Partition plate nozzle structure of pre-combustion chamber

A pre-combustion chamber and fuel nozzle technology, which is applied in the field of pre-chamber partition nozzle structure, can solve the problems that the partitions for injecting oxidant and fuel have not been used yet, so as to broaden the stable working range, ensure temperature uniformity, Effect of suppressing tangentially unstable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in conjunction with accompanying drawing.

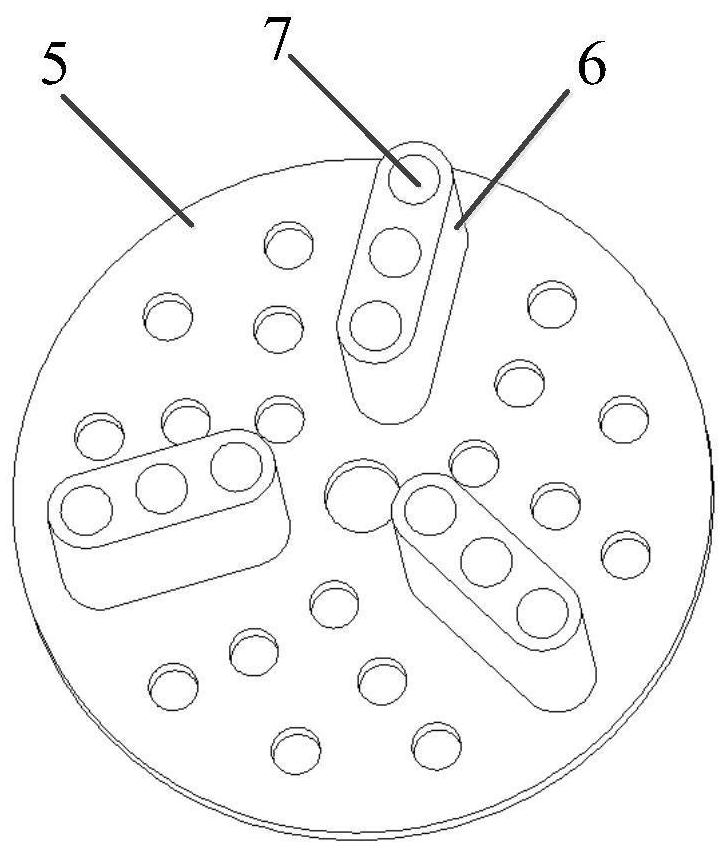

[0027] like Figure 1~5 As shown, a pre-chamber partition nozzle of the present invention is mainly composed of an oxidizer nozzle 1, a fuel nozzle 2 and a bottom 3. Wherein, one end of the oxidant nozzle 1 protrudes into the fuel nozzle 2 and forms an annular gap 4 with the fuel nozzle 2 .

[0028] The partition sleeves 6 are evenly distributed in three rows along the circumferential direction on the panel 5 . The panel 5 and the partition sleeve 6 are integrally formed to form a bottom 3 . A fuel nozzle 2 is installed on the bottom 3 at the position where the baffle sleeve 6 is arranged;

[0029] The first base 3 is made of copper alloy material.

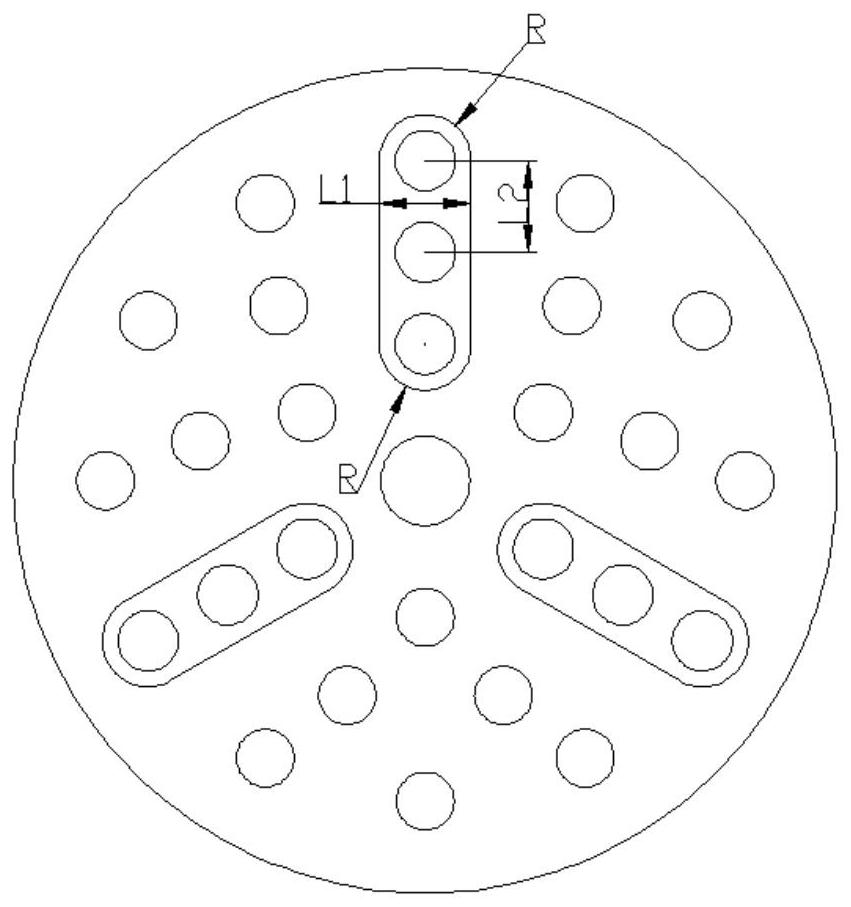

[0030] The width L1 of the baffle sleeve 6 is equal to the distance L2 between the centers of the through holes 7 of adjacent baffles.

[0031] The radius R of the arc at both ends of the partition sleeve 6 is half of the distance L2 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com