Slurry dewatering and conversion of biosolids to a renewable fuel

a biosolids and slurry technology, applied in biological water/sewage treatment, combustion types, lighting and heating apparatuses, etc., can solve the problems of limited landfill gas, limited new sites, environmental opposition, etc., and achieve the effect of reducing the oxygen content of biosolids, reducing the risk of environmental pollution, and reducing the amount of was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

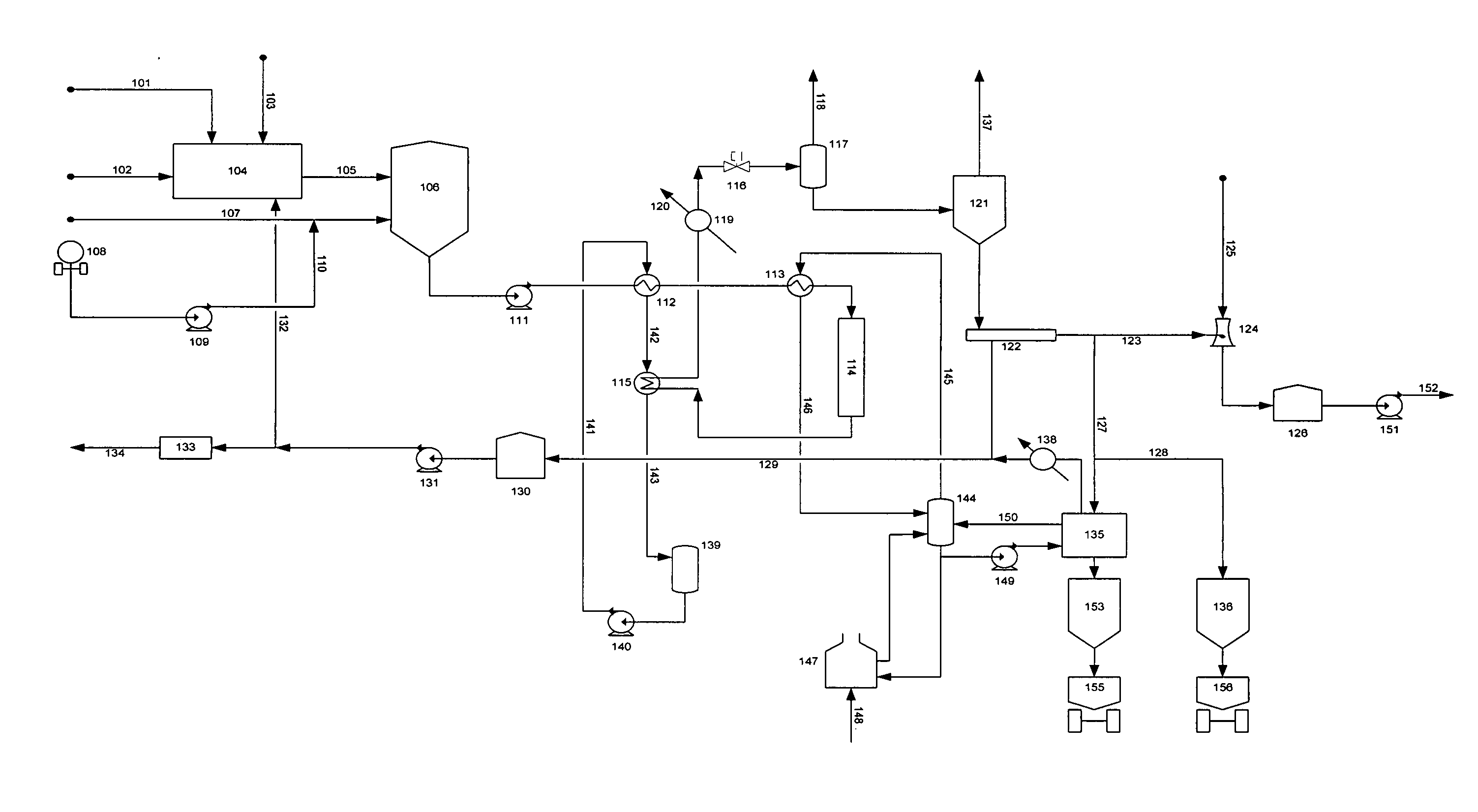

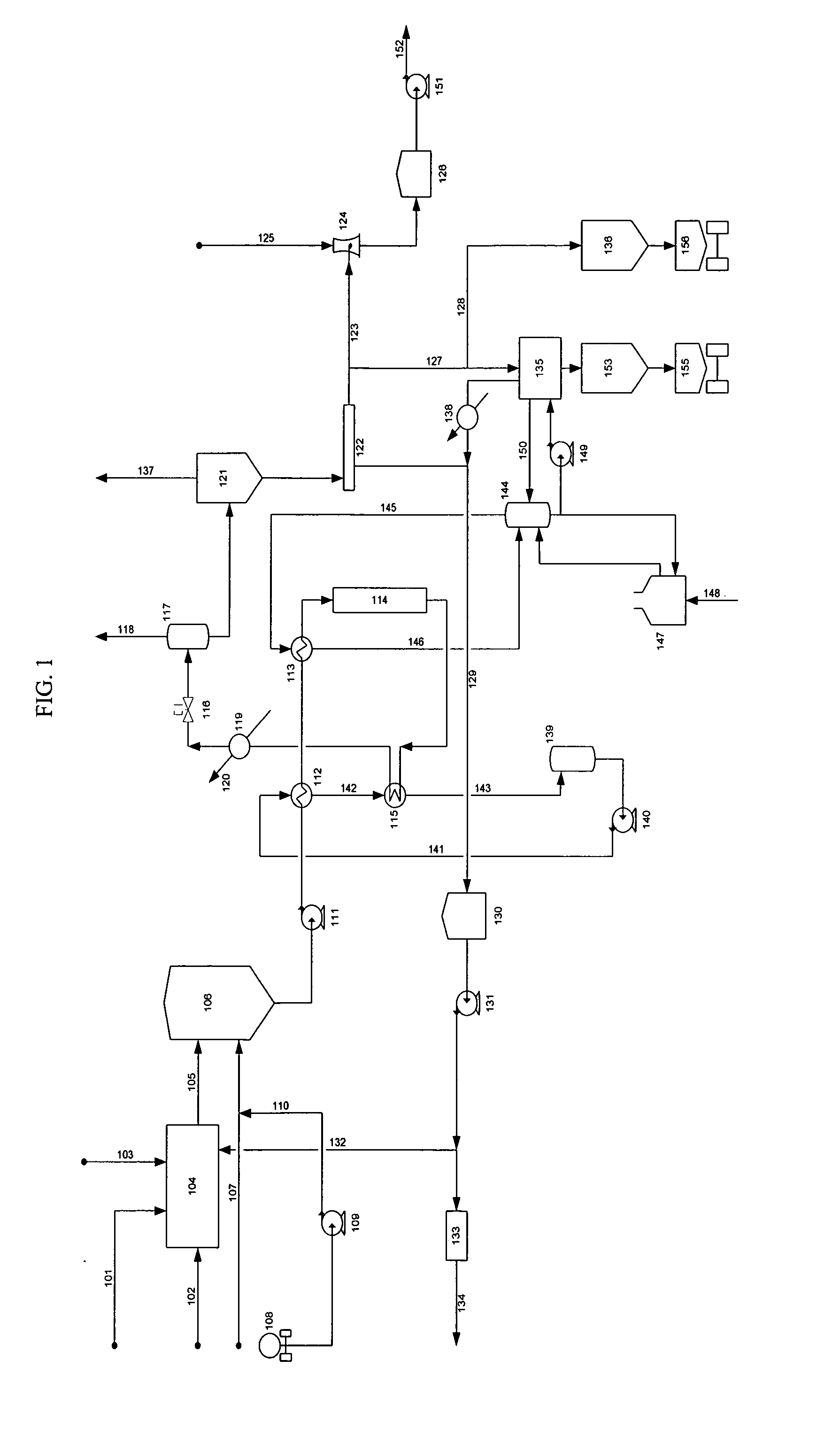

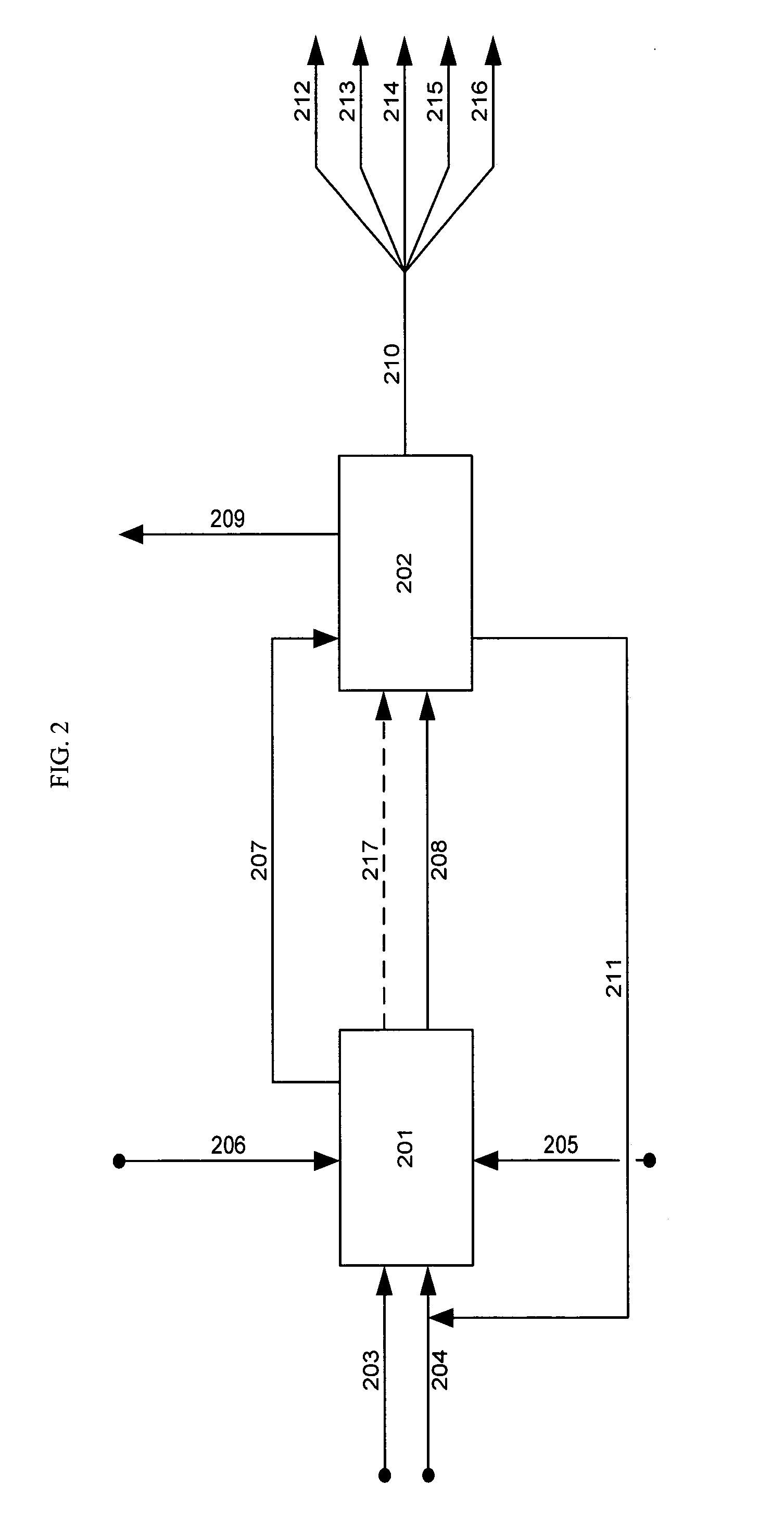

Method used

Image

Examples

example 1

[0112] Biosolids from two wastewater treatment plants, one in Atlanta, Ga., and one in Riverside, Calif., were subjected to the earlier described treatment in a continuous pilot plant, resulting in the following feed and product analyses, reported on a moisture and ash-free basis:

Atlanta RawRiverside RawBiosolidsBiosolidsCarbon57.7362.53Hydrogen7.489.26Nitrogen7.907.52Sulfur3.021.17Oxygen23.8619.52Total100.00100.00

[0113]

Atlanta CharRiversideProductChar ProductCarbon70.1969.98Hydrogen8.857.68Nitrogen8.638.45Sulfur1.428.86Oxygen10.915.04Total100.00100.00

[0114] As would be expected, the splitting off of carbon dioxide has resulted in an increase in carbon content and a corresponding decrease in oxygen content.

[0115] The off-gas composition of the two runs was as follows:

Atlanta OffRiverside OffGasGasCarbon Dioxide89.7%92.8%Volatile Organics10.0%6.0%Sulfur Compounds0.3%1.2%Total100.0%100.0%

theoretical example 1

[0116] A cement kiln in the southwestern U.S. has a production capacity of 3,200 tons / day. To reach temperatures required to form cement “clinker”, it fires low-grade coal, supplemented to some extent by charging scrap rubber tires. Sensible heat in the flue gas, after preheating mineral charge and combustion air, may be taken advantage of to dry and incinerate 20 tons / day (dry basis) of biosolids from area wastewater treatment plants. Although every ton of dry biosolids constituents is accompanied by about four tons of water (giving the biosolids a negative heating value), revenue from the tipping fee offsets the cost of extra coal that must be fired. However, the amount is limited by the thermal capacity to evaporate the water and by the increased volume of flue gas, increasing pressure drop and fan horsepower.

[0117] Using this invention, the kiln may use biosolids dewatered and deoxidized in accordance with the present invention at one or more of the nearby WWTPs. As such, about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com