Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2218 results about "Centrifugal compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

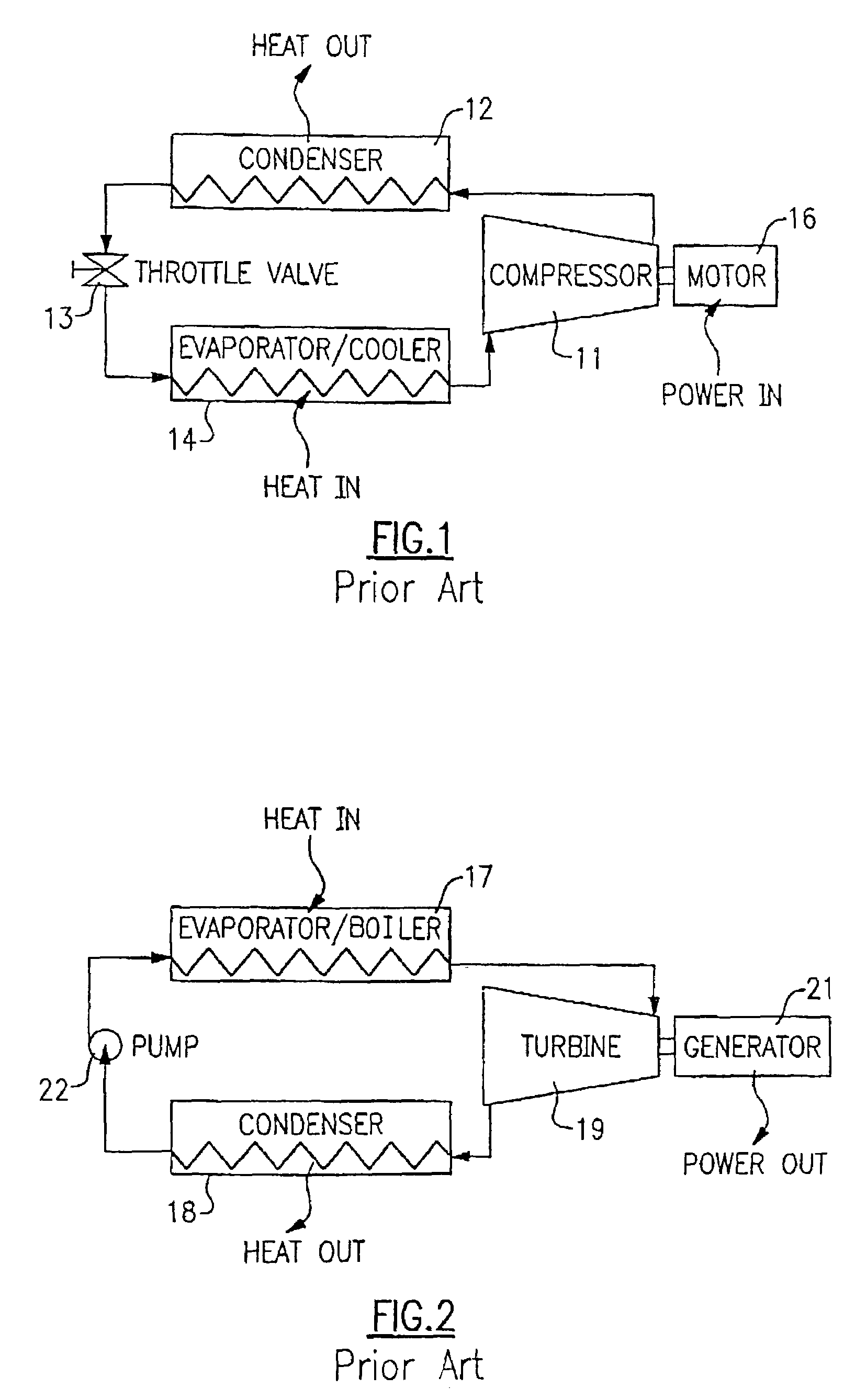

Centrifugal compressors, sometimes called radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. They achieve a pressure rise by adding kinetic energy/velocity to a continuous flow of fluid through the rotor or impeller. This kinetic energy is then converted to an increase in potential energy/static pressure by slowing the flow through a diffuser. The pressure rise in the impeller is in most cases almost equal to the rise in the diffuser.

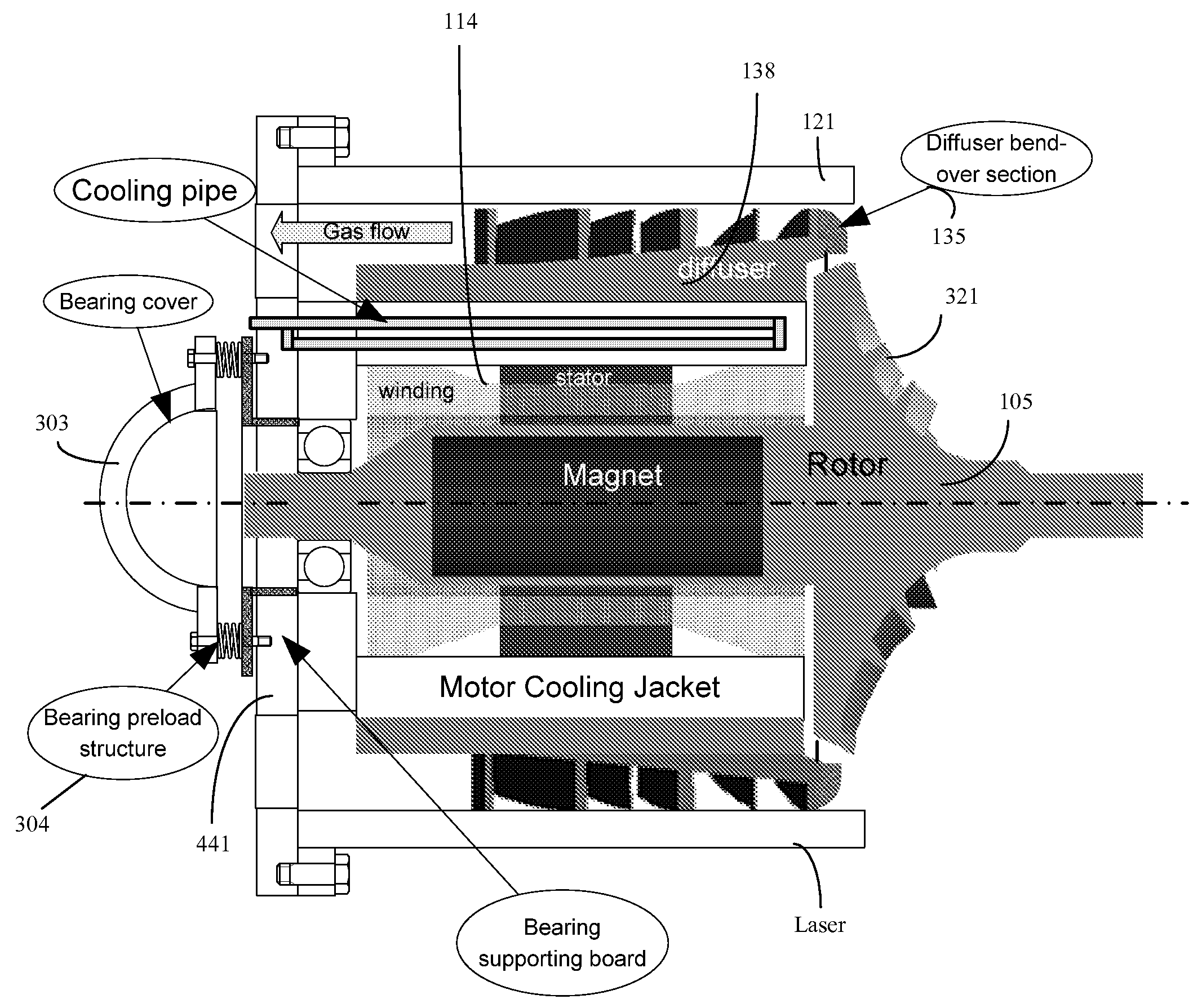

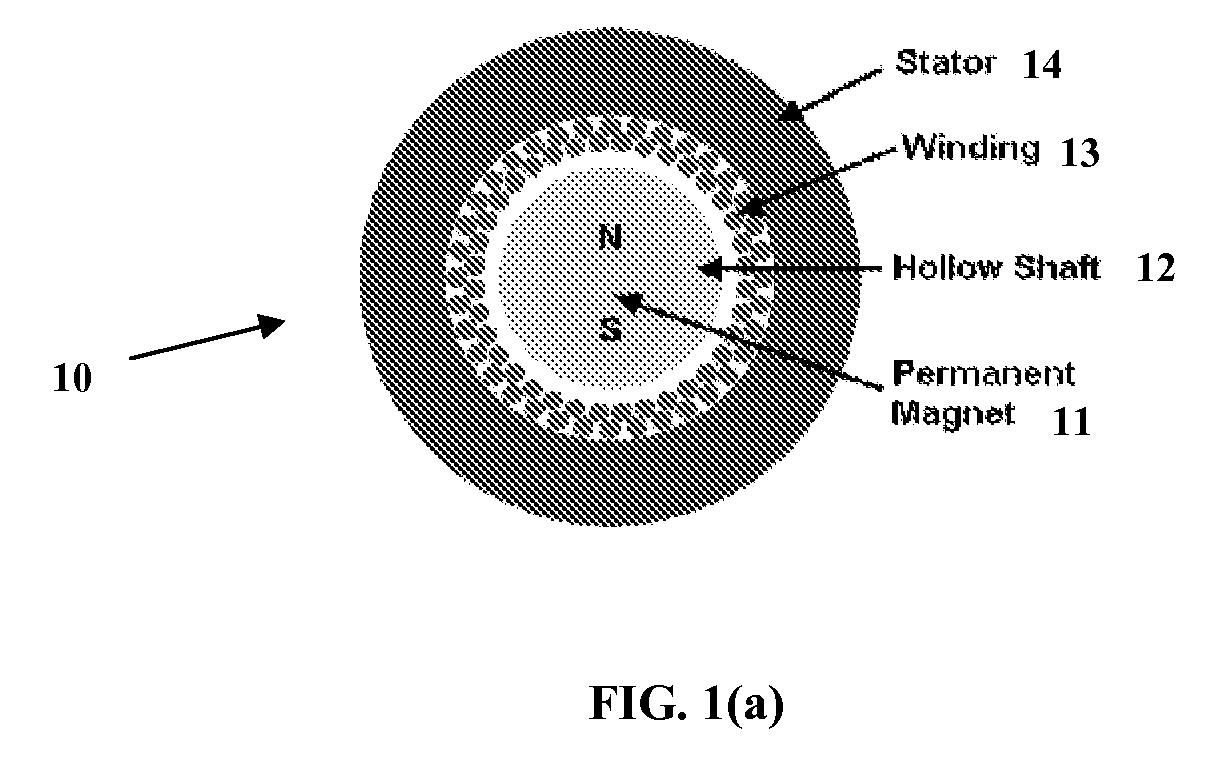

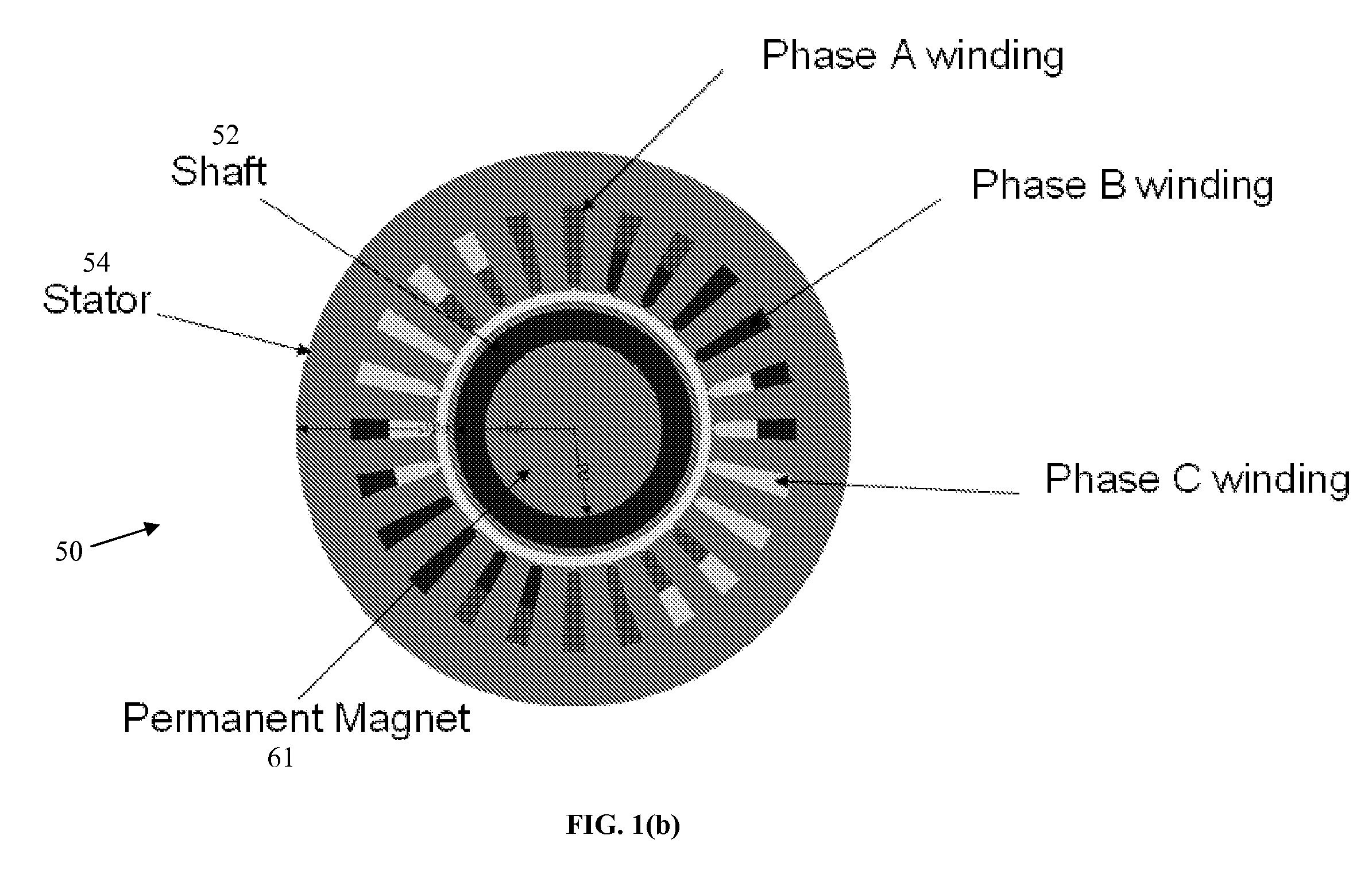

Miniature high speed compressor having embedded permanent magnet motor

InactiveUS20070269323A1Improve rigidityEasy to implementPositive displacement pump componentsEfficient regulation technologiesRigid rotorBall bearing

A high speed centrifugal compressor for compressing fluids includes a permanent magnet synchronous motor (PMSM) having a hollow shaft, the being supported on its ends by ball bearing comprising supports. A permanent magnet core is embedded inside the shaft. A stator with a winding is located radially outward of the shaft. The PMSM includes a rotor including at least one impeller secured to the shaft or integrated with the shaft as a single piece. The rotor is a high rigidity rotor providing a bending mode speed of at least 100,000 RPM which advantageously permits implementation of relatively low-cost ball bearing comprising supports.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Motor driven centrifugal compressor/blower

This invention provides a small, high efficiency, oil free motor driven compressor / blower suitable for providing pressurized, contamination-free gas and or air to transportation, industrial and aerospace fuel cell systems or other contaminant-intolerant applications. The motor driven compressor / blower rotor assembly is supported by foil air bearings and rotates at high speed by using a high frequency drive. The impeller is a centrifugal type design. The MDC can be easily integrated into the air management system of a fuel cell.

Owner:R & D DYNAMICS

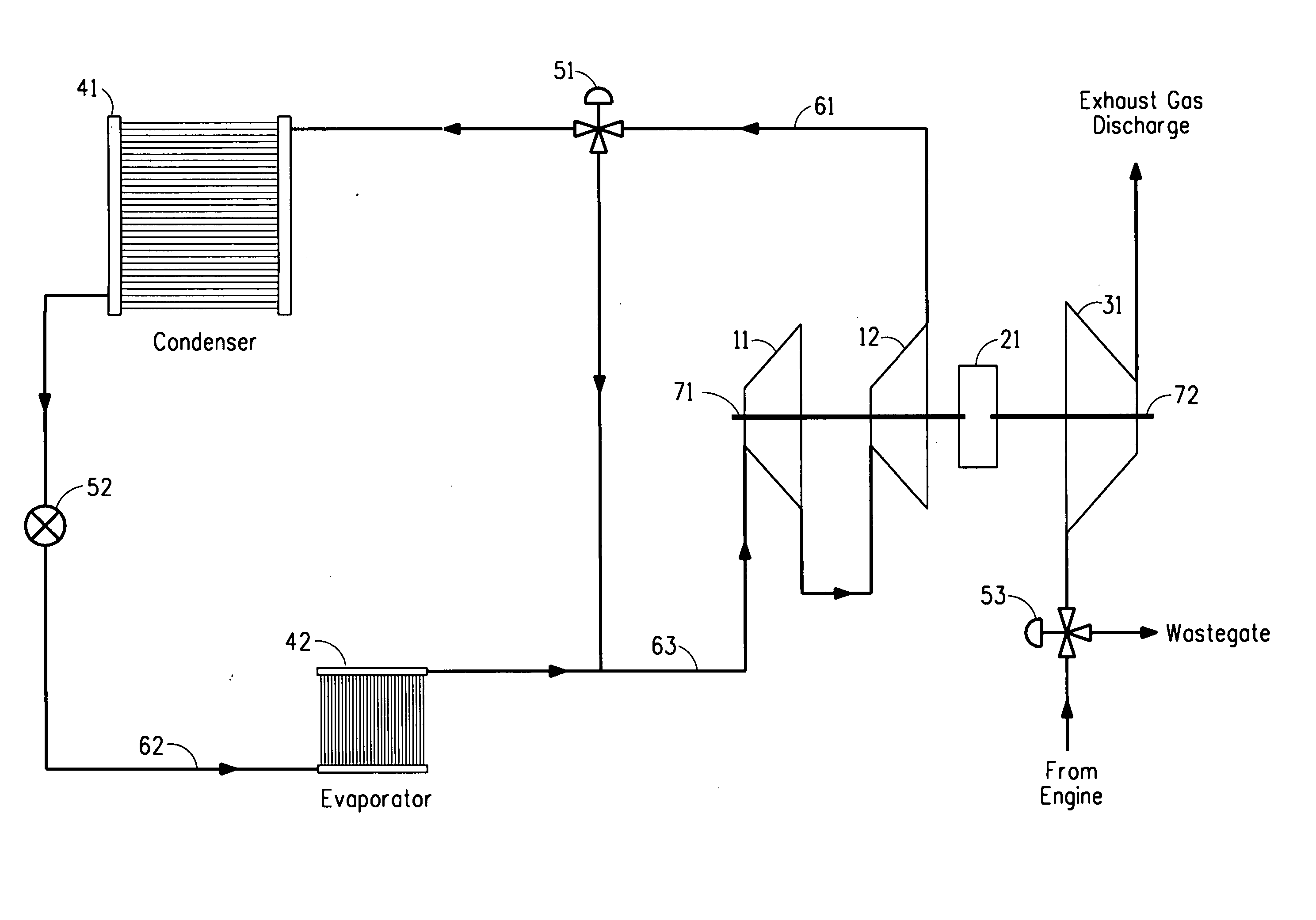

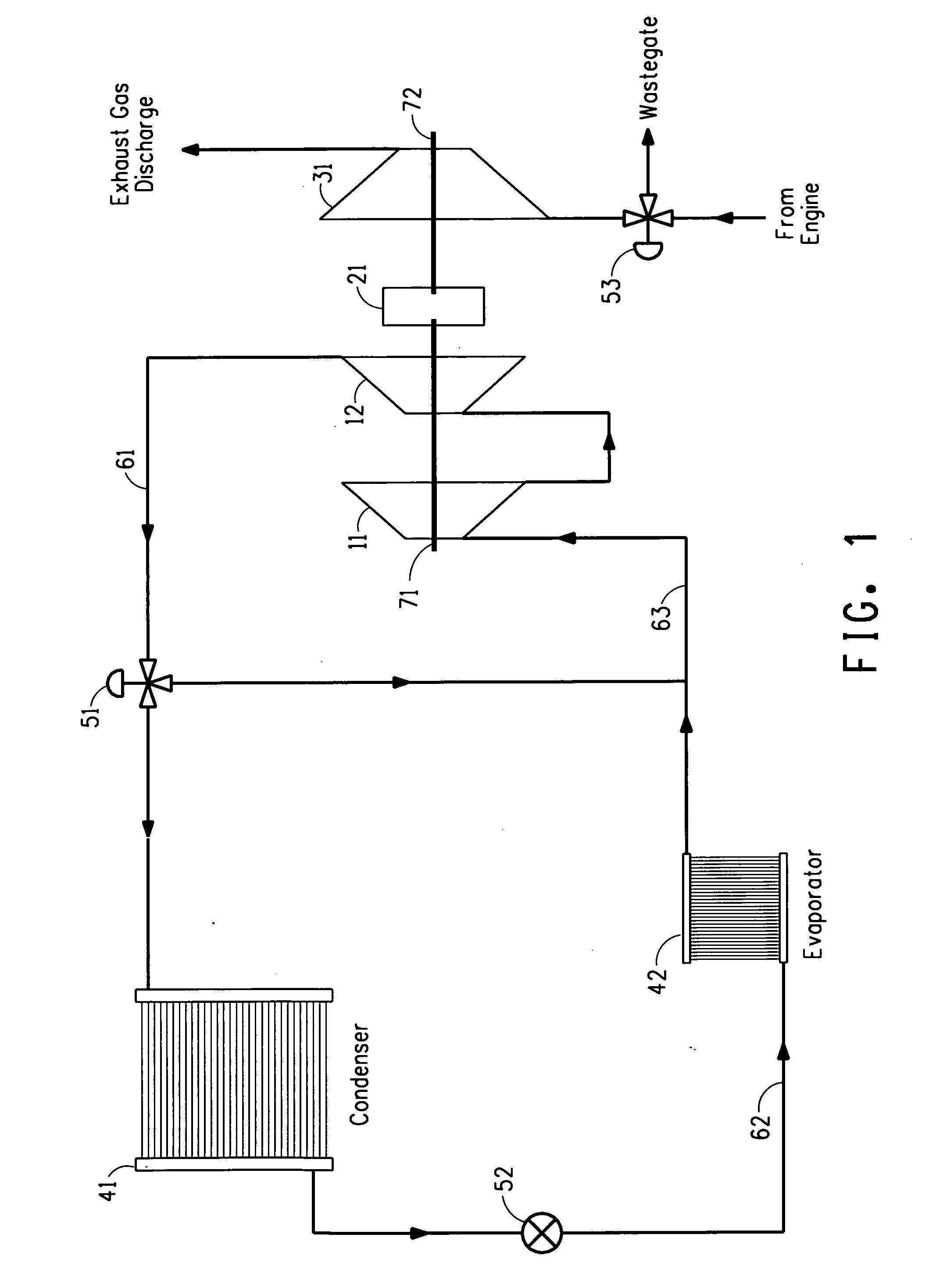

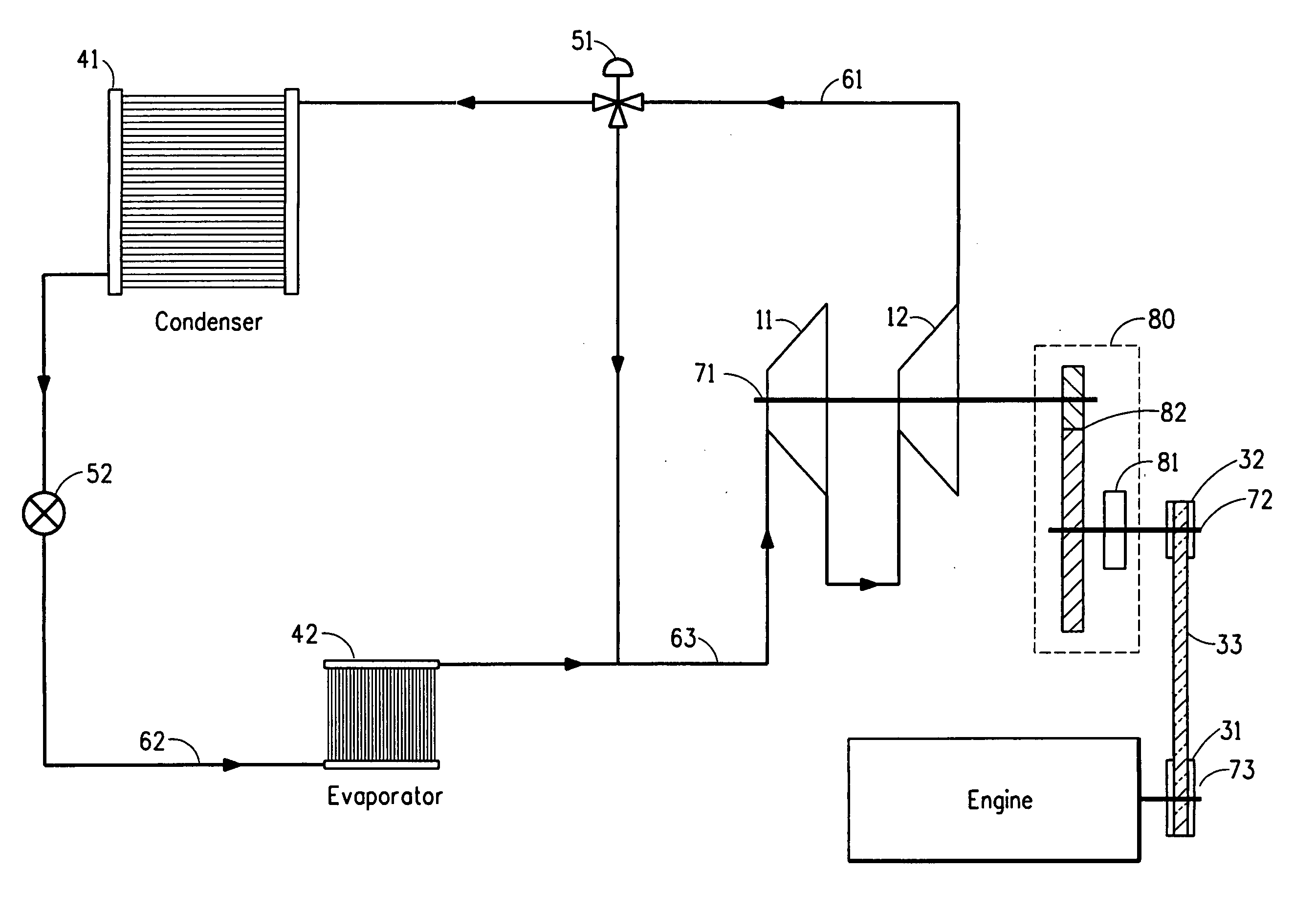

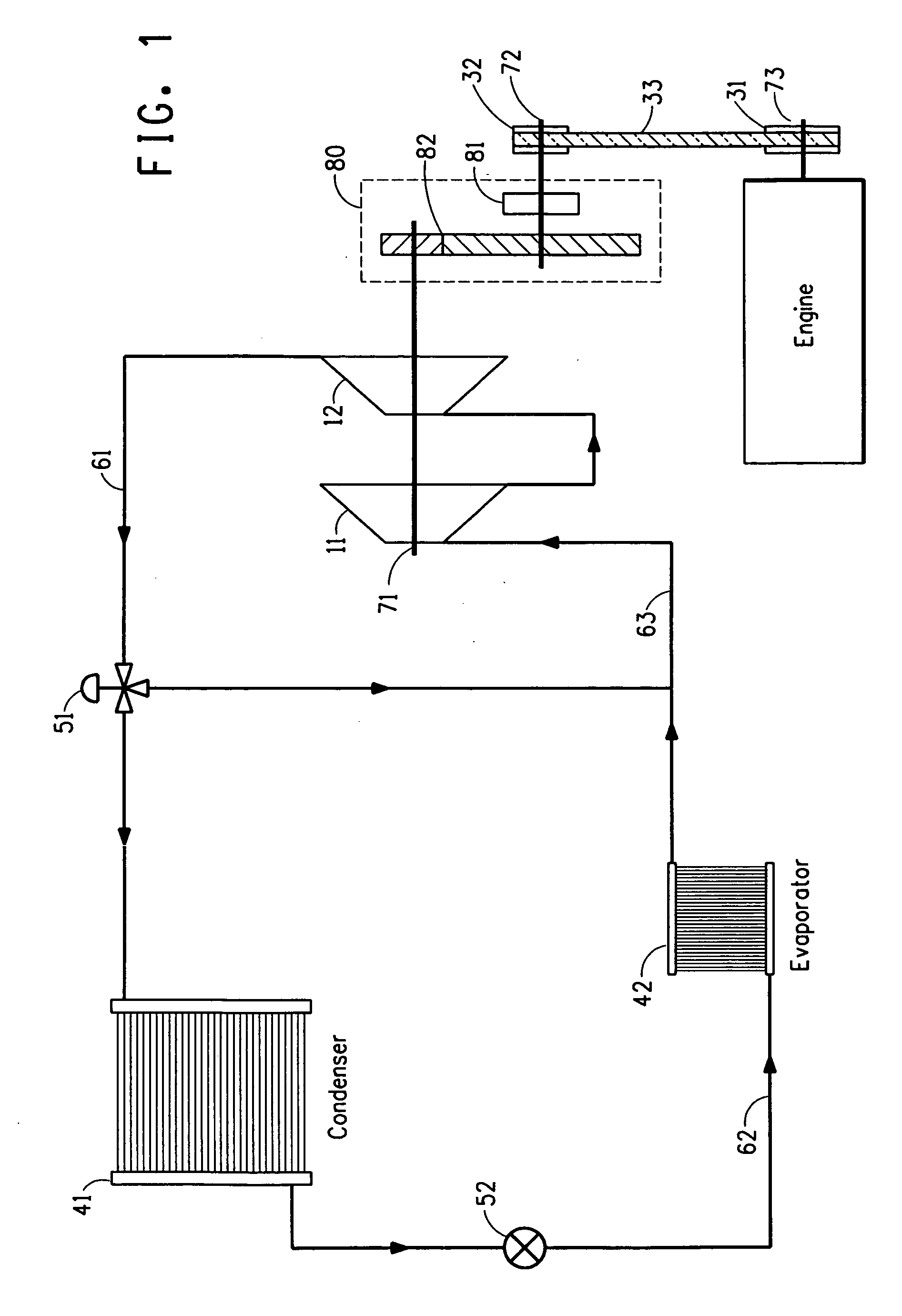

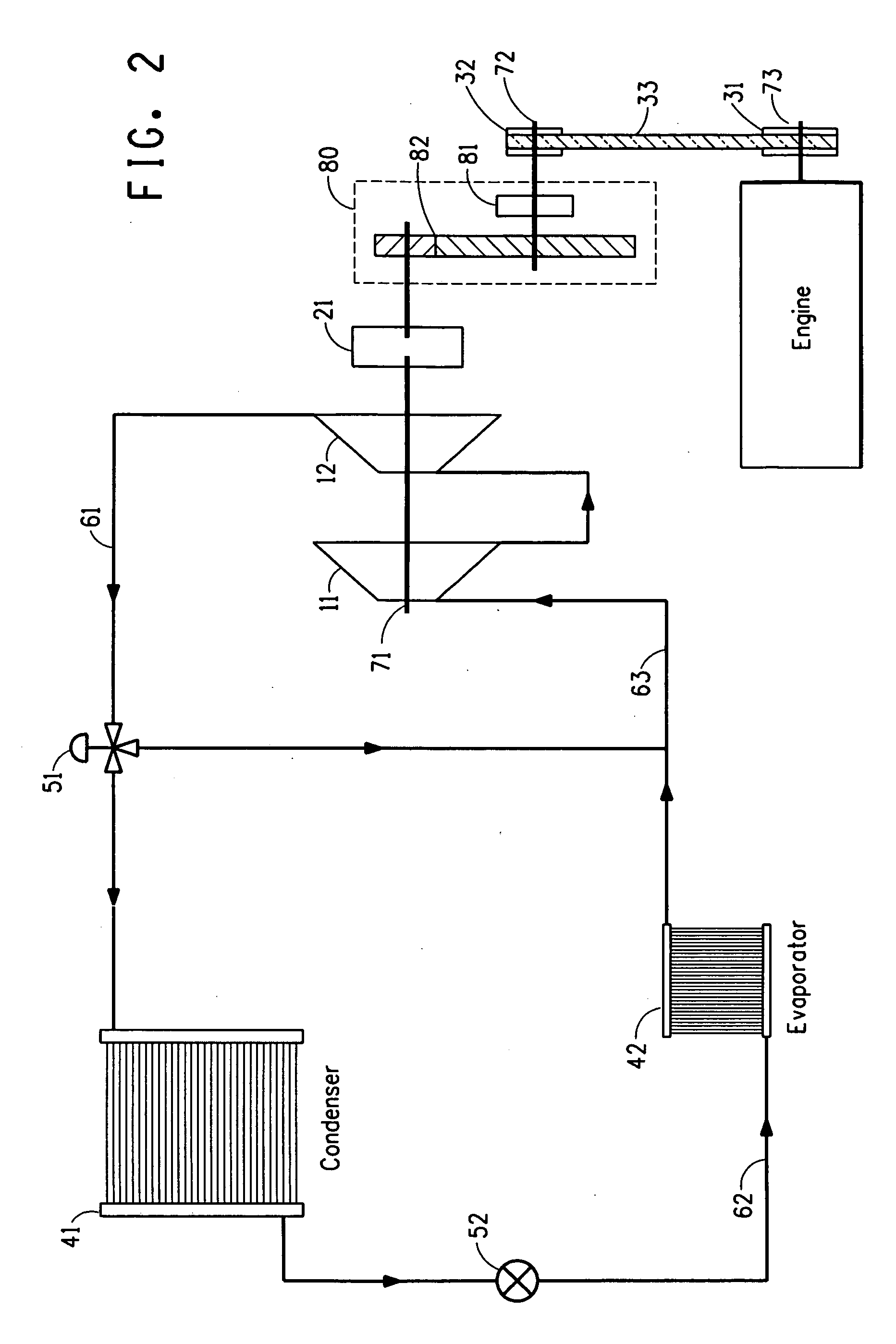

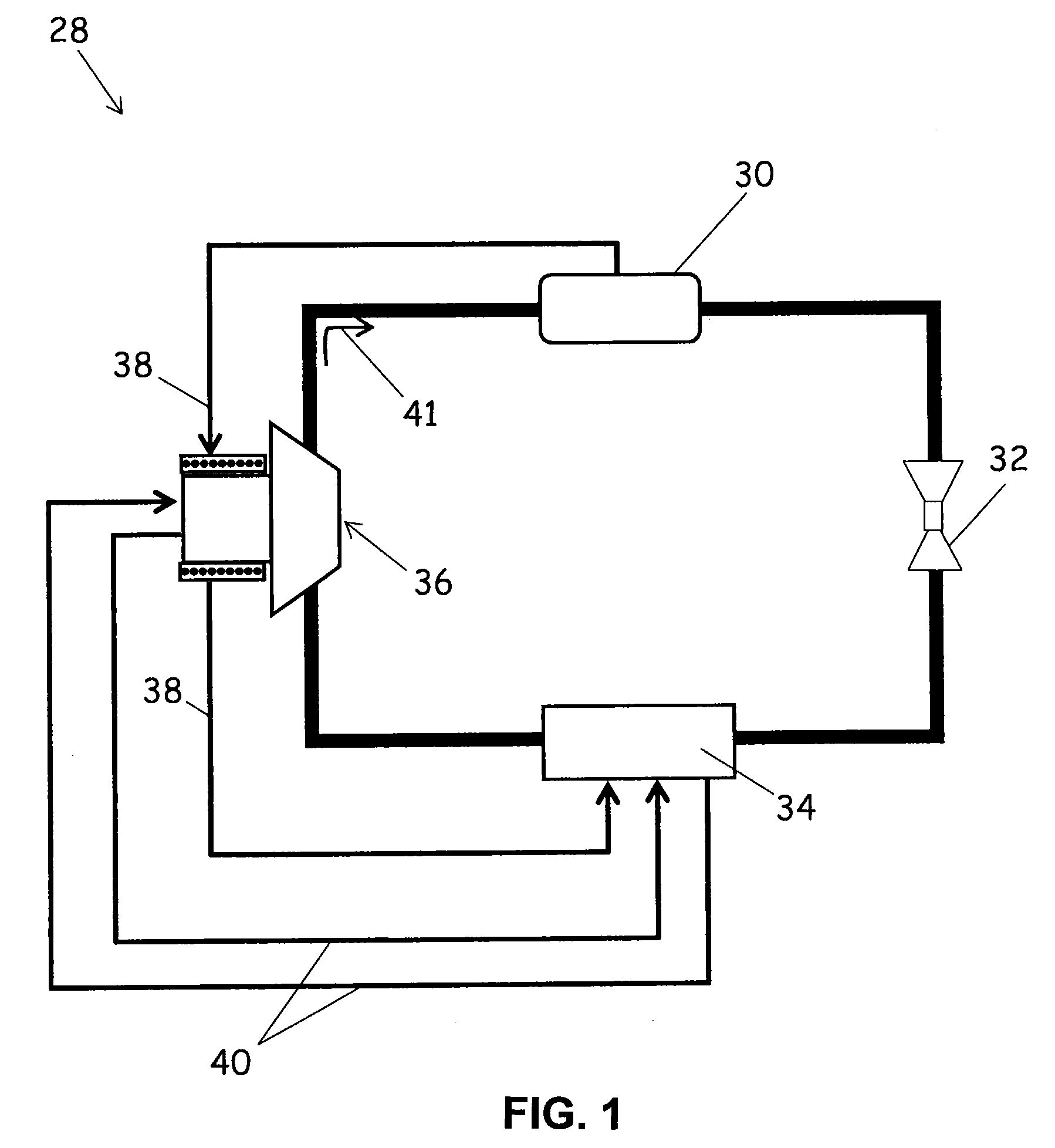

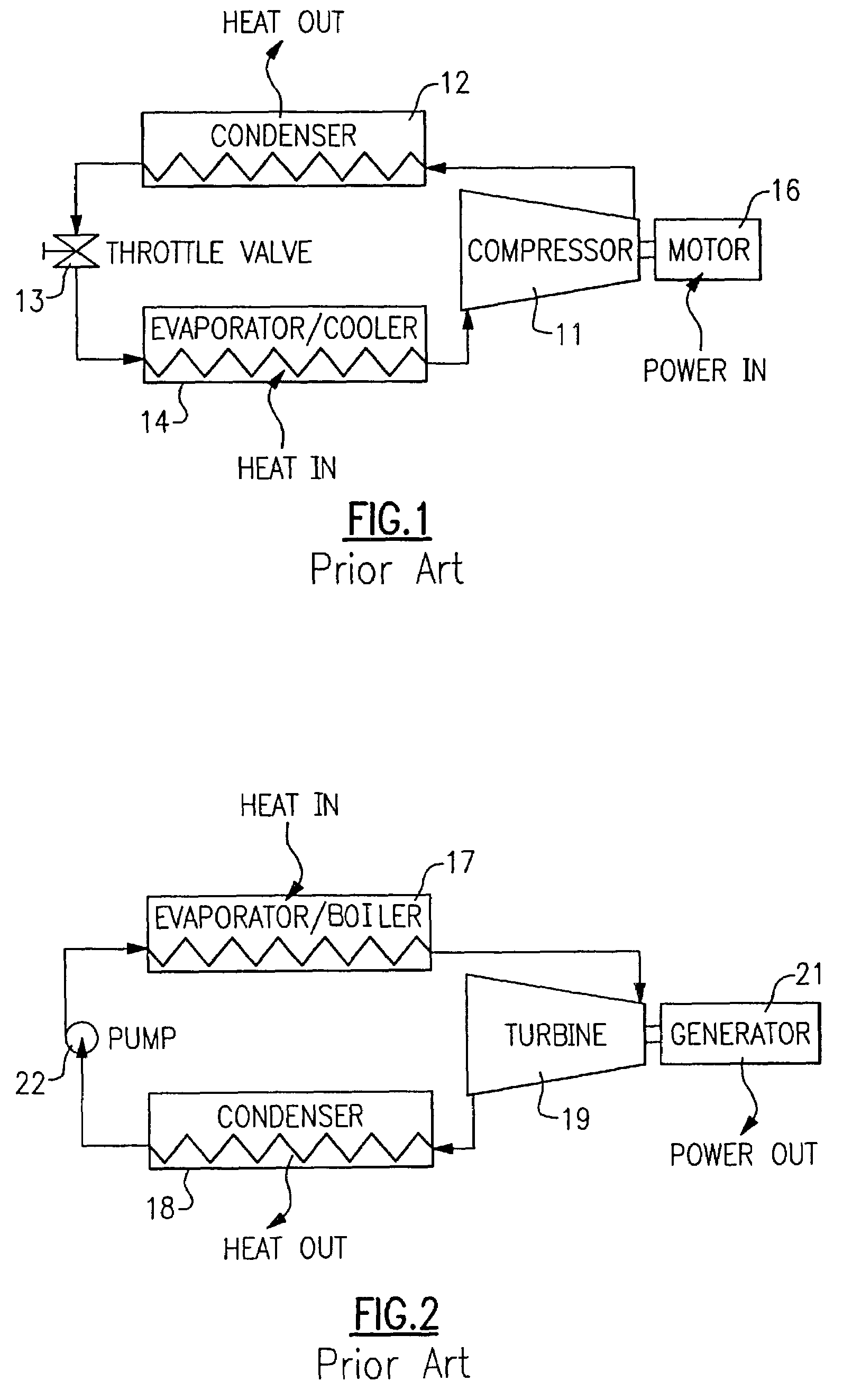

Refrigeration/air-conditioning apparatus powered by an engine exhaust gas driven turbine

InactiveUS20060242985A1Vary amountClimate change adaptationCompression machines with non-reversible cycleAir conditioningRefrigeration

Owner:EI DU PONT DE NEMOURS & CO

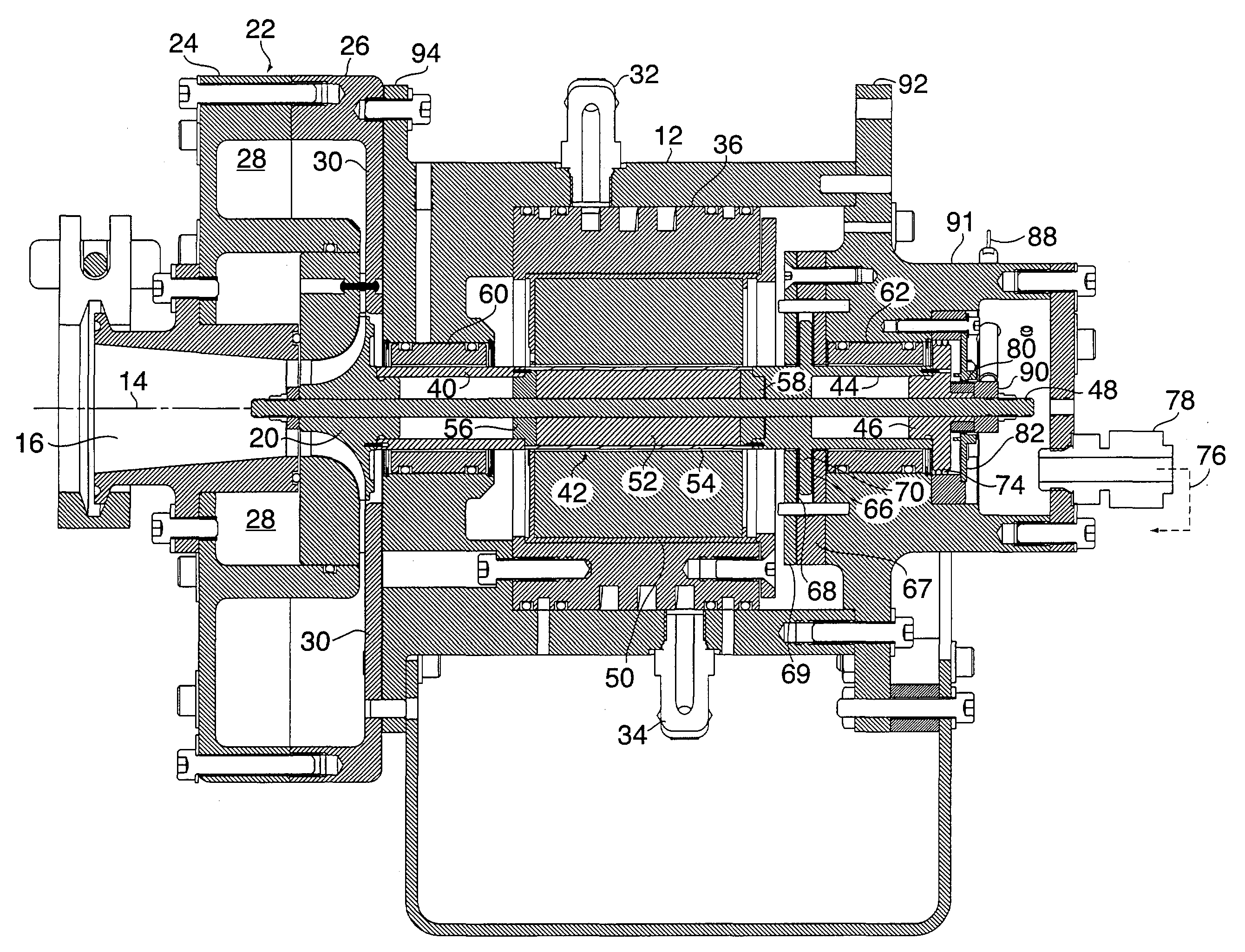

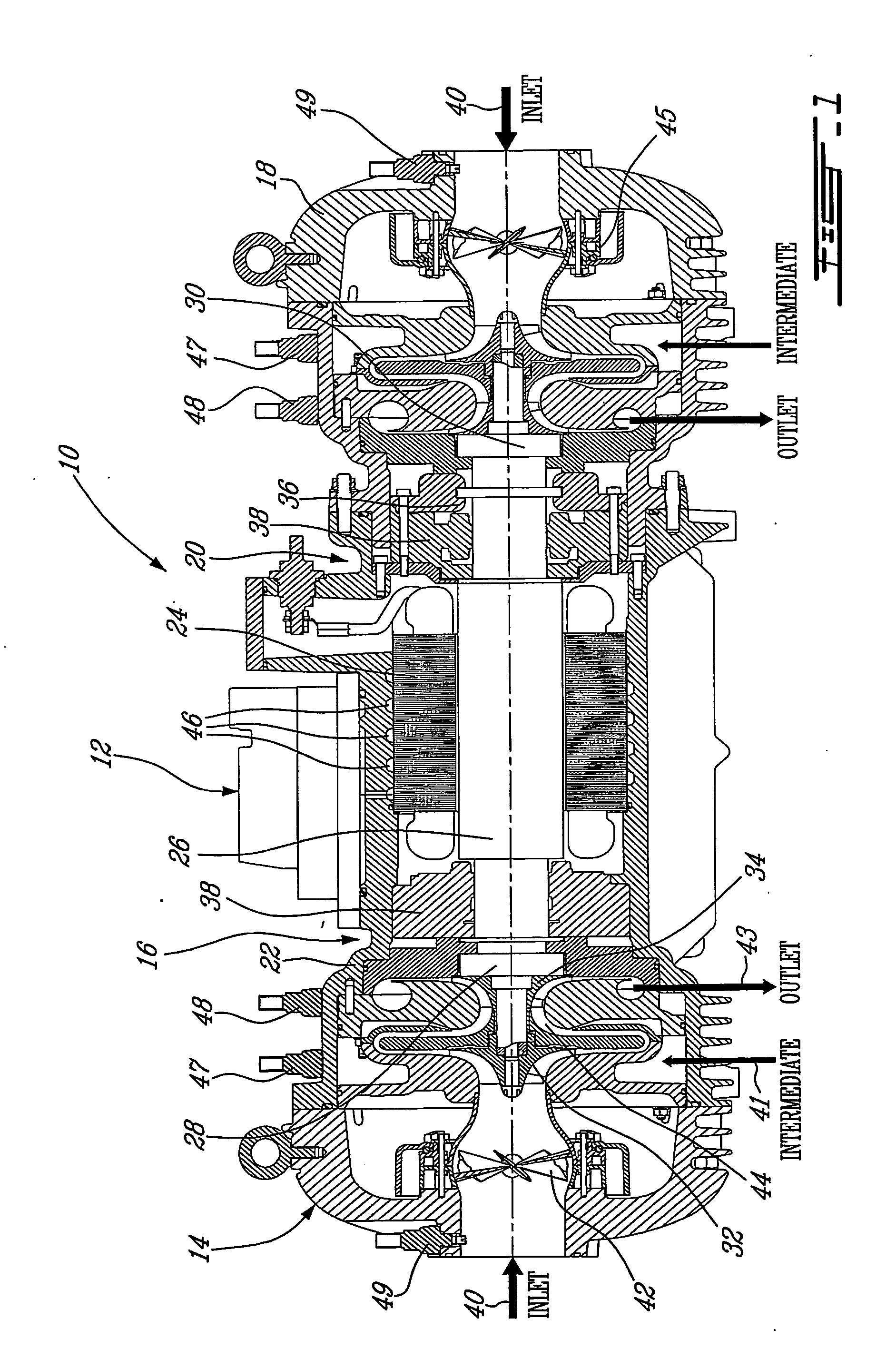

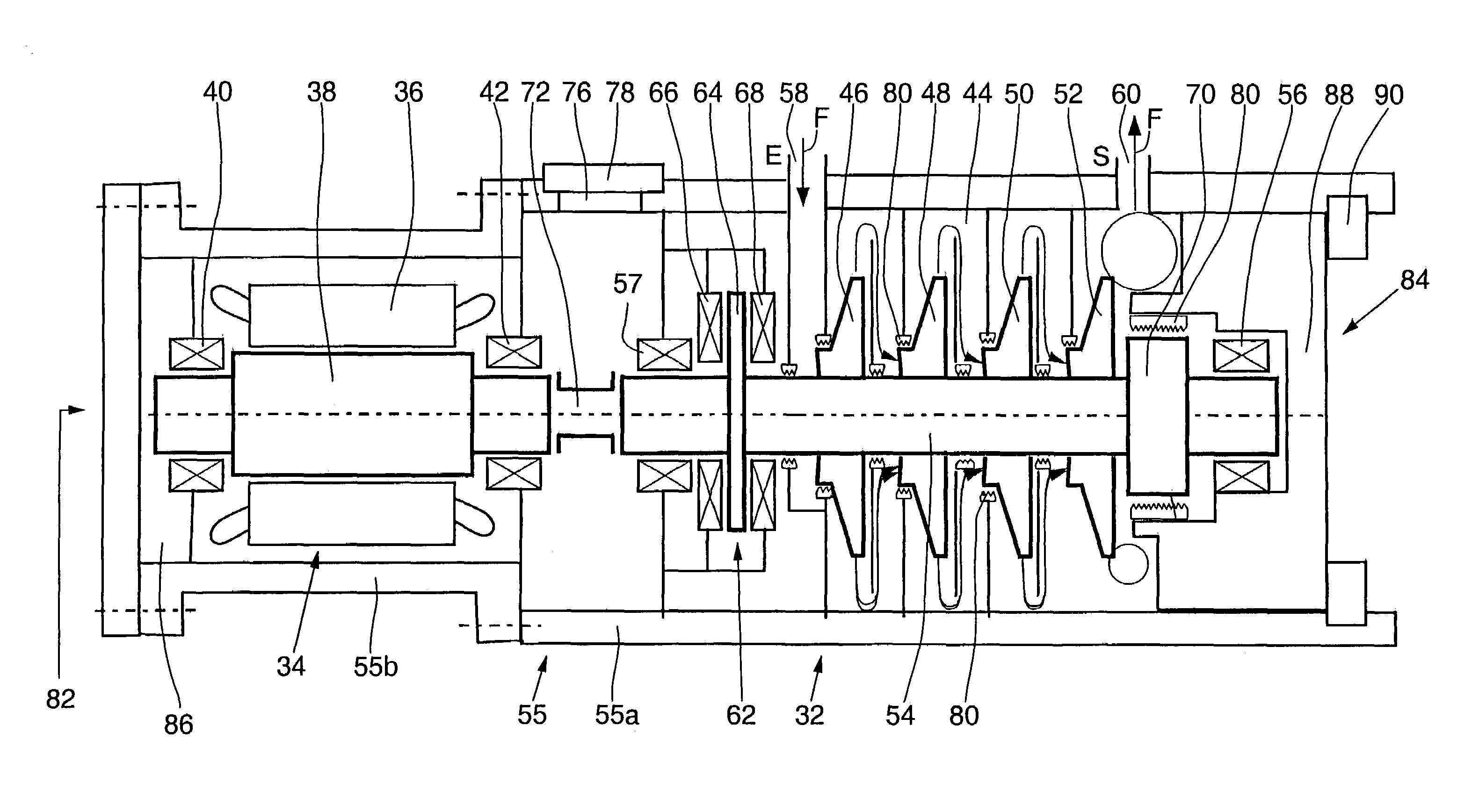

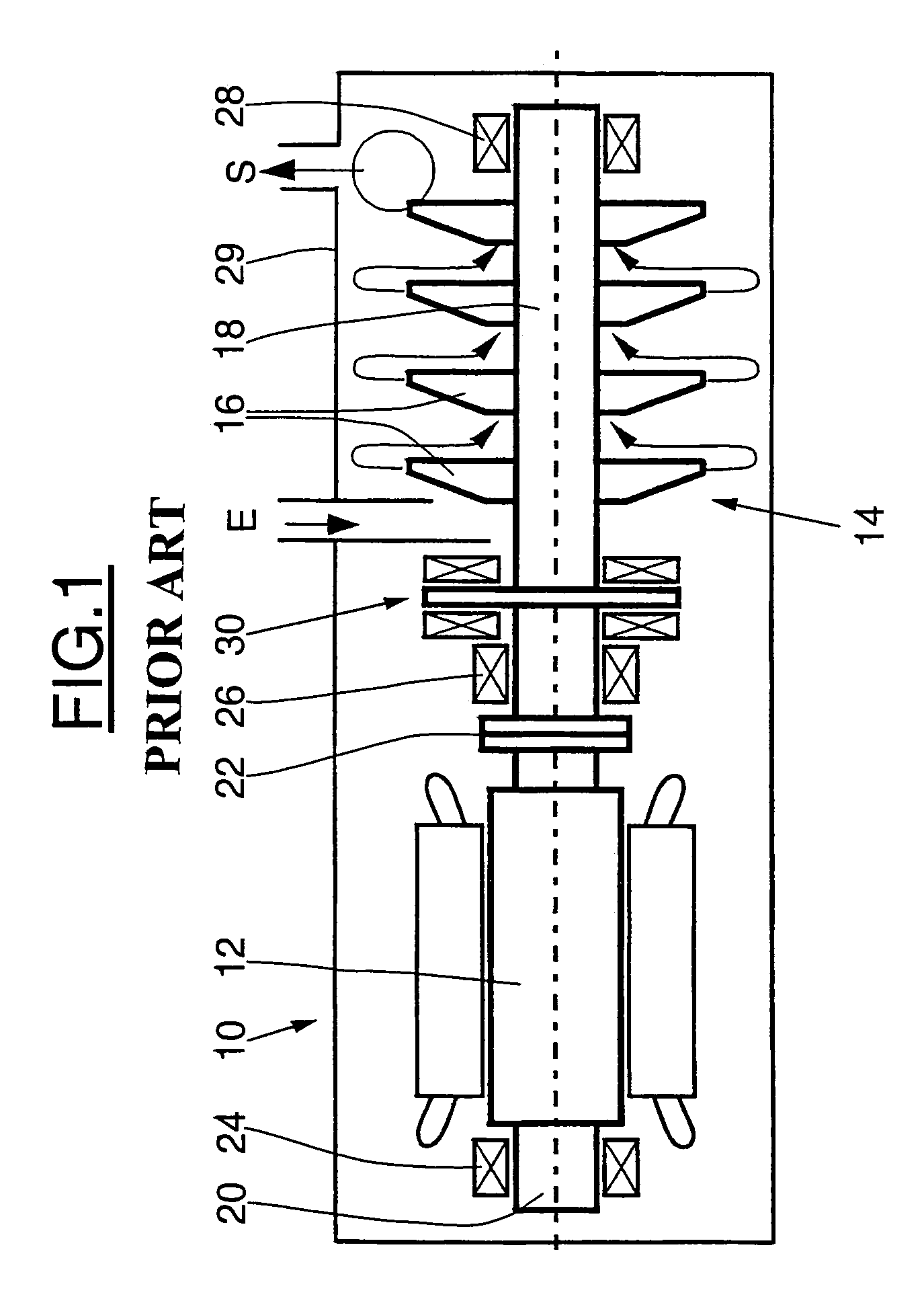

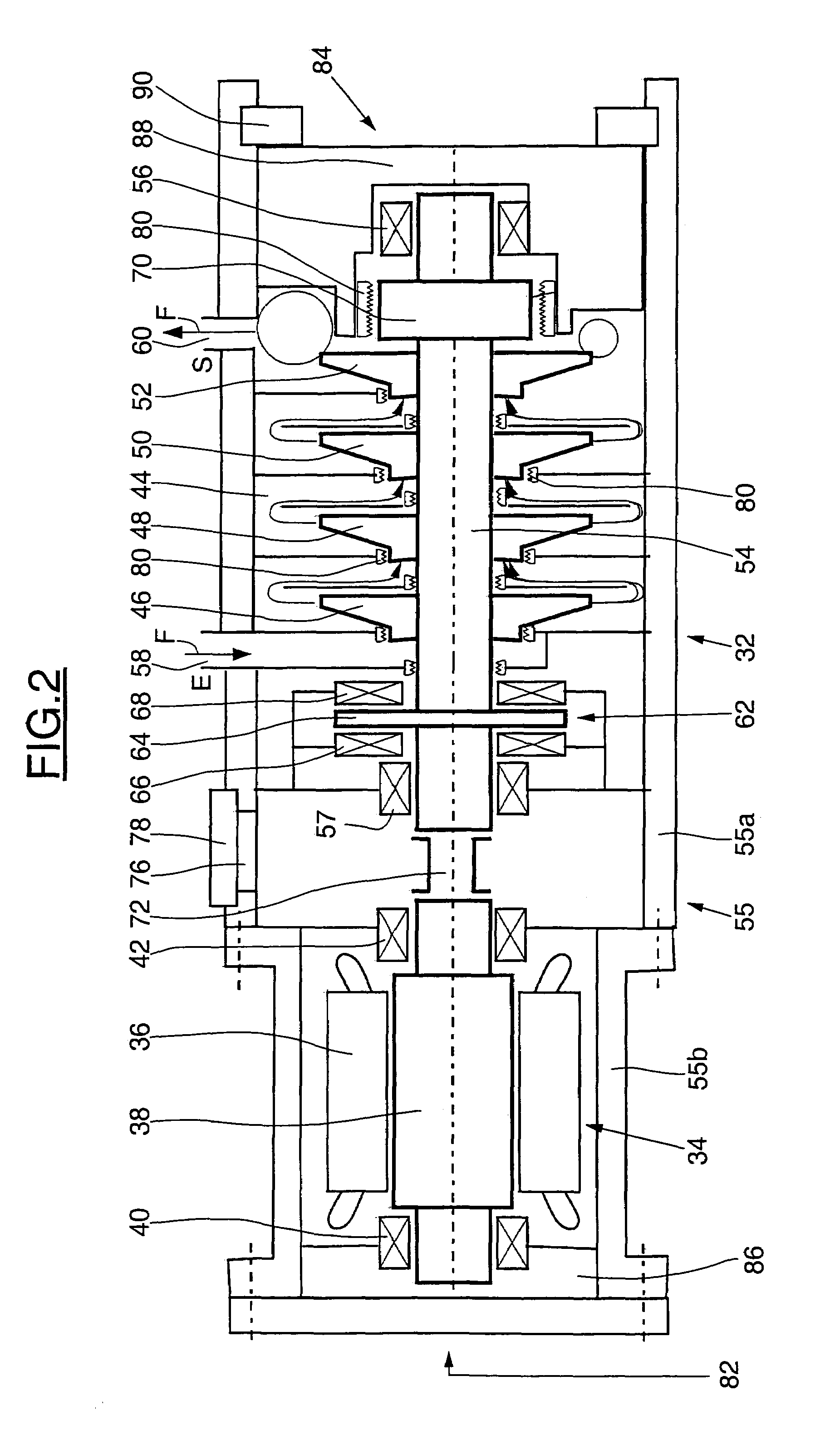

Centrifugal compressor

ActiveUS20050223737A1Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

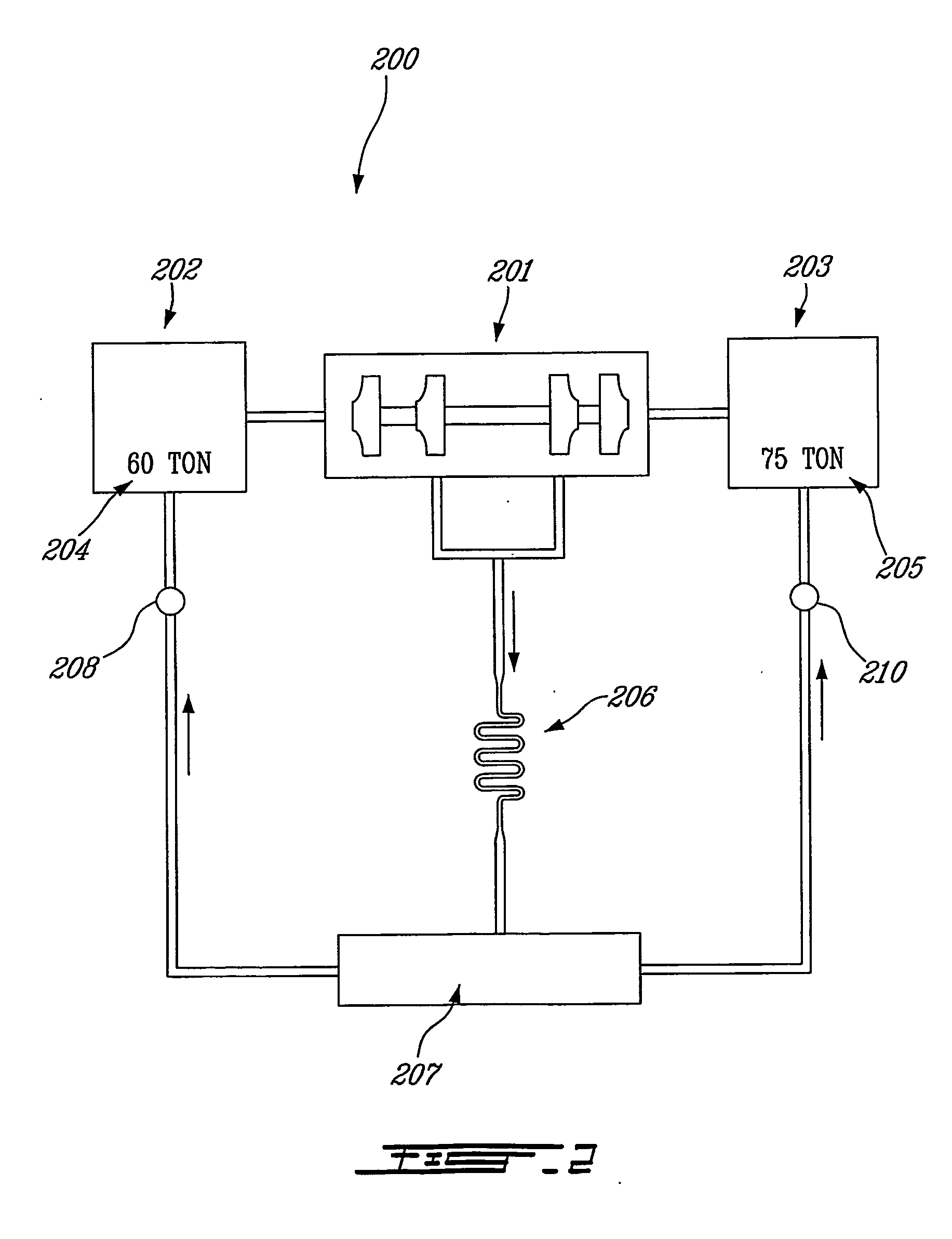

High capacity chiller compressor

ActiveUS20080115527A1Improve efficiencyIncrease power outputWind motor controlEfficient regulation technologiesMagnetic bearingEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

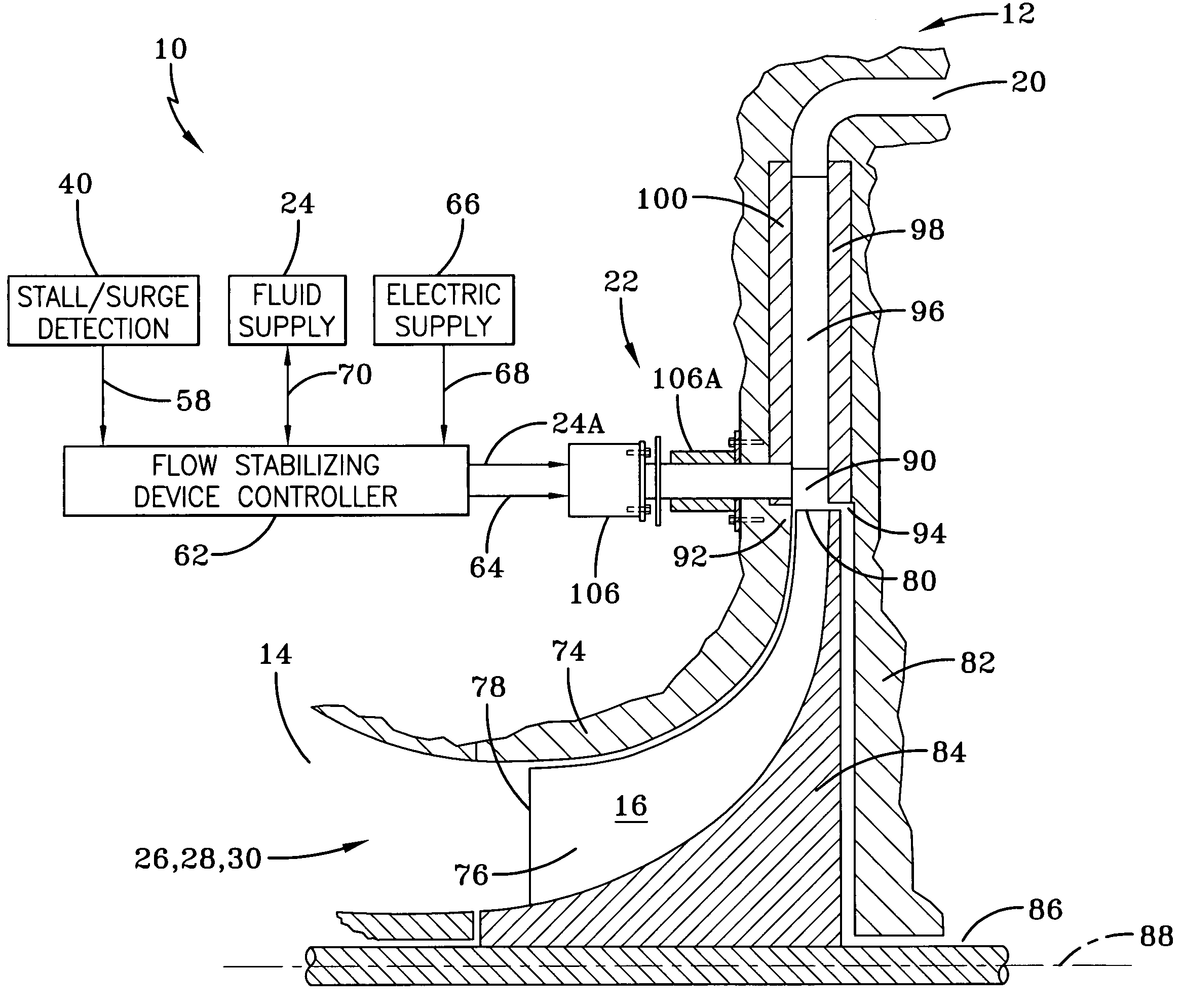

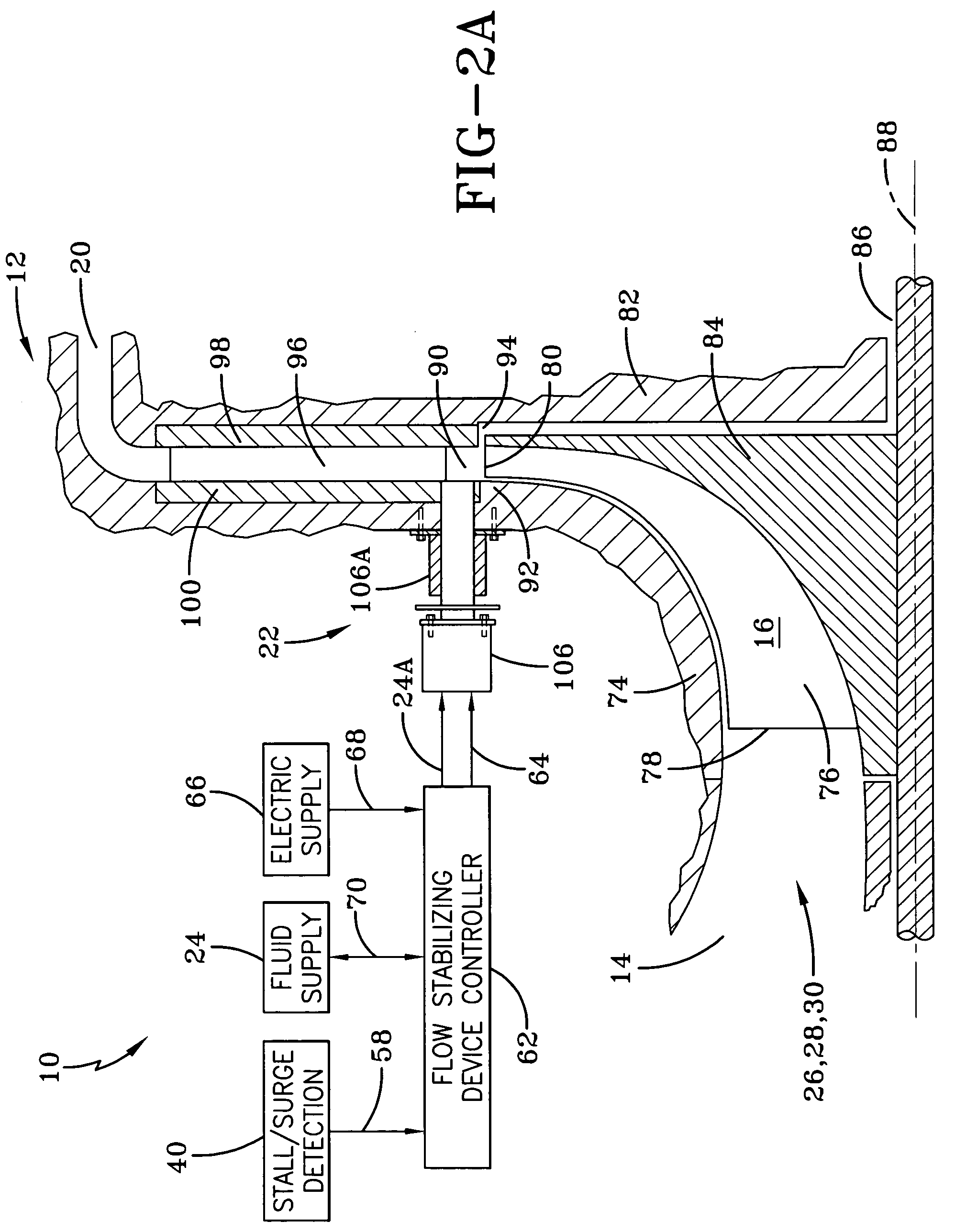

Devices and methods of operation thereof for providing stable flow for centrifugal compressors

InactiveUS7326027B1Process stabilityAvoid adjustmentEngine manufactureWind motor controlEngineeringInjection air

Centrifugal compressor flow stabilizing devices and methods of operation thereof are disclosed that act upon the flow field discharging from the impeller of a centrifugal compressor and modify the flow field ahead of the diffuser vanes such that flow conditions contributing to rotating stall and surge are reduced or even eliminated. In some embodiments, shaped rods and methods of operation thereof are disclosed, whereas in other embodiments reverse-tangent air injection devices and methods are disclosed.

Owner:NASA

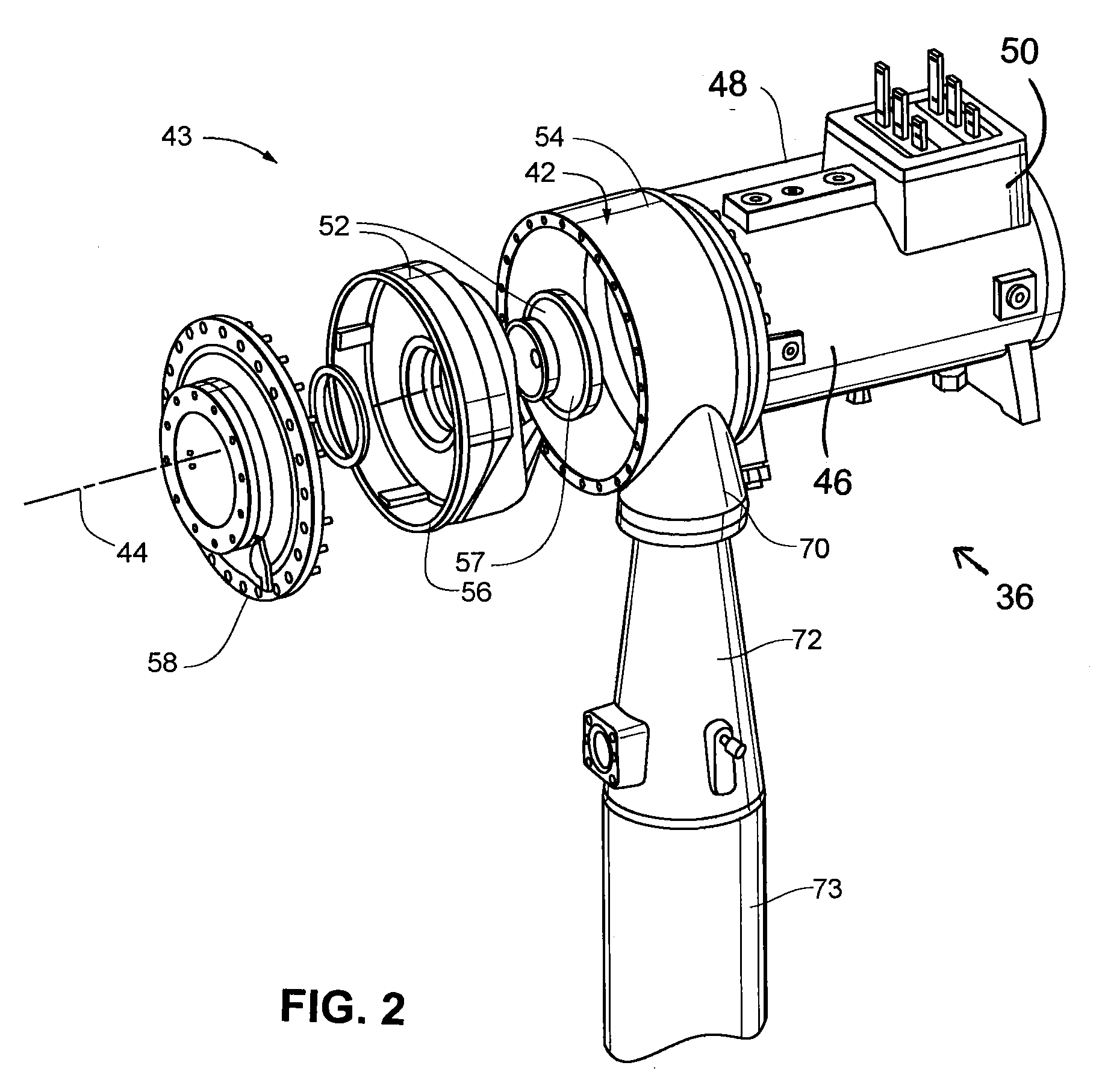

Centrifugal compressor having a flexible coupling

This compressor unit comprises a motor (34) and at least one compressor (44) comprising a driven shaft (54) driven by the rotor of the motor and bladed wheels fitted on the driven shaft (54), the assembly composed of the motor and the compressor being installed in a common casing (55) leak tight to the gas manipulated by the compressor unit. The rotor and the driven shaft are connected through a flexible coupling (72) placed in the casing.

Owner:THERMODYN

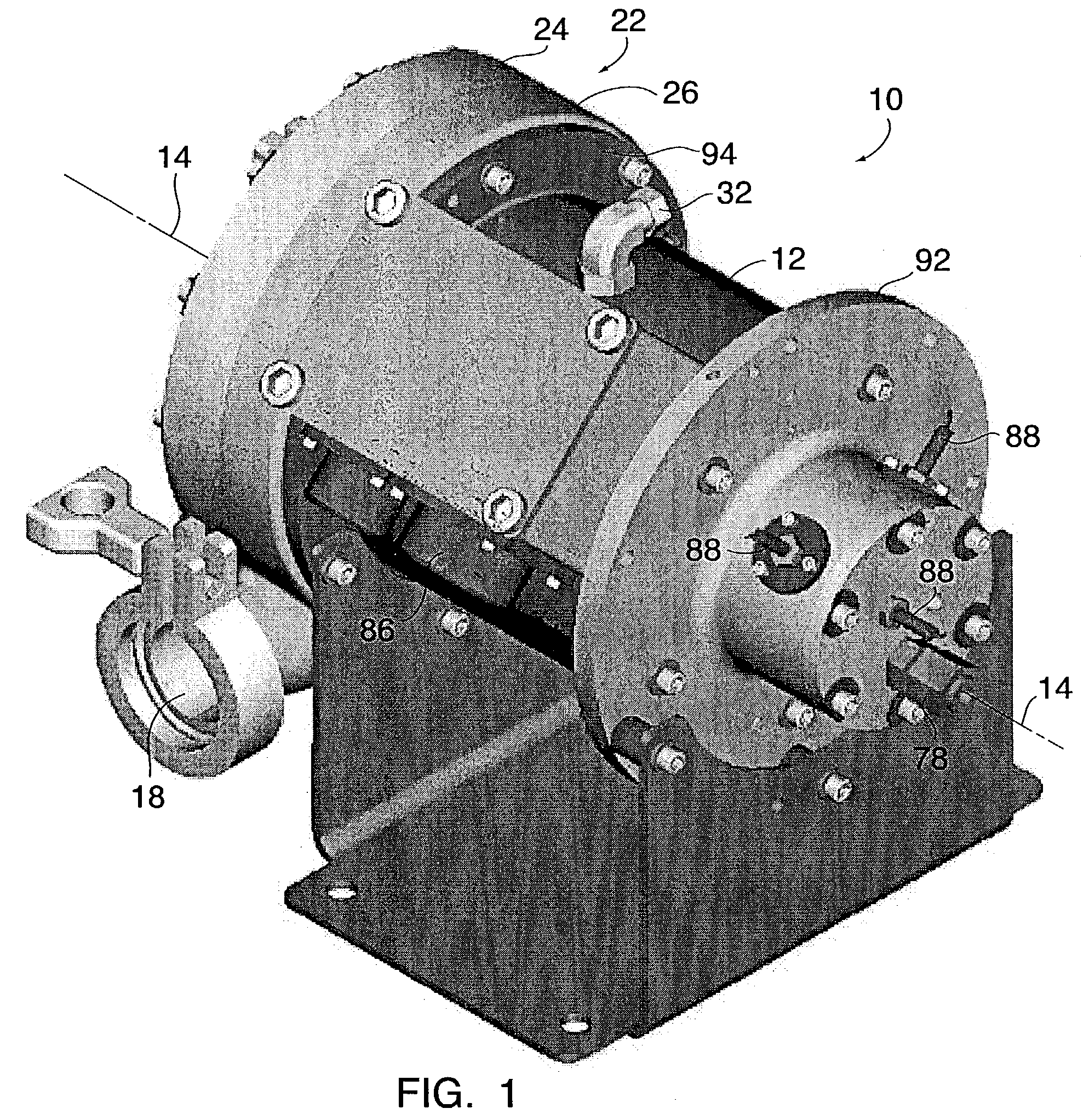

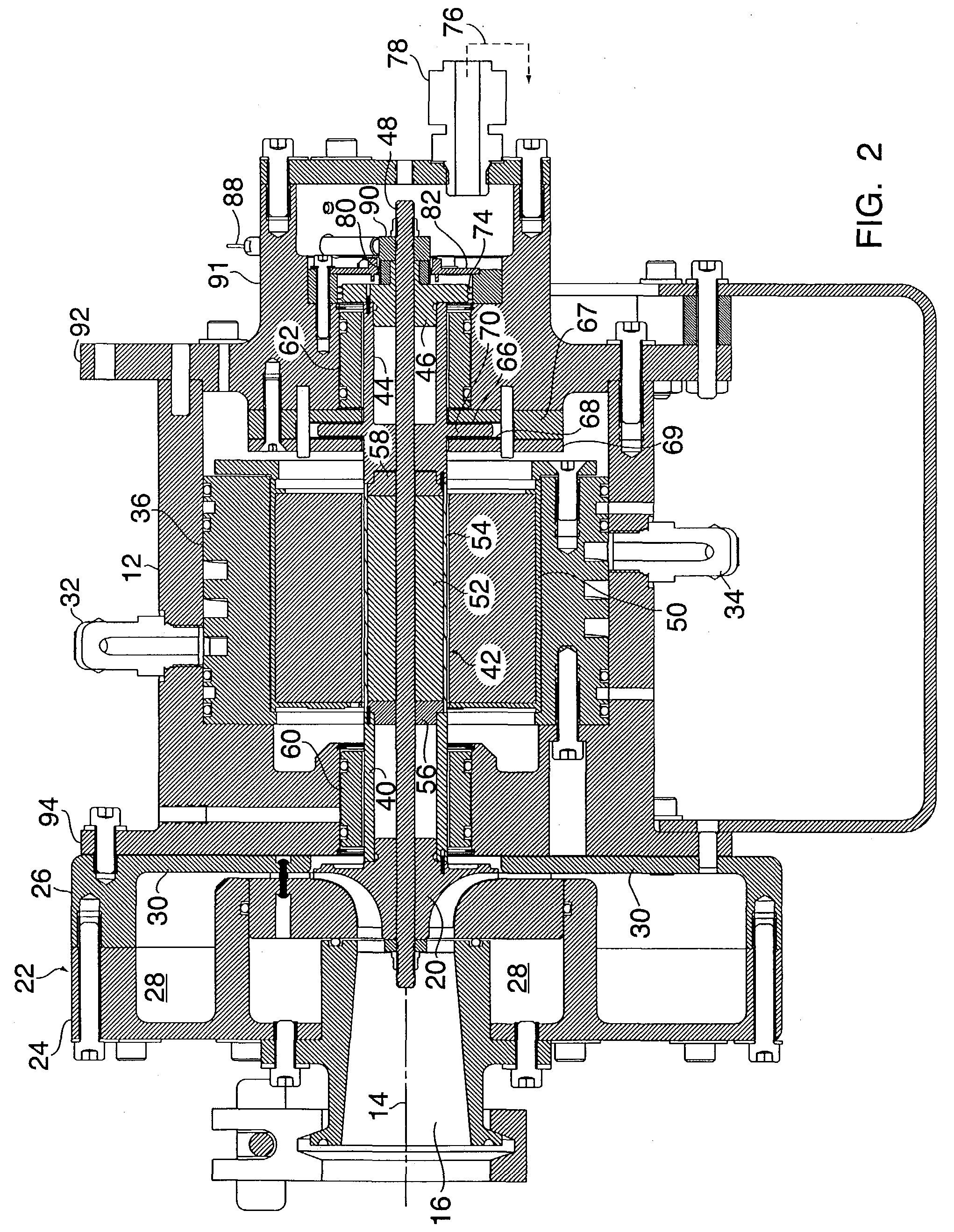

Cooling apparatus powered by a ratioed gear drive assembly

InactiveUS20060245944A1Easy to operateVehicle heating/cooling devicesPiston pumpsGear driveEngineering

The present invention relates to a cooling apparatus comprising a refrigeration or air-conditioning apparatus. In particular the present invention relates to refrigeration or air-conditioning apparatus utilizing a mini-centrifugal compressor with rotational power provided by a ratioed gear drive assembly coupled to an internal combustion engine.

Owner:EI DU PONT DE NEMOURS & CO

Seal for a compressor and centrifugal compressor equipped with such a seal

A seal for a rotary compressor comprises a casing, at least one assembly having a rotating seal face ring which rotates as one with a sleeve intended to be mounted on a shaft of the compressor and of a stationary seal face ring mounted on the casing, the seal face rings being urged to press against one another via their rubbing face. The seal design further incorporates fluid circulation for heating leaks of compressible fluid conveyed by the compressor that occur between the seal face rings, this fluid circulation being formed in the casing and extending at least partially downstream of the seal face rings with respect to the direction of flow of the fluid stream.

Owner:THERMODYN

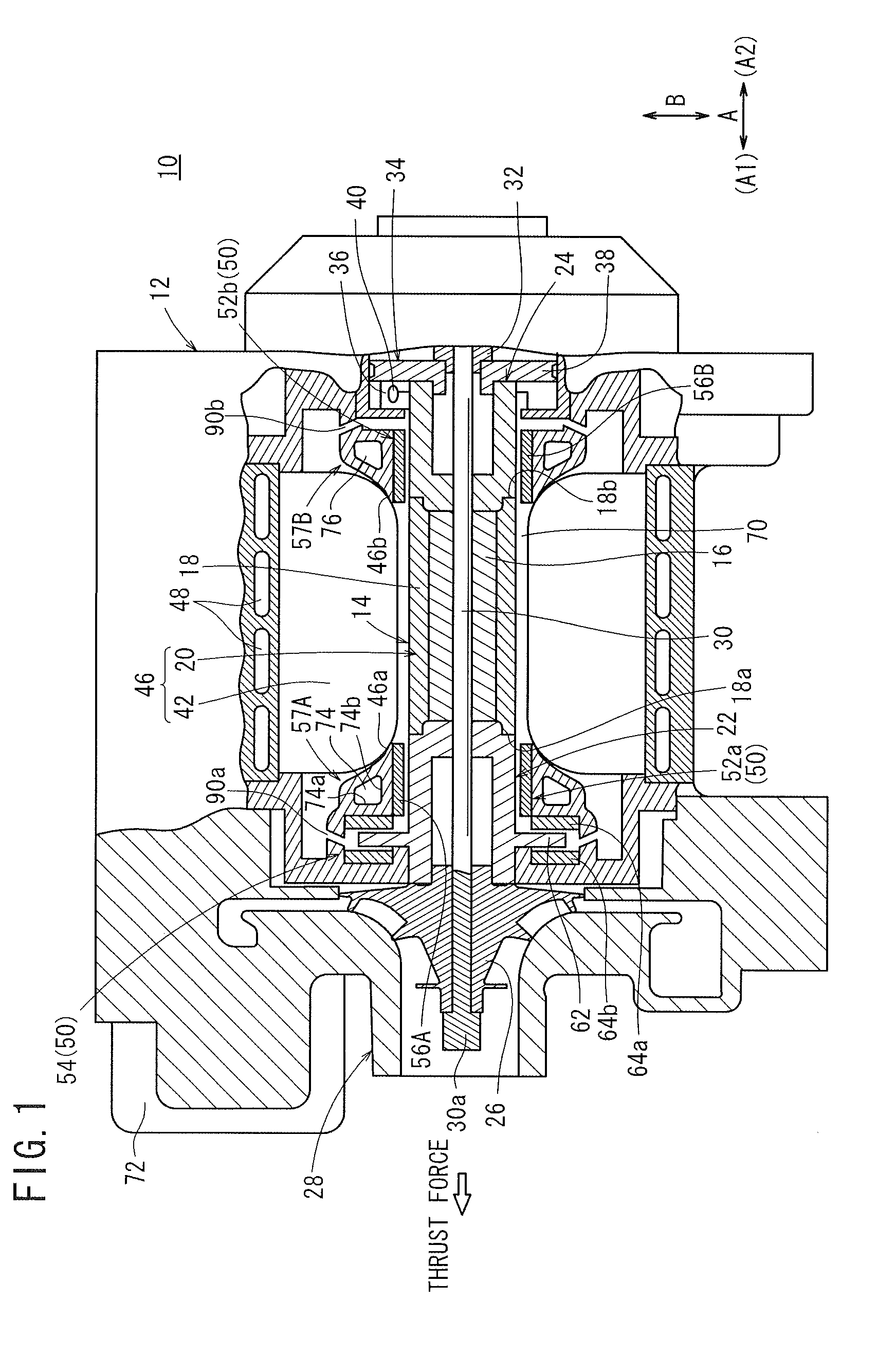

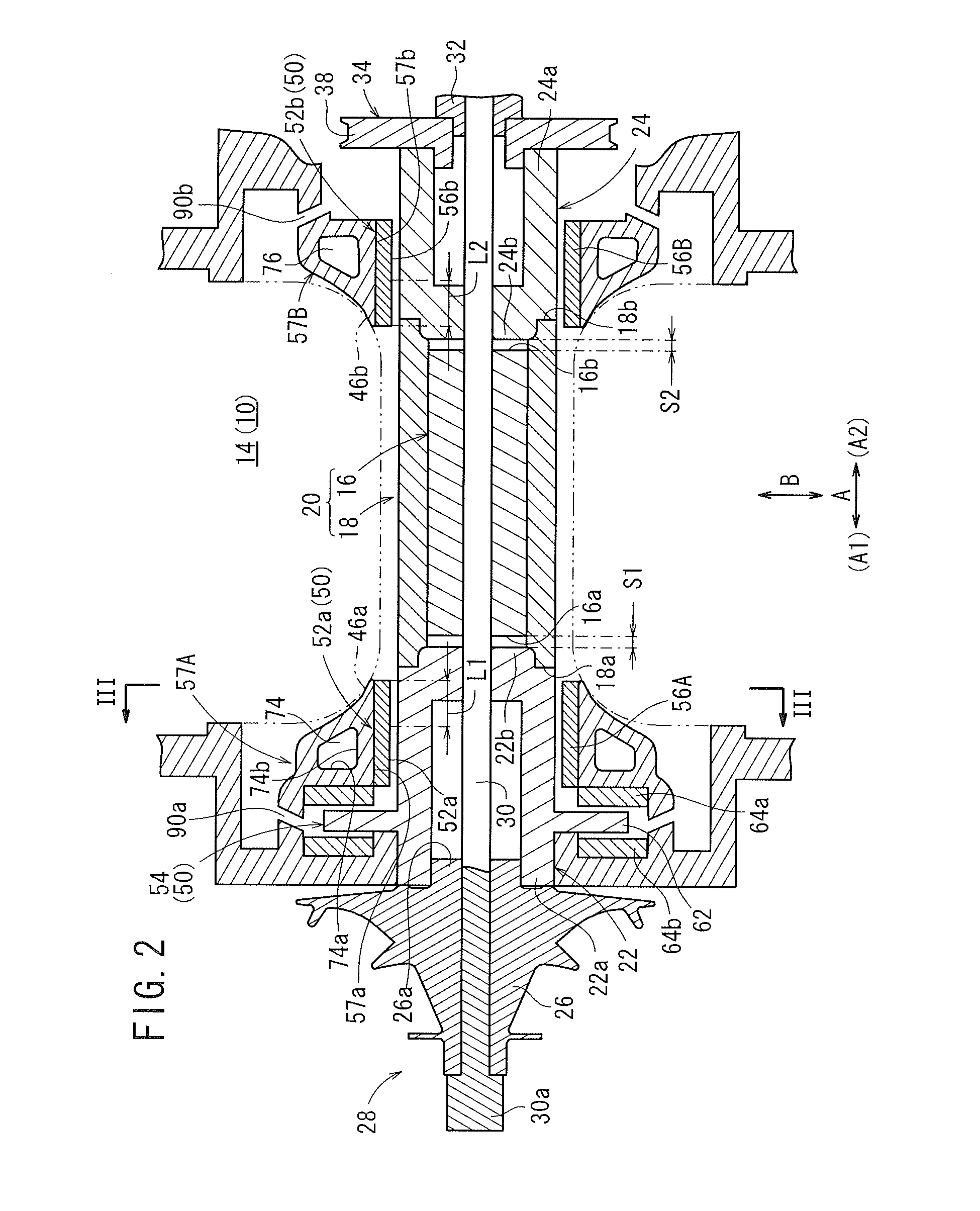

Motor-driven centrifugal compressor

InactiveUS20110243762A1Simple and compact structureEffective coolingPump componentsCombustion enginesMotor driveAir bearing

A motor-driven centrifugal compressor includes a journal air bearing having a bump foil and a top foil for restraining a bearing shaft in a resting state and forming an air layer between the top foil and the bearing shaft in a rotating state. The top foil and the bump foil are fixed to an inner circumferential surface of a ring member, which is fixed to an inner circumferential surface of a first stationary holding member of the ring member. The first stationary holding member has a coolant water channel defined therein. The bearing shaft, the air layer, the top foil, the bump foil, and the coolant water channel are arranged in the order named along a normal direction.

Owner:HONDA MOTOR CO LTD

Centrifugal compressor

ActiveUS7240515B2Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

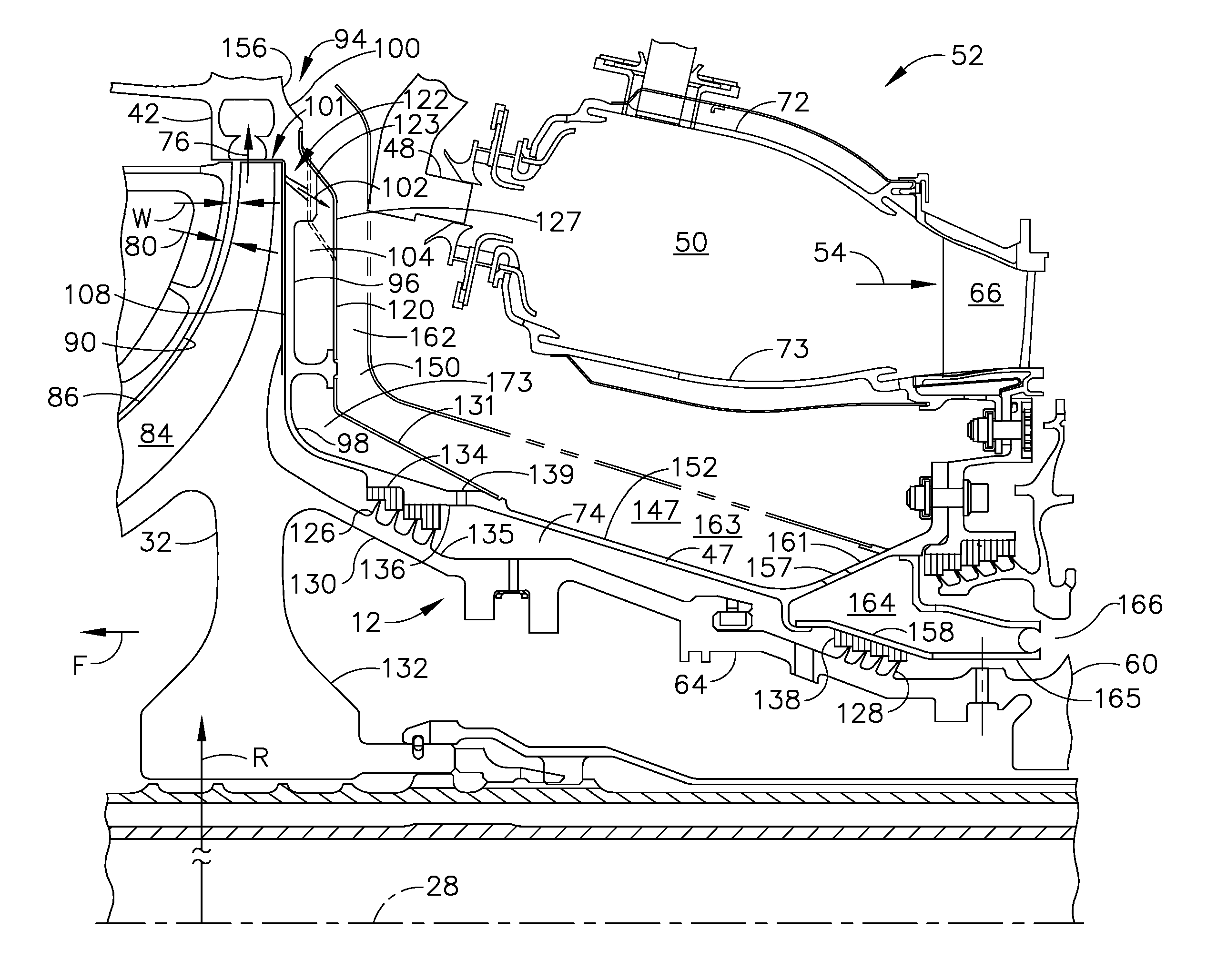

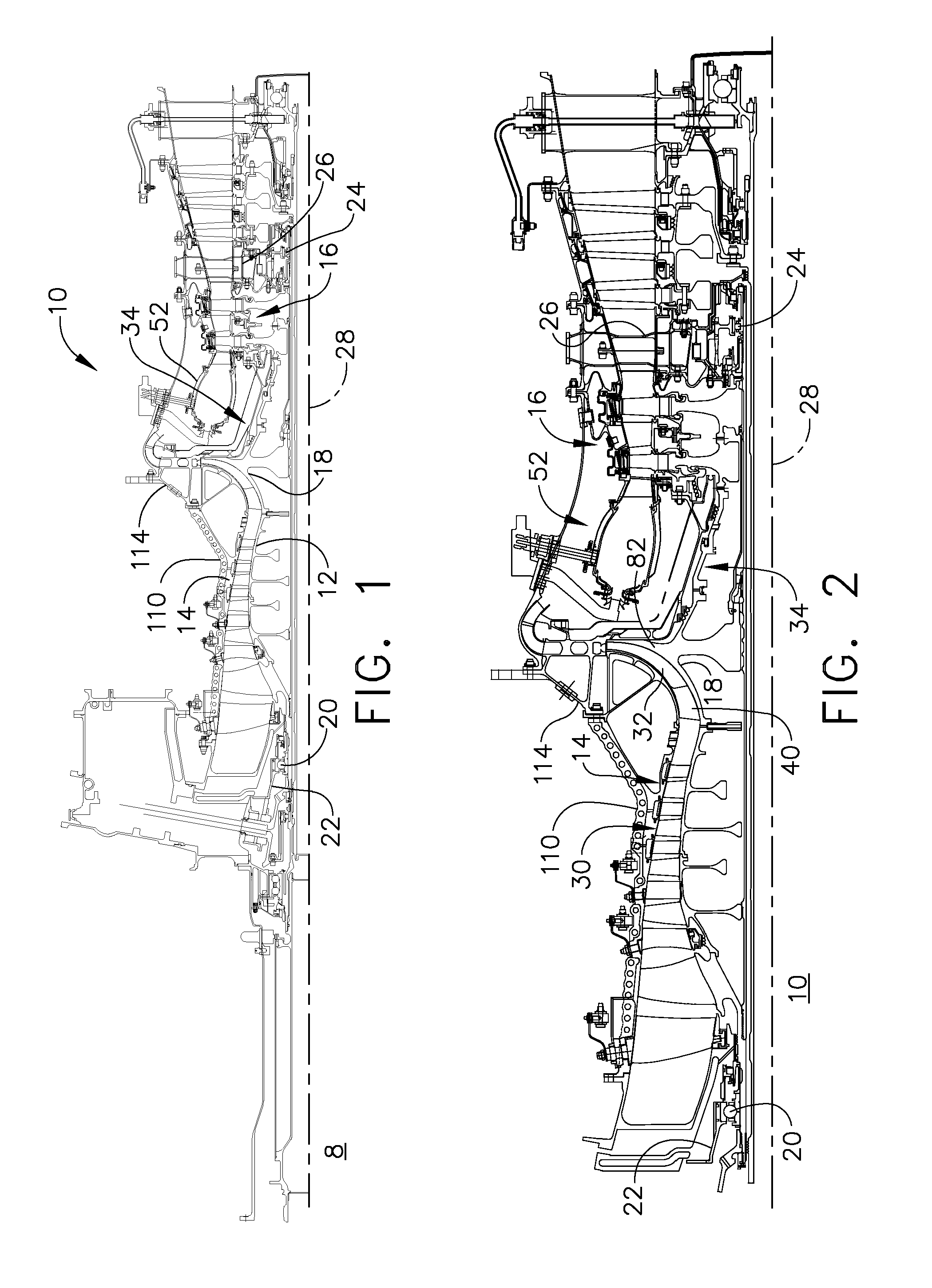

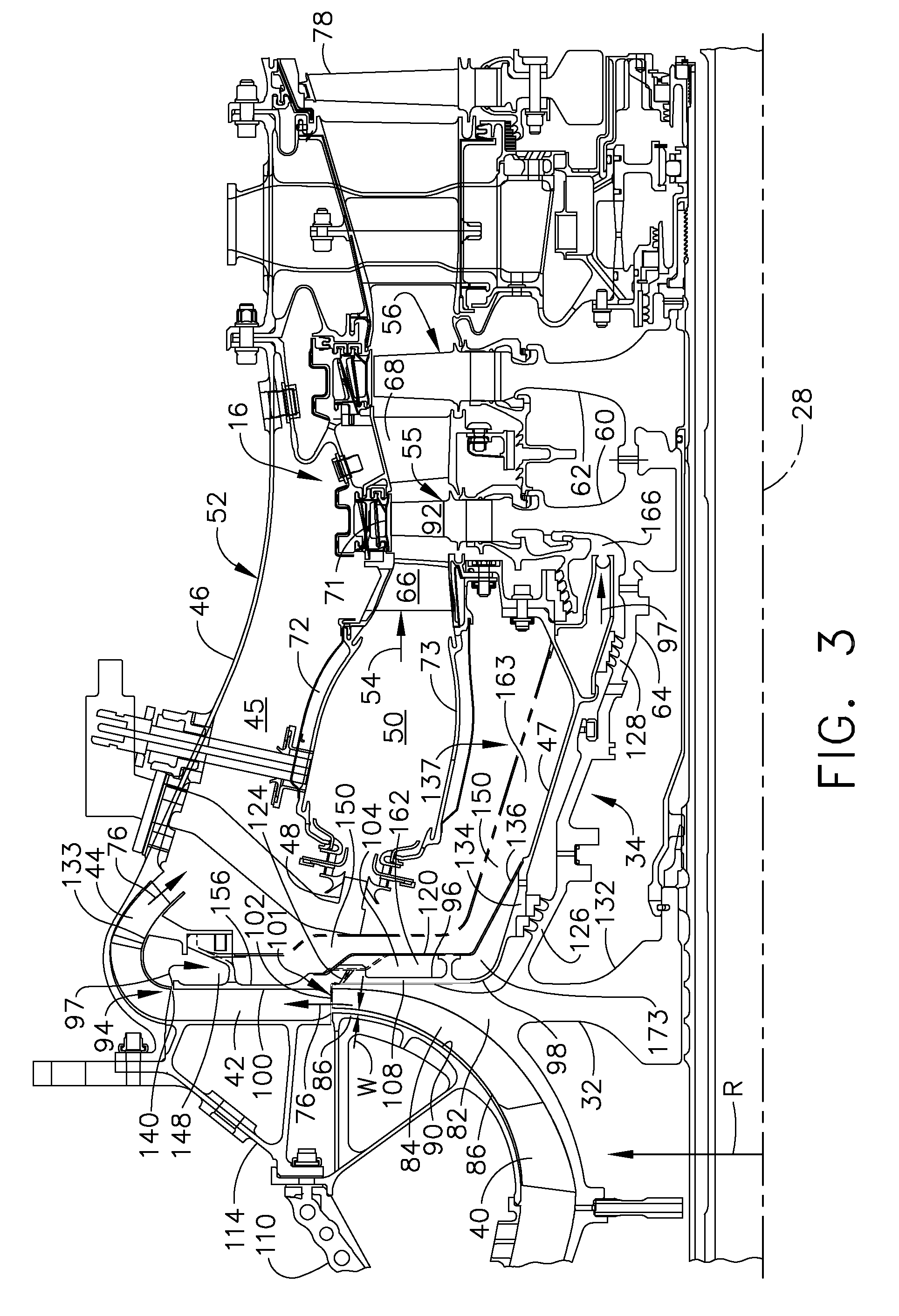

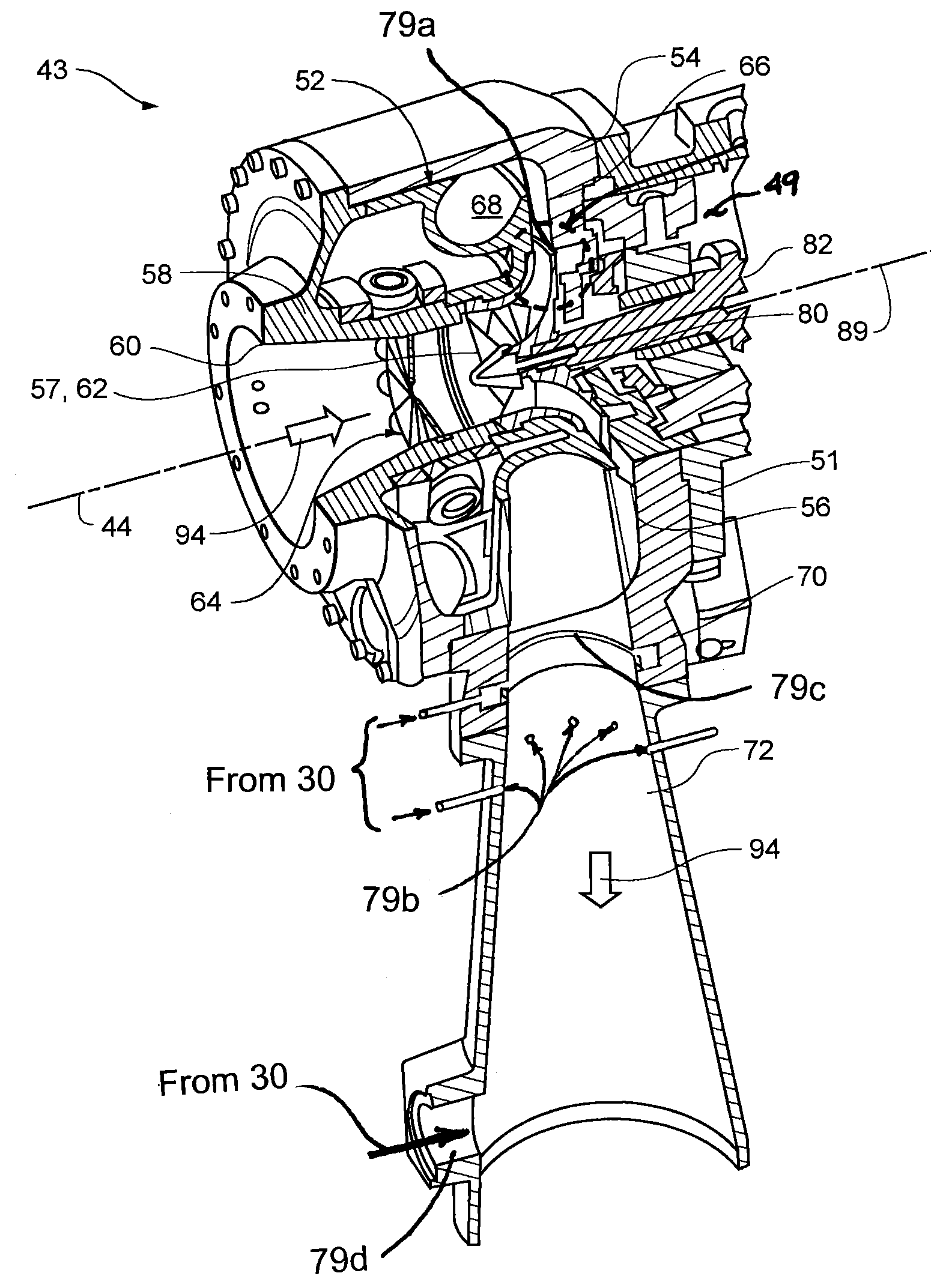

Turbine cooling air from a centrifugal compressor

A gas turbine engine turbine cooling system includes an impeller and a diffuser directly downstream of the impeller, a bleed for bleeding clean cooling air from downstream of the diffuser, and one or more channels in fluid communication with the bleed. Each of the channels having a generally radially extending section followed by a generally axially aftwardly extending section terminating at an annular cooling air plenum connected to accelerators. The radially and axially aftwardly extending sections may be connected by a bend section of the cooling air channel and the axially aftwardly extending section may be angled radially inwardly going from the bend section to the cooling air plenum. Each of the cooling channels includes an inner wall formed by a forward end wall extending radially outwardly from an inner combustor casing, an annular cover covering a radially inner portion of the forward end wall, and the inner combustor casing.

Owner:GENERAL ELECTRIC CO

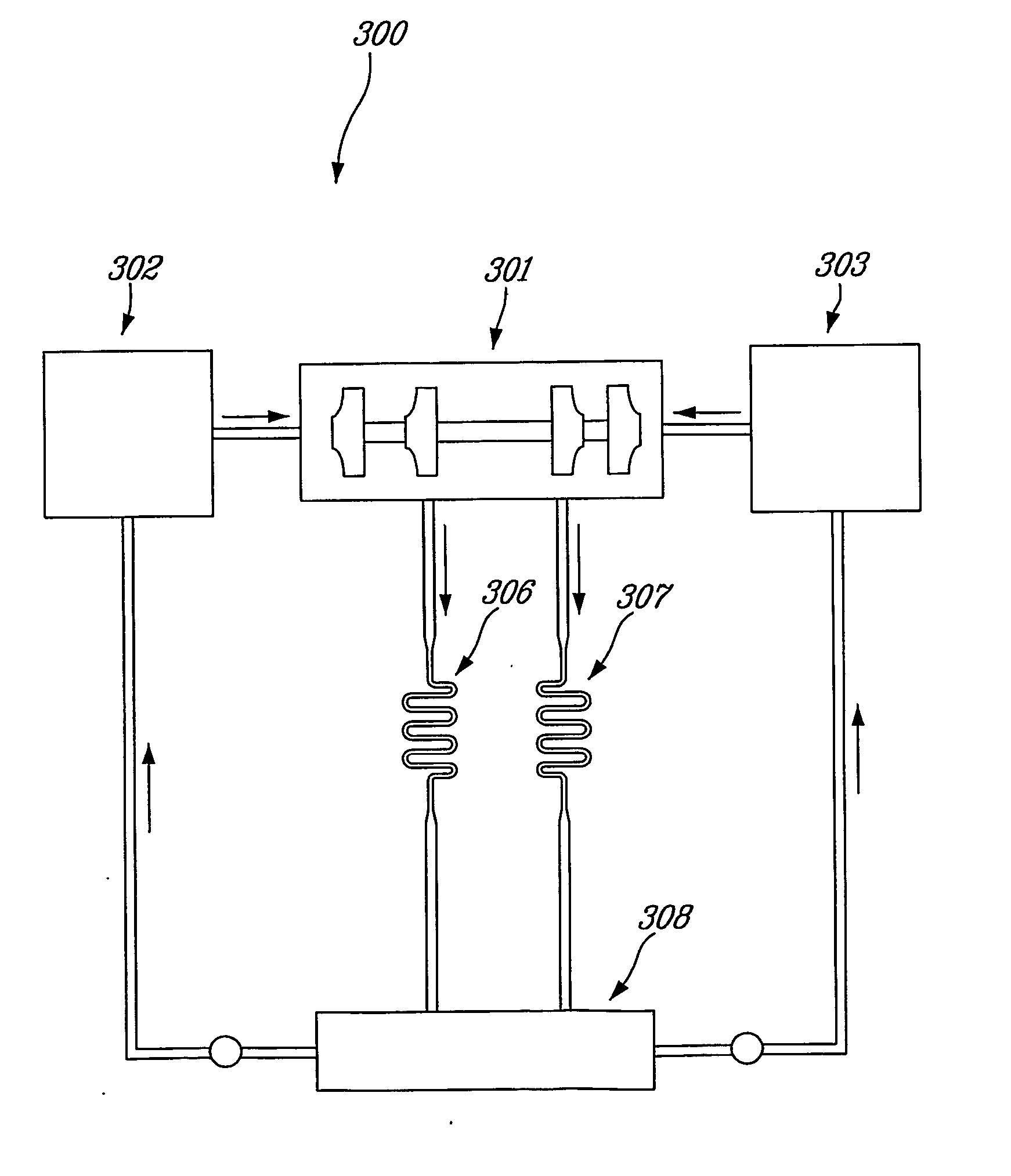

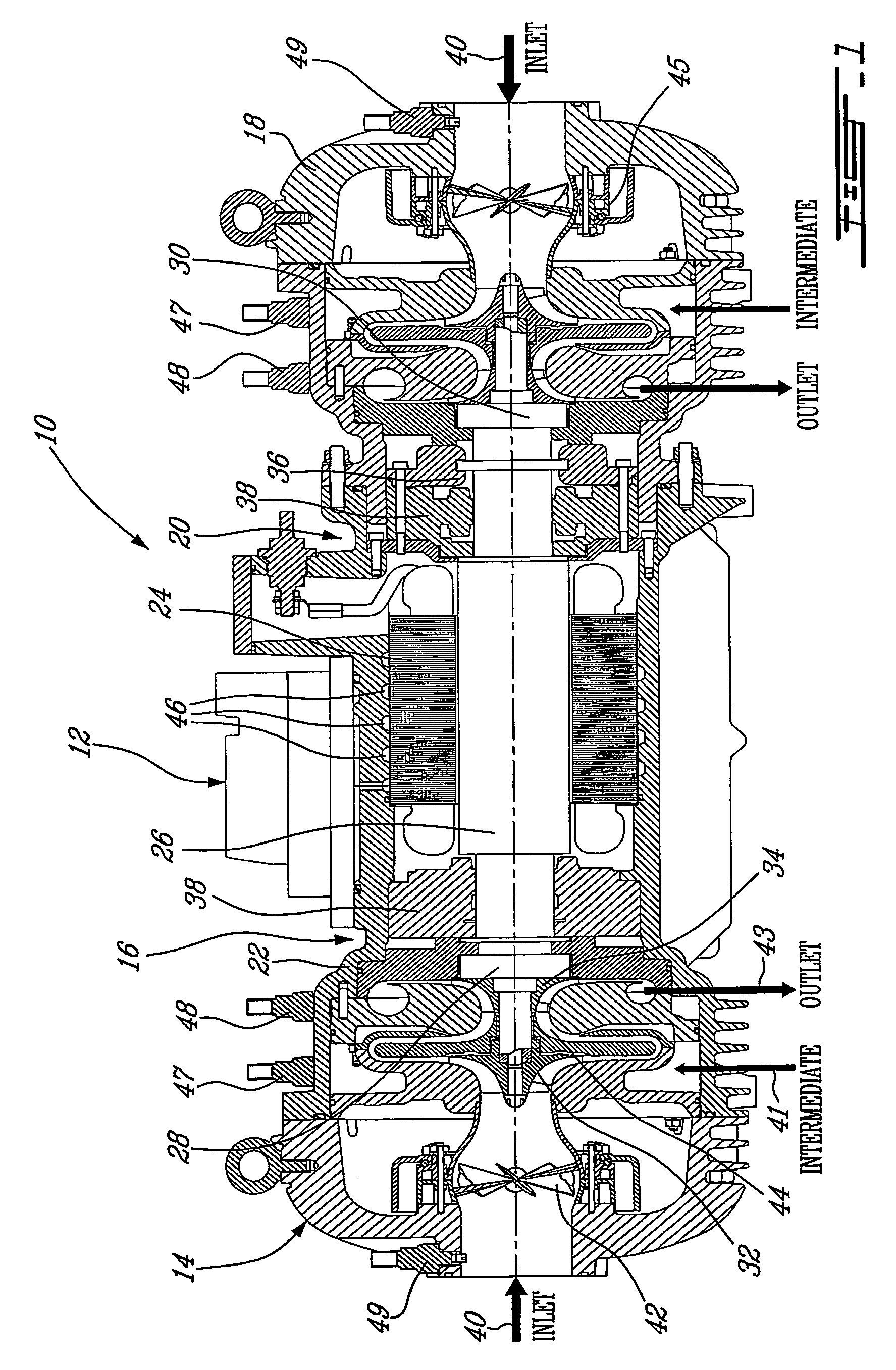

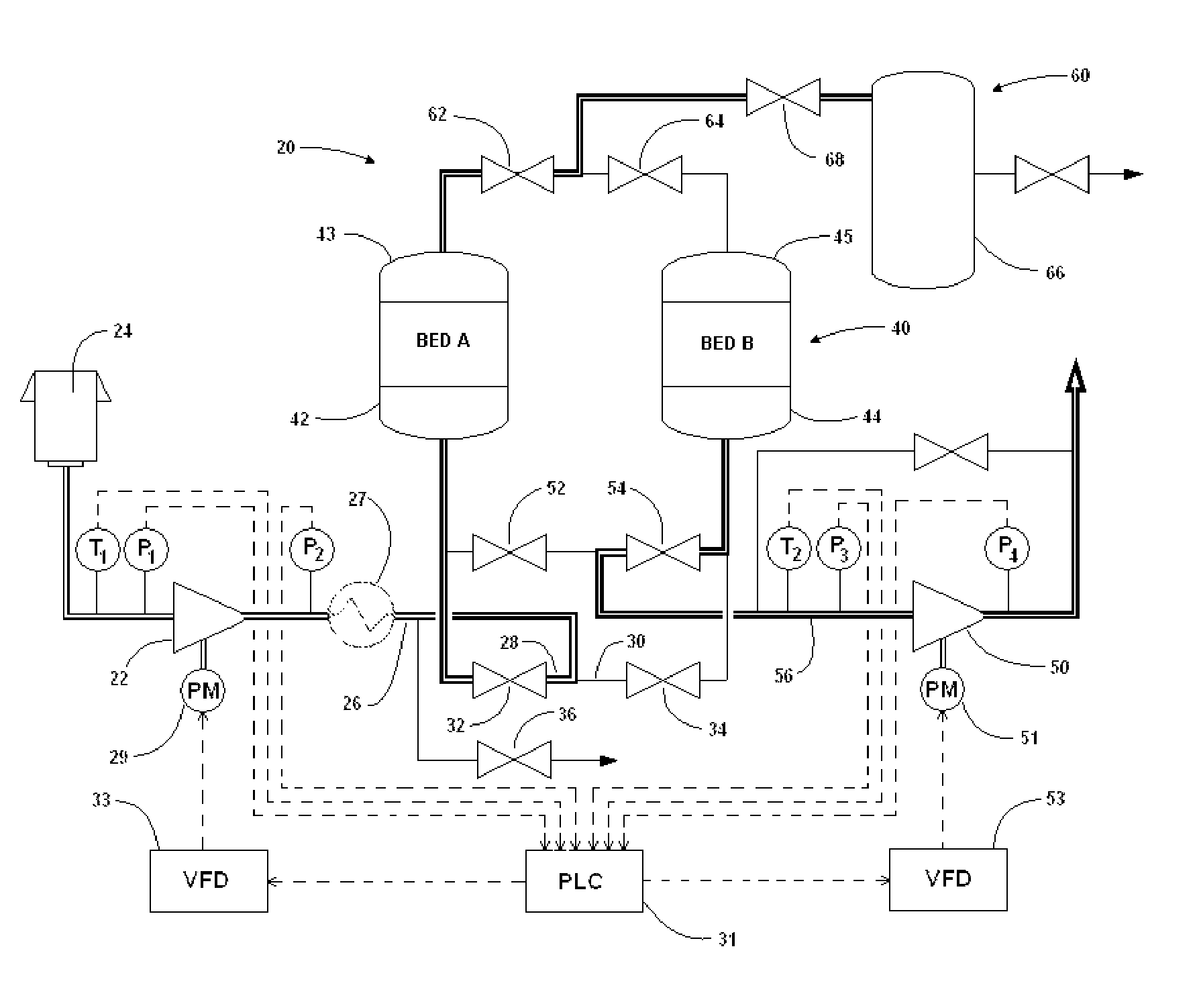

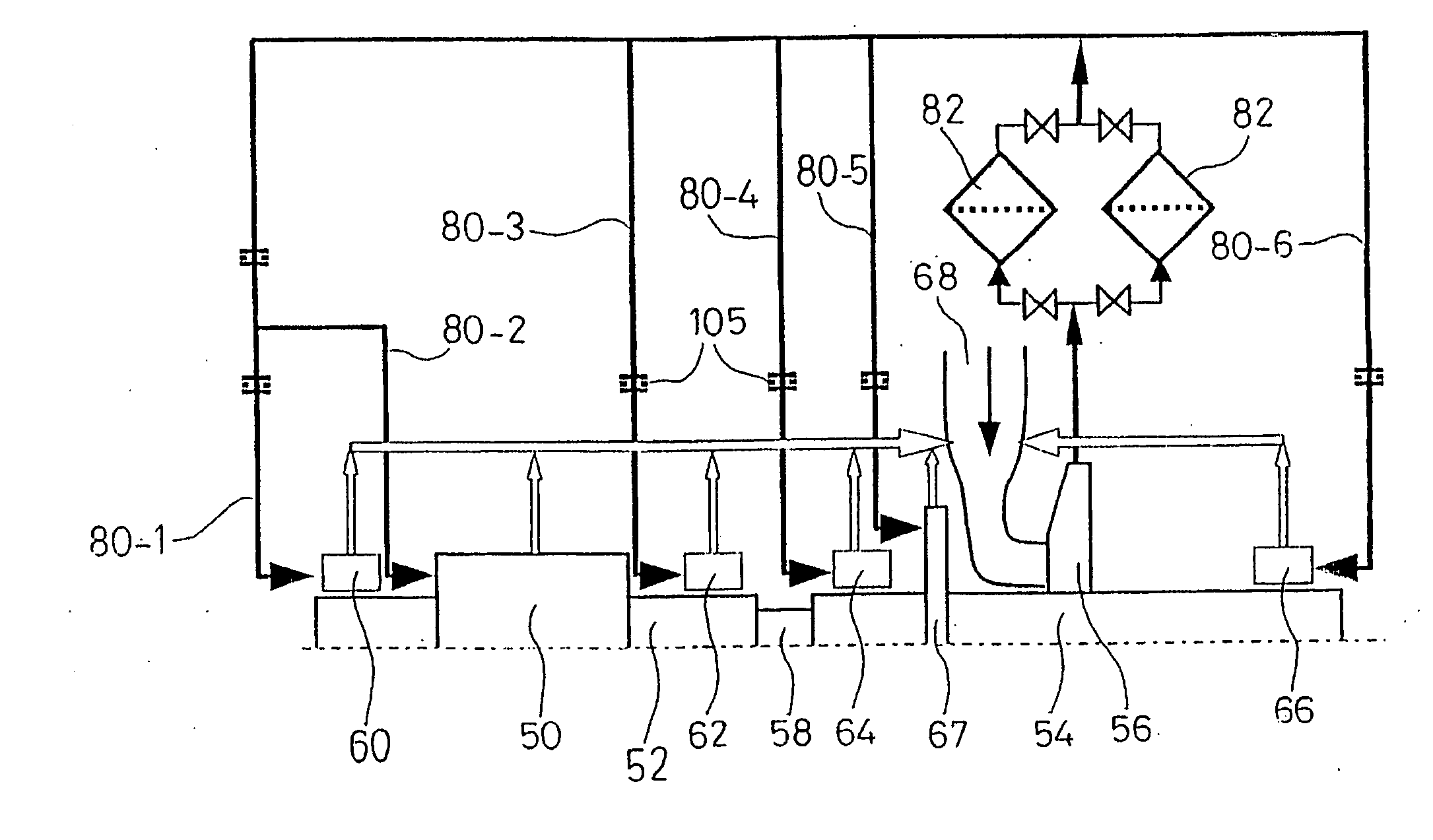

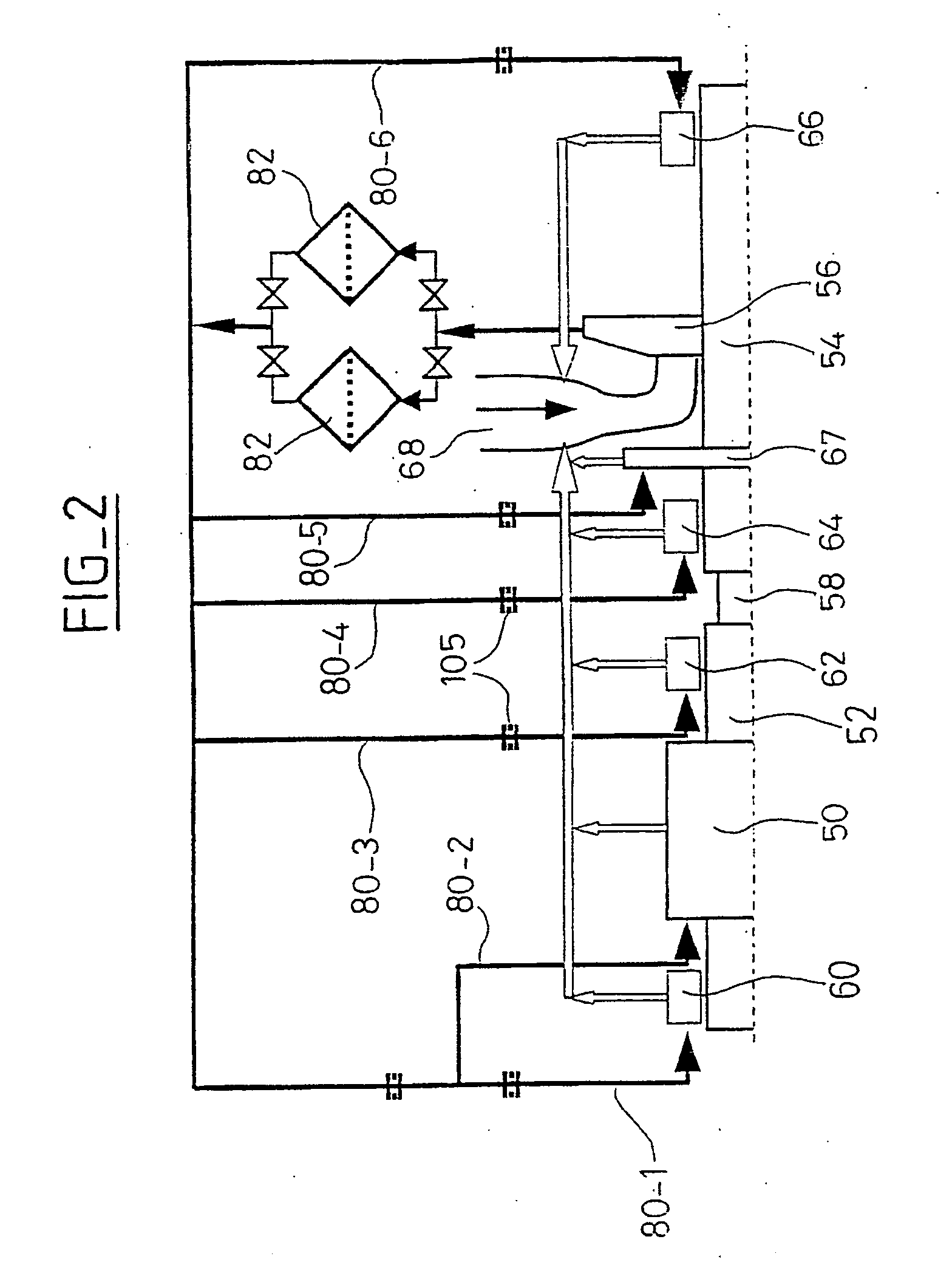

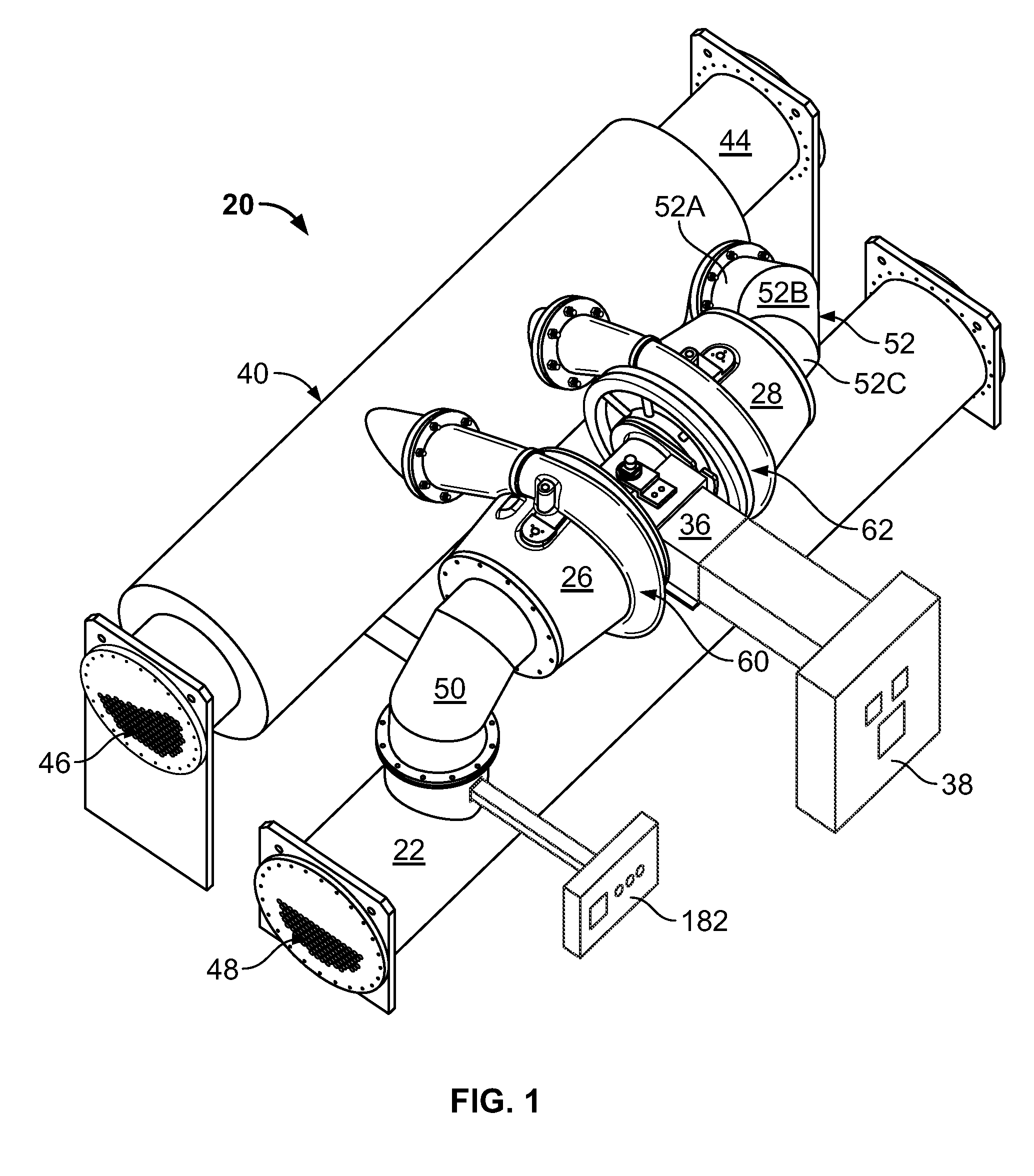

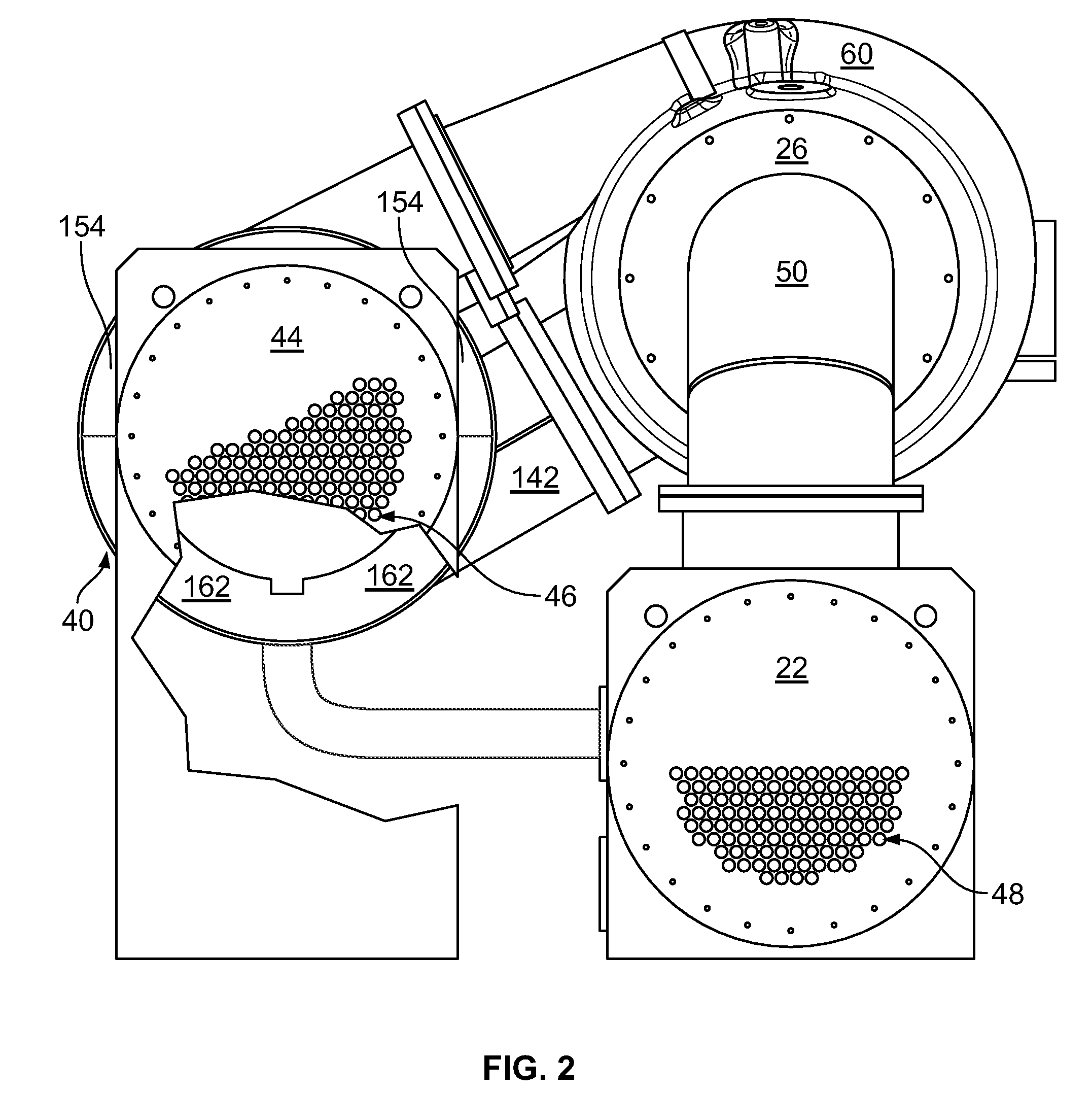

Systems and methods for gas separation using high-speed induction motors with centrifugal compressors

ActiveUS8529665B2Improve efficiencySlow down the centrifugal compressorGas treatmentDispersed particle filtrationVacuum pressureInduction motor

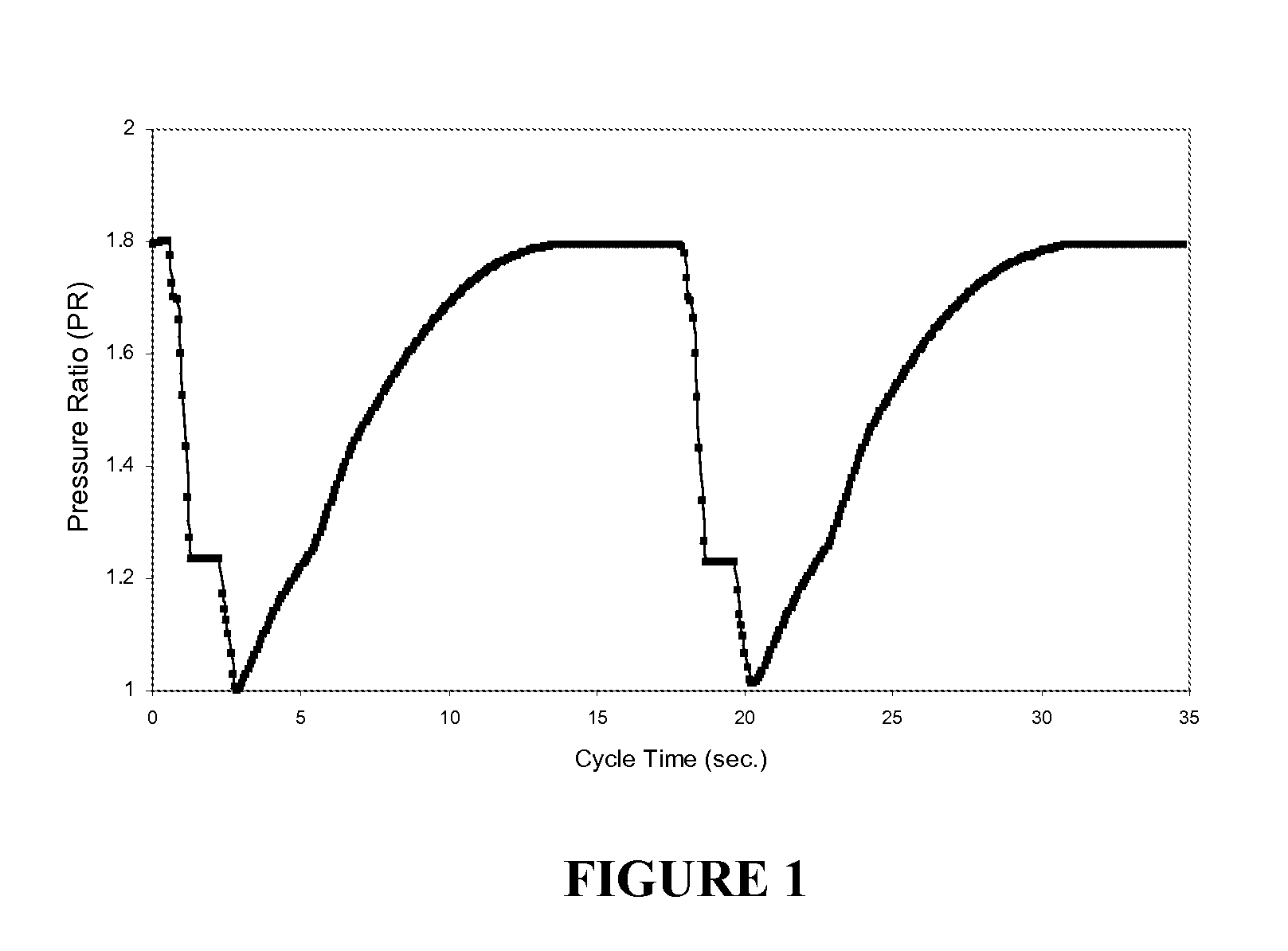

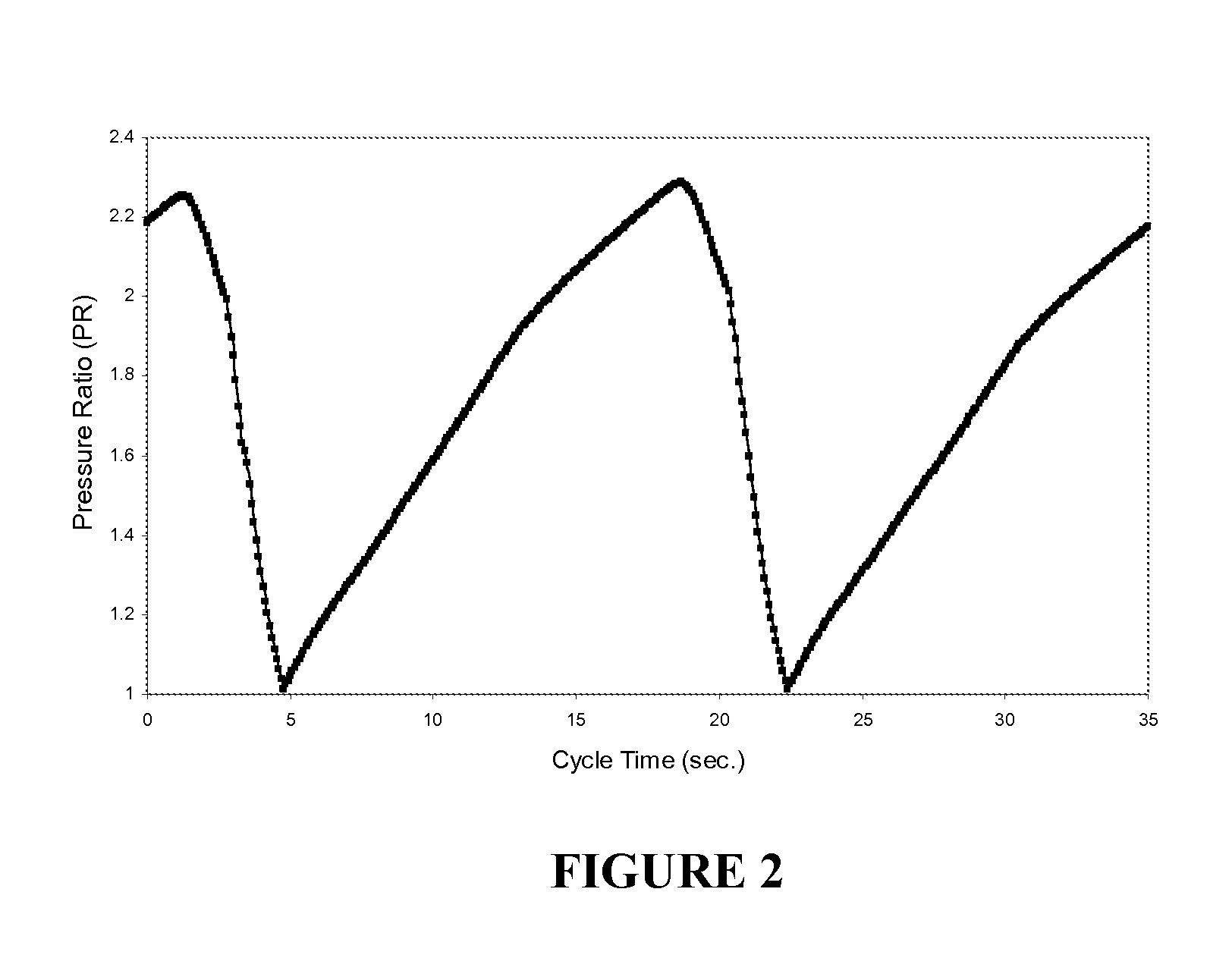

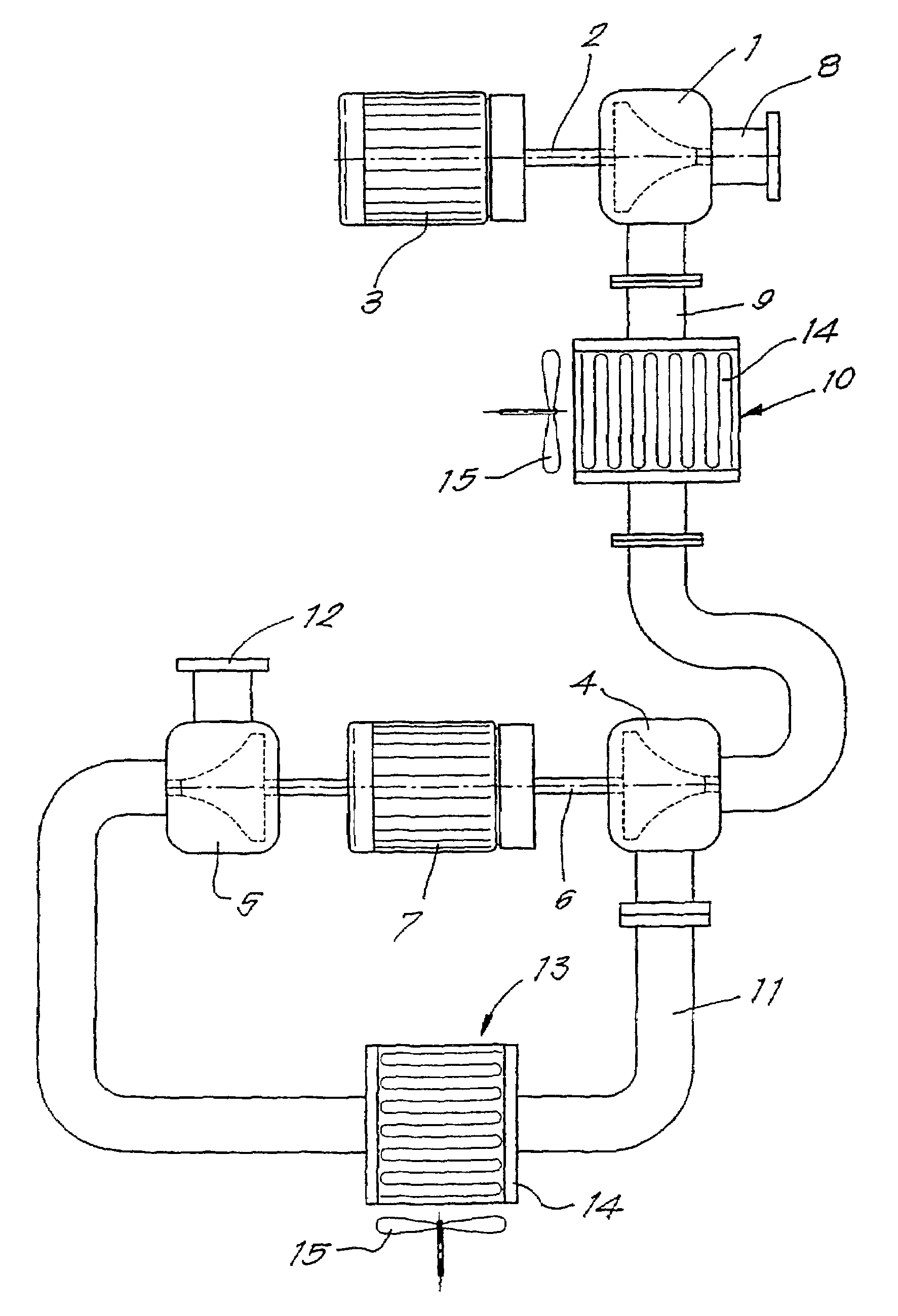

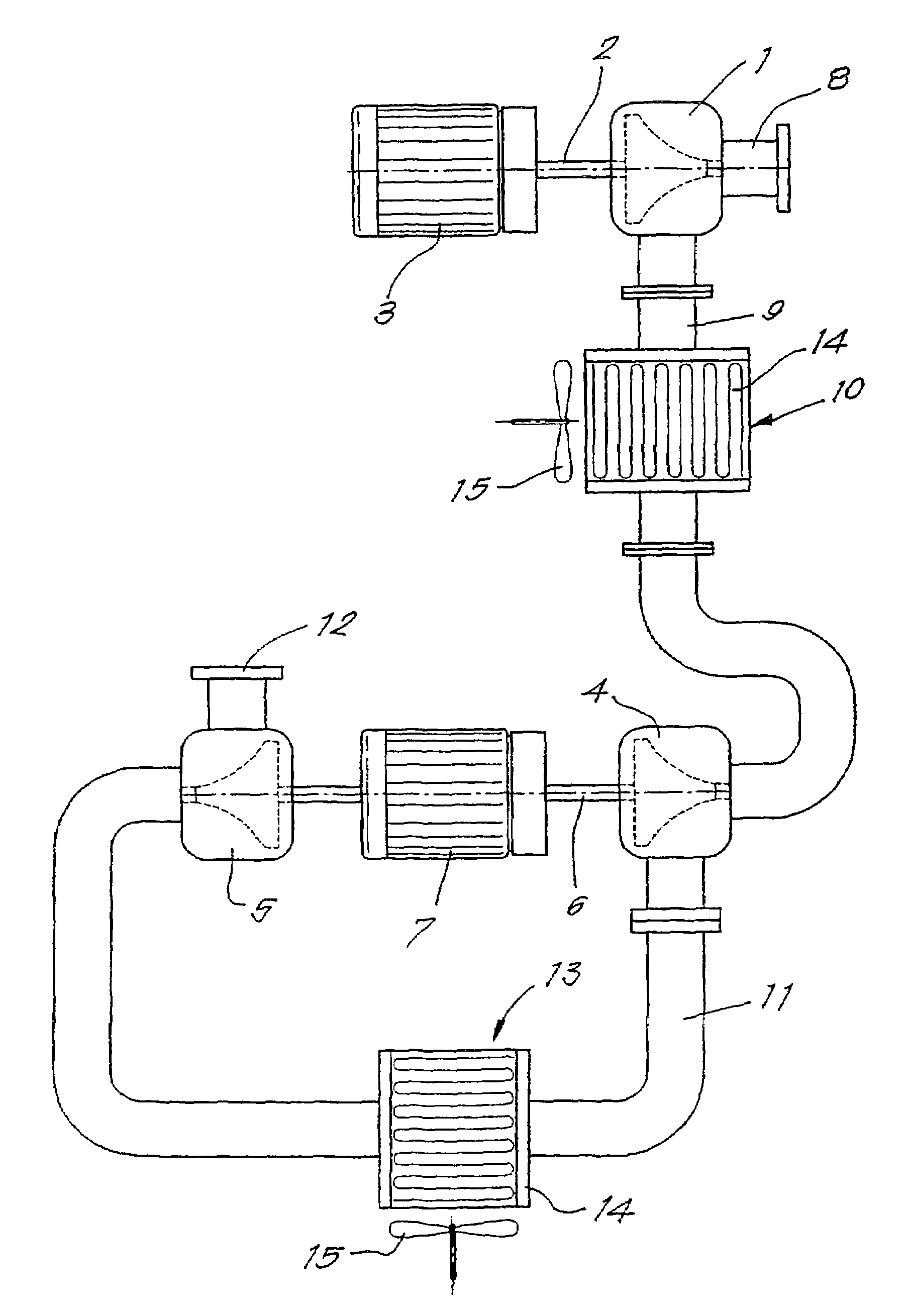

Systems and processes are provided for gas separation using high-speed induction variable-speed motors to accelerate and decelerate centrifugal compressors suitable for use in pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA) processes.

Owner:PRAXAIR TECH INC +1

High-pressure multi-stage centrifugal compressor

InactiveUS7044716B2Reduce the ratioShorten speedRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringHigh pressure

A high-pressure multi-stage centrifugal compressor is provided containing at least three compressor elements which are arranged in series as compressor stages, and at least two electric motors to drive these compressor elements. At least one compressor element forms a low-pressure stage which is driven by an electric motor. At least two compressor elements form high-pressure stages, and are arranged in series and driven by one and the same second electric motor.

Owner:ATLAS COPCO AIRPOWER NV

Compositions comprising bromofluoro-olefins and uses thereof

InactiveUS20060266976A1Reduce flammabilityReduced GWPHeat-exchange elementsEngineeringAir conditioning

The present invention relates to compositions for use in refrigeration and air-conditioning systems comprising at least one bromofluoro-olefin. The present invention further relates to refrigerant and heat transfer fluid compositions comprising a flammable refrigerant and a bromofluoro-olefin. The present invention further relates to compositions for use in refrigeration apparatus and air-conditioning apparatus employing a centrifugal compressor comprising at least one bromofluoro-olefin. Further, the present invention relates to the utility of the present refrigerant and heat transfer fluid compositions in processes for producing heat and cooling, methods for reducing flammability of a refrigerant, methods for lowering GWP of a refrigerant, methods for replacing refrigerants and other uses.

Owner:EI DU PONT DE NEMOURS & CO

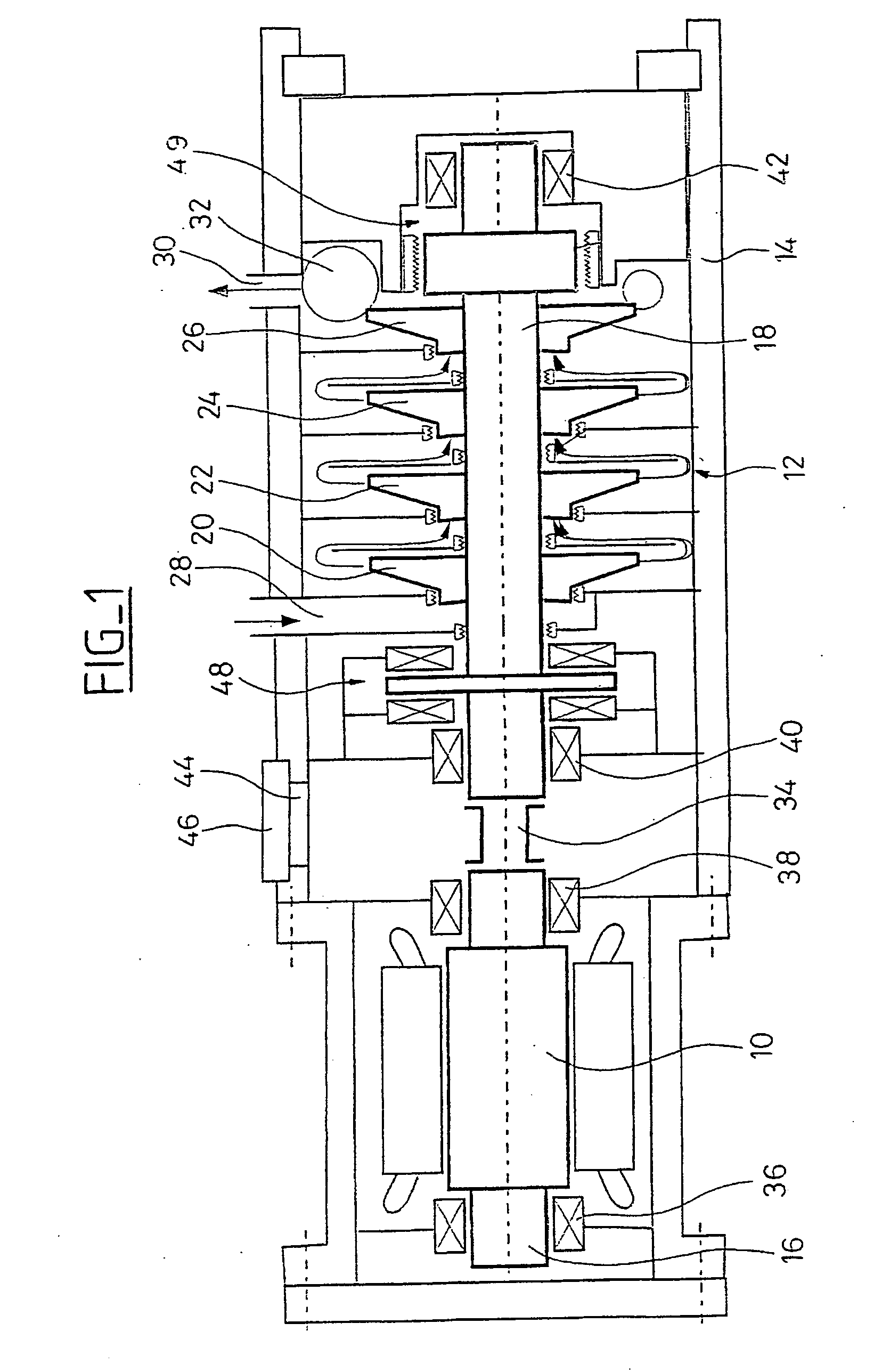

Centrifugal motor-compressor unit

ActiveUS20070172363A1Improve cooling effectAccelerate the lossPositive displacement pump componentsShaftsDrive shaftCentrifugal compressor

A centrifugal compressor unit includes a driving means for rotatably driving a rotor, and at least one compressor including a statoric body and an arrangement of blade wheels mounted on a shaft which is rotatably driven by the rotor in the statoric body. The group formed by the motor and / or each compressor being mounted in a common housing is sealed from the gas used by the compressor. The compressor unit also includes an arrangement of active bearings for axially and radially guiding the rotor and the driven shaft, and a means for cooling the driving means and the guiding bearings by withdrawing the gas used by the compressor at the outlet of a first compression stage. The cooling means includes a set of internal conduits for supplying the driving means and the bearings with cooling gas. The cooling gas flow in the motor and the cooling gas flow in the bearing is separated and then converge upstream of the first compression stage.

Owner:THERMODYN

Hydrofluorocarbon refrigerant compositions and uses thereof

Disclosed herein are hydrofluorocarbon refrigerant or heat transfer fluid compositions that are useful in refrigerain or air conditioning apparatus or as heat transfer fluids. The compositions of the present invention are also useful in centrifugal compressor apparatus that employ two-stage compressors or single slab.single pass heat exchangers.

Owner:EI DU PONT DE NEMOURS & CO

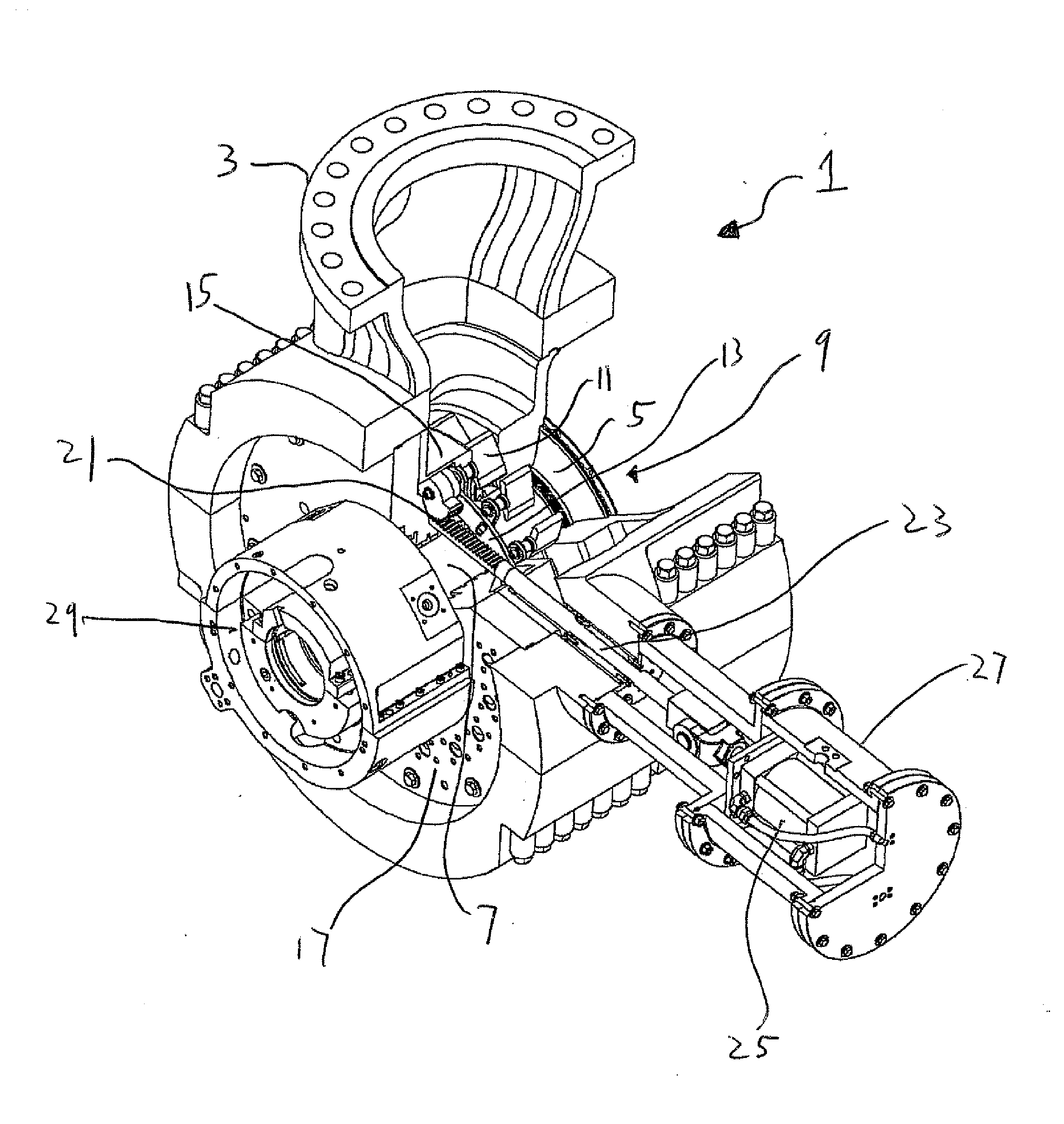

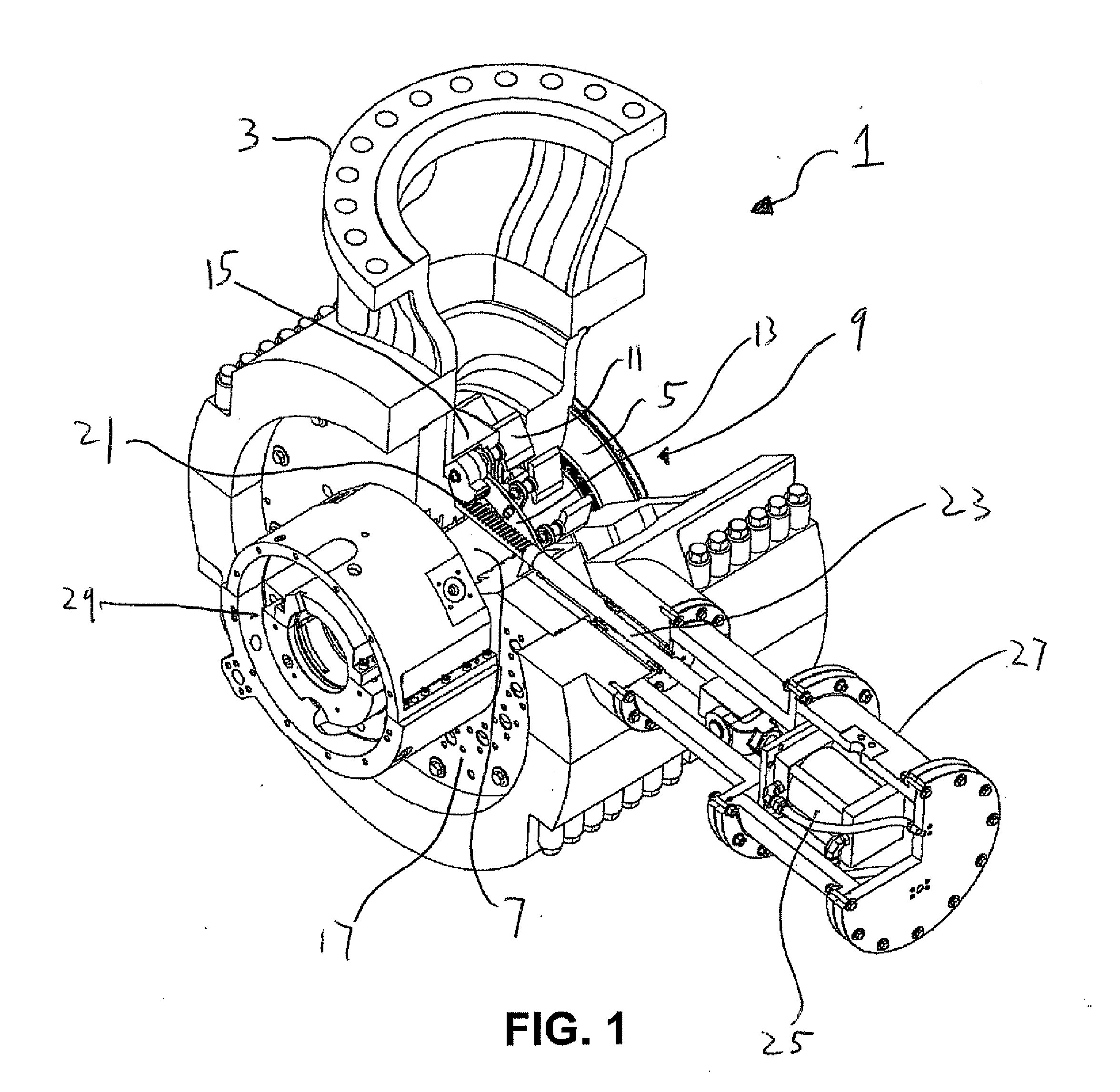

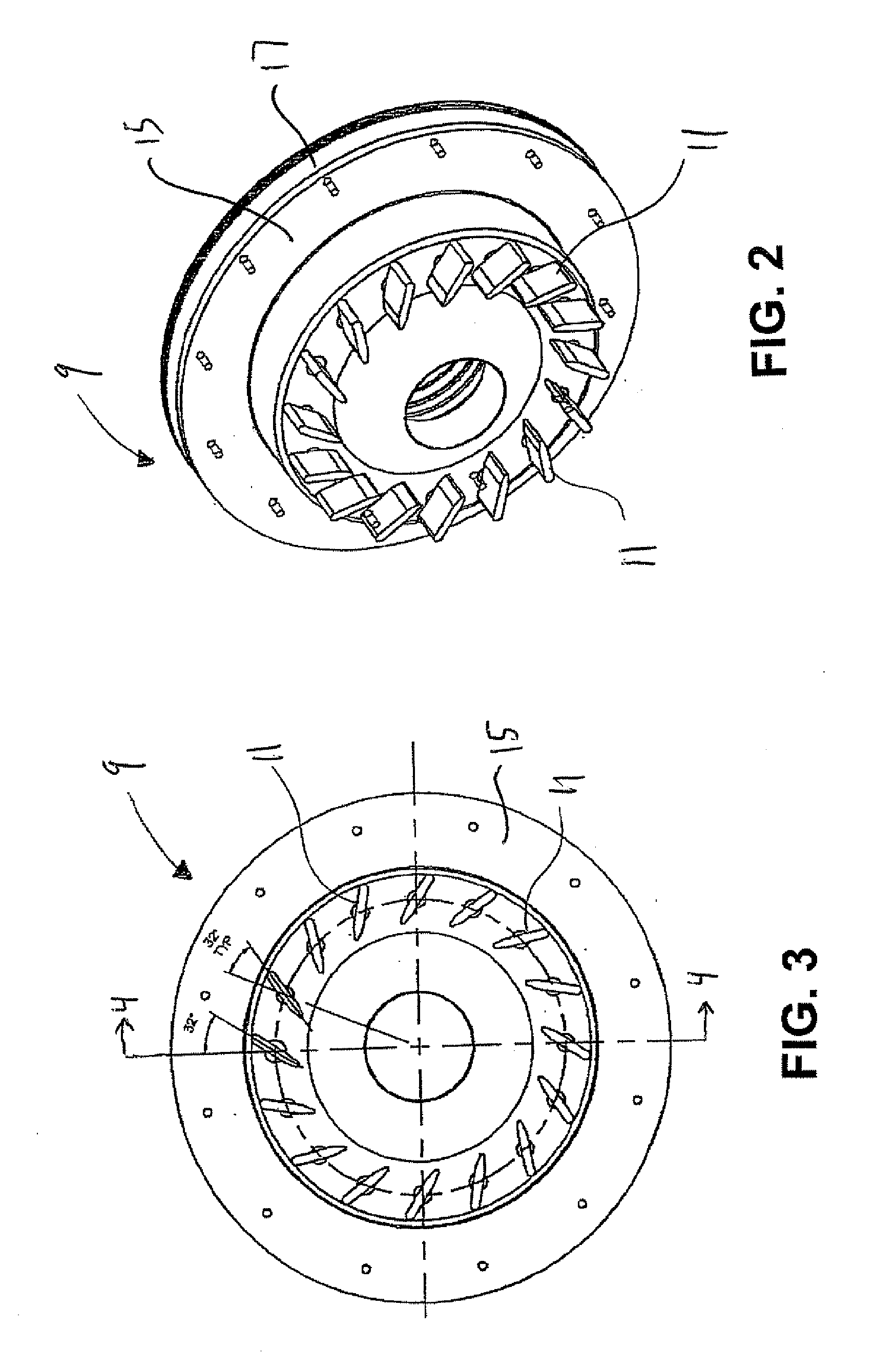

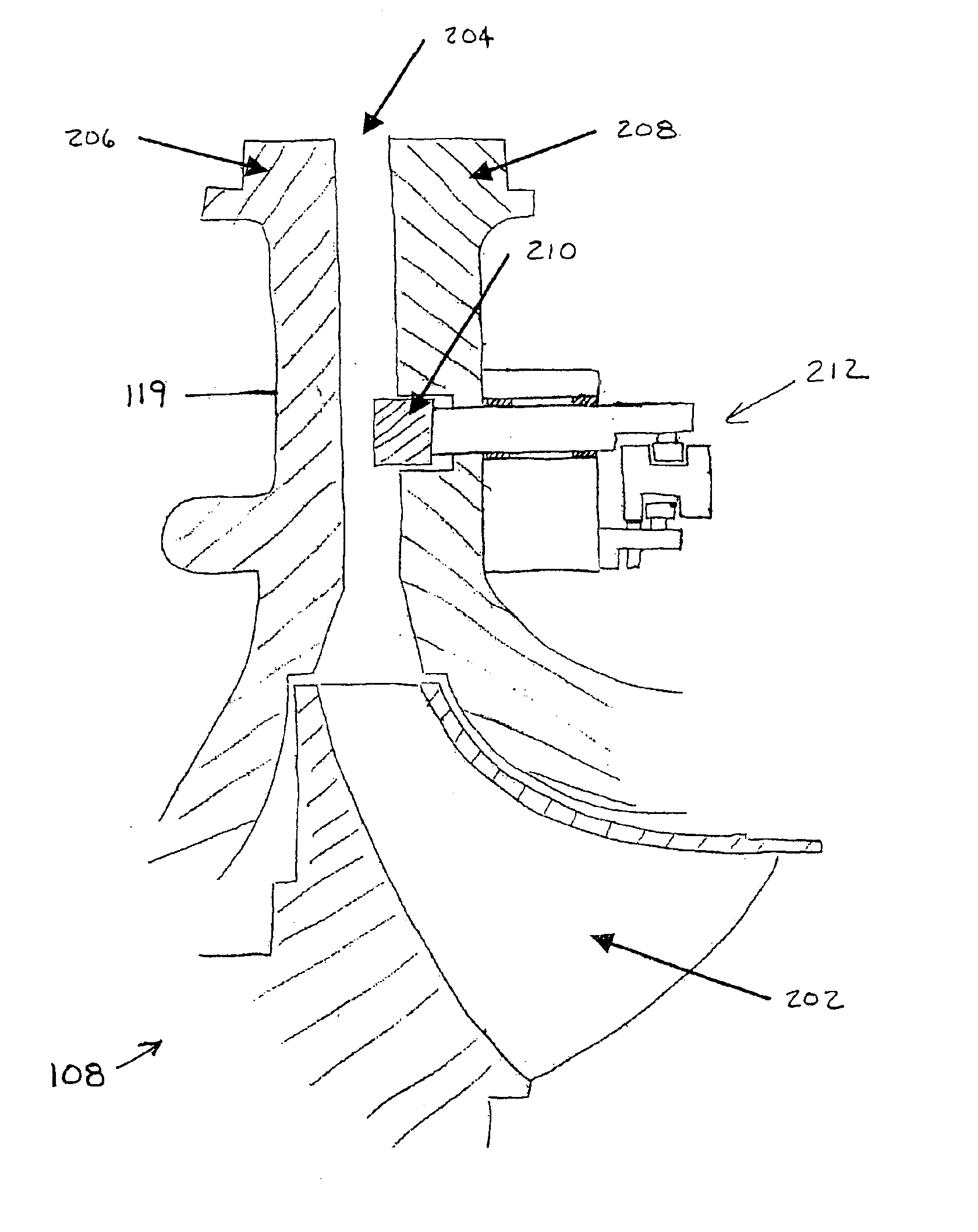

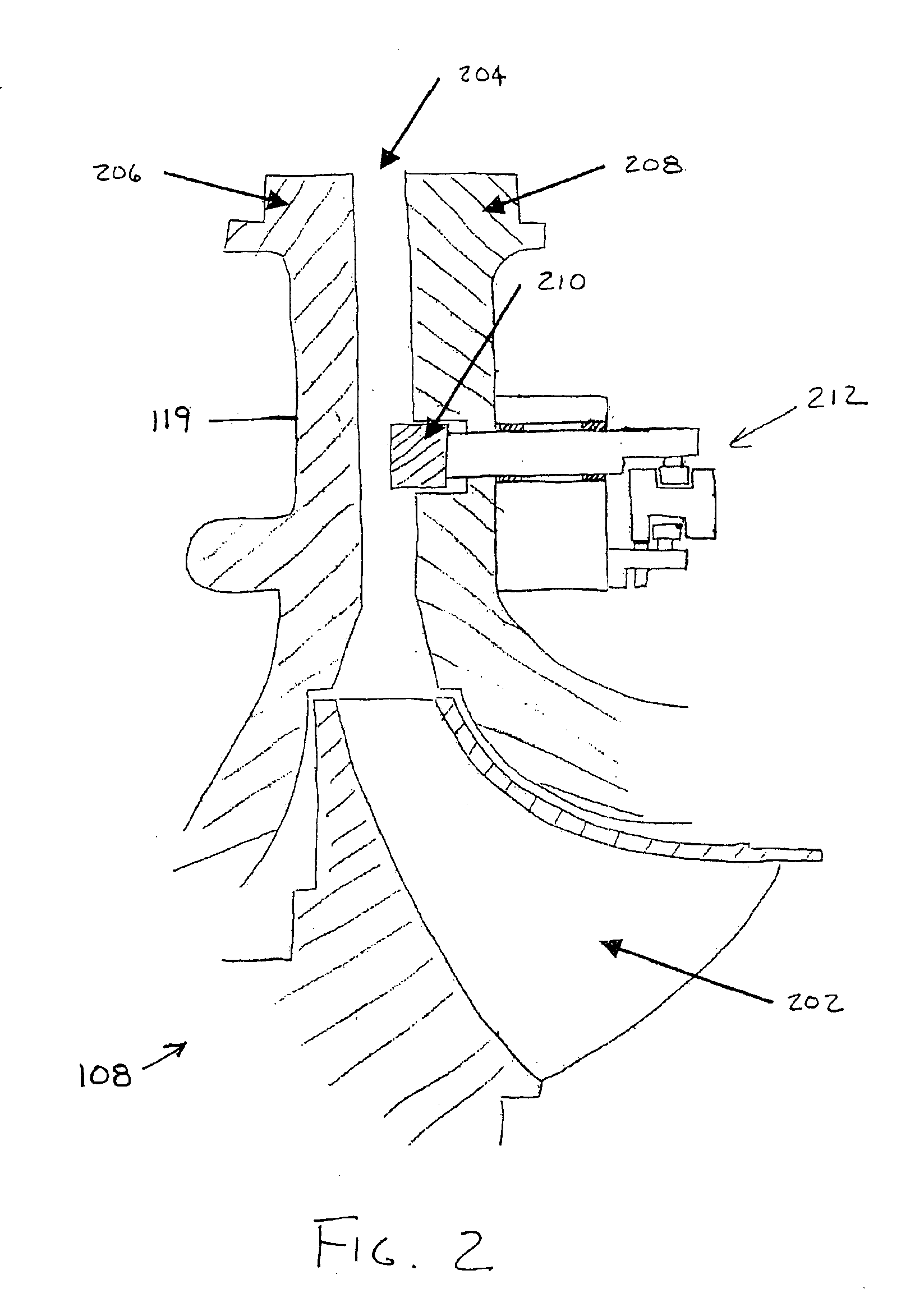

Centrifugal compressor having adjustable inlet guide vanes

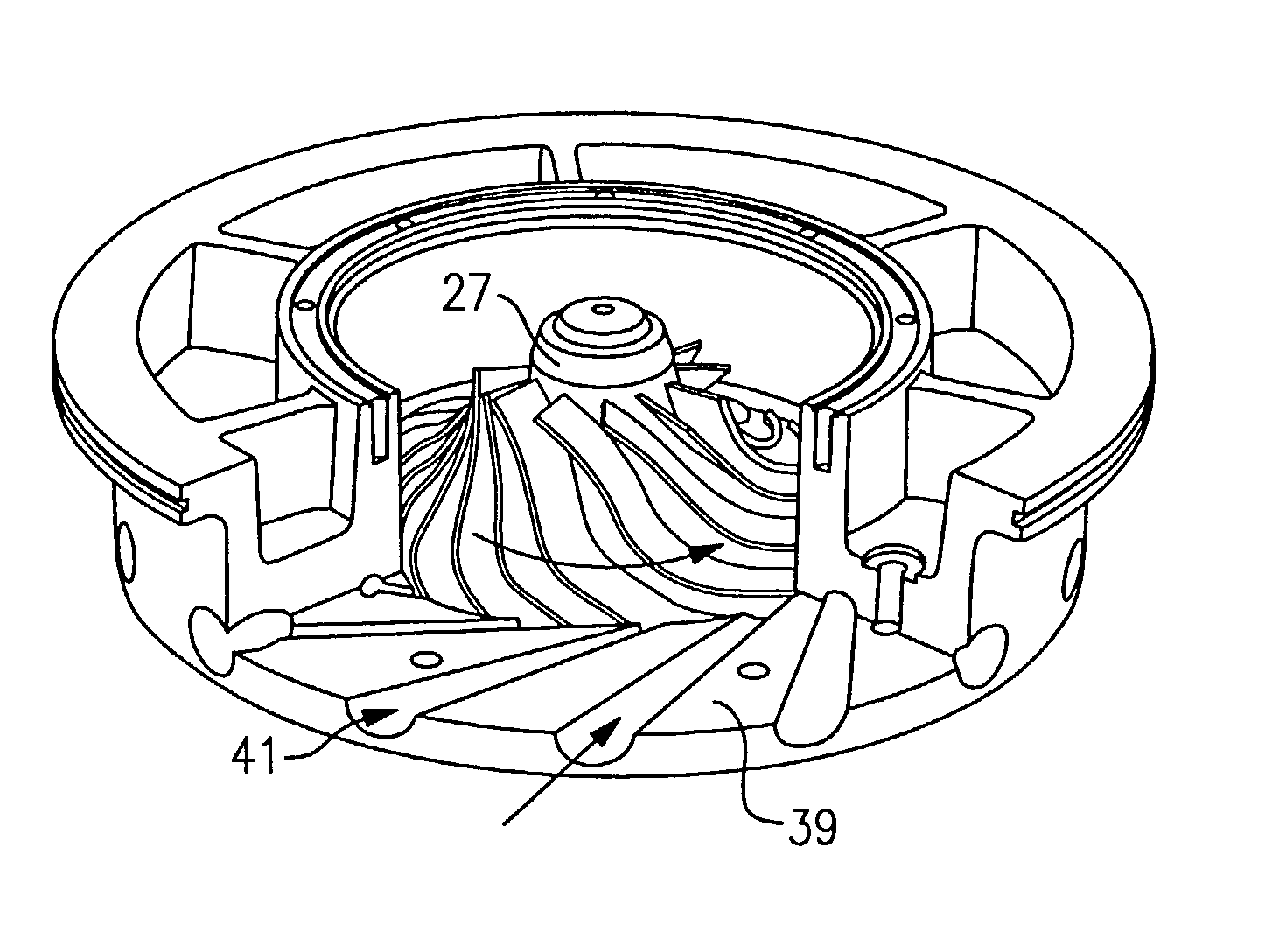

An apparatus for adjustment of inlet guide vanes of a compressor includes a ring having a plurality of slots spaced around a circumference thereof; a plurality of lever arm assemblies each having a pin that includes a body with a first end and a second end and a lever arm extending perpendicularly from the second end of the body of the pin; a plurality of vanes each coupled to an end of one of the plurality of lever arms by a shaft; and a rack and pinion drive mechanism. The pin of each of the lever arm assemblies is configured to be positioned within each of the plurality of slots such that the first end of the pin extends into the slot. The rack and pinion drive mechanism includes a pinion coupled to the shaft of one of the plurality of vanes, thereby creating a drive vane; and a driven rack operationally coupled to the pinion. The drive vane is configured to rotate the ring via the rack and pinion drive mechanism, thereby adjusting an angular position of the plurality of vanes.

Owner:ELLIOTT CO

Dual-use radial turbomachine

The impeller is preferably modified to use back swept, radial or forward swept blades to accommodate relatively low, medium and high lift, respectively applications for both centrifugal compressor and turbine rotor use.

Owner:RTX CORP

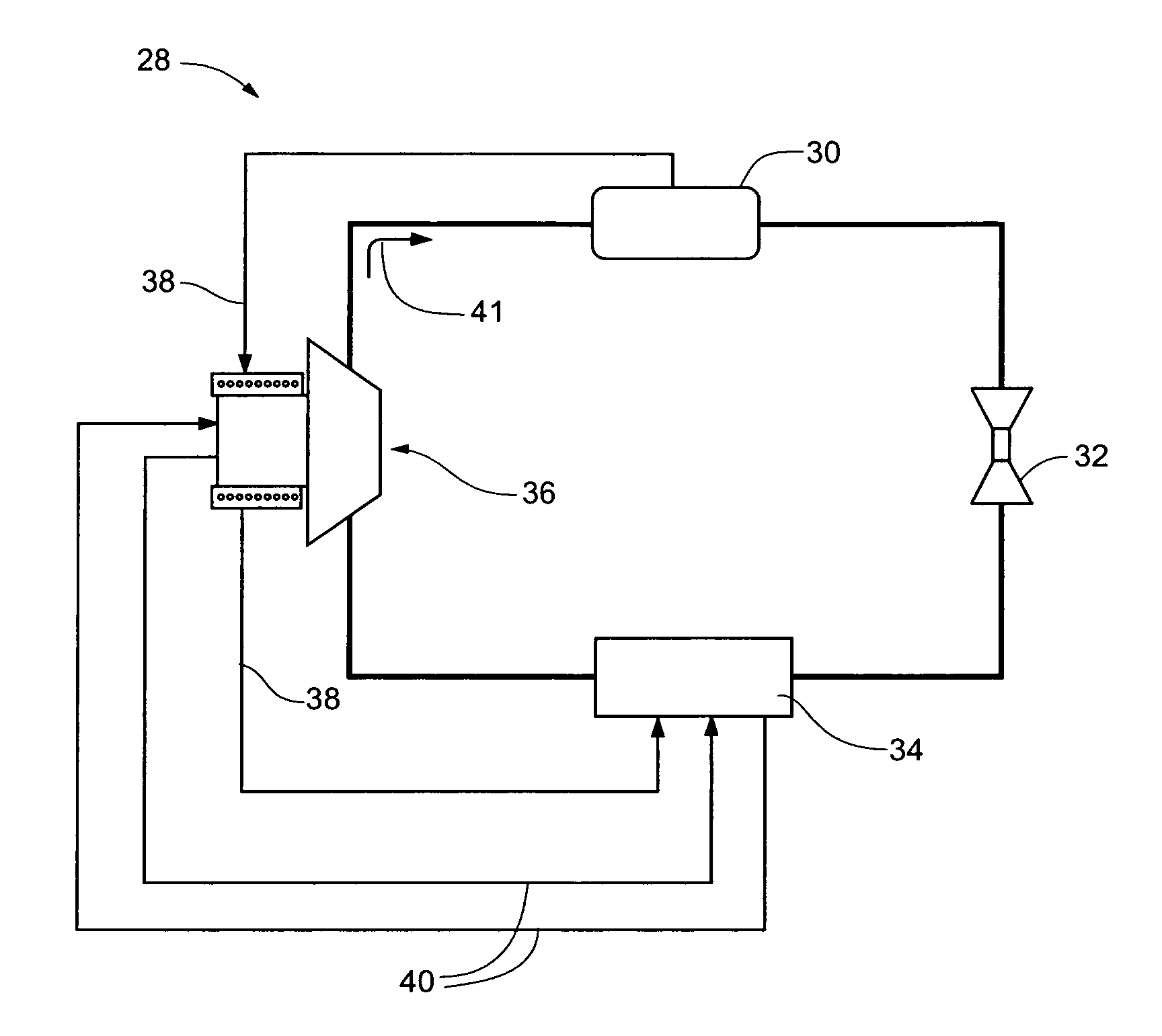

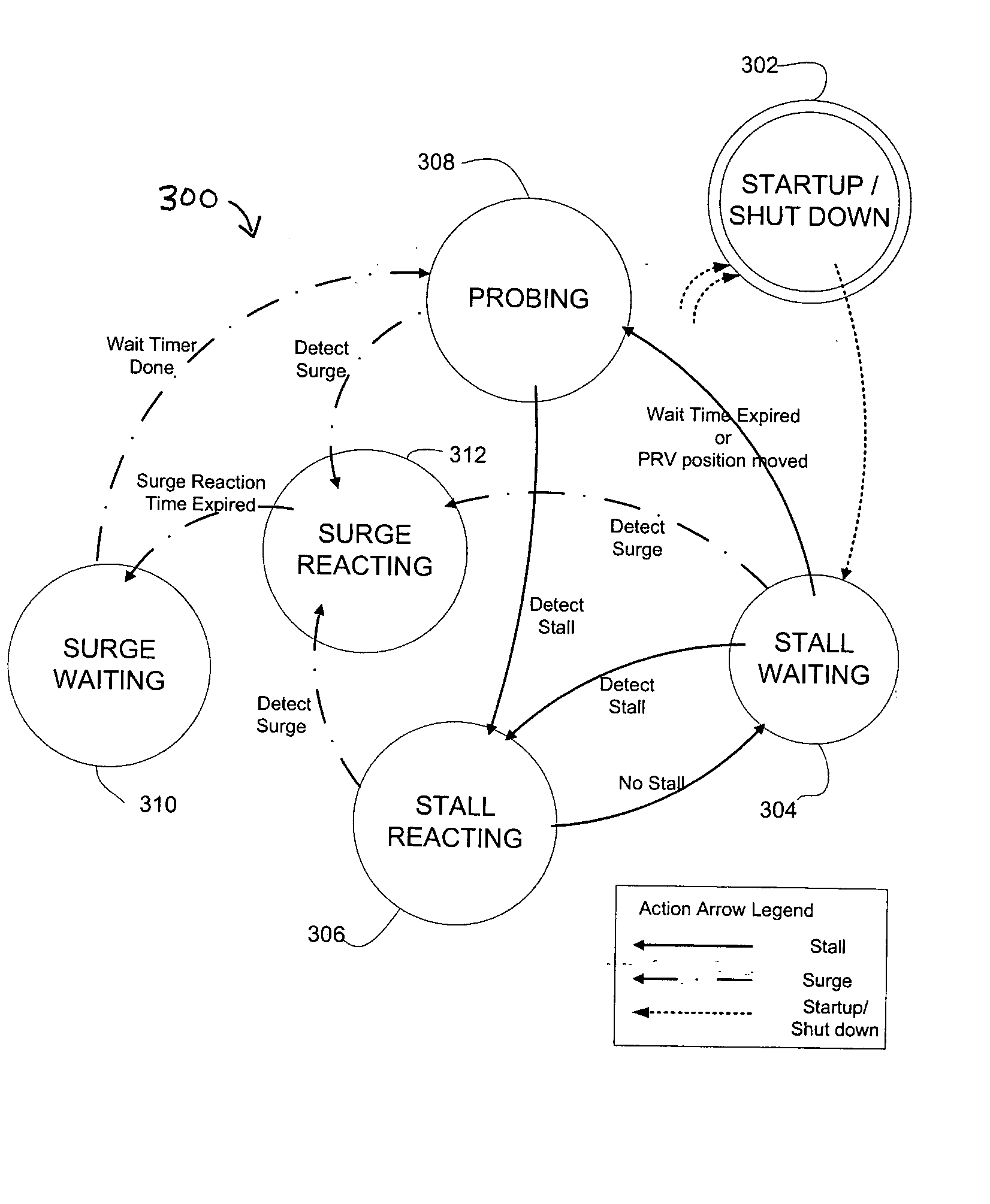

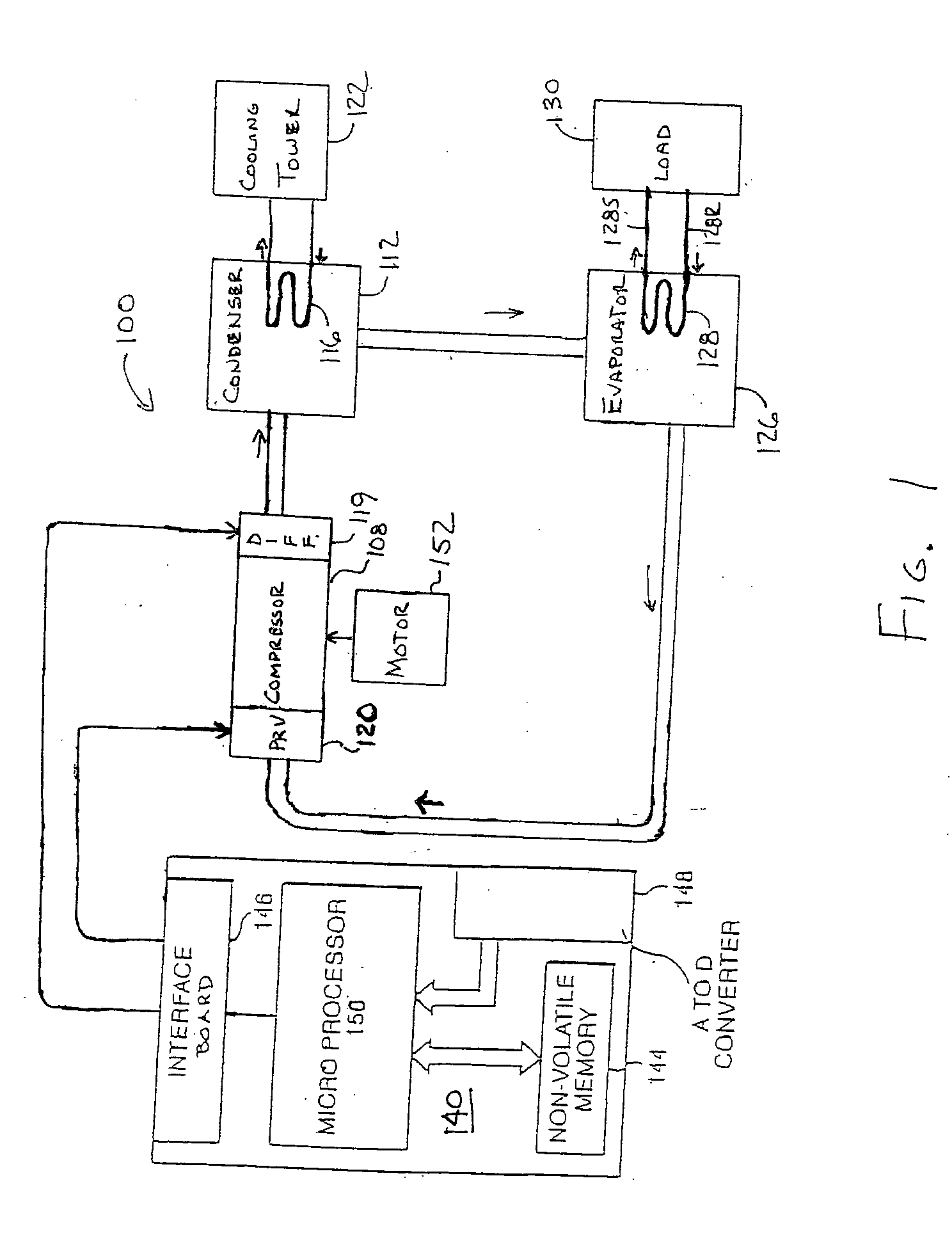

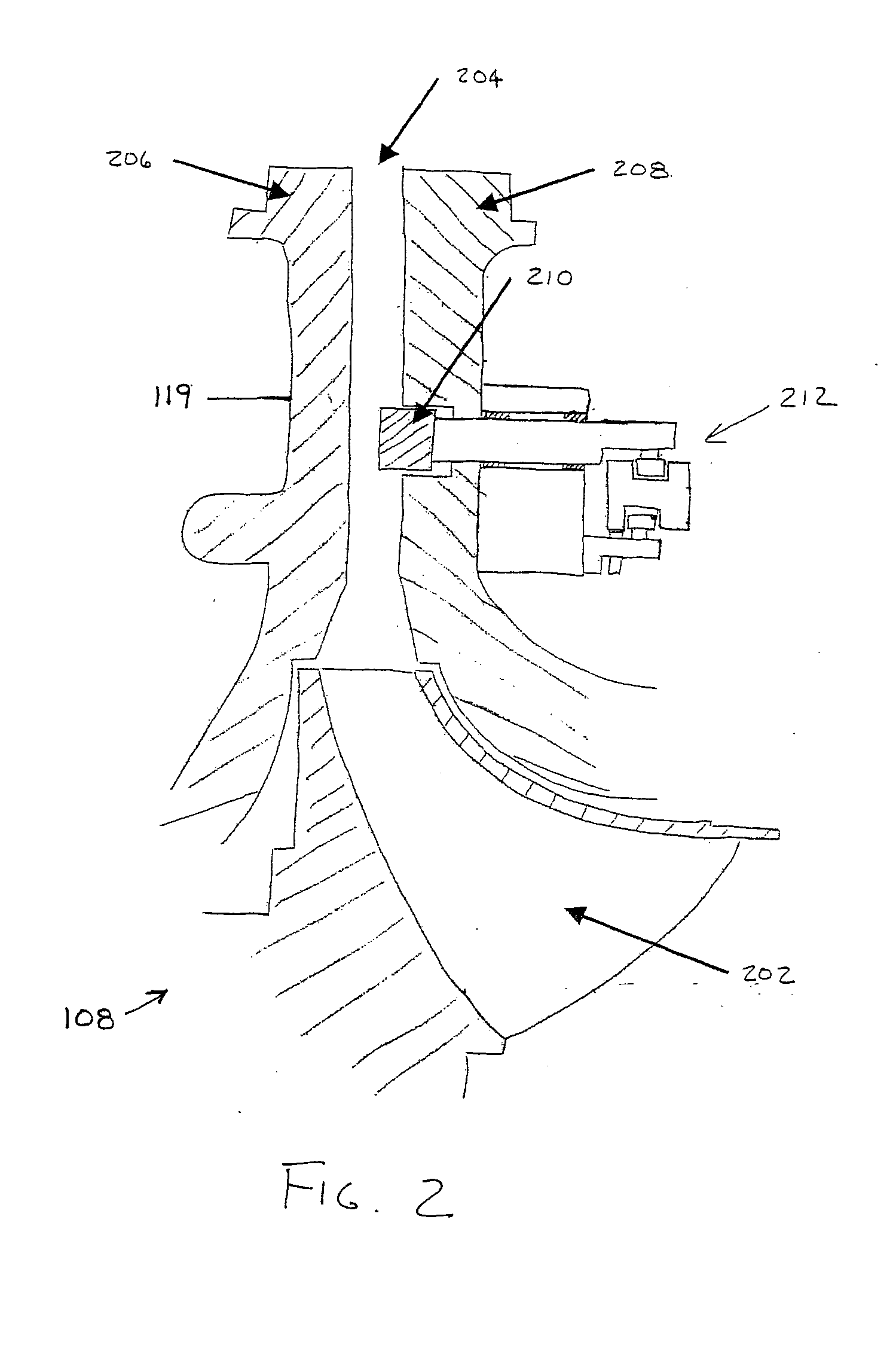

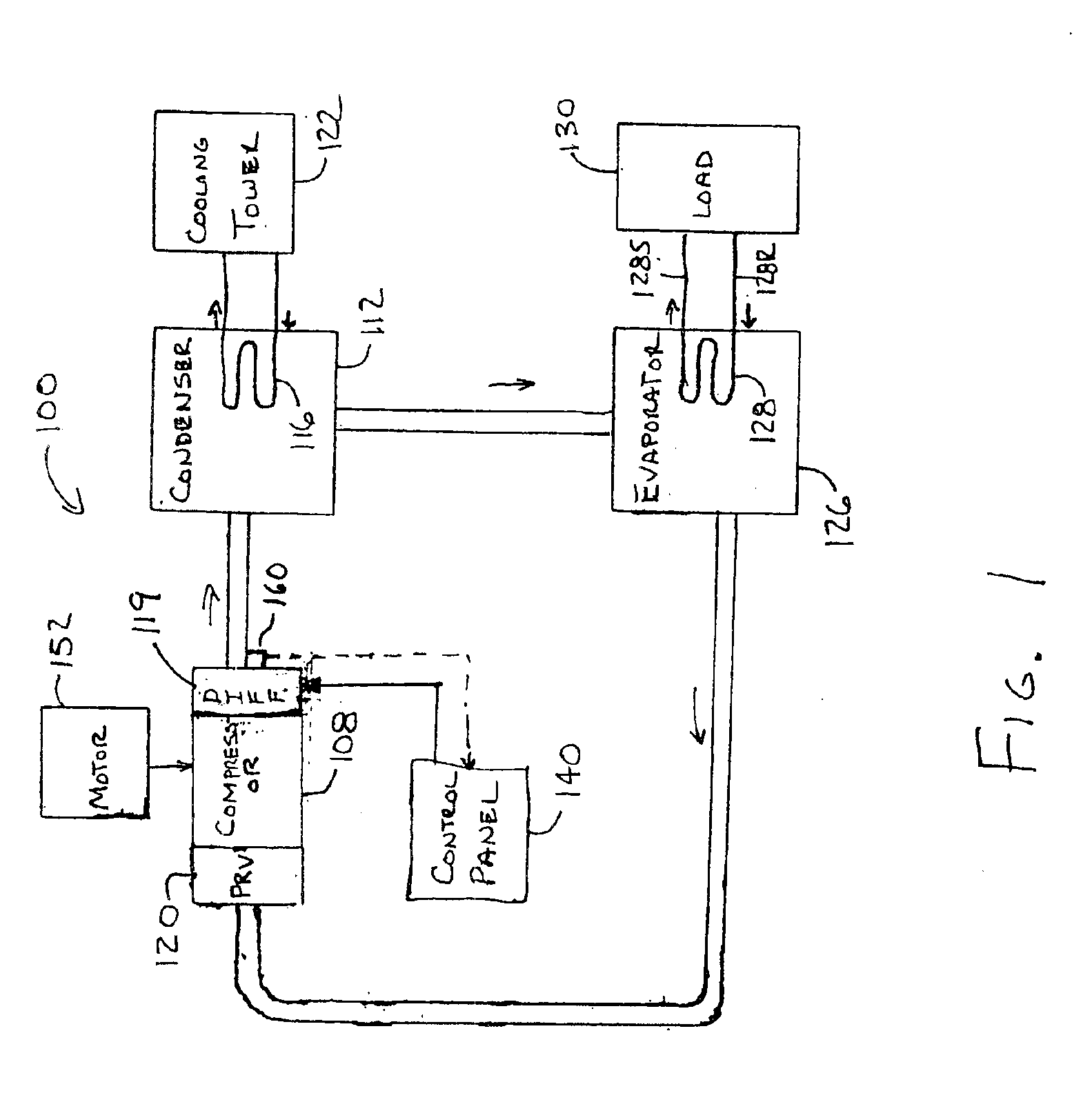

System and method for stability control in a centrifugal compressor

ActiveUS20050076656A1Efficient responseImprove energy efficiencyEngine manufactureWind motor controlInstabilityVariable geometry

A stability control algorithm is provided for a centrifugal compressor. The stability control algorithm is used to control a variable geometry diffuser and a hot gas bypass valve (when provided) in response to the detection of compressor instabilities. The stability control algorithm can adjust the position of a diffuser ring in the variable geometry diffuser in response to the detection of a surge condition or a stall condition. In addition, the diffuser ring in the variable geometry diffuser can be adjusted to determine an optimal position of the diffuser ring. The stability control algorithm can also be used to open a hot gas bypass valve in response to the detection of continued surge conditions.

Owner:JOHNSON CONTROLS TECH CO +1

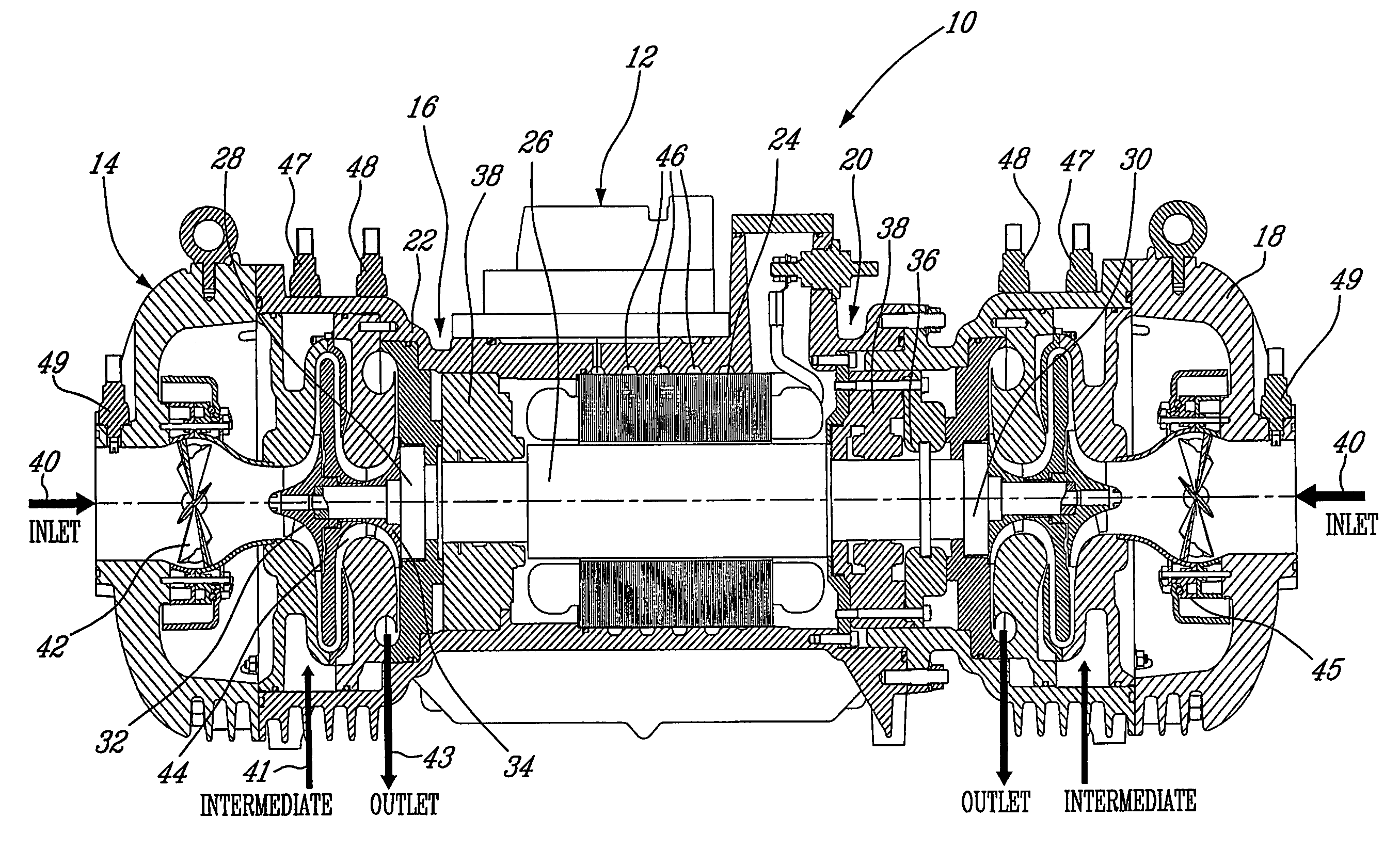

High capacity chiller compressor

ActiveUS20090229280A1Improve efficiencyIncrease power outputCompressorPositive displacement pump componentsSingle stageEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. A cooling system provides direct, two-phase cooling of the rotor by combining gas refrigerant from the evaporator section with liquid refrigerant from the condenser section to affect a liquid / vapor refrigerant mixture. Cooling of the stator with liquid refrigerant may be provided by a similar technique. A noise suppression system is provided by injecting liquid refrigerant spray at points between the impeller and the condenser section. The liquid refrigerant may be sourced from high pressure liquid refrigerant from the condenser section.

Owner:DAIKIN IND LTD

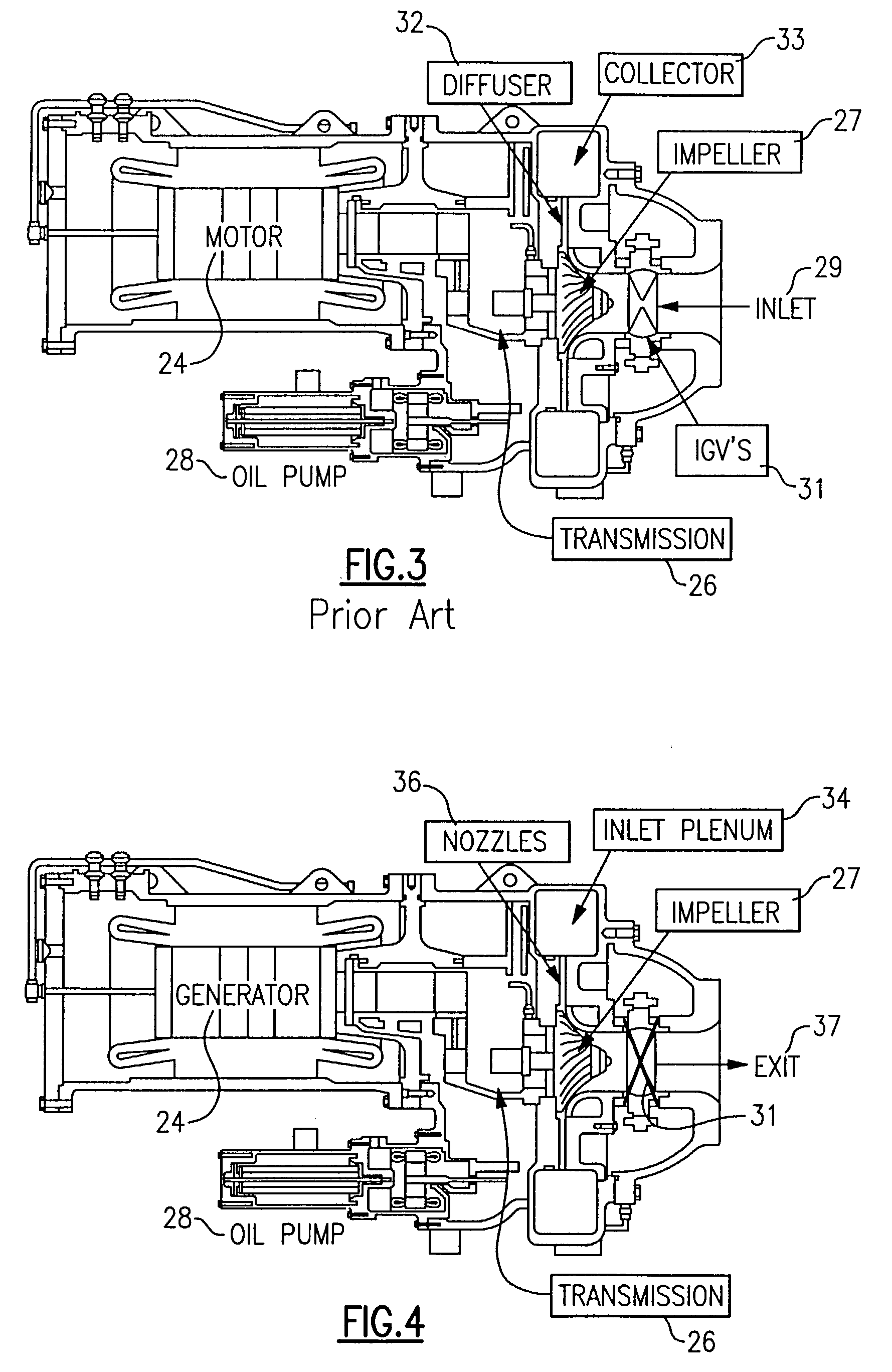

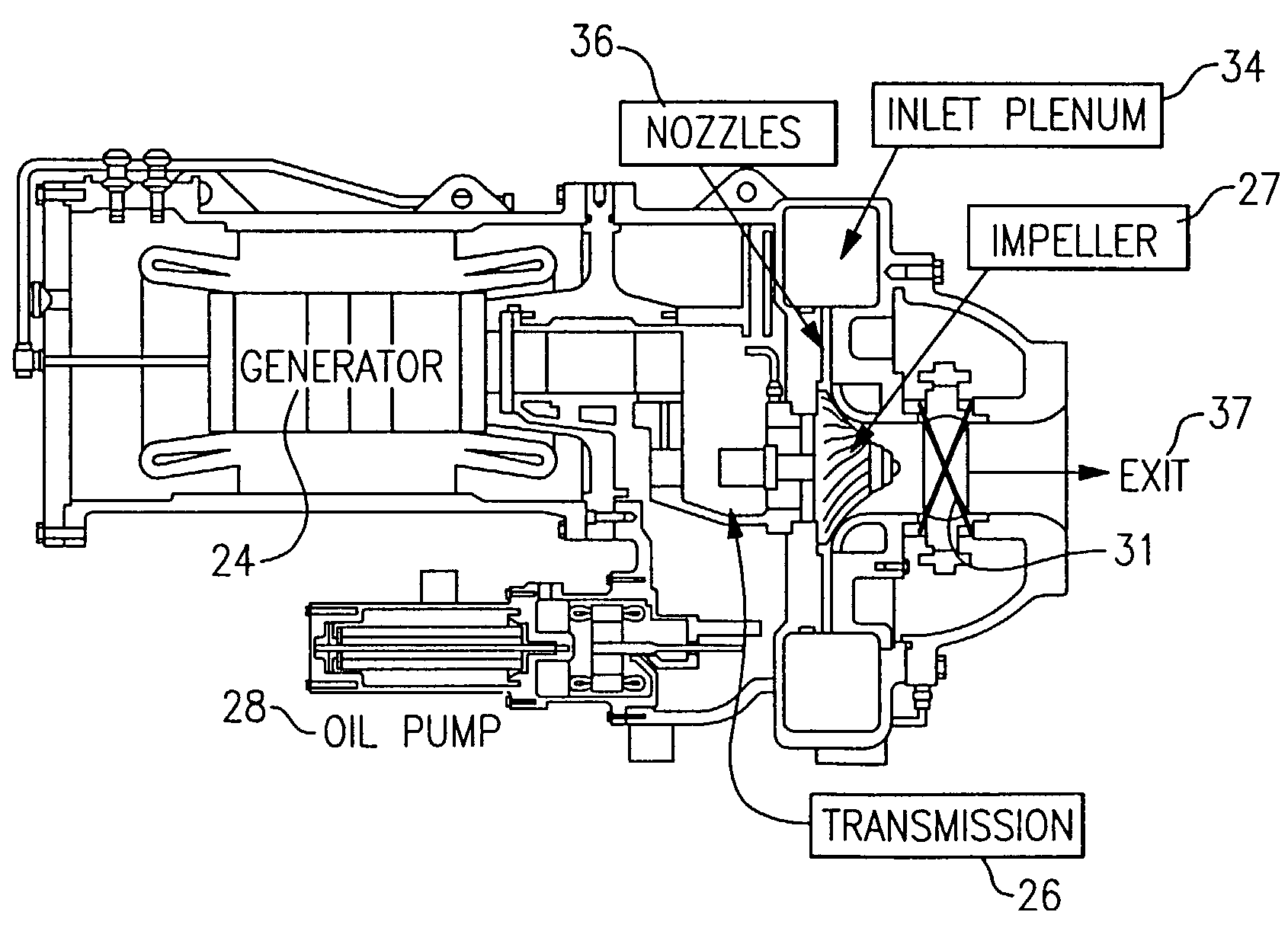

Turbine with vaned nozzles

InactiveUS7254949B2Efficient use ofEasy to useEngine manufacturePump componentsOrganic Rankine cycleProcess engineering

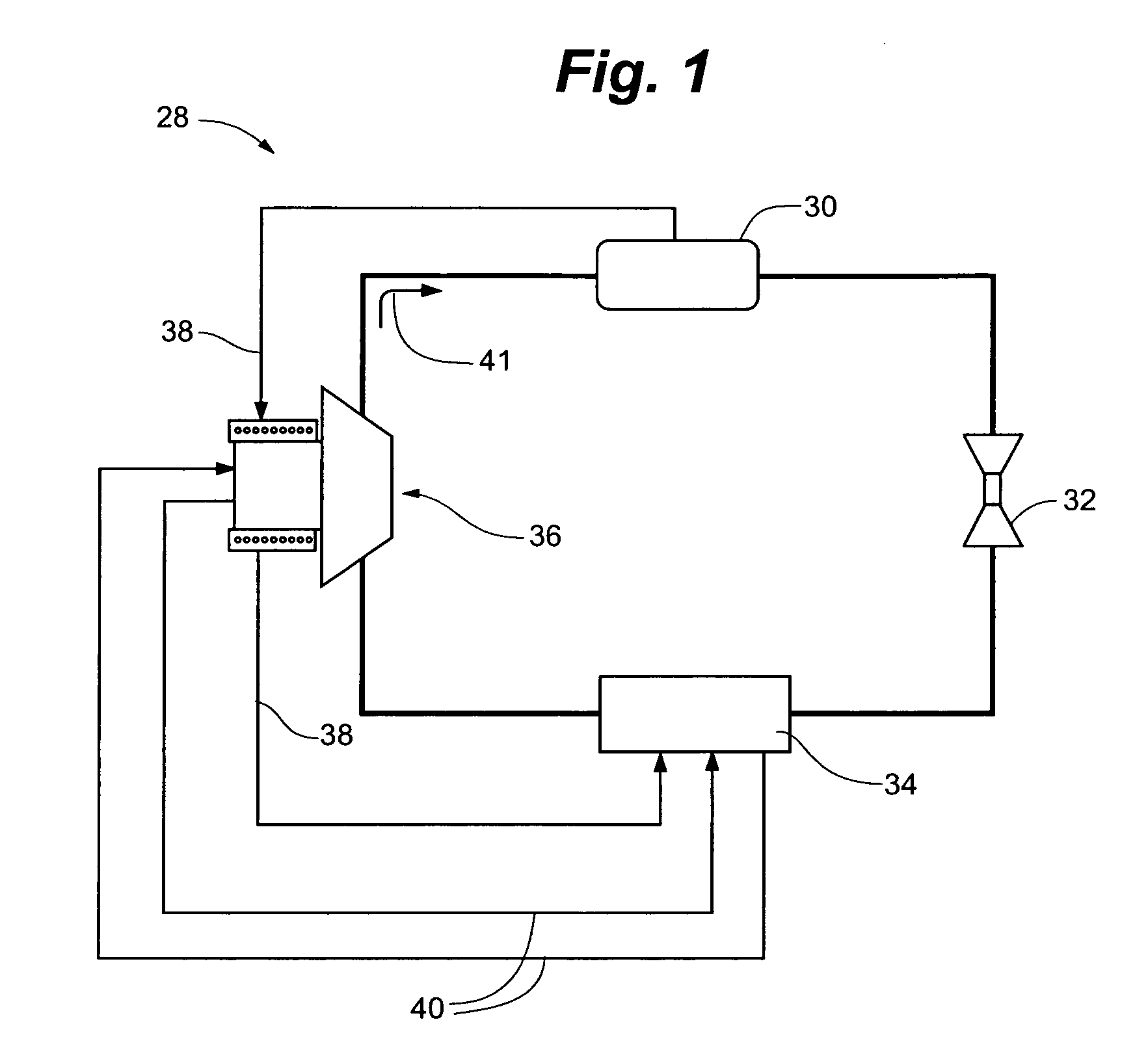

A machine designed as a centrifugal compressor is applied as an organic rankine cycle turbine by operating the machine in reverse. In order to accommodate the higher pressures when operating as a turbine, a suitable refrigerant is chosen such that the pressures and temperatures are maintained within established limits. Such an adaptation of existing, relatively inexpensive equipment to an application that may be otherwise uneconomical, allows for the convenient and economical use of energy that would be otherwise lost by waste heat to the atmosphere.

Owner:UNITED TECH CORP

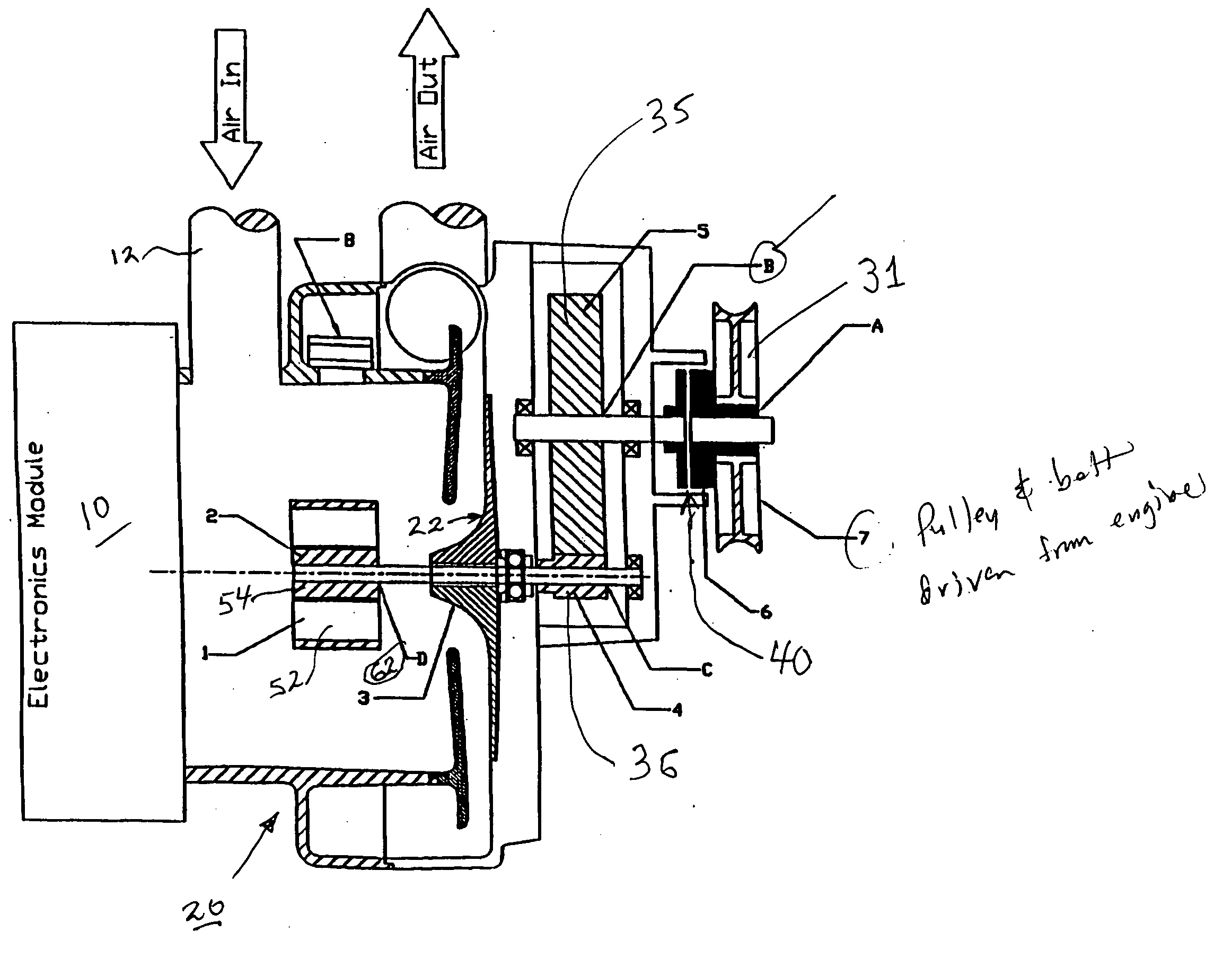

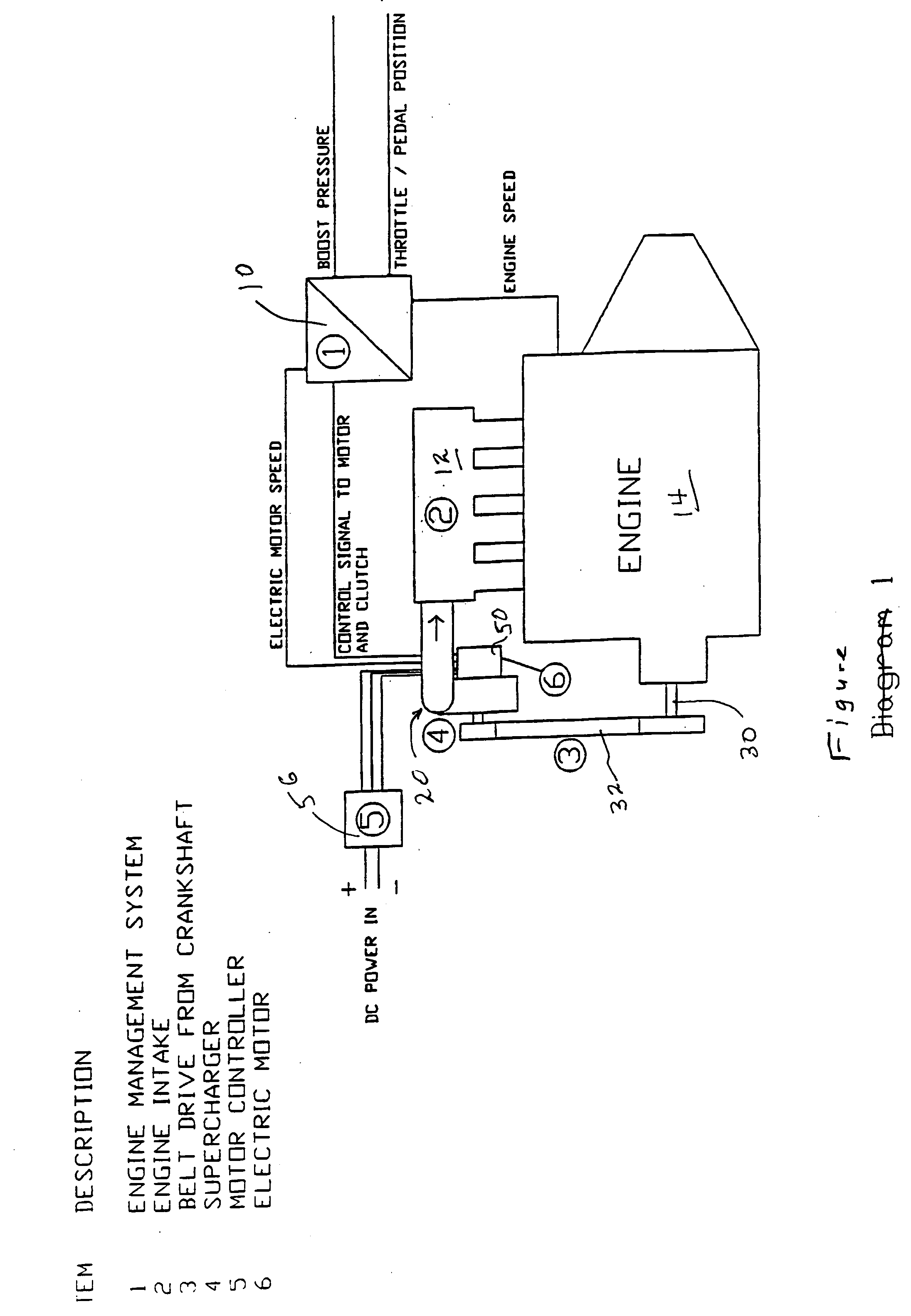

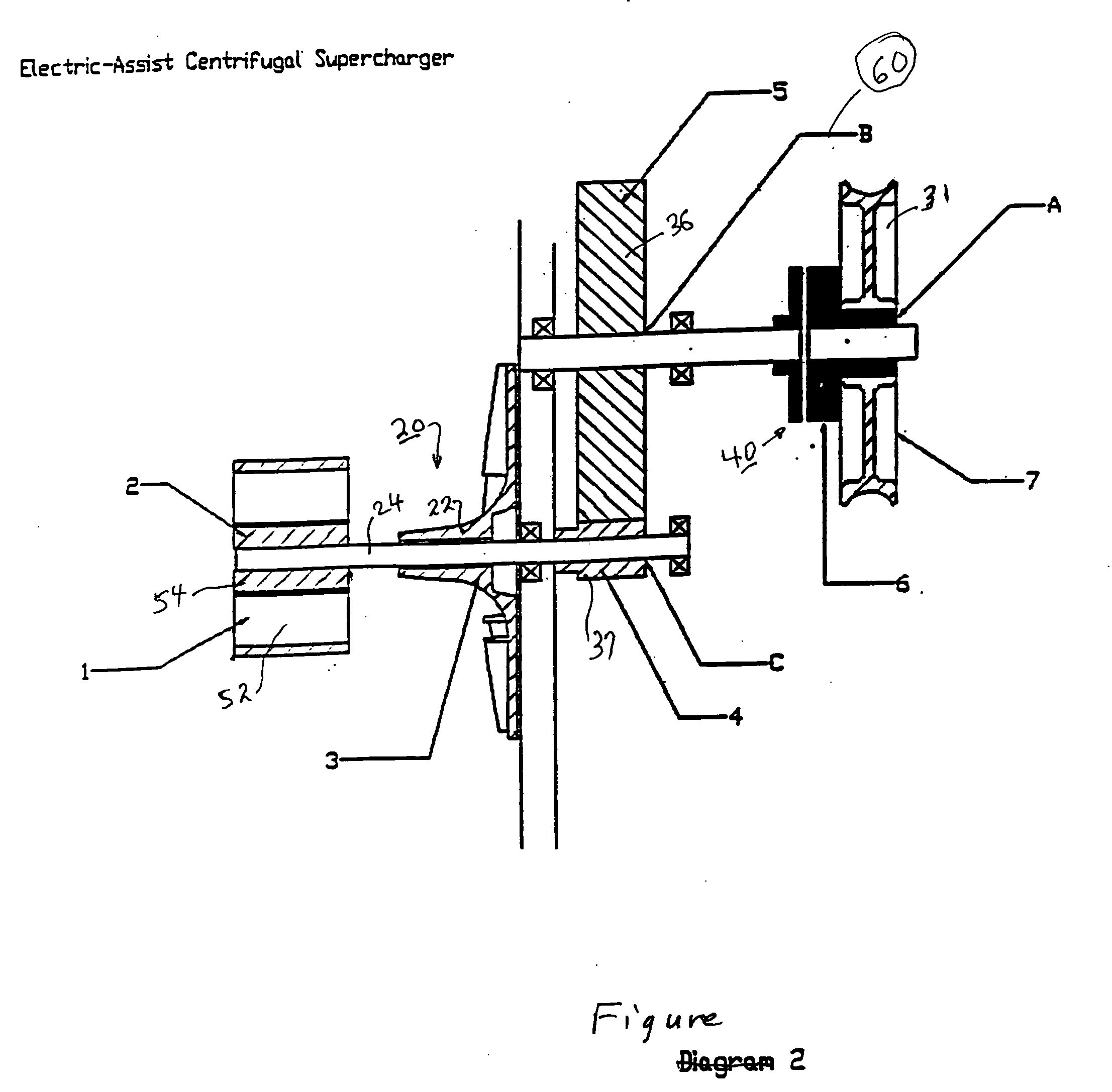

Motor assisted mechanical supercharging system

InactiveUS20060180130A1High operating requirementsReducing parasitic drag on the engineCombustion enginesEngine componentsDrive shaftElectric machine

Internal combustion engine with a centrifugal compressor or positive displacement air supercharger incorporating a high speed electric motor on the drive shaft for the purpose of acceleration and generation of pressurized air at low engine speeds and incorporation of one-way and / or magnetic clutches for efficient operation.

Owner:ST JAMES DAVID

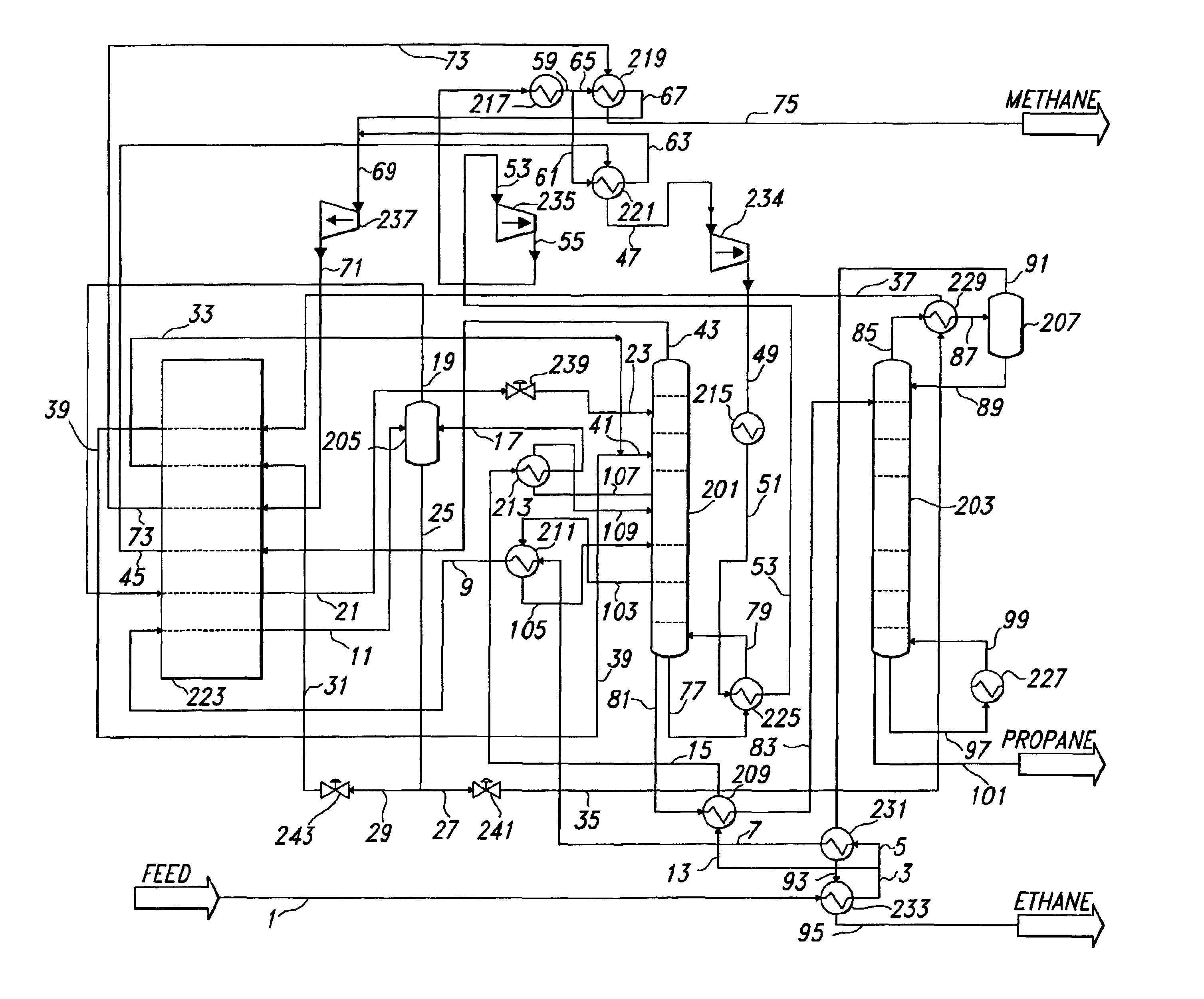

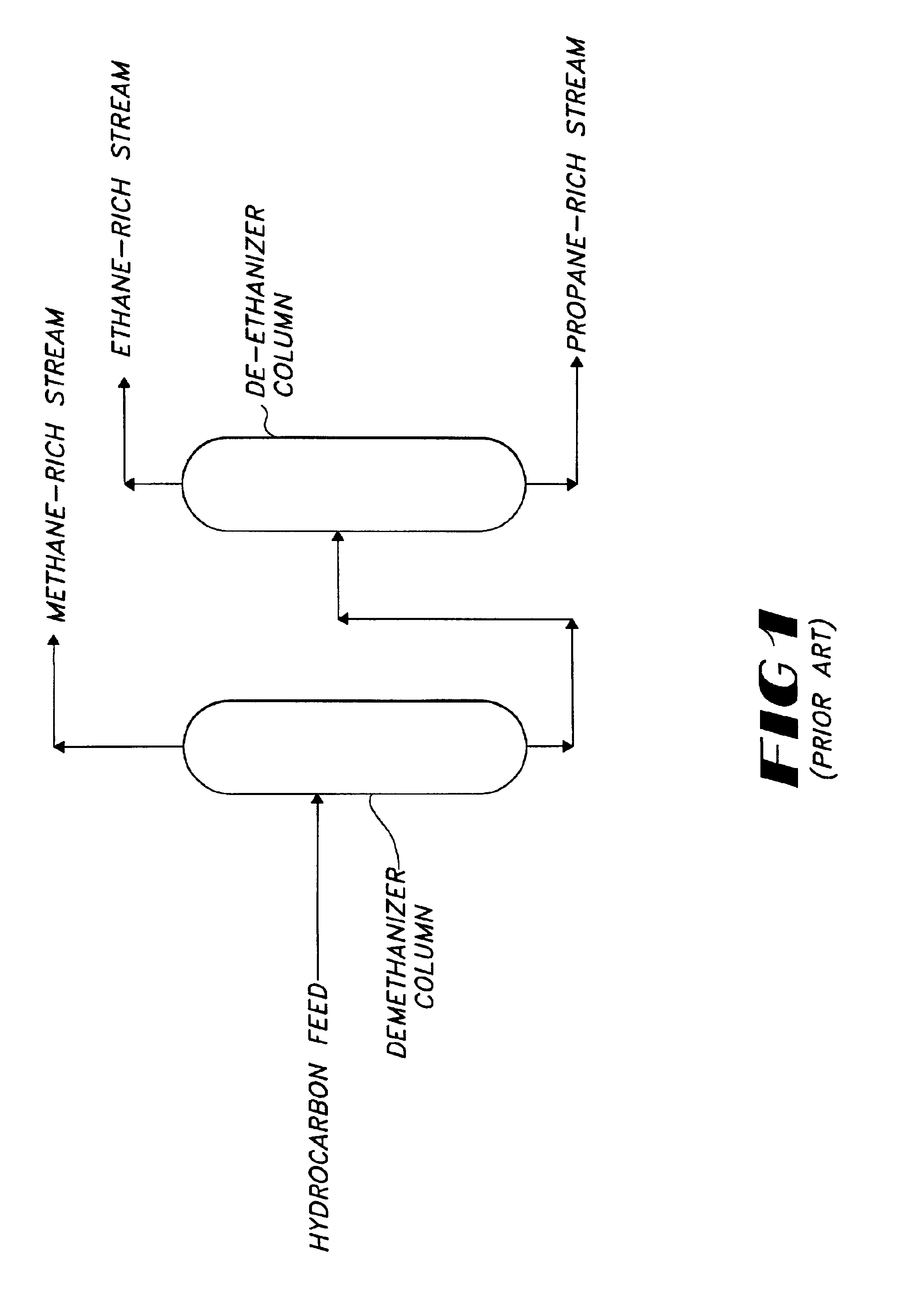

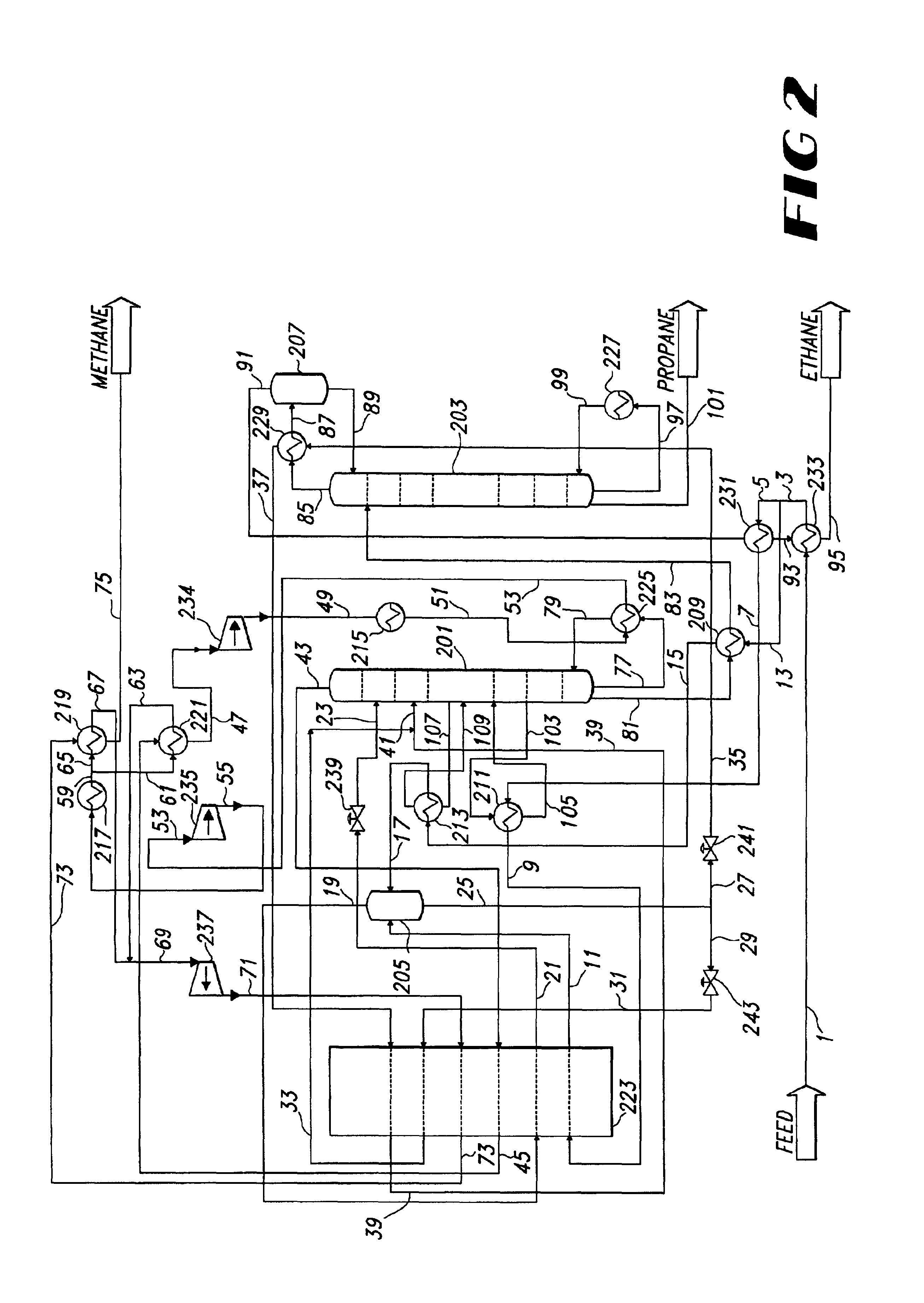

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

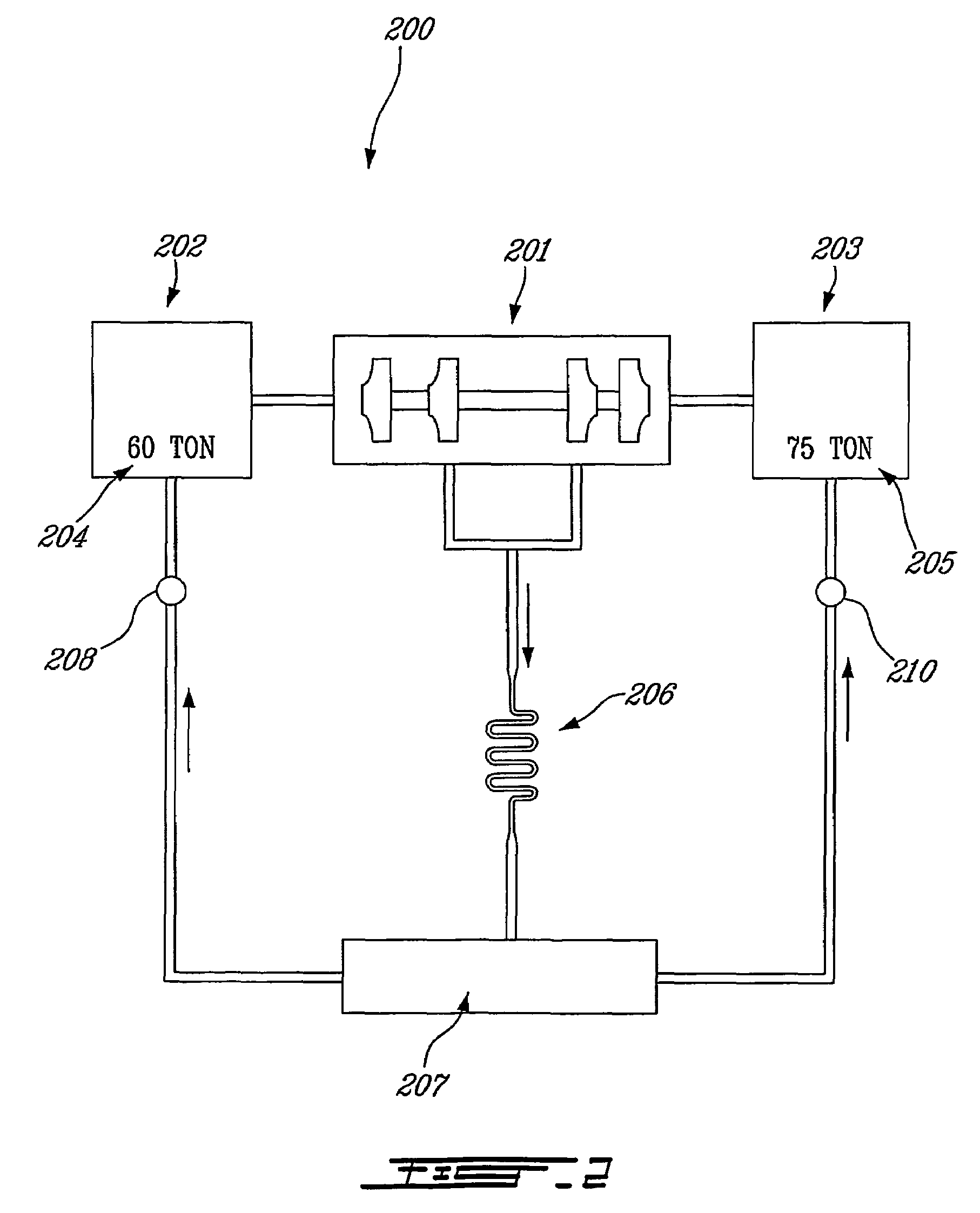

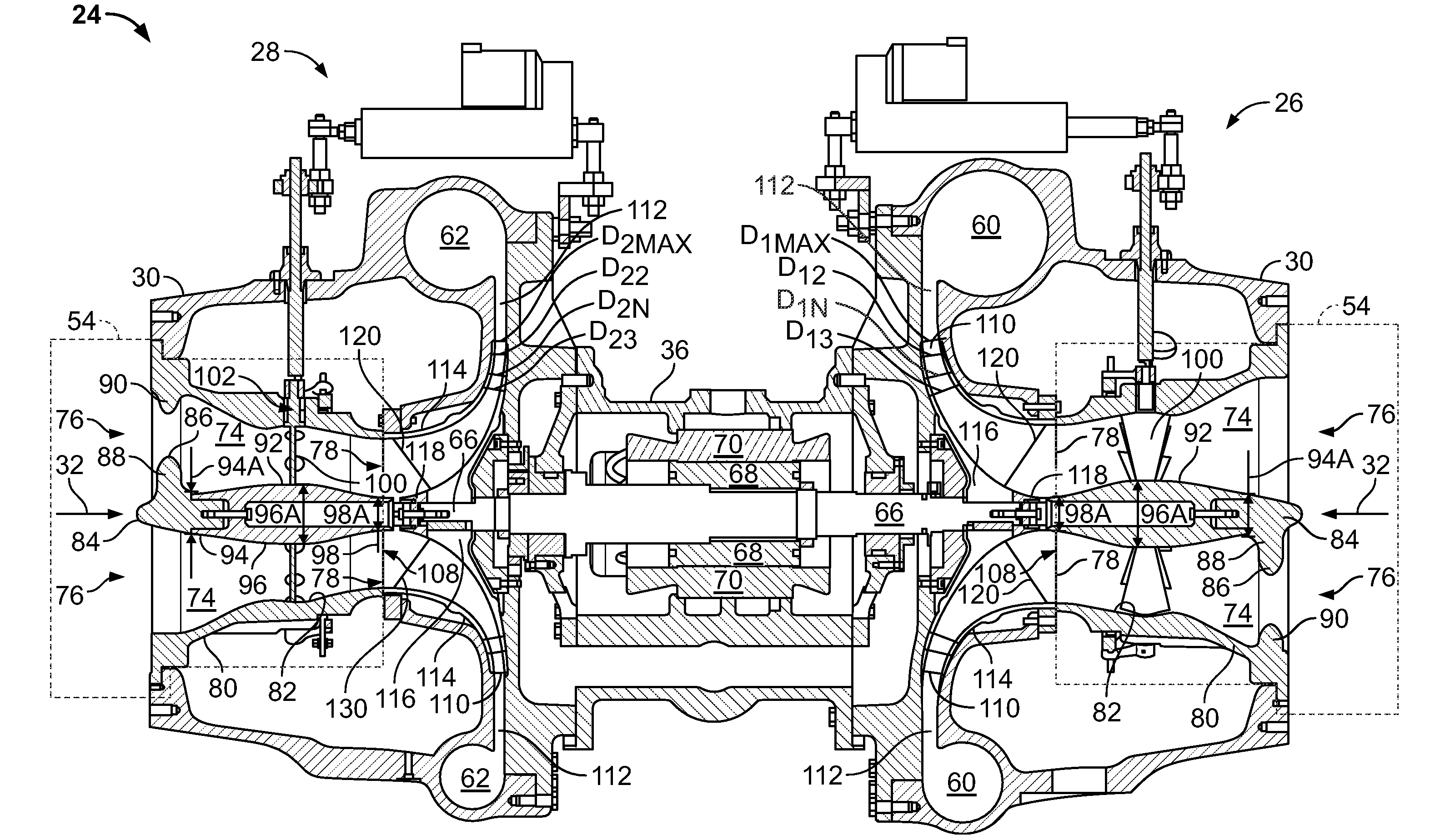

Centrifugal compressor assembly and method

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

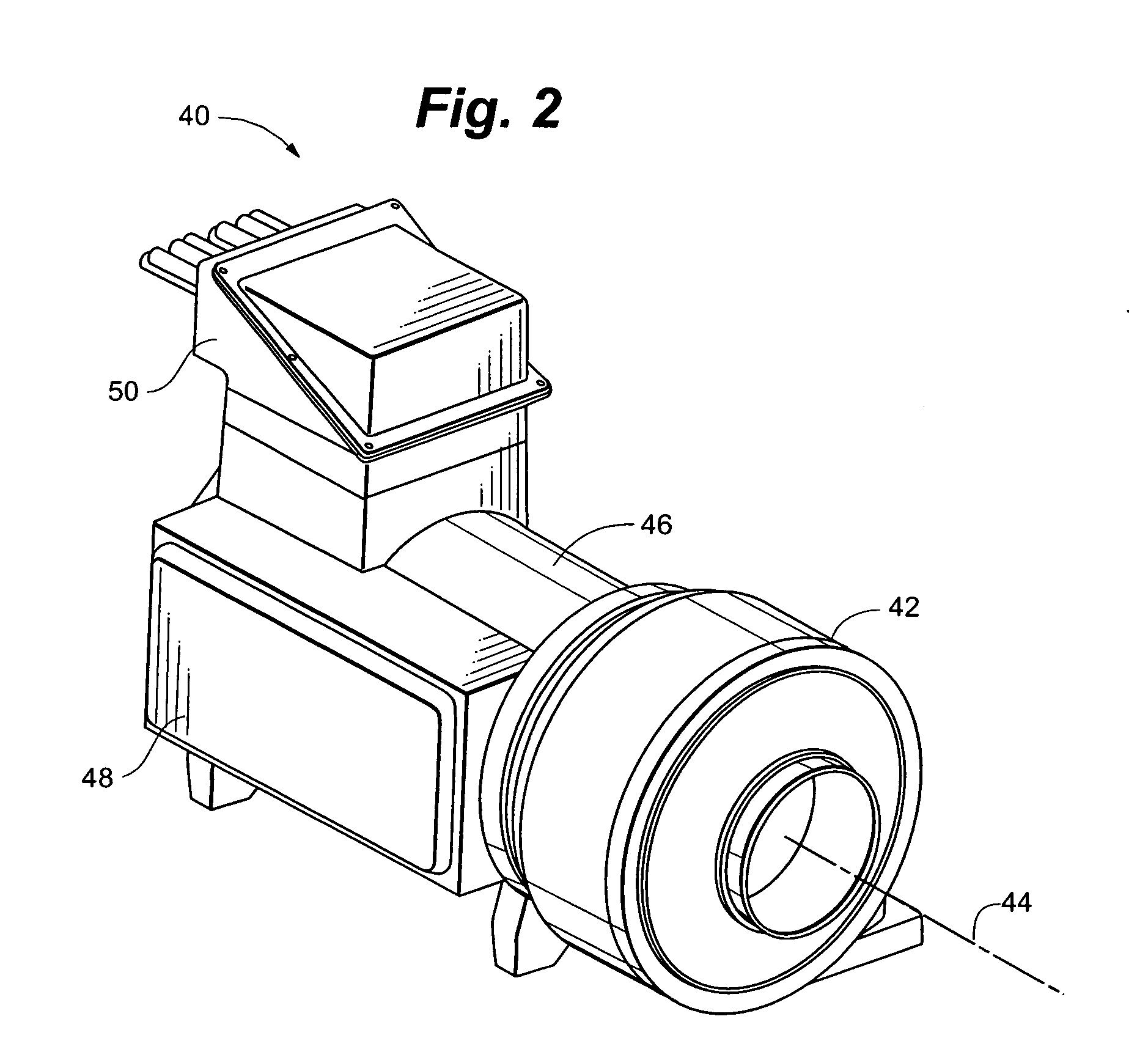

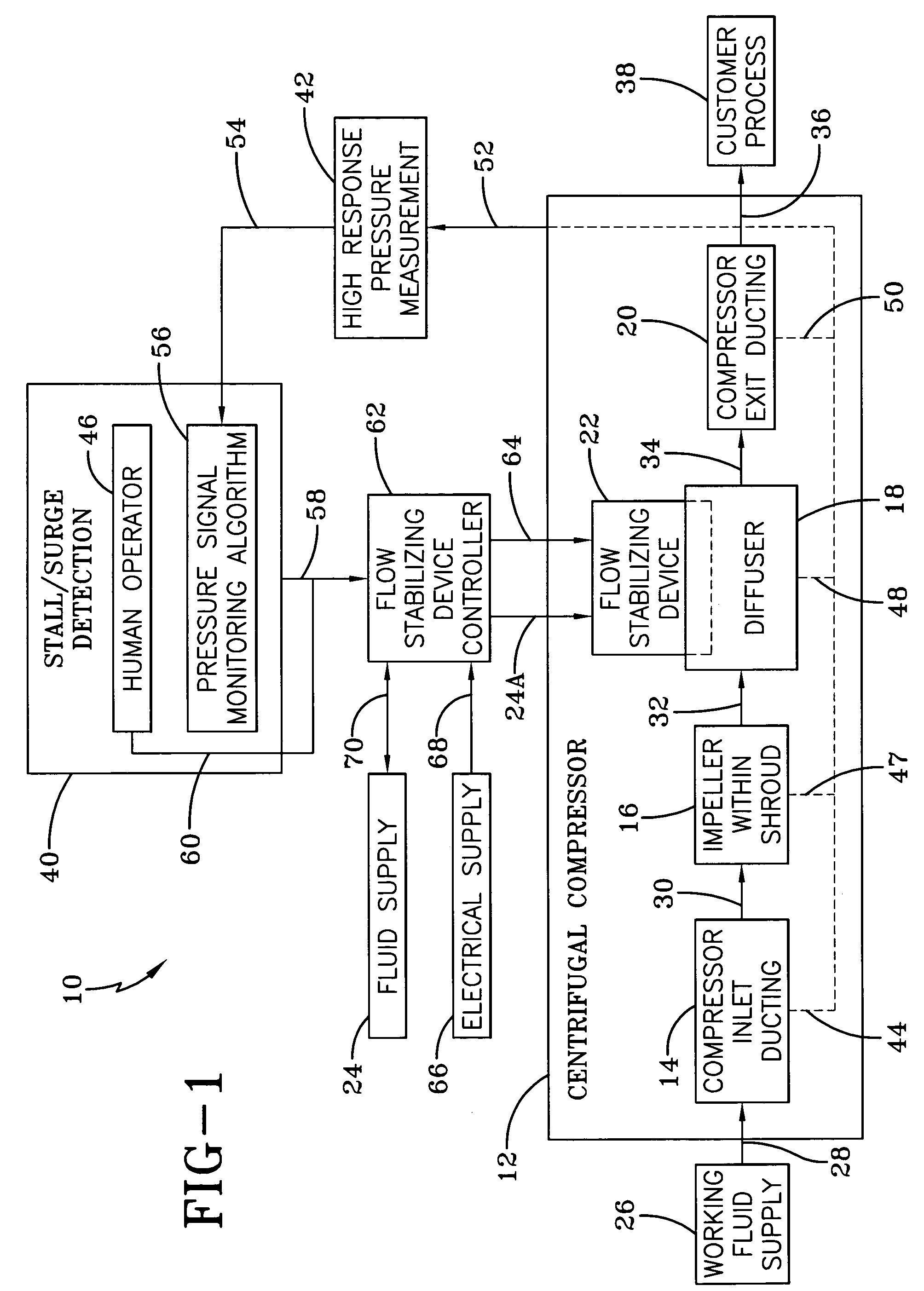

System and method for detecting rotating stall in a centrifugal compressor

ActiveUS6857845B2Simple packagingReduce and eliminate rotating stall noiseEngine manufactureWind motor controlAcoustic energyTransducer

A system and method is provided for detecting and controlling rotating stall in the diffuser region of a centrifugal compressor. The process begins with the detection or sensing of acoustic energy associated with the onset of rotating stall. A pressure transducer is placed in the gas flow path downstream of the impeller, preferably in the compressor discharge passage or the diffuser, to measure the sound or acoustic pressure phenomenon. Next, the signal from the pressure transducer is processed either using analog or digital techniques to determine the presence of rotating stall. Rotating stall is detected by comparing the detected energy amount, which detected energy amount is based on the measured acoustic pressure, with a predetermined threshold amount corresponding to the presence of rotating stall. Finally, an appropriate corrective action is taken to change the operation of the centrifugal compressor in response to the detection of rotating stall.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

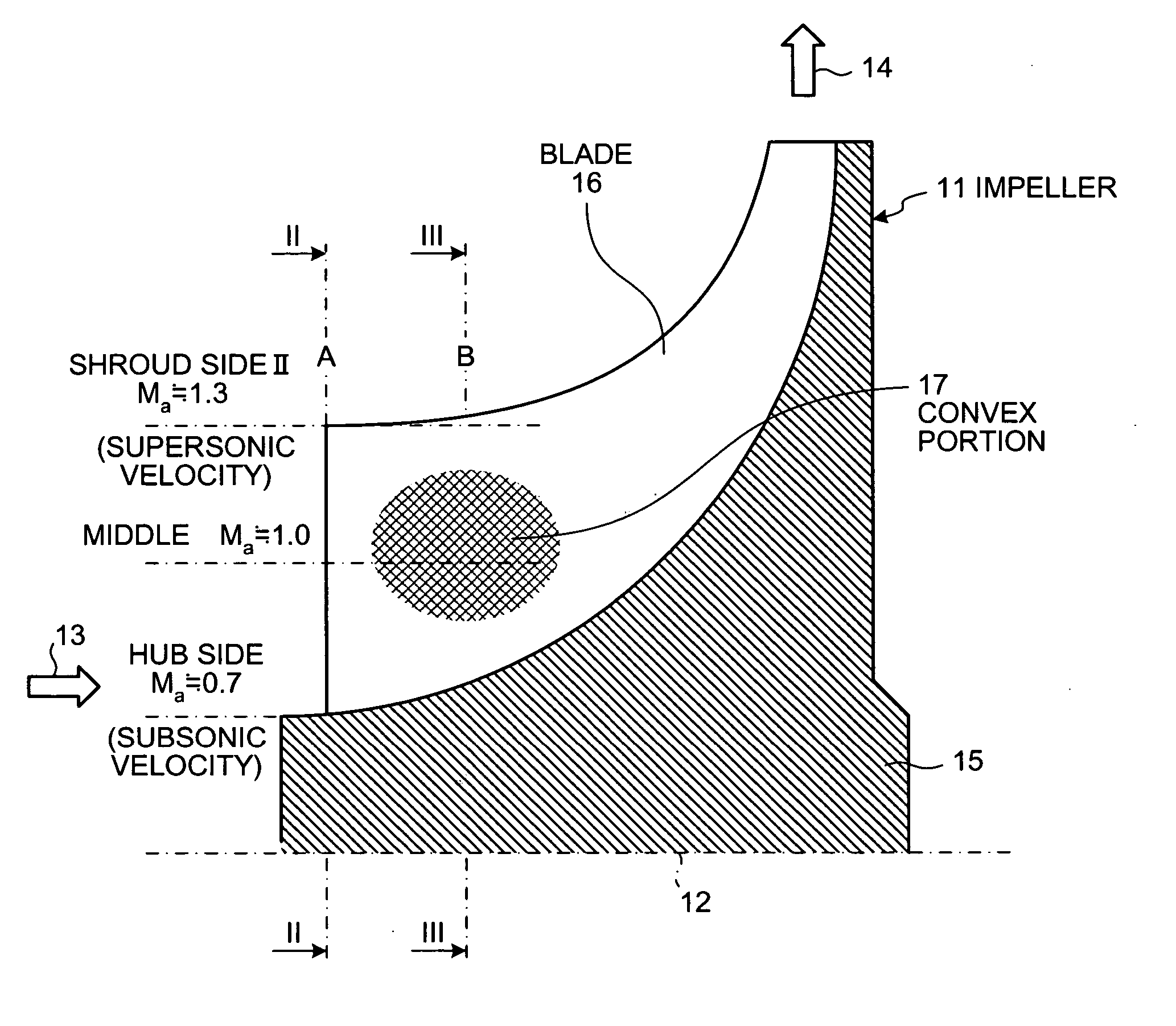

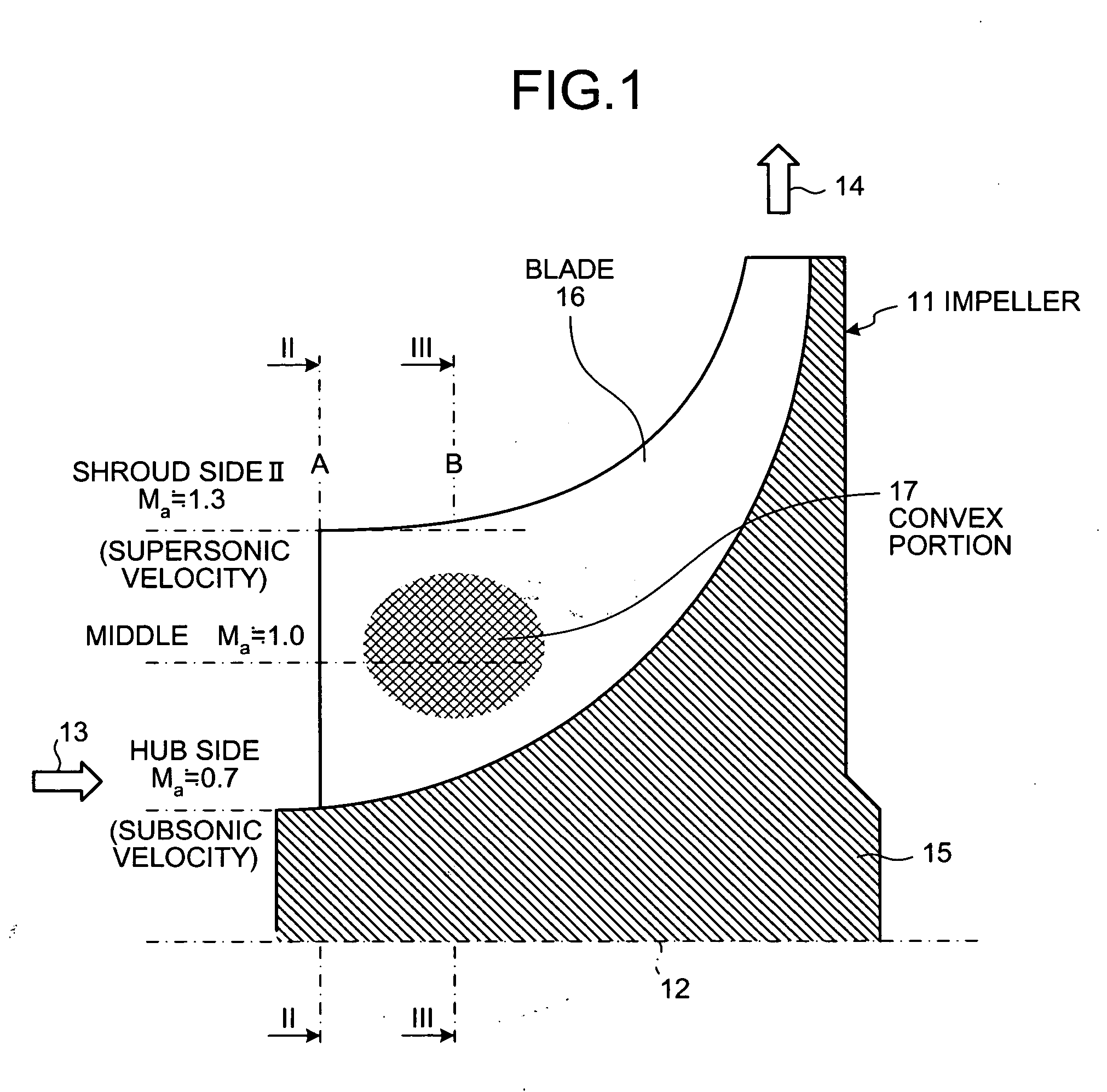

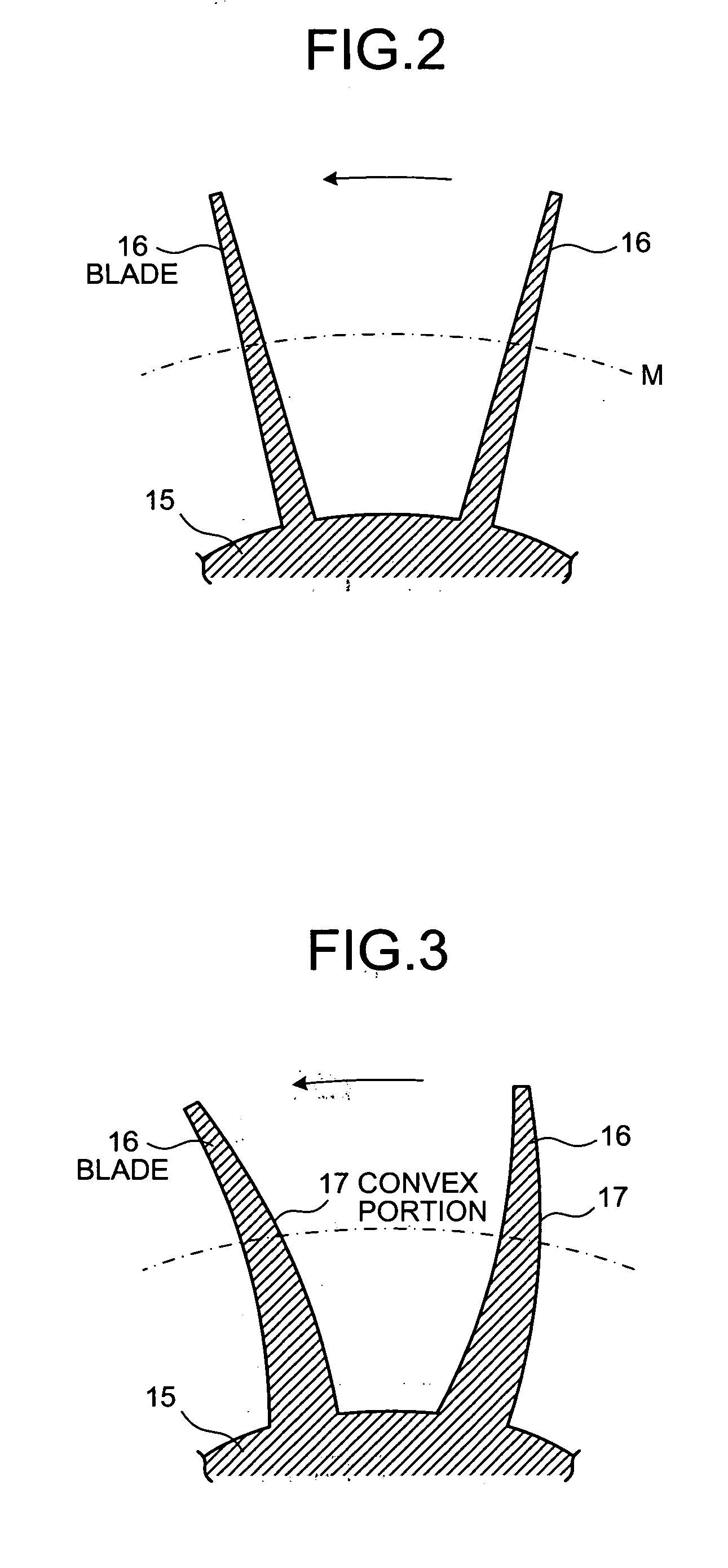

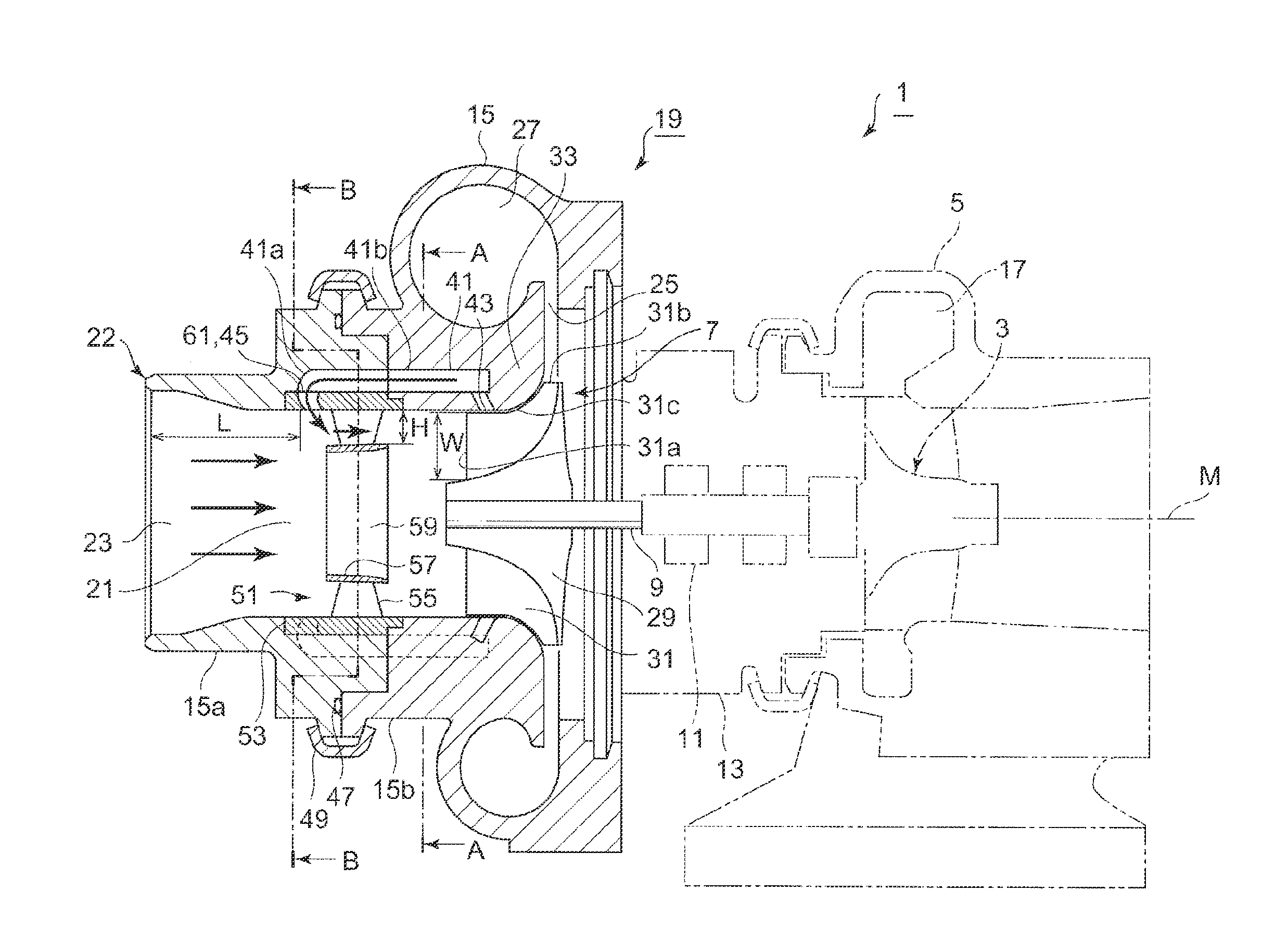

Centrifugal compressor and manufacturing method for impeller

InactiveUS20050260074A1Fall in efficiencyFall in performancePropellersSupersonic fluid pumpsEngineeringFront edge

On a suction surface side of a blade in an impeller, a convex portion is formed to assume a curved line from a front edge portion to a throat portion substantially in the middle in a radial direction, and this convex portion is formed to be flat assuming a curved line from the throat portion toward a rear edge portion, whereby this convex portion is formed in a position where a relative inlet velocity of fluid into the impeller is Mach number Ma≅1.

Owner:MITSUBISHI HEAVY IND LTD

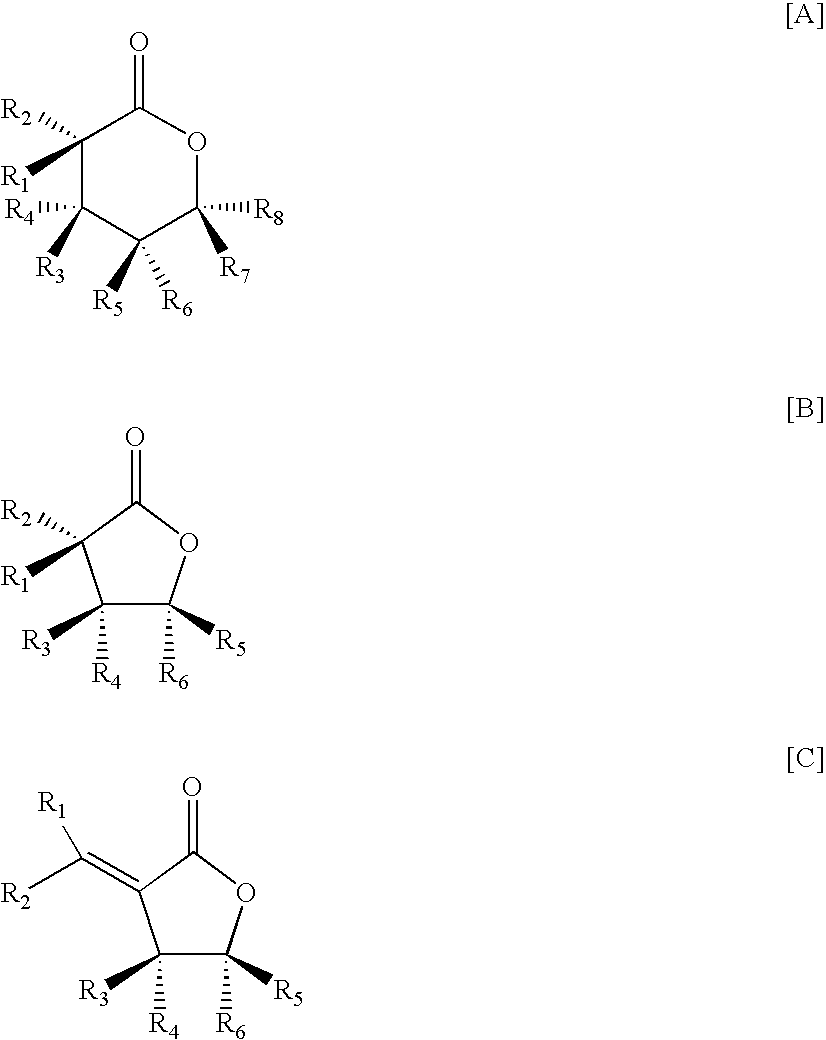

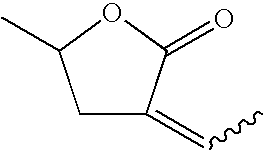

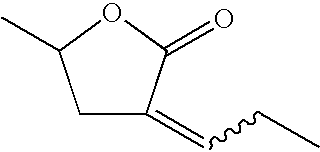

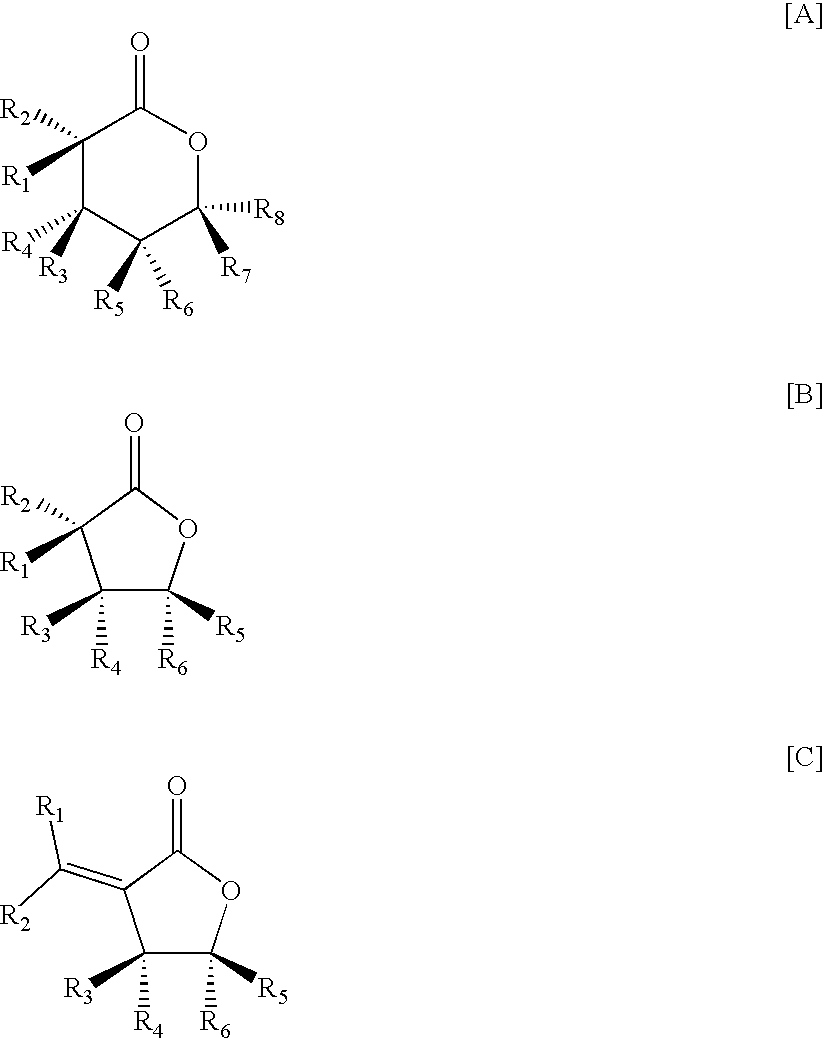

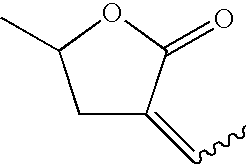

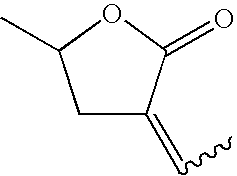

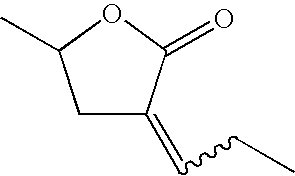

Heat-transfer fluid for a centrifugal compressor

ActiveUS20130061613A1Reduce wearReduce speedCompressorCompression machines with non-reversible cycle1,1-Difluoroethane1,3,3,3-Tetrafluoropropene

The invention relates to a process for cooling or heating a fluid or a body by means of a vapour compression circuit comprising a centrifugal compressor and containing a heat-transfer fluid, the heat-transfer fluid comprising at least two compounds selected from 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,1,2-tetrafluoropropene, 1,1-difluoroethane and 3,3,3-trifluoropropene, in which: the ratio of the Mach number of the centrifugal compressor to the Mach number which the centrifugal compressor has under the same operating conditions if the heat-transfer fluid is replaced with 1,1,1,2-tetrafluoroethane in the vapour compression circuit is greater than or equal to 0.97 and less than or equal to 1.03; the compression ratio of the centrifugal compressor is less than or equal to the compression ratio which the centrifugal compressor has under the same operating conditions if the heat-transfer fluid is replaced with 1,1,12-tetrafluorethane in the vapour compression circuit. The invention also relates to equipment suitable for implementing this cooling or heating process, and also to a process for converting existing equipment.

Owner:ARKEMA FRANCE SA

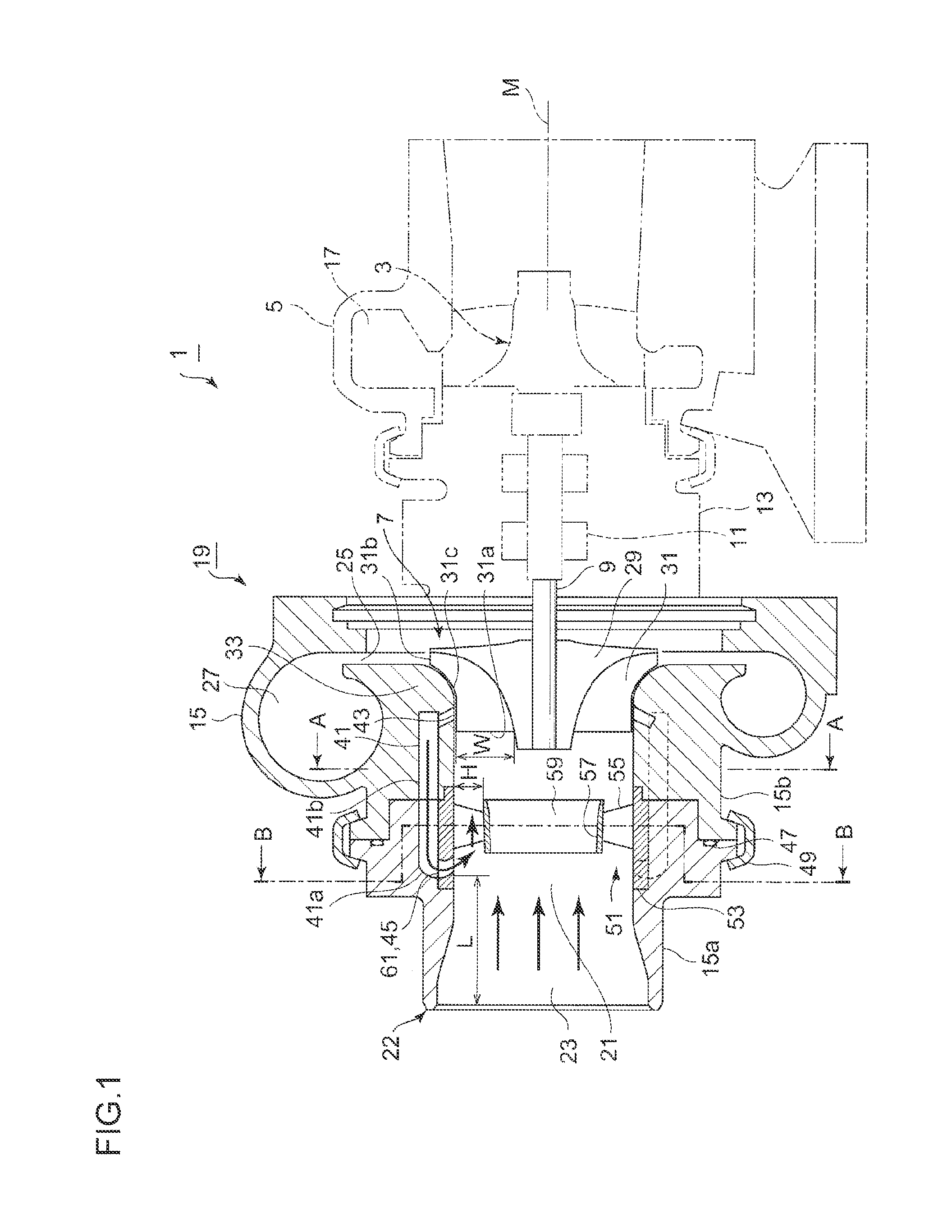

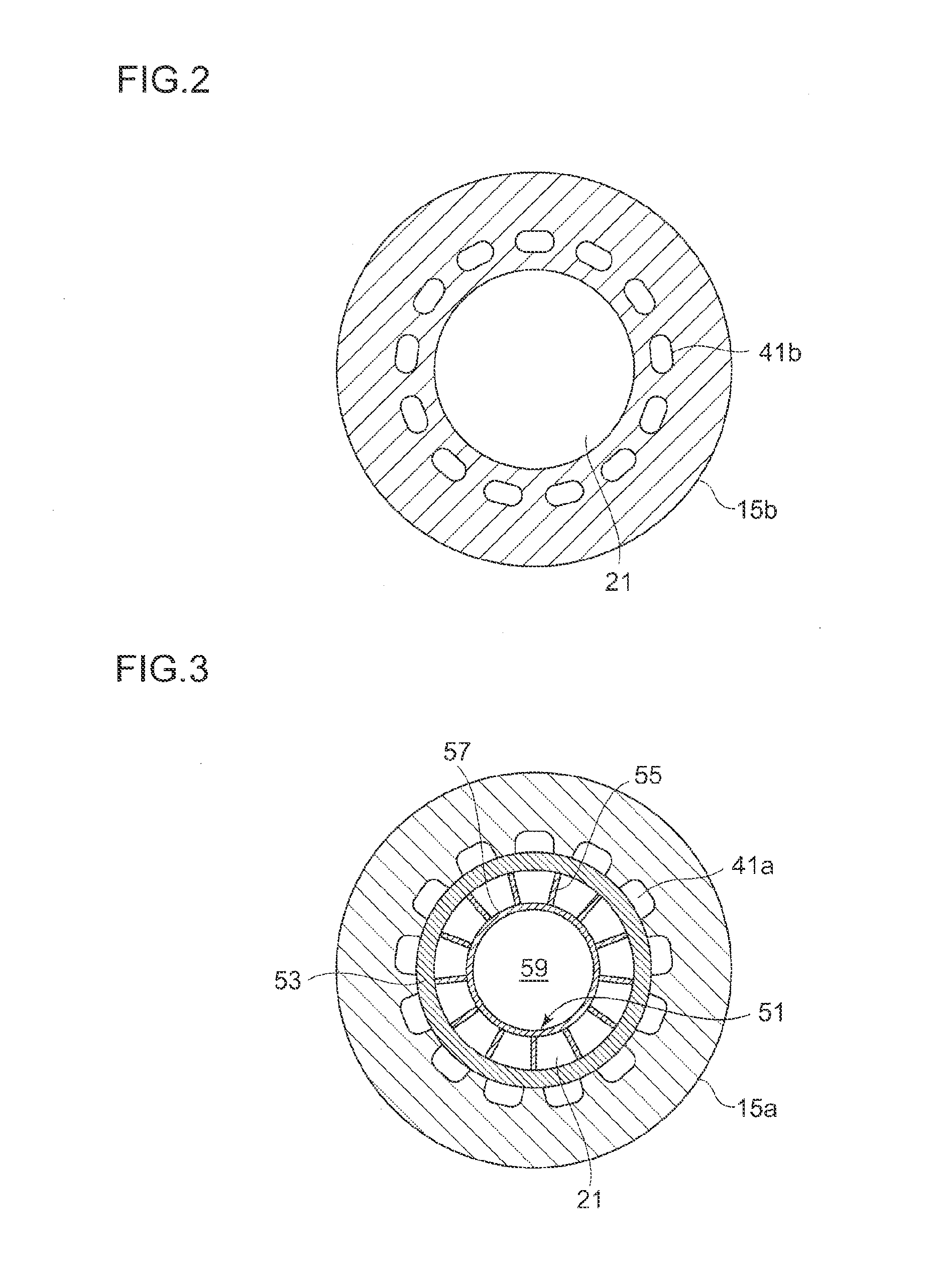

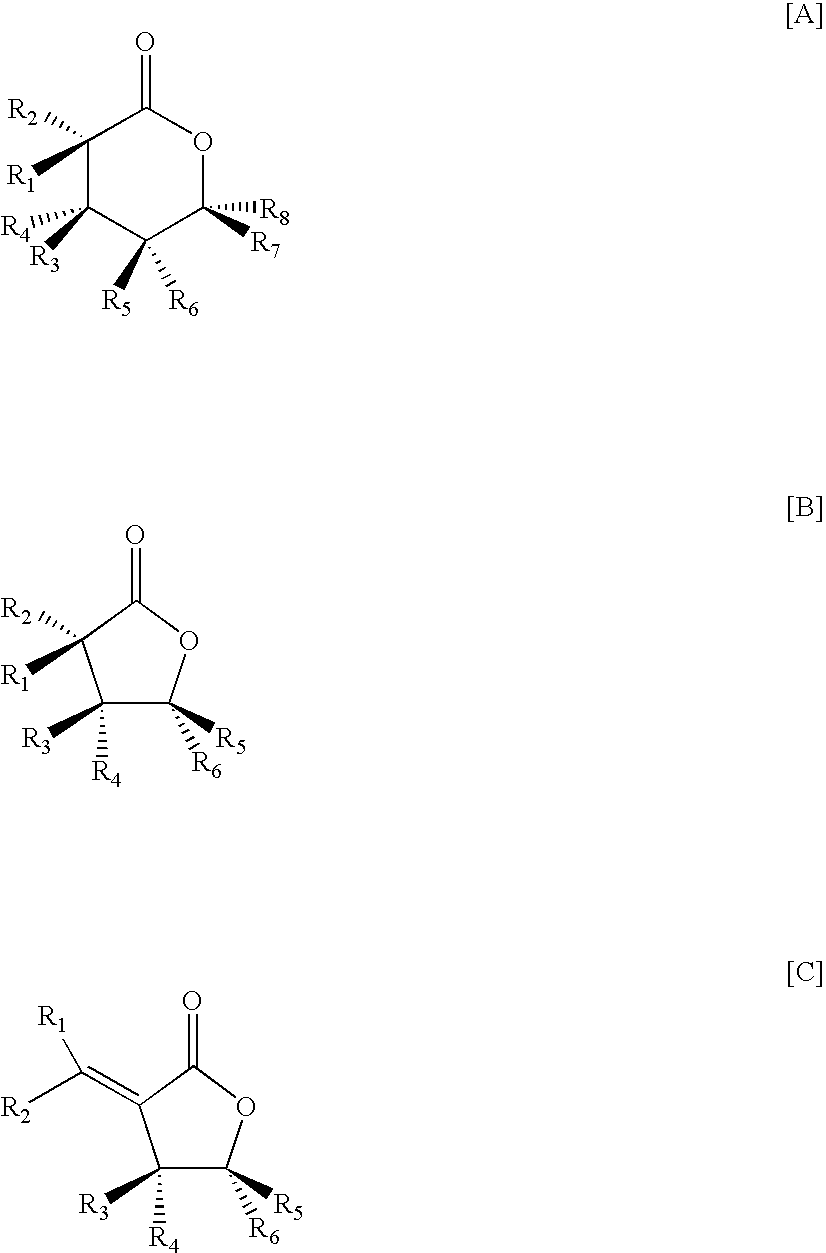

Centrifugal compressor

ActiveUS20150192147A1Improve surge marginReducing choke flowInternal combustion piston enginesEngine manufactureRotational axisChoked flow

An object is to position a plurality of guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict the decrease in a choke flow rate, thereby increasing an operation range of a compressor. A compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas flowing in from an intake-air inlet 23, a swirl-flow generating part including a plurality of guide vanes 55 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 and which swirls the intake gas from the intake-air inlet 23 around the rotational axis, and a central intake-air flow path 59 formed inside the guide vanes 55 to allow intake gas to flow to the impeller wheel 7 without passing through the guide vanes 55.

Owner:MITSUBISHI HEAVY IND LTD

Hydrofluorocarbon refrigerant compositions and uses thereof

InactiveUS20070289317A1Organic chemistryCompression machines with non-reversible cycleAir conditioningHeat transfer fluid

Disclosed herein are hydrofluorocarbon refrigerant or heat transfer fluid compositions that are useful in refrigerain or air conditioning apparatus or as heat transfer fluids. The compositions of the present invention are also useful in centrifugal compressor apparatus that employ two-stage compressors or single slab.single pass heat exchangers.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com