Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Good cooling properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

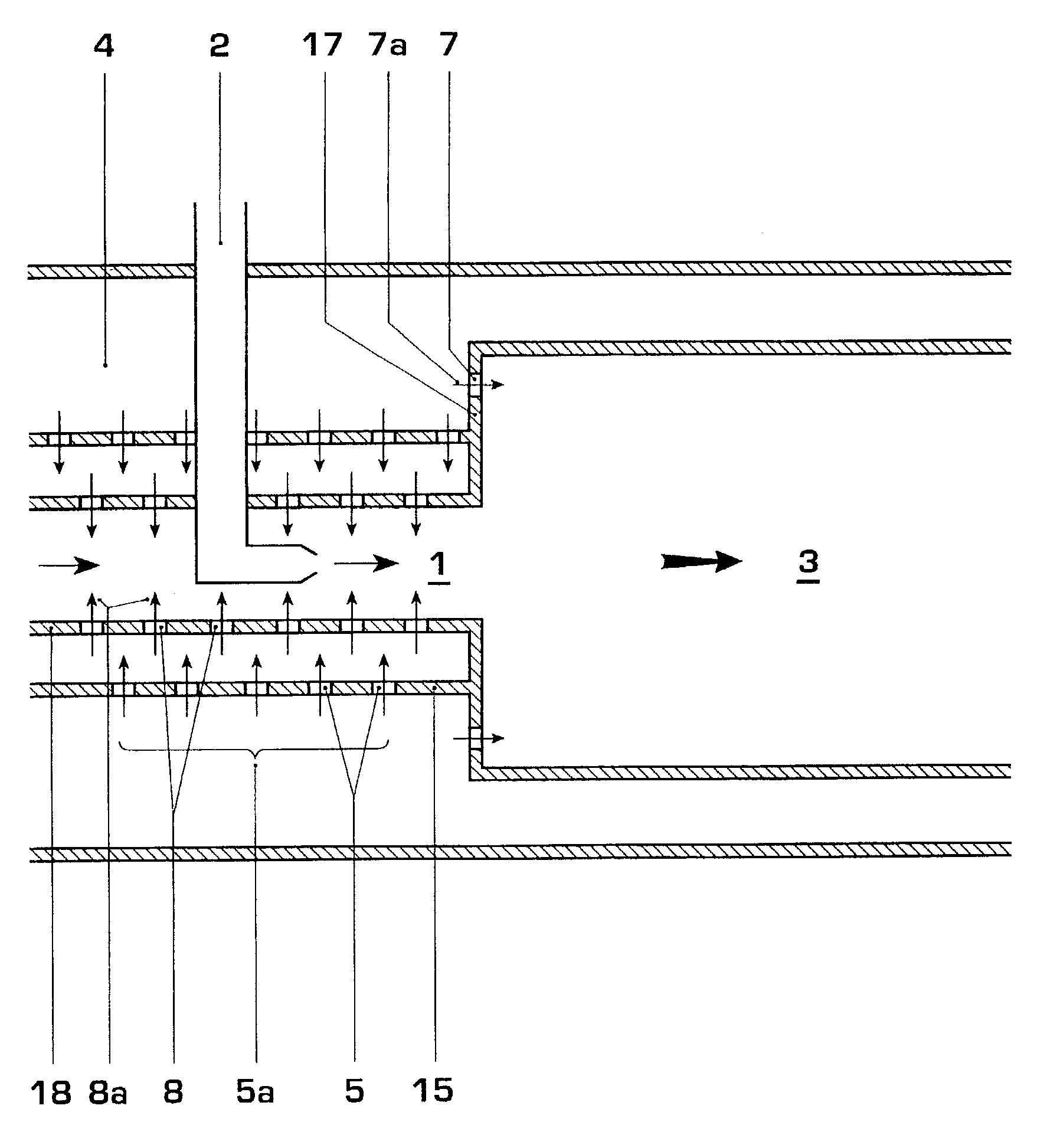

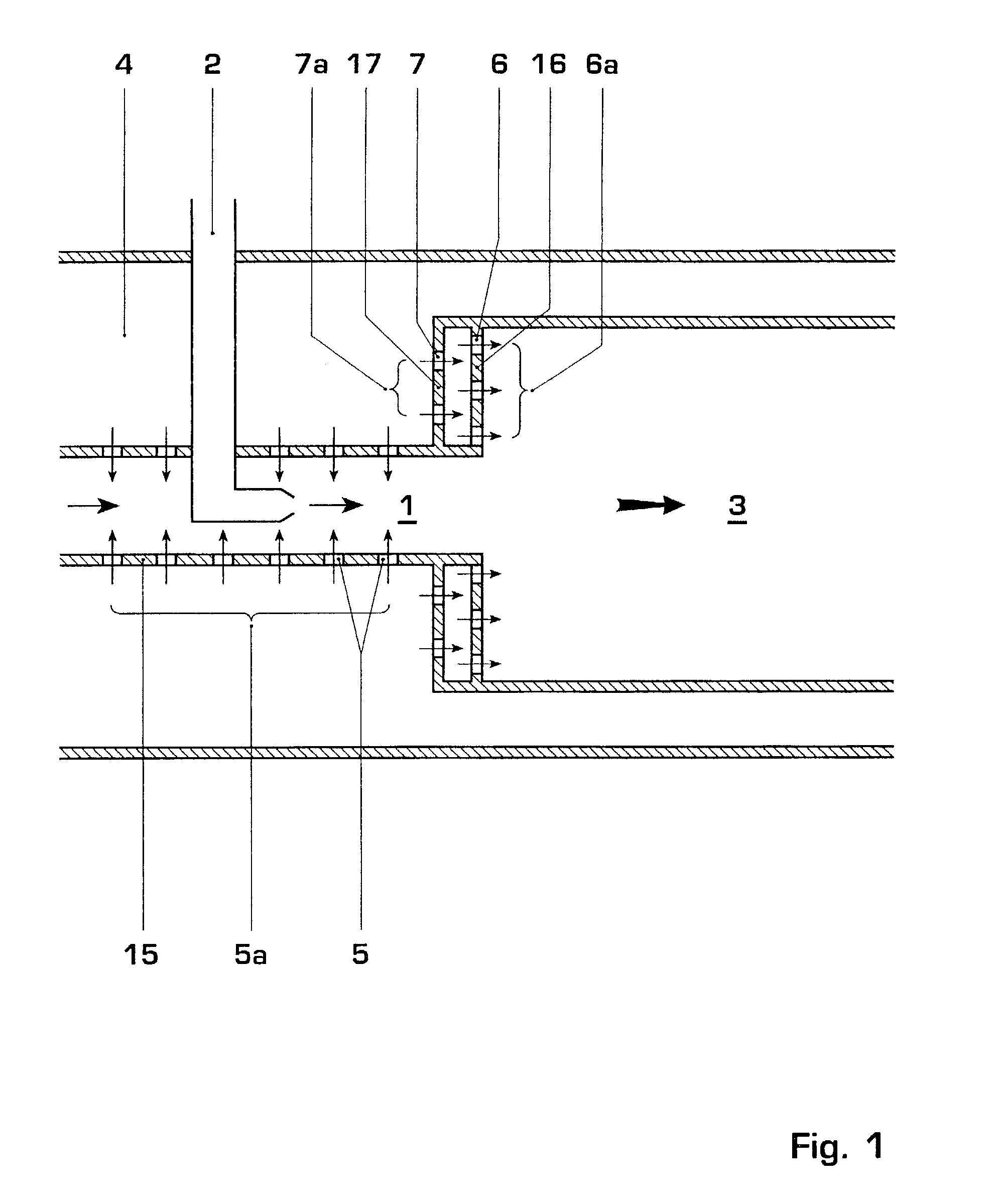

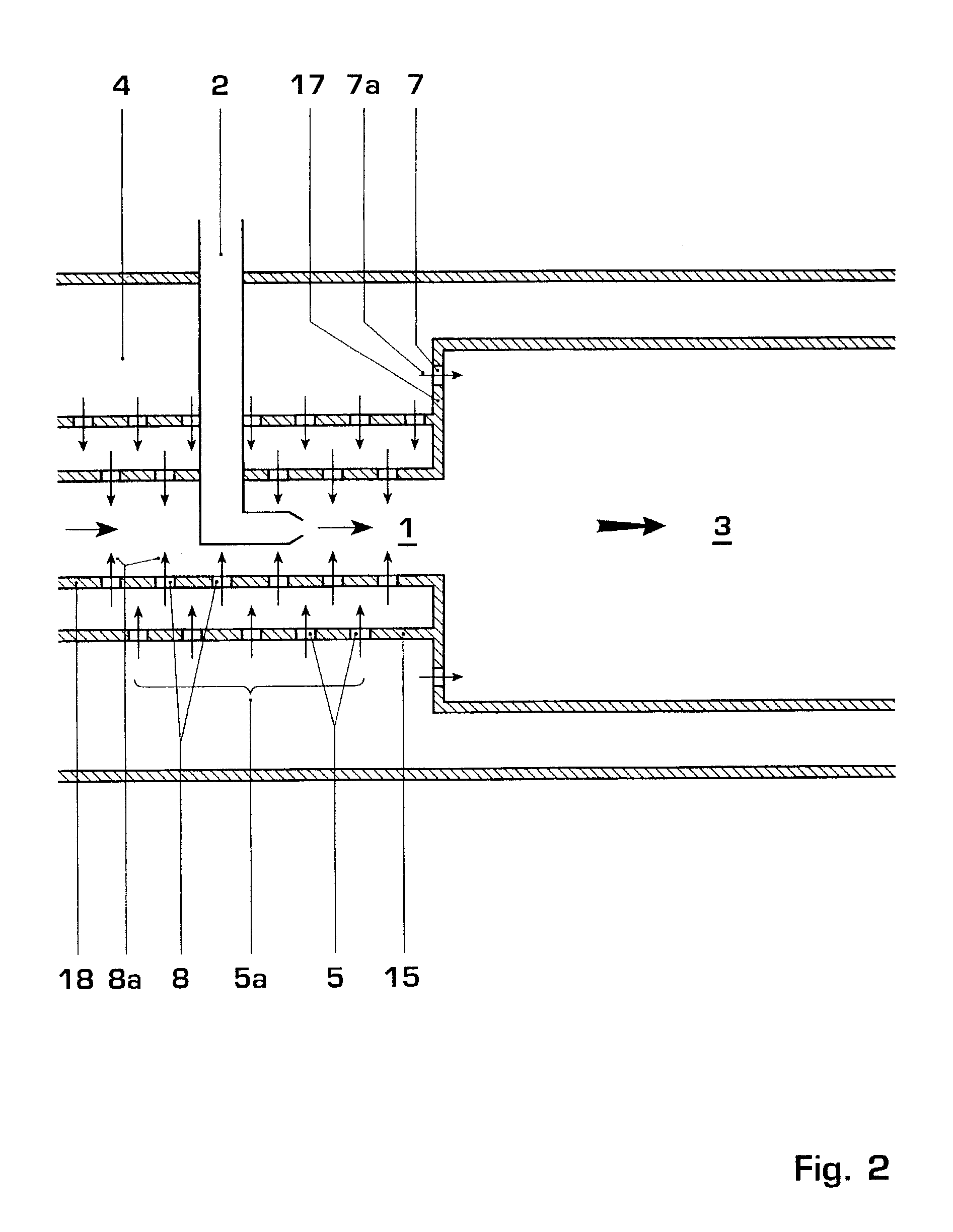

Reheat combustion system for a gas turbine

ActiveUS6981358B2Good cooling propertiesDamp pulsationBurnersContinuous combustion chamberCombustion systemCombustion chamber

A reheat combustion system for a gas turbine comprises a mixing tube adapted to be fed by products of a primary combustion zone of the gas turbine and by fuel injected by a lance; a combustion chamber fed by the said mixing tube; and at least one perforated acoustic screen. The or each said acoustic screen is provided inside the mixing tube or the combustion chamber, at a position where it faces, but is spaced from, a perforated wall thereof. In use, the perforated wall experiences impingement cooling as it admits air into the combustion system for onward passage through the perforations of the said acoustic screen, and the acoustic screen damps acoustic pulsations in the mixing tube and combustion chamber.

Owner:ANSALDO ENERGIA IP UK LTD

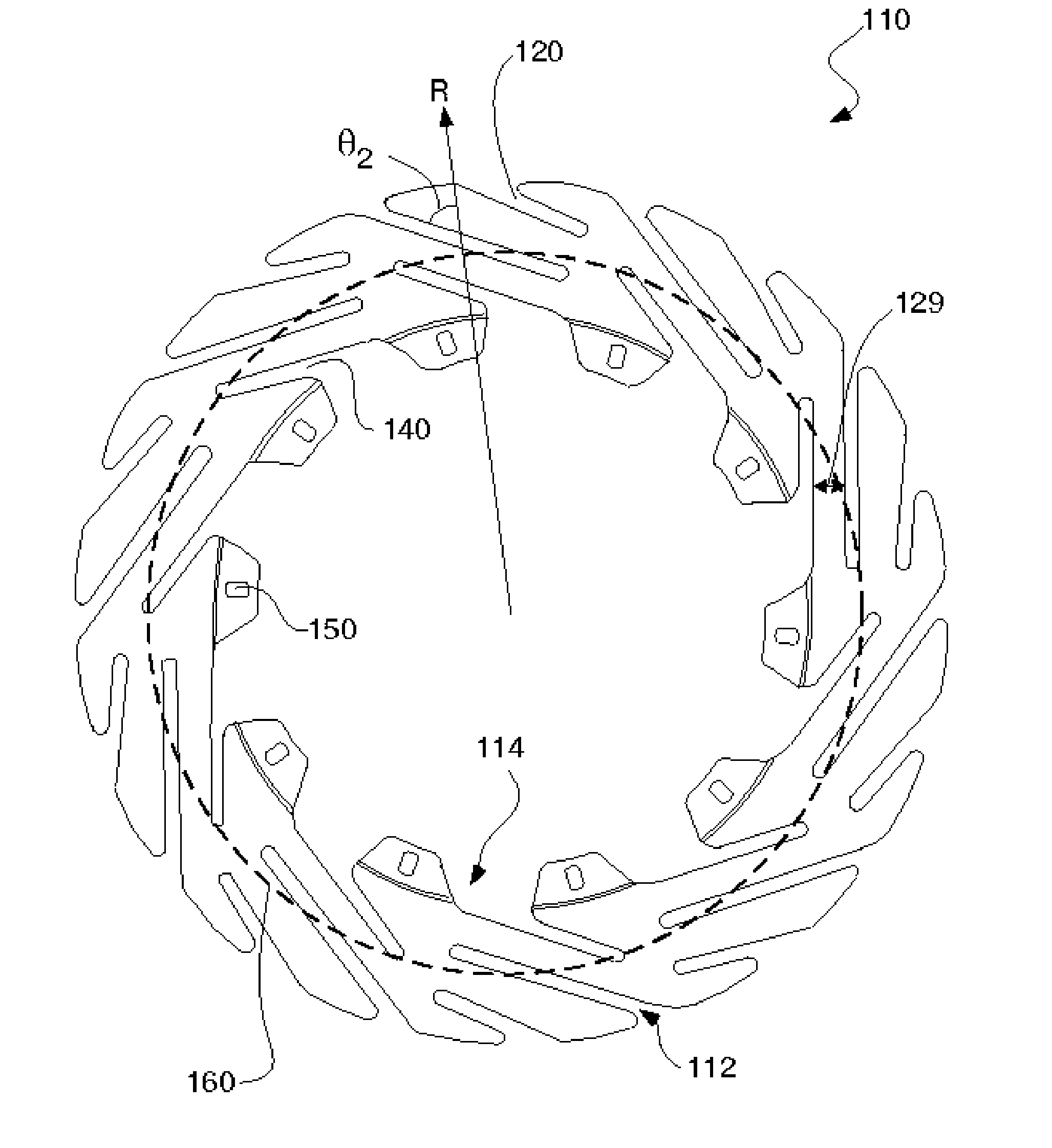

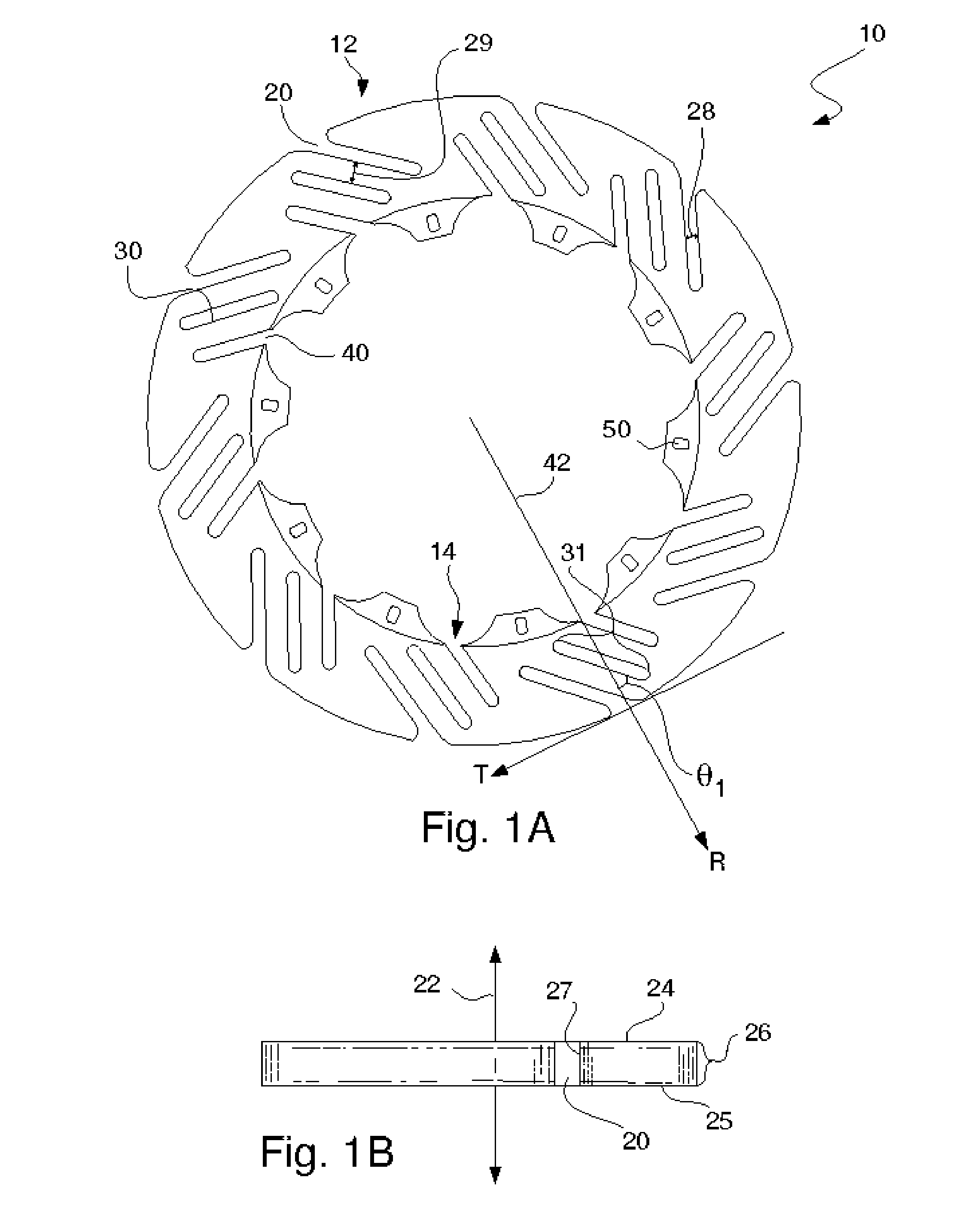

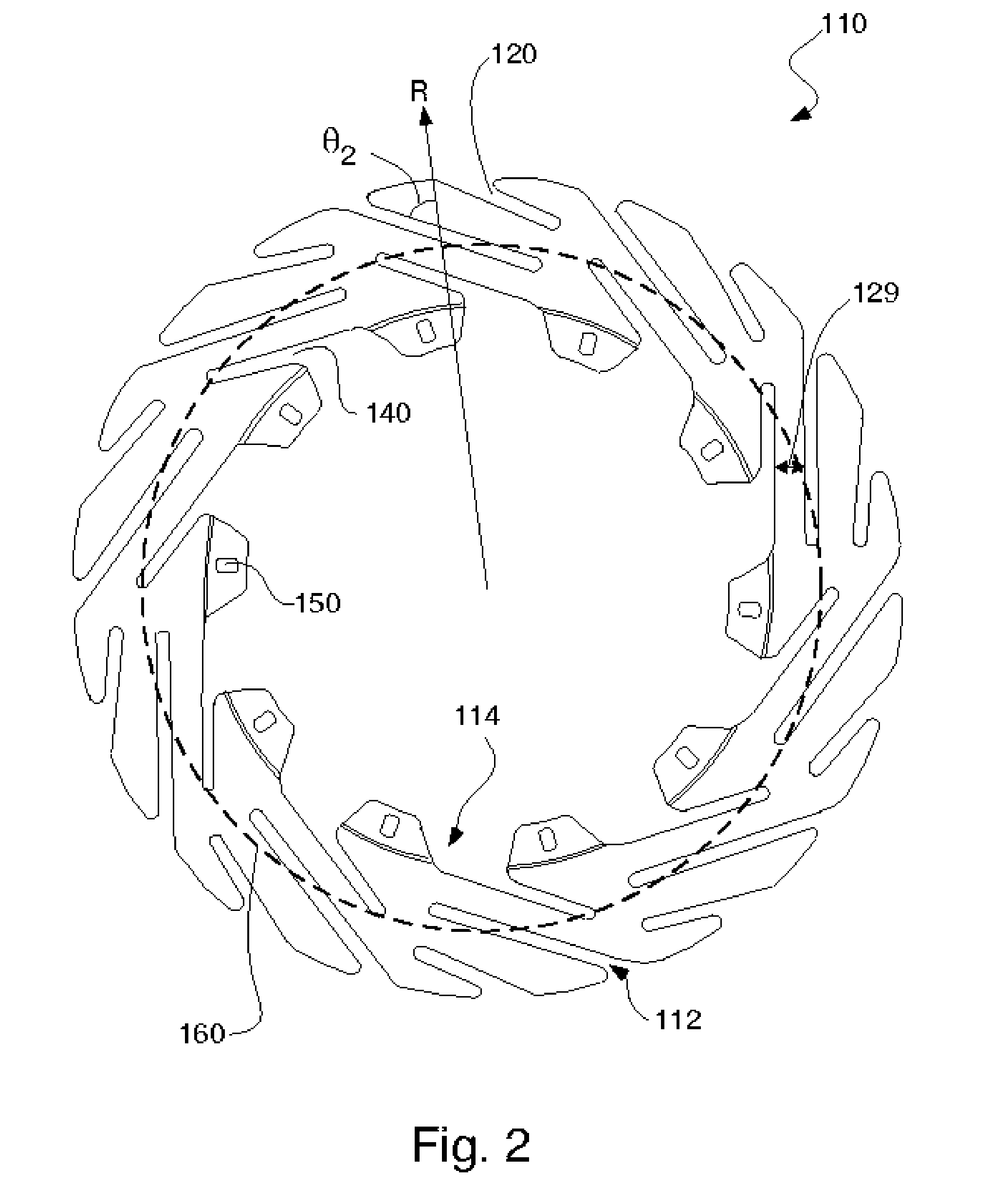

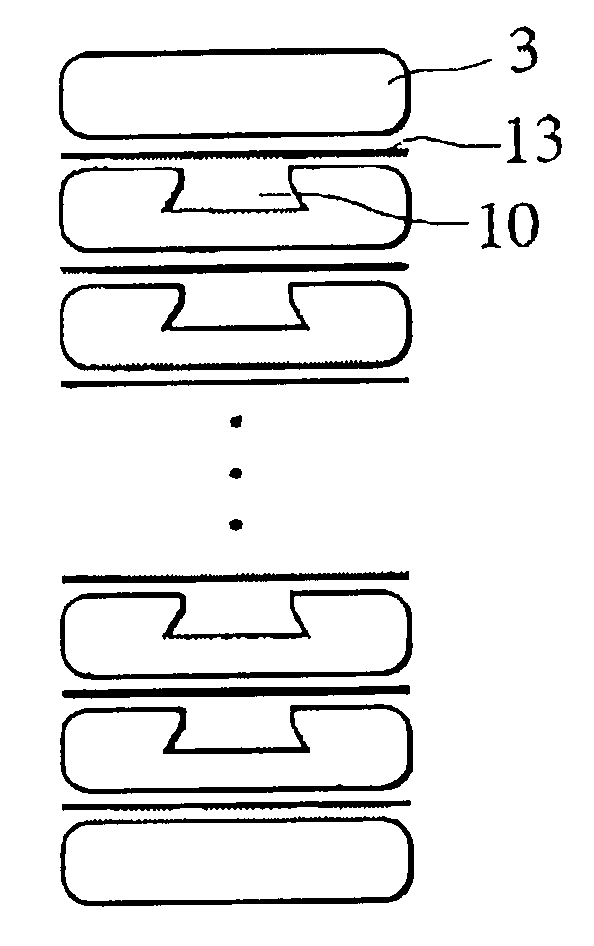

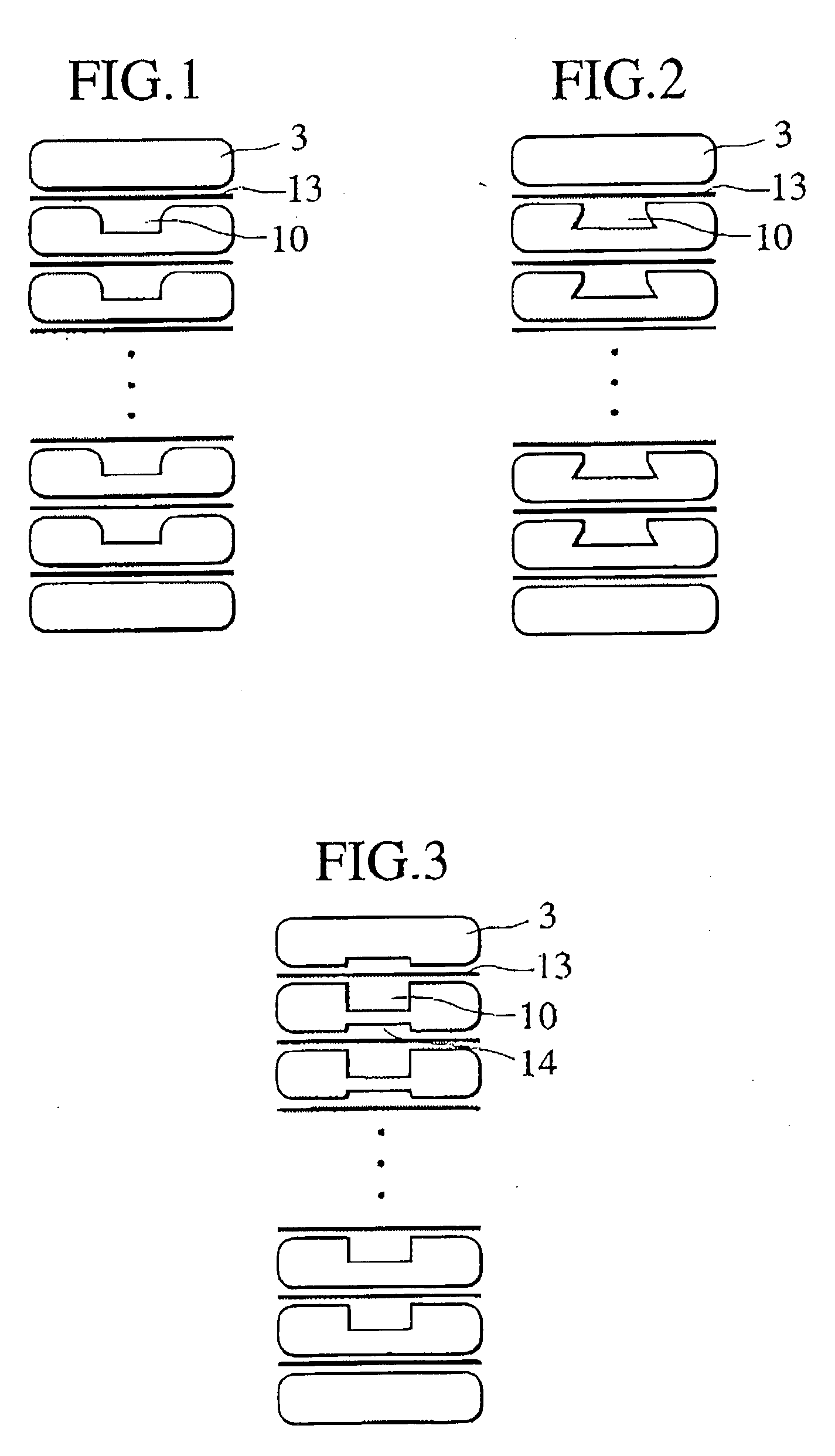

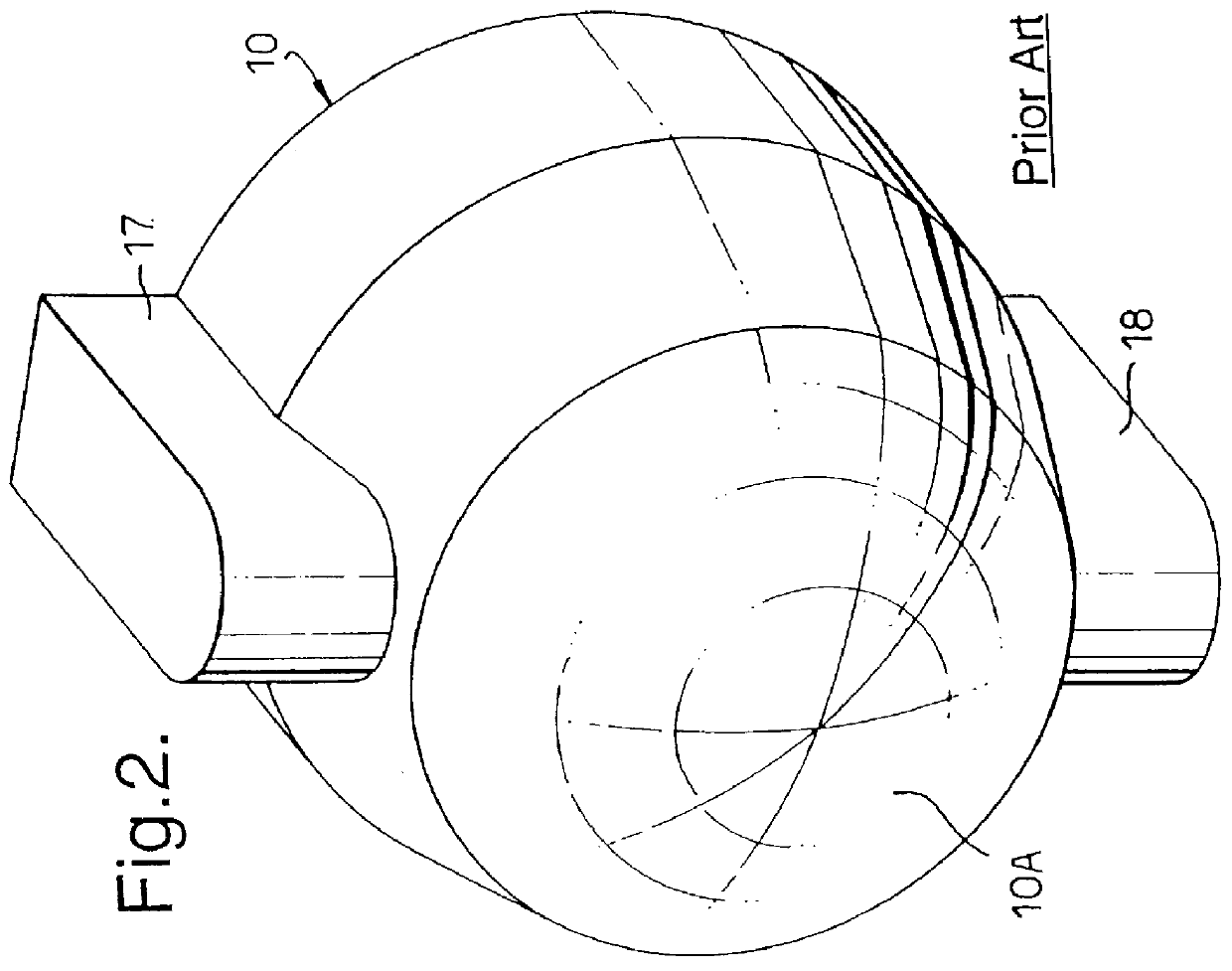

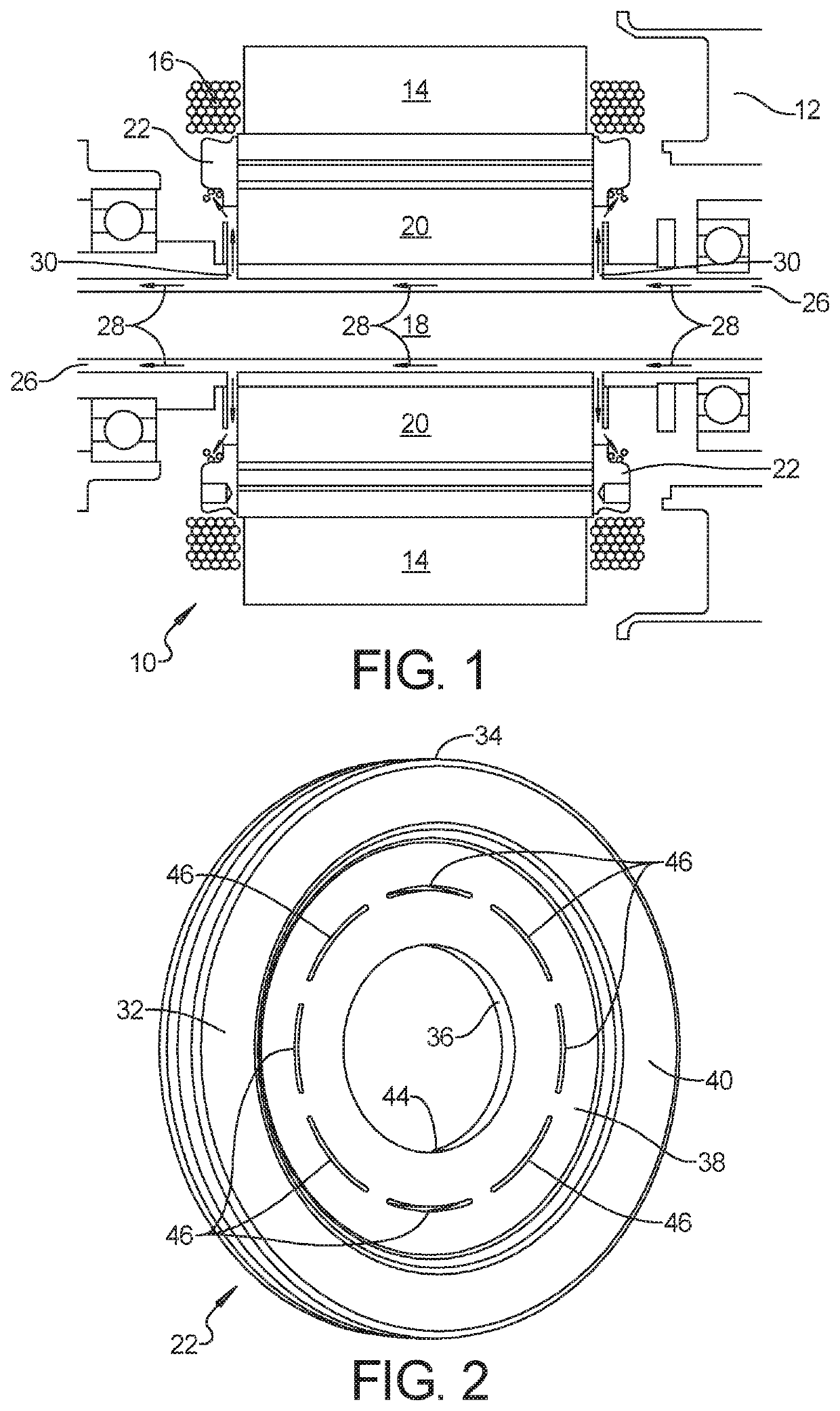

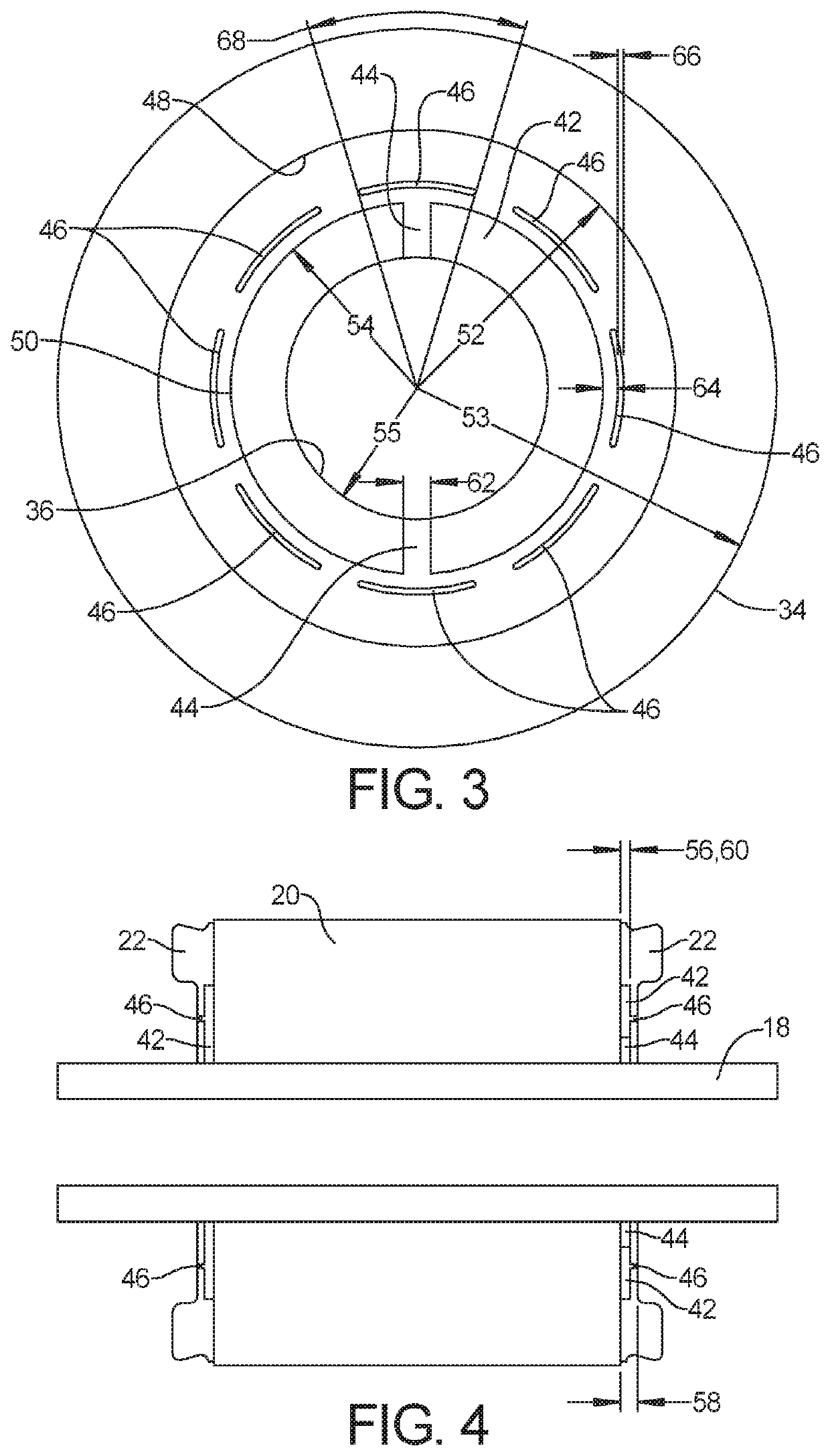

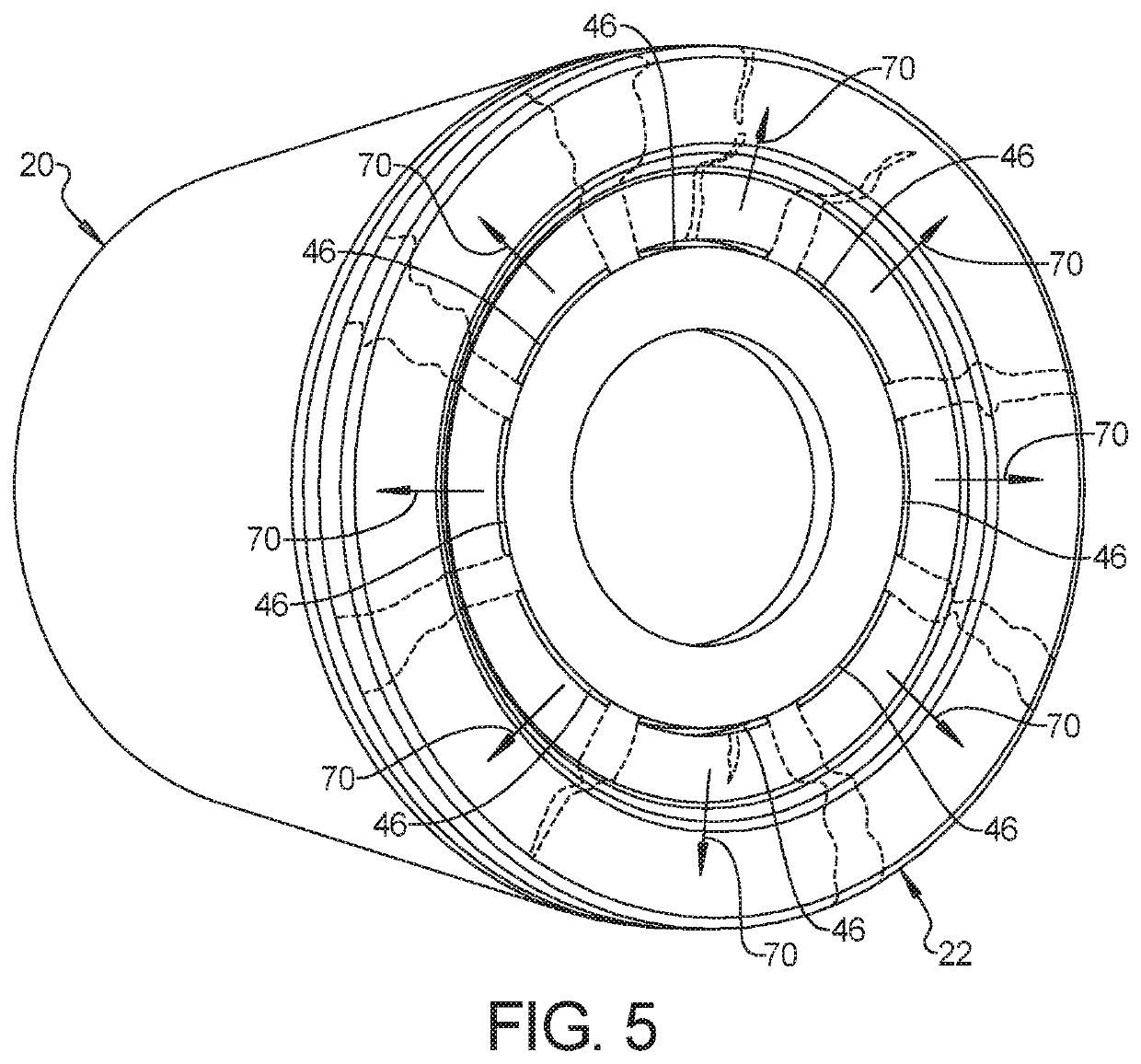

Method of making brake discs and rotors with open slots and brake discs and rotors made therewith

InactiveUS20050252739A1Improve cooling effectGood cooling propertiesBraking element arrangementsAxially engaging brakesEngineering

The present invention broadly comprises a brake disc having superior cooling characteristics and a method for manufacturing brake discs with superior cooling characteristics. The brake disc has at least one slot arranged at an angle greater than zero degrees and less than ninety degrees with respect to a radius of said disc passing through said slot. The angle can be selected to enhance cooling under specified conditions. Slots in the disc can open to an inner or outer perimeter of the disc or may be fully enclosed within the disc. The shape and width of the slots and the spacing between the slots can be selected to enhance cooling properties of the disc.

Owner:CALLAHAN FRED J +1

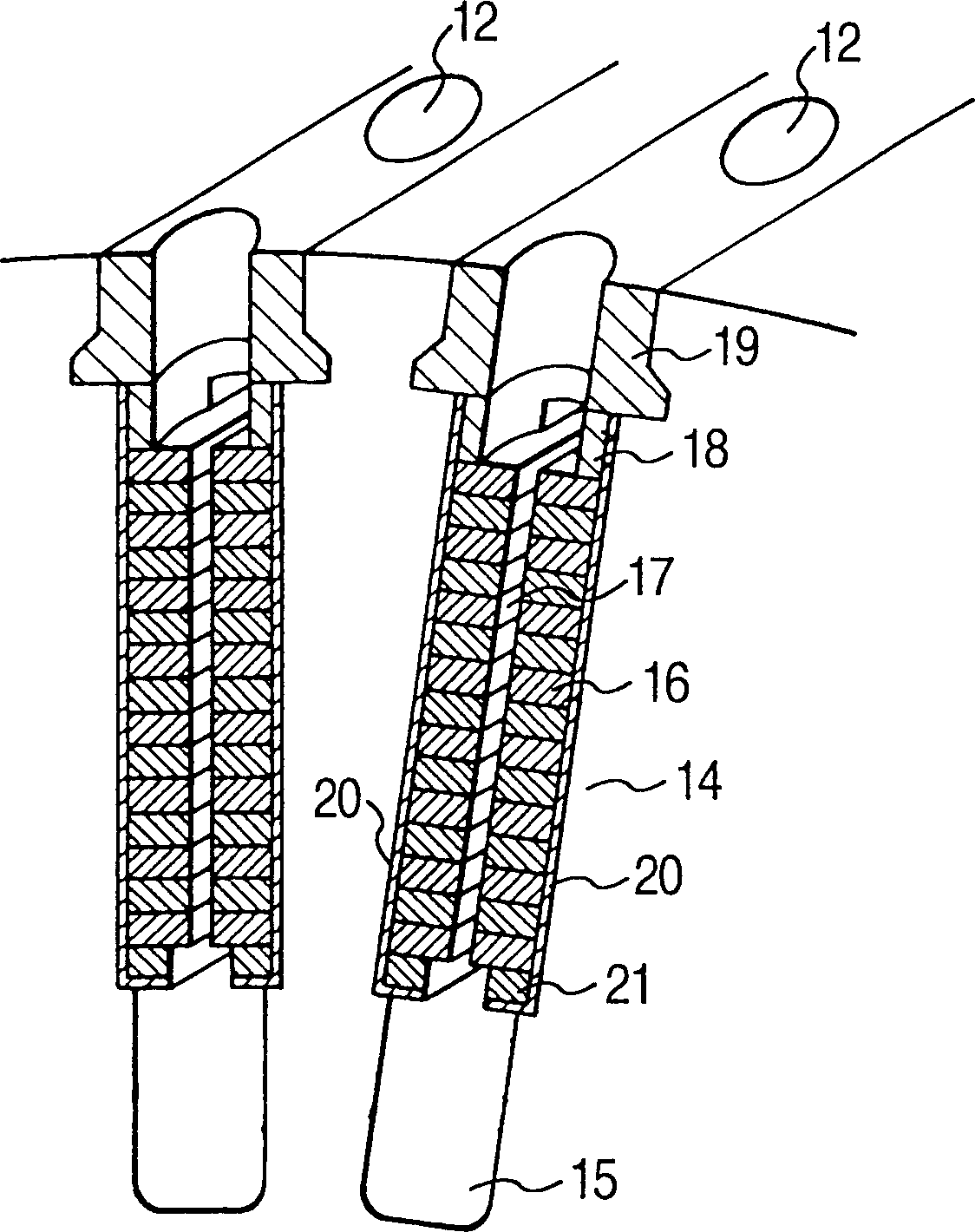

Multiple parallel conductor for electrical machines and devices

InactiveUS6563413B1Without impairing electrical characteristicGood cooling propertiesTransformers/inductances coolingTransformers/inductances coils/windings/connectionsElectrical conductorElectric machinery

Multiple parallel conductor for an electrical machine and process. The conductor includes a plurality of adjacent subconductors combined to form a subconductor bundle having an outer surface with a plurality of contiguous surface sections arranged in a longitudinal direction, and a flat protective insulation covering at least one of the plurality of surface sections. At least one of the plurality of surface sections remains uncovered by the flat protective insulation covering. A mesh sheathing further covers the plurality of surface sections.

Owner:ASTA ELEKTRODRAHT GMBH

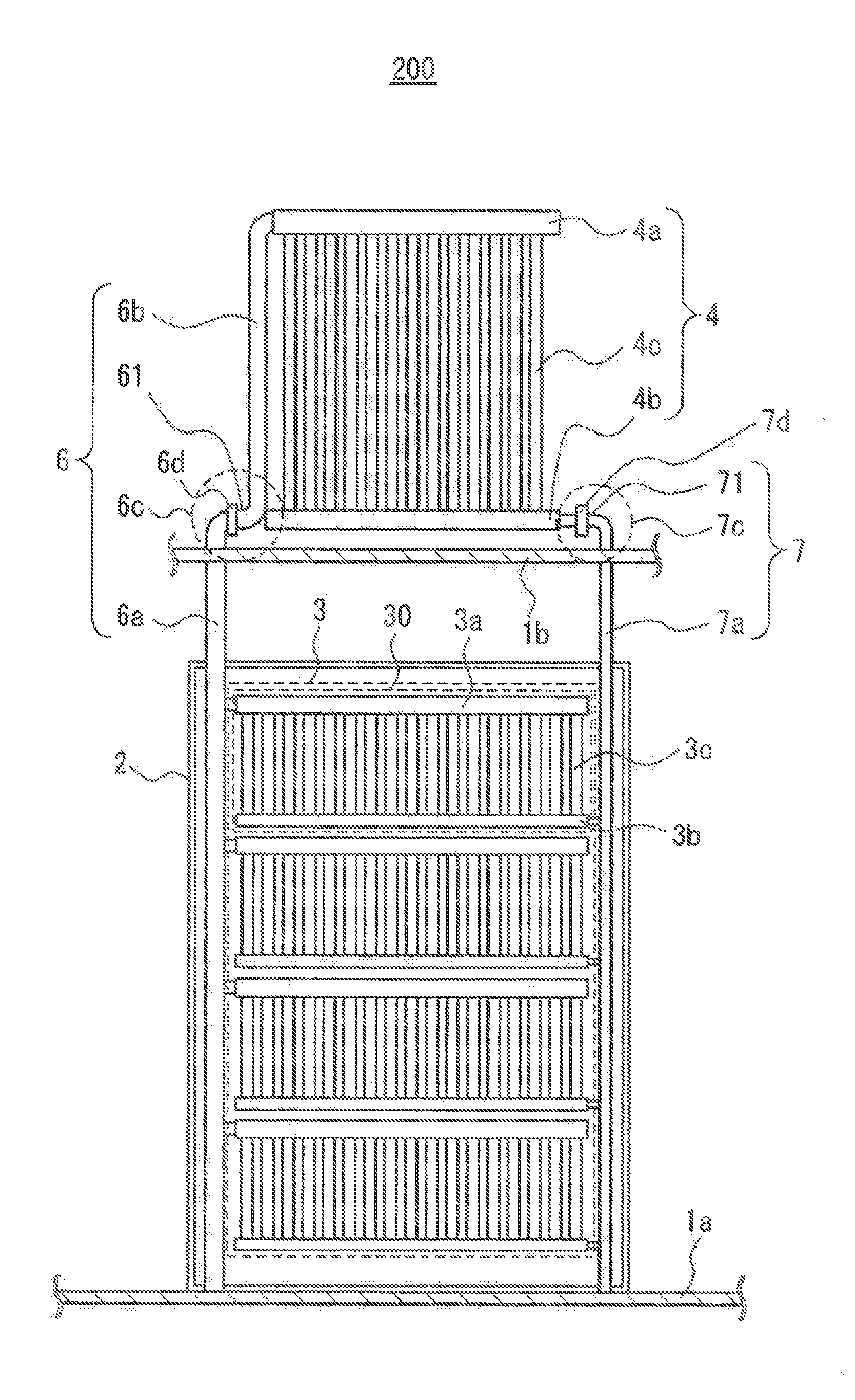

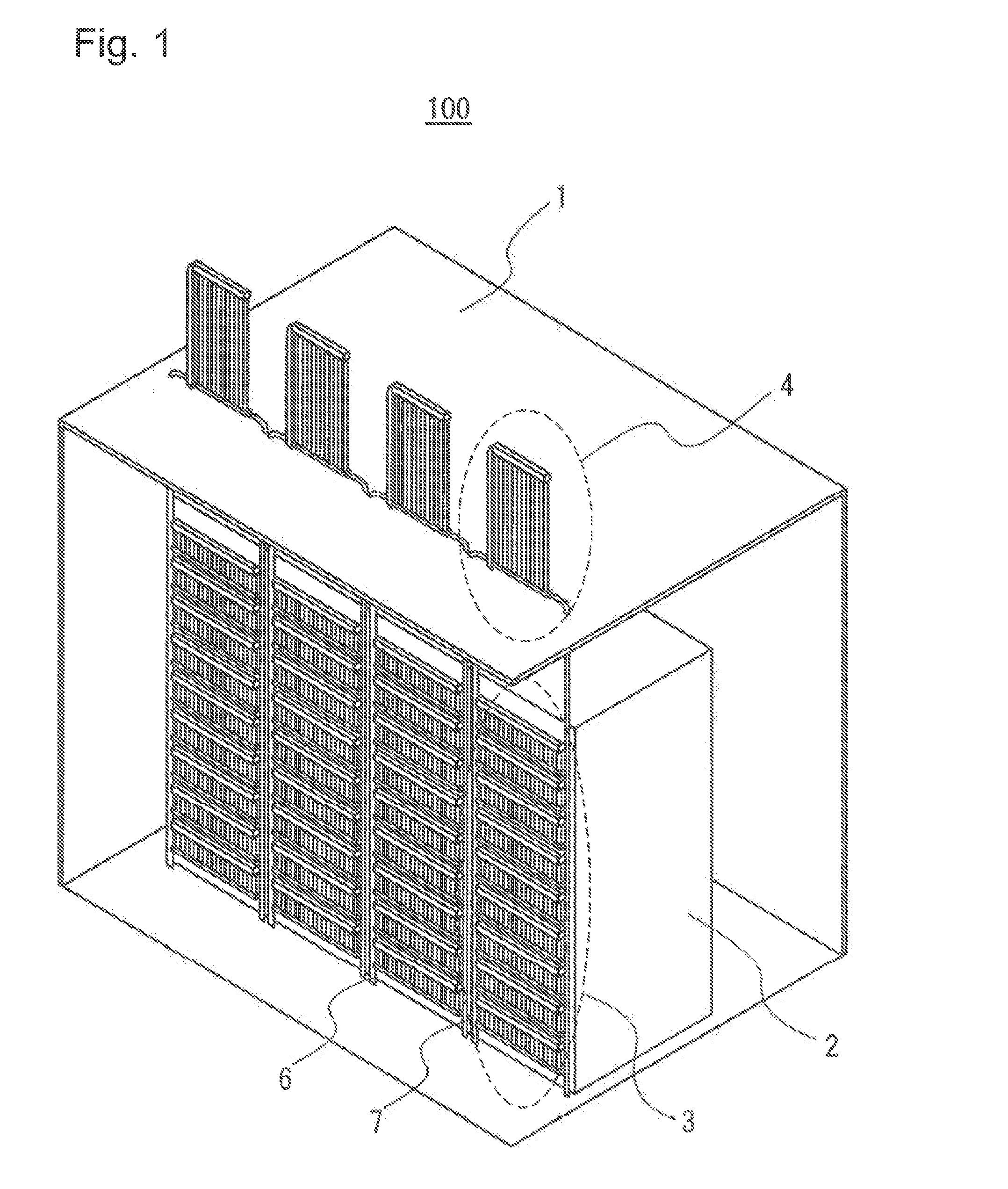

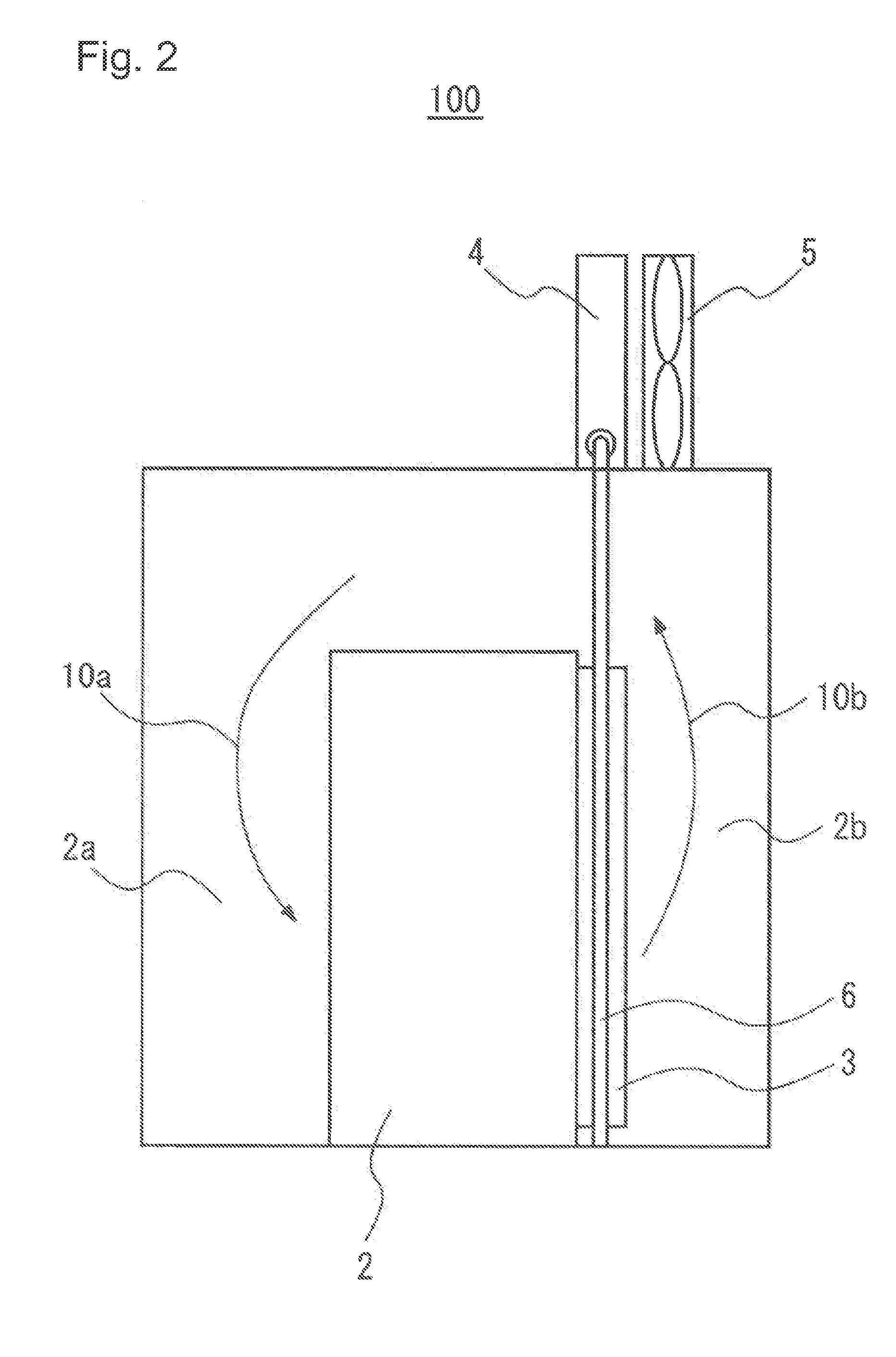

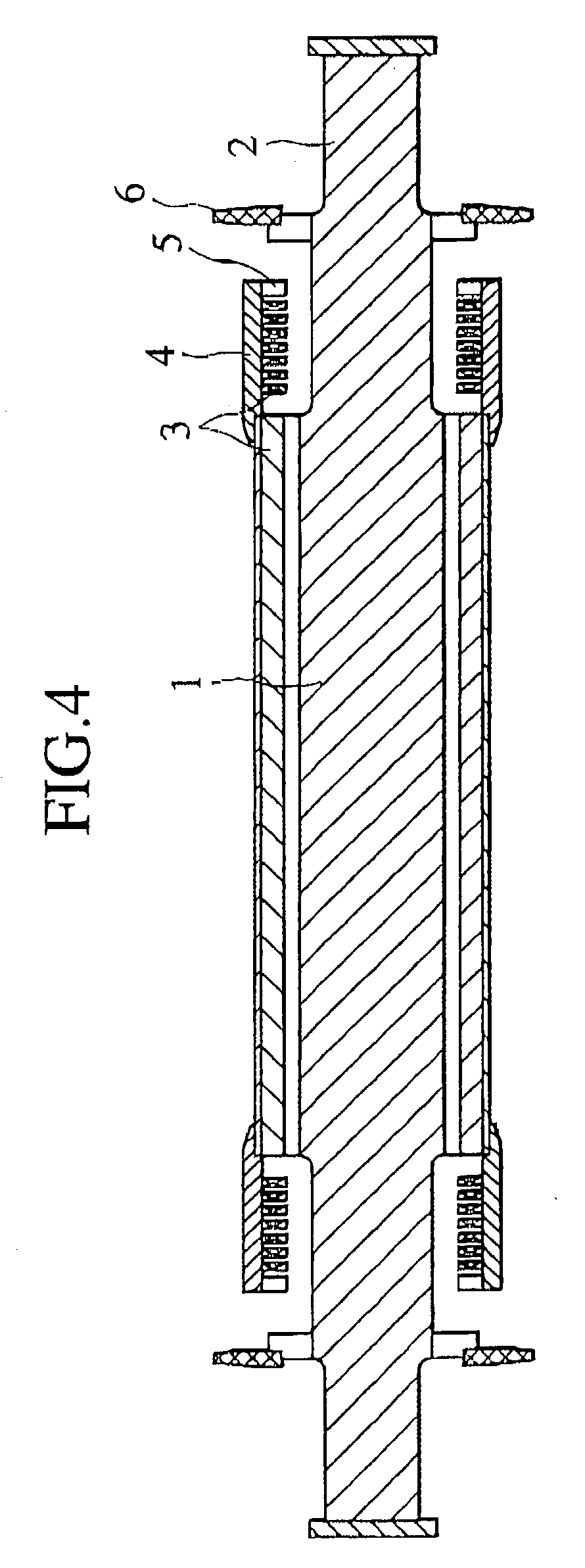

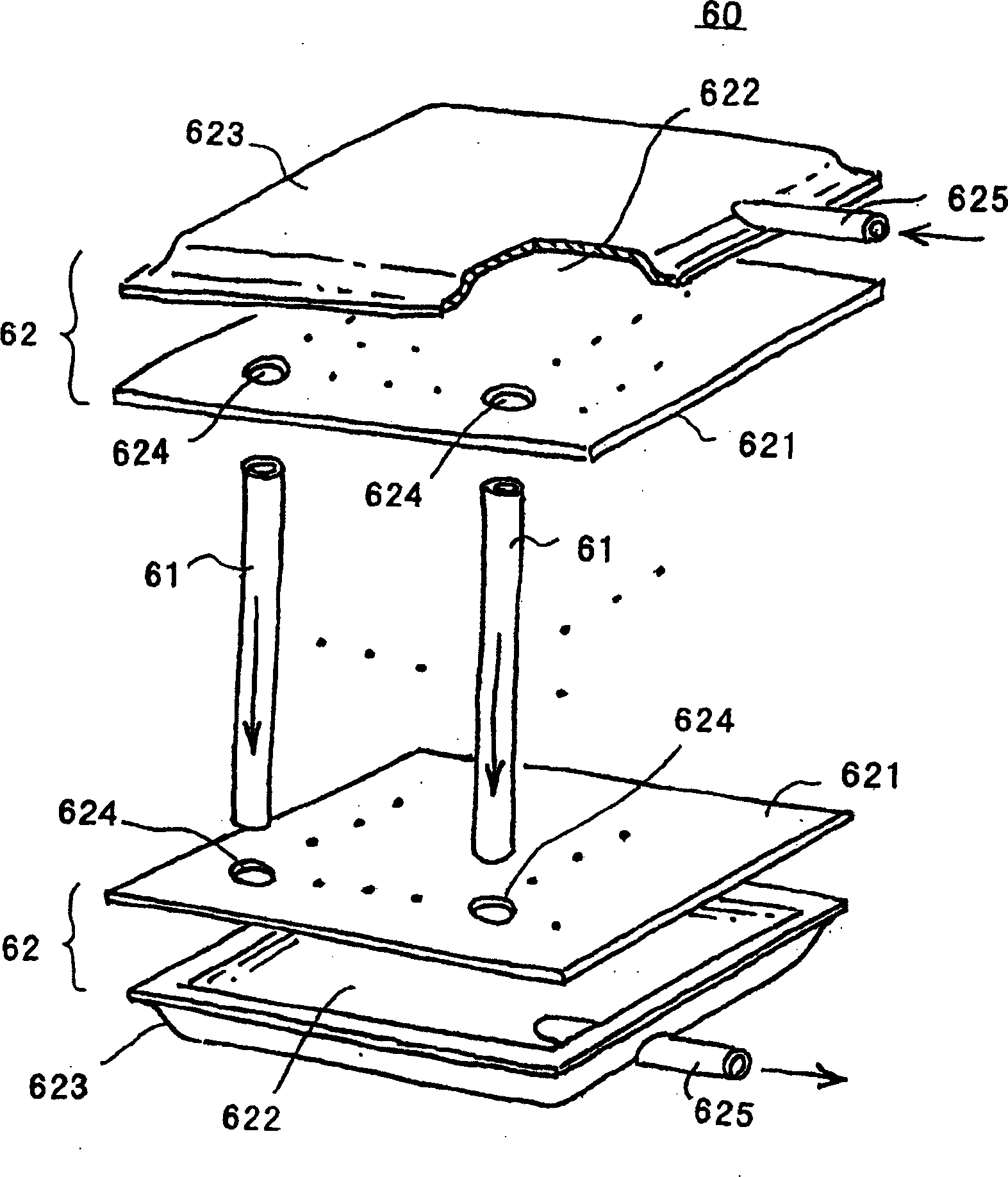

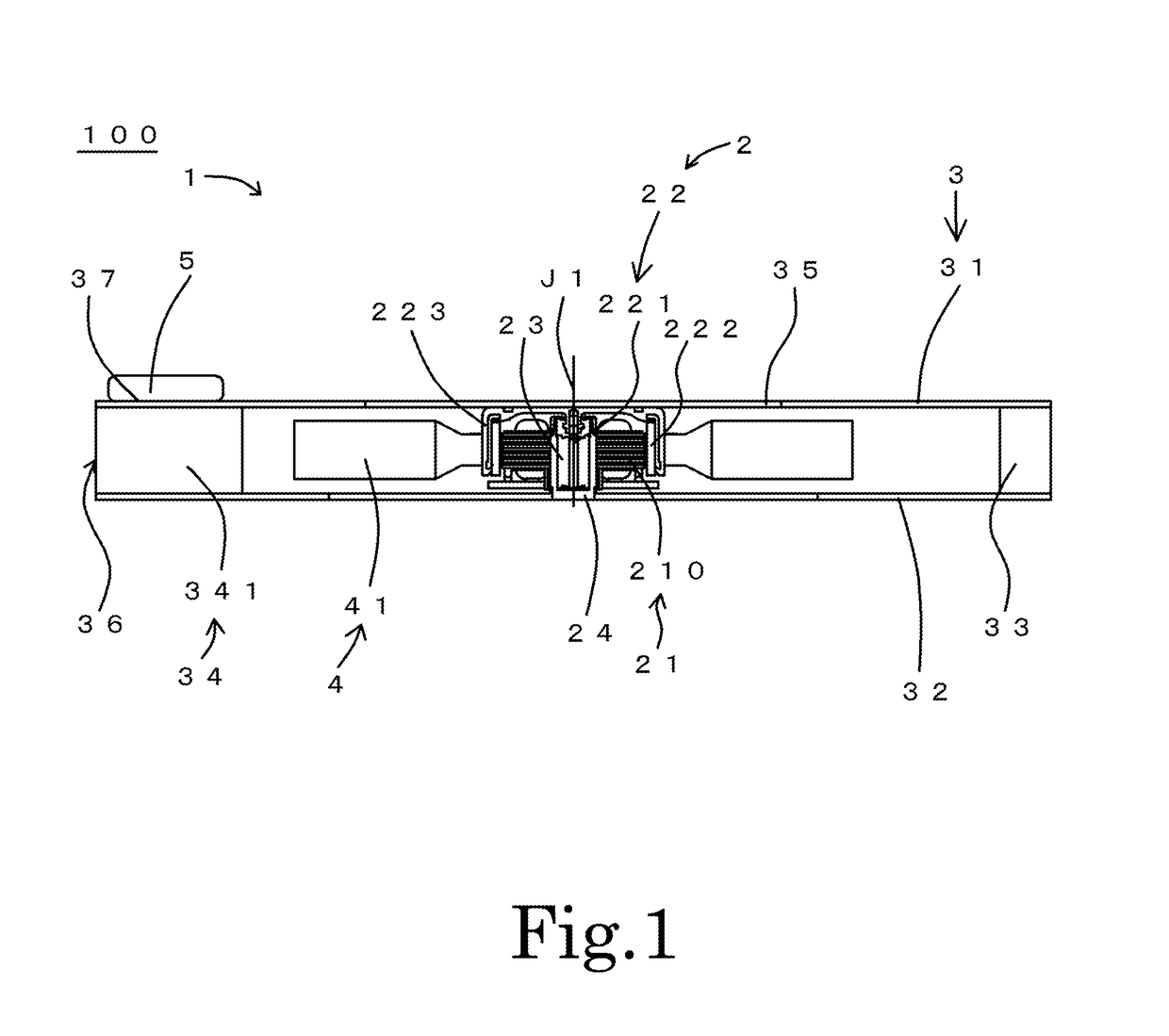

Electronic apparatus cooling system and electronic apparatus cooling system fabrication method

InactiveUS20160014933A1Good cooling propertiesDigital data processing detailsIndirect heat exchangersNuclear engineeringGas phase

[Problem]To provide an electronic apparatus cooling system having superior cooling characteristics and portability.[Solution] A rack 2 is installed within a container 1. A heat receiving apparatus 3 is disposed on a lateral face of the rack 2, and receives heat emitted within the rack 2 by a liquid-phase cooling medium gasifying and becoming a gaseous-phase cooling medium. A gaseous-phase tube 6 is disposed extending in plumb direction, and transports the gaseous-phase cooling medium from the heat receiving apparatus 3. A heat radiating apparatus 4 is disposed above the rack 2 outside the container 1, and radiates the heat which the heat receiving apparatus 3 has received by cooling the gaseous-phase cooling medium flowing from the gaseous-phase tube 6, making said gaseous-phase cooling medium into the liquid-phase cooling medium. A liquid-phase tube 7 transports the liquid-phase cooling medium from the heat radiating apparatus 4 to the heat receiving apparatus 3. The gaseous-phase tube 6 further comprises a gaseous-phase tube bend part 6c whereat cooling medium droplets, which arise from the condensation of the gaseous phase cooling medium as a result of the gaseous-phase tube 6 being exposed to the environment external to the container 1, are collected.

Owner:NEC CORP

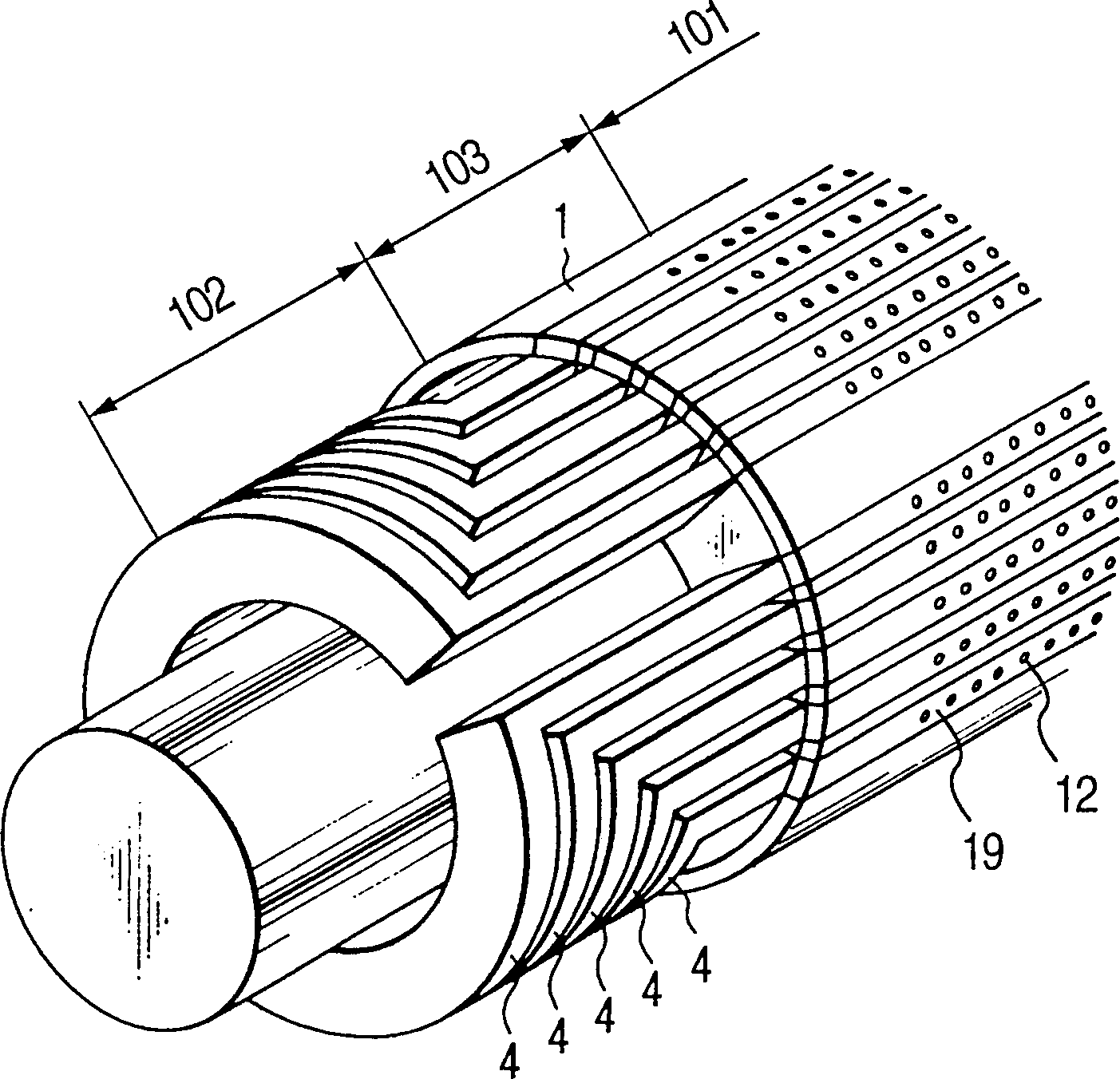

Rotor for rotating electric machine

InactiveUS20060028074A1Reduce peak pressureIncrease mean pressureMagnetic circuit rotating partsCooling/ventillation arrangementElectrical conductorElectric machine

A rotor for a rotating electric machine comprises a rotor core, and a plurality of rotor conductors wound on the rotor core. At least one of the rotor conductors is provided with a cooling groove, and edges of at least one of the cooling grooves are rounded by a radius process to reduce peak stresses that may be induced around the edges of the cooling groove.

Owner:HITACHI LTD

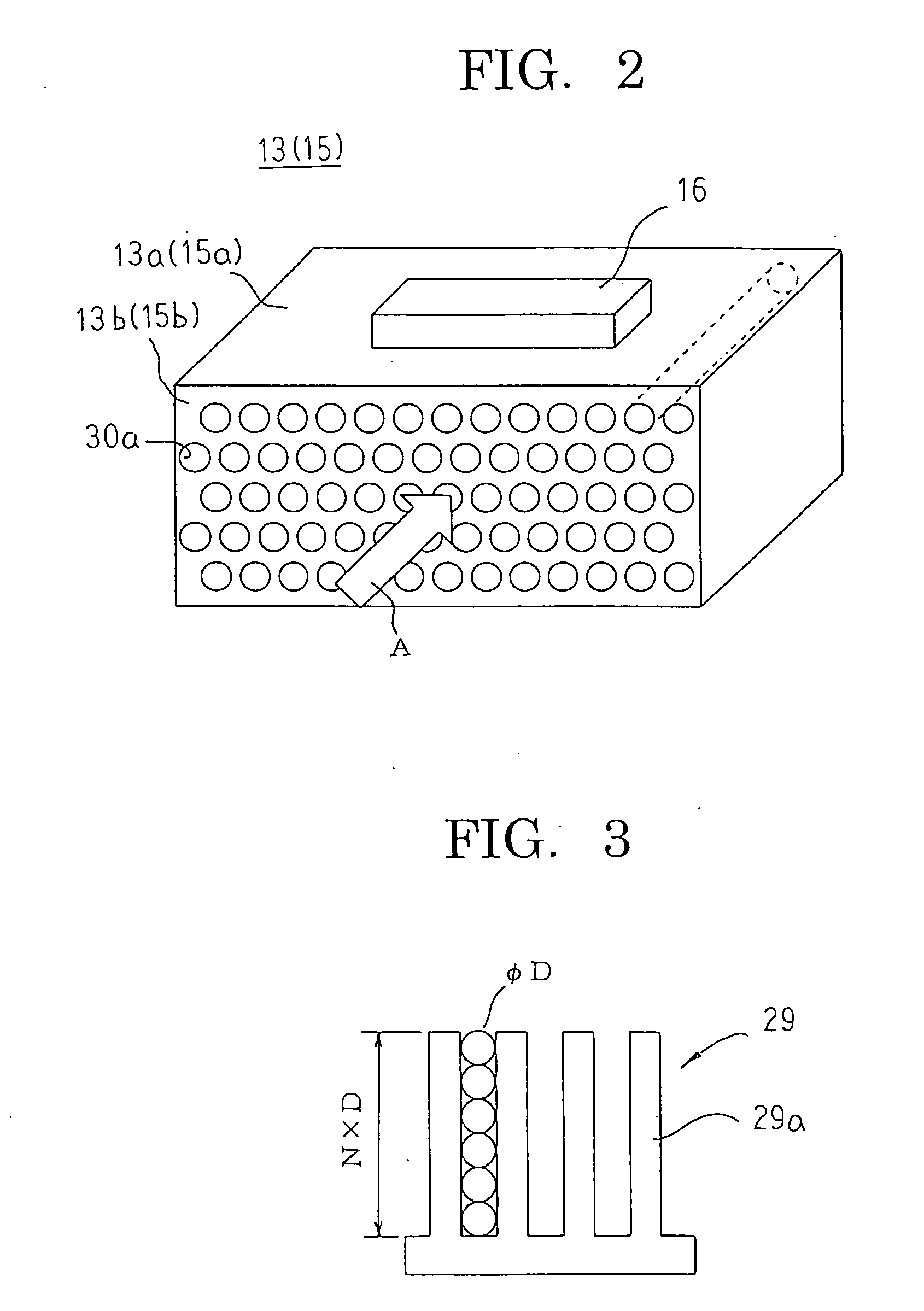

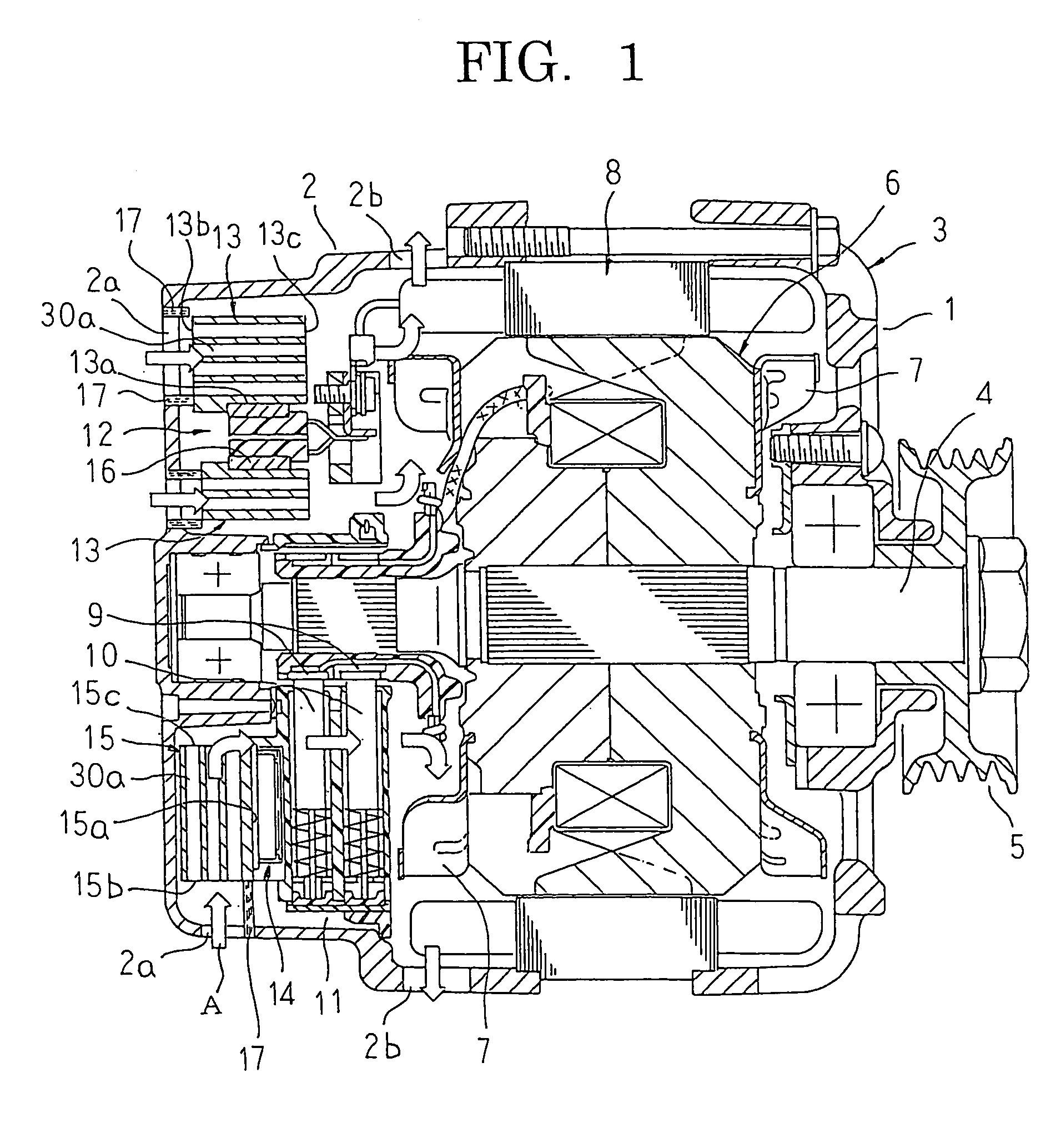

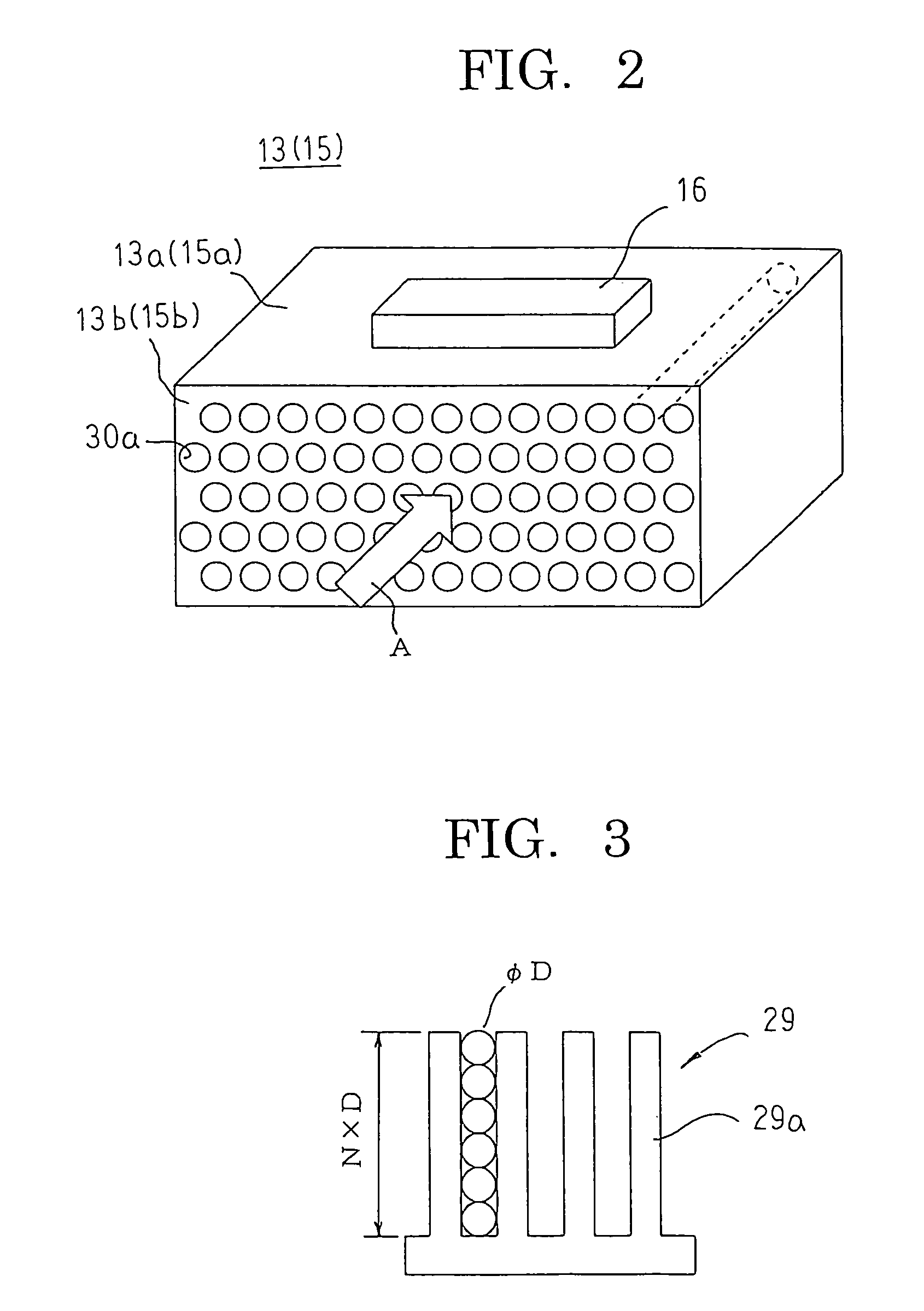

Automotive dynamoelectric machine

ActiveUS20070046112A1Improve heat radiation performanceStable operationMagnetic circuit rotating partsDC commutatorAirflowEngineering

A large number of ventilating apertures that have a circular cross section are disposed through the heatsink so as to extend from an air intake apertured surface to an air discharge apertured surface so as to have aperture directions that are parallel to each other and parallel to an element mount surface, and the heatsink is disposed such that the air intake apertured surface faces an air intake aperture and the aperture directions of the ventilating apertures are aligned in a direction of flow of a cooling airflow.

Owner:MITSUBISHI ELECTRIC CORP

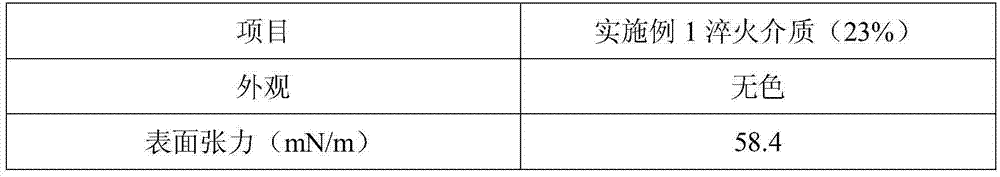

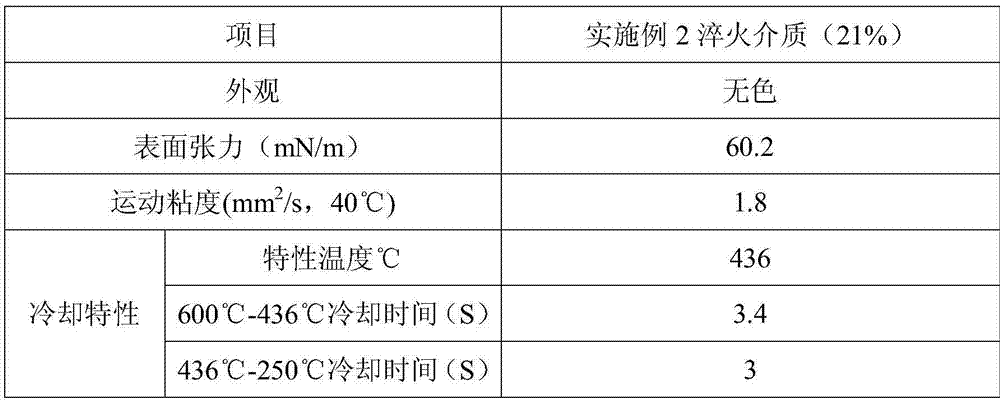

Water-soluble quenching medium for aluminum alloy precision part

InactiveCN104726656AReduce deformation stressReduce residual stressQuenching agentsWater solubleMechanical property

The invention discloses a water-soluble quenching medium for an aluminum alloy precision part and belongs to the metal heat treatment quenching agent technology. The water-soluble quenching medium comprises, by weight, 18-22% of polyalkylene glycol (with molecular weight of 8000), 0.6-1.0% of an antiseptic, a proper amount of an antifoaming agent and a settling agent, and the balance water. The water-soluble quenching medium has the advantages that 1, the problem that cold water as an aluminum alloy quenching medium has a fast cooling rate so that quenched residual stress is very large and the part can deform and crack is solved, and 2, it is solved that in hot water quenching, a cooling rate can be adjusted but quenching effects do not satisfy usage requirements. The water-soluble quenching medium can reduce an aluminum alloy initial cooling speed, has a strong cooling capability at a temperature of 440-250 DEG C, has good cooling characteristics and does not corrode a workpiece. The water-soluble quenching medium can reduce aluminum alloy part quenched residual stress, does not influence quenching effects and mechanical properties after aging and belongs to the field of metal heat treatment quenching agents.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

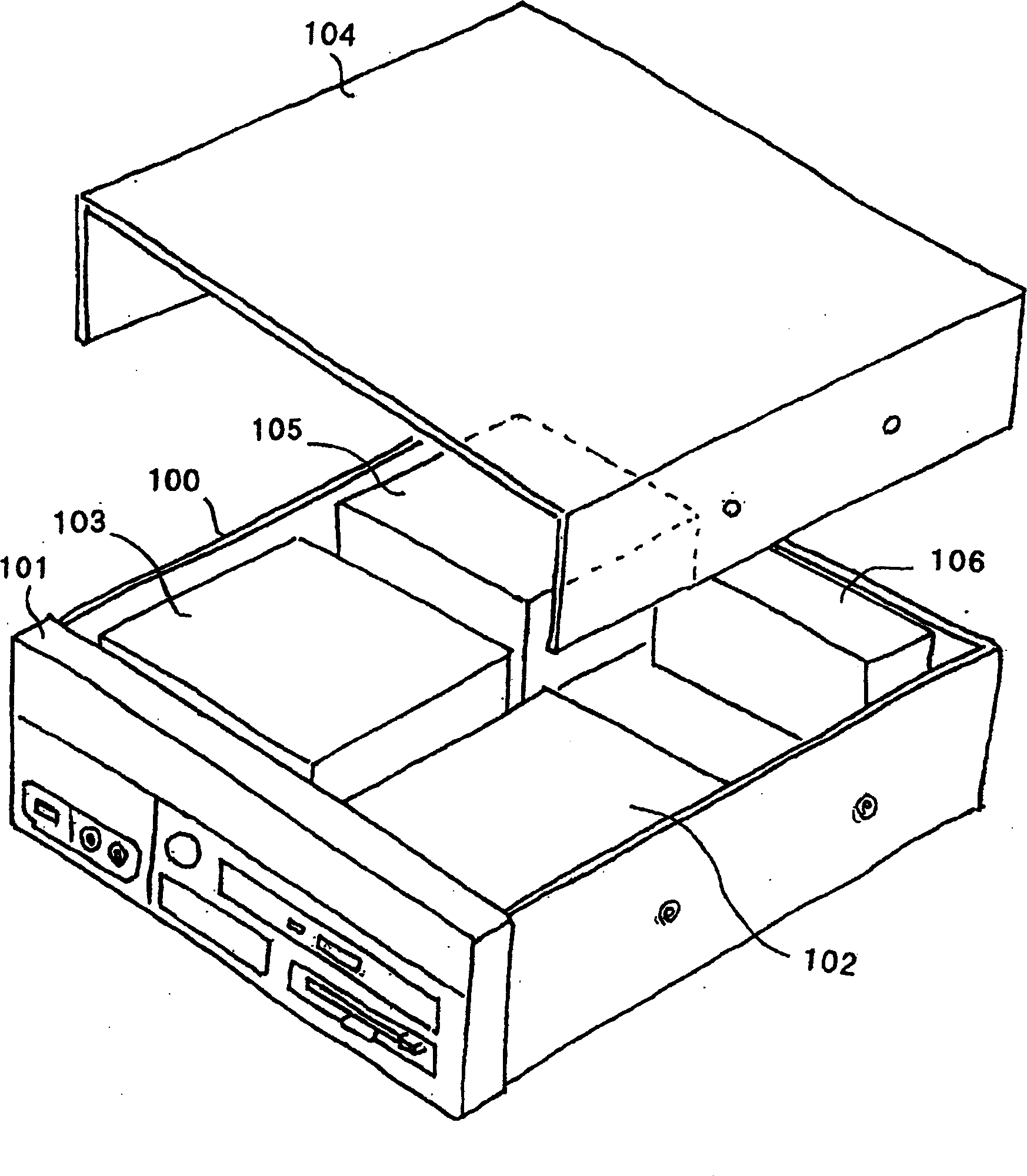

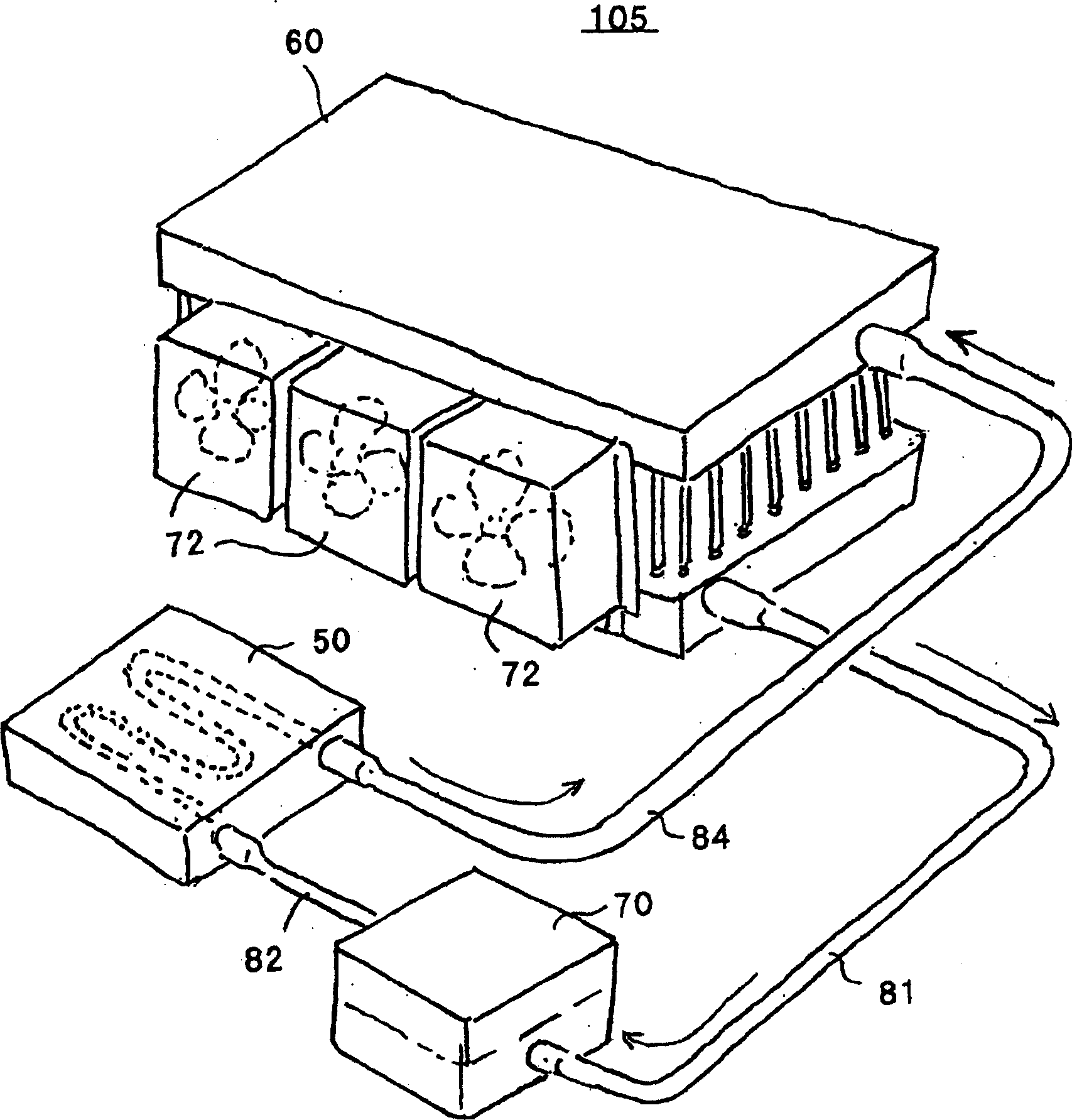

Electronic apparatus having cooling system, radiator thereof, and method for manufacturing thereof

InactiveCN1658121AChange shapeCheap manufacturingDomestic cooling apparatusDigital data processing detailsLiquid cooling systemEngineering

In an electronic apparatus having a liquid cooling system, and enabling optimal cooling characteristic for capacity with the aid of a radiator, which can be disposed or located fitting in a narrow space within a housing thereof, wherein a CPU (200) in need of cooling is installed within the housing (100), and the liquid cooling system for cooling the CPU comprises a cooling jacket (50) and a radiator (60)therein, wherein the radiator has a pair of headers (62) and (62), being constructed with disposing a large number of metal thin tubes (61,61...) there between, aligned in parallel to each other, and an outer configuration thereof can be changed easily and freely, and therefore it can be positioned even in the narrow space. Further, a cooling fan (64) or (66) for cooling the radiator (60) may be disposed therein, and in that case it is also possible to maintain a position for setting up a motor (65) or (67) for rotationally driving the fan, included therein.

Owner:HITACHI LTD

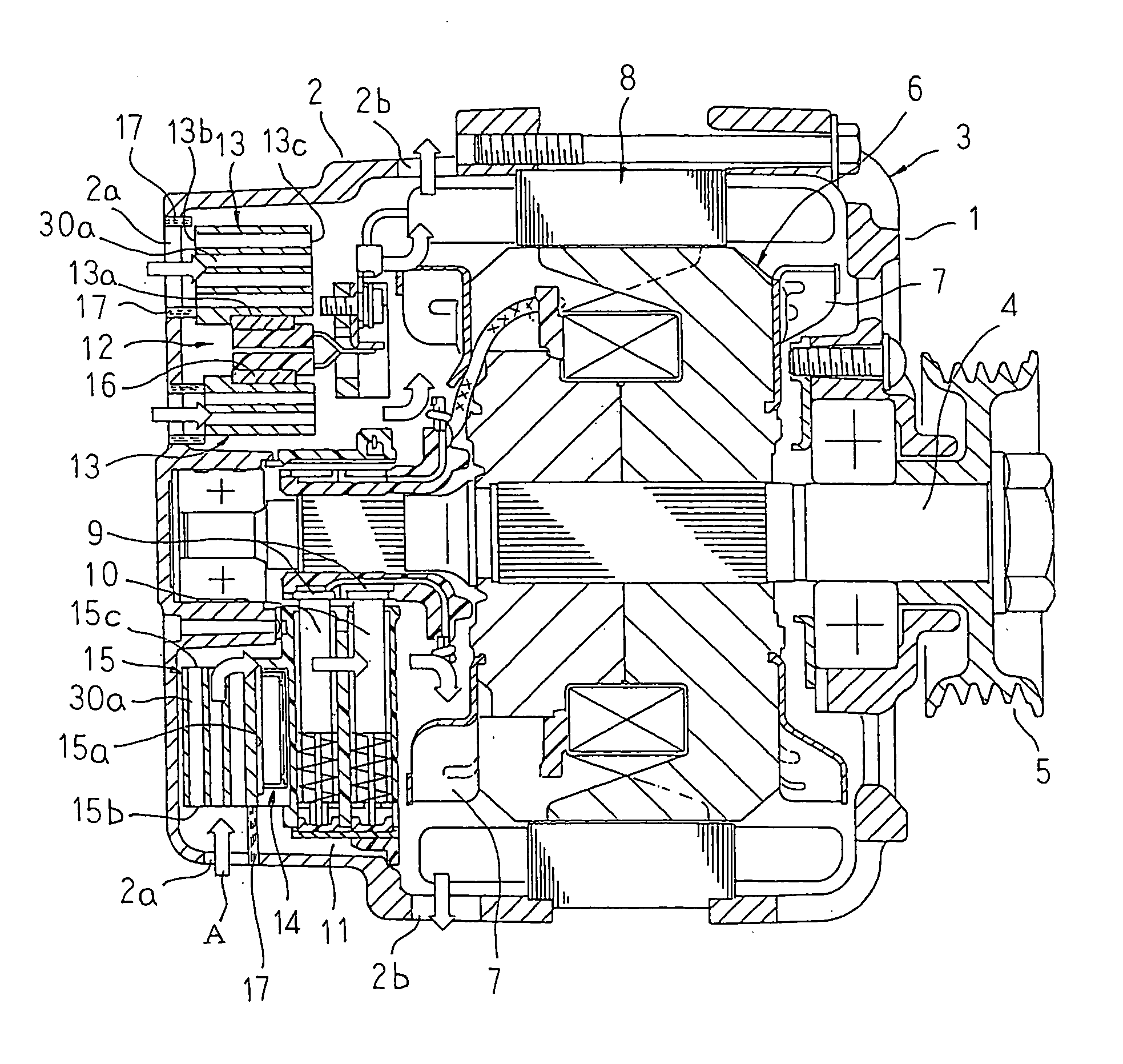

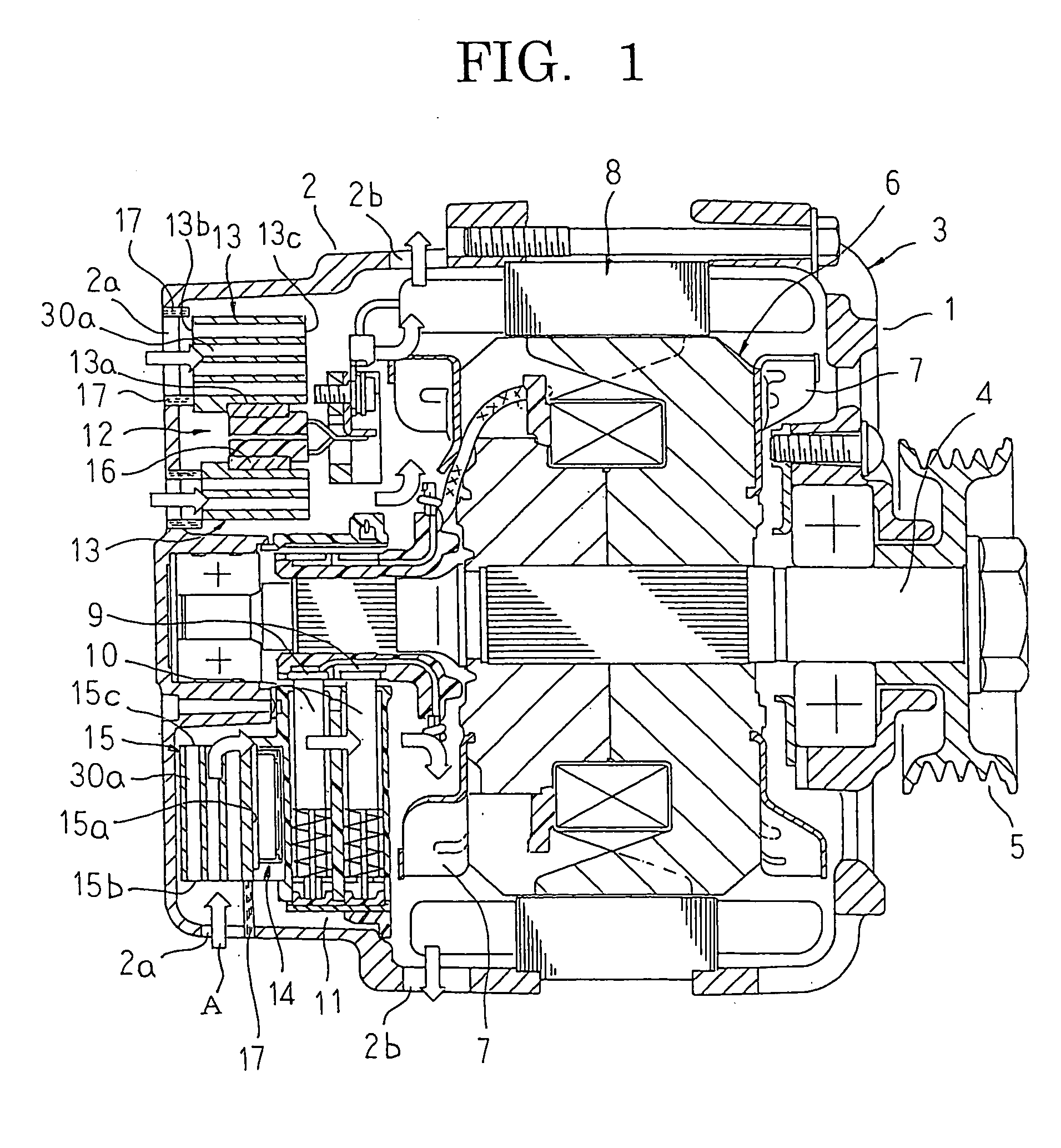

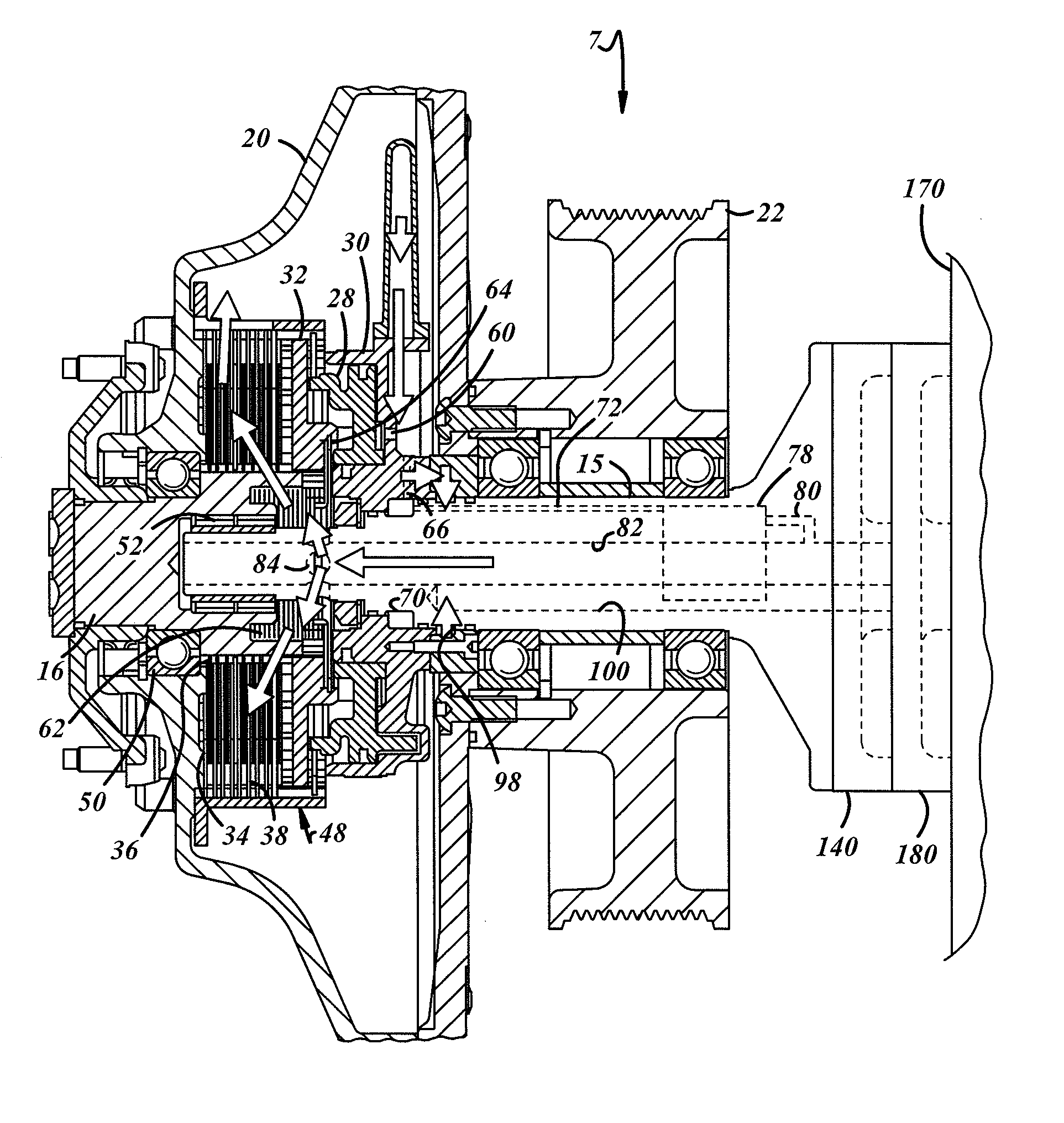

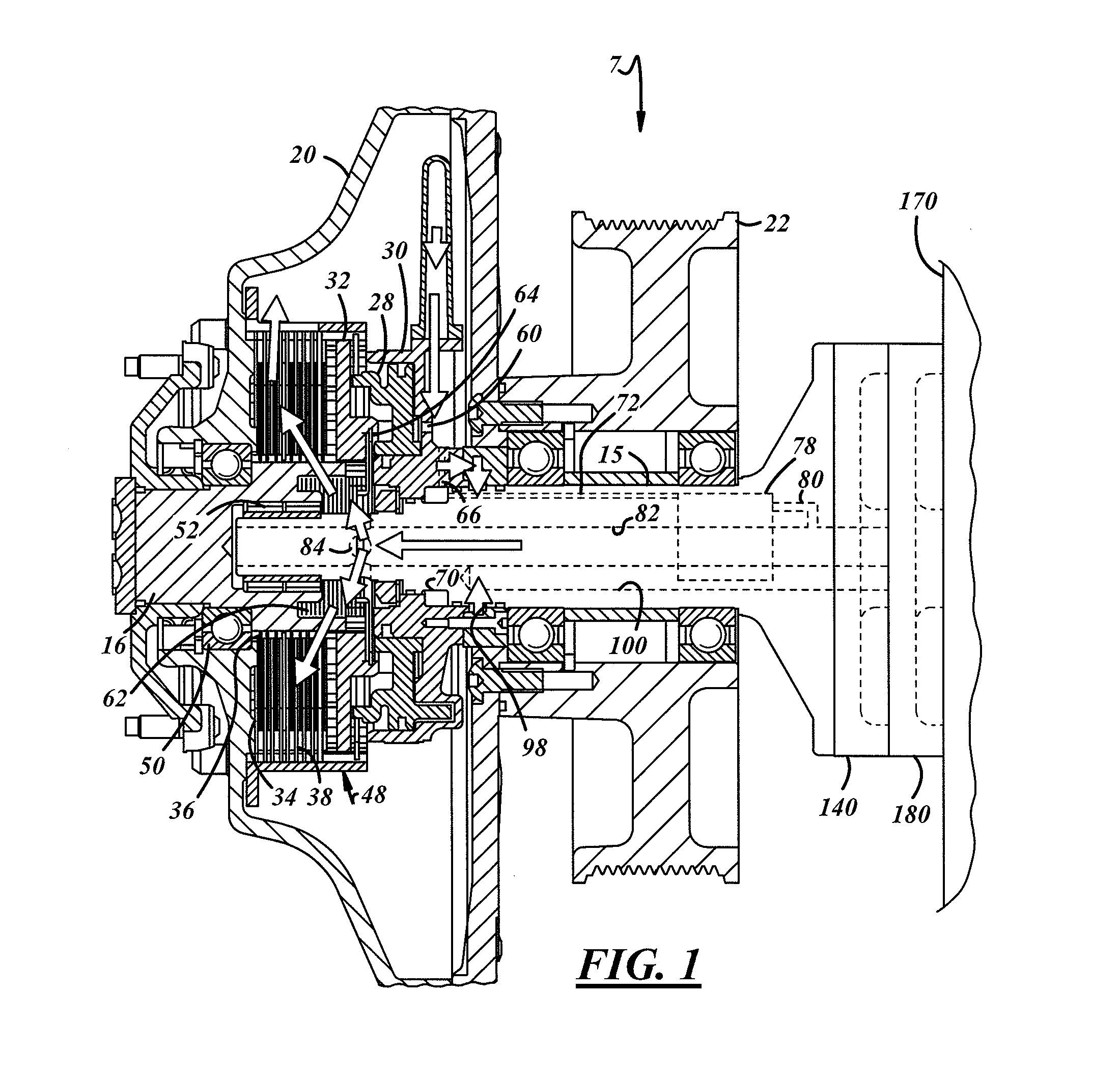

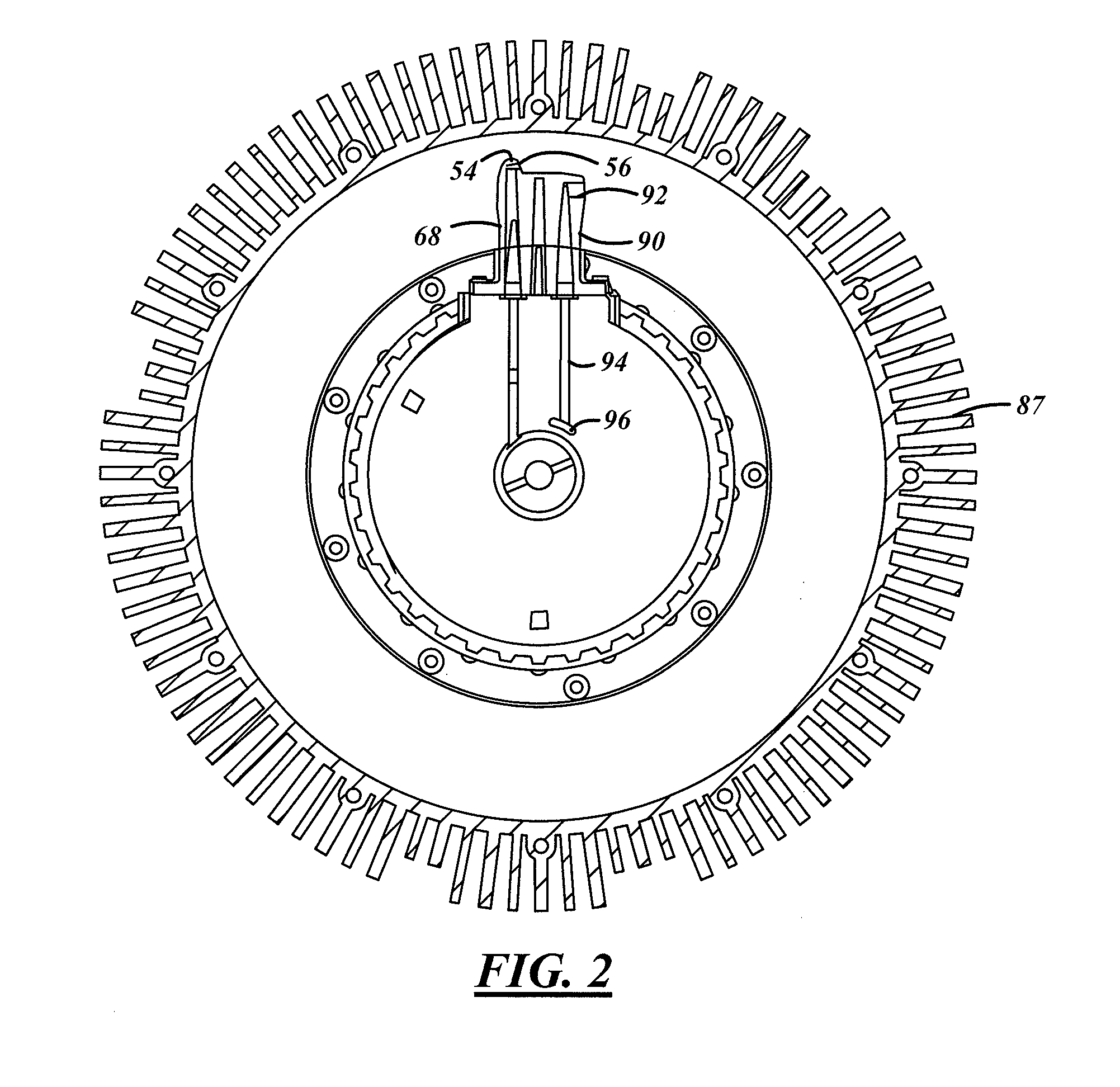

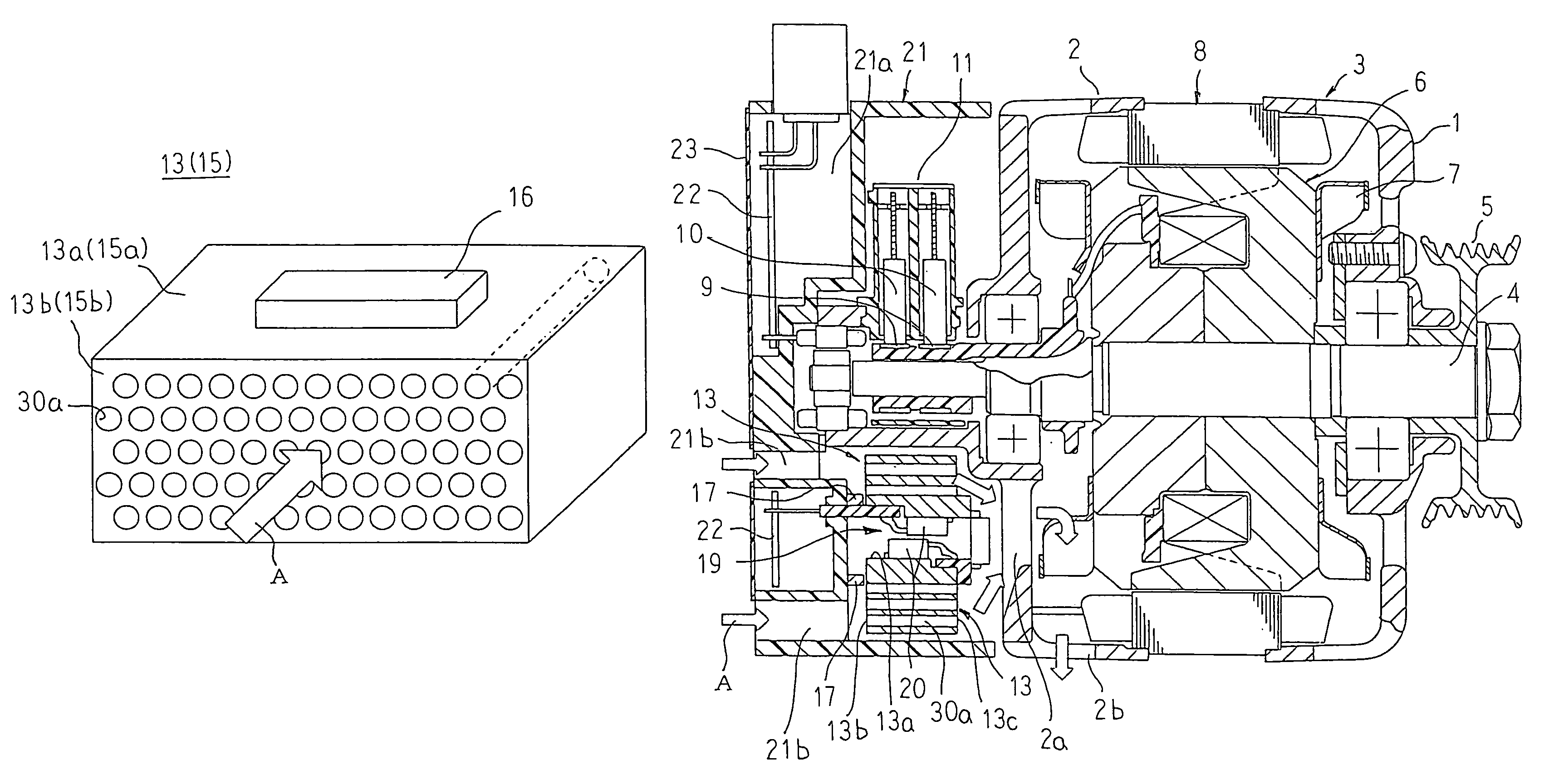

Cool logic with an integrated cooler into the clutch/engine base

InactiveUS20120048672A1Good cooling propertiesEasy to operateCoolant flow controlFluid actuated clutchesClutchPiston

A fan drive system is provided having a housing connected with a pulley. A fan shaft is rotatably mounted to the housing by a clutch. A piston actuates the clutch. A pressure tube is provided for delivering pressure to the piston. A valve controls pressure against the piston. A fixed shaft rotatably supports the housing and the pulley and has passages extending through the pulley. A base connects the support shaft to a vehicle structure. An oil plate has inlets and outlets with the shaft passages. The oil plate circulates the hydraulic fluid. A coolant plate is juxtaposed between the oil plate and the structure supporting the support shaft. The coolant plate has inlets and outlets for coolant from a remote cooler.

Owner:BORGWARNER INC

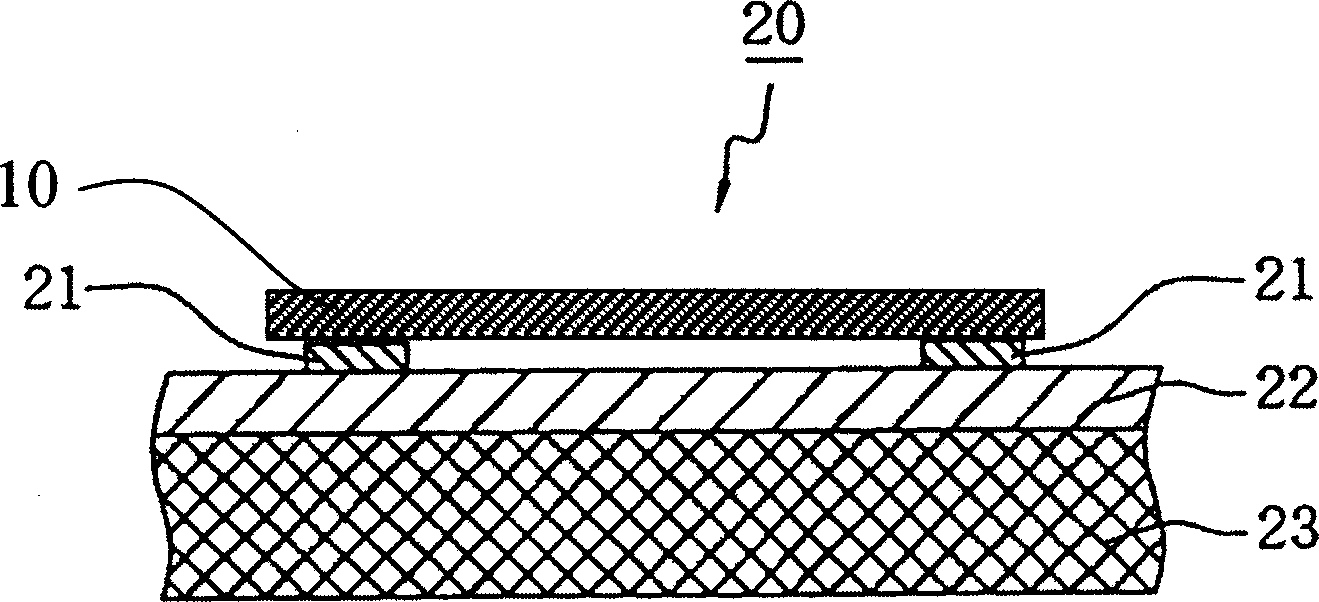

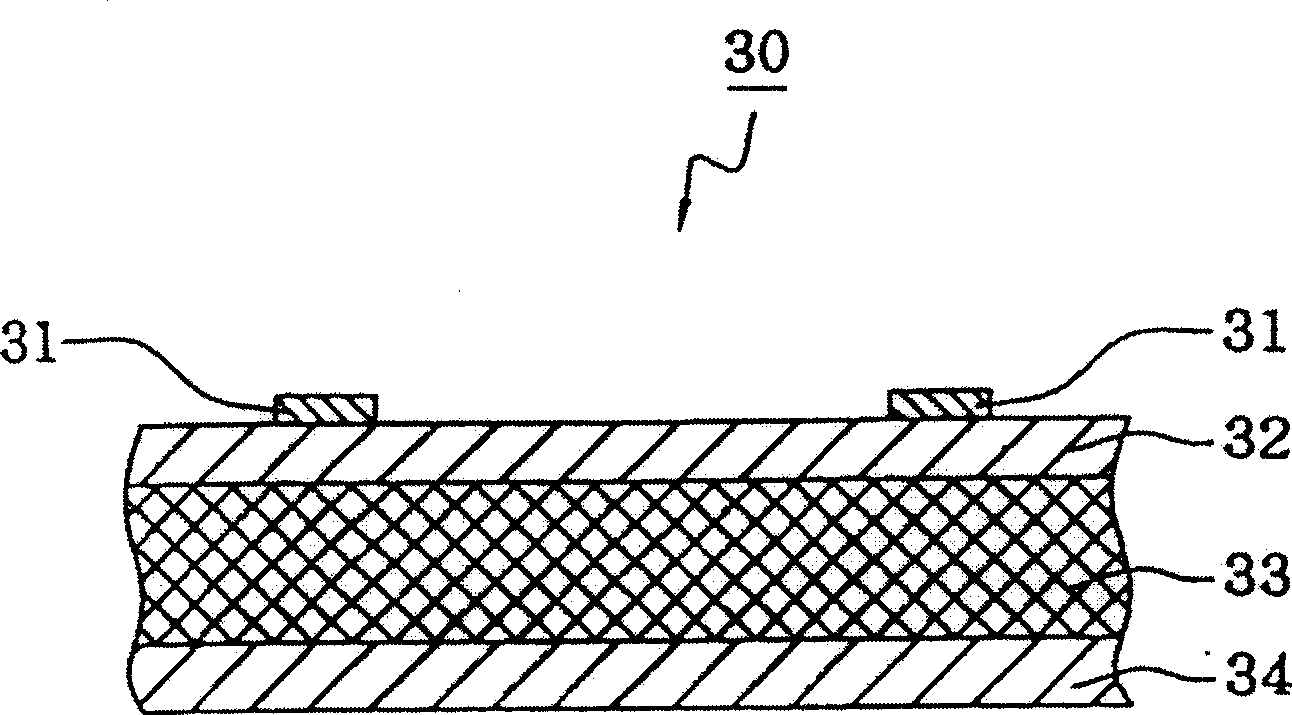

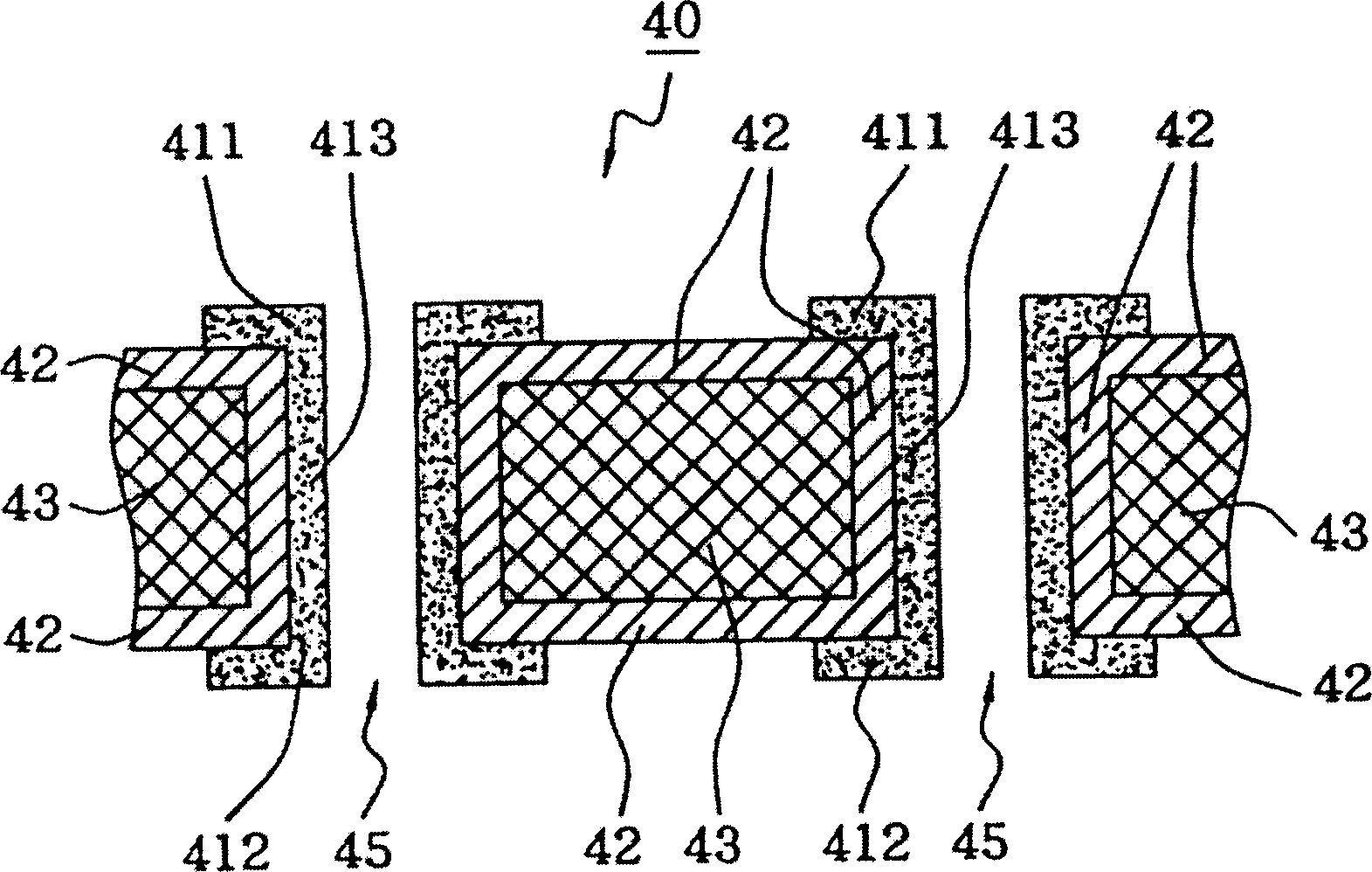

Chip module with high radiating performance and its substrate

InactiveCN1614770AGood cooling propertiesReduce structural weightSemiconductor/solid-state device detailsSolid-state devicesAluminum matrix compositesCopper wire

The chip module consists of a high thermal diffusivity base board, at least one chip mounted on base board. The high thermal diffusivity base board is made by forming insulation layer on metal compound material sheet and then mounting copper wire layer on the insulation layer. The copper wire layer can be used in adhering chip. For the material of base board, the aluminum base with high coefficient of heat-transfer is selected.

Owner:GIGA BYTE TECH CO LTD

Partition plate nozzle structure of pre-combustion chamber

ActiveCN114165358AImprove stable working rangeSuppression of tangentially unstable combustionInternal combustion piston enginesRocket engine plantsThermodynamicsCombustion chamber

A pre-combustion chamber partition plate nozzle comprises an oxidizing agent nozzle, a fuel nozzle and a bottom. One end of the oxidant nozzle extends into the fuel nozzle and forms an annular gap with the fuel nozzle; a plurality of columns of partition plate sleeves are uniformly distributed on the panel along the circumferential direction; the panel and the partition plate sleeve are integrally formed to form a bottom; a fuel nozzle is mounted at the position, provided with the partition plate sleeve, of one bottom; longitudinal partition plate through holes are formed in the partition plate sleeve, and the partition plate through holes and the fuel nozzles are in one-to-one correspondence and are communicated with each other; a rotational flow hole is formed in the end head of one end of the fuel nozzle installed at the bottom and enables two end faces of the end head to be communicated, and a radial hole is formed in the end, connected with the oxidizing agent nozzle, of the fuel nozzle. By means of the reasonable design of the partition plate nozzle structure, unstable combustion is effectively restrained, and meanwhile high combustion efficiency and good outlet gas temperature uniformity are guaranteed.

Owner:BEIJING AEROSPACE PROPULSION INST

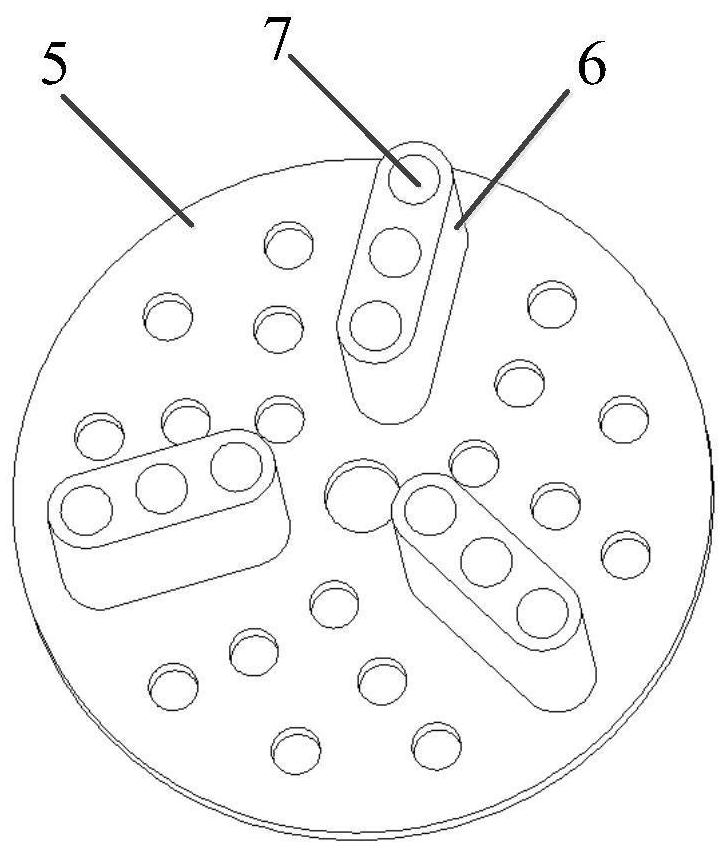

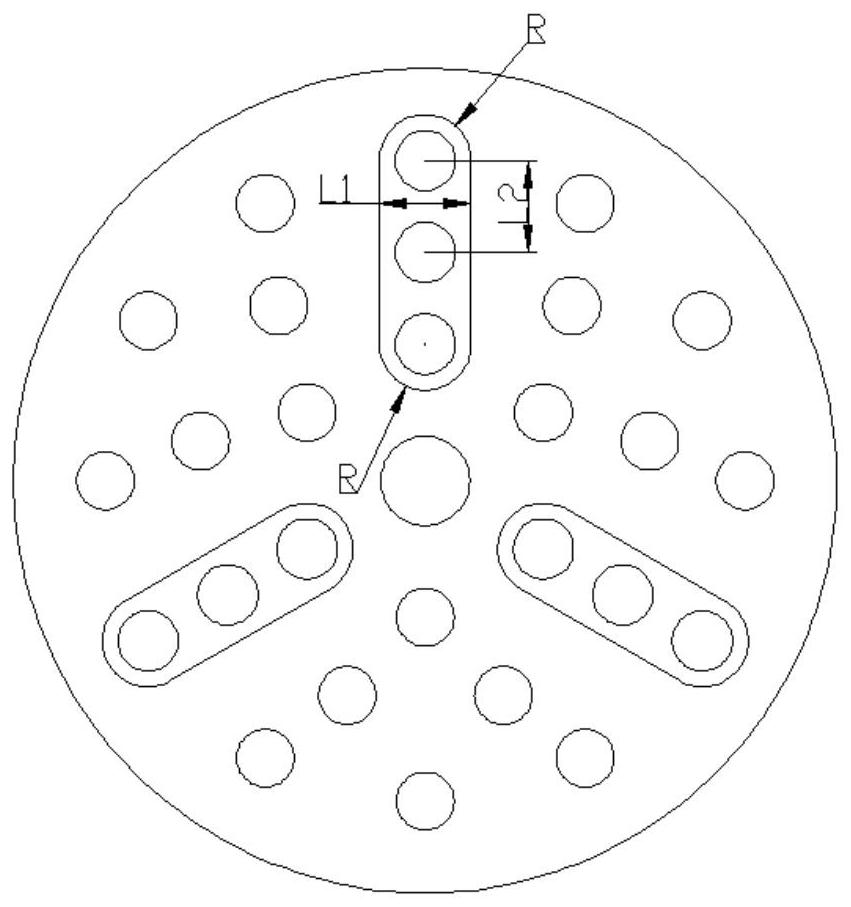

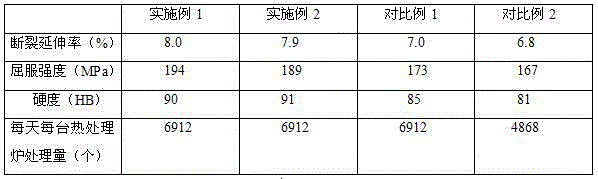

Wheel hub heat treatment speed-up technology

ActiveCN104694727AFast heat absorptionEvenly heatedFurnace typesQuenching agentsThermodynamicsEngineering

The invention belongs to the field of wheel hub machining, and particularly relates to a wheel hub heat treatment speed-up technology. The heat treatment method comprises three stages, namely a solid solution stage, a quenching stage and an aging stage. The flow of the wheel hub heat treatment speed-up technology comprises the steps that a casted aluminum wheel hub passes through an X-ray machine and a dead head punching machine, and then the aluminum wheel hub is subjected to heat treatment, wherein the heat treatment comprises the solid solution stage, the quenching stage and the aging stage; the temperature for the solid solution stage is set between 540 DEG C to 550 DEG C, the heating-up time ranges from 25 minutes to 28 minutes, the heat-preserving time ranges from 110 minutes to 115 minutes, the wheel hub enters the quenching stage while maintaining the temperature of the solid solution stage; the quenching time is below 20 seconds, the wheel hub is soaked into a quenching medium for 5 minutes at a temperature ranging from 80 DEG C to 90 DEG C, and the wheel hub enters the aging stage; the temperature of the aging stage ranges from 155 DEG C to 165 DEG C, and the heat-preserving time is 60 minutes.

Owner:盛旺汽车零部件(昆山)有限公司

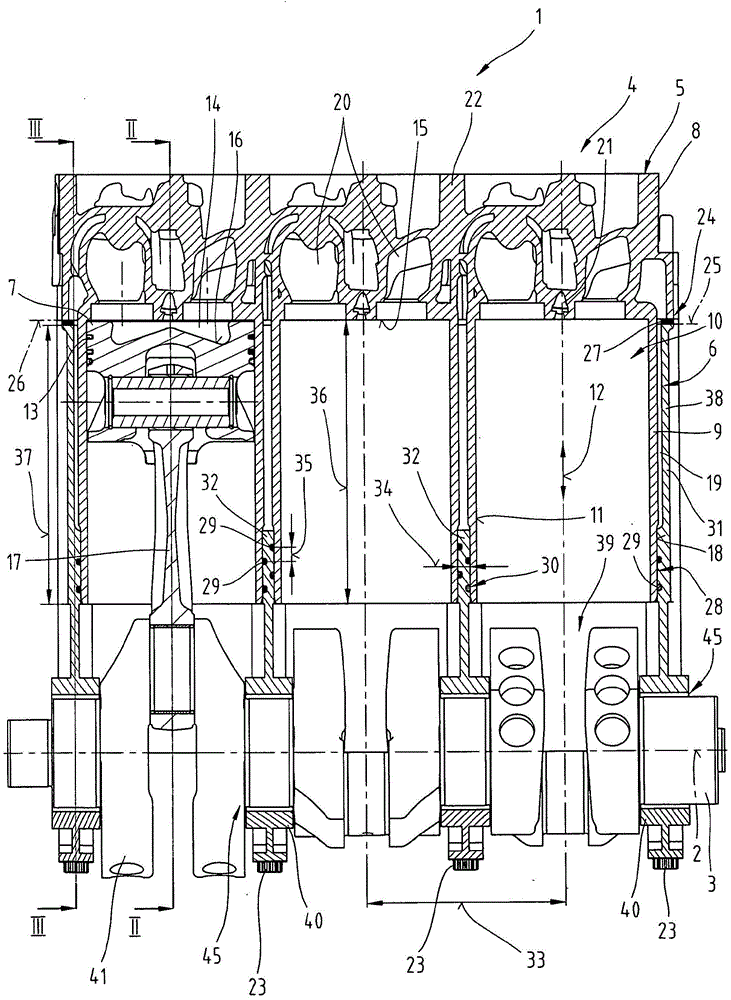

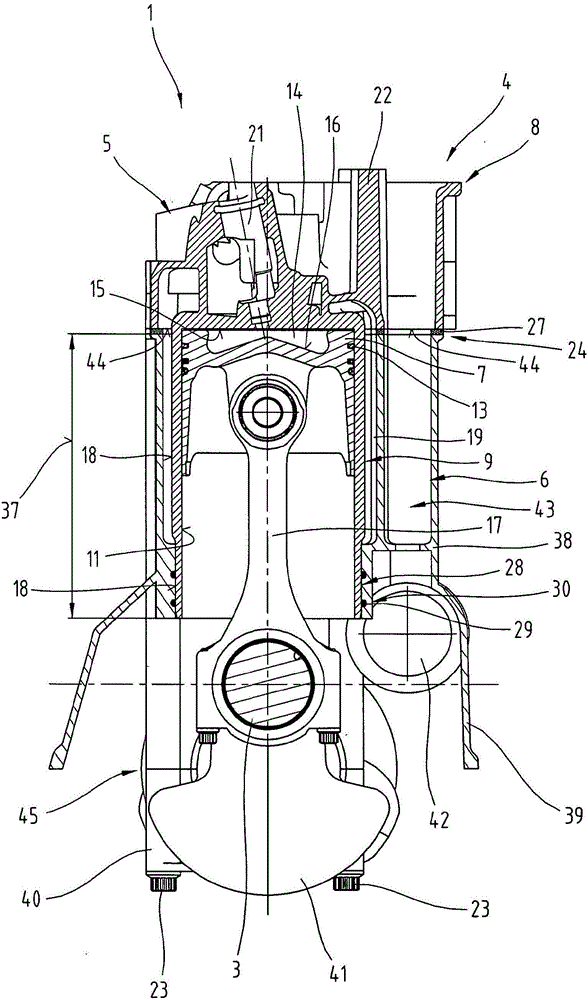

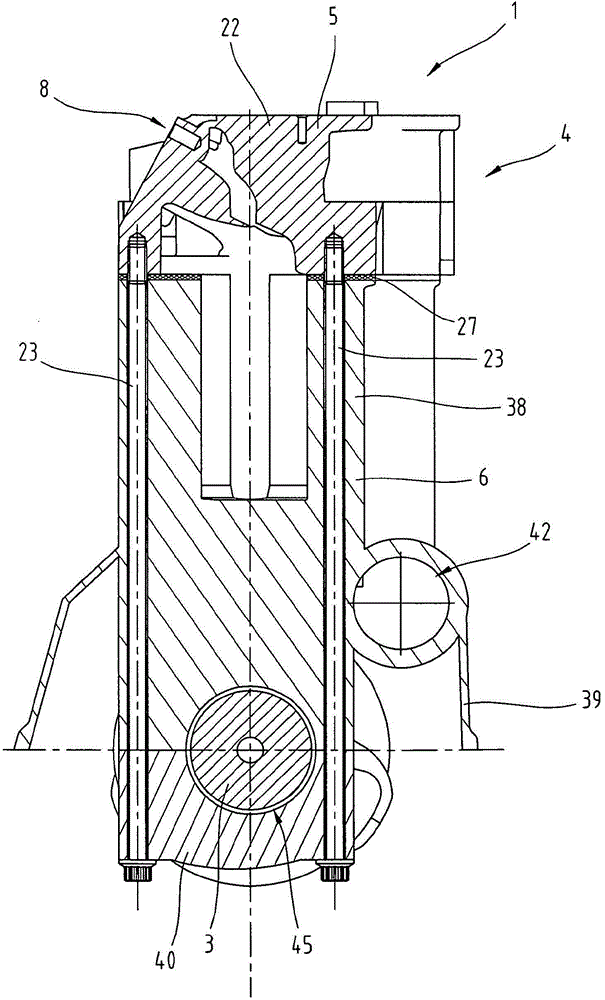

Engine housing of a combustion engine and combustion engine equipped with the same

InactiveCN104343574AEasy to assembleEfficient heat transferCasingsCylinder headsCombustionCylinder head

The invention relates to an engine housing (4) with a cylinder block (6) and a cylinder head unit (5) comprising a head portion (8) and at least one integrally cast cylinder portion (9) with an internally lying piston bearing surface (11). The cylinder portion (9) of the cylinder head unit (5) can be pushed at least partially in the axial direction of the cylinder portion (12) into the cylinder block (6). The cylinder head unit (5) can also be clamped in the axial direction of the cylinder portion (12) against the cylinder block (6) by means of at least one fixing element (23).

Owner:STEYR MOTORS GMBH

Low foaming, lubricating, water based emulsions

ActiveUS7396803B2Improve the lubrication effectGood cooling propertiesWork treatment devicesAdditivesWater basedEmulsion

Mixtures of water immiscible components and water dispersible components, in combination with an optional coemulsifier and an optional coupling agent, provide synthetic (water based) emulsions that have enhanced lubricity, provide excellent cooling characteristics, are low foaming and biostable and can be made effectively transparent.

Owner:CRODA AMERICAS +1

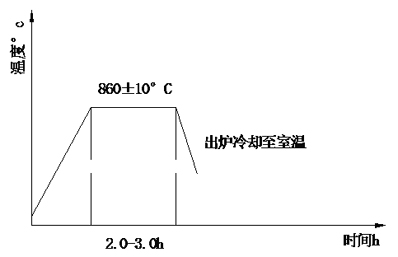

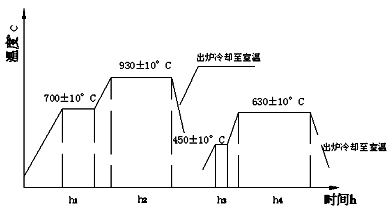

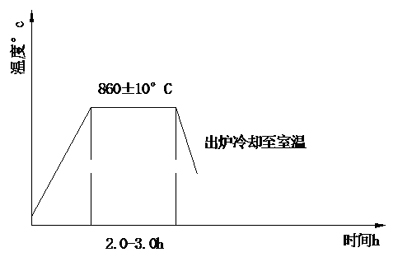

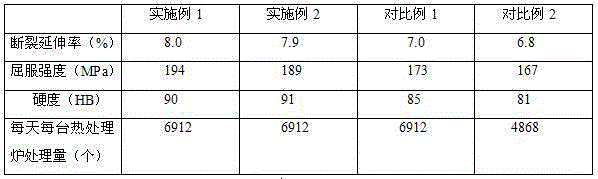

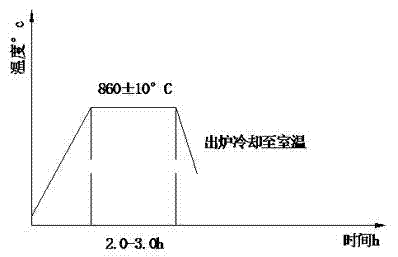

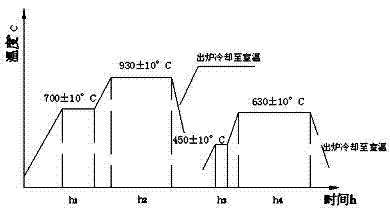

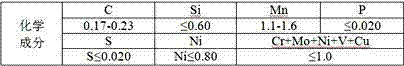

Heat treatment process for ASDO clamp products

InactiveCN101982549AGood cooling propertiesGrain refinementFurnace typesHeat treatment process controlThermodynamicsRoom temperature

The invention discloses a heat treatment process for ASDO clamp products, comprising the following steps: normalizing: firstly heating the workpieces to 860+ / -10 DEG C and preserving the heat for 2-3h and then discharging the workpieces and cooling the workpieces to the room temperature; quenching: firstly heating the normalized workpieces to 700+ / -10 DEG C and preserving the heat for 3-4.5h, secondly continuing raising the temperature to 930+ / -10 DEG C and preserving the heat for 4-6h, thirdly discharging the workpieces and quenching the workpieces in PQG quenching liquid with temperature being not more than 38 DEG C and mass concentration being 10-12% for 10-20min and finally cooling the quenched workpieces in a water-cooling pool to 200-300 DEG C until water exits and slightly airing the workpieces; and tempering: firstly heating the quenched workpieces to 450+ / -10 DEG C and preserving the heat for 1-2h, secondly raising the temperature to 630+ / -10 DEG C and preserving the heat for 7-11h and finally discharging the workpieces, air-cooling the workpieces to 500 DEG C, then cooling the workpieces in the water-cooling pool to 200-300 DEG C until water exits and cooling the workpieces to the room temperature. The heat treatment process is adopted for processing the close-distance clamp products, ensures that the mechanical performance of the processed close-distance clamp products can meet the design and construction requirements, reduces the product reject rate and improves the labor efficiency.

Owner:JIANGSU JINSHI CASTING & FORGING

Automotive dynamoelectric machine

ActiveUS7545642B2Good cooling propertiesIncrease heat radiationMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringHeat spreader

A large number of ventilating apertures that have a circular cross section are disposed through the heatsink so as to extend from an air intake apertured surface to an air discharge apertured surface so as to have aperture directions that are parallel to each other and parallel to an element mount surface, and the heatsink is disposed such that the air intake apertured surface faces an air intake aperture and the aperture directions of the ventilating apertures are aligned in a direction of flow of a cooling airflow.

Owner:MITSUBISHI ELECTRIC CORP

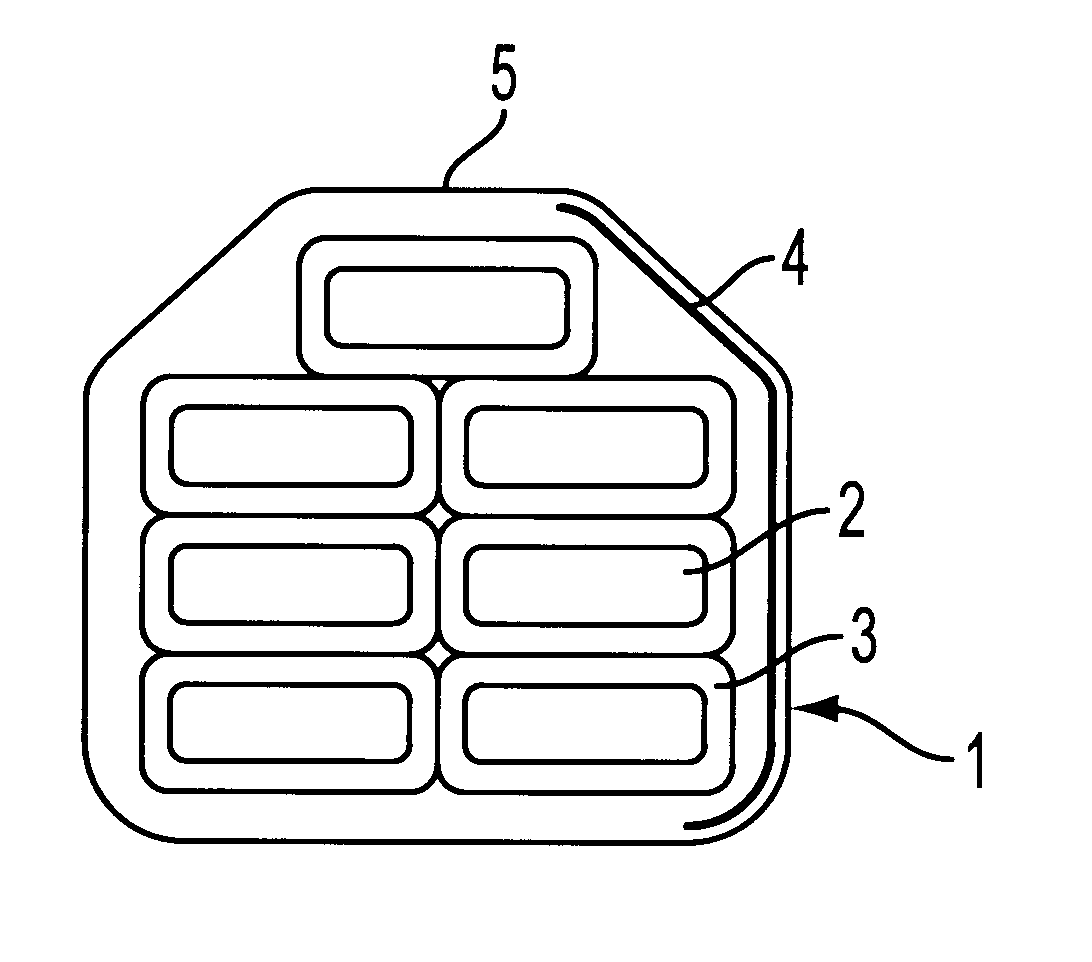

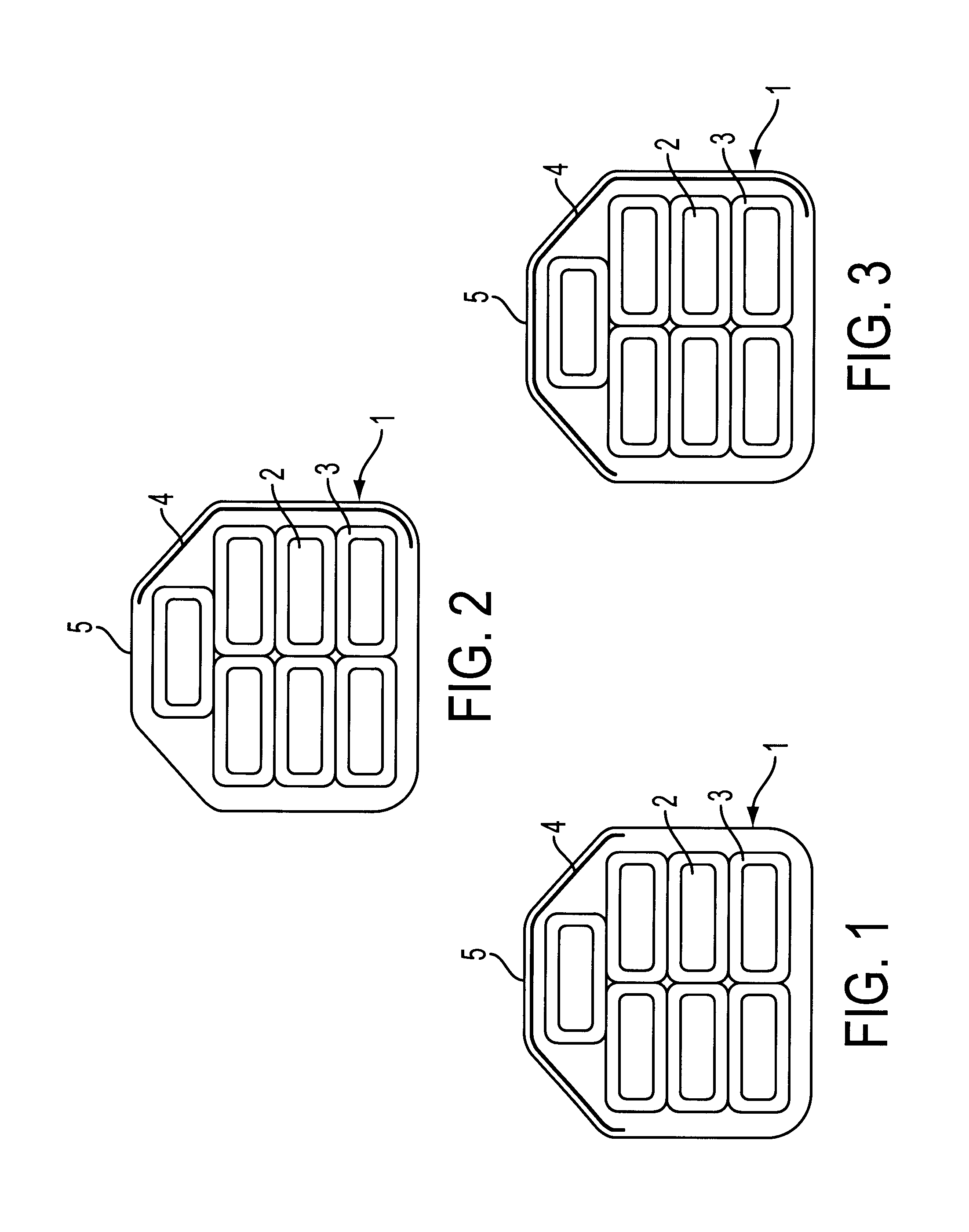

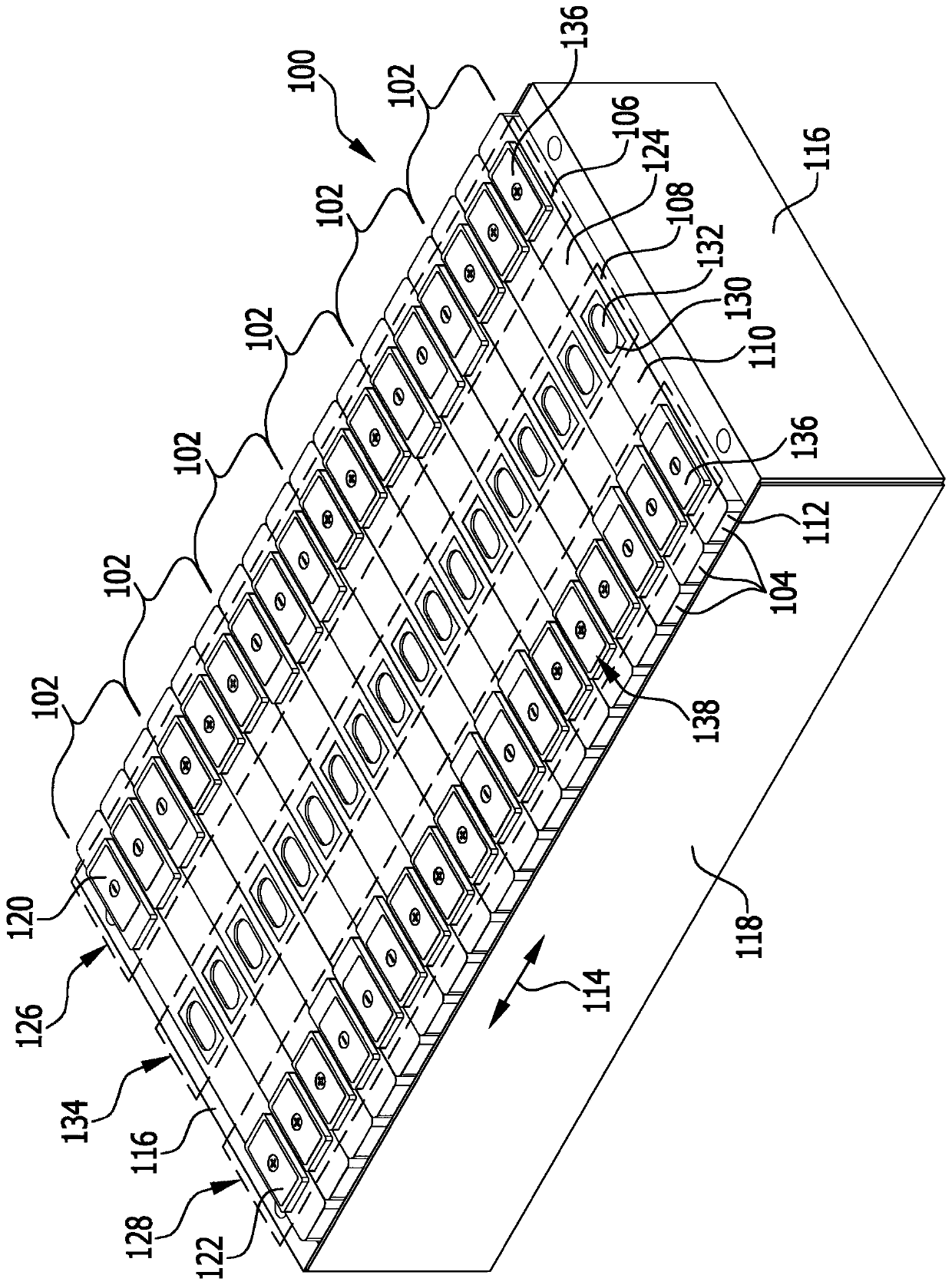

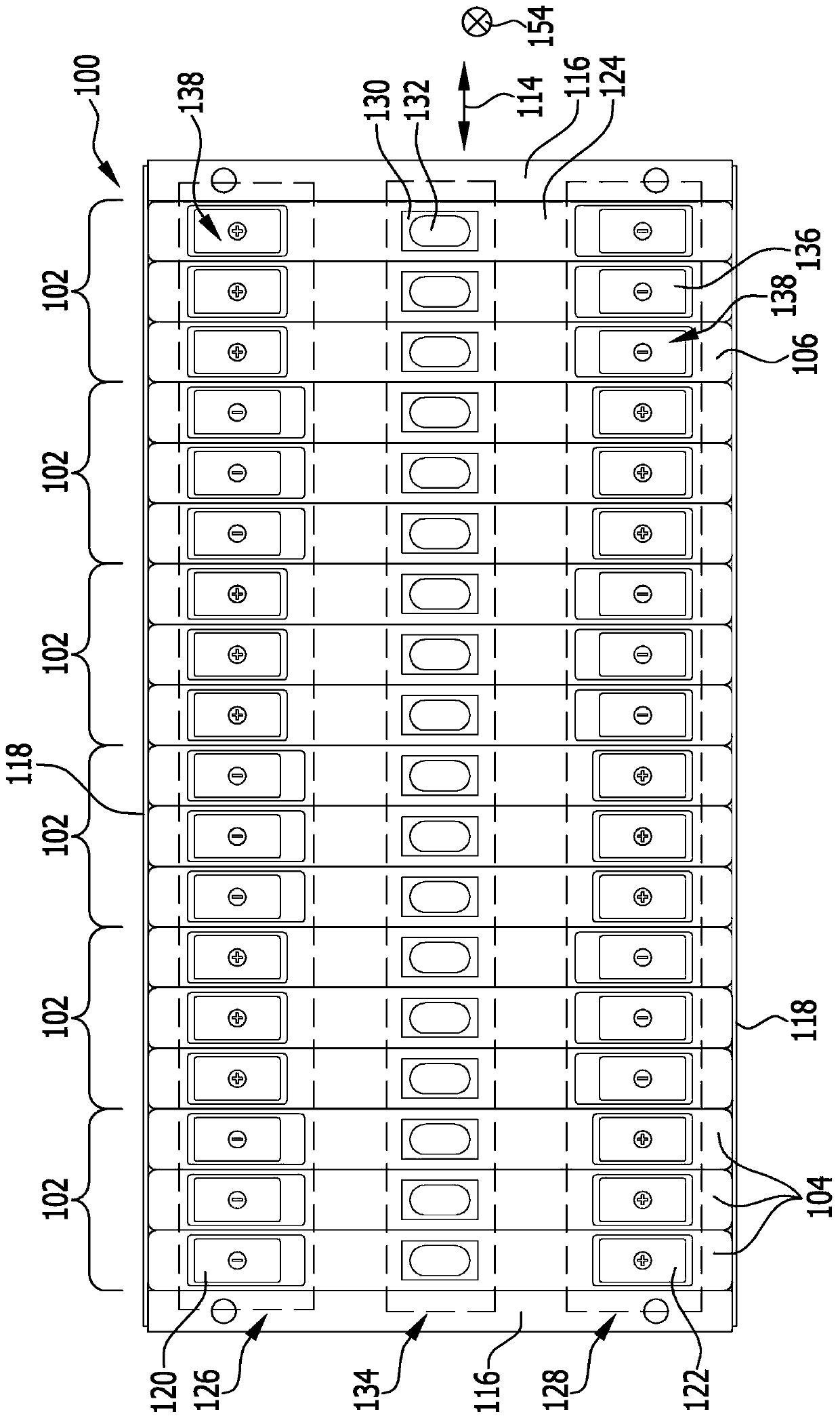

Cell contacting system for an electrochemical device

ActiveCN109997245ASame polarityGood cooling propertiesSmall-sized cells cases/jacketsVent arrangementsEngineeringElectrochemical cell

Owner:ELRINGKLINGER AG

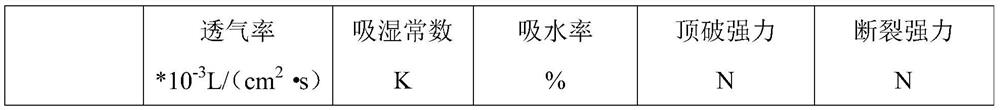

Cool skin-friendly PP spun-bonded non-woven fabric and preparation method thereof

PendingCN113106632ALarge hygroscopic constantImprove water absorptionConjugated synthetic polymer artificial filamentsNon-woven fabricsMaleic anhydridePolypropylene

The invention discloses a cool skin-friendly PP spun-bonded non-woven fabric and a preparation method thereof. The cool skin-friendly PP spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight of 60 to 70 parts of polypropylene, 22 to 30 parts of a polyurethane elastomer, 2 to 3 parts of porous diatomite, 6 to 9 parts of sepiolite powder, 2 to 2.5 parts of silicon dioxide porous ceramic powder, 3 to 5 parts of nano titanium dioxide, 1.8 to 2.5 parts of nano zirconium oxide, 8 to 12 parts of metallocene linear low-density polyethylene and 1.5 to 2.5 parts of maleic anhydride grafted polyethylene. The cool skin-friendly PP spun-bonded non-woven fabric is large in moisture absorption constant, high in water absorption rate, high in air permeability and good in hydrophilic and skin-friendly performance; a good cool feeling can be provided and the cool feeling is uniformly distributed; the addition amount of an inorganic filler can be reduced on the premise that the cool feeling is good; and it is guaranteed that the cool skin-friendly PP spun-bonded non-woven fabric has good mechanical properties and skin-friendly and hydrophilic comfort.

Owner:福建澳杰无纺布科技有限公司

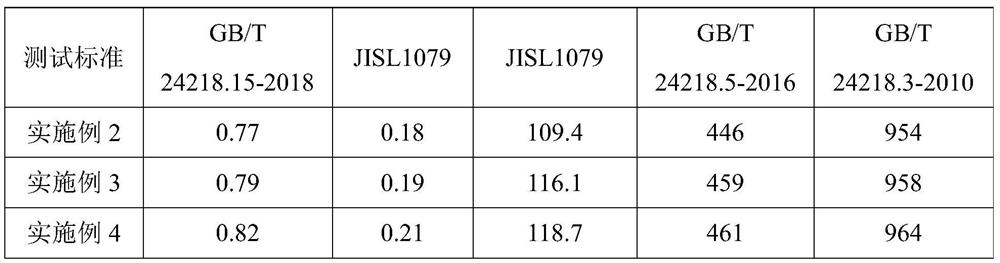

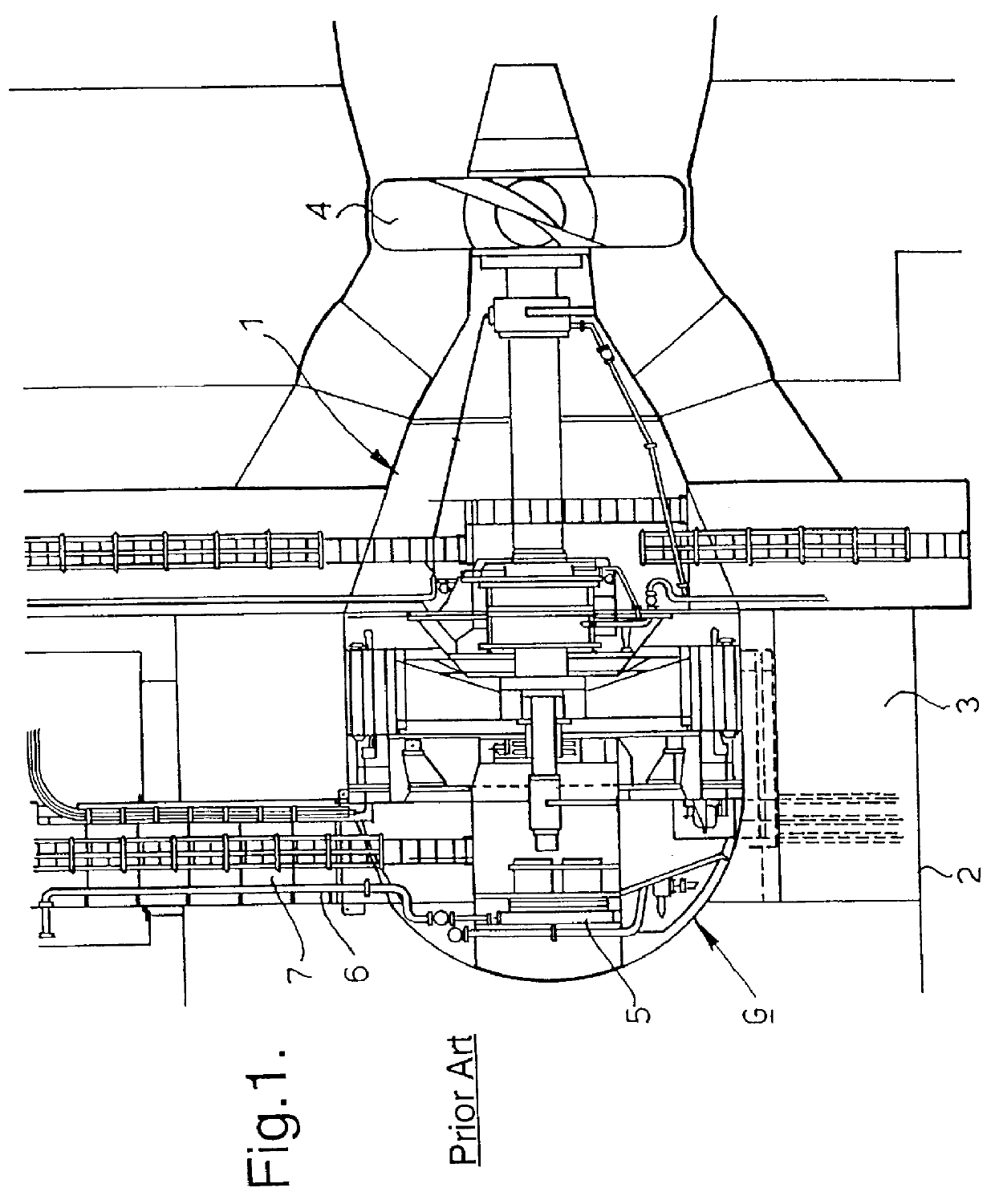

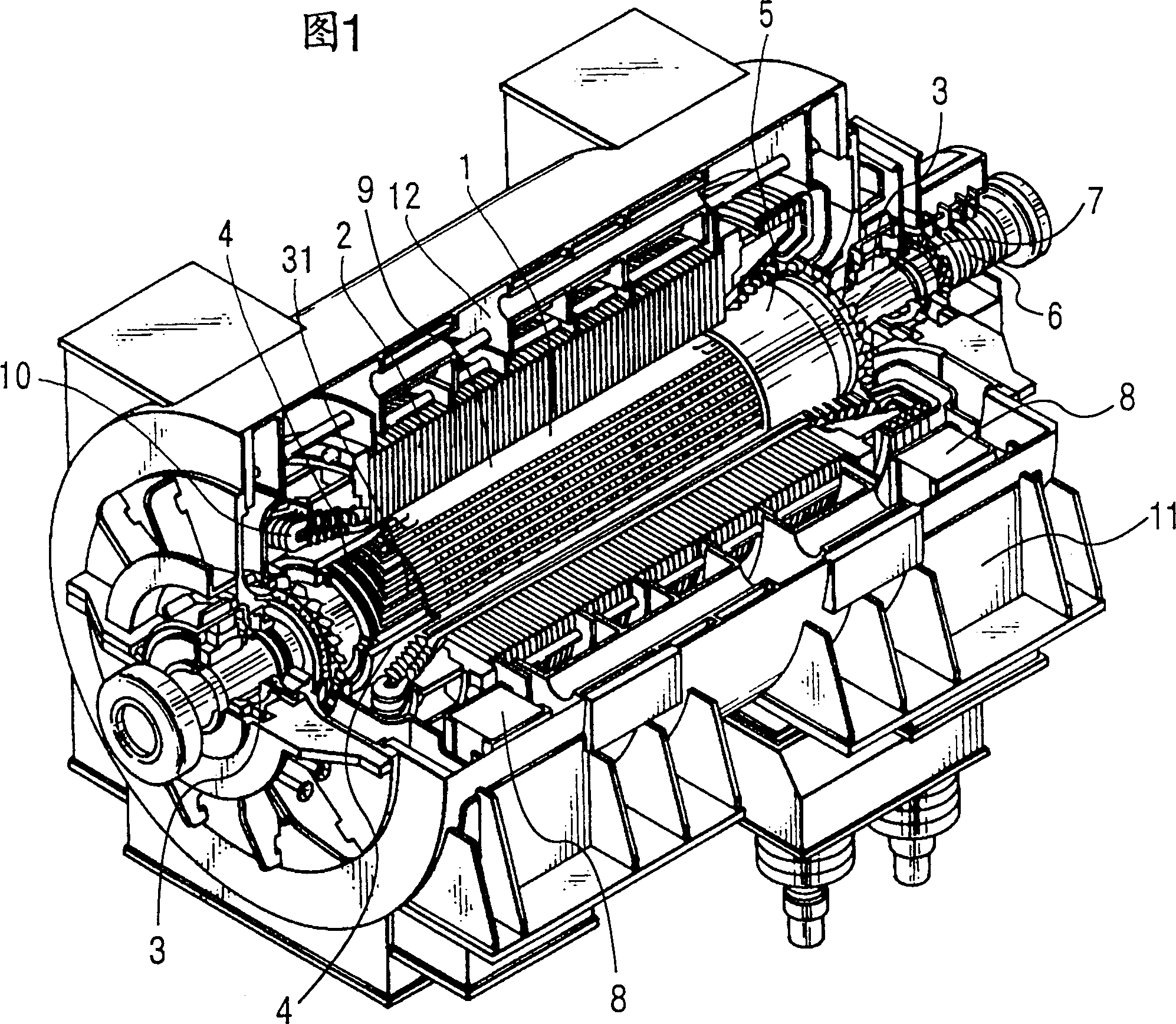

Arrangement in a bulb generator

InactiveUS6028380AGood cooling propertiesAvoid disadvantagesPump componentsEngine fuctionsWater flowEngineering

PCT No. PCT / NO96 / 00213 Sec. 371 Date Jun. 8, 1998 Sec. 102(e) Date Jun. 8, 1998 PCT Filed Aug. 29, 1996 PCT Pub. No. WO97 / 09771 PCT Pub. Date Mar. 13, 1997The present invention relates to an arrangement in a bulb generator (G), comprising a generator housing (1, 10, 110, 210, 310, 410) arranged in a water flow for letting turbine water flow there along and towards the turbine (4), which arrangement comprises means for removing surplus heat generated during operation of the generator, which mean comprise elements which are assembled as flow channels for coolant and / or heated generator air for indirect or direct cooling of the generator air, and for the purpose of providing a cooling system which to a large degree is independent of the quality of the river water or turbine water, and which also comprises elements which are non-costly as regards manufacturing and assembly, it is according to the present invention suggested that said means (111; 411) comprise, as known per se, extruded elements, especially elements which either comprise channels or by assembly define channels (112; 412) for circulating coolant, especially circulating air, or any other appropriate coolant, and that an outer surface of the extruded elements is exposed to bypassing turbine water.

Owner:ALSTOM TECH LTD

Rotor end ring with oil jacket

ActiveUS20210336510A1Good cooling propertiesMagnetic circuit rotating partsCooling/ventillation arrangementStatorStructural engineering

An electric motor includes a housing, a stator having end turn windings, a rotatable central shaft, a rotor mounted onto the central shaft, and a rotor end ring mounted onto the central shaft adjacent the rotor, the rotor end ring including an annular disk shaped body having a circumferential outer diameter and a circumferential inner diameter and being formed from a thermally conductive material, a recess formed within a face of the body, an oil jacket formed within a back side of the body, the oil jacket comprising an annular channel having a circumferential outer wall and a circumferential inner wall, two inlets, each inlet extending radially between the inner diameter of the body and the inner wall of the oil jacket, a plurality of outlets, each outlet comprising a circumferential slot, the plurality of outlets equidistantly spaced around the face adjacent the circumferential inner wall of the oil jacket.

Owner:GM GLOBAL TECH OPERATIONS LLC

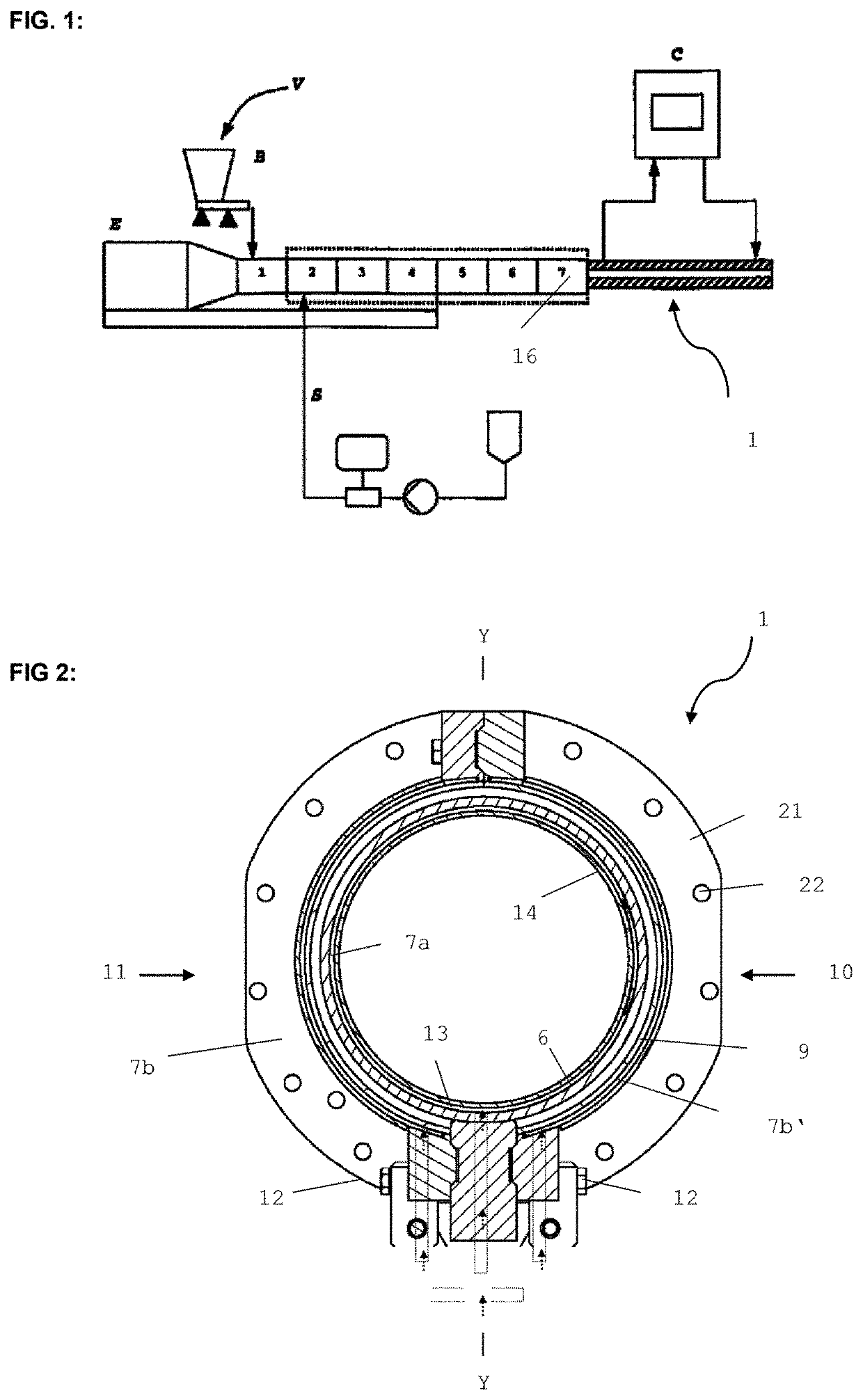

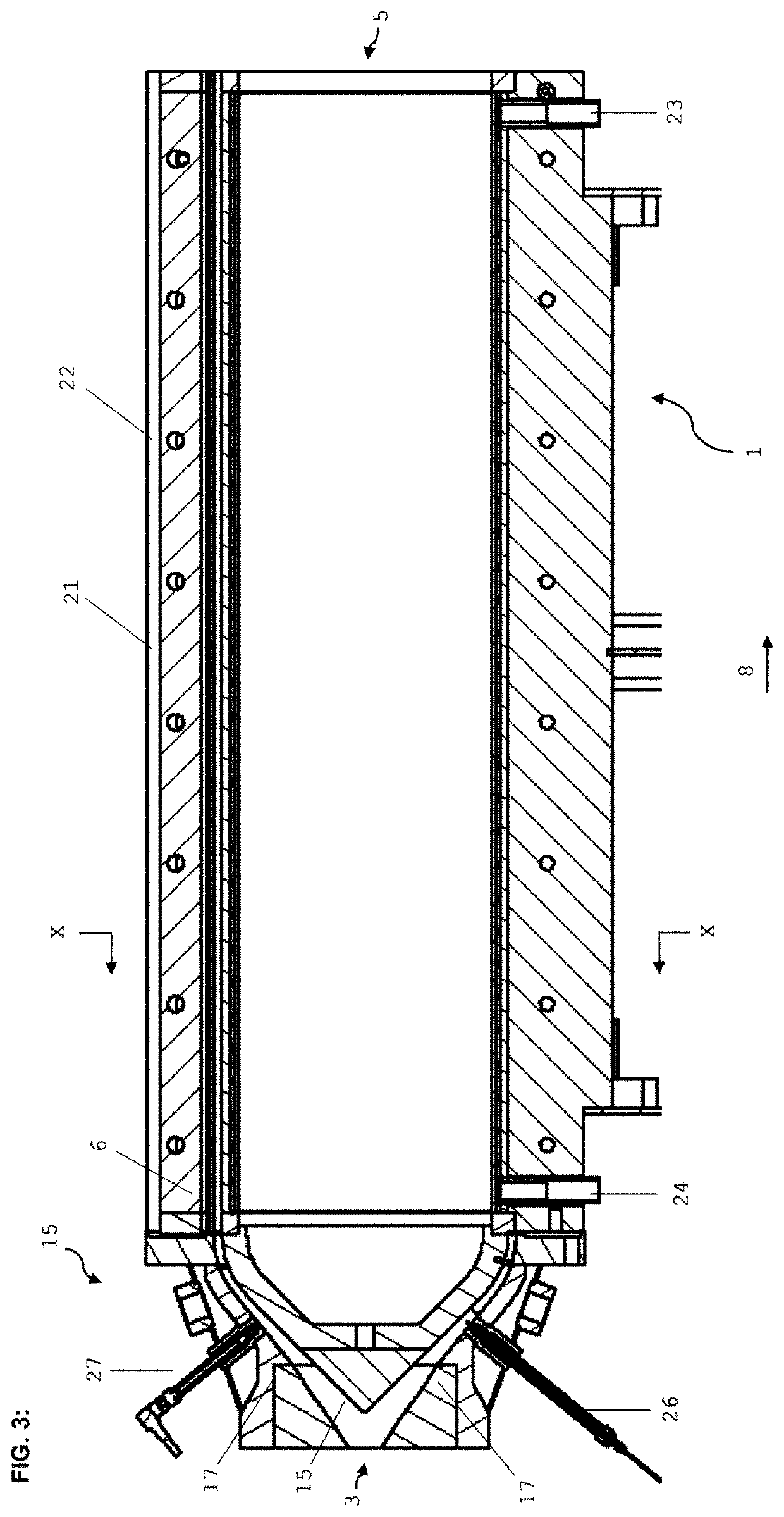

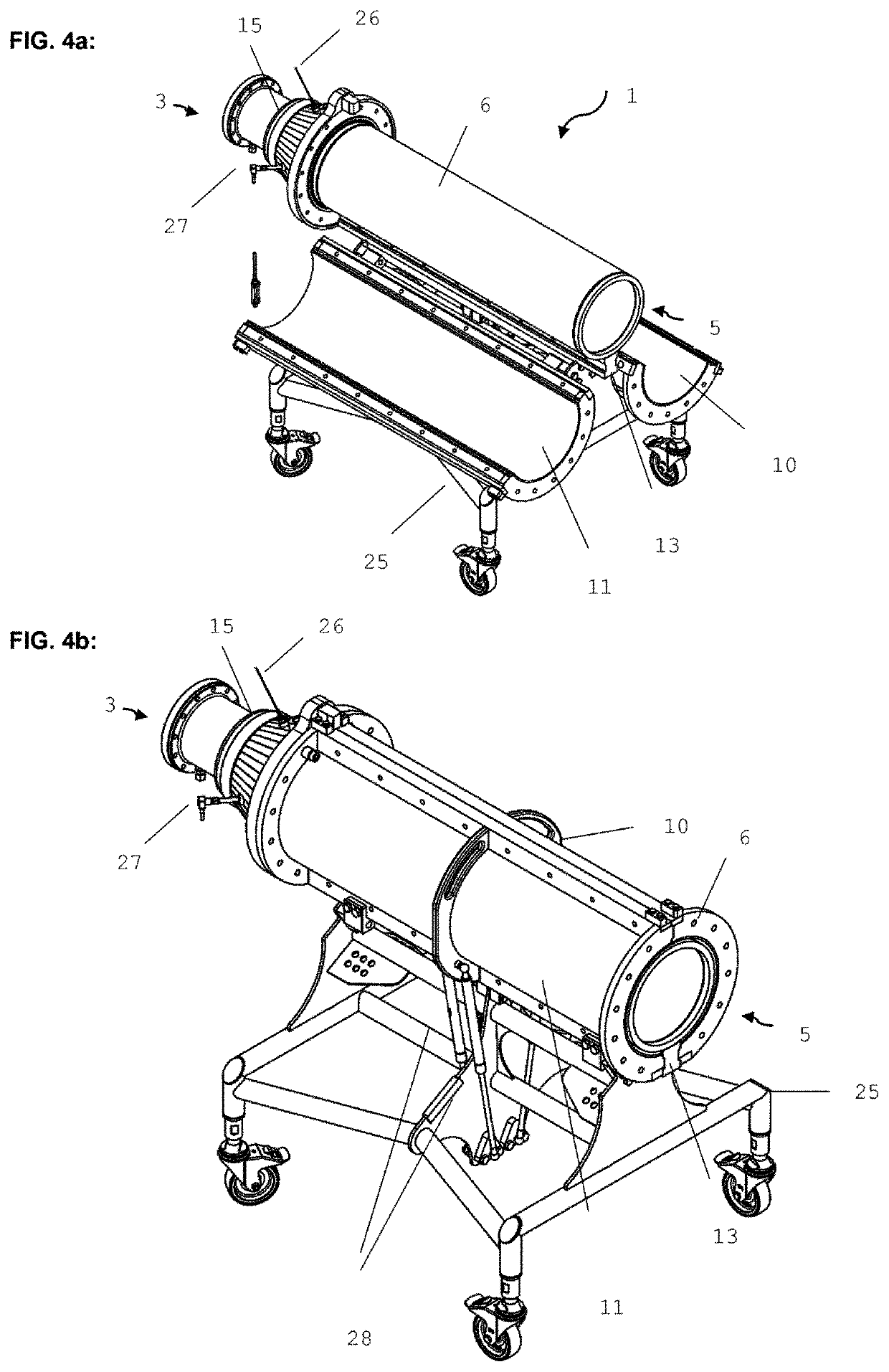

Cooling tool for an extruder

ActiveUS20210046690A1Good cooling propertiesSimple structureFeeding-stuffWorking-up animal fodderThermodynamicsCoolant flow

A cooling tool (1) for a food or an animal feed extruder (E), the cooling tool has: an inlet end (3) at which extrudate (4) can be led into the cooling tool (1); an outlet end (5) where the cooled extrudate can be discharged; an extrudate flow channel (6) extending from the inlet end to the outlet end; and at least one coolant flow channel (7a, 7b, 7b′) connected to the extrudate flow channel in a heat-transmitting manner. In a cross section (X-X) along the primary flow direction (8), the extrudate flow channel is substantially formed as a ring section; and the outer wall (9) of the extrudate flow channel (6) is formed at least from first and second segments (10, 11). The first and second segments are connected to each other by mechanical connection elements (12). The cooling tool is suitable for wet texturing of food and animal feed.

Owner:BUEHLER AG

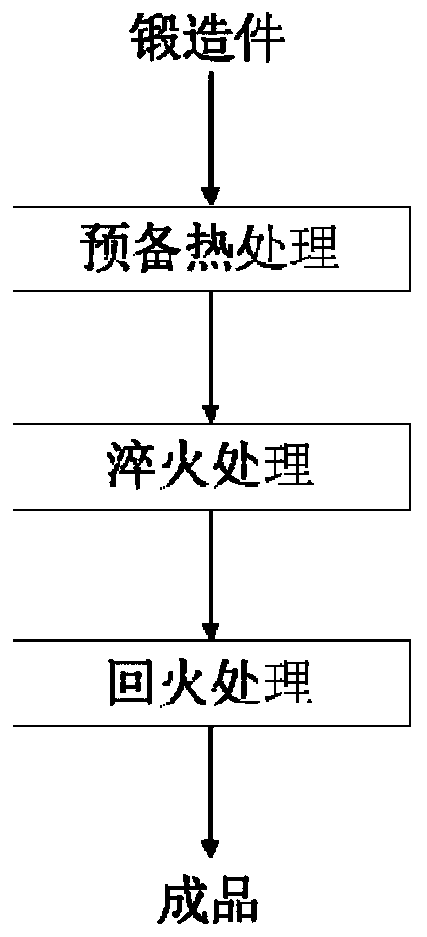

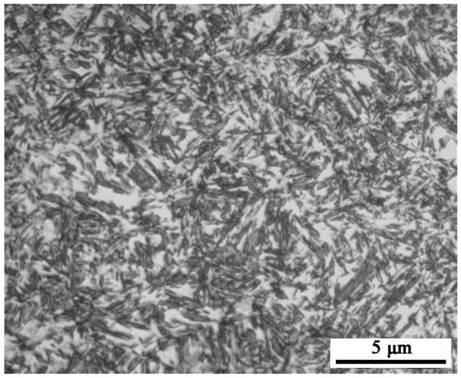

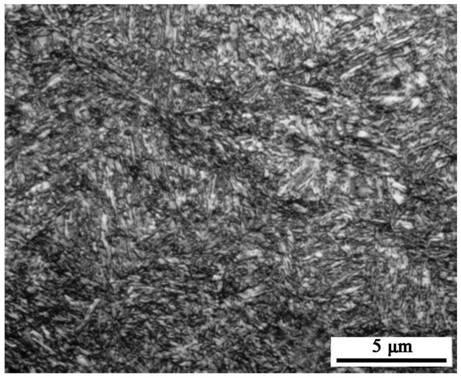

High-wear-resistant-edge mold material and heat treatment process thereof

InactiveCN110527919AHigh strengthImprove wear resistanceQuenching agentsWear resistantRoom temperature

The invention discloses a high-wear-resistant edge mold material and a heat treatment process thereof, and belongs to the technical field of mold materials. The high-wear-resistant edge mold materialcomprises the following components in percentage by mass: 0.45%-0.55% of C, 0.9%-1.2% of Si, 0.3%-0.6% of Mn, 4.9%-5.5% of Cr, 1.3%-1.6% of V, 1.3%-1.6% of Mo, P <= 0.03%, S<= 0.03% and the balance Feand inevitable impurities. The heat treatment process comprises the following steps: 1, pre-heat treatment: heating an edge mold material to 830-870 DEG C, keeping the temperature for 2-3 hours, andair-cooling to room temperature; 2, quenching treatment, specifically, the edge mold material treated in the step 1 is heated to 820-840 DEG C, and after heat preservation is conducted for 5-7 hours,the edge mold material is put into a quenching medium to be cooled to the room temperature; and thirdly, tempering treatment, specifically, tempering treatment is conducted on the blade mold materialtreated in the second step. By improving the components of the edge mold material and the heat treatment process, the wear resistance and comprehensive mechanical properties of the blade mold materialare greatly improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

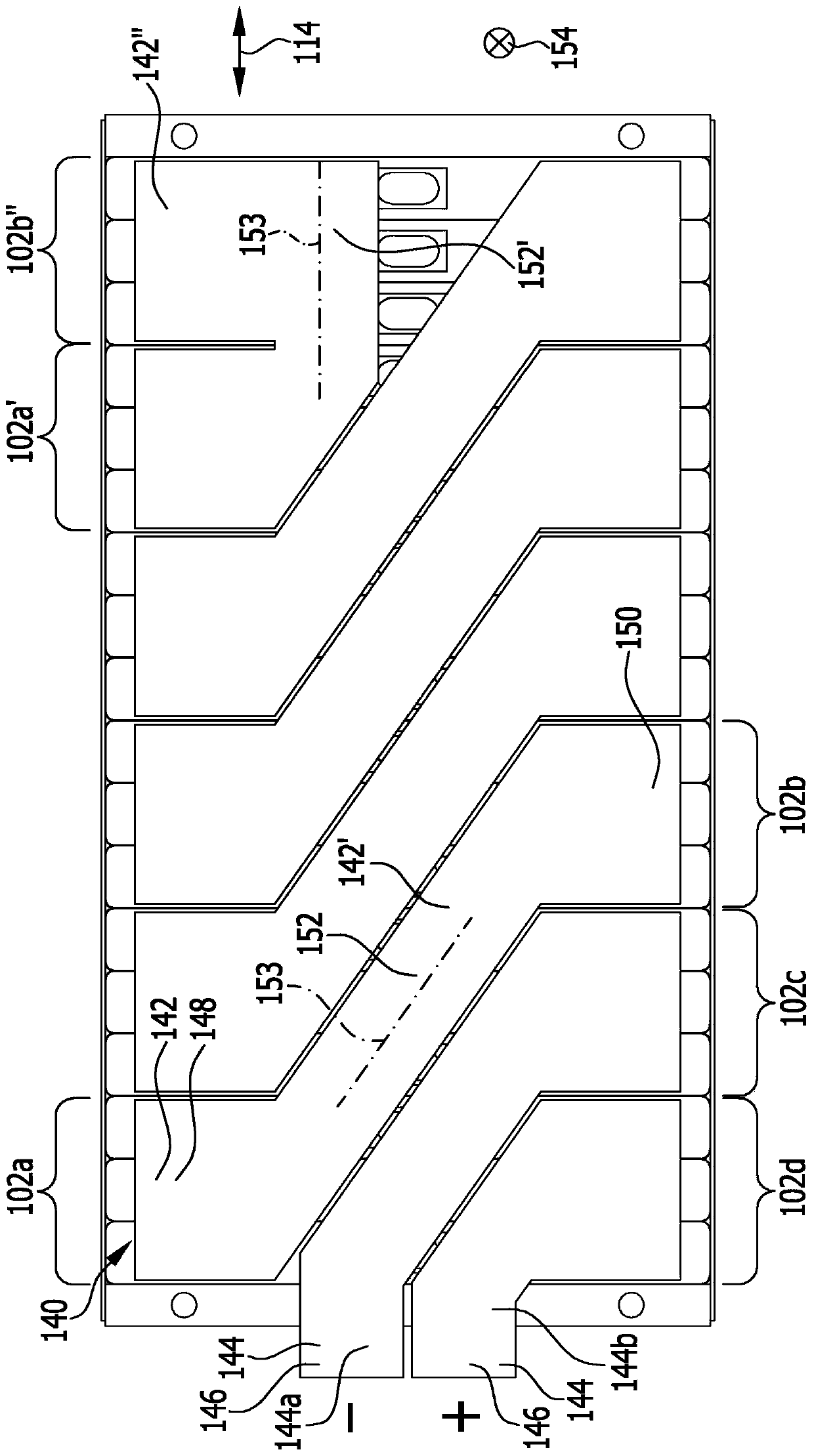

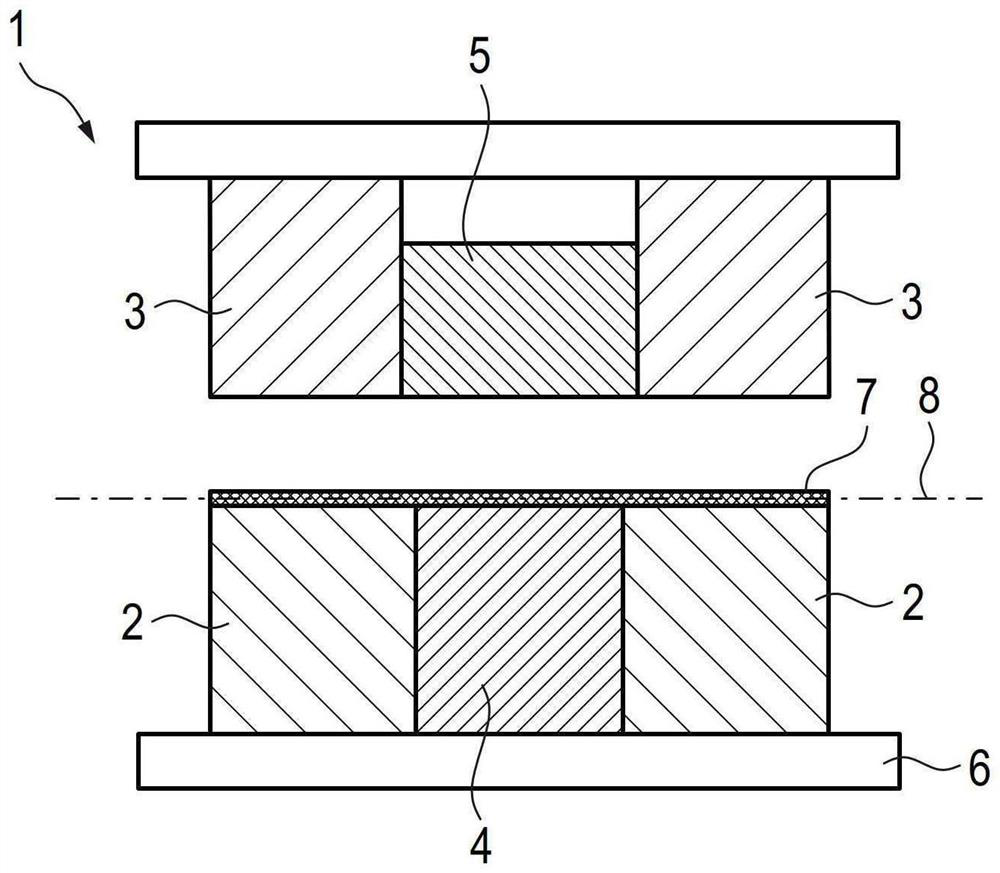

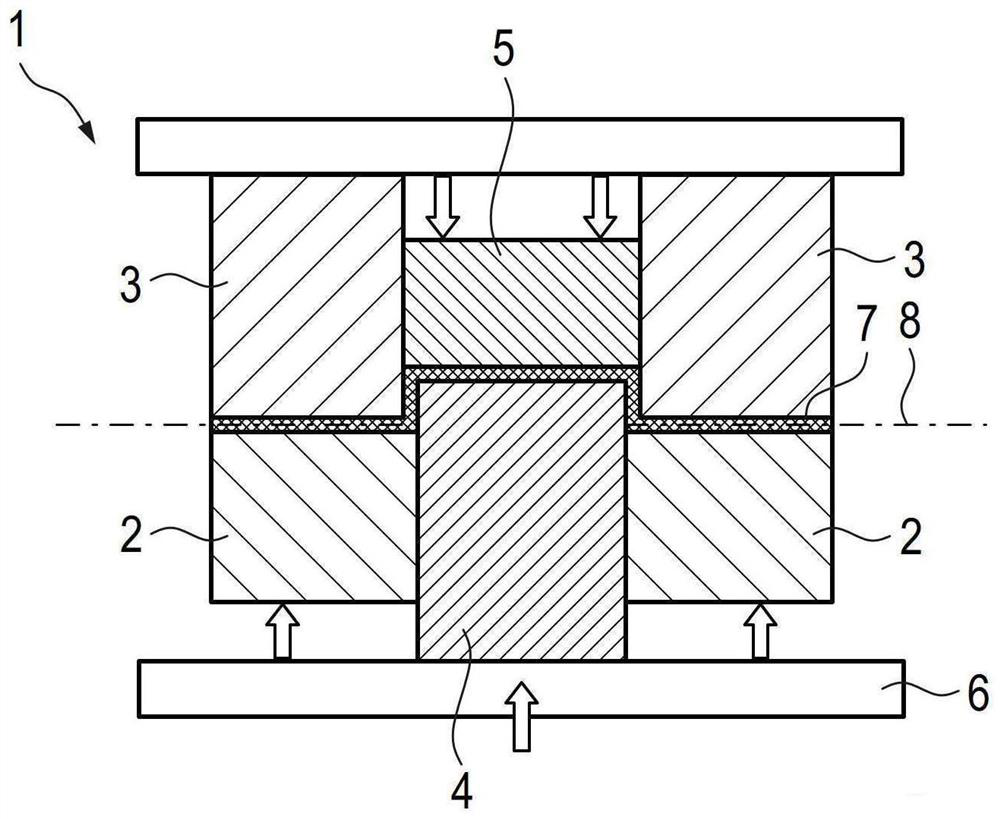

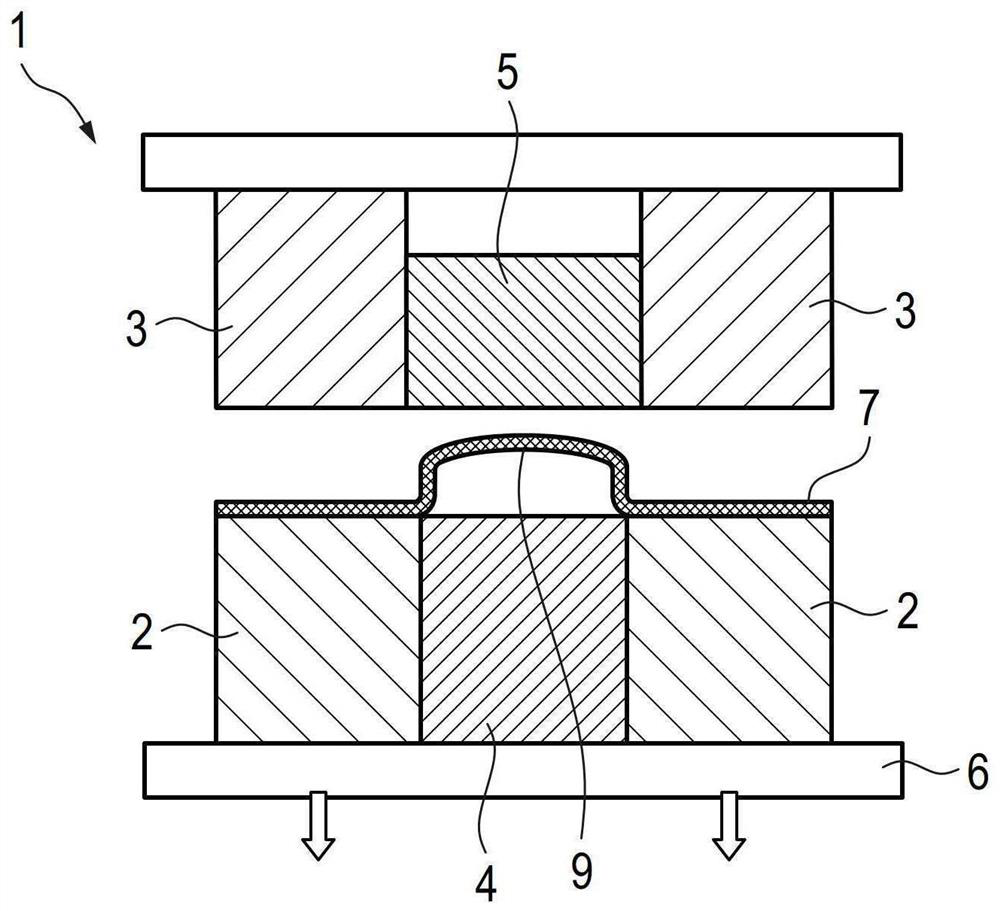

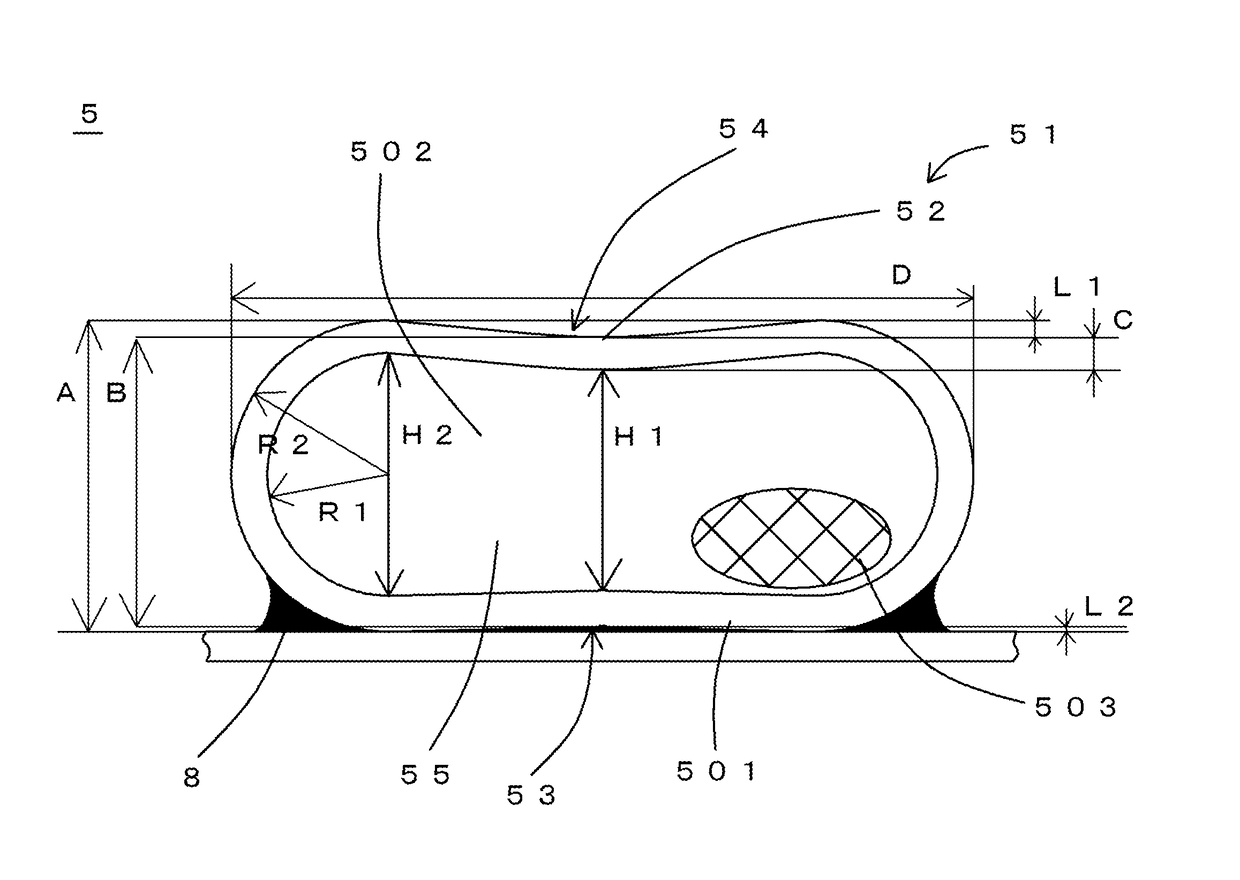

Method for deformation forming of metal composite foil and forming equipment

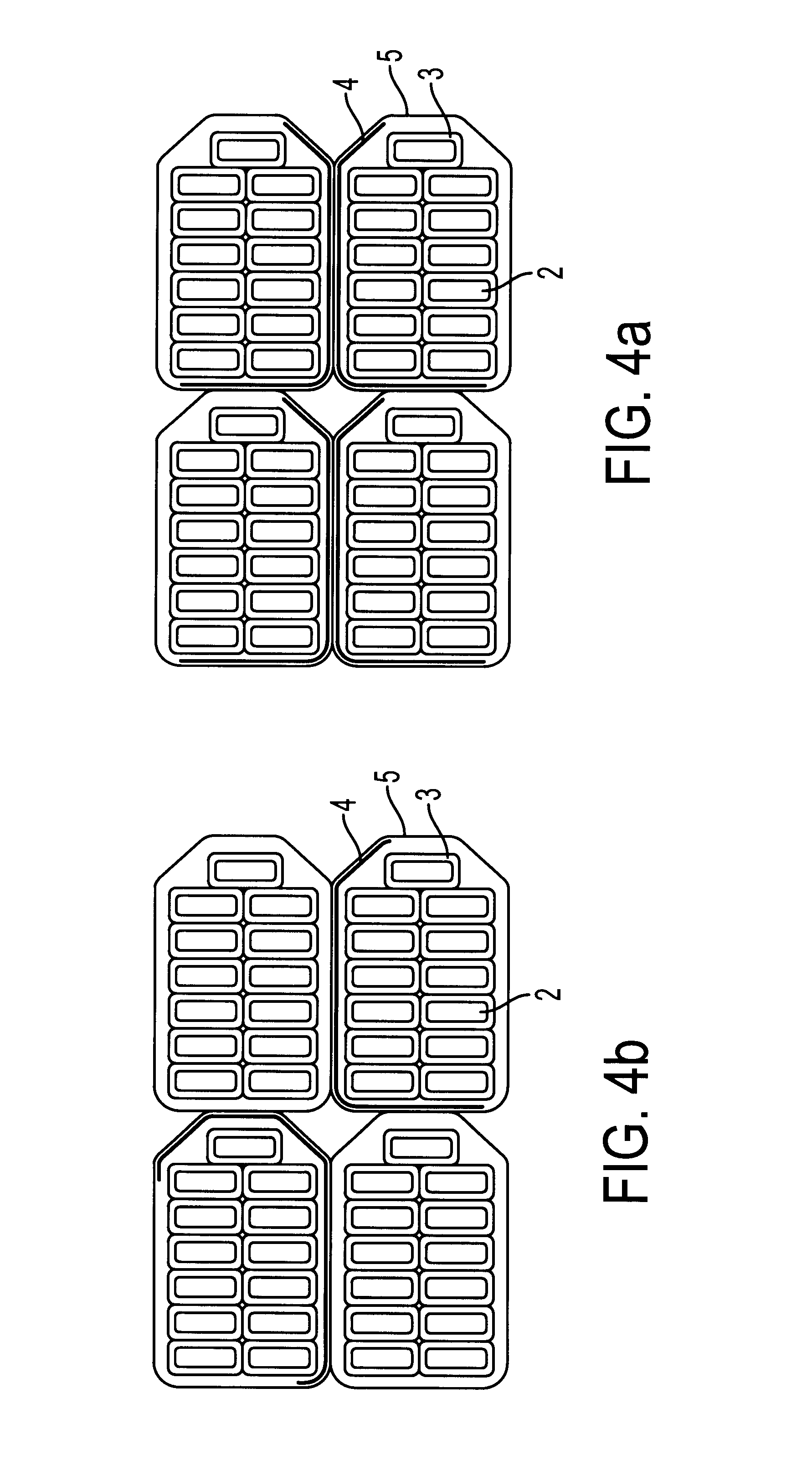

PendingCN114850300AEasy to manufactureReliable wrappingShaping toolsCell component detailsBattery cellComposite material

The invention relates to a method for shaping a metal composite foil (7) for battery cells (33), comprising at least the following steps: a) placing the metal composite foil (7) in a shaping device (1) having a plurality of sheet metal holders (2, 11), a plurality of forms (3, 10) and a first punch (4); b) fixing a first fixing region (13) of the metal composite foil (7) by closing the first sheet holder (3) and the first pattern (3); c) fixing a second fixing region (14) of the metal composite foil (7) by closing a second sheet holder (11) and a second pattern (10); d) deforming the second fastening region (14) at least partially in the first direction (16) by moving the second sheet holder (11) and the second pattern (10); e) deforming the deformation region (15) at least partially in the second direction (19) by moving the punch (4). The invention further relates to a shaping device (1) for shaping a metal composite foil (7) for a battery cell.

Owner:VOLKSWAGEN AG

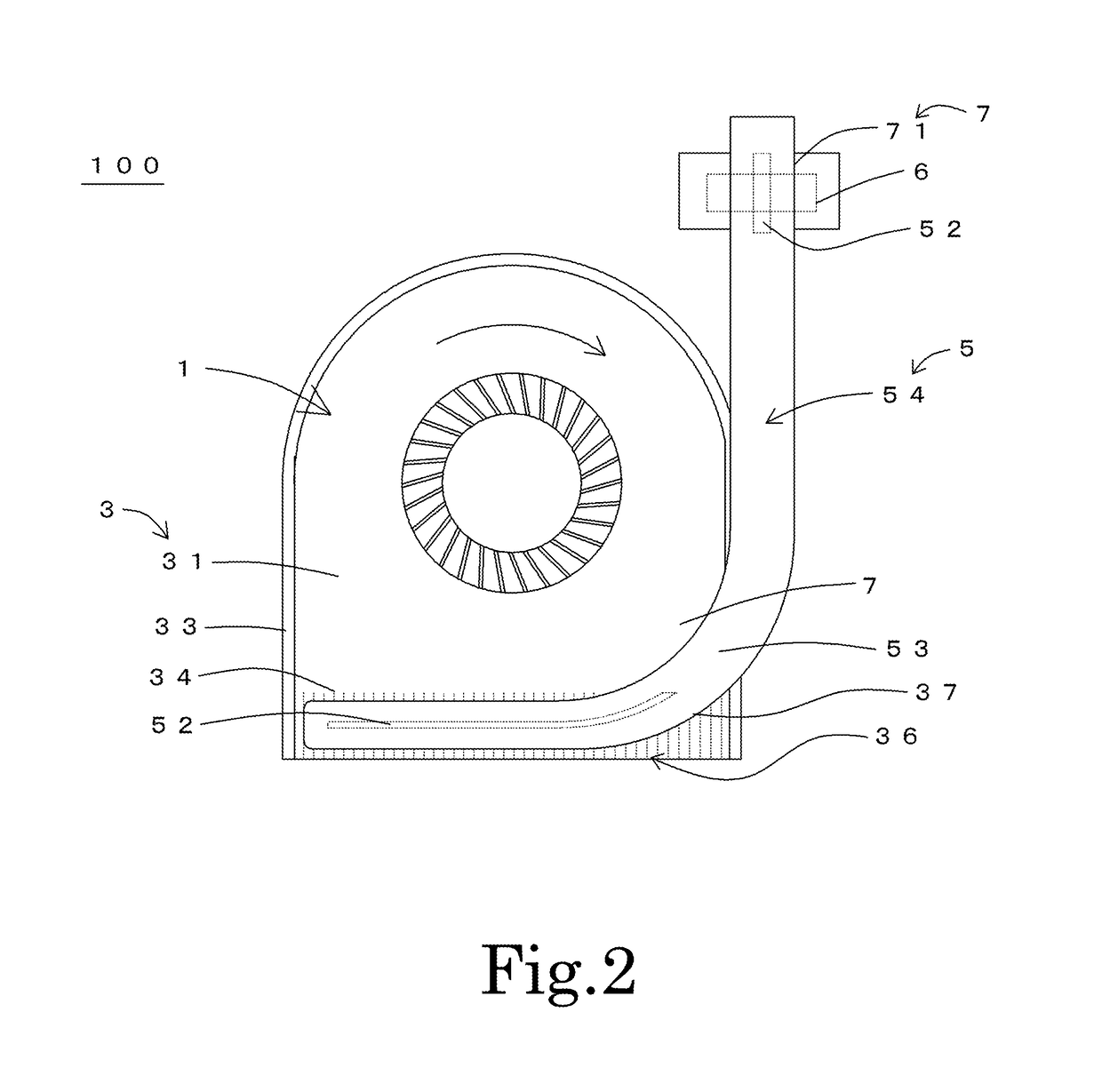

Heat module

ActiveUS9909813B2Good cooling propertiesReduce thicknessDigital data processing detailsIndirect heat exchangersEngineeringThermal contact

A heat module includes a fan and a heat pipe. A flat portion of the heat pipe includes a recessed portion being recessed toward a center of the heat pipe in a cross section. A heat receiving portion arranged between the heat source and the heat pipe includes a heat source contact portion arranged to be in thermal contact with the heat pipe. In at least a portion of the heat pipe which extends between a portion of the heat pipe which is in thermal contact with the fan contact portion and a portion of the heat pipe which is in thermal contact with the heat source contact portion, a difference between a maximum axial height of the heat pipe and a minimum axial height of a portion of the heat pipe where the recessed portion is defined is smaller than a wall thickness of the recessed portion.

Owner:NIDEC CORP

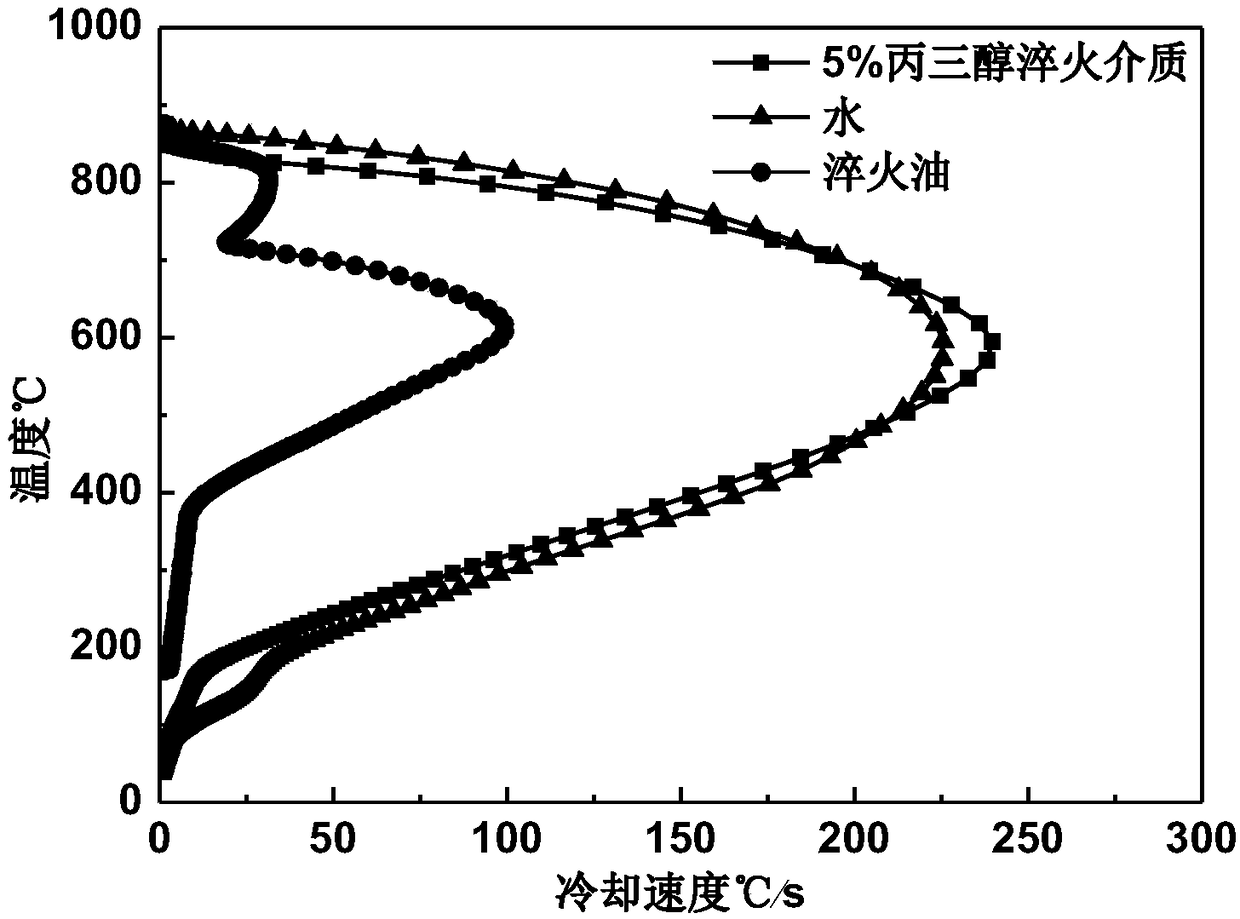

A kind of glycerol aqueous solution quenching cooling medium and preparation method thereof

ActiveCN106591548BGood cooling propertiesReduce manufacturing costQuenching agentsWater basedEnvironmental resistance

Owner:深圳市先力得热处理有限公司

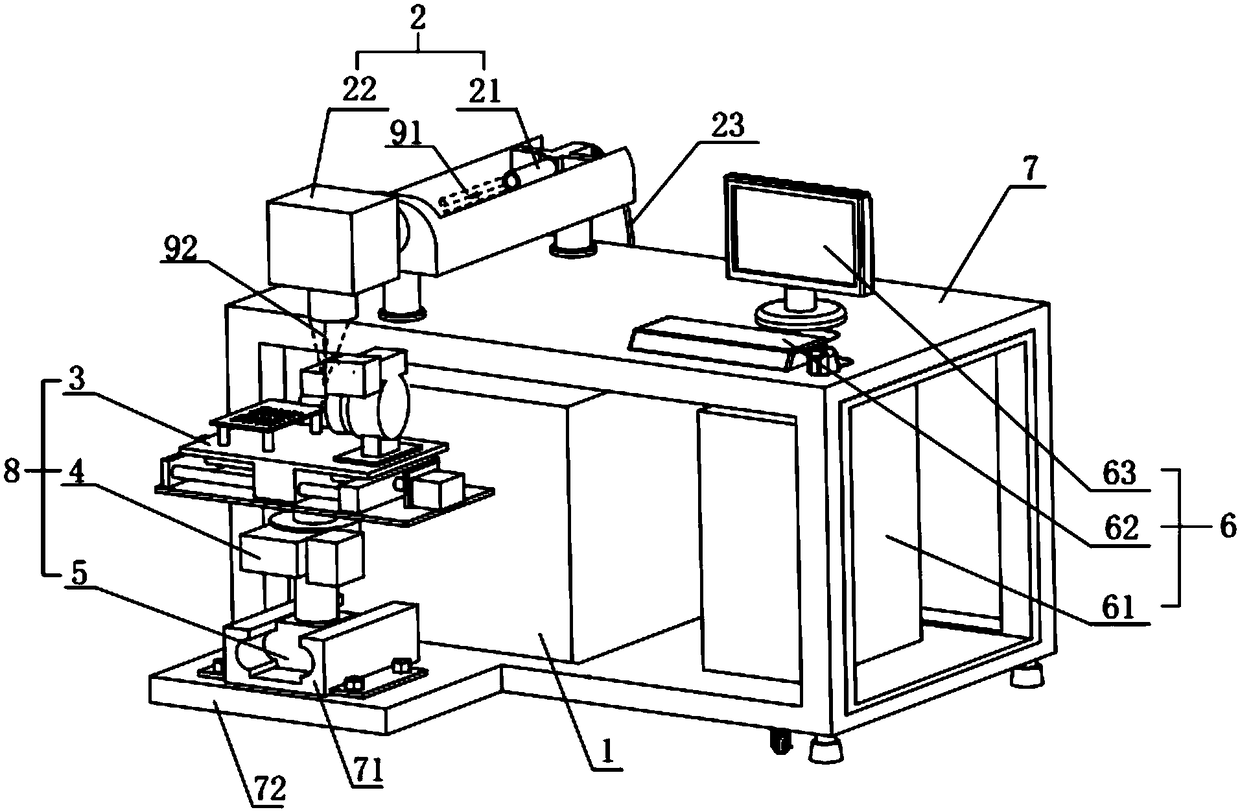

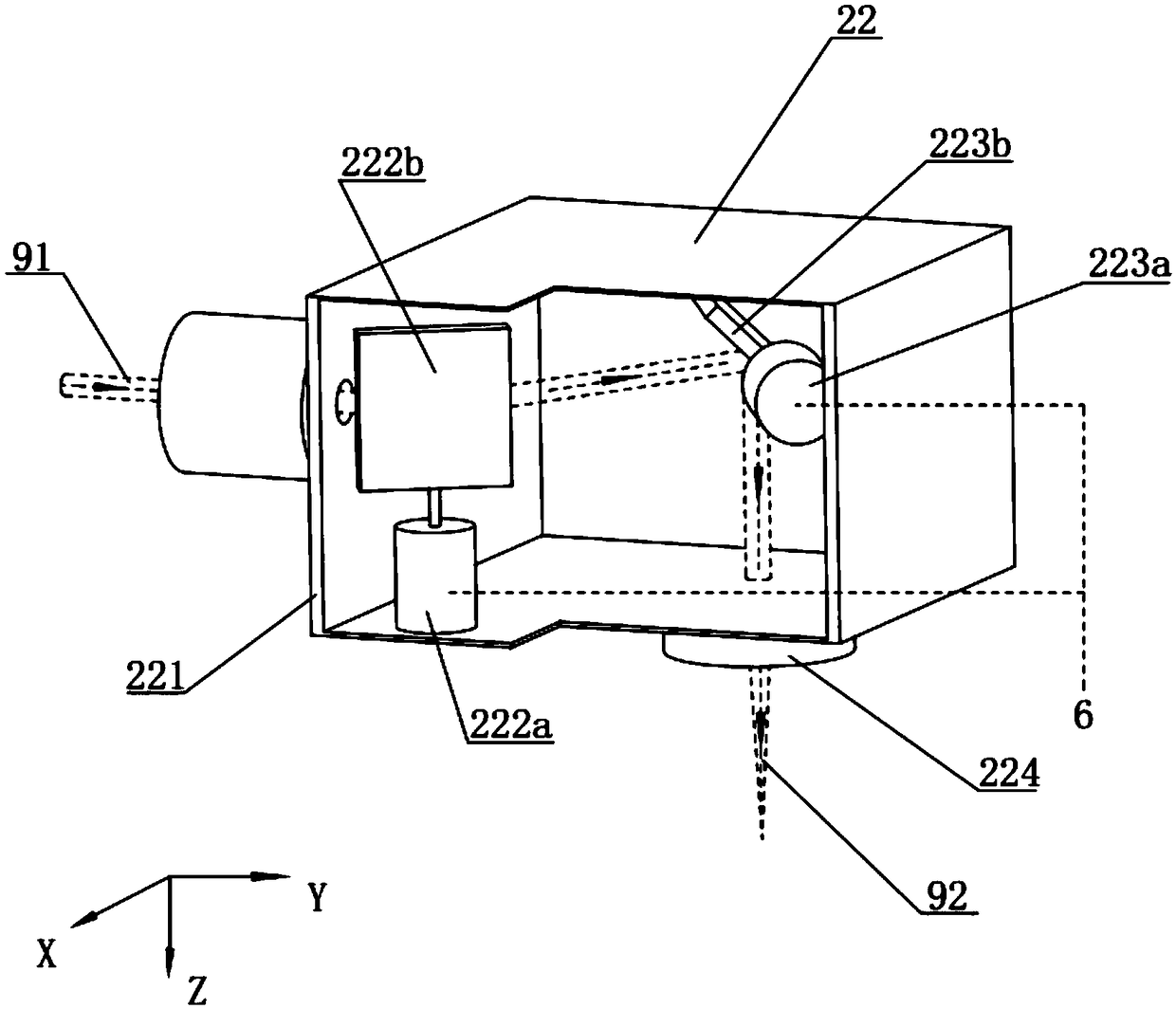

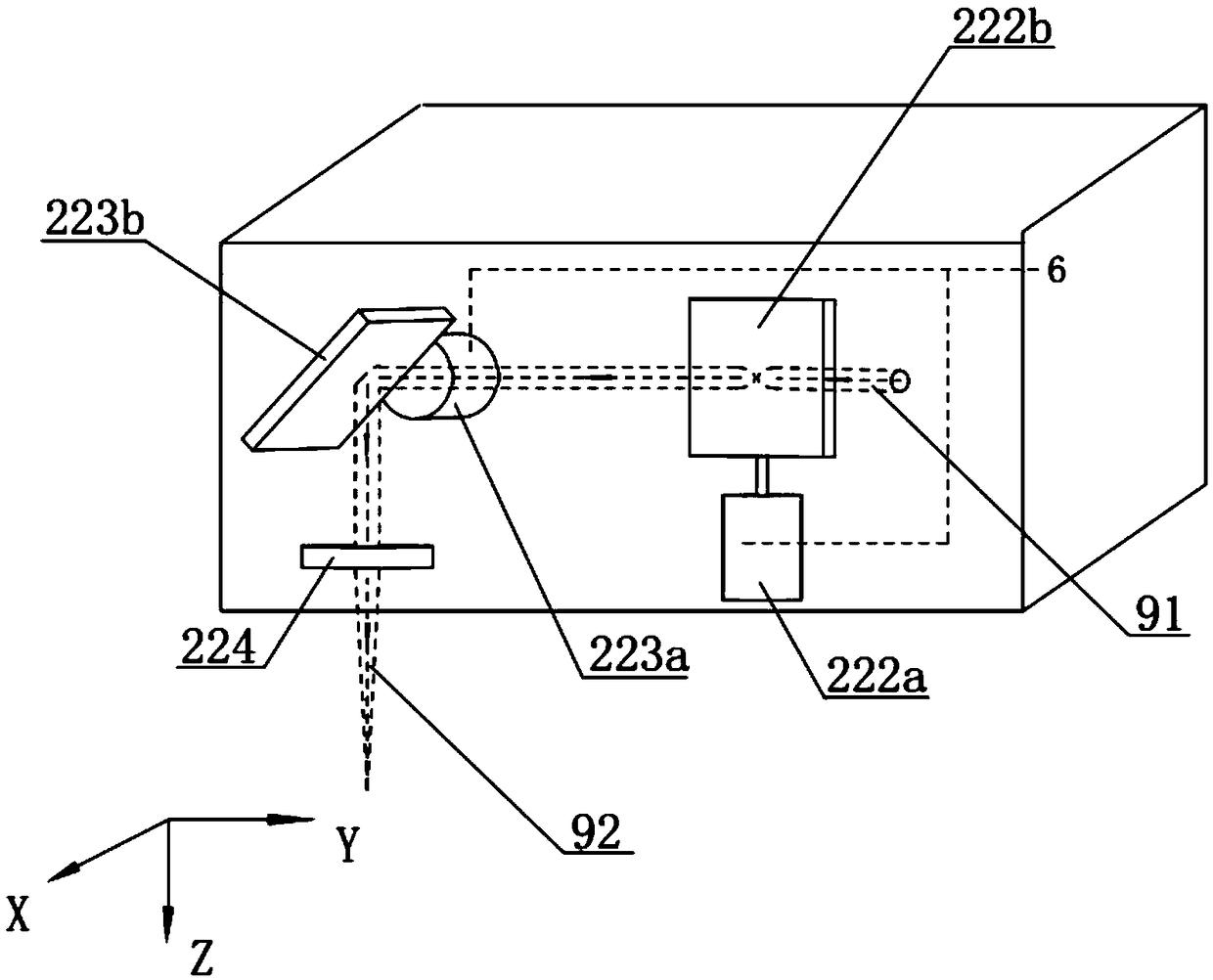

A laser heat treatment platform for the surface of small-sized metal parts

InactiveCN107177723BHeating fastReduce impactFurnace typesHeat treatment furnacesControl systemGalvanometer

The invention provides a small-sized metal part surface laser heat treatment platform which is mainly composed of a laser device, a laser optical path system, a combined material bearing device and a control system. The control system is electrically connected with the laser optical path system. The laser optical path system comprises a collimation device and a two-dimensional scanning galvanometer system. The combined material bearing device sequentially comprises an upper screw rod guide rail transmission material bearing device, a middle worm gear screw rod lifting device and a bottom sliding device from top to bottom. The upper screw rod guide rail transmission material bearing device is located under the two-dimensional scanning galvanometer system and comprises a supporting plate which is connected with the middle worm gear screw rod lifting device and a material bearing table which is arranged on the supporting plate in a slideable mode and can move in the Y direction. The material bearing table is provided with a platy metal clamping platform and a columnar metal clamping device. The bottom sliding device is arranged on a bottom plate of a workbench in a slideable mode and can move in the X direction. The X direction, the Y direction and the lifting direction are perpendicular to each other in a pairwise mode. The small-sized metal part surface laser heat treatment platform has the beneficial effects that one machine can achieve multiple purposes, precision is high and errors are small.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A wheel heat treatment speed-increasing process

ActiveCN104694727BFast heat absorptionEvenly heatedFurnace typesQuenching agentsHeating timeThermal insulation

The invention is the field of wheel machining, which involves a speed -up process of wheel heat treatment.The thermal treatment method is divided into three stages, solid solution, quenching, and timeliness. The process is: the cast aluminum wheels passing through the X -ray machine, and then passed through the rushing machine and then reached the thermal treatment.The temperature of the solubility stage is 540-550 ° C, the heating time is 25-28 minutes, the thermal insulation time is 110-115 minutes, and then the wheels maintain the temperature of the solid-soluble stage to enter the quenching.Infertile for 5 minutes, and then enter the time-effective cooker. The temperature stage temperature is 155-165 ° C, and the insulation time is 60 minutes.

Owner:盛旺汽车零部件(昆山)有限公司

Rotary electric generator

InactiveCN1131584CGood cooling propertiesLow costMagnetic circuit rotating partsManufacturing dynamo-electric machinesEngineeringTurbine

A turbine electric power generator is provided with winding slots and sub-slots of a rotor; rotor windings having conductors and insulation materials laminated alternately thereon; wedges; and radial ventilation flow passages communicating the sub-slots with through holes of the wedges. In this turbine electric power generator, a projection is provided on an inner face of the radial ventilation flow passages, and the projection height is changed at a rotational axial position. In this manner, there can be provided a gas cooling type rotary electric power generator for turbine with its high cooling performance and high reliability at a low cost.

Owner:HITACHI LTD

Heat treatment process for ASDO clamp products

InactiveCN101982549BGood cooling propertiesGrain refinementFurnace typesHeat treatment process controlThermodynamicsRoom temperature

The invention discloses a heat treatment process for ASDO clamp products, comprising the following steps: normalizing: firstly heating the workpieces to 860+ / -10 DEG C and preserving the heat for 2-3h and then discharging the workpieces and cooling the workpieces to the room temperature; quenching: firstly heating the normalized workpieces to 700+ / -10 DEG C and preserving the heat for 3-4.5h, secondly continuing raising the temperature to 930+ / -10 DEG C and preserving the heat for 4-6h, thirdly discharging the workpieces and quenching the workpieces in PQG quenching liquid with temperature being not more than 38 DEG C and mass concentration being 10-12% for 10-20min and finally cooling the quenched workpieces in a water-cooling pool to 200-300 DEG C until water exits and slightly airing the workpieces; and tempering: firstly heating the quenched workpieces to 450+ / -10 DEG C and preserving the heat for 1-2h, secondly raising the temperature to 630+ / -10 DEG C and preserving the heat for7-11h and finally discharging the workpieces, air-cooling the workpieces to 500 DEG C, then cooling the workpieces in the water-cooling pool to 200-300 DEG C until water exits and cooling the workpieces to the room temperature. The heat treatment process is adopted for processing the close-distance clamp products, ensures that the mechanical performance of the processed close-distance clamp products can meet the design and construction requirements, reduces the product reject rate and improves the labor efficiency.

Owner:JIANGSU JINSHI CASTING & FORGING

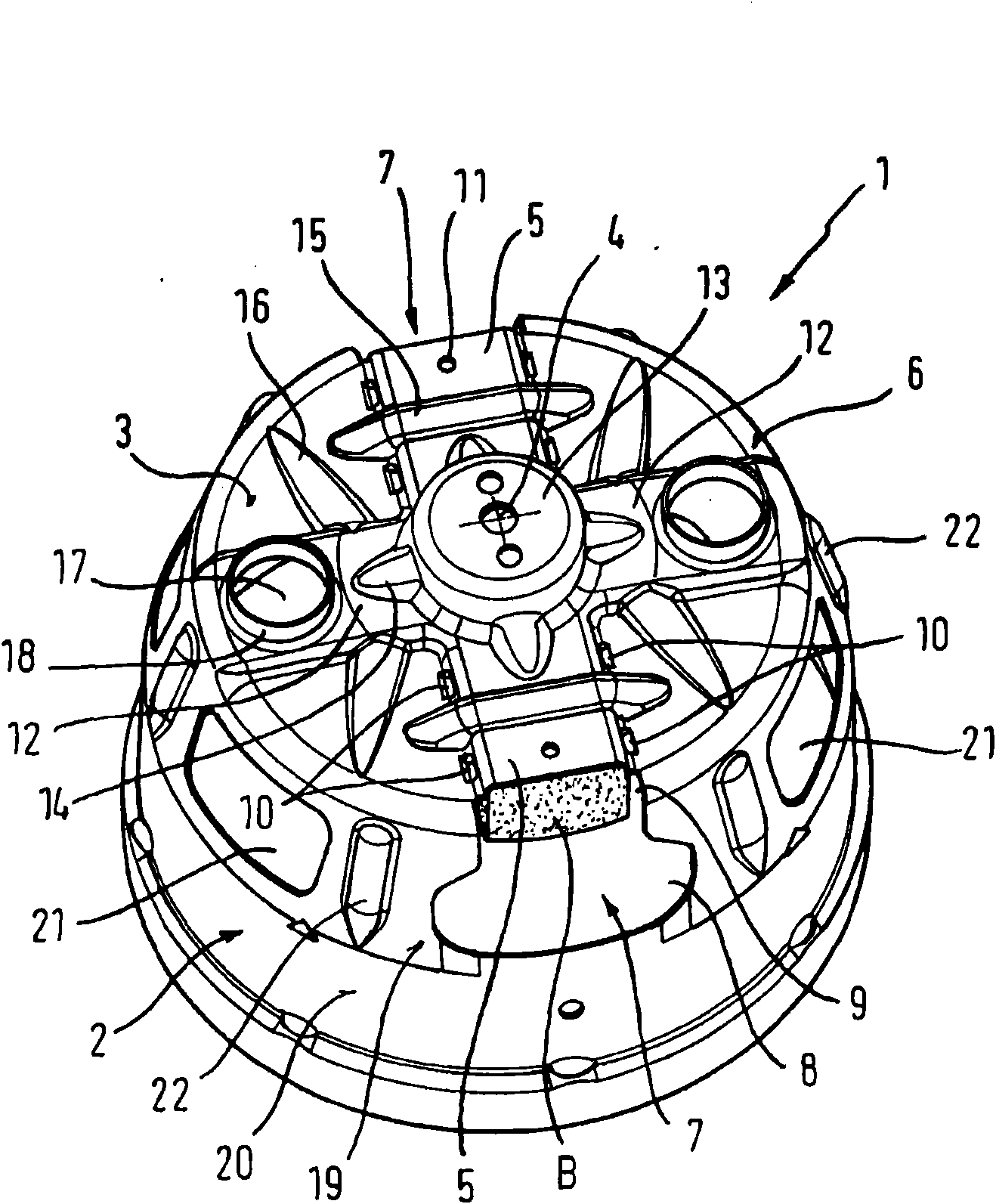

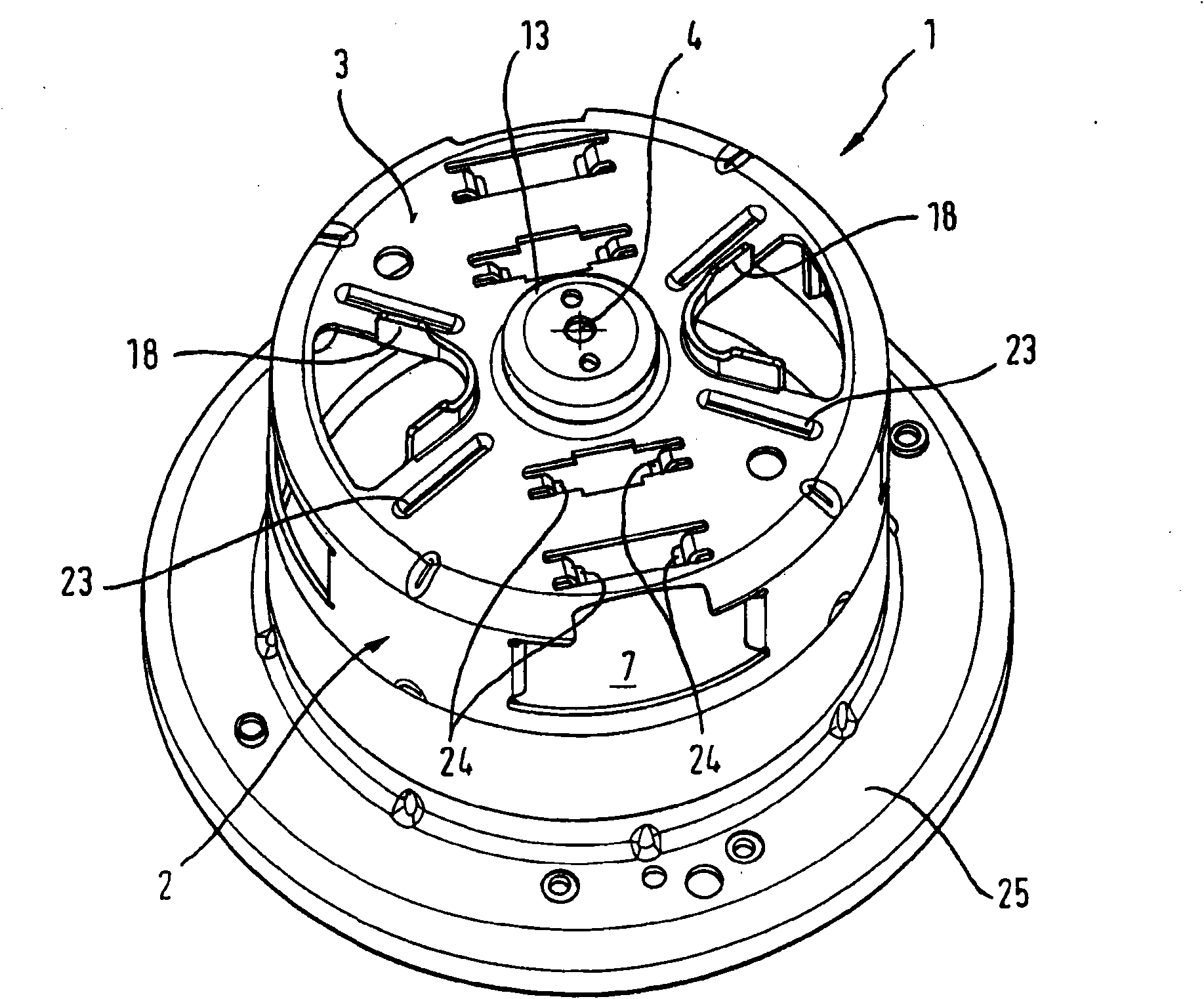

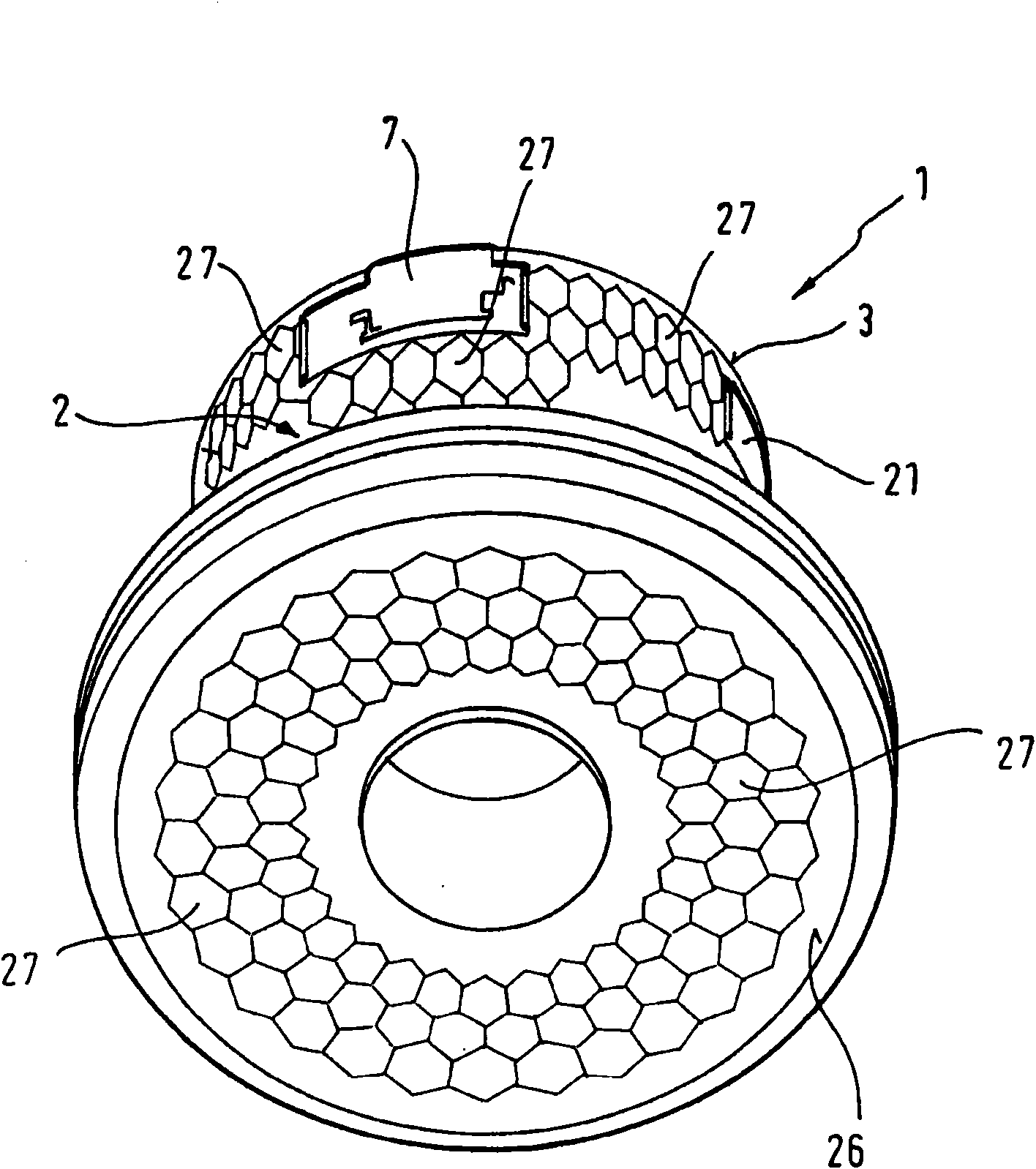

Housing for the drive of an electrical device, particularly a household appliance

ActiveCN101953053AGood cooling propertiesReduce wall thicknessSuction cleanersSupports/enclosures/casingsNoise generationElectricity

The invention relates to a housing (1) for the drive of an electrical device, particularly a household appliance, comprising a radial wall (2) and a front wall (3) having one or more embossments. According to the invention, at least one first embossment (5) in the front wall is designed like a channel and extends between areas of the circumference (6) of the front wall (3) opposite each other. The first channel-like embossment (5) preferably opens into recesses (7) located opposite each other, through which the brush arrangement (B) of the electrical drive can be inserted into the channel-like embossment (5) and secured. A second channel-like embossment (12) preferably extends perpendicular to the first embossment (5), meeting the first embossment in the center (4) of the front wall (3) and a dome-like embossment (13) located there for receiving a bearing arrangement. The invention further relates to a housing (1) for the drive of an electrical device, wherein areas of the radial wall (2), the first front wall (3), and / or a second front wall (26) have honeycomb-shaped embossments (27) in the form of multidimensional arch structures. Savings in materials can be advantageously achieved by the invention. The cooling power can also be increased and noise generation reduced.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com