Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2472results about "After-treatment apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas distribution plate fabricated from a solid yttrium oxide-comprising substrate

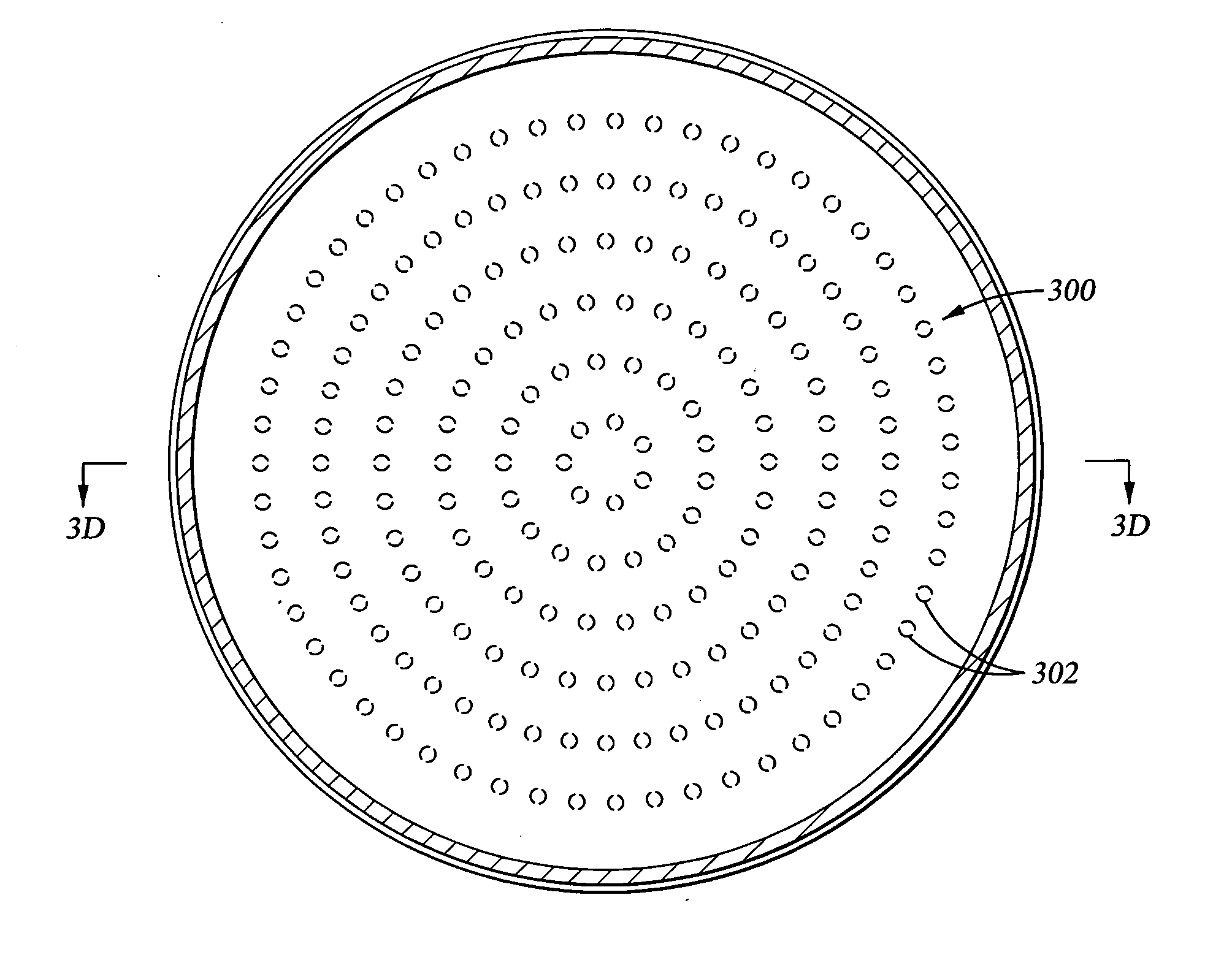

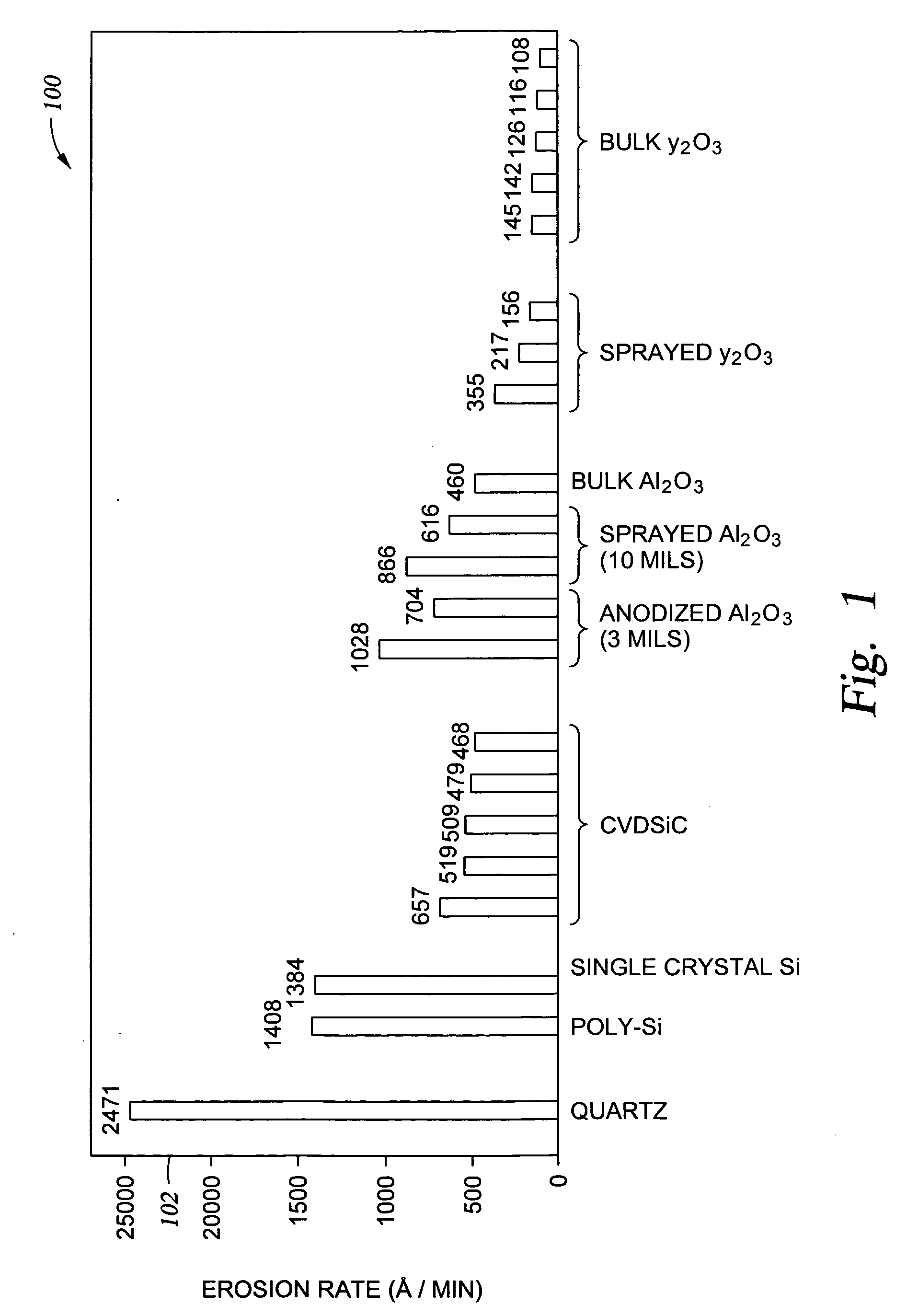

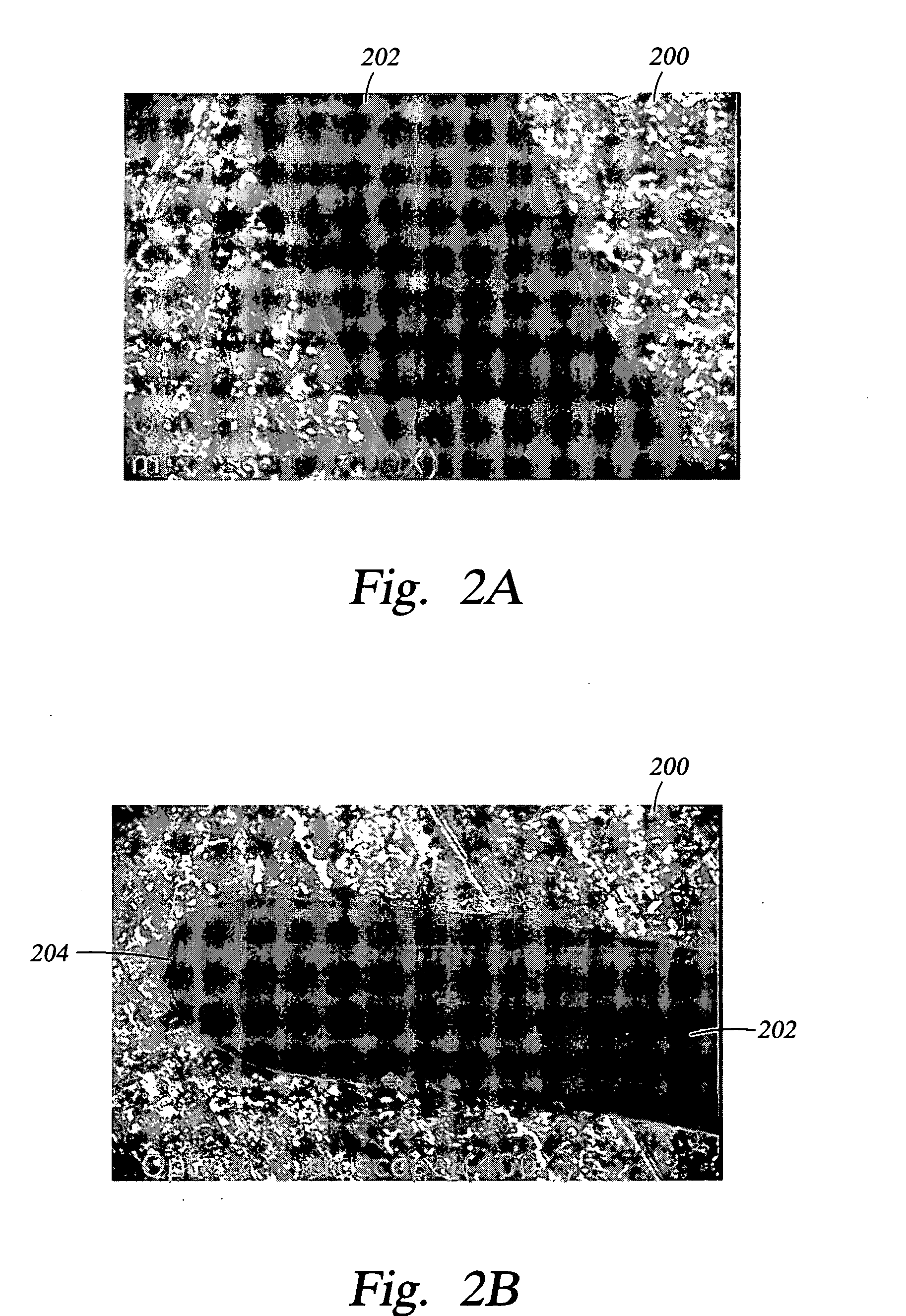

InactiveUS20050056218A1Extended service lifePromote resultsAfter-treatment apparatusElectric discharge tubesVolumetric Mass DensityYttrium

Disclosed herein is a gas distribution plate for use in a gas distribution assembly for a processing chamber, where the gas distribution plate is fabricated from a solid yttrium oxide-comprising substrate, which may also include aluminum oxide. The gas distribution plate includes a plurality of through-holes, which are typically crescent-shaped. Through-holes which have been formed in the solid yttrium oxide-comprising substrate by ultrasonic drilling perform particularly well. The solid yttrium oxide-comprising substrate-typically comprises at least 99.9% yttrium oxide, and has a density of at least 4.92 g / cm3, a water absorbency of about 0.02% or less, and an average grain size within the range of about 10 μm to about 25 μm. Also disclosed herein are methods for fabricating and cleaning the yttrium oxide-comprising gas distribution plate.

Owner:APPLIED MATERIALS INC

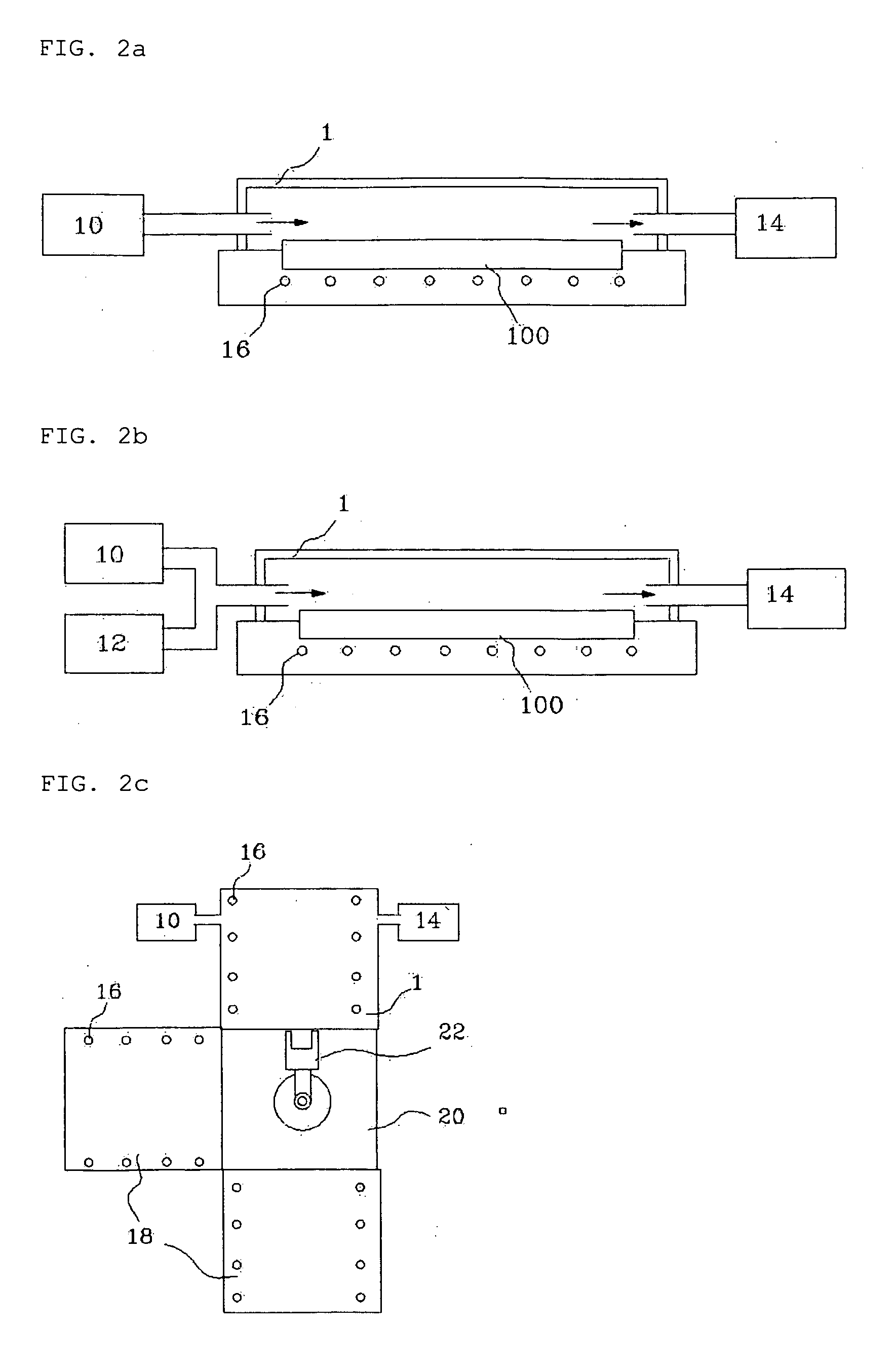

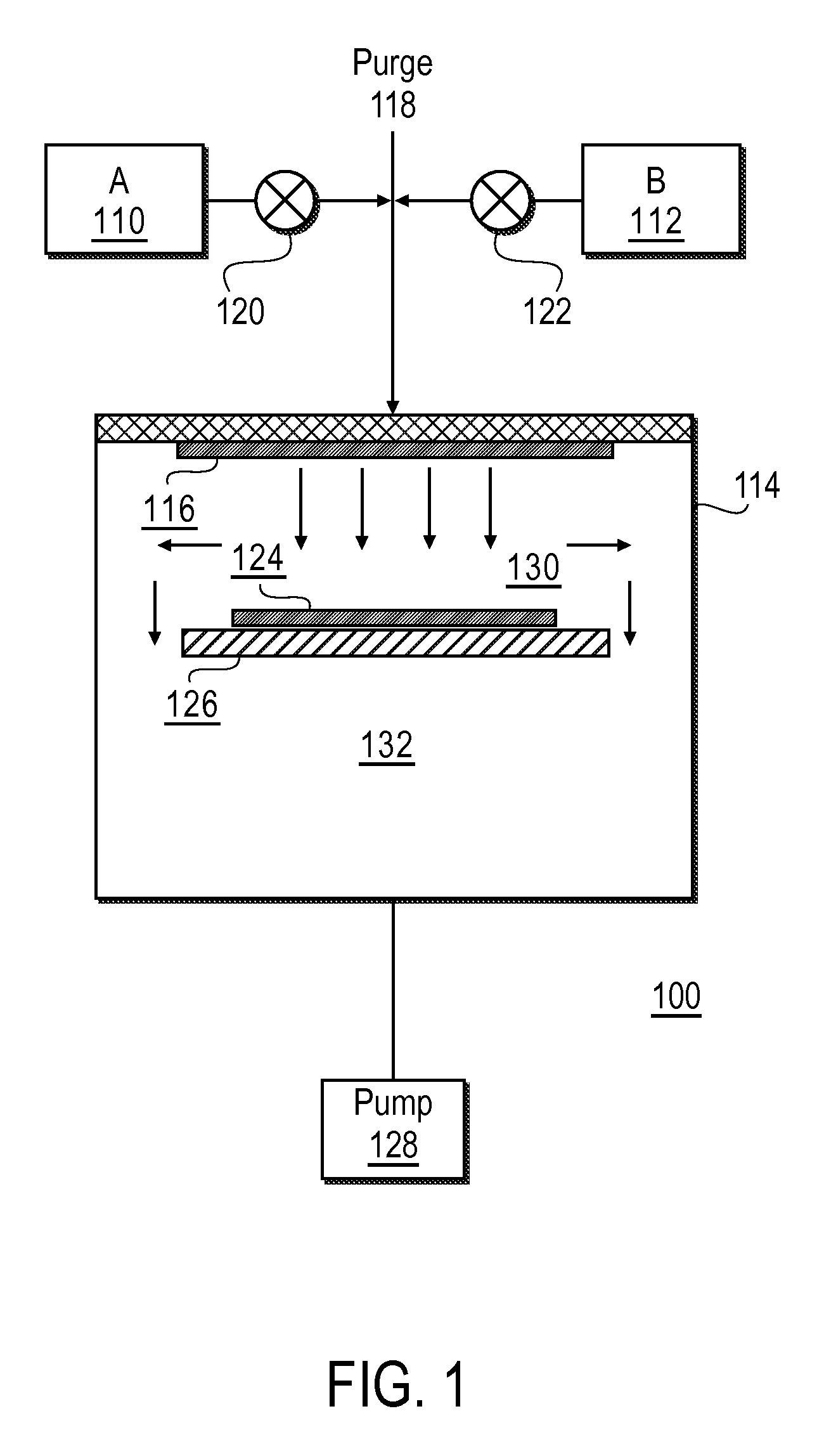

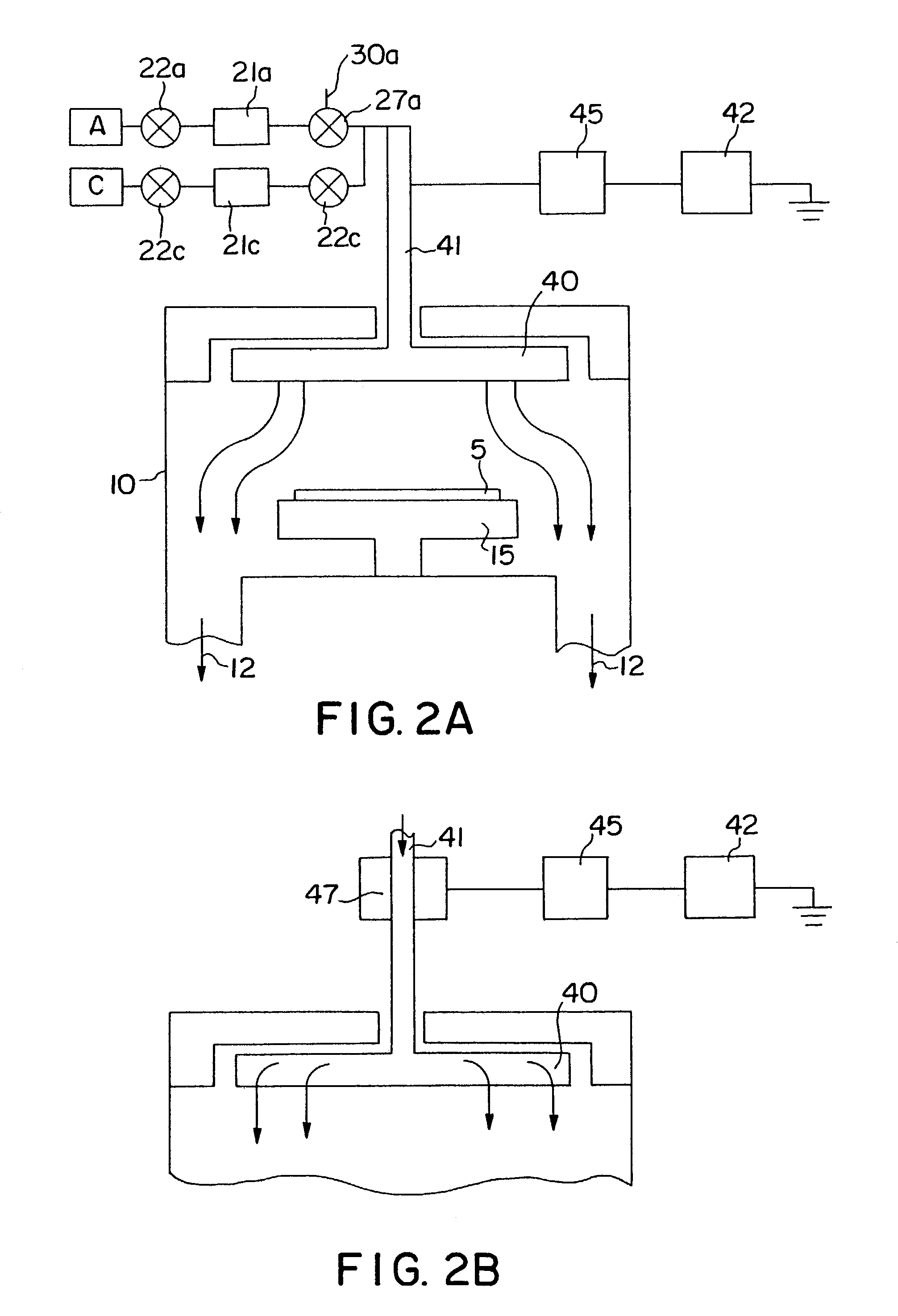

Reaction system for growing a thin film

ActiveUS20060266289A1Easy to cleanEliminates and significantly reduces dead pocketAfter-treatment apparatusSemiconductor/solid-state device manufacturingEngineeringReaction system

An atomic deposition (ALD) thin film deposition apparatus includes a deposition chamber configured to deposit a thin film on a wafer mounted within a space defined therein. The deposition chamber comprises a gas inlet that is in communication with the space. A gas system is configured to deliver gas to the gas inlet of the deposition chamber. At least a portion of the gas system is positioned above the deposition chamber. The gas system includes a mixer configured to mix a plurality of gas streams. A transfer member is in fluid communication with the mixer and the gas inlet. The transfer member comprising a pair of horizontally divergent walls configured to spread the gas in a horizontal direction before entering the gas inlet.

Owner:ASM IP HLDG BV

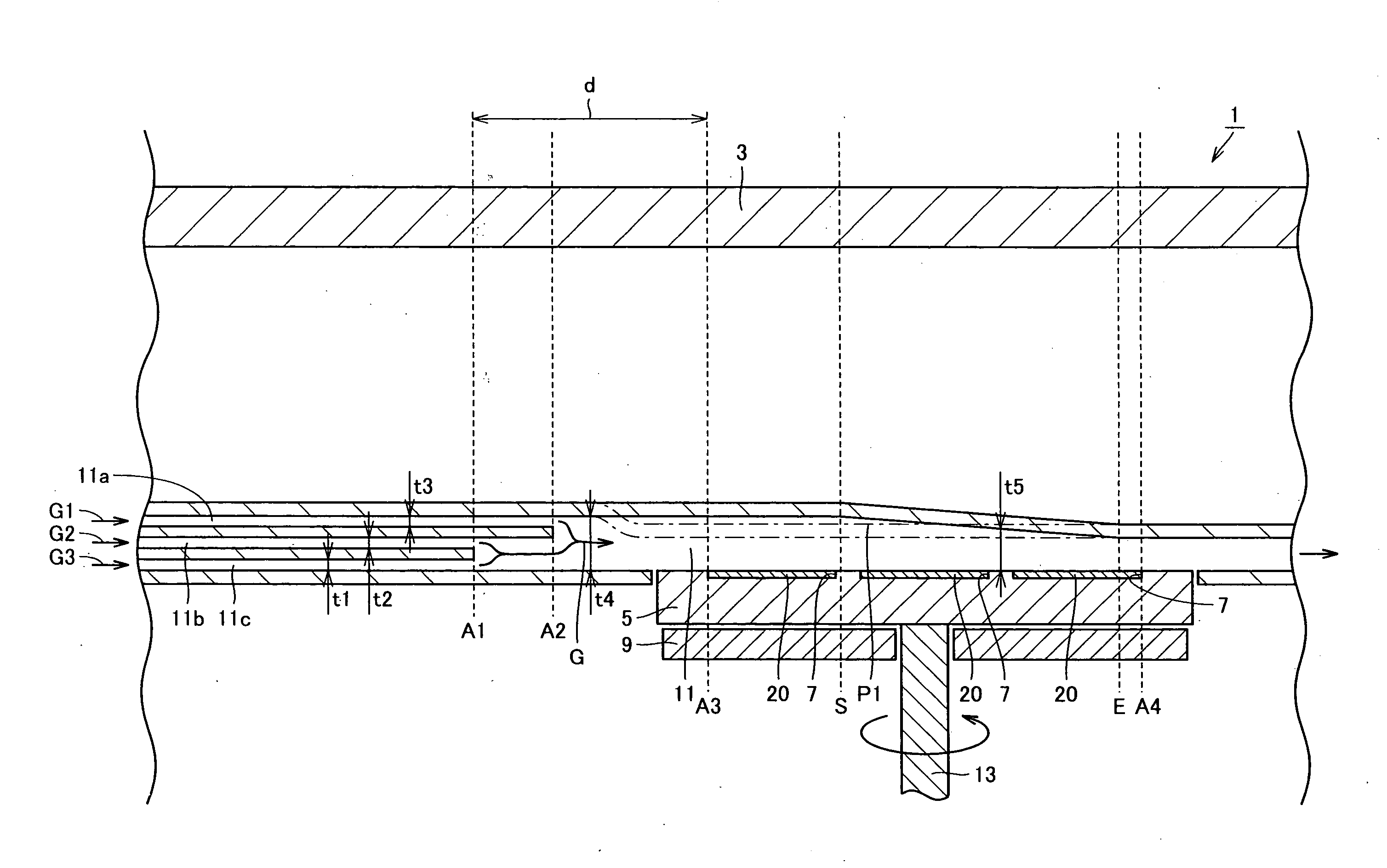

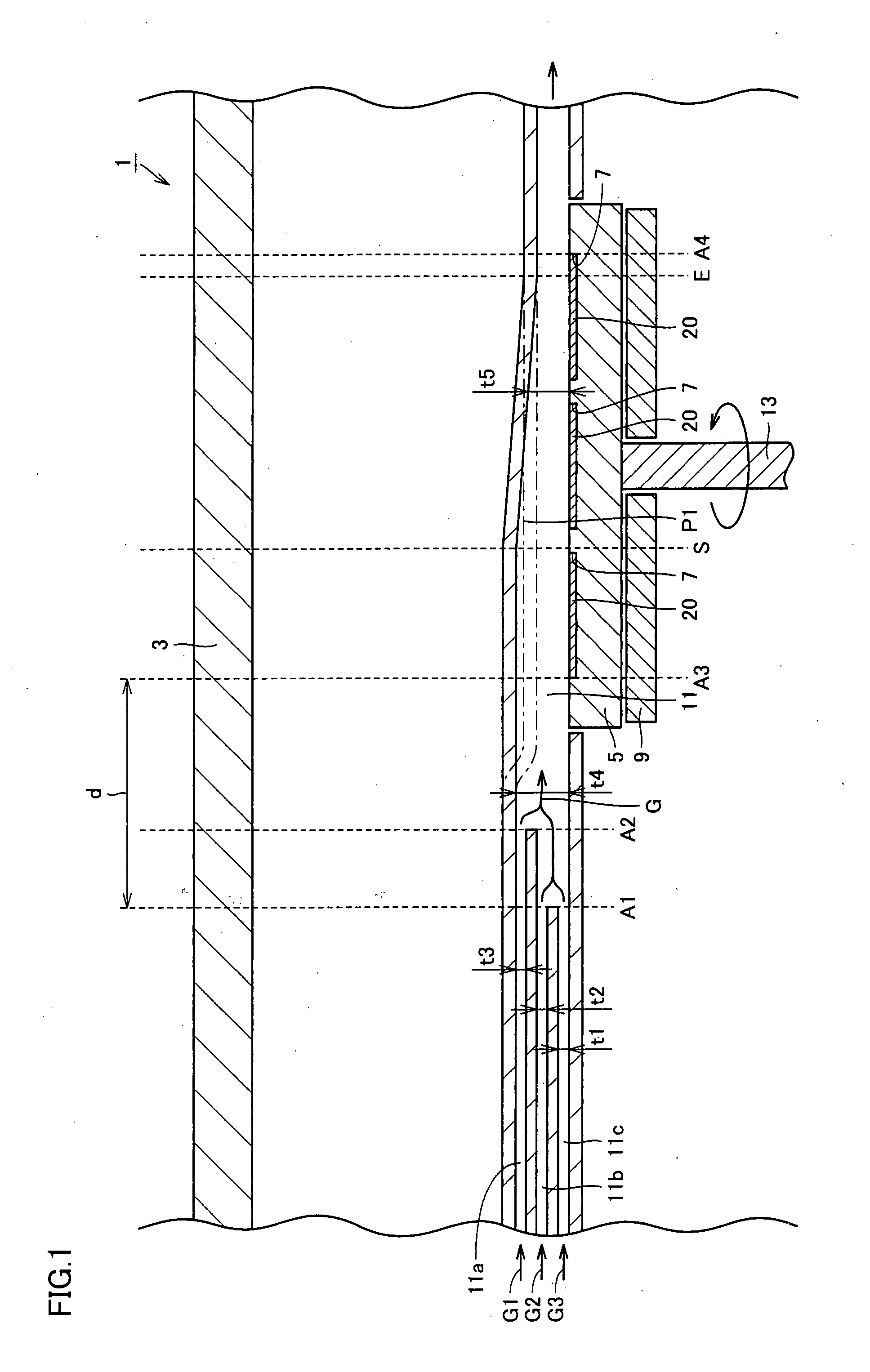

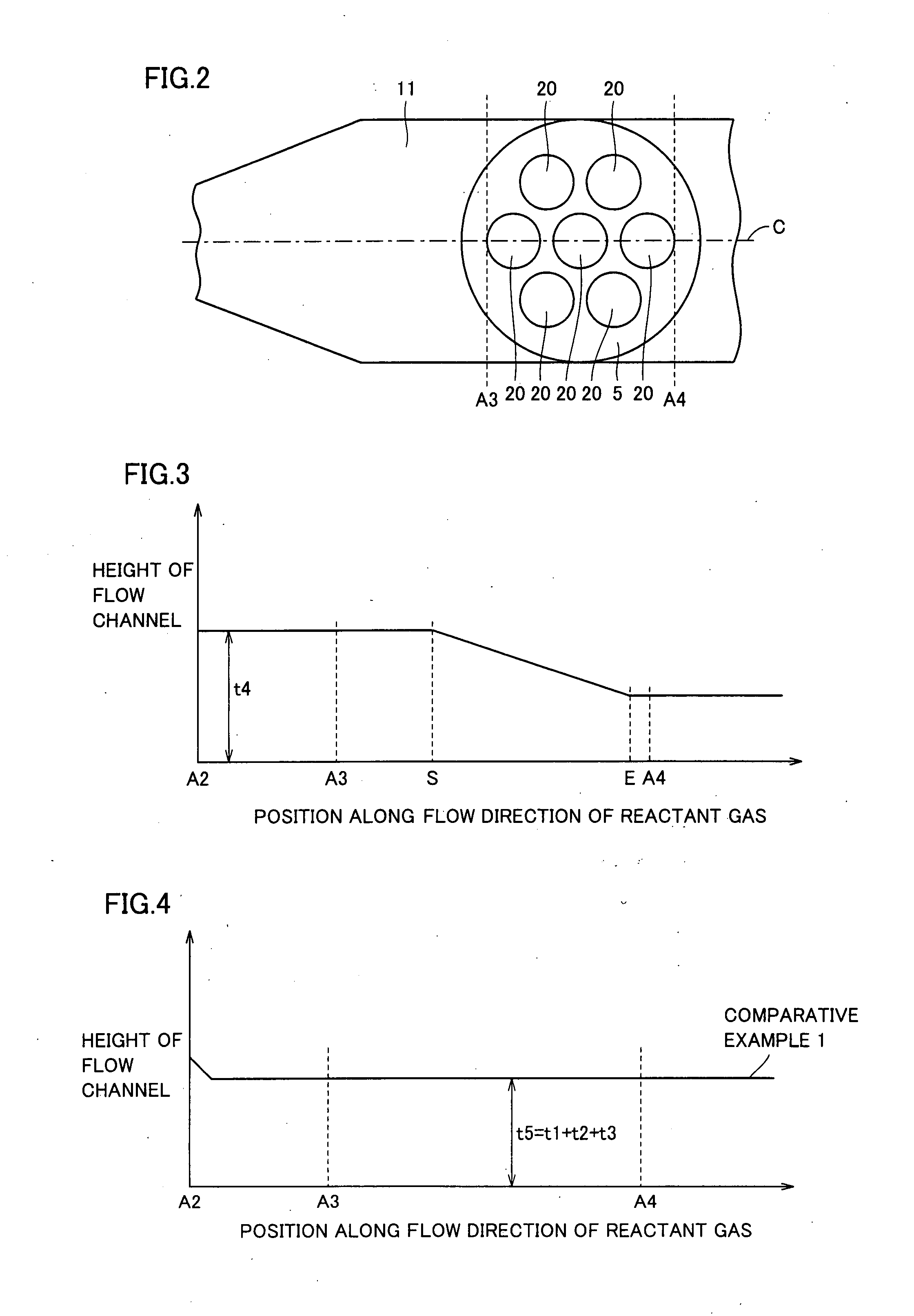

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

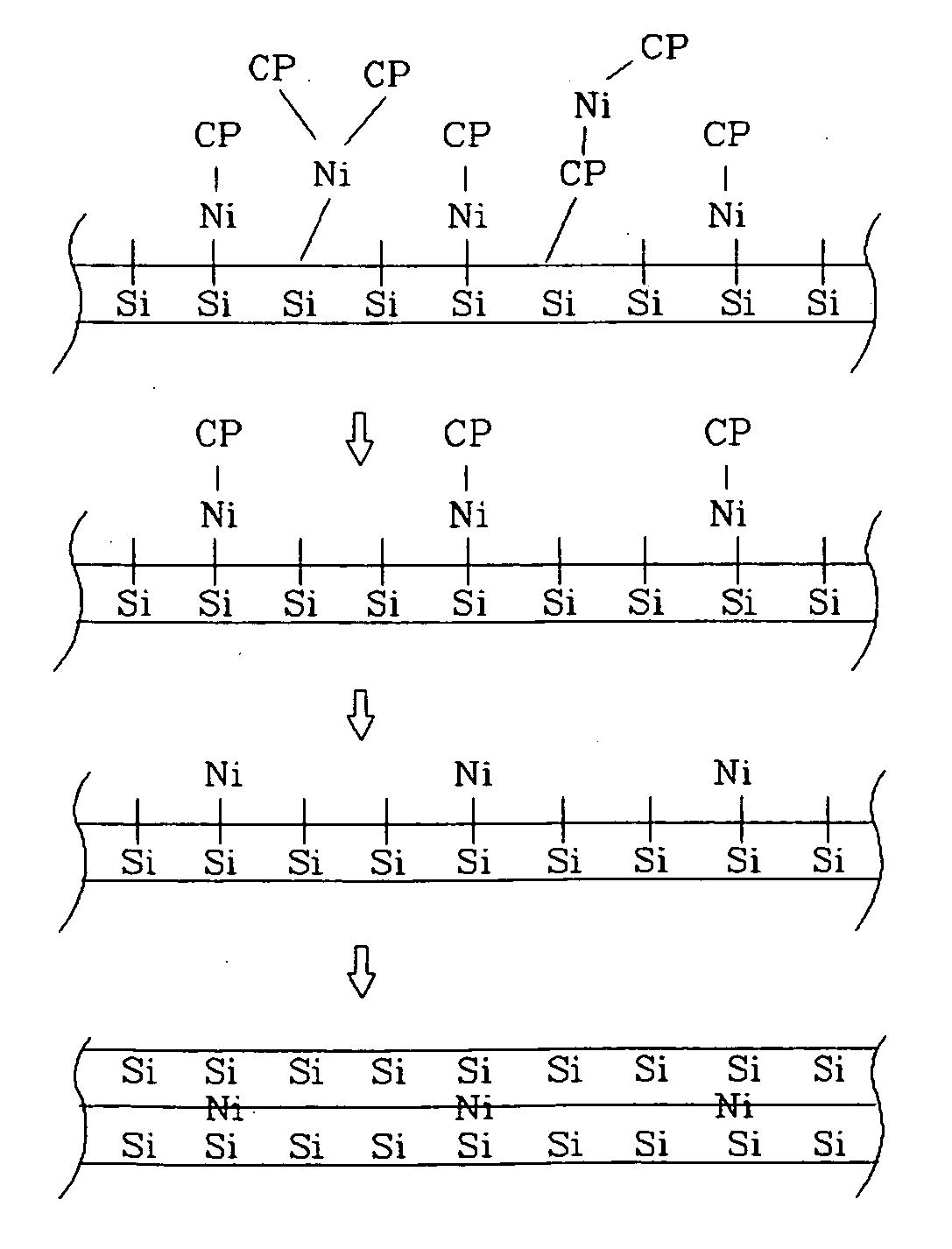

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

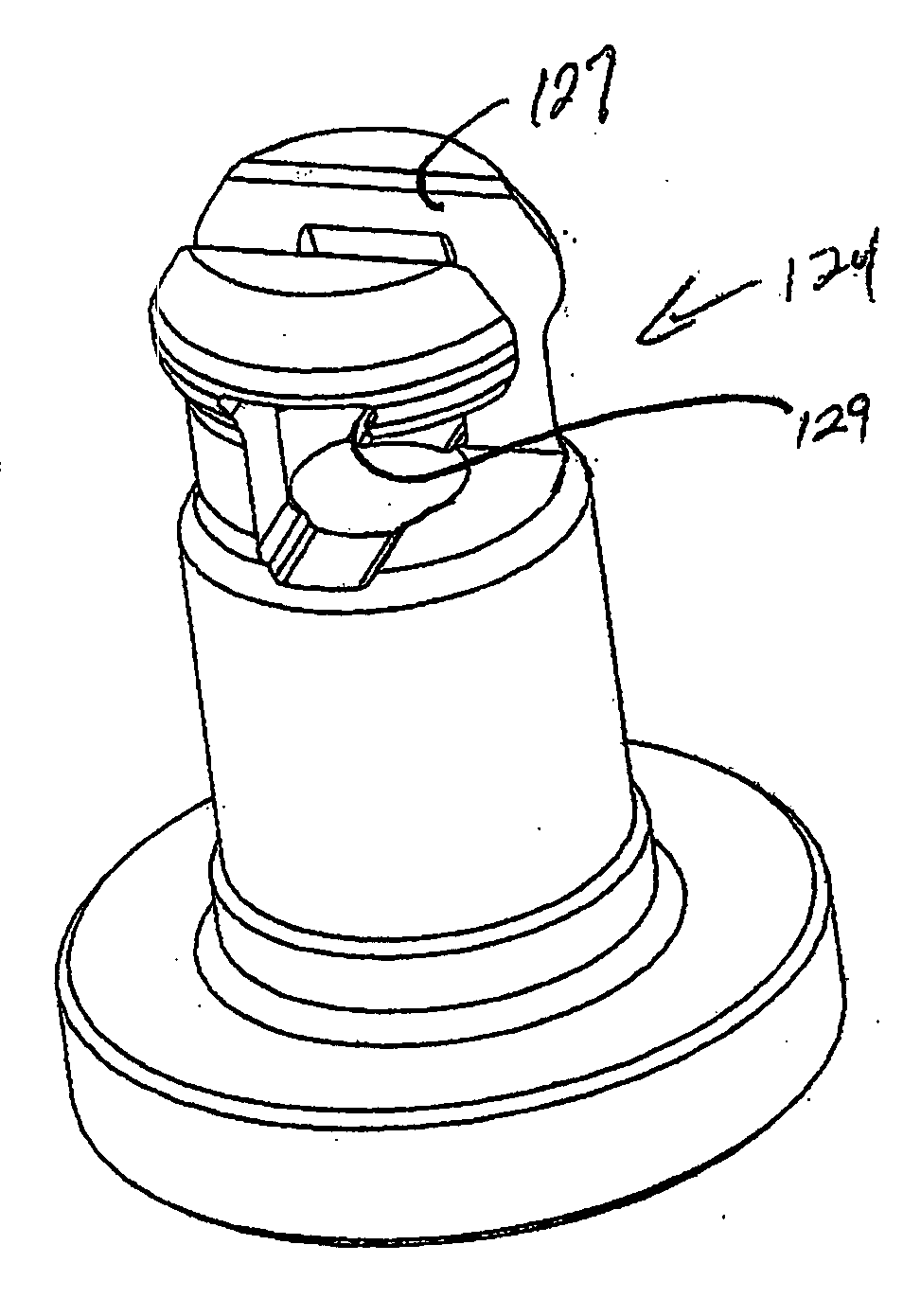

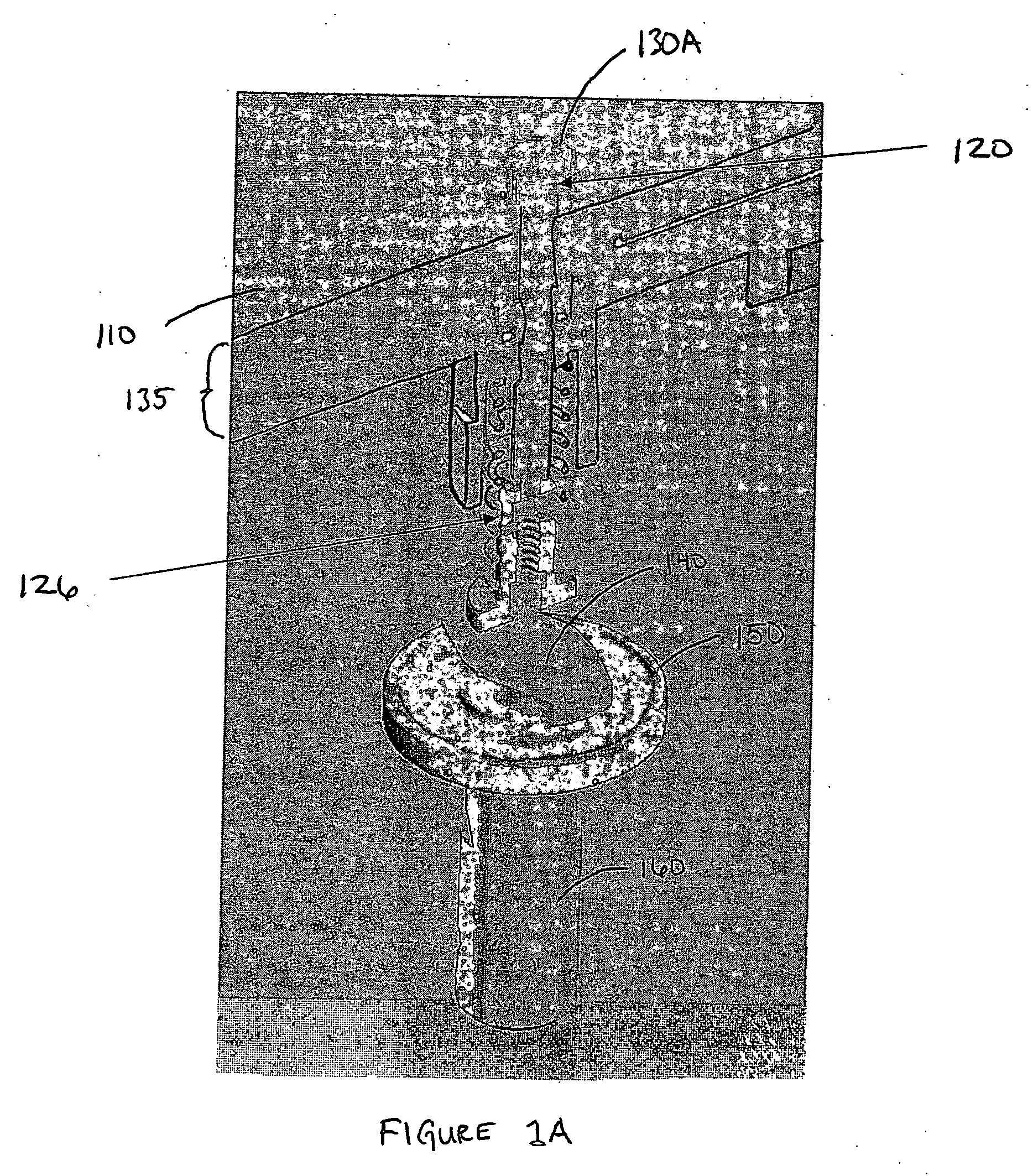

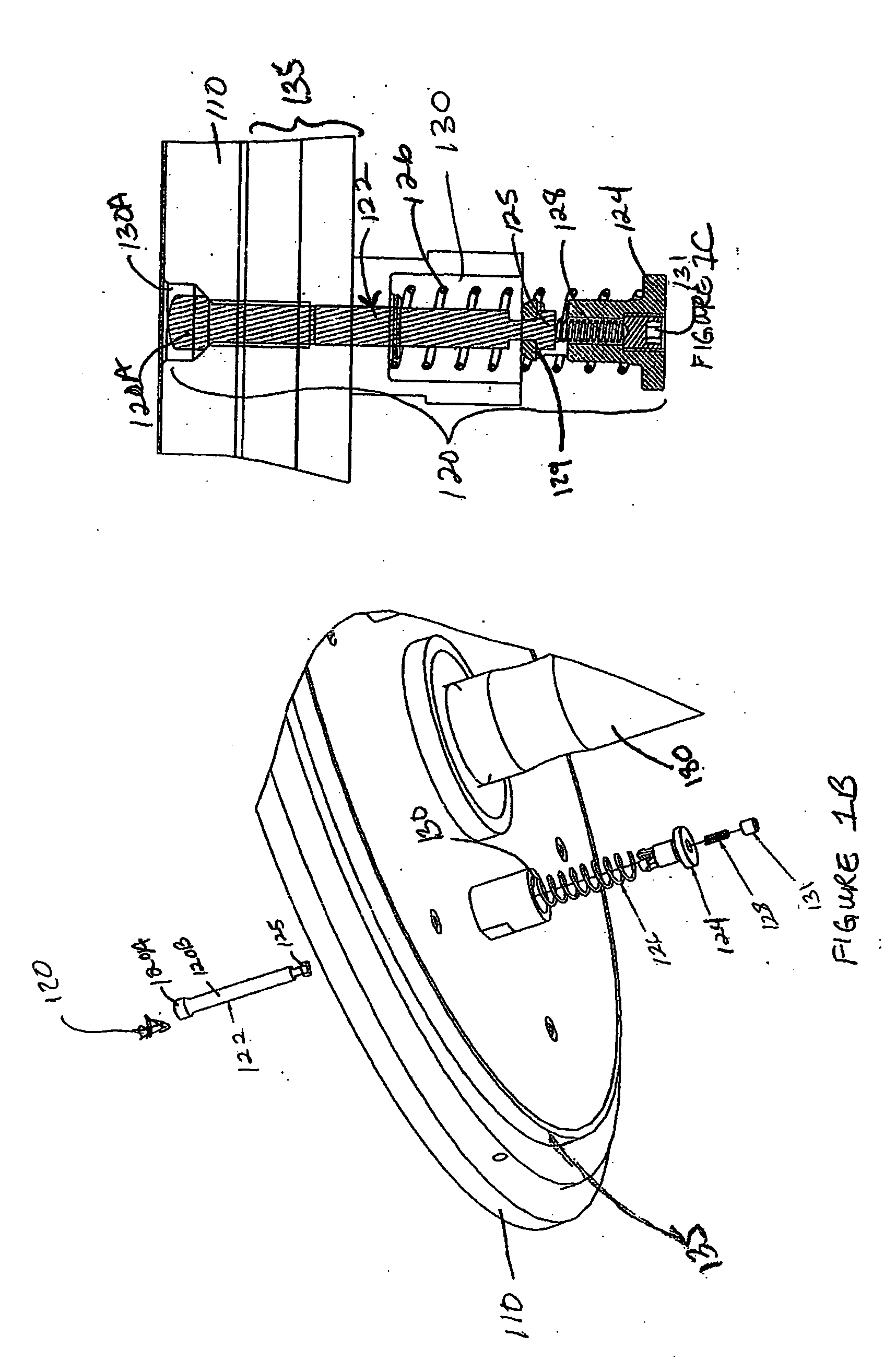

Wafer support pin assembly

InactiveUS20060156981A1After-treatment apparatusSemiconductor/solid-state device manufacturingSusceptorFast release

A semiconductor wafer support pin assembly. A susceptor has at least three support pins configured to raise a wafer above the top surface of the susceptor. Each support pin includes and upper pin and a lower pin, which lock together by means of a quick-release mechanism in the form of a bayonet mount. The upper pin is made of a non-metallic material, such as polybenzimidazole. The susceptor is driven up and down by a lifting mechanism, driven by an electric motor or pneumatic cylinder. The susceptor moves up and down, relative to the support pins.

Owner:ASM AMERICA INC

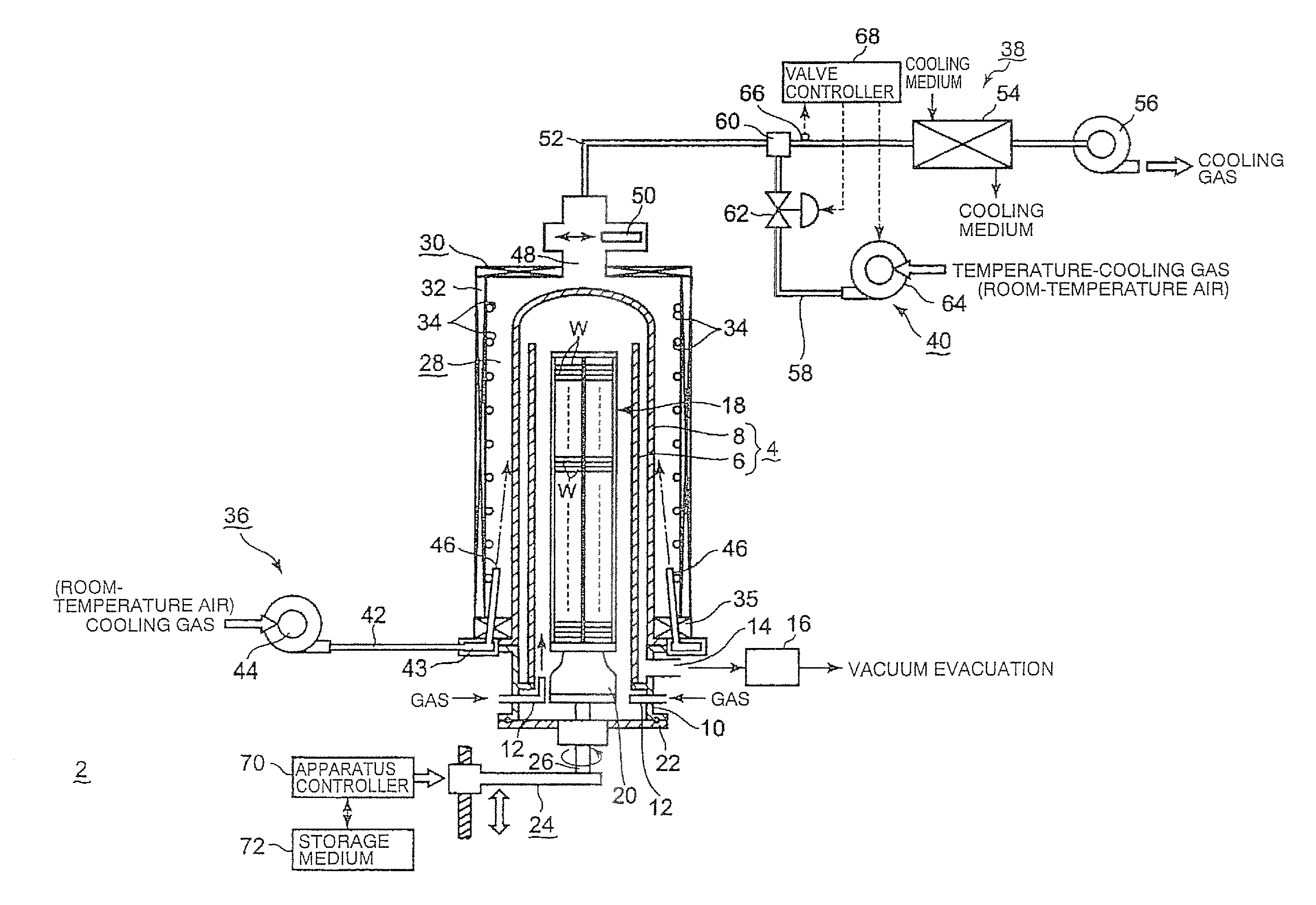

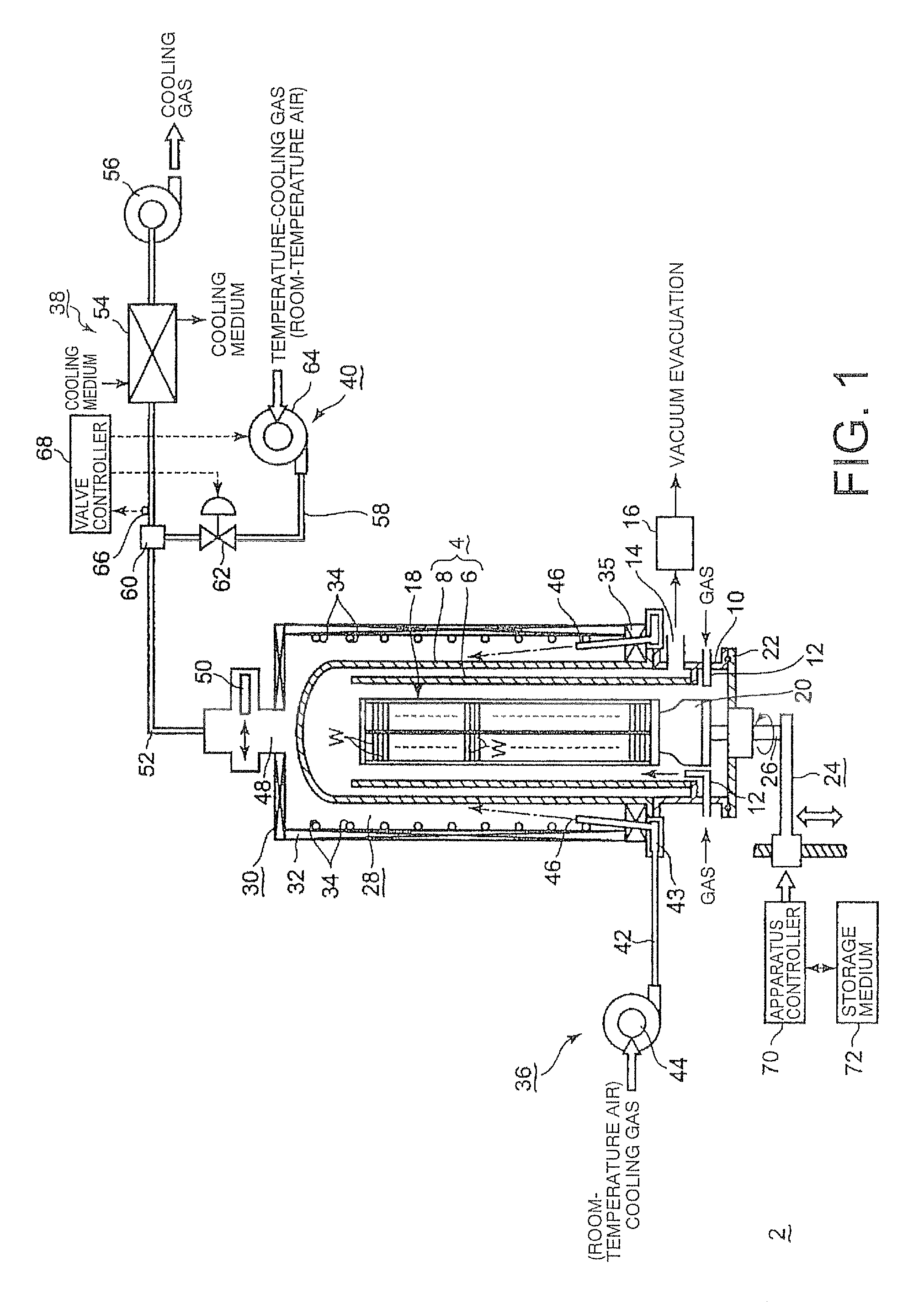

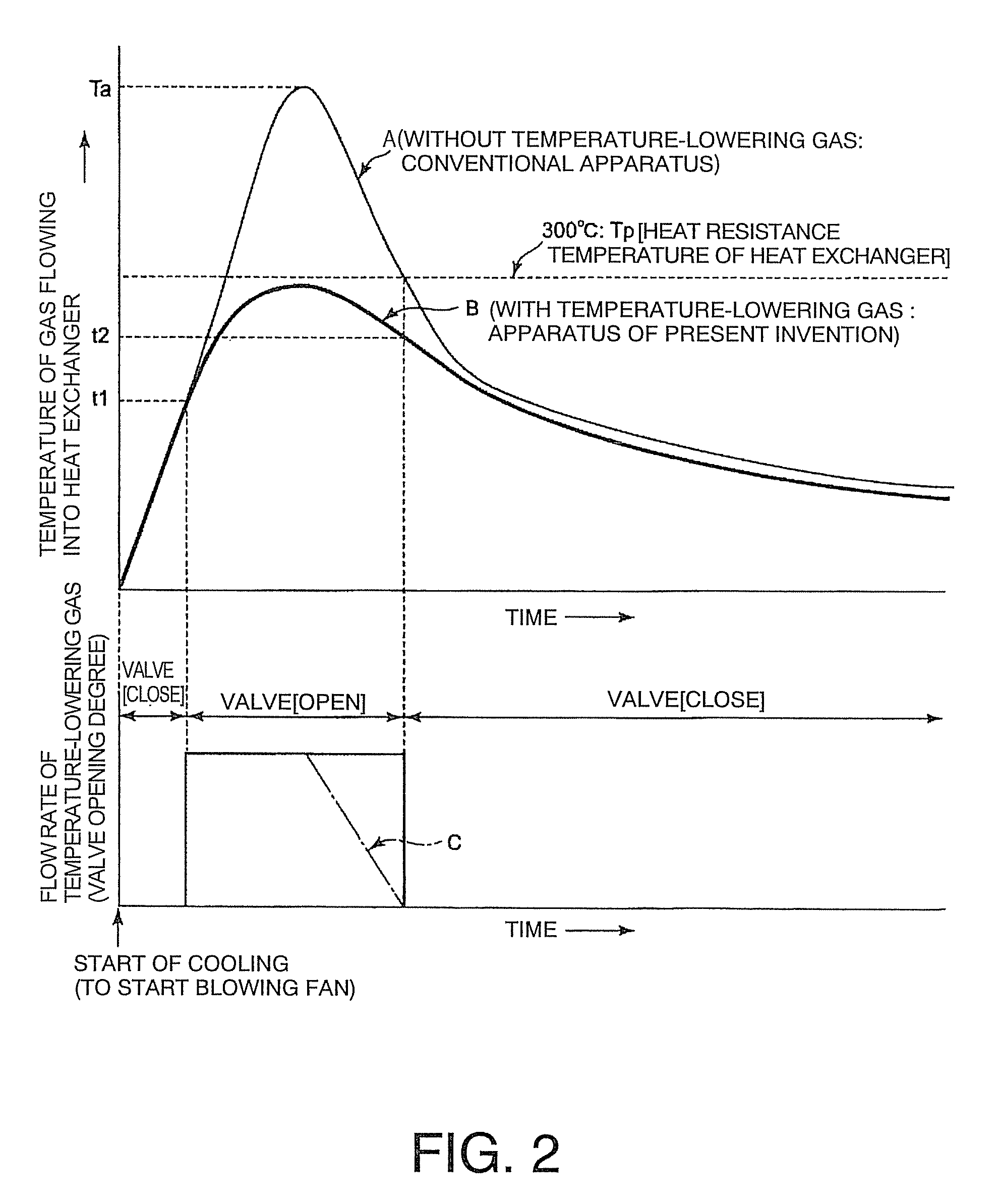

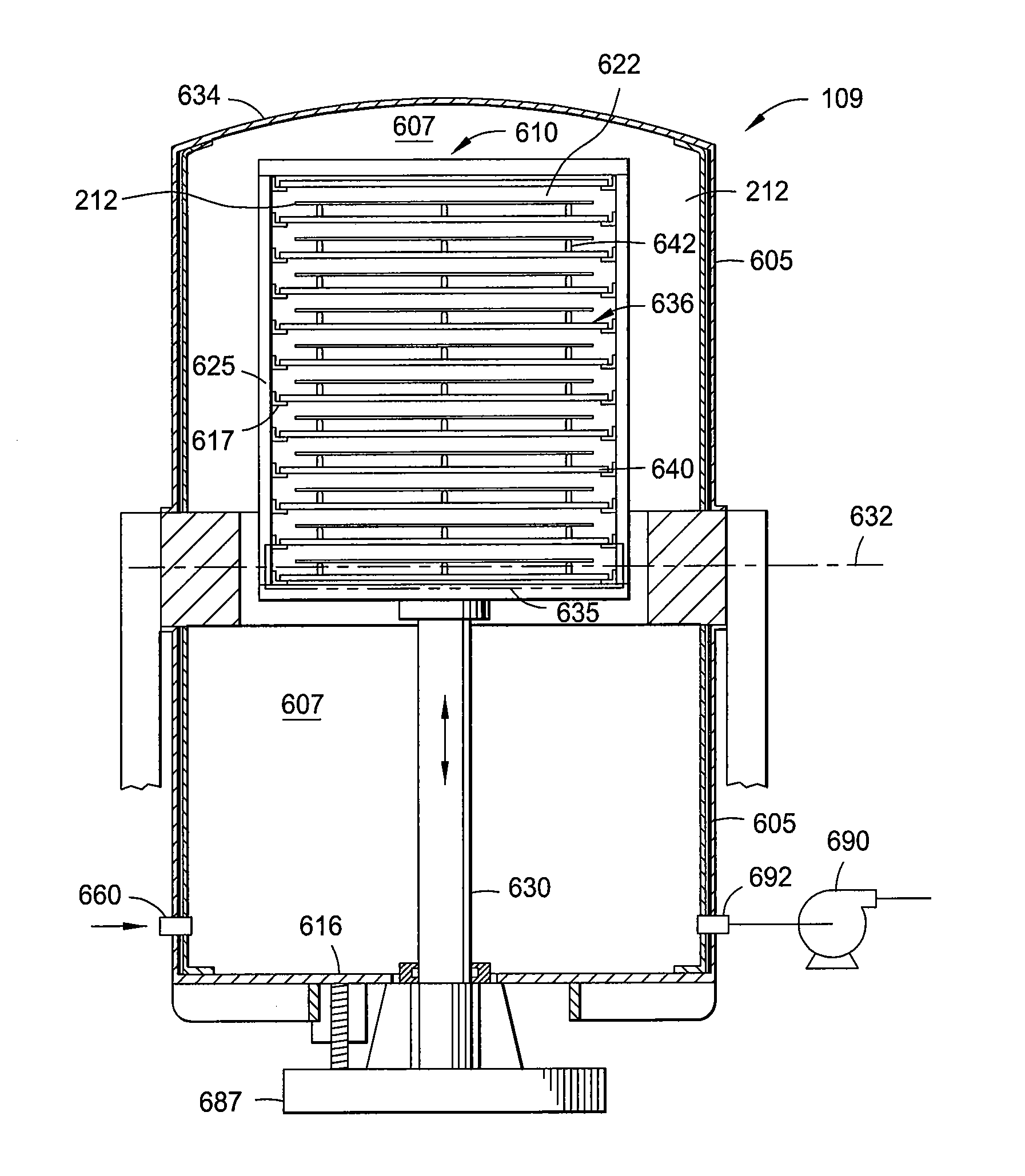

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

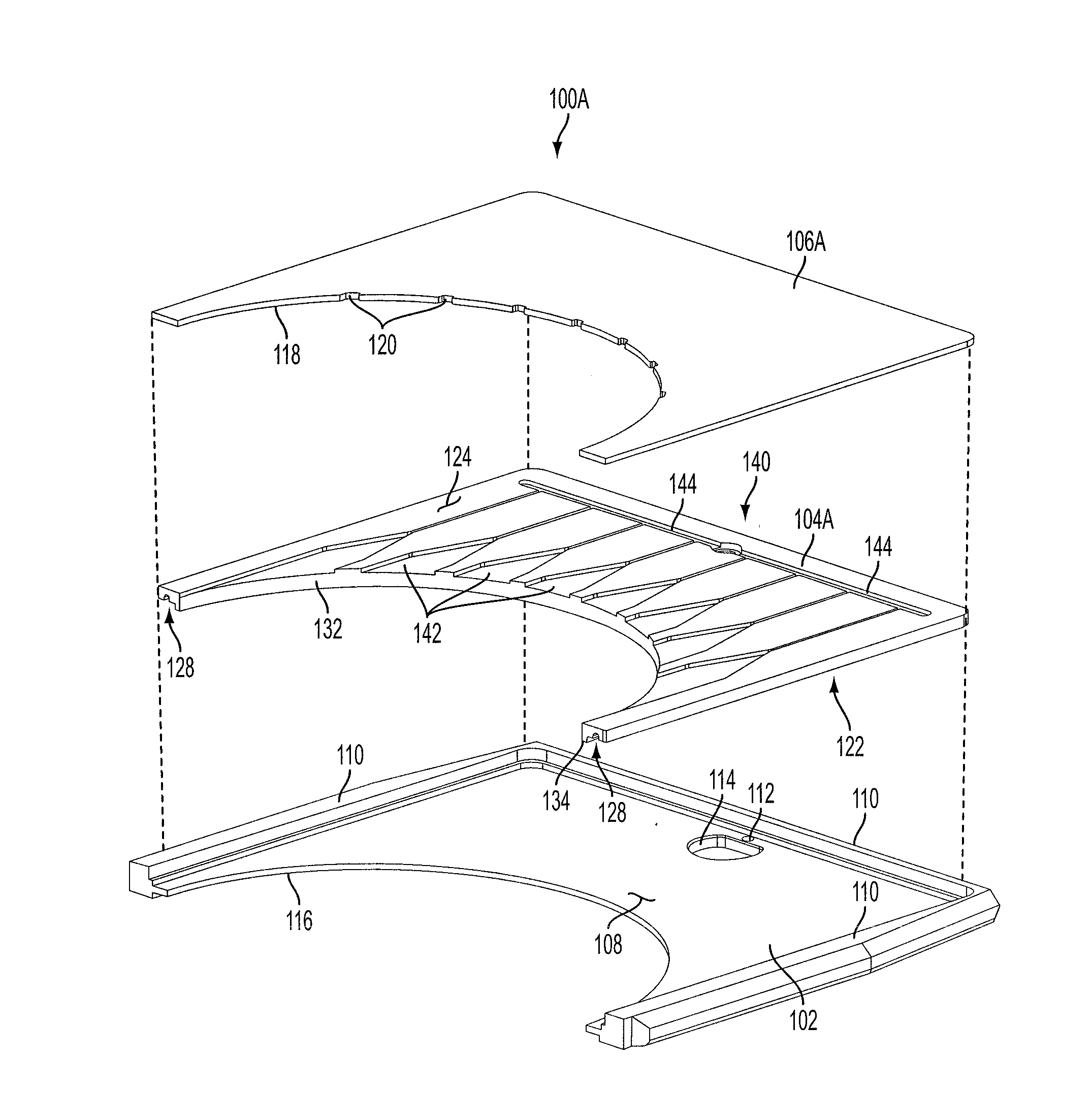

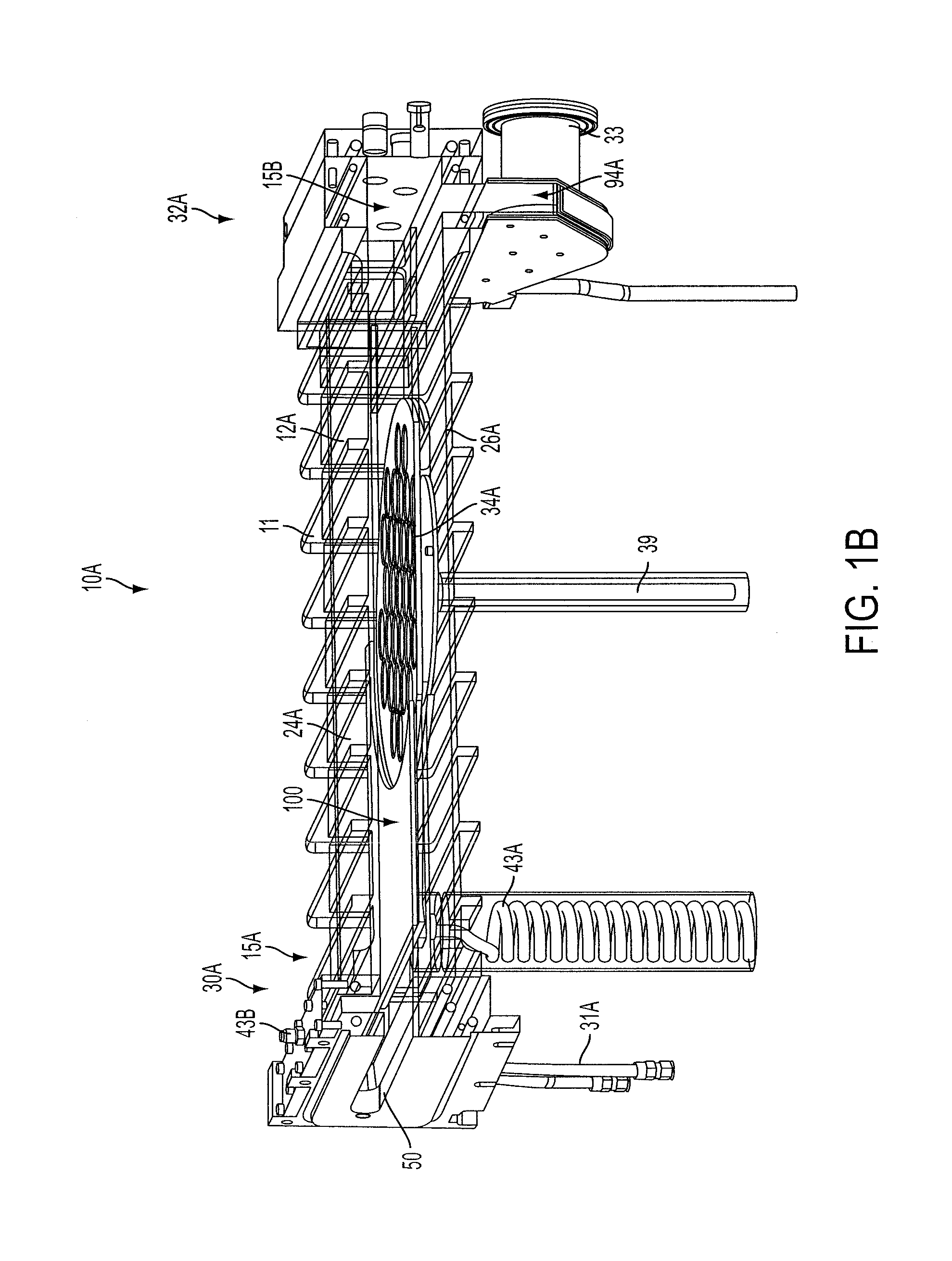

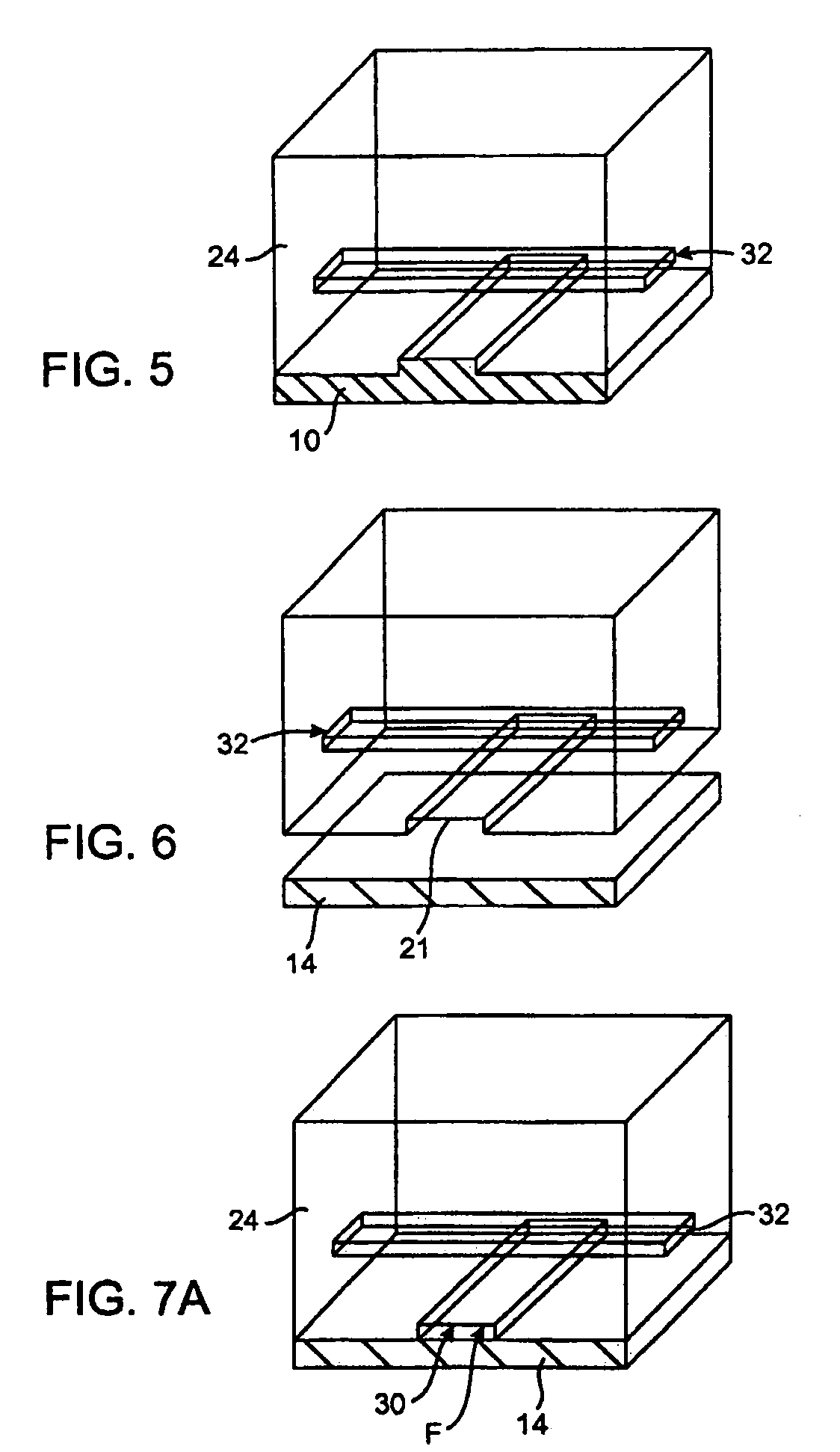

Deposition systems having interchangeable gas injectors and related methods

InactiveUS20150292088A1After-treatment apparatusPolycrystalline material growthGas syringeEngineering

A deposition system includes two or more gas injectors that may be interchangeably used in a chamber of the deposition system. Each of the gas injectors may be configured to generate a sheet of flowing gas over a substrate support structure. The sheets may have differing widths, such that the gas injectors may be used with substrates having different diameters, which may enable use of the system with different substrates while maintaining efficient use of precursor gas. A method of forming such a deposition system includes forming and configuring such gas injectors to be interchangeably used at a common location within the deposition chamber. A method of using such a deposition system includes using two or more such gas injectors to deposit material on substrates having different sizes.

Owner:SOITEC SA

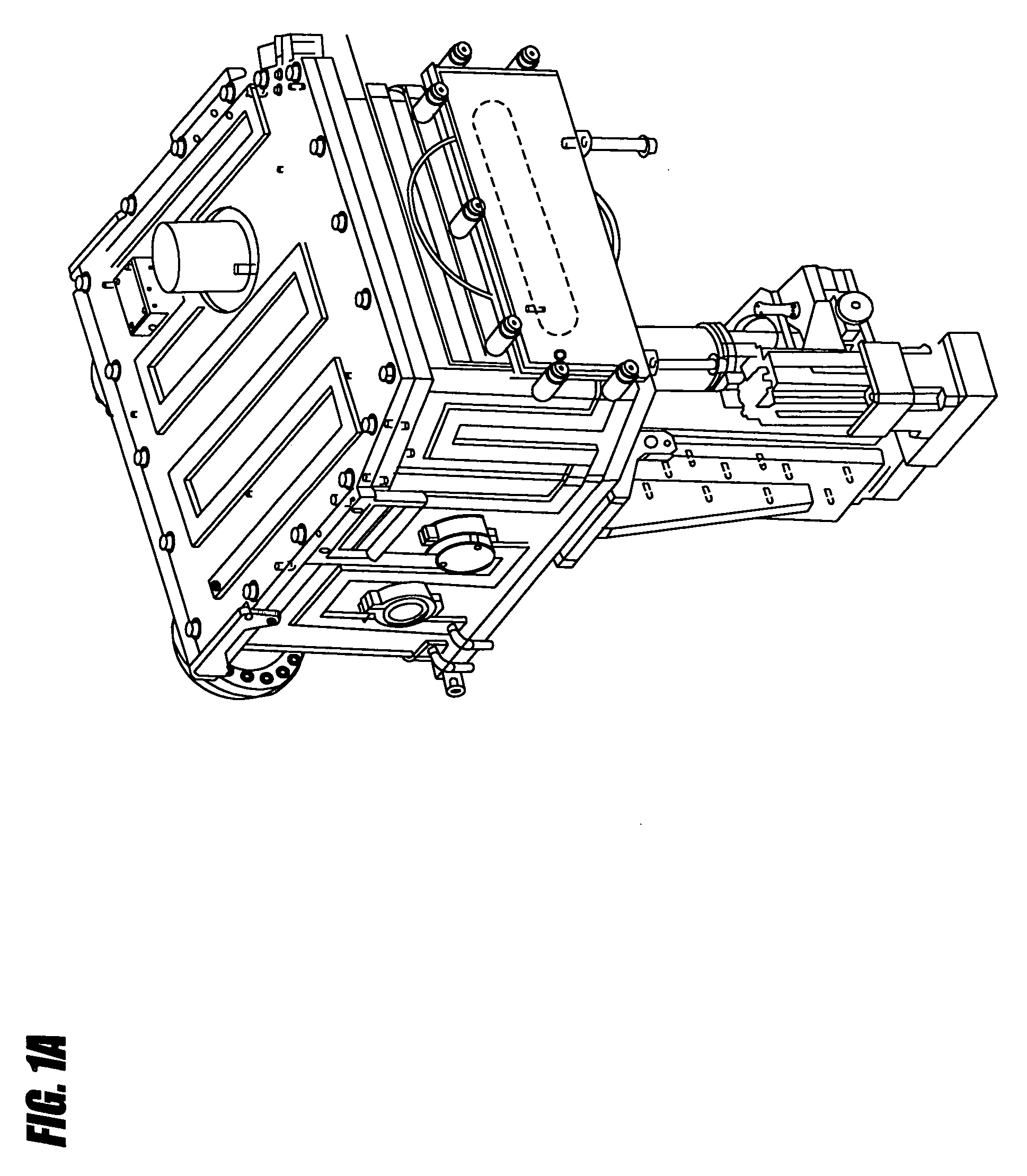

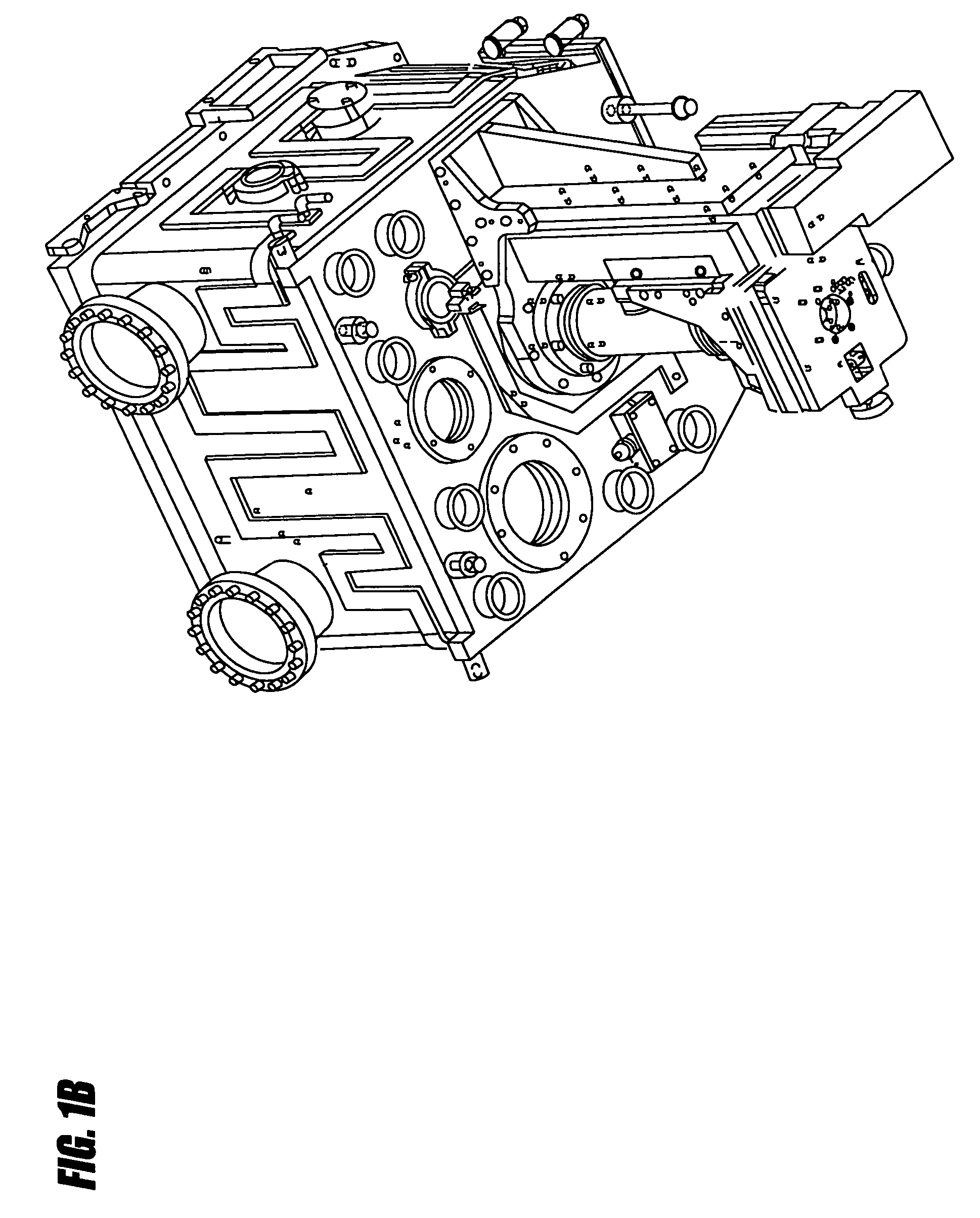

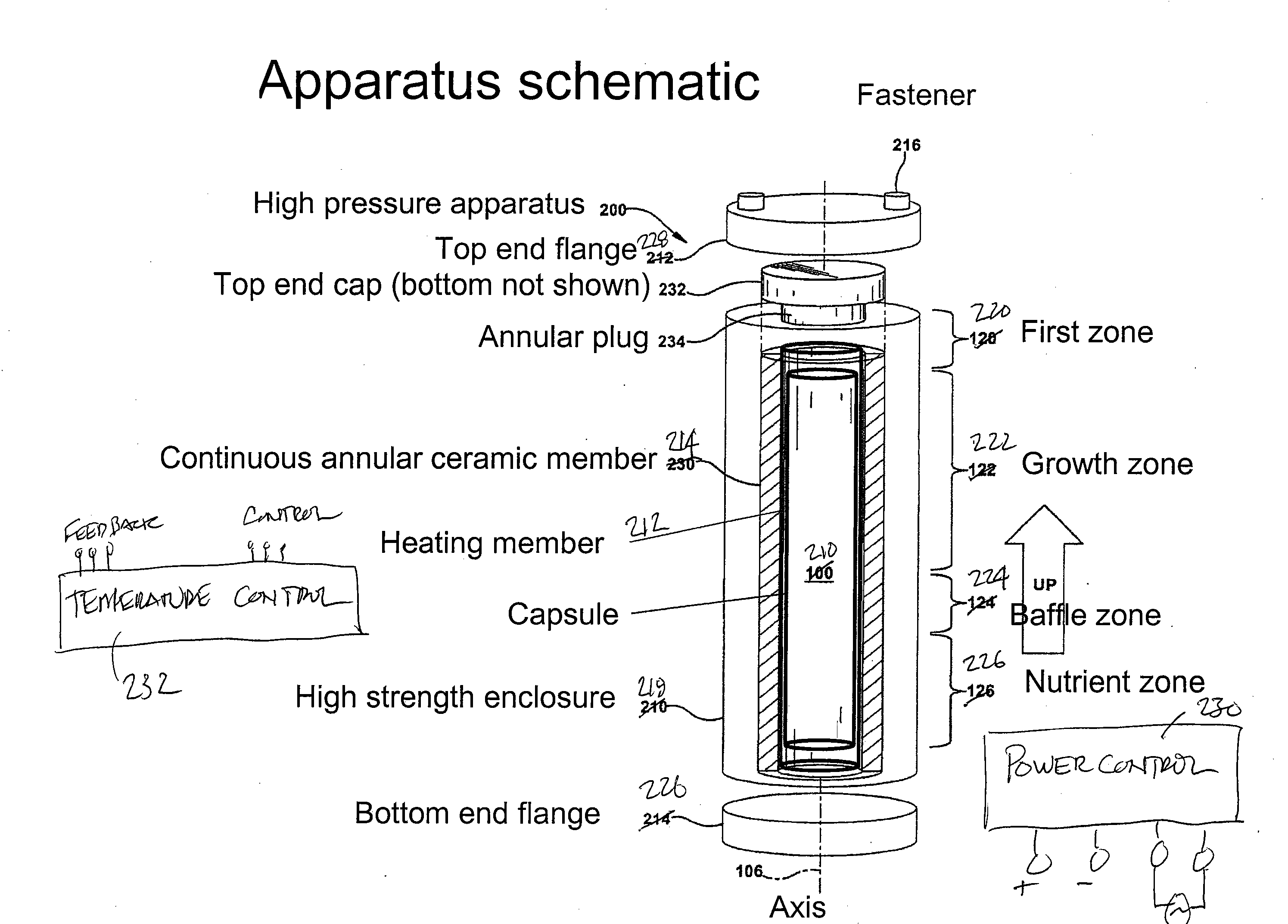

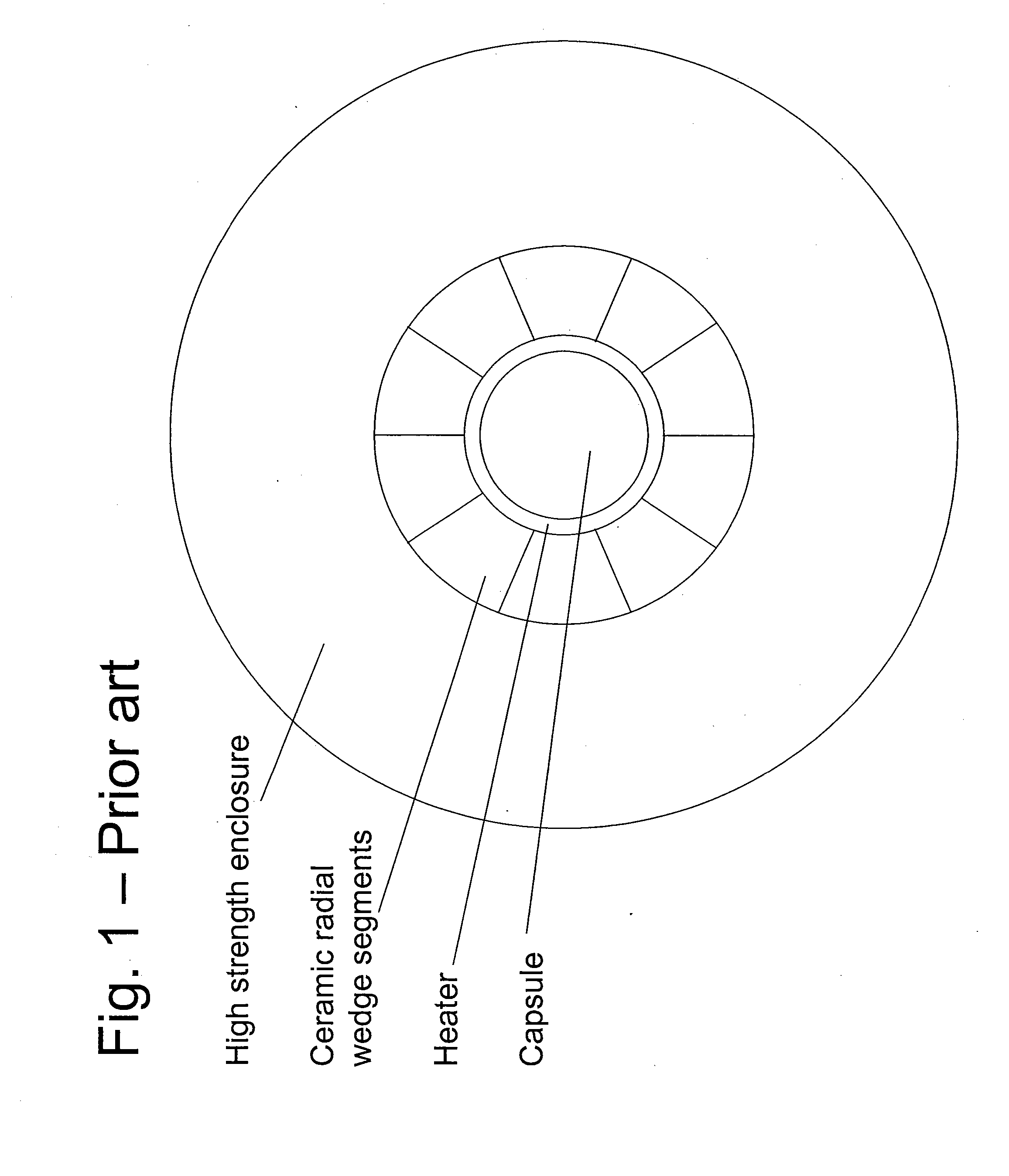

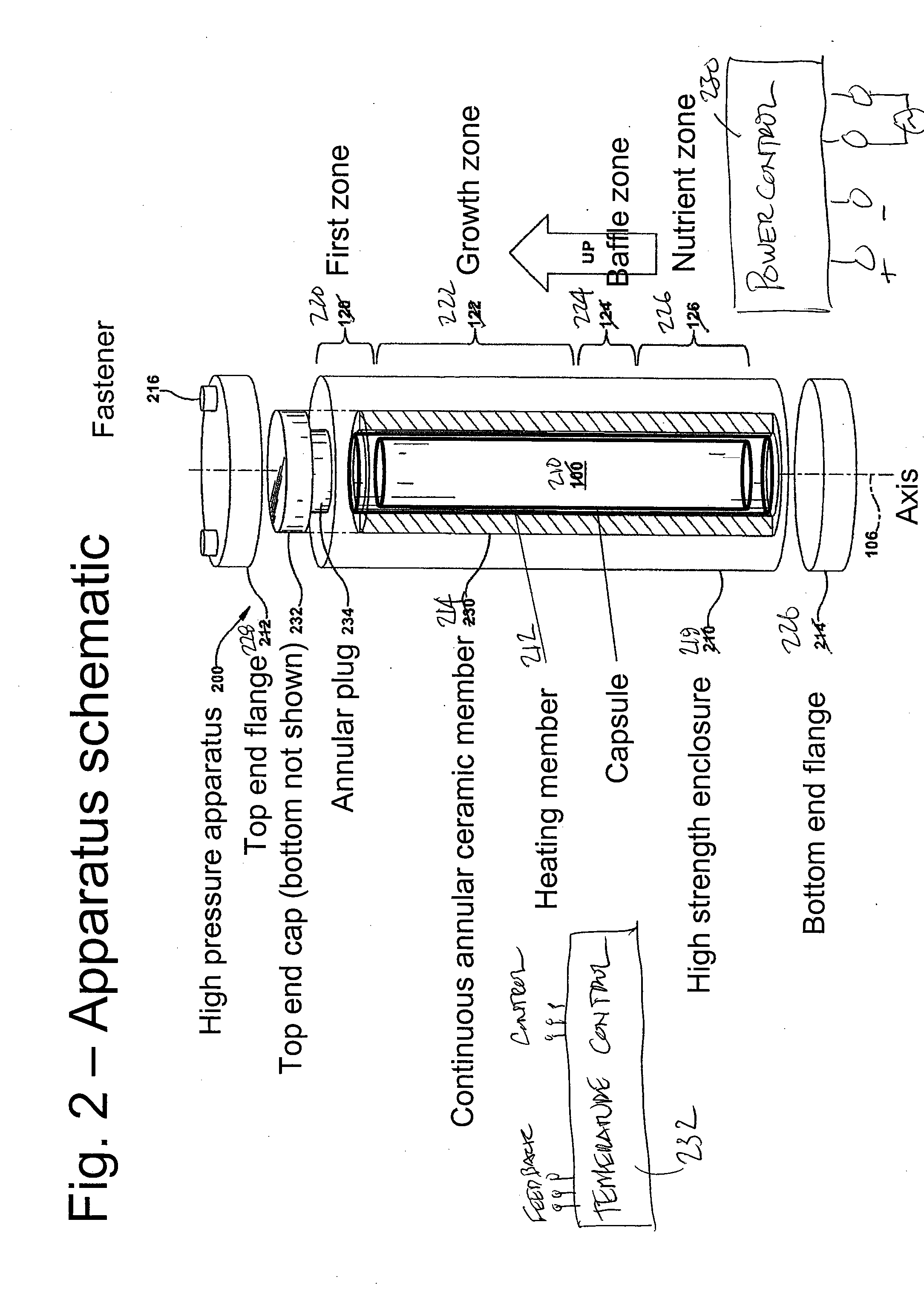

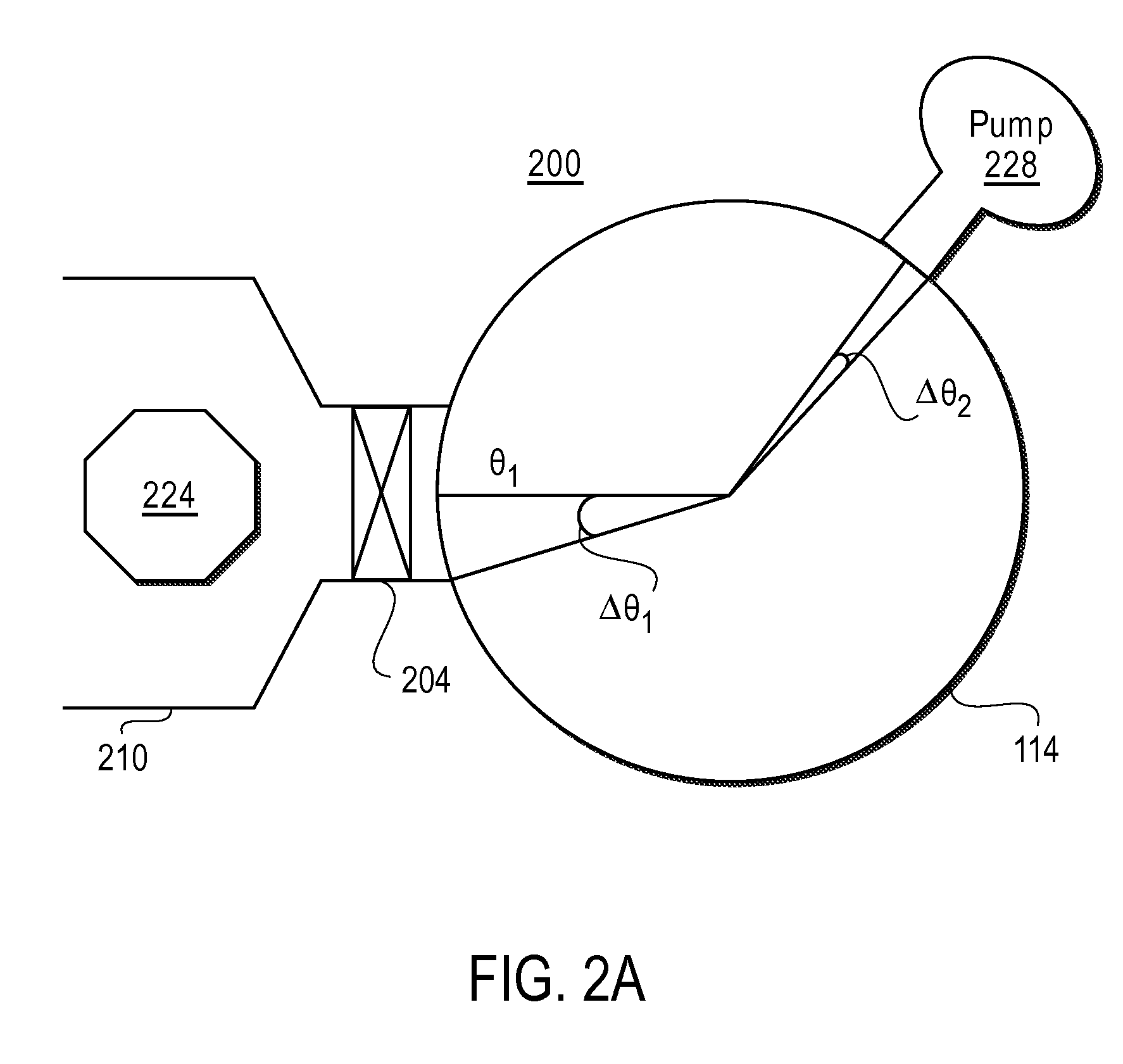

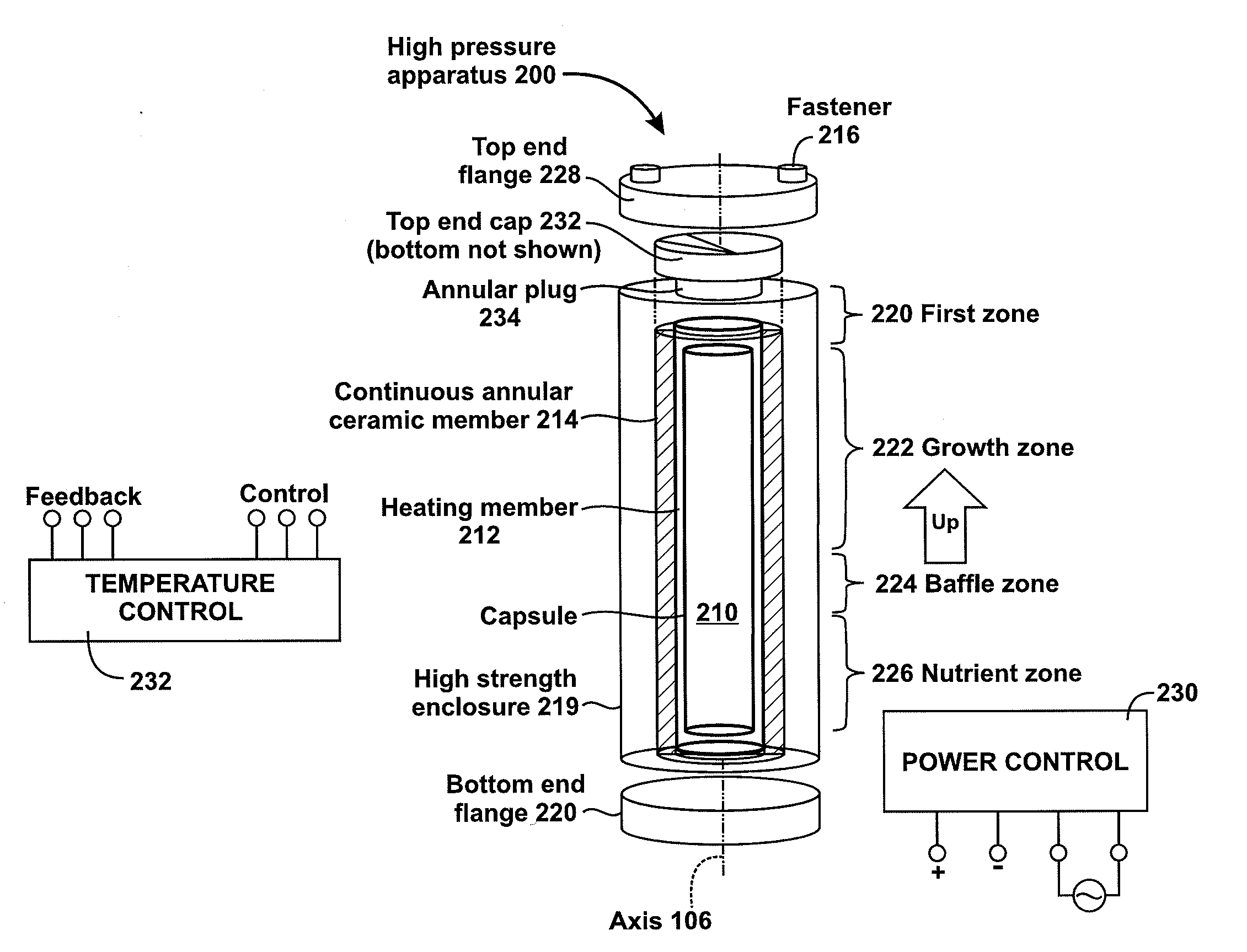

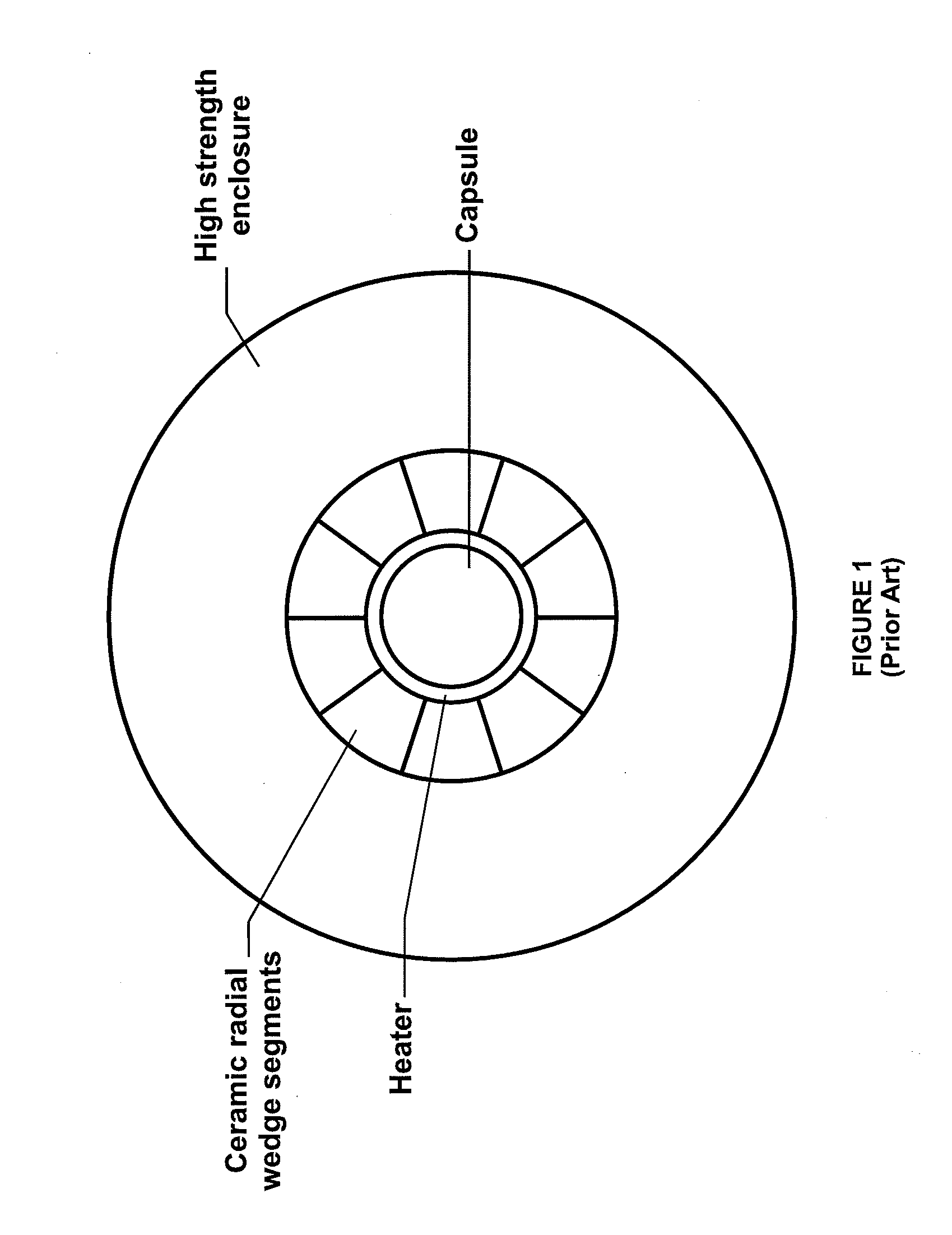

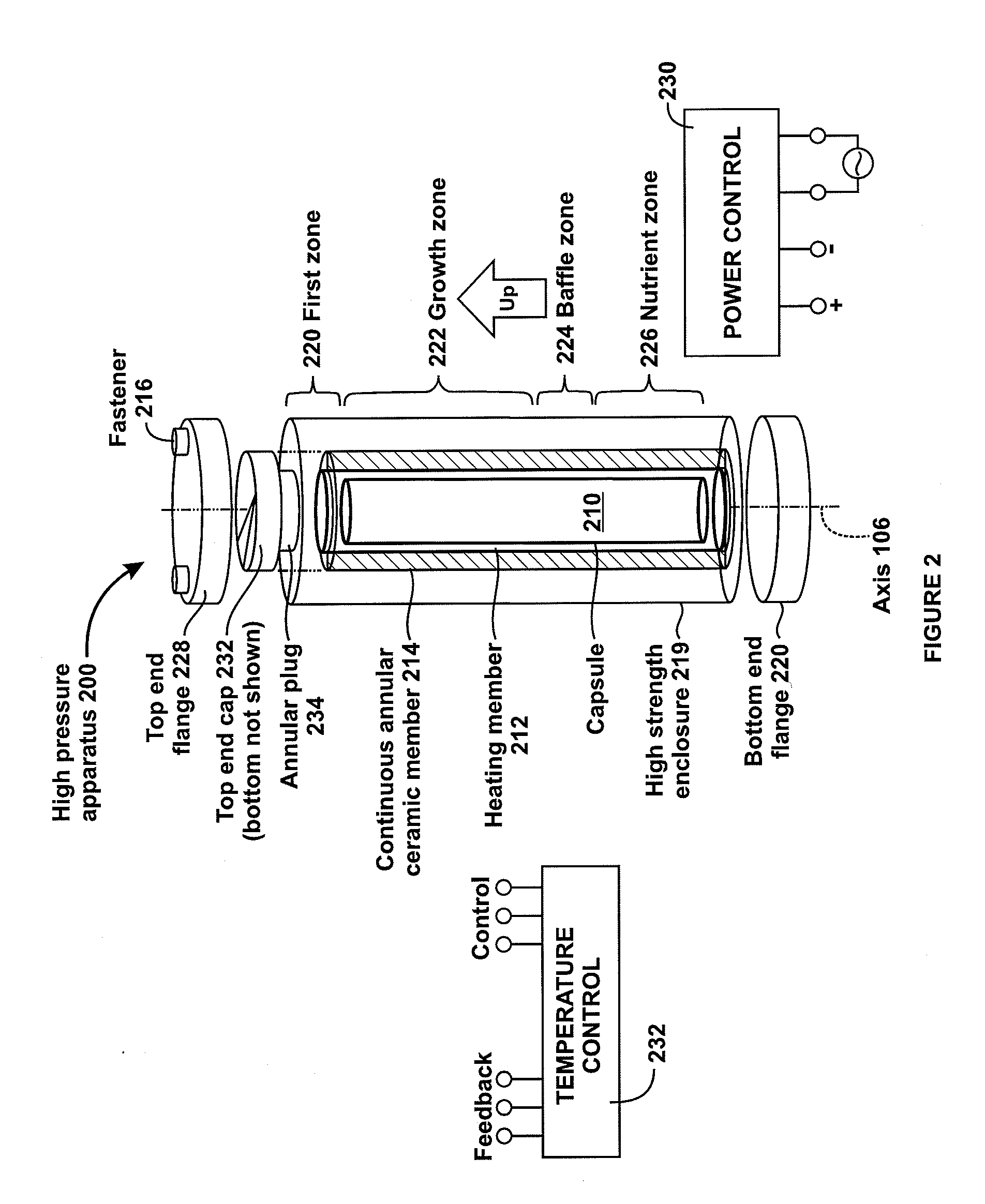

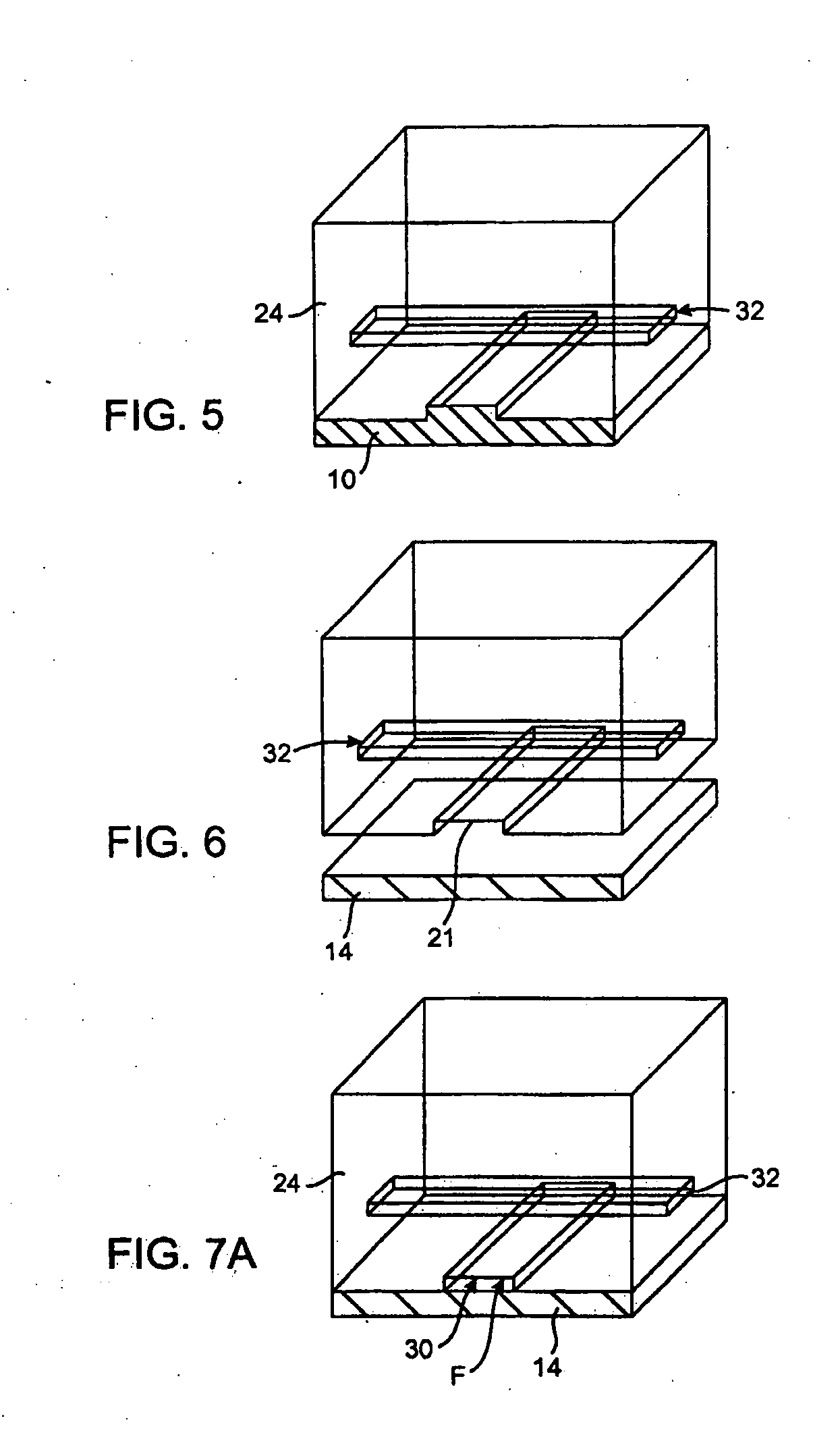

High pressure apparatus and method for nitride crystal growth

ActiveUS20090301387A1Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. IN a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

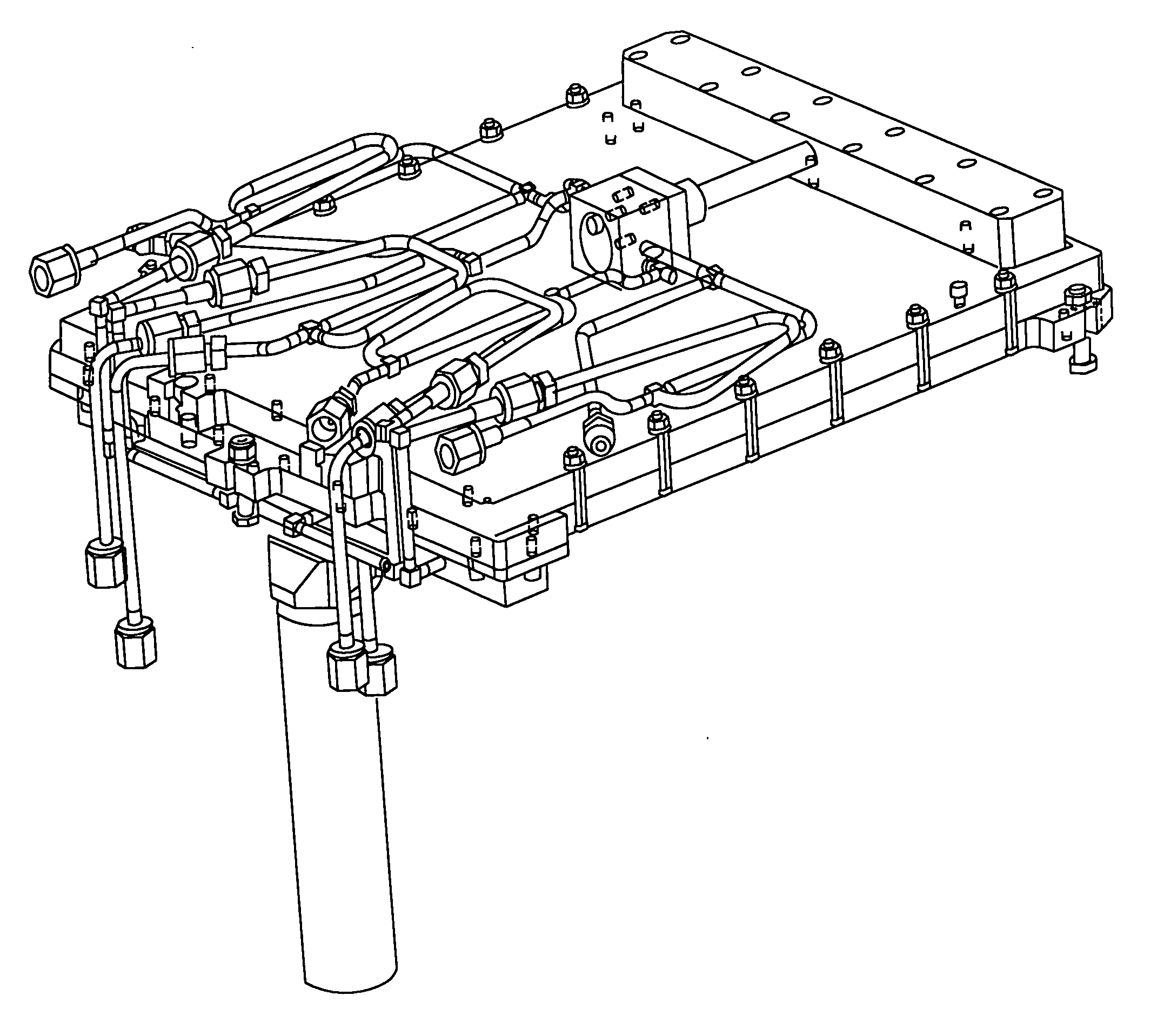

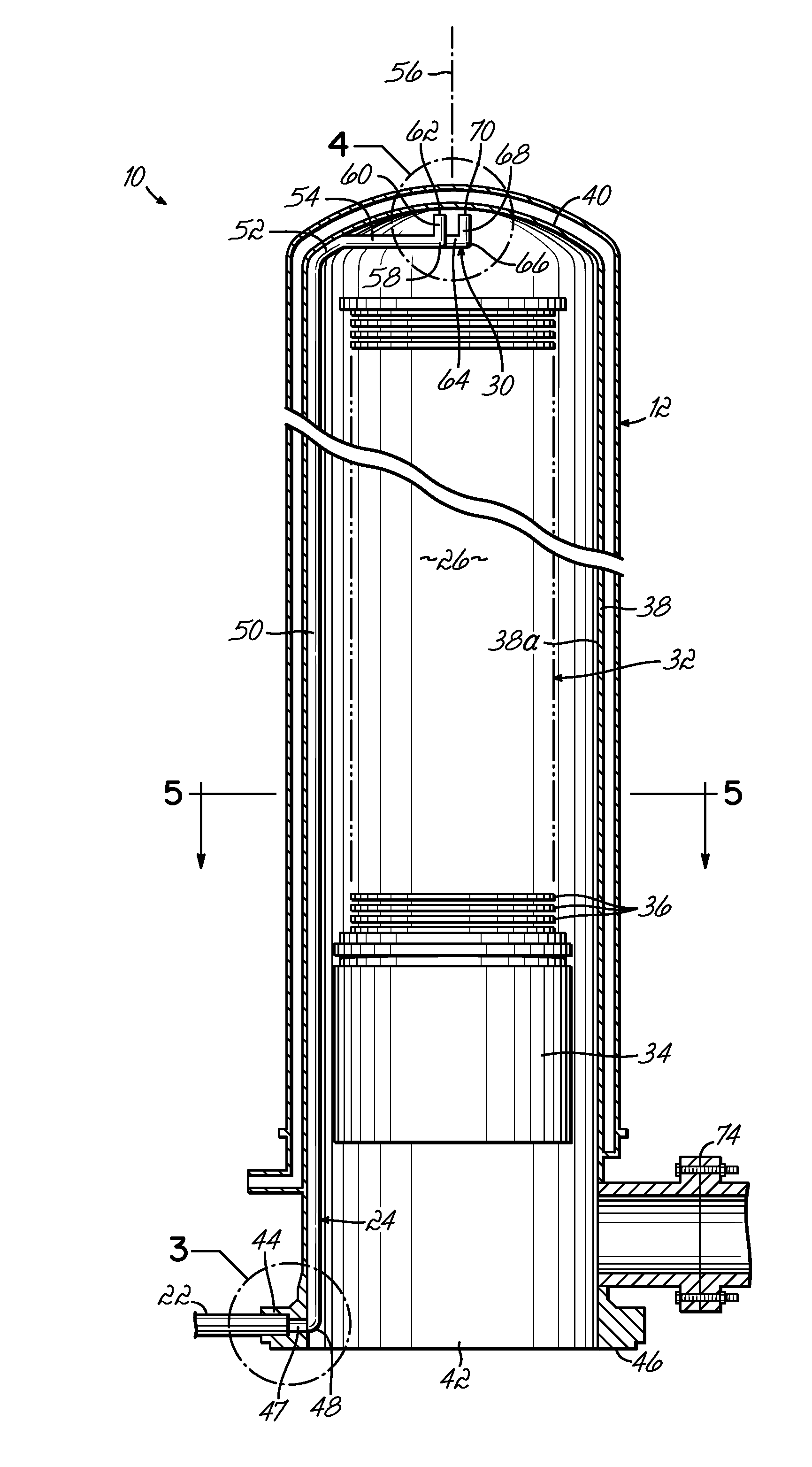

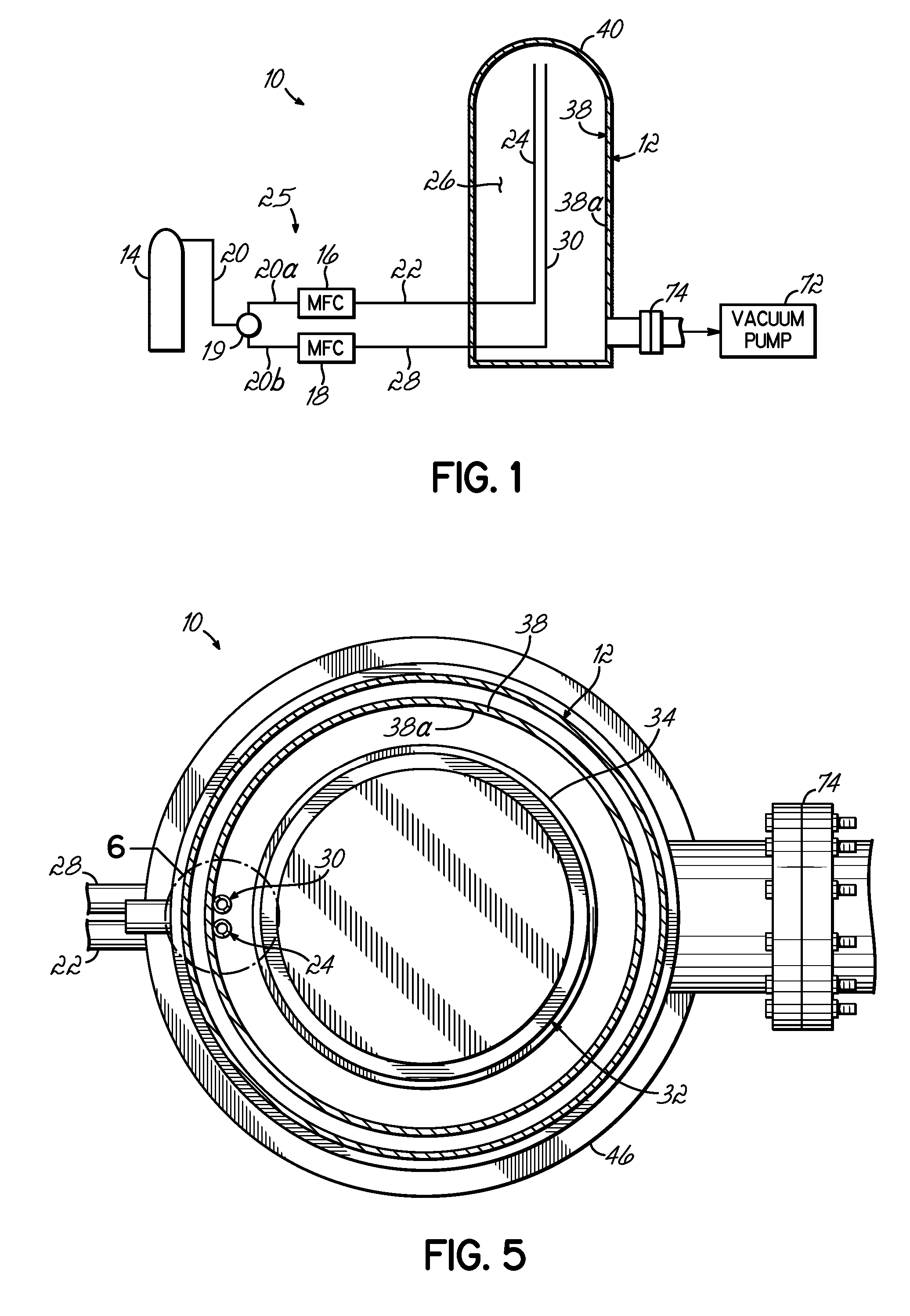

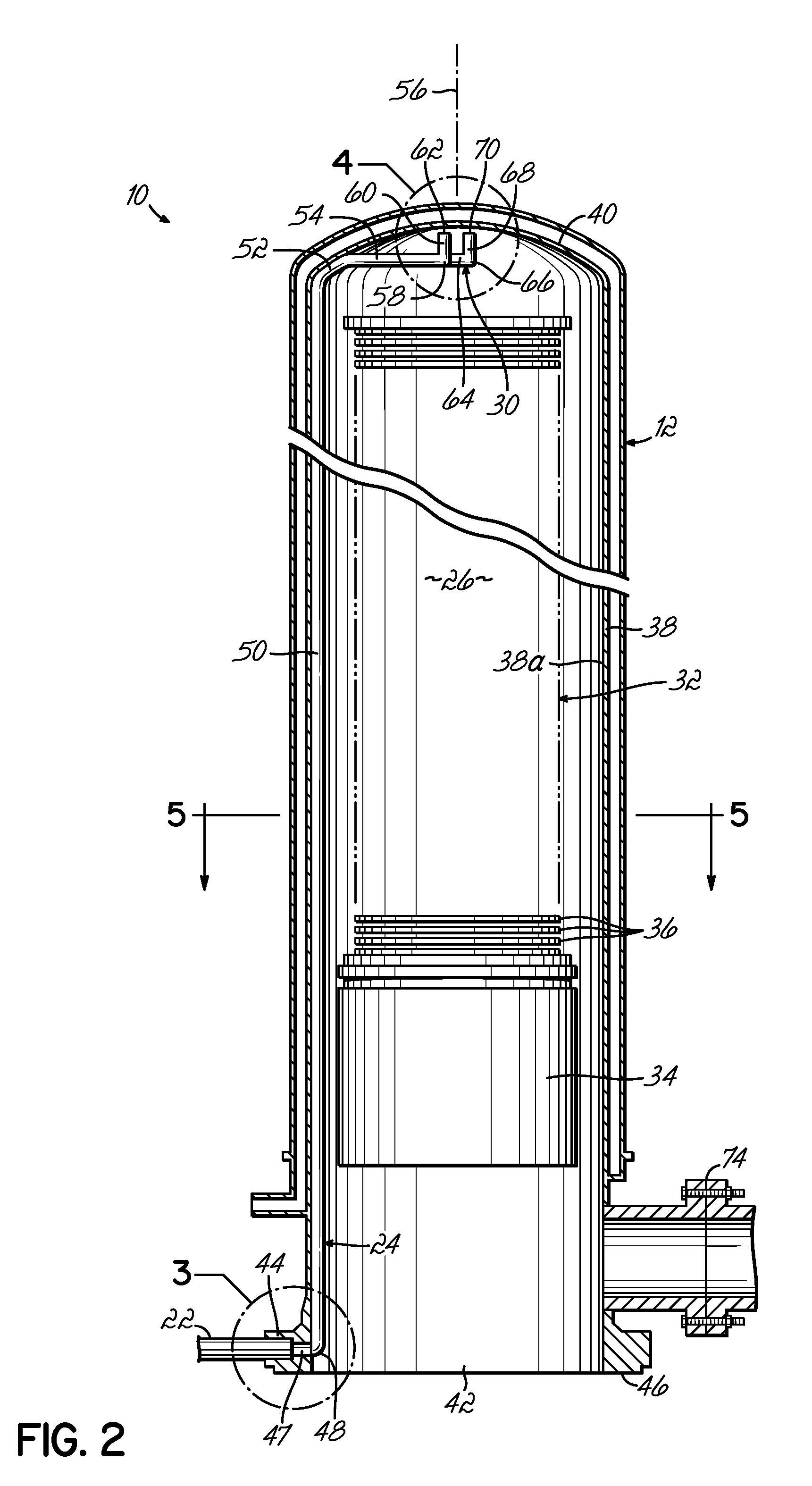

Thermal processing furnace, gas delivery system therefor, and methods for delivering a process gas thereto

InactiveUS7910494B2After-treatment apparatusCombustion using gaseous and pulverulent fuelProcess engineeringGas supply

A gas delivery system for supplying a process gas from a gas supply to a thermal processing furnace, a thermal processing furnace equipped with the gas delivery system, and methods for delivering process gas to a thermal processing furnace. The gas delivery system comprises a plurality of regulators, such as mass flow controllers, in a process gas manifold coupling a gas supply with a thermal processing furnace. The regulators establish a corresponding plurality of flows of a process gas at a plurality of flow rates communicated by the process gas manifold to the thermal processing furnace. The gas delivery system may be a component of the thermal processing furnace that further includes a liner that surrounds a processing space inside the thermal processing furnace.

Owner:TOKYO ELECTRON LTD

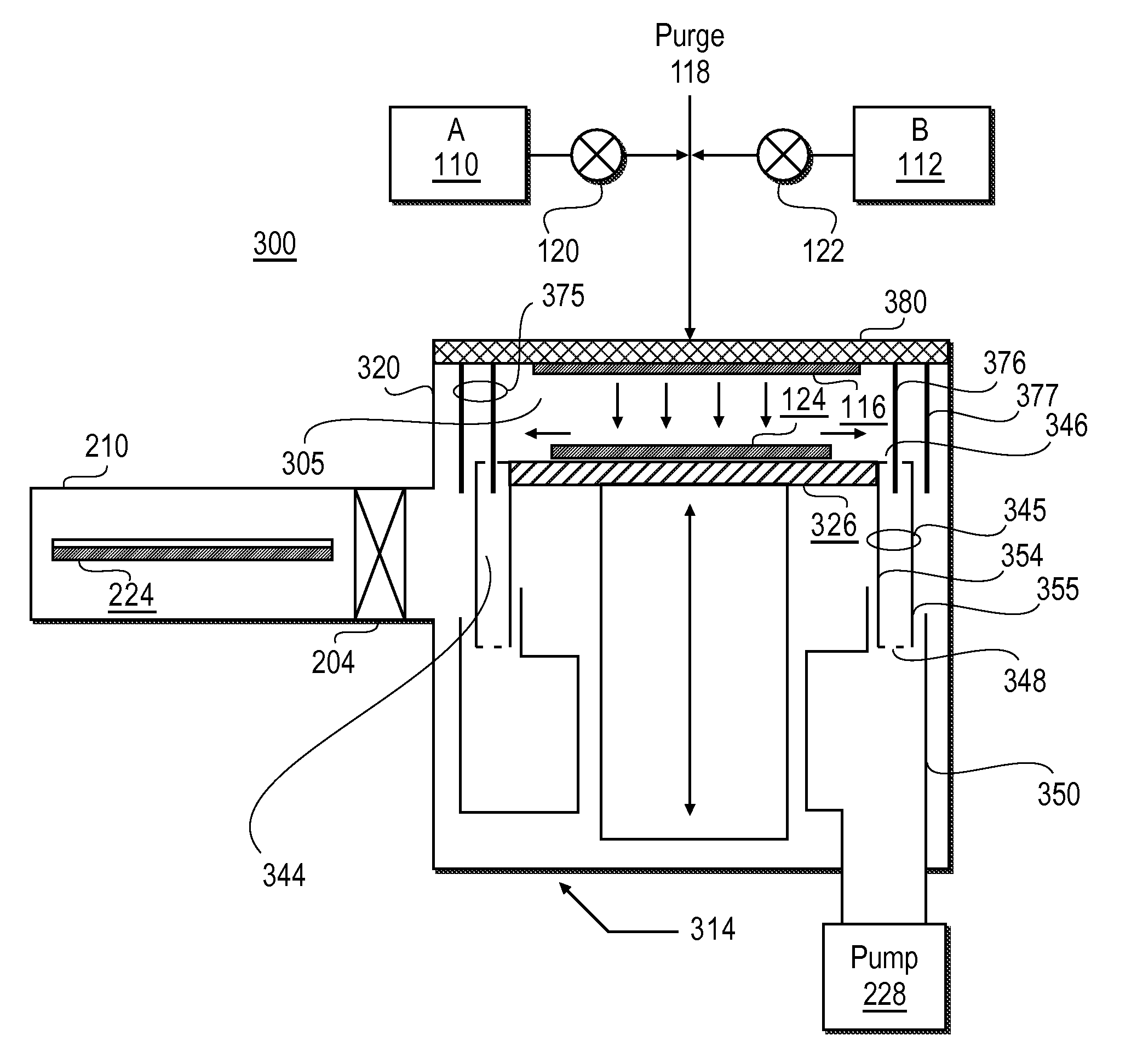

Small volume symmetric flow single wafer ald apparatus

InactiveUS20080072821A1Advance in maintenance benefitGood benefitAfter-treatment apparatusFrom chemically reactive gasesSusceptorEngineering

A reaction chamber apparatus includes a vertically movable heater-susceptor with an attached annular attached flow ring that performs as a gas conduit. The outlet port of the flow ring extends below the bottom of a wafer transport slot valve when the susceptor is in its process (higher) position, while the gas conduit formed by the flow ring has an external surface at its edge that isolates the outer space of the reactor above the wafer from the confined reaction space. In some cases, the outer edge of the gas conduit is in proximity to a ring attached to the reactor lid and, together, the ring and conduit act as a tongue-in-groove (TIG) configuration. In some cases, the TIG design may have a staircase contour, thereby limiting diffusion-backflow of downstream gases to the outer space of the reactor.

Owner:AIXTRON INC

High pressure apparatus and method for nitride crystal growth

ActiveUS20090320744A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

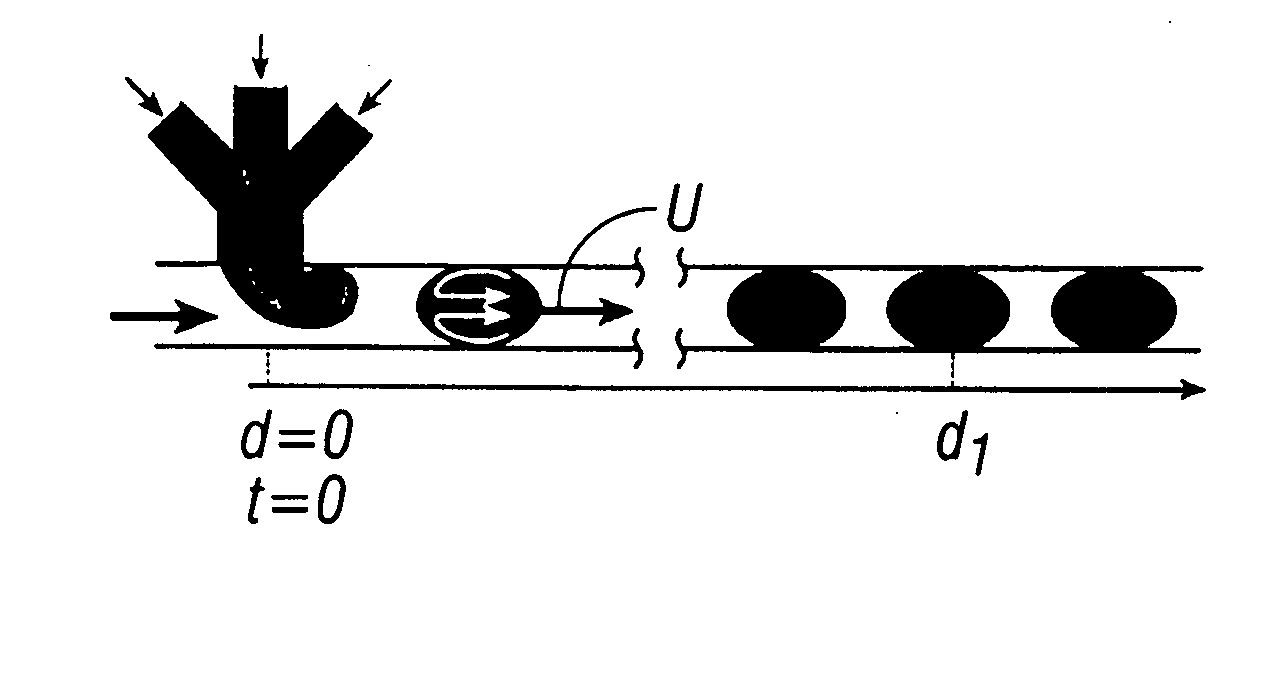

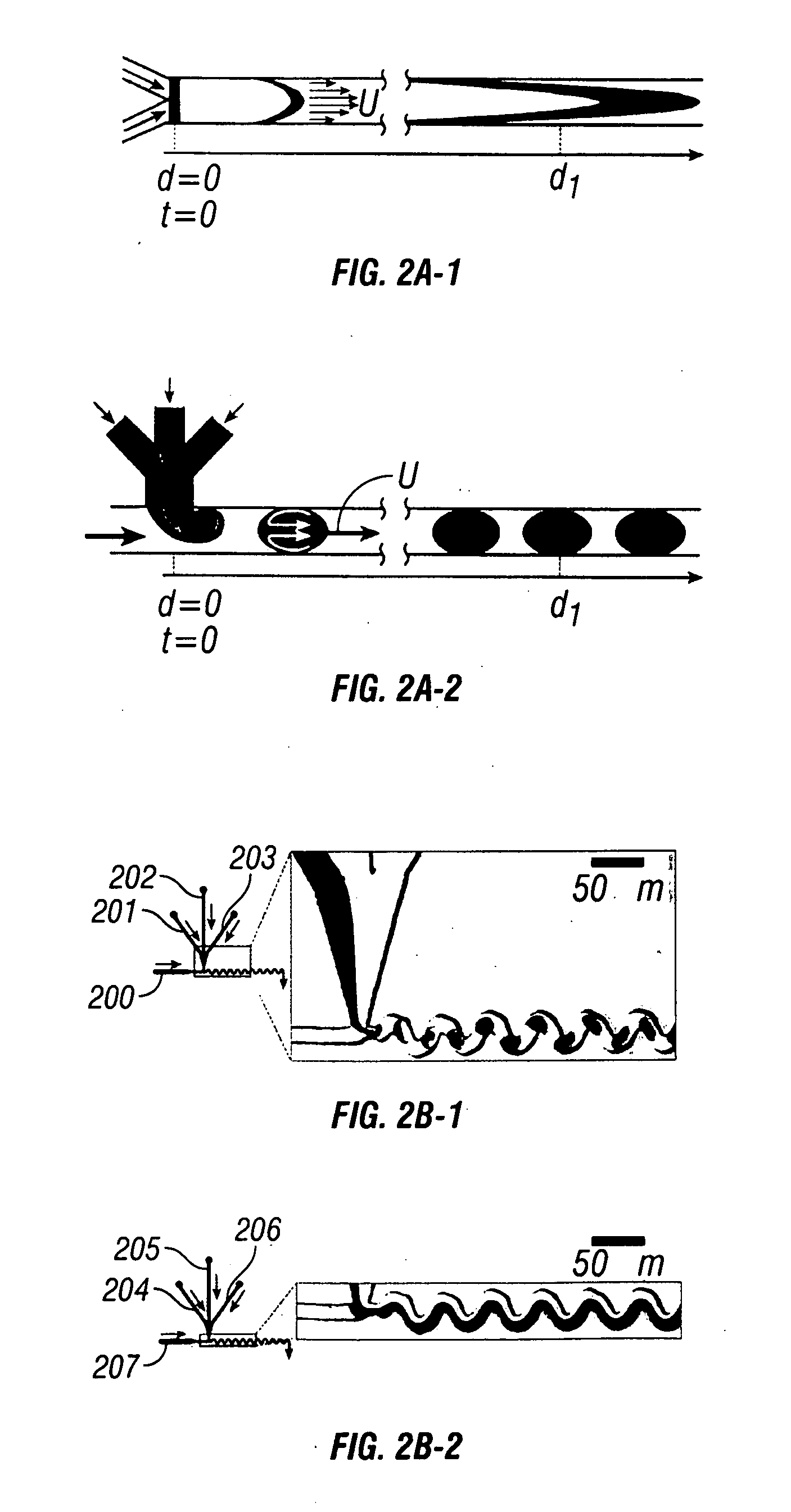

Device and method for pressure-driven plug transport and reaction

ActiveUS20050087122A1Eliminate evaporationWell mixedMaterial nanotechnologySequential/parallel process reactionsPressure.driveCarrier fluid

Owner:UNIVERSITY OF CHICAGO

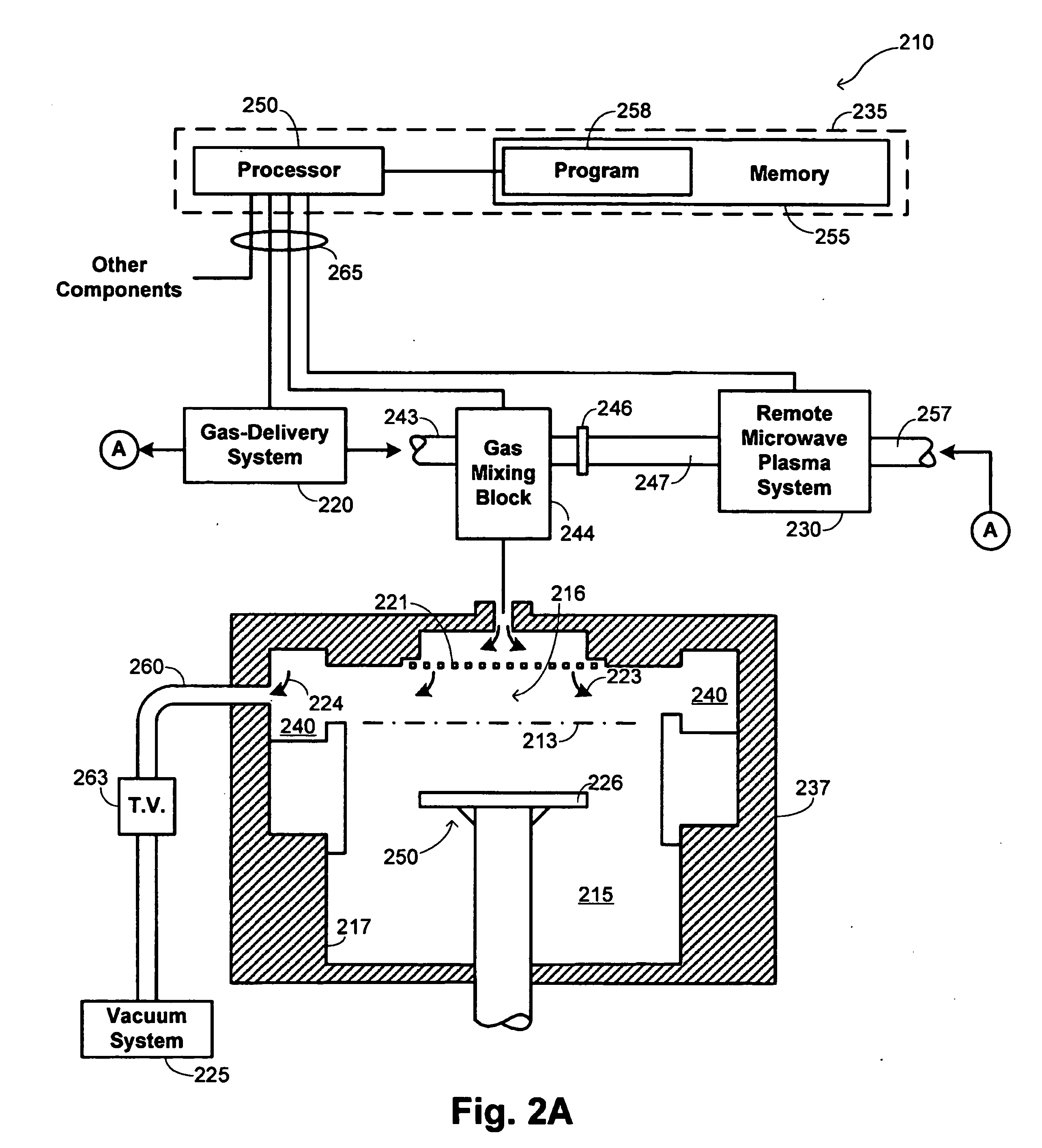

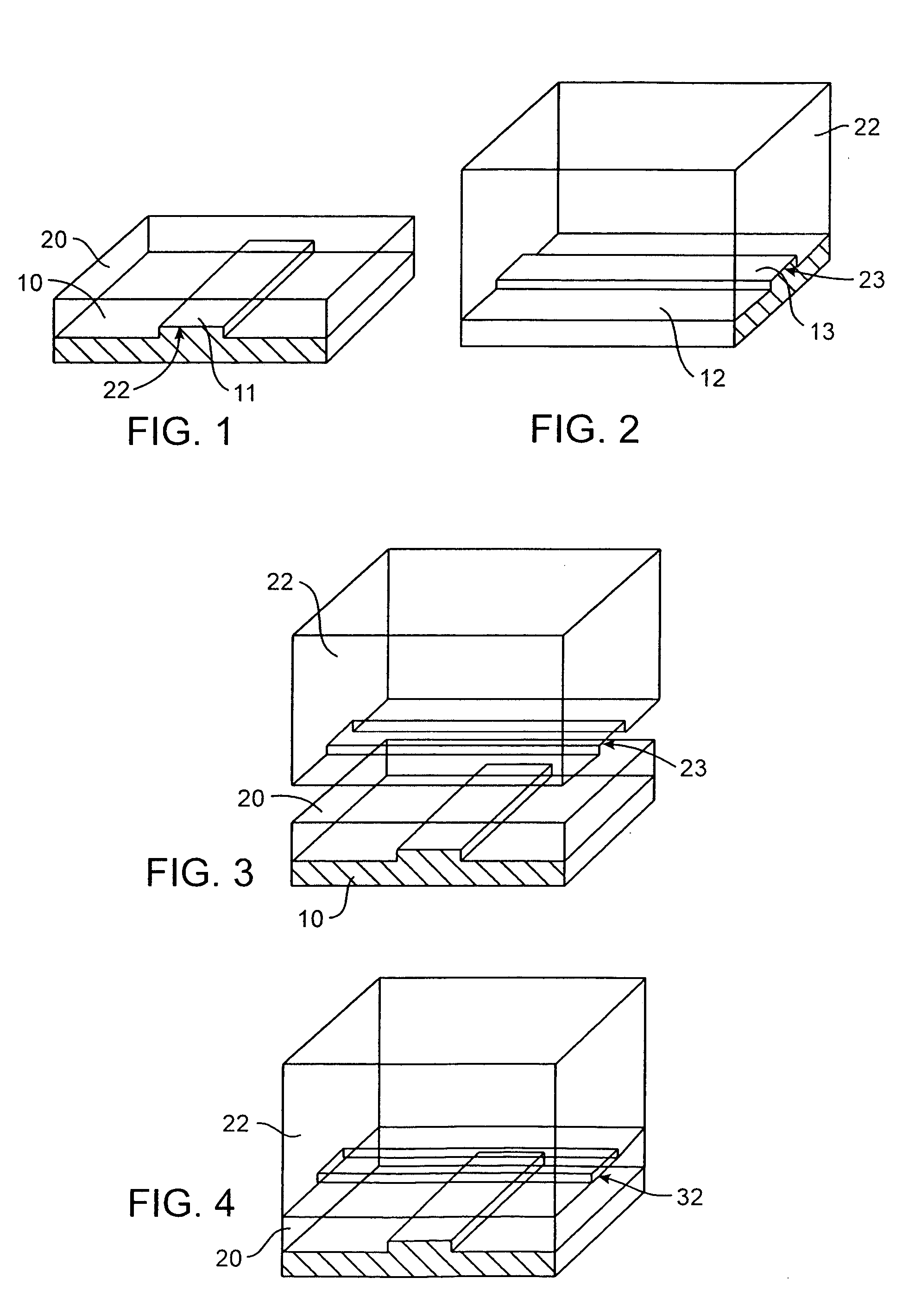

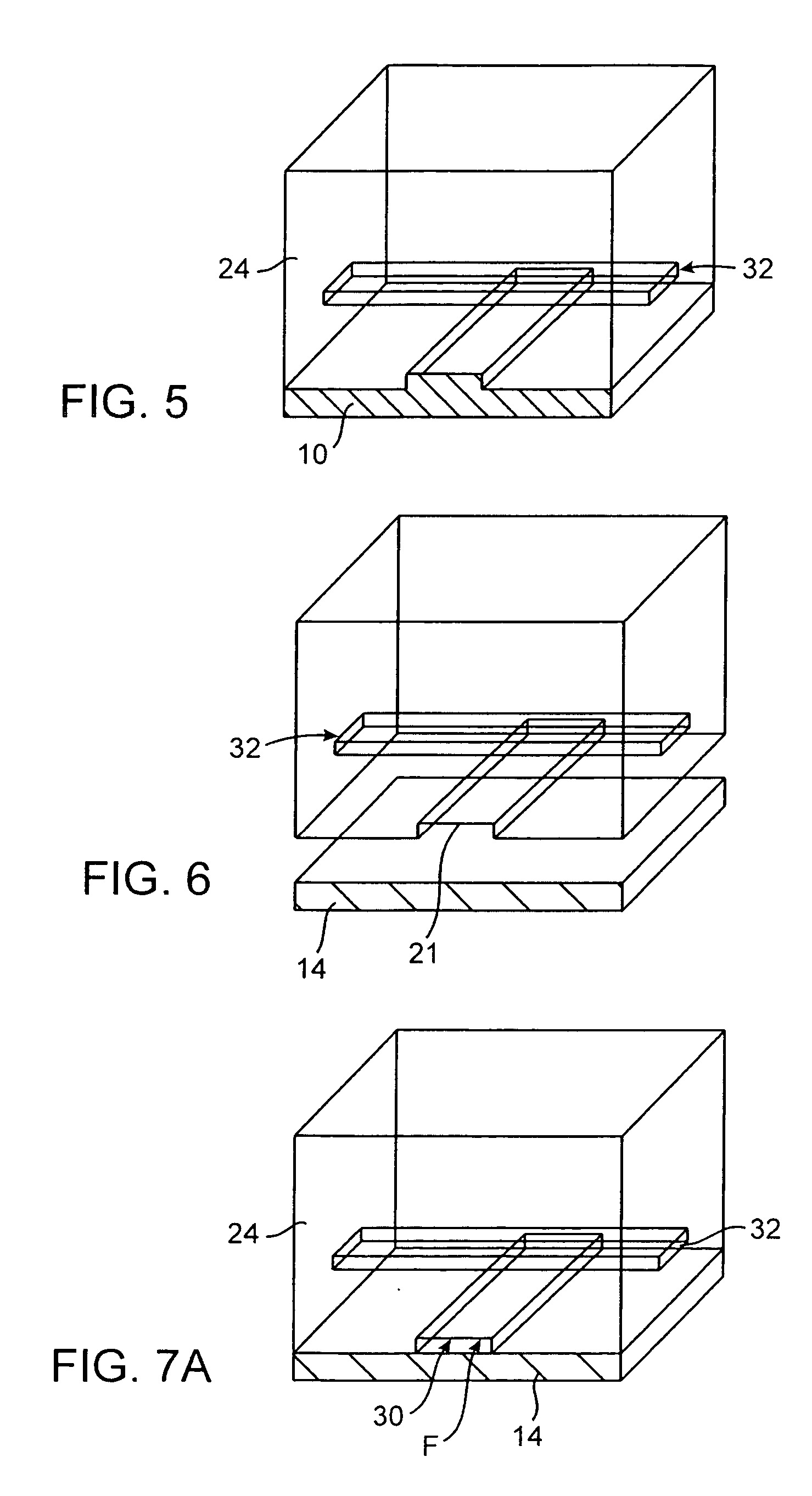

Apparatus and method for growth of a thin film

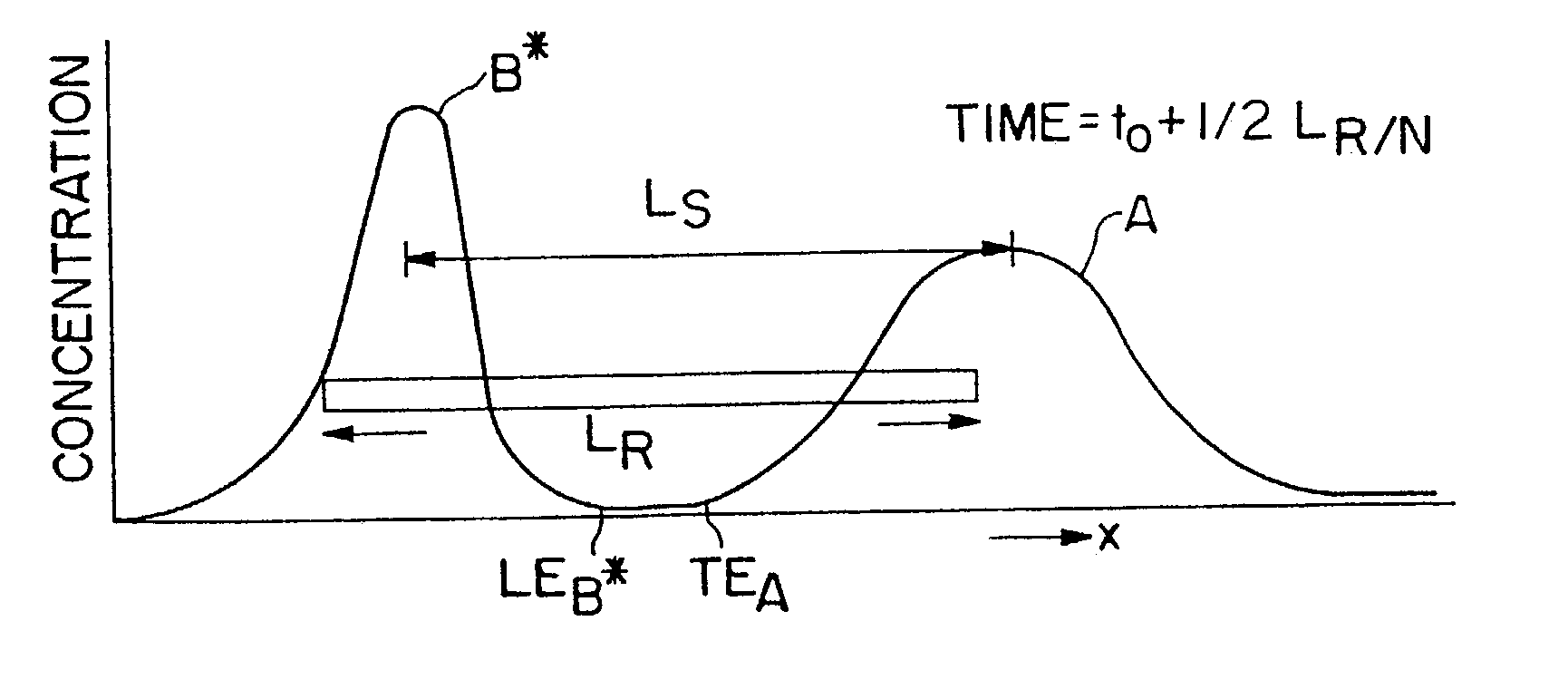

InactiveUS7141499B2Minimize undesirable reactionImprove processing speedAfter-treatment apparatusPolycrystalline material growthGas phaseDelayed time

An improved apparatus and method for substrate layer deposition in which substrate layers are grown by carrier gas delivery of sequential pulses of reactants to the substrate surface. At least one of the reactants comprises excited species, e.g., radicals. In a specific embodiment, the apparatus of this invention provides sequential repeated pulses of reactants in a flow of carrier gas for reaction at a substrate surface. The reactant pulses are delivered with sufficient intervening delay times to minimize undesirable reaction between reactants in adjacent pulses in the gas phase or undesired uncontrolled reactions on the substrate surface.

Owner:ASM IP HLDG BV

Crystal growth devices and systems, and methods for using same

Owner:FLUIDIGM CORP

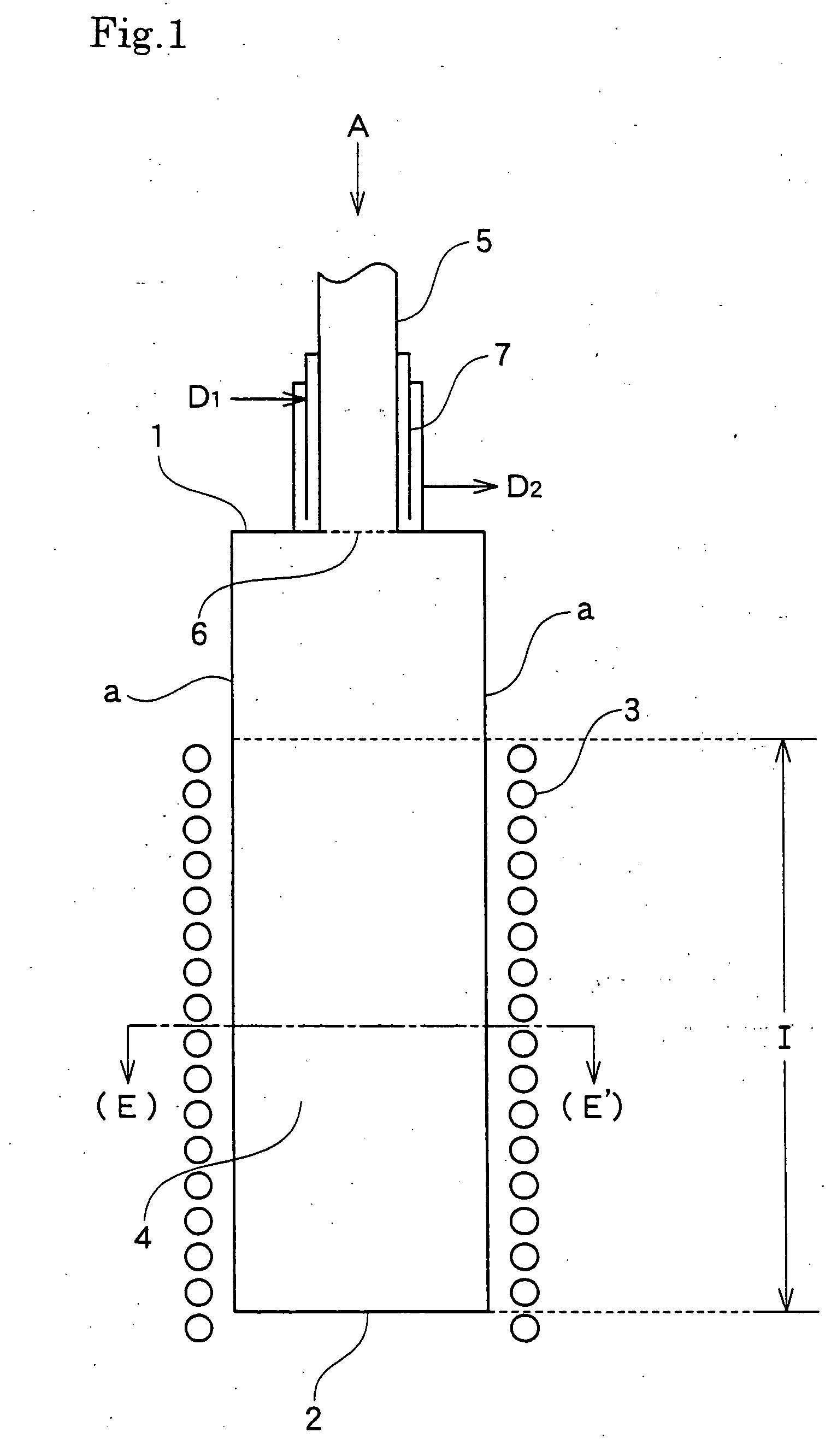

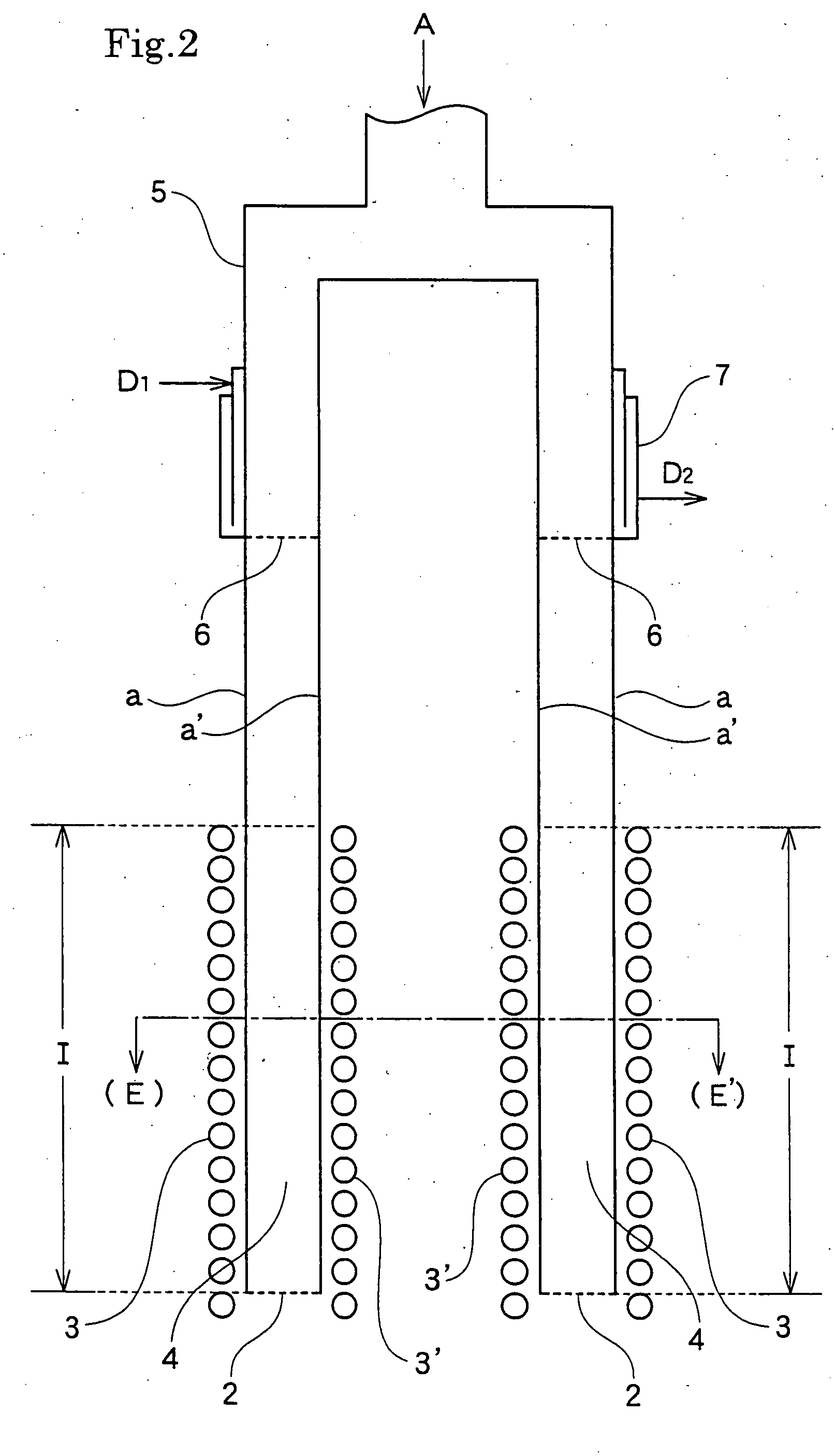

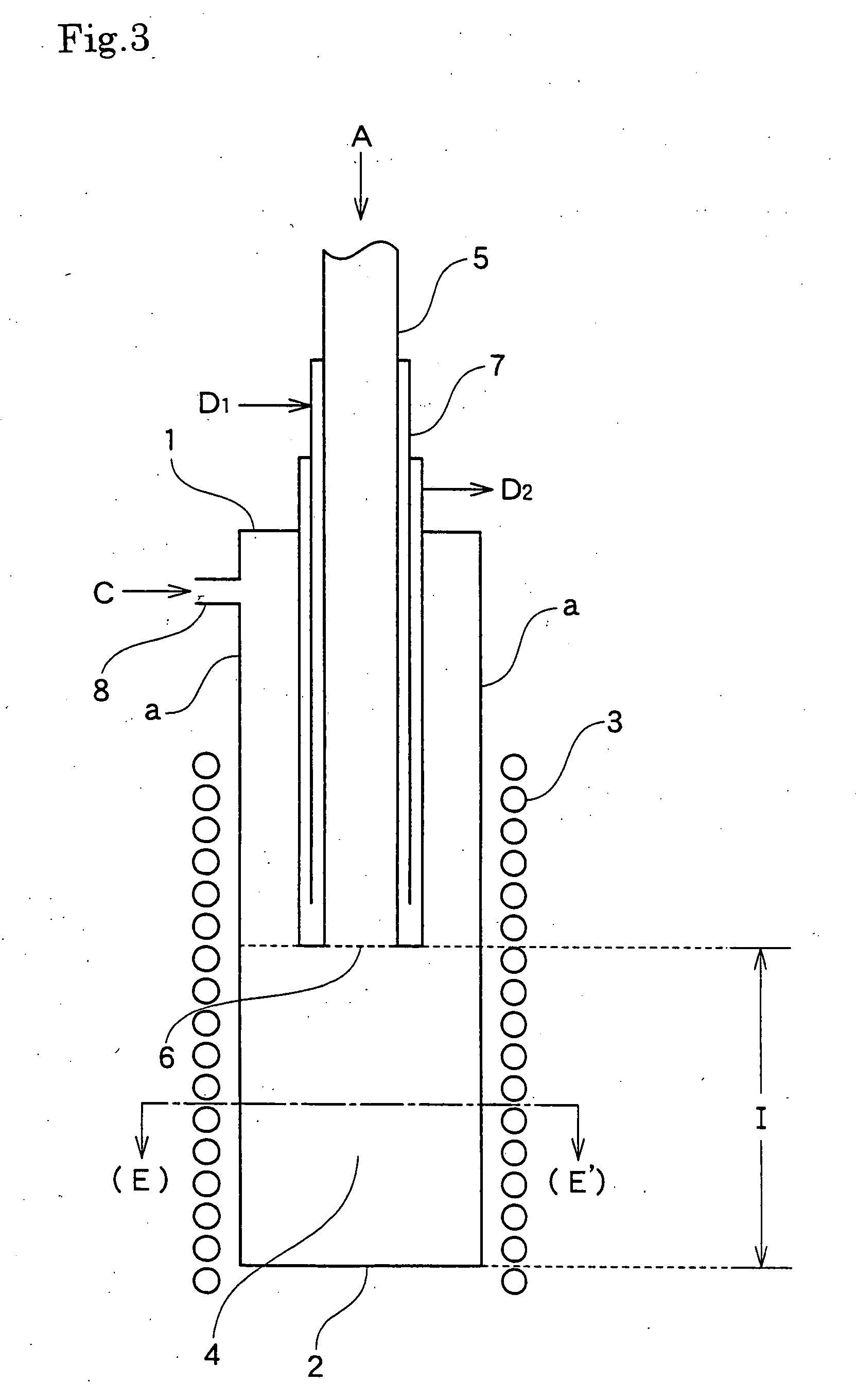

Reaction apparatus for producing silicon

ActiveUS20050201908A1Reduce spacingReduce distanceAfter-treatment apparatusSiliconProcess engineeringSilicon

A silicon production reactor comprising a reaction vessel and heating means, said reaction vessel comprising a vertically extending wall and a space surrounded by the wall, said heating means being capable of heating at least a part, including lower end portion, of the wall's surface facing the space to a temperature of not lower than the melting point of silicon, said silicon production reactor being adapted to flow raw gas for silicon deposition from an upper part of the space of the reaction vessel toward a lower part thereof, characterized in that the space of the reaction vessel is of slit form in cross-sectional view. This silicon production reactor is capable of attaining improvement with respect to problems encountered at apparatus scaleup, such as decrease of reactivity of raw gas and generation of by-products, thereby accomplishing a striking enhancement of production efficiency.

Owner:TOKUYAMA CORP

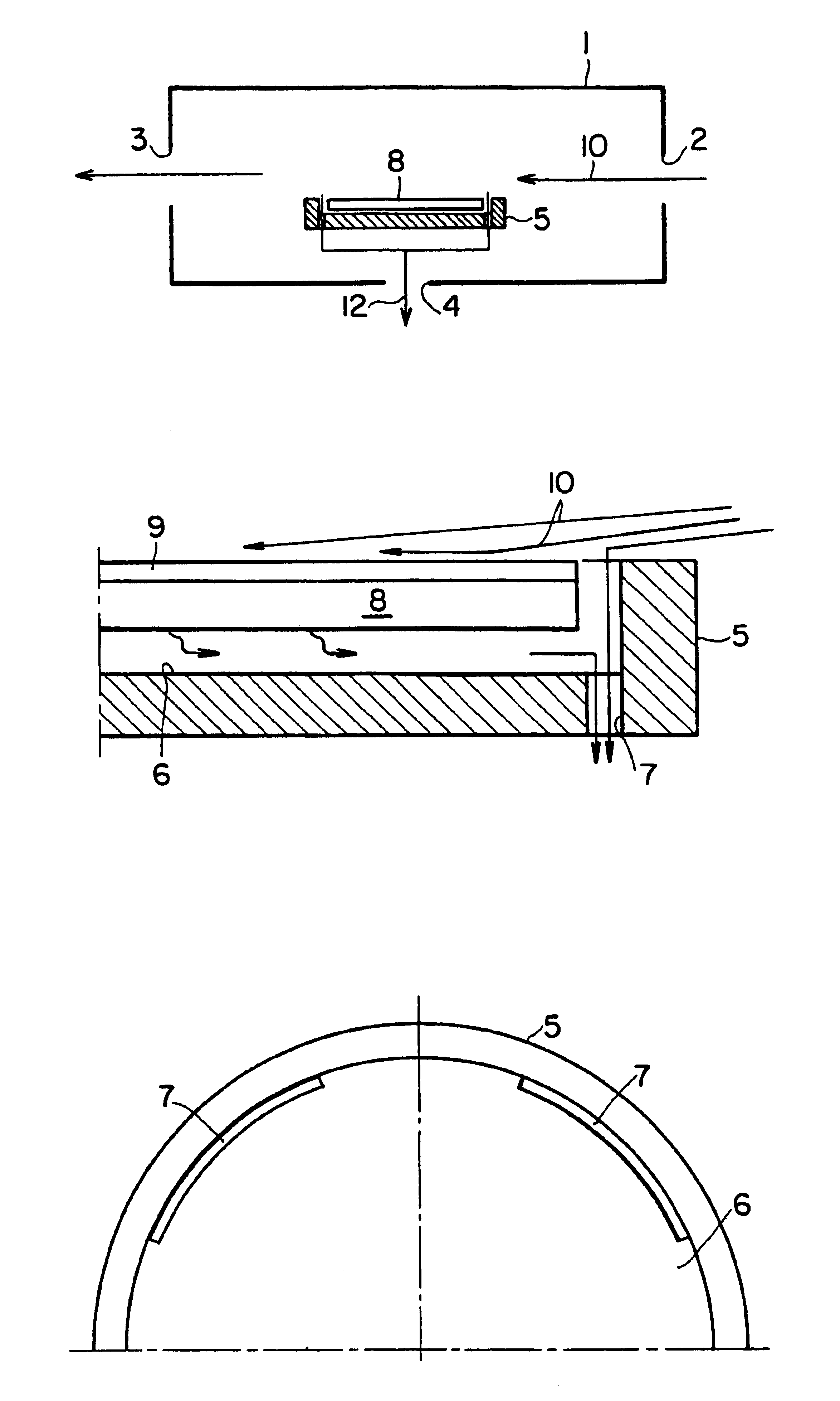

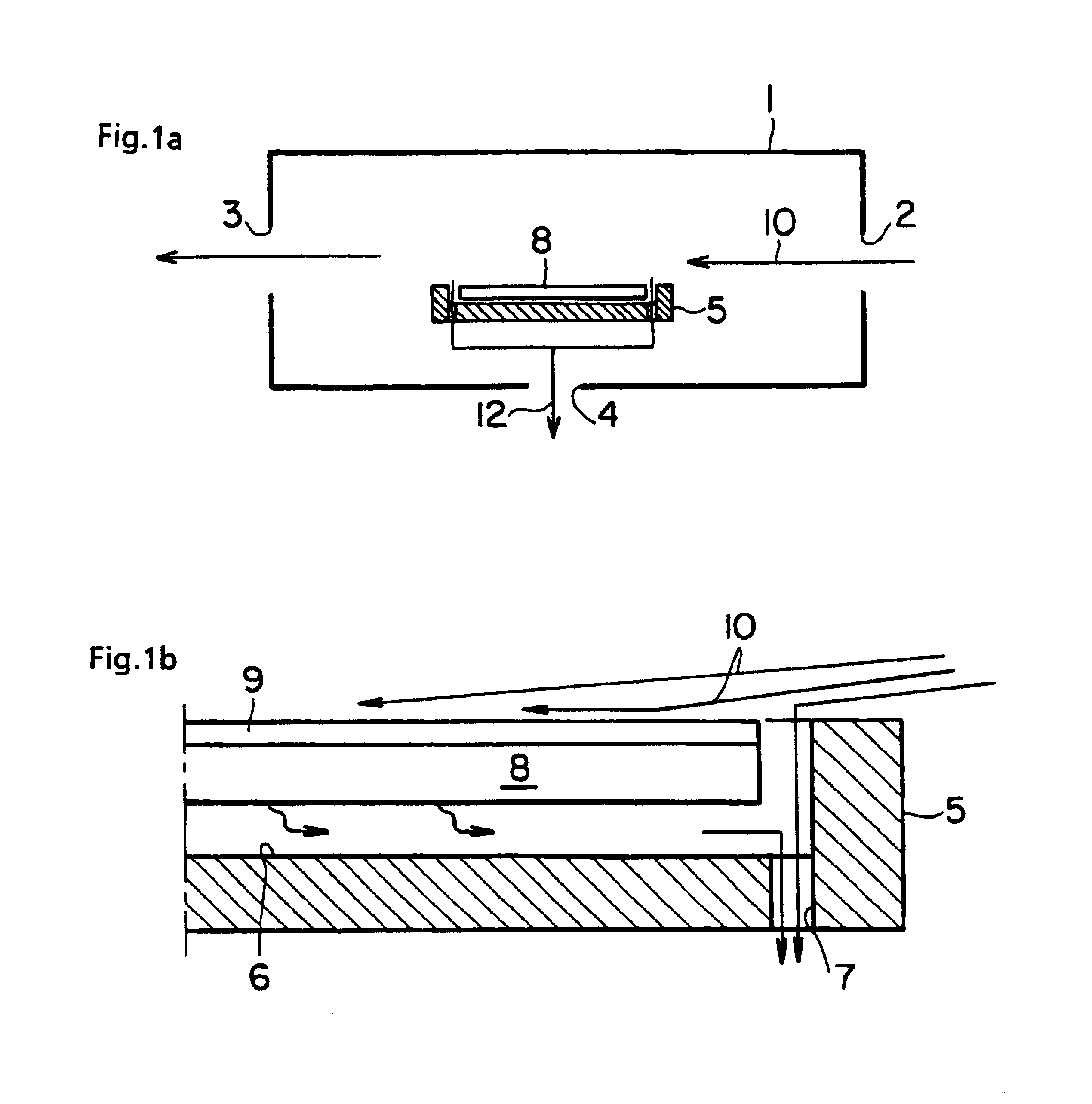

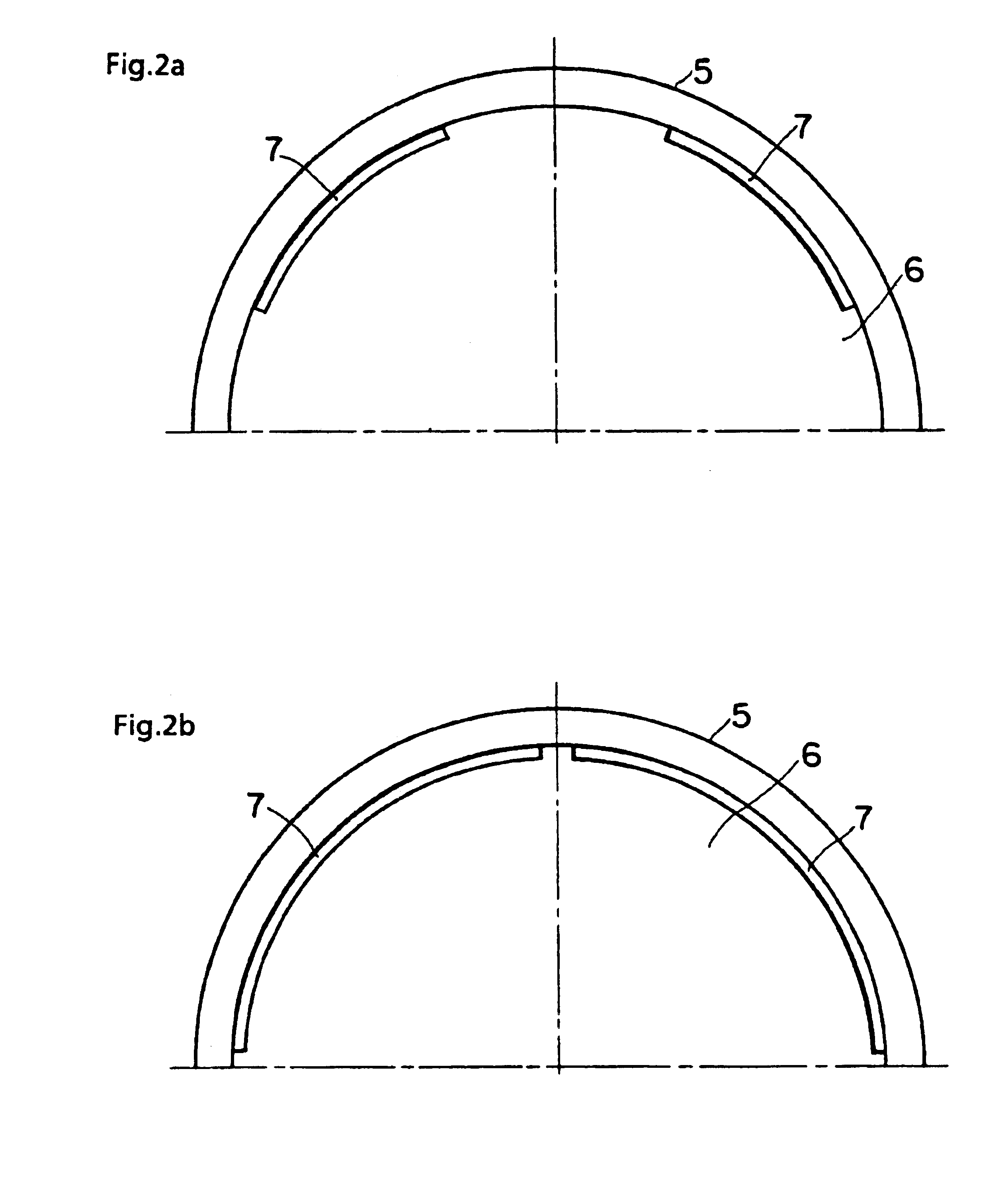

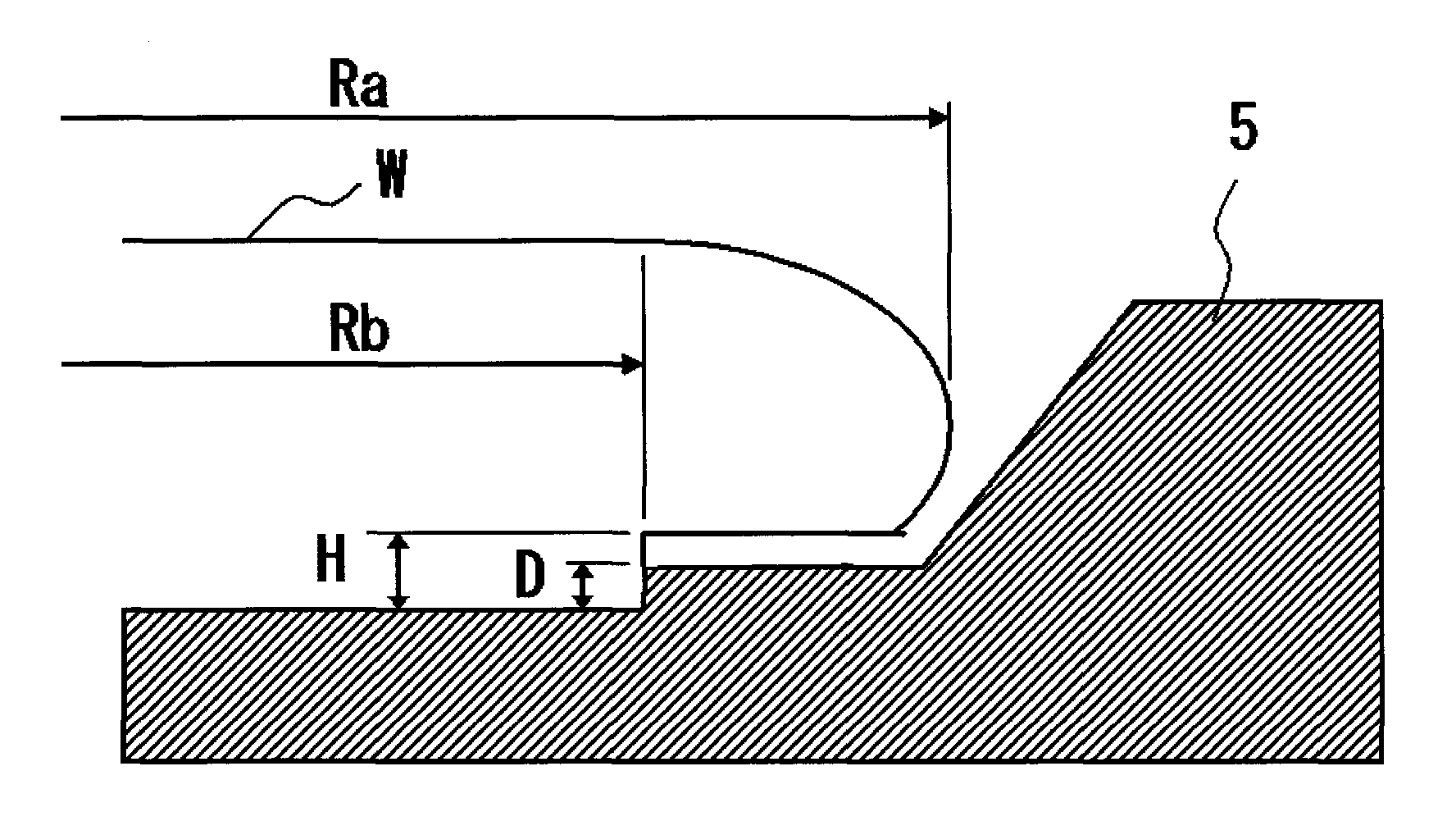

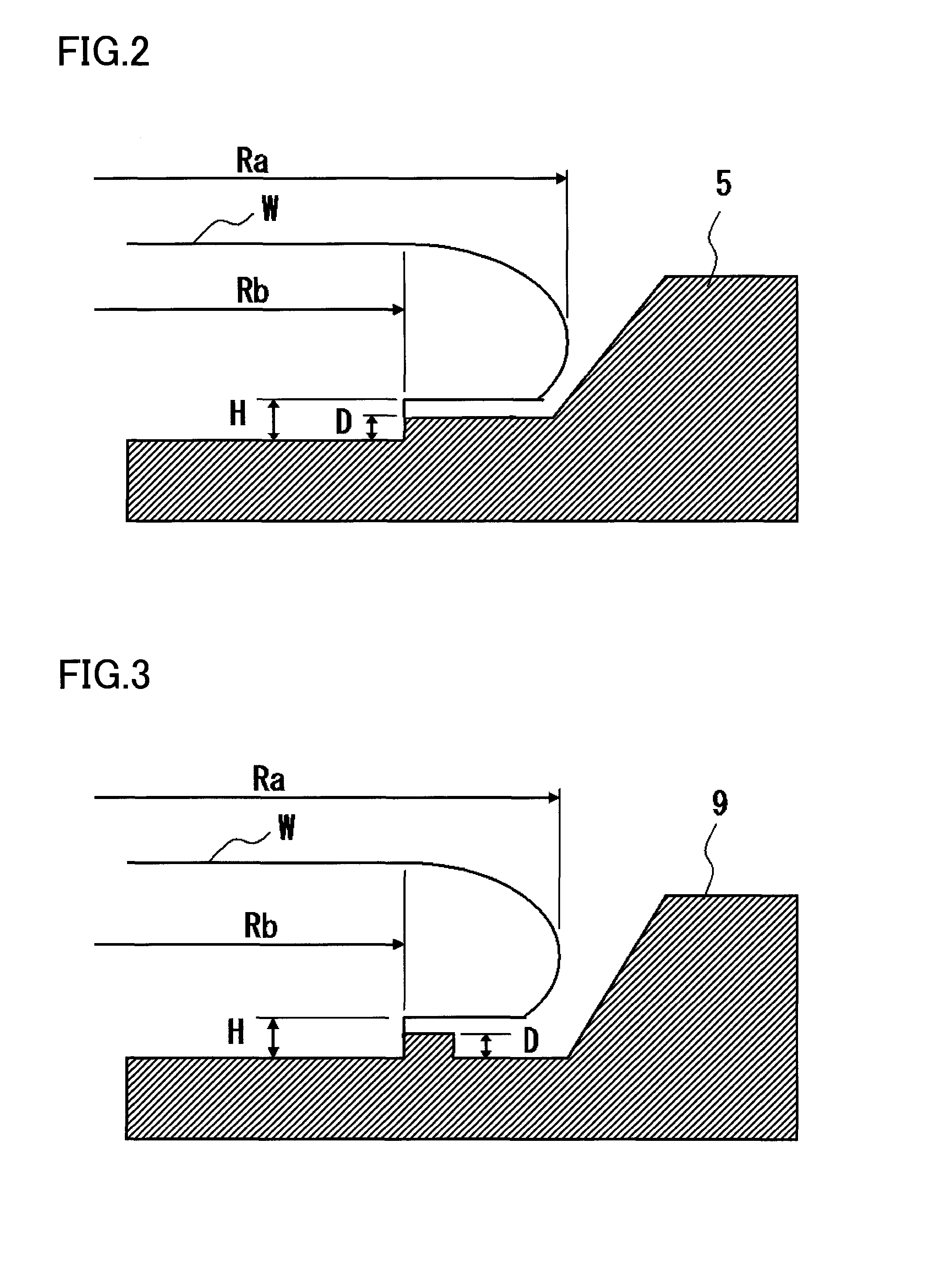

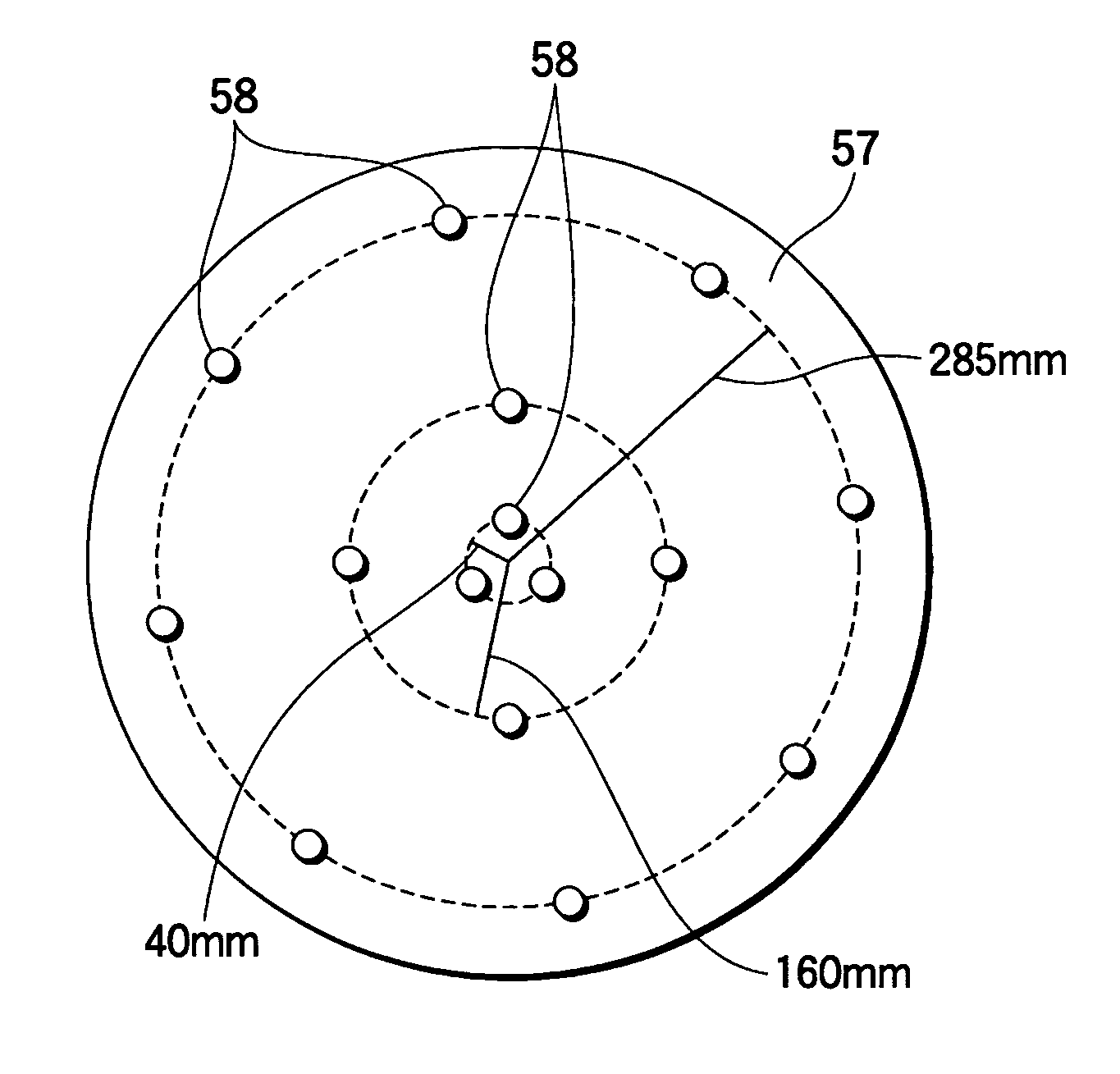

Susceptor for vapor-phase growth apparatus

InactiveUSRE38937E1Unwanted flowImprove efficiencyAfter-treatment apparatusPolycrystalline material growthDopantSusceptor

It was an objective of the present invention to provide a susceptor which can prevent a increasing phenomenon of the dopant concentration of the epitaxial layer at the peripheral portion of the wafer. By providing a through-hole 7 passing through to a rear side at the outer peripheral side of the wafer inside the wafer pocket 6, a down flow of a reacting source gas from the upper surface of the susceptor 5 is formed, so that the unwanted flow of the dopant species being exhausted at the rear surface onto the wafer surface can be avoided. As a result, a raise in the dopant concentration at the outer peripheral portion of the epitaxial layer 9 can be controlled.

Owner:SUMITOMO MITSUBISHI SILICON CORP

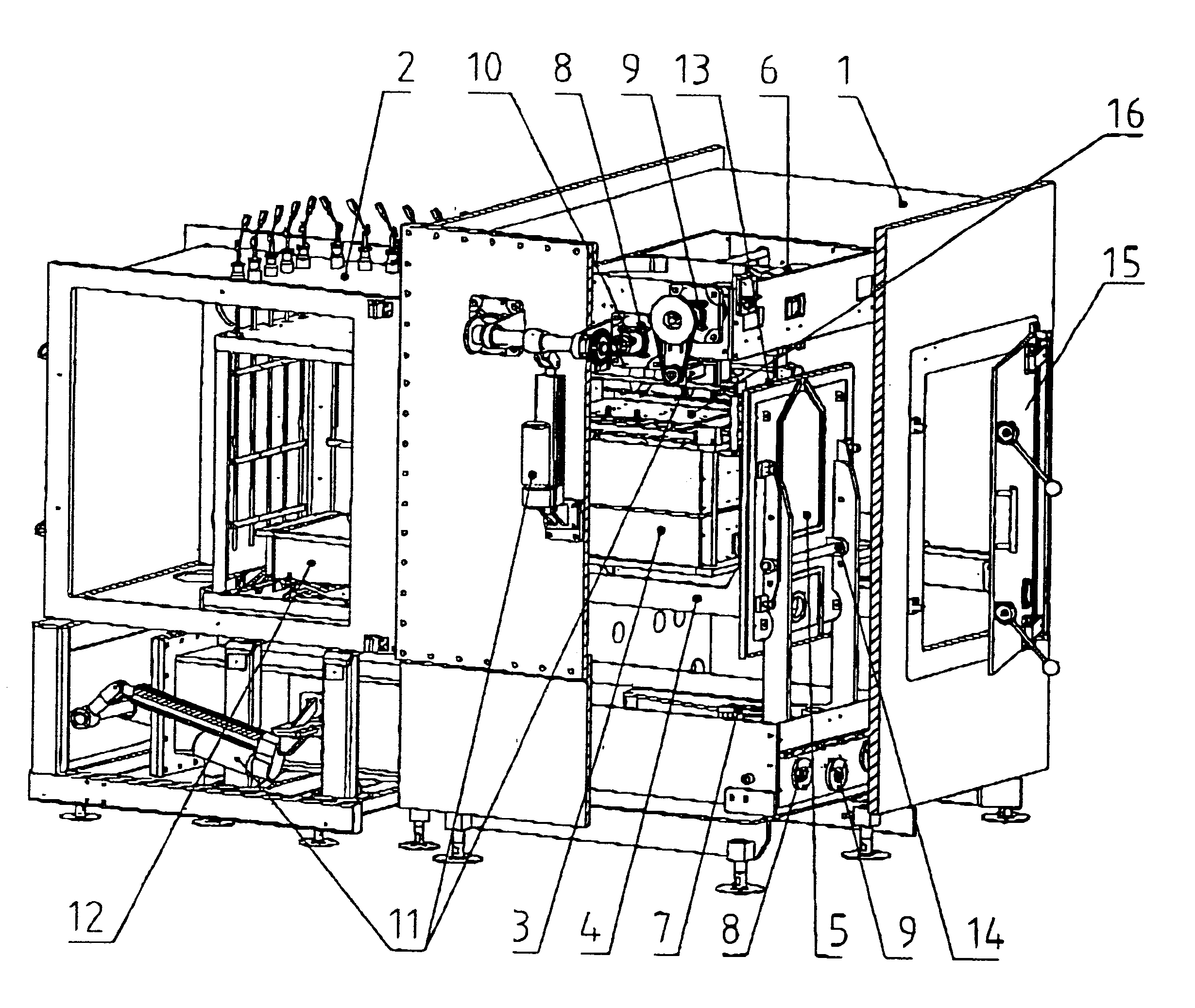

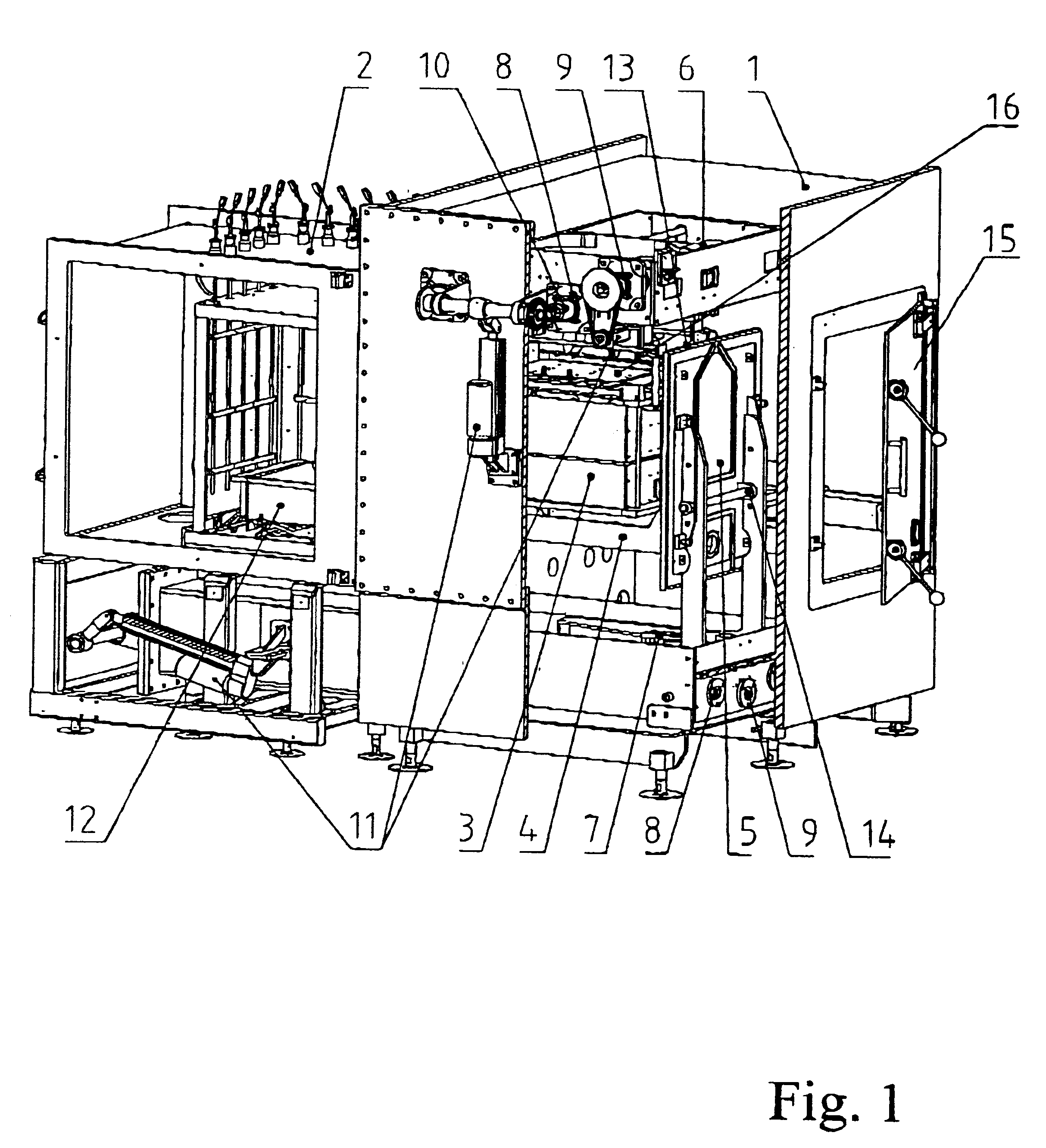

Equipment for manufacturing semiconductor

InactiveUS20140190410A1Avoid formingAfter-treatment apparatusPolycrystalline material growthSemiconductorMaterials science

Provided is an equipment for manufacturing a semiconductor. The equipment for manufacturing a semiconductor includes a cleaning chamber in which a cleaning process is performed on substrates, an epitaxial chamber in which an epitaxial process for forming an epitaxial layer on each of the substrates is performed, and a transfer chamber to which the cleaning chamber and the epitaxial chamber are connected to sides surfaces thereof, the transfer chamber including a substrate handler for transferring the substrates, on which the cleaning process is completed, into the epitaxial chamber.

Owner:EUGENE TECH CO LTD

Equipment for manufacturing semiconductor

InactiveUS20140174357A1Avoid formingAfter-treatment apparatusSemiconductor/solid-state device manufacturingSemiconductorMaterials science

Provided is an equipment for manufacturing a semiconductor. The equipment for manufacturing a semiconductor includes a cleaning chamber in which a cleaning process is performed on substrates, an epitaxial chamber in which an epitaxial process for forming an epitaxial layer on each of the substrates is performed, and a transfer chamber to which the cleaning chamber and the epitaxial chamber are connected to sides surfaces thereof, the transfer chamber including a substrate handler for transferring the substrates, on which the cleaning process is completed, into the epitaxial chamber. The cleaning chamber is performed in a batch type with respect to the plurality of substrates.

Owner:EUGENE TECH CO LTD

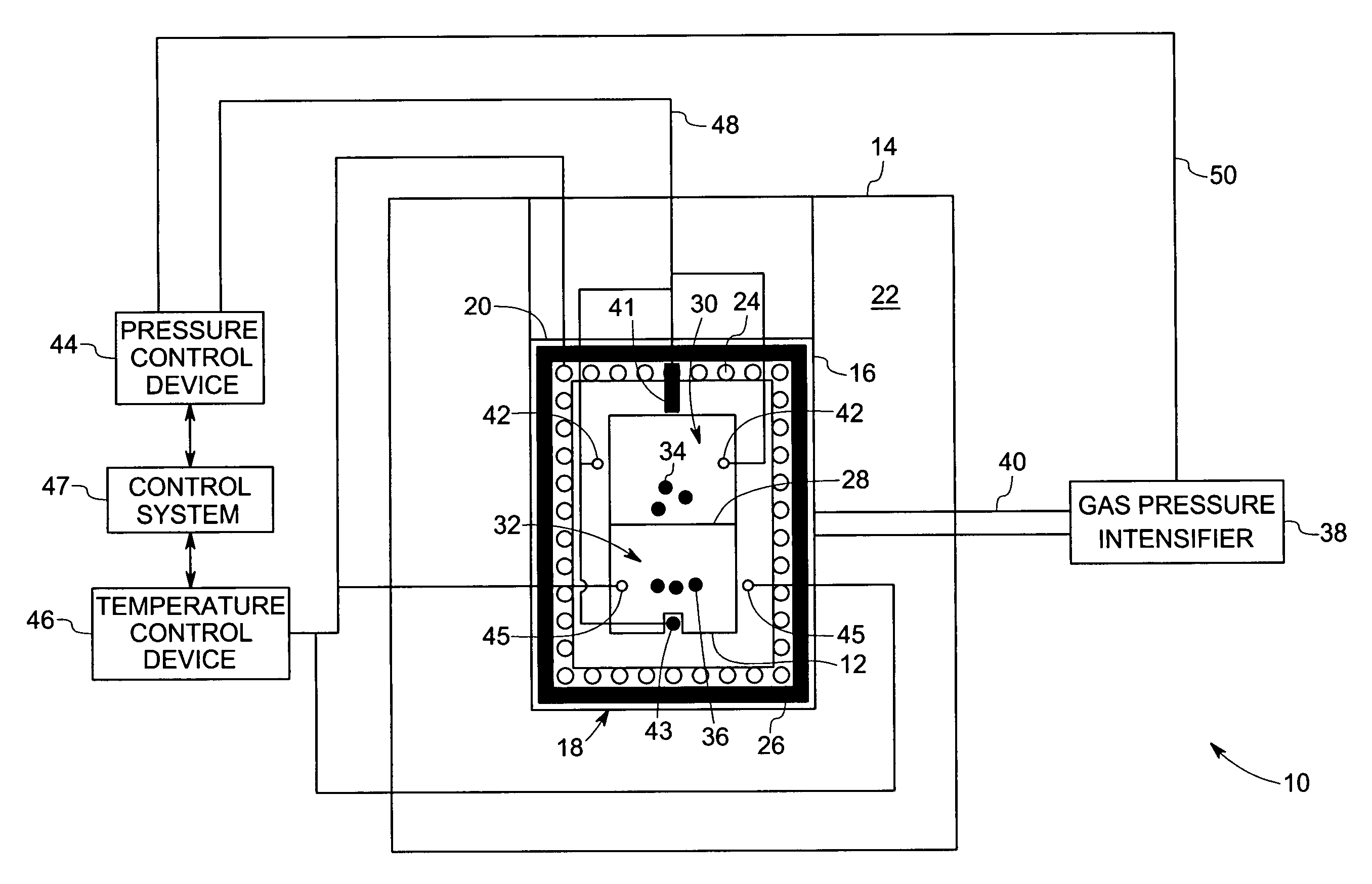

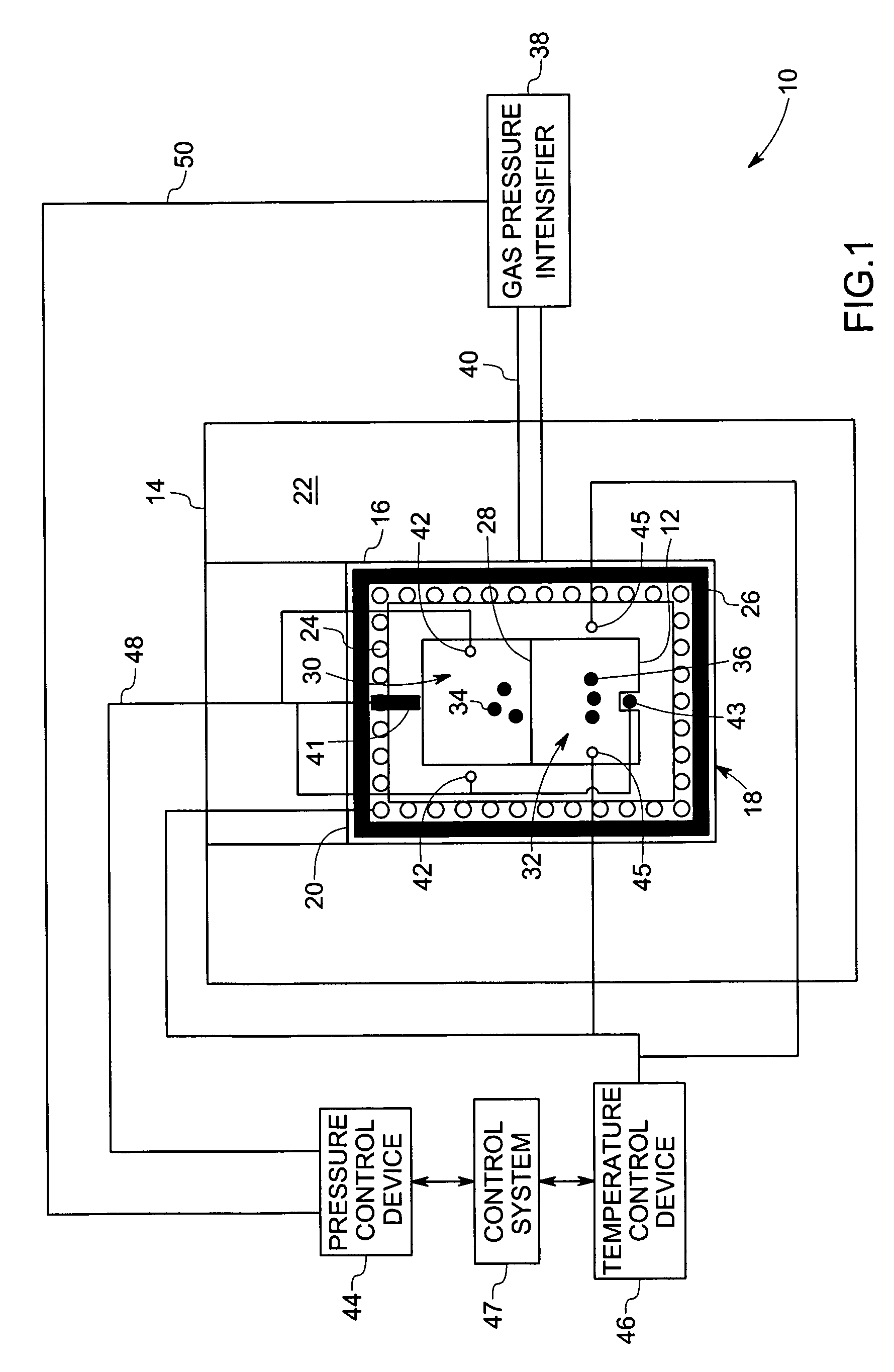

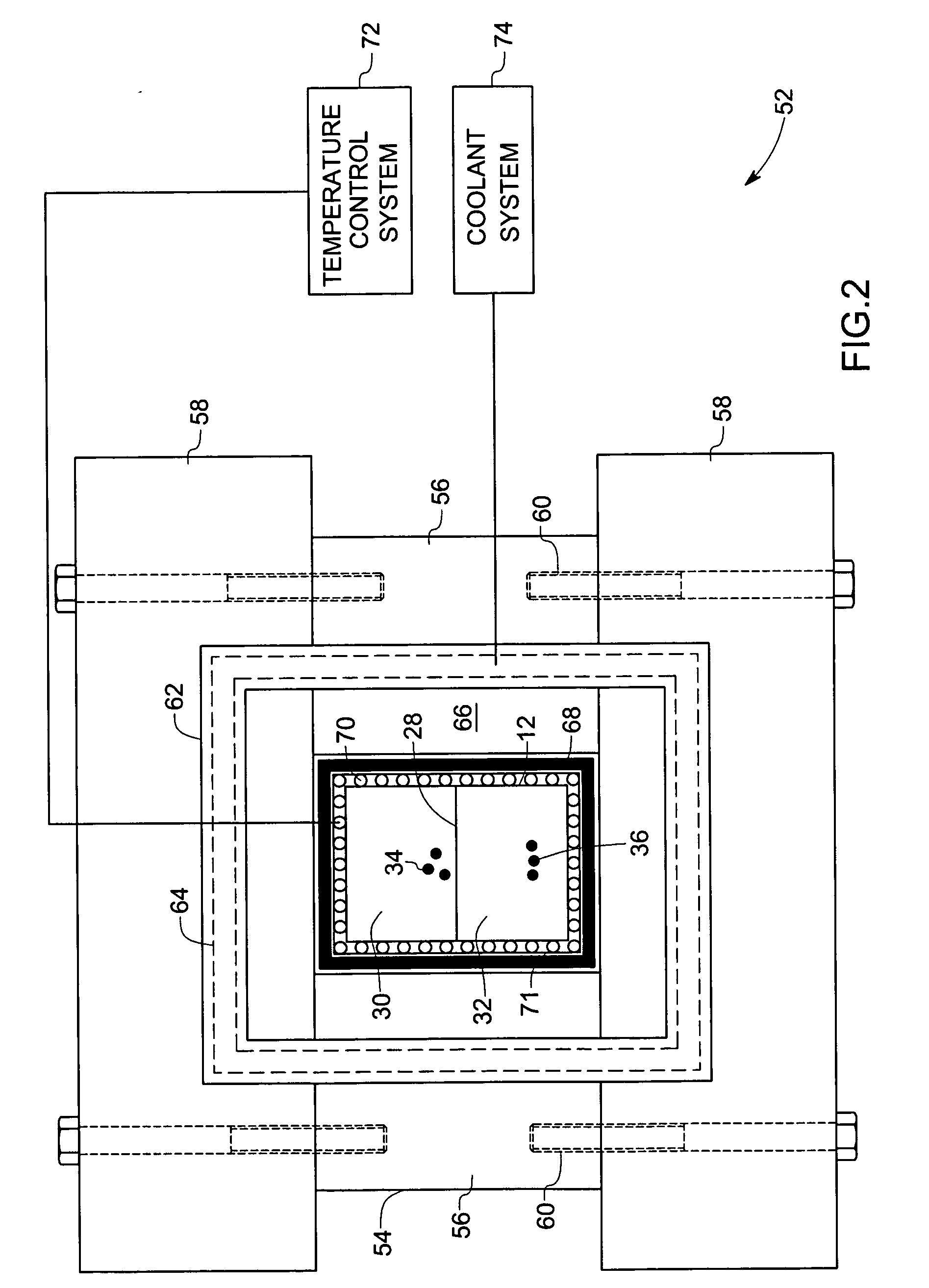

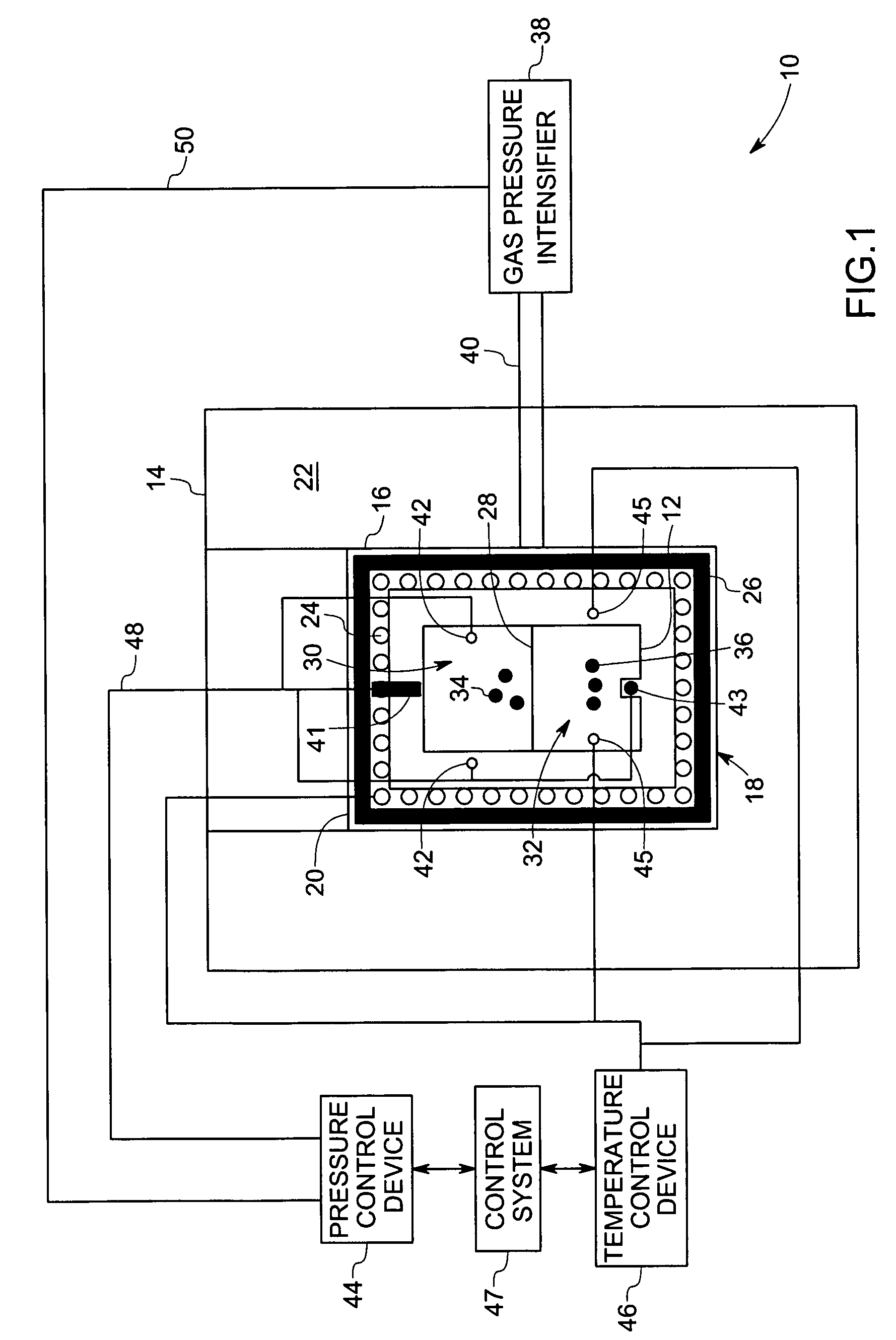

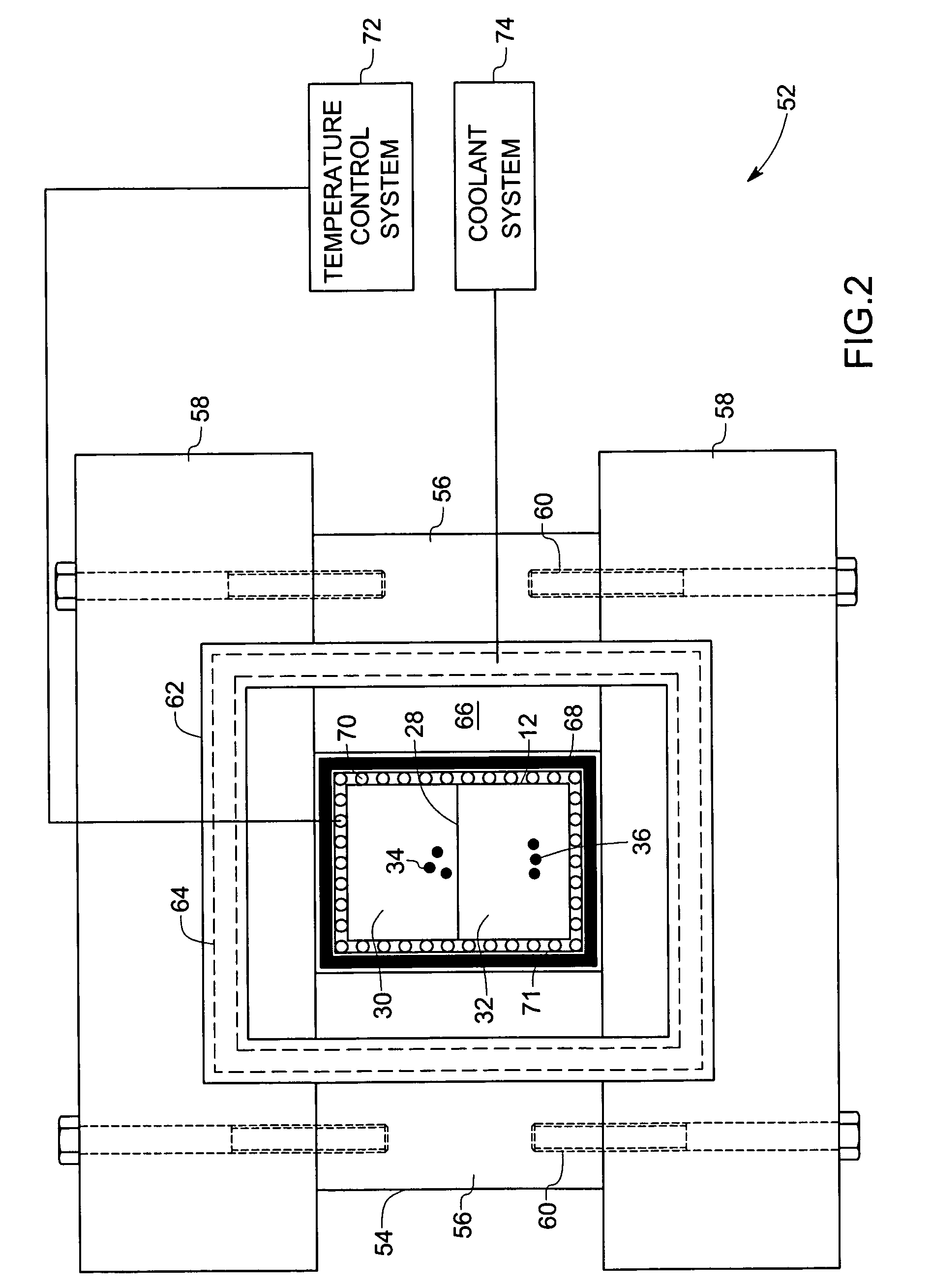

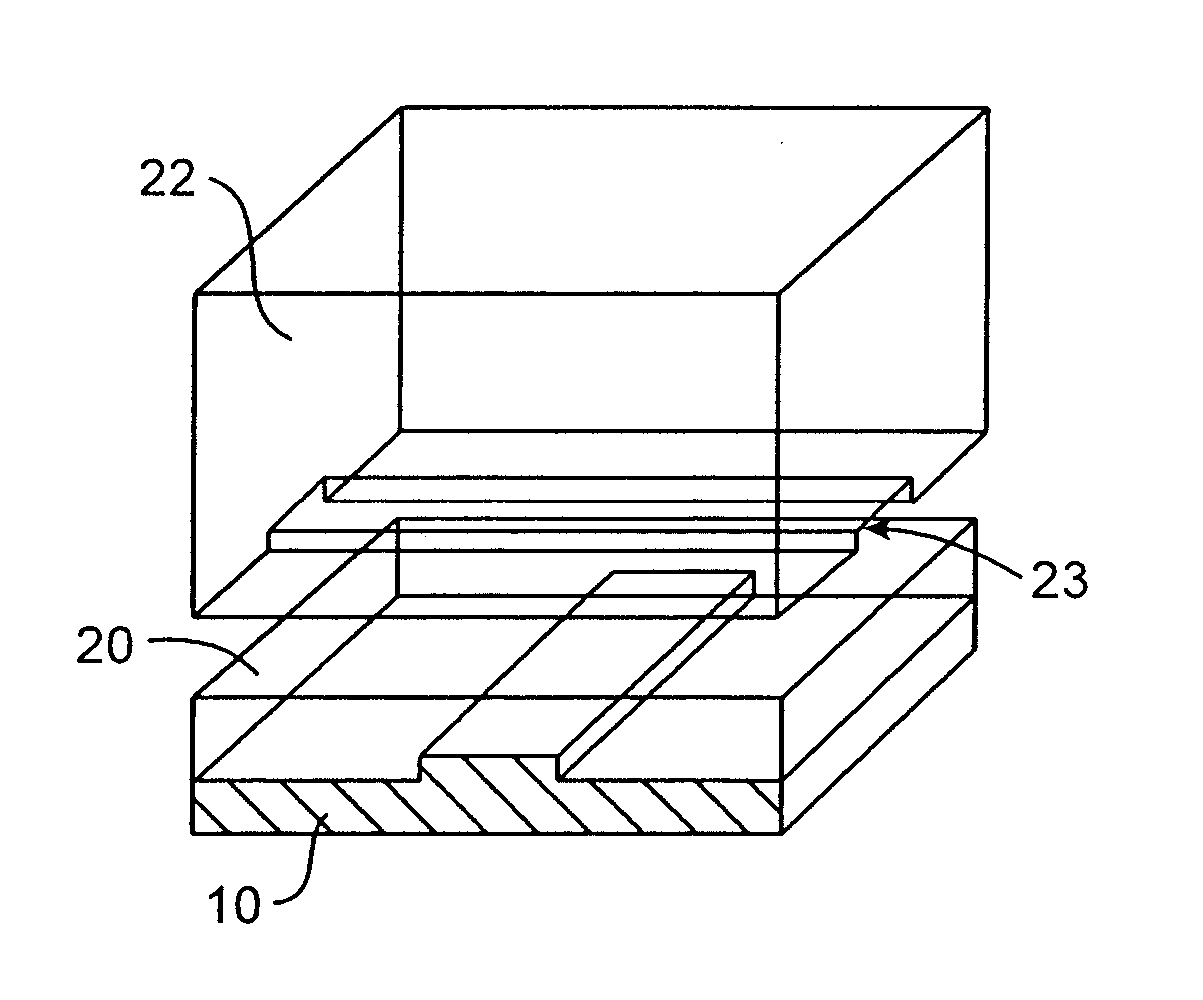

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS20060177362A1After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

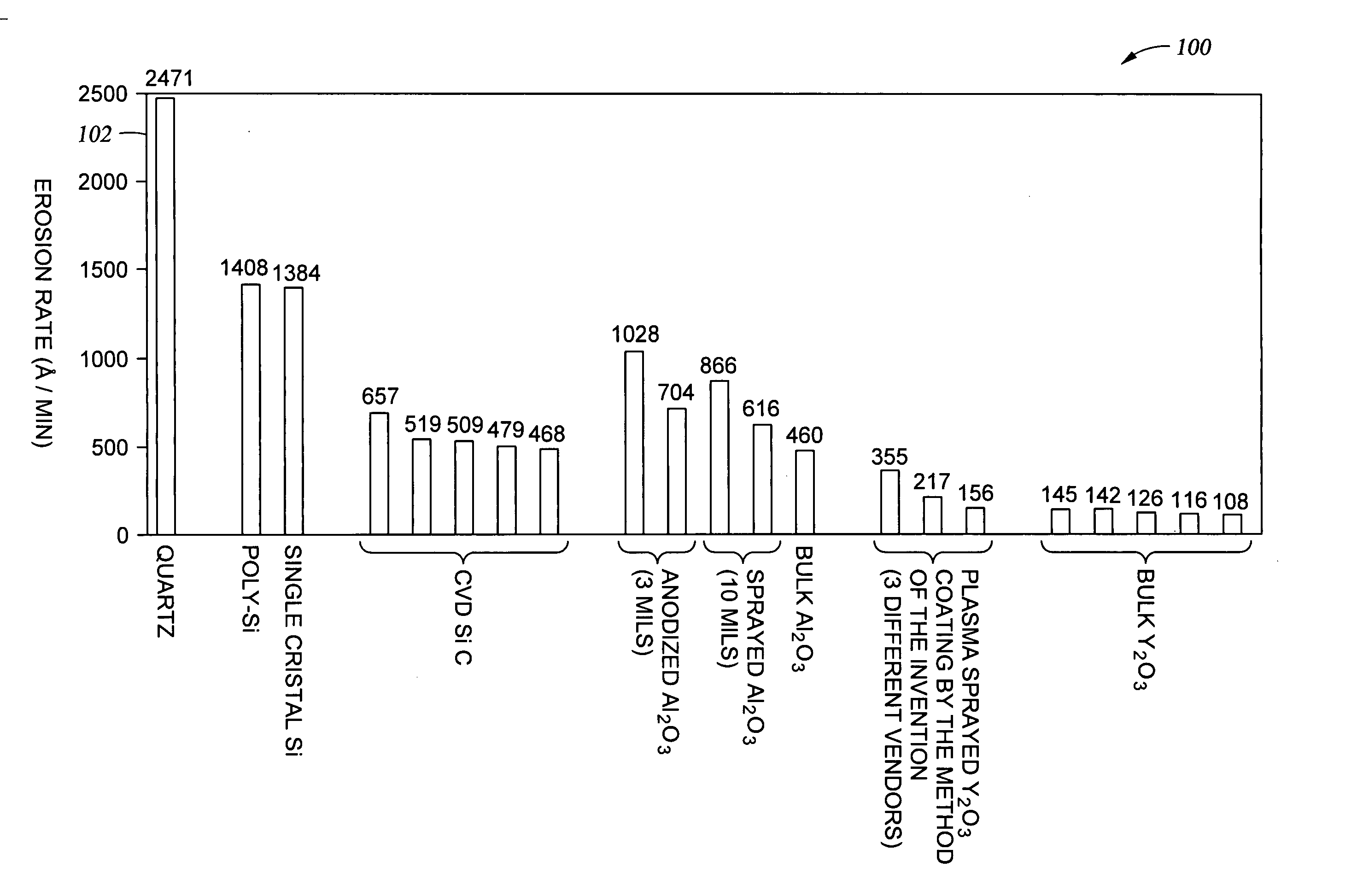

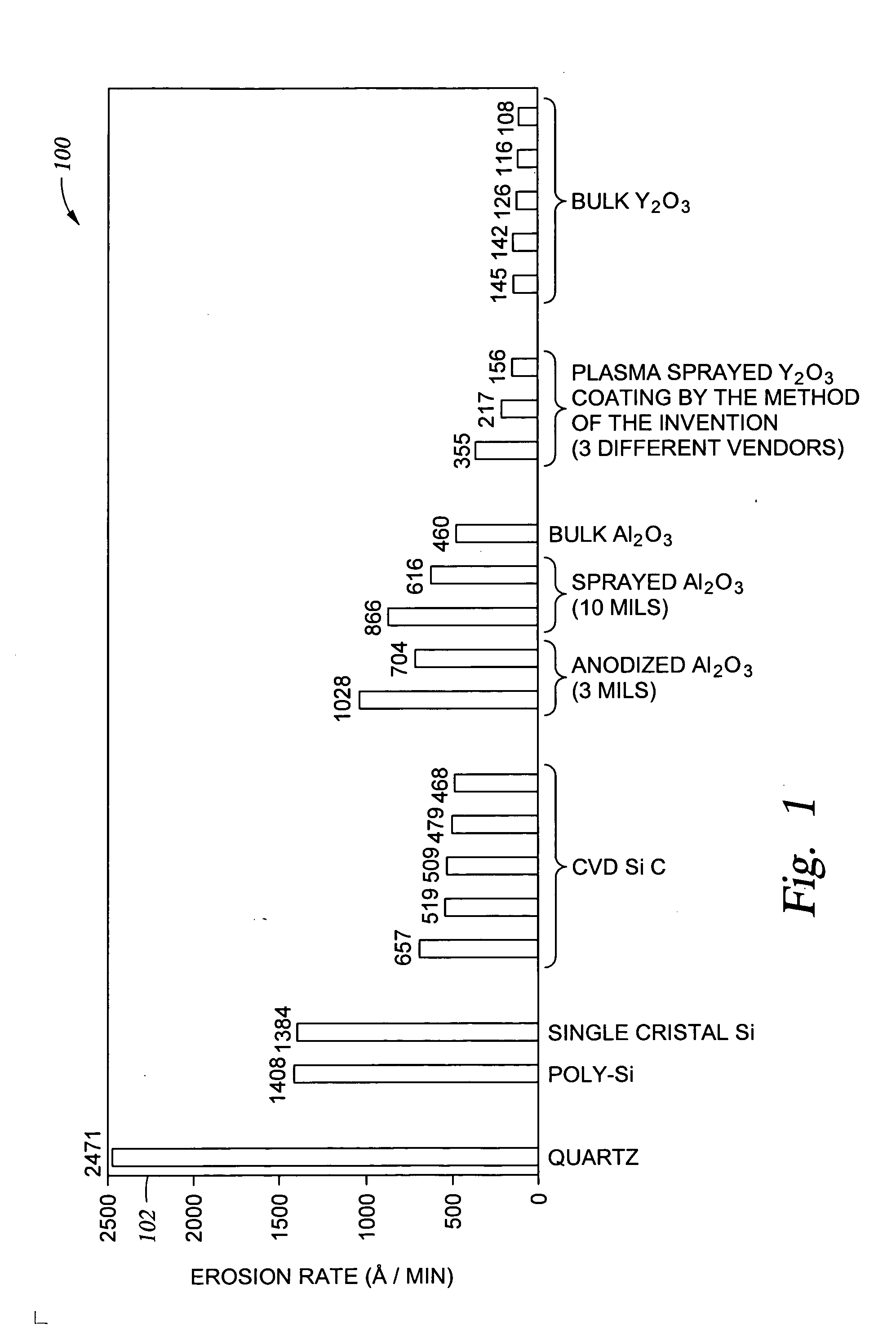

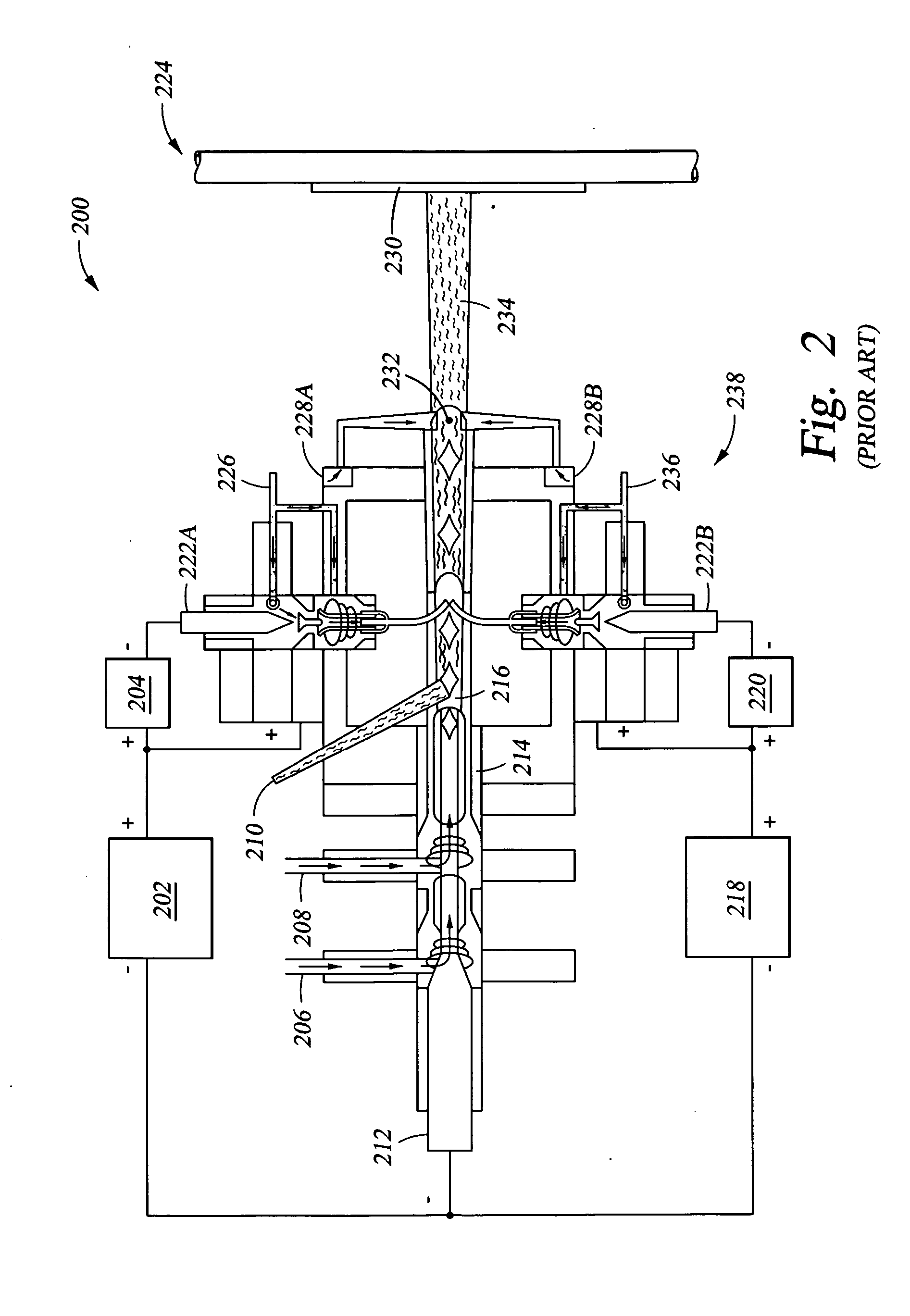

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

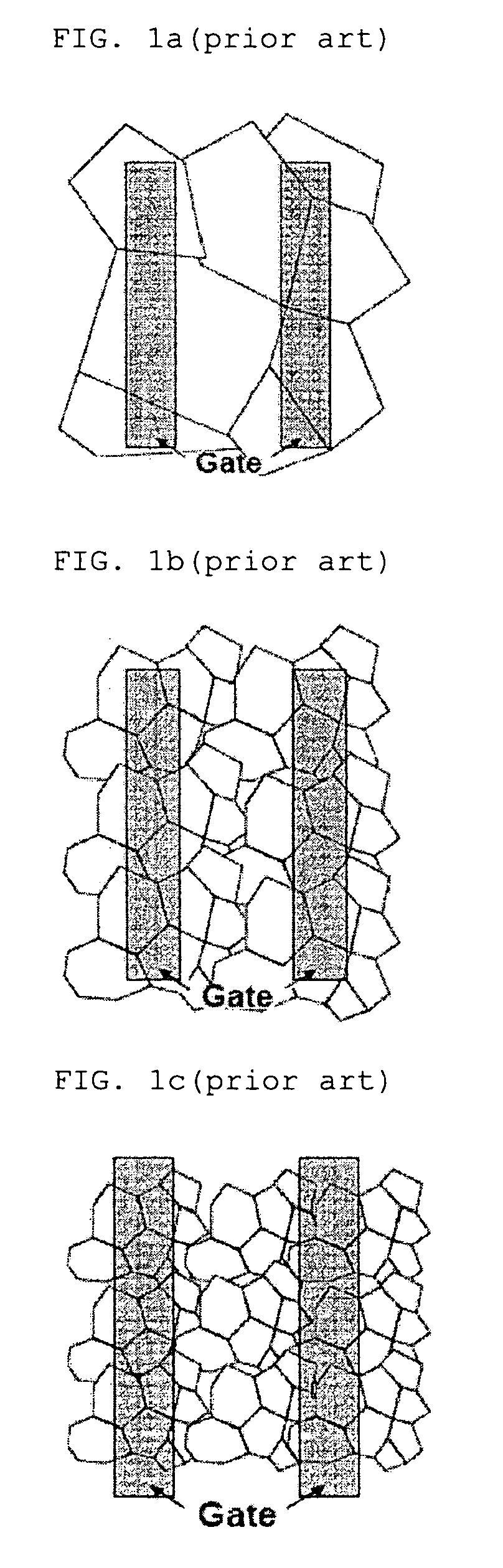

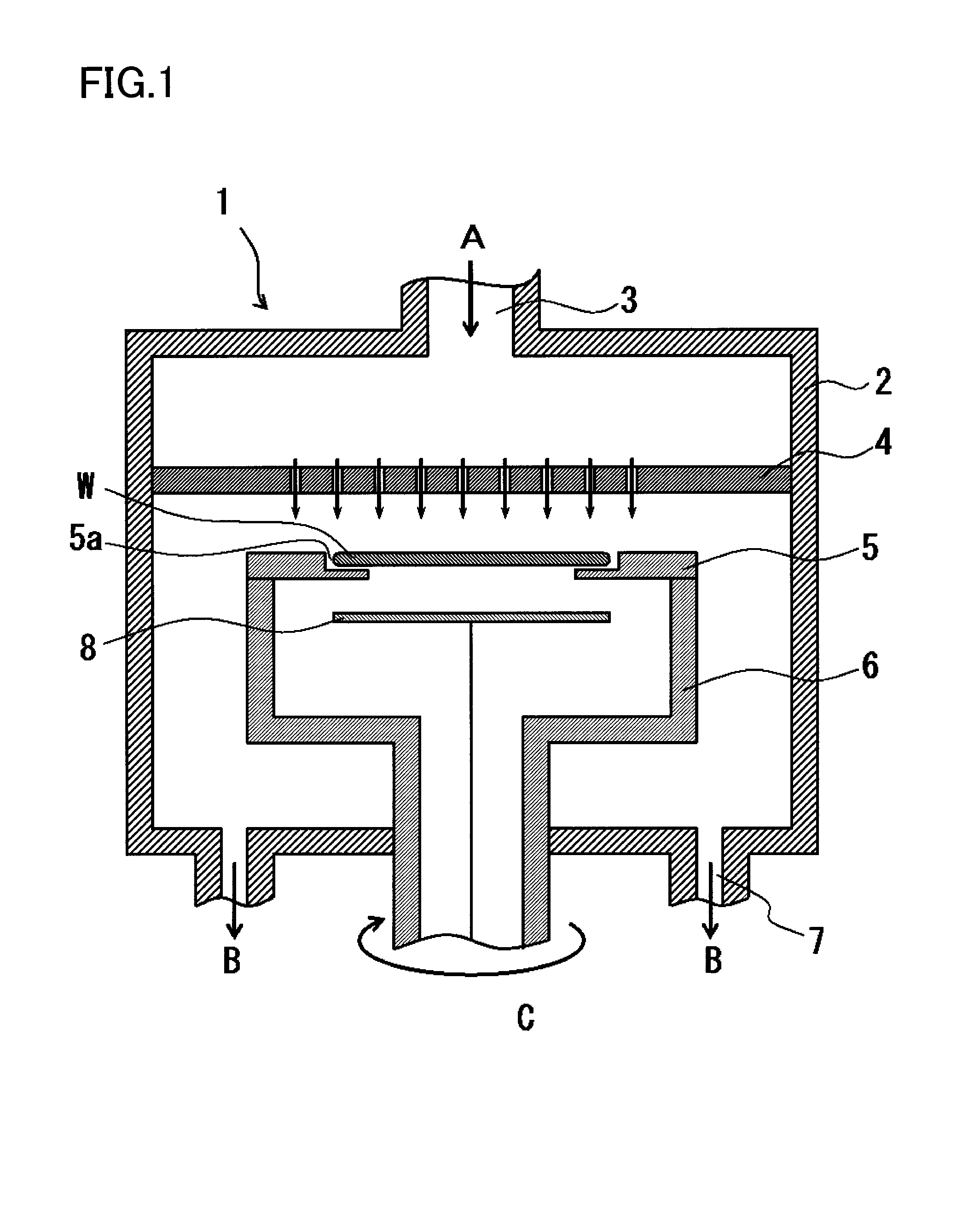

Epitaxial growth film formation method

ActiveUS8404044B2Avoid stickingAvoid formingAfter-treatment apparatusPolycrystalline material growthEngineeringVapor growth

An epitaxial growth film formation method allowing to adequately prevent the sticking phenomenon spreading over both a wafer and a susceptor when a horizontal disc-like susceptor is used to form an epitaxial growth film is provided. The epitaxial growth film formation method is a method of forming a vapor growth film on the wafer by placing the wafer having a diameter smaller than that of the susceptor approximately horizontally in substantially a center section on the horizontal disc-like susceptor, wherein the vapor growth film is formed on the wafer by bringing a circumferential recess step adjacent to a bottom inside from an edge part of the wafer and a convex step provided on a circumference of an upper surface inside from the edge part of the susceptor into contact.

Owner:NUFLARE TECH INC

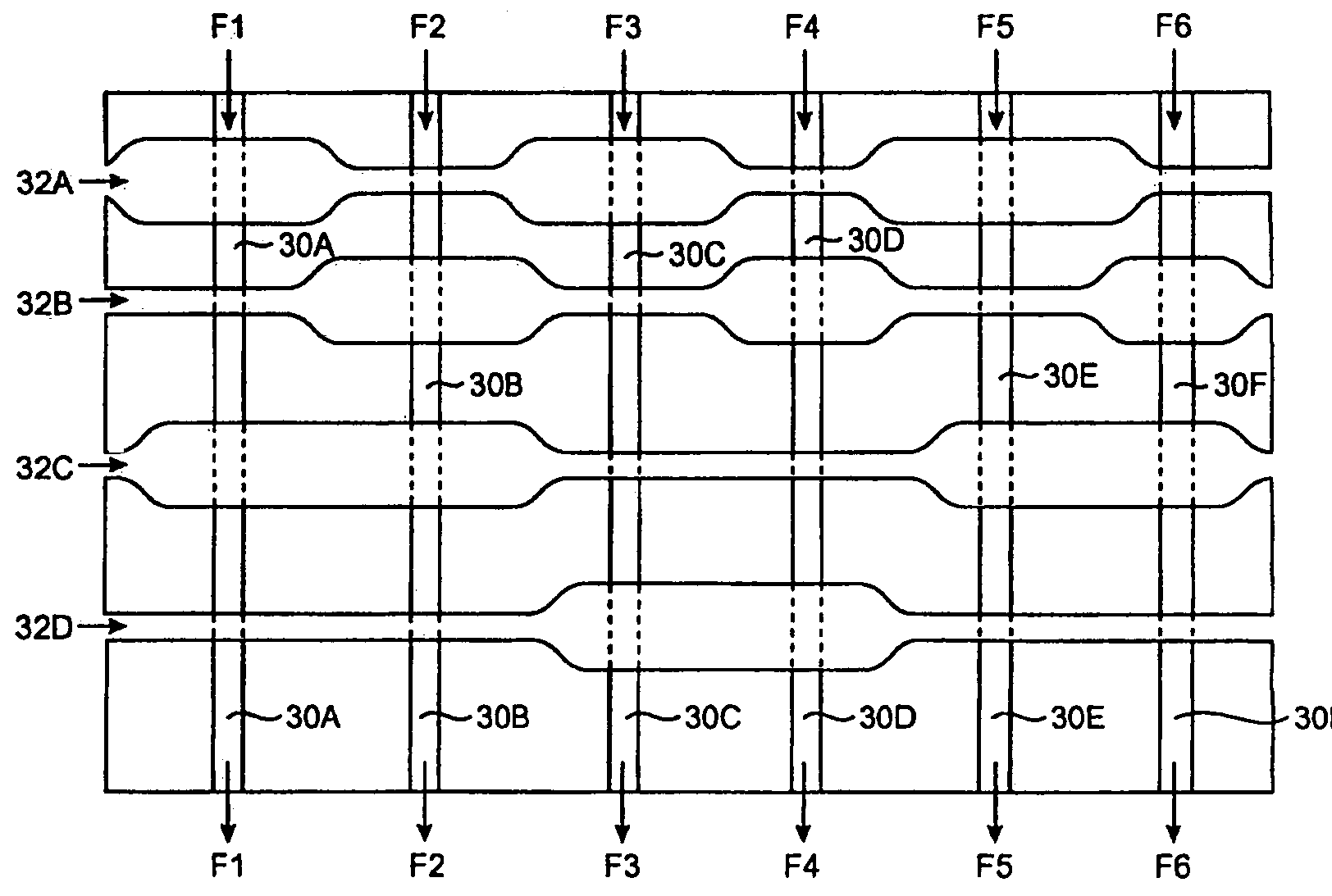

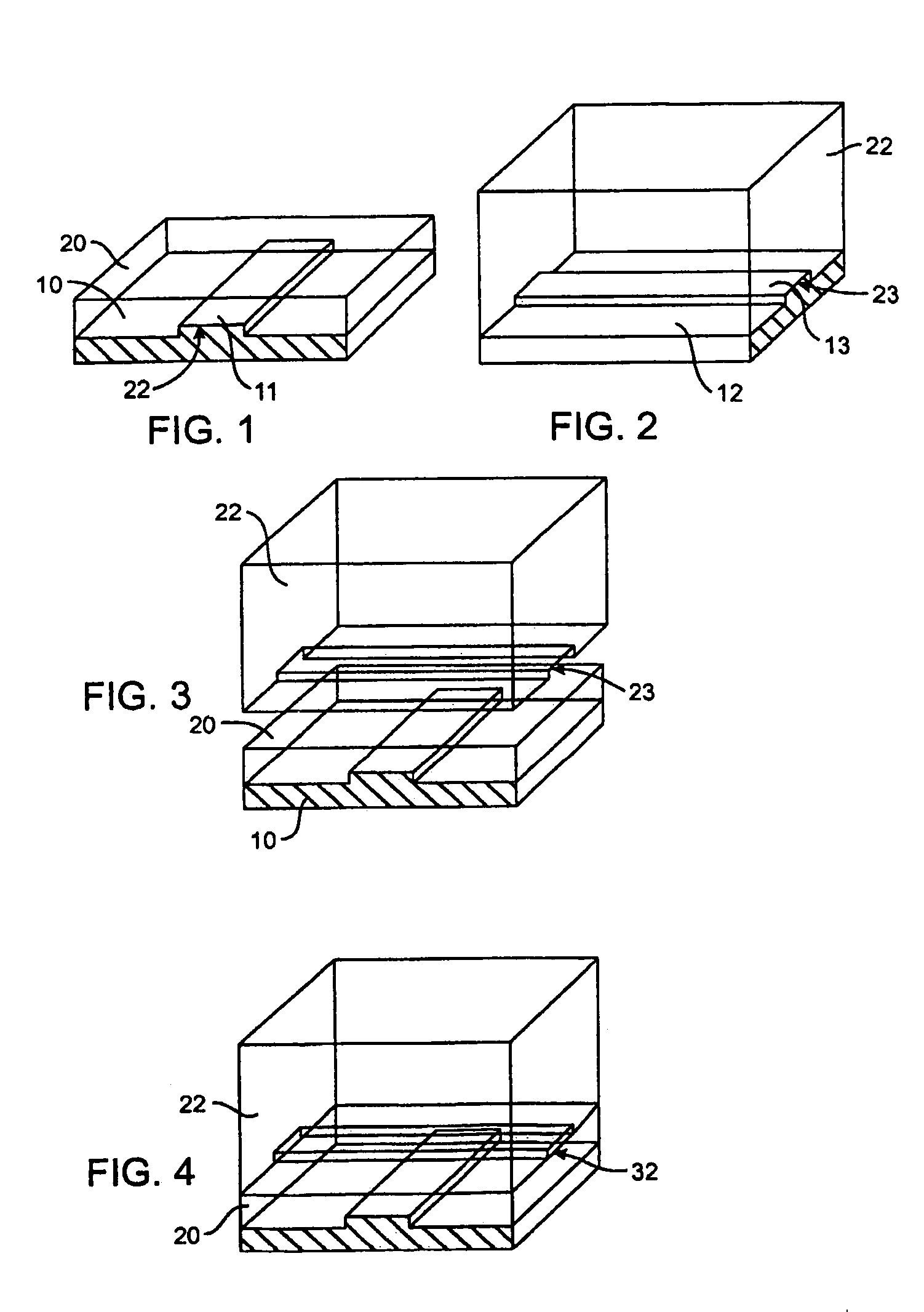

Apparatus for growing thin films

InactiveUS6447607B2Uniform thicknessAvoid possibilityAfter-treatment apparatusPolycrystalline material growthEngineeringVapor phase

The invention relates to an apparatus for growing thin films onto the surface of a substrate by exposing the substrate to alternately repeated surface reactions of vapor-phase reactants. The apparatus comprises at least one process chamber having a tightly sealable structure, at least one reaction chamber having a structure suitable for adapting into the interior of said process chamber and comprising a reaction space of which at least a portion is movable, infeed means connectable to said reaction space for feeding said reactants into said reaction space, and outfeed means connectable to said reaction space for discharging excess reactants and reaction gases from said reaction space, and at least one substrate adapted into said reaction space. At least one loading chamber is arranged to cooperate with said process chamber so as to permit said reaction space or a portion thereof to be moved into said process chamber and away from said process chamber and, further, the operating pressure of the loading chamber is arranged to be controllable independently from said pressure chamber.

Owner:ASM INTERNATIONAL

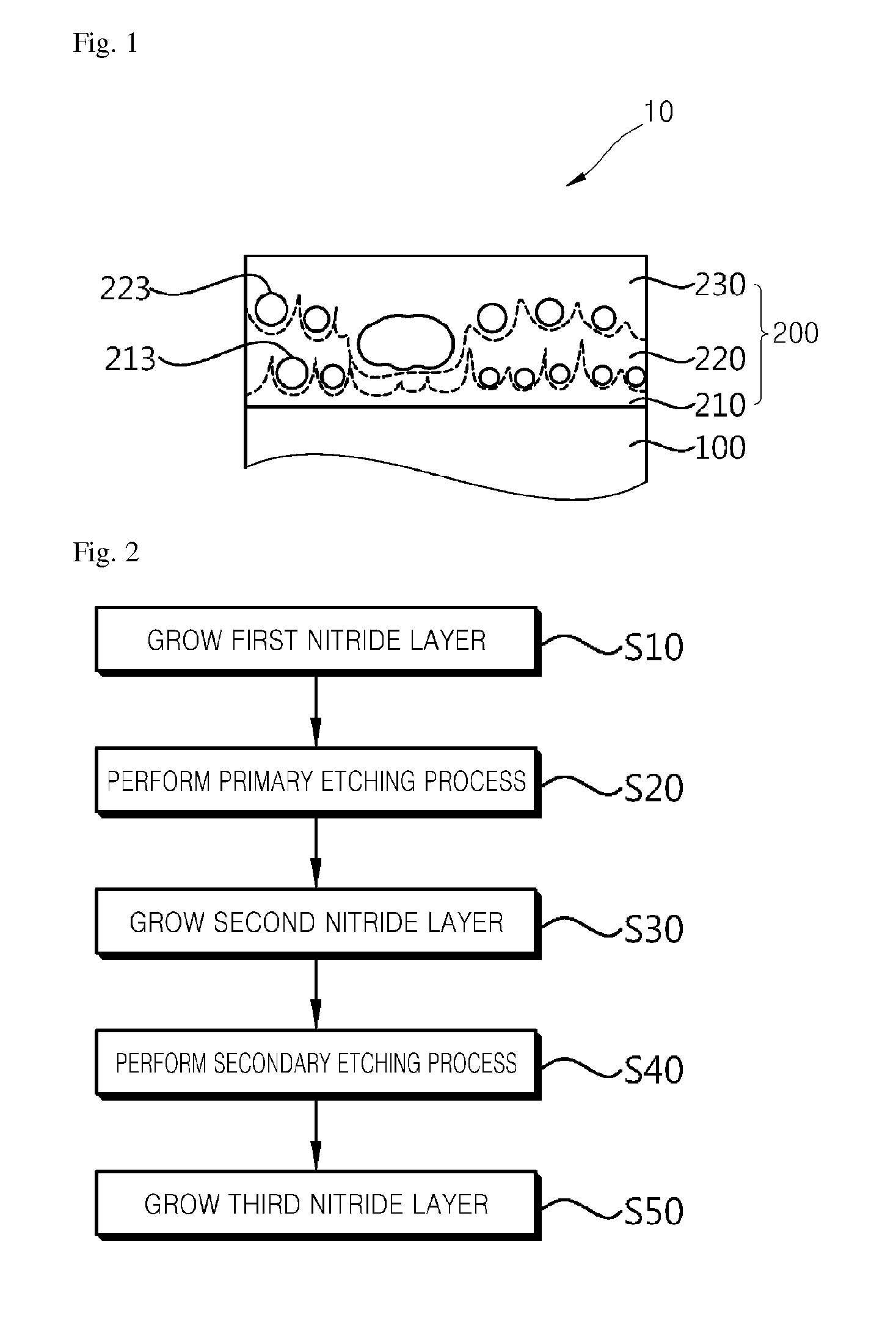

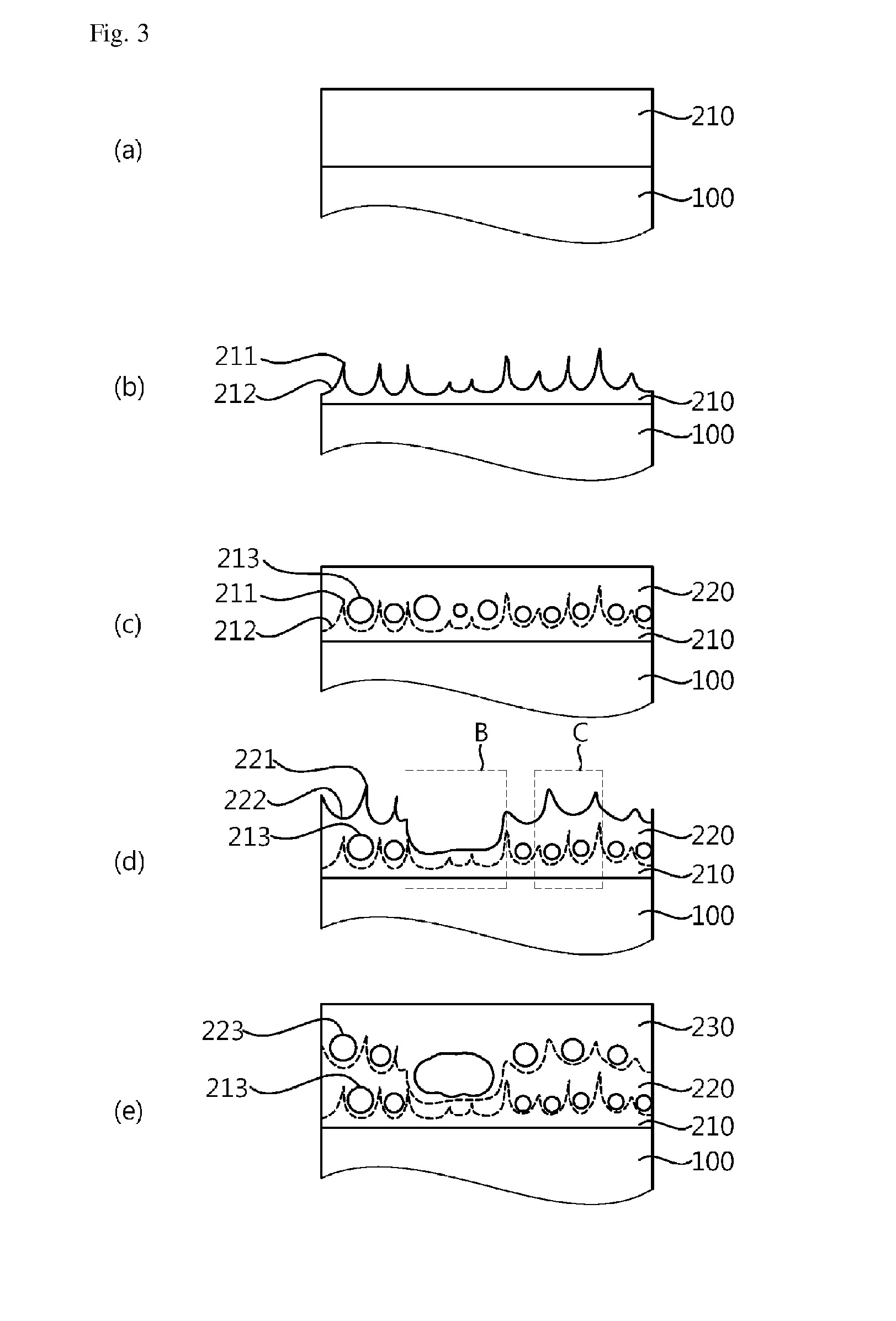

Template, method for manufacturing the template and method for manufacturing vertical type nitride-based semiconductor light emitting device using the template

InactiveUS20120187444A1Relieve pressureAvoid misalignmentAfter-treatment apparatusPolycrystalline material growthChlorideLight emitting device

Disclosed herein is a method for manufacturing a template. The method includes growing a first nitride layer on a substrate; etching a top surface of the first nitride layer by supplying a chloride-based etching gas thereto; forming a plurality of first voids by growing a second nitride layer on the top surface of the first nitride layer; etching a top surface of the second nitride layer by supplying the etching gas thereto; and forming a plurality of second voids by growing a third nitride layer on the top surface of the second nitride layer. A method for manufacturing a nitride-based semiconductor light emitting device using the template is also disclosed. As a result, stress between lattices and dislocation defects are reduced by a plurality of voids formed in a nitride buffer layer, thereby improving quality of nitride layers grown in a template. In the case where a light emitting device is manufactured using the template, it is possible to improve workability of the manufacturing process and to enhance luminous efficacy of the light emitting device.

Owner:SEMIMATERIALS +1

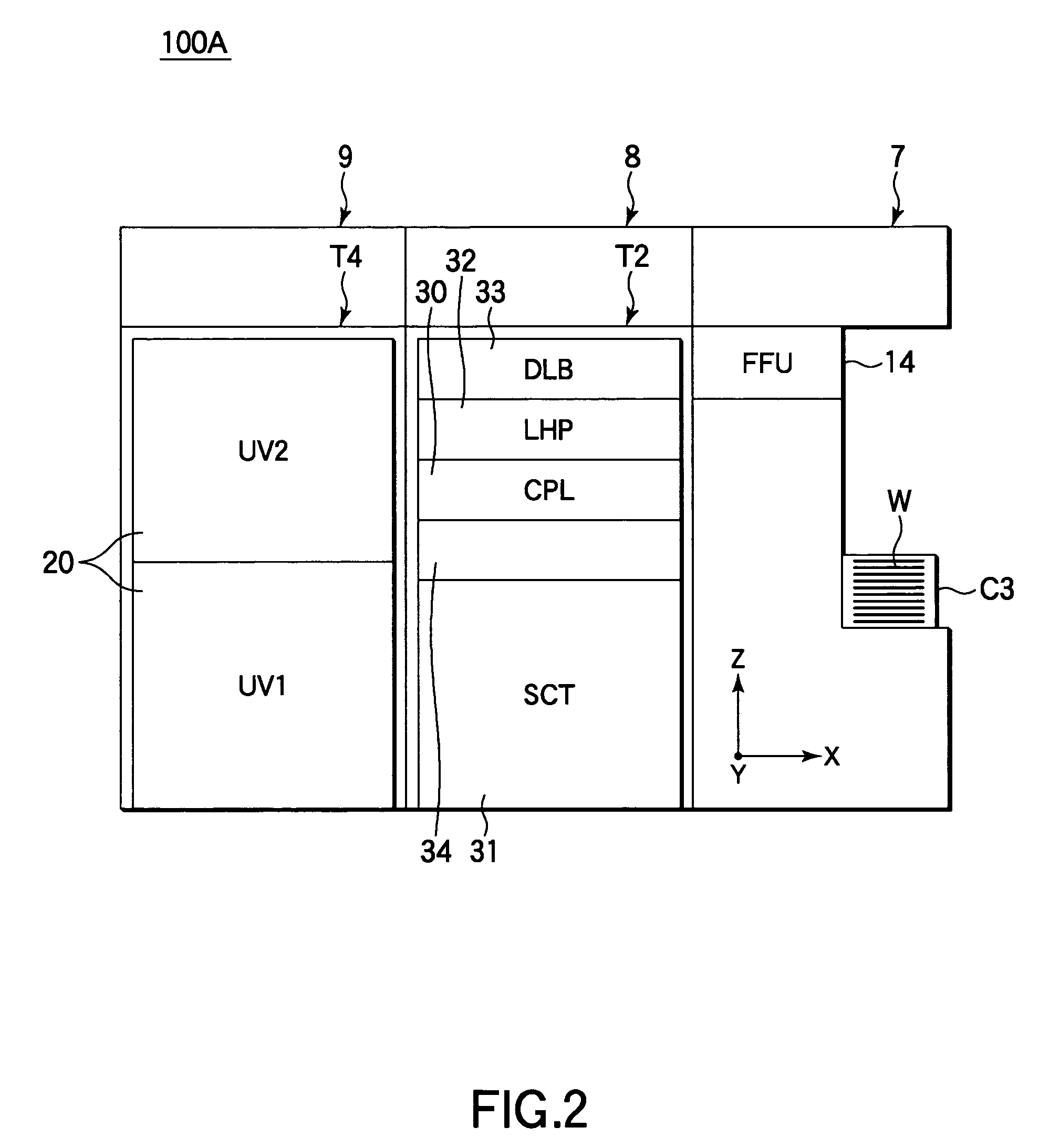

Substrate processing apparatus and method

InactiveUS7867926B2Low costStable controlAfter-treatment apparatusSemiconductor/solid-state device manufacturingTarget surfaceEngineering

A substrate processing apparatus is used for radiating UV rays onto a target film formed on a target surface of a substrate to perform a curing process of the target film. The apparatus includes a hot plate configured to heat the substrate to a predetermined temperature, a plurality of support pins disposed on the hot plate to support the substrate, and a UV radiating device configured to radiate UV rays onto the target surface of the substrate supported on the support pins. The support pins are preset to provide a predetermined thermal conductivity to conduct heat of the substrate to the hot plate. The hot plate is preset to have a predetermined thermal capacity sufficient to absorb heat conducted through the support pins.

Owner:TOKYO ELECTRON LTD

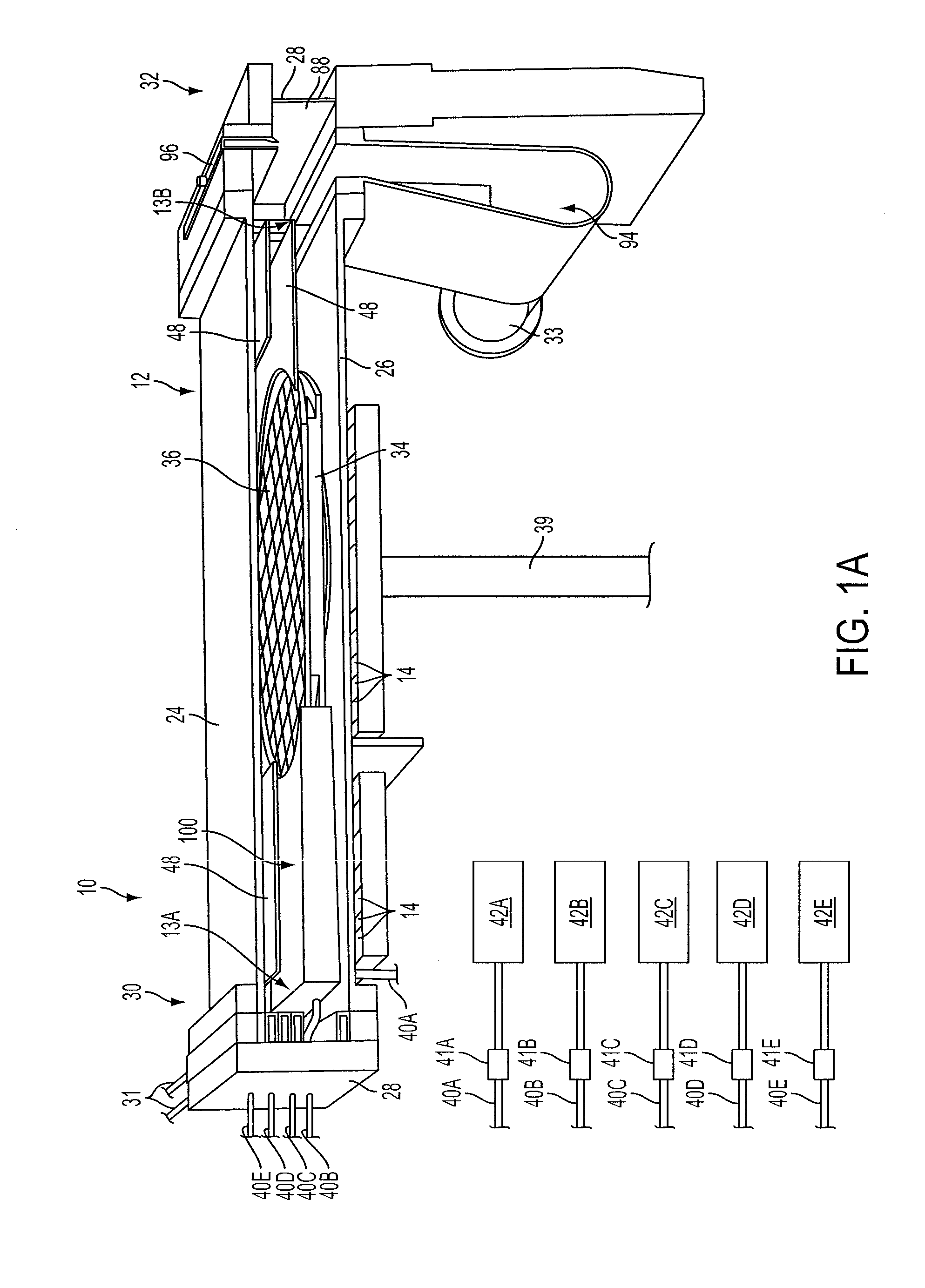

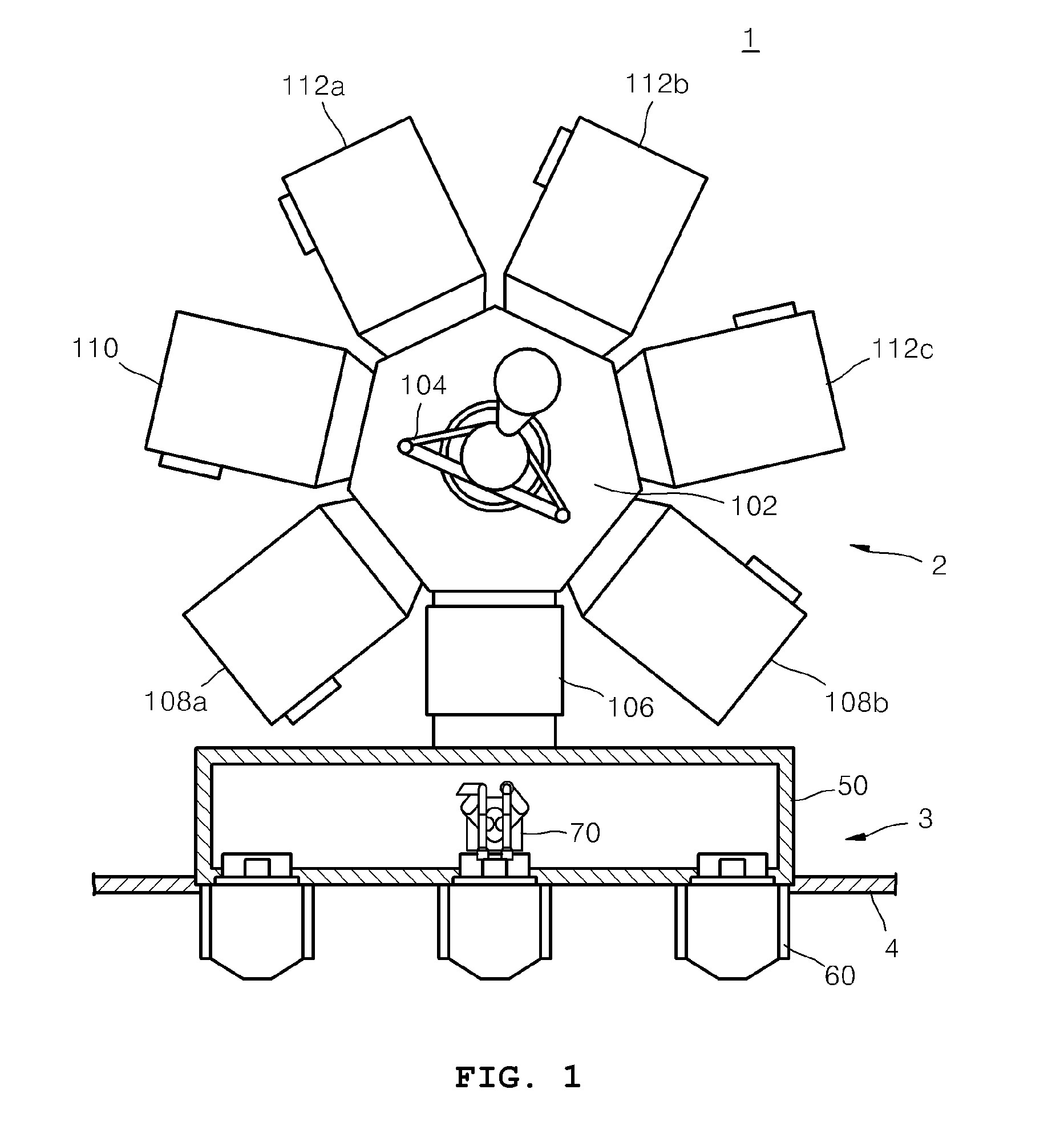

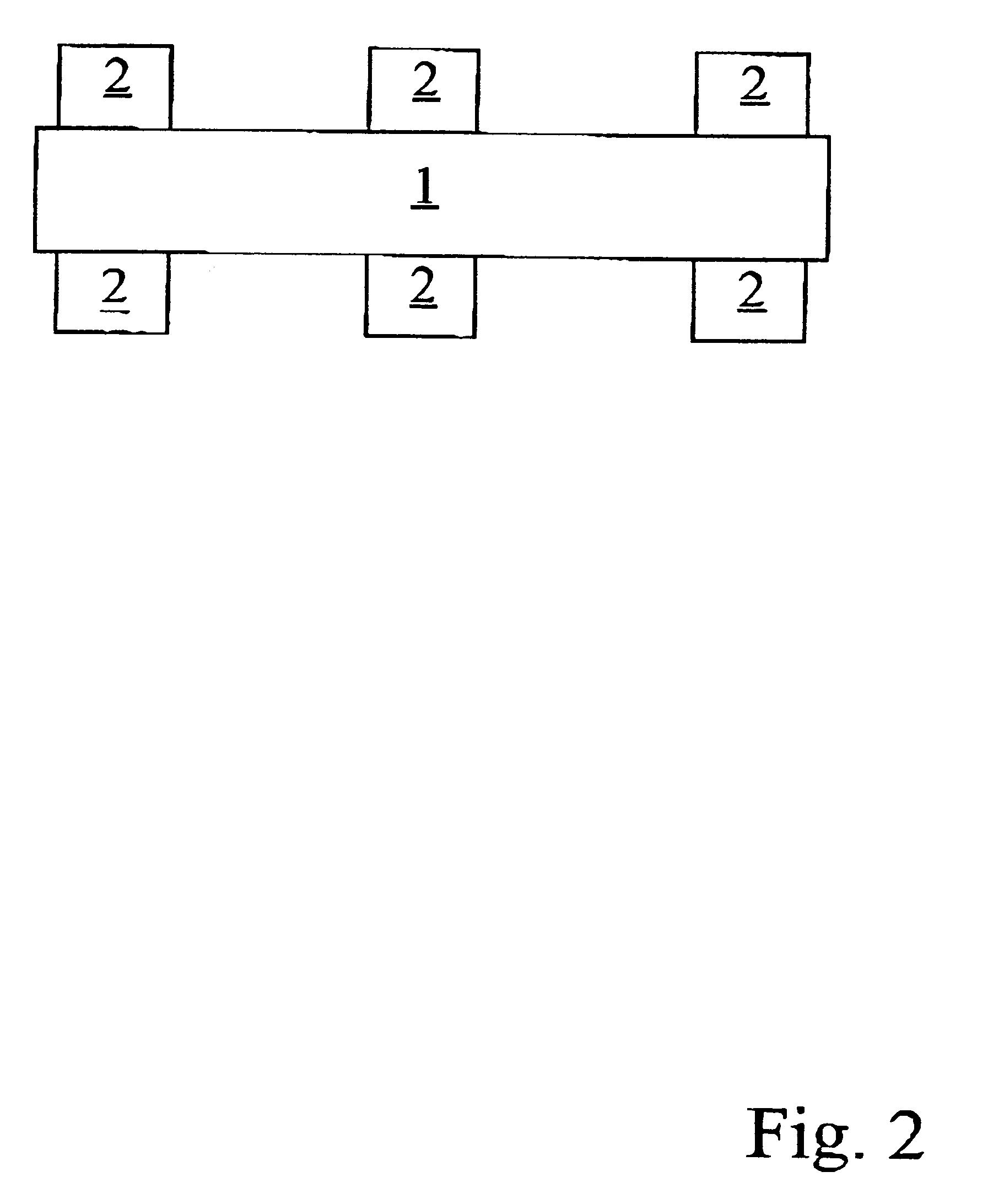

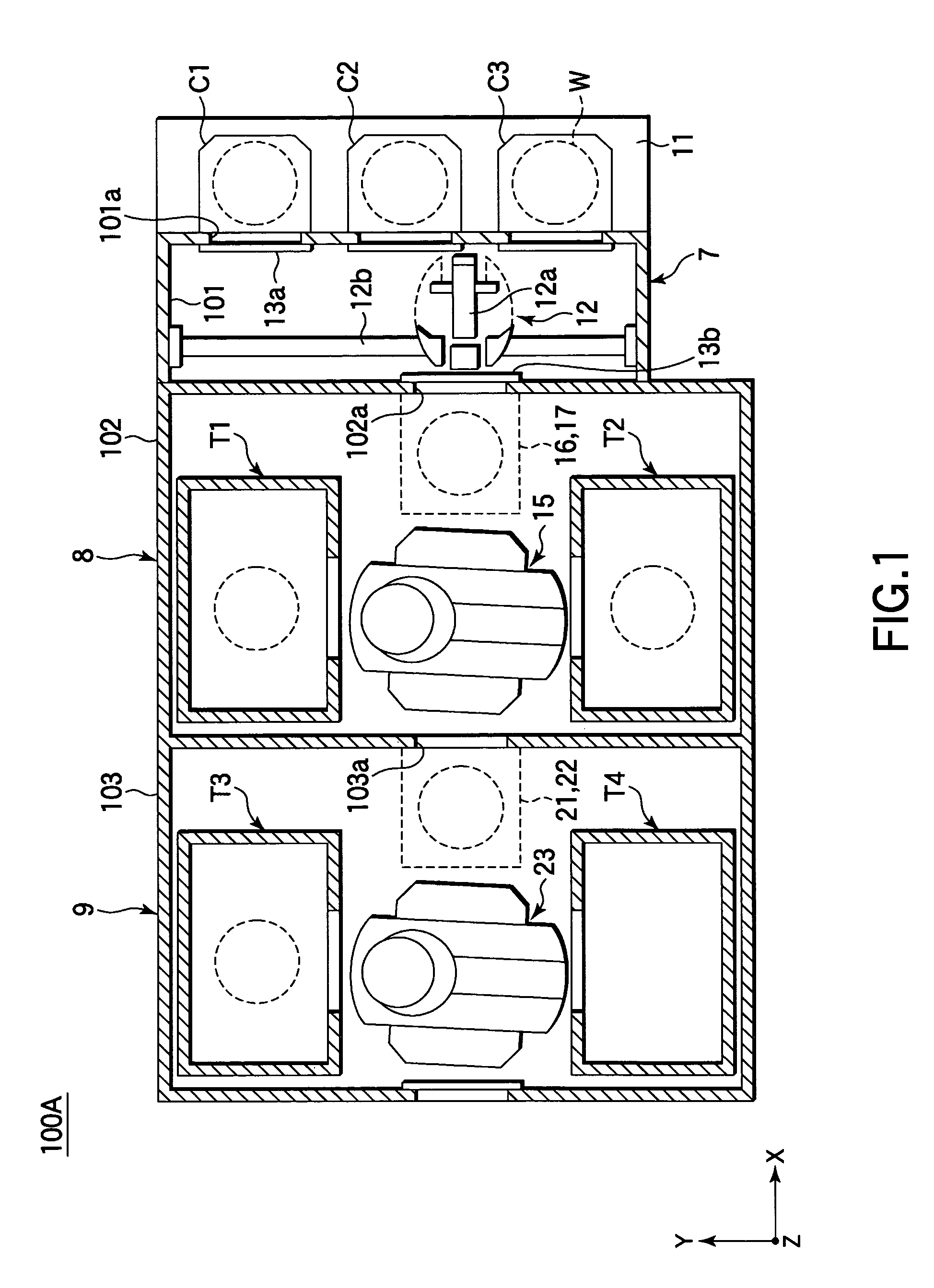

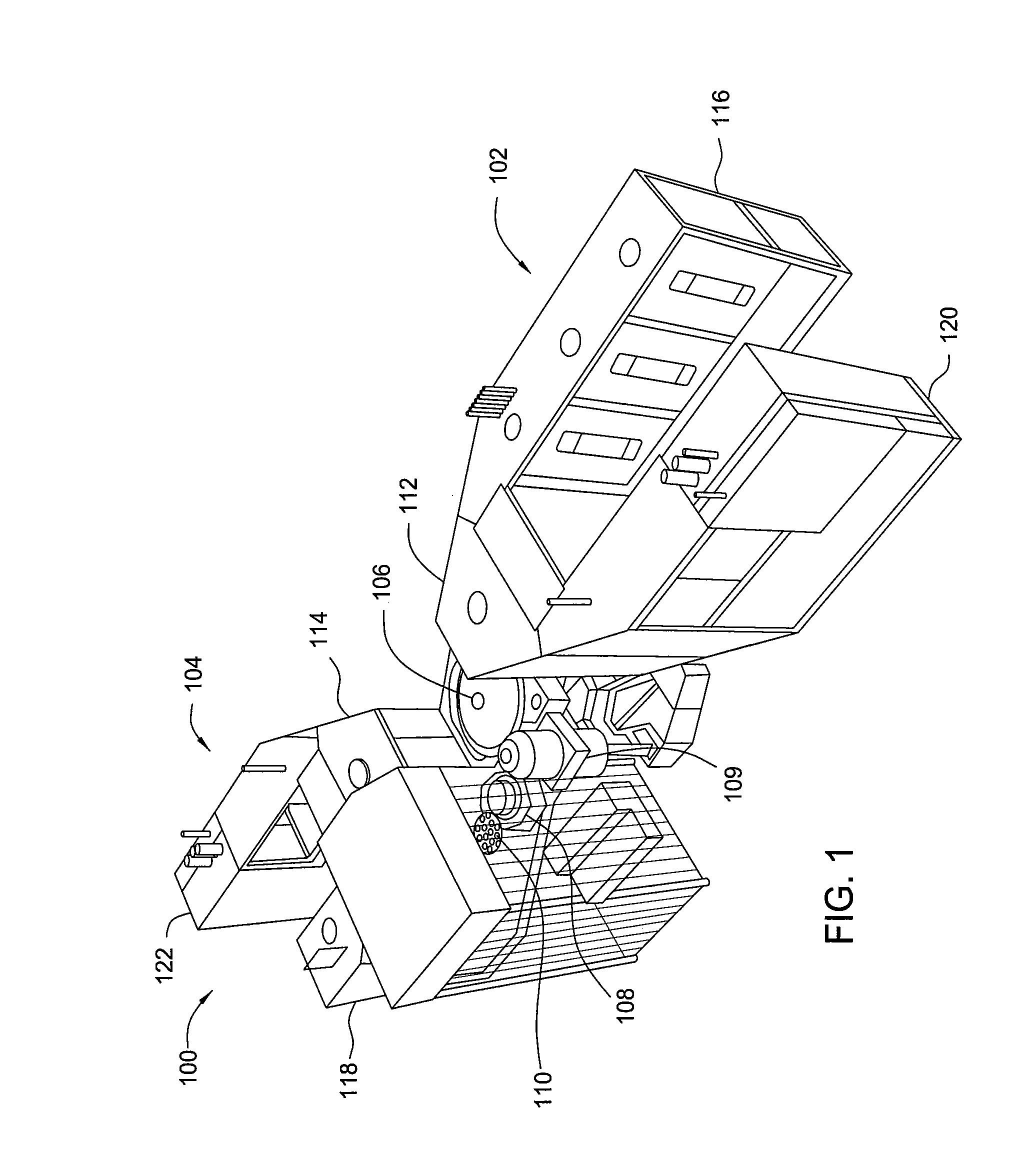

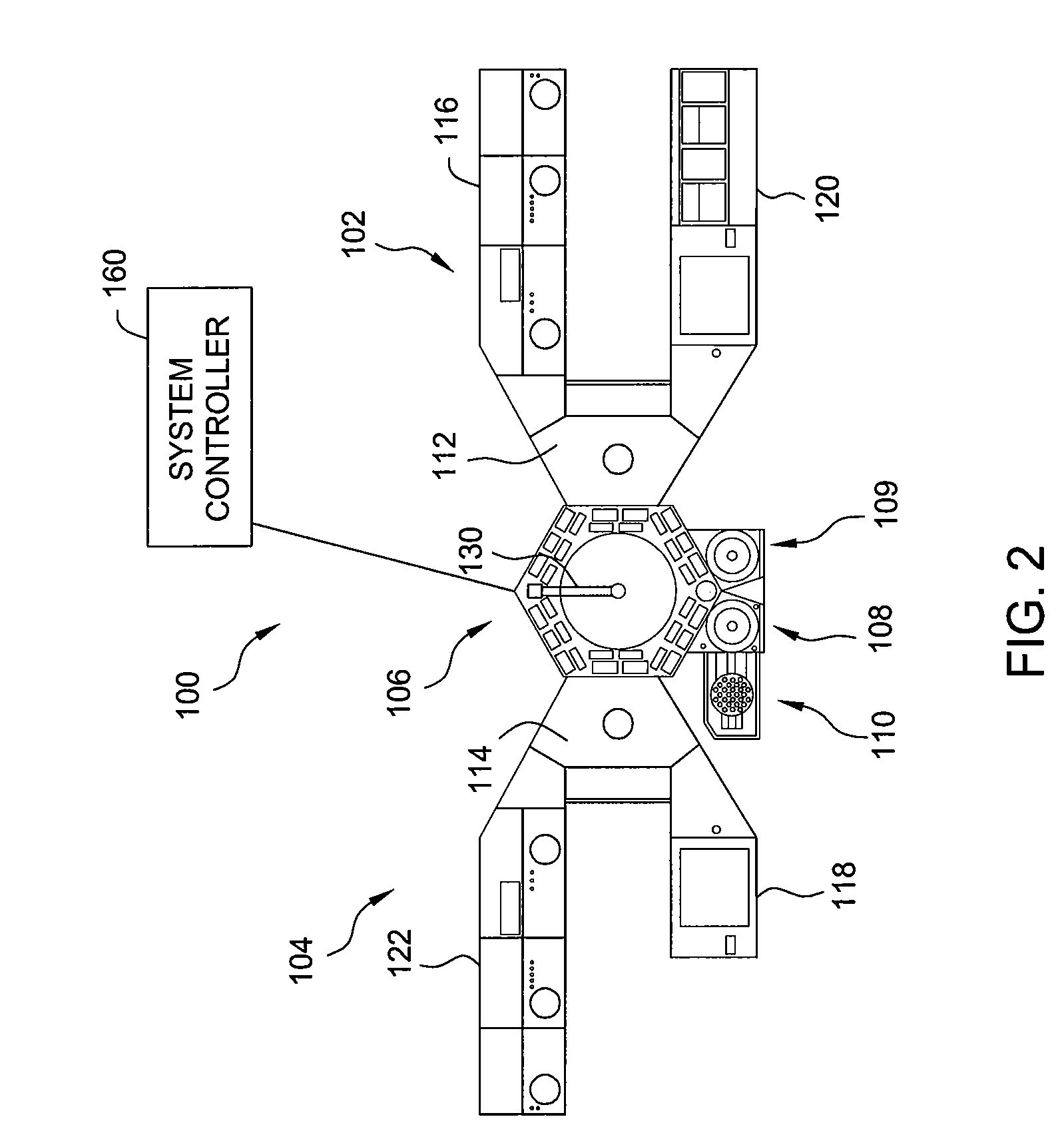

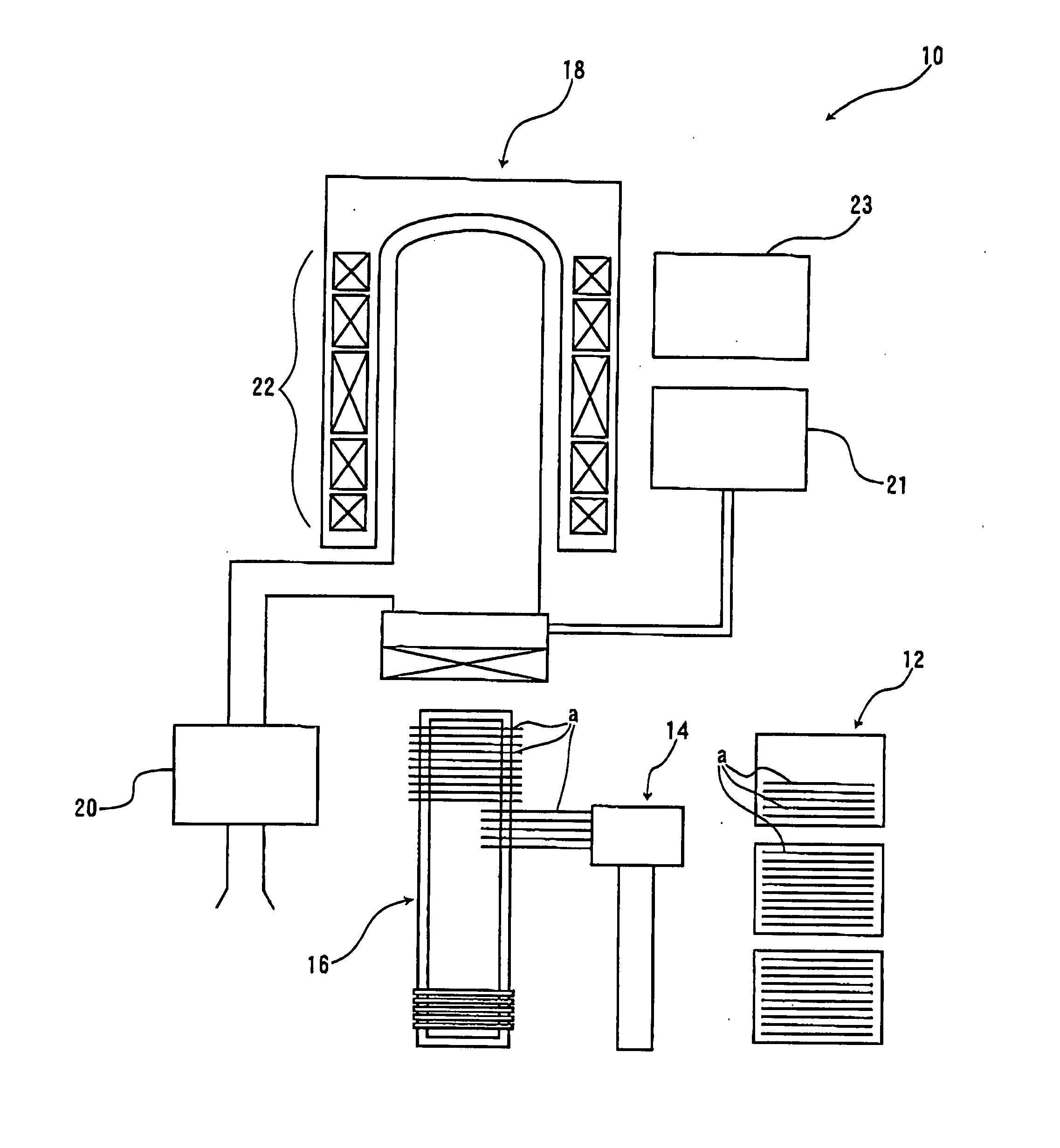

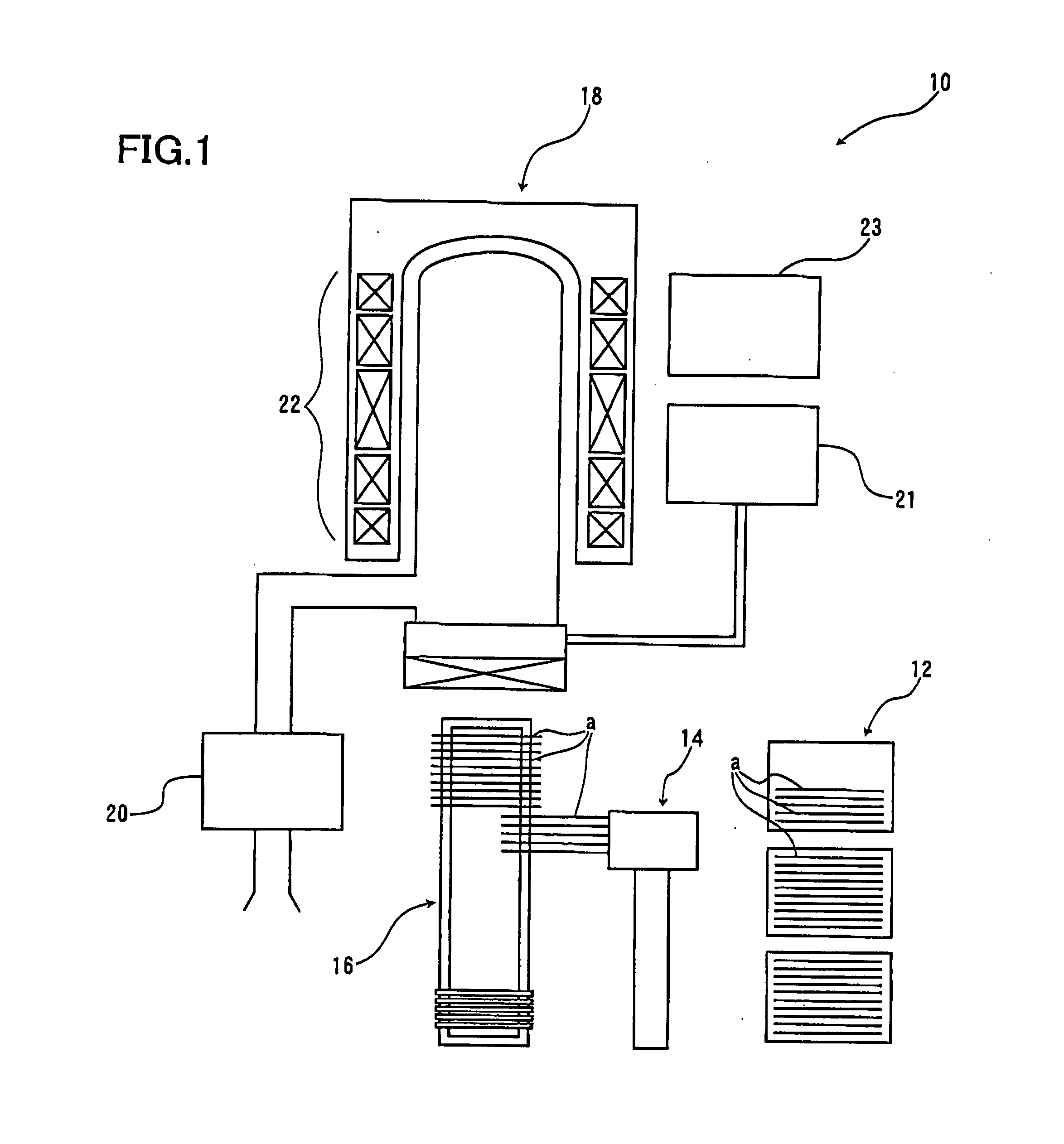

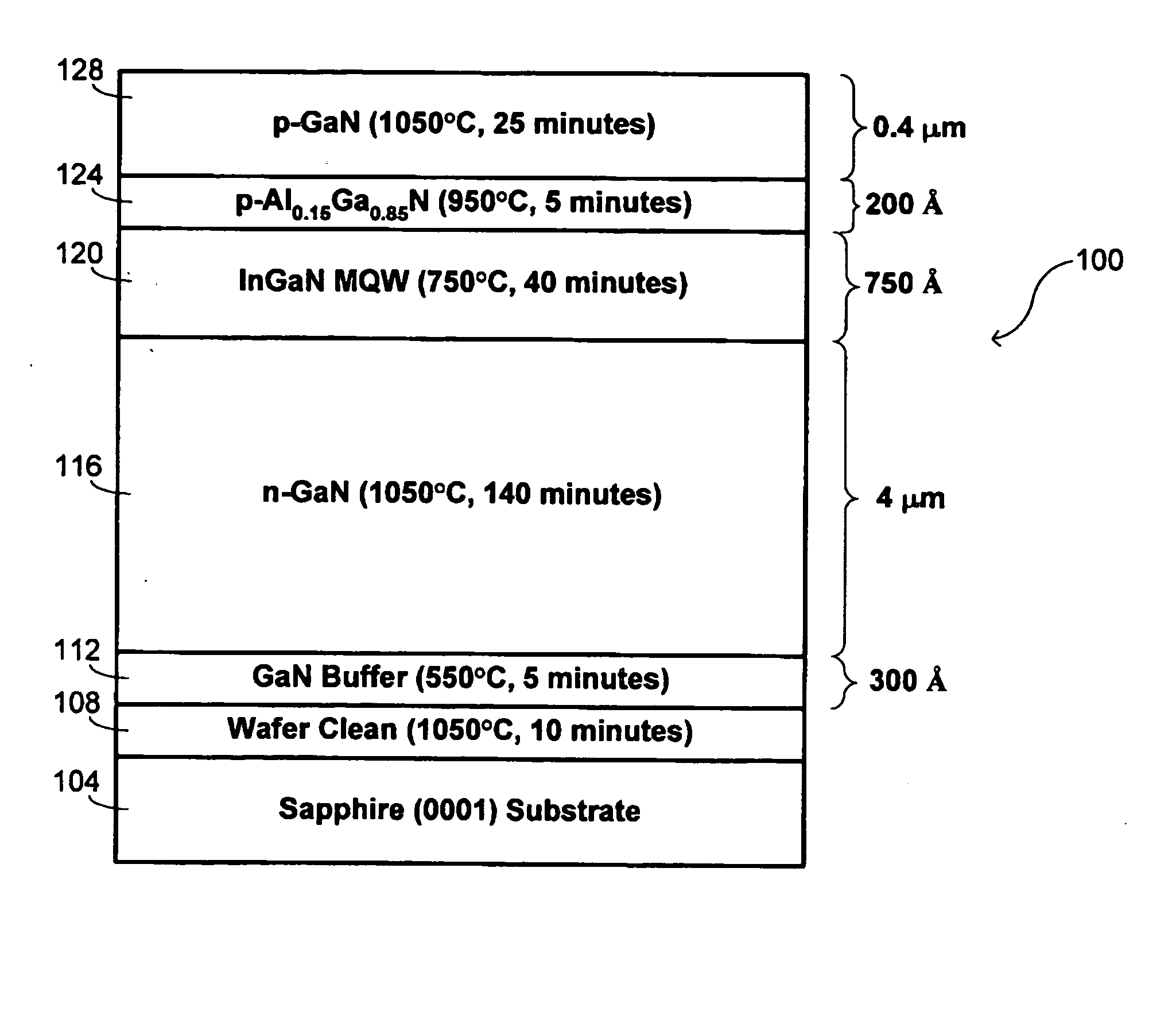

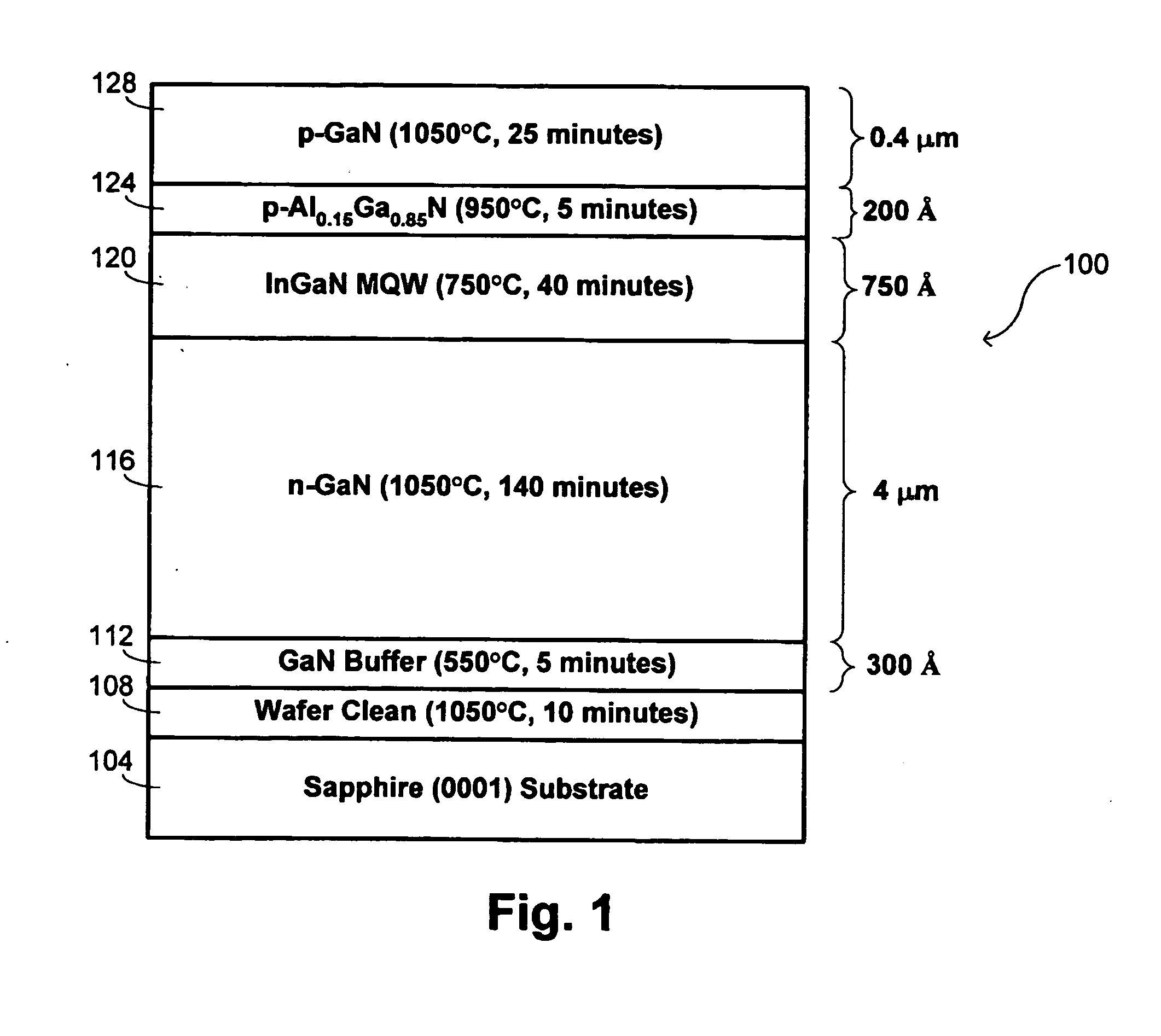

Processing system for fabricating compound nitride semiconductor devices

InactiveUS20090194026A1Expands available process windowImprove system throughputAfter-treatment apparatusPolycrystalline material growthCompound structureEngineering

One embodiment of a processing system for fabricating compound nitride semiconductor devices comprises one or more processing chamber operable with form a compound nitride semiconductor layer on a substrate, a transfer chamber coupled with the processing chamber, a loadlock chamber coupled with the transfer chamber, and a load station coupled with the loadlock chamber, wherein the load station comprises a conveyor tray movable to convey a carrier plate loaded with one or more substrates into the loadlock chamber. Compared to a single chamber reactor, the multi-chamber processing system expands the potential complexity and variety of compound structures. Additionally, the system can achieve higher quality and yield by specialization of individual chambers for specific epitaxial growth processes. Throughput is increased by simultaneous processing in multiple chambers.

Owner:APPLIED MATERIALS INC

Substrate treatment device

InactiveUS20080135516A1Prevent particle generationExcellent etching propertiesAfter-treatment apparatusPolycrystalline material growthSpray nozzleProduct gas

It is intended to provide a substrate treatment device capable of adjusting both of a growth speed and an etching speed in a selective epitaxial growth, avoiding particle generation from nozzles, and achieving good etching characteristics. A substrate treatment device for selectively growing an epitaxial film on a surface of a substrate by alternately supplying a raw material gas containing silicon and an etching gas to a treatment chamber, the substrate treatment device being provided with a substrate support member for supporting the substrate in the treatment chamber, a heating member provided outside the treatment chamber for heating the substrate and an atmosphere of the treatment chamber, a gas supply system provided inside the treatment chamber, and a discharge port opened on the treatment chamber, wherein the gas supply system comprises first gas supply nozzles for supplying the raw material gas and second gas supply nozzles for supplying the etching gas.

Owner:KOKUSA ELECTRIC CO LTD

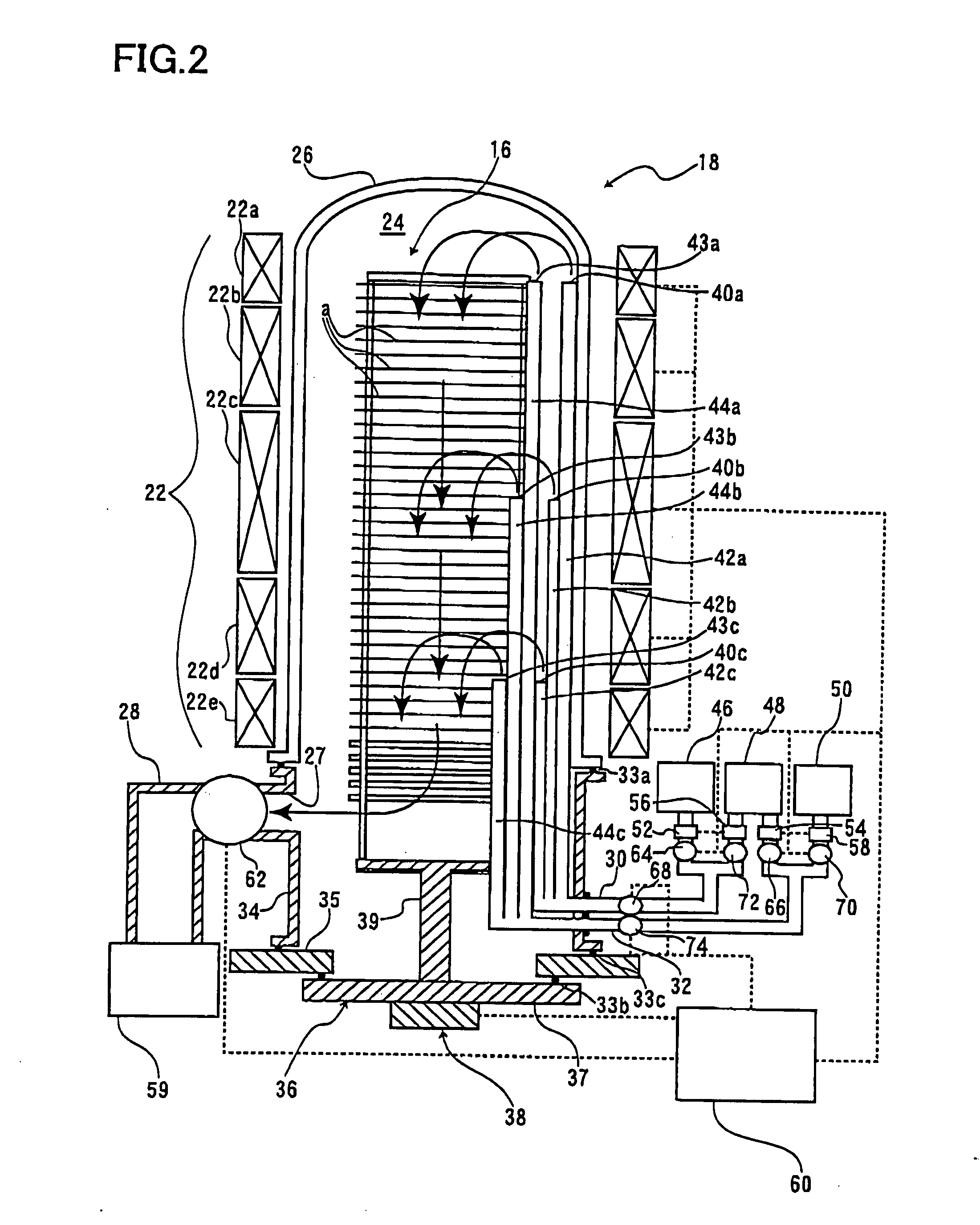

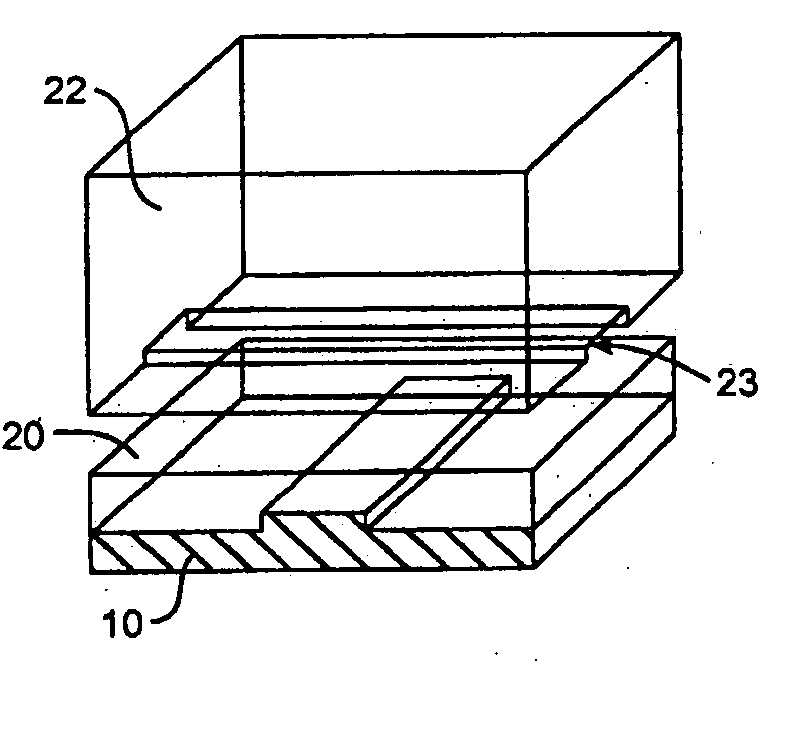

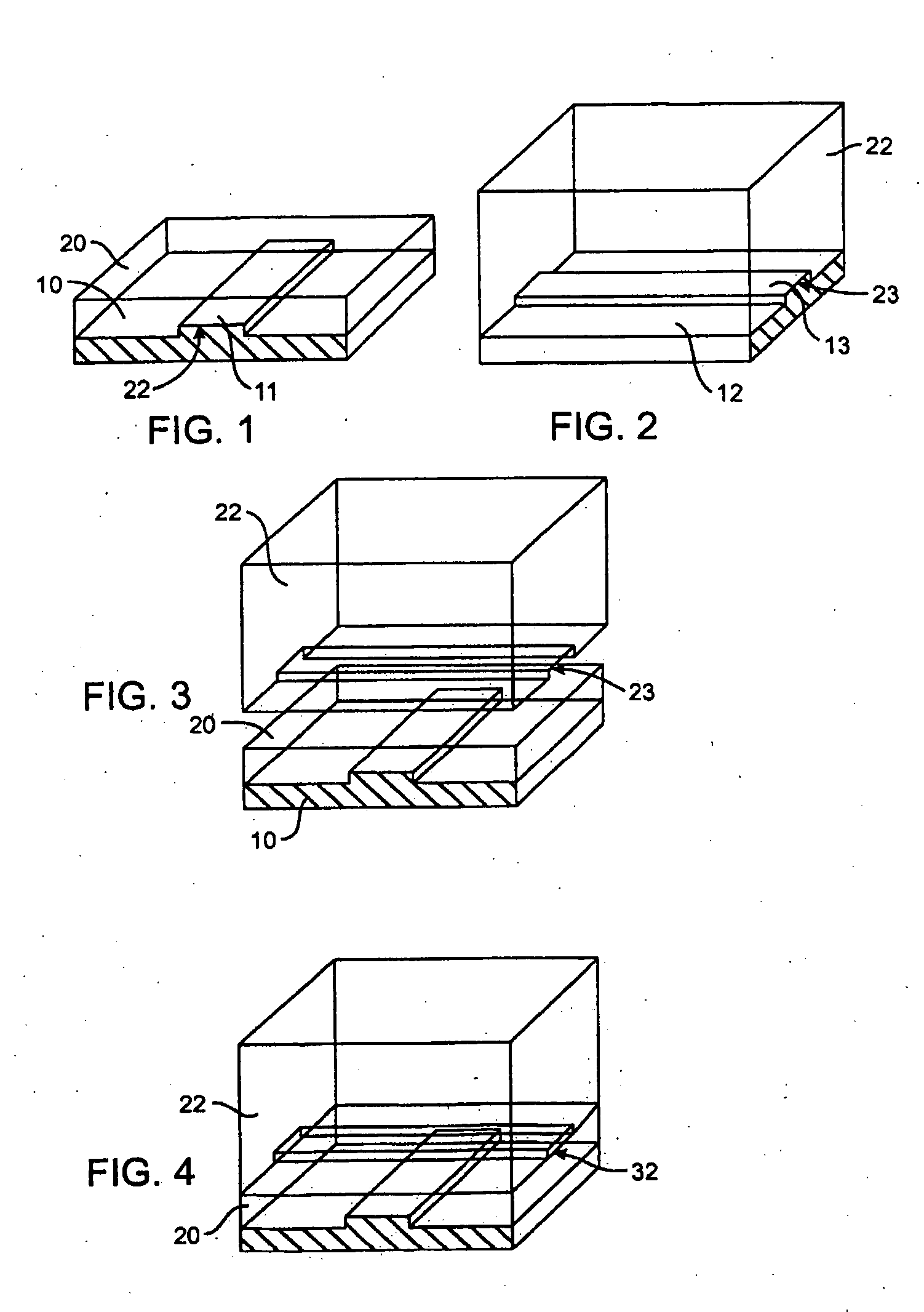

Epitaxial growth of compound nitride semiconductor structures

InactiveUS20070240631A1Quick upgradeImprove uniformityAfter-treatment apparatusPolycrystalline material growthGas phaseThermal chemical vapor deposition

Apparatus and methods are described for fabricating a compound nitride semiconductor structure. Group-III and nitrogen precursors are flowed into a first processing chamber to deposit a first layer over a substrate with a thermal chemical-vapor-deposition process. The substrate is transferred from the first processing chamber to a second processing chamber. Group-III and nitrogen precursors are flowed into the second processing chamber to deposit a second layer over the first layer with a thermal chemical-vapor-deposition process. The first and second group-III precursors have different group-III elements.

Owner:APPLIED MATERIALS INC

Crystal growth devices and systems, and methods for using same

High throughput screening of crystallization of a target material is accomplished by simultaneously introducing a solution of the target material into a plurality of chambers of a microfabricated fluidic device. The microfabricated fluidic device is then manipulated to vary the solution condition in the chambers, thereby simultaneously providing a large number of crystallization environments. Control over changed solution conditions may result from a variety of techniques, including but not limited to metering volumes of crystallizing agent into the chamber by volume exclusion, by entrapment of volumes of crystallizing agent determined by the dimensions of the microfabricated structure, or by cross-channel injection of sample and crystallizing agent into an array of junctions defined by intersecting orthogonal flow channels.

Owner:FLUIDIGM CORP

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS7704324B2After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

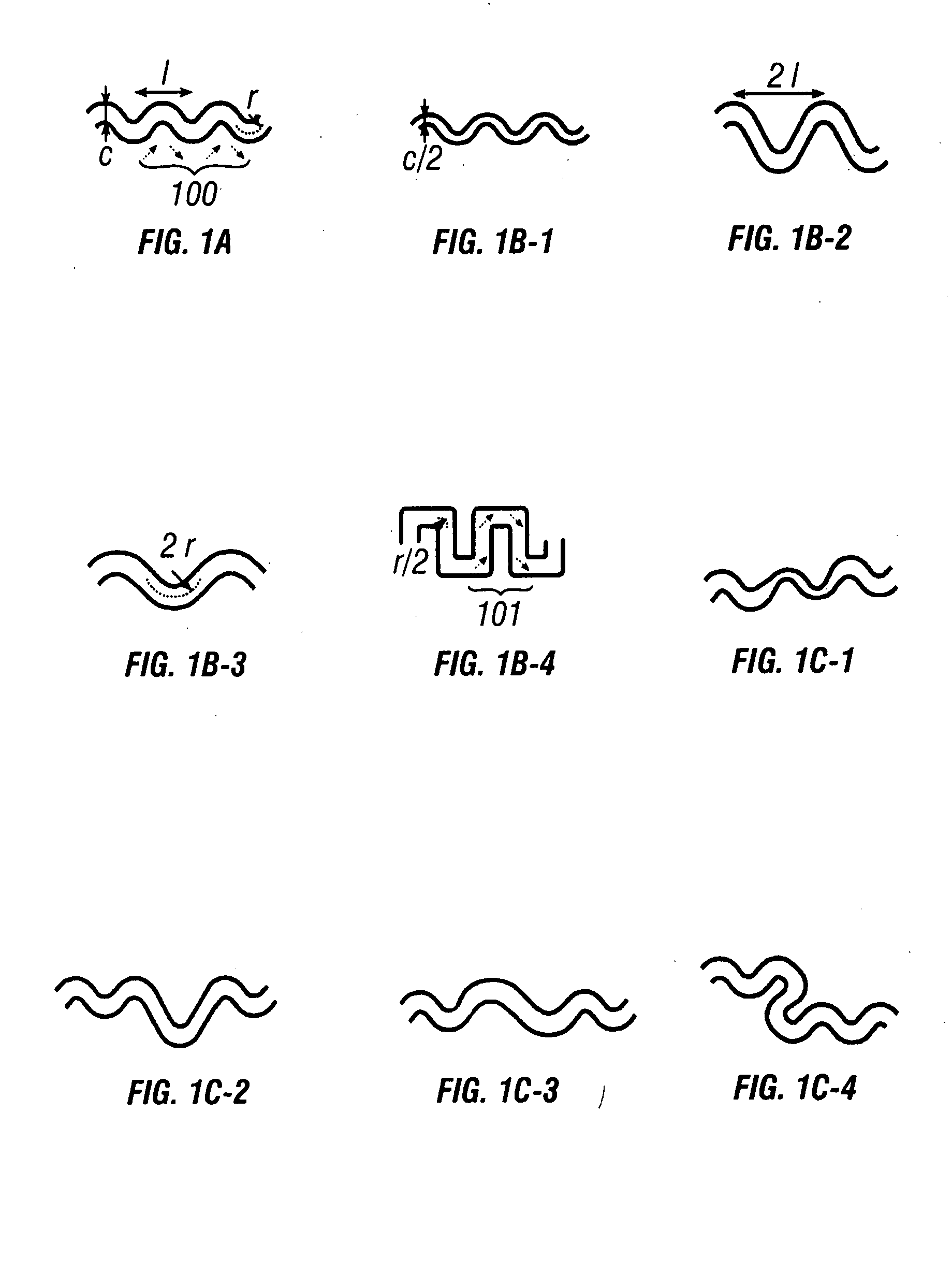

Microfluidic protein crystallography

InactiveUS20050205005A1High throughput screeningImprove throughputValve arrangementsPeptide librariesHigh-Throughput Screening MethodsAgent Combination

The use of microfluidic structures enables high throughput screening of protein crystallization. In one embodiment, an integrated combinatoric mixing chip allows for precise metering of reagents to rapidly create a large number of potential crystallization conditions, with possible crystal formations observed on chip. In an alternative embodiment, the microfluidic structures may be utilized to explore phase space conditions of a particular protein crystallizing agent combination, thereby identifying promising conditions and allowing for subsequent focused attempts to obtain crystal growth.

Owner:CALIFORNIA INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com