Hydroprocessing catalyst and its prepn process

A hydrotreating and catalyst technology, applied in the treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of poor molecular sieve dispersion effect and lack of synergistic effect, and achieve the effect of high isomeric selectivity, high product yield and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In the process of preparing the TON structure molecular sieve provided by the present invention, other raw materials and operating conditions can be determined according to the prior art, such as various TON structure molecular sieves (ZSM-22, Theta-1, ISI-1, KZ-2 in the prior art) and NU-10) raw materials and operating conditions used in the preparation process. Its change is: the templating agent described in step (a) is a double templating agent, that is, it is composed of two templating agents, wherein the main templating agent is a diamine compound, which can be C2 -C 10 The diamine, preferably C 5 -C 8 diamine, more preferably hexamethylenediamine; the auxiliary templating agent is generally a nitrogen-containing heterocyclic compound, preferably a pyrrole derivative, more preferably pyrrolidine. Said auxiliary agent can be C 5 -C 10 Alkanes, preferably C 5 -C 8 n-alkanes or naphthenes, more preferably C 5 -C 7 Naphthenic. The IVA element compound in the ...

Embodiment 1~3

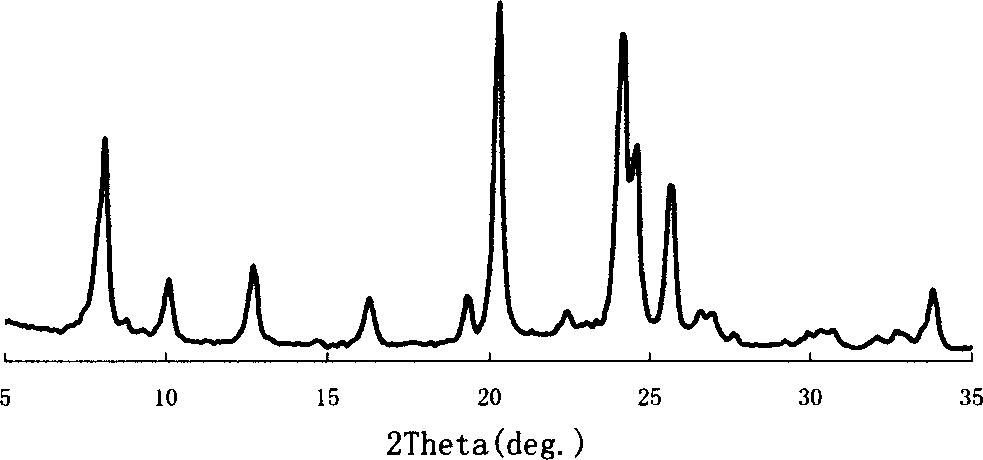

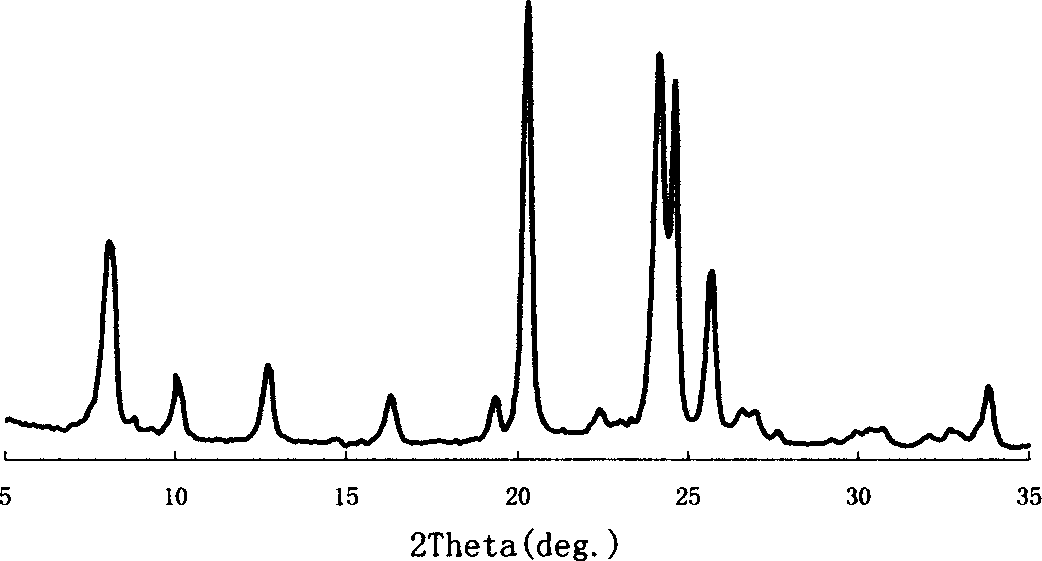

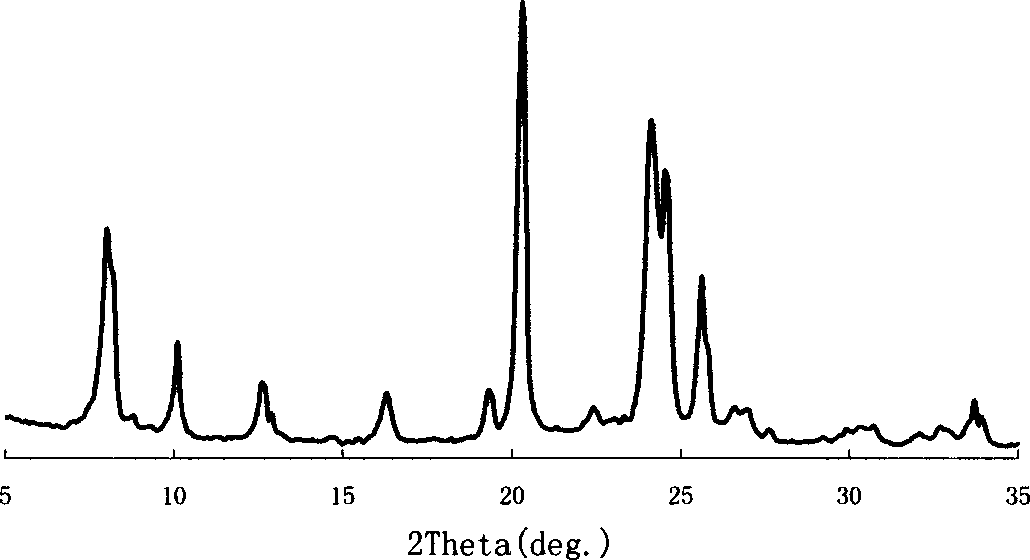

[0040] The preparation method of the TON type molecular sieve involved in the catalyst of the present invention.

[0041] Take a certain amount of water and put it in a beaker, add silicon source, aluminum source and alkali in turn, mix thoroughly, then add the main template agent, auxiliary template agent and auxiliary agent in turn, or mix the three organic substances and add them together, after fully mixing , moved into an autoclave for crystallization, and samples E-1, E-2, E-3, and C-1 were obtained after post-treatment. Samples E-1, E-2, and E-3 were kept at 550°C for 2 hours to remove the membrane plate agent; ammonium was exchanged twice, and the condition was to exchange 4 times at 80°C with 10% ammonium nitrate solution whose weight was 5 times that of the molecular sieve. Hours, then roasted at 550°C for 4 hours; then use a mixed acid solution with a molar concentration of nitric acid of 0.5mol / L and a molar concentration of tartaric acid of 0.2mol / L, and treat it ...

Embodiment 4

[0056] A kind of preparation method of catalyst of the present invention

[0057] The preparation of the catalyst was the same as that in Comparative Example 2, except that 650 g of the TON molecular sieve prepared in Example 1 was used to replace the SAPO-11 molecular sieve, and only Pt was contained in the impregnation solution, and finally the catalyst of the present invention containing 0.6w% Pt was obtained, and the number was E-4 , the evaluation conditions and results are shown in Table 3 and Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com