Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3128results about How to "Lower surface energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

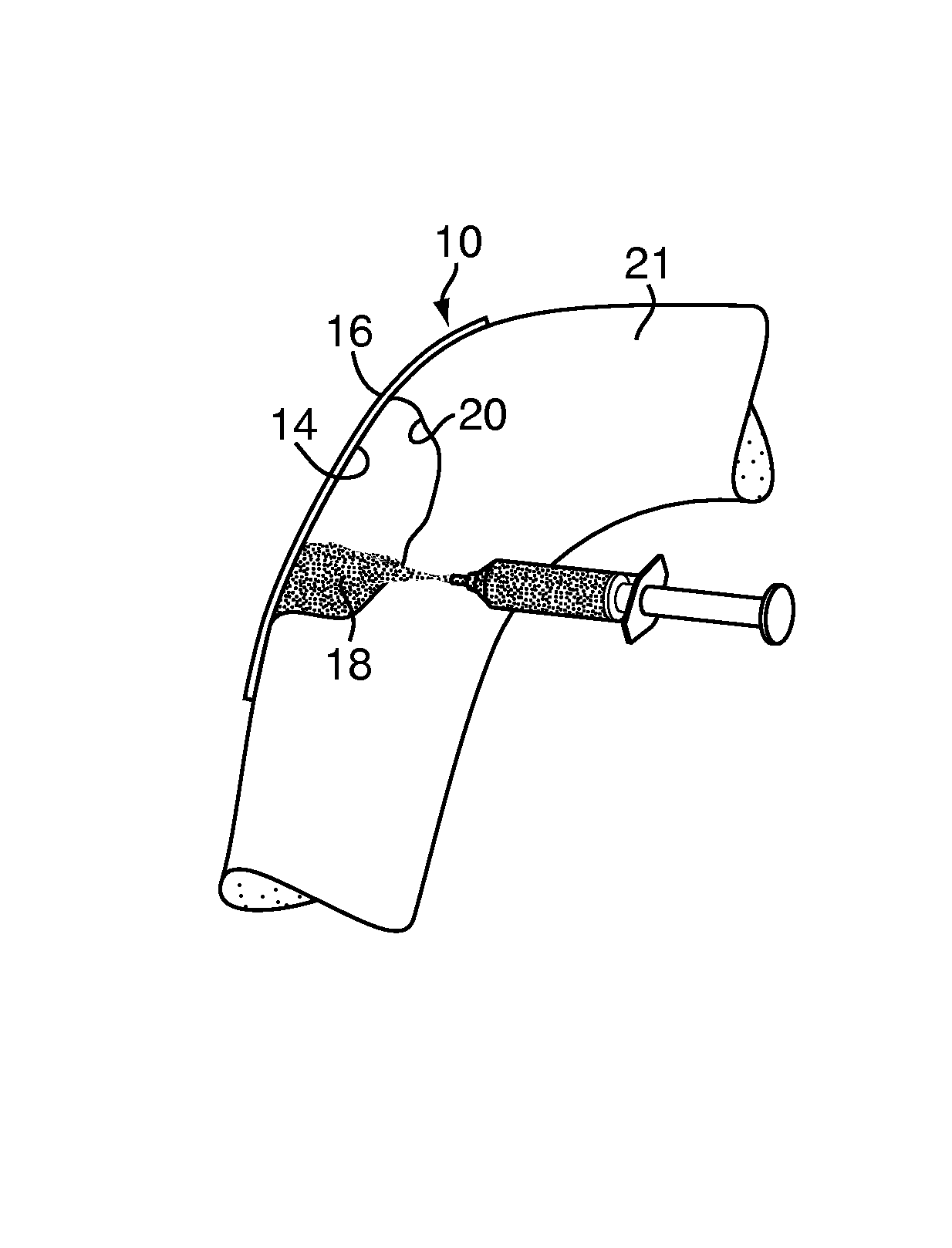

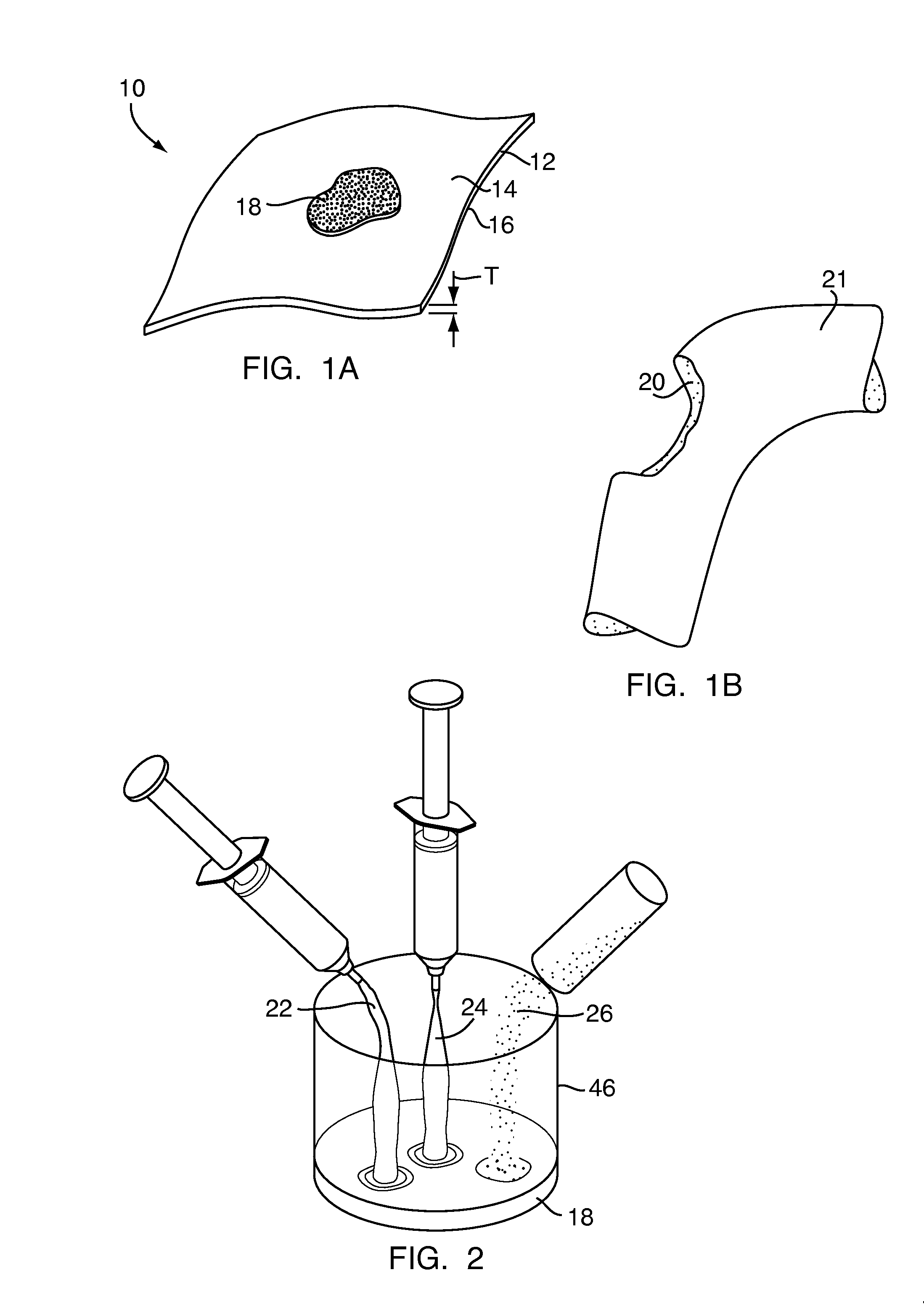

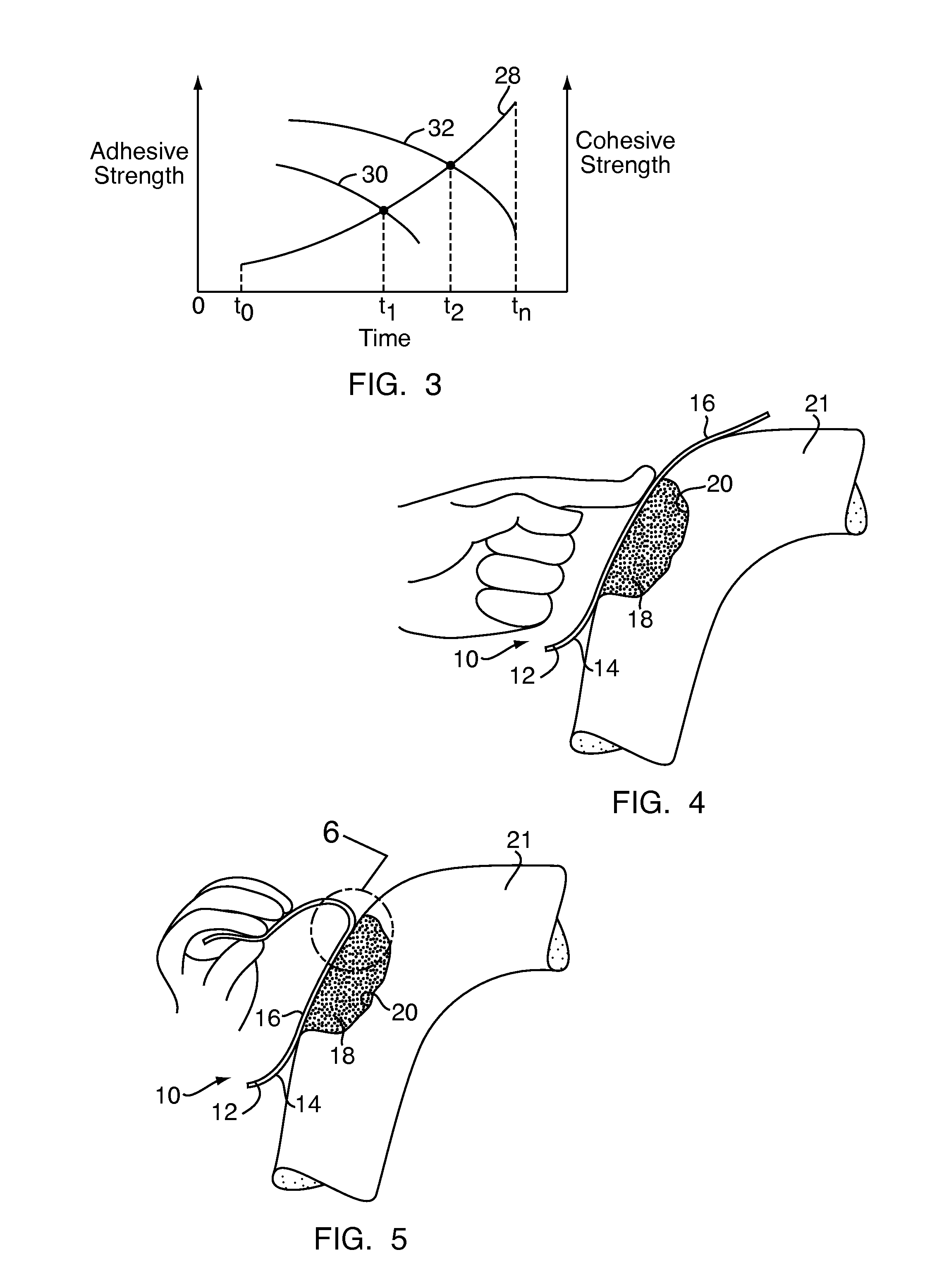

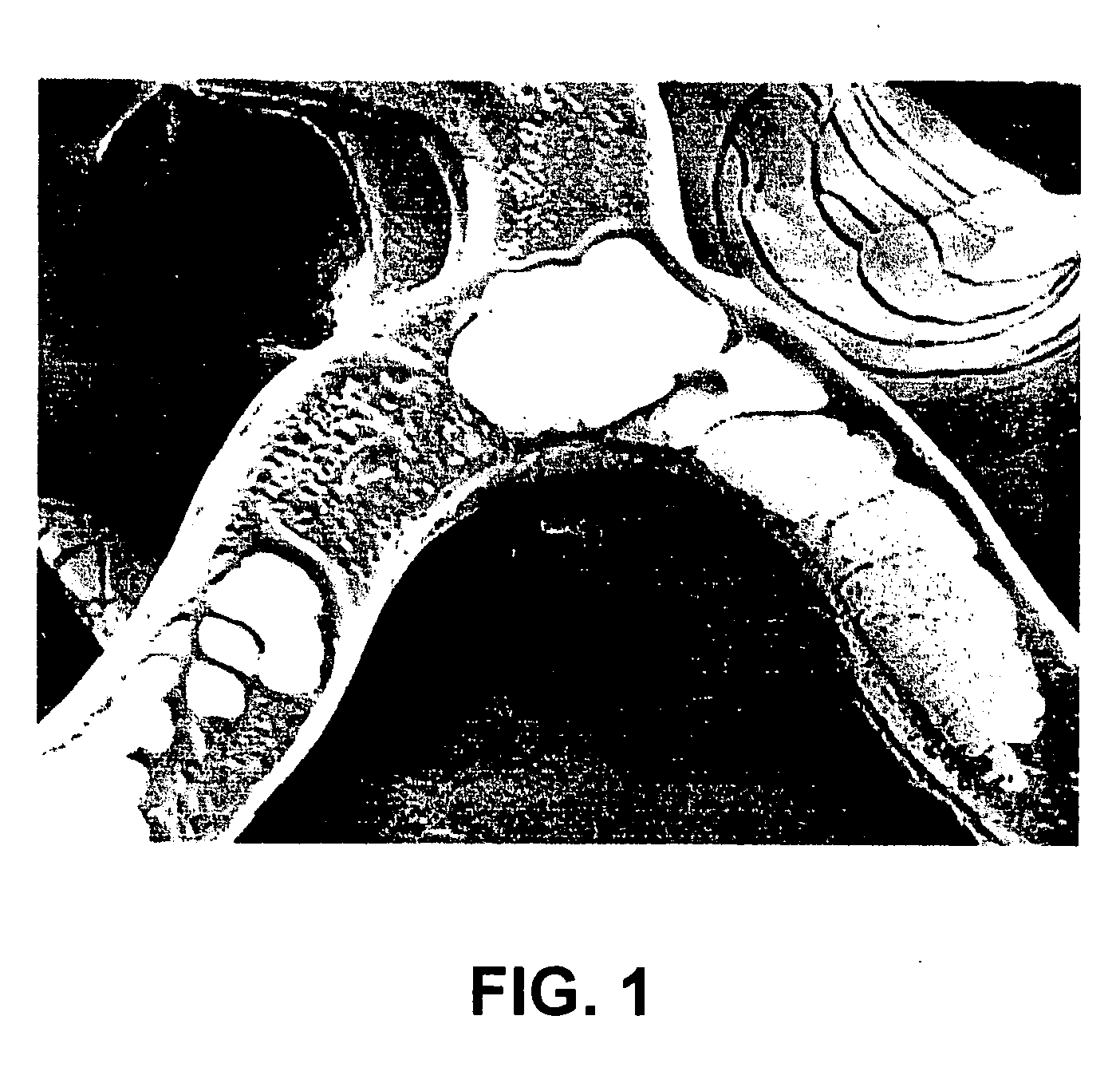

Method and device for handling bone adhesives

A bone adhesive application device has a pliable structure with an application surface upon which a bone adhesive may be applied. The application surface has a surface energy substantially equal to or less than a surface energy of the bone adhesive to reduce adhesion between the bone adhesive and the bone adhesive application device. The bone adhesive application device may be included in a kit for repairing bone defects having a bone adhesive formed from a reactive biocompatible polyurethane material. The bone adhesive may be applied to a bone defect by positioning the pliable structure over at least a portion of the bone defect, delivering the bone adhesive to the bone defect and removing the pliable structure from the bone adhesive.

Owner:ABYRX

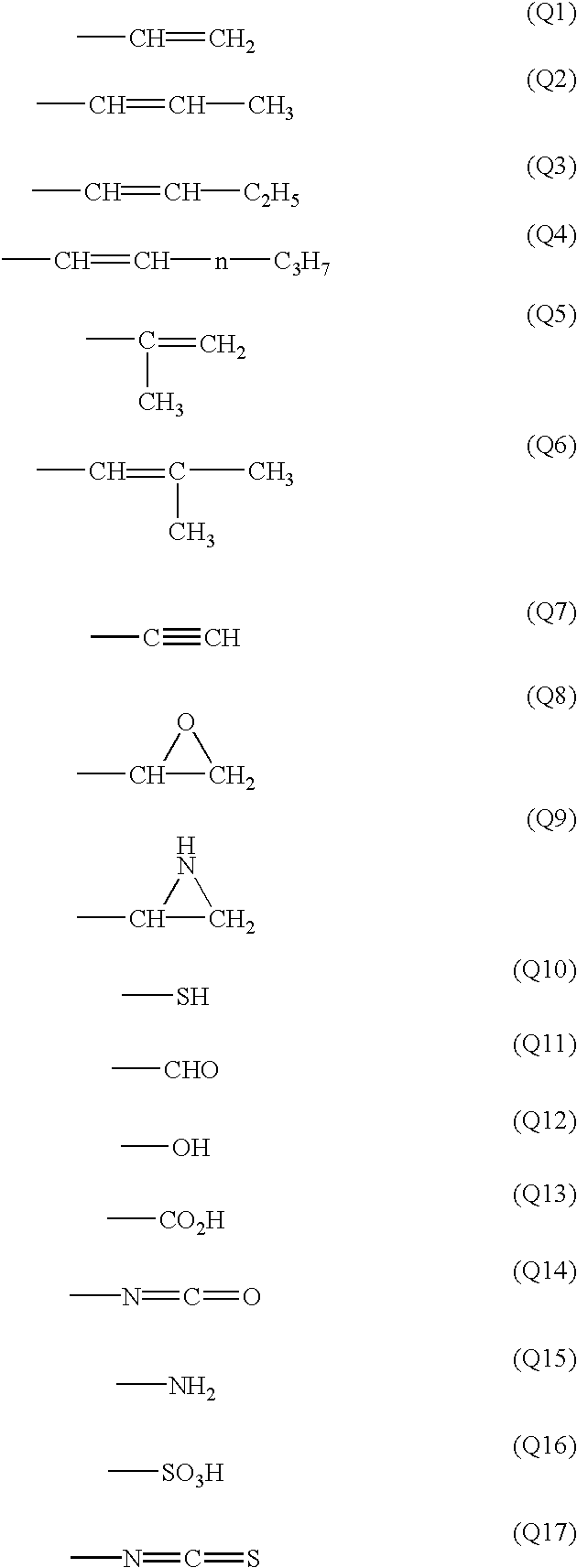

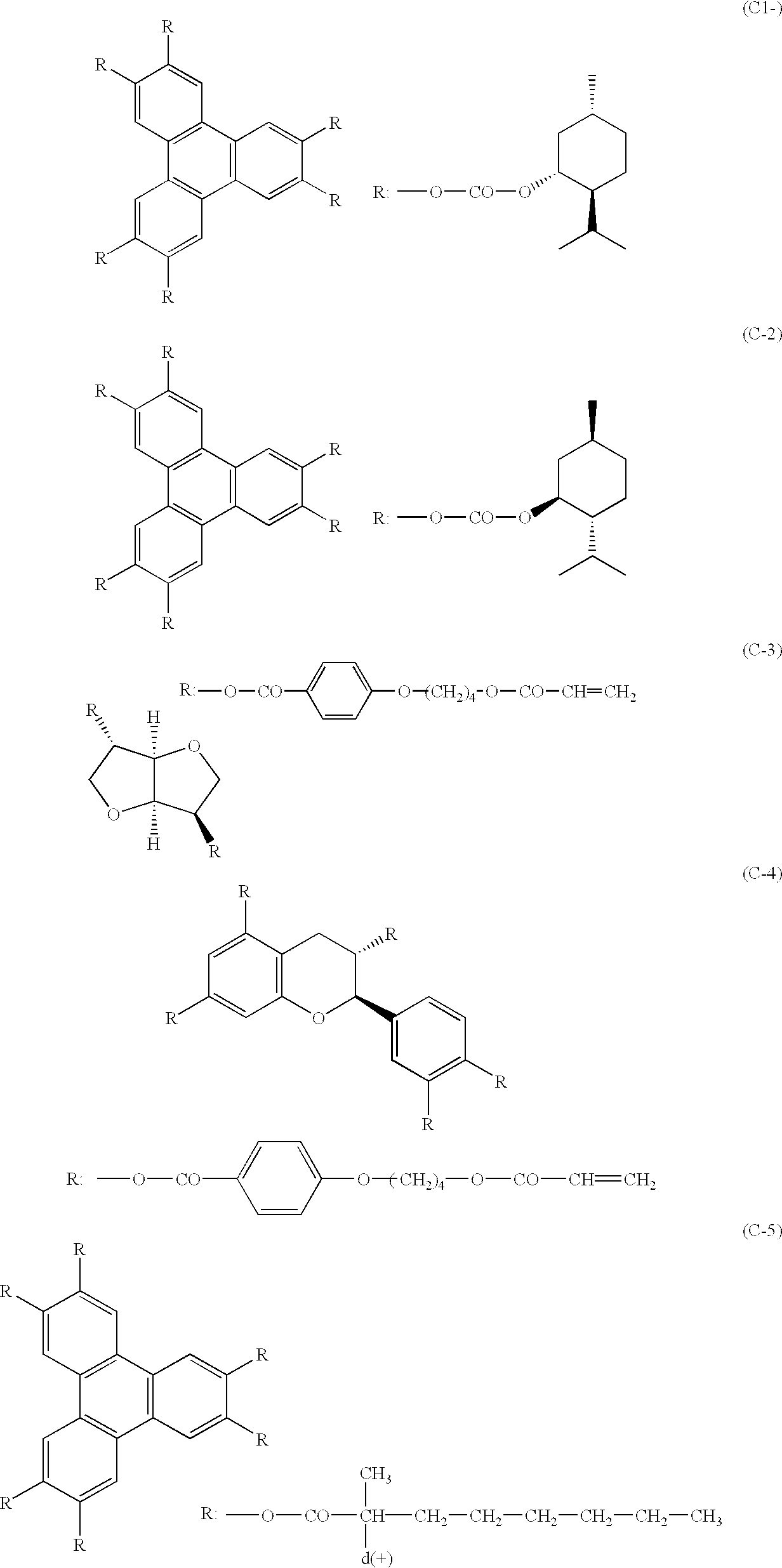

Quarter wave plate comprising two optically anisotropic layers

InactiveUS20020159005A1Improve adhesionReduce yieldPolarising elementsNon-linear opticsOptical propertyLength wave

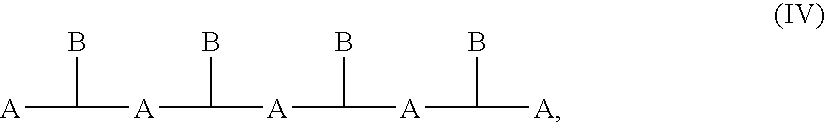

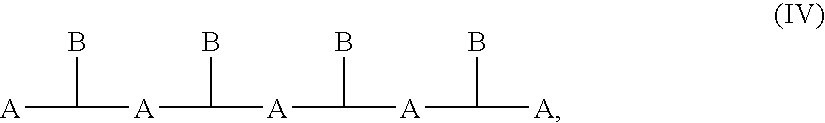

A circularly polarizing plate comprises a linearly polarizing membrane and a quarter wave plate. The quarter wave plate comprises an optically anisotropic layer A and an optically anisotropic layer B. The quarter wave plate has such an optical characteristic that a retardation value essentially is a quarter of a wavelength when the retardation value is measured at the wavelength of 450 nm, 550 nm and 650 nm. One of the optically anisotropic layers A and B is a layer made from liquid crystal molecules, and the other is a polymer film or a layer made from liquid crystal molecules.

Owner:FUJIFILM CORP

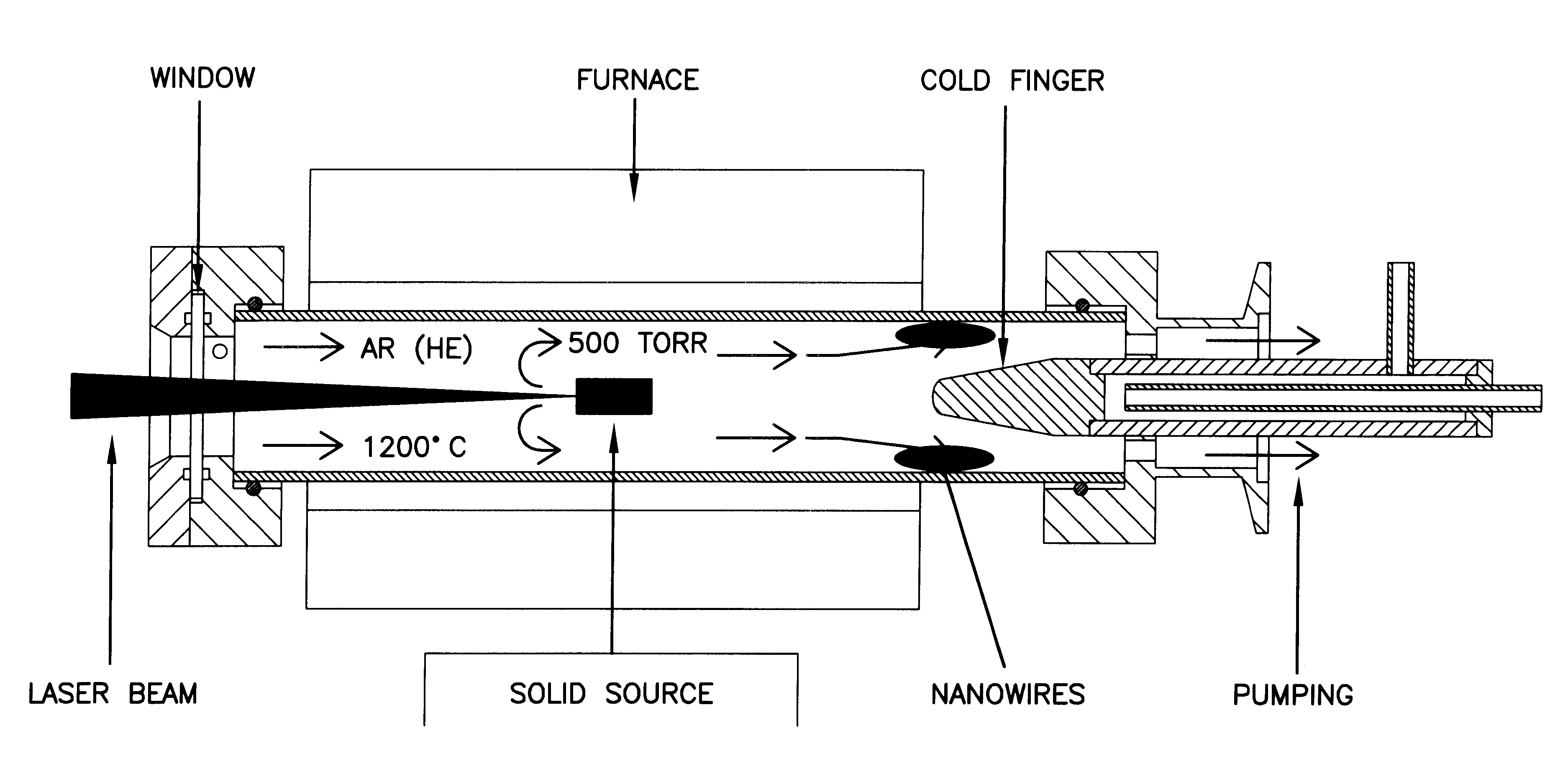

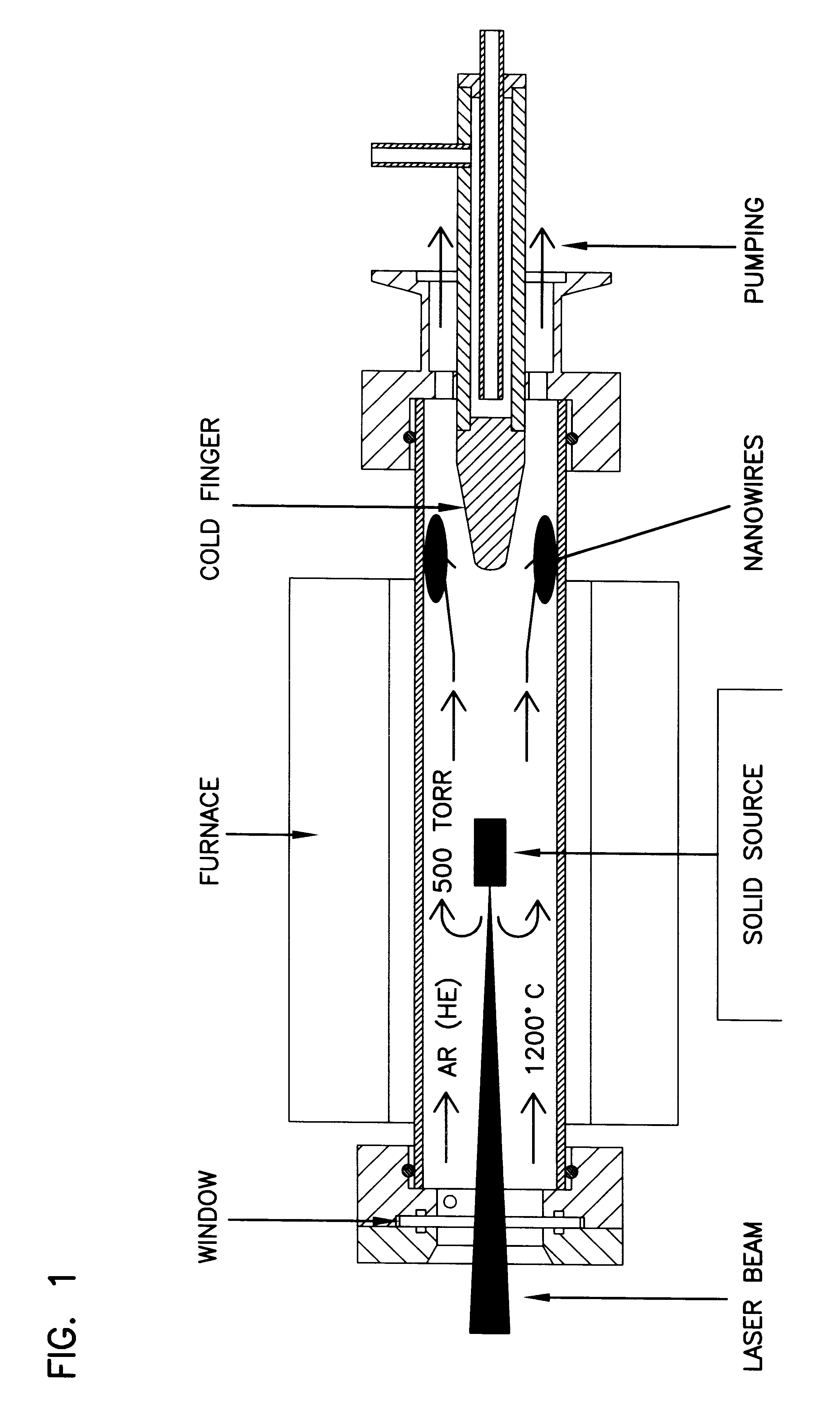

Growth method for silicon nanowires and nanoparticle chains from silicon monoxide

InactiveUS6313015B1Enhance one-dimensional growthLowering of total energy of systemPolycrystalline material growthNanotechSputteringSilicon monoxide

Silicon nanowires and silicon nanoparticle chains are formed by the activation of silicon monoxide in the vapor phase. The silicon monoxide source may be solid or gaseous, and the activation may be by thermal excitation, laser ablation, plasma or magnetron sputtering. The present invention produces large amounts of silicon nanowires without requiring the use of any catalysts that may cause contamination.

Owner:HONG KONG CITY UNIV OF

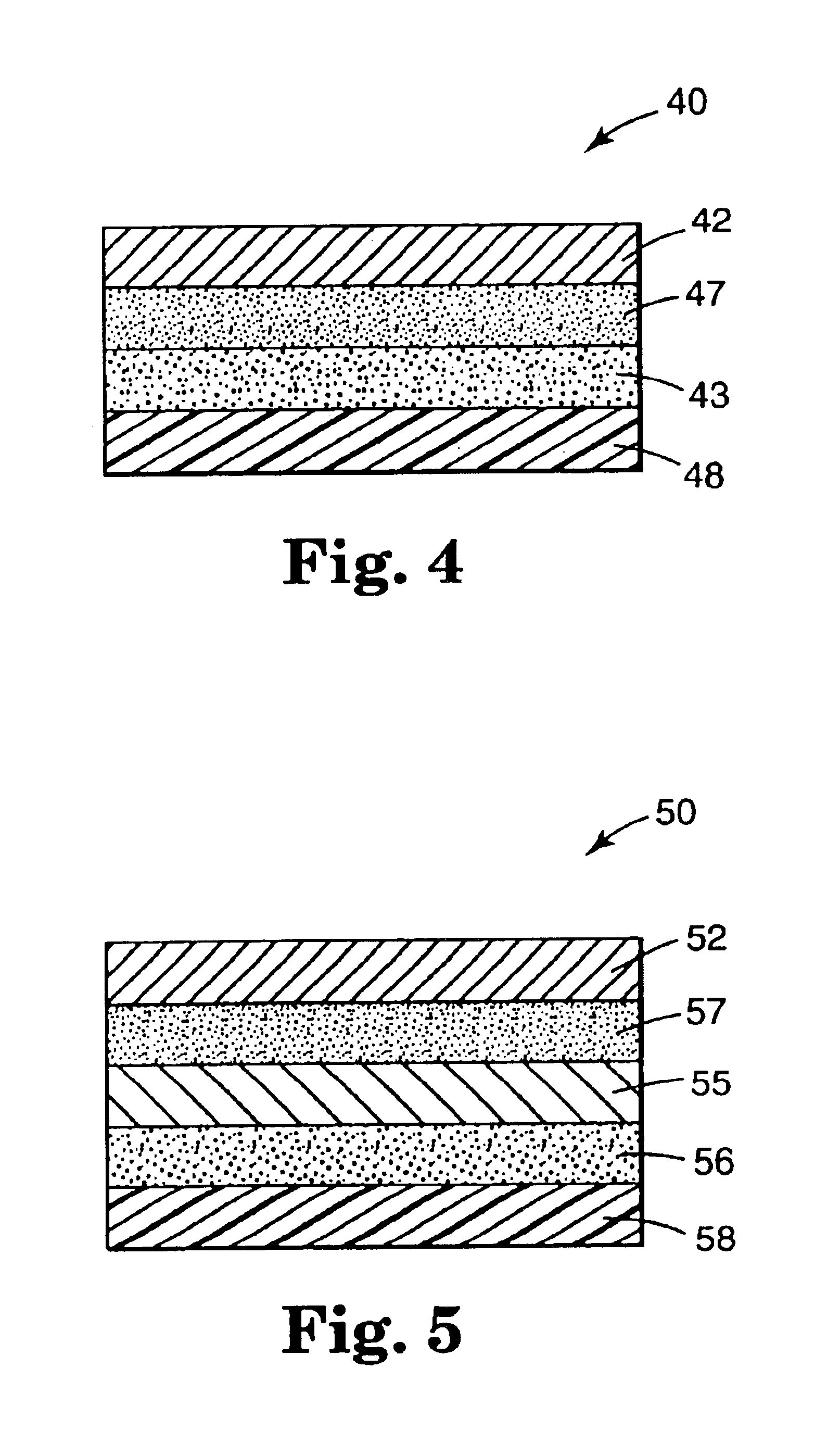

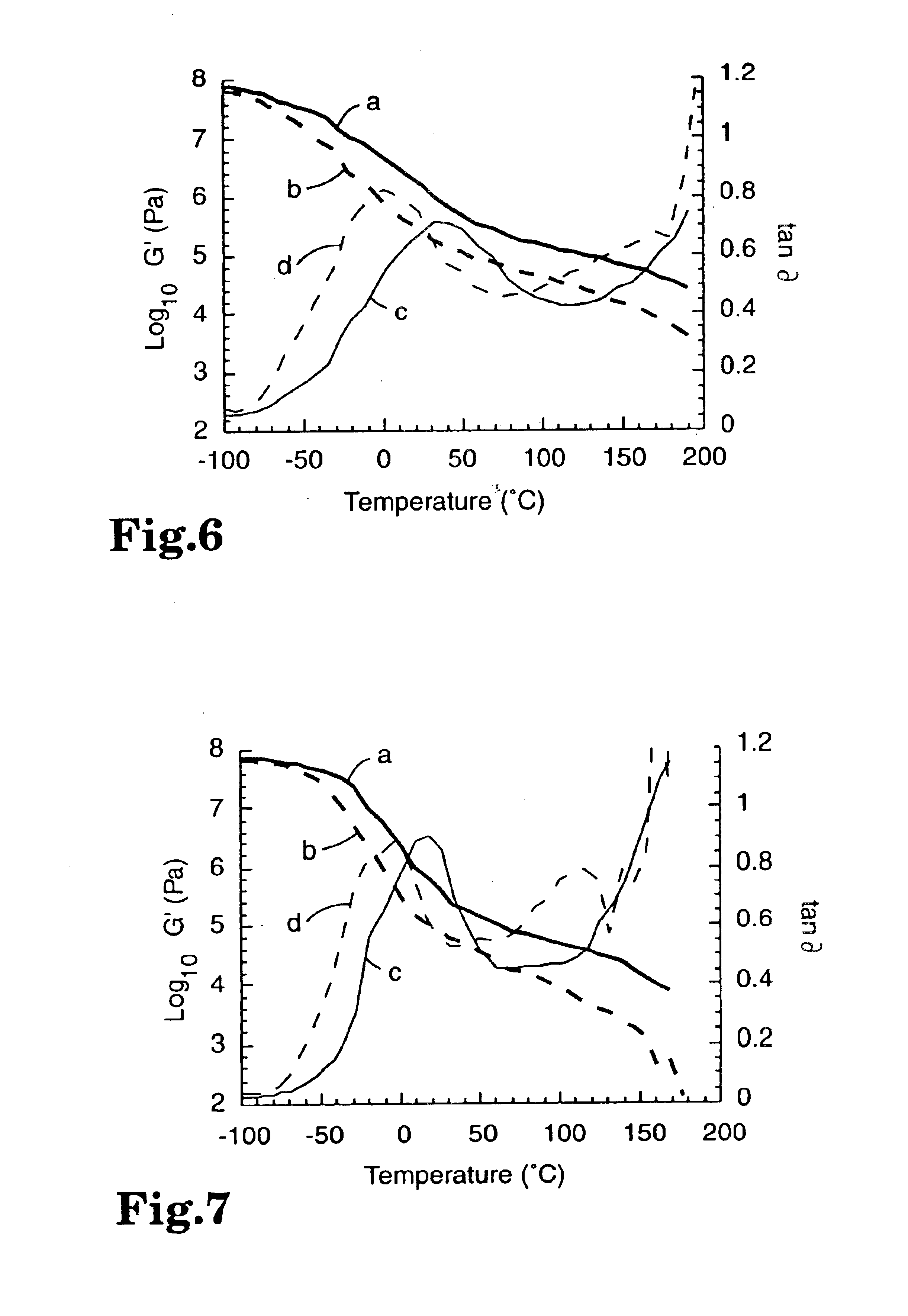

Polymer mixtures containing polydiorganosiloxane urea-containing components

InactiveUS6846893B1Varied damping characteristicImprove adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesThermoplasticUrea

A mixture is provided comprising (a) at least one of an elastomeric thermoplastic, a non-elastomeric thermoplastic, an elastomeric thermoset and mixtures thereof, excluding polydiorganosiloxane fluids and (b) a polymer having soft polydiorganosiloxane units, hard polyisocyanate residue units, optionally, soft and / or hard organic polyamine residue units and terminal groups. The hard polyisocyanate residue and the hard polyamine residue comprise less than 50% by weight of the polydiorganosiloxane urea containing component. The polyisocyanate residue is the polyisocyanate minus the —NCO groups and the polyamine residue is the polyamine minus the —NH2 groups. The polyisocyanate residue is connected to the polyamine residue by urea linkages. The terminal groups are non-functional groups or functional groups. The polydiorganosiloxane urea containing component may be reactive under free-radical or moisture curing conditions. The mixture may also optionally contain tackifying materials, free radical initiators, crosslinking agents, cure catalysts, and nonreactive additives such as fillers, pigments, stabilizers, antioxidants, flame retardants, plasticizers, compatibilizers and the like.

Owner:3M CO

Poly(ester amide) coating composition for implantable devices

InactiveUS20050271700A1Improve mechanical propertiesImprove surface propertiesSurgeryPharmaceutical containersPercent Diameter StenosisImplanted device

Owner:ABBOTT CARDIOVASCULAR

Pressure-sensitive adhesives derived from 2-alkyl alkanols

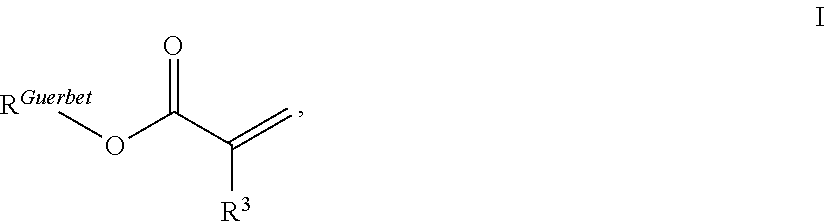

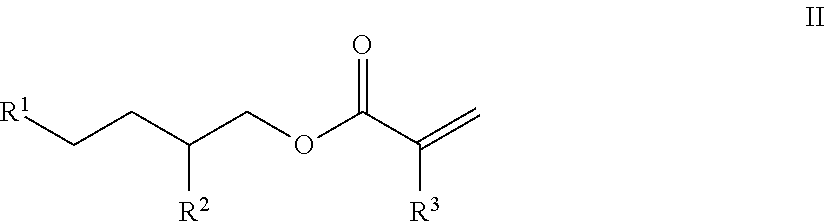

ActiveUS8137807B2Improve adhesionReduce the temperatureFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveSurface energy

Pressure-sensitive adhesives are prepared from (meth)acrylate esters of 2-alkyl alkanols. The adhesives are characterized by exhibiting an overall balance of adhesive and cohesive characteristics and exceptional adhesion to low surface energy substrates.

Owner:3M INNOVATIVE PROPERTIES CO

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

Fire extinguishing agent and preparation method thereof

ActiveCN103007478AImprove fire extinguishing efficiencyReduce dispersion speedFire extinguisherSURFACTANT BLENDLiquid gas

The invention provides a fire extinguishing agent. The fire extinguishing agent is prepared by evenly mixing 1-25 parts of hydrophilic solid powder and 100 parts of water or water solution, and then adding 0.001-2 parts of surfactant for evenly mixing; and then adding 2-100 parts of hydrophobic solid particles. The invention provides a preparation method of the fire extinguishing agent. Compared with the existing fire extinguishing agent, the fire extinguishing agent can simultaneously play stifling, cooling and chemical inhibition roles, and the fire extinguishing efficiency is high; according to the fire extinguishing agent, due to addition of the surfactant in the water phase, the dispersion of rotating speed in preparation process can be lowered, the dispersion time can be shortened, and the preparation efficiency can be improved; and with the fire extinguishing agent, the adhesion property of solid gas interface and liquid gas interface can be greatly improved, the usage amount for extinguishing fire can be greatly reduced, and the fire extinguishing property can be obviously improved.

Owner:广州神州安防科技有限公司

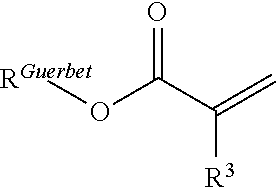

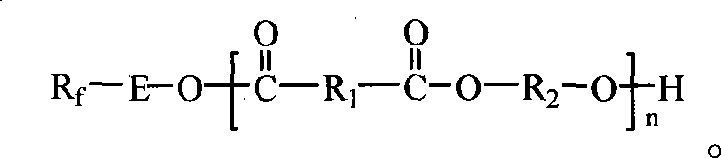

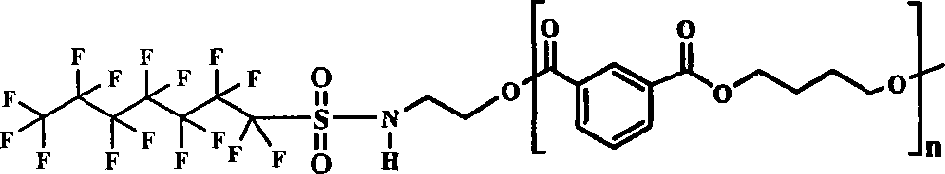

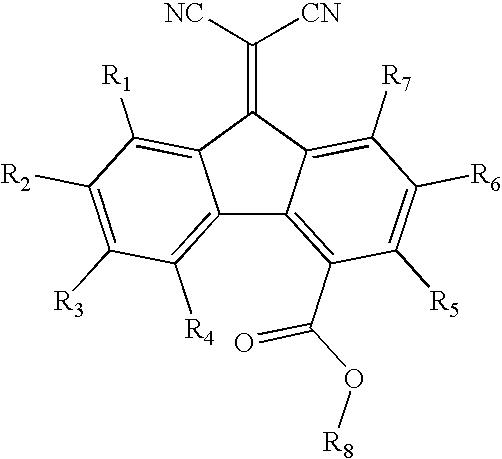

Fluorinated polyesters with low surface energy and preparation method thereof

The present invention belongs to the field of mnacromolecule, relating to the fluorine-containing polyester of low surface energy and the preparation method of the fluorine-containing polyester. The polyester has the following chemical structure (1): wherein R f C is the straight chain of 2 - 21 C or the branch-chain pseudo-perfluoroalkyl; R1, R2 is the alkyl, aryl, or naphthenic base of the C1-C8; E is -(CH2) m-; formula (3) or formula (4); R' is H or the straight chain or the branch-chain alkyl under C4; m is an integer between 0 or 10. The polyester preparation method is that dibasic acid or the correspondent diester, dihydric alcohol and perfluoroalkane, which are 0.05 percent to 10 percent of the total material weight, are fused and polymerized under vacuum condition. The polyester preparation method at the pseudo-perfluoroalkyl sealed end is simple, and is of good drainage and oil dredging properties. The present invention can be widely used in antifouling coatings, and is of important development and application value.

Owner:DALIAN UNIV OF TECH

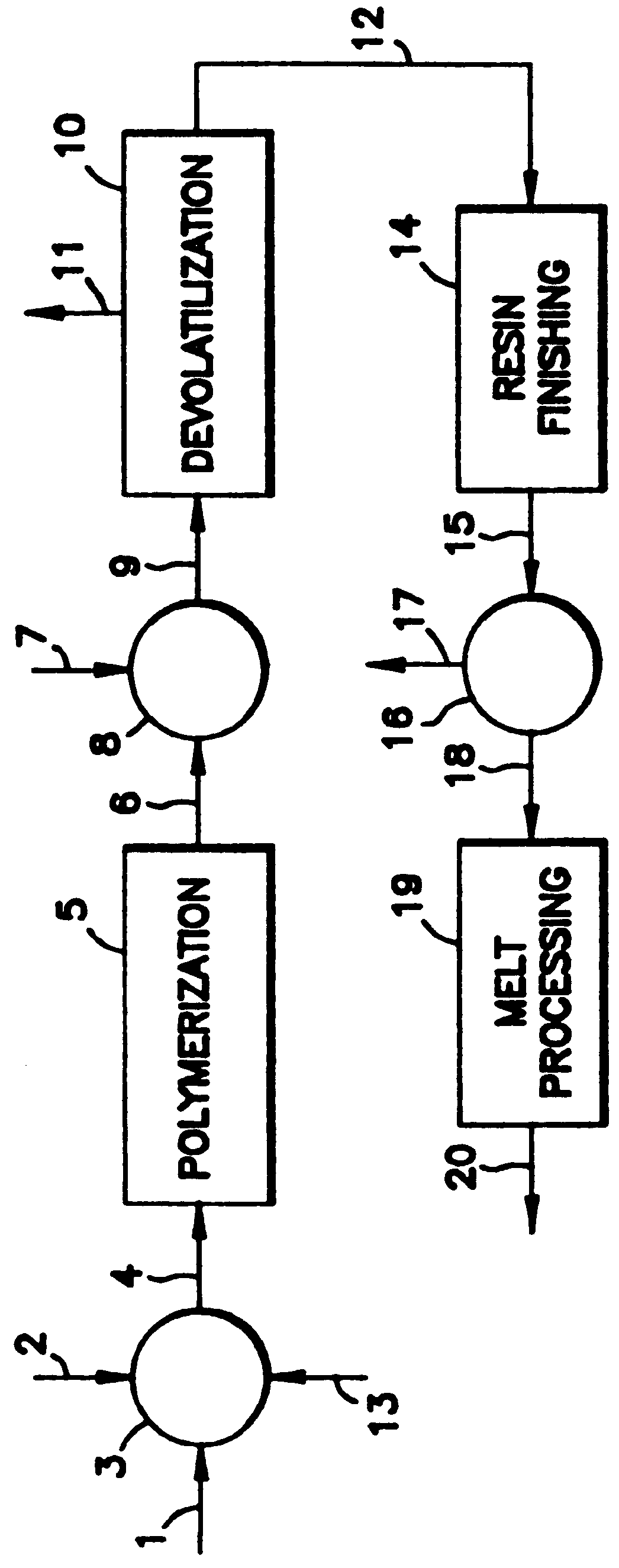

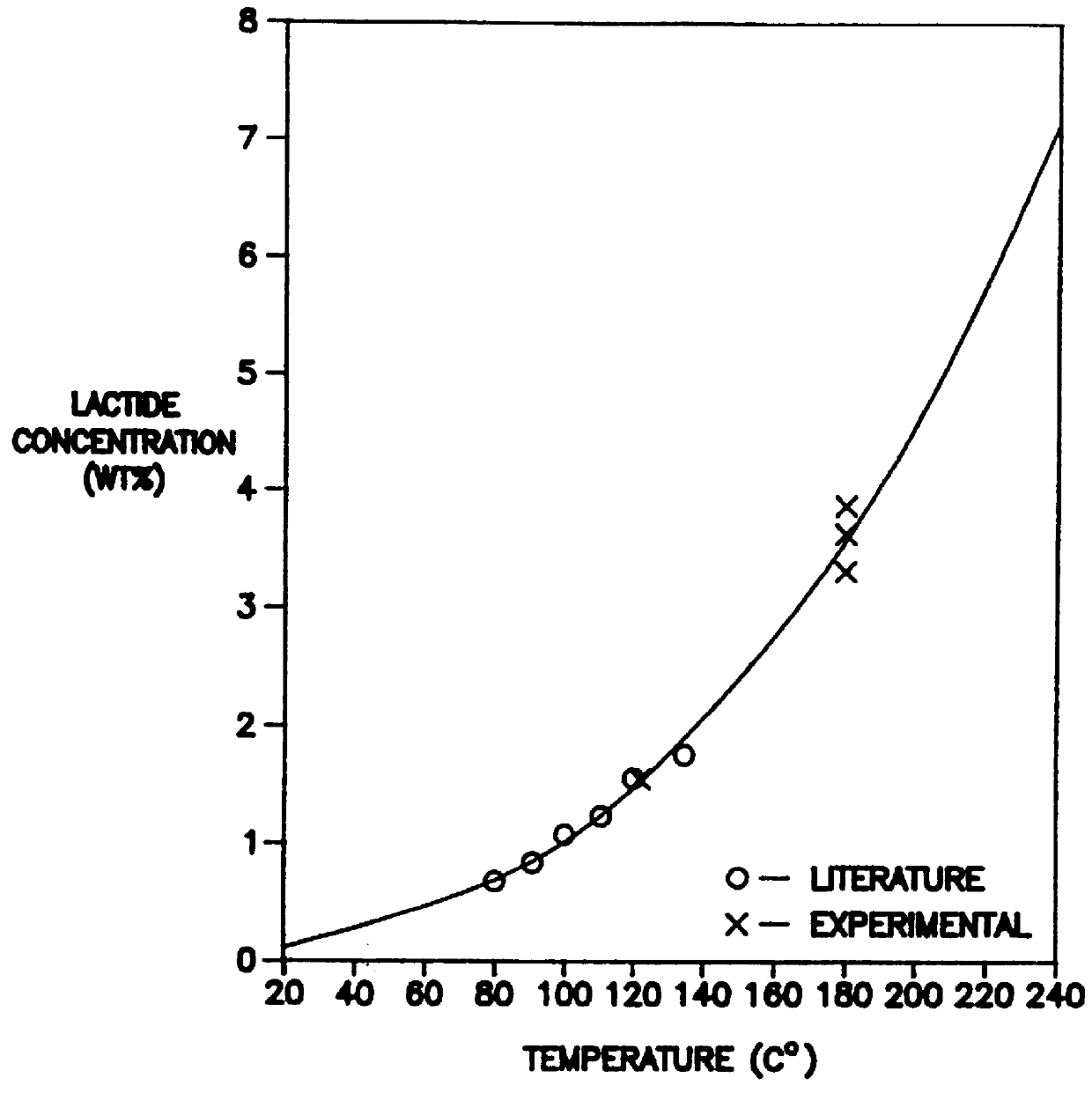

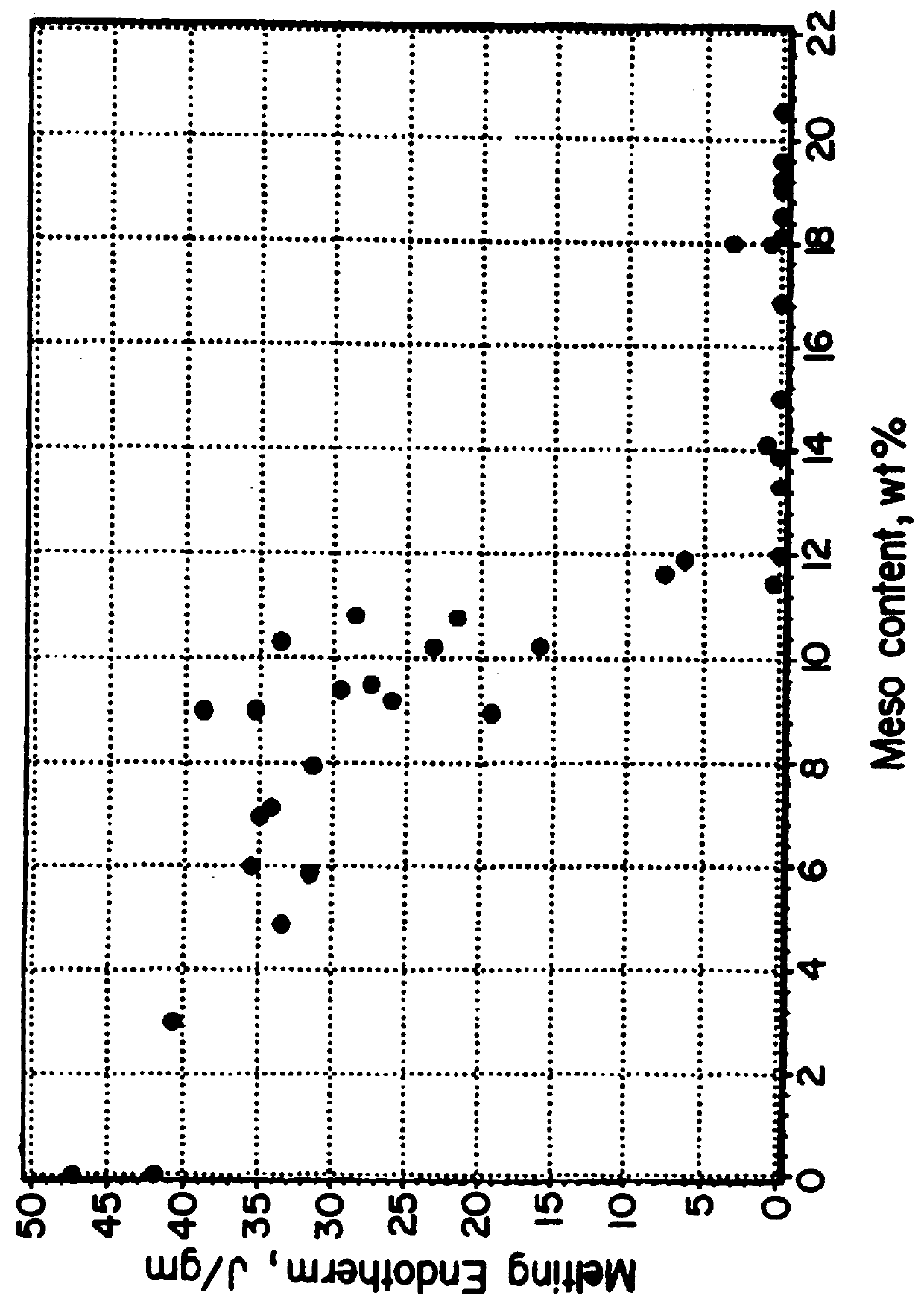

Melt-stable semi-crystalline lactide polymer film and process for manufacture thereof

InactiveUS6121410AHigh surface energyEasy to printCoatings with pigmentsSurgeryLactidePolymer chemistry

A semi-crystalline film comprised of a lactide polymer. The lactide polymer comprises a plurality of poly(lactide) polymer chains, residual lactide in concentration of less than about 5 percent and water in concentration of less than about 2000 parts-per-million. A process for manufacturing a semi-crystalline film with the lactide polymer composition is also disclosed.

Owner:CARGILL INC

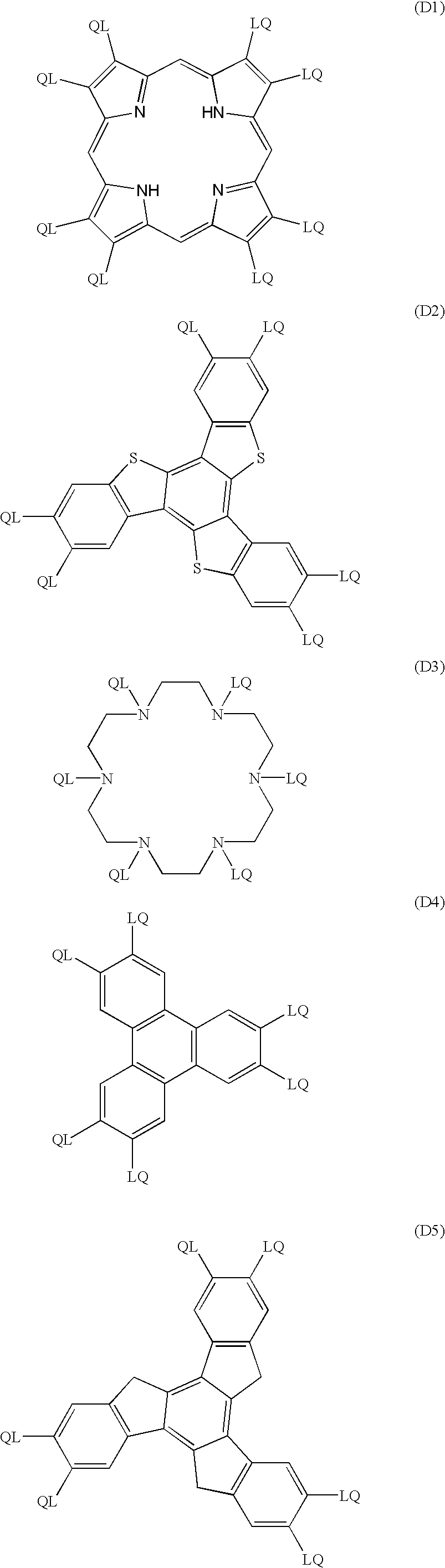

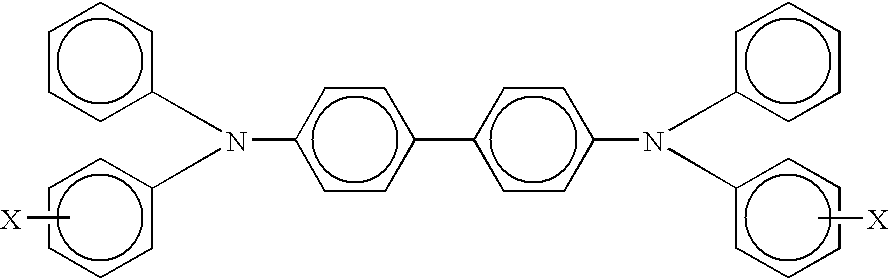

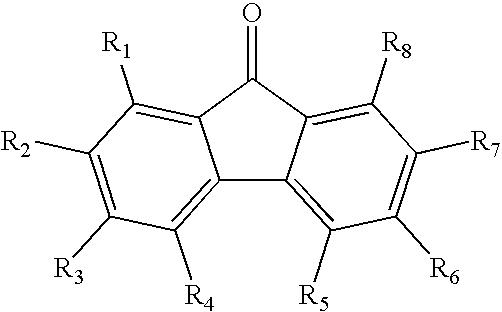

Imaging members

InactiveUS6756169B2Few stepsLow costElectrographic process apparatusElectrographic processes using charge patternQuinoneThiopyran

A member including for example, a supporting layer and a single photogenerating layer, the photogenerating layer comprising particles including hydroxygallium phthalocyanine phthalocyanine Type V, x polymorph metal free phthalocyanine, or chlorogallium phthalocyanine dispersed in a matrix comprising an arylamine hole transporter and an electron transporter selected from the group consisting of N,N'bis(1,2-dimethylpropyl)-1,4,5,8-naphthalenetetracarboxylic diimide, 1,1'-dioxo-2-(4-methylphenyl)-6-phenyl-4-(dicyanomethylidene)thiopyran, and a quinone selected from the group consisting of carboxybenzylhaphthaquinone, and tetra (t-butyl) diphenoquinone, and mixtures thereof, and a film forming binder.

Owner:XEROX CORP

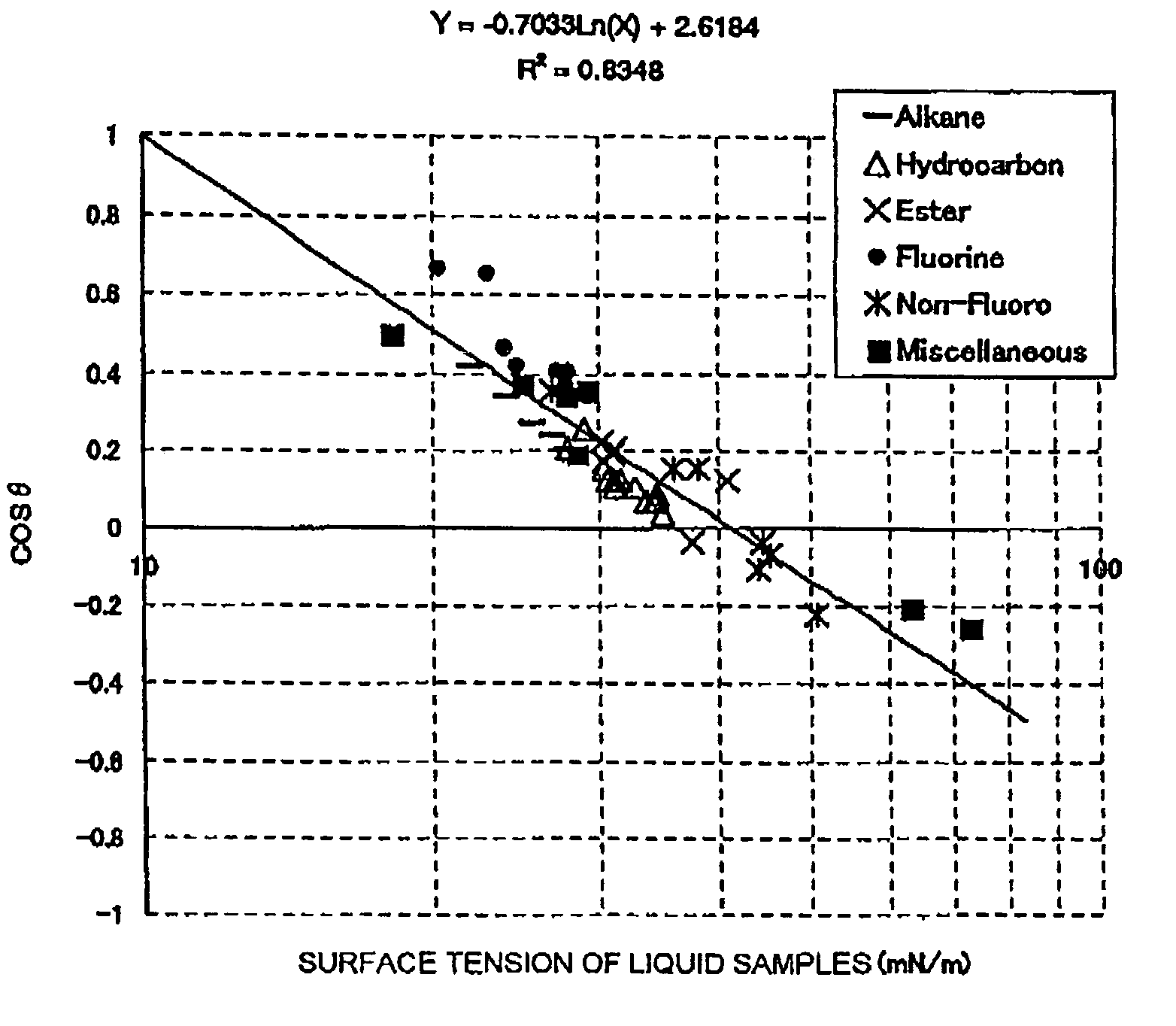

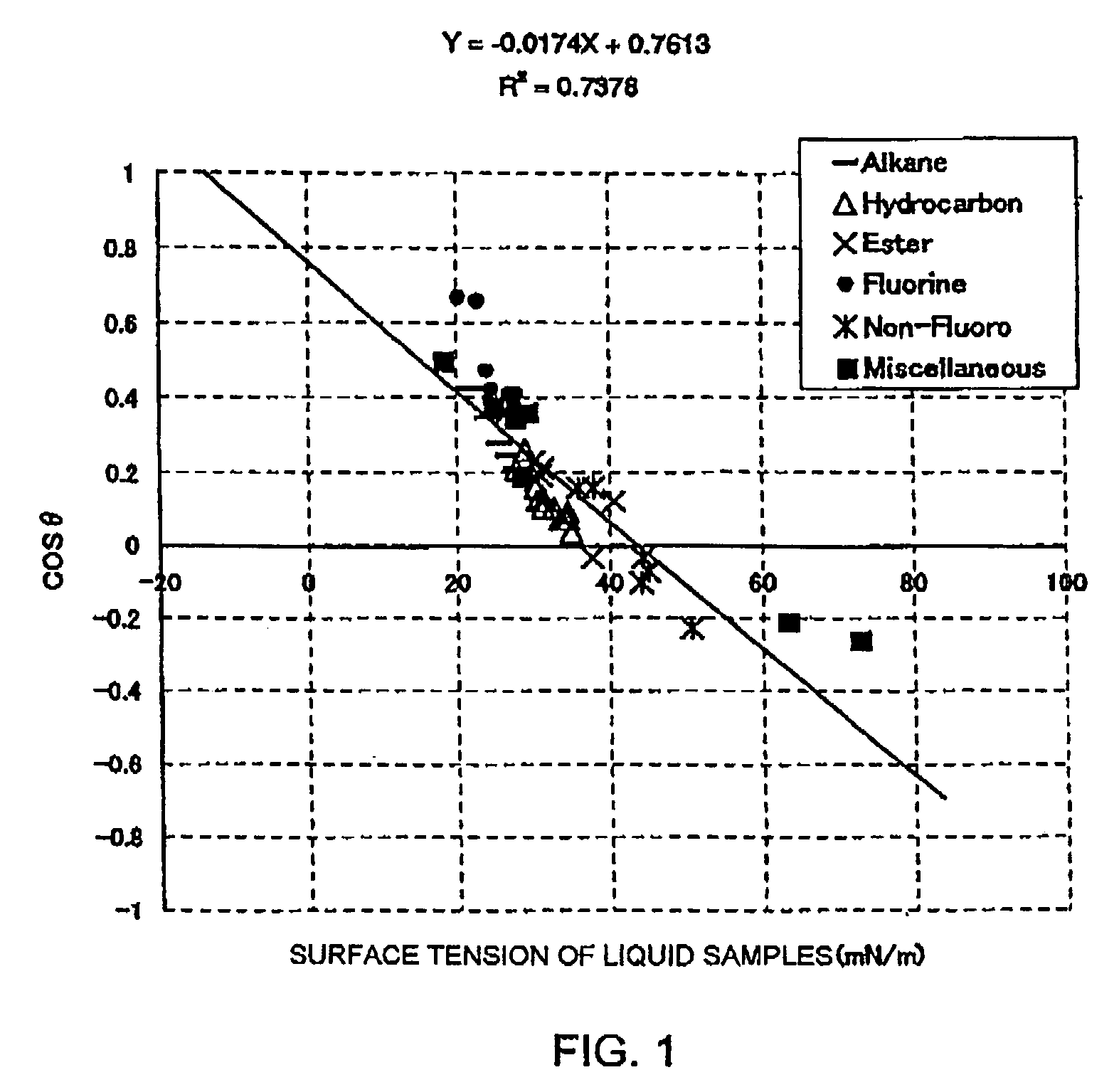

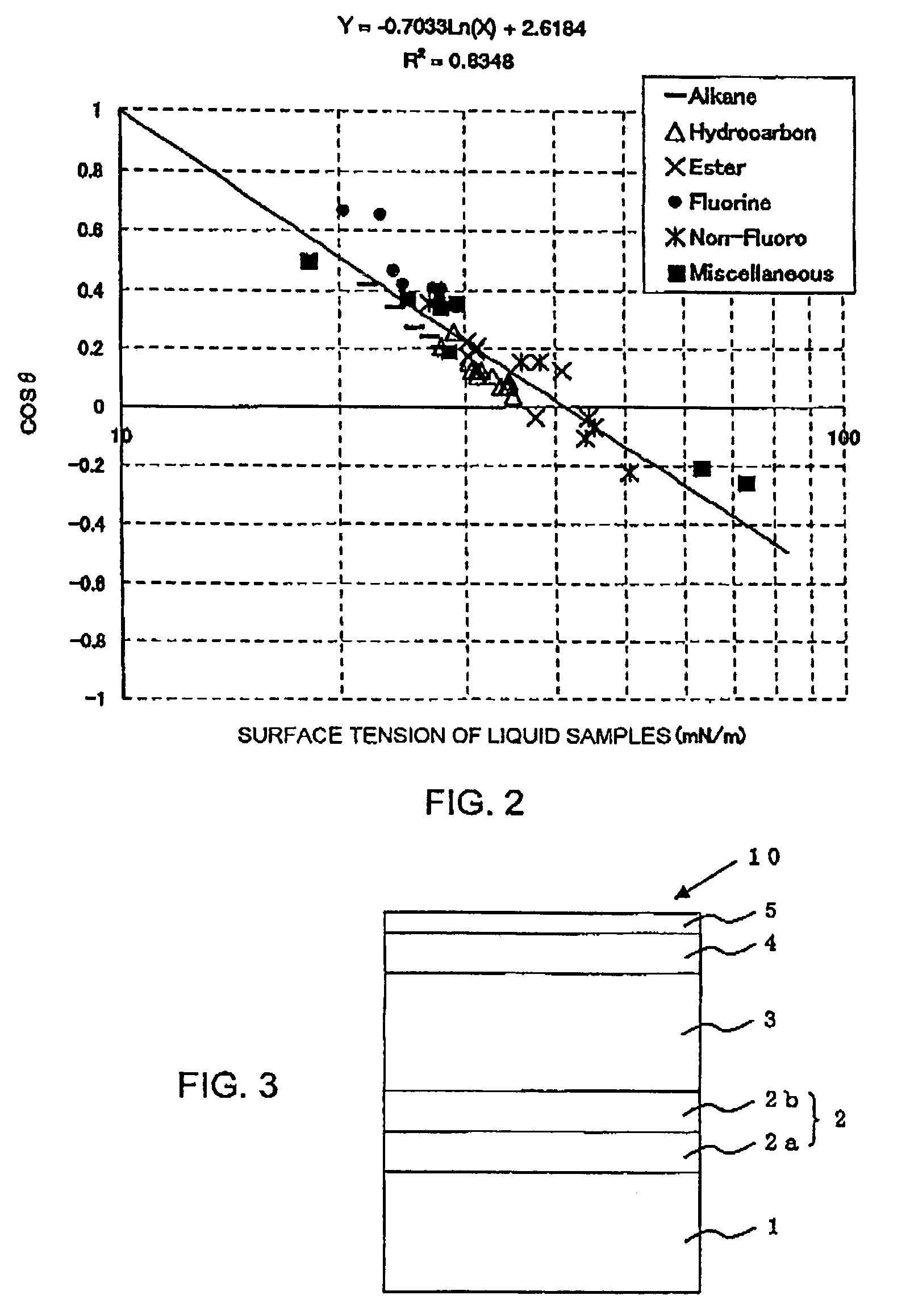

Solid body surface evaluation method, magnetic disk evaluation method, magnetic disk, and manufacturing method thereof

InactiveUS7174775B2Effective tensionSolve the real problemVehicle testingElectronic circuit testingBiomedical engineeringBody surface

In a method of evaluating surface tension of a solid body surface, selection is made of at least three liquid samples having different surface tensions, and contact angles between the respective liquid samples and the solid body surface are measured. Thereby, a correlation between cosines (Y) of the contact angles and surface tensions (X) of the liquid samples is derived as a logarithmic function. Surface tension of the solid body surface is evaluated by the use of a value of X that is calculated by substituting 1 for Y in the correlation. When evaluated by the foregoing evaluation method, a magnetic disk has a surface where the value of X, when 1 is substituted for Y, is greater than 0 and no greater than 17 mN / m.

Owner:WD MEDIA SINGAPORE PTE

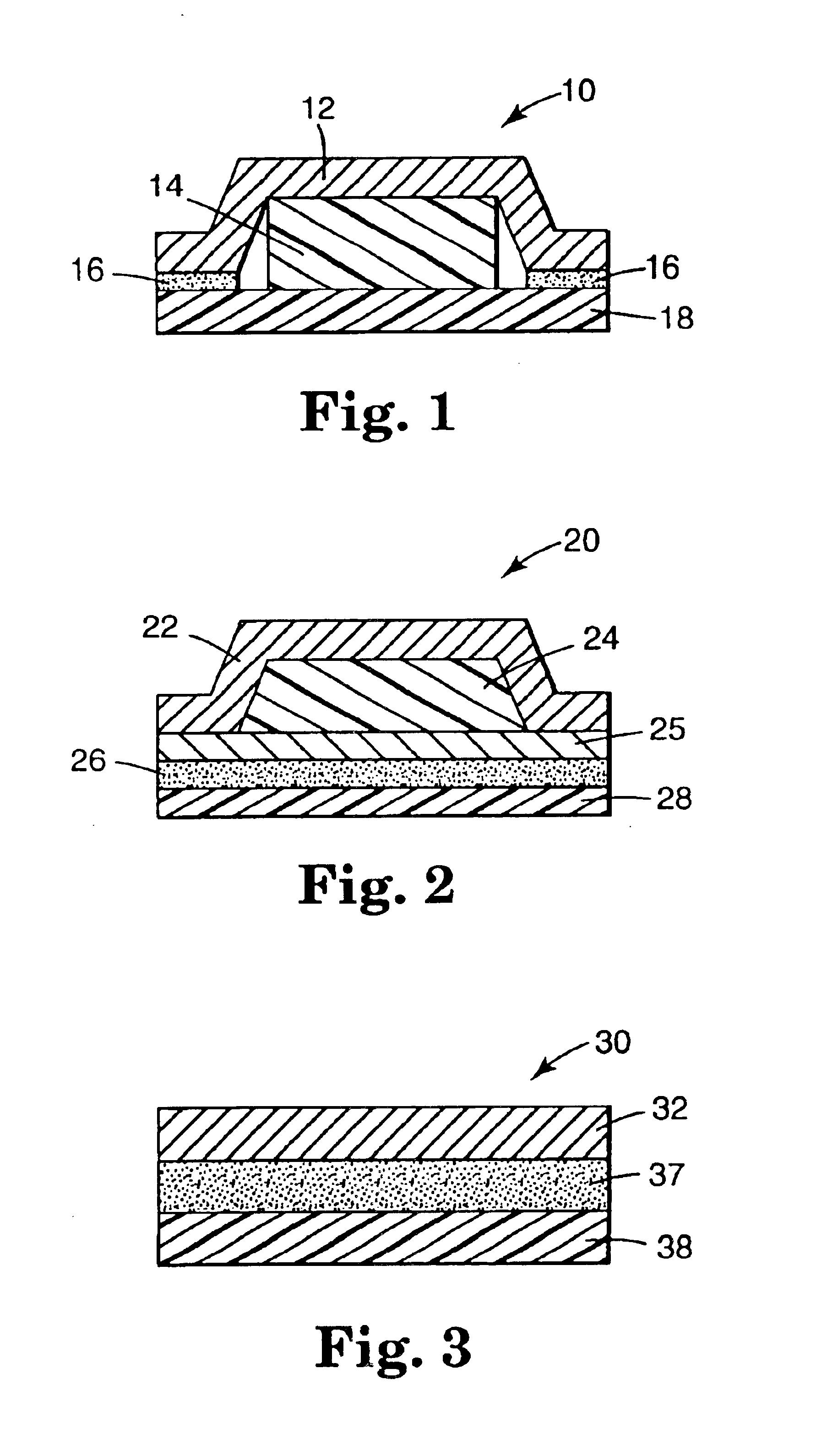

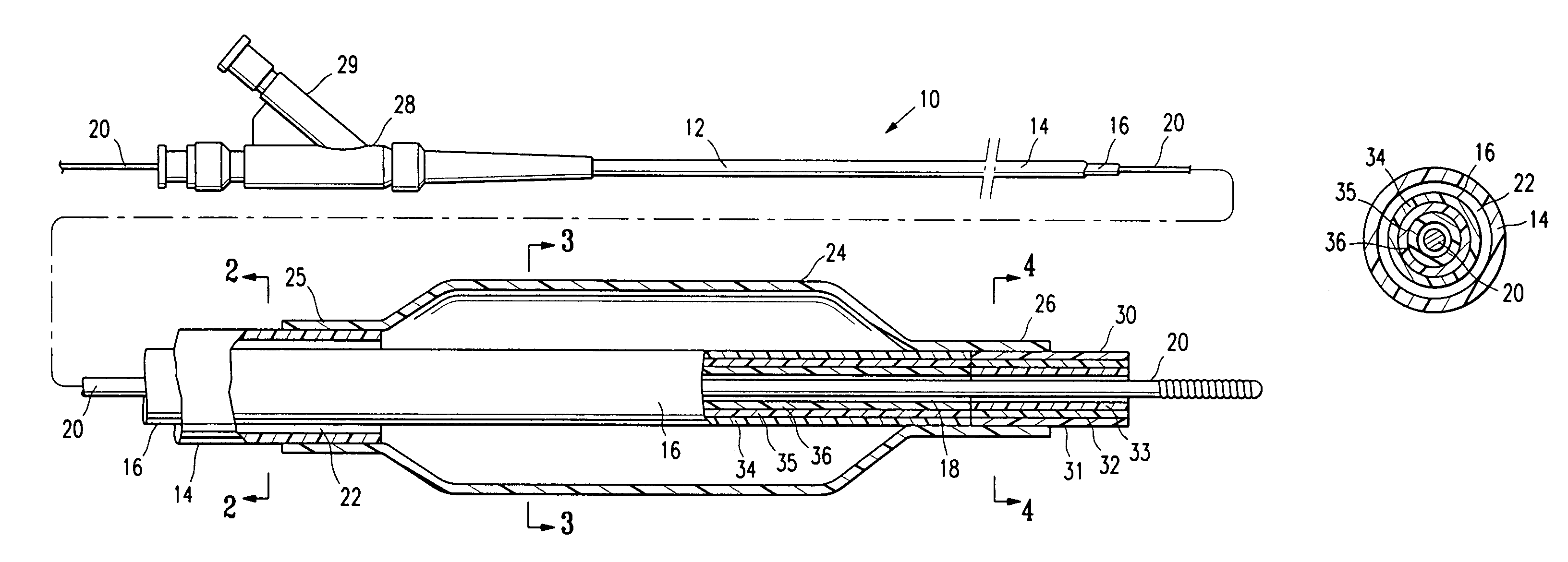

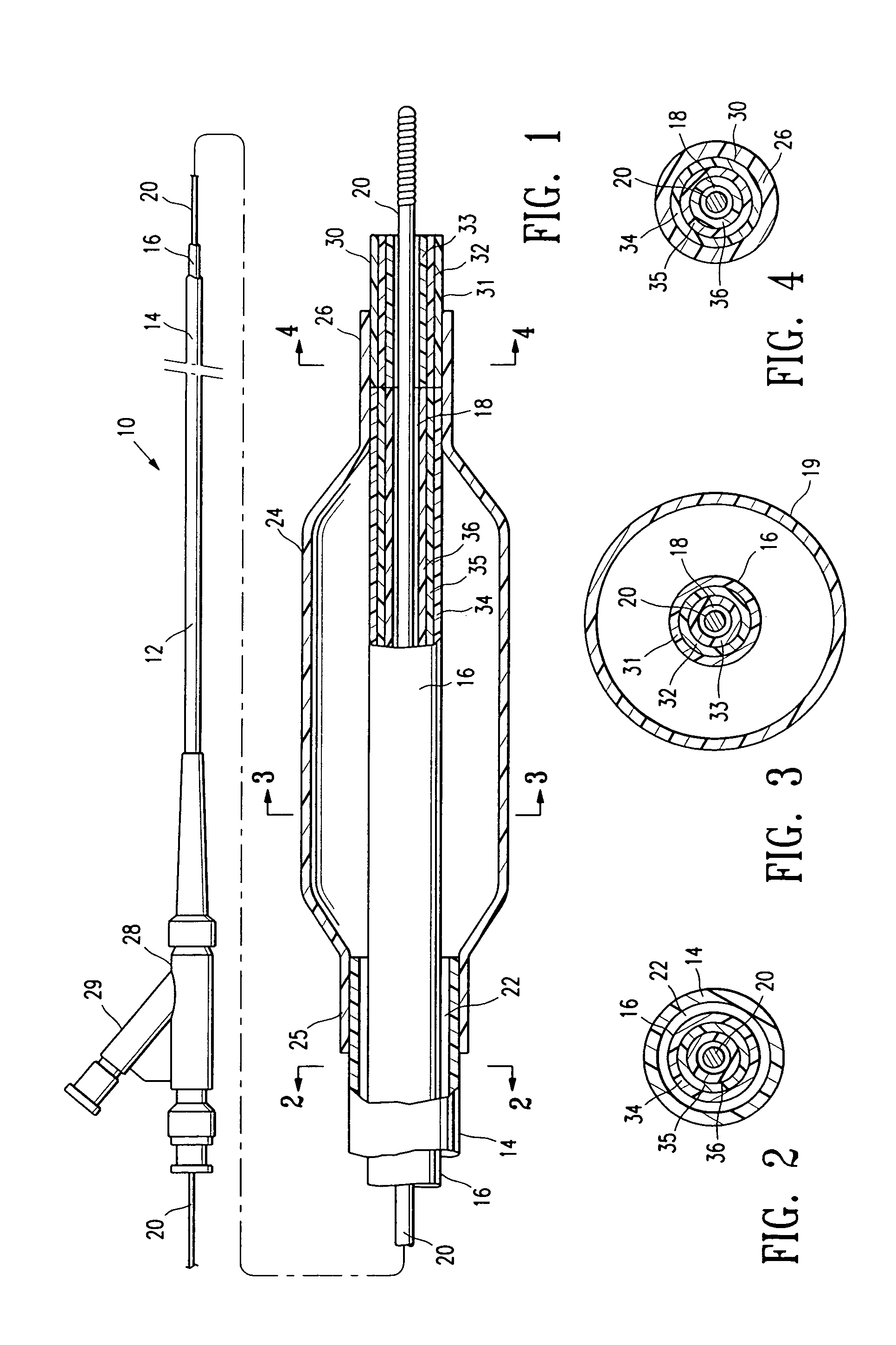

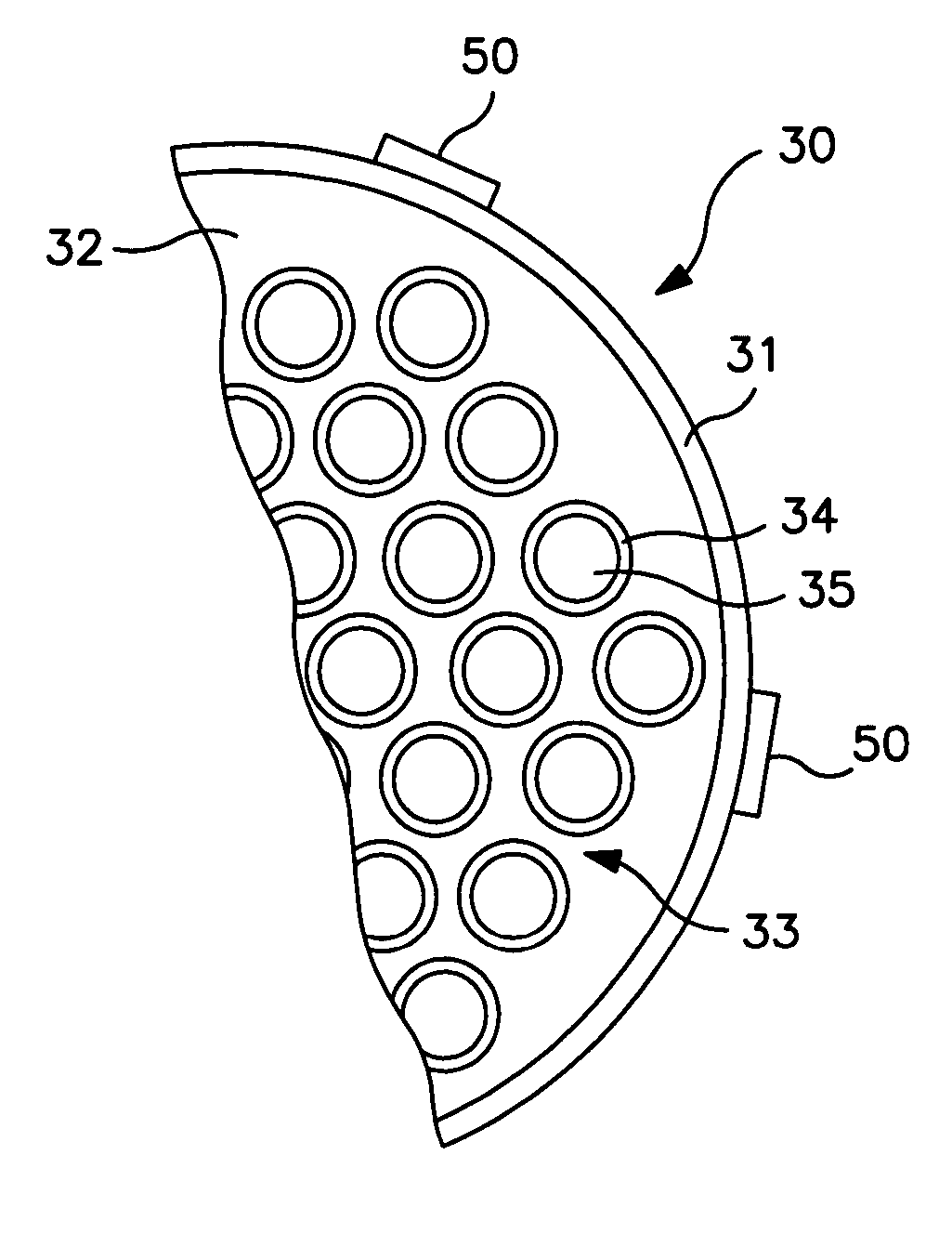

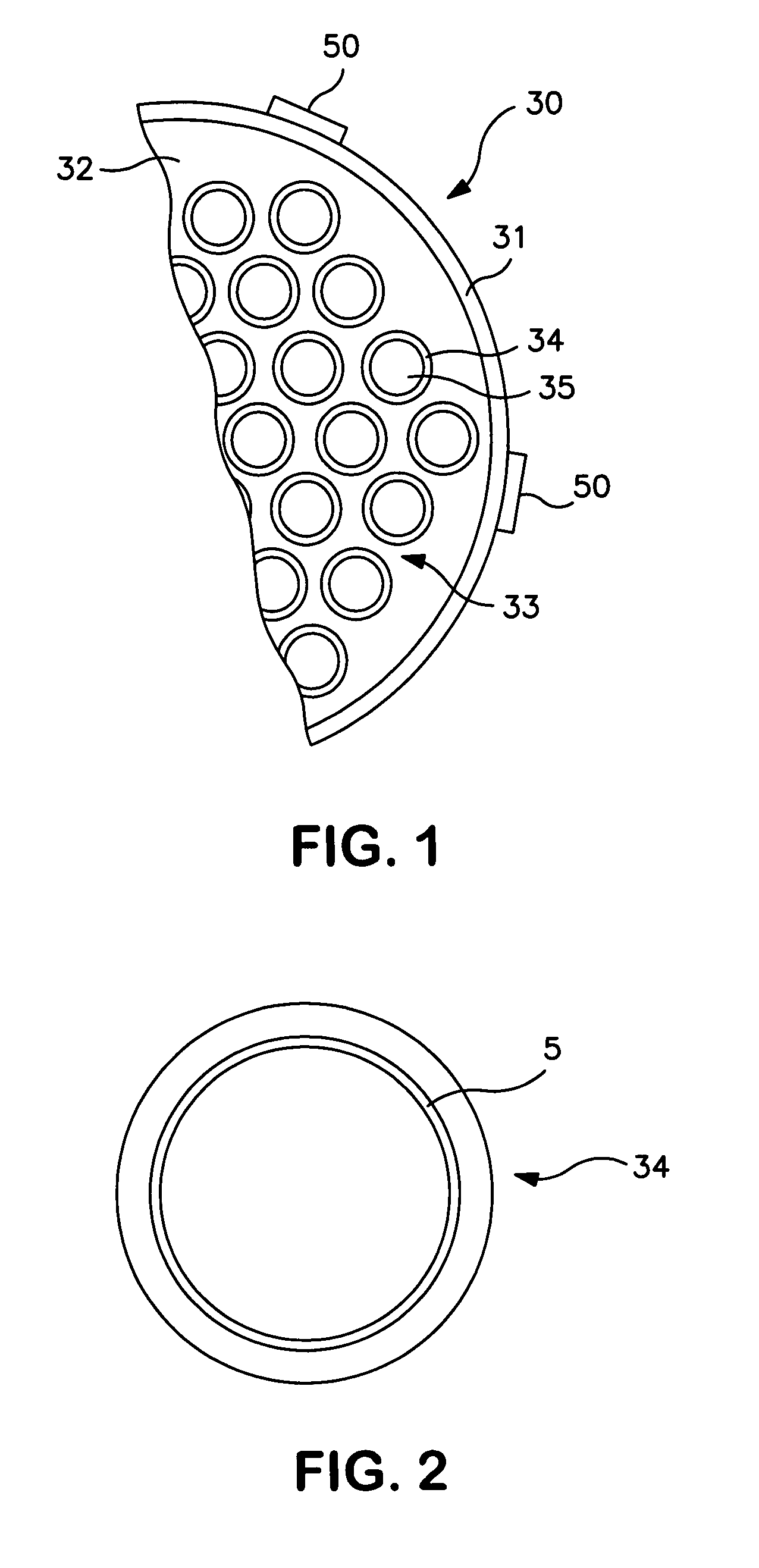

Balloon catheter having a multilayered distal tip

ActiveUS7341571B1Reduce coefficient of frictionDrag minimizationBalloon catheterSurgeryBalloon catheterBlood coagulations

A catheter having a distal tip with an inner layer formed of a polymeric material having a coefficient of friction and surface energy which are relatively low, such that the inner layer has a lubricious, non-polar inner surface repulsive to polar liquids. As a result, blood coagulation in the distal tip, and adherence of the distal tip on the guidewire are prevented or minimized.

Owner:ABBOTT CARDIOVASCULAR

Reduction of fouling in heat exchangers

InactiveUS20080073063A1Reduce amountCost savingCorrosion preventionVibration cleaningCorrosionPetroleum

A method for reducing the formation of deposits on the inner walls of a tubular heat exchanger through which a petroleum-based liquid is flowing comprises applying one of fluid pressure pulsations to the liquid flowing through the tubes of the exchanger and vibration to the heat exchanger to effect a reduction of the viscous boundary layer adjacent the inner walls of the tubular heat exchange surfaces. Reduction of the viscous boundary layer at the tube walls not only reduces the incidence of fouling with its consequential beneficial effect on equipment life but it also has the desirable effect of promoting heat transfer from the tube wall to the liquid in the tubes. Fouling and corrosion are further reduced by the use of a coating on the inner wall surfaces of the exchanger tubes.

Owner:EXXON RES & ENG CO

Coatings for Electrowetting and Electrofluidic Devices

ActiveUS20130171546A1Low surface energy polymersHigh dielectric strengthElectrostatic separatorsSludge treatmentGas phaseUltimate tensile strength

Electrowetting devices coated with one or more polymeric layers and methods of making and using thereof are described herein. The coatings may be formed in a single layer or as multiple layers. In one embodiment the first layer deposited serves as an insulating layer of high dielectric strength while the second layer deposited serves as a hydrophobic layer of low surface energy. These materials may themselves be deposited as multiple layers to eliminate pinhole defects and maximize device yield. In one embodiment the insulating layer would be a vapor deposited silicone polymeric material including, but not limited to, polytrivinyltrimethylcyclotrisiloxane or polyHVDS. In another embodiment the insulating layer may be a vapor deposited ceramic such as SiO2 with very little carbon content. In a further embodiment the insulating layer may be composed of alternating layers of a siloxane material and a ceramic material.

Owner:GVD CORP

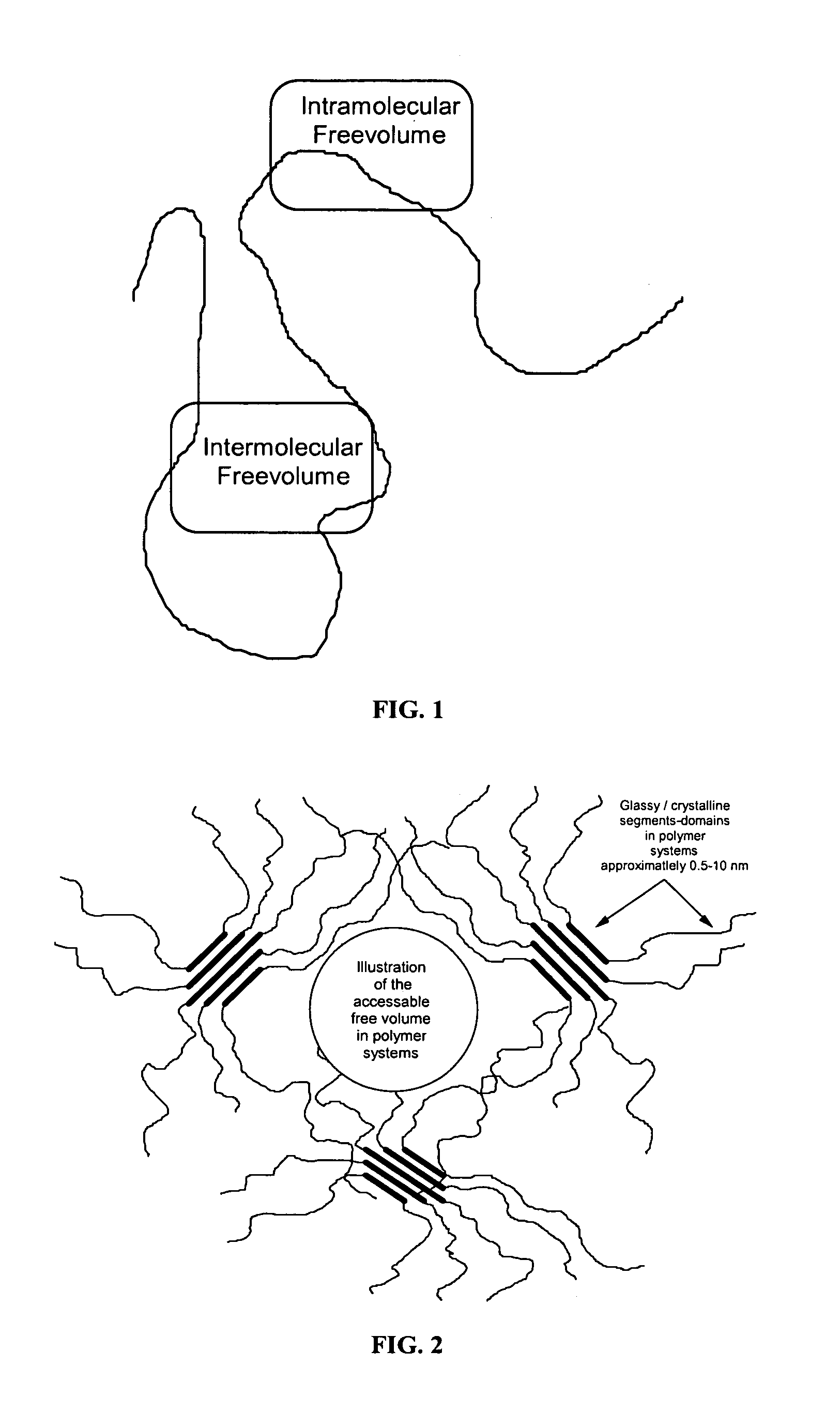

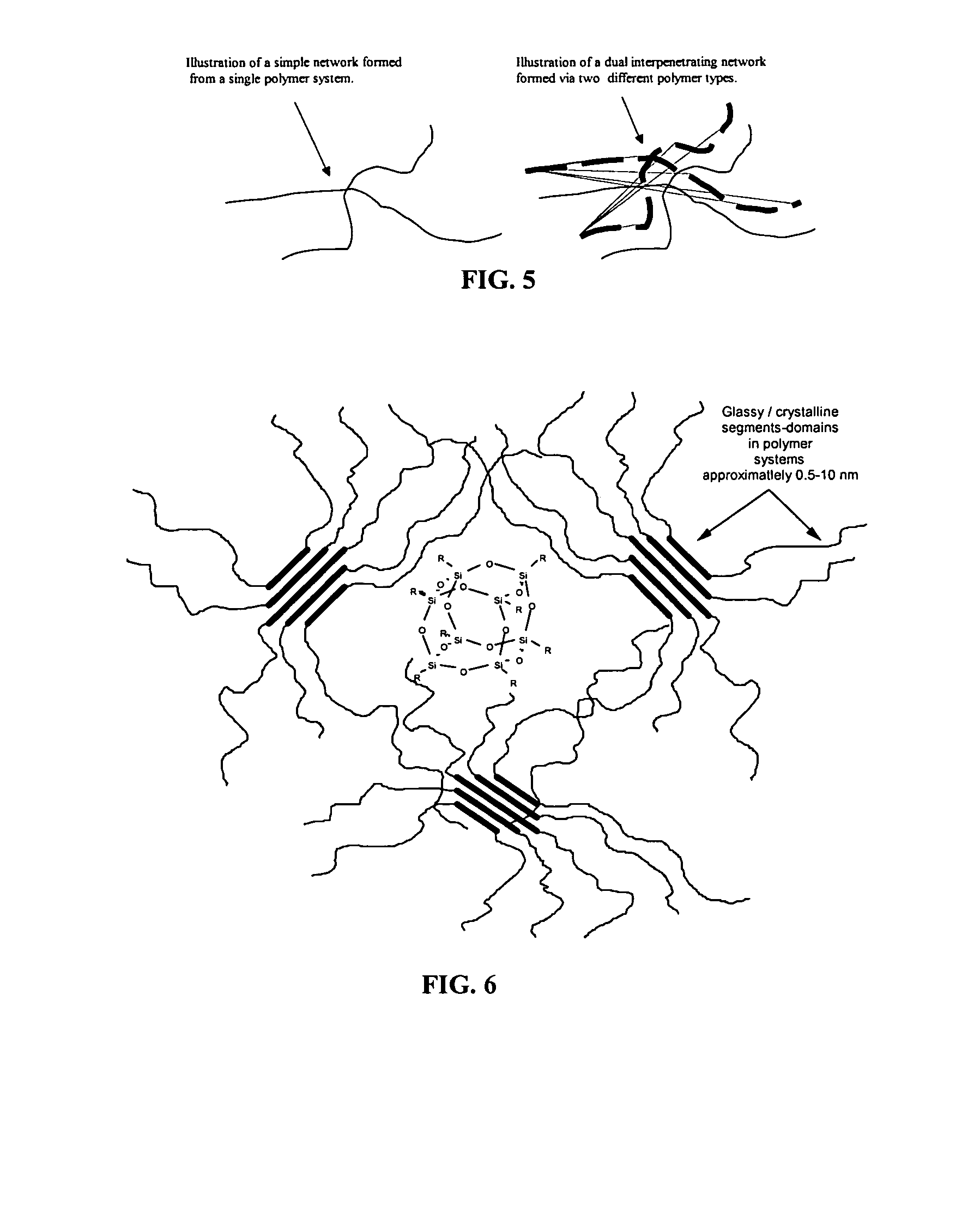

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

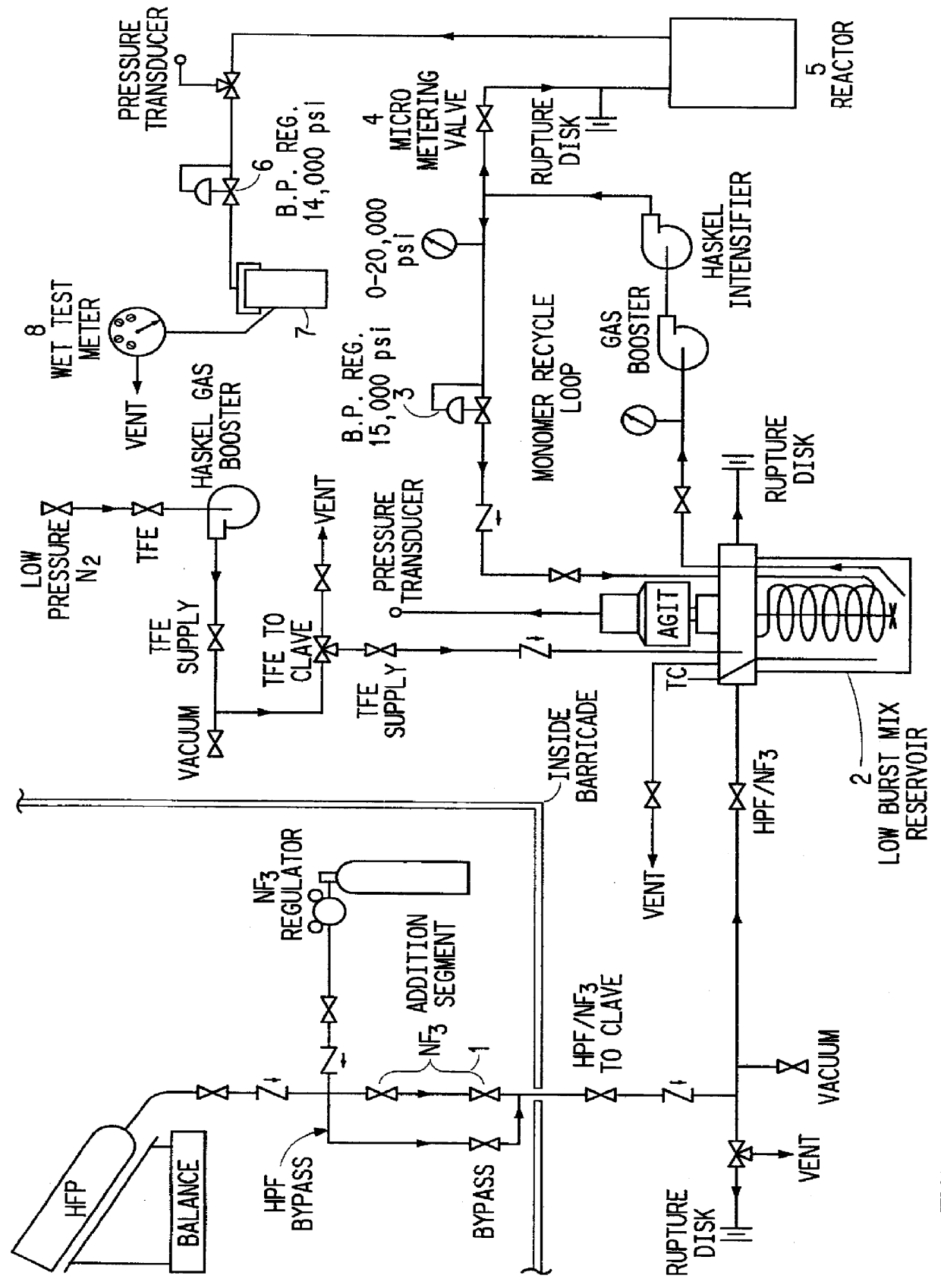

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

InactiveUS6133389AThin coatingIncrease coating thicknessOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:THE CHEMOURS CO FC LLC

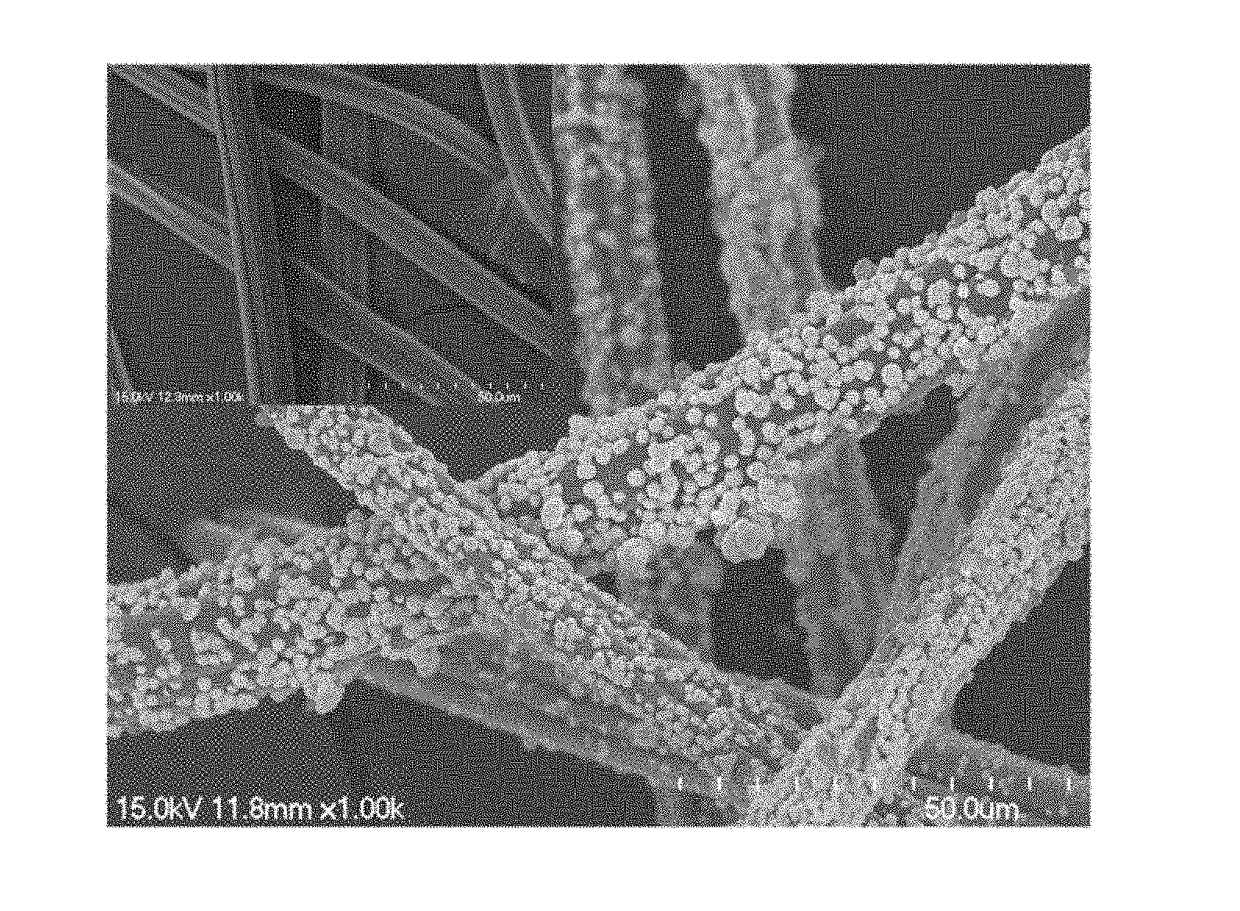

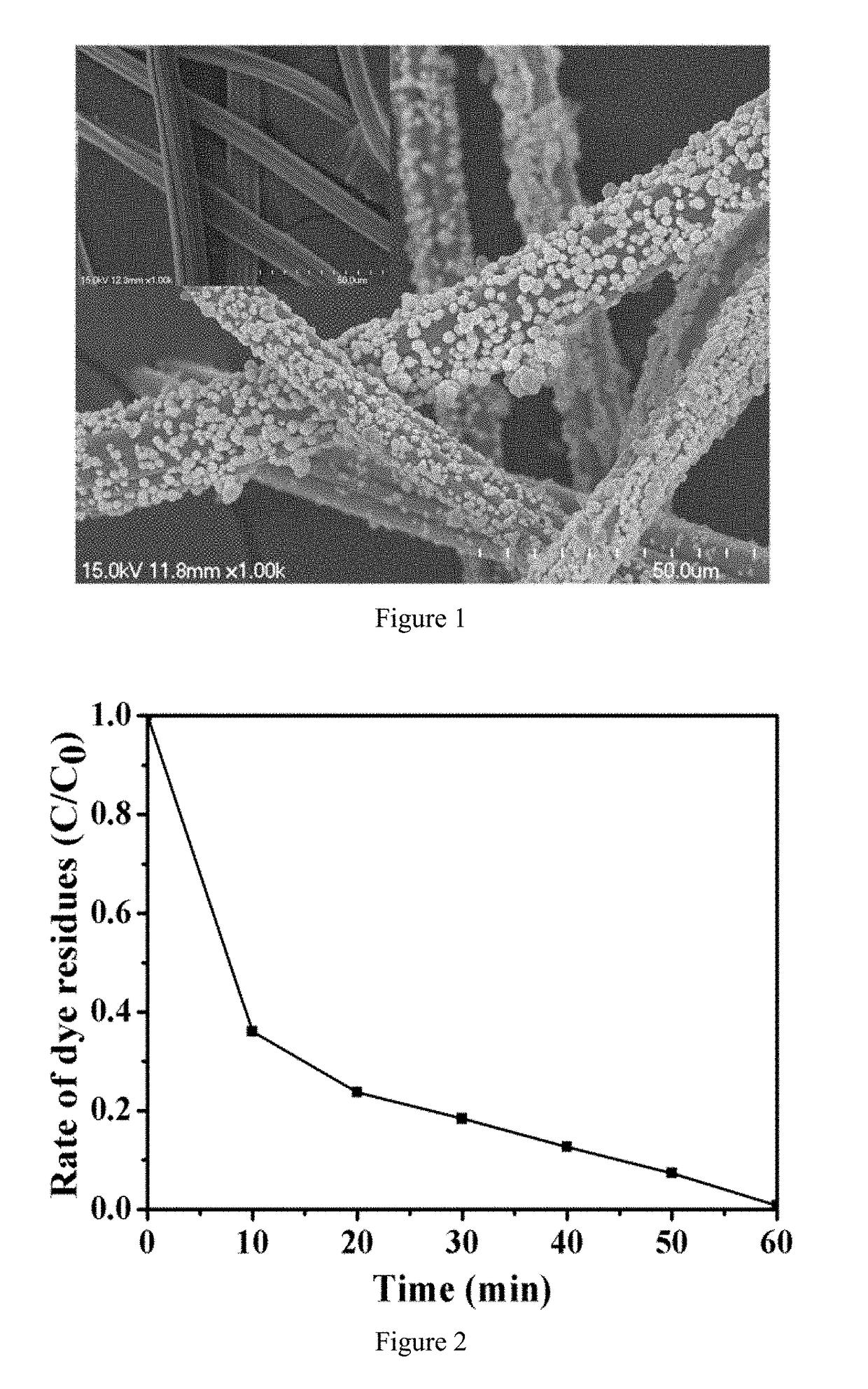

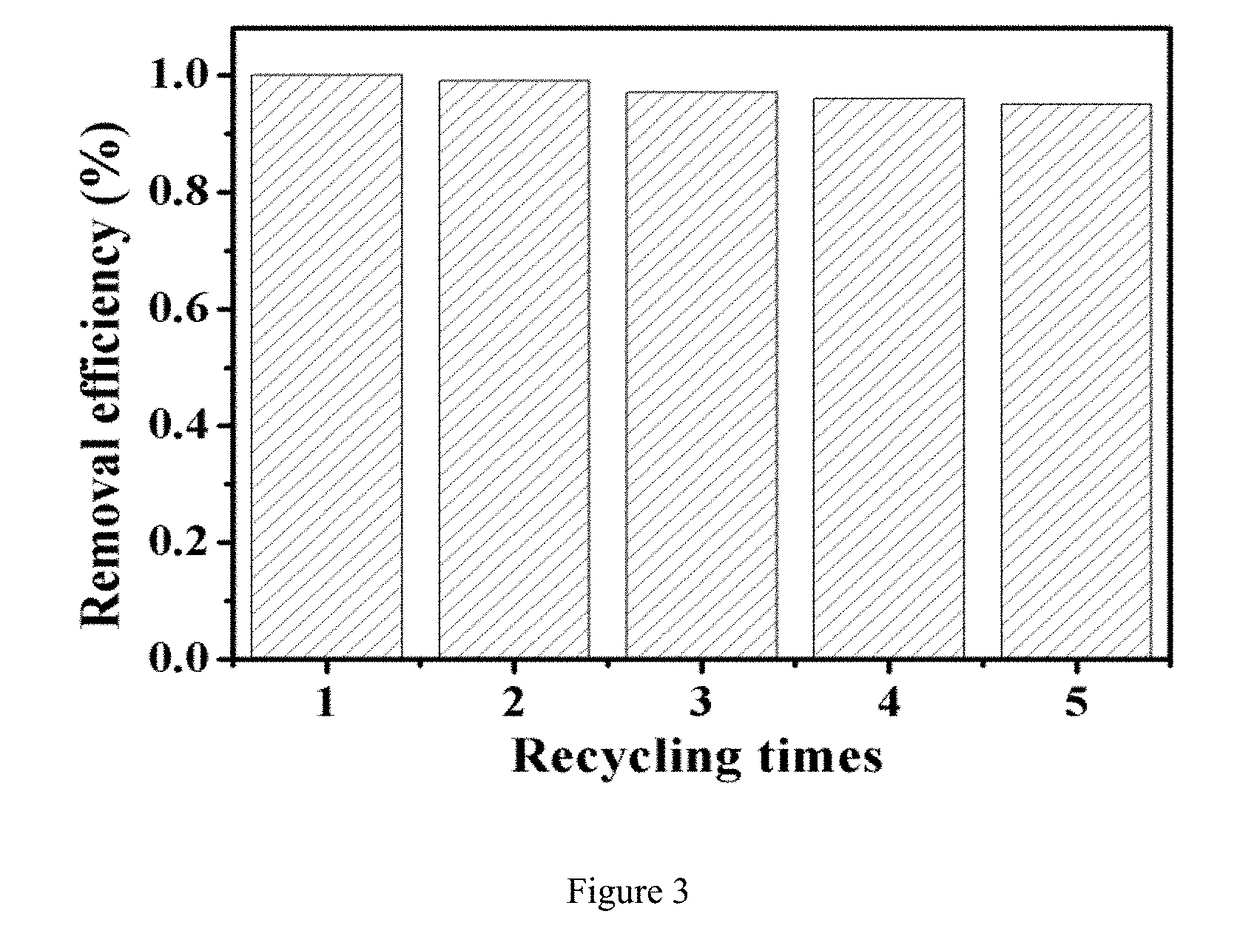

Composite with synergistic effect of adsorption and visible light catalytic degradation and preparation method and application thereof

InactiveUS20180008953A1Improve photocatalytic performanceEfficient implementationWater/sewage treatment by irradiationOther chemical processesActivated carbonFiber

The invention discloses a composite with an adsorption-visible light catalytic degradation synergistic effect and a preparation method and application thereof. The preparation method includes the specific steps that firstly, a bismuth oxyiodide / bismuth oxychloride composite nano-particle loaded activated carbon fiber composite ACF@BiOIxCl1-x is synthesized; then, the fiber surface is grafted with polyethyleneimine, and the end composite PEI-g-ACF@BiOIxCl1-x is obtained. The composite can rapidly adsorb pollutants in water, and meanwhile the pollutants are efficiently degraded with a photocatalyst loaded on the surface of the composite; besides, the purpose of recycling and reusing the photocatalyst is achieved, the comprehensive treatment capability of the composite is improved, the service life of the composite is prolonged, and the use cost is lowered.

Owner:SUZHOU UNIV

Silica coating for enhanced hydrophilicity

InactiveUS20100092765A1Less attractiveDelayed adhesionMaterial nanotechnologyPigmenting treatmentSilica nanoparticlesOligomer

A coating composition is provided comprising a) an aqueous dispersion, having a pH of less than 7.5, of silica nanoparticles having average particle diameters of 40 nanometers or less, b) an alkoxysilane oligomer; c) a silane coupling agent, and d) optionally a metal β-diketone complexing agent. The compositions may be used to prepare coated articles wherein the coating is substantially uniform in thickness, durably adheres to the substrate, and provides hydrophilic and / or antireflection surface properties to the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Ultraviolet-cured hard coating and application thereof

ActiveCN102236113AImprove wear resistanceImprove antifouling performanceLayered productsPolyurea/polyurethane coatingsUltravioletPliability

The invention discloses an ultraviolet-cured hard coating and an application thereof. The ultraviolet-cured hard coating comprises a transparent supporting body and a scratch-proof coating coated on the transparent supporting body; the scratch-proof coating comprises the following components in part by weight: 5 to 90 parts of light-cured prepolymer, 5 to 90 parts of thinning agent, 1 to 10 parts of photoinitiator, 0 to 80 parts of active thinning agent, 0 to 20 parts of inorganic nanopadding and 0 to 18 parts of aid. By the invention, the defects that the conventional hard coating is not hard enough, the scratch resistance and the wear resistance are limited, the flexibility is relatively low and the like are overcome; and the ultraviolet-cured hard coating has relatively low surface energy, relatively good antifouling effect, high strength, relatively good scratch resistance and wear resistance, and excellent adhesion, flexibility and transparence.

Owner:中国航天科技集团公司第四研究院第四十二所

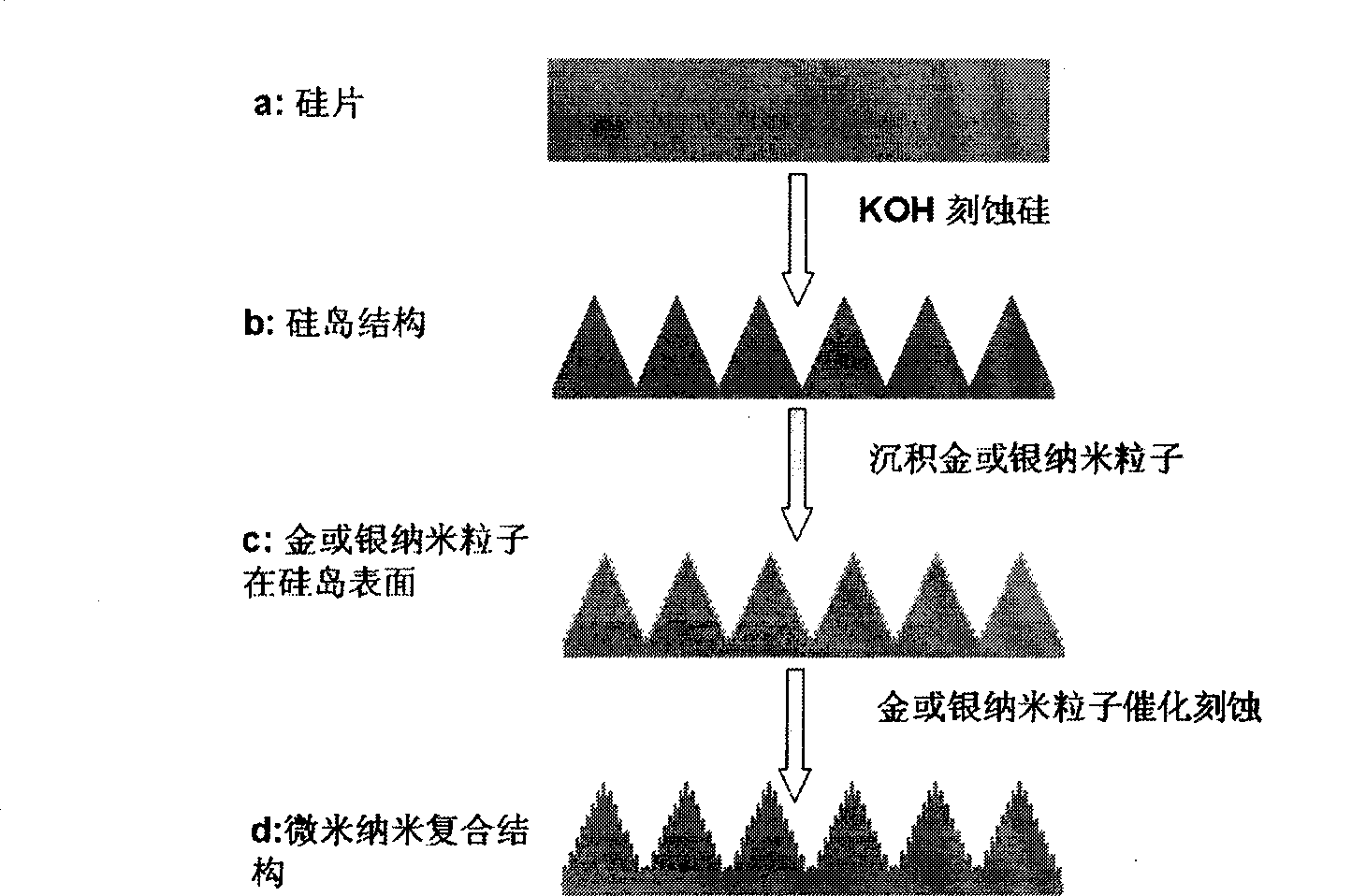

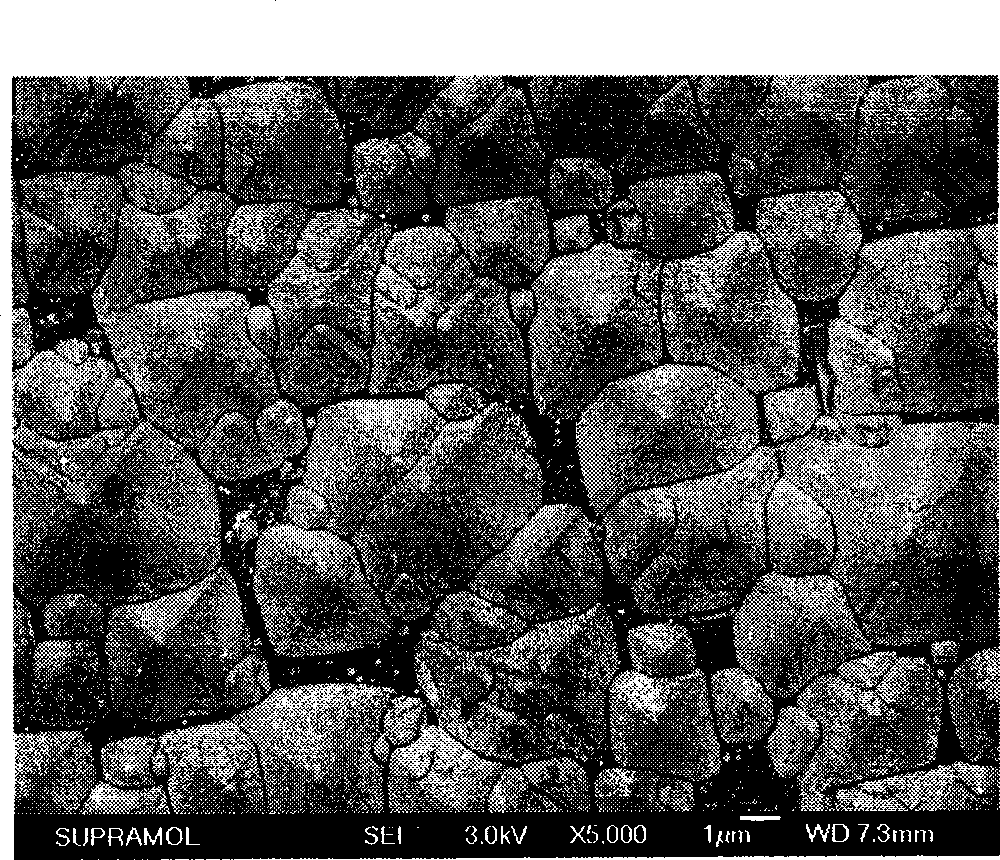

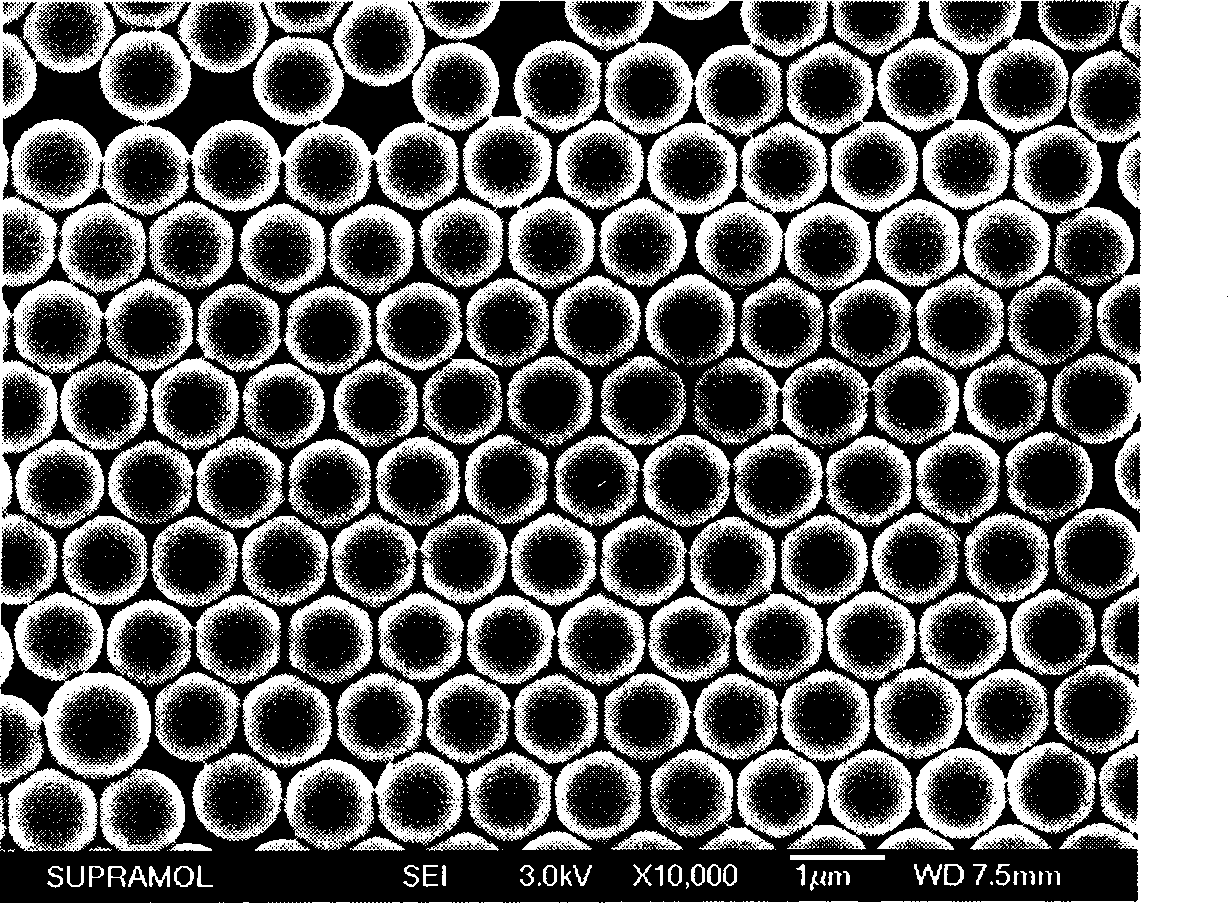

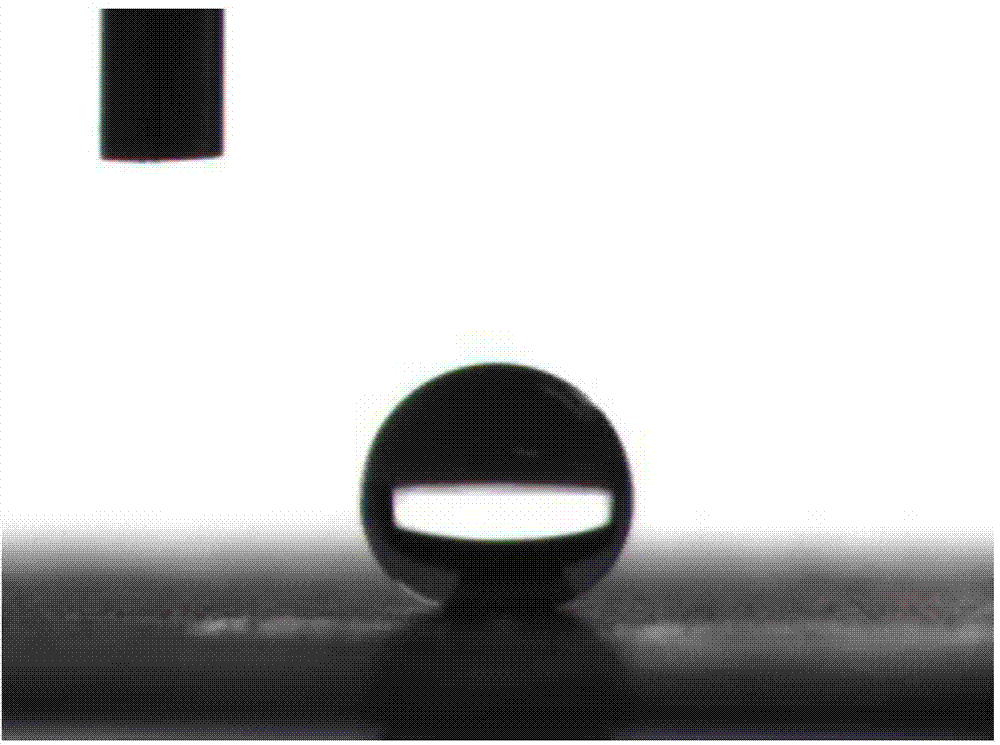

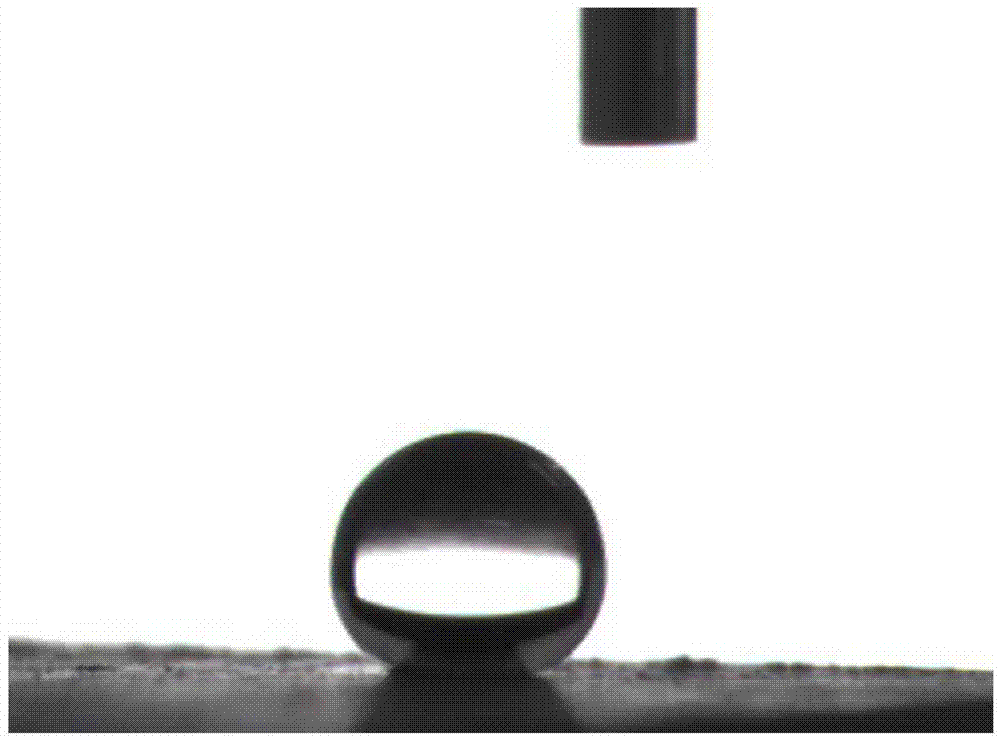

Method for preparing super-hydrophobic antireflex micron and nano composite structure surface

The invention belongs to the technical field of preparing the surface of a composite structure, and in particular relates to a method for preparing super-hydrophobic antireflective silicon surface with a micron and nanometer composite structure. The method comprises the following steps: cleaning a silicon chip; preparing a micron-level silicon island and a gridding structure on the surface of the silicon chip; carrying out catalytic etching taking silver or aurum nanoparticles as blockage; obtaining the surface of the micron and nanometer composite structure; and carrying out chemical modification of the surface of the composite structure. A static contact angle between the super-hydrophobic antireflective material surface prepared by the method and water is more than 150 degrees, and a static rolling angle of water is less than 3 degrees. The surface has superior antireflective performance, and in particular, the light reflectivity within the wavelength range between 800 and 1,100 nm is less than 3 percent. With application of the method, the super-hydrophobic antireflective silicon surface of the micron and nanometer composite structure can be produced on scale, can be widely applied to a solar cell, a microfluidic chip, a photoelectric device, and the like, and has good industrial application prospect.

Owner:JILIN UNIV

Super-hydrophobic and oleophobic composite coating and preparation method thereof

InactiveCN104745045AImprove hydrophobicity and oleophobicityHydrophobic and oleophobicPretreated surfacesEpoxy resin coatingsGas phaseSolvent

The invention discloses a super-hydrophobic and oleophobic composite coating which comprises a super-hydrophobic and oleophobic primer coat layer and a super-hydrophobic and oleophobic finishing coat layer. The coating is characterized in that the super-hydrophobic and oleophobic finishing coat layer is located on the super-hydrophobic and oleophobic primer coat layer; the super-hydrophobic and oleophobic primer coat layer is coated by a super-hydrophobic and oleophobic primer coat which is a composition containing epoxy resin, an auxiliary A, extinction powder and a solvent; the super-hydrophobic and oleophobic finishing coat layer is coated by a super-hydrophobic and oleophobic finishing coat which is a composition containing fumed silica, an auxiliary B, an auxiliary C, a mixed solution A and a mixed solution B. Compared with the prior art, the super-hydrophobic and oleophobic composite coating disclosed by the invention not only has a super-hydrophobic performance, but also can resist greasy dirt and has a super-oleophobic performance as well as good wear resistance and stability; the preparation process is simple, and realization of industrialized production is facilitated.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

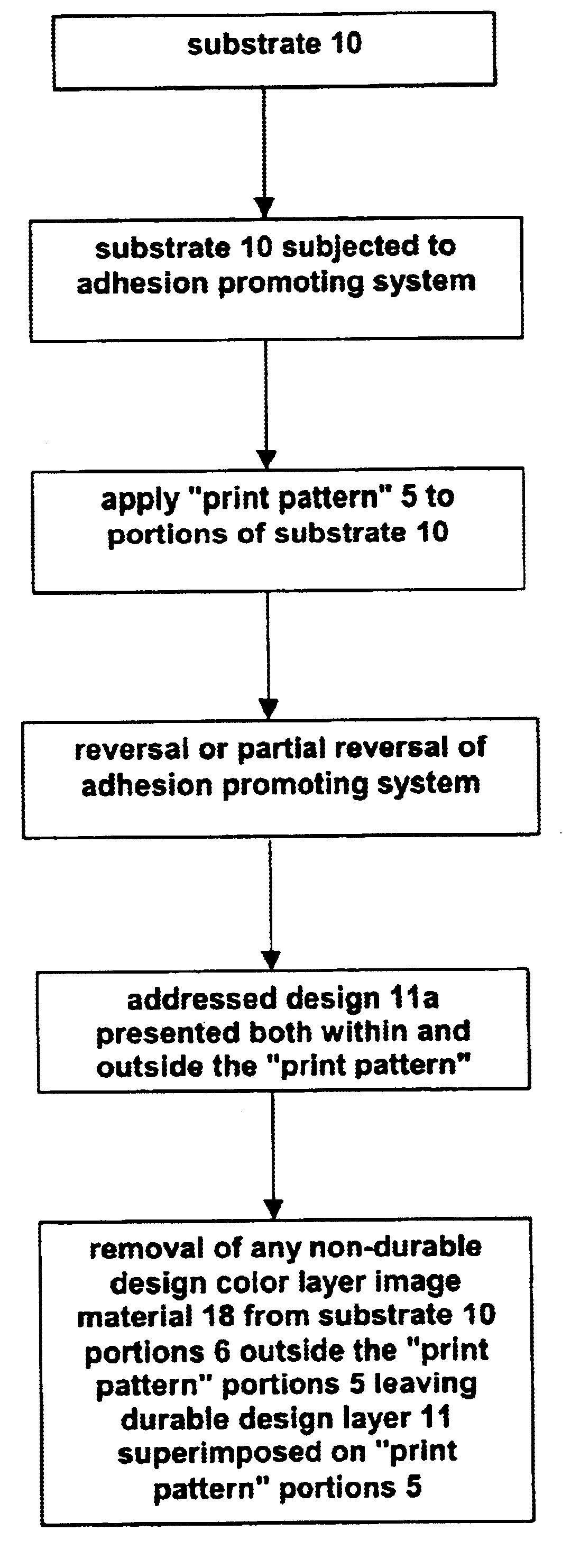

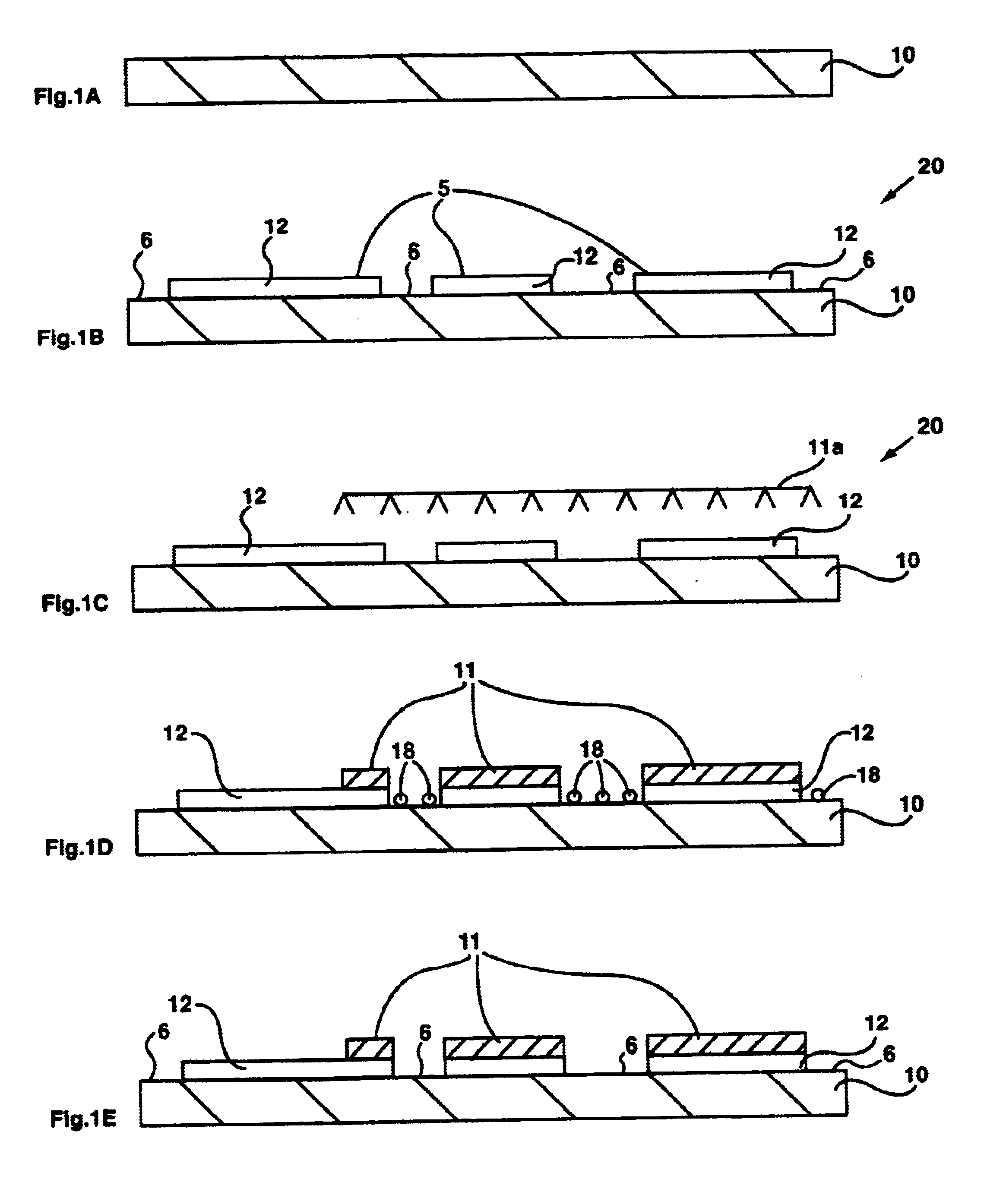

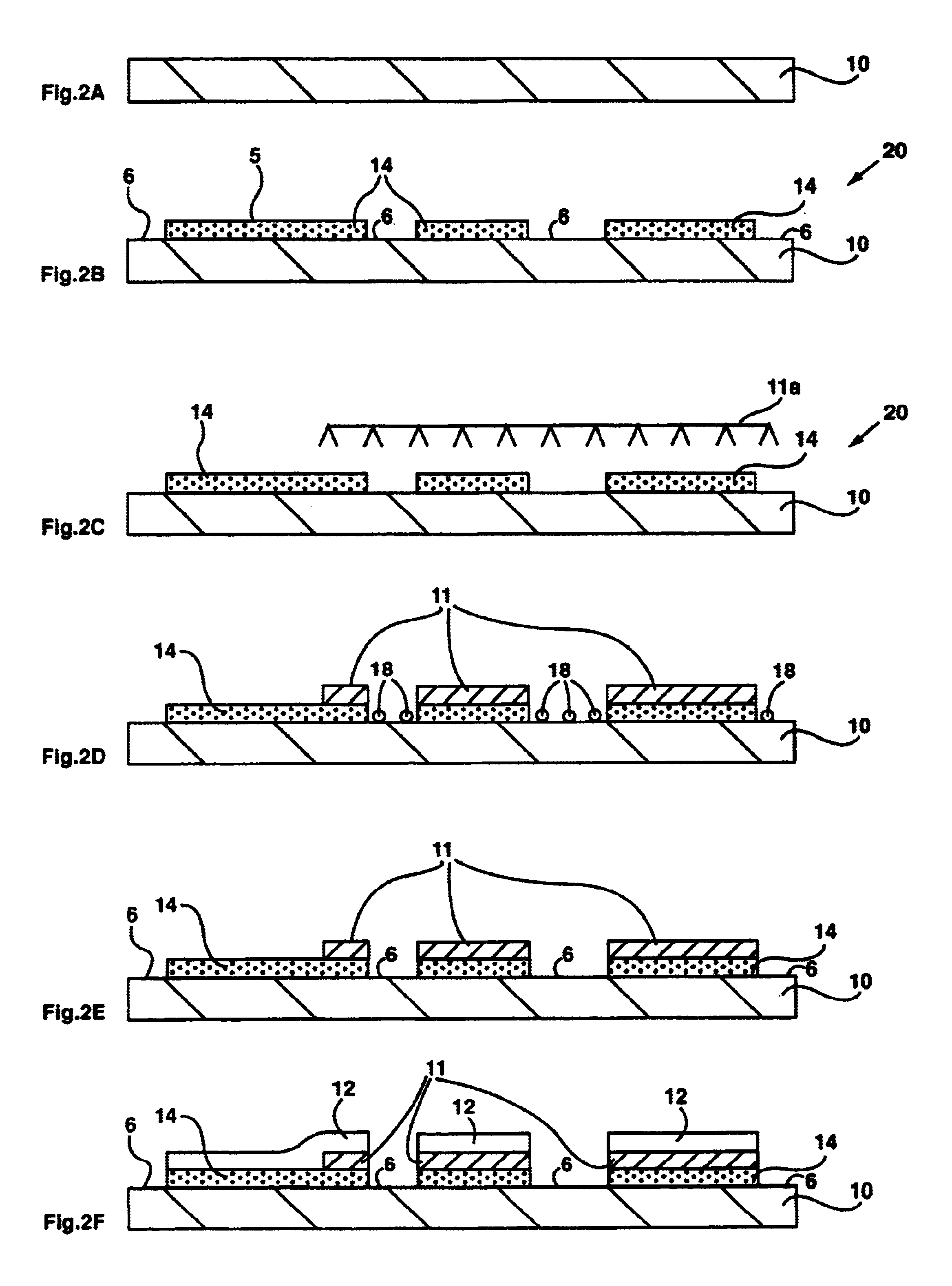

Printing with differential adhesion

InactiveUS6899775B2Facilitates subsequent removalLower surface energyElectric discharge heatingRadiation applicationsEngineeringHigh surface

This invention relates to the printing of a substrate having a pre-printed “print pattern” with a “design layer” of ink where there is differential adhesion within and without the print pattern. The print pattern is receptive to an ink, and the design layer ink forms a durable image material with good bond to the print pattern, but the ink does not form a durable image material on the portions of the substrate outside the print pattern. The design layer ink is a UV-curable ink, and the print pattern may have a higher surface energy than the portions of the substrate outside the print pattern.

Owner:CONTRA VISION

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Medical devices having polymeric regions that contain fluorocarbon-containing block copolymers

ActiveUS20070117925A1Lower surface energyReduce surface tackHeart valvesCoatingsFluorocarbonGlass transition

In one aspect, the present invention provides implantable or insertable medical devices, which contain at least one polymeric region. The polymeric region contains at least one fluorocarbon-containing block copolymer, which, in turn, contains (a) at least one fluorocarbon-containing, low glass transition temperature (low Tg) copolymer chain and (b) at least one glass transition temperature (high Tg) polymer chain.

Owner:BOSTON SCI SCIMED INC

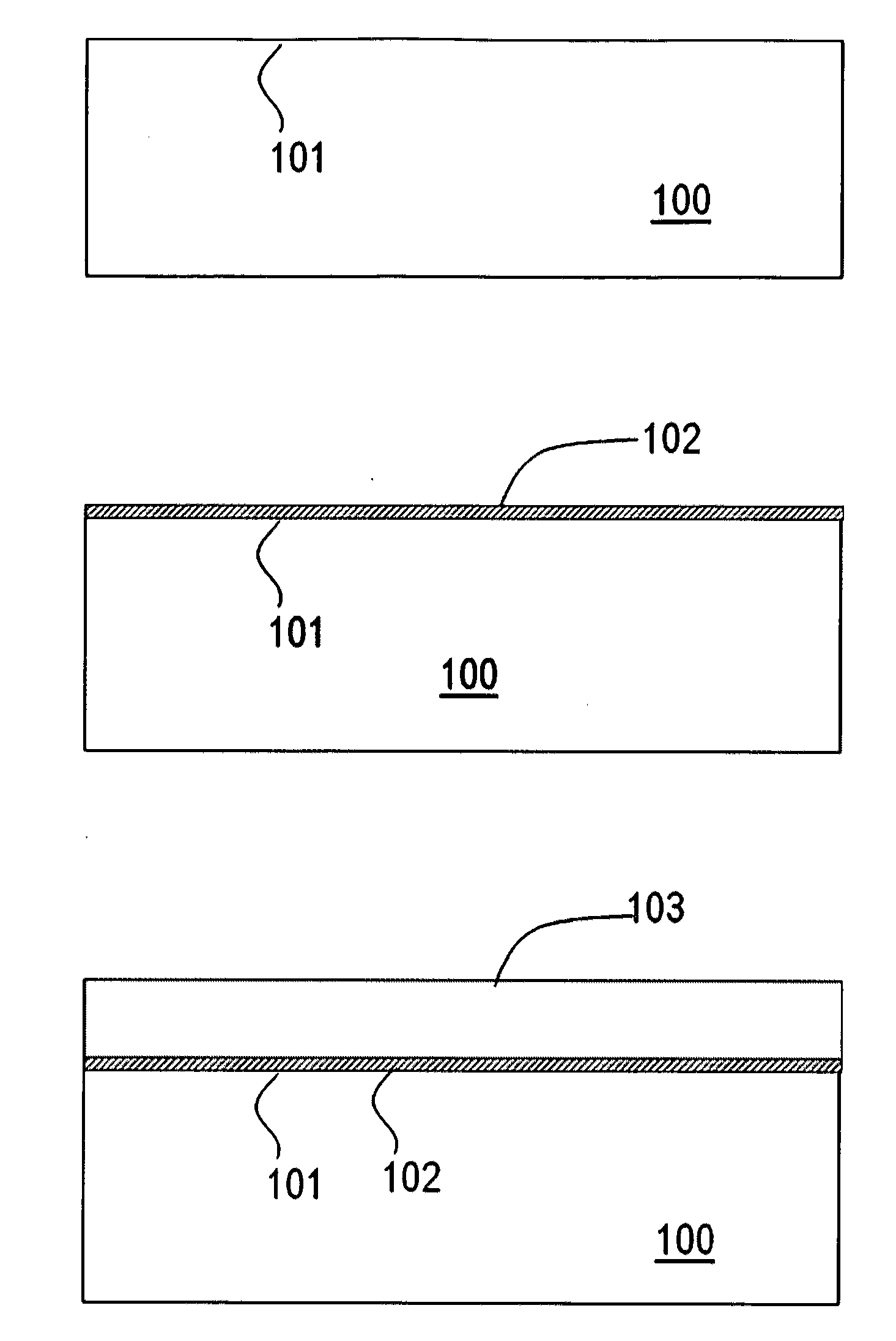

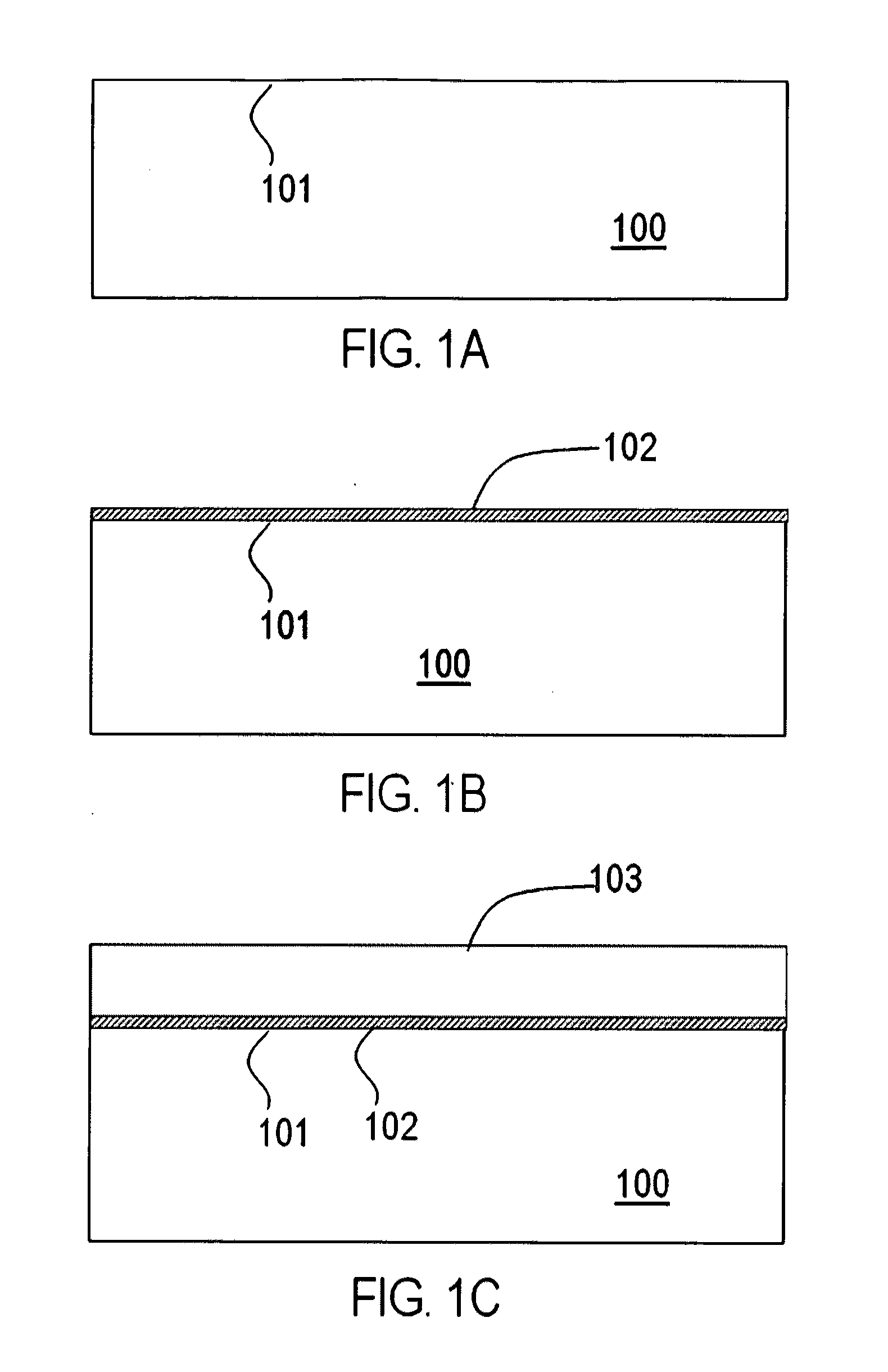

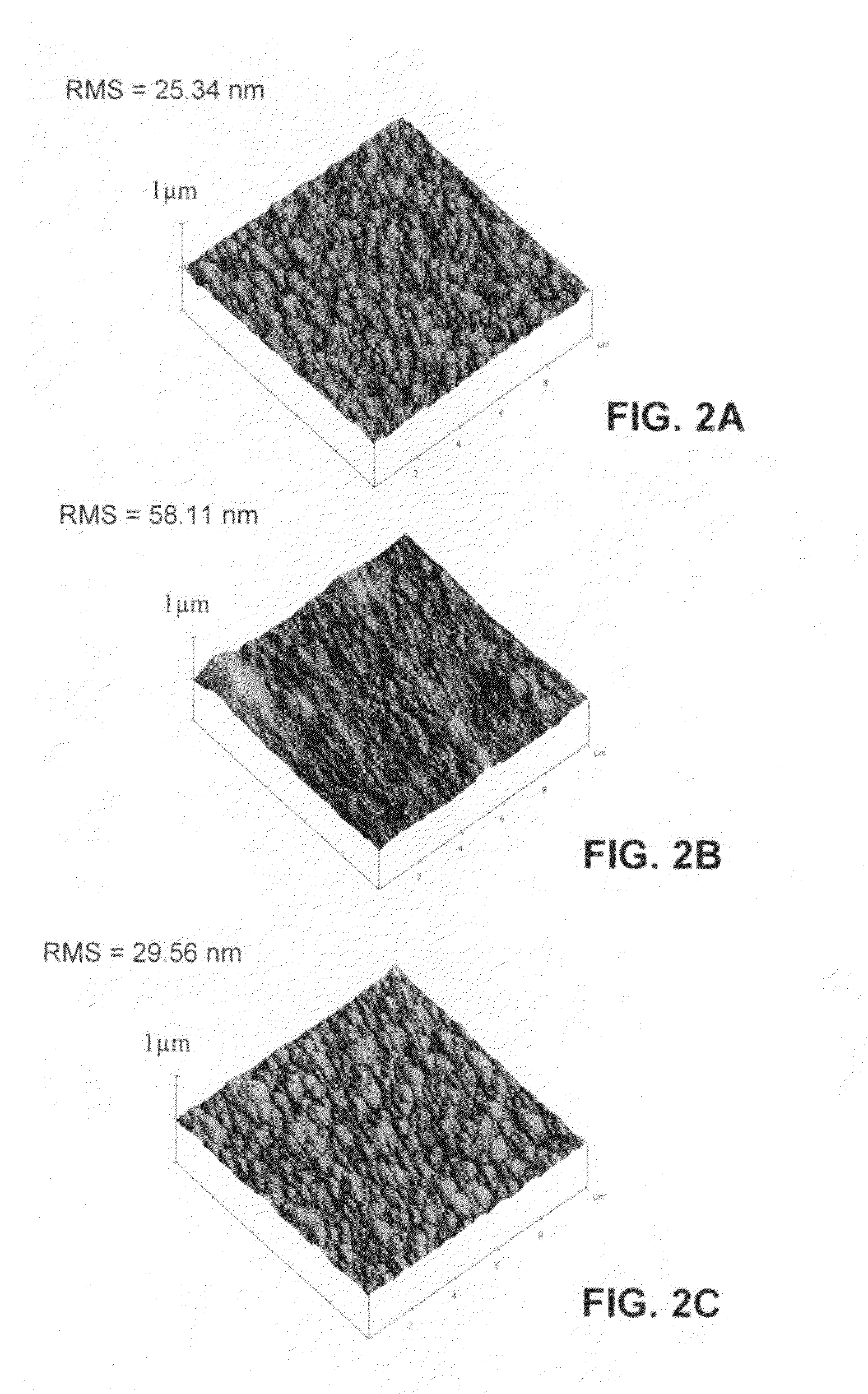

Metal deposition using seed layers

InactiveUS20120217165A1Easy to operateLower surface energySuperimposed coating processNanoparticleSilanes

Methods of forming a conductive metal layers on substrates are disclosed which employ a seed layer to enhance bonding, especially to smooth, low-roughness or hydrophobic substrates. In one aspect of the invention, the seed layer can be formed by applying nanoparticles onto a surface of the substrate; and the metallization is achieved by electroplating an electrically conducting metal onto the seed layer, whereby the nanoparticles serve as nucleation sites for metal deposition. In another approach, the seed layer can be formed by a self-assembling linker material, such as a sulfur-containing silane material.

Owner:GMZ ENERGY +2

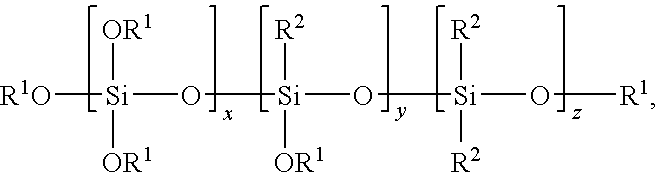

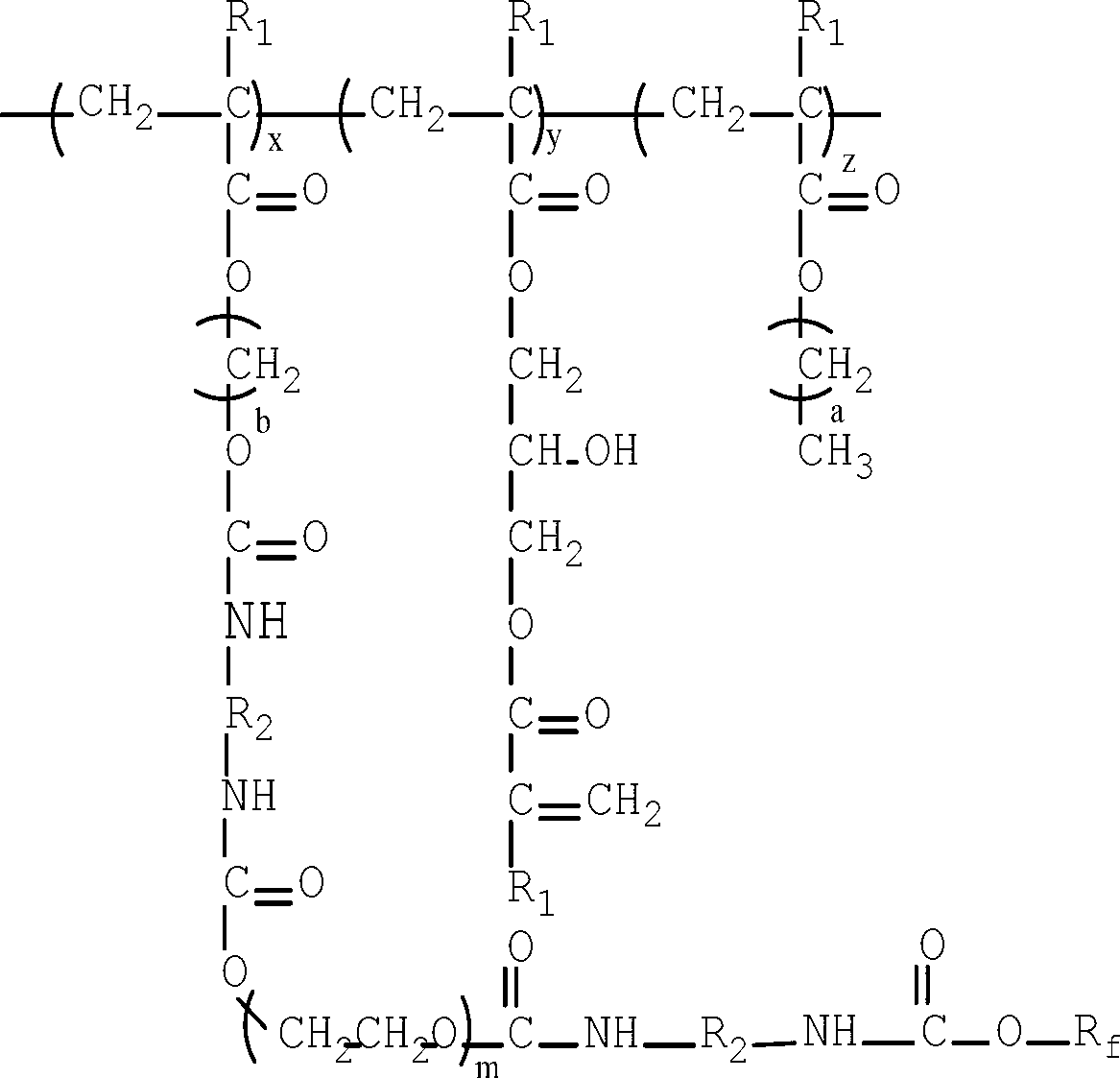

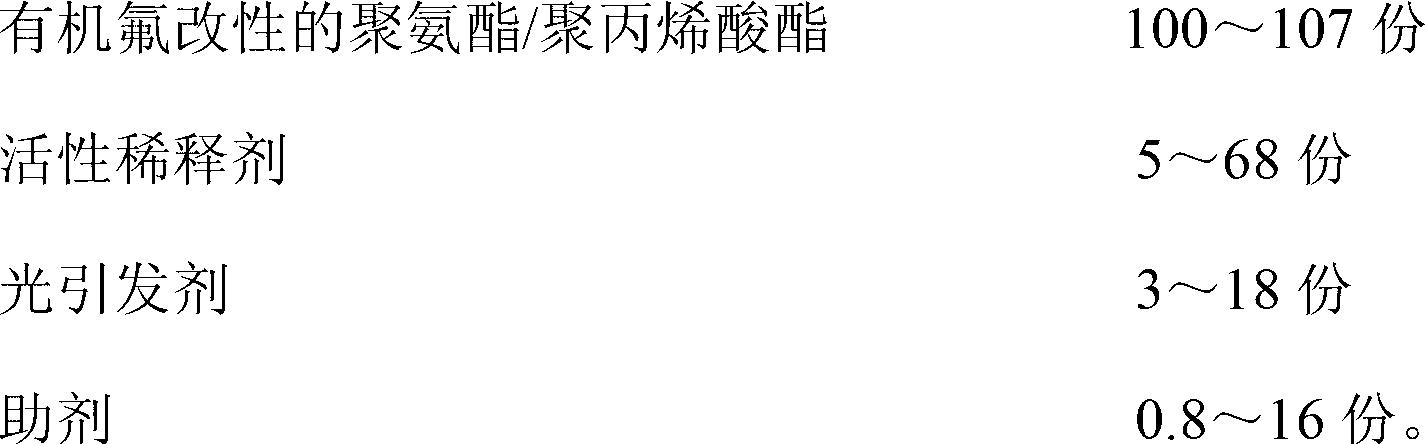

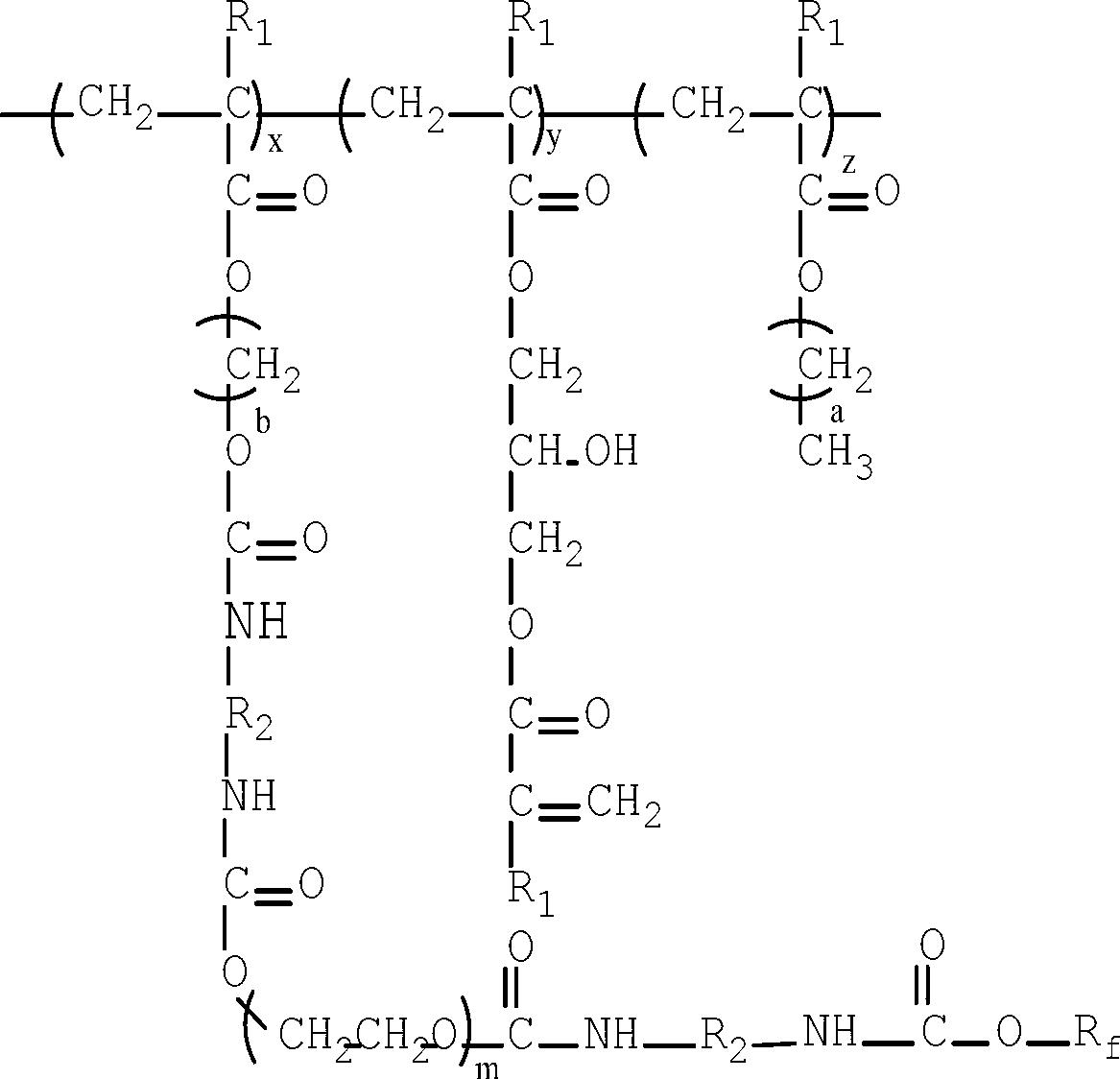

Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

The invention belongs to the field of coatings, and particularly relates to a polyurethane / polyacrylate copolymer modified by organic fluoride and an ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer. A method for preparing the polyurethane / polyacrylate copolymer modified by organic fluoride comprises the following steps: 1), preparing a polyurethane prepolymer modified by organic fluoride; 2), preparing a (methyl) acrylate prepolymer; and 3), preparing the polyurethane / polyacrylate copolymer modified by organic fluoride. A method for preparing an ultraviolet curing agent by taking the polyurethane / polyacrylate copolymer modified by organic fluoride as a raw material comprises the steps that taking 100-107 parts of polyurethane / polyacrylate, 50-68 parts of an reactive diluent, 13-18 parts of a photoinitiator and 8-16 parts of an auxiliary; stirring fully for 5-15 minutes until all the materials are mixed uniformly; and obtaining the polyurethane / polyacrylate copolymer modified by organic fluoride and the ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

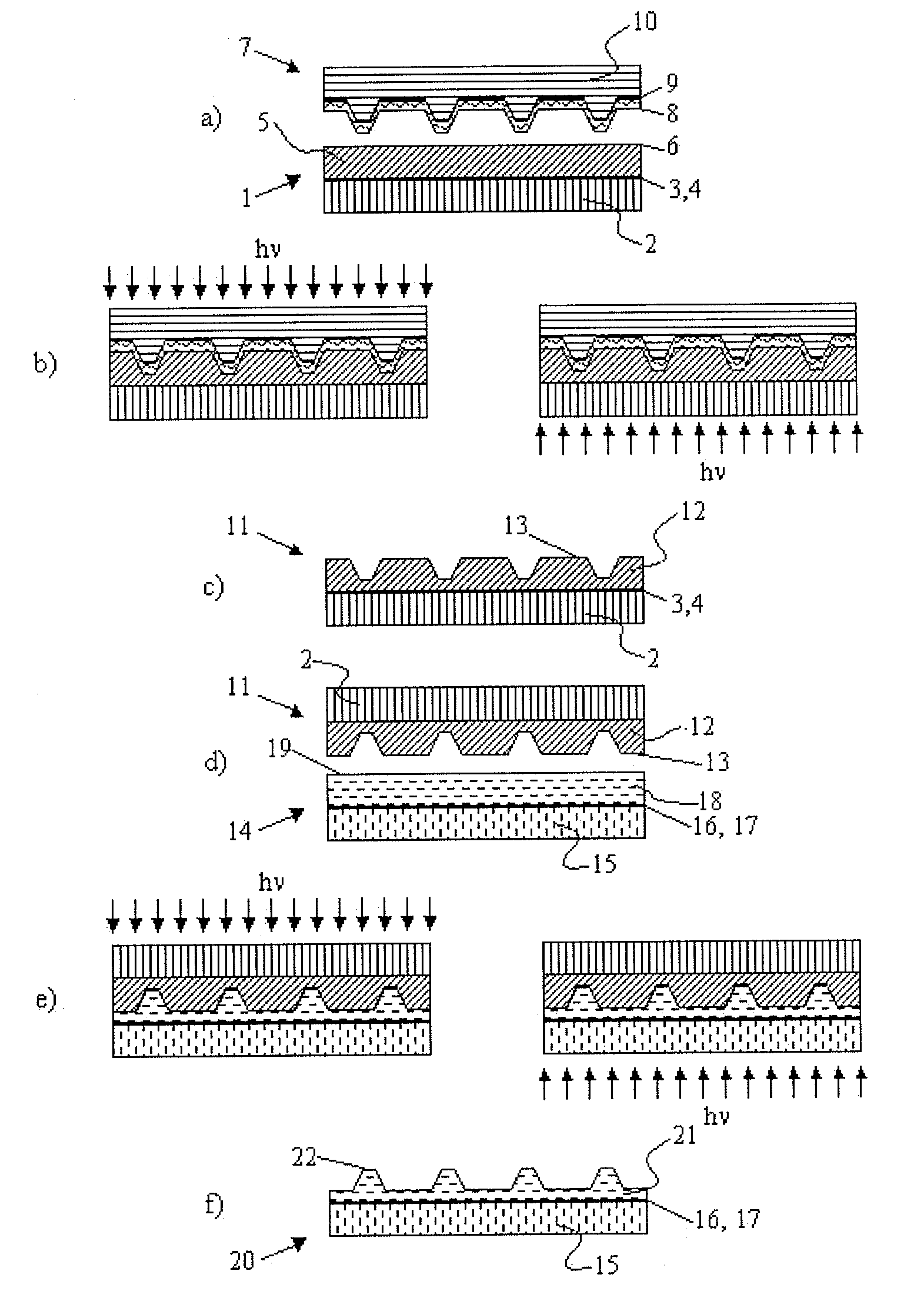

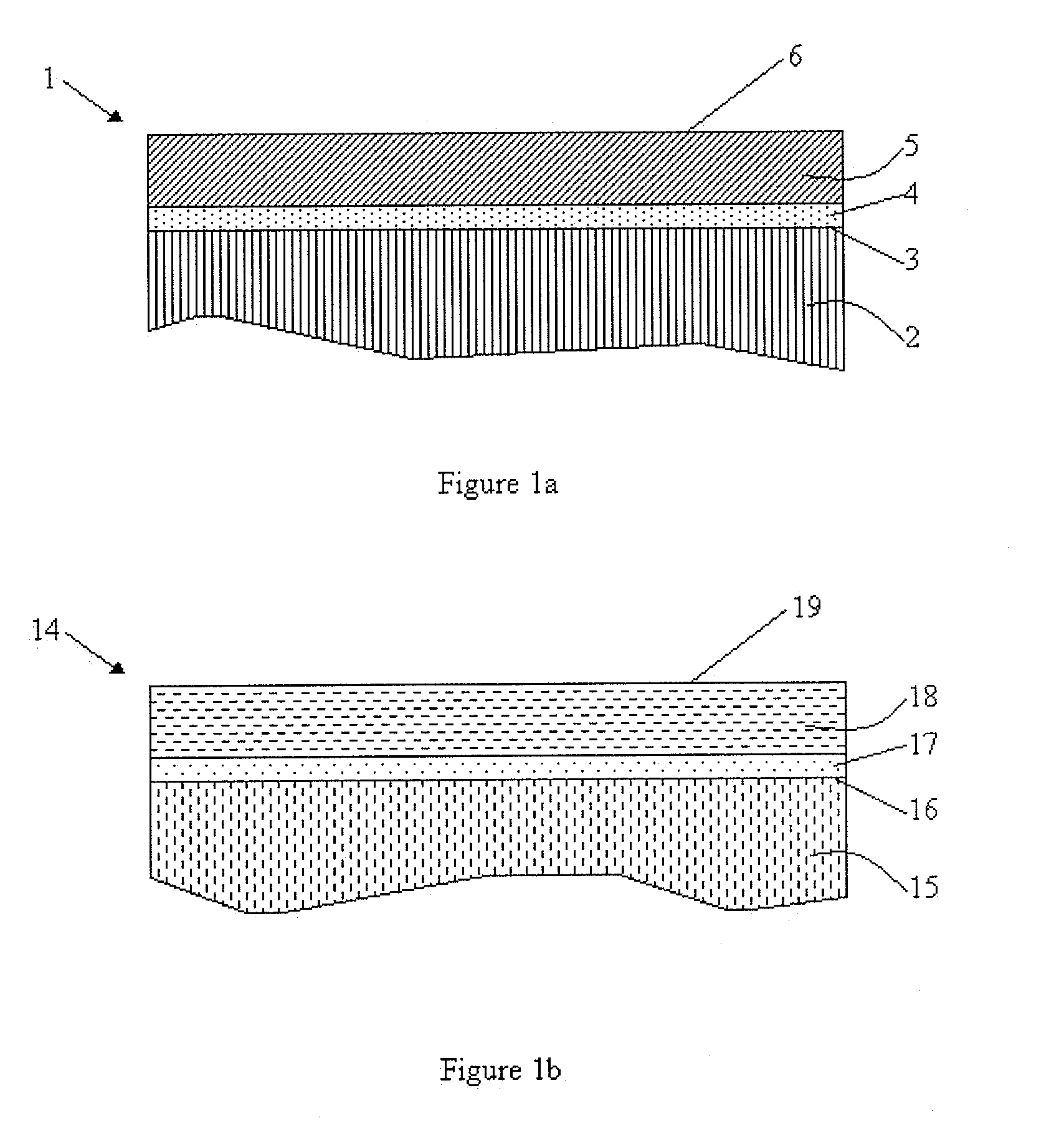

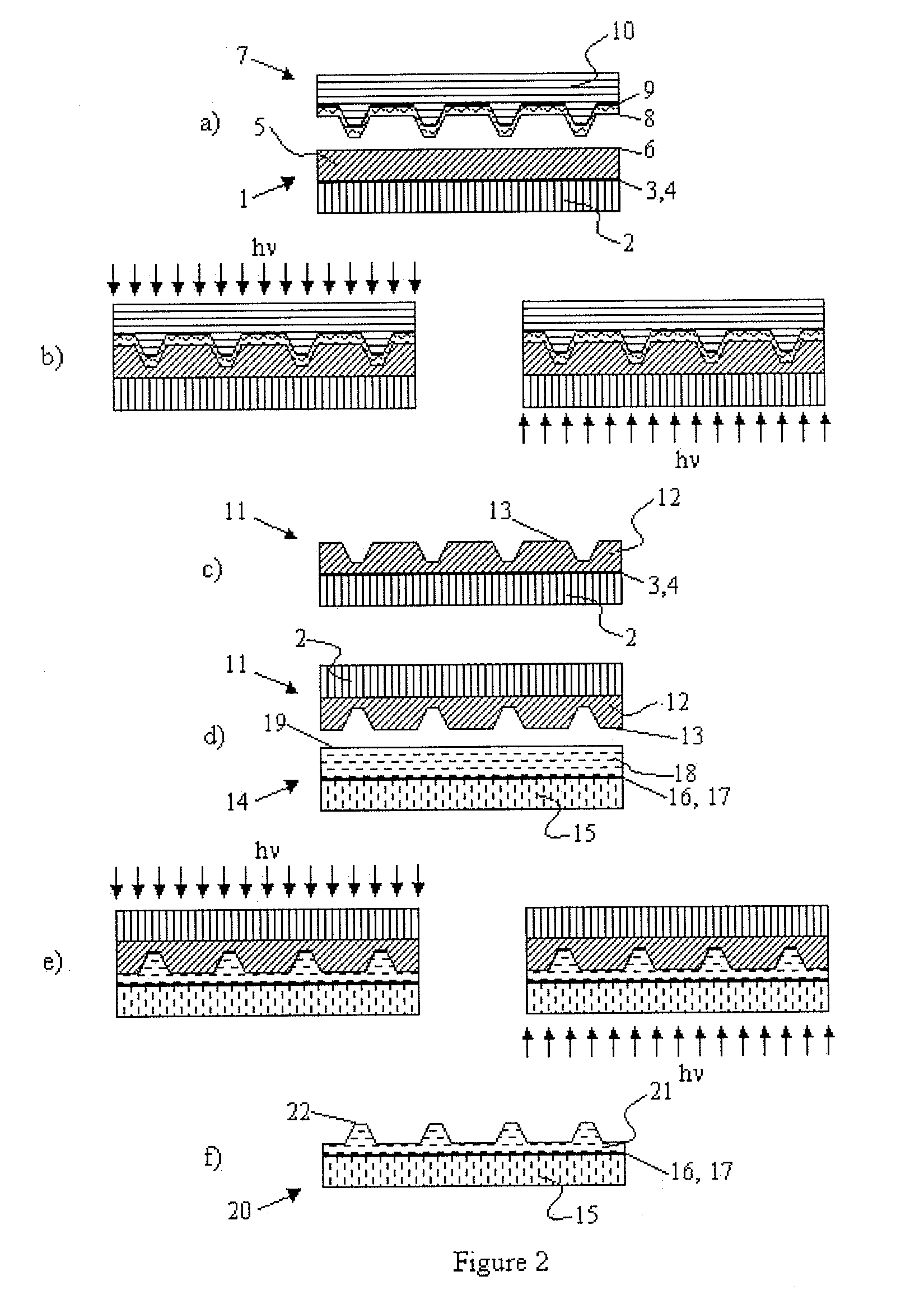

Process and method for modifying polymer film surface interaction

ActiveUS20100155988A1High replication fidelityEasy and suitable to employ industriallyNanoinformaticsSynthetic resin layered productsPolymer scienceLithography process

The invention provides a modification of a polymer film surface interaction properties. In this process a polymer carrier object is covered by a chemical composition, comprising photo-polymerizable compounds, photo-initiators or catalysts with the ability to initiate polymerization and semi-fluorinated molecules. The so-produced polymer mold contains semi-fluorinated moieties, which are predominantly located on the surface and on the surface near region of the patterned surface. The polymer mold is suitable as a template with modified properties in a nano-imprint lithography process.

Owner:OBDUCAT AB SE

Initiator system and adhesive composition made therewith

InactiveUS6027813ALower Level RequirementsGood solvent resistanceSynthetic resin layered productsEster polymer adhesivesSolventAcid anhydride

Systems for initiating the polymerization of acrylic monomers comprising (1) organoborane amine complexes and (2) decomplexers comprising at least one anhydride group. Adhesive compositions prepared from the initiator systems advantageously exhibit low levels of mobile constituents, excellent solvent resistance, and good adhesion to low energy surfaces.

Owner:3M INNOVATIVE PROPERTIES CO

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com