Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5386results about How to "Effective cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

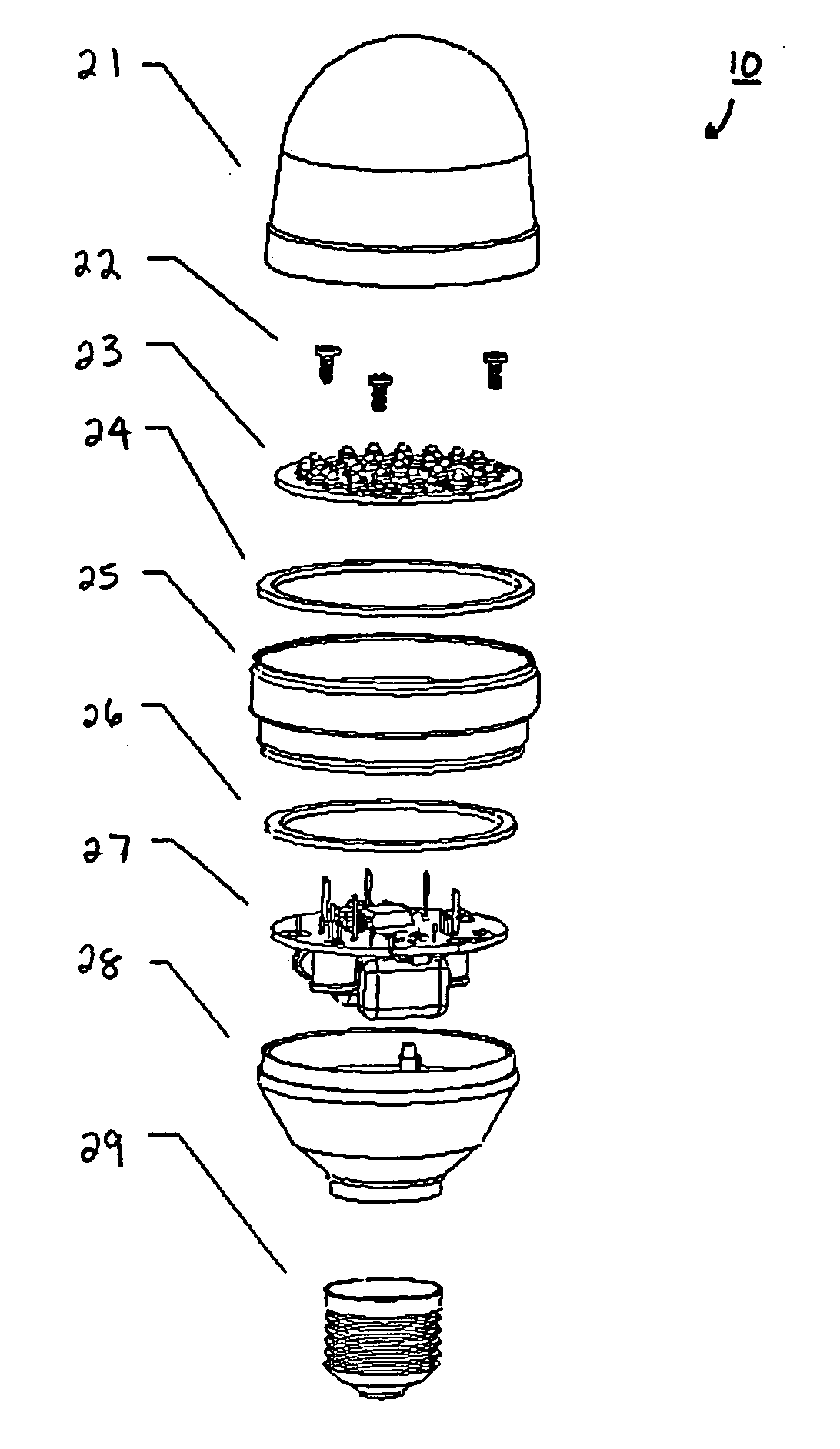

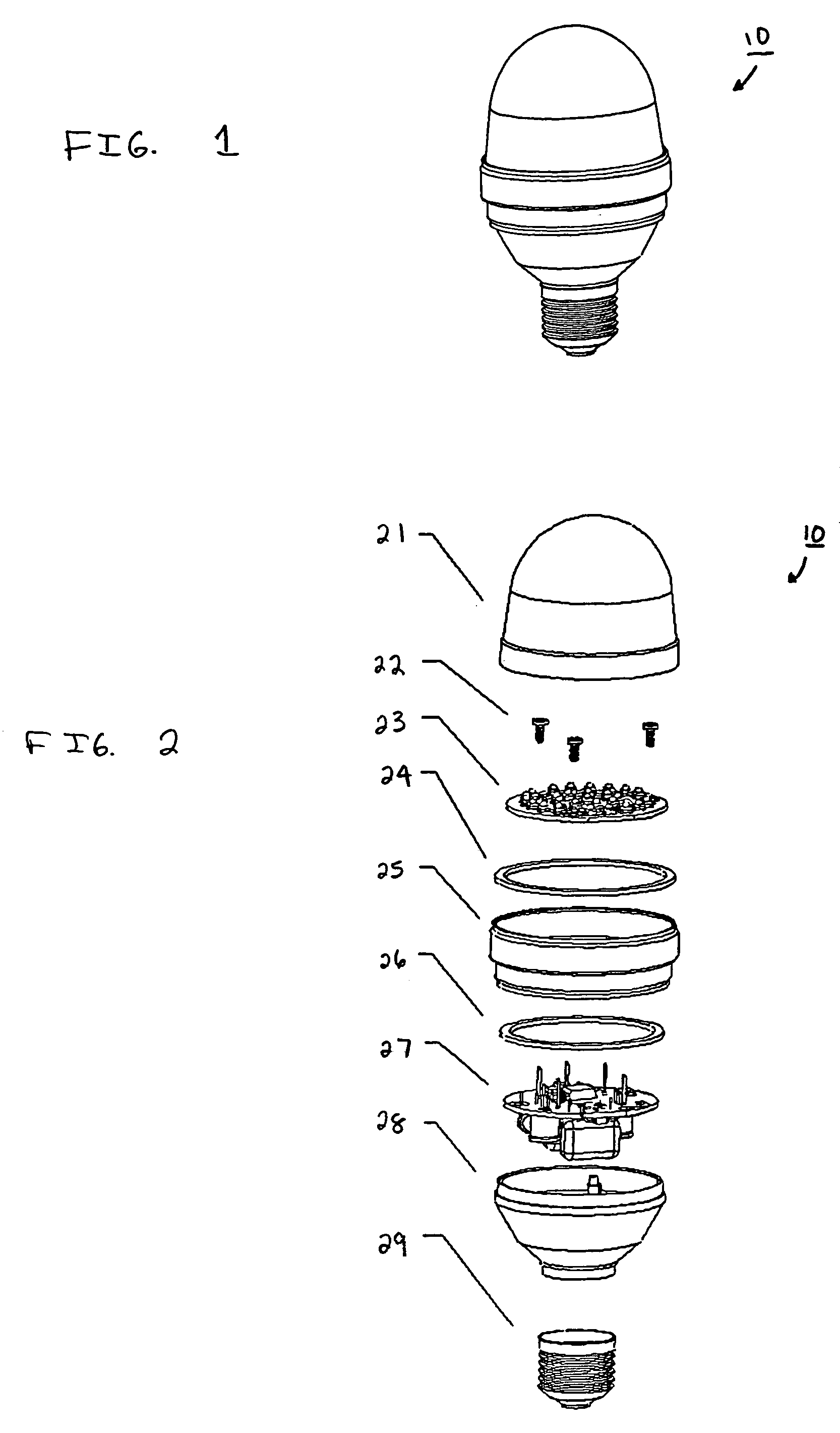

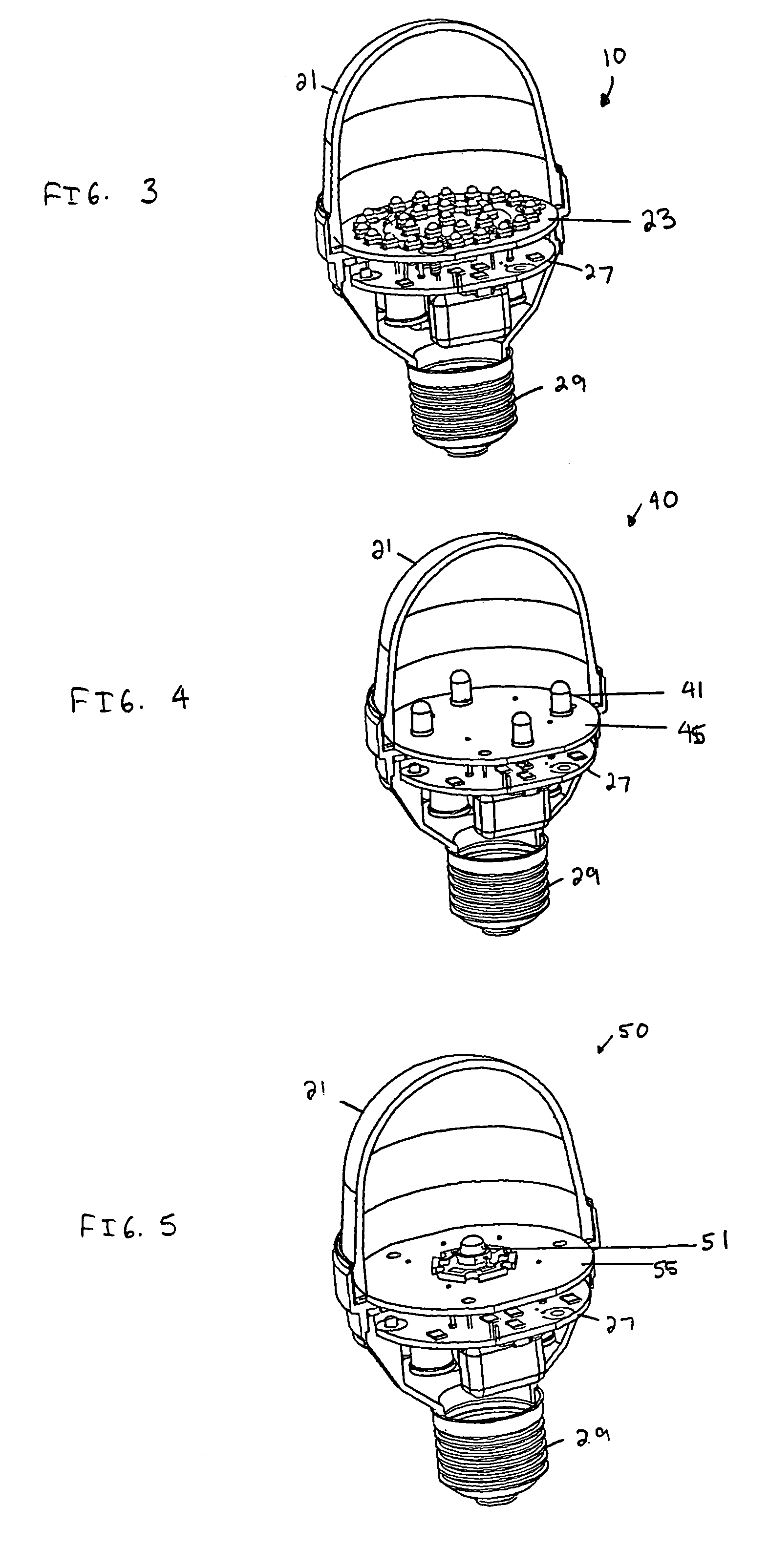

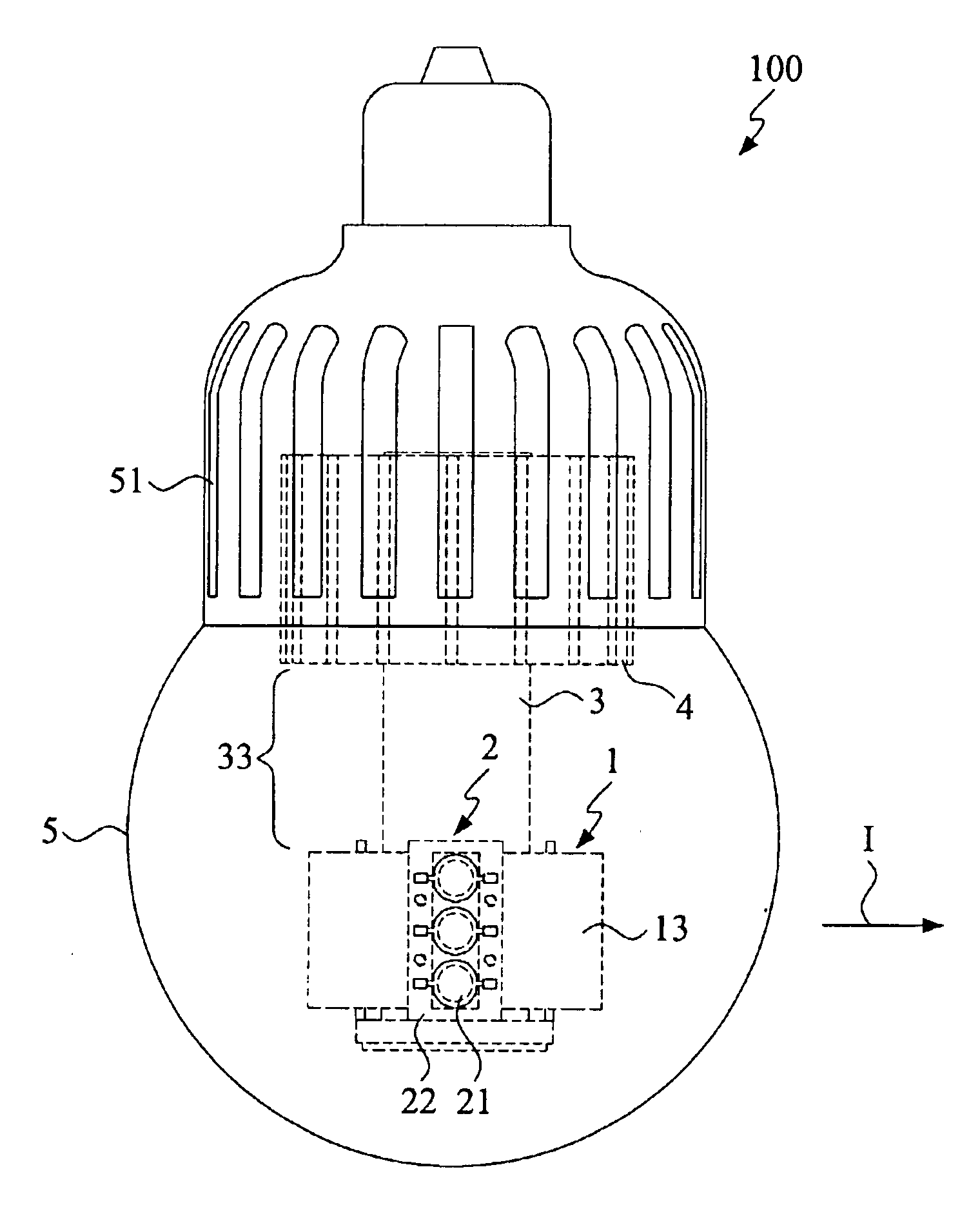

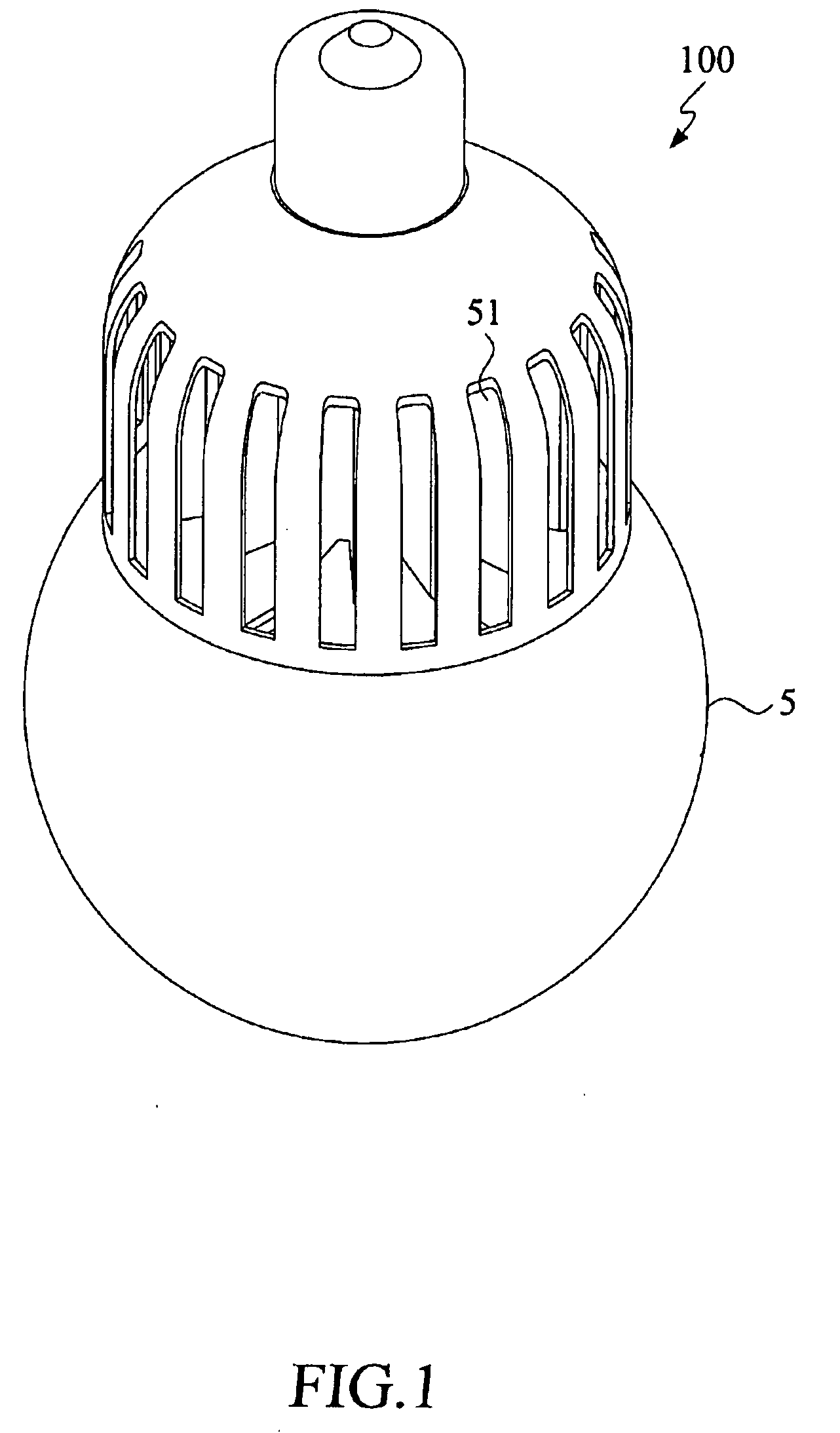

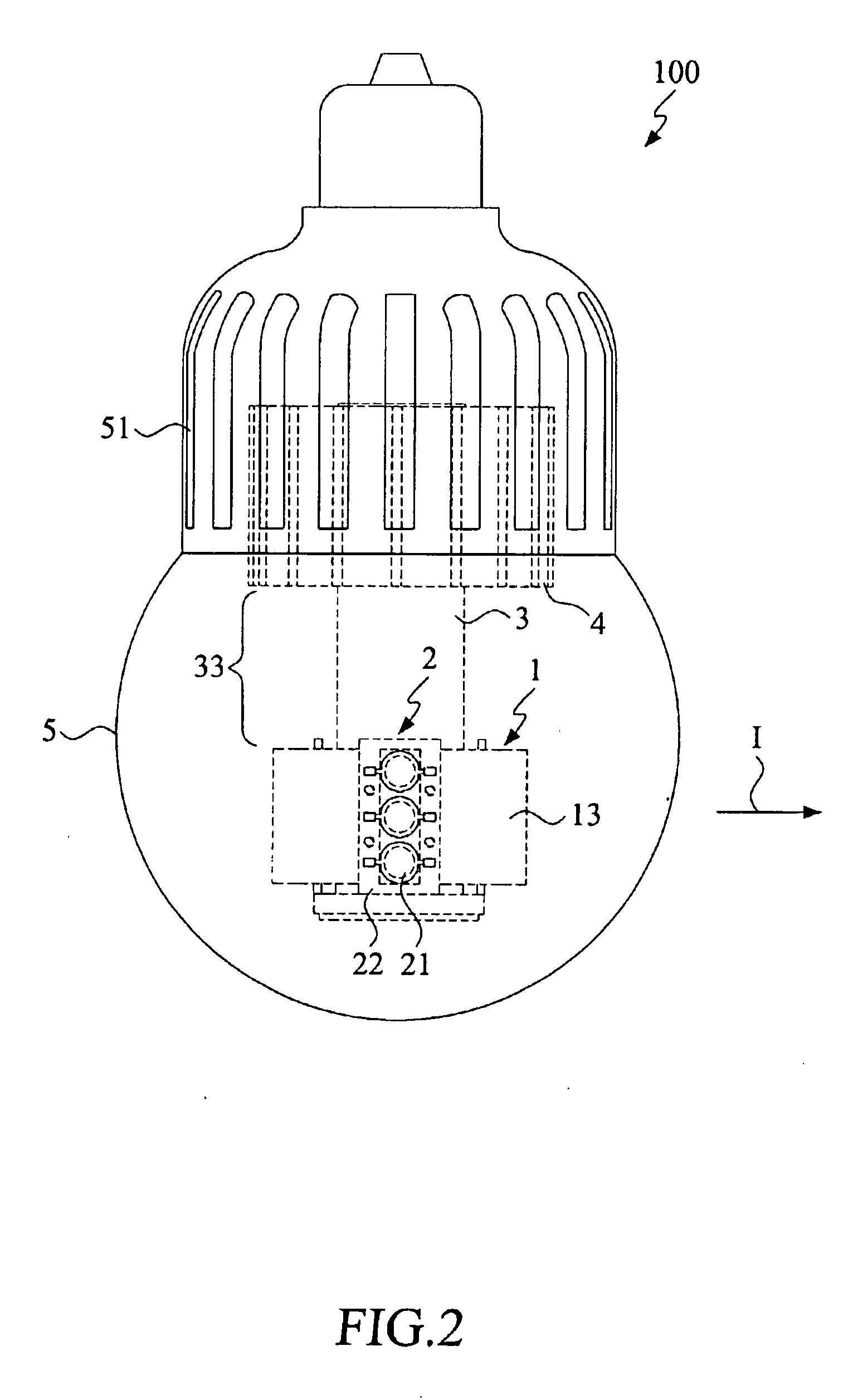

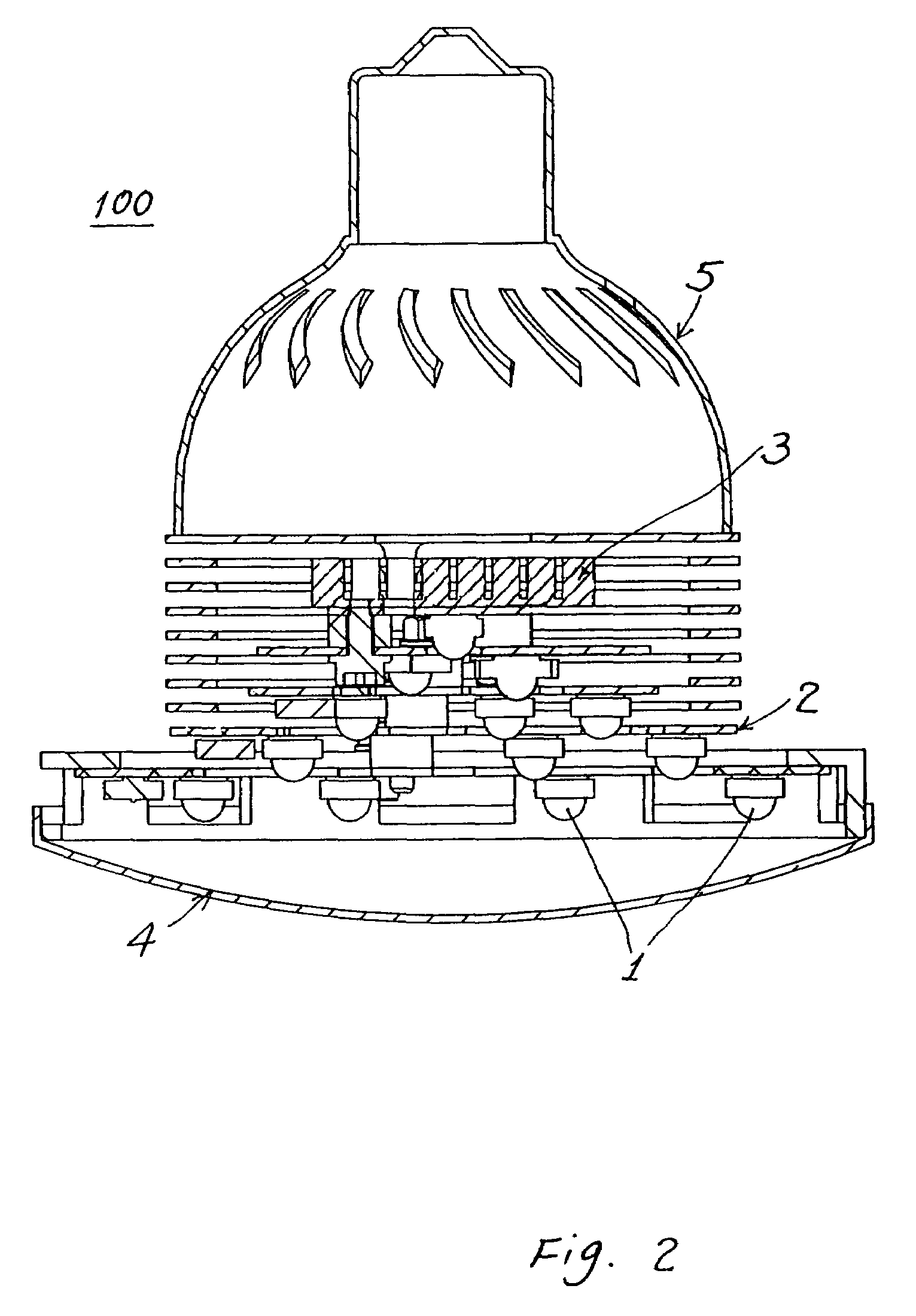

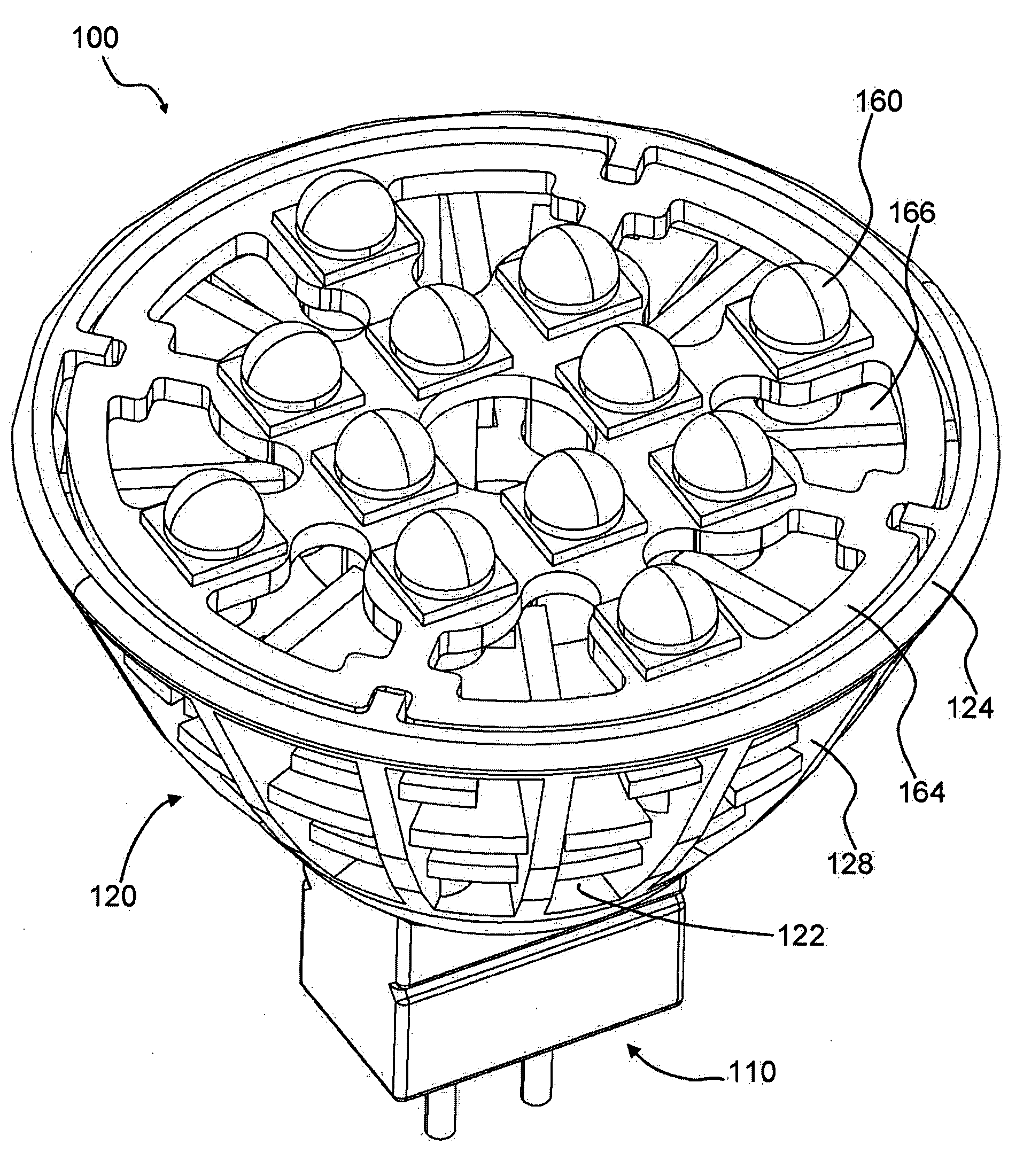

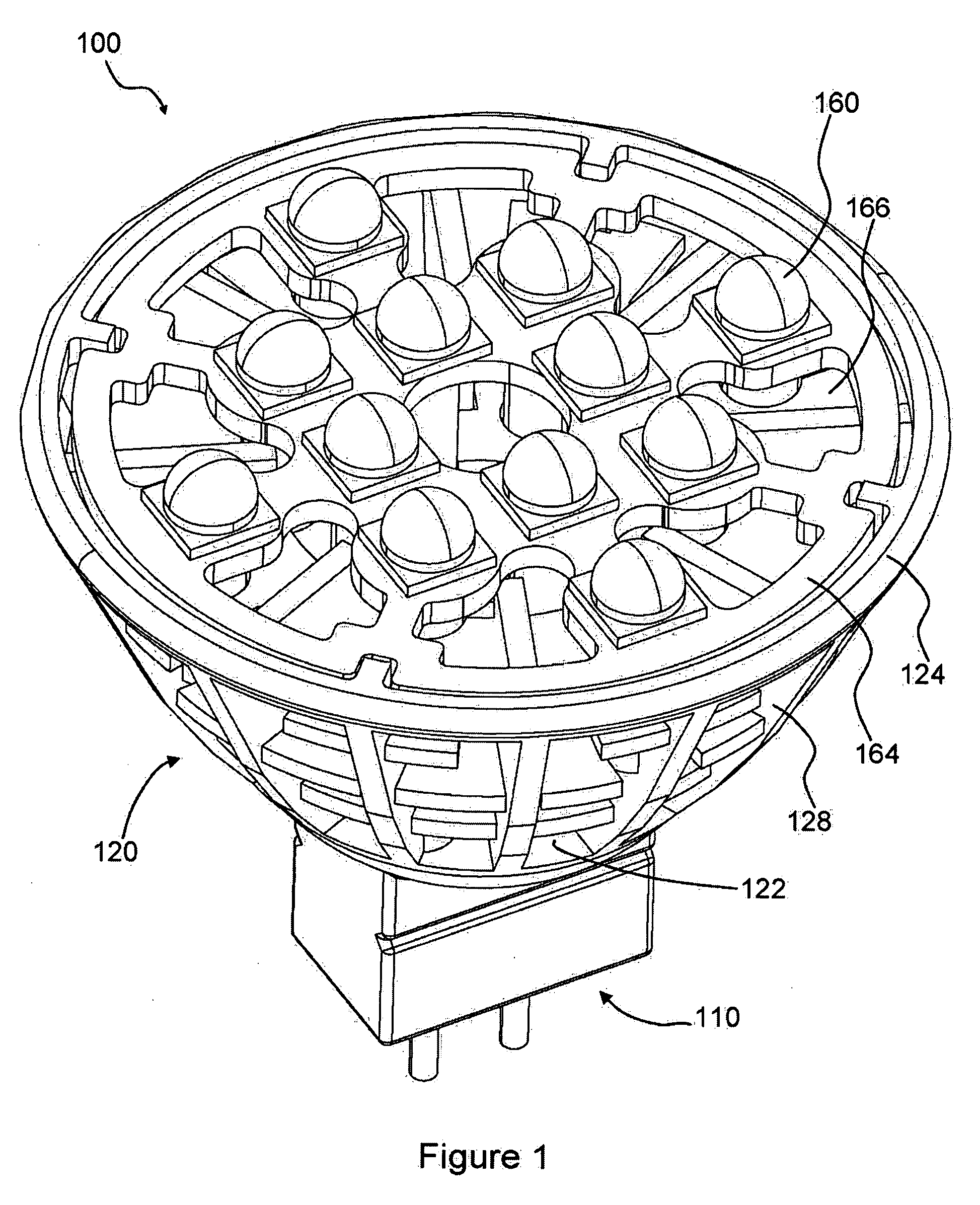

Light emitting diode (LED) light bulbs

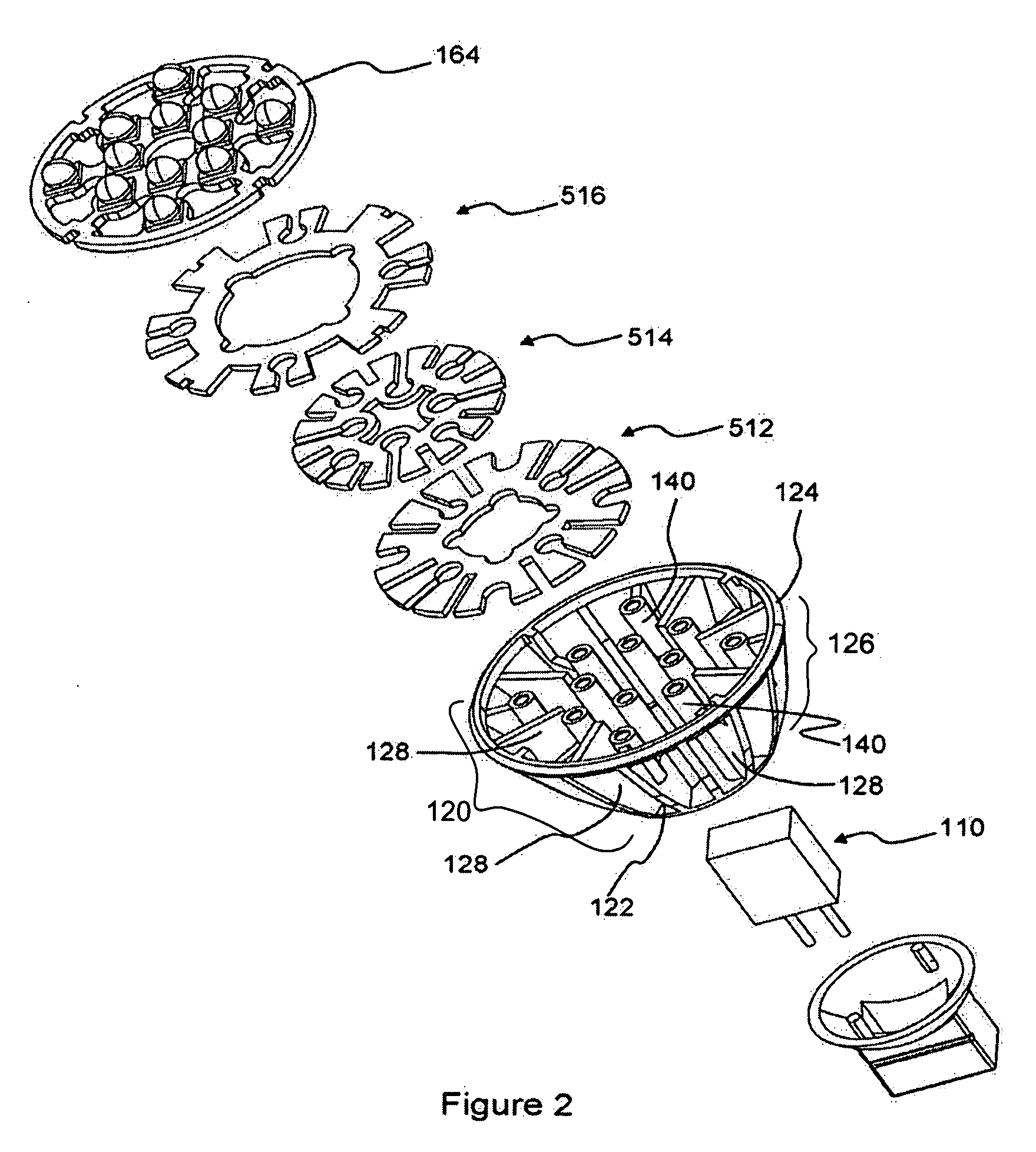

ActiveUS6948829B2Improve performanceEasy to manufactureFurnace componentsPoint-like light sourceEngineeringPrinted circuit board

A light emitting diode (LED) light bulb that includes plural individual elements as sub-assembly elements of the overall light bulb. Different sub-assembly elements of a lens, a LED printed circuit board, a housing also functioning as a heat sink, a lower housing, and other individual sub-assembly components are utilized. The LED printed circuit board sub-assembly containing the LEDs can also be provided relatively close to a base.

Owner:DIALIGHT CORP

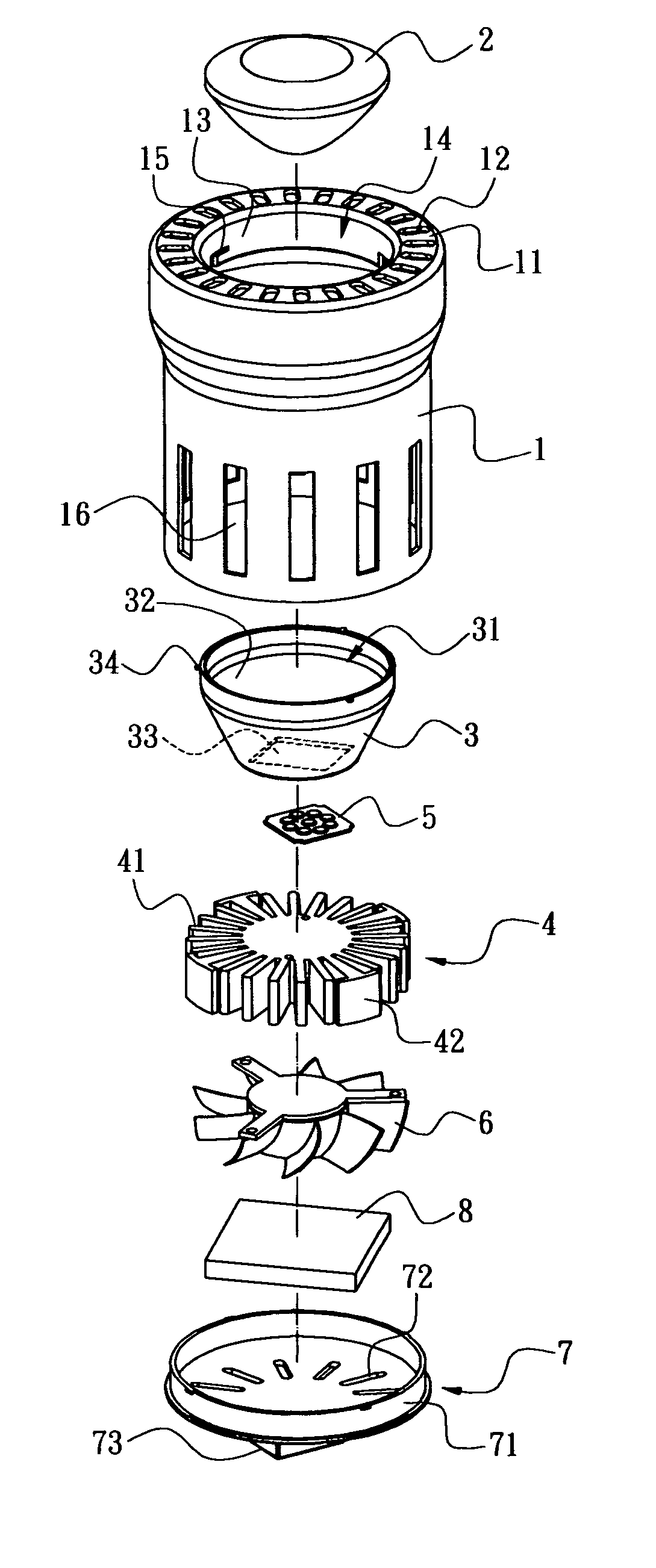

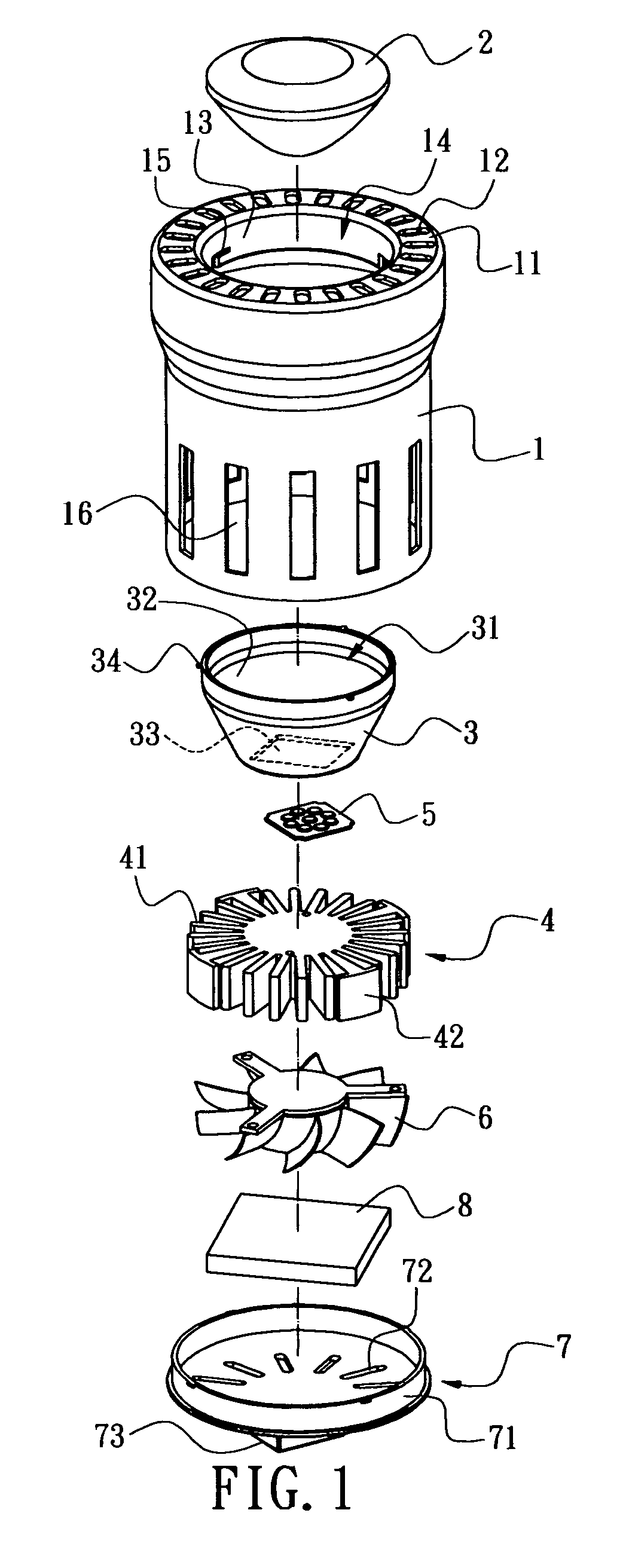

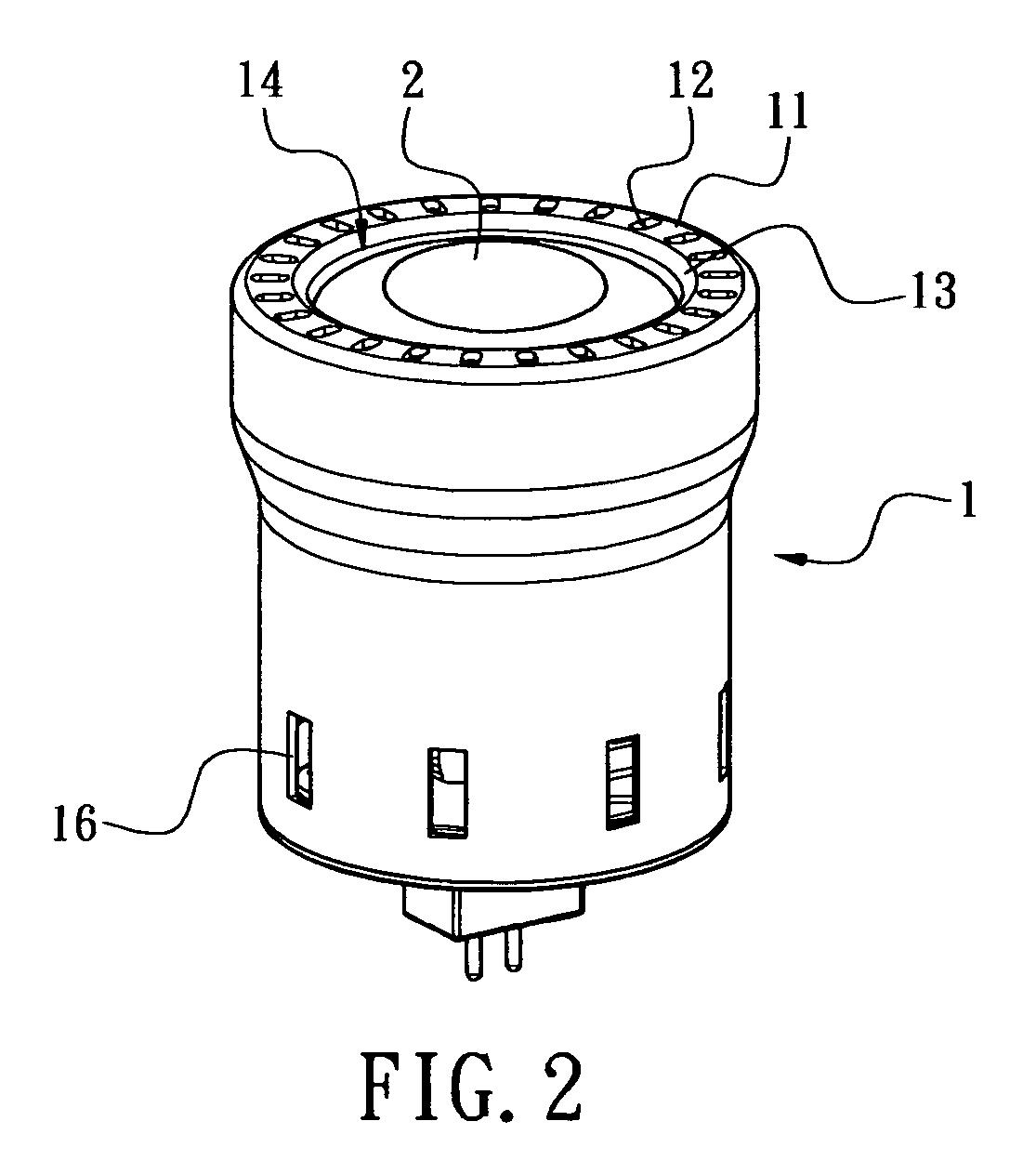

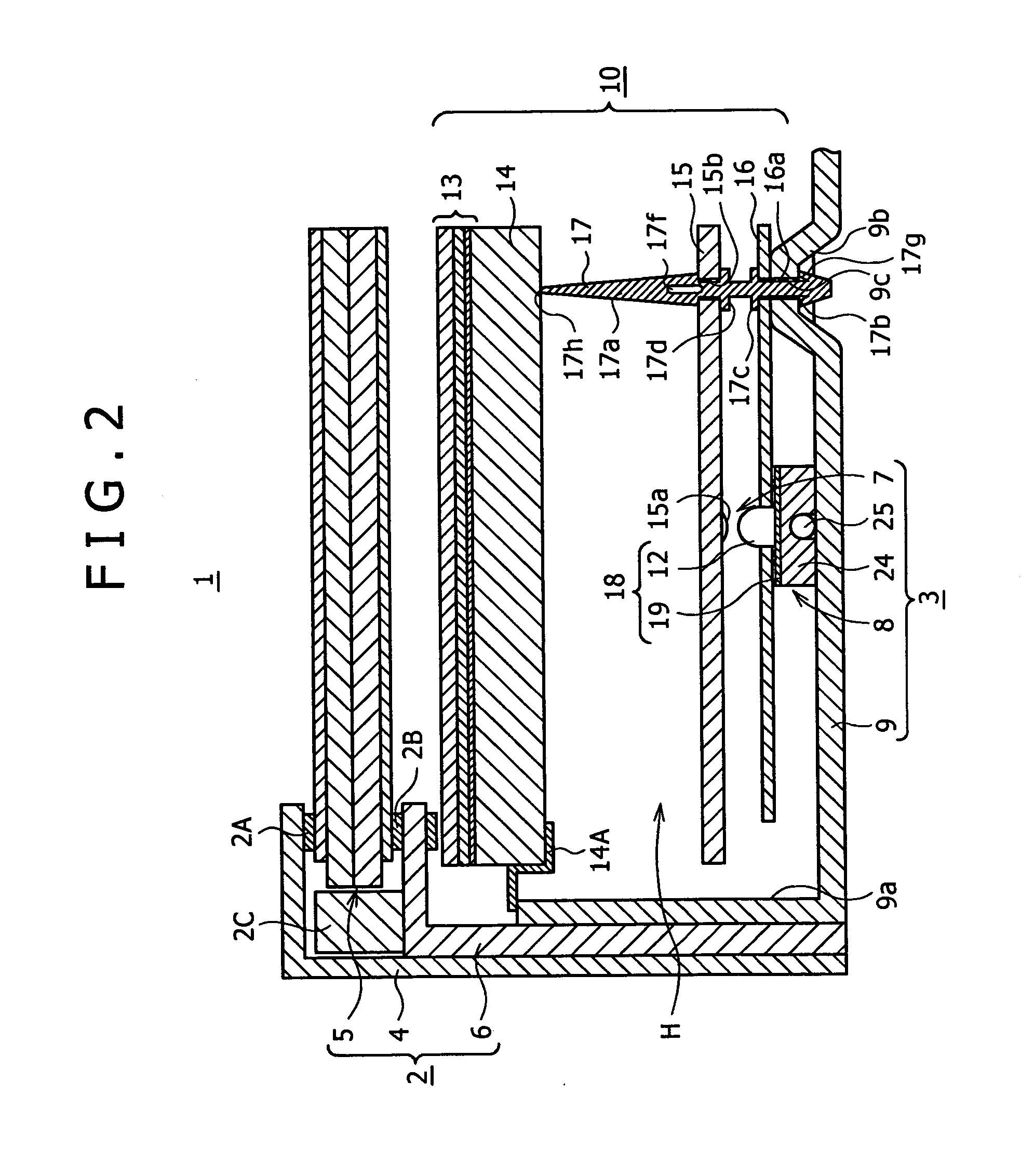

Heat dissipating apparatus for lighting utility

InactiveUS20060193139A1Versatile operation modeEffective coolingPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

Owner:EDISON-OPTO

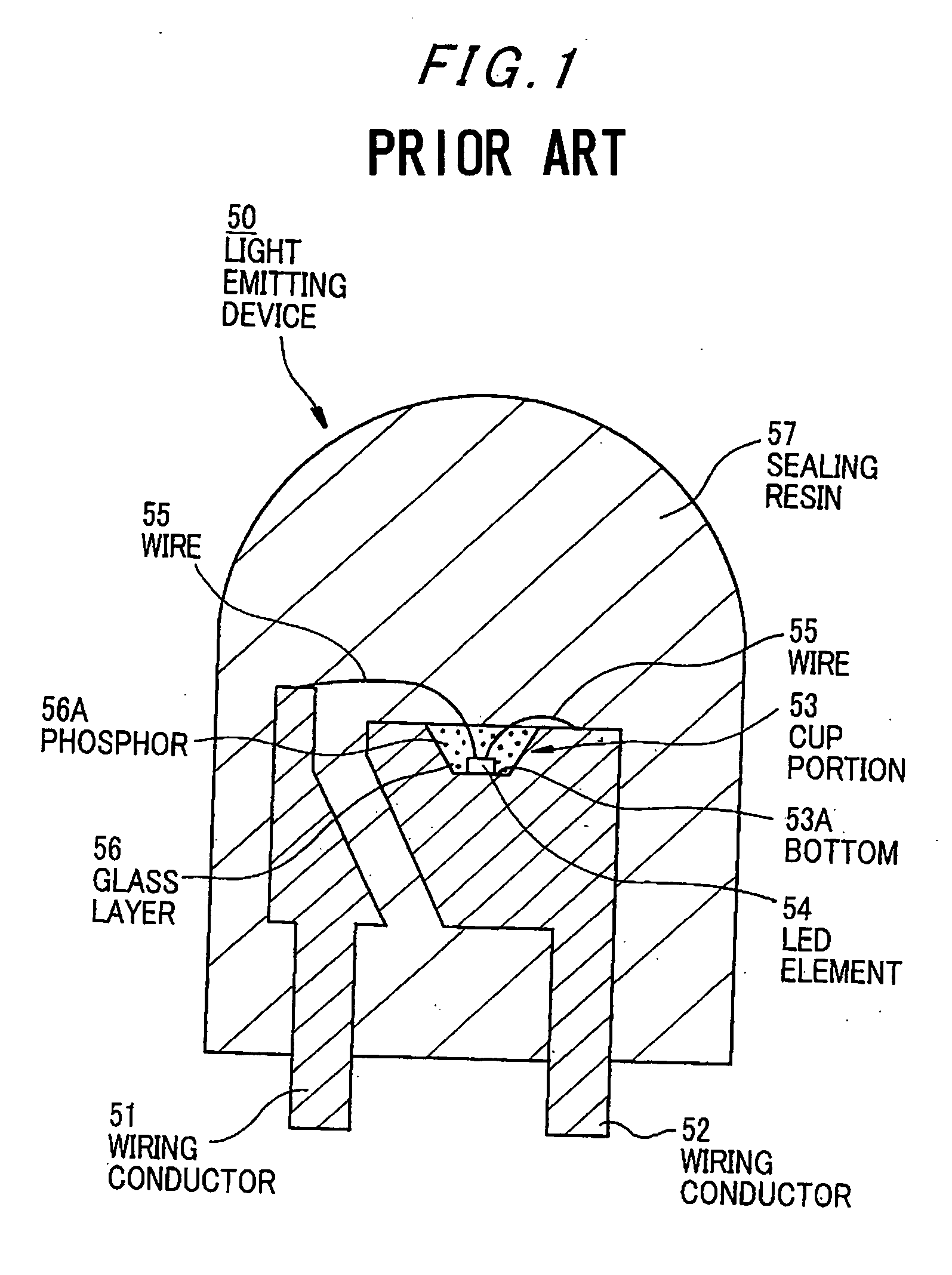

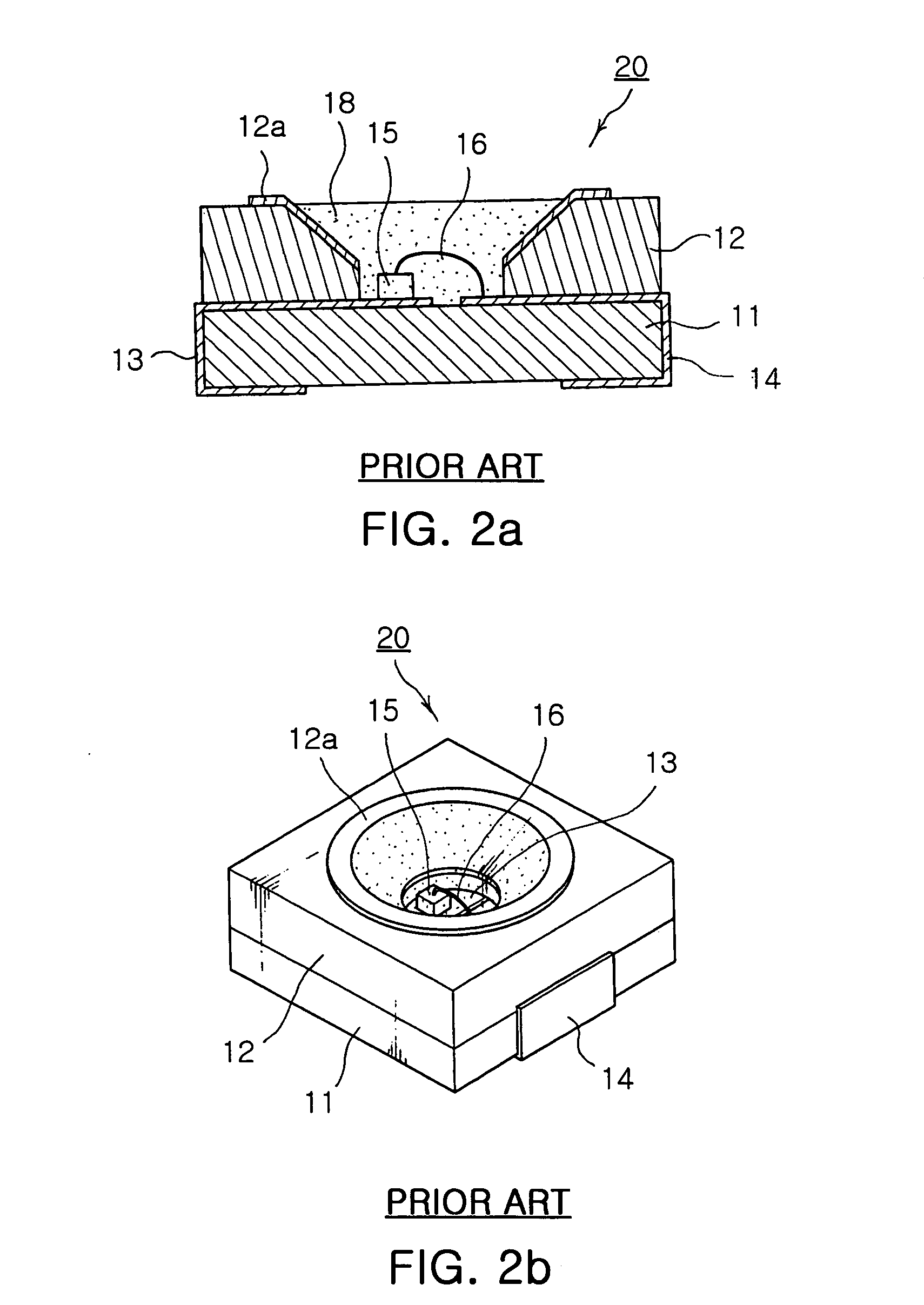

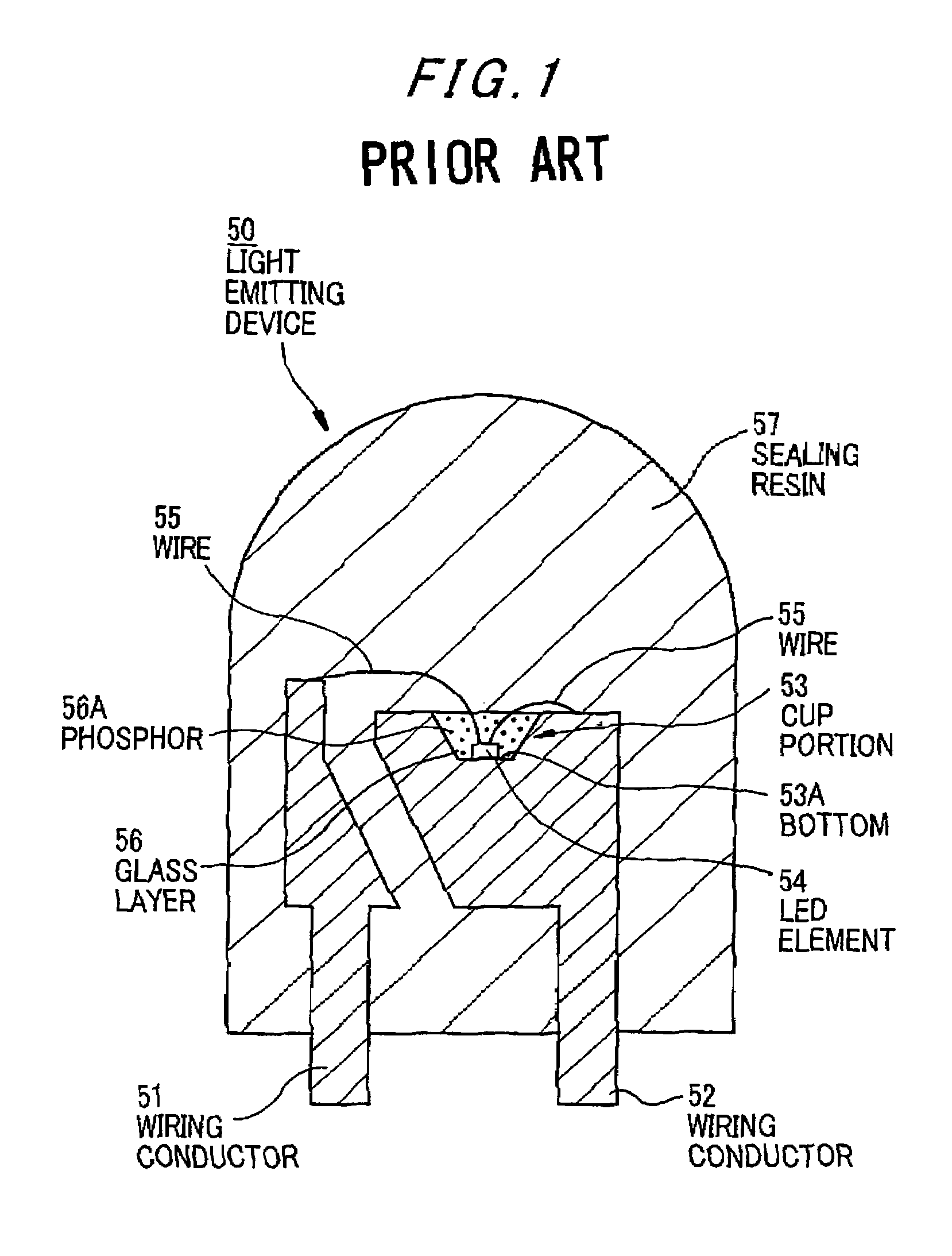

Light emitting device

ActiveUS20060012299A1Avoiding pressure injuriesDifference in stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

High power LED lighting assembly incorporated with a heat dissipation module with heat pipe

InactiveUS20080253125A1Reduce power consumptionIncrease powerPoint-like light sourceLighting heating/cooling arrangementsThermal energyWorking fluid

A high power light emitting diode (LED) lighting assembly incorporated with heat dissipation module is provided. The LED lighting assembly includes a heat exchange base, at least one LED array, at least one heat pipe and a heat dissipation module. The heat exchange base includes at least one LED configuration plan for mounting of the LED array and at least a hollow part for insertion of the heat pipe. The LED array is arranged at a predetermined projecting angle at the LED configuration plane. The heat pipe includes a heated section, a cooling section and a conducting section, and contains a working fluid therein. The heat exchange base is mounted to the heated section and the heat dissipation module is mounted to the cooling section. The thermal energy generated by the LEDs is conducted from the heat exchange base to the heated section of the heat pipe, whereby allowing the working fluid in the heat pipe to be heated and vaporized, and flows, from the conducting section to the cooling section for dissipation at the heat dissipation module.

Owner:TAMKANG UNIVERSITY

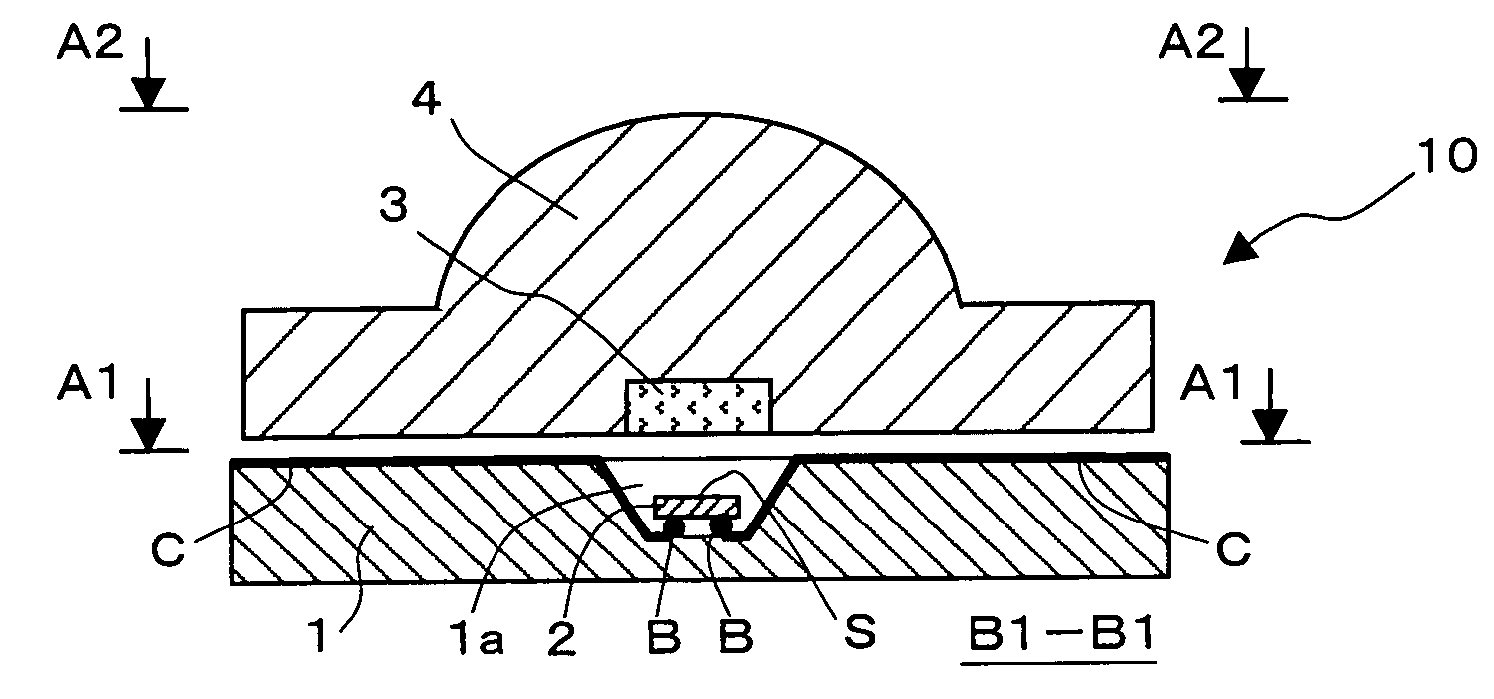

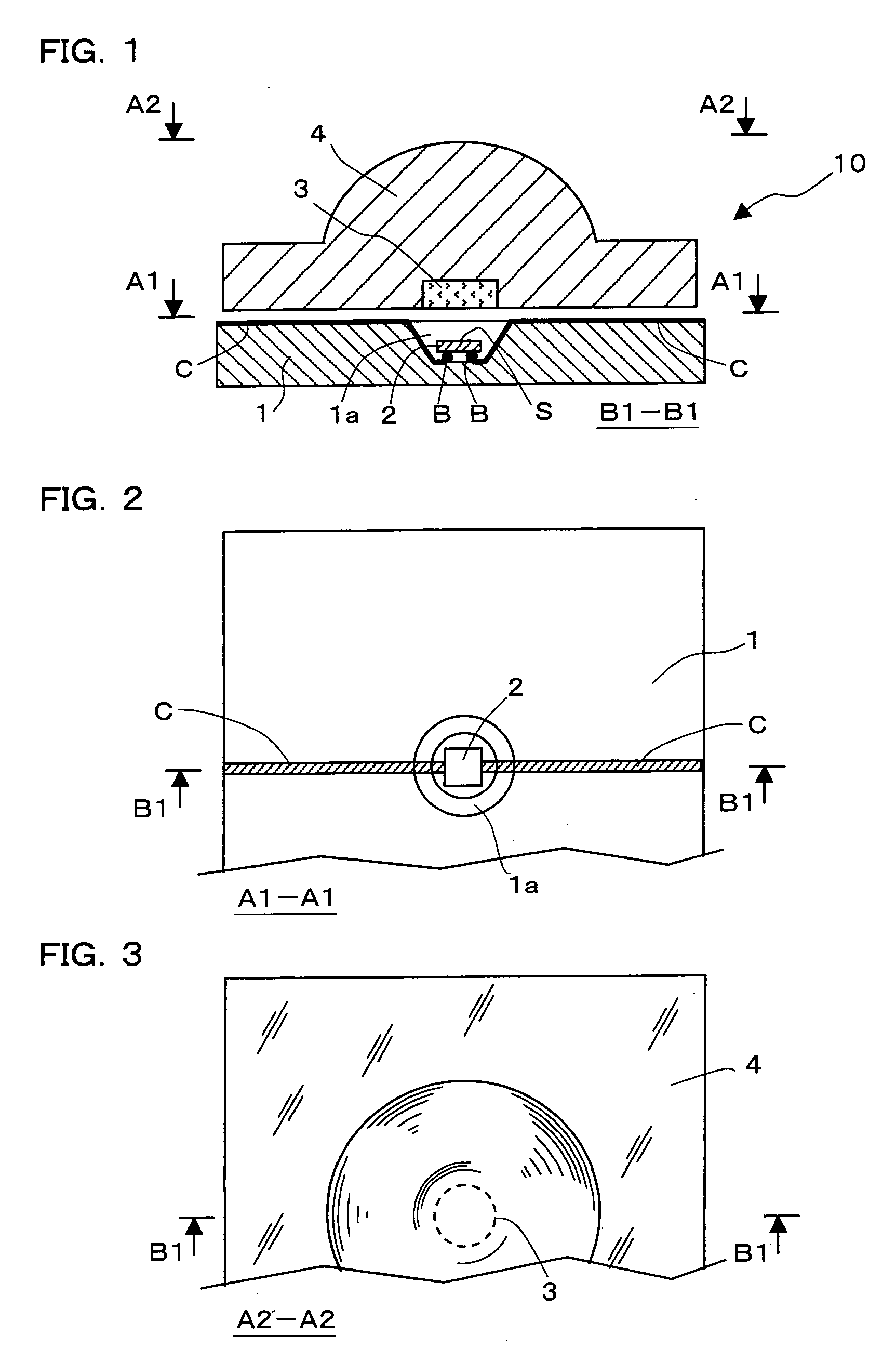

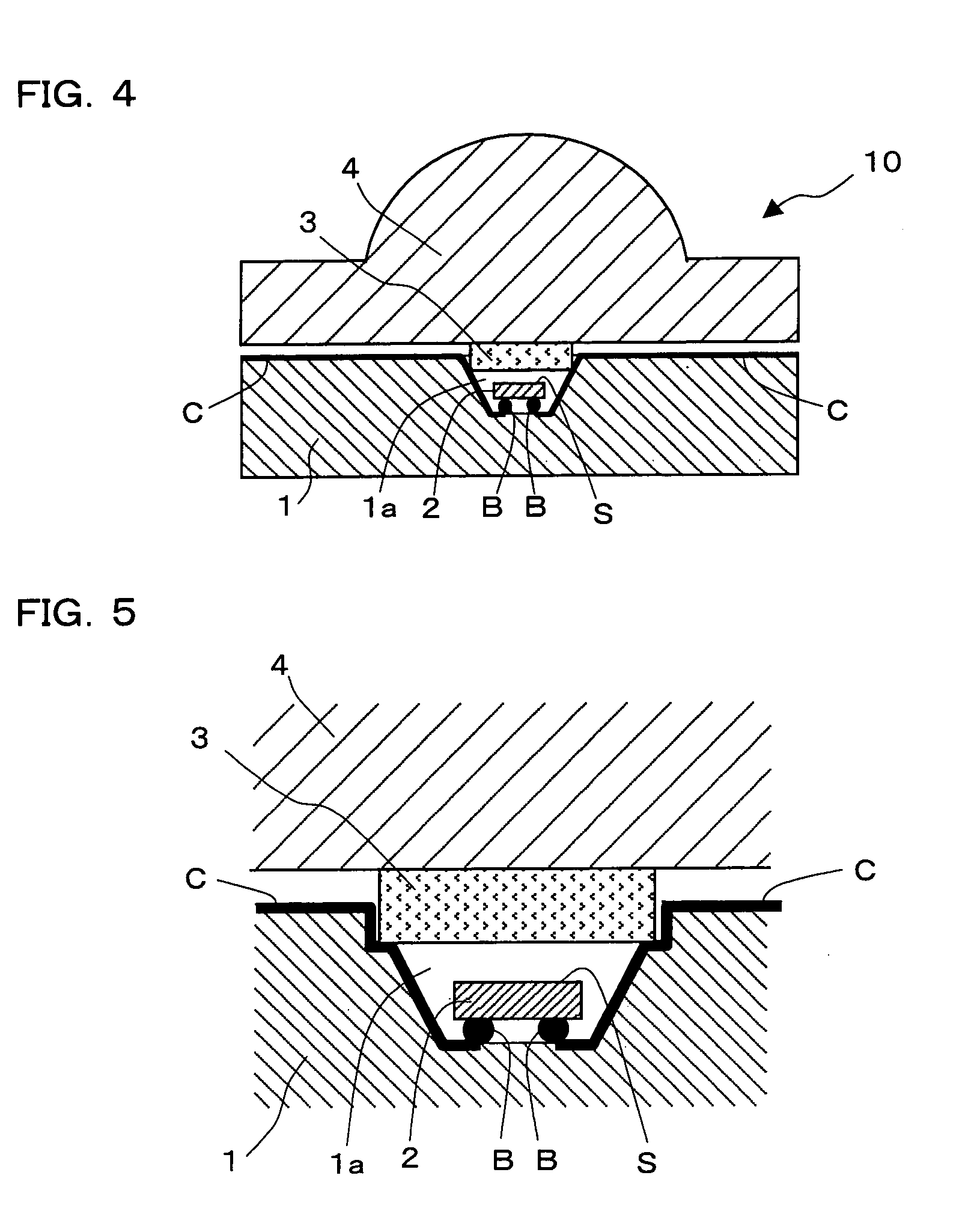

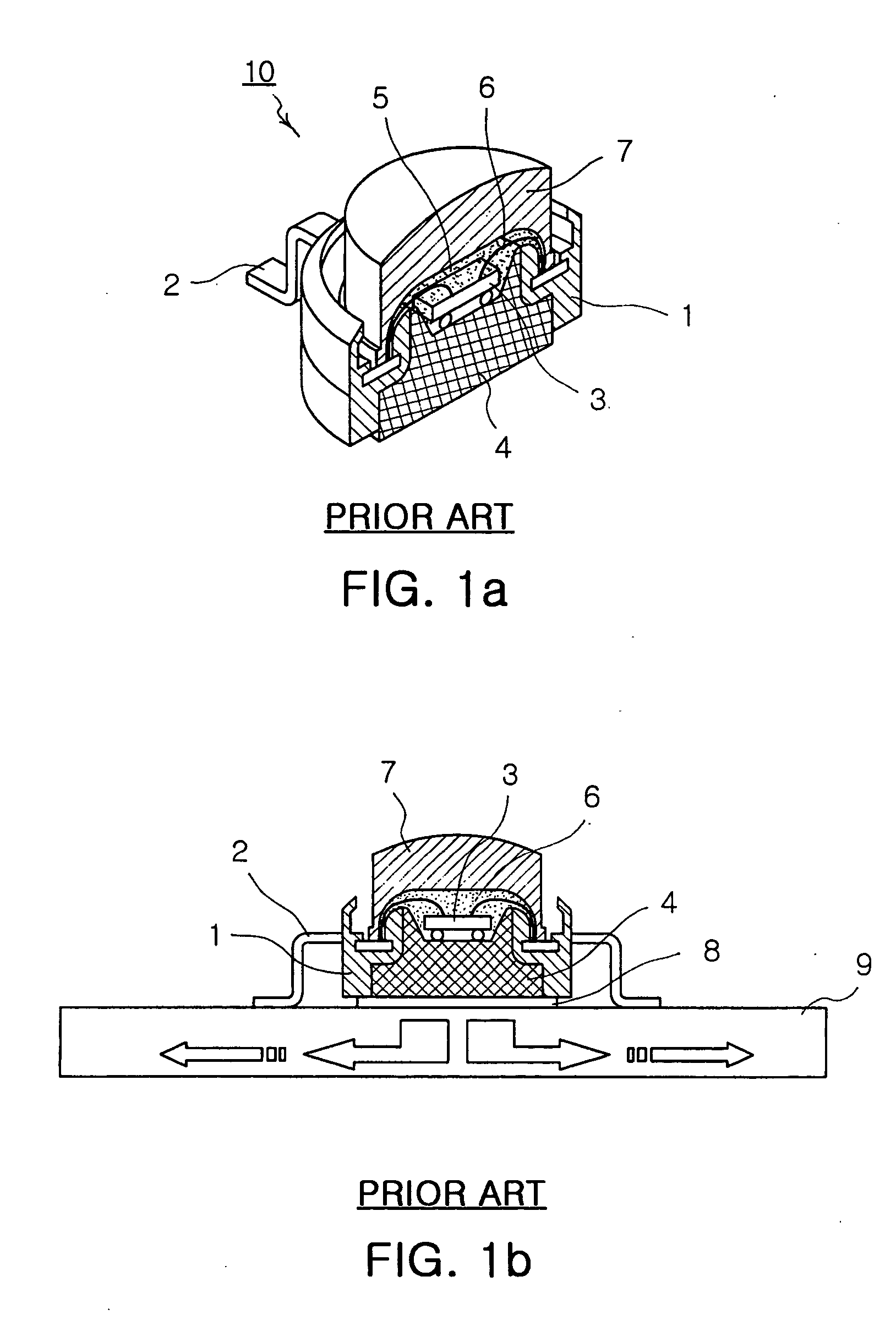

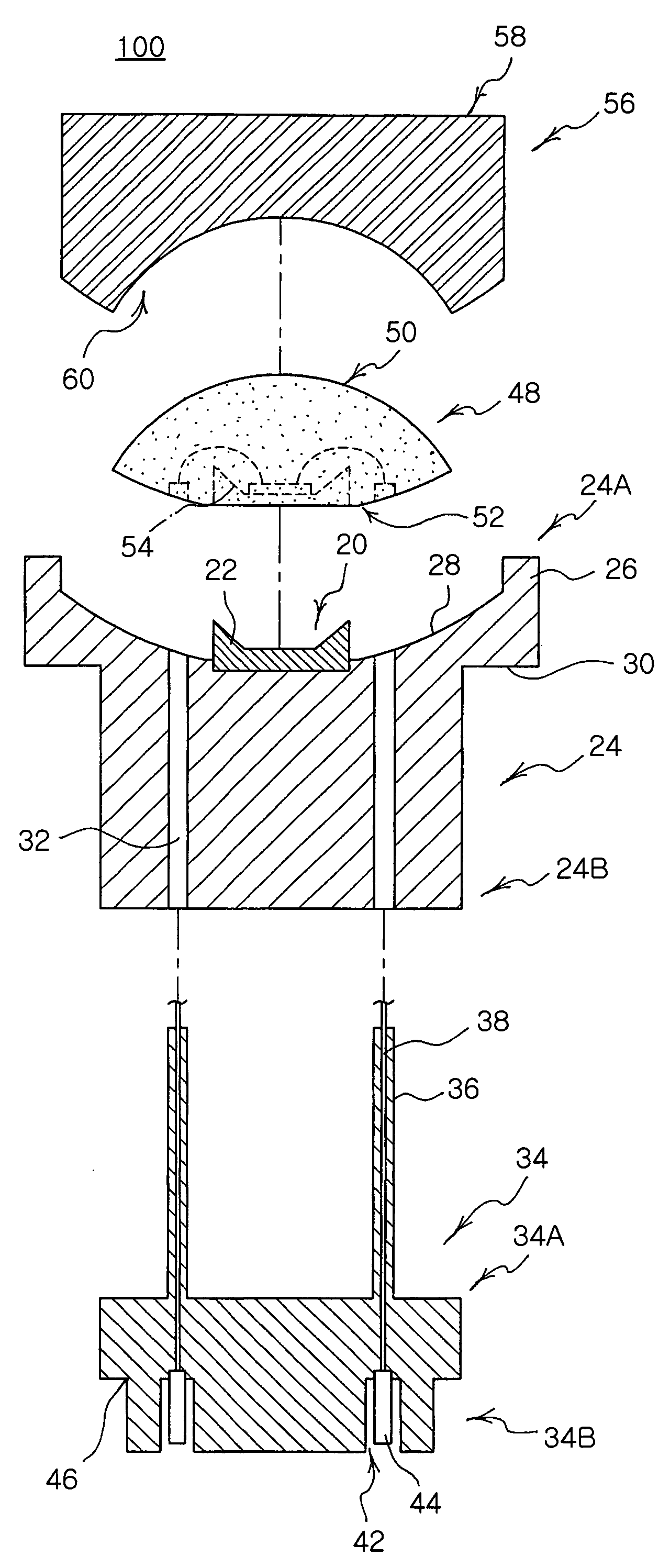

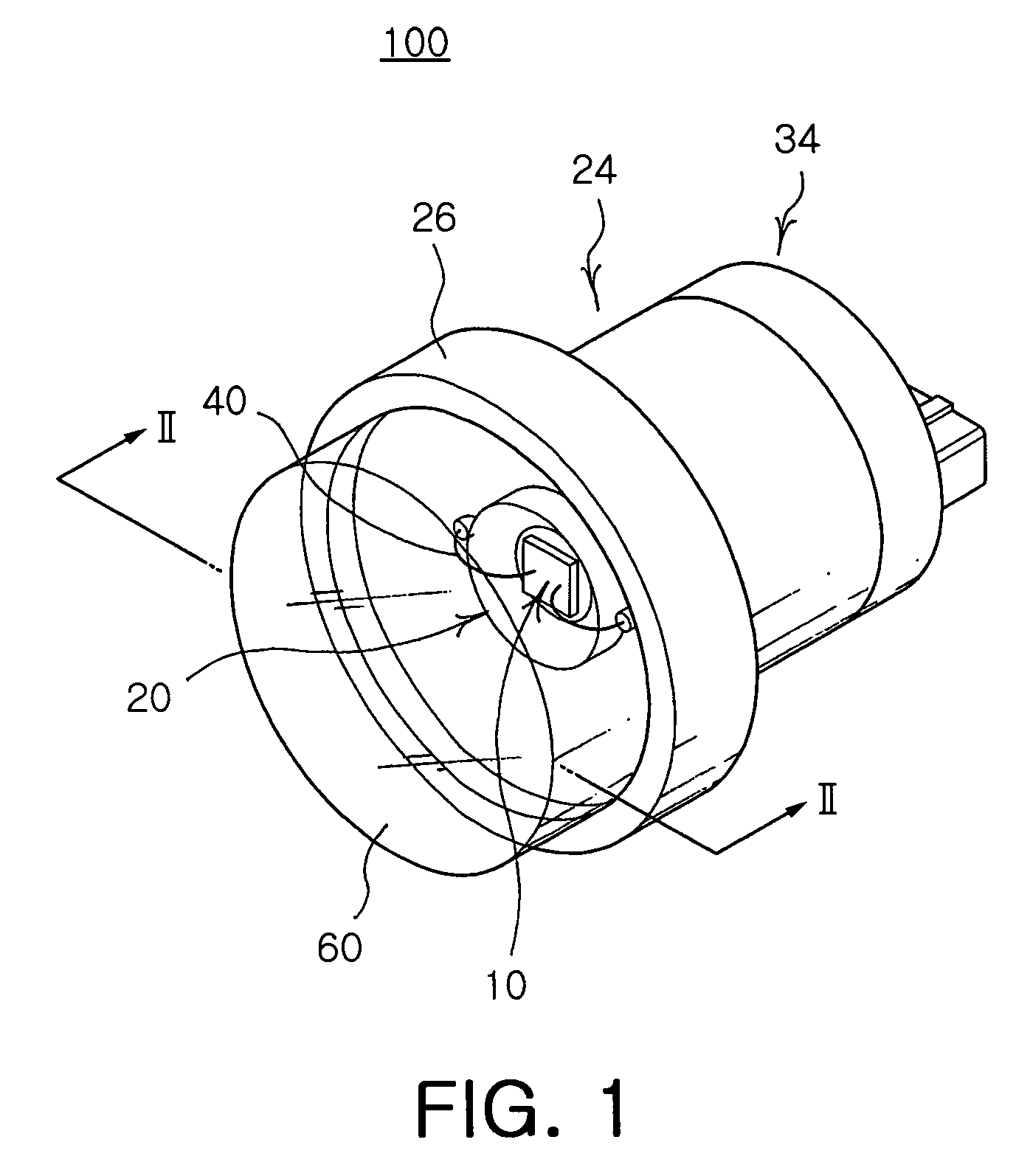

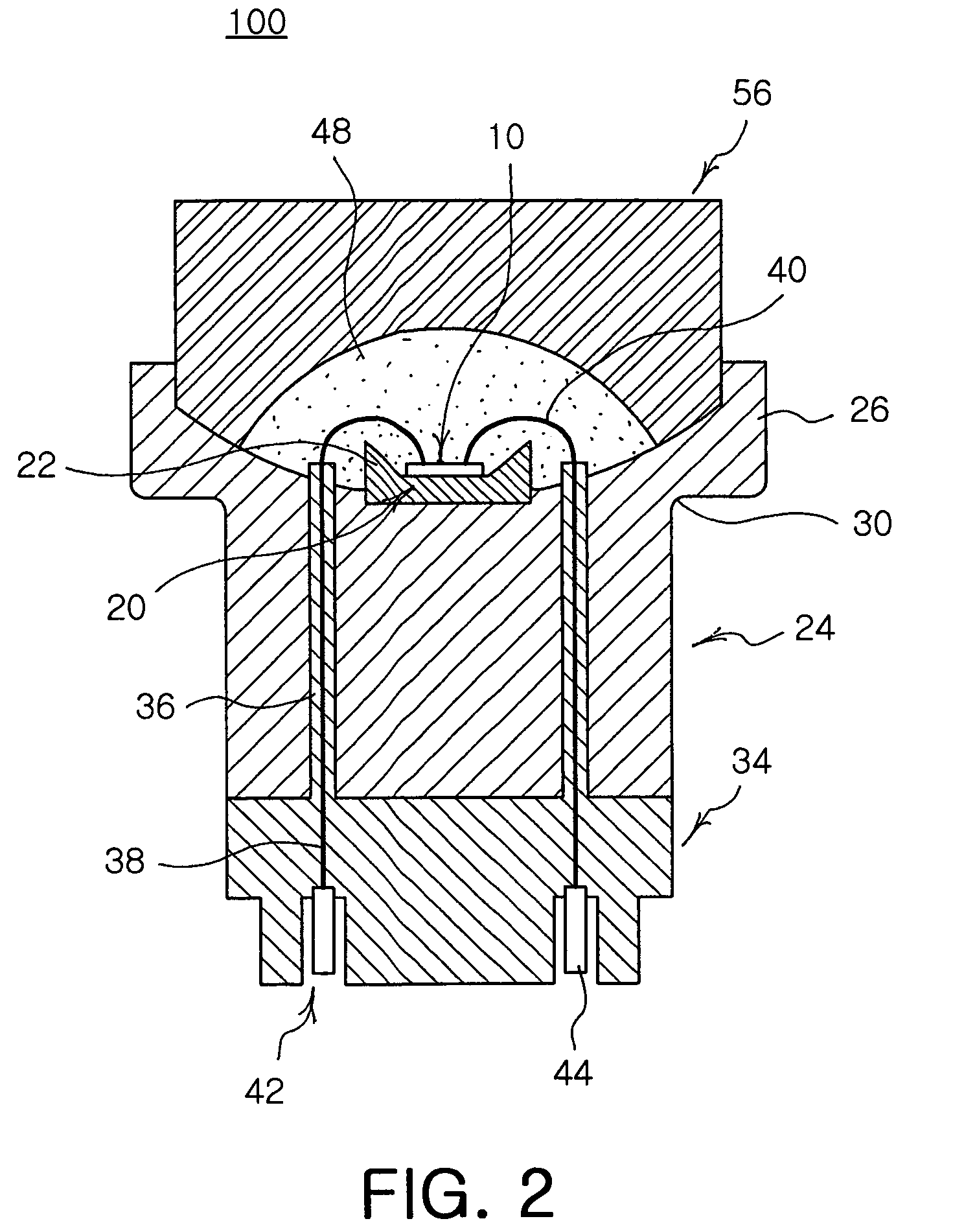

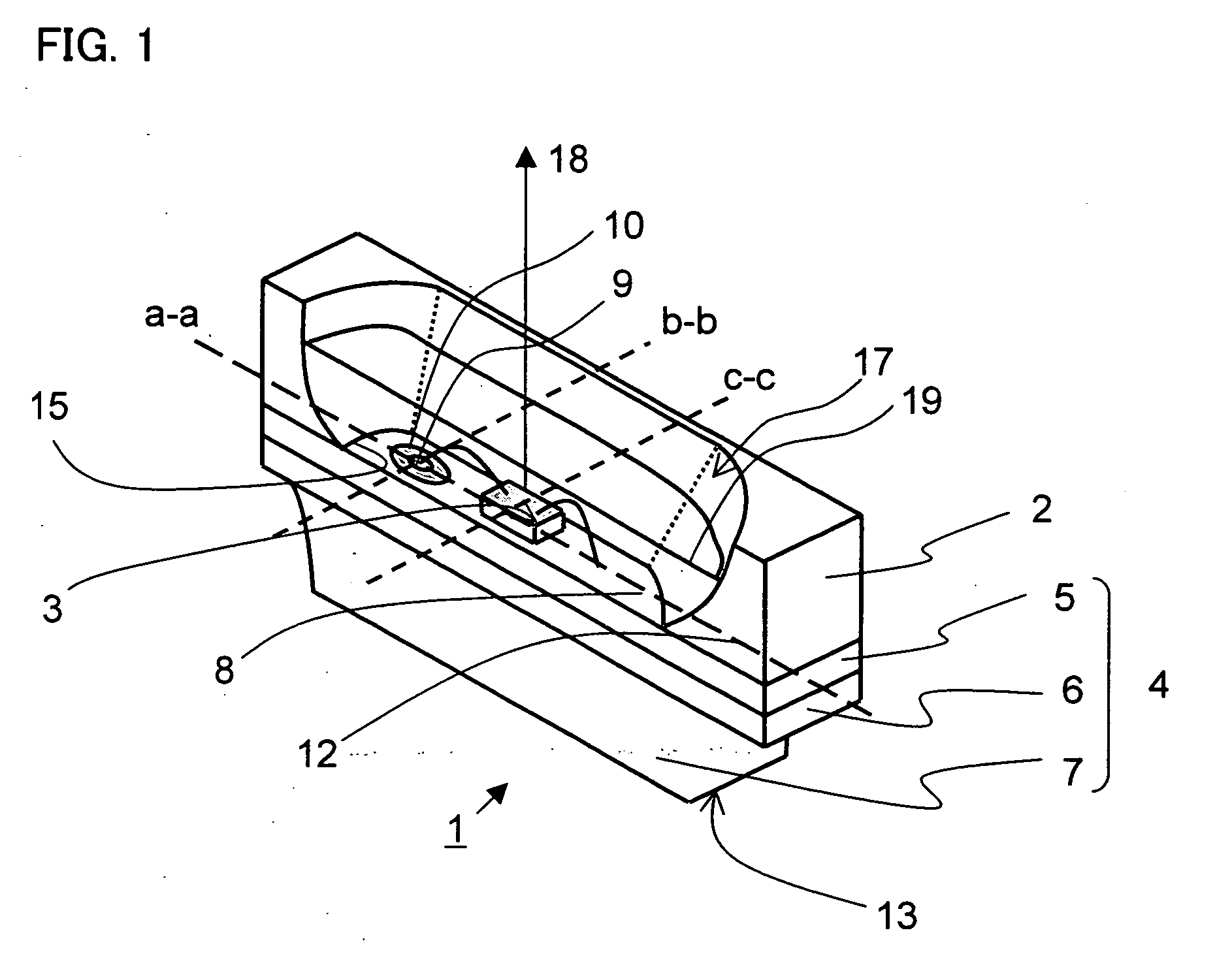

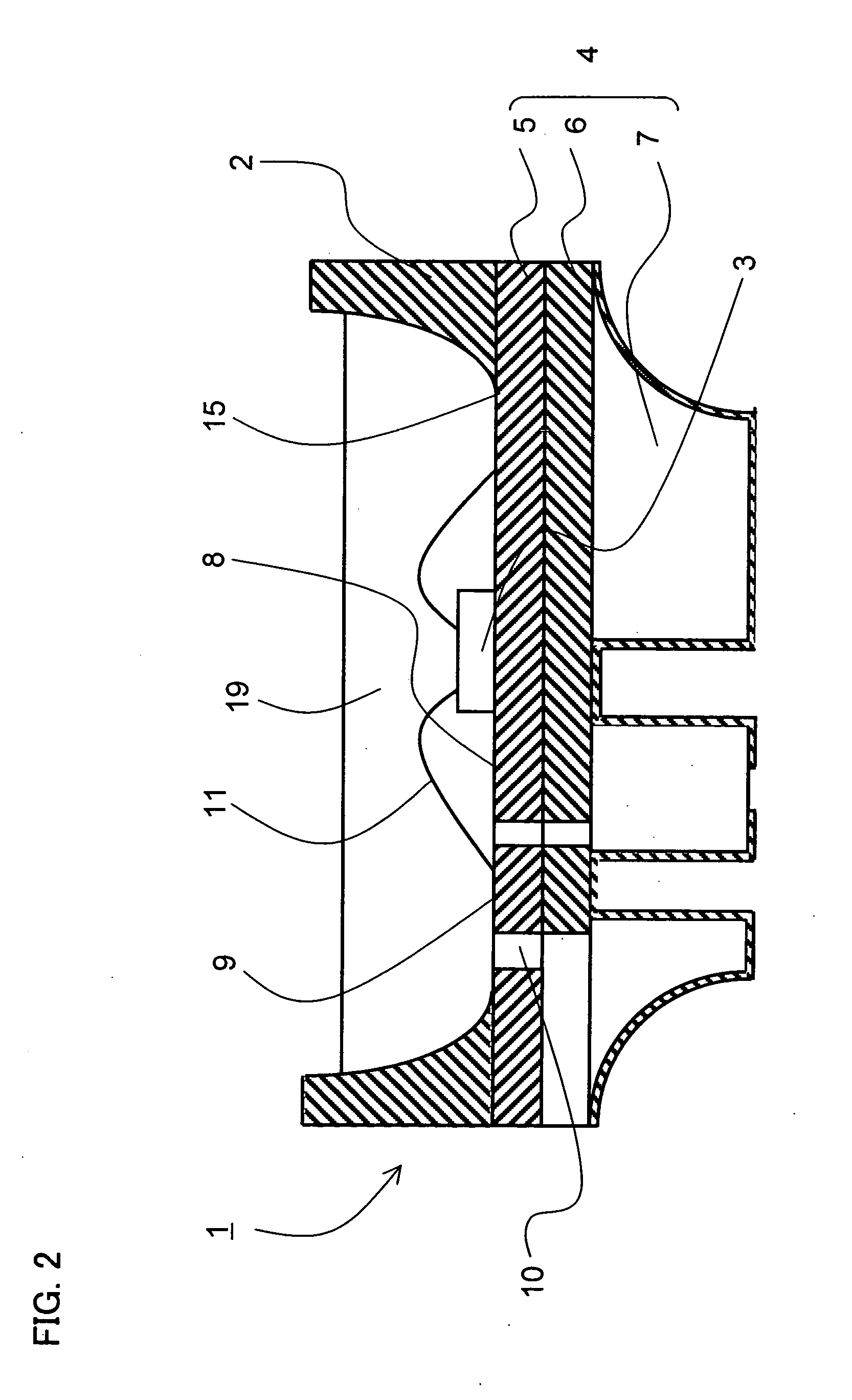

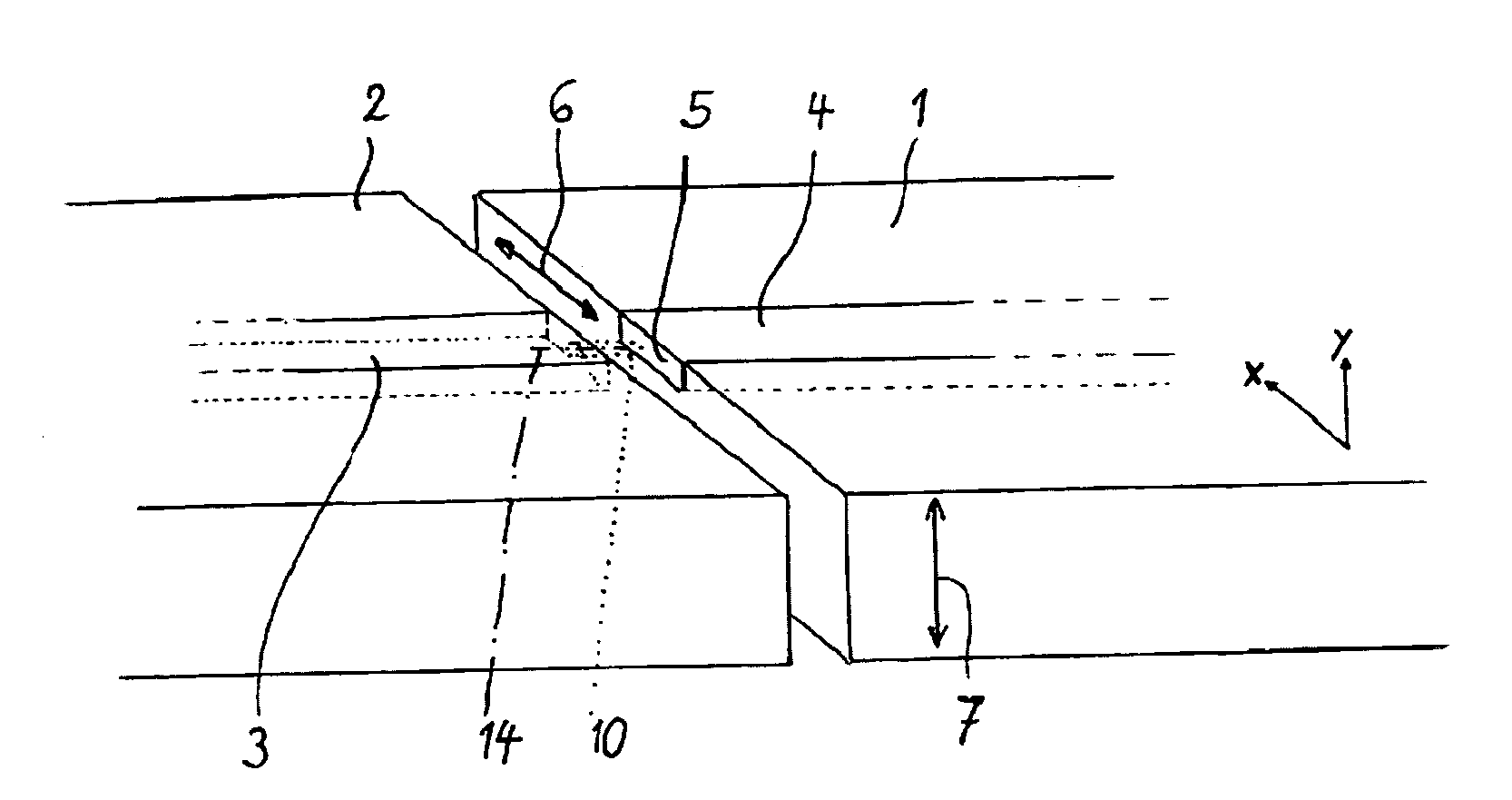

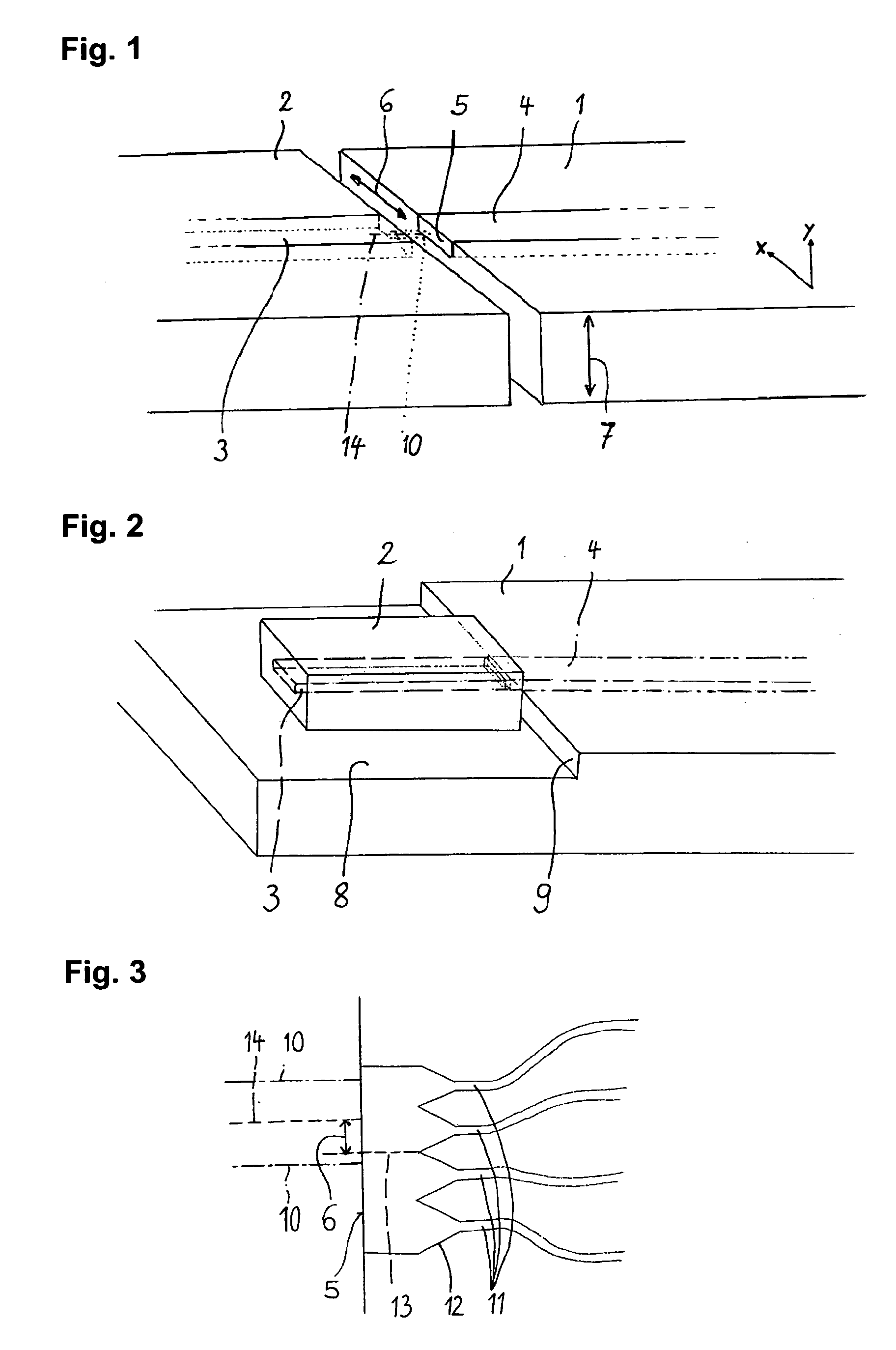

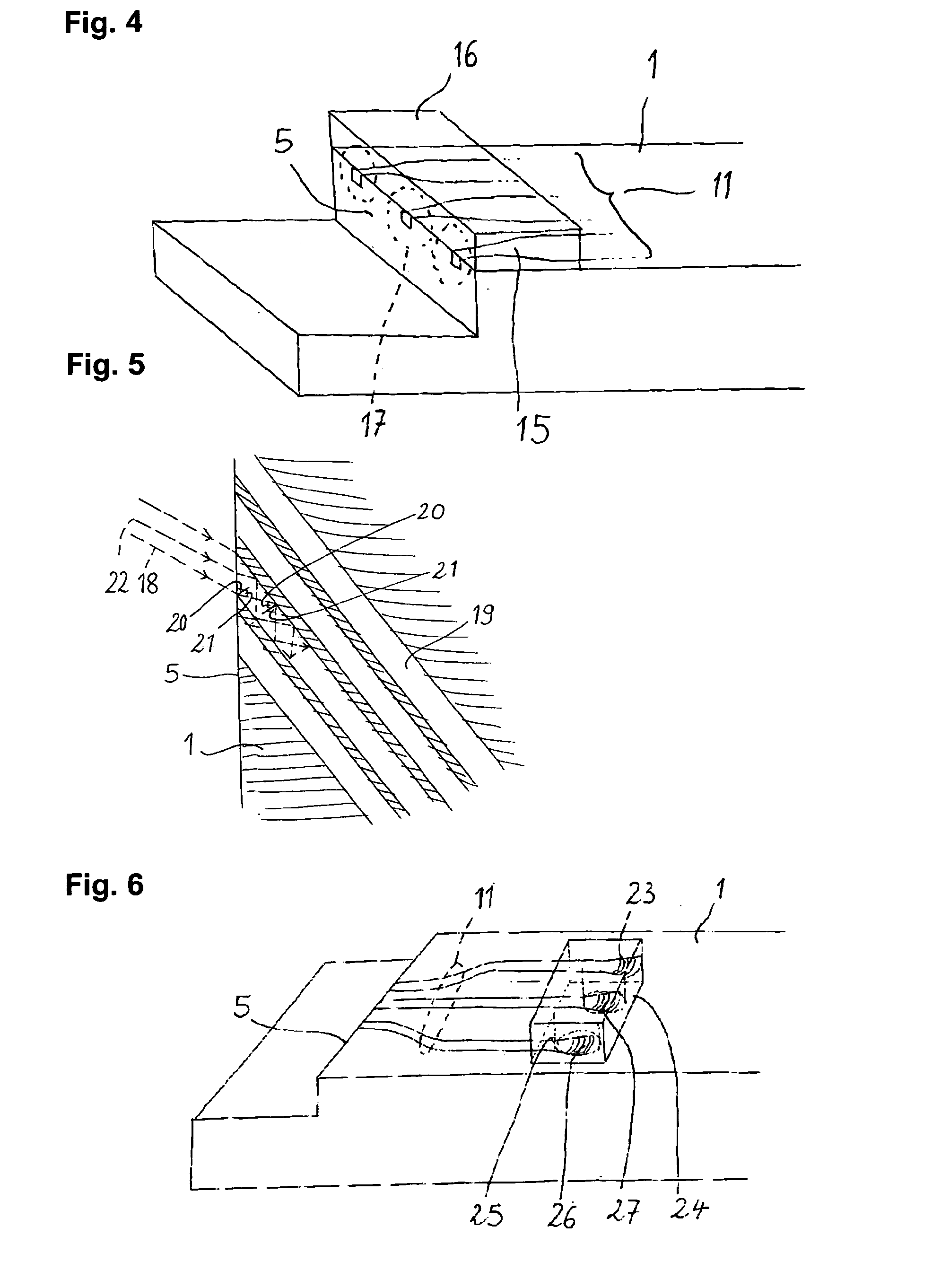

Light emitting device using led

InactiveUS20040190304A1Extended service lifeEffective coolingDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

A light-emitting device (10) using an LED is proposed. This light-emitting device (10) is provided with a packaging substrate (1), a light-emitting element (2) which is mounted on this packaging substrate (1) with its face down, a fluorescent member (3) that is arranged face to face with a light-extracting surface (S) of the light-emitting element (2) without contacting the light-emitting element (2) and an optical member (4) which receives light that has been emitted from the light-emitting element (2) and made incident thereon through the fluorescent member (3), and aligns the incident light toward the outside of the device. Light, emitted from the light-emitting element (2), is made incident on the fluorescent member (3) to excite the fluorescent material so that the fluorescent material re-emits light having a wavelength different from that of the incident light. Those light rays, emitted from the light-emitting element (2), which have not been absorbed by the fluorescent member (3) and have passed through the fluorescent member (3) and those light rays that have been emitted from the fluorescent material are made incident on the optical member (4) and are aligned. Because the fluorescent member (3) is not made in contact with the light-emitting element (2), it does not receive the heat from the light-emitting element (2) through heat conduction, and consequently becomes less susceptible to degradation due to heat. Moreover, with the face-down mounting structure, the fluorescent member (3) and the optical member (4) can be placed closer to the light-emitting element (2) as long as they dose not contact the light-emitting element (2). Consequently, the service life of the fluorescent material or the fluorescent-material-mixed resin that tends to deteriorate can be lengthened, lights can be extracted more efficiently, and light rays can be properly aligned in a predetermined direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

High power light emitting diode package and fabrication method thereof

InactiveUS20050139846A1Improve cooling effectSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

Disclosed is a high power LED package. In the LED package, a lower board has a heat radiation member in an LED mounting area and at least one via hole around the heat radiation member. First and second bottom electrodes are formed in the underside of the lower board, and connected to the heat radiation member and the via hole. An insulation layer is formed on the lower board to cover the heat radiation member. First and second electrode patterns on the insulation layer are connected to the first and second bottom electrodes through the via hole.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Radiator for light emitting unit, and backlight device

InactiveUS20070019419A1Increase brightnessGuaranteed uptimeMeasurement apparatus componentsLighting heating/cooling arrangementsHeat spreaderClose contact

Owner:SONY CORP

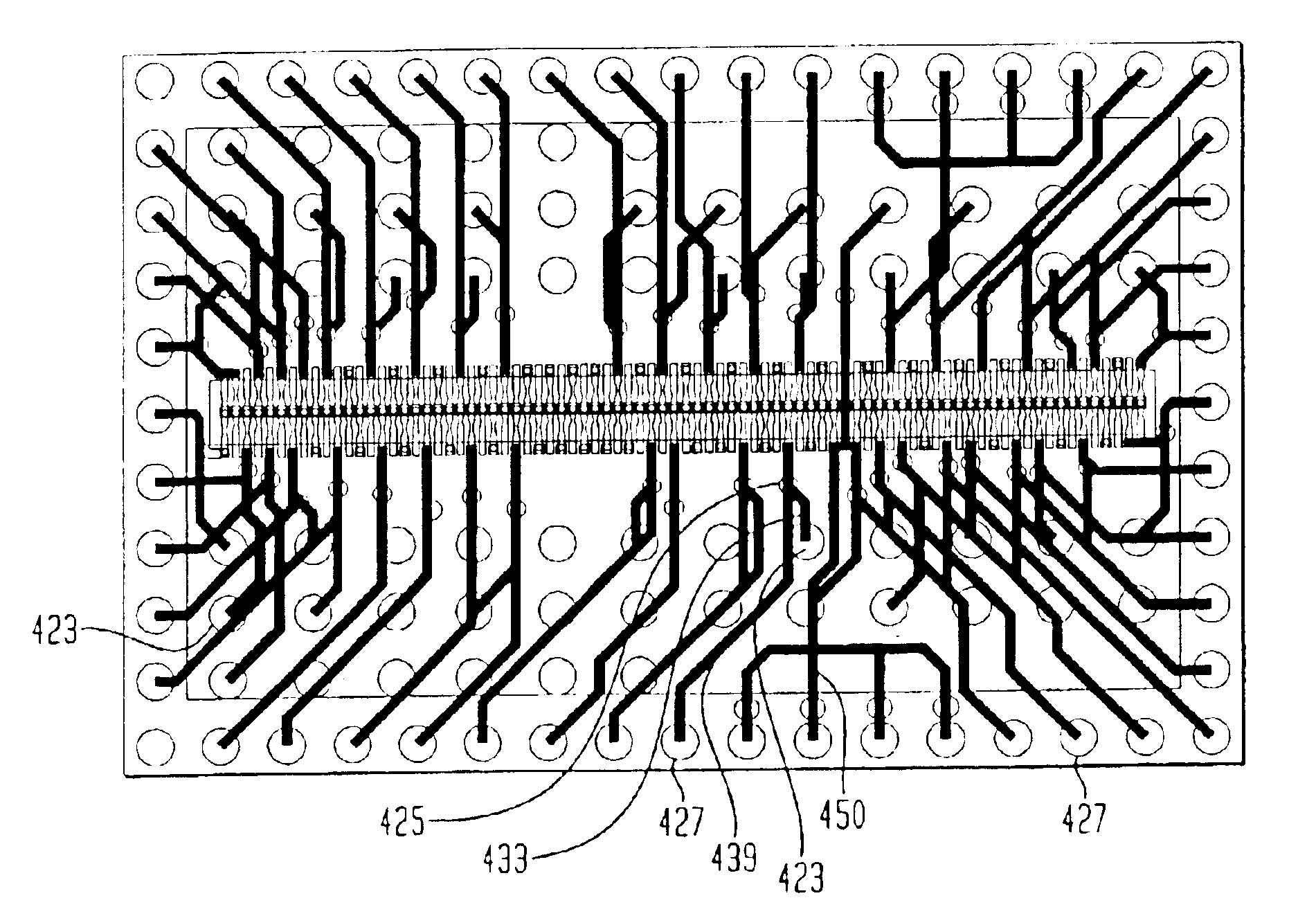

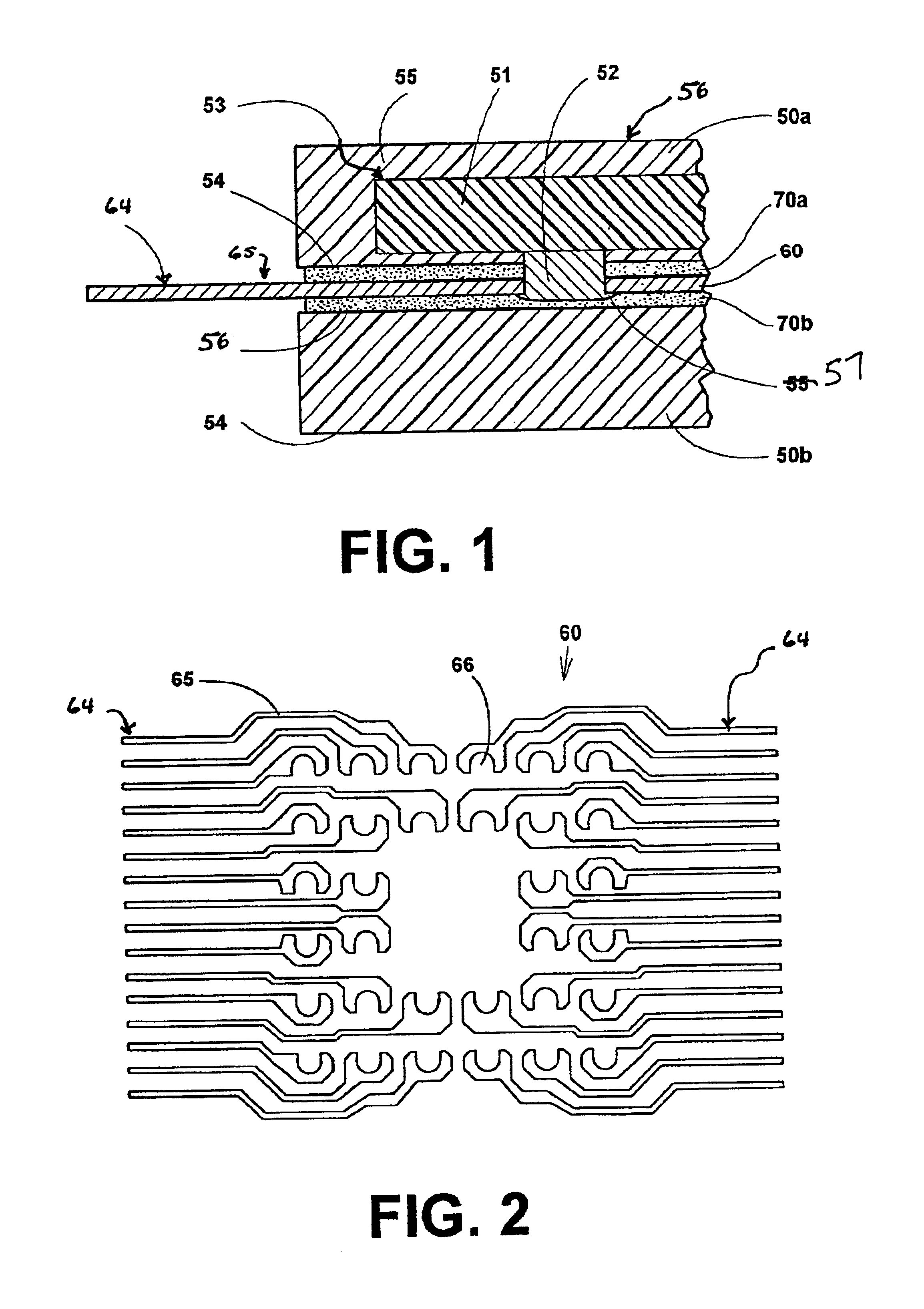

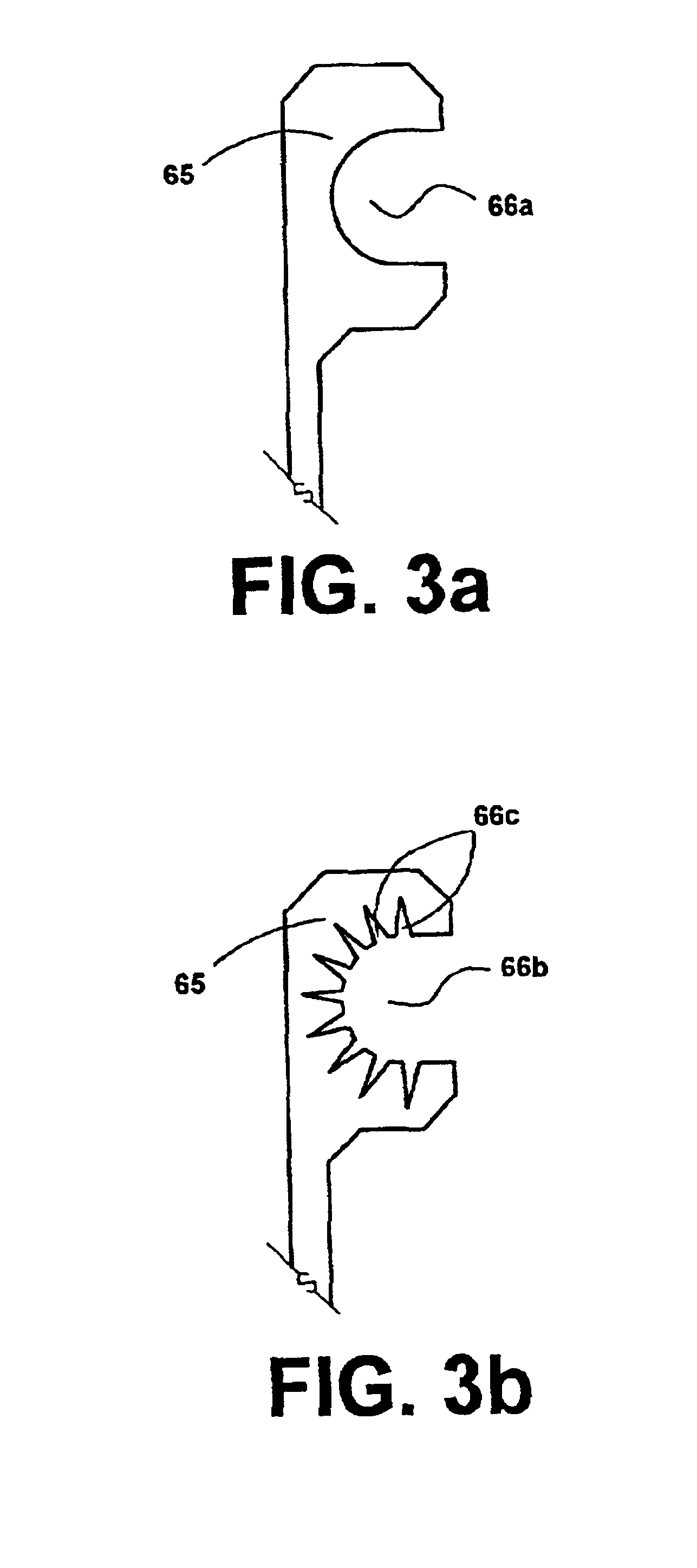

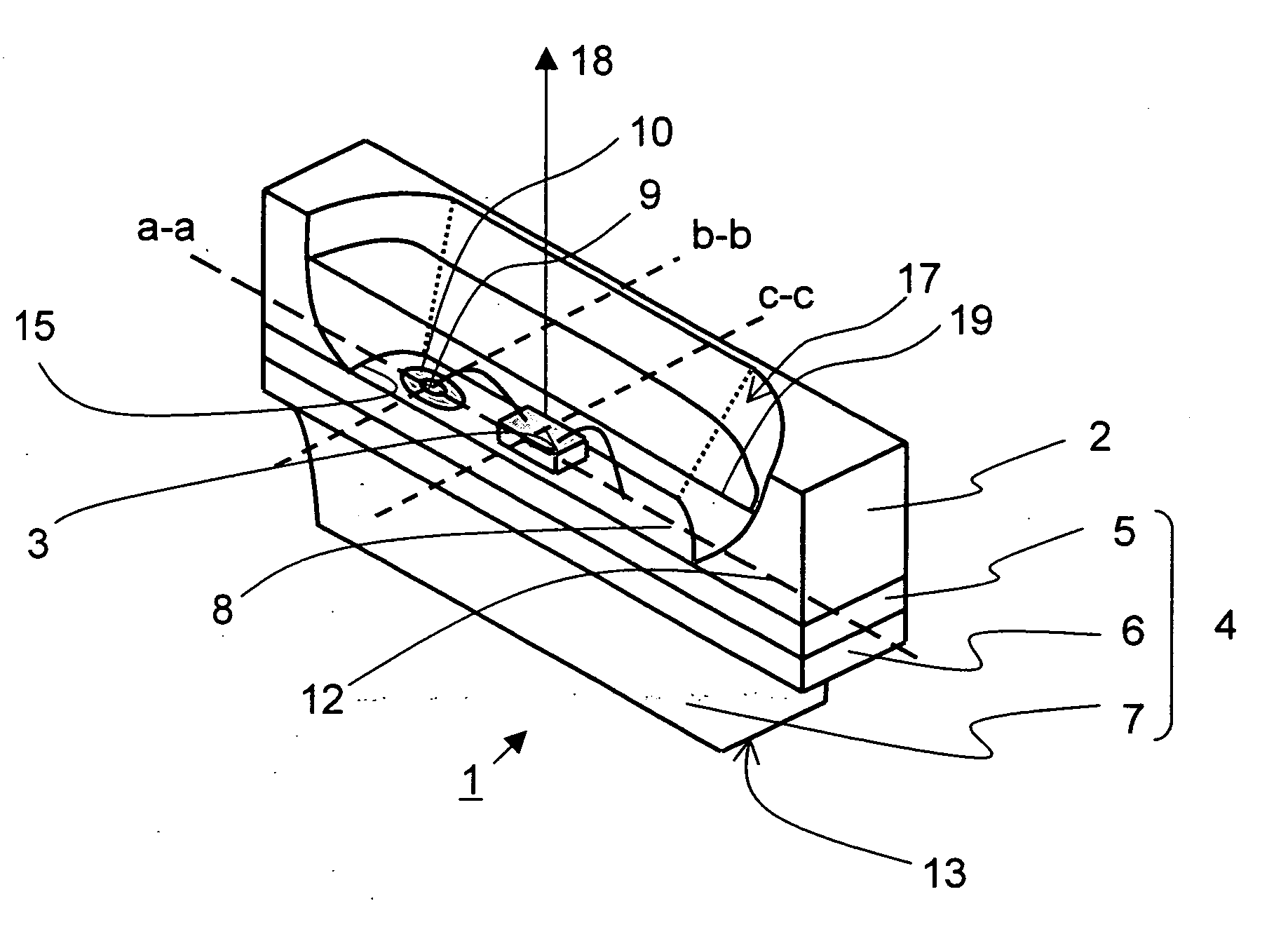

Stacked packages

InactiveUS6977440B2Well formedSimplifying handling and stockingPrinted circuit detailsFinal product manufactureSolder ballChip select

A stacked chip assembly includes individual units having chips mounted on dielectric layers and traces on the dielectric layers interconnecting the contacts of the chips with terminals disposed in peripheral regions of the dielectric layers. At least some of the traces are multi-branched traces which connect chip select contacts to chip select terminals. The units are stacked one above the other with corresponding terminals of the different units being connected to one another by solder balls or other conductive elements so as to form vertical buses. Prior to stacking, the multi-branched traces of the individual units are selectively connected, as by forming solder bridges, so as to leave chip select contacts of chips in different units connected to different chip select terminals and thereby connect these chips to different vertical buses. The individual units desirably are thin and directly abut one another so as to provide a low-height assembly with good heat transfer from chips within the stack.

Owner:TESSERA INC

Light emitting diode module for automobile headlights and automobile headlight having the same

ActiveUS7128454B2Prevent penetrationEffective coolingLighting support devicesPoint-like light sourceEngineeringLight-emitting diode

The present invention relates to an LED module for automobile headlights. The LED module comprises a water proof structure together with a heat radiating structure in order to prevent the permeation of external moisture while efficiently radiating heat to the outside. The LED module may be combined with a lamp housing and a radiator to constitute an automobile headlight.

Owner:SEMILED INNOVATIONS LLC

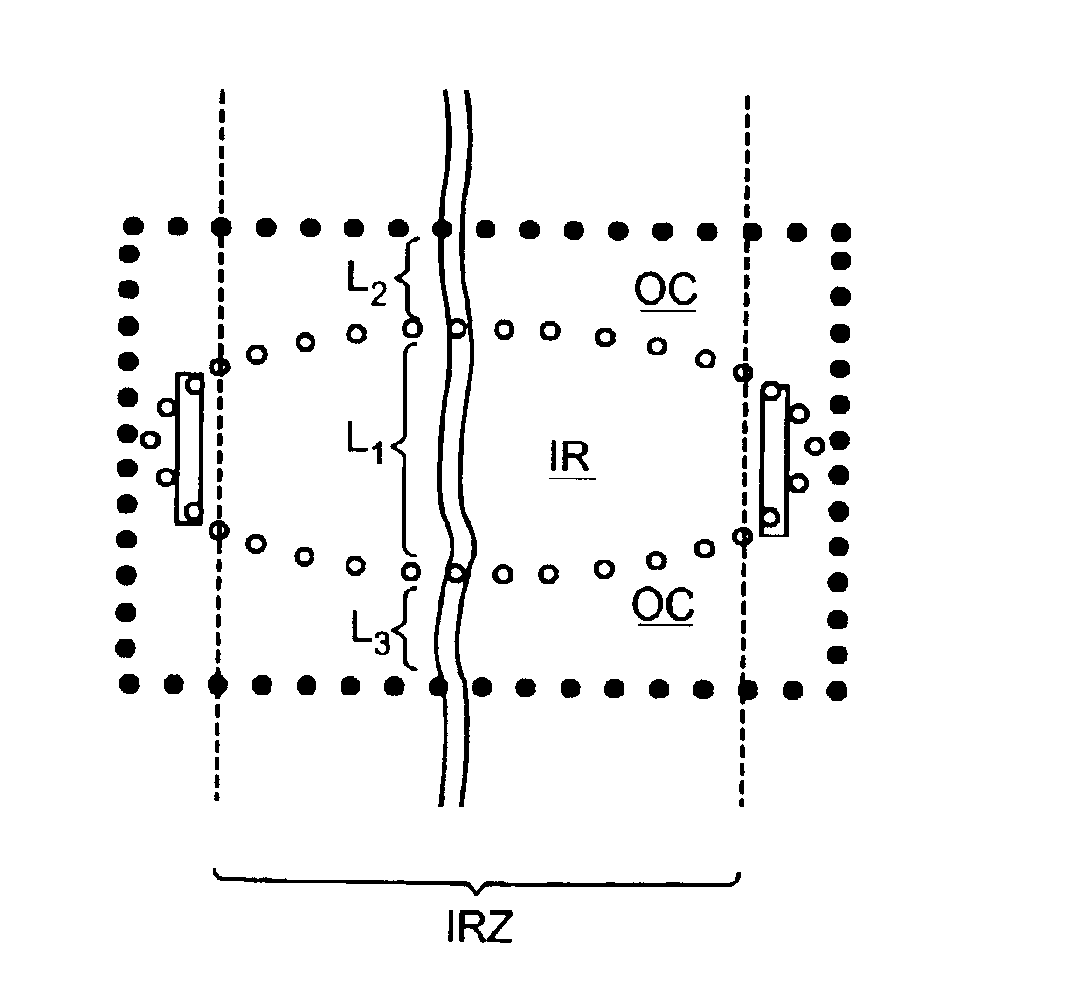

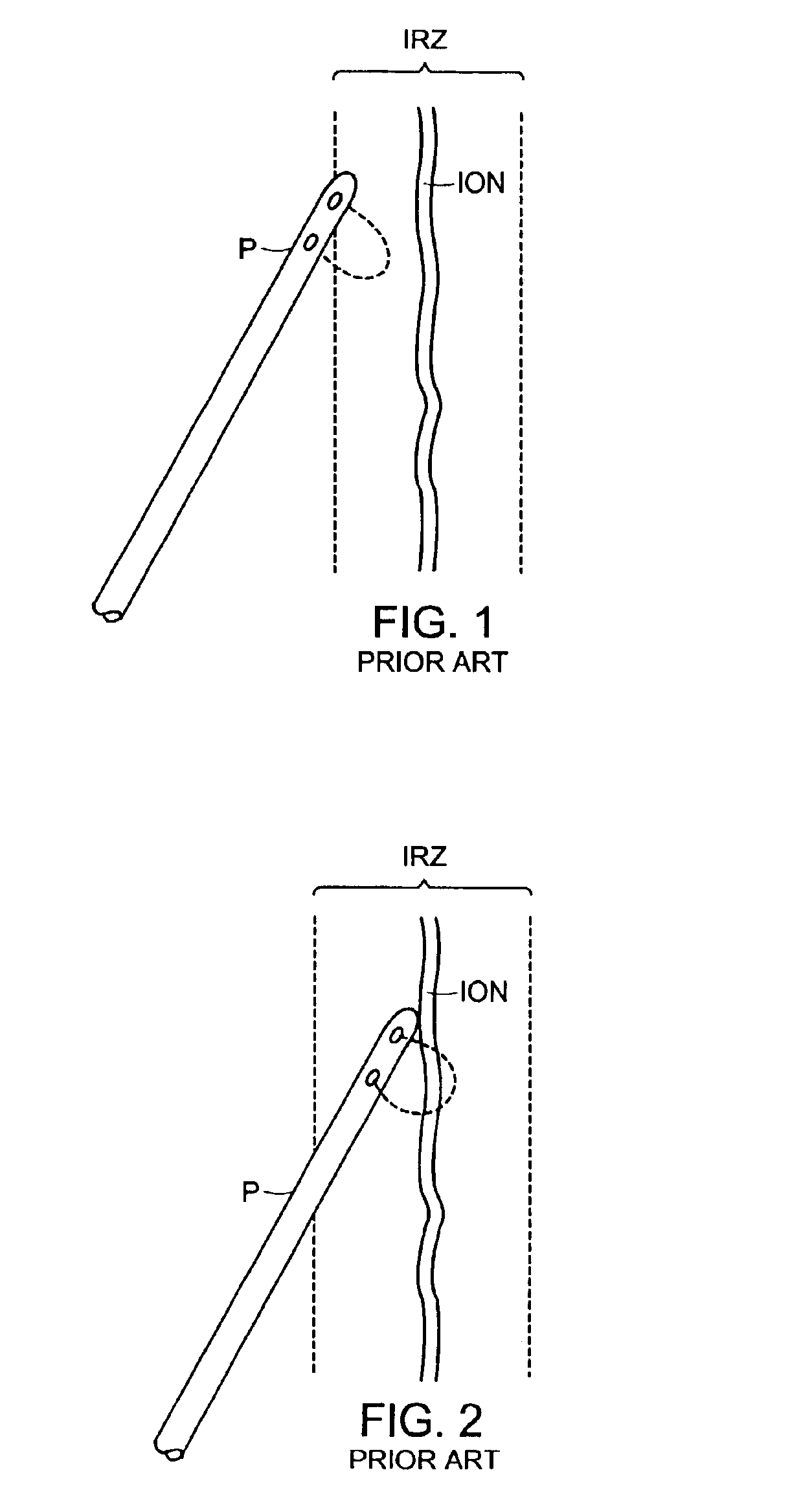

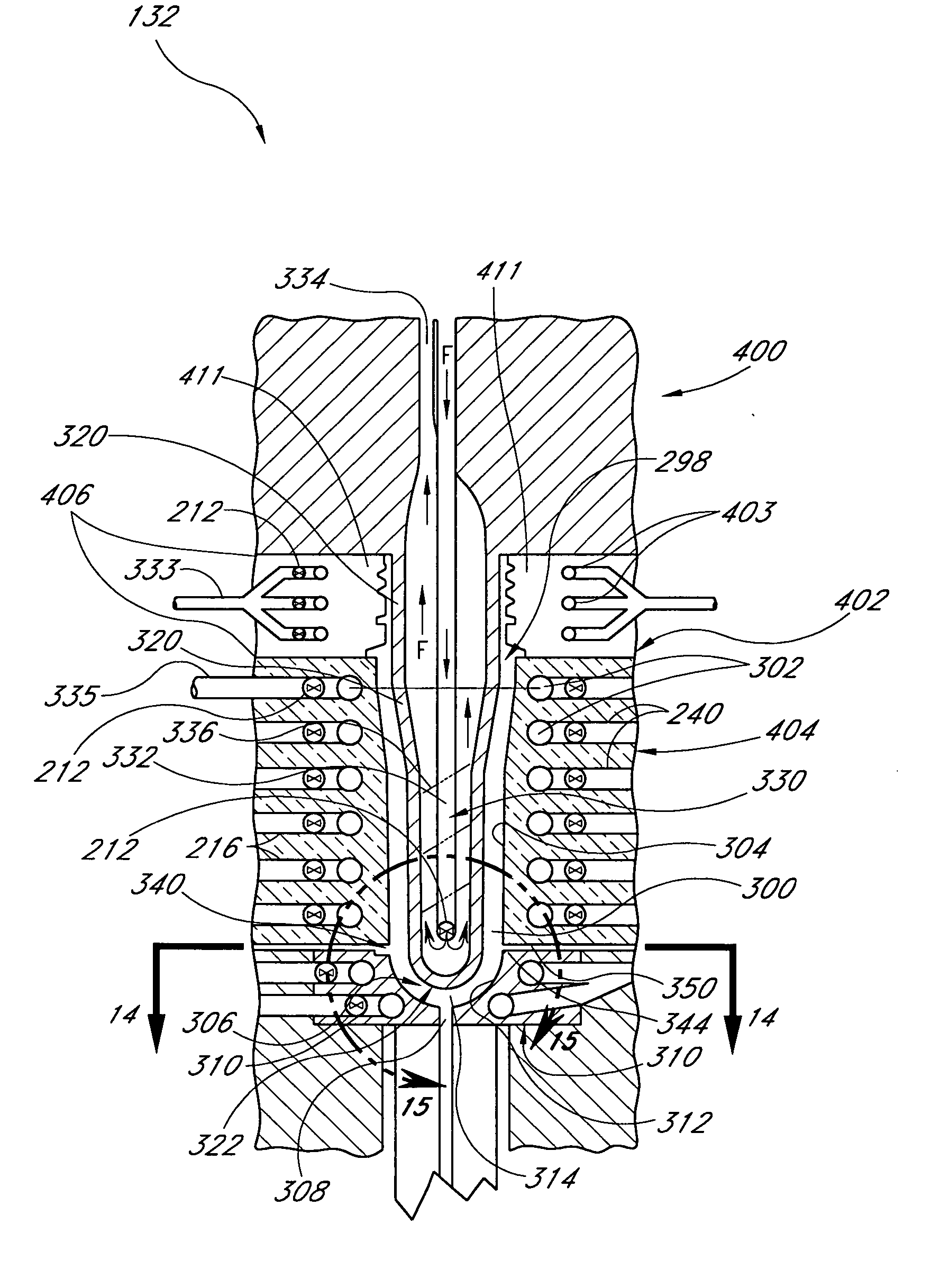

Method of straddling an intraosseous nerve

InactiveUS6907884B2Minimized volumeEffective coolingDiagnosticsSurgical needlesAnatomyTherapeutic treatment

This invention relates to a method of straddling an intraosseous nerve with an energy transmitting device to improve the therapeutic treatment of the nerve.

Owner:DEPUY ACROMED INC +1

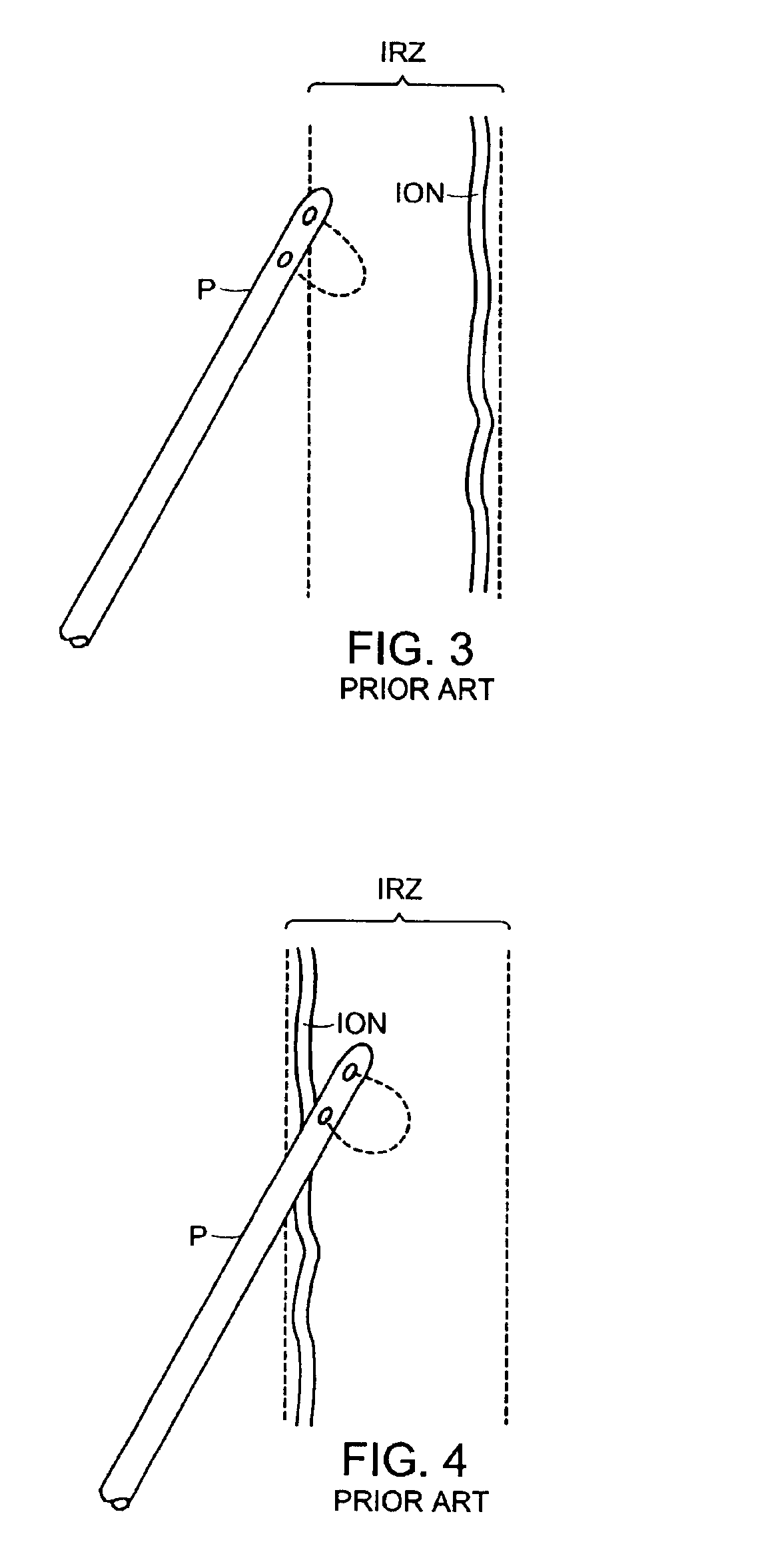

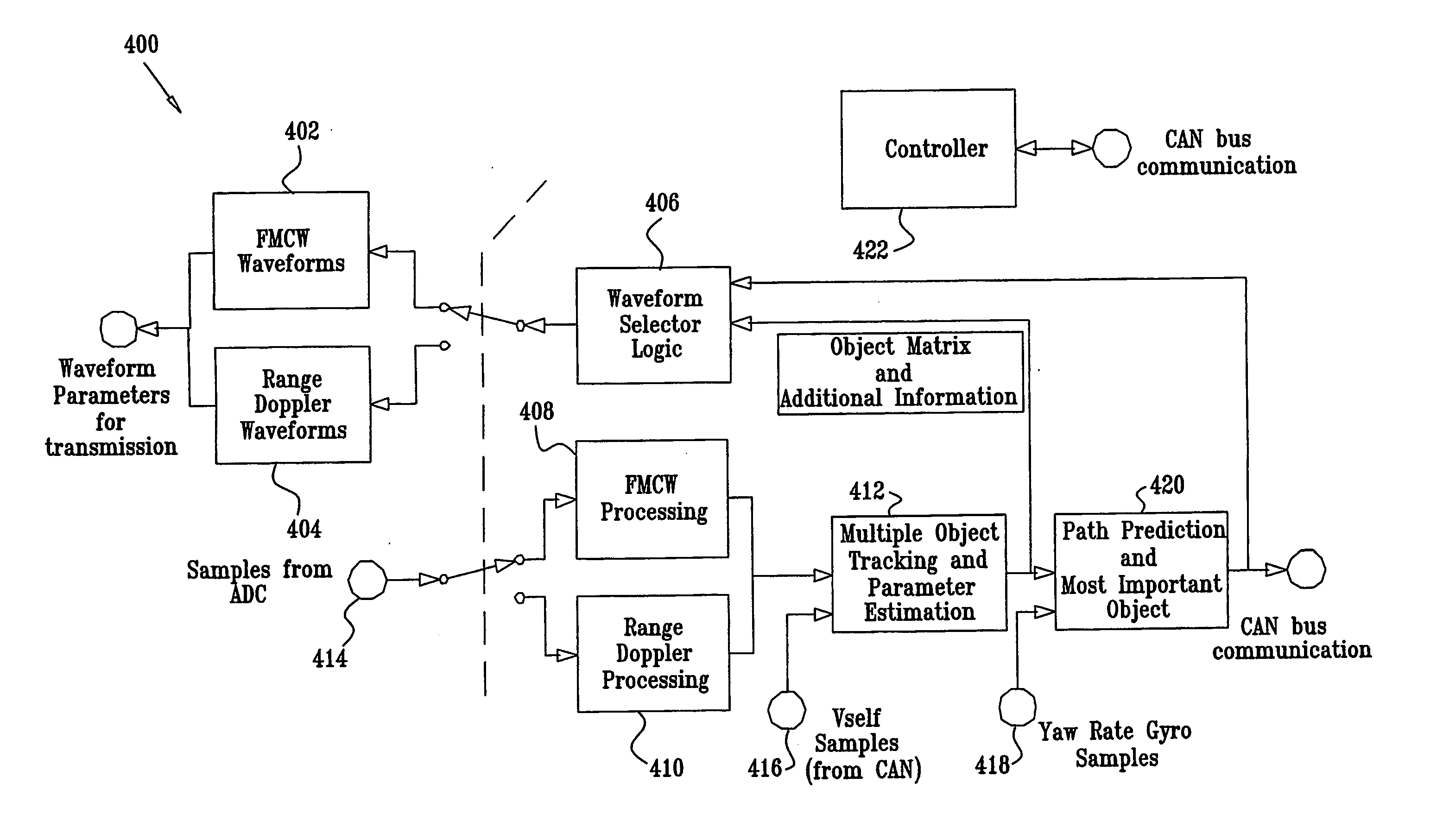

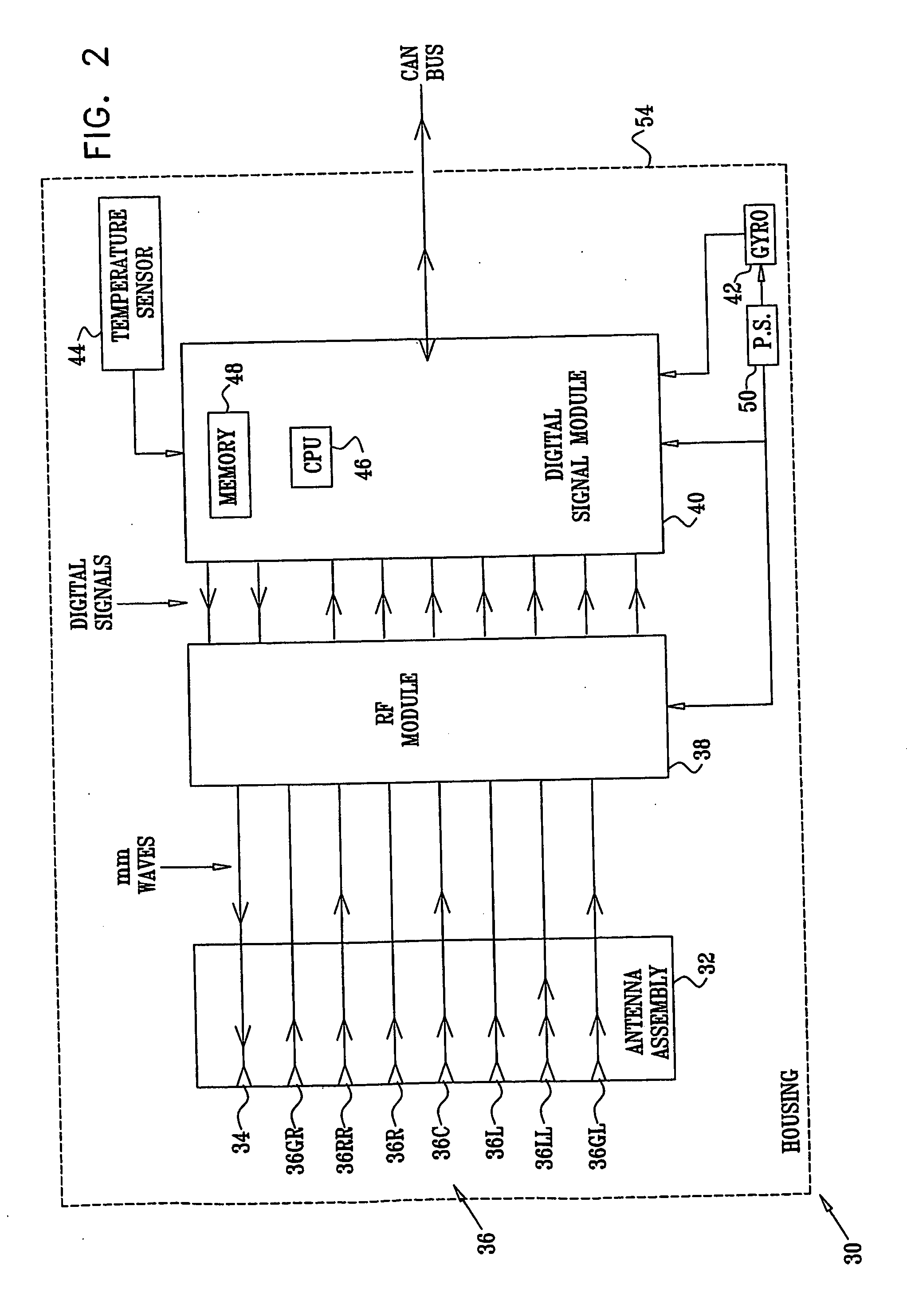

Forward-looking radar system

InactiveUS20050285773A1Improve discriminationPrecise maintenanceAntenna adaptation in movable bodiesRadio wave reradiation/reflectionElectricityRadar systems

An assembly for receiving and transmitting millimeter (mm) waves, including at least one mm wave reflector (84, 86, 88)and at least one mm transmission wave feed (72) configured in a transmission feed location (34) within the at least one mm wave reflector. The assembly also includes a plurality of receiving mm wave feeds (72) configured in respective receiving feed locations (36) within the at least one mm wave reflector; and a radio frequency (RF) module (38). The RF module is coupled to the at least one mm transmission wave feed and to the plurality of the receiving mm wave feeds, so as to drive the at least one mm transmission wave feed to transmit outgoing mm waves and to simultaneously receive incoming mm waves from all of the plurality of the receiving mm wave feeds.

Owner:GROENEVELD TRANSPORT EFFICIENCY

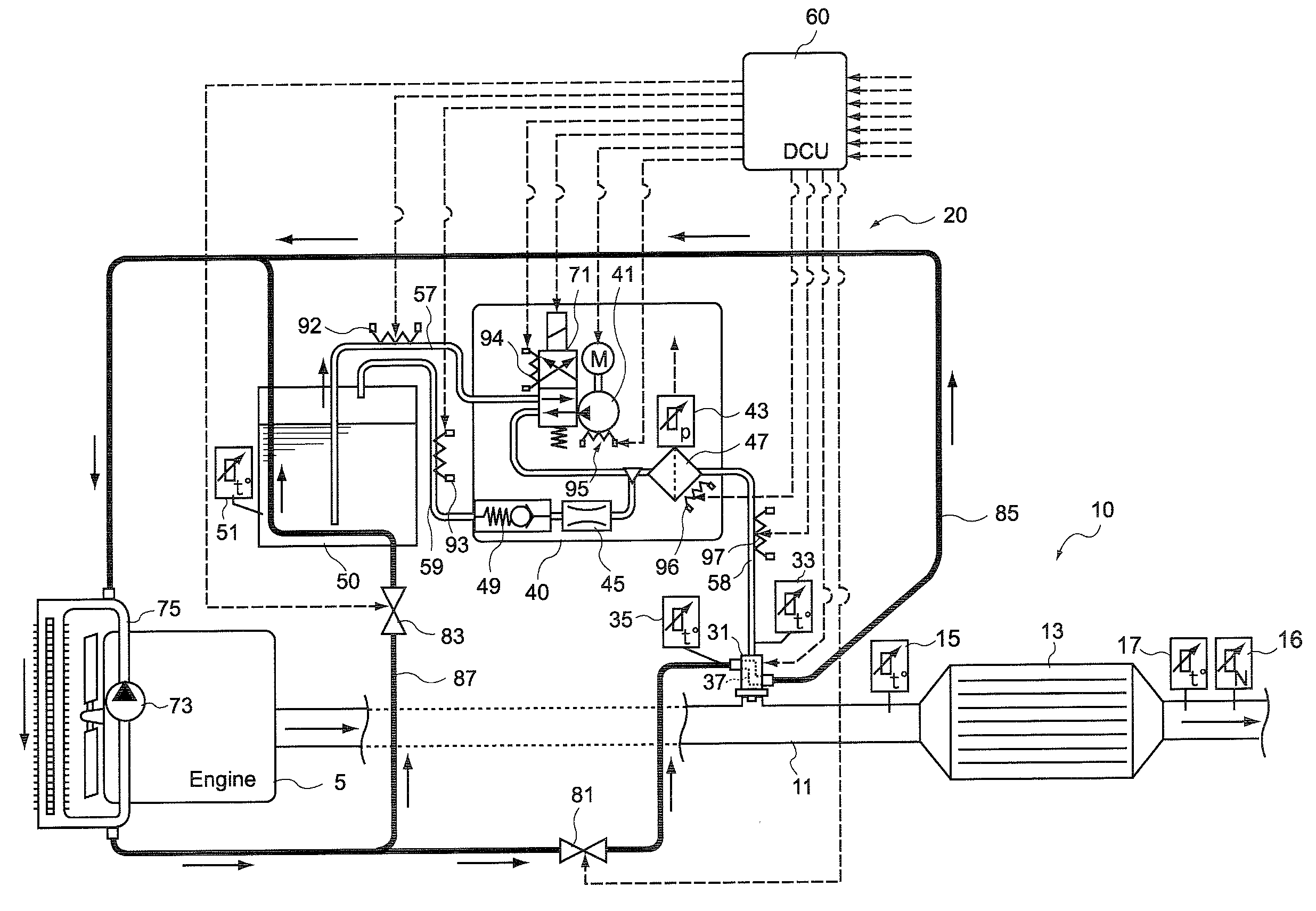

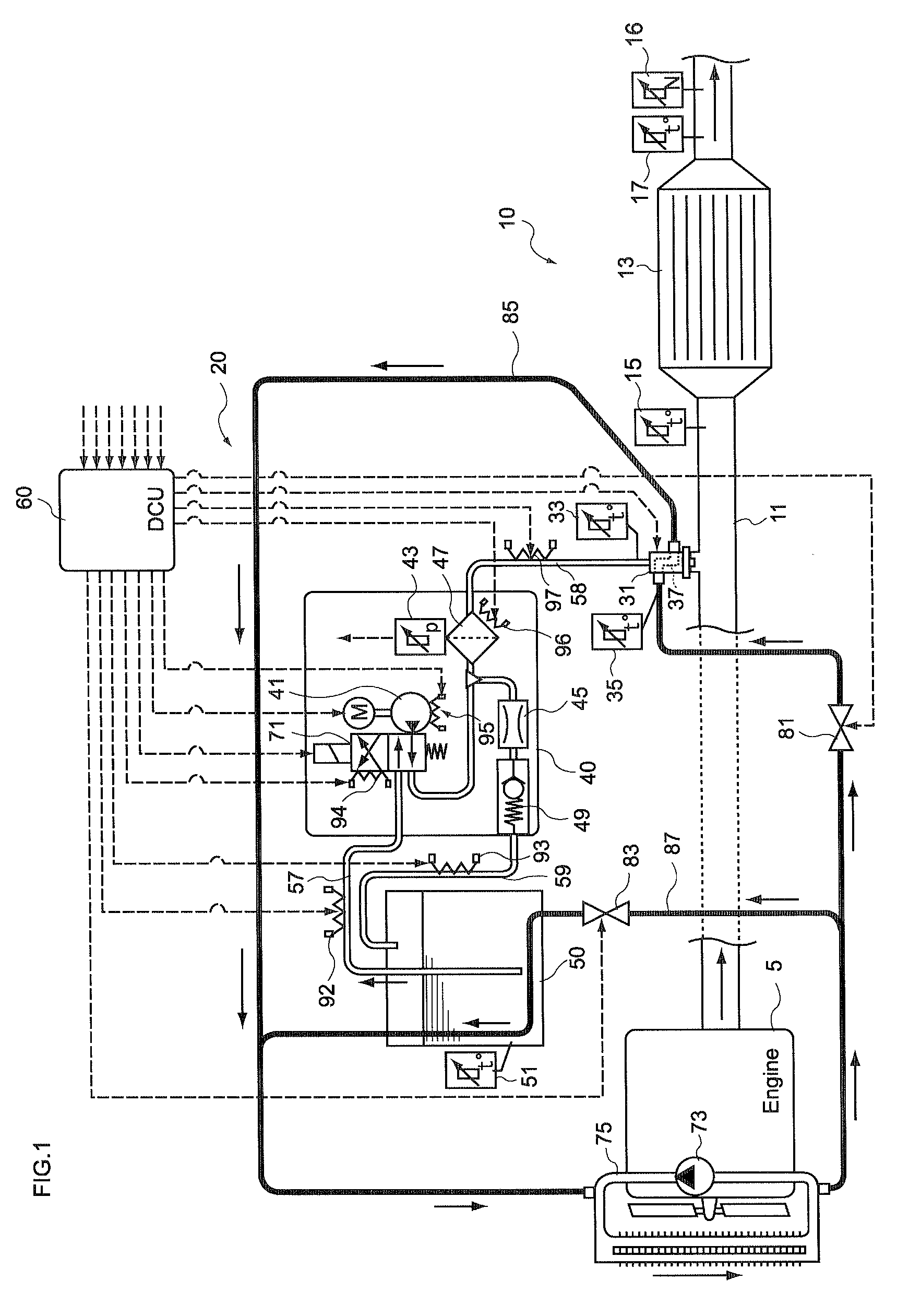

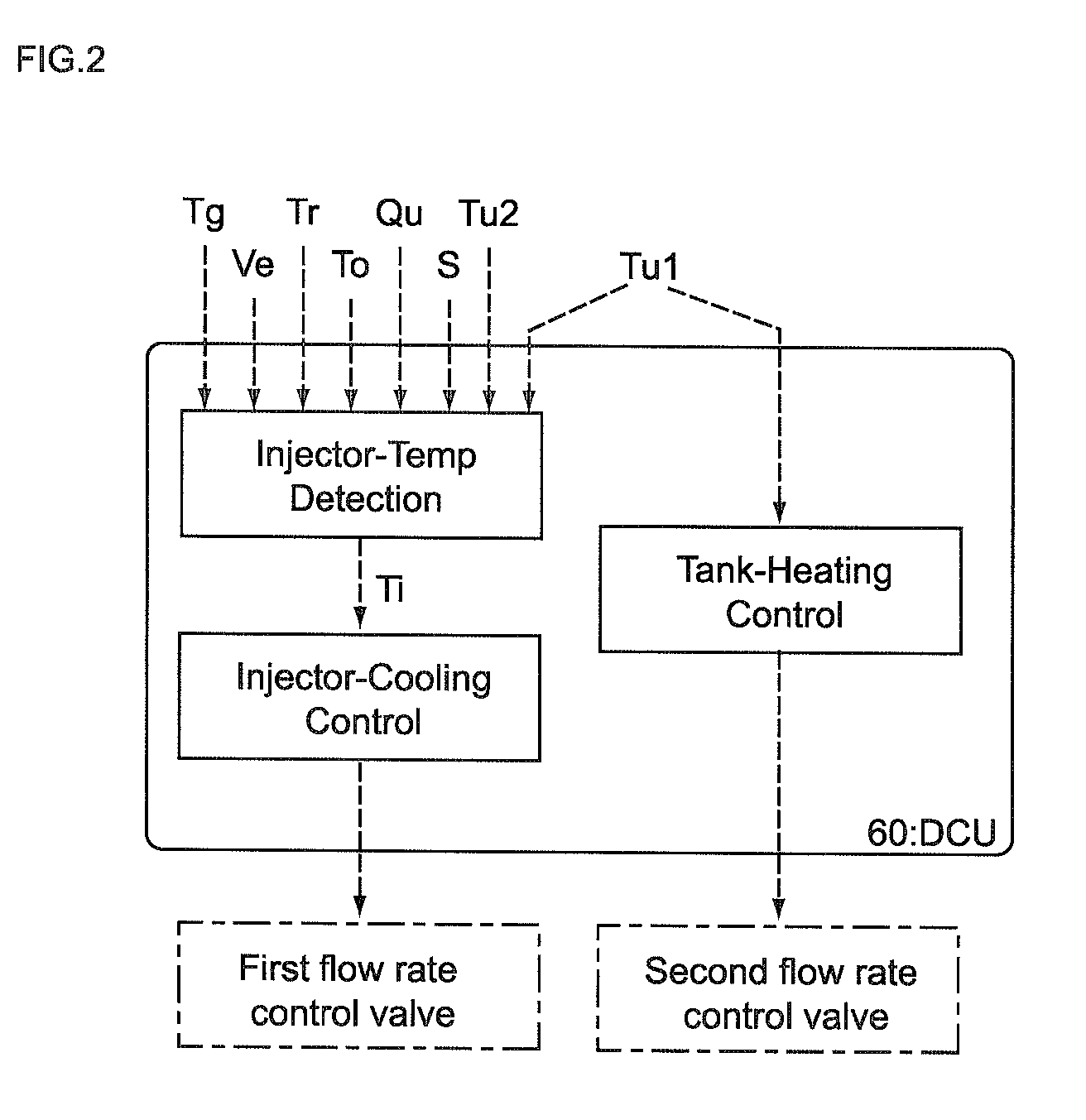

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

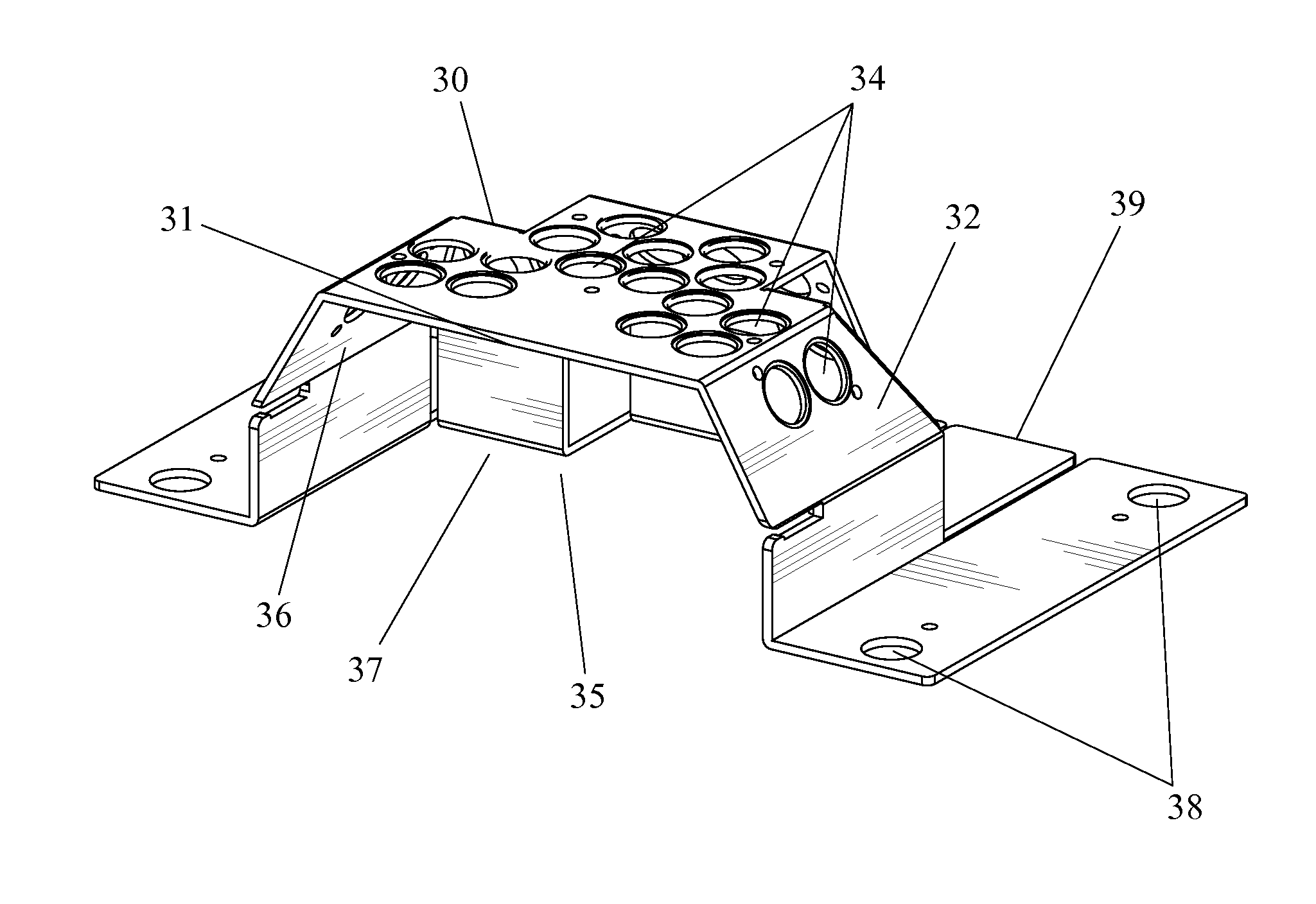

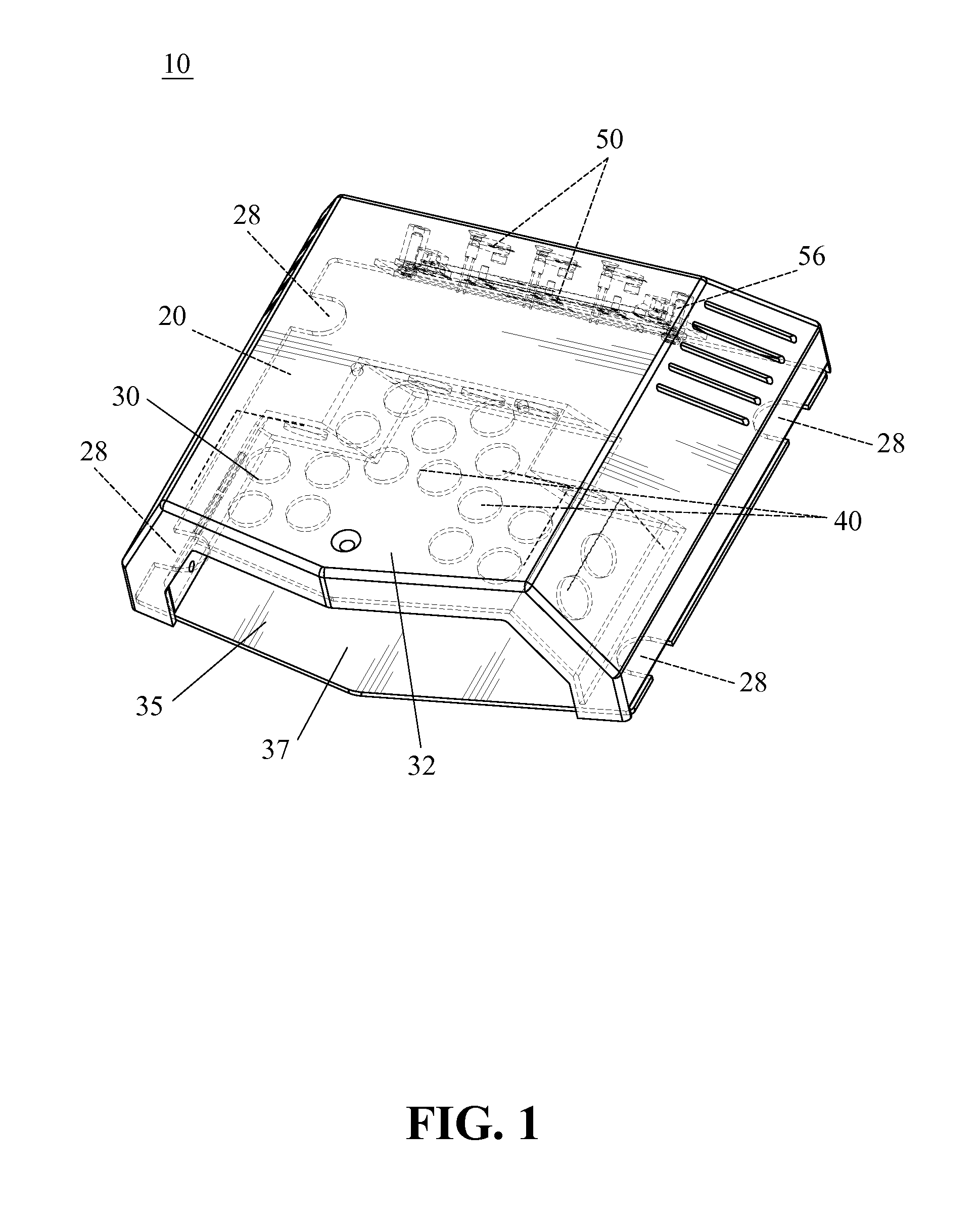

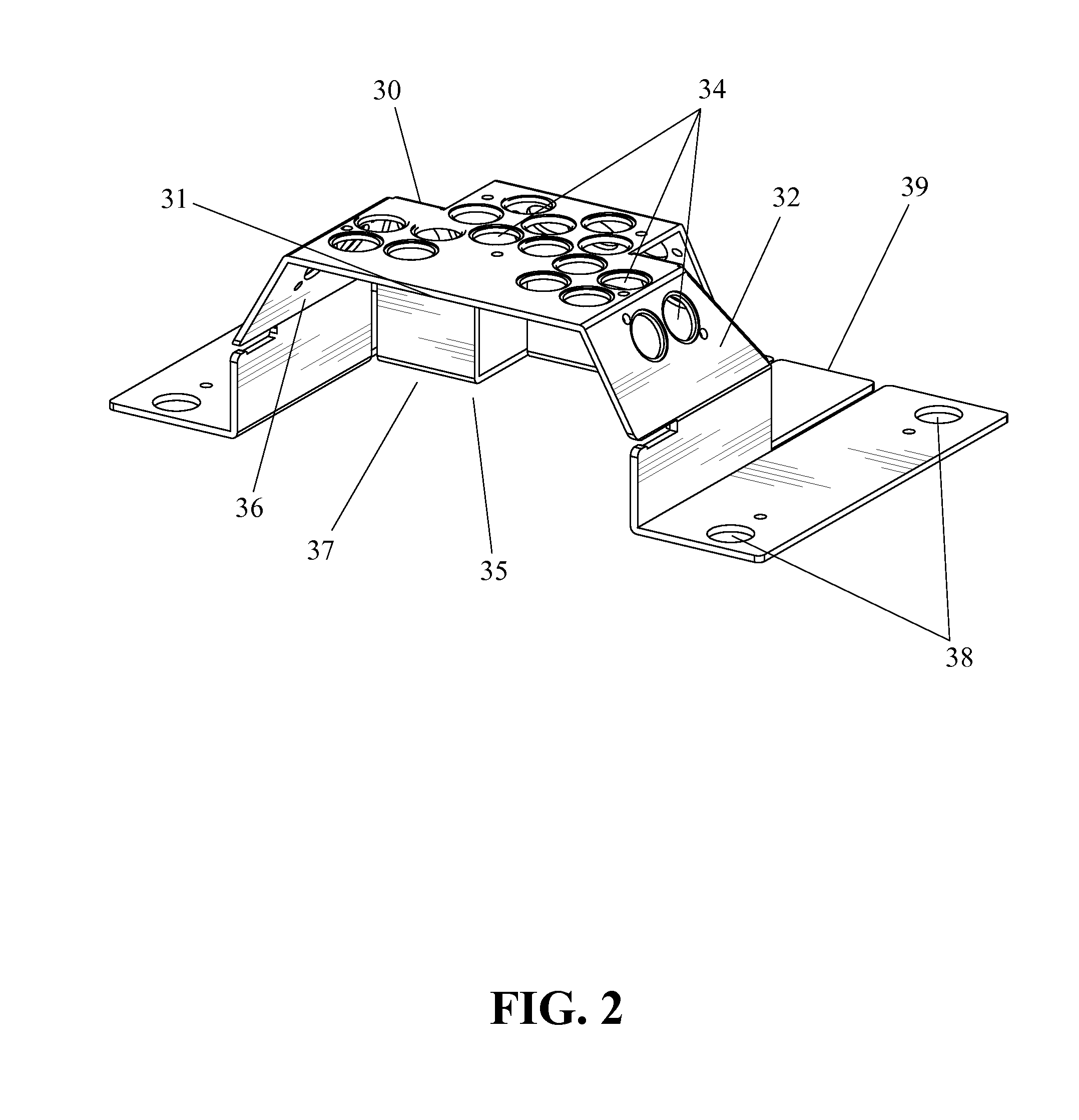

UV LED Curing Apparatus with Improved Housing and Switch Controller

InactiveUS20110277338A1Improve securityImprove reliabilityDrying solid materials with heatElectric circuit arrangementsAutomatic controlEngineering

The present invention is related to an UV LED curing apparatus, and more particularly, to an UV LED curing apparatus with improved housing and switch controller. The UV LED curing apparatus of the present invention is preferably provided for curing UV hardening gel applied onto the nails of multiple fingers or toes all at once and with automatic controls; the UV LED curing apparatus comprises a light reflective inner casing enclosing a curing chamber having a front opening, an outer casing detachably attached to the inner casing and an UV LED light source disposed on the inner casing and capable of providing an illumination covering a large space in the curing chamber. The automatic controls of the apparatus may be achieved by a switch controller having a photo interrupter, timer and current regulator such that the UV light from the UV LED light source is triggered to an on-state by the sensor of the photo interrupter and switched to an off-state by the timer and current regulator with reference to a preset curing time automatically. The UV LED light source is preferably to be of a wavelength between 360 nm and 460 nm. The light reflective inner casing is preferably provided as an effective UV light reflector and as a supporting substrate of the UV LED light source while being capable of transmitting heat from the UV LED light source away for further heat dissipation to the ambient by the outer casing. The outer casing is detachably attached to the inner casing and allows a greater user interaction for decorative and entertainment purposes while also being a protective and heat dissipation means.

Owner:NAIL ALLIANCE

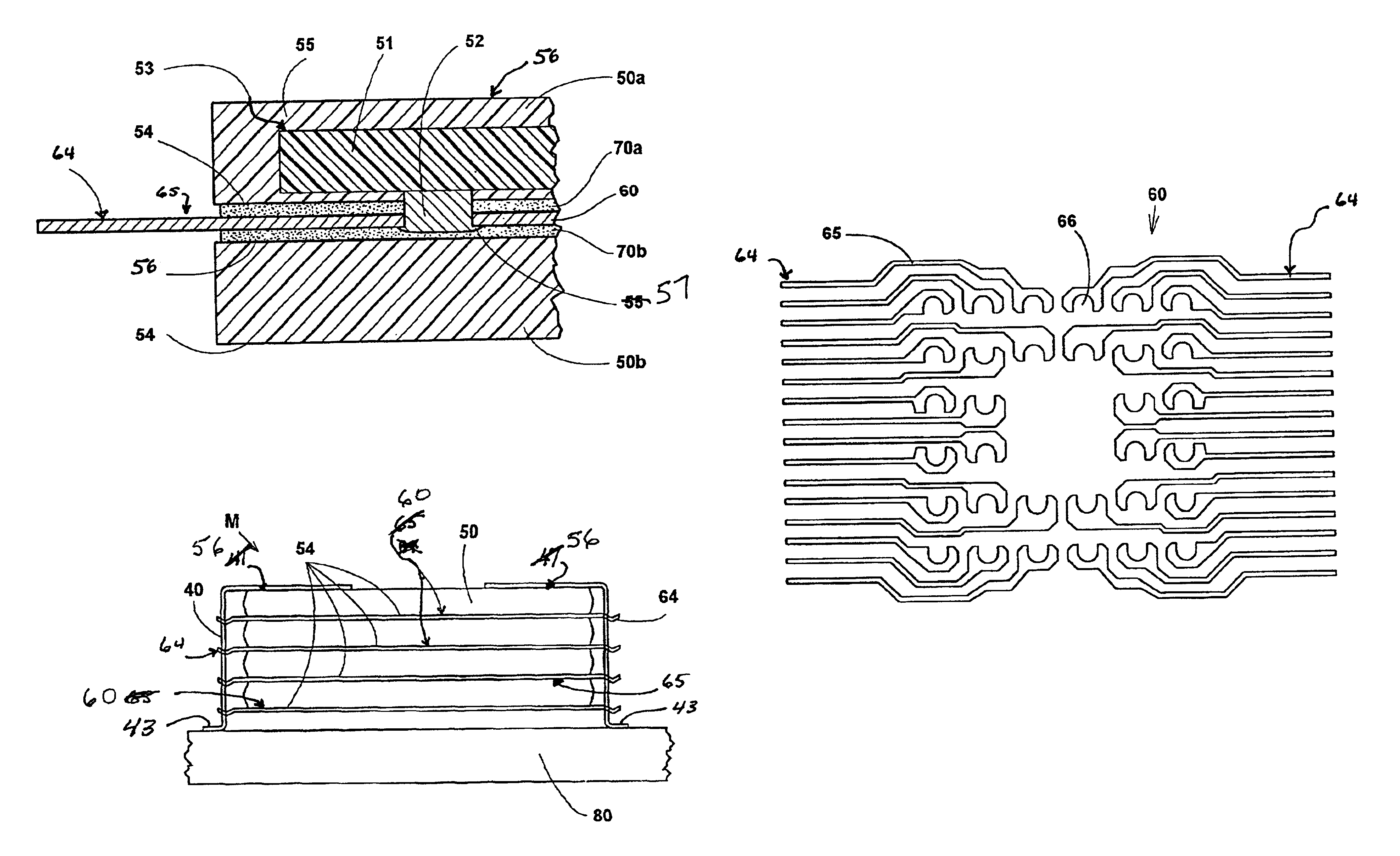

Liquid crystal polymer film, laminate, method of making them and multi-layered parts-mounted circuit board

InactiveUS6274242B1With balanceImprove thermal conductivityLiquid crystal compositionsLamination ancillary operationsThermal deformationPolymer chemistry

A polymer film capable of forming an optically anisotropic melt phase is, after having been laminated on a base material capable of supporting the shape of the film during heat treatment, is heat-treated at a temperature of from the thermal deformation temperature Tdef of the film to a temperature lower by alpha (alpha=10 to 35° C.) than the melting point Tm of the film until the fusion peak temperature TA of the film attains a temperature which is higher by beta (beta=5 to 30° C.) than the melting point Tm of the film before the heat treatment and is subsequently heat-treated at a temperature of from a temperature not lower than the melting point Tm of the film to a temperature lower than the fuision peak temperature TA for a length of time over which the TA increases by gamma (gamma=5 to 20° C.), and thereafter the base material is removed to produce the film.

Owner:KURARAY CO LTD

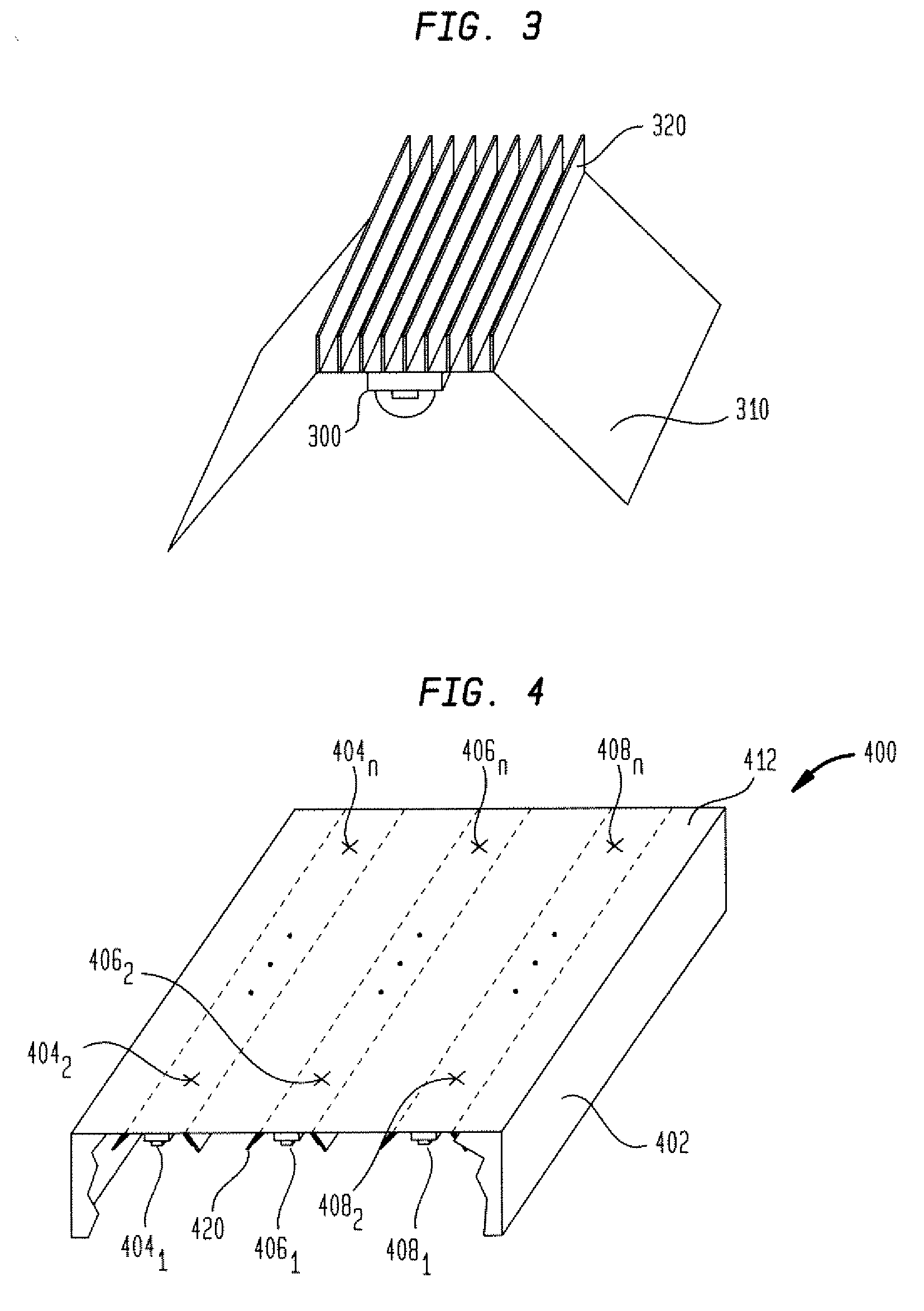

Methods and Apparatus for Improved Heat Spreading in Solid State Lighting Systems

ActiveUS20080089069A1Reduce weightEfficient transferLighting support devicesPoint-like light sourceEngineeringLED lamp

A solid state lighting subassembly or fixture includes an anisotropic heat spreading material. A heat spreading layer may be placed between a light emitting diode (LED) and luminaire or reflector and serves to spread heat laterally away from the LED. Low profile, low weight heat spreading may be utilized both to retrofit existing light fixtures with. LEDs or to replace existing incandescent and fluorescent fixtures with LED based fixtures.

Owner:IDEAL IND LIGHTING LLC

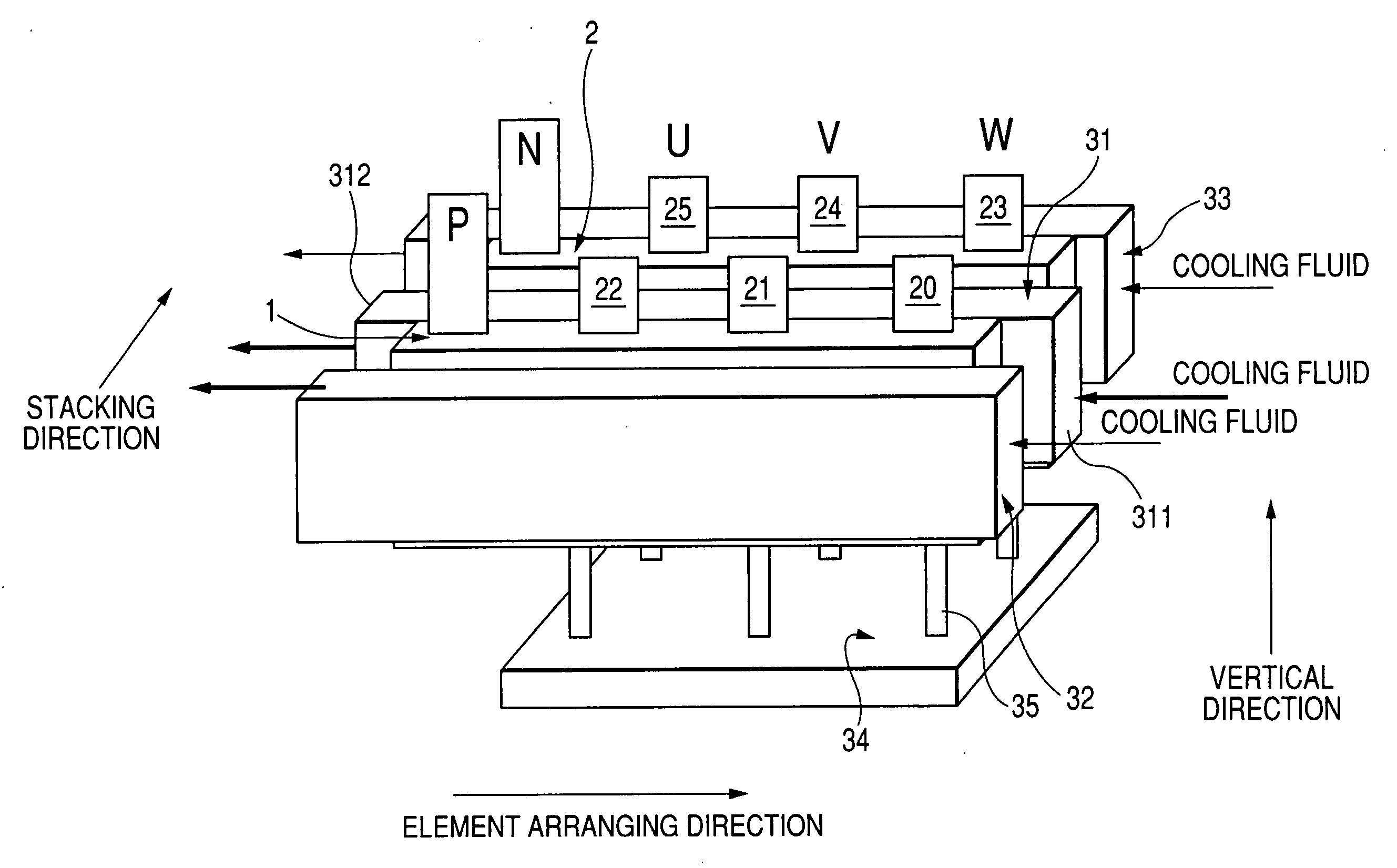

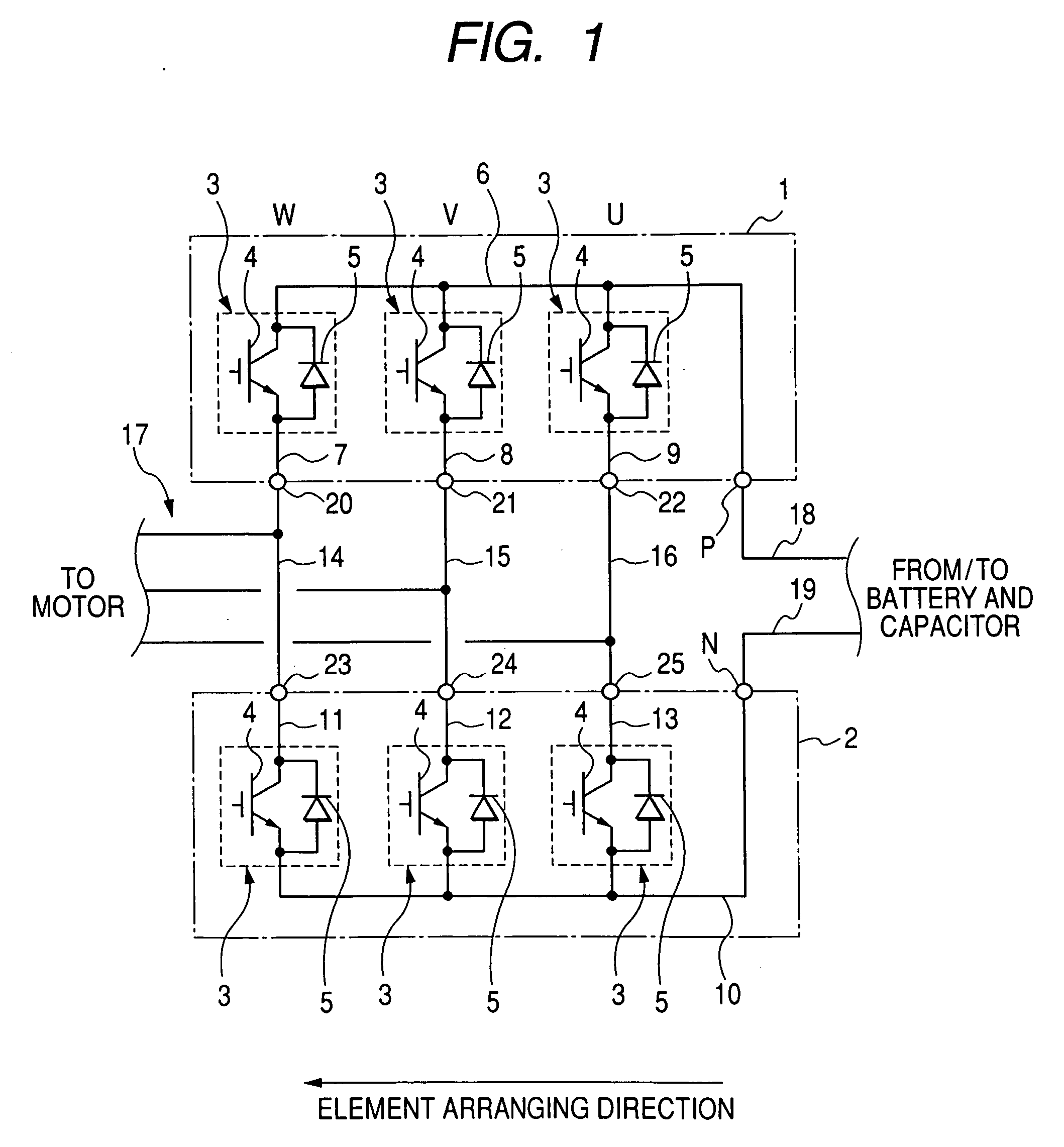

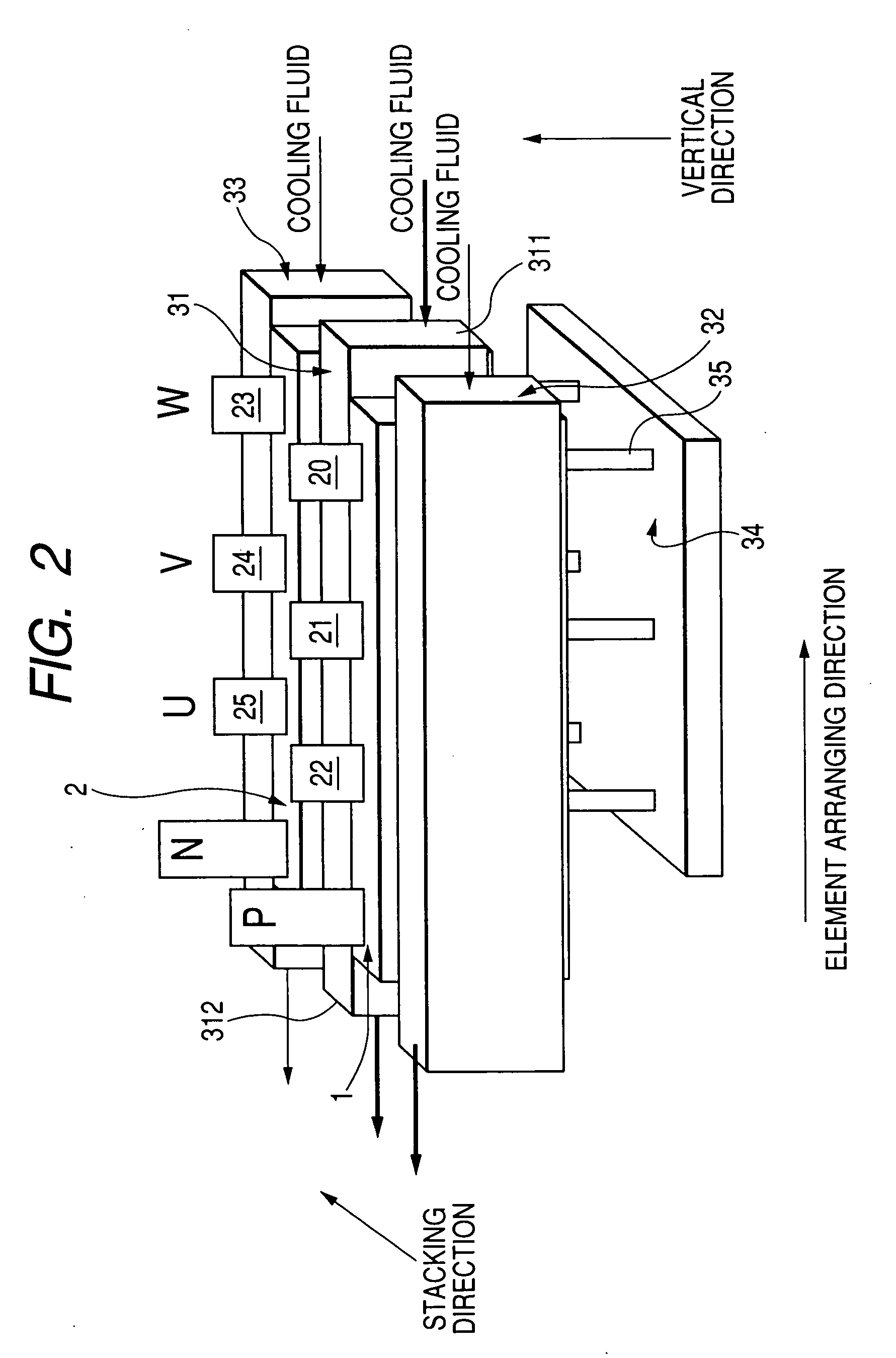

Module type multiphase inverter

ActiveUS20070076355A1Easy to manufactureEasy wiringConversion constructional detailsSubstation/switching arrangement cooling/ventilationEngineeringAlternating current

A multiphase inverter has two card shaped arm modules facing each other along a stacking direction. Each module has semiconductor switching elements disposed along an element arranging direction substantially perpendicular to the stacking direction, a common heat sink plate connecting direct current electrodes of the elements with one of terminals of the power source, and phase heat sink plates connecting respective alternating current electrodes of the elements with respective multiphase terminals of a motor. The elements of each module correspond to all phases of an alternating current. Each common heat sink plate forms a principal surface of the corresponding module, and the phase heat sink plates of each module forms another principal surface. The principal surfaces of each module face each other along the stacking direction.

Owner:DENSO CORP

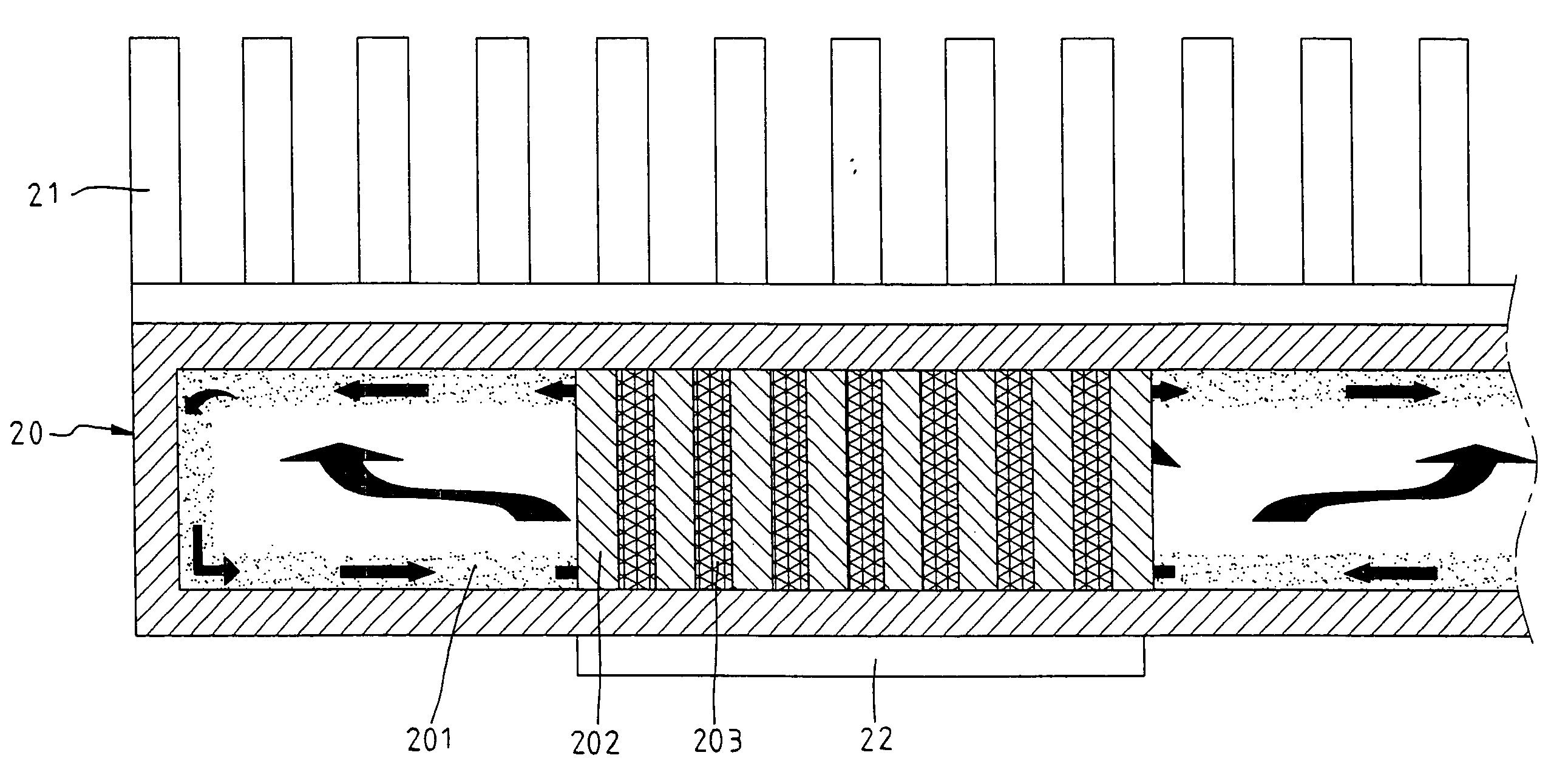

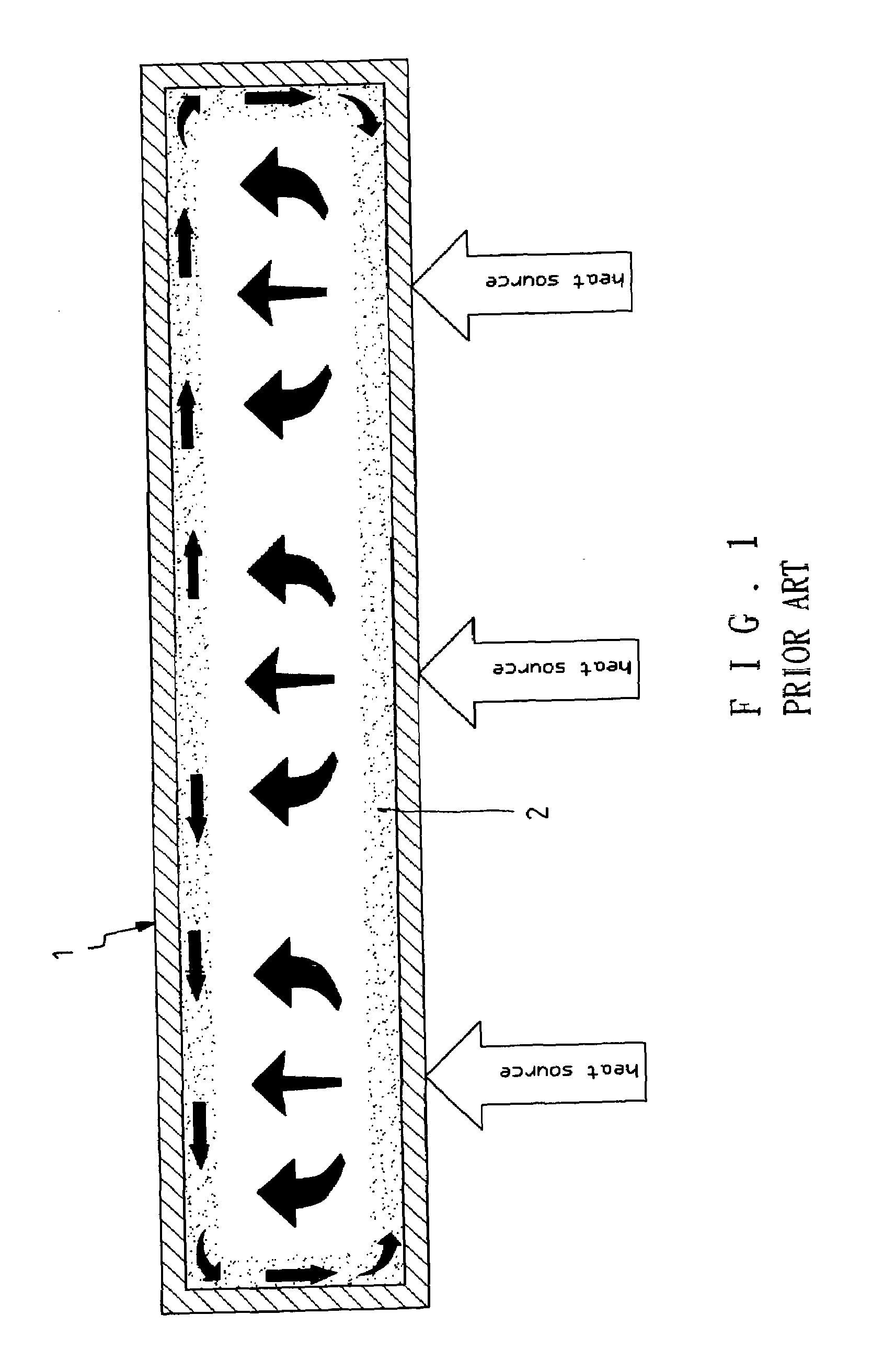

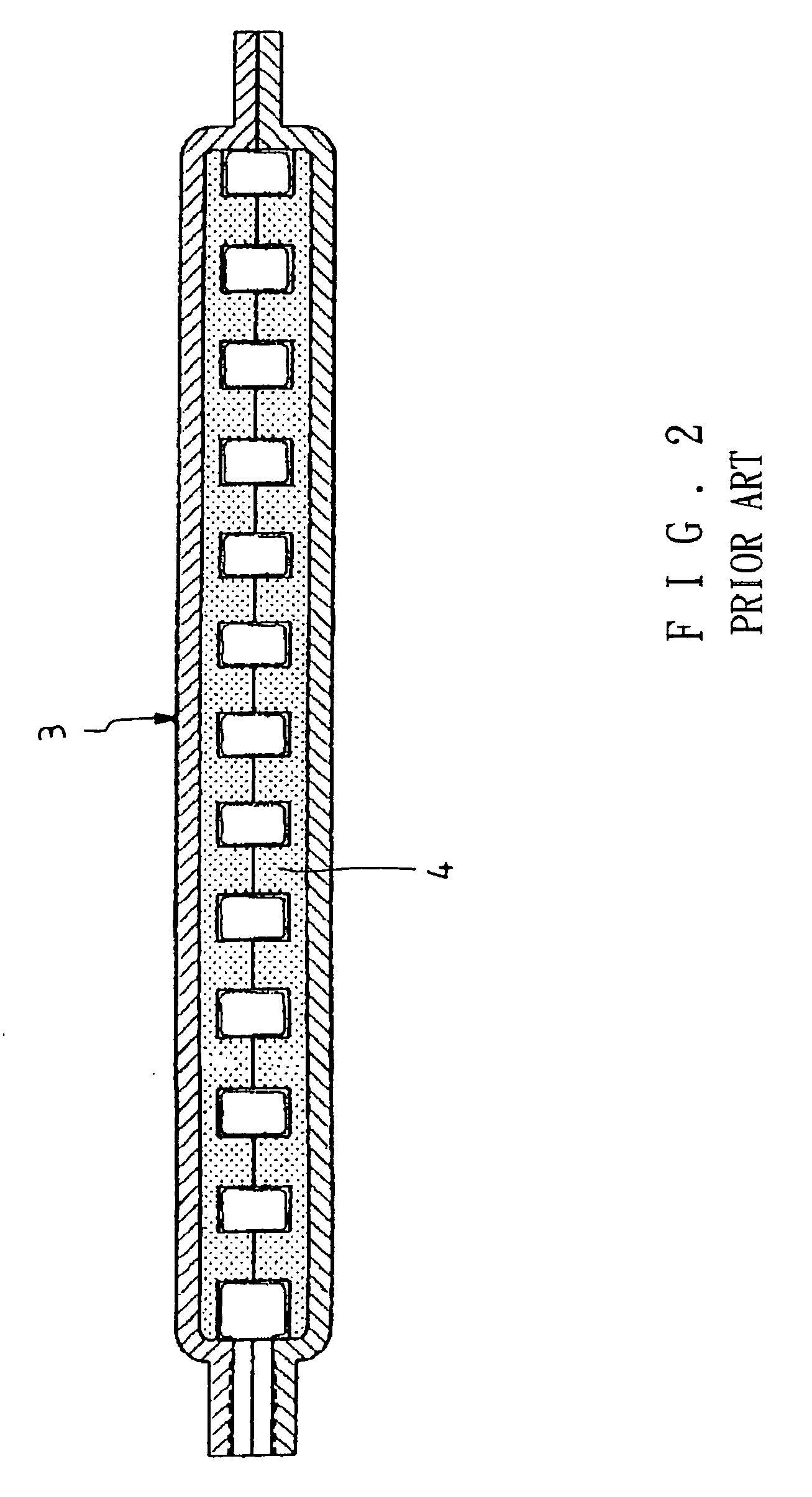

Flat heat pipe provided with means to enhance heat transfer thereof

ActiveUS6901994B1Improve cooling effectUniform temperature distributionSemiconductor/solid-state device detailsSolid-state devicesCyclic processWorking fluid

A flat heat pipe has a vacuum chamber, an evaporator connected to a heating element, and a condenser connected to a cooling device. The vacuum chamber is provided in an interior with a wick structure and a working fluid by which an evaporation-condensation cyclic process is effected. The vacuum chamber is further provided in the interior with a plurality of heat conduction pillars, which are confined to the area of the evaporator and are connected with an upper wall and a lower wall of the interior of the chamber. The heat conduction pillars serve to enhance the heat conduction to the condenser from the evaporator.

Owner:IND TECH RES INST

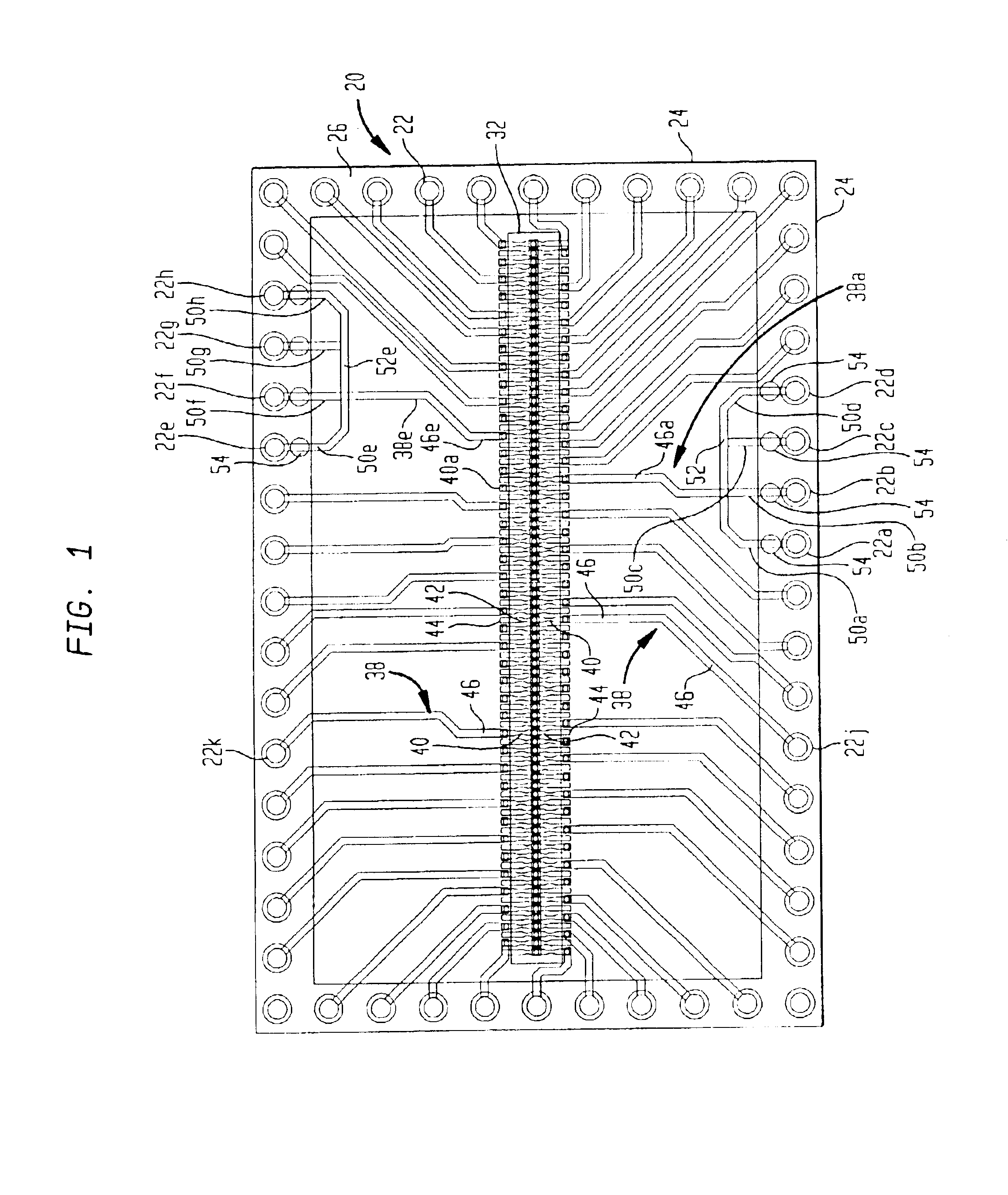

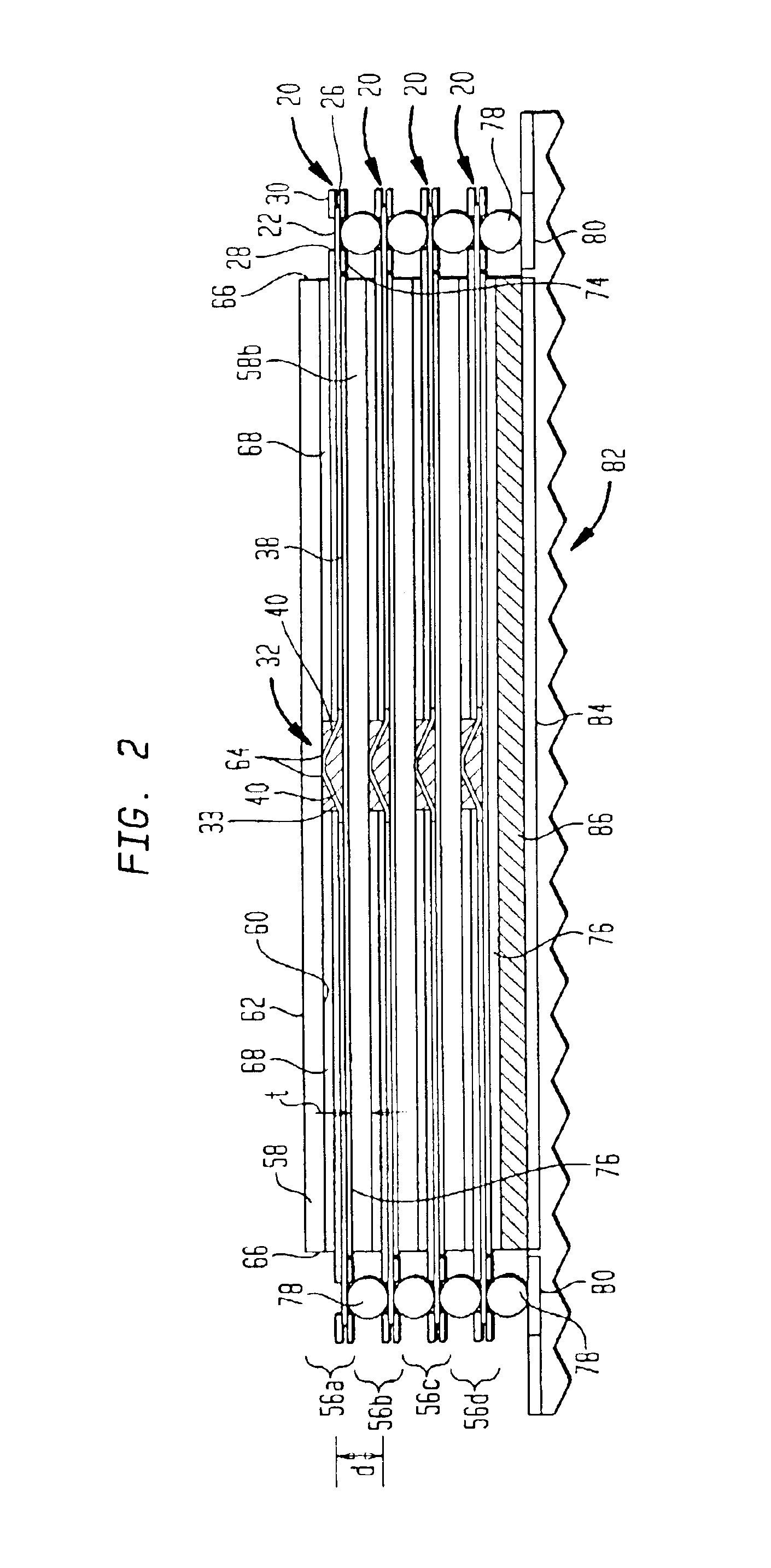

High density integrated circuit module

InactiveUS6919626B2Improve cooling effectImprove space efficiencyPrinted circuit assemblingLine/current collector detailsAdhesiveFlexible circuits

The present invention provides a method and apparatus for fabricating densely stacked ball-grid-array packages into a three-dimensional multi-package array. Integrated circuit packages are stacked on one another to form a module. Lead carriers provide an external point of electrical connection to buried package leads. Lead carriers are formed with apertures that partially surround each lead and electrically and thermally couple conductive elements or traces in the lead carrier to each package lead. Optionally thin layers of thermally conductive adhesive located between the lead carrier and adjacent packages facilitates the transfer of heat between packages and to the lead carrier. Lead carriers may be formed of custom flexible circuits having multiple layers of conductive material separated by a substrate to provide accurate impedance control and providing high density signal trace routing and ball-grid array connection to a printed wiring board.

Owner:OVID DATA CO

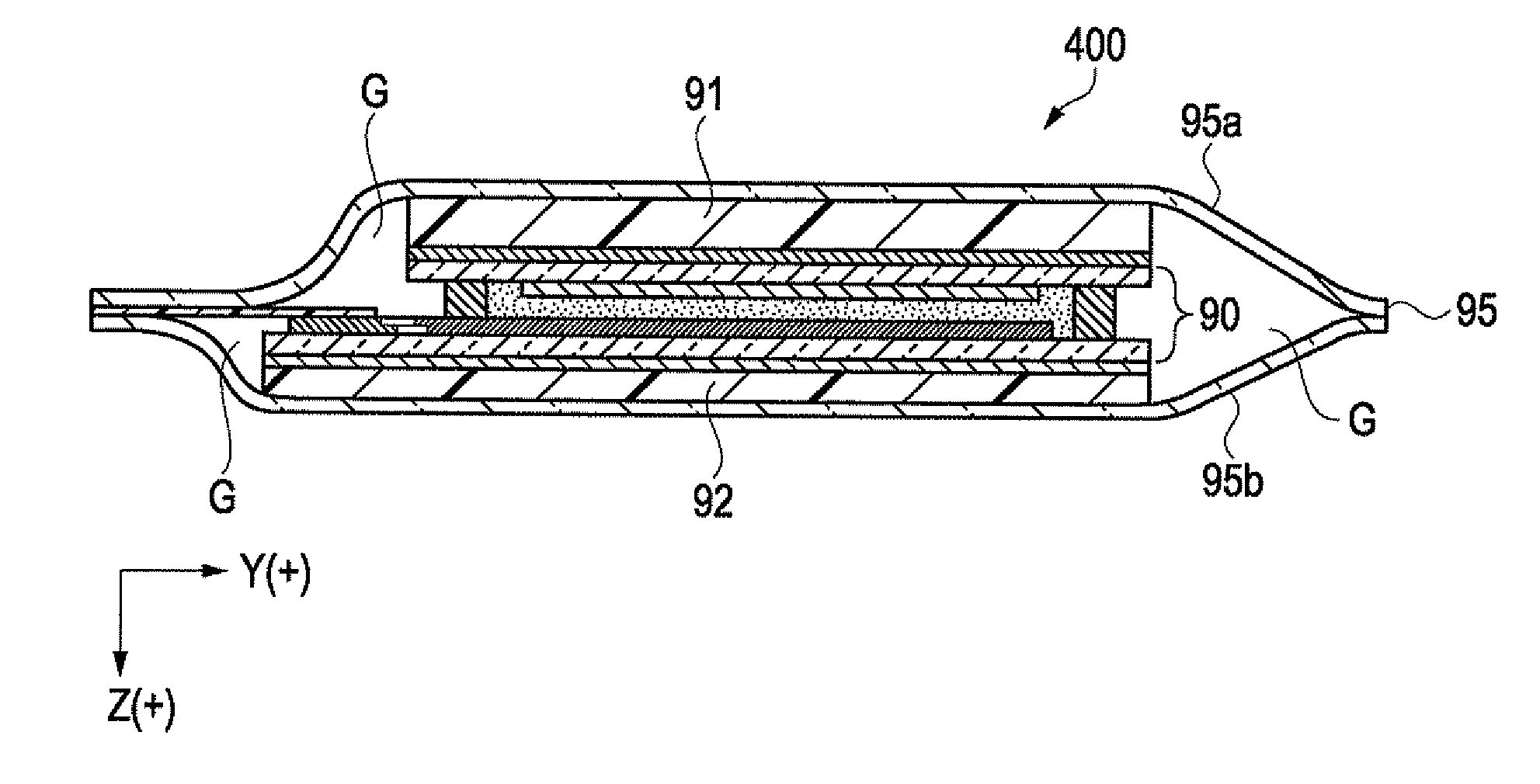

Light emitting element, production method thereof, backlight unit having the light emitting element, and production method thereof

InactiveUS20070114555A1Effective coolingIncrease light intensitySolid-state devicesOptical light guidesDriving currentOptoelectronics

A light emitting element includes: A light emitting element, includes: at least one LED chip provided on an installation surface of a substrate; a metallic reflecting plate, provided upright in a light projecting direction of the LED chip on the installation surface so as to surround an entire periphery of the LED chip, the metallic reflecting plate reflecting light projected from the LED chip to guide the light to a light projecting surface provided in the light projecting direction; and a first metallic portion and a second metallic portion, respectively connected to the LED chip as electrode terminals for supplying a driving current to the LED chip, each being formed in an area surrounded by the metallic reflecting plate on the installation surface, wherein an insulating section is formed surrounding the second metallic portion, to electrically insulate the second metallic portion from other portion in the area, and the first metallic portion is formed outside the insulating section in the area as an installation surface metallic reflecting film so as to be in contact with the metallic reflecting plate.

Owner:BIOGENTIS +1

Laser to Chip Coupler

ActiveUS20130209112A1Improve efficiencyHigh yieldCoupling light guidesElectromagnetic receiversPhotonic ChipLight beam

A method and an apparatus for butt-coupling an input beam incoming from a photonic device of a second optical element to a primary photonic chip at an input interface of the primary photonic chip is disclosed. The primary photonic chip comprises a coupling apparatus. The light from the input beam is butt-coupled to the coupling apparatus. The coupling apparatus comprises a plurality of more than one single mode optical paths on the primary photonic chip. The single mode optical paths are strongly coupled to each other at the input interface of the primary photonic chip. Regions of strongly coupled single mode optical paths can correspond to one or both of distinct but highly coupled waveguides or waveguides fully merged into a multi-mode section.

Owner:RWTH AACHEN UNIV

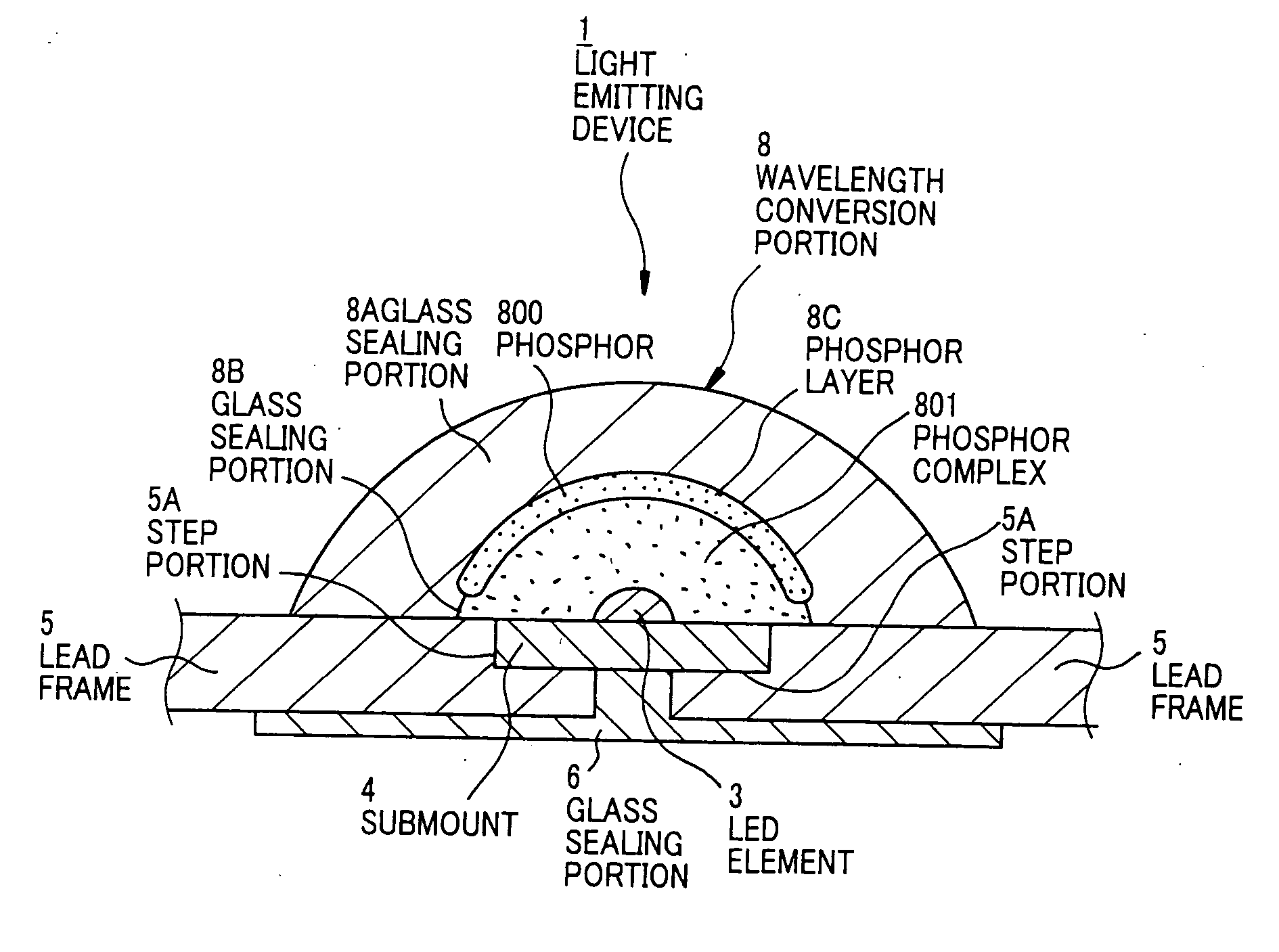

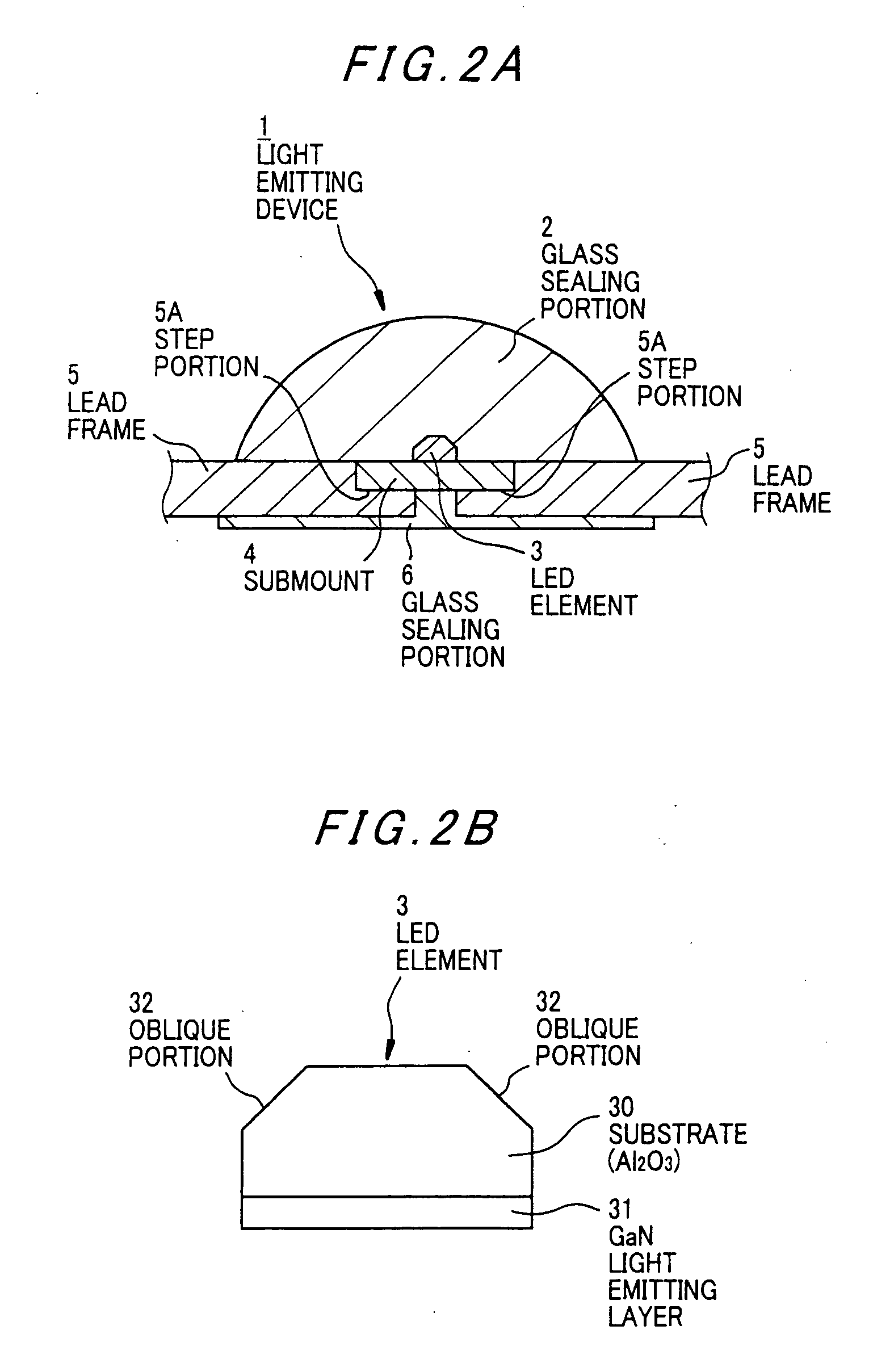

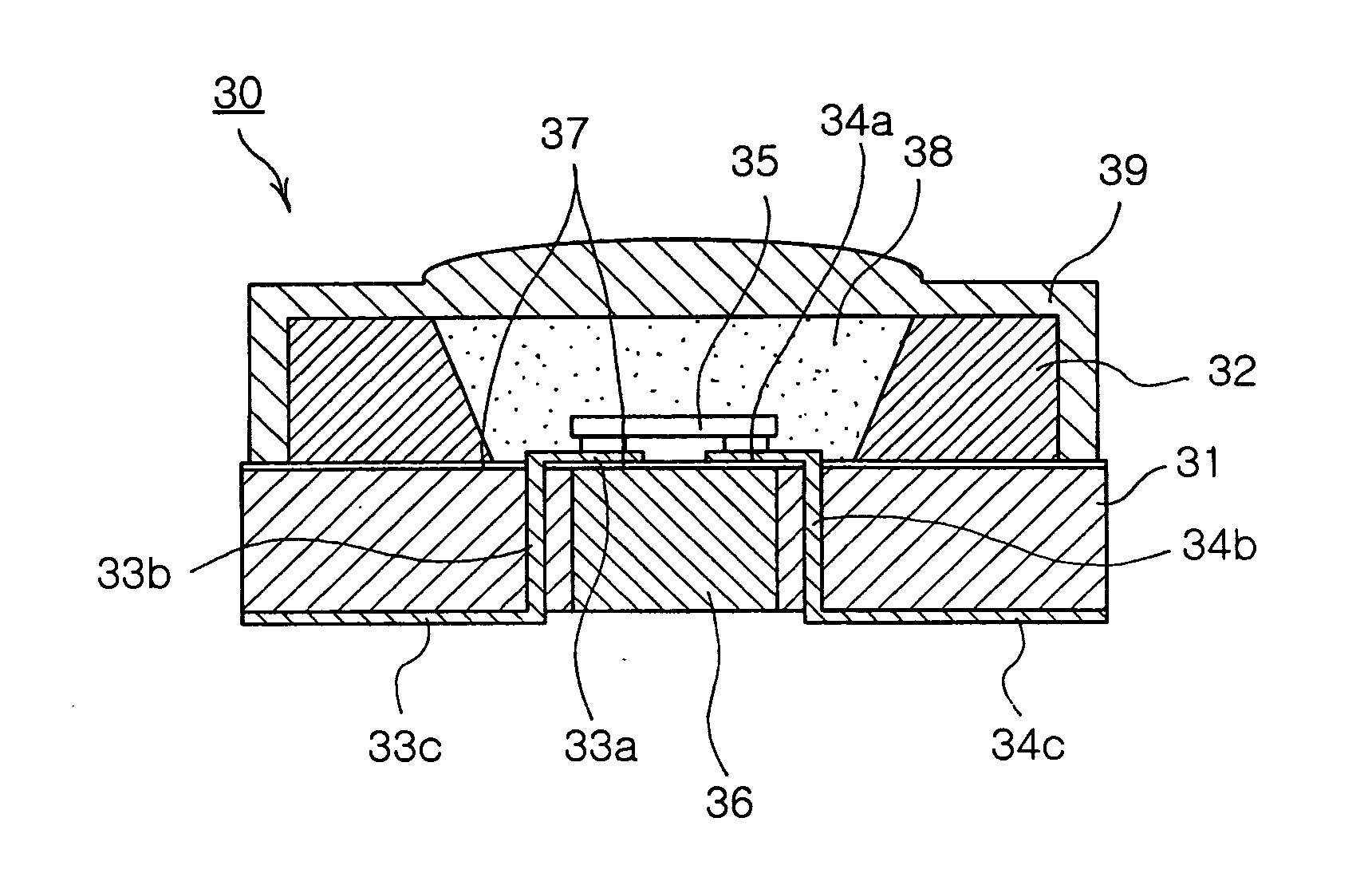

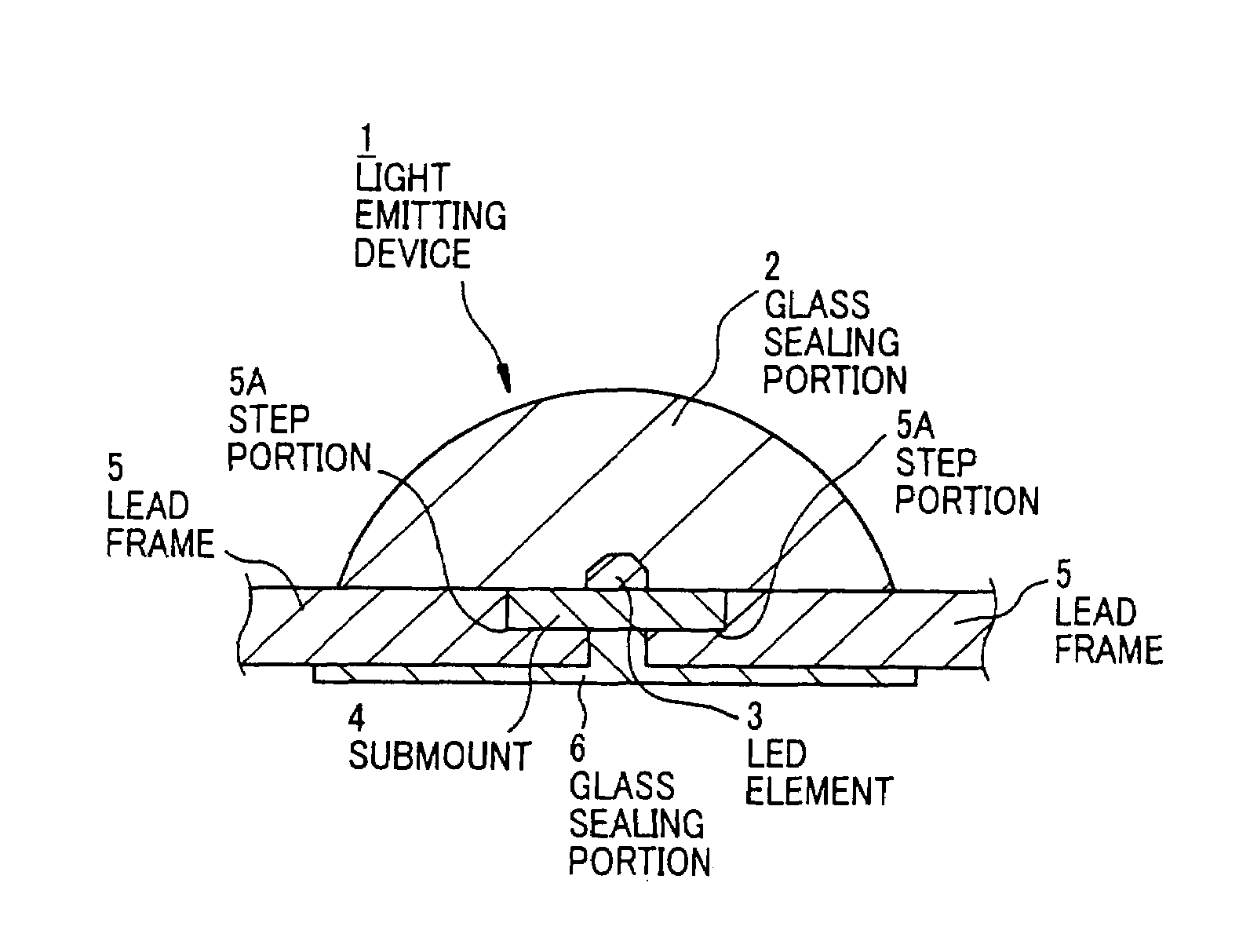

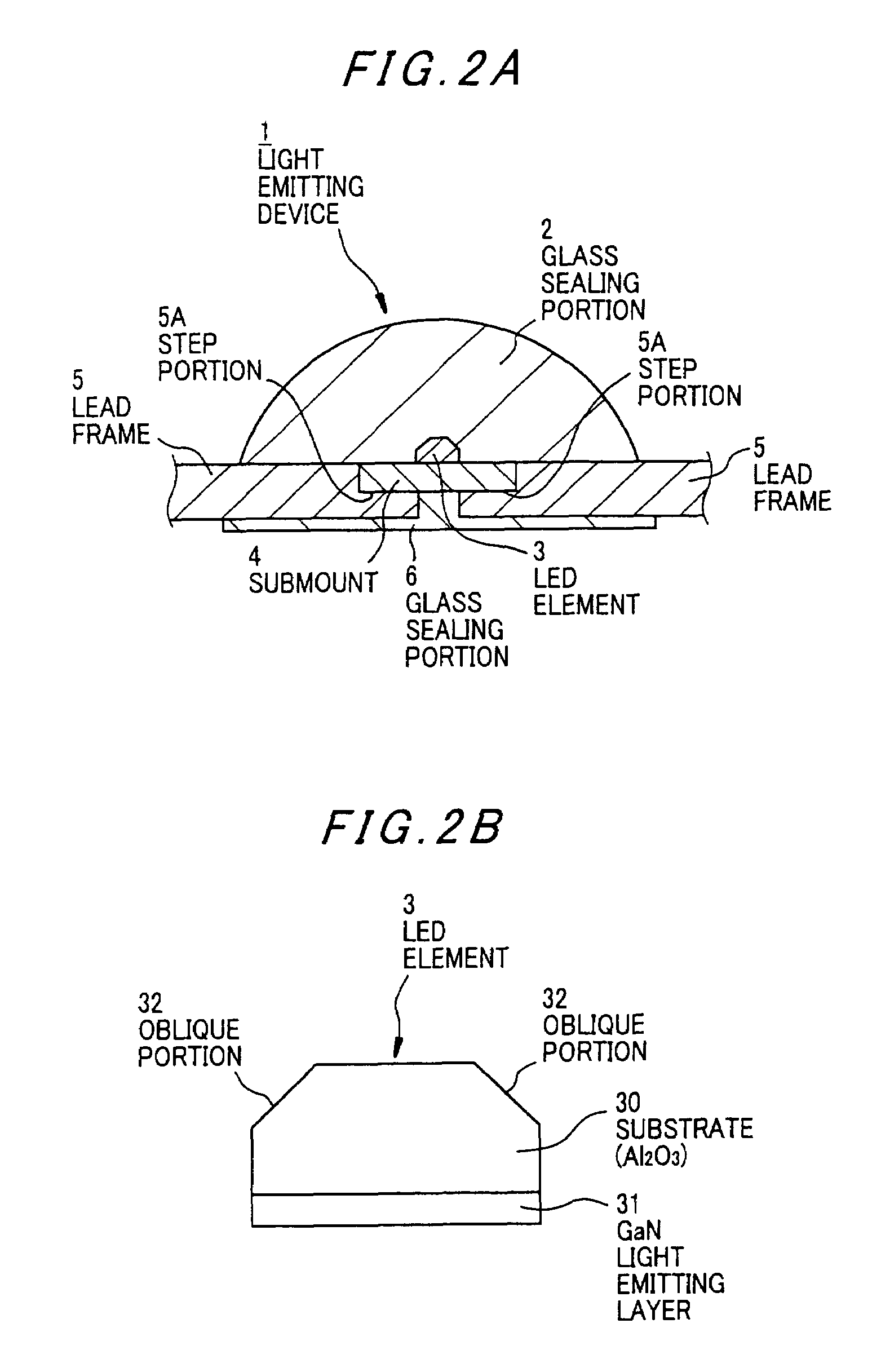

Light emitting device provided with a submount assembly for improved thermal dissipation

ActiveUS7391153B2Lowing of residual bubbleReduce internal stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

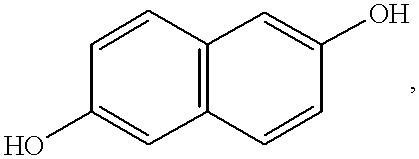

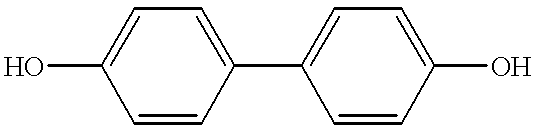

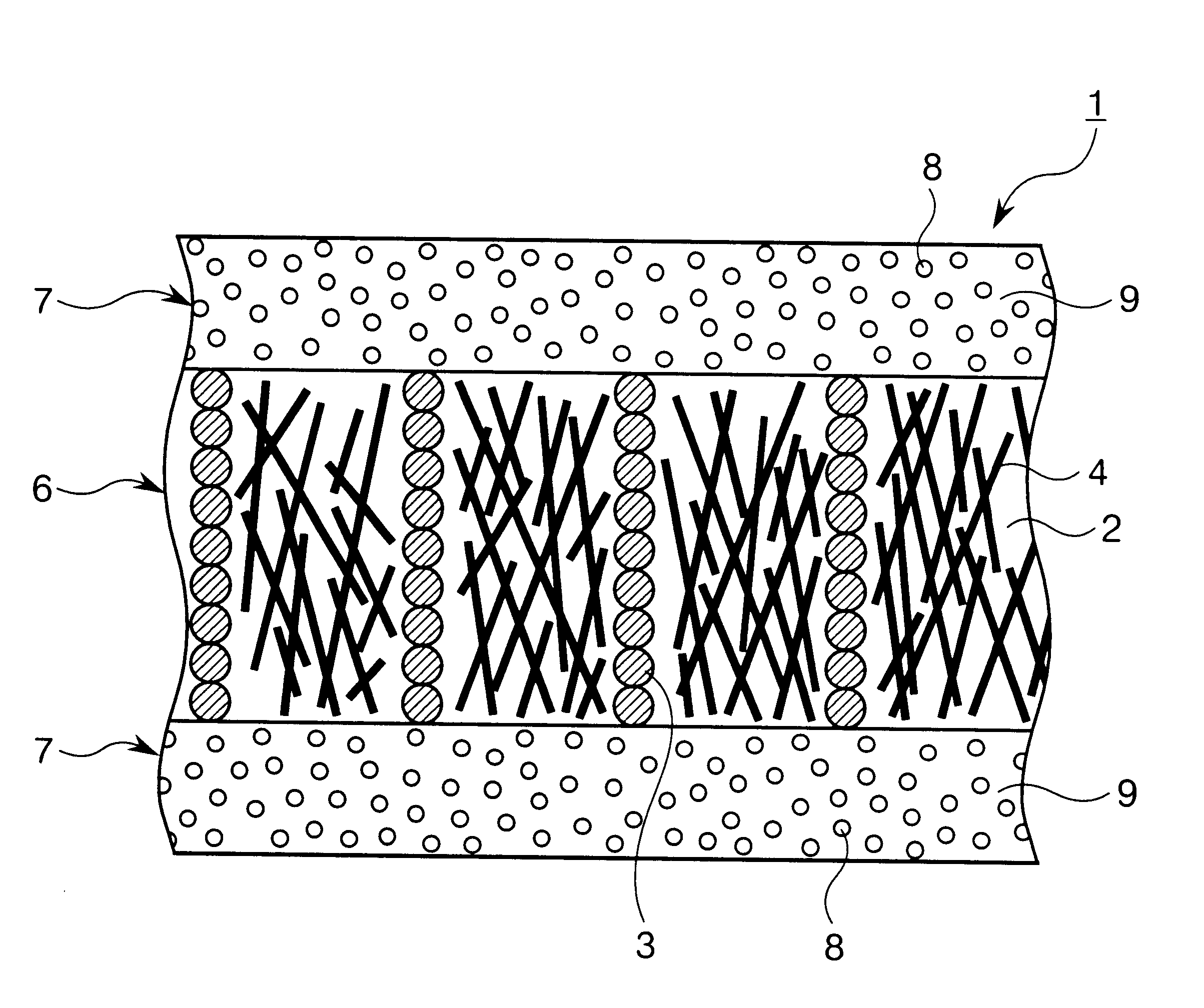

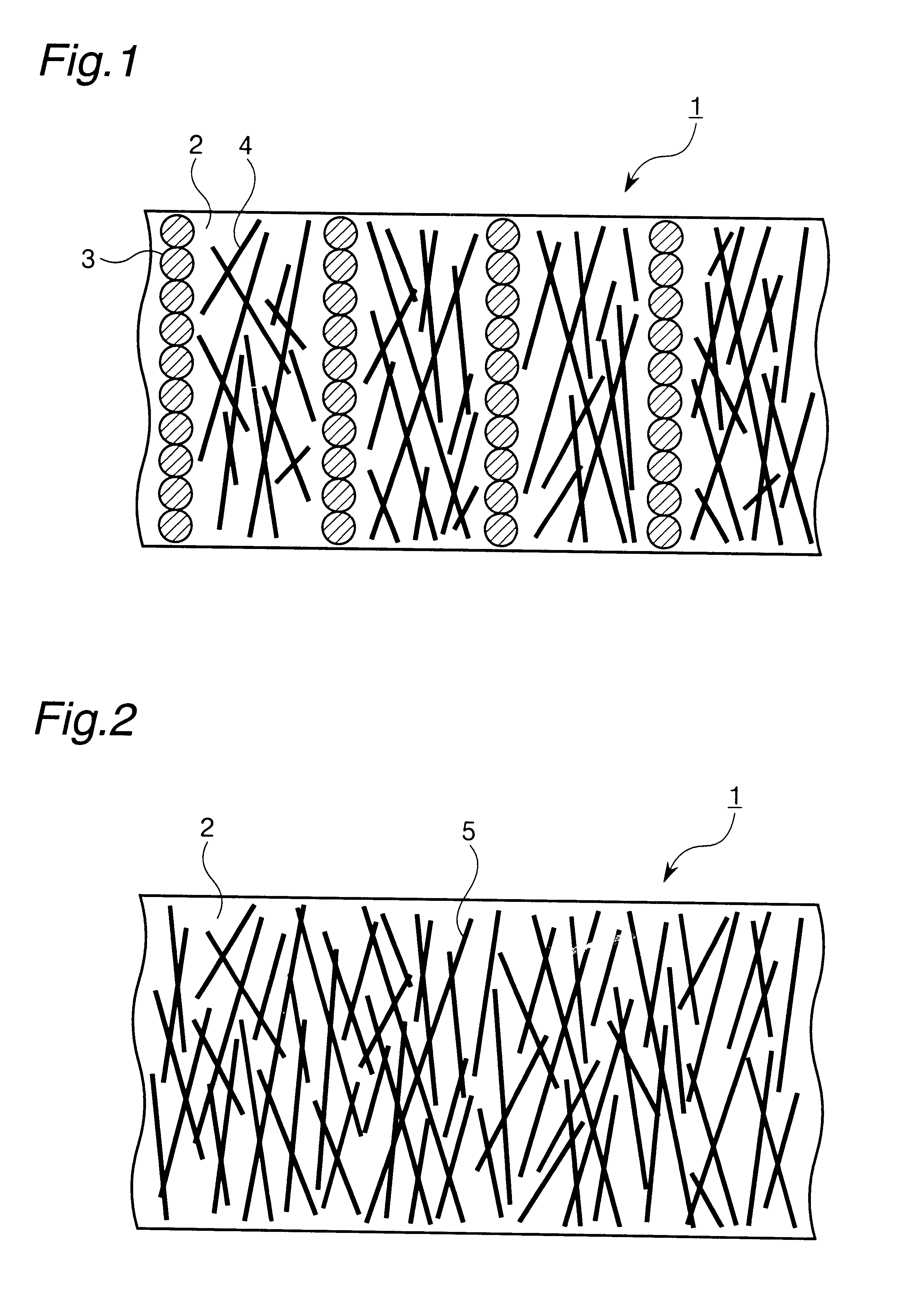

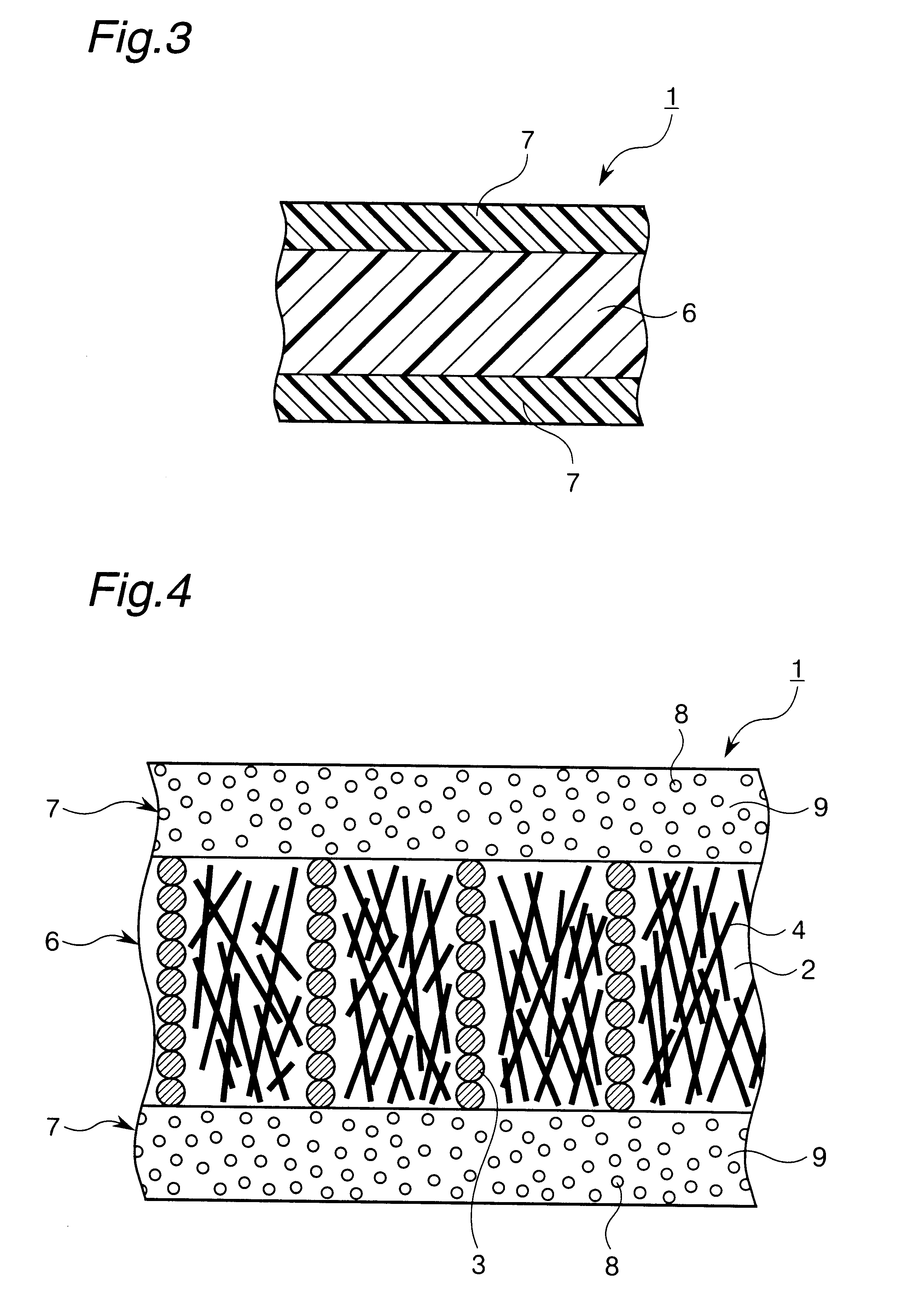

Curing composition for forming a heat-conductive sheet, heat-conductive sheet, production thereof and heat sink structure

InactiveUS6517744B1High heat conductivityImprove adhesionNon-metal conductorsConductive materialFiberCarbon fibers

A heat-conductive sheet comprising a cured or semi-cured binder wherein a carbon fiber is orientated in the direction of the thickness of the heat-conductive sheet. This heat-conductive sheet exhibits a high anisotropic heat conductivity along the direction of the thickness thereof to thereby enable efficiently releasing heat from a heating element such as a semiconductor element or semiconductor package. Moreover, the heat-conductive sheet is excellent in not only heat resistance, durability and mechanical strength but also adherence to the heating element.

Owner:JSR CORPORATIOON

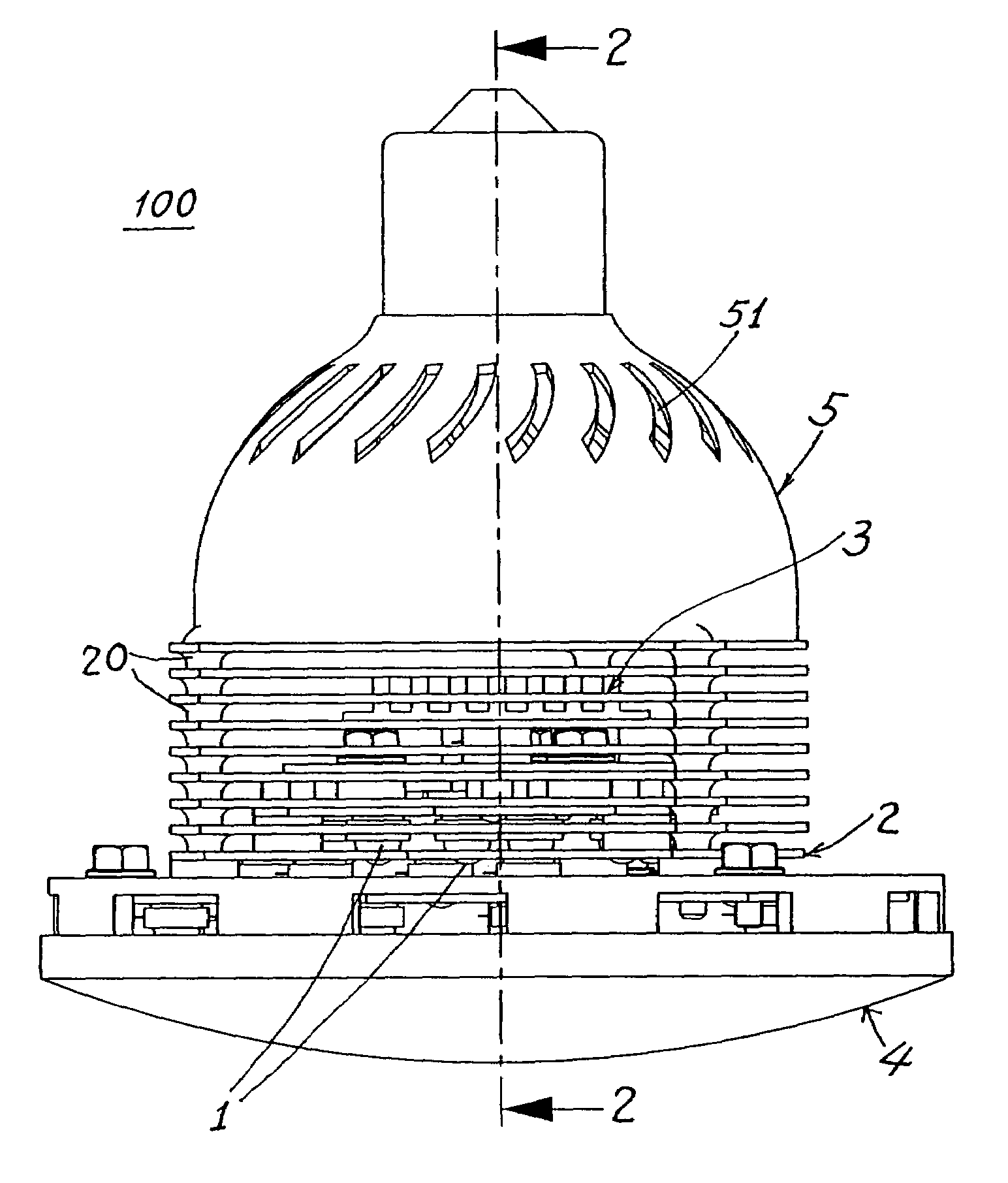

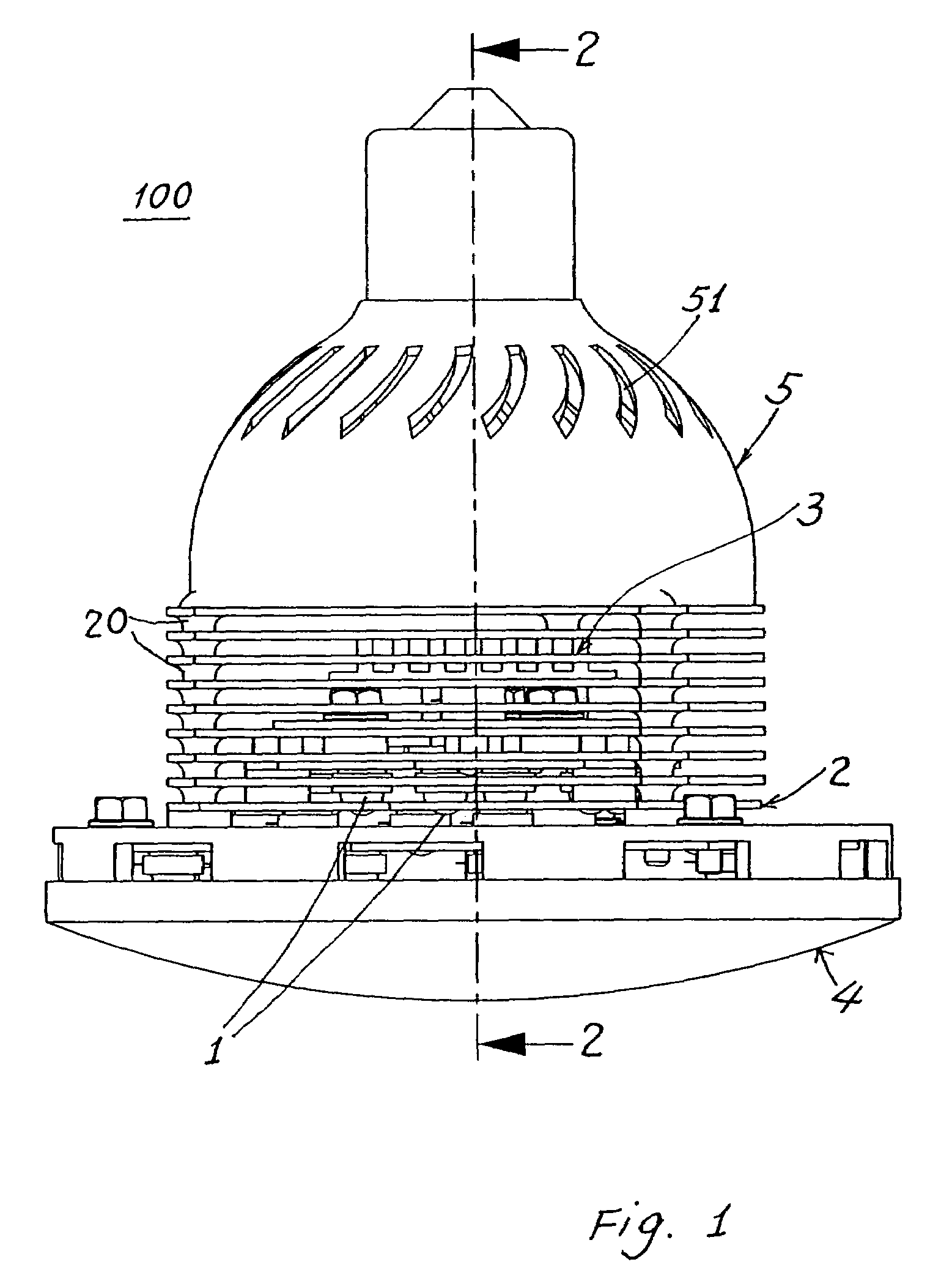

LED lamp instantly dissipating heat as effected by multiple-layer substrates

InactiveUS7607802B2Effective coolingInhibit deteriorationPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

A LED lamp includes: a plurality of substrates juxtapositionally formed as multiple layers, each substrate having a plurality of light emitting diodes (LEDs) mounted thereon, whereby upon generation of heat by the LEDs when lit up, each substrate will form as a heat-dissipating plate in-situ in order that the multiple-layer substrates will instantly effectively dissipate the heat produced from the LEDs of the lamp outwardly for preventing deterioration of the illumination quality of the LED lamp.

Owner:TAMKANG UNIVERSITY

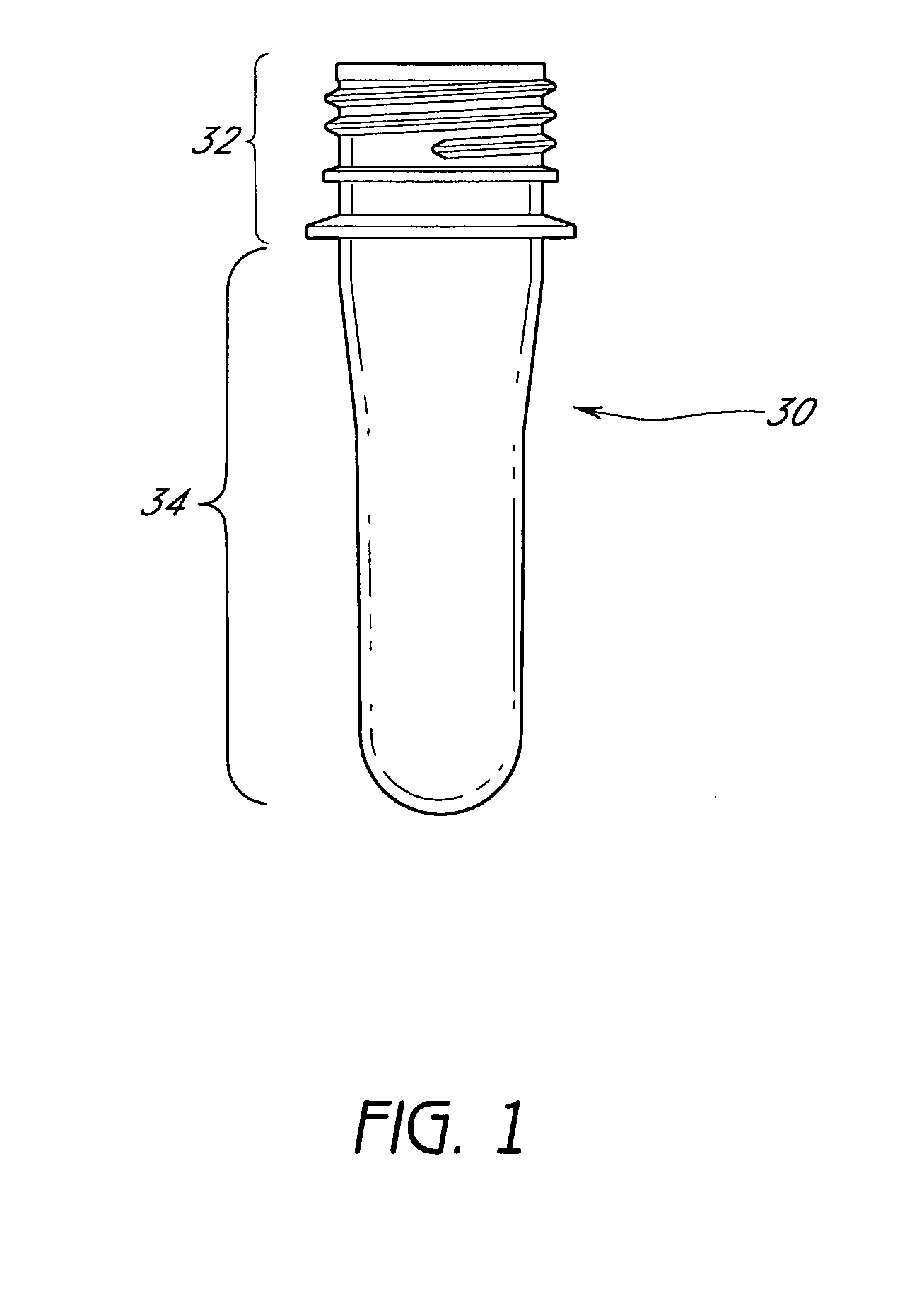

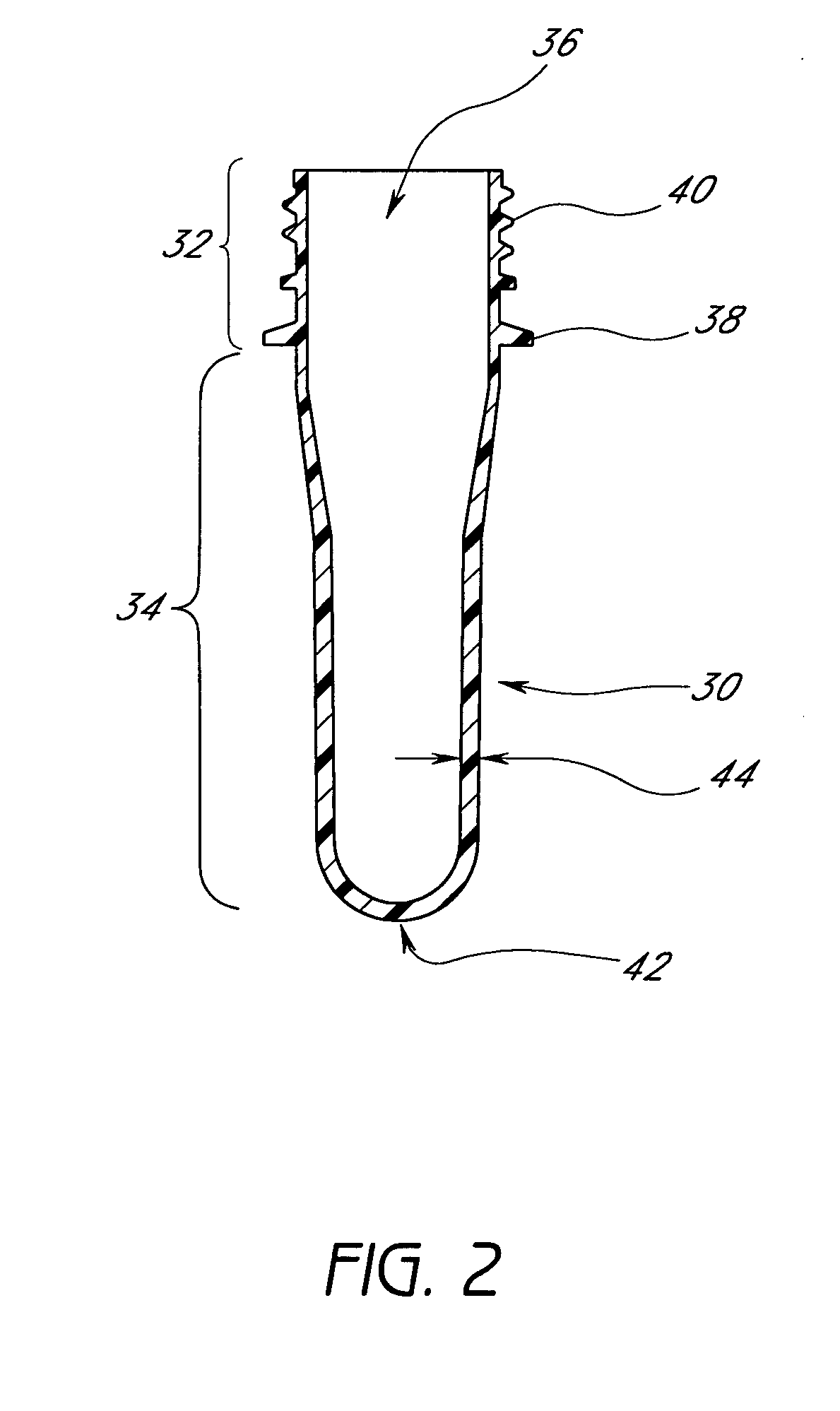

Methods and systems for controlling mold temperatures

InactiveUS20060051451A1Effective coolingEfficient heatingFood shapingTemperature controlControl system

Disclosed is a preferred mold design for producing plastic, molded preforms, which may be blow-molded into a container of a final, desired shape. A preferred mold includes a temperature control system for maintaining the preform mold at a desired temperature. The temperature control system can pass fluid through channels within the preform mold to cool plastic that is injected into the preform mold. In some arrangements, a mold comprises a neck finish mold, the neck finish mold comprising high heat transfer material positioned to transfer heat away from melt within a mold cavity of the mold.

Owner:CONCENTRATE MFG OF IRELAND

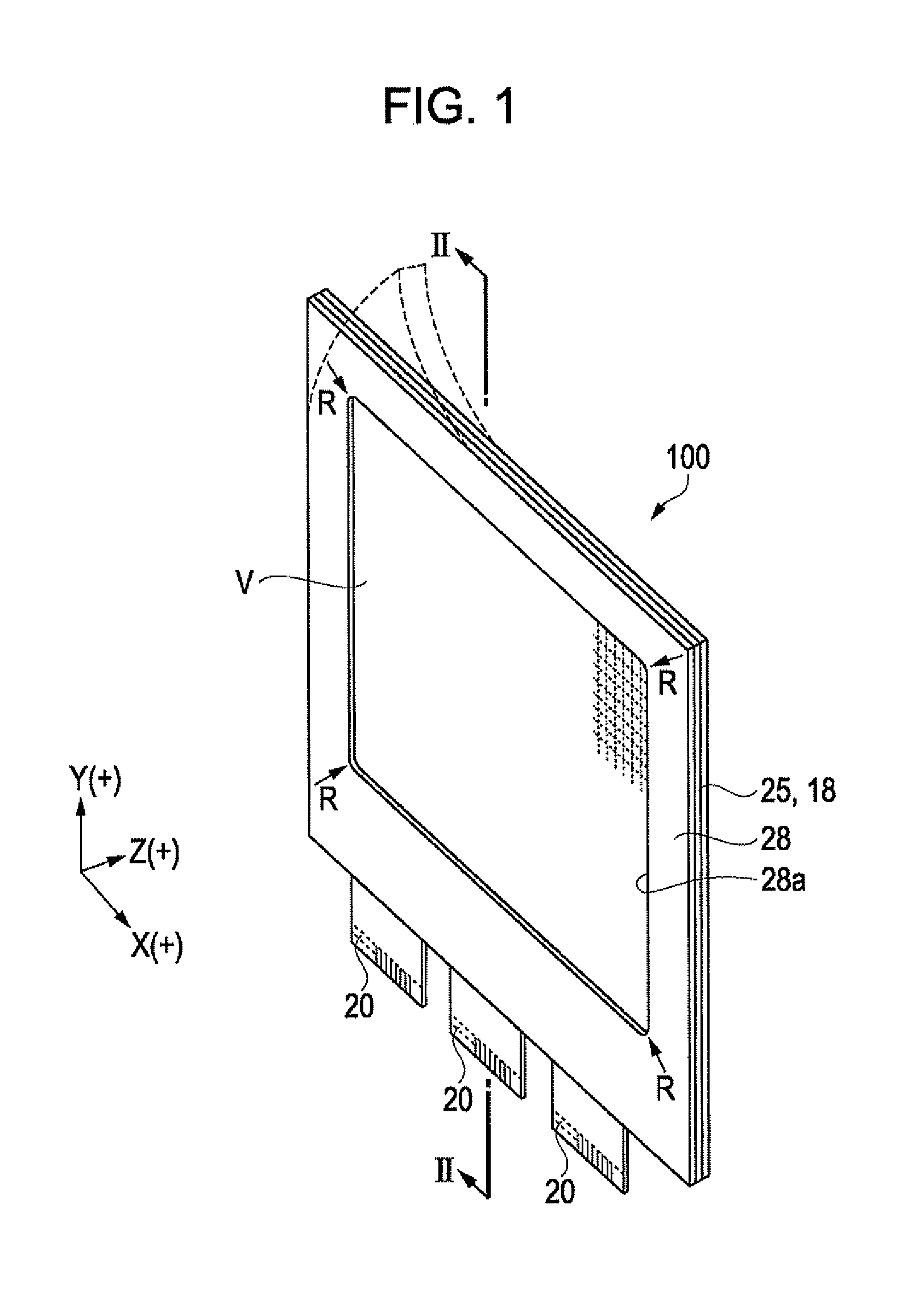

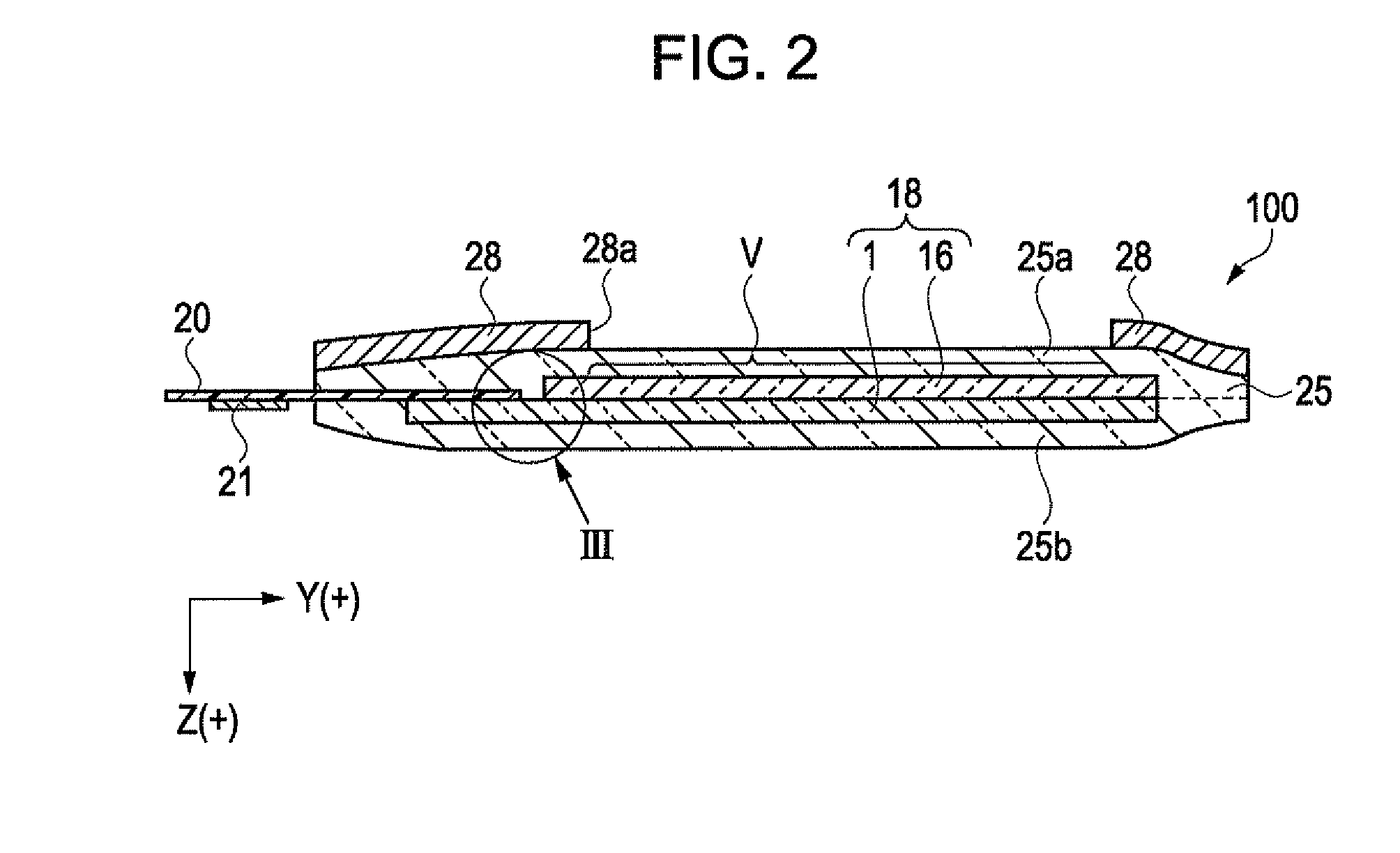

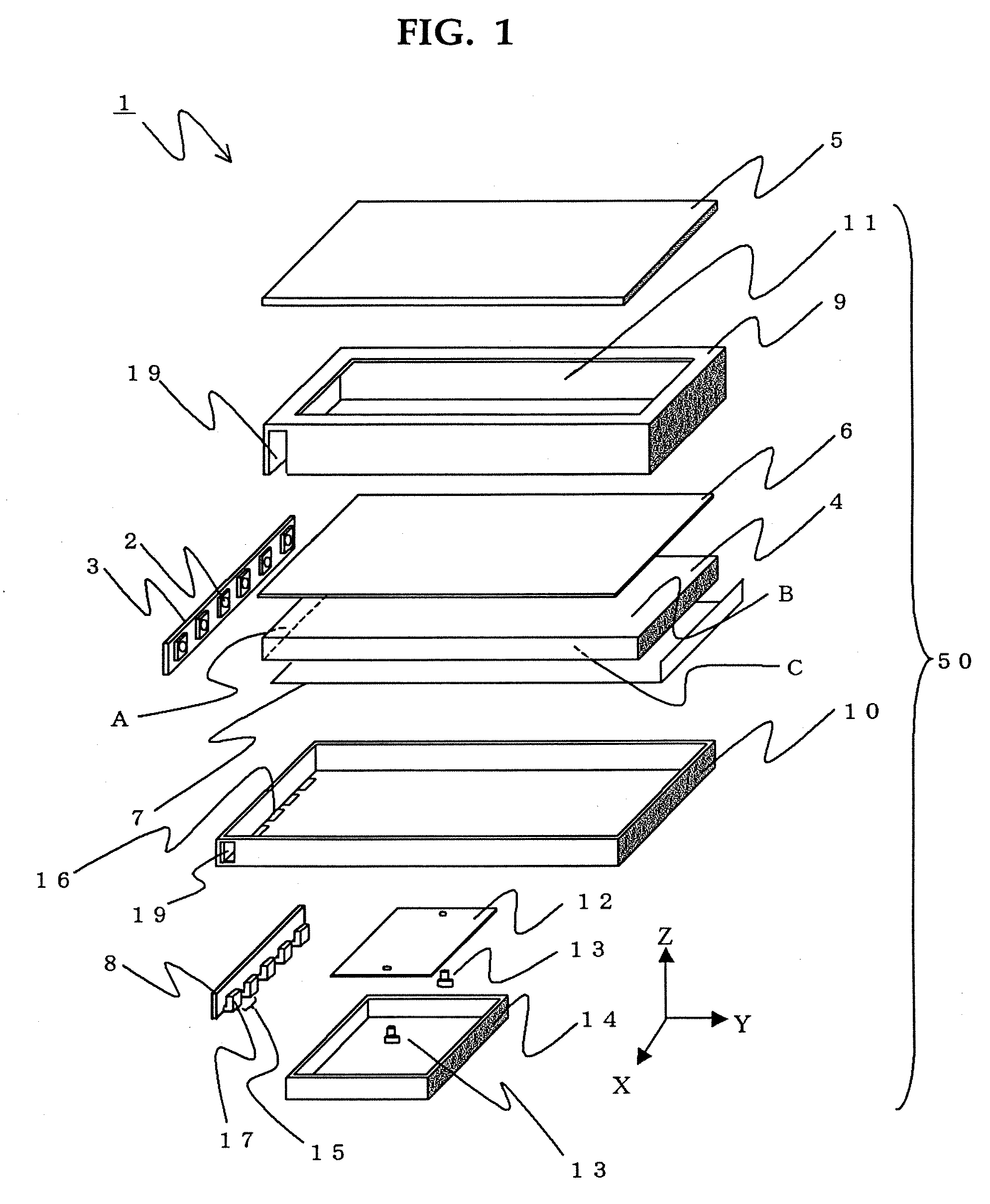

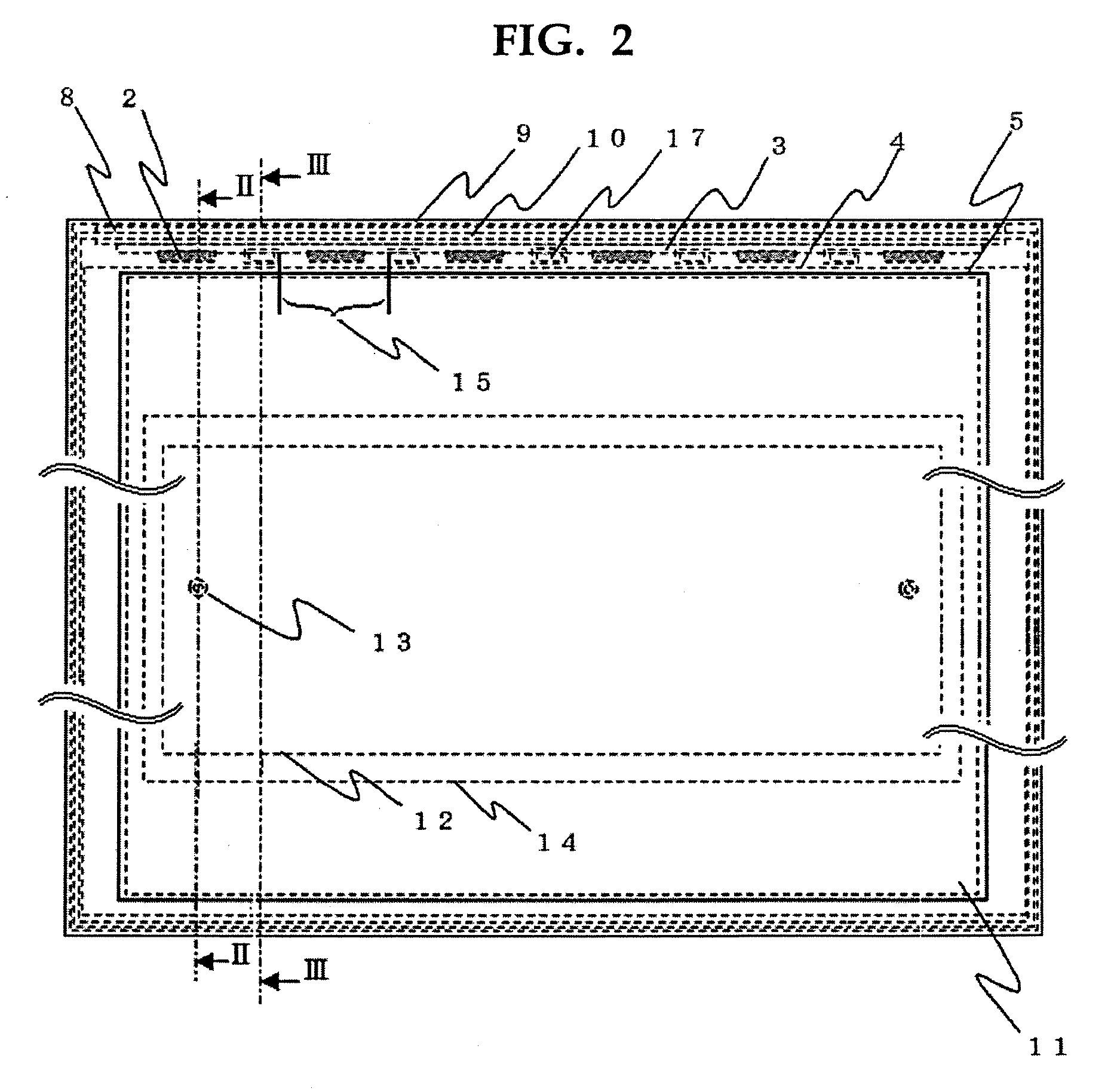

Electro-optical device, electronic device, and illumination apparatus

ActiveUS20100327737A1High tensile strengthReduce deformation rateDischarge tube luminescnet screensSpotlightingEngineeringElectron

An electro-optical device includes a display panel having an electro-optical layer, a first resin film stacked on the display panel to cover a first surface on the side of a display area of the display panel, and a second resin film stacked on the display panel to cover a second surface opposite the first surface, and at least one reinforcing member disposed on at least one of the first resin film and the second resin film.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

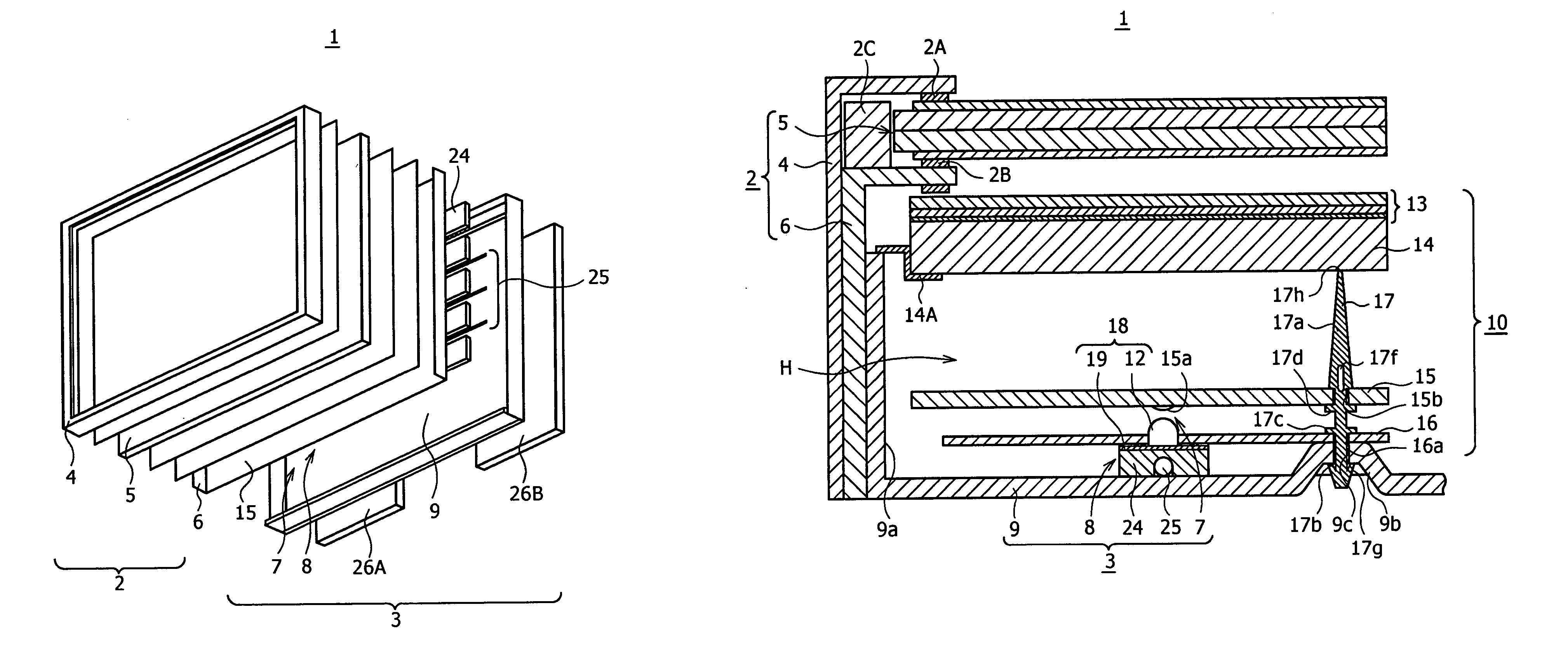

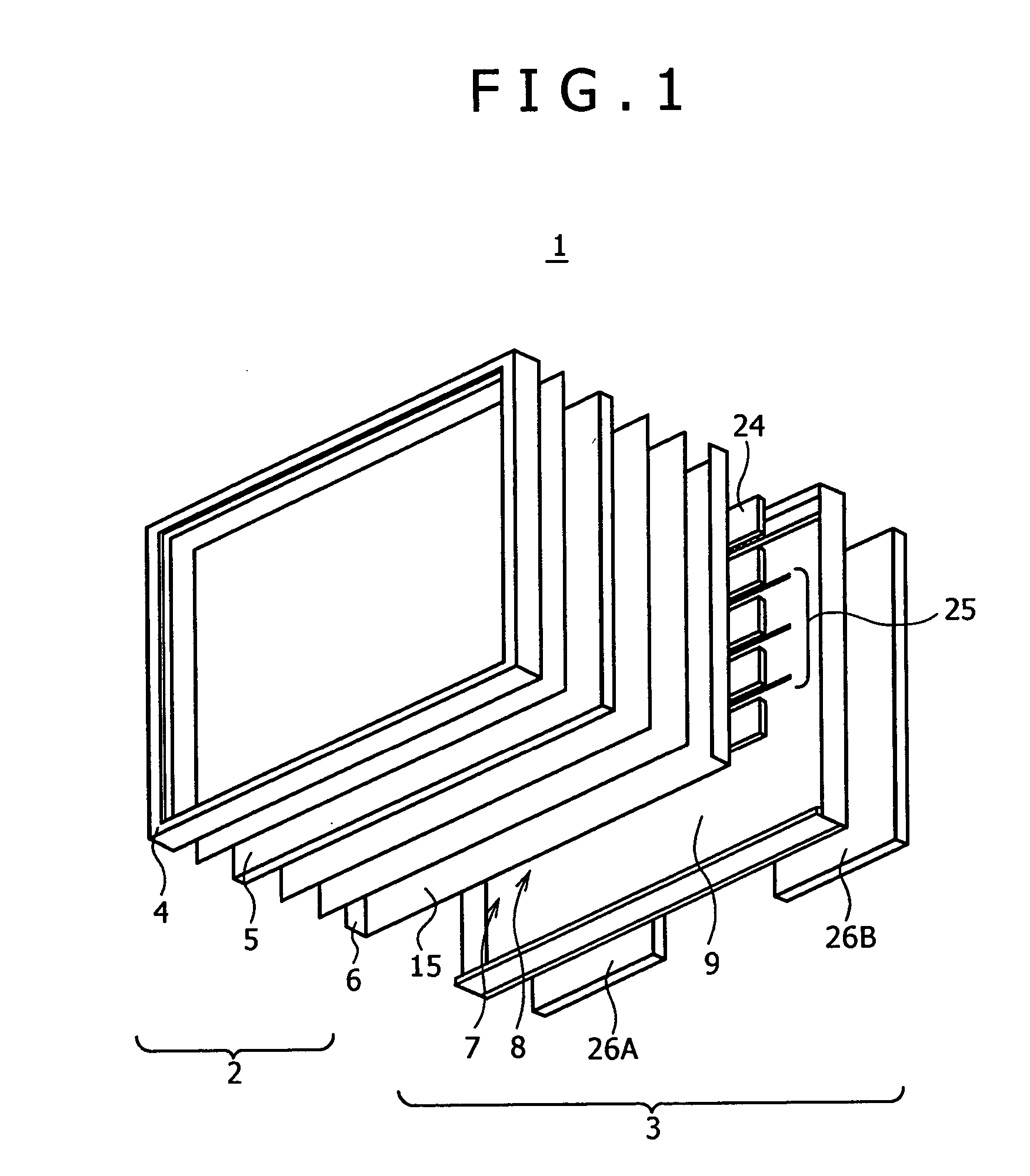

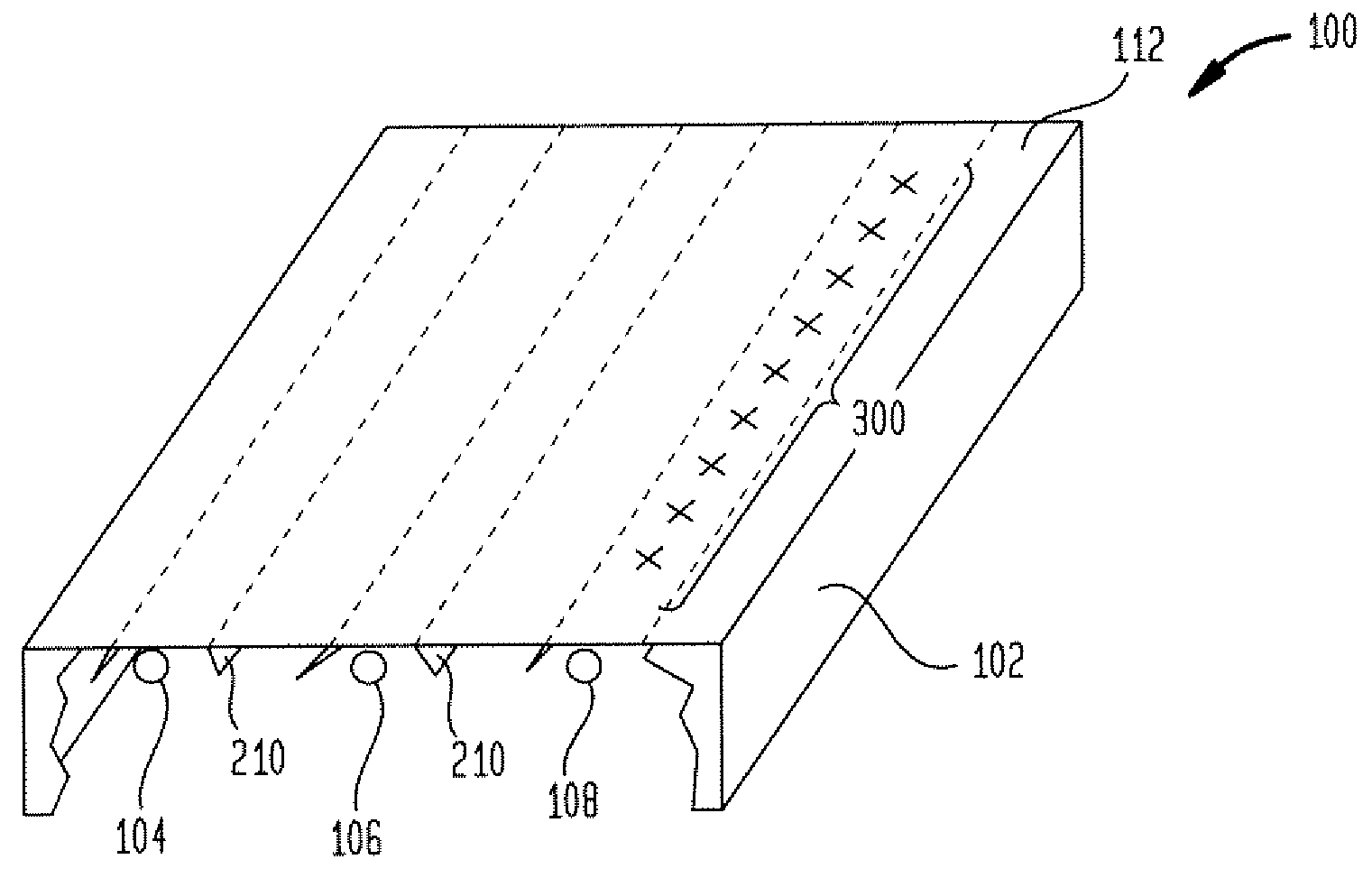

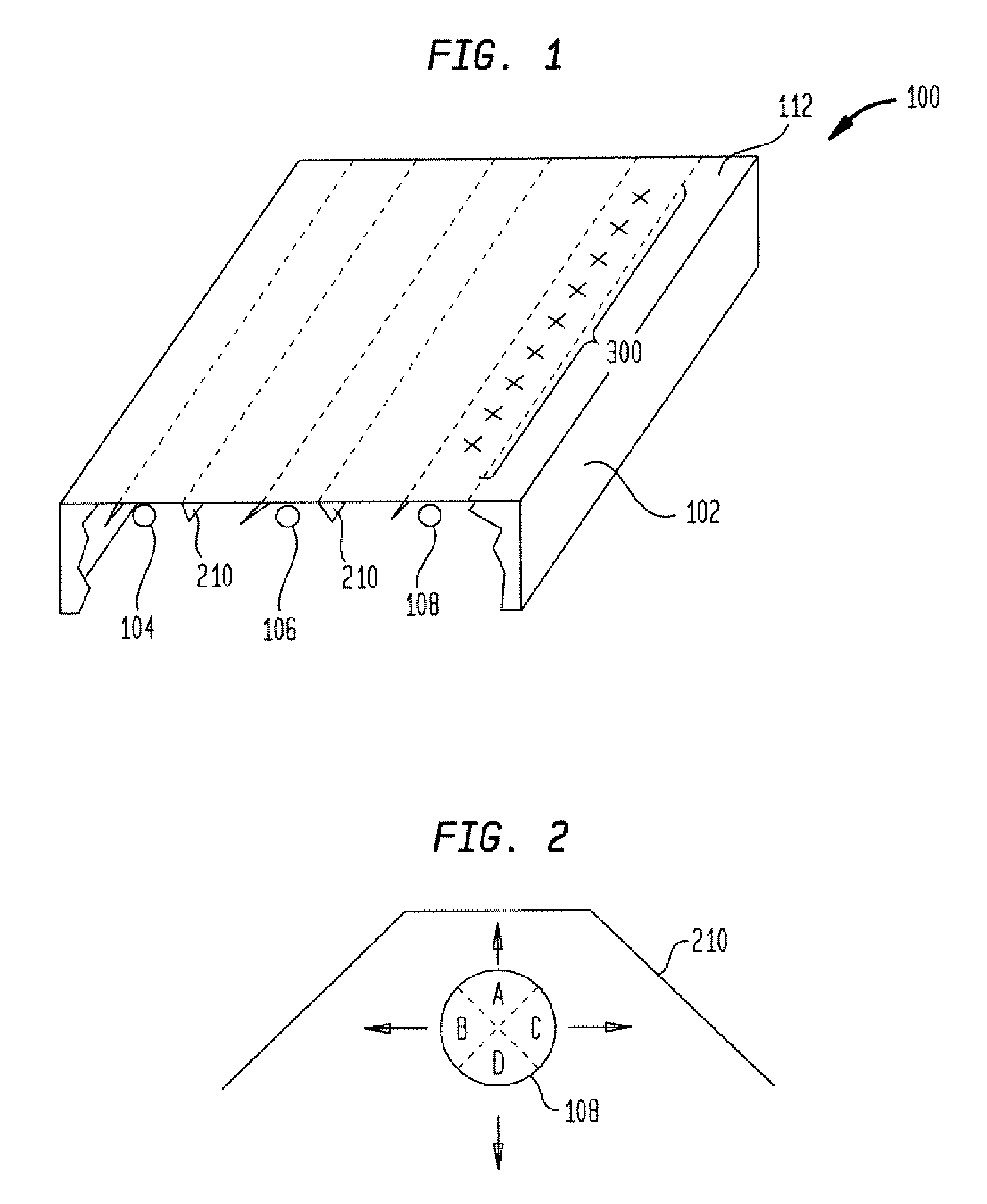

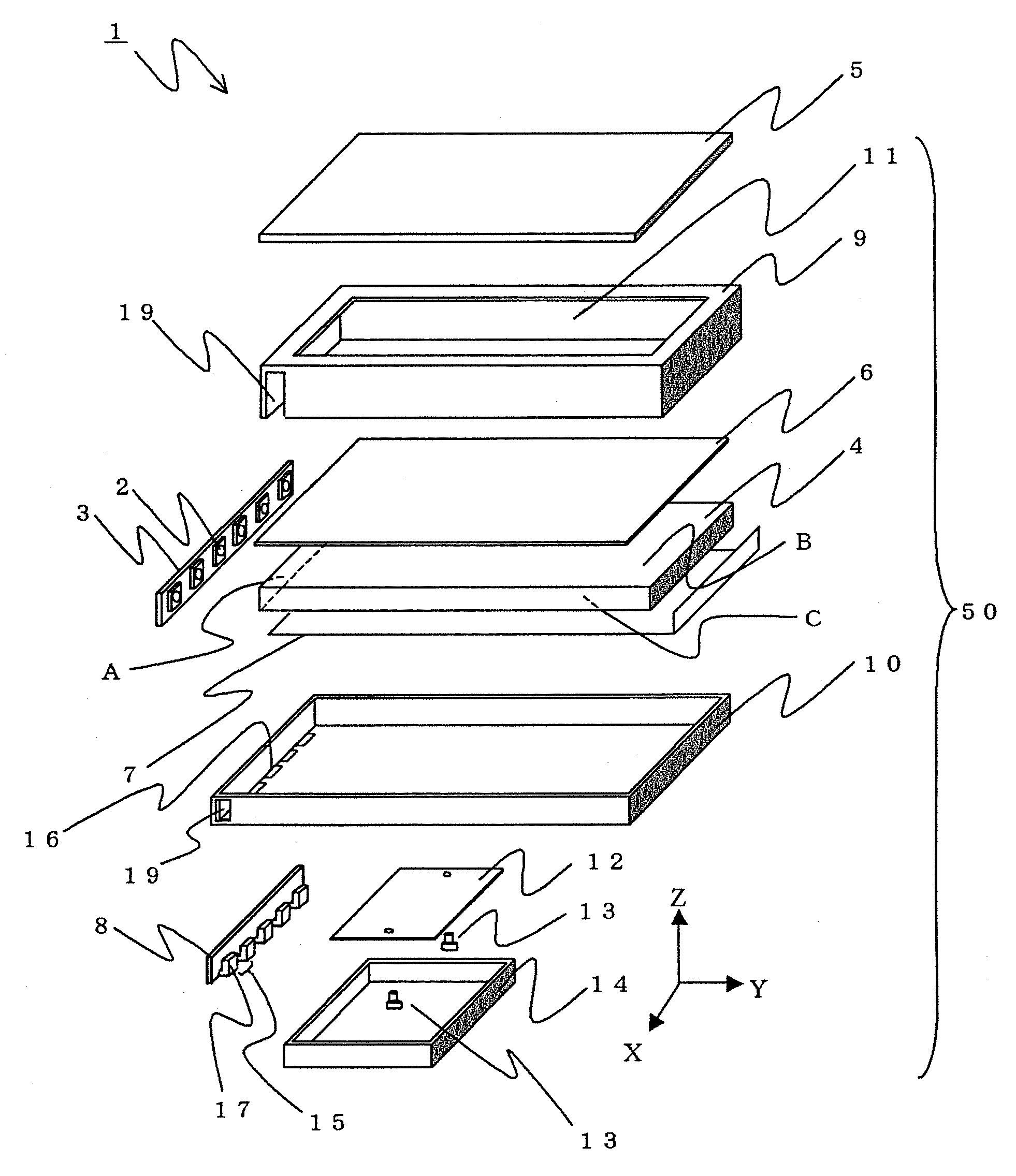

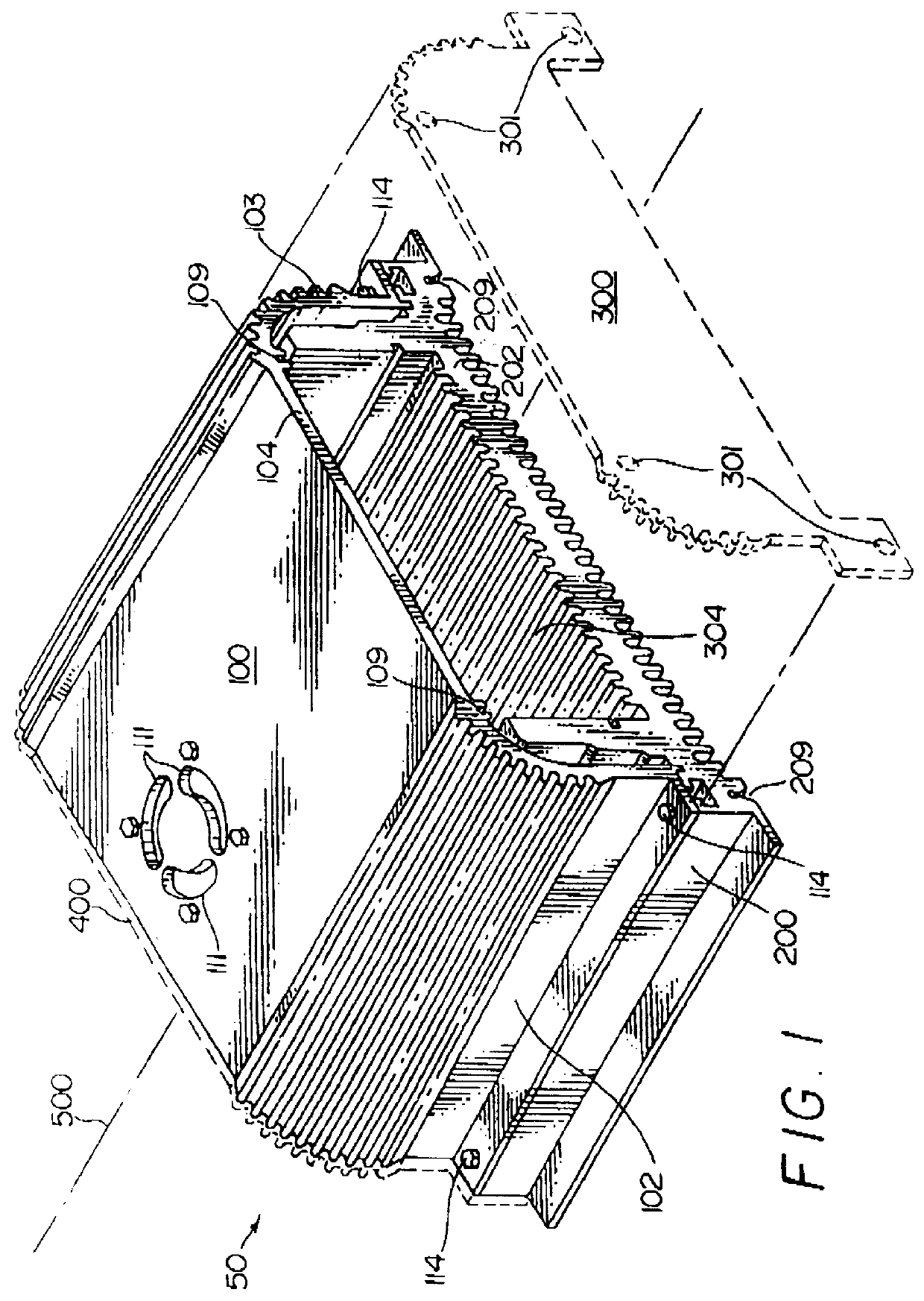

Surface light source device

ActiveUS20070247870A1Effective coolingImprove reliabilityMechanical apparatusLight guides for lighting systemsPoint lightLight guide

A surface light-source device (50) includes: a plurality of point light sources (2); a light-guide plate (4) arranged for emitting from its emitting surface the light incident on one lateral side thereof from the point light sources (2); a lower case (10) having a lateral side formed approximately in parallel to the incident surface of the light-guide plate (4); and a light-source substrate (3) on which the plurality of point light sources (2) are arranged at predetermined intervals, disposed on the light-guide plate (4) side; wherein the surface light-source device (50) is provided with a substrate holder (8) that clamps the light-source substrate (3) and the lateral side of the lower case (10) by projections arranged on the substrate holder (8) between adjacent two of the light sources (2).

Owner:TRIVALE TECH LLC

Lighting device

ActiveUS20080049399A1Maintain temperatureEffective coolingPoint-like light sourceSemiconductor/solid-state device detailsElectricityEffect light

A lighting device contains a plurality of light emitting sources mounted on a thermally conductive housing and electrically connected to a circuit board. The housing includes a base portion which is spaced apart from the circuit board, and an intermediate heat dissipation structure which is disposed between the circuit board and the base portion of the housing, for promoting cooling by convection. The plurality of light emitting sources are in thermal communication with the intermediate heat dissipation structure.

Owner:HONG KONG APPLIED SCI & TECH RES INST

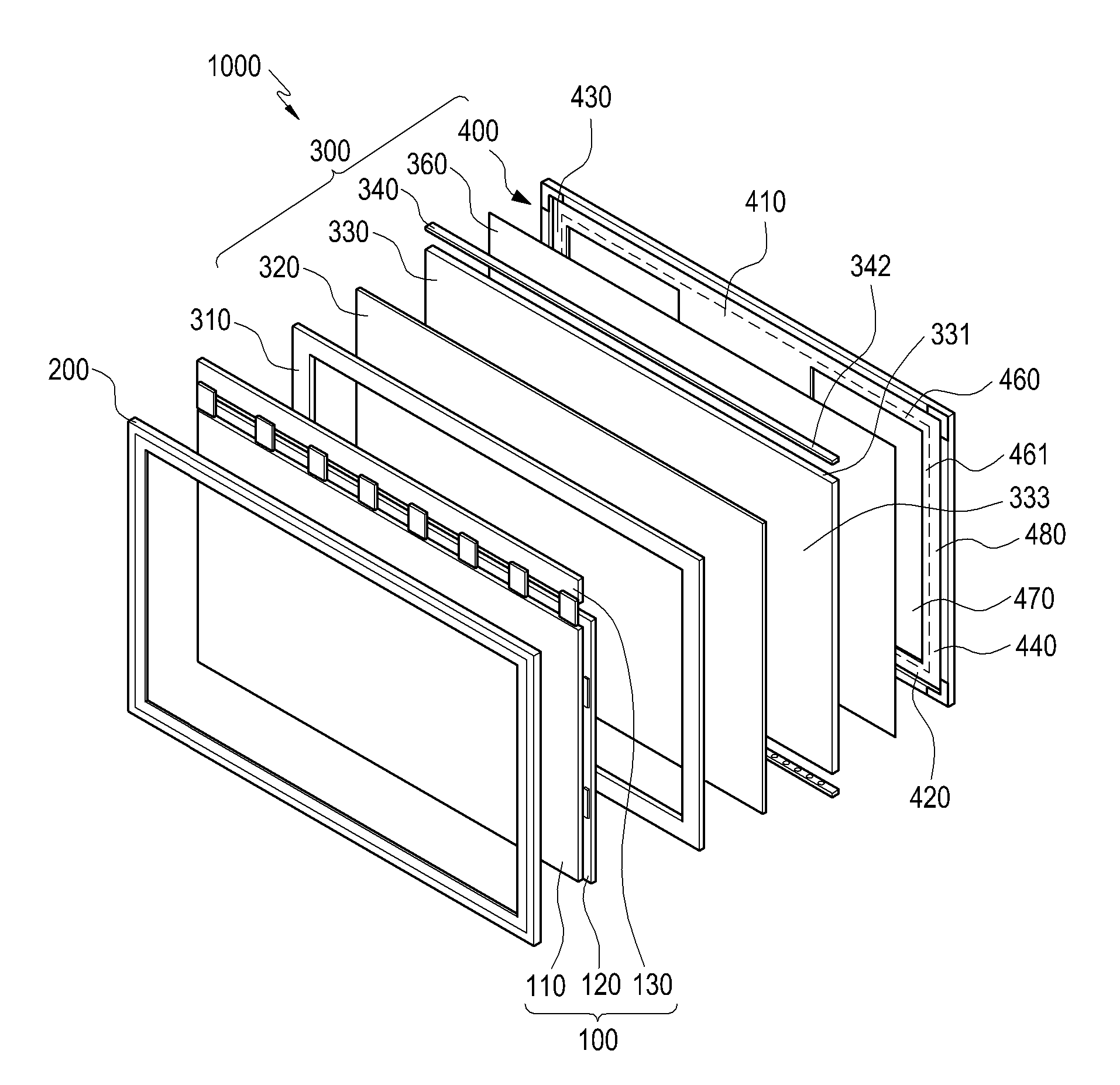

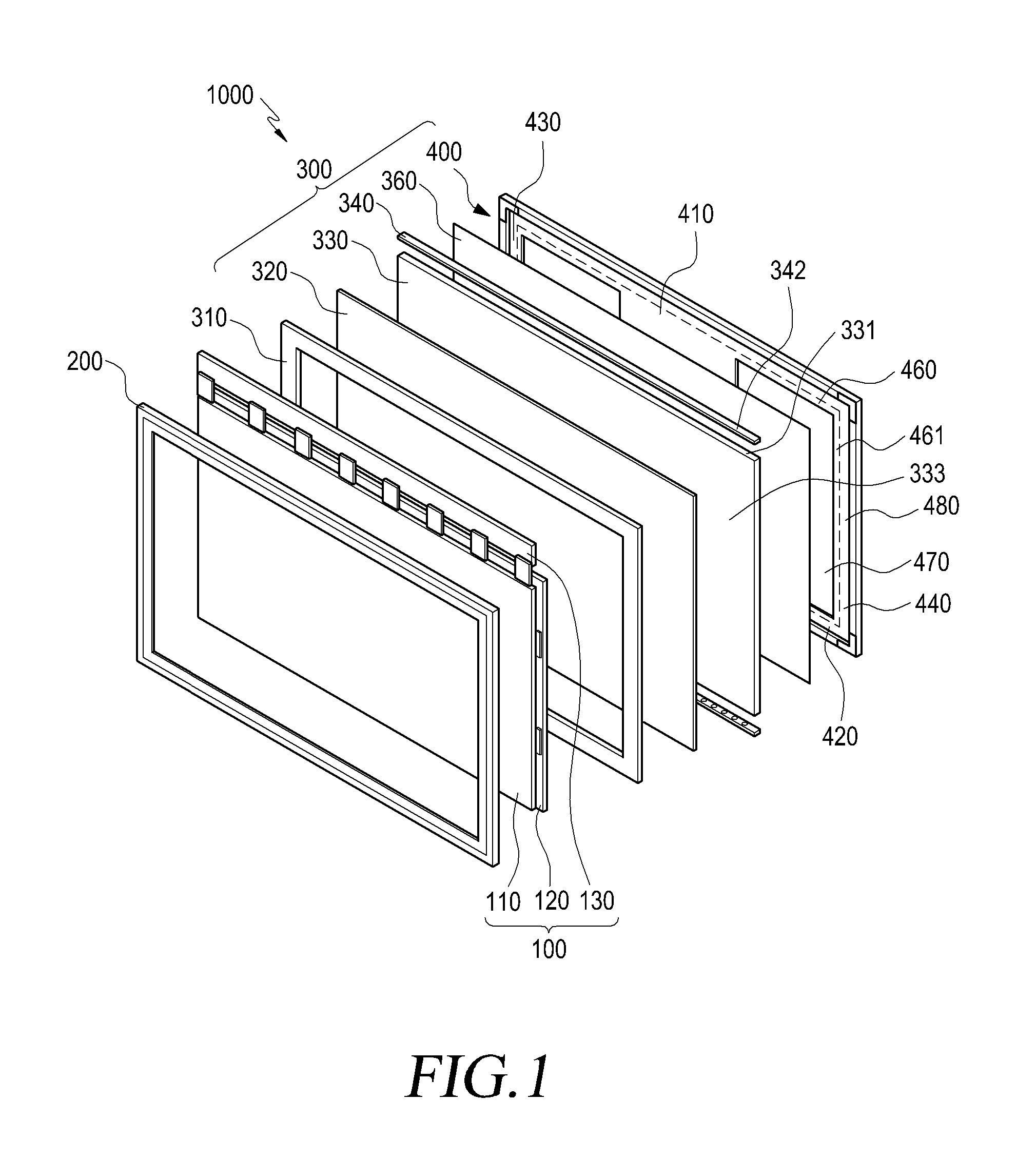

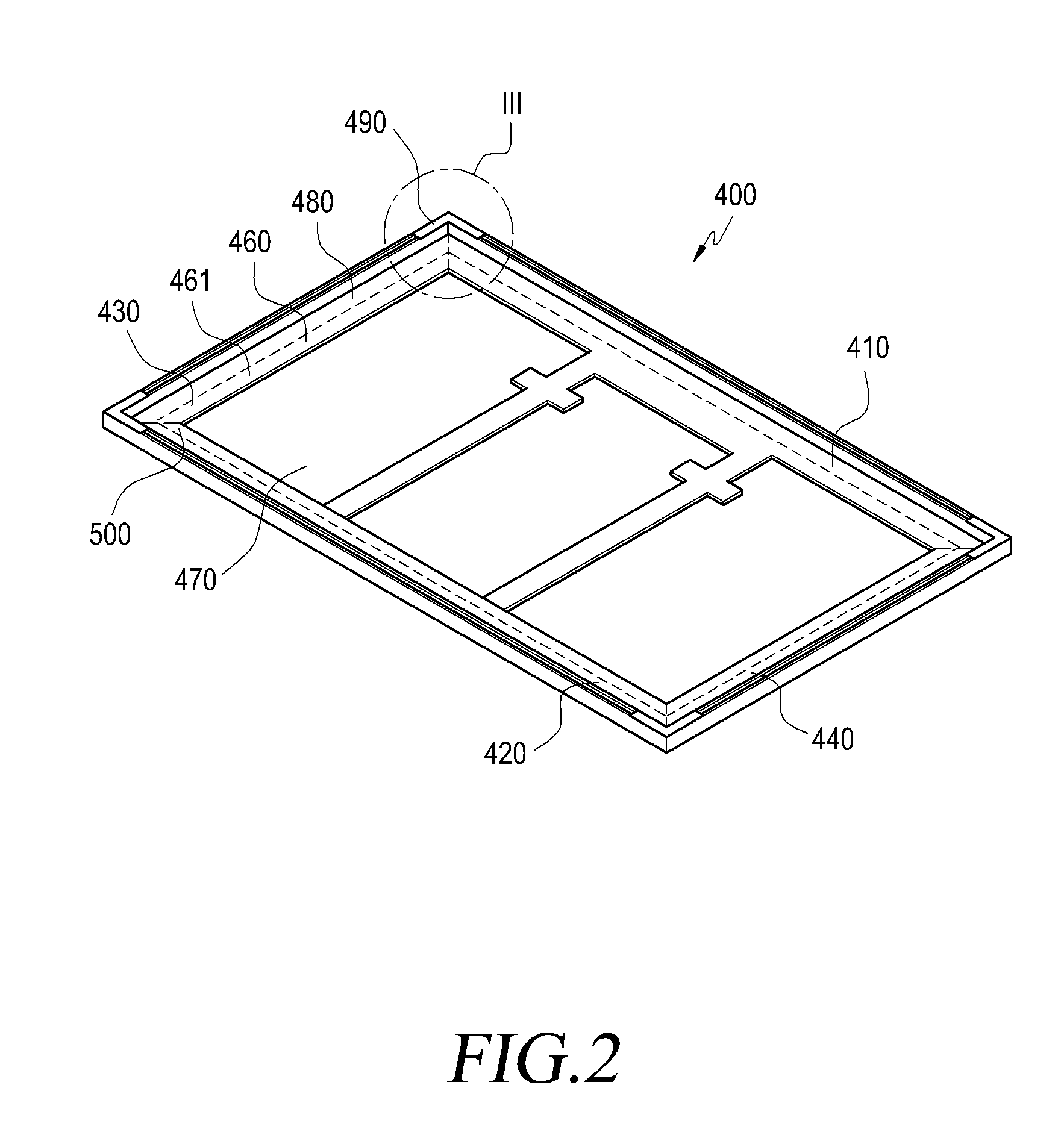

Backlight assembly, and liquid crystal display module and liquid crystal display device having the same

ActiveUS20110292315A1Easy to shapeSimple structureMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayLight guide

A liquid crystal display (“LCD”) module includes a backlight assembly emitting light, a LCD panel overlapping the backlight assembly, and an upper cover. The backlight includes a light source module emitting the light, a light guide plate (“LGP”) including edges and a middle portion, and a LGP support overlapping the edges of the LGP. The LGP support includes a plurality of LGP supporting pieces connected to each other so as to form a polygonal shape, each of the LGP supporting pieces including a LGP supporting portion including a LGP supporting surface overlapping the edges of the LGP, and the LGP supporting surfaces of each of the LGP supporting pieces of the LGP support are placed on a same plane. Opposing LGP supporting pieces are interconnected by an LCD module mounting member.

Owner:SAMSUNG DISPLAY CO LTD

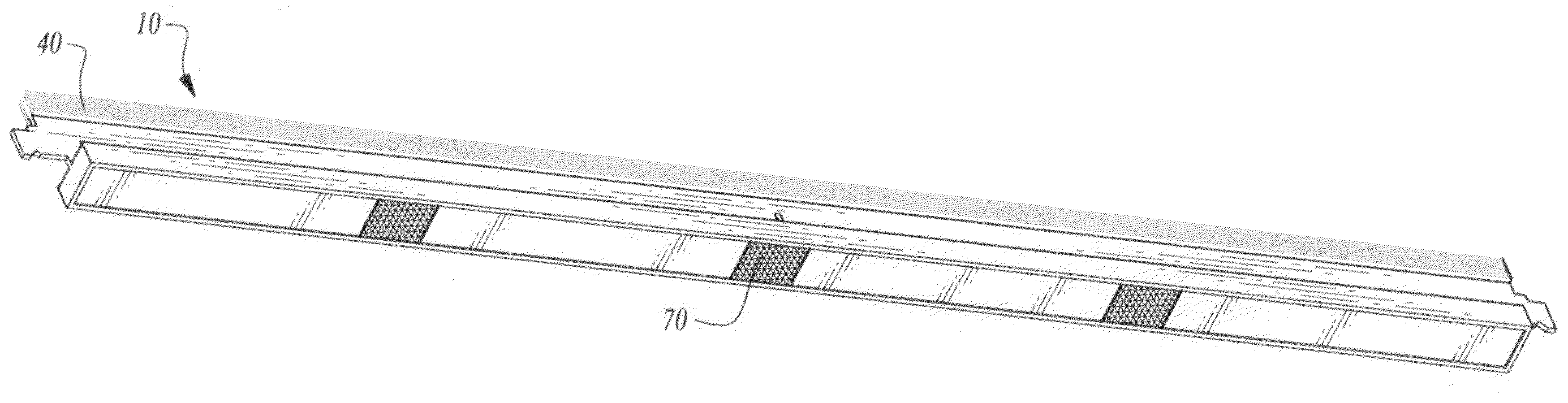

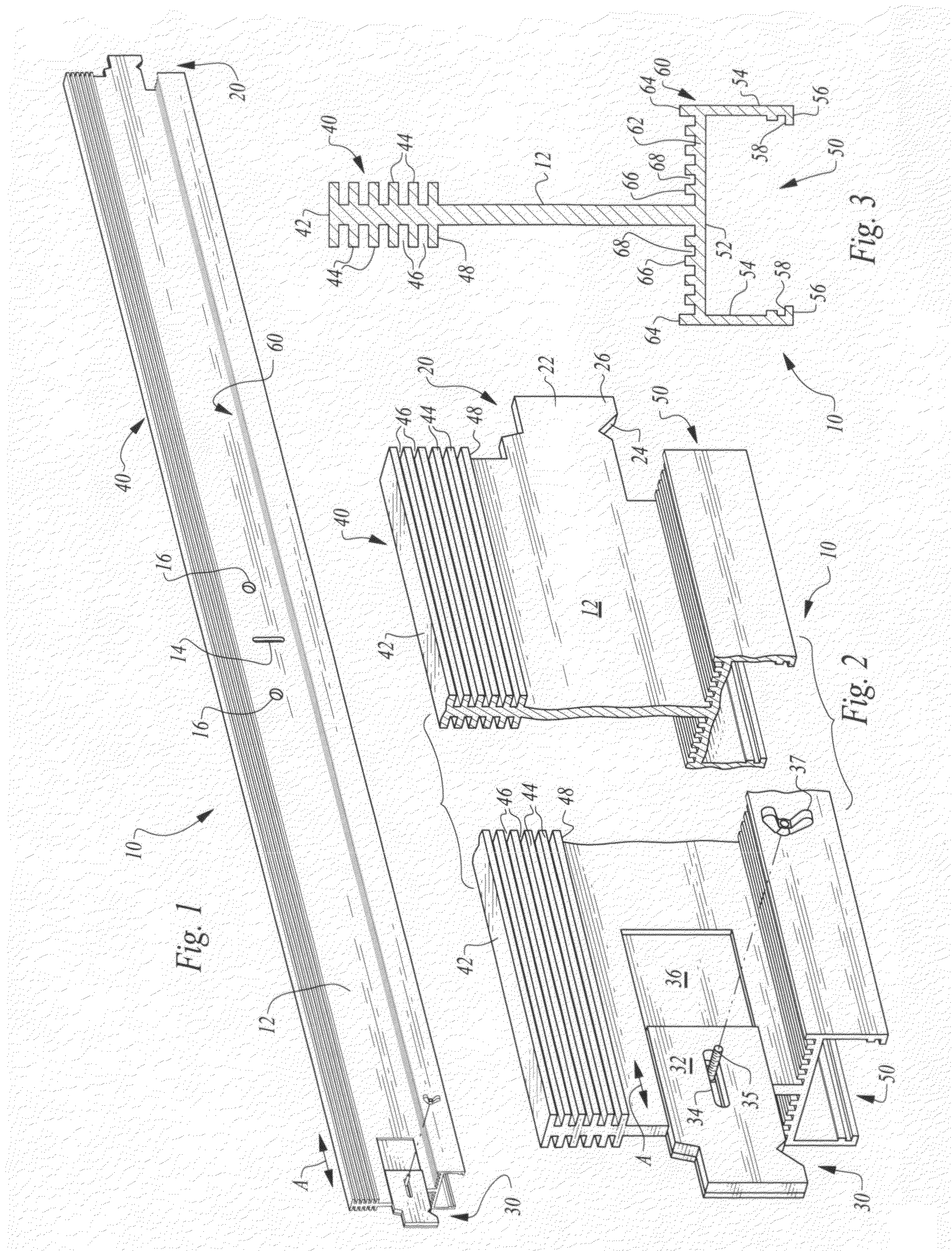

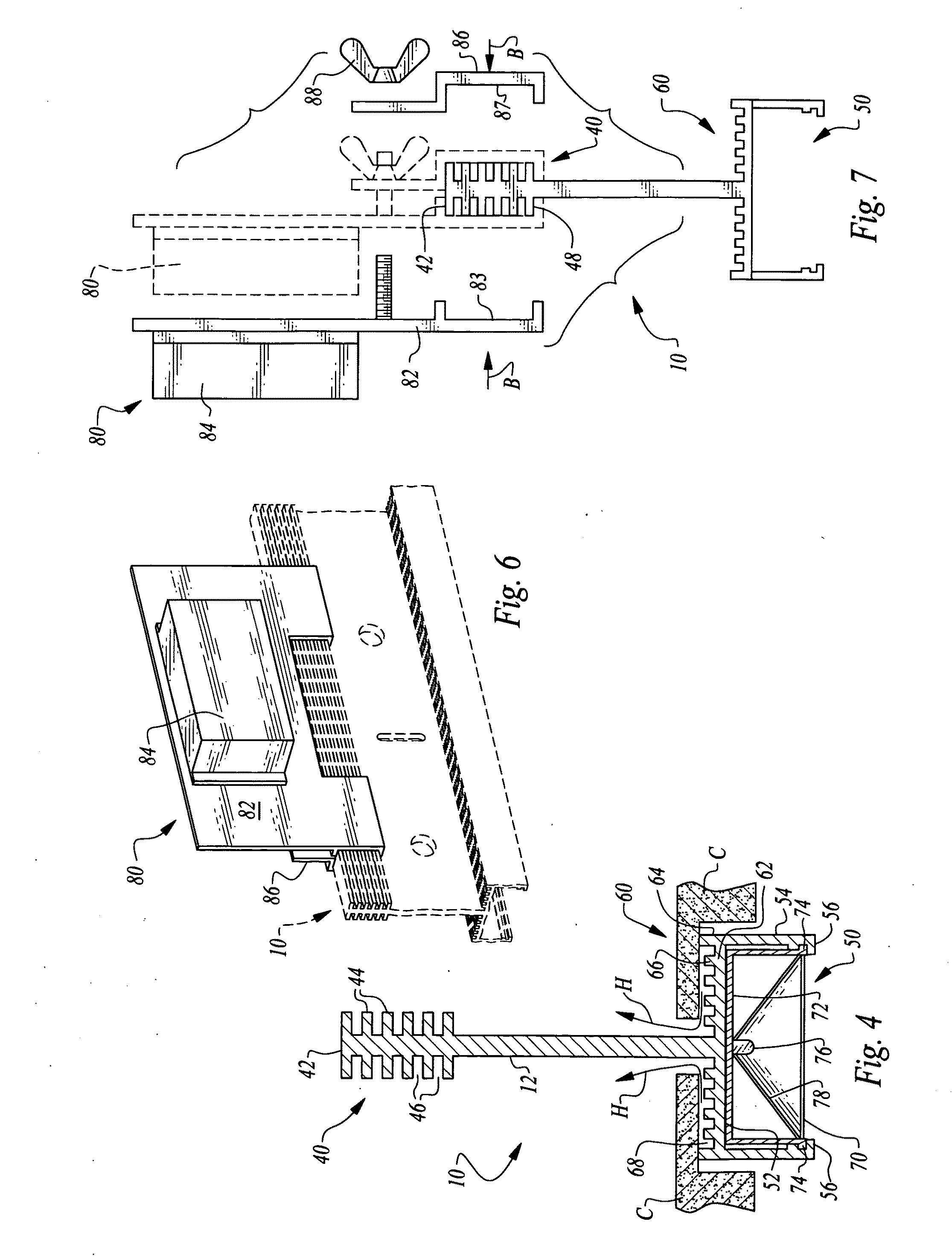

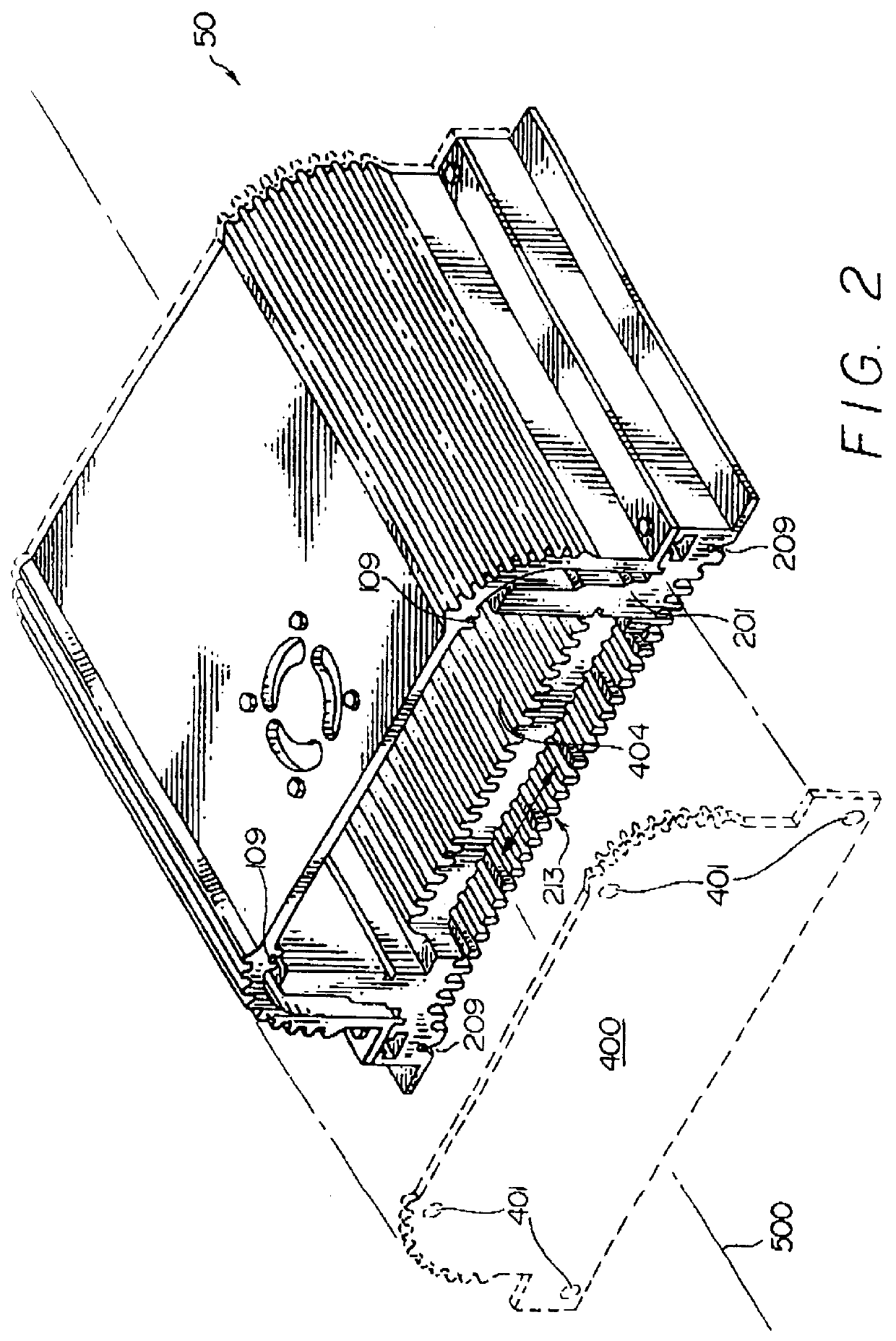

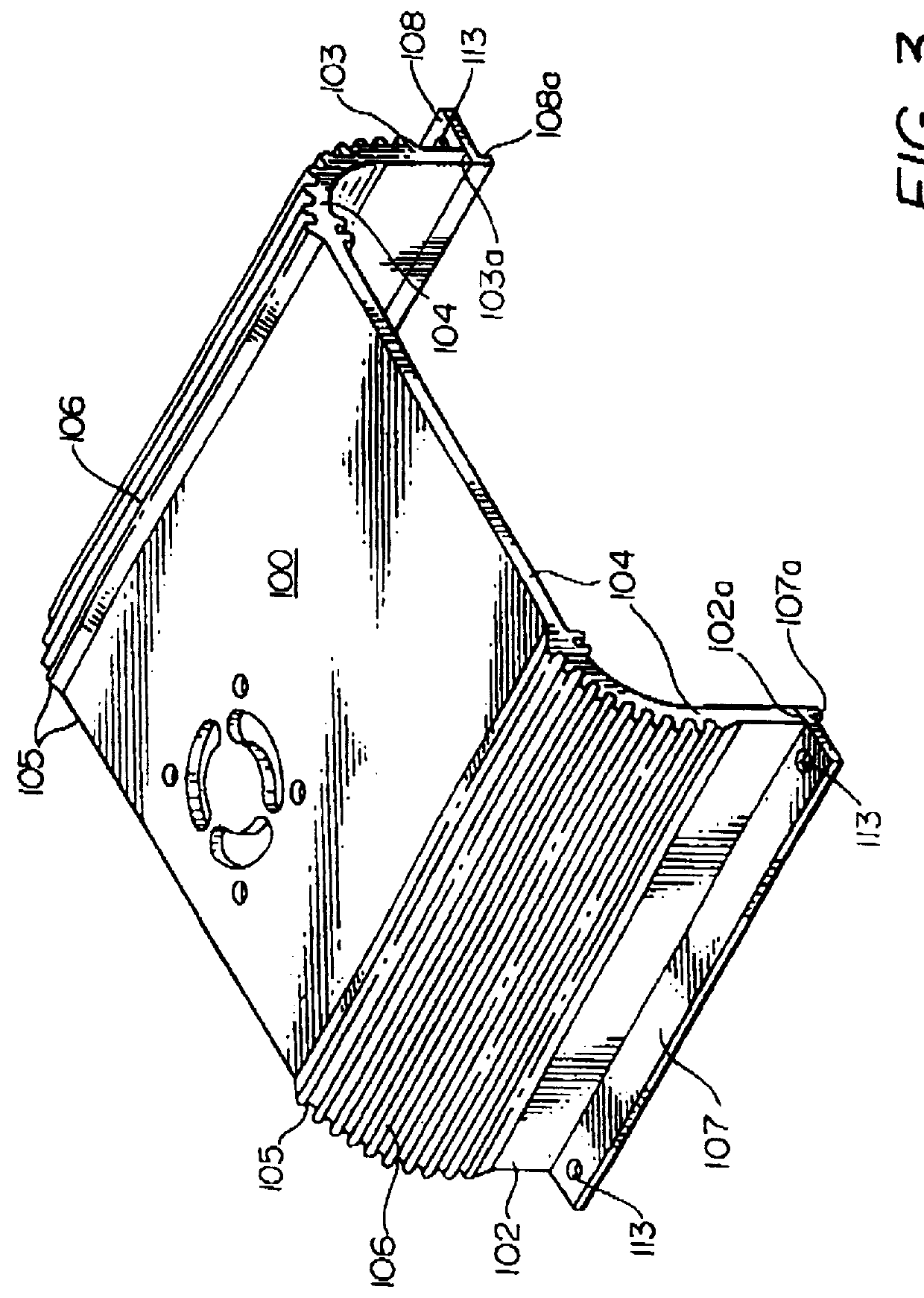

T-bar for suspended ceiling with heat dissipation system for LED lighting

ActiveUS20110222270A1Improve lighting effectsMinimize energy utilizedPlanar light sourcesCeilingsEffect lightEngineering

The T-bar includes an elongate rigid spine extending between terminal ends including either a fixed anchor or adjustable anchor for attachment to adjacent T-bars or other supports. An upper heat sink is provided on an upper portion of the spine to enhance heat transfer from the T-bar to air surrounding upper portions of the T-bar. A light housing is provided on a lower portion of the T-bar which is configured to support a lighting module therein, such as a light emitting diode (LED) light. A lower heat sink is provided above this light housing and integrated into a rest shelf which supports ceiling tiles adjacent the T-bar. A power supply is provided which can be removably attached to the T-bar and provide appropriately conditioned power for the lighting module.

Owner:JLC TECH IP LLC

Heat dissipating housing for electronic components

InactiveUS6144556AEffective coolingIncrease the areaCooling/ventilation/heating modificationsElectronic circuitMultiple pass

The present invention provides a heat dissipating housing for electronic circuits and associated components, wherein the housing includes a top, two side panels, and a bottom to form a cavity or chamber for installing therein electronic circuit boards and the like. A first end panel and a second end panel, which are attached to opposite ends of the housing, complete the housing enclosure. For superior heat dissipation efficiency, a fan or other air moving device is attached to the housing to move air through the housing. The housing structure and the electronic components positioned therein are configured so as to direct the cooling air in multiple passes through the housing in a serpentine manner before exiting the housing. The multiple pass feature of the present invention provides superior cooling for the electronic components installed inside the housing.

Owner:LANCLOS KENNETH W

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com