Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8256results about How to "Low reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

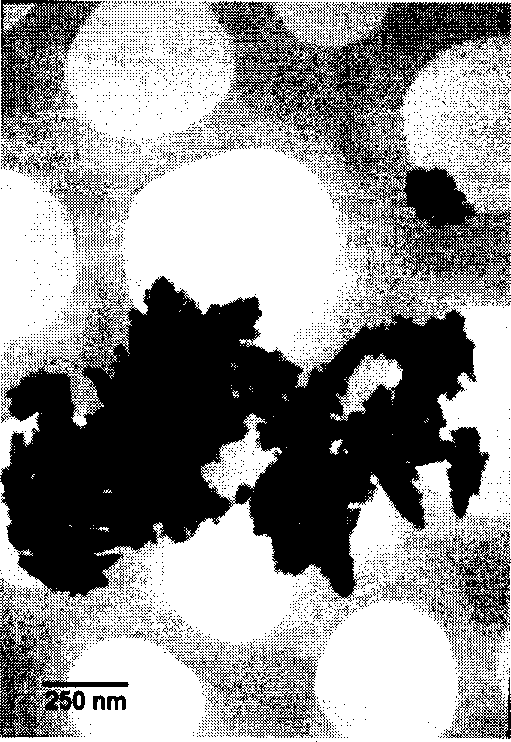

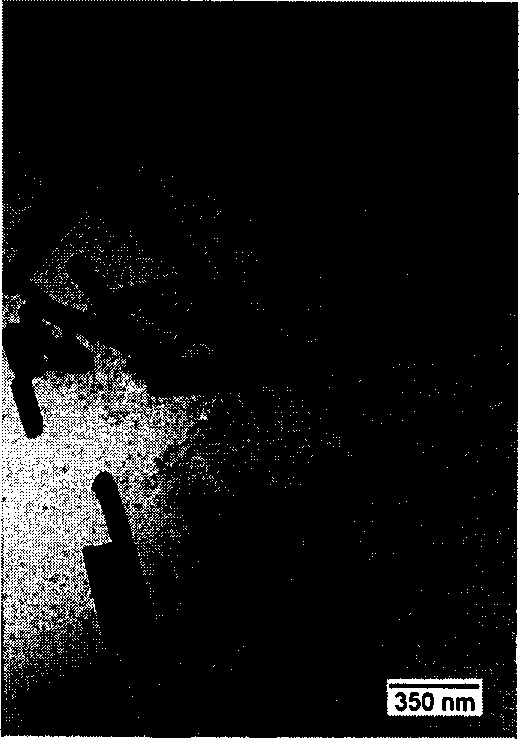

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Process for the production of esters from alcohols using acetic acid as acetylating and clays as catalysts

InactiveUS6472555B2Easy to adaptLow reaction temperatureOrganic compound preparationOrganic chemistry methodsAcetic acidAlcohol

The present invention relates to a process for the preparation of esters from alcohols using acetic acid as acetylating agent and clays as catalysts, which comprises the preparation of esters in a single step from the reaction of aliphatic, acyclic, cyclic, heterocyclic, alpha,beta-unsaturated and aromatic alcohols with carbon atoms in the range of C1 to C10 with acetic acid in a molar ratio of 1:3 to 11 using reusable natural montmorillonite / metal ion-exchanged clay catalysts in the solvent medium of aliphatic, aromatic, or chlorinated hydrocarbons at 30-140° C. for a period in the range of 0.02 to 3.0 hrs, and recovering the corresponding esters by simple work-up procedure.

Owner:COUNCIL OF SCI & IND RES

Nanometer grade low carbon paraffin dehydrogen catalyst

InactiveCN1911502ALarge specific surface areaHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon nanotube

The present invention relates to one kind of nanometer level low carbon alkane dehydrogenating catalyst, and features that the C3-C5 low carbon alkane dehydrogenating catalyst comprises carrier of single wall or multiple wall carbon nanotube and two active components selected from chromic oxide in 2-30 wt%, alumina in 2-25 weight and nickel oxide in 2-30 wt%. The catalyst has high catalysis activity, increased active structures, long service life, low catalytic dehydrogenation reaction temperature, high conversion rate, high selectivity and other advantages.

Owner:DAQING PETROLEUM ADMINISTRATION

Catalyst for C4 liquefied petroleum gas aromatization and its preparing method

InactiveCN1586721ALess modification stepsLow costMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFixed bed

The present invention belongs to the field of catalyst preparation in petrochemical technology, and especially one kind of catalyst for the aromatization of liquefied C4 petroleum gas in fixed bed reactor and its preparation process. Technologically, the catalyst features that its mother substance is high-silicon zeolite with crystal granulation of 10-500 nm and the zeolite is alumina formed and prepared into the hydrogen type catalyst via conventional process, and the hydrogen type catalyst is vapor treated to regulate the acidity and acid treated to expand the pores and restore the pore passage. The catalyst is used in the aromatization of liquefied C4 petroleum gas, and has low reaction temperature, high olefin converting rate and high carbon deposition resistance.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

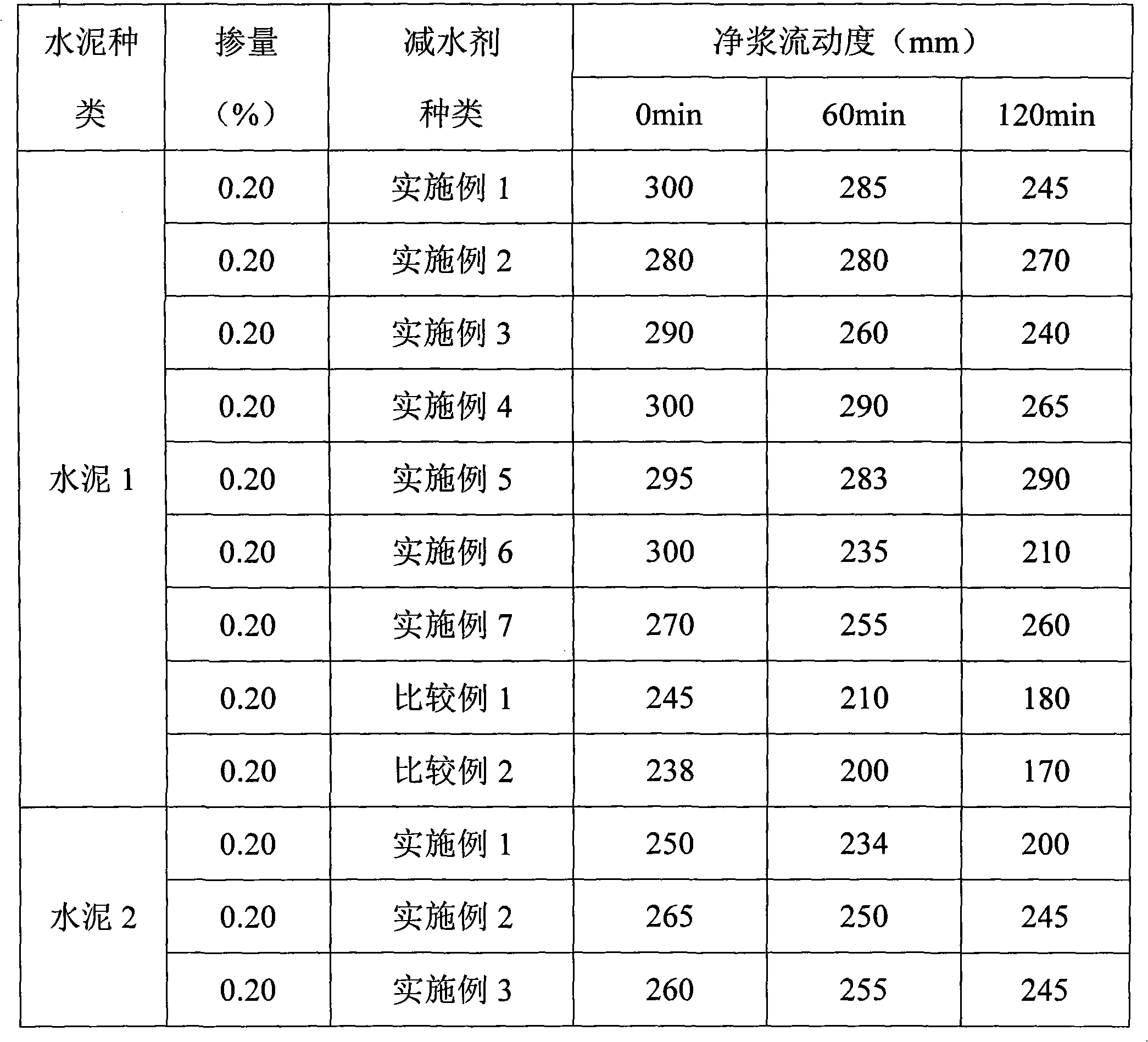

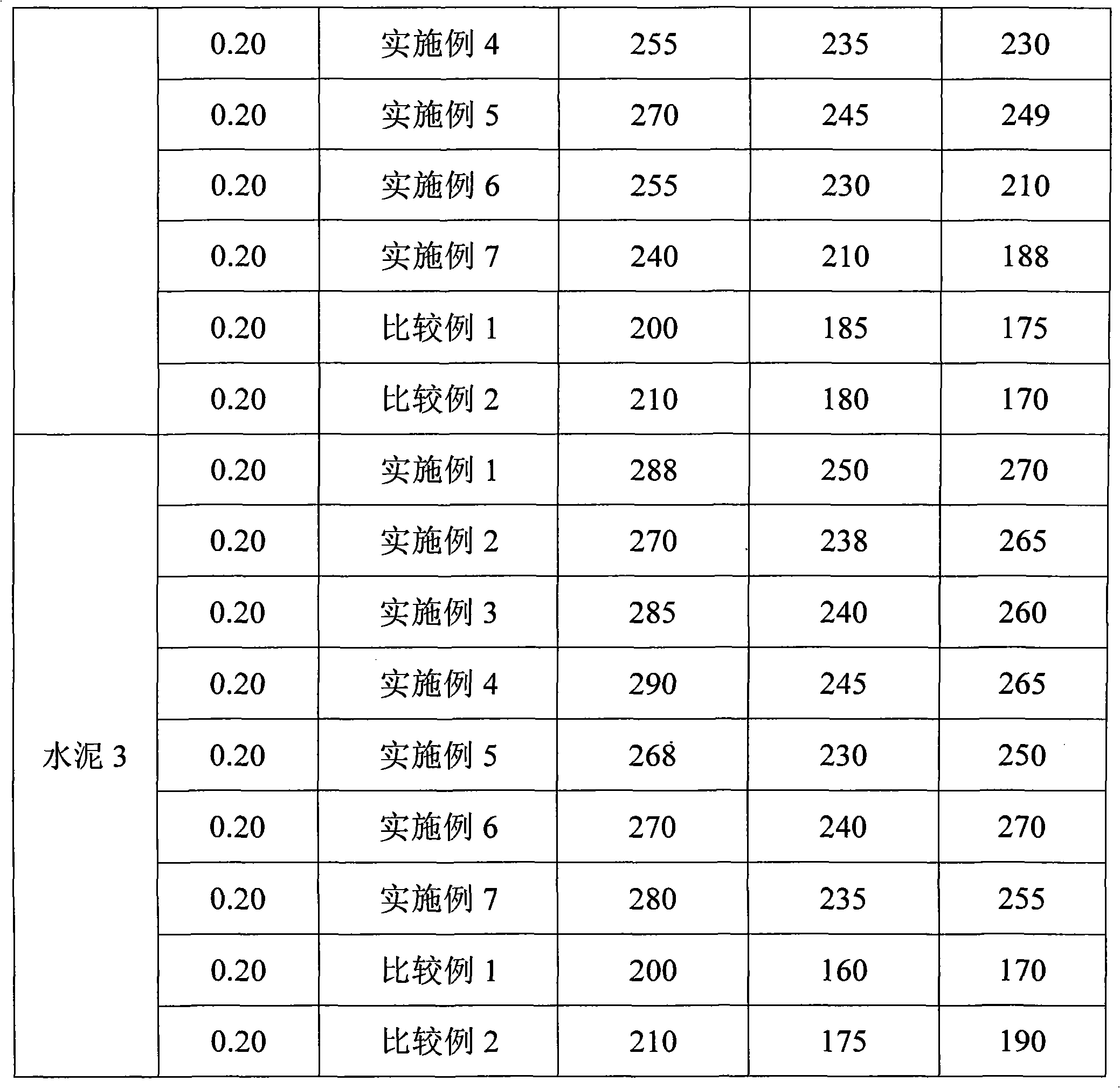

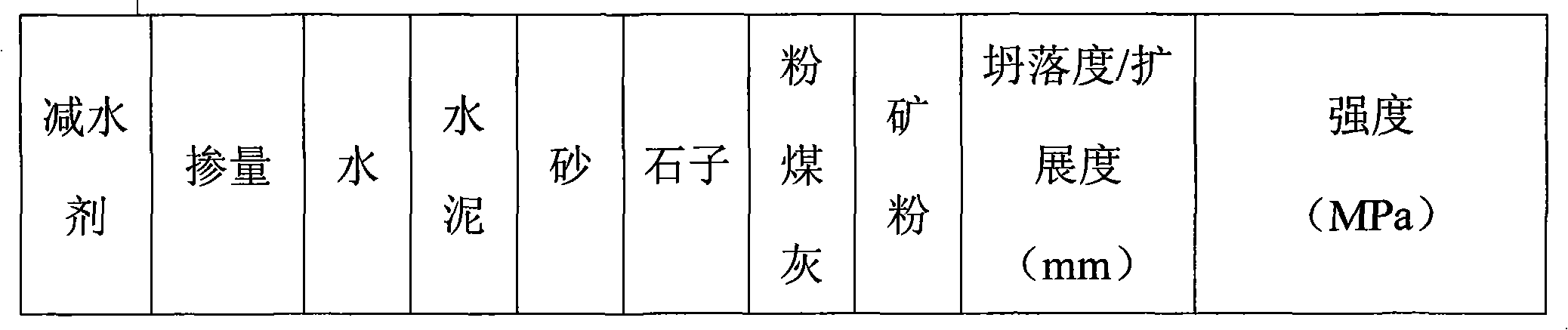

Normal-temperature synthesis method for polycarboxylic acid water-reducing agent

The invention discloses a normal-temperature synthesis method for a polycarboxylic acid water-reducing agent, and belongs to the field of cement concrete water-reducing agents. The water-reducing agent is prepared by the following steps of: copolymerizing polyoxyethylene ether monomer or polyoxyethylene ester monomer a containing unsaturated double bonds, unsaturated monocarboxylic acid and derivative monomer thereof b, unsaturated dicarboxylic acid c and unsaturated sulfonic acid or salt monomer thereof d in aqueous solution under the action of an oxidation reduction initiator, and finally neutralizing the solution by using alkali solution to obtain the water-reducing agent. The reaction can be performed at room temperature by adopting an oxidation reduction initiating system, and the appropriate reaction temperature is between 5 and 30 DEG C; and the synthesis process does not need heating, so energy is saved, and high-temperature side reaction is effectively controlled. The prepared polycarboxylic acid high-performance water-reducing agent has the characteristics of high water-reducing rate and good collapse protecting performance. The water-reducing agent has wide application range, and the method has low production process requirement and is suitable for industrialized large-scale production.

Owner:BEIJING UNIV OF TECH

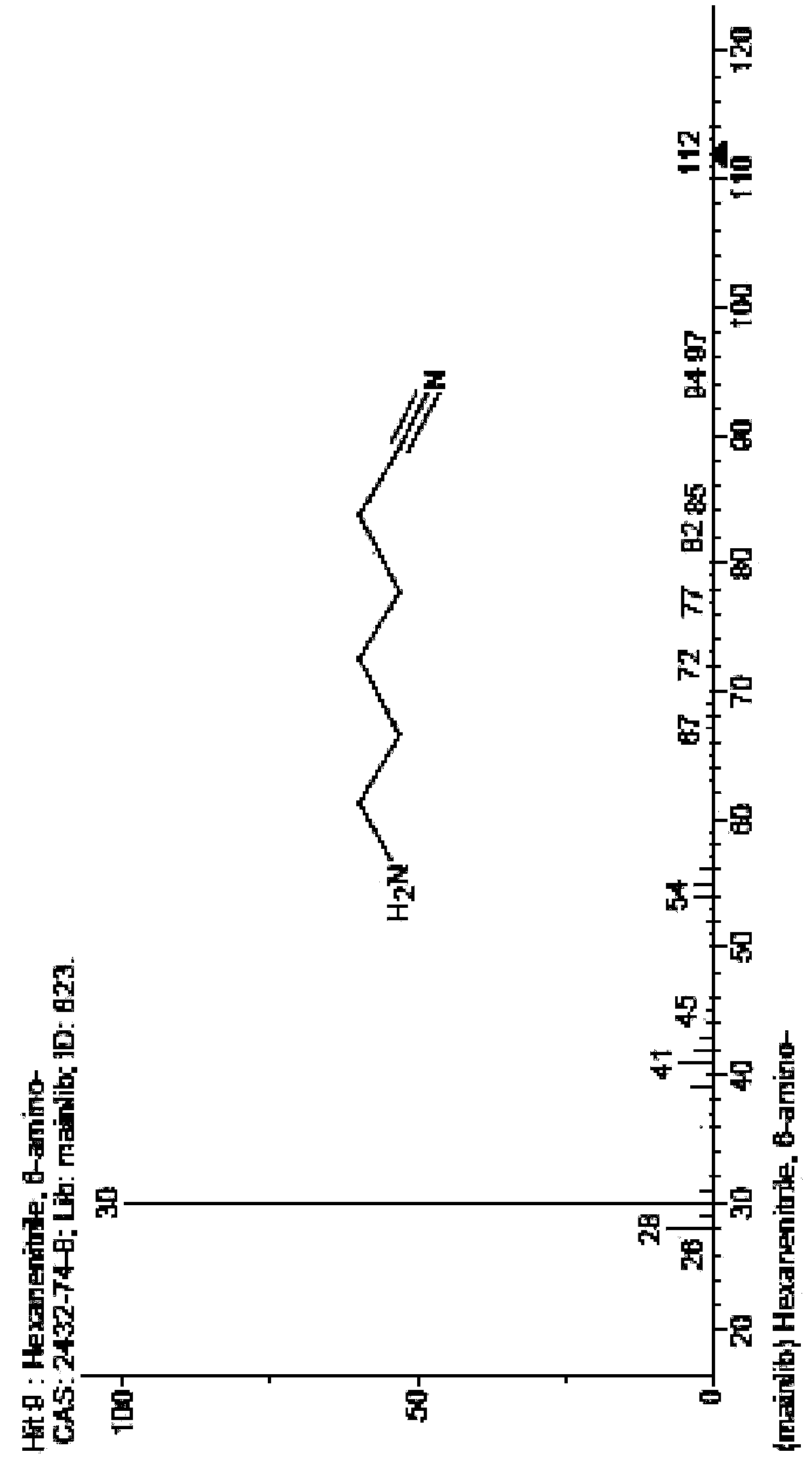

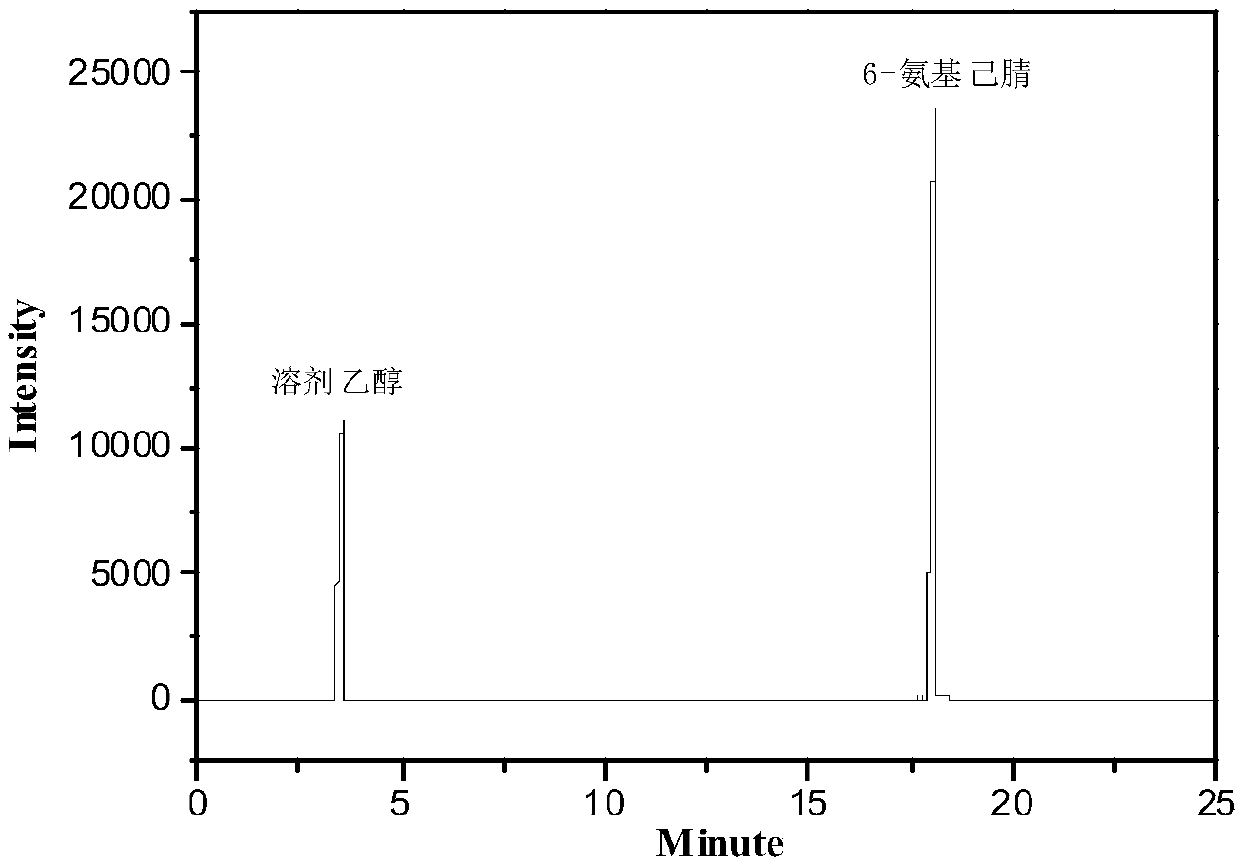

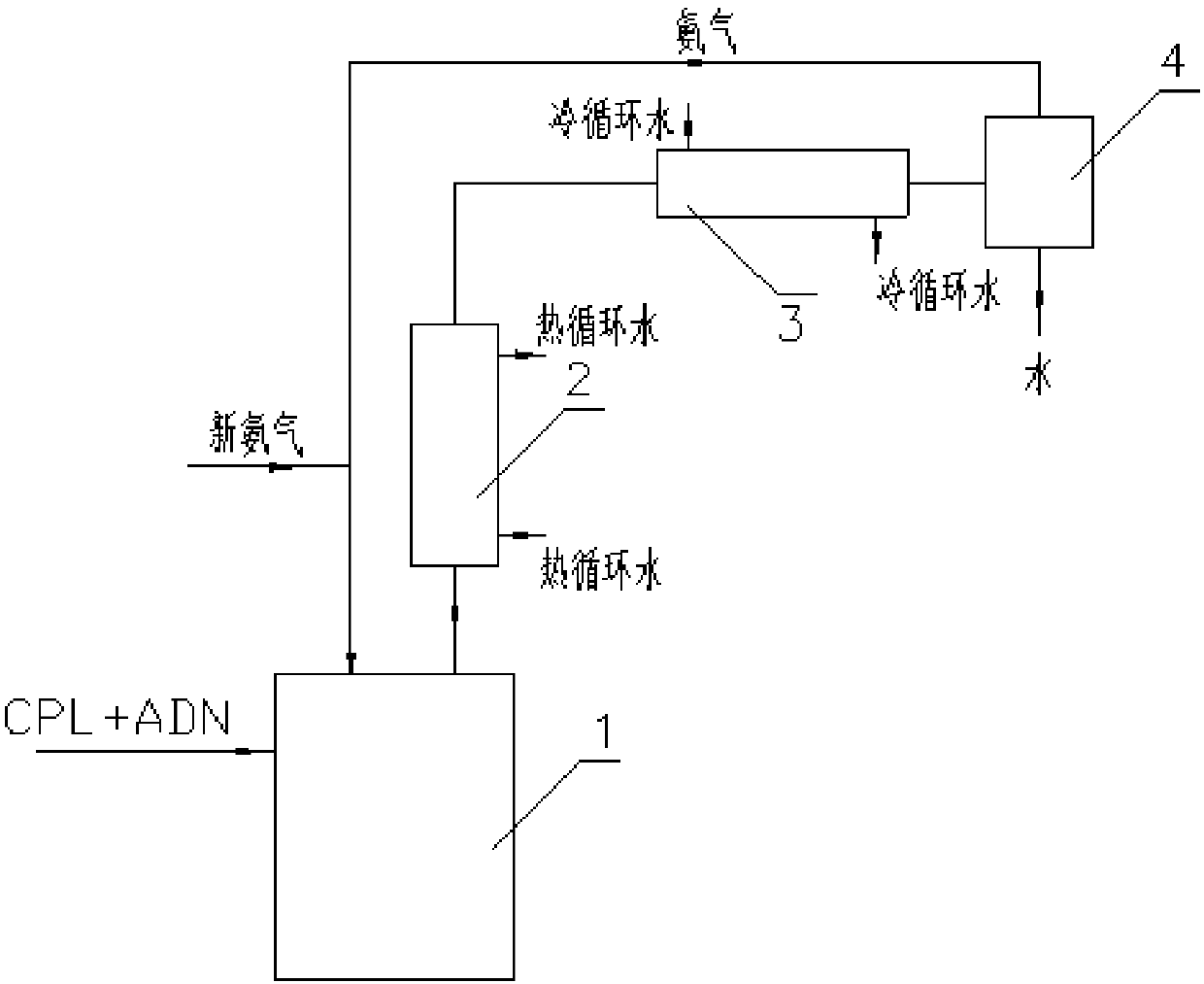

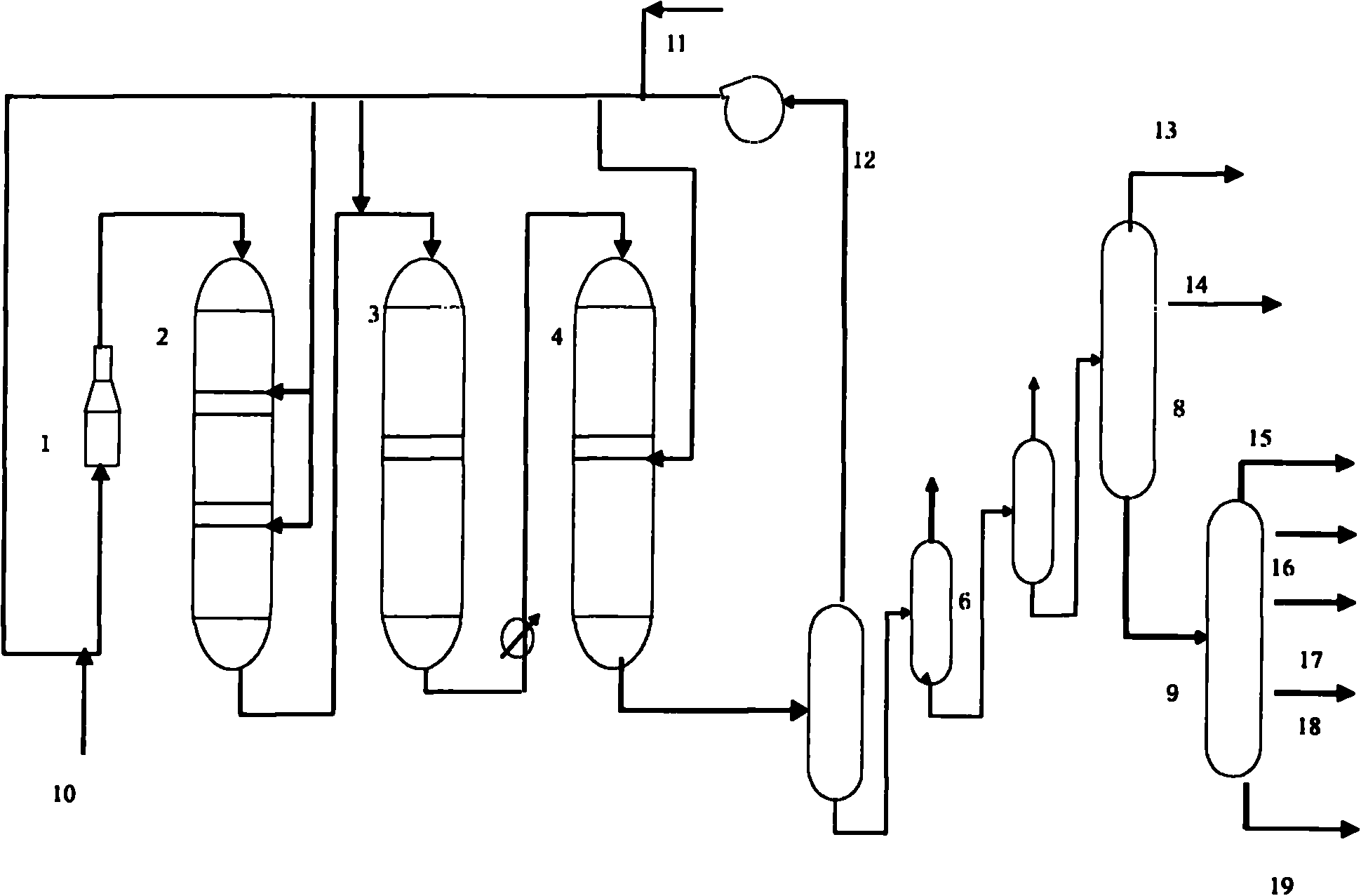

Method and device for preparing 6-amino-capronitrile with caprolactam liquid phase method

InactiveCN107739318AHigh reaction conversion rateGood choicePreparation by carboxylic acid amide dehydrationOrganic solventCaprolactam

The invention provides a method and device for preparing 6-amino-capronitrile from caprolactam by adopting a liquid phase method. In the method for preparing the 6-amino-capronitrile, the caprolactamis taken as a raw material; the method for preparing the 6-amino-capronitrile comprises the following step: S1: mixing the caprolactam, an organic solvent and a catalyst at a certain mass ratio, so asto obtain a mixed solution, adding the mixed solution into a reaction kettle and stirring and heating the mixed solution; S2: when the mixed solution in step S1 reaches certain temperature, introducing ammonia gas into the mixed solution for a reaction; S3, after the reaction in step S2 is ended, rectifying and purifying a reaction product, so as to obtain pure 6-amino-capronitrile. In the methodfor preparing the 6-amino-capronitrile, the caprolactam is taken as the raw material, the reaction conversion rate is comparatively high, and the preparation process is simple.

Owner:CHINA TIANCHEN ENG +1

Isomerization dewaxing catalyst and preparing method thereof

InactiveCN1488733AHigh reactivityHigh selectivityMolecular sieve catalystsPetroleum wax recoveryMolecular sieveIsomerization

The present invention discloses an isodewaxing catalyst for producing base oil of lubricating oil and its preparation method. Said catalyst contains a new-type phosphorus silicon aluminium molecular sieve with AEL structure and active metal component, and the surface acidity of said molecular sieve is strong, and its mesopore distribution is more. Said catalyst is used for isodewaxing reaction of lubricating oil fraction, and has the characteristics of low reaction temp. high base oil yield, low product pour point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

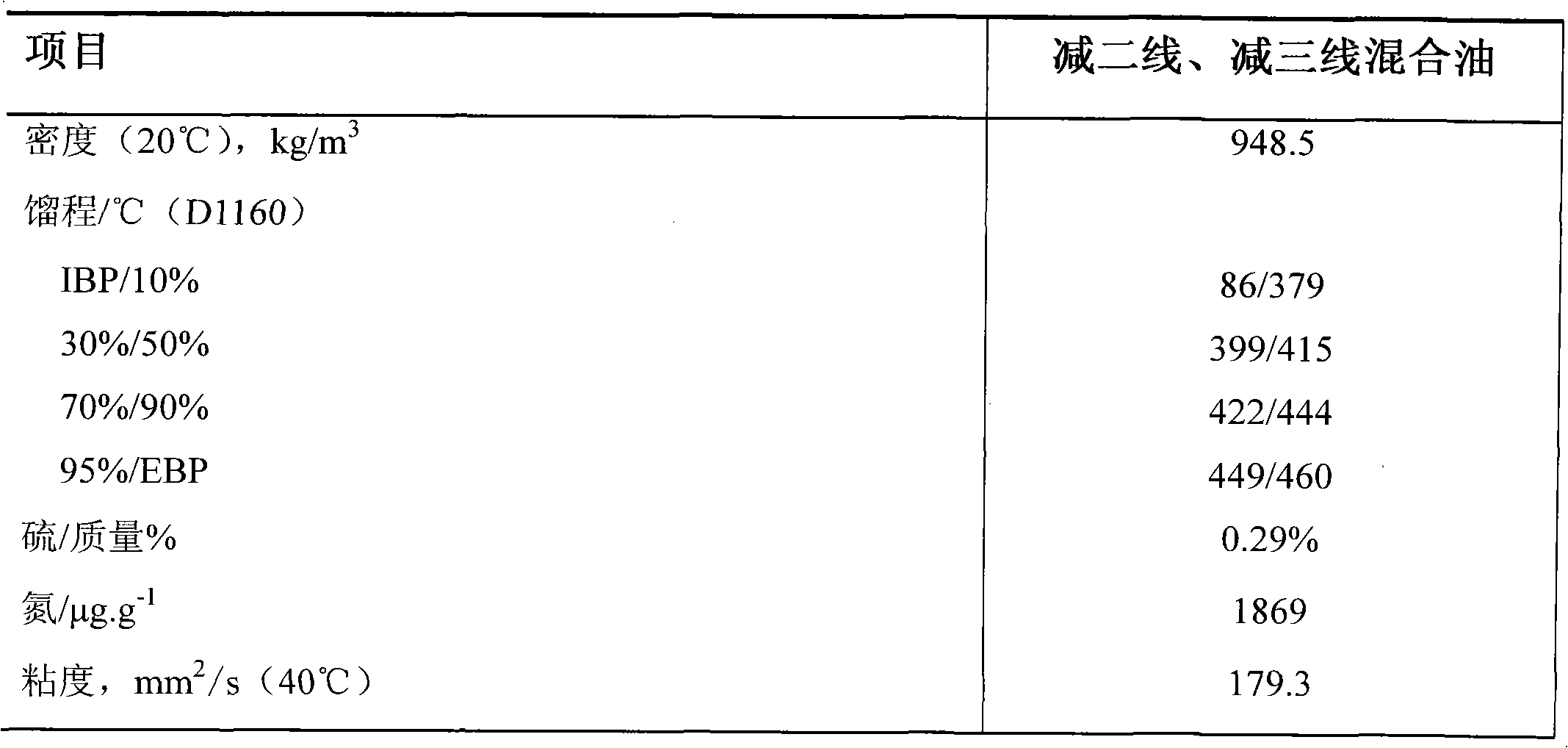

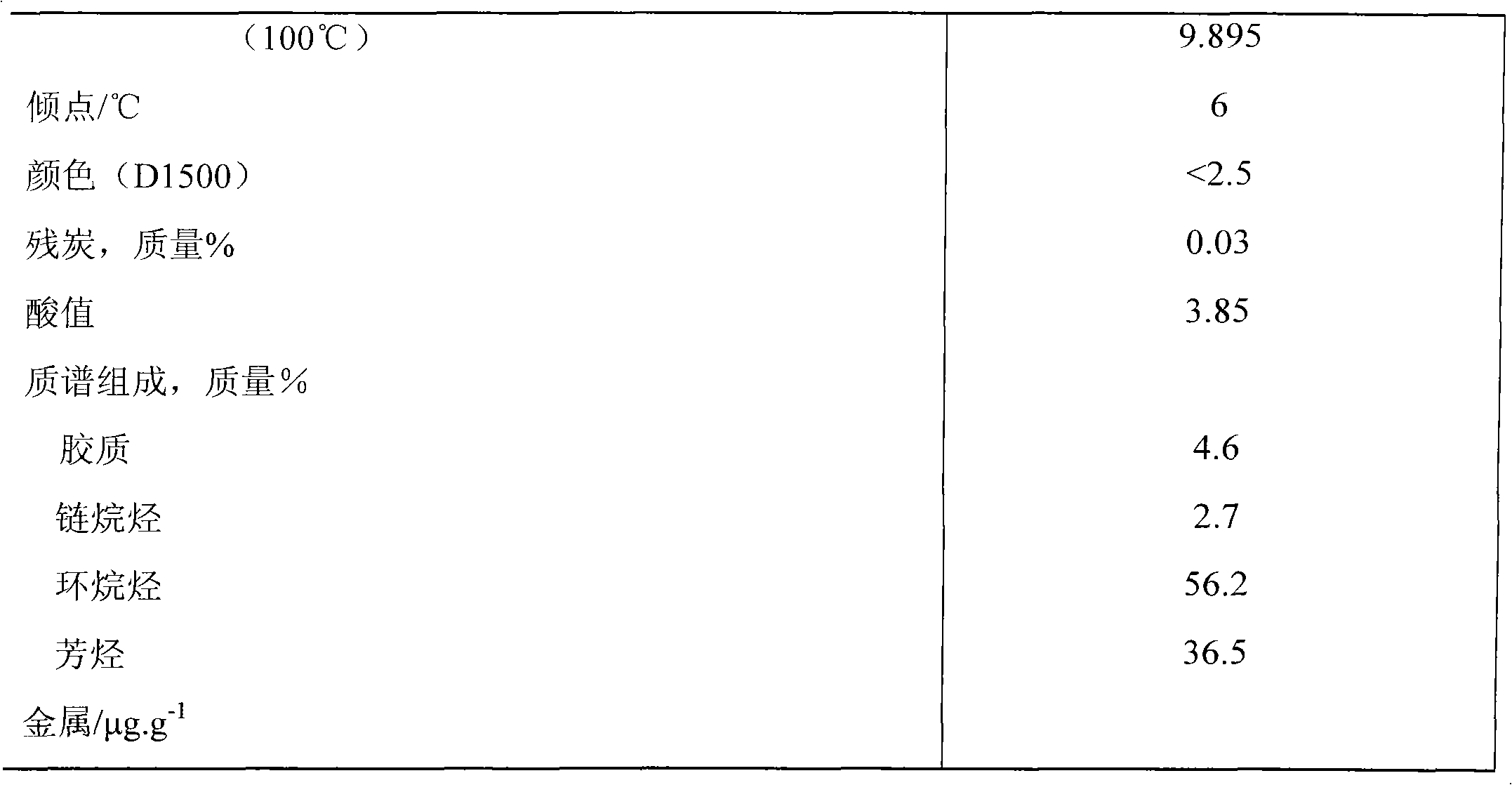

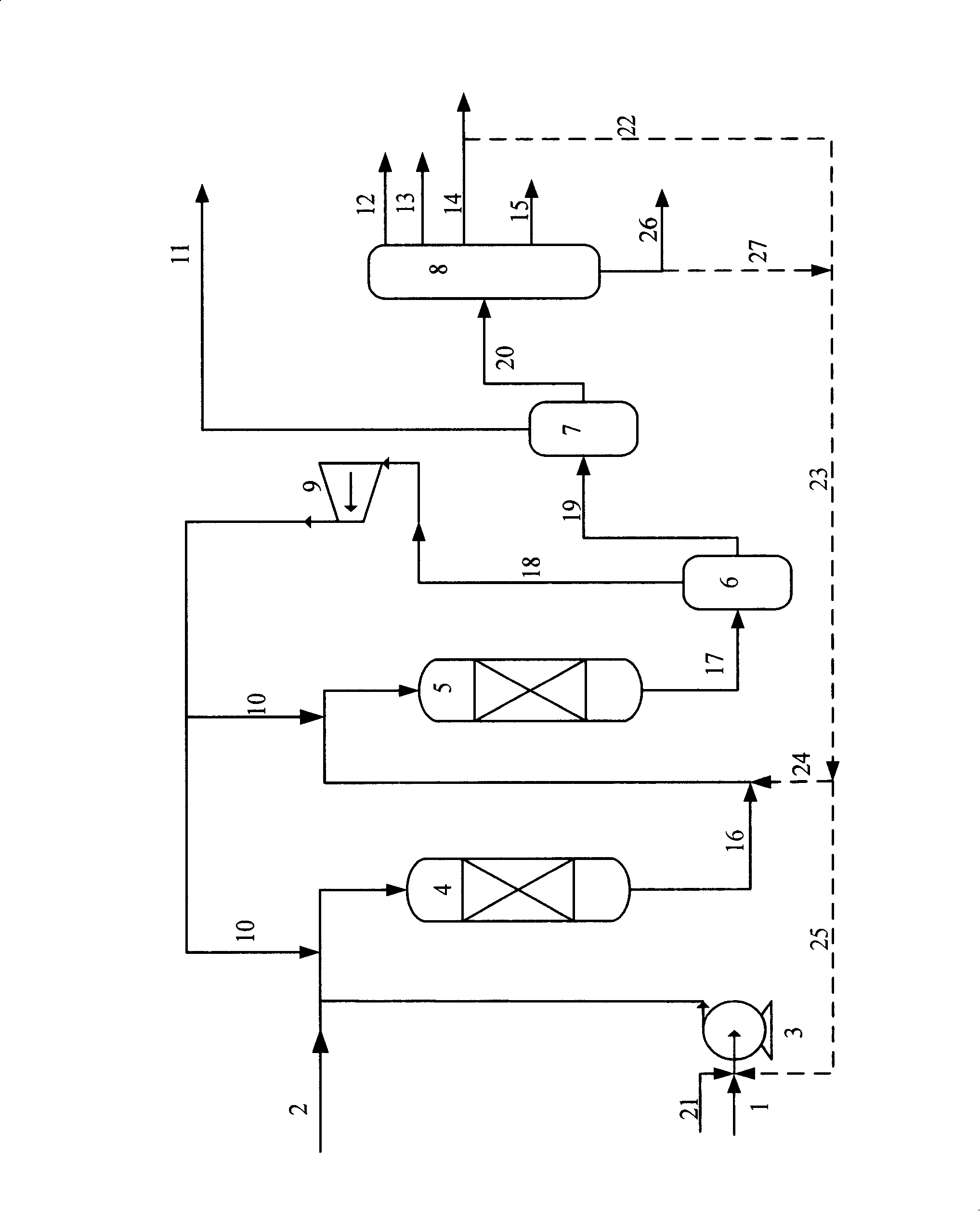

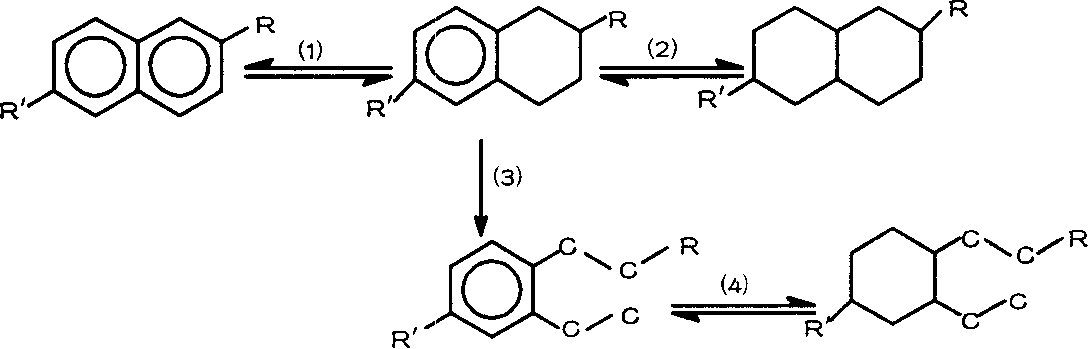

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785AWeak acidSmall grainTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Carbon dioxide methanation catalyst and preparation method thereof

InactiveCN101773833AHigh catalytic activityGood choiceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCarbon dioxideOxide

The invention discloses a carbon dioxide methanation catalyst and a preparation method thereof. The carbon dioxide methanation catalyst takes an aerogel oxide as a vector, an additive is added, nickel is used as an active component, the additive is alkali metal or alkali earth metal, and the aerogel oxide vector is silicon dioxide, titanium dioxide, zirconium dioxide, aluminum oxide or a compoundthereof. The catalyst comprises the following components in percentage by weight: 5-40wt.% of nickel and 0.01-30wt.% of the additive. The catalyst of the invention has high catalytic activity and stability, and can effectively catalyze carbon dioxide to be hydrogenated into methane at normal pressure under the reaction conditions that the air speed is 2000-20000h<-1>, the ratio of H2 to CO2 is 4:1, and the temperature is 300-500 DEG C. The maximum conversion rate of CO2 is higher than 90% and the maximum selectivity of CH4 is 99.9%. The preparation method of the catalyst of the invention has the advantages of simplicity, easy operation, lower cost and certain application prospects.

Owner:SHANXI UNIV

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation modification process for low grade gasoline

ActiveCN1621495AGood activity at low temperatureLow reaction temperatureRefining by aromatic hydrocarbon hydrogenationRefining to eliminate hetero atomsPre treatmentLow graded

The inferior gasoline hydrogenating modification process includes cutting the material gasoline at 60-90 deg.c into light fraction and heavy fraction; mixing the heavy fraction with hydrogen, reacting with hydrogenating and desulfurizing catalyst via contact, and reacting the effluent with aromatizing modification catalyst for aromatizing modification to obtain high octane number and low sulfur gasoline fraction; and mixing the modified heavy gasoline fraction with the light fraction or the light fraction after mercaptol eliminating pre-treatment to obtain the product gasoline. The said process makes the gasoline product possess S content not more than 150 ppm, olefin content not more than 20 %, arene content not more than 40 % and 1-3 unit raised RON.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method for preparing semi-aromatic nylon

The invention discloses a method for preparing semi-aromatic nylon and belongs to the technical field of macromolecular material synthesis. The method comprises the following steps: (1) uniformly mixing aliphatic diamine and water of which the weight is two to ten times that of the aliphatic diamine, heating the mixture to the temperature of between 50 and 90 DEG C, adding aromatic diacid into the mixture with stirring till a pH value of the solution reaches 7.0-7.7, continuously stirring for 1 to 5 hours, cooling the solution to room temperature, continuously stirring the solution for 1 to 5 hours again, and filtering and drying to obtain nylon salt for later use; and (2) adding the prepared nylon salt and a solvent to a polymerization kettle in a certain mixture ratio (0.5 to 3.0 g / mL), raising the temperature to between 190 and 230 DEG C under the protection of inert gas, keeping the pressure in the kettle between 2.0 and 3.0 MPa, discharging gas after 1 to 5 hours to make the pressure in the kettle reduced to normal pressure within 1 to 5 hours, raising the temperature to between 210 and 270 DEG C, and continuing to react for 1 to 5 hours, and discharging to obtain a powdery semi-aromatic nylon product. The method has mild reaction condition and low energy consumption; the product is easy to mold and machine; and the method solves the difficult problem of difficult discharging of the semi-aromatic nylon, and is applicable to industrialized production.

Owner:青岛智库生物技术有限公司

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

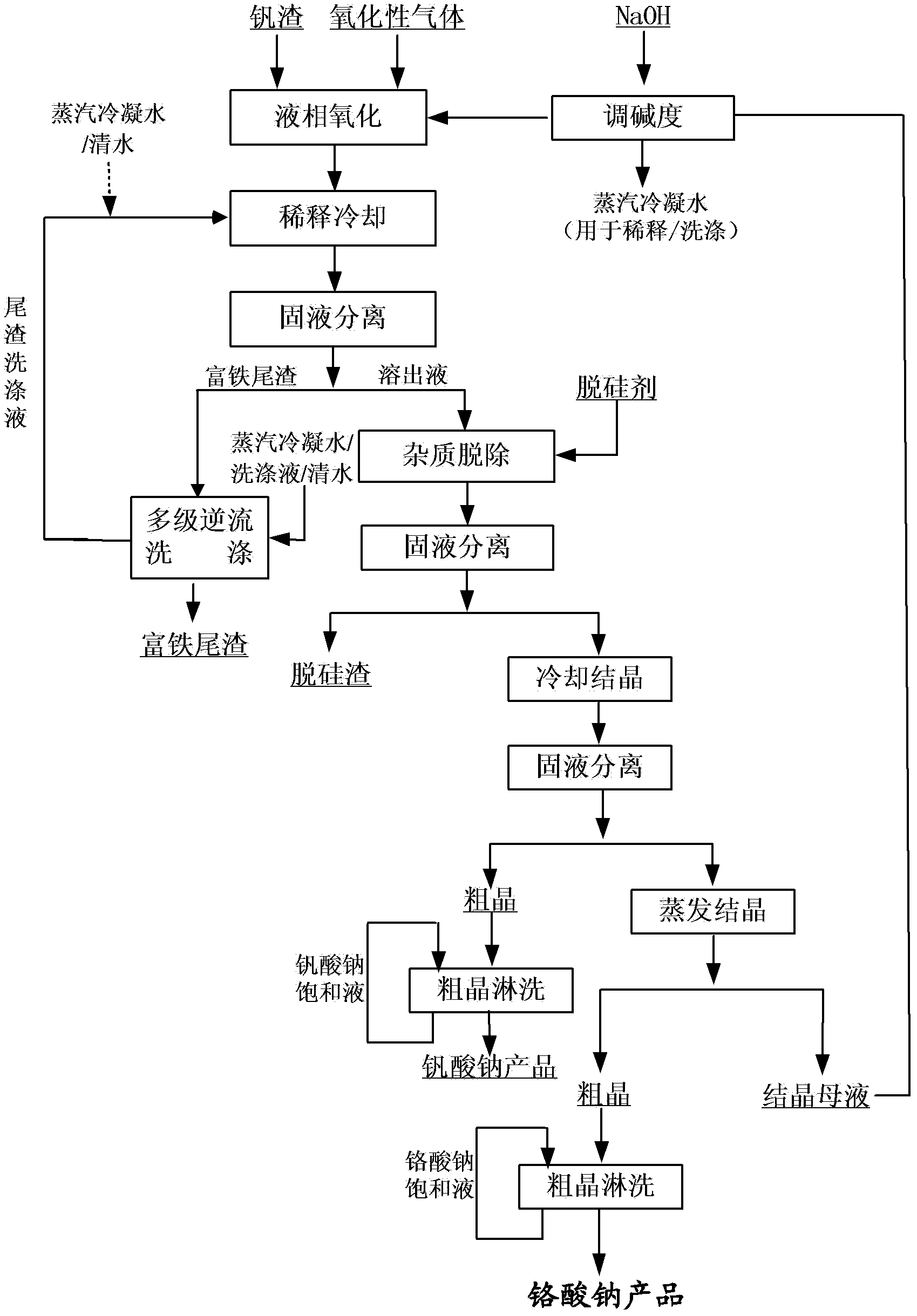

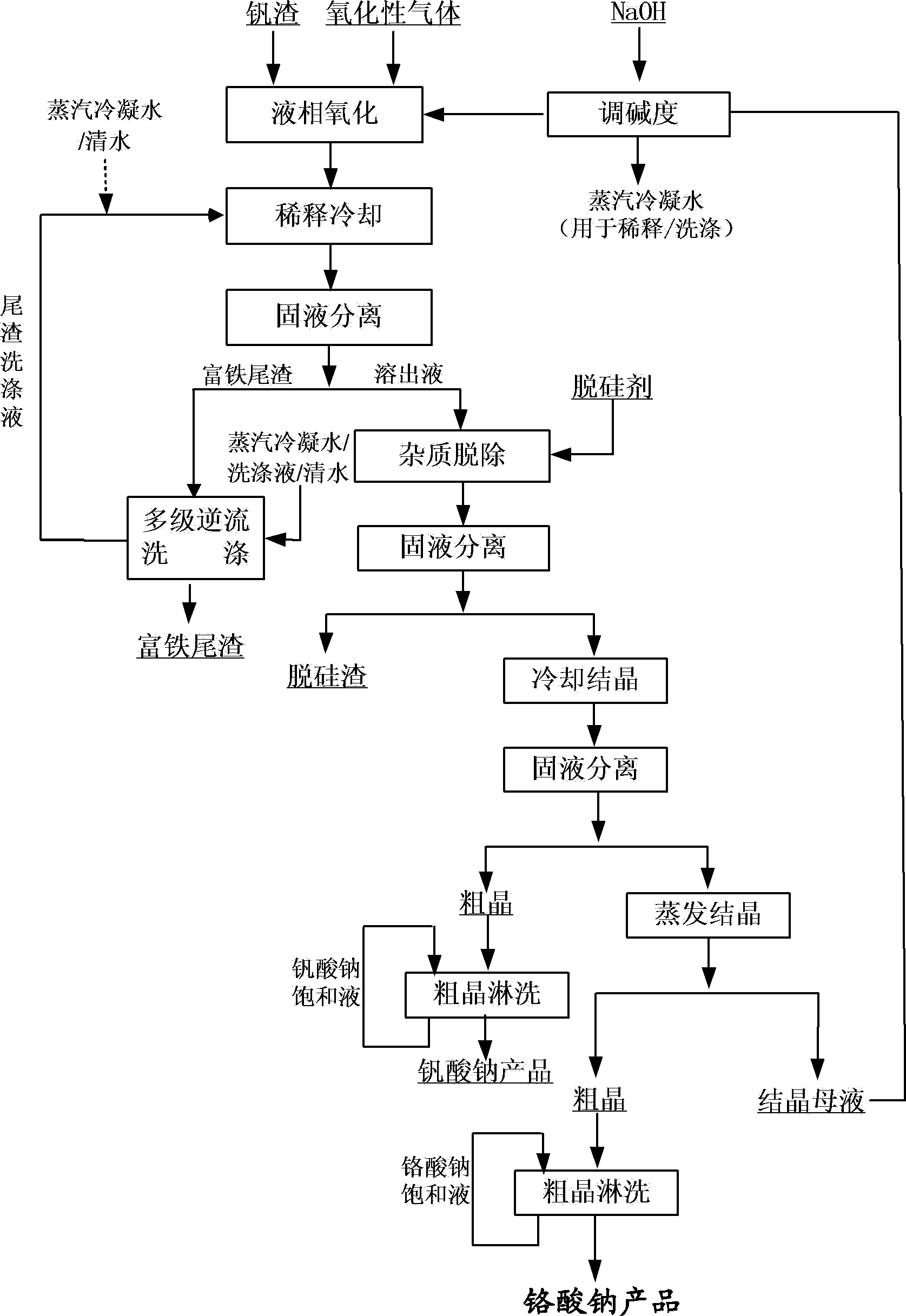

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for producing iron phosphate for producing iron lithium phosphate material

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

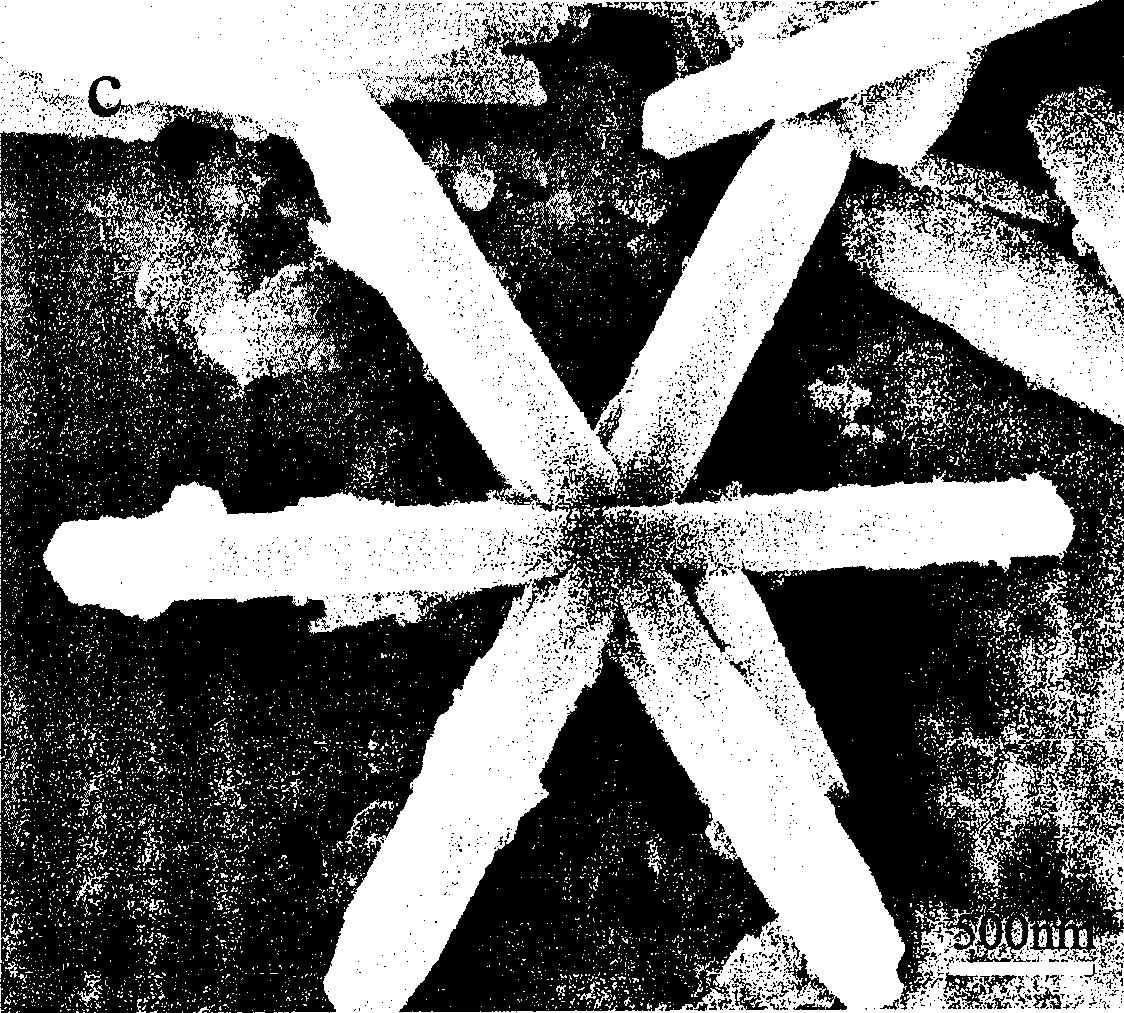

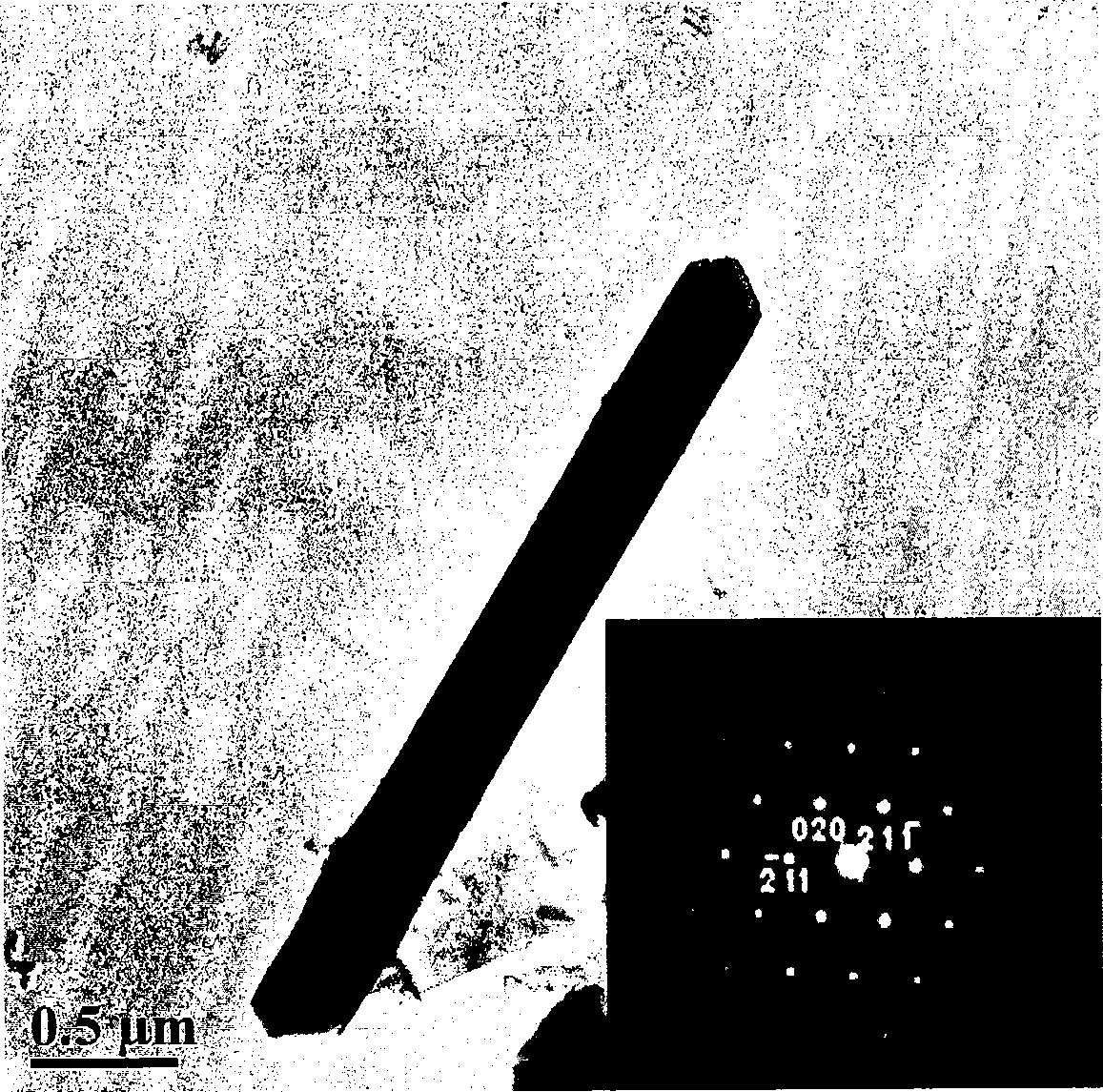

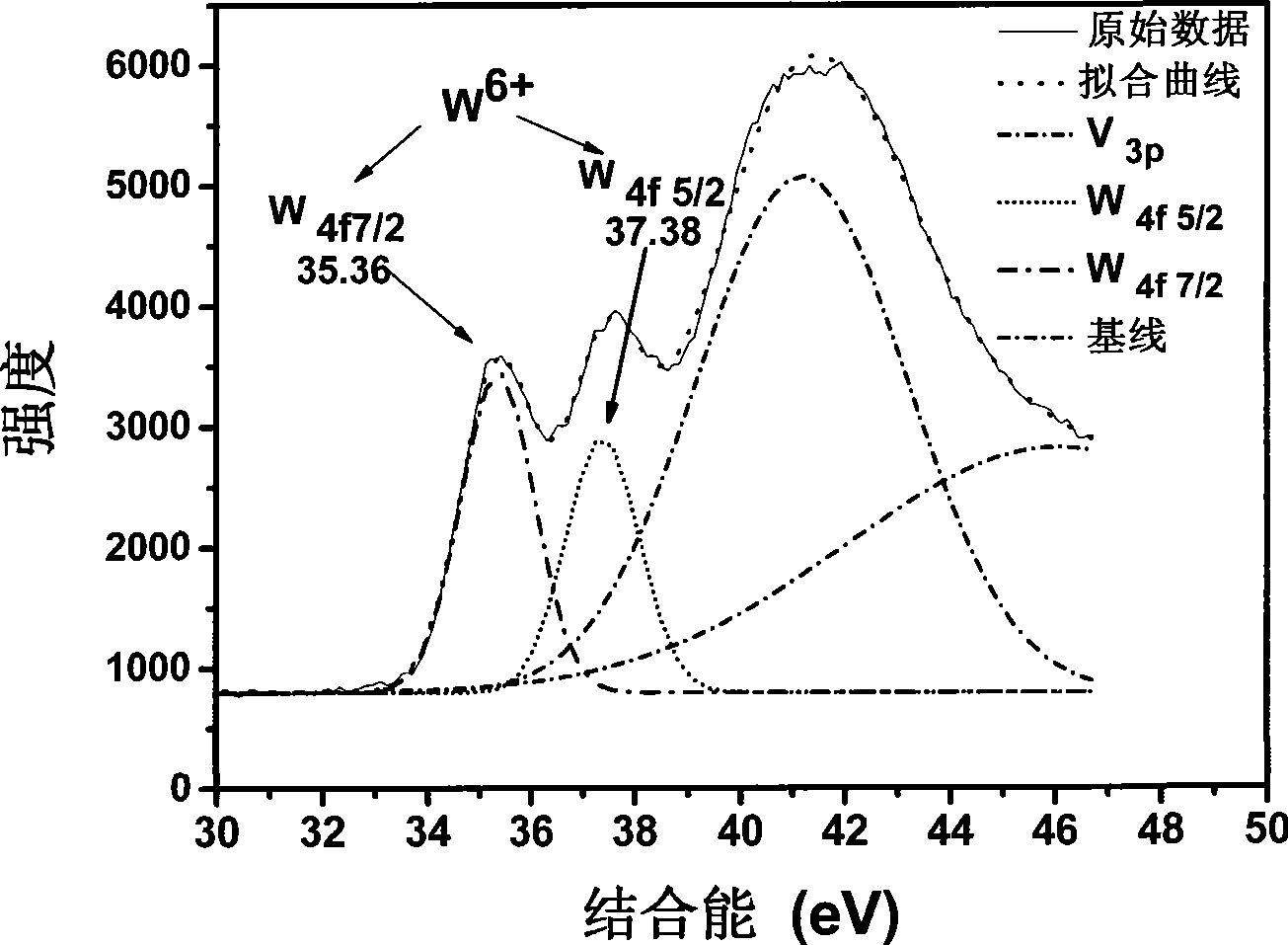

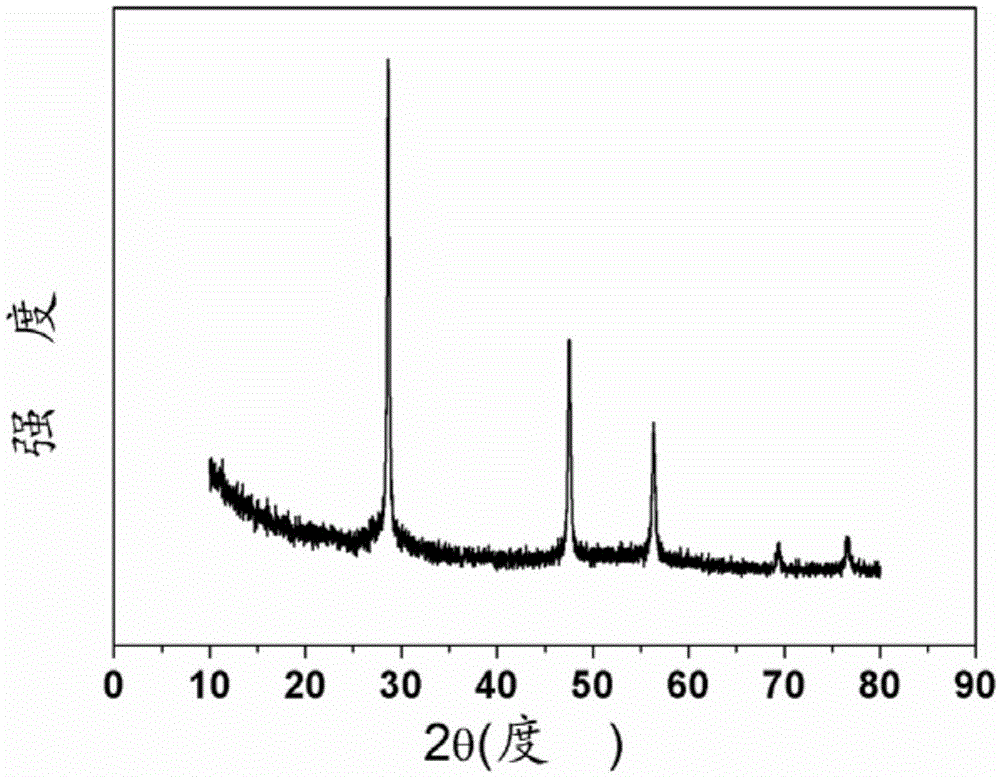

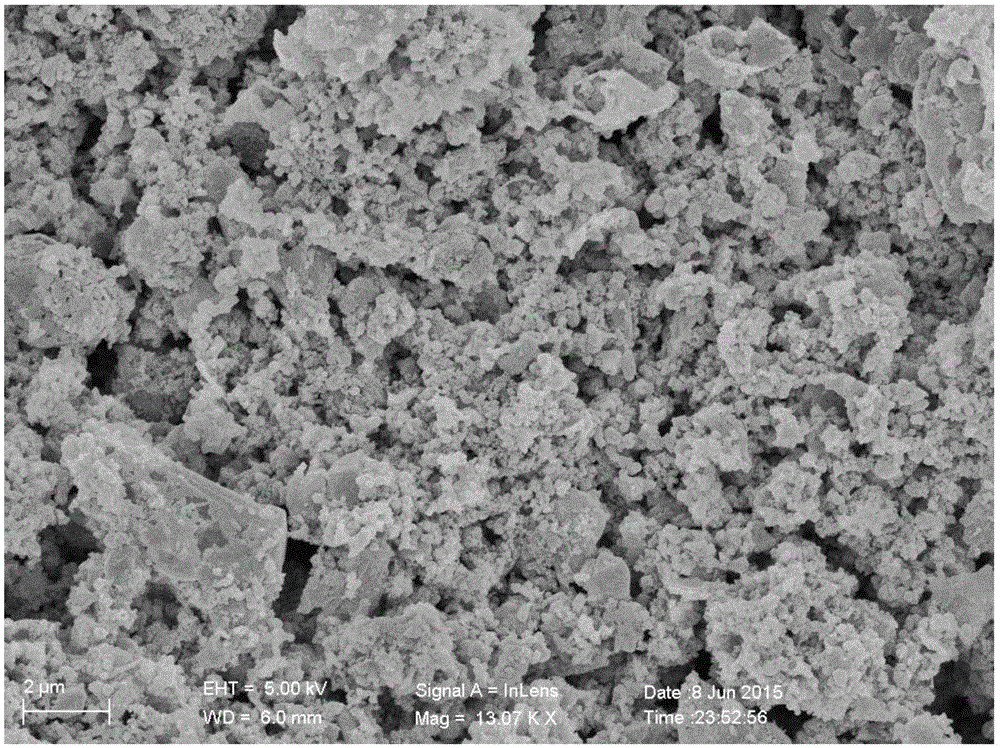

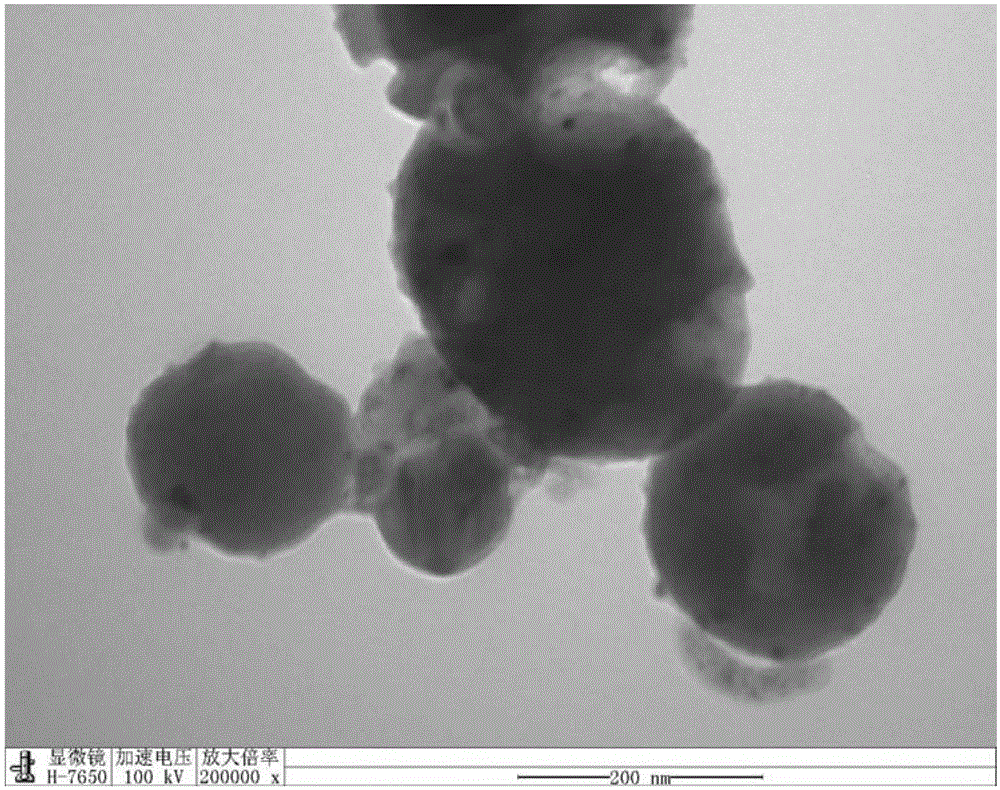

Method for preparing rutile phase hypovanadic oxide powder

The invention relates to a method for preparing rutile-phase vanadium dioxide powder, in particular to a method for preparing rutile-phase vanadium dioxide powder through a hydrothermal method. The method for preparing rutile-phase vanadium dioxide powder adopts the conditions of different vanadium materials, dopants and doping ratios, and the like, to obtain rutile-phase vanadium dioxide powders with good crystallization performance and in shapes of grains, nanometer rods and snowflake-shaped grains. The temperature for transforming the powder from semiconductor phase to conductor phase can be reduced approximately to the room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

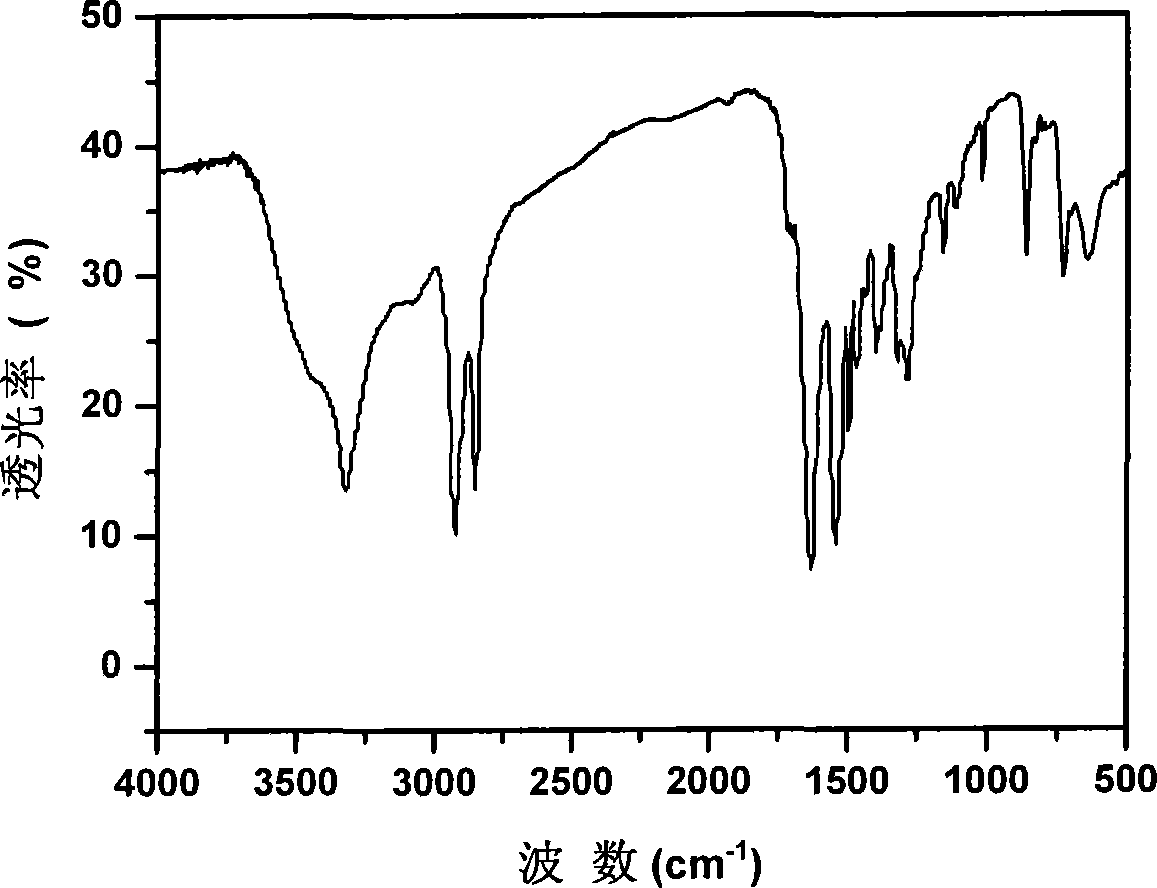

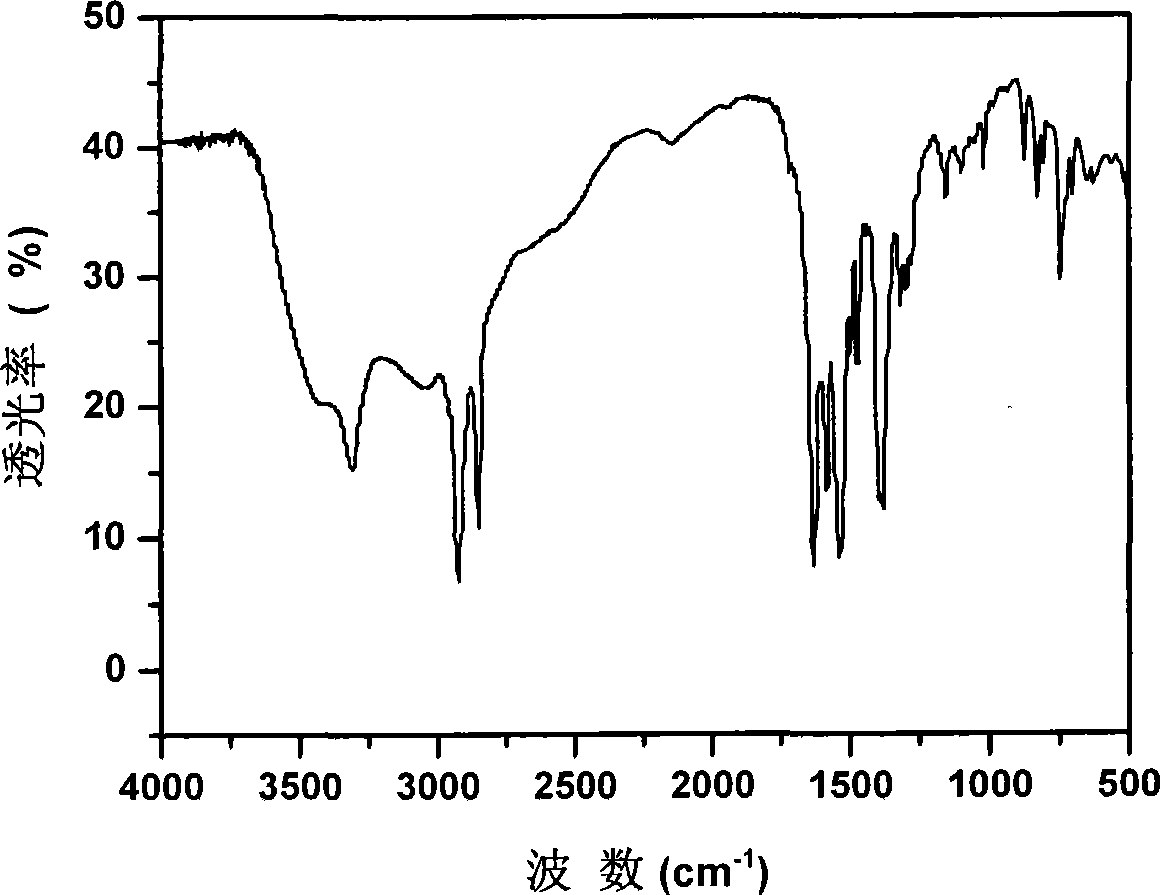

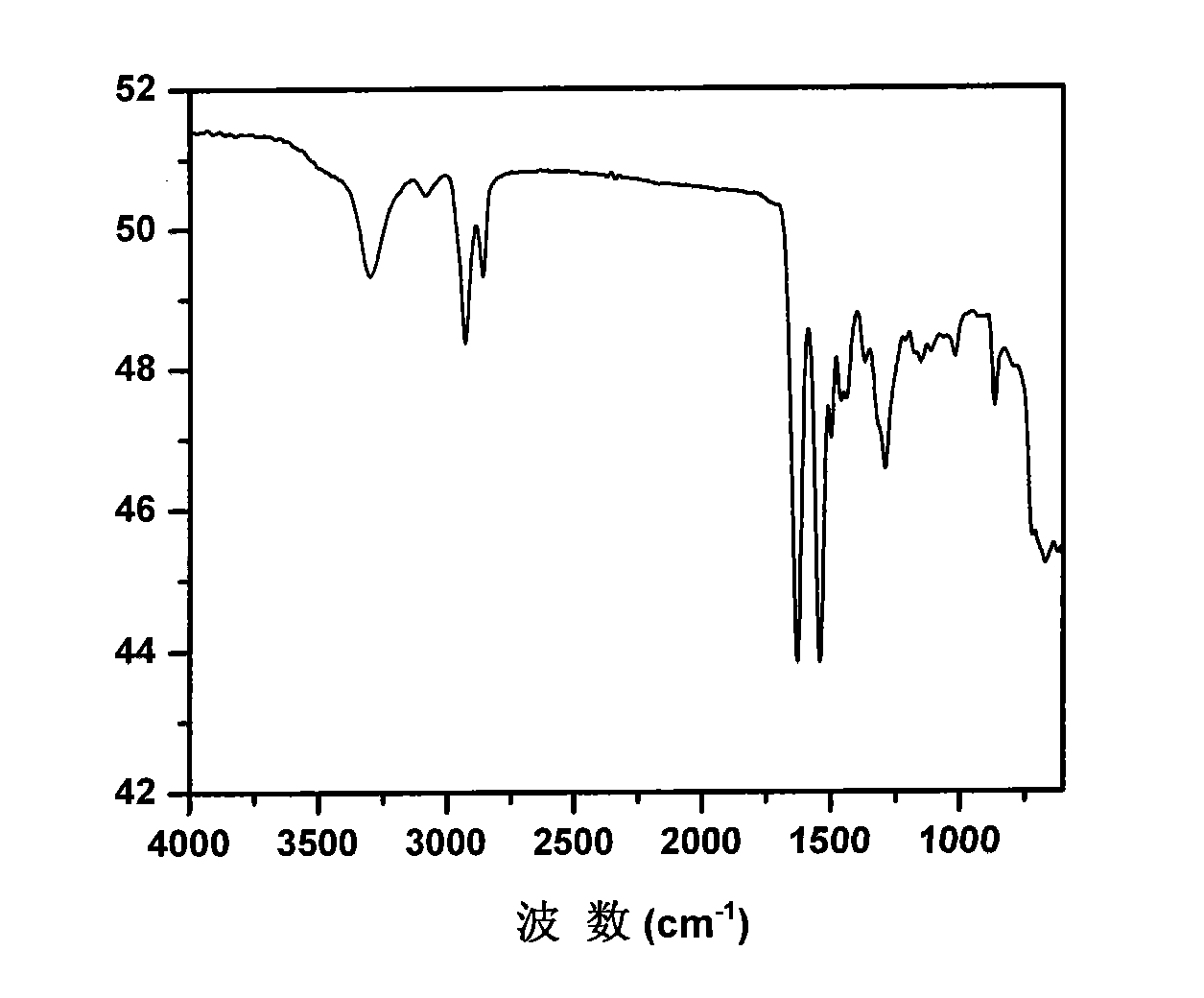

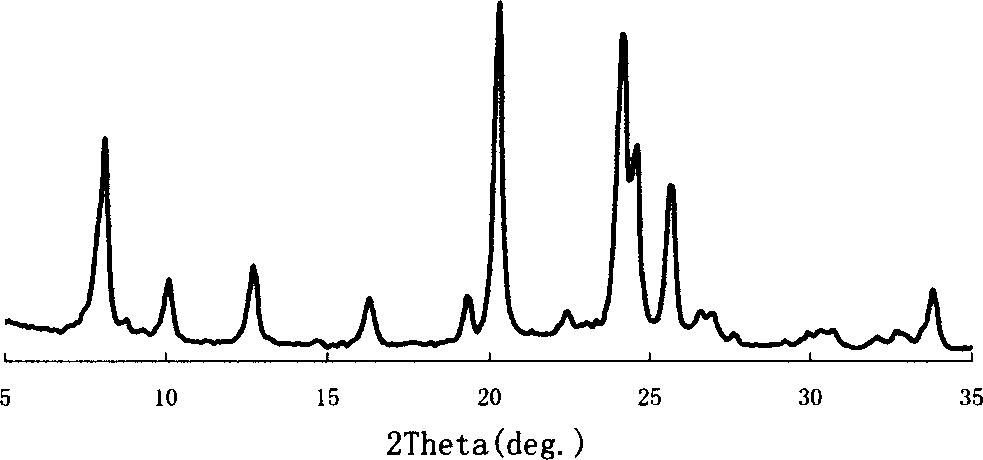

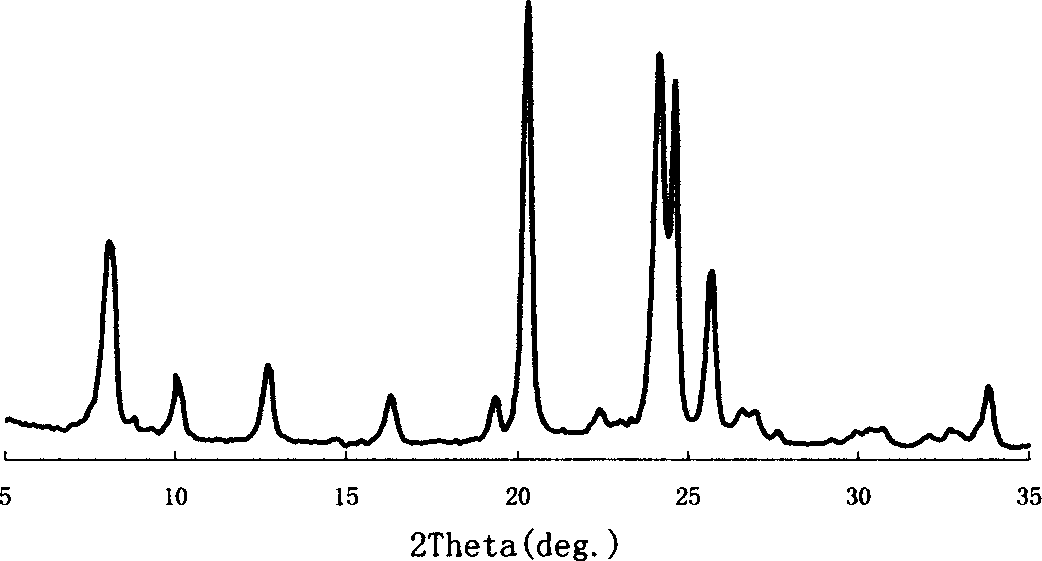

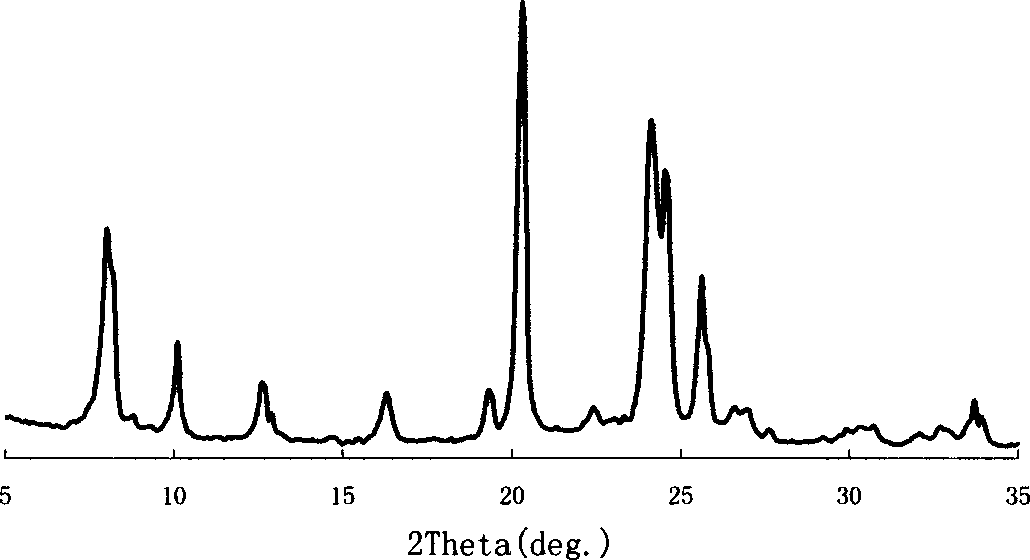

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

Hydroprocessing catalyst and its prepn process

The present invention is hydroprocessing catalyst and its preparation process. The catalyst includes one kind of molecular sieve with TON type structure and active metal component, and the molecular sieve has the features of surface Si / Al ratio higher than the bulk Si / Al ratio, proper acidity and channel structure for paraffin hydrocarbon to generate shape-selective cracking-isomerizing reaction, etc. The catalyst is used in hydroprocessing intermediate fraction oil and heavy fraction product, and has the features of high activity, high isomerizing selectivity, low cracking performance, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low carbon olefin by coupled catalytic cracking of petroleum hydrocarbon

A process for preparing lower carbon number hydrocarbons through linkage petroleum hydrocarbon catalysis decomposition, wherein petroleum hydrocarbon and organic oxygen compounds are used as raw material, and fluid bed reactor is utilized under the action of solid acid catalyst and high temperature water vapor through linkage petroleum hydrocarbon catalysis decomposition to prepare lower carbon number hydrocarbons. The reaction condition is, temperature 500-720 deg.C, the weight ratio of the catalyst and the petroleum hydrocarbons is 5-40:1, the weight ratio of the organic oxygen compounds and the petroleum hydrocarbons is 0-2:1, the weight ratio of the water vapor and the petroleum hydrocarbons is 0-1:1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

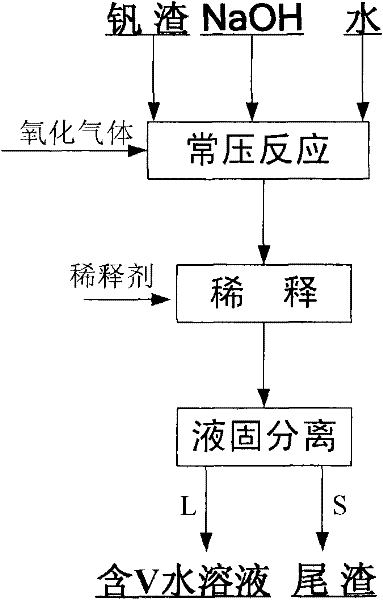

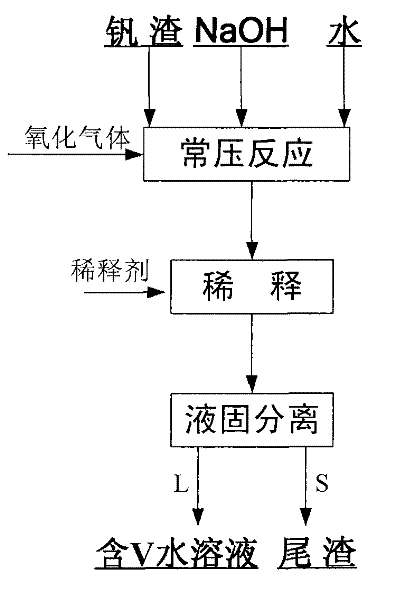

Method for decomposing vanadium slag under normal pressure with sodium hydroxide solution

ActiveCN102127655ALow reaction temperatureHigh extraction rateProcess efficiency improvementSodium chromateCALCIUM HYDROXIDE SOLUTION

The invention relates to a method for extracting vanadium by decomposing vanadium slag under normal pressure with sodium hydroxide solution. The method comprises the following steps of: adding vanadium slag or preprocessed vanadium slag, water and NaOH into a normal pressure reactor, wherein the mass ratio of NaOH to the vanadium slag is (2-6): 1, and the mass concentration of the sodium hydroxide solution is 65-90wt%; oxidizing in the presence of an oxidizing gas at the temperature 180-260 DEG C for 0.5-6 hours, and then diluting the obtained reaction sizing agent with diluent, thus mixed sizing agent containing sodium hydroxide, sodium vanadate, sodium chromate and slag tailing is obtained; and filtering and separating the mixed sizing agent at the temperature of 80-130 DEG C, thus the slag tailing and aqueous solution containing vanadium are obtained. The method provided by the invention has the advantages that the operating temperature is below the boiling temperature of solution, the process can be carried out under normal pressure, the operation is easy, and the safety is good; and the operating temperature is far less than the operating temperature of the traditional vanadium extracting process, the extraction ratio of vanadium is high, and the total vanadium content in the slag tailing is 0.5-1wt% (taking the weight of V2O5 as the basis).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

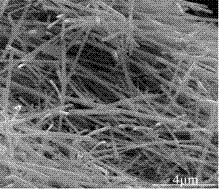

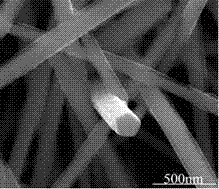

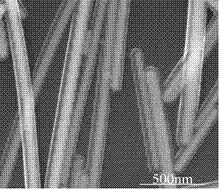

Preparation method of metal silver nanowires with adjustable length and diameter

InactiveCN102328095ALow reaction temperatureLow costPolycrystalline material growthSingle crystal growth detailsAlcoholReaction temperature

The invention discloses a preparation method of metal silver nanowires with adjustable length and diameter. The method comprises the following steps: dissolving silver nitrate in polyhydric alcohol for preparing solution; dissolving an alkali metal halide and a reducing compound in the polyhydric alcohol for preparing the solution; mixing the two types of the solution, and fully reacting under stirring to get the mixed solution; heating the polyhydric alcohol to 120-160 DEG C, dripping into the mixed solution, keeping the temperature and reacting for 15-44 hours; and performing centrifugal separation on reaction solution after the reaction, and washing lower-layer precipitate to get the silver nanowires. According to the preparation method, inert gas does not need to be introduced for protection, the reaction temperature is low, the preparation process is simple, the yield is high, the cost is low, and the insufficiencies of complex preparation procedure, low yield, high cost and the like in the template plate, the seeding method, the traditional polyhydroxy reduction method and the like can be overcome, thereby having important significance for large-batch industrial production and actual application thereof of the silver nanowires.

Owner:UNIV OF JINAN

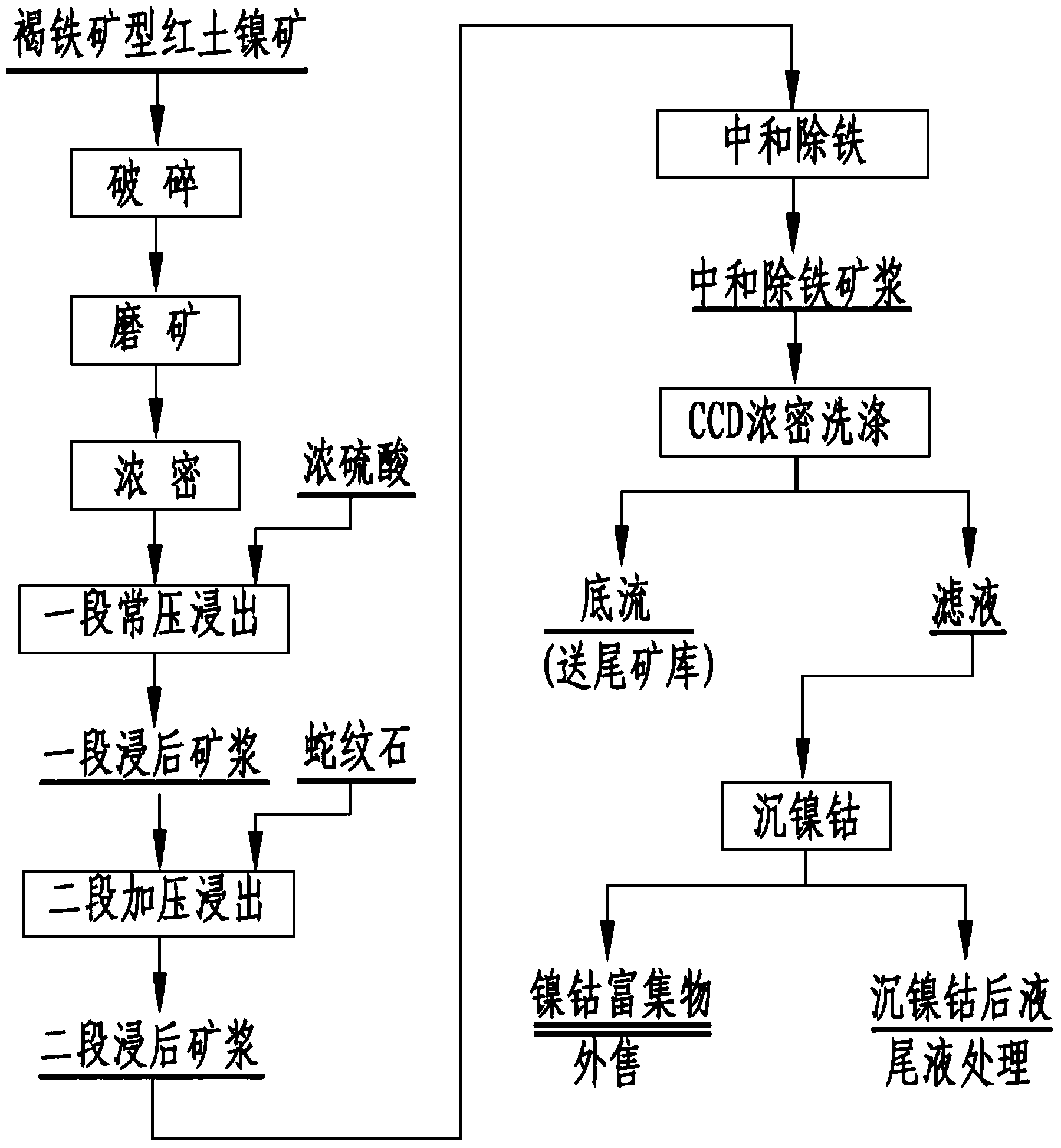

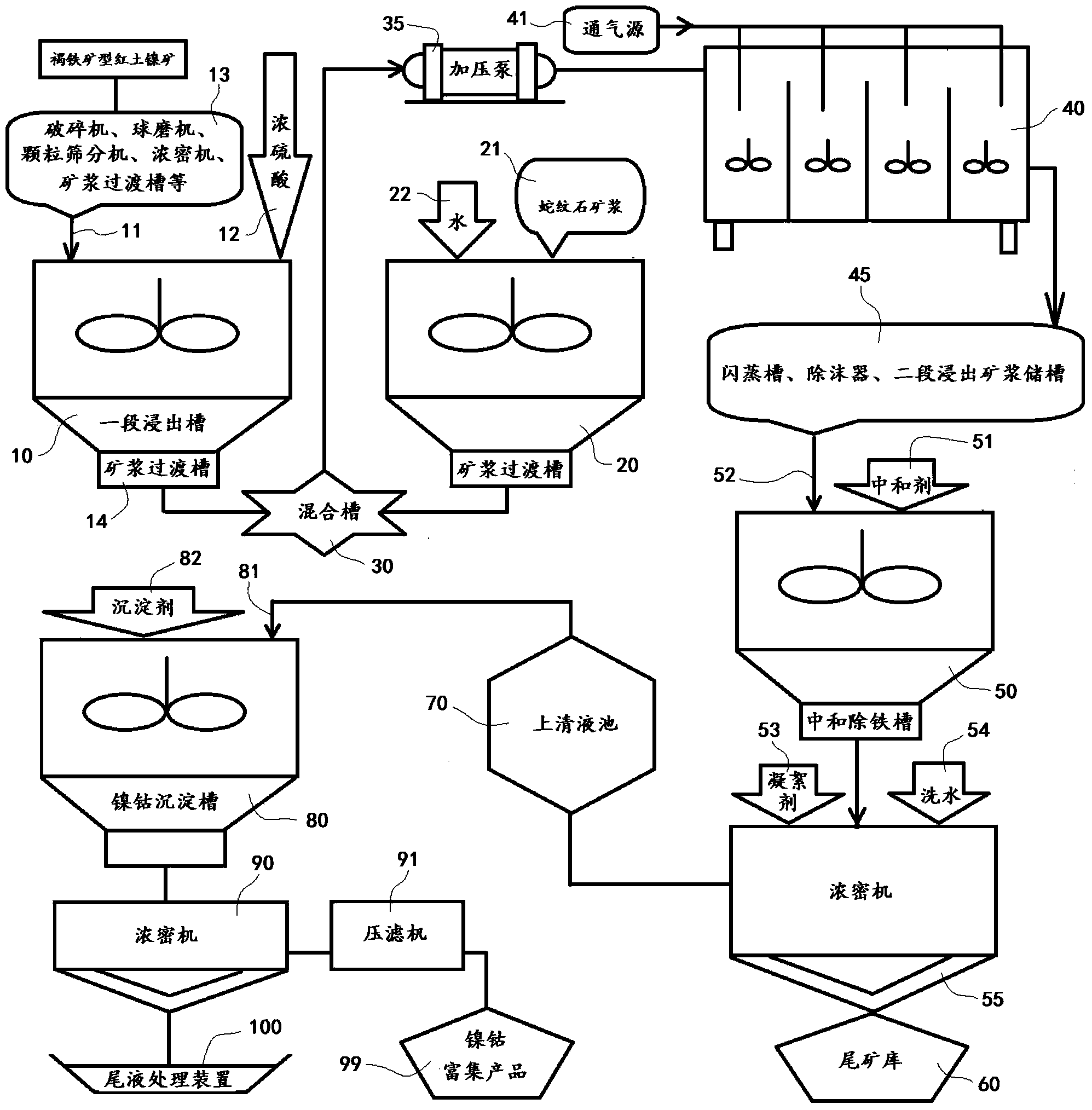

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Organic silicon modified acrylate emulsion and preparation method thereof

The invention relates to organic silicon modified acrylate emulsion and a preparation method thereof. A core-shell structure synthesis method is adopted for preparation, a core layer / shell layer glass transition temperature is designed to be -30- -25 DEG C / 0-5 DEG C and lower than conventional core-shell emulsion. The emulsion comprises core-shell emulsion monomers, initiator accounting for 0.4-0.6% of the total mass of the monomers, composite emulsifier accounting for 2.5-4.5% of the total mass of the monomers, pH (potential hydrogen) buffering agent accounting for 0.4-0.6% of the total mass of the monomers and the balance deionized water. The emulsion preparation method includes (1) pre-emulsifying, (2) core-layer emulsion preparation, and (3) core-shell emulsion preparation. The emulsion which is aqueous emulsion is environment-friendly and high in stability, bonding power and tensile strength, has functions of softening, smoothening and the like for surface treatment of fabrics and the like, and is widely applicable to the fields of spinning, papermaking, leather, painting, water-based ink and the like.

Owner:DONGHUA UNIV

Nitrogen-doped carbon material supporting cobalt catalyst and method therewith of catalytic hydrogenation reductive amination to produce amine compounds

InactiveCN106552661AEasy to prepareReduce manufacturing costOrganic compound preparationCatalyst activation/preparationReaction temperatureNitrogen gas

The invention discloses a nitrogen-doped carbon material supporting cobalt catalyst and a method therewith of catalytic hydrogenation reductive amination to produce primary amine compounds. The catalyst is prepared through the steps of: 1) preparing a MOF material ZIF-67; and 2) under protection of nitrogen gas, calcining the MOF material ZIF-67 at 200-1000 DEG C for 1-10 h to produce the nitrogen-doped carbon material supporting cobalt catalyst Co / N-C. The method of catalytic hydrogenation reductive amination to produce the primary amine compounds with the catalyst includes the steps of: in an organic solvent, adding a carbonyl compound, ammonia water and the nitrogen-doped carbon material supporting cobalt catalyst, feeding hydrogen gas, and performing a reaction at 50-150 DEG C under 0.1-5 MPa for 0.5-20.0 h to produce the amine compounds. The preparation method of the catalyst is simple in operations. The catalyst can be used for producing the primary amine compounds in a manner of catalytic hydrogenation reductive amination. In the method, the primary amine compounds are produced with the carbonyl compound as a raw material through catalytic hydrogenation by means of the catalyst, so that the method has mild reaction conditions and is high in yield.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Preparation method for silicon nano material and application

ActiveCN105084365ASave raw materialsLow reaction temperatureMaterial nanotechnologyCell electrodesOrganic solventReaction temperature

Owner:UNIV OF SCI & TECH OF CHINA

Catalyst used for methanation of carbon dioxide, preparation method therefor and applications thereof

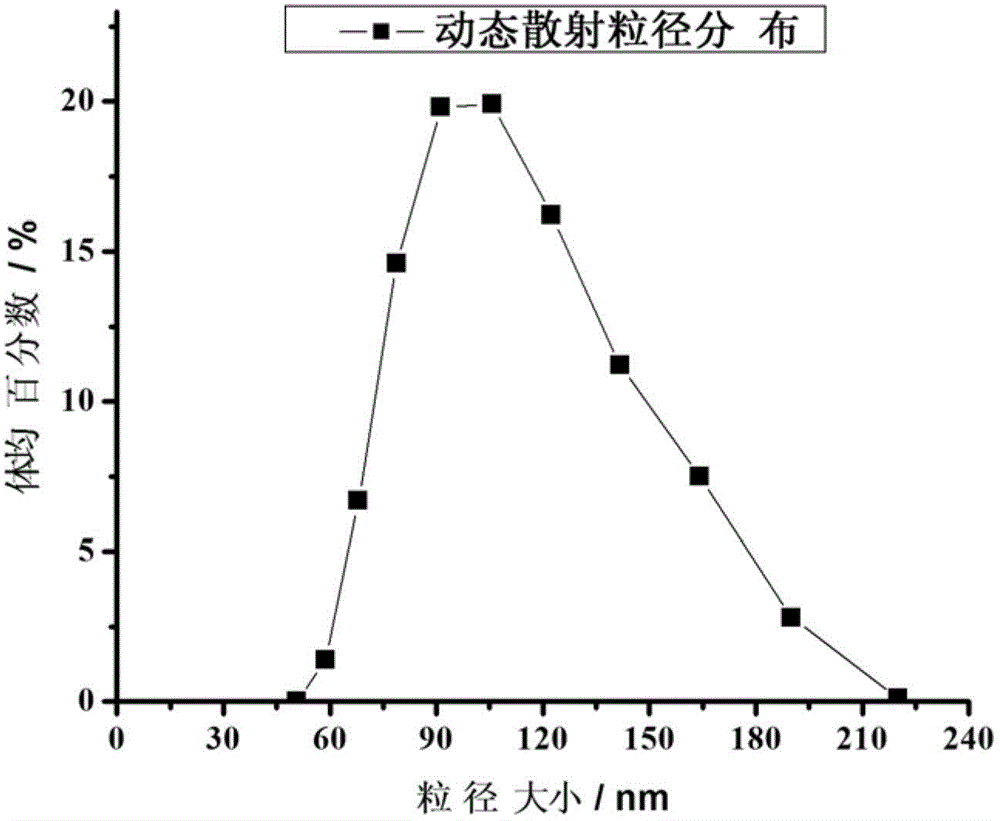

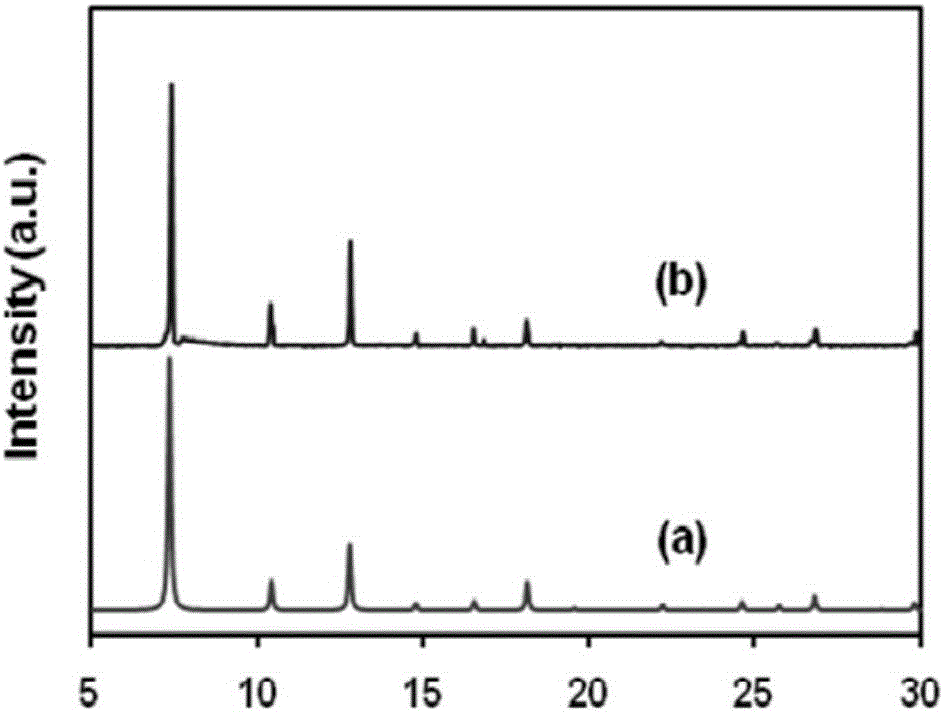

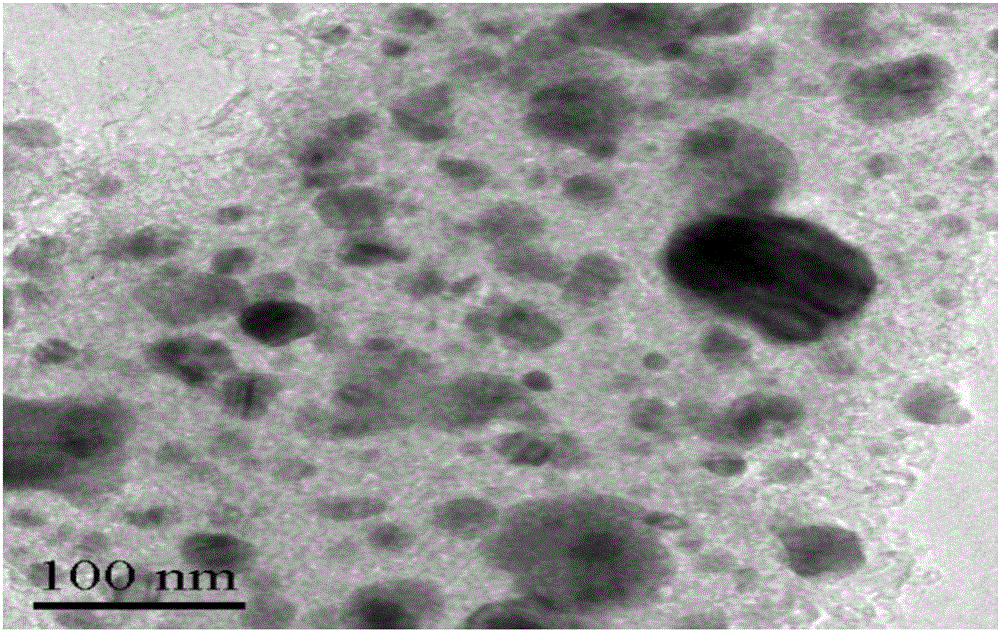

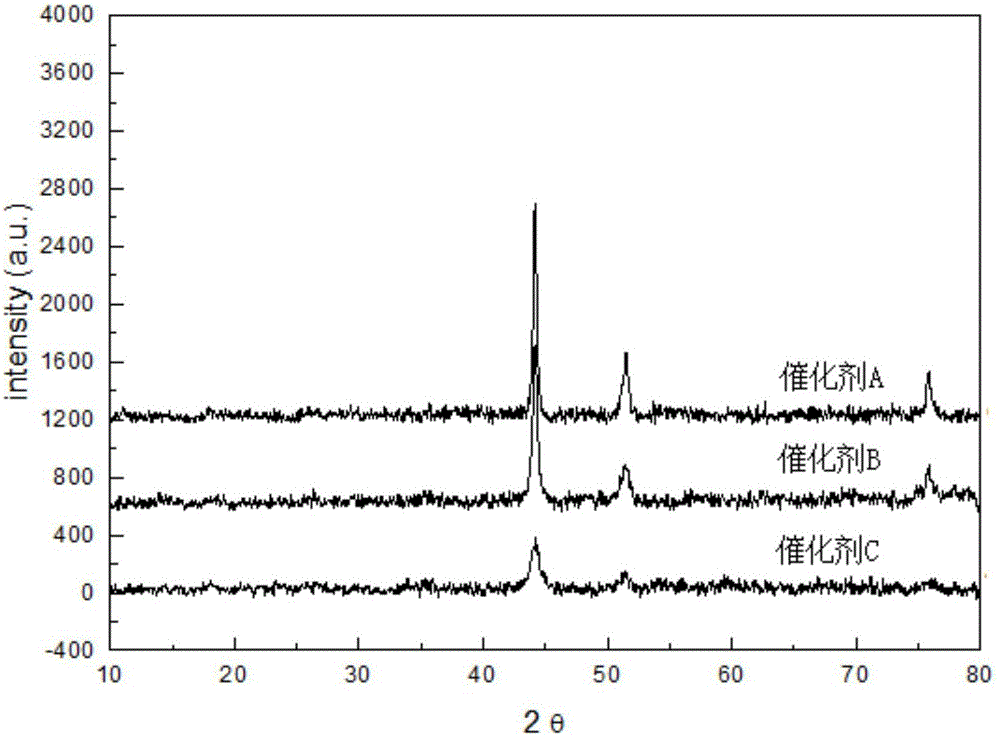

ActiveCN104148065ASmall particle sizeNarrow distributionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsElectrolysisMethanation

The invention provides a catalyst used for methanation of carbon dioxide, a preparation method therefor and applications thereof. The catalyst employs precious metal Ru or Rh as a main catalytic activity component, employs one or more selected from elements of the I and II main groups and the II, III and VII subgroups as auxiliary agents, and employs one or more selected from SiO2, TiO2, Al2O3, CeO2 and ZrO2 as carriers. The above catalyst is used in graininess or the carriers, the auxiliary agents and the activity component are subjected to coating (wall loading) on a whole structural catalyst and metal honeycombs. The catalyst has characteristics of high activity and selectivity and wide temperature and pressure operation windows. The catalyst can be used for hydrogenation methanation removal of CO2 in a space station, then generated H2O is subjected to electrolysis, and circulation supply of oxygen is achieved. The catalyst also can be used for processes of other CO2 conversion utilization of coal-made natural gases and process gases and the like and new energy development and energy saving and emission reduction are achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

Method of making biodiesel oil by subcritical methanol phase solid acid alkali catalytic oil fat ester exchange

InactiveCN1718679ASolve interphase mass transfer problemsShort reaction timeBiofuelsLiquid hydrocarbon mixture productionOil and greaseGlycerol

A process for preparing biologic diesel oil from plant oil and methanol includes such steps as proportionally adding plant oil and methanol into high-pressure reactor, adding solid catalyst, reaction, separating out catalyst, laying aside for layering, distilling the mixture of methanol and methyl ester of fatty acid on upper layer to obtain methyl ester of fatty acid (biologic diesel oil ) and distilling the mixture of methanol and glycerine on lower layer to obtain glycerine.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com