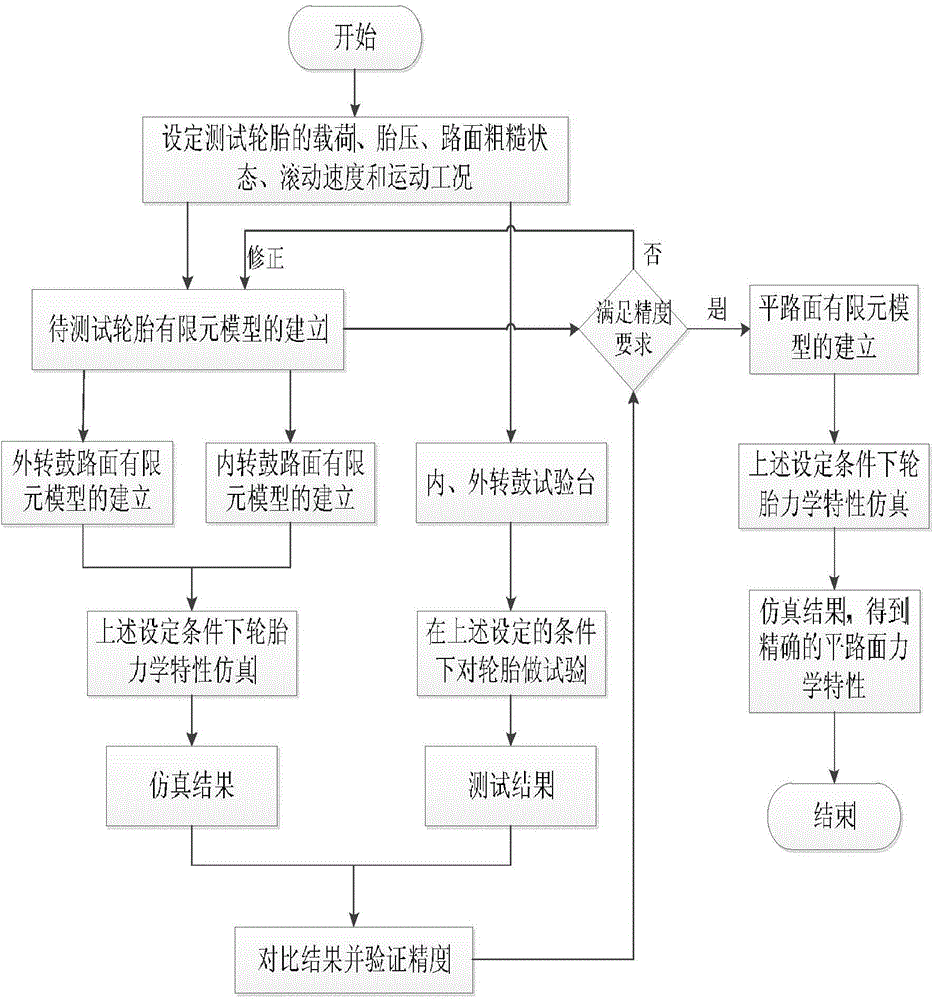

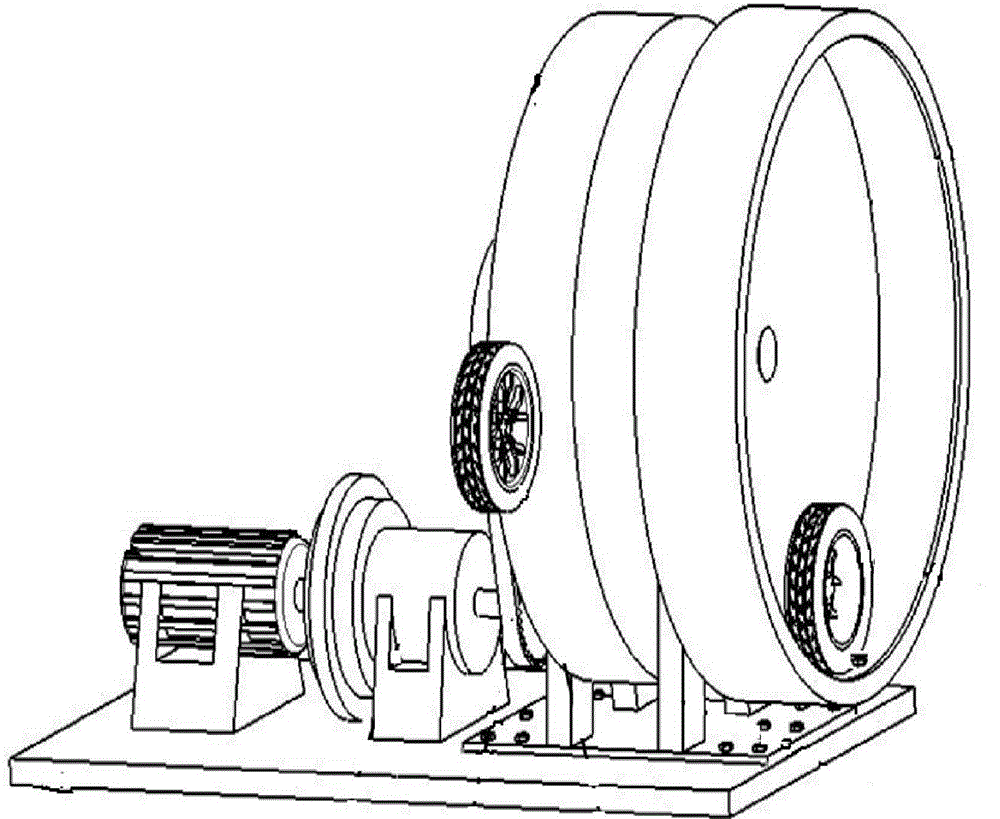

Method of predicating flat-pavement mechanical properties of tyre based on test data of rotary drum test bed

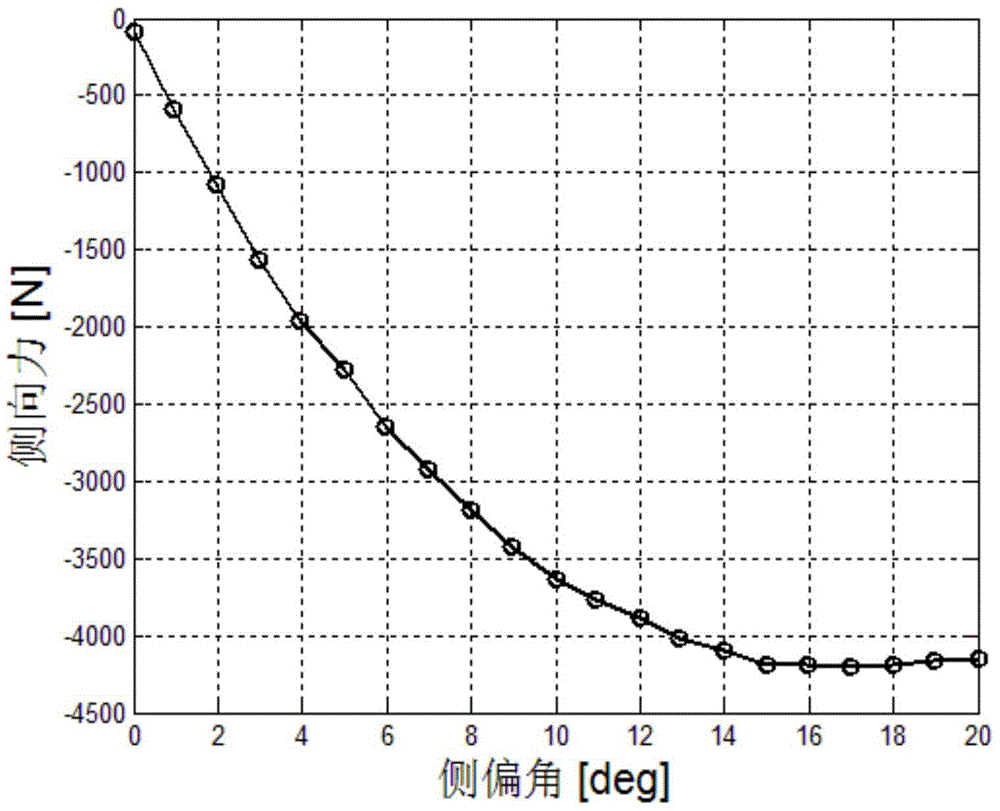

ActiveCN104390794AReliable CorrectionThe mechanical properties of flat pavement are accurately obtainedVehicle tyre testingFinite element techniqueRoad surface

The invention discloses a method for predicating flat-pavement mechanical properties of a tyre based on test data of a rotary drum test bed. The method comprises the following steps of: setting load, tyre pressure, pavement rough state, rolling speed and movement working conditions (lateral deviation, lateral inclination, and the like) of the tested tyre, and implementing the tests and the simulations in the following steps under the conditions; establishing a model for the tested tyre by utilizing ABAQUS software, and respectively stimulating movement of the tyre on inner rotary drum pavement and outer rotary drum pavement; simultaneously correcting the tyre model by using the test data of the inner rotary drum test bed and the outer rotary drum test bed; simulating the tyre movement under the special condition on the flat pavement by using the corrected precise tyre model so as to precisely predicate the flat-pavement mechanical properties of the tyre. The method disclosed by the invention can be used for effectively eliminating influences of the pavement curvature by utilizing the tested data of the rotary drum test bed through a finite element technology to obtain the mechanical properties of the tyre on the flat pavement, has the advantages of simple needed test equipment and high predication precision. Meanwhile, the method is suitable for all tyres including large-load and high-rotation-speed aircraft tyres.

Owner:JILIN UNIV

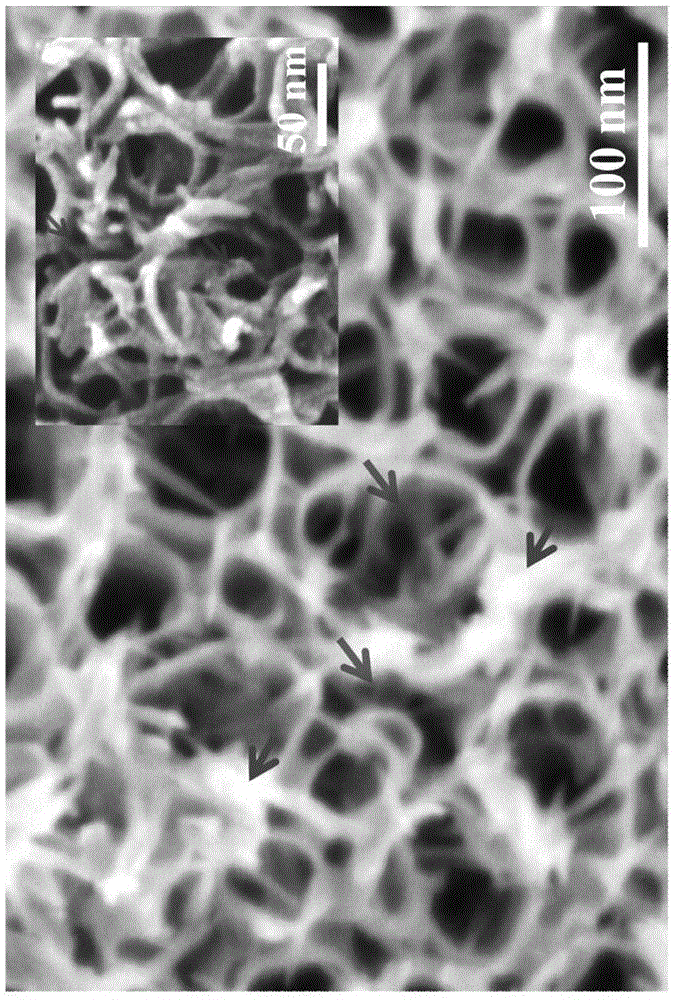

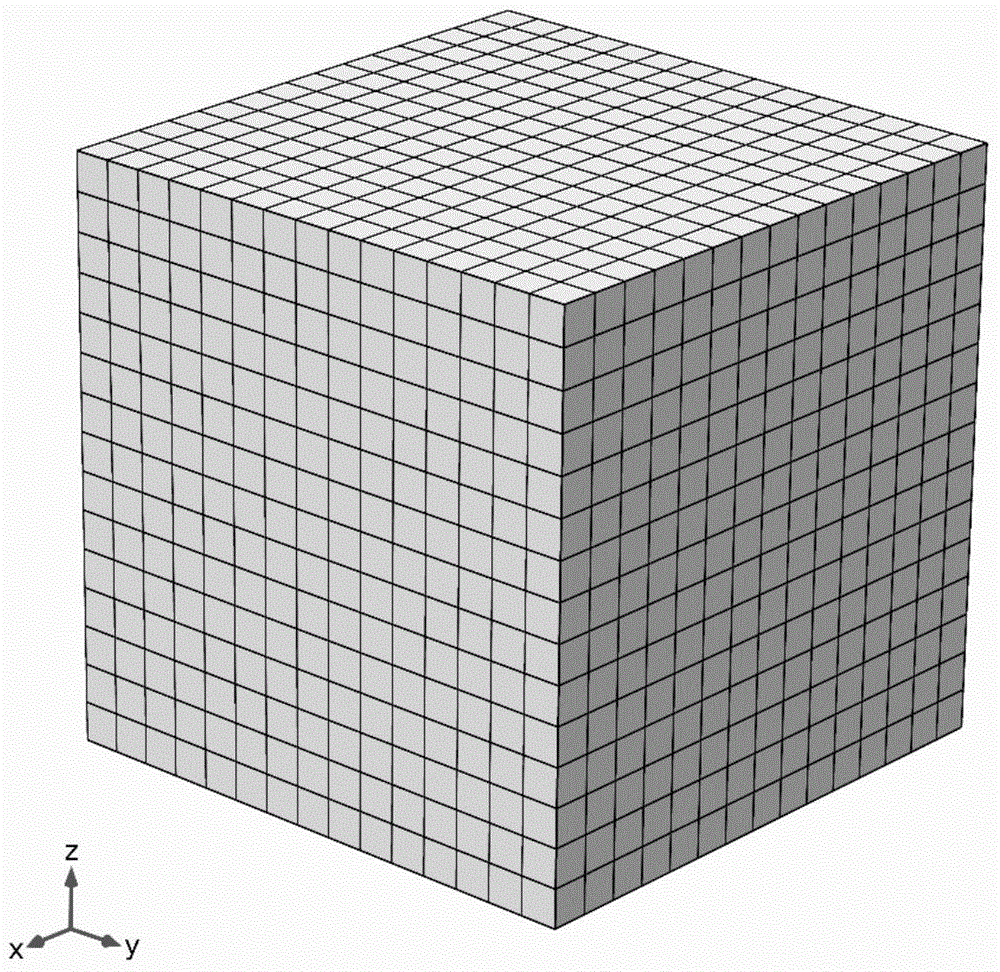

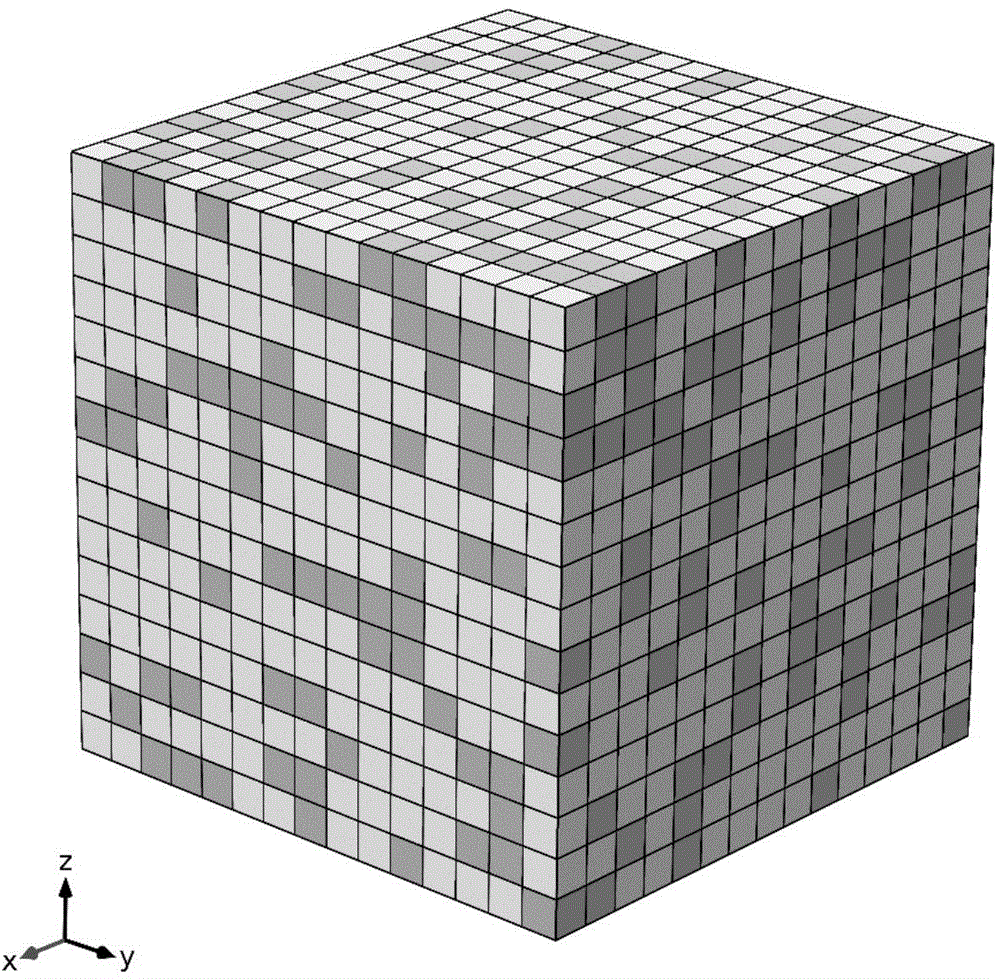

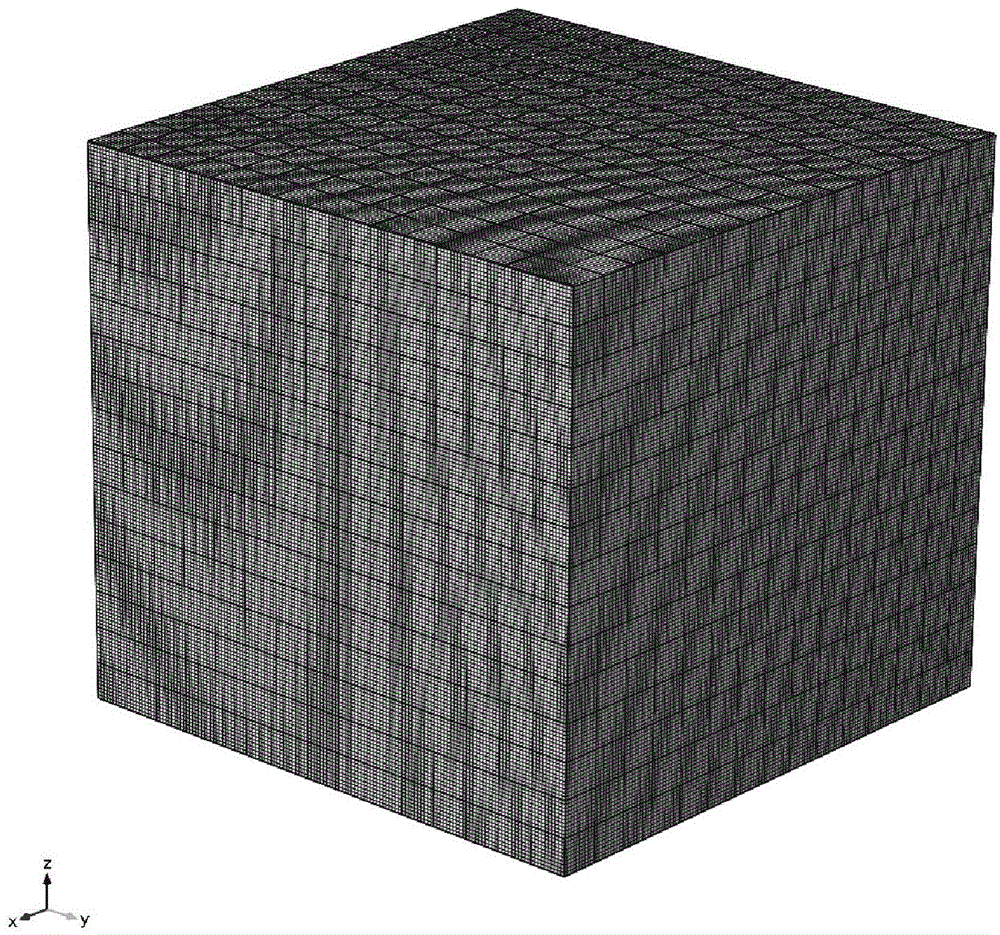

Method for predicting gas transmission curvature factors of solid oxide fuel cell electrode

ActiveCN104156539AAvoid defectsOvercome the disadvantages of free stacking methodSpecial data processing applicationsFinite element techniquePore distribution

The invention discloses a method for predicting gas transmission curvature factors of a solid oxide fuel cell electrode. The method specially comprises the steps that equivalent volume units of the electrode are built; the physical property of a small cube is designated randomly, according to distribution randomness of a solid part and a pore part in the electrode, part of the small cubes is randomly designated to pores according to the requirement of porosity epsilon, the remaining part of the small cube is designated to a solid body, and building of the porous electrode is completed; on the basis of the finite element method and the effective medium theory, effective diffusion coefficients Deff are calculated; on the basis of a capillaries model, the curvature factors are obtained through strict theoretical derivation. On the basis of randomness and finite element technology of pore distribution, defects of the experimentation method and the ball accumulation method are overcome, and a new simple, efficient and accurate method is provided for predication of the gas transmission curvature factors of the solid oxide fuel cell electrode.

Owner:JIANGSU UNIV OF SCI & TECH

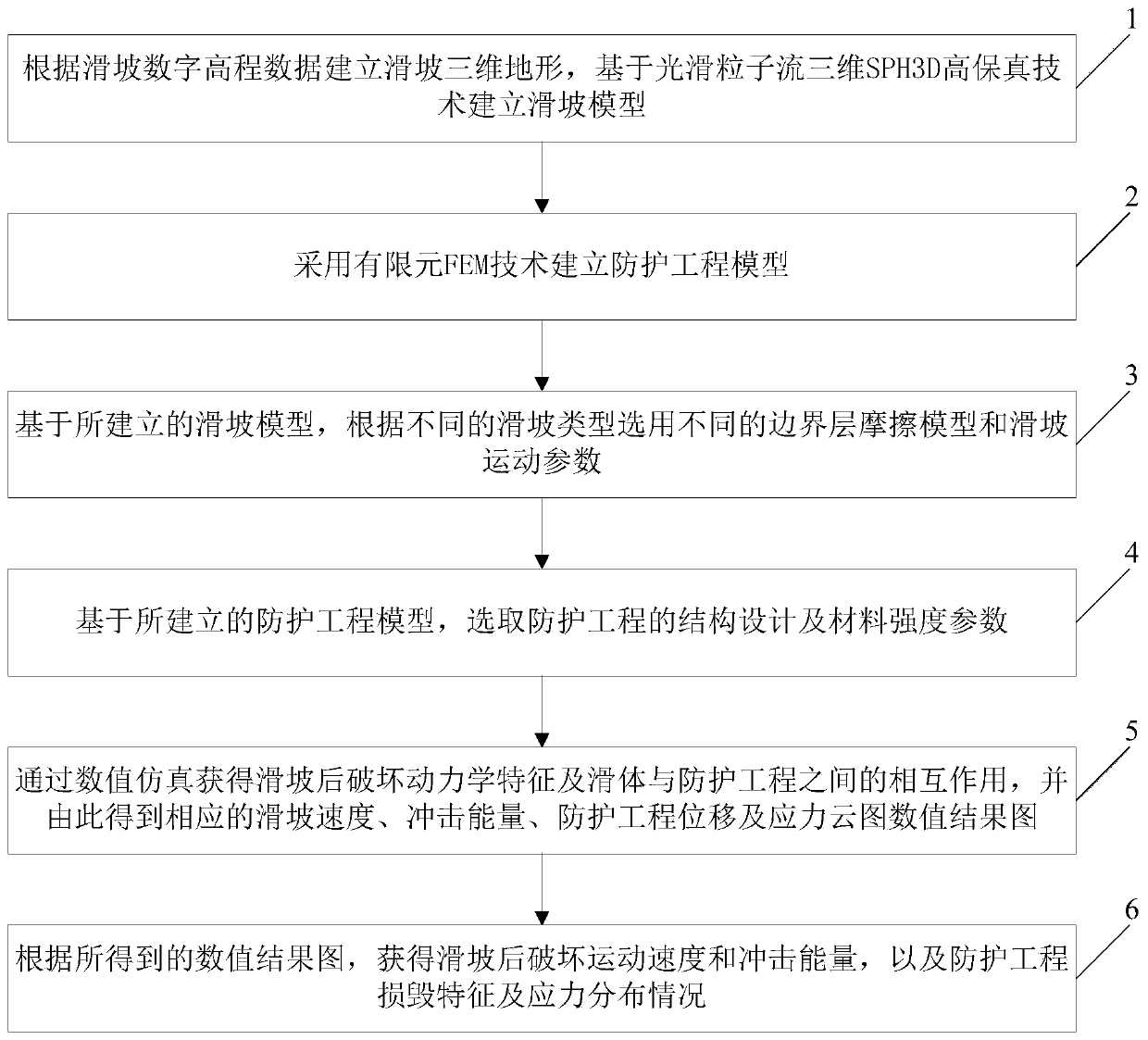

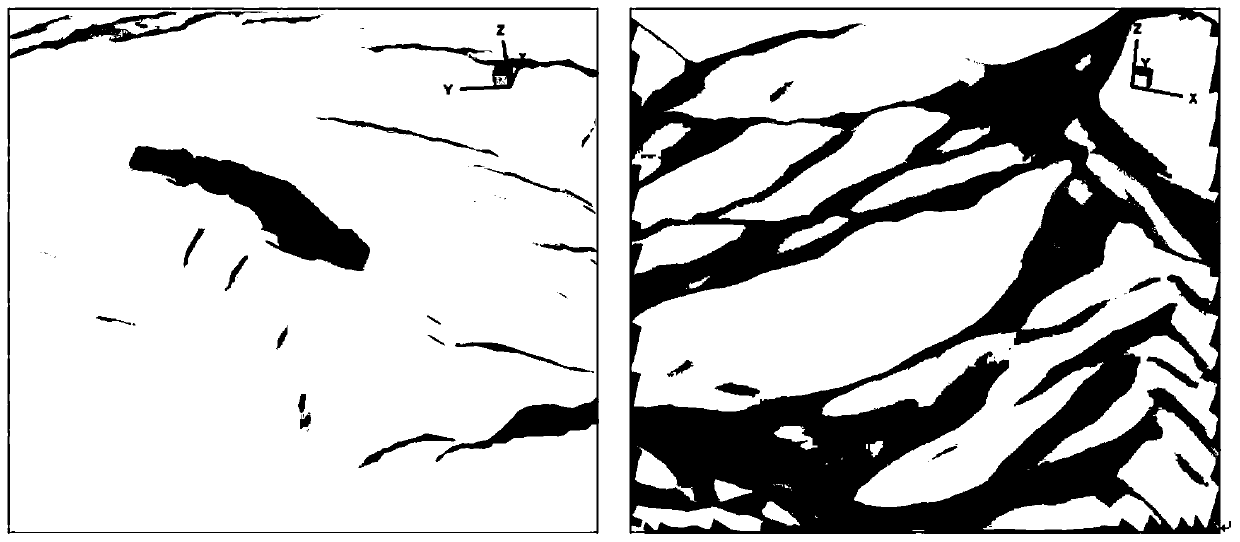

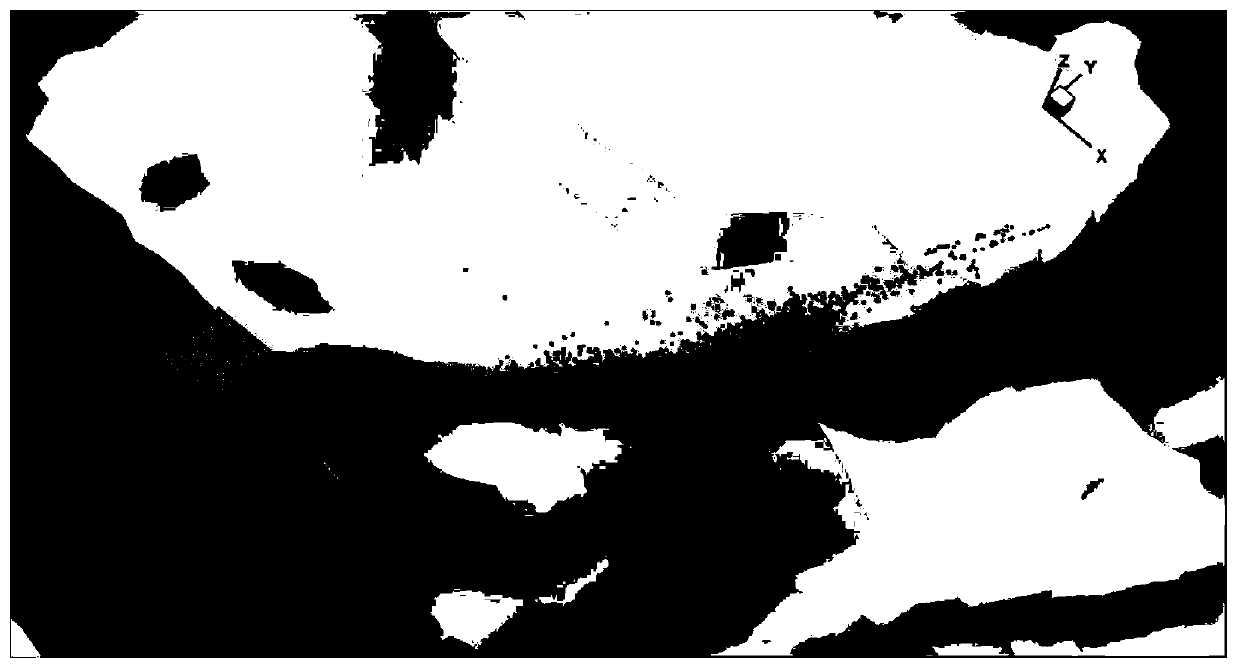

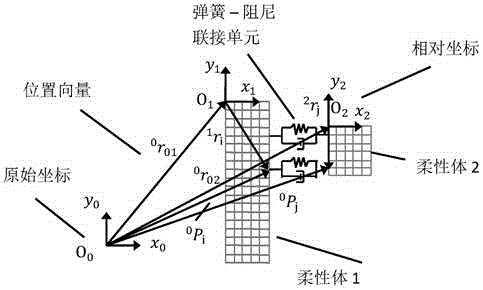

Method for predicting damage engineering protection effect after high-position remote landslide

The invention discloses a prediction method for a damage engineering protection effect after high-position remote landslide, and the method comprises the steps: building a landslide three-dimensionalterrain according to landslide digital elevation data, and building a landslide model based on a smooth particle flow three-dimensional SPH3D high-fidelity technology; establishing a protection engineering model by adopting the finite element (FEM) technology; selecting different boundary layer friction models and landslide motion parameters; selecting structural design and material strength parameters of protection engineering; acquiring the damage dynamic characteristics after landslide and interaction between a sliding body and a protection project through numerical simulation, and accordingly, acquiring a corresponding landslide speed, impact energy, protection project displacement and stress cloud chart numerical result chart; according to the obtained numerical value result graph, acquiring the damage movement speed, impact energy and other conditions after landslide. According to the method, the dynamic characteristics of the post-landslide damage can be completely and repeatedly obtained for multiple times, and the quantitative distribution condition of the stress and strain of the protection engineering in the post-landslide damage process is quantitatively analyzed.

Owner:INST OF GEOMECHANICS +1

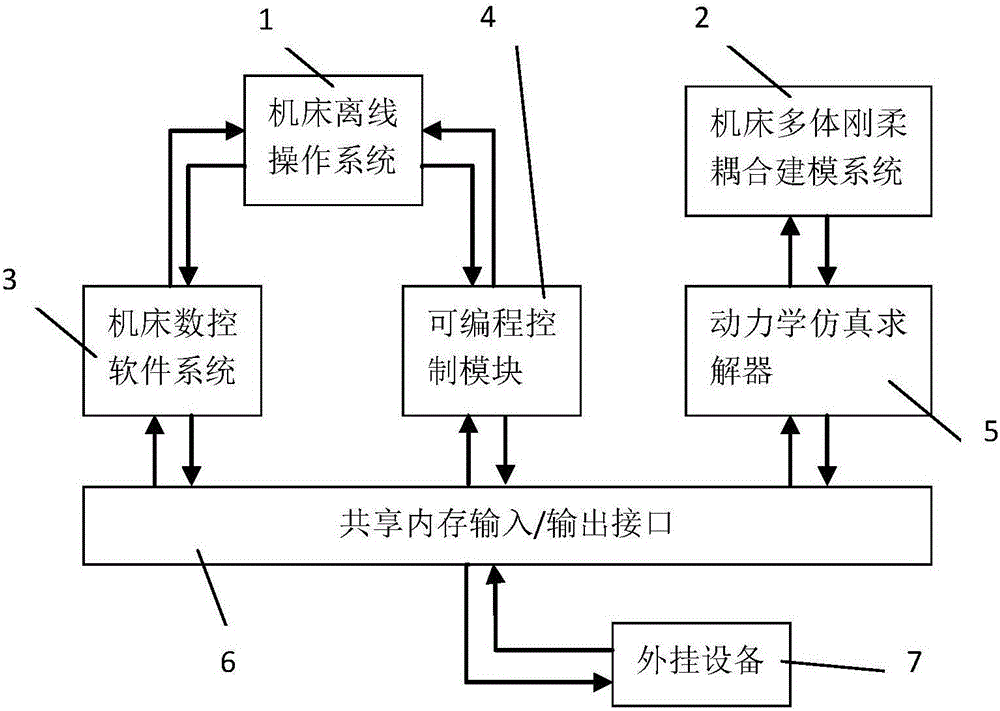

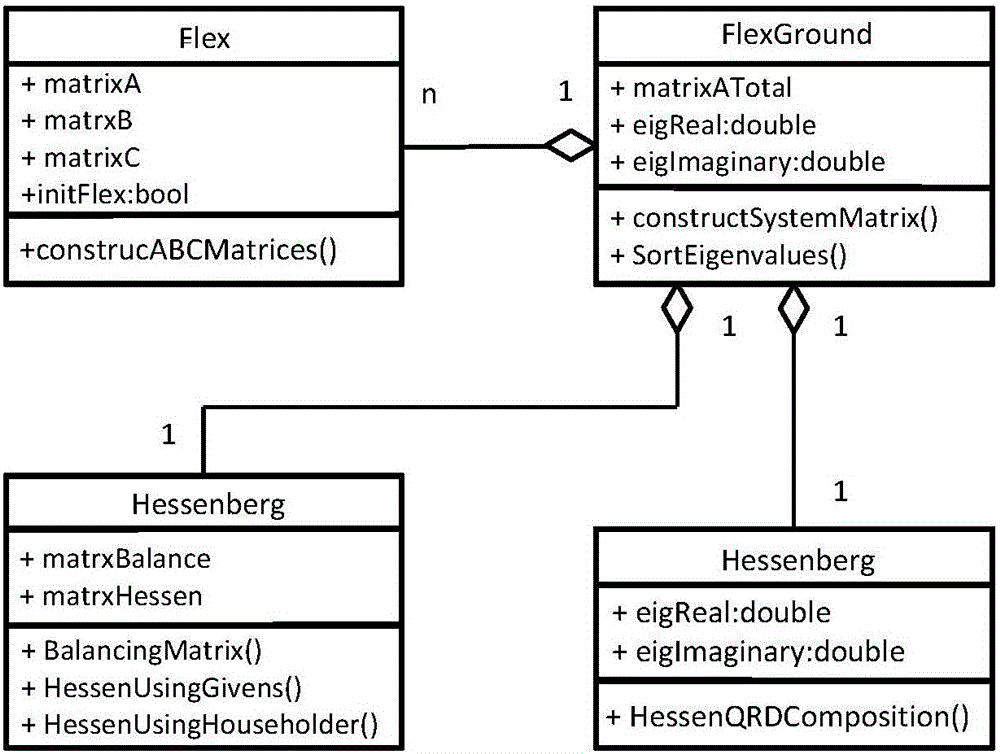

Method for dynamic characteristic simulation of numerically controlled machine tool and integration with numerical control system

ActiveCN105938329APrecise Adaptive ControlFully Adaptive ControlSimulator controlInternal memoryFinite element technique

The invention, which belongs to the field of the numerical control system field of the numerically controlled machine tool, provides a method for dynamic characteristic simulation of a numerically controlled machine tool and integration with a numerical control system. The method comprises: on the basis of a finite element technology, a dynamics multi-body coupling model of a machine tool system at a real-time position is obtained by using a multi-body rigid and flexible coupling modeling system of a numerically controlled machine tool; a dynamics simulation solver is used for obtaining a vibration characteristic of the machine tool at each real-time position by a numerically controlled machine tool feeding unit; interaction of a dynamic characteristic simulation signal of the real-time position of the numerically controlled machine tool and a signal from a numerically controlled software system of the numerically controlled machine tool is realized by using shared internal memory input / output interfaces of the numerically controlled machine tool; and an object-oriented programming technology is applied to a programmable control module, thereby realizing integration of a dynamics simulation solver and a machine tool numerically-controlled software system. The method has the following advantages: the multi-body rigid and flexible coupling modeling system of the numerically controlled machine tool and the real-time solving system are used for replacing an expensive and complicated machine tool dynamic characteristic sensor monitoring system; and thus a precise and comprehensive adaptive control system of the numerically controlled machine tool is realized.

Owner:BEIJING WENLI TECH CO LTD

Determining film stress from substrate shape using finite element procedures

ActiveUS7418353B2Accurately determine film stressFlow propertiesForce measurementNODALFinite element technique

A method for determining the stresses in a film applied to a substrate from measured substrate shape. The substrate is first analyzed using finite element techniques to obtain nodal forces at the surface of the substrate to which the film is applied, based on measured distortion data of the substrate surface. The film is then analyzed to calculate the film stresses from the applied nodal forces using finite element techniques. The invention may be applied to determine stresses in thin films applied to a variety of substrates, including those used for micro-electronic (e.g., integrated circuit) and micro-mechanical devices and / or for the lithography masks or other optical / projection systems used to fabricate such devices.

Owner:WISCONSIN ALUMNI RES FOUND

Wear prediction method for fine blanking dies based on finite-element technique and artificial neural network

ActiveCN102103646BImprove forecast accuracyQuick responseBiological neural network modelsSpecial data processing applicationsFinite element techniqueGeometric relations

The invention relates to the technical field of fine blanking, in particular relates to a wear prediction method for fine blanking dies based on a finite-element technique and an artificial neural network. The method provided by the invention comprises the following steps: building a finite-element analysis model, namely, simulating a fine blanking process on a finite-element analysis and calculation platform, and calculating the wear extent of a fine blanking die in the fine blanking process by using an Archard wear model; building a neural network model, namely, training a designed neural network model by using a finite-element analysis result guided by an orthogonal experimental design so as to obtain a functional relation between the wear extent of the fine blanking die and fine blanking parameters; obtaining the fine blanking parameters, namely, obtaining the functional relations between the fine blanking parameters and the wear extent, blanking time, and the like of the fine blanking die according to geometrical relationships and production practices; and building and simulating a fine blanking wear prediction model. The method provided by the invention has the advantages ofhigh prediction precision, fast response speed and strong operability.

Owner:武汉客车制造股份有限公司

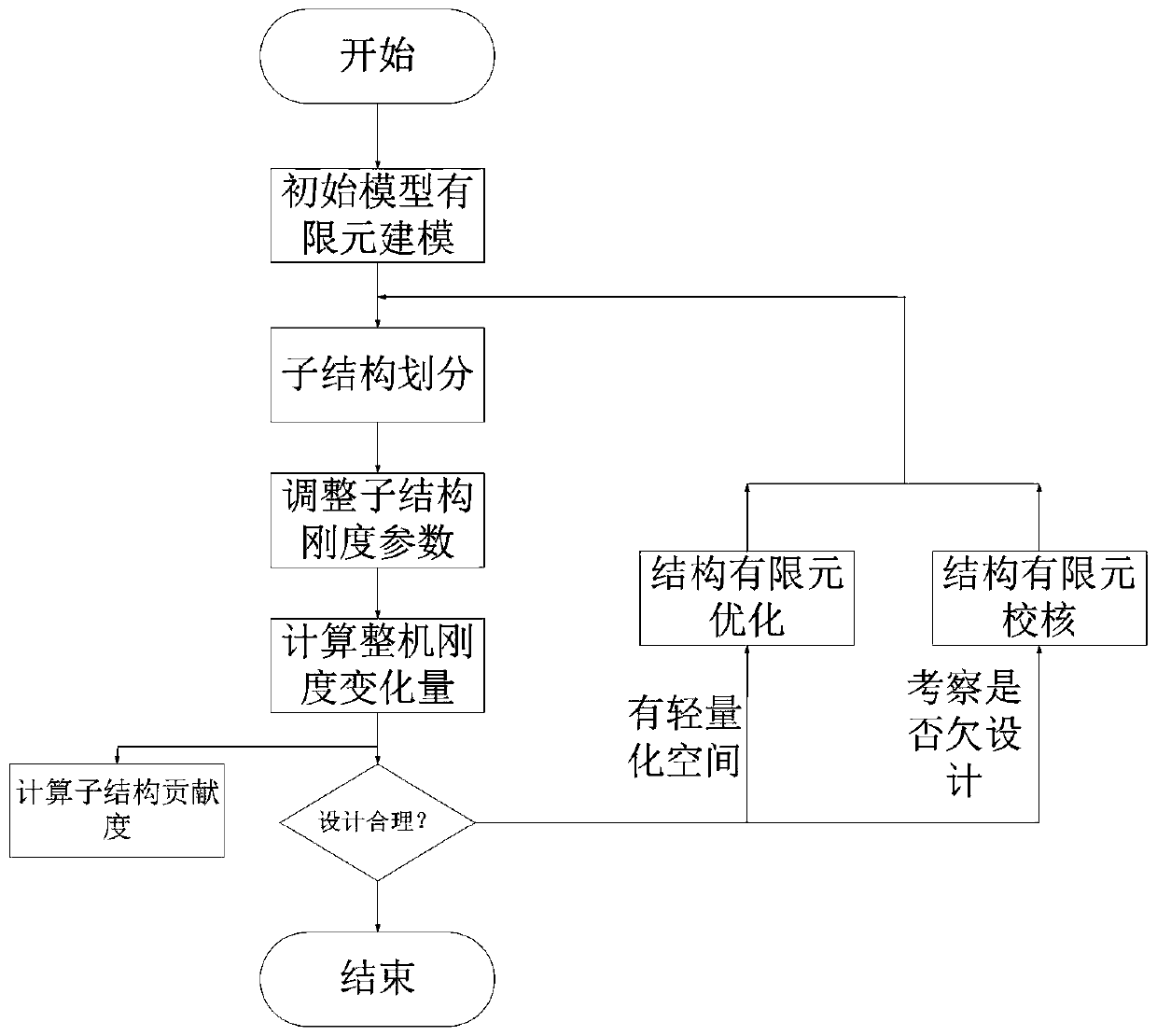

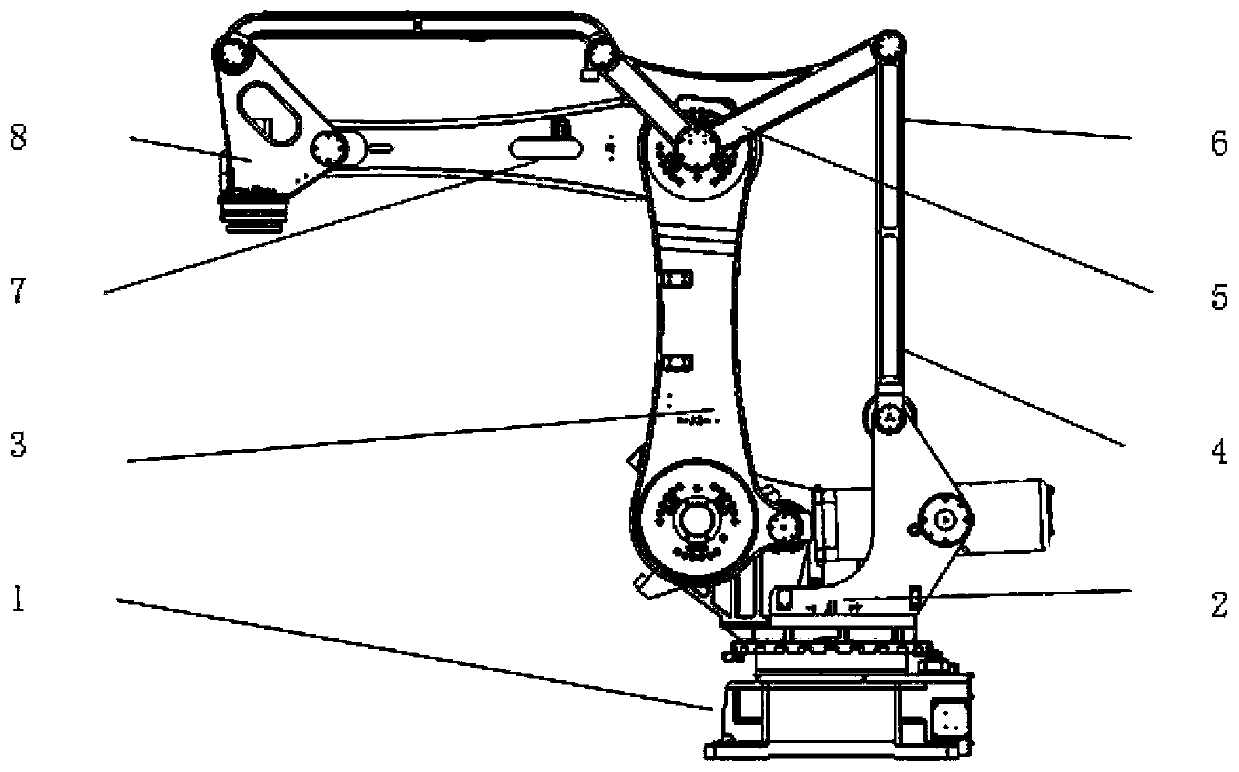

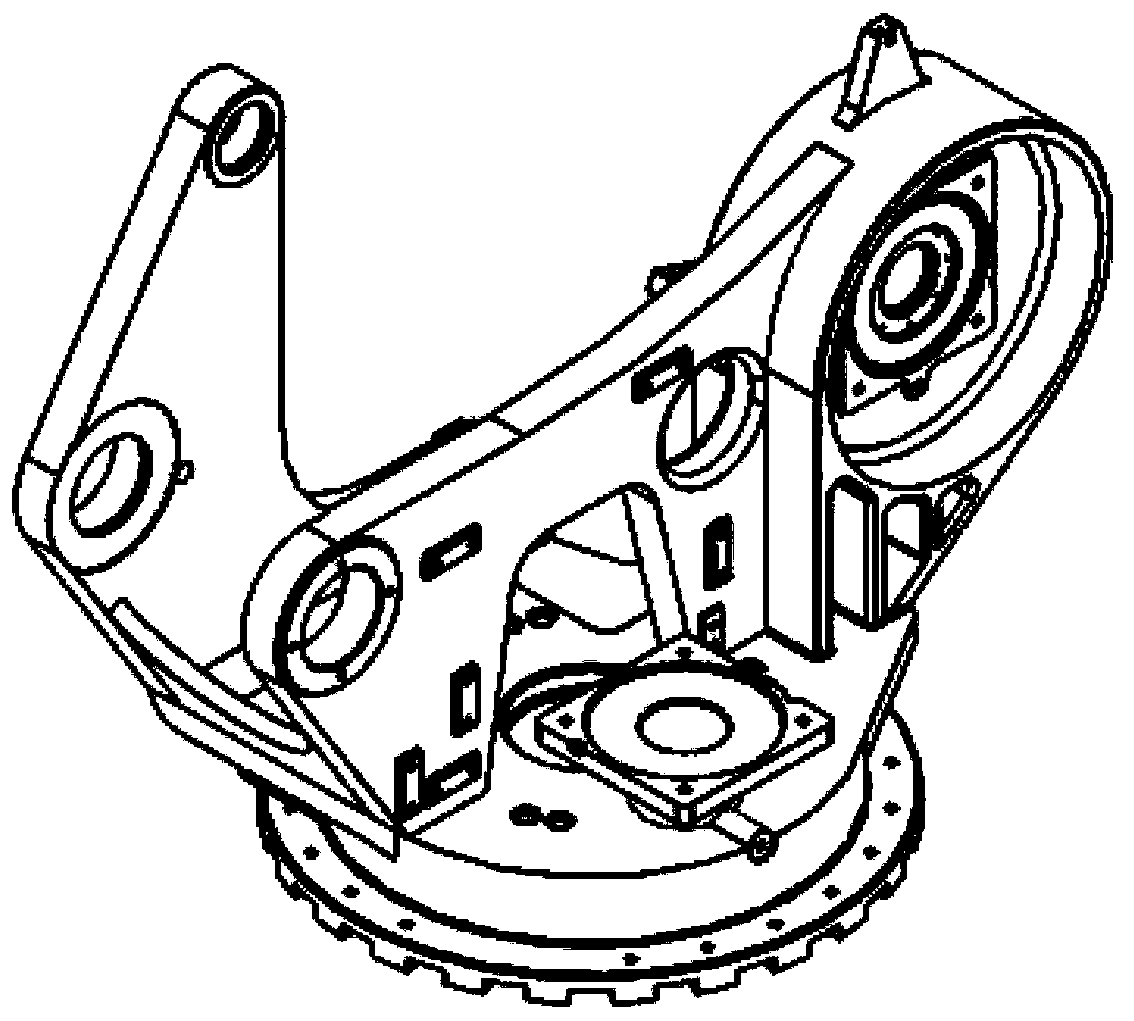

Industrial robot complete machine rigidity optimization method based on finite element technology

ActiveCN111444644AGuaranteed lightweight designShorten the design and development cycleGeometric CADDesign optimisation/simulationFinite element techniqueElement model

The invention relates to the field of robot rigidity optimization design, in particular to an industrial robot complete machine rigidity optimization method based on a finite element technology, whichcomprises the following specific steps: s1, carrying out finite element modeling on an initial model; s2, carrying out substructure division; s3, adjusting sub-structure rigidity parameters; s4, calculating the rigidity variation of the complete machine; s5, judging whether the design is reasonable or not; s6, optimizing the structure. A finite element means is utilized to establish a complete machine model to analyze the design rationality of the complete machine rigidity and the part rigidity, the analysis efficiency is greatly improved, and the robot design and development period is shortened; the design problem and defects are exposed in advance through the finite element technology and the normalization method, the fatality problem occurring in the prototype stage is avoided, the development cost is reduced, the method can be designed and developed with any industrial robot, and the lightweight design of the whole robot can be guaranteed while the rigidity level of the whole robot is improved.

Owner:EFORT INTELLIGENT EQUIP CO LTD

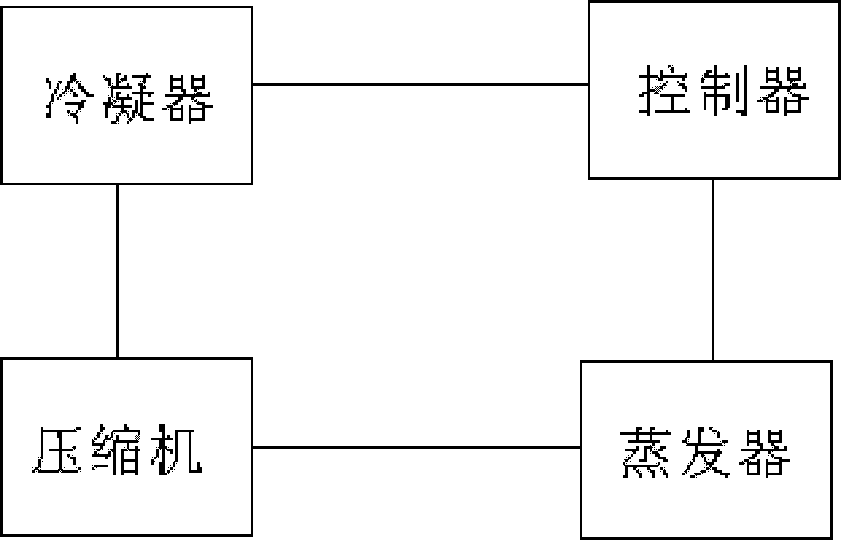

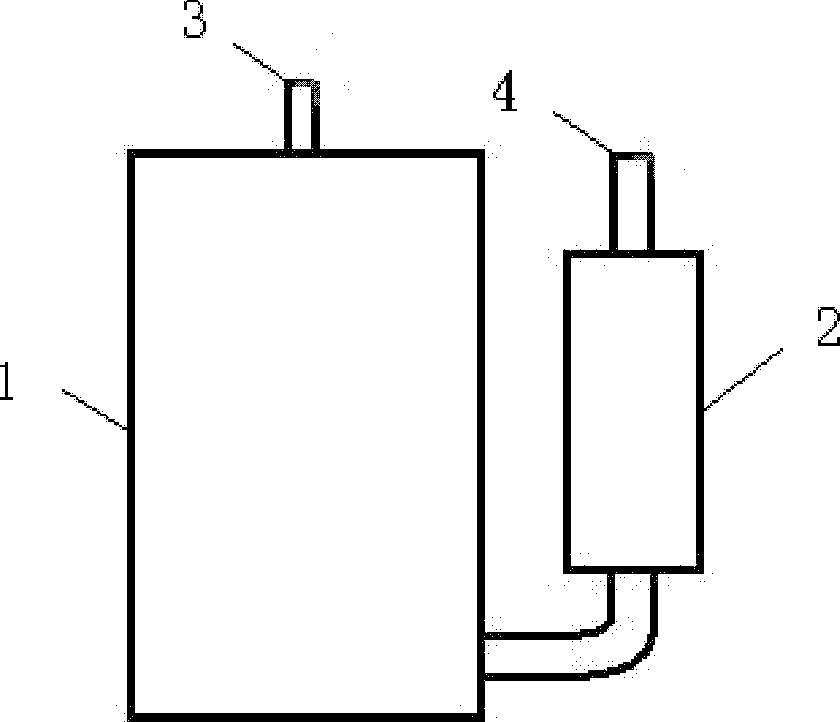

Load testing-analyzing method of rotor compressor for refrigeration plant

ActiveCN102562568BLower requirementEasy programmingPump testingPositive-displacement liquid enginesFinite element techniqueTransfer matrix

The invention discloses a load testing-analyzing method of a rotor compressor for a refrigeration plant. The load testing-analyzing method is characterized in that the amplitudes of two testing points are tested by an experiment, the finite element technology is utilized for calculating transfer matrixes of the displacement to all the testing points, caused by the force and moment on loading action points, and displacement matrixes of all the testing points, so that the loading value of the compressor can be obtained in a reversing manner. The loading value of the rotor compressor can be obtained by a simple and feasible testing method, so that the work stress of a pipe distribution structure can be analyzed and calculated conveniently.

Owner:HEFEI UNIV OF TECH

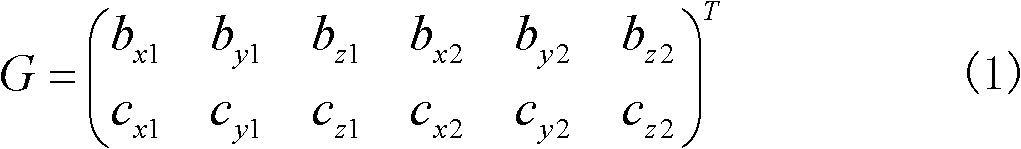

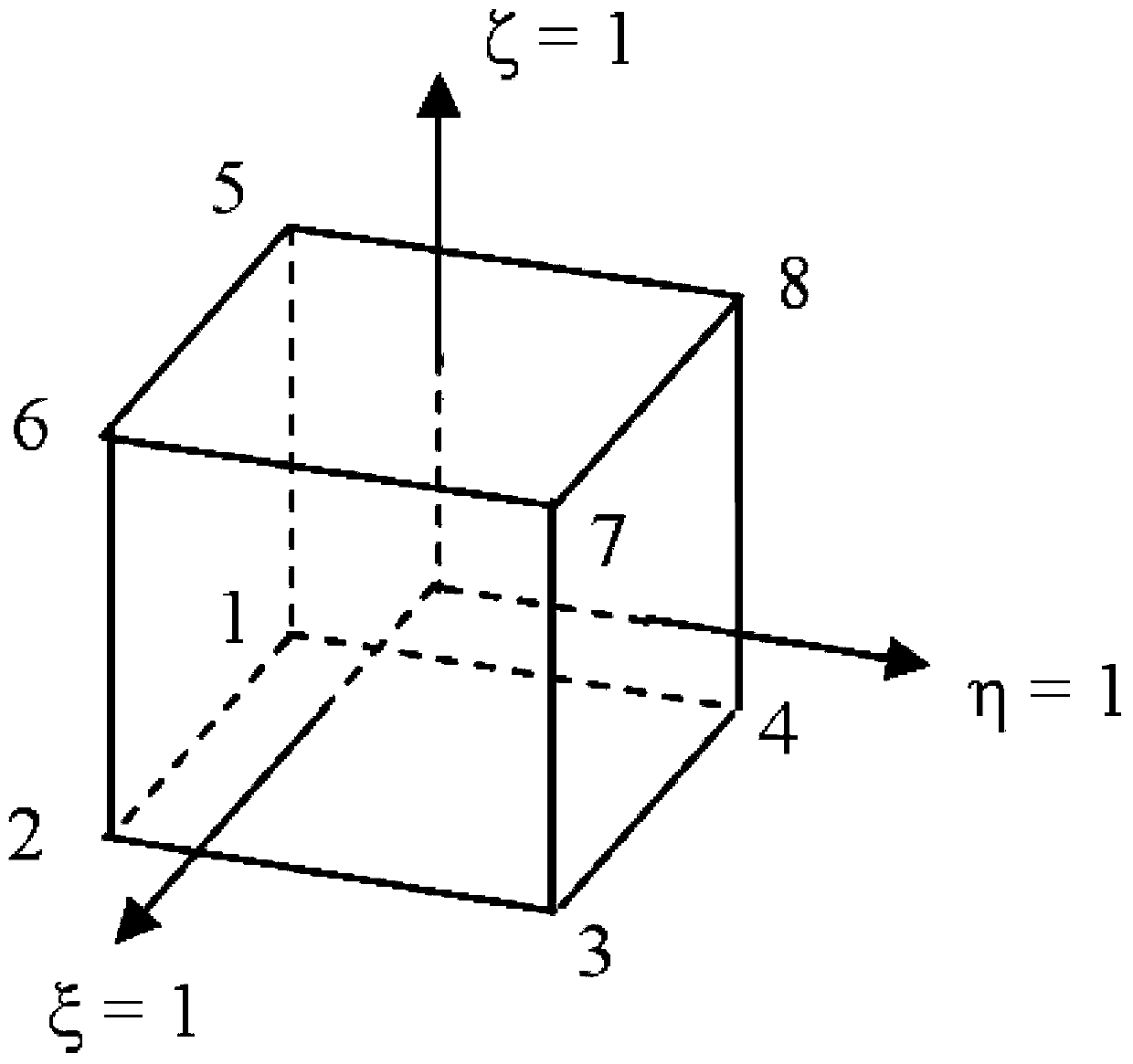

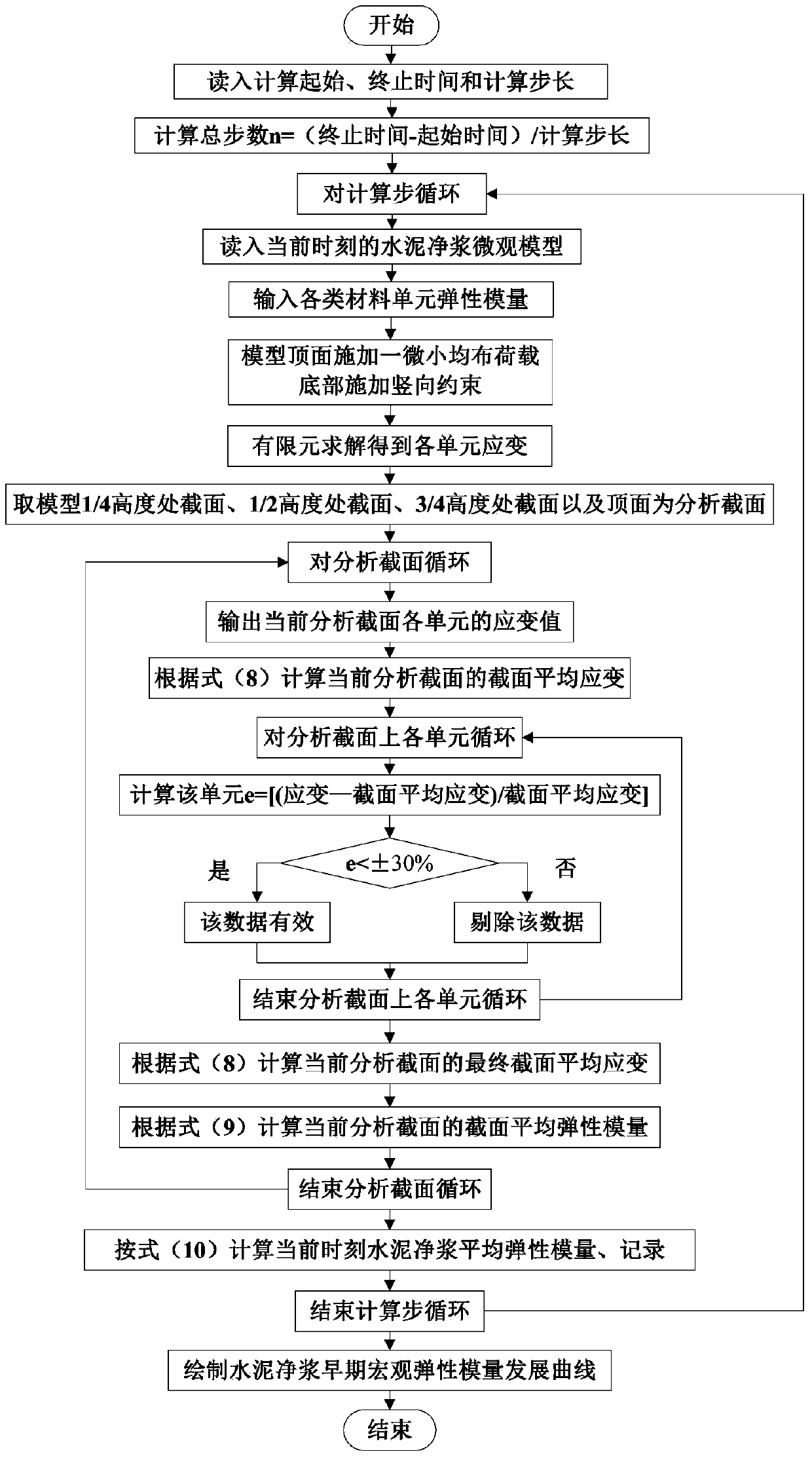

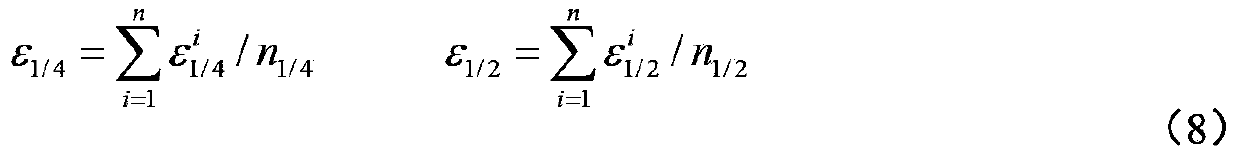

Method for counting early-stage macroscopic elasticity modulus of cement paste under axle center stress state

The invention provides a method for counting an early-stage macroscopic elasticity modulus of cement paste under an axle center stress state and particularly provides a finite element analysis method which is intuitional in concept, is easy to handle and use and is used for counting the early-stage macroscopic elasticity modulus of the cement paste under the axle center stress state on the basis of properties of known cement paste micro models and various hydrate materials. According to the method, the average strain of each unit of the micro models under the axle center stress state is counted by virtue of a finite element emulation technique on the basis of the properties of the known cement paste micro models and the various hydrate materials, and in combination of an elasticity modulus basic definition, the average elasticity modulus of the cement paste micro models is counted, thus realizing combined innovation and expansion application of a micromechanic theory and a finite element technique of cement-based materials. According to the method, a development law of the early-stage macroscopic elasticity modulus of the cement paste can be obtained, and a foundation is laid for analyzing the influences of composition, distribution, porosity and pore size distribution of a cement hydration product to the macroscopic elasticity modulus of the cement paste. The method is simple in algorithm and clear in concept, and can be easily handled and extended by a user.

Owner:JINLING INST OF TECH

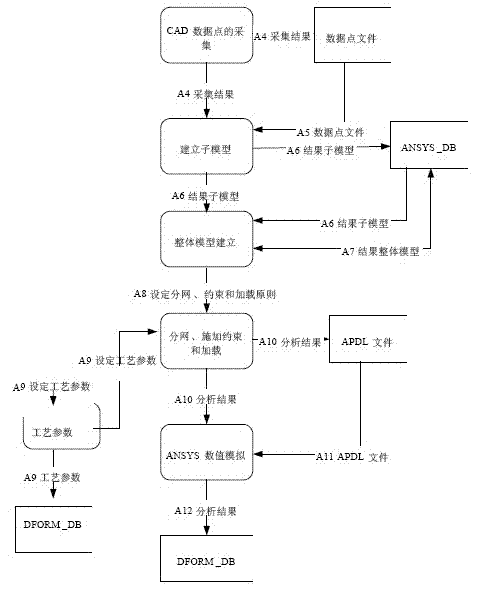

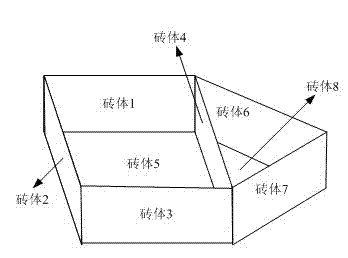

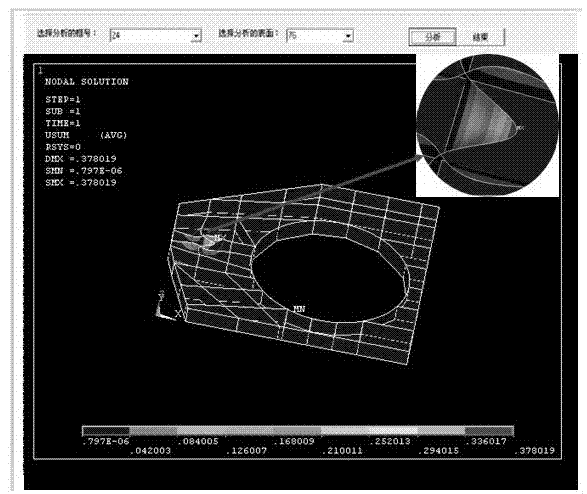

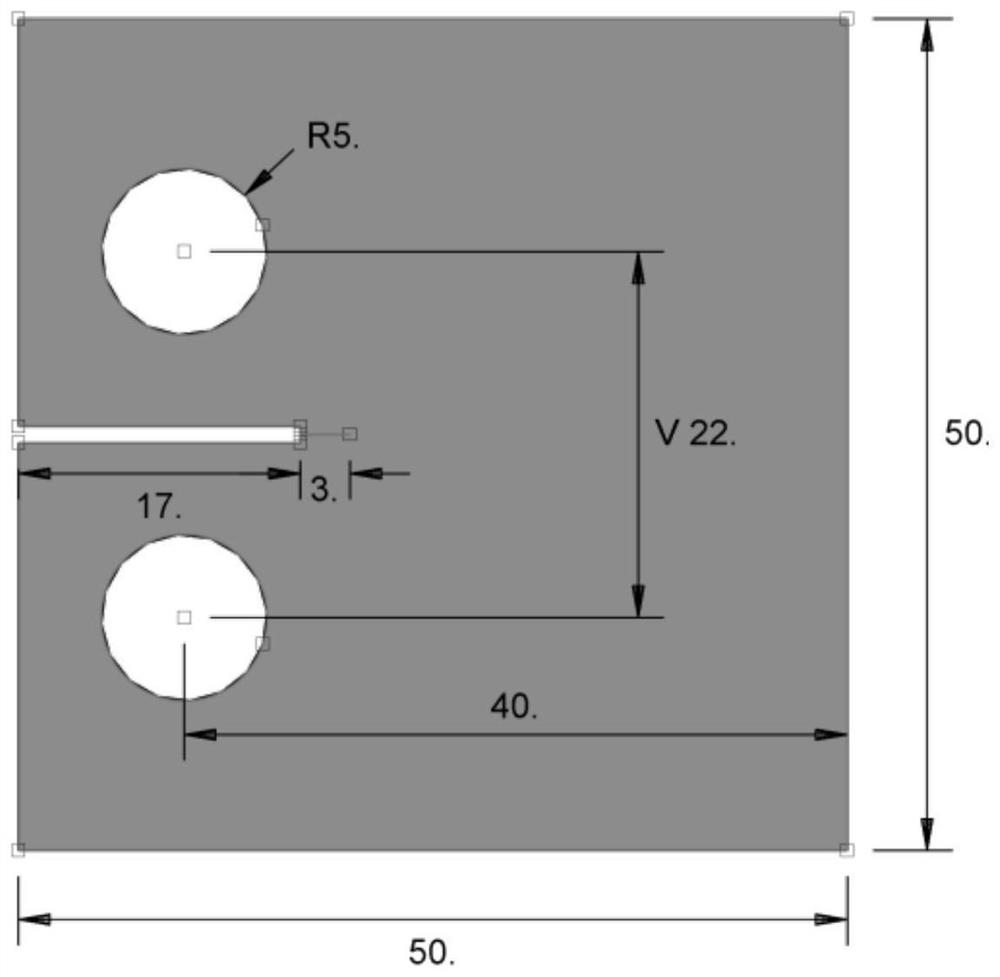

Follow-up forecast method for milling deformation of complex integral structural components

InactiveCN103177163AAvoid dependencyReal-timeSpecial data processing applicationsFinite element techniqueStructure analysis

For a defect in the prior art that the milling deformation control on complex integral structural components is overly dependent on artificial experiences, the invention discloses a follow-up forecast method for the milling deformation of complex integral structural components. The method is implemented through carrying out feature modeling on the integral structural component through an analysis technology of deformation in machining (CAE); completing structure analysis and machining simulation by virtue of a finite element technology; then importing analysis and simulation results into a deformation decision support module (DMSS), so that the analysis on deformation data is completed in the module; and finally, providing forecast information for technicians. The method solves the dependence of the milling deformation forecast of complex integral structural components on artificial experiences, has a real-time property, a dynamic property and reliability, reduces the production cost, shortens the trial production and production cycles of products, and improves the production efficiency.

Owner:CHANGZHOU INST OF TECH

Residual stress introduced CT sample stress field and crack propagation analysis method

ActiveCN112307664AEnable crack analysisImpact forecastDesign optimisation/simulationComputational theoretical chemistryFinite element techniqueElement model

The invention relates to a residual stress introduced CT sample stress field and crack propagation analysis method, which comprises the following steps of: establishing a CT sample finite element model by adopting ABAQUS finite element analysis software, and endowing a CT sample with initial stress by a direct assignment method and a file input numerical method; and calculating a stress intensityfactor of the CT sample and carrying out finite element simulation analysis on crack propagation by applying a cloud picture integration and expansion finite element technology. According to the method, the influence of different stress conditions on the crack propagation trend is fully considered, the finite element model for precisely calculating the high-temperature alloy CT sample crack tip stress intensity factor with introduced residual stress and predicting the crack propagation law is obtained, and the influence of stress on the crack propagation trend is effectively predicted; the simulation method can be widely applied to the field of aerospace, and a new thought is provided for research on prediction of residual stress and pretreatment on crack propagation behaviors.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

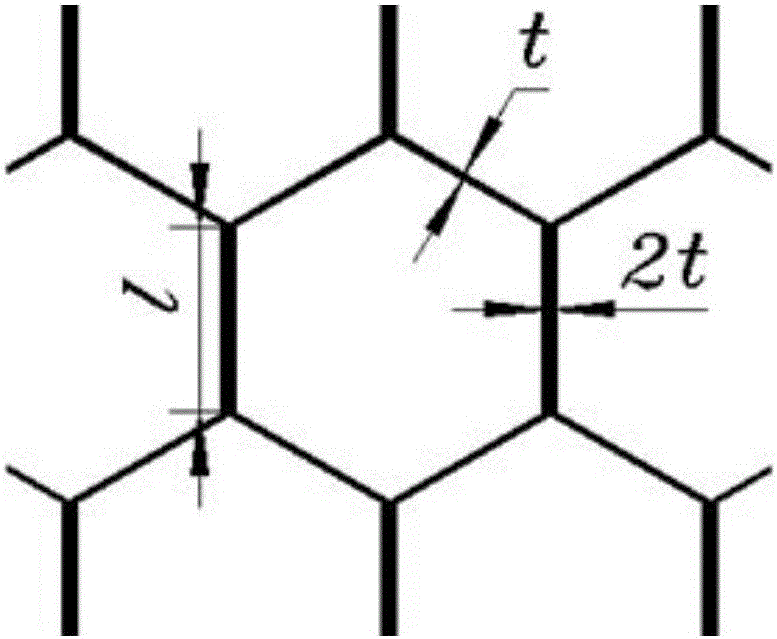

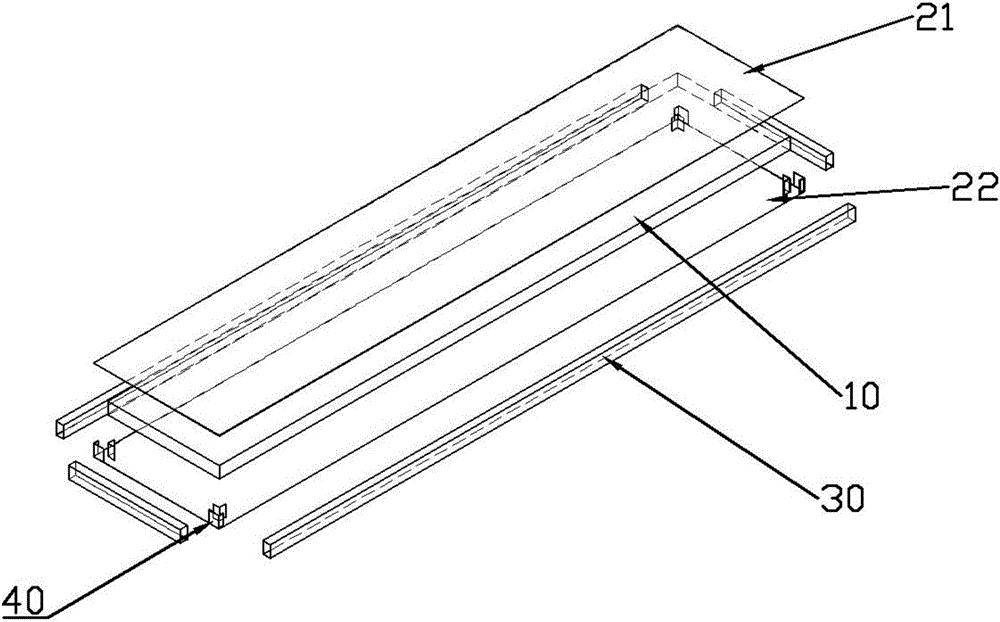

Design and manufacturing method for hexagonal honeycomb aluminum platform

InactiveCN106844891ASolve design problemsSolving Manufacturing ChallengesGeometric CADDesign optimisation/simulationFinite element techniqueSolid structure

The invention relates to the technical field of PCB machine tools, in particular to a design and manufacturing method for a hexagonal honeycomb aluminum platform. The design and manufacturing method for a hexagonal honeycomb aluminum platform comprise the steps that a honeycomb aluminum core is form into an orthotropic uniform and continuous solid structure in an equivalent mode and engineering parameters of the uniform and continuous solid structure are calculated; a whole simulation model of the uniform and continuous solid structure and an external frame is established, and performance of the whole simulation model is analyzed by a finite element technology; if the performance of the whole simulation model meets the requirements, the corresponding hexagonal honeycomb aluminum platform is manufactured and a related performance test is carried out. According to the design and manufacturing method for the hexagonal honeycomb aluminum platform, the difficulties of designing and manufacturing a hexagonal honeycomb aluminum platform are solved, the platform performance is prejudged, the platforms which meet the design and manufacture requirements are quickly designed and manufactured, the production cost is reduced, the reliability of the design and manufacture is improved, at the same time the platform performance is optimized scientifically and the performance standard for use is met.

Owner:HANS CNC SCI & TECH

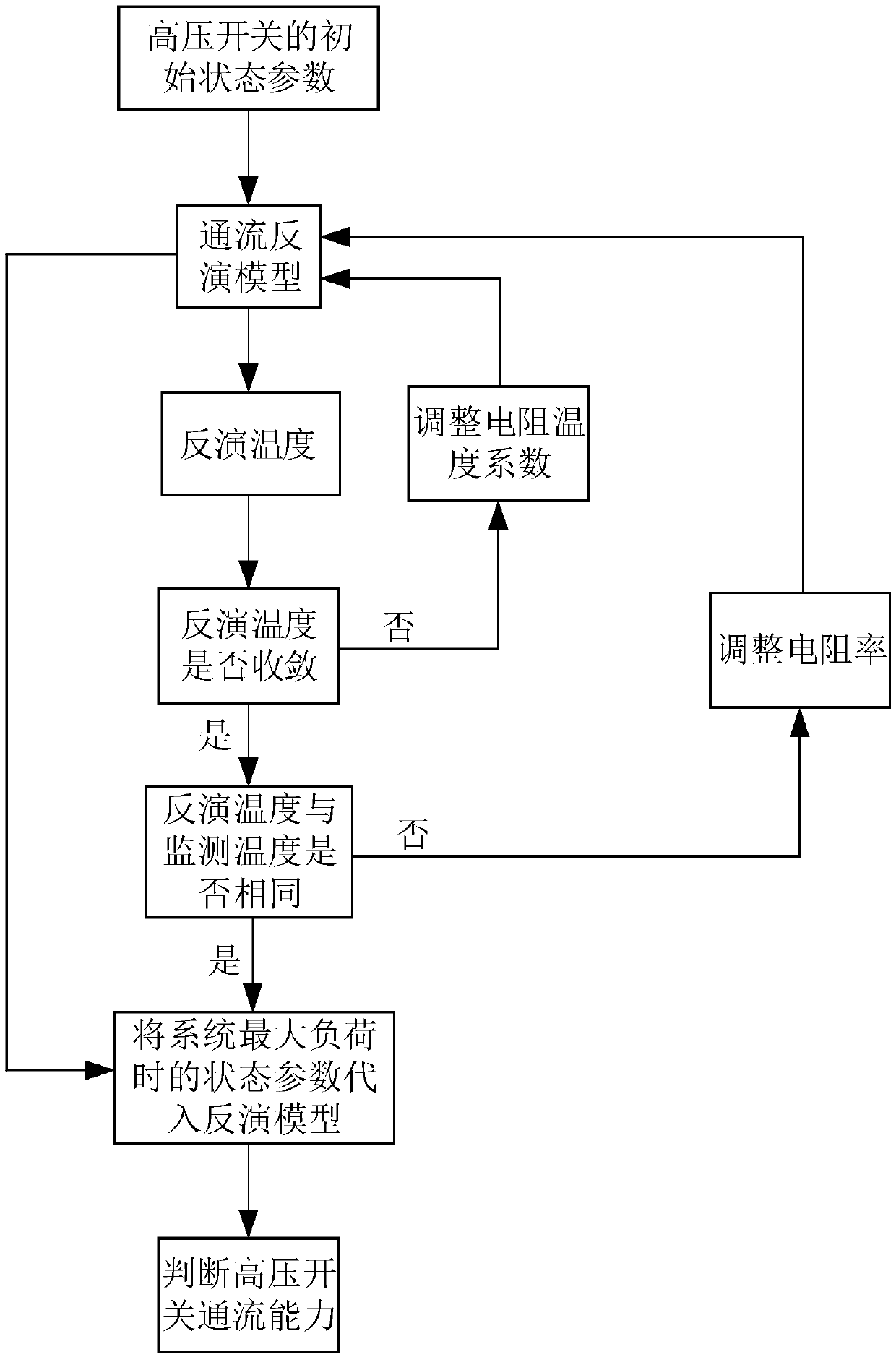

Inversion method and device for current-through fault of high-voltage switch

ActiveCN110837041AEffectively judge faultsImprove the efficiency of operation and maintenanceCircuit interrupters testingFinite element techniqueSwitched current

The invention relates to the field of high-voltage equipment monitoring, in particular to an inversion method and device for a current-through fault of a high-voltage switch. The inversion method comprises the steps of firstly, taking monitoring data as an input condition of a simulation model by building a finite element technology- and CFD technology-based high-voltage switch current-through fault inversion model, and obtaining an inversion temperature by running the inversion model; secondly, adjusting a parameter in the inversion model according to a comparison result of a monitoring temperature; and finally, judging whether the high-voltage switch has current-through capability or not at maximum load according to the inversion model after parameter adjustment. Model inversion simulation can be performed according to monitoring data, so that whether a fault occurs in the high-voltage switch or not is effectively judged, an improved scheme is proposed, real-time early warning of thefault can be achieved, and the operation and maintenance efficiency of the high-voltage switch is improved.

Owner:PINGGAO GRP +1

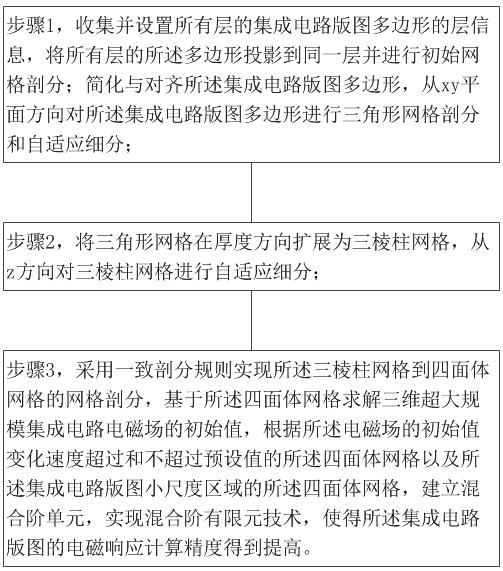

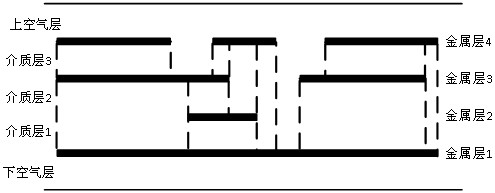

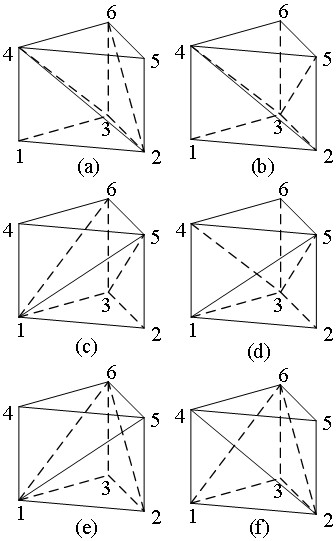

Mixed order finite element method and device for triangular prism mesh generation of integrated circuit

ActiveCN112131774AElectromagnetic Response Calculation Accuracy ImprovementImprove orderDesign optimisation/simulationSpecial data processing applicationsFinite element techniqueVery large scale integrated circuits

The invention provides a mixed order finite element method and device for triangular prism mesh generation of an integrated circuit. The method comprises the steps of: collecting and setting layer information of polygons of an integrated circuit layout, projecting the polygons to the same layer, and performing initial mesh generation; simplifying and aligning the integrated circuit layout polygon,and performing triangular mesh generation and self-adaptive subdivision on the integrated circuit layout polygon from the xy direction; expanding the triangular mesh into a triangular prism mesh in the thickness direction, and performing adaptive subdivision on the triangular prism mesh in the z direction; adopting a consistent subdivision rule to realize subdivision from a triangular prism gridto a tetrahedral grid, and solving an initial value of a three-dimensional super-large-scale integrated circuit electromagnetic field based on the tetrahedral grid; and establishing a mixed order unitaccording to the tetrahedral mesh of which the initial value change speed of the electromagnetic field exceeds or does not exceed a preset value and the tetrahedral mesh of the small-scale region ofthe integrated circuit layout, thereby realizing a mixed order finite element technology. Rapid and high-quality triangular prism mesh generation is realized; and the electromagnetic response calculation precision is improved.

Owner:北京智芯仿真科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com