Industrial robot complete machine rigidity optimization method based on finite element technology

A technology of industrial robots and optimization methods, applied in design optimization/simulation, geometric CAD, CAD numerical modeling, etc., can solve problems such as low robot positioning accuracy, and achieve the effect of improving analysis efficiency, reducing development costs, and shortening development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

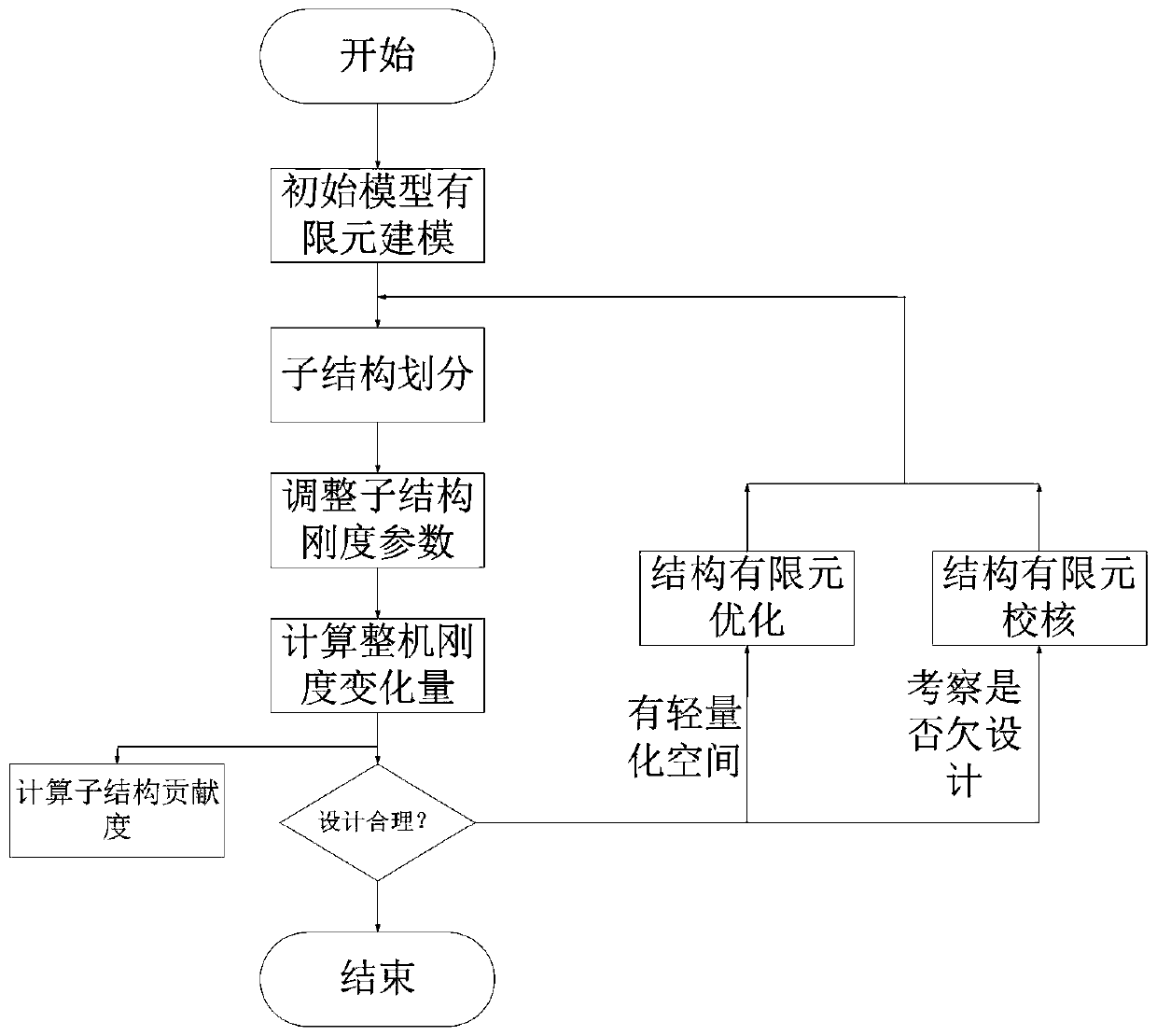

[0025] Such as Figure 1 to Figure 4 As shown, an industrial robot machine stiffness optimization method based on finite element technology, the specific steps are as follows:

[0026] S1: Finite element modeling of the initial model: establish the finite element model of the whole robot, and calculate the comprehensive stiffness K of the whole machine w and three-way stiffness K x 、K y 、K z ;

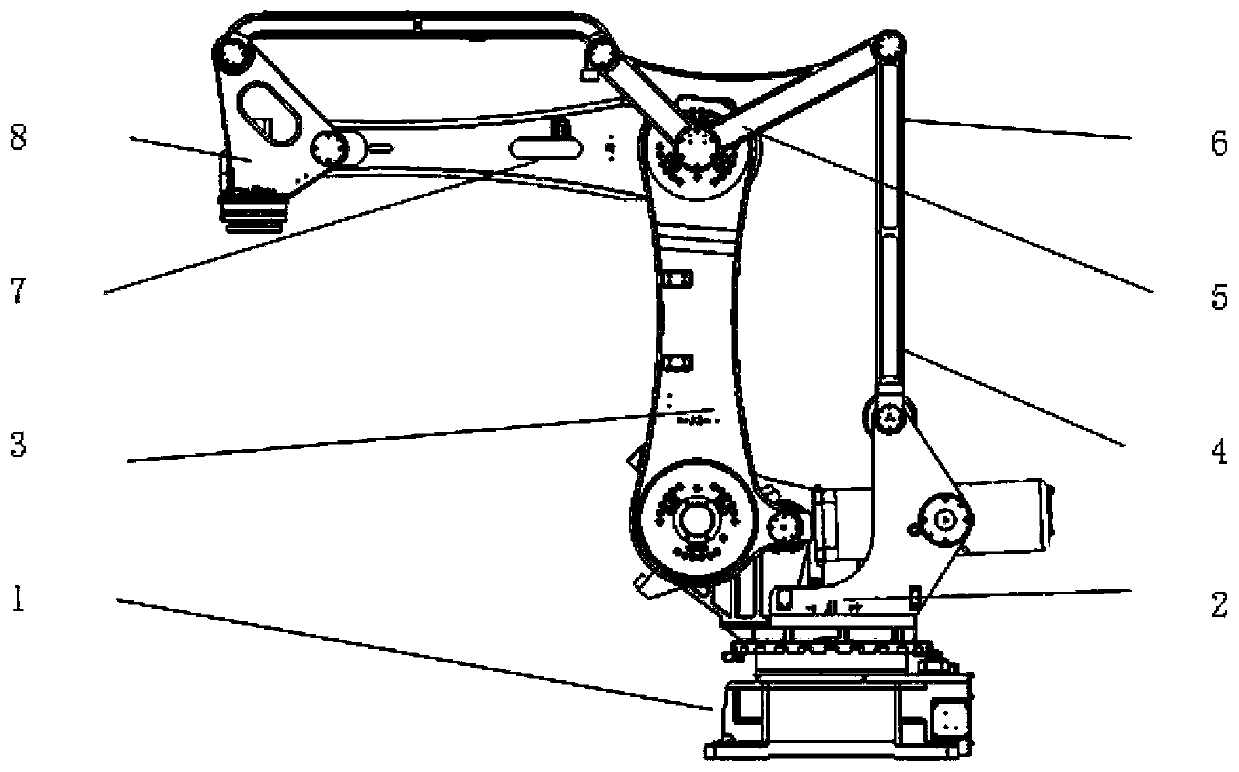

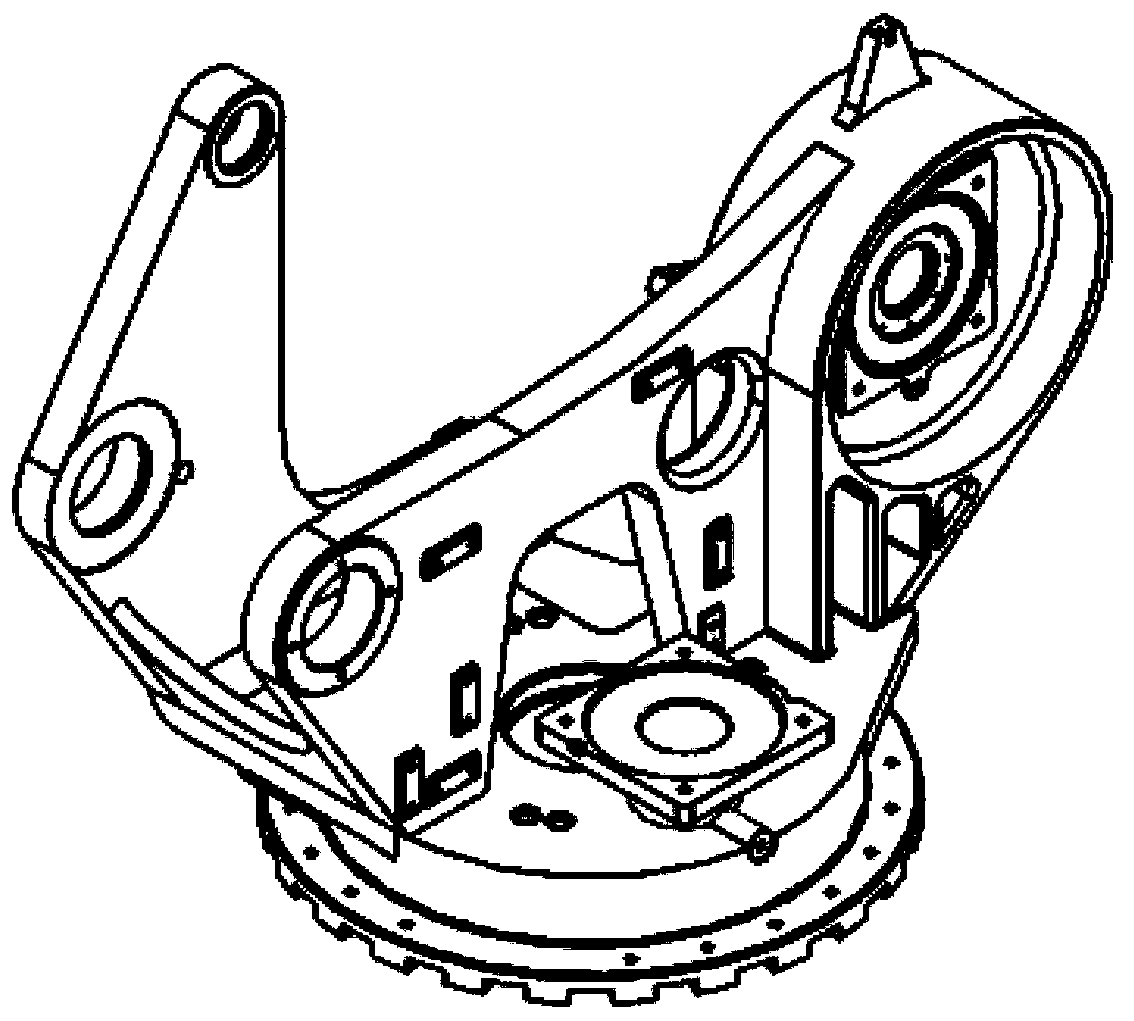

[0027] S2: Sub-structure division: Divide the robot into i sub-structures according to the rods and joints. Arm 7, wrist body 8;

[0028] S3: Adjust the stiffness parameters of the substructure: adjust the stiffness parameters of each substructure in the finite element model, load the three-direction component force at the end of the robot: Fx=200N, Fy=-500N and Fz=-200N, and calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com