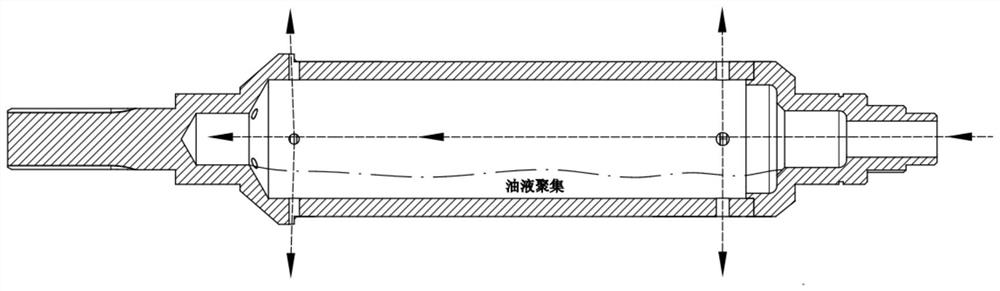

An oil-cooled hollow shaft structure

A shaft structure, cold hollow technology, applied in the field of oil-cooled hollow shaft structure, can solve the problems of failing to meet the requirements of lightweight design, increasing the dynamic unbalance value of the rotor, and reducing the NVH performance, so as to improve the NVH performance and reduce the dynamic Unbalanced effects, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

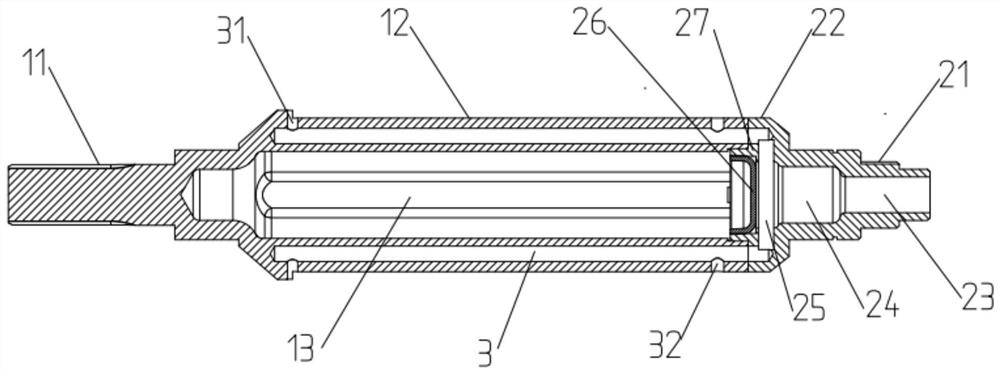

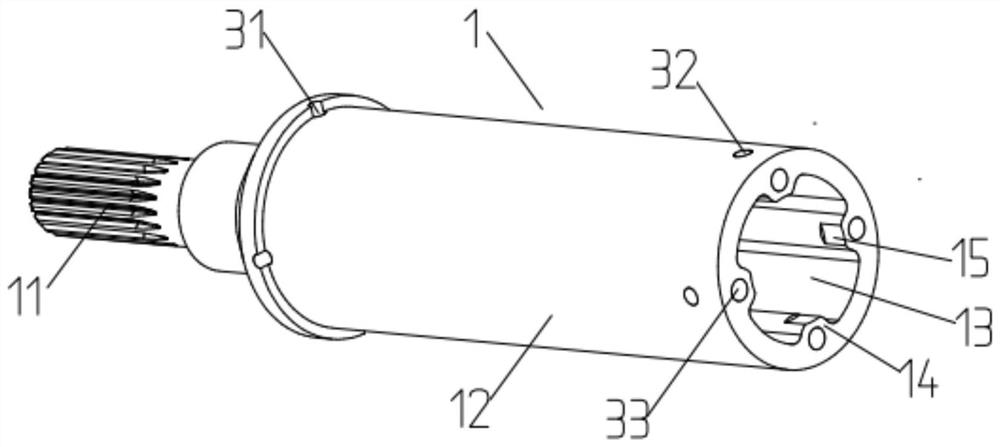

[0025] The second shaft end 21 is provided with an oil inlet 23 and a first inner cavity 24 that communicate with each other, and the second shaft body 22 is provided with a second inner cavity

[0027] During the processing, the first connecting portion 1 and the second connecting portion 2 can be formed by forging and then rough machining,

[0031] It should be understood that the above-described specific embodiments of the present invention are only used to illustrate or explain the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com