Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8279results about How to "Improve tensile properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

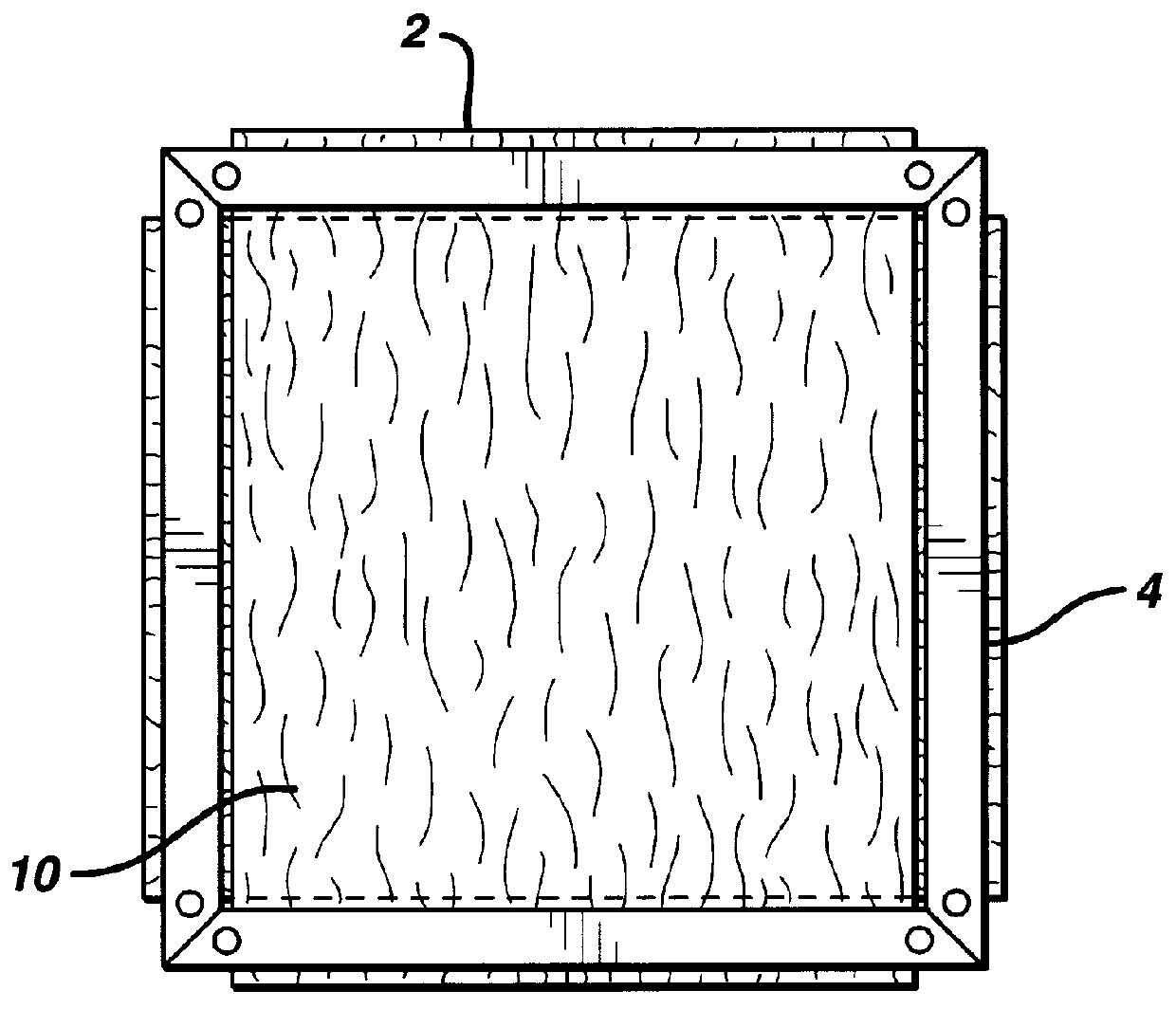

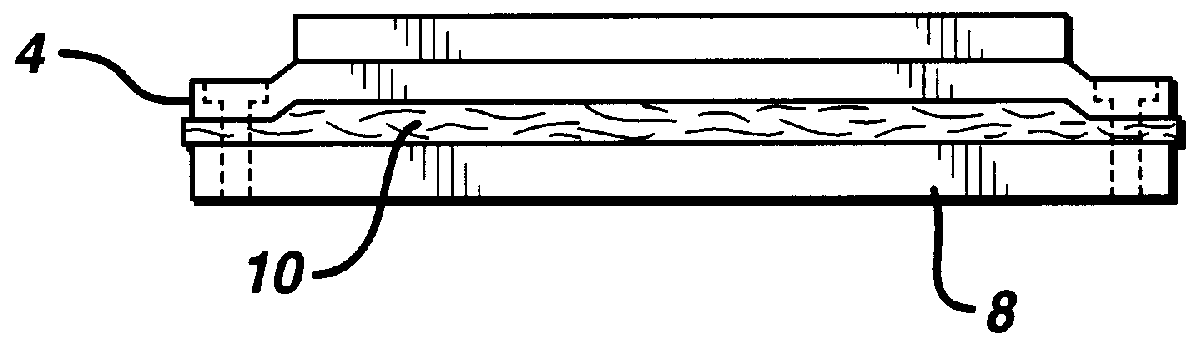

Fabrication of biocompatible polymeric composites

InactiveUS6147135ASure easyImprove performanceSuture equipmentsCosmetic preparationsFiberPolymer science

Composite materials formed from biocompatible polymer fibers and biodegradable polymers are disclosed. The heat treatment conditions for the reinforcing fibers are described so that the mechanical properties of the fibers can be retained during composite consolidation process. The processing conditions and set-ups to consolidations are constrained to the temperatures lower than fiber heat treatment temperatures. The reinforcing fibers are restrained under tension so that the minimum relaxation occurs during consolidation process.

Owner:ETHICON INC

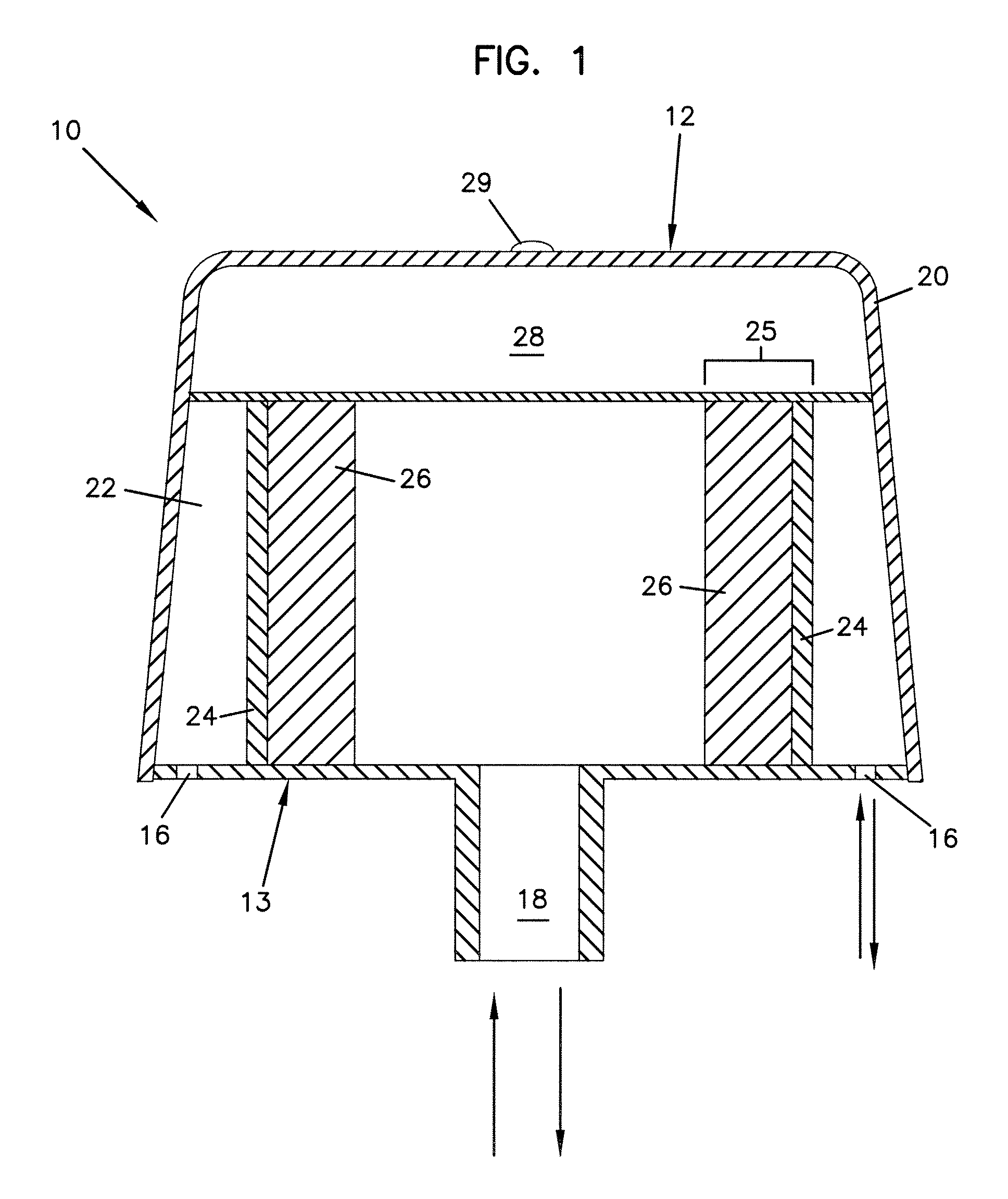

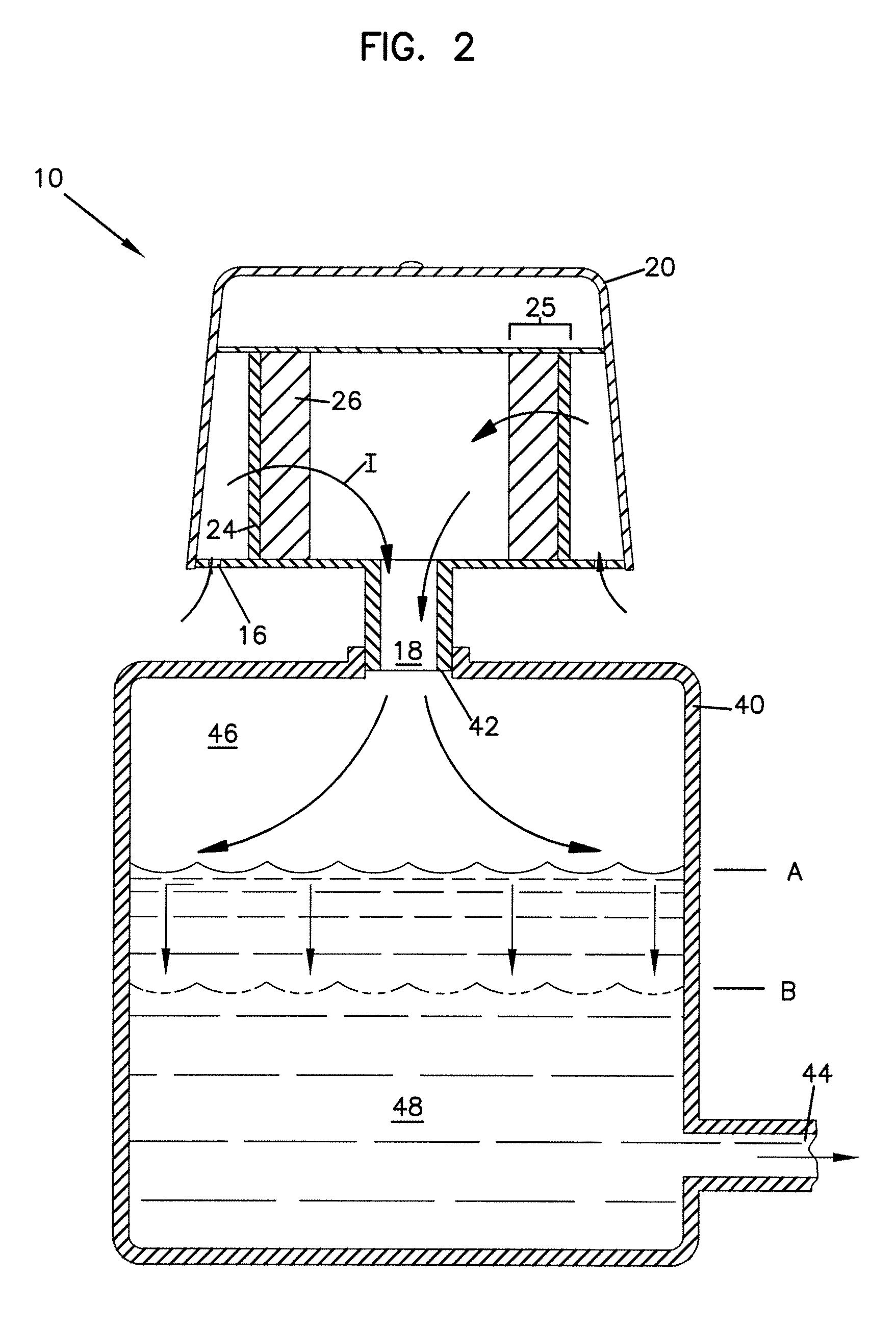

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

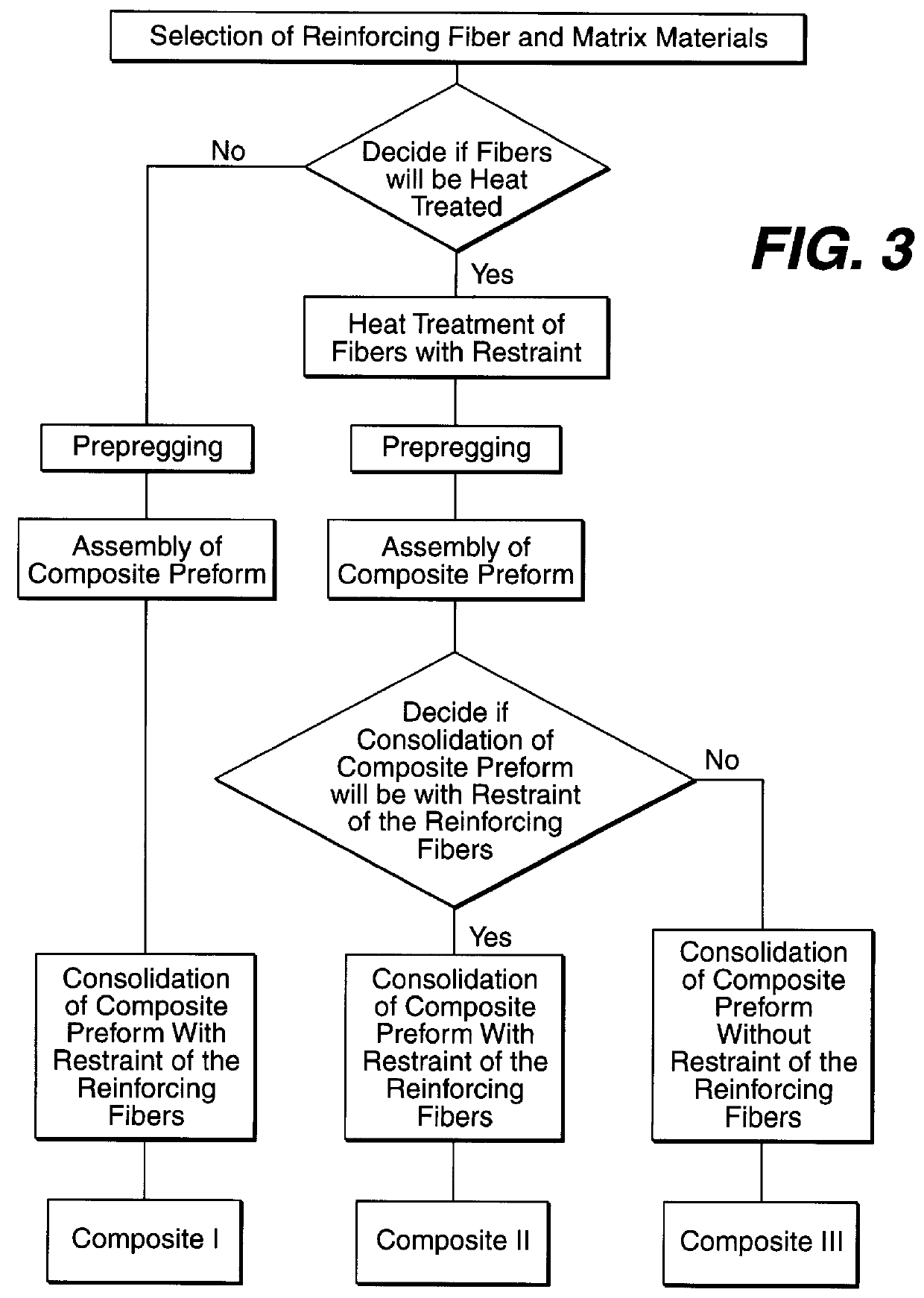

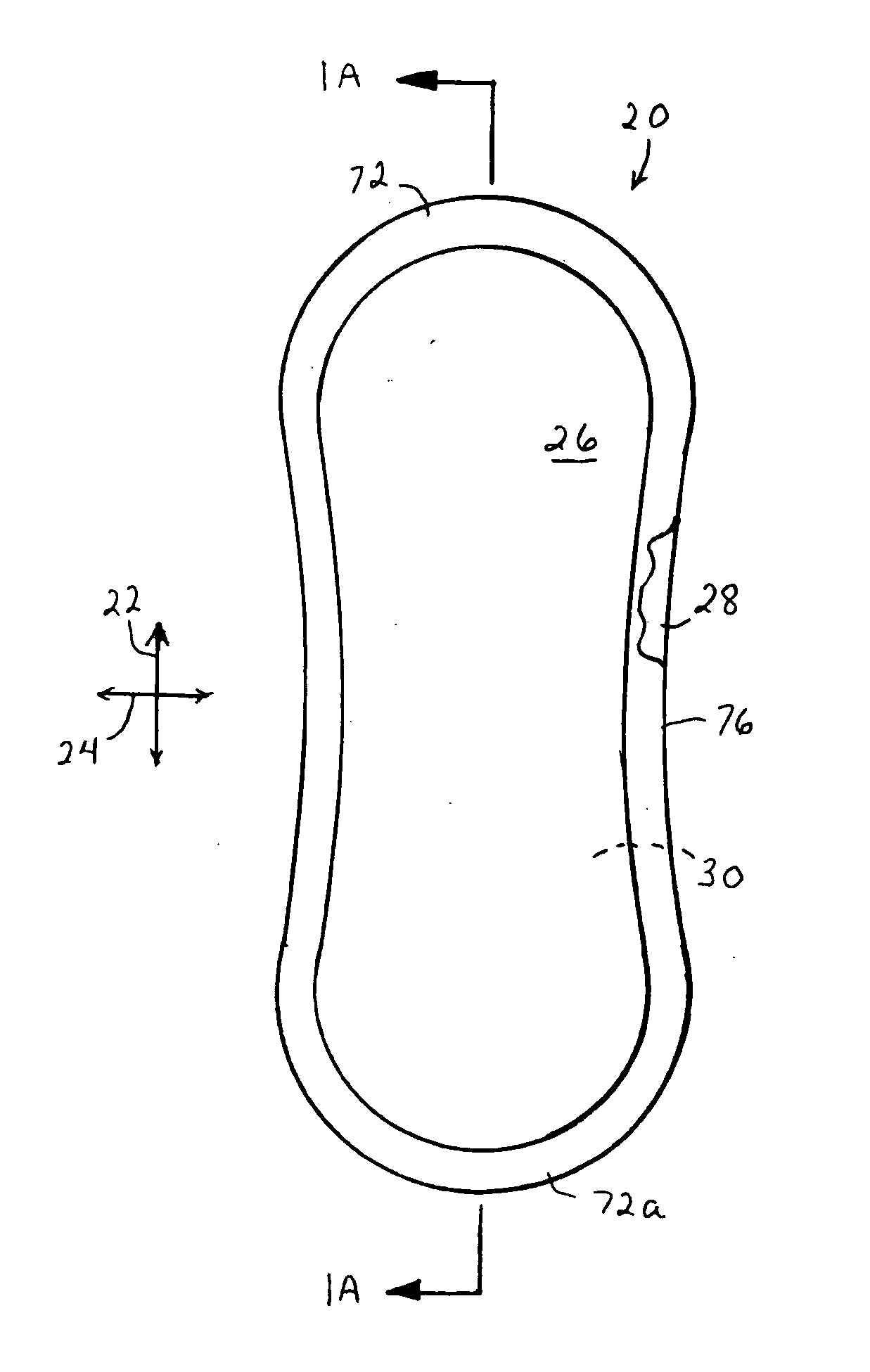

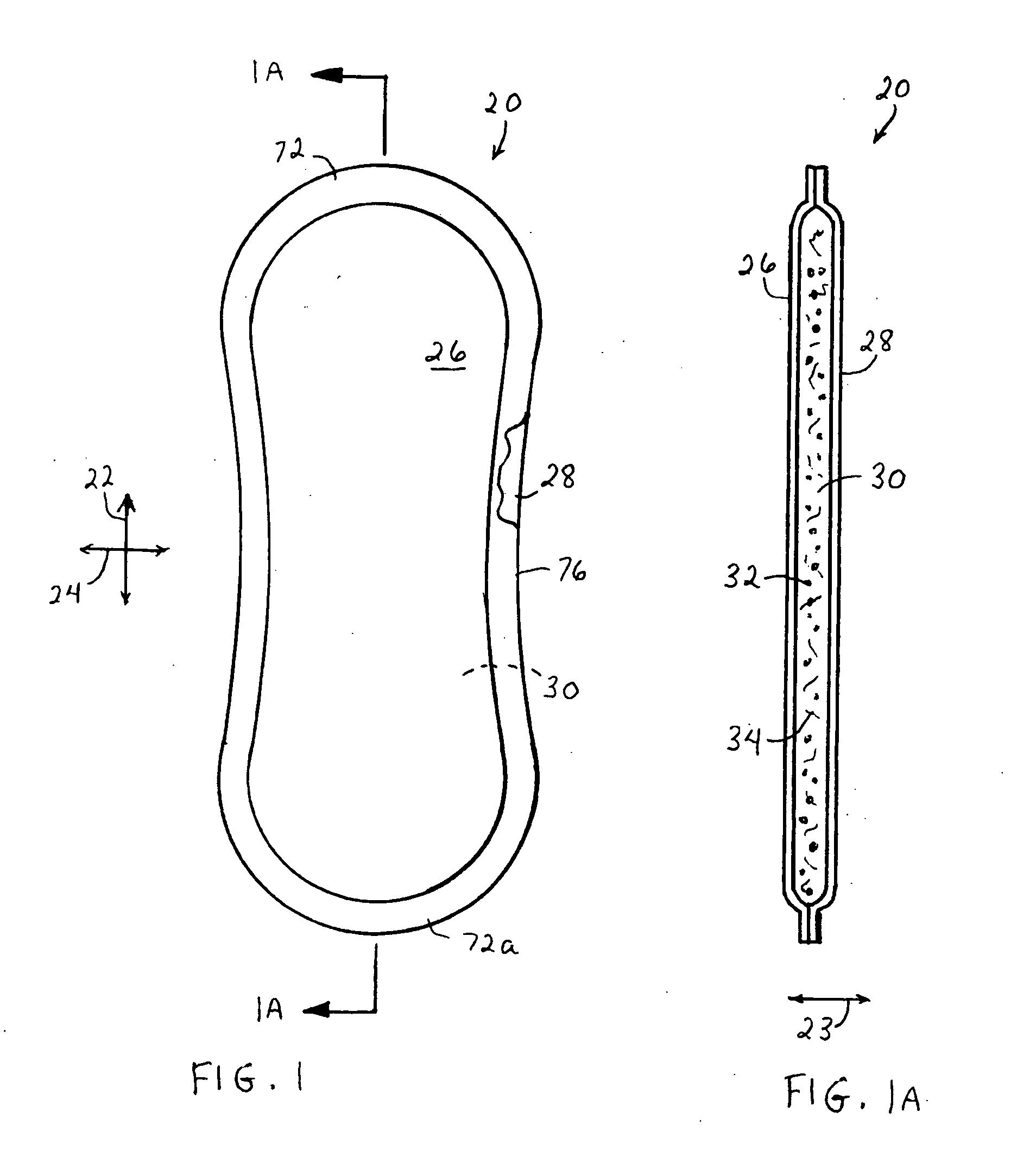

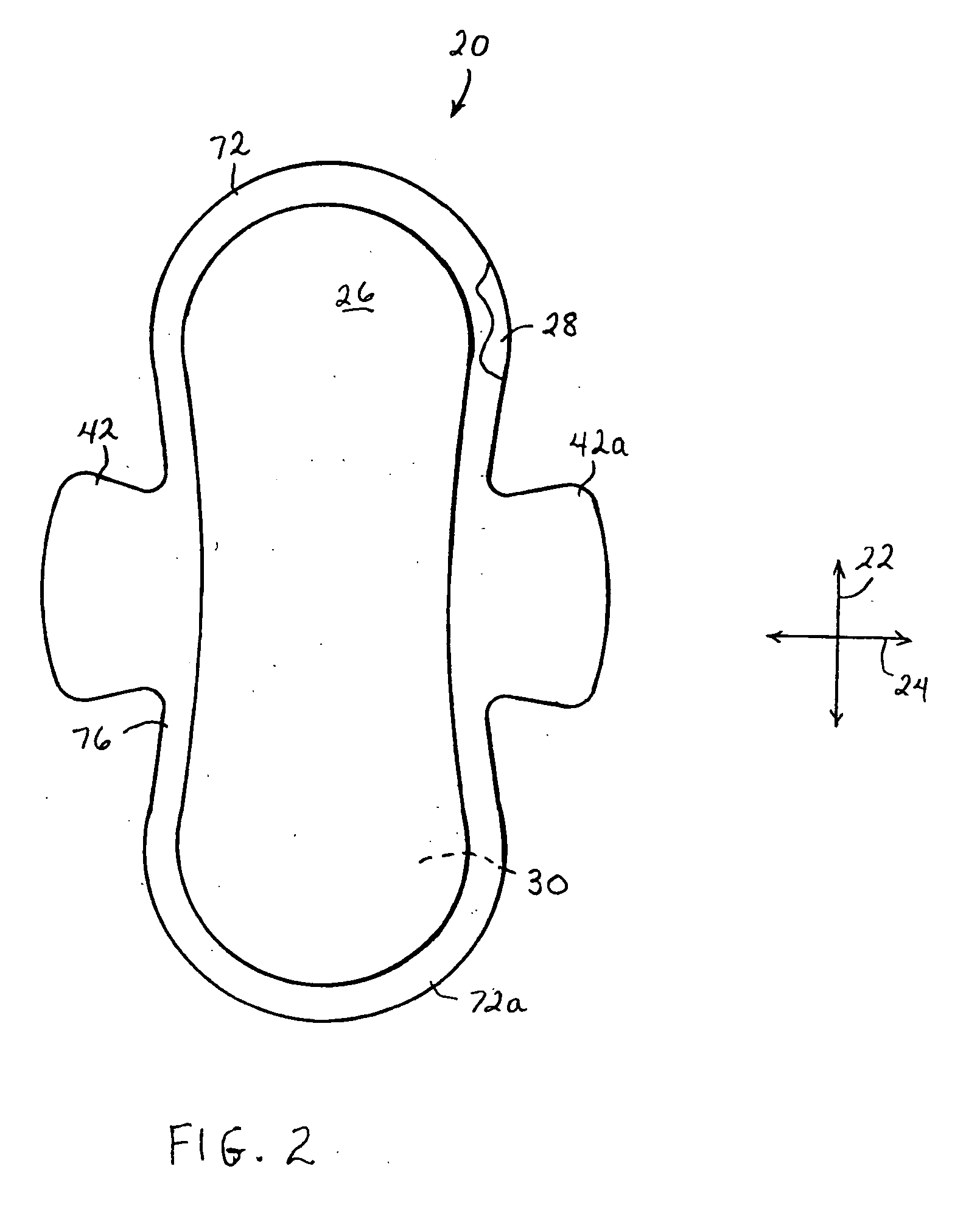

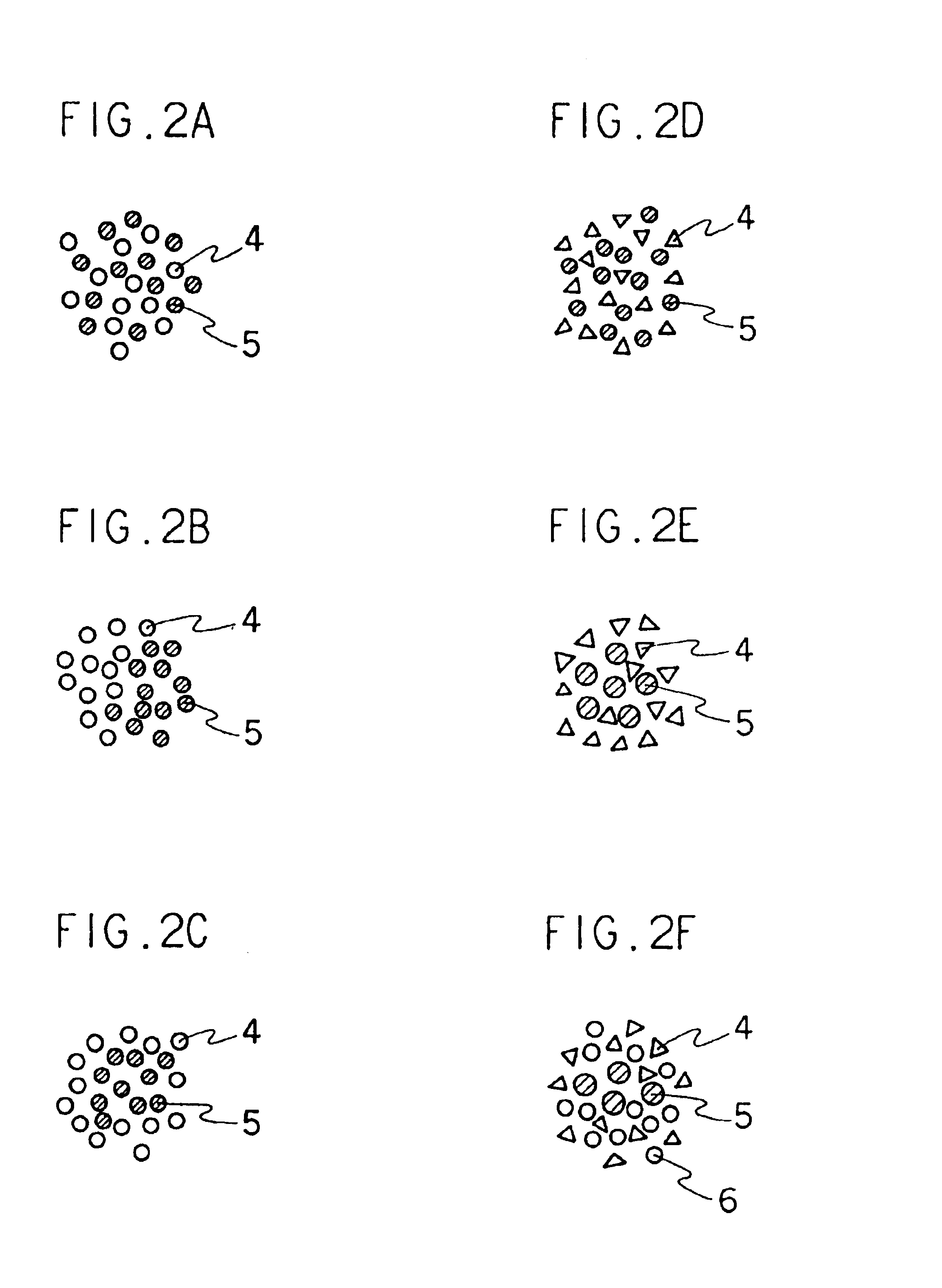

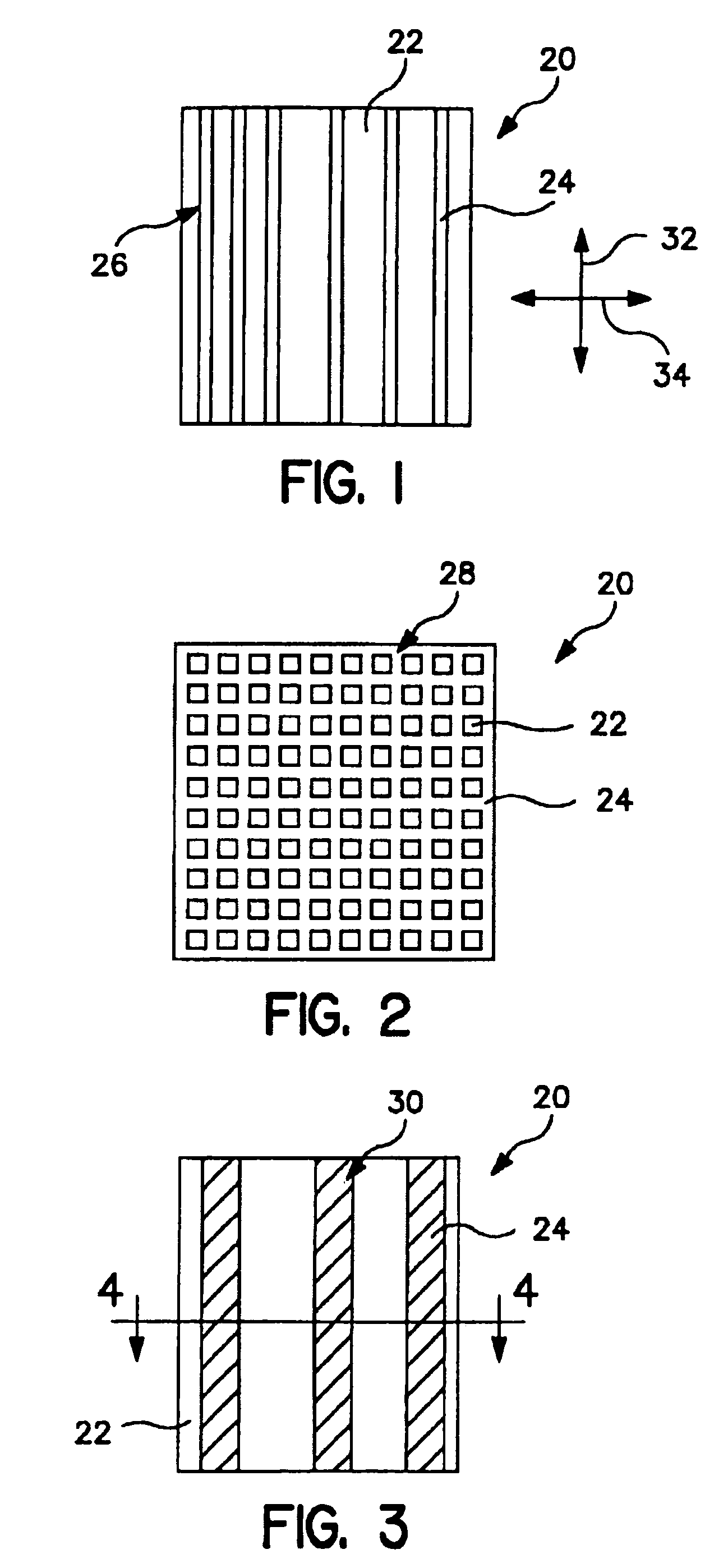

Stretchable absorbent composite with low superaborbent shake-out

InactiveUS20060004336A1Improve tensile propertiesReduce vibrationBaby linensCoatingsWater solubleFiber

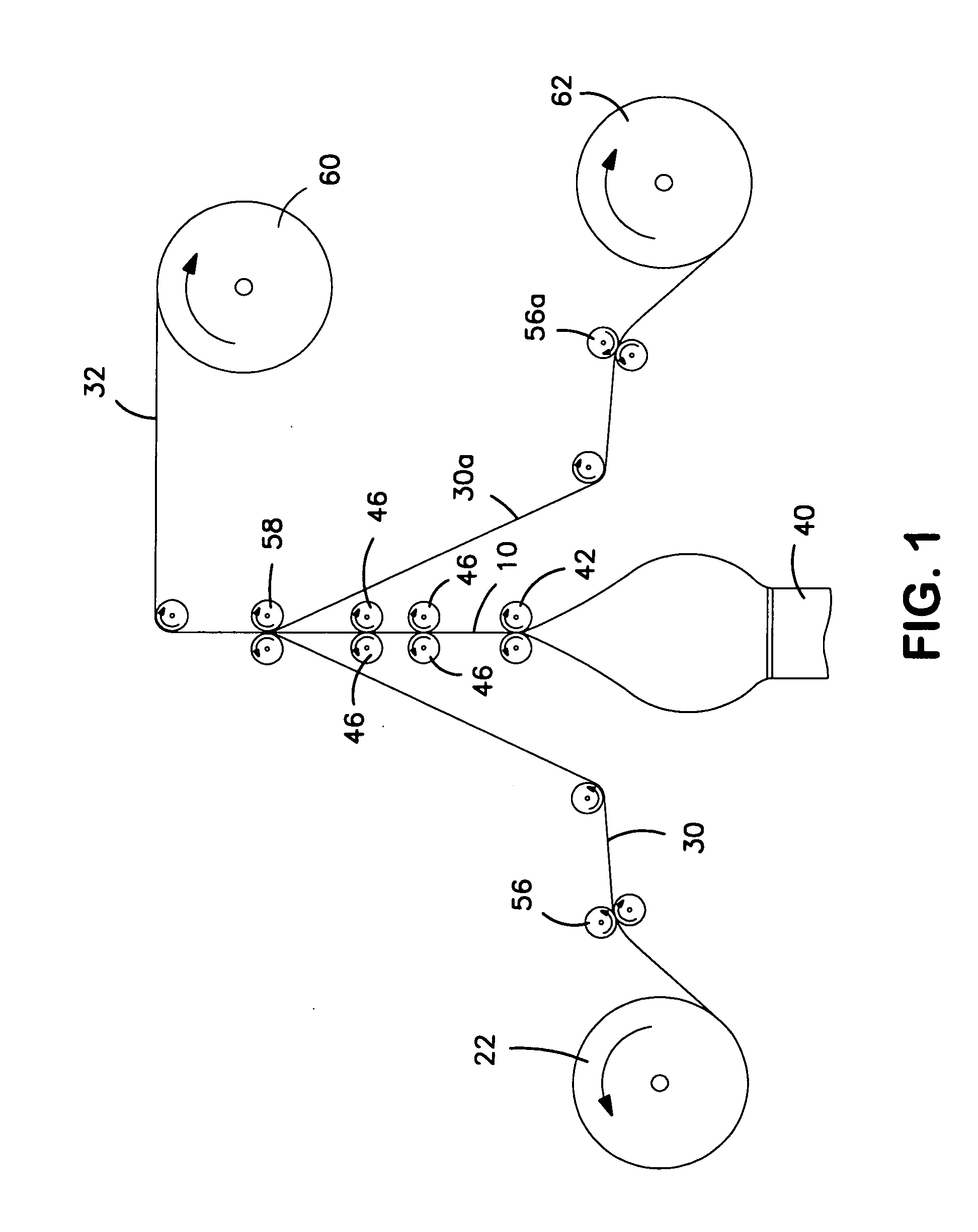

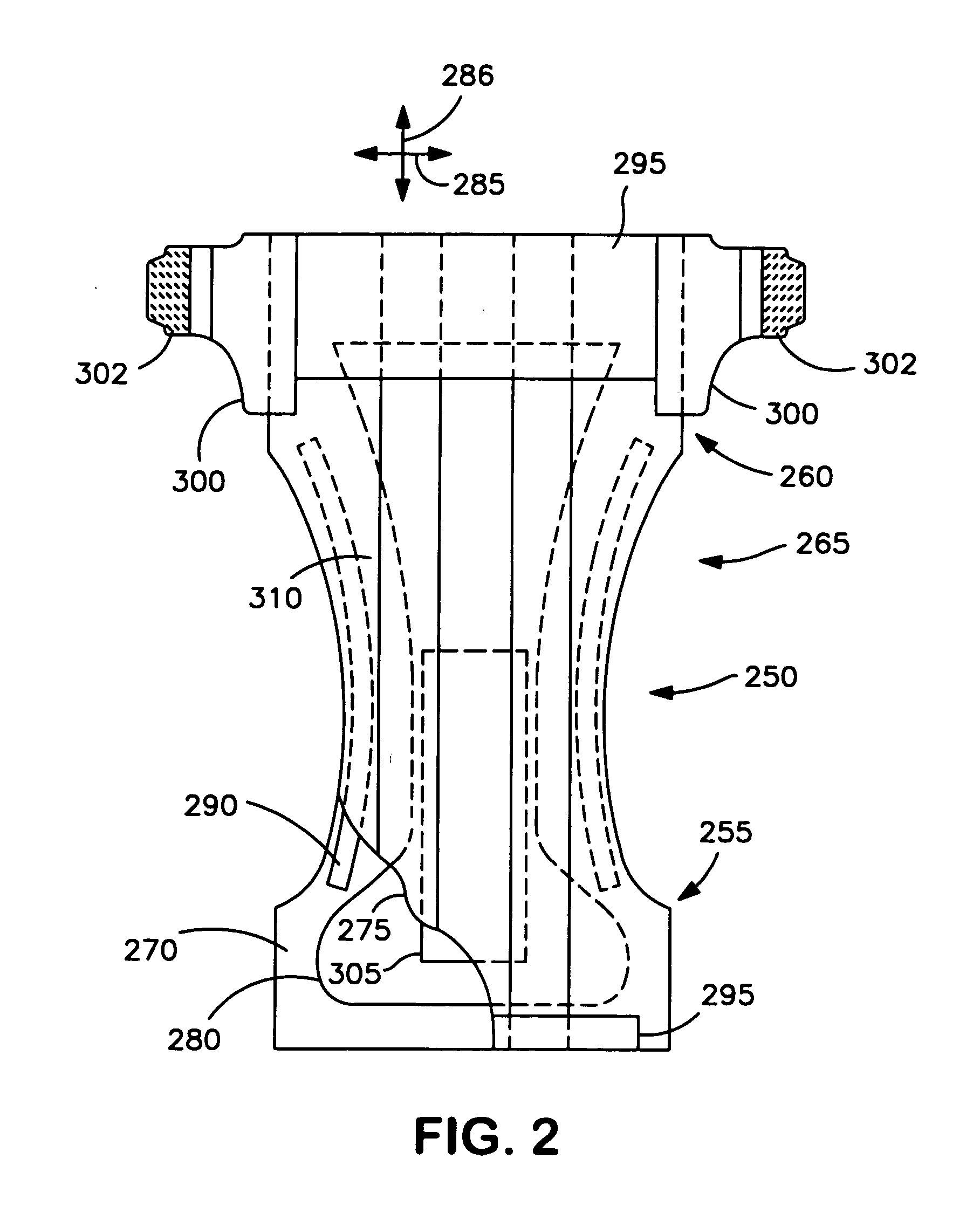

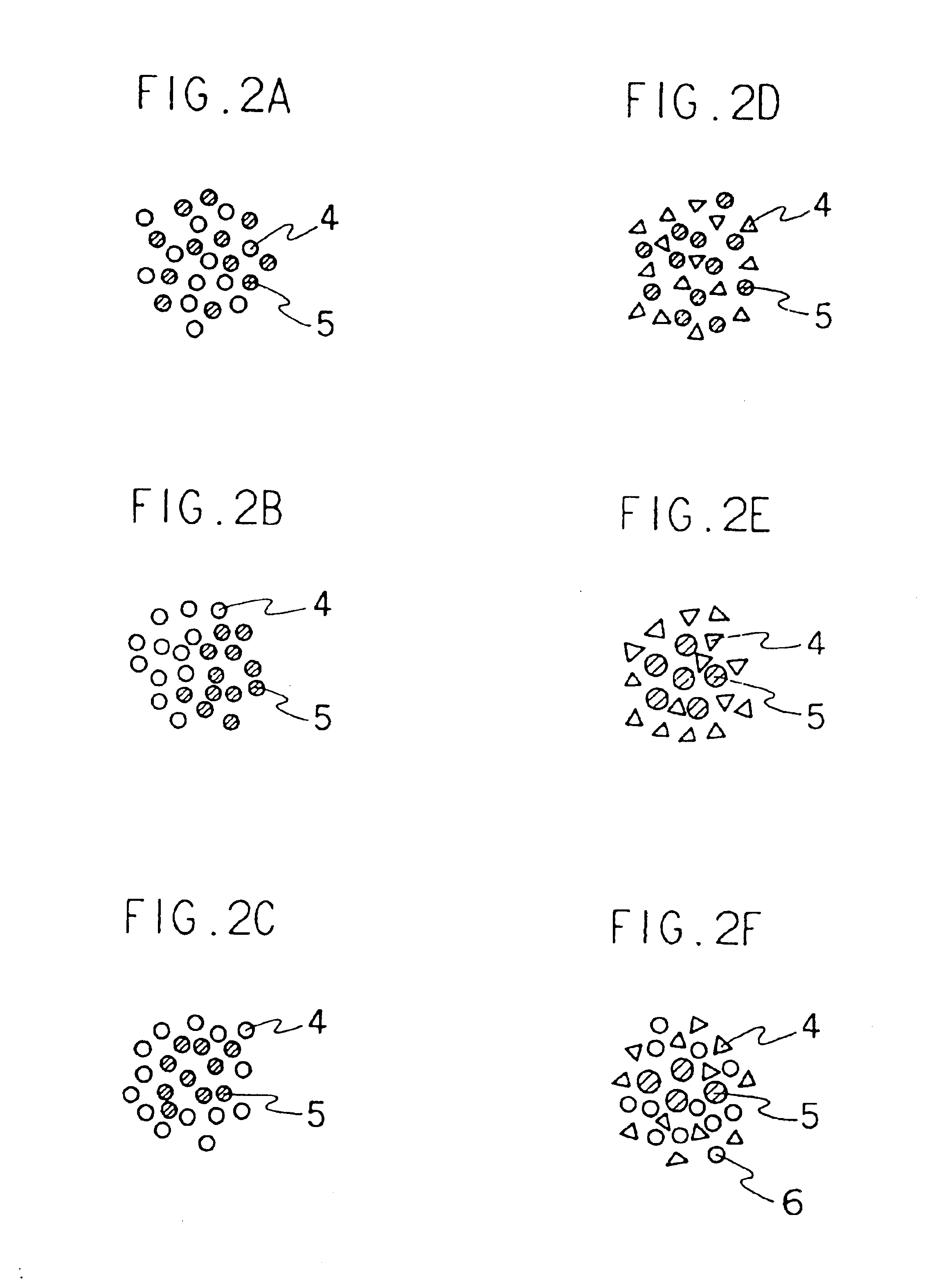

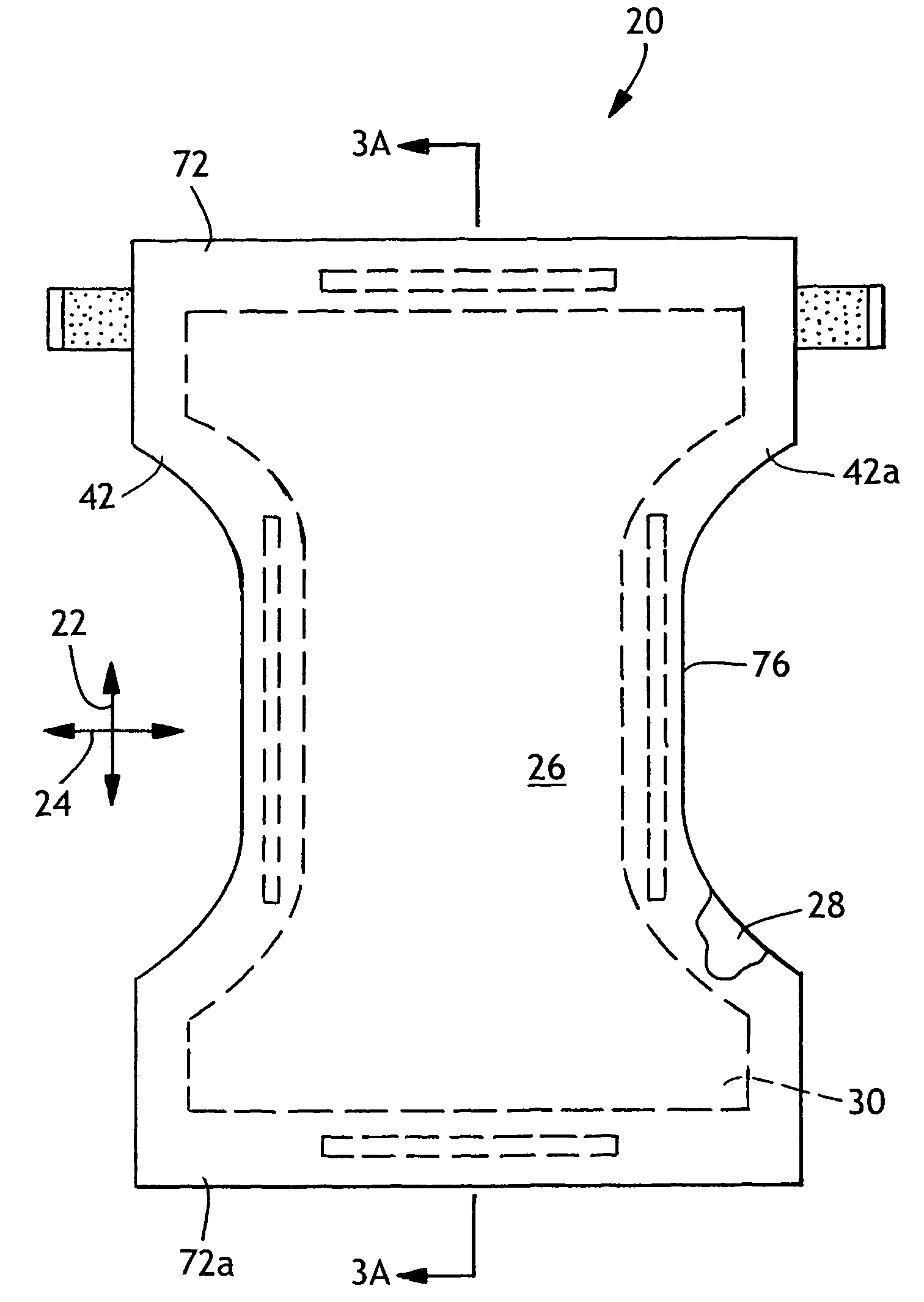

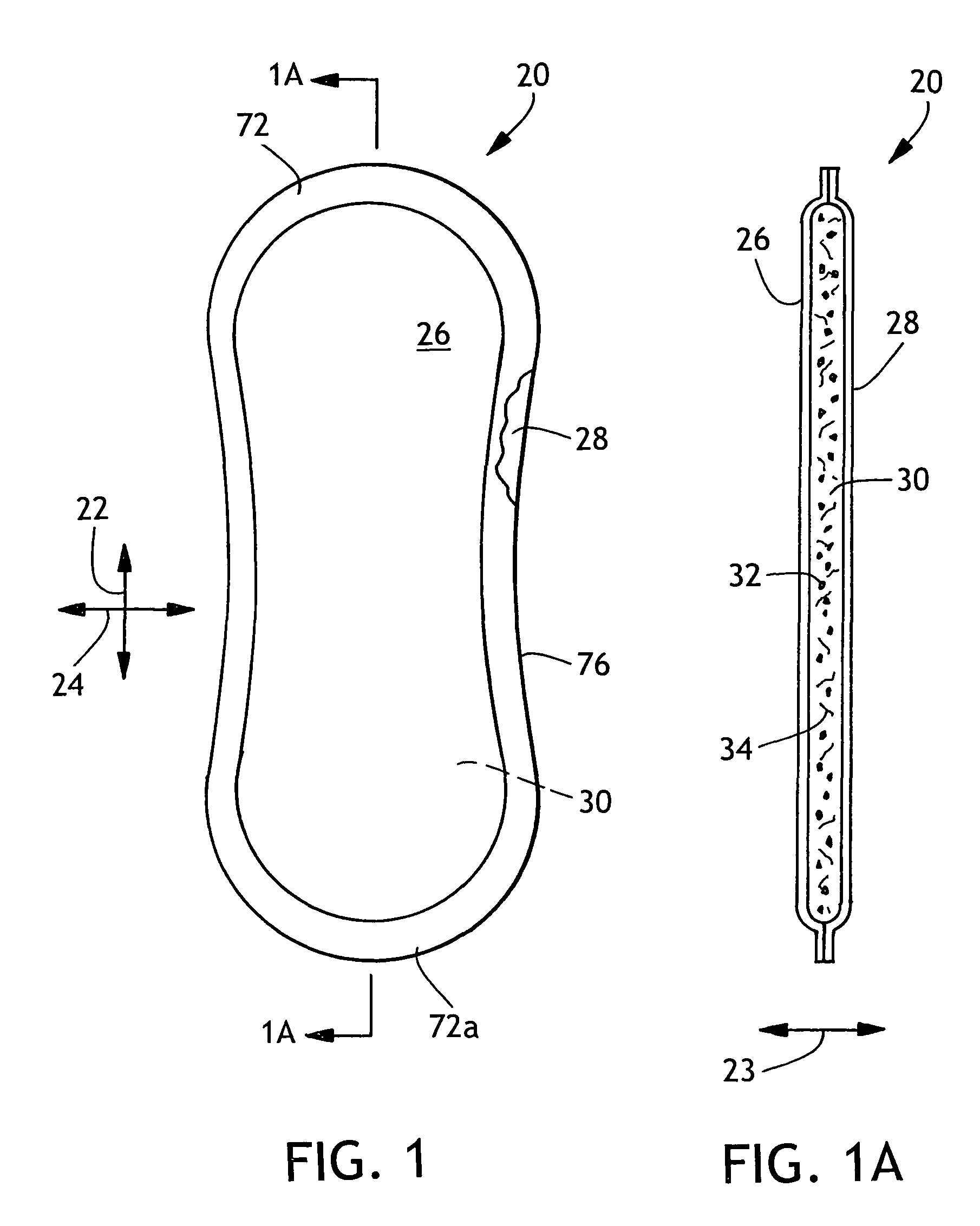

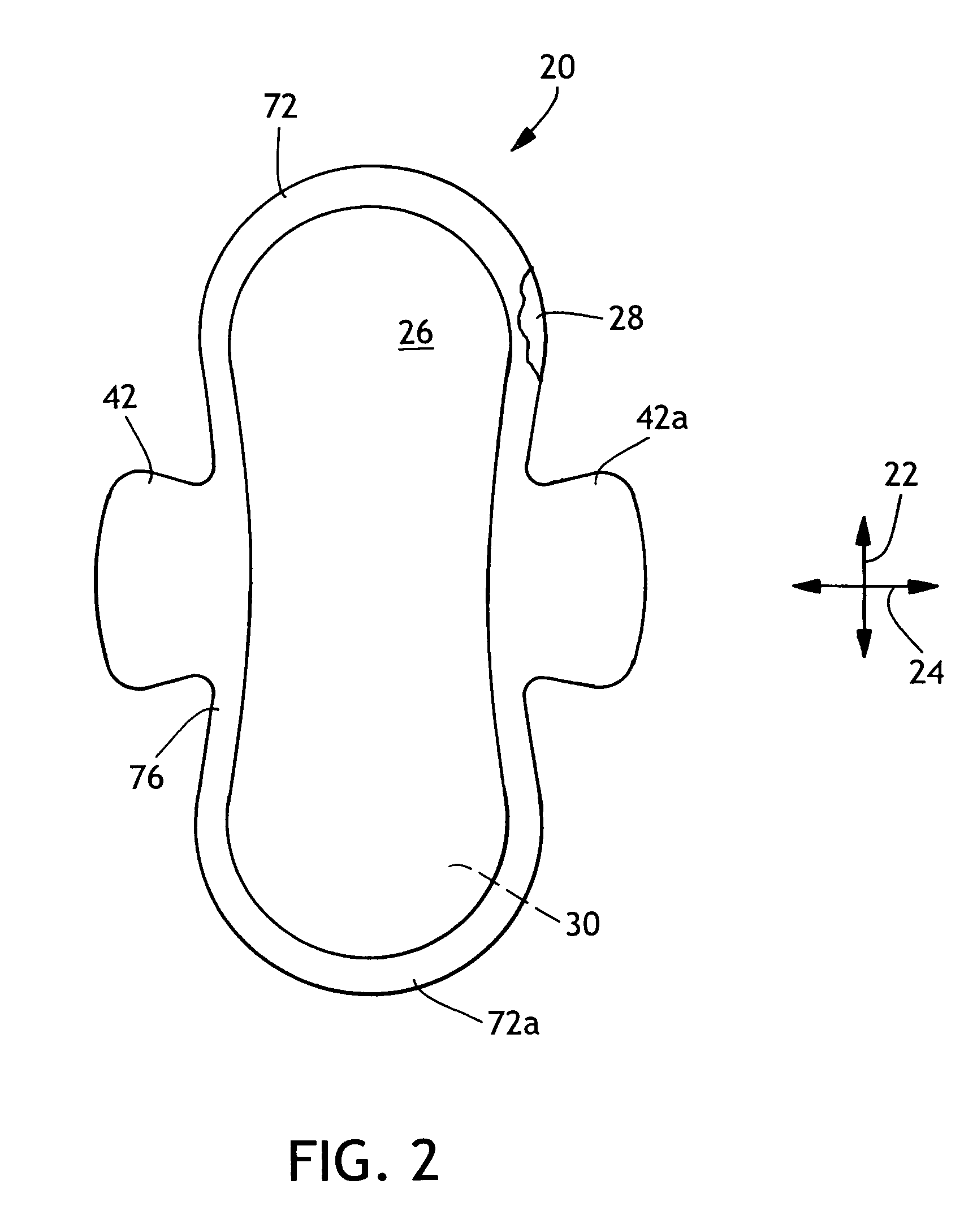

An article comprises a stretchable absorbent composite (30) that includes a quantity of superabsorbent particles (32) which are operatively contained within a matrix of elastomeric polymer fibers (34). In particular aspects, the composite article can include at least about 60 wt % of the superabsorbent particles and not more than about 40 wt % of the elastomeric polymer fibers, based on a total weight of the composite. In other aspects, the composite article can provide a high stretchability. Additional aspects can provide a low shake-out. Particular configurations can, for example, provide a stretchability value of at least about 30%. Additional aspects can include a configuration that provides a shake-out value of not more than about 2%. In other aspects, the invention can provide a shake-out value of not more than about 1.2%. In further aspects, the absorbent composite can include superabsorbent particles having a coating of treatment-material that is thermally processible. Additional aspects can include a treatment-material which is water soluble.

Owner:KIMBERLY-CLARK WORLDWIDE INC

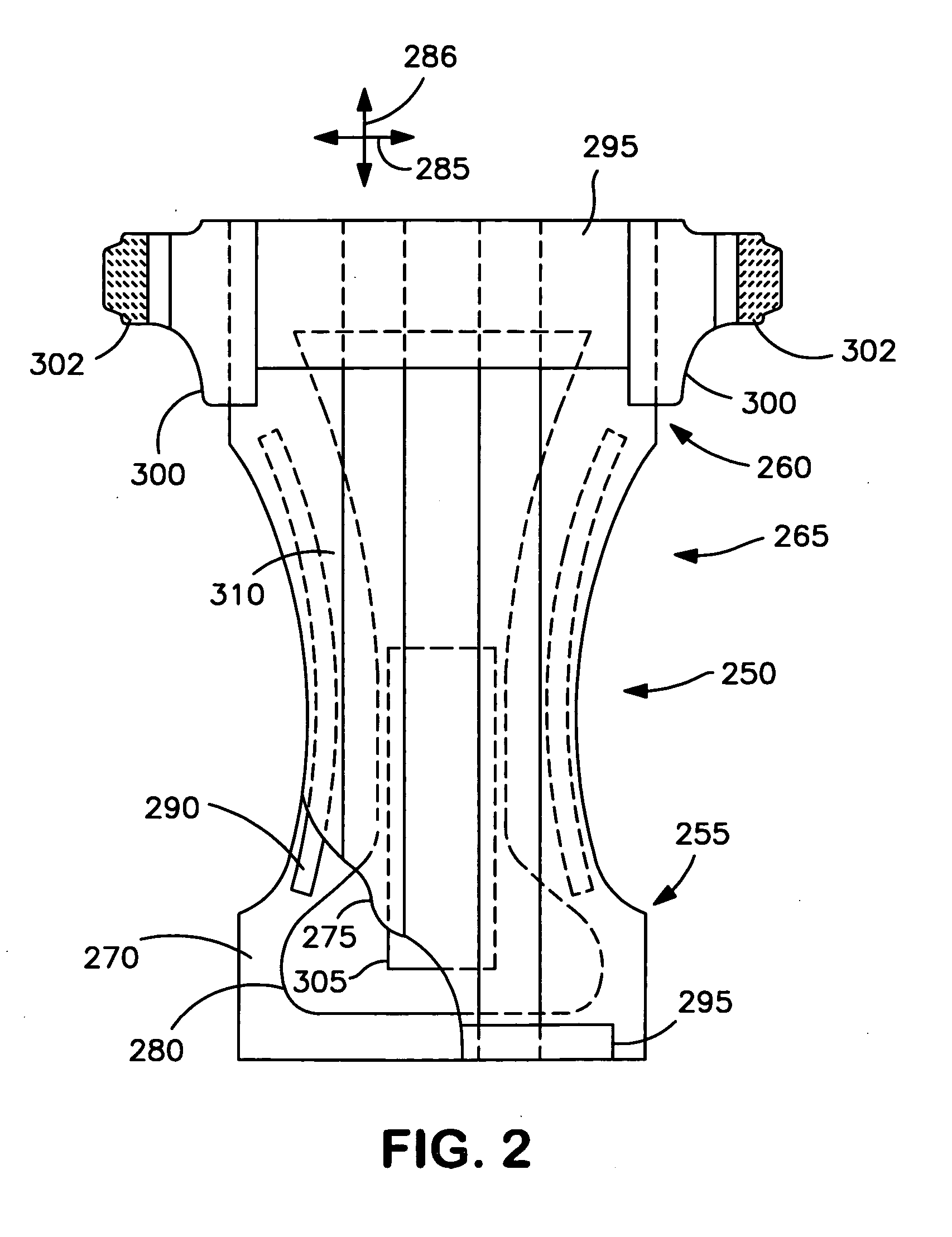

Joint Arthroplasty Devices Having Articulating Members

InactiveUS20080109081A1Improve wear resistanceAvoid Strength LossAnkle jointsJoint implantsJoint arthroplastyPolyether ether ketone

Articulating devices for replacing damaged or degenerated weight bearing joints are provided. The devices may have two or more surfaces that articulate against one another that are coated or fully formed of PEEK or similar materials to provide improved wear capabilities while maintaining sufficient strength to operate in a weight bearing capacity.

Owner:PIONEER SURGICAL TECH INC

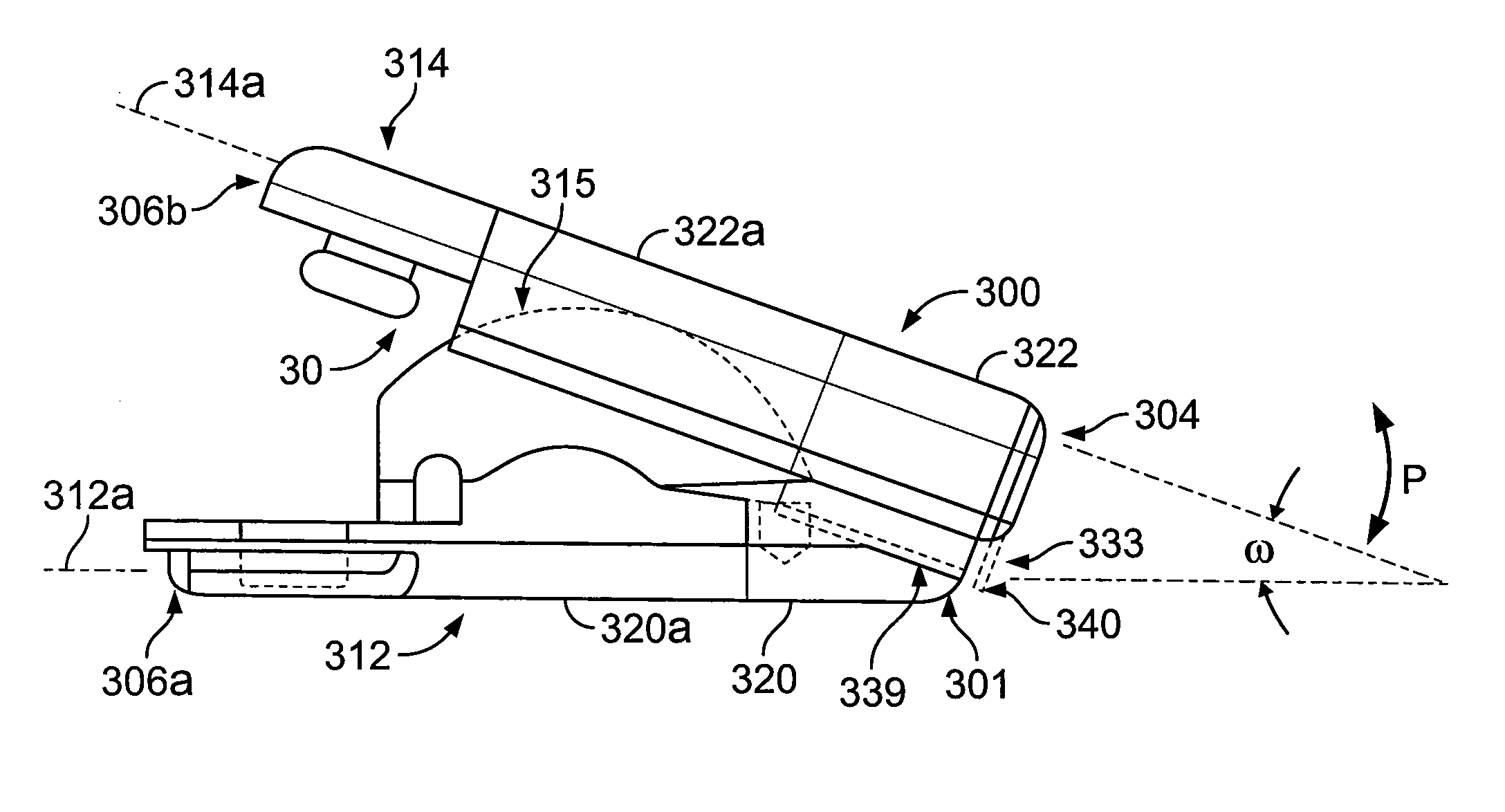

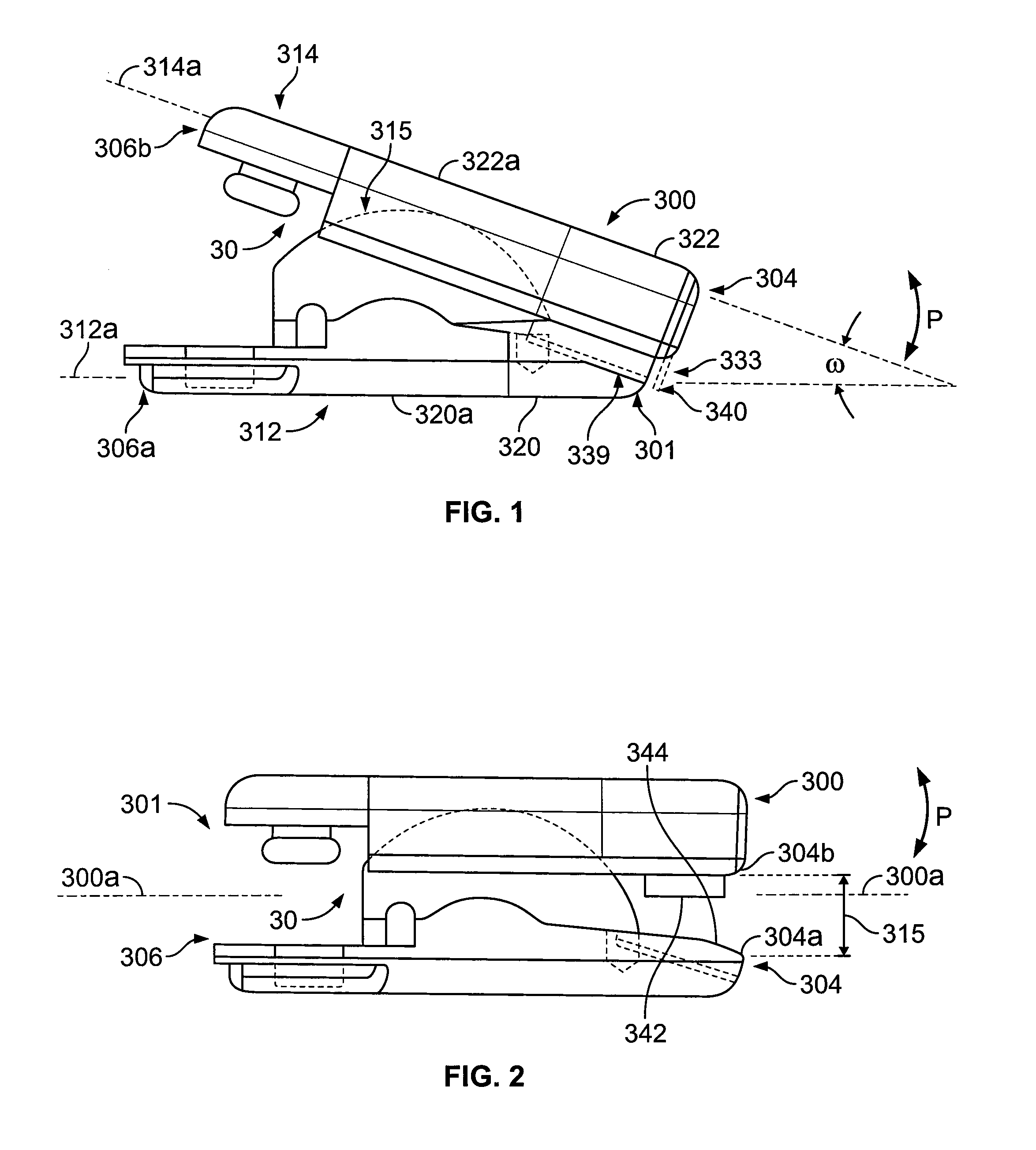

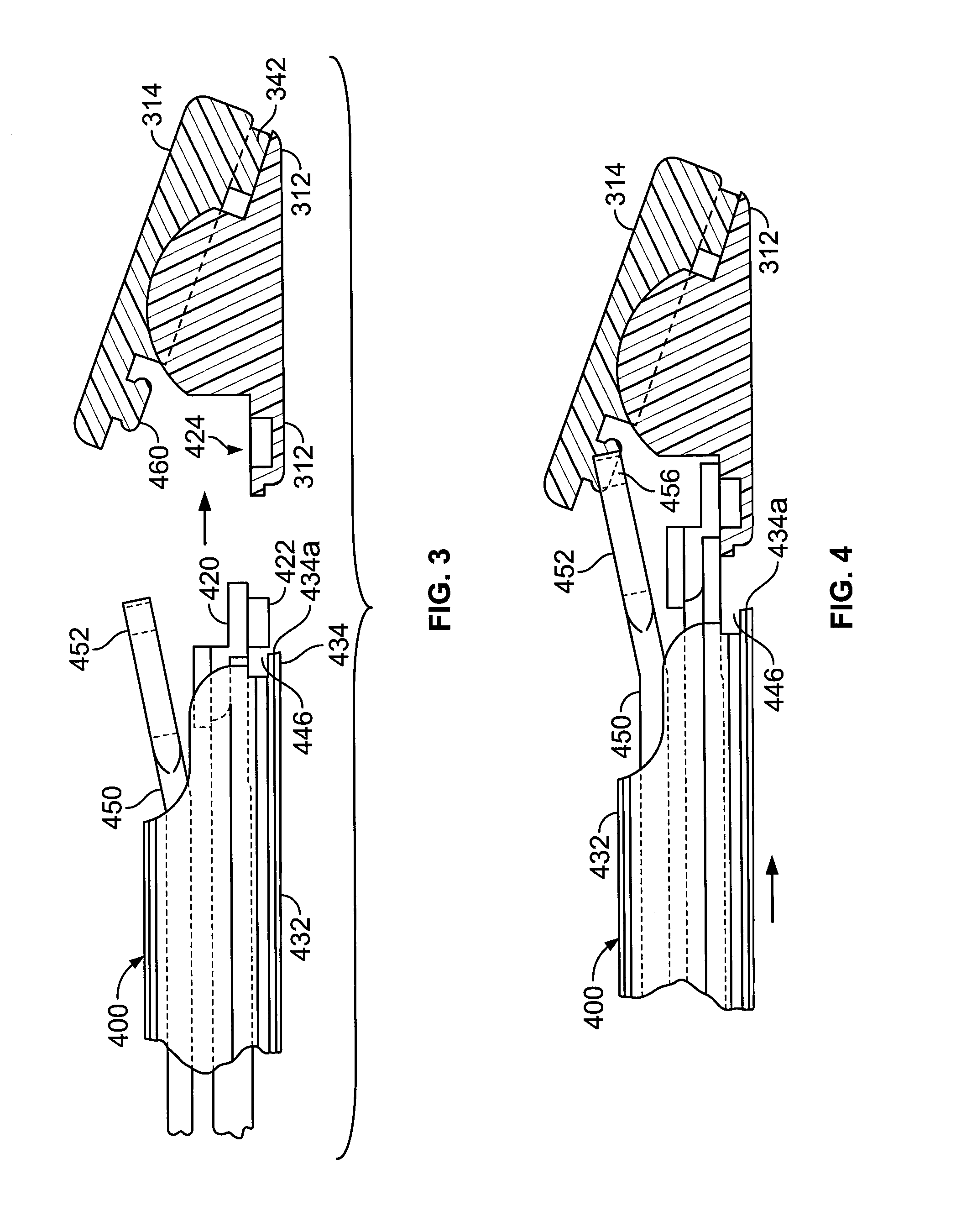

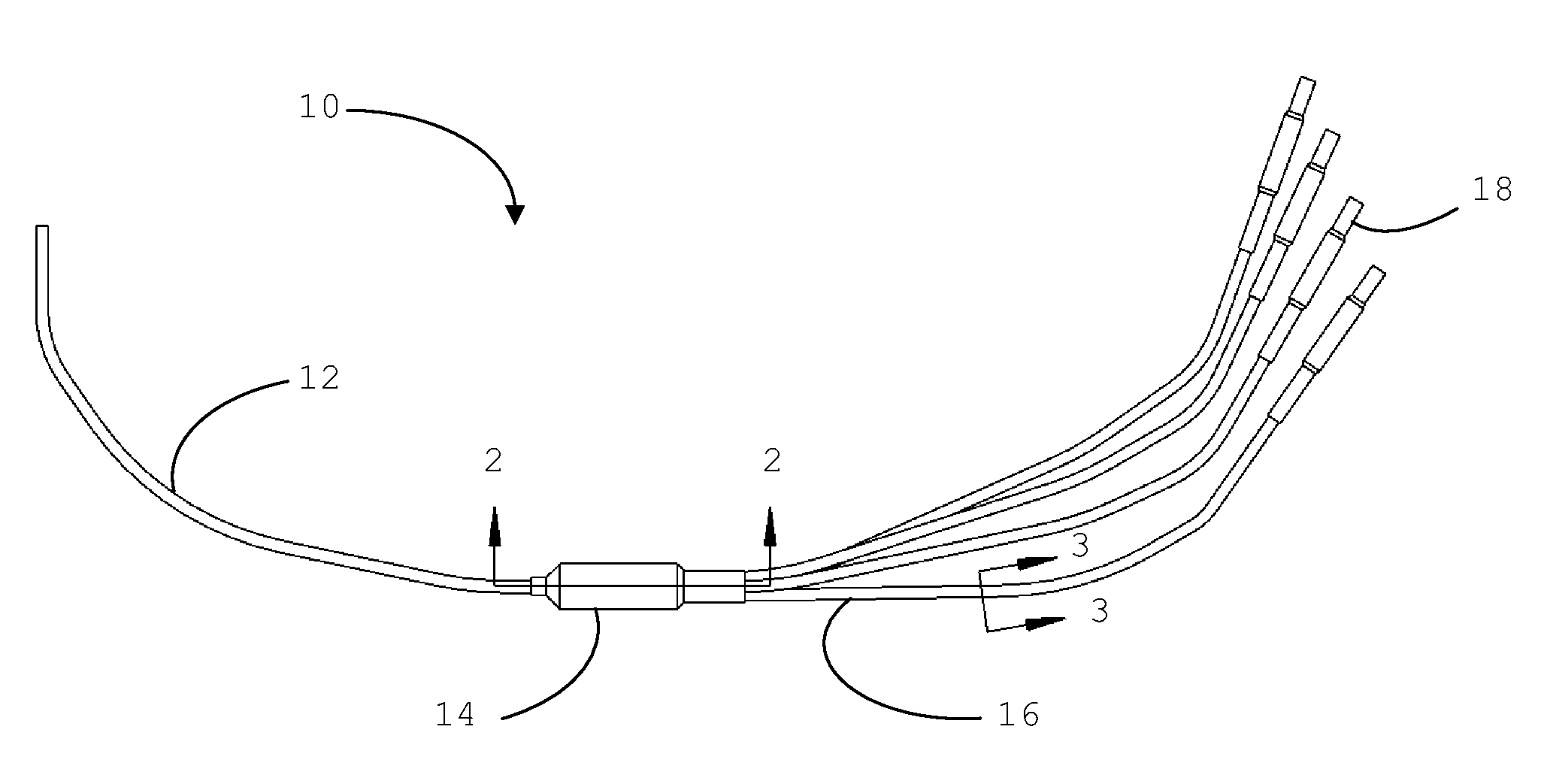

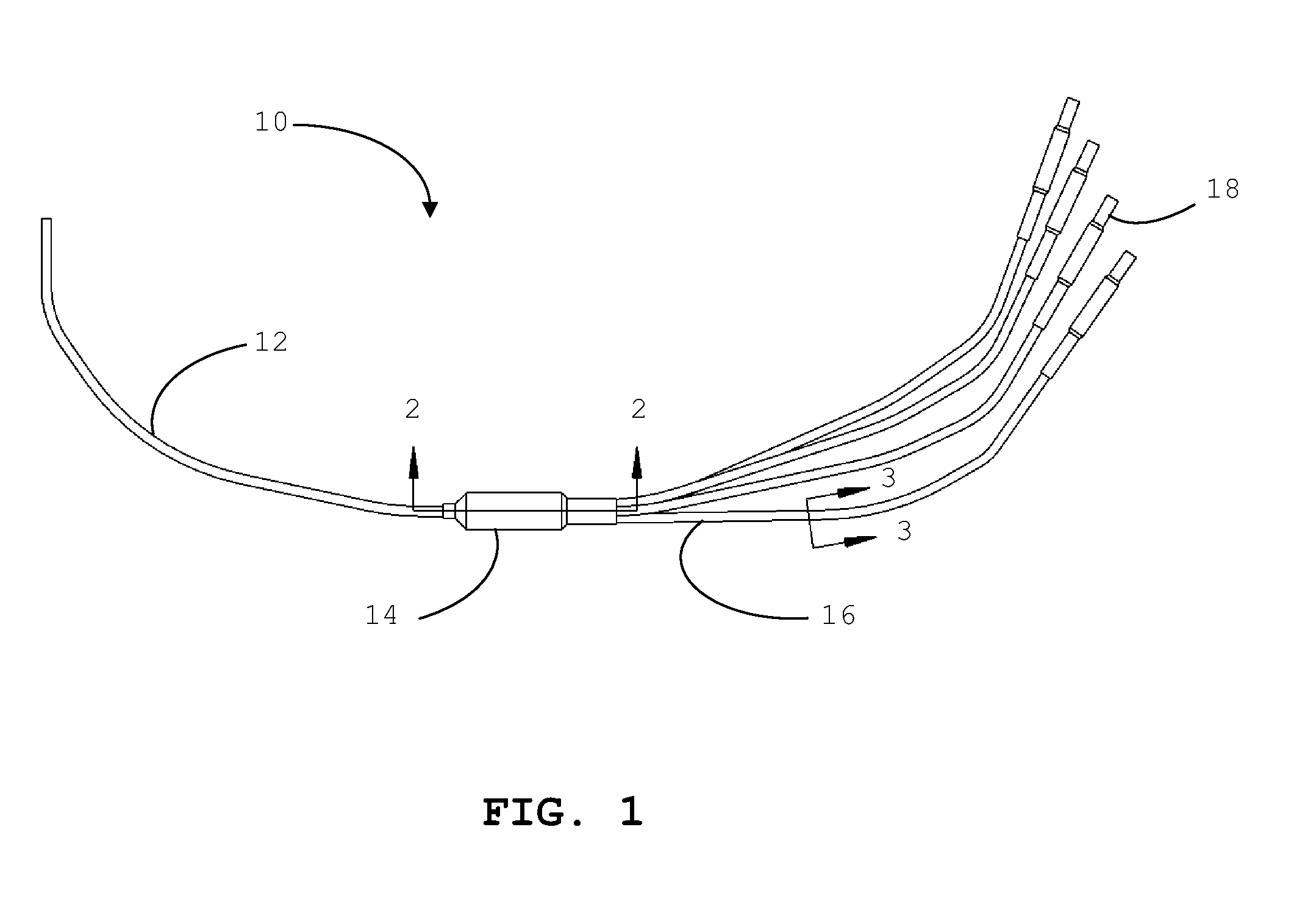

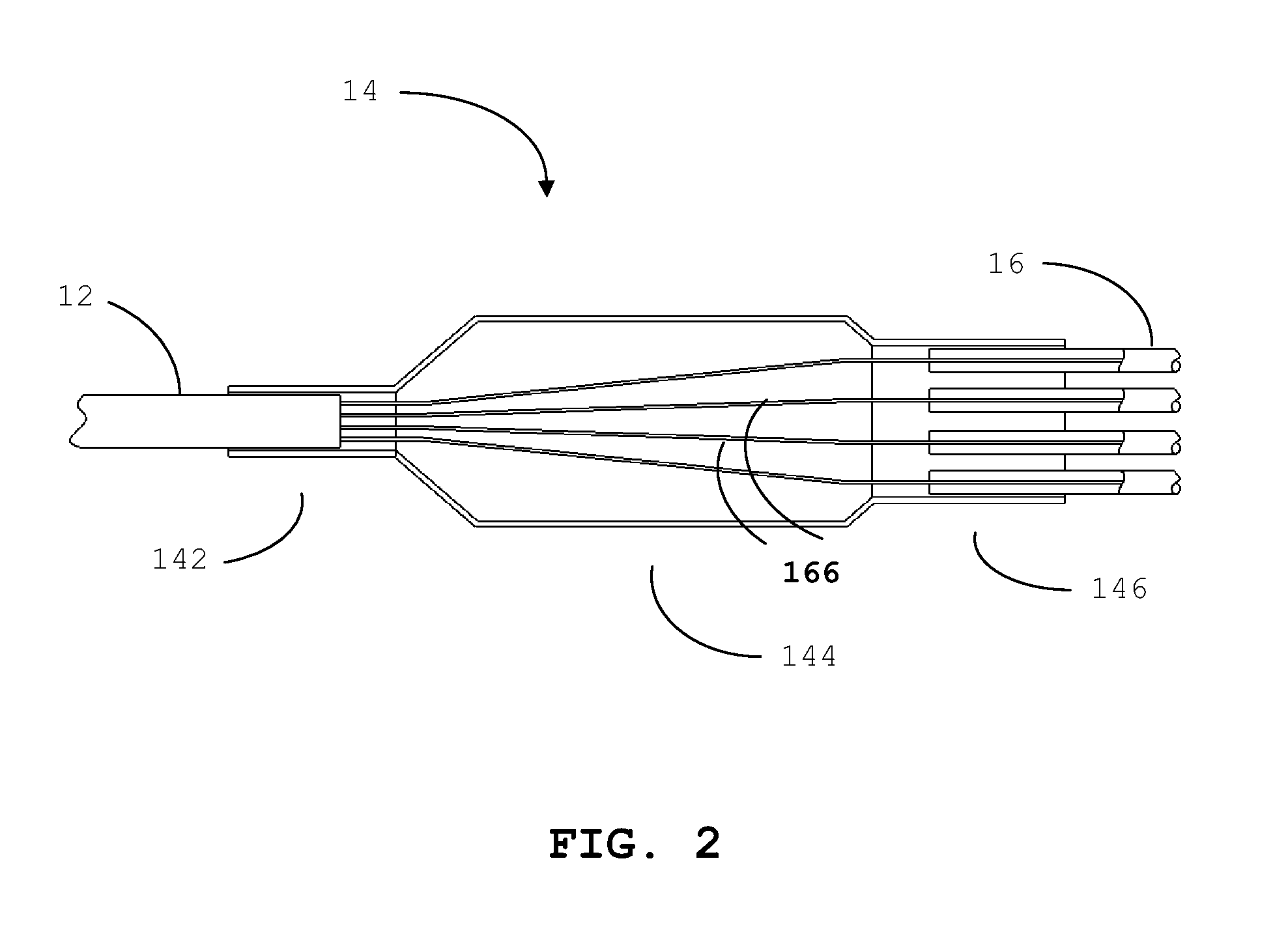

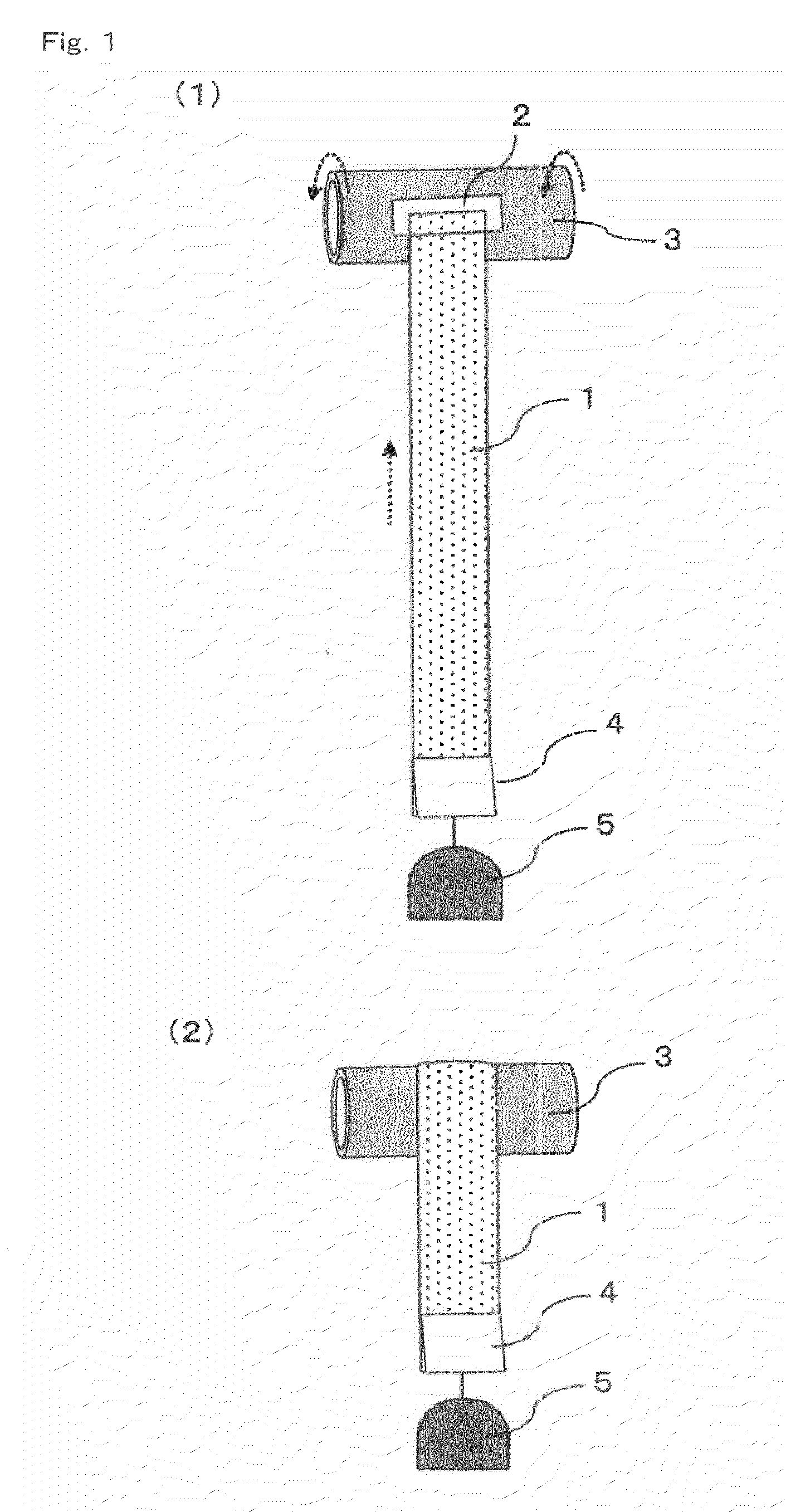

Optical Fiber Cable Assembly

InactiveUS20100092135A1Reduced flexibilityEasy to operateCoupling light guidesFibre mechanical structuresFiberEngineering

The present invention provides optical fiber communication cable assemblies useful for separating and conveying individual fibers from a multiple optical fiber cable to connectors in a protective manner. The optical fiber cable assembly is suitable for outdoor use and includes a (i) cable with multiple optical fibers; (ii) a furcation unit attached to the cable for directing individual optical fibers from the cable to furcation legs; and (iii) multiple furcation legs receiving at least one of the optical fibers. The furcation legs include (i) a buffer tube surrounding the optical fiber; (ii) strength members surrounding the buffer tube; and (iii) a jacket surrounding the strength members. The furcation legs typically exhibit a tensile rating of at least about 50 pounds (lbf), more typically 100 pounds (lbf) or more. Moreover, the furcation legs typically exhibit total shrinkage of less than about 2 percent when cycled from +23° C. to −40° C. to +70° C. to −40° C.

Owner:DRAKA COMTEQ BV

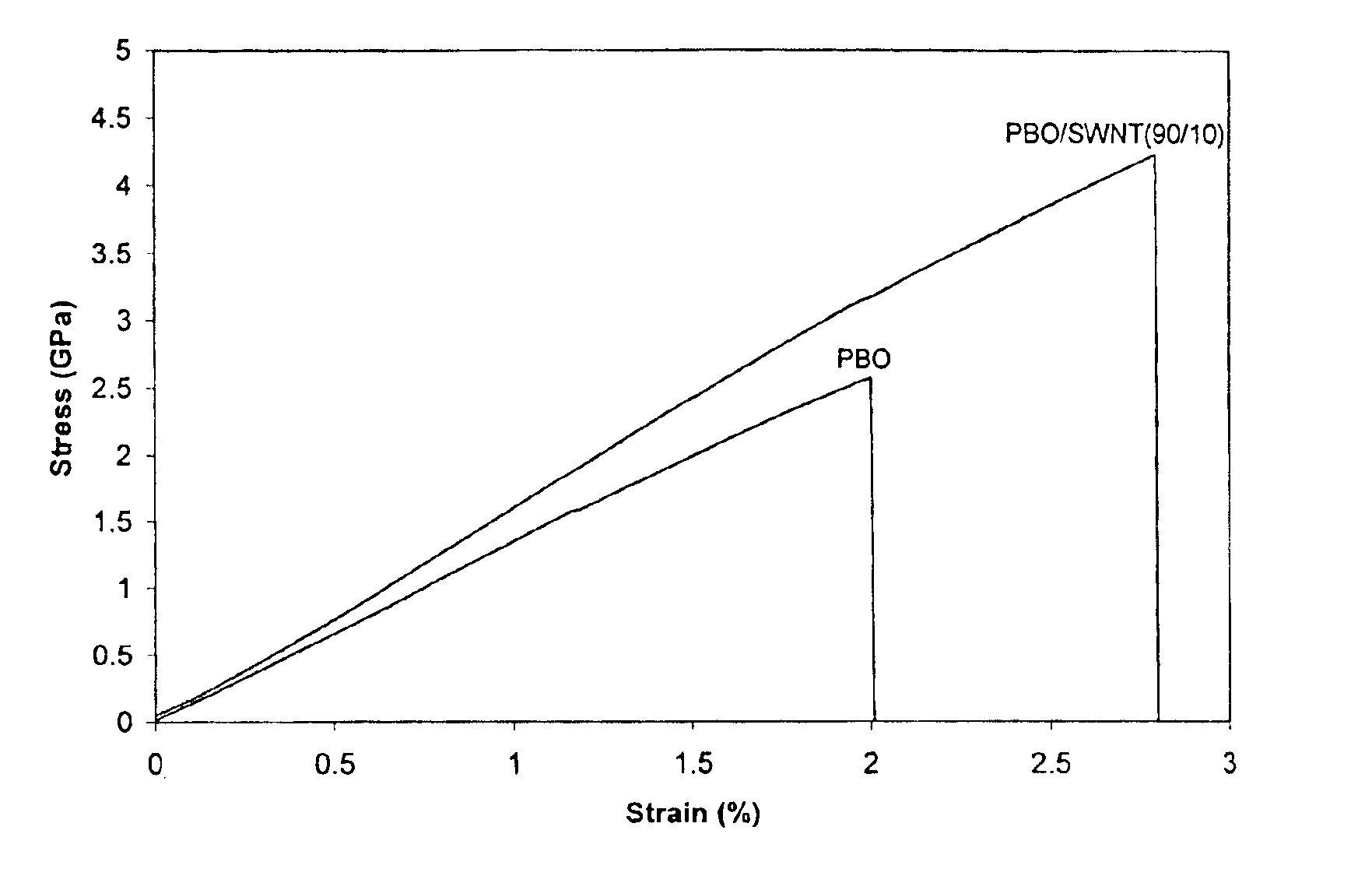

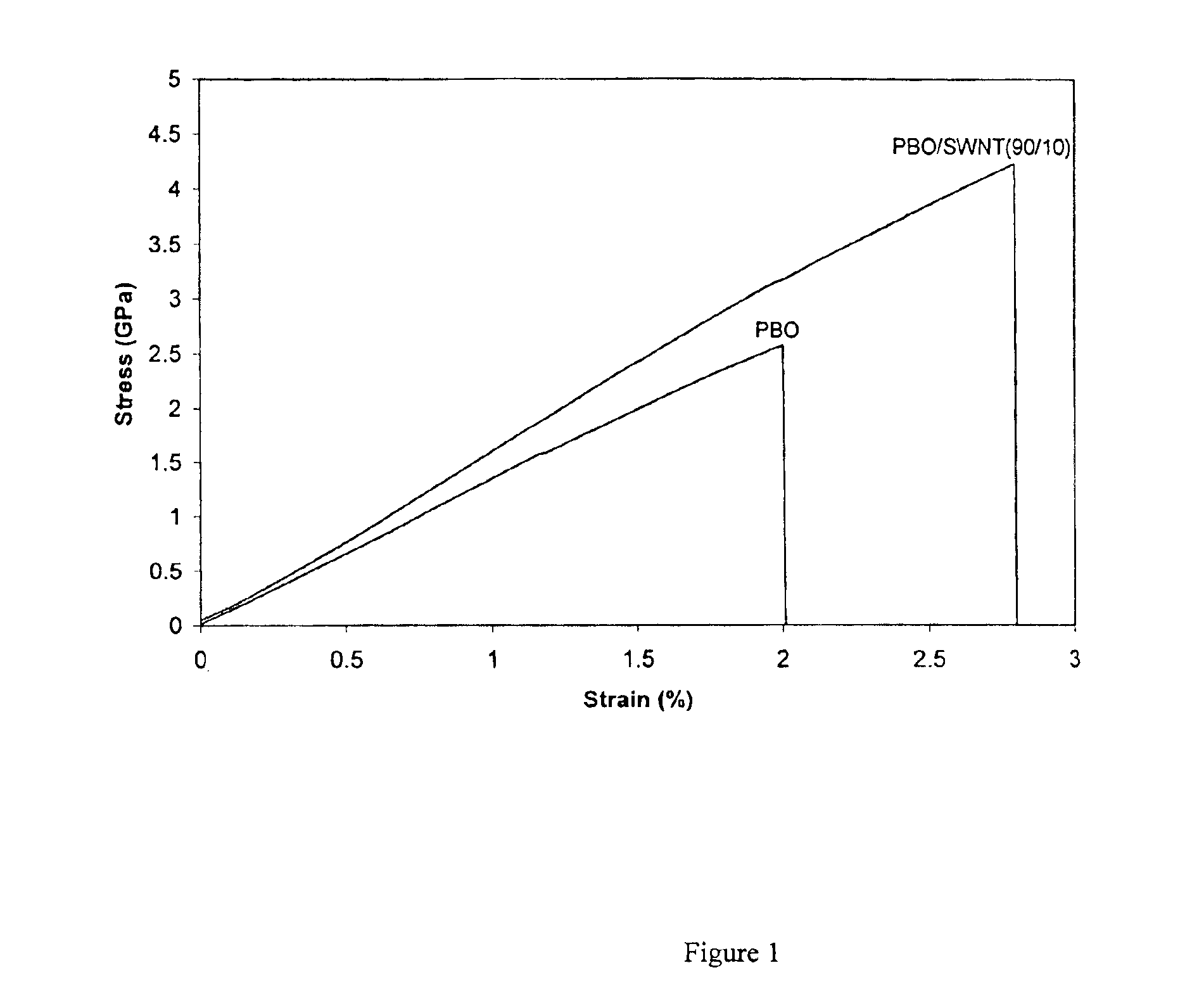

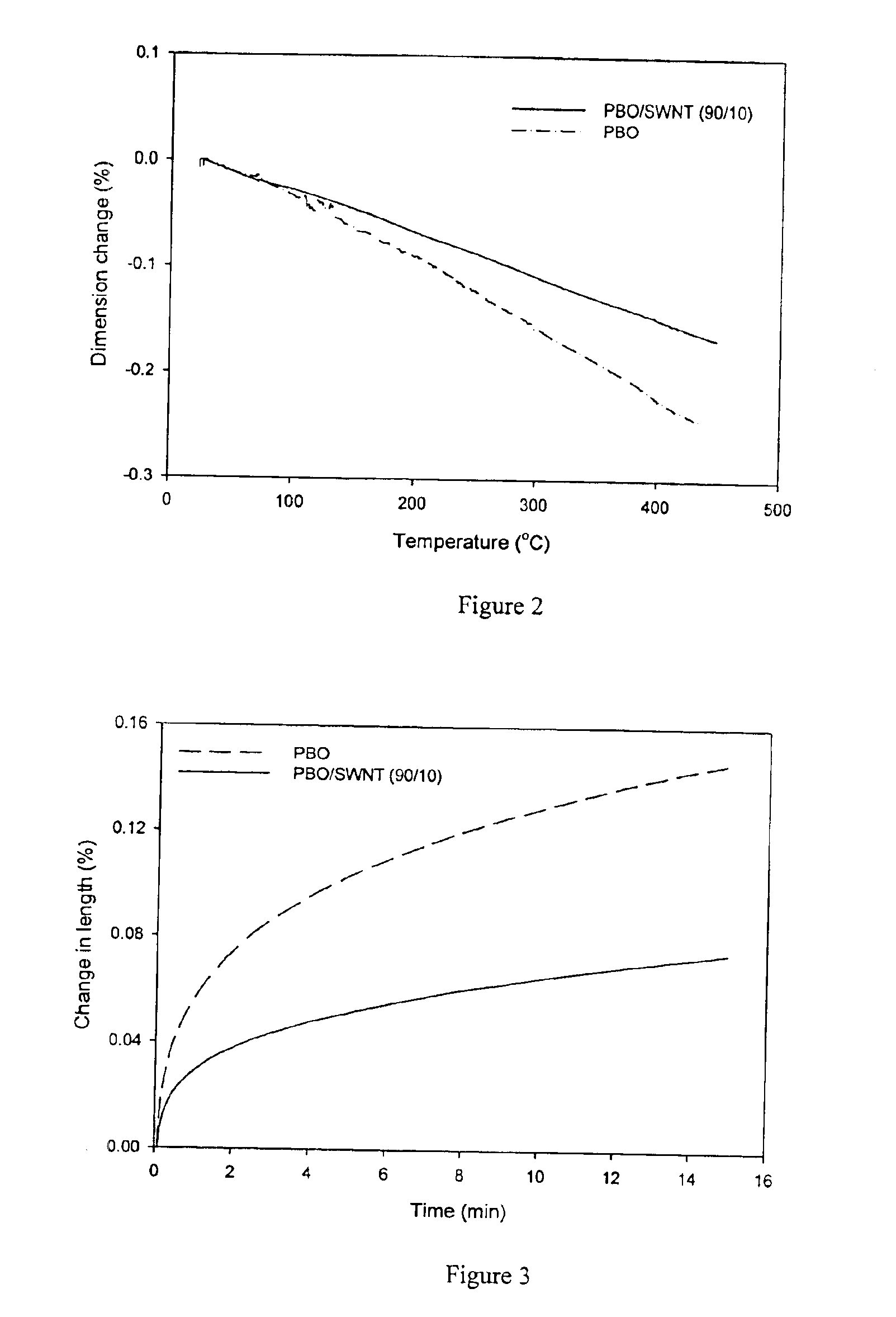

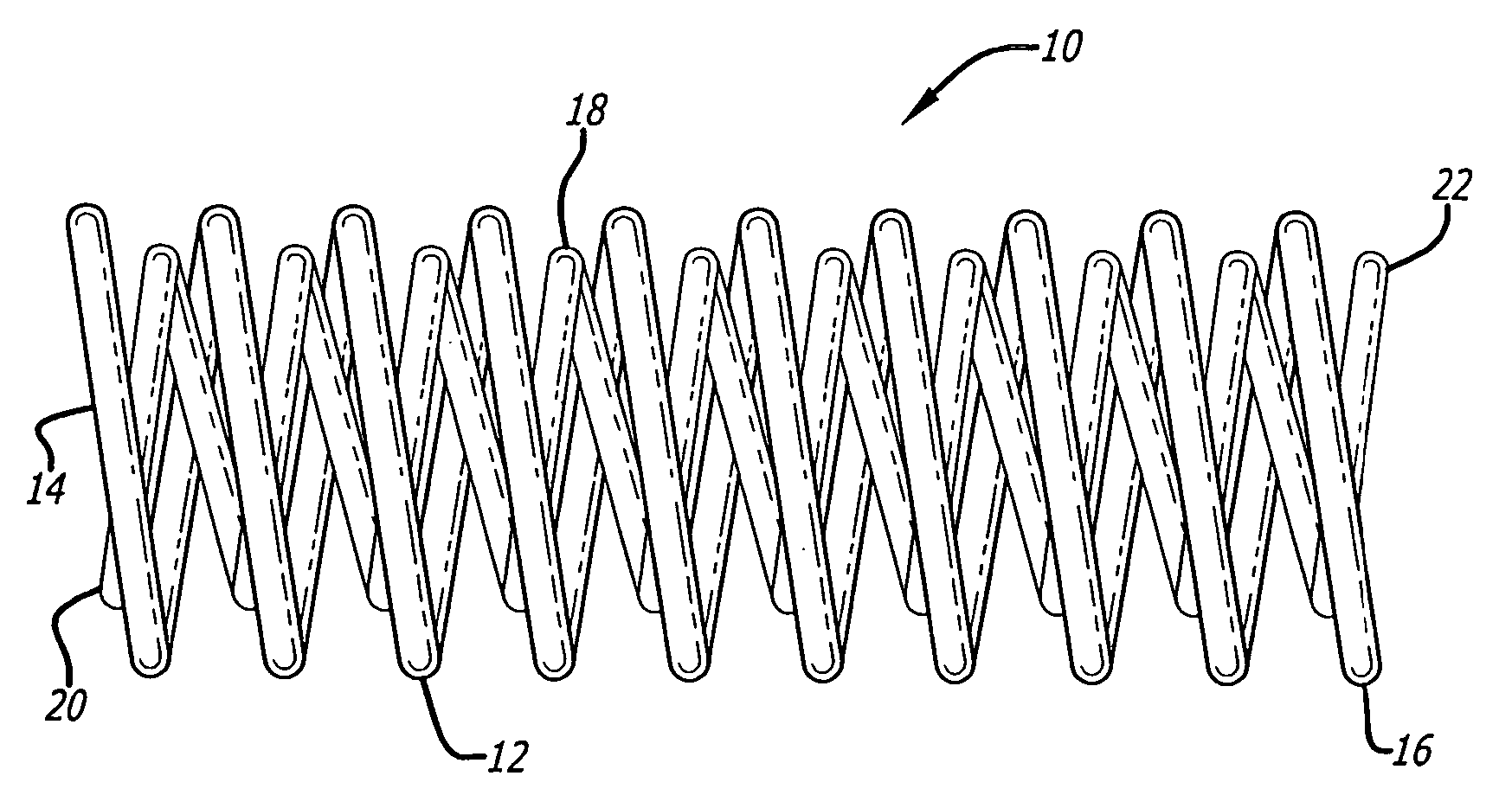

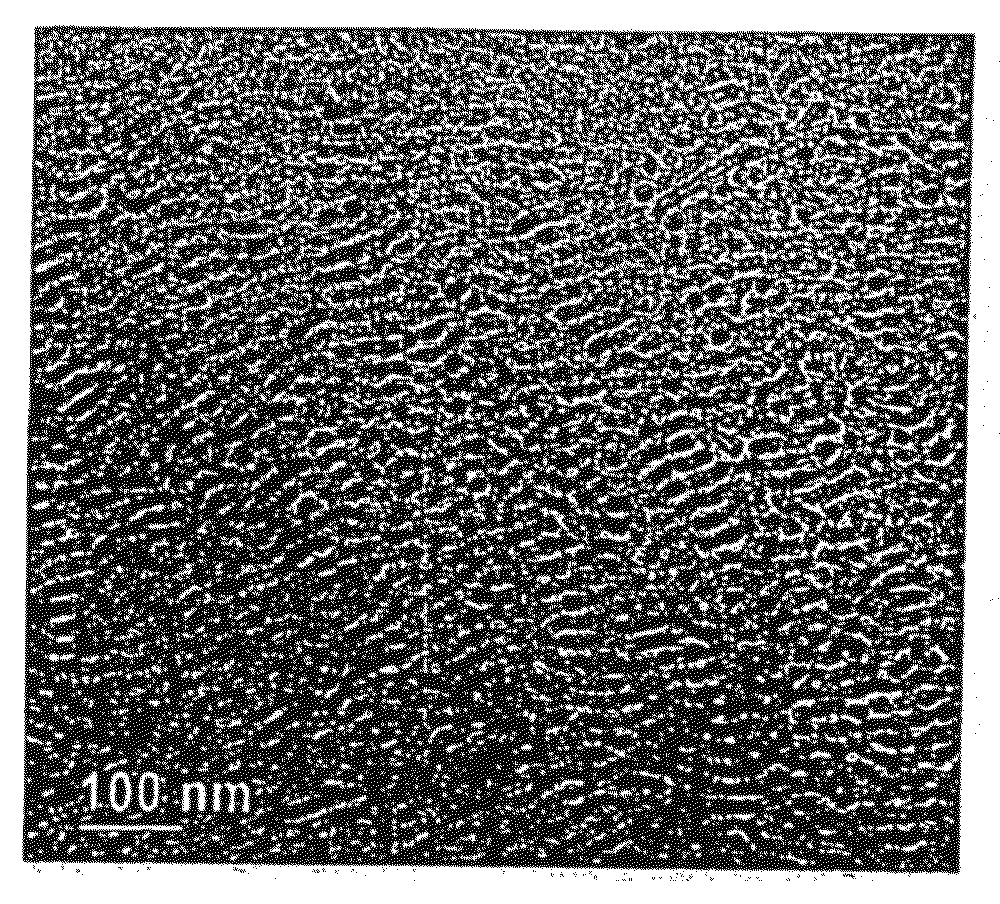

Compositions comprising rigid-rod polymers and carbon nanotubes and process for making the same

InactiveUS6900264B2High modulusHigh stiffnessMaterial nanotechnologySpecial tyresFiberLiquid crystalline

The present invention relates to compositions comprising rigid-rod polymers and carbon nanotubes. The compositions comprise dispersed carbon nanotubes aligned with rigid-rod polymers. The alignment of the nanotubes and polymers can be liquid crystalline. The rigid-rod polymers of this invention include, but are not limited to, polymers and copolymers comprising benzobisazole, pyridobisimidazole and benzamidazobenzo-phenanthroline repeat units. Dispersion of carbon nanotubes is achieved by in-situ polymerization in the presence of the carbon nanotubes, which may be either single-wall or multi-wall or a combination of both. The polymer compositions comprising carbon nanotubes may be spun into fibers or formed into films. The strength of the resulting fibers of the present invention is significantly greater than that of fibers without carbon nanotubes.

Owner:GEORGIA TECH RES CORP

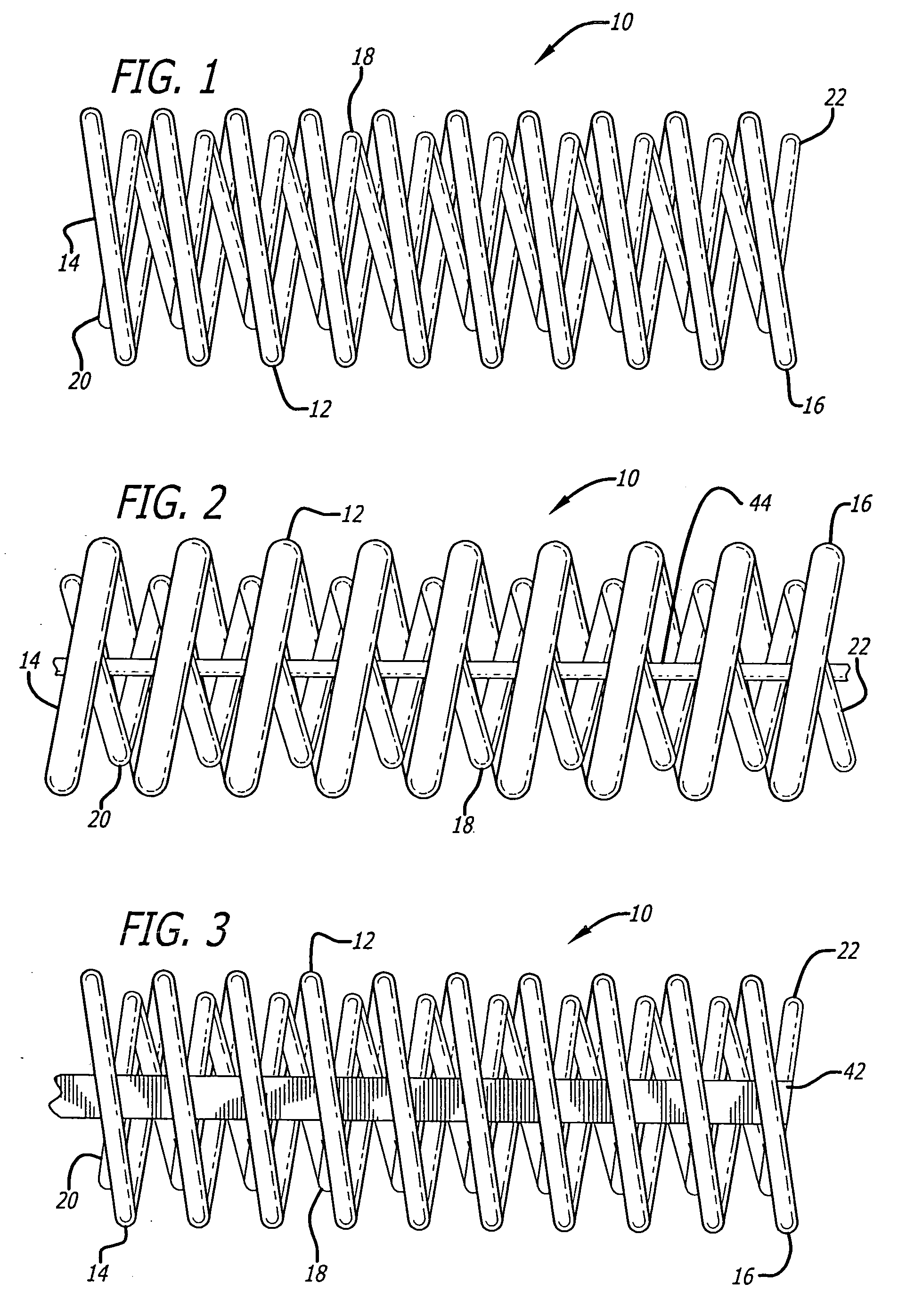

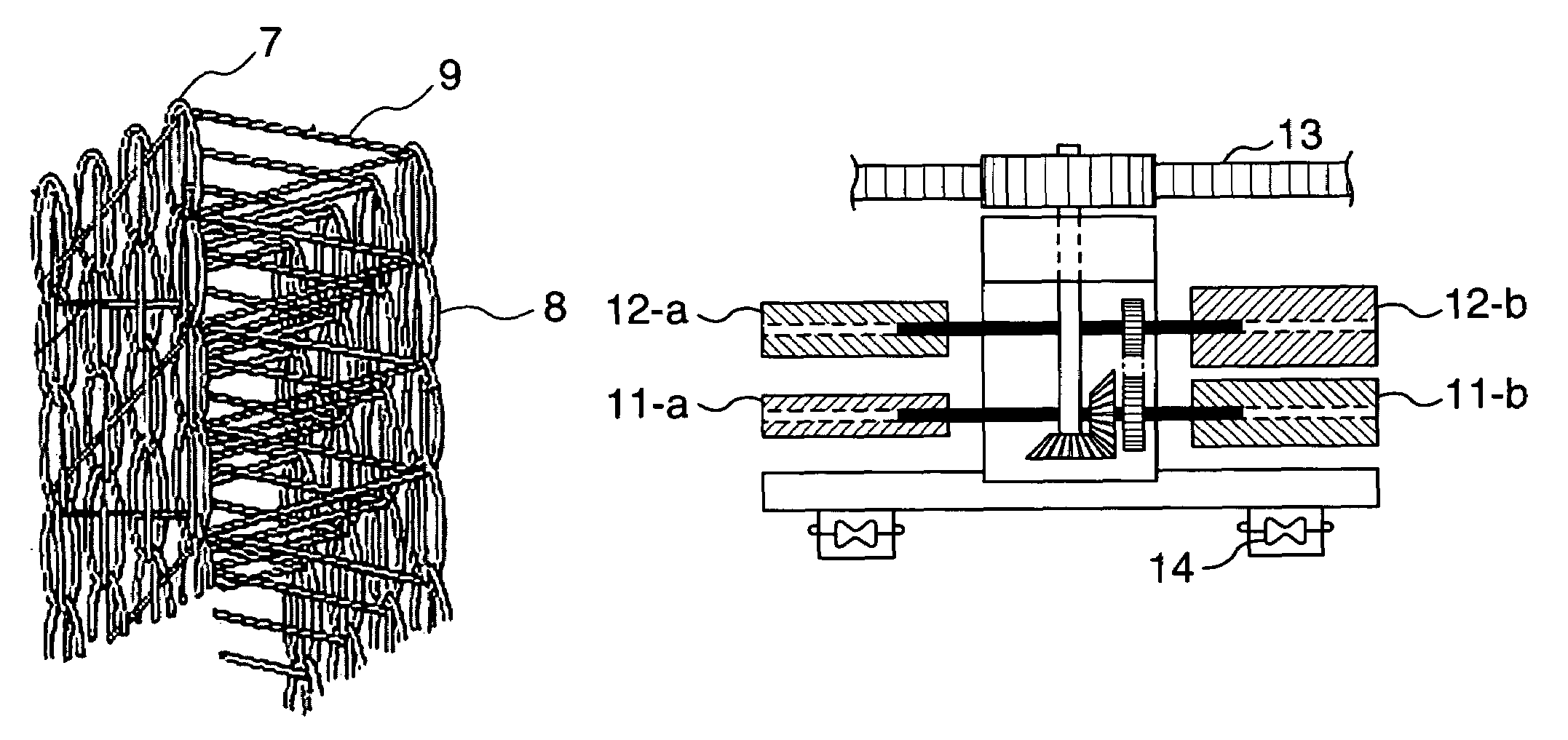

Vasoocclusive coil with biplex windings to improve mechanical properties

InactiveUS20060079926A1Improve mechanical propertiesEliminate kinksDiagnosticsDilatorsVascular surgeryInterventional therapy

The vasoocclusive device for use in interventional therapy and vascular surgery adapted to be inserted into a portion of a vasculature, includes a vasoocclusive coil disposed about an inner reinforcement coil wherein said vasoocclusive coil is helically wound and the inner reinforcement coil forms a reverse helical winding opposite the vasoocclusive coil winding, thereby forming a biplex wound coil. The vasoocclusive device biplex winding provides improved mechanical properties to the device. An inner reinforcement stretch resistant member attached within the biplex windings limits coil stretchability.

Owner:DEPUY SYNTHES PROD INC

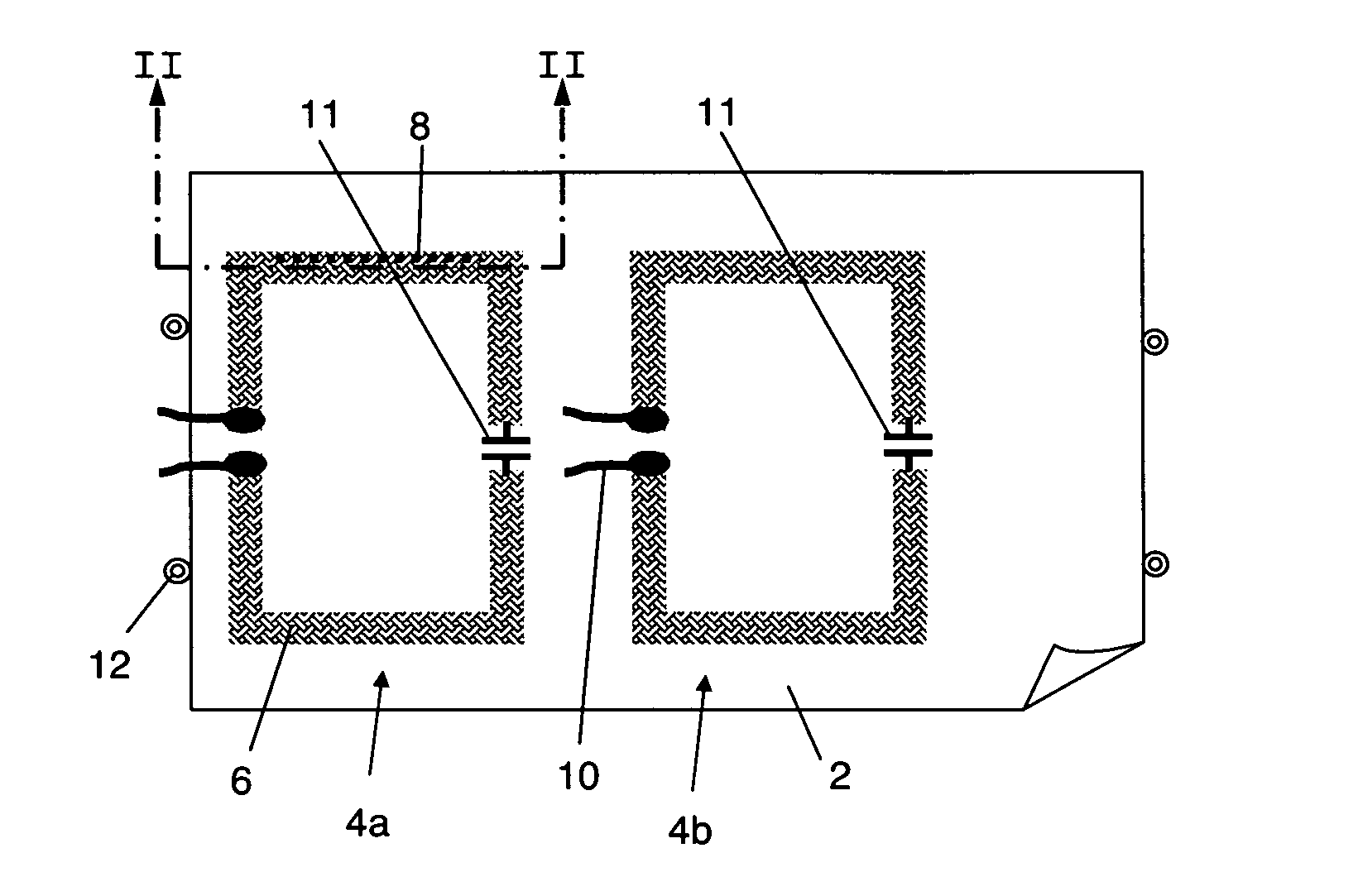

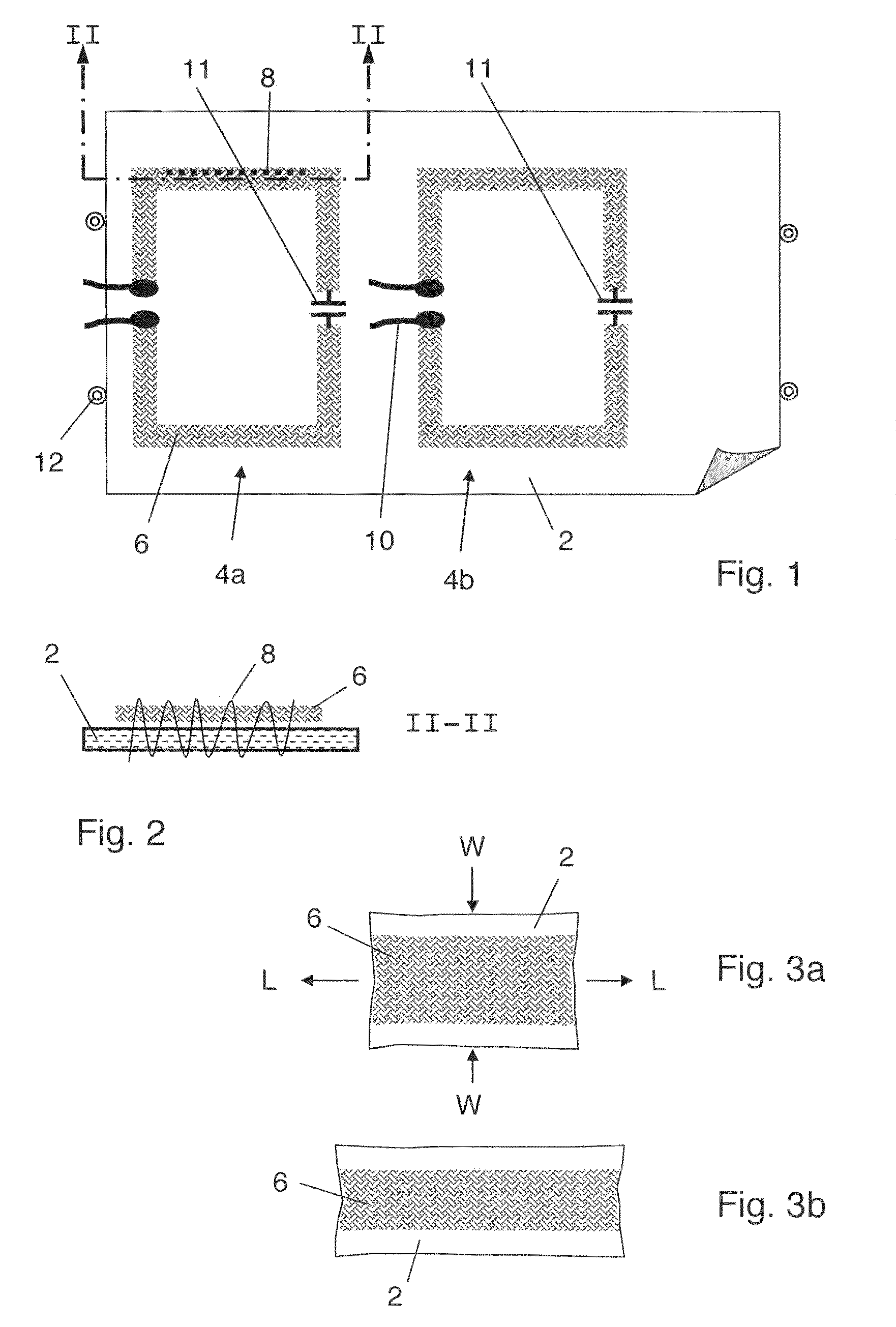

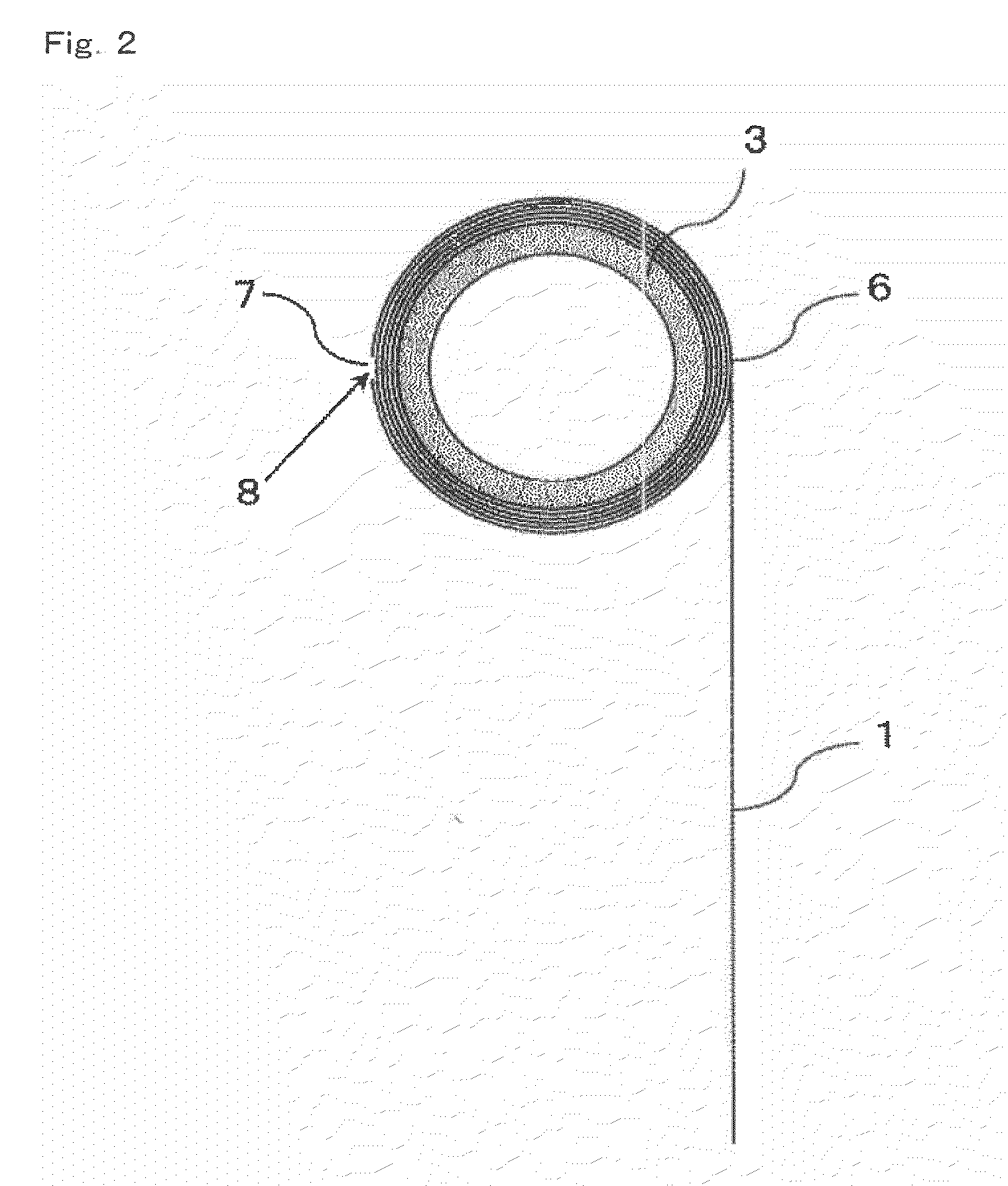

Coil assembly and multiple coil arrangement for magnetic resonance imaging

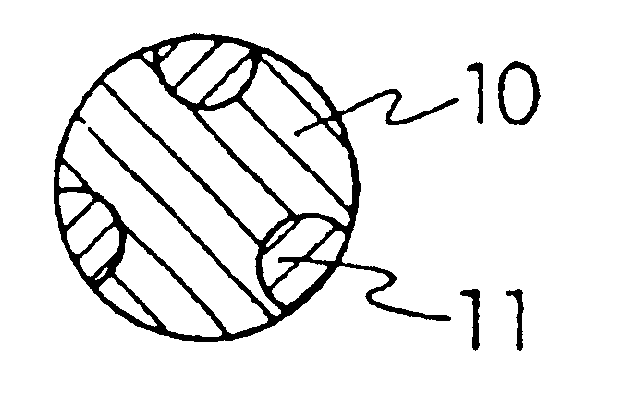

ActiveUS20090261828A1Easy to cleanMeet the requirementsMagnetic measurementsElectric/magnetic detectionElectrical conductorRadio frequency signal

A coil assembly for magnetic resonance imaging comprises a sheet (2) of flexible and stretchable dielectric material and at least one electrically conducting coil (4a, 4b) for receiving and / or emitting a radio frequency signal. The coil is attached to and extends along a face of the flexible sheet. At least part of the coil is made of a ribbon shaped braided conductor (6) that is arranged in substantially flat contact with the face.

Owner:UNIV ZURICH +1

Latent elastic nonwoven composite

InactiveUS20080003910A1Improve tensile propertiesPersonal careSynthetic resin layered productsElastomerPolyolefin

A nonwoven composite that exhibits latent elastic properties is provided. More specifically, latent elasticity may be imparted by blending a thermoplastic elastomer with a polyolefin that is capable of forming semi-crystalline domains among the amorphous elastomeric chains, and then forming a film from the blend. The film is then stretched in one or more directions to orient the amorphous elastomer chains. Without intending to be limited by theory, the present inventors believe that the oriented state of the amorphous chains may be held in place by the relatively stiff semi-crystalline olefin domains. Subsequently, the stretched film may be activated (e.g., heated) to shrink the film and provide it with “latent” stretchability. For instance, the stretched film may be heated at or above the softening temperature of the polyolefin to soften the crystalline domains and allow the amorphous chains to return to their unoriented state. As a result of the present invention, the elastic film may be extended and recover from its unoriented state.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Production of meta-block copolymers by polymer segment interchange

Meta-block copolymers and a process for preparing a product mixture comprising meta-block copolymers by contacting a metathesis catalyst under metathesis conditions with a composition comprising two or more ethylenically unsaturated polymers, said unsaturation defining one or more polymer segments in each ethylenically unsaturated polymer, at least one polymer segment in at least one ethylenically unsaturated polymer being chemically distinguishable from at least one polymer segment in at least one other ethylenically unsaturated polymer, characterized in that each meta-block copolymer in the product mixture comprises a random distribution of said chemically distinguishable polymer blocks.

Owner:DOW GLOBAL TECH LLC +1

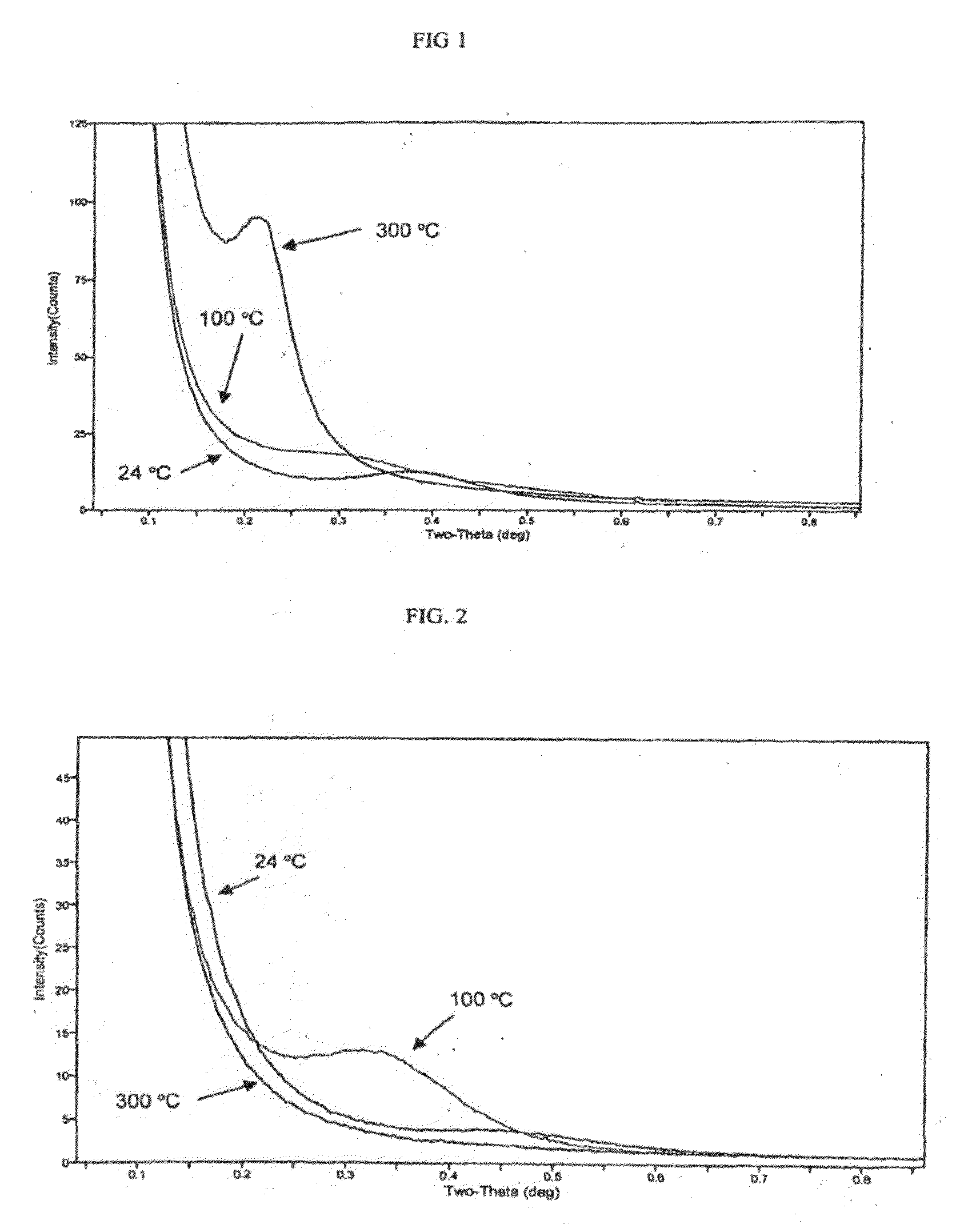

Natural rubber, rubber composition and pneumatic tire

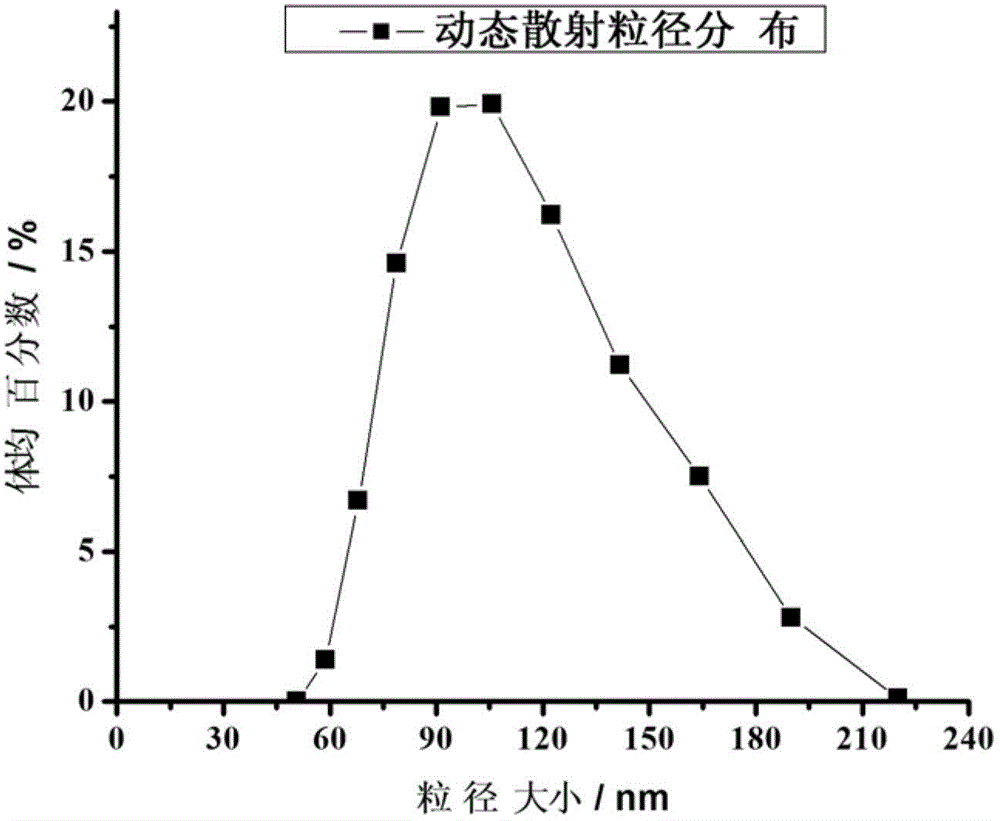

ActiveUS20050148723A1Improve processabilityImprove tensile propertiesSpecial tyresInflatable tyresNatural rubber latexAdverse effect

Natural rubber obtained by a deproteinizing treatment of a natural rubber latex and has a total nitrogen content adjusted in the range of 0.12 to 0.30% by weight and a rubber composition and a pneumatic tire using the natural rubber. The processability of natural rubber can be improved without adverse effects on the physical properties proper to natural rubber. The rubber composition exhibits an improved low hysteresis loss property and improved abrasion resistance and can be advantageously used for the tire case members and the tire tread of pneumatic tires.

Owner:BRIDGESTONE CORP

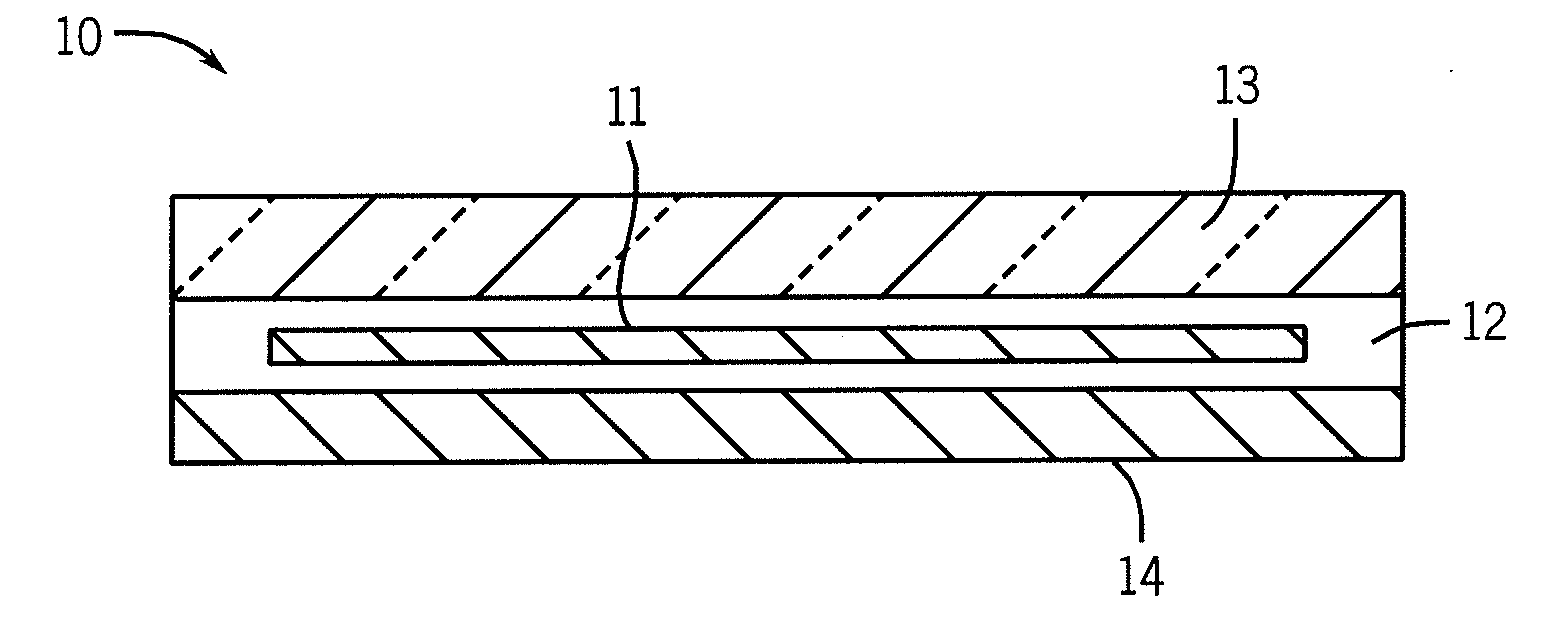

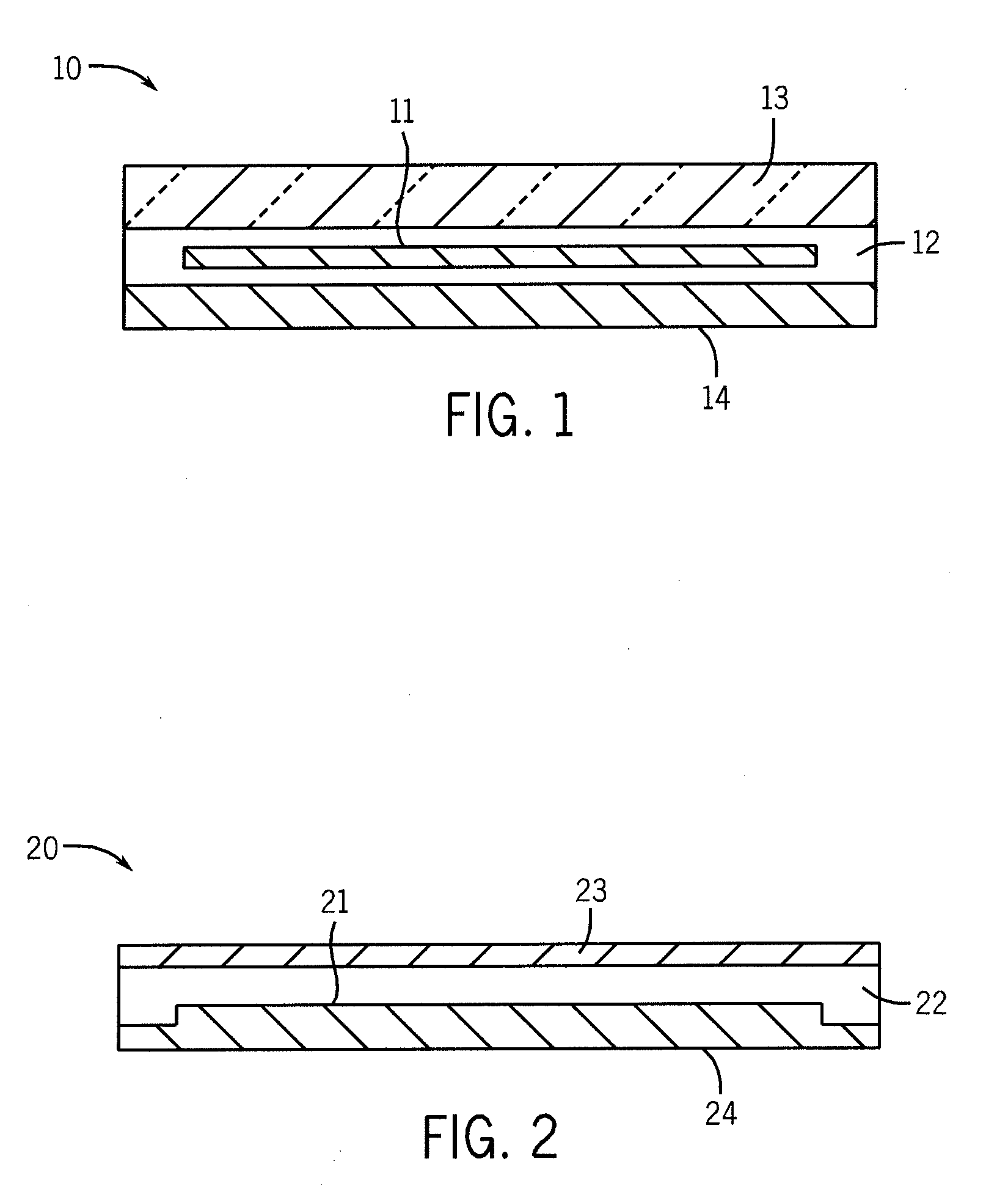

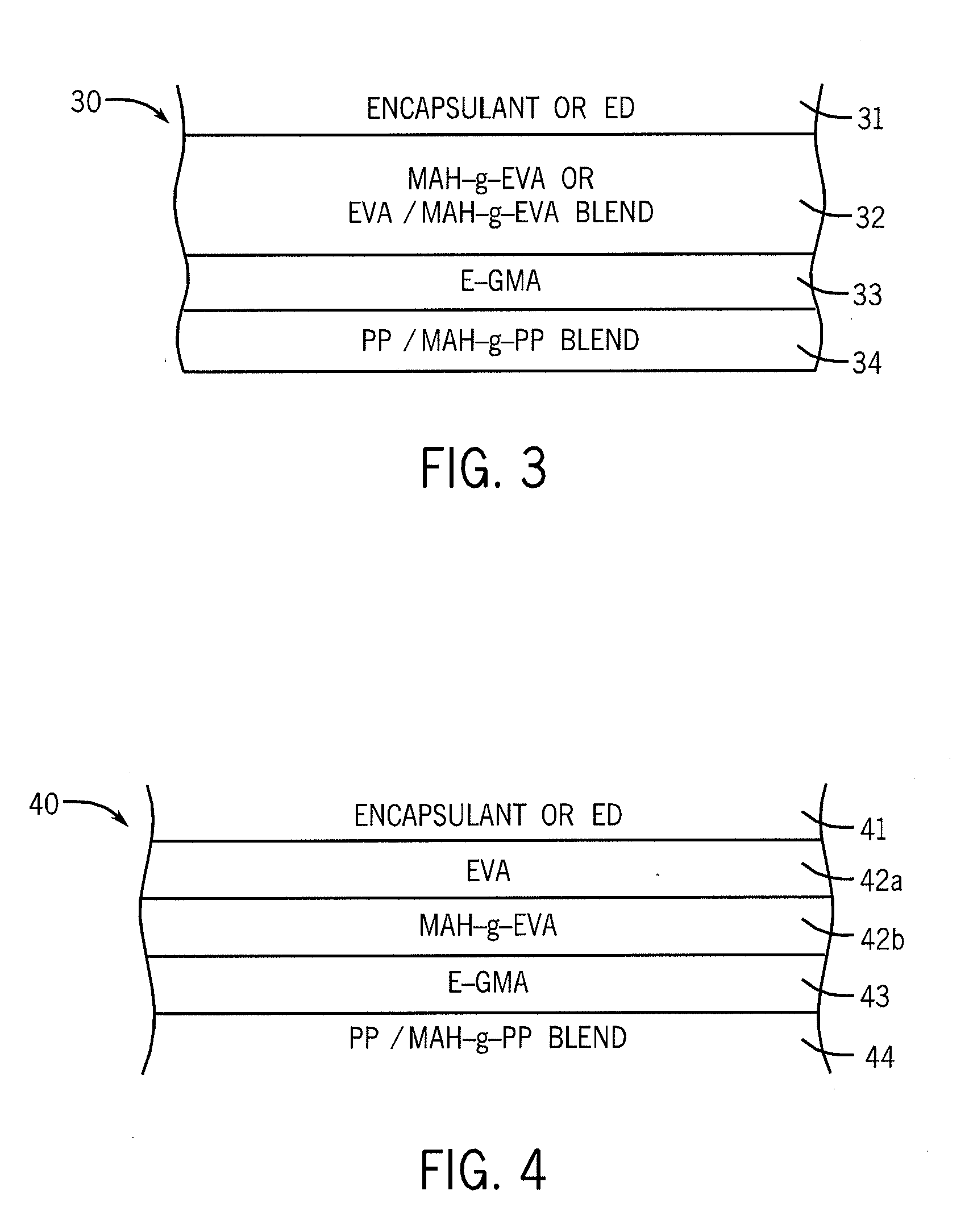

Co-Extruded, Multilayered Polyolefin-Based Backsheet for Electronic Device Modules

ActiveUS20100108128A1Improve tensile propertiesLiquid crystal compositionsSynthetic resin layered productsPolyolefinPolypropylene

Multilayer structures useful as a backsheet for an electronic device, e.g., a photovoltaic cell, comprise (A) a top layer comprising a polyolefin resin, e.g., ethylene vinyl acetate, and having a top facial surface and a bottom facial surface, (B) a tie layer comprising an adhesive, e.g., an ethylene glycidyl methacrylate, having a top facial surface and a bottom facial surface, the top facial surface in adhering contact with the bottom facial surface of the top layer, and (C) a bottom layer comprising a polyolefin having at least one melting peak greater than 125° C., e.g., a polypropylene, and having a top facial layer and a bottom facial surface, the top facial surface in adhering contact with the bottom facial surface of the tie layer.

Owner:DOW GLOBAL TECH LLC

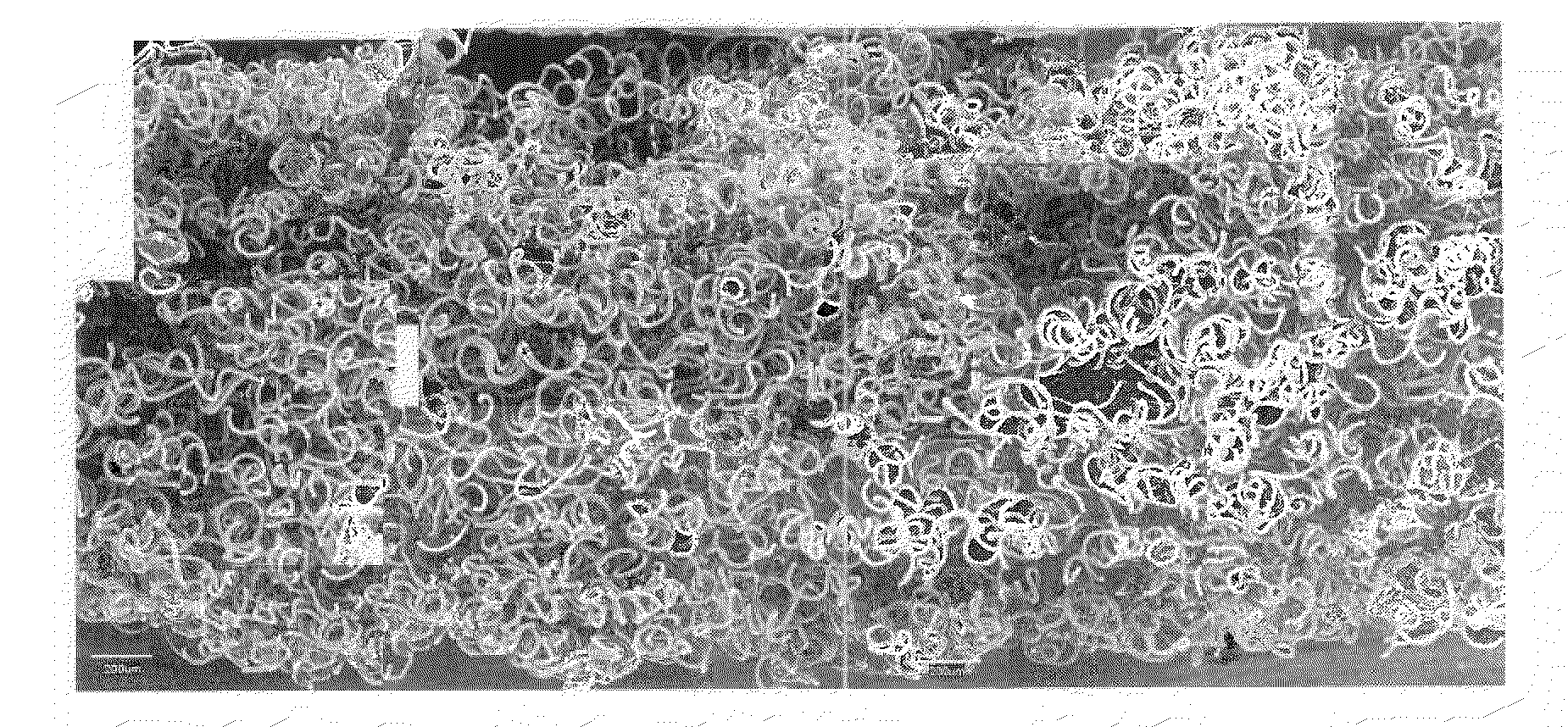

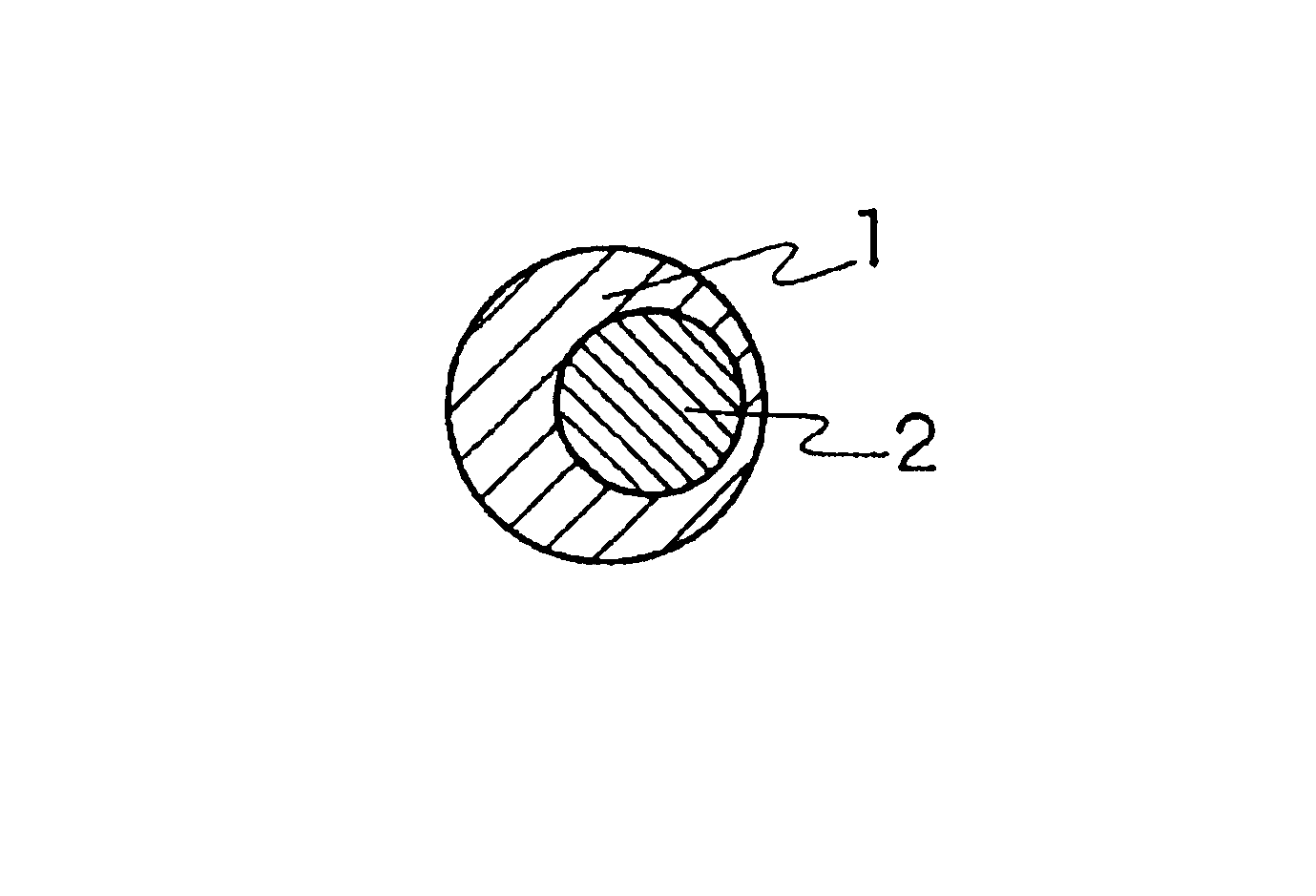

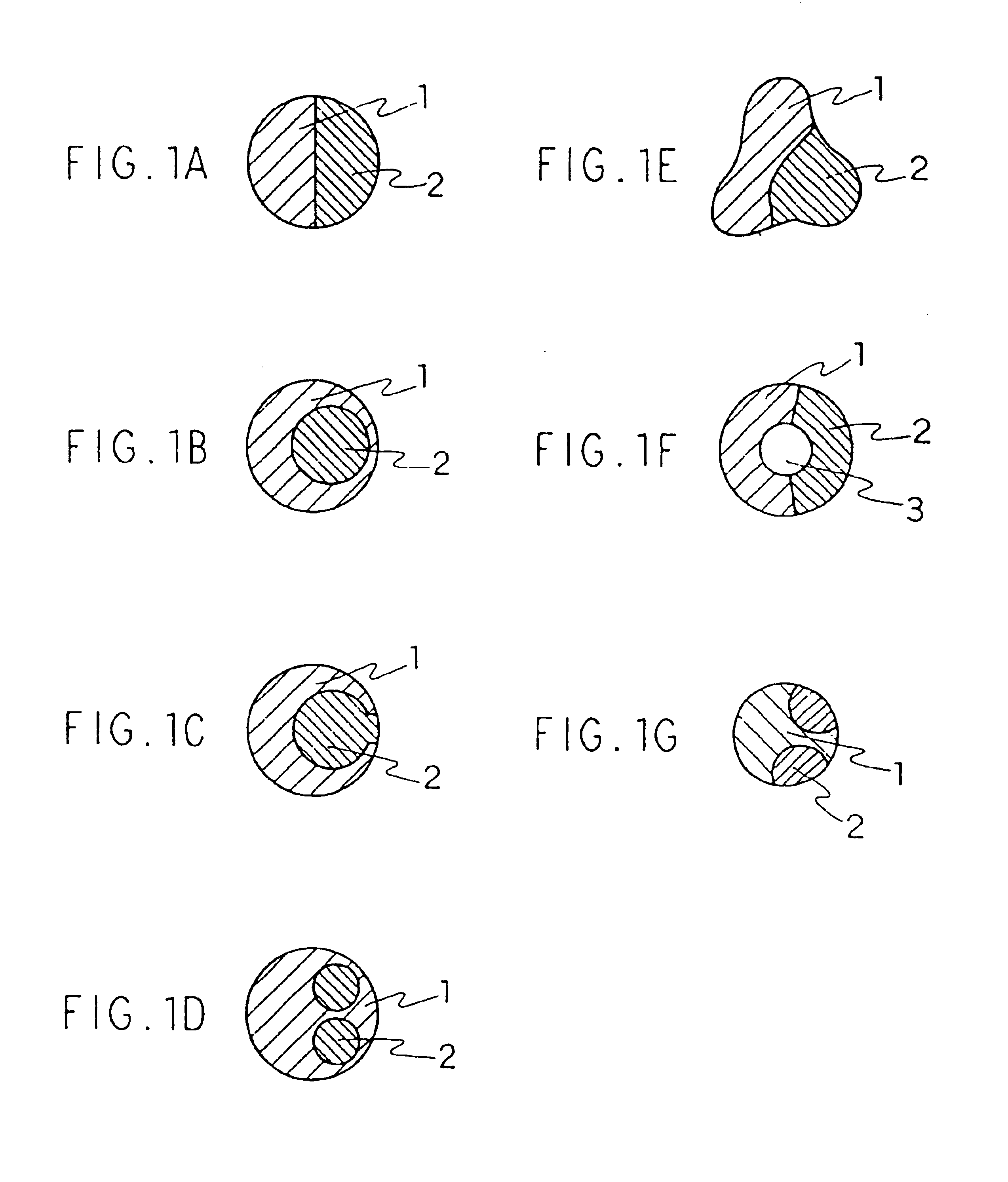

Stretchable nonwoven fabric and tape

ActiveUS20100035500A1High stretchabilitySafe to useAdhesive dressingsFibre disintegrationThermal shrinkageNonwoven fabric

To produce a nonwoven fabric comprising a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure. In the nonwoven fabric, the conjugated fibers are arranged in a direction approximately parallel to a surface direction of the nonwoven fabric and crimped. In addition, the conjugated fibers have an average curvature radius of fiber crimp of 20 to 200 μm and the crimps are distributed approximately uniformly in a thickness direction of the nonwoven fabric. The nonwoven fabric is substantially free from an adhesive agent. In the nonwoven fabric, each fiber is substantially not melt-bonded to another. The conjugated fiber may comprise a polyalkylene arylate-series resin and a modified polyalkylene arylate-series resin and have a side-by-side or eccentric sheath-core form. Since the bimetal form conjugated fibers having specific crimps are appropriately entangled with each other, the nonwoven fabric has a high stretchability and is easily torn by hand, without using scissors. The nonwoven fabric is suitable for a tape such as a bandage or a supporter.

Owner:KURARAY CO LTD

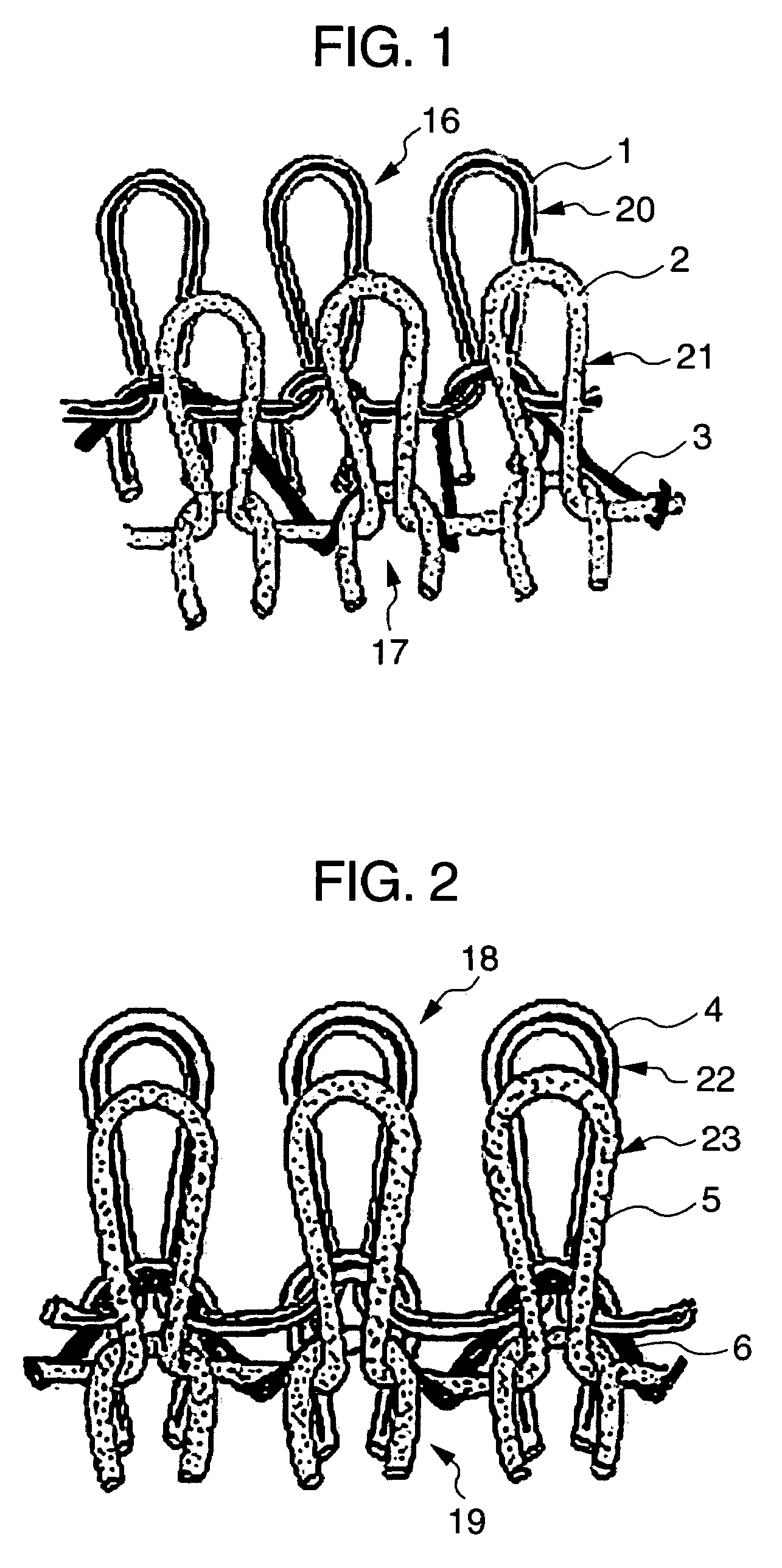

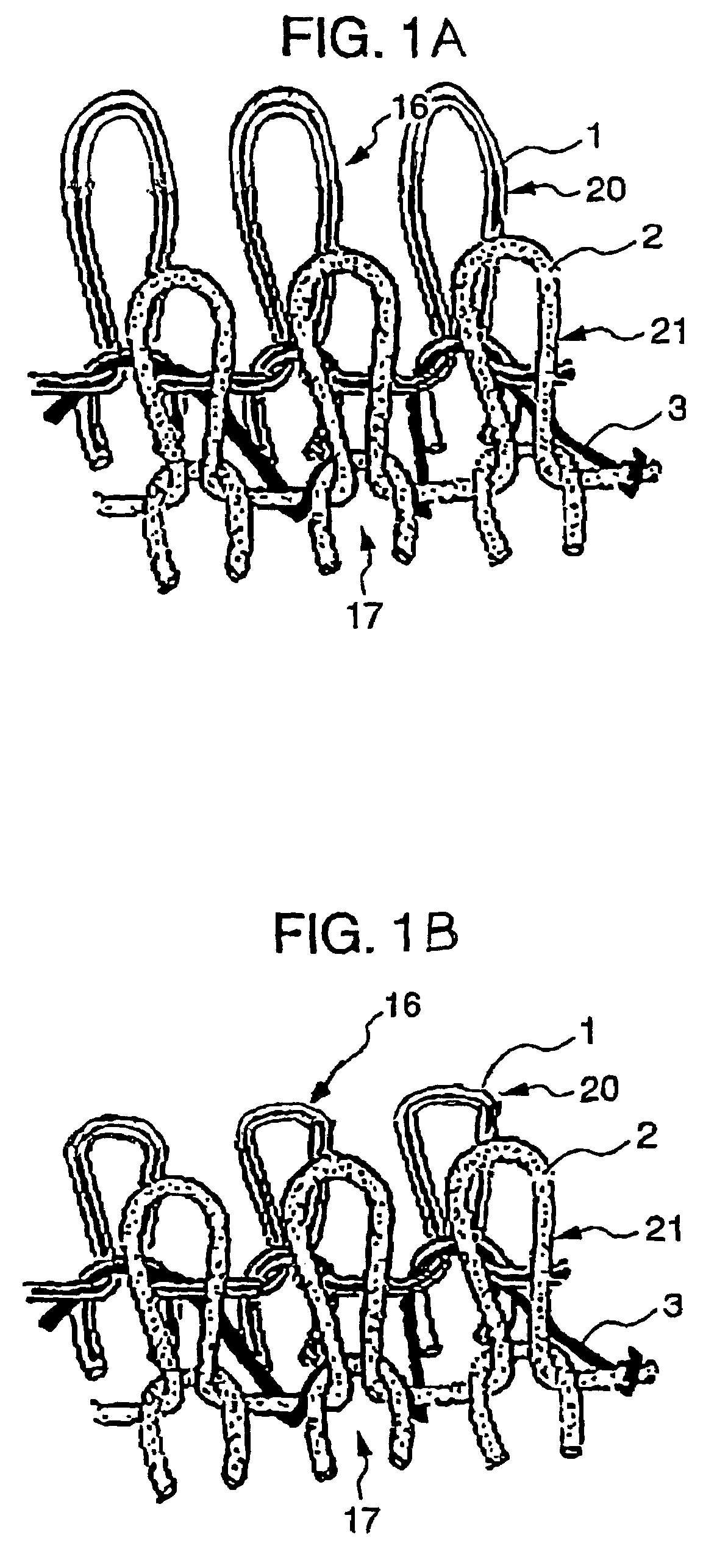

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

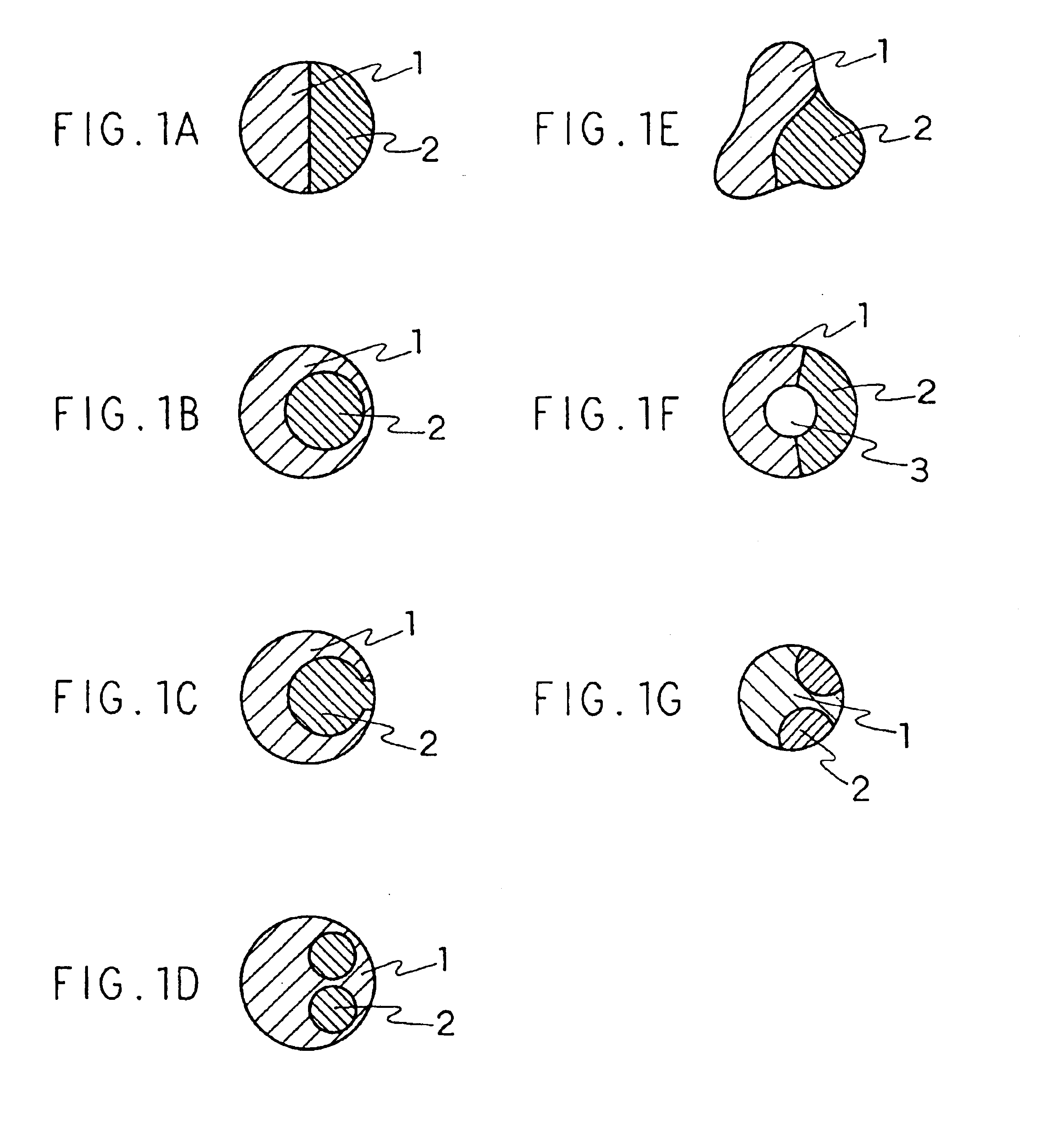

Spontaneously degradable fibers and goods made thereof

InactiveUS6844062B2Easy to splitGood bulkinessSynthetic resin layered productsFilament/thread formingYarnPolyester

A spontaneously degradable fiber excellent in bulkiness, softness, stretchability and feeling, which comprises (A) a low heat-shrinkable fiber component comprising a high crystalline aliphatic polyester and (B) a high heat-shrinkable fiber component comprising an aliphatic polyester, e.g., a low crystalline or non-crystalline aliphatic polyester, and a block copolymer or a mixture the main component of which is an aliphatic polyester and which comprises a high-melting component and a low-melting component. Further, fibers excellent in self-crimpability or self-adhesion property and dividable fibers are obtained by suitably combining the fiber components (A) and (B) to form conjugated fibers or composite yarns.

Owner:TORAY IND INC

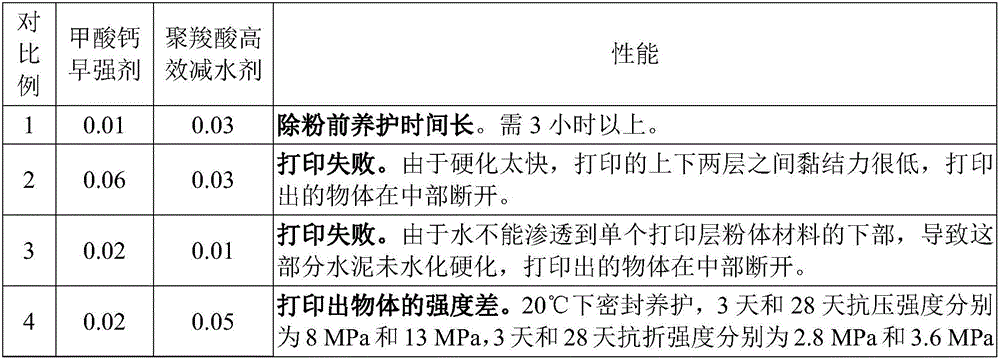

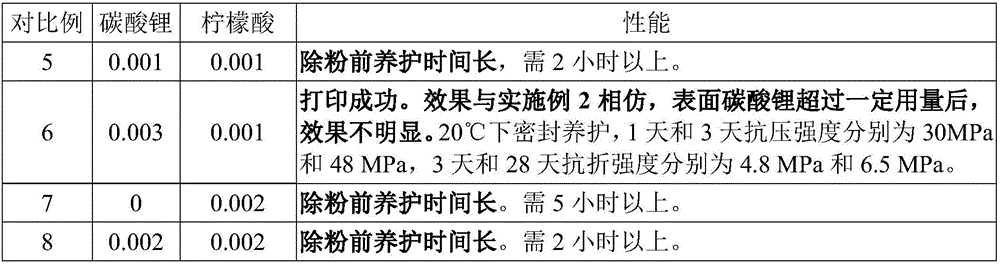

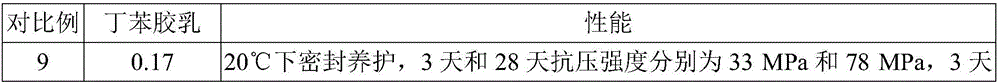

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

Nonwoven-film composite with latent elasticity

InactiveUS20080119102A1Improve tensile propertiesSynthetic resin layered productsLaminationElastomerPolyolefin

A nonwoven composite that exhibits latent elastic properties is provided. The composite is formed from an elastic film laminated to a nonwoven web facing. Latent elasticity may be imparted to the elastic film through the combination of a thermoplastic elastomer and a polyolefin capable of forming semi-crystalline domains among the amorphous elastomeric chains. More specifically, the elastic film may be stretched in one or more directions to orient the elastomer chains. Without intending to be limited by theory, the present inventors believe that the oriented state of the chains may be held in place by the relatively stiff semi-crystalline domains of the polyolefin. The stretched elastic film may subsequently be relaxed and bonded to a nonwoven web facing to form the composite. The composite may be later activated (e.g., heated) to shrink the elastic film and provide it with “latent” stretchability. For instance, the composite may be heated at or above the softening temperature of the polyolefin to soften the crystalline domains and allow the chains to return to their unoriented state. As a result of the present invention, the elastic film may be extended and recover from its unoriented state.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for improving graphene and copper basal body binding force in copper-based graphene composite material

The invention provides a method for improving graphene and copper basal body binding force in a copper-based graphene composite material; and the method prepares the composite material by a spark plasma sintering technology through adding a small amount of alloy elements in a copper basal body and mixing the alloy elements with graphene. Experiments prove that the method improves the interface binding force of the basal body and a graphene reinforcement phase in the composite material; and compared with a composite material prepared by adding no alloy element, high tensile resistance is achieved. In addition, the copper-based graphene composite material with excellent heat conductivity, electricity conductivity and wear resistance can be obtained by optimizing the adding quantity of the alloy elements and the mass of the graphene, so that excellent application prospect is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

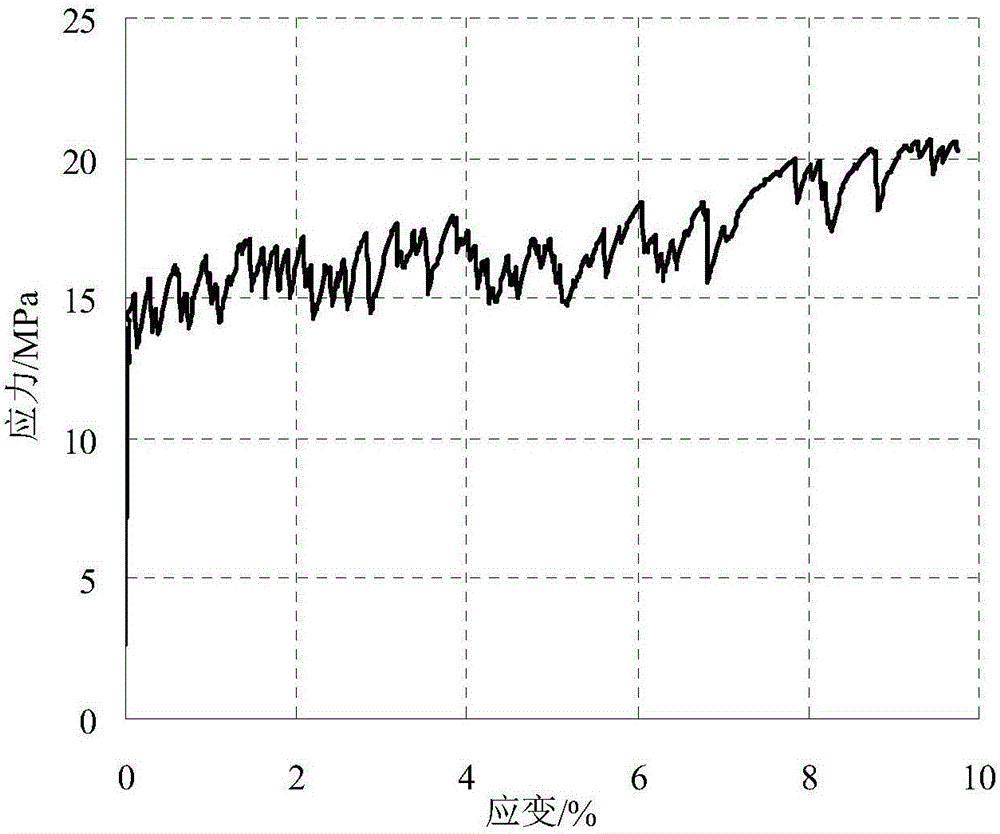

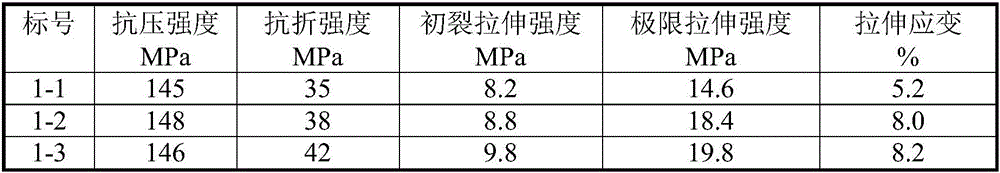

High-strength ultra-high-toughness concrete and preparation method thereof

The invention relates to high-strength ultra-high-toughness concrete and a preparation method thereof. The concrete is prepared from, by weight, 400-800 parts of cement, 100-250 parts of silica fume, 200-500 parts of slag powder, 200-500 parts of fly ash, 200-500 parts of quartz powder, 800-1,000 parts of quartz sand, 20-40 parts of a water reducing agent, 180-250 parts of water and 15-25 parts of polyethylene fibers. When the concrete is prepared, the cement, the silica fume, the slag powder, the fly ash, the quartz powder and the quartz sand are added into a stirrer by weight, and the dry powder is stirred for 2-3 min and fully mixed to be uniform; after stirring is finished, the mixed dry powder is transferred into a mold, vibrating is conducted for 1-2 min for molding, curing and demolding are conducted, and then the high-strength ultra-high-toughness concrete is prepared. Compared with the prior art, the concrete has the advantages that the compressive strength reaches 120-150 MPa, the breaking strength reaches 30-50 MPa, the tensile strength reaches 15-22 MPa, and the tensile elongation reaches 4%-8% and has the very good application prospect.

Owner:上海同延建筑科技有限公司

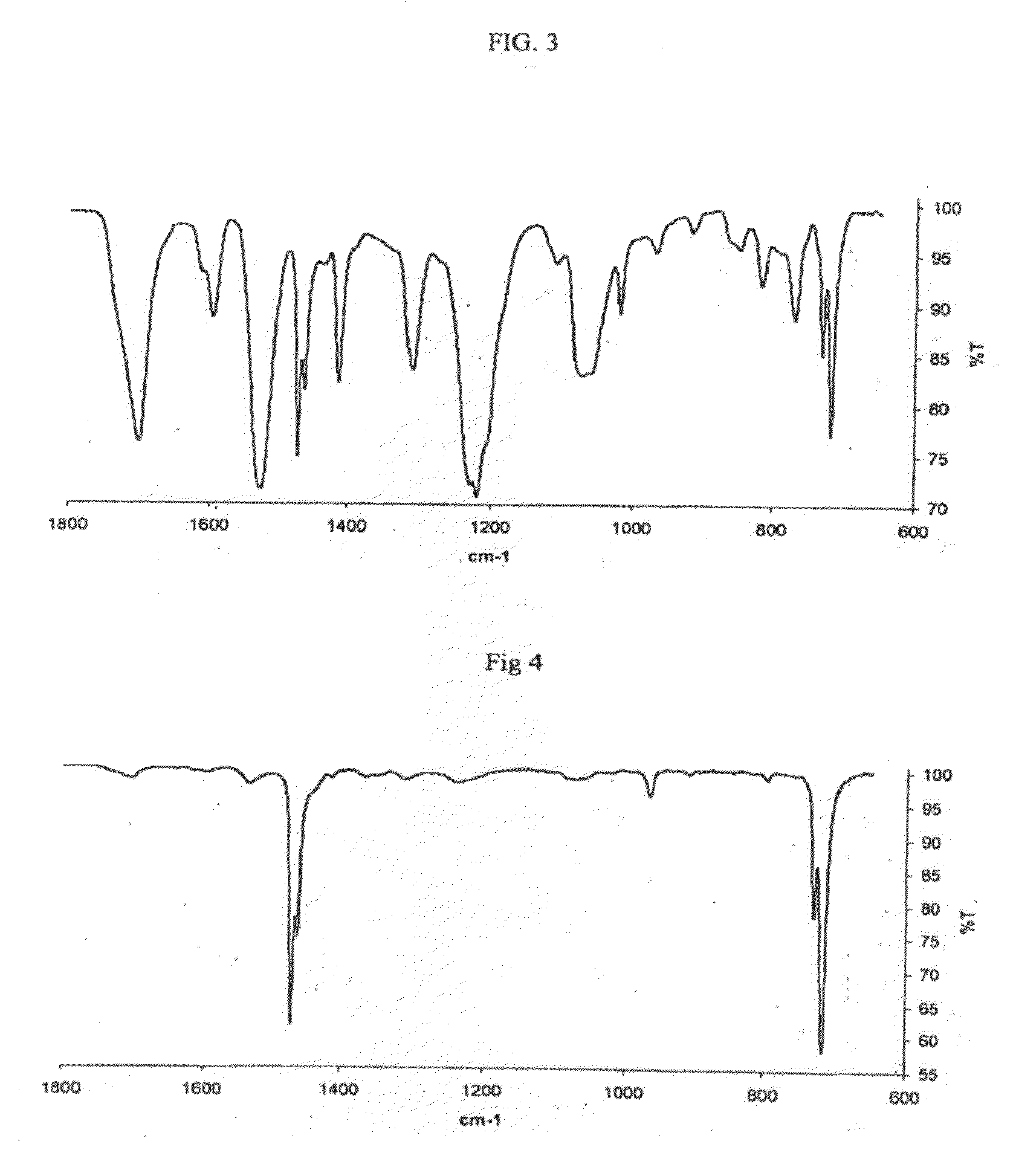

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

Fine metal particles and fine metal oxide particles in dry powder form, and use thereof

ActiveUS20070051927A1Simple preparation processImprove dispersionPigmenting treatmentMaterial nanotechnologyStable stateOrganic solvent

The present invention provides a process for simply and easily producing fine metal particles or fine metal oxide particles in the form of a dry powder which can be used as extremely fine particles in a good dispersion state without causing coagulation for a long time even if not stored in a dispersion solvent. Fine metal particles or fine metal oxide particles in the form of a dry powder are prepared using a dispersion in which fine metal particles or fine oxide metal particles having a surface oxidation film are dispersed in an organic solvent in a stable state, while once covering the particle surface with covering agent molecules containing, at a terminal, a functional group having an oxygen atom, a nitrogen atom, or a sulfur atom as a group capable of forming a coordinative bond with metal, and by removing the dispersion solvent, washing and removing excess covering agent molecules with a polar solvent without damaging the covering agent molecule layer covering the fine particle surface, finally evaporating the polar solvent used for washing and drying.

Owner:HARIMA CHEM INC

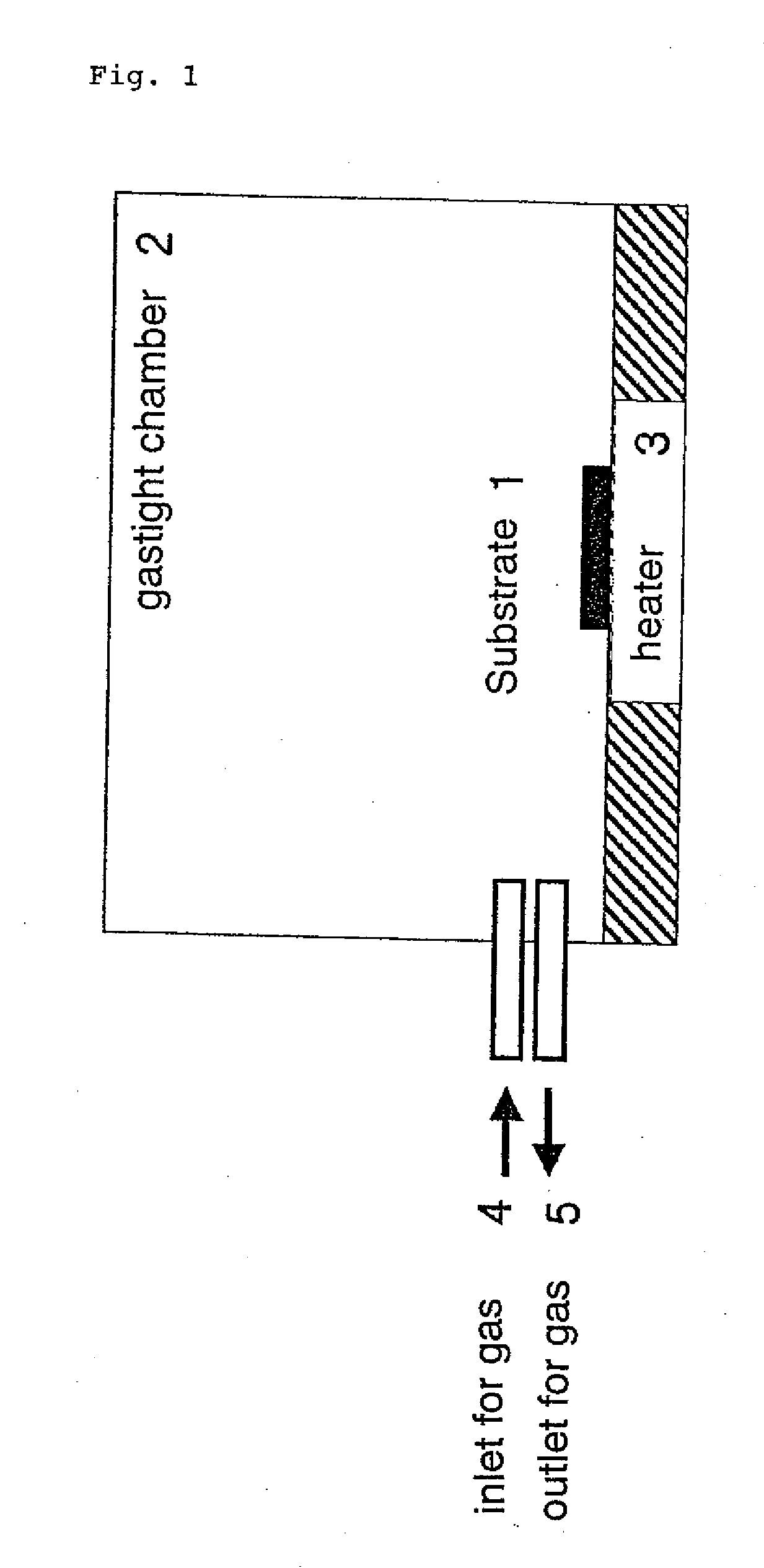

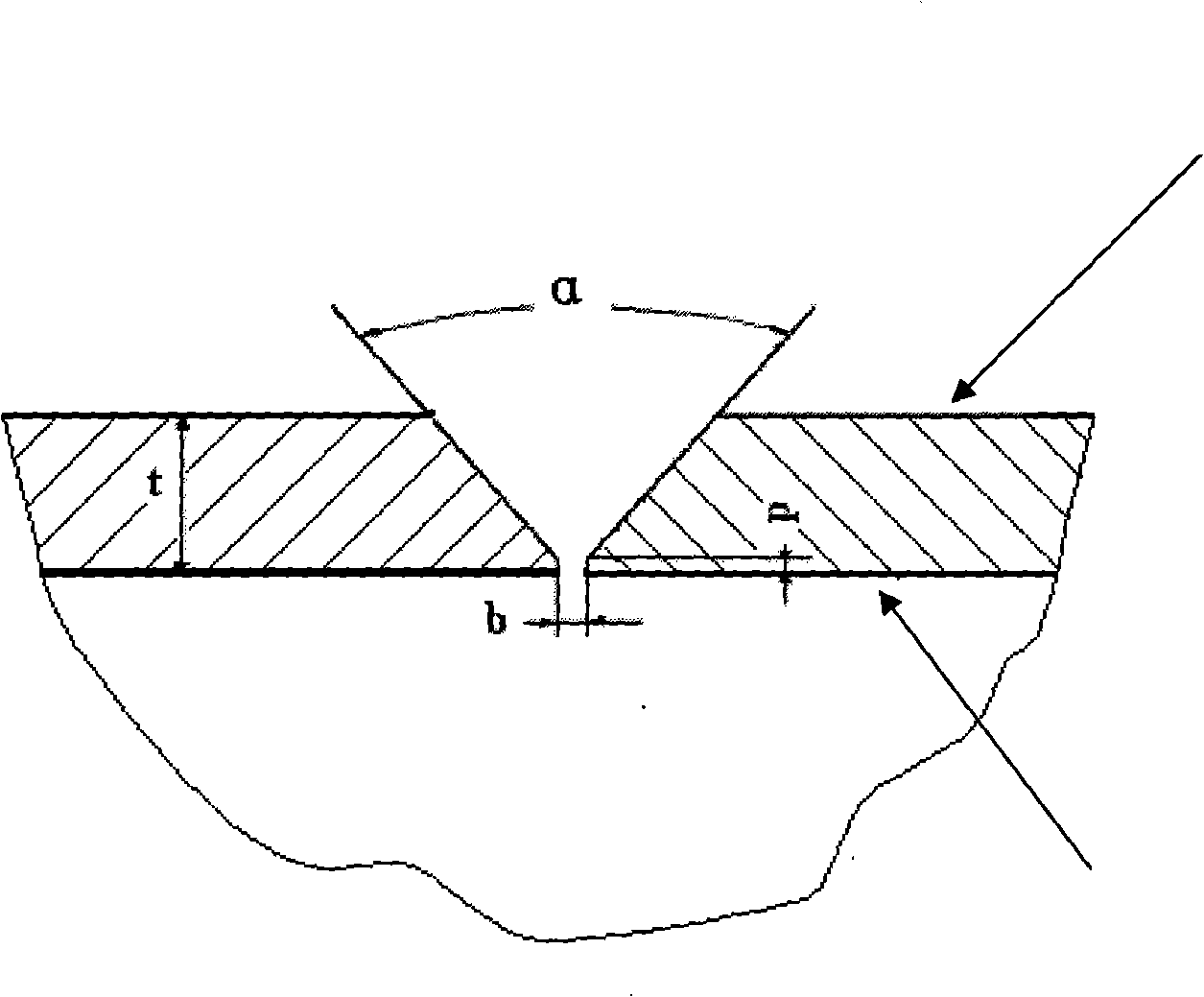

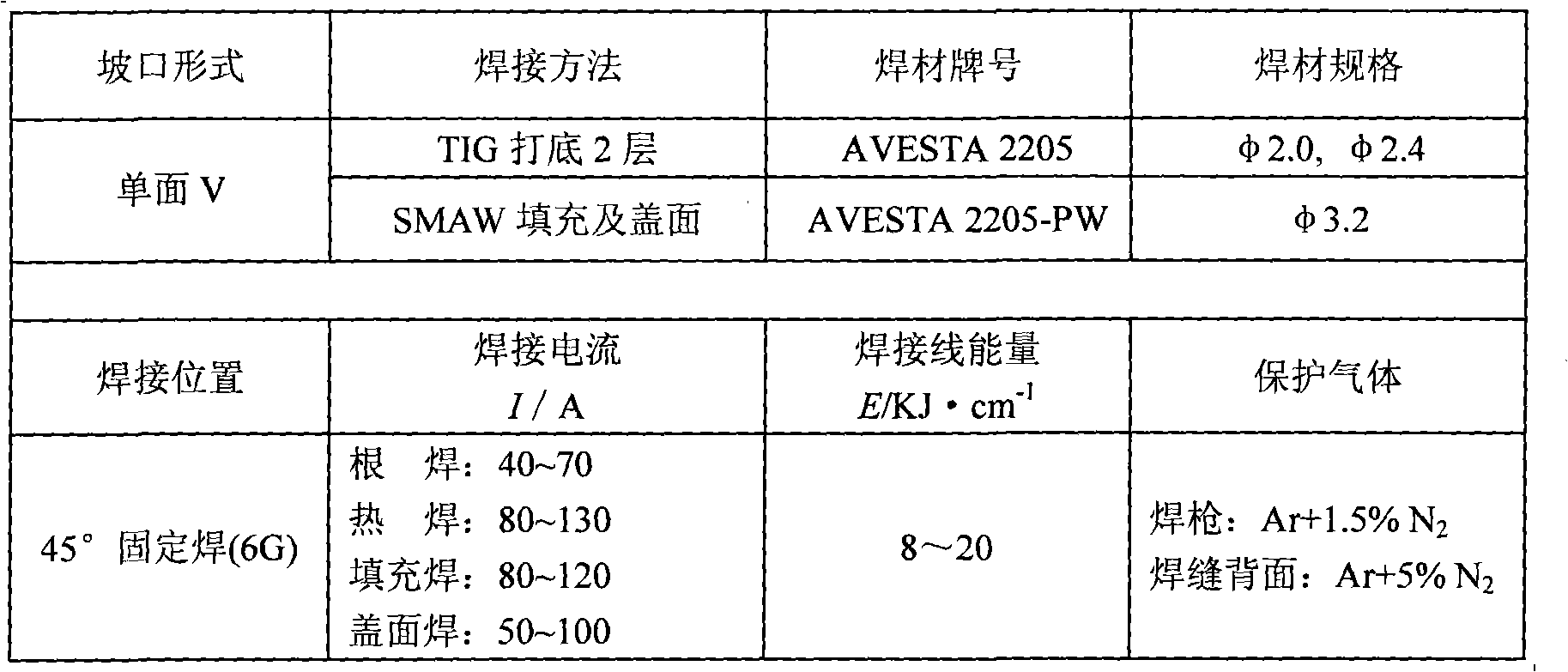

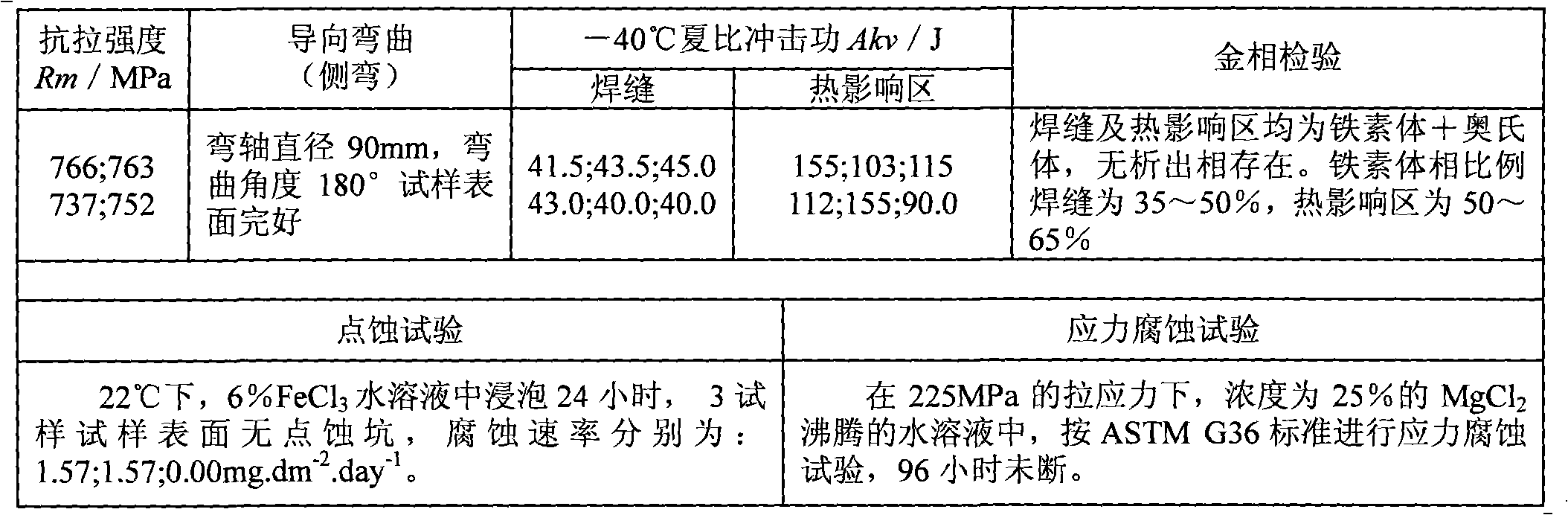

22Cr duplex phase stainless tube welding method

InactiveCN101288918AImprove tensile propertiesImprove low temperature impact toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesMicrostructurePitting corrosion

The invention relates to a welding method of 22Cr duplex stainless steel corrosion resistant alloy pipe, which adopts a gas mixture of 99.995 percent pure Ar and 98 to 99 percent Ar plus 2 percent N2 or a gas mixture of 90 to 95 percent of N2 plus 5 to 10 percent H2 to weld the two laterals within the range equal to or more than 100mm inside the pipe; back welding, fill welding and cap welding are implemented when the oxygen content is equal to or less than 50ppm; the welding and filling metal deposit includes the following components according to the weight percentage: C is equal to or less than 0.04, Cr is 22.0 to 23.5, Ni is 8.5 to 10.5, Mo is 3.0 to 3.5, Mn is 0.5 to 2.0, Si is equal to or less than 0.9, P is equal to or less than 0.04, S is equal to or less than 0.03, N is 0.15 to 0.20 and Cu is equal to or less than 0.75. A balanced austenitic-ferritic microstructure is obtained with good joint tensility and low-temperature shock toughness, as well as good corrosion performances of anti-pitting corrosion of chloride, stress corrosion and simulated environment medium corrosion resistance.

Owner:CNPC TUBULAR GOODS RES INST

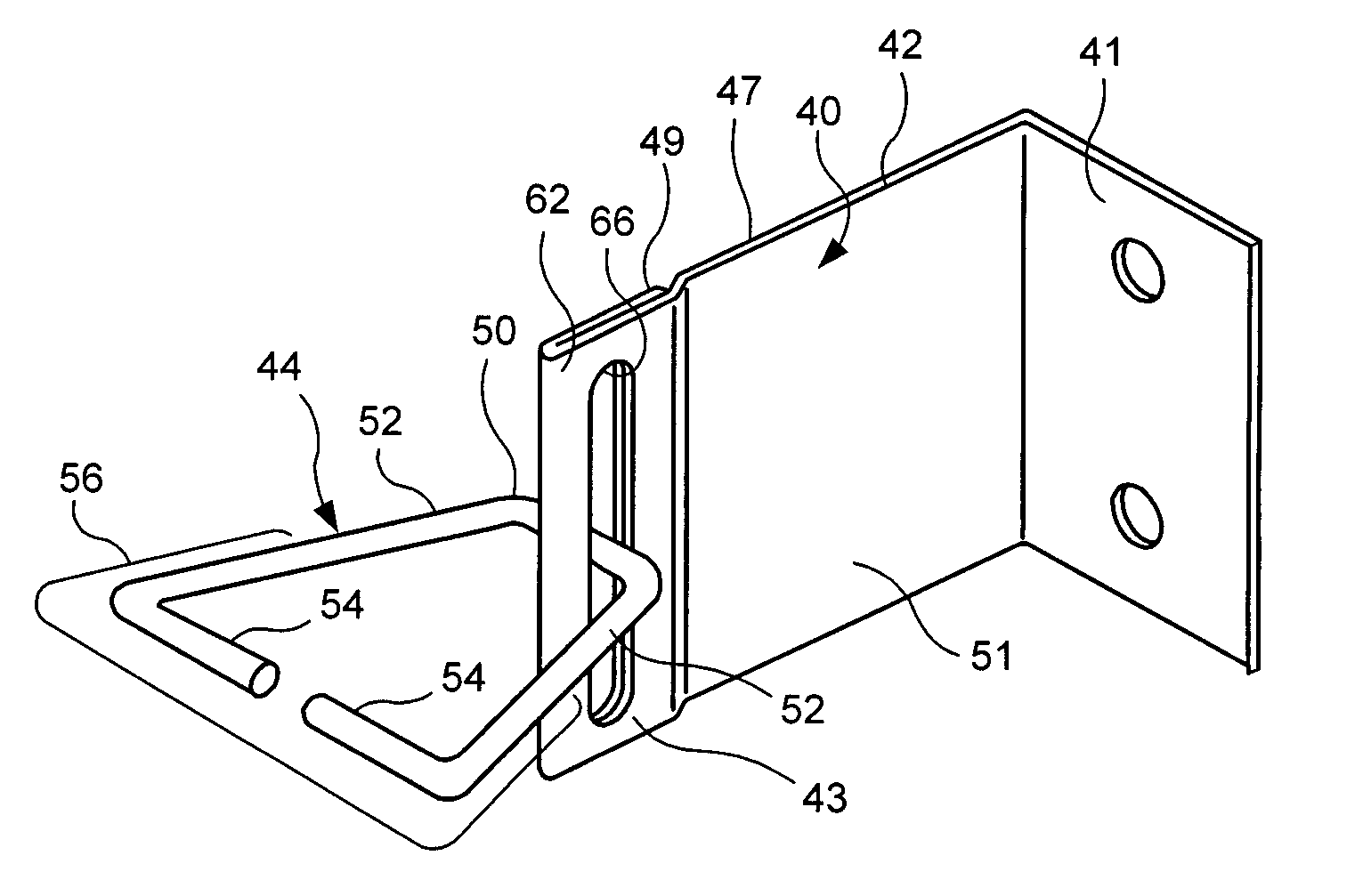

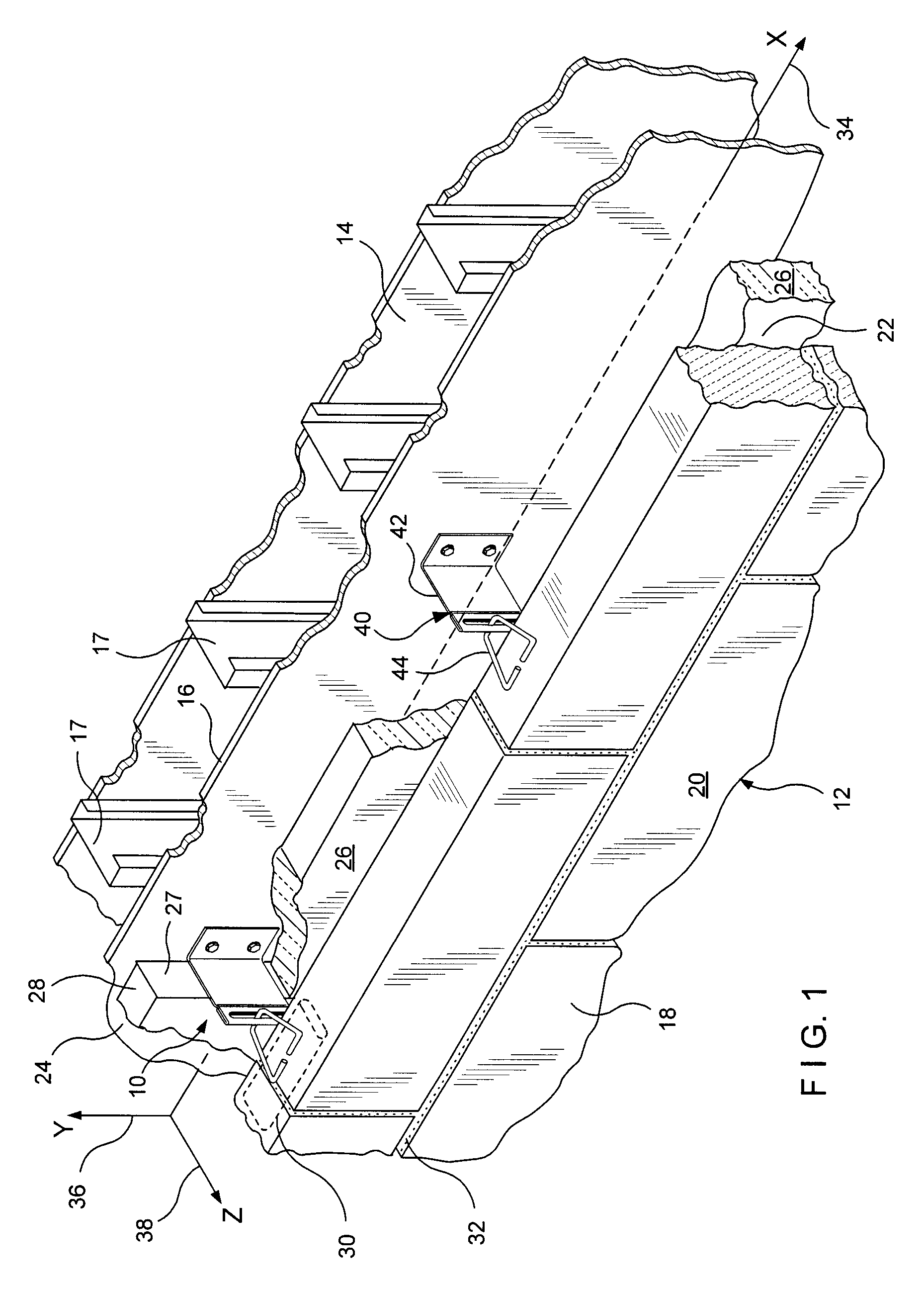

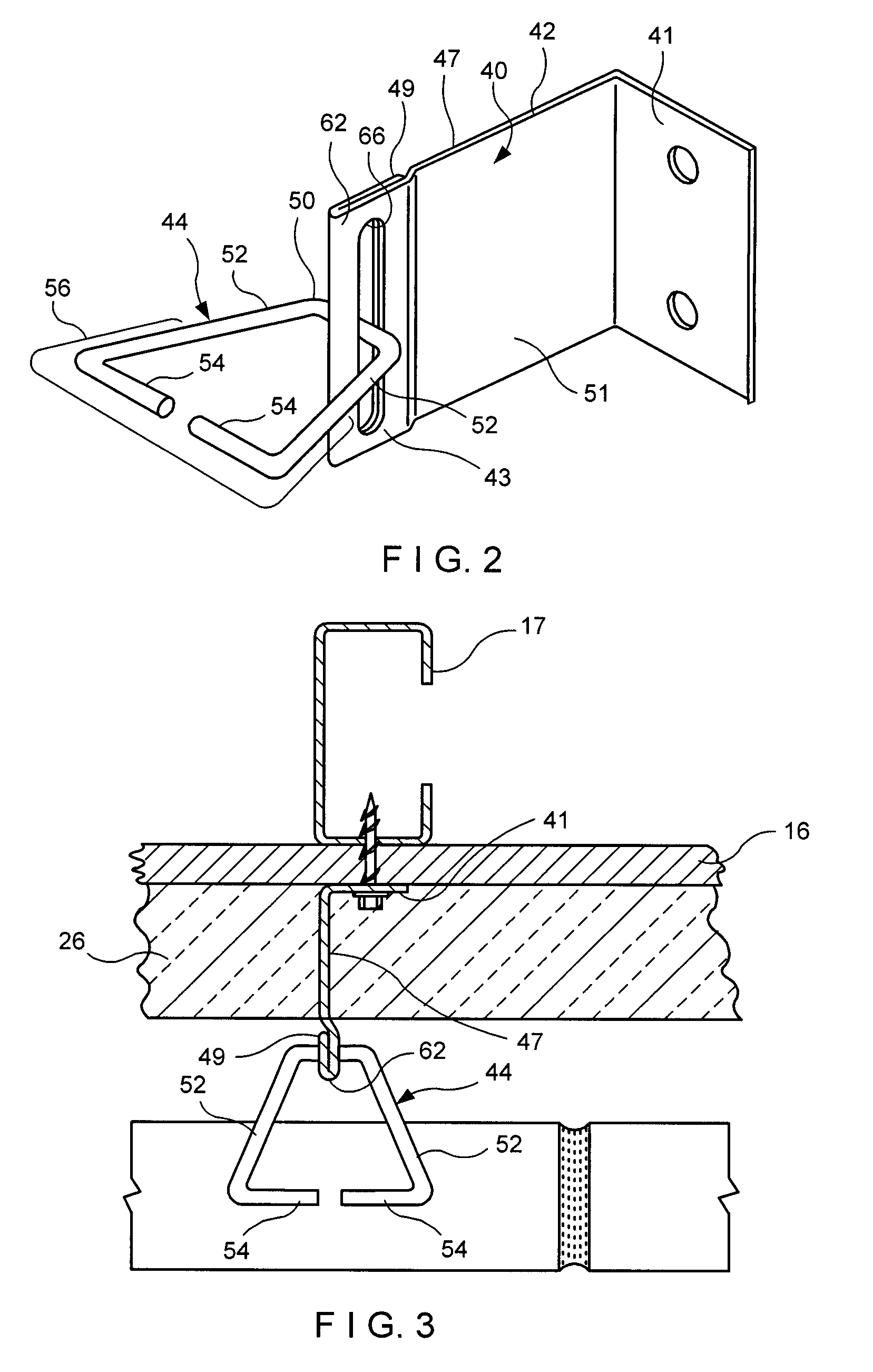

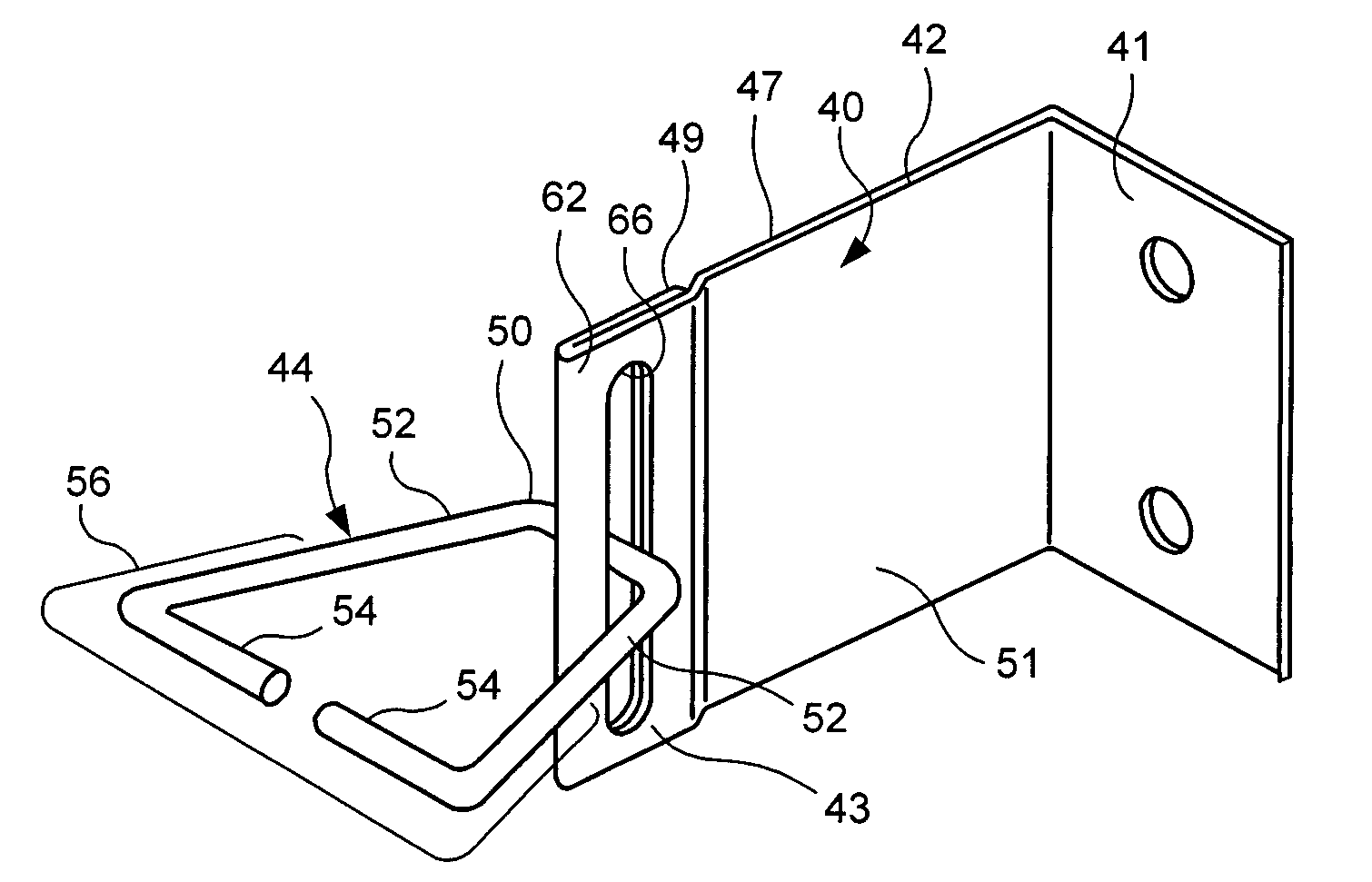

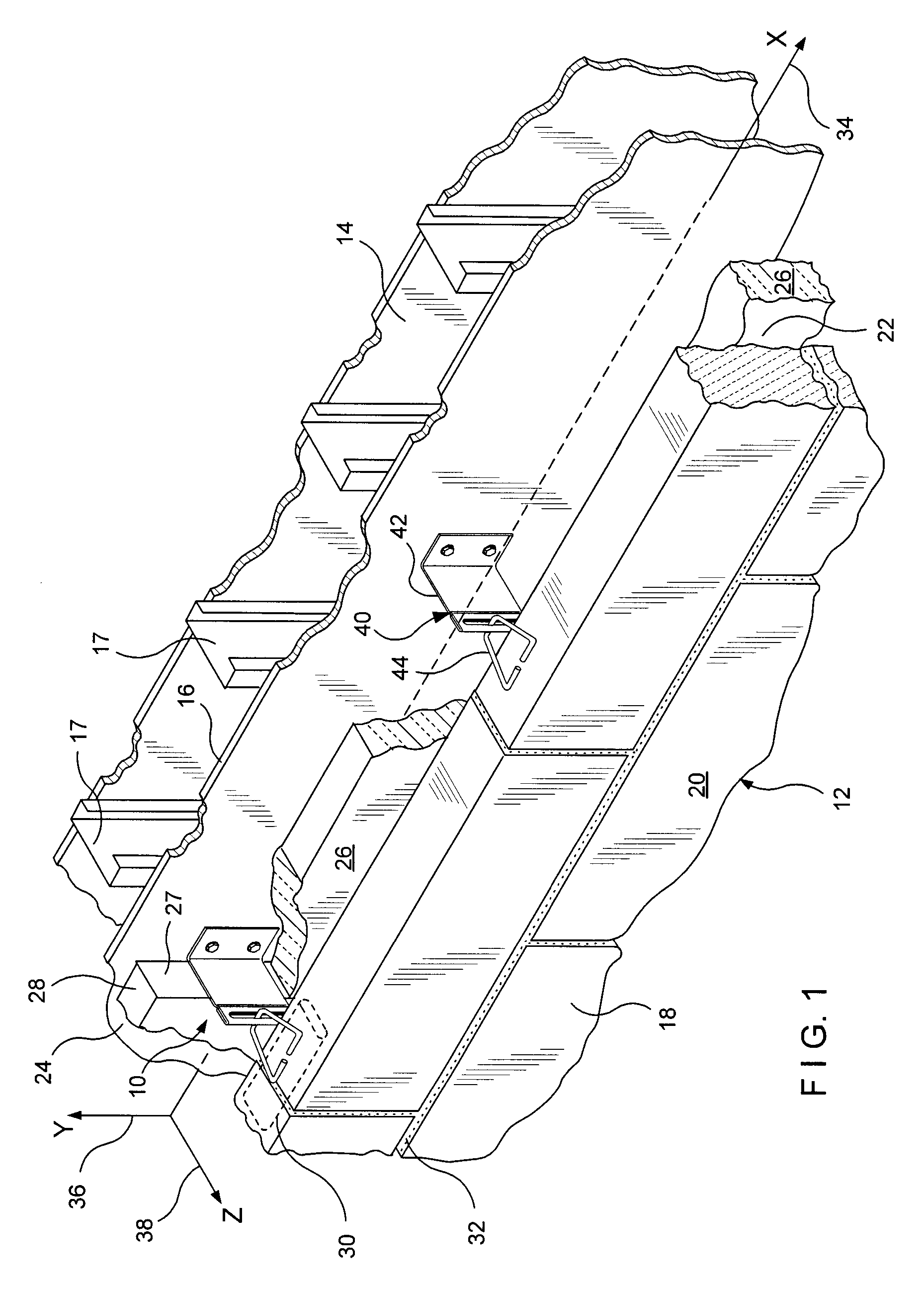

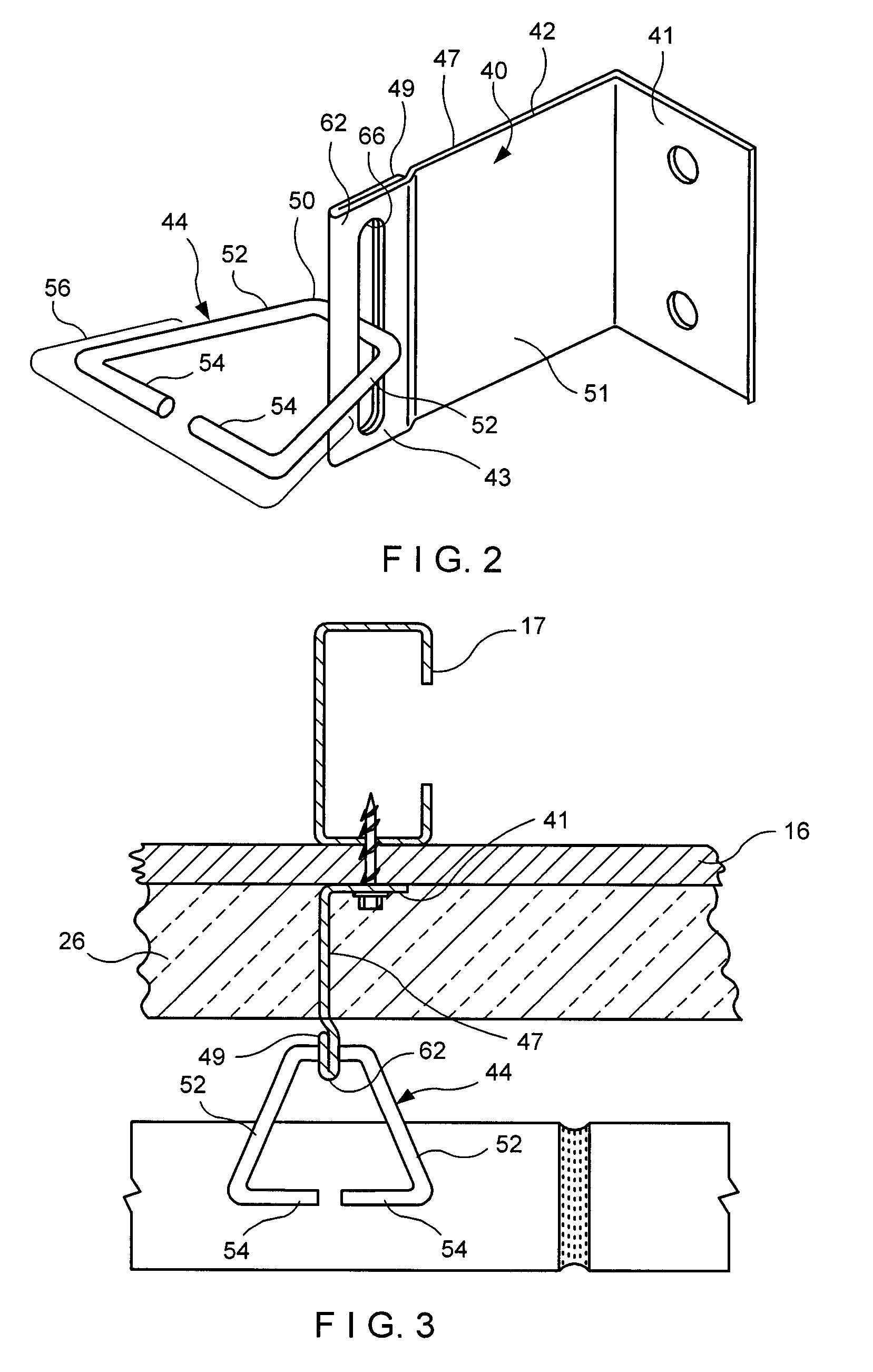

Wind load anchors and high-wind anchoring systems for cavity walls

ActiveUS8201374B2Improve tensile propertiesHigh strengthCeilingsConstruction materialEngineeringCavity wall

High-wind load wall anchors and high-wind load wall anchoring systems for cavity walls are described which utilize double-walled anchor constructs with interengaging wire formative veneer ties. The high wind load anchors are mounted upon an interior cavity wall and the veneer ties are embedded within joints of an exterior cavity wall. The anchors have an aperture, for threading the veneer ties therethrough and restricting undesired movement, coupled with a double-walled wing structure to resist anchor deformation by high-wind forces. For resistance against seismic forces, the high-wind load wall anchoring system has a reinforcement wire which snaps into contoured veneer ties.

Owner:HOHMANN & BARNARD INC

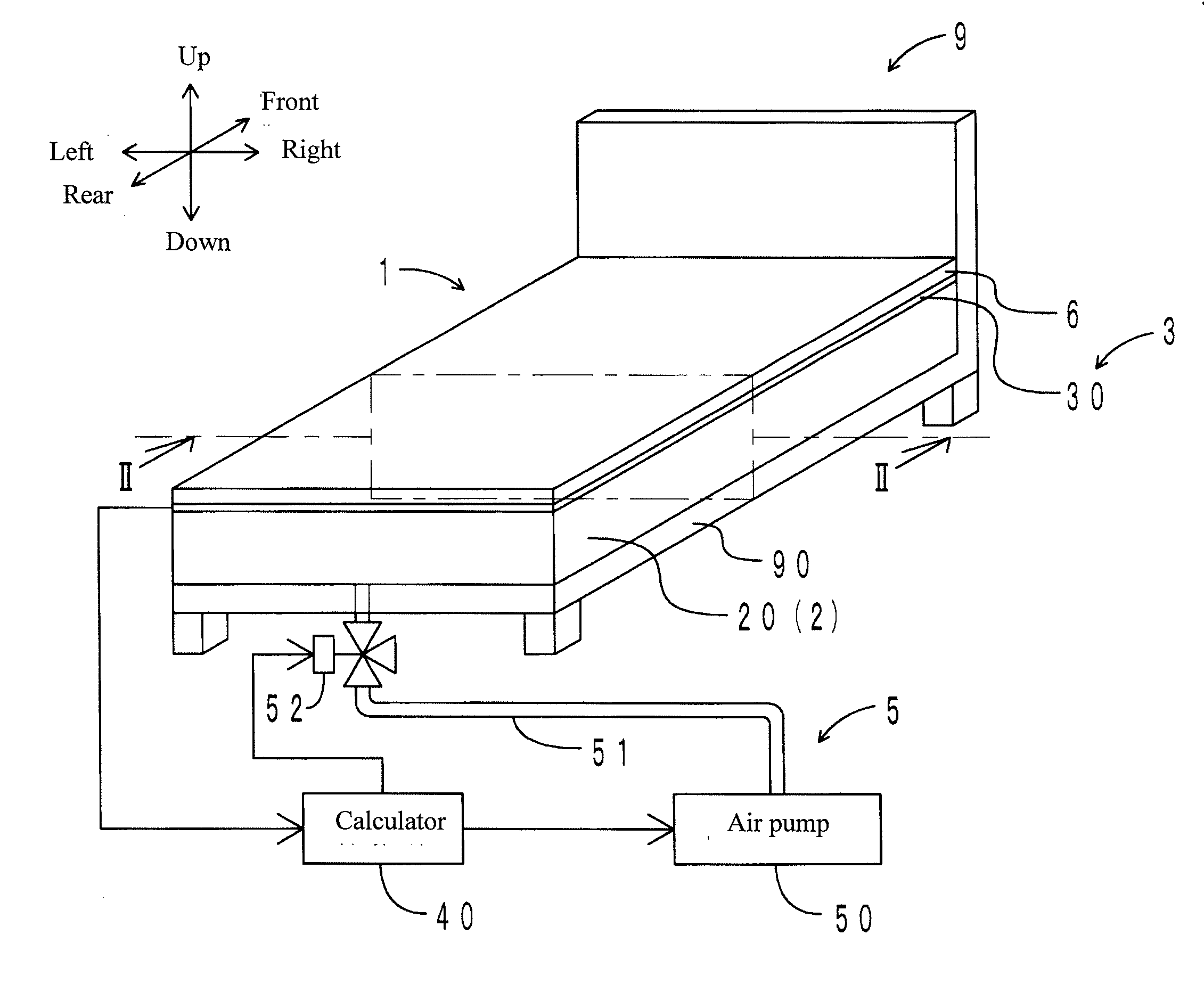

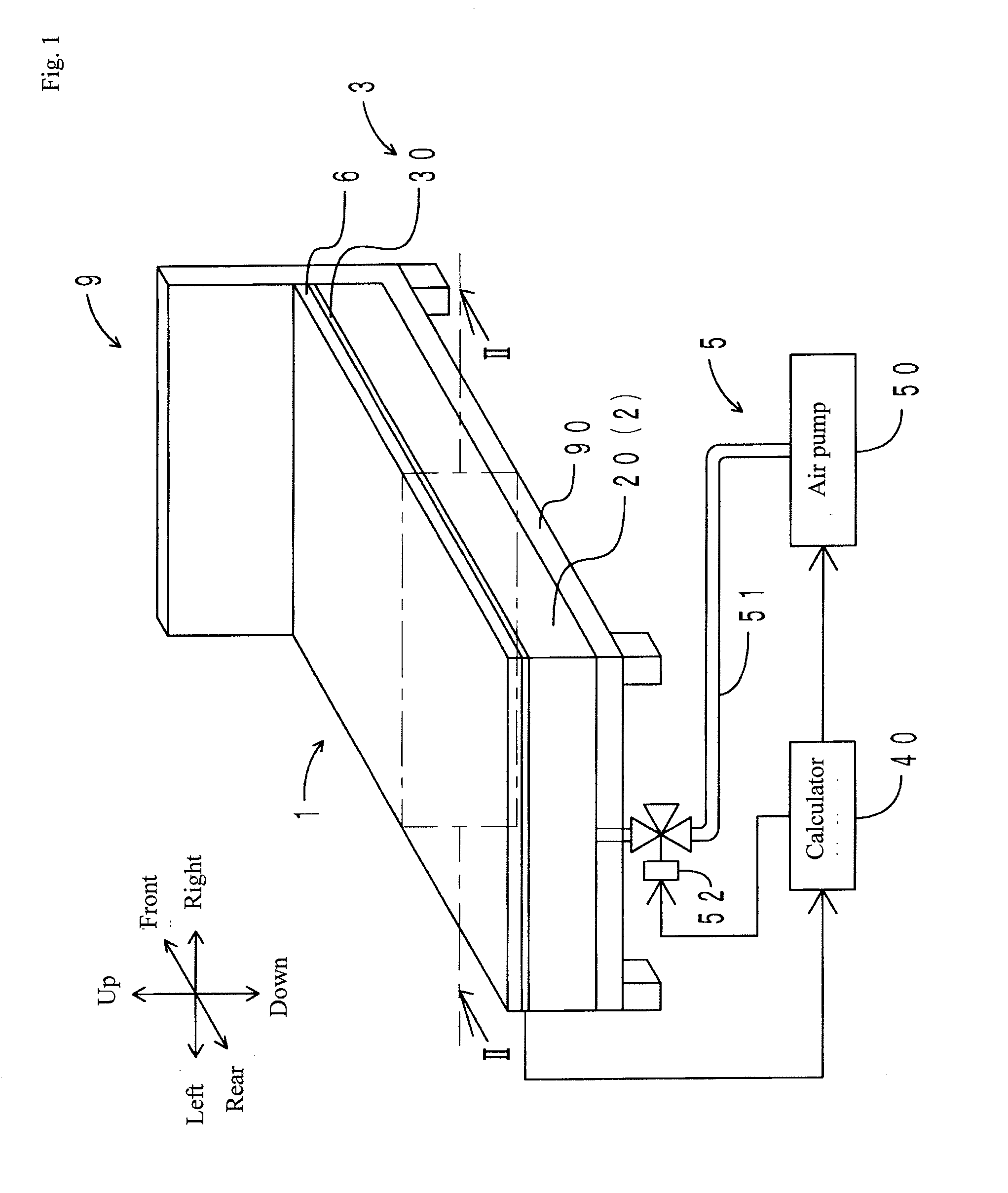

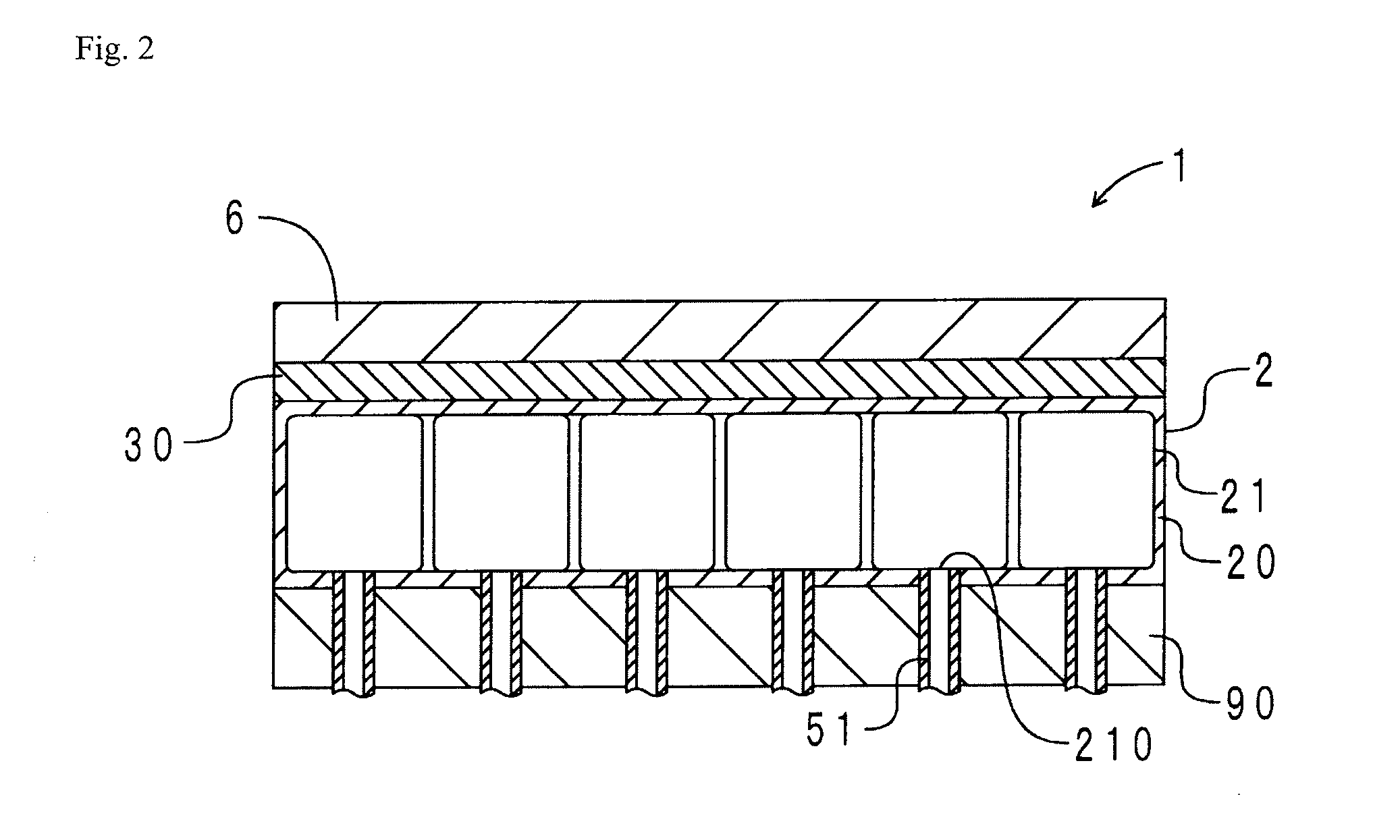

Body position and pressure control apparatus

ActiveUS20110308019A1Improve tensile propertiesImprove abilitiesStuffed mattressesSpring mattressesElastomerBody positions

A body position and pressure control apparatus is provided capable of highly accurately detecting body pressure distribution without causing a sense of discomfort for a sleeper, changing body positions, and distributing body pressure. The body position and pressure control apparatus has a mattress provided with a plurality of divided portions and supporting a sleeper, an elastomer sensor, and a body pressure adjuster controlling each of the divided portions based on an instruction from the elastomer sensor and thereby changing the body pressure distribution of the sleeper. The elastomer sensor has a sheet sensor main body and a calculator, the sensor main body having an elastomer sensor thin film, a plurality of electrodes, and a plurality of detectors corresponding to the divided portions provided between the electrodes.

Owner:SUMITOMO RIKO CO LTD

Spontaneously degradable fibers and goods made thereof

InactiveUS6844063B2Easy to splitGood bulkinessSynthetic resin layered productsFilament/thread formingPolyesterYarn

A spontaneously degradable fiber excellent in bulkiness, softness, stretchability and feeling, which comprises (A) a low heat-shrinkable fiber component comprising a high crystalline aliphatic polyester and (B) a high heat-shrinkable fiber component comprising an aliphatic polyester, e.g., a low crystalline or non-crystalline aliphatic polyester, and a block copolymer or a mixture the main component of which is an aliphatic polyester and which comprises a high-melting component and a low-melting component. Further, fibers excellent in self-crimpability or self-adhesion property and dividable fibers are obtained by suitably combining the fiber components (A) and (B) to form conjugated fibers or composite yarns.

Owner:TORAY IND INC

Stretchable absorbent composite with low superaborbent shake-out

Owner:KIMBERLY-CLARK WORLDWIDE INC

Wind load anchors and high-wind anchoring systems for cavity walls

ActiveUS20100257803A1High strengthPrevent disengagementCeilingsConstruction materialWind forcingWind force

High-wind load wall anchors and high-wind load wall anchoring systems for cavity walls are described which utilize double-walled anchor constructs with interengaging wire formative veneer ties. The high wind load anchors are mounted upon an interior cavity wall and the veneer ties are embedded within joints of an exterior cavity wall. The anchors have an aperture, for threading the veneer ties therethrough and restricting undesired movement, coupled with a double-walled wing structure to resist anchor deformation by high-wind forces. For resistance against seismic forces, the high-wind load wall anchoring system has a reinforcement wire which snaps into contoured veneer ties.

Owner:HOHMANN & BARNARD INC

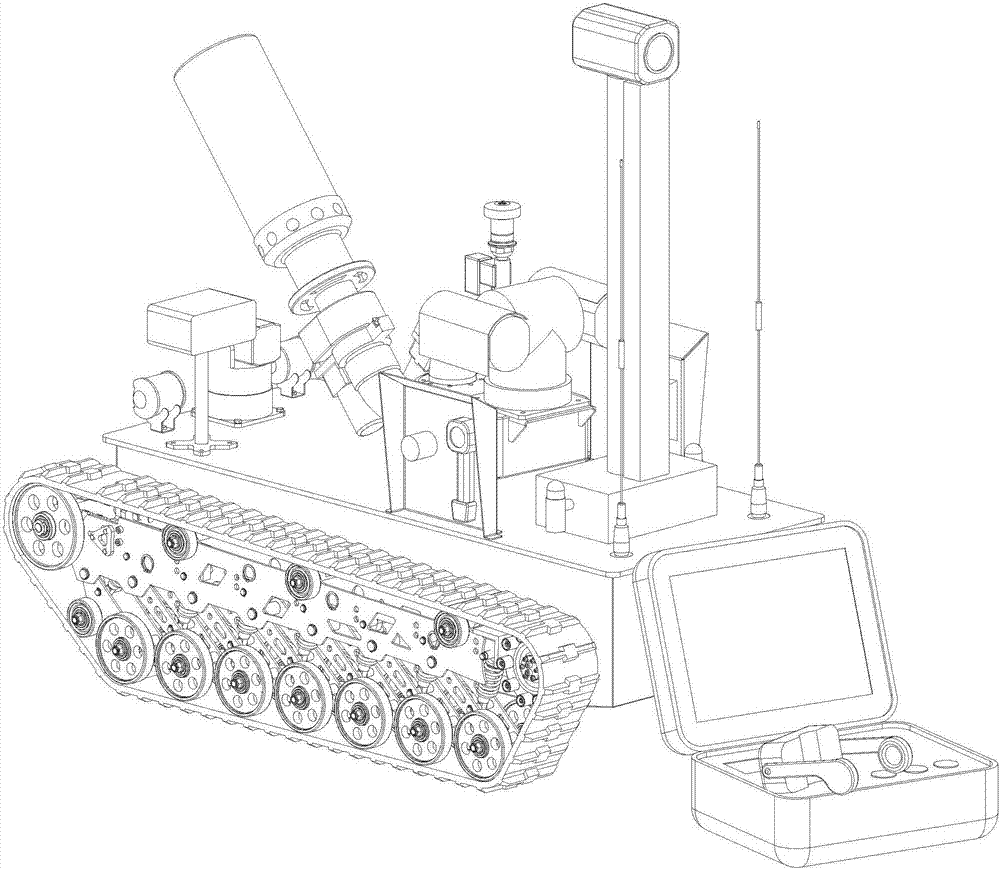

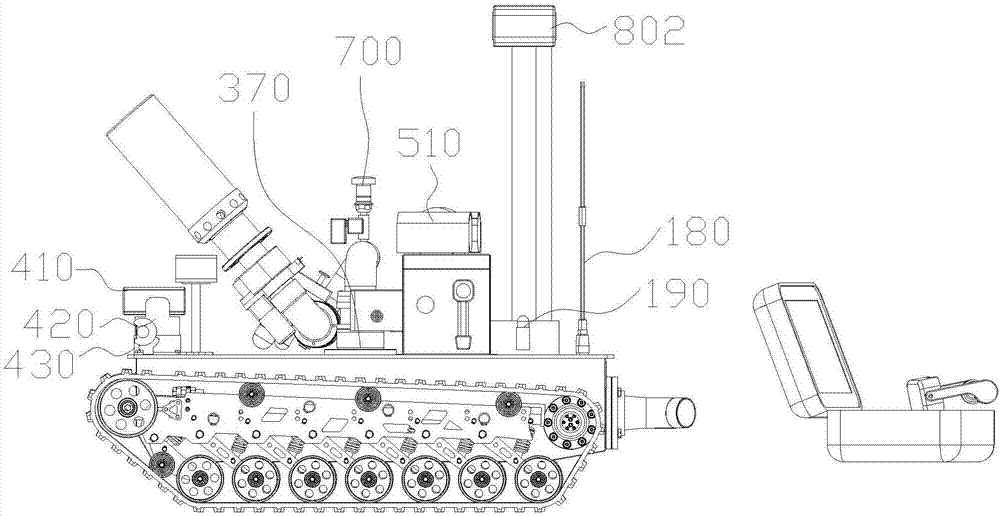

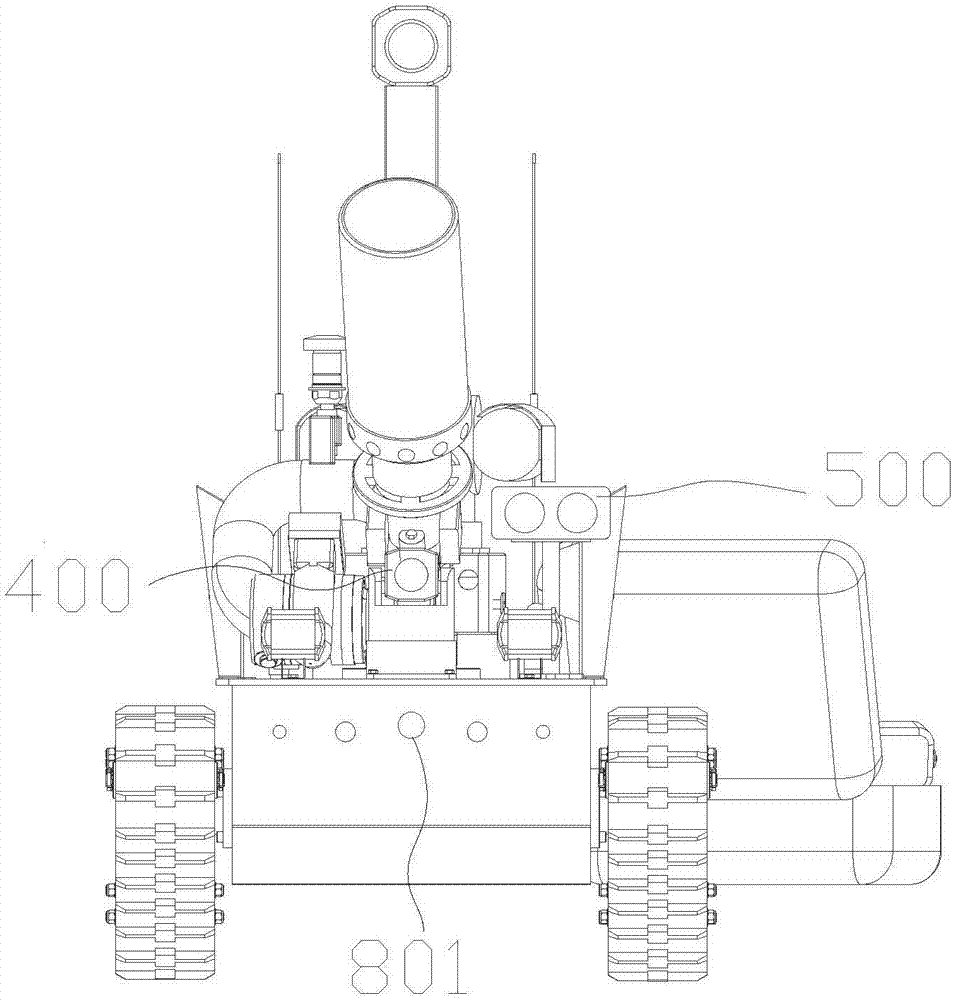

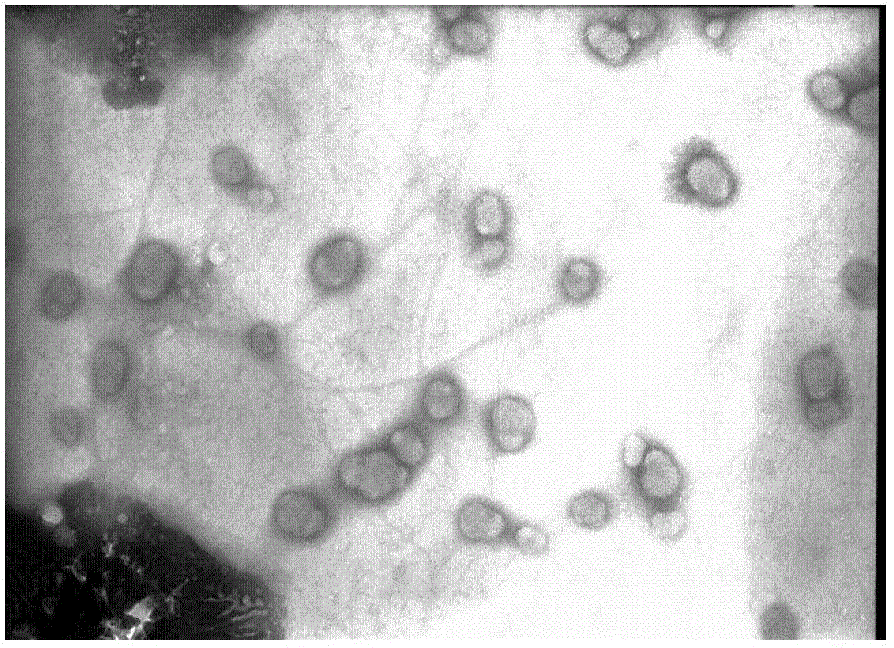

Fire-fighting robot facing complex ground environment

InactiveCN107875550AIncrease load capacityIncrease the success rate of self-insuranceFire rescueAutomatic controlEnvironment of Albania

The invention relates to a fire-fighting robot facing a complex ground environment. The fire-fighting robot includes a fire-fighting robot device, a controlling table, a fire-fighting water monitor, afire detection assembly, a flame automatic targeting assembly, a water belt automatic shedding assembly, a self-sprinkler assembly and an environmental parameter collection module. The movement performance and safety in a complex ground fire-fighting environment can be ensured or improved; the loading capacity of the fire-fighting robot is improved; when dragging a fire fighting water hose in theback, the resistance capacity to tension, the obstacle climbing capacity, the stair climbing capacity and the capacity of passing an uneven unilateral bridge are improved; the fact that the fire-fighting robot can also move when the flame burns the fire-fighting robot body or a caterpillar band is ensured; the automatic shedding assembly of the fire-fighting water monitor connection mouth is improved so that the success self-preservation rate when the robot retreats is improved; the device of the fire-fighting robot of automatic searching for the flame and automatic controlling of collimationof the fire-fighting water monitor is added; so that fire-fighting efficiency and the degree of automation of the fire-fighting robot are improved.

Owner:SHANDONG GUOXING SMARTECH CO LTD +1

Organic silicon modified acrylate emulsion and preparation method thereof

The invention relates to organic silicon modified acrylate emulsion and a preparation method thereof. A core-shell structure synthesis method is adopted for preparation, a core layer / shell layer glass transition temperature is designed to be -30- -25 DEG C / 0-5 DEG C and lower than conventional core-shell emulsion. The emulsion comprises core-shell emulsion monomers, initiator accounting for 0.4-0.6% of the total mass of the monomers, composite emulsifier accounting for 2.5-4.5% of the total mass of the monomers, pH (potential hydrogen) buffering agent accounting for 0.4-0.6% of the total mass of the monomers and the balance deionized water. The emulsion preparation method includes (1) pre-emulsifying, (2) core-layer emulsion preparation, and (3) core-shell emulsion preparation. The emulsion which is aqueous emulsion is environment-friendly and high in stability, bonding power and tensile strength, has functions of softening, smoothening and the like for surface treatment of fabrics and the like, and is widely applicable to the fields of spinning, papermaking, leather, painting, water-based ink and the like.

Owner:DONGHUA UNIV

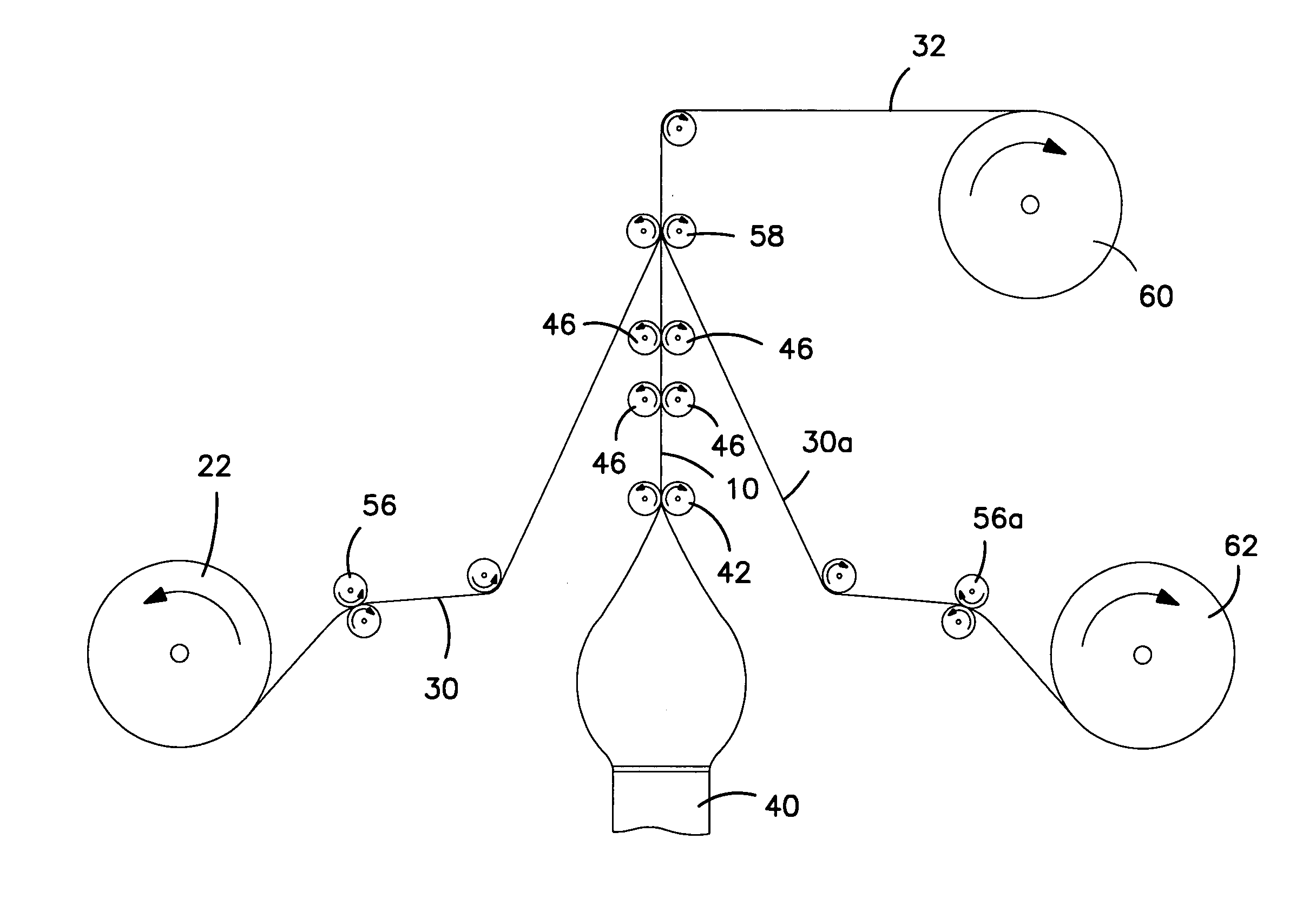

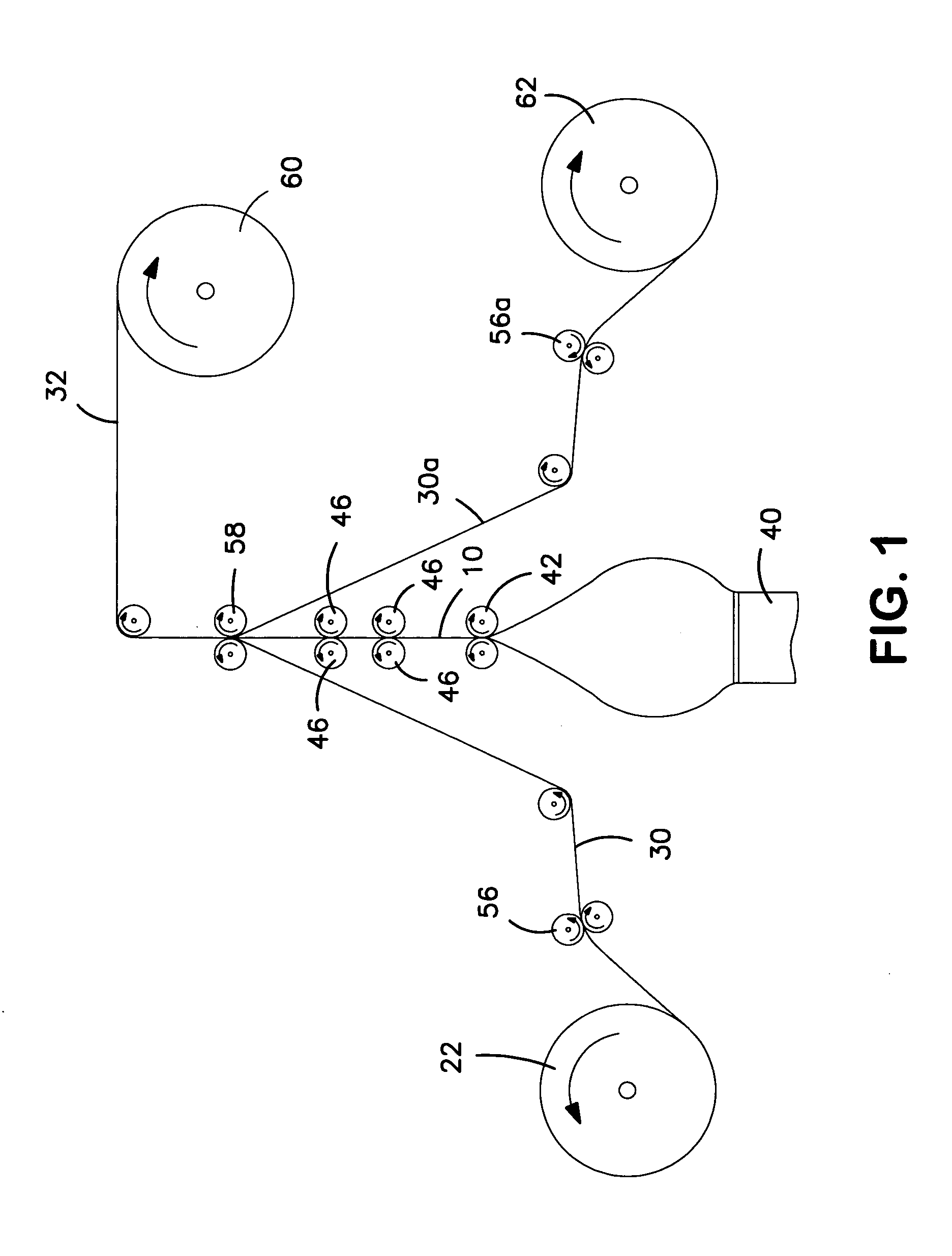

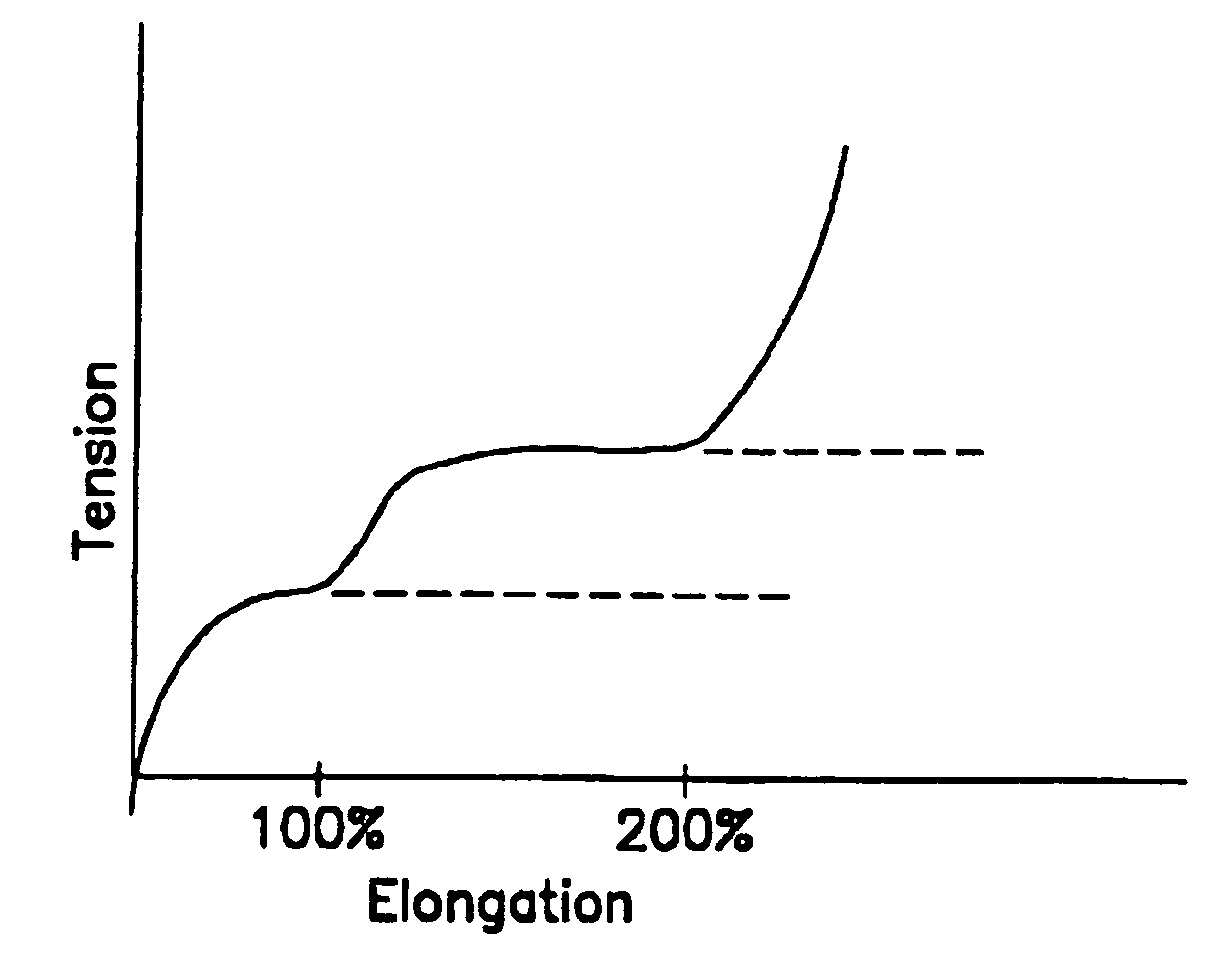

Stretchable film laminates and methods and apparatus for making stretchable film laminates

Stretchable film laminates including a layer of elastomeric openwork, such as a plurality of elastic strands or an elastomeric mesh structure. The stretchable film laminates may include a film layer bonded to the layer of elastomeric openwork, with the film layer having cross-directional stretch and the laminate having a multi-phase stretchability profile. The stretchable film laminates may be made by extruding a film from a die, stretching the film, forming and stretching a layer of elastomeric openwork, conveying the stretched elastomeric openwork onto the film while the film is stretched, and passing the film and the elastomeric openwork through a nip. The invention also includes a machine capable of producing machine-direction, cross-direction, and biaxial stretch materials. The machine includes at least one extruder, at least one filament die and at least one film die both attached to the extruder(s), and at least one nip downstream of the extruder(s).

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com