Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Prevent particle generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

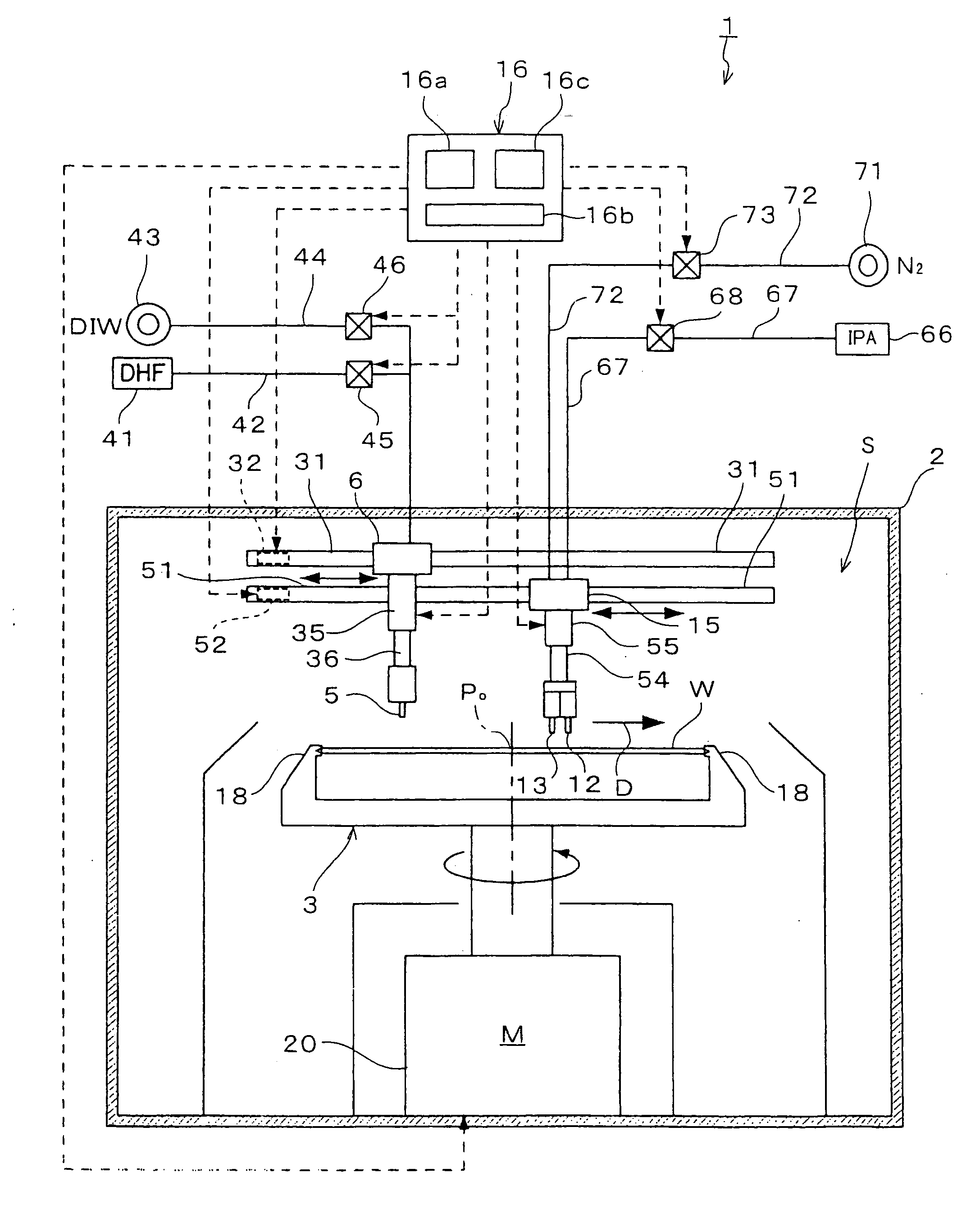

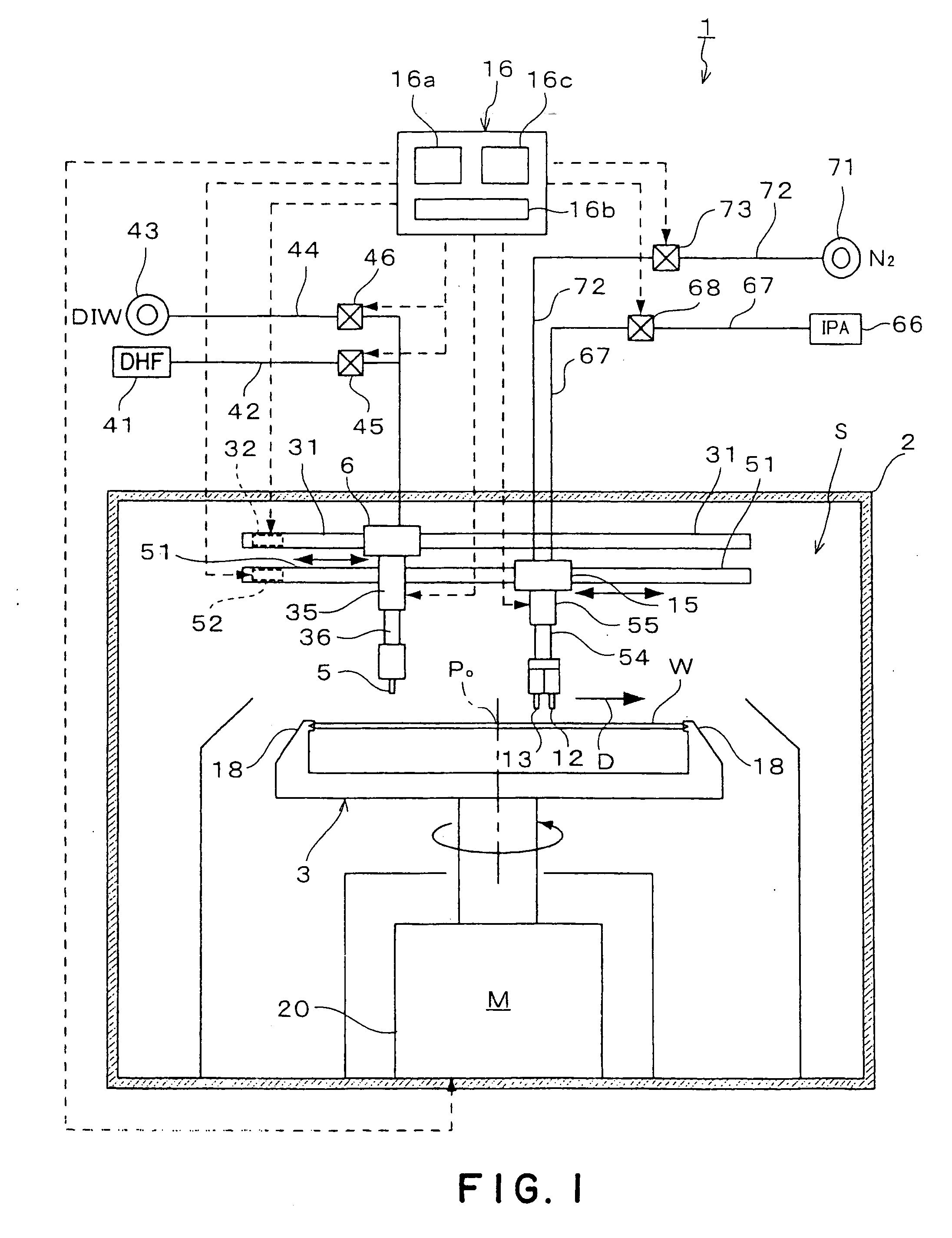

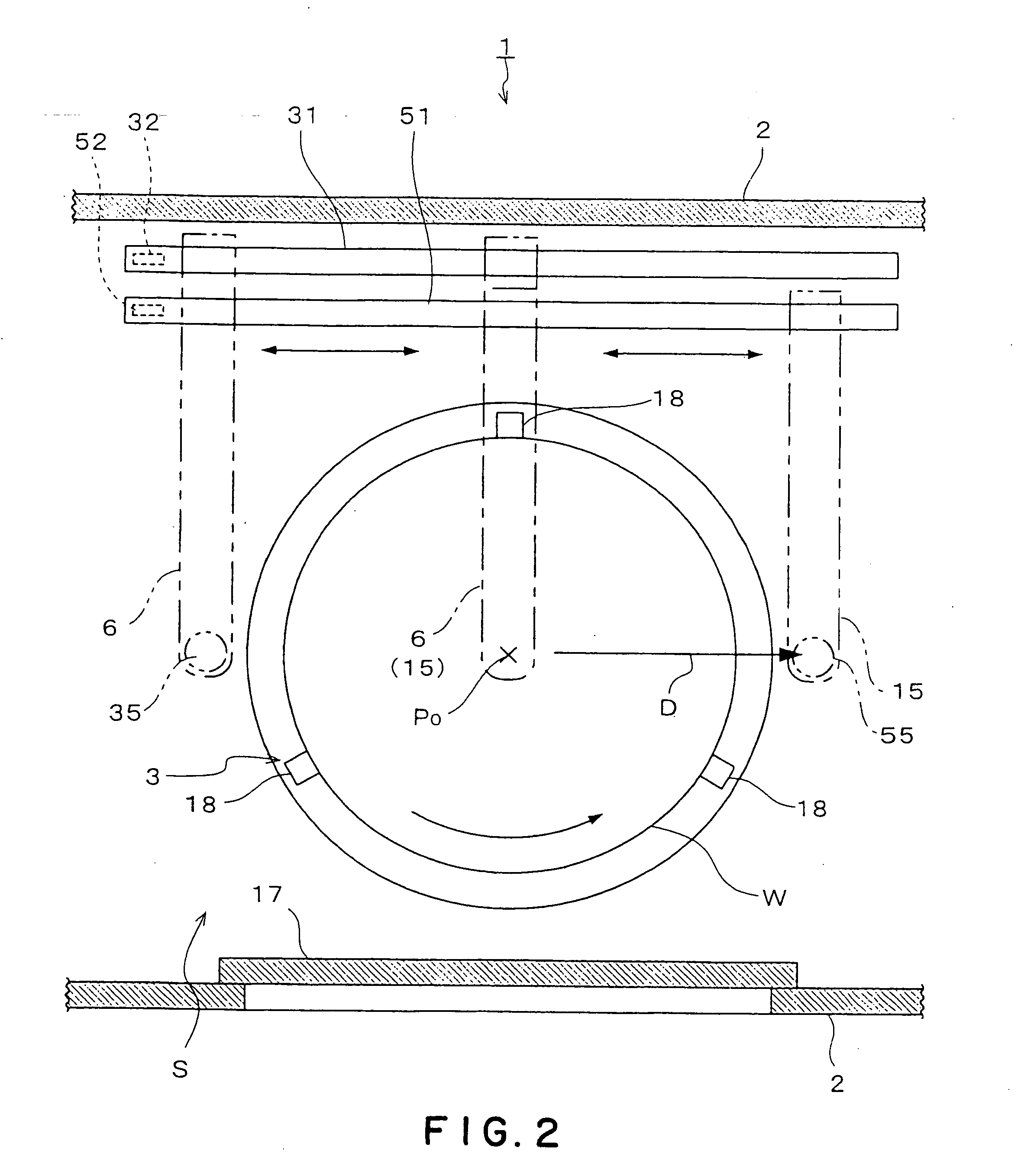

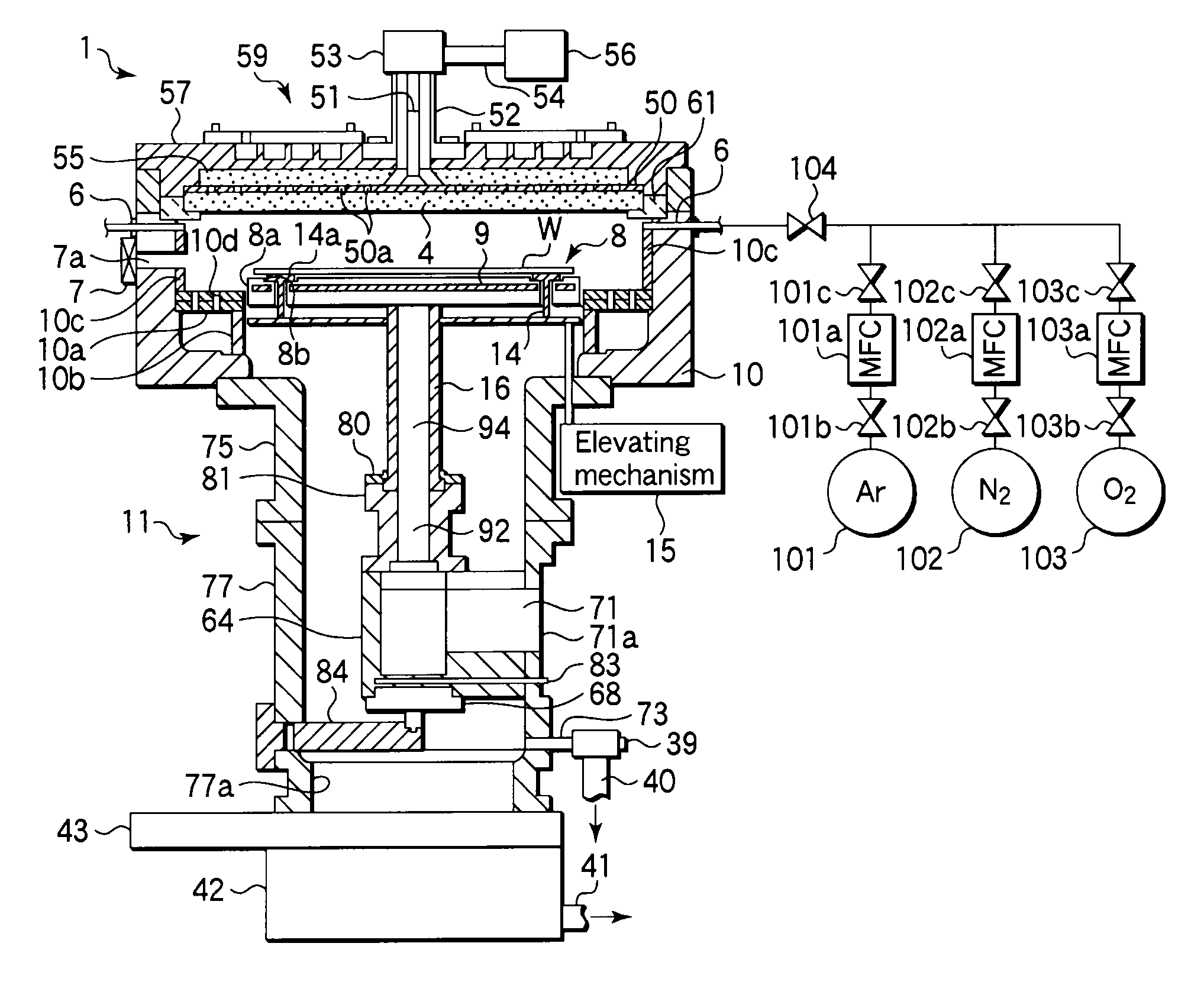

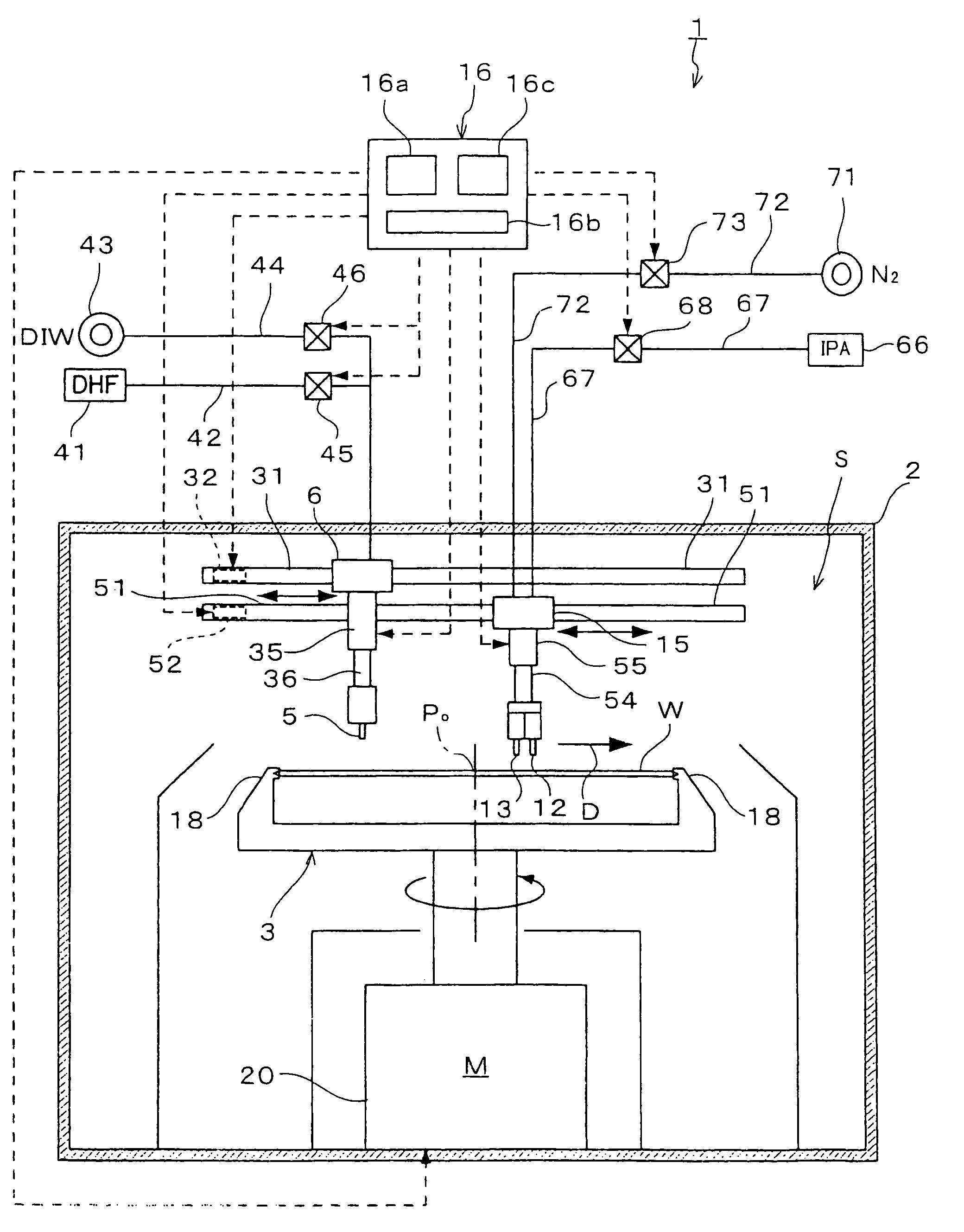

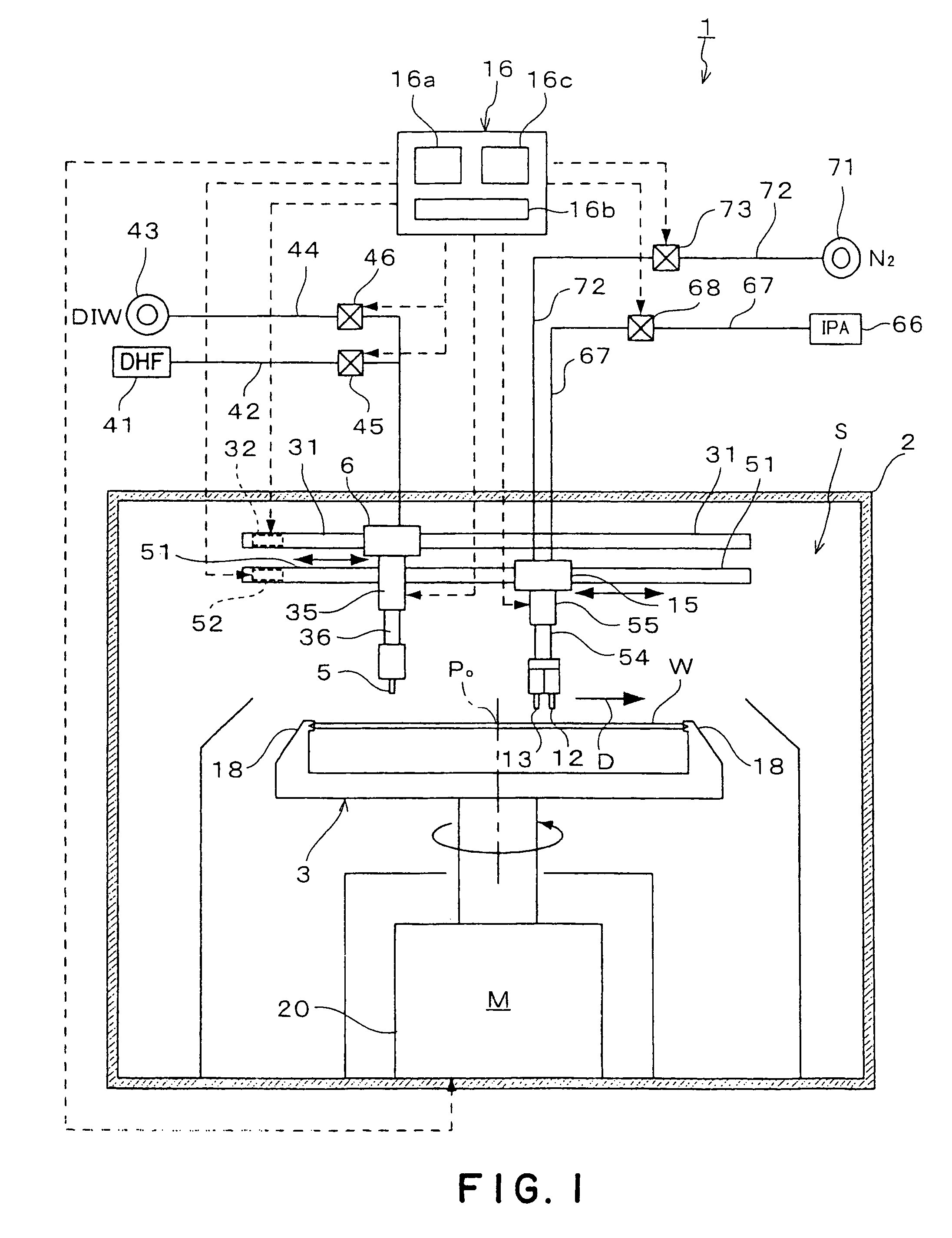

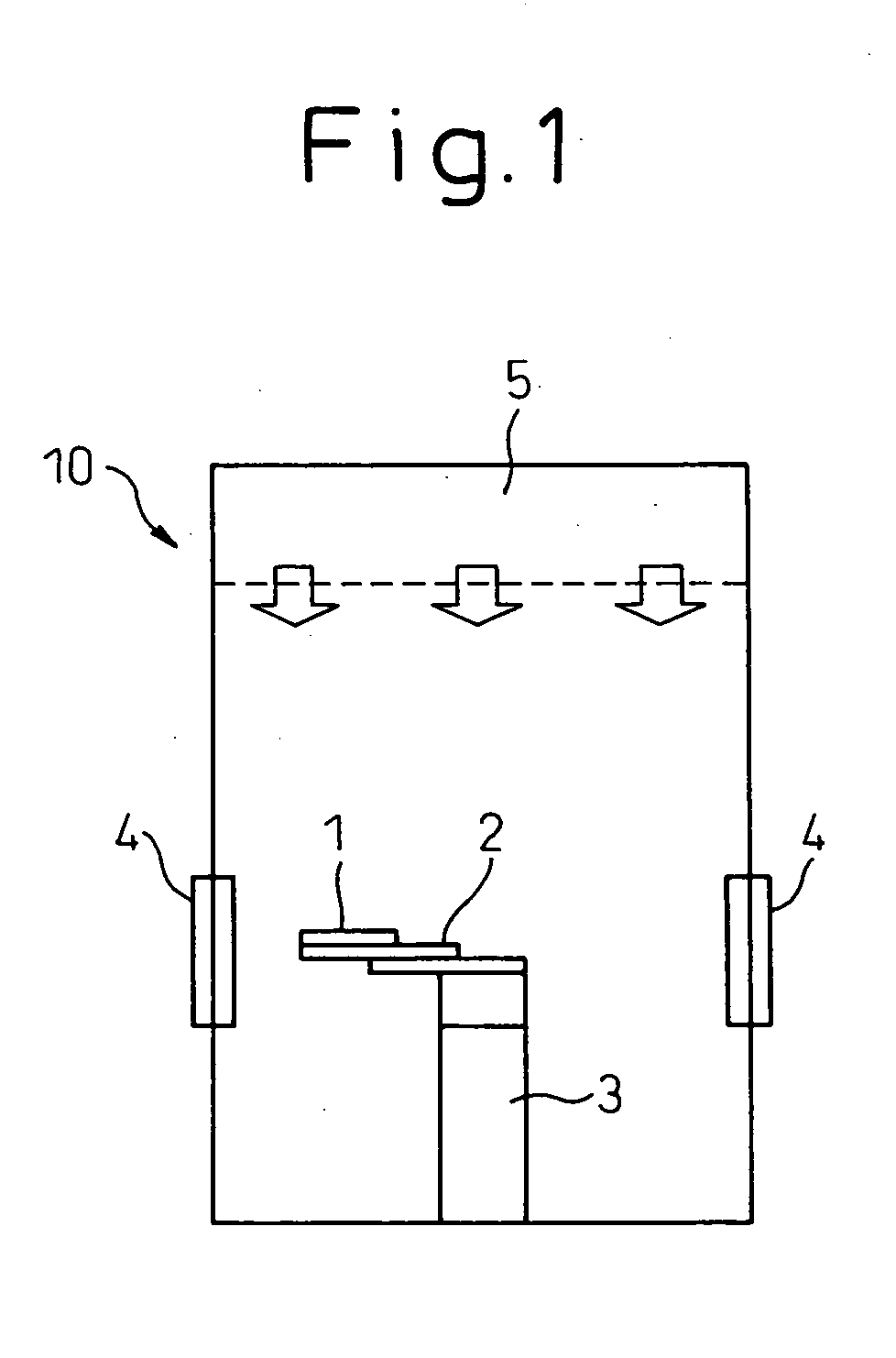

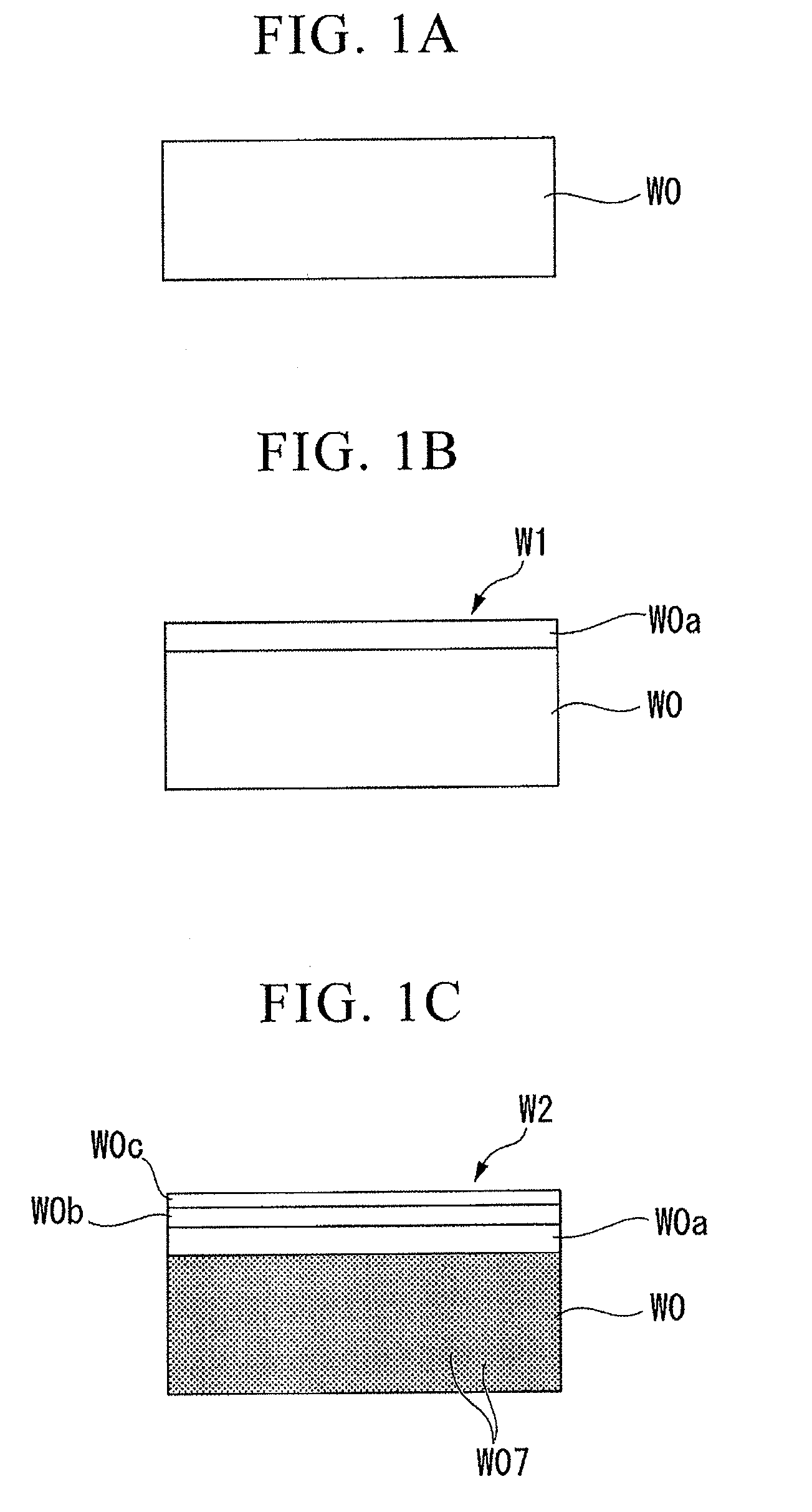

Substrate Processing method and substrate processing apparatus

ActiveUS20070017555A1Decreasing amount of usedAvoid it happening againSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringIon

A substrate (W) is processed with the use of a process liquid such as a deionized water. Then, a first fluid which is more volatile than the process liquid is supplied to an upper surface of the substrate (W) from a fluid nozzle (12) to form a liquid film. Next, a second fluid which is more volatile than the process liquid is supplied to the upper surface of the substrate (W) from the fluid nozzle (12), while the wafer (W) is being rotated. During this supply operation, a supply position (Sf) of the second fluid to the substrate (W) is moved radially outward from a rotational center (Po) of the substrate (W). As a result, it is possible to prevent the generation of particles on the substrate (W) after it is dried by using the first and second fluids.

Owner:TOKYO ELECTRON LTD

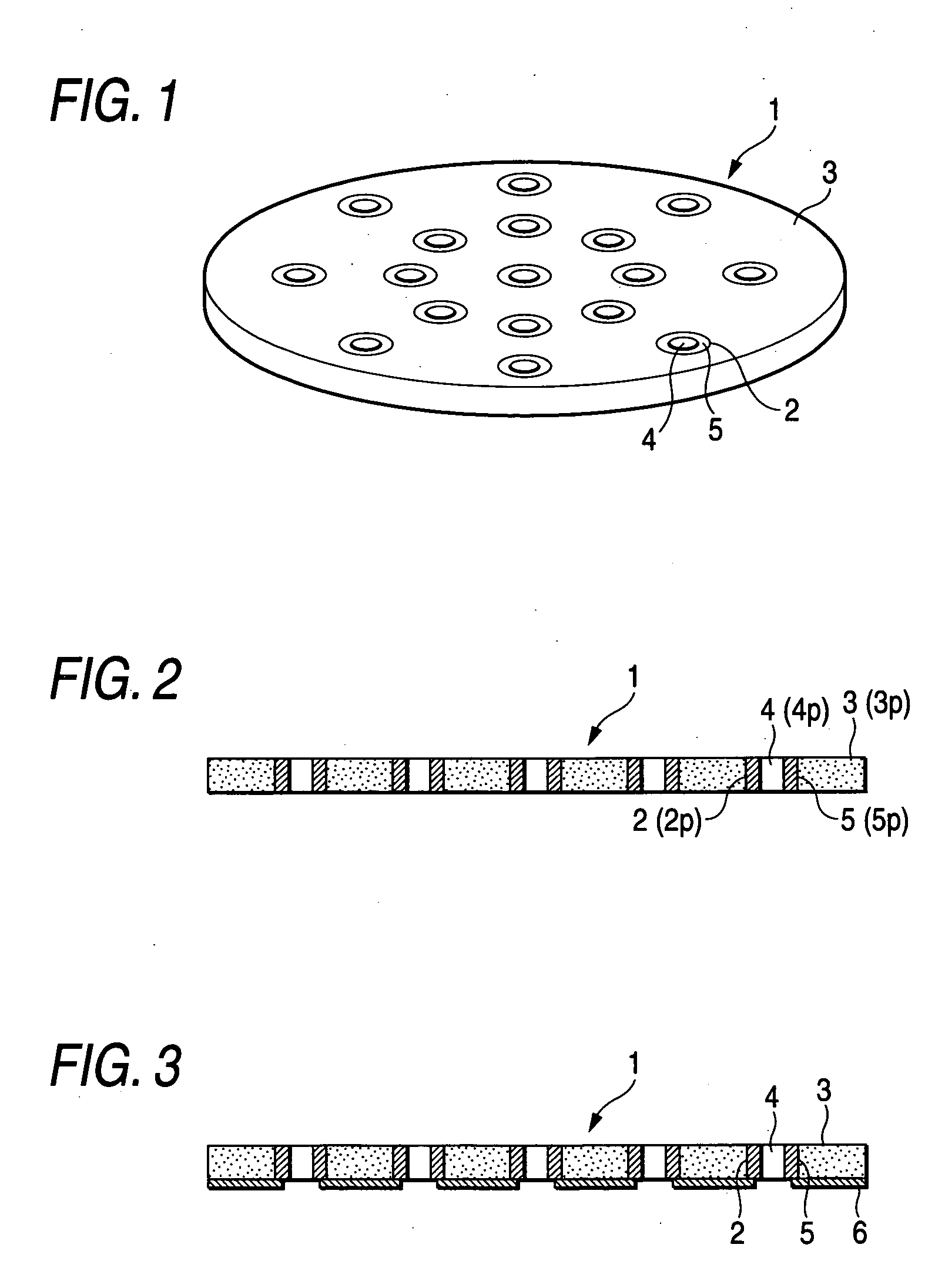

Gas diffusion plate and manufacturing method for the same

InactiveUS20060073354A1Improve manufacturing yieldPrevent generation of particleMolten spray coatingElectric discharge tubesAluminiumAluminium oxide

Owner:COVALENT MATERIALS CORP

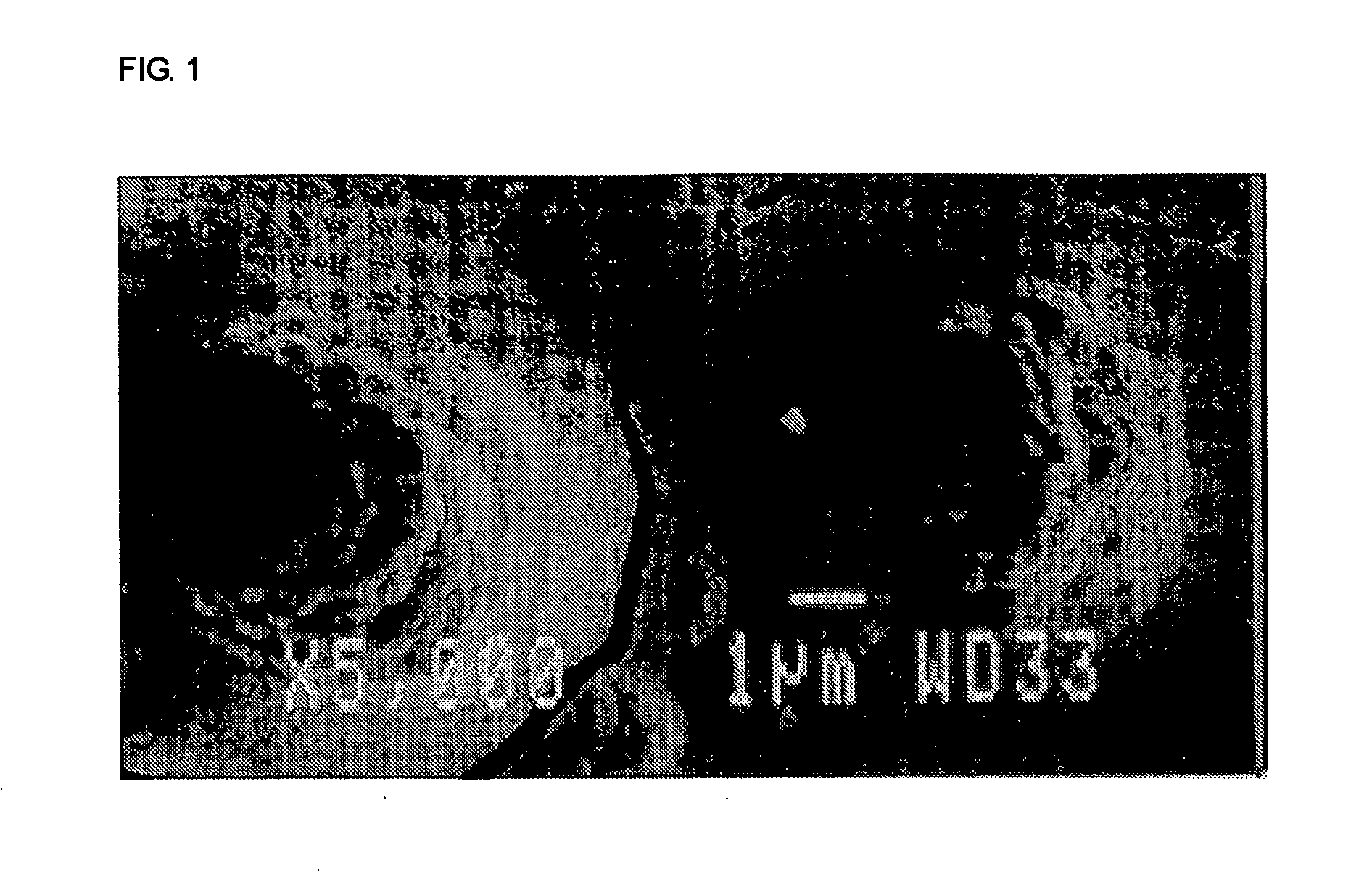

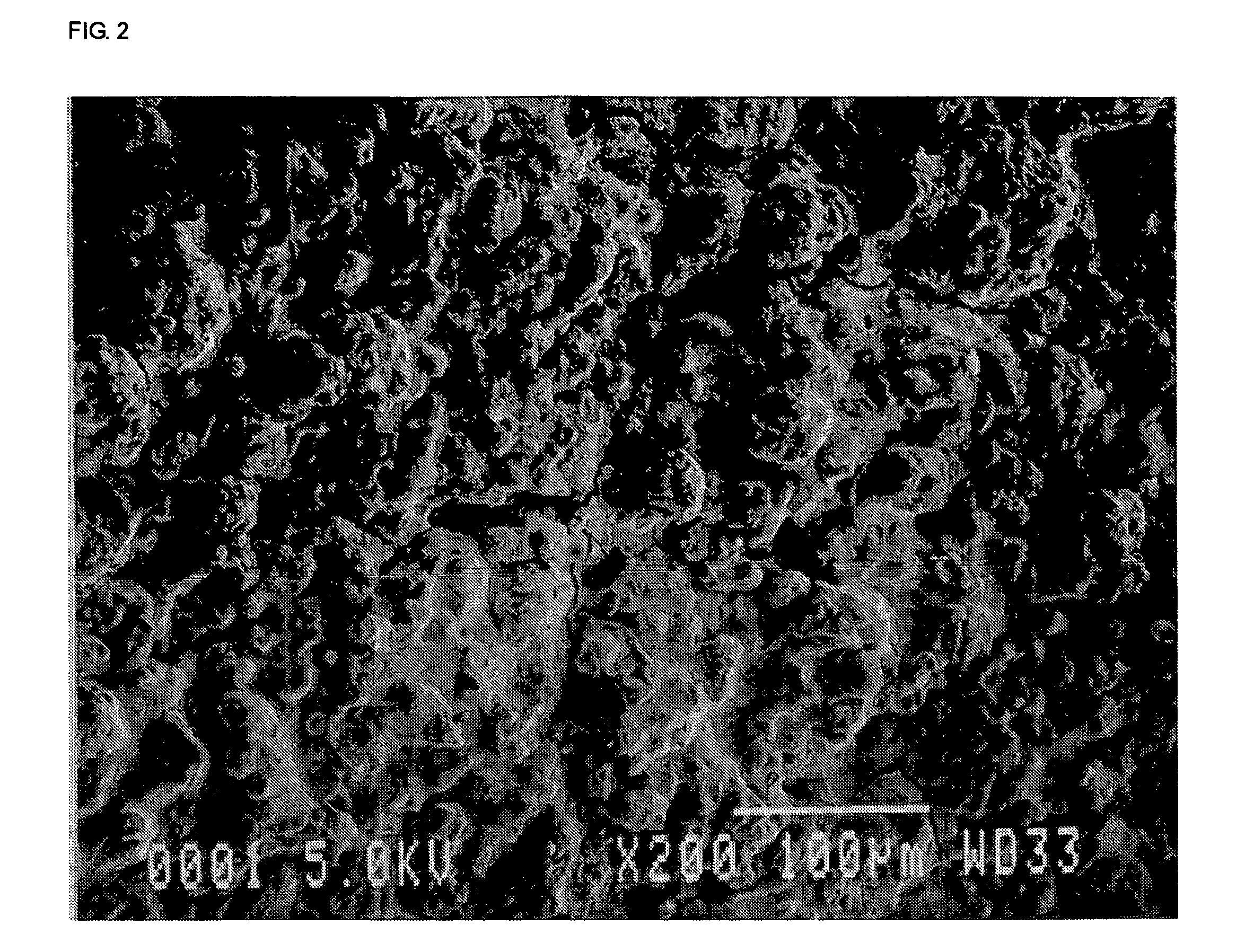

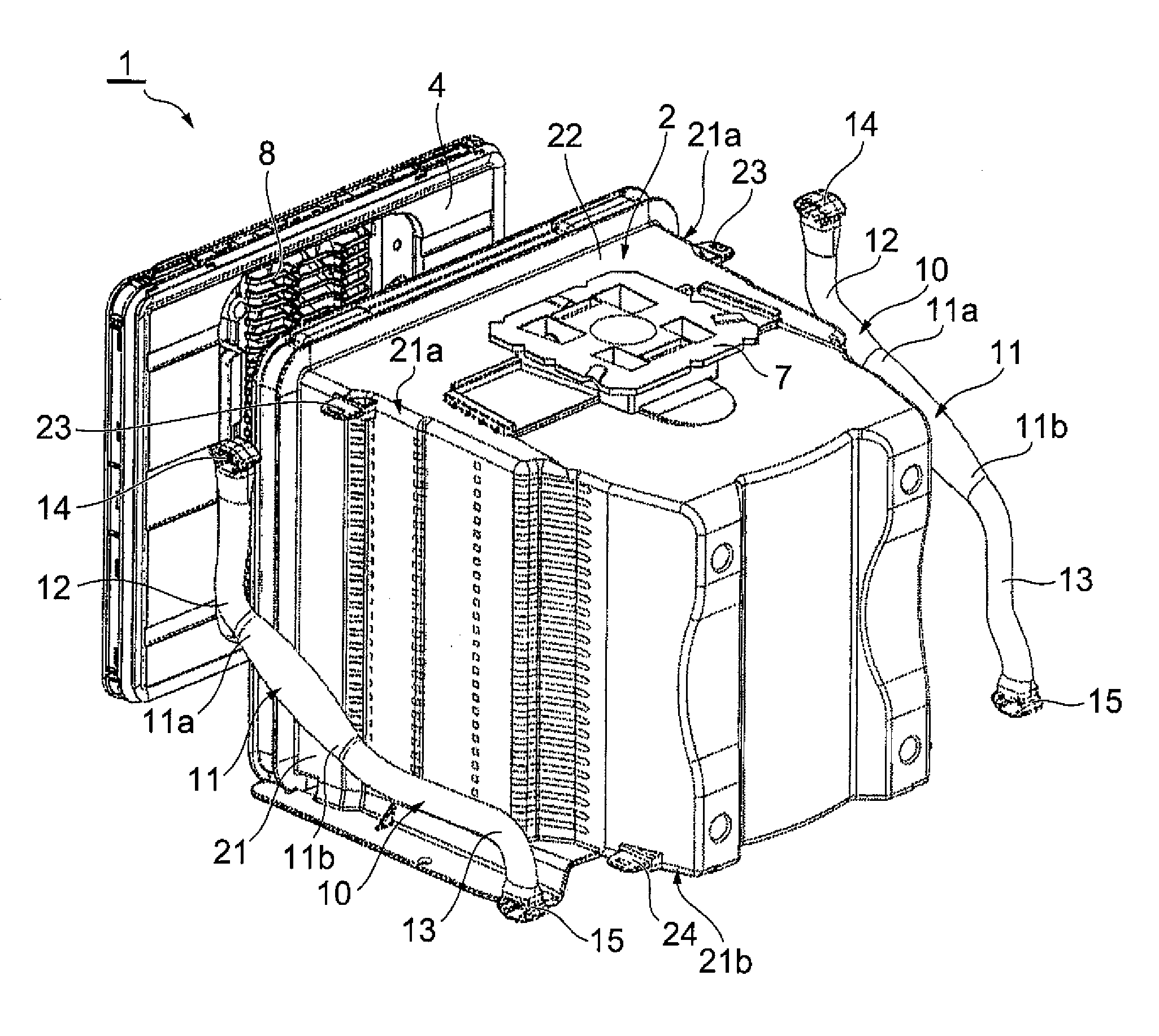

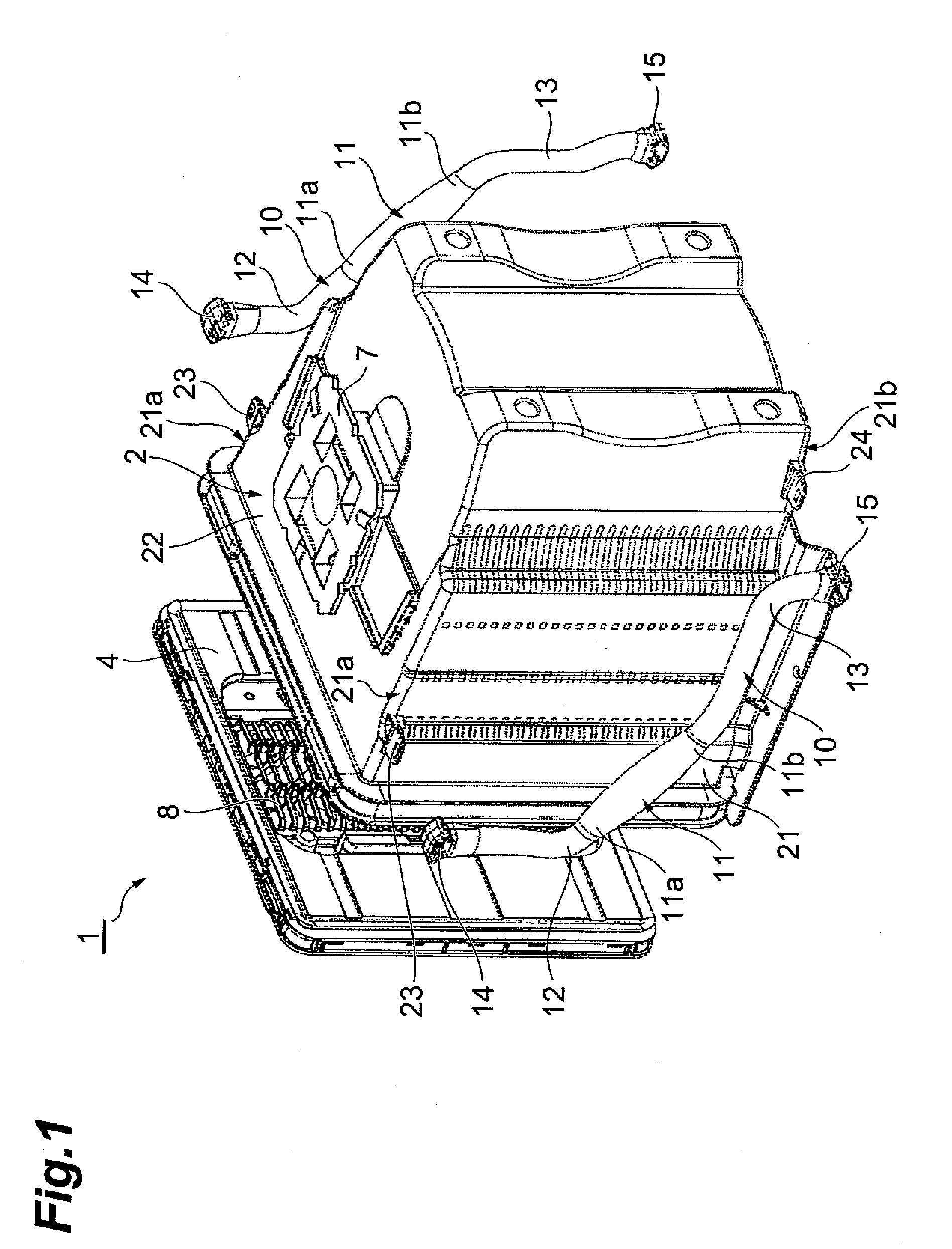

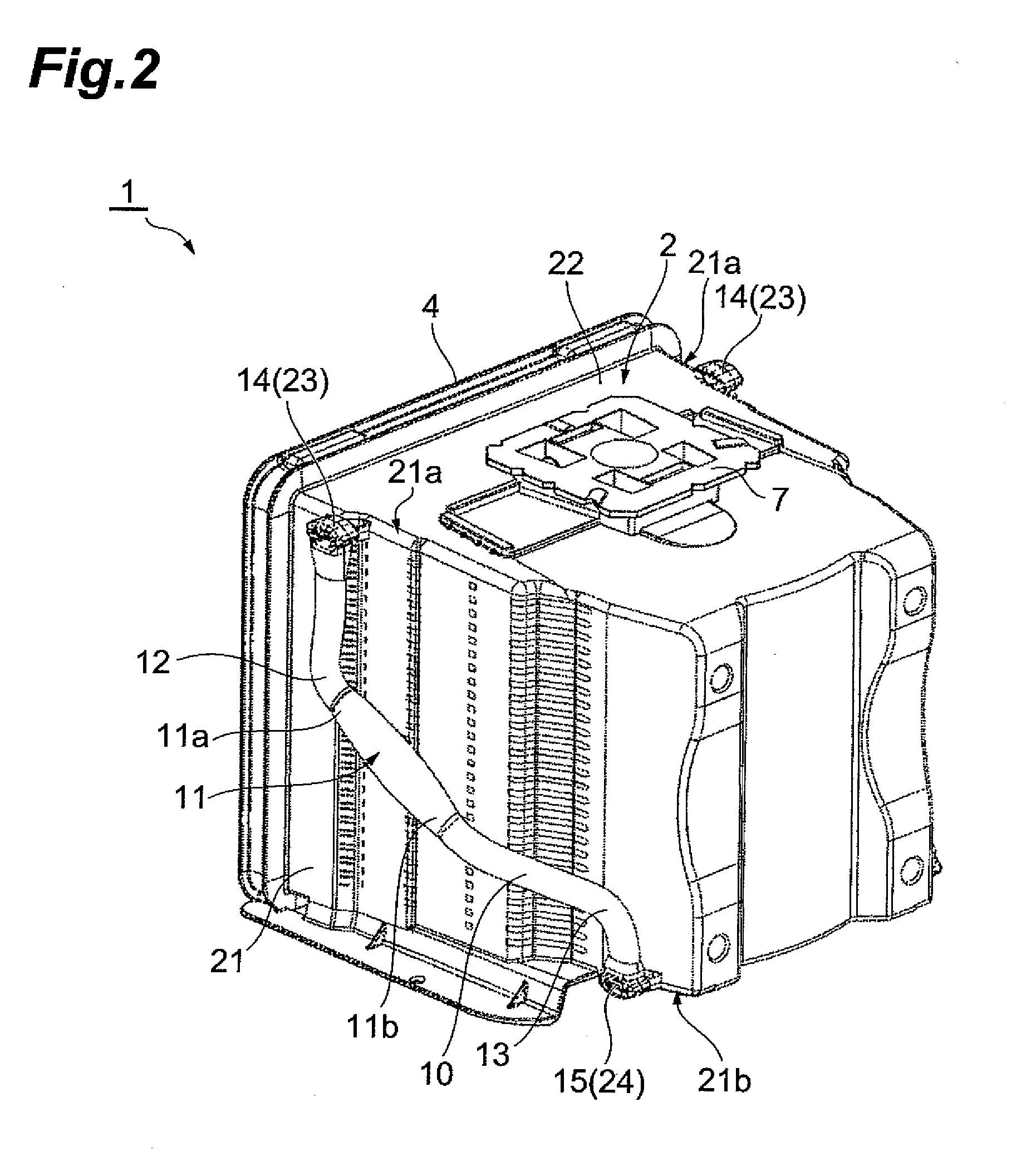

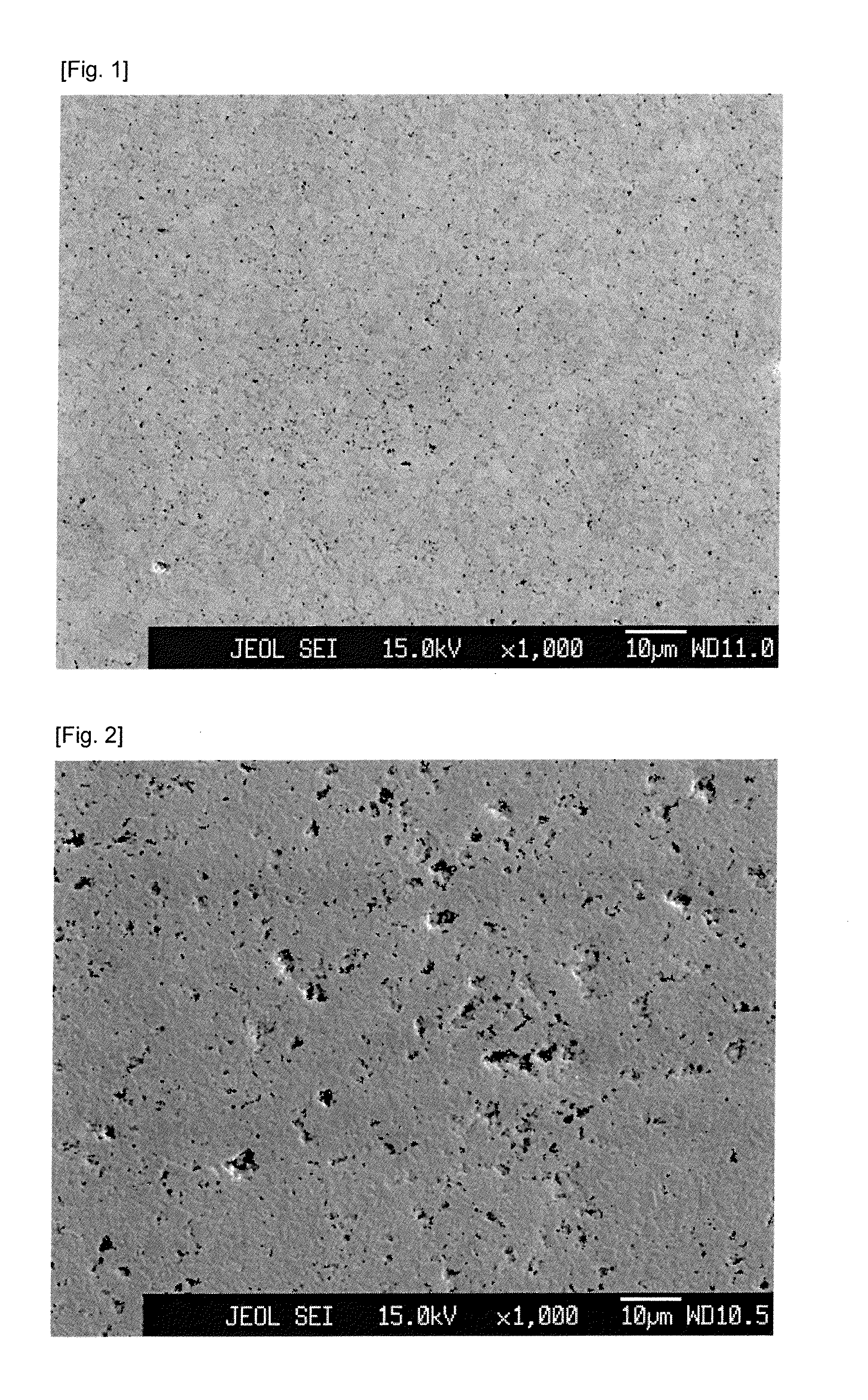

Component for vacuum apparatus, production method thereof and apparatus using the same

InactiveUS20050084654A1Prevent particle generationMolten spray coatingVacuum evaporation coatingPorosityContinuous use

A component for a vacuum apparatus for use in a plasma processing apparatus or a film forming apparatus for a semiconductor or the like, in which a surface is covered with a ceramic and / or metallic thermal spray film and projection-shaped particles of a width of 10-300 μm, a height of 4-600 μm and an average height / width ratio of 0.4 or higher are present within a range of 20-20,000 particle / mm2 on the surface of the thermal spray film. The thermal spray film has a porosity of 10-40%, shows a high adhering property to a film-shaped substance, is free from a product contamination by particles generated by a peeling of the film-shaped substance and can be continuously used over a prolonged period.

Owner:TOSOH CORP

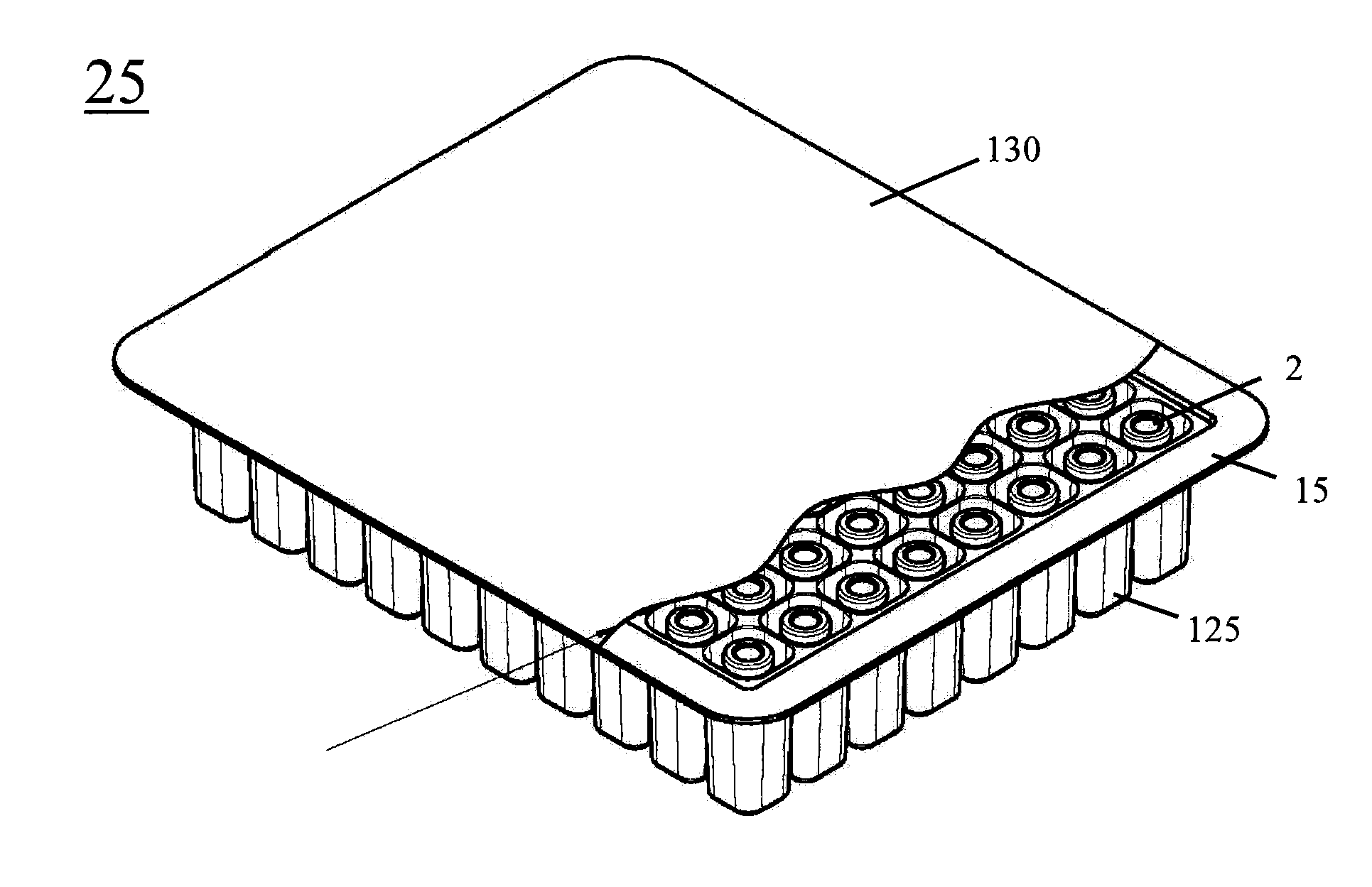

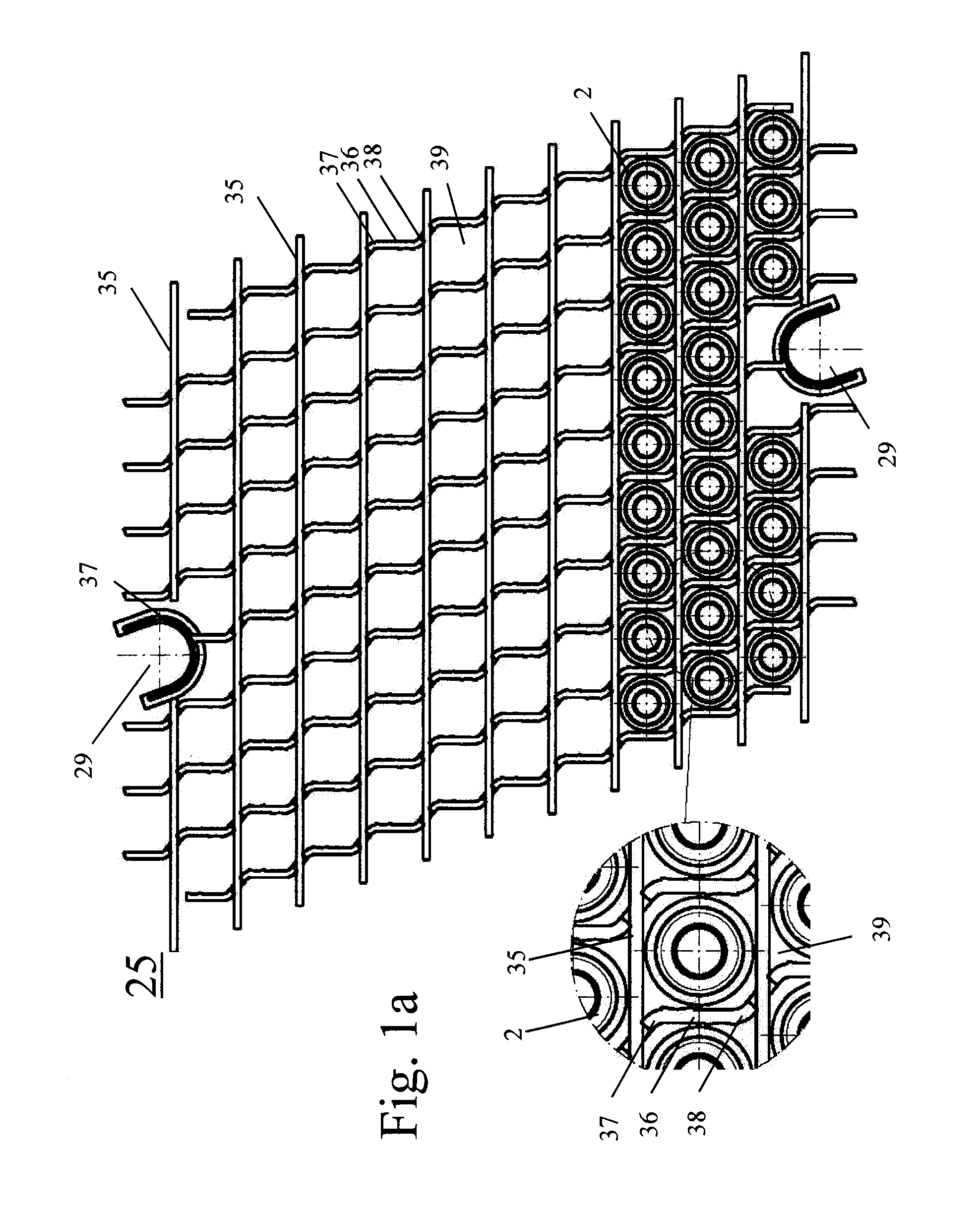

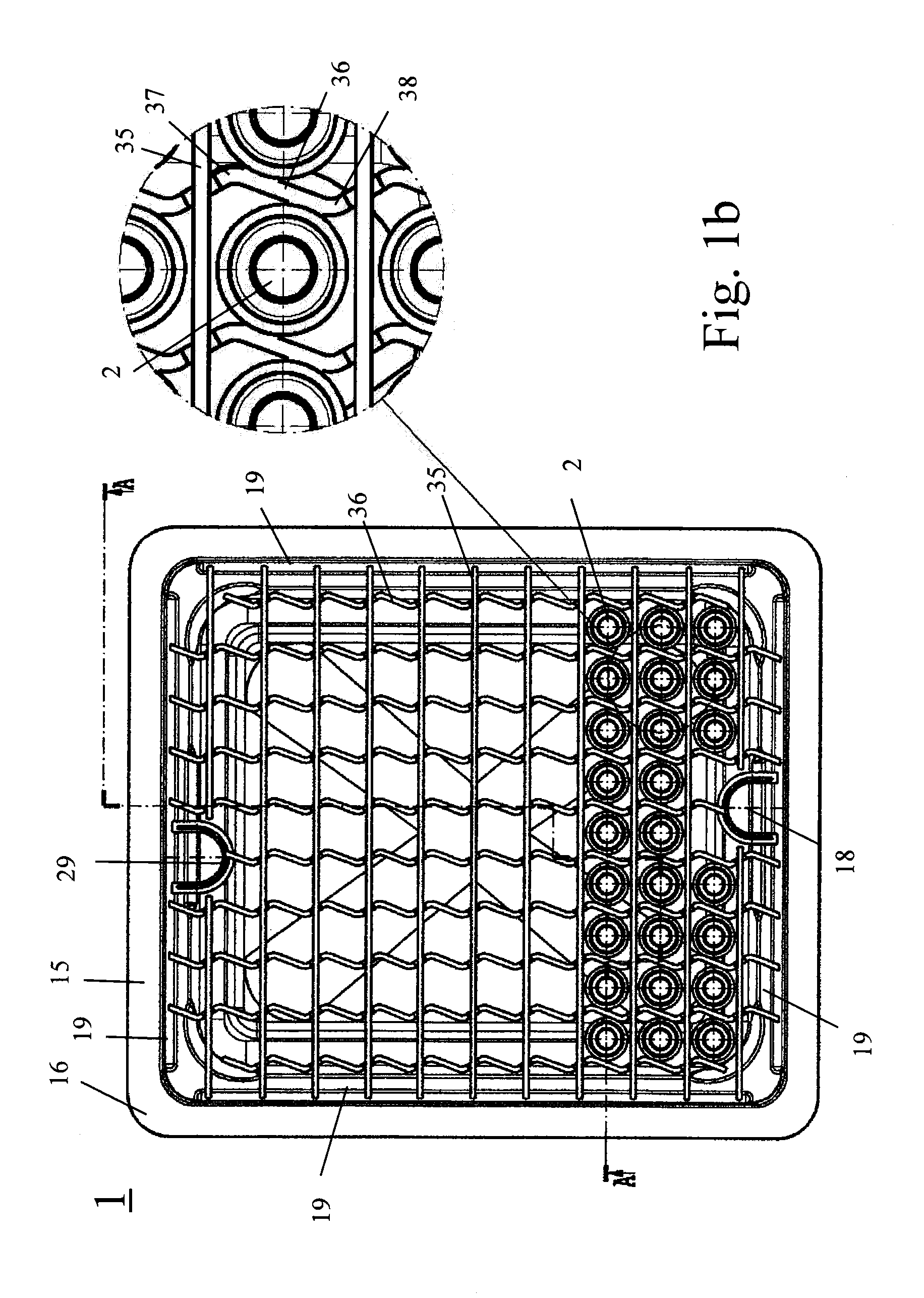

Holding structure for simultaneously holding a plurality of containers for medical, pharmaceutical or cosmetic applications and transport or packaging container comprising such a holding structure

InactiveUS20140027333A1Increase heightAdd support structureDiagnosticsSurgical needlesEngineeringMechanical engineering

Owner:SCHOTT AG

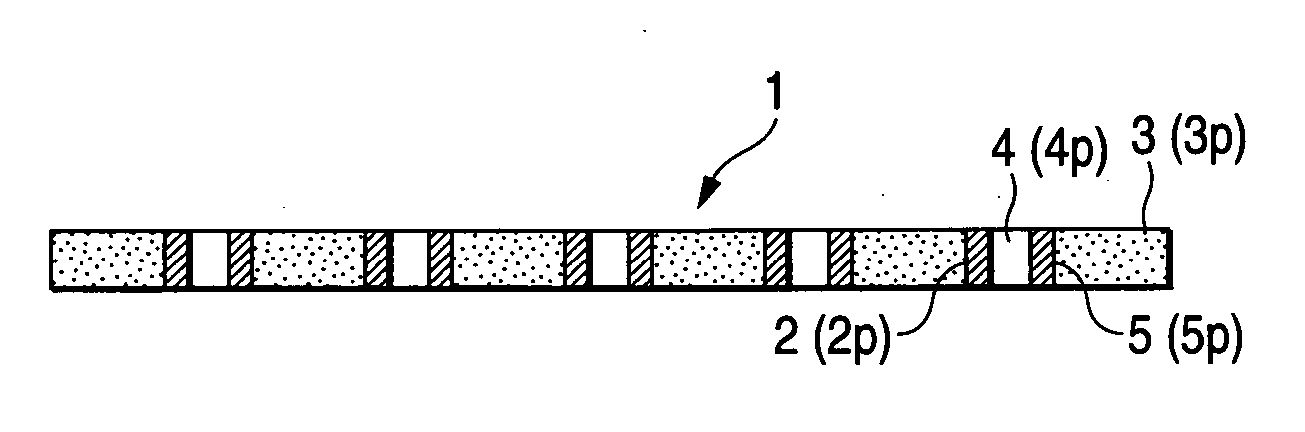

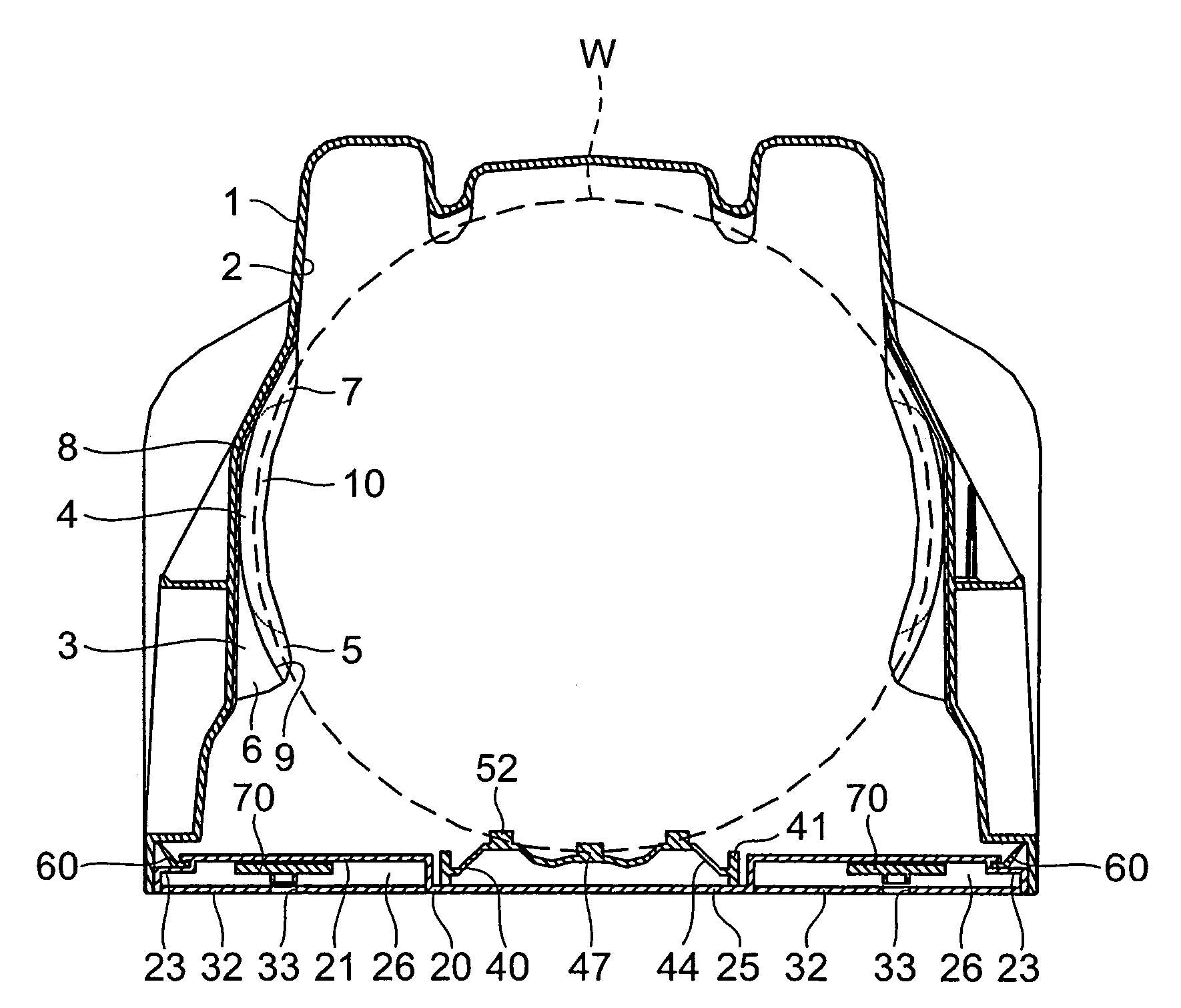

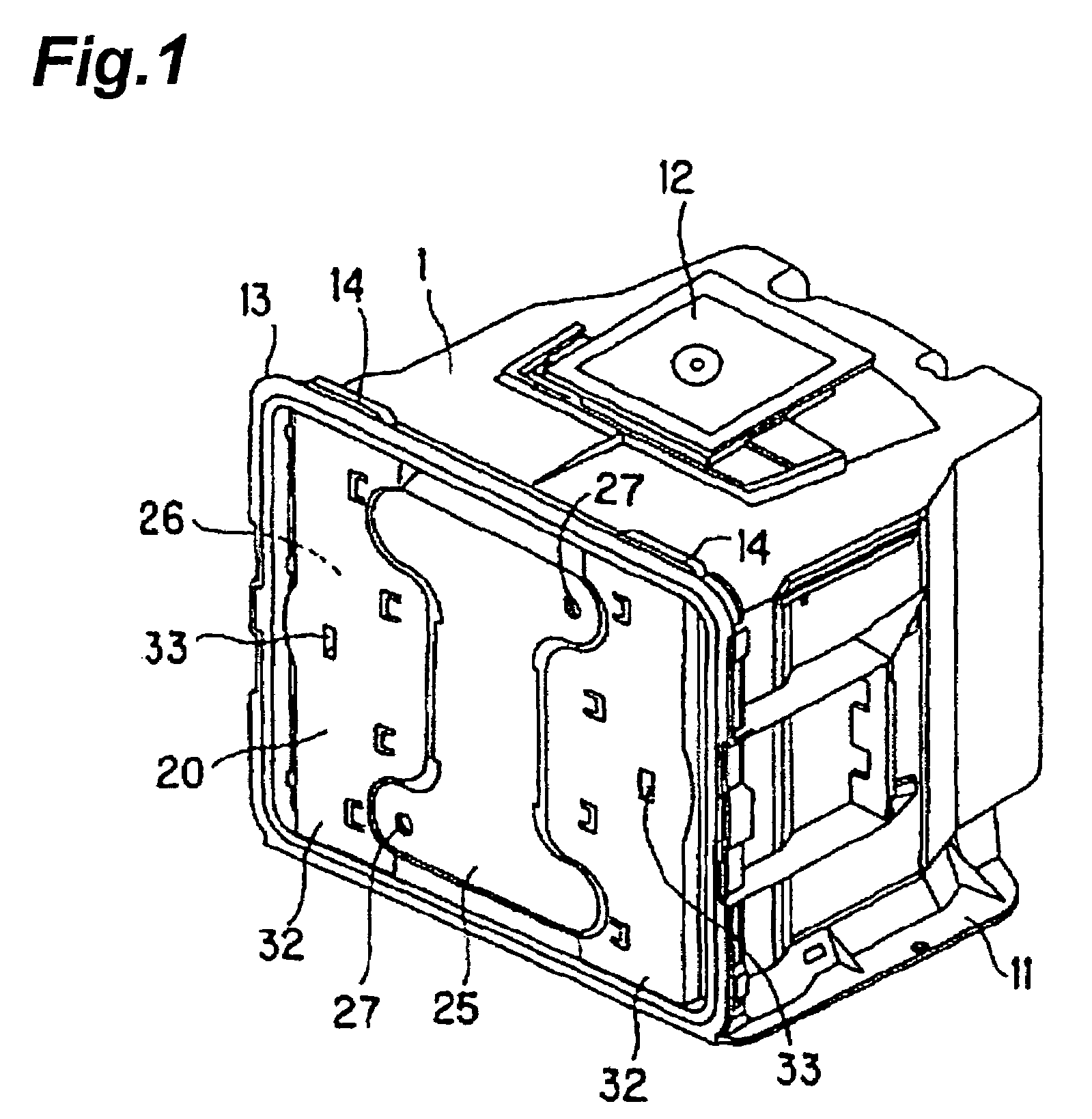

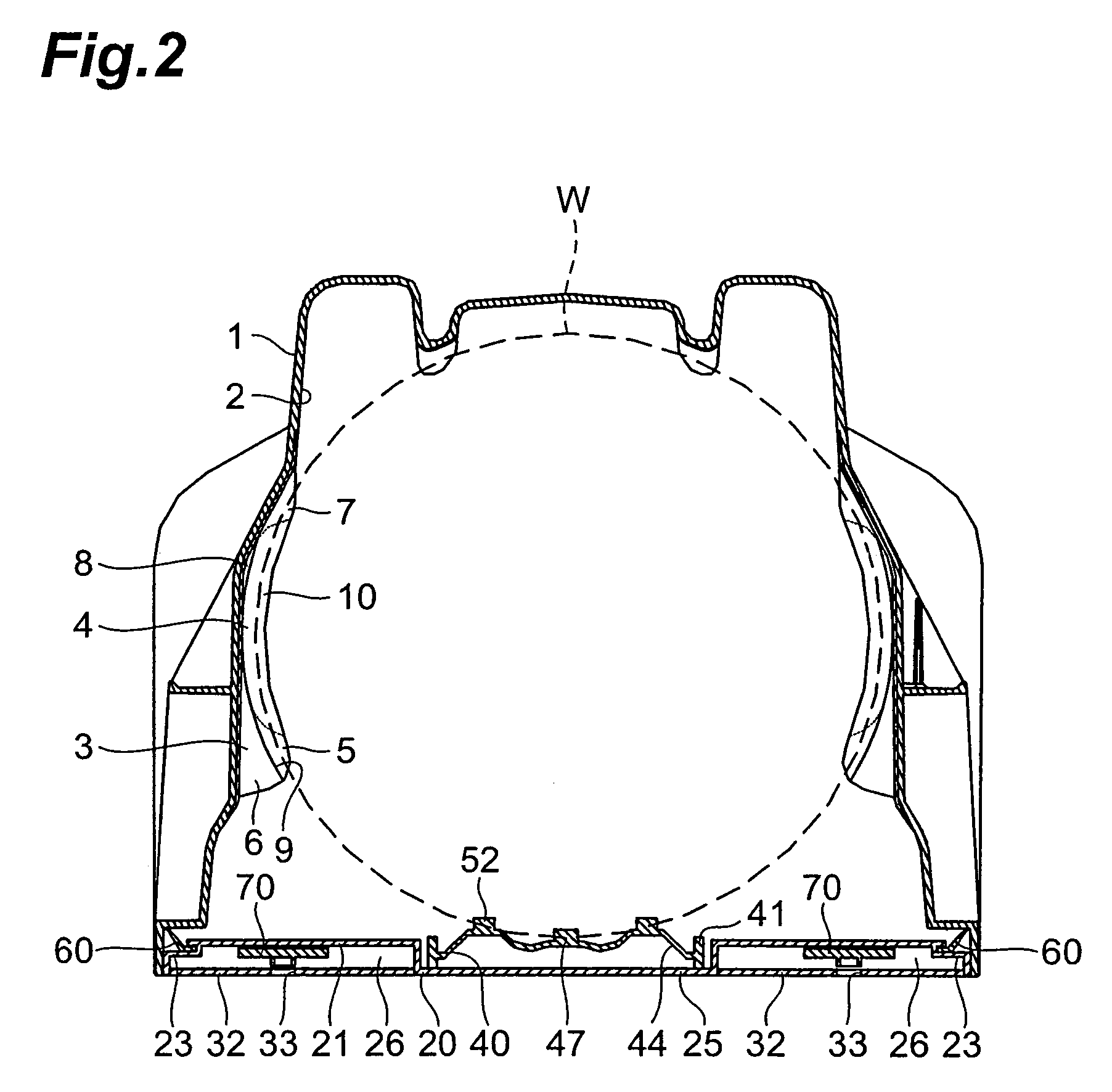

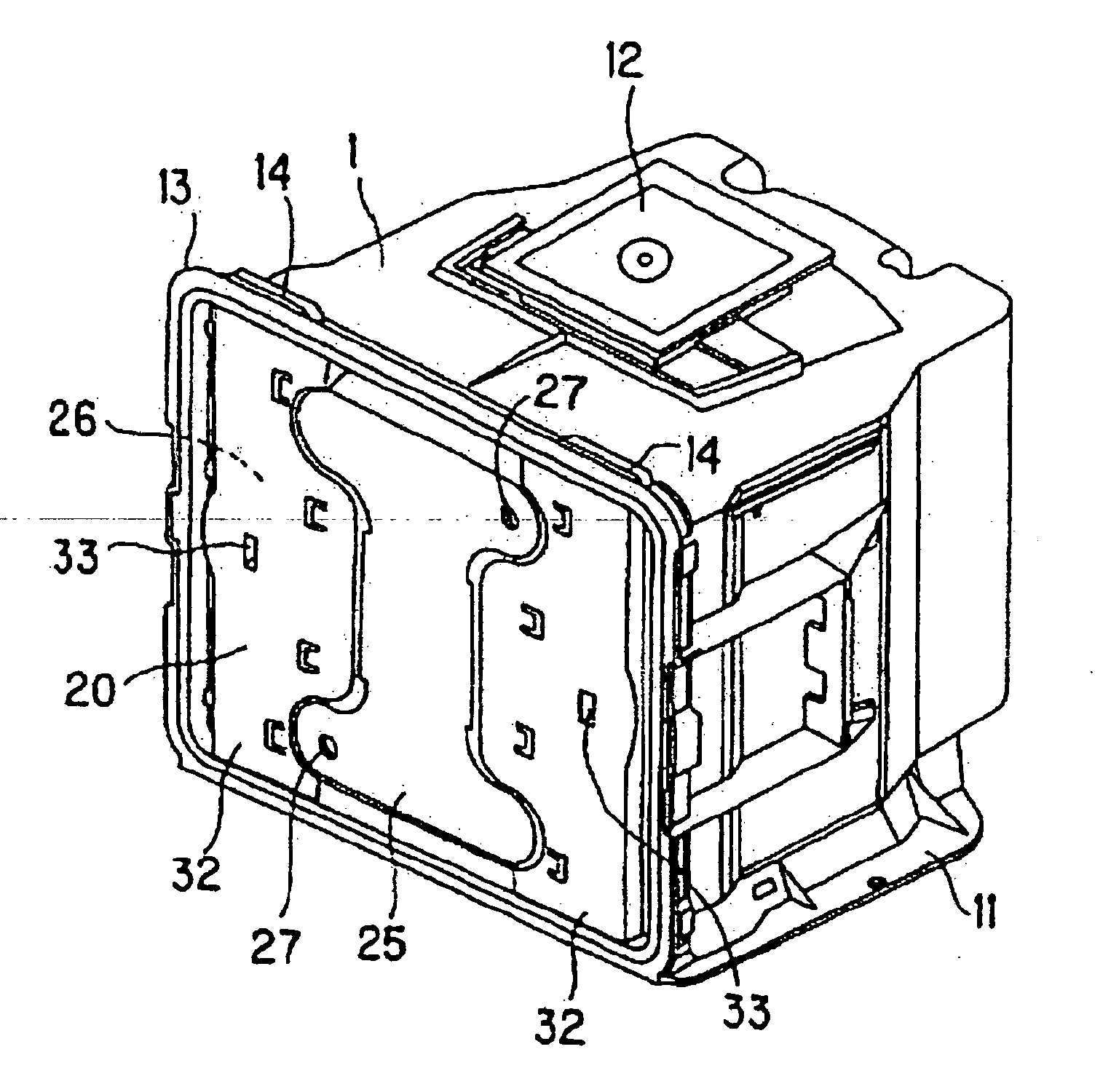

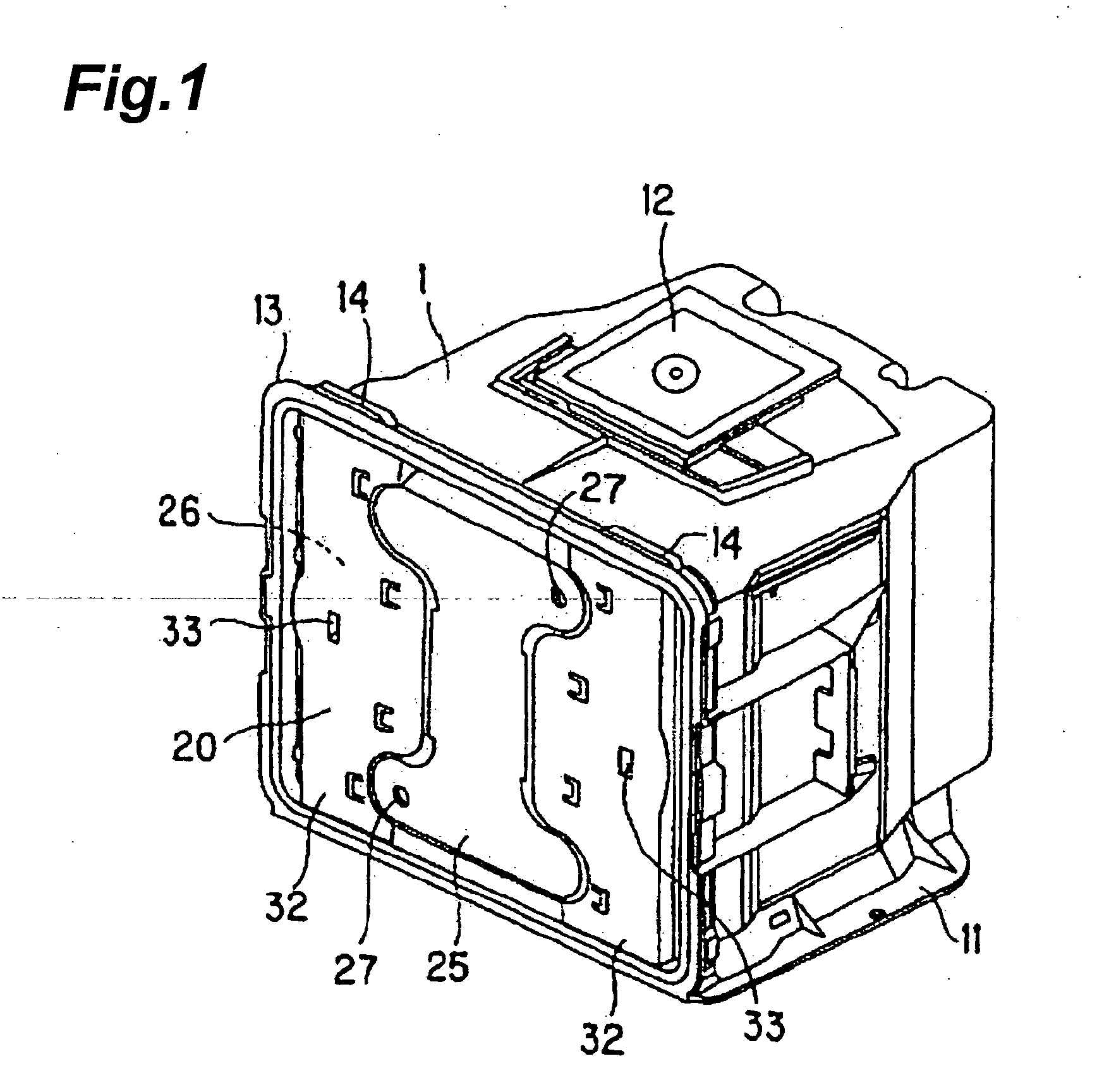

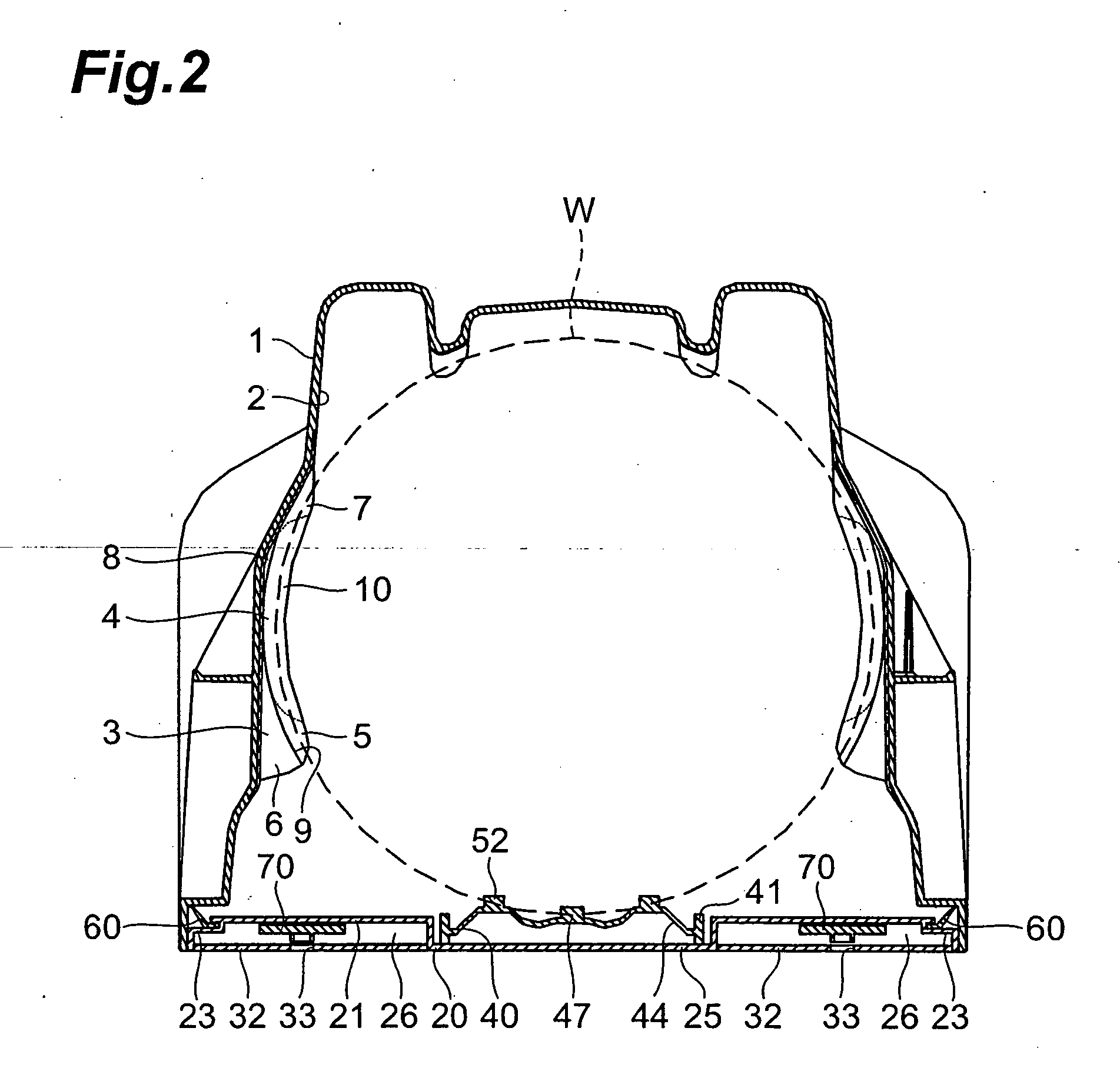

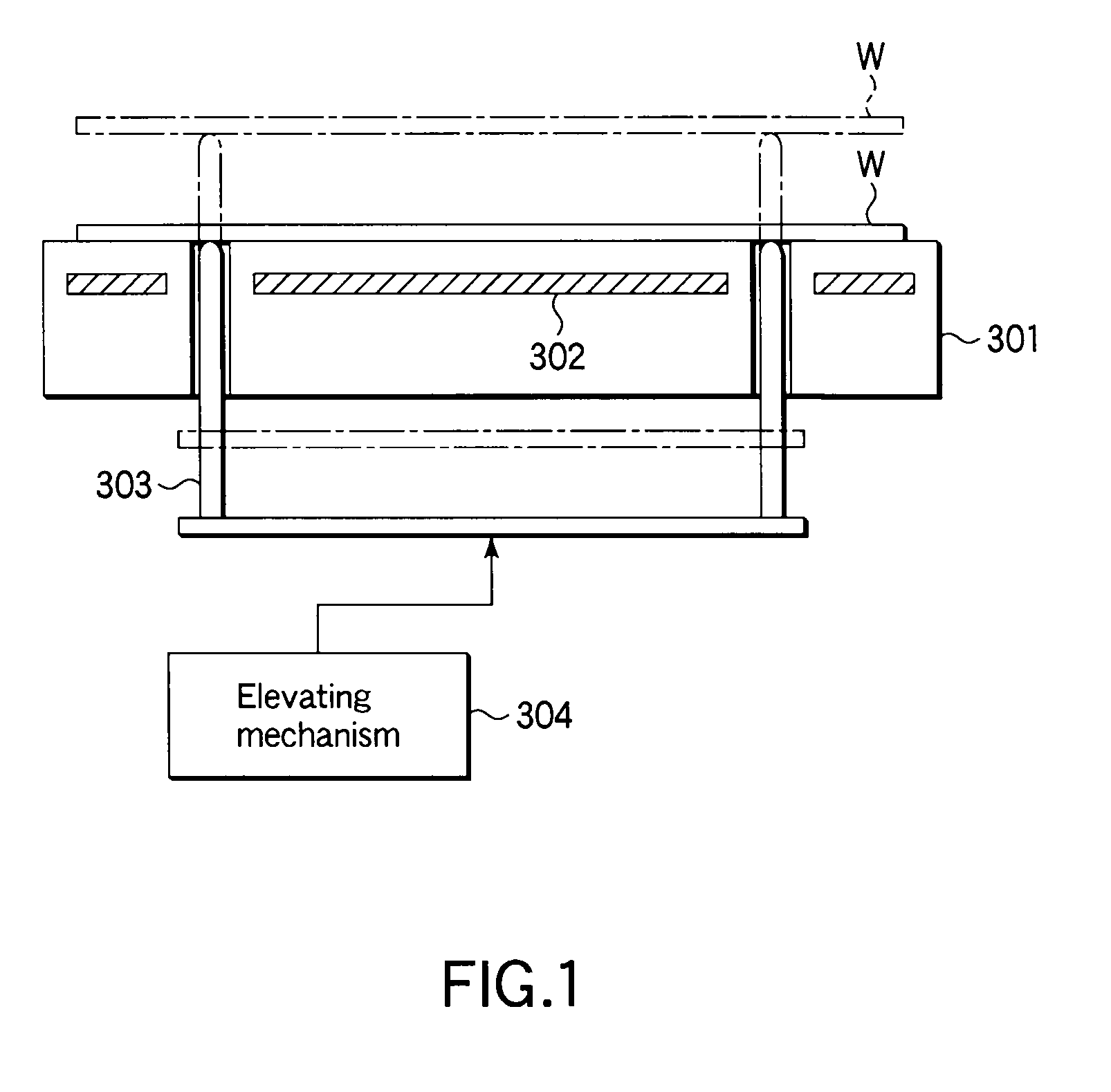

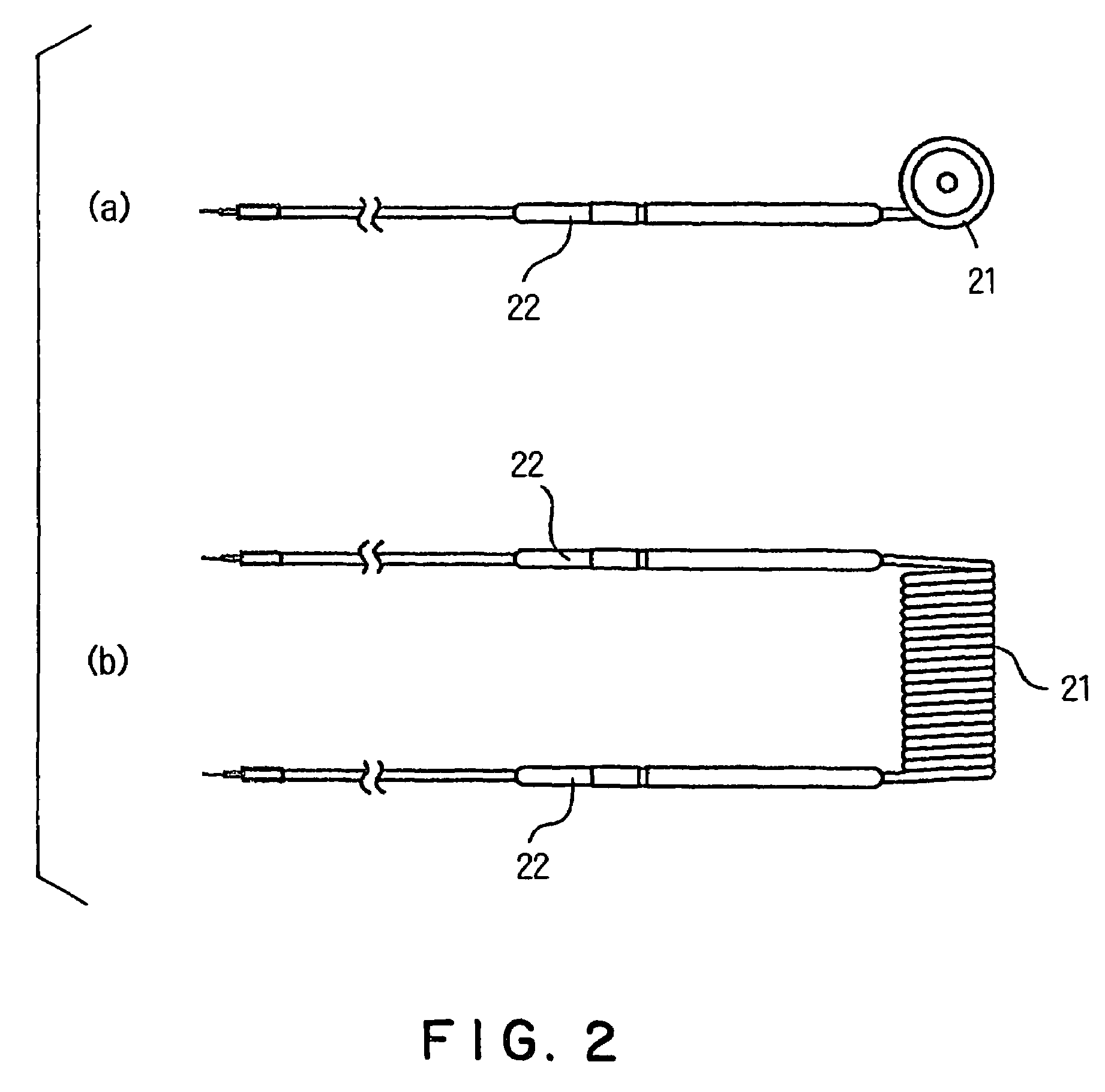

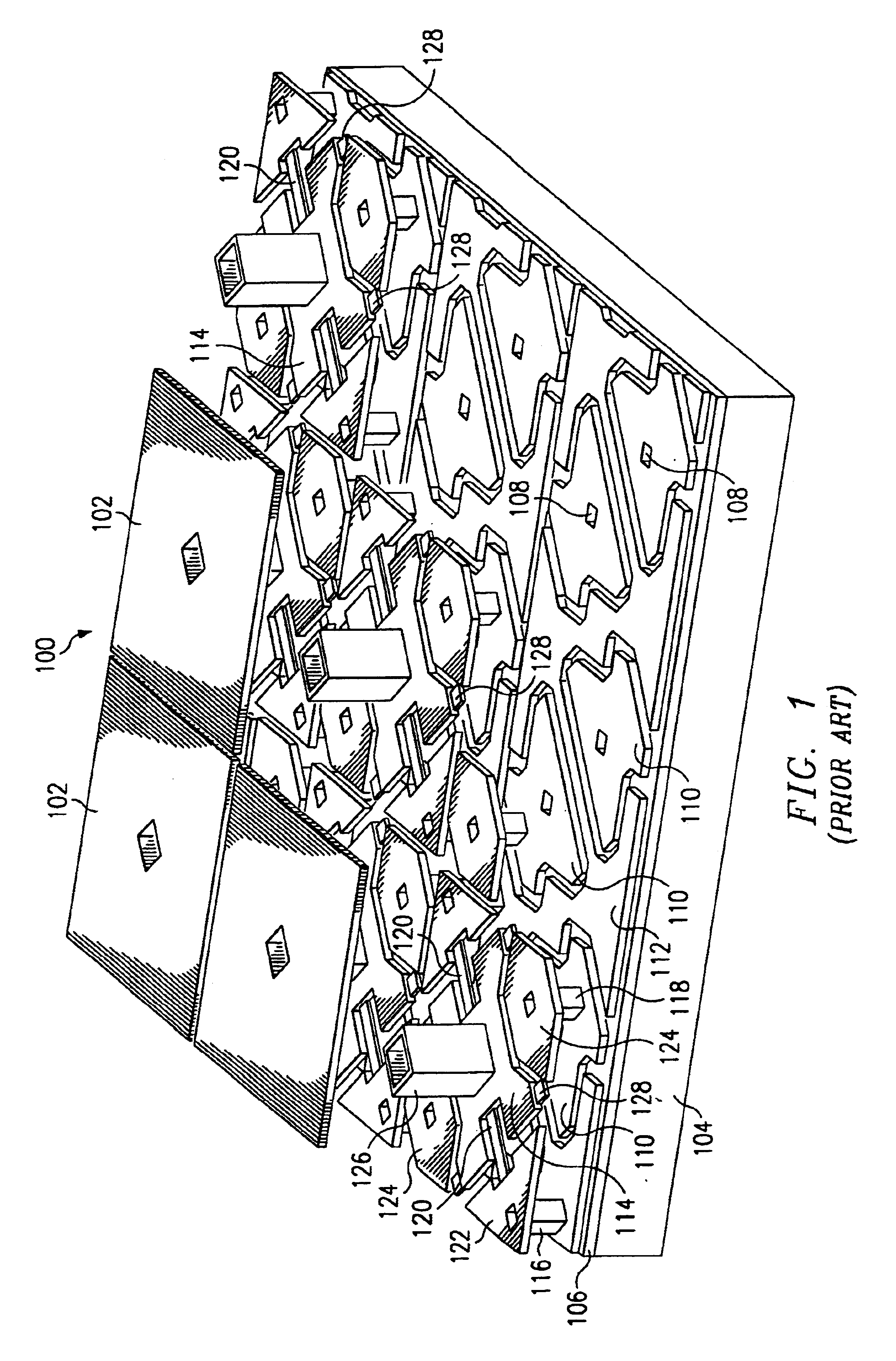

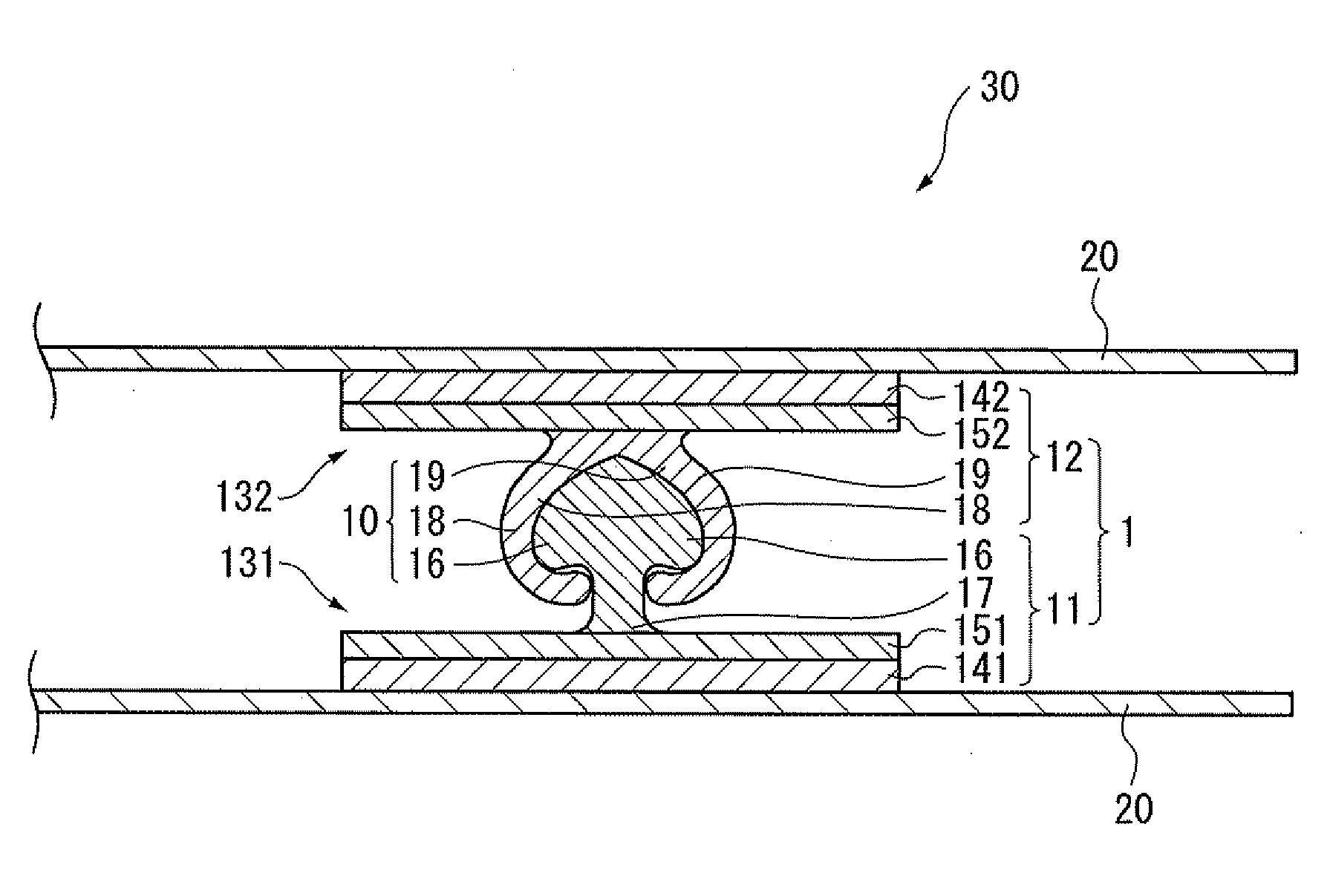

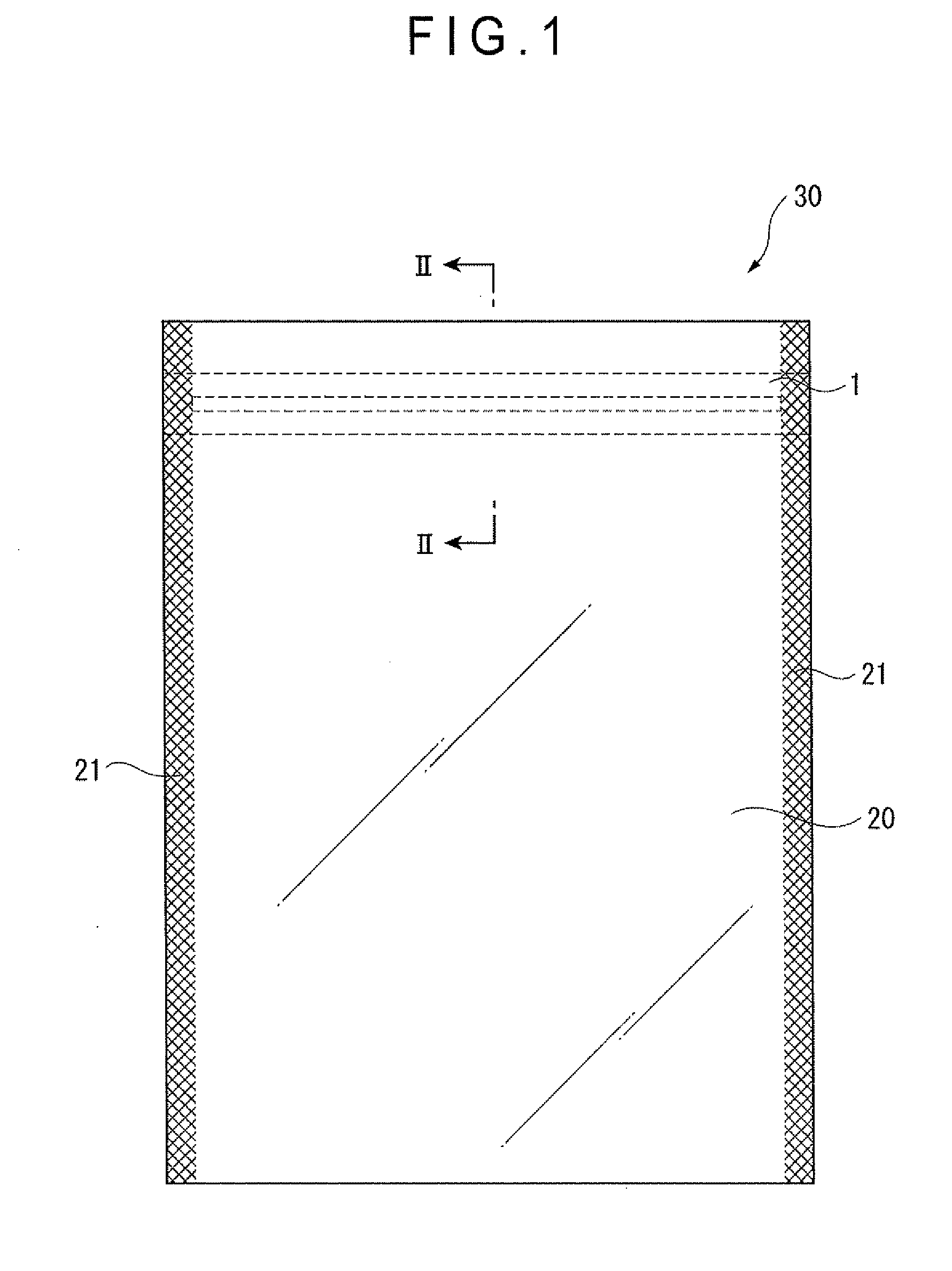

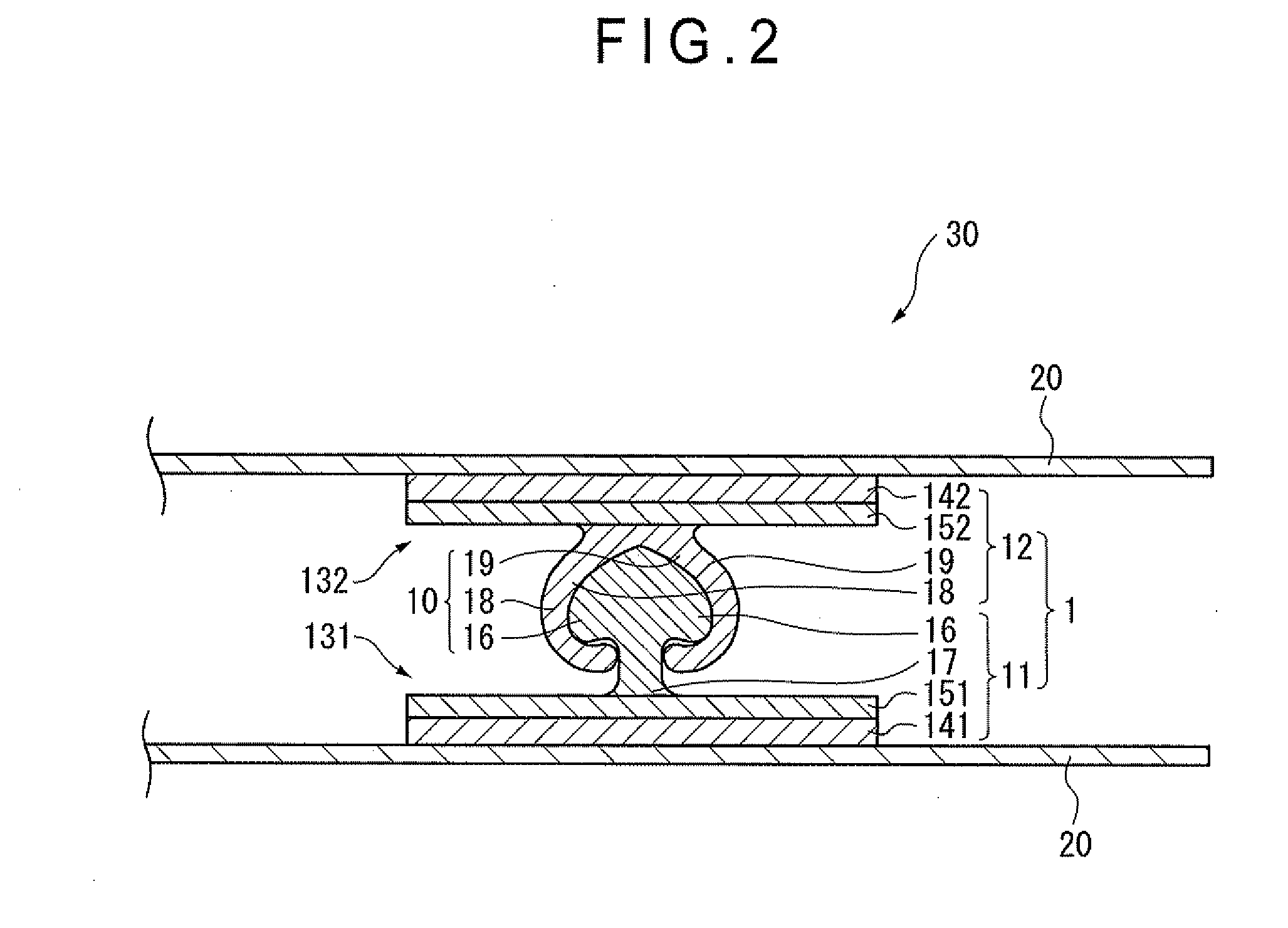

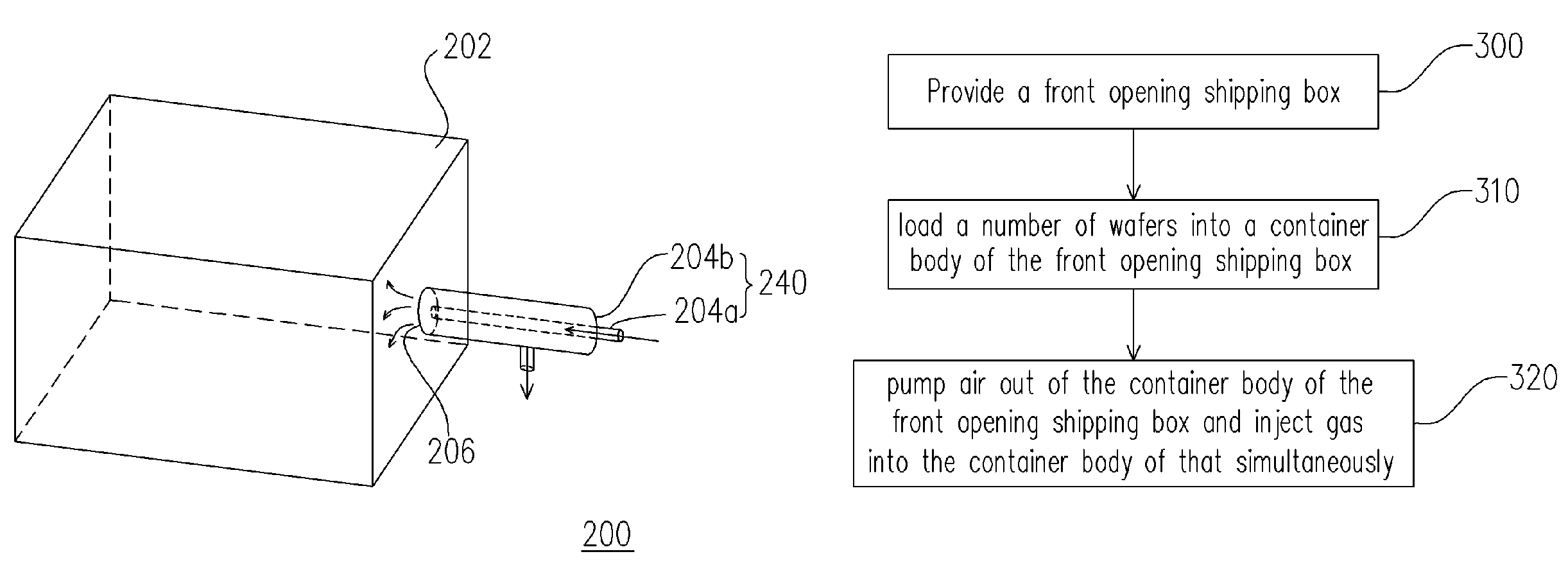

Substrate storage container

ActiveUS7344031B2Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesEngineeringGasket

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover; and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

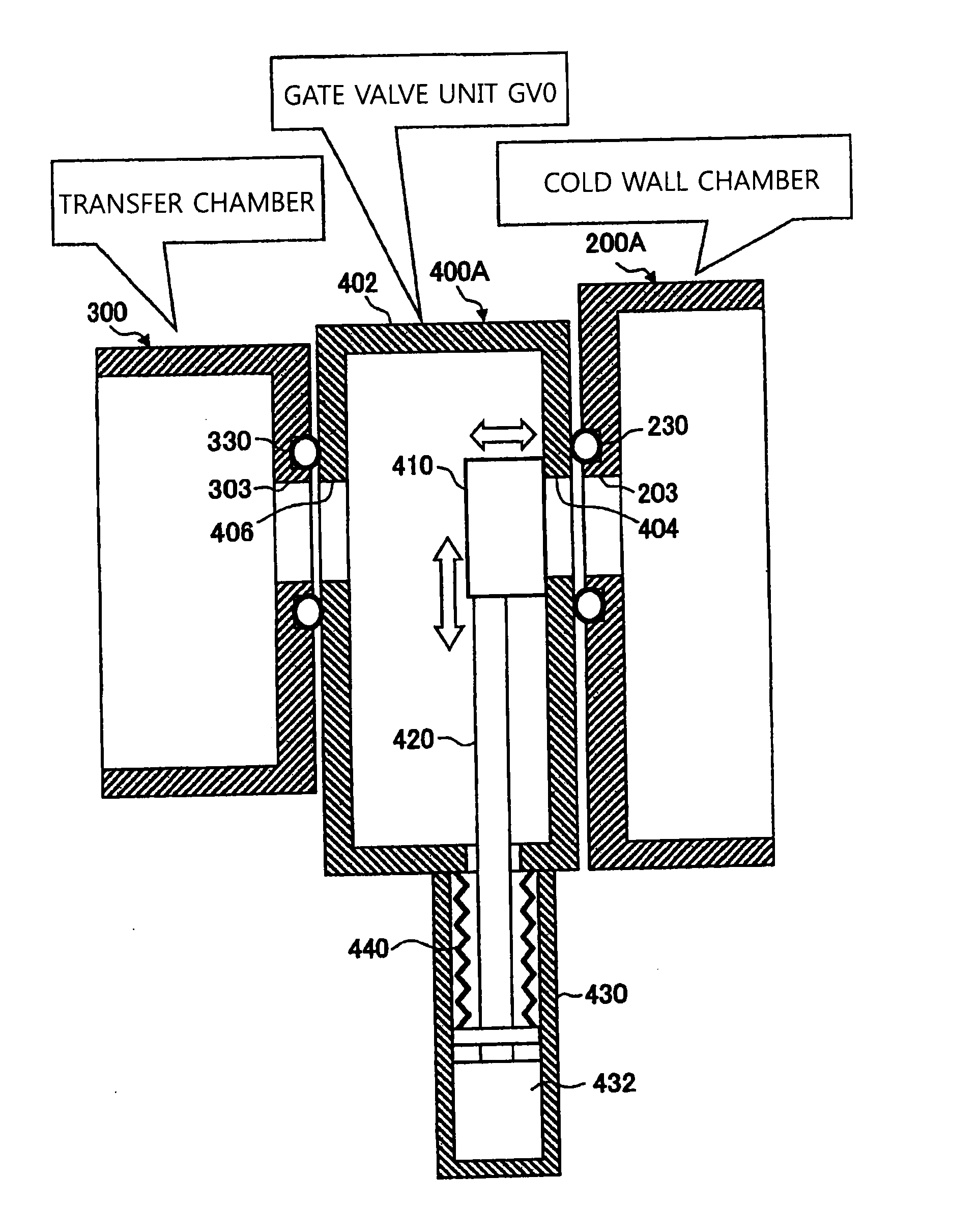

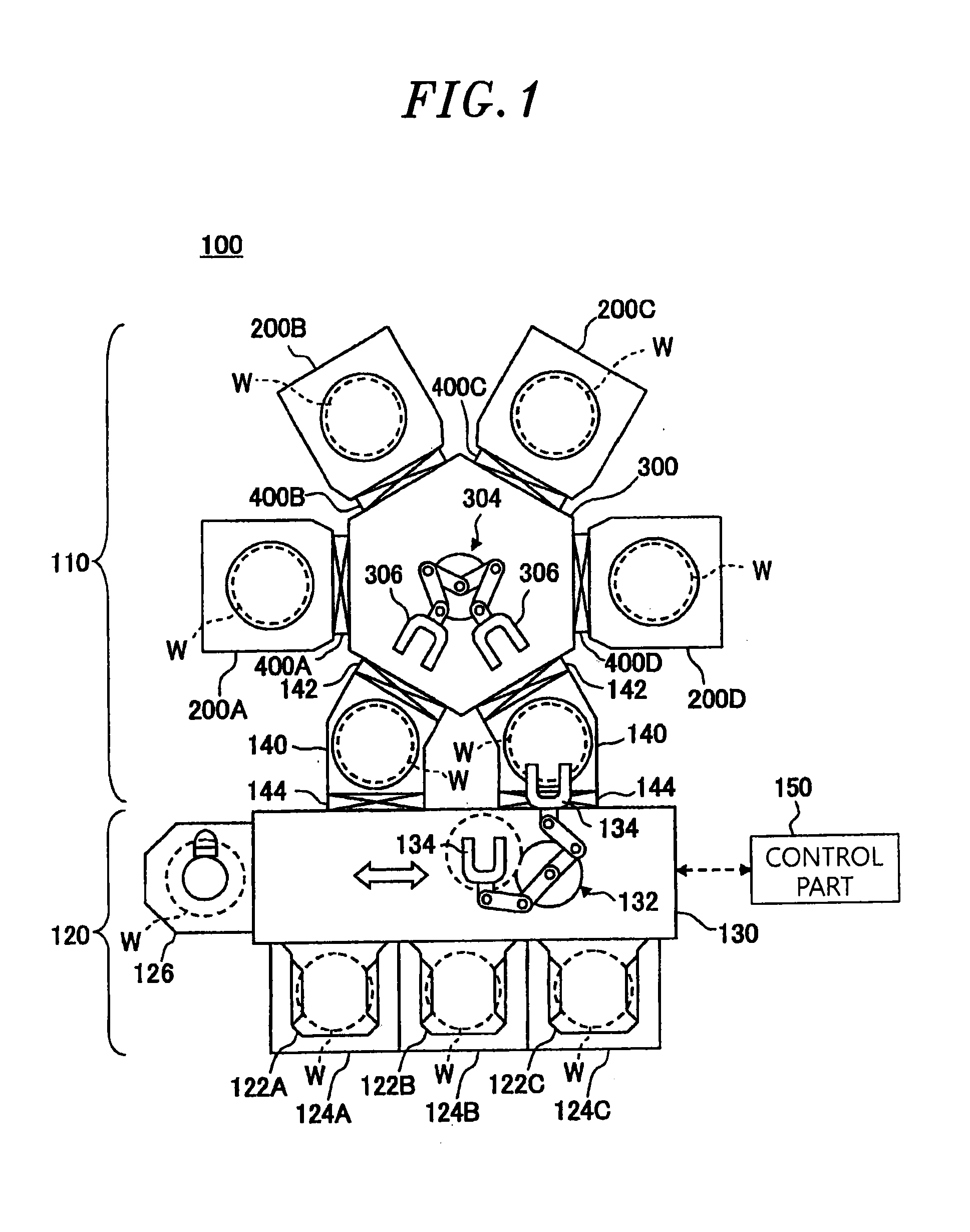

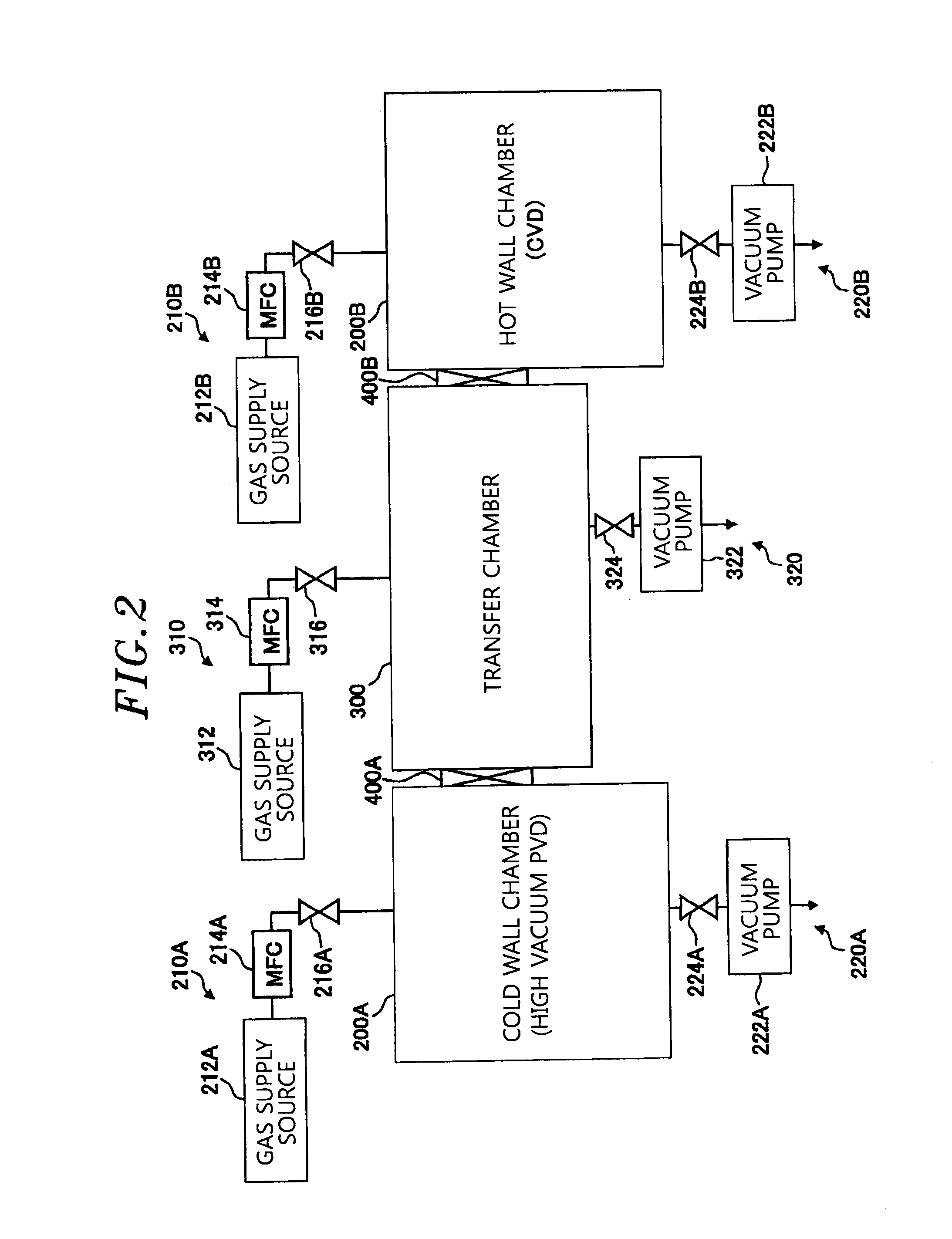

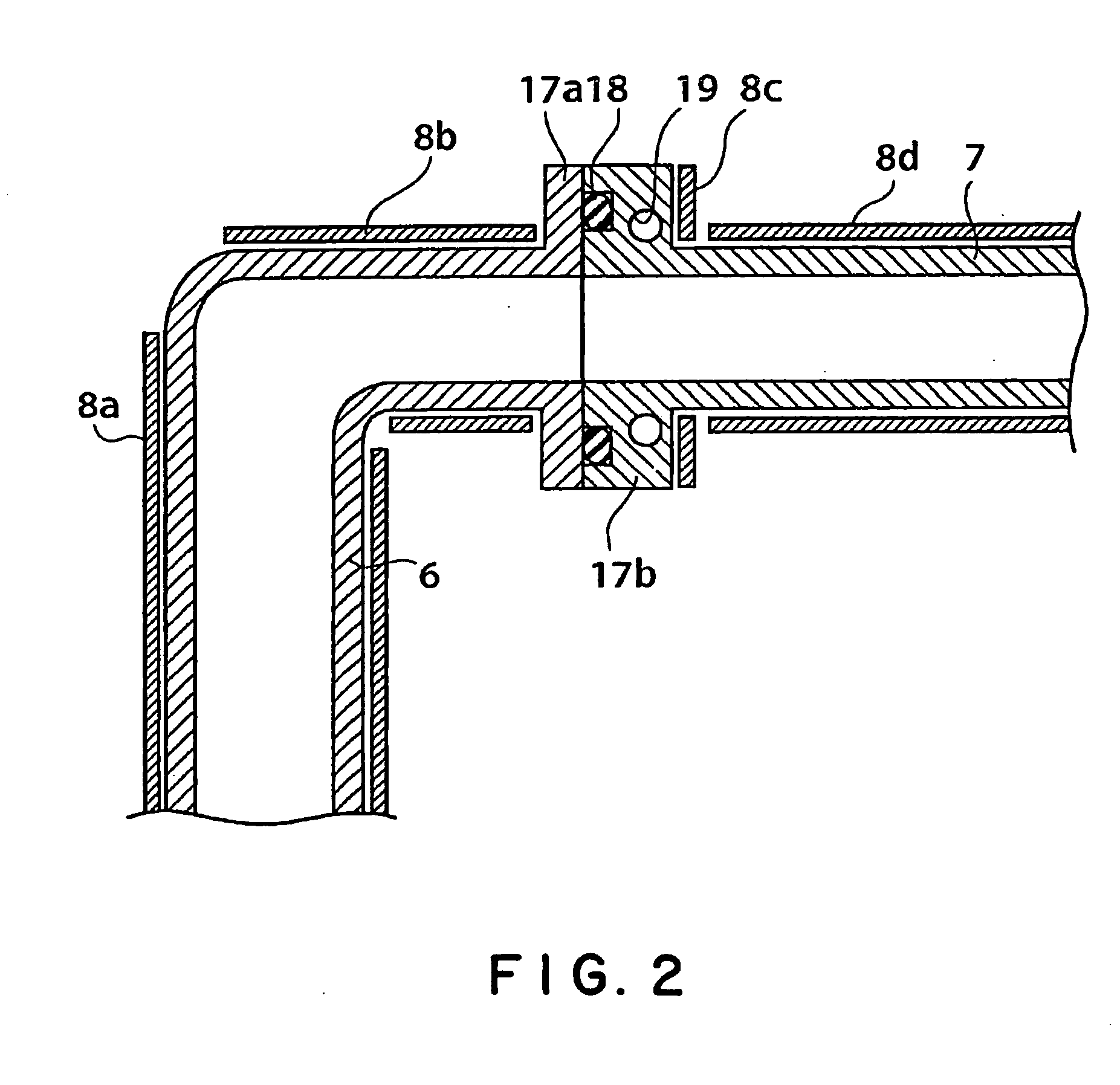

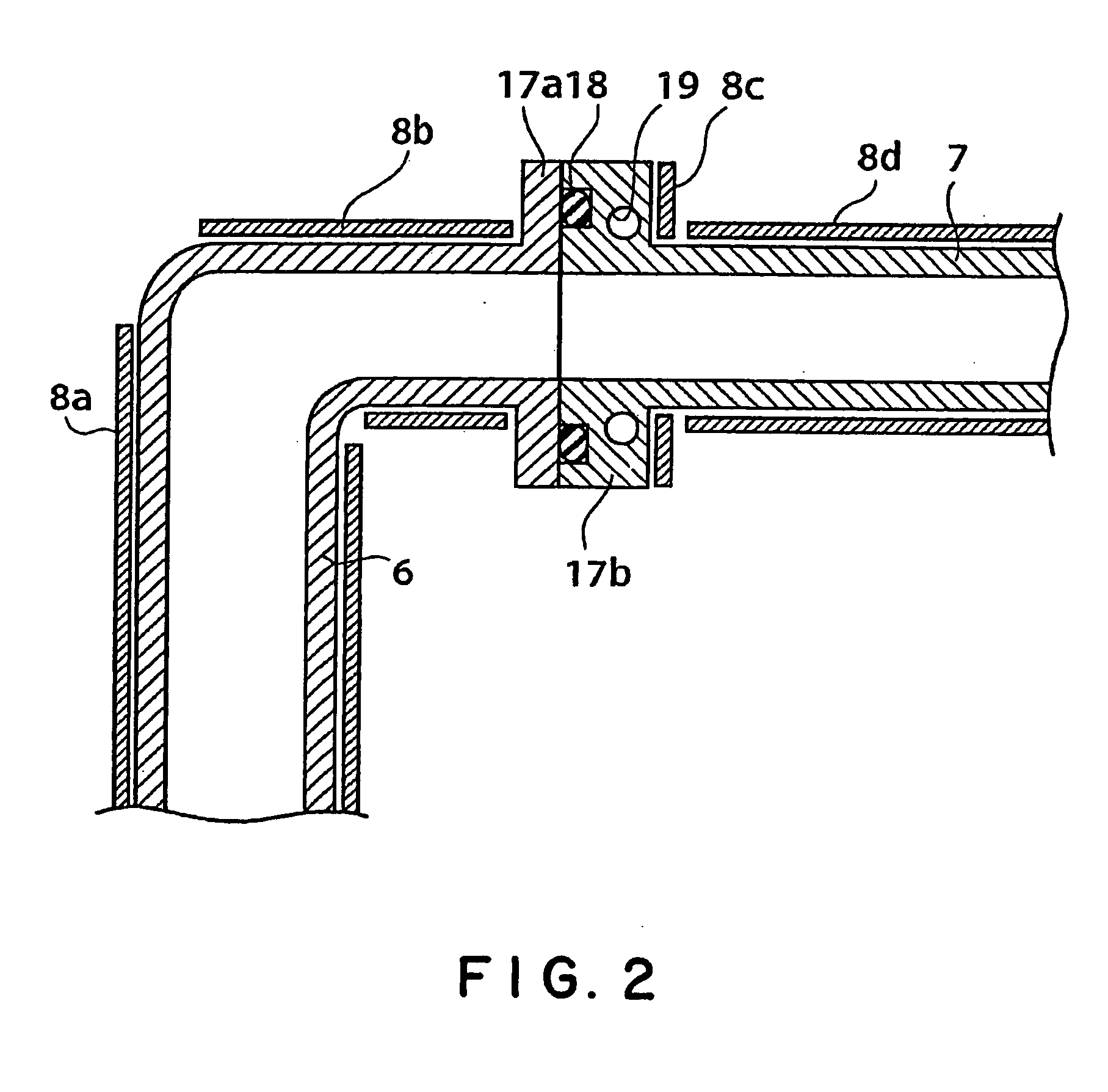

Gate valve unit, substrate processing device and substrate processing method thereof

ActiveUS20140003892A1Reduction in sealing functionIncrease vacuumVacuum evaporation coatingSemiconductor/solid-state device manufacturingInterior spaceRoom temperature

A substrate processing device includes a depressurizable hot wall chamber having a sidewall with a temperature which becomes higher than room temperature and a first substrate transferring port provided in the sidewall, a depressurizable transfer chamber having a transfer arm mechanism and a second substrate transferring port, and a gate valve unit provided between the hot wall chamber and the transfer chamber. The gate valve unit includes: a housing having a sidewall provided with communicating holes, a first housing substrate transferring port, and a second housing substrate transferring port; a valve body which is elevatable in the housing; and a double sealing structure having a first sealing member and a second sealing member provided at an outer side of the first sealing member. The communicating holes communicate a gap between the first sealing member and the second sealing member with an internal space of the housing.

Owner:TOKYO ELECTRON LTD

Substrate storage container

ActiveUS20050274645A1Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesGasketEngineering

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover, and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

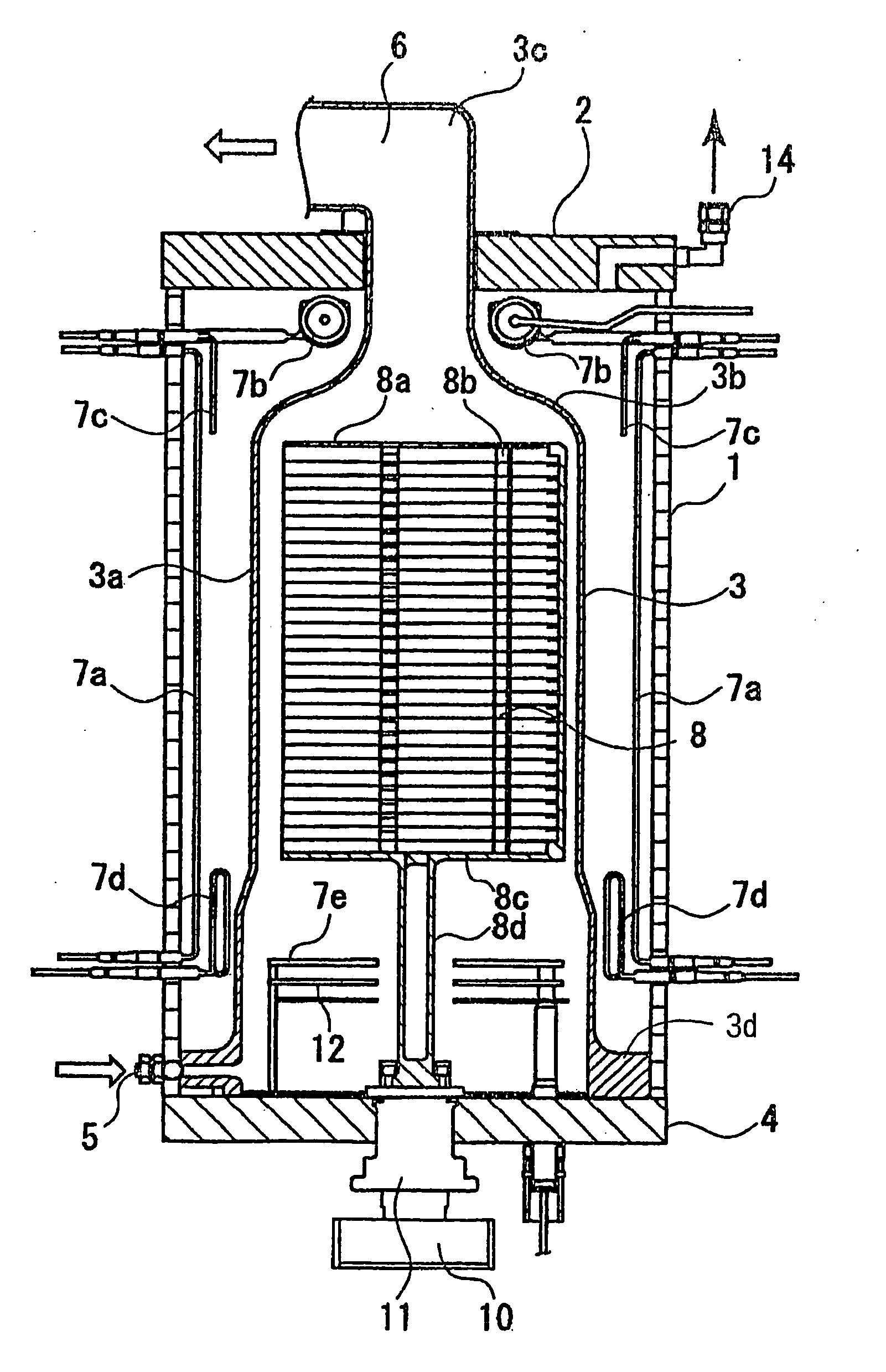

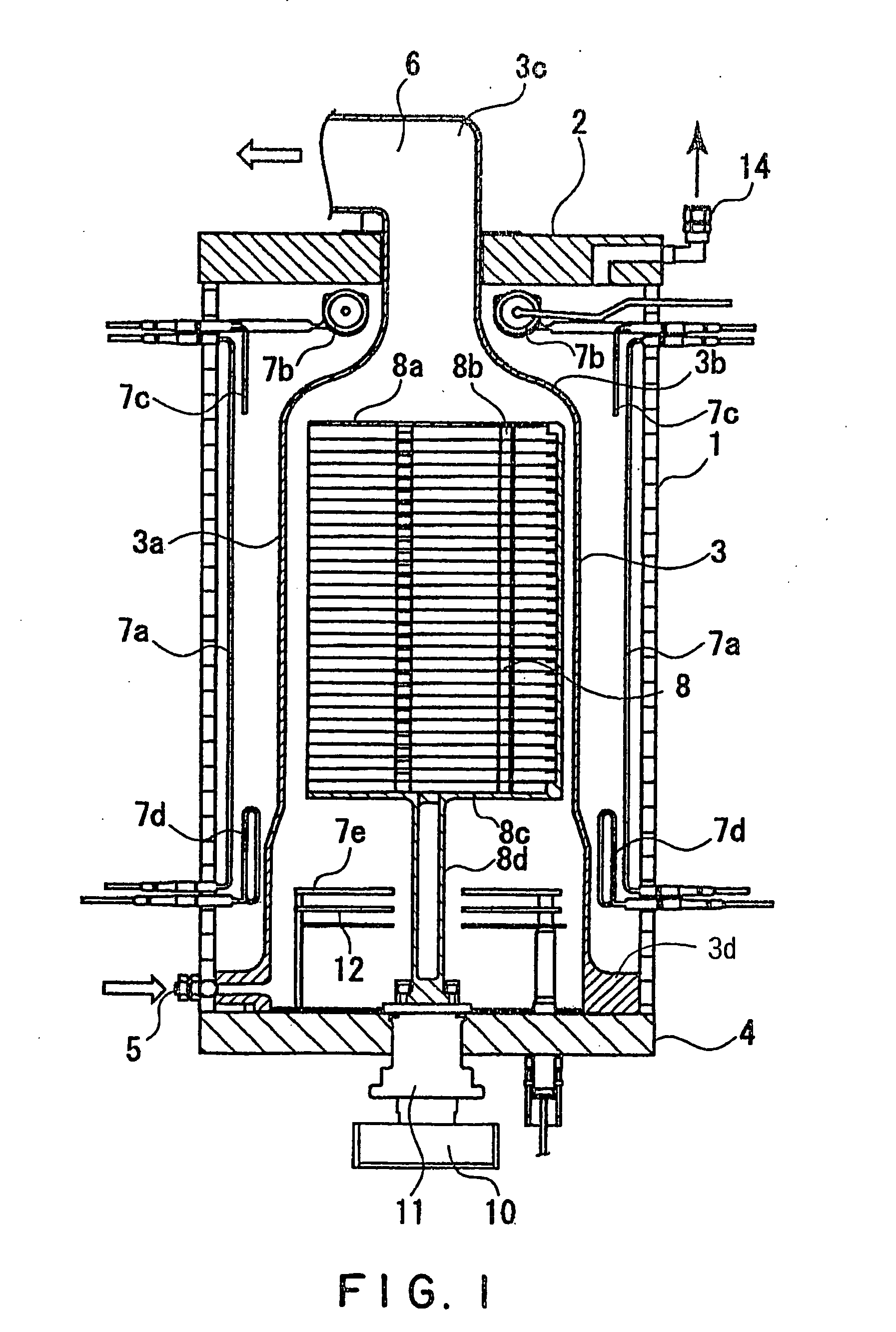

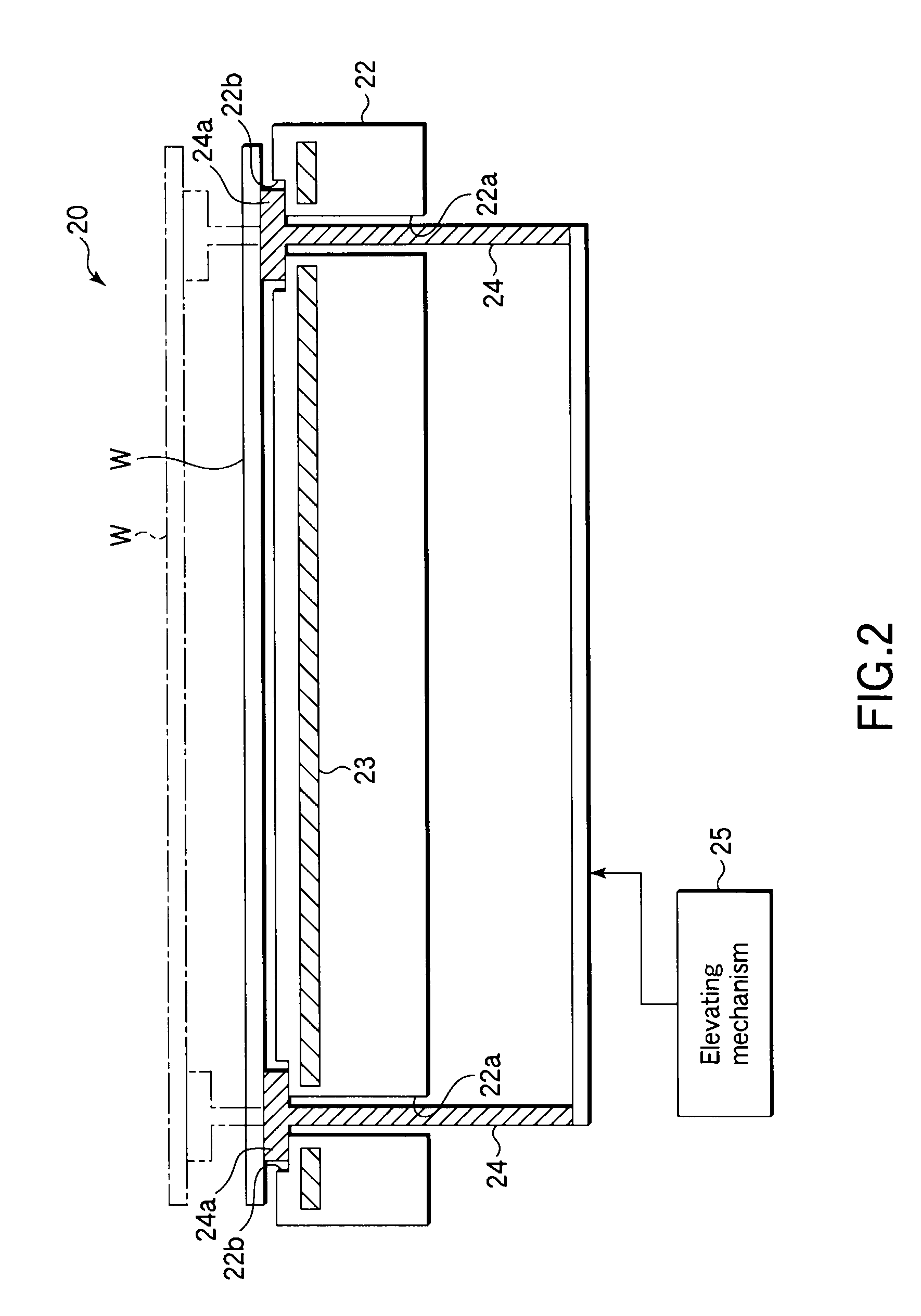

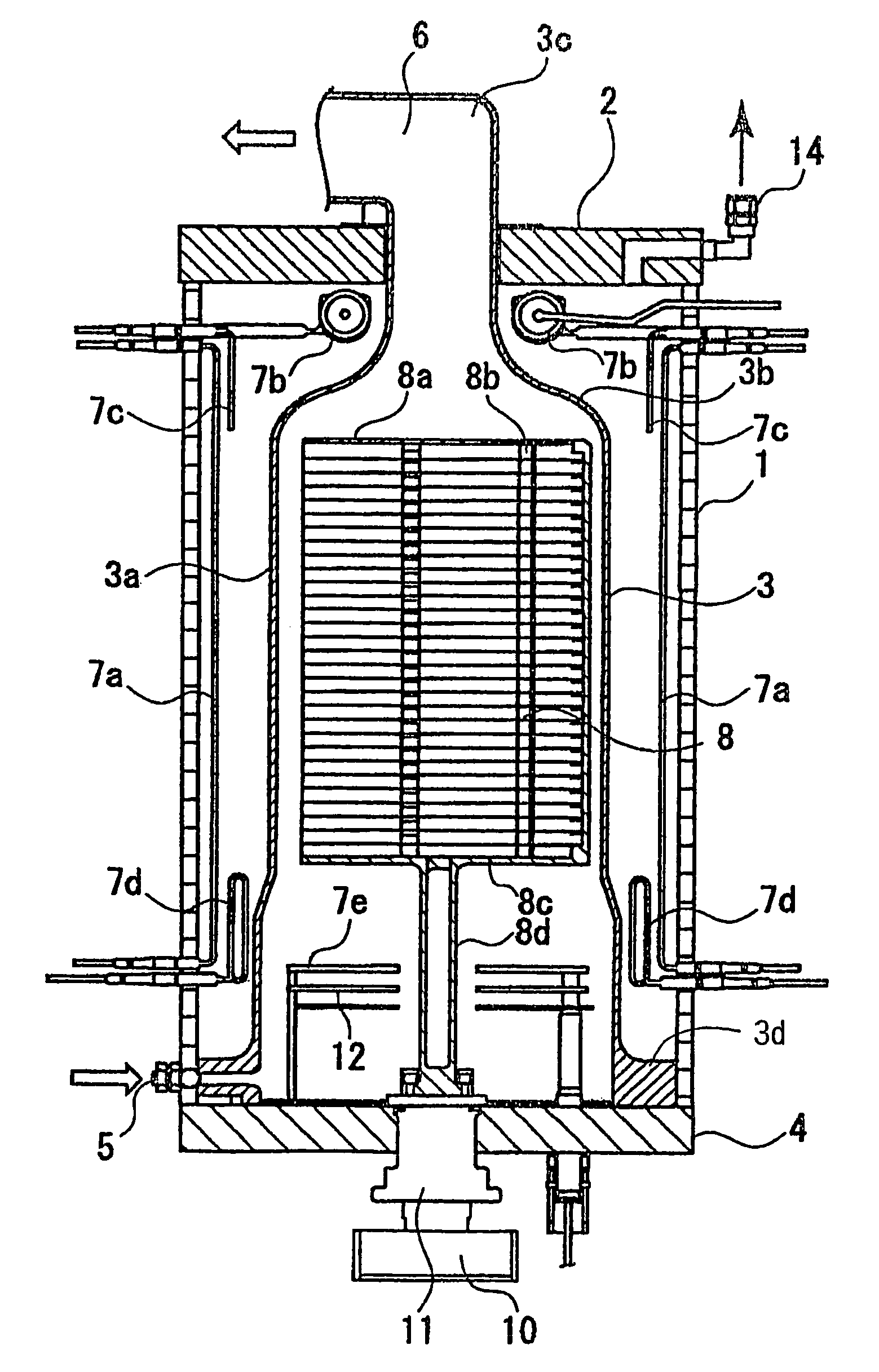

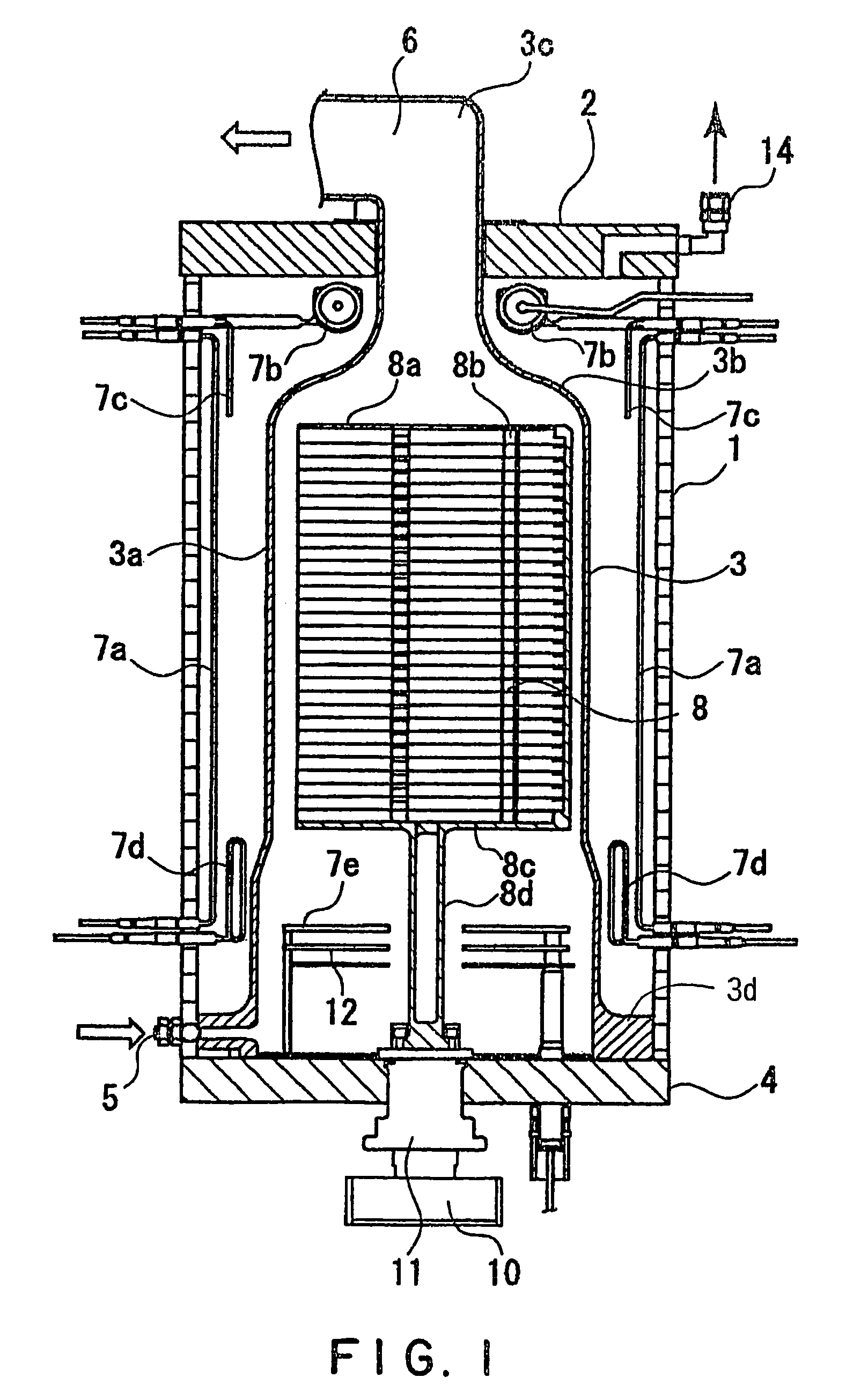

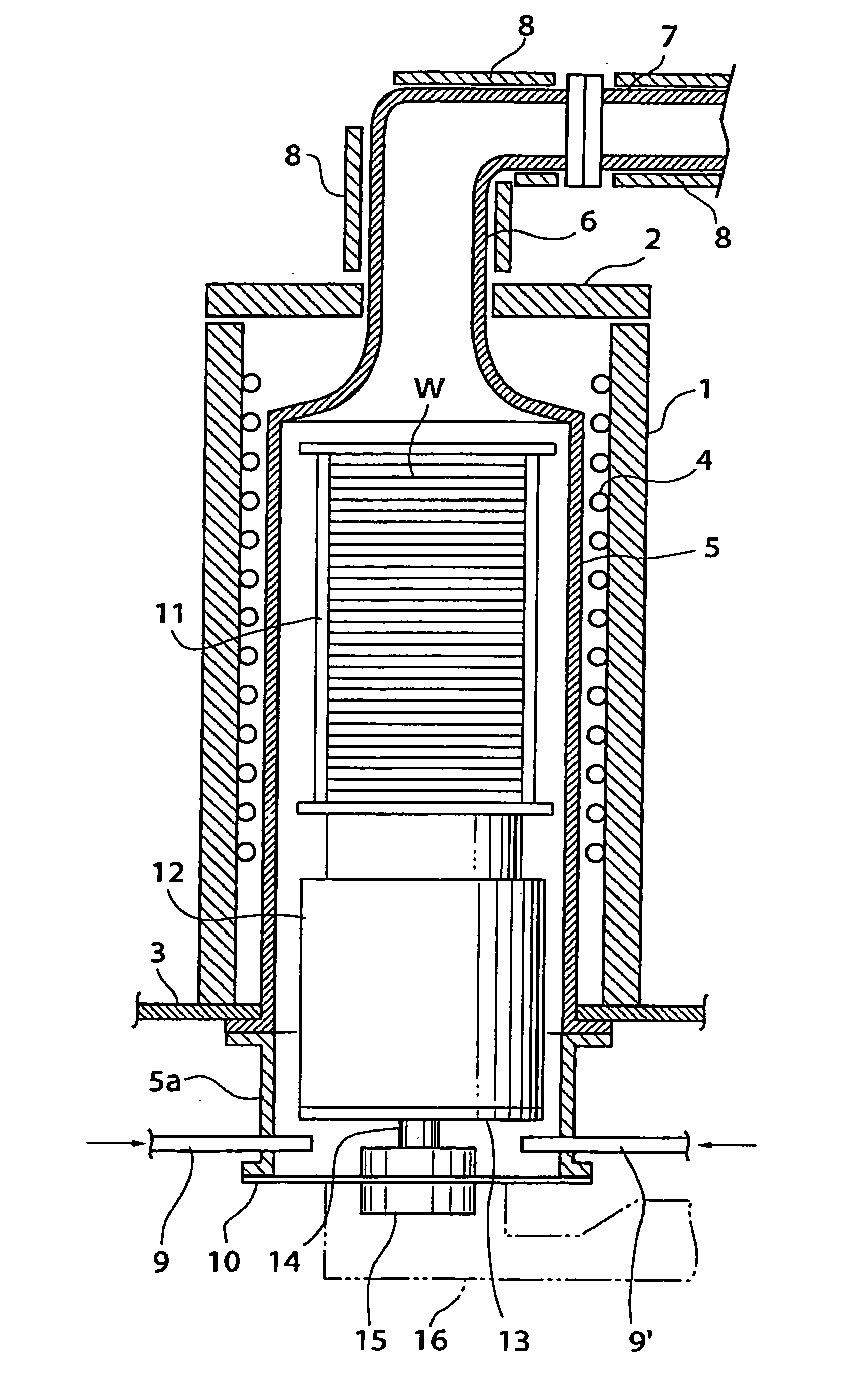

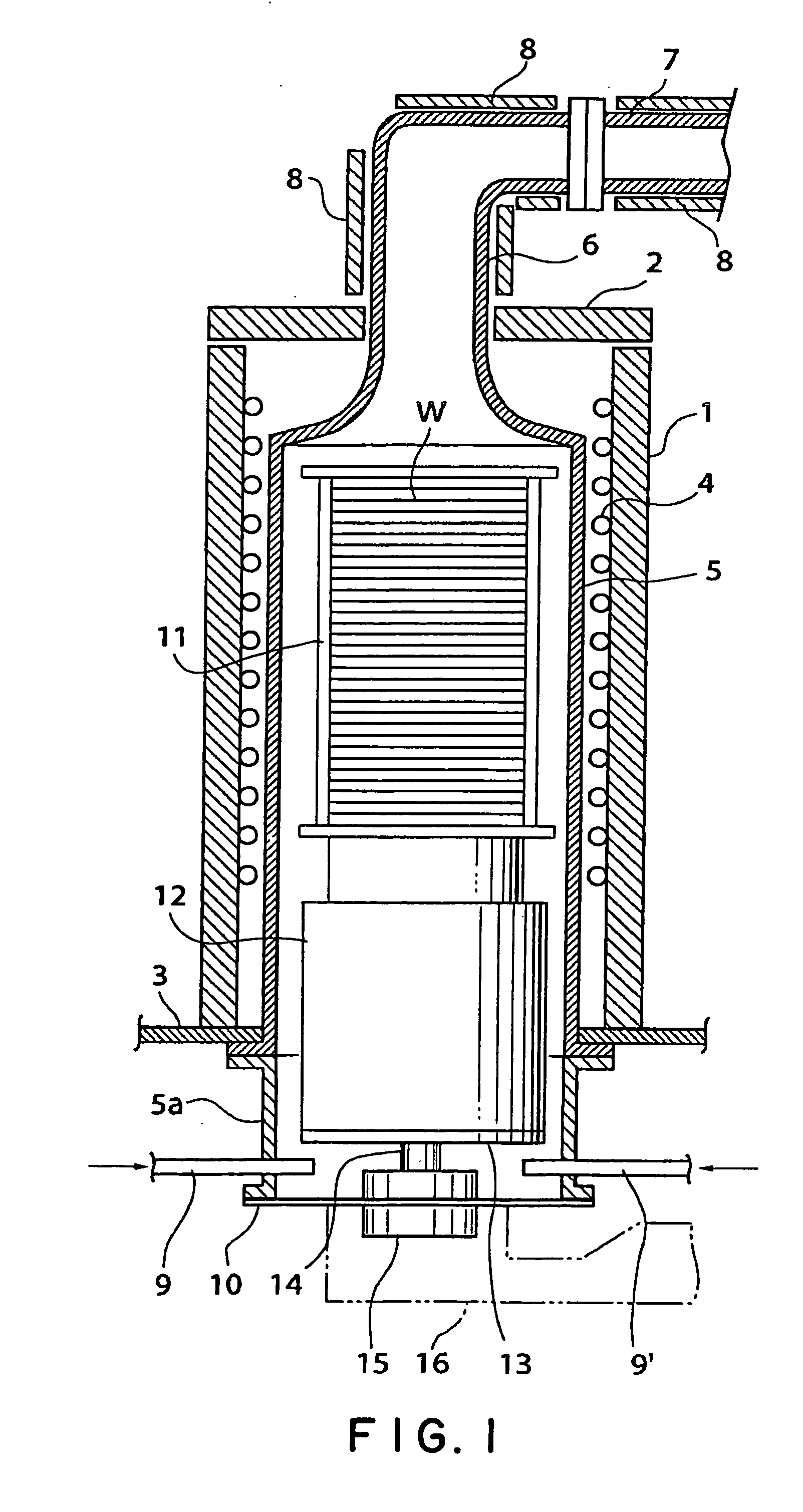

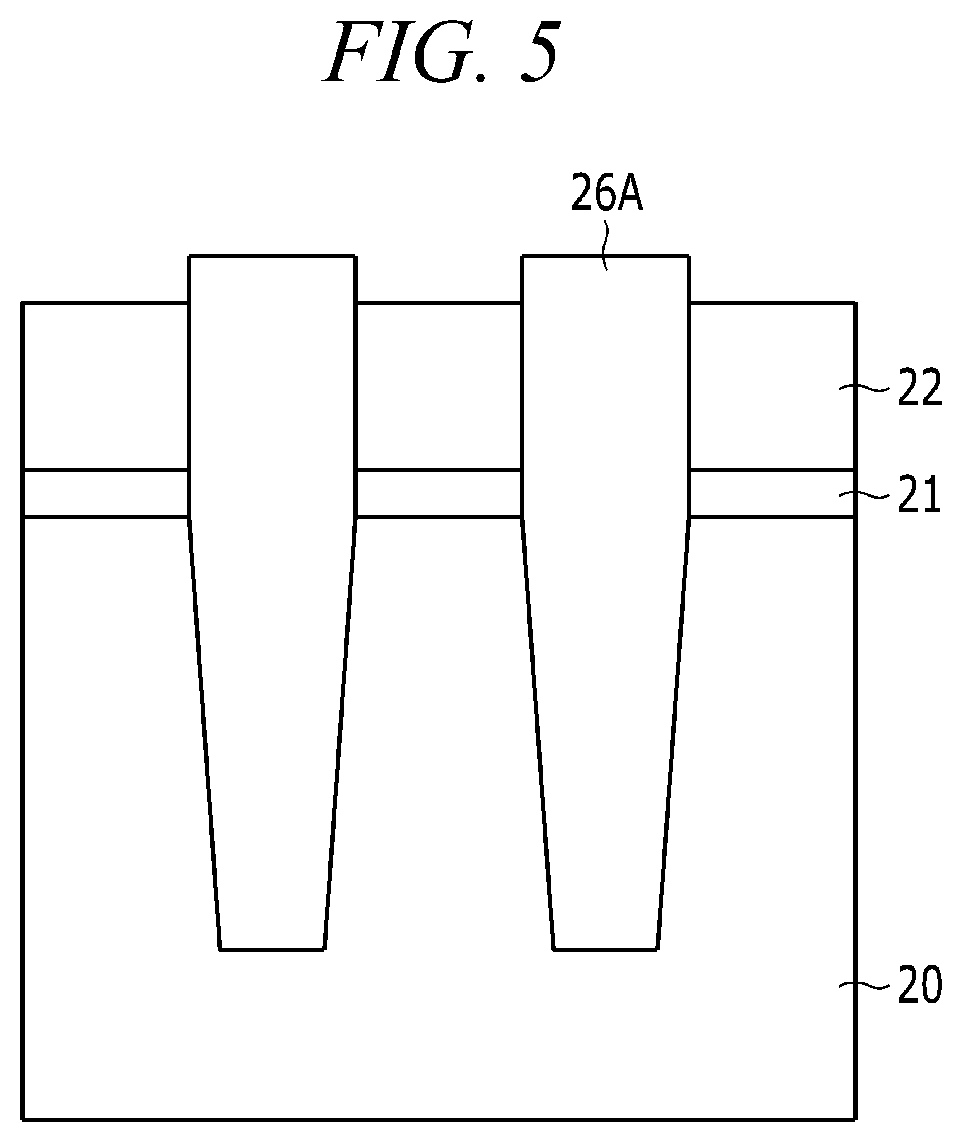

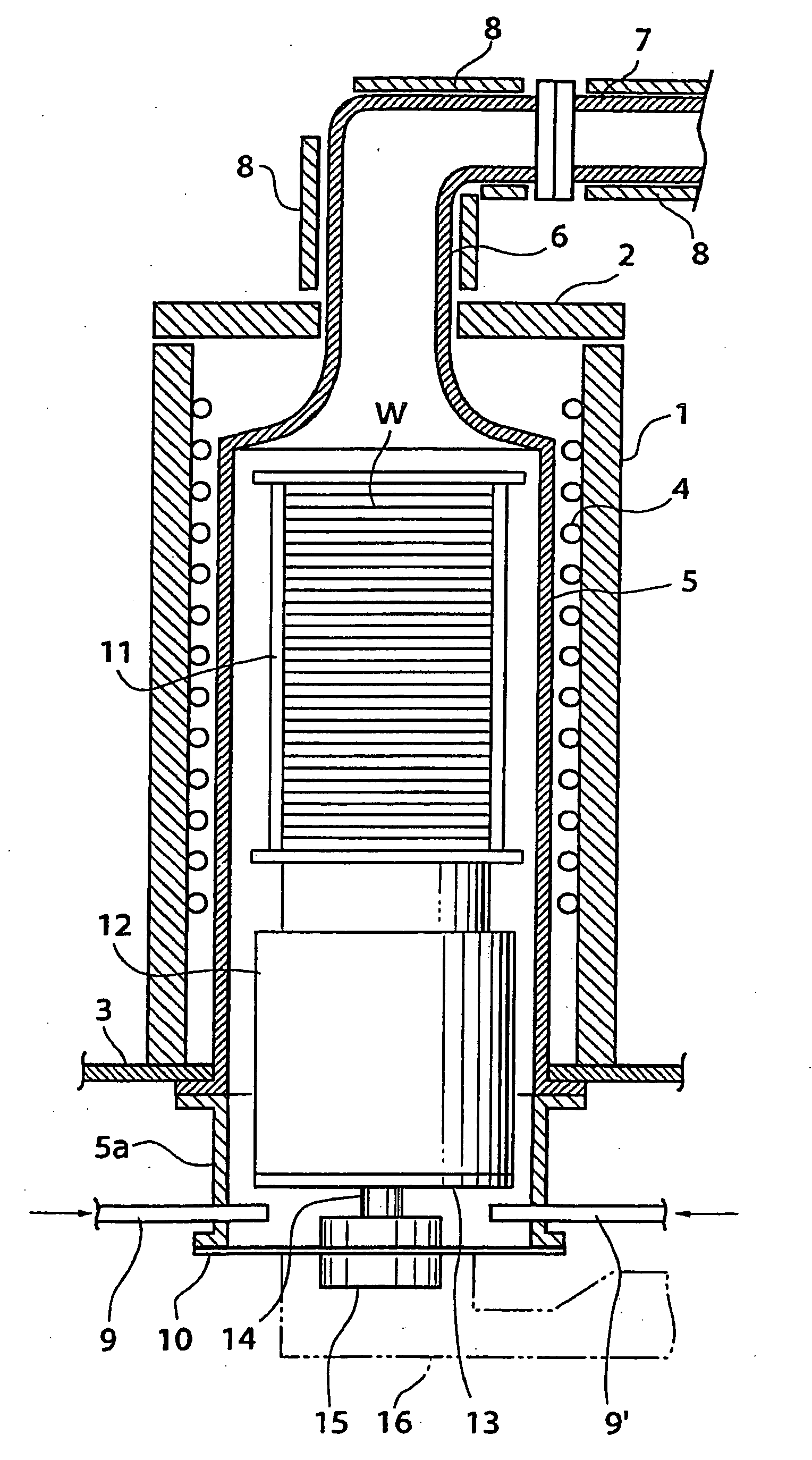

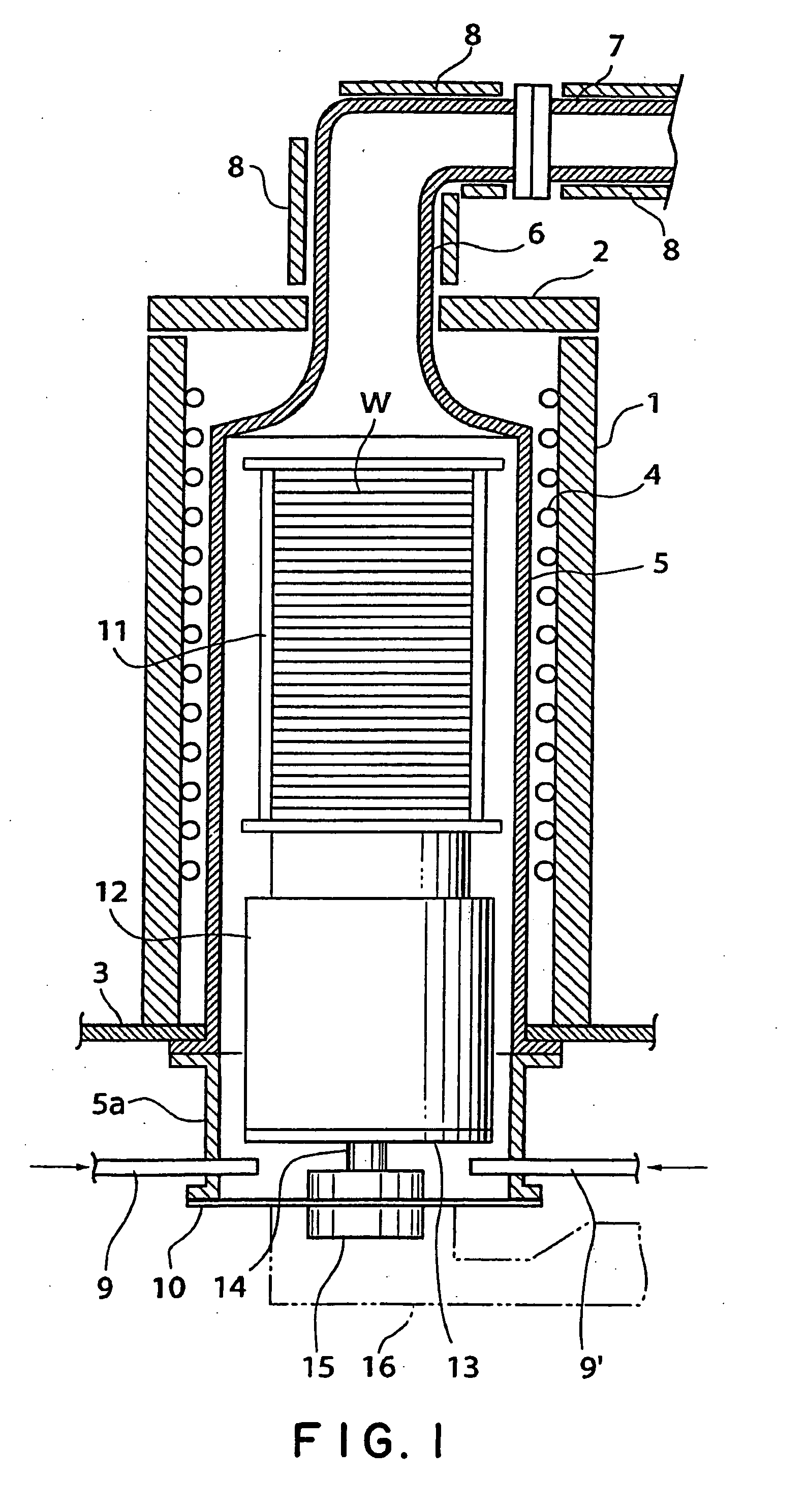

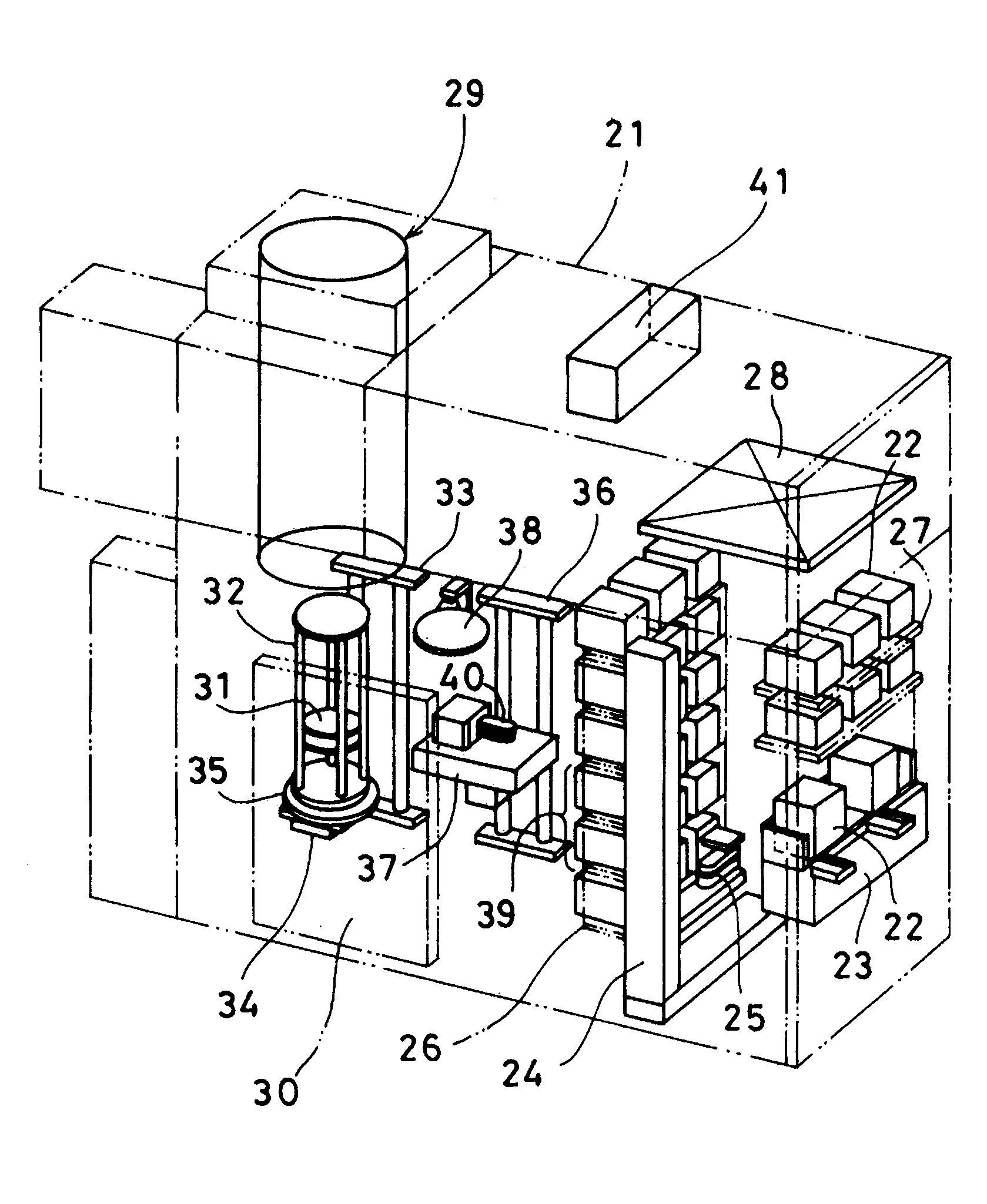

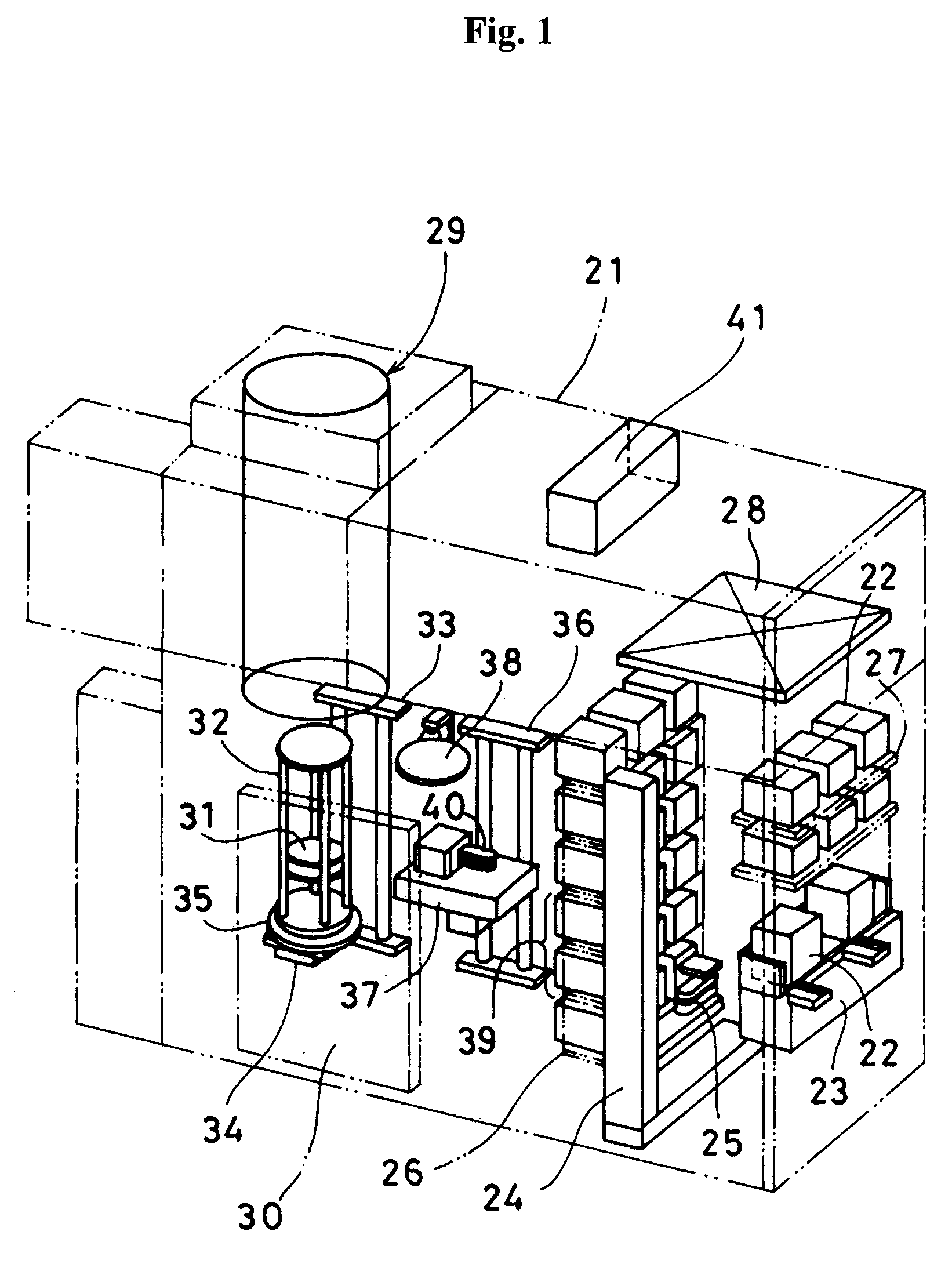

Heat treatment apparatus

ActiveUS20060021582A1Inhibition effectHeating fastMuffle furnacesSemiconductor/solid-state device manufacturingProcess supportEngineering

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a reaction tube consisting of a single tube contained in the heating-furnace body; a gas-discharging-unit connecting portion formed at an upper portion of the reaction tube, the gas-discharging-unit connecting portion having a narrow diameter; a substrate-to-be-processed supporting member for supporting a substrate to be processed, contained in the heating-furnace body; and a heating unit for heating the substrate to be processed supported by the substrate-to-be-processed supporting member. The heating unit has: a first heating portion arranged around the reaction tube, a second heating portion arranged around the gas-discharging-unit connecting portion, a third heating portion arranged around an upper portion of the reaction tube, a fourth heating portion arranged around a lower portion of the reaction tube, and a fifth heating portion arranged under the substrate-to-be-processed supporting member.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus, substrate placing table used for same, and member exposed to plasma

InactiveUS20090041568A1Improve temperature uniformityPrevent particle generationConveyorsSemiconductor/solid-state device manufacturingEngineeringStructural engineering

A substrate table includes a substrate table main body provided with a heater embedded therein and having an upper surface serving as a heating face for heating a target substrate, and lifter pins inserted in the substrate table main body and configured to be moved up and down. Recessed portions are formed in the heating face of the substrate table main body at positions corresponding to the lifter pins and have a bottom lower than the heating face. Each of the lifter pins includes a lifter pin main body and a head portion formed at a distal end of the lifter pin main body and having a diameter larger than the lifter pin main body, the head portion being formed to correspond to each recessed portion and to be partly accommodated in the recessed portion. The head portion has a head portion upper end for supporting the target substrate and a head portion lower surface opposite to the head portion upper end. The lifter pins are movable between a first state where the head portion lower surface engages with the bottom of the recessed portion, and a second state where the head portion lower surface separates upward from the bottom of the recessed portion.

Owner:TOKYO ELECTRON LTD

Substrate processing method and substrate processing apparatus

ActiveUS7806989B2Avoid it happening againDecreasing amount of usedSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringNozzle

A substrate (W) is processed with the use of a process liquid such as a deionized water. Then, a first fluid which is more volatile than the process liquid is supplied to an upper surface of the substrate (W) from a fluid nozzle (12) to form a liquid film. Next, a second fluid which is more volatile than the process liquid is supplied to the upper surface of the substrate (W) from the fluid nozzle (12), while the wafer (W) is being rotated. During this supply operation, a supply position (Sf) of the second fluid to the substrate (W) is moved radially outward from a rotational center (Po) of the substrate (W). As a result, it is possible to prevent the generation of particles on the substrate (W) after it is dried by using the first and second fluids.

Owner:TOKYO ELECTRON LTD

Lithium-Containing Transition Metal Oxide Target, Process for Producing the same and Lithium Ion Thin Film Secondary Battery

Proposed are a lithium-containing transition metal oxide target formed from a sintered compact of lithium-containing transition metal oxides showing a hexagonal crystalline system in which the sintered compact has a relative density of 90% or higher and an average grain size of 1 μm or greater and 50 μm or less, and a lithium-containing transition metal oxide target formed from a sintered compact of lithium-containing transition metal oxides showing a hexagonal crystalline system in which the intensity ratio of the (003) face, (101) face and (104) face based on X-ray diffraction using CuKα ray satisfies the following conditions: (1) Peak intensity ratio of the (101) face in relation to the (003) face is 0.4 or higher and 1.1 or lower; and (2) Peak ratio of the (101) face in relation to the (104) face is 1.0 or higher. In addition to this lithium-containing transition metal oxide target optimal for forming a thin film positive electrode for use in a thin film battery such as a three-dimensional battery and a solid state battery, also proposed are its production method and a lithium ion thin film secondary battery. In particular, the present invention aims to propose a positive electrode target capable of obtaining a thin film with superior homogeneity.

Owner:JX NIPPON MINING& METALS CORP

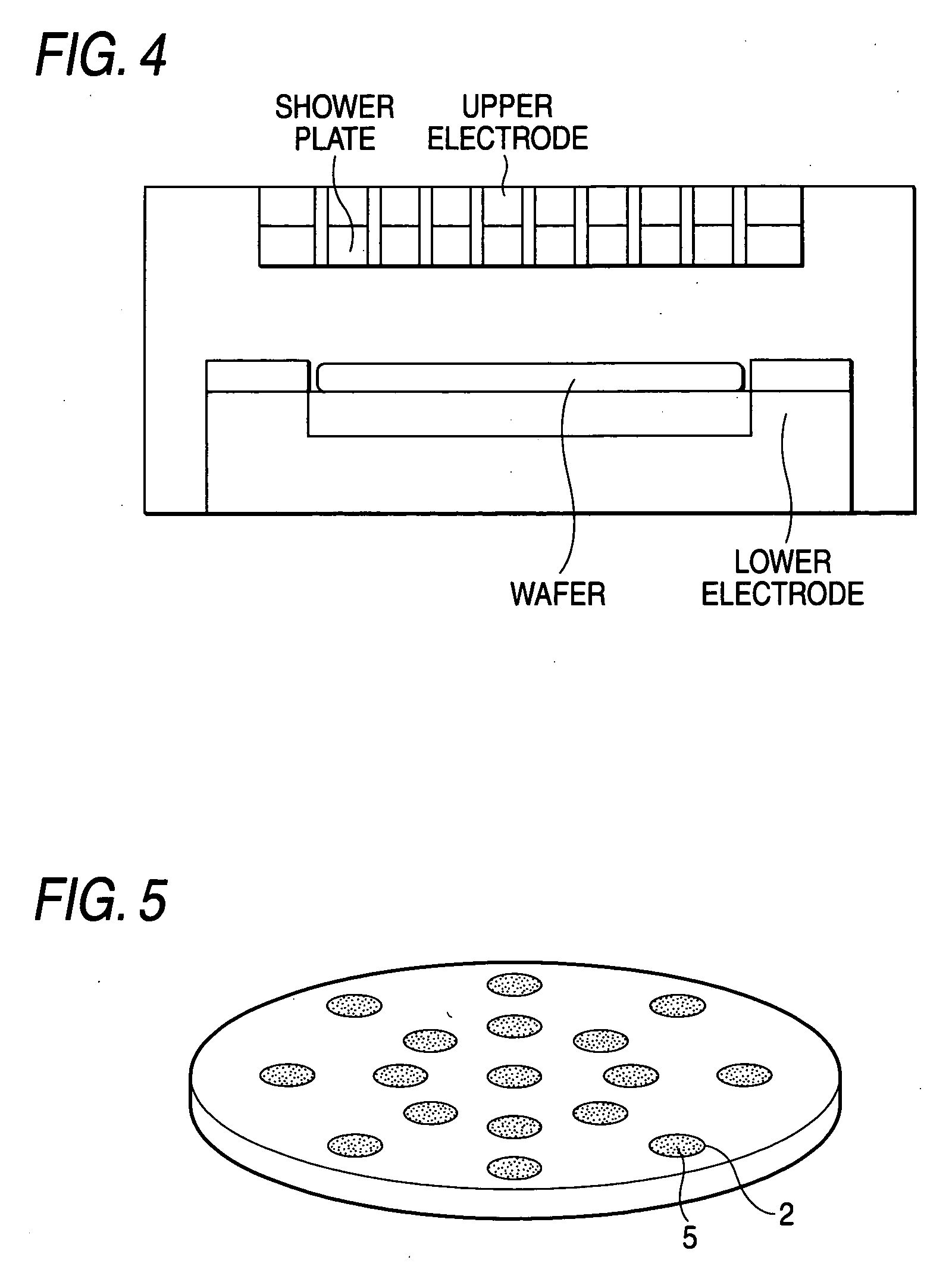

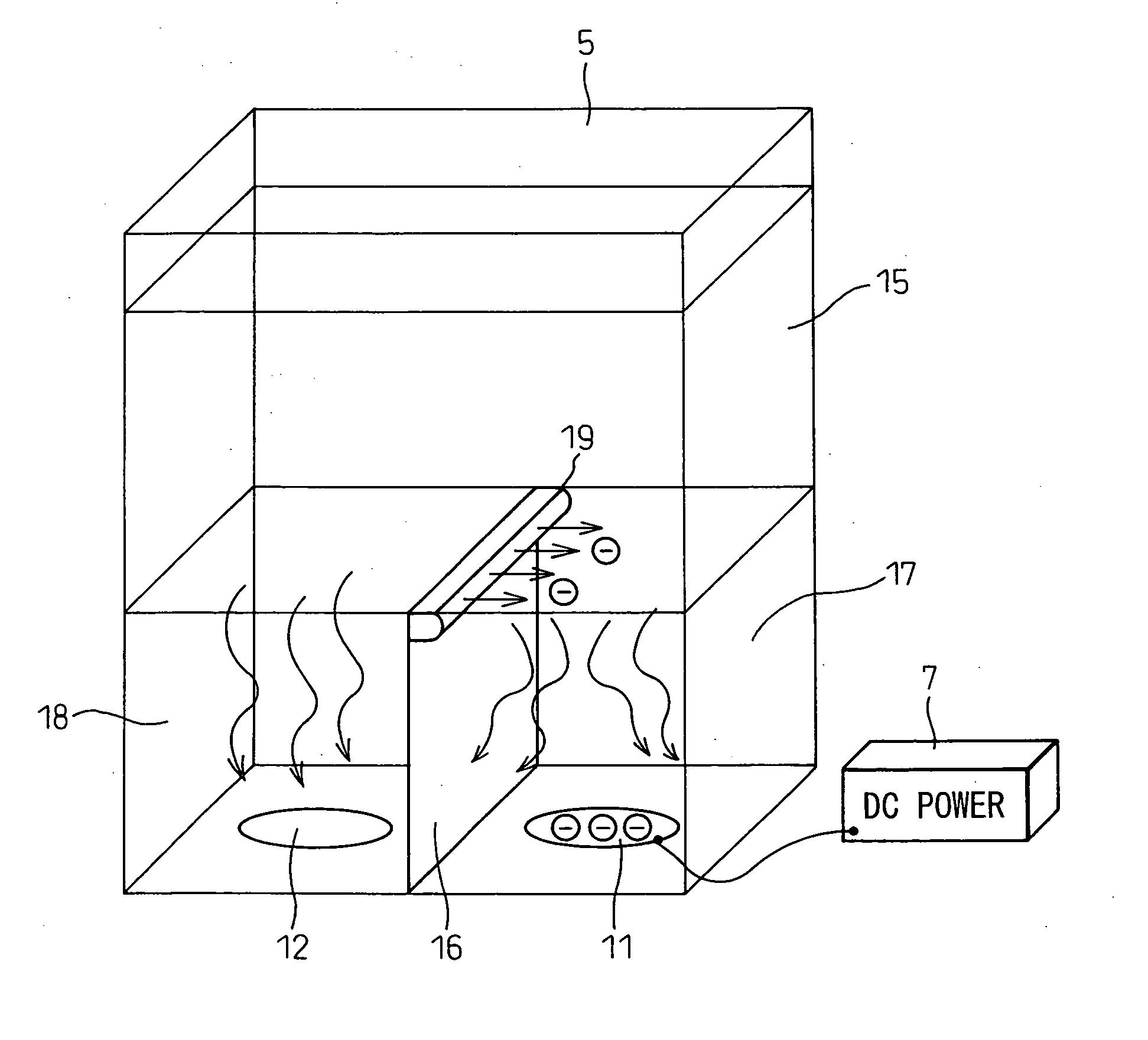

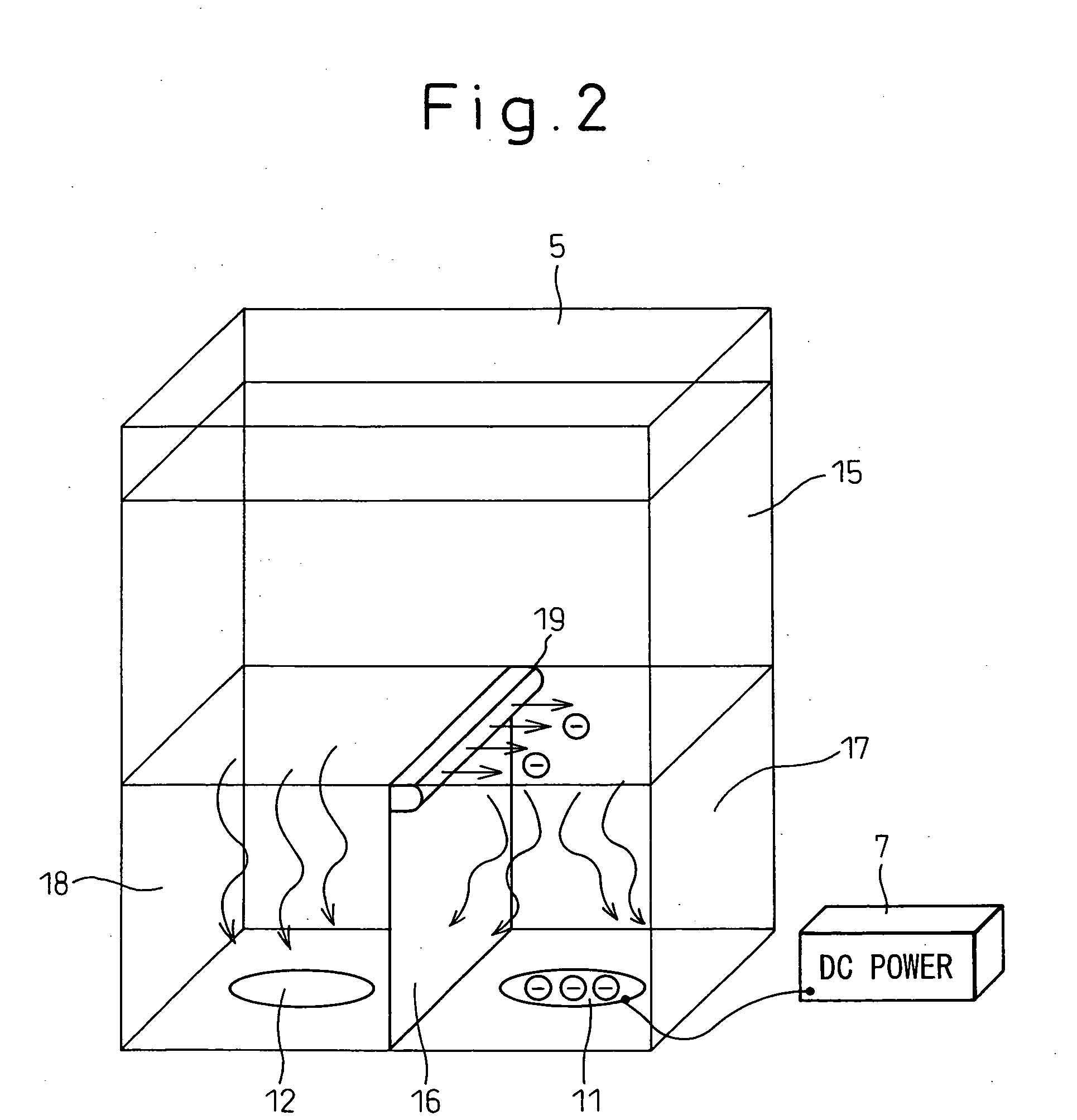

Particle sticking prevention apparatus and plasma processing apparatus

InactiveUS20050087136A1Increase powerAvoid stickingSemi-permeable membranesElectric discharge tubesElectrical polarityGas plasma

In order to prevent particles within a unit from sticking to a substrate in a substrate processing process, an ion generator charges the particles. At the same time, a direct current voltage of the same polarity as the charged polarity of the particles is applied from a direct current power source to the substrate. In order to prevent generation of particles when producing gas plasma, a high-frequency voltage is applied to the upper and lower electrodes at multiple stages to produce plasma. In other words, at a first step, a minimum high-frequency voltage at which plasma can be ignited is applied to the upper and lower electrodes, thereby producing a minimum plasma. Thereafter, the applied voltage is increased in stages to produce predetermined plasma.

Owner:TOKYO ELECTRON LTD

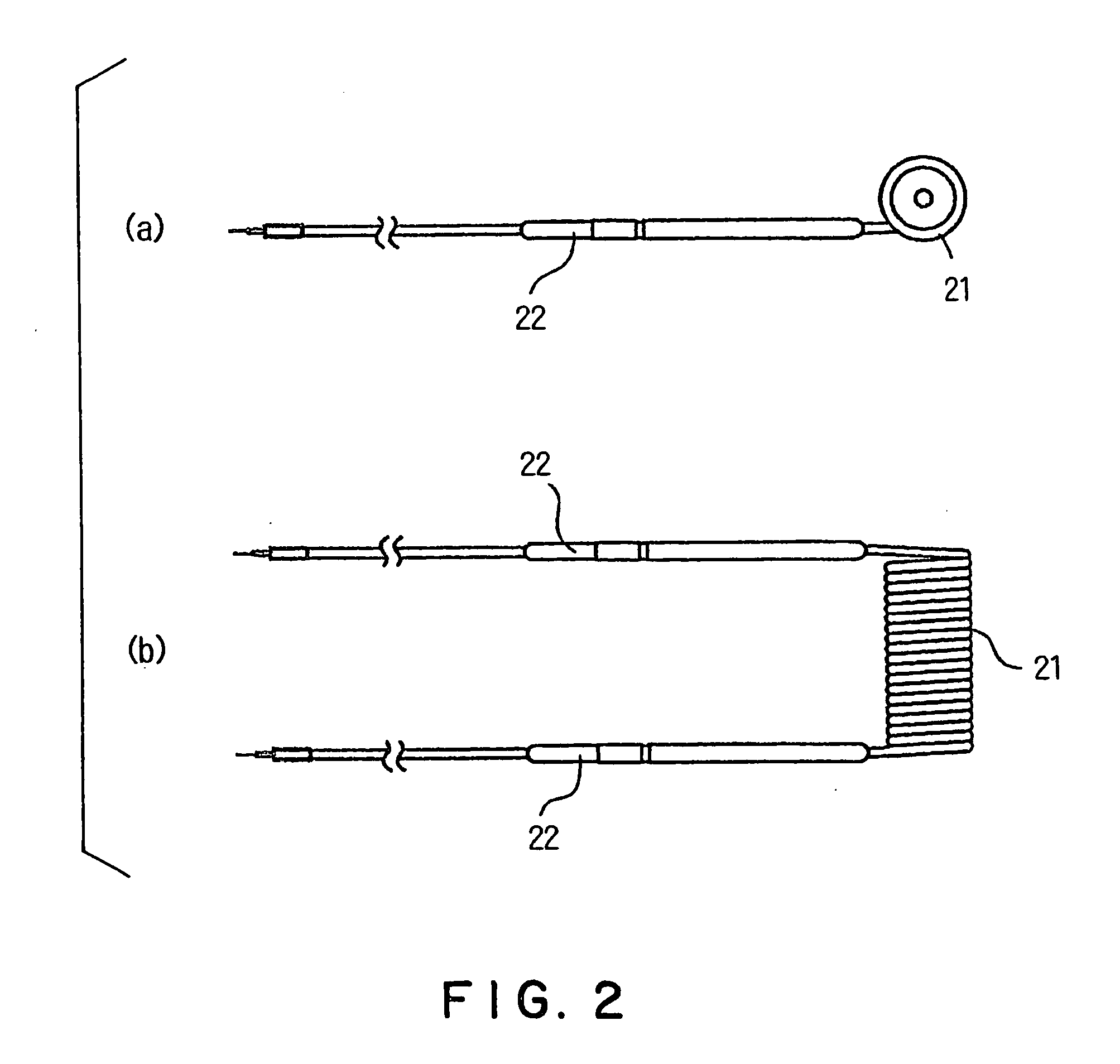

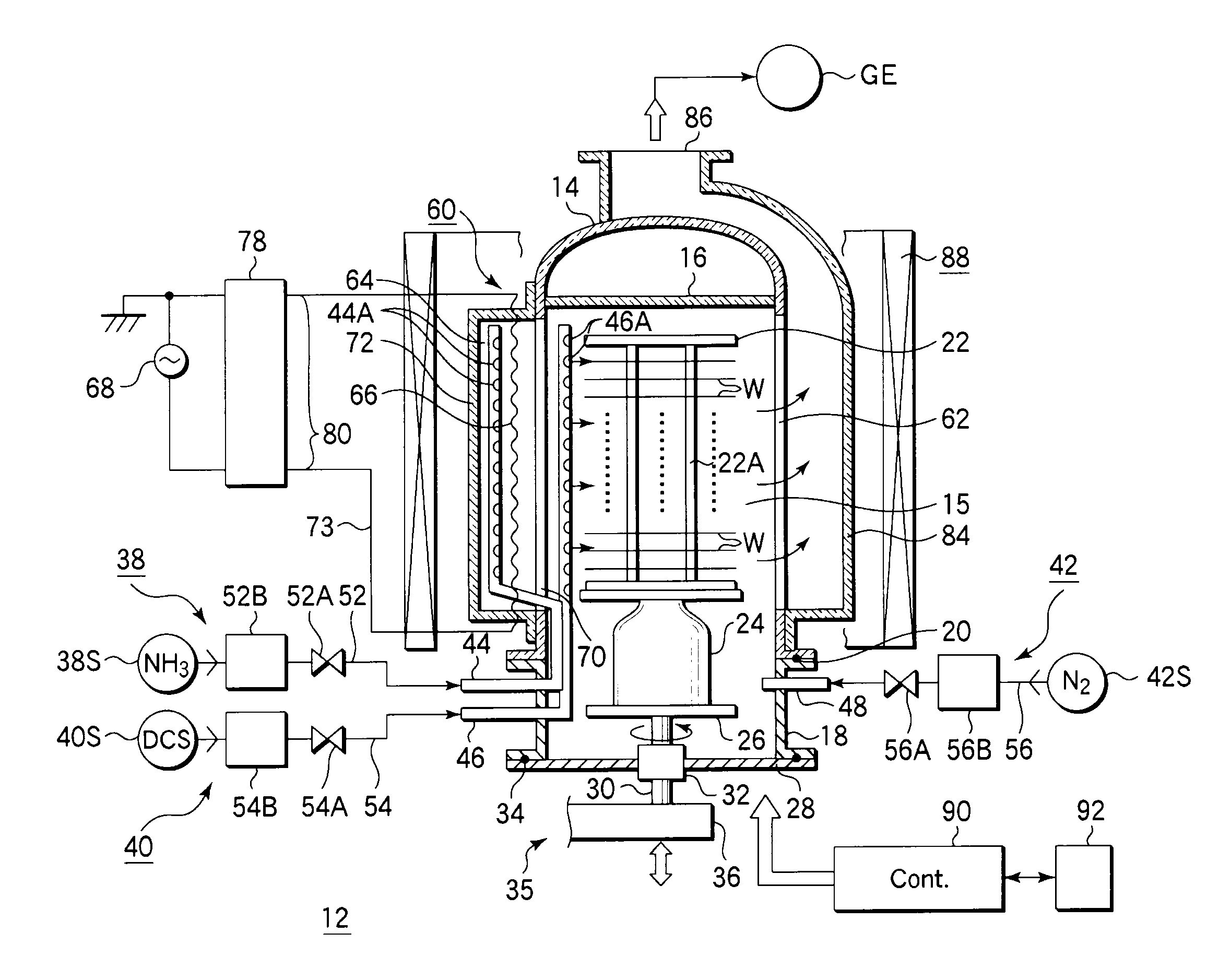

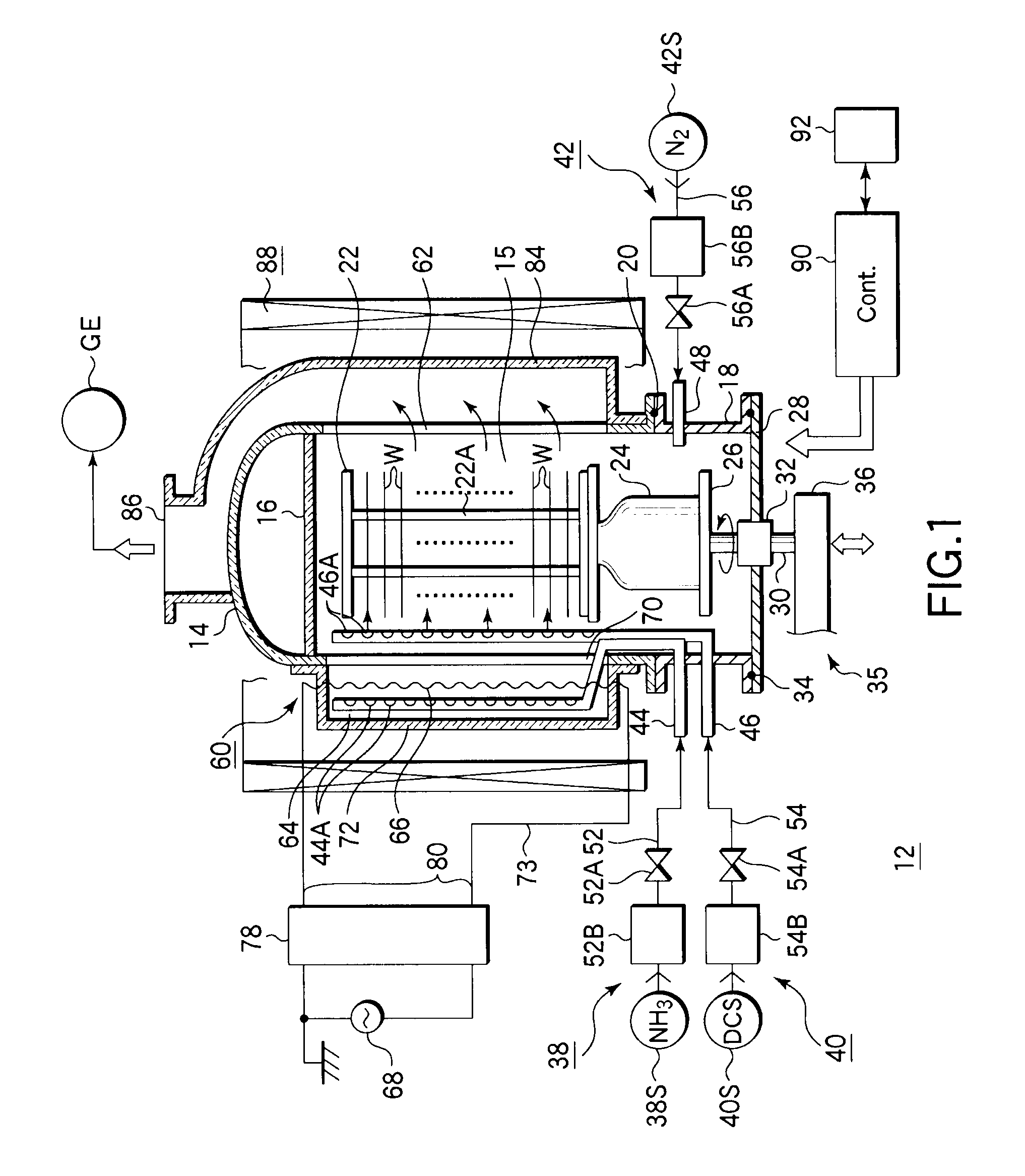

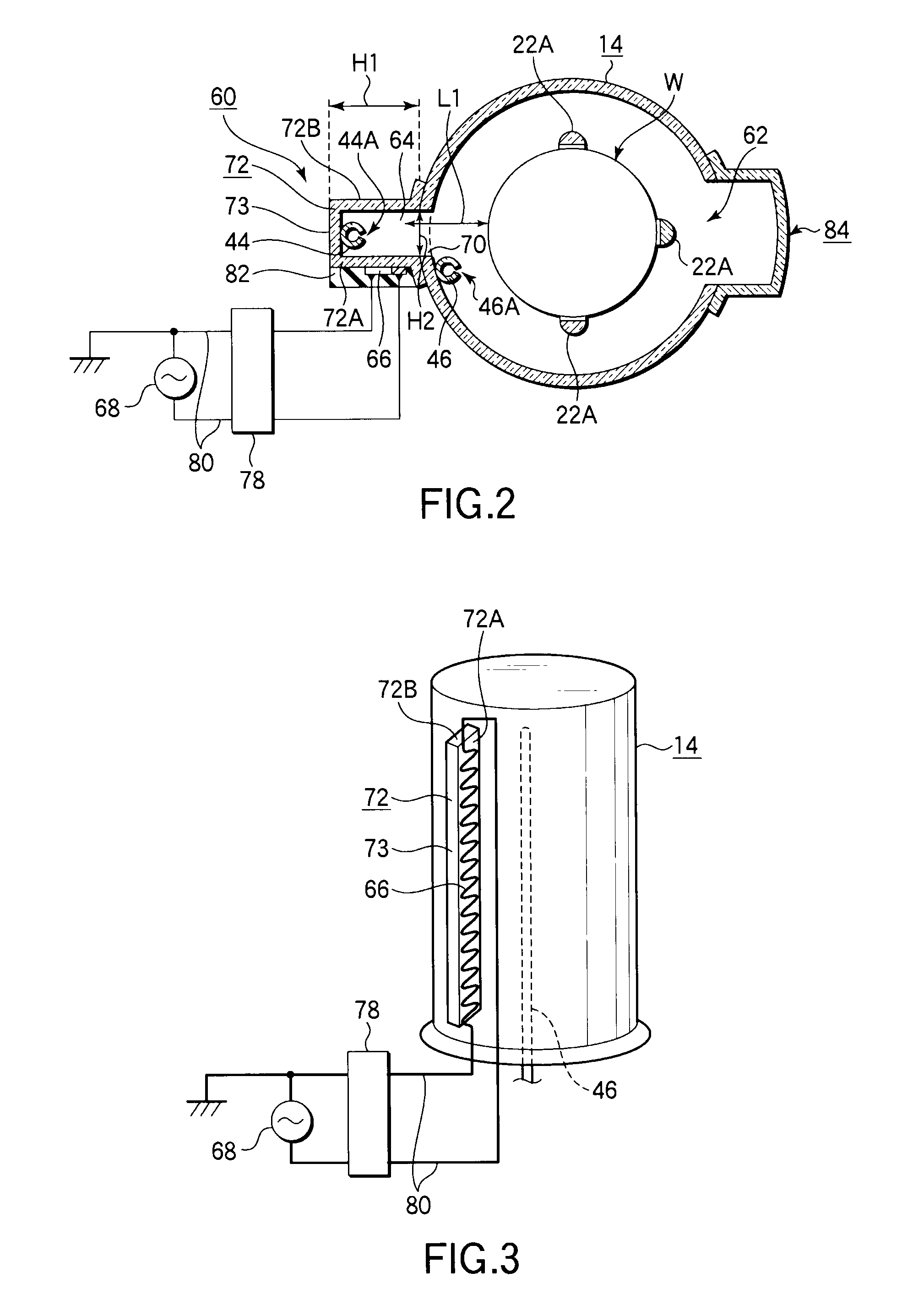

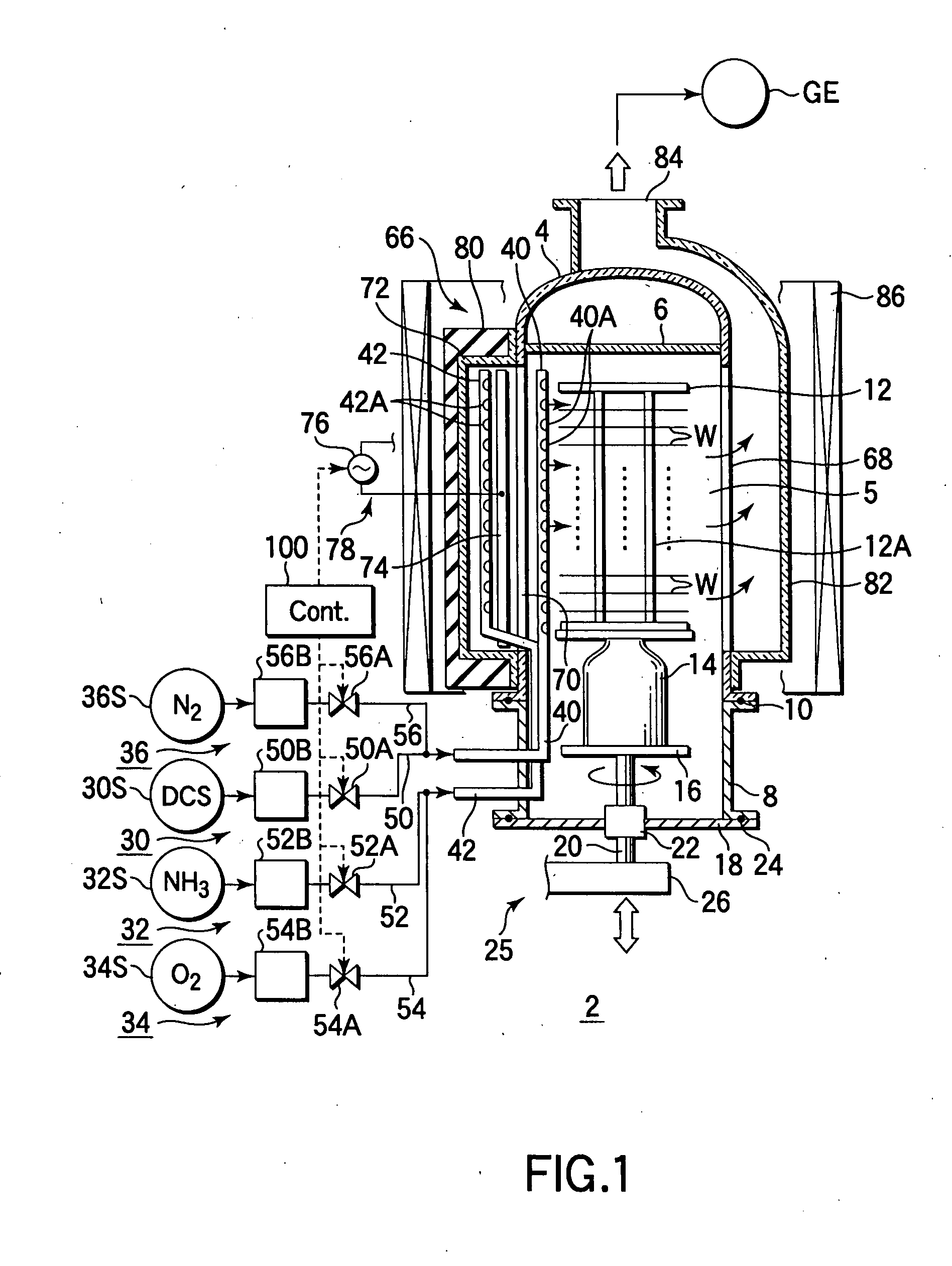

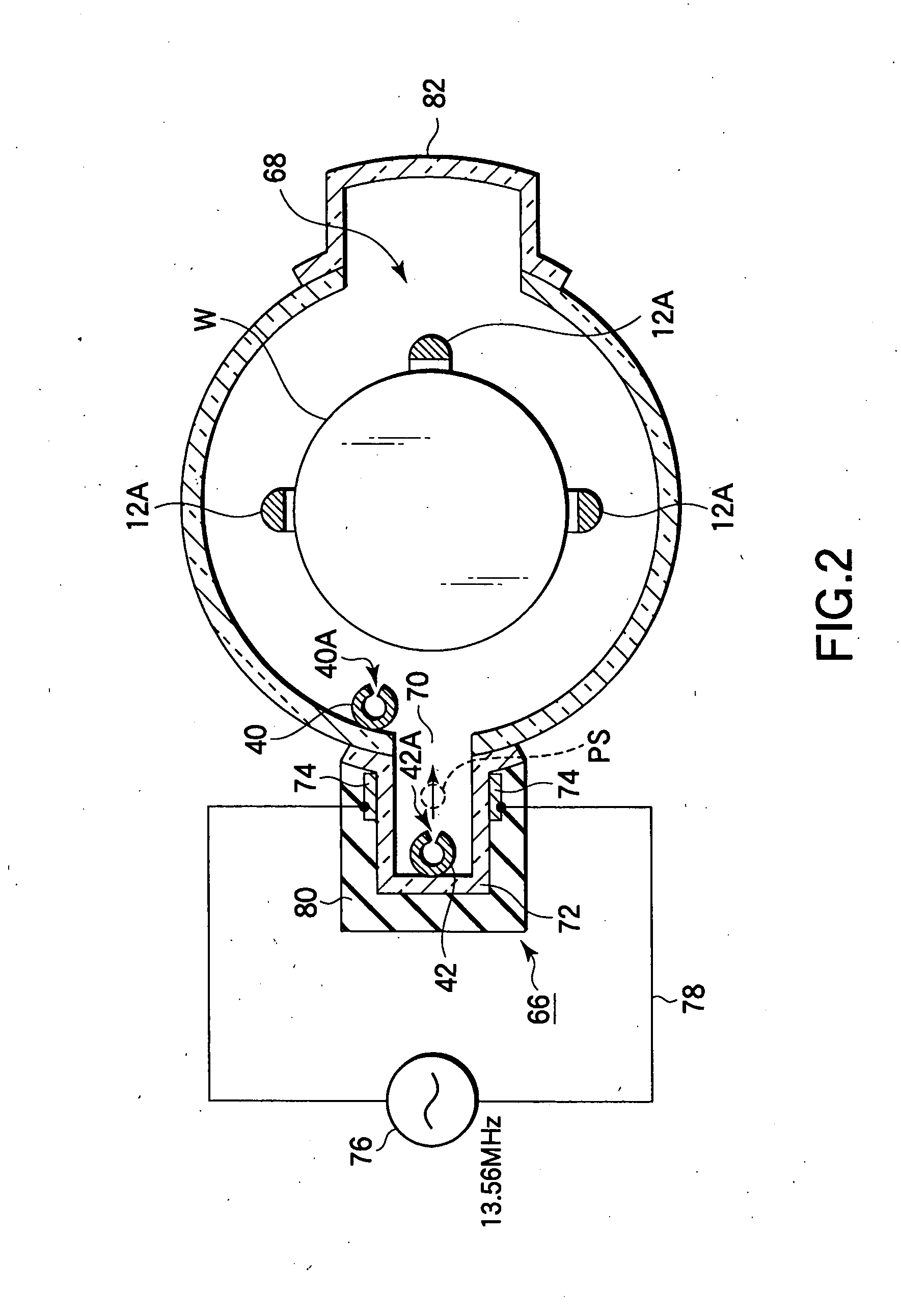

Plasma processing apparatus

ActiveUS20100186898A1Prevent particle generationIncrease radical generation amountElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionEngineering

A vertical plasma processing apparatus for performing a plasma process on a plurality of target objects together at a time includes an activation mechanism configured to turn a process gas into plasma. The activation mechanism includes a vertically elongated plasma generation box attached to a process container at a position corresponding to a process field and confining a plasma generation area airtightly communicating with the process field, an ICP electrode disposed outside the plasma generation box and extending in a longitudinal direction of the plasma generation box, and an RF power supply connected to the ICP electrode. The ICP electrode includes a separated portion separated from a wall surface of the plasma generation box by a predetermined distance.

Owner:TOKYO ELECTRON LTD

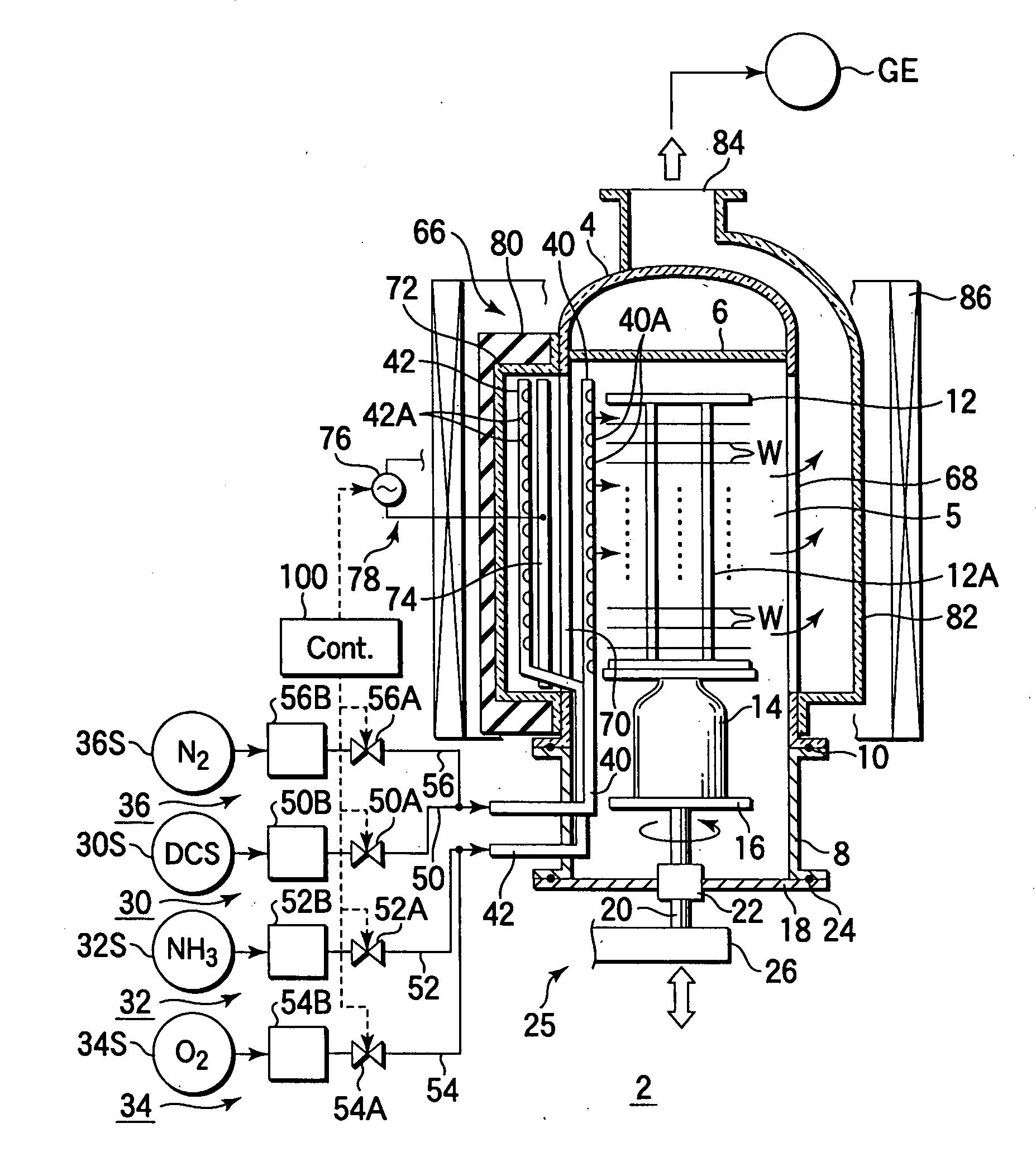

Film formation apparatus for semiconductor process and method for using the same

InactiveUS20080132083A1Without lowering productivityPrevent particle generationLiquid surface applicatorsElectric discharge tubesNitrogenProcess engineering

A method is provided for using a film formation apparatus including a process container having an inner surface, which contains as a main component a material selected from the group consisting of quartz and silicon carbide. The method includes performing a film formation process to form a silicon nitride film on a product target substrate inside the process container, and then, unloading the product target substrate from the process container. Thereafter, the method includes supplying an oxidizing gas into the process container with no product target substrate accommodated therein, thereby performing an oxidation process to change by-product films deposited on the inner surface of the process container into a composition richer in oxygen than nitrogen, at a part of the by-product films from a surface thereof to a predetermined depth.

Owner:TOKYO ELECTRON LTD

Heat treatment apparatus

ActiveUS7311520B2Heating fastRapid coolingMuffle furnacesSemiconductor/solid-state device manufacturingProcess supportHeating furnace

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a reaction tube consisting of a single tube contained in the heating-furnace body; a gas-discharging-unit connecting portion formed at an upper portion of the reaction tube, the gas-discharging-unit connecting portion having a narrow diameter; a substrate-to-be-processed supporting member for supporting a substrate to be processed, contained in the heating-furnace body; and a heating unit for heating the substrate to be processed supported by the substrate-to-be-processed supporting member. The heating unit has: a first heating portion arranged around the reaction tube, a second heating portion arranged around the gas-discharging-unit connecting portion, a third heating portion arranged around an upper portion of the reaction tube, a fourth heating portion arranged around a lower portion of the reaction tube, and a fifth heating portion arranged under the substrate-to-be-processed supporting member.

Owner:TOKYO ELECTRON LTD

Thermal treating apparatus

InactiveUS20050028738A1Rapid heatingRapid coolingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHeating furnace

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a heating unit provided on an inside wall of the heating-furnace body; a reaction container consisting of a single tube contained in the heating-furnace body; a gas-discharging-pipe connecting portion formed at an upper portion of the reaction container; and a first temperature controlling unit provided around the gas-discharging-pipe connecting portion.

Owner:TOKYO ELECTRON LTD

Substrate container and handle thereof

InactiveUS20080251415A1Improve rigidityReduce distortionSemiconductor/solid-state device manufacturingOther accessoriesEngineeringMechanical engineering

A substrate container includes: a container main body including an opening and containing a substrate; a lid body closing the opening; and a pair of handles provided on a pair of opposing side walls of the container main body, and the handle is secured to an edge portion of the side wall.

Owner:SHIN-ETSU POLYMER CO LTD

Sb-Te-Based Alloy Sintered Compact Sputtering Target

InactiveUS20120279857A1Eliminate the effects ofImprove uniformityCellsVacuum evaporation coatingAlloyBoron

Provided is an Sb—Te-based alloy sintered compact sputtering target having Sb and Te as its main component and which contains 0.1 to 30 at % of carbon or boron and comprises a uniform mixed structure of Sb—Te-based alloy particles and fine carbon (C) or boron (B) particles, wherein the average grain size of the Sb—Te-based alloy particles is 3 μm or less and the standard deviation thereof is less than 1.00, the average grain size of C or B is 0.5 μm or less and the standard deviation thereof is less than 0.20, and, when the average grain size of the Sb—Te-based alloy particles is X and the average grain size of carbon or boron is Y, Y / X is within the range of 0.1 to 0.5. The present invention aims to improve the structure of the Sb—Te-based alloy sputtering target, inhibit the generation of cracks in the sintered target, and prevent the generation of arcing in the sputtering process.

Owner:JX NIPPON MINING& METALS CORP

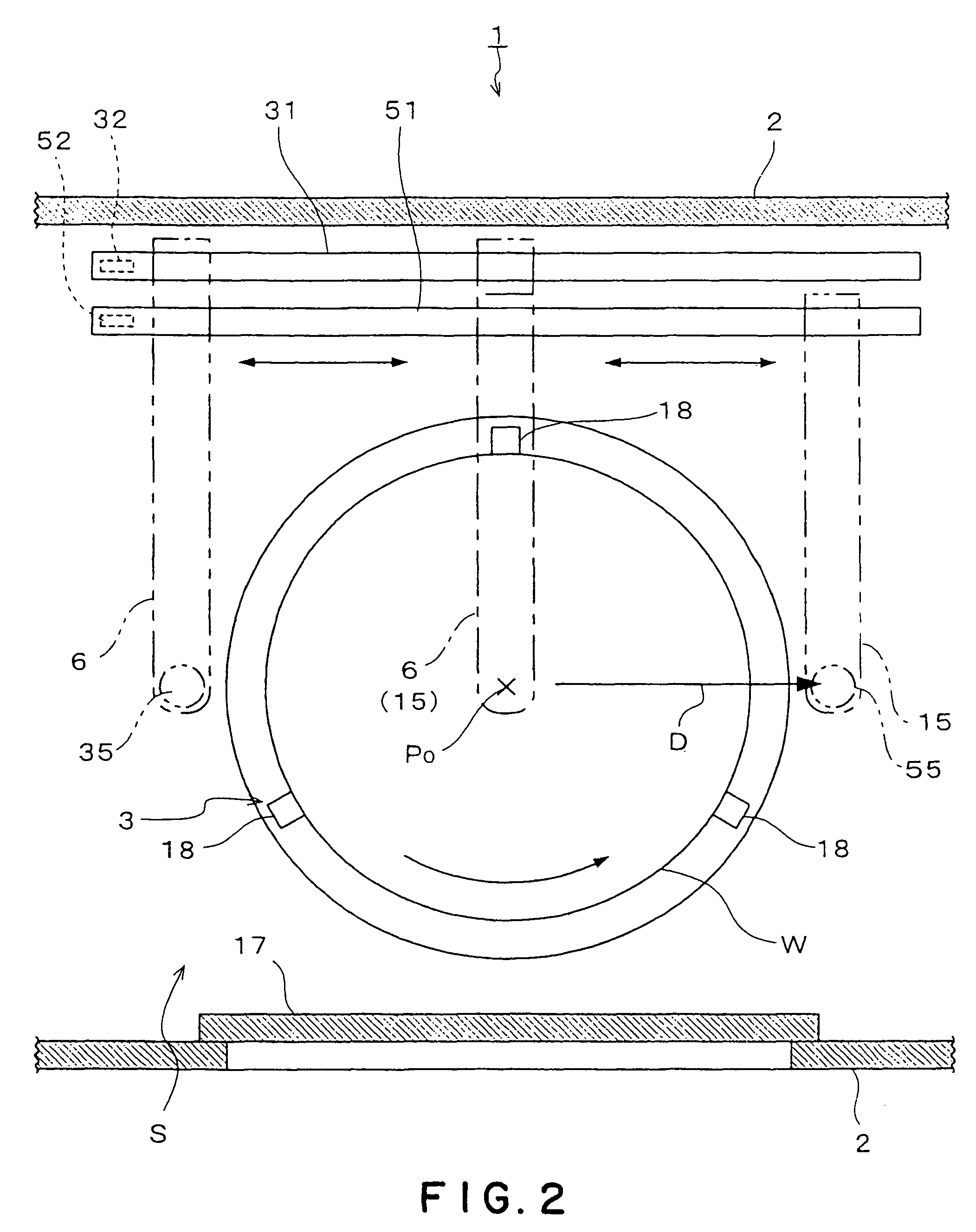

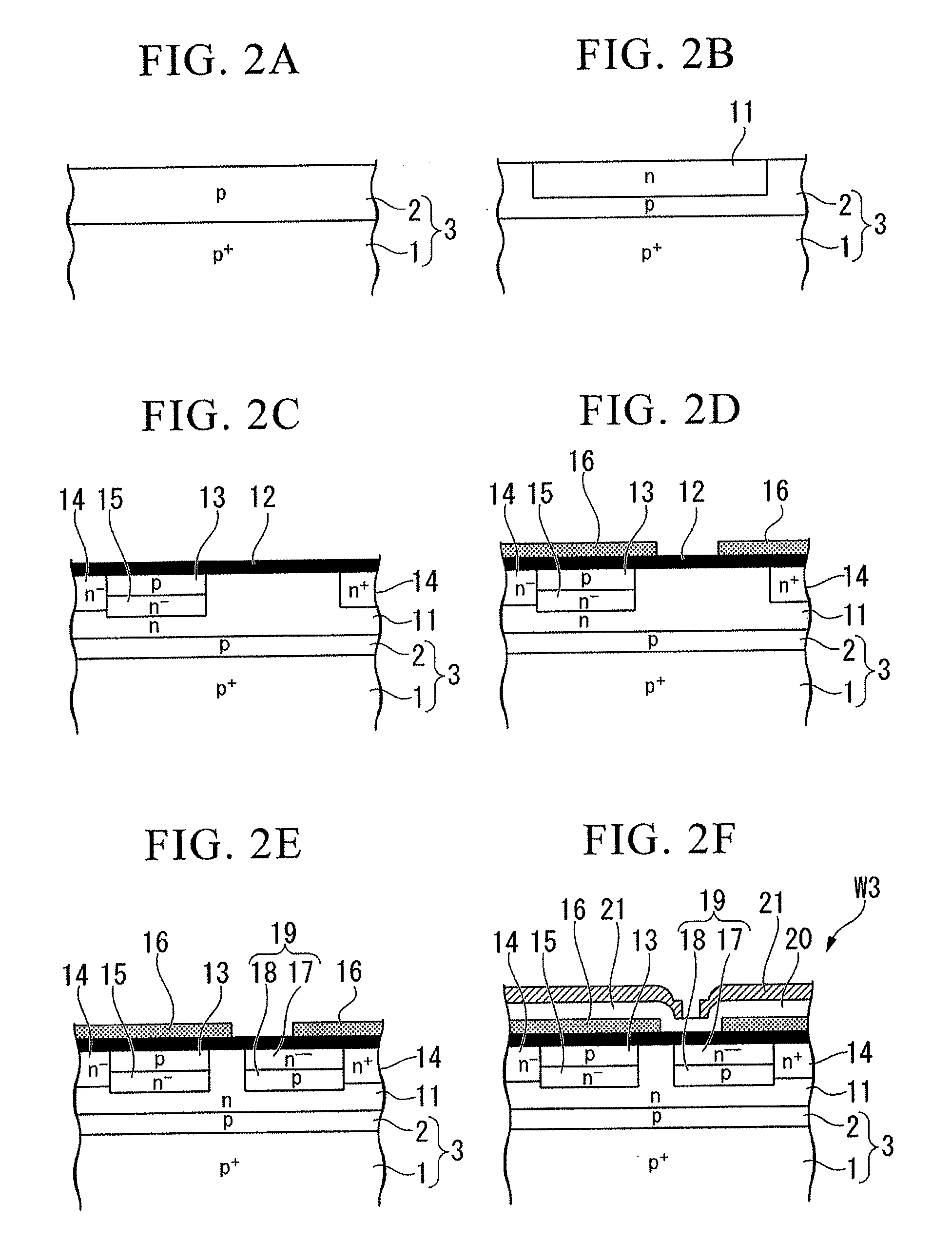

Chuck for edge bevel removal and method for centering a wafer prior to edge bevel removal

ActiveUS20170294332A1Reduce wearPrevent particle generationSemiconductor/solid-state device manufacturingCleaning using liquidsWaferingCam

A chuck useful for supporting a wafer during an edge bevel removal (EBR) process comprises a rotatable center hub having a plurality of support arms extending outwardly from the rotatable center hub, support pins on ends of the support arms, gas passages extending through upper surfaces of the support pins, and gas conduits in the support arms, the gas conduits configured to supply gas to the gas passages or apply a vacuum to the gas passages. The support arms can include alignment cams which are rotatable from an outer non-alignment position away from a periphery of the wafer to an inner alignment position at which the wafer is centered. To supply gas or apply a vacuum force to the gas outlets in the support pins, the rotatable center hub can have a gas inlet and a plurality of gas delivery ports in fluid communication with the gas delivery conduits in the support arms. Gas can be supplied to the gas outlets by a source of pressurized gas connected to the gas inlet and suction can be applied to the gas outlets by a vacuum source connected to the gas inlet. During centering, the wafer is floated on a gas cushion which reduces wear of the support pins.

Owner:LAM RES CORP

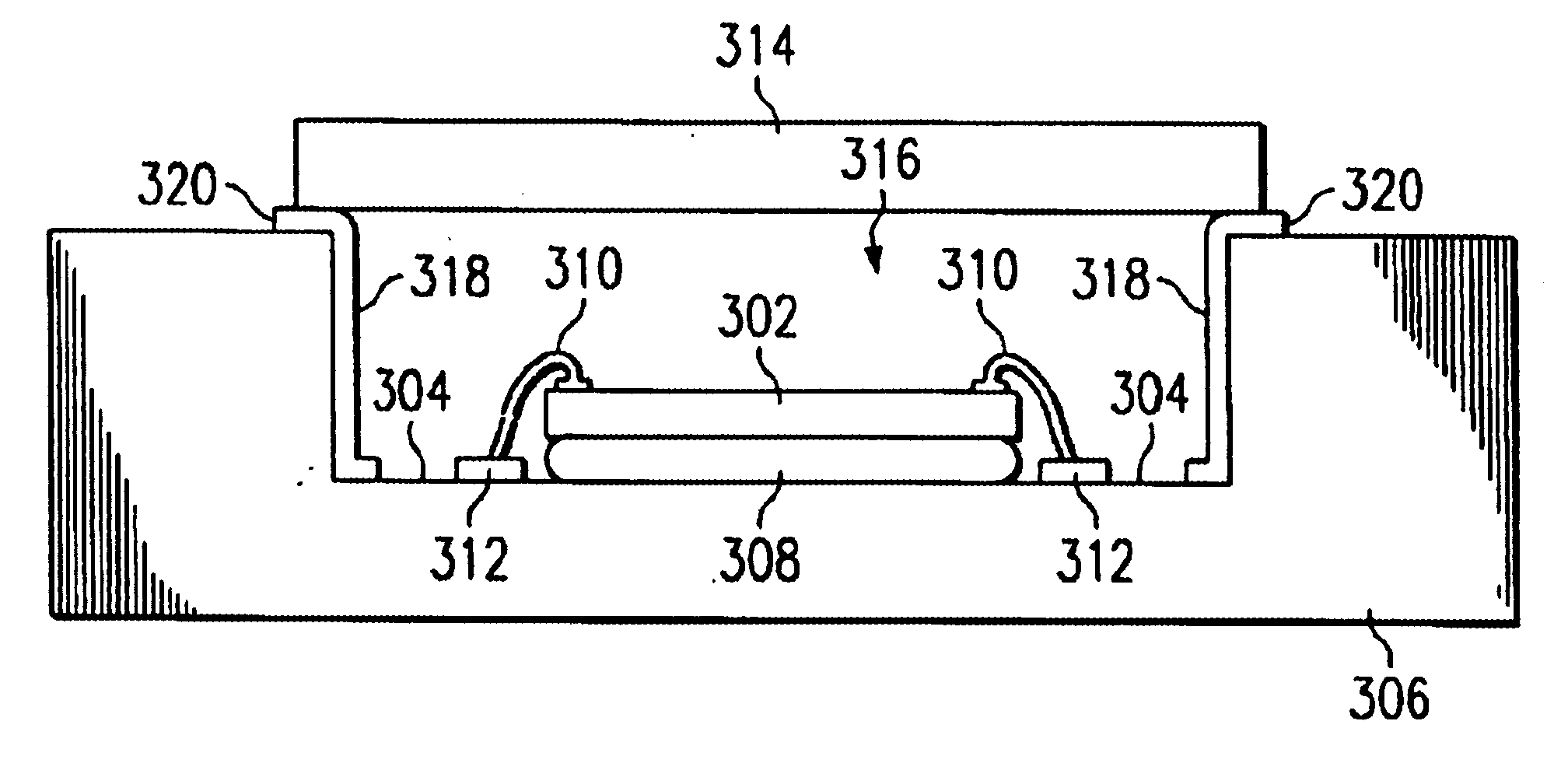

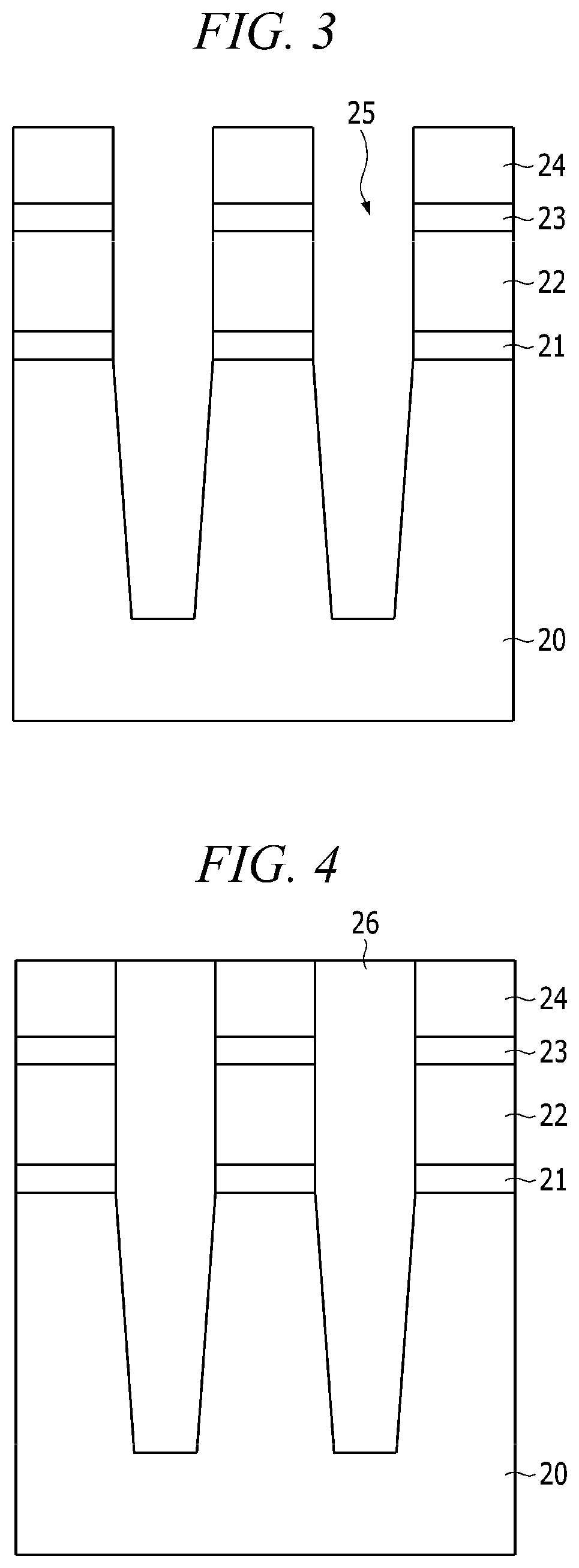

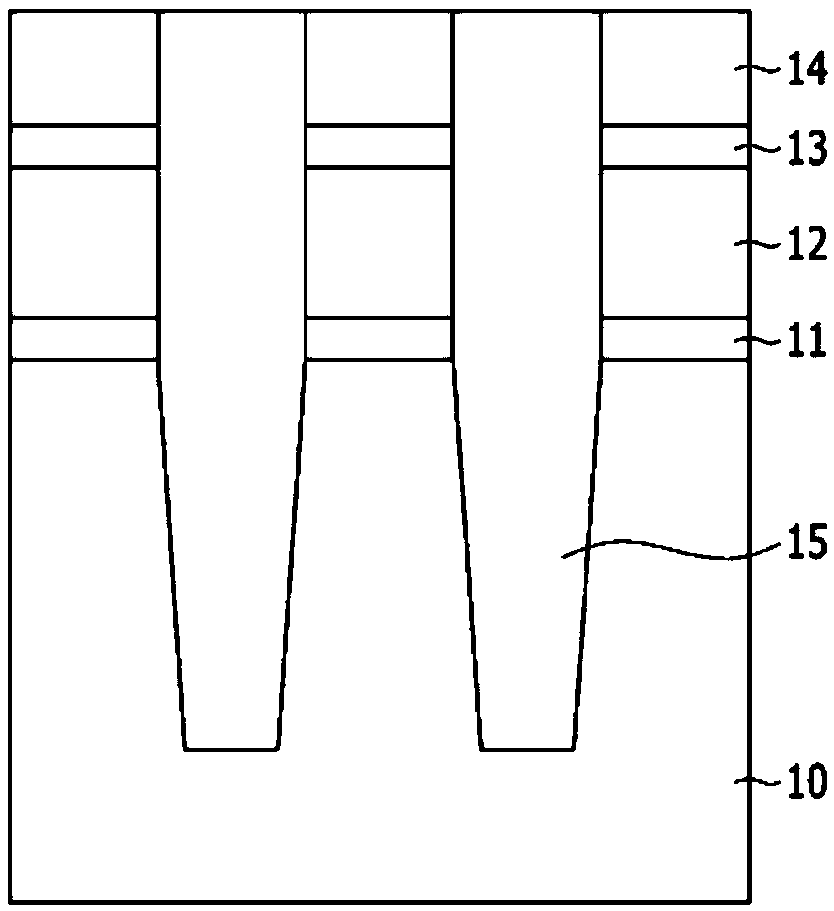

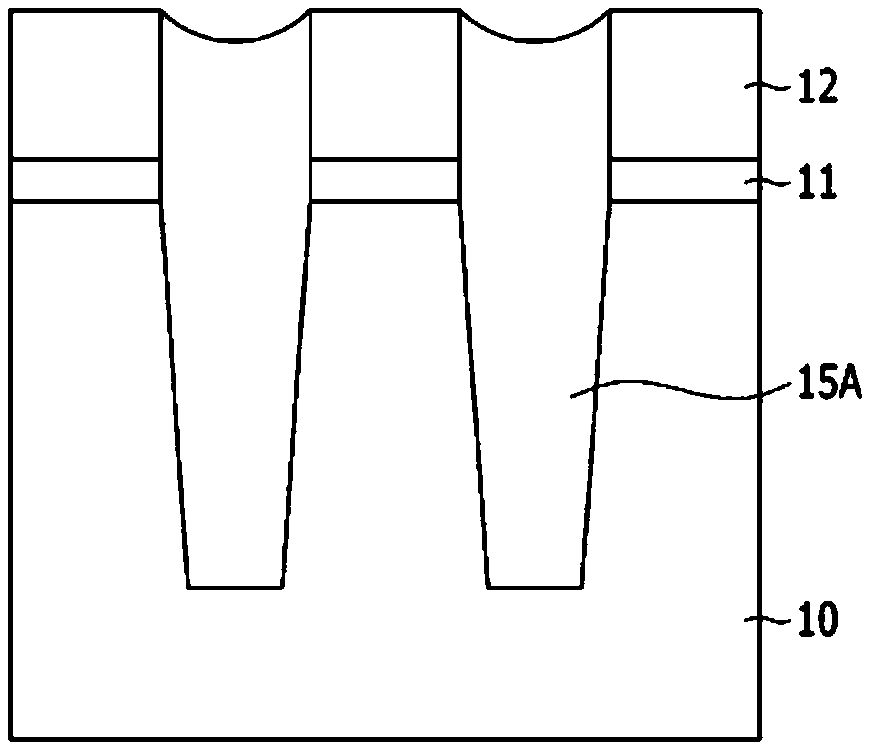

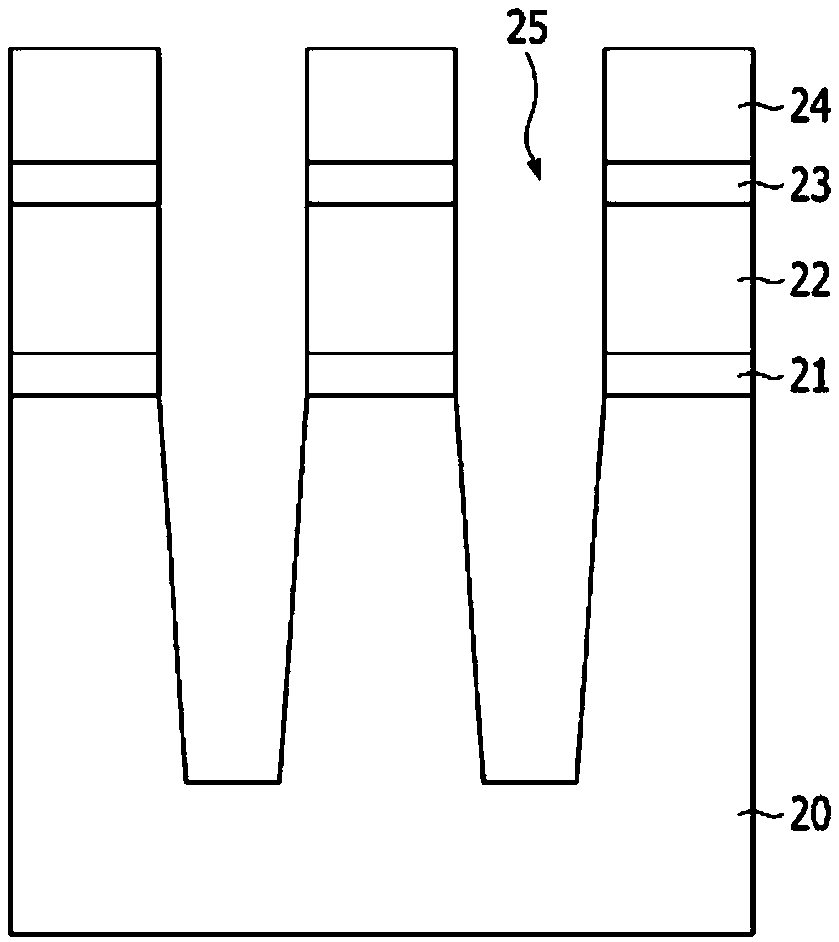

Masking layer in substrate cavity

InactiveUS6876071B2Prevent particle generationSemiconductor/solid-state device detailsSolid-state devicesEpoxyElectrical connection

A package that resists creation of particles in a package cavity. A package according to one embodiment of the present invention contains a mechanical device attached to the floor of the package substrate. Epoxy typically is used to attach the device. Electrical connections are provided by bond wires connecting bond pads on the substrate with bond pads on the device. A window is attached to the substrate to form a cavity around the device. A thin masking layer on portions of the package cavity surface prevents the surface from generating particles. The thin masking layer may be any material that resists particle generation. The masking layer on the cavity walls optionally extends out of the cavity and onto the upper surface of the package.

Owner:TEXAS INSTR INC

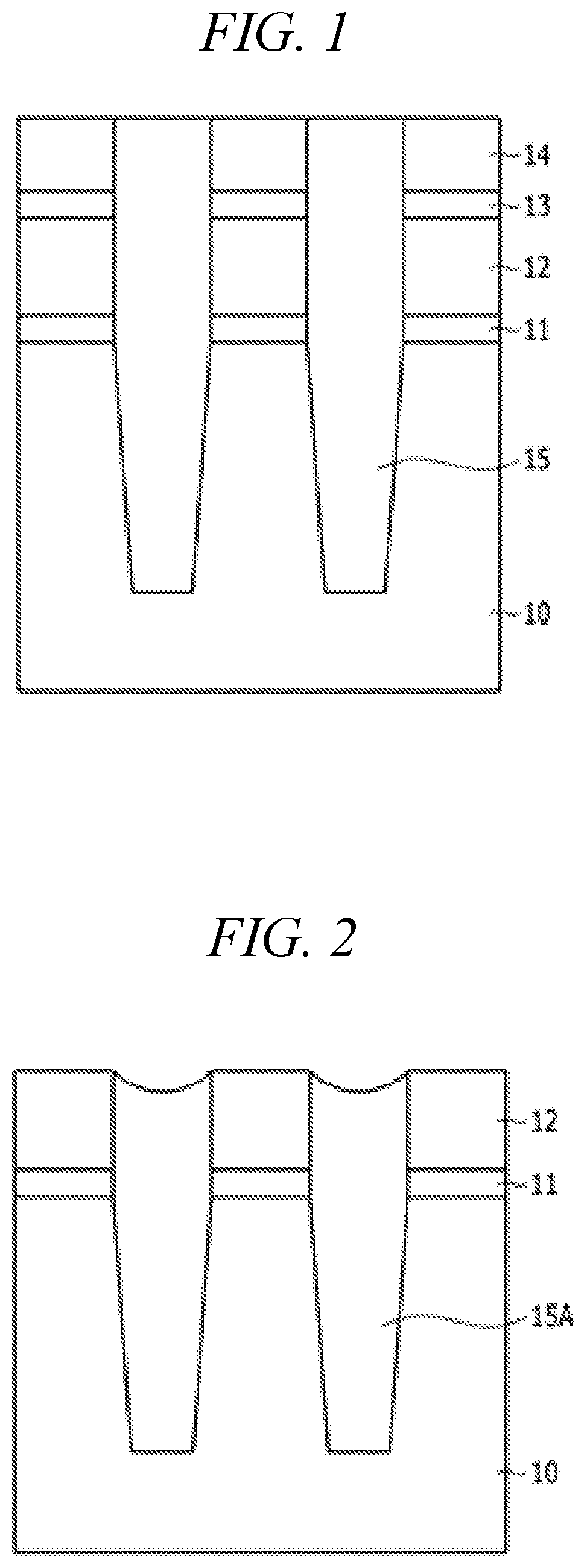

Composition for etching and method for manufacturing semiconductor device using same

ActiveUS20200263087A1Easy to superviseImprove etch selectivitySemiconductor/solid-state device manufacturingSurface treatment compositionsPhosphorous acidDevice material

A composition for etching and a method of manufacturing a semiconductor device, the method including an etching process of using the composition for etching, are provided. The composition for etching includes a first inorganic acid; any one first additive selected from the group consisting of phosphorous acid, an organic phosphite, a hypophosphite, and mixtures thereof; and a solvent. The composition for etching is a high-selectivity composition for etching that can selectively remove a nitride film while minimizing the etch rate for an oxide film and does not have a problem such as particle generation, which adversely affects device characteristics.

Owner:SOULBRAIN CO LTD

Thermal processing unit

InactiveUS20060258170A1Heating fastRapid coolingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlEngineering

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a heating unit provided on an inside wall of the heating-furnace body; a reaction container consisting of a single tube contained in the heating-furnace body; a gas-discharging-pipe connecting portion formed at an upper portion of the reaction container; and a first temperature controlling unit provided around the gas-discharging-pipe connecting portion.

Owner:TOKYO ELECTRON LTD

Interlocking device and packaging bag with interlocking device

Owner:IDEMITSU UNITECH CO LTD

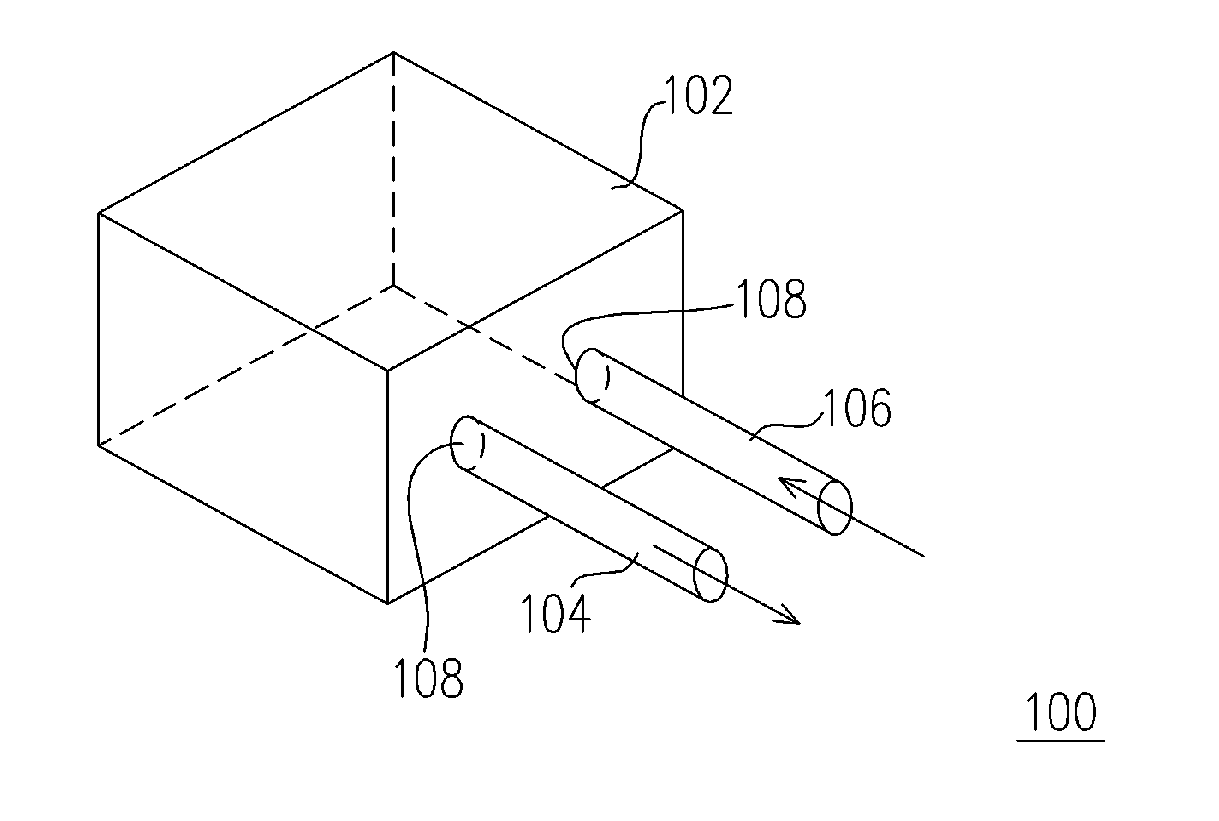

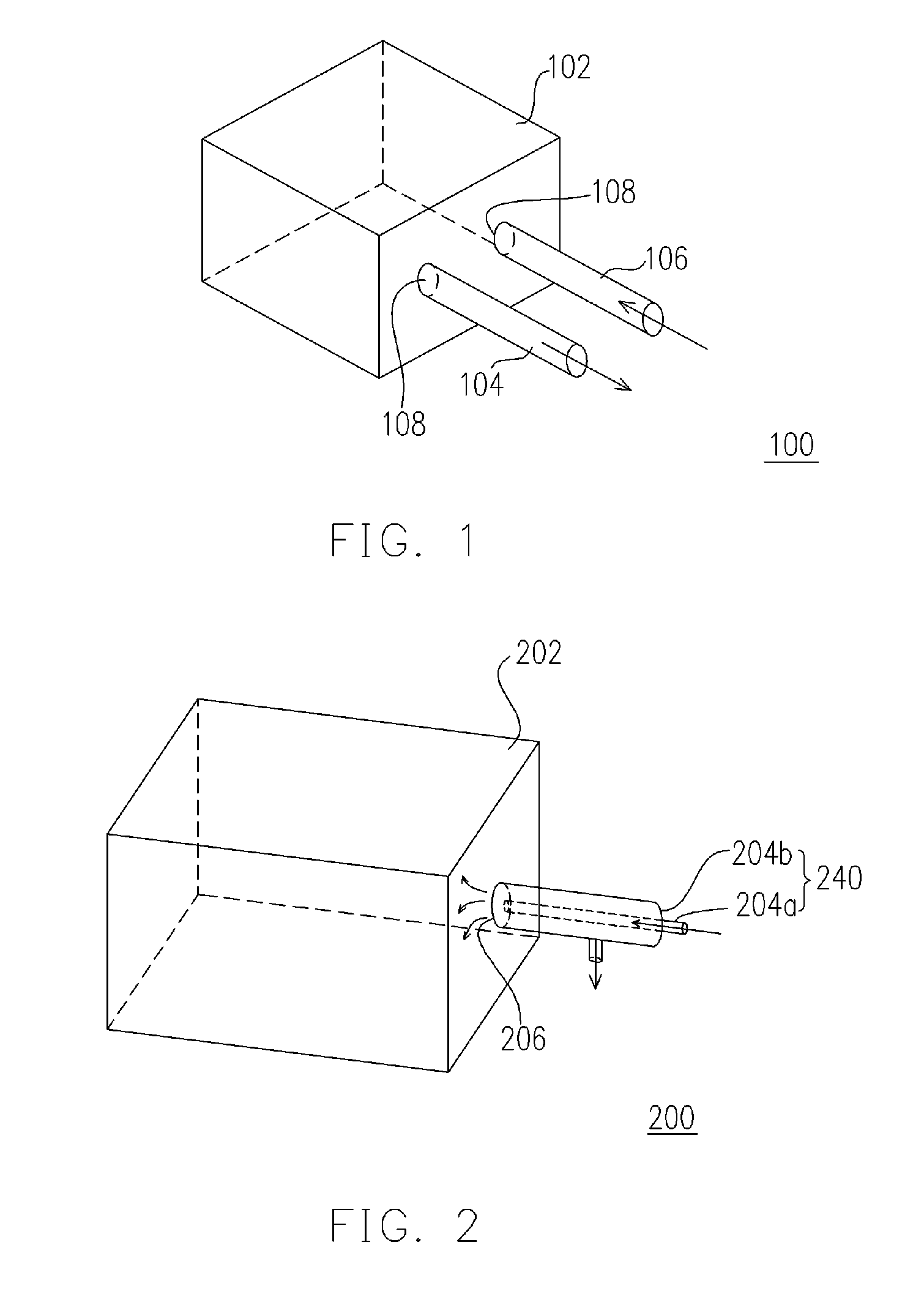

Substrate processing apparatus

InactiveUS20090241834A1Prevent particle generationSuppress of degradationChemical vapor deposition coatingProduct gasProcess engineering

A substrate processing apparatus comprises: a processing chamber configured to accommodate a substrate; and a gas supply unit configured to supply gas into the process chamber. The gas supply unit comprises: an evaporator configured to evaporate a liquid material; a first gas supply pipe configured to supply an evaporated gas from the evaporator into the process chamber; a second gas supply pipe configured to supply an inert gas into the process chamber; and a joint part at which the first gas supply pipe and the second gas supply pipe are joined. The joint part includes a diffusion chamber. A flow rate diaphragm having an inner diameter narrowing toward a direction of the diffusion chamber is installed at the front end of the downstream side of the second gas supply pipe. The evaporated gas from the evaporator is introduced into the diffusion chamber and simultaneously the inert gas is introduced through the flow rate diaphragm installed at the front end of the second gas supply pipe.

Owner:KOKUSA ELECTRIC CO LTD

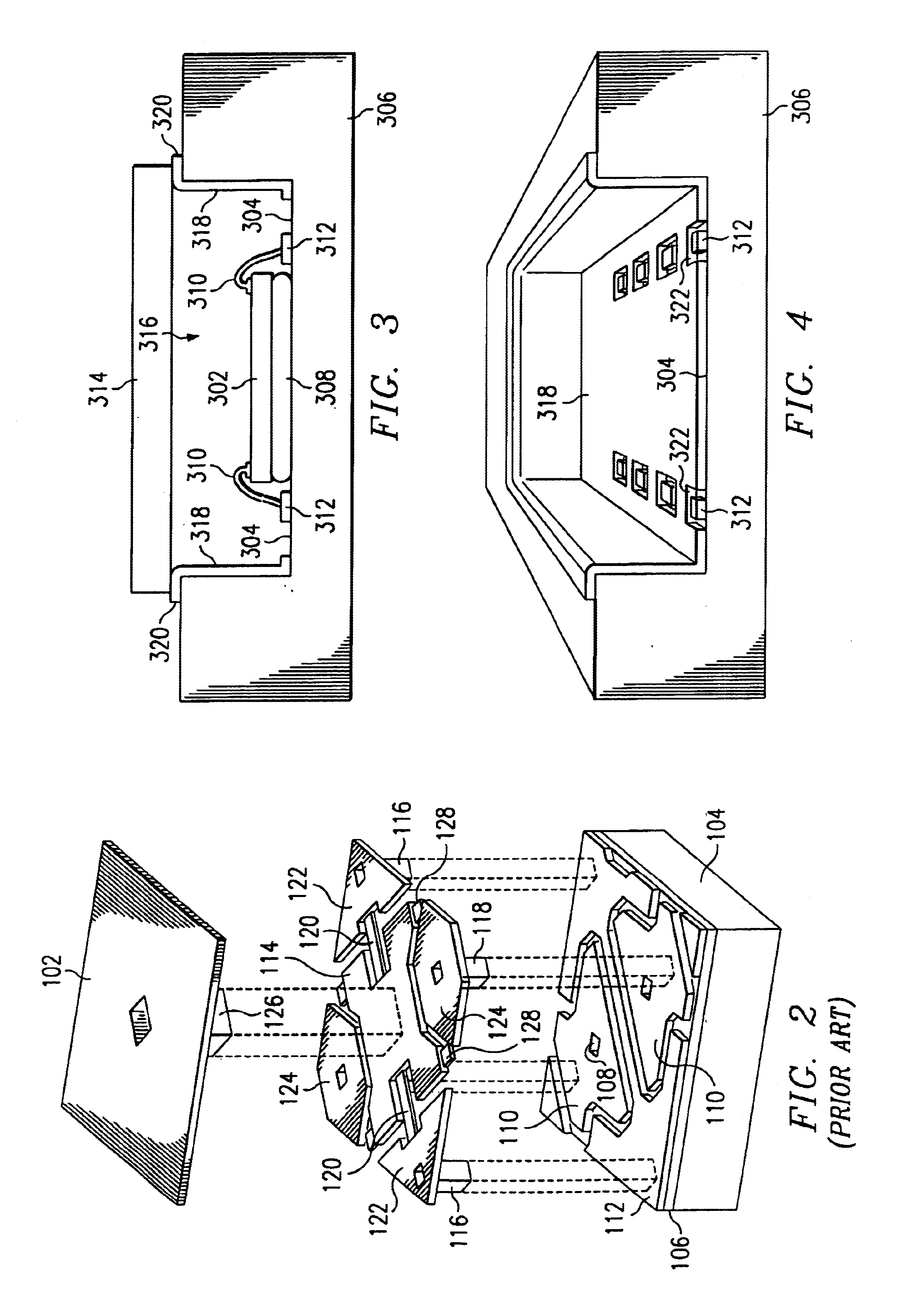

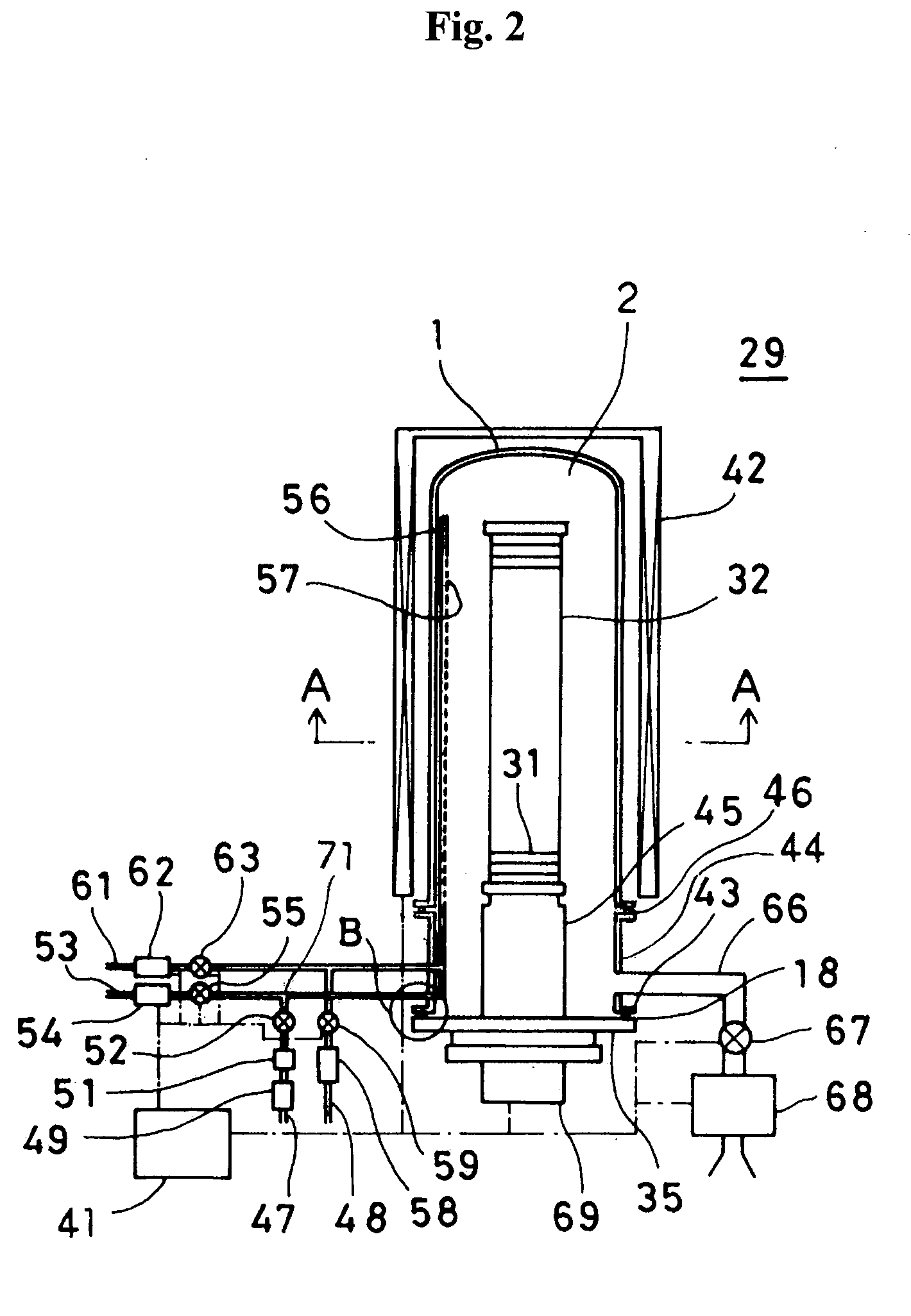

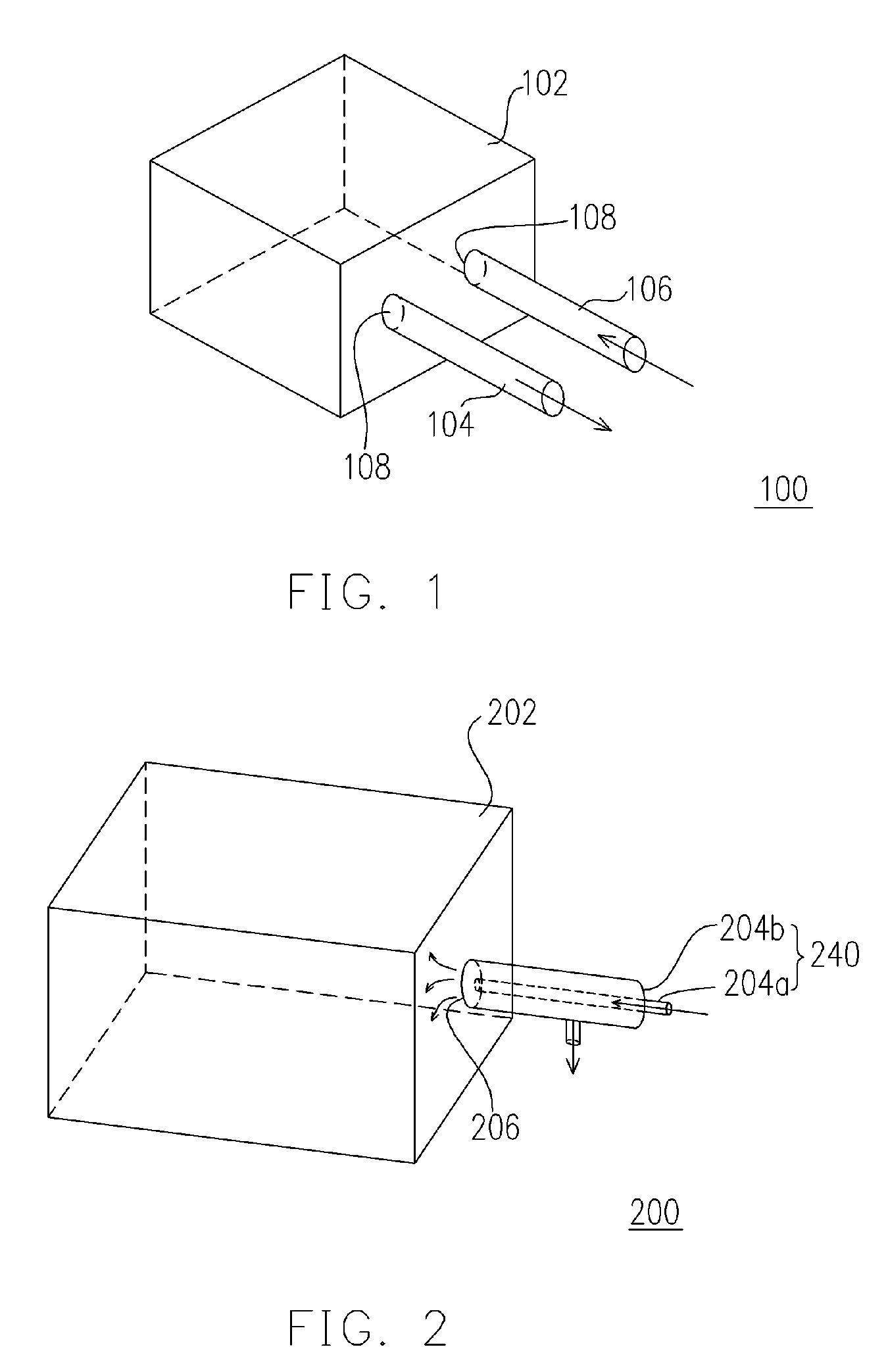

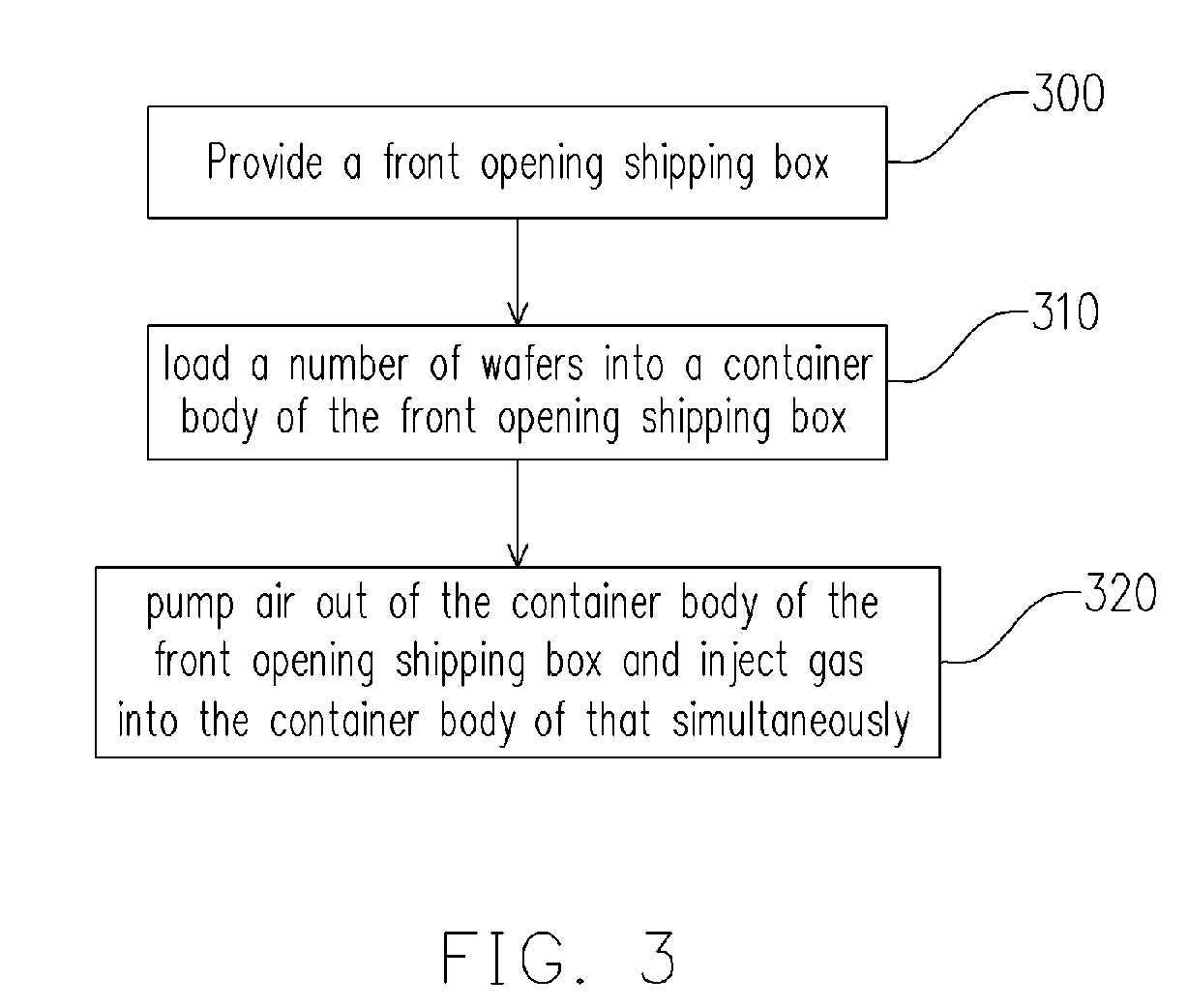

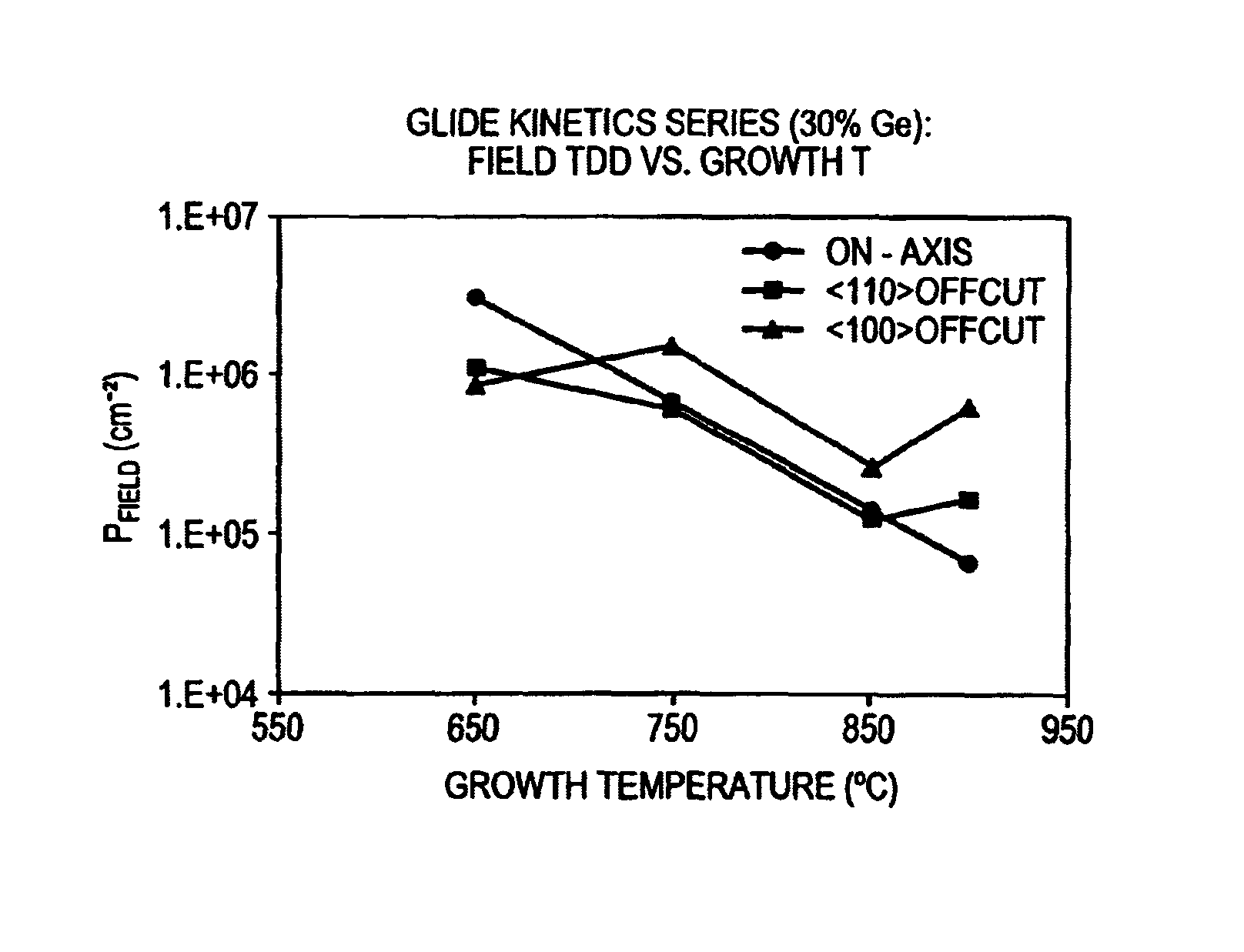

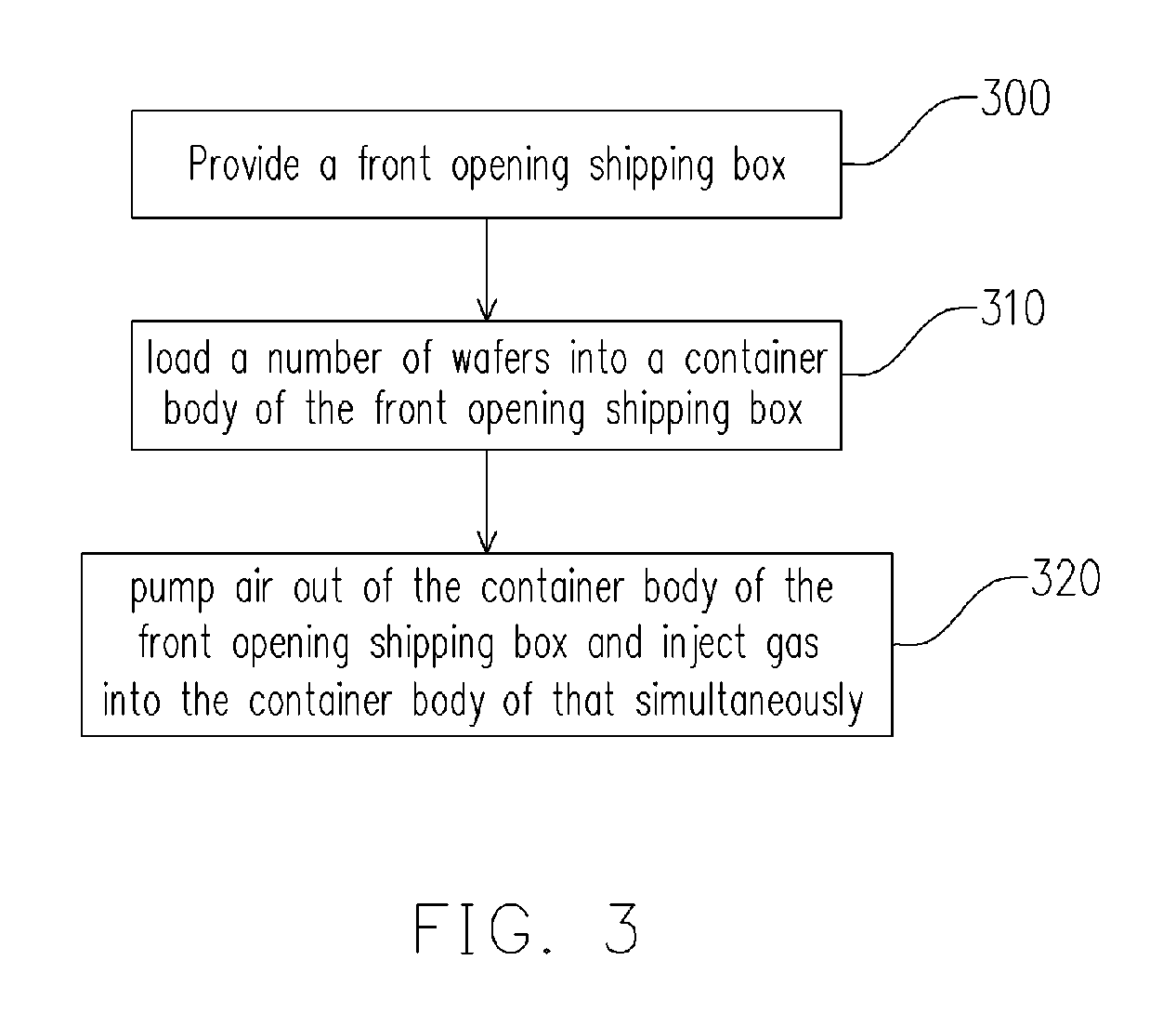

Front opening shipping box and method of operating the same

ActiveUS7299603B2Avoid it happening againReduce harmSemiconductor/solid-state device manufacturingPackaging by pressurising/gasifyingEngineeringMechanical engineering

Owner:UNITED MICROELECTRONICS CORP

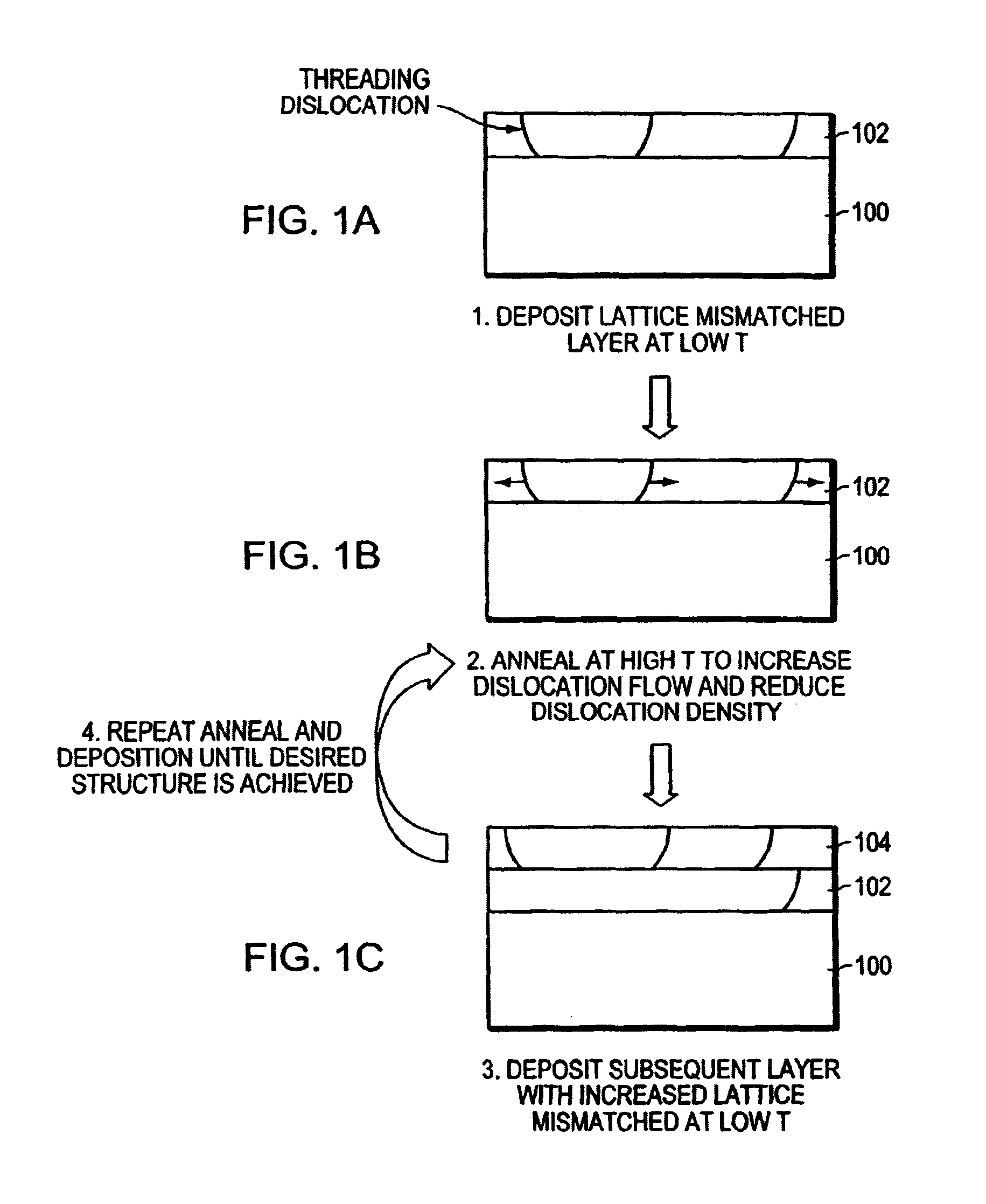

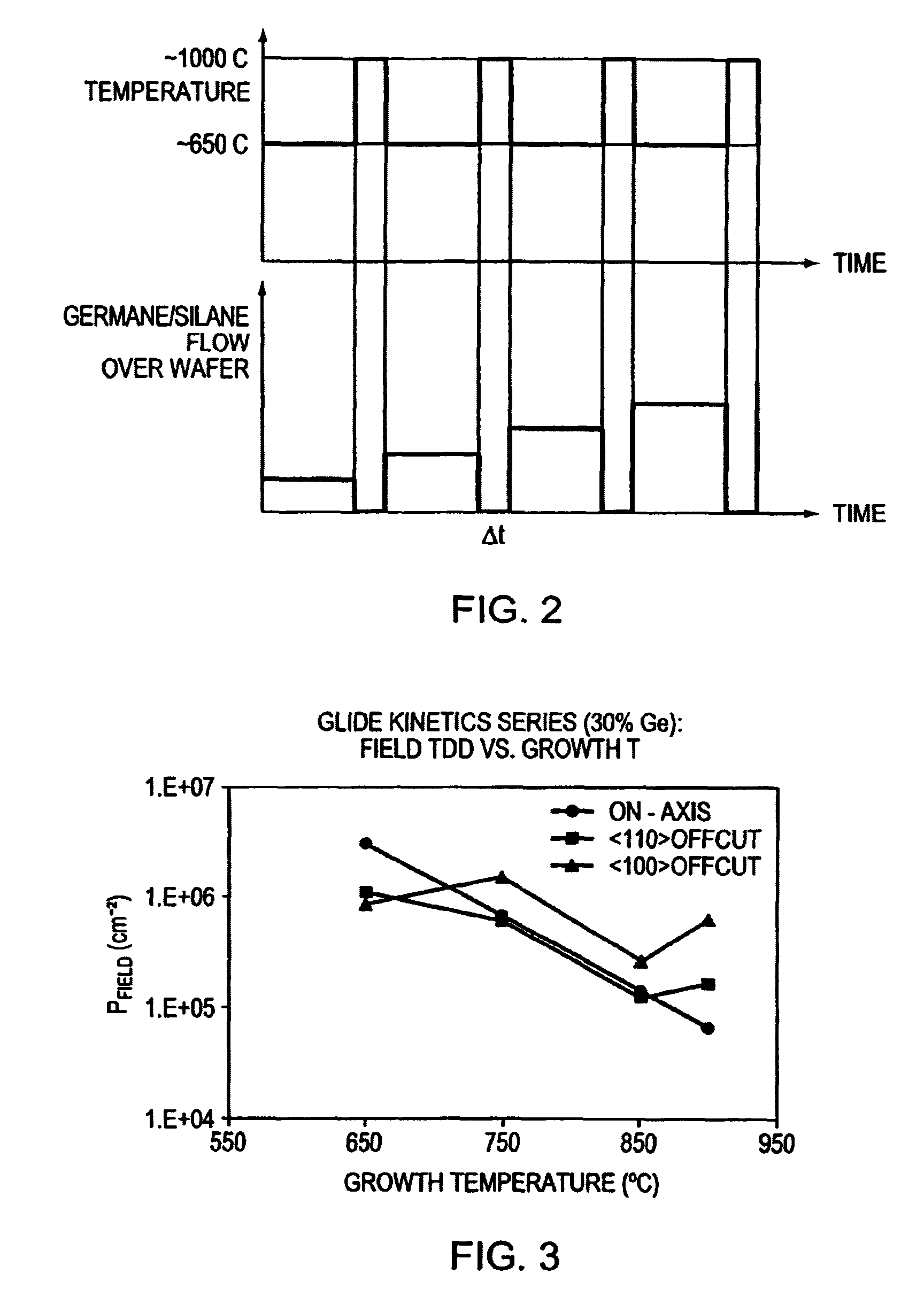

Low threading dislocation density relaxed mismatched epilayers without high temperature growth

InactiveUS6864115B2Avoiding germane particle generationShorten threadPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureElectrical conductor

A semiconductor structure and method of processing same including a substrate, a lattice-mismatched first layer deposited on the substrate and annealed at a temperature greater than 100° C. above the deposition temperature, and a second layer deposited on the first layer with a greater lattice mismatch to the substrate than the first semiconductor layer. In another embodiment there is provided a semiconductor graded composition layer structure on a semiconductor substrate and a method of processing same including a semiconductor substrate, a first semiconductor layer having a series of lattice-mismatched semiconductor layers deposited on the substrate and annealed at a temperature greater than 100° C. above the deposition temperature, a second semiconductor layer deposited on the first semiconductor layer with a greater lattice mismatch to the substrate than the first semiconductor layer, and annealed at a temperature greater than 100° C. above the deposition temperature of the second semiconductor layer.

Owner:TAIWAN SEMICON MFG CO LTD

Sb-Te Alloy Sintered Compact Target and Manufacturing Method Thereof

ActiveUS20100025236A1Reduce generationLow oxygenCellsTransportation and packagingTarget surfaceSputtering

Provided is an Sb—Te alloy sintered compact target using atomized powder consisting of substantially spherical particles of an Sb—Te alloy, wherein the spherical atomized powder consists of particles that were crushed and flattened, and the flattened particles exhibiting a ratio (flatness ratio) of short axis and long axis of 0.6 or less occupy 50% or more of the overall particles. With this Sb—Te alloy sintered compact target, particles exhibiting a long axis orientation aligned within ±45° in a direction that is parallel to the target surface occupy 60% or more of the overall particles. In addition, the oxygen concentration in this Sb—Te alloy sintered compact target is 1500 wtppm or less. Thus, the Sb—Te alloy sputtering target structure can be uniformalized and refined, generation of cracks in the sintered target can be inhibited, and generation of arcing during sputtering can be inhibited. Further, surface ruggedness caused by sputter erosion can be reduced in order to obtain a high quality Sb—Te alloy sputtering target.

Owner:JX NIPPON MINING& METALS CORP

Method of manufacturing silicon substrate

InactiveUS20090226736A1Avoid it happening againIncrease productionPolycrystalline material growthAfter-treatment detailsSingle crystalOxygen

A method of manufacturing a silicon substrate includes: growing a silicon single crystal having a carbon concentration in the range of 1.0×1016 atoms / cm3 to 1.6×1017 atoms / cm3 and an initial oxygen concentration in the range of 1.4×1018 atoms / cm3 to 1.6×1018 atoms / cm3 using a CZ method; slicing the silicon single crystal; forming an epitaxial layer on the sliced silicon single crystal; and performing a heat treatment thereon as a post-annealing process at a temperature in the range of 600° C. to 850° C.

Owner:SUMCO CORP

Front opening shipping box and method of operating the same

ActiveUS20070214747A1Avoid problemsAvoid it happening againSemiconductor/solid-state device manufacturingPackaging by pressurising/gasifyingEngineeringMechanical engineering

Owner:UNITED MICROELECTRONICS CORP

Etching composition, and method for producing semiconductor element by utilizing same

PendingCN109689838APrevents damage to film quality or deterioration of electrical characteristicsPrevent particle generationSemiconductor/solid-state device manufacturingAqueous dispersionsSolventEtching rate

The present invention relates to an etching composition, and a method for producing a semiconductor element comprising an etching process that utilizes the etching composition, the etching compositioncomprising a first inorganic acid, a first additive, and a solvent. The etching composition can minimize the etching rate of oxide film while selectively removing nitride film, and does not have issues that adversely affect the quality of the element, such particle generation, and is highly selective.

Owner:SOULBRAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com