Carbon fiber ridge horn antenna unit and manufacturing method thereof

An antenna unit and carbon fiber technology, applied in the microwave field, can solve problems such as complex molding process, achieve good sealing effect, significant light weight, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

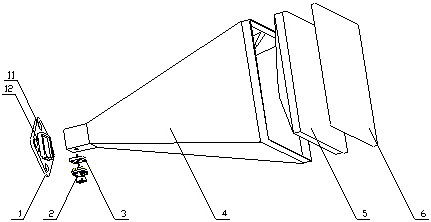

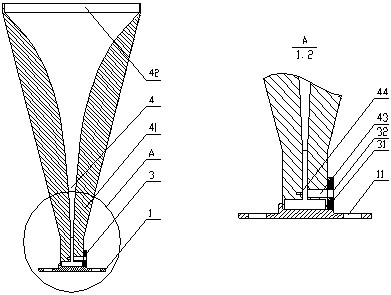

[0027] Such as figure 1 As shown, the outdoor waterproof carbon fiber ridge horn antenna unit of the present invention includes a carbon fiber base 1, a bayonet type double-sealed SMA connector 2, an aluminum alloy mounting flange 3, a carbon fiber ridge horn 4, polyethersulfone foam 5, and glass cloth 6.

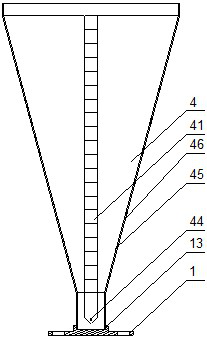

[0028]The carbon fiber ridge speaker 4 and the carbon fiber base 13 are bonded firmly with epoxy resin, and the carbon fiber ridge speaker 4 and the aluminum alloy flange 31 are bonded with epoxy resin to ensure structural strength, and Spread conductive glue around to ensure good electrical continuity between the outer surface of the carbon fiber ridge horn 4 and the aluminum alloy flange 3; Molding, the inner surface 45 is selected as the bonding surface of the mold core 8. Since the thickness of the ridge is obviously greater than the thickness of the outer wall 46 of the horn, in order to avoid defects such as bridging, discounting, and air trapping when laying layers w...

Embodiment 2

[0032] A method for manufacturing a carbon fiber ridge horn antenna unit. The carbon fiber ridge horn antenna unit manufactured by the method includes: a carbon fiber base 1, a bayonet type double-sealed SMA connector 2, an aluminum alloy mounting flange 3, a carbon fiber ridge horn 4, and polyethersulfone Foam 5, glass cloth 6; the main body of the antenna unit includes a carbon fiber ridge horn, a carbon fiber base and an aluminum alloy flange; the method includes the following steps:

[0033] Step 1. The carbon fiber ridge speaker 4 and the carbon fiber base 13 are bonded firmly with epoxy resin, and the carbon fiber ridge speaker 4 and the aluminum alloy flange 31 are bonded with epoxy resin to ensure the structure strength, and apply conductive glue around to ensure good electrical continuity between the outer surface of the carbon fiber ridge horn 4 and the aluminum alloy flange 3; The male mold is used for molding, and the inner surface 45 is selected as the bonding sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com