Organic silicon modified acrylate emulsion and preparation method thereof

An acrylate and organosilicon technology, applied in the field of organosilicon modified acrylate emulsion and its preparation, can solve the problems of poor water resistance, easy to become brittle, easy to stick, and achieve good emulsion stability, strong cohesion, The effect of reaction temperature saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

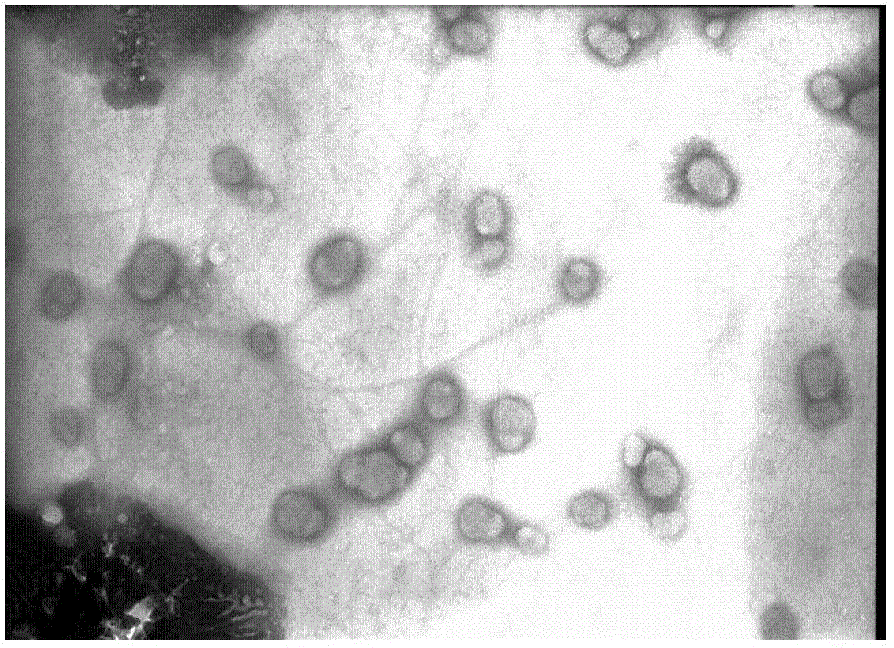

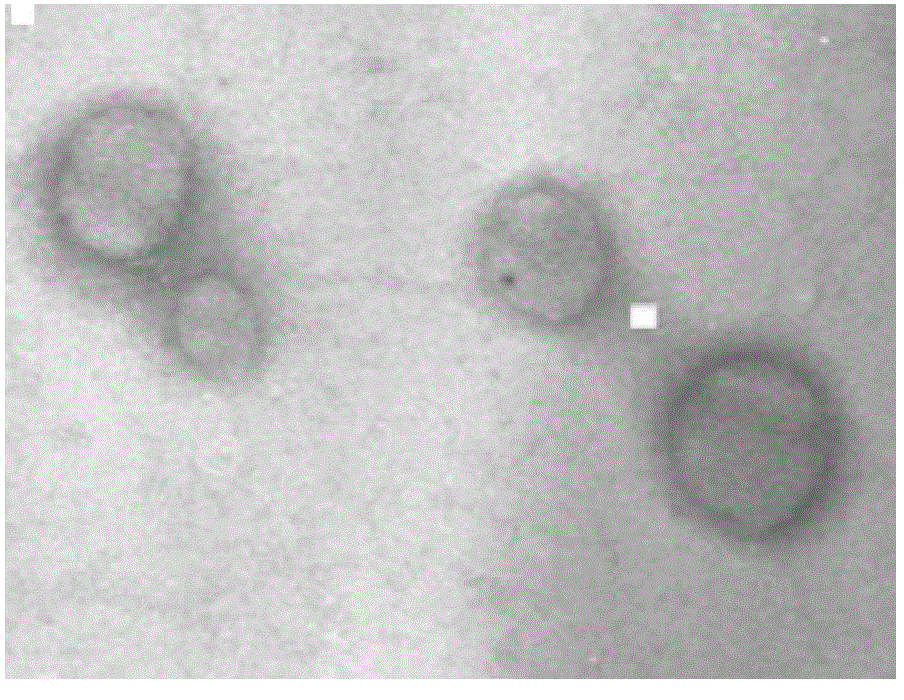

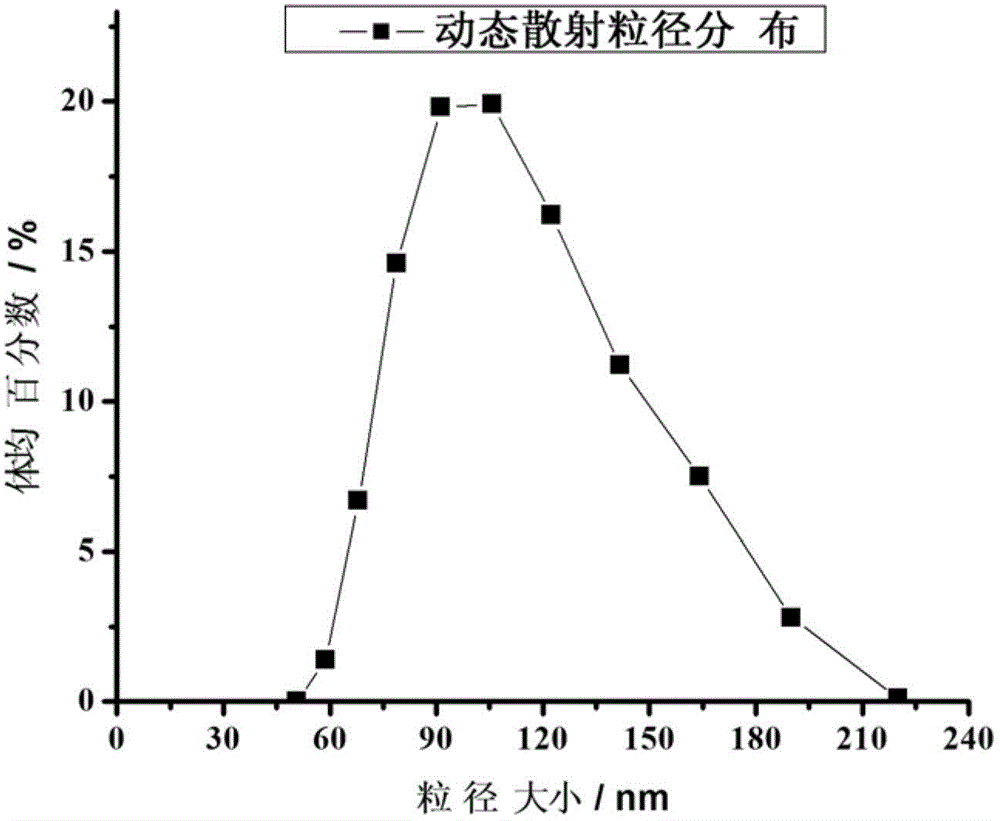

Image

Examples

Embodiment 1

[0049] The application examples given below can synthesize the core-shell emulsion described in this patent, and the ratio of experimental raw materials is listed in Table 1.

[0050] ⑴ Pre-emulsification

[0051] ① Pre-emulsification of the core layer: add a part of the composite emulsifier, a part of deionized water, the acrylate mixed monomer of the core layer, and vinyl polysiloxane prepolymer into the pre-emulsification kettle a in sequence, and the temperature rises to 45±0.2 ℃, with a rotation speed of about 1000r / min, stir mechanically for 30-45 minutes to prepare the core layer pre-emulsion, pour it into the core layer pre-emulsion dripping kettle, and set aside.

[0052] ② Shell pre-emulsification: add a part of composite emulsifier, a part of deionized water, shell acrylate mixed monomer, hydrophilic monomer and cross-linking monomer into the pre-emulsification tank b in sequence, and the temperature is raised to 45 ±0.2°C, stir mechanically for 30 minutes at a rot...

Embodiment 2

[0064] The preparation method is the same as in Example 1, and the reaction temperature, mechanical stirring speed, heat preservation time, etc. can be appropriately changed, wherein the experimental raw material proportioning is listed in Table 2.

[0065] Table 2 Components of silicone-modified acrylate emulsion with core-shell structure

[0066]

[0067] Note: 1) The emulsifier is divided into two parts, and the mass fraction of the core-shell layer is 63.00% and 37.00% respectively.

Embodiment 3

[0069] Preparation method is with embodiment 2, and wherein experimental raw material proportioning is listed in table 3.

[0070] Table 3 Components of silicone-modified acrylate emulsion with core-shell structure

[0071]

[0072] Note: 1) The emulsifier is divided into two parts, and the mass fraction of the core-shell layer is 66.00% and 34.00%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com