Flexible casing treatment centrifugal compressor

A centrifugal compressor and casing processing technology, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as limiting the stability expansion capability, affecting the maximum efficiency of the compressor, and achieving the effect of preventing the reduction of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

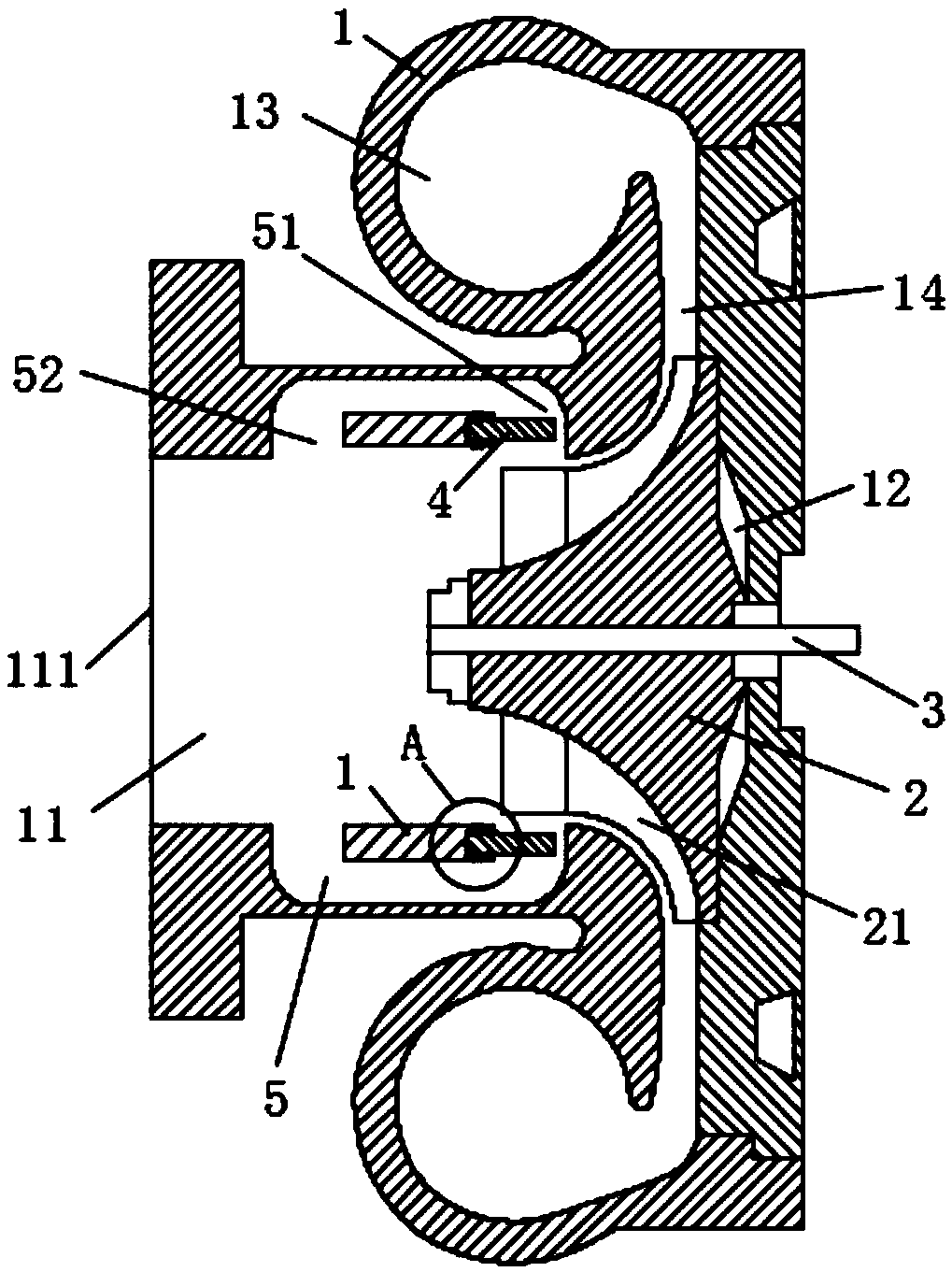

[0021] refer to figure 1 and figure 2 As shown, the present invention provides a flexible case processing centrifugal compressor, including a volute 1 and an impeller 2, characterized in that: a rotating shaft 3 is fixedly inserted in the middle of the impeller 2, and the impeller 2 is fixedly installed on the surface inside the volute 1 There are multiple groups of blades 21, the inner middle of the volute 1 is provided with an air inlet channel 11 horizontally, the volute 1 is provided with an impeller installation cavity 12 at the impeller 2, and the inner two sides of the volute 1 are provided with an air outlet channel 13, the impeller 2 Installed in the impeller installation chamber 12, the front side surface of the volute 1 is provided with an air inlet 111 in the air inlet passage 11, and the inner two sides of the volute 1 are provided with an air outlet 14 at the outlet passage 13, and the impeller installation chamber 12 is respectively It communicates with the ai...

Embodiment 2

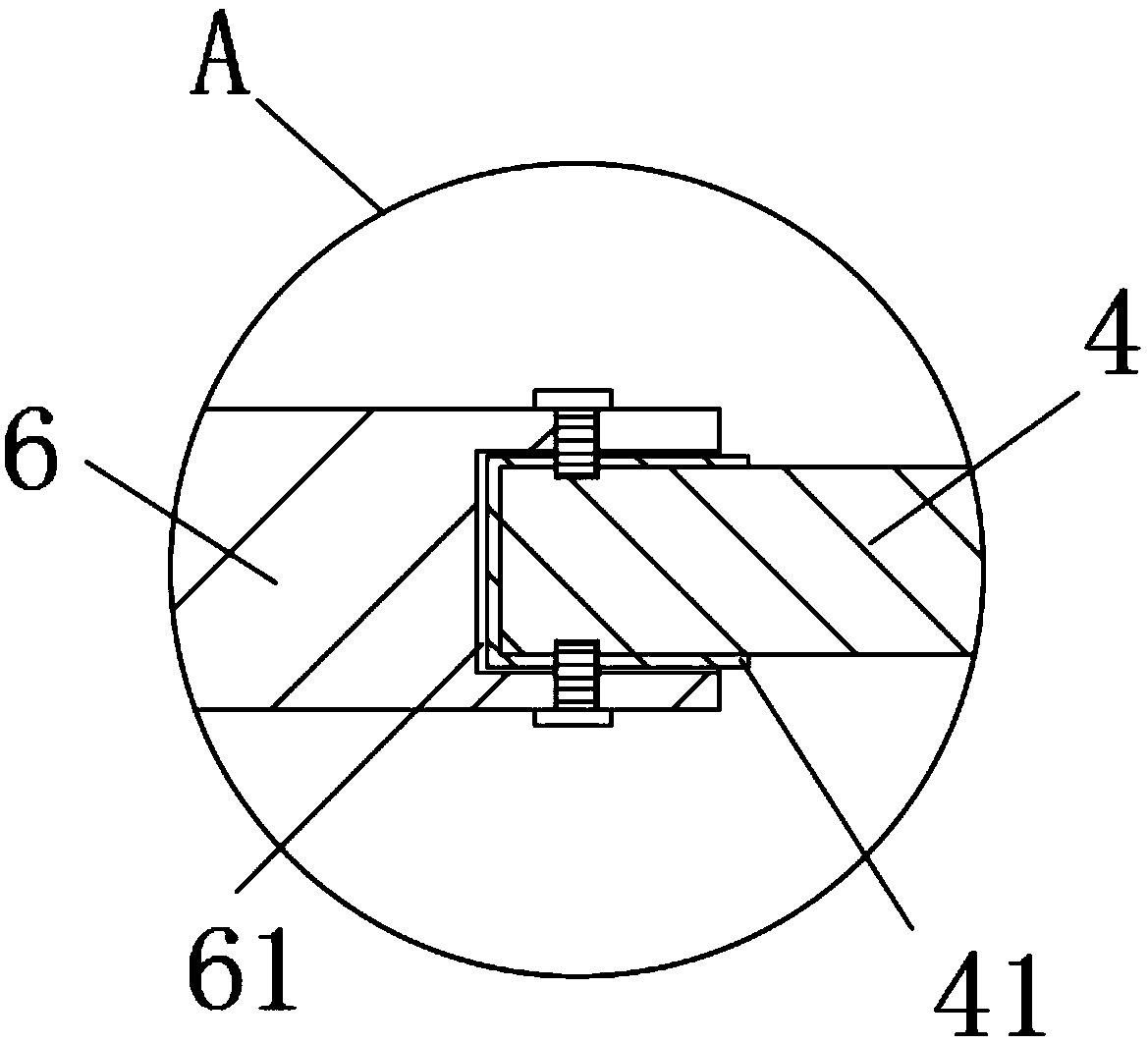

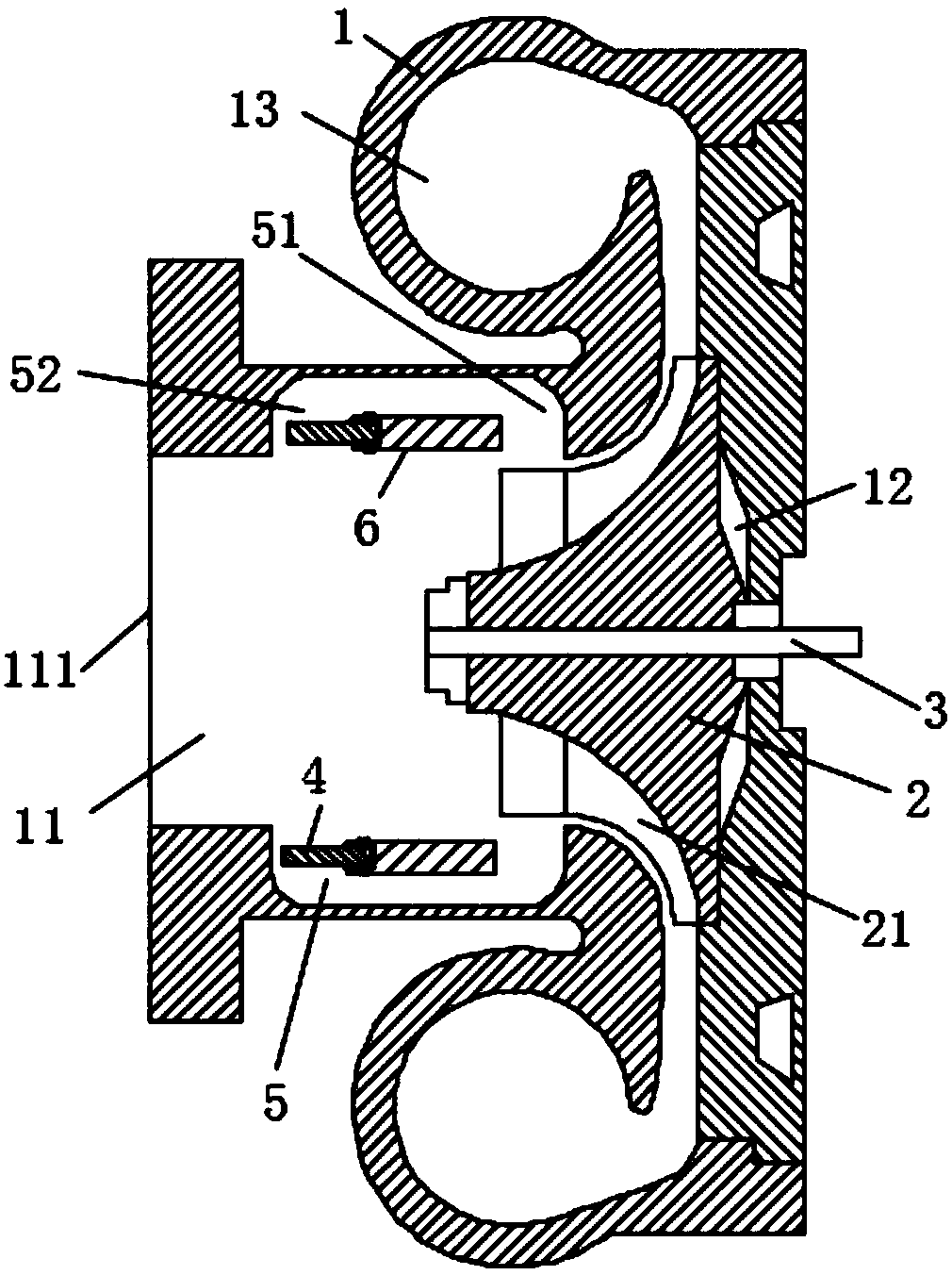

[0023] refer to image 3 The difference between this embodiment and Embodiment 1 is that the splint 41 is fixedly engaged on the end surface of the flexible baffle 4 close to the partition 6, and the surface of the partition 6 near the air inlet 111 is provided with a mounting groove 61 , the flexible baffle 4 is inserted into the installation groove 61 through the splint 41, the outer surface of the partition 6 is provided with screws at the installation groove 61, and the partition 6 fixes the flexible baffle 4 and the splint 41 in the installation groove 61 through the screws , the nut end of the screw is fixedly welded on the outer surface of the partition plate 6 .

Embodiment 3

[0025] refer to image 3 The difference between this embodiment and Embodiment 1 is that: the end surface of the flexible baffle 4 close to the partition 6 is fixedly engaged with a splint 41, and the partition 6 corresponds to the middle part of the bottom surface of the casing groove 5. There is an installation groove 61, and the flexible baffle 4 is inserted into the installation groove 61 through the splint 41. The outer surface of the partition 6 is provided with screws at the installation groove 61, and the partition 6 fixes the flexible baffle 4 and the splint 41 on the In the mounting groove 61 , the nut end of the screw is fixedly welded on the outer surface of the partition plate 6 .

[0026] Working principle: Under normal circumstances, the pressure near the channel of the impeller 2 is not much different from the ambient pressure. The bending degree of the flexible baffle 4 is small, and the gas is not easy to flow out of the casing groove 5, which reduces the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com