Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1371results about How to "High dielectric strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

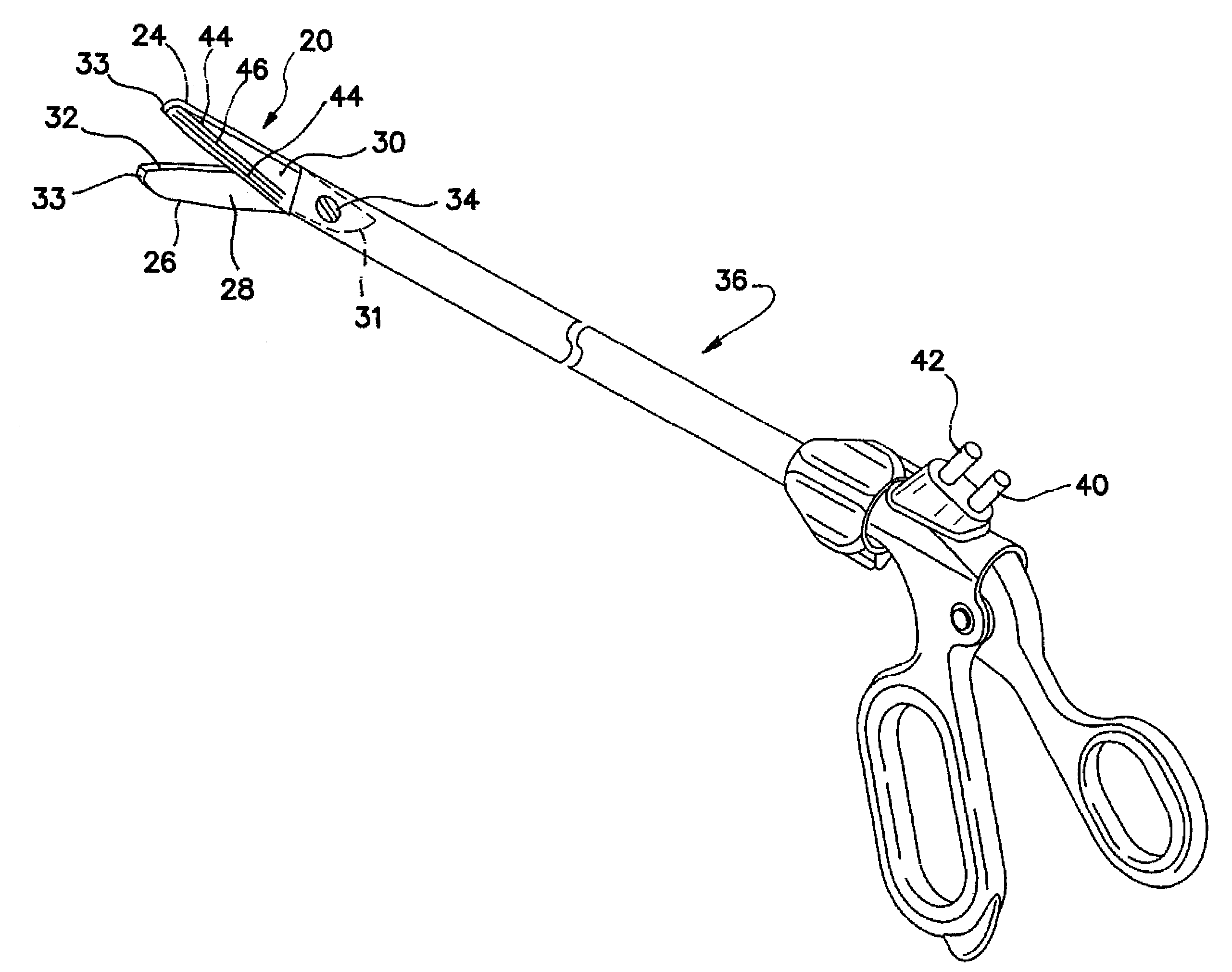

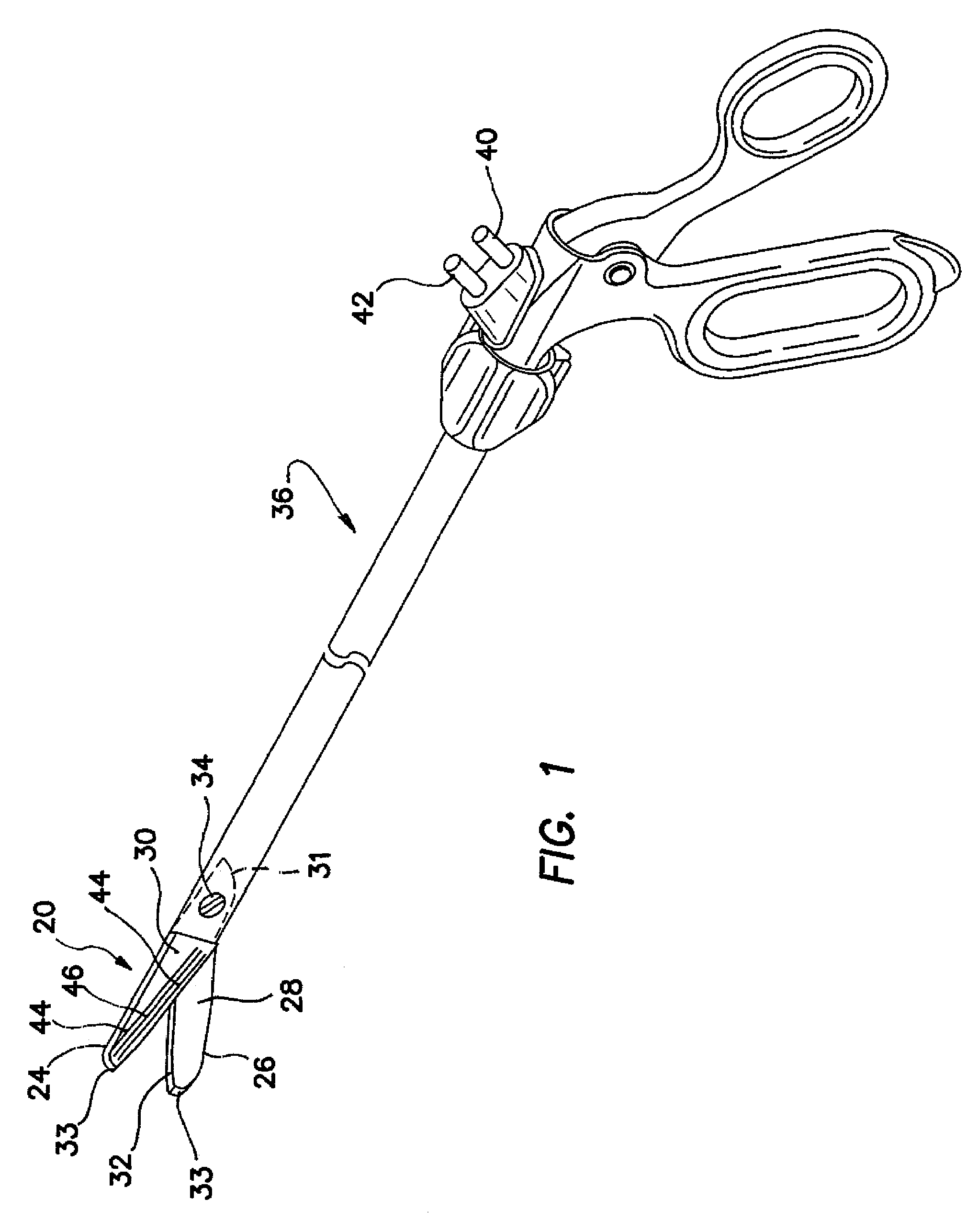

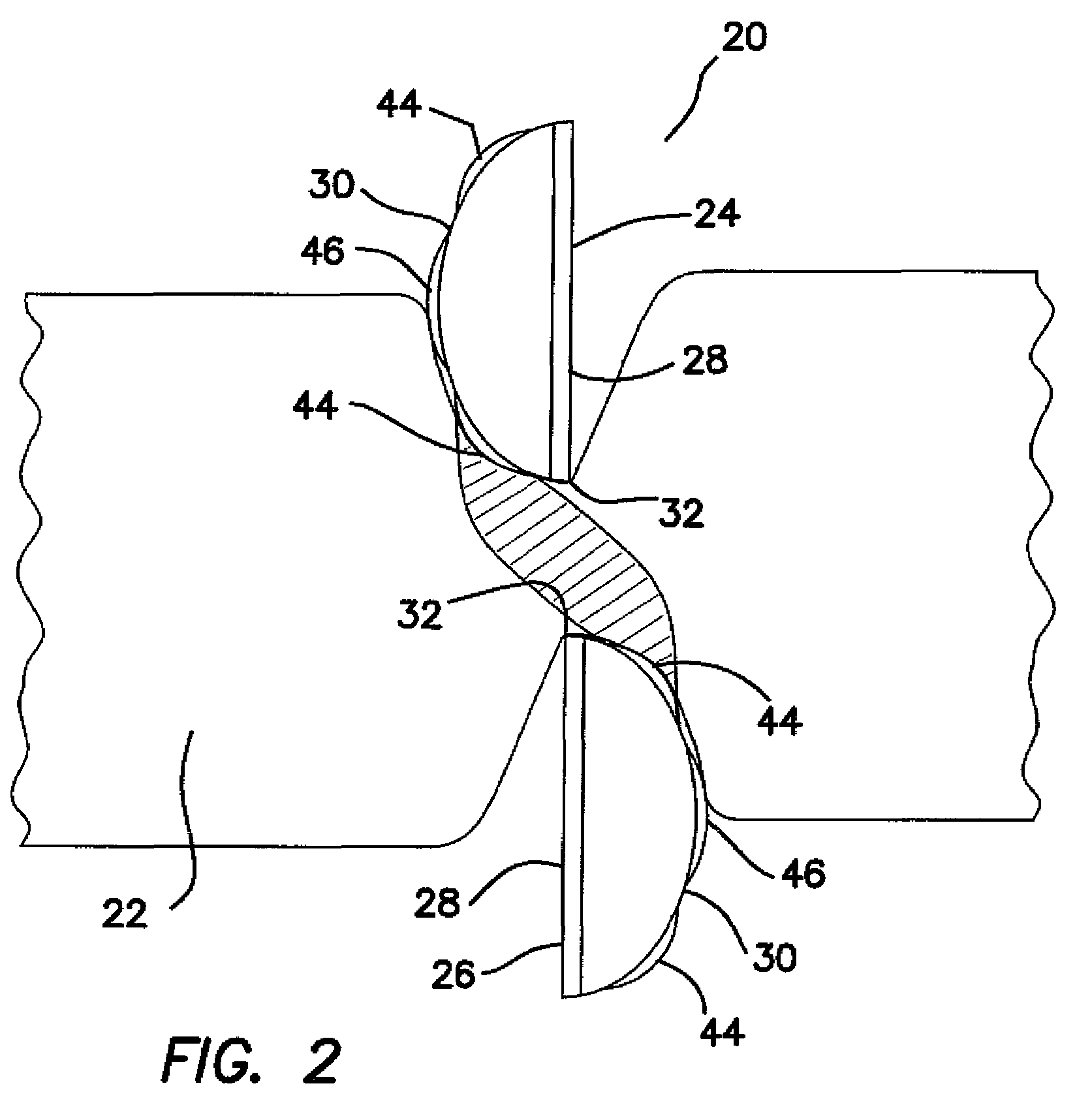

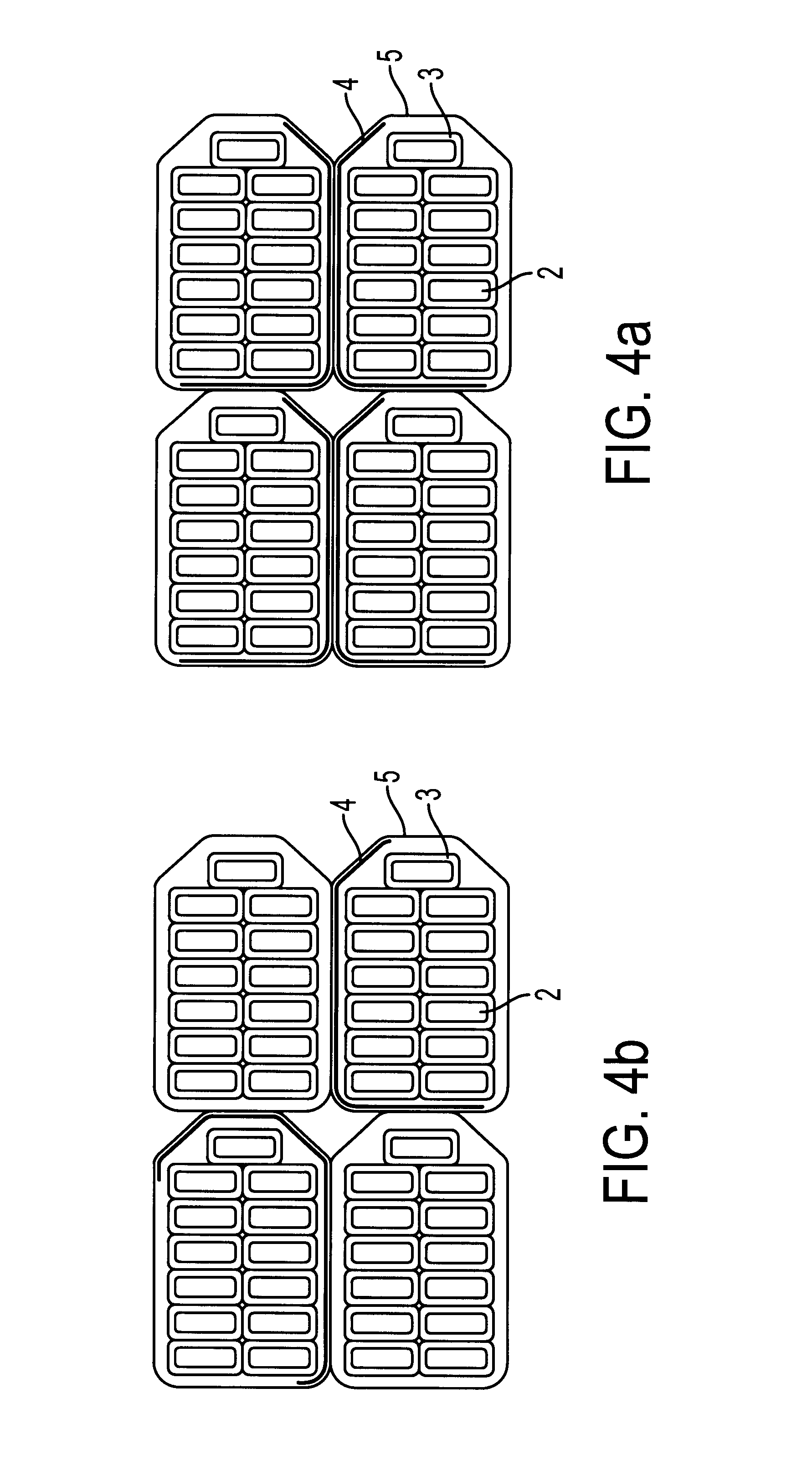

Bipolar electrosurgical scissors

ActiveUS7419490B2High dielectric strengthSurgical instrument detailsSurgical forcepsBipolar electrosurgeryElectrical polarity

Bipolar electrosurgical scissors for treating biological tissue include first and second scissor blades. A shearing surface and cutting edge of each blade is electrically neutral. The scissors include a pair of electrical connections for receiving electrical currents of opposing polarities. Each blade includes at least one first electrode and at least one second electrode positioned on a surface opposite the shearing surface The at least one first electrode on the first blade and the at least one second electrode on the second blade are coupled to the first electrical connection. The at least one second electrode on the first blade and the at least one first electrode on the second blade are coupled to the second electrical connection. In a first energized state, the electrical connections deliver electrical current only to the first electrodes. In a second energized state, the electrical connections deliver electrical current to all of the electrodes.

Owner:APPL MEDICAL RESOURCES CORP

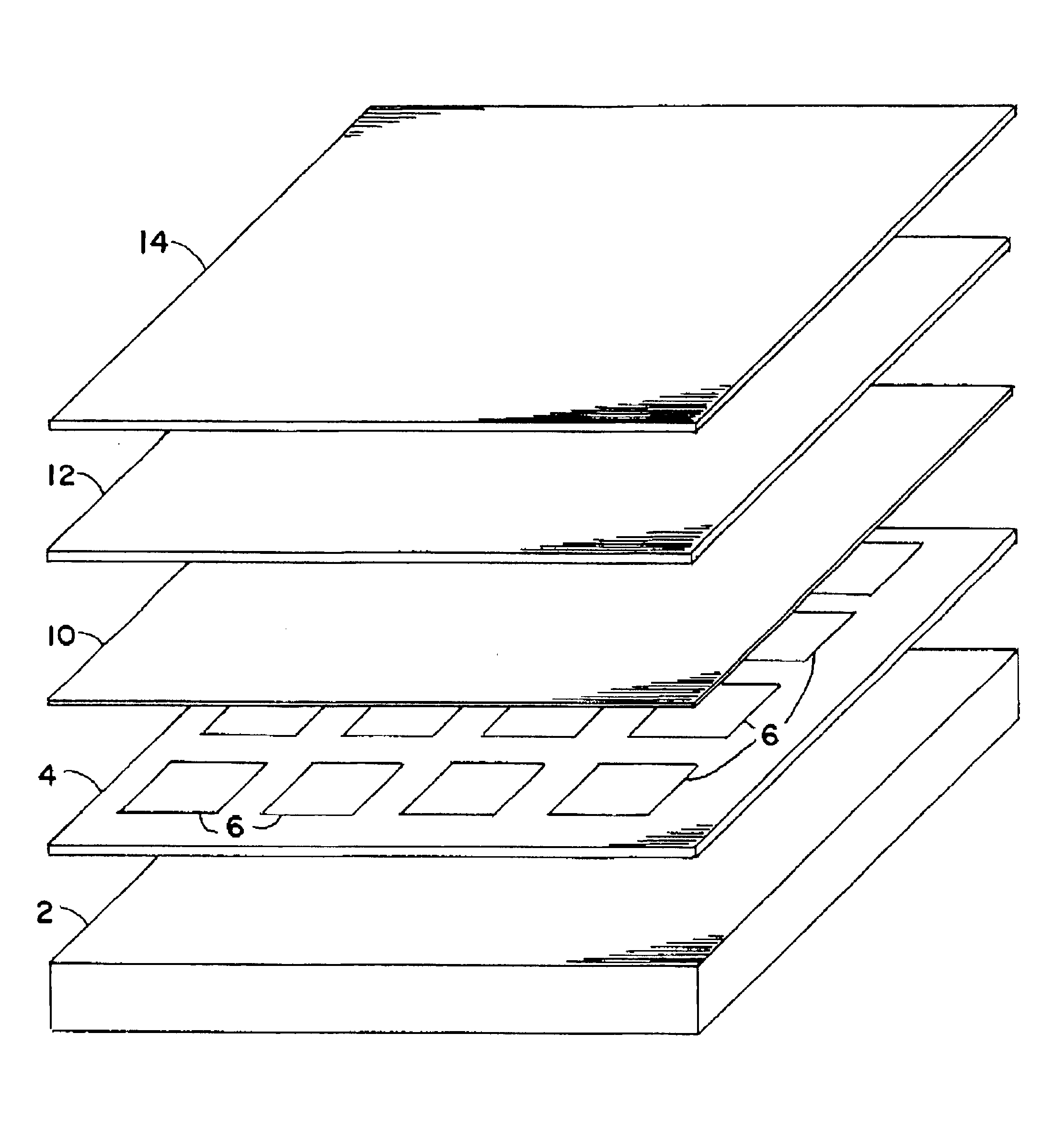

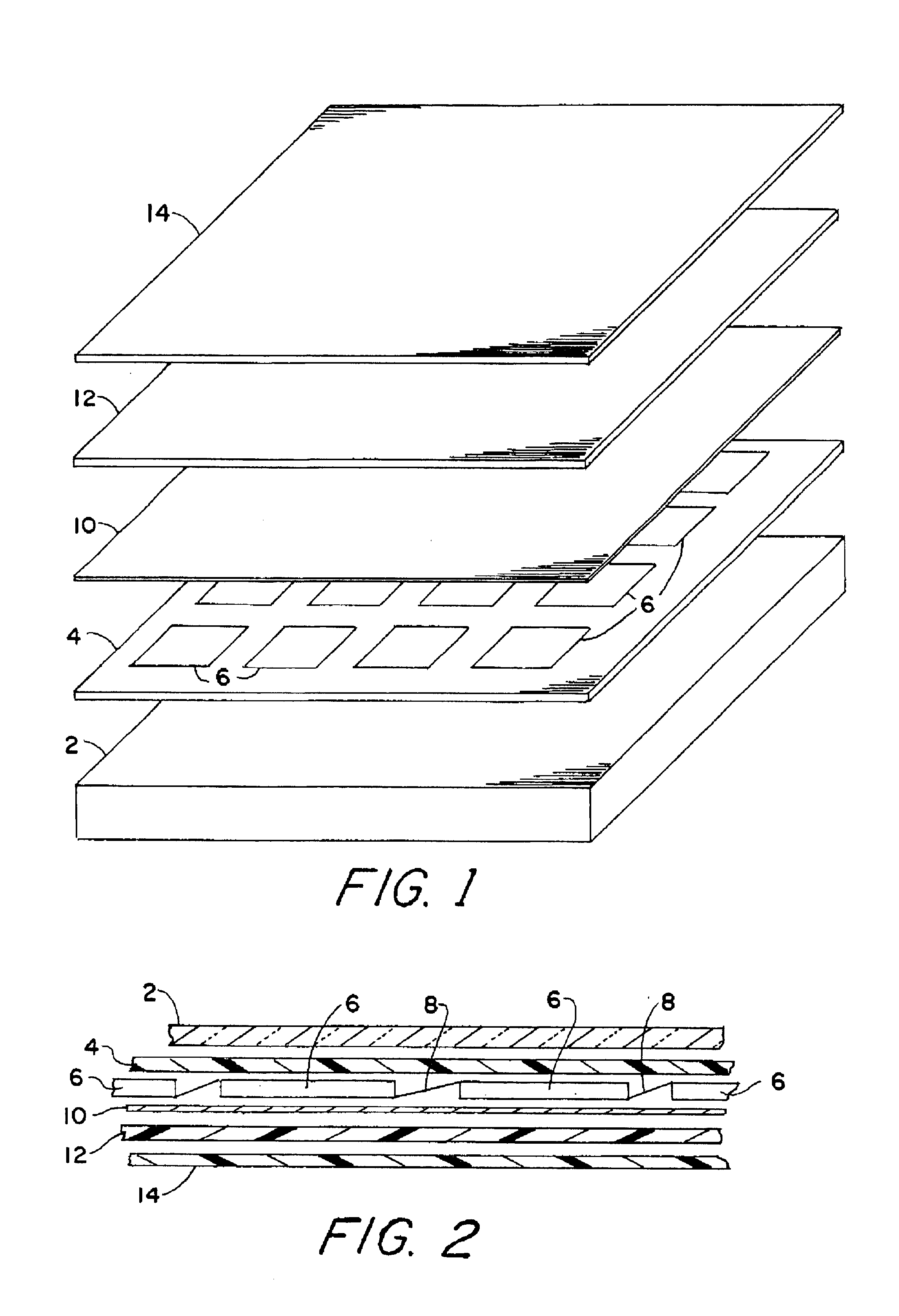

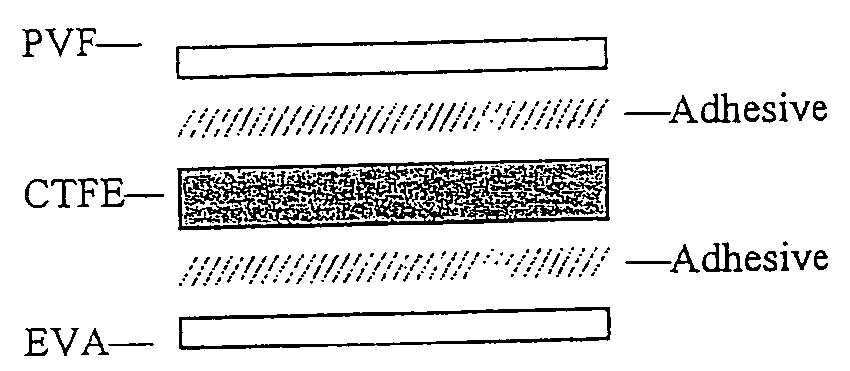

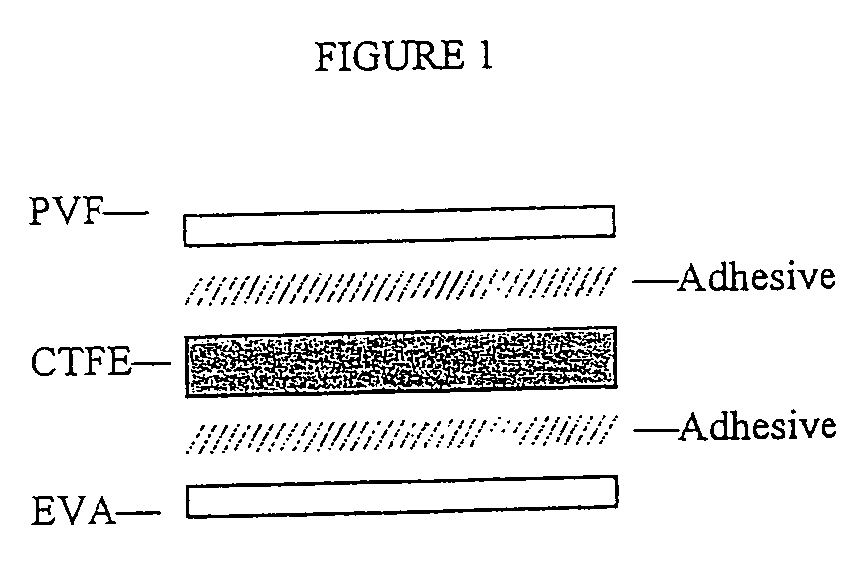

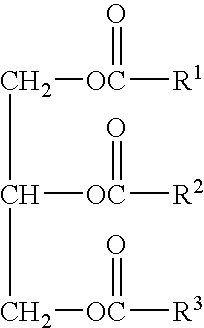

Solar cell modules with improved backskin

InactiveUS6660930B1High dielectric strengthExtended service lifePV power plantsSemiconductor/solid-state device detailsIonomerEngineering

A laminated solar cell module comprises a front light transmitting support, a plurality of interconnected solar cells encapsulated by a light-transmitting encapsulant material, and an improved backskin formed of an ionomer / nylon alloy. The improved backskin has a toughness and melting point temperature sufficiently great to avoid any likelihood of it being pierced by any of the components that interconnect the solar cells.

Owner:SCHOTT SOLAR AG (DE)

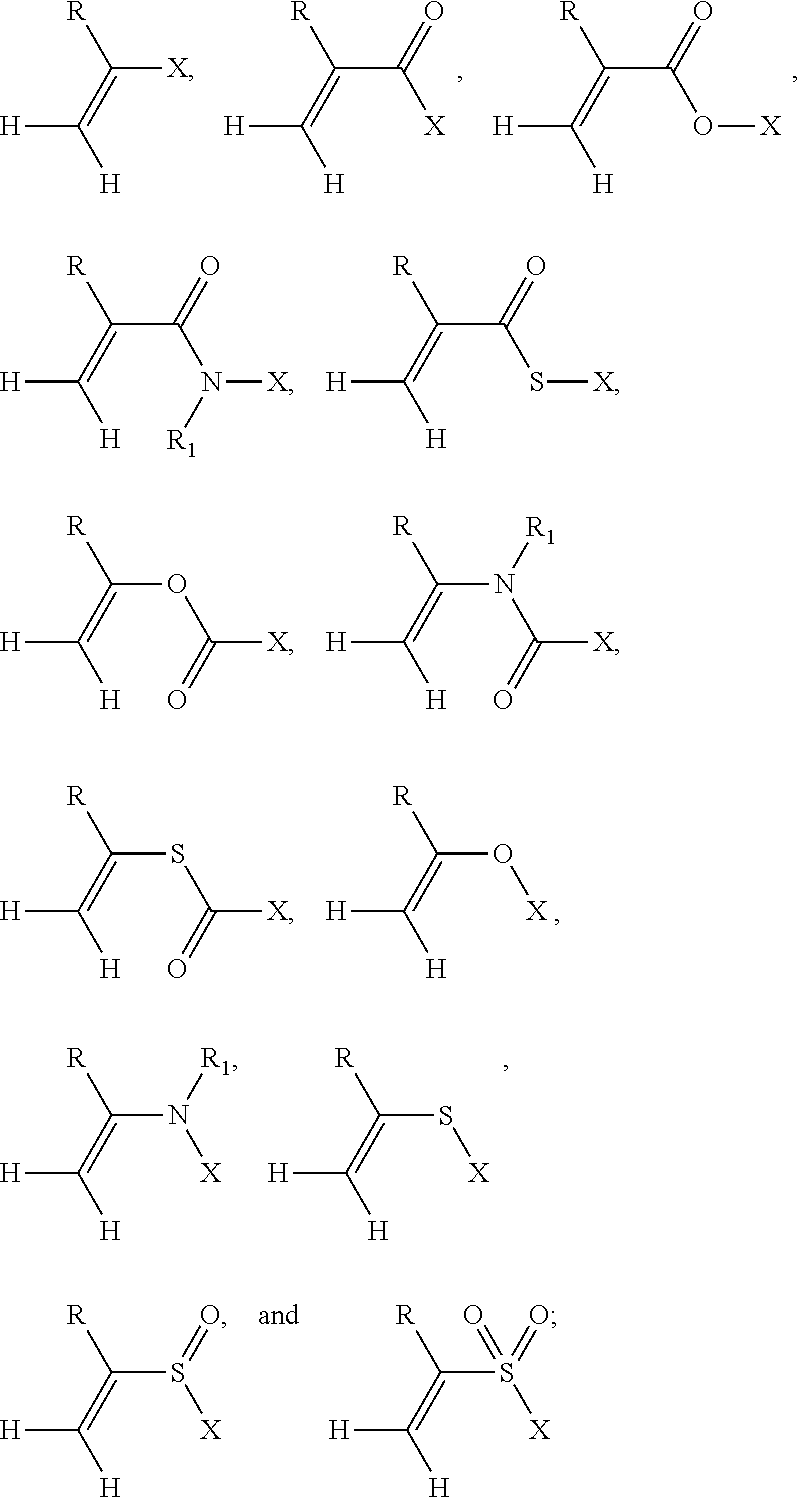

Coatings for Electrowetting and Electrofluidic Devices

ActiveUS20130171546A1Low surface energy polymersHigh dielectric strengthElectrostatic separatorsSludge treatmentGas phaseUltimate tensile strength

Electrowetting devices coated with one or more polymeric layers and methods of making and using thereof are described herein. The coatings may be formed in a single layer or as multiple layers. In one embodiment the first layer deposited serves as an insulating layer of high dielectric strength while the second layer deposited serves as a hydrophobic layer of low surface energy. These materials may themselves be deposited as multiple layers to eliminate pinhole defects and maximize device yield. In one embodiment the insulating layer would be a vapor deposited silicone polymeric material including, but not limited to, polytrivinyltrimethylcyclotrisiloxane or polyHVDS. In another embodiment the insulating layer may be a vapor deposited ceramic such as SiO2 with very little carbon content. In a further embodiment the insulating layer may be composed of alternating layers of a siloxane material and a ceramic material.

Owner:GVD CORP

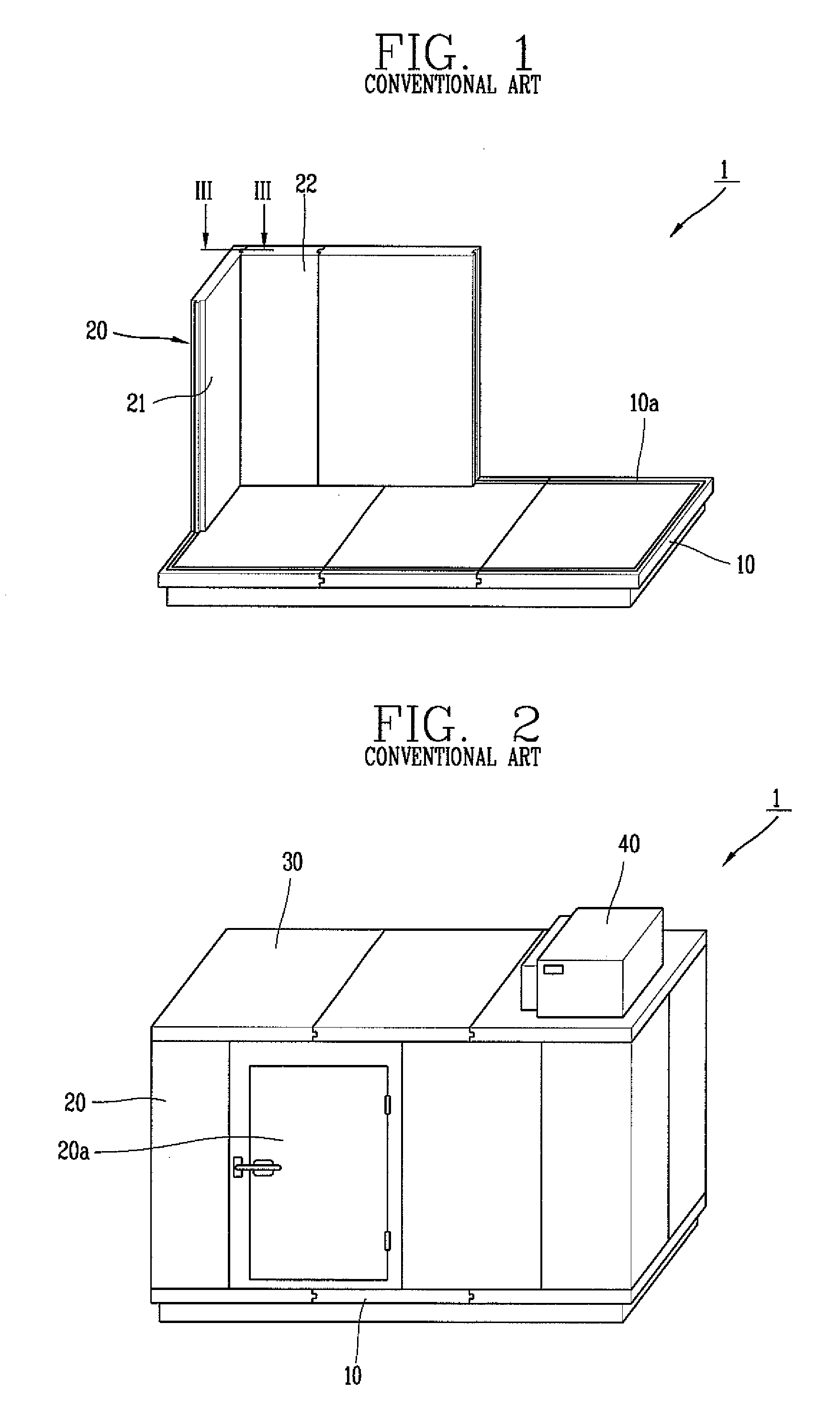

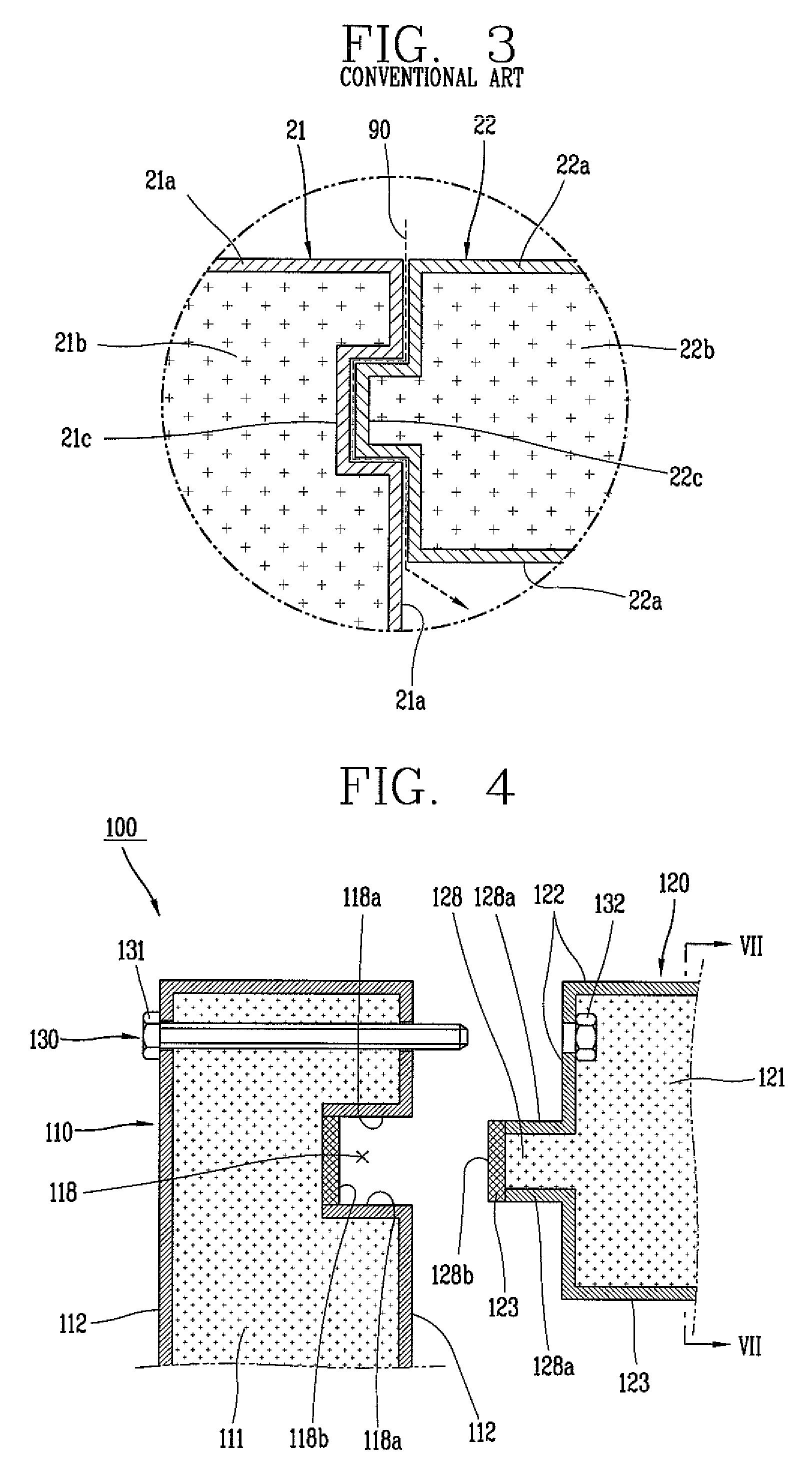

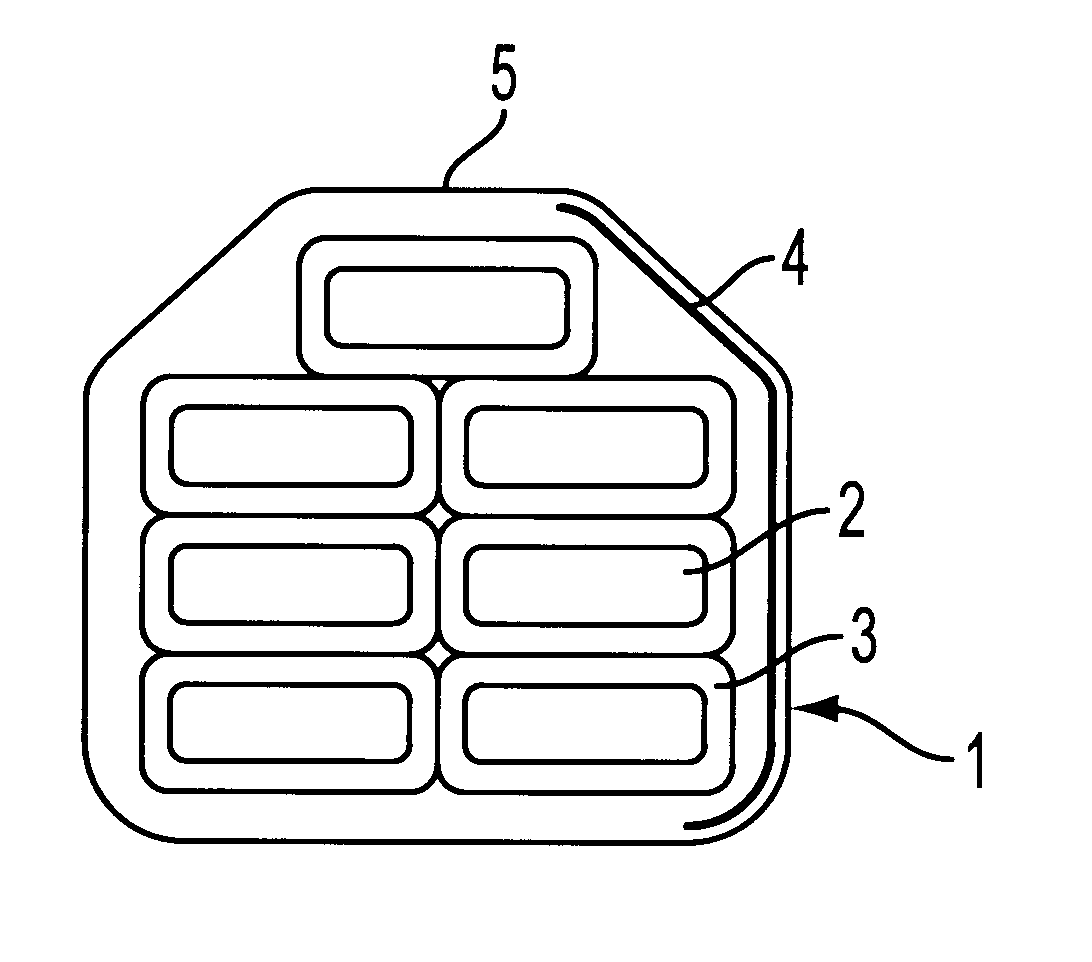

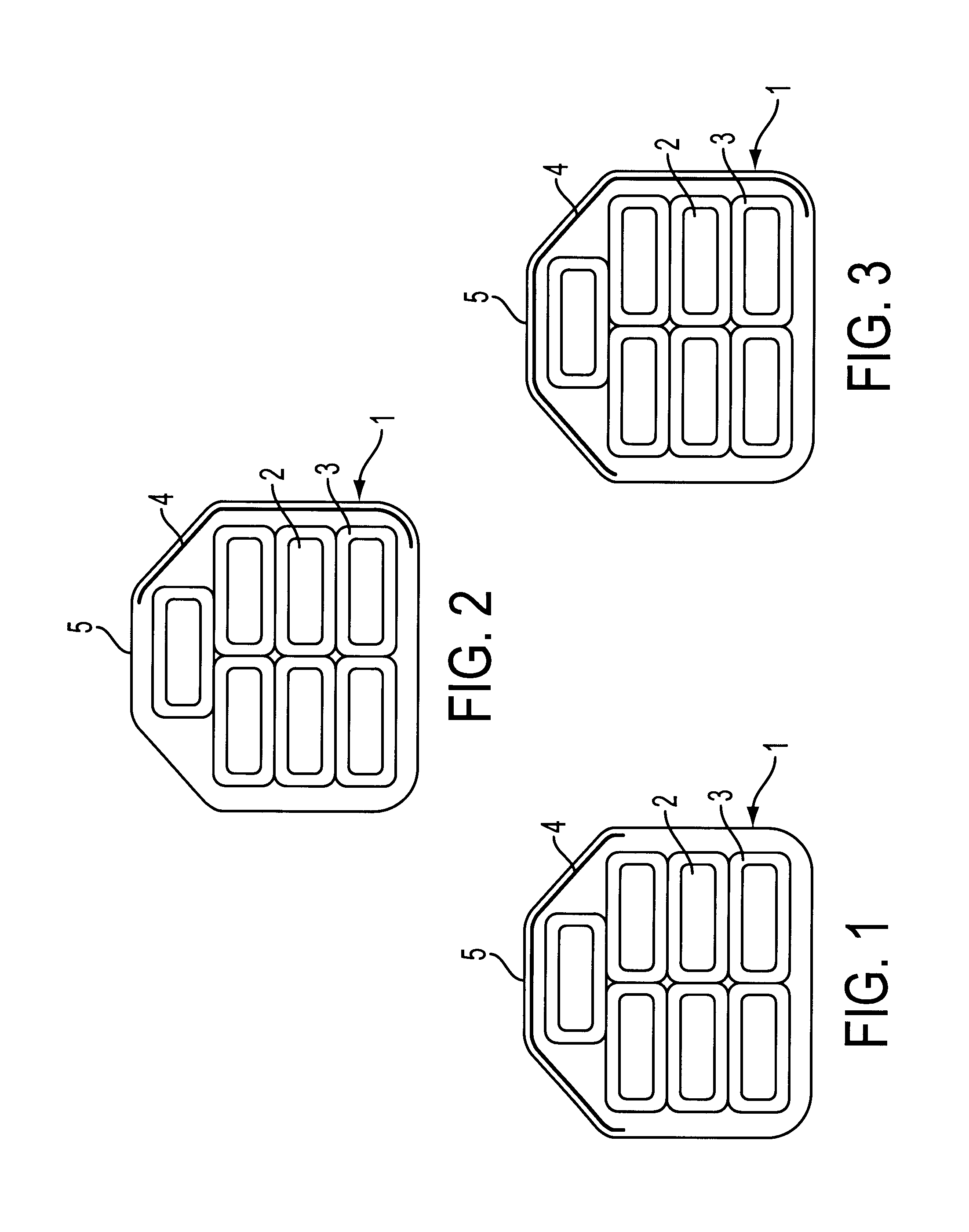

Fixing structure of insulation panel of prefabricated refrigerator and prefabricated refrigerator having the same

ActiveUS20070152551A1High insulation efficiencyImprove efficiencyShow cabinetsLighting and heating apparatusHeat flowRefrigerated temperature

Disclosed are a fixing structure of insulation panels and a prefabricated refrigerator with the same. The fixing structure of insulation panels includes a recess recessed on one surface of a first insulation panel having an insulation portion inside a casing, and a protrusion formed to be inserted into the recess, on one surface of a second insulation panel having an insulation portion inside a casing, wherein the insulation portions of nonmetal material are exposed to a bottom of the recess and a front end of the protrusion so as to shield a transmission path of heat flowed along a casing contact surface of the insulation panels, thereby improving insulation efficiency.

Owner:LG ELECTRONICS INC

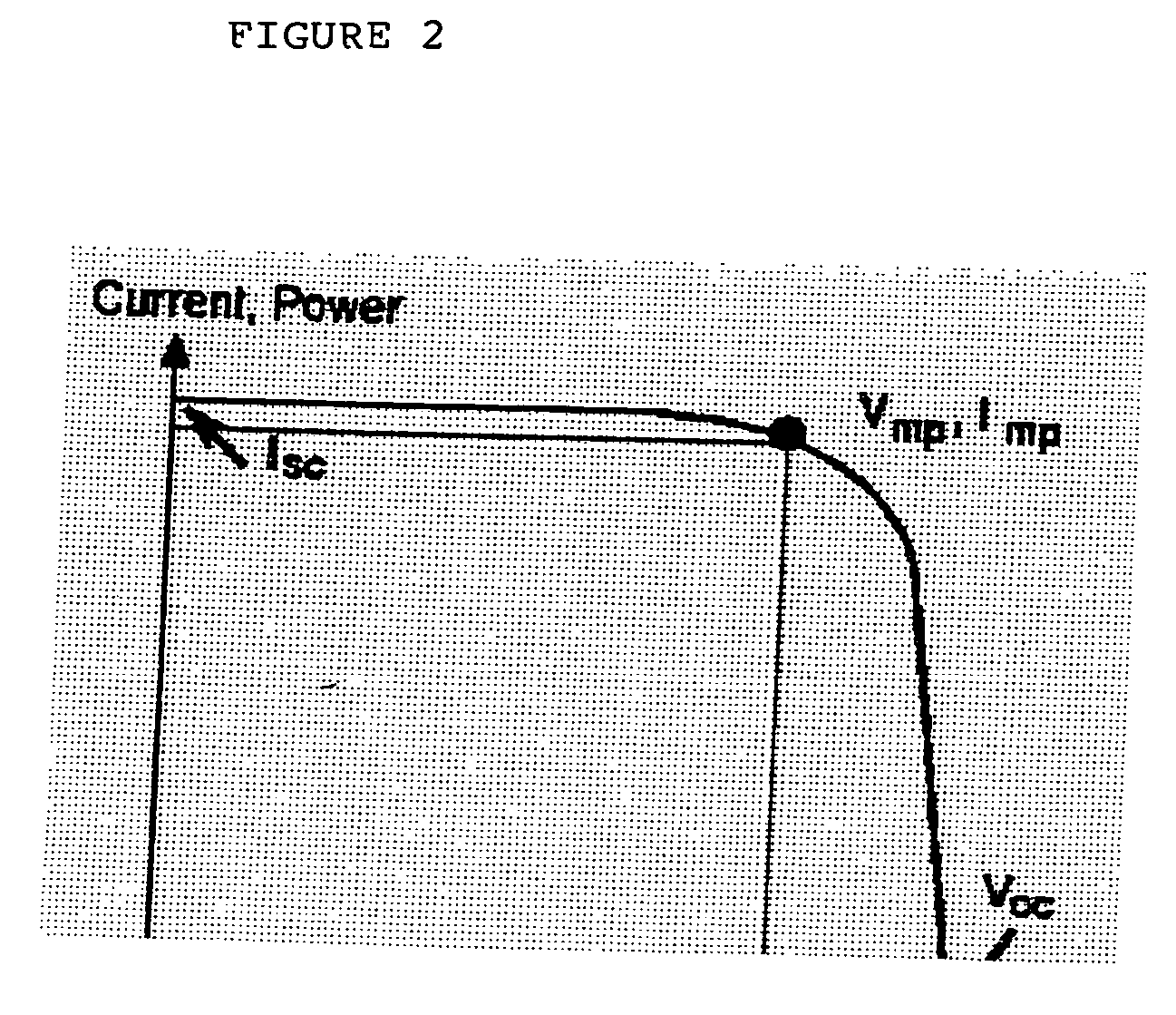

Bright white protective laminates

InactiveUS20060234038A1Increased power outputHigh dielectric strengthPV power plantsSynthetic resin layered productsEngineeringElectrical and Electronics engineering

Laminates of having a first outer layer of weatherable film, at least one mid layer, and a second outer layer containing an opacifying quantity of white pigment. The laminates are particularly useful for protecting photovoltaic cells, solar panels, and circuit boards. In photovoltaic cells, the laminates result in increased power generation.

Owner:MADICO INC

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

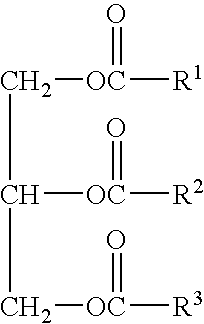

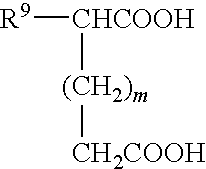

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Multiple parallel conductor for electrical machines and devices

InactiveUS6563413B1Without impairing electrical characteristicGood cooling propertiesTransformers/inductances coolingTransformers/inductances coils/windings/connectionsElectrical conductorElectric machinery

Multiple parallel conductor for an electrical machine and process. The conductor includes a plurality of adjacent subconductors combined to form a subconductor bundle having an outer surface with a plurality of contiguous surface sections arranged in a longitudinal direction, and a flat protective insulation covering at least one of the plurality of surface sections. At least one of the plurality of surface sections remains uncovered by the flat protective insulation covering. A mesh sheathing further covers the plurality of surface sections.

Owner:ASTA ELEKTRODRAHT GMBH

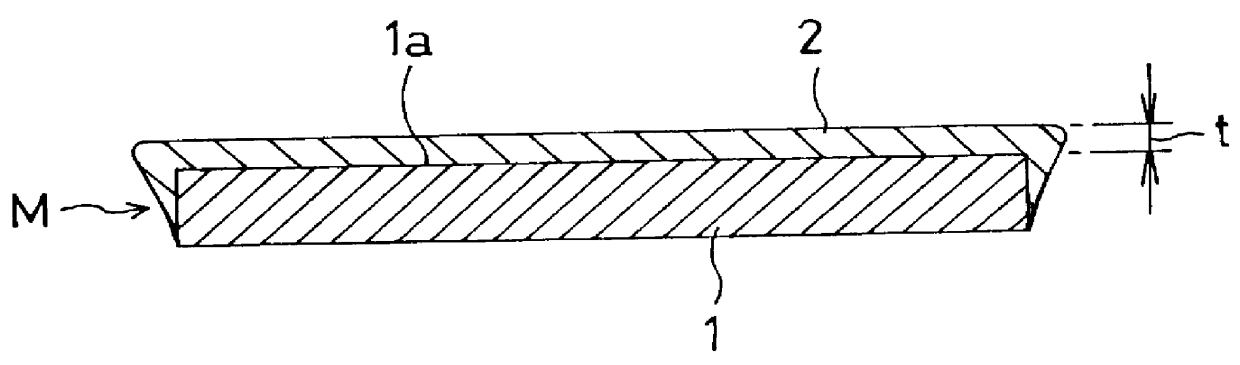

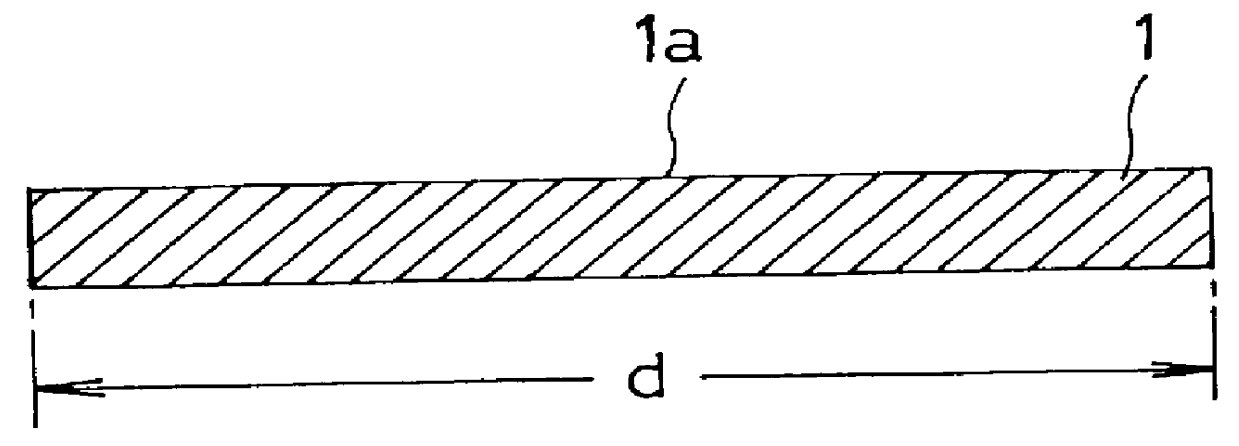

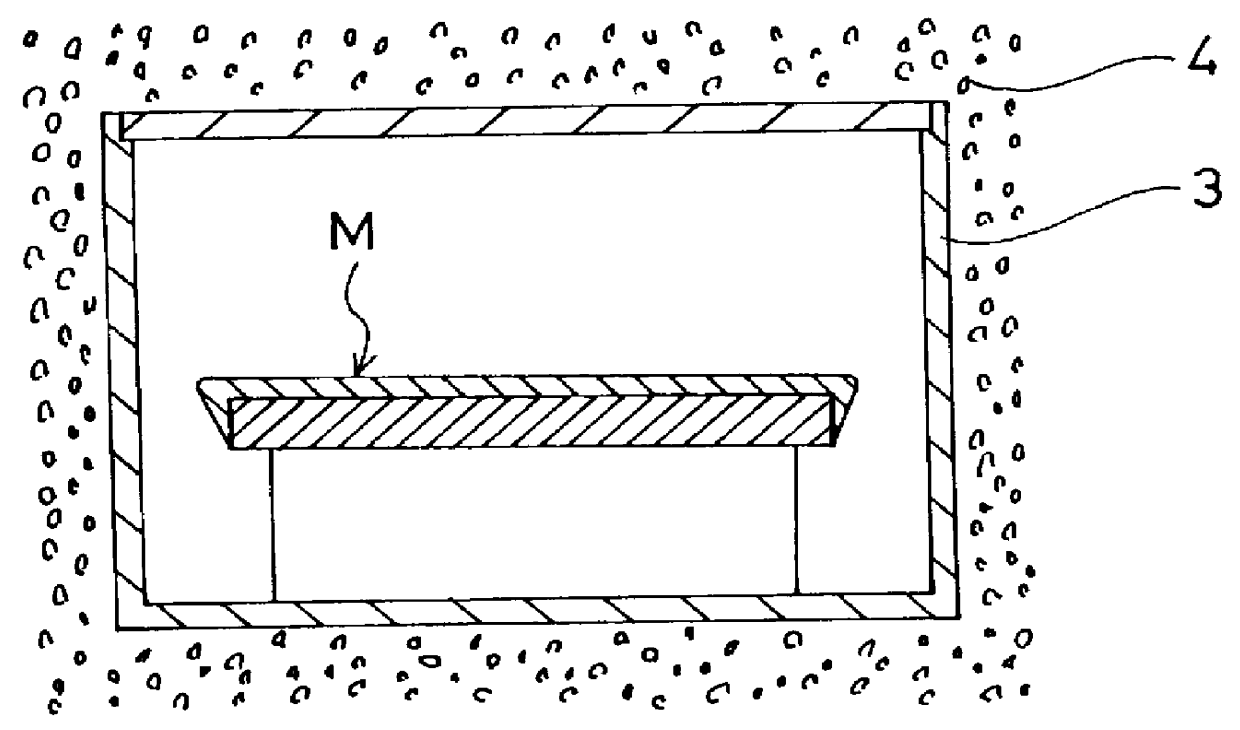

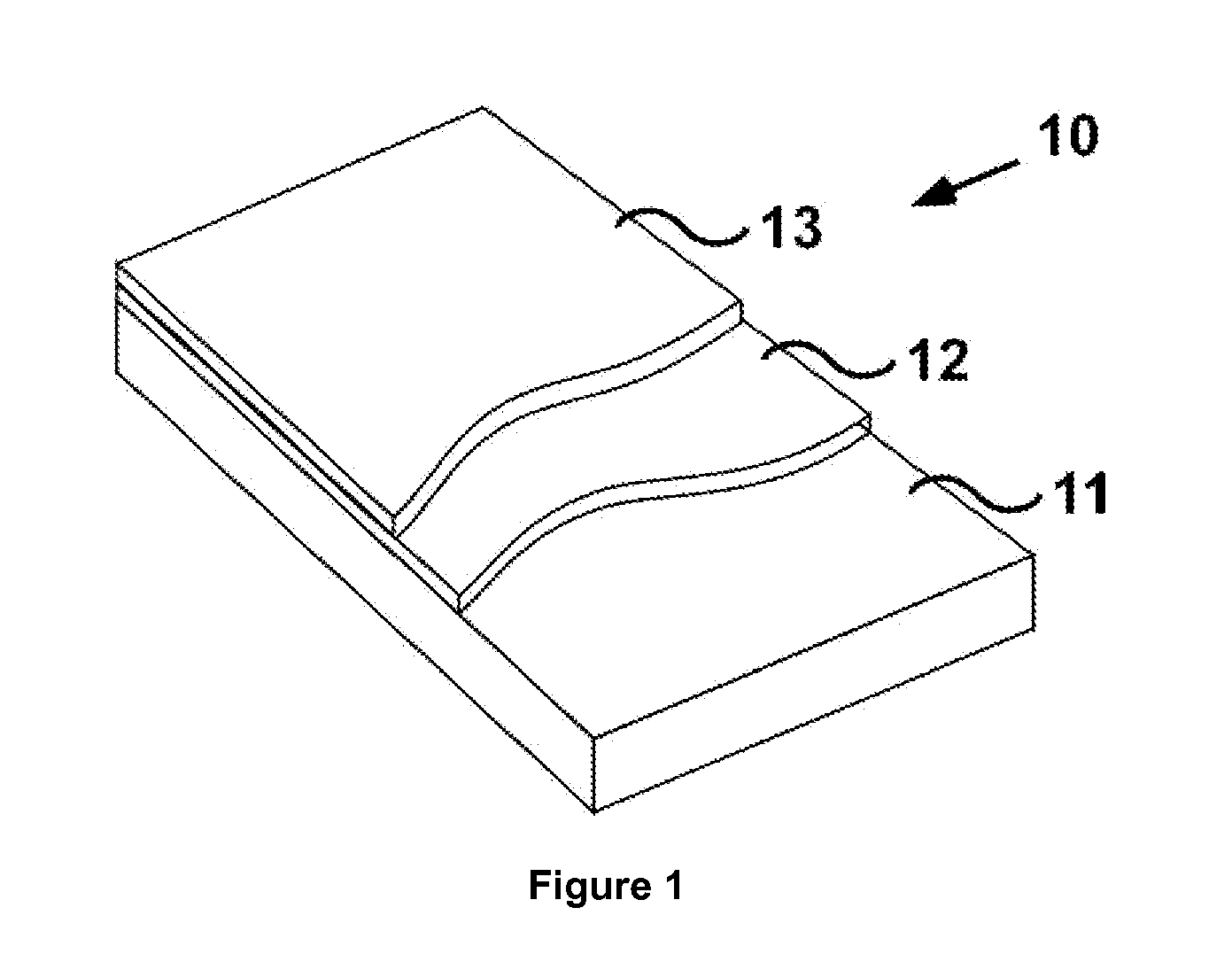

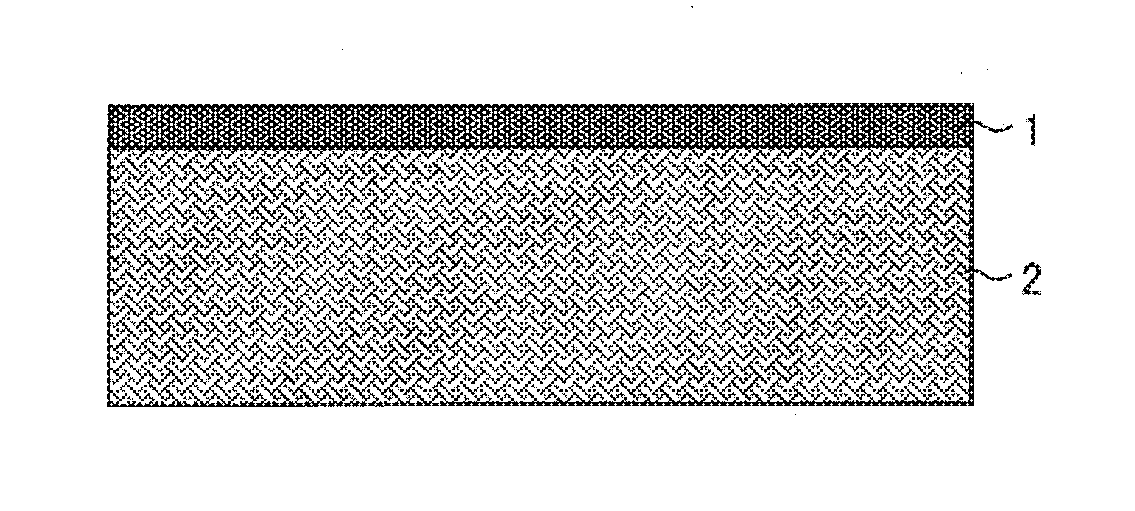

Single crystal SiC and a method of producing the same

InactiveUS6053973AEasily eliminate mismatchStably and efficiently obtainFrom gel statePolycrystalline material growthPorous carbonSurface roughness

The surface 1a of a single crystal alpha -SiC substrate 1 is adjusted so as to have a surface roughness equal to or lower than 2,000 angstroms RMS, and preferably equal to or lower than 1,000 angstroms RMS. On the surface 1a of the single crystal alpha -SiC substrate 1, a polycrystalline alpha -SiC film 2 is grown by thermal CVD to form a complex is placed in a porous carbon container and the carbon container is covered with alpha -SiC powder. The complex is subjected to a heat treatment at a temperature equal to or higher than a film growing temperature, i.e., in the range of 1,900 to 2,400 DEG C. in an argon gas flow, whereby single crystal alpha -SiC is integrally grown on the single crystal alpha -SiC substrate 1 by crystal growth and recrystallization of the polycrystalline alpha -SiC film 2. It is possible to stably and efficiently produce single crystal SiC of a large size which has a high quality and in which any crystal nucleus is not generated.

Owner:NISSIN ELECTRIC CO LTD

Communications cable and method for making same

InactiveUS6844500B2Increase heightLeveling precisionPlastic/resin/waxes insulatorsPower cables including communication wiresElectrical conductorTwisted pair

Owner:BAILEY MAURICE

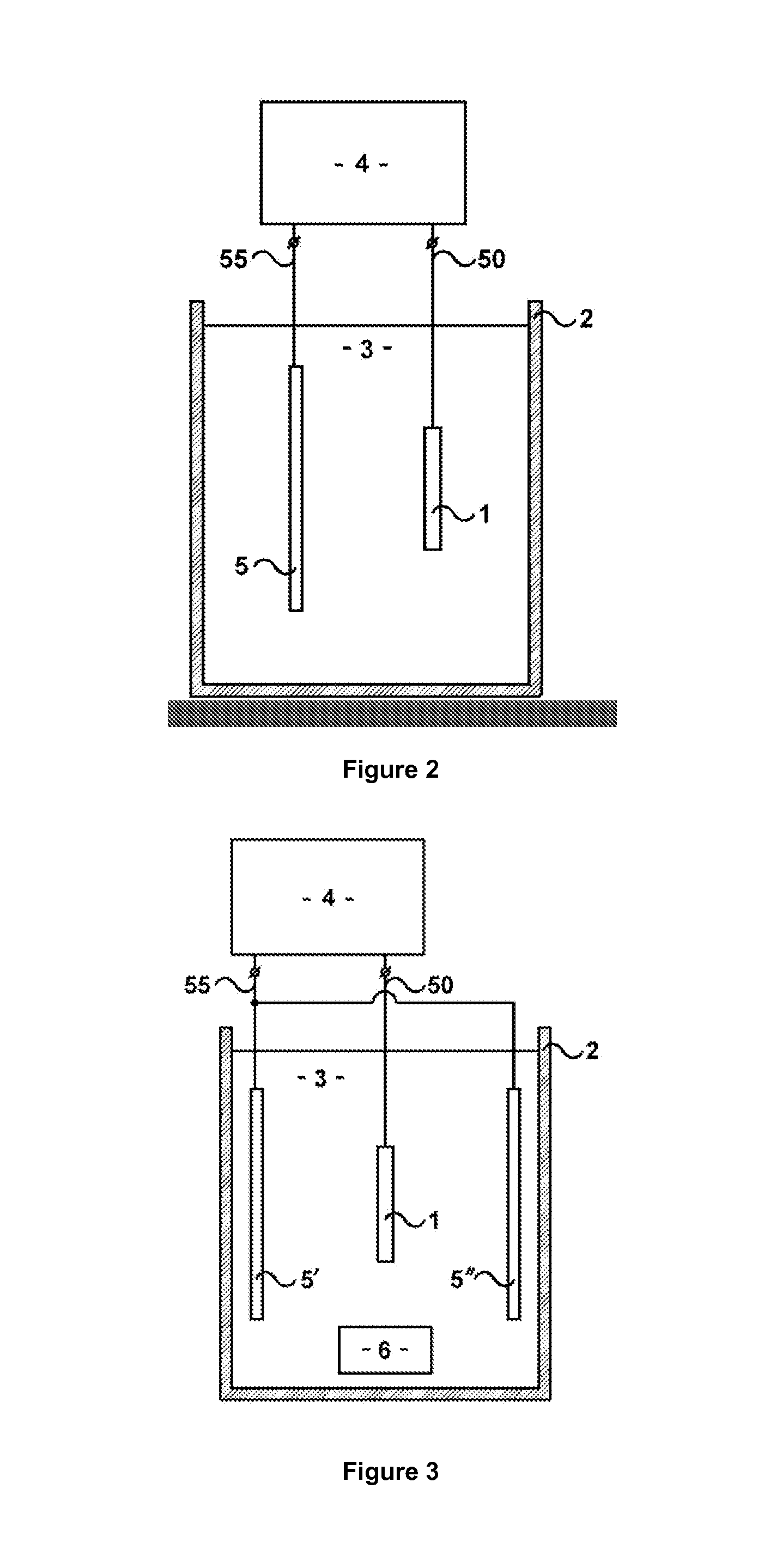

Method of making a composite article comprising a ceramic coating

InactiveUS6919012B1Improve propertiesSuperior physical/mechanical and protective propertyAnodisationCellsSurface layerCeramic coating

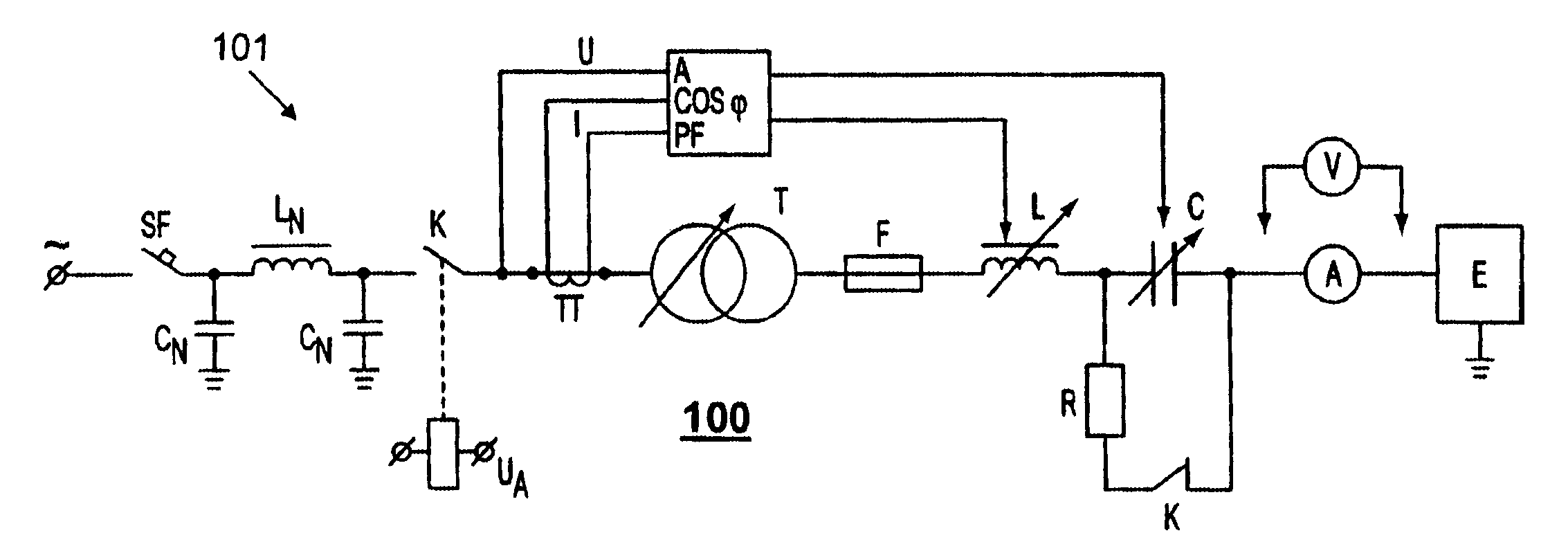

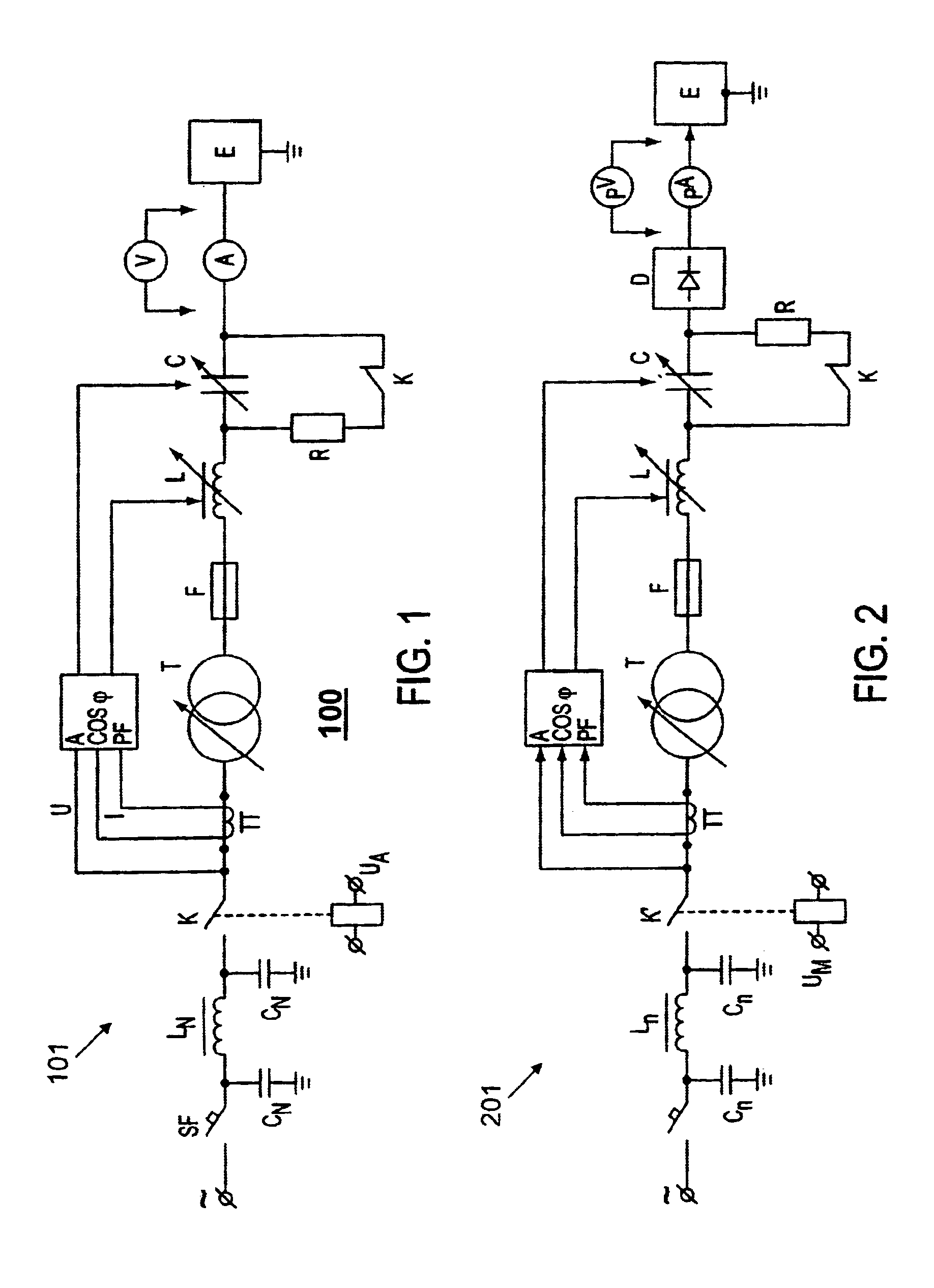

A ceramic coating is formed on a conductive article by immersing a first anodic electrode, including the conductive article, in an electrolyte comprising an aqueous solution of alkali metal hydroxide and an alkali metal silicate, providing a second cathodic electrode in contact with the electrolyte, and passing an alternating current from a resonant power source through the first electrode and to the second electrode while maintaining the angle φ between the current and the voltage at zero degree, while maintaining the voltage within a predetermined range. The resulting ceramic coated article comprises a coating which includes a metal, silicon, and oxygen, wherein the silicon concentration increases in the direction from the article surface toward an outer surface of the ceramic coating surface layer.

Owner:OLIMEX GROUP

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

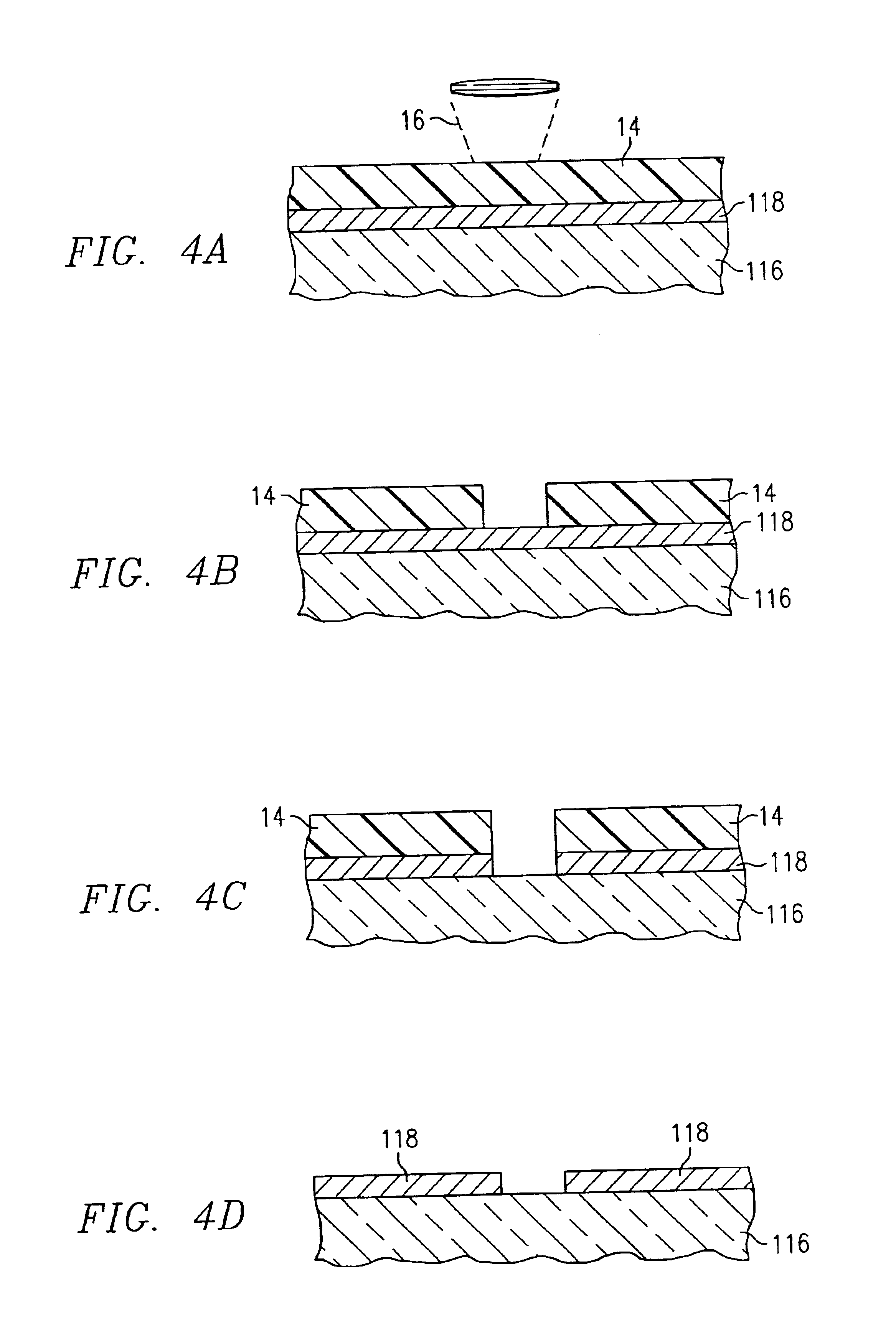

Damage resistant photomask construction

InactiveUS6841309B1Improve the immunityReduce risk of damageOriginals for photomechanical treatmentMaterials sciencePellicle membrane

A method for fabricating a damage resistant photomask includes forming a photomask pattern on a substrate and forming a transparent, protective coating on the photomask pattern. The protective coating may be an electrical insulator (e.g., spin-on glass). In addition, an antireflective layer may be applied to the protective coating. A pellicle may also be attached over the protective coating. The protective coating may prevent electrostatic energy from forming on or arcing between features on the photomask pattern and damaging the features. The protective layer may also prevent the photomask pattern from being damaged by or reacting with other substances, such as cleaning solutions.

Owner:TOPPAN PHOTOMASKS INC

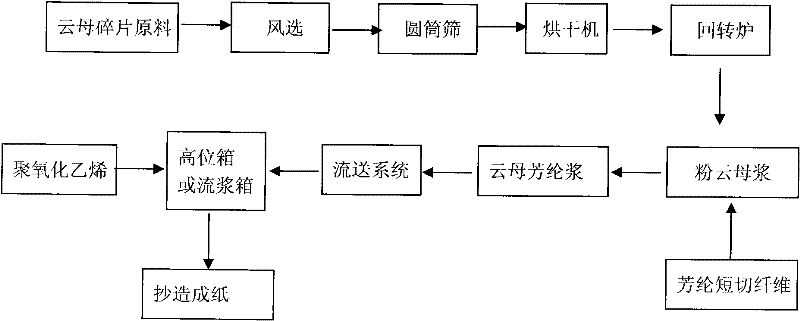

Method for making mica paper by reinforcement of aramid short fiber and chemical pulping

InactiveCN101748648AHigh strengthHigh dielectric strengthSynthetic cellulose/non-cellulose material pulp/paperPulp material addition processesEngineeringRotary furnace

The invention relates to a method for making mica paper by reinforcement of aramid short fiber and chemical pulping. The method comprises the following steps: cleaning mica flakes to remove impurities; putting the mica flakes to an intermittent heating rotary furnace for calcination to remove a part of crystal water in the crystal of mica and generate remarkable expansion and delamination along the vertical direction of a cleavage plane so as to make the mica loose and flexible; dipping the mica in acid or alkali solution at a certain concentration, delaminating into mica sheets, and classifying the mica sheets into chemical mica pulp with certain beating degree; and adding 3 to 15 percent of aramid fiber (based on the mass of the mica flakes) into the pulp, preparing mica aramid pulp, and making the mica aramid pulp into paper by a paper machine. The framework effect of the aramid improves the strength of the mica paper.

Owner:SHAANXI UNIV OF SCI & TECH

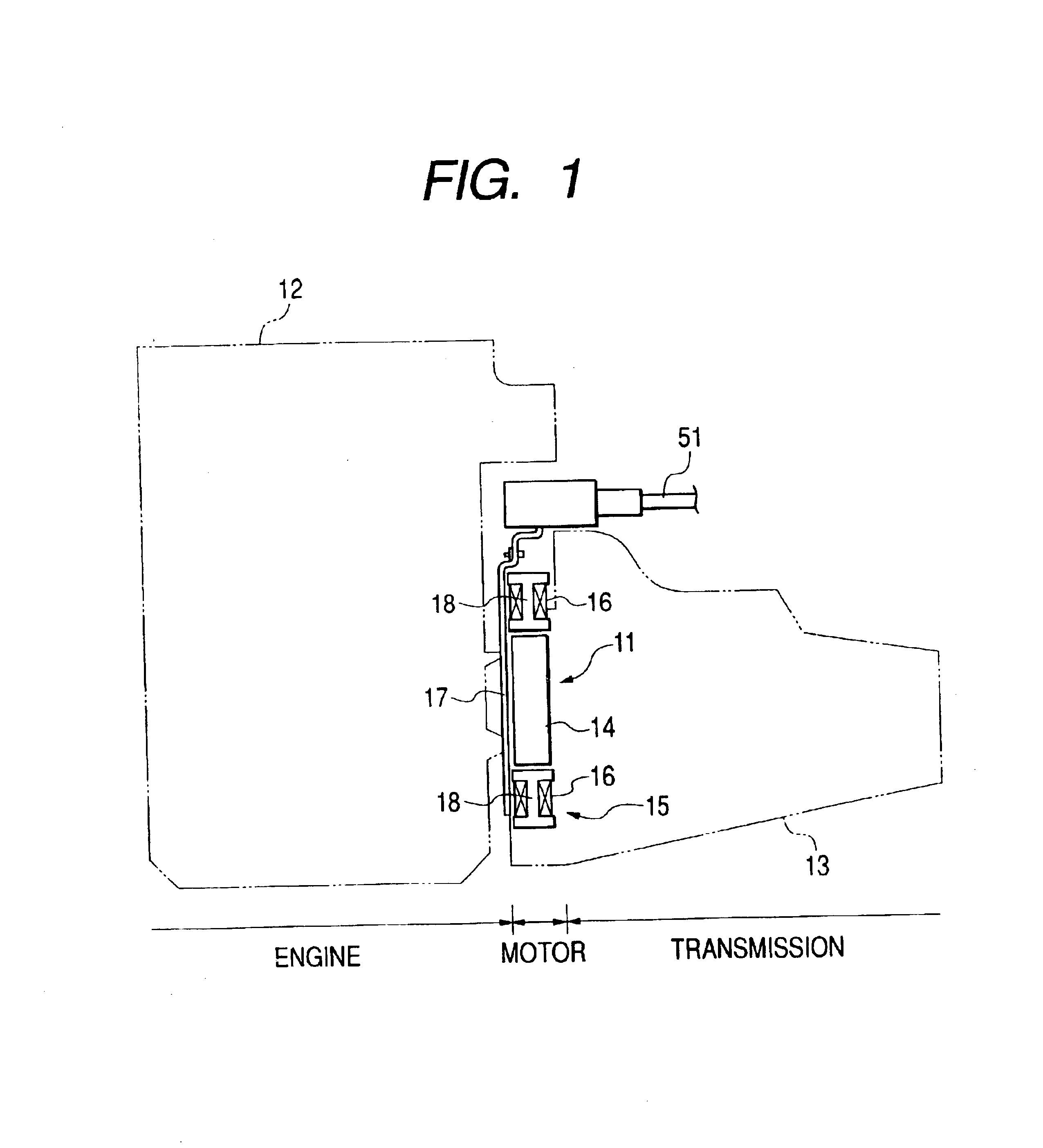

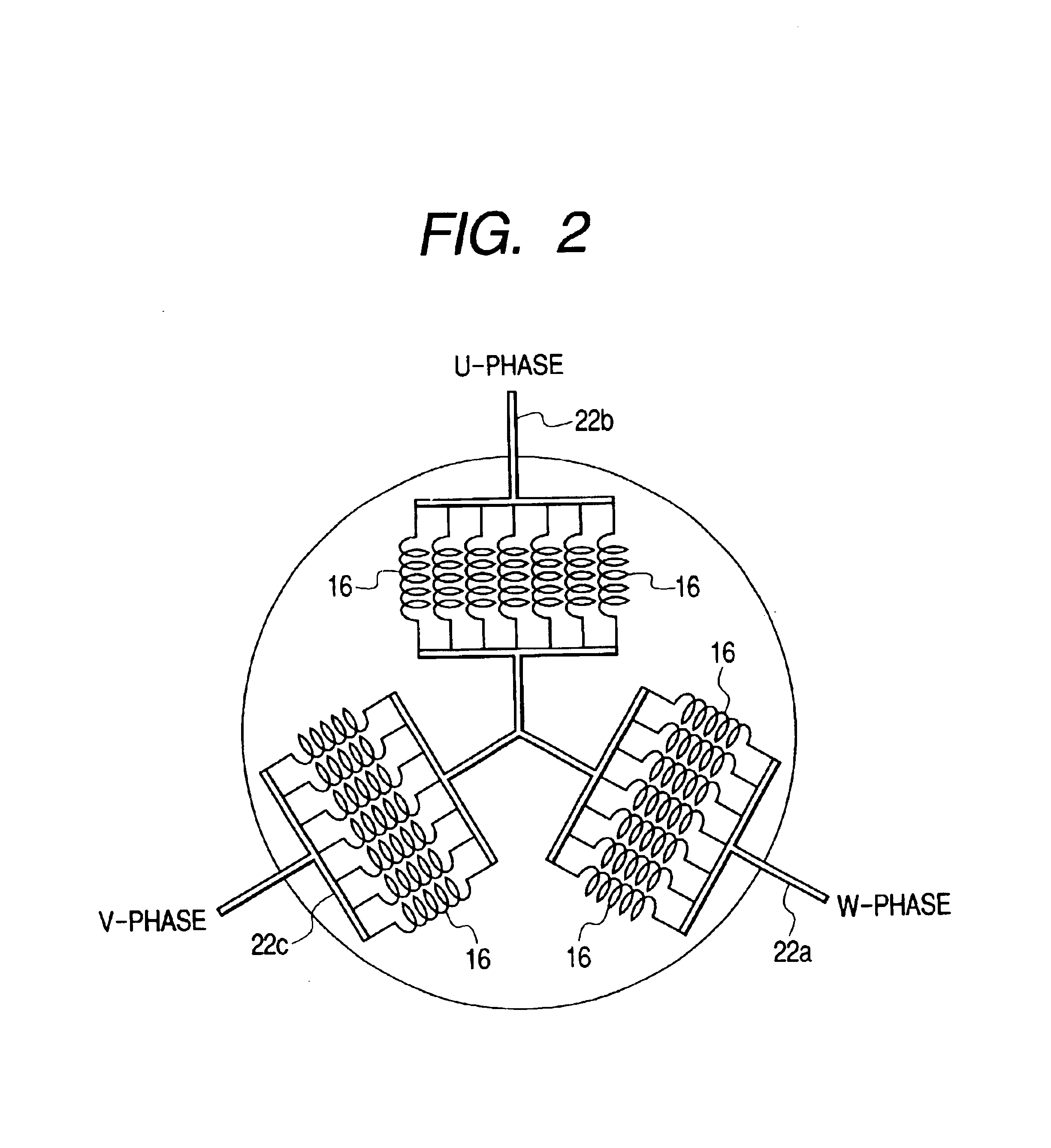

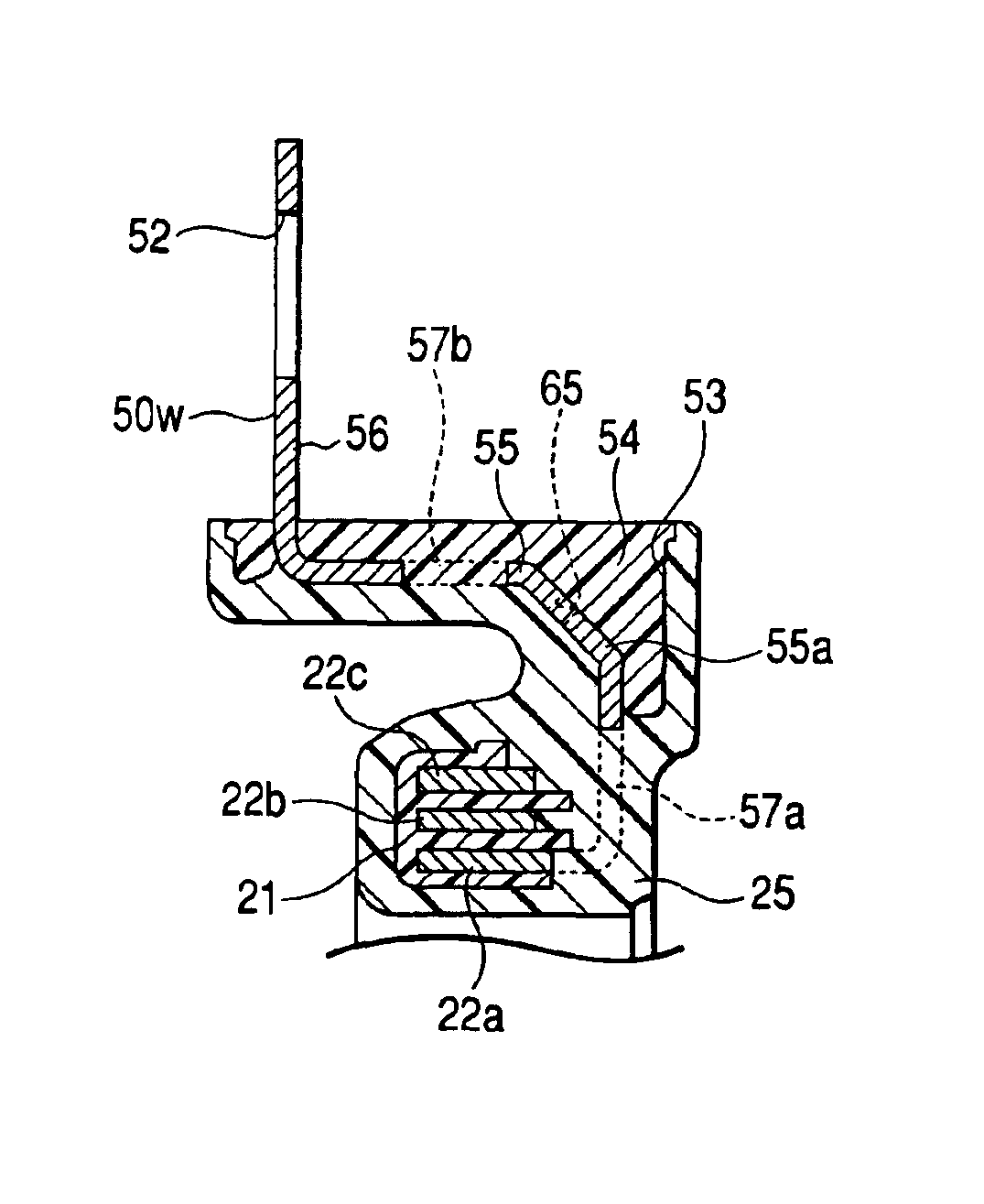

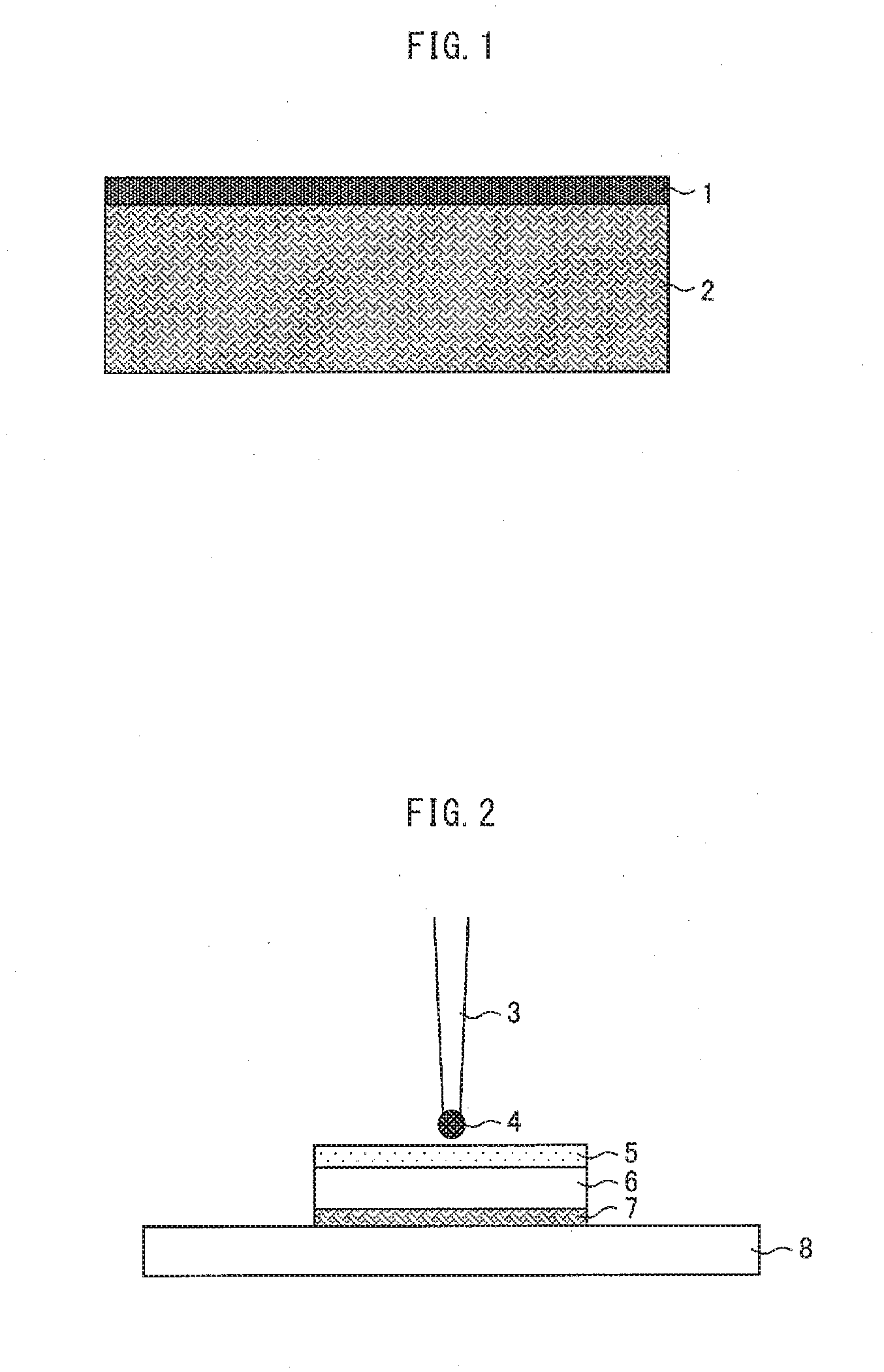

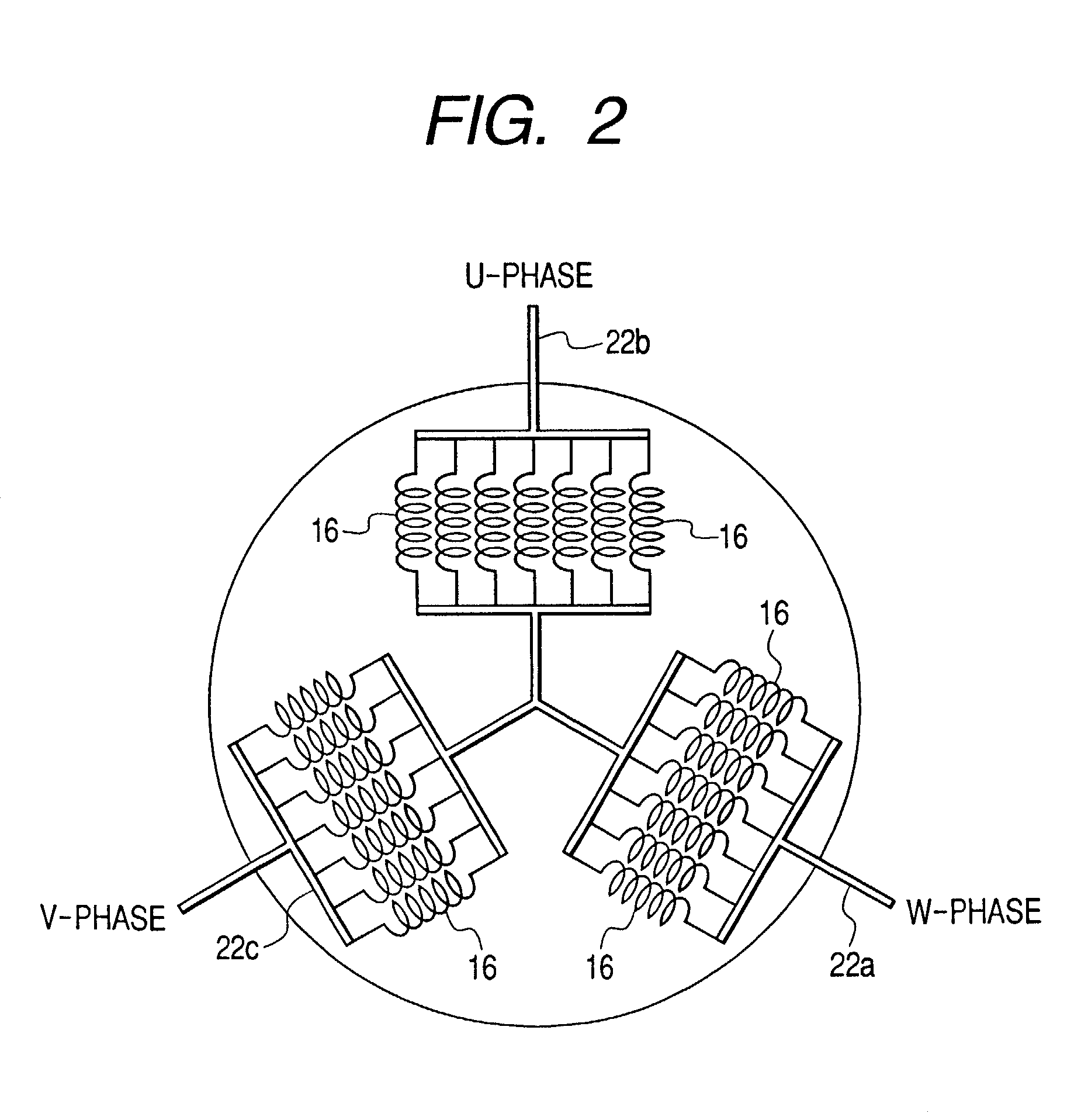

Thin brushless motor having resin-insulated concentric ring-shaped bus bars

InactiveUS6856057B2Improve heat resistanceHigh mechanical strengthRotary current collectorWindingsBrushless motorsInsulation layer

A centralized power distribution unit for a vehicular thin brushless motor includes a plurality of bus bars, a resin insulation layer that covers the bus bars, and an insulating holder having a plurality of holding grooves that hold the bus bars. The bus bars are pre-bent in a thickness direction to be formed into a substantially annular shape. Each of the bus bars is provided correspondingly with a phase of the motor. The holding grooves are formed in parallel extending along a circumferential direction of the centralized power distribution unit. The bus bars are respectively inserted into the holding grooves, and are thus stacked in a radial direction of the centralized power distribution unit. The insulating holder and the bus bars are covered by the resin insulation layer.

Owner:SUMITOMO WIRING SYST LTD +1

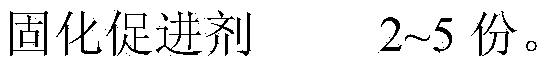

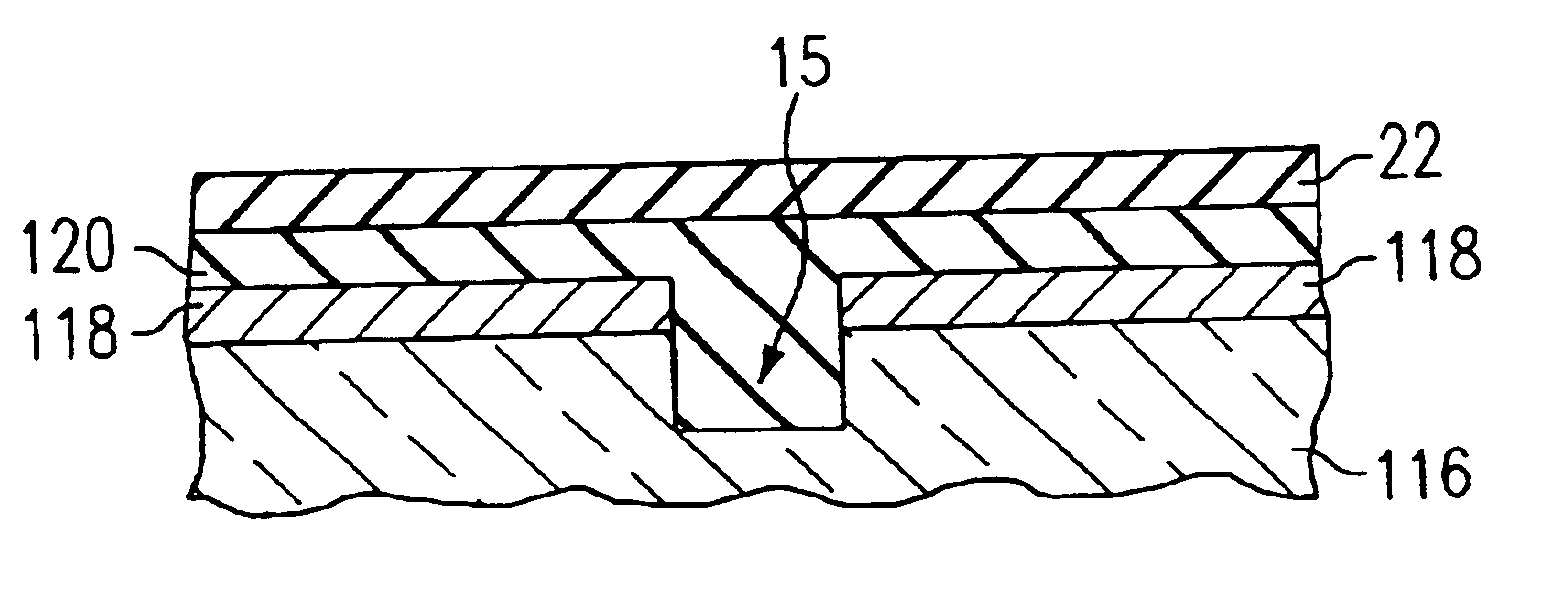

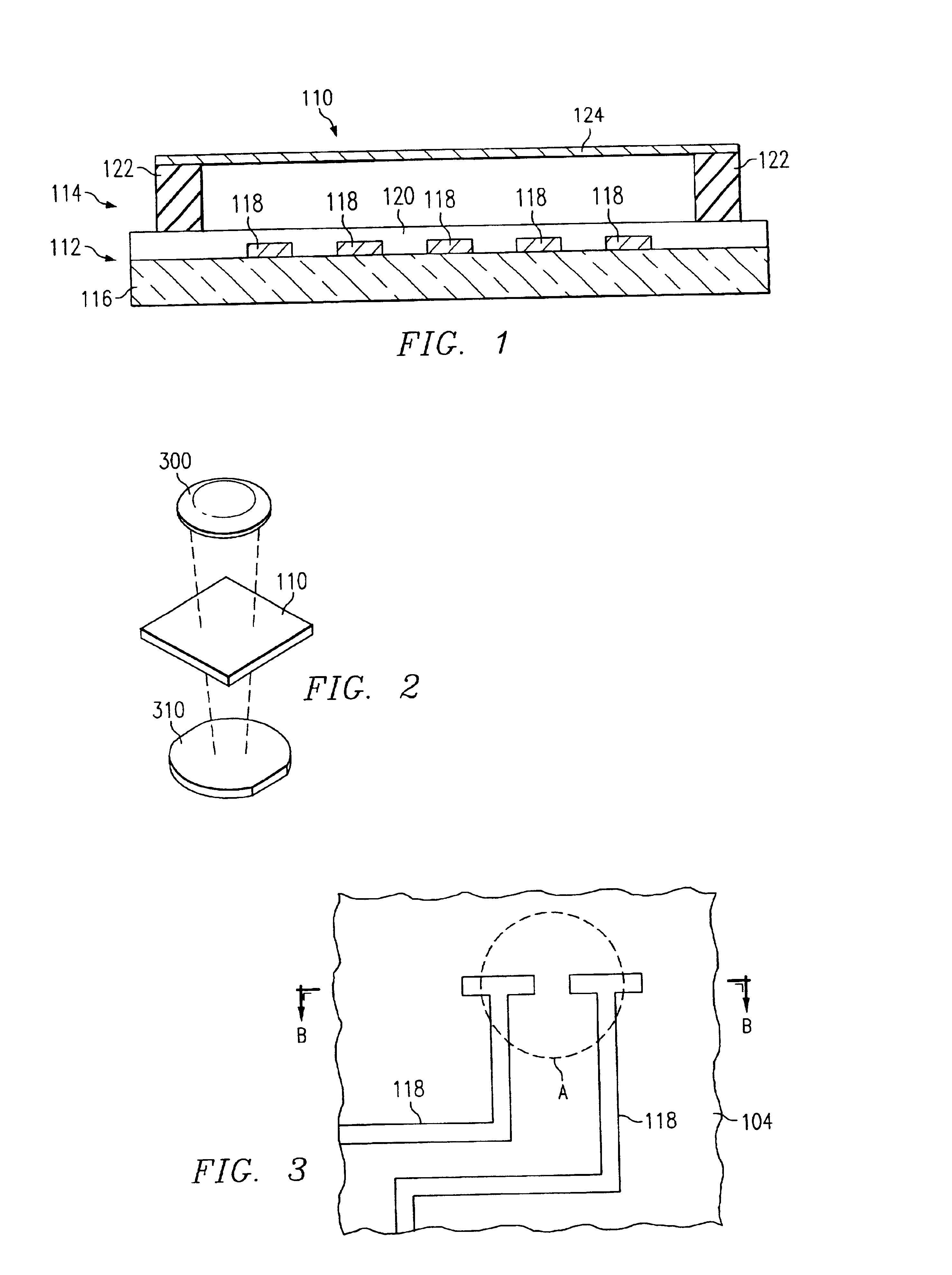

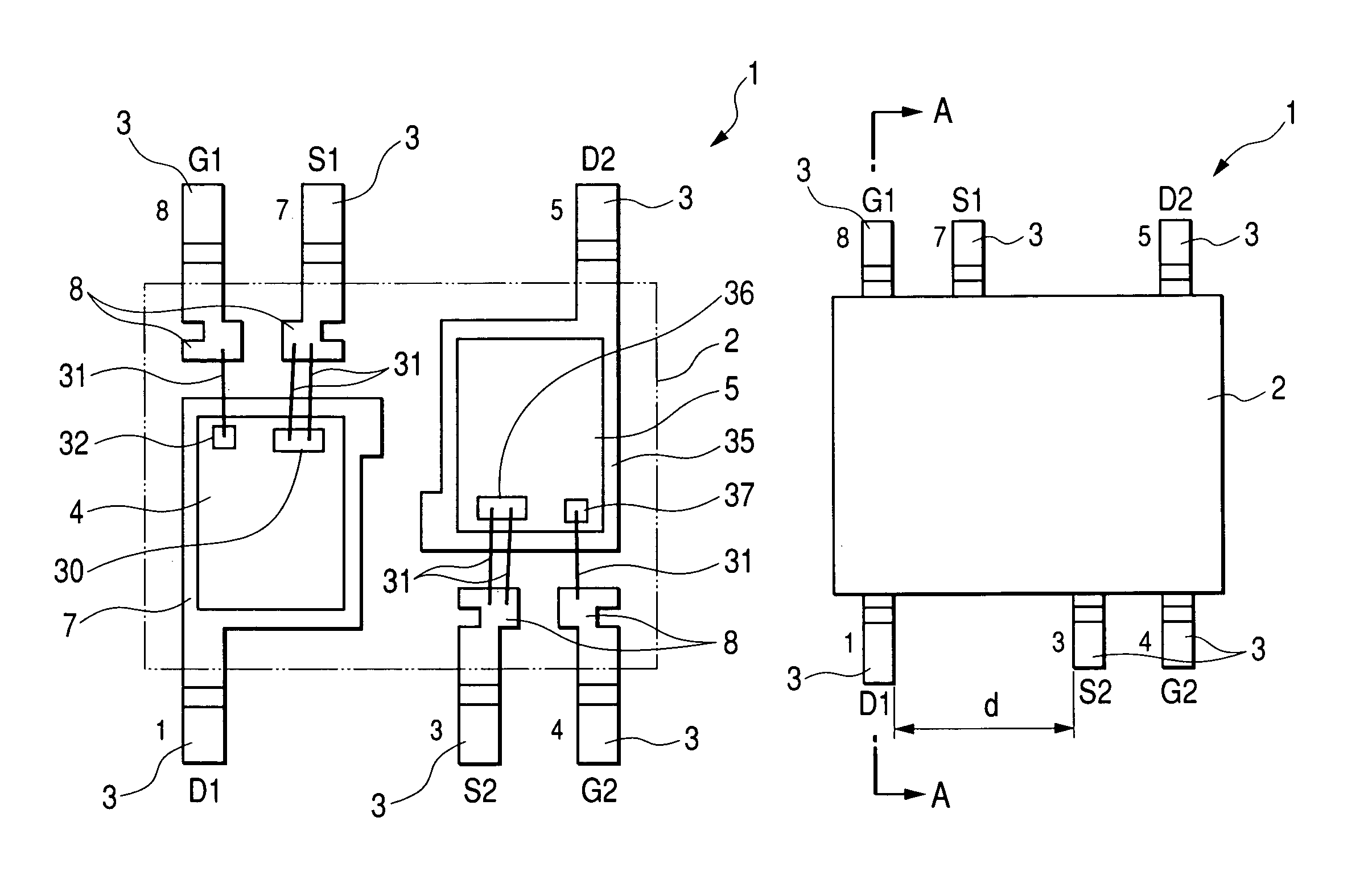

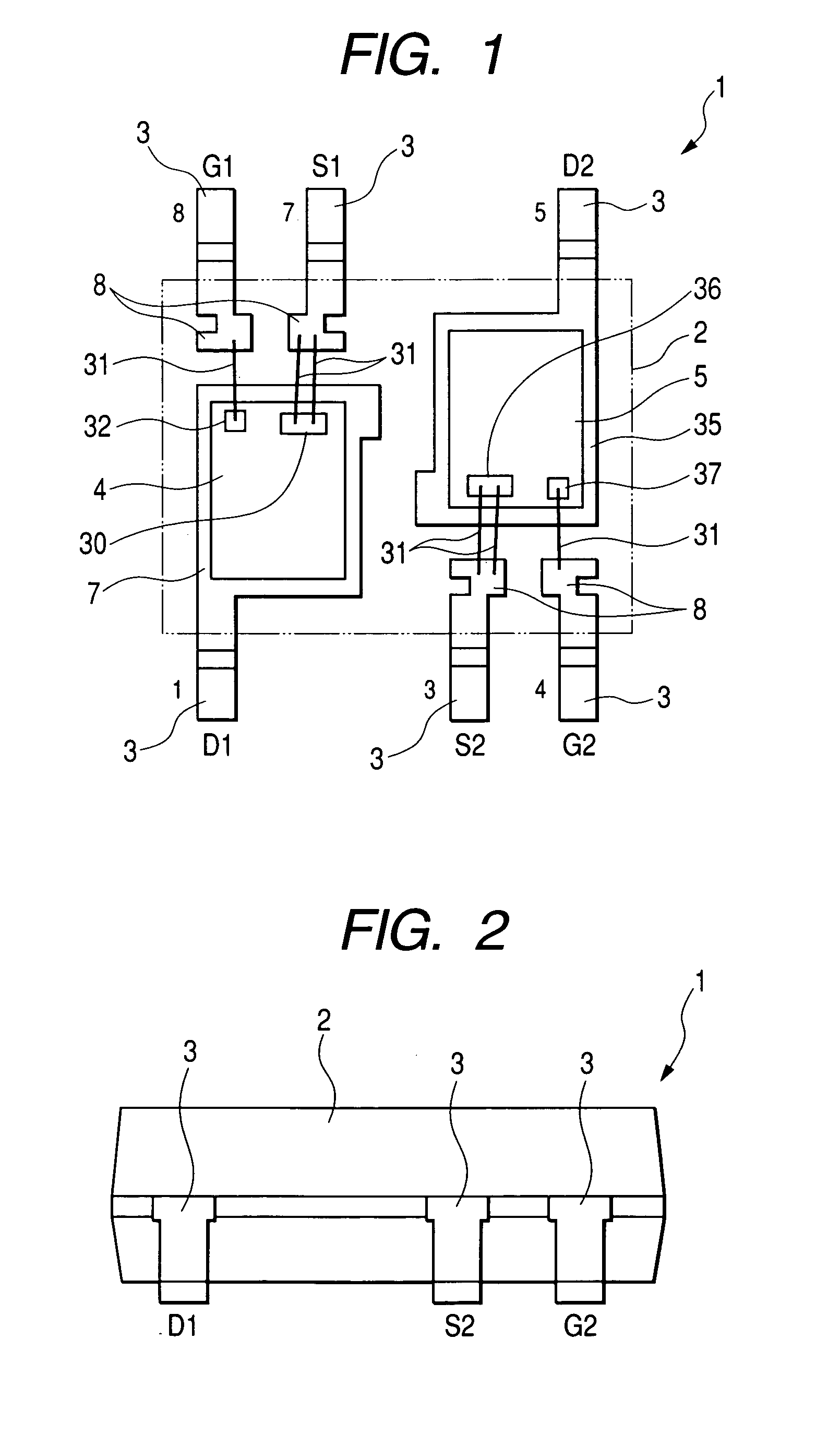

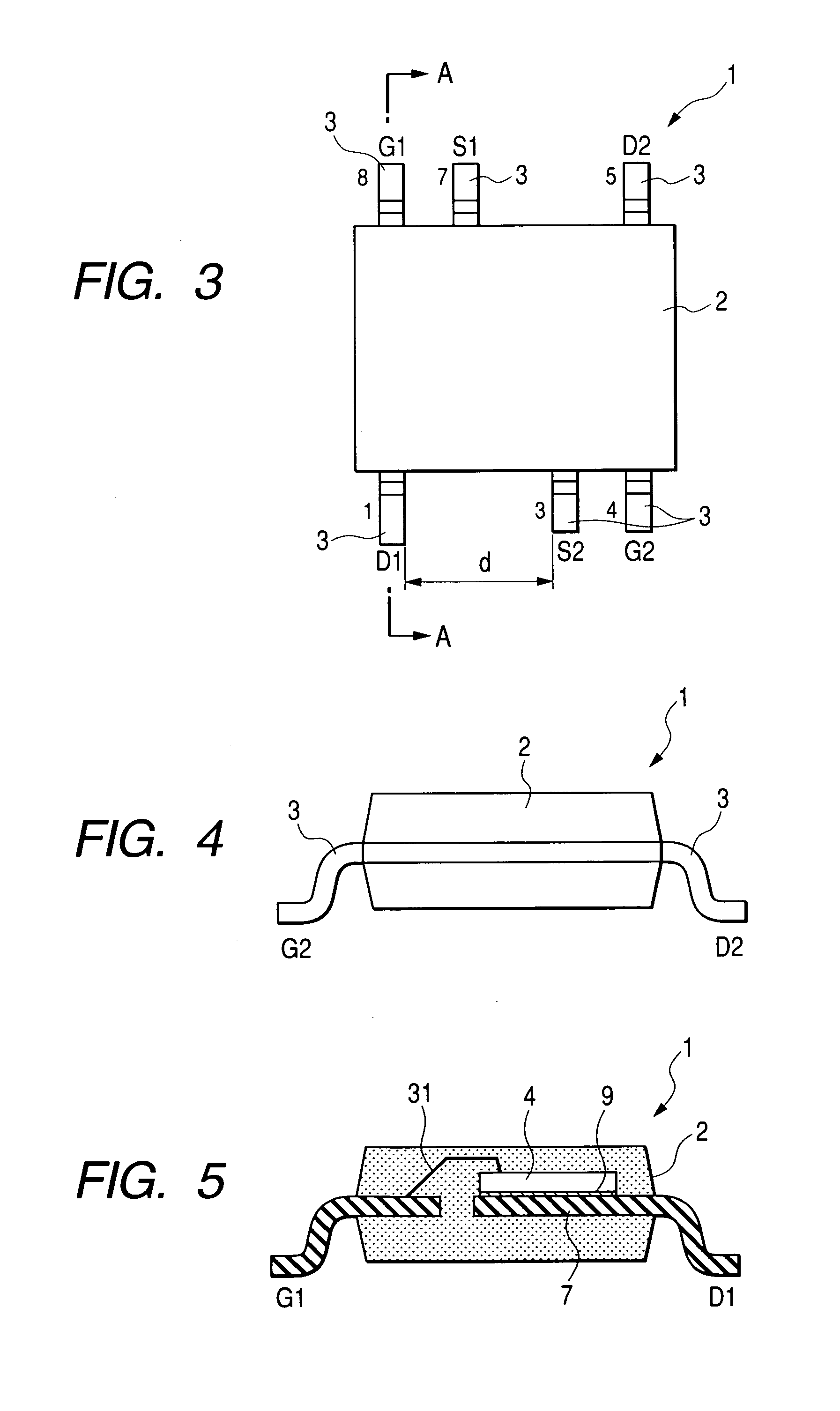

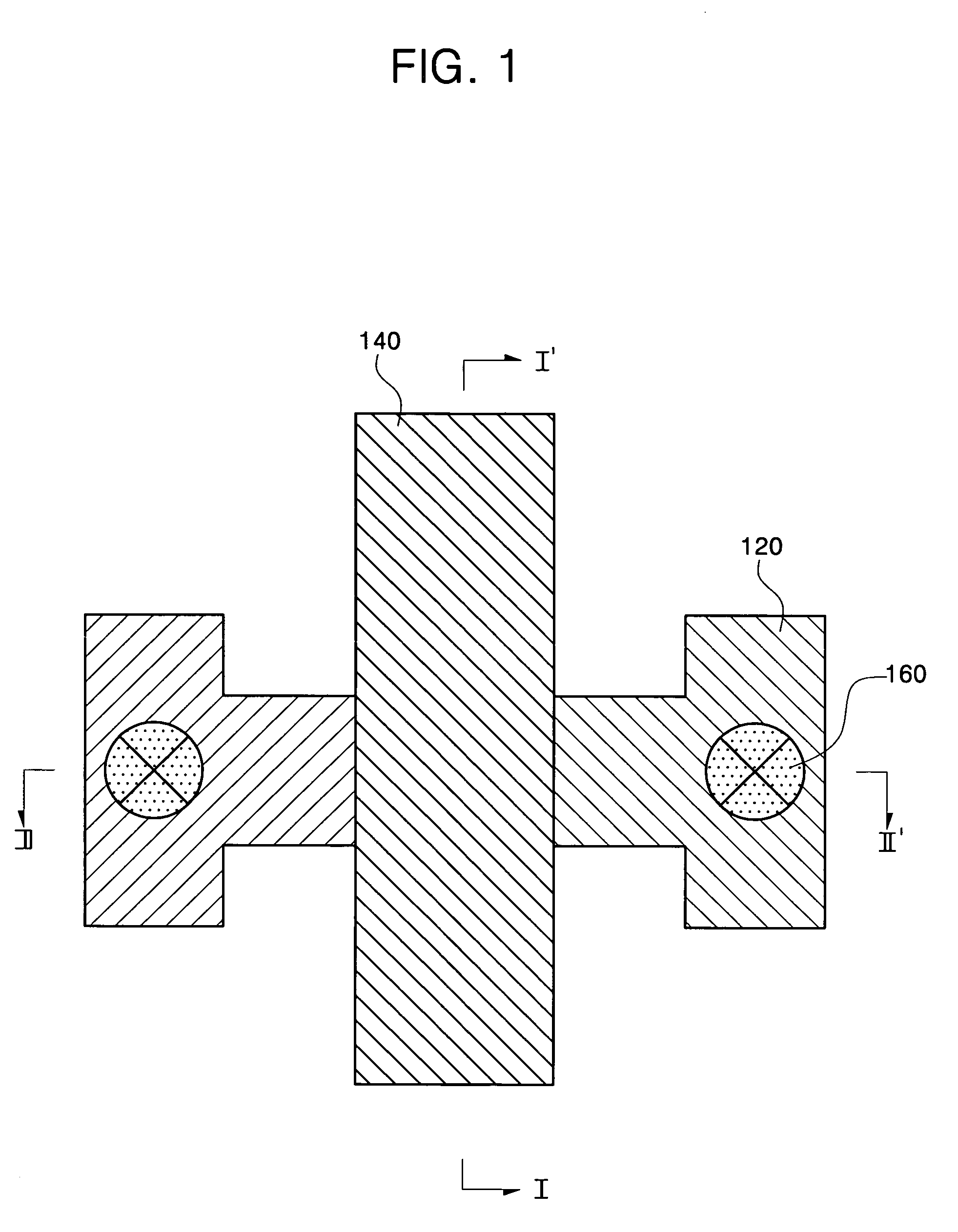

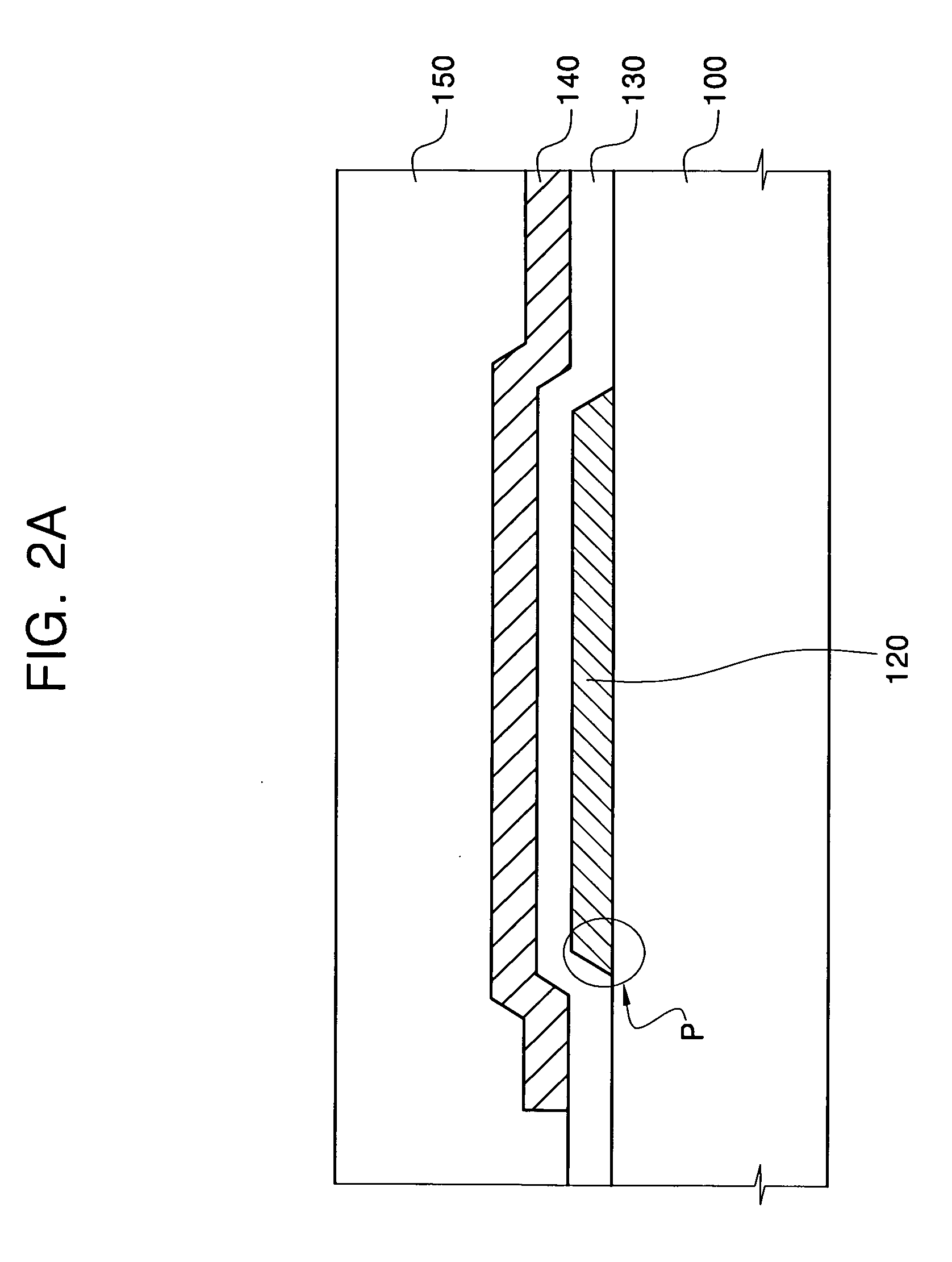

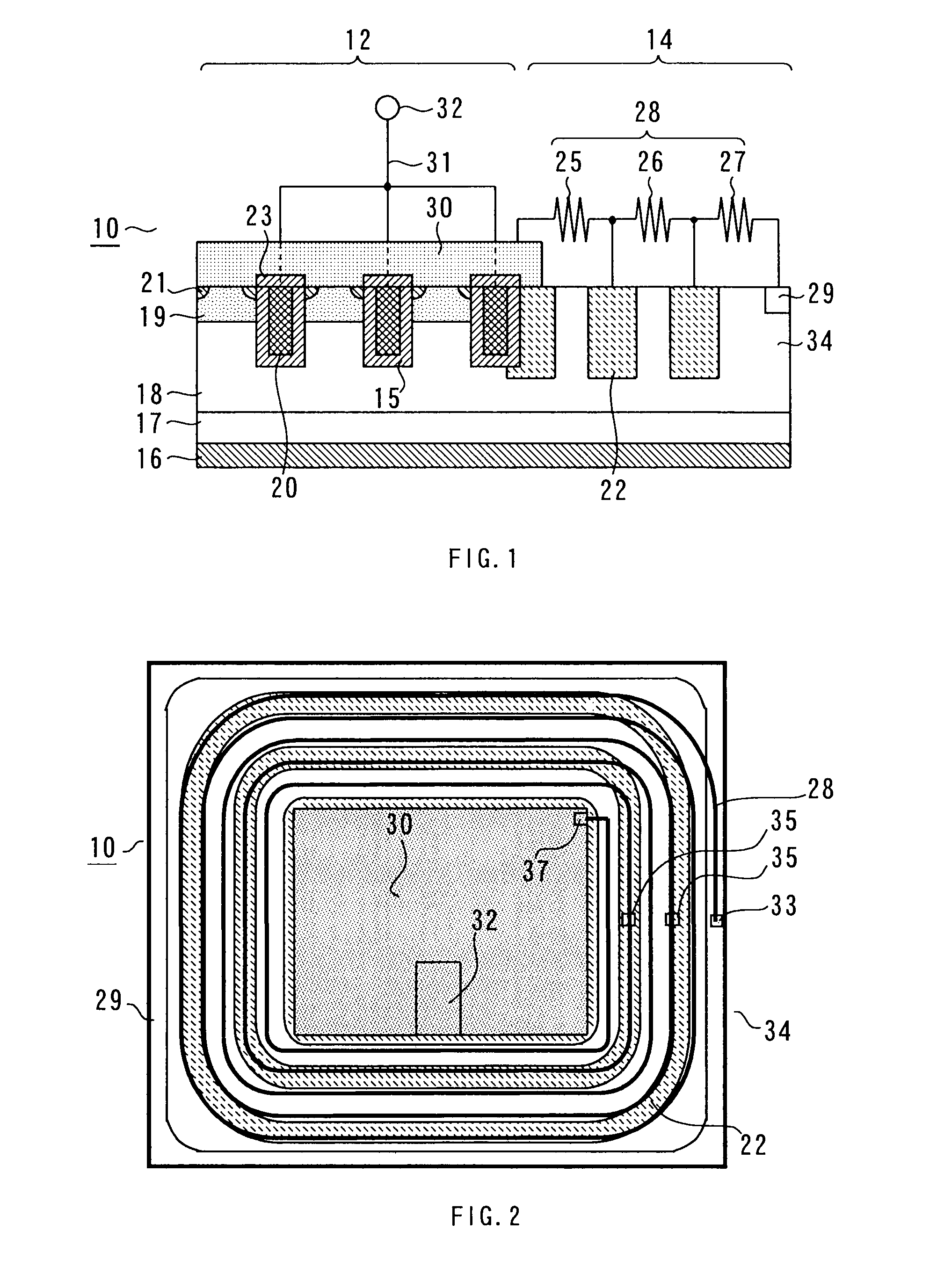

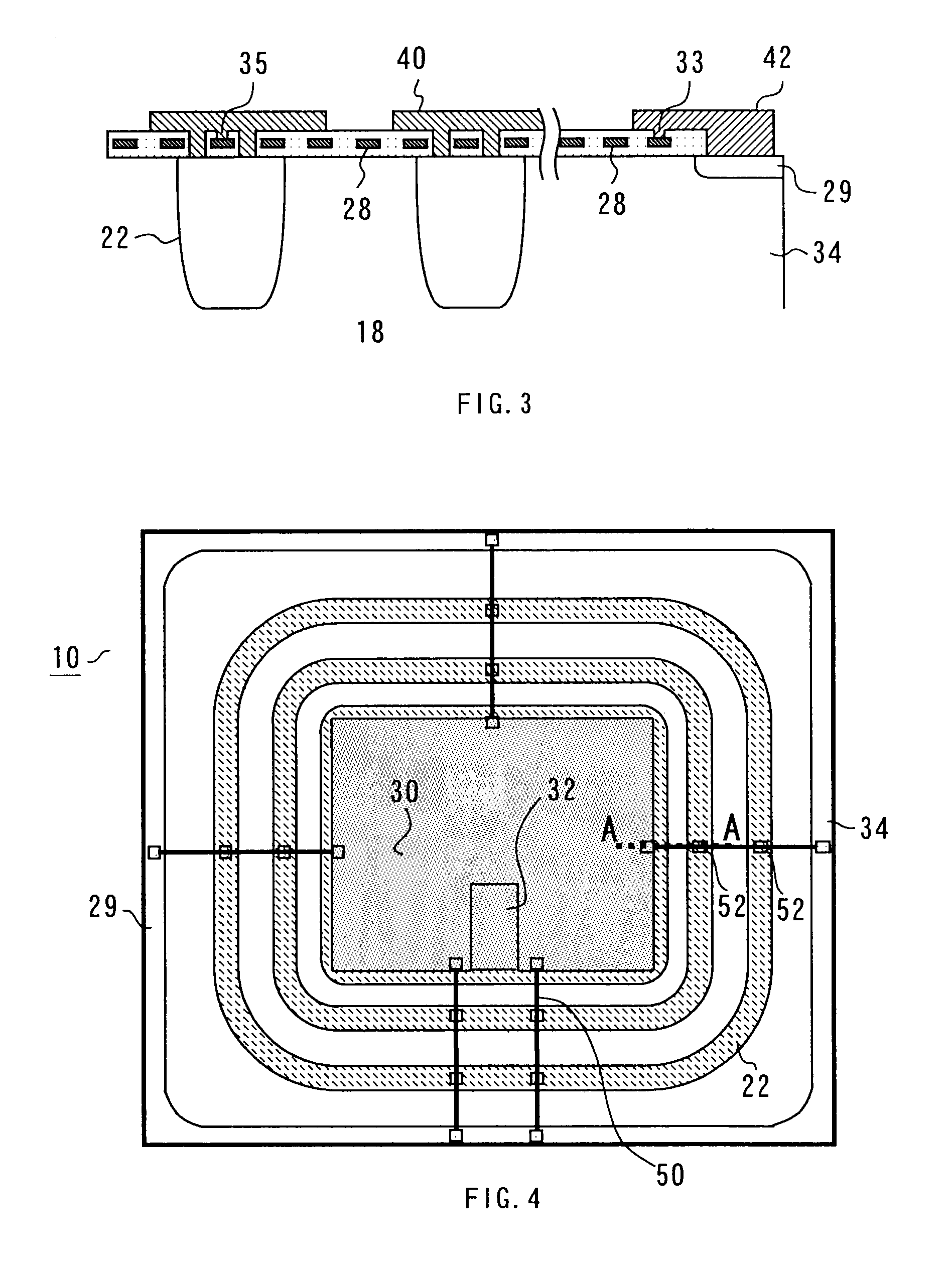

Semiconductor device

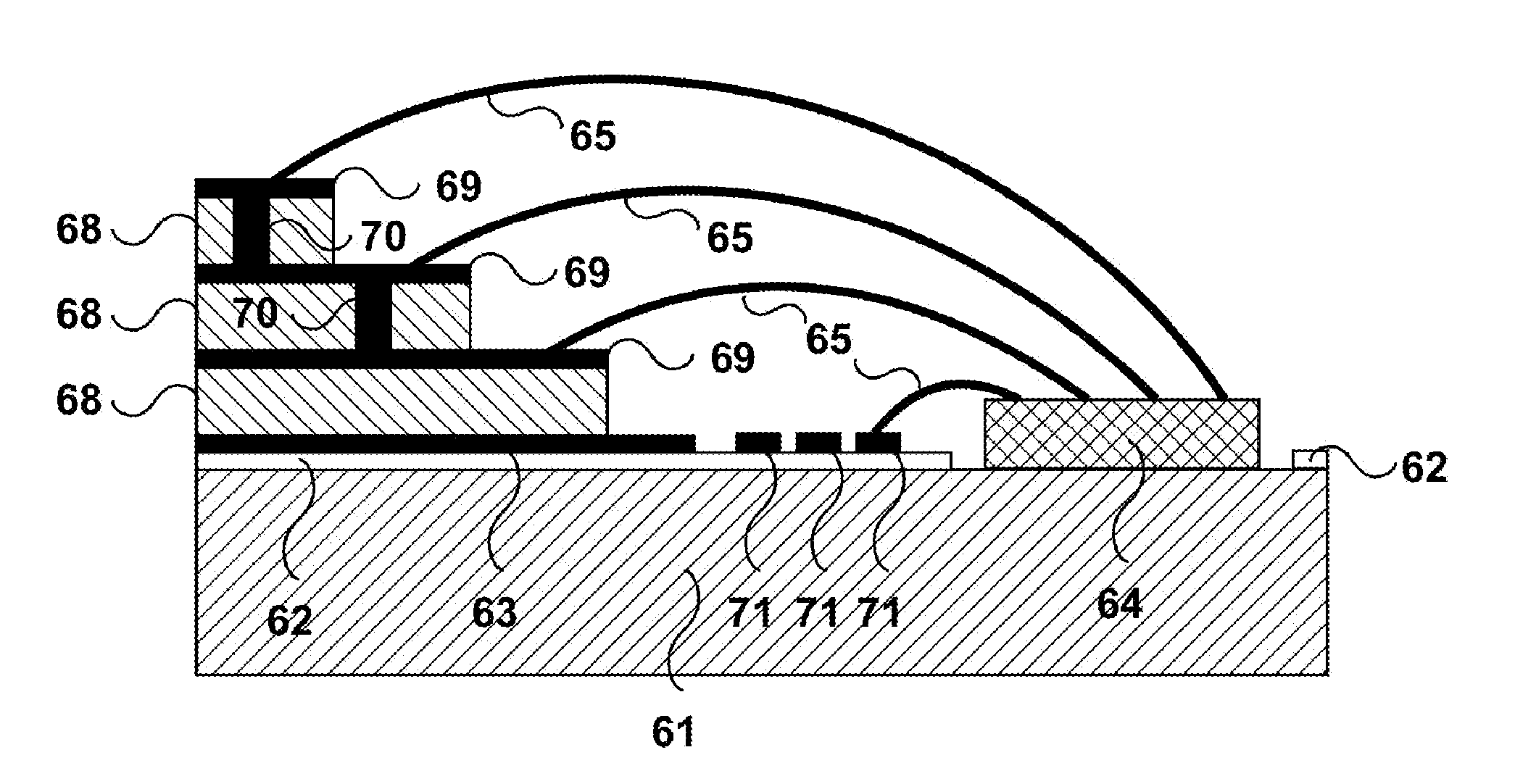

ActiveUS7173333B2Avoid problemsHigh dielectric strengthTransistorSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor device includes: a package; two semiconductor chip fixing parts located adjacently to each other in the package; and first and the second semiconductor chips, each of which is fixed on the semiconductor chip fixing part and has a field effect transistor formed therein. A gate lead G1, a source lead S1, and a drain lead D2 are arranged from left to right on the first surface of the package and a drain lead D1, a source lead S2, and a gate lead G2 are arranged from left to right on the second surface. A gap between the source lead S1 and the drain lead D2 is two times a gap between the gate lead G1 and the source lead S1, and a gap between the drain lead D1 and the source lead S2 is two times a gap between the source lead S2 and the gate lead G2.

Owner:RENESAS ELECTRONICS CORP

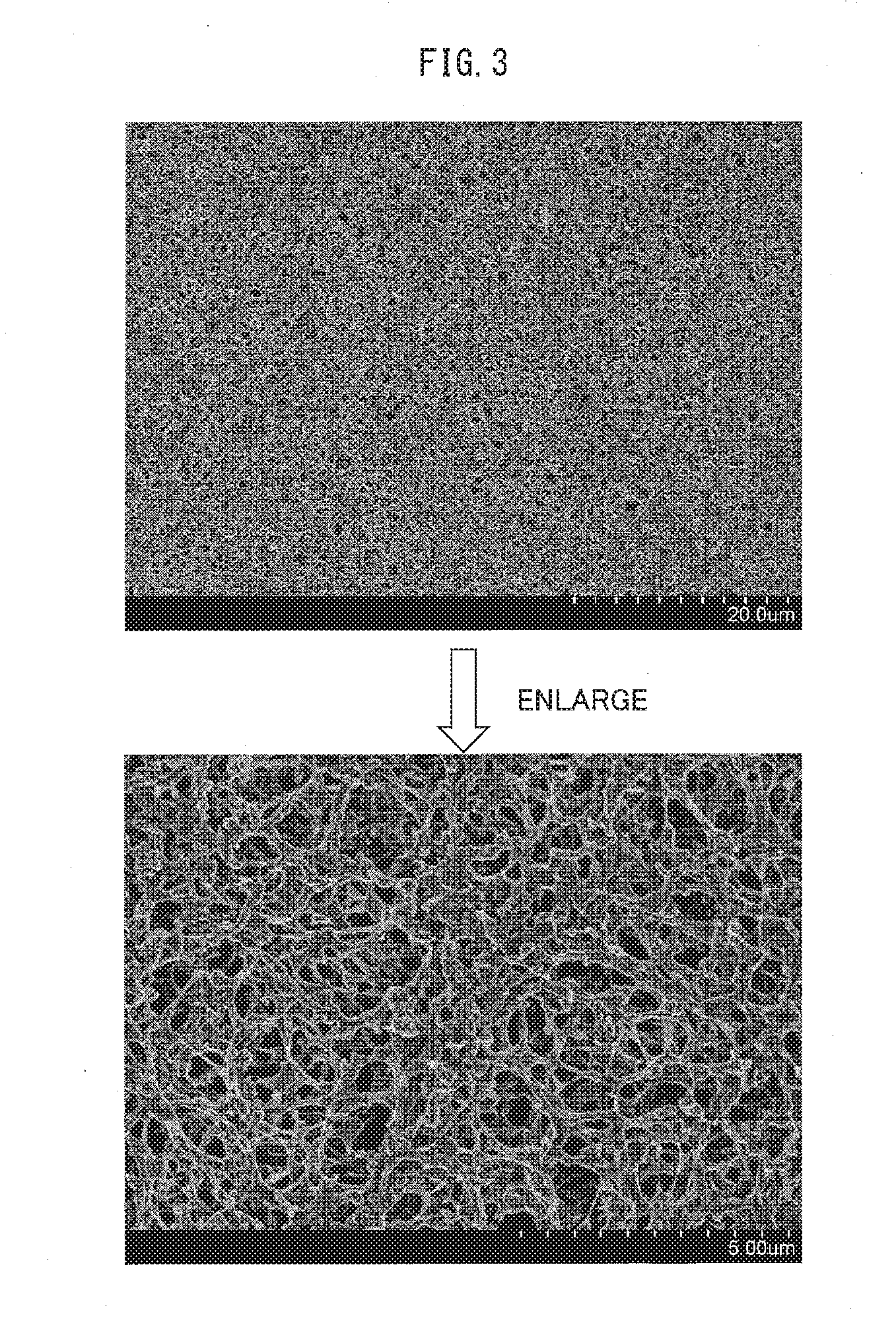

Insulated metal substrate

InactiveUS20140293554A1Improve propertiesSmall sizeCell electrodesSurface reaction electrolytic coatingCeramic coatingUltimate tensile strength

An insulated metal substrate (IMS) for supporting a device comprises a metallic substrate having a ceramic coating formed at least in part by oxidation of a portion of the surface of the metallic substrate. The ceramic coating has a dielectric strength of greater than 50 KV mm−1 and a thermal conductivity of greater than 5 Wm−1K−1.

Owner:CAMBRIDGE NANOTHERM

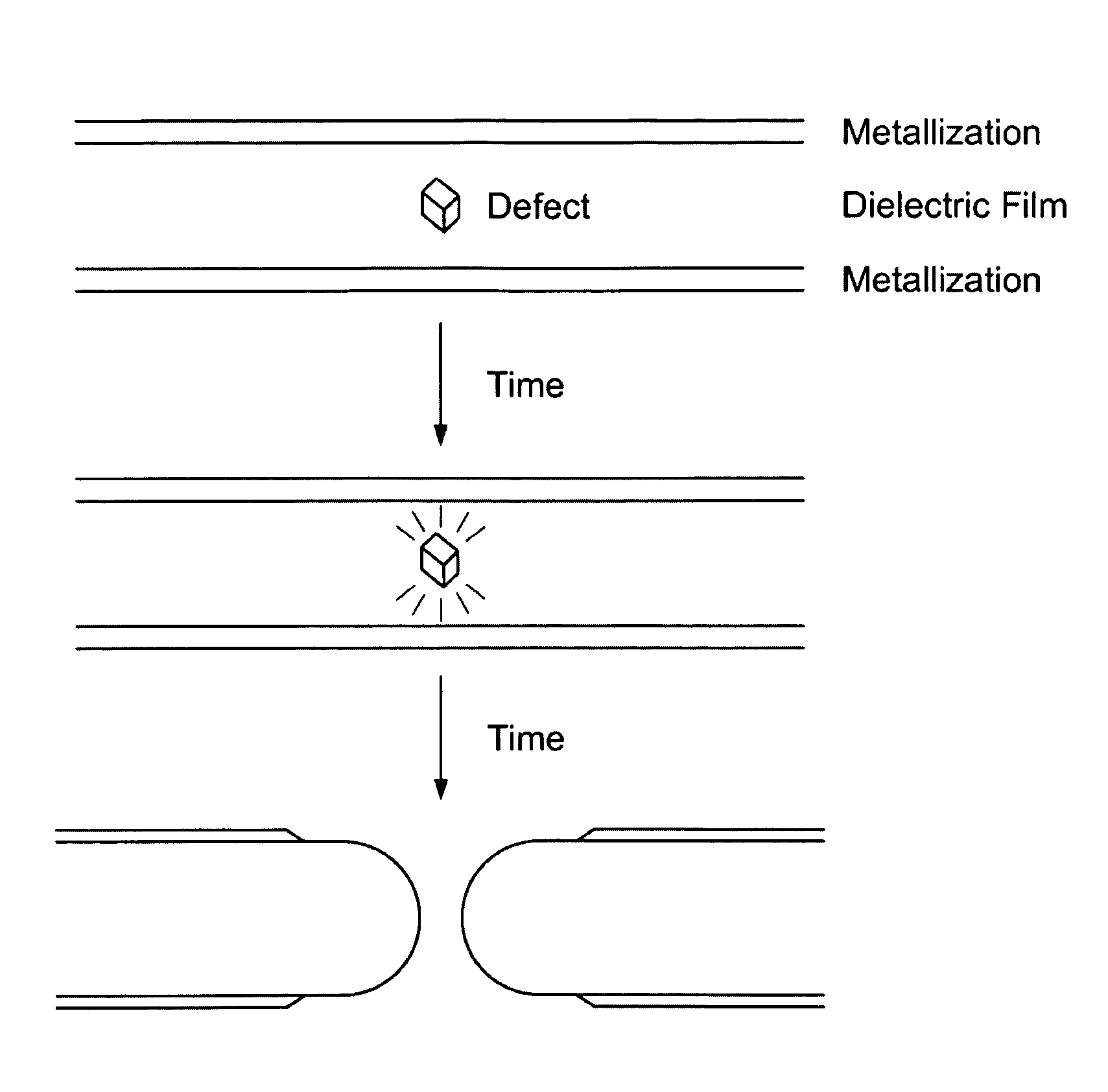

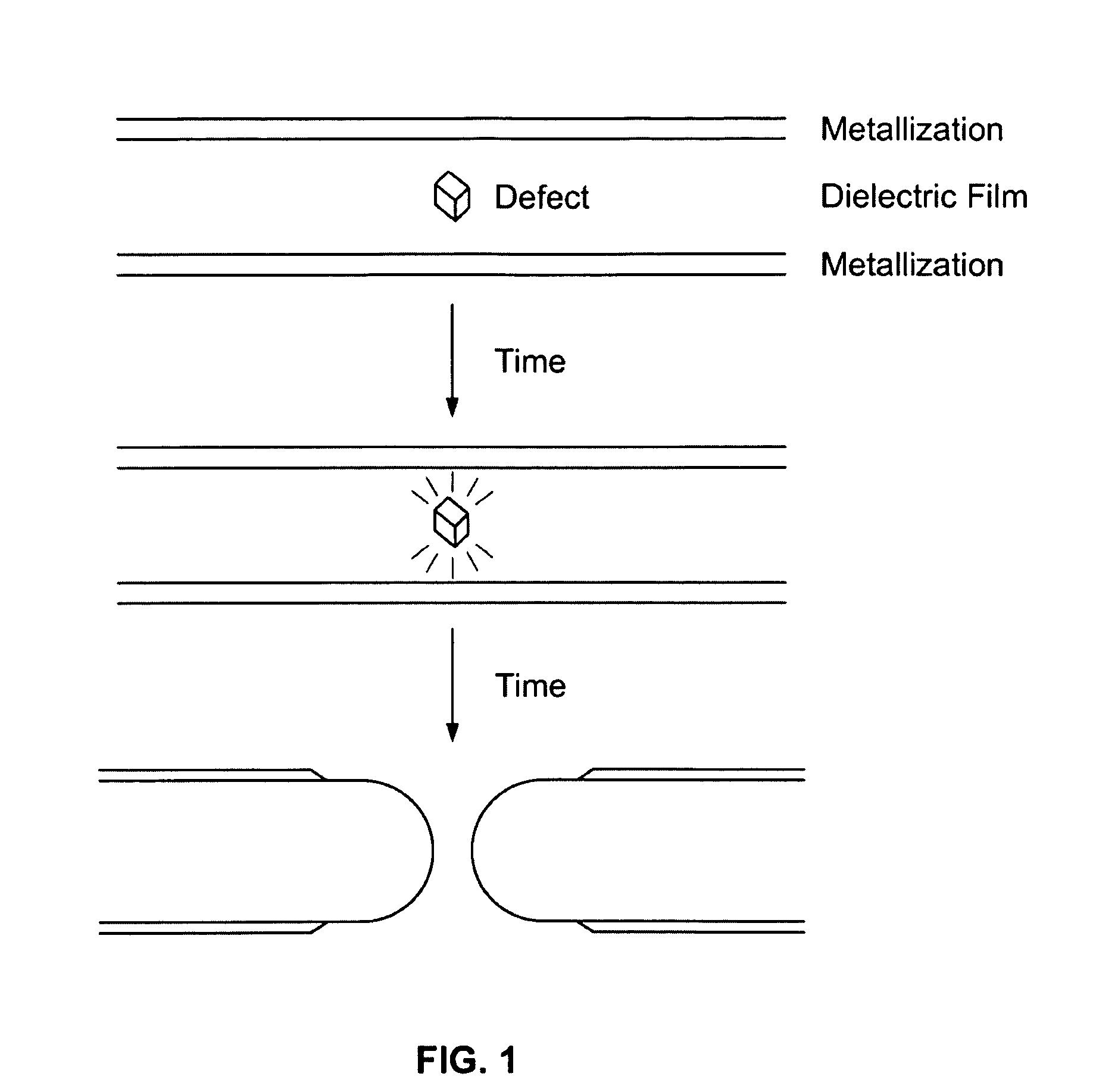

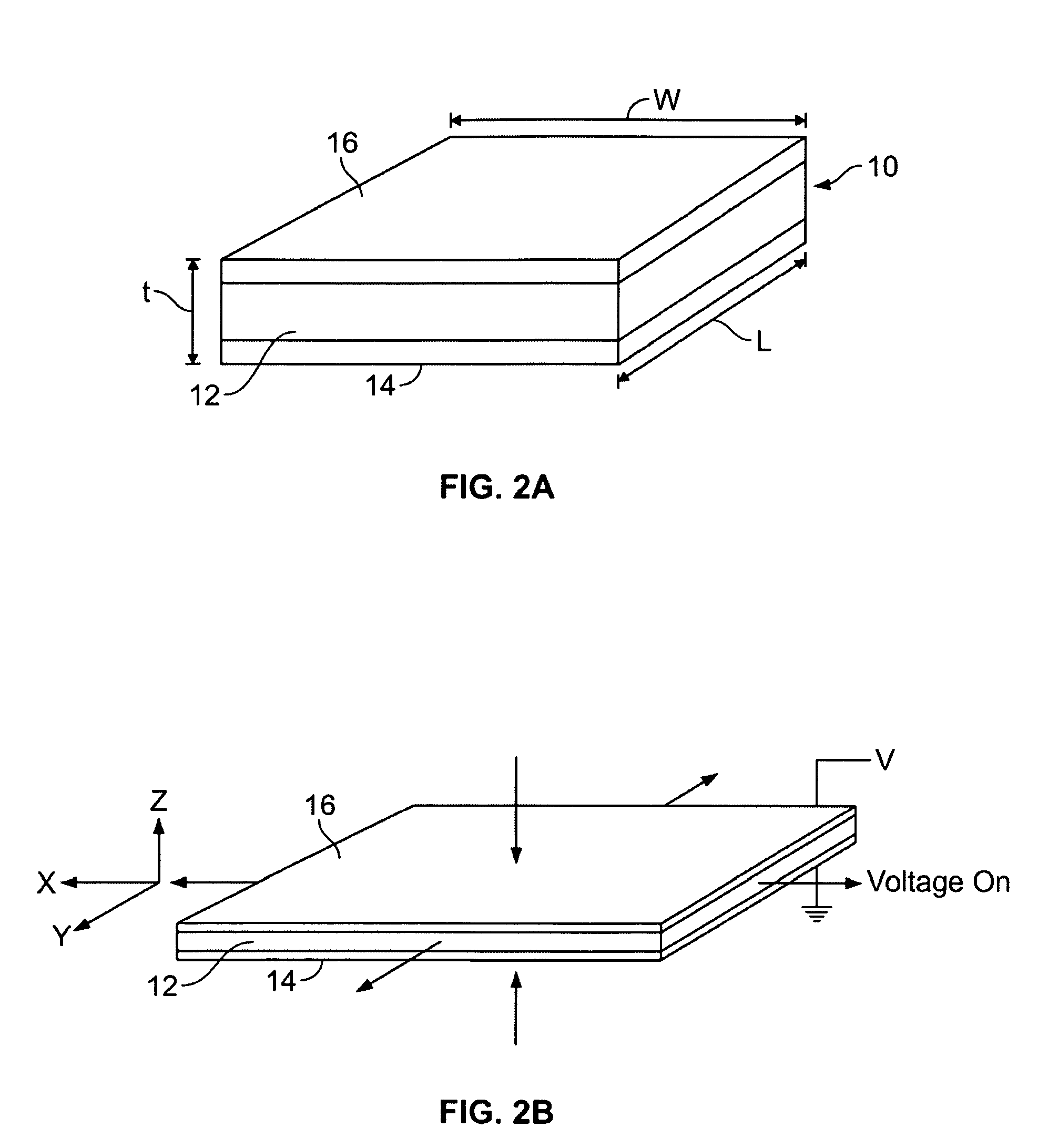

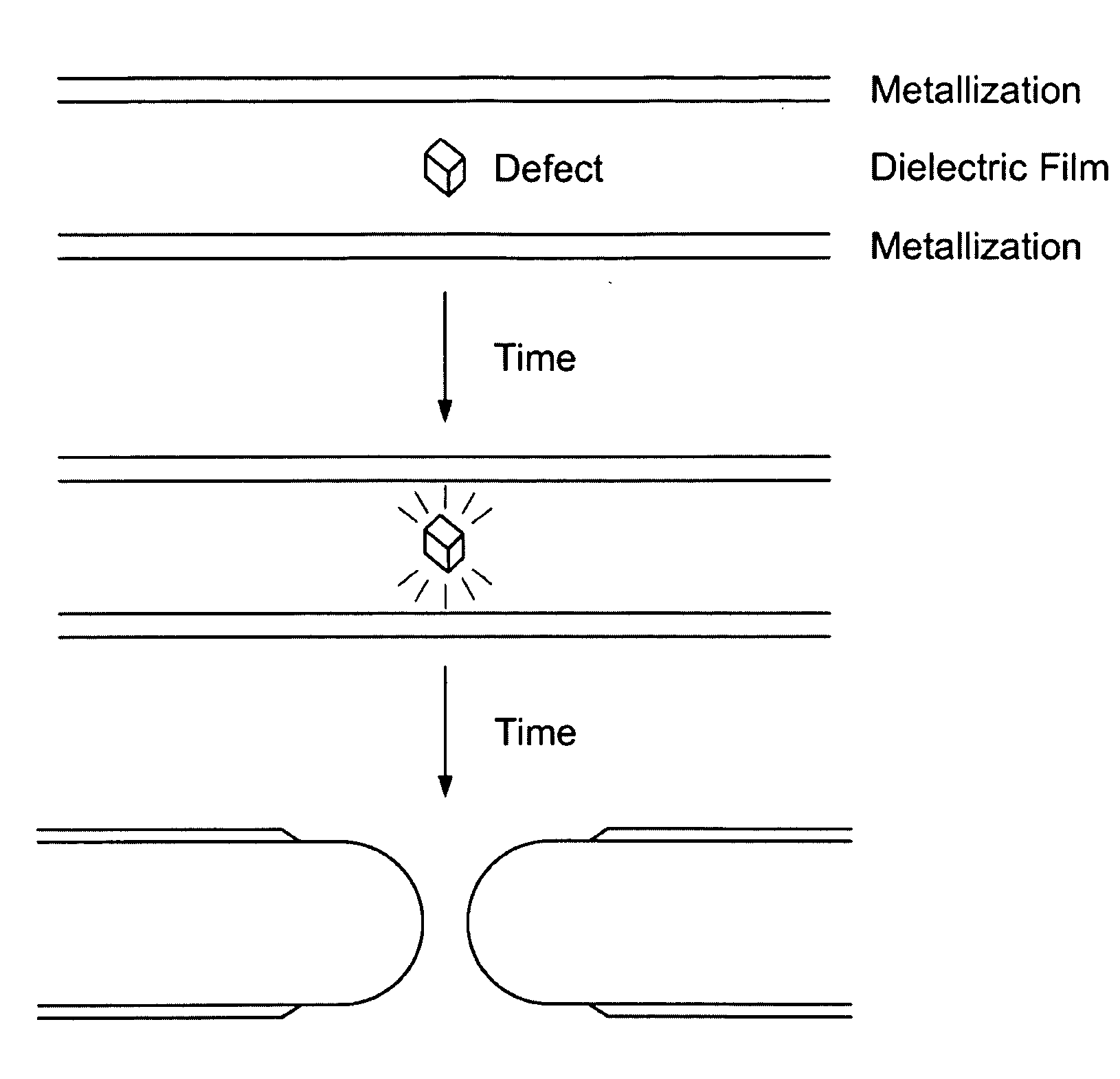

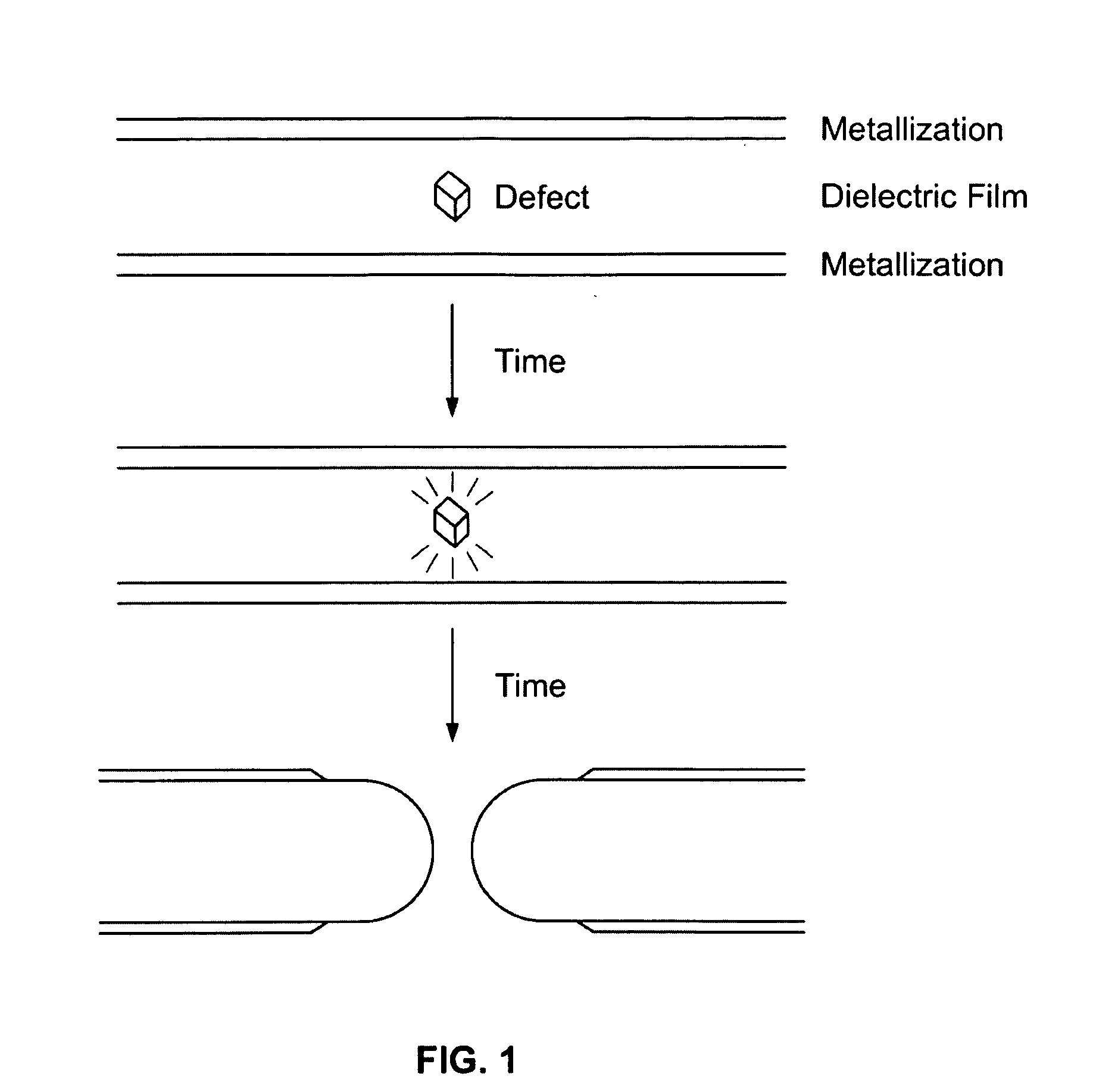

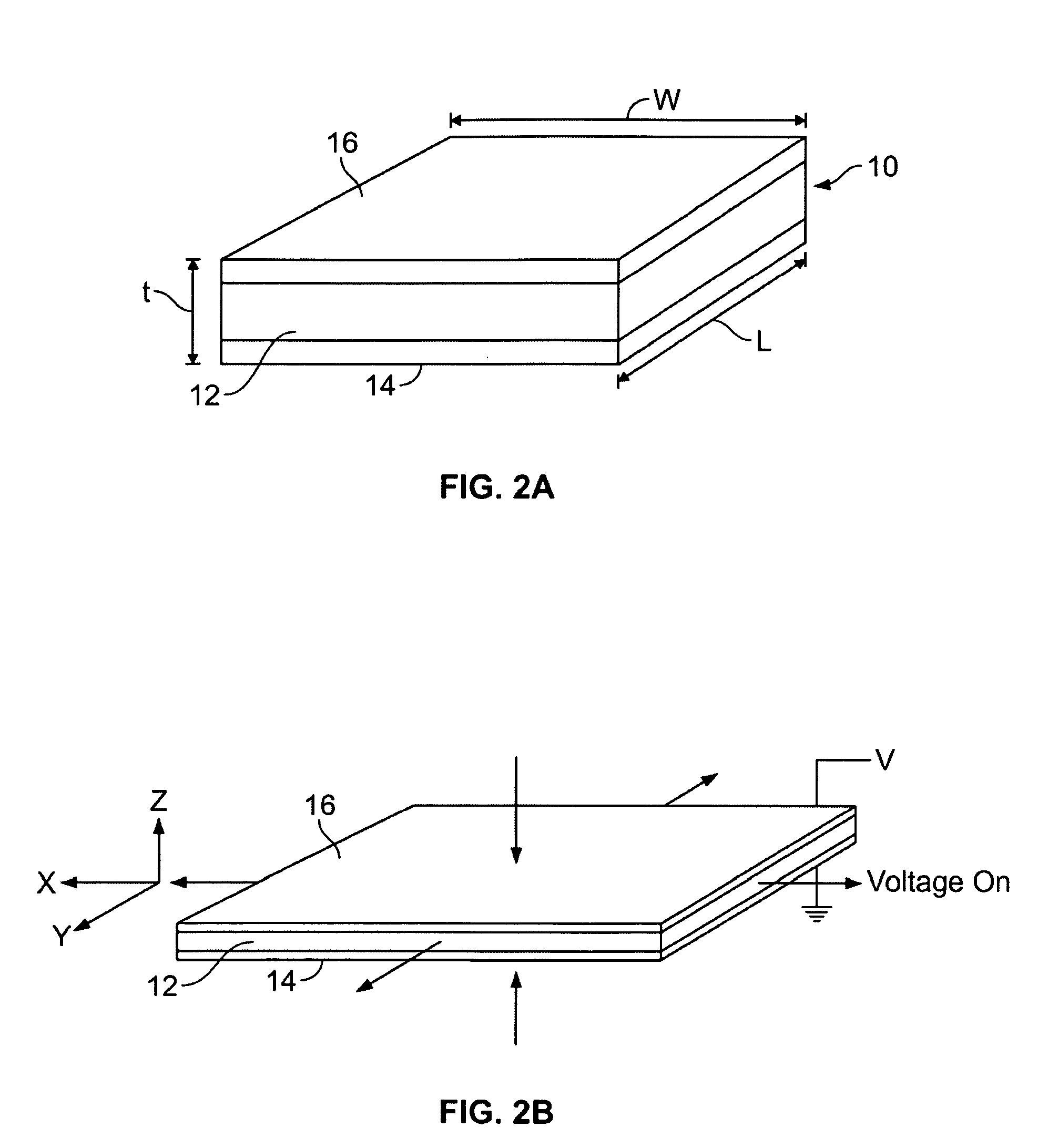

Fault-tolerant materials and methods of fabricating the same

ActiveUS7911761B2Effectively and efficiently isolateOptimize fault tolerancePiezoelectric/electrostrictive device manufacture/assemblyMechanically variable capacitor detailsSelf-healingMaterials science

The present invention provides compliant / stretchable electroactive materials and devices made from those materials which exhibit fault-tolerant properties, i.e., self-healing / clearing properties. The present invention also provides systems, which incorporate the subject materials and / or devices, as well as methods of fabricating the subject materials and devices.

Owner:COVESTRO DEUTSCHLAND AG

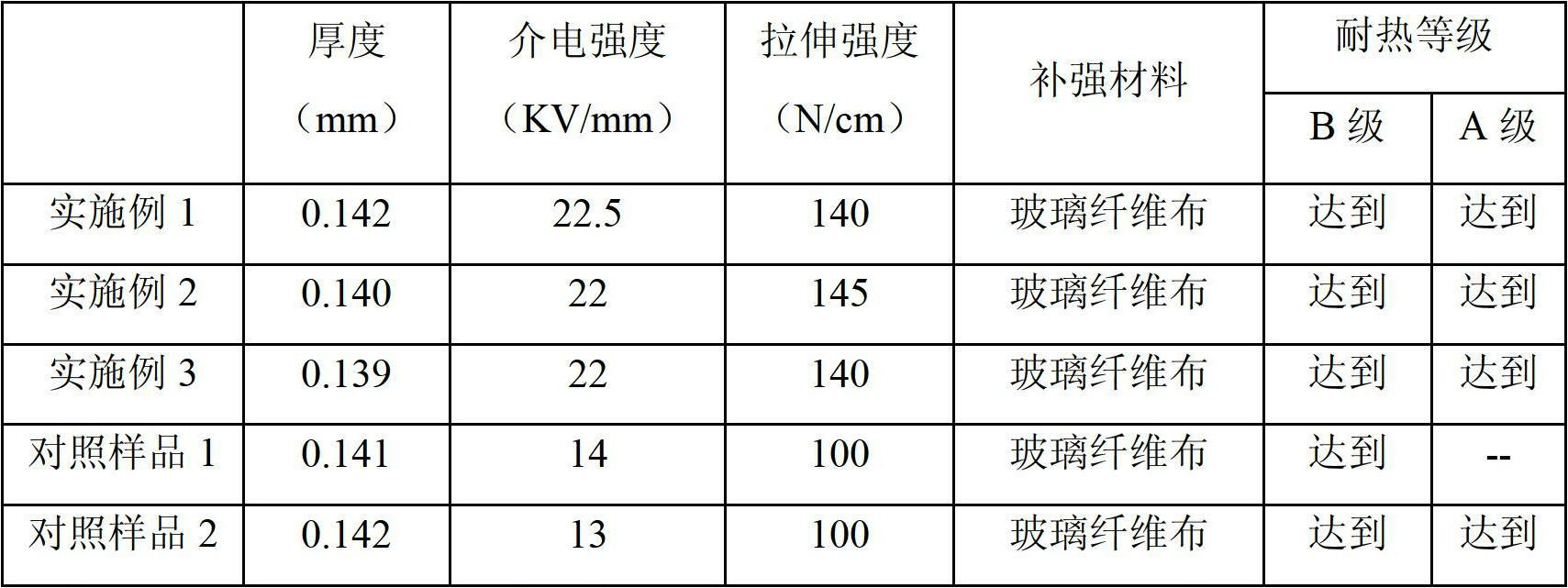

Method for manufacturing calcined high-temperature and high-pressure resistant mica paper tape

InactiveCN102651262AHigh dielectric strengthGuarantee product qualityInsulating bodiesPapermakingHigh pressure

The invention belongs to the field of insulating materials, particularly relating to a method for manufacturing a calcined high-temperature and high-pressure resistant mica paper tape, and aiming to solve the technical problem that the traditional mica paper tape is easily broken down due to the low dielectric strength. The method for manufacturing the calcined high-temperature and high-pressure resistant mica paper tape comprises the following steps of: a. selecting a mica raw material; b. calcining; c. preparing pulp; d. papermaking; and e. compounding. The mica paper tape manufactured by the method provided by the invention has high dielectric strength, and is suitable for both a B-grade cable and an A-grade cable.

Owner:SICHUAN MEIFENG MICA IND

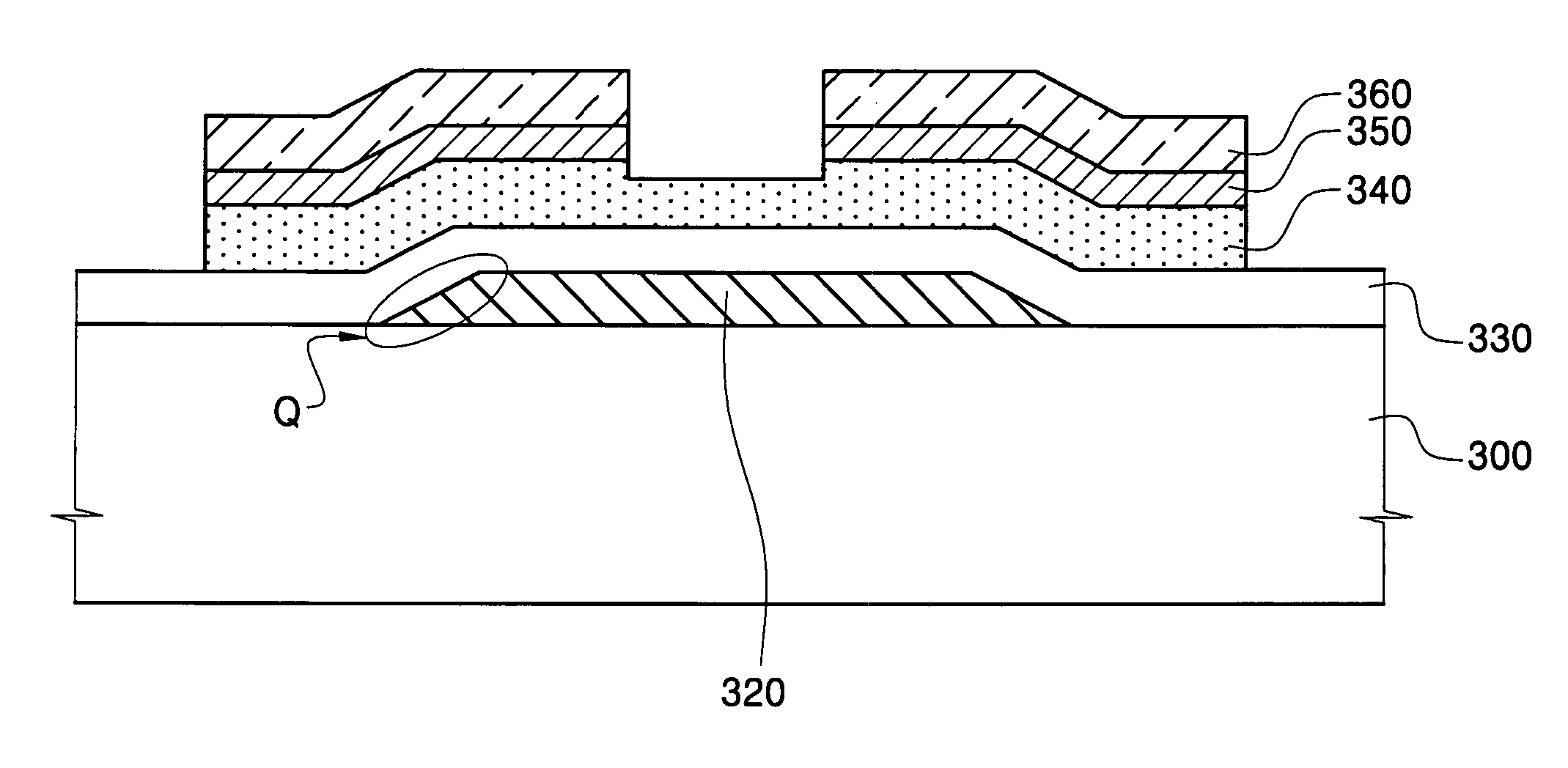

Thin film transistor

InactiveUS20050116305A1High dielectric strengthTransistorSolid-state devicesDielectric strengthTransistor

A thin film transistor according to the present invention may include a gate insulating layer; and a lower pattern placed below the gate insulating layer to contact therewith and having an edge with a taper angle of at most about 80°. With this design, dielectric strength of the gate insulating layer can be enhanced. The lower pattern can be a gate electrode layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

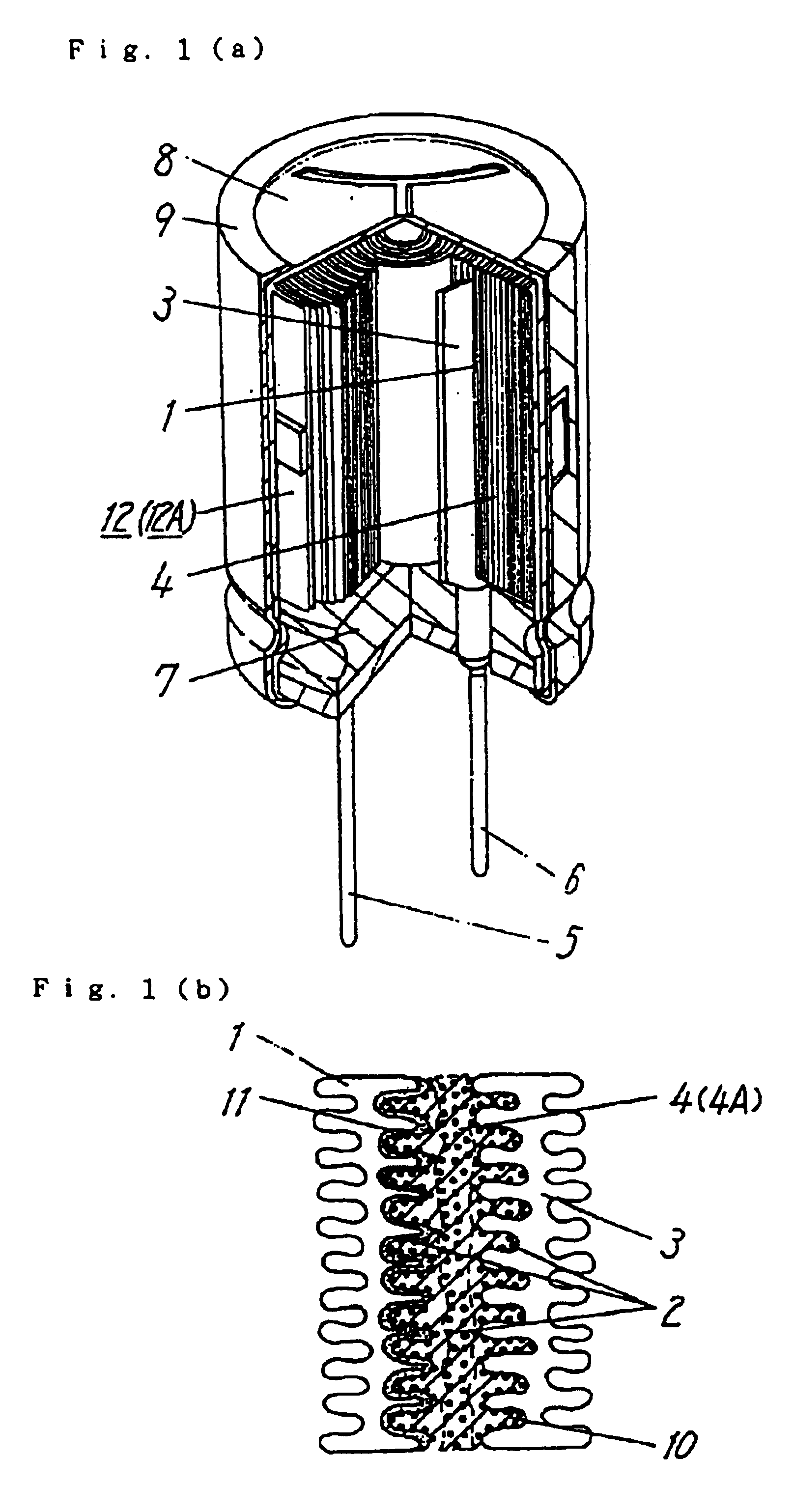

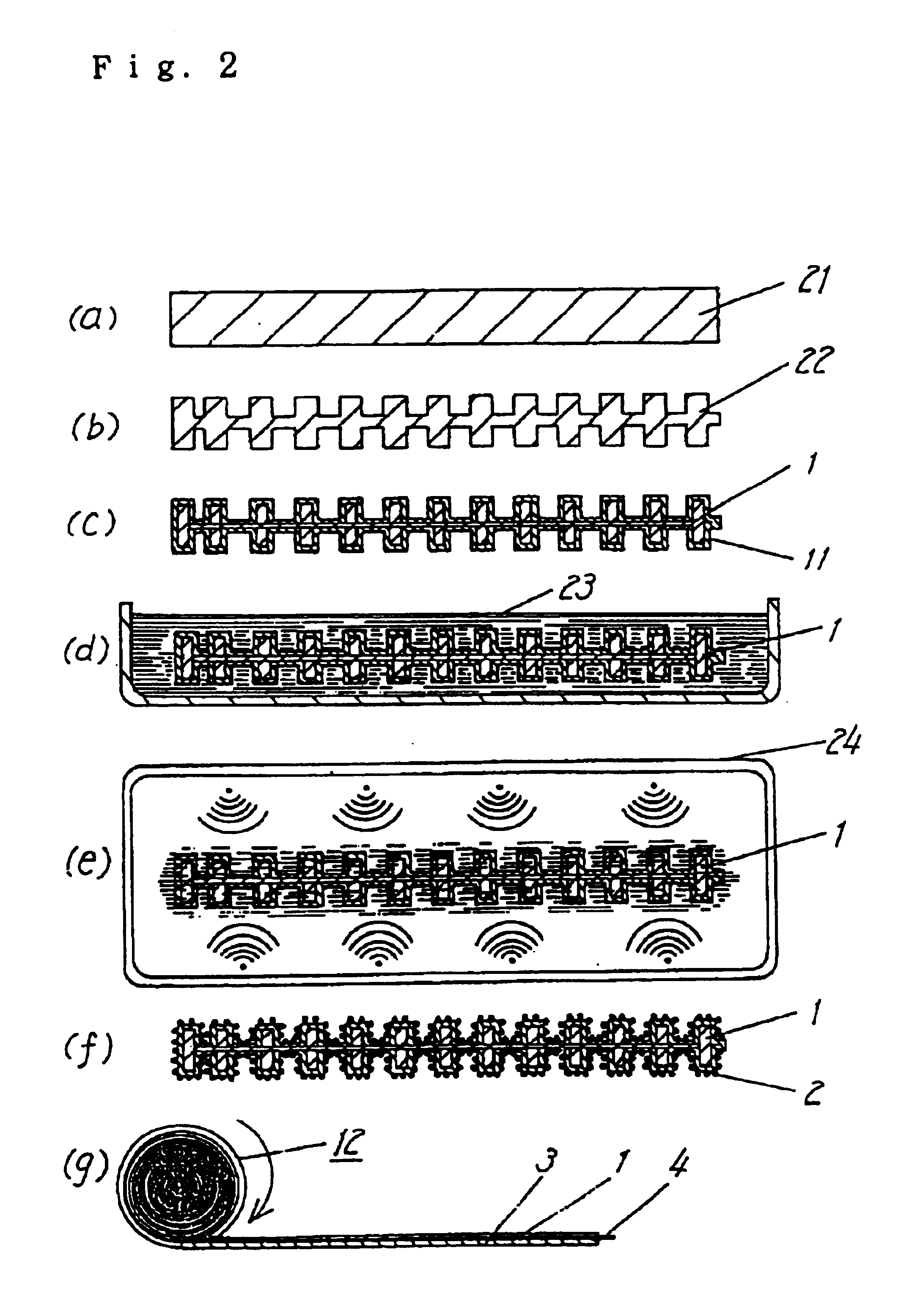

Electrolytic capacitor and its manufacturing method

InactiveUS6962612B1Improve impedance characteristicsHigh dielectric strengthCapacitor electrolytes/absorbentsCapacitor electrodesConductive polymerConductive materials

A electrolytic capacitor includes(a) a capacitor element having a positive electrode, a negative electrode, and a solid organic conductive material disposed between the positive electrode and the negative electrode,(b) an electrolyte,(c) a case for accommodating the capacitor element and the electrolyte, and(d) a sealing member disposed to cover the opening of the case.The solid organic conductive material has at least one of organic semiconductor and conductive polymer. In this constitution, an electrolytic capacitor having excellent impedance characteristic, small current leak, excellent reliability, and high dielectric strength is obtained.

Owner:PANASONIC CORP

Fault-tolerant materials and methods of fabricating the same

ActiveUS20080180875A1Optimize fault toleranceHigh performance featuresPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor electrodesSelf-healingElectroactive materials

Compliant / stretchable electroactive materials which exhibit self-healing / clearing properties are disclosed.

Owner:COVESTRO DEUTSCHLAND AG

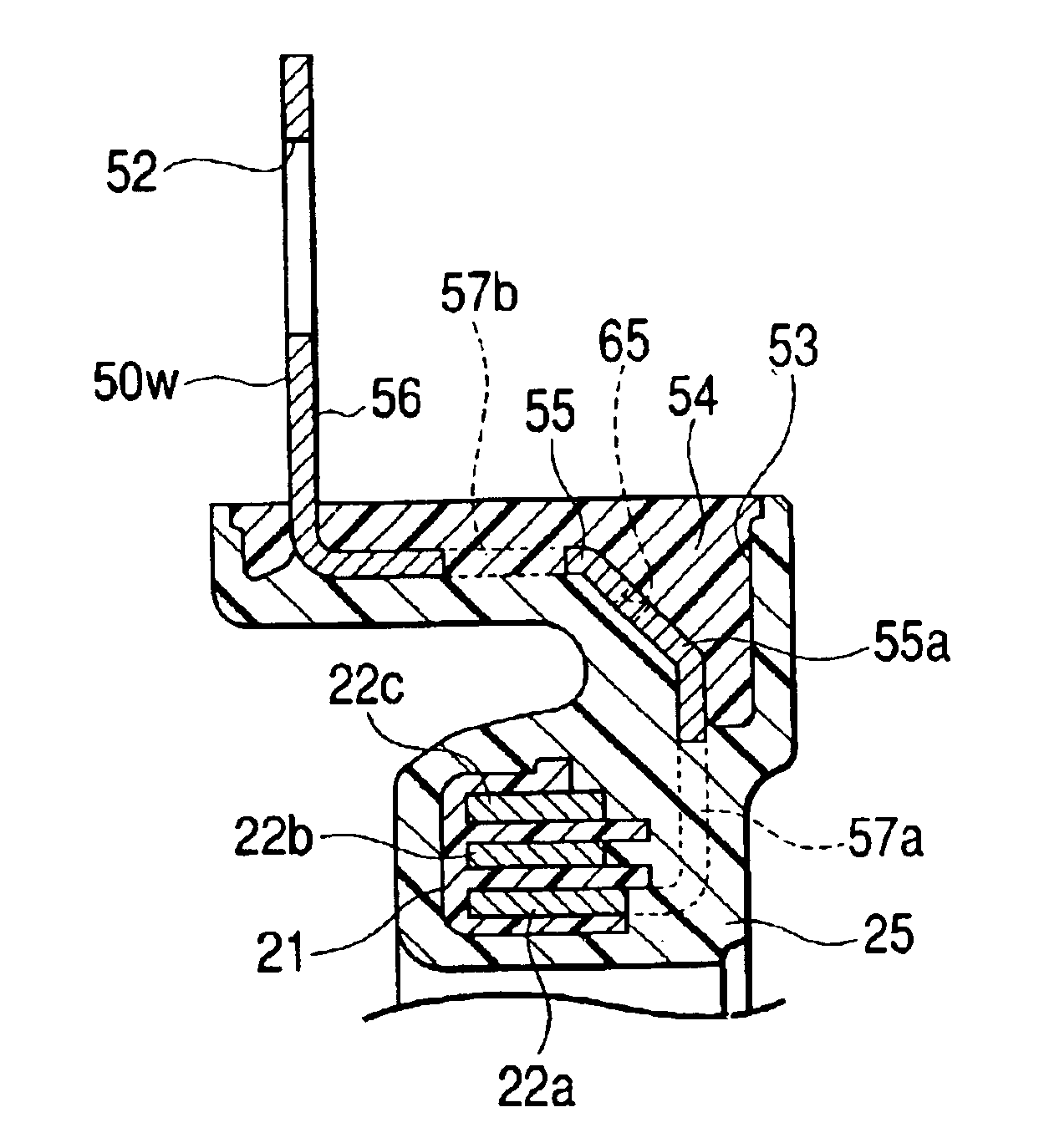

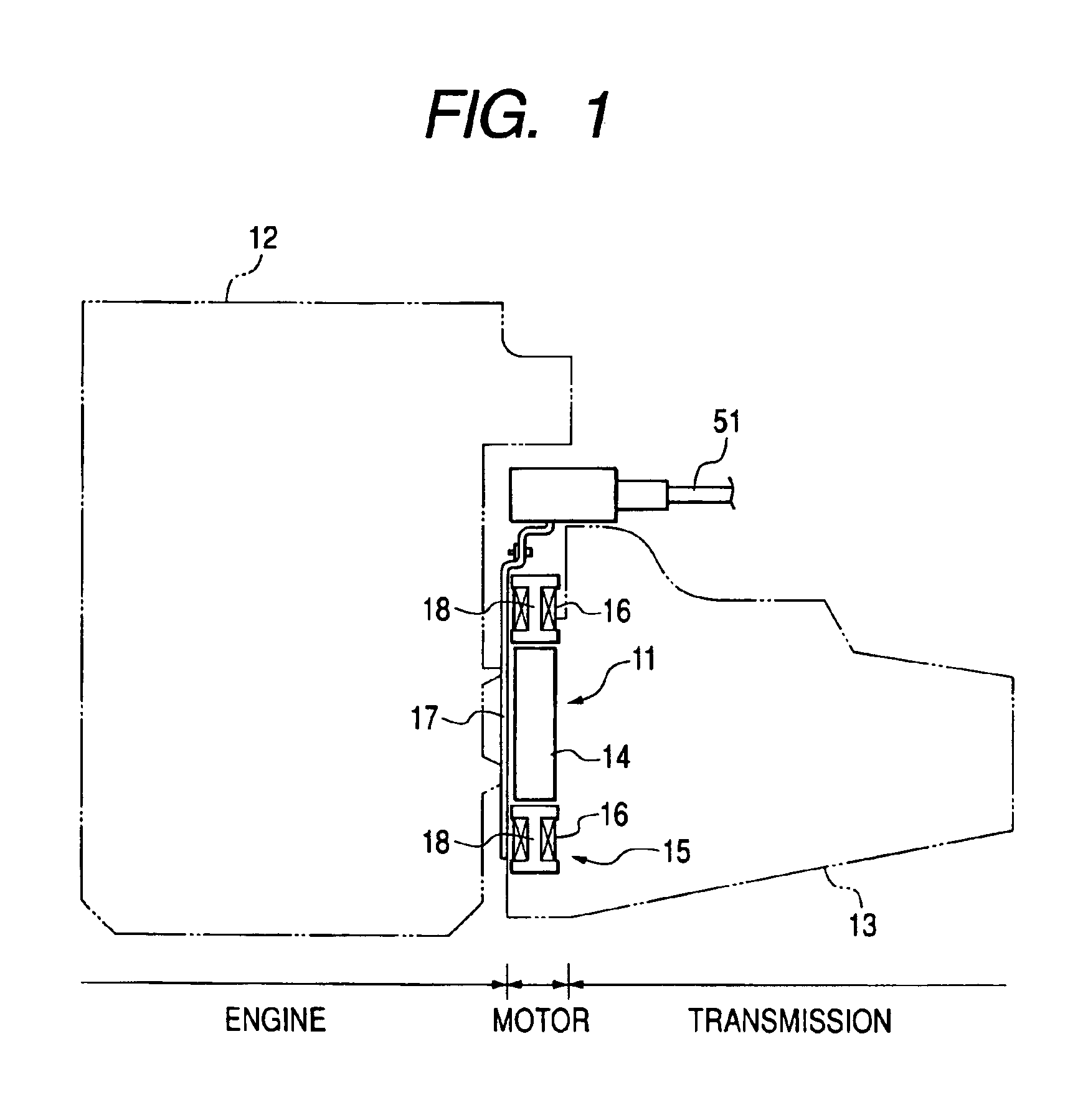

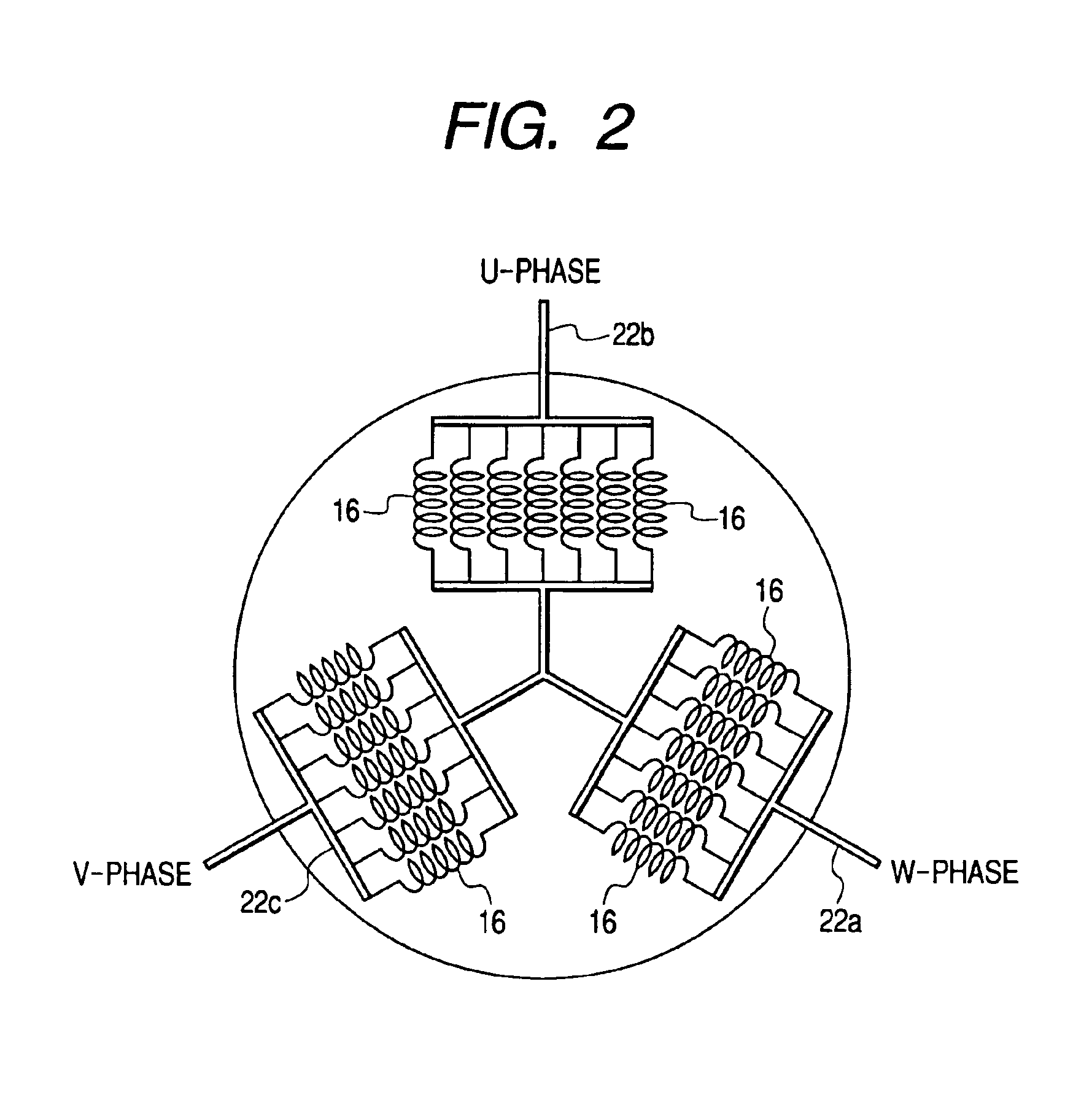

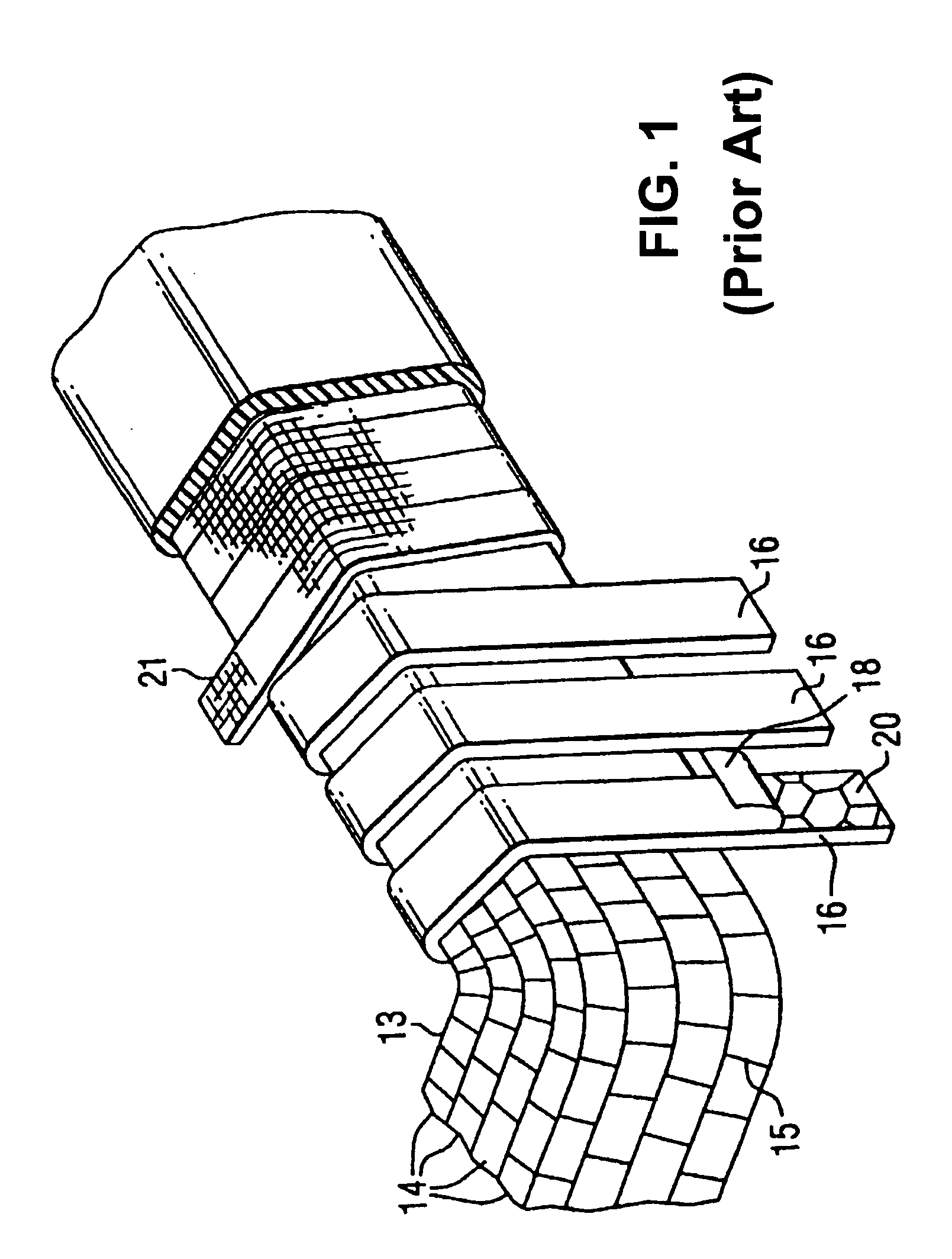

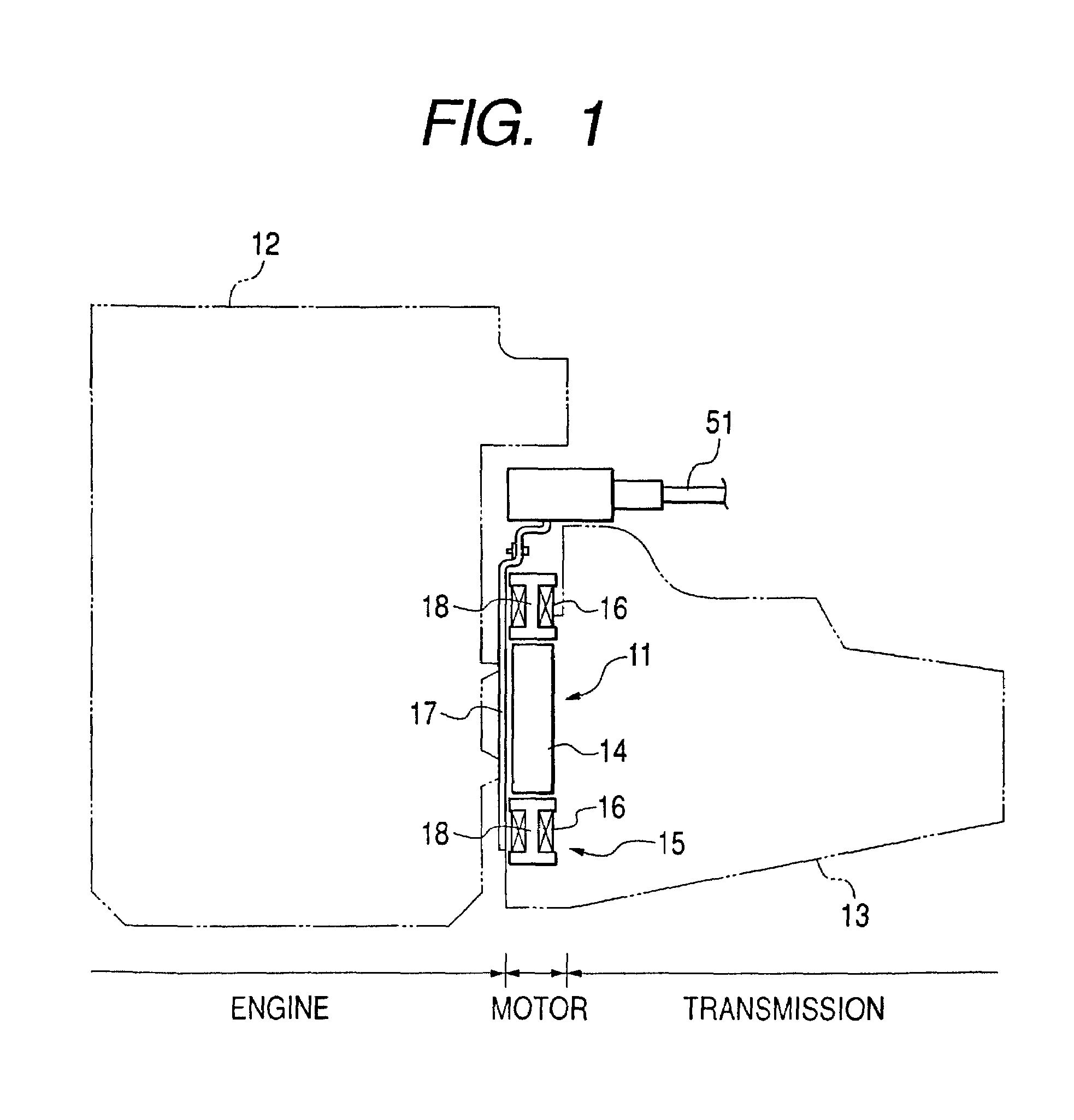

Centralized power distribution unit having bus bars accommodated in holding grooves of insulating holders

InactiveUS6930418B2Reduced in thickness and production cost and weightHigh demand for a vehicular motorPrinted circuit assemblingRotary current collectorBrushless motorsElectrical battery

A centralized power distribution unit for a vehicular thin brushless motor includes a plurality of bus bars, an insulating holder that holds the bus bars to form a predetermined gap between the bus bars, and a resin insulating layer that covers the bus bars. Each of the bus bars has a terminal portion to be connected to a power source, such as a battery, and a tab to be connected to a winding of a stator. The bus bars are disposed correspondingly with phases of the motor. A plurality of holding grooves are formed in the insulating holder. The bus bars, which are pre-bent in a thickness direction to be shaped into a substantially annular shape, are respectively accommodated in the holding grooves. The pre-bending is preferably carried out by a bending machine.

Owner:SUMITOMO WIRING SYST LTD +1

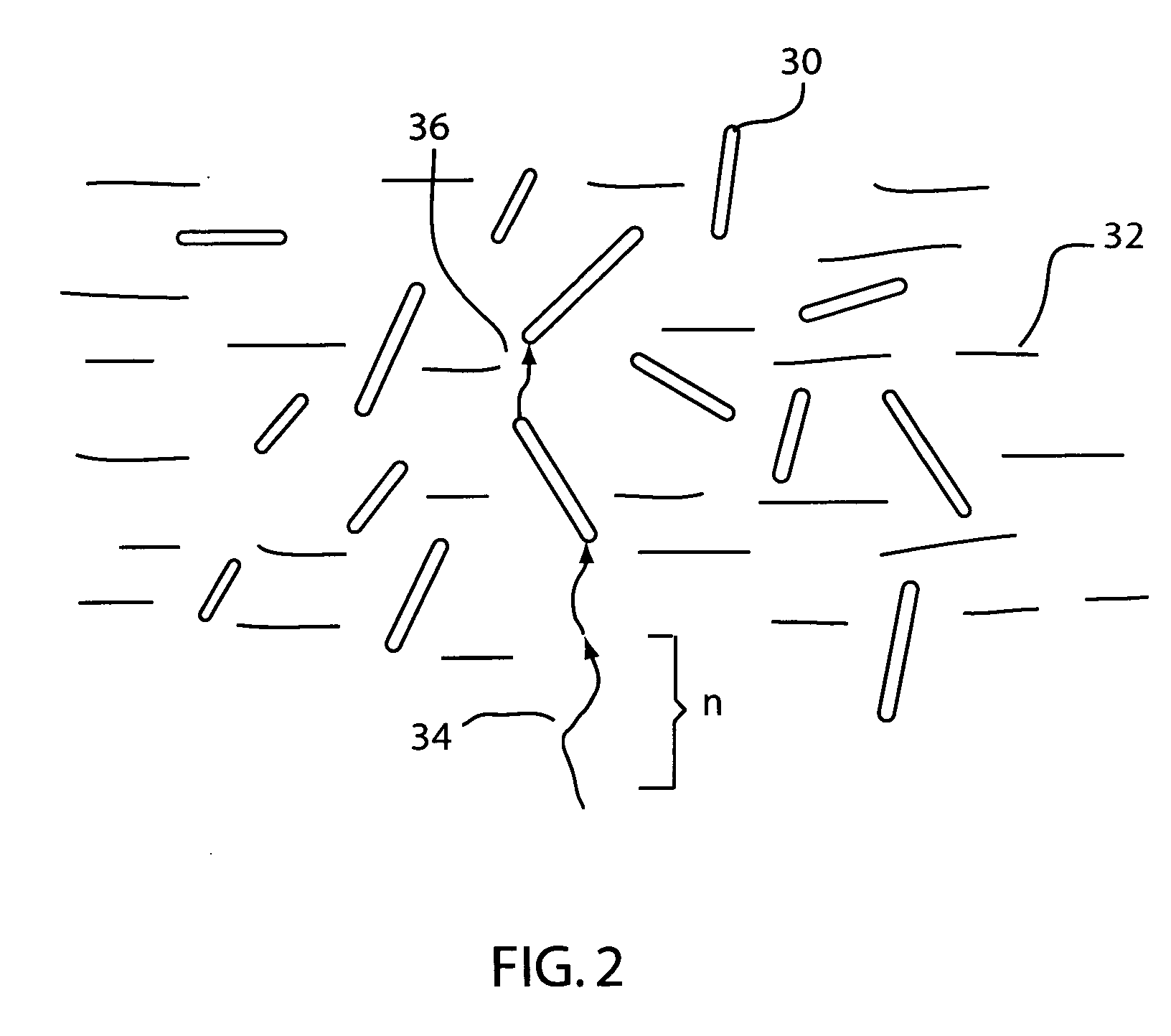

Mix of grafted and non-grafted particles in a resin

InactiveUS20060281833A1Easy to transportReduce distanceSynthetic resin layered productsSpecial tyresResin matrixMaterials science

In one application the mix grafted and non grafted invention provides for high thermal conductivity resin that comprises a host resin matrix 32 with a first class of grafted 31 high thermal conductivity particles that are grafted to the host resin matrix. Also a second class of non-grafted 30 high thermal conductivity particles that are not directly grafted the host resin matrix 32. The first class and the second class comprise approximately 2-60% by volume of the high thermal conductivity resin. The first class of grafted particles and the second class of non-grafted particles are high thermal conductivity fillers are from 1-1000 nm in length, and have an aspect ratio of between 3-100.

Owner:SIEMENS ENERGY INC

Fluoropolymer/particulate filled protective sheet

InactiveUS20100092759A1Low moisture transmissionOpacity of be controlMouldsSynthetic resin layered productsEngineeringElectrical and Electronics engineering

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

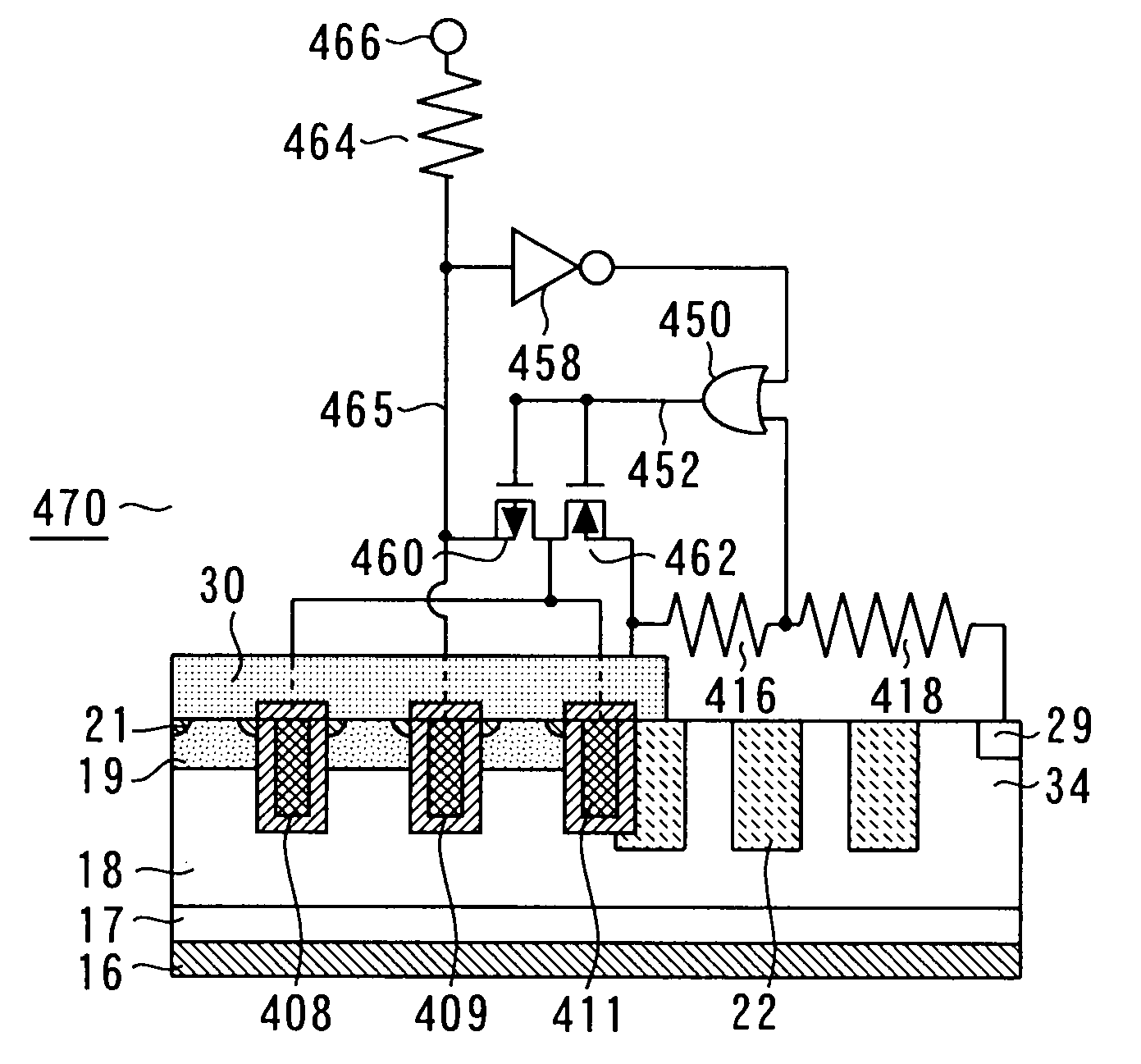

Semiconductor device

InactiveUS20100118455A1High dielectric strengthTransistorSemiconductor/solid-state device detailsDevice formSemiconductor package

A semiconductor device includes a semiconductor substrate including a semiconductor layer, a power device formed in the semiconductor substrate, a plurality of concentric guard rings formed in the semiconductor substrate and surrounding the power device, and voltage applying means for applying successively higher voltages respectively to the plurality of concentric guard rings, with the outermost concentric guard ring having the highest voltage applied thereto.

Owner:MITSUBISHI ELECTRIC CORP

Two-way stretched polyester thin-film of capacitor and its production

InactiveCN1897178AHigh dielectric strengthImprove thermal stabilityFixed capacitor dielectricPolyesterFrictional coefficient

A biaxially oriented polyester film with high dielectric intensity in thin type can be used on capacitor and it has features as surface resistance being greater than 1x1014, relative dielectric constant being greater than 2.8, DC dielectric intensity being greater than 450 and frictional coefficient being less than 0.60. Its preparing method includes using proper additives and polyester pellets as raw material, utilizing special polyester film production device and applying biaxially oriented polyester film process to prepare said biaxially oriented polyester film.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

Laminated body, separator, and nonaqueous secondary battery

ActiveUS20170033348A1Easy injectionHigh dielectric strengthFinal product manufactureLayered productsPolyolefinPorous layer

A laminated body of the present invention includes: a porous film containing a polyolefin as a main component; and a porous layer containing a resin, the laminated body satisfying (A)>(B), where (A) represents the amount of an increase in the dielectric strength with respect to the amount of an increase in the amount of the resin contained per unit area of the porous layer, and (B) represents the amount of an increase in the dielectric strength with respect to the amount of an increase in the amount of the polyolefin contained per unit area of the porous film. The laminated body is usable as a secondary battery separator having a higher dielectric strength.

Owner:SUMITOMO CHEM CO LTD

Method for producing centralized distribution unit of thin brushless motor for vehicle

InactiveUS6993829B2Superior waterproof-nessSuperior airtight-ness functionLine/current collector detailsWindingsBrushless motorsInsulation layer

In a method of producing a centralized distribution unit of a thin brushless motor for a vehicle having superior waterproof-ness and airtight-ness functions, and high dielectric strength, an insulating holder is provided with bearing recesses. Bus bars are bent from a substantially linear shape into a substantially annular shape, and inserted into holding grooves formed in the insulating holder. The insulating holder and bus bars are disposed in a molding cavity, and distal ends of holder supports that project from an inner wall of the molding cavity are engaged with the bearing recesses of the insulating holder. Resin is supplied into the molding cavity to form an insulation layer that covers the bus bars and an entire periphery of the insulating holder.

Owner:SUMITOMO WIRING SYST LTD

Diamond dotted glue composite dielectric paper and preparation method thereof

ActiveCN101424060AImprove performanceHigh dielectric strengthPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsFiberPolyester

The invention discloses rhombus dispensing composite insulating paper, which is characterized in that the insulating paper consists of a polyester film layer, polyester fiber non-woven fabric layers for electrician insulation adhered to the upper surface and the lower surface of the polyester film layer by an F grade polyurethane adhesive, and a modified epoxy resin coated on the surfaces of the polyester fiber non-woven fabric layers for the electrician insulation in a rhombus shape. A method for preparing the rhombus dispensing composite insulating paper comprises the steps of preparing three layers of composite materials and preparing the rhombus dispensing composite insulating paper and so on. The adoption of the method has good product performance and a simple production technology, can save the manufacturing cost for an oil-immersed power transformer, and improve the quality; and a product of the invention is particularly suitable for insulating materials which are used for inter-layer insulation and inter-turn insulation of a foil winding coil of the oil-immersed power transformer and the inter-turn insulation of a mutual inductor.

Owner:绵阳国顺电气有限公司

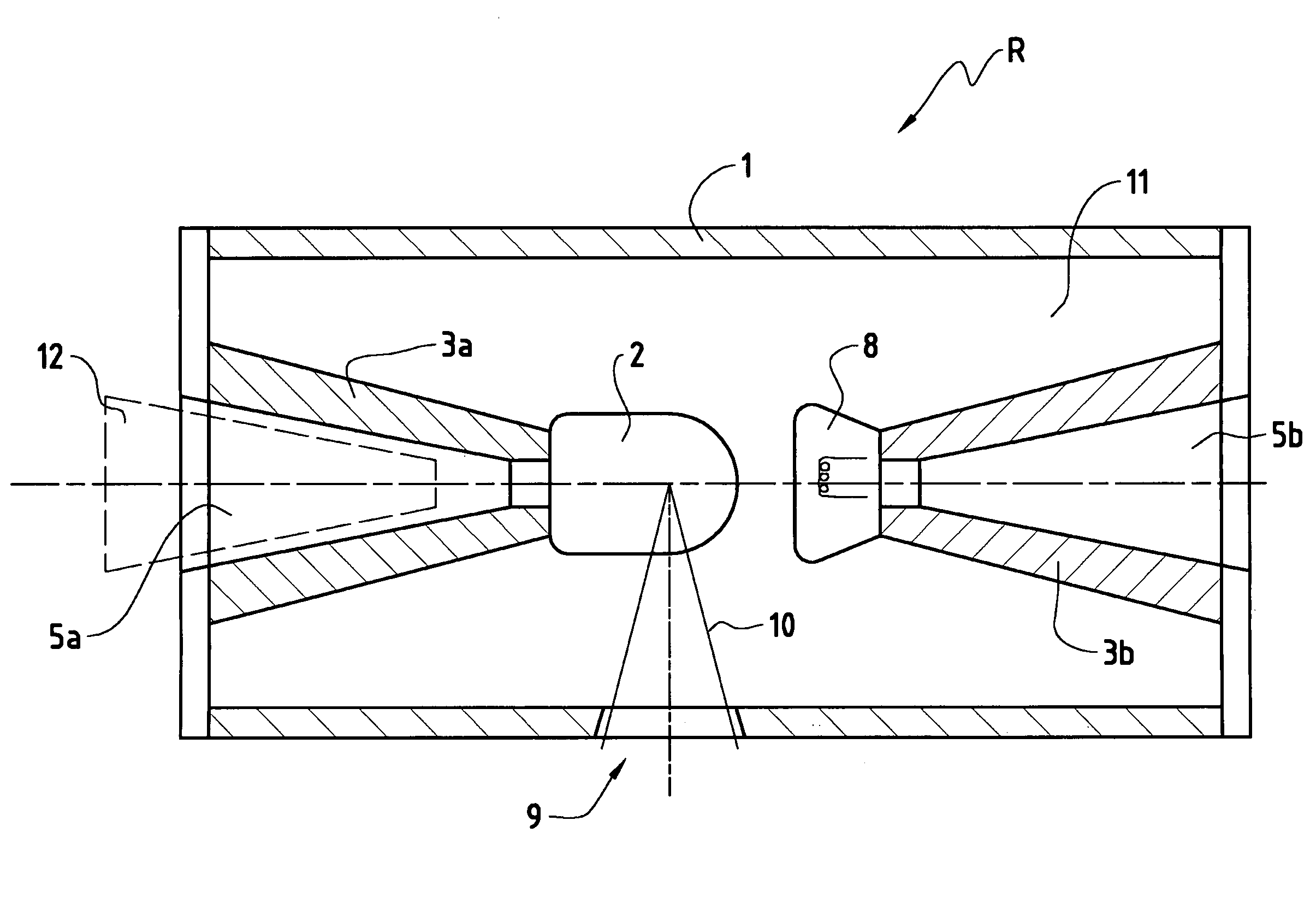

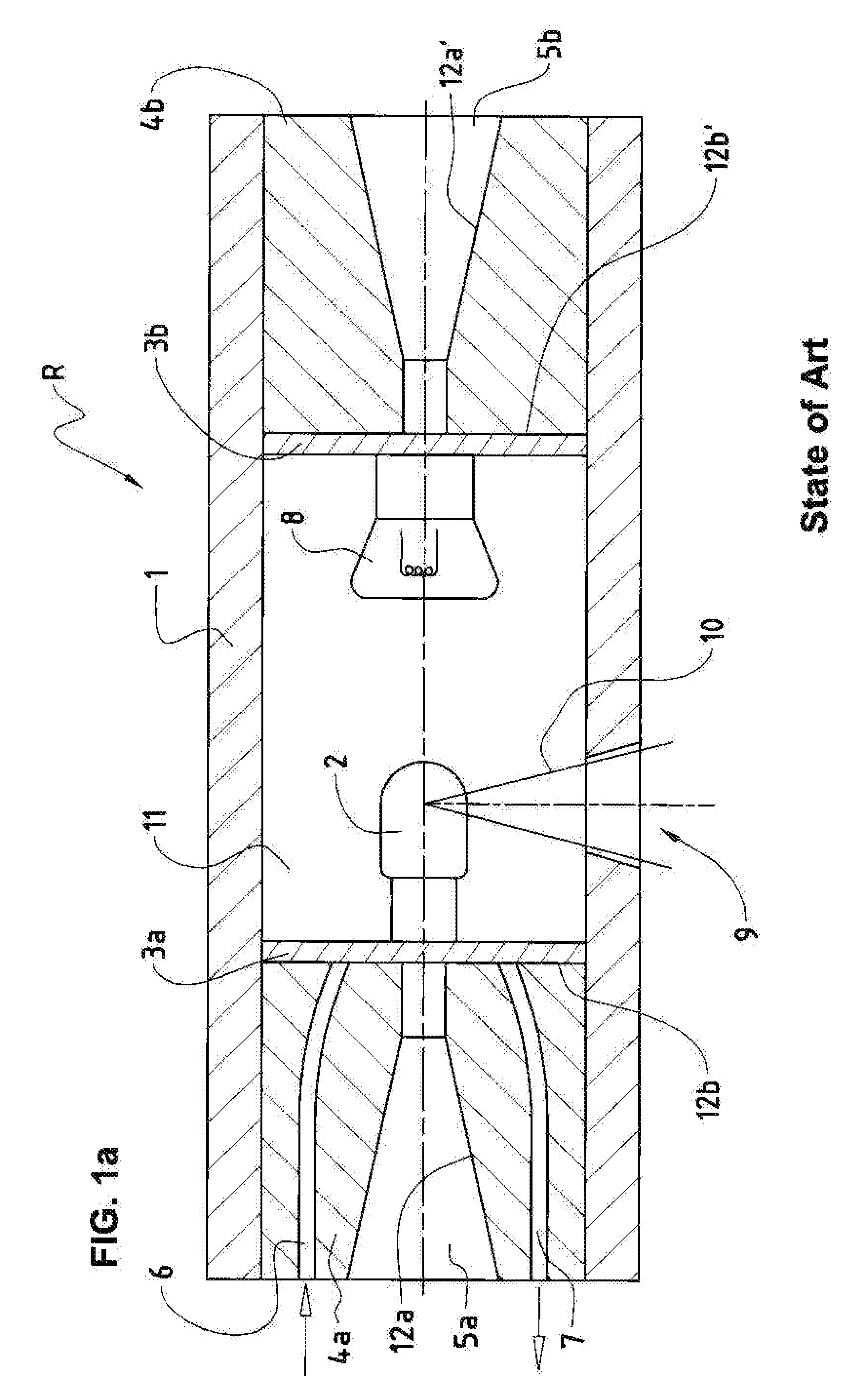

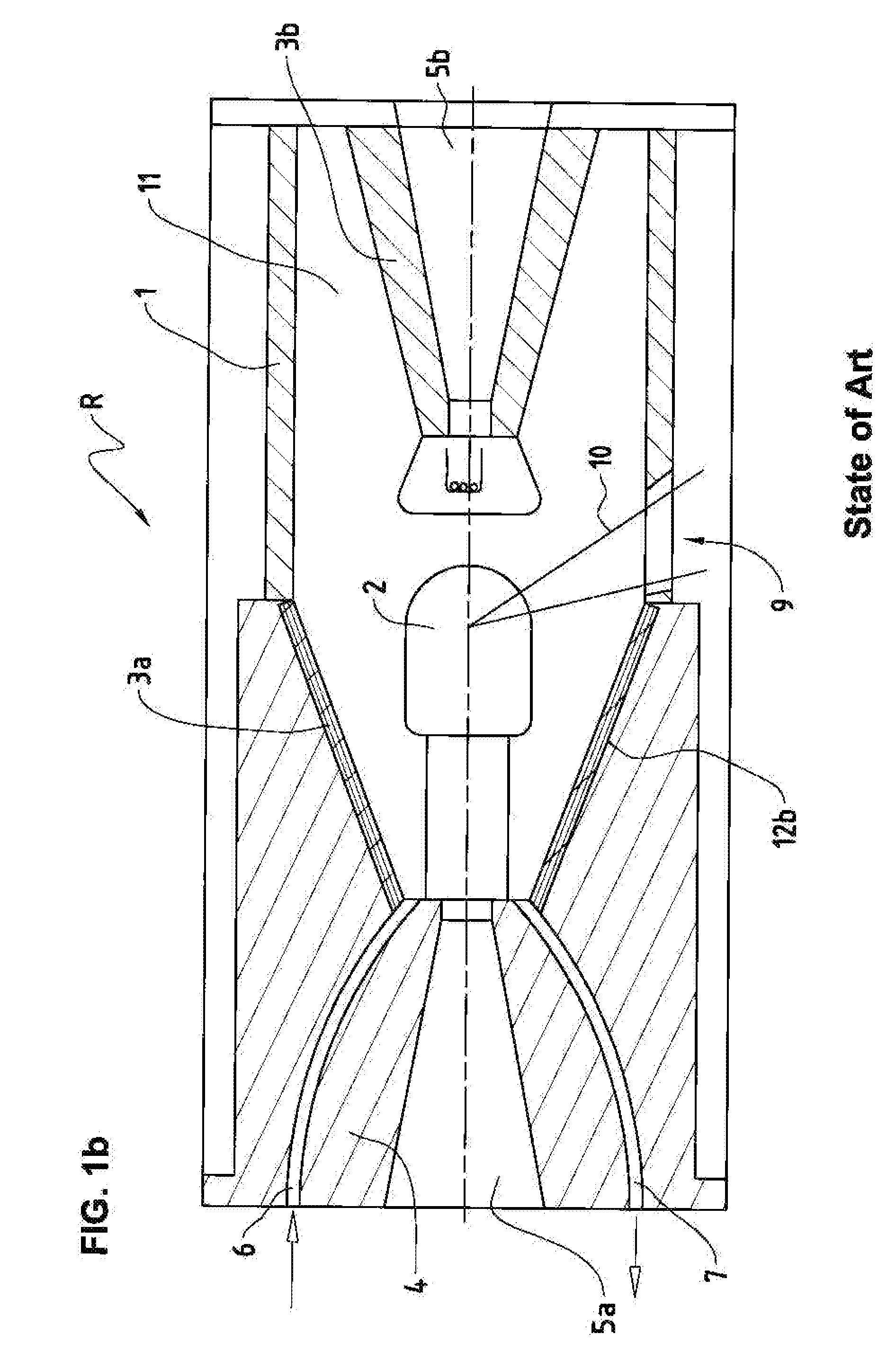

X-ray tube with an anode isolation element for liquid cooling and a receptacle for a high-voltage plug

ActiveUS20100111265A1Easy to controlOptimize pipeline structureX-ray tube electrodesX-ray tube vessels/containerElectrical conductorHigh pressure

The present invention relates to a high-voltage x-ray tube (R) with an inner vacuum chamber (11) in which lie, oriented opposite one another, a cathode (8) held at a negative high voltage during operating conditions and an anode (2) held at a positive high voltage during operating conditions, wherein the anode (2) is affixed to an anode isolation element (3a) such that the anode isolation element (3a) has a cylindrical form or a form tapering toward the anode (2) and comprises an opening (5a) to receive a high-voltage plug (12) and has a conductor structure (6 / 7) via which a coolant can be supplied to the anode (2). This coolant can be, in particular, an insulating oil or another electrically nonconductive liquid. The conductor structure (6 / 7) can, for example, be integrated completely into the interior of the anode isolation element (3a) but can also be integrated into the surface of the high-voltage plug (12). In another possible solution, the conductor structure (6 / 7) is integrated into an intermediate element (13) which lies between the anode isolation element (3a) and the high-voltage plug (12).

Owner:COMET HOLDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com