Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9861results about "Hydrocarbon oils treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

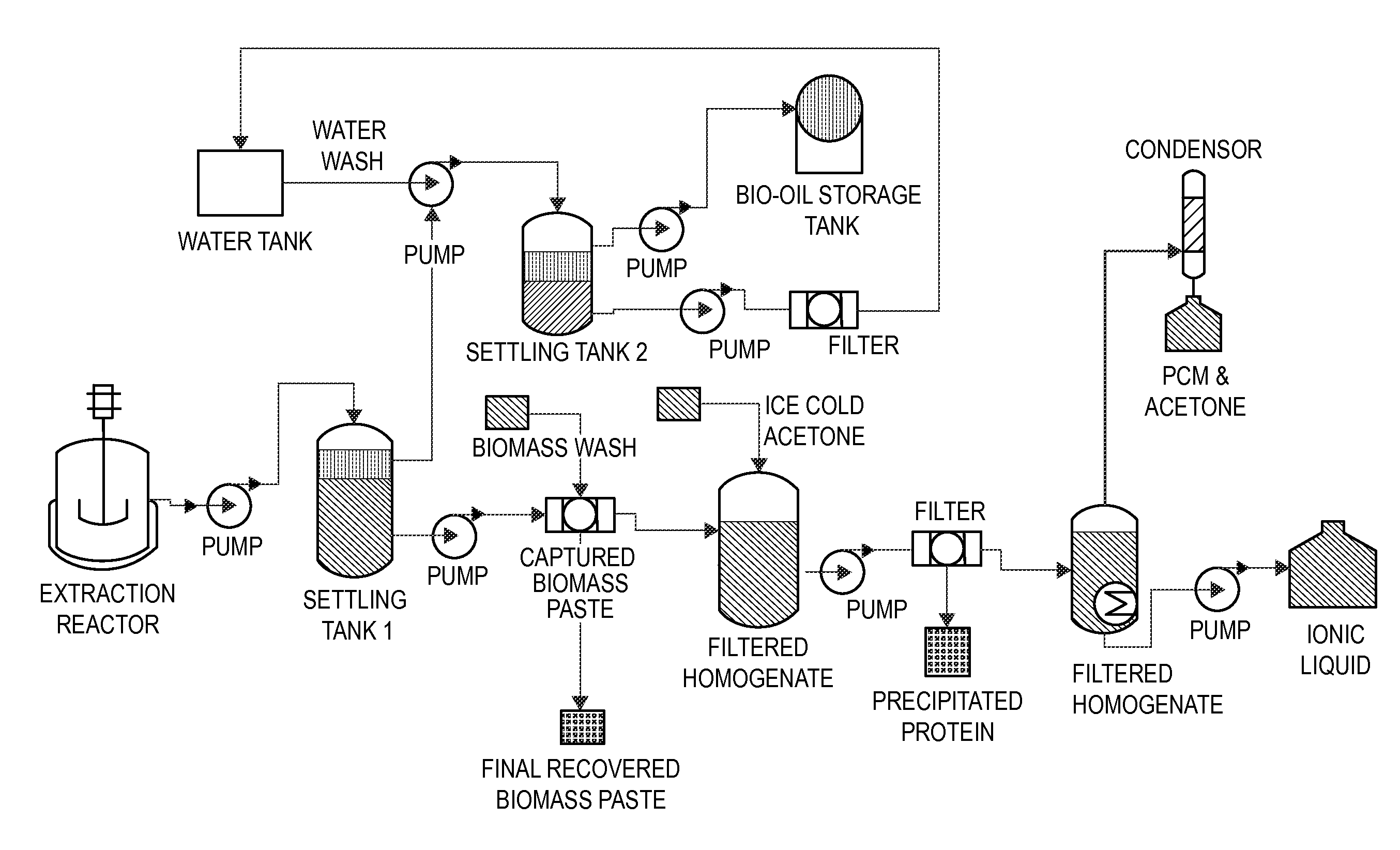

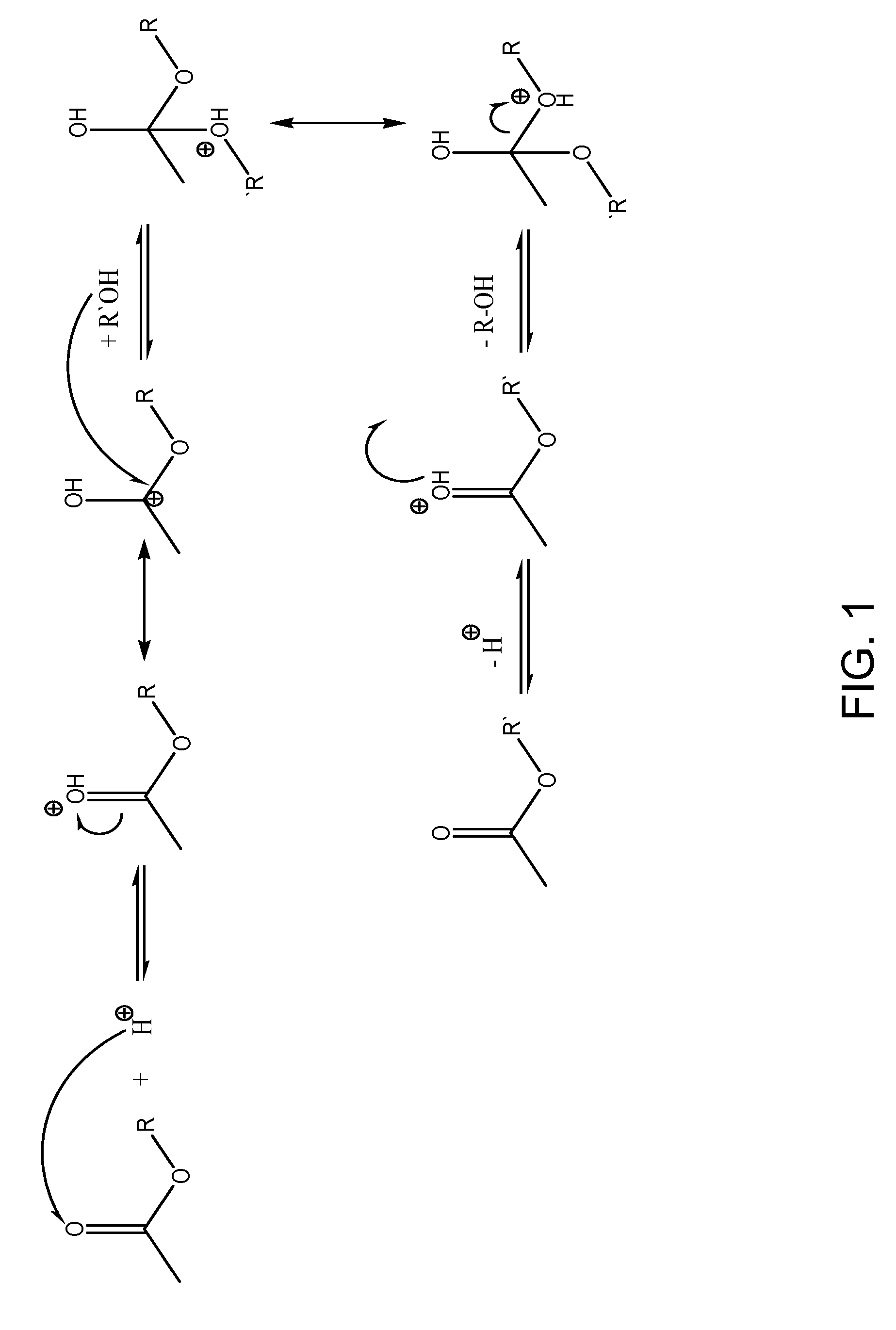

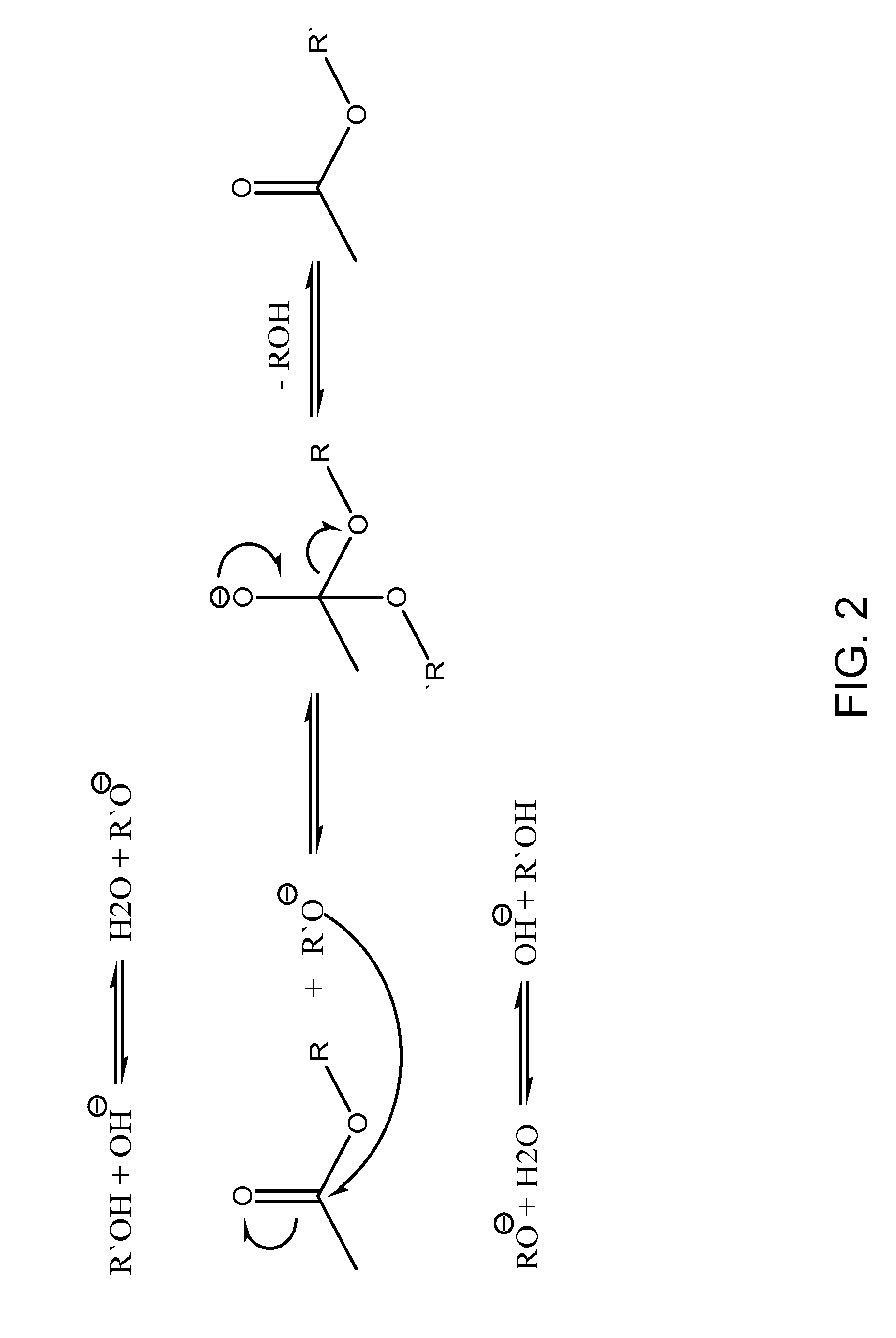

Methods and compositions for extraction and transesterification of biomass components

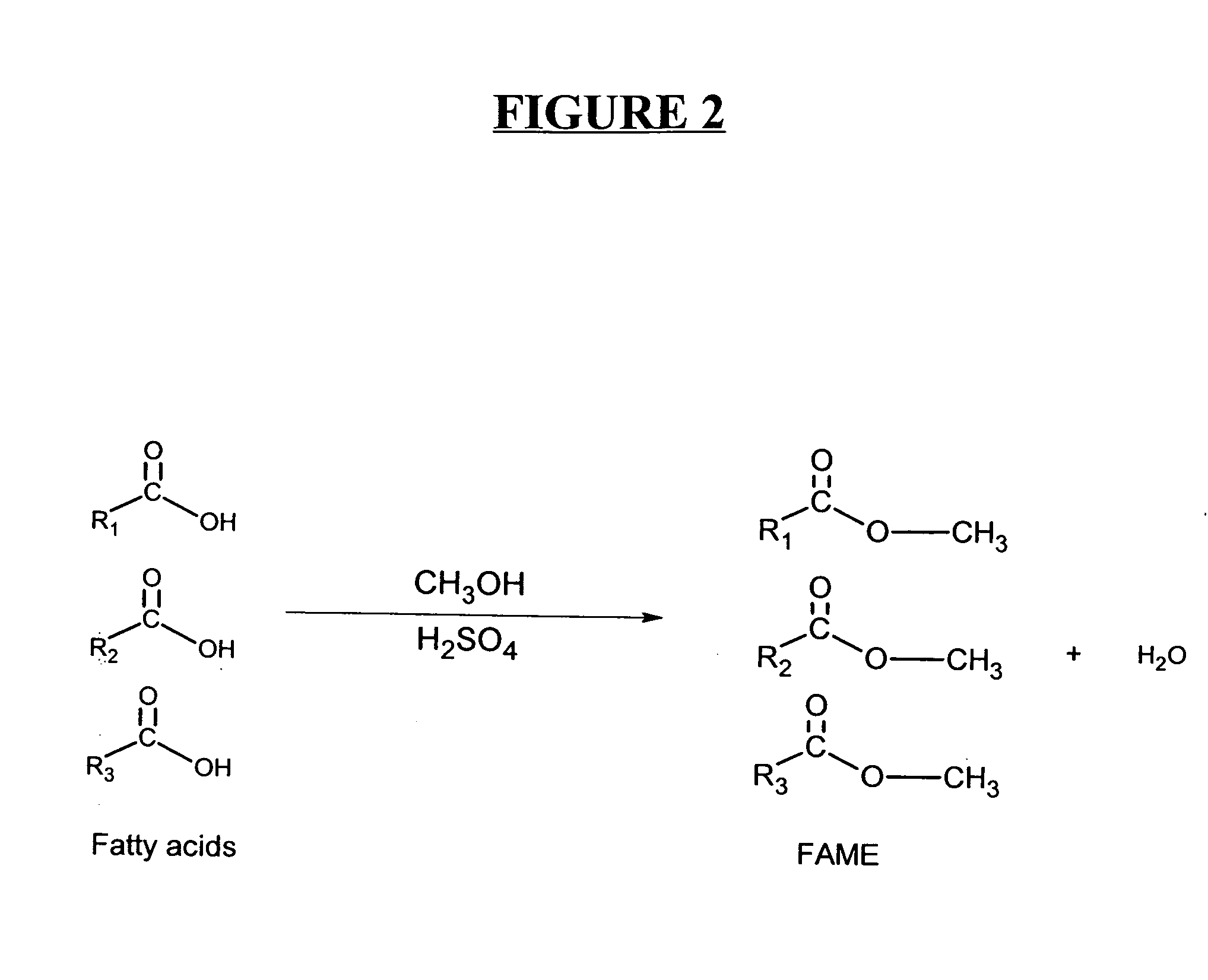

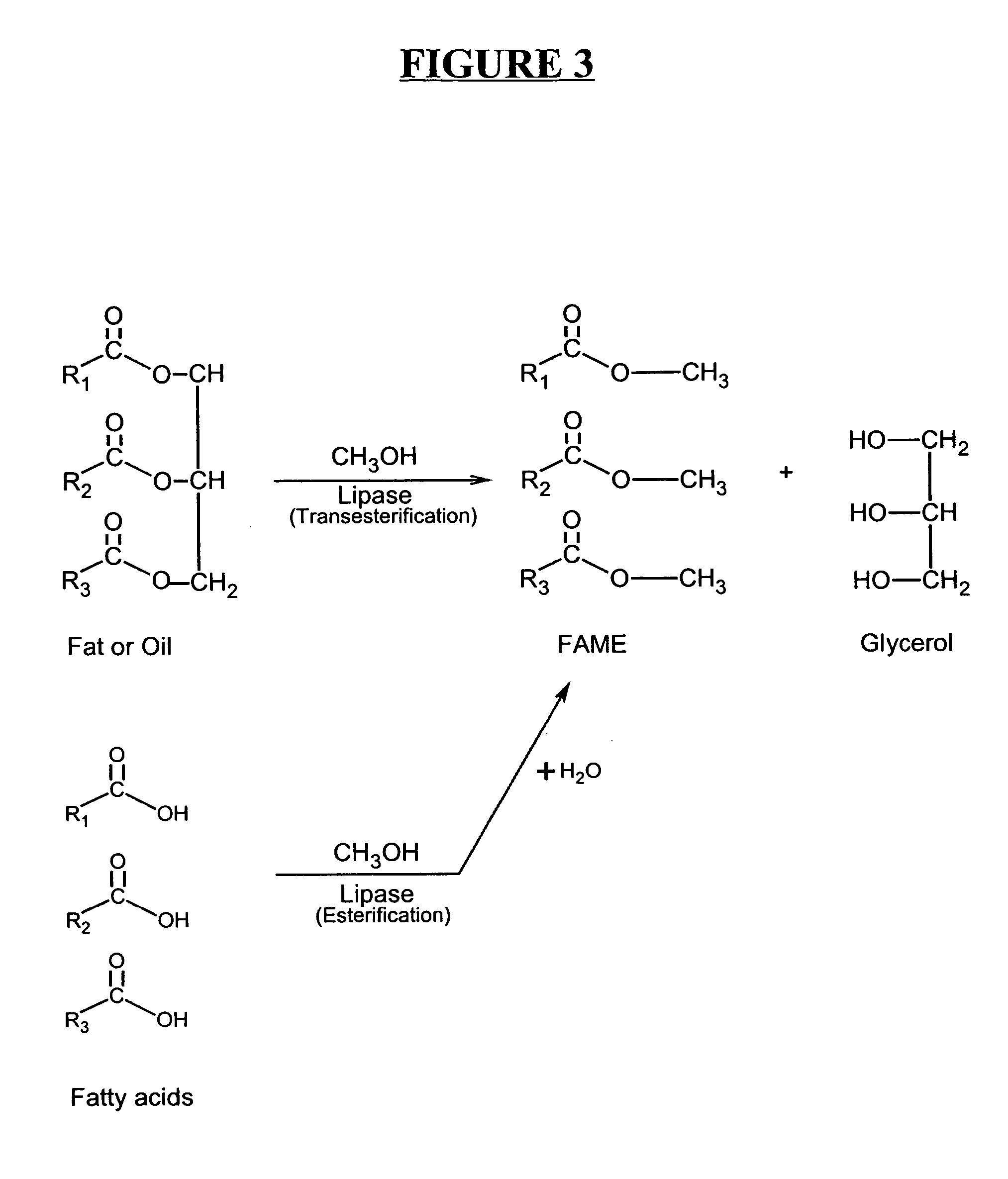

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

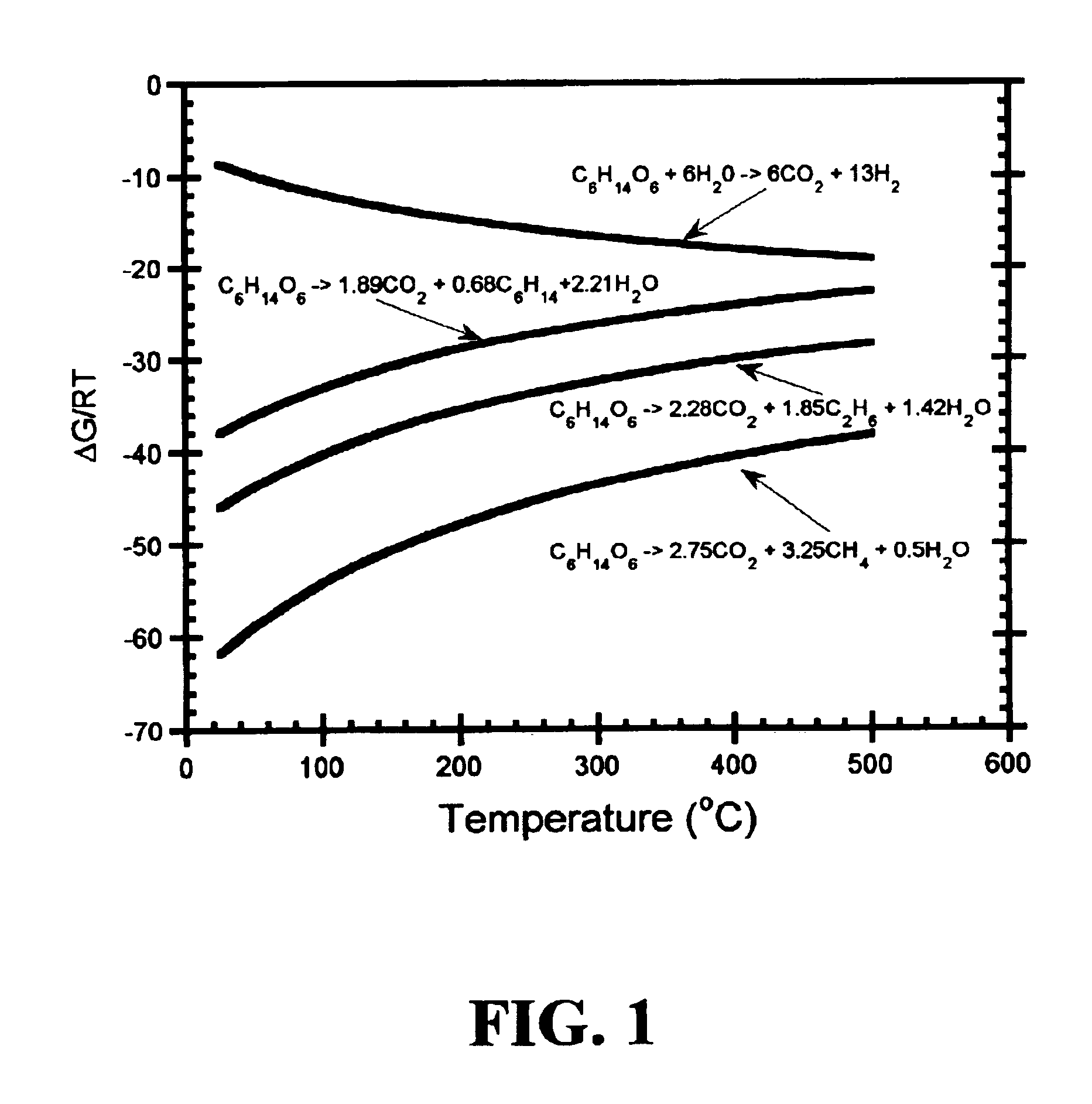

Low-temperature hydrocarbon production from oxygenated hydrocarbons

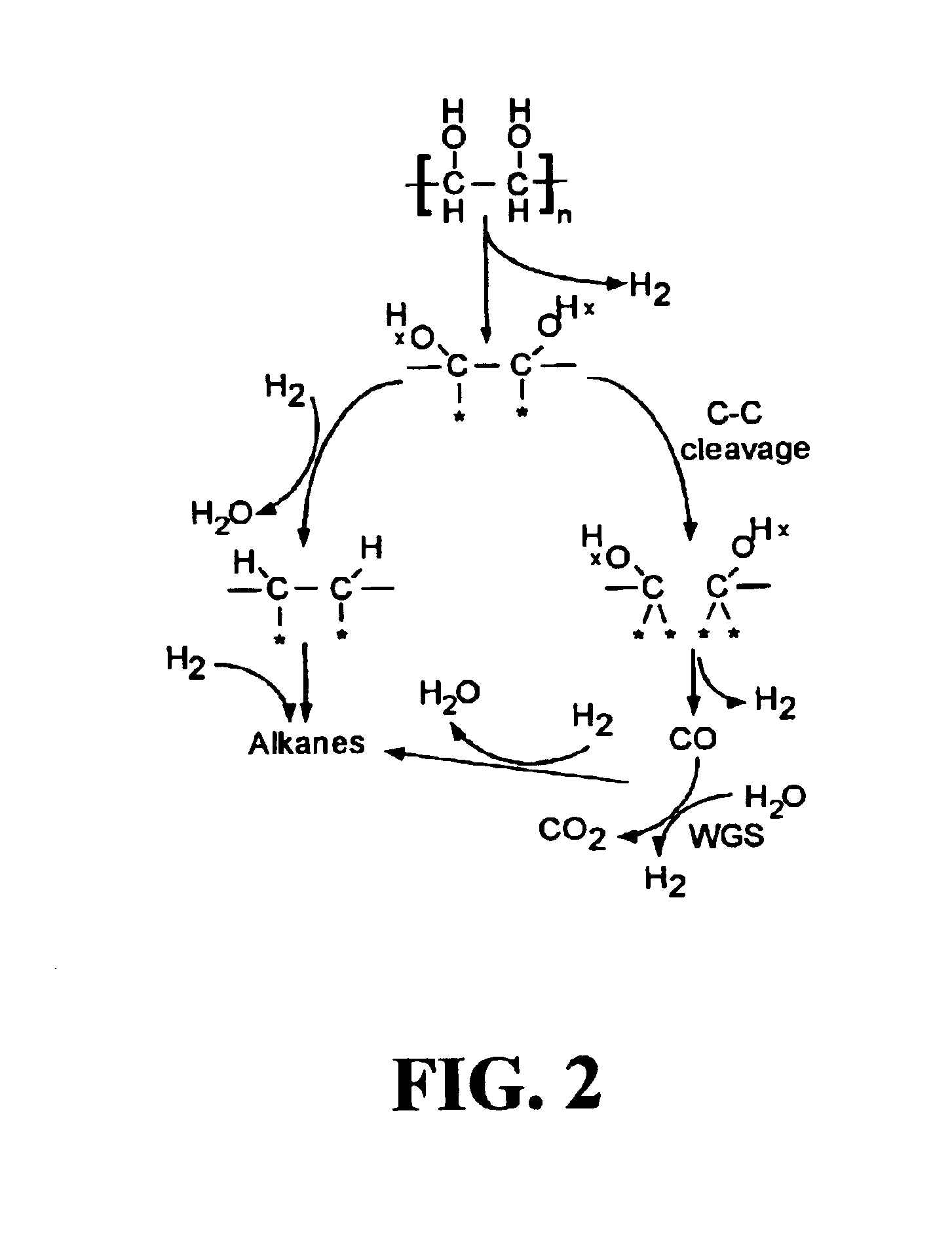

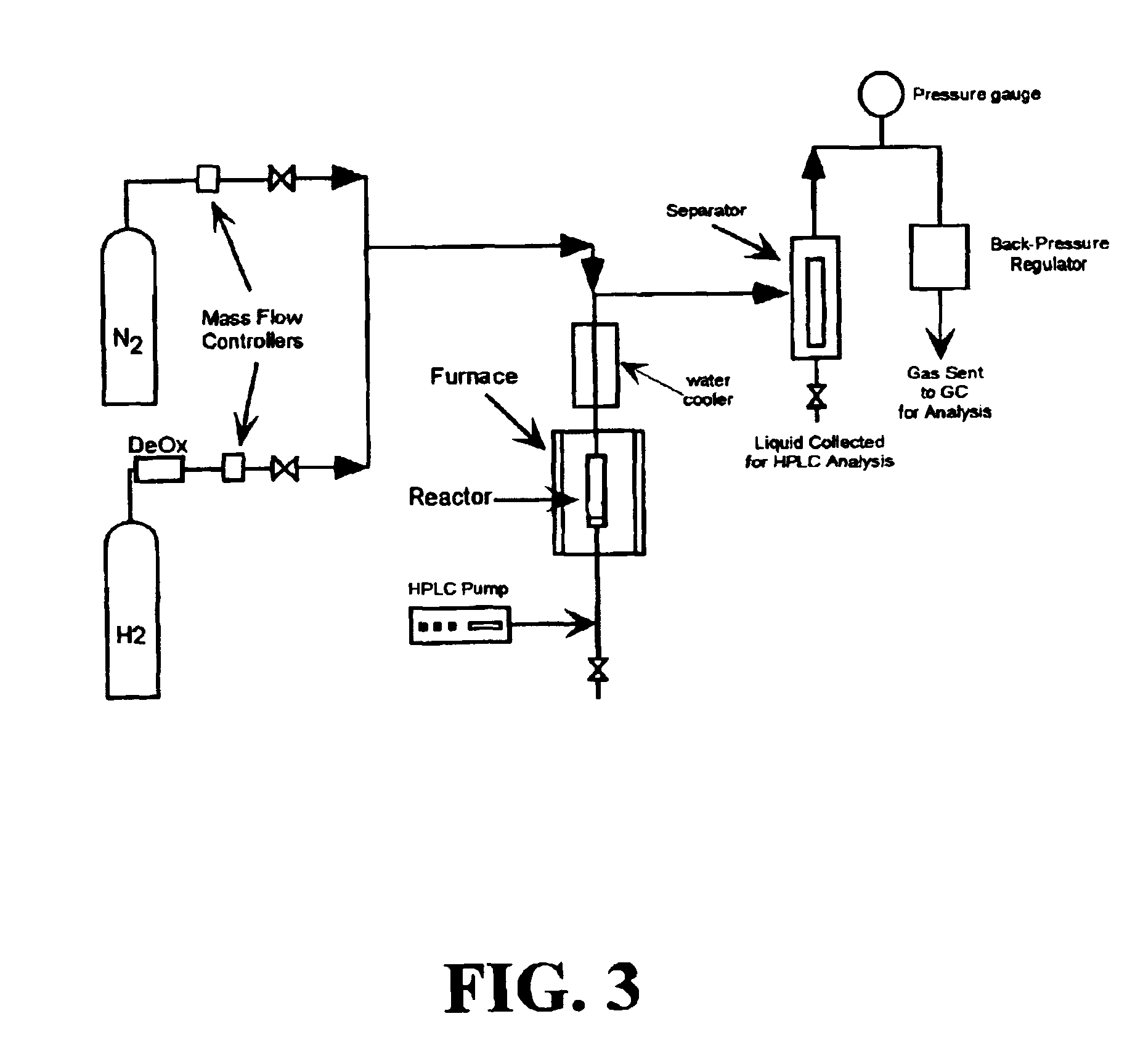

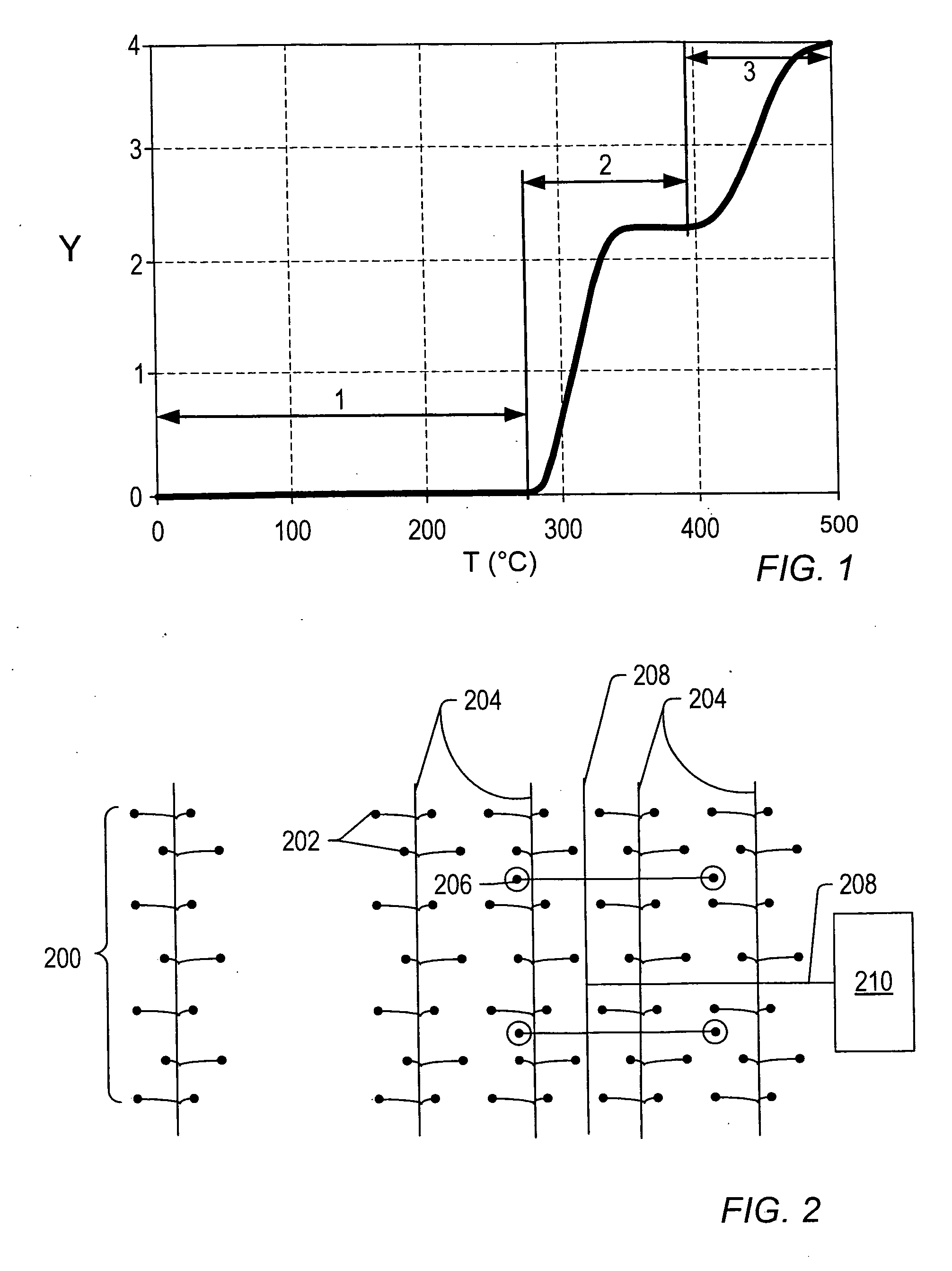

Disclosed is a method of producing hydrocarbons from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase (preferably in the condensed liquid phase). The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. These metals are supported on supports that exhibit acidity or the reaction is conducted under liquid-phase conditions at acidic pHs. The disclosed method allows the production of hydrocarbon by the liquid-phase reaction of water with biomass-derived oxygenated compounds.

Owner:WISCONSIN ALUMNI RES FOUND

Method for producing a crude product with reduced tan

InactiveUS20070000810A1Catalytic crackingRefining with metal saltsOrganic chemistryContact condition

Contacting a crude feed with one or more catalysts to produce a total product that includes the crude product is described. The crude feed has a TAN of at least 1. At least one of the catalysts includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table. Contacting conditions are controlled contacting such that the crude product has a TAN from about 0.001 to about 0.5.

Owner:SHELL OIL CO

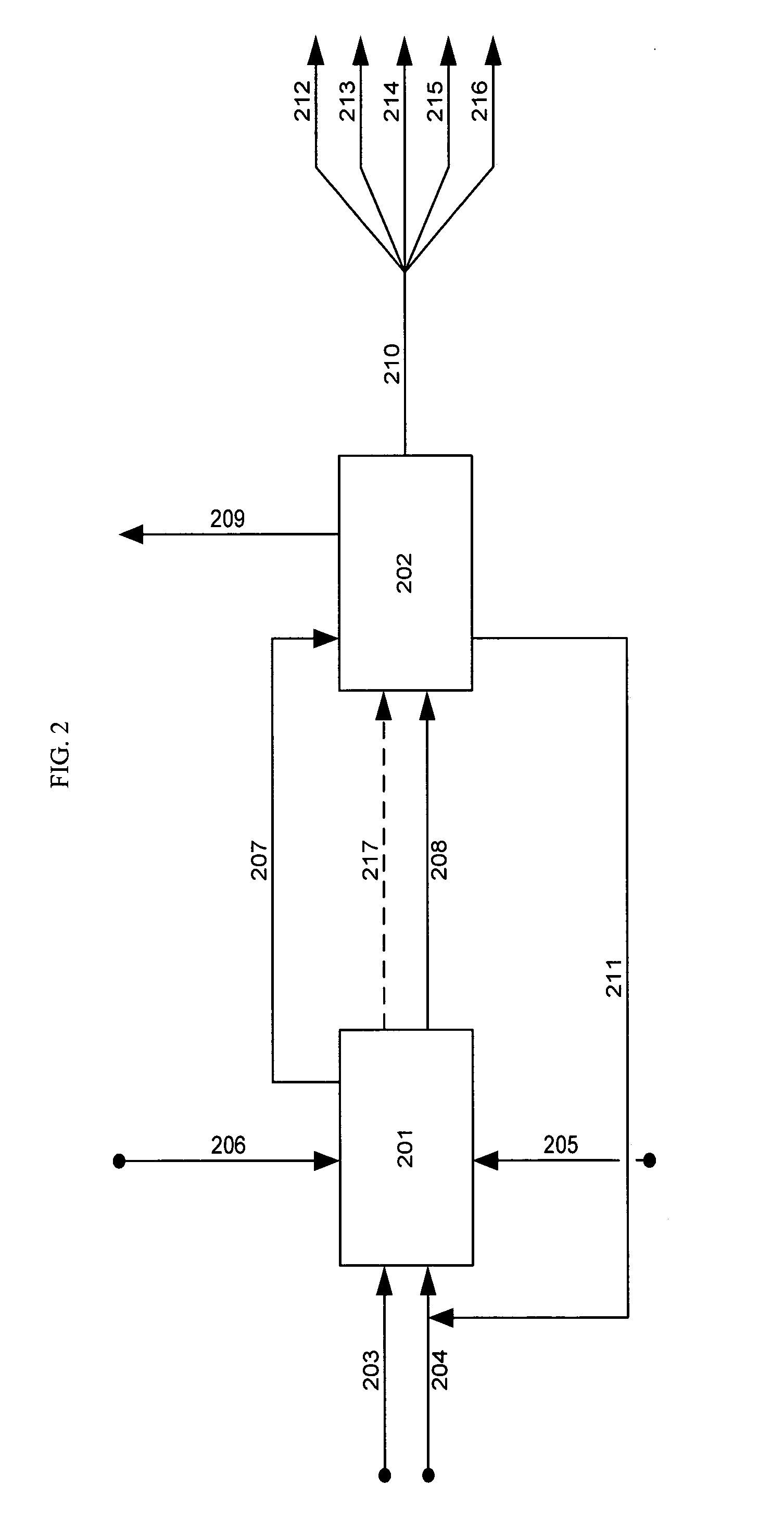

Methods and devices for the production of Hydrocarbons from Carbon and Hydrogen sources

InactiveUS20080283411A1Reduce the environmentEasy to controlPhotography auxillary processesInternal combustion piston enginesElectrolysisAtmospheric air

Devices and methods are described for converting a carbon source and a hydrogen source into hydrocarbons, such as alcohols, for alternative energy sources. The influents may comprise carbon dioxide gas and hydrogen gas or water, obtainable from the atmosphere for through methods described herein, such as plasma generation or electrolysis. One method to produce hydrocarbons comprises the use of an electrolytic device, comprising an anode, a cathode and an electrolyte. Another method comprises the use of ultrasonic energy to drive the reaction. The devices and methods and related devices and methods are useful, for example, to provide a fossil fuel alternative energy source, store renewable energy, sequester carbon dioxide from the atmosphere, counteract global warming, and store carbon dioxide in a liquid fuel.

Owner:PRINCIPLE ENERGY SOLUTIONS

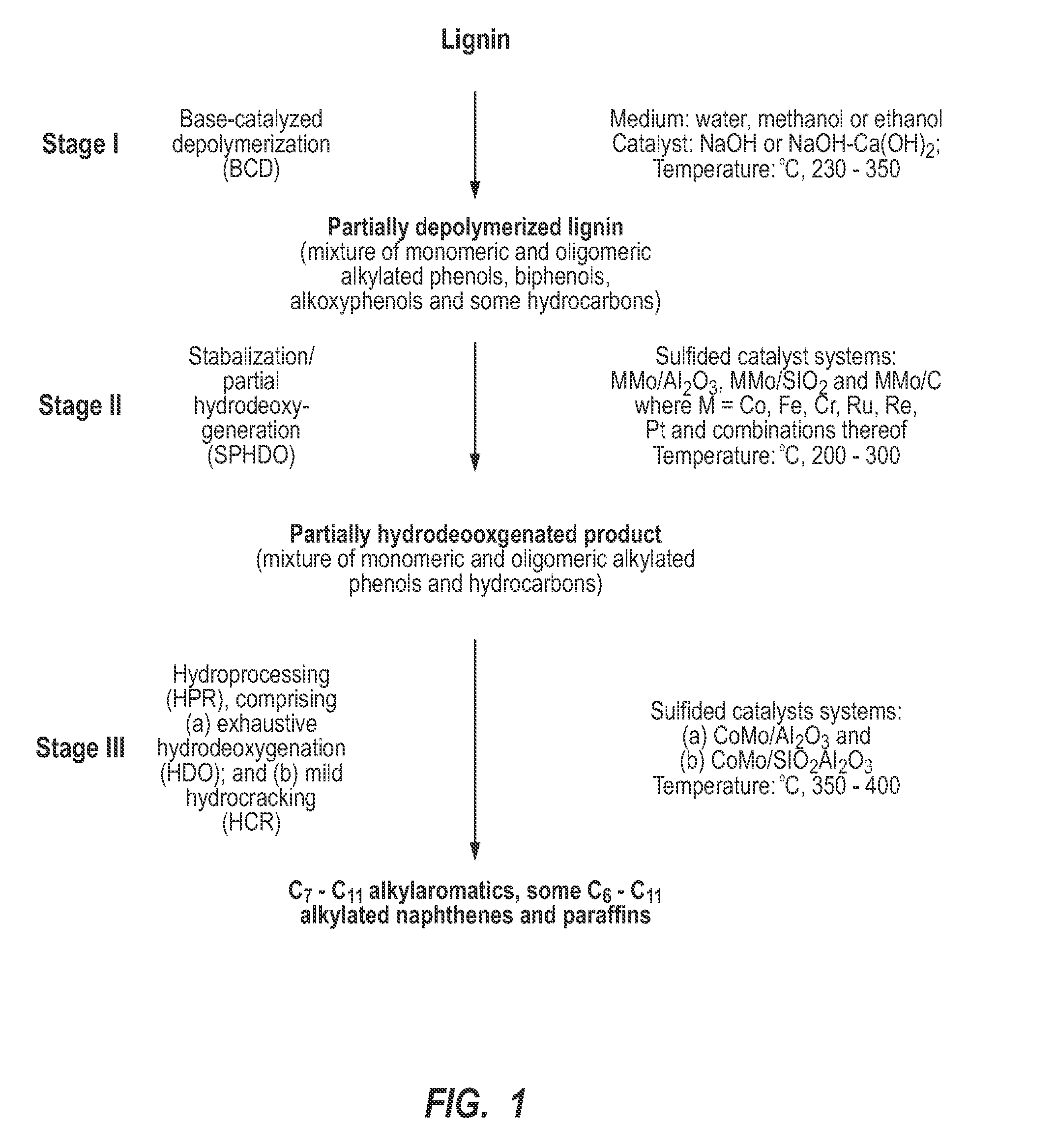

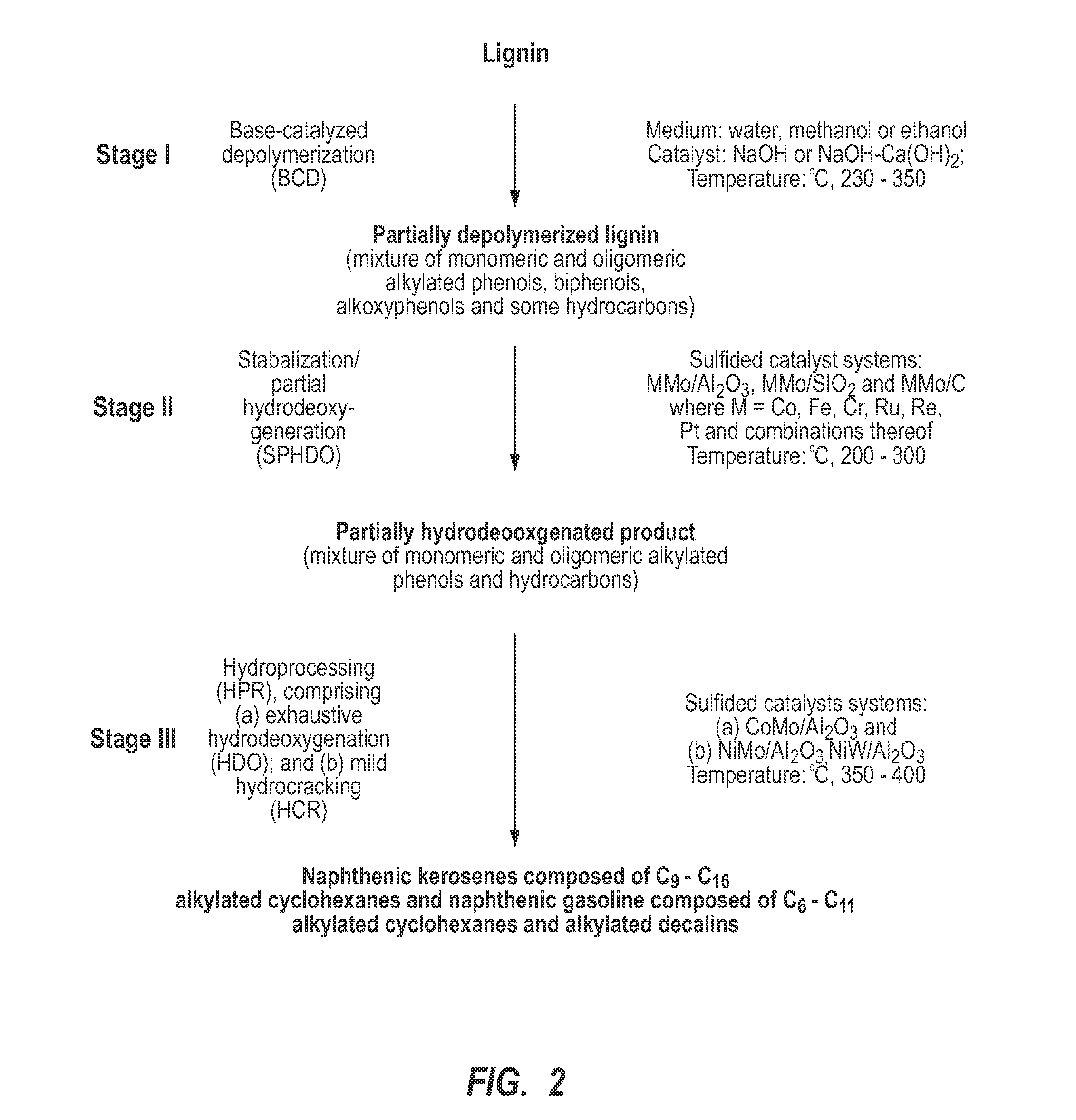

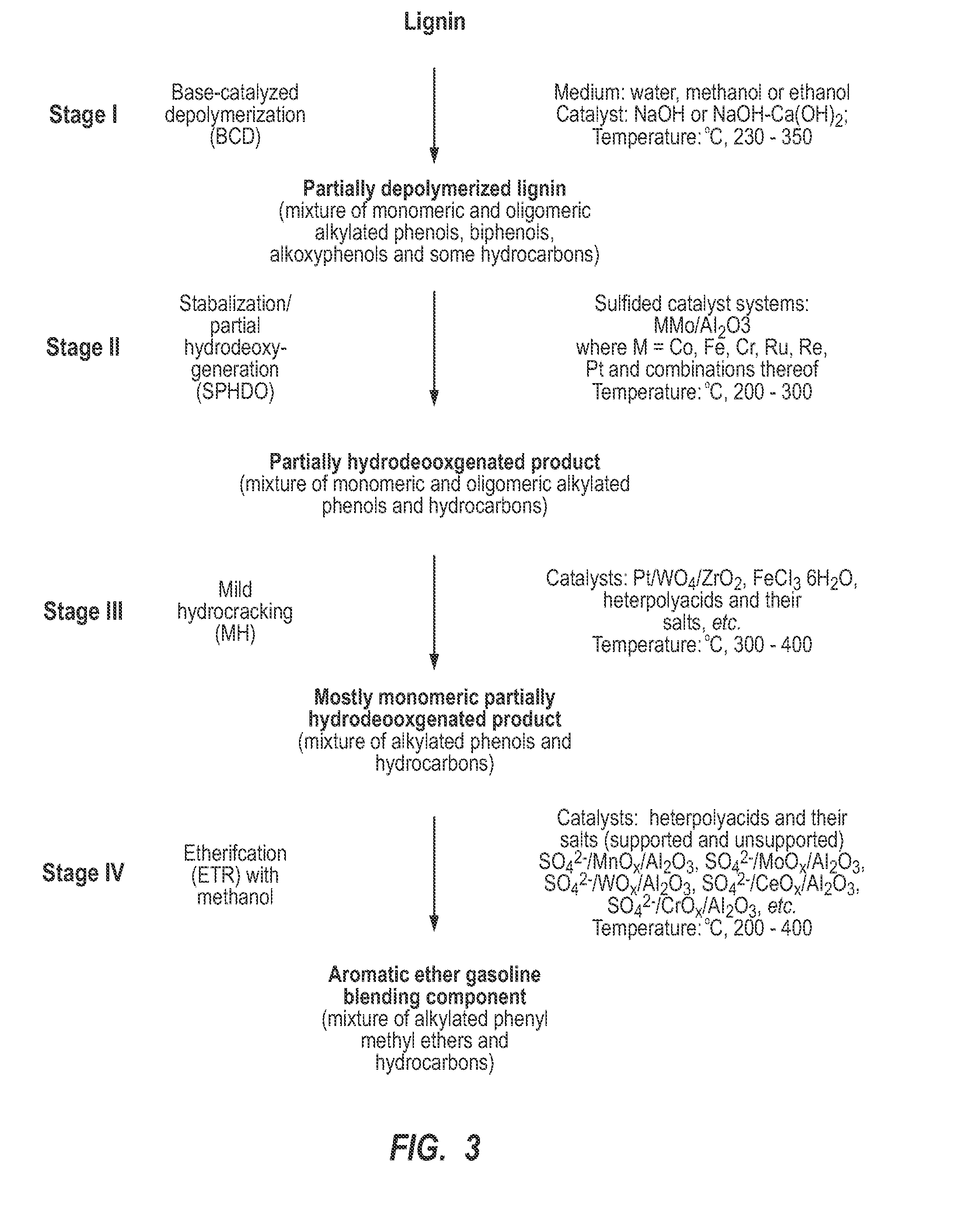

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

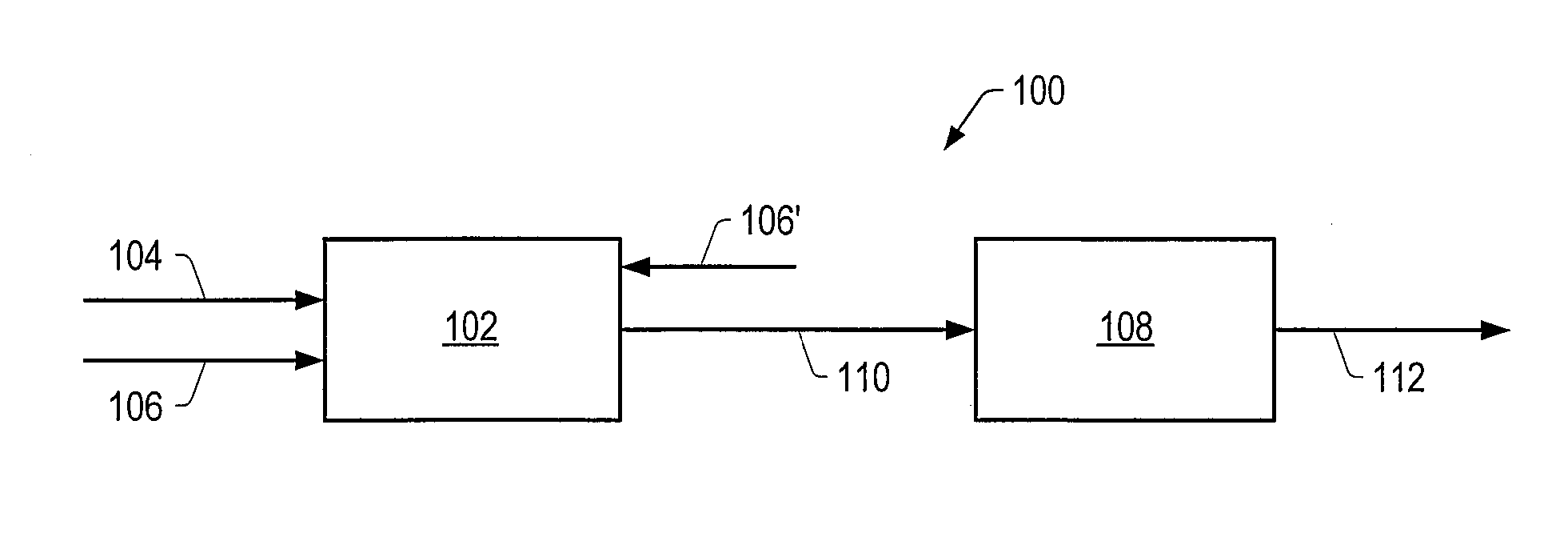

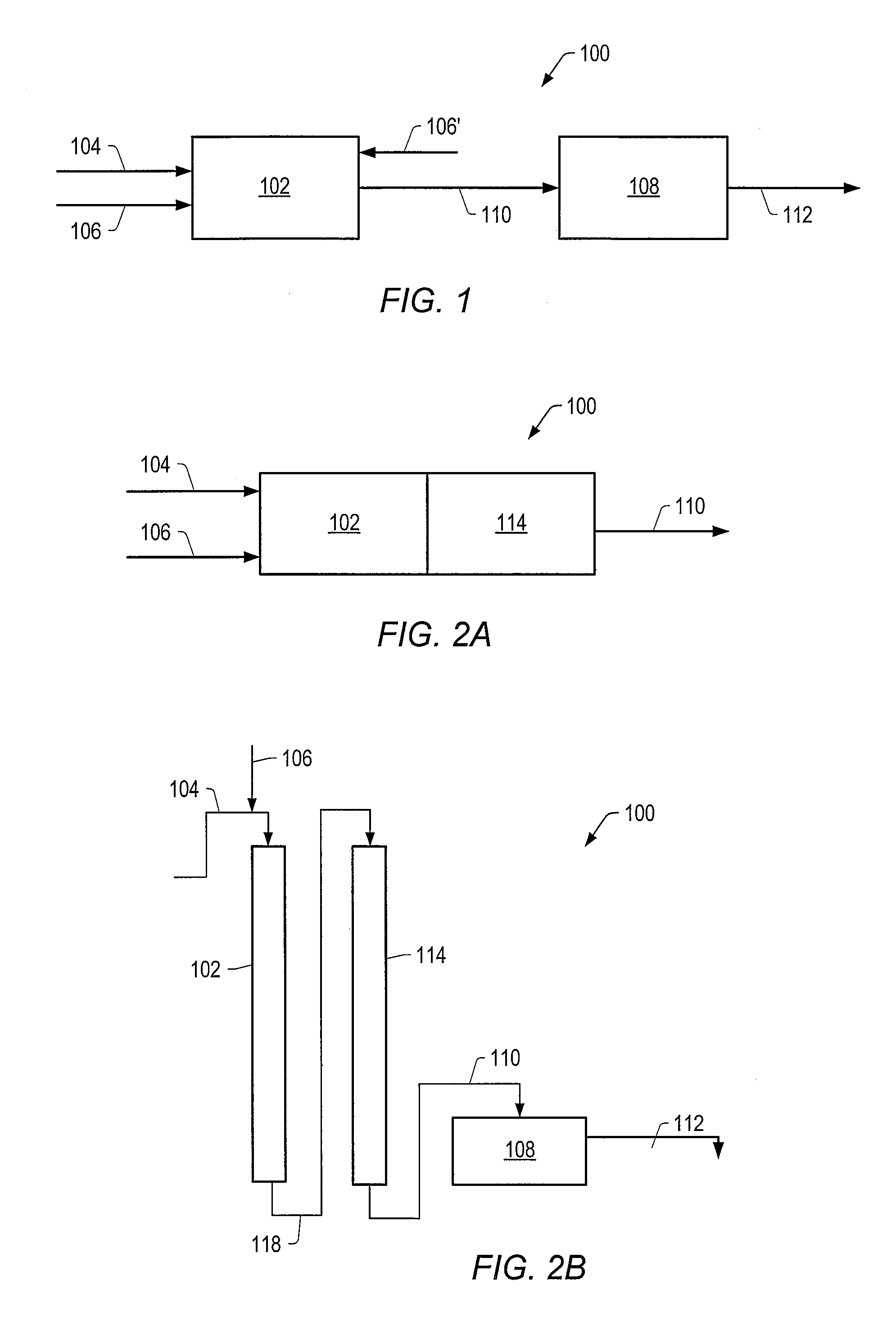

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

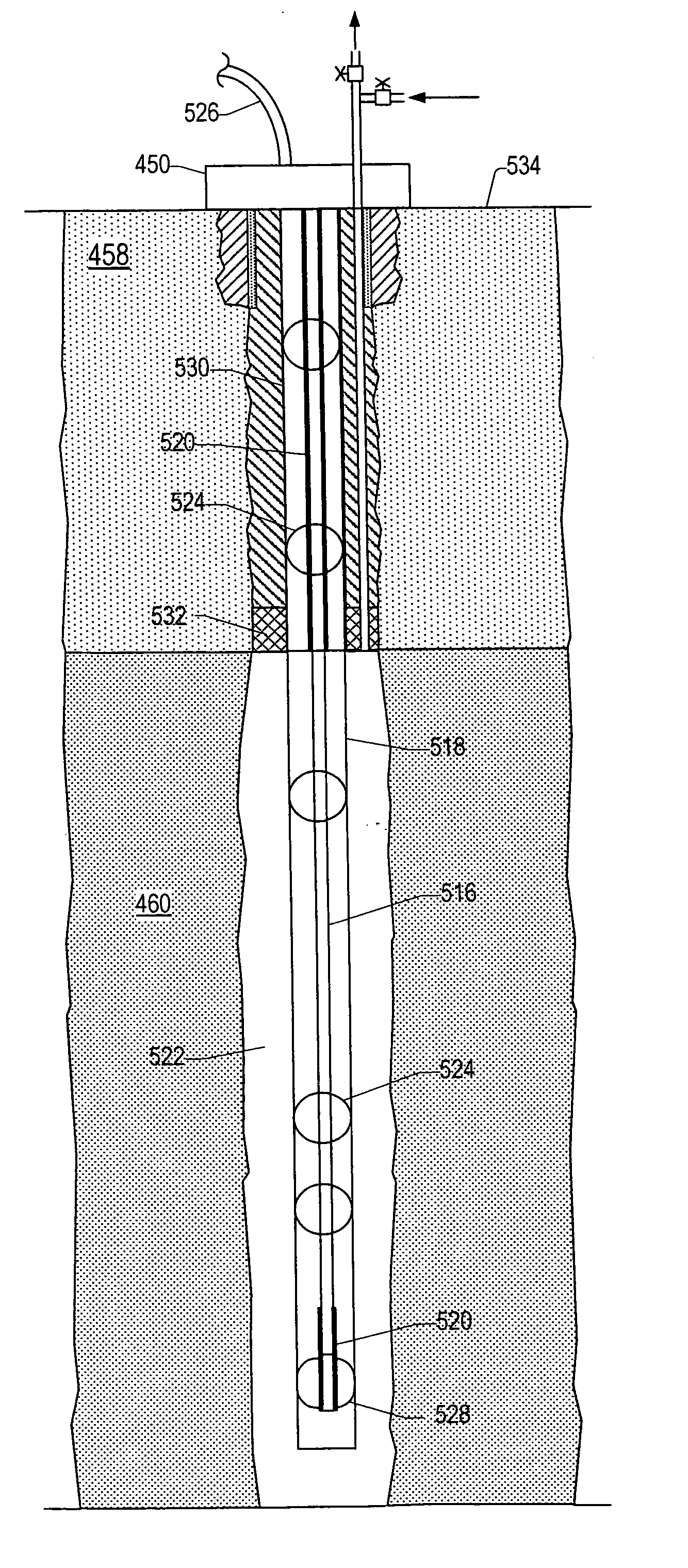

Subsurface heaters with low sulfidation rates

Owner:SHELL OIL CO

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

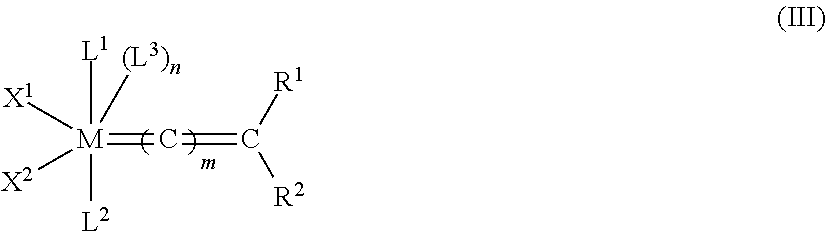

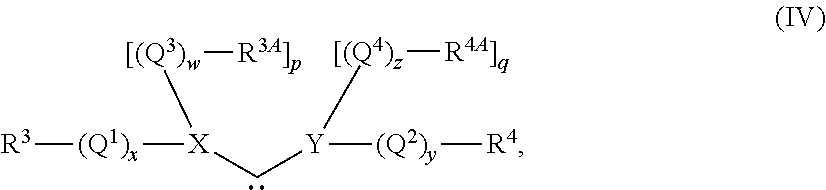

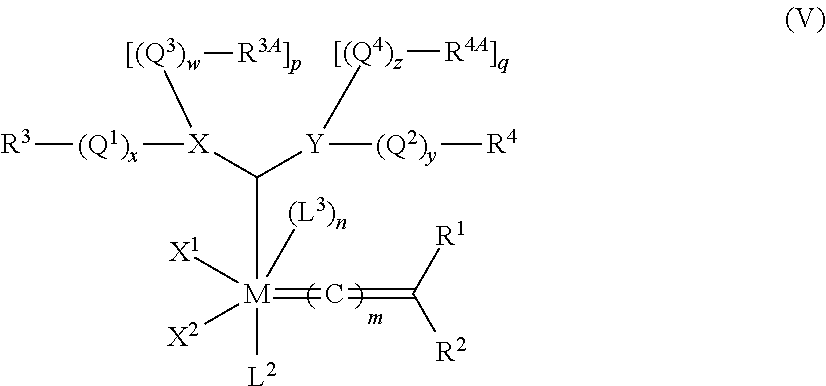

Chemical methods for treating a metathesis feedstock

ActiveUS20110160472A1Reduce starting peroxide valueFatty acid chemical modificationOrganic compound preparationChemical treatmentNatural oils

Owner:WILMAR TRADING PTE LTD

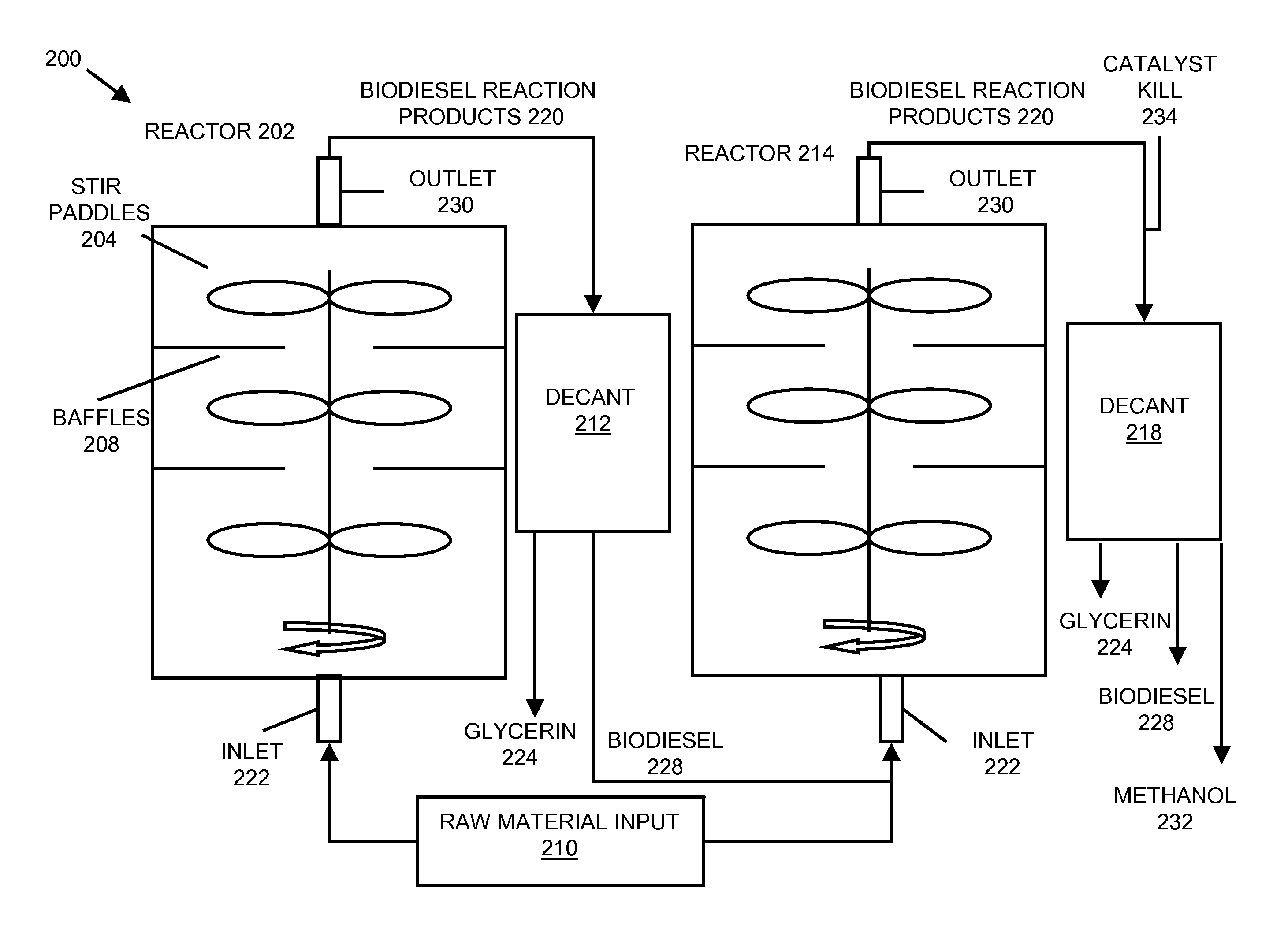

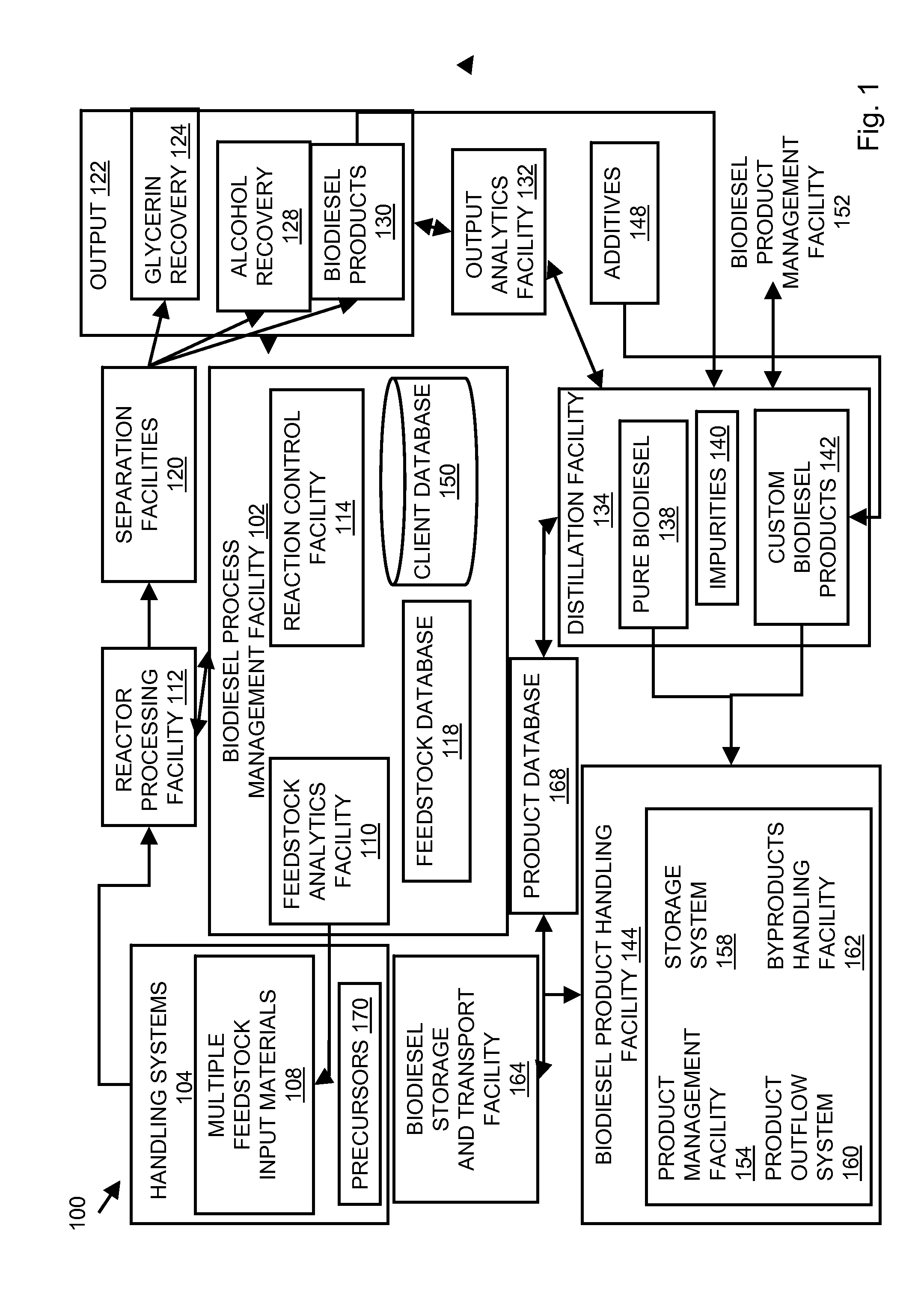

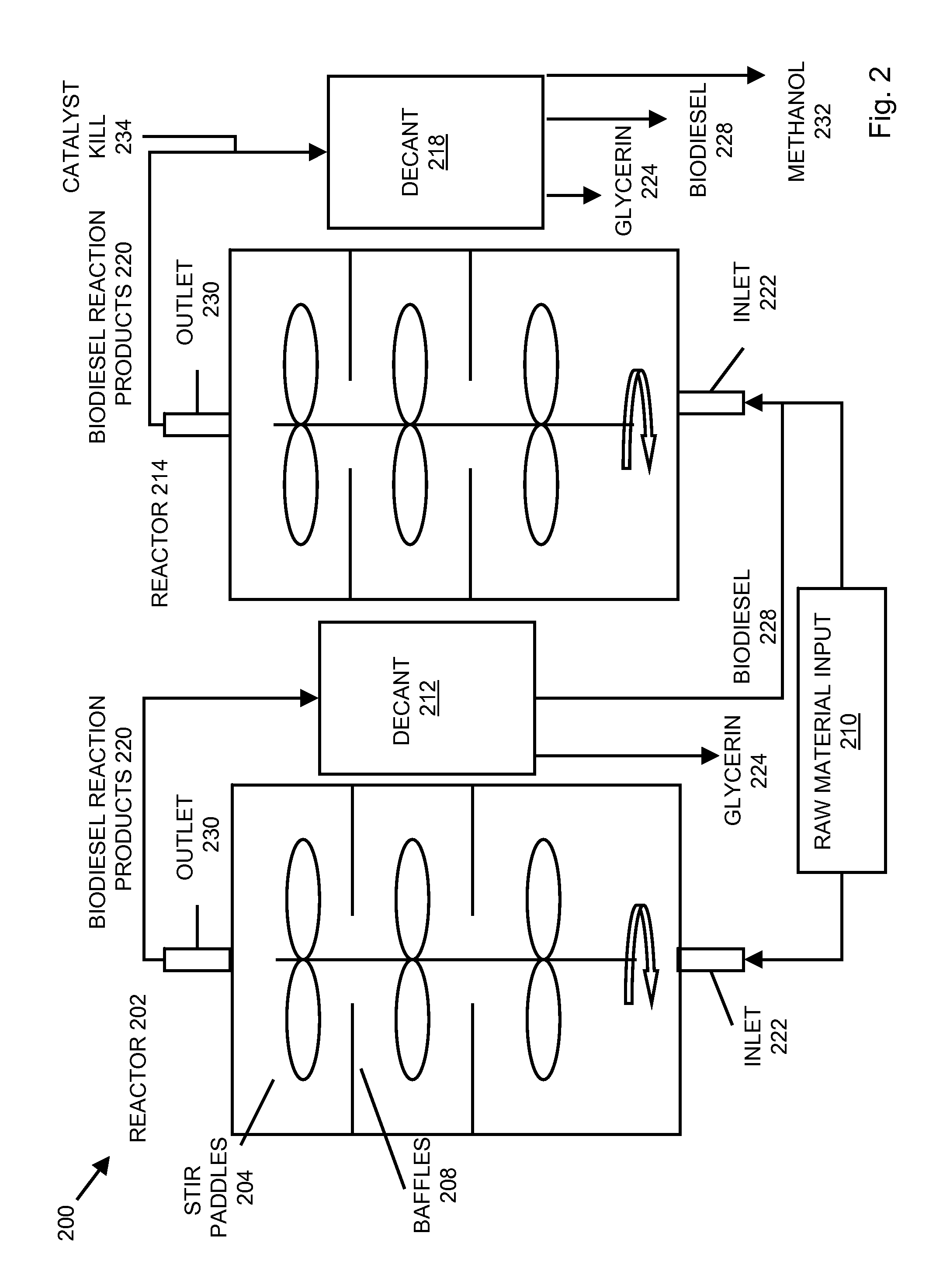

System and process for producing biodiesel

InactiveUS20080282606A1Reducing filter blocking tendencyEnhance biodiesel stabilityFatty acid esterificationFatty acids production/refiningBiodieselDistillation

In embodiments of the present invention, systems for producing a biodiesel product from multiple feedstocks may include a biodiesel reactor, a decanter, a flash evaporator and a distillation column. In other embodiments of the present invention, a process for producing a biodiesel comprises distilling a biodiesel reaction product to remove tocopherols and sterol glucosides and, optionally, adding biodiesel stabilizers to the resultant biodiesel to enhance thermal stability. The components of the system are interrelated so that parameters may be regulated to allow production of a custom biodiesel product.

Owner:IMPERIUM PROCESS TECH

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

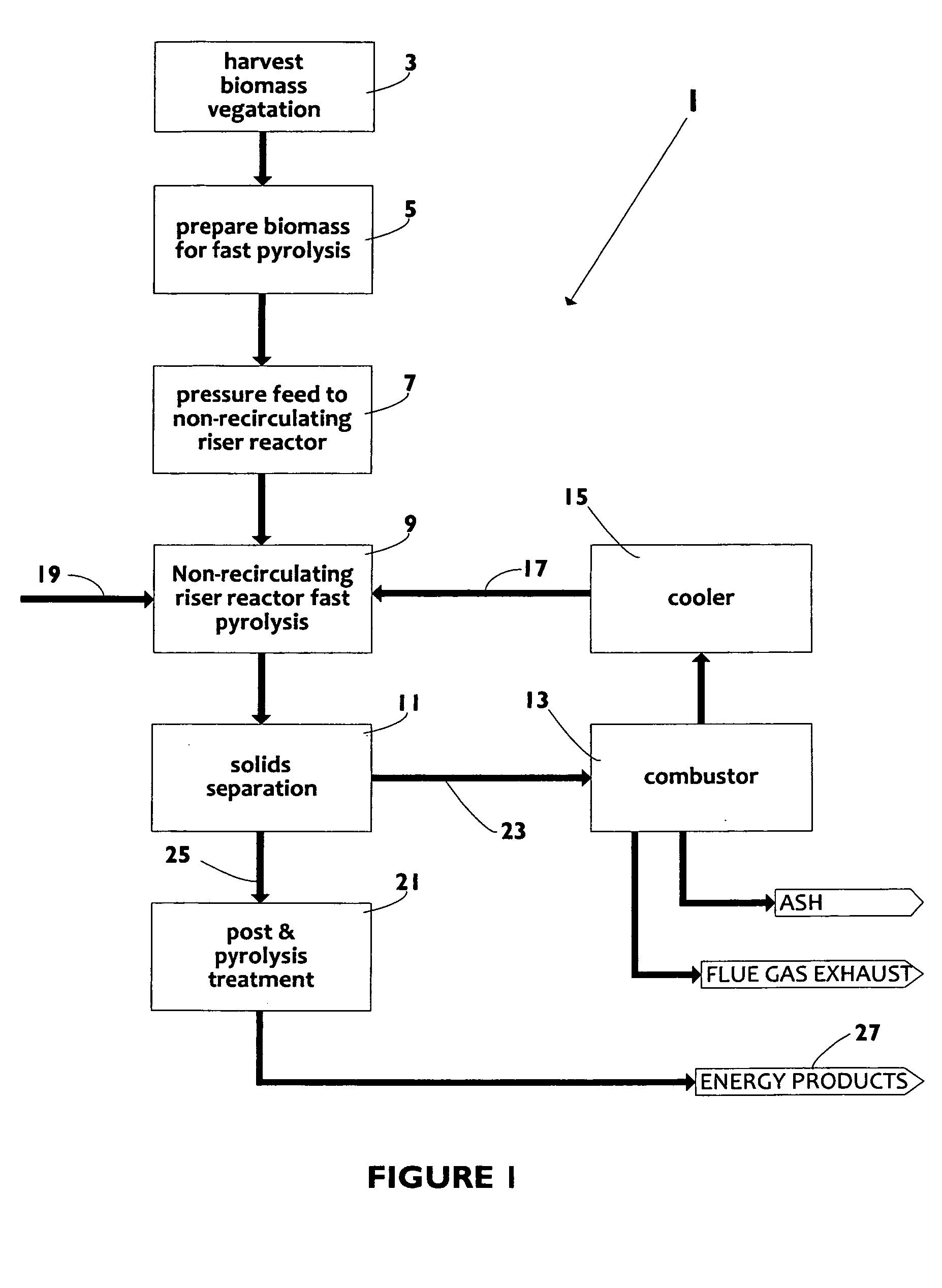

Biomass fast pyrolysis system utilizing non-circulating riser reactor

A biomass fast pyrolysis system for conversion of biomass vegetation to synthetic gas and liquid fuels includes: a) a non-circulating riser reactor for pyrolysis of biomass vegetation feedstock utilizing a heat carrier, the non-circulating riser reactor being physically structured and adapted to have a rate of reaction of at least 8,000 biomass vegetation feedstock lbs / hr / ft2, utilizing a ratio of heat carrier to biomass vegetation feedstock of about 7:1 to about 11.5:1, the riser reactor having a base input region at its bottom, a central reaction region and an output region at its top, the riser reactor including a cyclone disengager at its output region for separation of pyrolysis resulting char and heat carrier from the pyrolysis product gases, the cyclone disengager having an output downcomer and an output upcomer, the cyclone disengager output downcomer being connected to and feeding into a side combustor unit, the riser reactor being a non-circulating riser reactor in that the heat carrier is not returned directly to the riser reactor from the cyclone disengager and travels first down the cyclone disengager output downcomer to the side combustor unit; and, b) the side combustor unit for combusting pyrolysis resultant char and reheating the heat carrier the side combustor having a heat carrier downcomer connected to the base input region of the riser reactor.

Owner:INNOVATIVE ENERGY GLOBAL

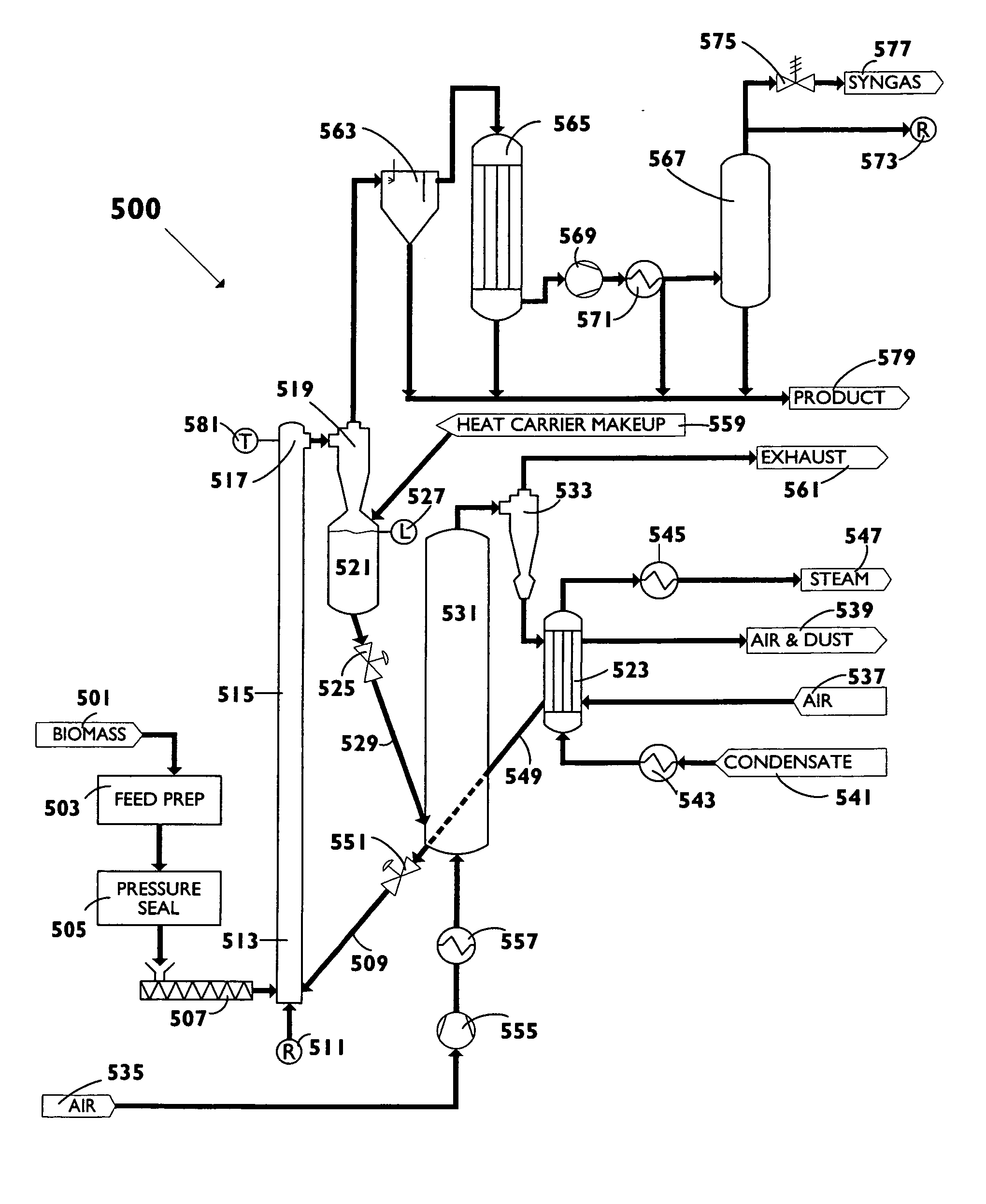

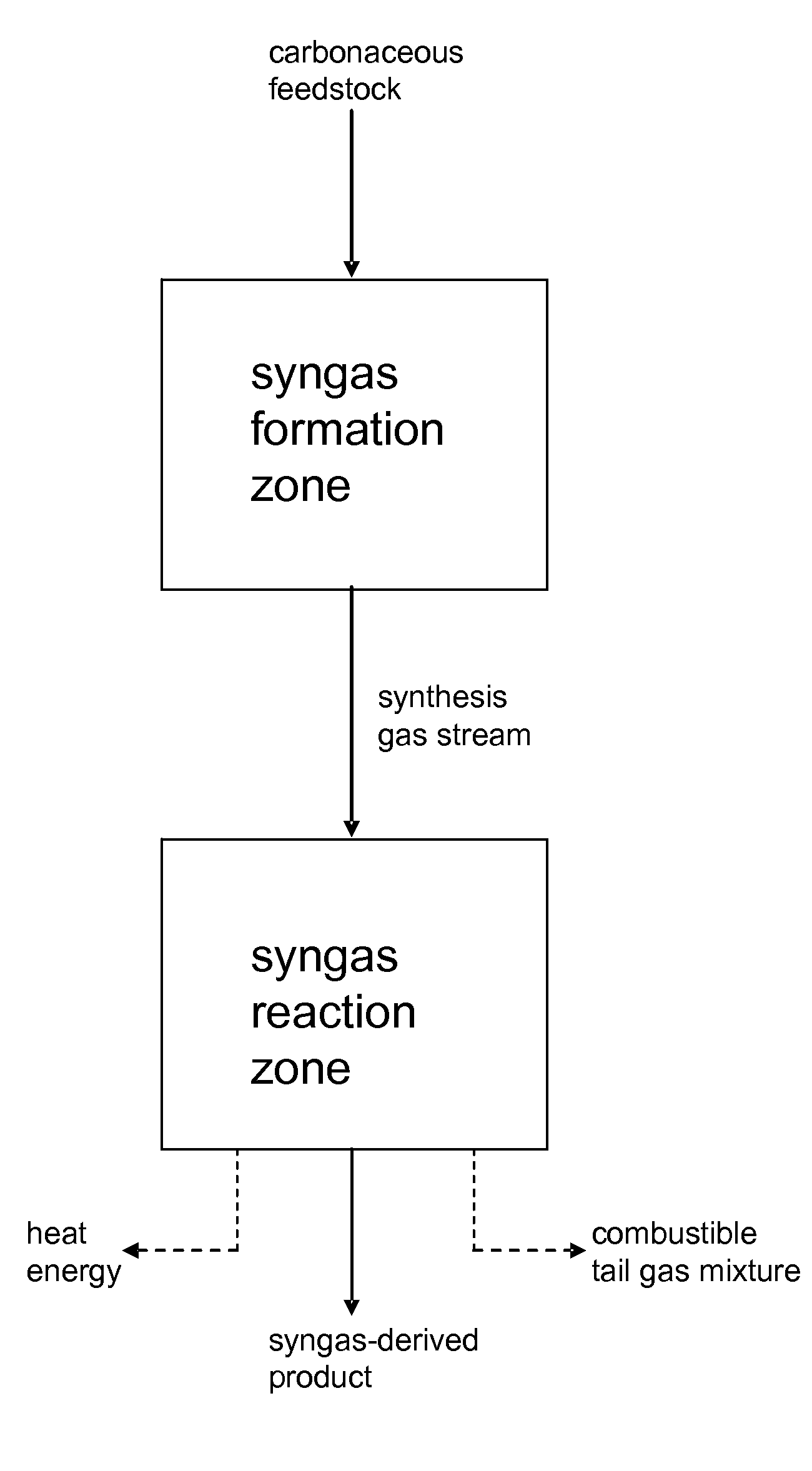

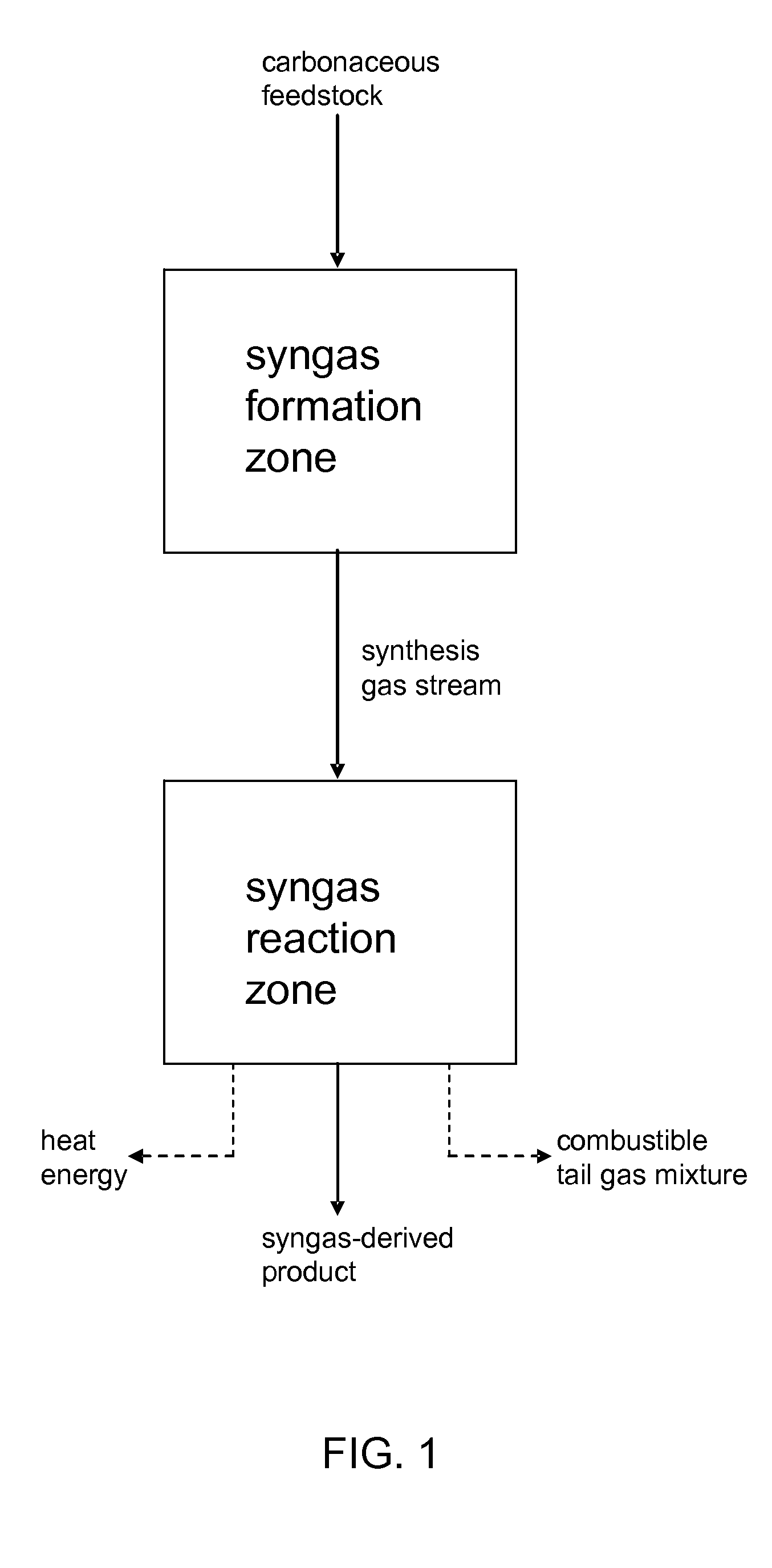

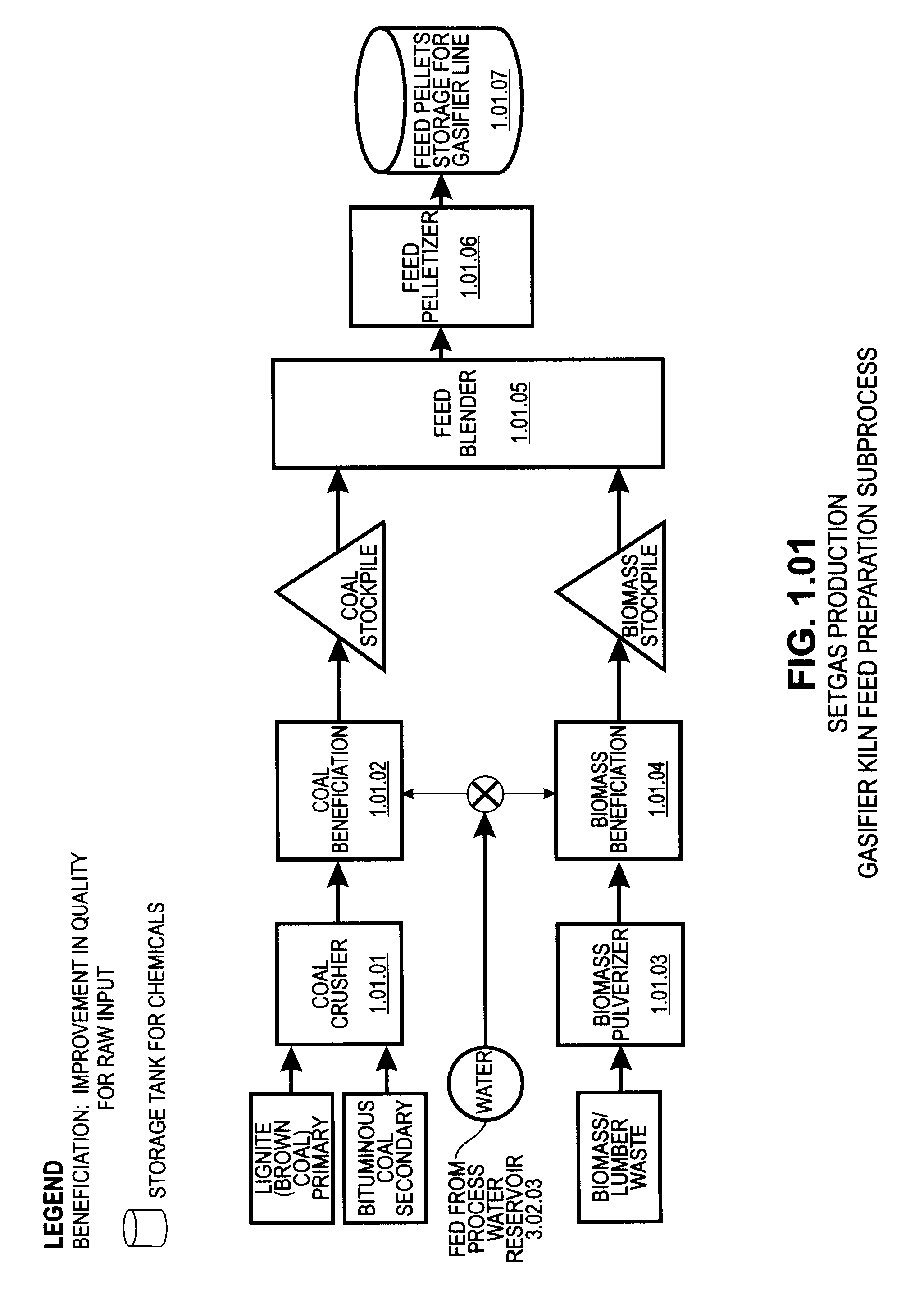

Processes for Making Syngas-Derived Products

The present invention provides processes for making syngas-derived products. For example, one aspect of the present invention provides a process for making a syngas-derived product, the process comprising (a) providing a carbonaceous feedstock; (b) converting the carbonaceous feedstock in a syngas formation zone at least in part to a synthesis gas stream comprising hydrogen and carbon monoxide; (c) conveying the synthesis gas stream to a syngas reaction zone; (d) reacting the synthesis gas stream in the syngas reaction zone to form the syngas-derived product and heat energy, a combustible tail gas mixture, or both; (e) recovering the syngas-derived product; and (f) recovering the heat energy formed from the reaction of the synthesis gas stream, burning the combustible tail gas mixture to form heat energy, or both.

Owner:SURE CHAMPION INVESTMENT LTD

Solution mining dawsonite from hydrocarbon containing formations with a chelating agent

A method for treating an oil shale formation comprising dawsonite includes providing heat from one or more heaters to the formation to heat the formation. Hydrocarbon fluids are produced from the formation. At least some dawsonite in the formation is decomposed with the provided heat. A chelating agent is provided to the formation to dissolve at least some dawsonite decomposition products. The dissolved dawsonite decomposition products are produced from the formation.

Owner:SHELL OIL CO

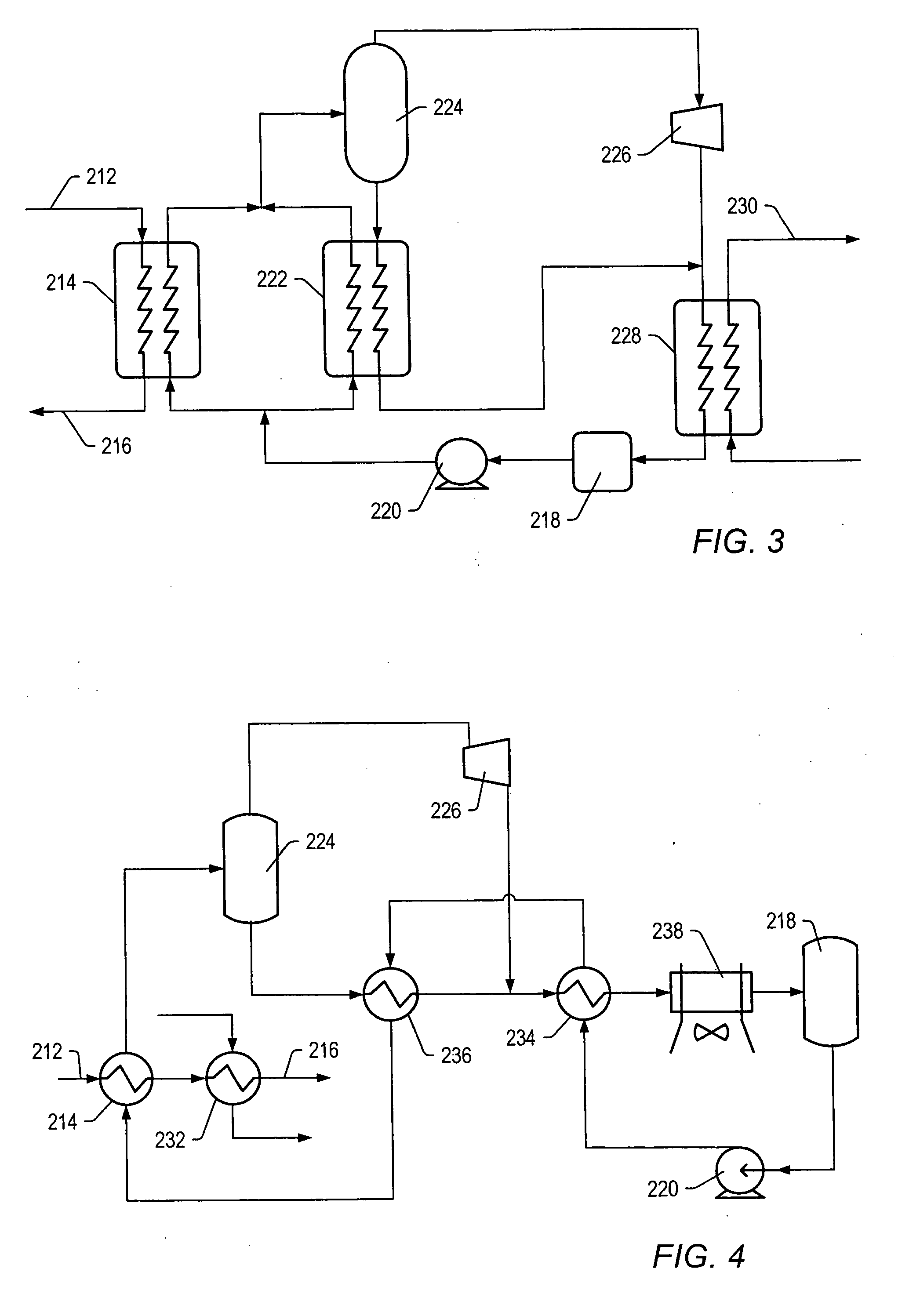

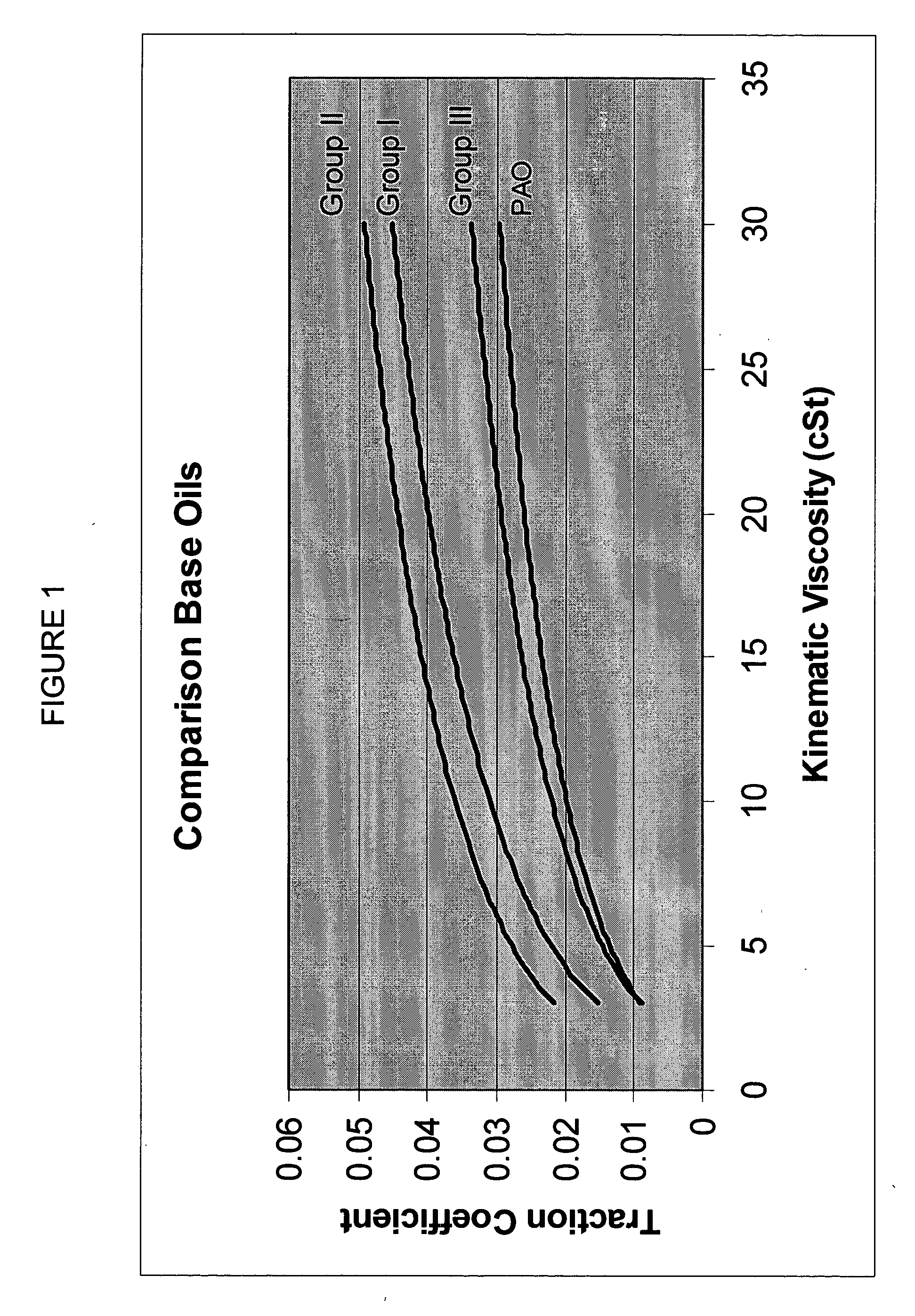

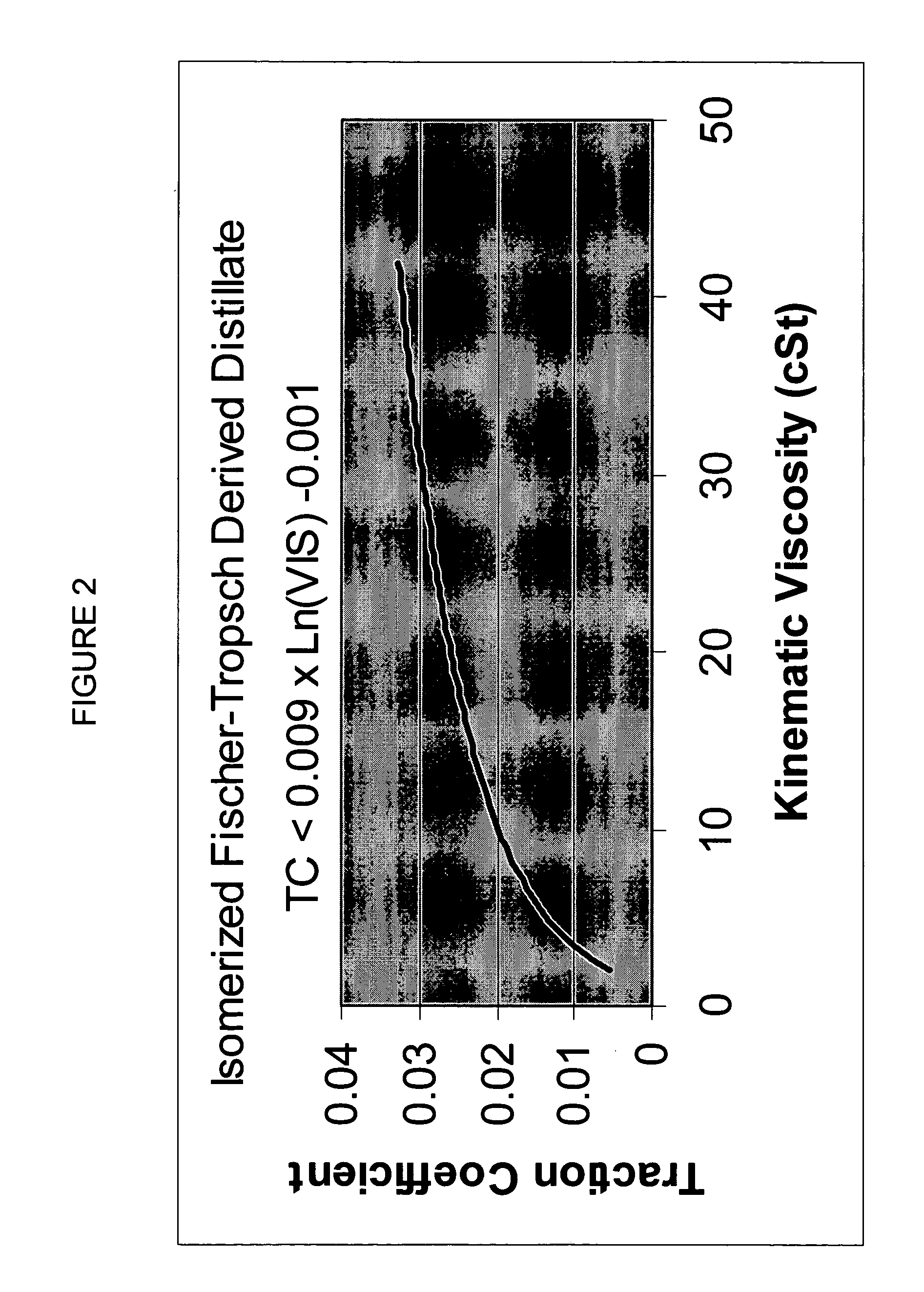

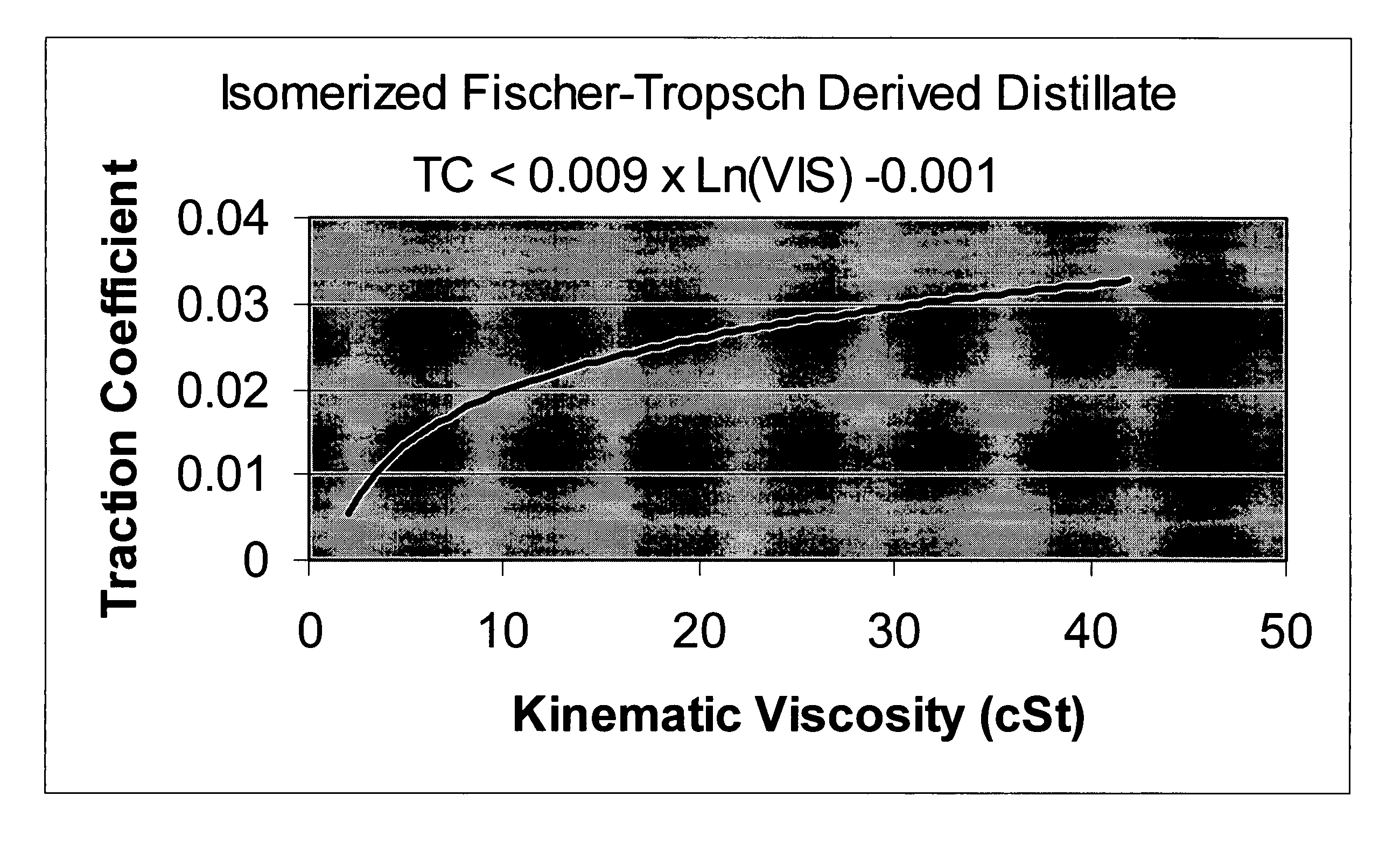

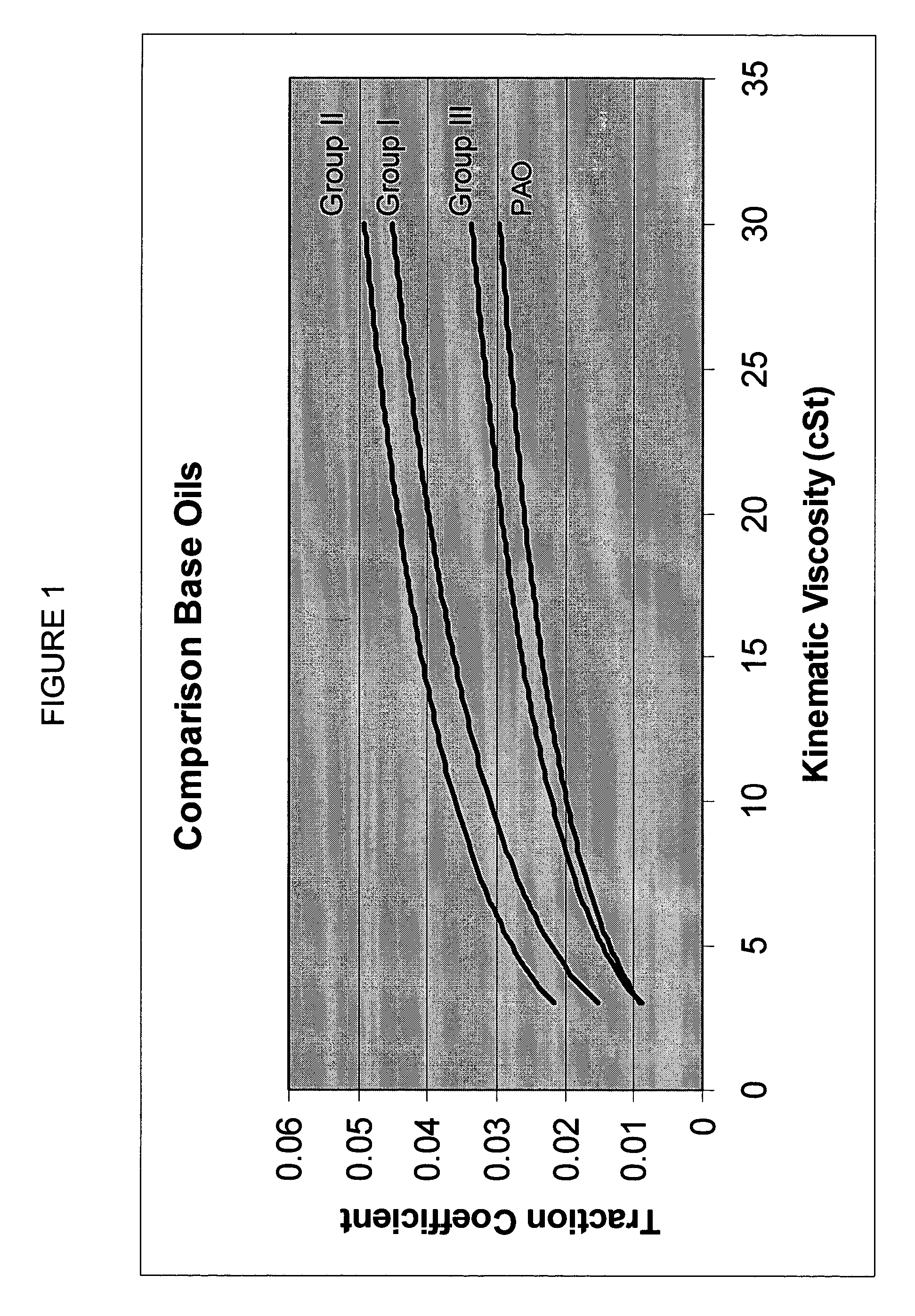

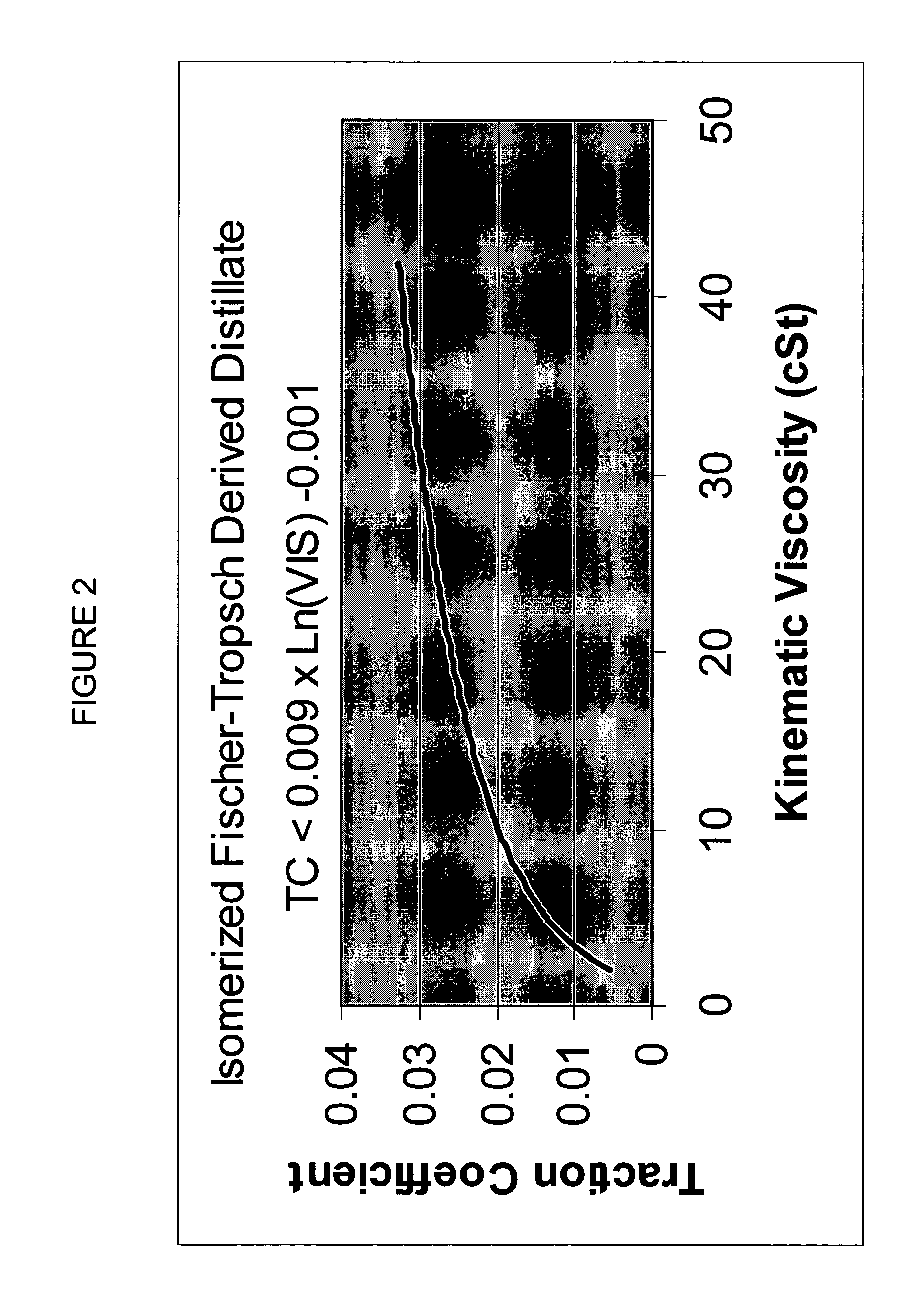

Method of operating a wormgear drive at high energy efficiency

InactiveUS20050241990A1Reducing traction coefficientToothed gearingsGear lubrication/coolingHigh energyBase oil

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133414A1Reduce contentCatalytic crackingRefining with metal saltsOxygen contentChemistry

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed may include Micro-Carbon Residue (MCR), oxygen, sulfur, or mixtures thereof. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a MCR residue and / or oxygen content of at most 90% of the MCR residue content and / or oxygen content of the crude feed. In some instances, the crude product may have a sulfur content of about 30% to about 70% of the sulfur content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133417A1Reduce contentCatalytic crackingRefining with metal saltsAcid valueTotal acid

Contact of a crude feed with one or more catalysts produces a total product that include a crude product. The crude feed may a total acid number of at least 0.3. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a total acid number of at most 90% of the total acid number of the crude feed. At least one of the catalysts may include one or more Column 6 metals of the Periodic Table and one or more Column 10 metals of the Periodic Table. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

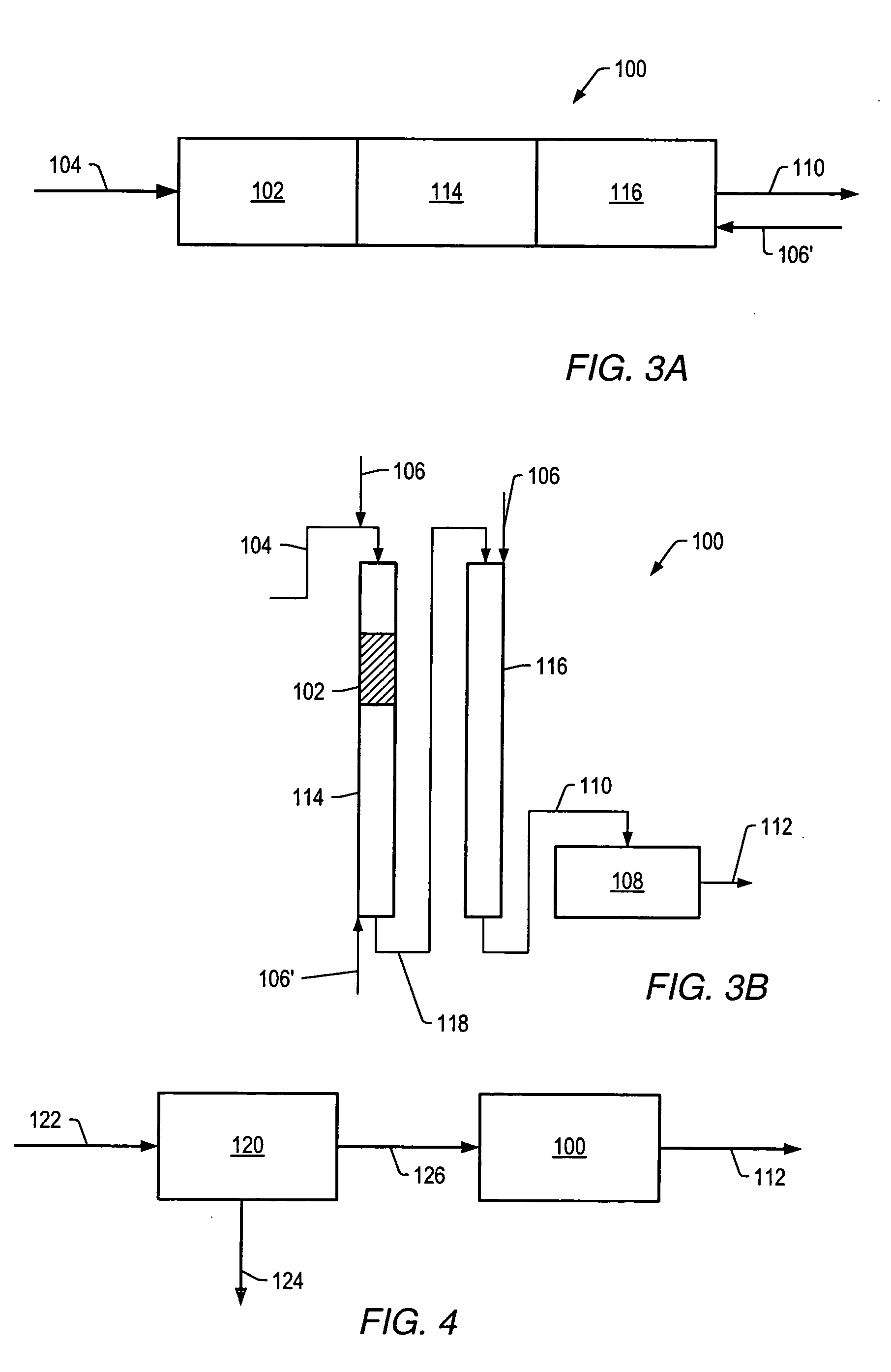

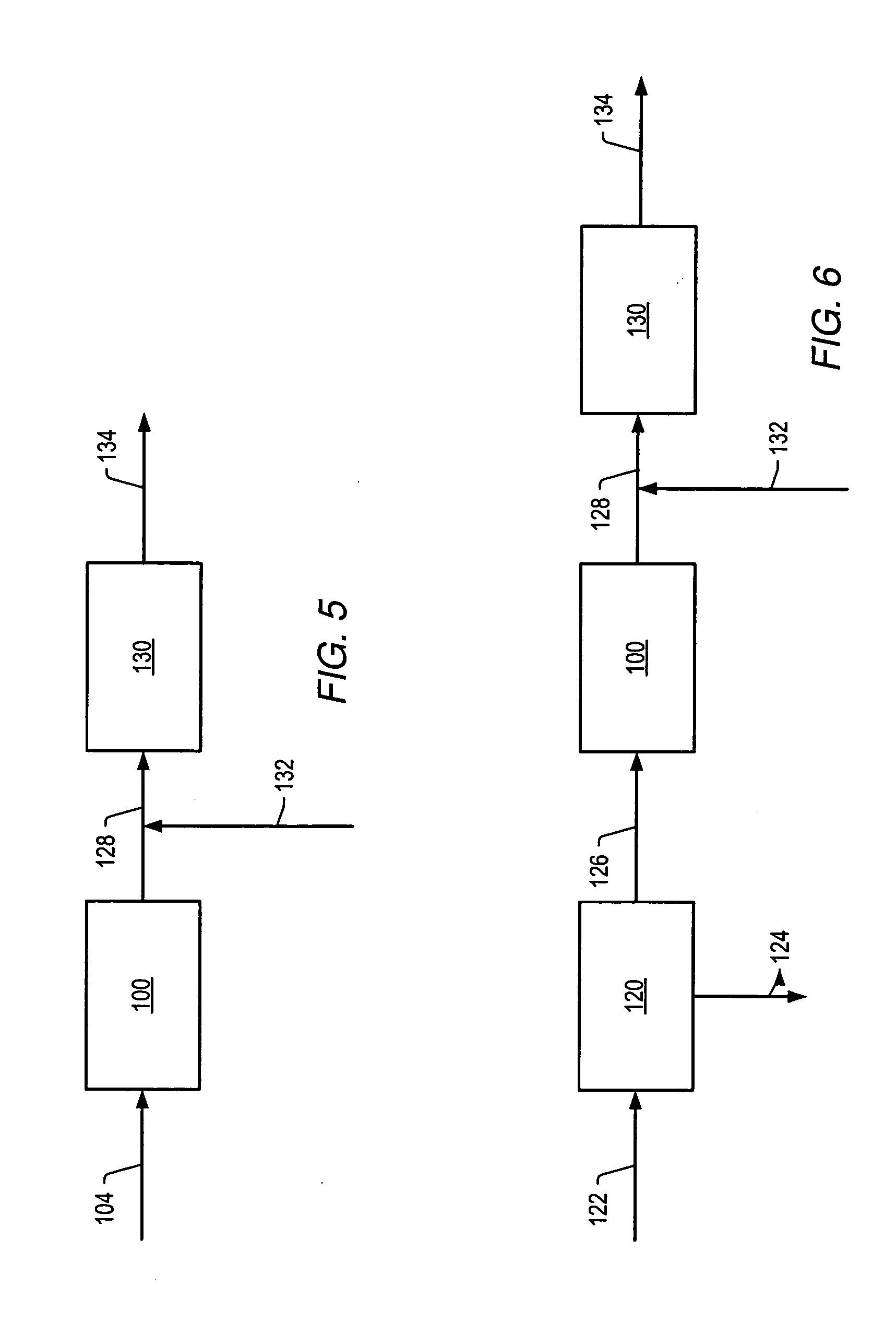

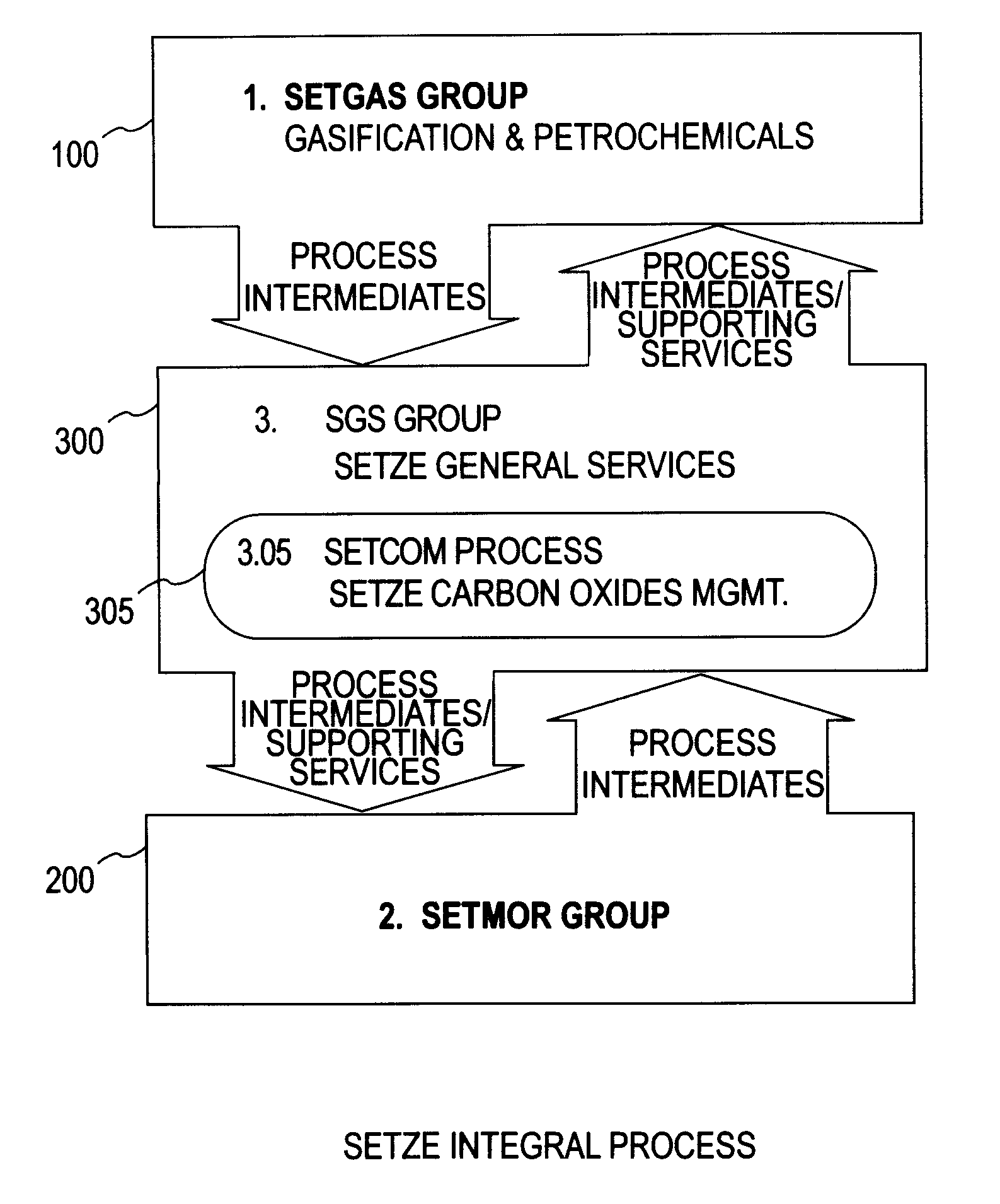

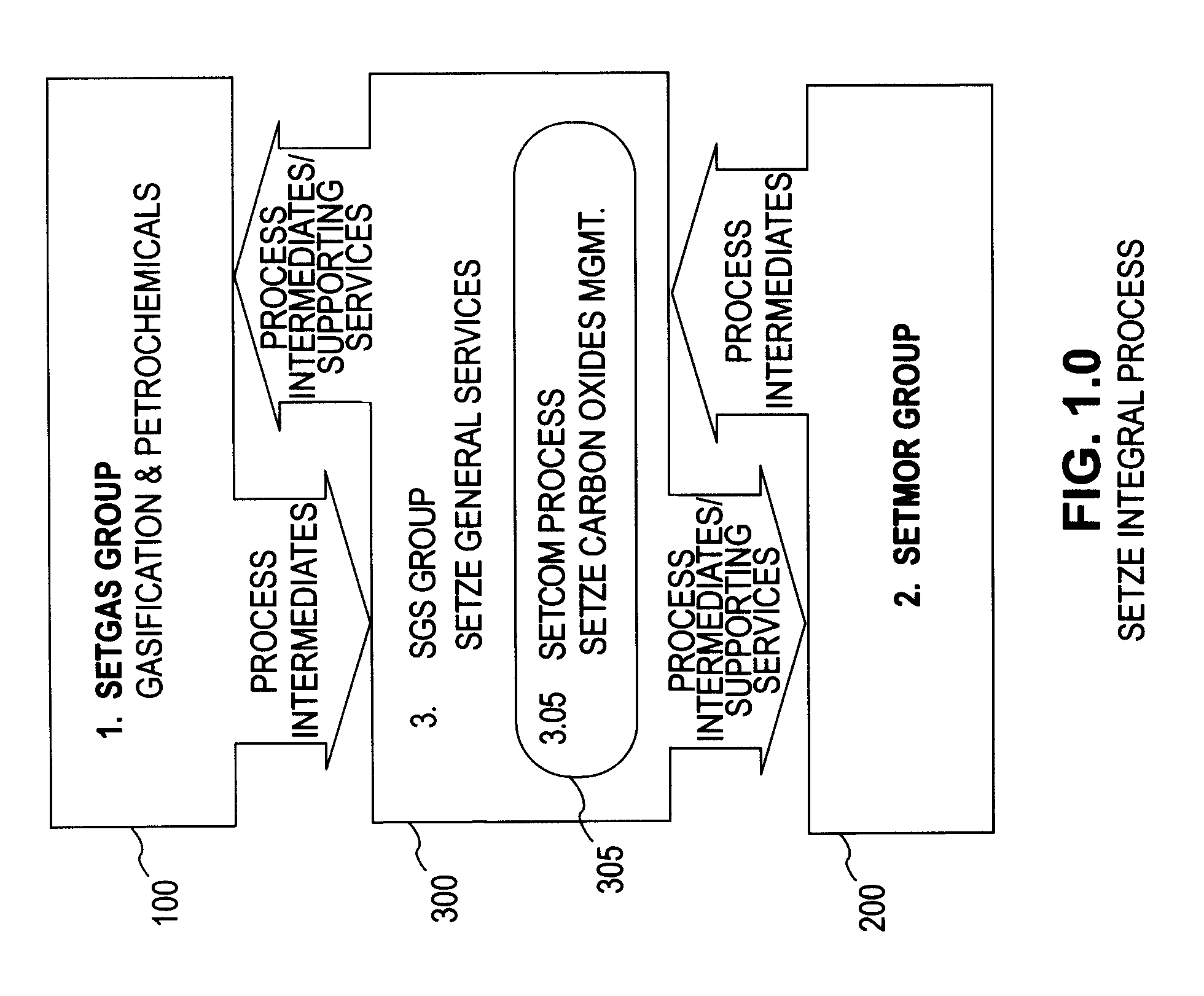

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

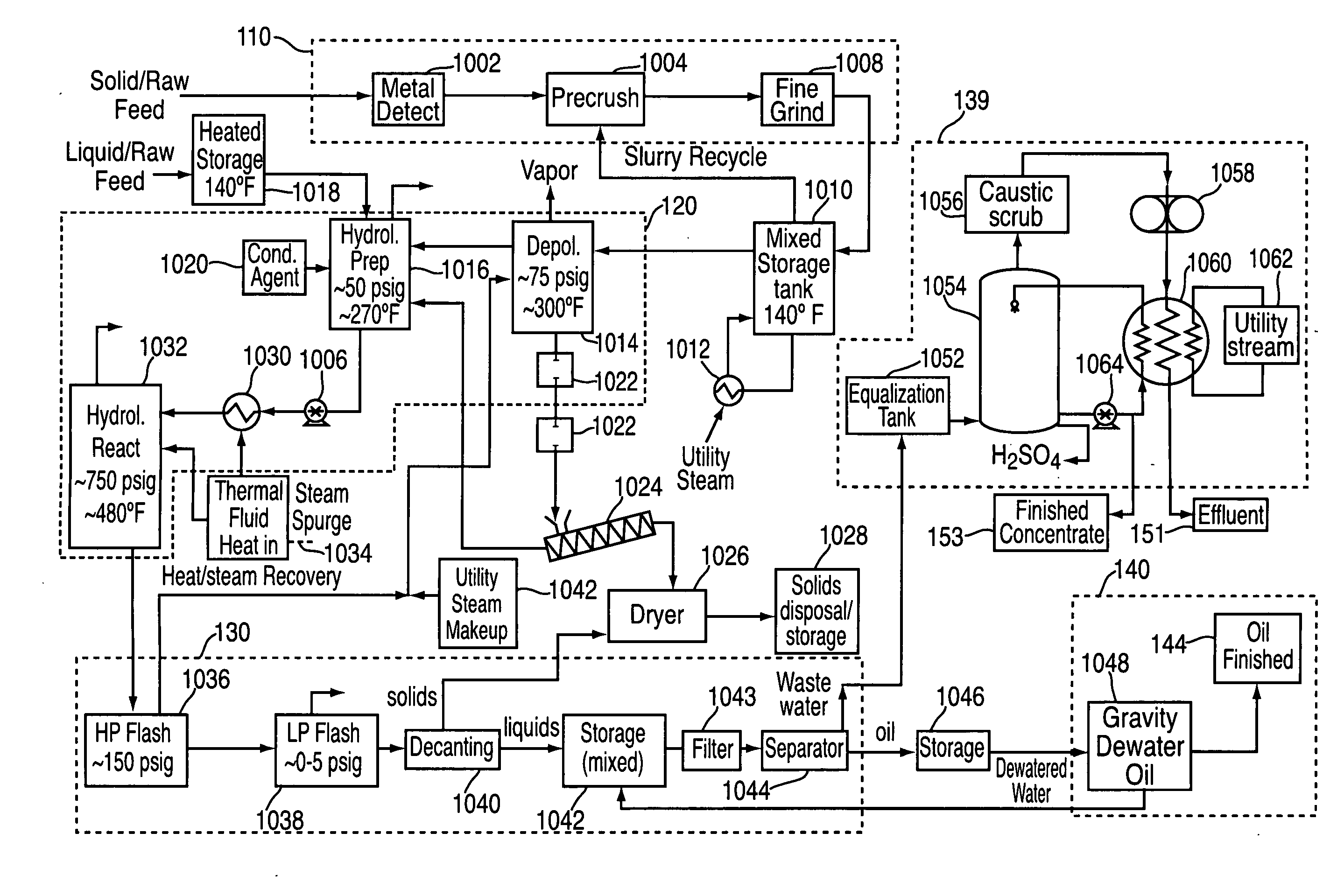

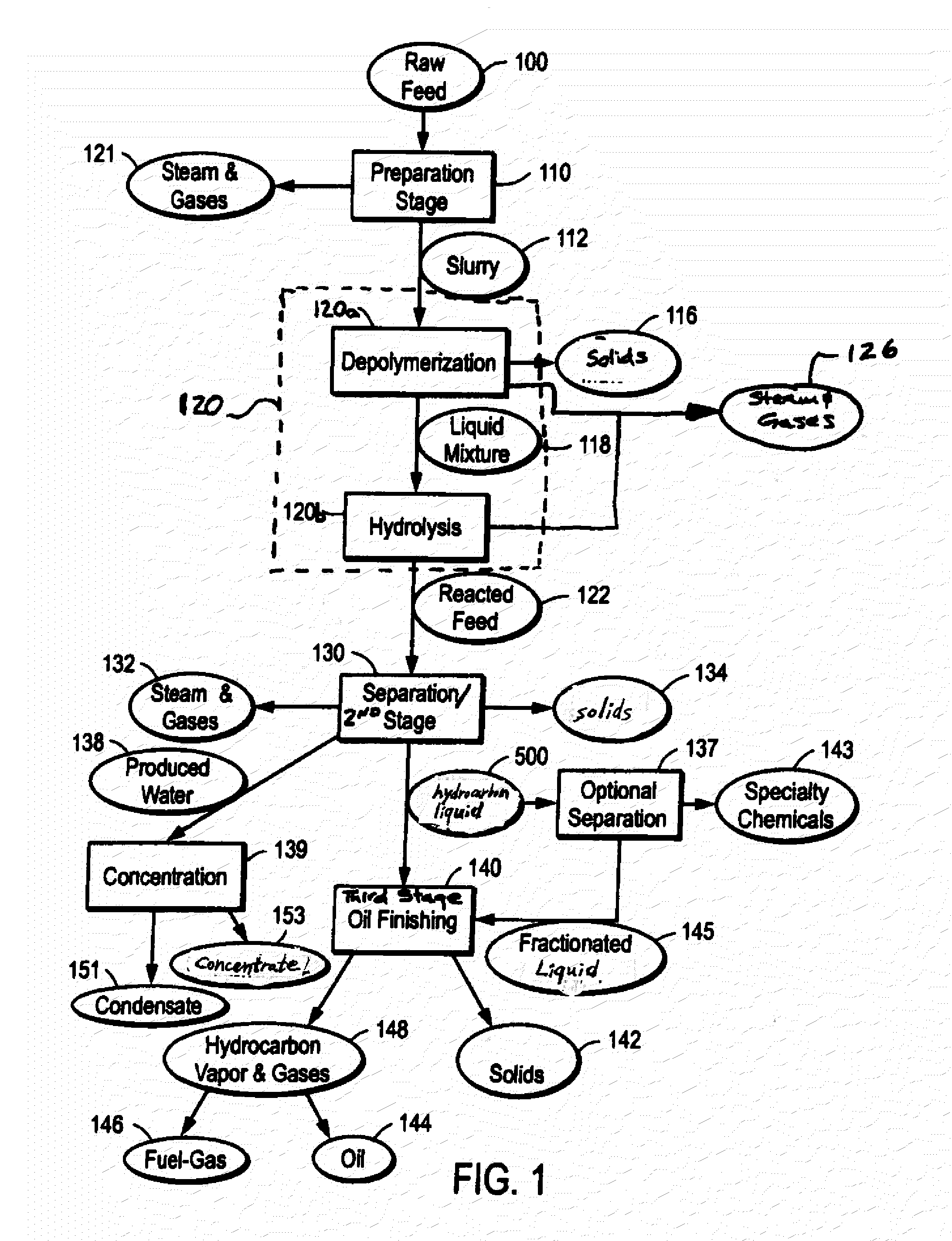

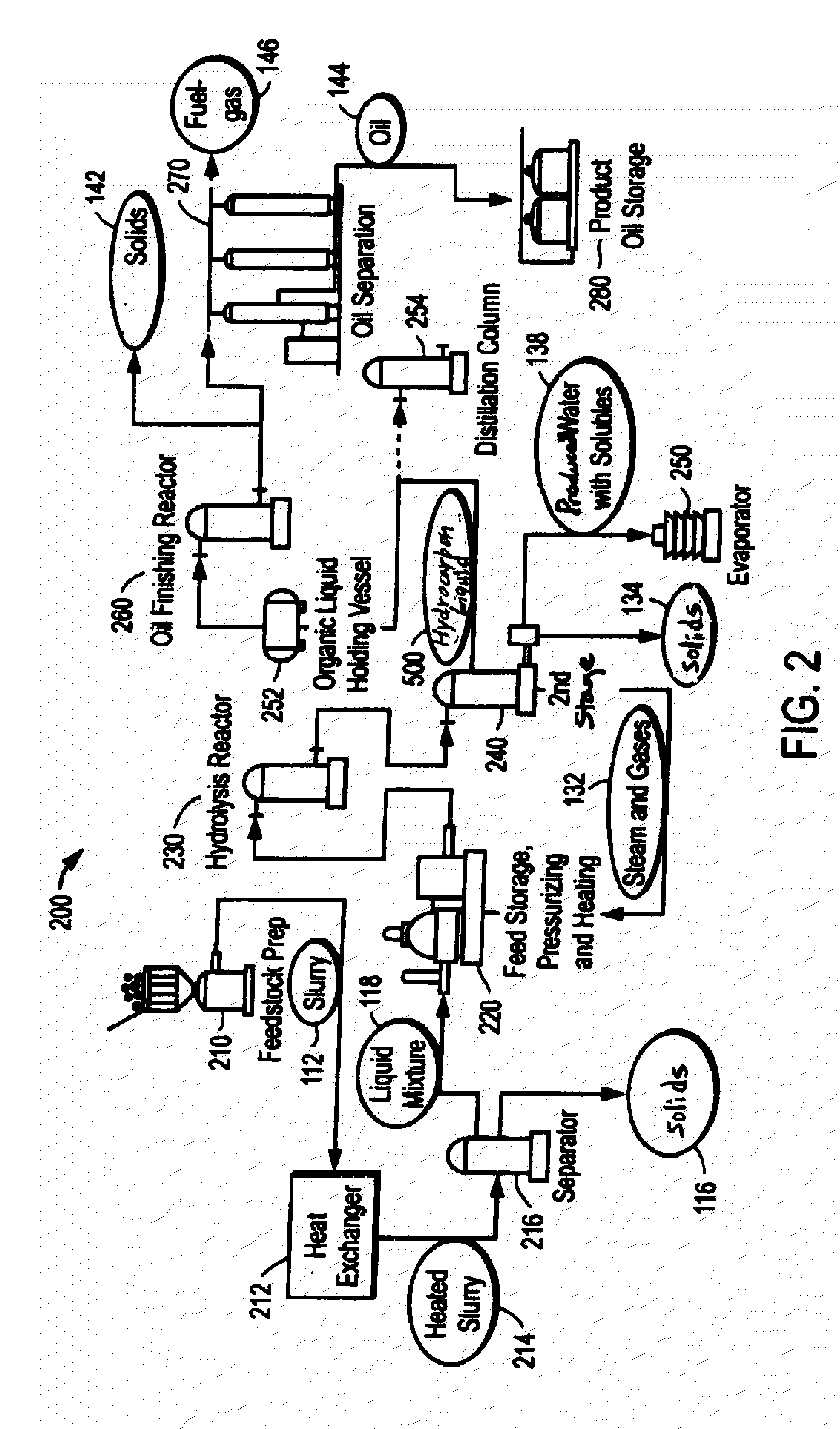

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS20090062581A1Effectively handle problematic wasteFree of contaminantsTransportation and packagingSolid waste disposalSpeciality chemicalsBiological waste

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

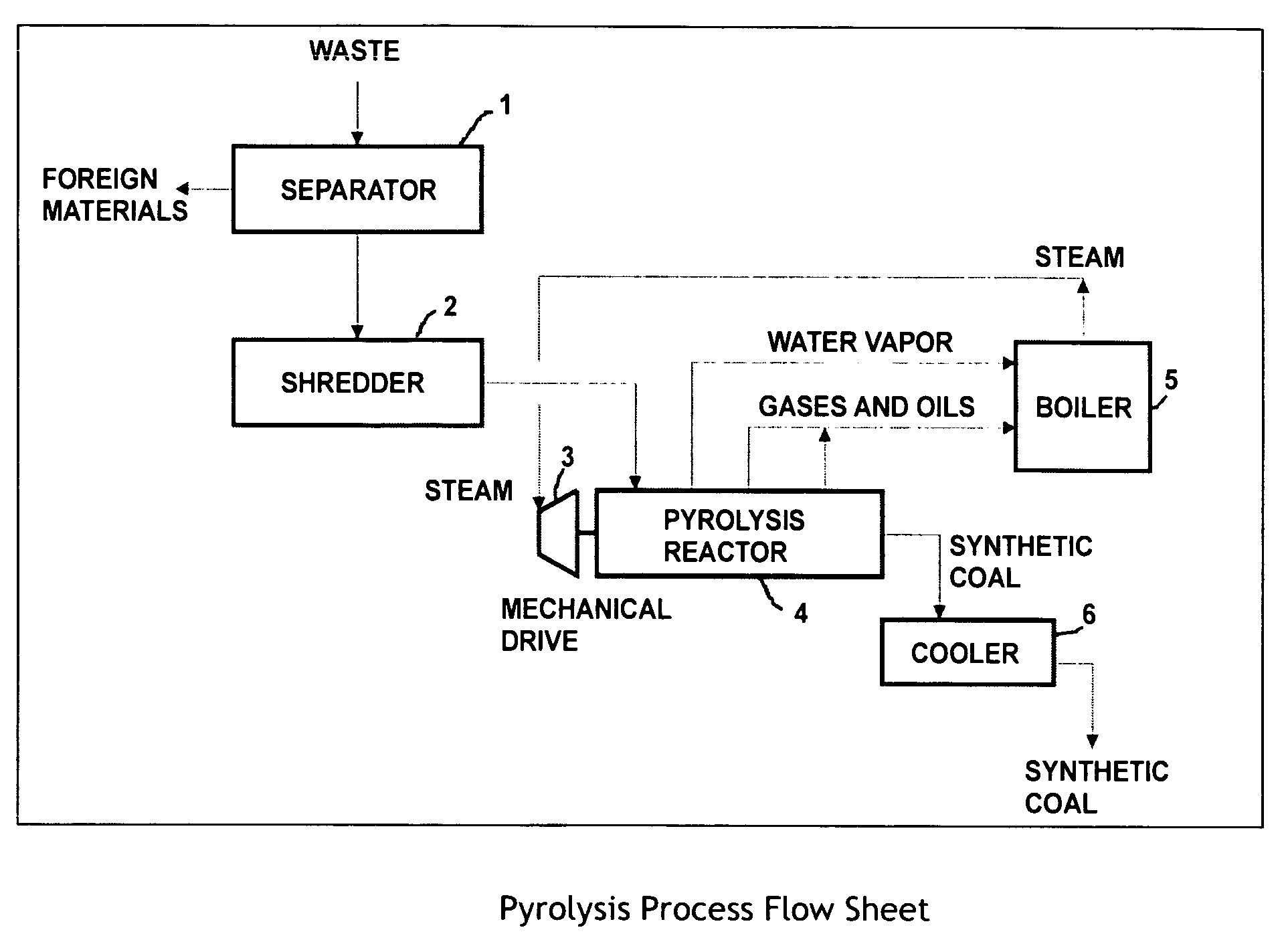

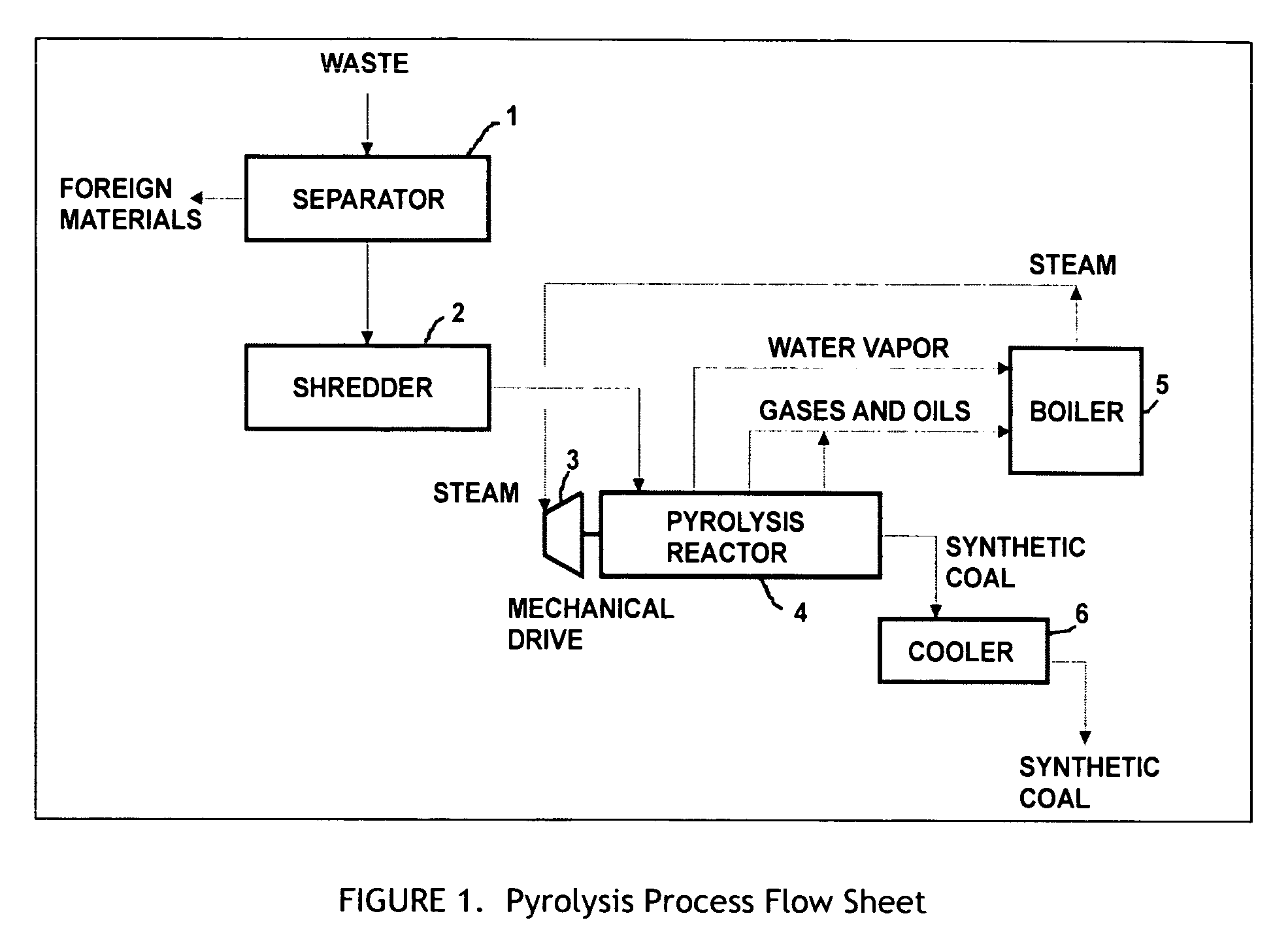

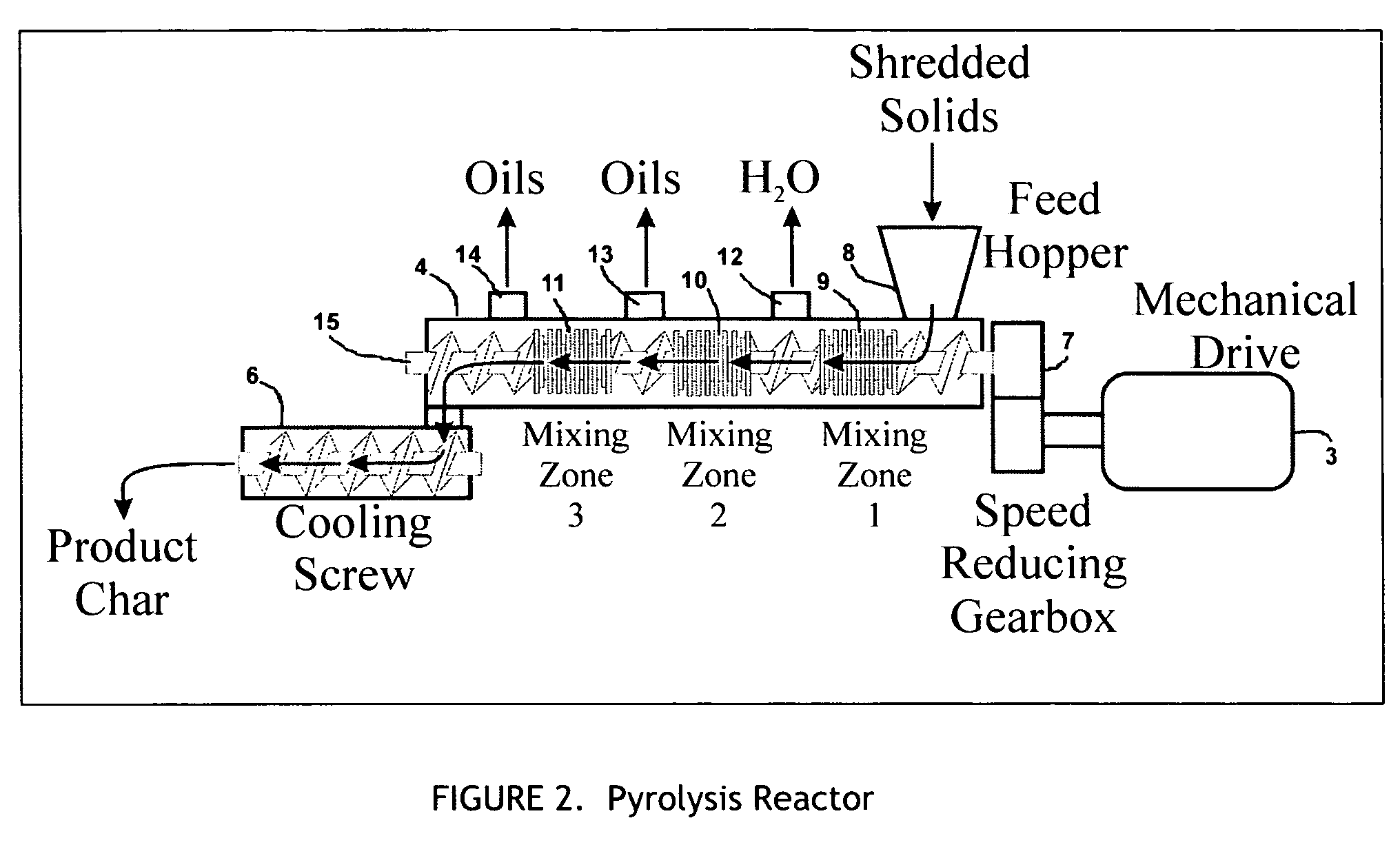

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

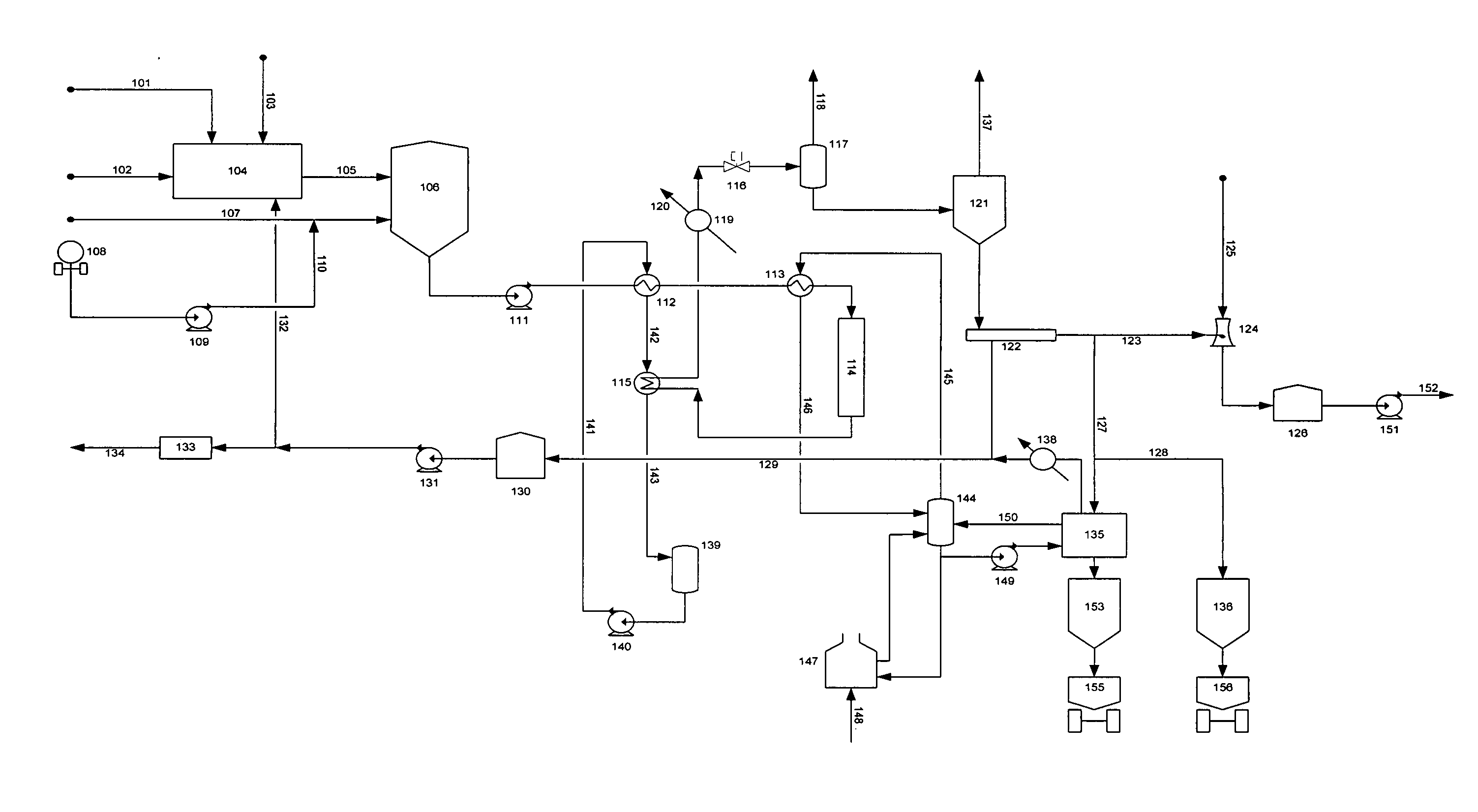

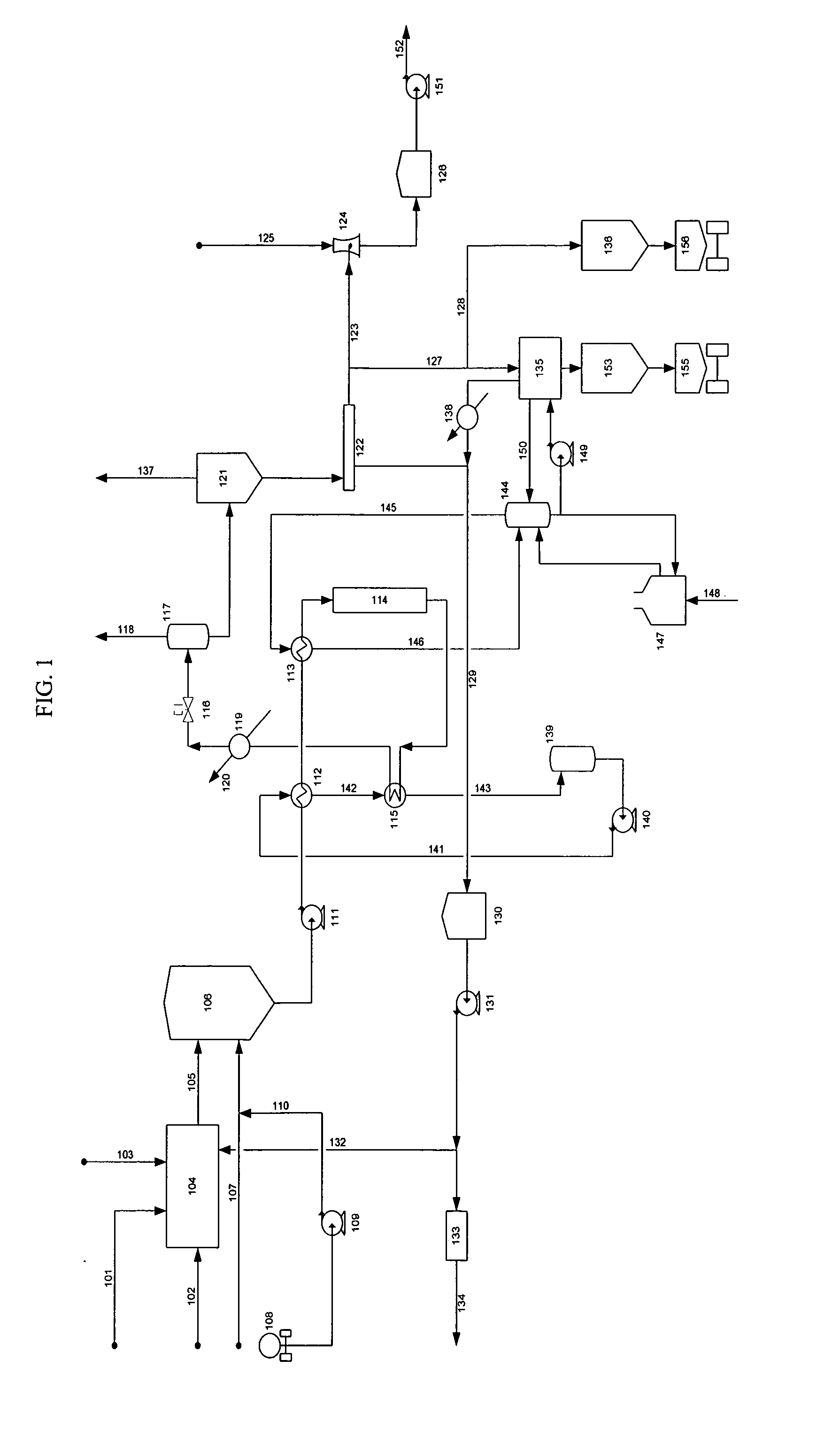

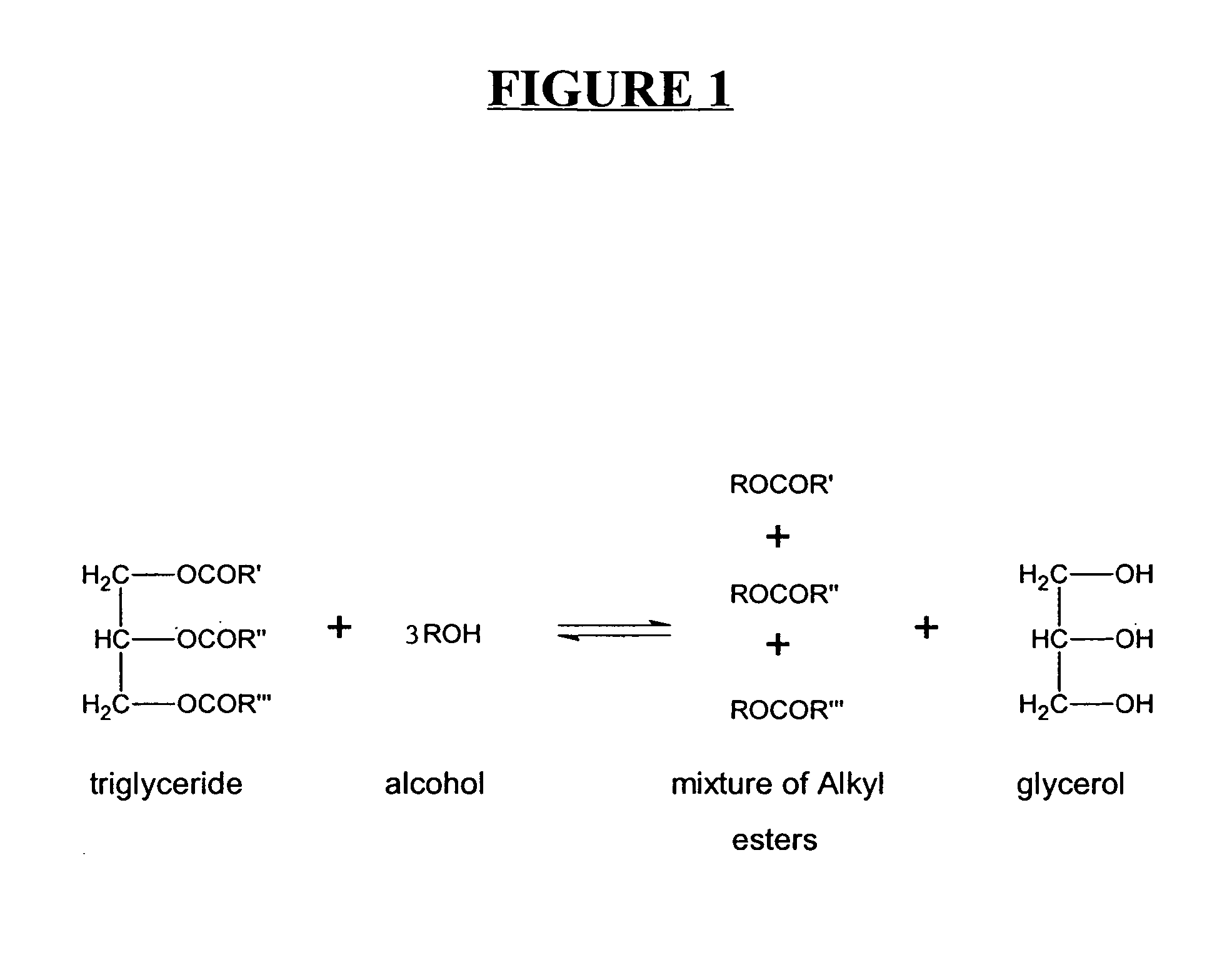

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

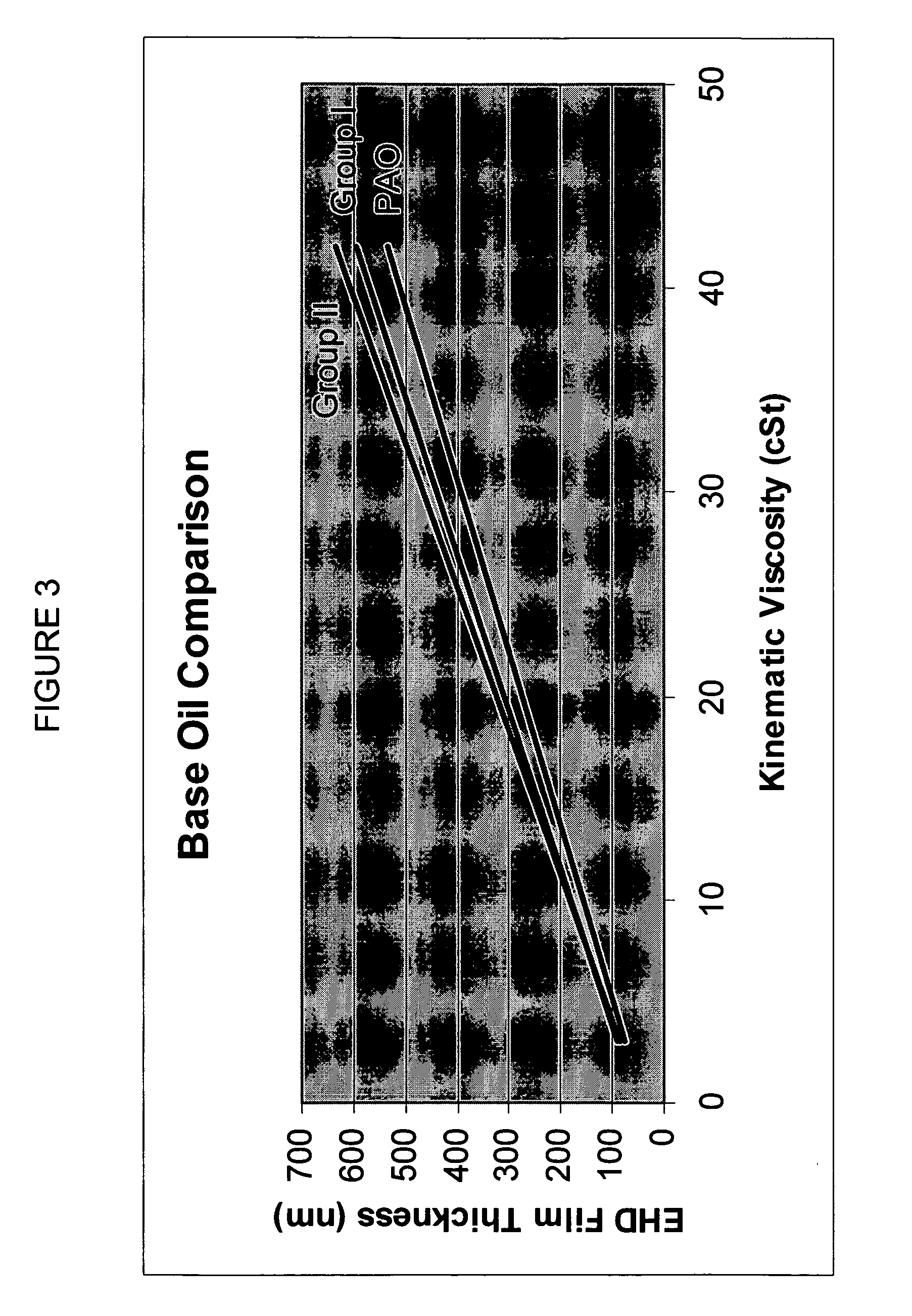

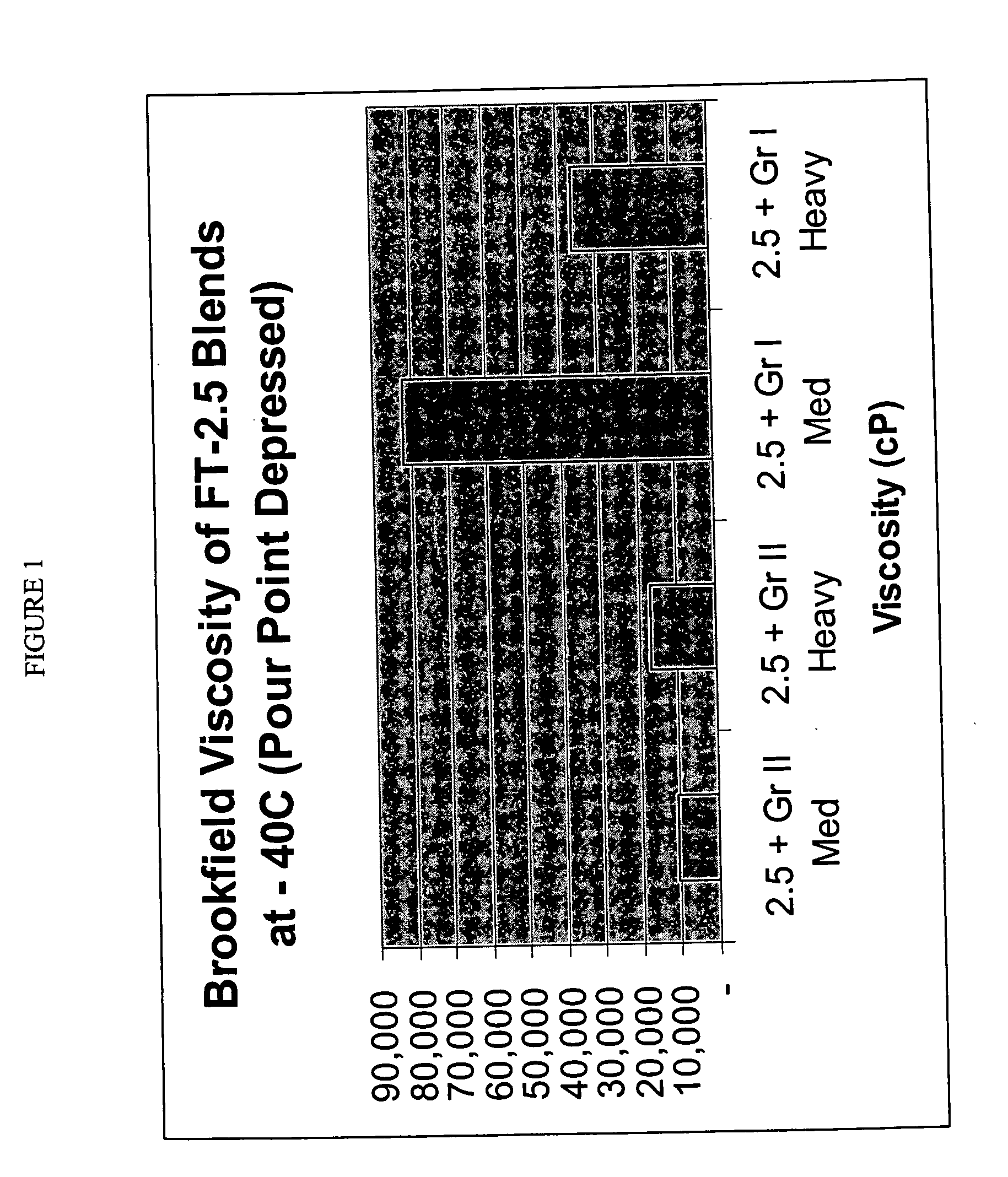

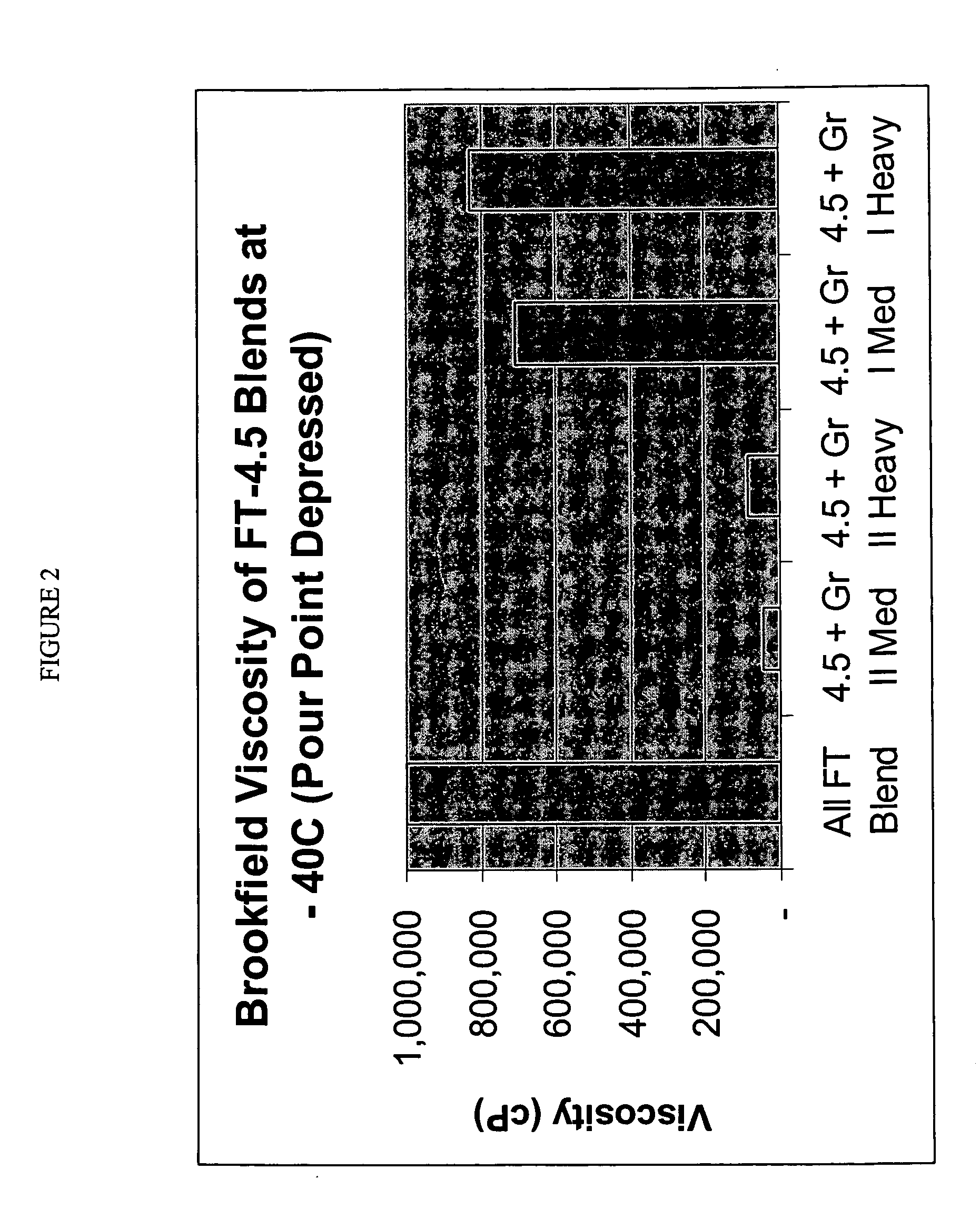

Lubricant blends with low brookfield viscosities

InactiveUS20050261147A1Improve low temperature performanceExcellent low Brookfield viscosityOrganic chemistryLiquid carbonaceous fuelsWaxSulfur

Lubricant blends and finished gear oils comprising a lubricant base oil fraction derived from highly paraffinic wax, a petroleum derived base oil, and a pour point depressant are provided. The lubricant base oil fraction derived from highly paraffinic wax comprises less than 0.30 weight percent aromatics, greater than 5 weight percent molecules with cycloparaffinic functionality, and a ratio of weight percent of molecules with monocycloparaffinic functionality to weight percent of molecules with multicycloparaffinic functionality greater than 15. The petroleum derived base oils comprises greater than 90 weight percent saturates and less than 300 ppm sulfur and is preferably selected from the group consisting of a Group II base oil, a Group III base oil, and mixtures thereof. These lubricant blends have surprising low Brookfield viscosities at −40° C.

Owner:CHEVROU USA INC

HVI-PAO in industrial lubricant and grease compositions

ActiveUS20070000807A1Good effectViscosity indexSolid fuelsLiquid carbonaceous fuelsViscosity indexWear resistance

The invention relates to industrial lubricant and grease compositions containing high viscosity index polyalphaolefins (HVI-PAO). The use of HVI-PAOs in industrial oils and greases application provides advantages in improved shear stability, wear property, foam property, energy efficiency and improved overall performance.

Owner:EXXONMOBIL CHEM PAT INC

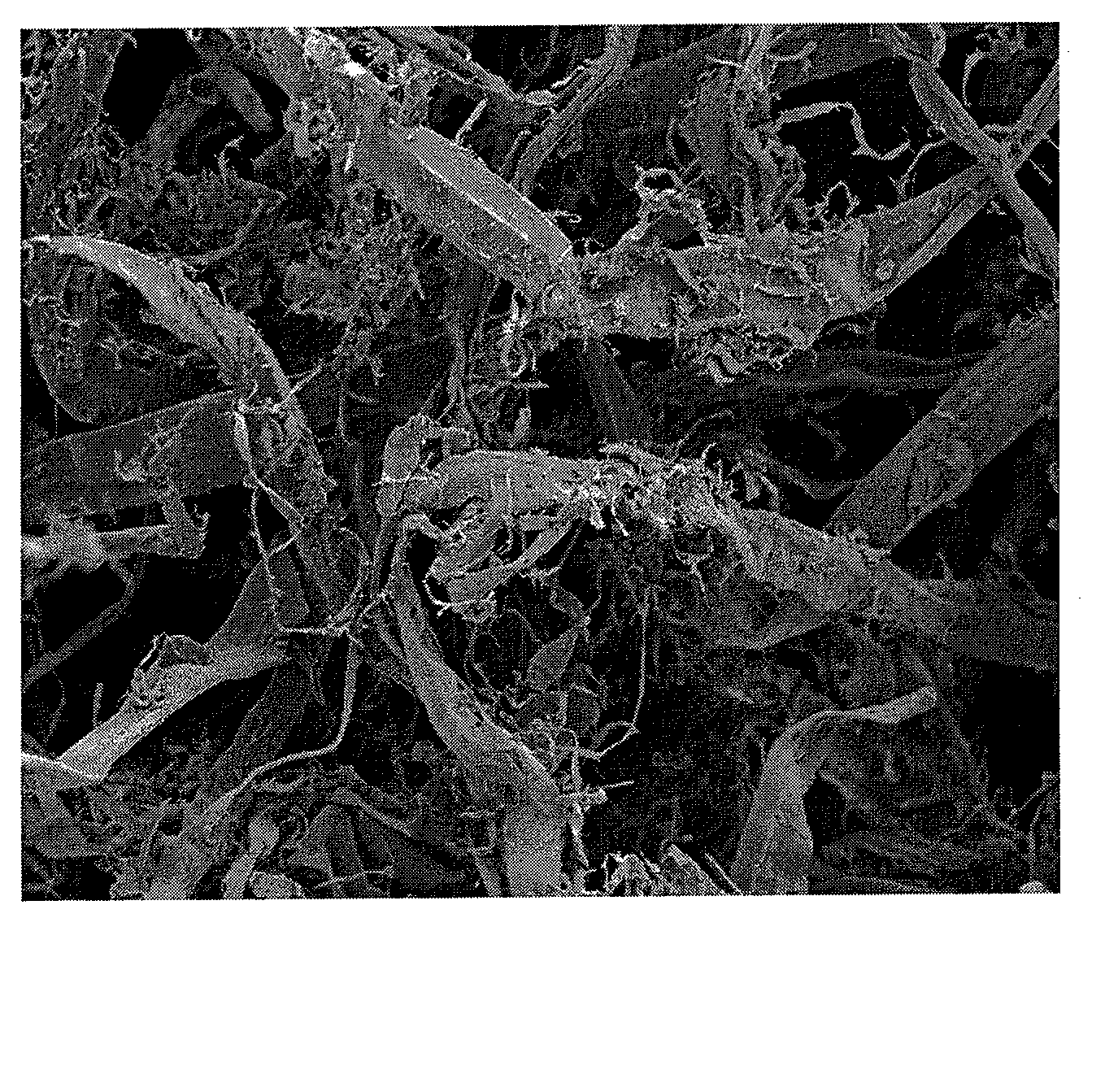

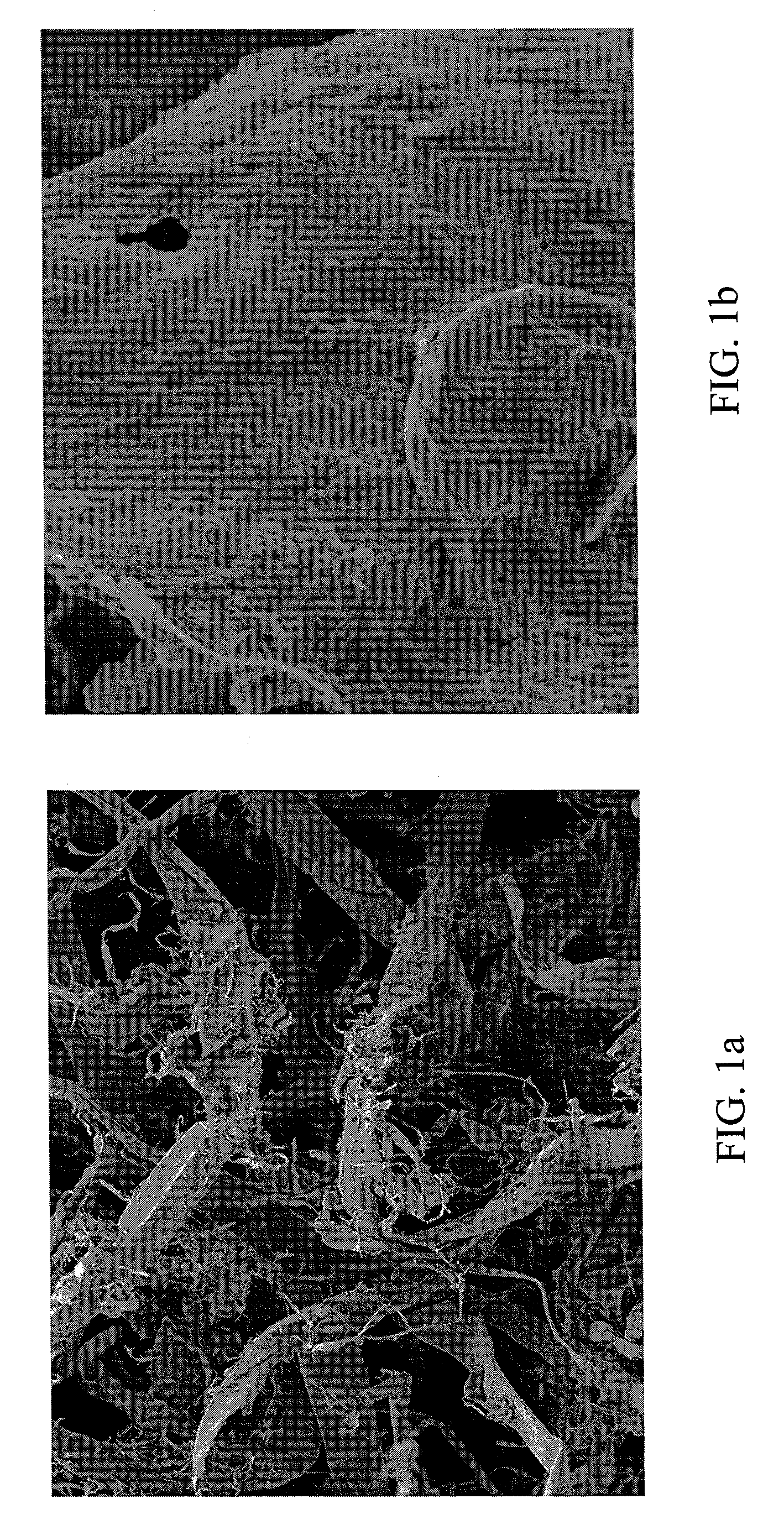

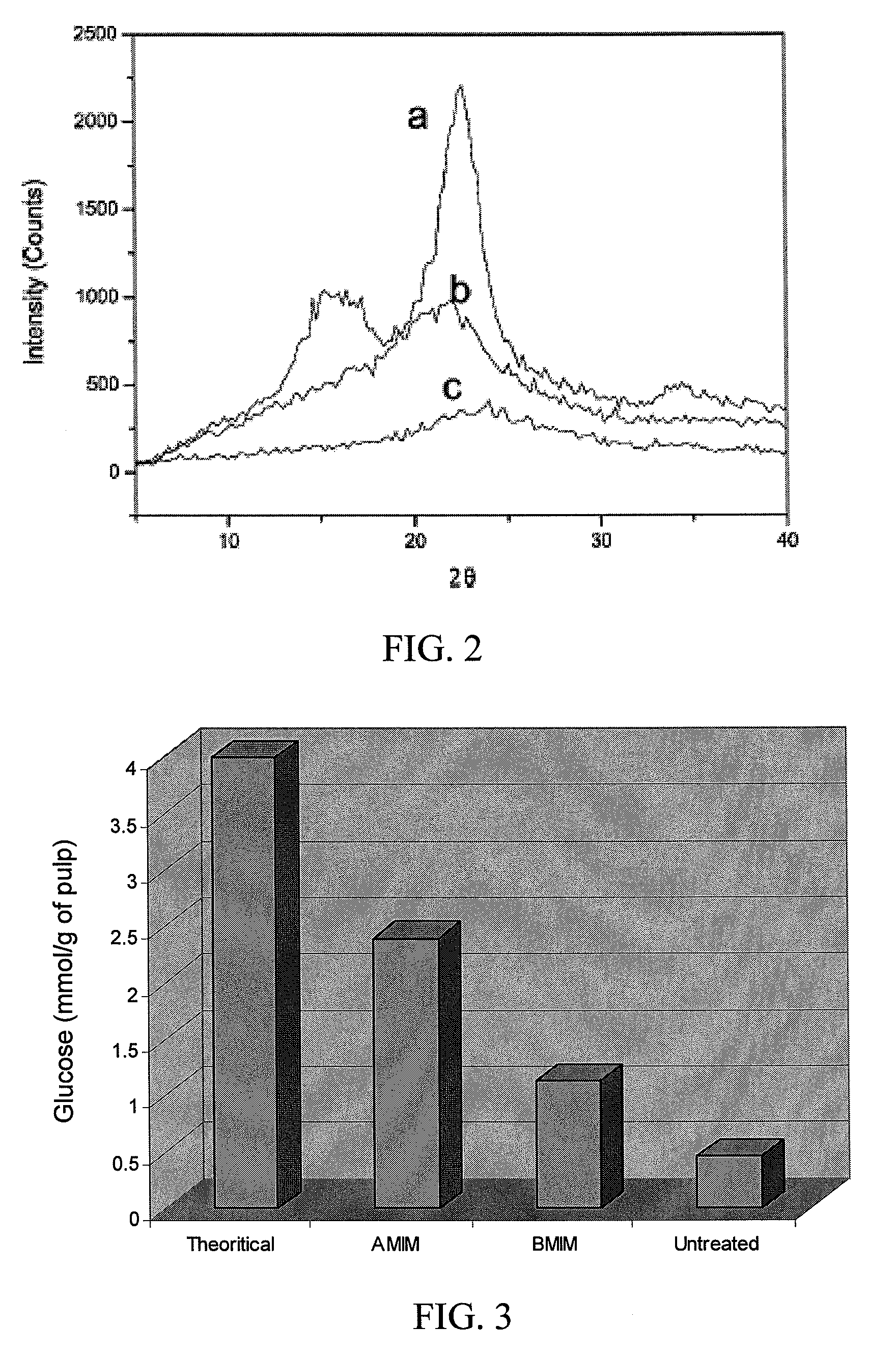

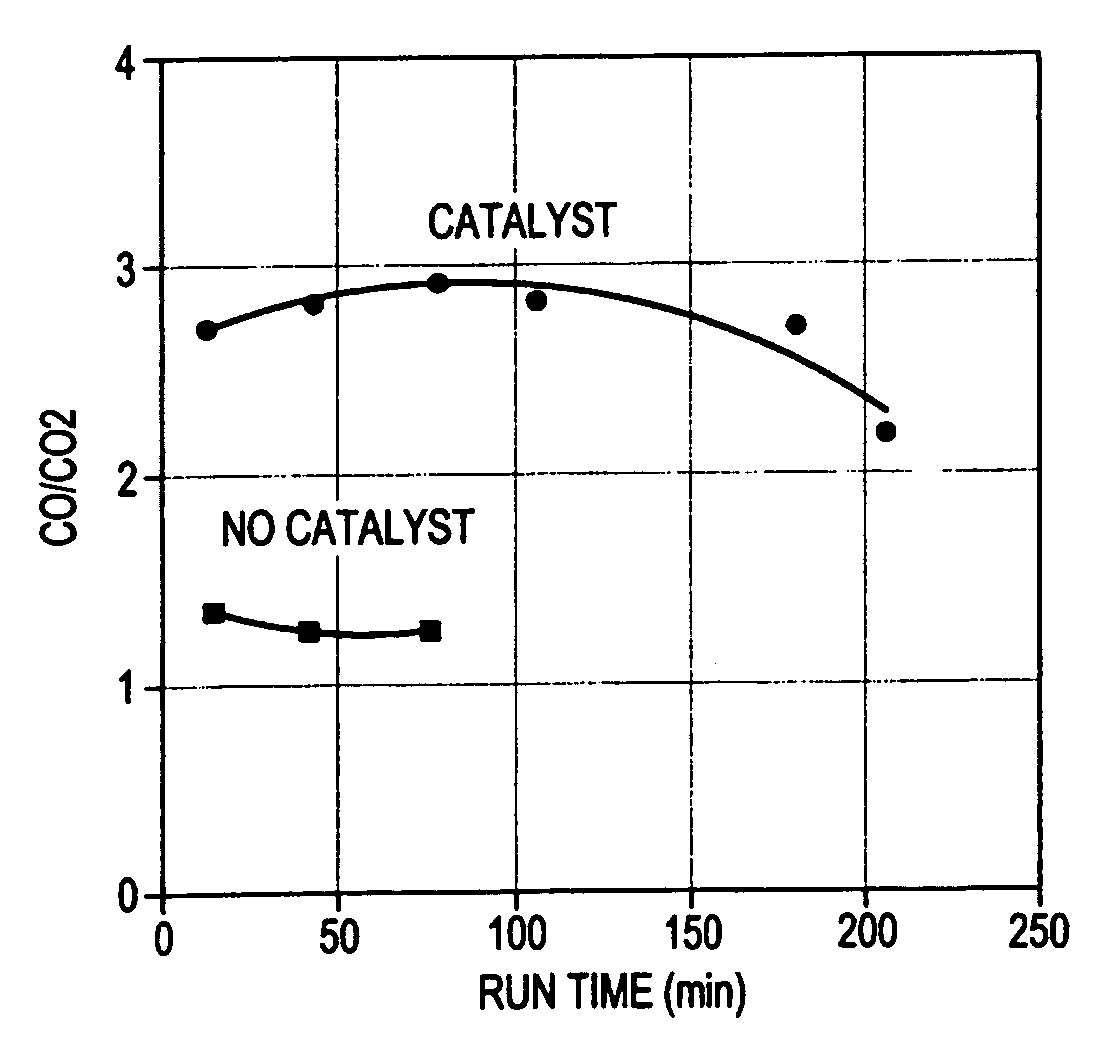

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

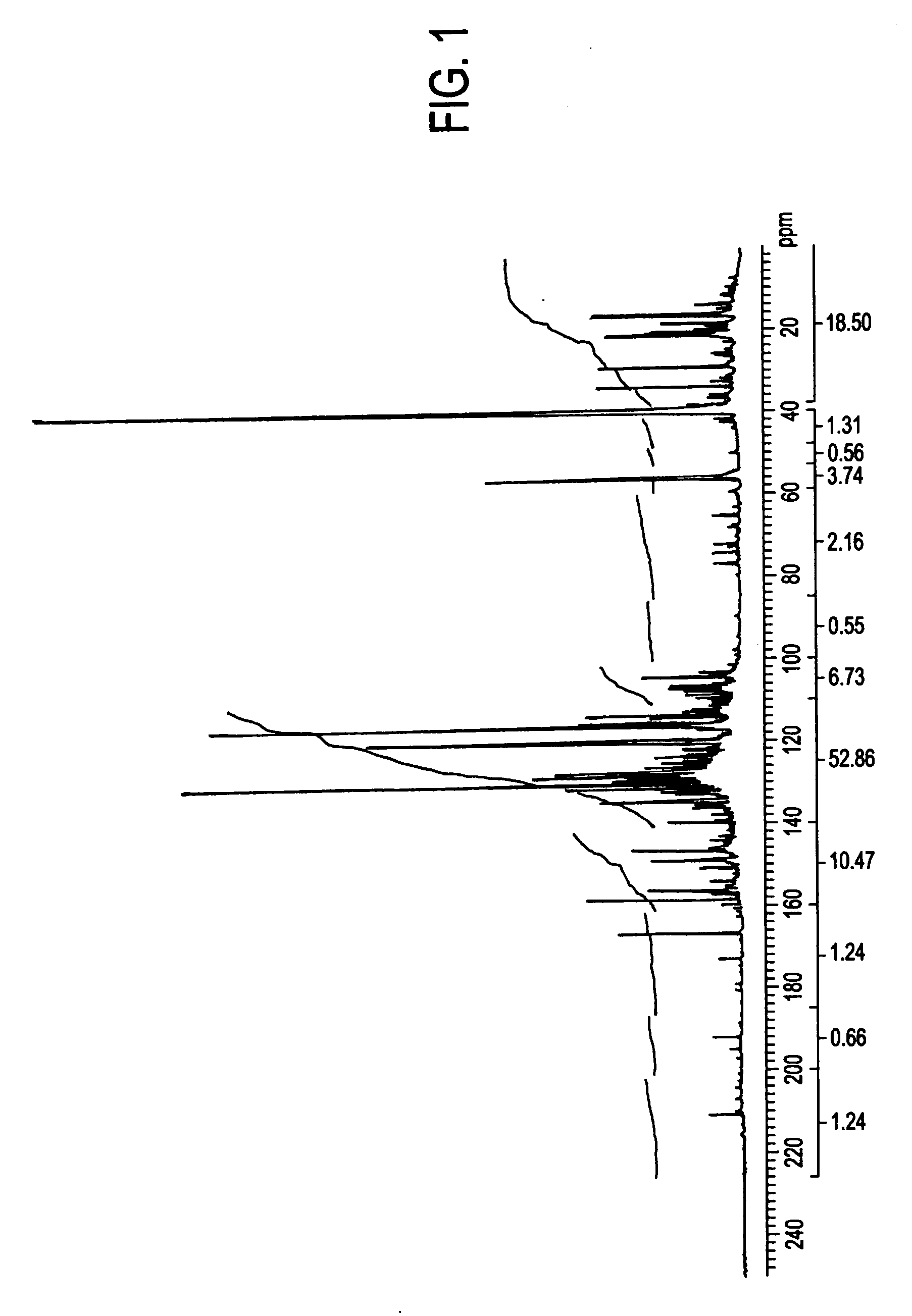

Fractional catalytic pyrolysis of biomass

ActiveUS20090165378A1Eliminate needBiofuelsIndirect heating destructive distillationCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

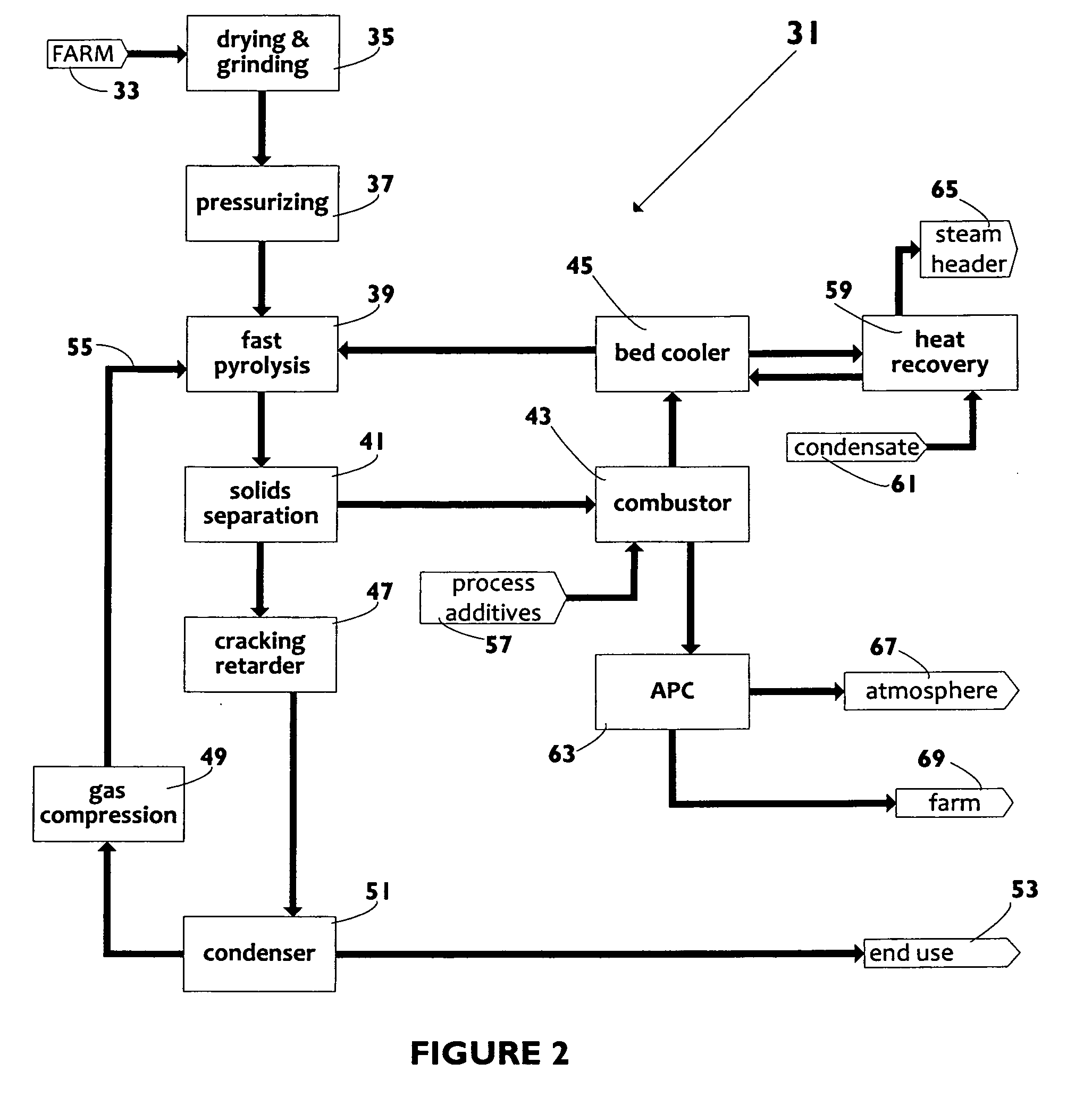

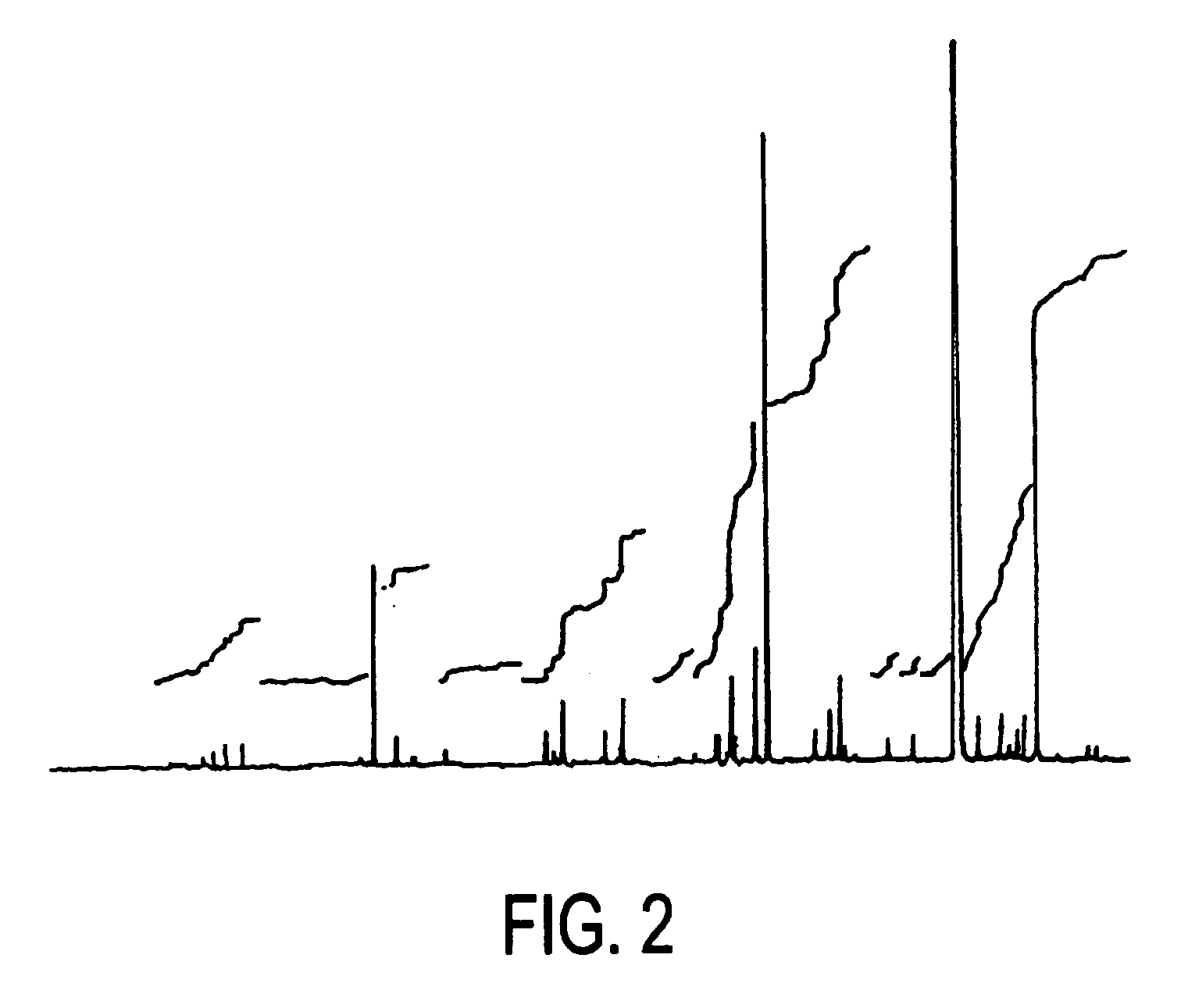

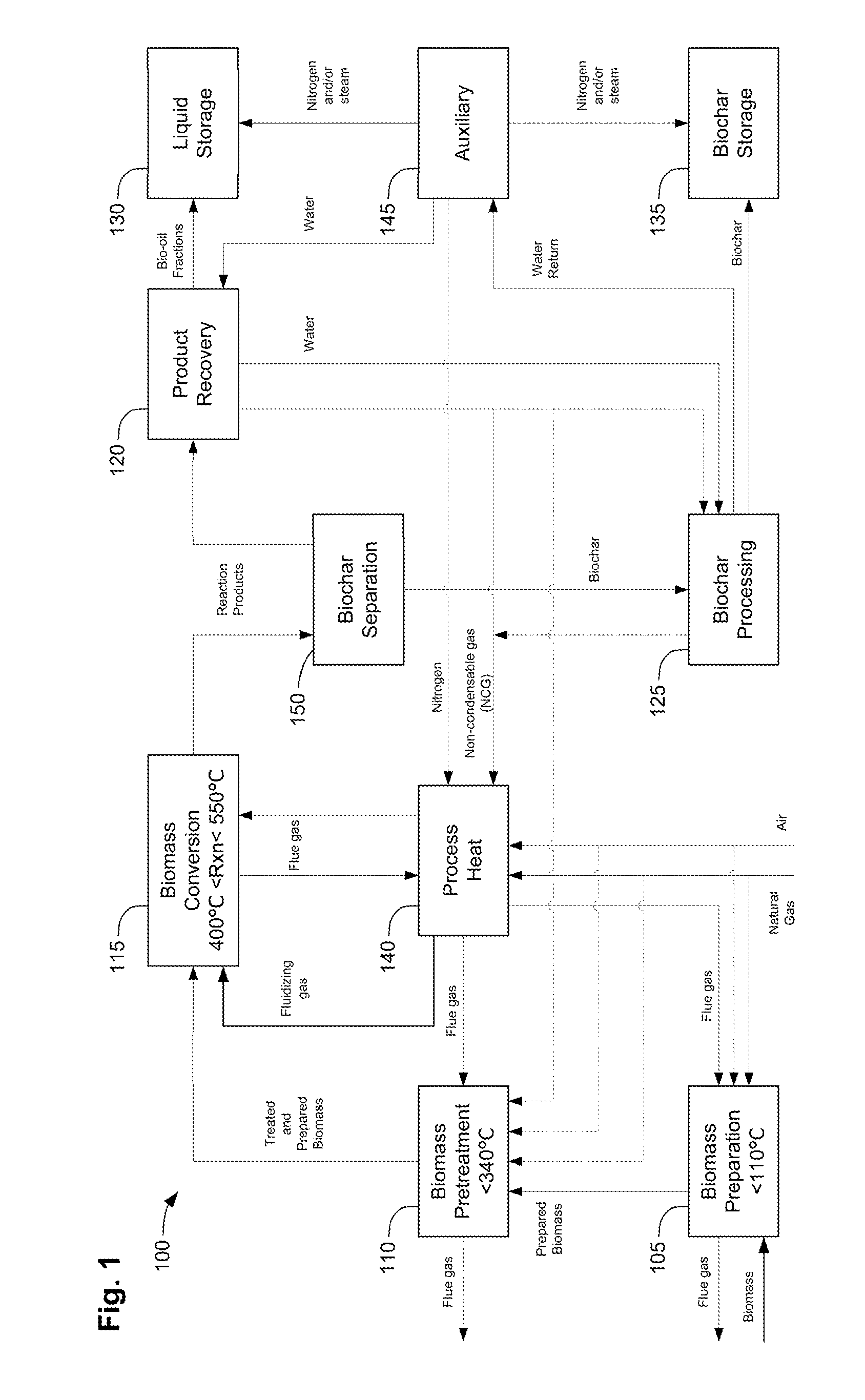

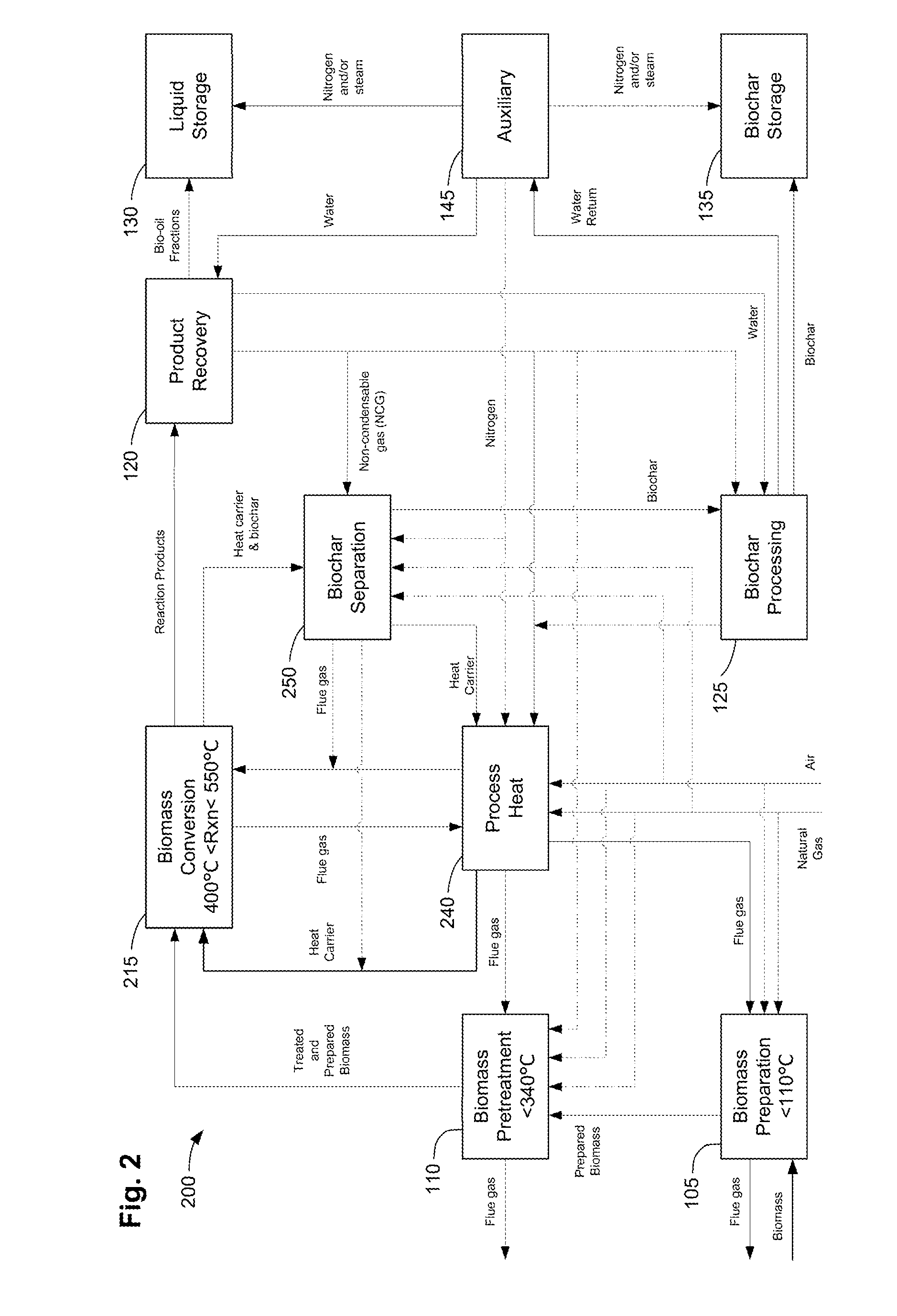

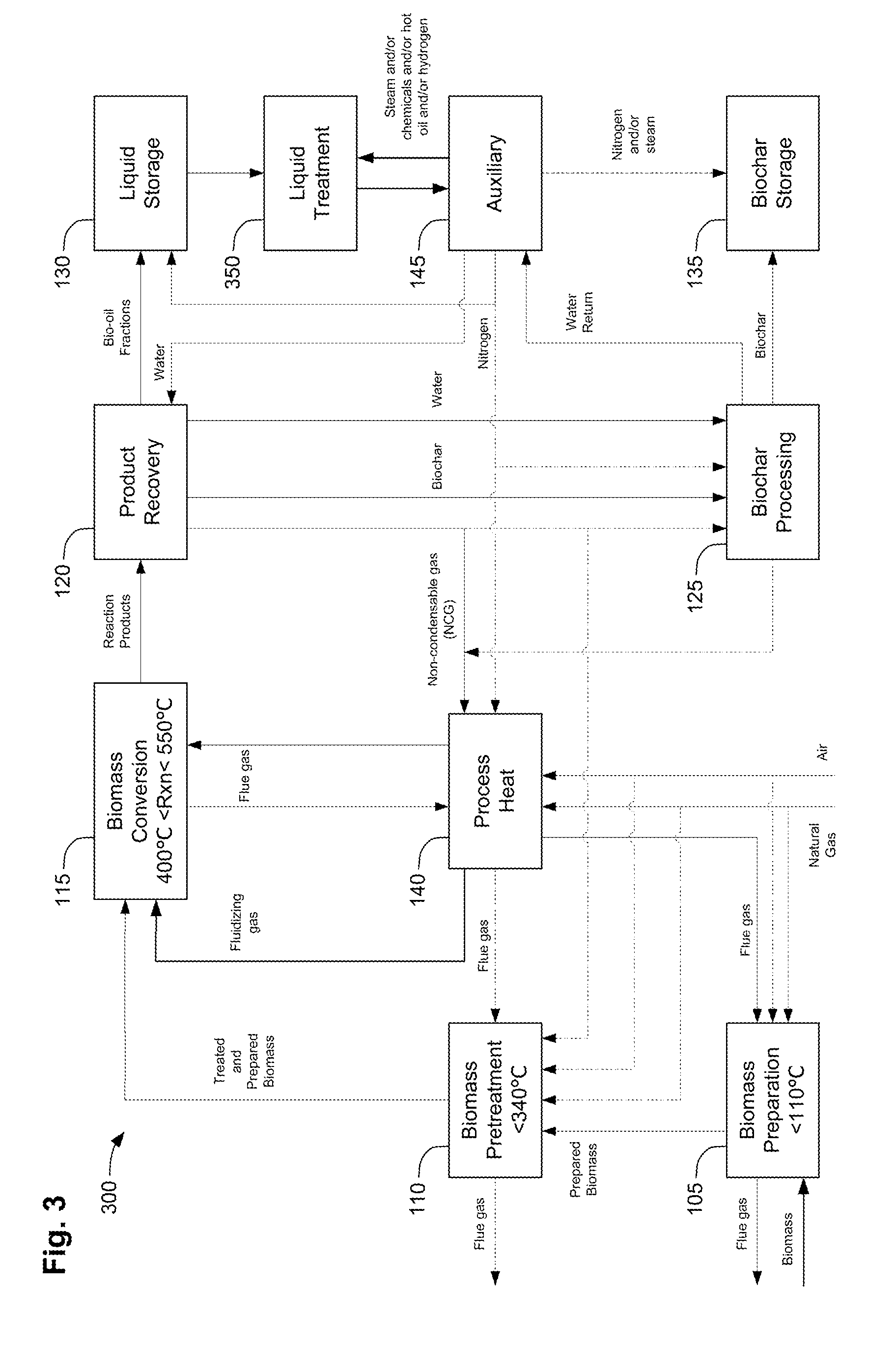

Methods for integrated fast pyrolysis processing of biomass

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

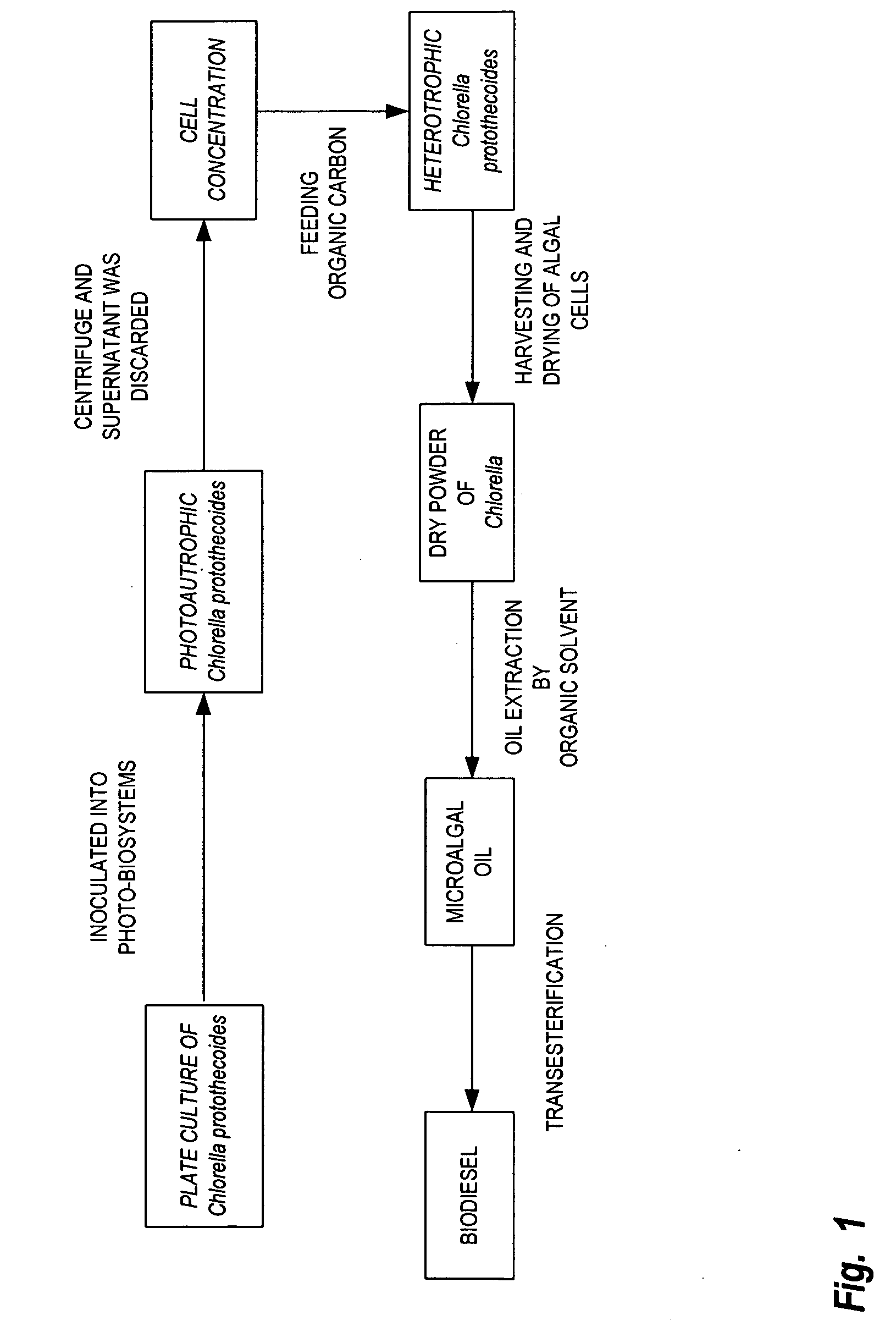

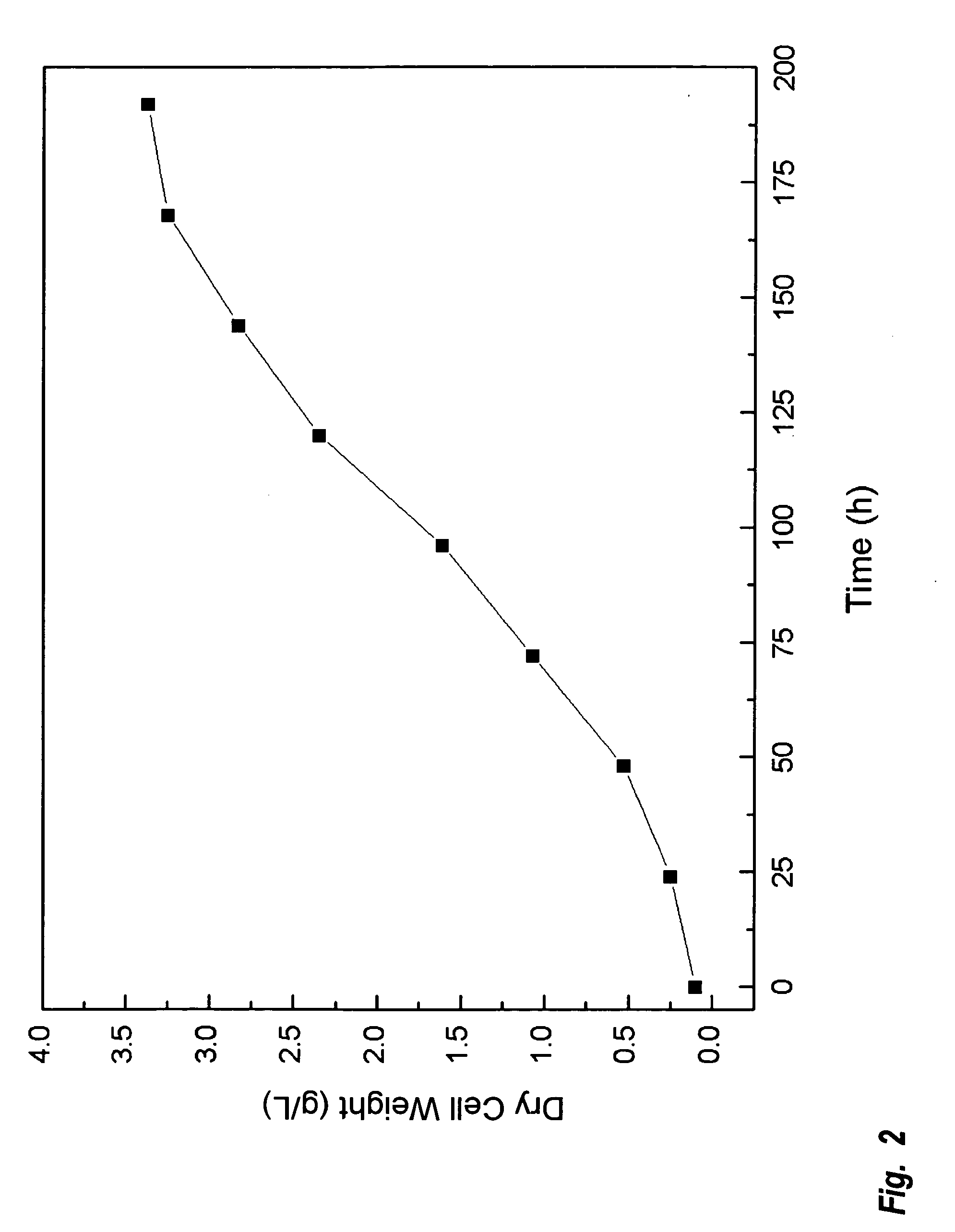

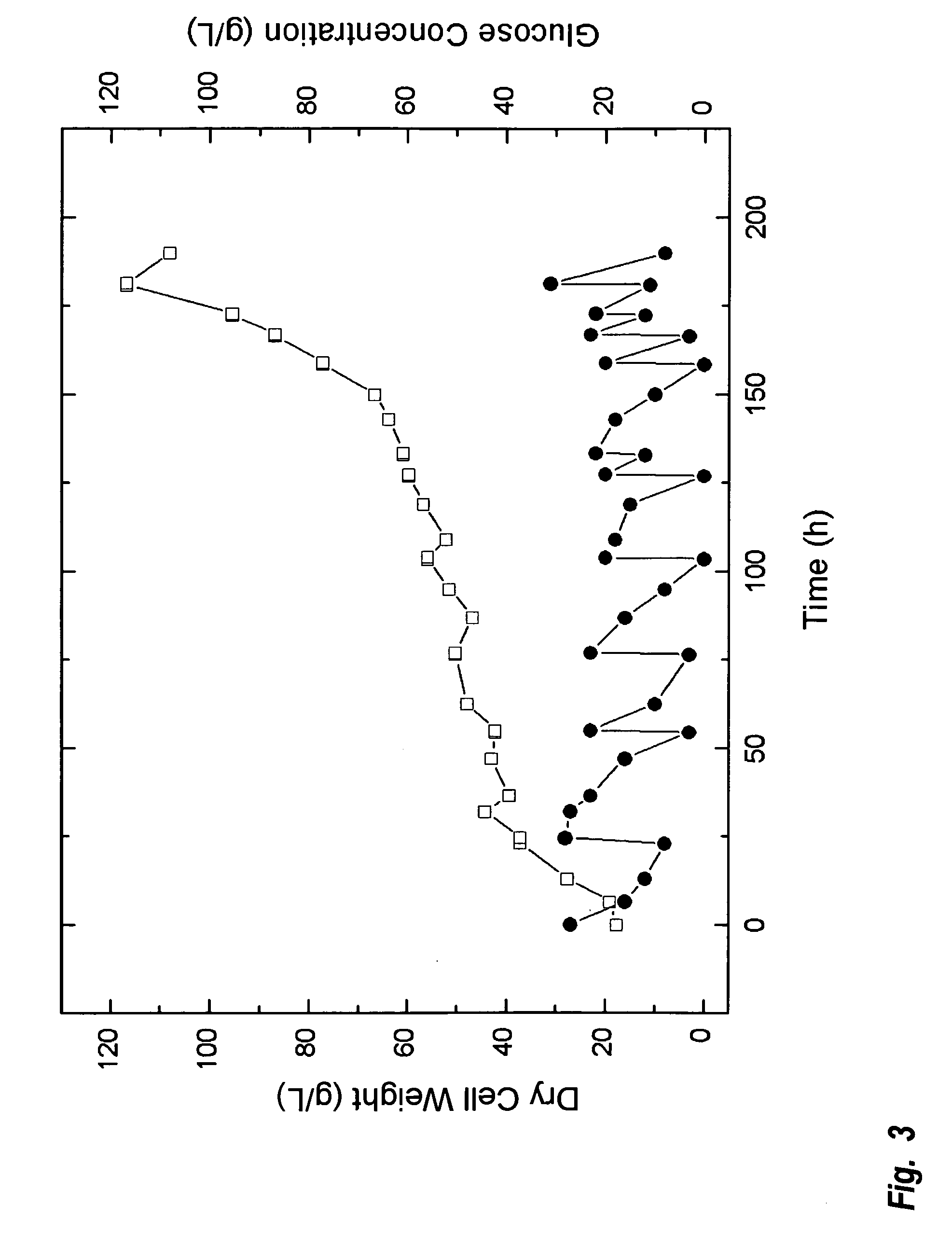

Method for producing biodiesel from an alga

InactiveUS20090298159A1Avoid Microbial ContaminationOrganic chemistryFatty acid esterificationMembrane lipid metabolismOrganism

A method is provided to produce biodiesel from algae using a two-stage, autotrophic and heterotrophic cultivations of chlorella for biodiesel production. This method includes a sequence of procedures: cultivating photoautotrophic algae, concentrating cells and then transferring them to a fermentor for heterotrophic cultivation. During the photoautotrophic cultivation stage, the culture is exposed to a light source, such as sunlight with carbon dioxide obtained from a carbon dioxide source or from air. antibacterial agents may be added to prevent contamination from undesired microorganisms. Organic carbons are added during heterotrophic cultivation stage. Fermentation conditions are optimized for maximizing lipid synthesis. High biomass is achieved to about 108 g / L with lipid content reaching about 52% of dry cell weight. After cultivation, biodiesel is made through extraction and transesterification of algae lipids.

Owner:TSINGHUA UNIV

Method of operating a wormgear drive at high energy efficiency

InactiveUS7045055B2Reducing traction coefficientGear lubrication/coolingToothed gearingsHigh energyFuel tank

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

Methods of hydrotreating a liquid stream to remove clogging compounds

A method includes producing formation fluid from a subsurface in situ heat treatment process. The formation fluid is separated to produce a liquid stream and a gas stream. At least a portion of the liquid stream is provided to a hydrotreating unit. At least a portion of selected in situ heat treatment clogging compositions in the liquid stream are removed to produce a hydrotreated liquid stream by hydrotreating at least a portion of the liquid stream at conditions sufficient to remove the selected in situ heat treatment clogging compositions.

Owner:SHELL OIL CO

Polyalphaolefin & fischer-tropsch derived lubricant base oil lubricant blends

InactiveUS20060199743A1Increase frictionImproved wear propertyTreatment with hydrotreatment processesAdditivesBase oilViscosity

Blended lubricant base oils and blended finished lubricants comprising ≧70 weight percent Fischer-Tropsch derived lubricant base oils comprising ≧6 weight % molecules with monocycloparaffinic functionality and less than 0.05 weight % molecules with aromatic functionality; at least one polyalphaolefin lubricant base oil with a kinematic viscosity at 100° C. greater than about 30 cSt and less than 150 cSt are provided. These blended lubricant base oils and blended finished lubricants exhibit superior friction and wear properties, in addition to other highly desired properties. Also provided are processes for making these blended lubricant base oils and blended finished lubricants.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com