power pack driven clip

A technology of power components and clips, applied in metal processing and other directions, to achieve the effect of small size, reduced load, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

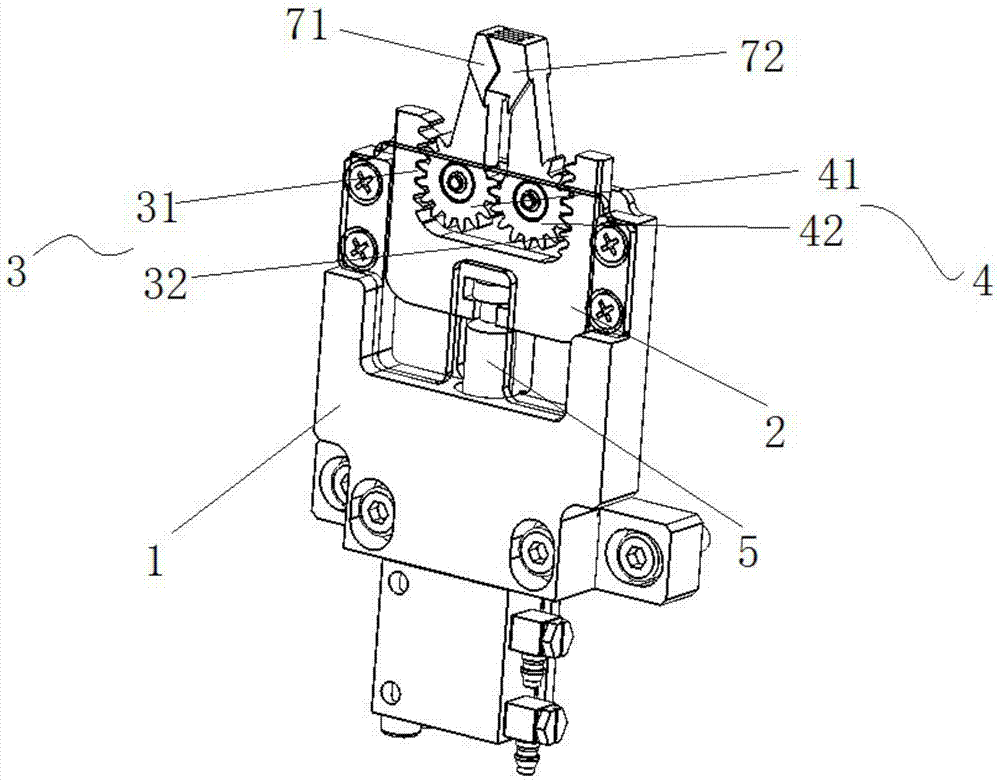

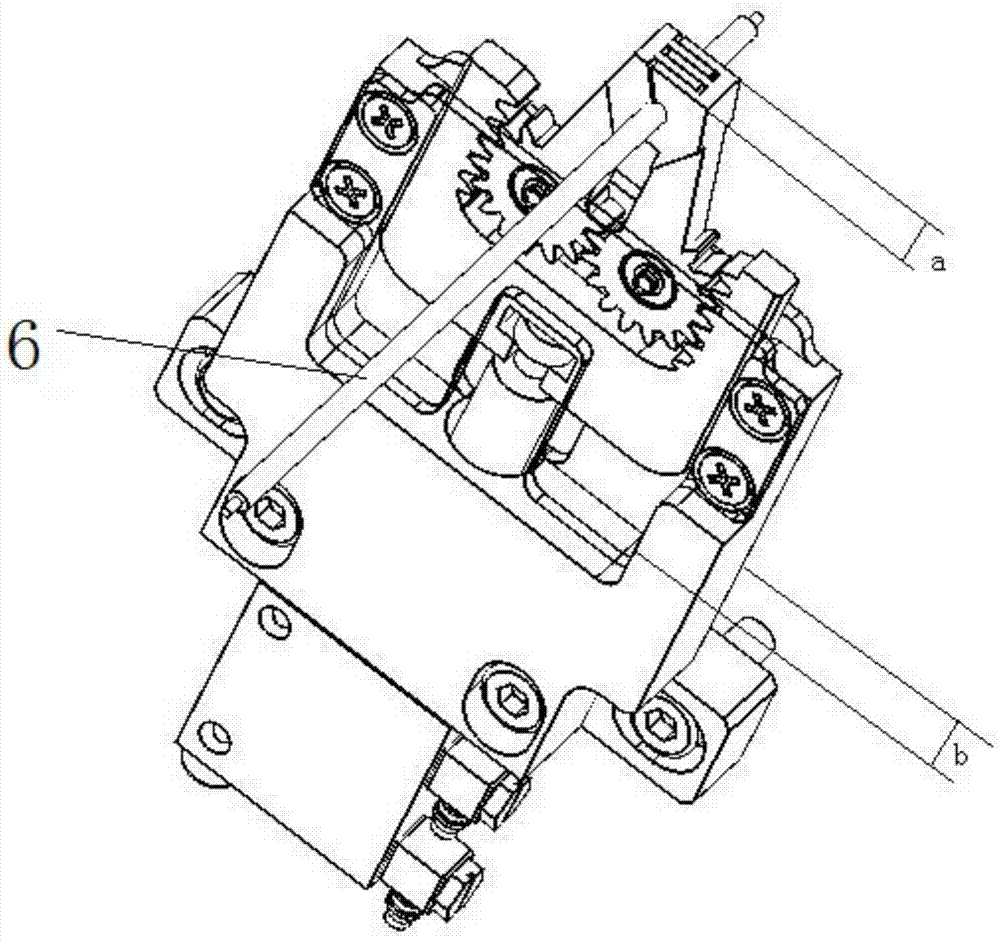

[0028] Such as Figure 1-Figure 2 As shown, a clamp driven by a power assembly includes a base 1, a clamping arm and a power assembly, one end of the clamping arm is rotatably connected to the base 1, and the other end of the clamping arm is provided with a 6, the clamping action of the workpiece 6 is realized by the closeness of at least two clamping parts, so the number of clamping arms is at least two; the power assembly drives the clamping arms to rotate through the transmission mechanism, so that The clamping parts on different clamping arms are brought together or separated.

[0029] The power unit drives the power assembly through the transmission mechanism, thereby driving the clamping arm to rotate, so that the clamping parts on different clamping arms are relatively close or separated, thereby realizing clamping or releasing the workpiece 6, the control end of the power unit and the automatic production line The control unit (such as PLC) is connected by communicati...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the forms of the power assembly and the transmission mechanism are as follows: a chute is provided on the base 1, and the power assembly includes a slider, a connecting rod and a crank. It is slidably installed in the slot, one end of the connecting rod is rotatably connected to the slider, the other end of the connecting rod is rotatably connected to the crank, and the crank is eccentrically fixedly connected to the rotating connection end of the clamping arm; the number of power components is two. The power output end of the power unit is connected to the slider, which drives the slider to reciprocate along the chute, so that the connecting rod drives the crank to move in a circle, and finally drives the clamping arm to rotate. The rotation angle can be determined by the travel switch set on the base 1 To control, the limit switch is used to detect the position of the clamping part, and the limit switch is...

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 is that the forms of the power assembly and the transmission mechanism are as follows: the power assembly includes two worms that are rotatably connected to the base 1, and the two worms are respectively the first worm and the second worm. Worm, the rotating connection ends of the two clamping arms are fixedly connected with a worm gear, the two worm gears are respectively the first worm gear and the second worm gear, the first worm is matched with the first worm gear, and the second worm is matched with the second worm gear . The power unit drives the first worm and the second worm to rotate directly or through the transmission mechanism, respectively making the first worm wheel and the second worm wheel rotate, thereby driving the two clamping arms to rotate, and the angle of rotation can also be adjusted by setting the base The limit switch on the seat 1 is controlled by the limit switch, which is used to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com