Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1842results about "Rope making machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

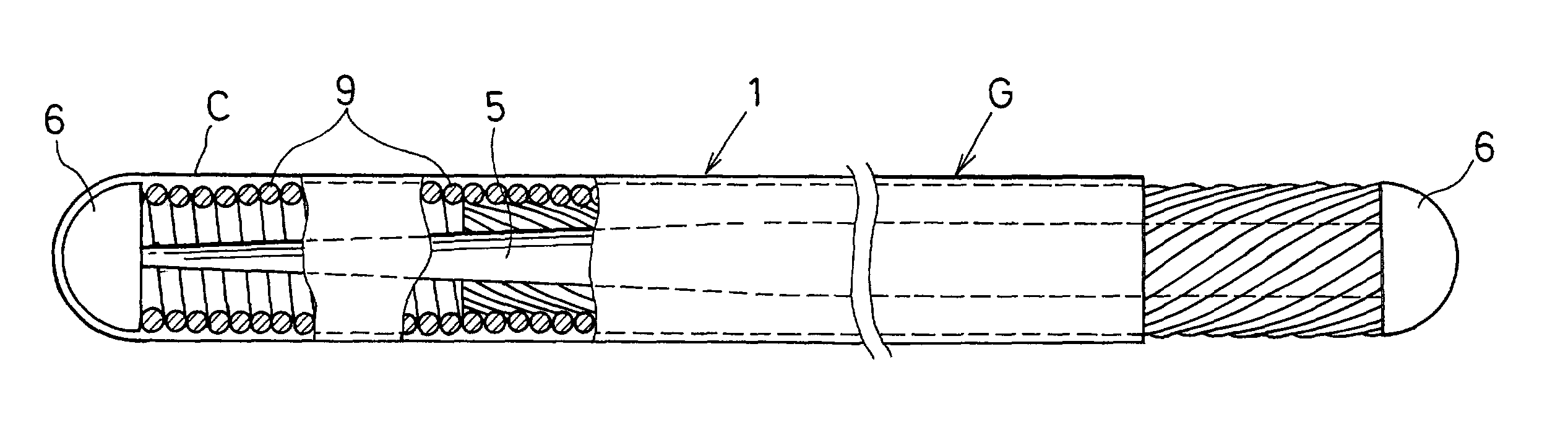

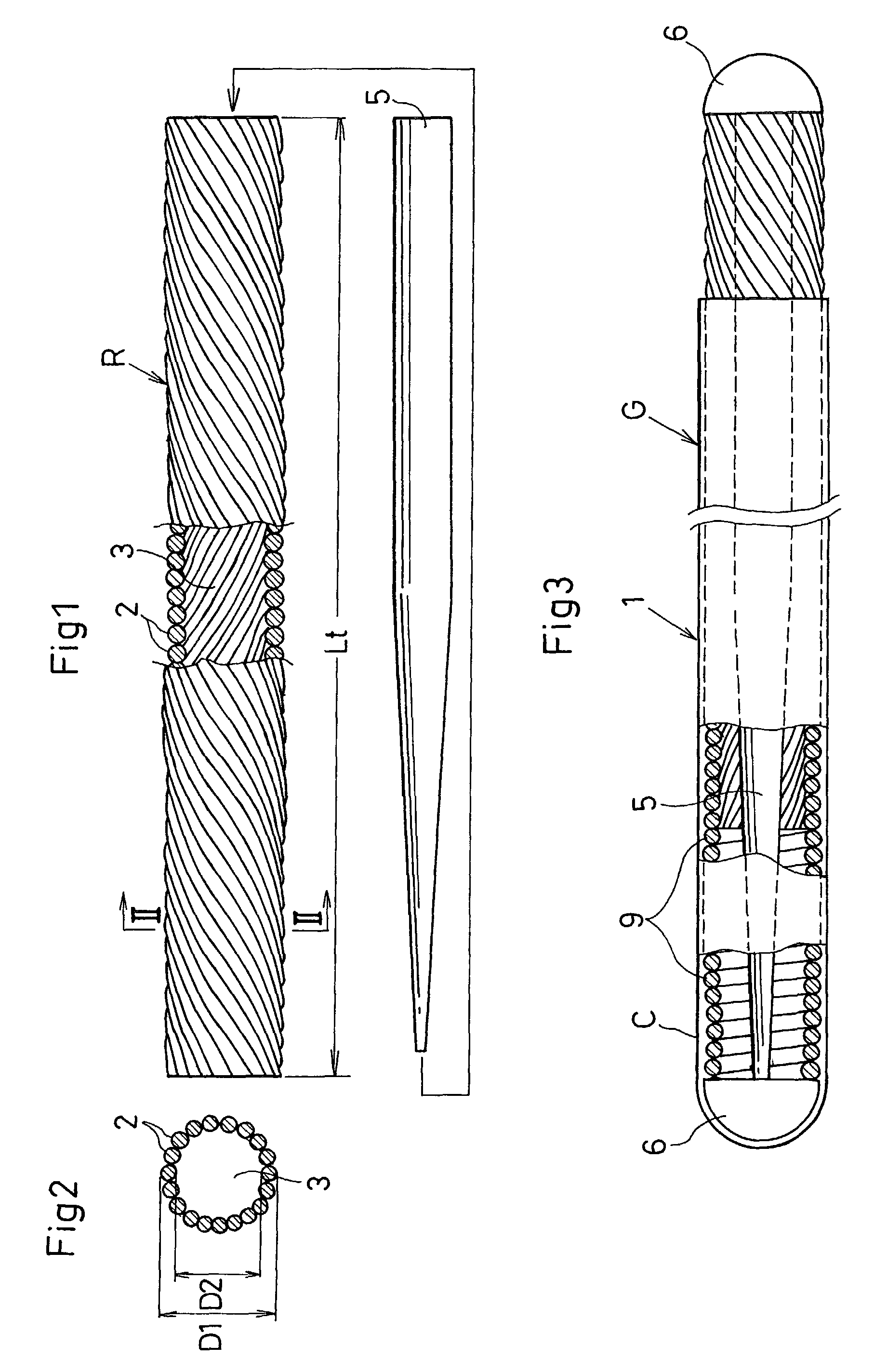

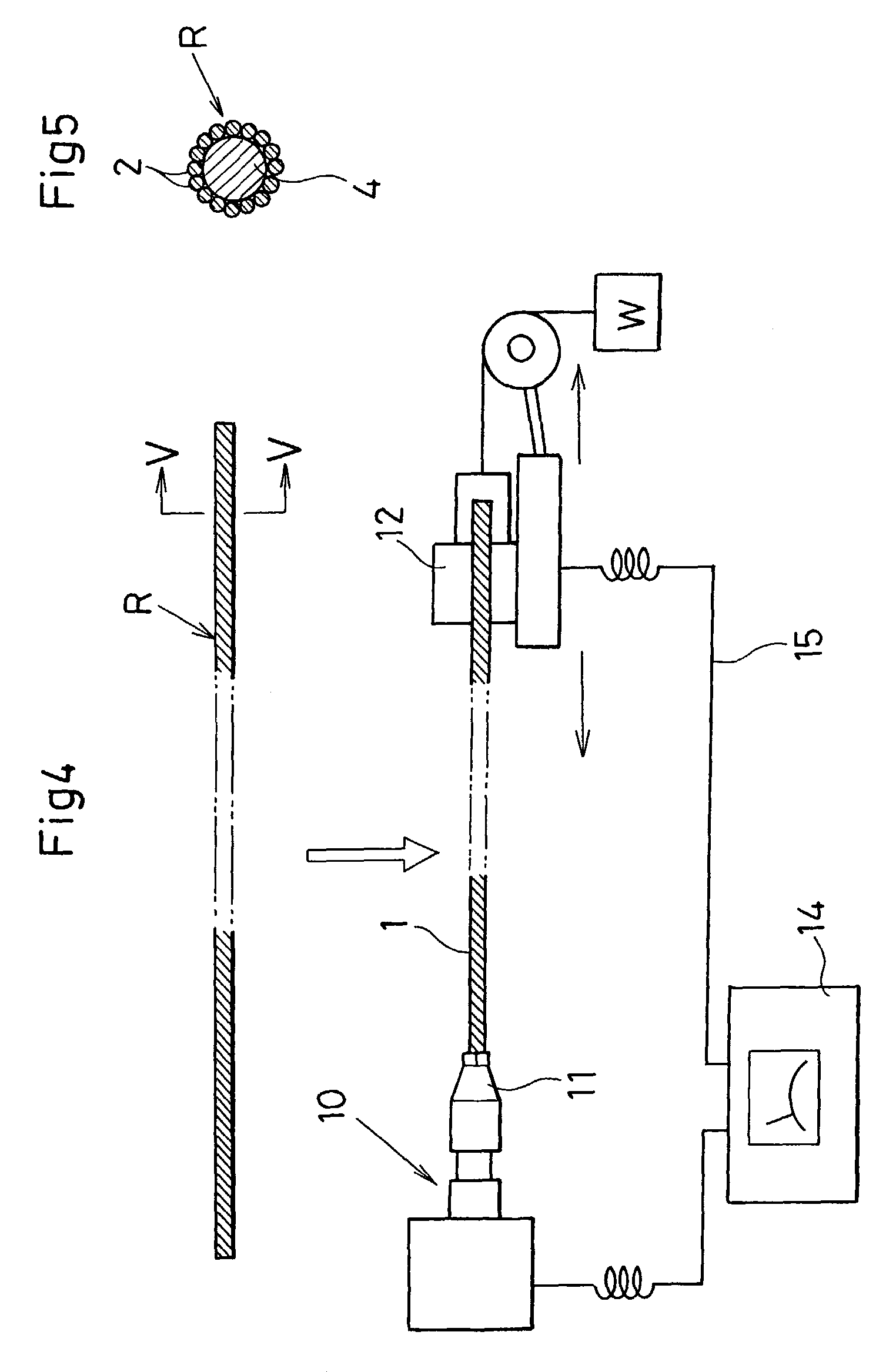

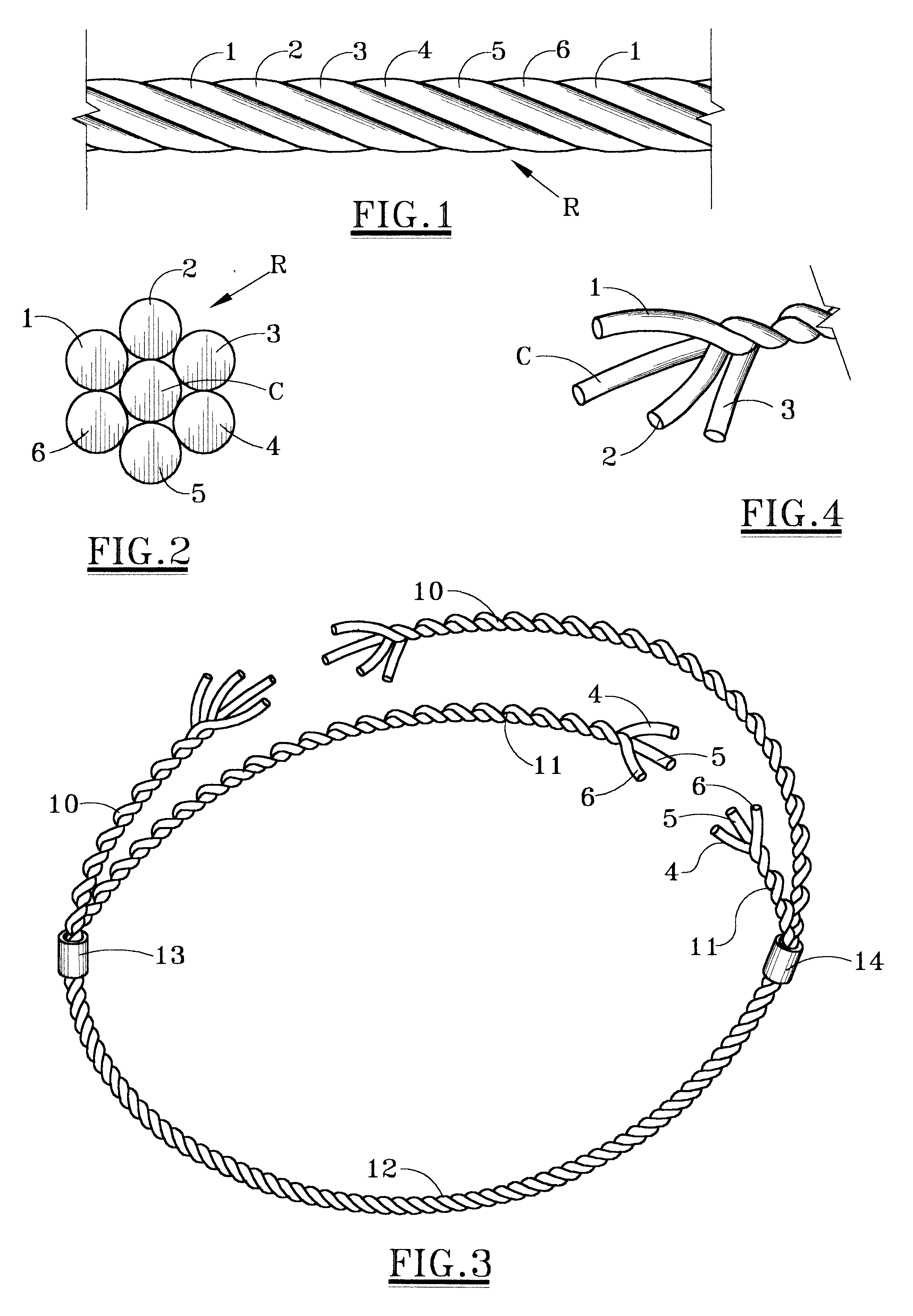

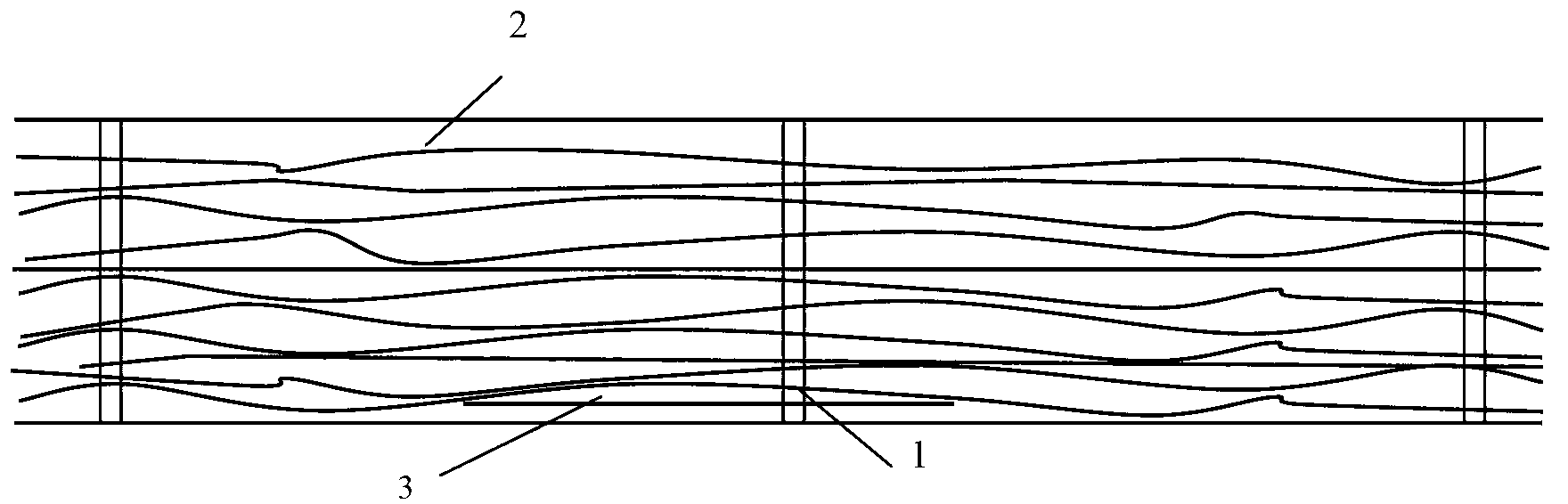

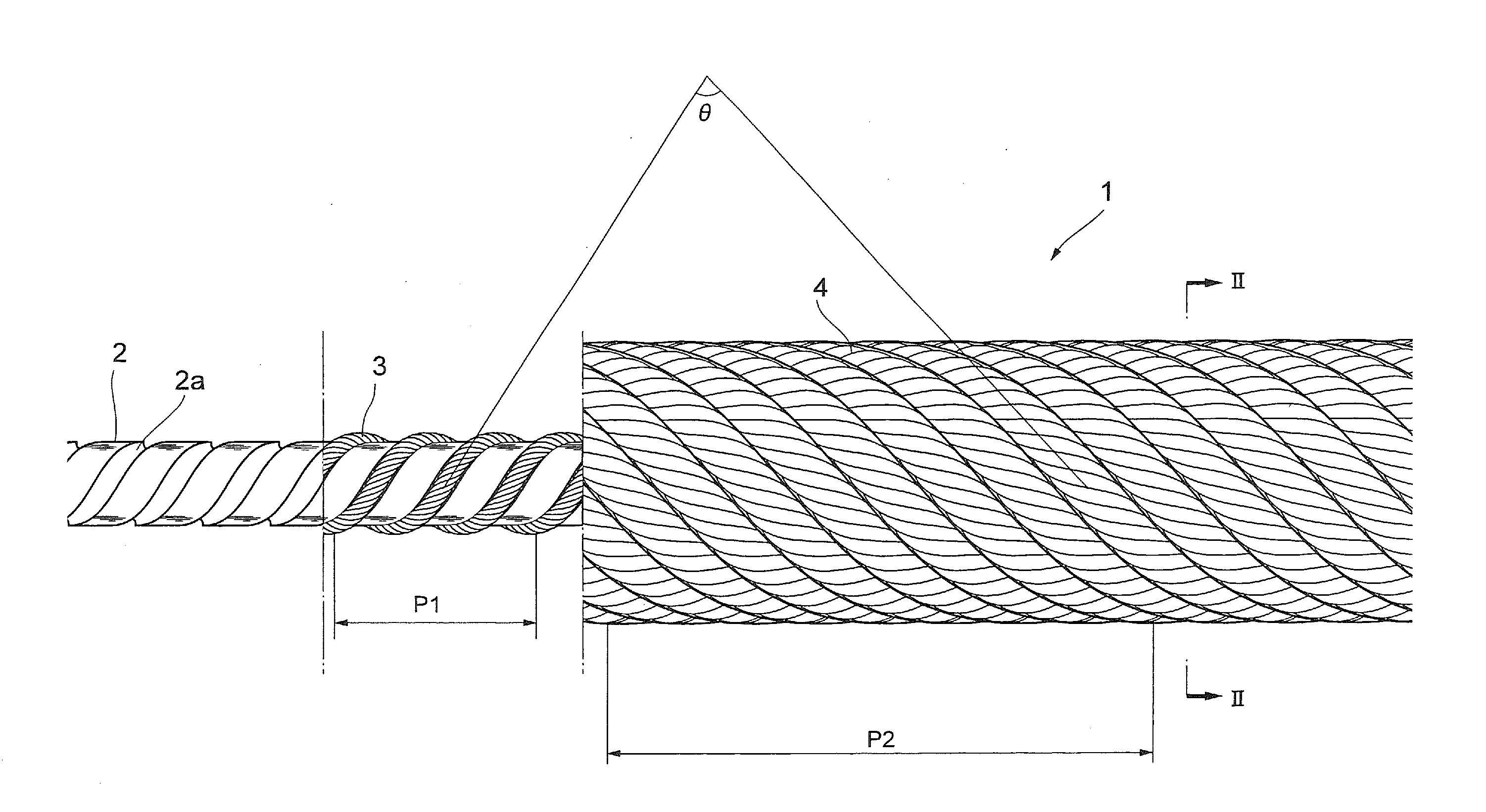

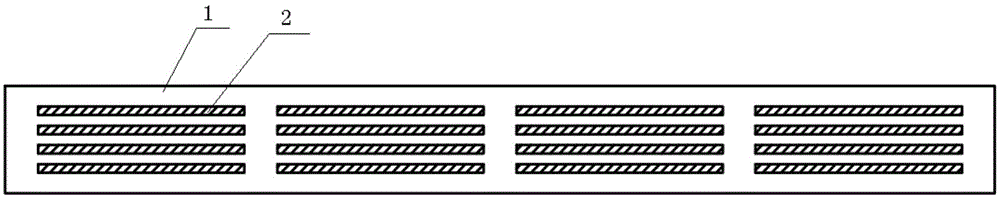

Wire-stranded hollow coil body, a medical equipment made therefrom and a method of making the same

InactiveUS7117703B2Improve rendering capabilitiesImprove straightnessStentsGuide wiresEngineeringMedical device

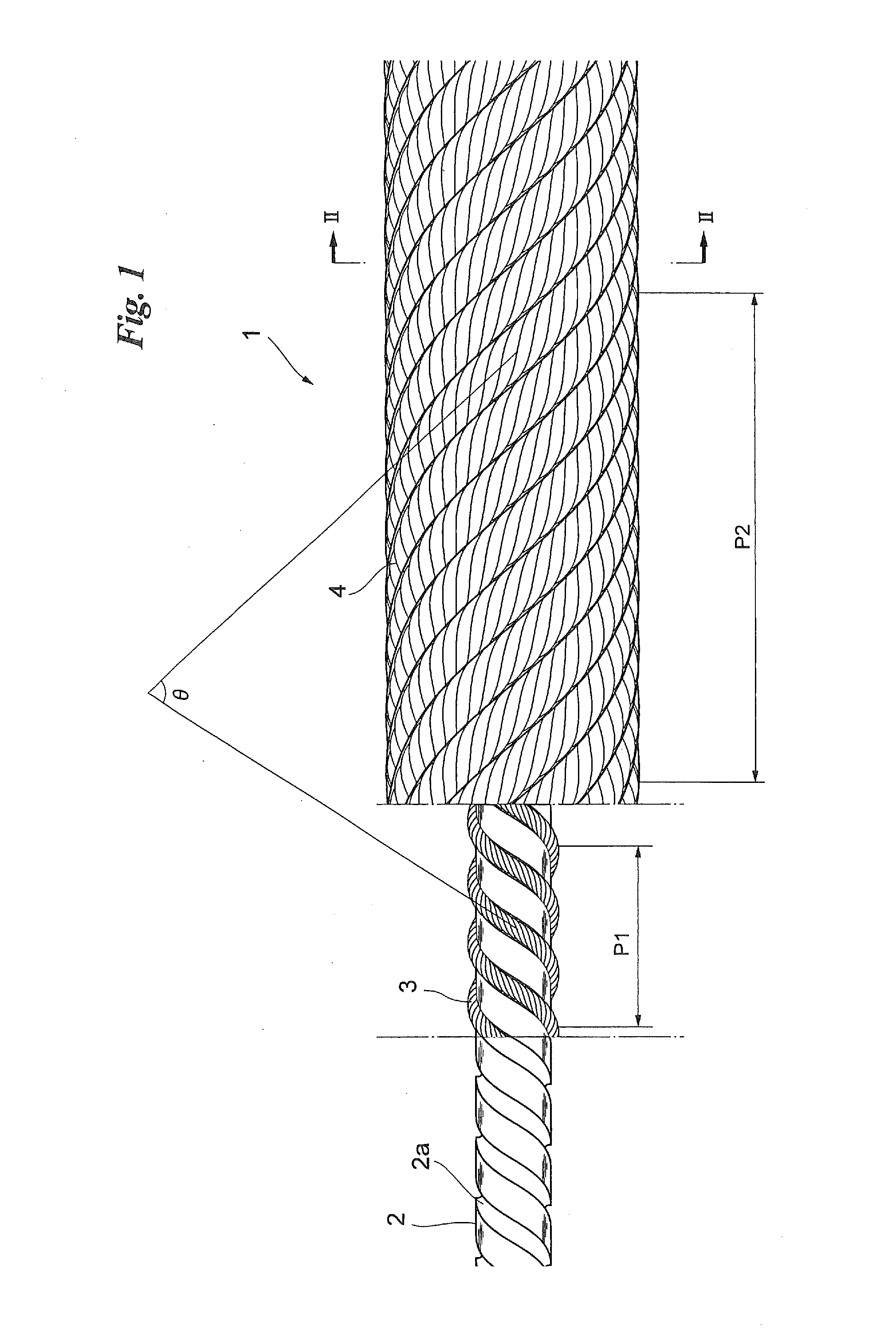

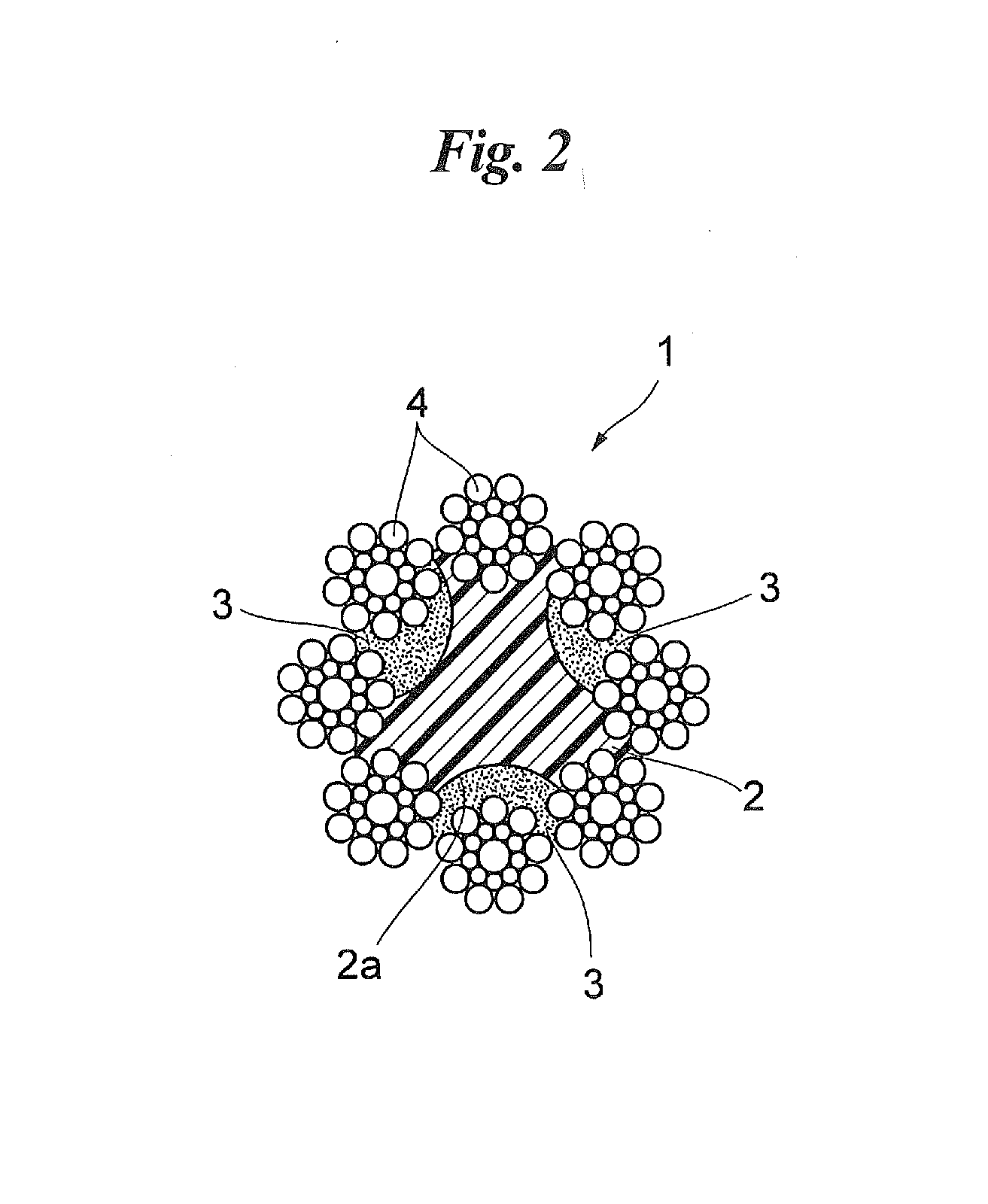

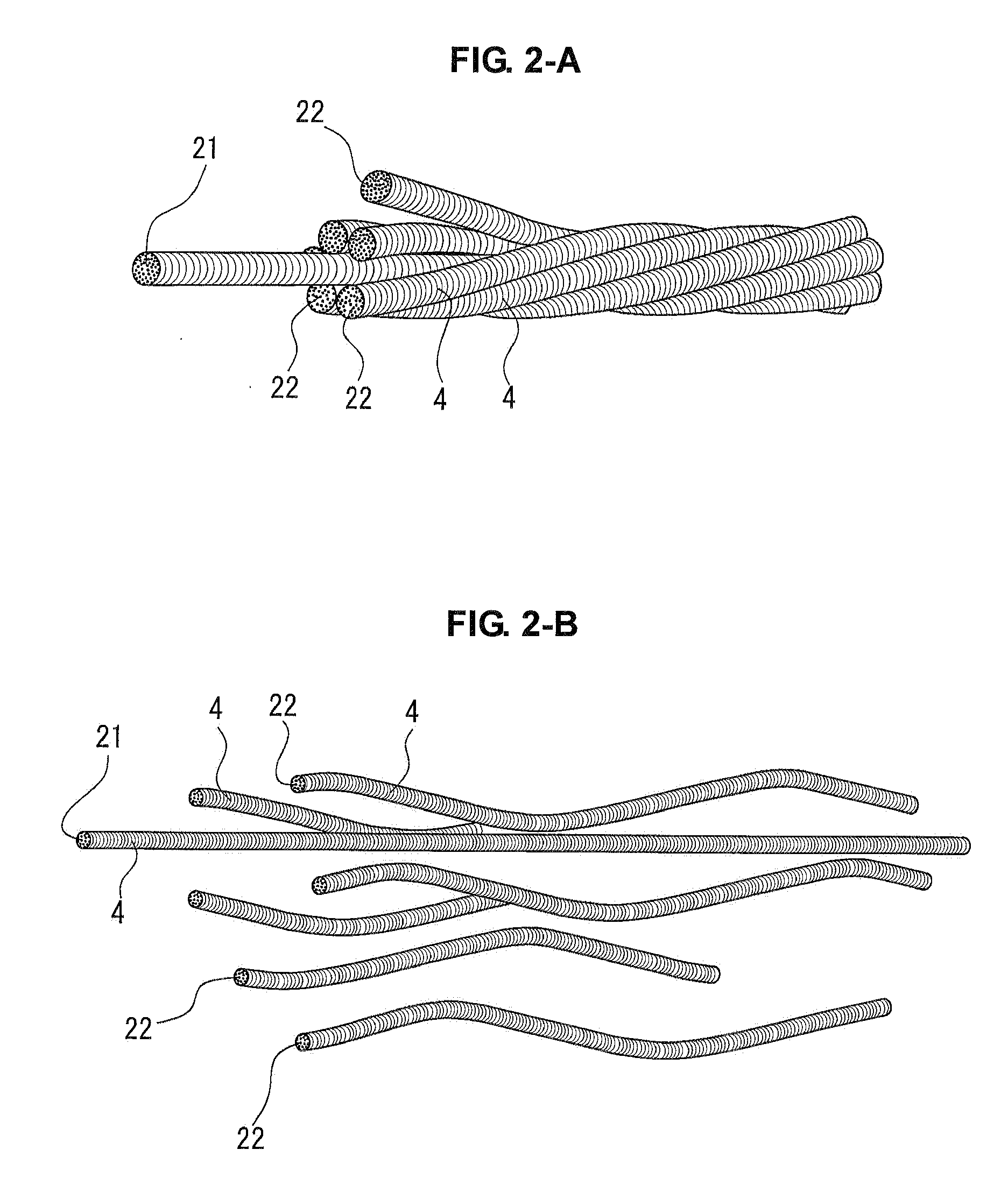

A wire-stranded hollow coil body (1) has a multitude of coil line elements (2) stranded along a predetermined circular line to form a flexible wire tube having a central axial hollow portion (3), the flexible wire tube is stranded under a strand-turn resistant load and heat treated to remove a residual stress upon formation so as to provide a high rotation-following capability and a high straightness. Further, a method provides a way to strand the coil line elements (2) under a strand-turn resistant load while heat treating the coil line elements (2).

Owner:ASAHI INTECC CO LTD

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

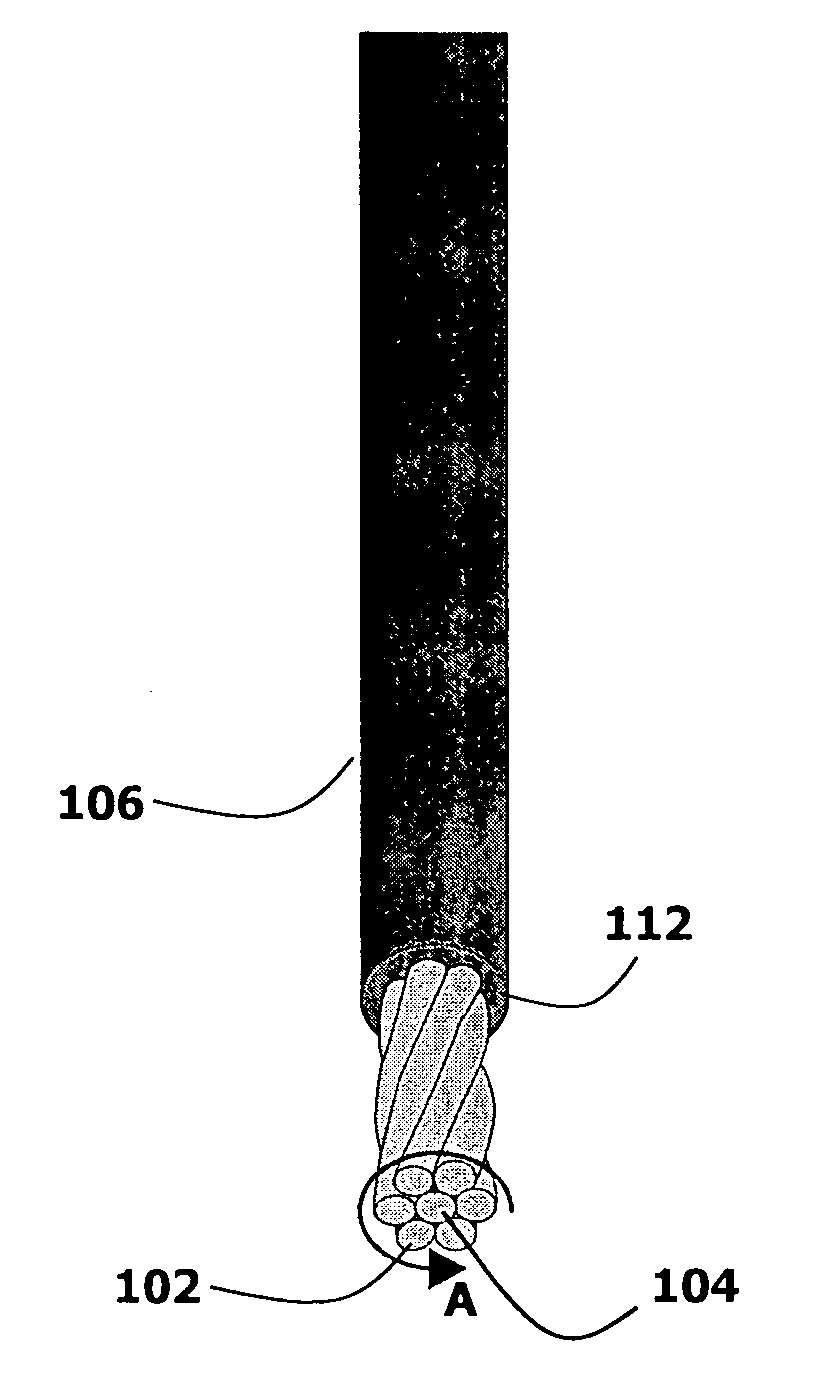

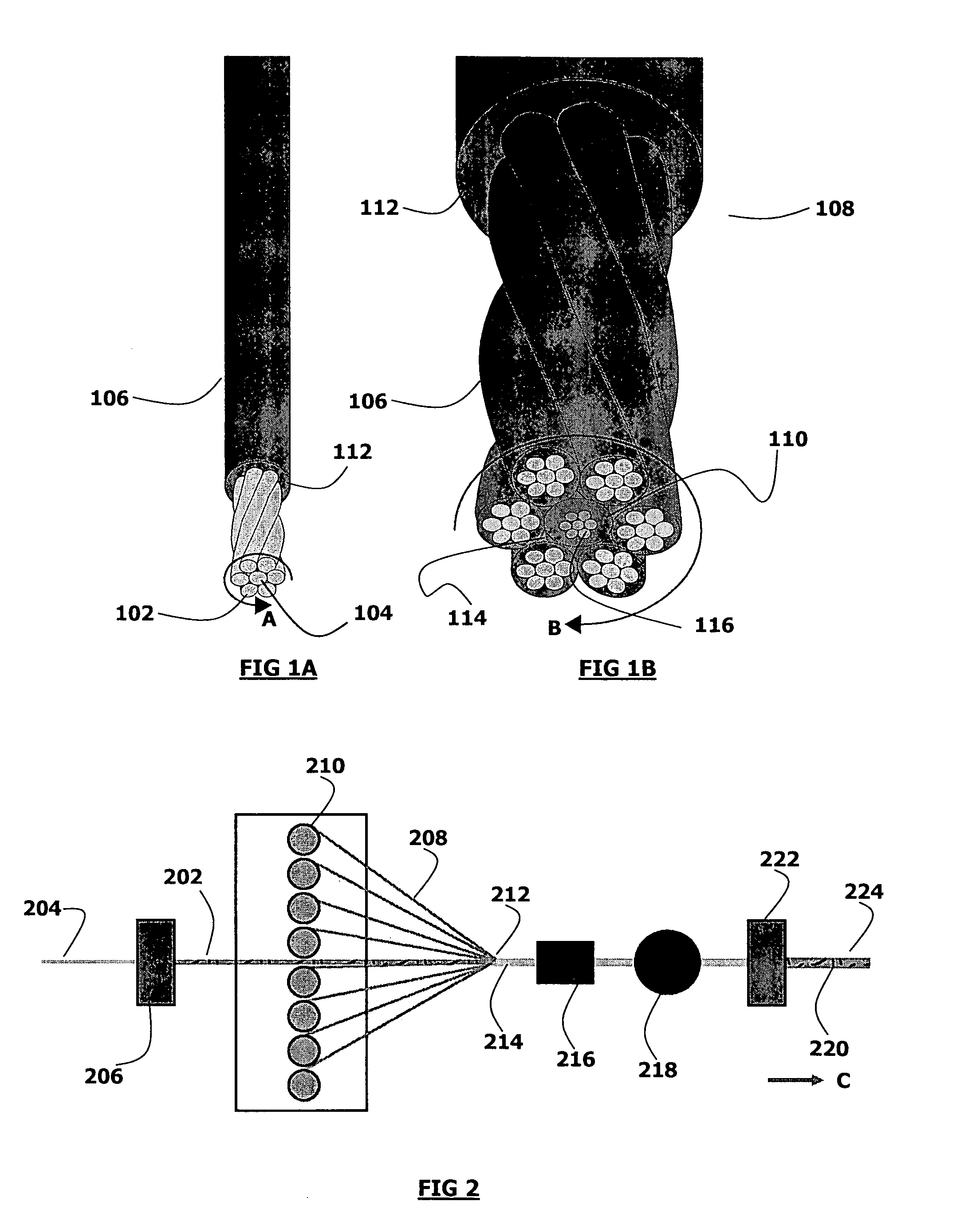

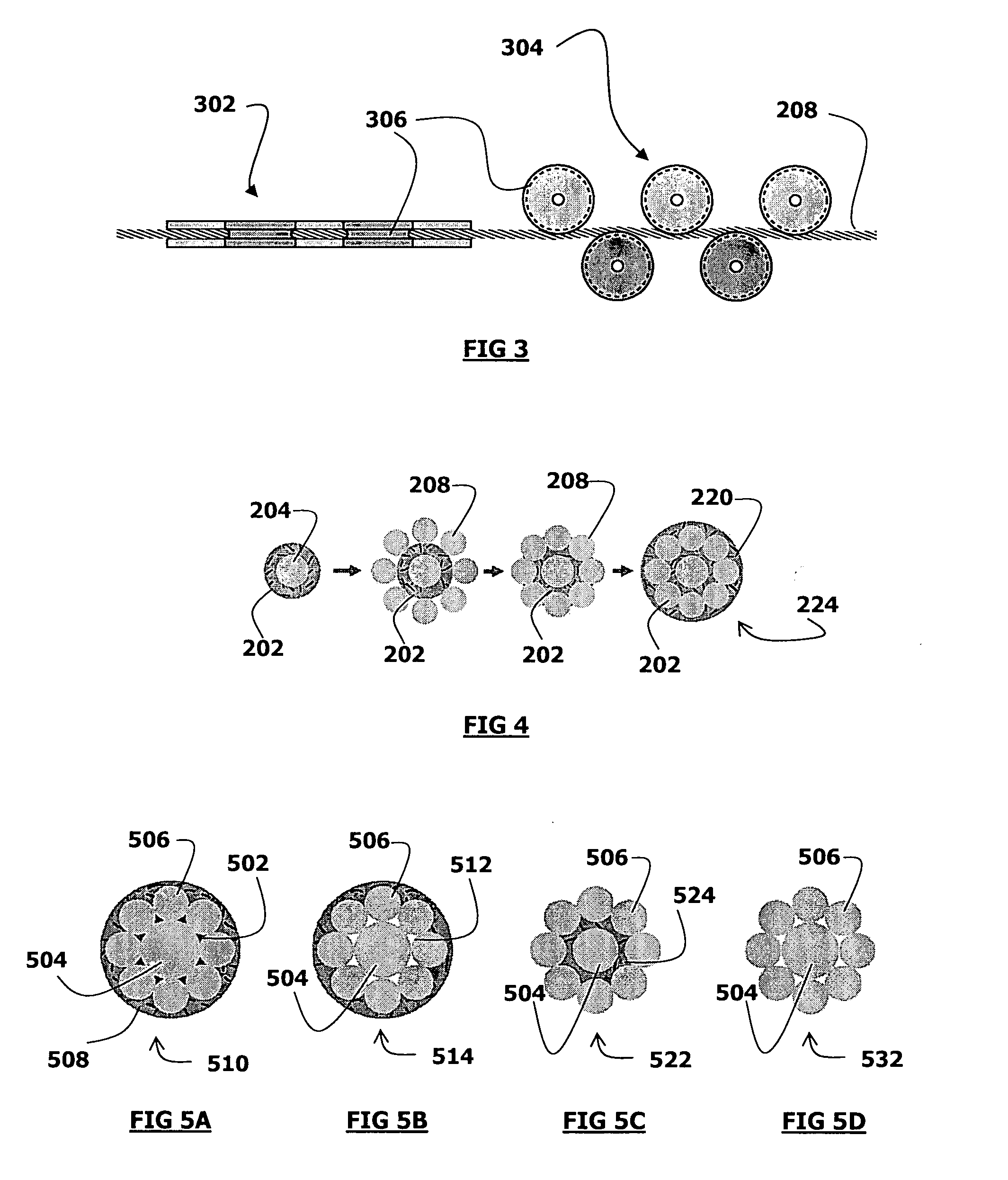

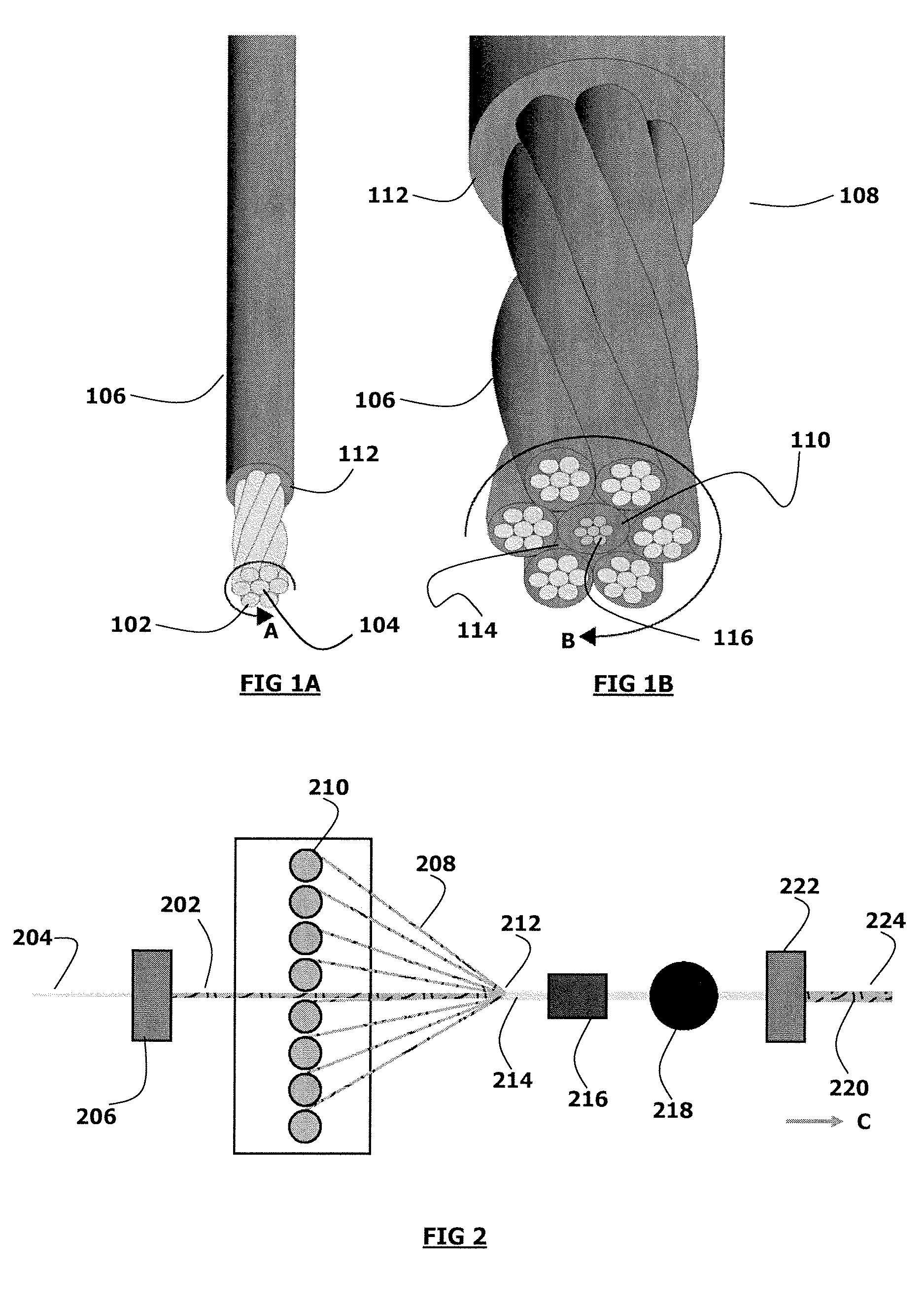

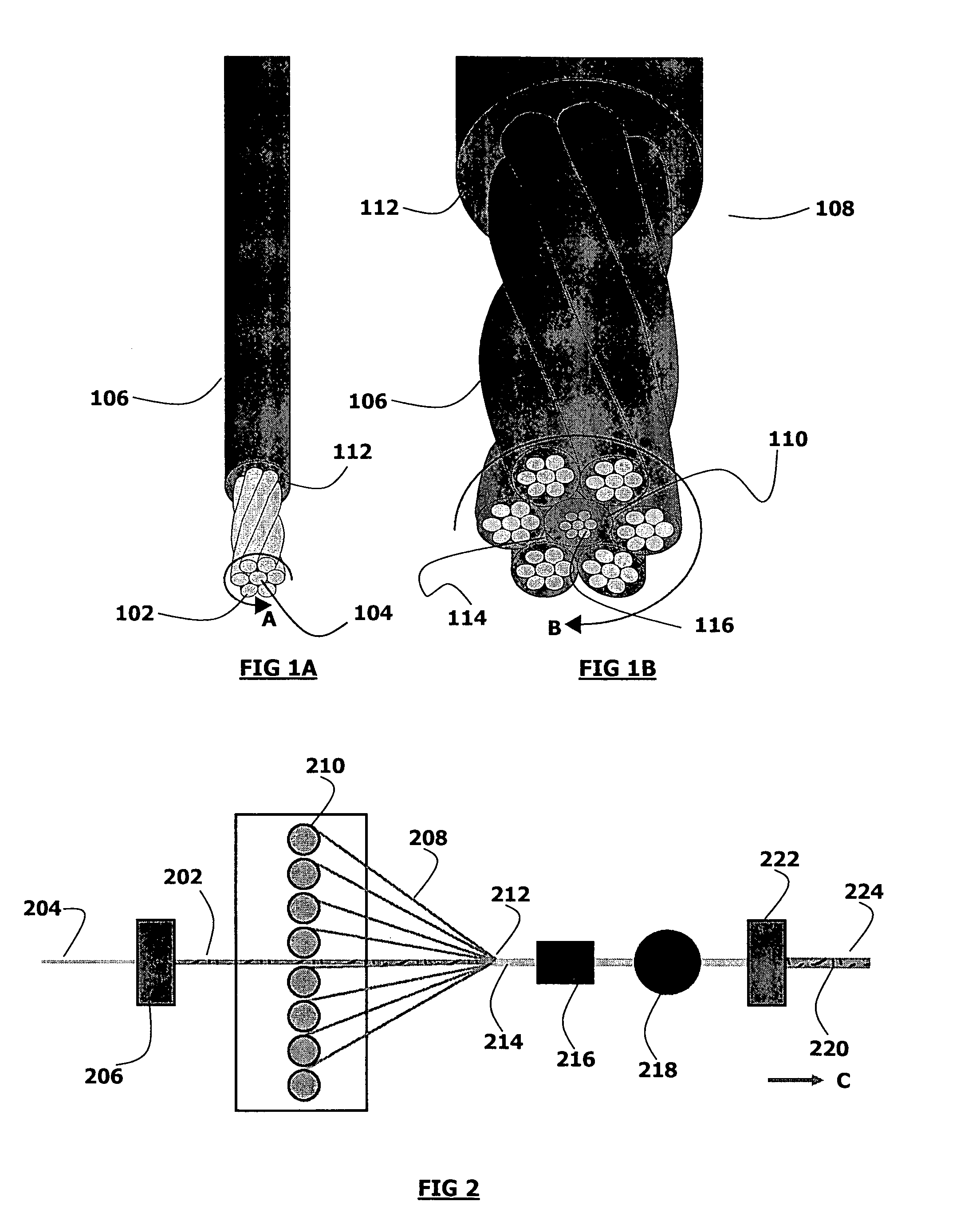

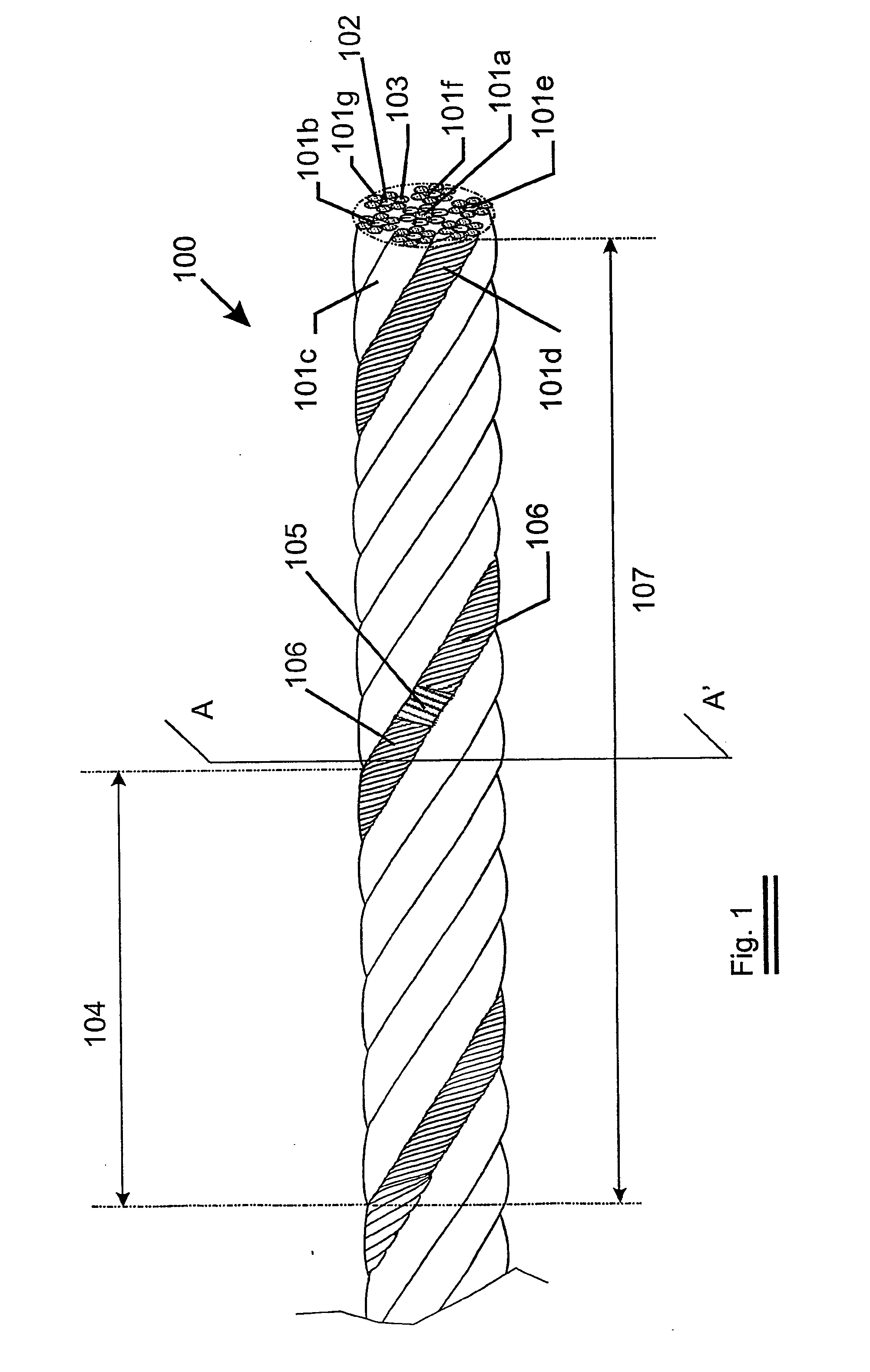

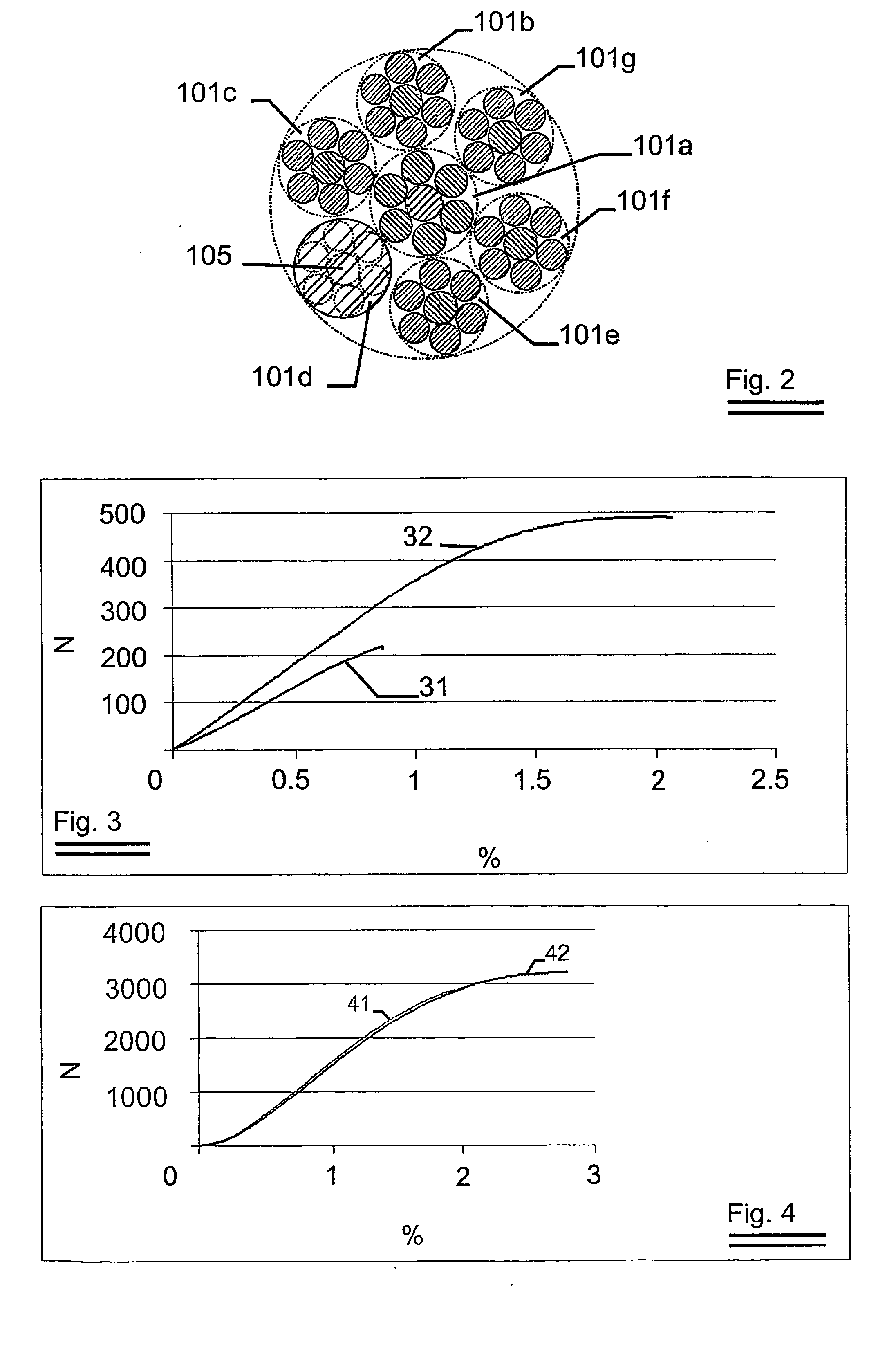

Electrical cables with stranded wire strength members

ActiveUS20070000682A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCoaxial cableEngineering

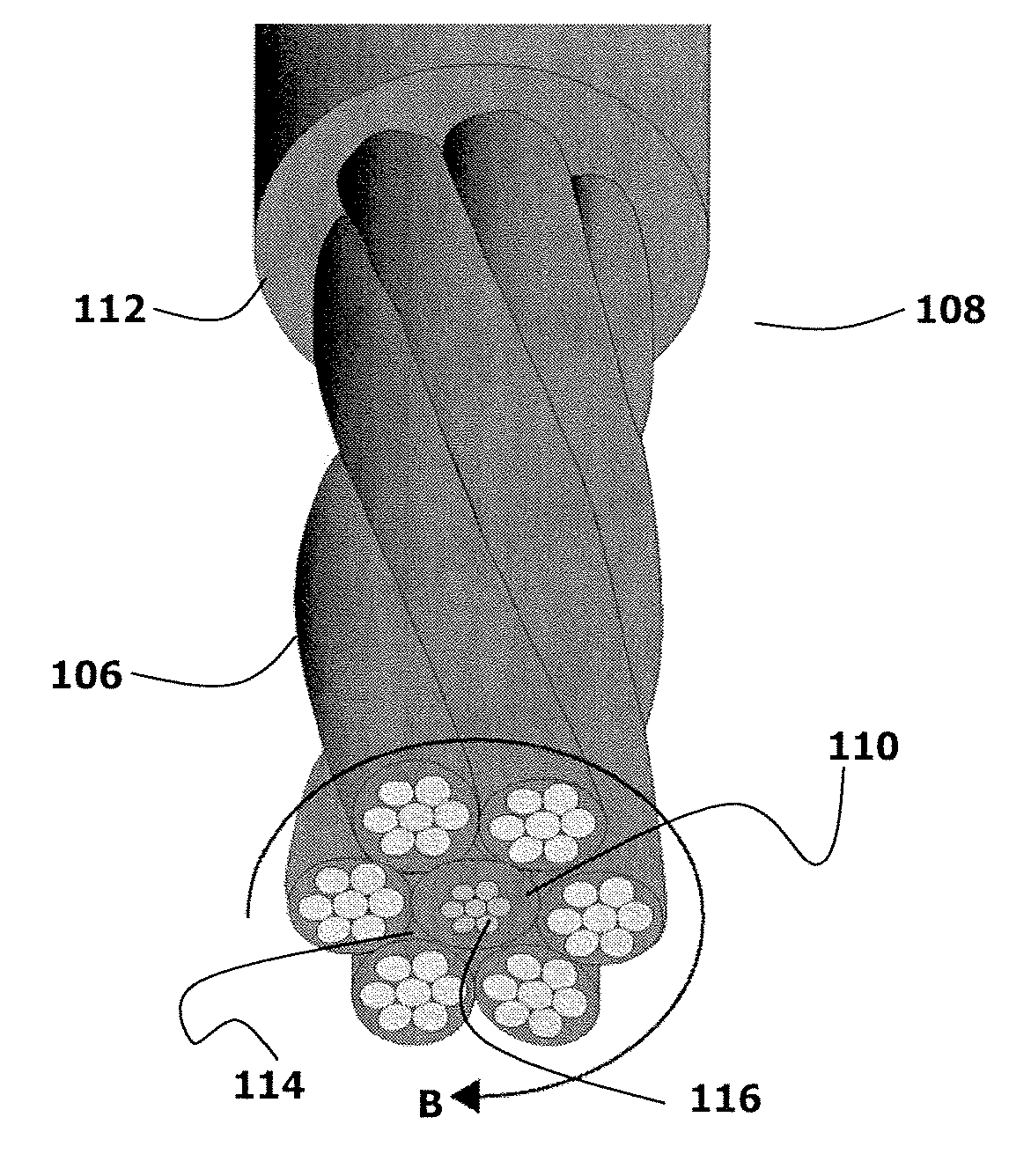

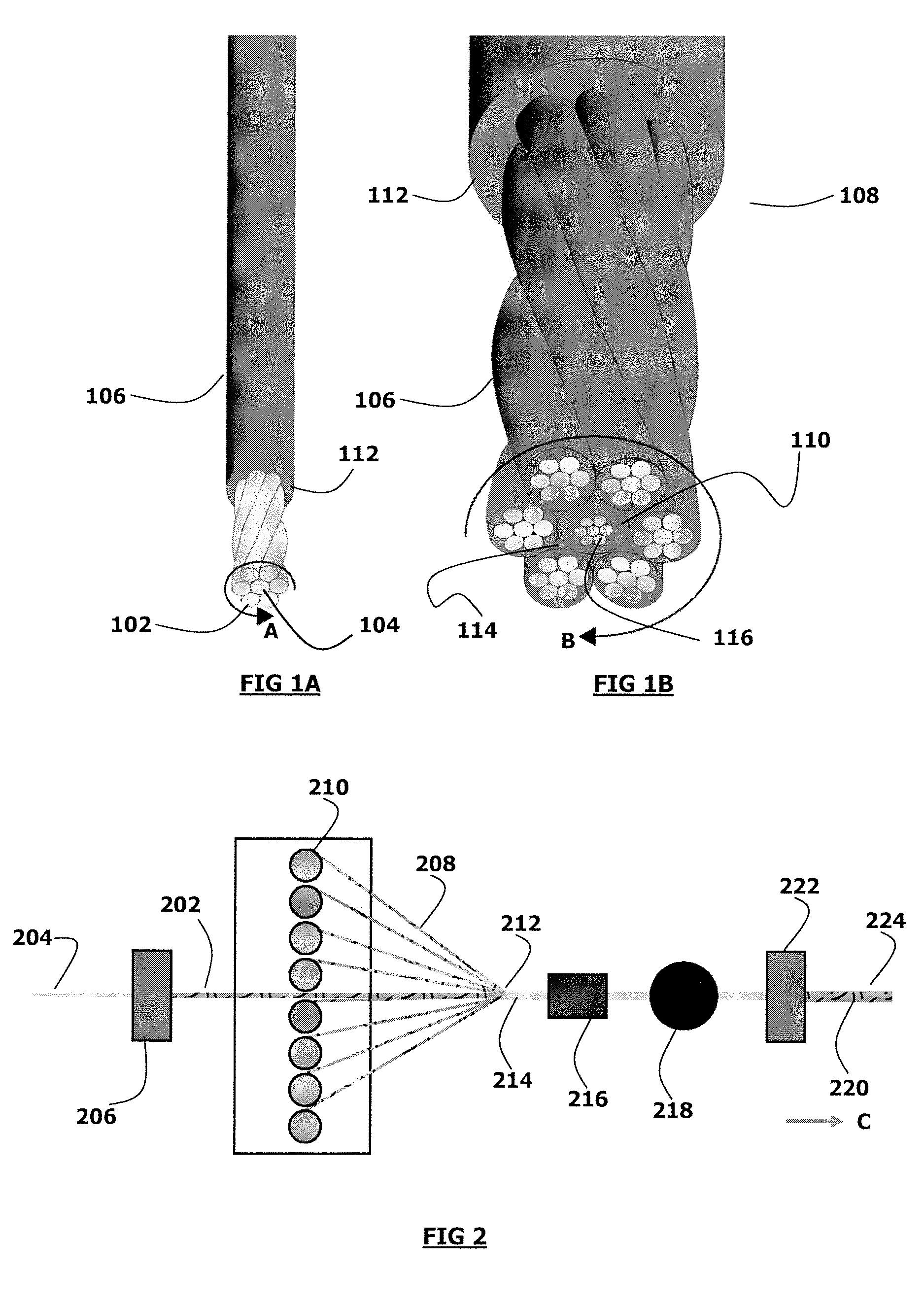

Disclosed are high strength wellbore electric cables, which are formed from a plurality of strength members. The strength members are formed from several stranded filament wires which may be encased within a jacket of polymeric material. The strength members may be used as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, etc., and have improved resistant to corrosion, torque balancing, and gas migration from a wellbore to the surface.

Owner:SCHLUMBERGER TECH CORP

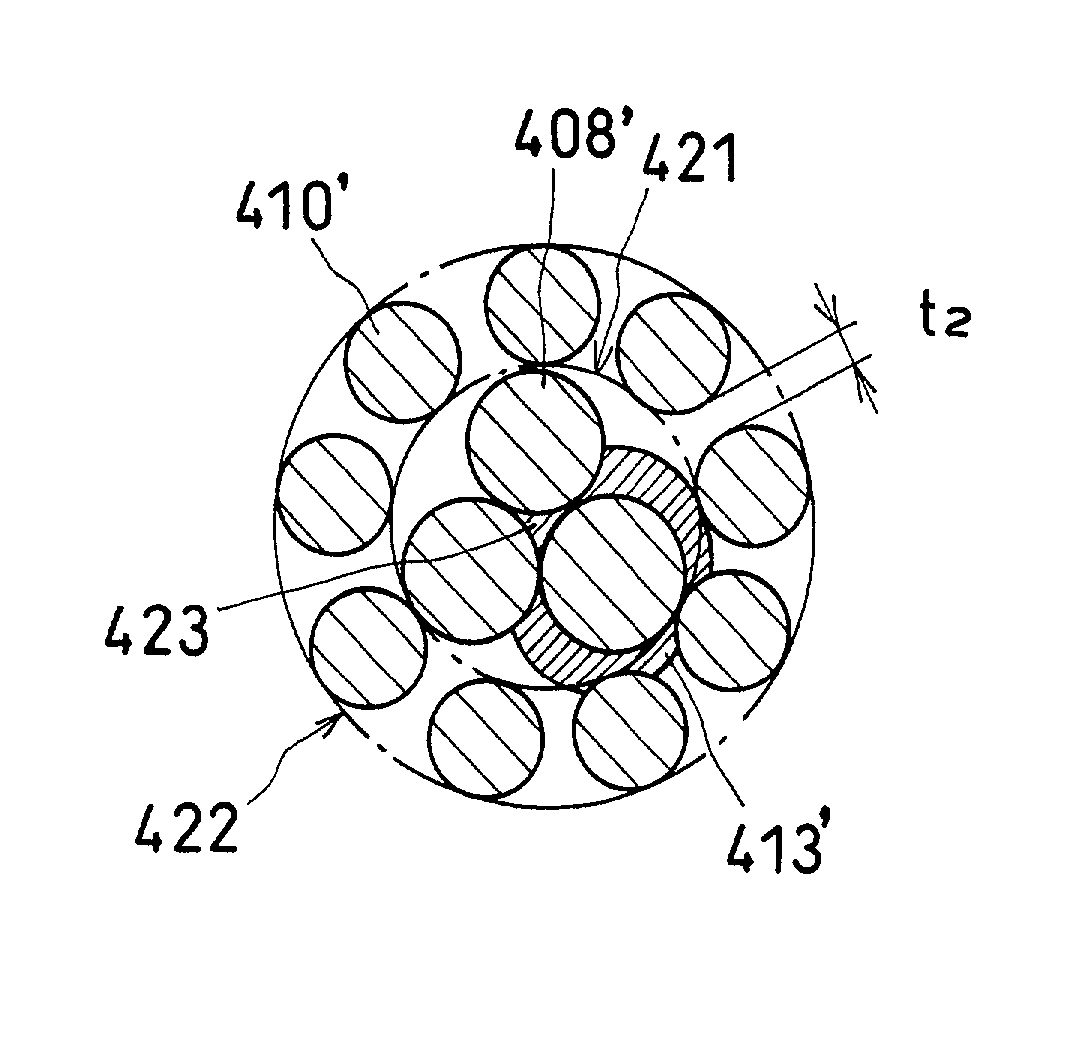

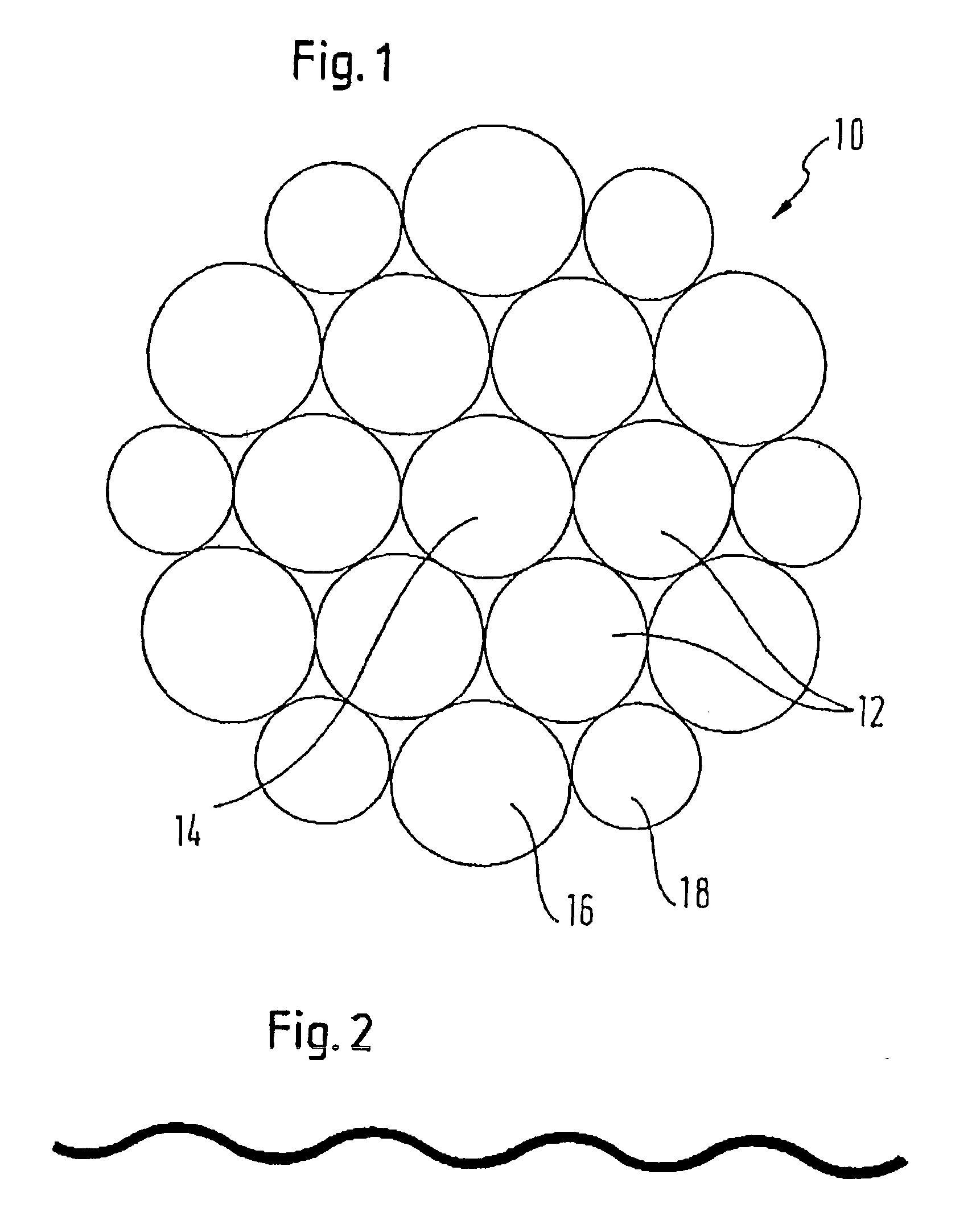

Elastomer and steel cord composite and process for producing the same

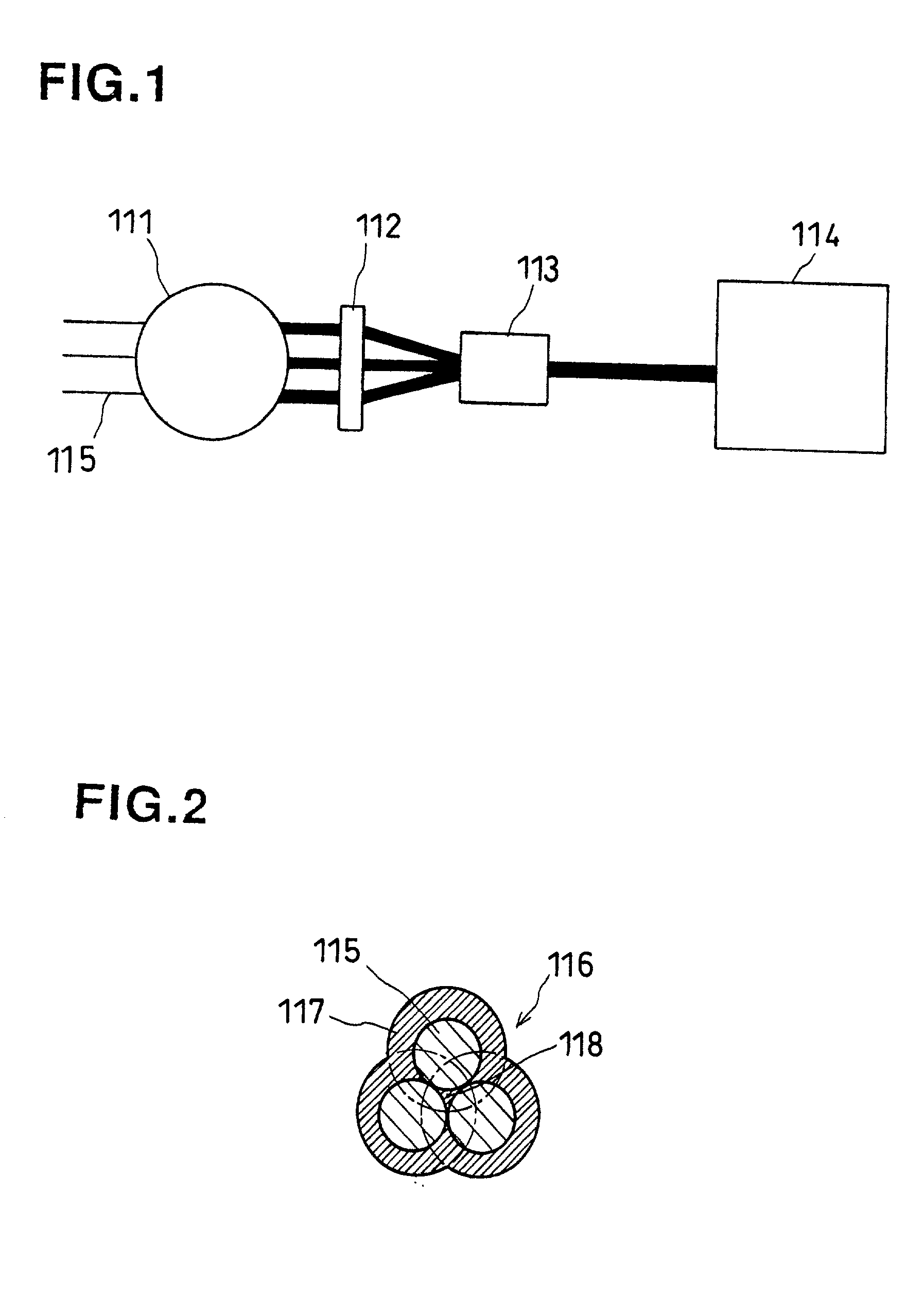

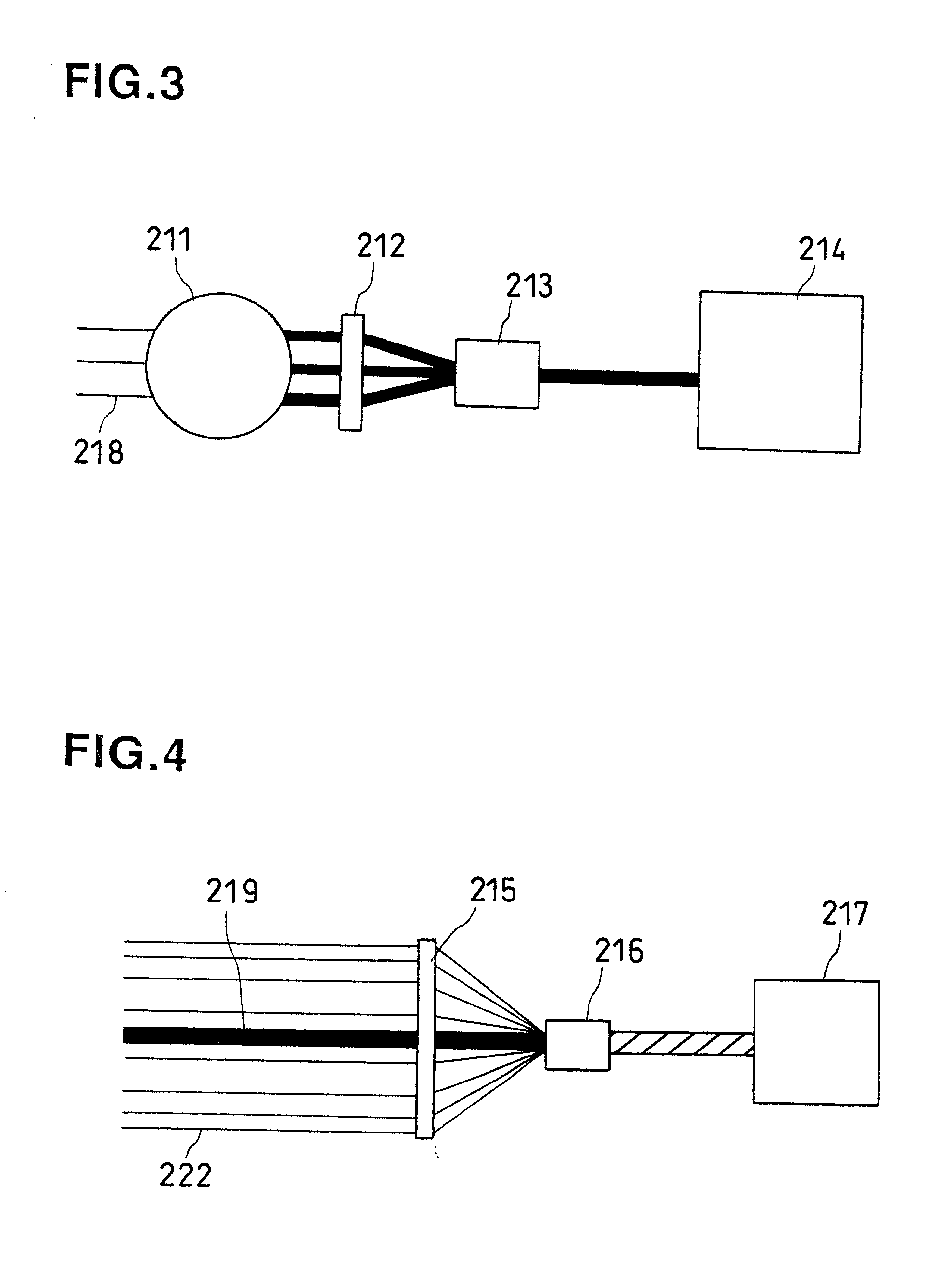

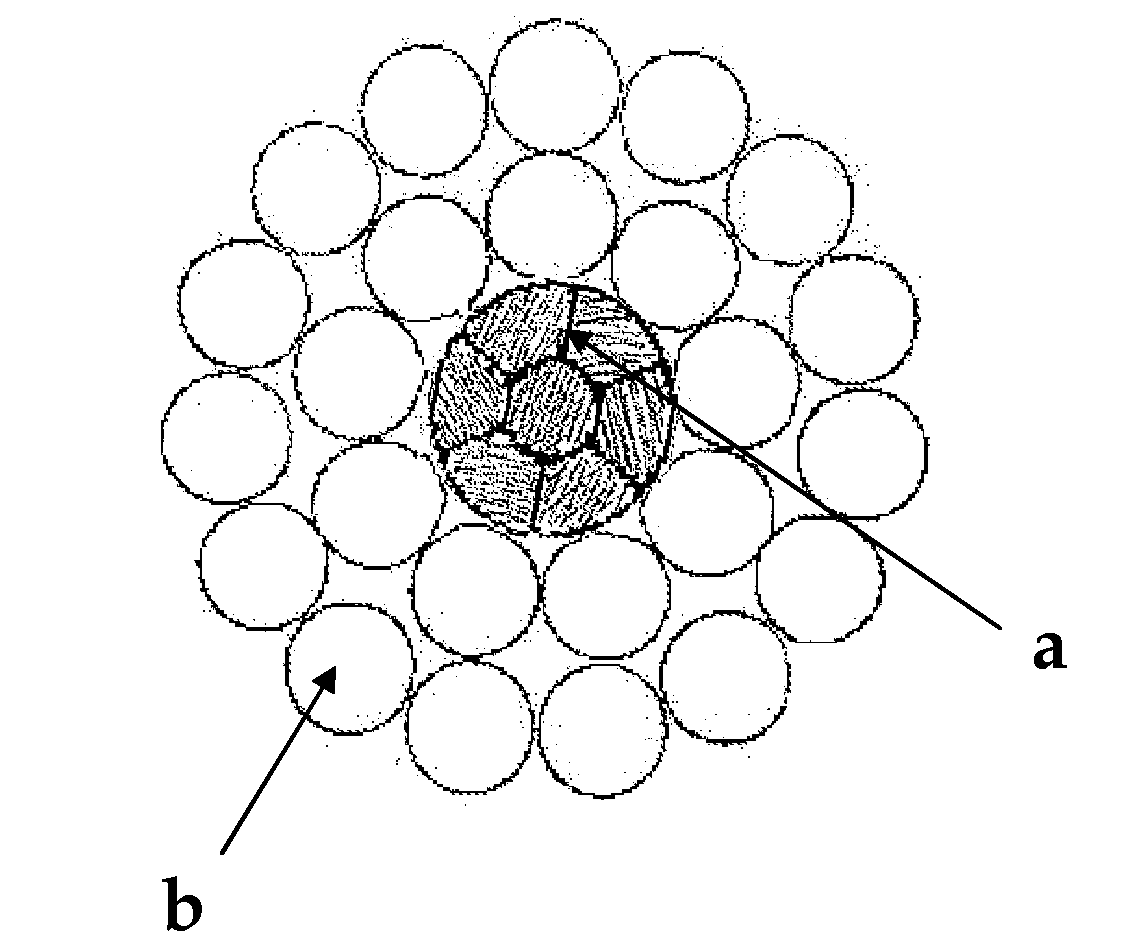

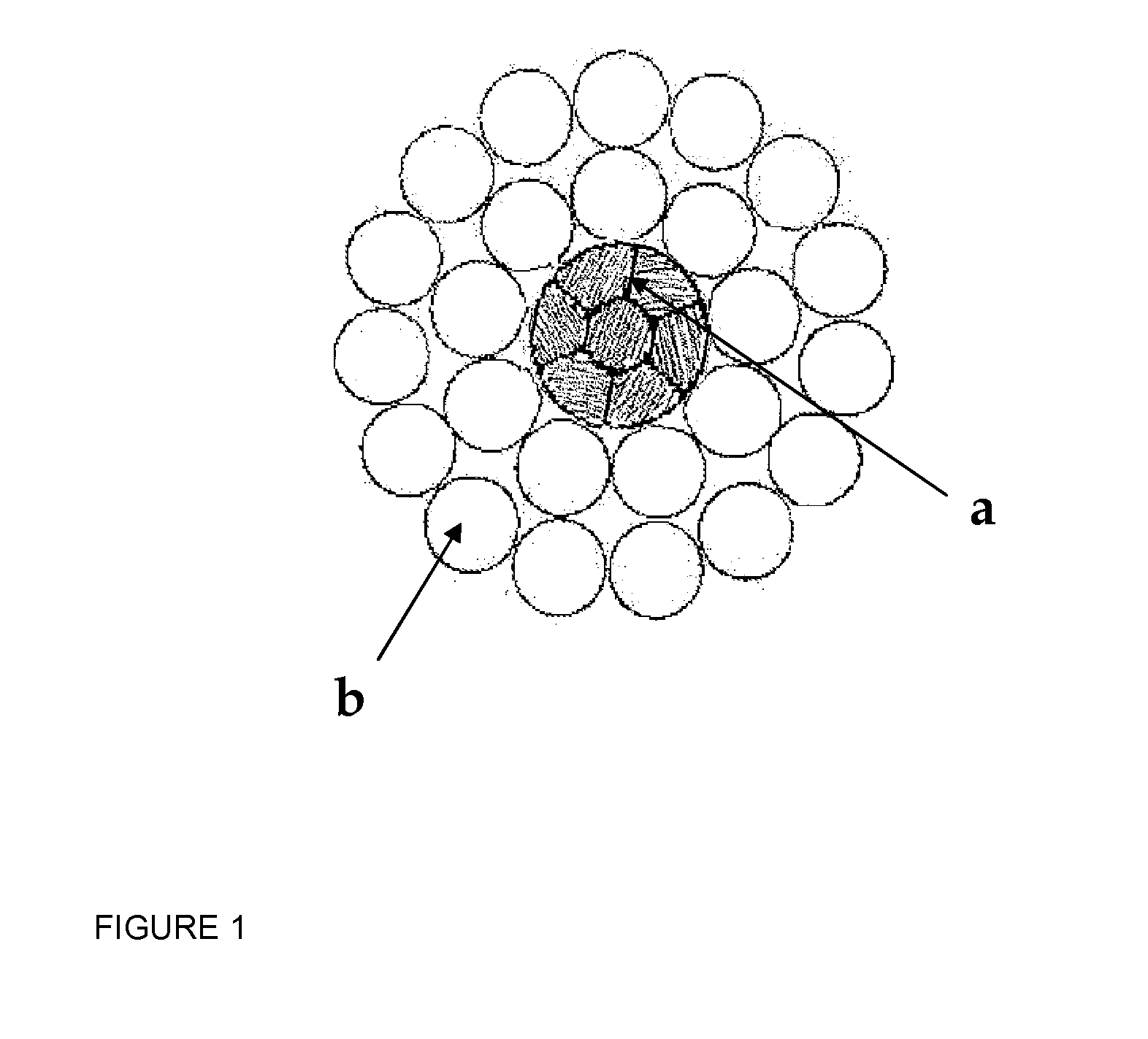

InactiveUS20020160213A1Reduce componentsSave energyPneumatic tyre reinforcementsRope making machinesElastomerMaterials science

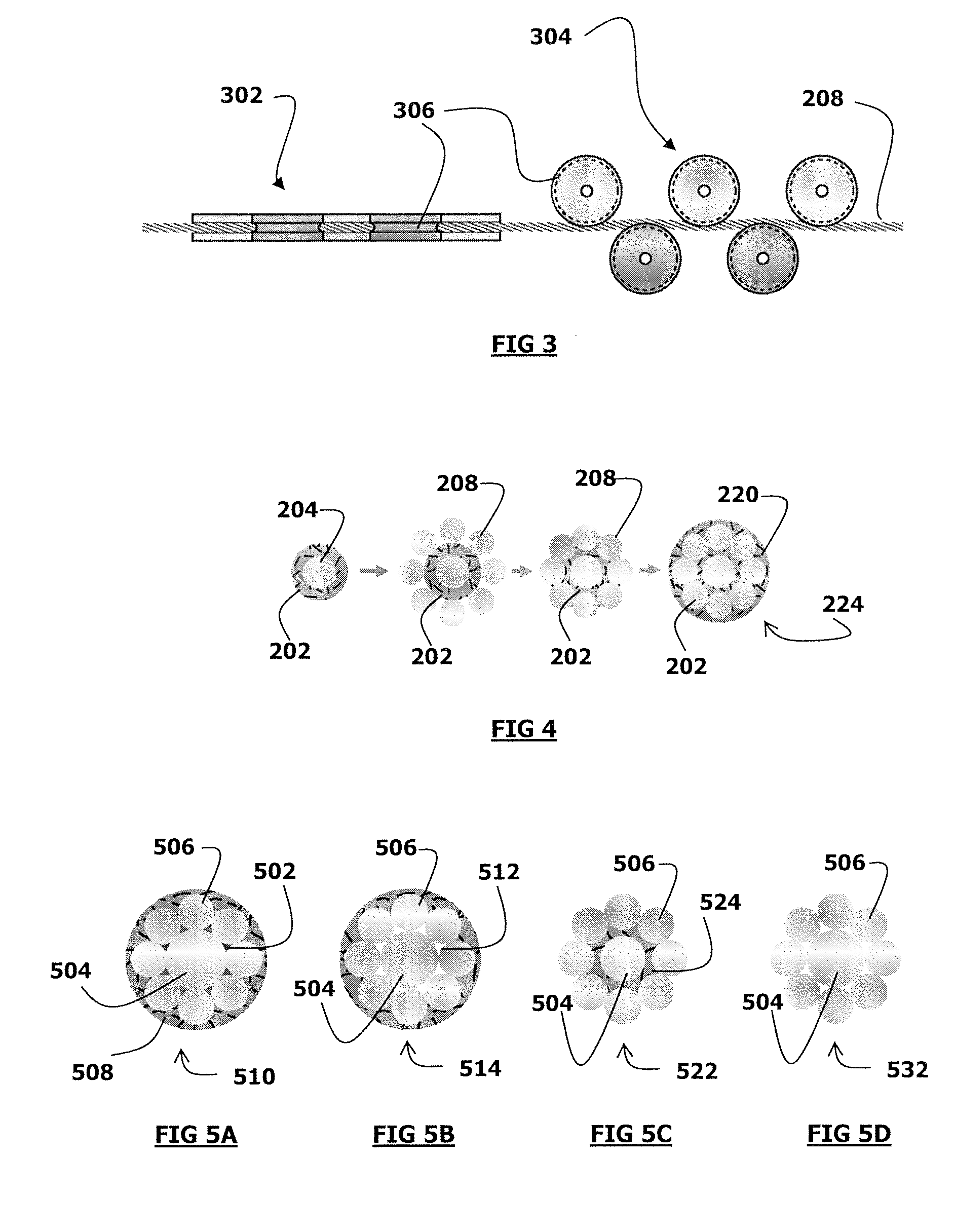

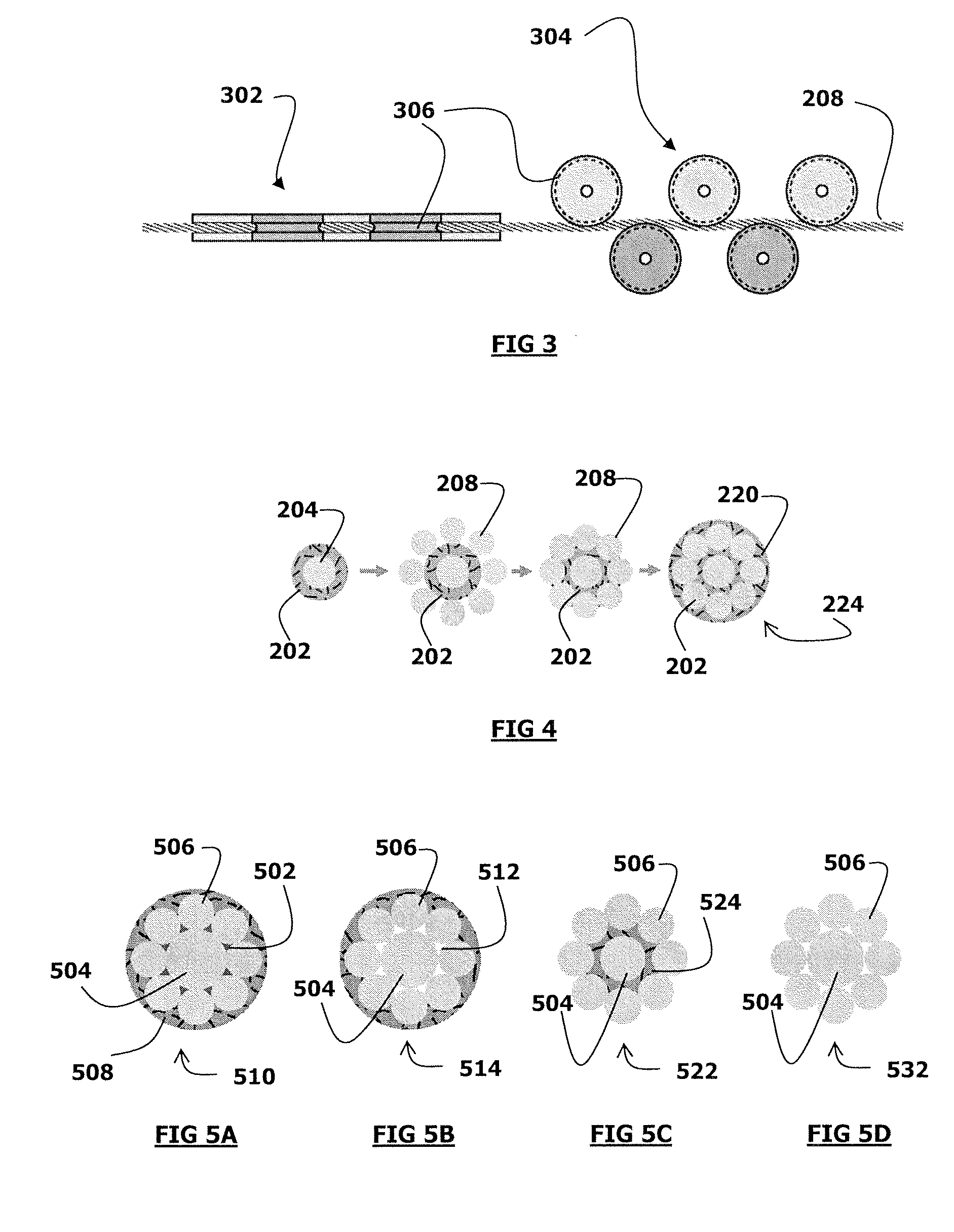

In order that spaces, including a space in the central portion, inside a steel cord used as a reinforcement by being embedded in a tire or the like are filled with an uncured rubber, the uncured rubber is coated on plural steel filaments 115 which are then stranded in case of a single layer steel cord, the uncured rubber is coated on all of plural core filaments 329 which are then stranded along with outer layer filaments 330 in the same direction at the same pitch in case of a 2-layer steel cord of 1 stranding process, and the uncured rubber is coated on all or 2 to 4 core filaments 218 or on at least one of 3 or 4 steel filaments 408, 408' to form a core strand and outer layer filaments 410, 410' are stranded therearound in case of 2-layer steel cord of 2 stranding process. Consequently, it is possible to exhibit satisfactory corrosion resistance and satisfactory fatigue resistance as a steel cord, shorten a curing time in tire component assembling or the like to attain energy saving and prolong the life of a steel cord itself and the life of a tire or the like using the same as a reinforcement. Further, production can be performed at low cost.

Owner:YOKOHAMA RUBBER CO LTD +1

Cables with stranded wire strength members

ActiveUS7326854B2Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

Cables with stranded wire strength members

ActiveUS20070044991A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

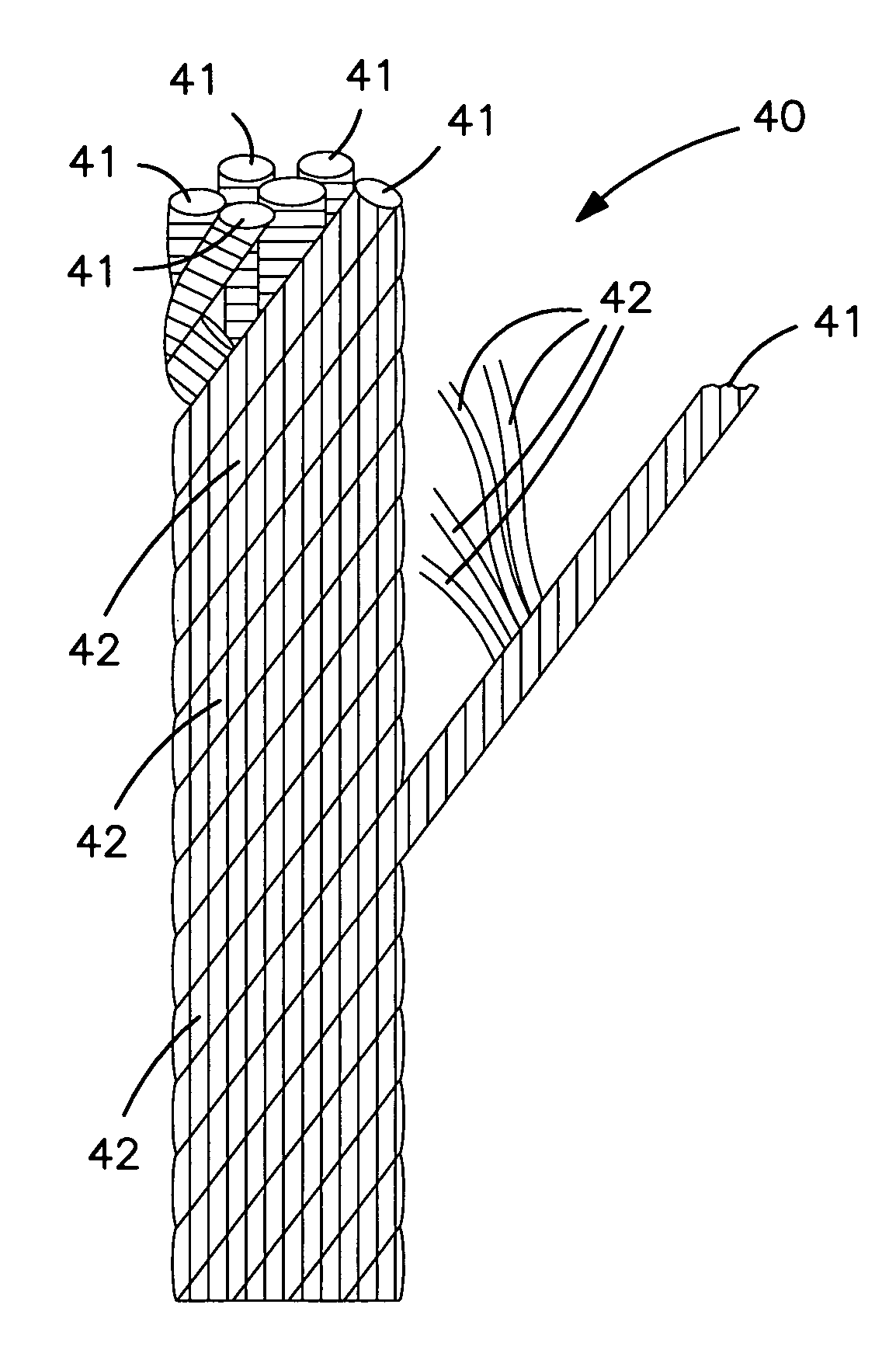

Electrical cables with stranded wire strength members

ActiveUS7462781B2Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCoaxial cableEngineering

Disclosed are high strength wellbore electric cables, which are formed from a plurality of strength members. The strength members are formed from several stranded filament wires which may be encased within a jacket of polymeric material. The strength members may be used as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, etc., and have improved resistant to corrosion, torque balancing, and gas migration from a wellbore to the surface.

Owner:SCHLUMBERGER TECH CORP

Production process of contact net anchorage steel wire rope

InactiveCN102517941AHigh breaking forceGood non-rotationRope making machinesExtrusion cleaning devicesIndustrial engineeringHeat treating

The invention discloses a production process of a contact net anchorage steel wire rope. The production process comprises the following steps: carrying out surface acid cleaning and phosphating; drawing; carrying out lead bath heat treatment; galvanizing; drawing; detecting; entwisting; stranding; forging; and greasing. The production process has the advantages of convenience in operation and time-saving and labor-saving properties; and the produced contact net anchorage steel wire rope has the advantages of high breaking force, long fatigue service life, good abrasion resistance and good corrosion resistance.

Owner:NANTONG GUANGMING STEEL WIRE PROD

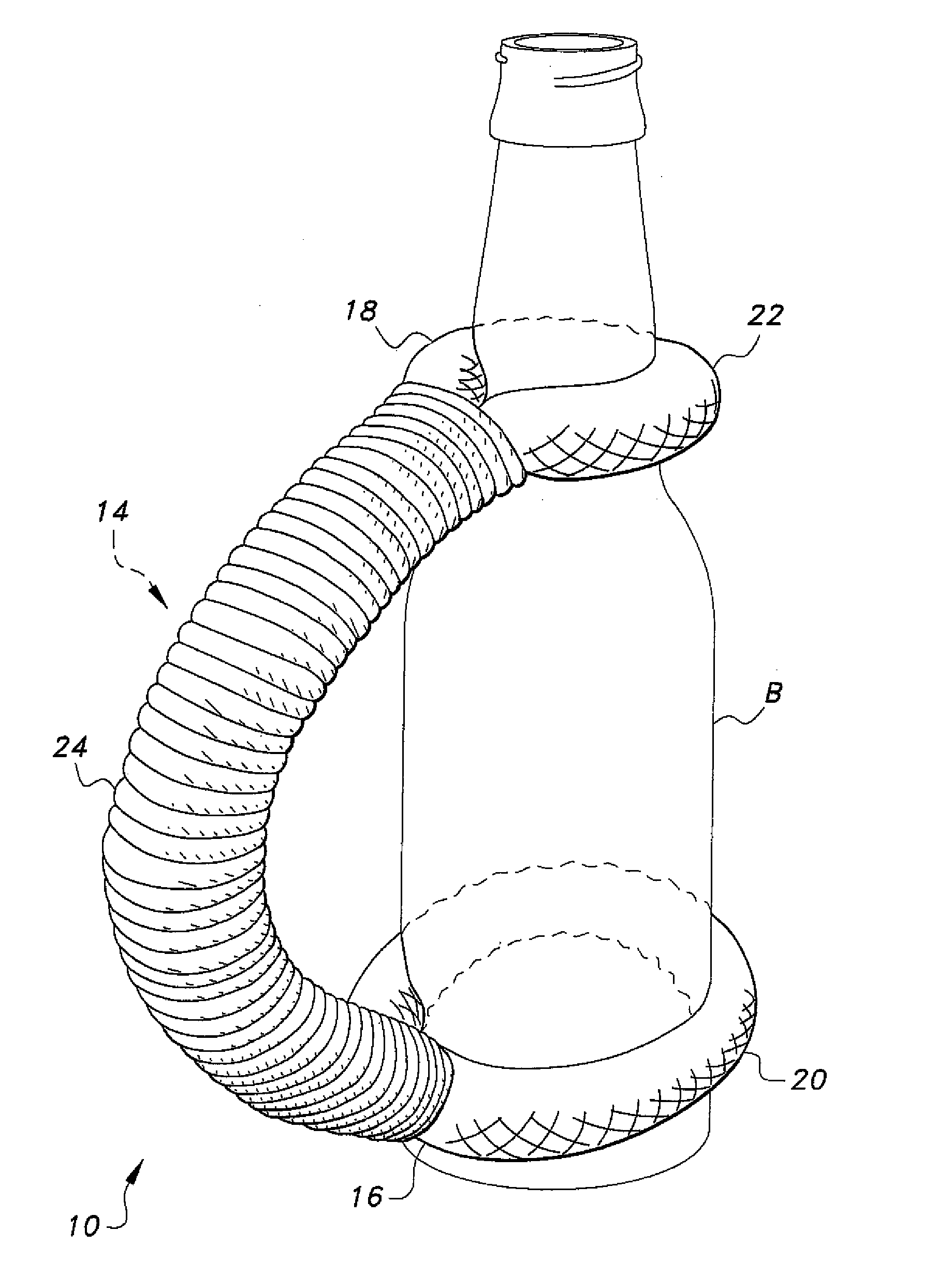

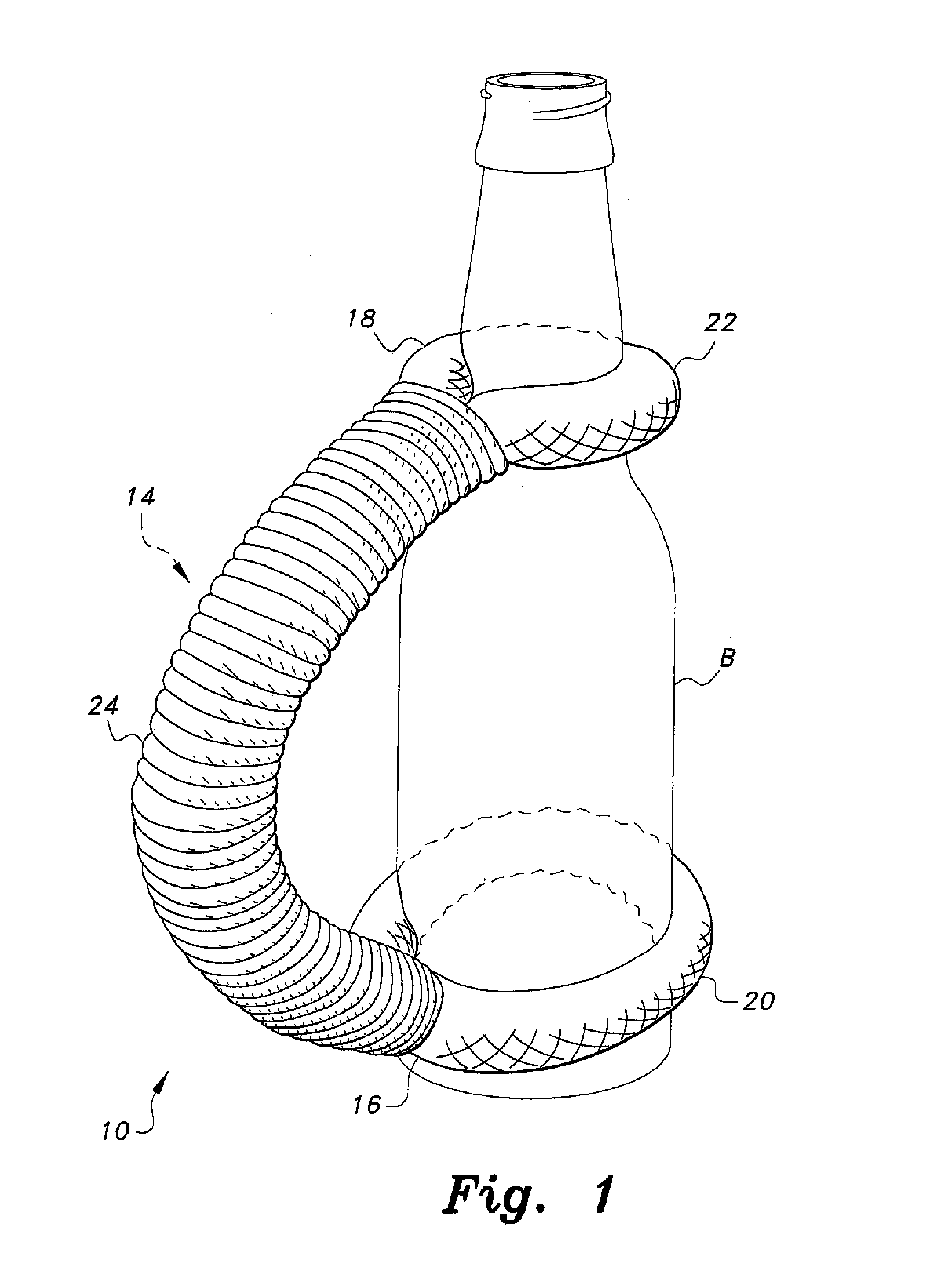

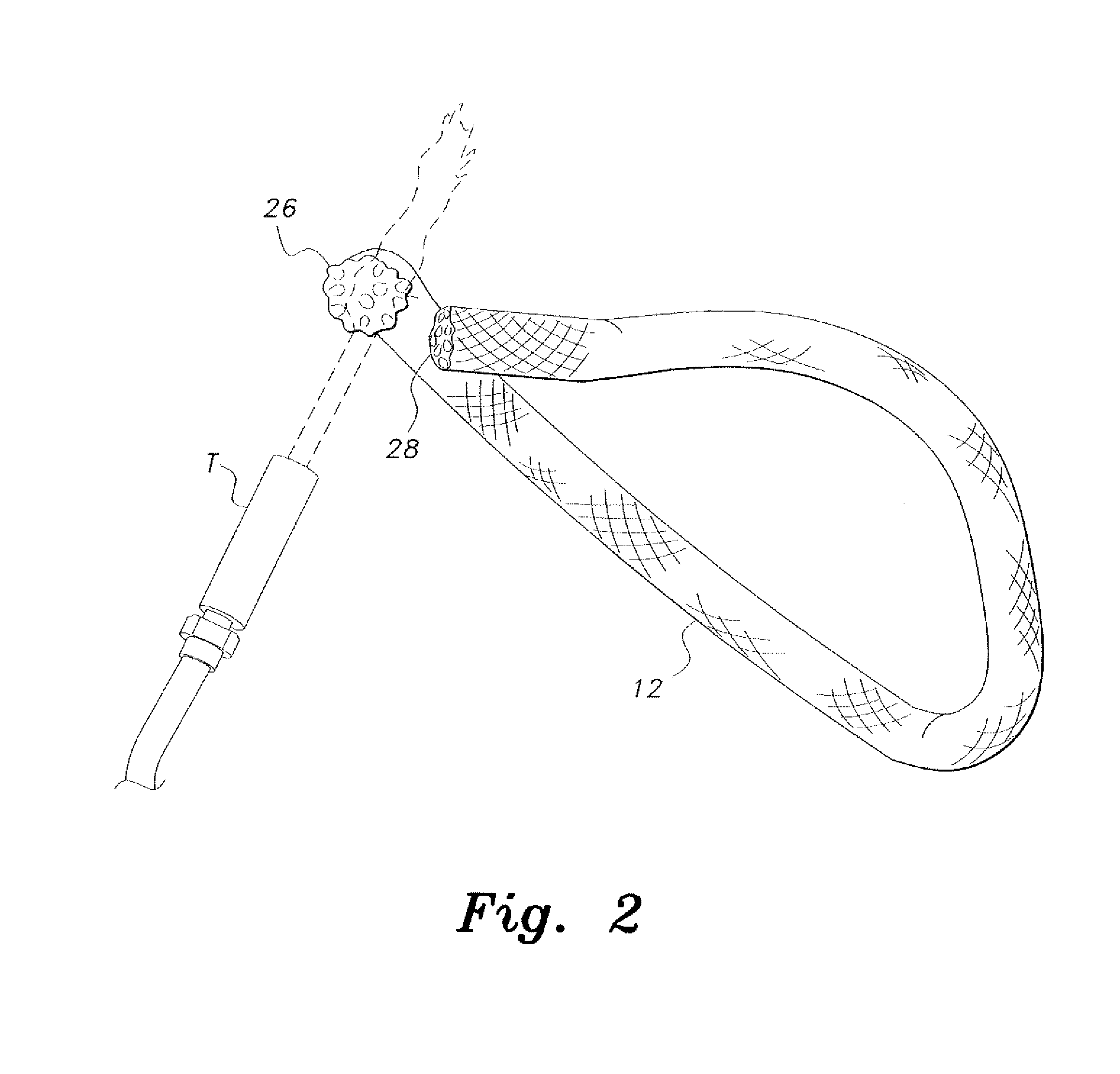

Bottle holder

The bottle holder is formed of a synthetic fiber rope, allowing various portions of the rope to be fused together by heat or solvent. The ends of the rope are melted and pressed together to form a relatively large endless loop. The facing portions of this loop are then partially melted and pressed together to form a single fused handgrip portion having loops extending from opposite ends thereof. One loop is preferably larger than the other, the larger loop being adapted to fit around the base of a beverage bottle and the smaller loop being adapted to fit about the bottleneck. The fused central or handgrip portion of this structure is then helically wound with a smaller diameter cord to form a handgrip, the ends of the cord being captured by the juncture of one of the rope loops and by a bight in the cord.

Owner:MCDONALD JOHN +1

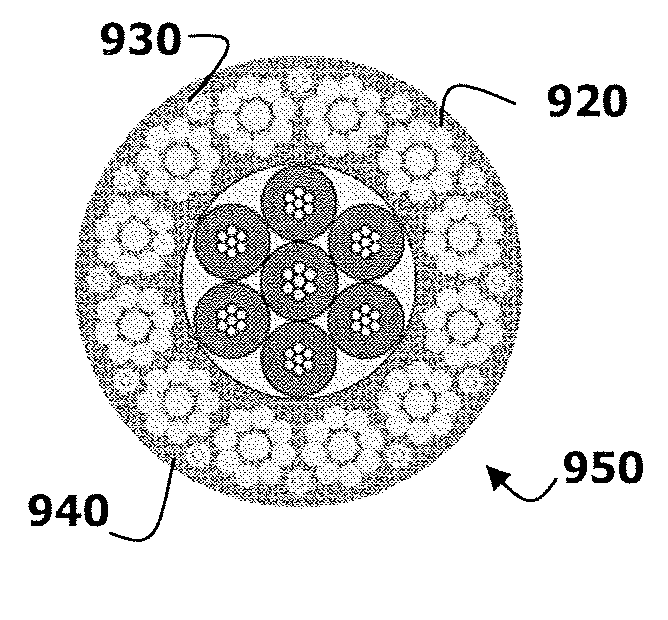

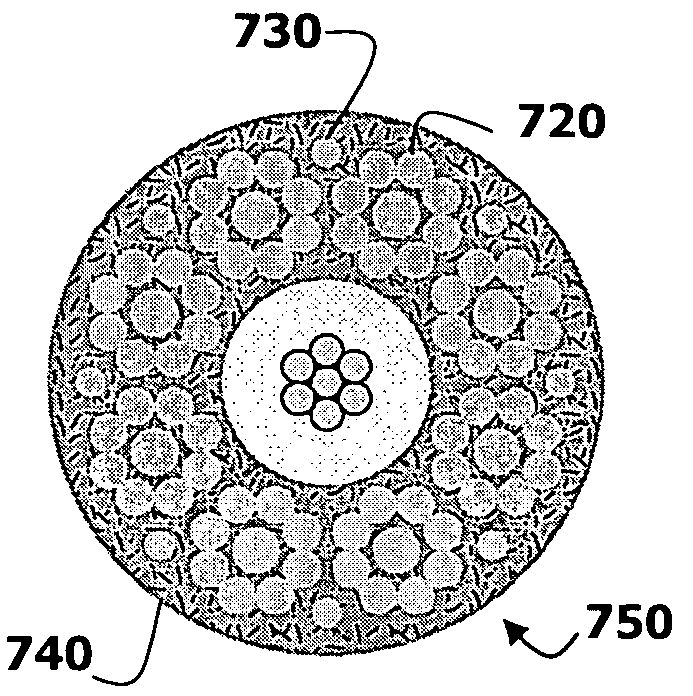

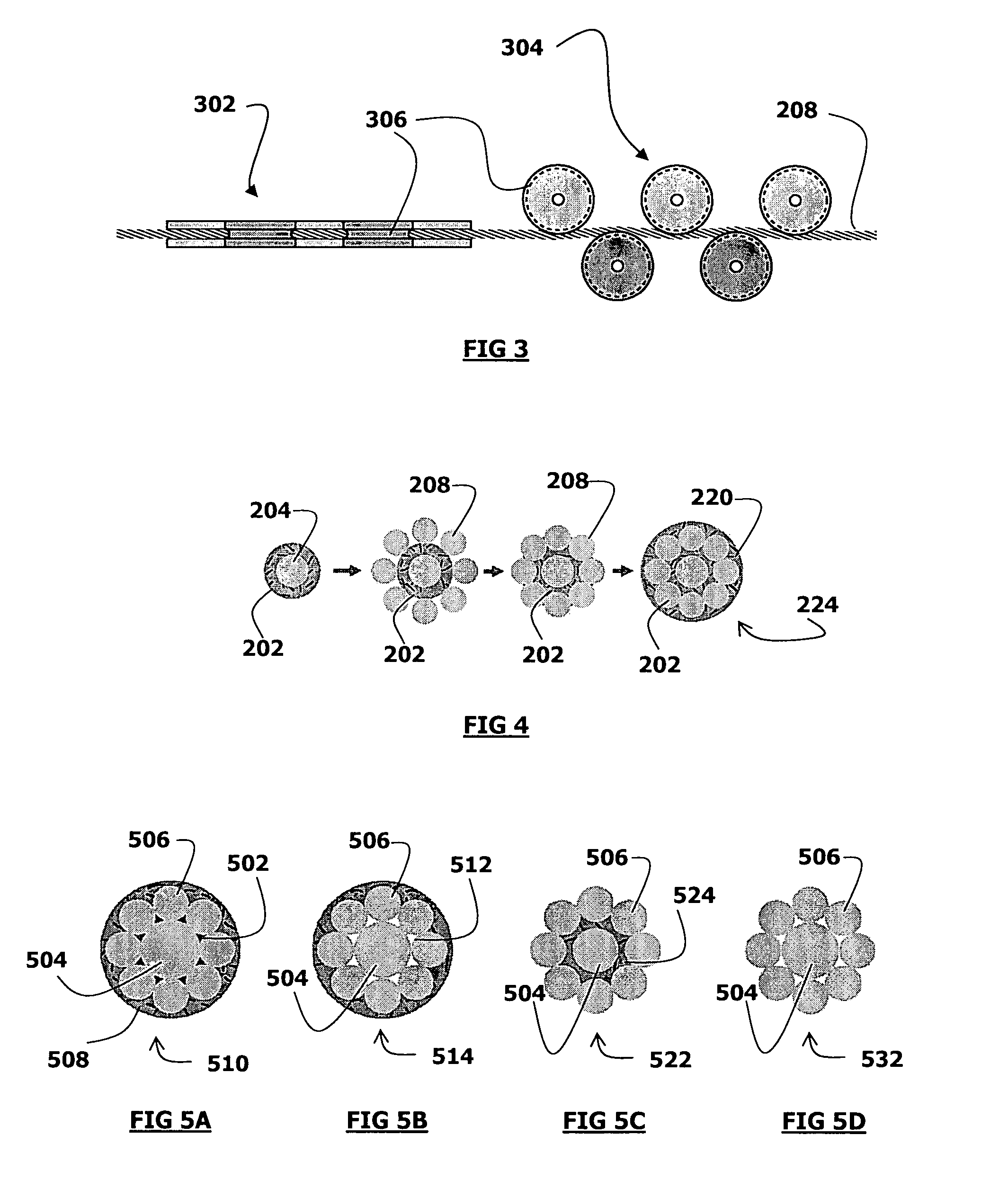

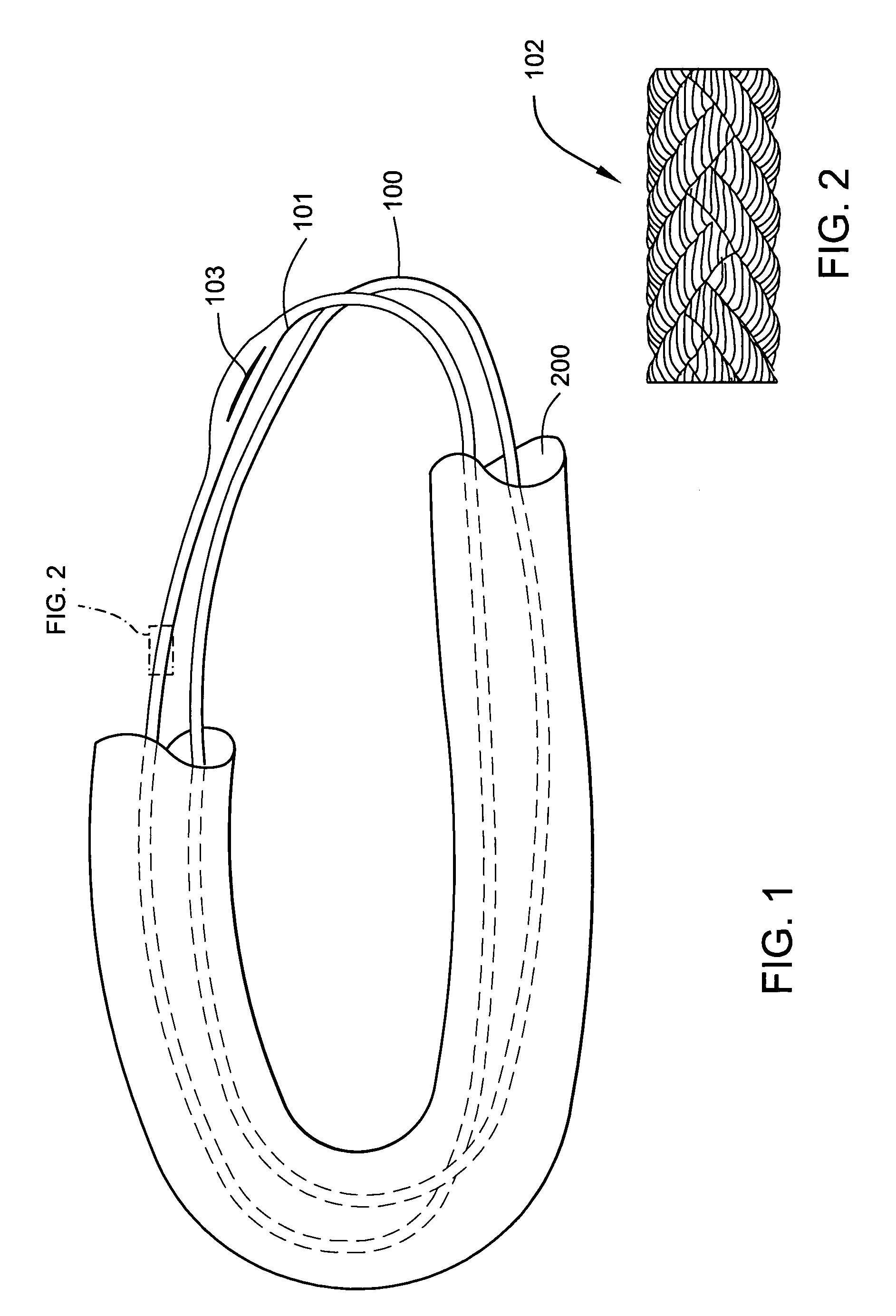

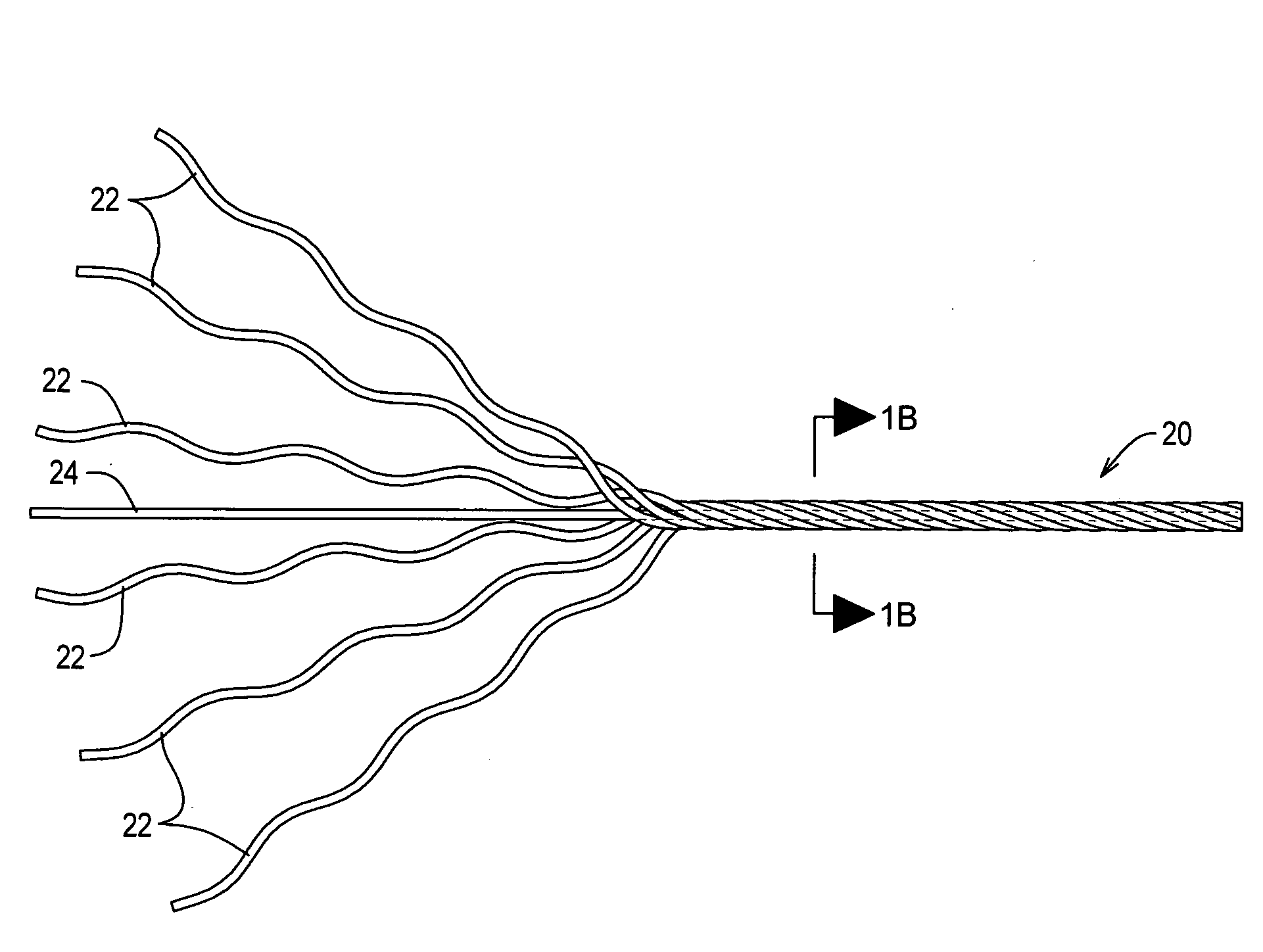

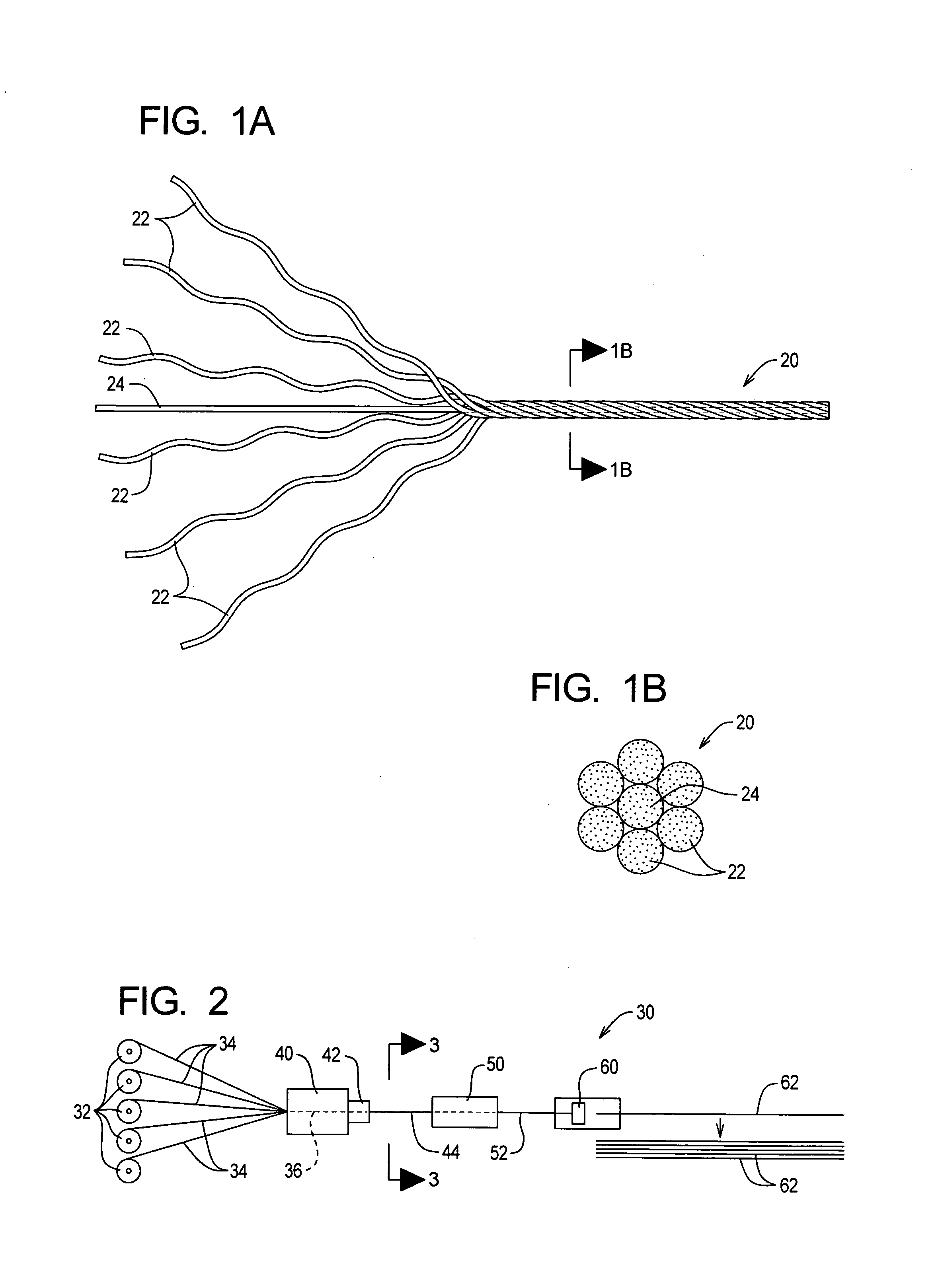

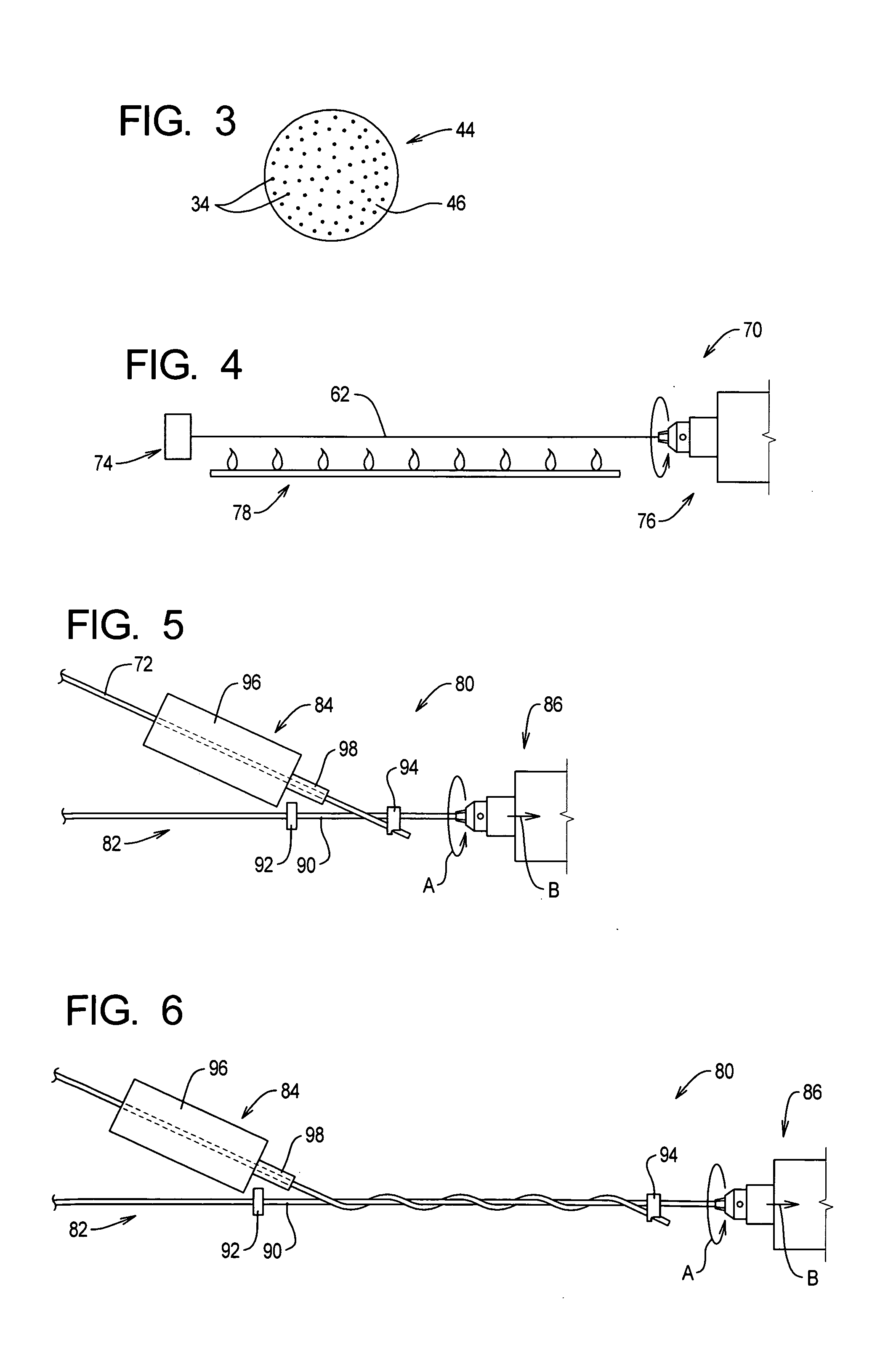

Fluoropolymer fiber composite bundle

ActiveUS20060179812A1Improve fatigue performanceHigh strengthRope making machinesWoven fabricsFiberFluoropolymer

A rope comprising a plurality of bundle groups, each of said bundle groups having a periphery and comprising a plurality of high strength fibers, at least one low coefficient of friction fiber disposed around at least a portion of the periphery of at least one of the bundle groups.

Owner:WL GORE & ASSOC INC

Preparation method and preparation system for ultralight composite traction belt

ActiveCN104552988AReduce internal defectsImprove tensile propertiesRope making machinesBeltsYarnAgricultural engineering

The invention discloses a preparation method and a preparation system for an ultralight composite traction belt, and provides a preparation method and a preparation system for the ultralight composite traction belt with uniform bearing and long service life. The preparation method comprises the following steps: a twist-free continuous monofilament is led out of a fiber yarn group, unfolded uniformly, and introduced into an impregnation tank for impregnation, wherein the impregnation tank is added with a glue solution, then arrangement is performed, and composite enhanced pieces are obtained after pultrusion and curing; the composite enhanced pieces are led out respectively, preheated and introduced into a head die of an extruder, an extruding die core corresponding to the section of the traction belt is arranged in the head die, the composite enhanced pieces are uniformly coated with molten thermoplastic resin in the head die and led out of the head die of the extruder, preliminary forming is realized, and the traction belt is obtained after cooling setting and cooling. The prepared traction belt is light in weight, high in strength, easy to bend, anti-fatigue, long in service life, low in maintenance cost and more applicable to a long-distance elevator.

Owner:TIANJIN GOLDSUN WIRE ROPE

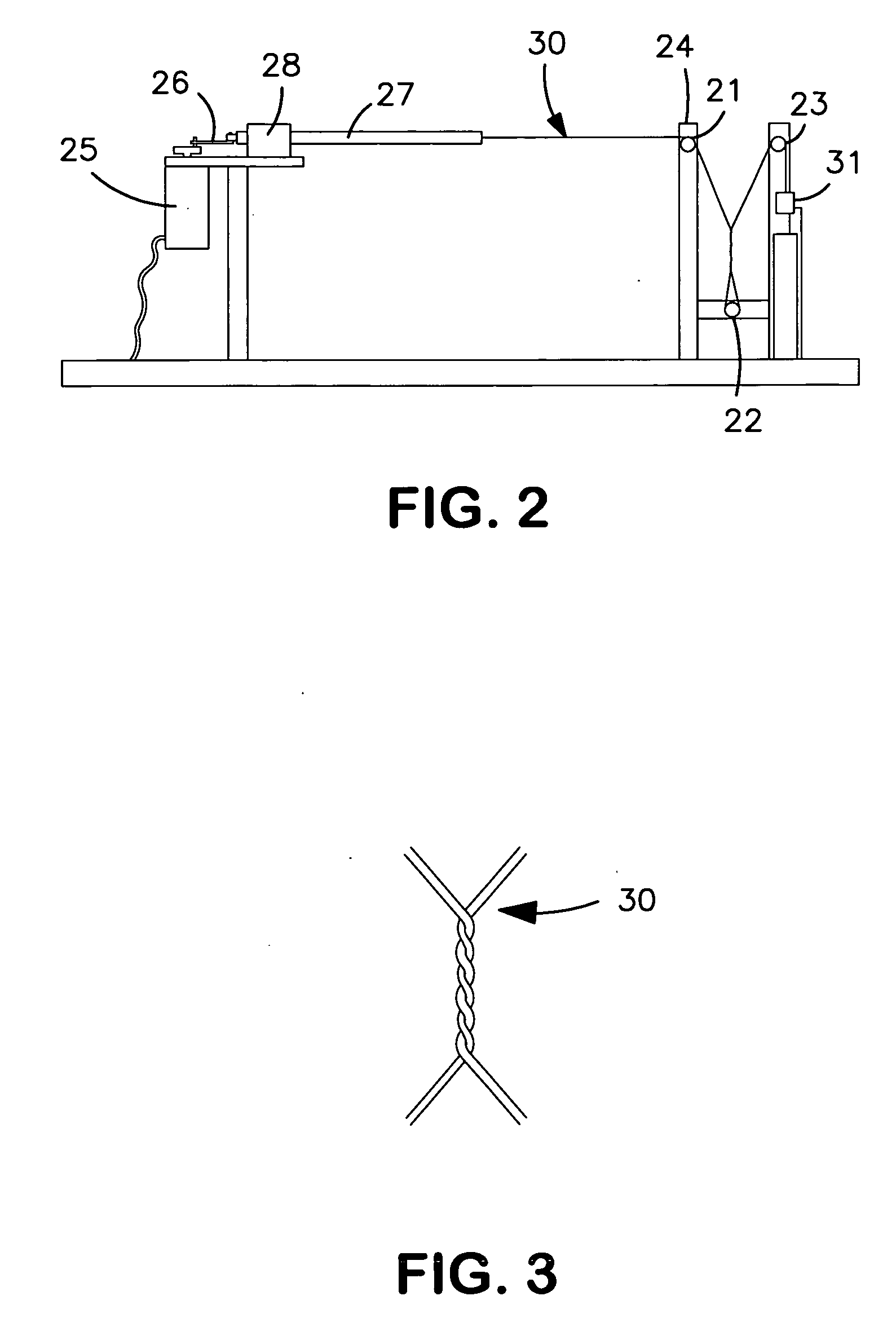

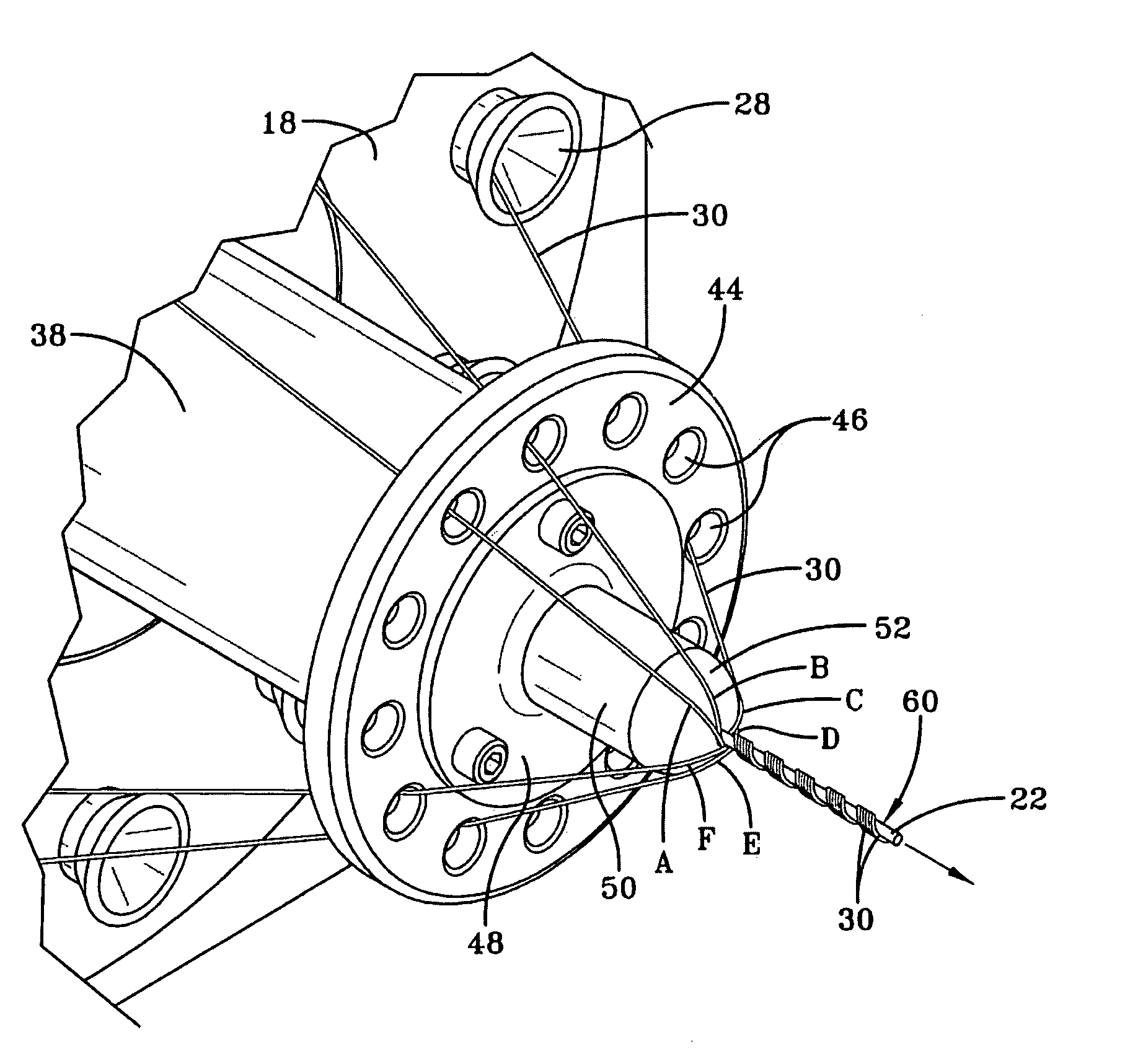

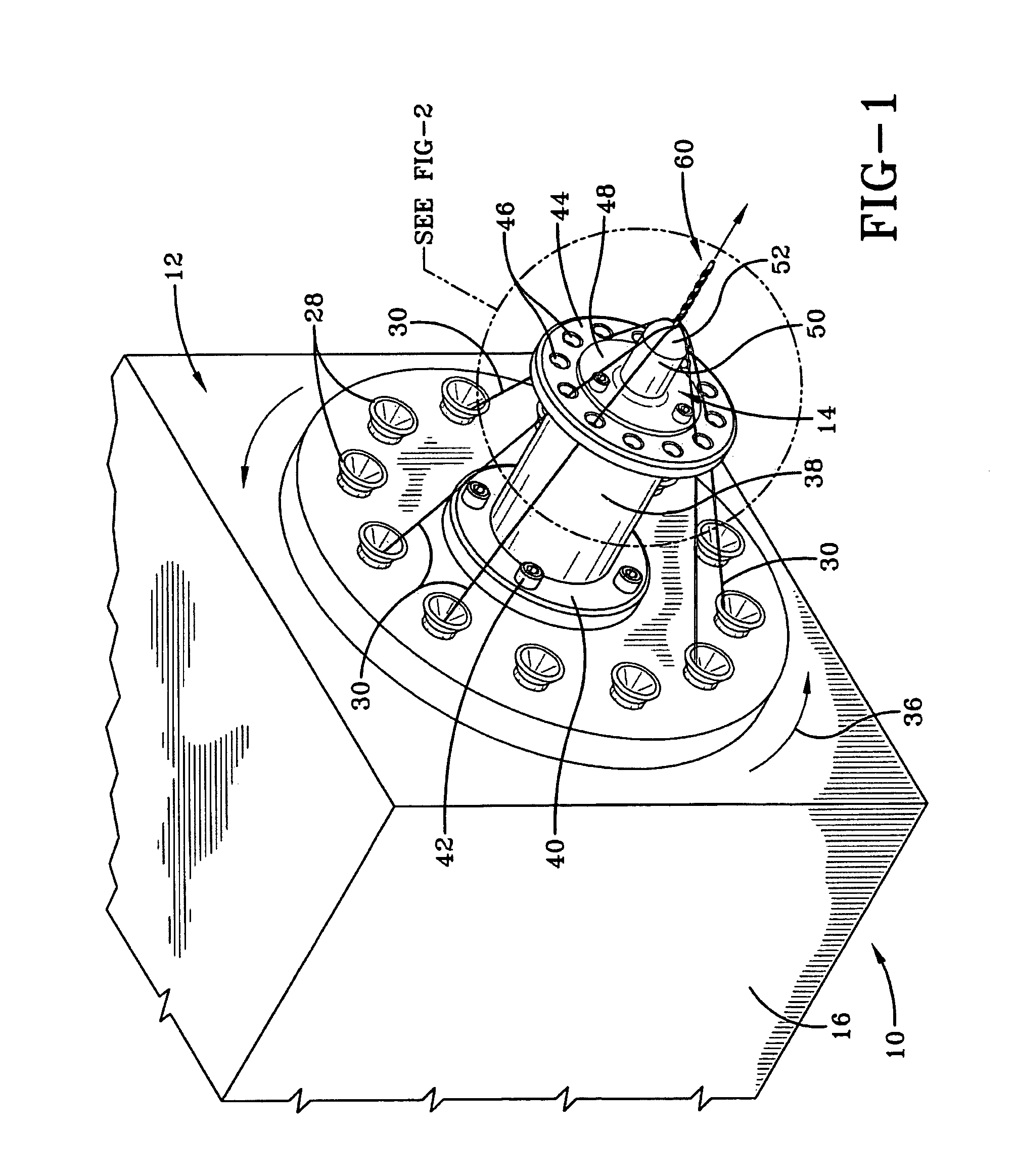

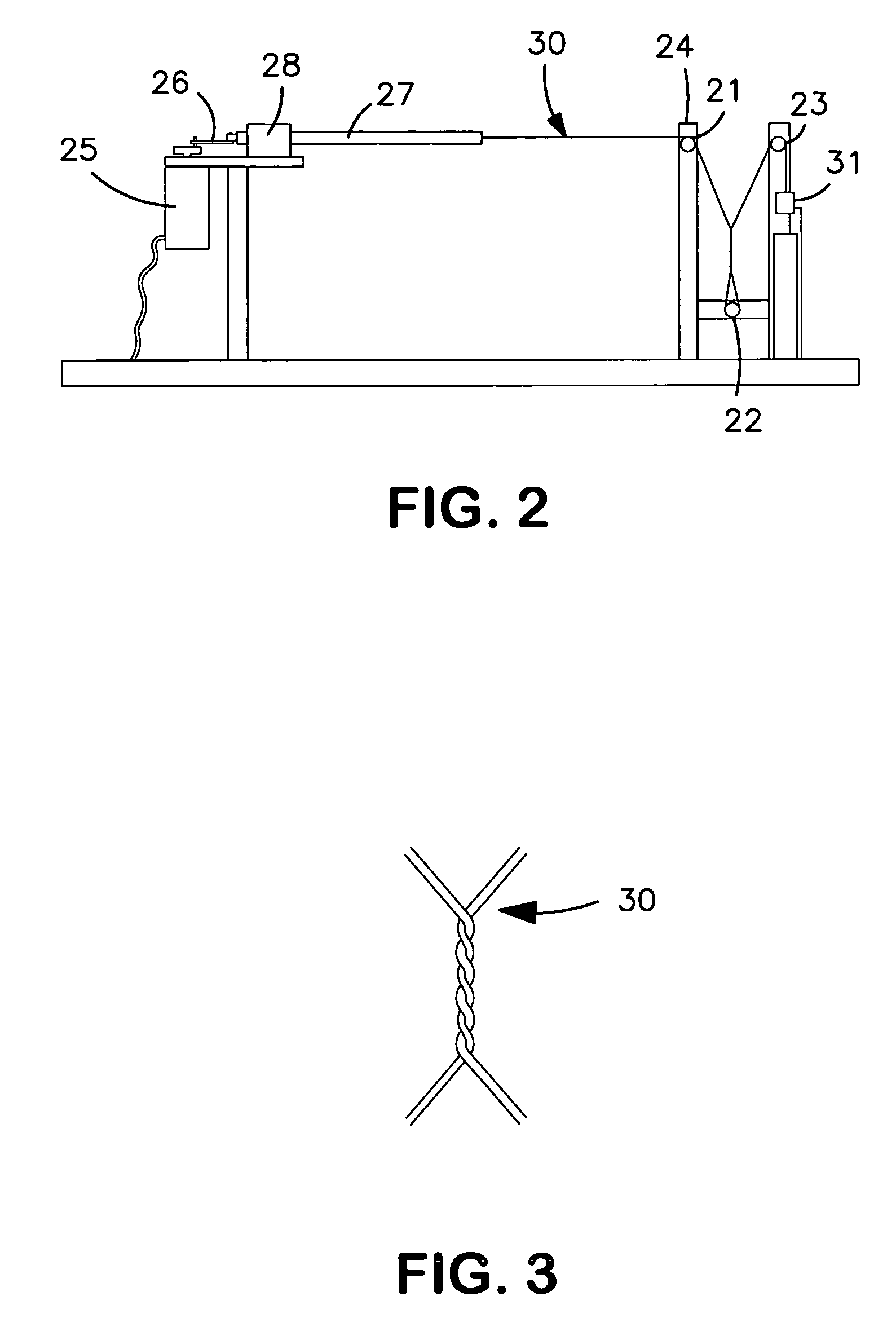

Mandrel for a tubular strander

A mandrel for use in a strander assembly includes a mandrel body having a forward radiused end and an axial cable core receiving passageway extending from a rearward to a forward end of the mandrel body. A cable core is routed through the mandrel body and one or more strands are positioned to converge on the mandrel radiused end. The strands engage the mandrel radiused end at a common approach angle and follow the radius of the mandrel forward end to intersect the cable core. Rotation of the strands relative to the cable core wraps the strands about the cable core, resulting in a finished wound cable construction.

Owner:THE GOODYEAR TIRE & RUBBER CO

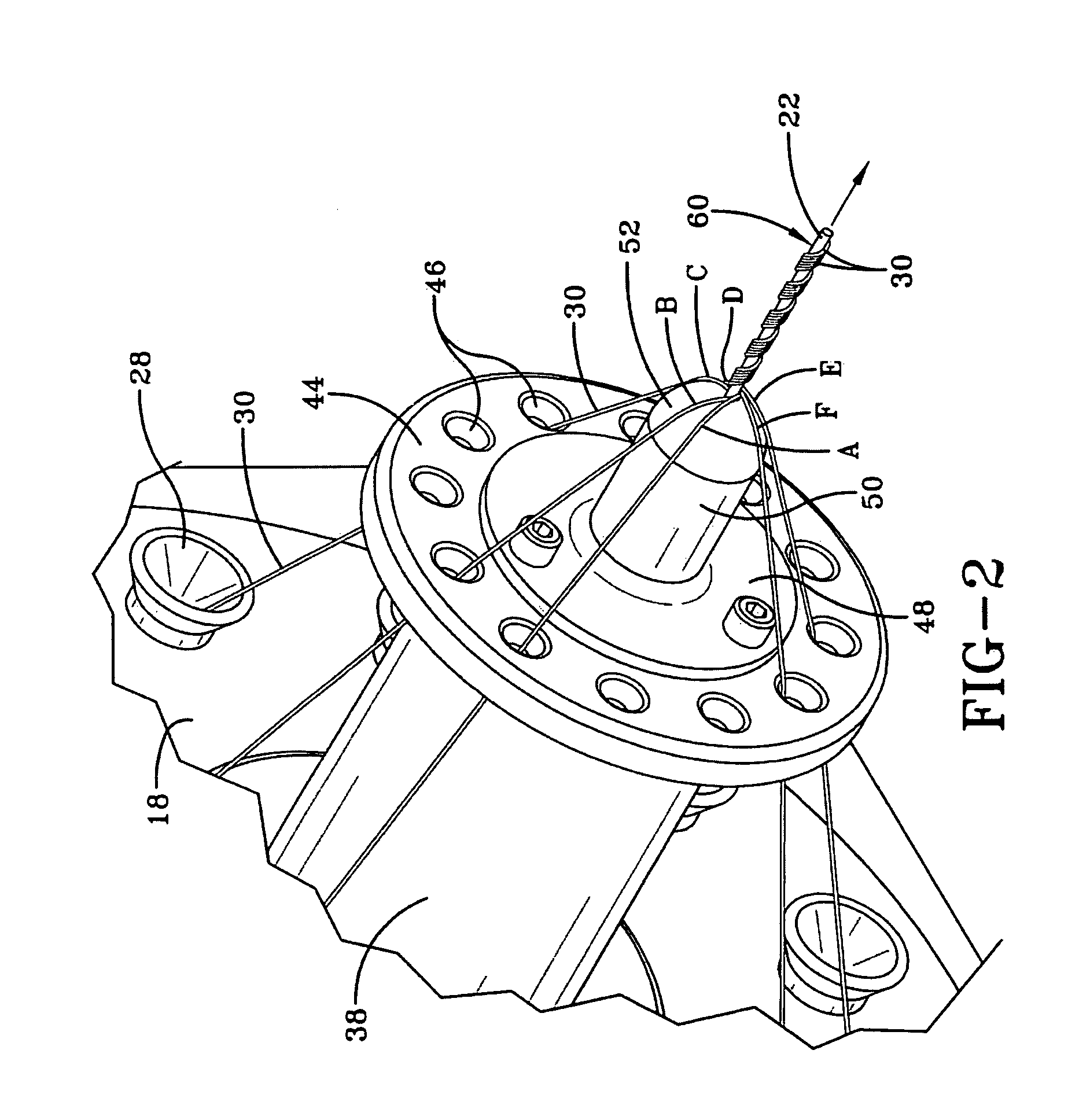

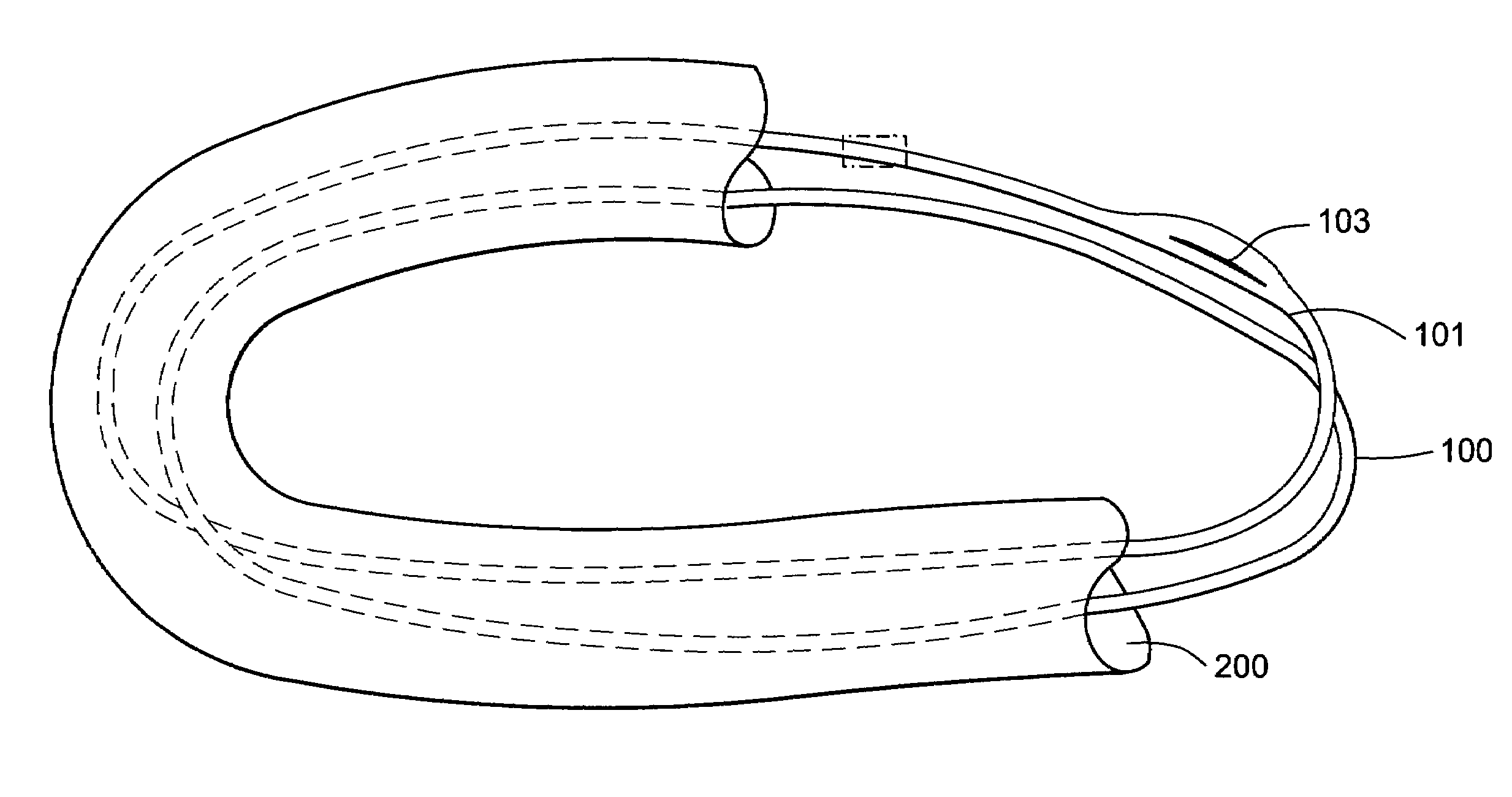

Roundsling

ActiveUS7240475B2Lower the volumeLittle changeRopes and cables for vehicles/pulleyTyresFiberElectrical and Electronics engineering

The invention is related to a roundsling in the form of an endless loop consisting of a core containing at least two turns of a load-bearing strand material comprising fibres with a tenacity of at least 10 cN / dTex and a protective covering around said core, wherein the strand material is in the form of a braided or laid rope, the terminal ends of which are connected with a splice. The invention further relates to a method for constructing a roundsling comprising a step of winding a braided or laid rope on two reels such that part of the turns is on the reels and another part is between the reels wherein the part between the reels is supported, and a step of making a splice in the two terminal ends of the rope.

Owner:AVIENT PROTECTIVE MATERIALS BV

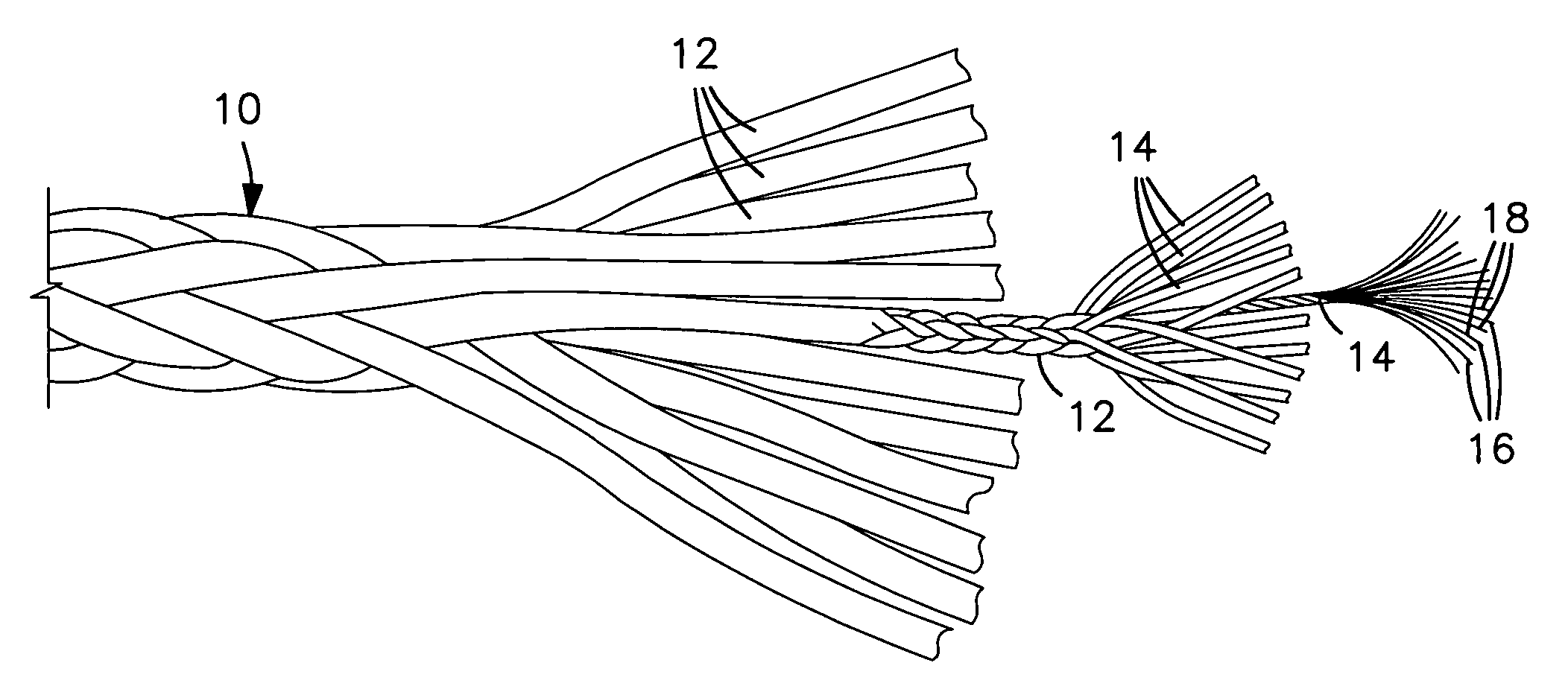

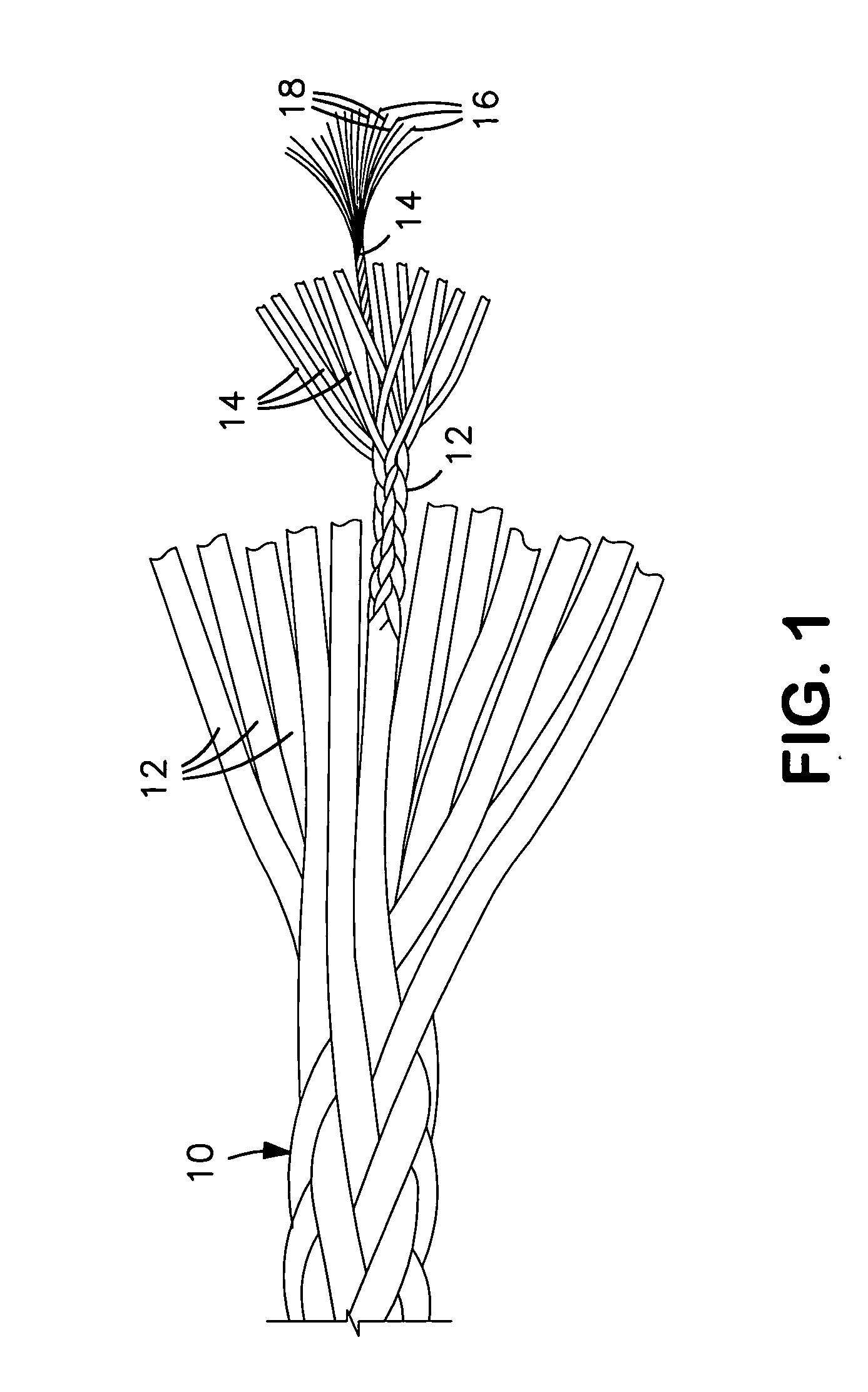

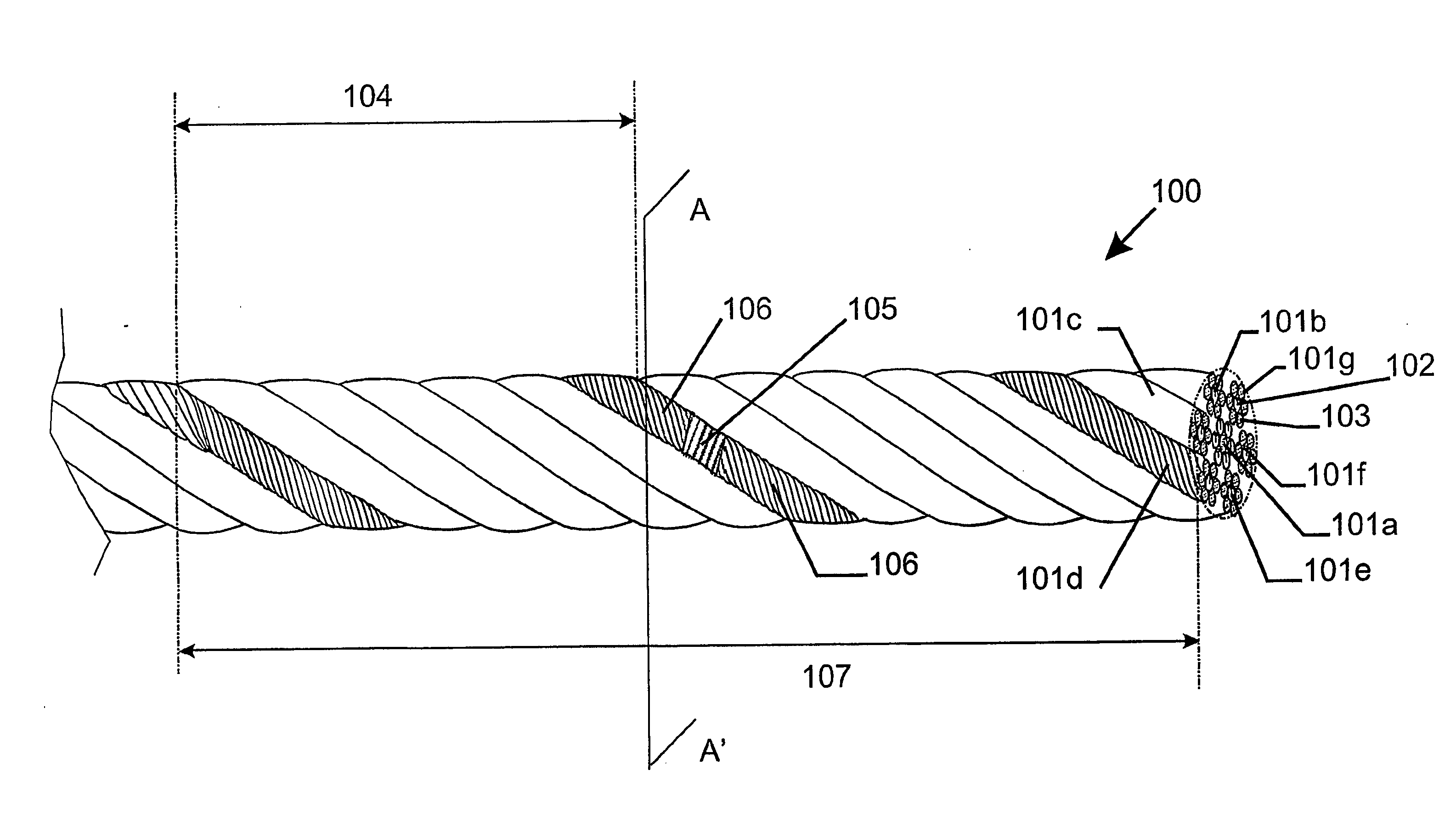

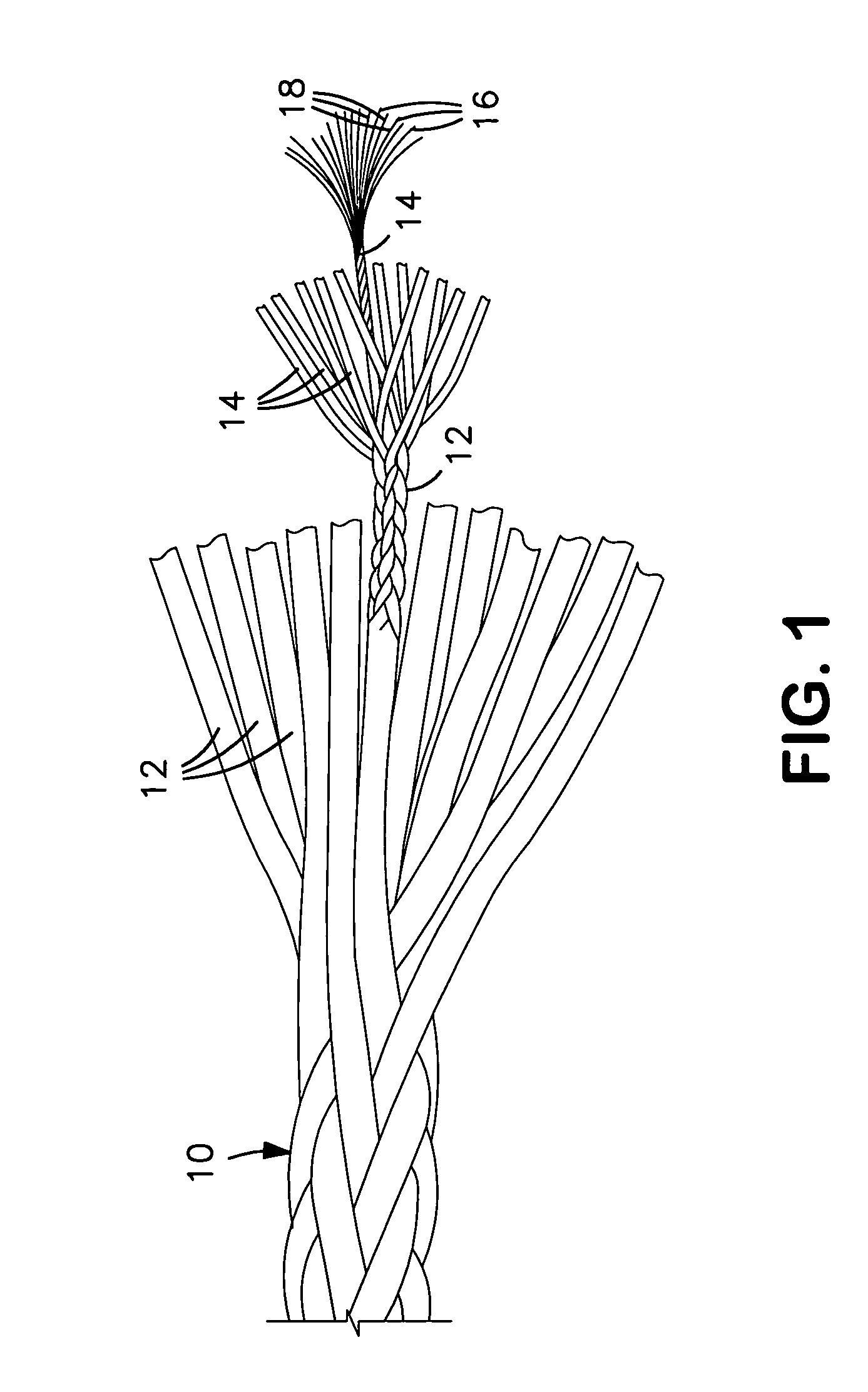

Composite rope structures and systems and methods for making composite rope structures

A rope structure comprising a plurality of formed composite strands. Each of the formed composite strands comprises fiber material and matrix material. The fiber material within the matrix material is twisted. The shapes of the plurality of formed composite strands are predetermined to facilitate combination of the plurality of composite strands into the rope structure.

Owner:SAMSON ROPE TECH

Metal cord

InactiveUS20050172605A1Problems of increase and decreaseIncrease and decrease of propertiesFilament handlingRope making machinesMaterials scienceMetal

Owner:BEKAERT ADVANCED CORDS AALTER NV

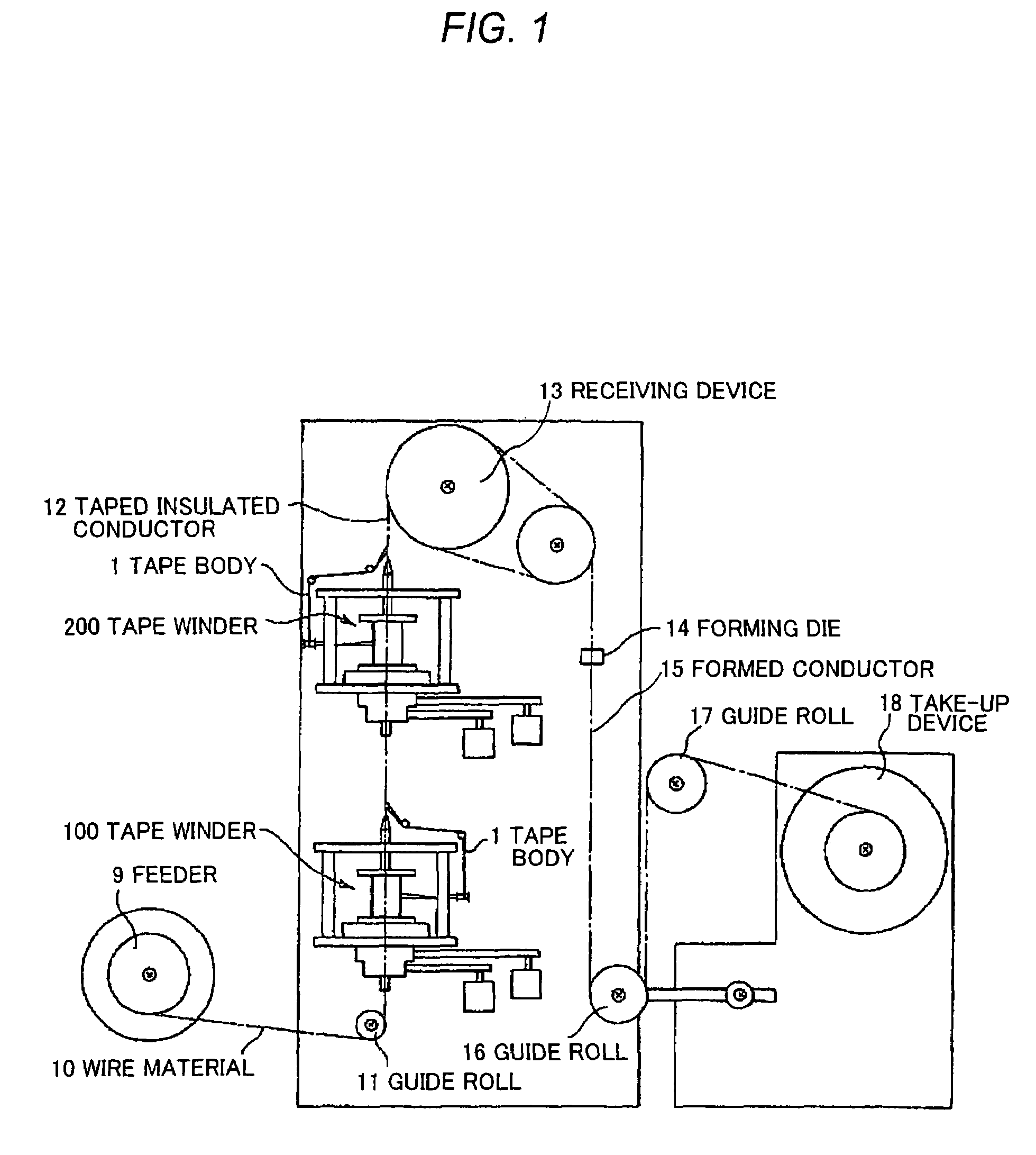

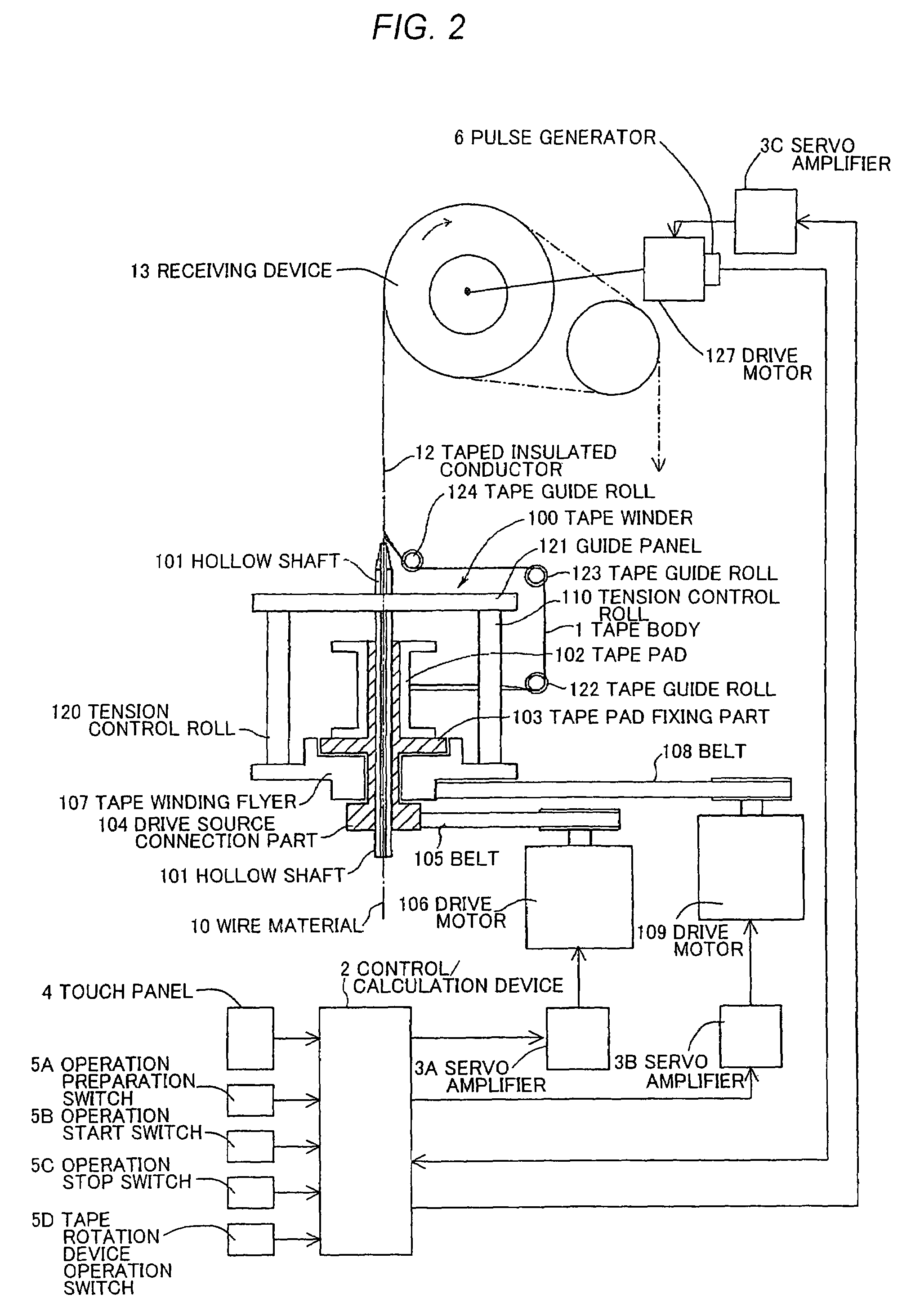

Apparatus for manufacturing taped insulated conductor and method of controlling tape winding tension

Owner:ADVANTEST CORP +1

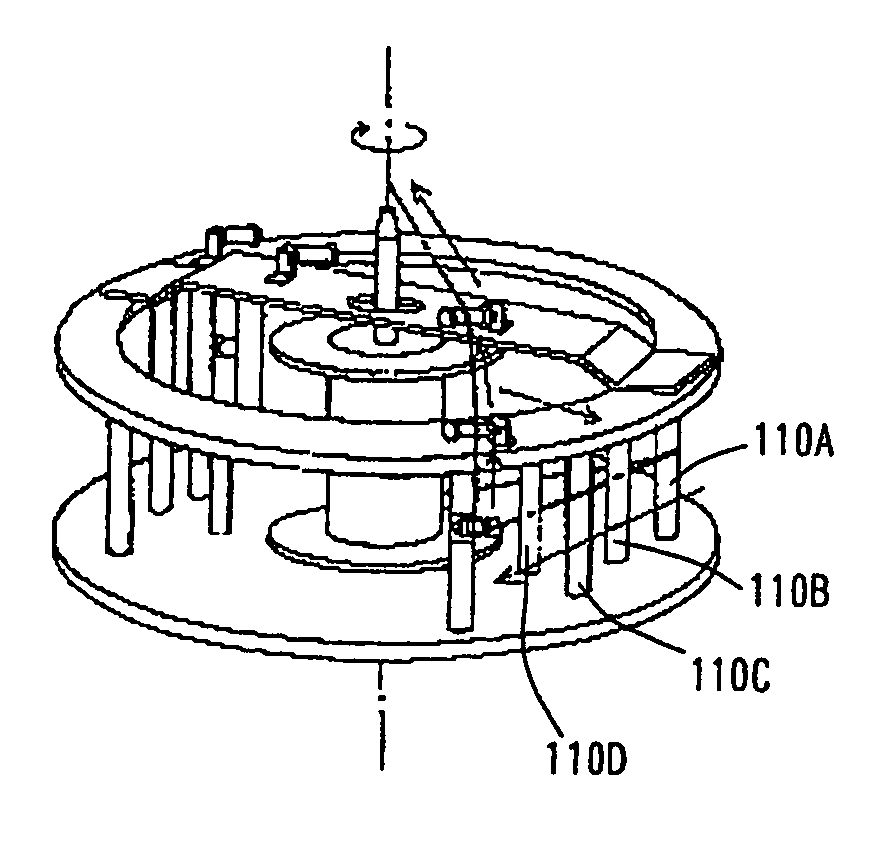

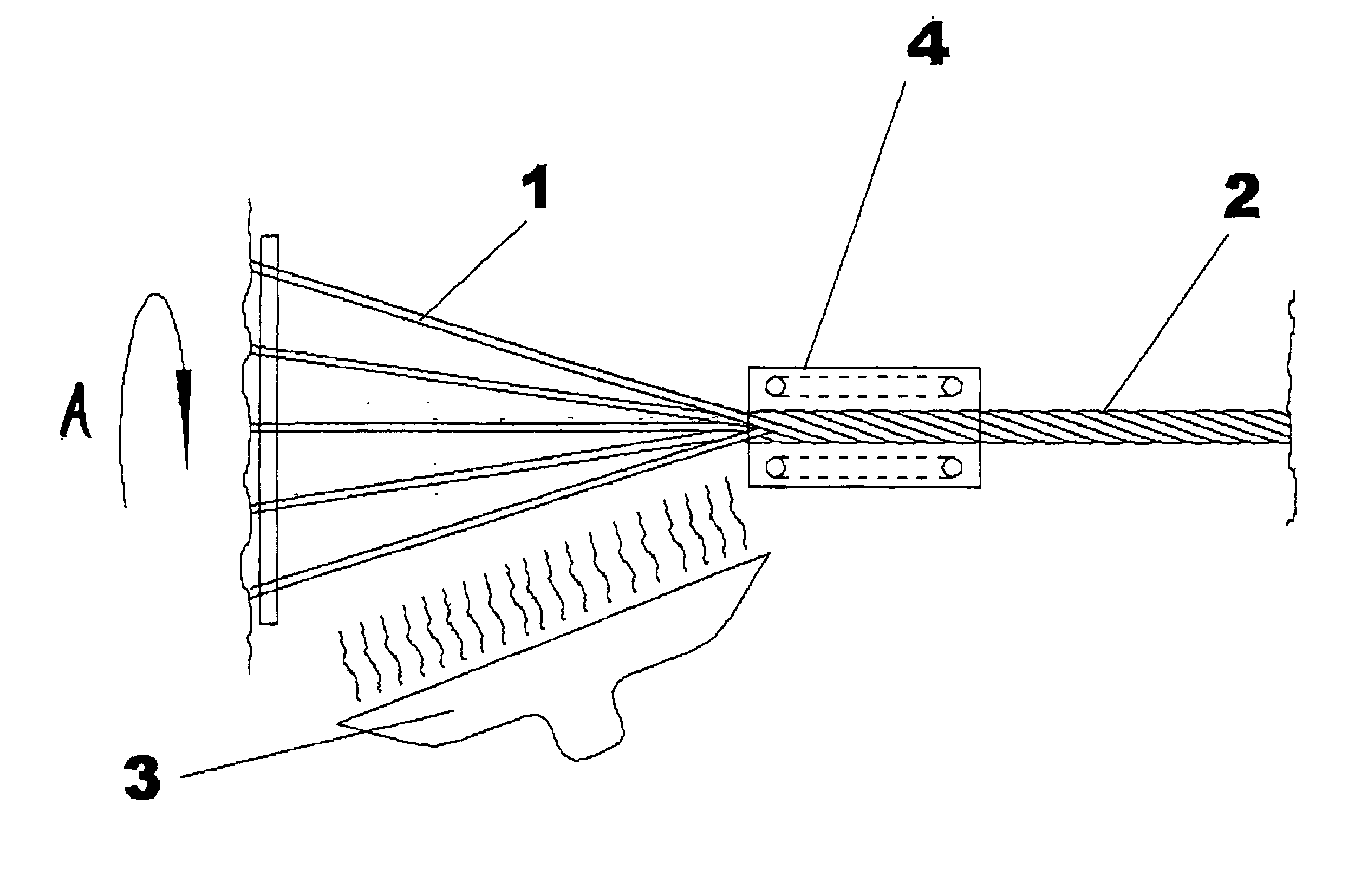

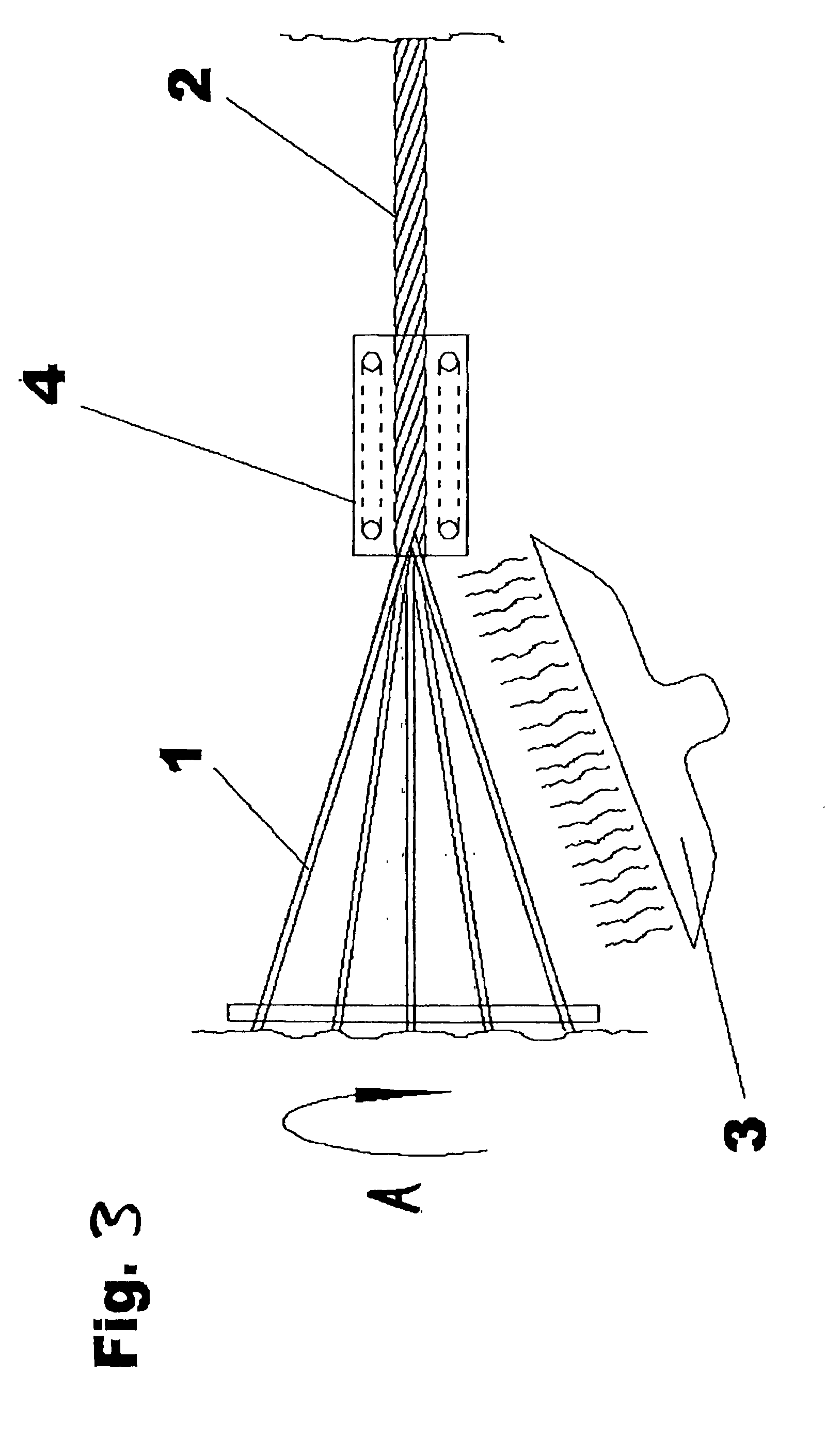

Method and stranding device for producing a cable or a cable element

A method for producing a cable or cable element from individual elements is provided. The method comprises heating the individual elements before or during a stranding process until they are at least close to plastification and cooling the individual elements to a solidification temperature of a plastic. A cable or cable element comprising individual elements that are twisted together to form the cable is also disclosed. The individual elements are heated either before or during a stranding process until they are at least close to plastification, and are subsequently cooled to a solidification temperature of the plastic until they leave a stranding machine. A stranding device for the production of a cable or cable element from individual elements is also disclosed. The stranding device comprises a heating device which acts on the individual elements and a cooling device located downstream of the heating device in a direction of processing.

Owner:DE REGT GERMANY

Aligning device for aligning cables and corresponding method

ActiveCN102366803AIdeal Straightening ResultsFilament handlingRope making machinesMechanical engineering

Owner:KOMAX HOLDING

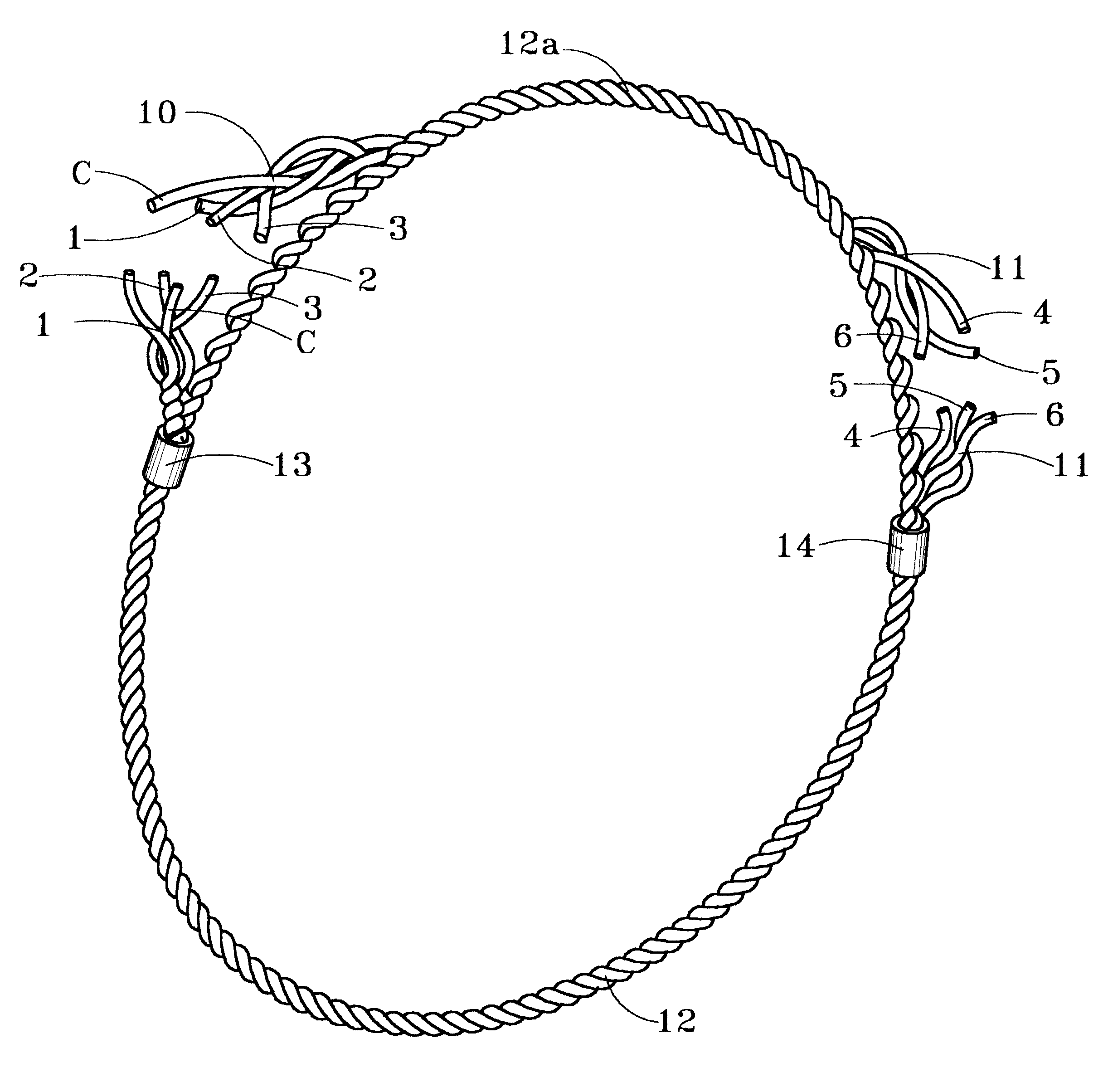

Wire rope sling and methods of making same

A wire rope sling made of wire rope having a core and multiple strands of wire helically laid around the core and cut from a predetermined length. Approximately half of the strands of wire are separated from the core and the remaining strands of wire, shifted, relative to the core, a predetermined distance and rewoven with the core and remaining strands of wire into a continuous loop. A splicing sleeve surrounds first and second ends of the approximately half of the strands and a continuous section of the core and remaining strands in a tightly engaged manner and another splicing sleeve surrounds first and second ends of the core and the remaining strands and a continuous section of the approximately half of the strands in a tightly engaged manner.

Owner:HOLLOWAY HOUSTON

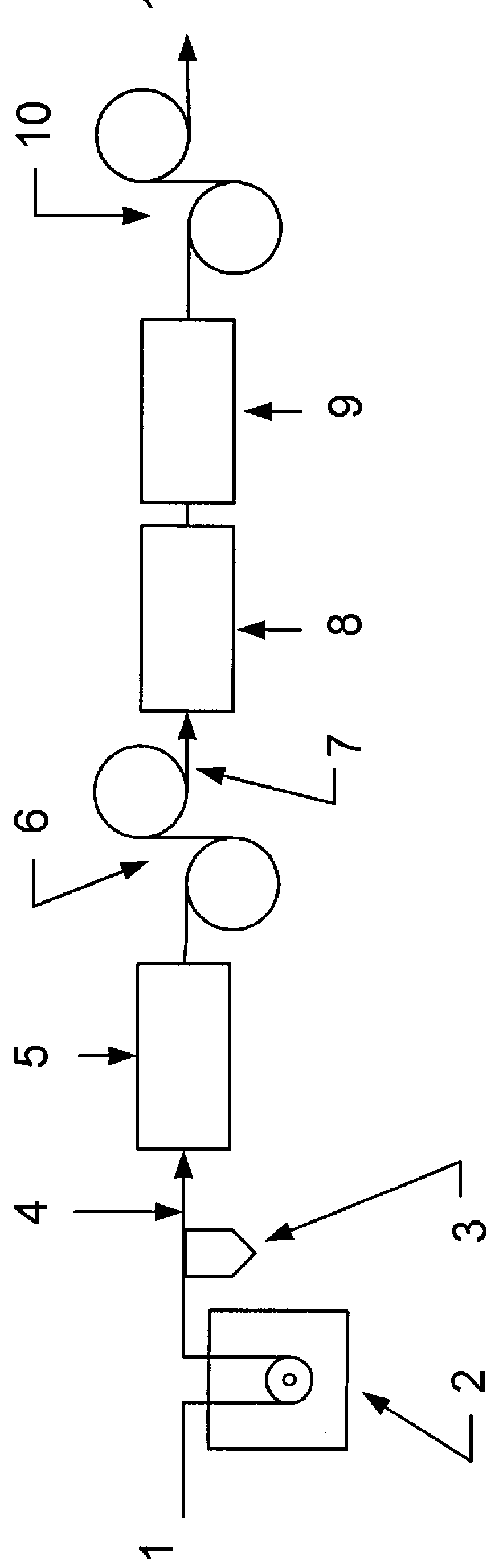

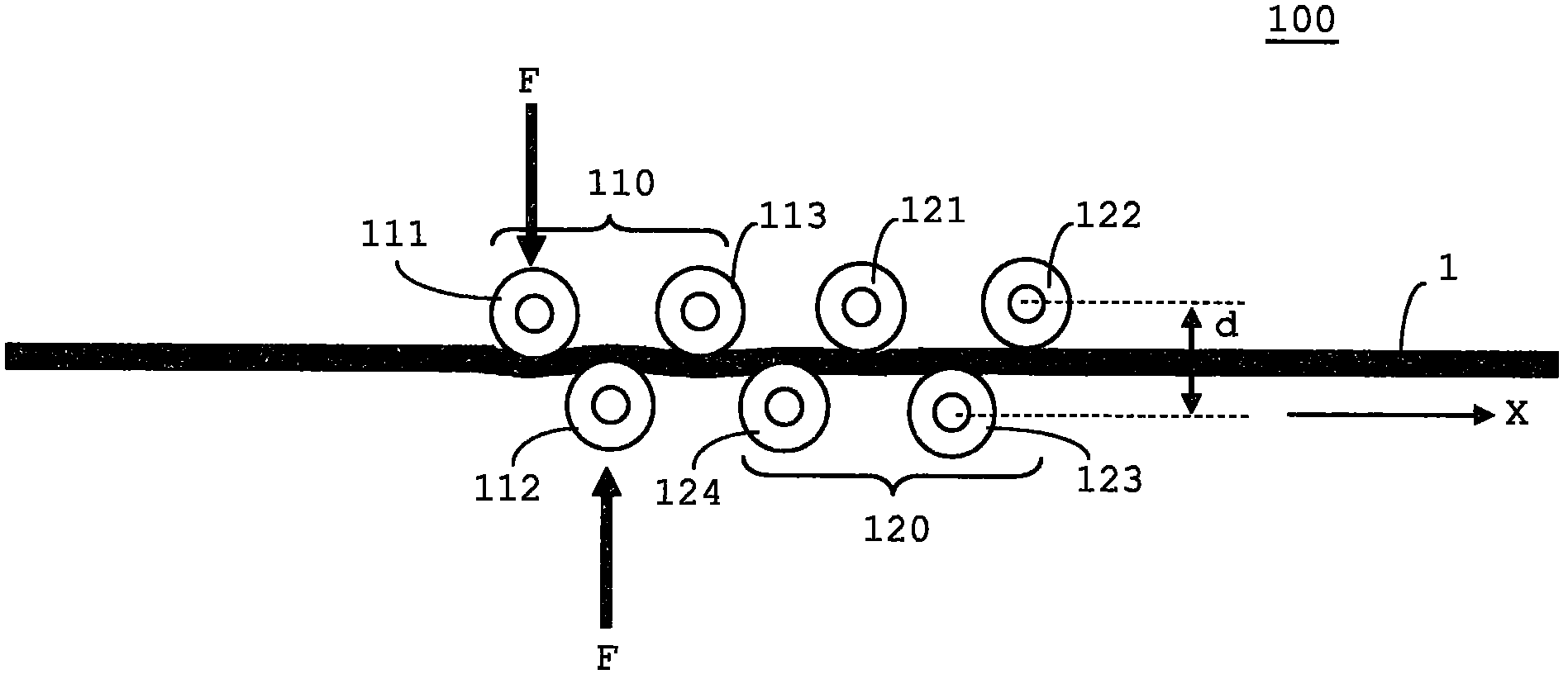

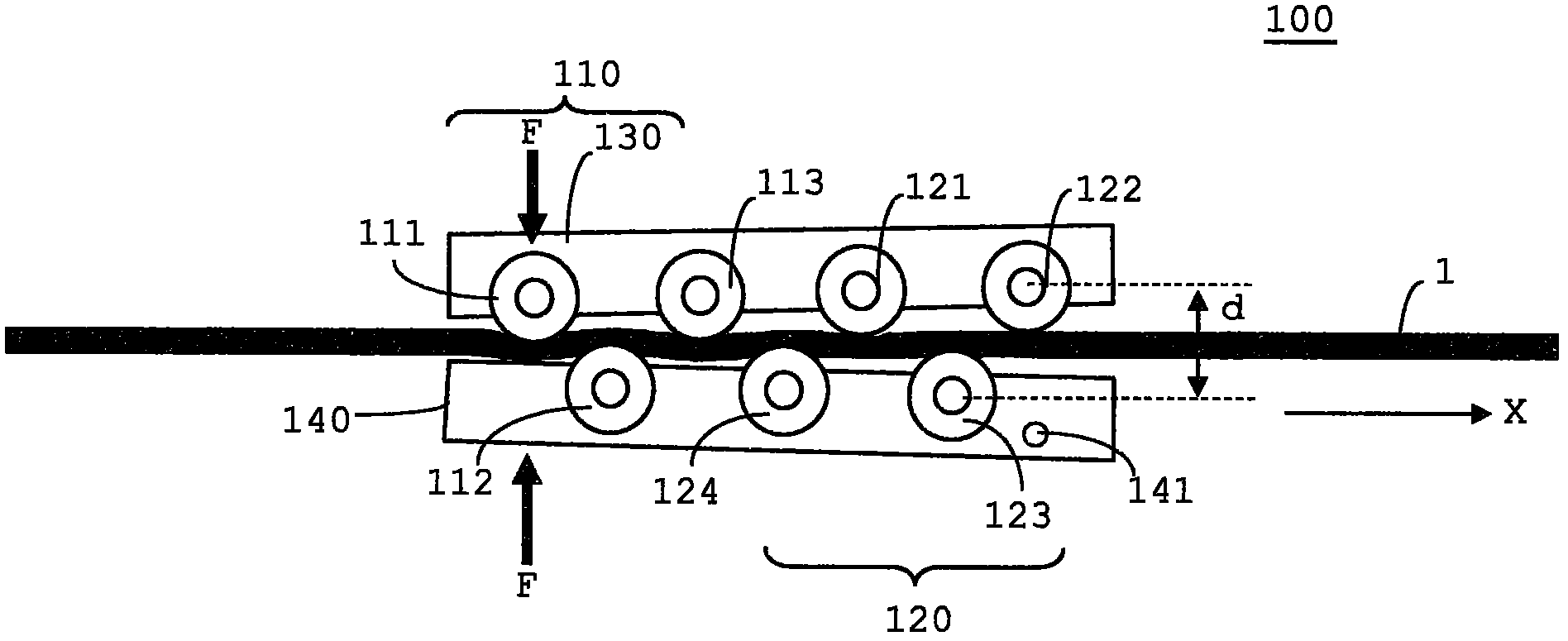

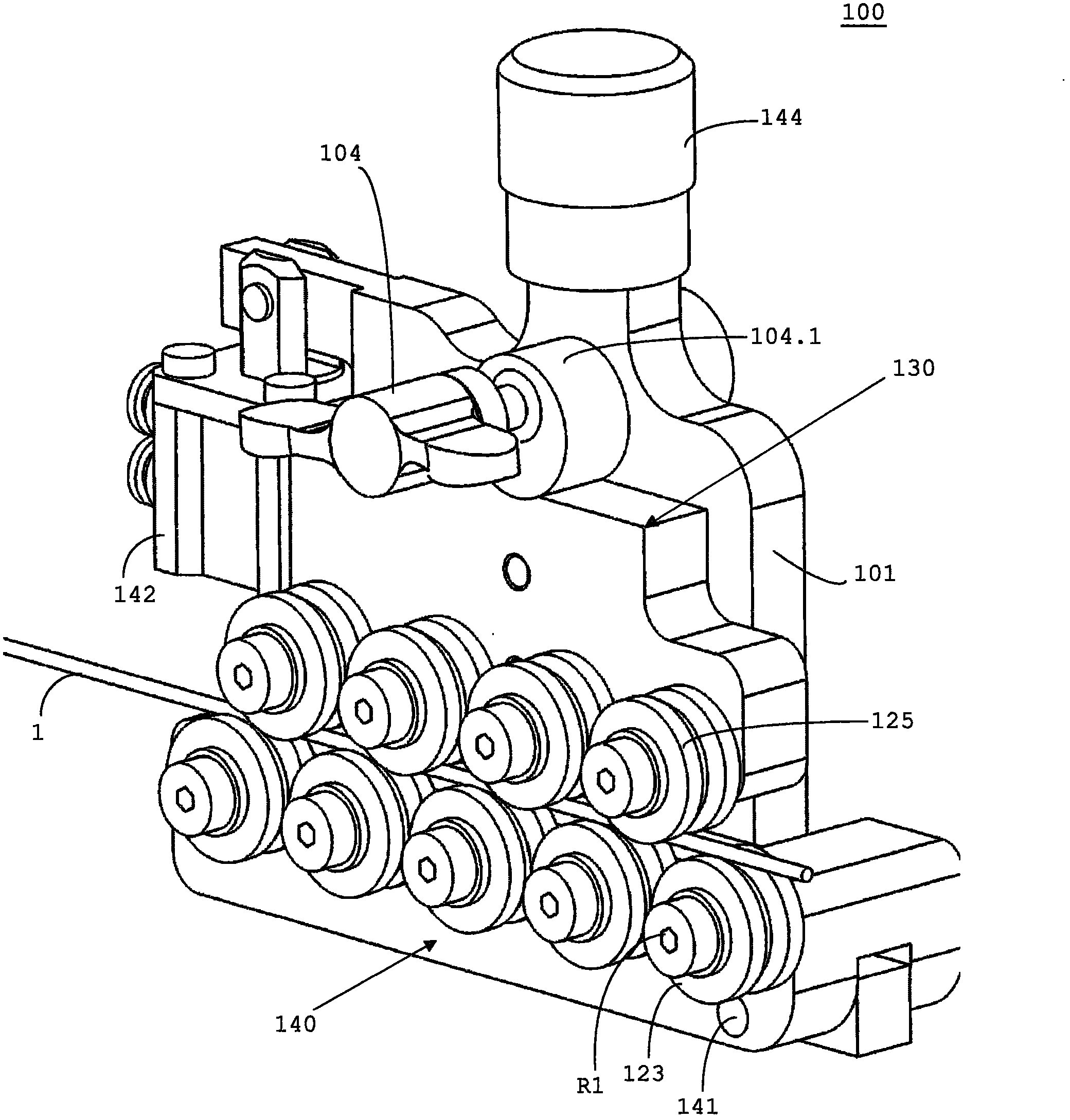

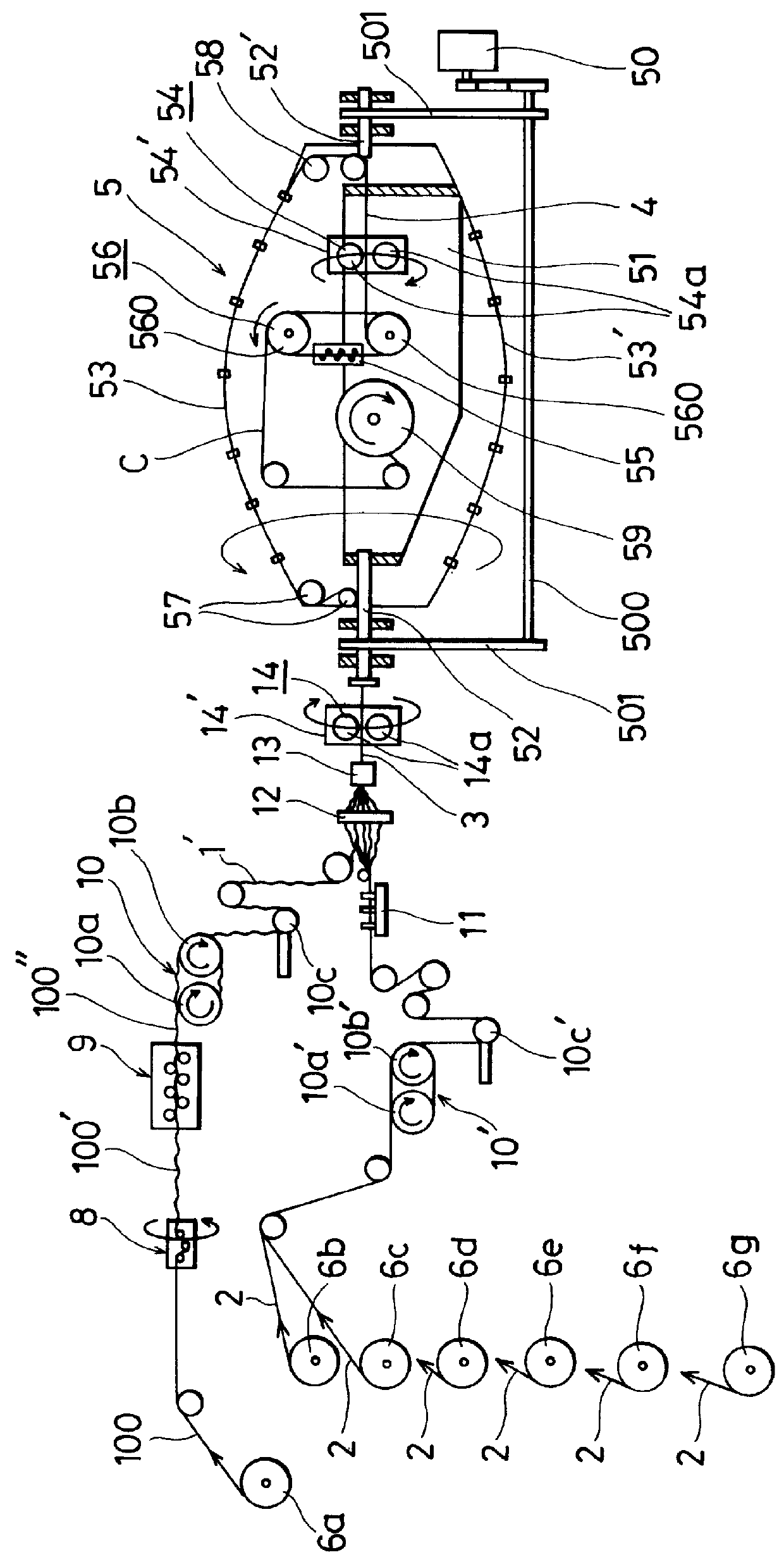

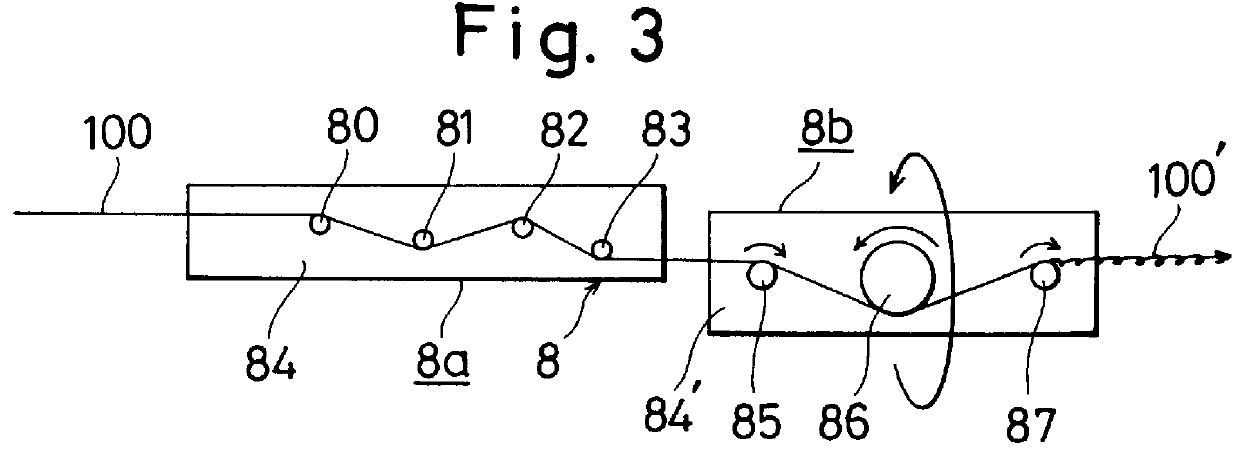

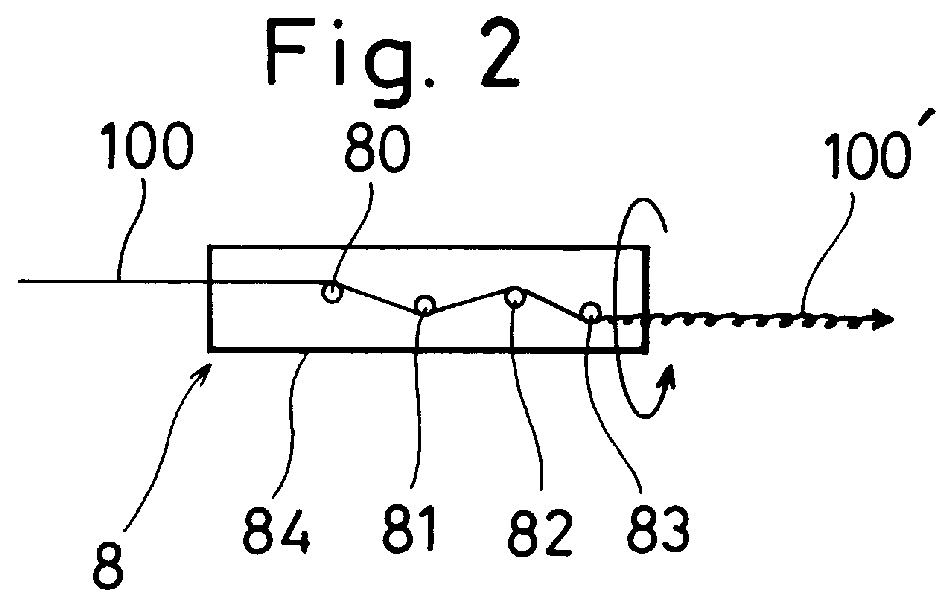

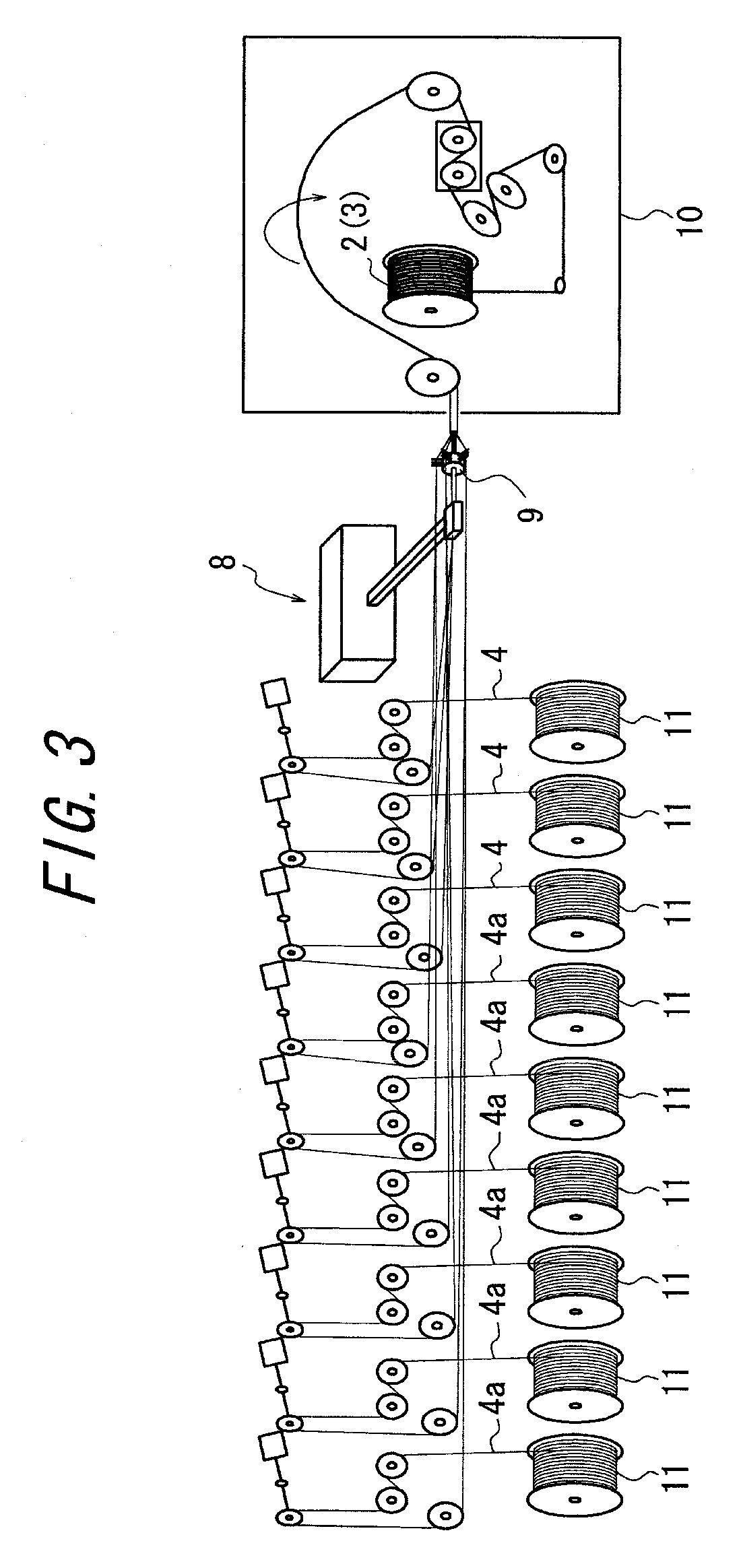

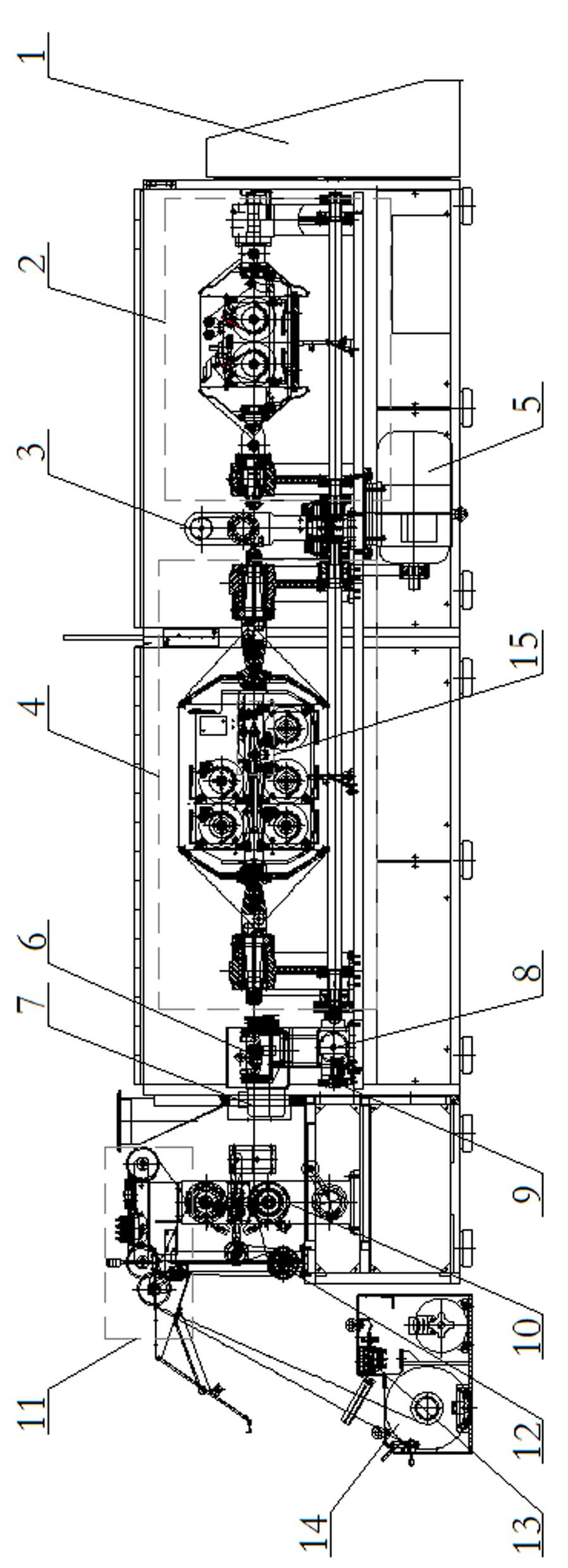

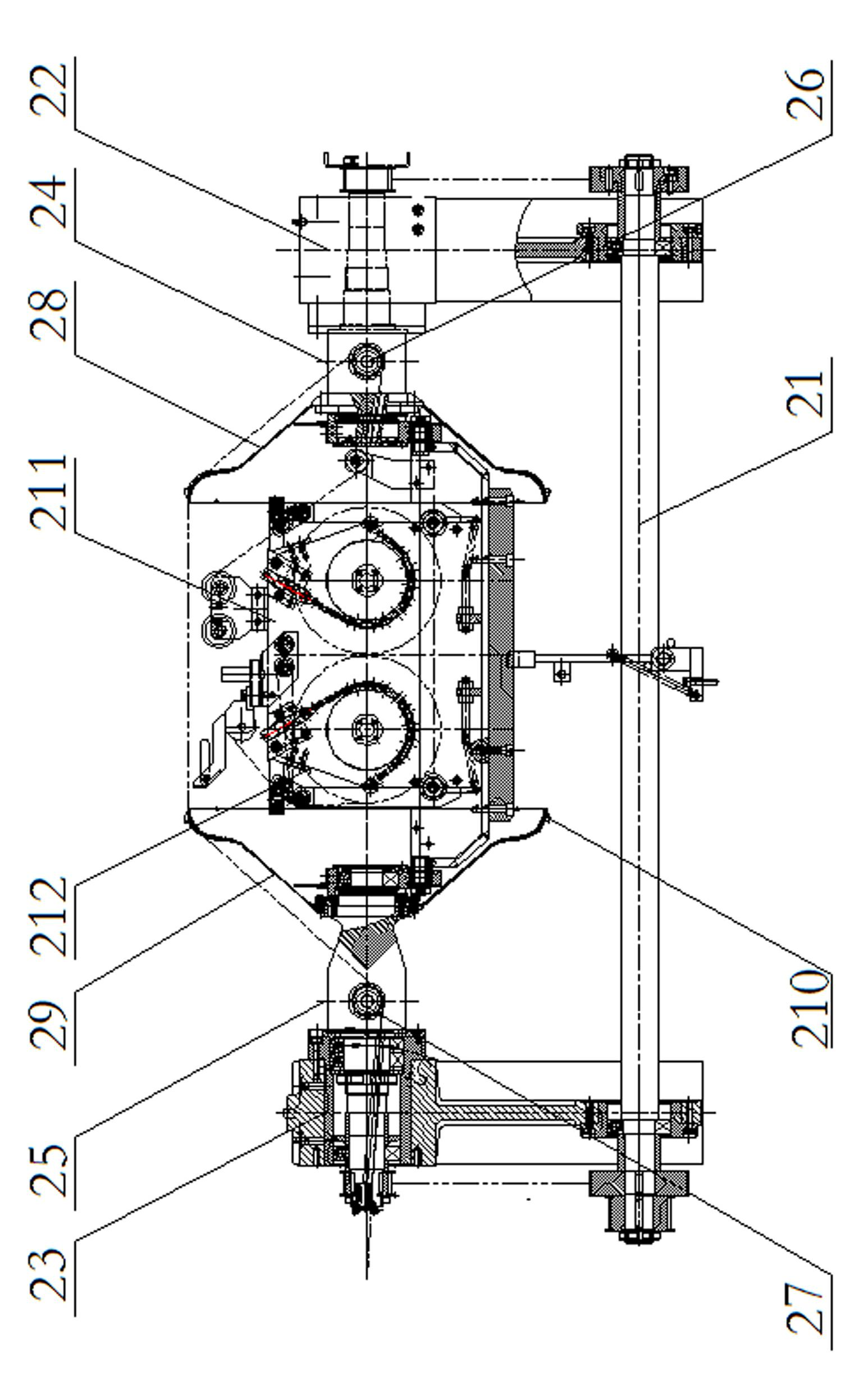

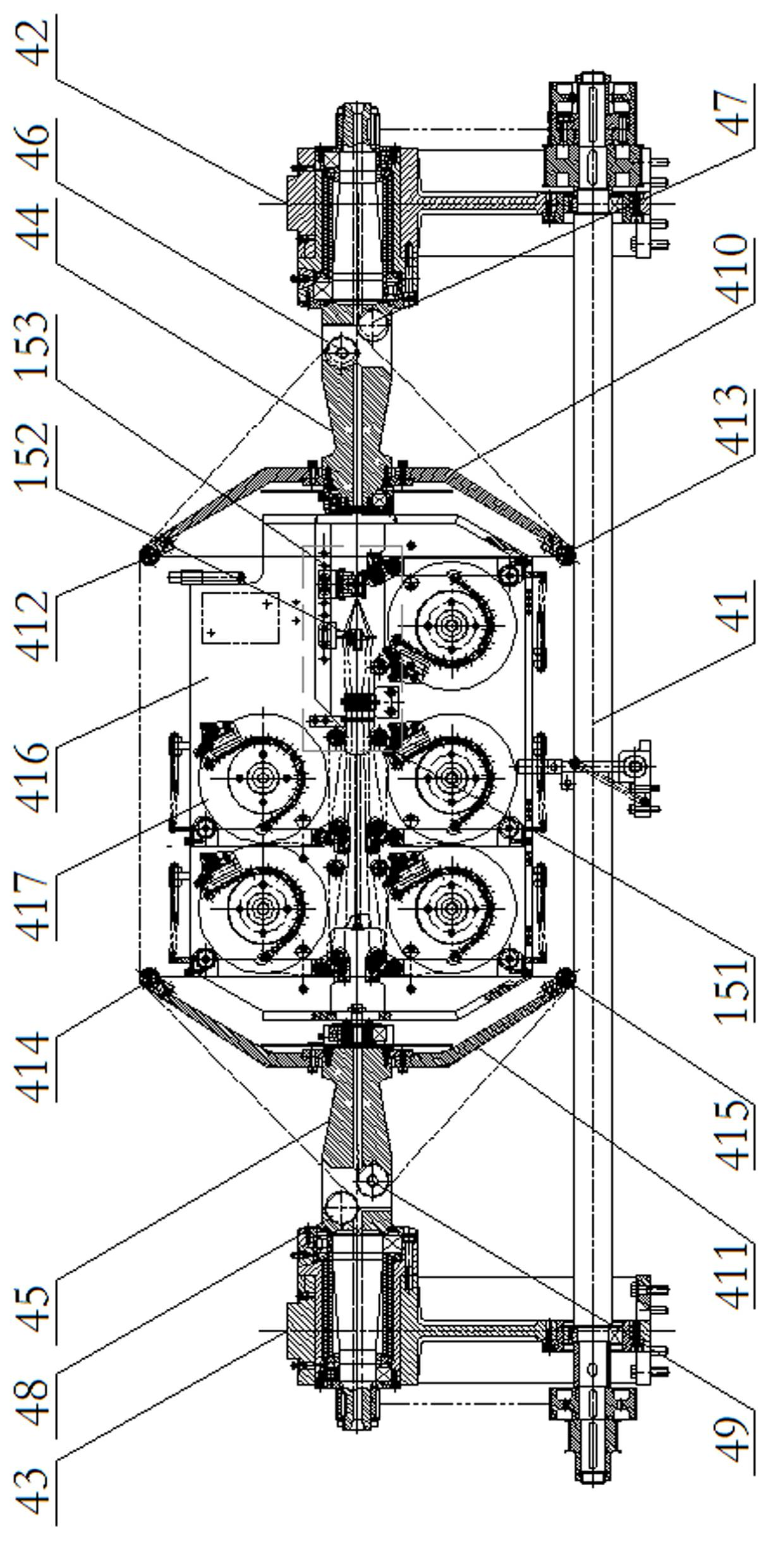

Manufacturing method and apparatus of steel cord for rubber product reinforcement

InactiveUS6016647AIncrease production capacityDesirable rangePneumatic tyre reinforcementsRope making machinesMechanical engineeringMaterials science

A method for using a bunching type twisting machine to manufacture a steel cord made up of one core filament having a continuous wavy form and five to eight sheath filaments not having a wavy form disposed around the core filament, the cross-sectional shape of the cord forming an ellipse whose orientation is substantially constant in the length direction of the cord. After a core filament is preformed with a helical wavy form of a smaller pitch than the cord twisting pitch, this is squashed to form a flat helical core filament at a stage before it is twisted together with sheath filaments, and then sheath filaments are twisted around this flat helical core filament to make an intermediate product cord and this intermediate product cord is then squashed and thereby flattened before being taken up on a reel.

Owner:TOKYO ROPE MFG

Cord, method of producing same, and rubber-cord composite body

InactiveUS20100170215A1Improve corrosion resistanceSuppressed twisting reductionRope making machinesYarnEngineeringCorrosion

A cord obtained by twisting a plurality of strands each composed of a plurality of filaments is provided. A circumferential surface of the filament is coated with unvulcanized rubber to improve rubber intrusion, thereby improving corrosion resistance and suppressing twisting-loss.

Owner:BRIDGESTONE CORP

Method for knitting high-strength rope from high-strength polyethylene fibers

The invention relates to a new production method for knitting a high-strength rope from high-strength polyethylene fibers, which is superior to the current production method for ropes. The method of the invention comprises the following concrete steps: selecting high-strength large-tow polyethylene fibers; by homogenizing tension by a fiber tension device, twisting and stranding multiple tows of fibers; homogenizing the tension of multiple strands of twisted fibers according to the specification requirements of the rope, combining the multiple strands of twisted fibers, and then homogenizing the tension of the combined single-strand tows; knitting 12 strands of ropes by a knitting machine; and coating resin on the surface, drying and shaping to form a high-strength polyethylene fiber rope. The rope produced by the invention has the advantages of convenient use, high strength, corrosion resistance, wear resistance, excellent toughness and flexibility, long service life and the like, and can be widely applied to the fields of industries, national defense, physical education, oceans and the like.

Owner:NINGBO DACHENG ADVANCED MATERIAL

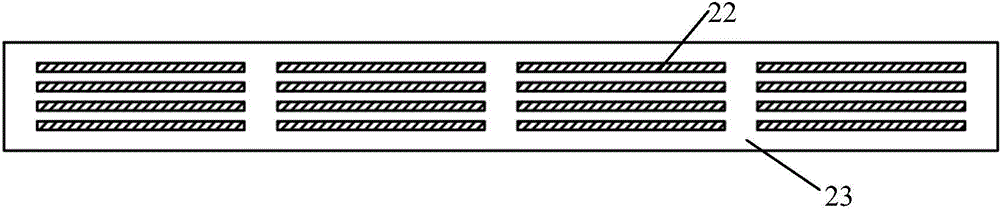

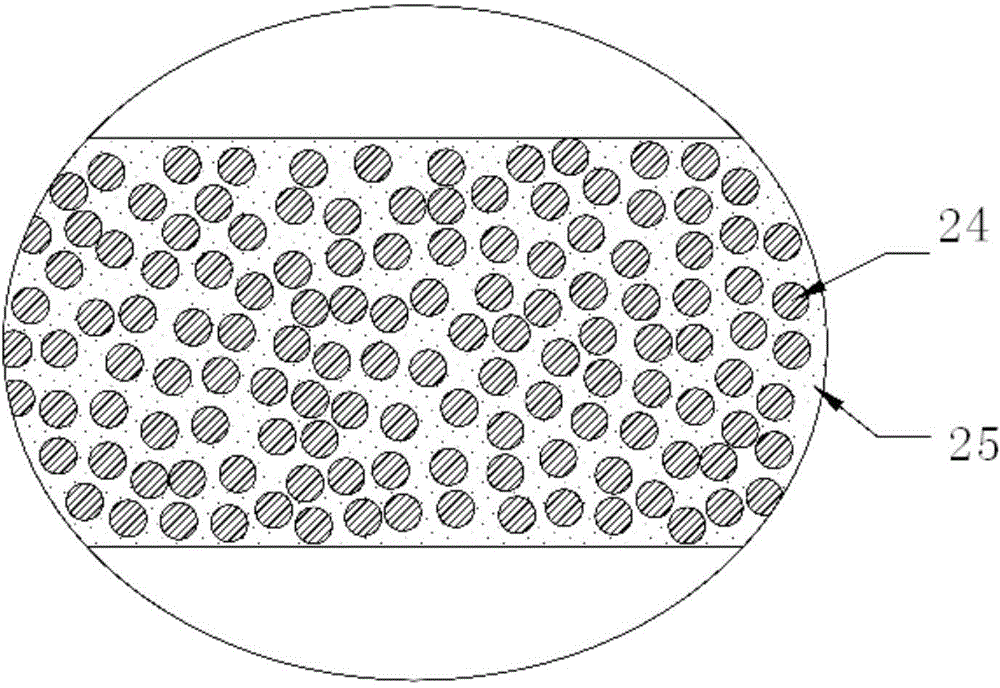

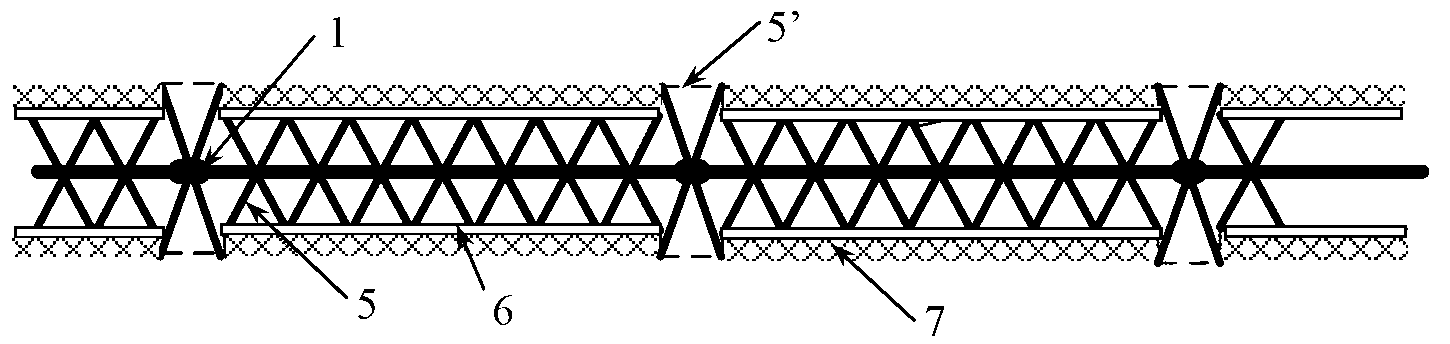

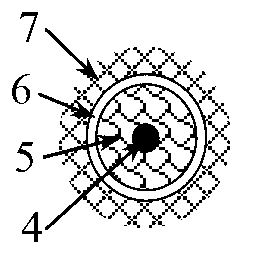

Intelligent FRP (Fiber Reinforced Polymer) composite rib based on carbon fiber distribution type sensing and large-scale production process thereof

InactiveCN102797185AImprove monitoring accuracyImprove Sensing PerformanceForce measurementRope making machinesFiberCarbon fibers

The invention discloses an intelligent FRP (Fiber Reinforced Polymer) composite rib based on carbon fiber distribution type sensing and a large-scale production process thereof. The intelligent FRP composite rib consists of a long-gauge carbon fiber sensing core and a wrapping FRP layer, wherein the long-gauge carbon fiber sensing core consists of a semi-finished carbon fiber sensing core, a non-conductive fiber wrapping layer, a glue isolating layer and a protective layer, the semi-finished carbon fiber sensing core consists of carbon fiber and a resin curing layer, an electrode is arranged on the carbon fiber, the non-conductive fiber wrapping layer is wound on the outer surface of the semi-finished sensing core, the thickness of the non-conductive wrapping layer at the electrode is larger than that of the non-conductive fiber wrapping layer at the non-electrode position, and the glue isolating layer and the protective layer are arranged on the outer surface of the non-conductive fiber wrapping layer at the non-electrode position in sequence. The intelligent FRP composite rib disclosed by the invention has a distribution type stable monitoring property and a good mechanical property, but production cost of the intelligent FRP composite rib is slightly higher that of a common FRP rib.

Owner:SOUTHEAST UNIV

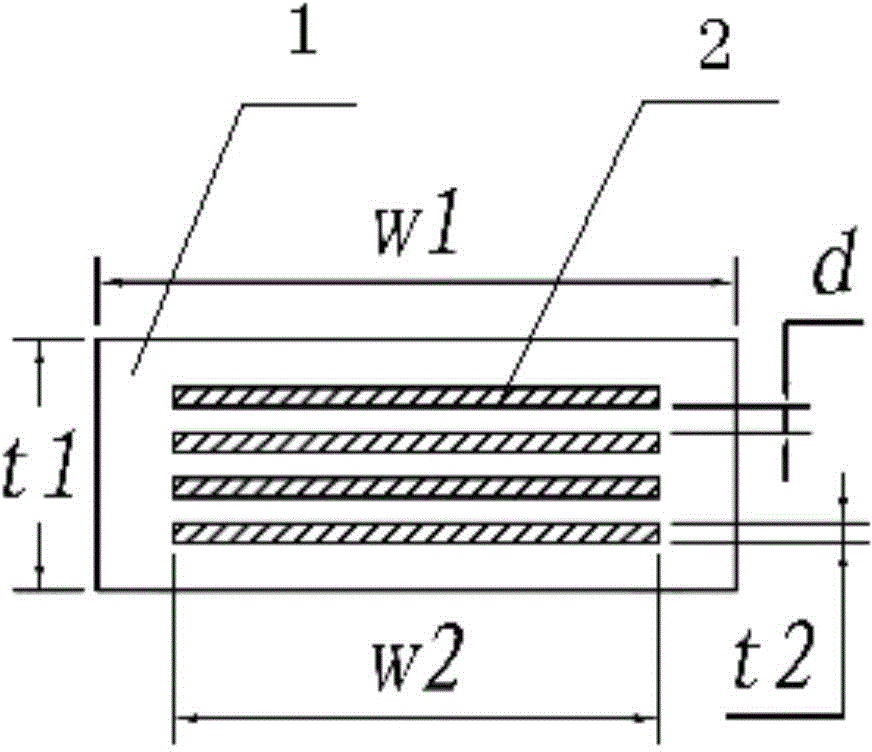

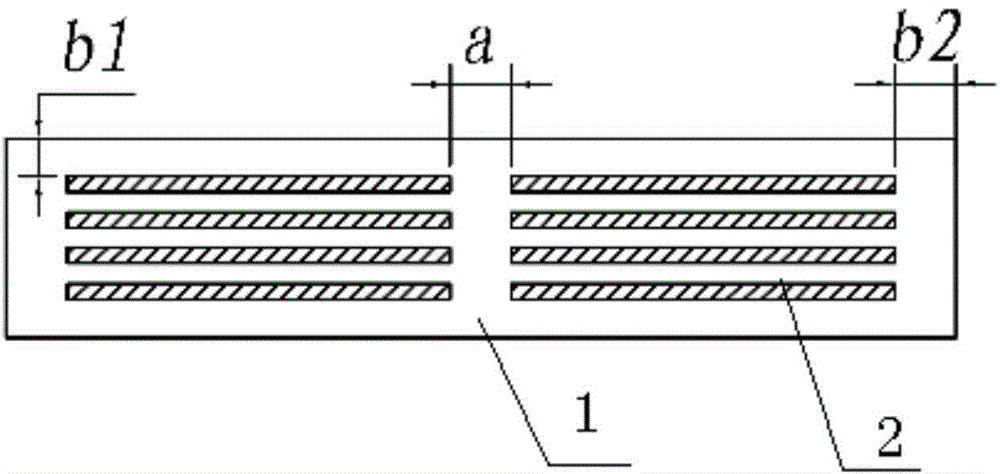

Fiber-woven flexible composite traction belt for elevator and manufacturing method thereof

ActiveCN102002872AReasonable bearing structureReduce weightSevering textilesRope making machinesThermoplasticGlass fiber

The invention discloses a fiber-woven flexible composite traction belt for an elevator and a manufacturing method thereof. The manufacturing method comprises the weaving mode of a fiber woven belt, the manufacturing method of the fiber-woven flexible composite traction belt and the manufacturing method of plastic coating layers. The composite traction belt is formed by weaving steel wires or synthetic fibers; closely adhered plastic coating layers are arranged at the periphery and the internal part of the composite traction belt; and the plastic coating layers are made of elastic thermoplastic plastic. The fiber woven belt (1) is in synthetic fiber weaving, and comprises any one material of aromatic polyamide fibers, glass fibers, ceramic fibers or carbon fibers, or is formed by weaving an optional combination of the aromatic polyamide fibers, the glass fibers, the ceramic fibers and the carbon fibers. The plastic coating layers protect the fiber woven belt from being worn and maintain the woven belt in a tensioned state. The fiber woven belt is in the form of a tiled flat belt, and has the advantages of flat belt structure, higher fatigue resisting performance after long-time bending, longer service life, lighter weight and higher bearing strength.

Owner:浙江速捷电梯有限公司

Fluoropolymer fiber composite bundle

ActiveUS7296394B2Reduce abrasionReduce wearRope making machinesWoven fabricsFiberStructural engineering

A rope comprising a plurality of bundle groups, each of said bundle groups having a periphery and comprising a plurality of high strength fibers, at least one low coefficient of friction fiber disposed around at least a portion of the periphery of at least one of the bundle groups.

Owner:WL GORE & ASSOC INC

Hybrid core rope

ActiveUS20130318937A1Accelerate the rate of decreaseReduce maintenance tasksRope making machinesYarnFiber bundleEngineering

The present invention is to provide a hybrid core rope which does not require maintenance or a hybrid core rope capable of reducing a maintenance task. The hybrid core rope includes a resin solid core in which a plurality of spiral grooves is formed in the longitudinal direction on an outer peripheral surface thereof, a plurality of fiber bundles respectively spirally wound around the outer peripheral surface of the resin solid core along the plurality of spiral grooves, the fiber bundles having thickness to fill the spiral grooves, and a plurality of steel strands spirally wound around the outer peripheral surface of the resin solid core around which the fiber bundles are wound. The fiber bundles and the strands are respectively wound so as to have angles which are not parallel to each other.

Owner:TOKYO ROPE MFG

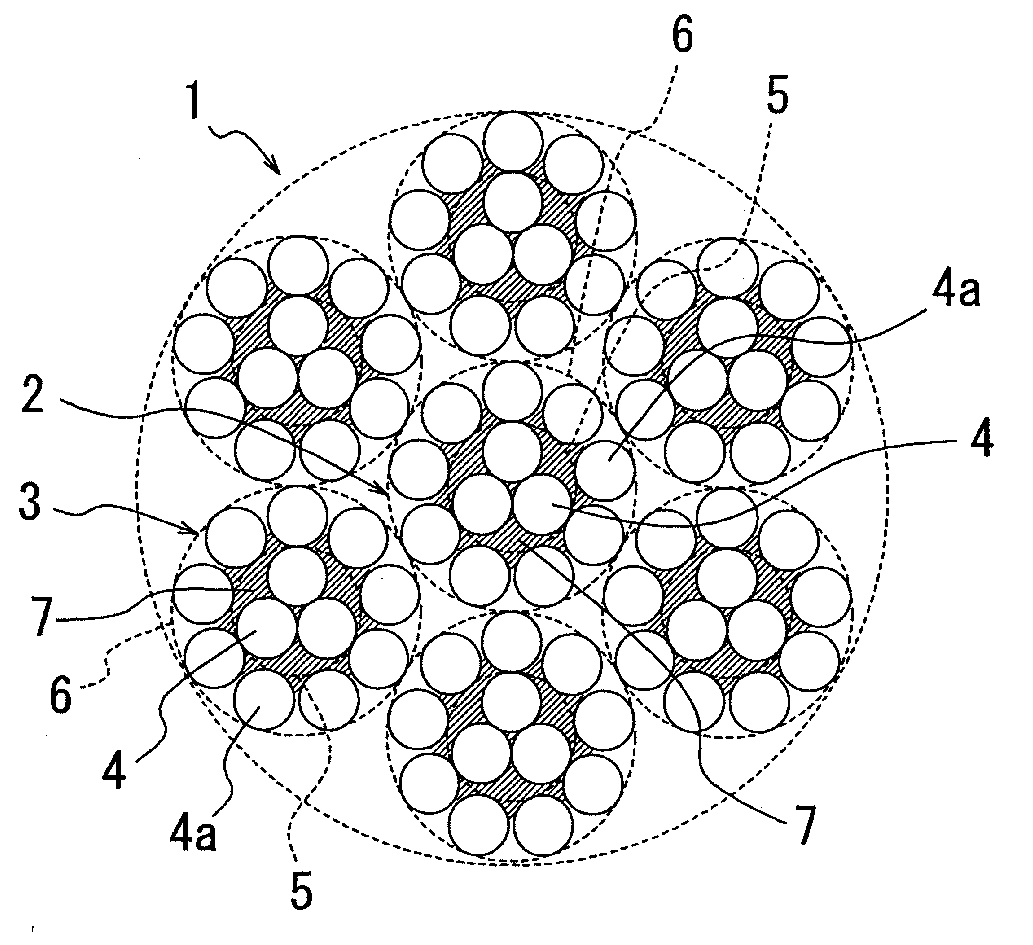

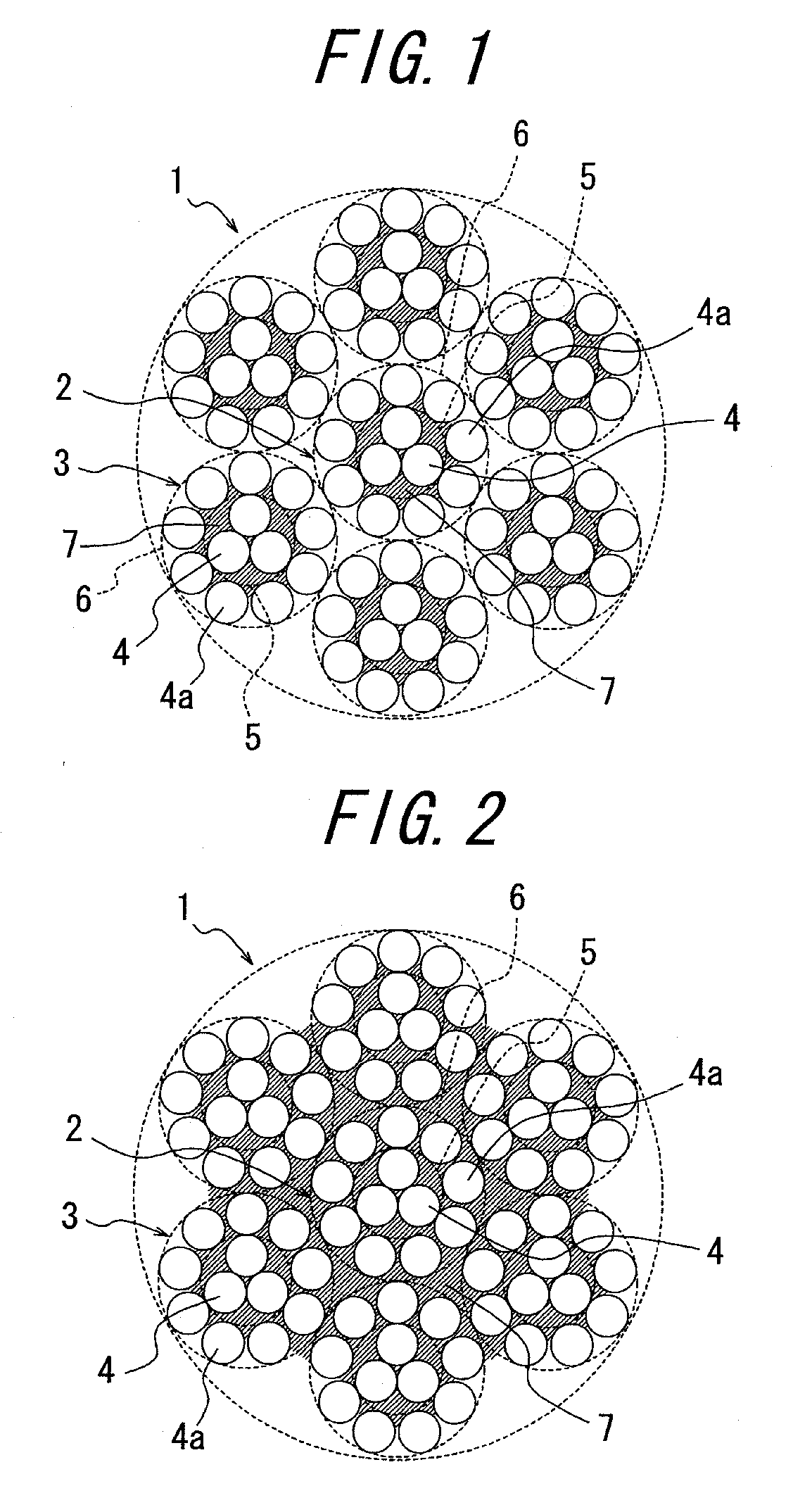

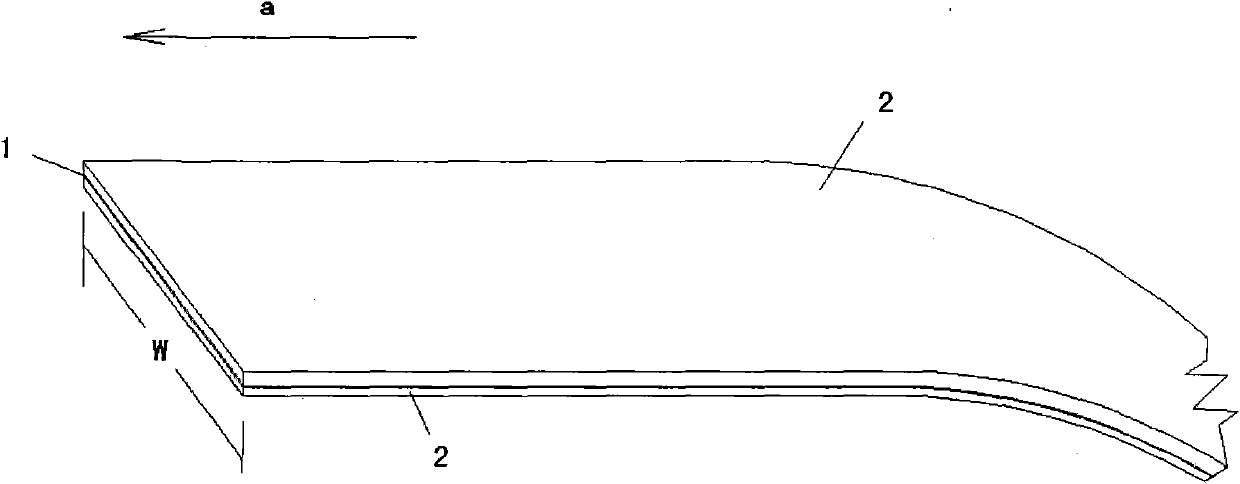

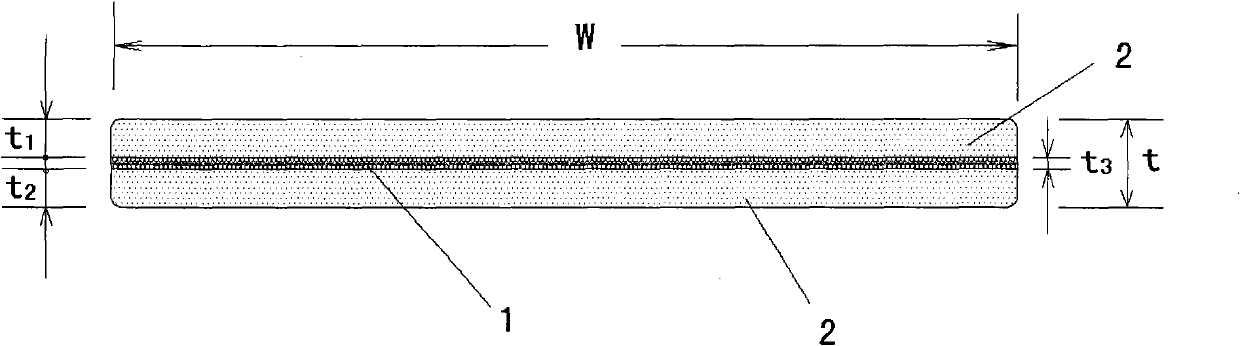

Fiber composite twisted cable

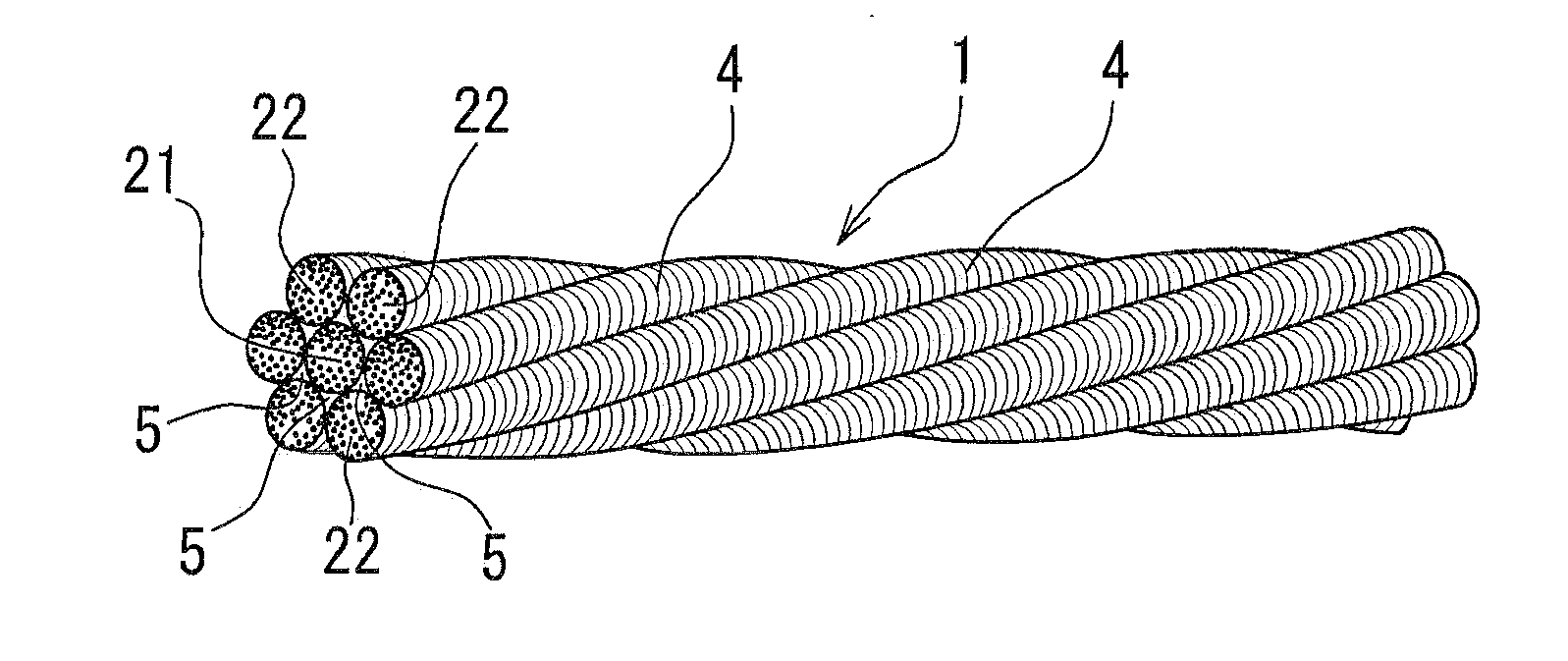

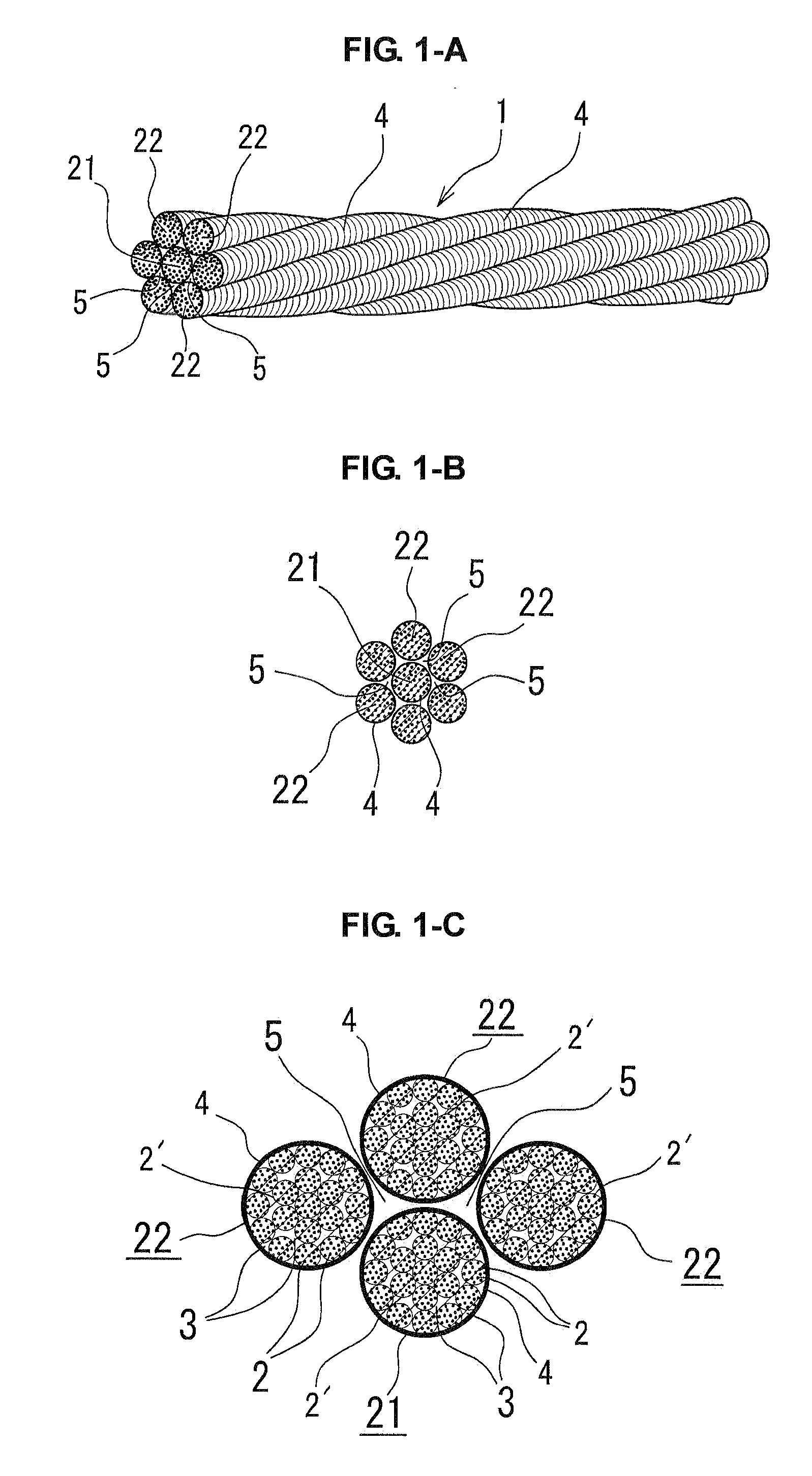

ActiveUS20110192132A1Preferable flexibilityGood transportabilityRope making machinesYarnFiberCarbon fibers

The invention relates to a composite twisted cable formed by impregnating carbon fibers with thermoplastic resin, and provides a fiber composite twisted cable which allows downsizing of a reel by being easy to be bent, can be transported to mountain areas which is normally hard to achieve a transport with a large vehicle, is hard to be curled, and is superior in workability. It is a cable having 1×n structure which is formed by impregnating bundles of carbon fibers with thermosetting resin, then twisting a plurality of strands each formed by covering an outer periphery of the bundle with a fiber, and then curing the thermosetting resin by applying the heat treatment, and a core strand and side strands which constitute the cable are separated and independent without being bonded so as to allow independent behavior of the respective strands when the cable is bent.

Owner:TOKYO ROPE MFG

Special metal wire twisting machine

InactiveCN102493239ASave installation spaceReduce running noiseRope making machinesLow noiseWire tension

The invention relates to a special metal wire twisting machine which mainly consists of a core wire and a surface wire pay-off rack, a core wire cradle K30, a core wire transmission assembly, a core wire tension and bridge assembly, a surface wire cradle K90, a surface wire transmission assembly, an over-twisting mechanism, a speed reducer, a speedometer, a traction mechanism, a meter counter, a straightening device, a wire arranging and take-up mechanism, a main motor and an electric control cabinet. The twisting mechanism has a compact structure, causes low noise, is stable in operation, is convenient to install and maintain, ensures table product quality, and can produce cores of 3+9*0.175, 3+9*0.22 and 3+8*0.22HTHC.

Owner:江苏金泰隆机电设备制造厂

Steel core for an electric transmission cable and method of fabricating it

Owner:NV BEKAERT SA

Dragging belt of composite materials

InactiveCN104528498AReduce the bending radius of curvatureEasy to bendRope making machinesElevatorsFiberThermoplastic polyurethane

The invention discloses a dragging belt of composite materials. The dragging belt is light in weight and good bending performance. The dragging belt comprises a plurality of inner bearing body layers and abrasion-resisting elastic bodies wrapped outside the inner bearing body layers. The inner bearing bodies are in a sheet shape which is continuous in the single length direction of the dragging belt. Each inner bearing body comprises a base body. A plurality of nonmetal non-twist continuous fiber monofilaments are arranged in the base bodies, the nonmetal non-twist continuous fiber monofilaments are not in contact, the base bodies of inner bearing body layers are made of thermosetting resin materials or thermoplastic resin materials, the abrasion-resisting elastic bodies are thermoplastic polyurethane or rubber elastic bodies. At least two inner bearing body layers are arranged in the thickness direction of the dragging belt. The thickness of the inner bearing body layers of the sheet-shaped structure of the dragging belt is small, under the premise that good bearing is achieved, bending curvature radius is greatly lowered, the obtained dragging belt is light in weight, high in intensity and easy to bend, abrasion resistance and whether resistance are achieved, anti-fatigue performance is achieved, service life is long, maintaining cost is low, and the dragging belt can be used for lifting of long-distance heavy objects.

Owner:TIANJIN GOLDSUN WIRE ROPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com