Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3103 results about "Curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming dielectric SiOCH film having chemical stability

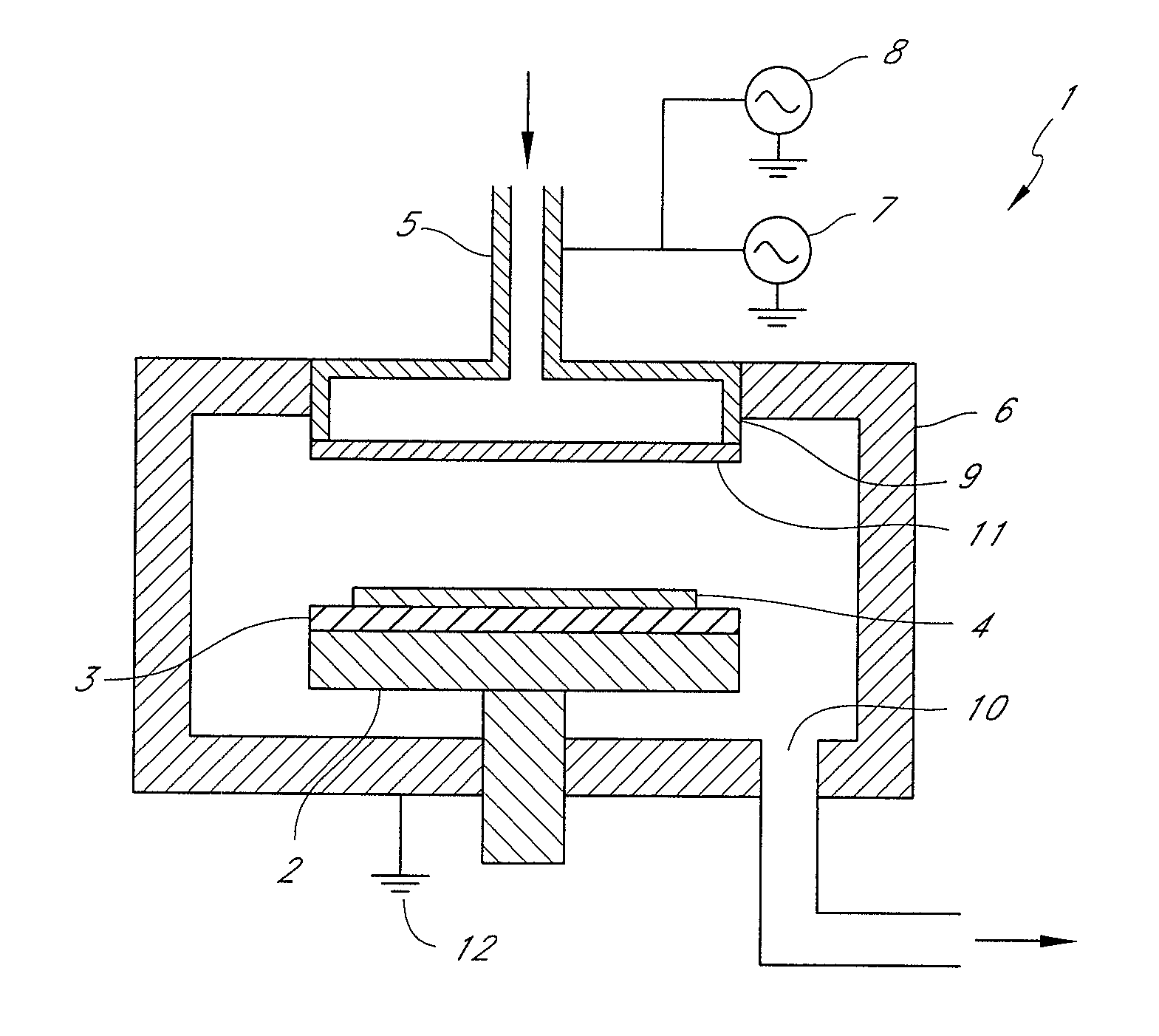

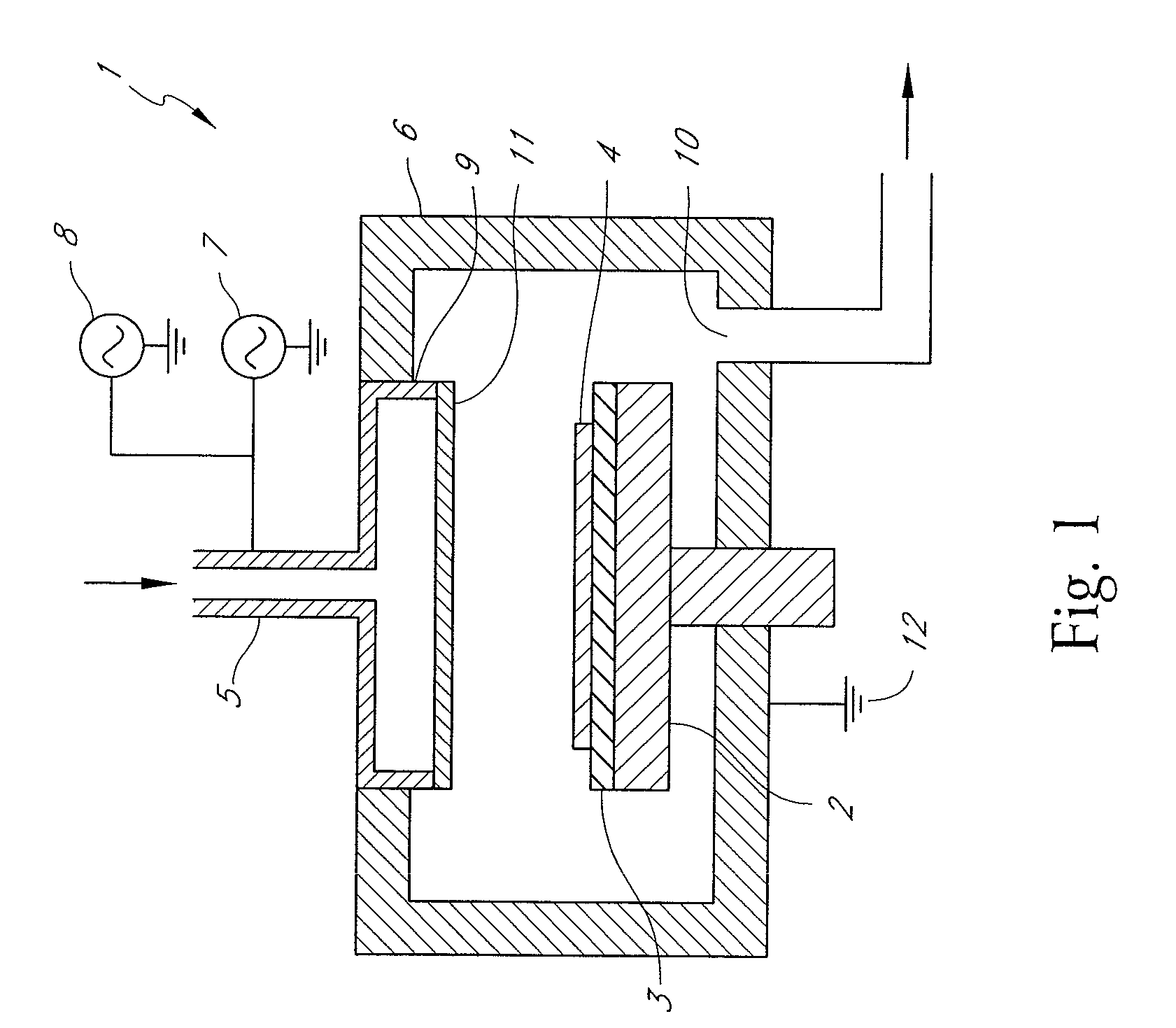

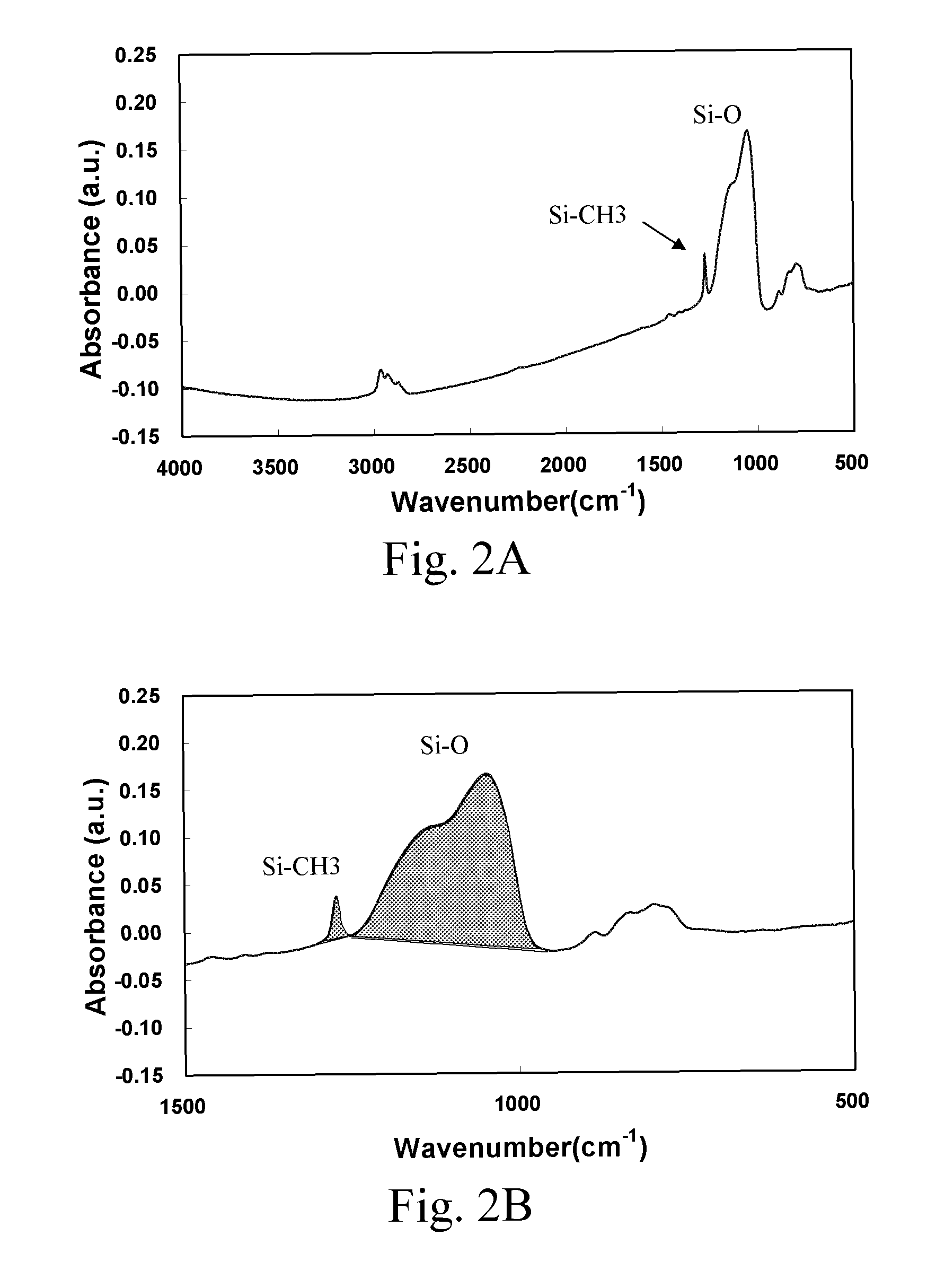

ActiveUS7807566B2Good chemical stabilityLow dielectric constantSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDielectricSusceptor

A method for determining conditions for forming a dielectric SiOCH film, includes: (i) forming a dielectric SiOCH film on a substrate under conditions; (ii) evaluating the conditions using a ratio of Si—CH3 bonding strength to Si—O bonding strength of the film as formed in step (i); (iii) if the ratio is 2.50 % or higher, confirming the conditions, and if the ratio is less than 2.50 %, changing the conditions by changing at least one of the susceptor temperature, the distance between upper and lower electrodes, the RF power, and the curing time; and (iv) repeating steps (i) to (iii) until the ratio is 2.50 % or higher.

Owner:ASM JAPAN

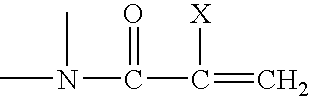

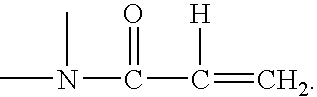

Method for making silicone hydrogel contact lenses

The invention provide a method for making silicone hydrogel based on the Lightstream Technology from a monomer mixture with a curing time of less than about 100 seconds. The present invention is also related to silicone hydrogel contact lenses made according to methods of the invention.

Owner:ALCON INC

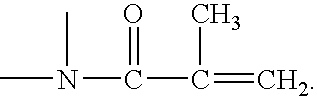

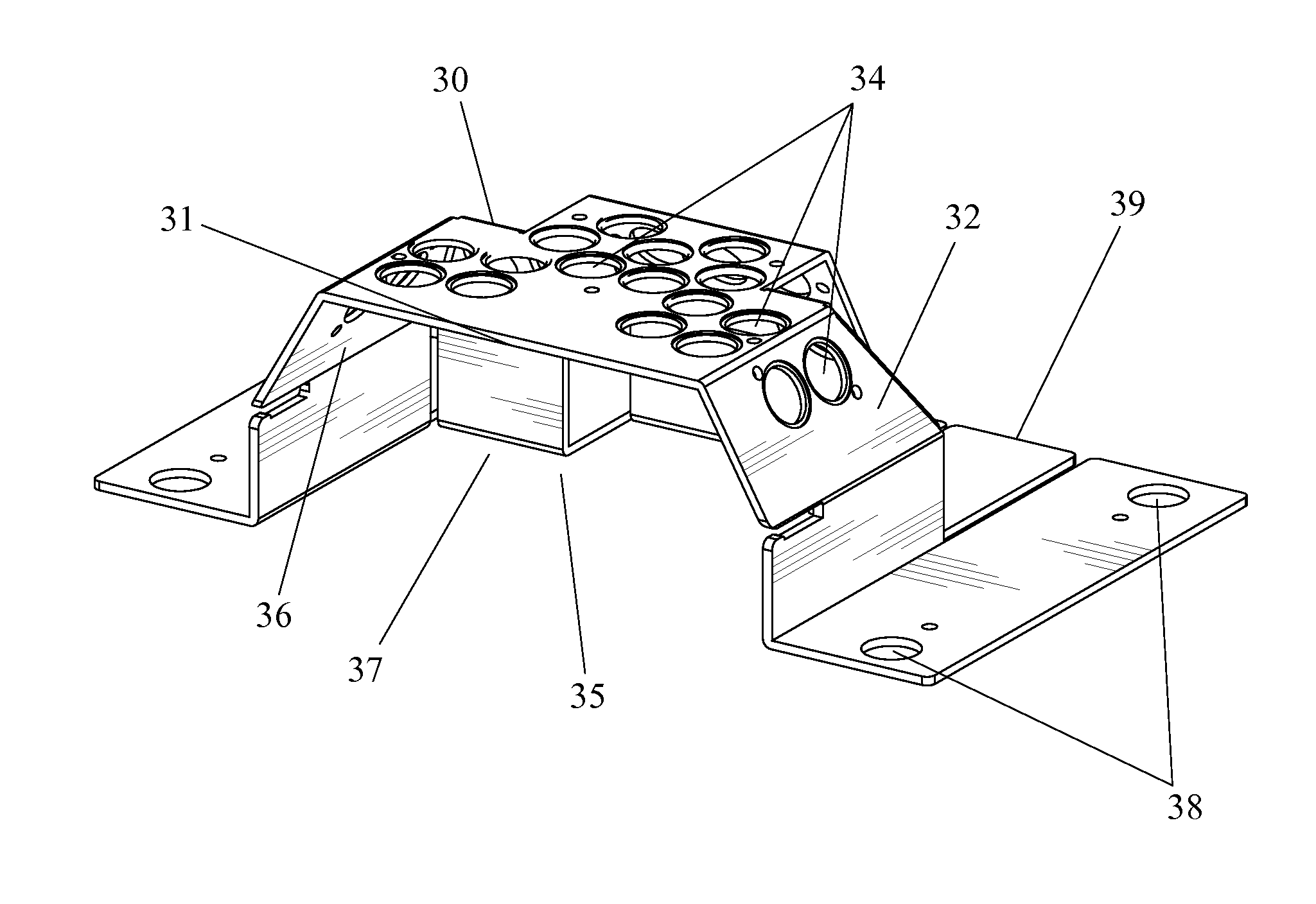

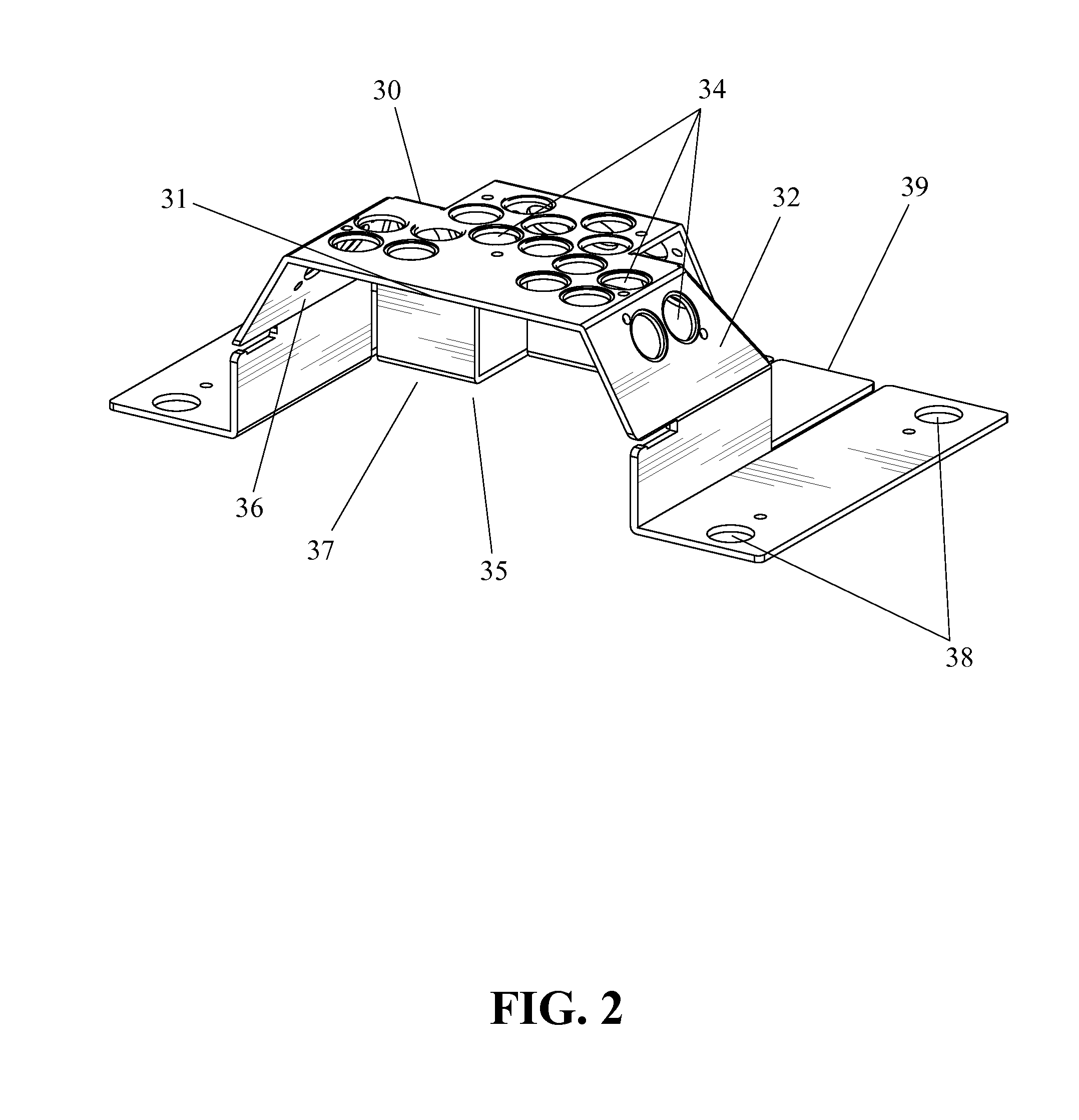

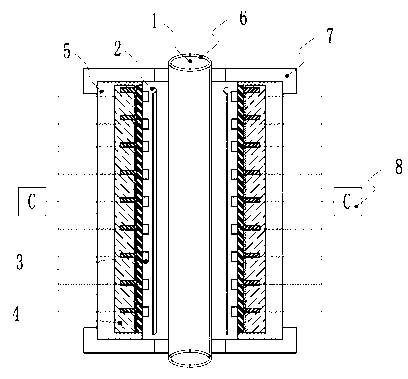

UV LED Curing Apparatus with Improved Housing and Switch Controller

InactiveUS20110277338A1Improve securityImprove reliabilityDrying solid materials with heatElectric circuit arrangementsAutomatic controlEngineering

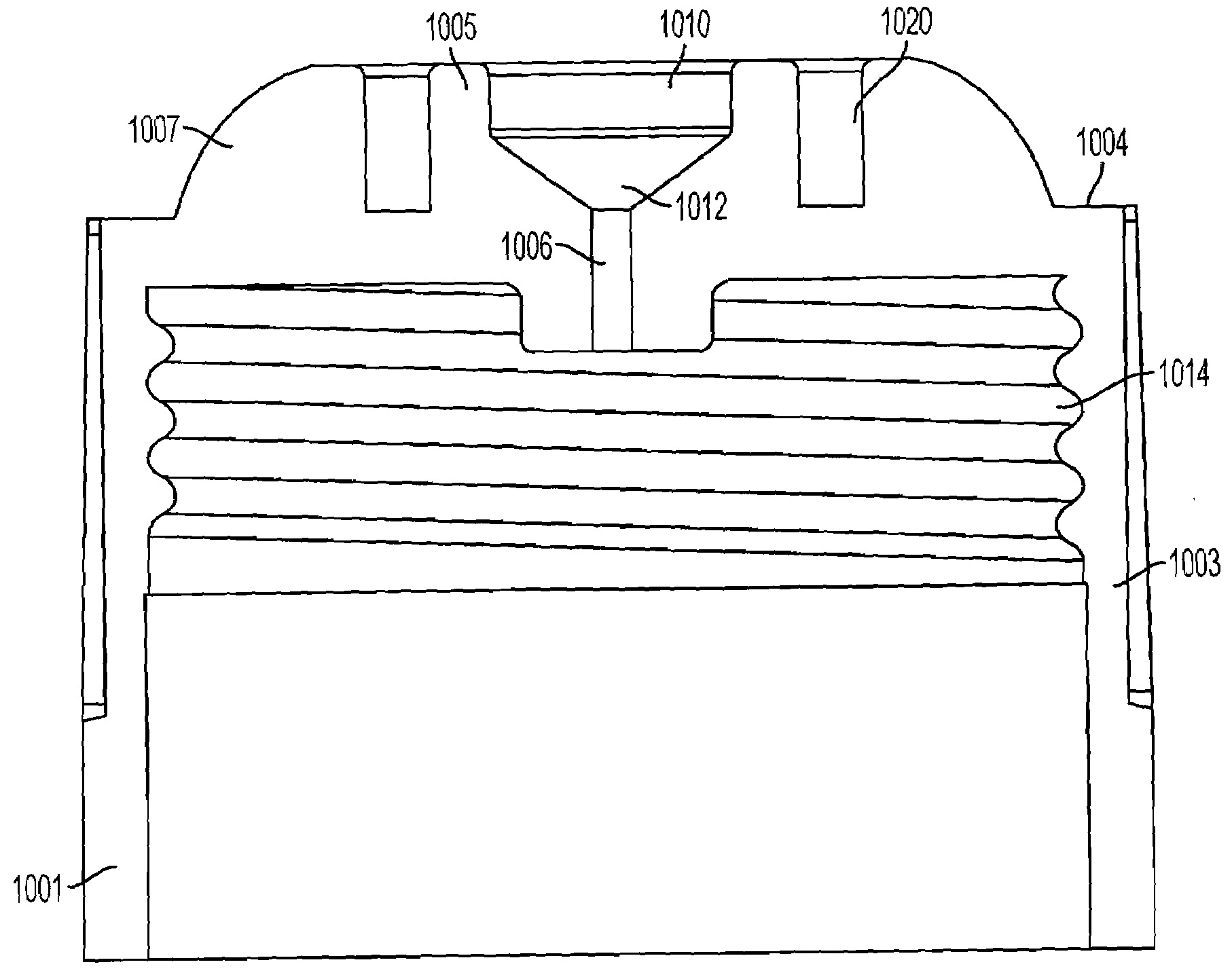

The present invention is related to an UV LED curing apparatus, and more particularly, to an UV LED curing apparatus with improved housing and switch controller. The UV LED curing apparatus of the present invention is preferably provided for curing UV hardening gel applied onto the nails of multiple fingers or toes all at once and with automatic controls; the UV LED curing apparatus comprises a light reflective inner casing enclosing a curing chamber having a front opening, an outer casing detachably attached to the inner casing and an UV LED light source disposed on the inner casing and capable of providing an illumination covering a large space in the curing chamber. The automatic controls of the apparatus may be achieved by a switch controller having a photo interrupter, timer and current regulator such that the UV light from the UV LED light source is triggered to an on-state by the sensor of the photo interrupter and switched to an off-state by the timer and current regulator with reference to a preset curing time automatically. The UV LED light source is preferably to be of a wavelength between 360 nm and 460 nm. The light reflective inner casing is preferably provided as an effective UV light reflector and as a supporting substrate of the UV LED light source while being capable of transmitting heat from the UV LED light source away for further heat dissipation to the ambient by the outer casing. The outer casing is detachably attached to the inner casing and allows a greater user interaction for decorative and entertainment purposes while also being a protective and heat dissipation means.

Owner:NAIL ALLIANCE

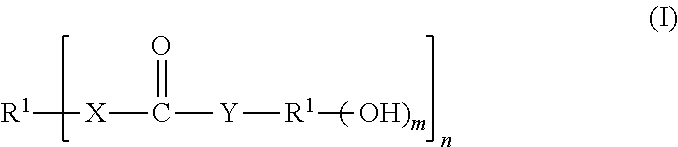

Accelerated and toughened two part epoxy adhesives

InactiveUS20150184039A1High dynamic impact peel strengthFast curing timeMacromolecular adhesive additivesEpoxy resin adhesivesFiberGlass fiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

Pen Needle Hub Having Increased Contact Area

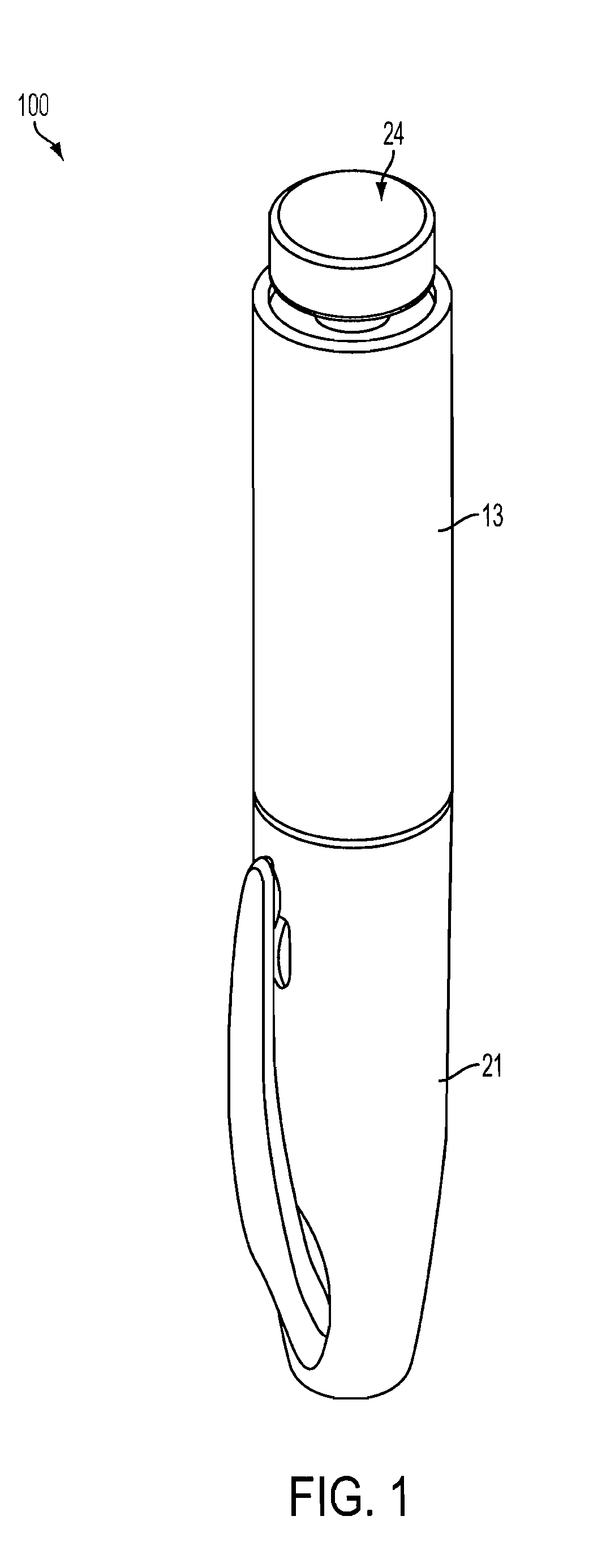

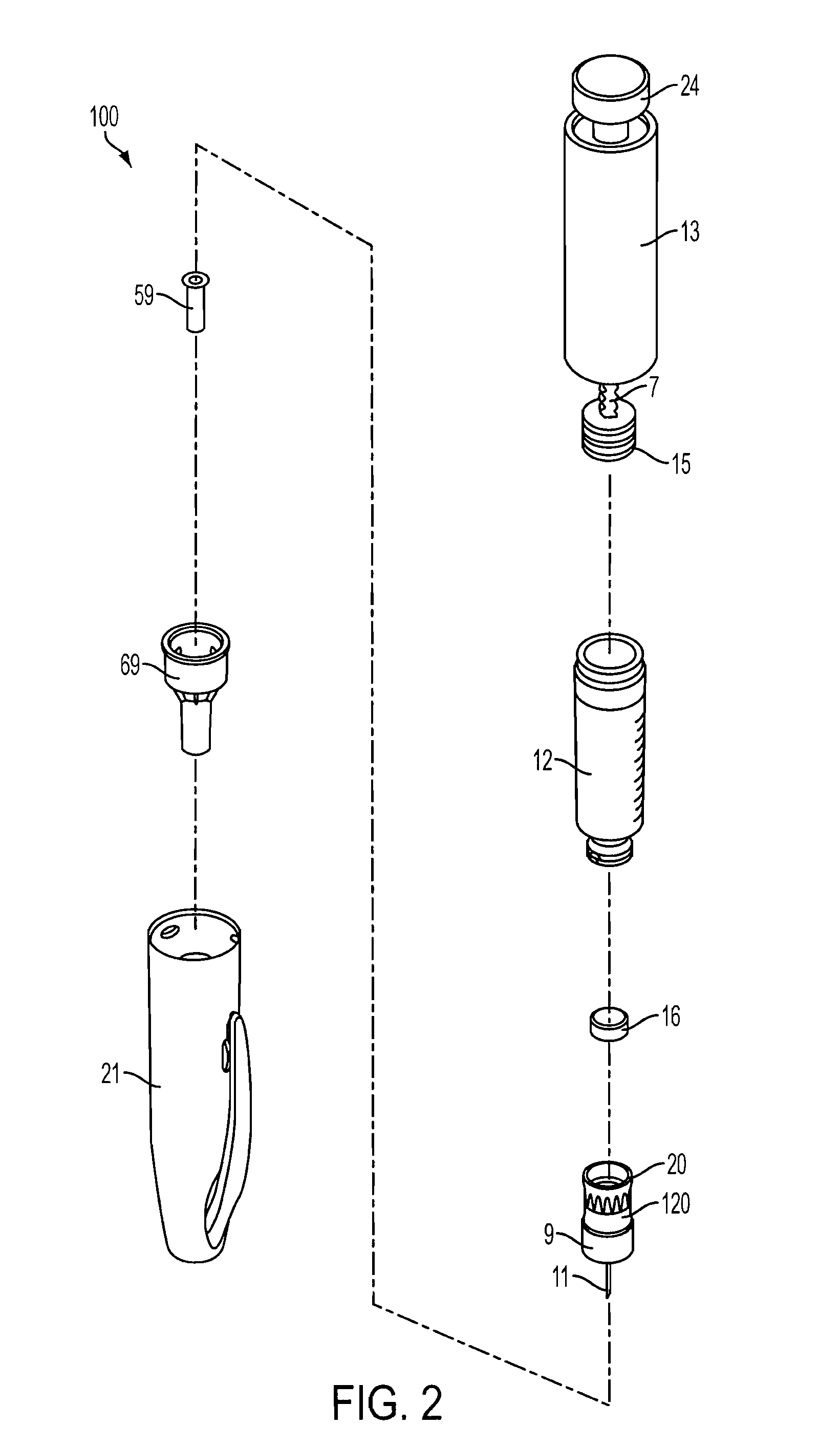

ActiveUS20090069755A1Improve comfortIncrease surface areaInfusion syringesInfusion needlesSkin contactUltimate tensile strength

A pen needle assembly having a hub with an increased surface area that contacts a patient's skin is provided. The increased contact area of the hub with the patient's skin during injection of a cannula decreases the pressure exerted against the patient's skin, thereby increasing the comfort of the patient. A bonding adhesive is disposed on an outer surface of the hub, thereby decreasing the required curing time of the adhesive. Additionally, the increased contact area, between the cannula adhesive and hub increases the strength of the bond therebetween.

Owner:EMBECTA CORP

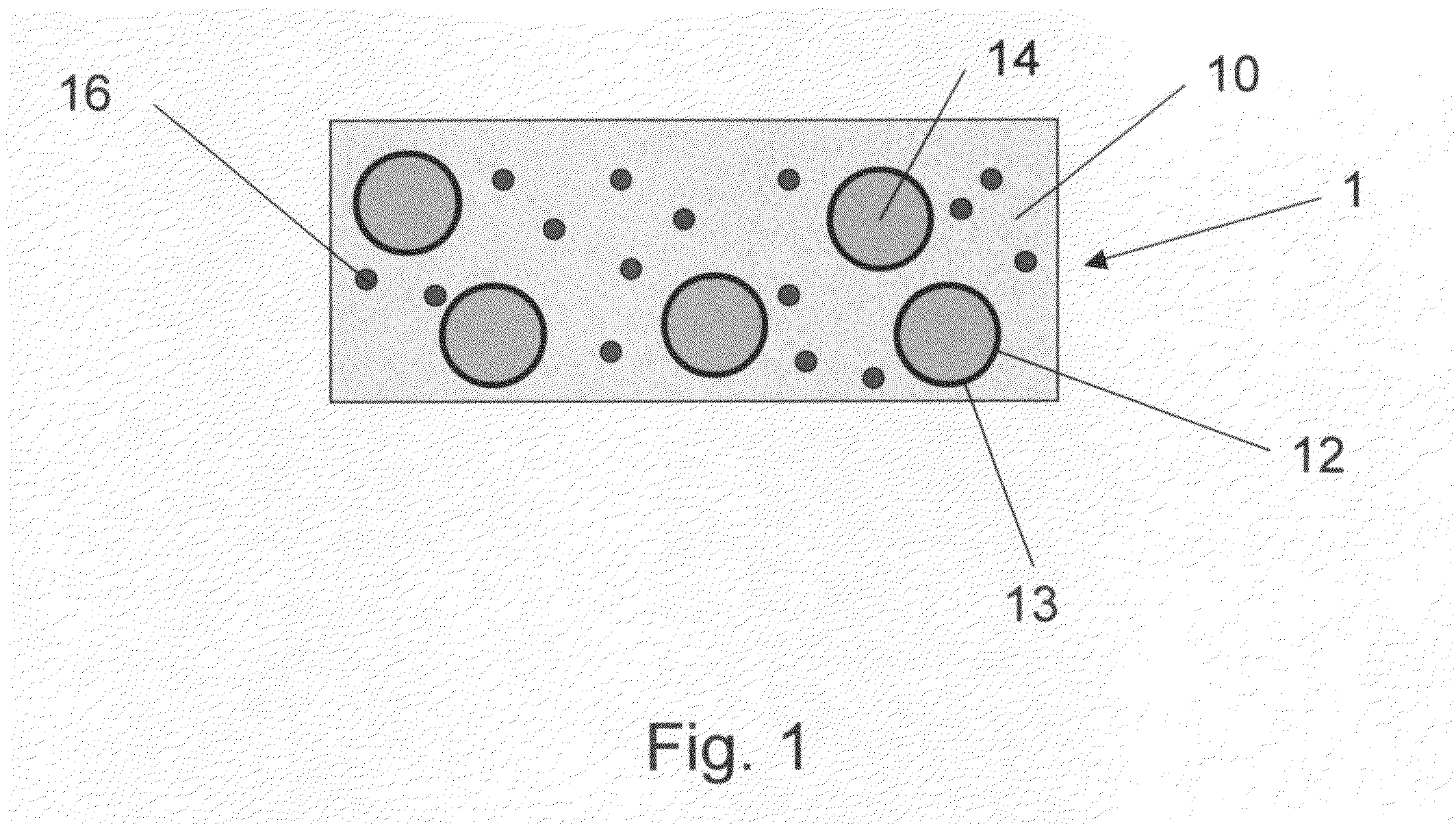

Self healing composite material and method of manufacturing same

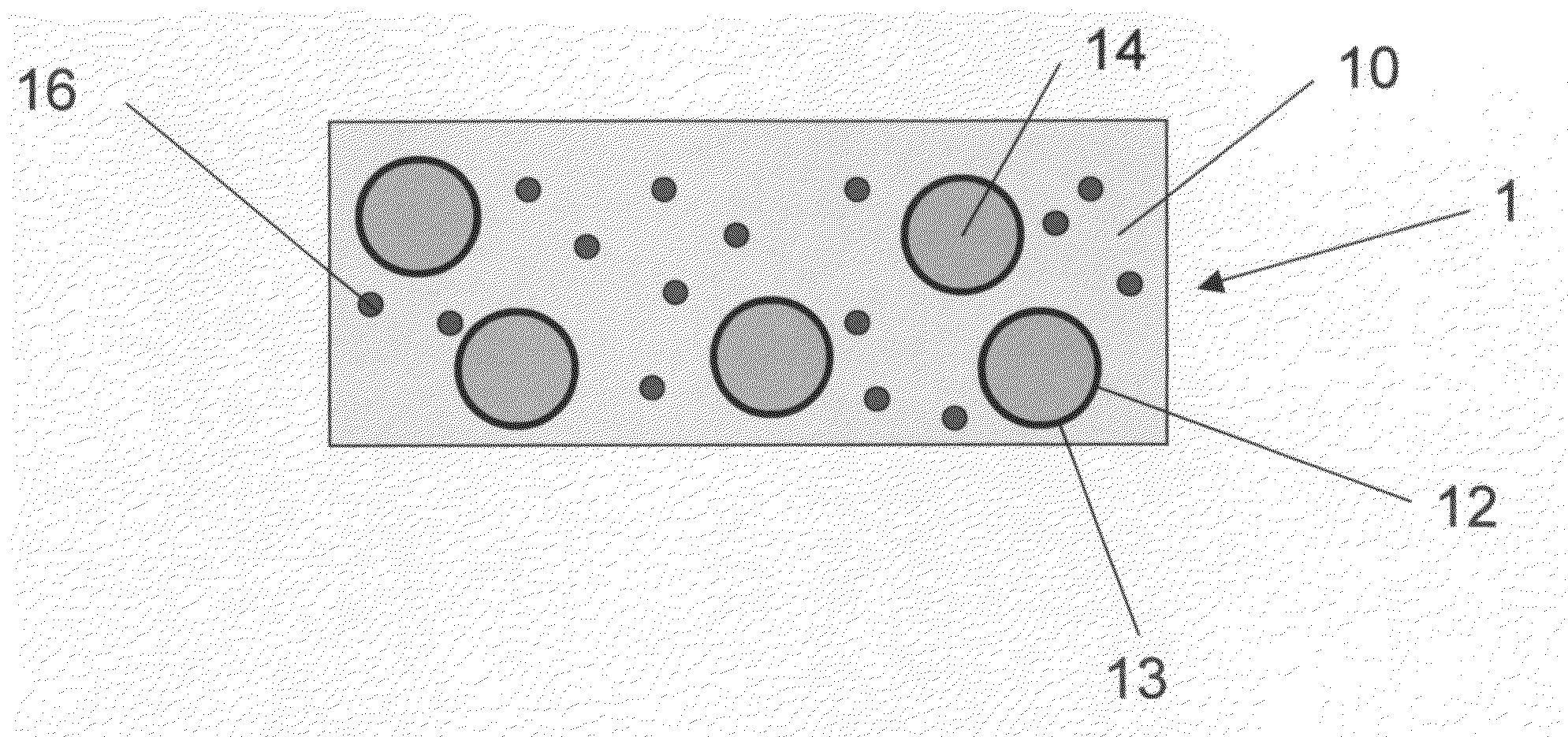

InactiveUS20090036568A1Large operating rangeFaster rate of healingRadio transmissionThin material handlingEmulsionRestorative material

A self-healing material comprises a matrix embedded with micro-pockets of a healing-agent releasable by a crack in the matrix. The healing-agent is able to bond to the matrix to repair the crack. The healing-agent is contained in microcapsules. A corresponding catalyst for the healing-agent is embedded in the matrix and contained in a plurality of microcapsules as an emulsion. The emulsion comprises an oil, a perfluorated solvent, a hydrophobic ionic liquid, or mixtures thereof. A method of manufacturing the self-healing material comprises the steps of identifying an operational temperature range of the material, providing at least one substance as the healing-agent, which substance remaining substantially in a liquid state within the operational temperature range, identifying an operational evaporation rate of the healing-agent and providing the substance with a curing time according to the evaporation rate.

Owner:MPB COMM +1

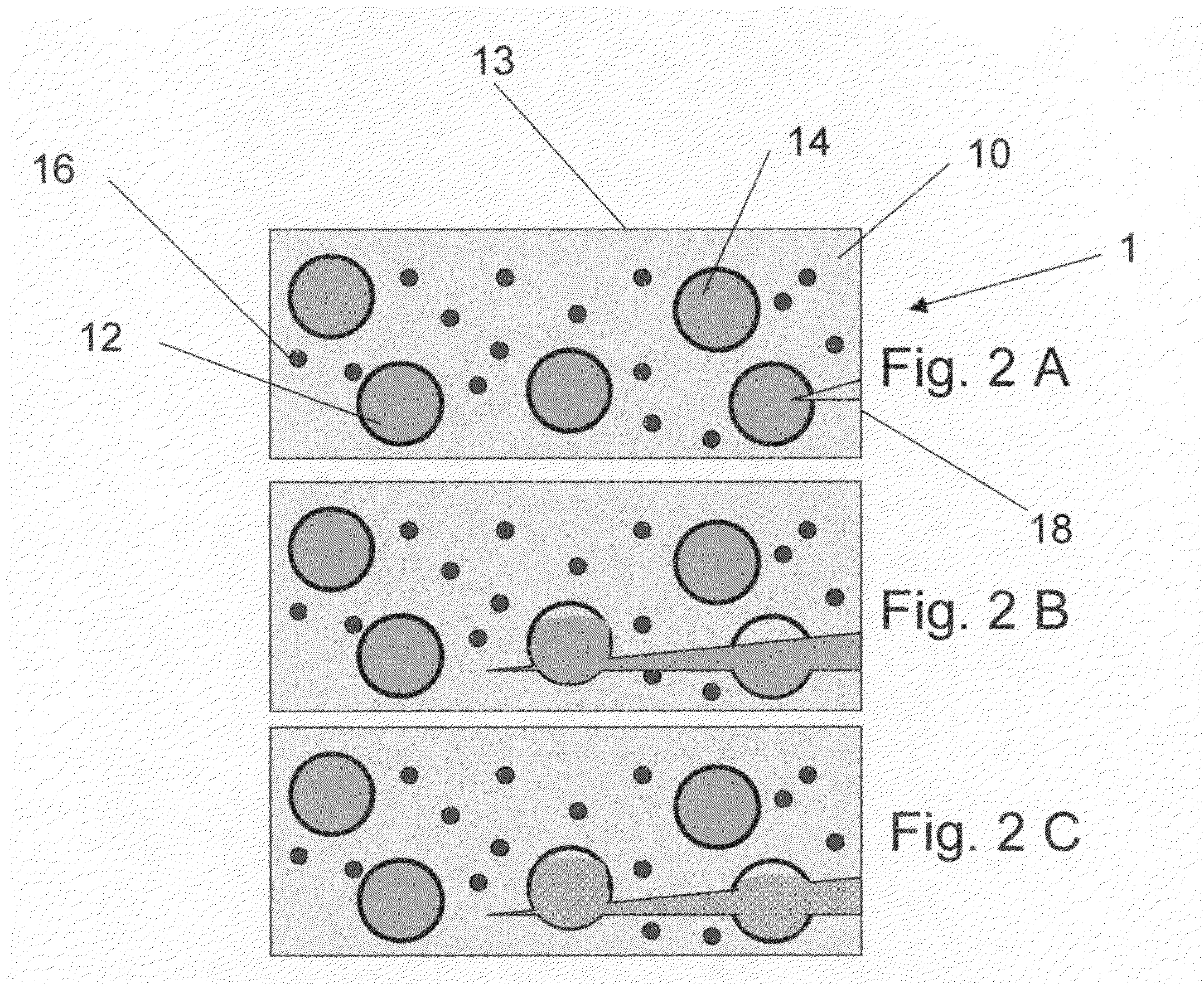

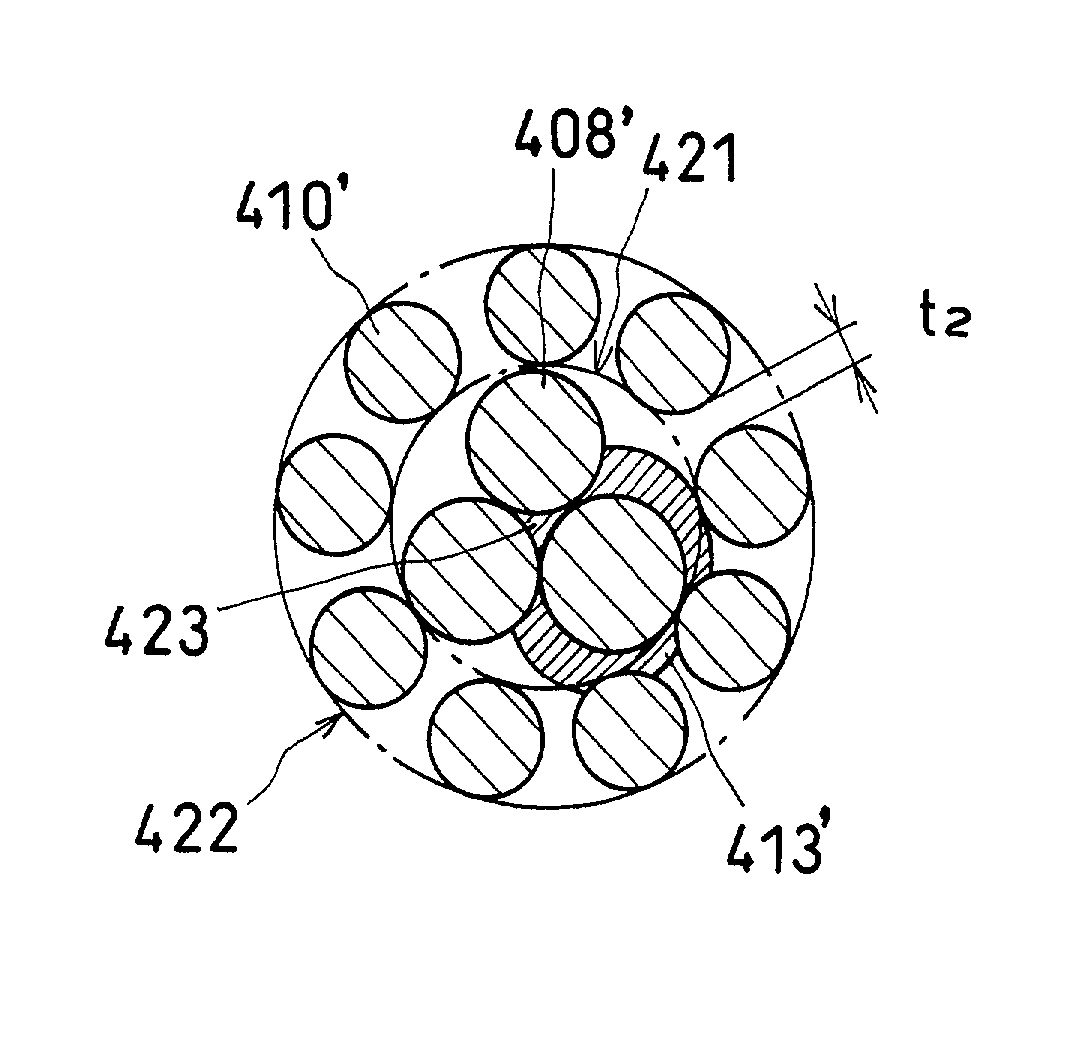

Elastomer and steel cord composite and process for producing the same

InactiveUS20020160213A1Reduce componentsSave energyPneumatic tyre reinforcementsRope making machinesElastomerMaterials science

In order that spaces, including a space in the central portion, inside a steel cord used as a reinforcement by being embedded in a tire or the like are filled with an uncured rubber, the uncured rubber is coated on plural steel filaments 115 which are then stranded in case of a single layer steel cord, the uncured rubber is coated on all of plural core filaments 329 which are then stranded along with outer layer filaments 330 in the same direction at the same pitch in case of a 2-layer steel cord of 1 stranding process, and the uncured rubber is coated on all or 2 to 4 core filaments 218 or on at least one of 3 or 4 steel filaments 408, 408' to form a core strand and outer layer filaments 410, 410' are stranded therearound in case of 2-layer steel cord of 2 stranding process. Consequently, it is possible to exhibit satisfactory corrosion resistance and satisfactory fatigue resistance as a steel cord, shorten a curing time in tire component assembling or the like to attain energy saving and prolong the life of a steel cord itself and the life of a tire or the like using the same as a reinforcement. Further, production can be performed at low cost.

Owner:YOKOHAMA RUBBER CO LTD +1

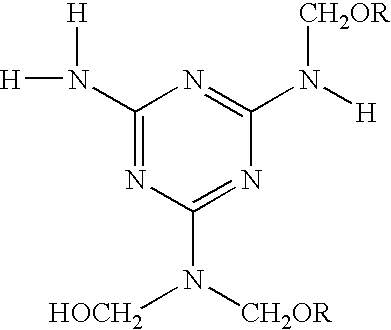

Fiberglass non-woven catalyst

The present invention relates to novel catalysts for use with a fiberglass non-woven binder. The catalyst can be a Lewis acid, an organic acid salt, a free-radical generator, or a mixture thereof. The catalyst provides stronger bonding, increased crosslinking density, reduced curing times, and reduced curing temperatures. Fiberglass mats made with polymer binder compositions containing the catalyst exhibit both flexibility and elasticity, allowing the mats to be compressed for storage, yet return to original thickness once the compressive forces are removed. Formaldehyde-free wood composites, such as plywood and fiberboard, may also be produced with polymer binder compositions containing the catalyst.

Owner:SIEMENS AG +1

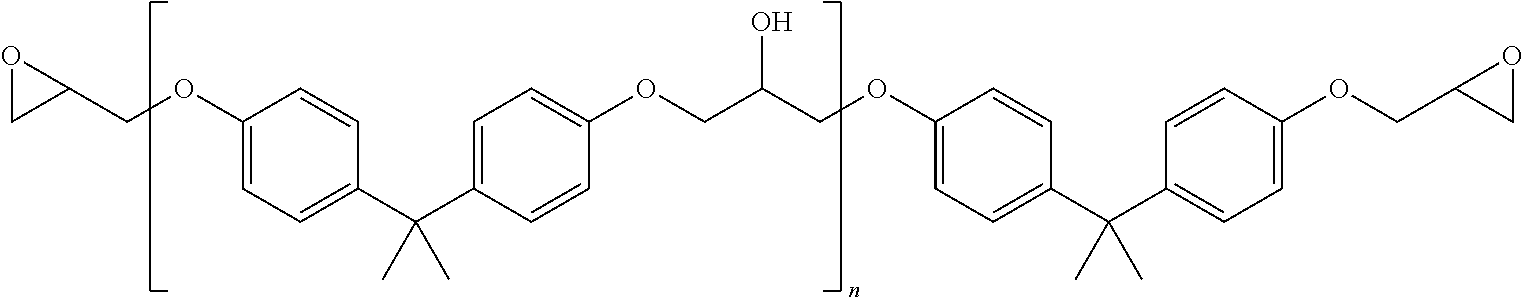

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

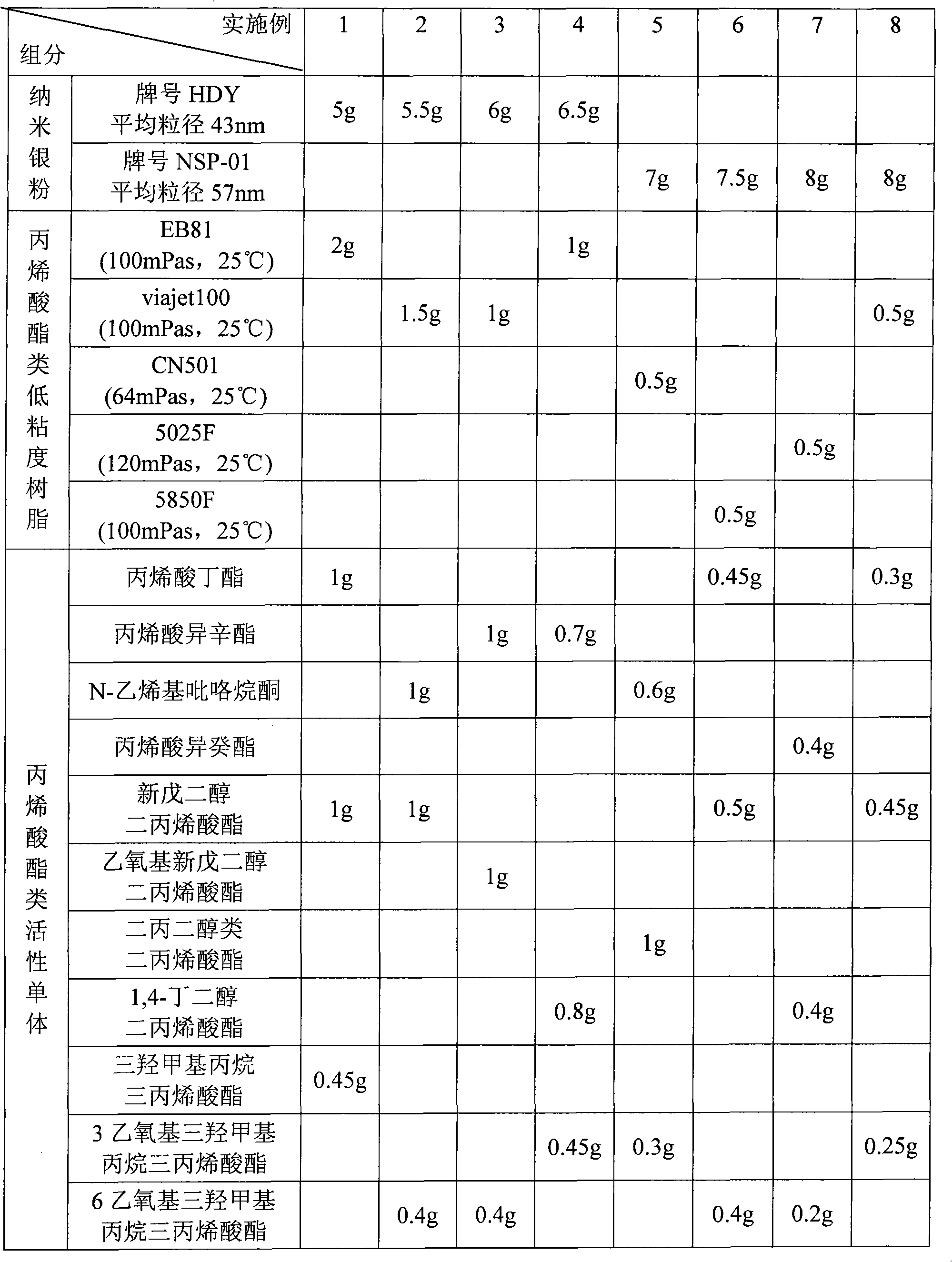

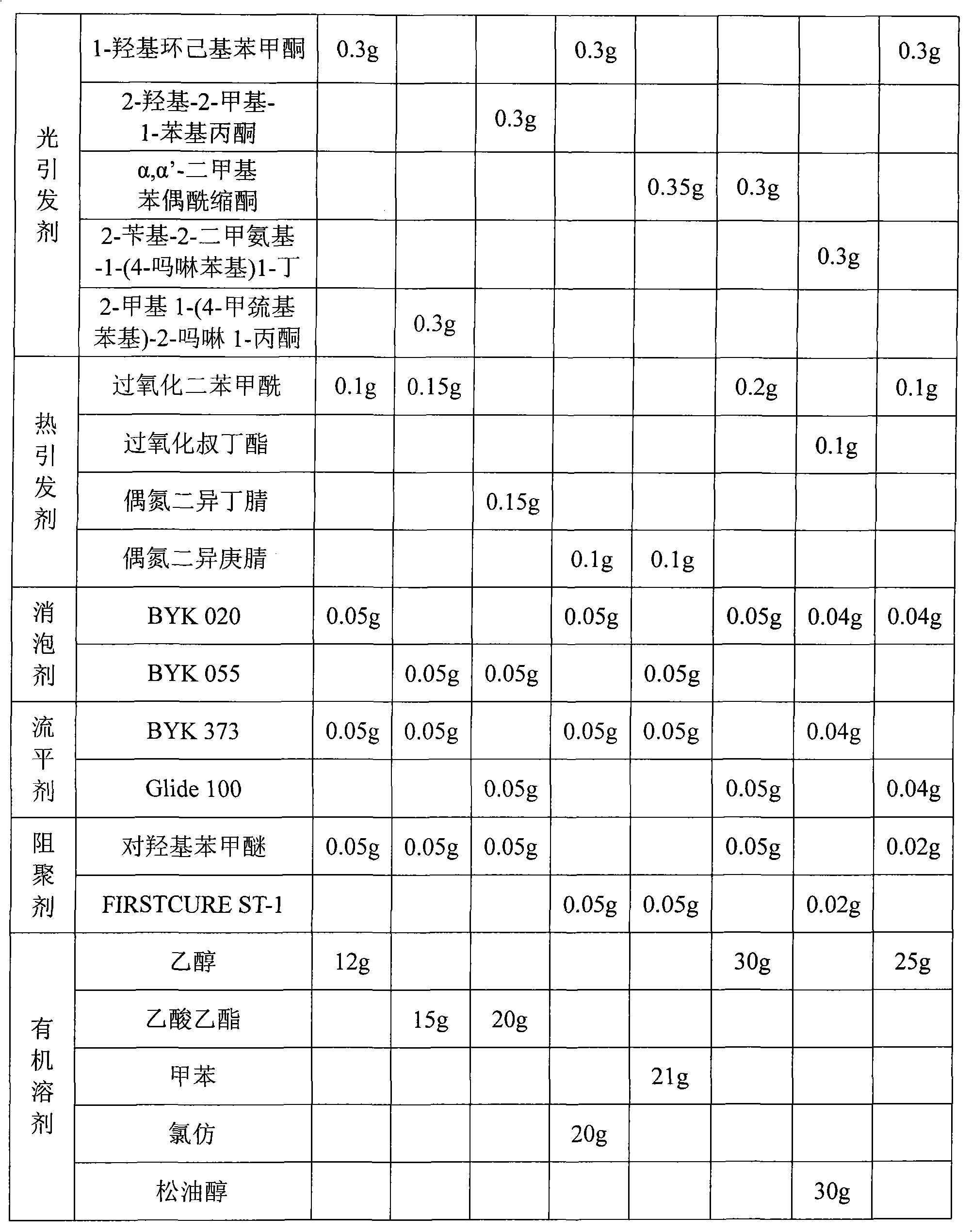

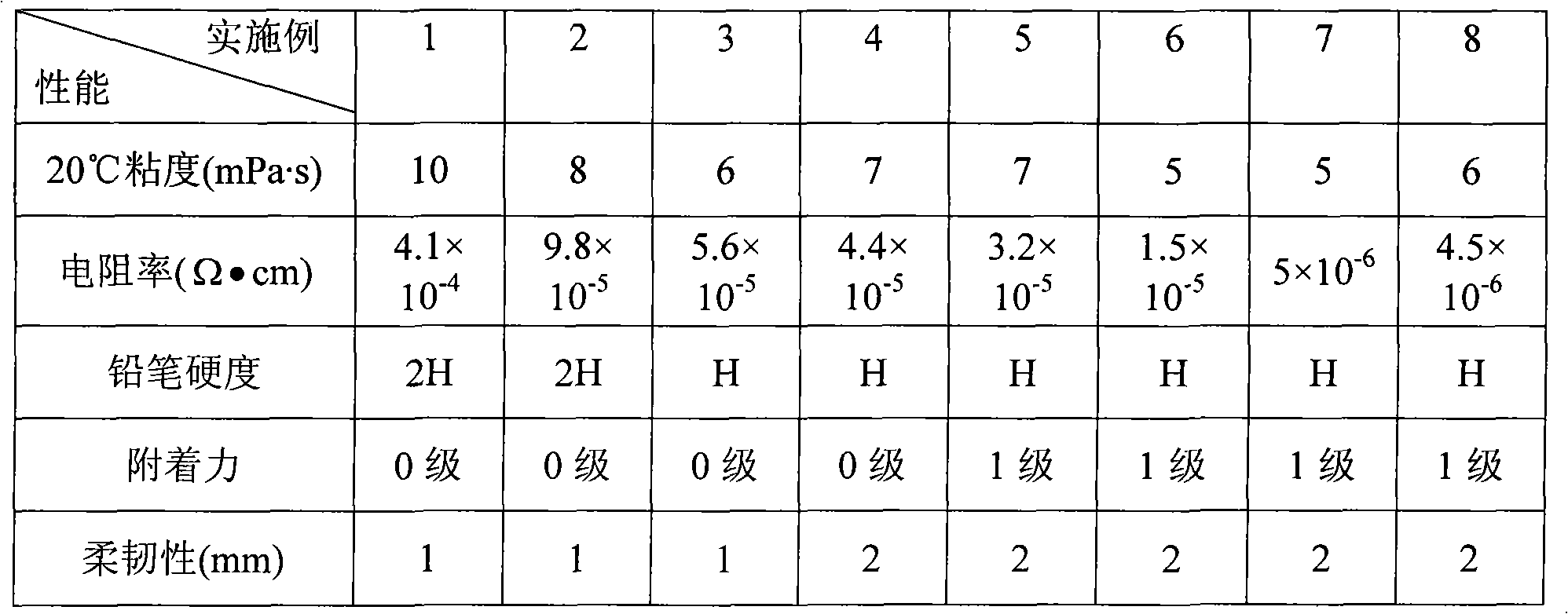

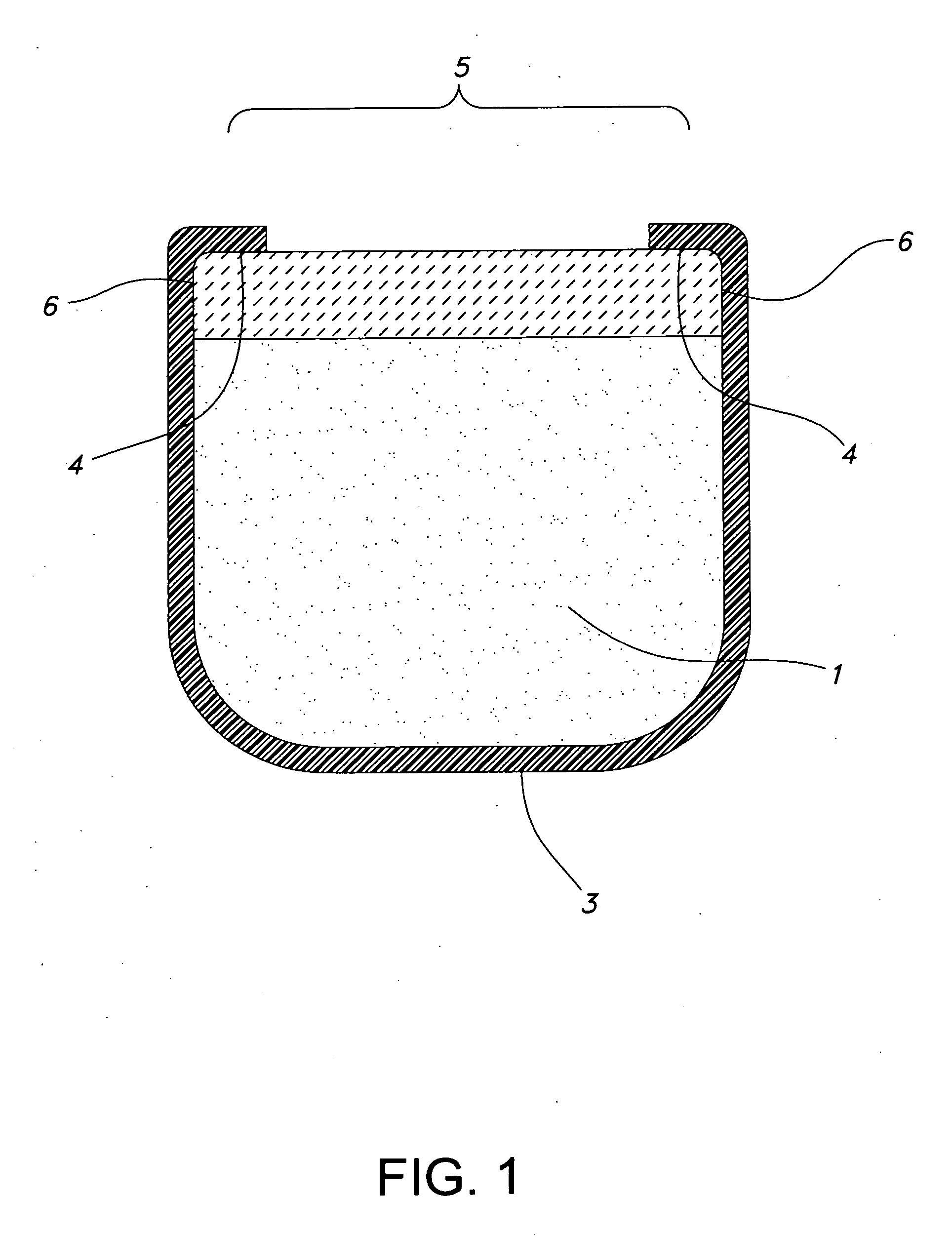

Photo-curing ink-jet nano conductive printing ink, and preparation and use method thereof

InactiveCN101348634AContinuous ejectionGuaranteed resistivityInksPrinted circuit manufactureDual curePliability

The invention relates to light-cured ink jet nanometer conductive printing ink for printed circuit boards, and preparation and use methods thereof. The preparation method comprises the following steps: an acrylic ester low viscosity resin and an acrylic ester active monomer are added into nanometer metal dispersing solution and the mixture adopts a double cured mode that the mixture is subjected to light cure firstly and heat treatment secondly, wherein the light-cured treatment ensures that a coat is cured rapidly and achieves good mechanical performance; and the heat treatment ensures that the nanometer metal is nodulized together to achieve good conductive performance. The light-cured ink jet nanometer conductive printing ink which adopts the ink jet technique can be painted in the specific area of a base material. A conductive path is obtained after the double cured treatment. The light-cured ink jet nanometer conductive printing ink has the advantages of short cured time, low cured temperature, good conductivity and high resolving capability. The manufactured conductive membrane has good adhesiveness, high hardness, good flexibility and excellent conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Process for preparing poly(vinyl alcohol) drug delivery devices

InactiveUS20060067978A1Pharmaceutical containersPharmaceutical delivery mechanismPolyvinyl alcoholMedicine

The present invention is a process for making a plurality of drug delivery devices for implantation in the eye of a patient. The plurality of drug delivery devices are made in part of poly(vinyl alcohol). During the manufacturing process the poly(vinyl alcohol) is cured. The poly(vinyl alcohol) may be in the form of separate pieces, a unitary sheet or may be incorporated into the drug delivery device at the time of curing. During the step of curing the humidity is controlled to ensure improved consistency during the curing process. The improved consistency results in inventories of drug delivery devices that have different cure times.

Owner:BAUSCH & LOMB INC

Stent fabrication via tubular casting processes

ActiveUS20100004734A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsStentsDip-coatingPolymer solution

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Process for preparing a high stability microcapsule product and method for using same

InactiveUS20070138672A1Improve stabilityLiposomal deliveryMicroballoon preparationPolymer scienceInstability

The present invention is directed to a process for preparing a capsule product through the increase in the polymerization cure temperature and cure time during the capsule-making process. The microcapsule products prepared according the process of the present invention exhibit enhanced retention of active materials in consumer products which promote instability.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

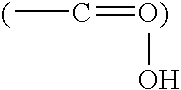

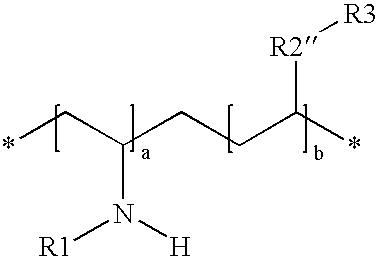

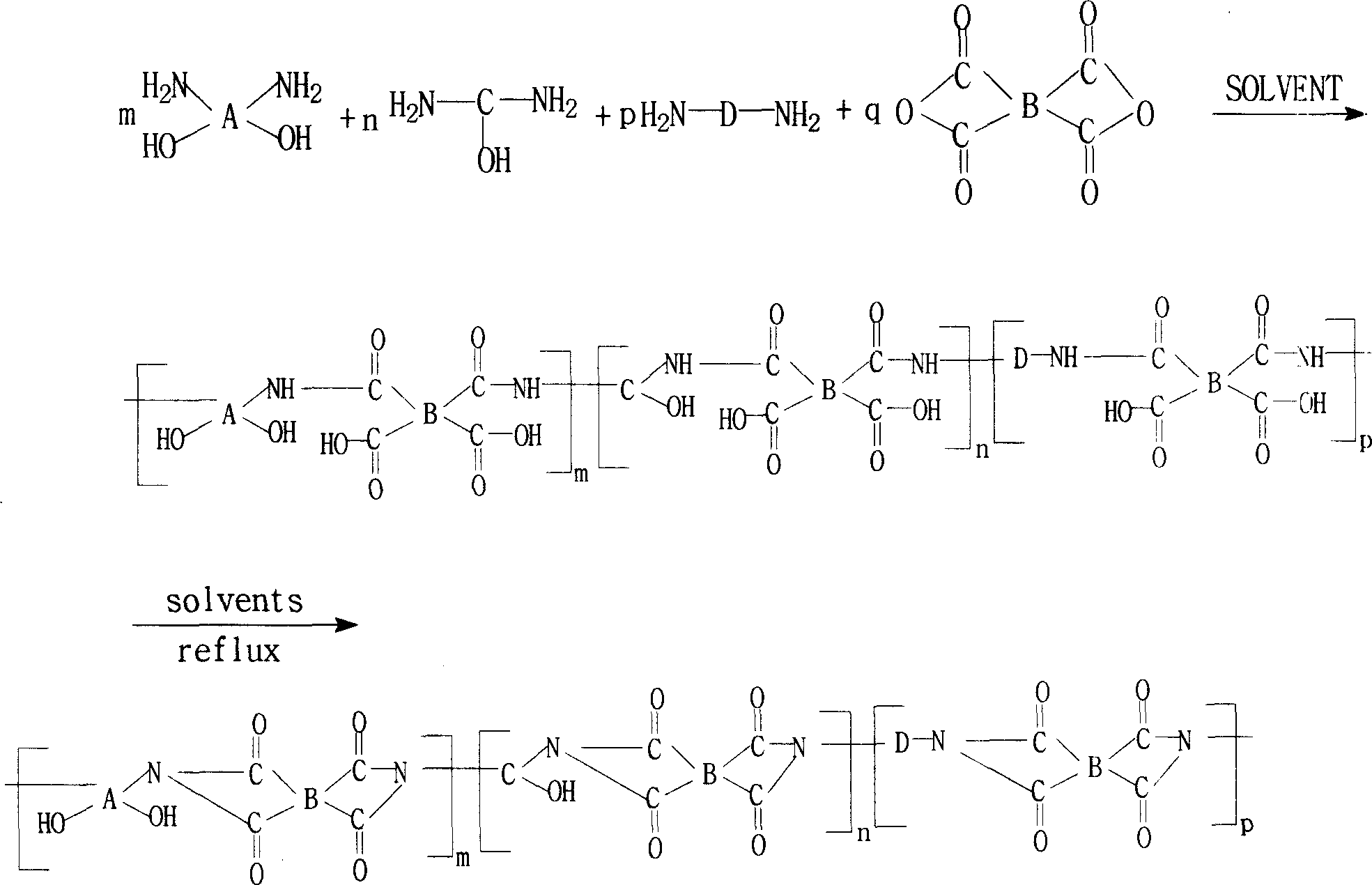

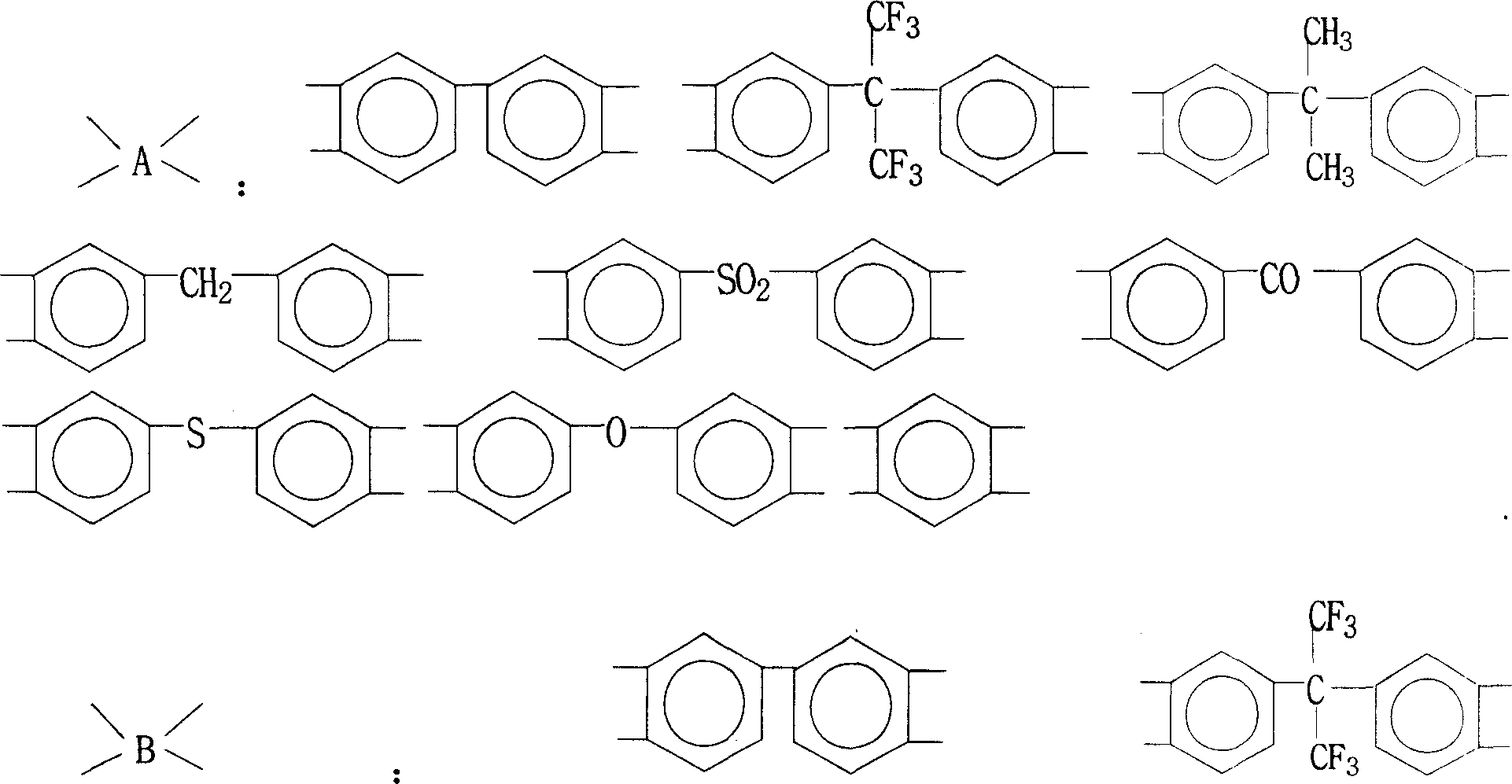

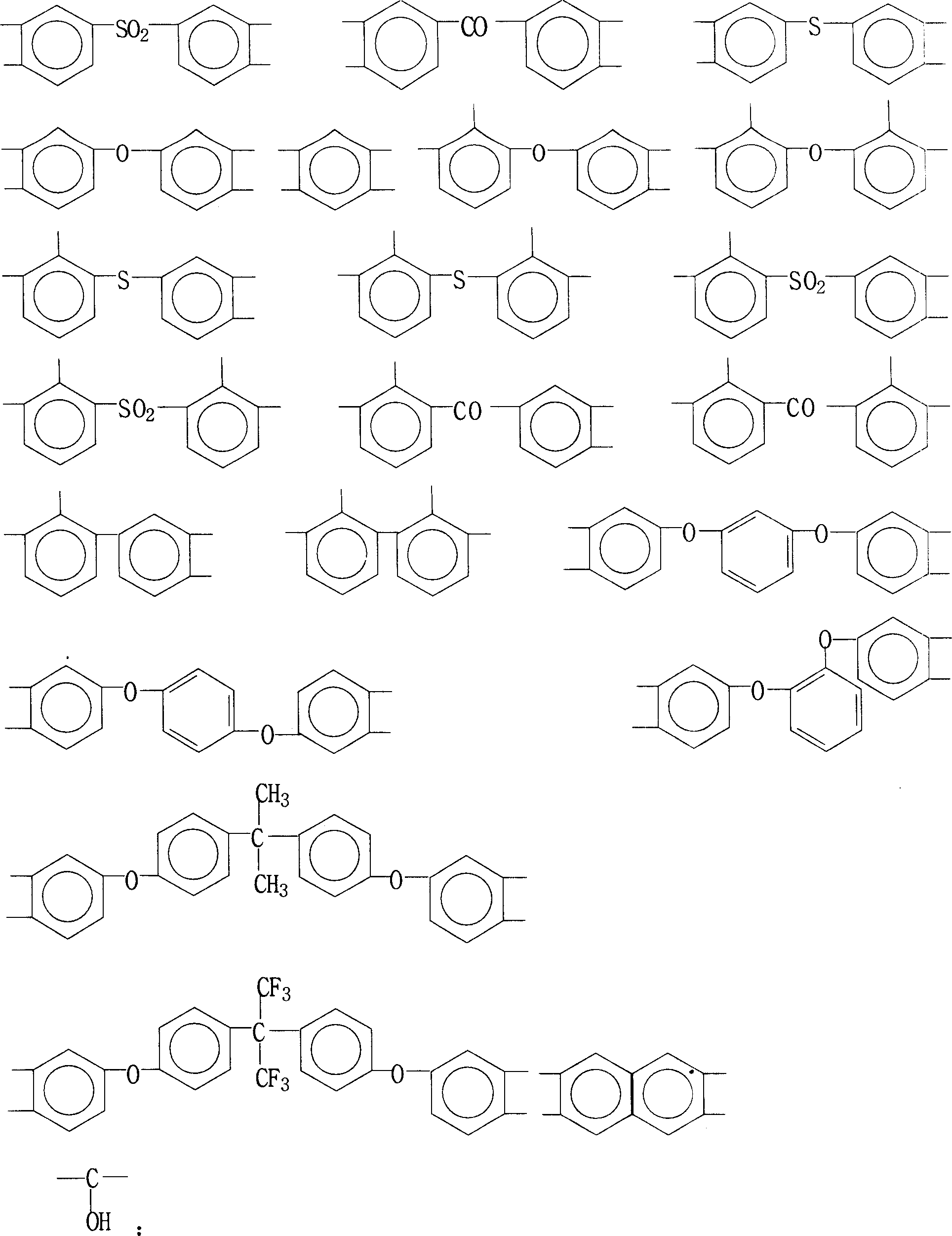

Method for preparing binder of polyimide of containing phenolic hydroxyl group

This invention discloses a method for preparing phenolic hydroxyl-containing polyimide adhesive. The method comprises: (1) reacting phenolic hydroxyl-containing aromatic diamine, or its mixture with other aromatic diamines, with aromatic dianhydride at a mol ratio of 1:1 in strongly polar non-proton organic solvent at 0-10 deg.C for 4-8 h to obtain uniform, transparent and viscose polyhydroxyamic acid solution; (2) adding azeotropic dehydrator in nitrogen atmosphere, heating, performing imidization reaction under refluxing and dehydration at 120-160 deg.C for 1-6 h, and cooling to room temperature to obtain phenolic hydroxyl-containing polyimide adhesive. The volume ratio of azeotropic dehydrator to strongly polar non-proton organic solvent is 1 :( 1-5). The method has such advantages as easy operation, no special requirement for equipment, and high product quality. The phenolic hydroxyl-containing polyimide adhesive has such advantages as short adhesion and curing time, low energy consumption, and high adhesiveness to copper foil and polyimide thin film, and can be used to produce bi-layer flexible printed circuit boards.

Owner:DONGHUA UNIV

High purity photo-thermal curing adhesive and preparation method thereof

InactiveCN101654607AHigh purityAdequate bond strengthModified epoxy resin adhesivesNon-linear opticsEpoxyAdhesive

Owner:YANTAI DARBOND TECH

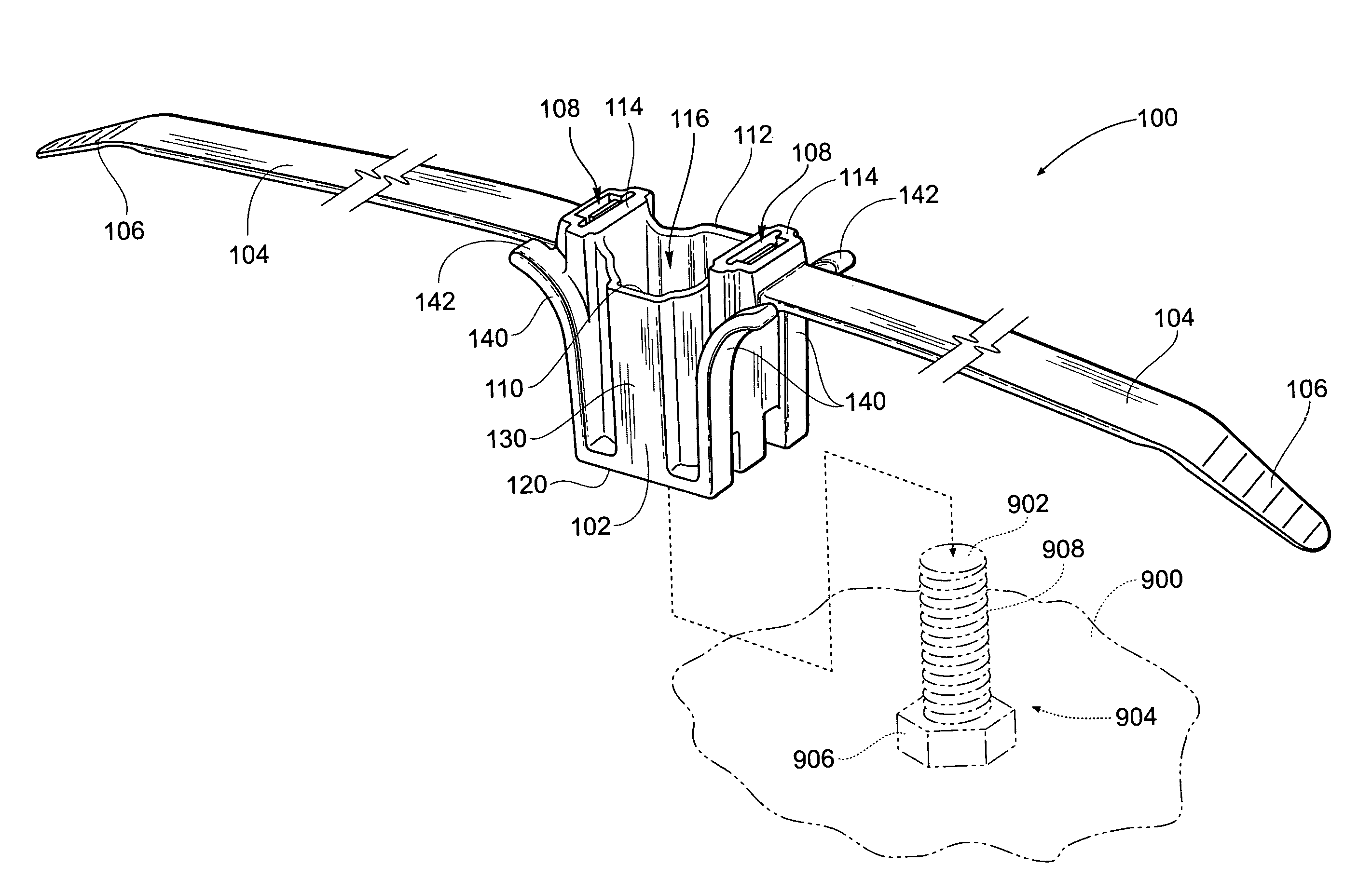

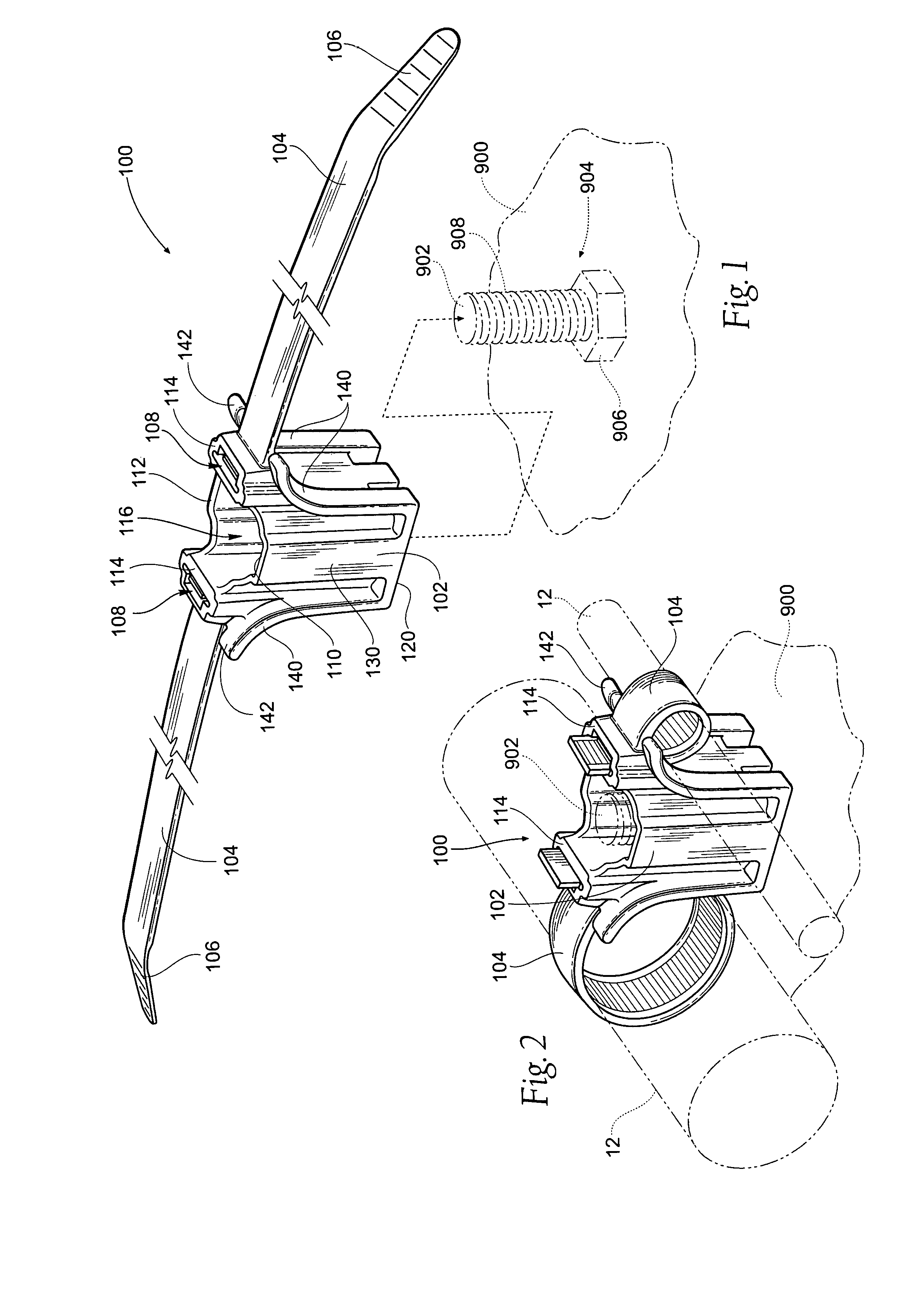

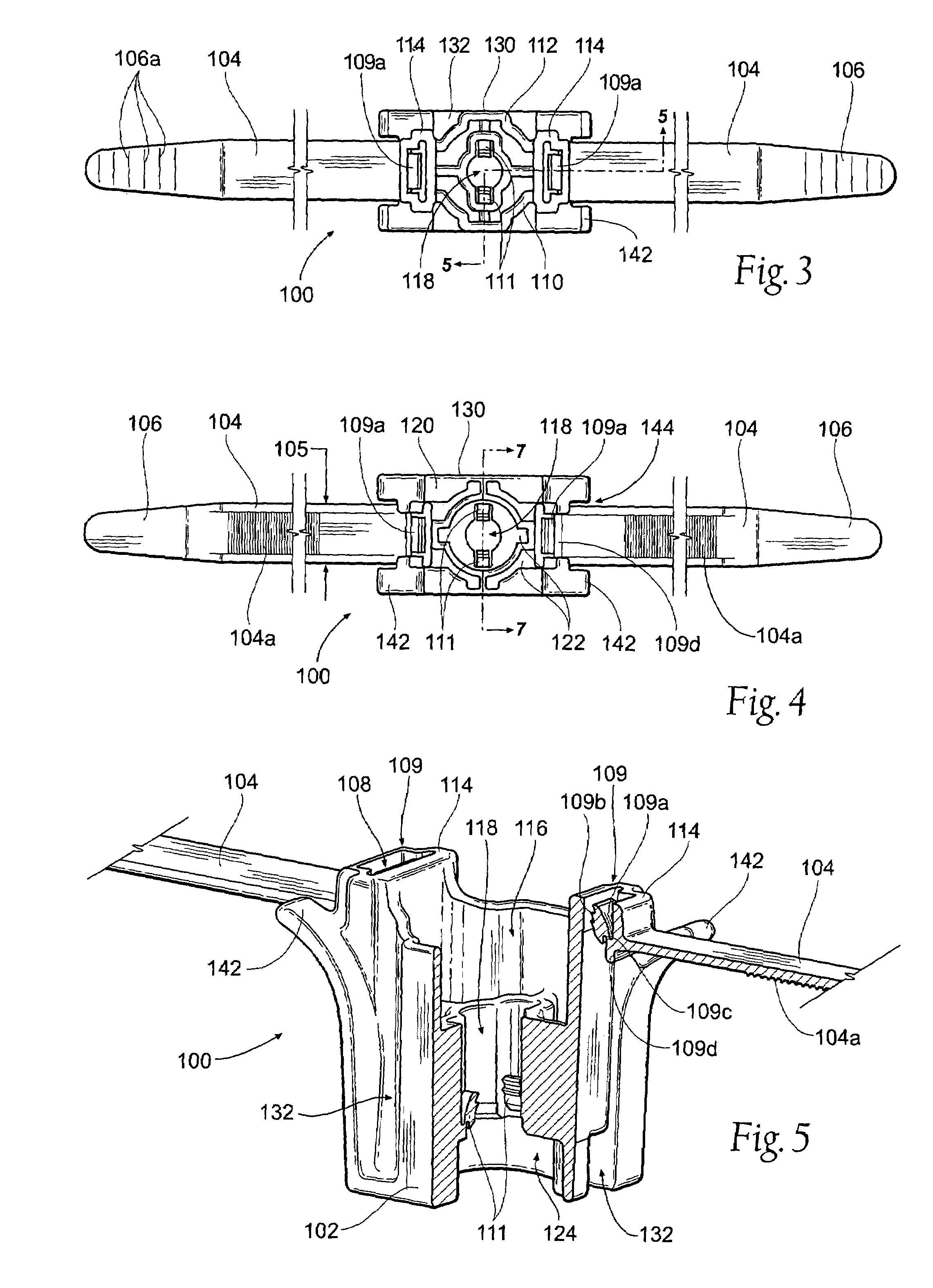

Clamp tie

A clamp tie includes a locking head and flexible straps extending therefrom. The straps are insertable through the locking head to form spaced loops, which may secure items in a spaced relationship. Pawl mechanisms in the locking head secure the straps in looped configuration. An aperture through the locking head is provided for securing the tie to a mounting structure such as a shouldered mounting stud. An additional pawl mechanism may be provided within the aperture to secure the tie to the stud. Arcuate surfaces extend from the locking head, spaced from the straps, to further engage secured items. The upper and lower surfaces of the locking head have counterbores to receive mounting hardware and provide minimal variance of wall thickness throughout the locking head to reduce cure time and materials required for manufacture.

Owner:HELLERMANNTYTON CORP

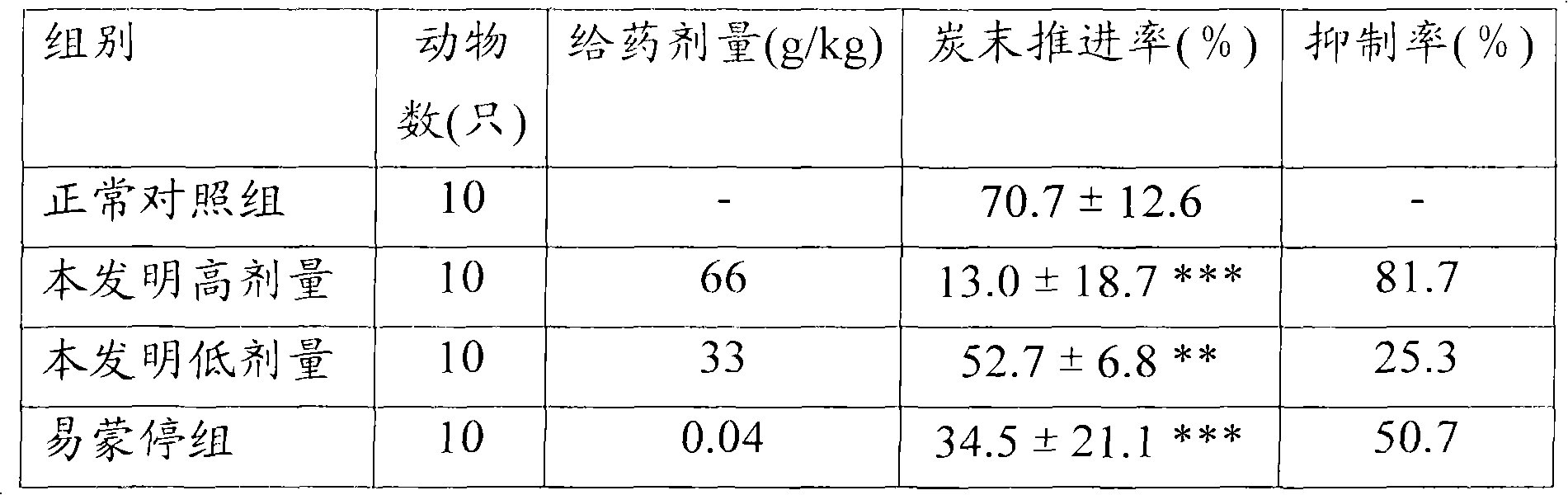

Chinese medicinal composition for treating infantile diarrhea and preparation method thereof

InactiveCN102048933AEasy to manufactureLow costDigestive systemMammal material medical ingredientsSide effectYang deficiency

The invention discloses a Chinese medicinal composition for treating infantile diarrhea. In the Chinese medicinal composition, medicaments for oral administration comprise the following raw materials: Chinese pasque herb, cinnamomvine, stir-fried gordon euryale seed, pomegranate rind, costus root, nutmeg, largehead atractylodes rhizome, Indian buead, kudzuvine root, longstamen onion bulb, areca peel, golden thread and tangerine peel. For damp-heat diarrhea, talc, swordlike atractylodes rhizome, officinal magnolia bark and coix seed are added into the raw materials; for wind-cold diarrhea, wrinkled gianthyssop herb, parslane herb, weeping forsythia and divaricate saposhnikovia root are added into the raw materials; and for poor appetite, aphagia and spleen and kidney-yang deficiency, charred triplet, chicken's gizzard-membrane, Chinese magnoliavine fruit and flos caryophyllata are added into the raw materials. In the Chinese medicinal composition, externally-applied medicaments comprise foeniculi, cassia bark, fistular onion stalk, raw malt, indigowoad leaf, manchurian wildginger, amur corktree bark and mongolian dandelion herb. The Chinese medicinal composition has the effects of relieving pain, regulating the flow of vital energy and tonifying spleen, tonifying spleen, lung and kidney, tonifying middle-Jiao and qi and invigorating splenic yang and stopping diarrhea, is mainly used for treating diarrhea caused by discord in spleen and stomach and weakness of spleen and stomach, has a simple preparation process and a small toxic or side effect, is convenient to administrate, has low cost, short cure time and relapse prevention after cure, is convenient to prepare and can reach focus directly.

Owner:崔守凤

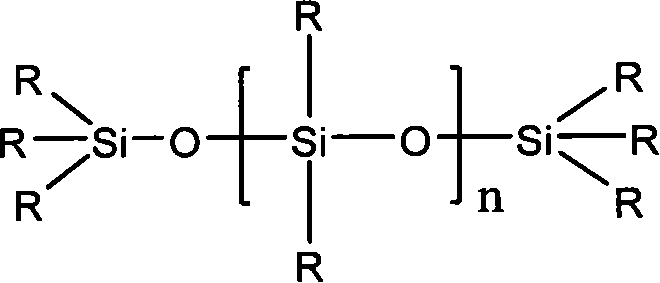

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

Method of forming semiconductor devices by microwave curing of low-k dielectric films

InactiveUS7557035B1Inhibition formationReduce thermal stressSemiconductor/solid-state device manufacturingUltimate tensile strengthMechanical property

The invention provides a method of exposing low-k dielectric films to microwave radiation to cure the dielectric films. Microwave curing reduces the cure-time necessary to achieve the desired mechanical properties in the low-k films, thus decreasing the thermal exposure time for the NiSi transistor contacts. A lower thermal budget for interconnect fabrication is necessary to prevent damage to the NiSi transistor contacts and minimize thermal stressing of previously formed interconnect layers. Microwave-cured dielectric films also have higher mechanical strength and strong adhesion to overlying layers deposited during subsequent semiconductor device manufacturing steps.

Owner:GLOBALFOUNDRIES US INC

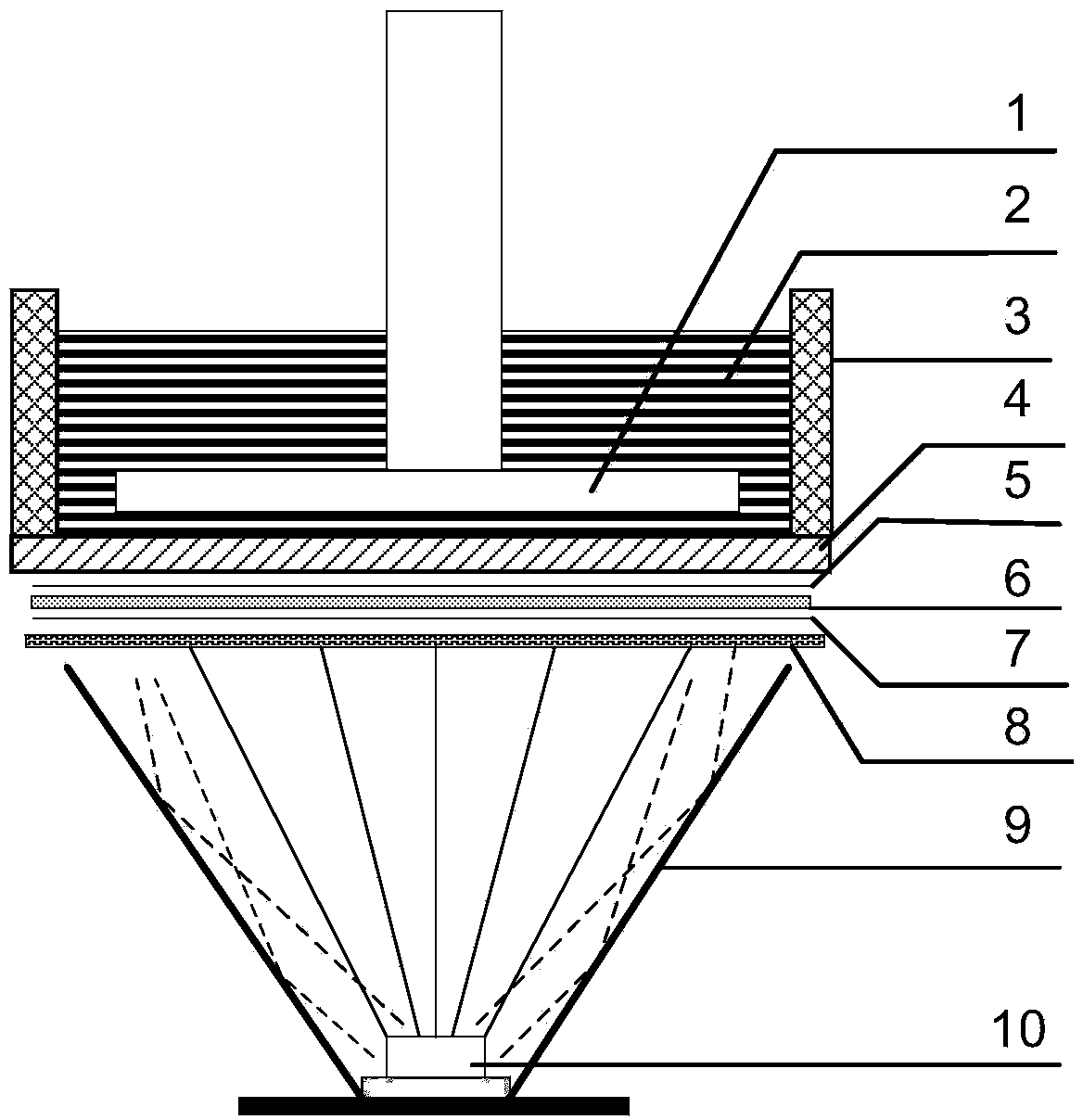

Quick resin forming method based on LCD (liquid crystal display) selective regional light transmission principle

The invention discloses a quick resin forming method based on an LCD (liquid crystal display) selective regional light transmission principle, belonging to the technical field of quick formation. The method is characterized by comprising the following steps: putting a resin liquid storage tank above an LCD screen, exposing layer by layer by adopting a contact exposure method, and putting a Fresnel lens between the LCD screen and a light source, wherein the thickness of each layer during curing is 200 microns to 400 microns, namely after the layer is exposed and cured, a forming piece supporting plate correspondingly moves up by 200 microns to 400 microns under the control of a Z-axis motion system, the curing time of the layer is 1 second to 8 seconds, and a model is washed by an organic solvent after being cured completely; the light source is a high-power LED light source; a glass substrate coated with silica gel is arranged at the bottom of the resin liquid storage tank, so that curing resin can be conveniently separated from the substrate. According to the method, the forming precision is high, the cost is low, and the curing time is quick. In addition, the LED light source is easy to replace, the power is adjustable; different types of resin can be cured and formed.

Owner:BEIJING UNIV OF TECH

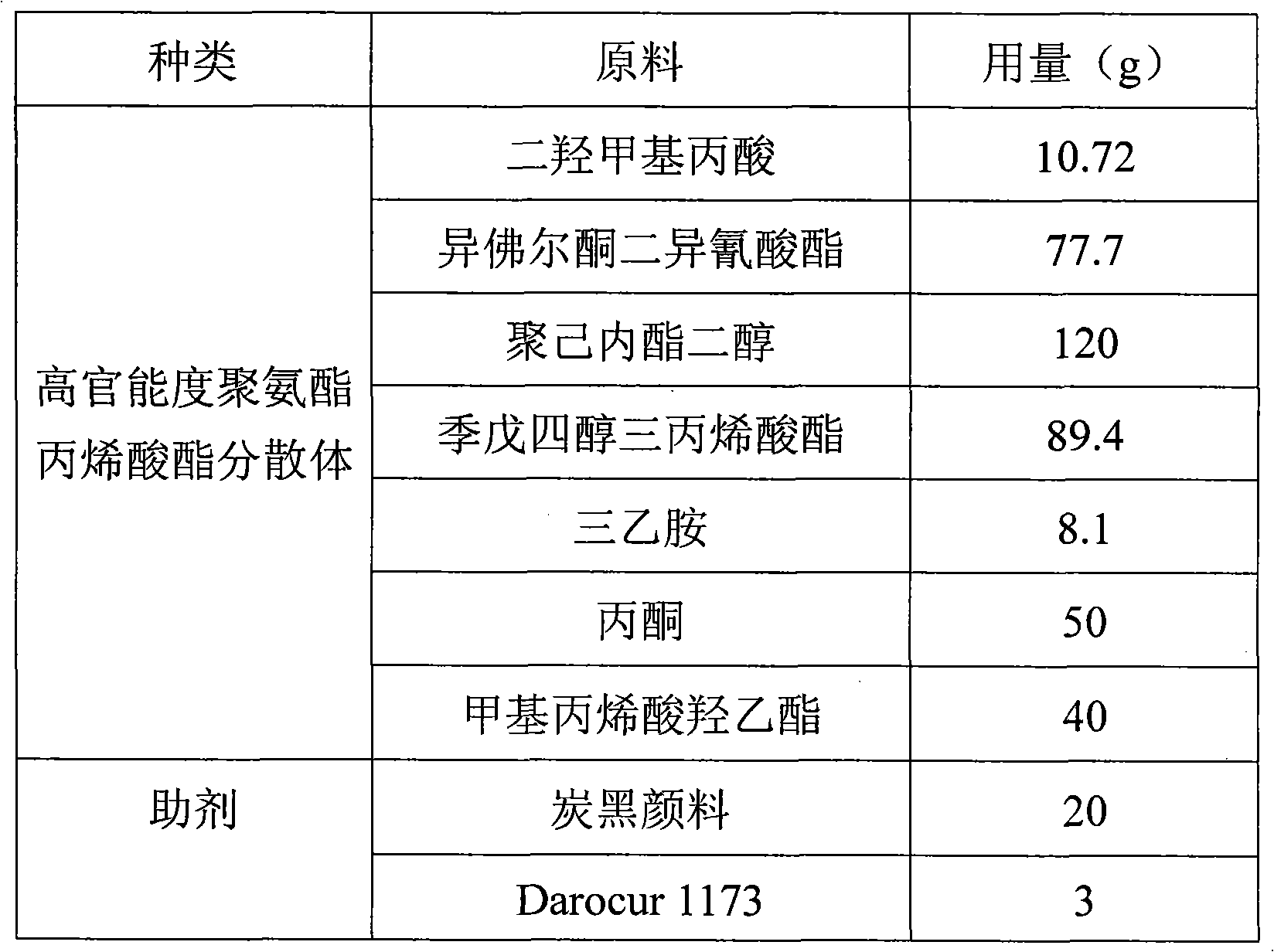

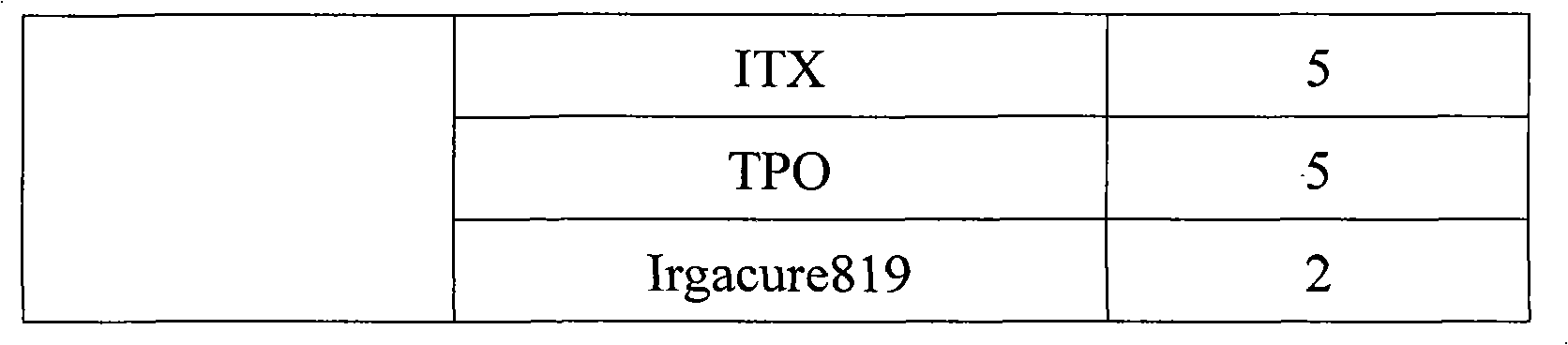

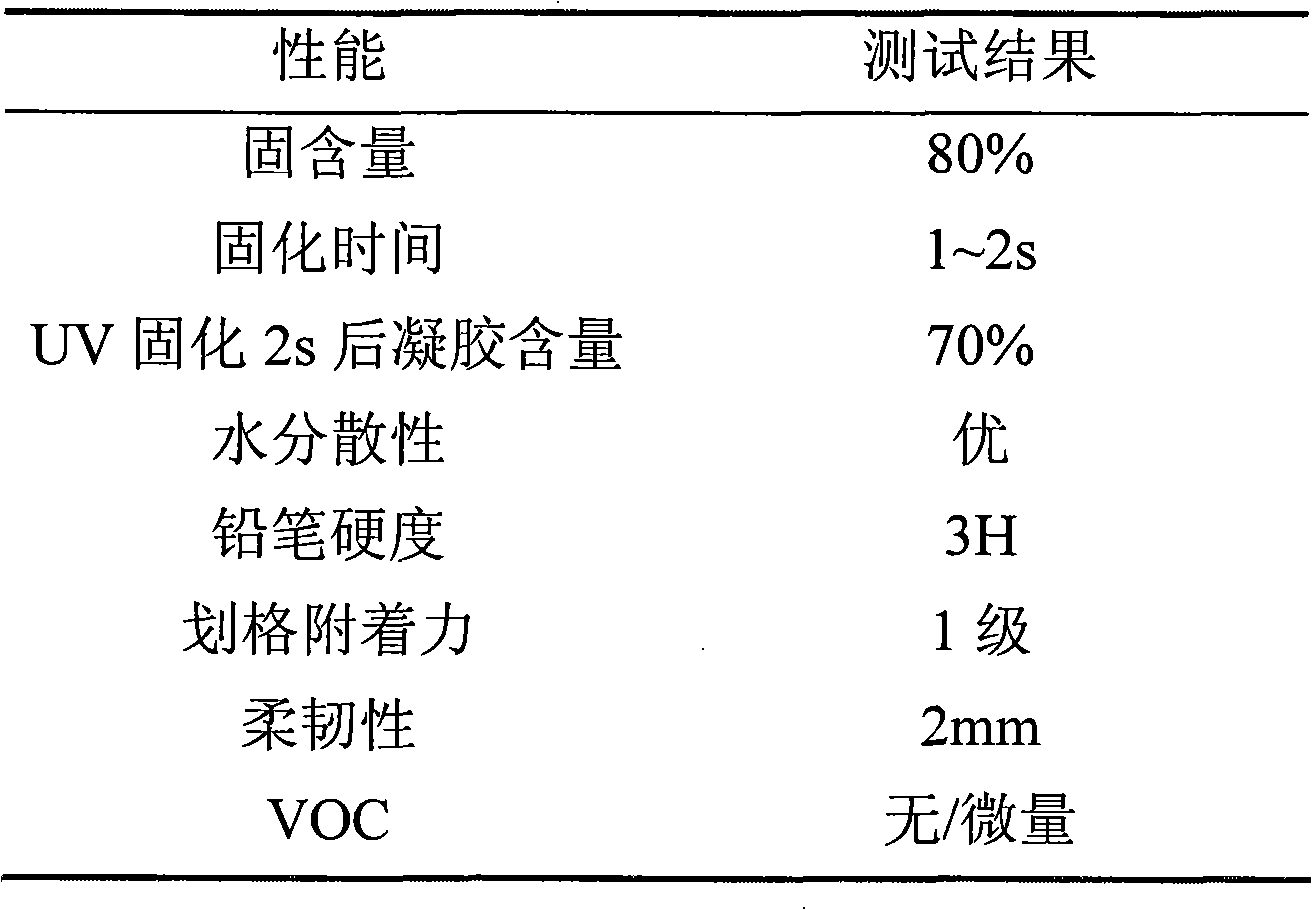

Water-based UV black ink with super-high solid content and preparation method thereof

InactiveCN101659809AEmissions are environmentally friendly and non-toxicHealthy littleInksWater basedPliability

The invention discloses water-based UV black ink with super-high solid content and a preparation method thereof. The black ink comprises the following components in percentage by weight: 20%-60% of high-functionality water-based polyurethane acrylate, 5%-8% of compound photoinitiator, 15%-35% of hydrophilic acrylate diluted body or prepolymer, 10%-25% of solvent and 5%-15% of nano-carbon black pigment. The light curing time of the water-based UV black colored paint of the invention is shorter than 5 seconds, the bottom layer can be completely cured, the comprehensive properties of adhesive force, hardness, toughness and the like are excellent, and the water-based UV black colored paint can be widely applied to the fields of ink, wood paint and the like; the solid content is as high as 80%;and the water-based UV black ink has short drying and curing time, simple construction technology and high production efficiency, can be diluted by water or ethanol or other nontoxic solvents for regulating the viscosity, is suitable for various production modes and production requirements, and is environment-friendly and nontoxic.

Owner:FOSHAN CITY SHUNDE DISTRICT DEMEI CHEM

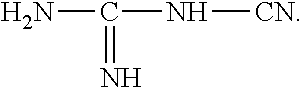

Method for preparing epoxy sheet mould plastic

The invention provides a method for preparing an epoxy sheet-like mold plastic, which comprises the following steps: thickening the mixed epoxide resin system with diisocyanate compound; strengthening the chopped strand; making the tectorial into non-stick hand and shear epoxy sheet-like mold plastic, that is, preparing the epoxide resin paste and the epoxy sheet-like mold plastic; ripening. The epoxy sheet-like mold plastic comprises the following parts: 100 quetient mixed epoxide resin, 4-10 quetient deflocculating agent, 15-80 quetient curing agent, 5-20 quetient thickener, 1-4 quetient internal releasing agent, 80-180 filler and 50-150 fiber, wherein the intermediate core material of the epoxy sheet-like mold plastic comprises fiber which is dipped epoxide resin paste, and the up-down surface is covered by PE thin film. The epoxy sheet-like mold plastic is provided with the good heat flow property, the short curing time, the long saving time and the corrosion resistant, which can be made high strength epoxide composite material part.

Owner:SHANGHAI MANSDA INDAL

A kind of high temperature resistant epoxy resin composition for rapid pultrusion

InactiveCN102286138AHigh strength, high toughness and impact resistanceImprove high temperature resistanceEpoxyEther

The invention relates to a high temperature resistant epoxy resin composition for rapid pultrusion and a preparation method thereof. The epoxy resin composition consists of 100 parts by mass of epoxy resin, 30-50 parts by mass of amine curing agent, 0.5-5.0 parts by mass of latent curing agent, 0.5-5.0 parts by mass of small epoxy group It is composed of molecular compound and 0.5-5.0 parts by mass of inorganic filler. The mixed epoxy resin of glycidyl ether epoxy resin and glycidyl amine resin or glycidyl ester epoxy resin is used as the resin matrix of the pultruded product, so that the pultruded product has high strength and high toughness impact resistance, and has Excellent high temperature resistance. Using a latent curing agent together with a mixed amine curing agent can make the pultruded product have a lower curing temperature and be cured quickly within a certain period of time, shortening the curing time, thereby improving the pultrusion speed and production efficiency.

Owner:BLUESTAR BEIJING CHEM MACHINERY

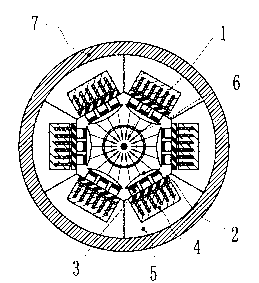

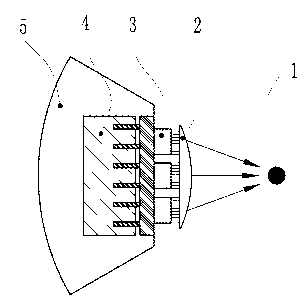

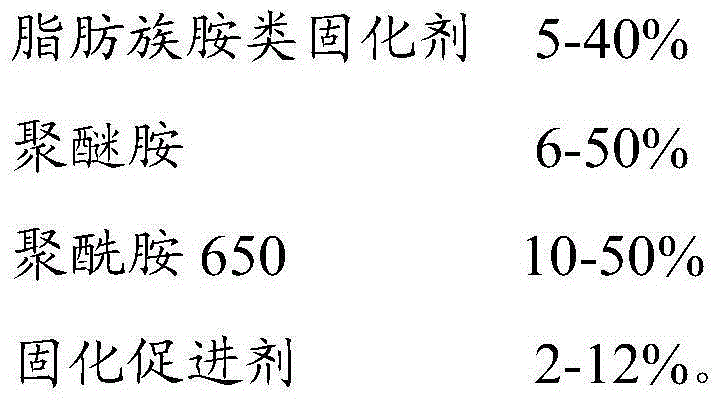

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

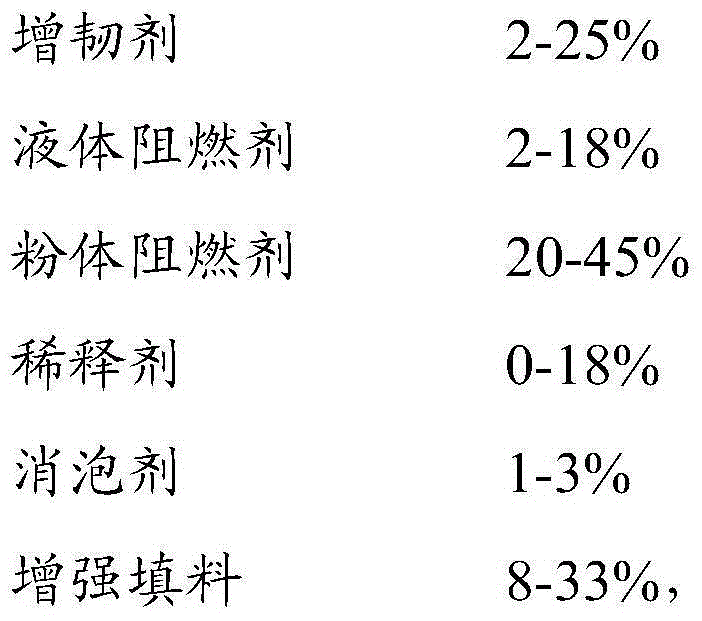

Two-component epoxy glue and preparation method thereof

ActiveCN105062395AReduced cured crosslink densityRelatively consistent viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAliphatic amine

The invention relates to two-component epoxy glue and a preparation method thereof. The two-component epoxy glue comprises a component A and a component B, and the component A comprises epoxy resin, a toughening agent, a liquid flame retardant, a powder flame retardant, a diluent, an antifoaming agent and reinforcing fillers; the component B comprises an aliphatic amine curing agent, polyether amine, polyamide 650 and a curing accelerator. According to the two-component epoxy glue and the preparation method thereof, screening is conducted on the components of the epoxy glue, performance complementation of the components is achieved, a two-component epoxy glue with excellent comprehensive performance is formed through synergetic cooperation, the toughness, the anti-stripping strength and the anti-impact performance of the epoxy glue are significantly improved, the flame-retardant performance can reach the grade UL94-V0, the operable time is more appropriate, the curing time is short, and the continuous production can be achieved.

Owner:GUANGZHOU BAIYUN CHEM IND

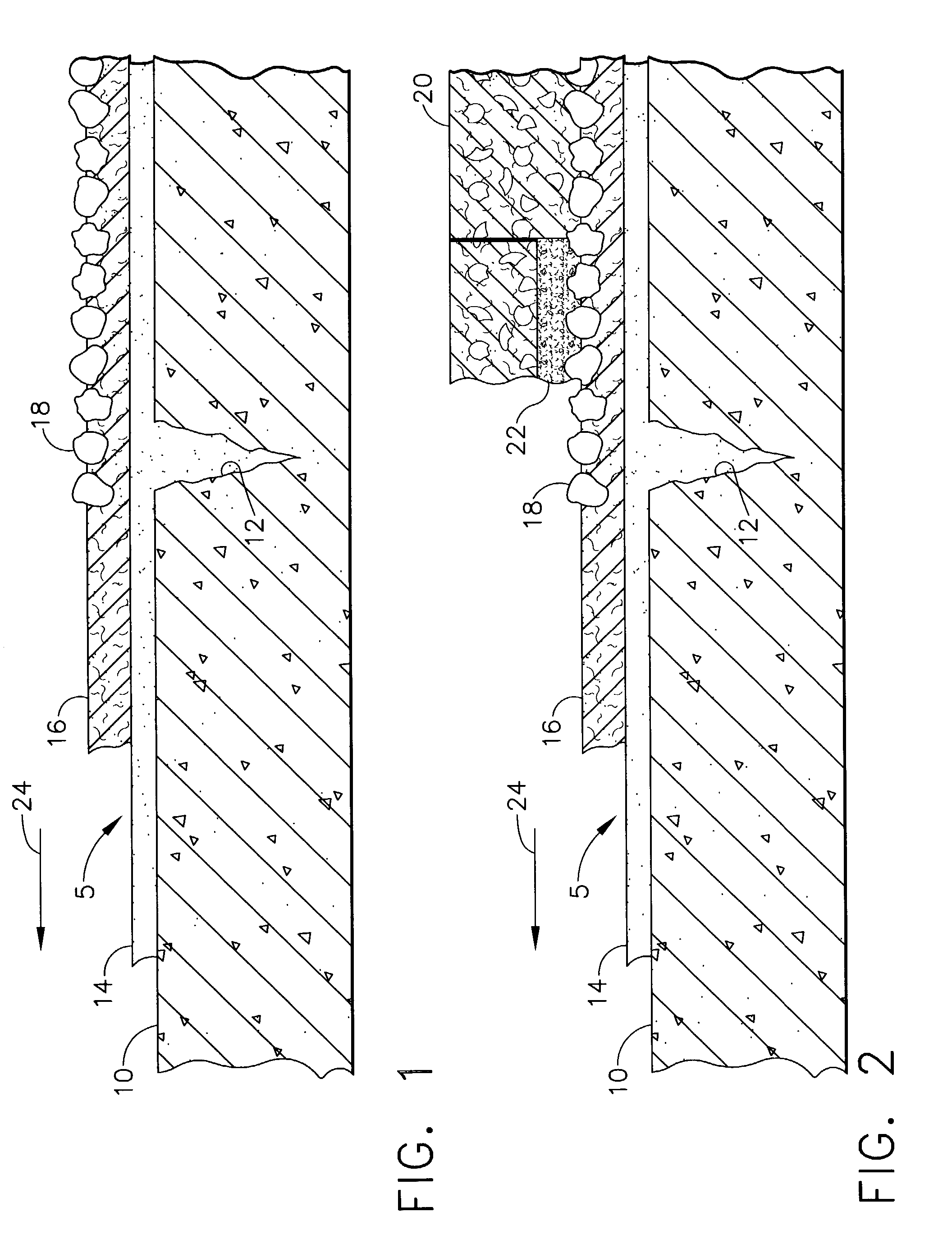

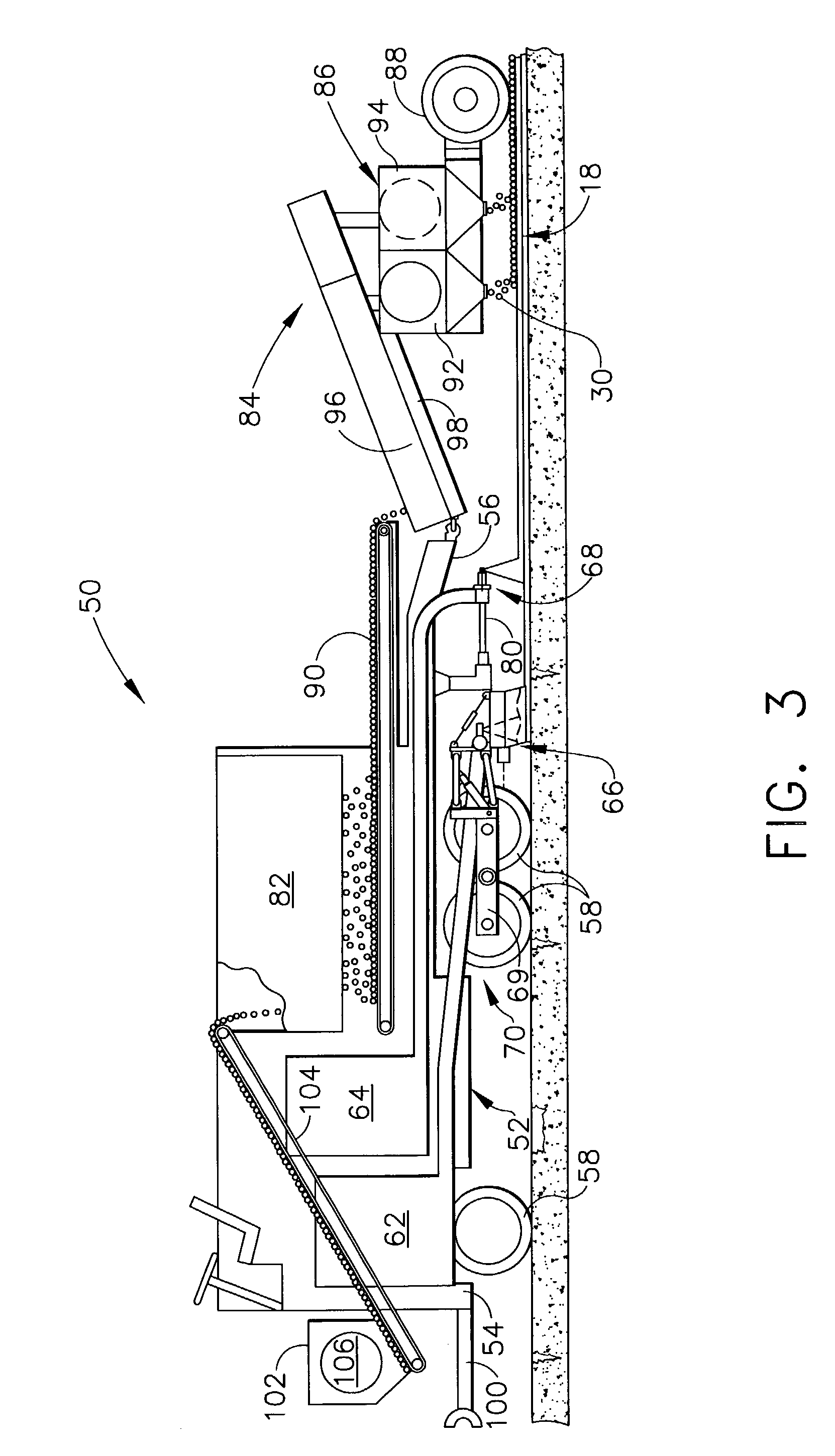

Apparatus for treating a pavement surface

An apparatus for treating a pavement surface with a plurality of layers in a single pass, including: a chassis having a forward end and a rear end; a plurality of rolling means spaced longitudinally along the chassis for supporting the chassis so it can roll along a particular direction of advance; a powerplant for moving the chassis along the direction of advance; a first storage tank mounted on the chassis for containing bituminous sealant; a second storage tank mounted on the chassis for containing bituminous emulsion; a main hopper mounted on the chassis for storing aggregate particles; a first mechanism in flow communication with the first storage tank for applying a layer of bituminous sealant at a predetermined temperature and application rate on the pavement surface; a second mechanism in flow communication with the second storage tank for applying a layer of bituminous emulsion at a predetermined temperature and application rate on the layer of bituminous sealant, wherein a thermal reaction occurs between the bituminous sealant and the bituminous emulsion so as to accelerate a material break and cure time for the layers; and, a third mechanism in flow communication with the main hopper for providing a layer of aggregate particles at a predetermined application rate on the layers of bituminous sealant and bituminous emulsion during the thermal reaction.

Owner:TERRY ASPHALT MATERIALS

Preparation method of modified AKD (Alkyl Ketene Dimer) neutral sizing agent

InactiveCN102337707AImprove water resistanceGood dispersionWater-repelling agents additionEnvironmental resistanceSizing

The invention relates to a modified AKD (Alkyl Ketene Dimer) neutral sizing agent which is a milk white liquid in appearance. The modified AKD neutral sizing agent comprises the following main materials: AKD, starch, paraffin, high molecular dispersant and other assistant materials. The modified AKD neutral sizing agent is mainly used for sizing paper pulp and improving the water resistance and impermeability of paper in the paper-making production process, and the consumption for every ton of paper is 10-20kg. Compared with like products, the quickly-cured modified AKD neutral sizing agent has the following advantages: (1) effective ingredient particles of the product are finer and more uniform and can be cured more tightly, the product has a longer quality guarantee period, and convenience is provided for transportation and storage; (2) the product is applicable to neutral paper pulp and can no longer result in the production of acidic paper-making sewage, thereby being beneficial to environmental protection; (3) the use effect of the product can act quickly, and the curing time is extremely short, thereby facilitating the effect monitoring and quality control in use, improving the production efficiency and enhancing the yield of paper; and (4) the consumption of the product is lower than that of other like products, thereby reducing the cost of production materials and improving the economic benefits of customers.

Owner:ZHEJIANG ZHANHANG BIO TECH

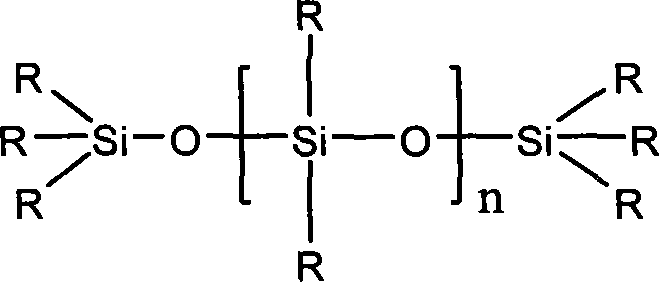

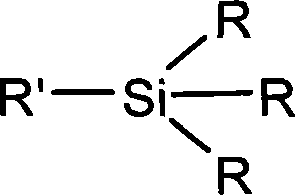

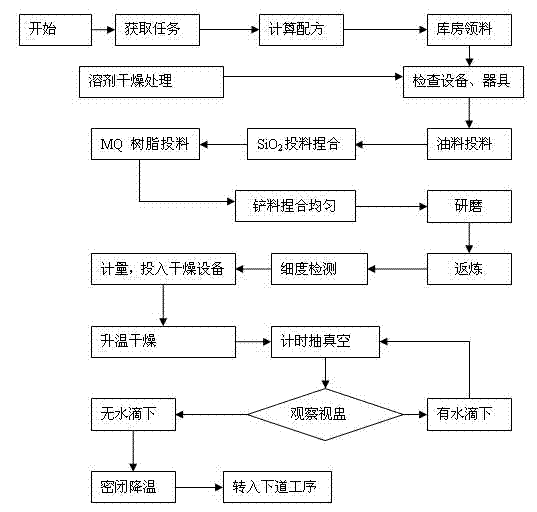

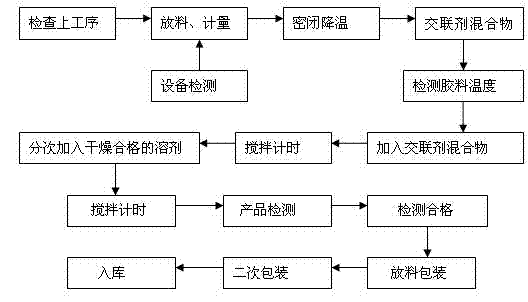

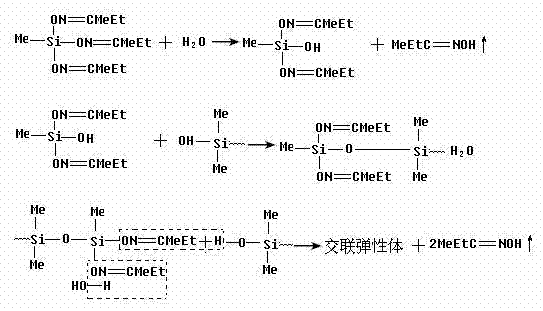

Organosilicon coating and preparation method thereof

The invention belongs to the field of organosilicon, and particularly relates to an organosilicon coating and a preparation method thereof. The organosilicon coating is characterized in that the organosilicon coating comprises 90 to 120 parts of Alpha, Omega-dihydroxy polydimethylpolysiloxane, 10 to 30 parts of MQ resin, 10 to 30 parts of white carbon black, 0.3 to 1 part of vulcanization accelerators, 2 to 3 parts of methyl-tri-(butanone-oxime) silane, 2 to 3 parts of vinyl tributanoximo silane, 1 to 3 parts of propylamino triethoxy silane, 1 to 2 parts of 3-glycidyl ether oxypropyl trimethoxysilane and 70 to 90 parts of solvent. The preparation method comprises the steps of raw material selection, raw material weighing, rubber compound drying, rubber compound preparation, and the like. The organosilicon elastic coating disclosed by the invention has low viscosity and high fluidity, can be rapidly self-leveled and filled after being coated, has a high curing speed at room temperature, needs short surface drying time and curing time, has excellent electric insulation performance, high strength, low hardness, high elasticity and good toughness after being cured, has self-repairing performance and an elongation percentage reaching 200 to 500 percent, has good bonding performance, has shear strength of 2 to 5MPa over aluminum, has little odor, cannot corrode a matrix, adopts solvent oil as the solvent, can effectively insulate and protect the surfaces of printed circuit boards (PCB) and electronic devices, and can also used as other elastic coatings needing insulation performance and anticorrosion performance.

Owner:CHENGDU TALY TECH CO LTD

3D printing composite material for mouth rehabilitation and preparation and using method of 3D printing composite material

ActiveCN105943406AImprove completion efficiencySave time at workAdditive manufacturing apparatusImpression capsOral ProsthesisMaterials science

The invention relates to a 3D printing composite material for mouth rehabilitation and a preparation and using method of the 3D printing composite material. The 3D printing composite material for mouth rehabilitation is characterized by comprising the following components in parts by weight: 10-40 parts of low-viscosity monomer, 10-40 parts of enhanced monomer or low polymer, 150-200 parts of ceramic powder, 5-20 parts of expansion monomer, 5-15 parts of a dispersing agent, 2-6 parts of a short-wave photoinitiator, 1-3 parts of a long-wave photoinitiator, 1-3 parts of an ultraviolet absorber and 2-5 parts of polymerizable quaternary ammonium salt anti-bacterial monomer. The 3D printing composite material for mouth rehabilitation is small in curing shrinkage, short in curing time and high in anti-bacterial property, and is suitable for manufacturing a dental prosthesis.

Owner:深圳长朗智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com