Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Damage can be suppressed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

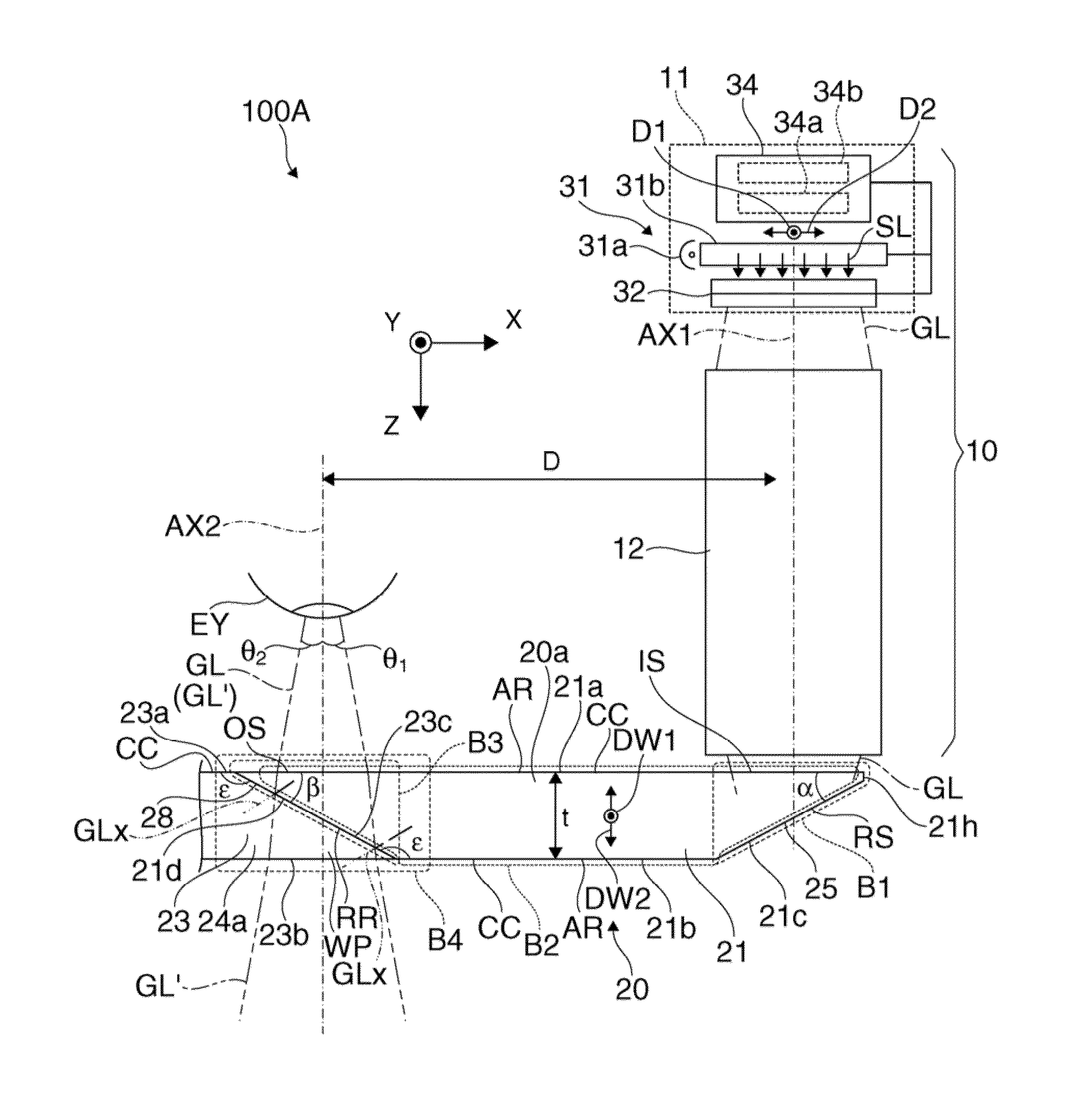

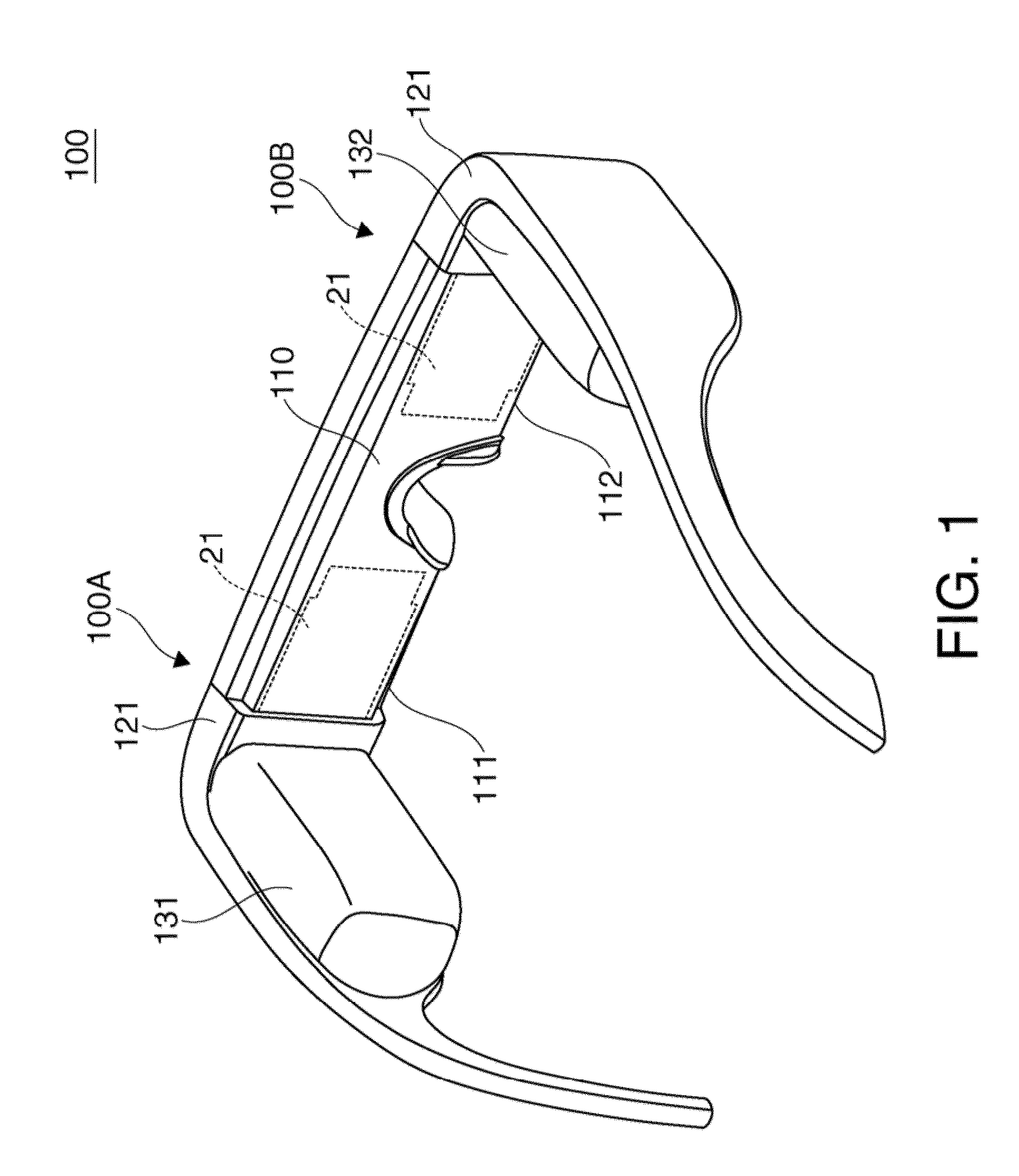

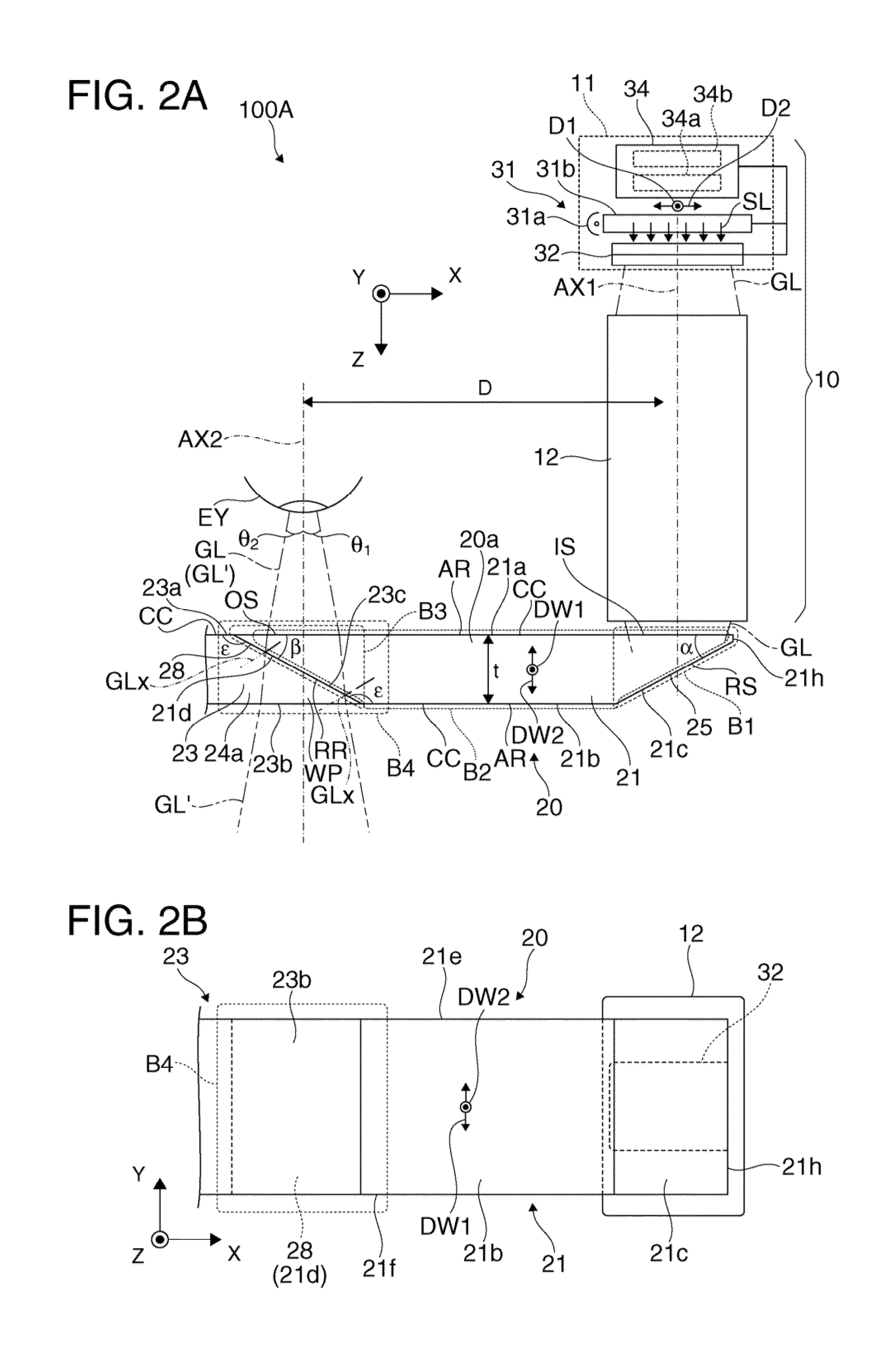

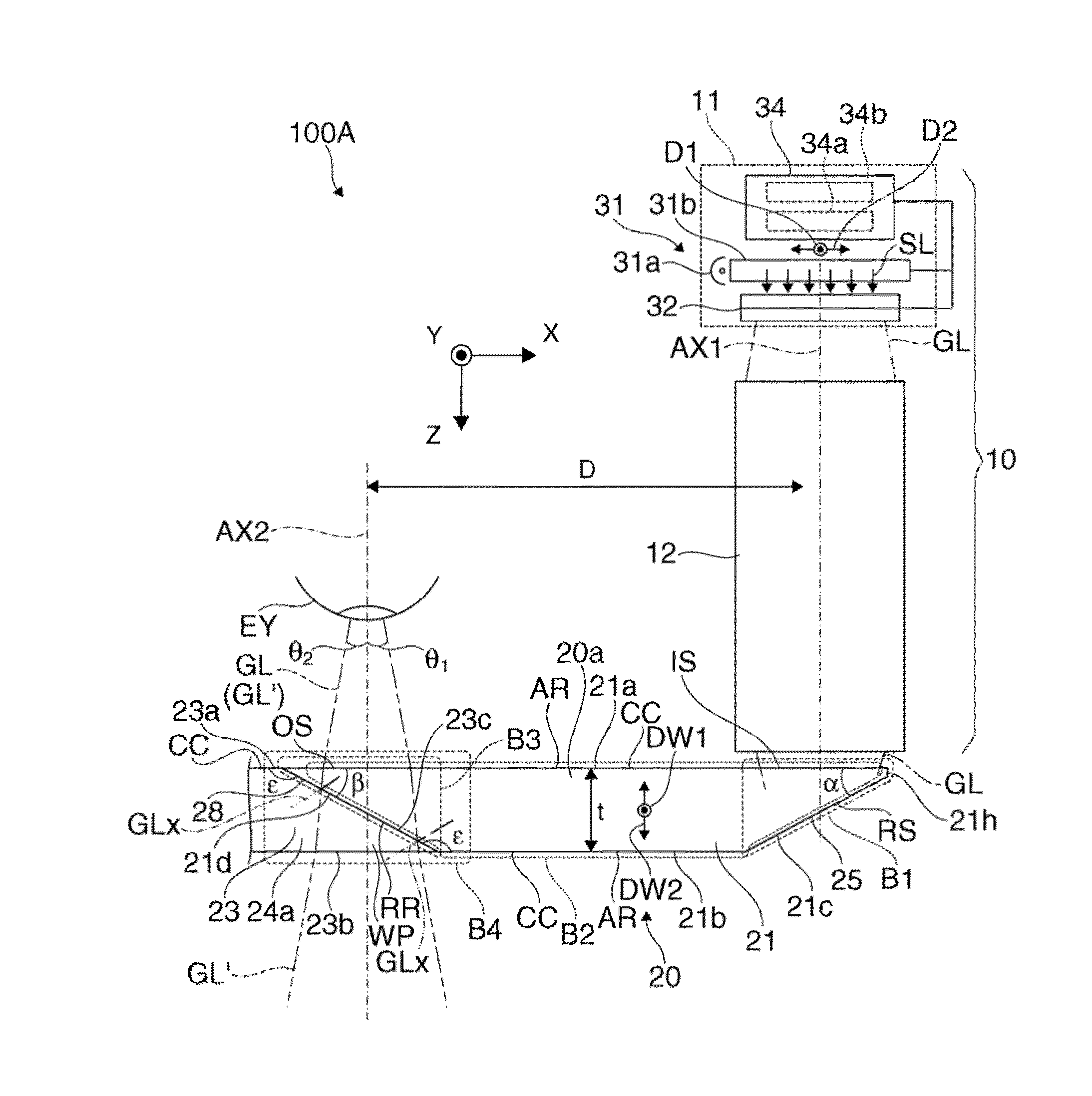

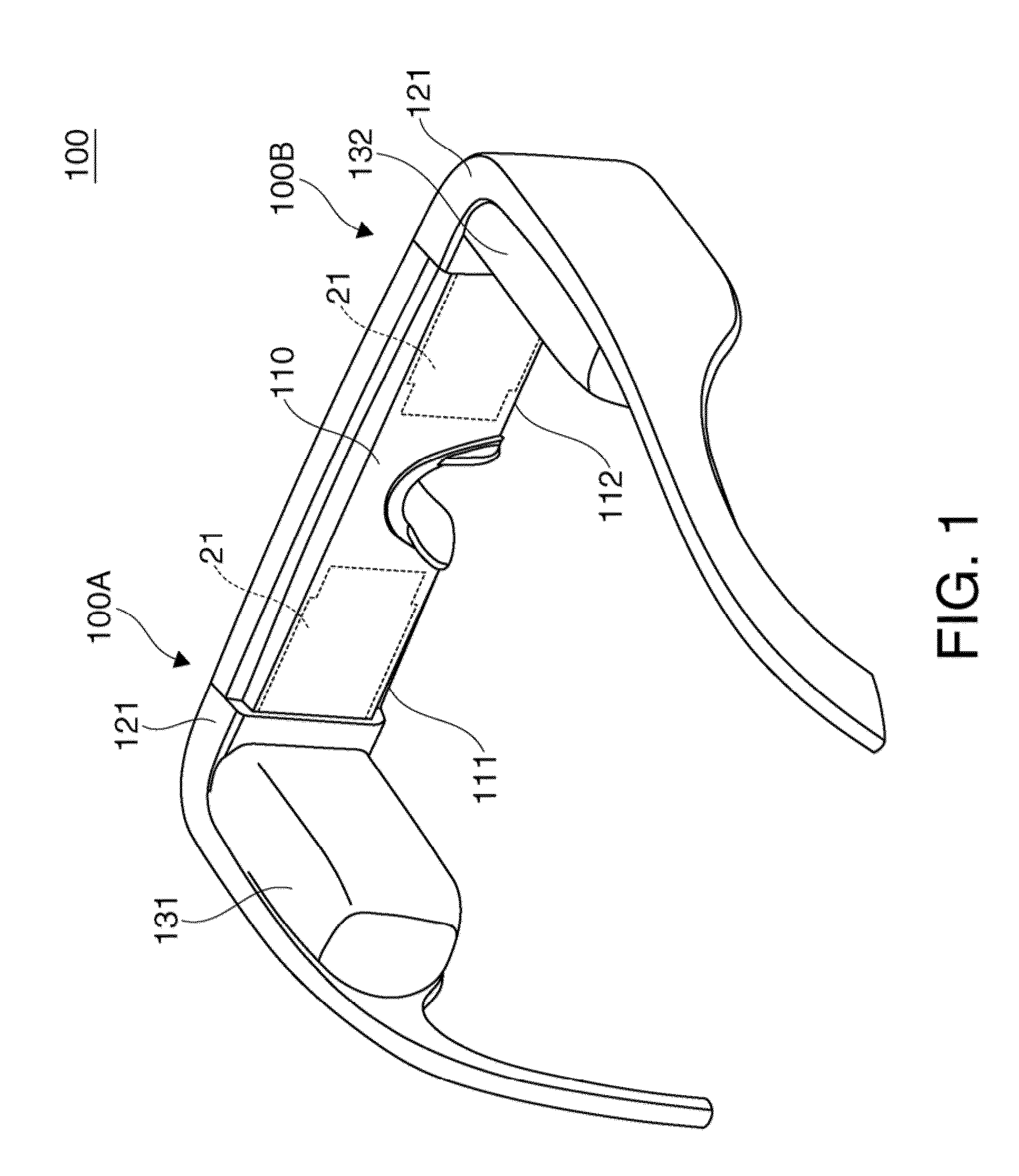

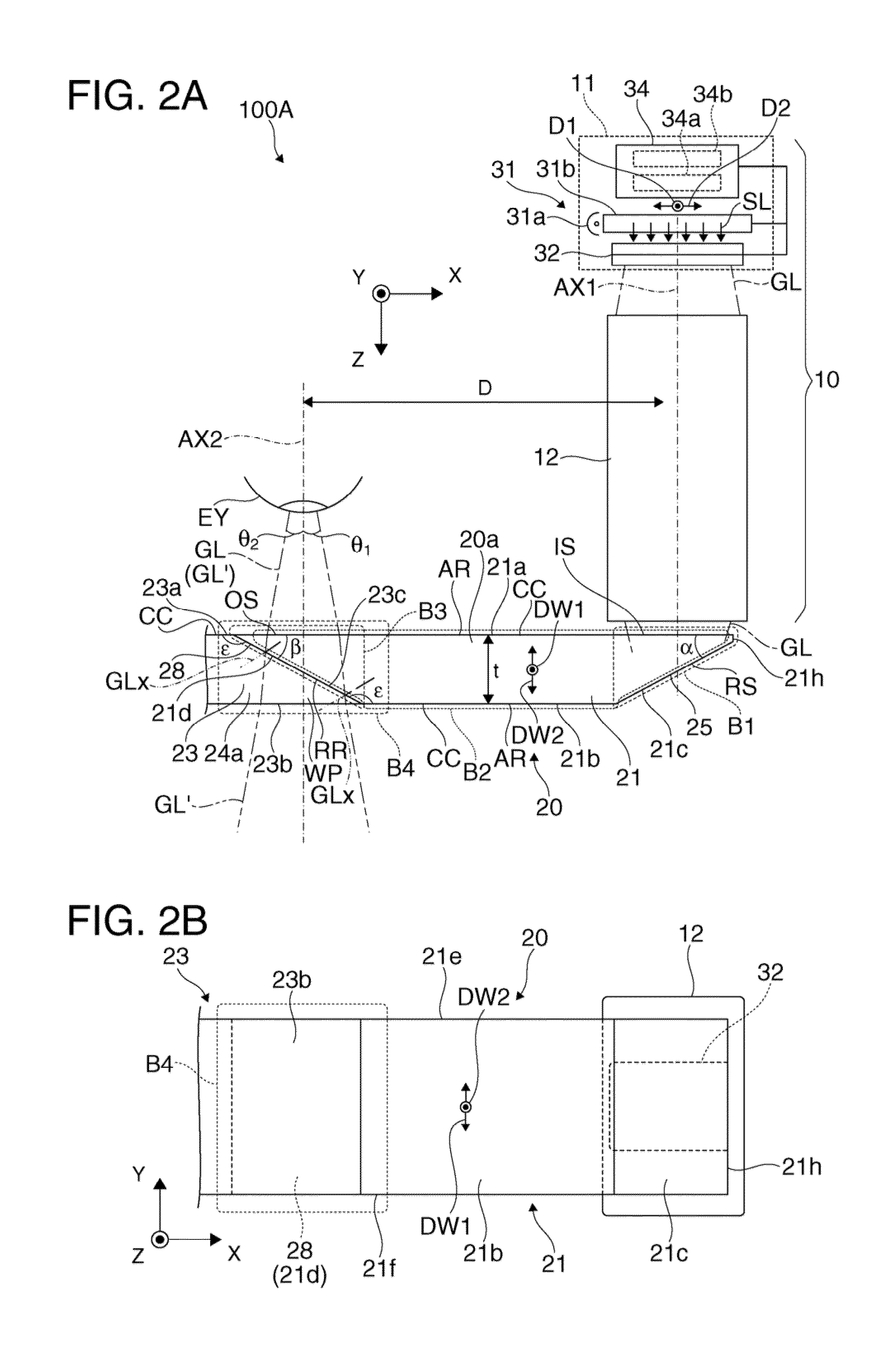

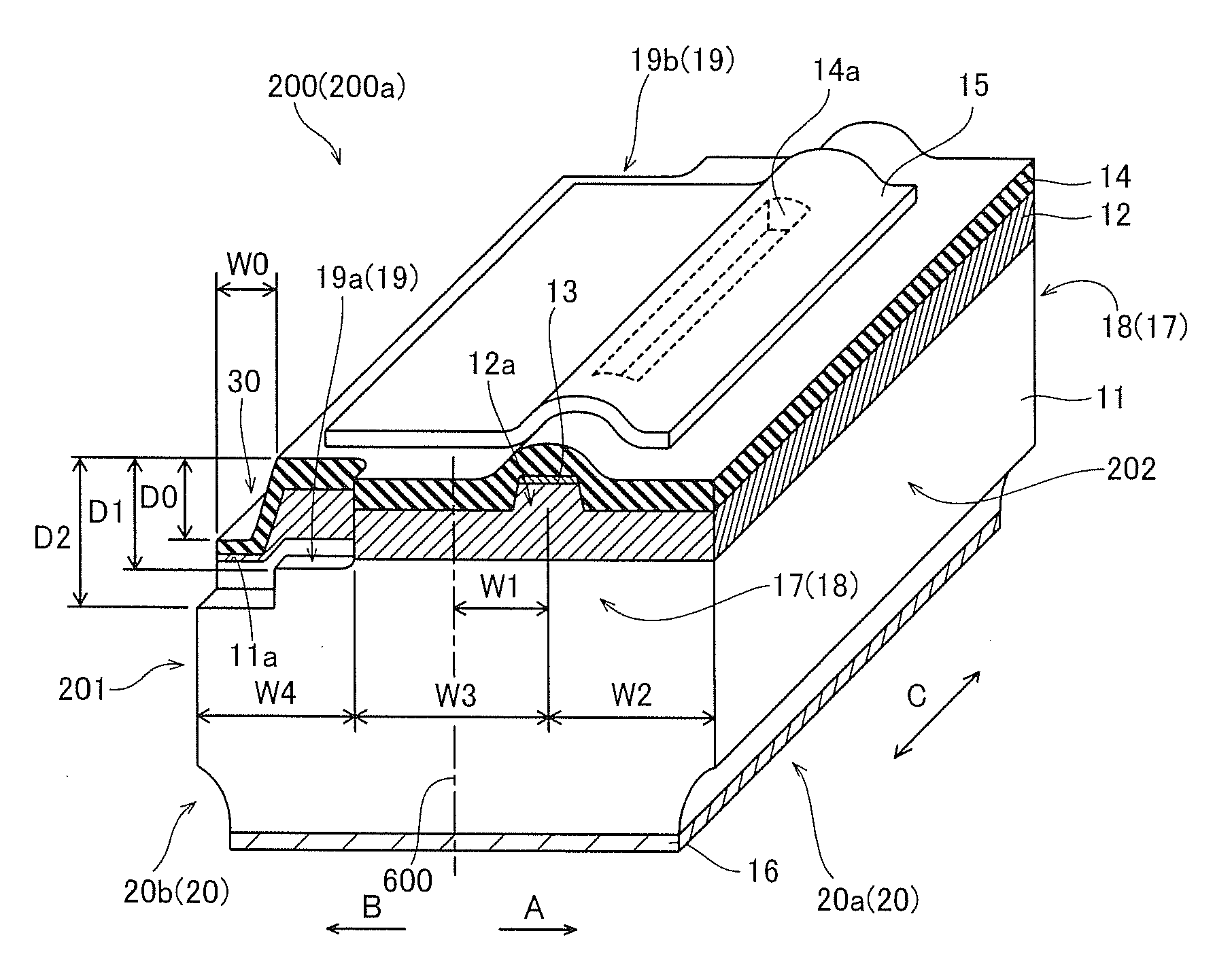

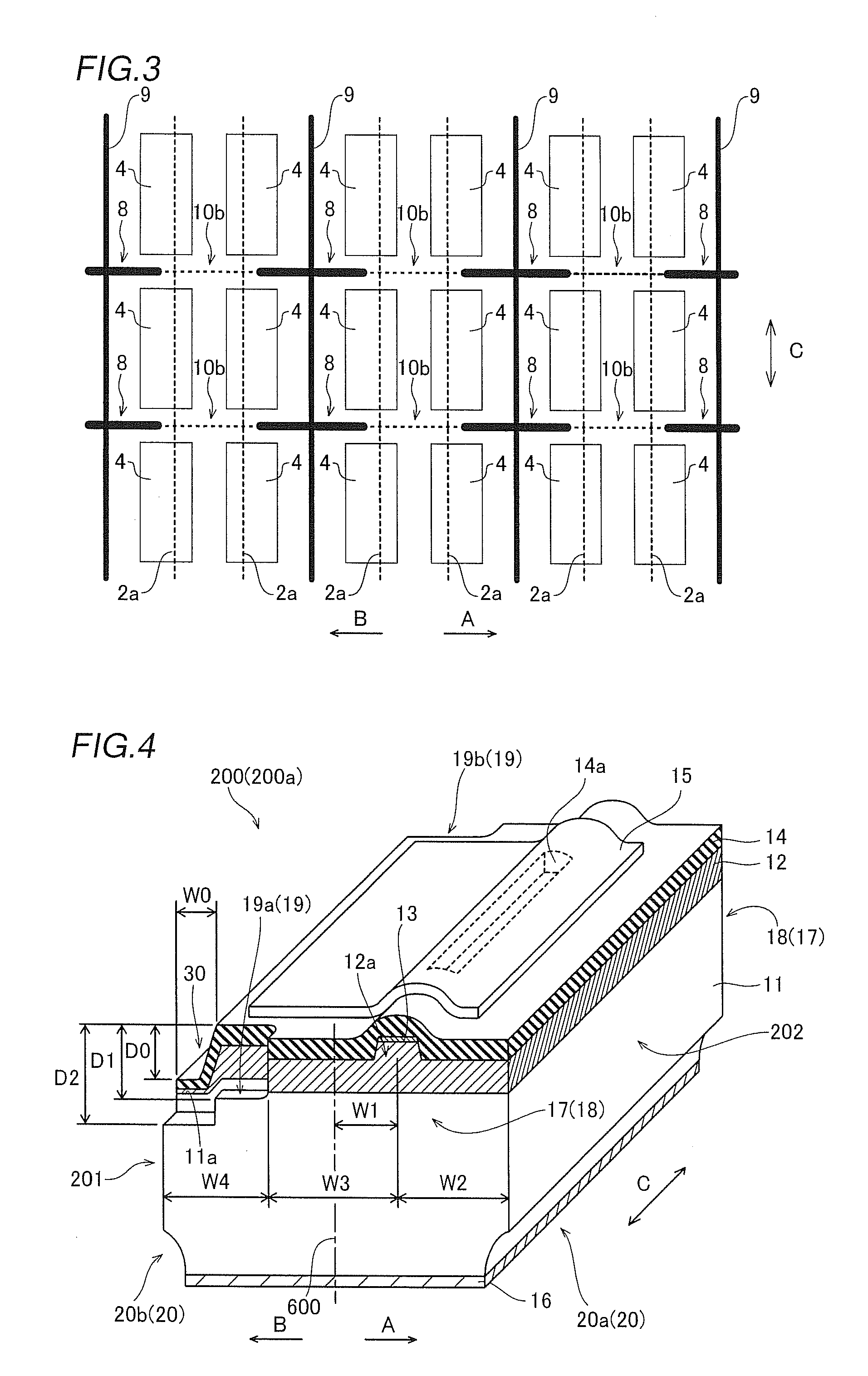

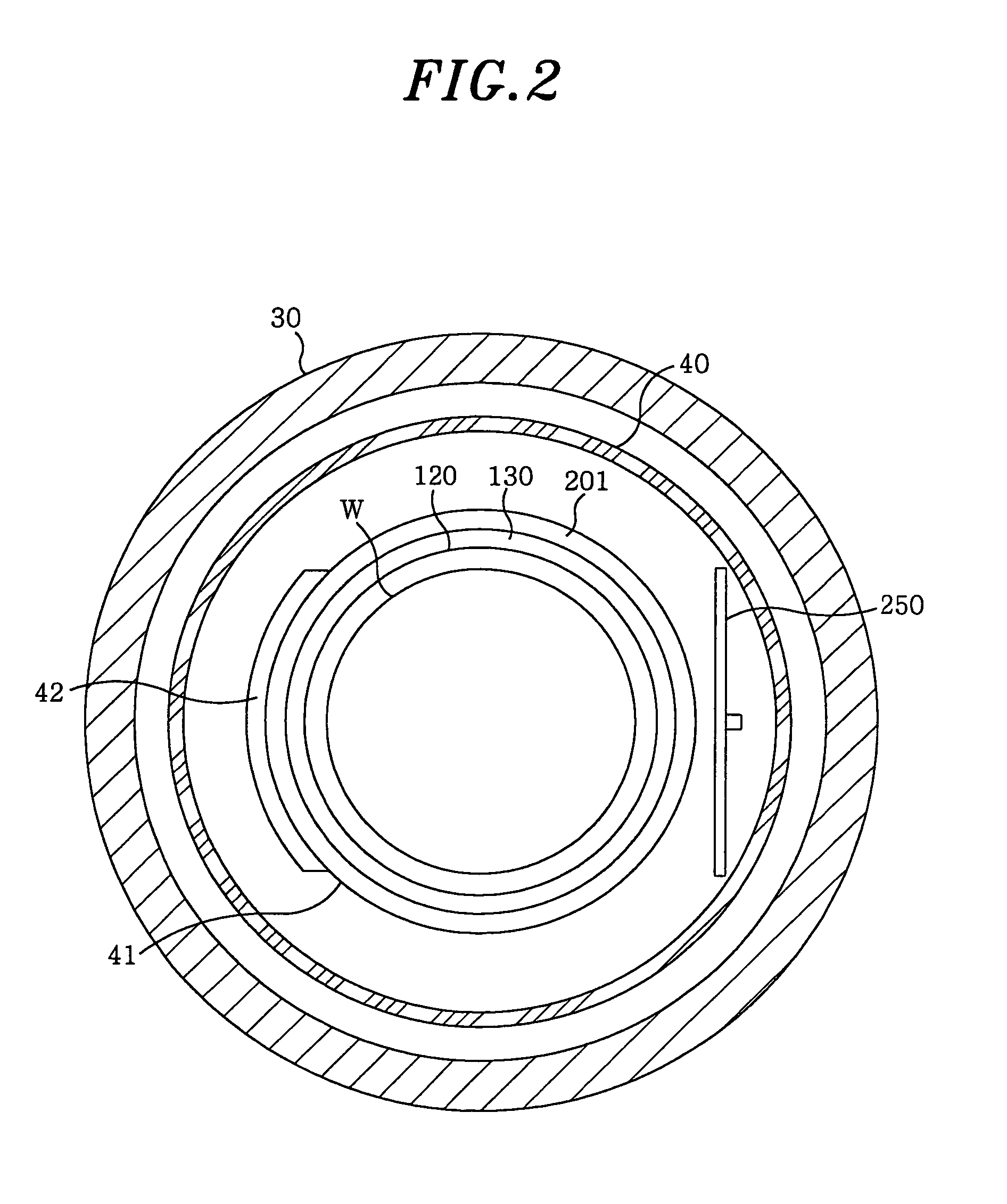

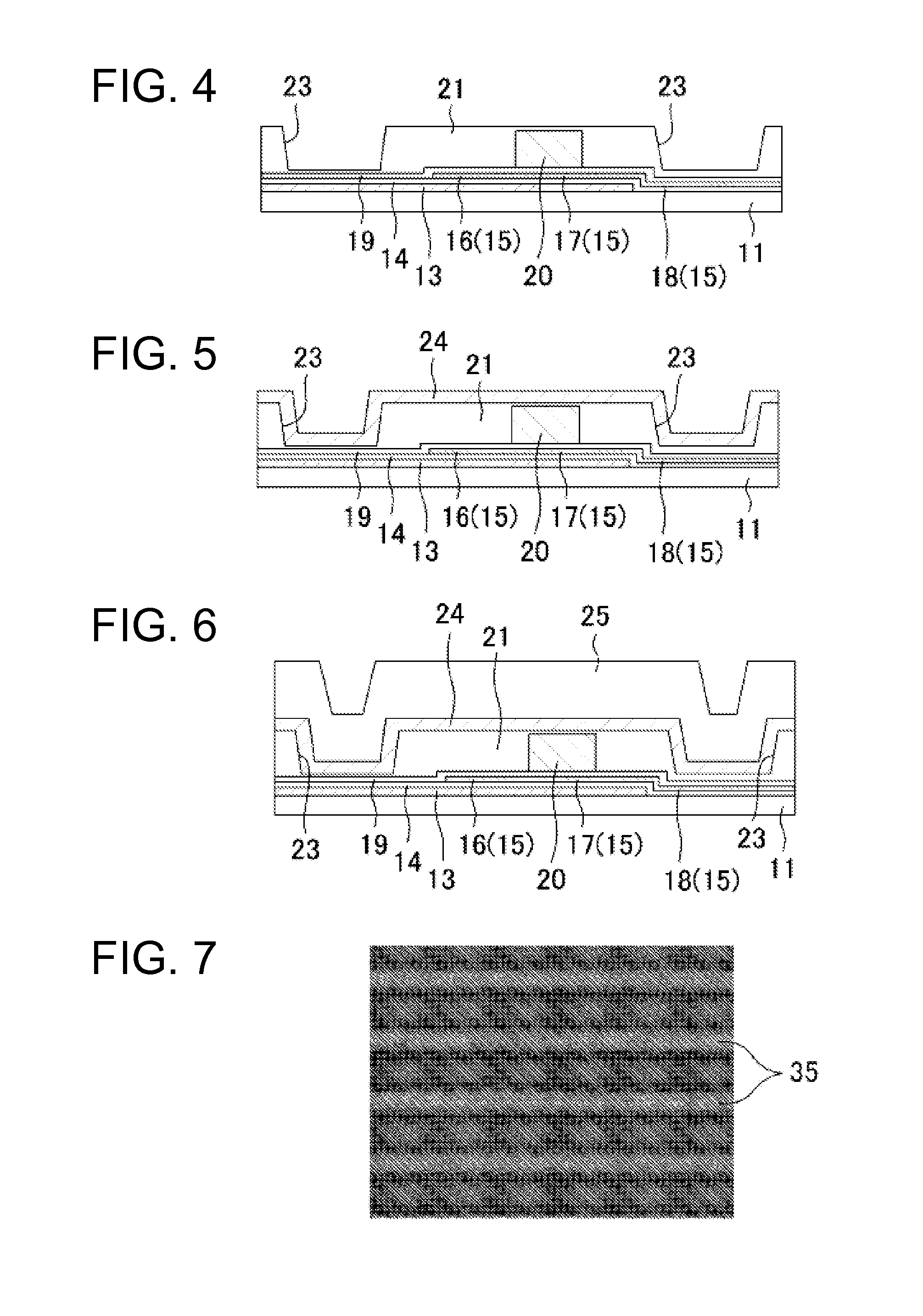

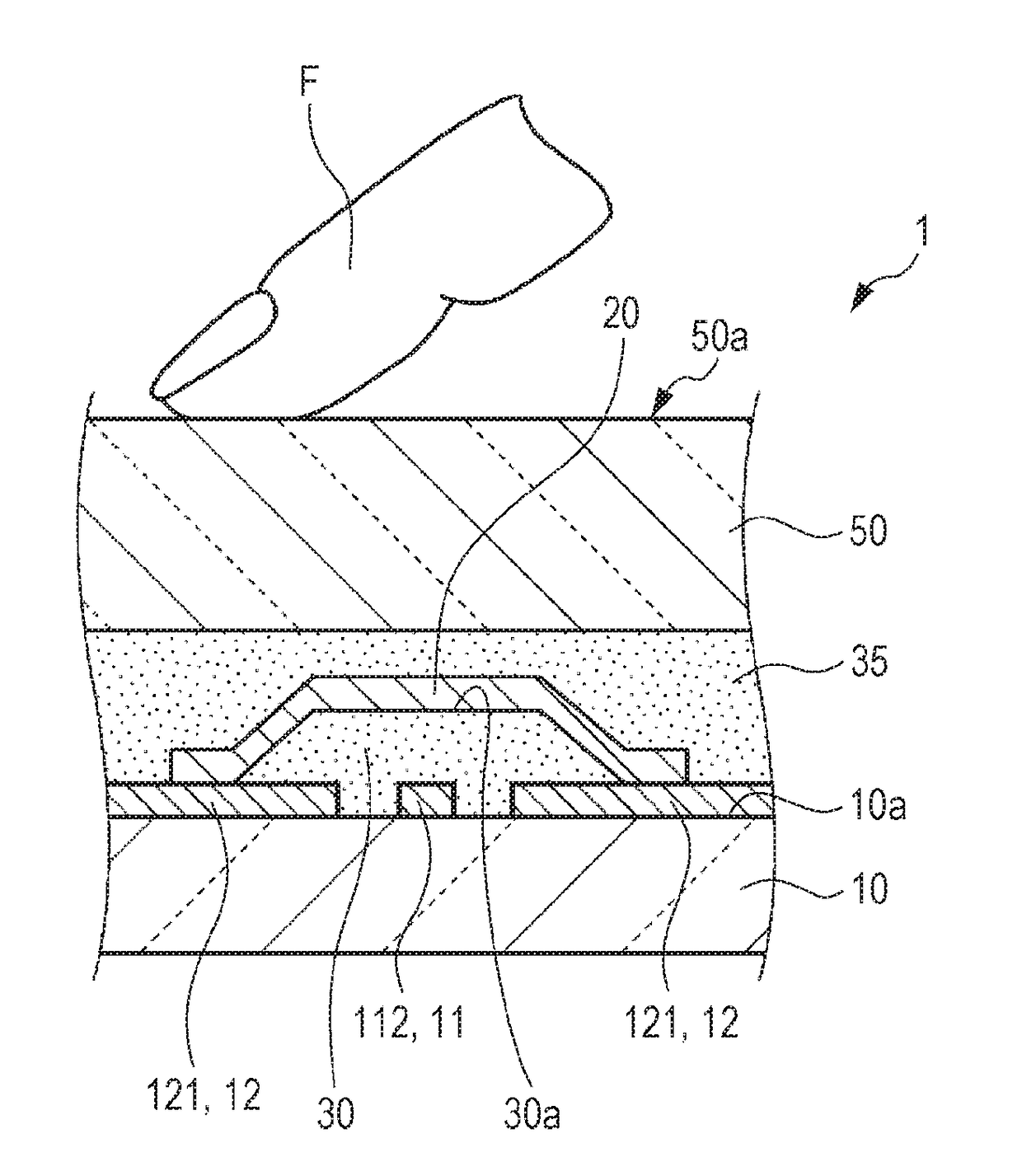

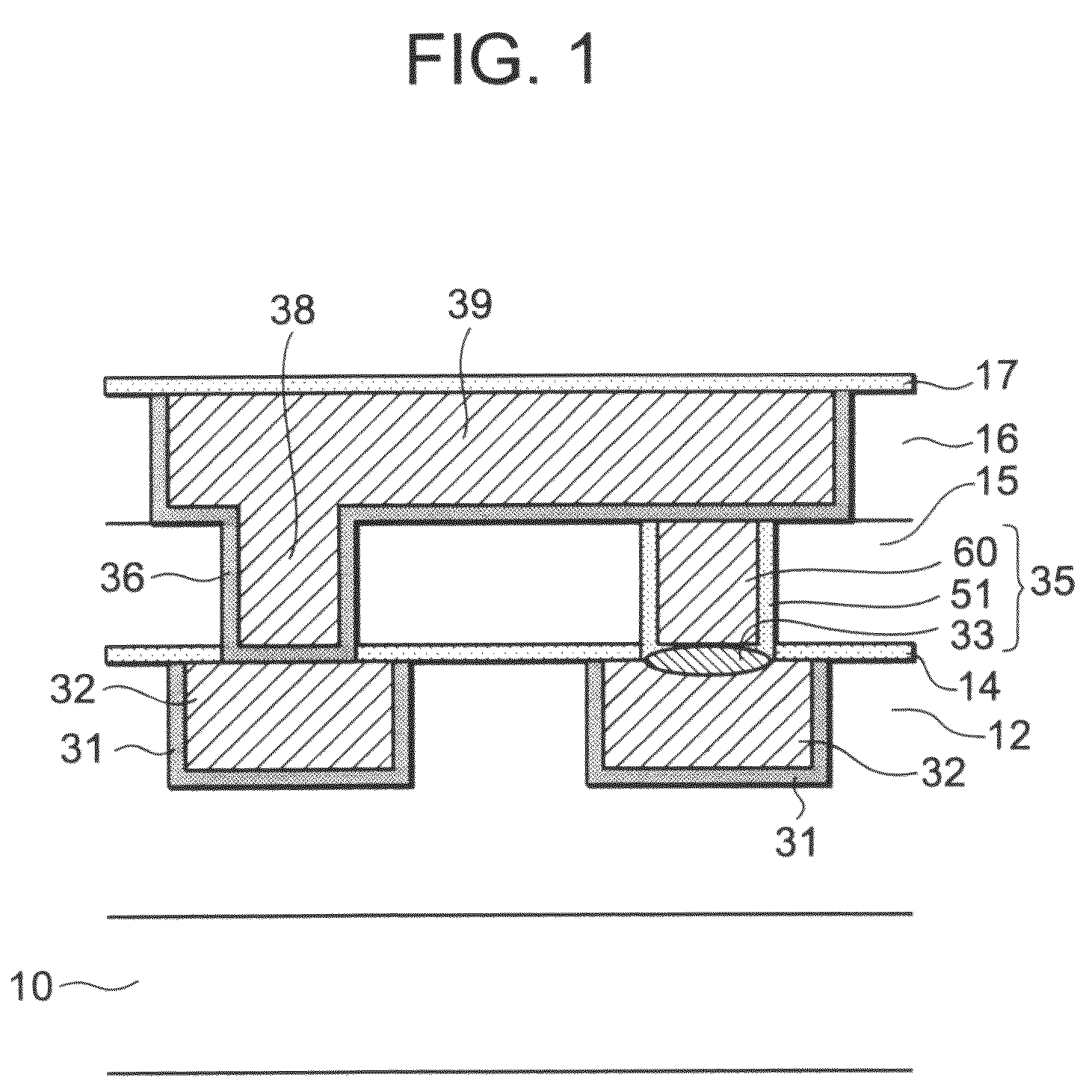

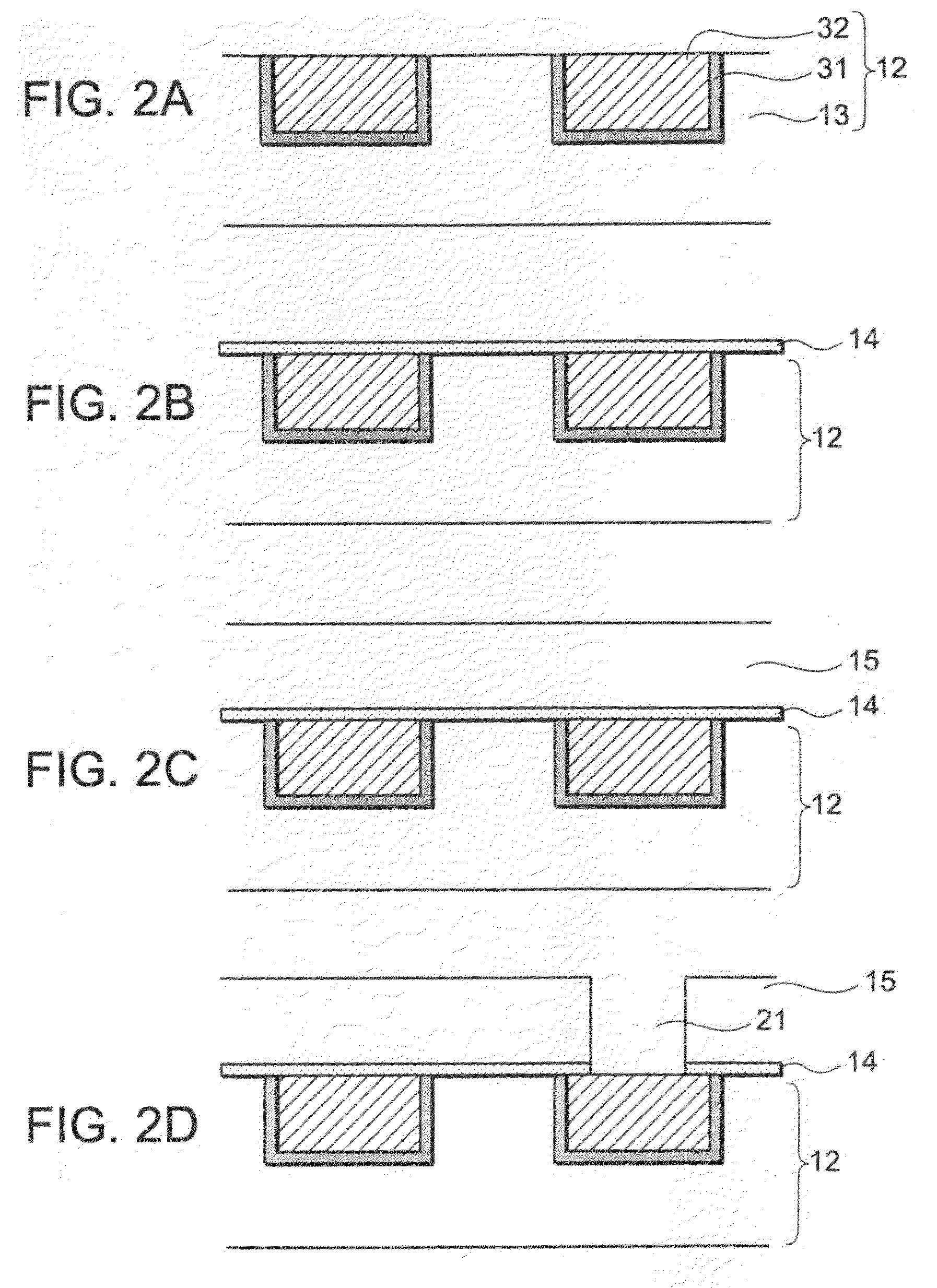

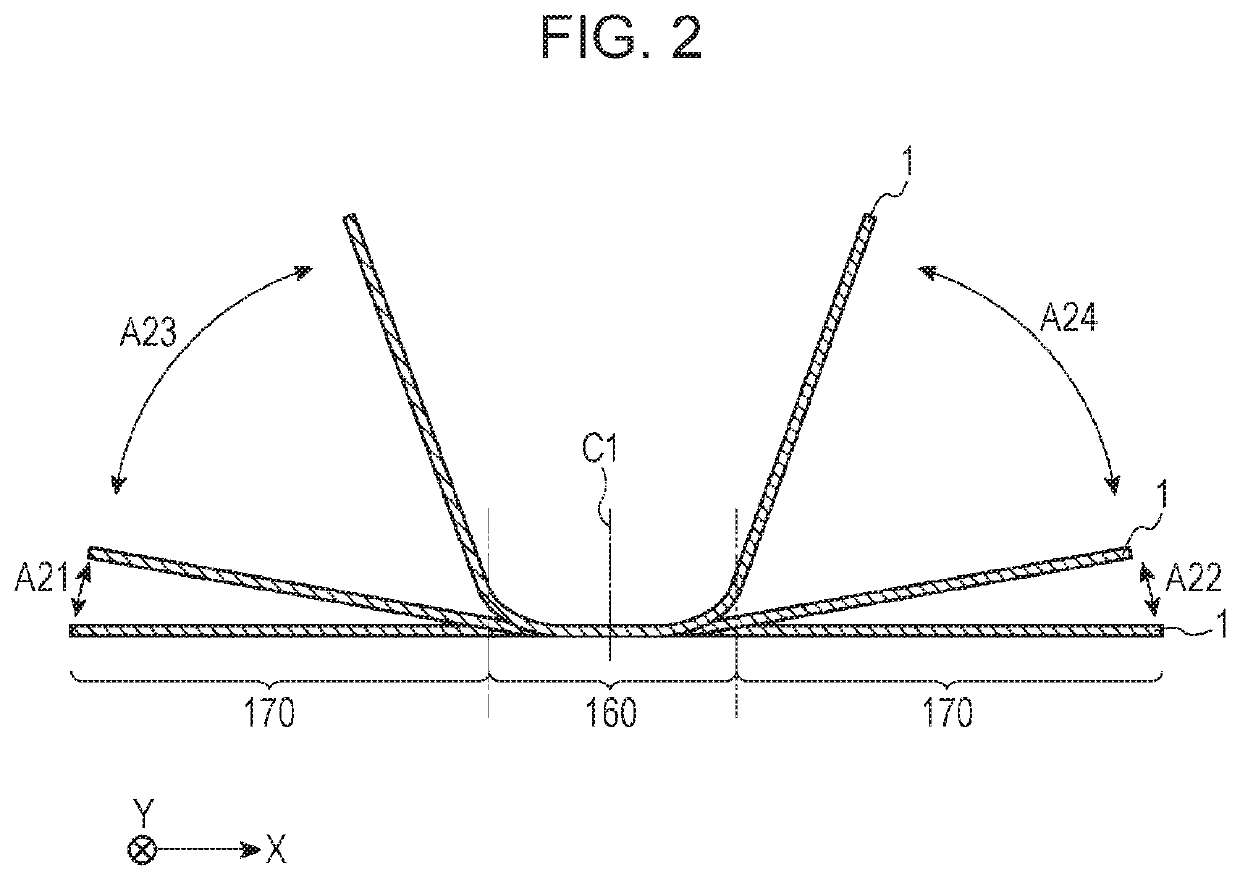

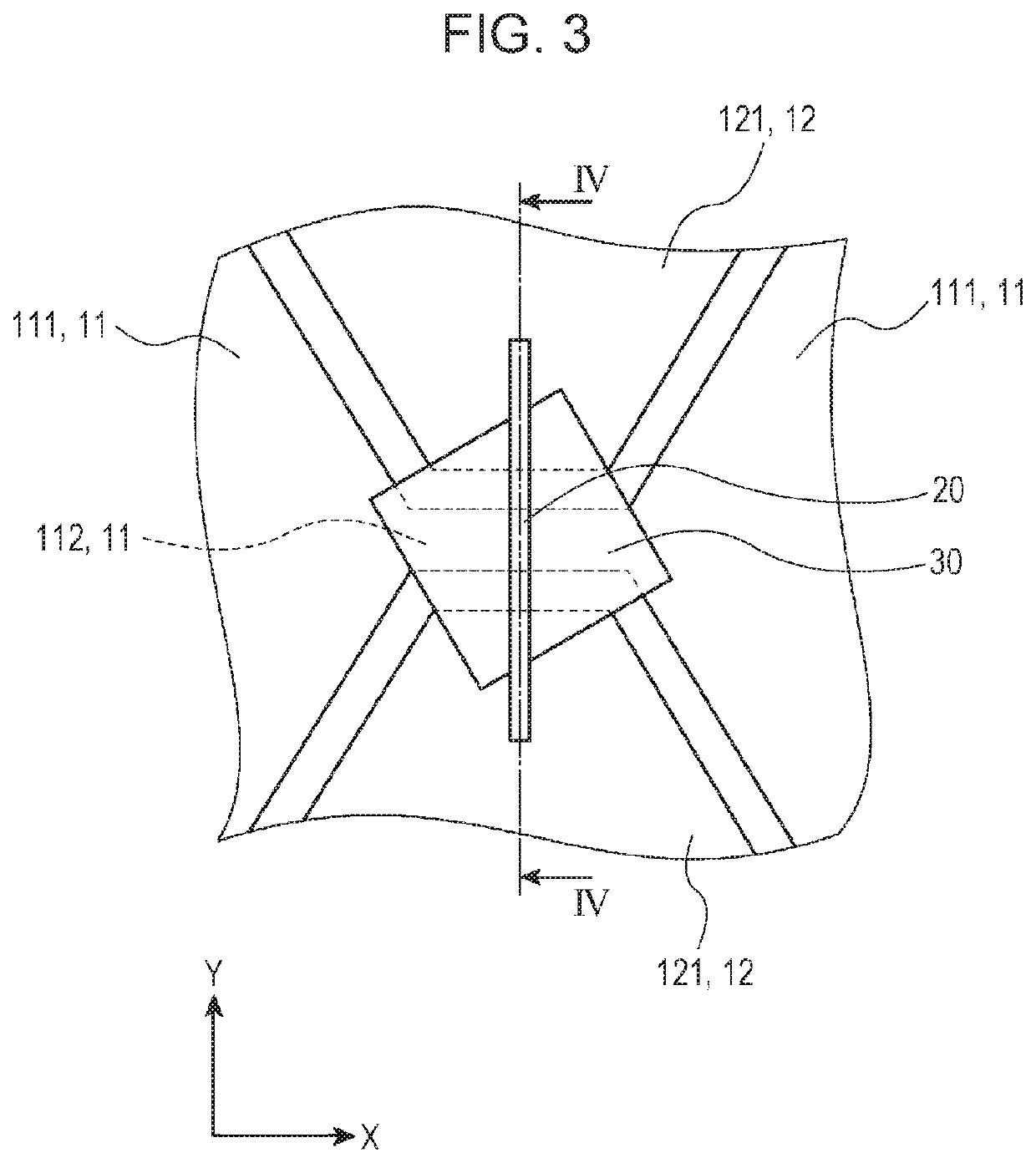

Virtual image display device and manufacturing method of virtual image display device

ActiveUS8711487B2Remove stainsOptimizationTelevision system detailsMirrorsOptical propertyLight guide

In fabrication of a light guiding unit, a half mirror layer as a reflection film for folding light is covered by a light transmission main body part as a coating member, i.e., a light transmission member, and a hard coating layer is deposited thereon. Therefore, even when the surfaces of a light guide main body part and the light transmission main body part forming the light guiding unit are cleansed as pre-processing of the deposition of the hard coating layer, the situations such that the half mirror layer is separated thereby may be avoided and optical properties of the half mirror layer may not be lost.

Owner:SEIKO EPSON CORP

Virtual image display device and manufacturing method of virtual image display device

ActiveUS20130070344A1Suppress damageSoil surfaceTelevision system detailsMirrorsVirtual imageLight guide

In fabrication of a light guiding unit, a half mirror layer as a reflection film for folding light is covered by a light transmission main body part as a coating member, i.e., a light transmission member, and a hard coating layer is deposited thereon. Therefore, even when the surfaces of a light guide main body part and the light transmission main body part forming the light guiding unit are cleansed as pre-processing of the deposition of the hard coating layer, the situations such that the half mirror layer is separated thereby may be avoided and optical properties of the half mirror layer may not be lost.

Owner:SEIKO EPSON CORP

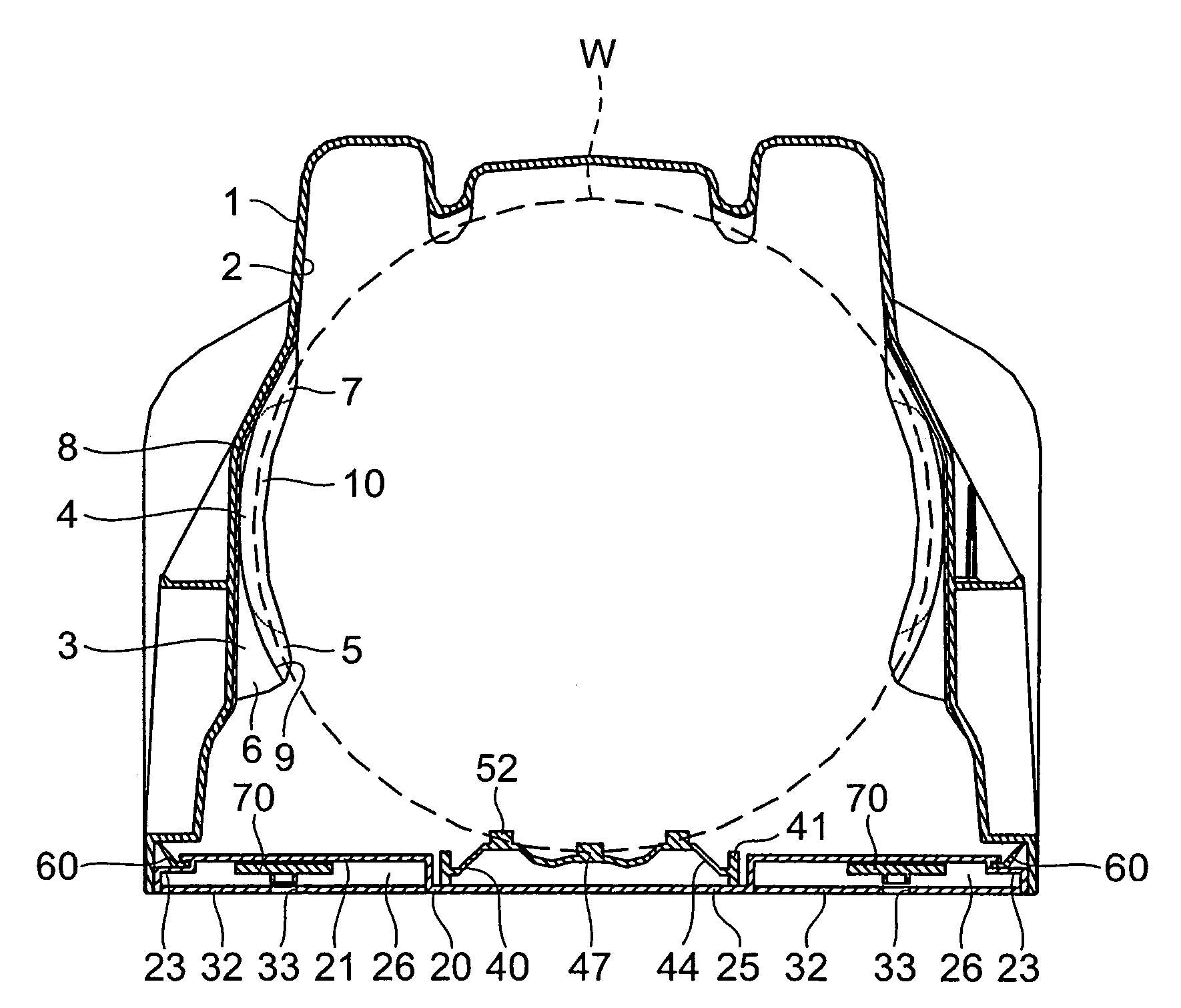

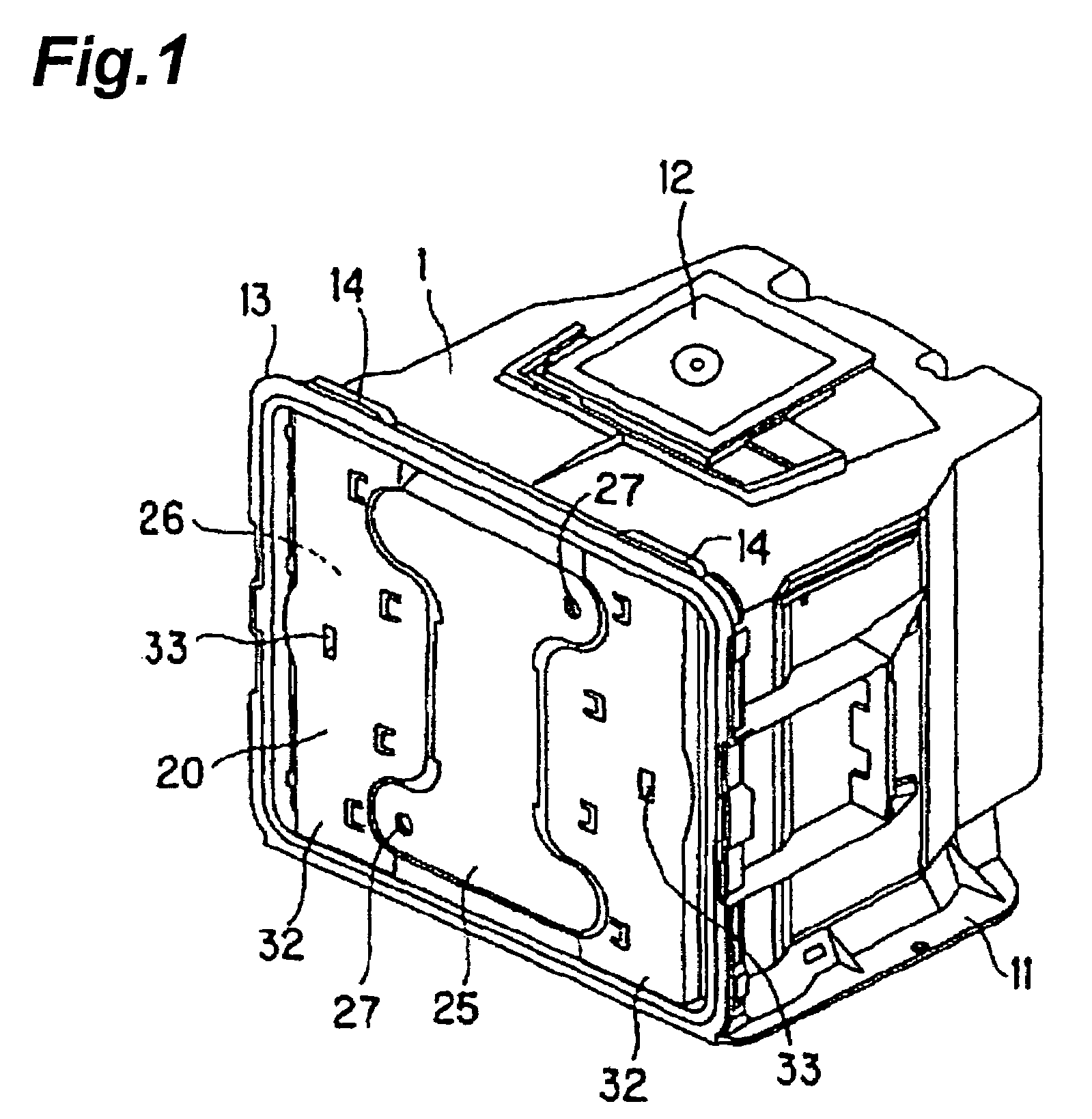

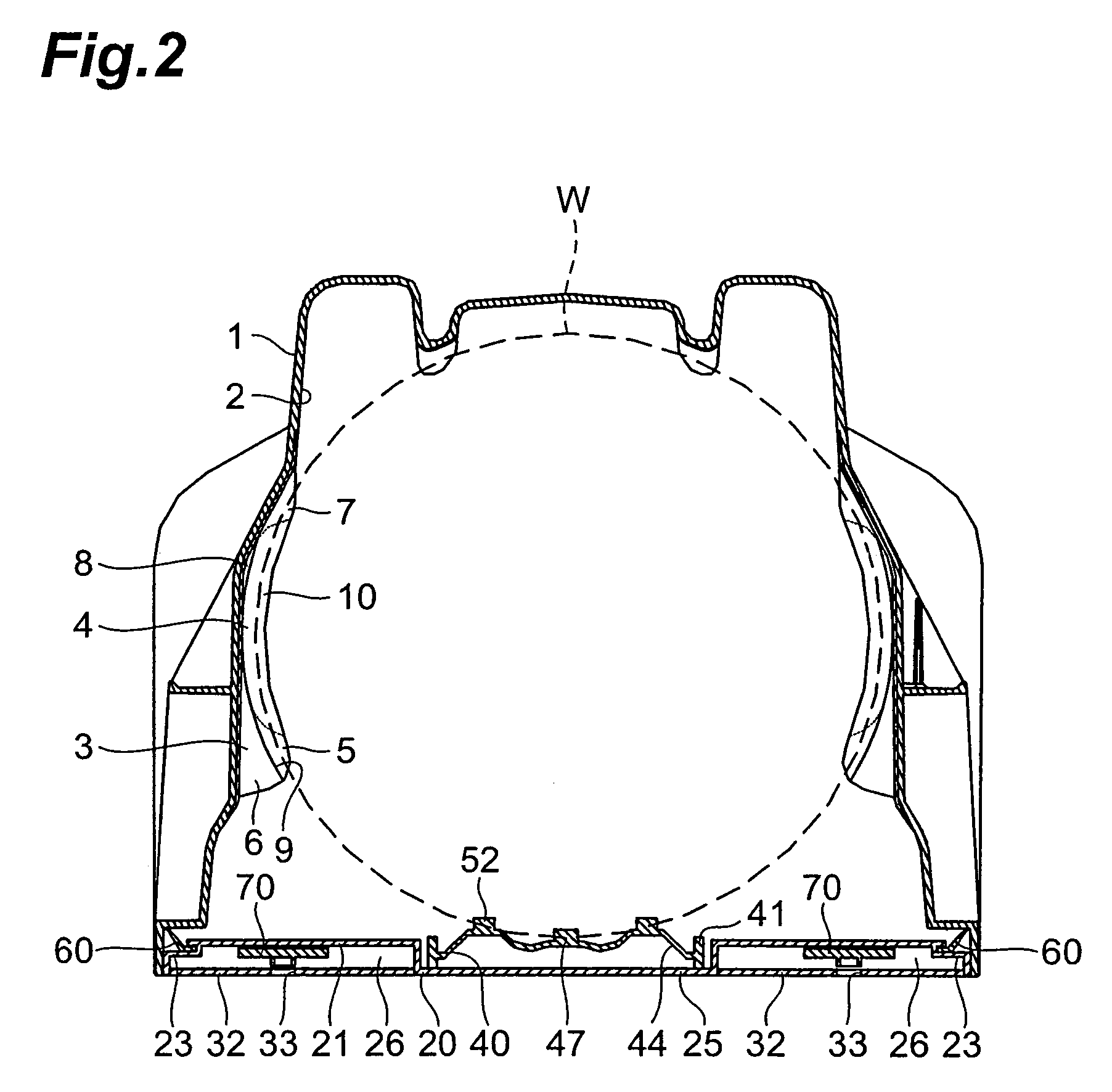

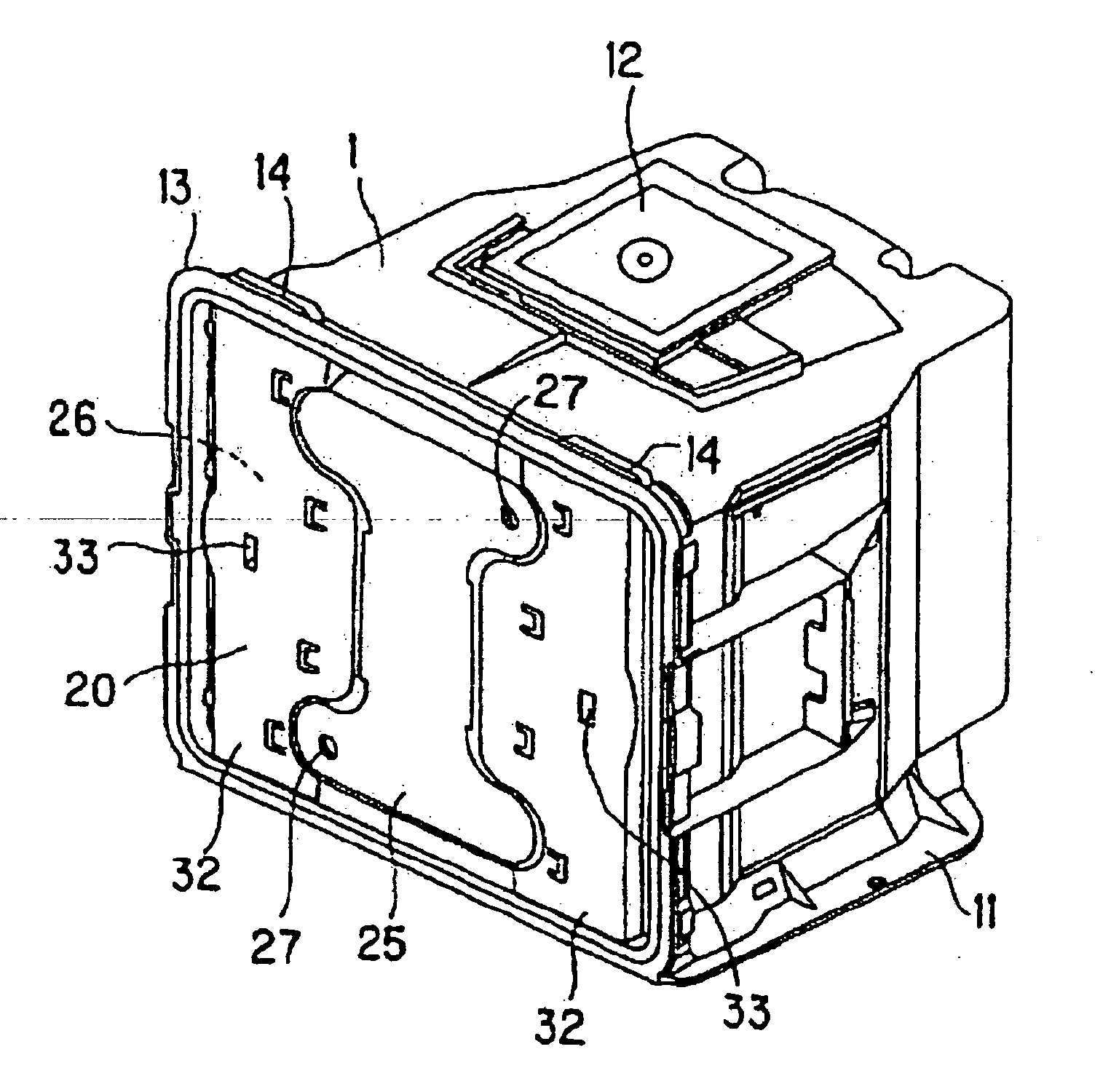

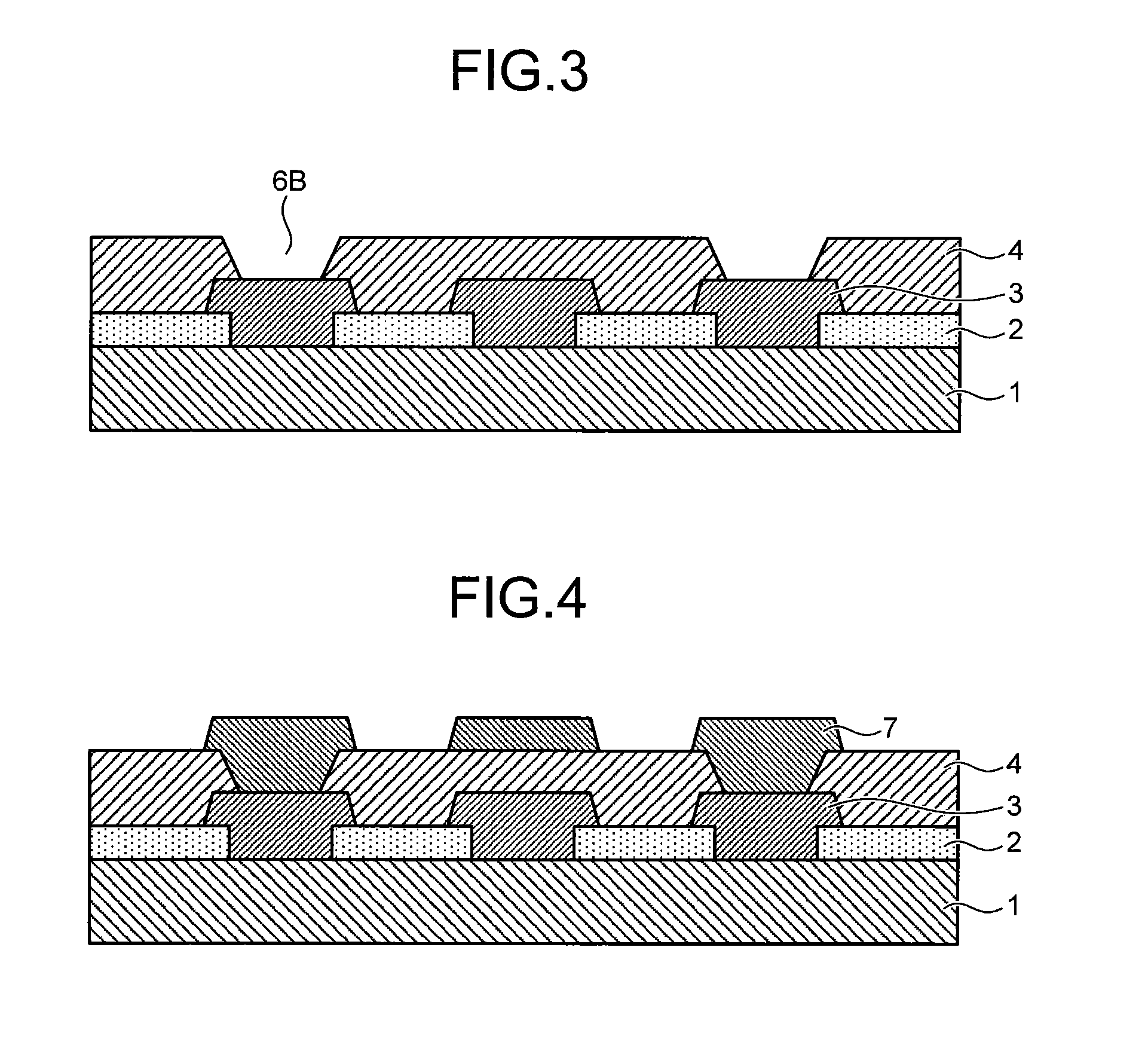

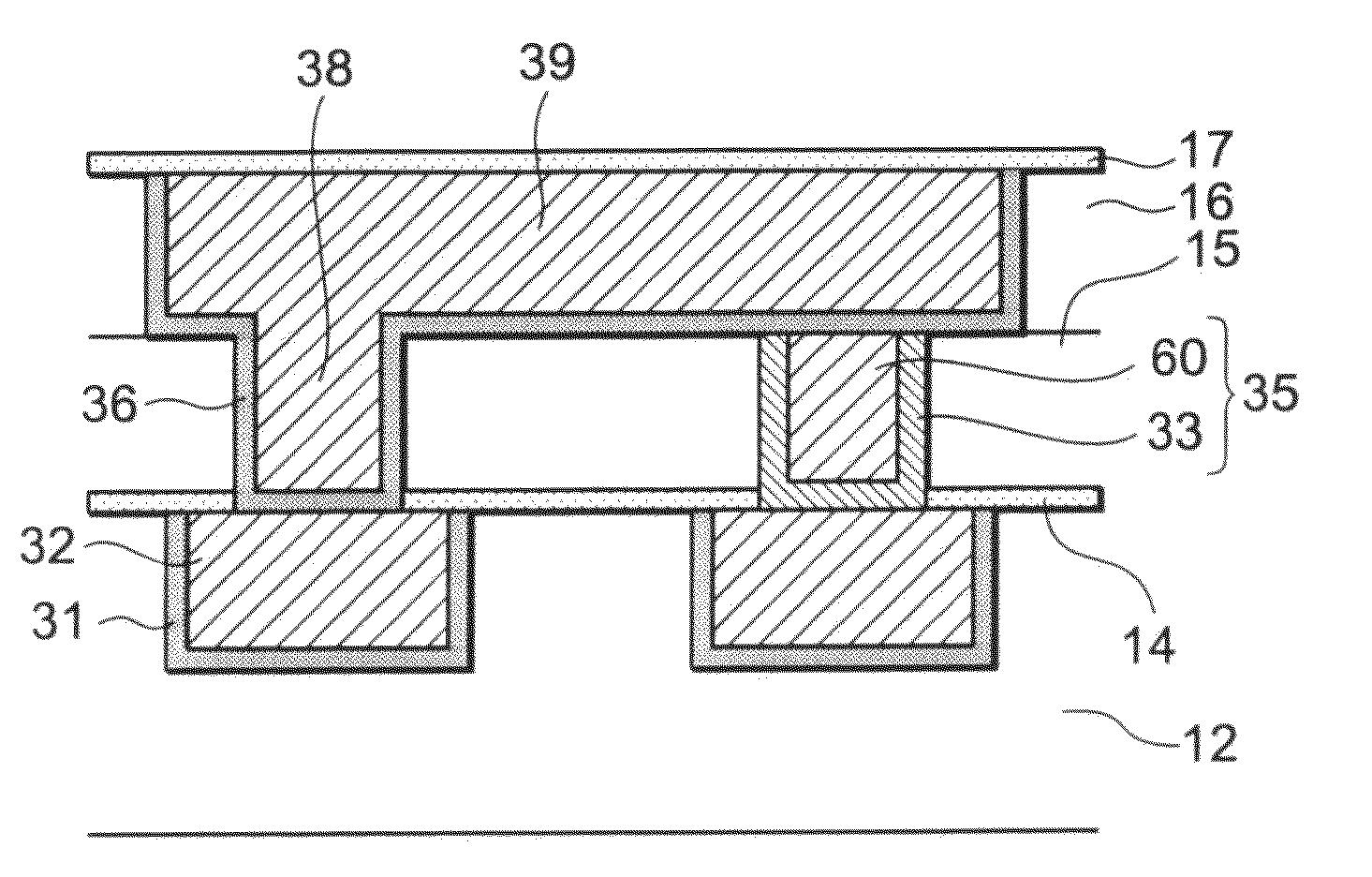

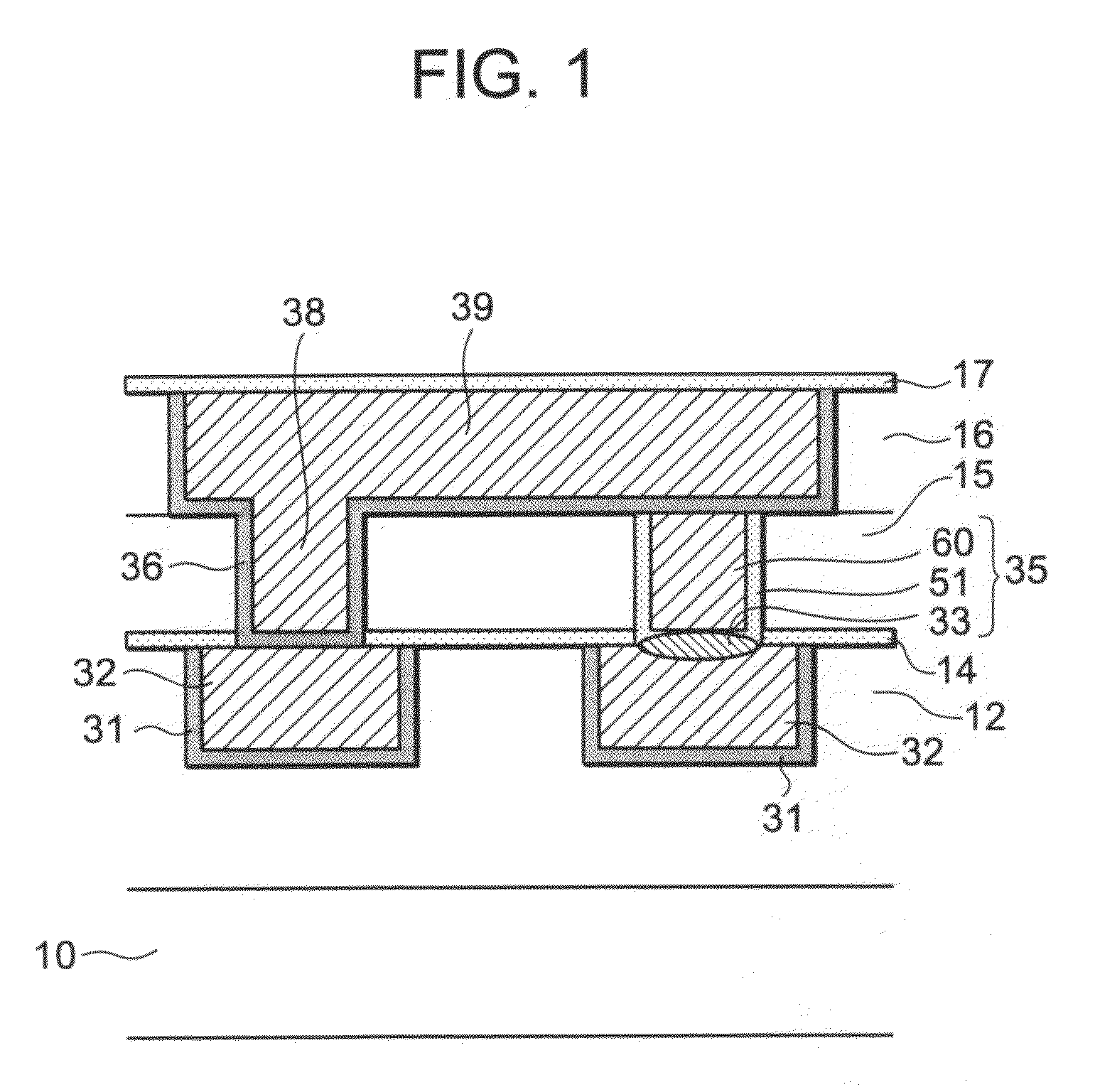

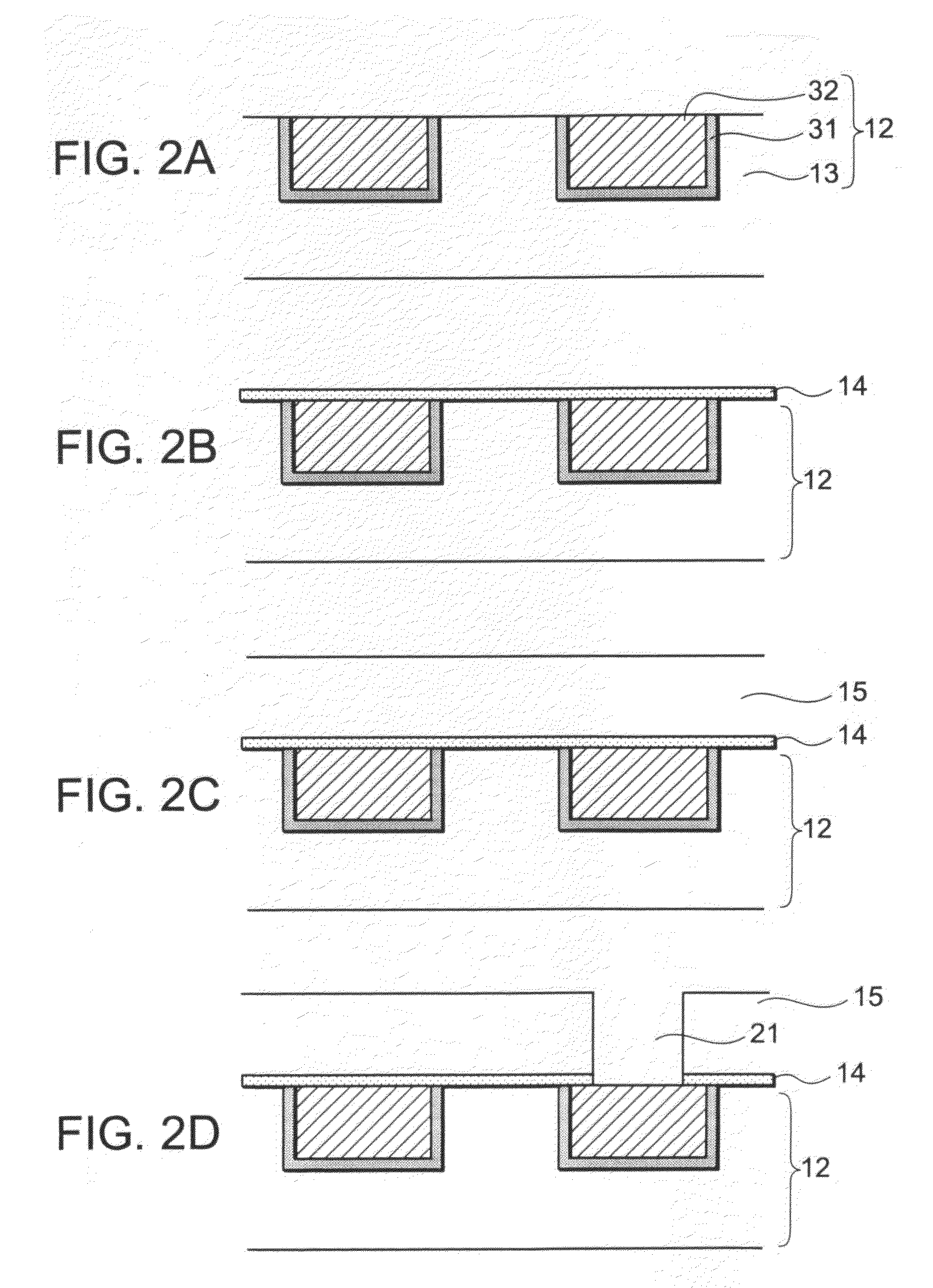

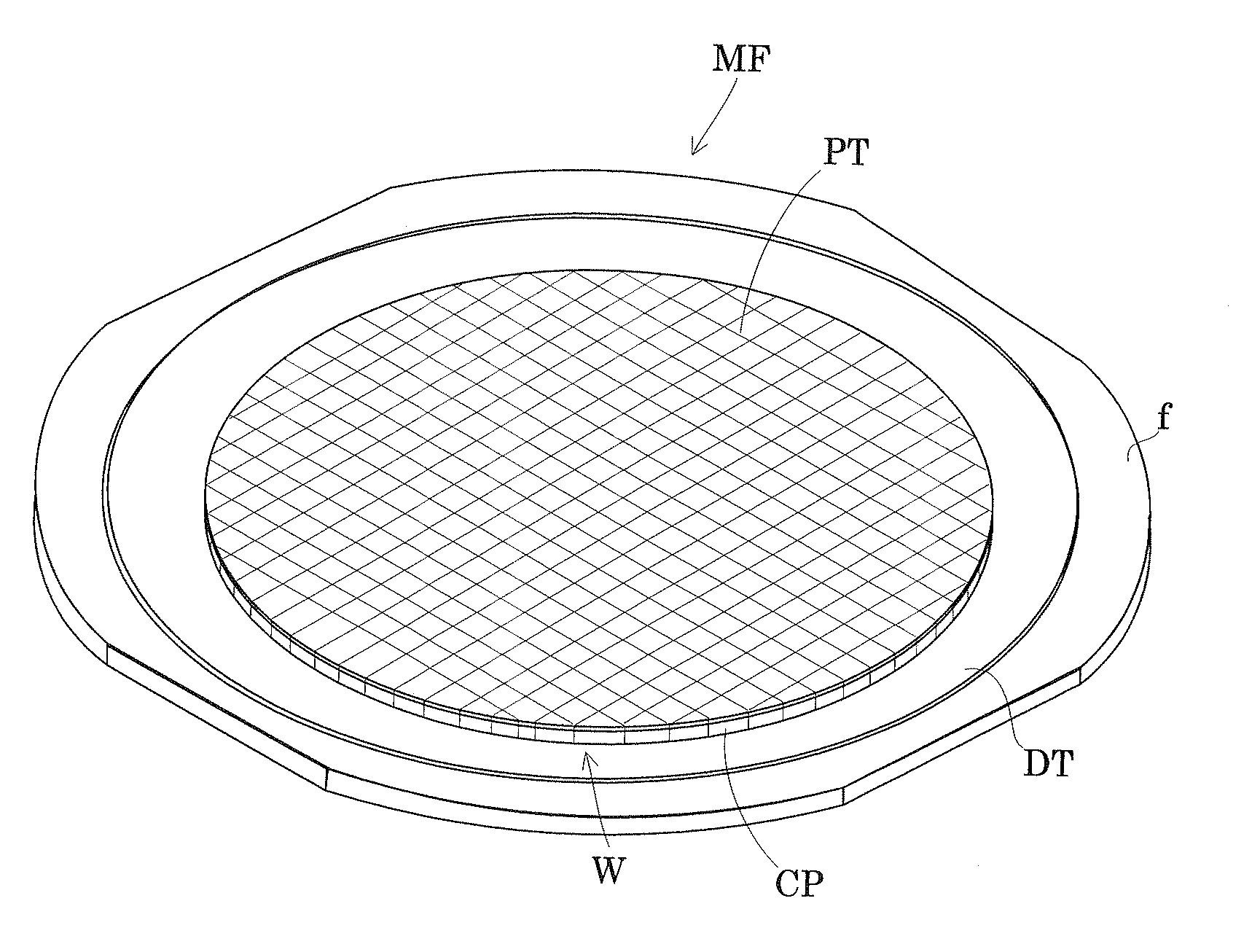

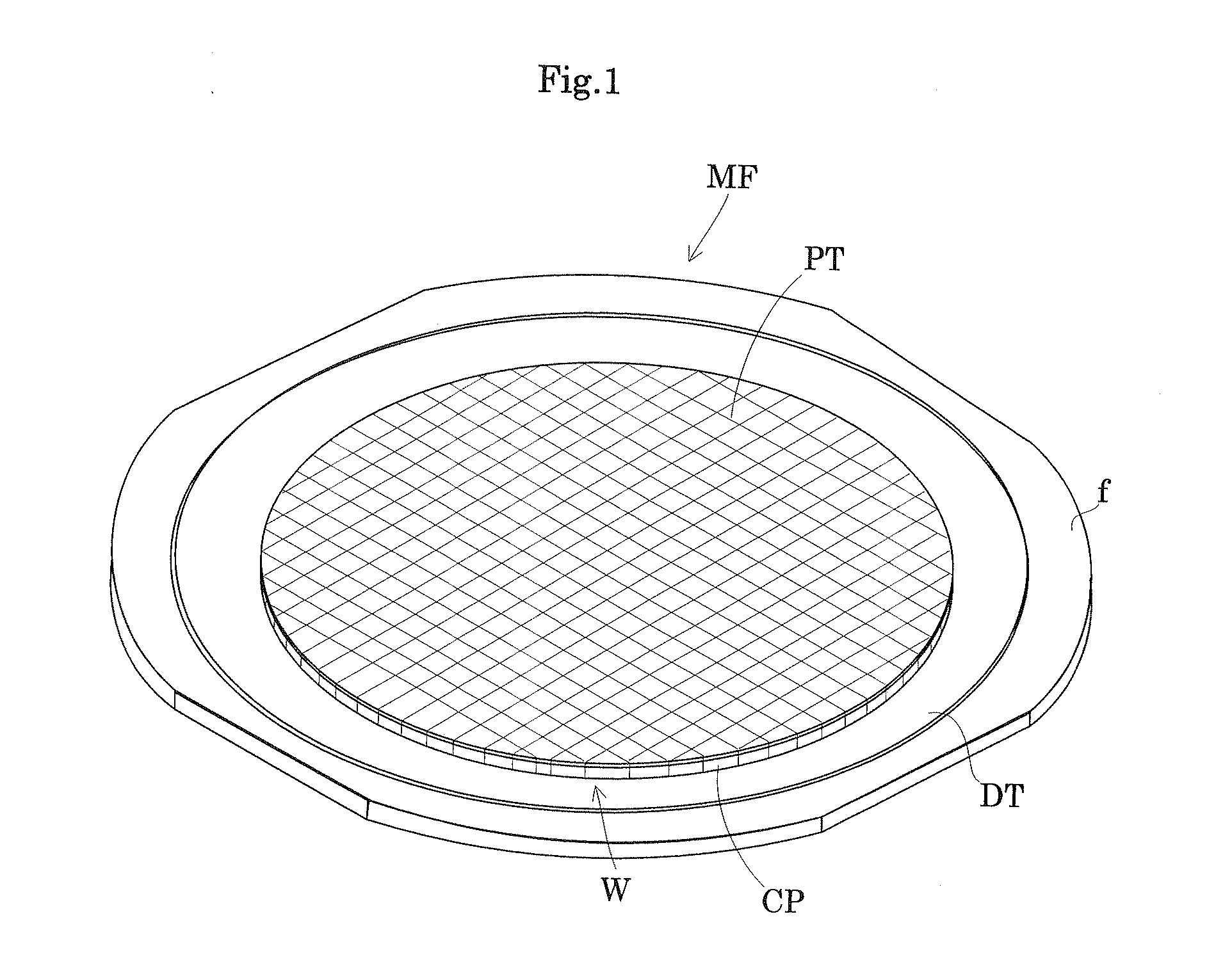

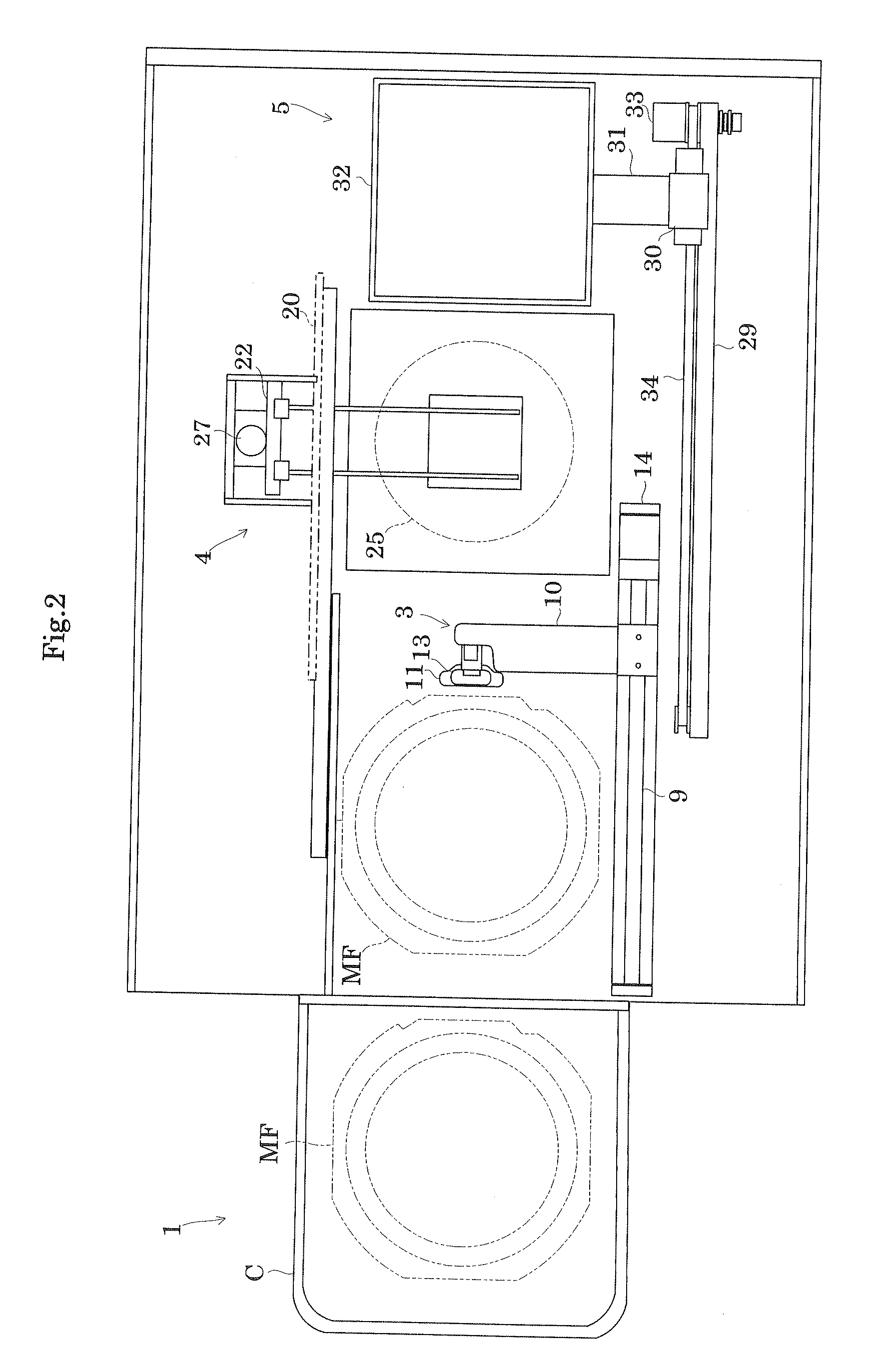

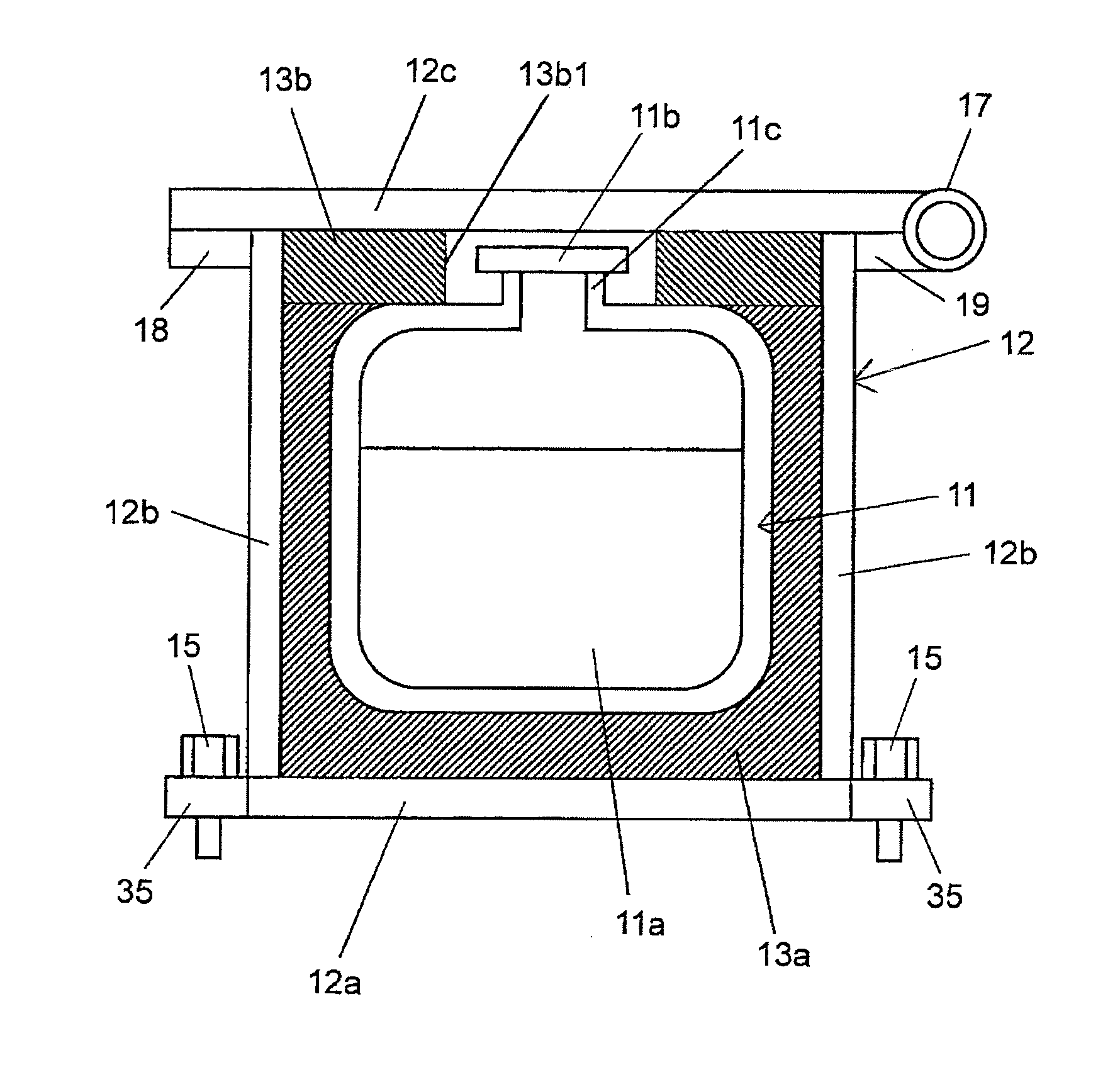

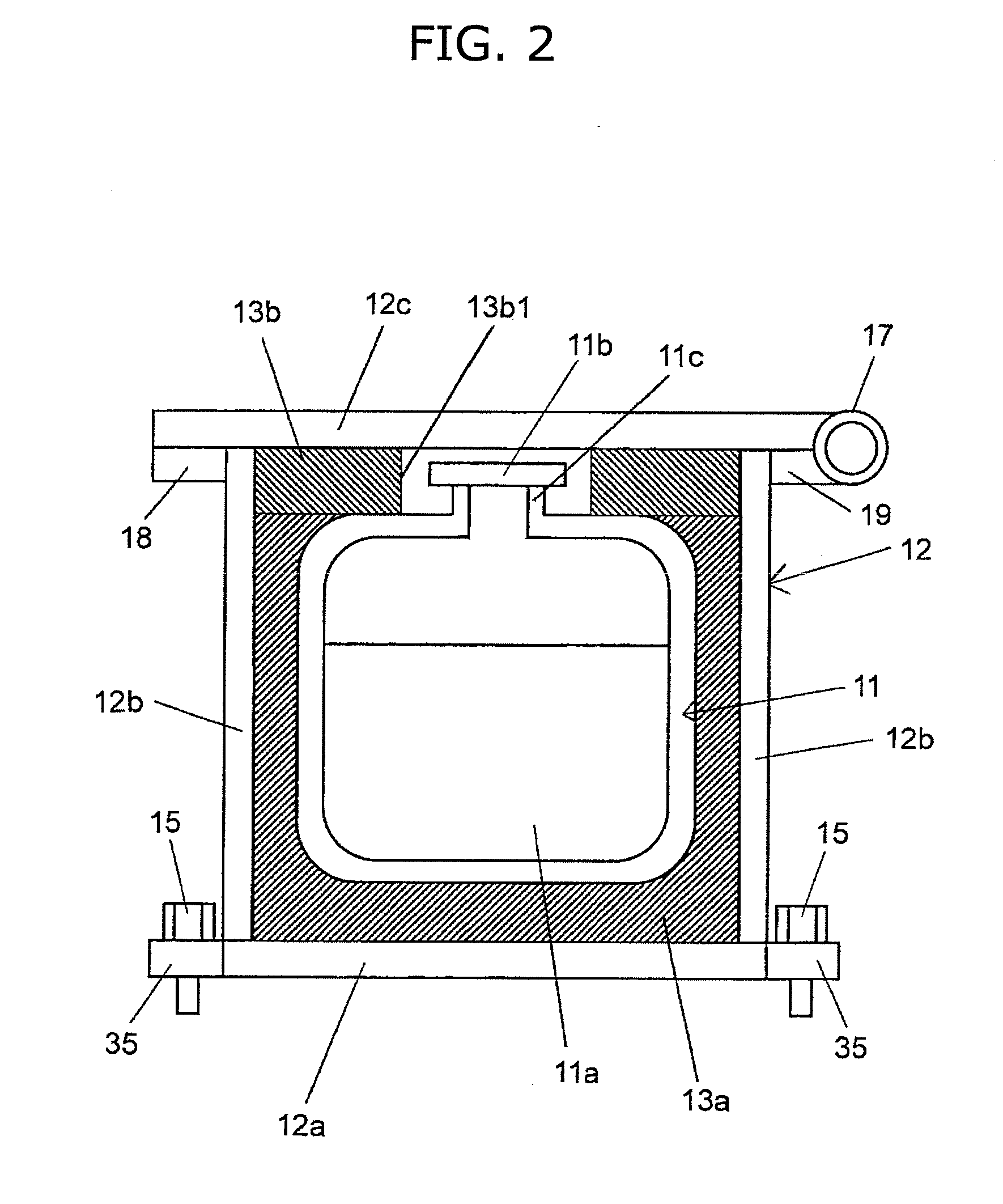

Substrate storage container

ActiveUS7344031B2Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesEngineeringGasket

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover; and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

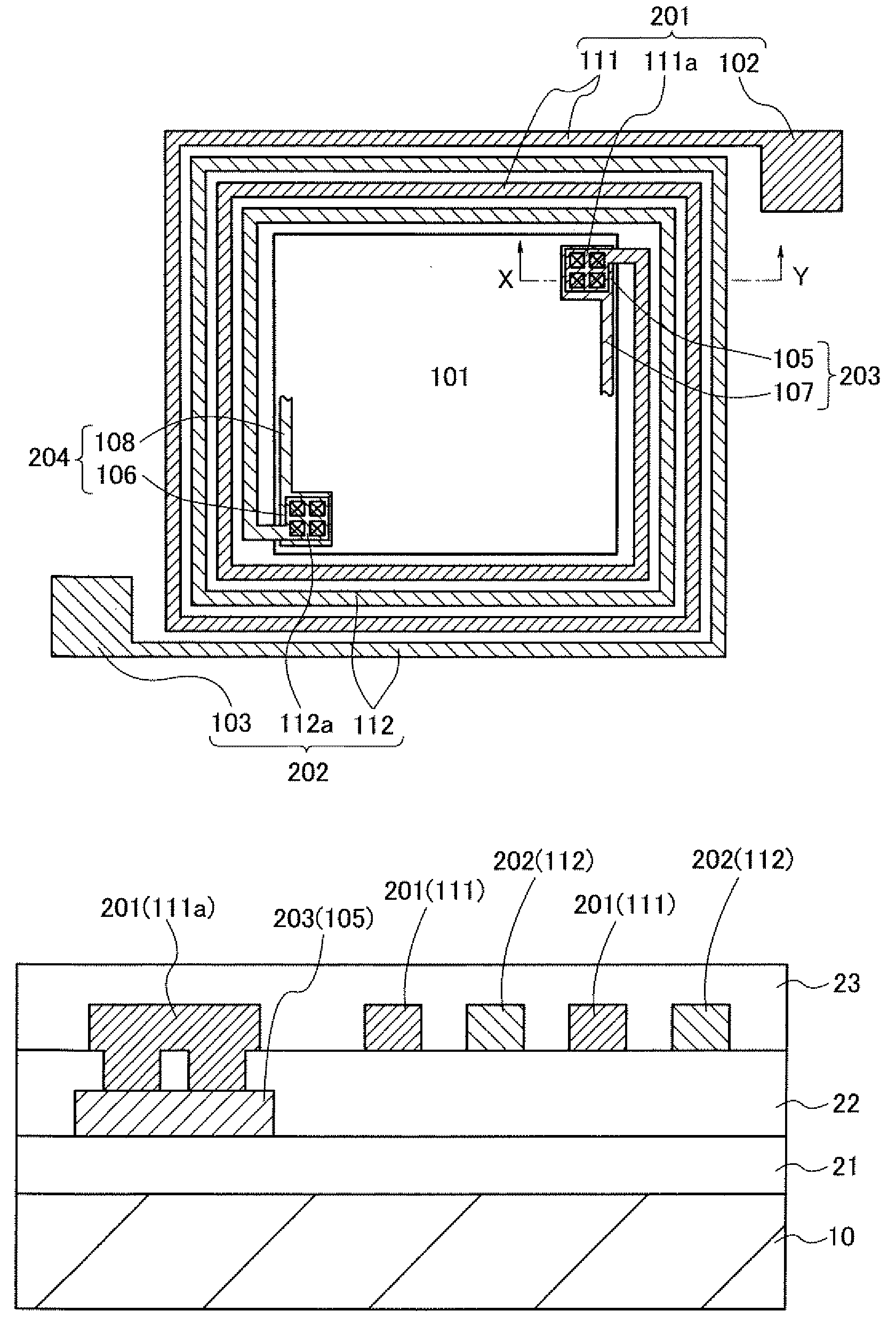

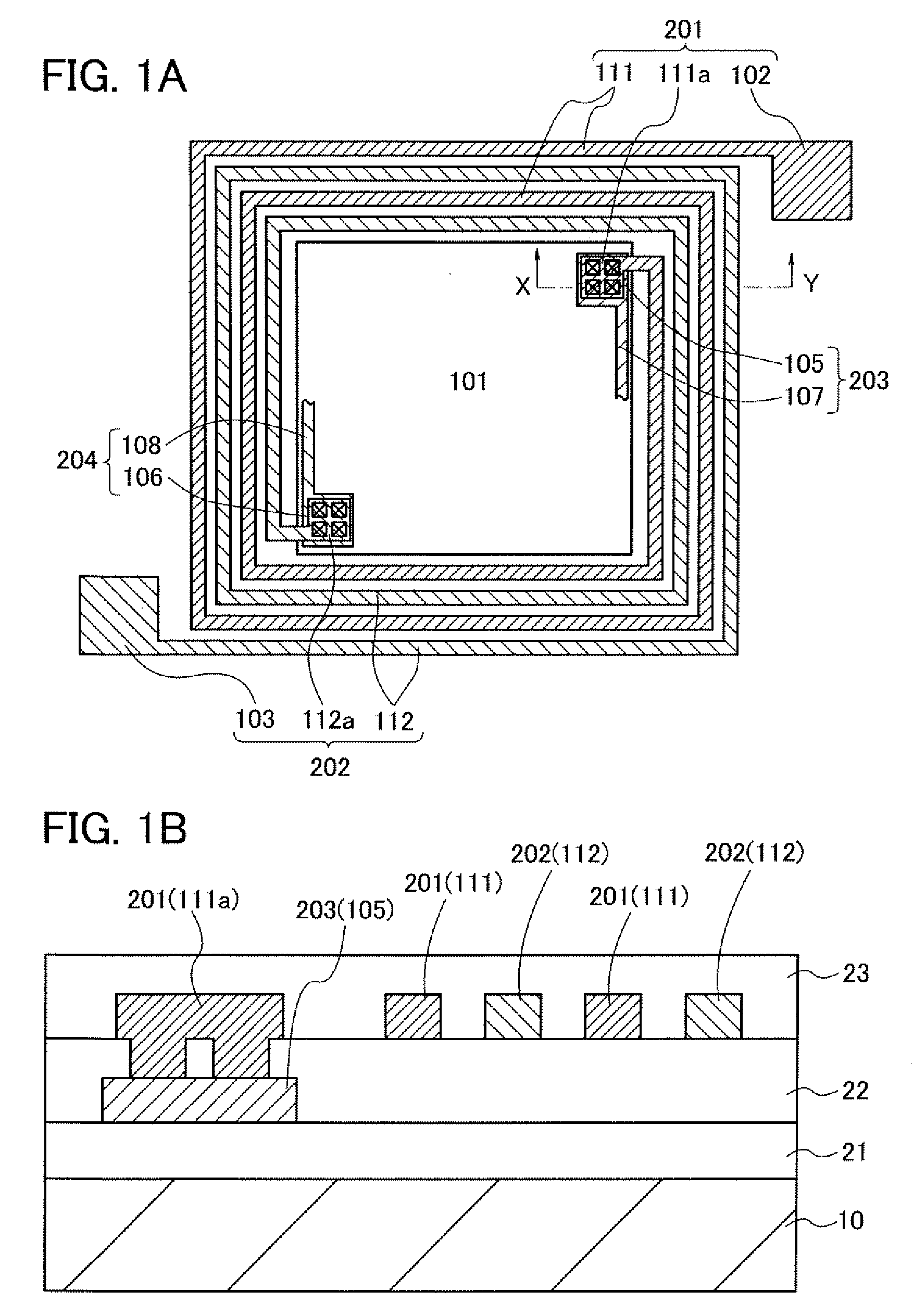

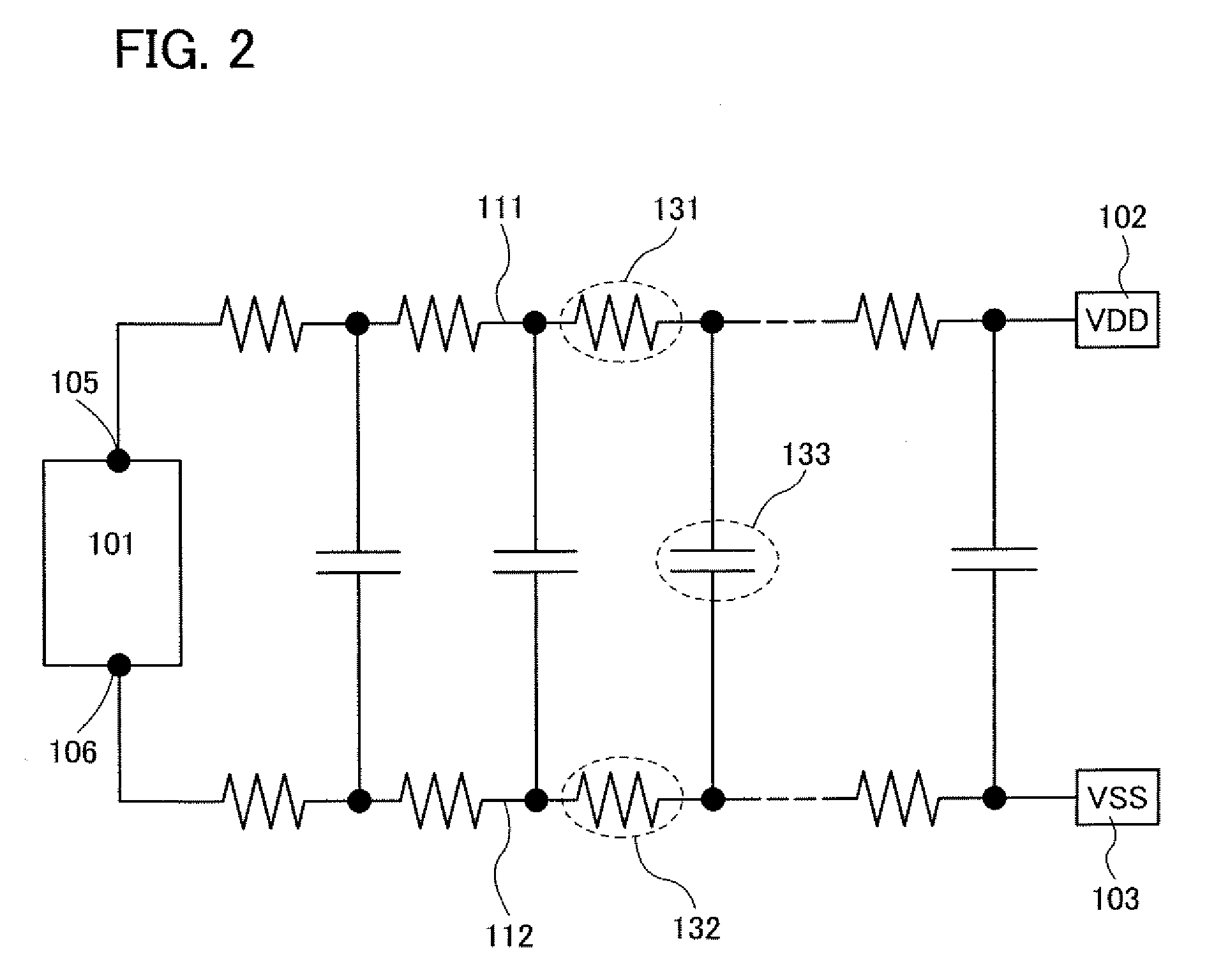

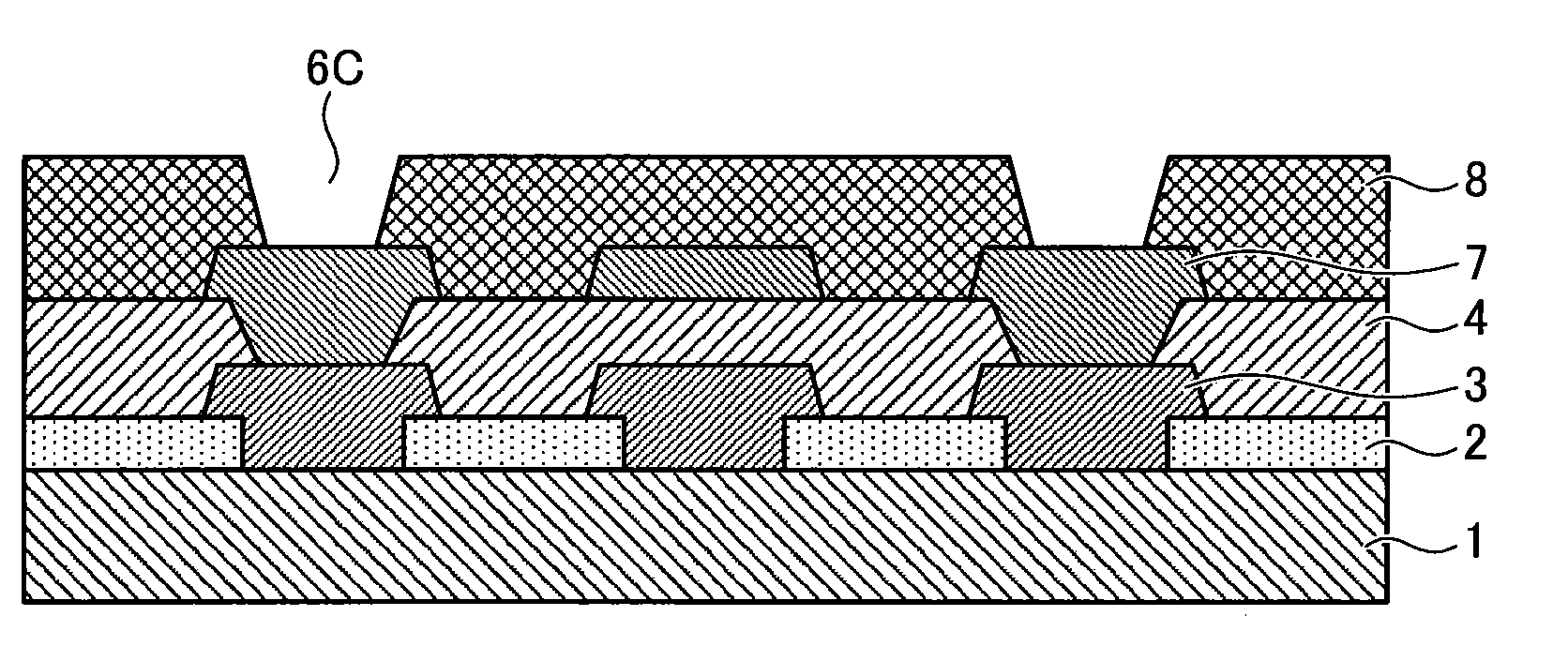

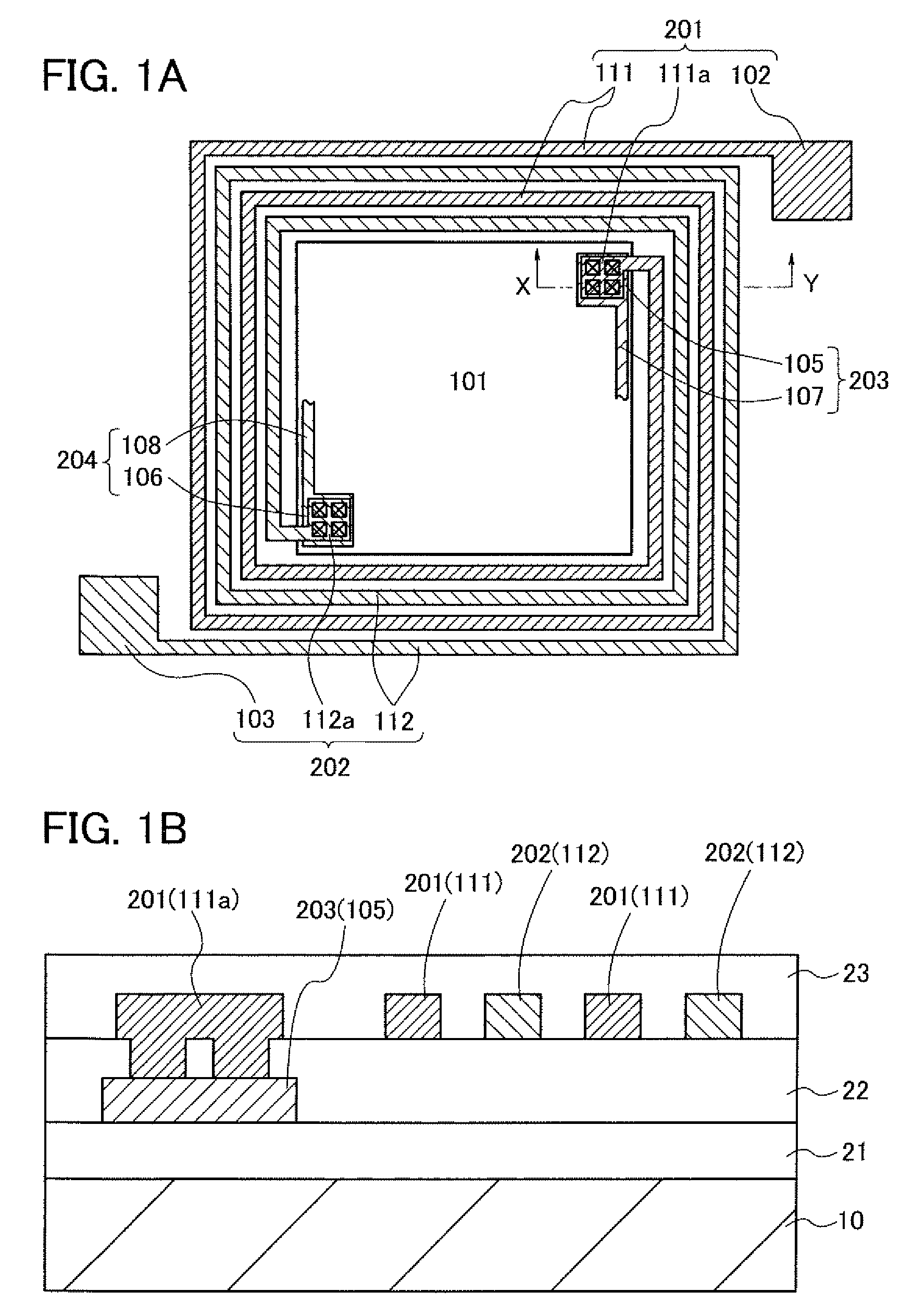

Semiconductor device

ActiveUS20090261444A1Damage can be suppressedDamage suppressionSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

A wiring electrically connected to a terminal to which a high power supply potential is applied and a wiring electrically connected to a terminal to which a low power supply potential is applied are formed adjacent to each other and are formed so as to surround the integrated circuit. Thus, wiring resistance can be added between the terminals and the integrated circuit and capacitance can be added between the two wirings. Even if overvoltage is applied to the terminals due to ESD or the like, the energy of the overvoltage is consumed by the wiring resistance and the added capacitor, so that damage of the integrated circuit can be suppressed.

Owner:SEMICON ENERGY LAB CO LTD

Substrate storage container

ActiveUS20050274645A1Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesGasketEngineering

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover, and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

Photosensitive resin composition, process for producing patterned hardened film with use thereof and electronic part

ActiveUS20100092879A1Increase chanceFormed surelyPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitizerChain structure

To provide a photosensitive resin composition in which a hardened film obtained from the photosensitive resin composition has properties comparable to those of a film hardened at a high temperature, a method for manufacturing a patterned hardened film using the photosensitive resin composition, and an electronic part. The photosensitive resin composition includes (a) a polybenzoxazole precursor having a repeating unit represented by a general formula (I):wherein U and V represent a divalent organic group, and at least one of U and V is a group containing an aliphatic chain structure having 1 to 30 carbon atoms; (b) a photosensitizer; (c) a solvent; and (d) a crosslinking agent capable of causing crosslinking or polymerization by heating.

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

Semiconductor laser device and method of manufacturing the same

InactiveUS20090185594A1Bonding can be suppressedDamage can be suppressedOptical wave guidanceLaser detailsWaveguideSemiconductor

A semiconductor laser device includes a substrate and a semiconductor layer formed on a surface of the substrate and having a waveguide extending in a first direction parallel to the surface, wherein the waveguide is formed on a region approaching a first side from a center of the semiconductor laser device in a second direction parallel to the surface and intersecting with the first direction, a first region separated from the waveguide on a side opposite to the first side of the waveguide and extending parallel to the first direction and a first recess portion separated from the waveguide on an extension of a facet of the waveguide, intersecting with the first region and extending in the second direction are formed on an upper surface of the semiconductor laser device, and a thickness of the semiconductor layer on the first region is smaller than a thickness of the semiconductor layer on a region other than the first region.

Owner:SANYO ELECTRIC CO LTD

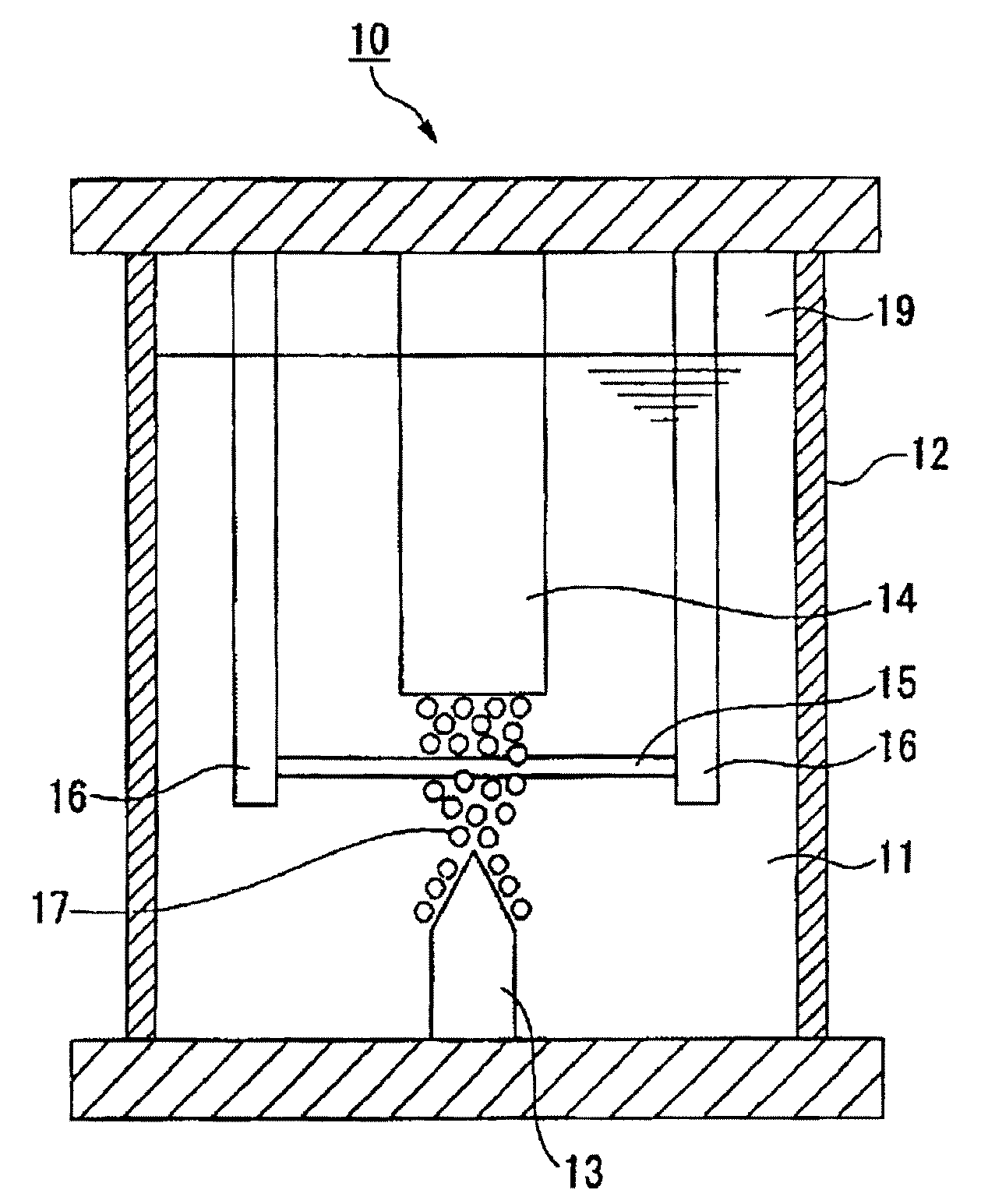

Method of etching and etching apparatus

InactiveUS20050142885A1Increase etch rateReduce harmSemiconductor/solid-state device manufacturingCleaning using liquidsAlcoholAnalytical chemistry

Owner:TOKYO ELECTRON LTD

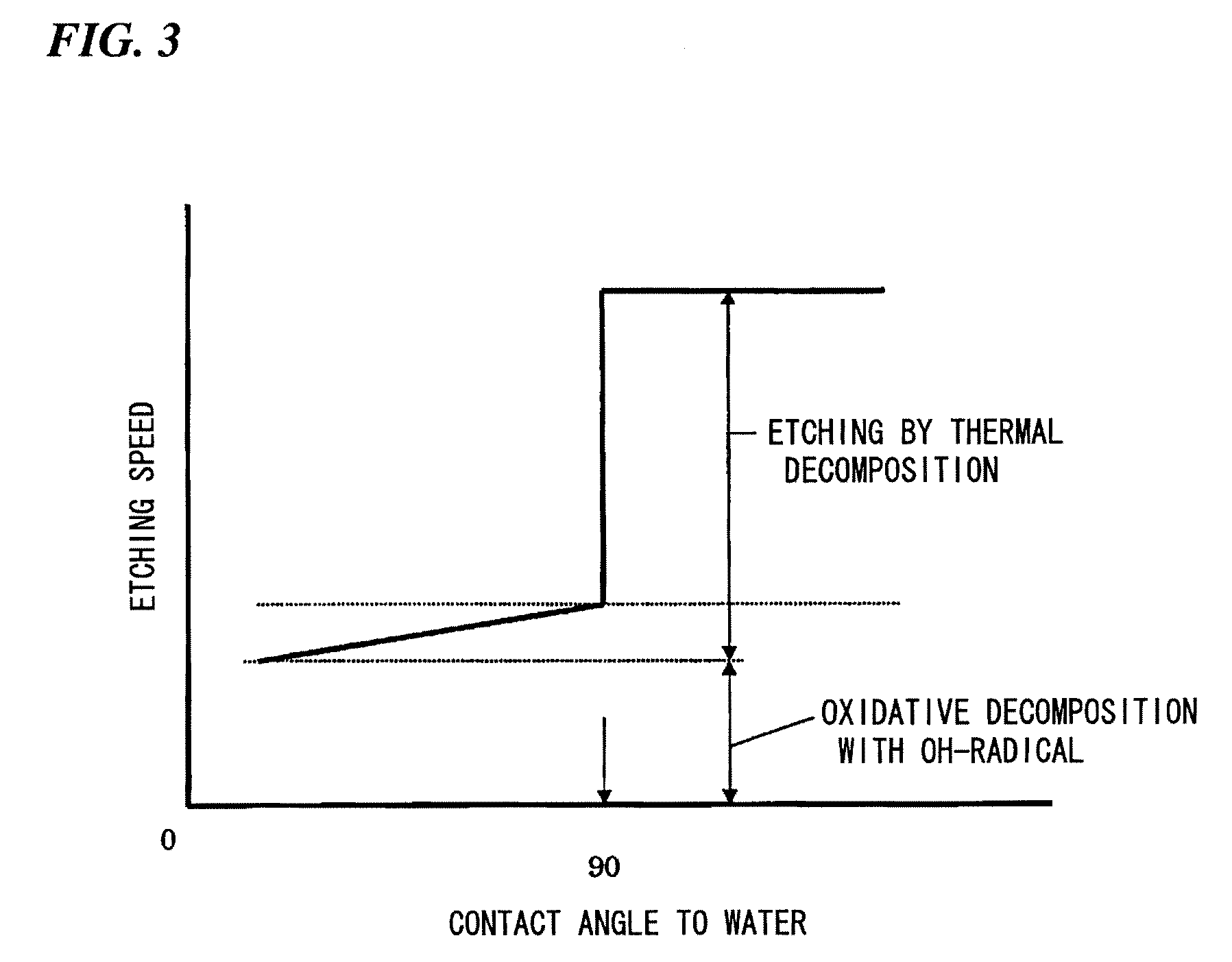

Method of Surface Treatment and Surface-Treated Article

InactiveUS20080210664A1Damage can be suppressedAvoid damageSemi-permeable membranesElectric discharge tubesWater vaporOrganic matter

Plasma generated in water vapor bubbles present in a water-containing liquid is brought into contact, in the liquid, with an article having a contact angle with water of 90° or less. The plasma is contacted with an organic substance adhering to the article to thereby remove the organic substance from the article. By bringing the plasma into contact with the article, the surface of the article is etched without breaking the article. The article may comprise a material composed of both a hydrophobic part having a contact angle with water exceeding 90° and a hydrophilic part having a contact angle with water of 90° or less. In this case only the hydrophobic part is etched by bringing the plasma into contact with the article.

Owner:MITSUBISHI RAYON CO LTD +1

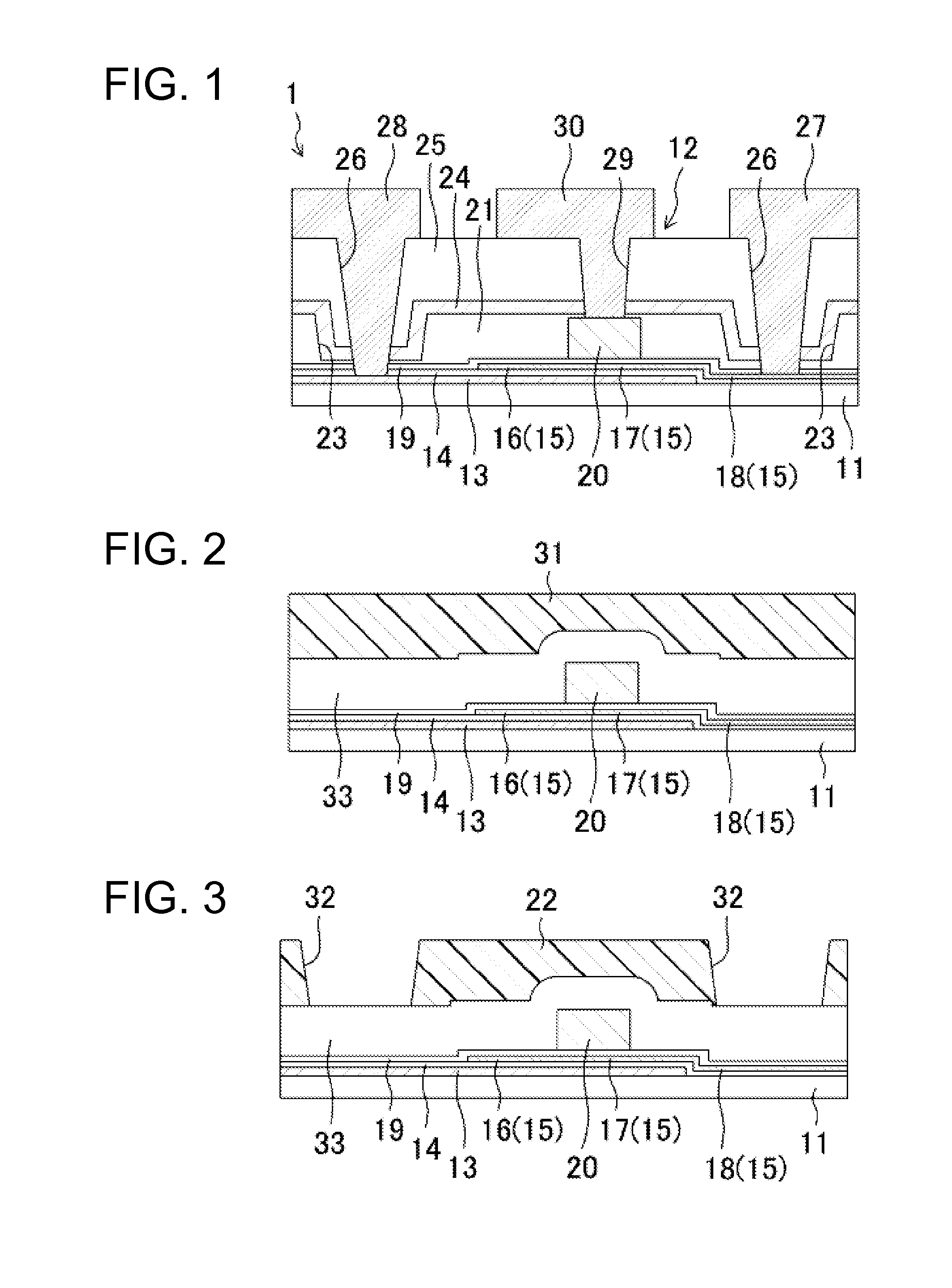

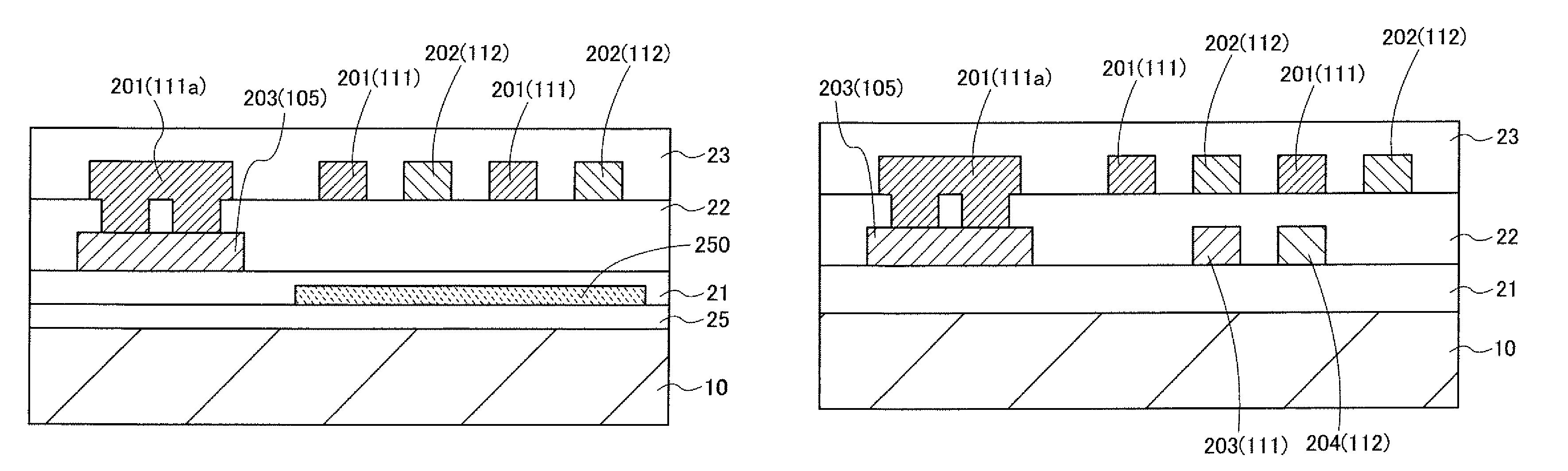

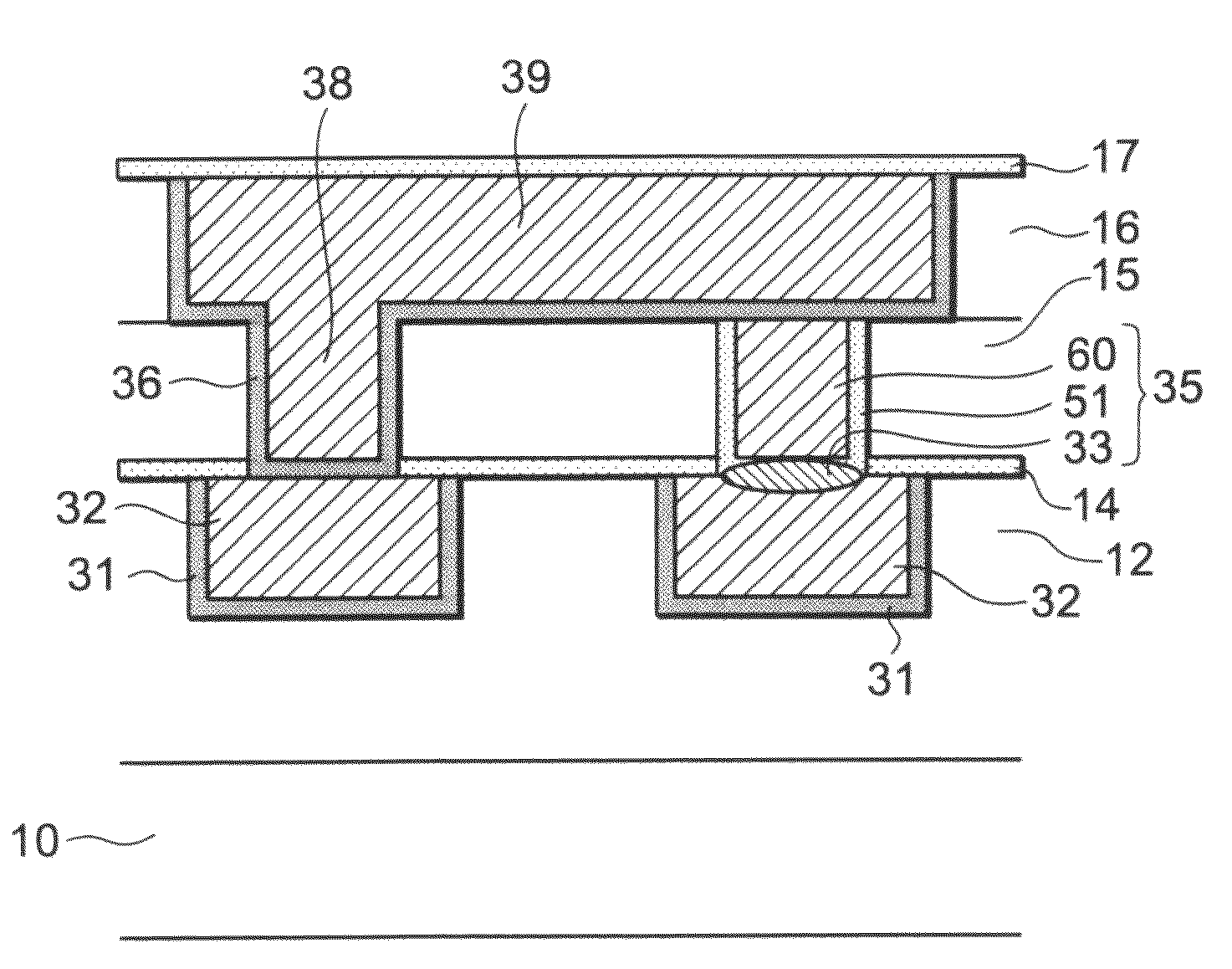

Semiconductor device and method of manufacturing semiconductor device

InactiveUS20100207093A1Deterioration of resistance changeDamage can be suppressedSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesEngineeringSemiconductor

Provided is a semiconductor device including a substrate, and a first wiring layer, a second wiring layer, and a switch via formed on the substrate. The first wiring layer has first wiring formed therein and the second wiring layer has second wiring formed therein. The switch via connects the first wiring and the second wiring. The switch via includes at least at its bottom a switch element including a resistance change layer. A resistance value of the resistance change layer changes according to a history of an electric field applied thereto.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device and method of producing same

ActiveUS20120032263A1Reduce etch timeReduce aspect ratioSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device has a planarizing layer that is made of an inorganic film, and has a recessed portion formed in a region thereof in which a conductive film is disposed. A first contact hole penetrating through at least an interlayer insulating film is formed on a first wiring layer, while a second contact hole penetrating through at least the interlayer insulating film is formed on the conductive film so as to run through the inside of the recessed portion.

Owner:SHARP KK

Protective tape separating method and apparatus

InactiveUS20110048630A1Reduce adhesionDamage can be suppressedLamination ancillary operationsLaminationSuction forceMechanical engineering

A chuck table adhesively holds a rear face of a mount frame subject to a dicing process with a protective tape joined thereto, and a suction plate having a heater embedded therein contacts and heats the protective tape. Consequently, an adhesion layer of the protective tape reduces its adhesive force due to foaming and expansion. Thereafter, the suction plate moves upward while keeping its suction force to separate the protective tape from all of chips.

Owner:NITTO DENKO CORP

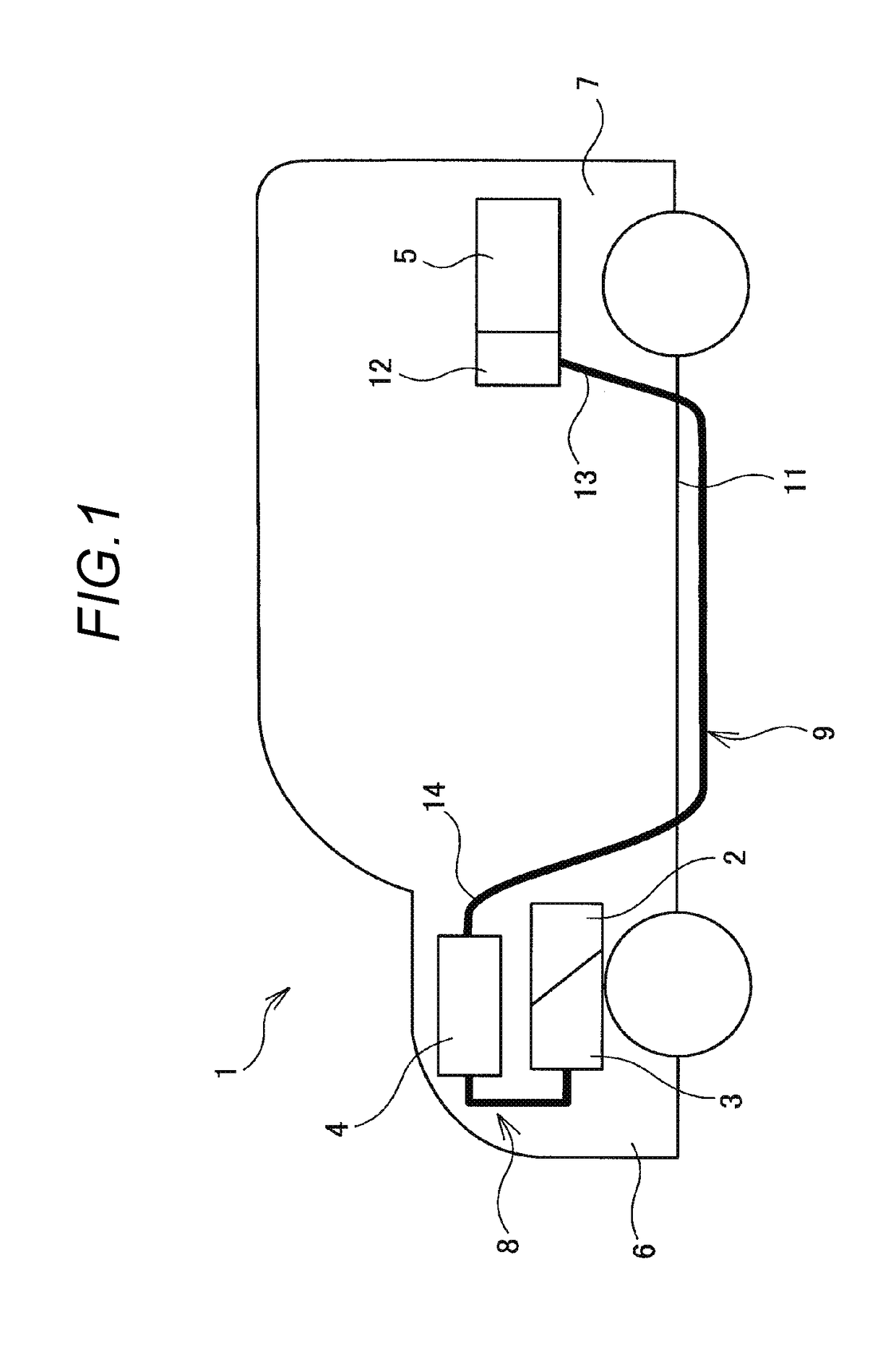

Power supply device

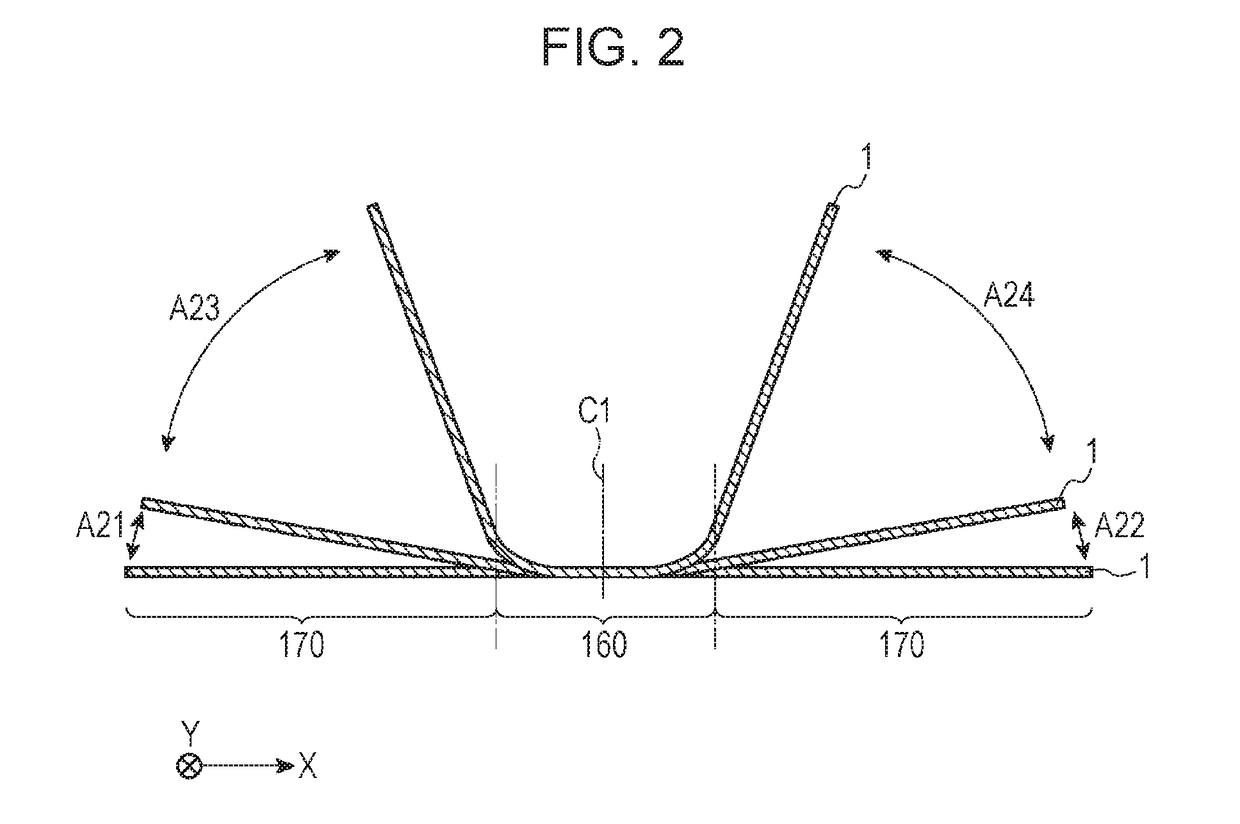

ActiveUS20190077343A1Reduce exposureInterferencePower-operated mechanismElectric/fluid circuitElectric powerCable harness

Provided is an electric power supply device in which exposure of a wire harness can be reduced in a slide door and interference with door trim can be minimized. When a slide door is half opened, a wire harness bends convexly downward, and one portion thereof is positioned lower than when the slide door is fully open or fully closed. Specifically, the wire harness is bent three-dimensionally. This makes it easier for the wire harness to be pulled out from a bottom end of door trim, and makes it possible for interference between the wire harness and the door trim to be minimized. The wire harness may be also bent three-dimensionally as appropriate in accordance with a shape of the door trim, reducing exposure of the wire harness in the slide door.

Owner:YAZAKI CORP

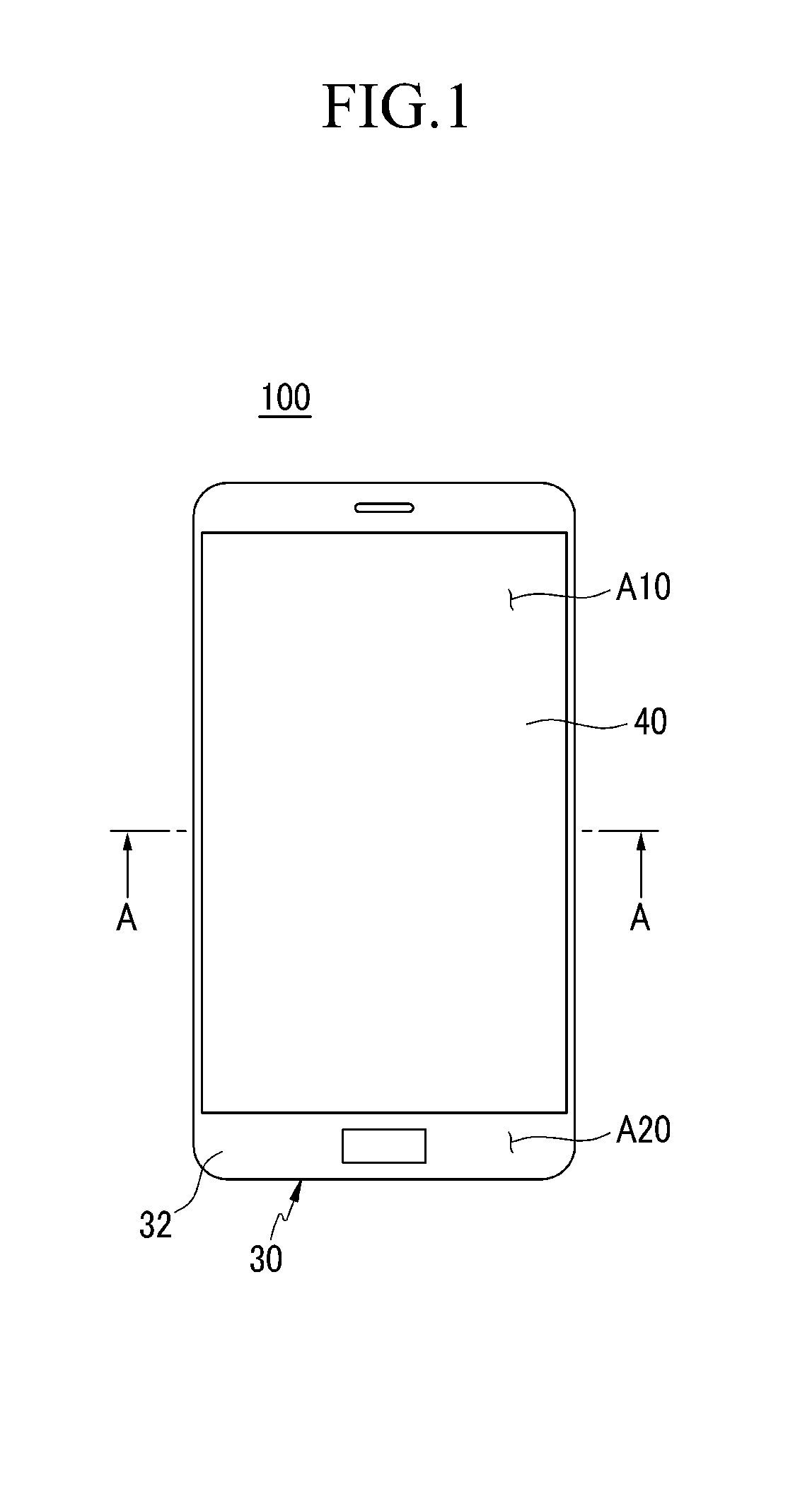

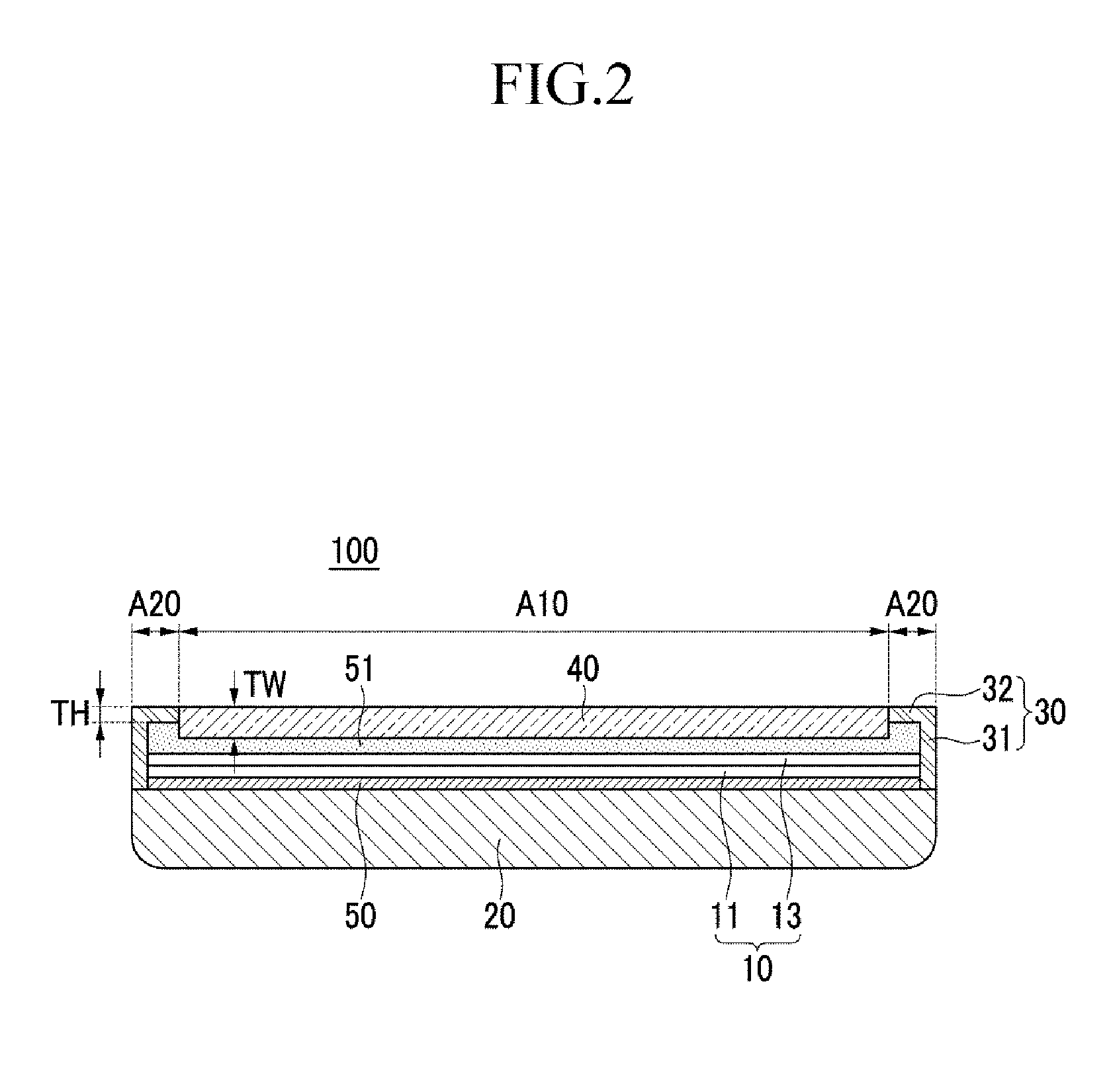

Organic light emitting diode display device

InactiveUS20140211431A1Reduce widthNarrow bezelCircuit arrangements on support structuresSubstation equipmentFixed frameDisplay device

An organic light emitting diode (OLED) display device includes: a display panel including a display area and a non-display area provided in an external side of the display area; a set frame disposed on a rear surface of the display panel and supporting the display panel; a side frame surrounding a side surface of the display panel and covering the non-display area; and a cover window covering the display area disposed in an inner space surrounded by the side frame.

Owner:SAMSUNG DISPLAY CO LTD

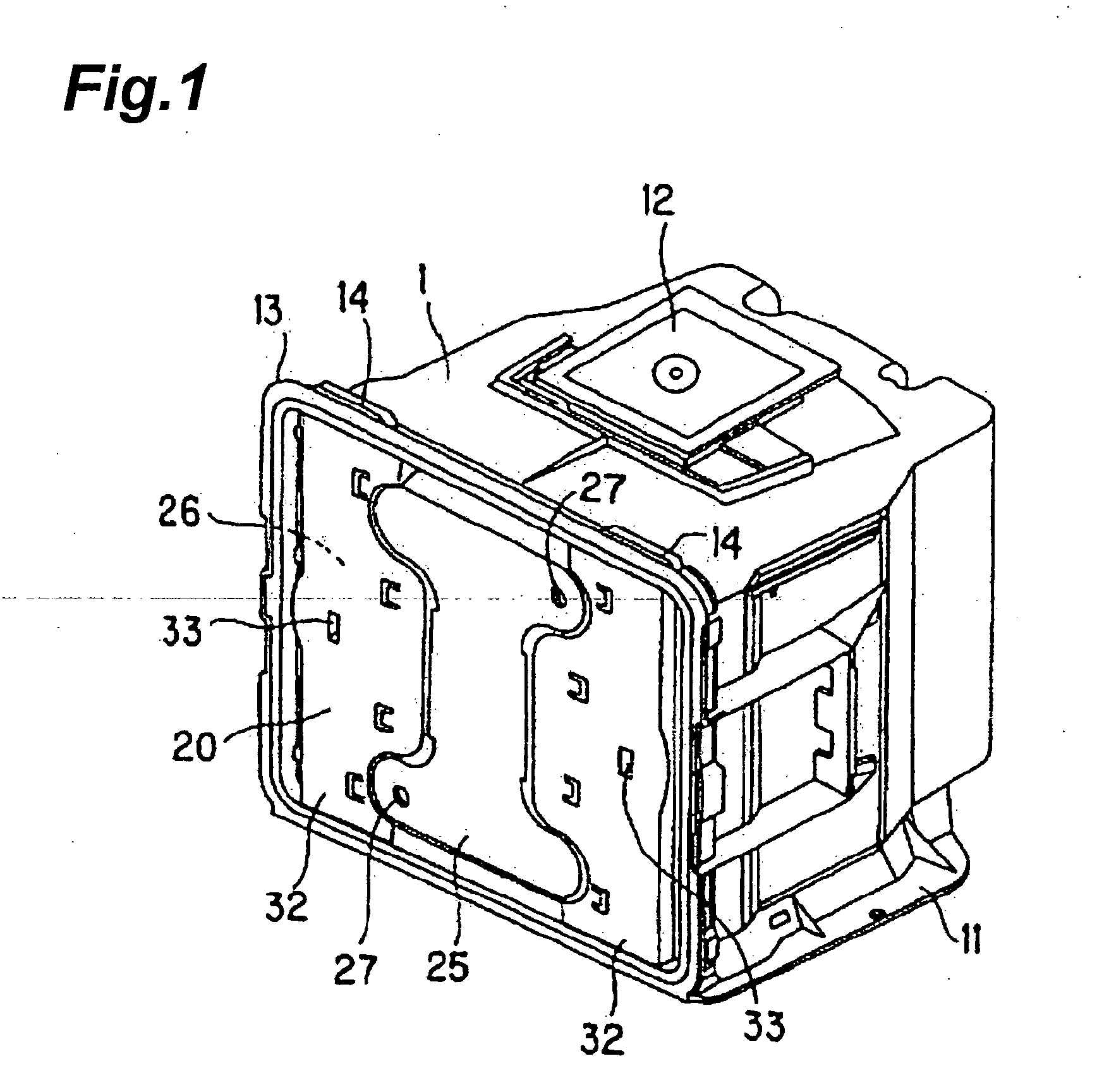

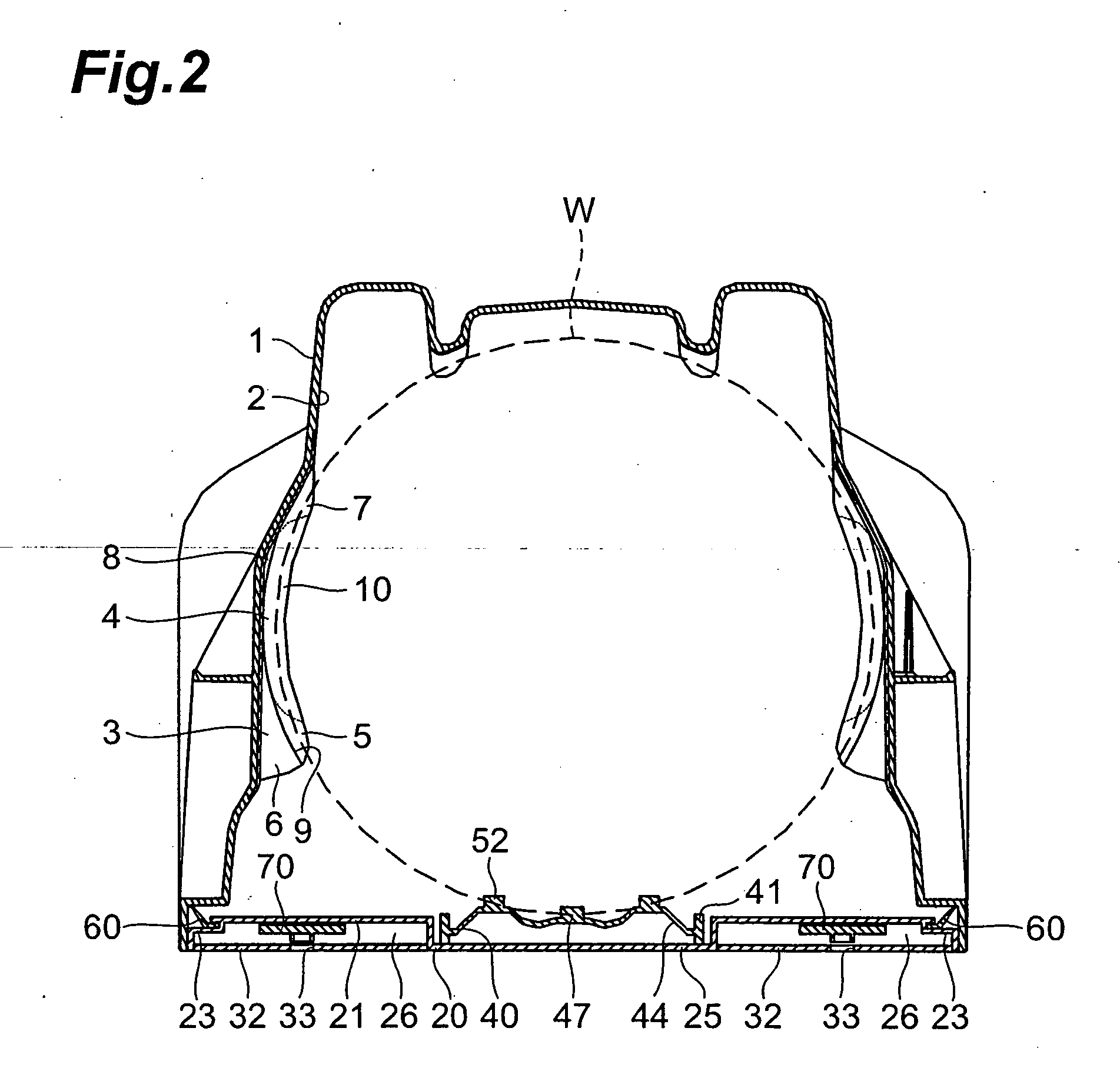

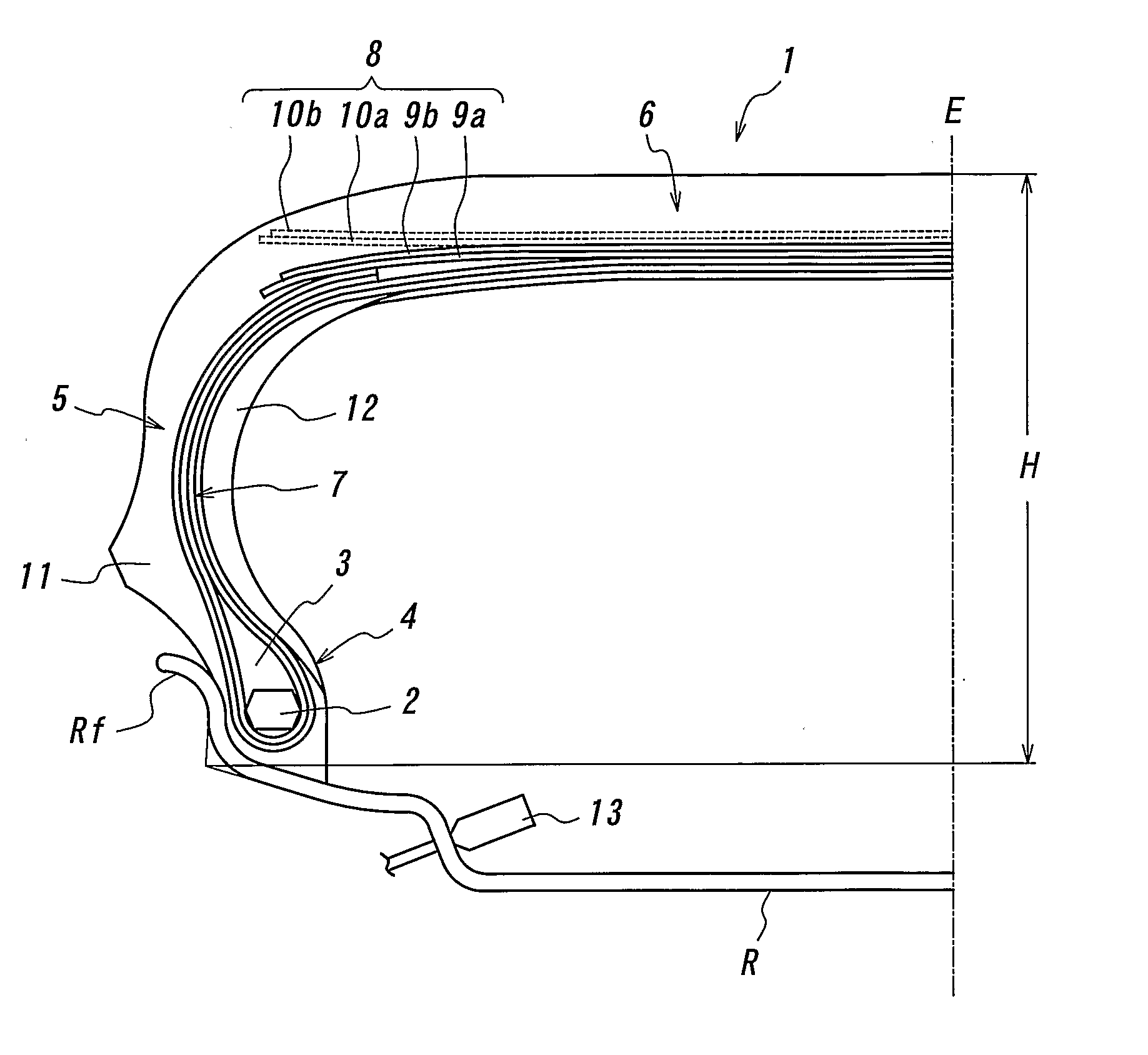

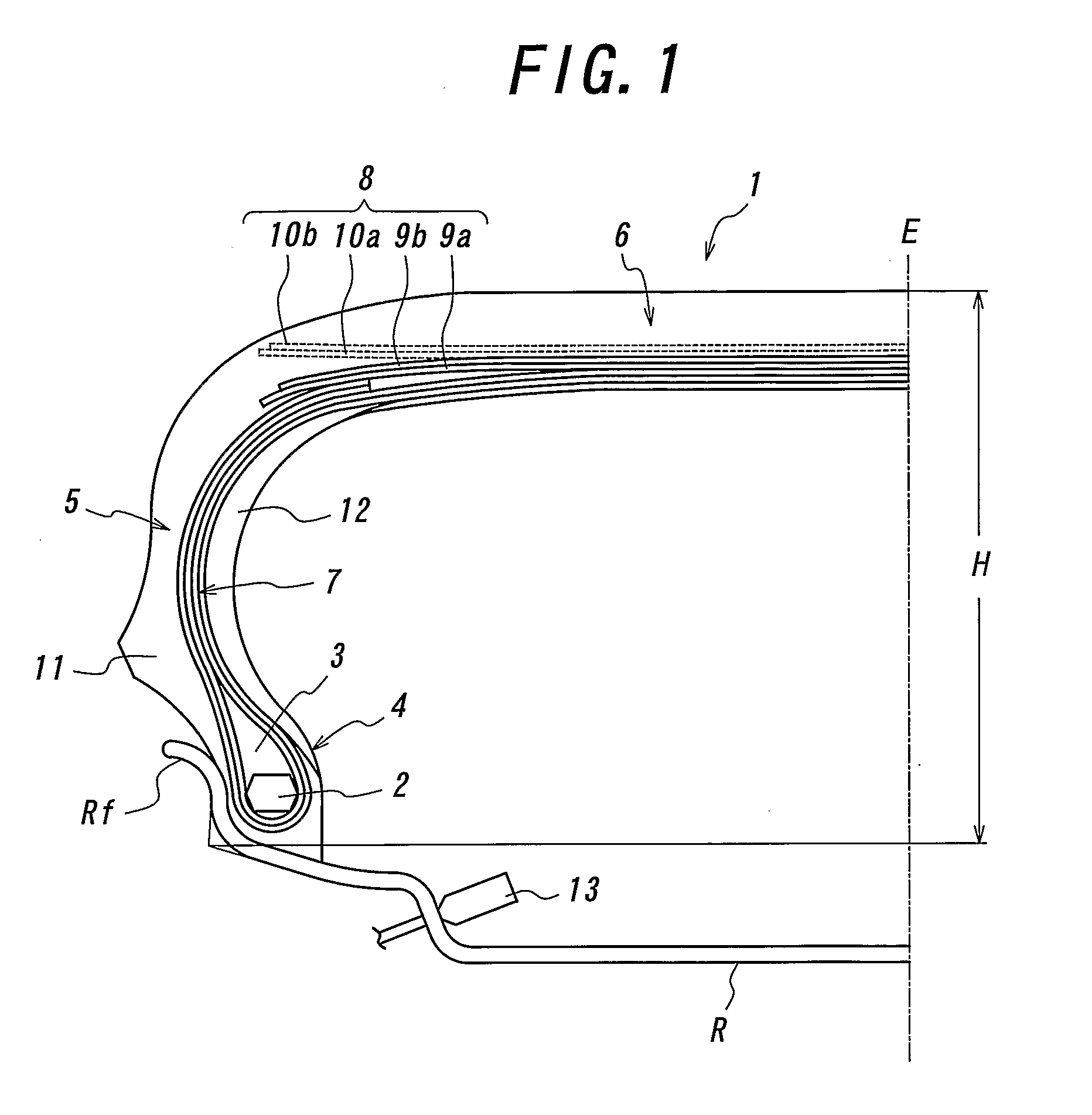

Process for Repairing Punctured Pneumatic Tire in Tire-Rim Assembly and Repairing System

ActiveUS20070289371A1Damage can be suppressedEasy maintenanceTyresTyre measurementsInternal pressureLoad capacity

A punctured pneumatic tire in a tire-rim assembly is repaired by mounting on a vehicle the tire-rim assembly provided with an internal pressure alarm means, said tire comprising an auxiliary load-supporting structure satisfying a requirement that an deformation quantity of the tire in a radial direction thereof at a rim-assembled state under a load corresponding to 90% of a maximum load capacity at an internal tire pressure of zero is within a range of 30-60% of a section height of the tire under no load at the internal tire pressure of zero; detecting a puncture of the tire produced during the running of the tire by the internal pressure alarm means; unavoidably running the punctured tire to a relatively short-range safe place to quickly stop the vehicle; and refilling gas to a given internal pressure by a gas filling means equipped on the vehicle while occluding a punctured hole with a puncture repairing means equipped on the vehicle.

Owner:BRIDGESTONE CORP

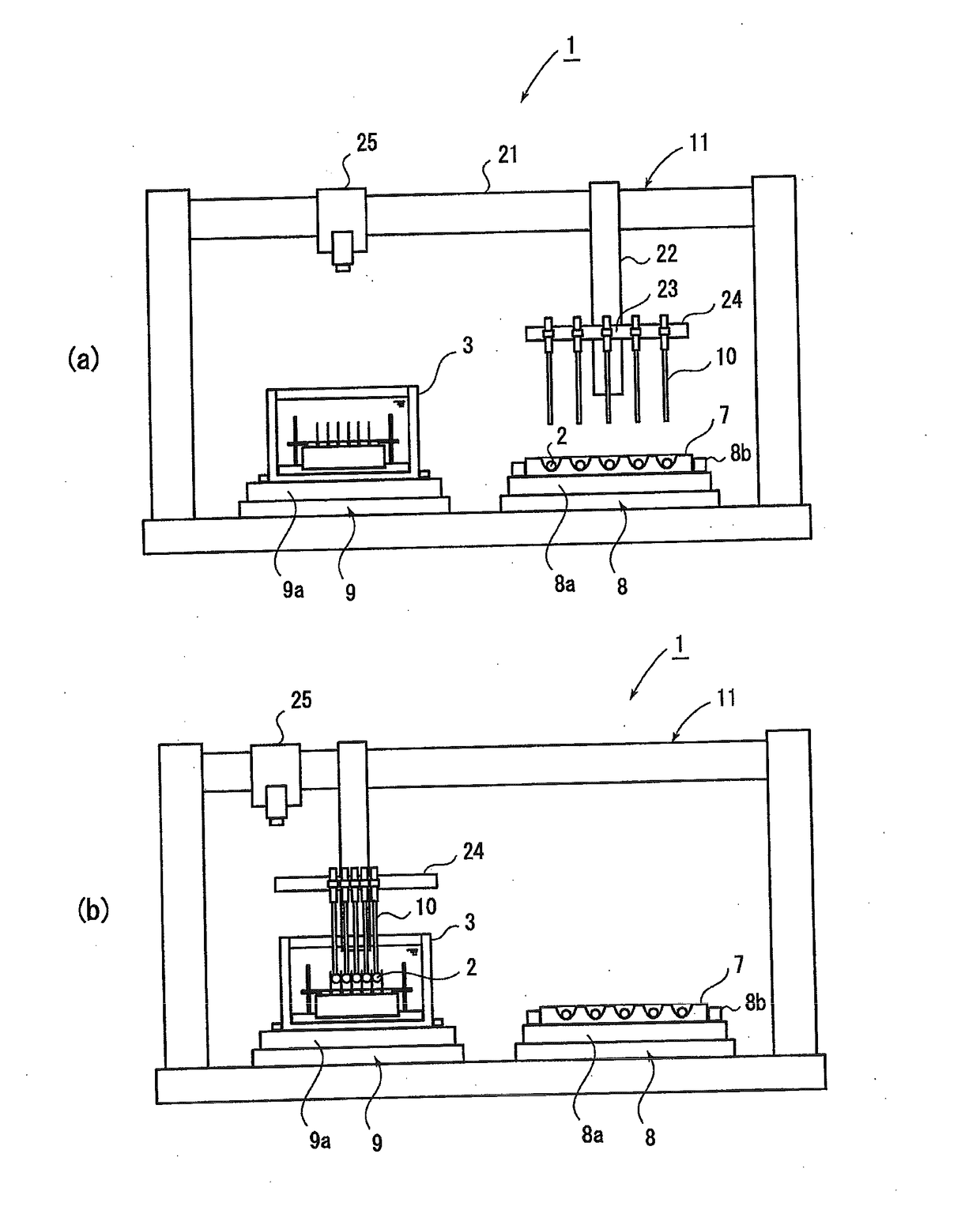

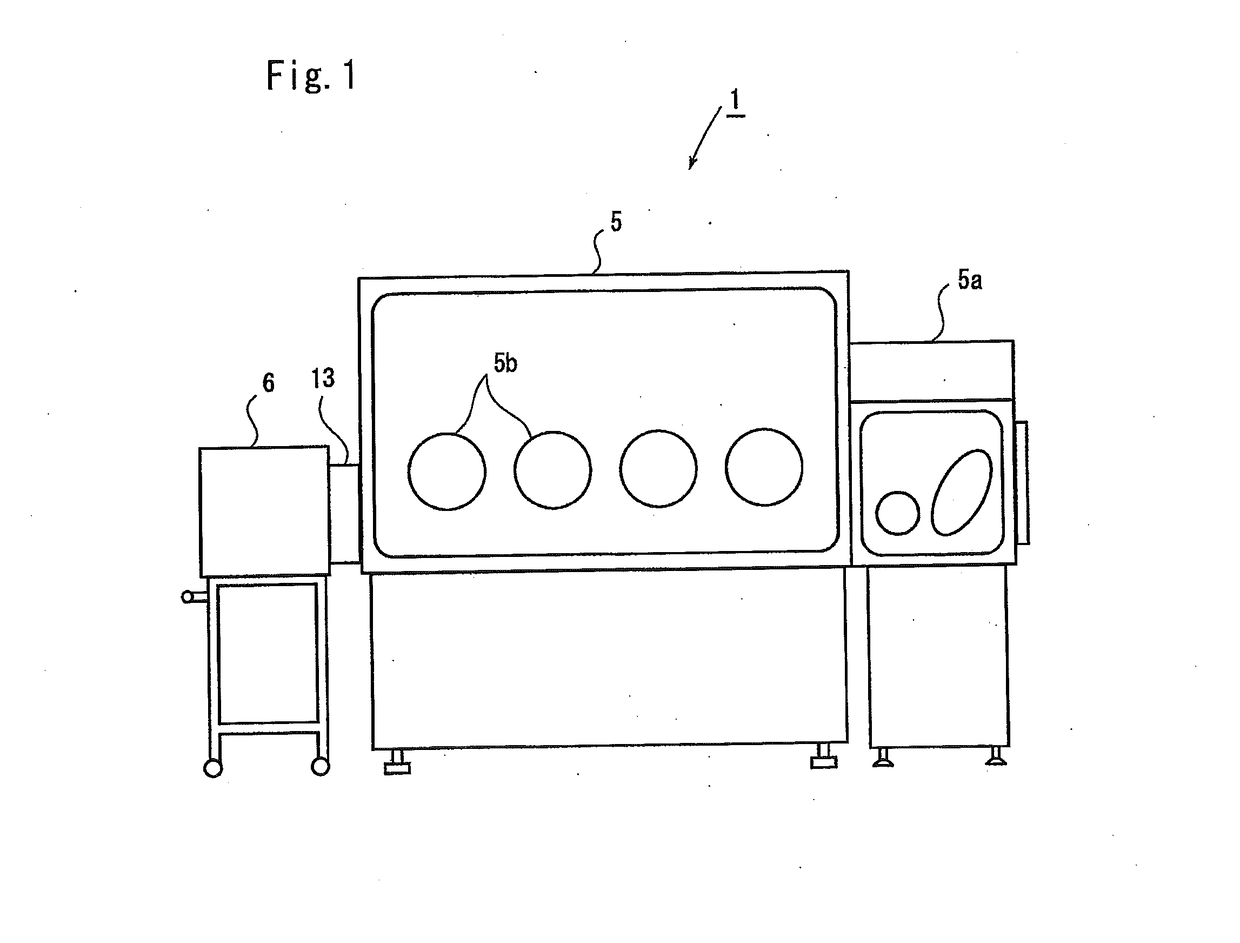

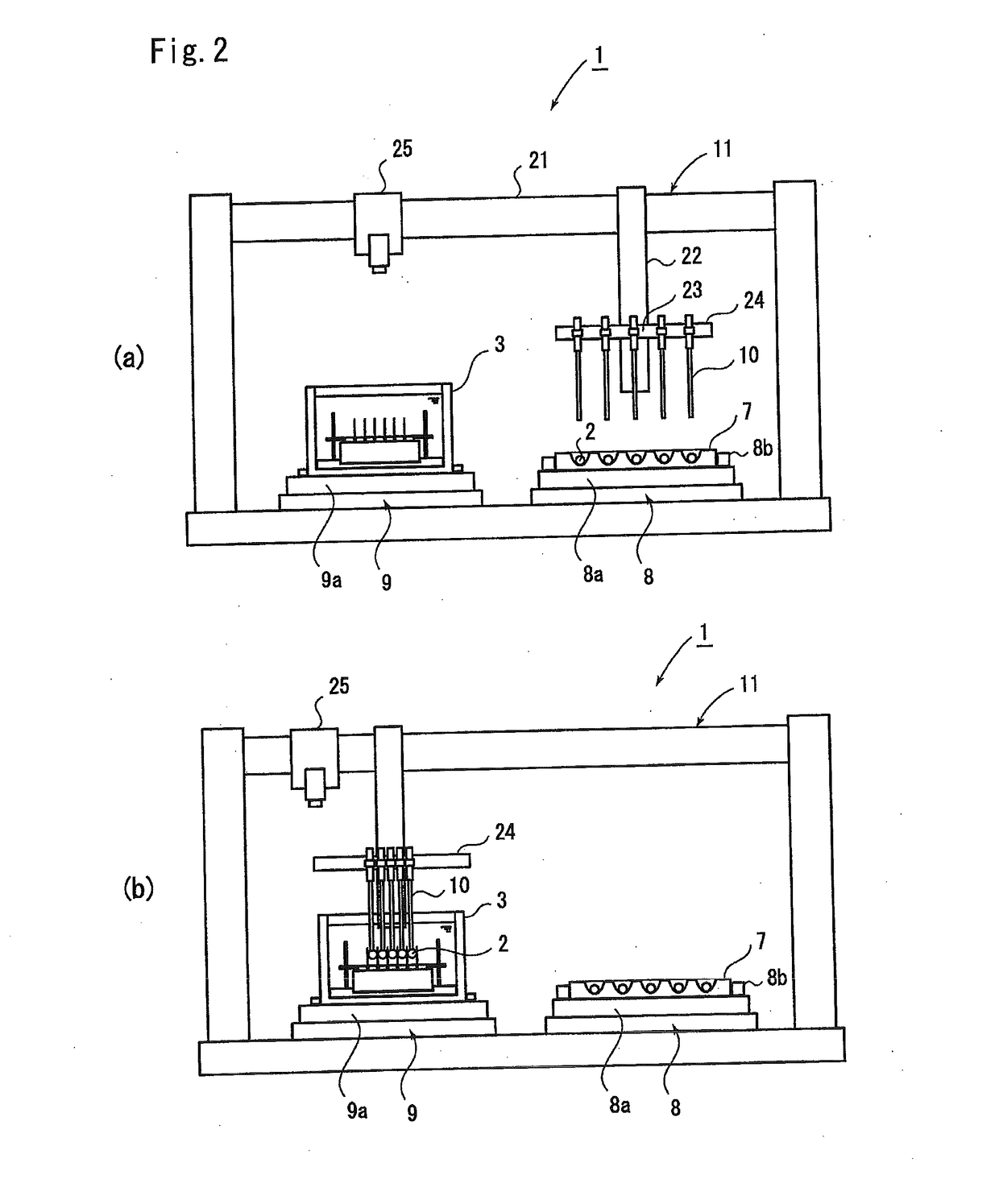

Method and apparatus for producing cell mass structure

InactiveUS20170121674A1Damage can be suppressedBioreactor/fermenter combinationsBiological substance pretreatmentsCell massEngineering

The present invention relates to a method for producing a cell mass structure, which produces a cell mass structure (adhesion pad 4) in which a plurality of cell aggregates 2 arranged inside a culture container 3 accommodating a culture liquid are fused to each other by being cultured. A plurality of pins 16 are erected inside the above-described culture container 3, the above-described cell aggregates 2 are accommodated by the plurality of pins 16 with parts between the plurality of pins 16 and pins 16 as accommodating portions H, and the cell aggregates 2 are cultured in a state of being accommodated in the plurality of adjacent accommodating portions H. It is possible to obtain a required shape and dimension, and the cell mass structure can be obtained without giving damage to cells further.

Owner:SHIBUYA IND CO LTD

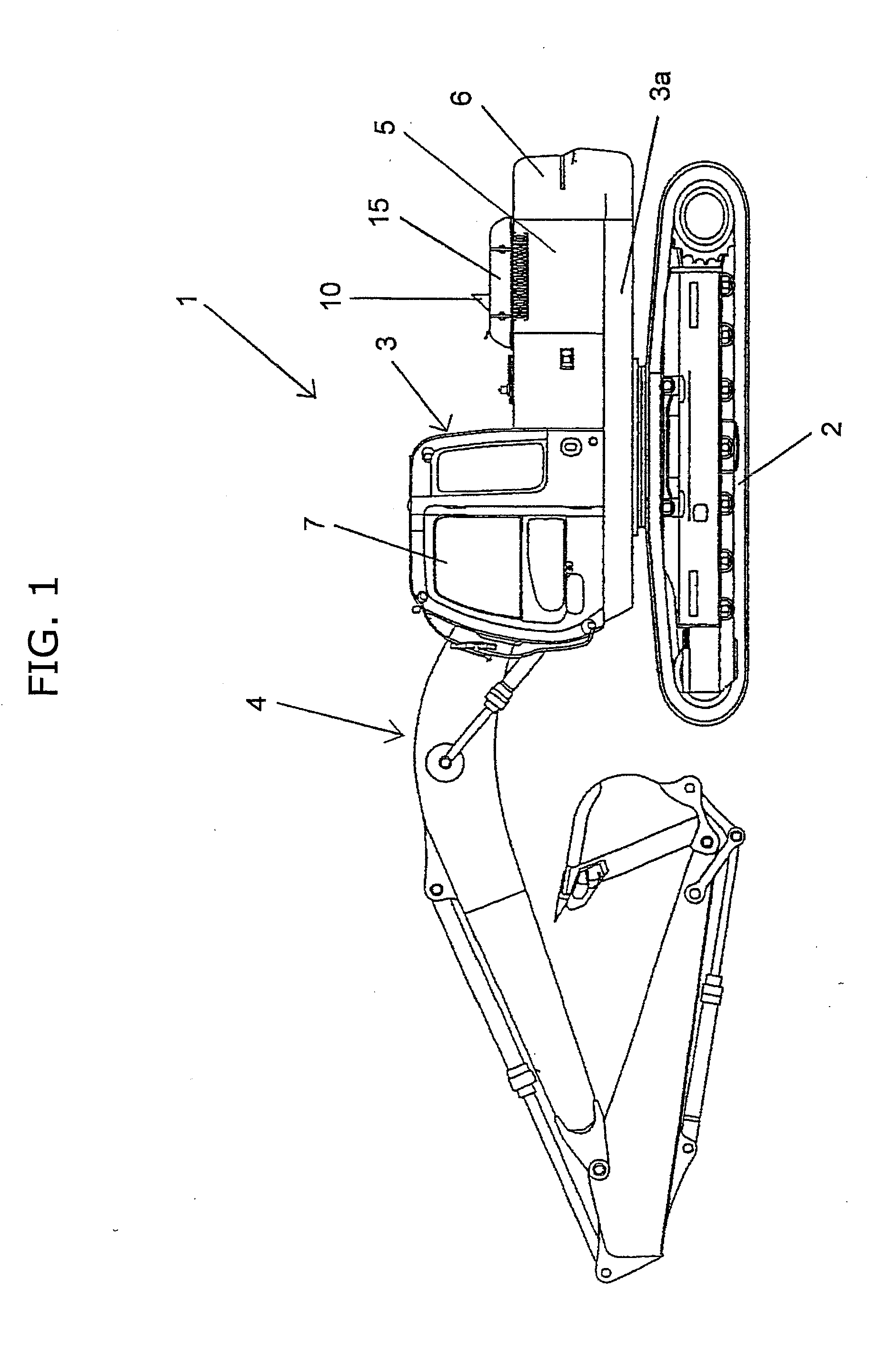

Aqueous Urea Tank Structure for Construction Machine

InactiveUS20130276922A1Reduce the amount requiredCorrosion and degradation of the aqueous urea tank by the ammonia can be suppressedInternal combustion piston enginesExhaust apparatusEnvironmental engineeringExcavator

An aqueous urea tank structure is provided for a construction machine, in which a temperature rise of the aqueous urea within the tank can be suppressed and the load applied to the tank due to vibration of a vehicle body can be reduced. The aqueous urea tank structure including an aqueous urea tank which is disposed within a revolving upperstructure of a hydraulic excavator to store aqueous urea that purifies the exhaust gas discharged from an engine, wherein the aqueous urea tank structure further includes a securing member which encloses the periphery of the aqueous urea tank to secure the aqueous urea tank within the revolving upperstructure, and heat insulating materials which are interposed between the securing member and the aqueous urea tank to hold the aqueous urea tank. The securing member contains a box.

Owner:NIHON KENKI CO LTD

Semiconductor device

ActiveUS8106474B2Damage suppressionHampering high integration of integratedSemiconductor/solid-state device detailsSolid-state devicesCapacitanceOvervoltage

A wiring electrically connected to a terminal to which a high power supply potential is applied and a wiring electrically connected to a terminal to which a low power supply potential is applied are formed adjacent to each other and are formed so as to surround the integrated circuit. Thus, wiring resistance can be added between the terminals and the integrated circuit and capacitance can be added between the two wirings. Even if overvoltage is applied to the terminals due to ESD or the like, the energy of the overvoltage is consumed by the wiring resistance and the added capacitor, so that damage of the integrated circuit can be suppressed.

Owner:SEMICON ENERGY LAB CO LTD

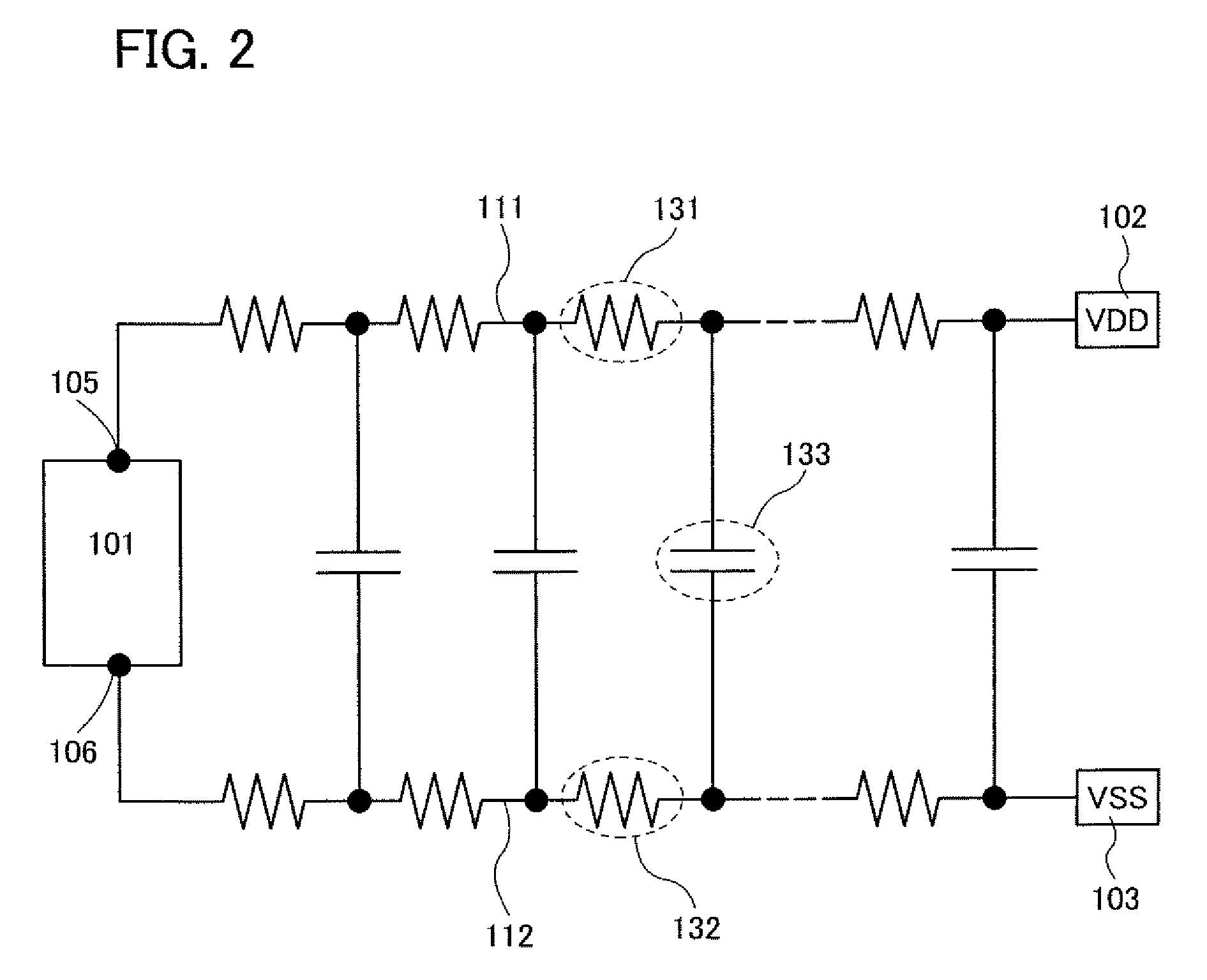

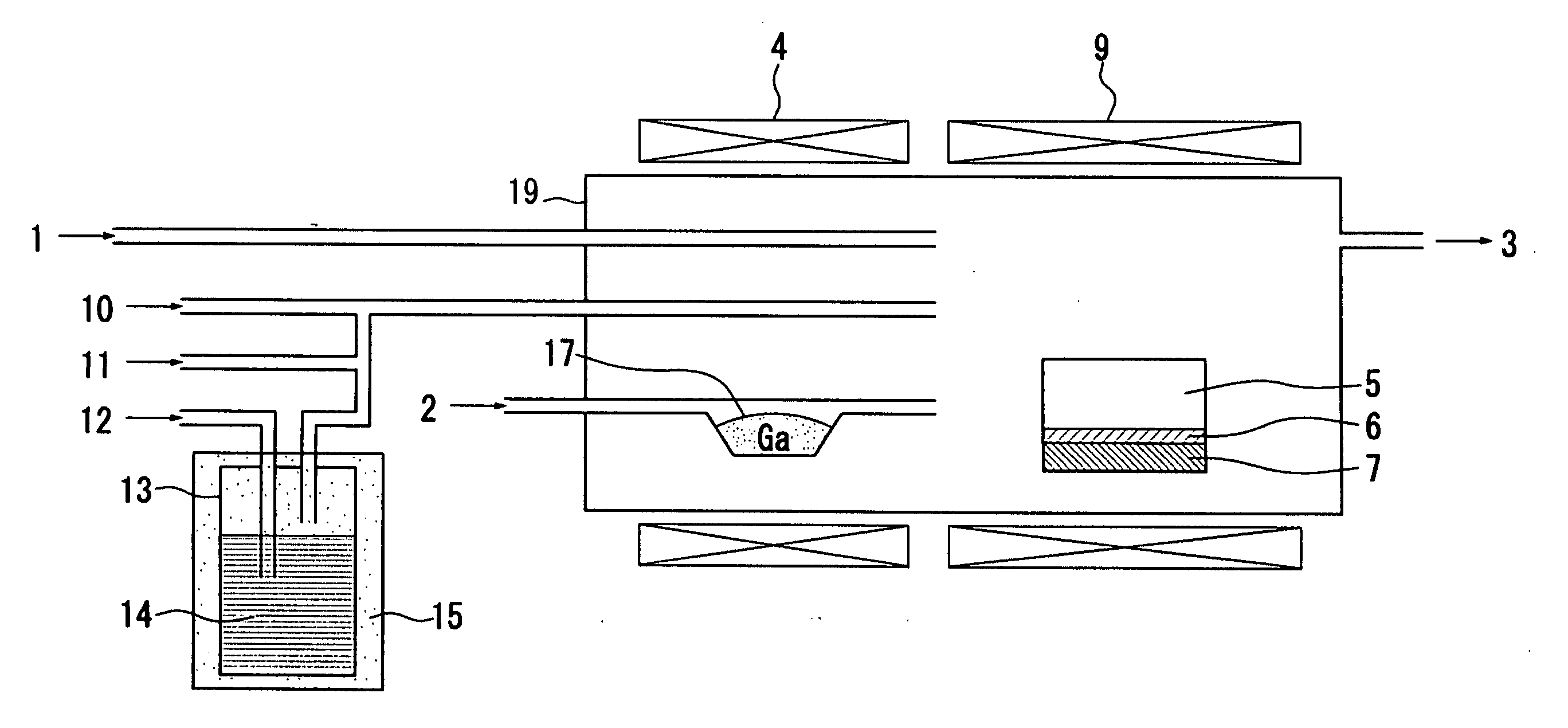

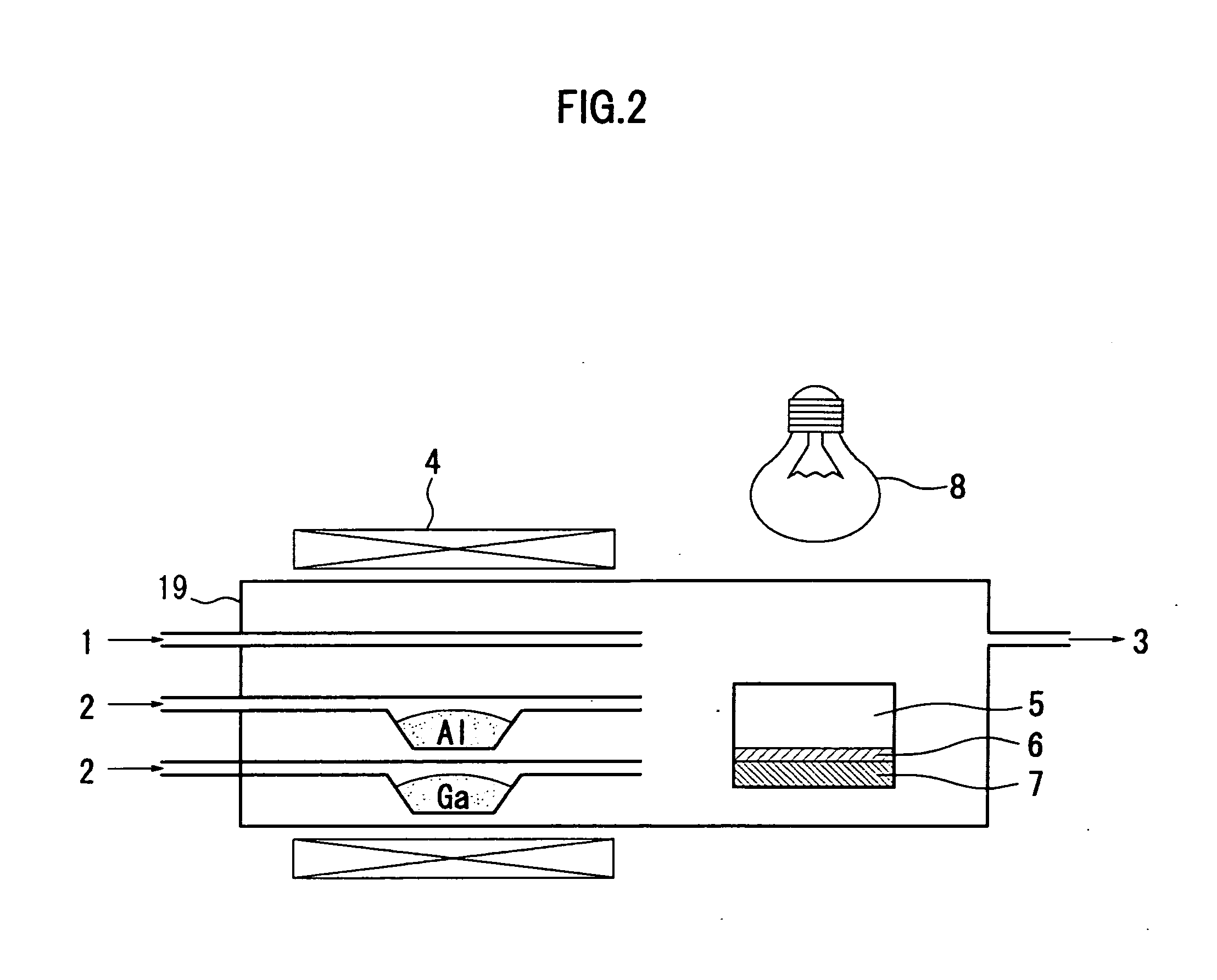

Method for manufacturing a group III nitride crystal, method for manufacturing a group III nitride template, group III nitride crystal and group III nitride template

InactiveUS20120104557A1Damage can be suppressedSuppress generationNon-metal conductorsPolycrystalline material growthHydrogen halideGas phase

A method for manufacturing a group III nitride crystal includes a step of mixing a group III source material and ammonia in a reactor including quartz, and growing a group III nitride crystal on a support substrate by a vapor deposition. The group III source material is an organic metal source material containing Al. The organic metal source material is mixed with a hydrogen halide gas and the mixture of the organic metal source material and the hydrogen halide gas is supplied to the reactor.

Owner:HITACHI CABLE

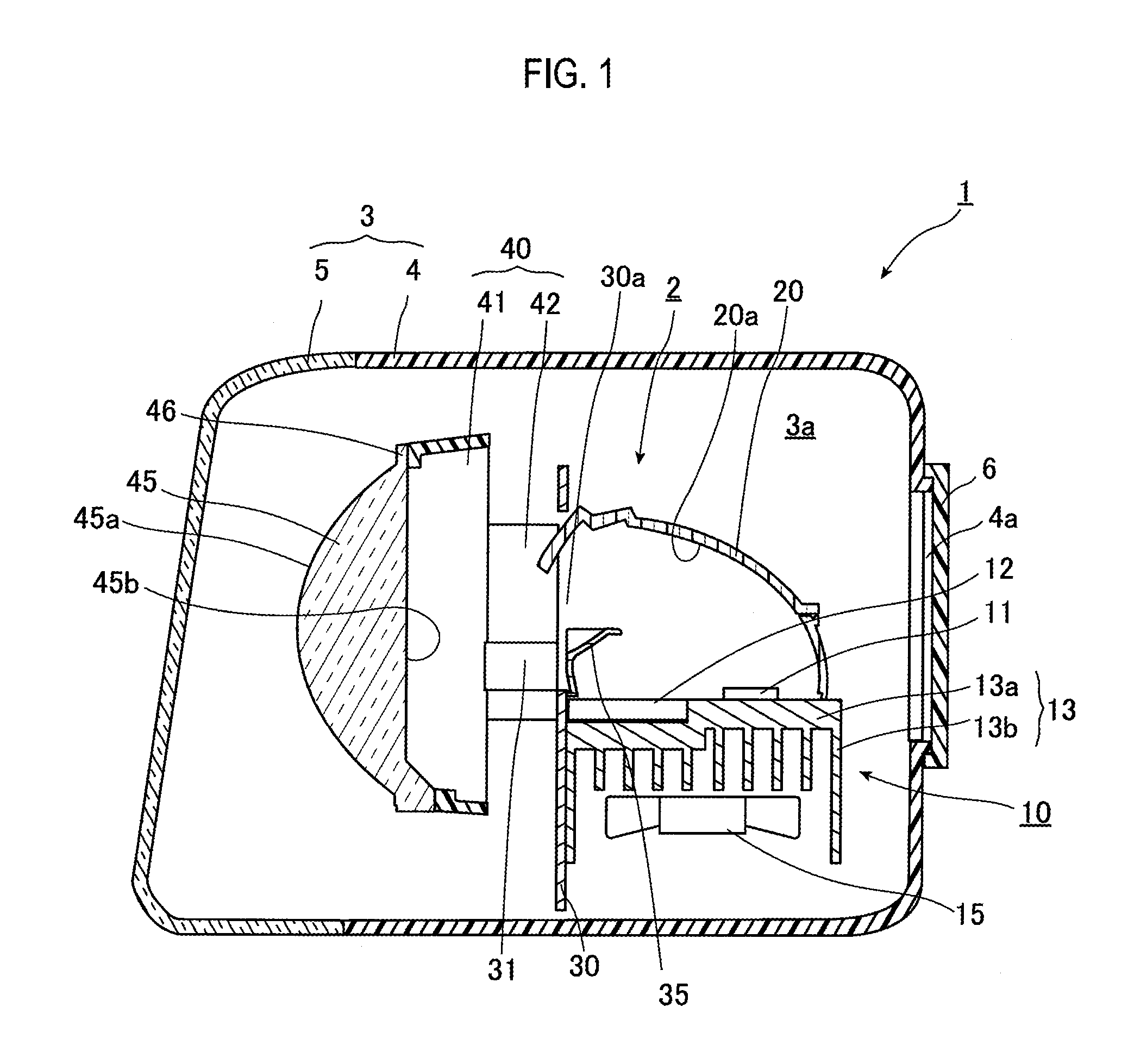

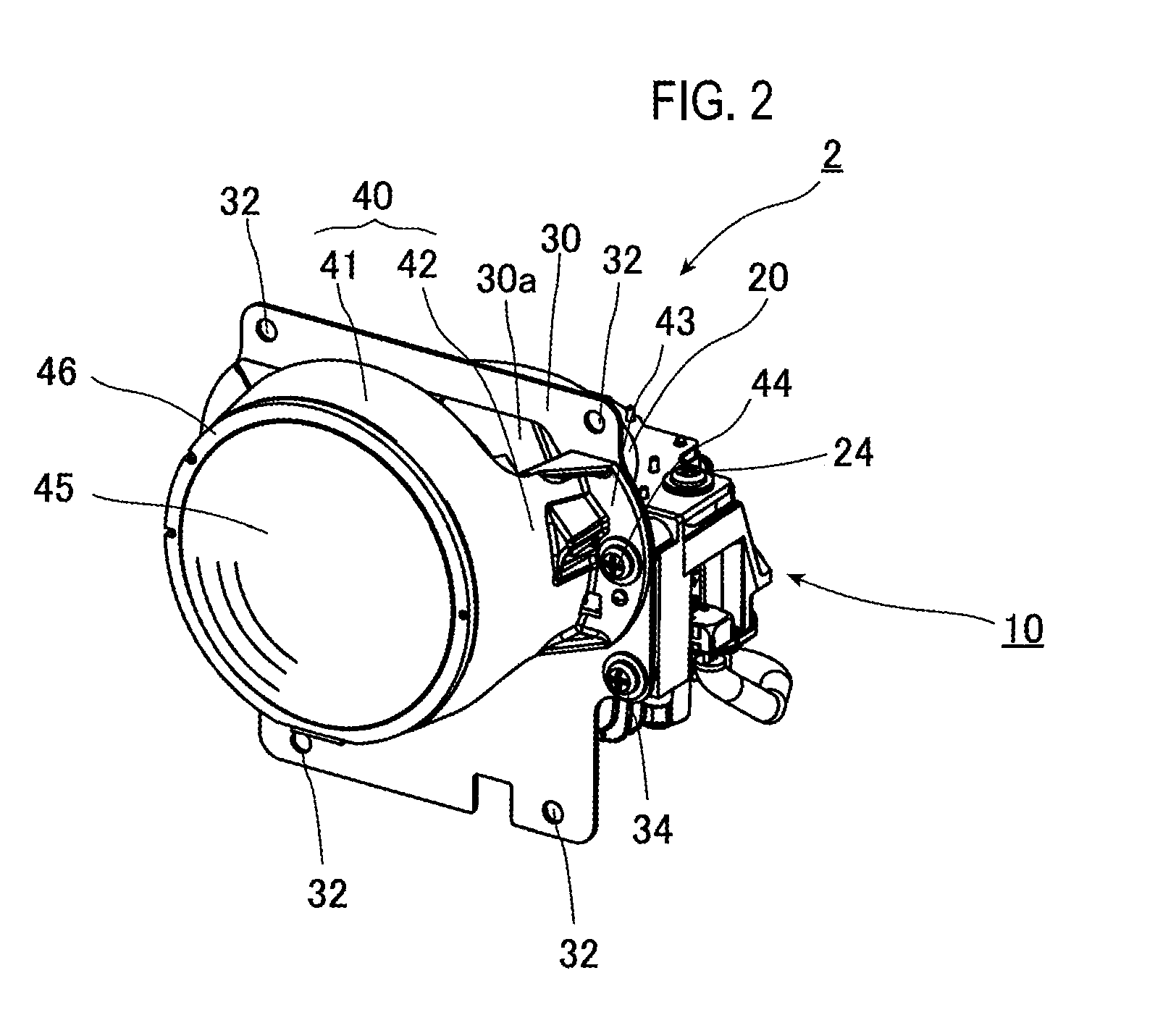

Lamp

ActiveUS20170059109A1Easy to manufactureSuppress lightVehicle headlampsVehicle lighting systemsOptoelectronicsProjection lens

A lamp includes a light source, a projection lens in which light from the light source is incident on one surface and the light is emitted from the other surface, a lens holder to which the projection lens is fixed and which extends to a side opposite to the direction of the light emitted from the projection lens, and a base plate disposed on the side opposite to a side of the lens holder to which the projection lens is fixed and having an opening through which the light from the light source passes. The base plate has a light shielding portion which is provided between the projection lens and the lens holder and extends toward the projection lens, and the light shielding portion is formed by bending a portion of the base plate.

Owner:KOITO MFG CO LTD

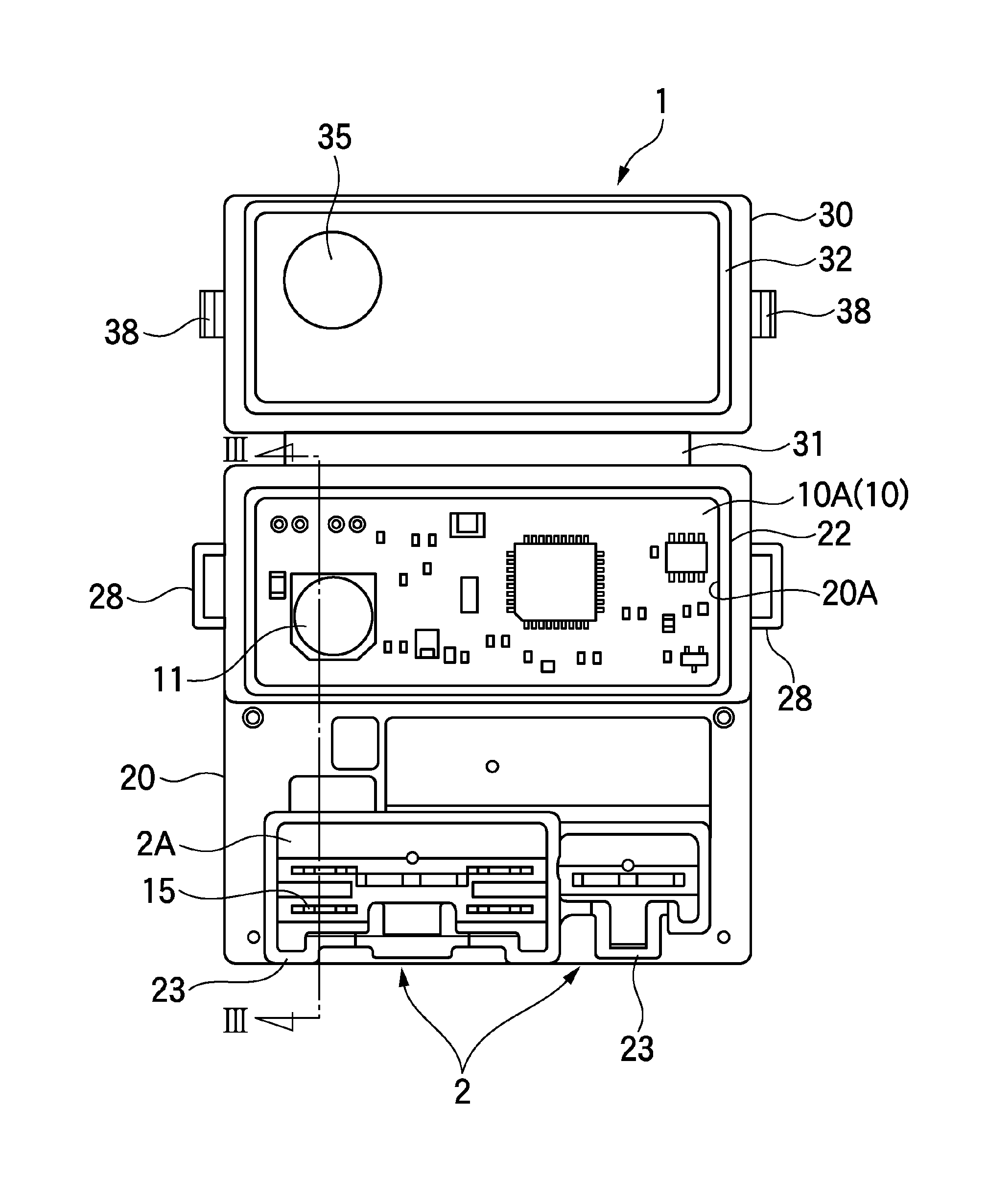

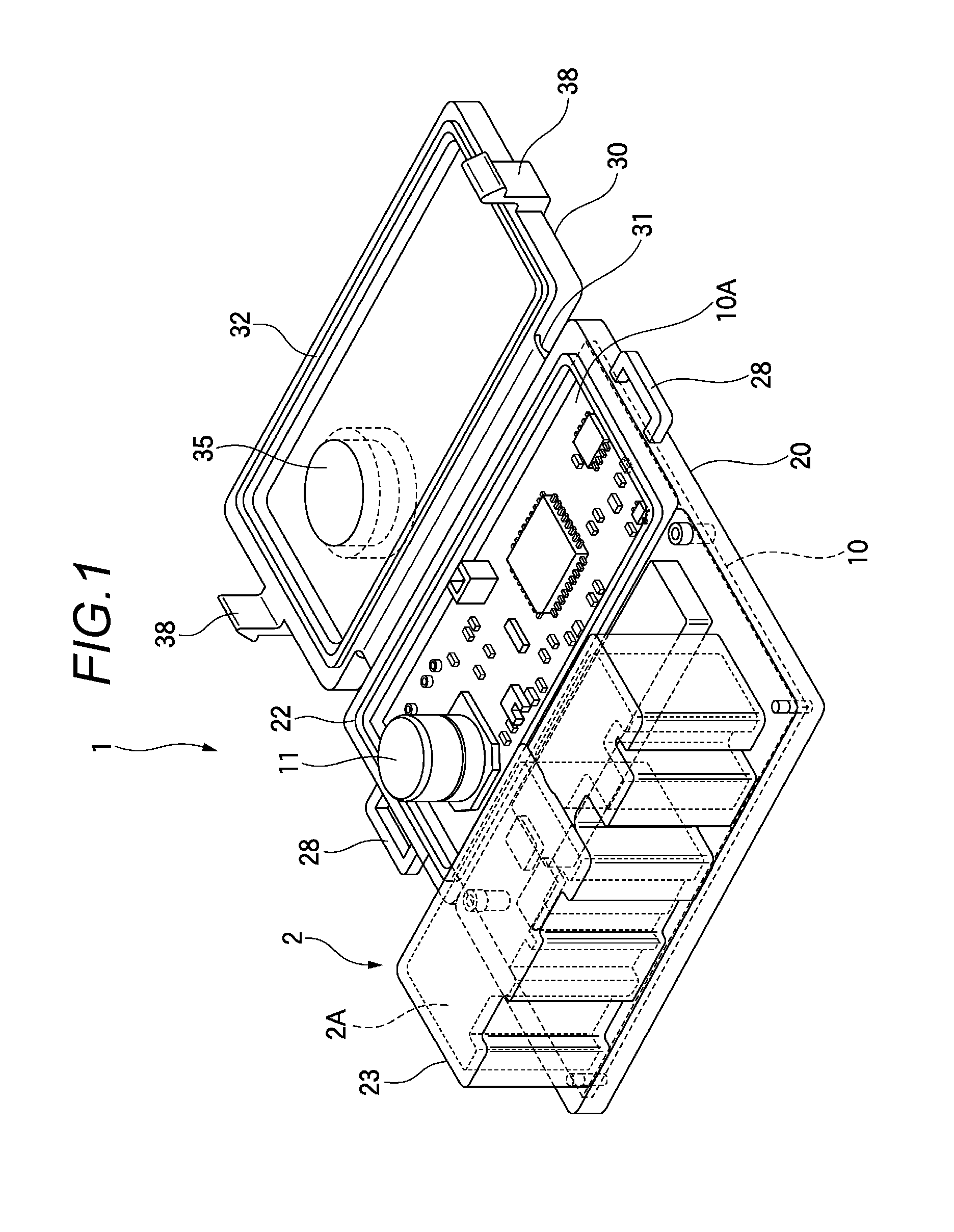

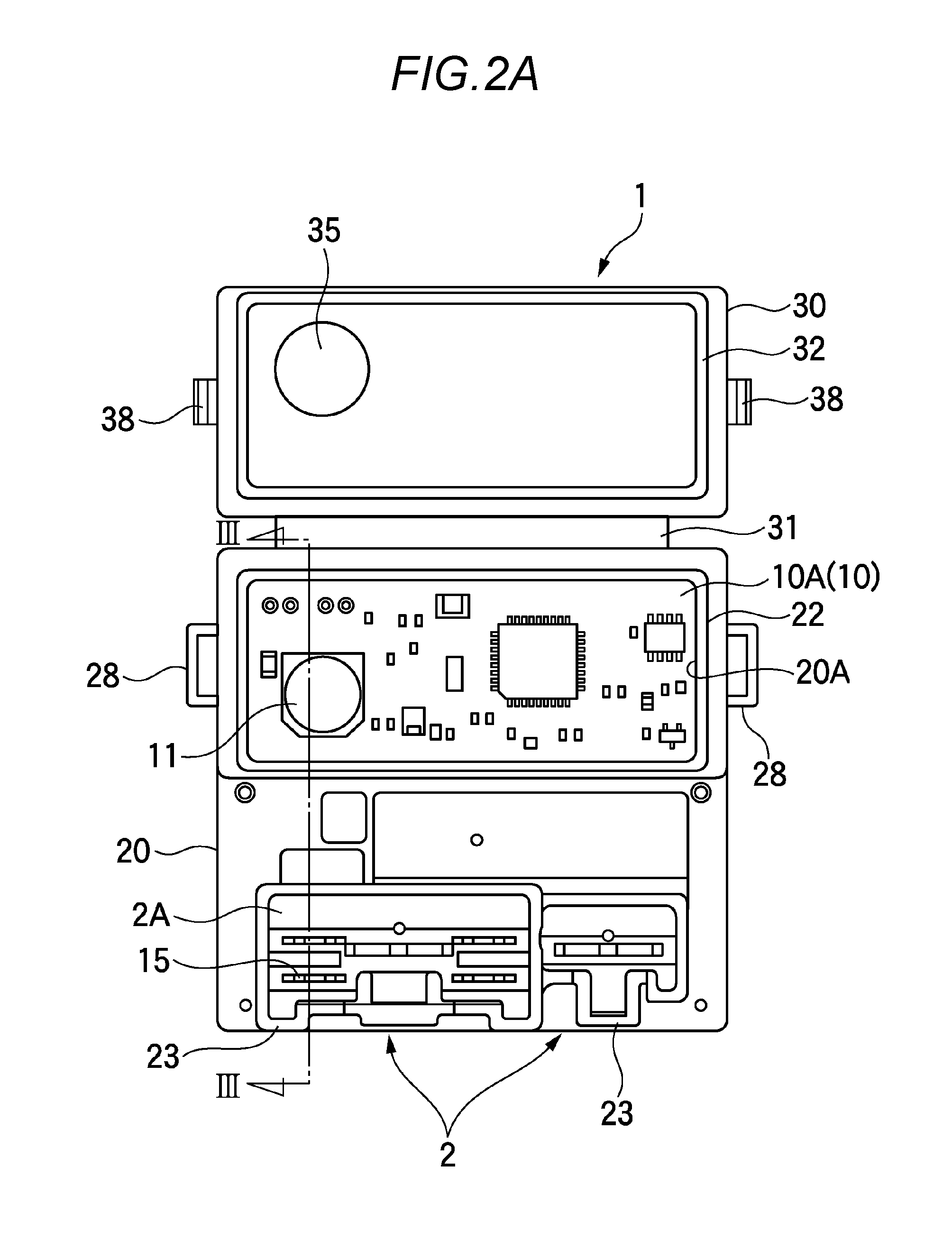

Electronic-circuit unit and manufacturing method thereof

ActiveUS20160278219A1Reduce pressureImprove liquidityPrinted circuit aspectsCasings/cabinets/drawers detailsMulti materialEngineering

An electronic circuit unit in which a mold exclusion part, having a rear surface side covered by mold resin and a front surface side exposed from an outer case, is provided at a part of a plate surface of a circuit board which is mounted with electronic components and is covered by the outer case formed by the mold resin. The outer case is multi-material molded using plural kinds of resin having different fluidities. A rear wall of the outer case located on the rear surface side of the mold exclusion part is made of one of the plural kinds of the resin having a fluidity higher than a fluidity of another one of the plural kinds of the resin constituting the other portion of the outer case.

Owner:YAZAKI CORP

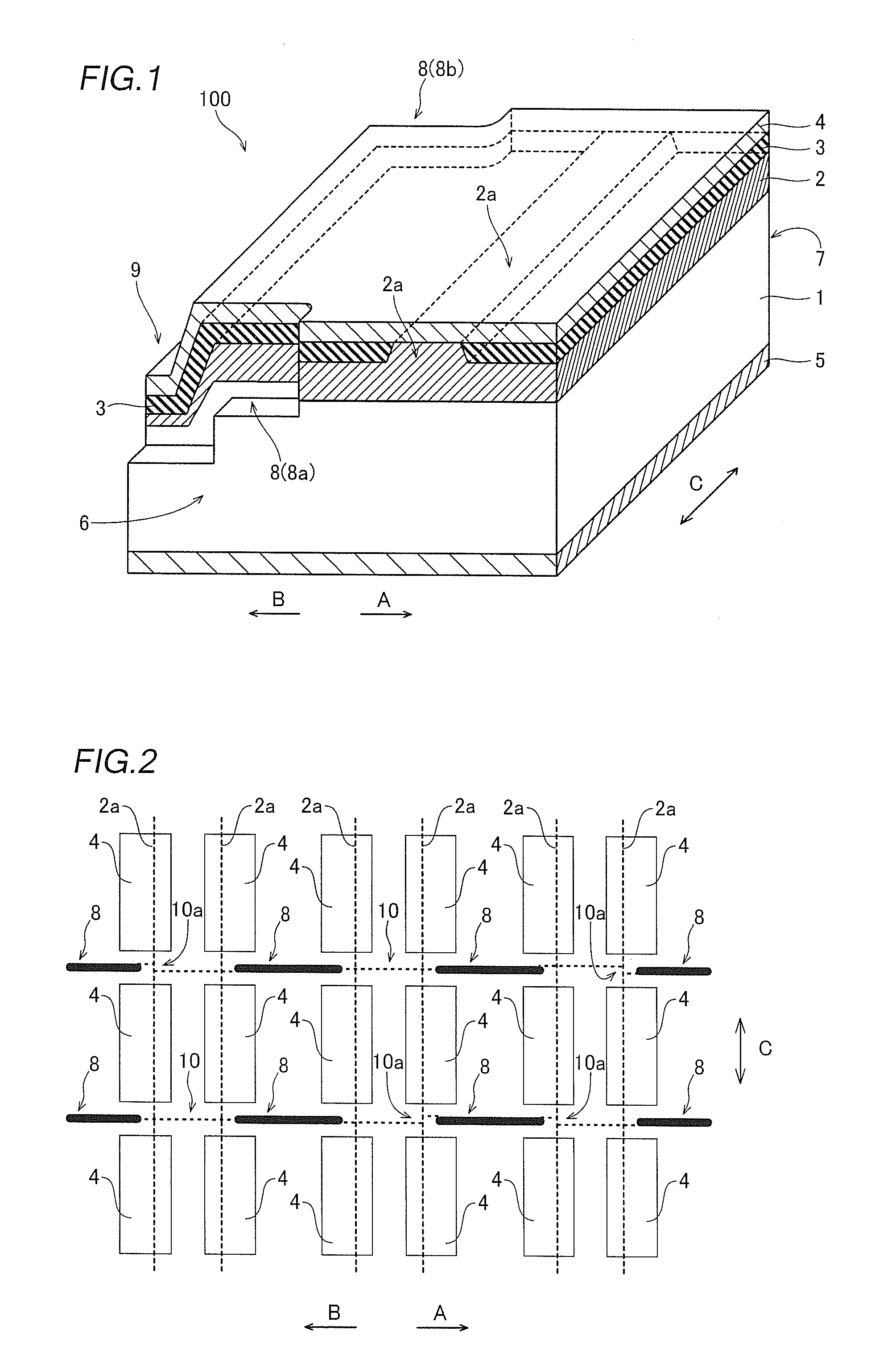

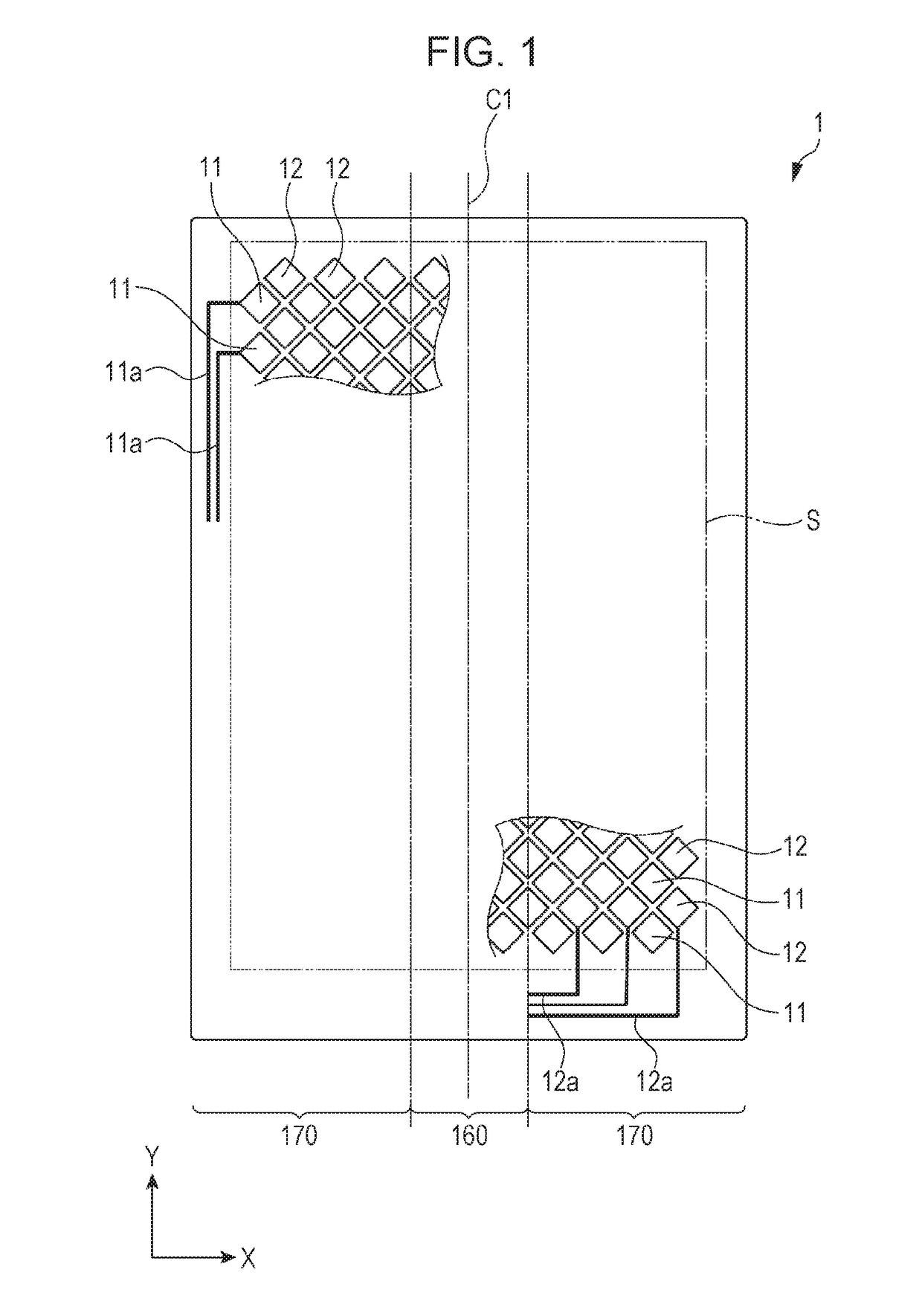

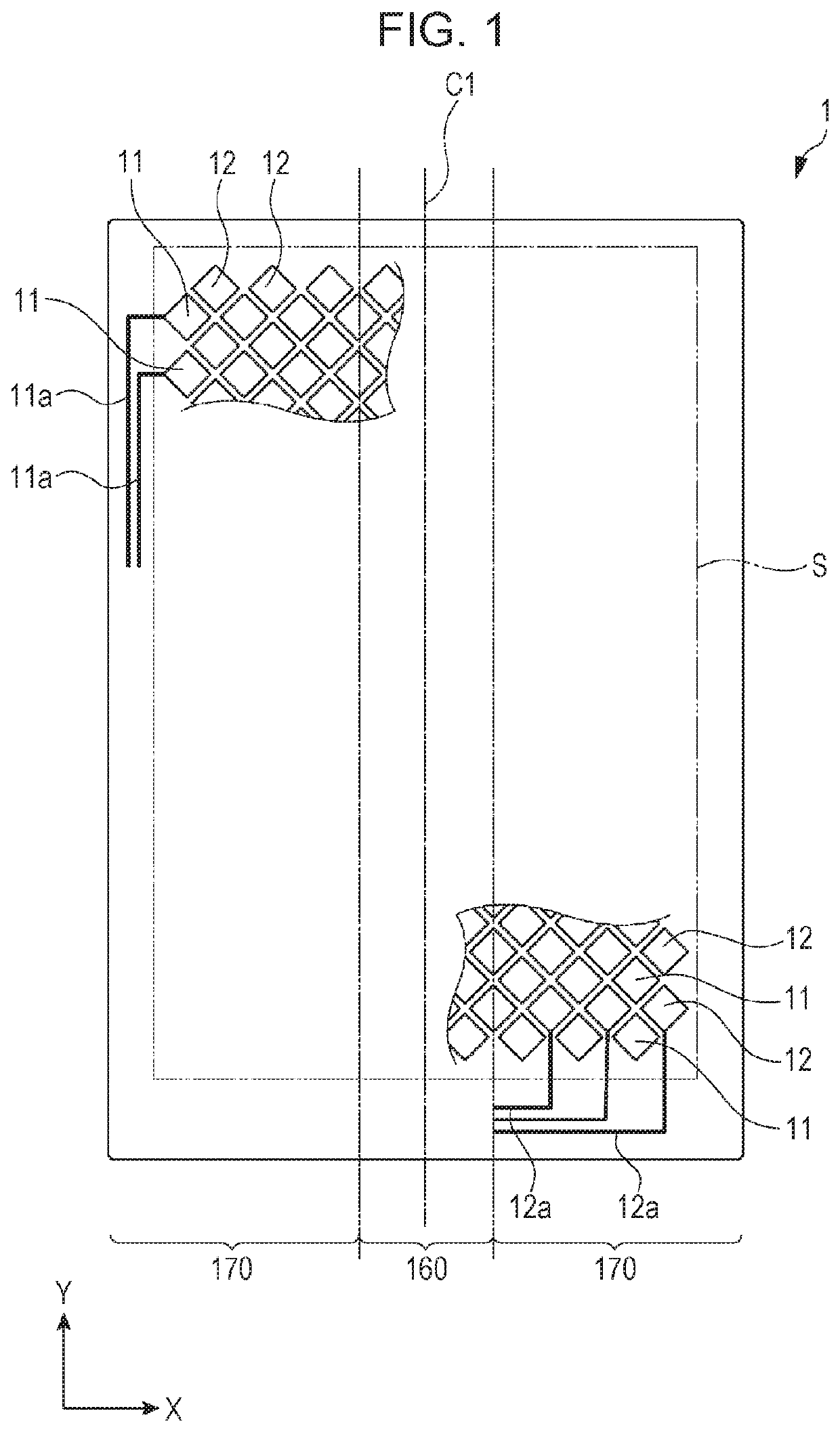

Capacitive sensor

ActiveUS20180224975A1Damage can be suppressedReduce the possibilityElectrical/magnetic solid deformation measurementInput/output processes for data processingCapacitive sensingEngineering

A capacitive sensor having a bending portion and a flat portion and bendable in the bending portion includes a plurality of first transparent electrodes, a plurality of second transparent electrodes, a coupling member, and a bridge wiring member. The first transparent electrodes are arranged in a first direction. The second transparent electrodes are arranged in a second direction crossing the first direction. The coupling member is provided integrally with either the first transparent electrodes or the second transparent electrodes. The bridge wiring member is provided separately from the first transparent electrodes or the second transparent electrodes, to which the coupling member is not provided, in a portion where the bridge wiring member crosses the coupling member. A direction in which the coupling member extends in the bending portion is different from a direction in which the coupling member extends in the flat portion.

Owner:ALPS ALPINE CO LTD

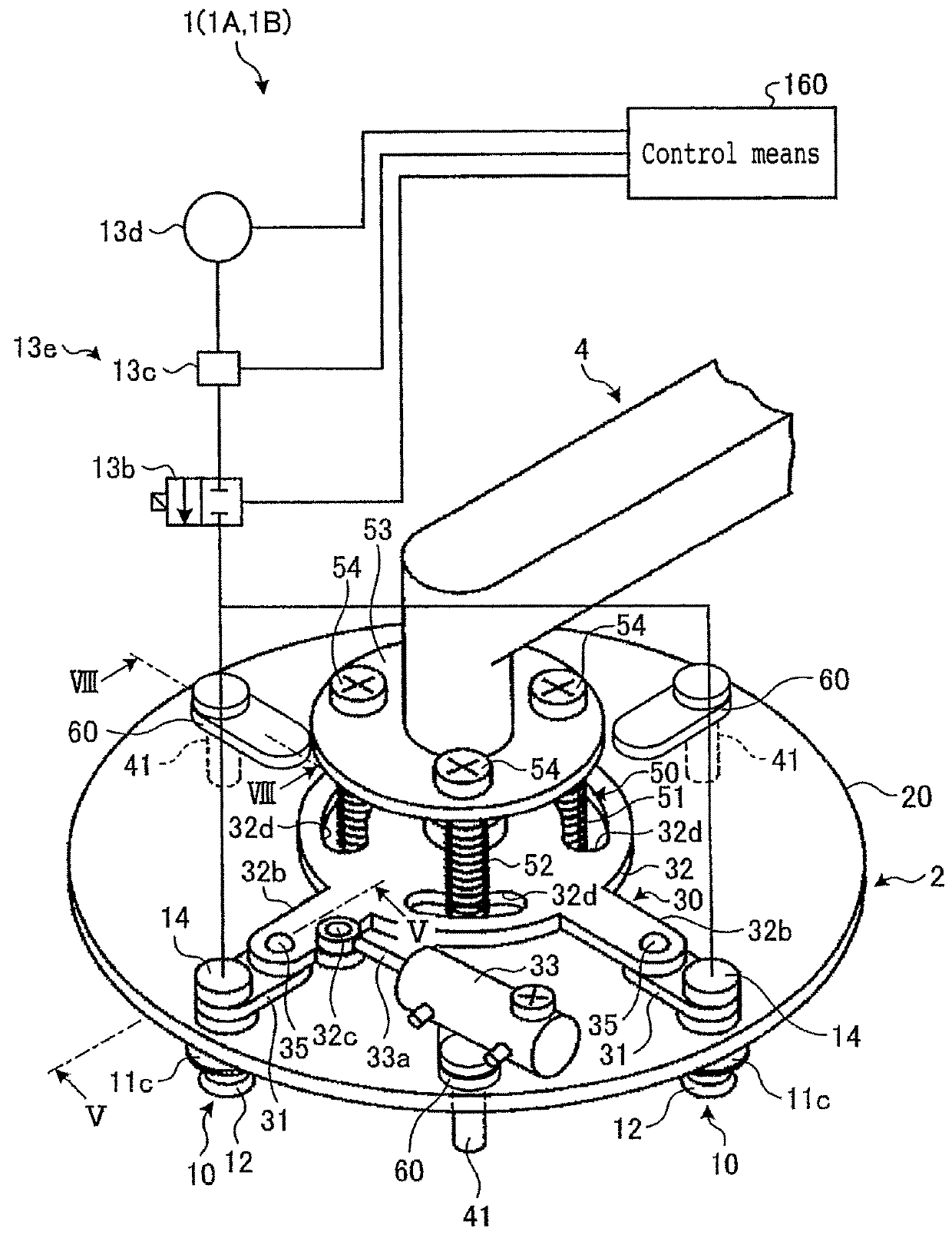

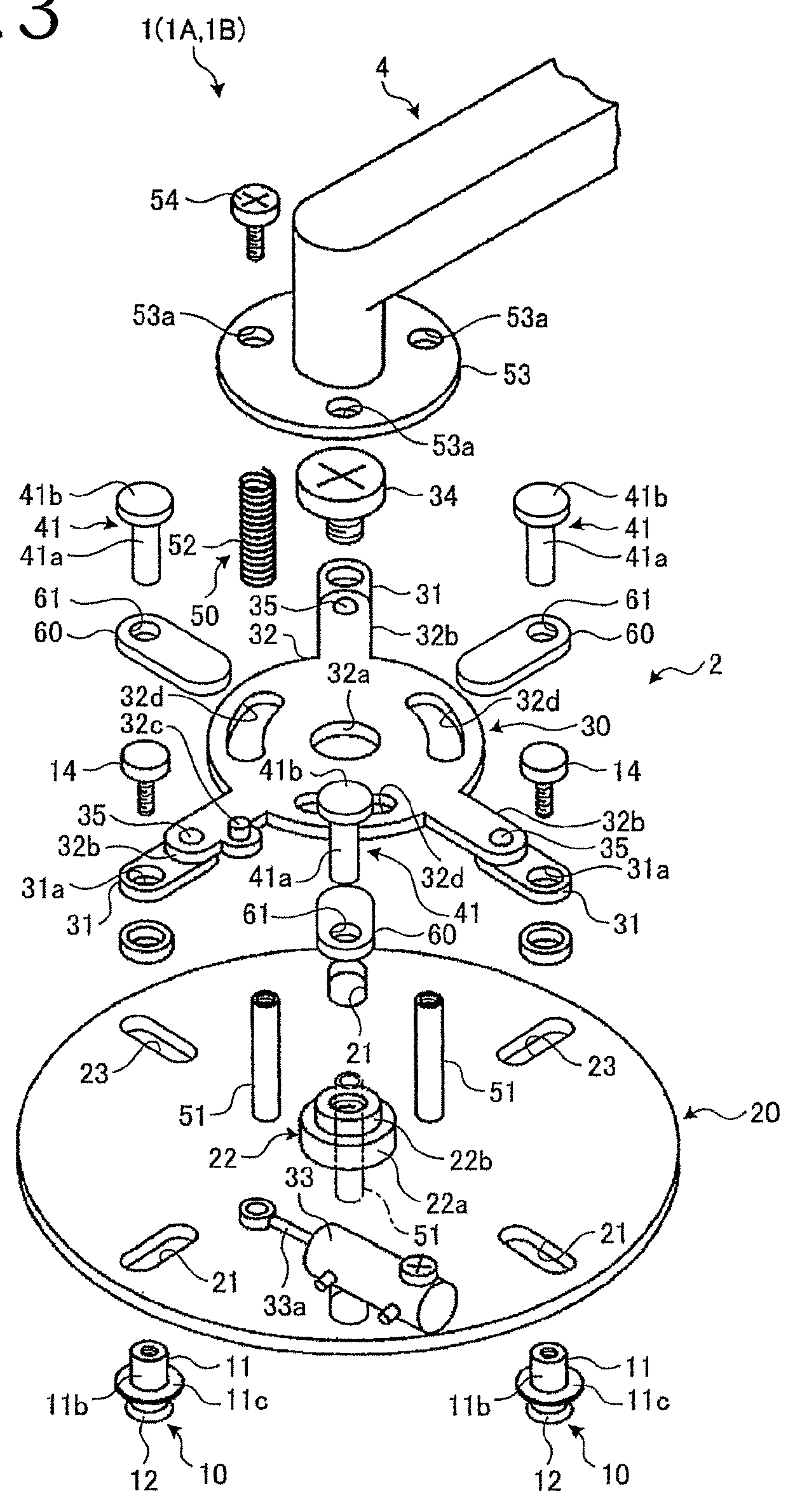

Plate-shaped workpiece transfer apparatus and processing apparatus

ActiveUS10040204B2Suppress possible damageDamage can be suppressedGripping headsSemiconductor/solid-state device manufacturingEngineeringNozzle

Apparatus transfers a plate-shaped workpiece to / from a holding surface of a chuck table. The apparatus includes a holding unit and a moving mechanism. The holding unit includes at least two holding members for holding the outer edge of the workpiece, a support plate for supporting the holding members so as to allow movement of the holding members toward or away from the outer edge of the workpiece, and a moving unit for moving the holding members. Each holding member includes a rod portion vertically movably extending downward through the support plate, an engaging portion formed on the outer circumference of the rod portion at the lower end thereof for engaging the outer edge of the workpiece, and a nozzle portion for discharging a fluid from the lower surface of the rod portion toward the holding surface to thereby float the workpiece from the holding surface.

Owner:DISCO CORP

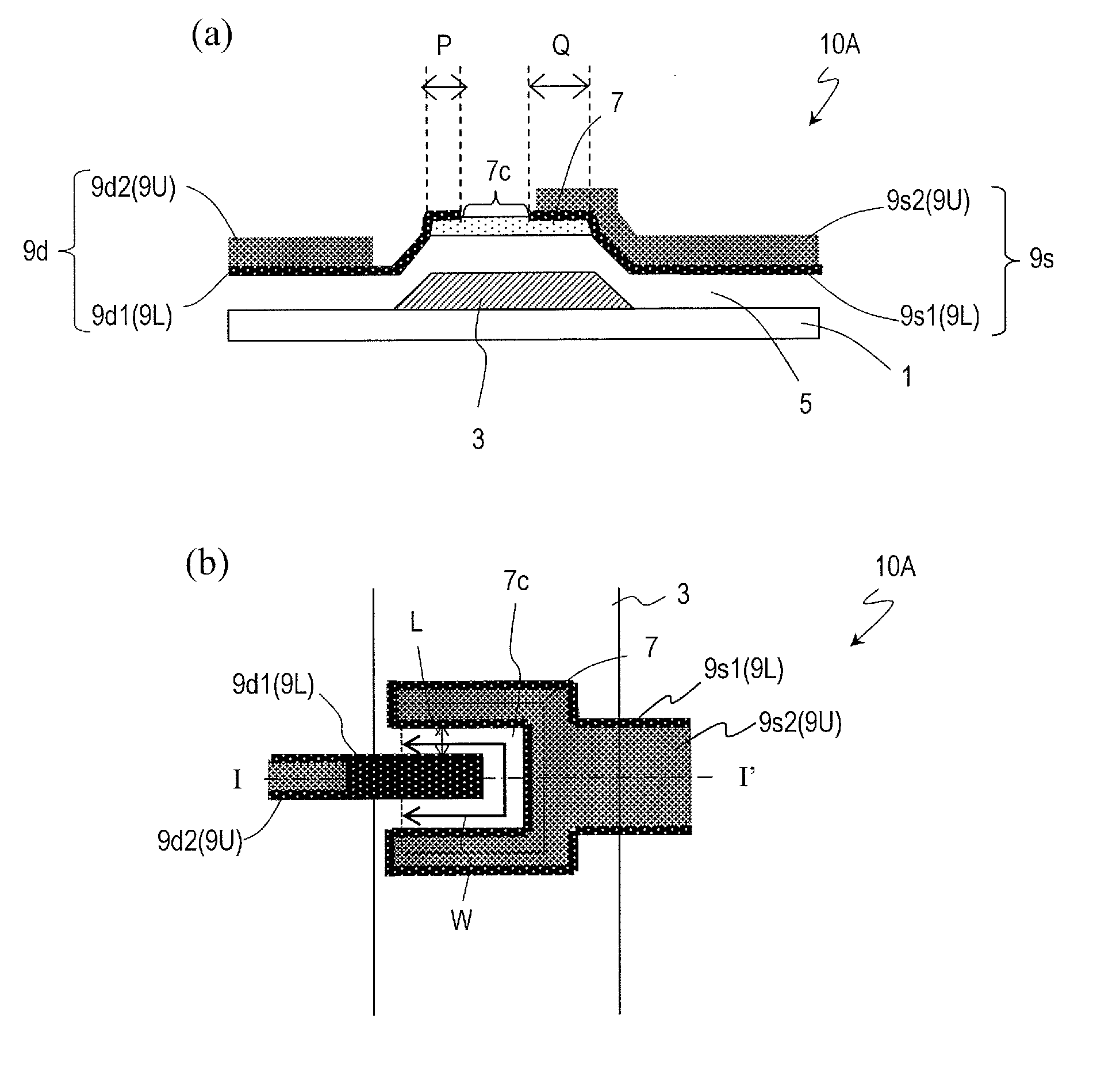

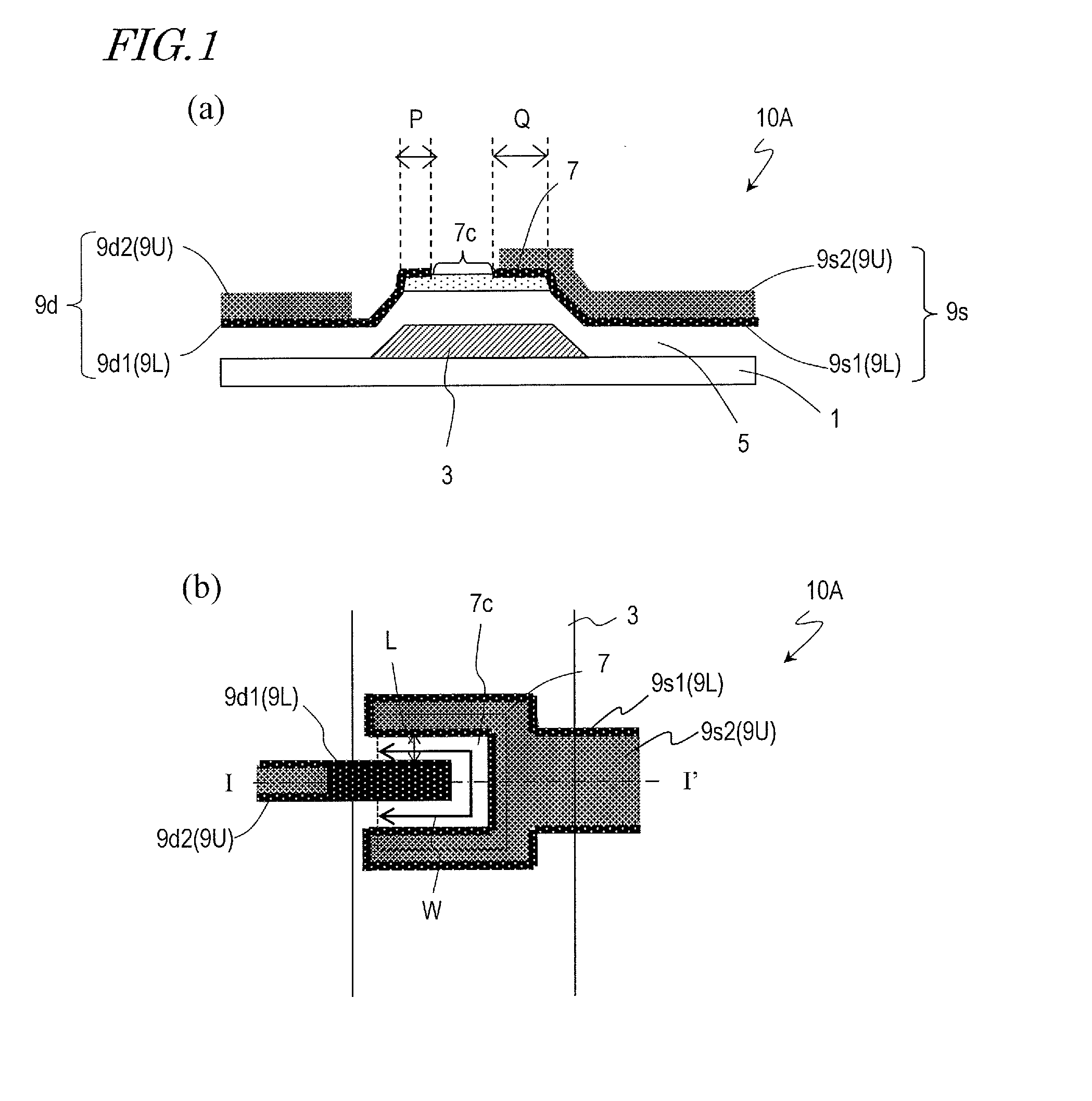

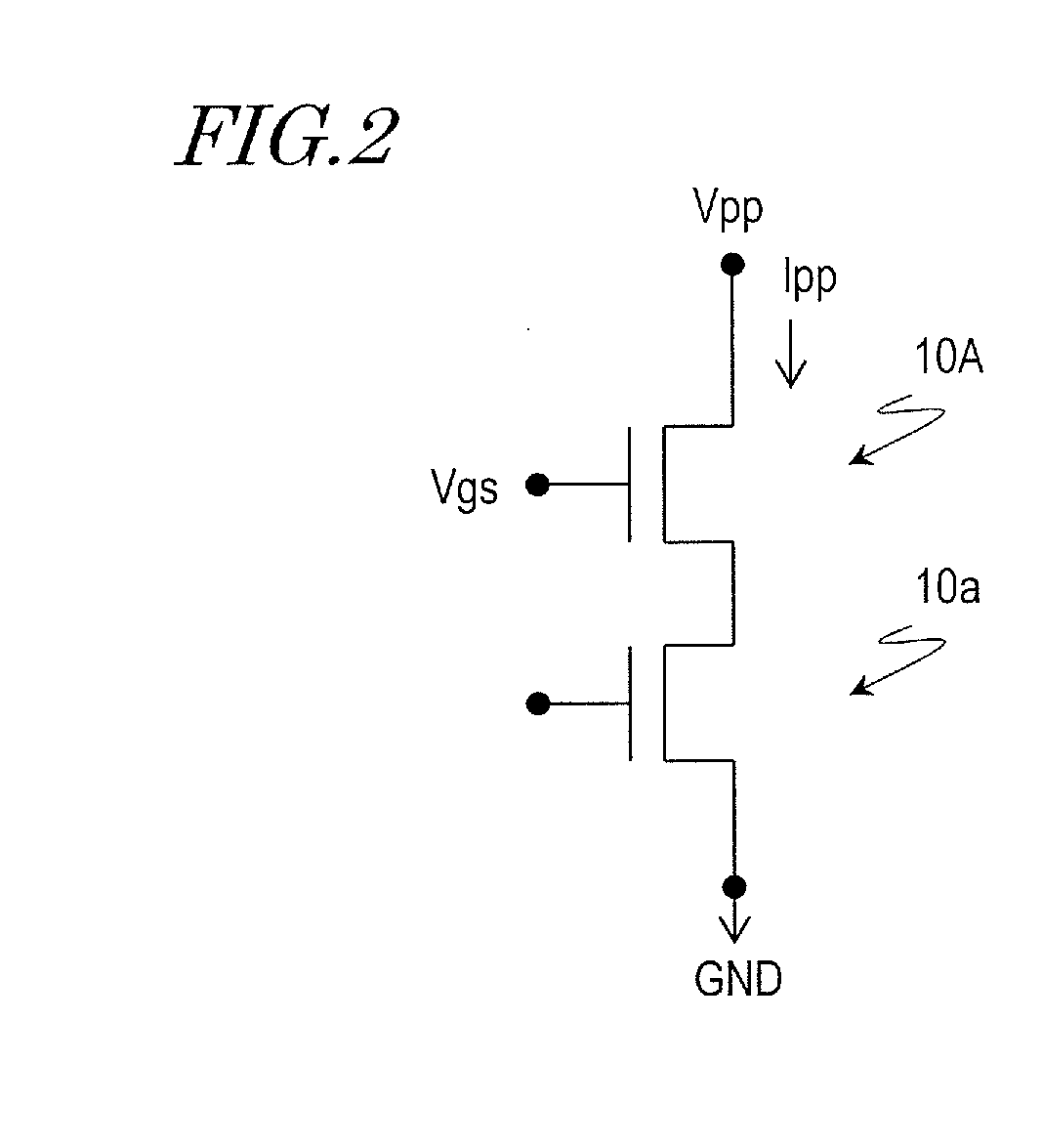

Semiconductor device

ActiveUS20160293613A1Improve reliabilityHeat suppressionTransistorStatic indicating devicesDevice materialDrain current

A semiconductor device includes a memory transistor (10A) which is capable of being irreversibly changed from a semiconductor state where drain current Ids depends on gate voltage Vg to a resistor state where drain current Ids does not depend on gate voltage Vg. The memory transistor (10A) includes a gate electrode (3), a metal oxide layer (7), a gate insulating film (5), and source and drain electrodes. The drain electrode (9d) has a multilayer structure which includes a first drain metal layer (9d1) and a second drain metal layer (9d2), the first drain metal layer (9d1) being made of a first metal whose melting point is not less than 1200° C., the second drain metal layer (9d2) being made of a second metal whose melting point is lower than that of the first metal. Part P of the drain electrode 9d extends over both the metal oxide layer (7) and the gate electrode (3) when viewed in a direction normal to a surface of the substrate. The part (P) of the drain electrode (9d) includes the first drain metal layer (9d1) and does not include the second drain metal layer (9d2).

Owner:SHARP KK

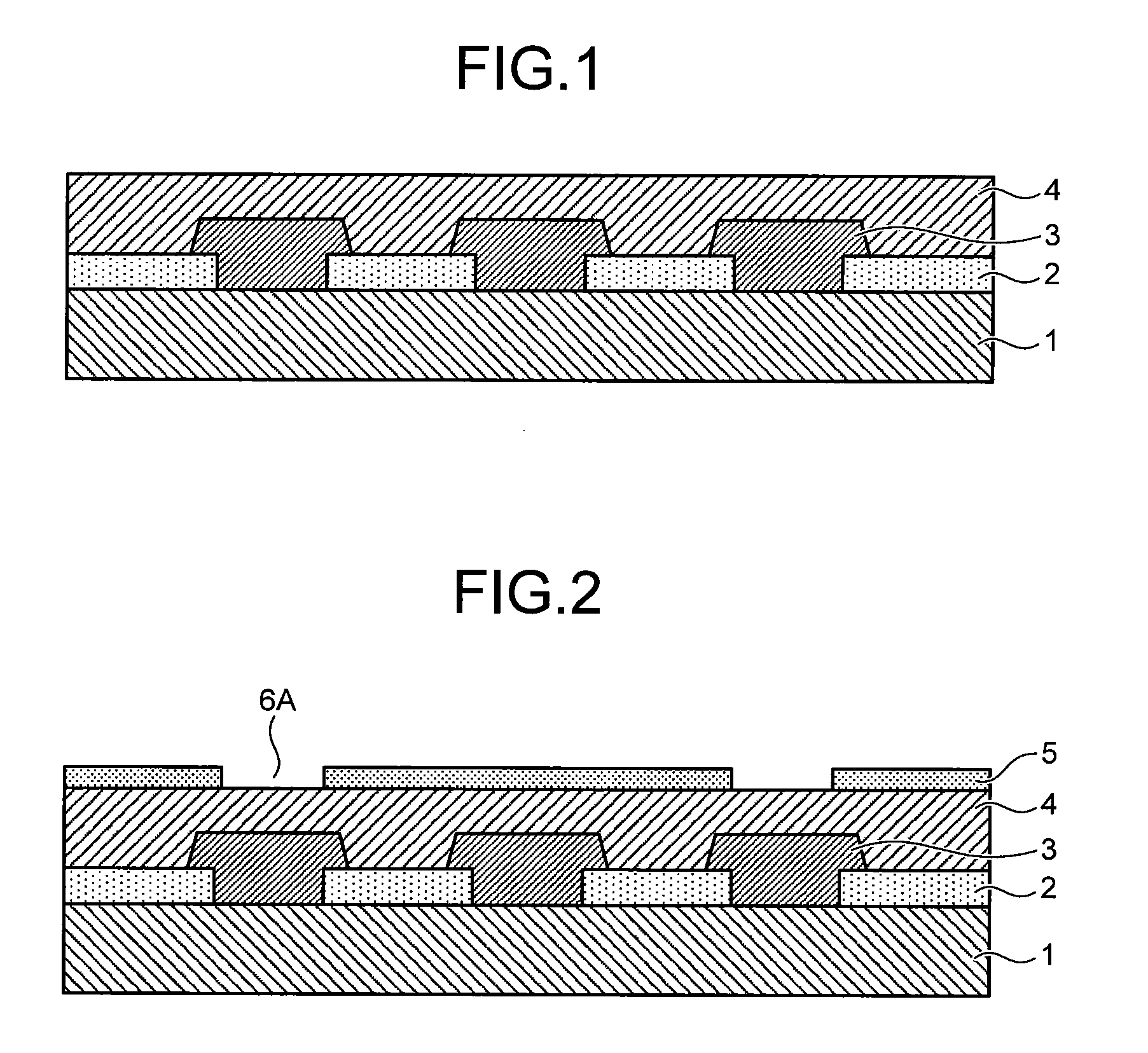

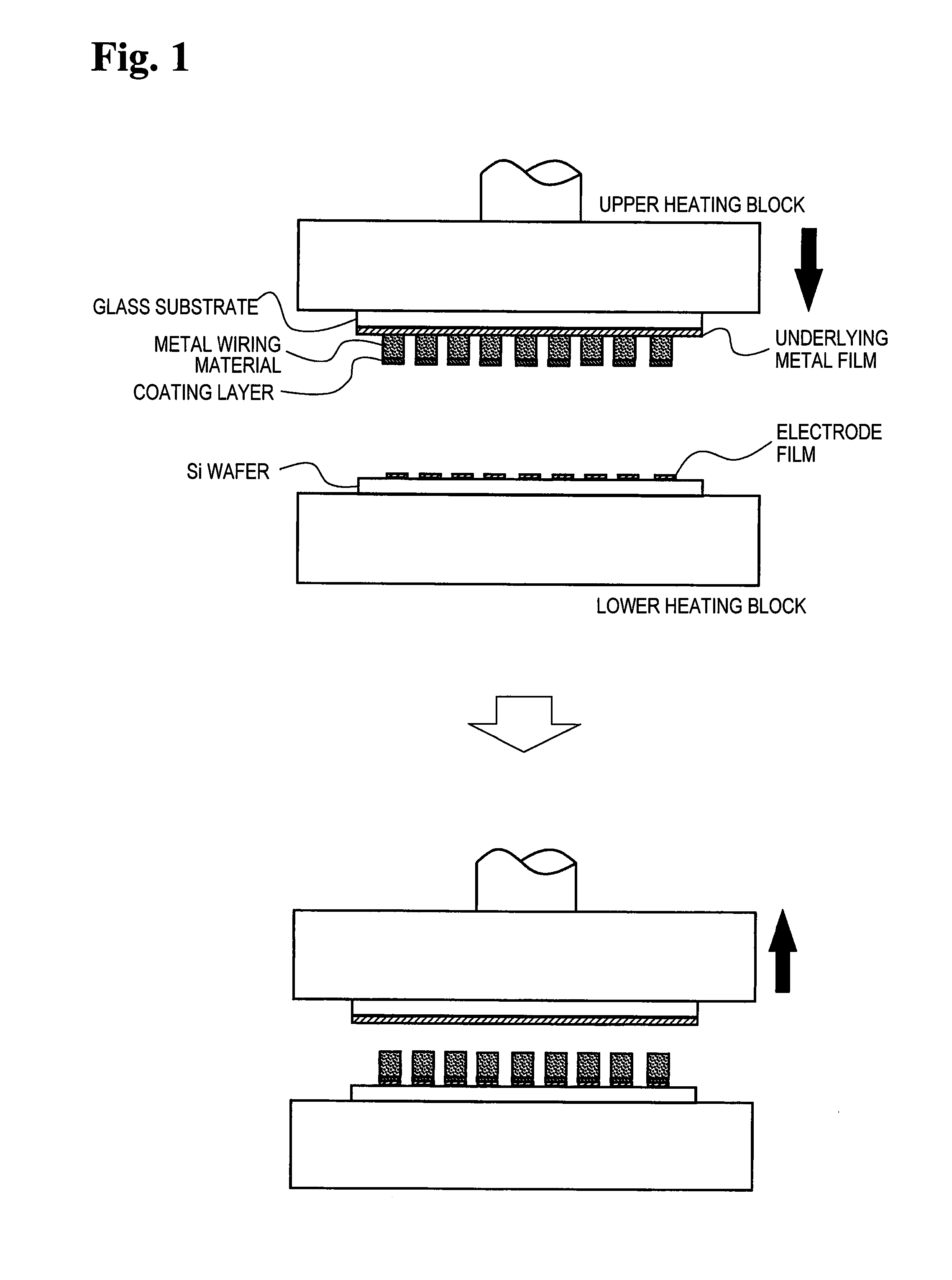

Transfer substrate for forming metal wiring line and method for forming metal wiring line by means of said transfer substrate

ActiveUS20140262003A1Smooth transferReduce loadLamination ancillary operationsSolid-state devicesAlloyTotal thickness

A transfer substrate for transferring a metal wiring material to a transfer target including a substrate, at least one metal wiring material formed on the substrate, at least one coating layer formed on a surface of the metal wiring material, and an underlying metal film formed between the substrate and the metal wiring material, in which the metal wiring material is a compact formed by sintering metal powder such as gold powder having a purity of 99.9 wt % or more and an average particle size of 0.01 μm to 1.0 μm, and the coating layer is a predetermined metal such as gold or an alloy having a different composition from that of the metal wiring material and has a total thickness of 1 μm or less, and the metal underlying film is made of a predetermined metal such as gold or an alloy. The transfer substrate can lower heating temperature on the transfer target side.

Owner:TANAKA PRECIOUS METAL IND

Semiconductor device and method of manufacturing semiconductor device including wiring via and switch via for connecting first and second wirings

InactiveUS8390124B2Deterioration of resistance changeDamage can be suppressedThyristorSemiconductor/solid-state device detailsPower semiconductor deviceSemiconductor

Provided is a semiconductor device including a substrate, and a first wiring layer, a second wiring layer, and a switch via formed on the substrate. The first wiring layer has first wiring formed therein and the second wiring layer has second wiring formed therein. The switch via connects the first wiring and the second wiring. The switch via includes at least at its bottom a switch element including a resistance change layer. A resistance value of the resistance change layer changes according to a history of an electric field applied thereto.

Owner:RENESAS ELECTRONICS CORP

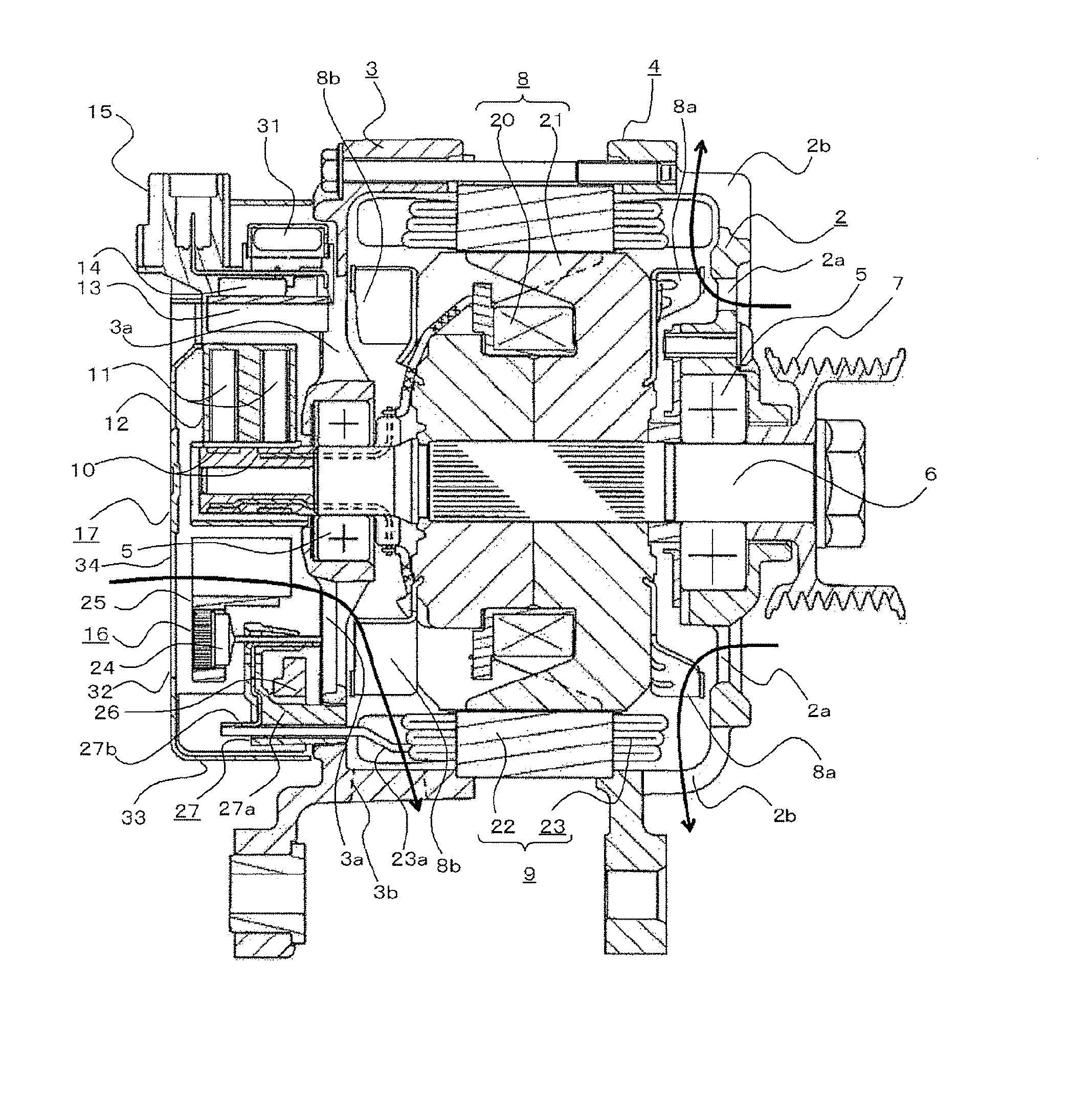

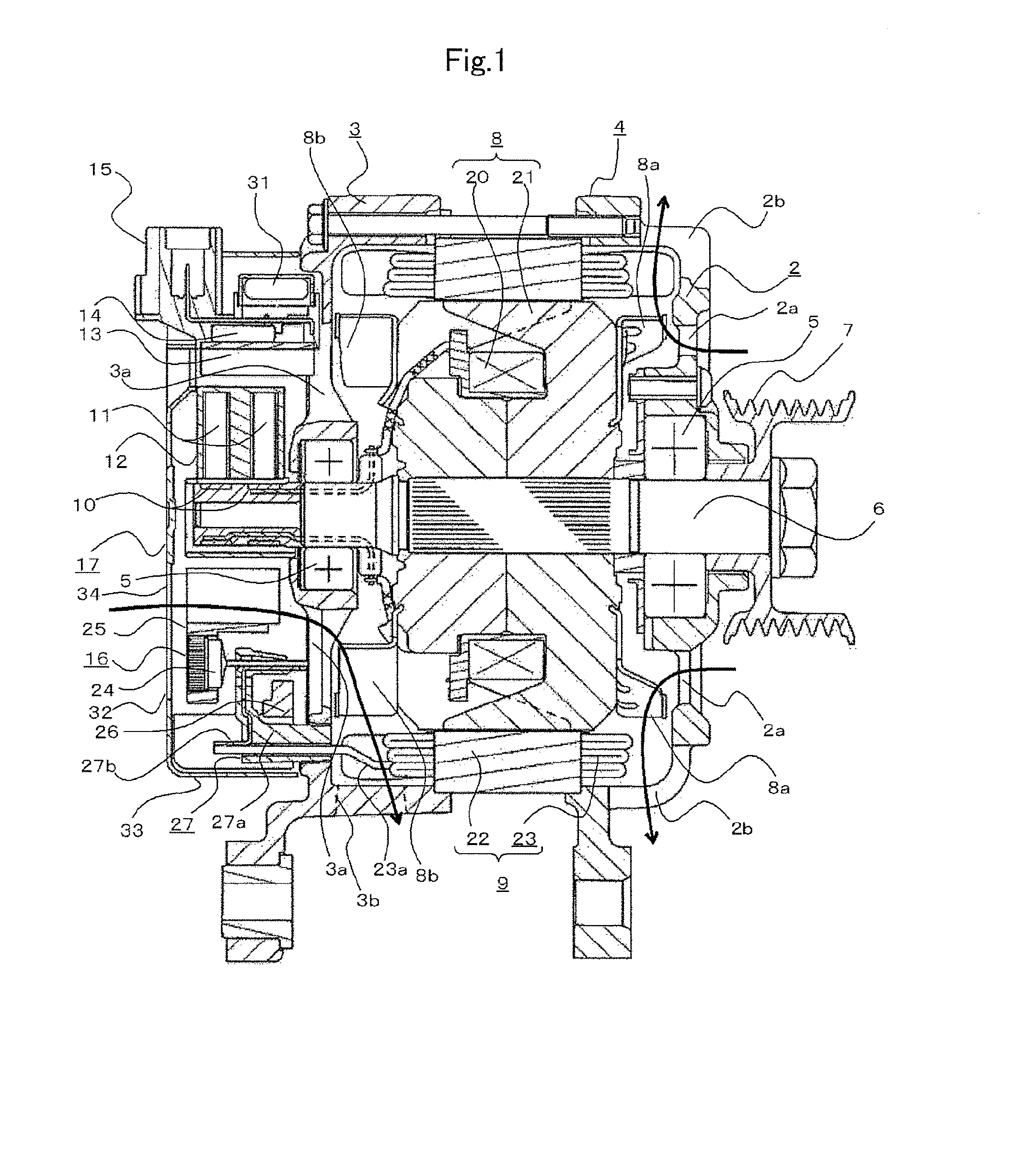

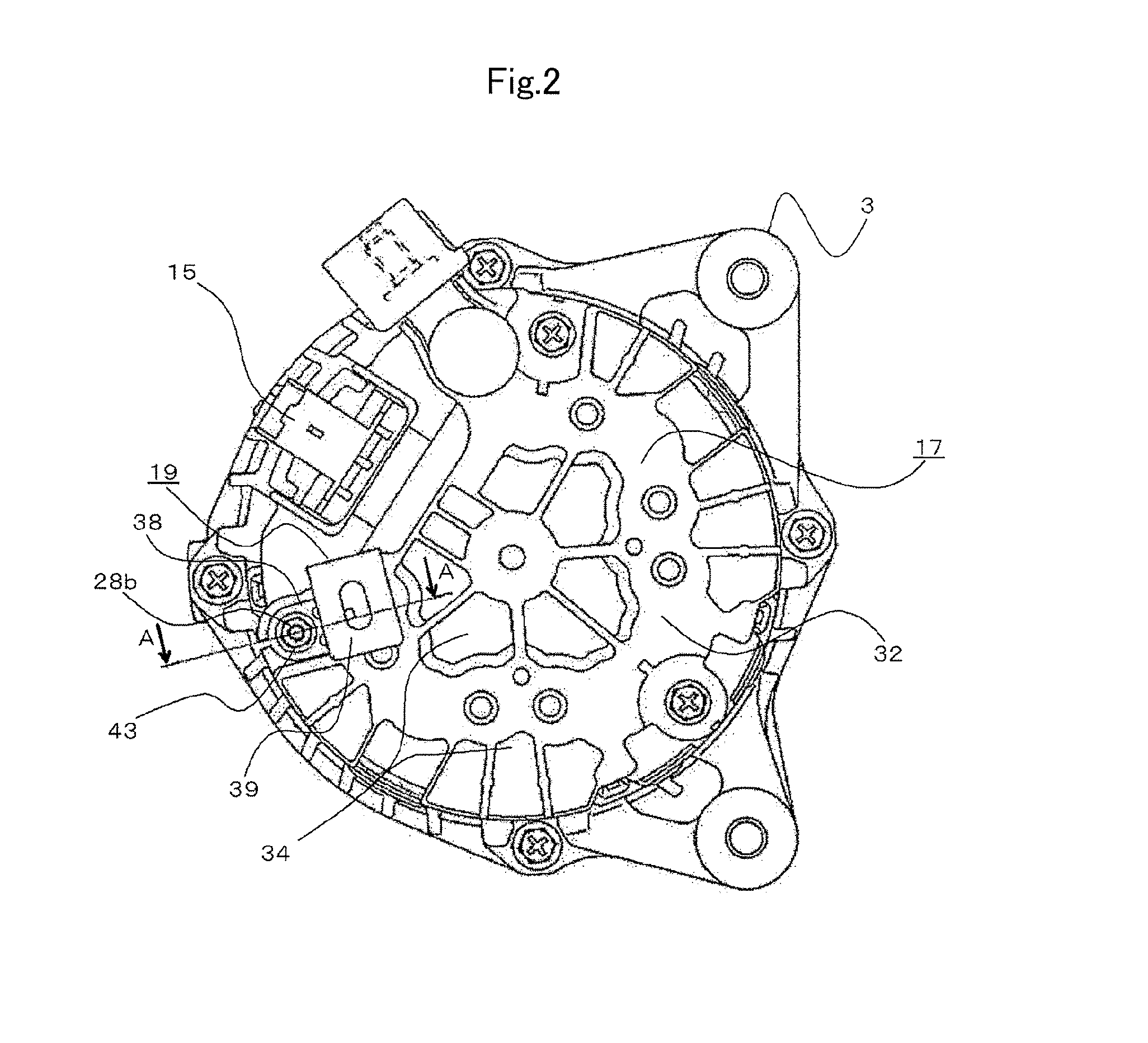

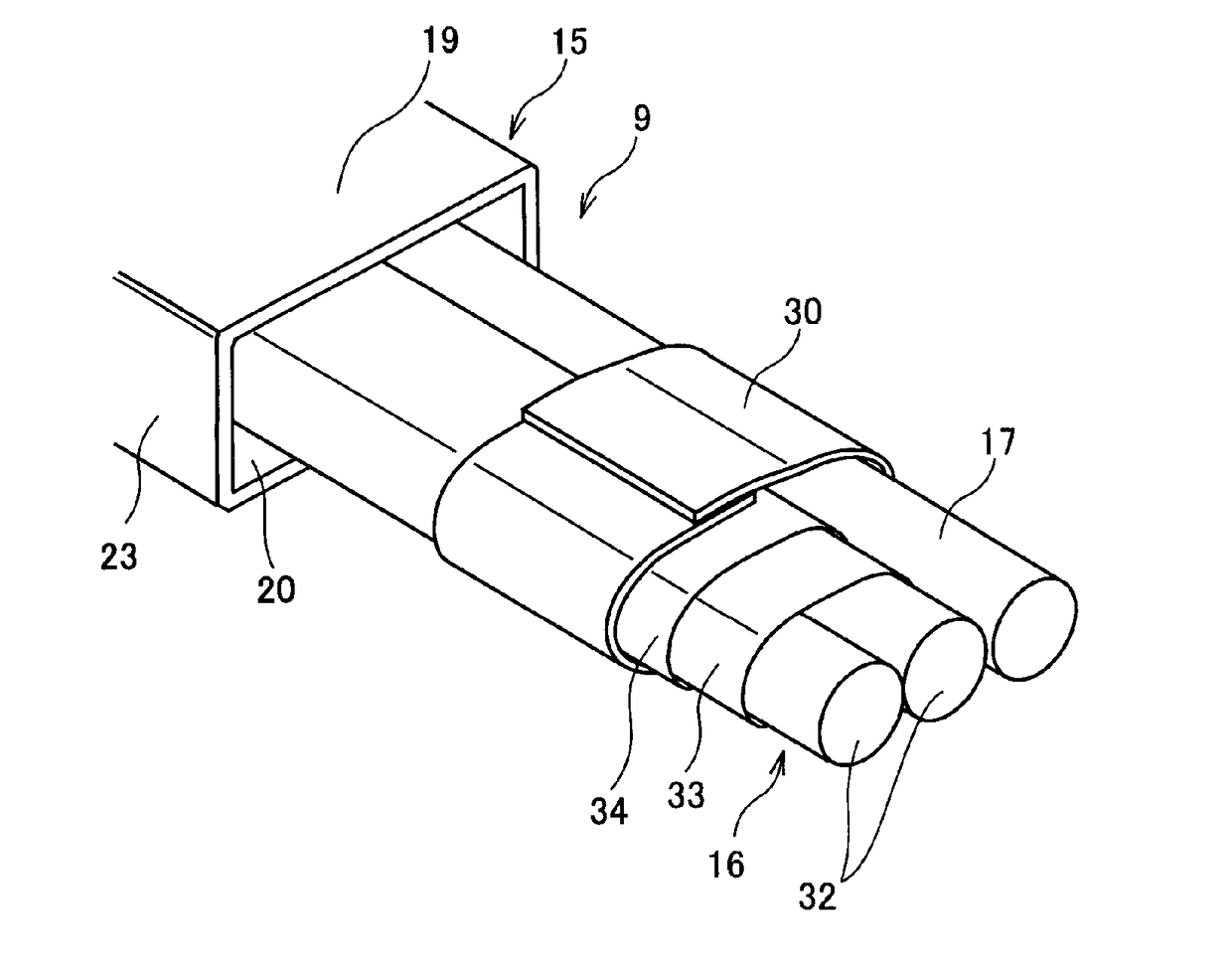

Rotating electrical machine for vehicle

ActiveUS20140203672A1Improve gripReduce vibrationCooling/ventillation arrangementSupports/enclosures/casingsElectric machineMechanical engineering

A rotating electrical machine for a vehicle includes a protective cover including a protruding portion projected to an opening side from a circumferential edge portion of a through hole formed in a bottom portion, a stud bolt that is inserted into the through hole to fix a rectifier to a portion of a casing at a position on one side in an axial direction, a mold resin including a projecting portion projected toward the protective cover, for electrically insulating the rectifier and the stud bolt from each other, and a fitting fixed to an extending portion of the stud bolt that extends from the through hole. A harness clamp is held by the fitting, and the projecting portion and the protruding portion are arranged at a position so that the projecting portion and the protruding portion are overlapped with each other in the axial direction of the stud bolt.

Owner:MITSUBISHI ELECTRIC CORP

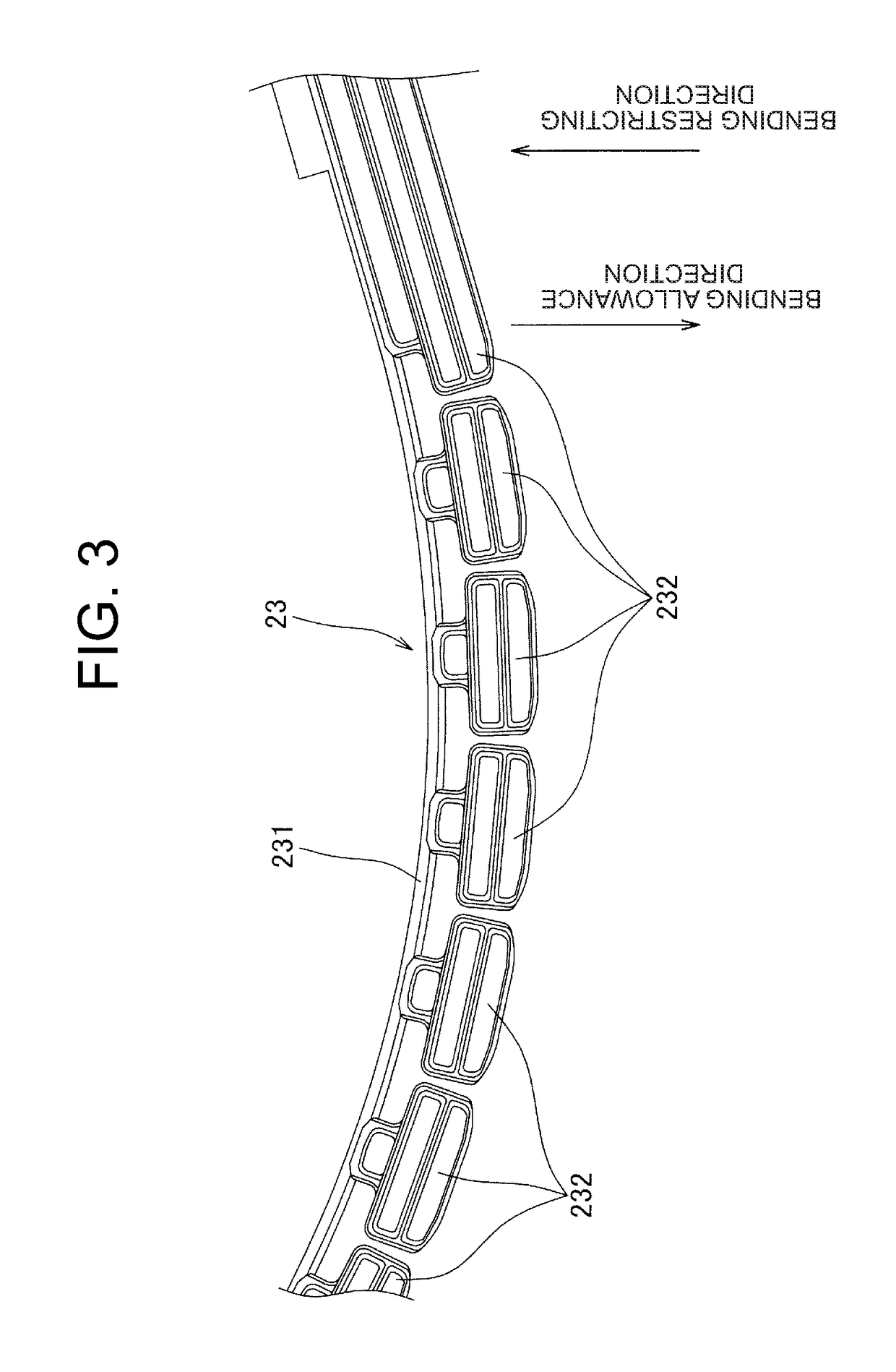

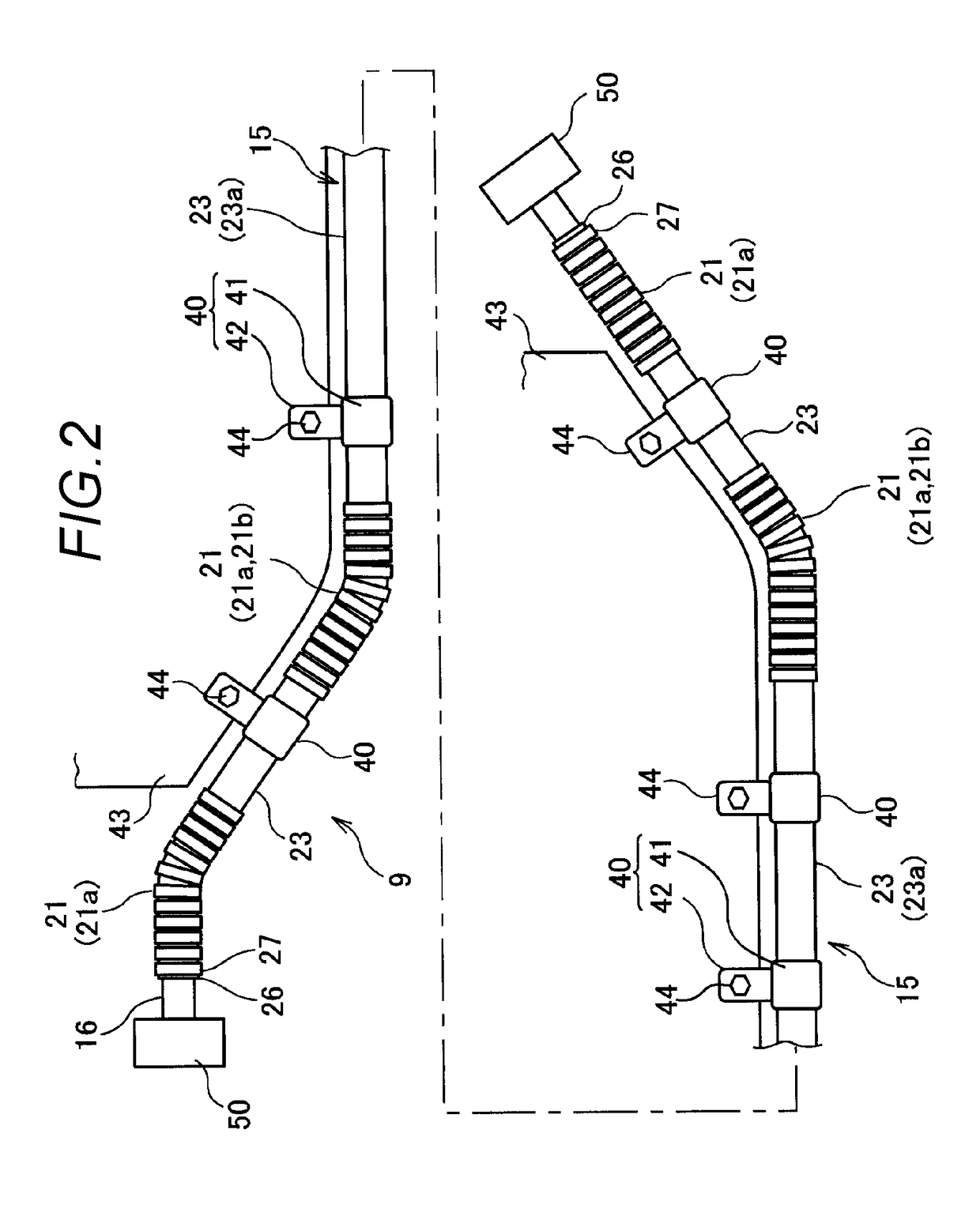

Wire harness

ActiveUS9776580B2Damage suppressionDamage can be suppressedElectrical apparatusElectric/fluid circuitBiomedical engineeringCable harness

A wire harness is provided with an electrically conductive path, a tubular sheath member which accommodates the electrically conductive path in an inner part, and a sheet member positioned between at least a part of a circumferential direction of the electrically conductive path and an inner peripheral surface of the sheath member. The sheet member may be wound on the electrically conductive path so as to cover an entire area in the circumferential direction. The sheet member may be intermittently arranged in an axial direction of a tube of the sheath member.

Owner:YAZAKI CORP

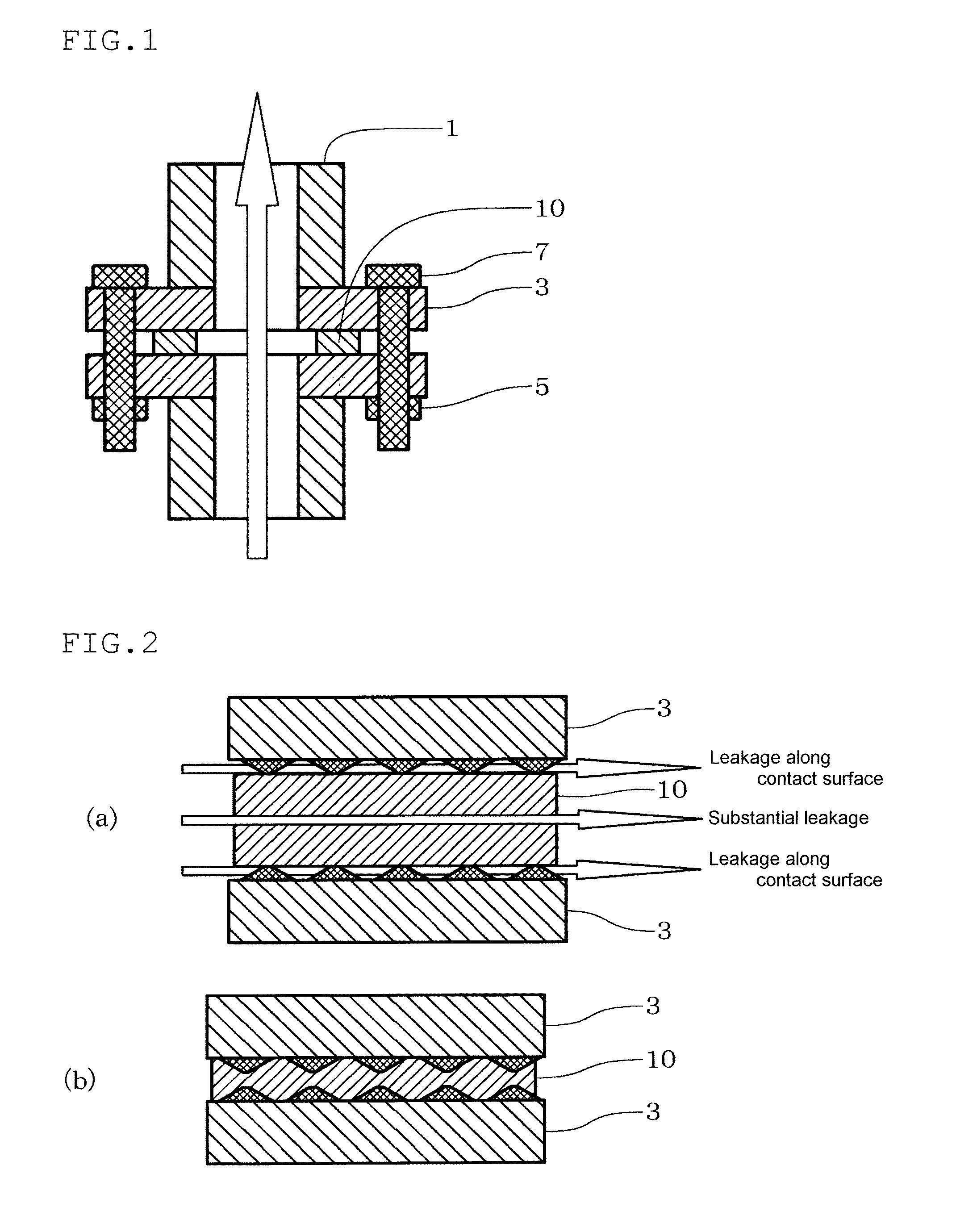

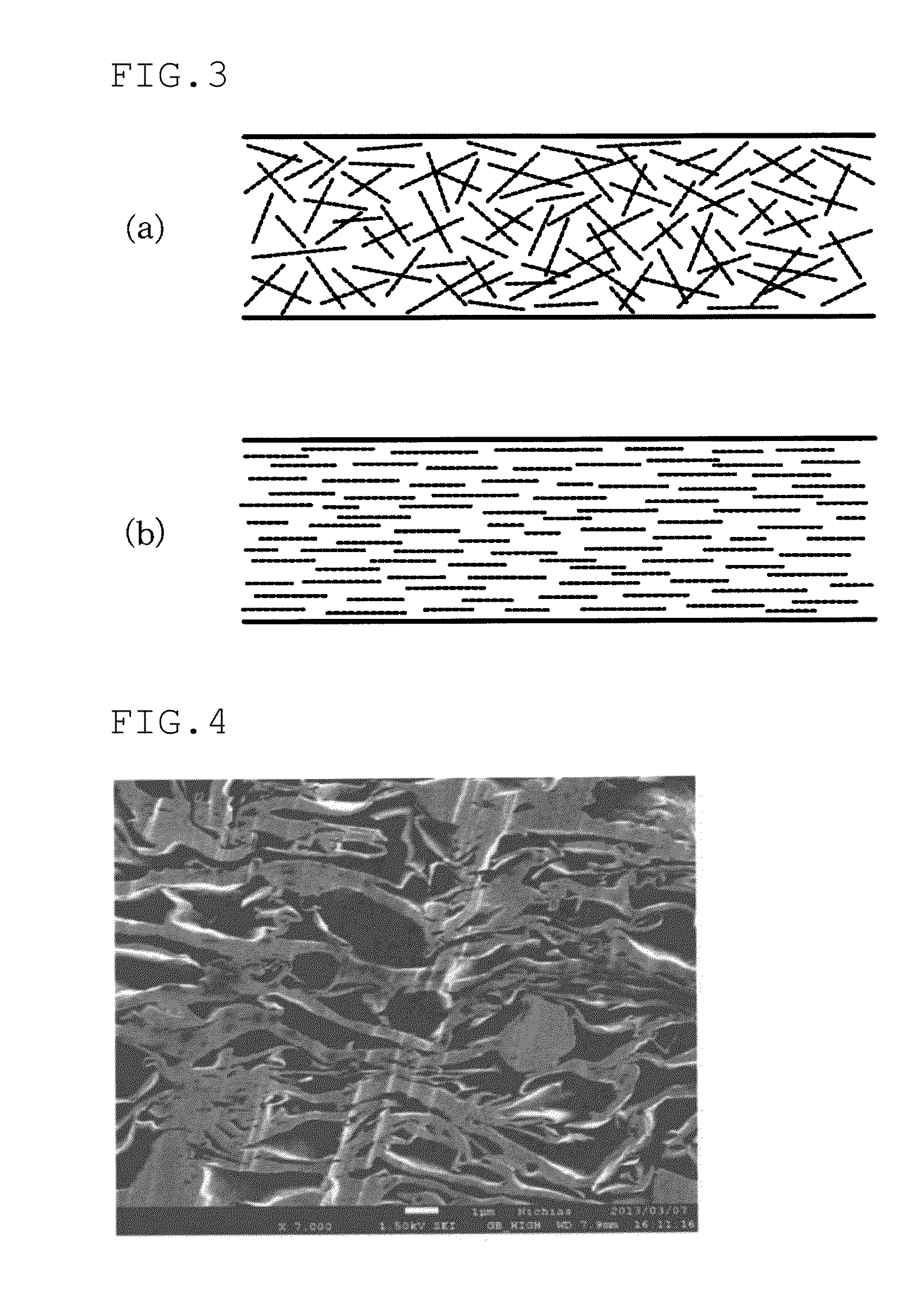

Sheet composed of exfoliated clay mineral and method for producing same

ActiveUS20160194536A1Damage can be suppressedImproved sealing propertyEngine sealsOther chemical processesCompression ratioMaterials science

A sheet including exfoliated clay minerals, having a density of 1.6 g / cm3 or less and a compression ratio of 20% or more.

Owner:NICHIAS CORP

Capacitive sensor having bending portion and flat portion

ActiveUS10564784B2Damage can be suppressedReduce the possibilityElectrical/magnetic solid deformation measurementInput/output processes for data processingEngineeringMechanical engineering

A capacitive sensor having a bending portion and a flat portion and bendable in the bending portion includes a plurality of first transparent electrodes, a plurality of second transparent electrodes, a coupling member, and a bridge wiring member. The first transparent electrodes are arranged in a first direction. The second transparent electrodes are arranged in a second direction crossing the first direction. The coupling member is provided integrally with either the first transparent electrodes or the second transparent electrodes. The bridge wiring member is provided separately from the first transparent electrodes or the second transparent electrodes, to which the coupling member is not provided, in a portion where the bridge wiring member crosses the coupling member. A direction in which the coupling member extends in the bending portion is different from a direction in which the coupling member extends in the flat portion.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com